Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

954 results about "Feedthrough" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A feedthrough is a conductor used to carry a signal through an enclosure or printed circuit board. Like any conductor, it has a small amount of capacitance. A "feedthrough capacitor" has a guaranteed minimum value of shunt capacitance built in it and is used for bypass purposes in ultra-high-frequency applications. Feedthroughs can be divided into power and instrumentation categories. Power feedthroughs are used to carry either high current or high voltage. Instrumentation feedthroughs are used to carry electrical signals (including thermocouples) which are normally low current or voltage. Another special type is what is commonly known as RF-feedthrough, specifically designed to carry very high frequency RF or microwave electrical signals.

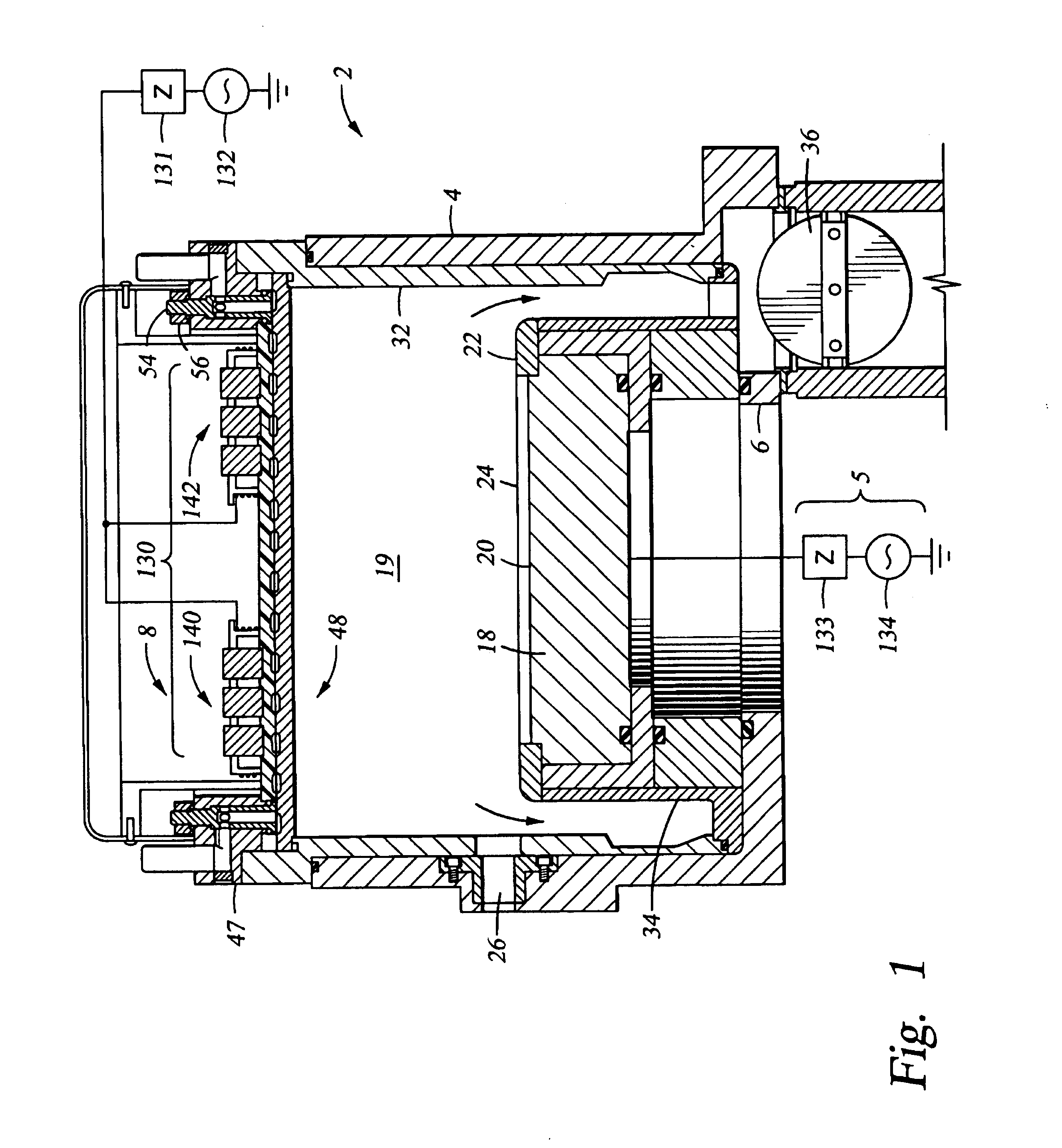

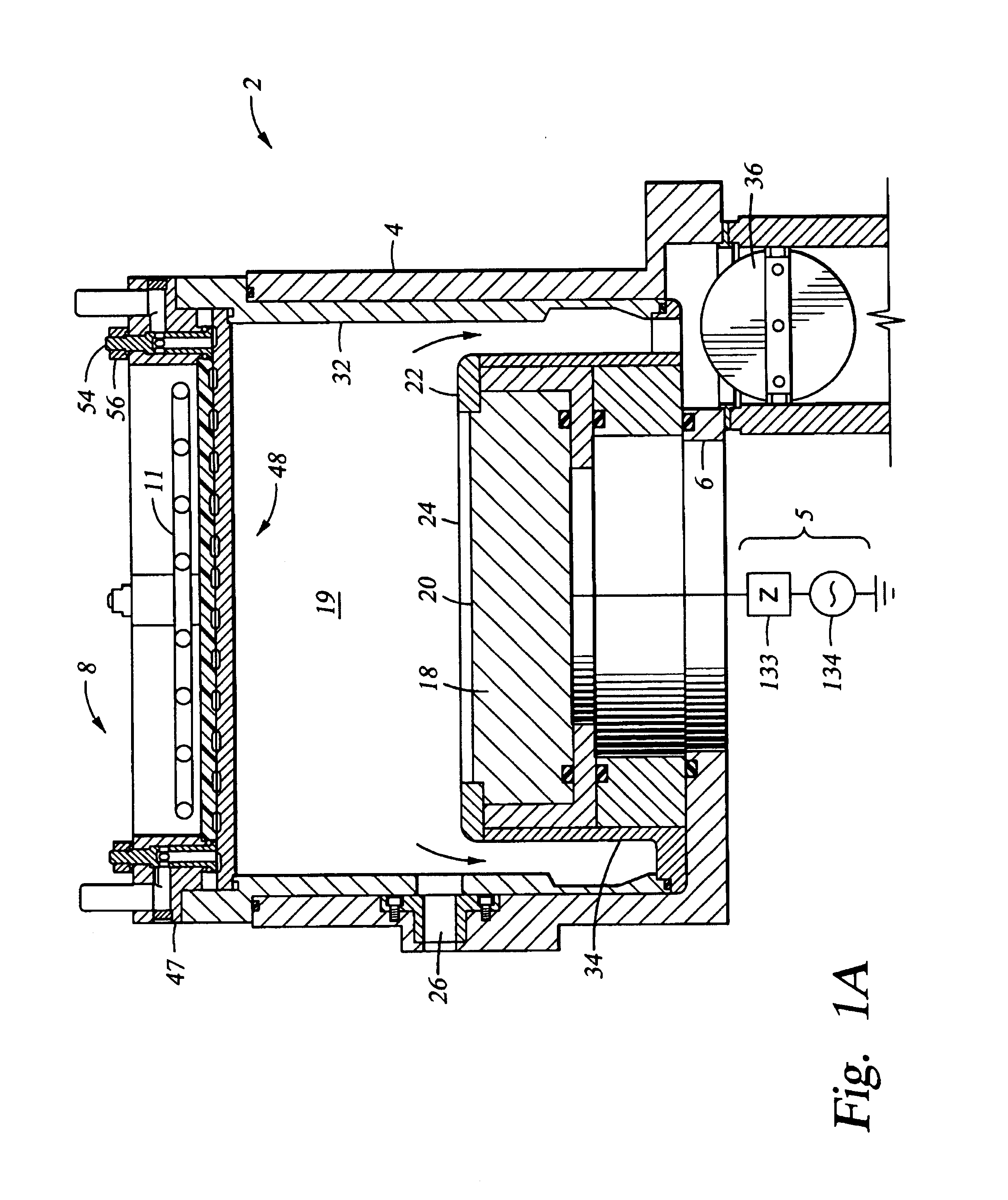

Thermal Processing System and Configurable Vertical Chamber

InactiveUS20070243317A1Semiconductor/solid-state device manufacturingLiquid/solution decomposition chemical coatingEngineeringIsothermal process

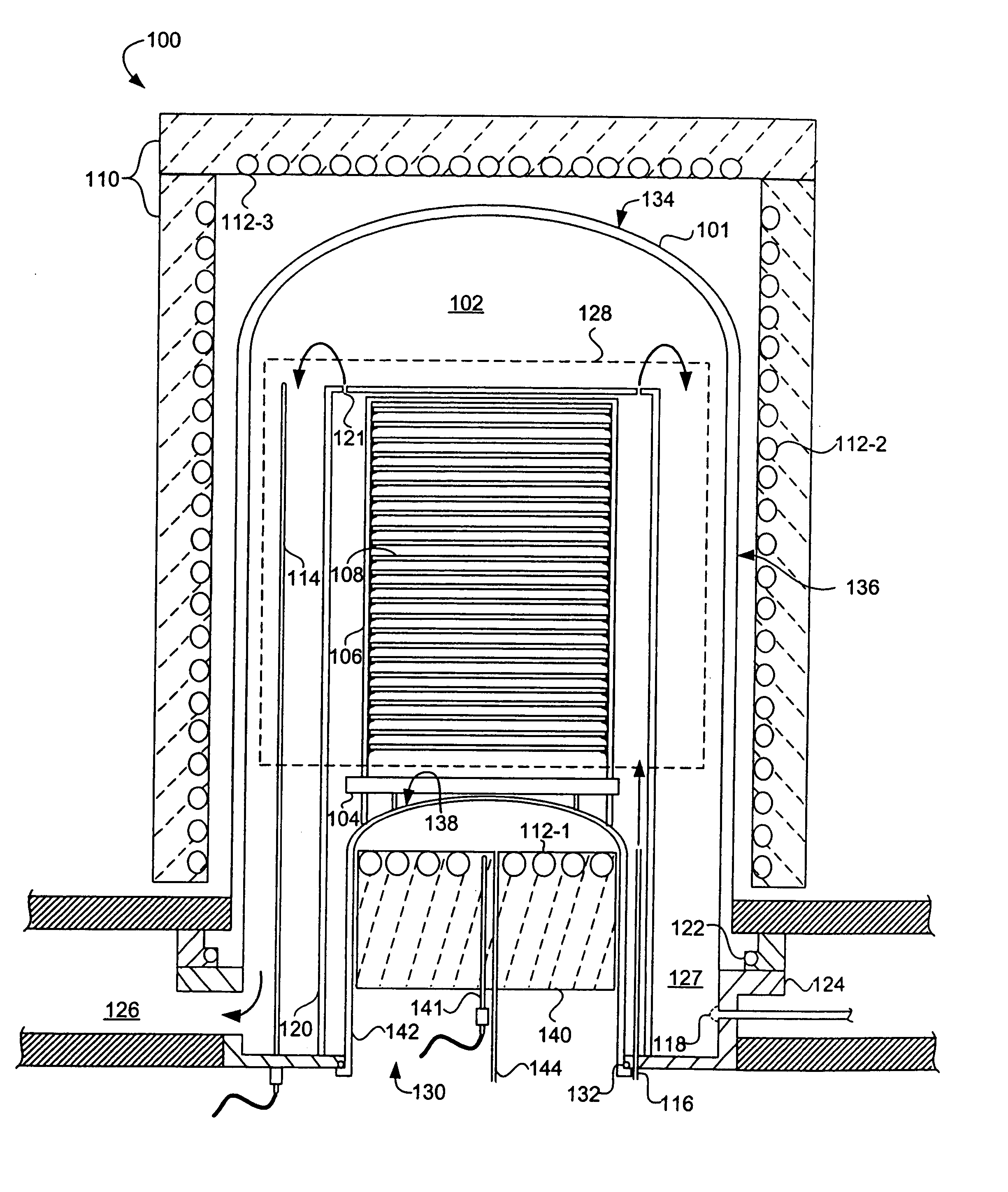

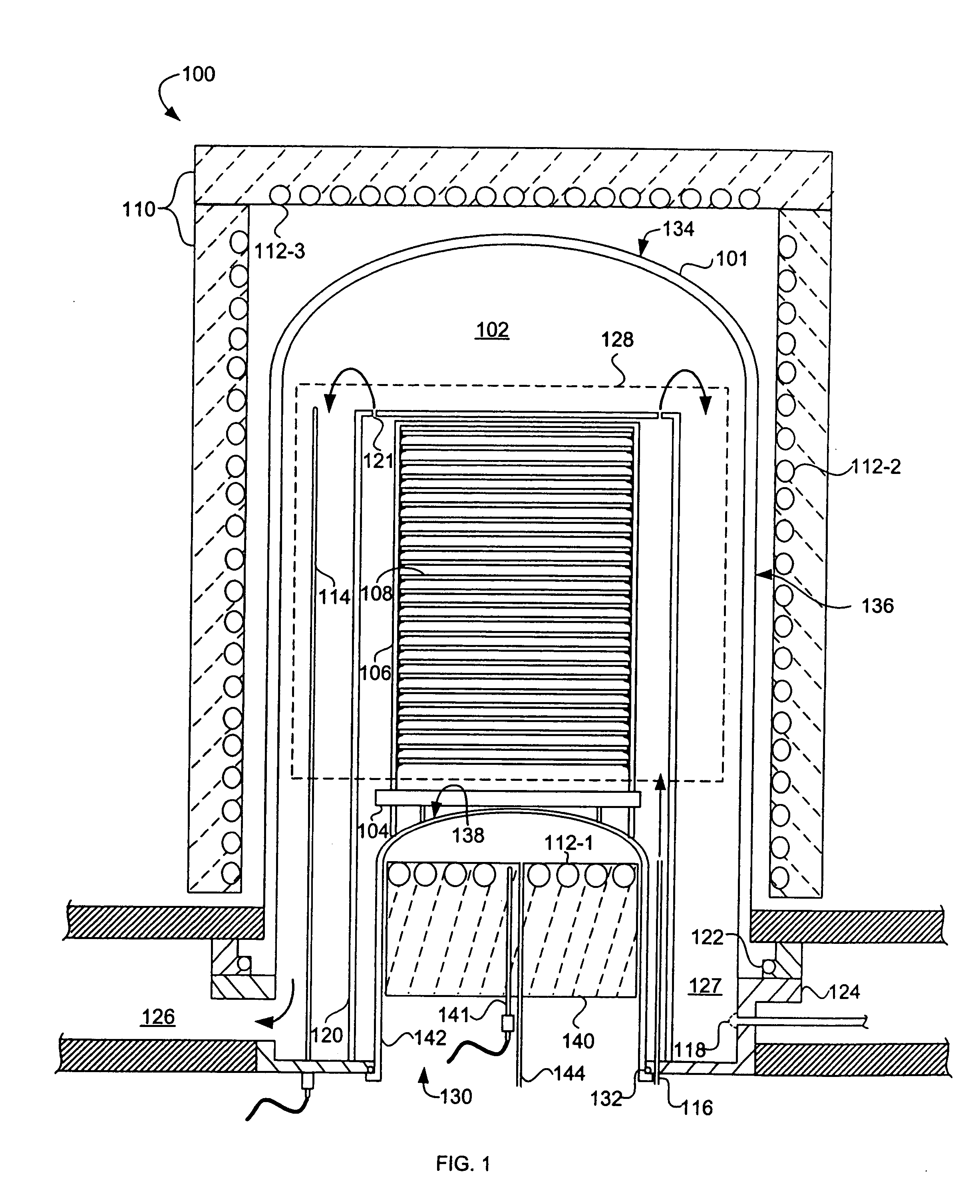

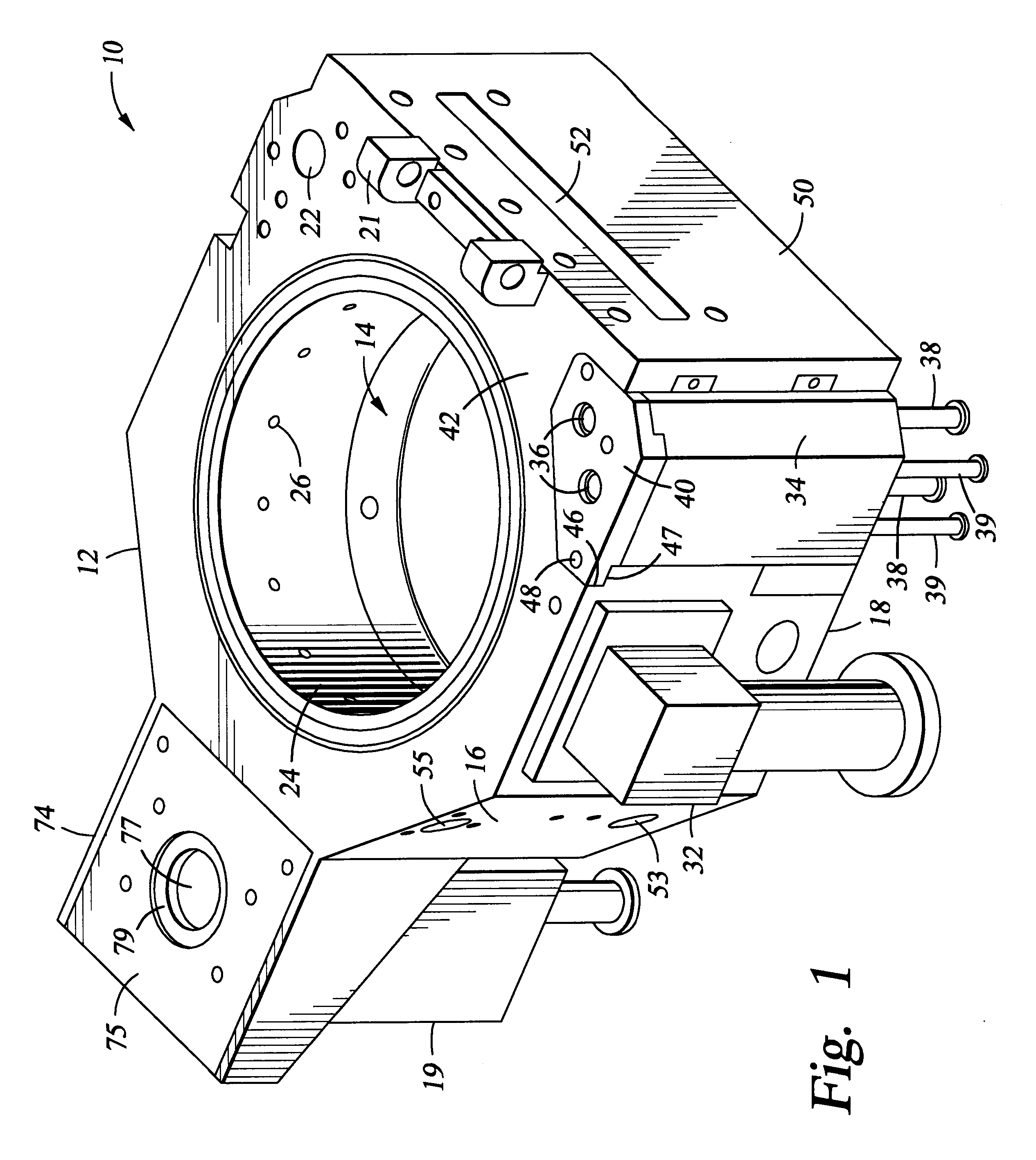

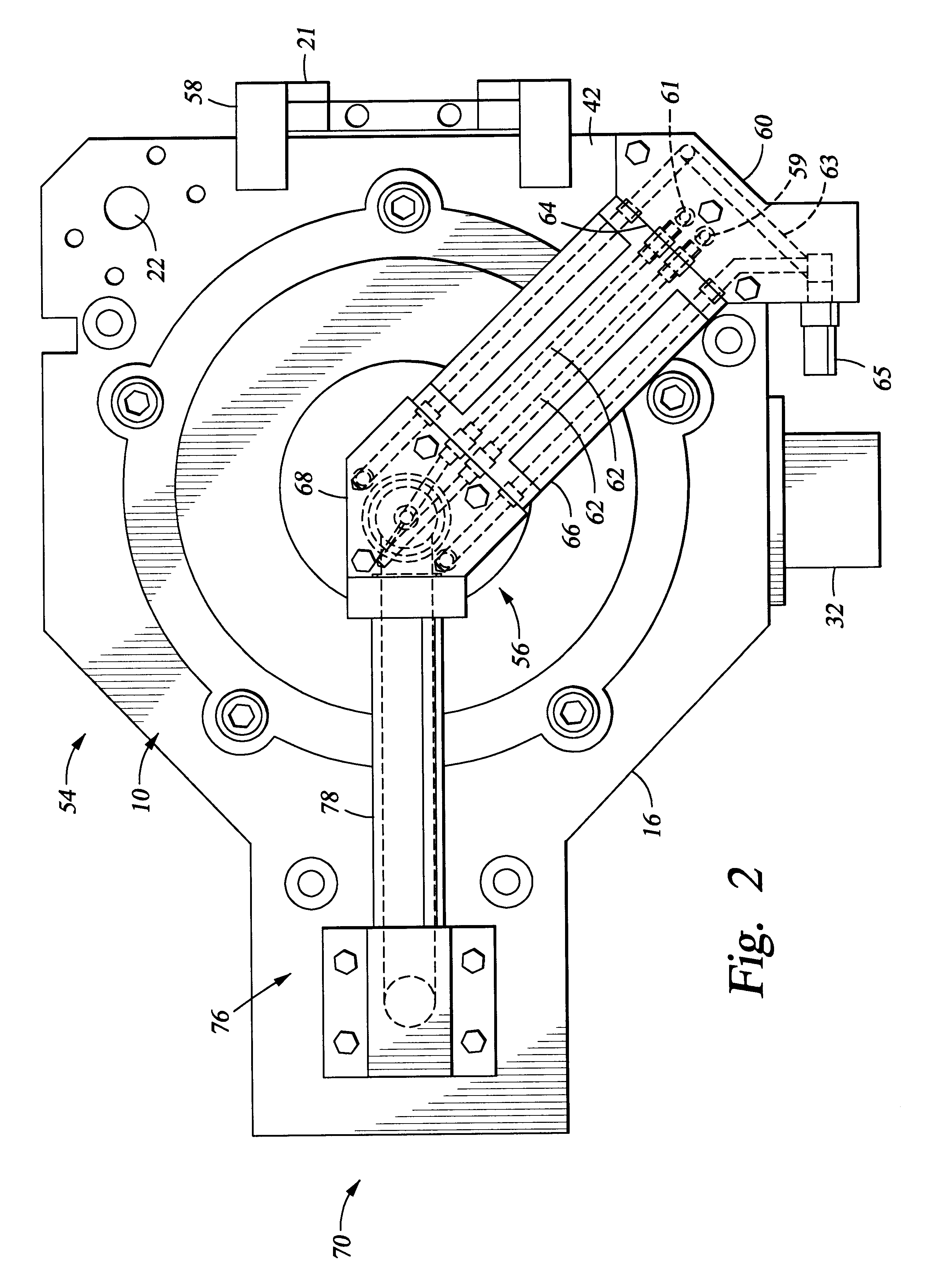

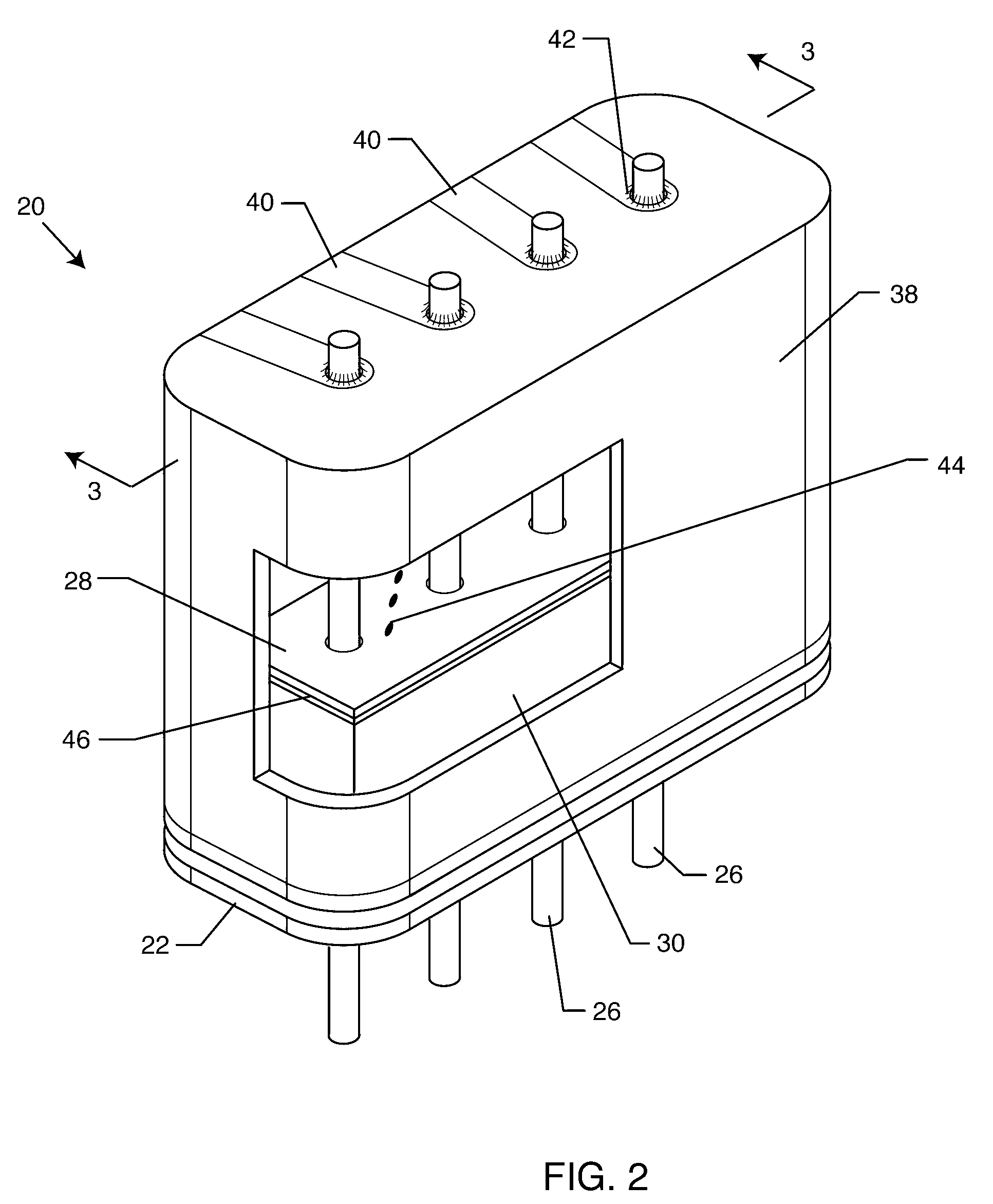

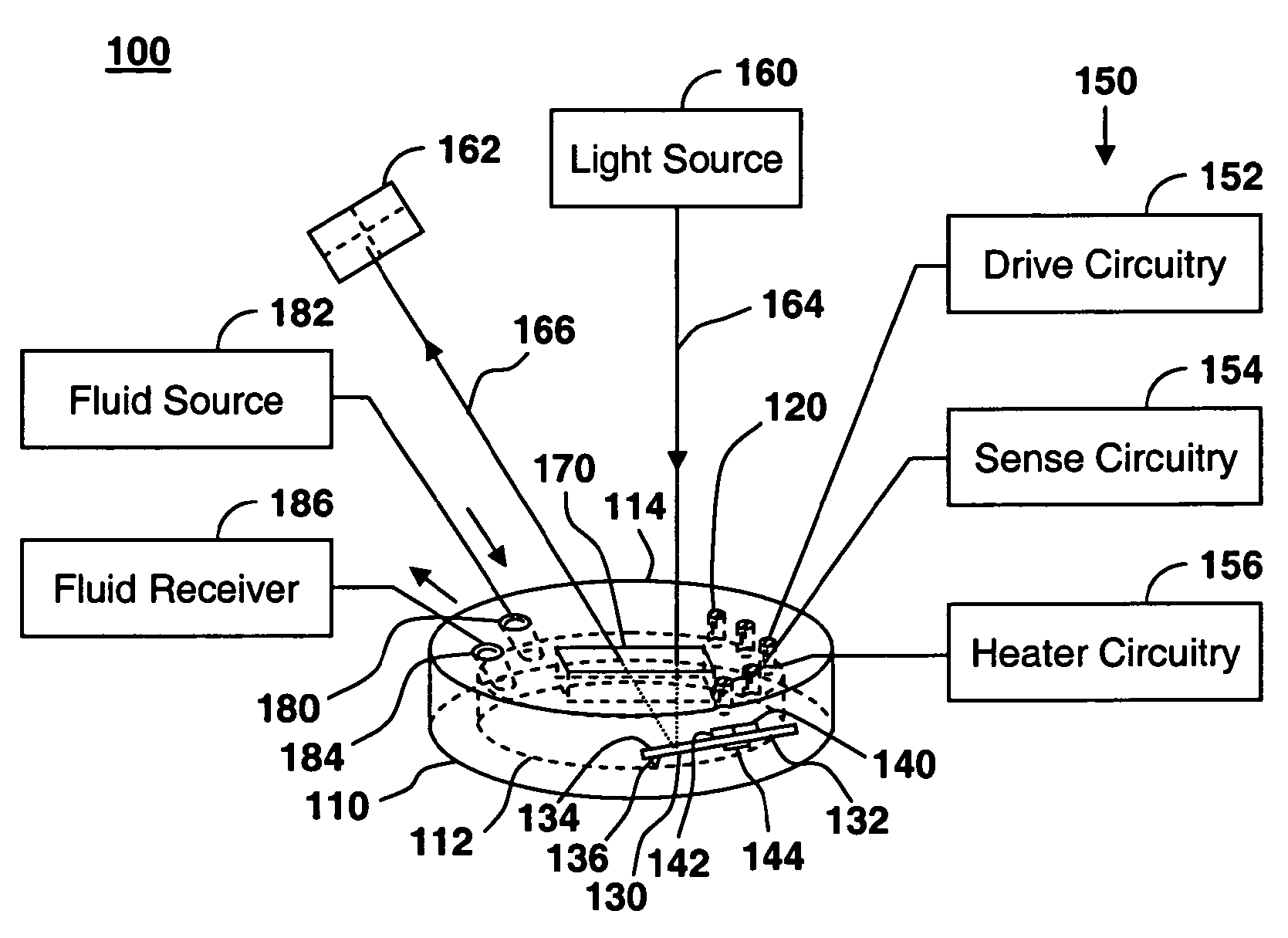

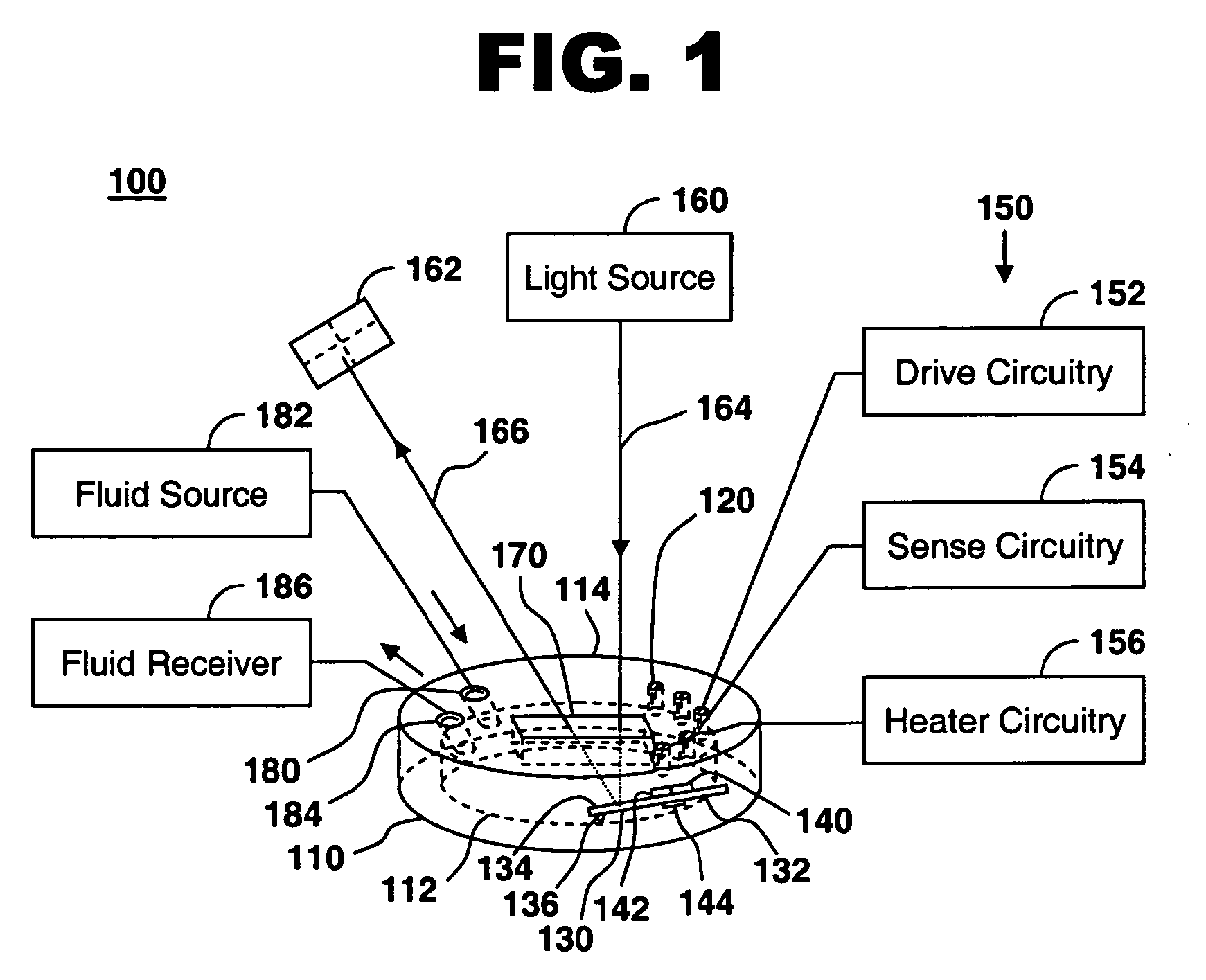

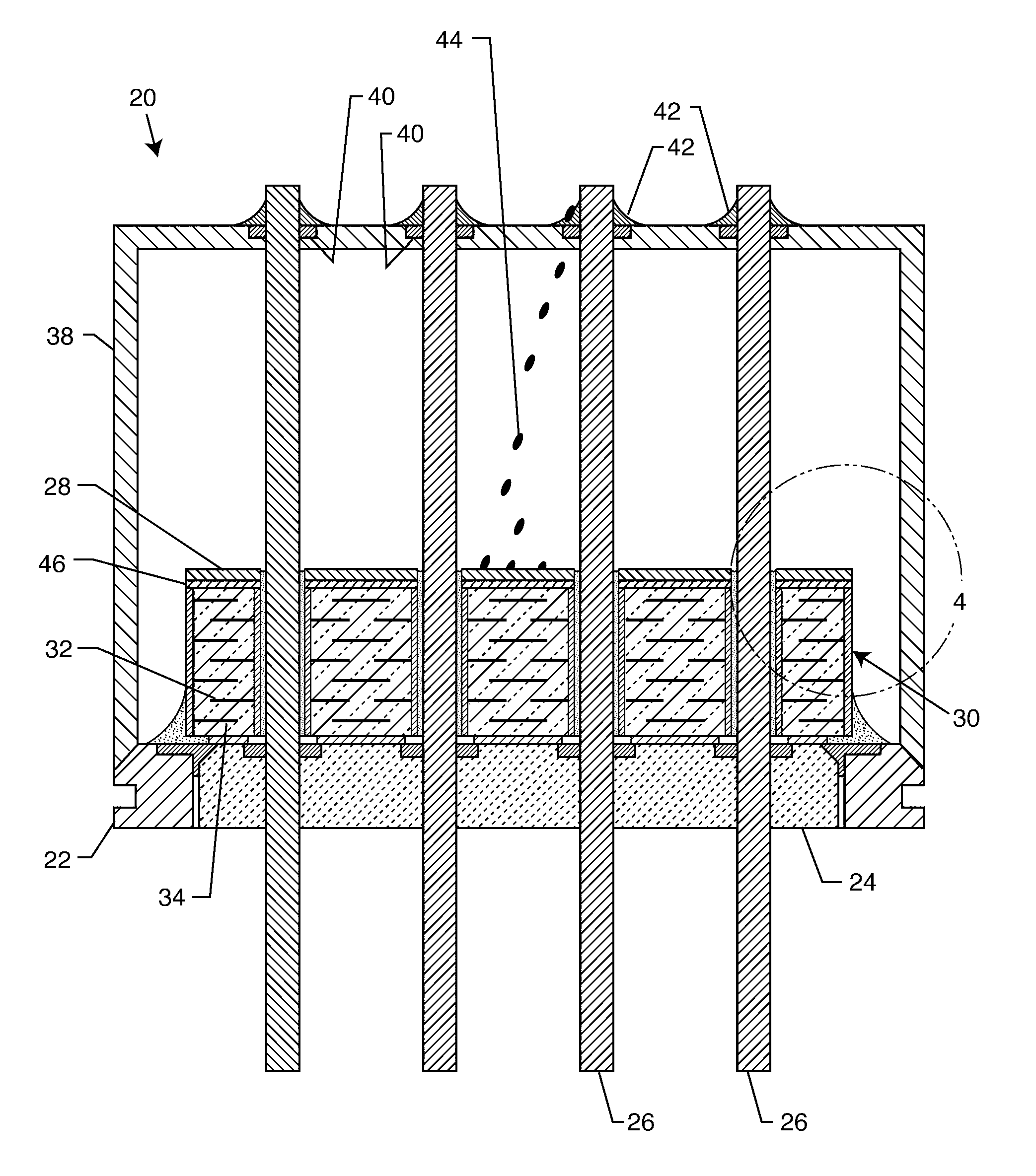

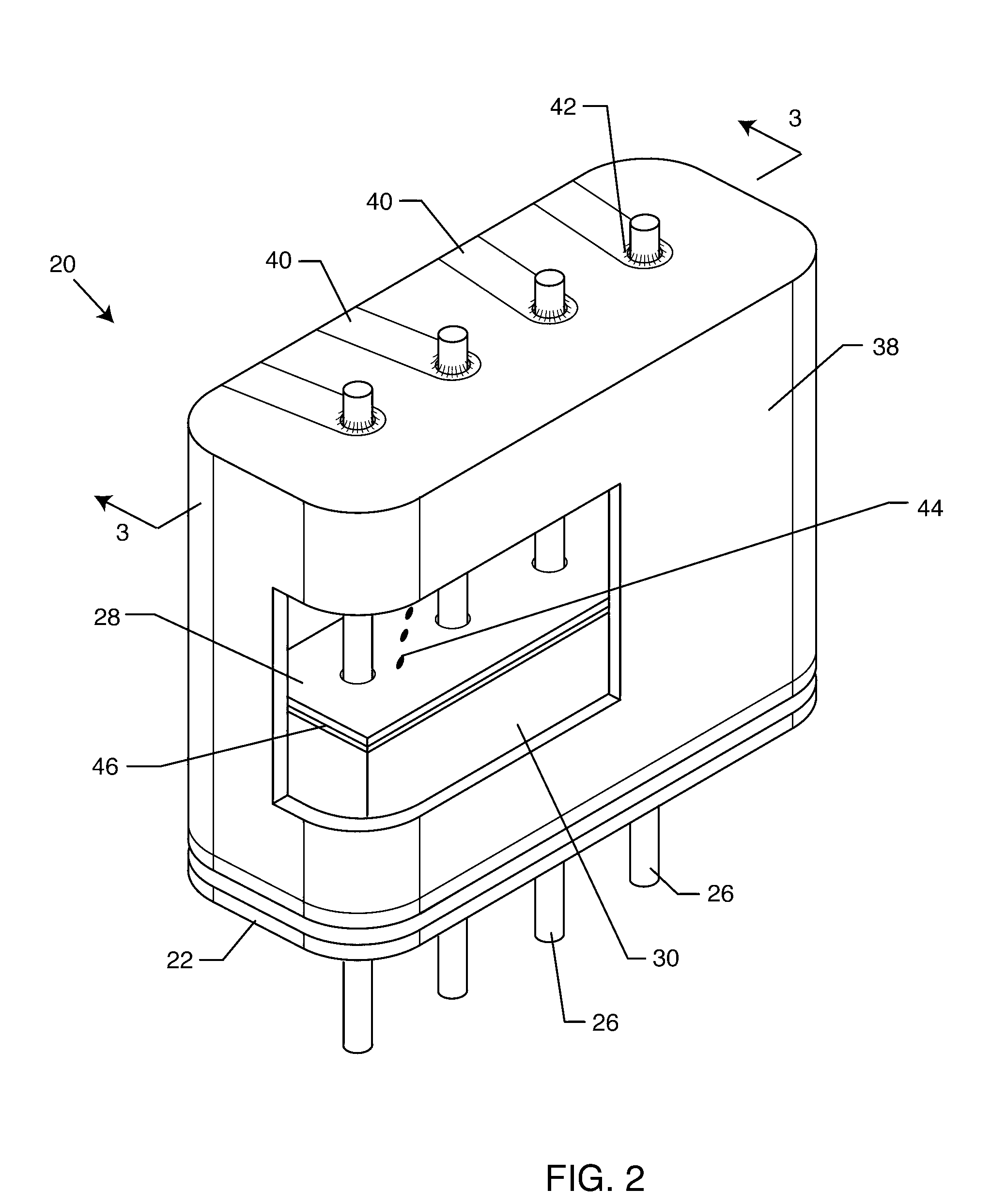

An apparatus (100) and method are provided for thermally processing substrates (108) held in a carrier (106). The apparatus (100) includes a vessel (101) having a top (134), side (136) and bottom (138), and a heat source (110) with heating elements (112-1, 112-2, 112-3) proximal thereto. The vessel (101) is sized to enclose a volume substantially no larger than necessary to accommodate the carrier (106), and to provide an isothermal process zone (128) extending throughout. In one embodiment, the bottom wall (138) includes a movable pedestal (140) with a bottom heating element therein (112-1), and the pedestal can be lowered and raised to insert the carrier (106) into the vessel (101). The apparatus (100) can include a movable shield (146) that is inserted between the pedestal (140) and the carrier (106) to shield the substrates (108) from the heating element (112-1) and to maintain pedestal temperature. A magnetically coupled repositioning system (162) repositions the carrier (106) during processing of the substrates (108) without use of a movable feedthrough into the volume enclosed by the vessel (101), and without moving the bottom heating element (112-1) in the pedestal (140).

Owner:DU BOIS DALE R +4

Apparatus and method for depositing low K dielectric materials

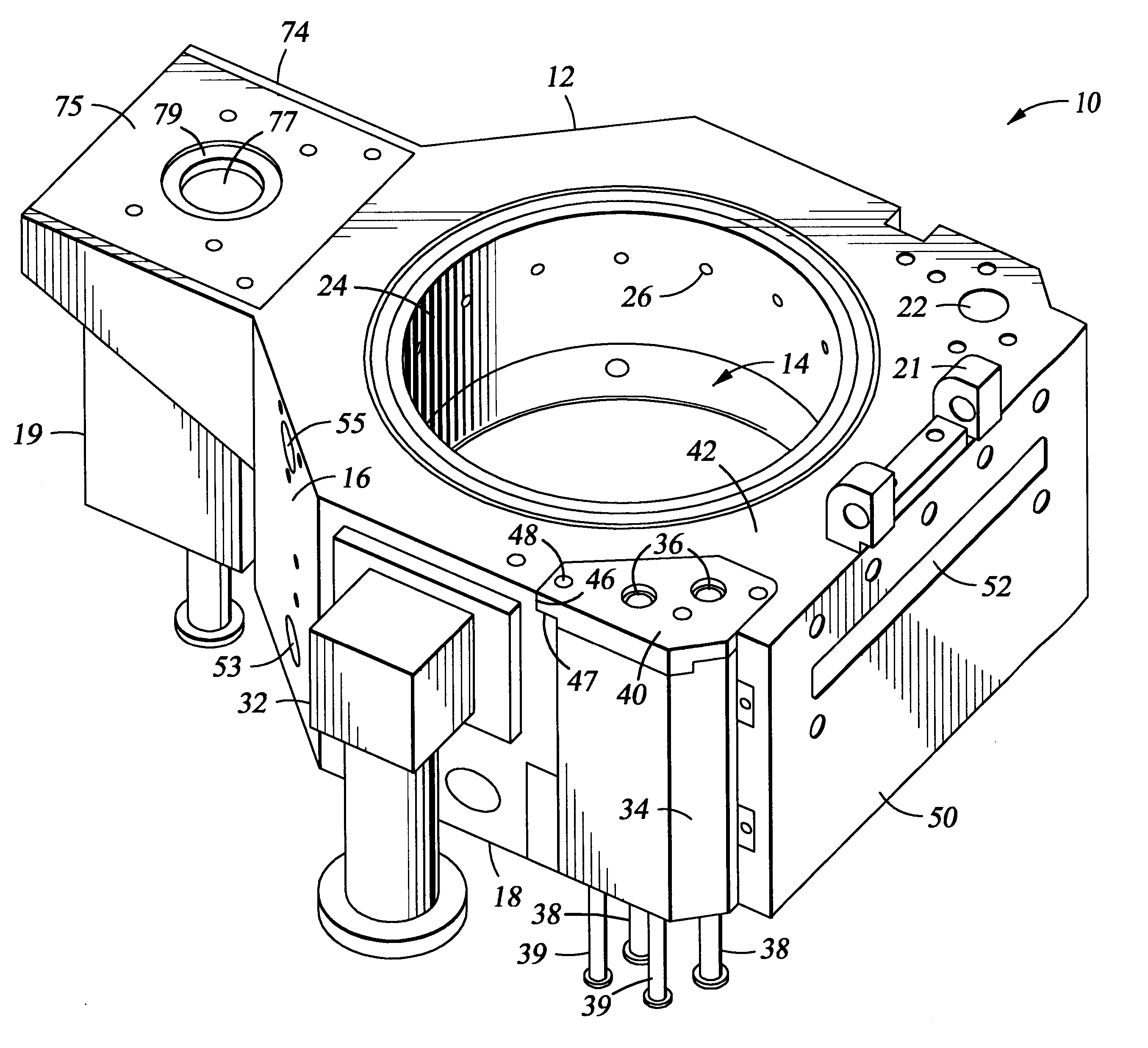

The invention provides a deposition system and methods of depositing materials onto substrates. In one aspect, a modular processing chamber is provided which includes a chamber body defining a processing region. The chamber body includes a removable gas feedthrough, an electrical feedthrough, a gas distribution assembly mounted on a chamber lid and a microwave applicator for generating reactive gases remote from the processing region.

Owner:APPLIED MATERIALS INC

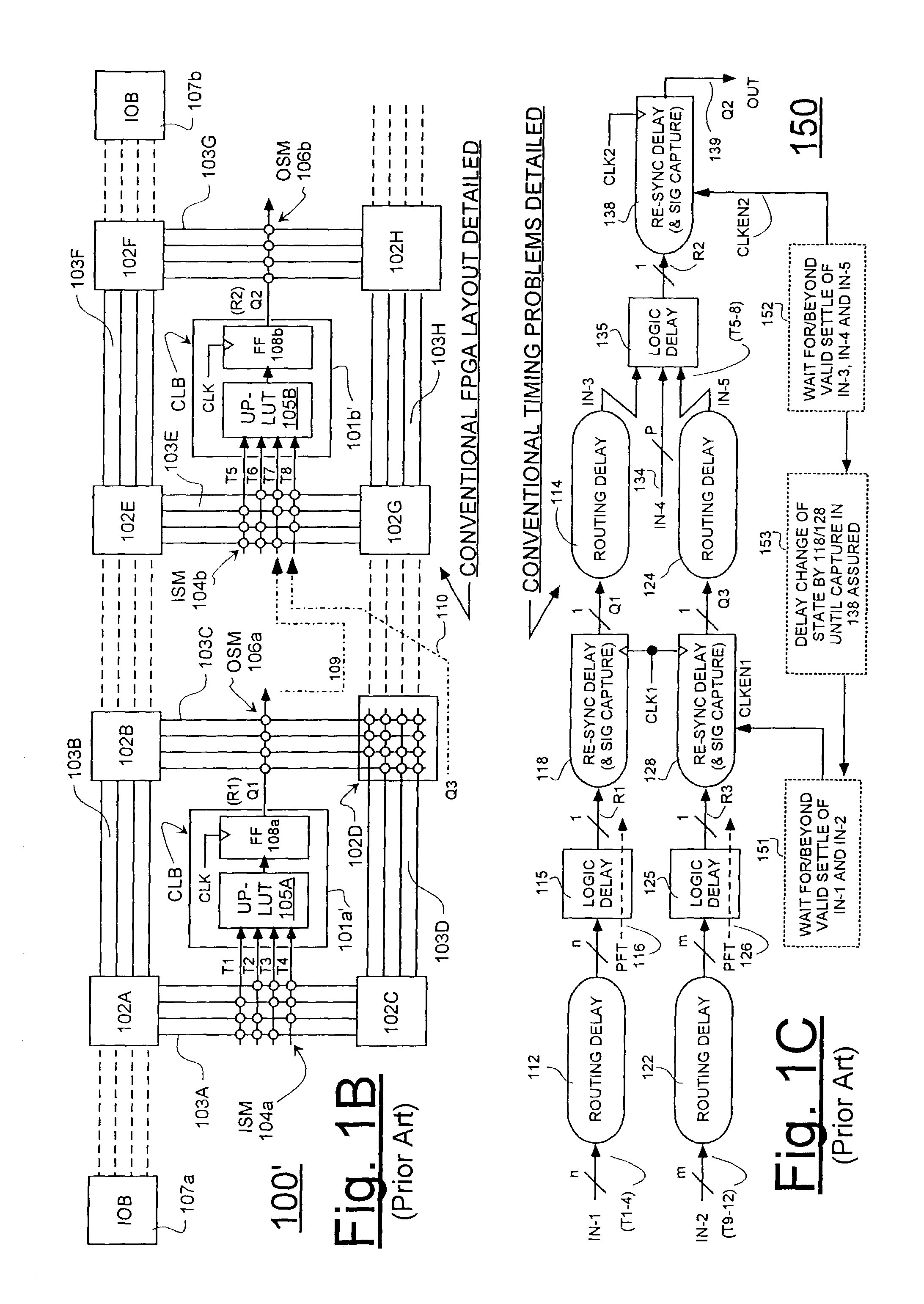

FPGA with register-intensive architecture

ActiveUS7028281B1Minimize resourceReduce consumptionSolid-state devicesCAD circuit designProcessor registerMultiplexer

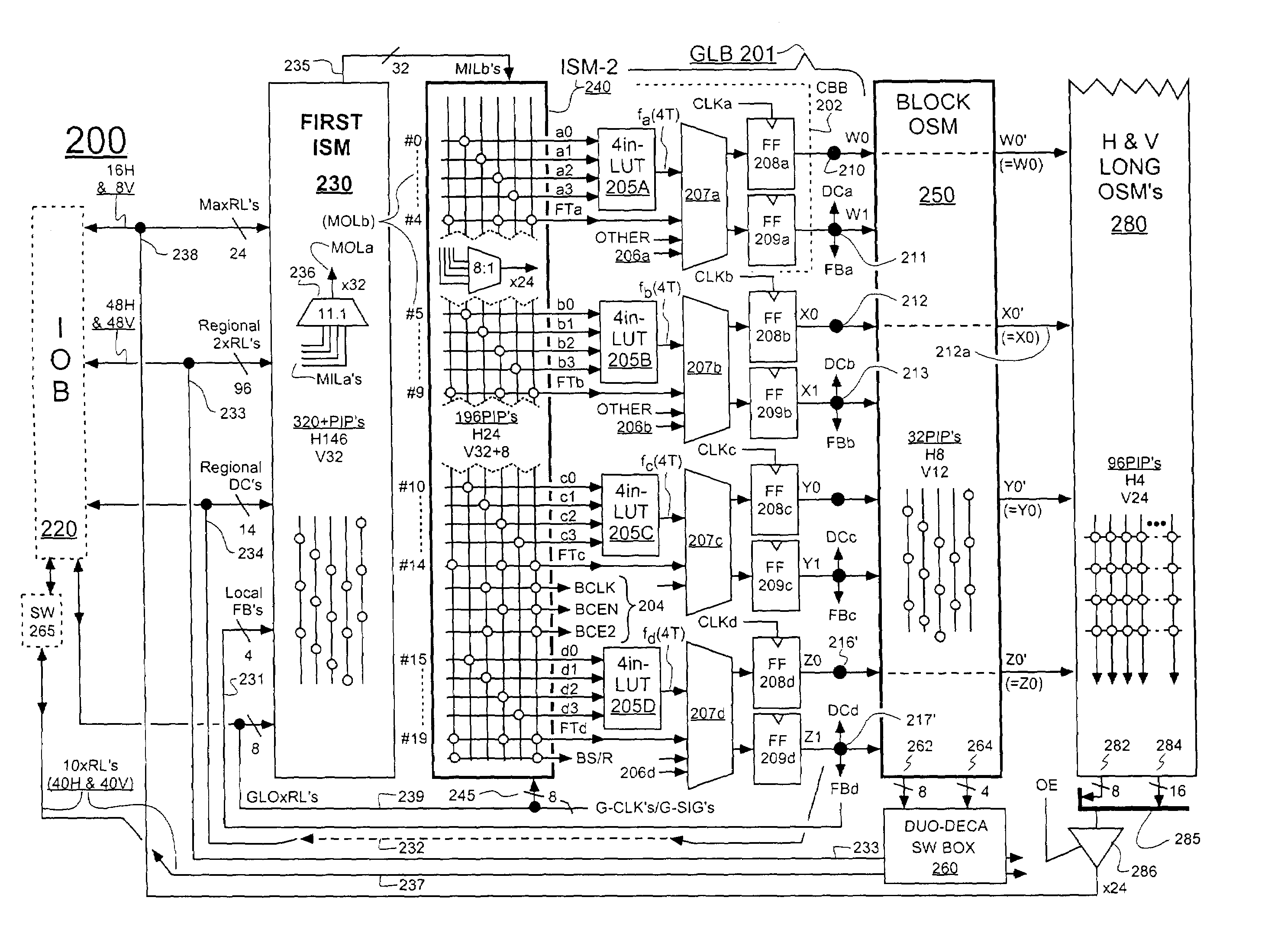

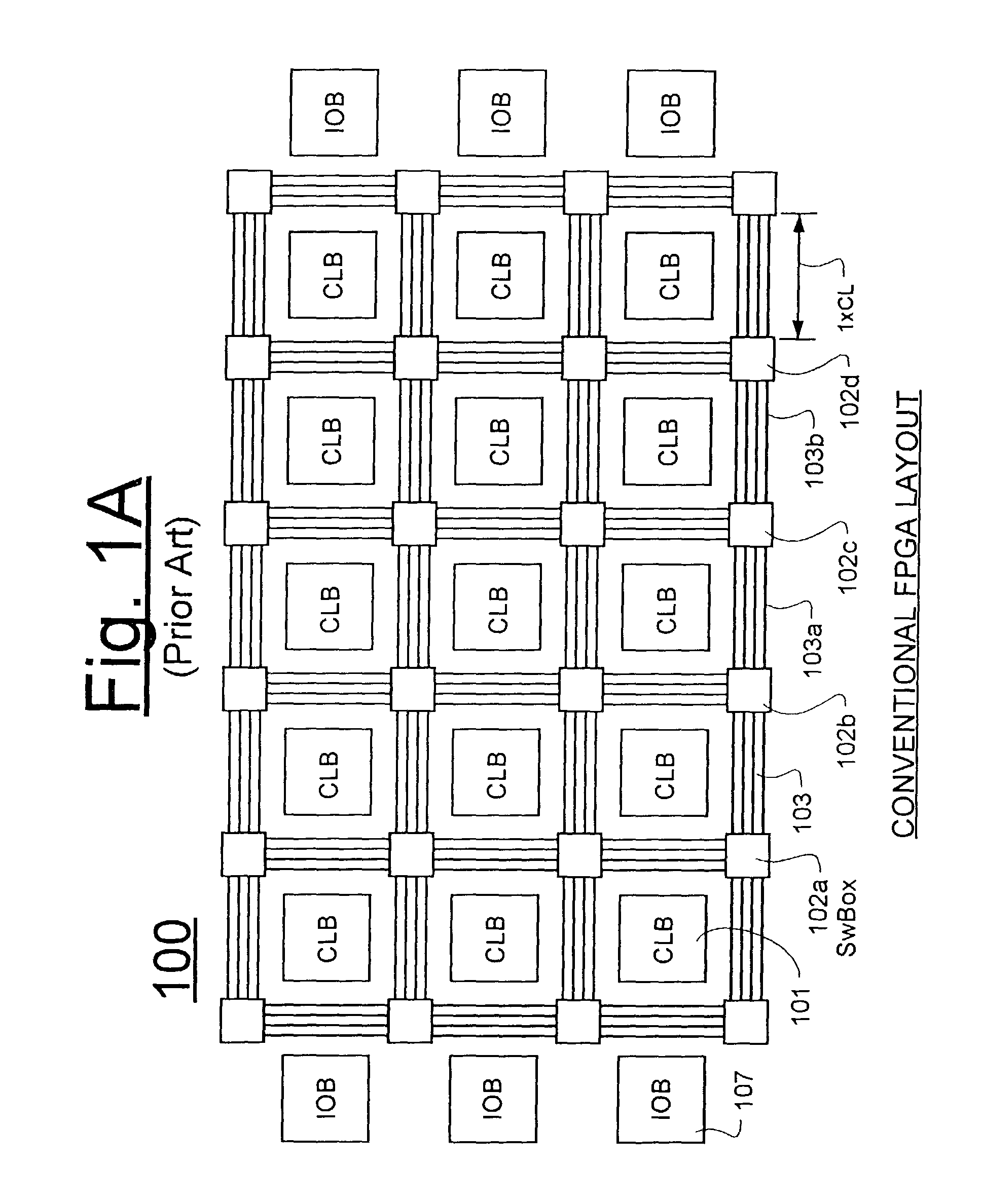

Field programmable gate arrays (FPGA's) may be structured in accordance with the disclosure to have a register-intensive architecture that provides, for each of plural function-spawning LookUp Tables (e.g. a 4-input, base LUT's) within a logic block, a plurality of in-block accessible registers. A register-feeding multiplexer means may be provided for allowing each of the plural registers to equivalently capture and store a result signal output by the corresponding, base LUT of the plural registers. Registerable, primary and secondary feedthroughs may be provided for each base LUT so that locally-acquired input signals of the LUT may be fed-through to the corresponding, in-block registers for register-recovery purposes without fully consuming (wasting) the lookup resources of the associated, base LUT. A multi-stage, input switch matrix (ISM) may be further provided for acquiring and routing input signals from adjacent, block-interconnect lines (AIL's) and / or block-intra-connect lines (e.g., FB's) to the base LUT's and / or their respective, registerable feedthroughs. Techniques are disclosed for utilizing the many in-block registers and / or the registerable feedthroughs and / or the multi-stage ISM's for efficiently implementing various circuit designs by appropriately configuring such register-intensive FPGA's.

Owner:LATTICE SEMICON CORP

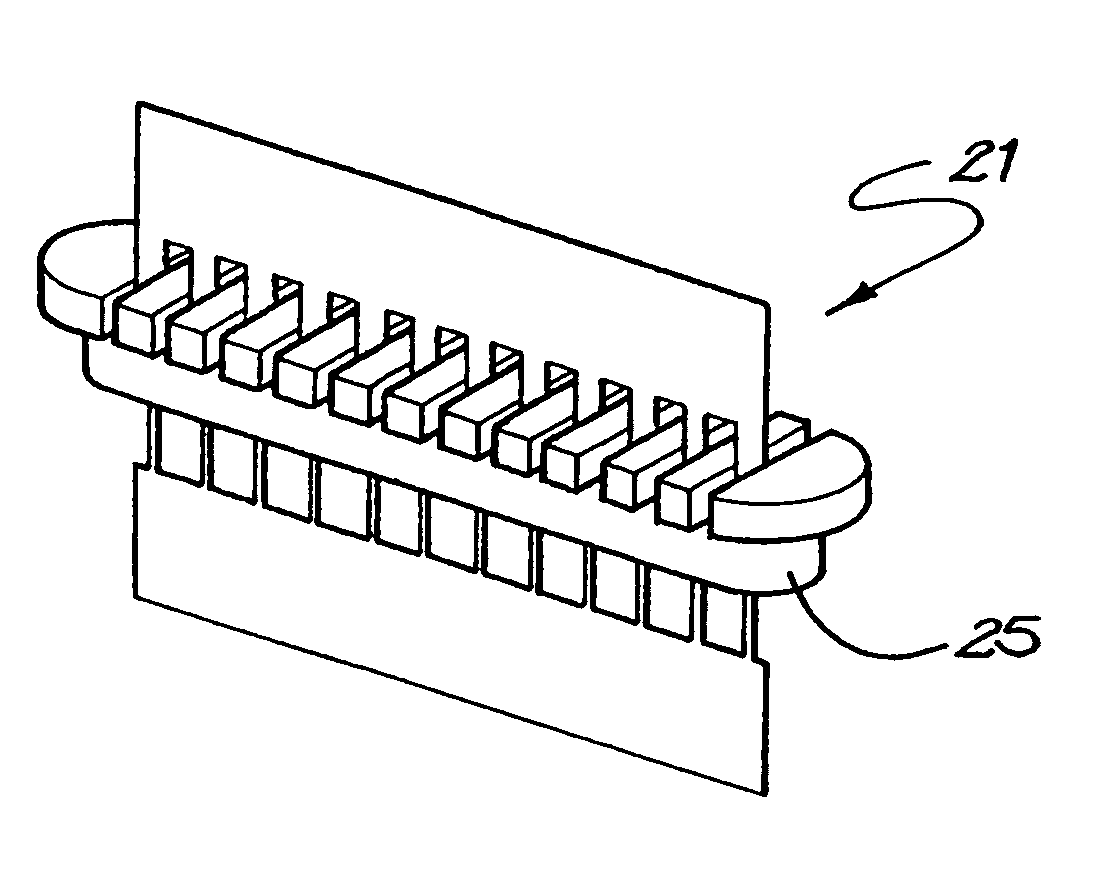

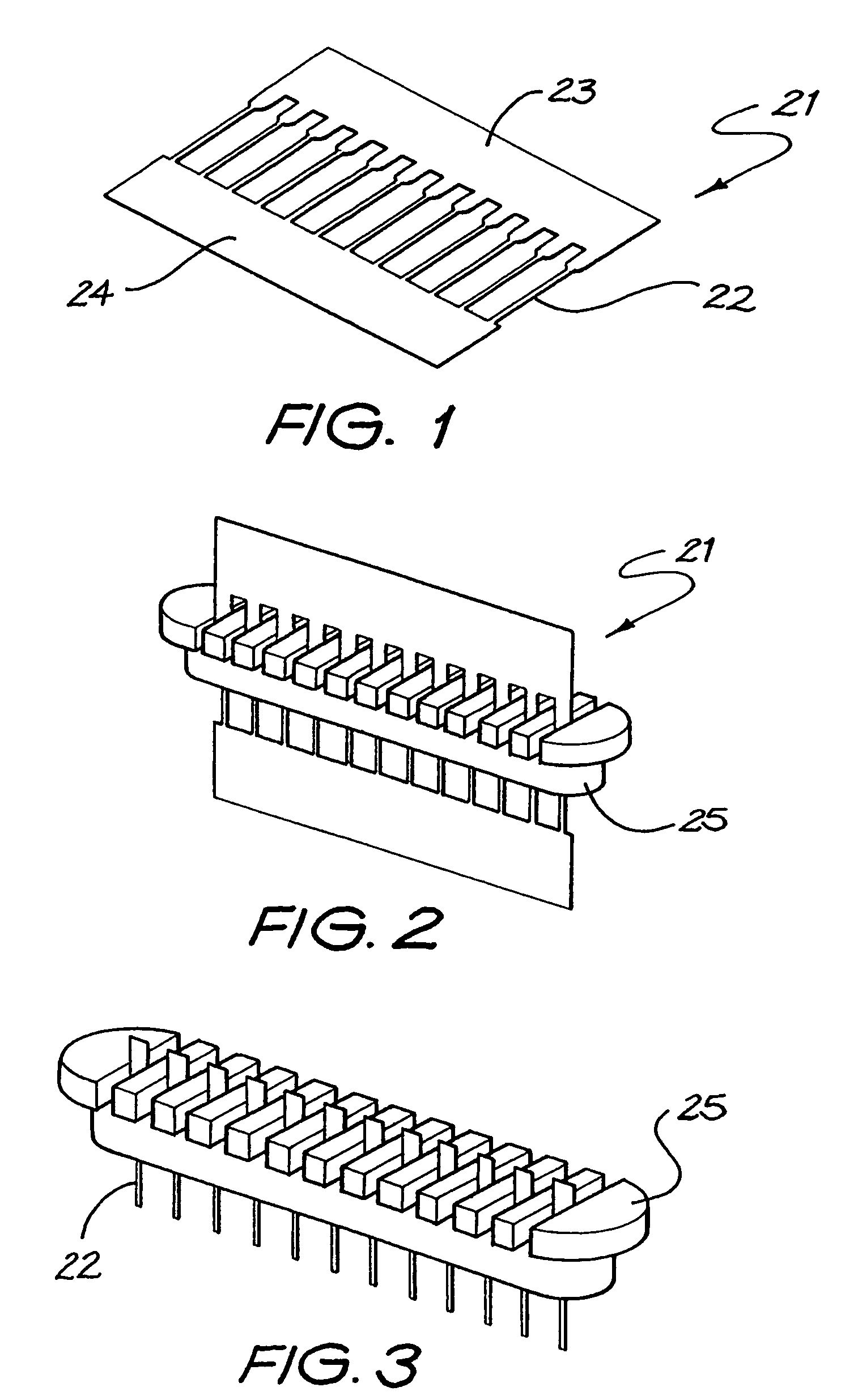

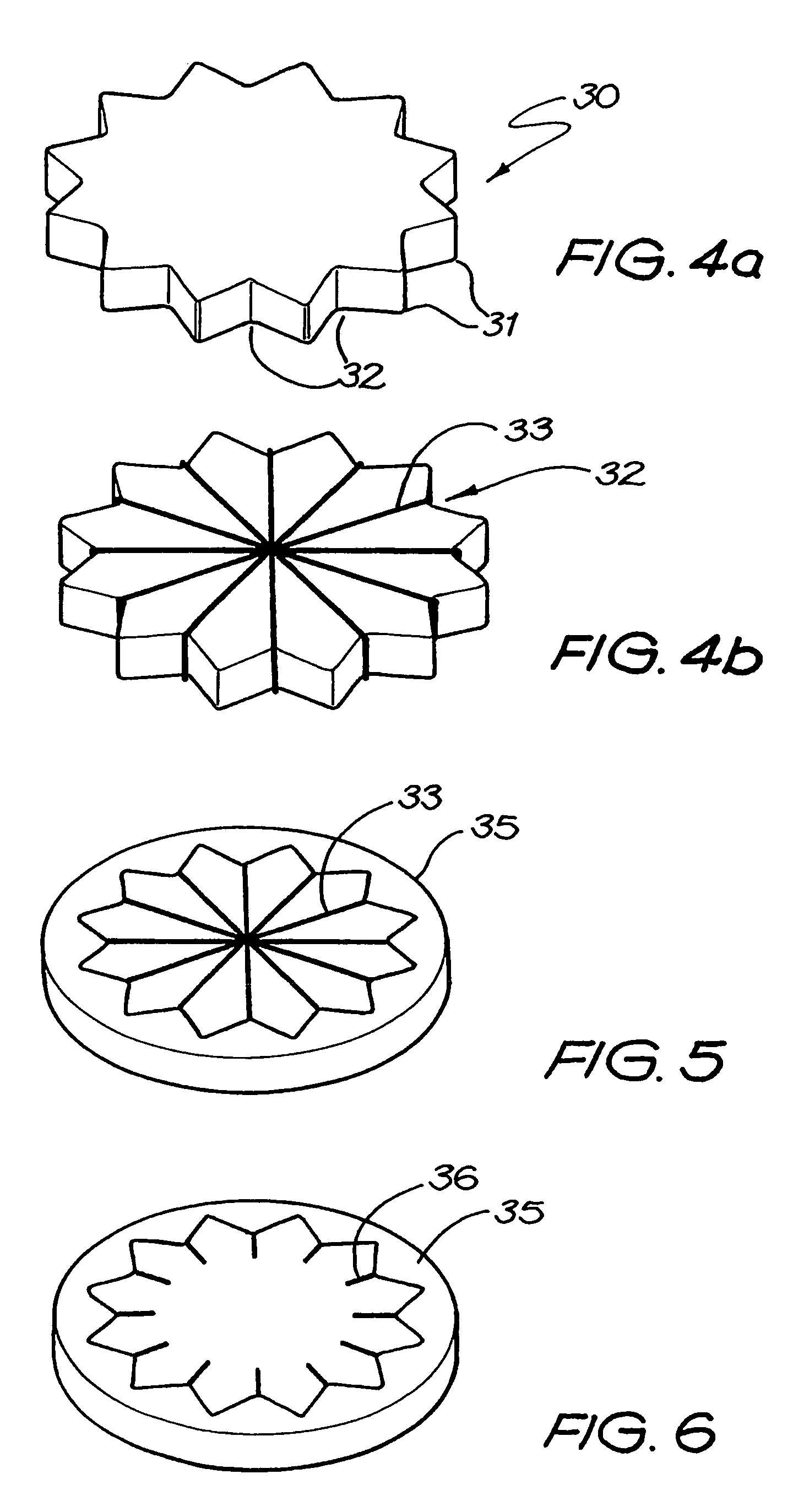

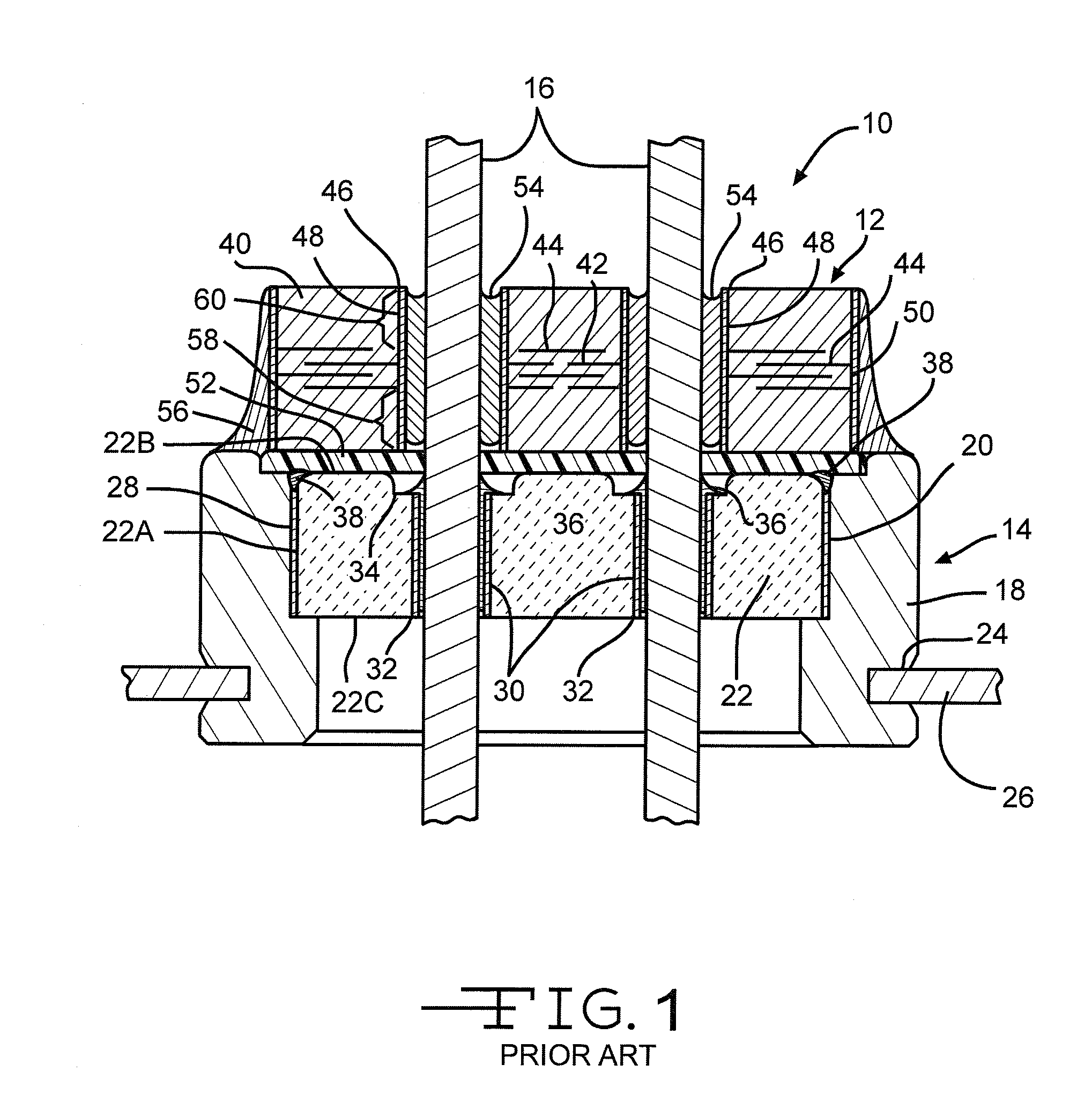

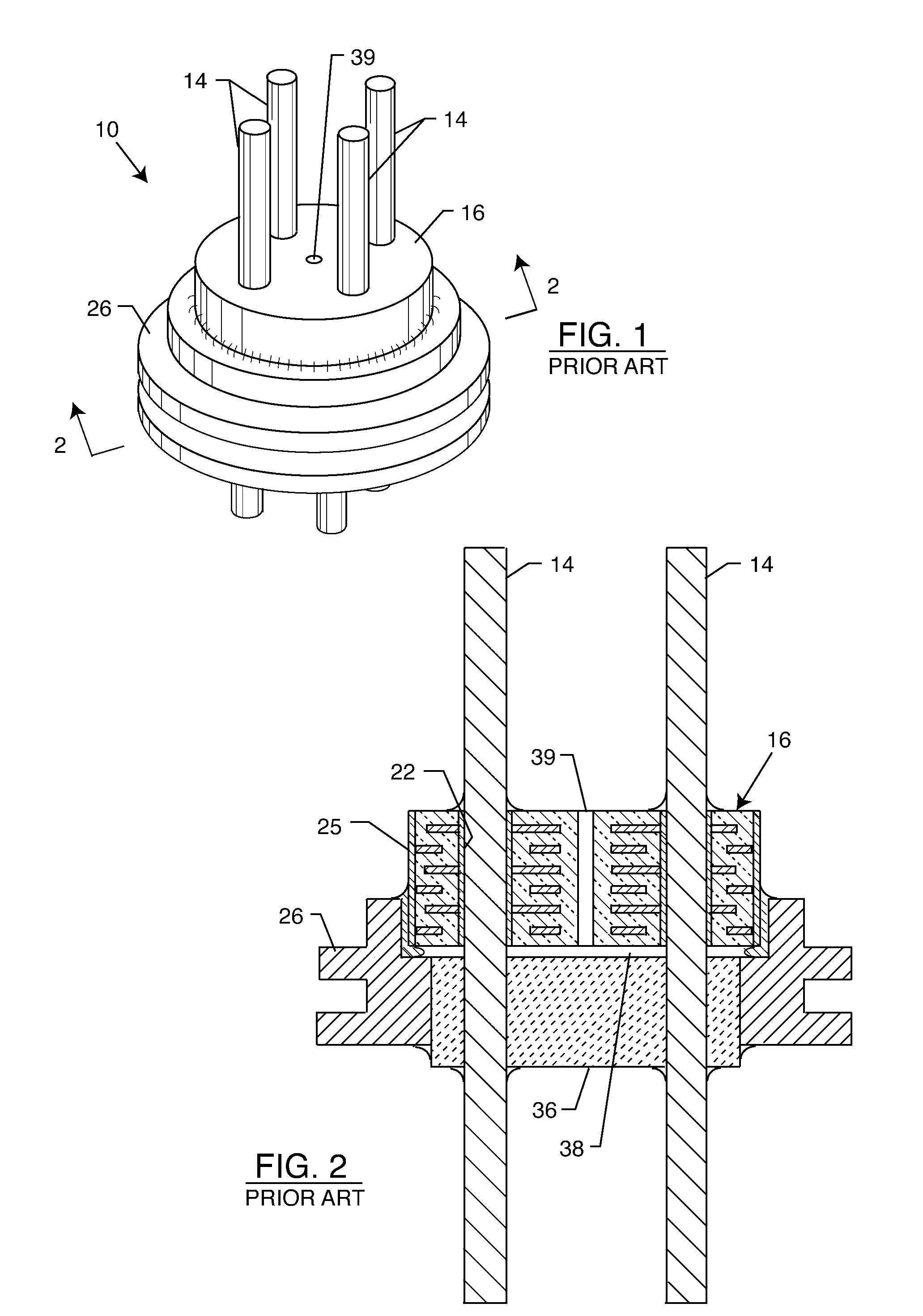

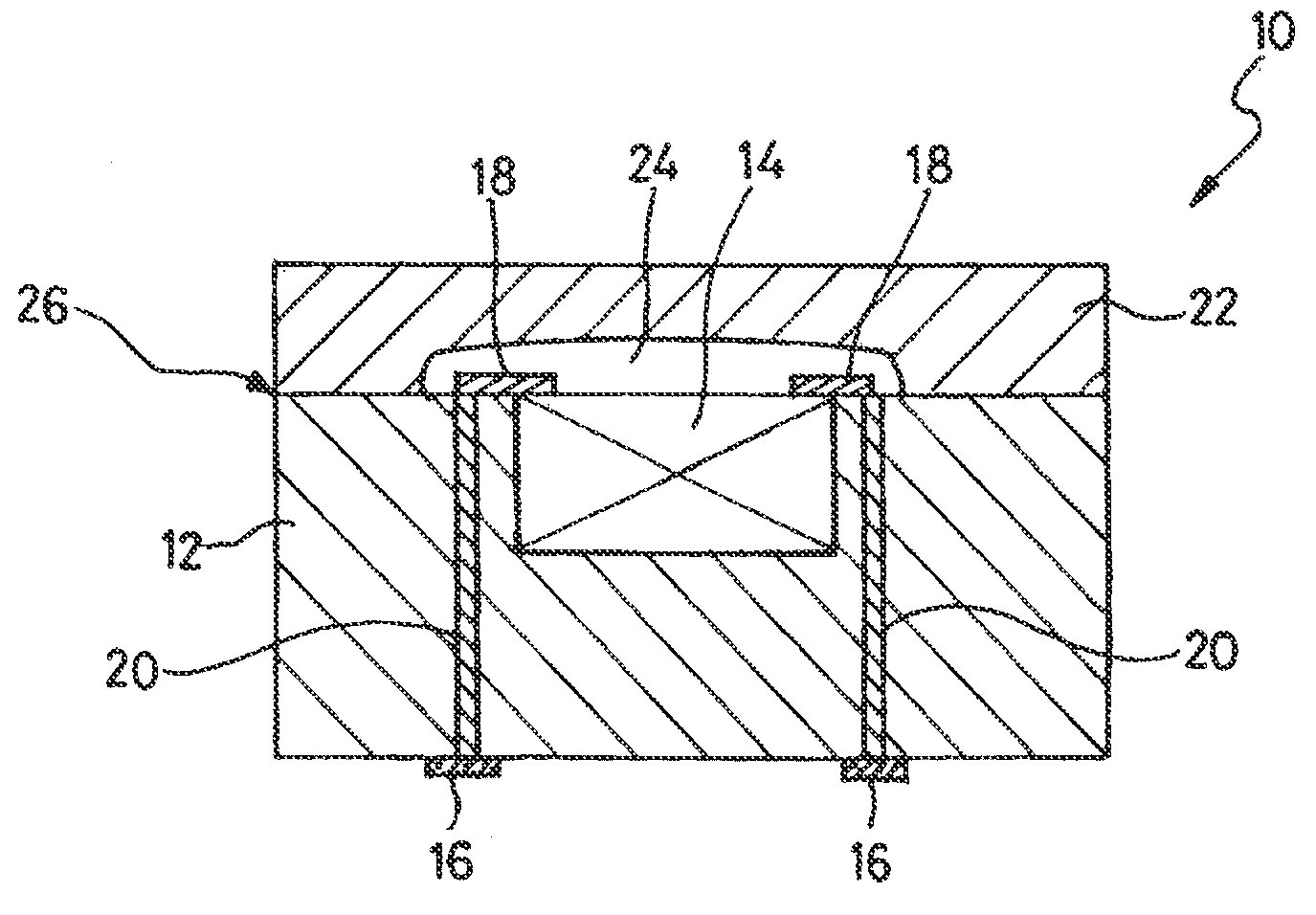

Feedthrough for electrical connectors

InactiveUS7396265B2Overall design flexibilityClosely spacedContact member manufacturingElectrically conductive connectionsElectrical connectionEngineering

A method (10) of forming an electrically conducting feedthrough. The method (10) comprises a first step (11) of forming an electrically conductive structure (21) comprising a sacrificial component and a non-sacrificial component. At least a portion of the non-sacrificial component can then be coated with a relatively electrically insulating material (35) prior to removal of at least a portion of the sacrificial component from the electrically conductive structure. The structure of the feedthrough provides electrical connection through the wall of a housing of an implantable component while preventing unwanted transfer of materials between the interior of the component and the surrounding environment.

Owner:COCHLEAR LIMITED

Hermetic feedthrough terminal assembly with wire bond pads for human implant applications

ActiveUS20060259093A1Consume energyReduce tensionMultiple-port networksAnti-noise capacitorsUltrasonic bondingMedical device

A feedthrough terminal assembly for active implantable medical devices includes a structural wire bond pad for a convenient attachment of wires from either the circuitry inside the implantable medical device or wires external to the device. Direct attachment of wire bond pads to terminal pins enables thermal or ultrasonic bonding of lead wires, while shielding the capacitor or other delicate components from the forces applied to the assembly during attachment of the wires.

Owner:WILSON GREATBATCH LTD

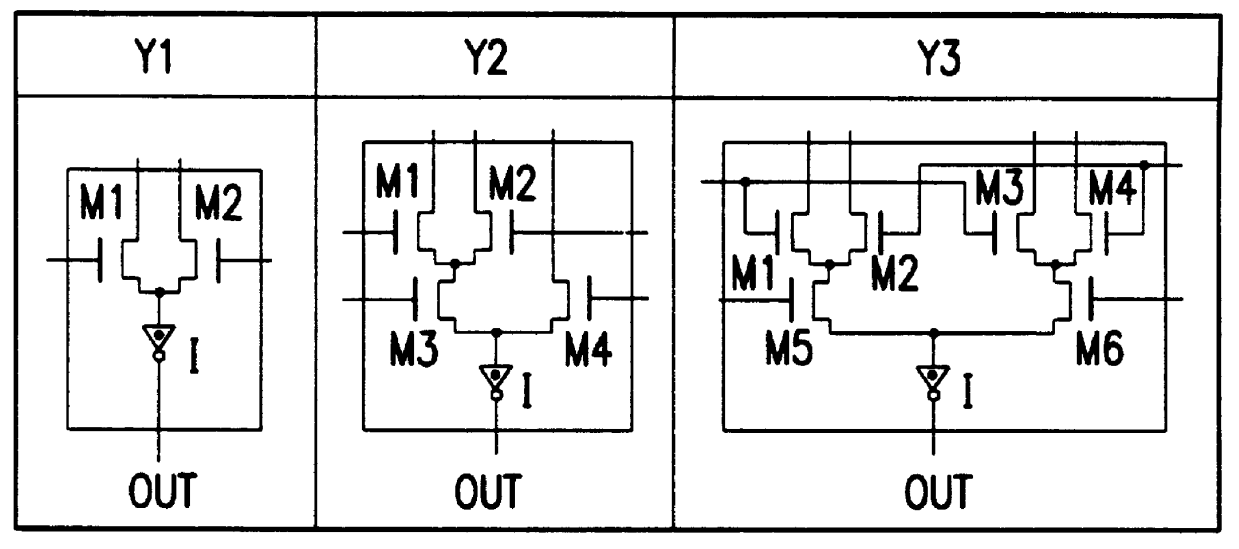

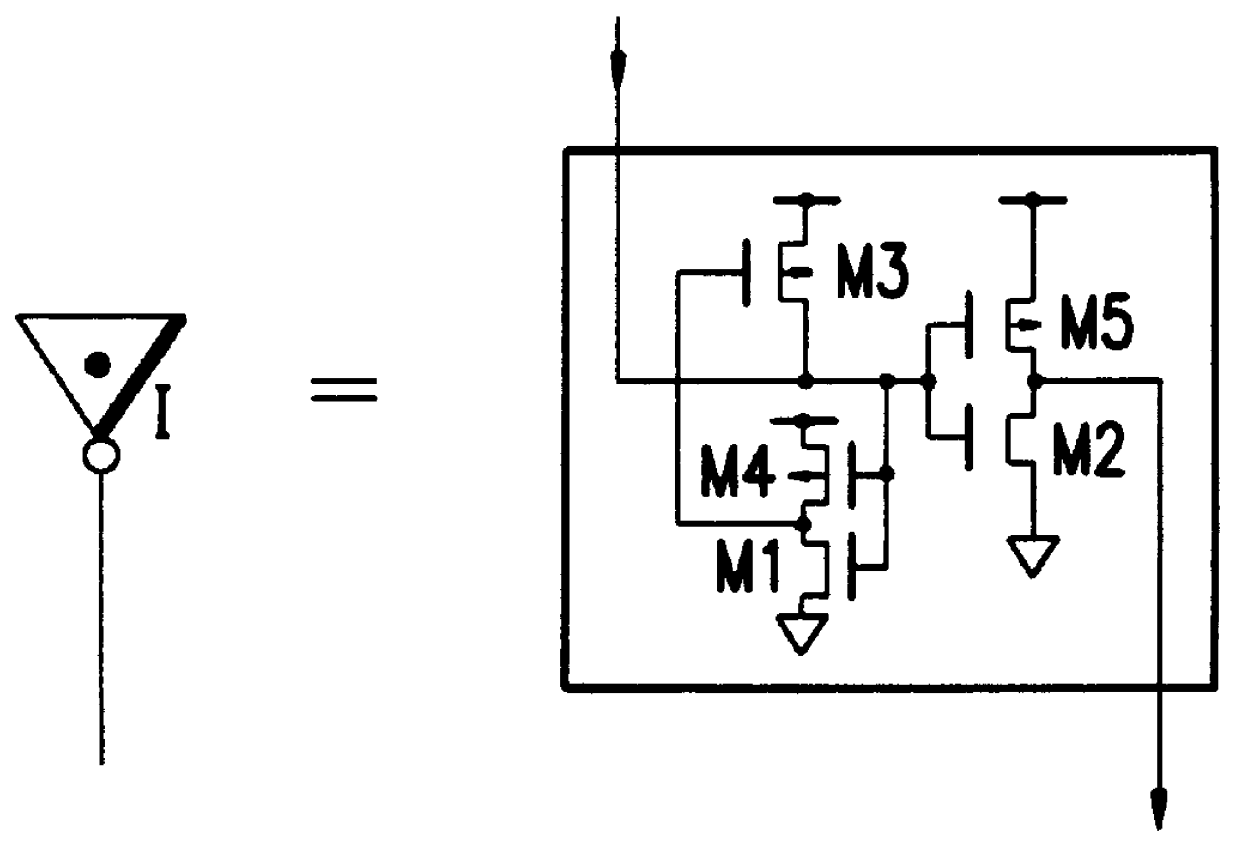

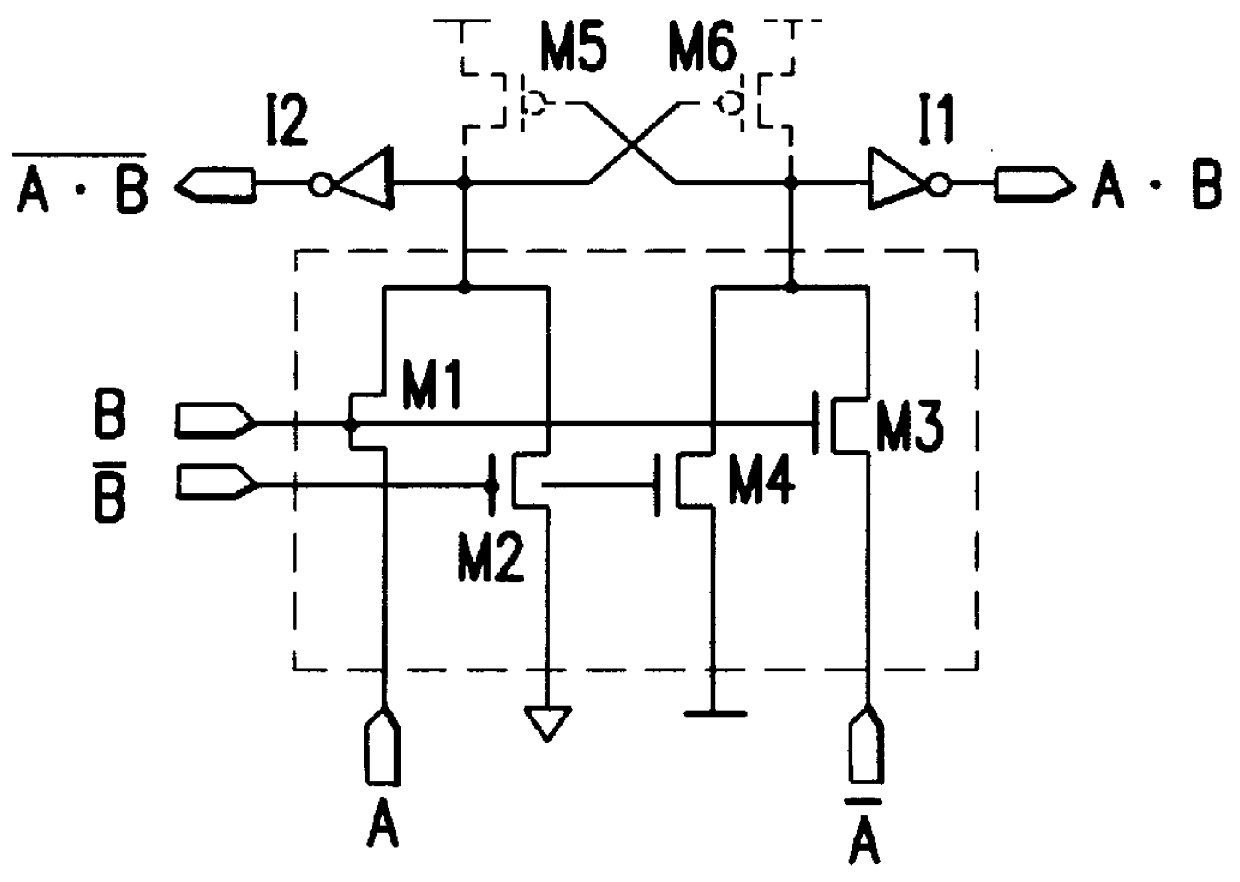

Logic circuit utilizing pass transistors and logic gate

InactiveUS6084437ATransistorReliability increasing modificationsCmos logic circuitsLogical operations

A logic circuit combines a plurality of pass-transistor logic trees and a multiple-input logic gate for receiving intermediate logic signals from the respective pass-transistor logic trees, and can express a complex logical operation while decreasing the number of stages in pass-transistor logic trees and improving operation speed. Even a logical operation that cannot be expressed efficiently by a known or conventional pass-transistor logic circuit can be expressed efficiently with performance higher than that of a known CMOS logic circuit. Furthermore, when a static feedthrough current of the multiple-input logic gate is suppressed, power consumption can be reduced. In some embodiments, since circuitry for suppressing a static feedthrough current of the multiple-input logic gate is arranged so that a probability of occurrence of logical collision with a preceding stage will decrease or will be nil, power consumption can further be reduced.

Owner:KAWASAKI MICROELECTRONICS

Implantable connector with protected contacts

InactiveUS7736191B1Avoid deformationAvoid accidental damageElectrotherapyCoupling device detailsElectrical conductorMedical device

An implantable connector electrically connects multi-conductor leads to an implantable medical device such as a neurostimulator. The connector is assembled directly into a hermetic feedthrough of the implantable device and utilizes the feedthrough housing as a sustaining structure for connector clamping. The receptacle contacts detachably connect proximal lead contacts to corresponding feedthrough pins, which provide pass-through connections to electronic circuitry contained in a hermetically sealed case. The receptacle contact has resilient contact tines designed to engage a corresponding lead contact in a sliding manner. The receptacle contact is integrated with a contact guard which protects the receptacle contact from inadvertent handling damage. The contact guard is substantially more rigid than the resilient contact to resist deformation. The contact guard protectively shields the receptacle contact tines and prevents unintended contact tine excursion. In one embodiment, the contact guard is pre-attached to the receptacle contact prior to joining to the feedthrough pin. In another embodiment, the contact guard is an integral part of the feedthrough pin. Numerous embodiments with contact preload are provided.

Owner:SOCHOR JERZY ROMAN

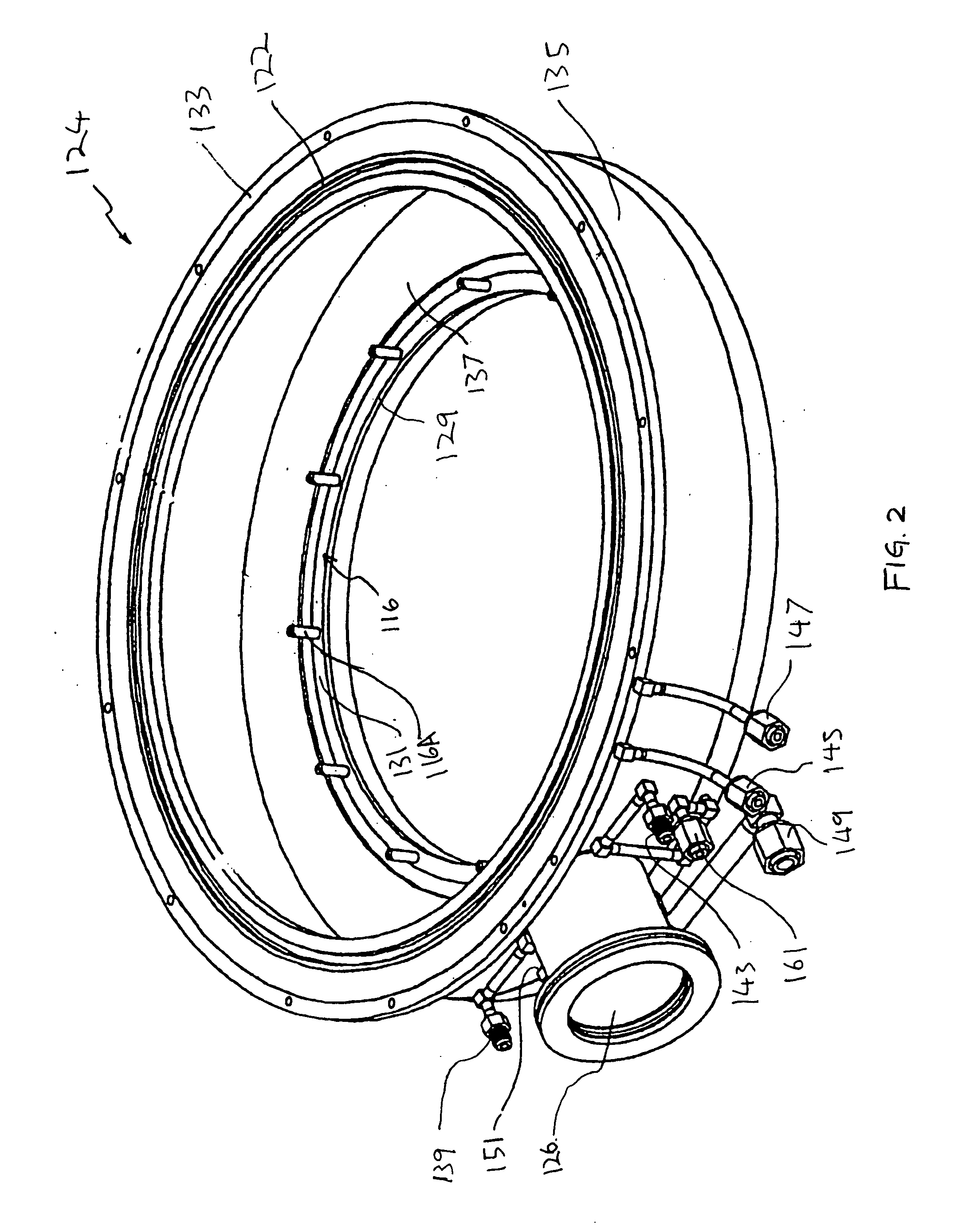

Temperature controlled window with a fluid supply system

The present invention provides a temperature controlled energy transparent window or electrode used to advantage in a substrate processing system. The invention also provides methods associated with controlling lid temperature during processing and for controlling etching processes. In a preferred embodiment the invention provides a fluid supply system for the lid which allows the fluid to flow through a feedthrough and into and out of a channel formed in the window or electrode. The fluid supply system may also mount the window or electrode to a retaining ring which secures the window or electrode to the chamber. In another aspect the invention provides a bonded window or electrode having a first and second plate having a channel formed in the plates so that when the plates are bonded together they form a channel therein through which a temperature controlling fluid can be flowed. An external control system preferably regulates the temperature of the fluid.

Owner:APPLIED MATERIALS INC

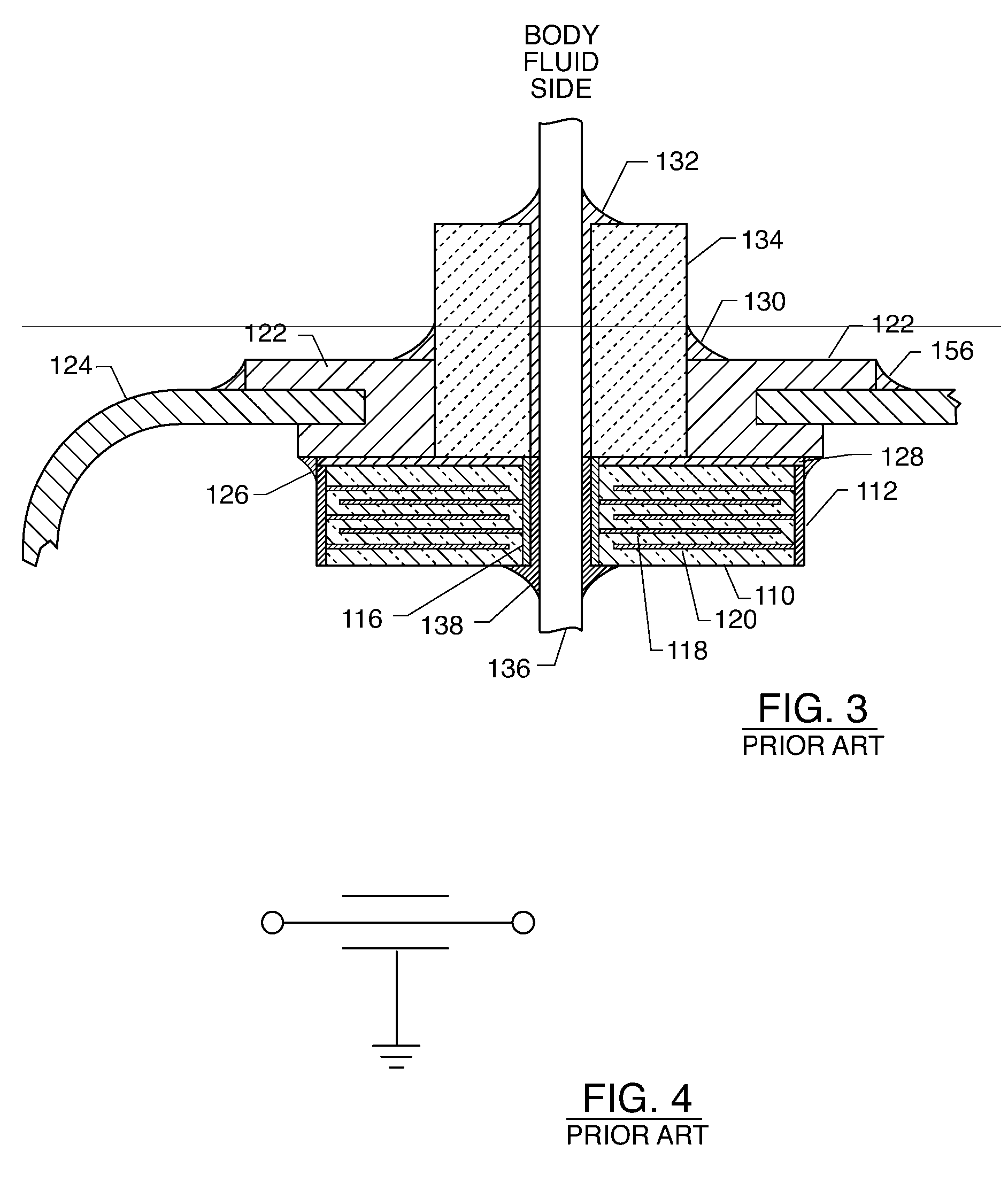

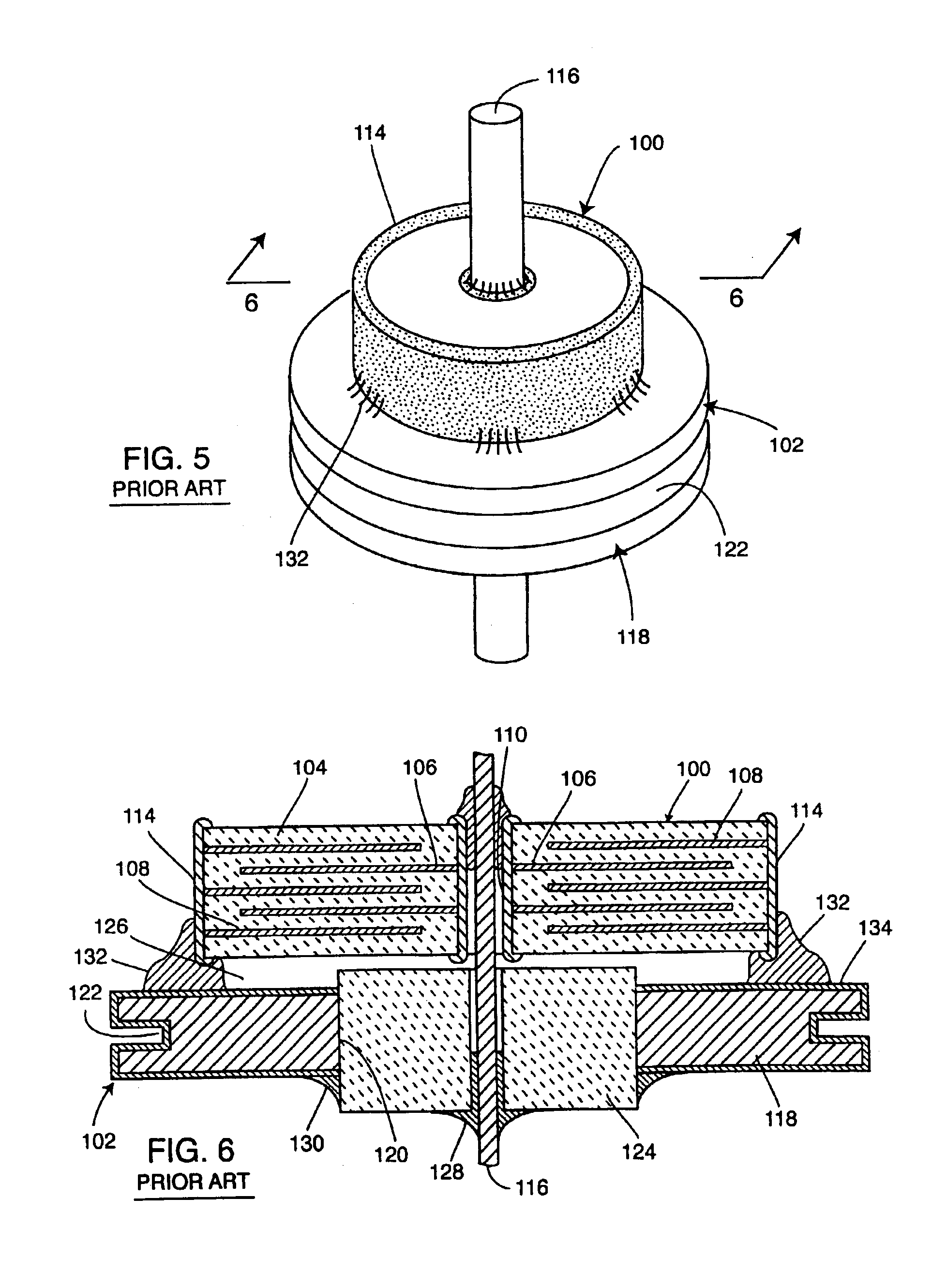

EMI feedthrough filter terminal assembly utilizing hermetic seal for electrical attachment between lead wires and capacitor

ActiveUS6888715B2Reliable electrical attachmentAnti-noise capacitorsElectrotherapyHermetic sealEngineering

EMI feedthrough filter terminal assembly includes a feedthrough filter capacitor having first and second sets of electrode plates, and a first passageway having a first termination surface conductively coupling the first set of electrode plates. At least one lead wire extends through the first passageway and is conductively attached to a first oxide resistant conductive pad. The first pad is conductively coupled to the first termination surface independently of the lead wire. The terminal assembly may also include a conductive ferrule through which the lead wire passes in non-conductive relation, and an insulator fixed to the ferrule for conductively isolating the lead wire from the ferrule. The ferrule and insulator form a pre-fabricated hermetic terminal pin sub-assembly. The capacitor may include a second passageway having a second termination surface conductively coupling the second set of electrode plates, and a conductive ground lead extending therethrough.

Owner:WILSON GREATBATCH LTD

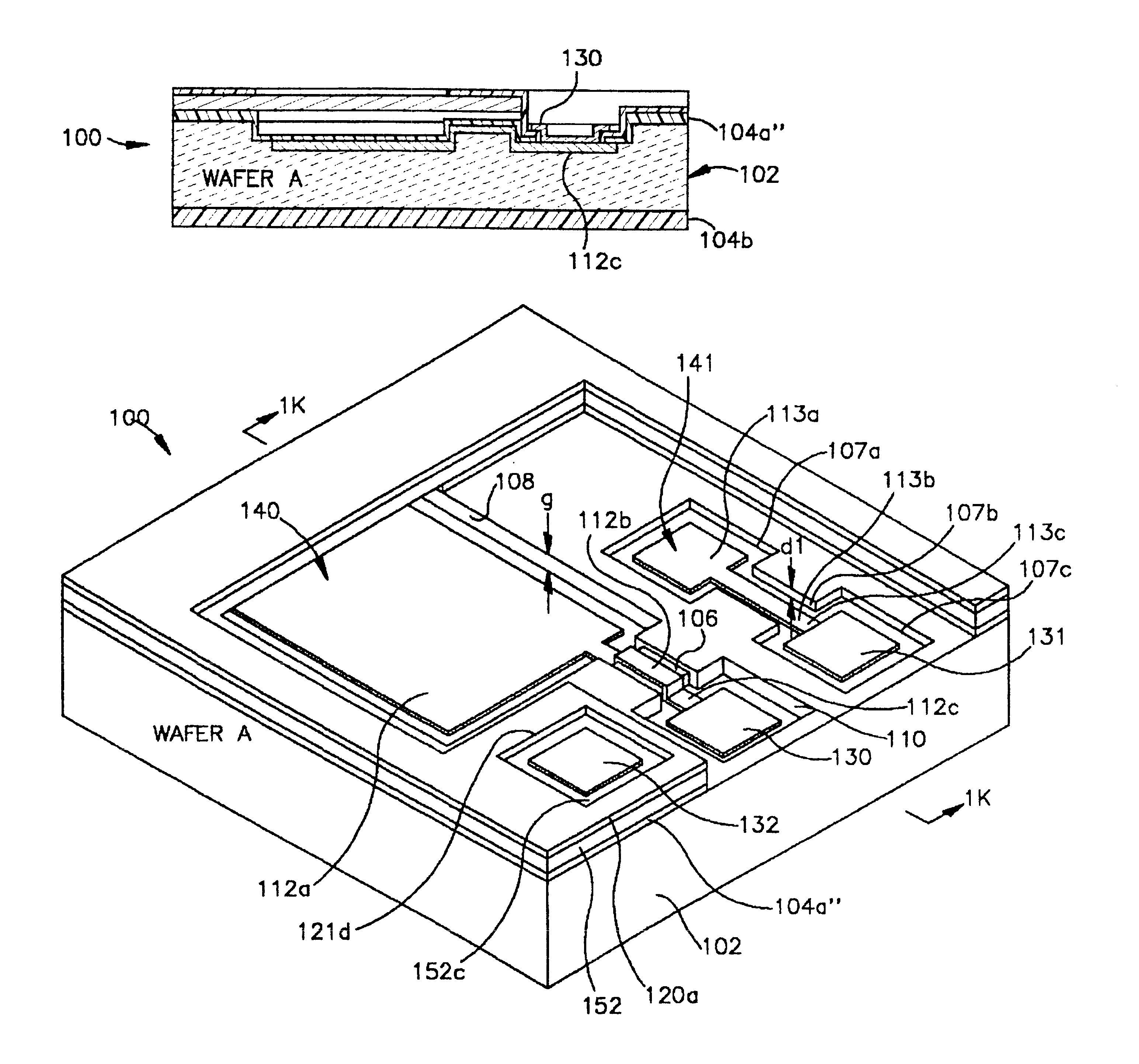

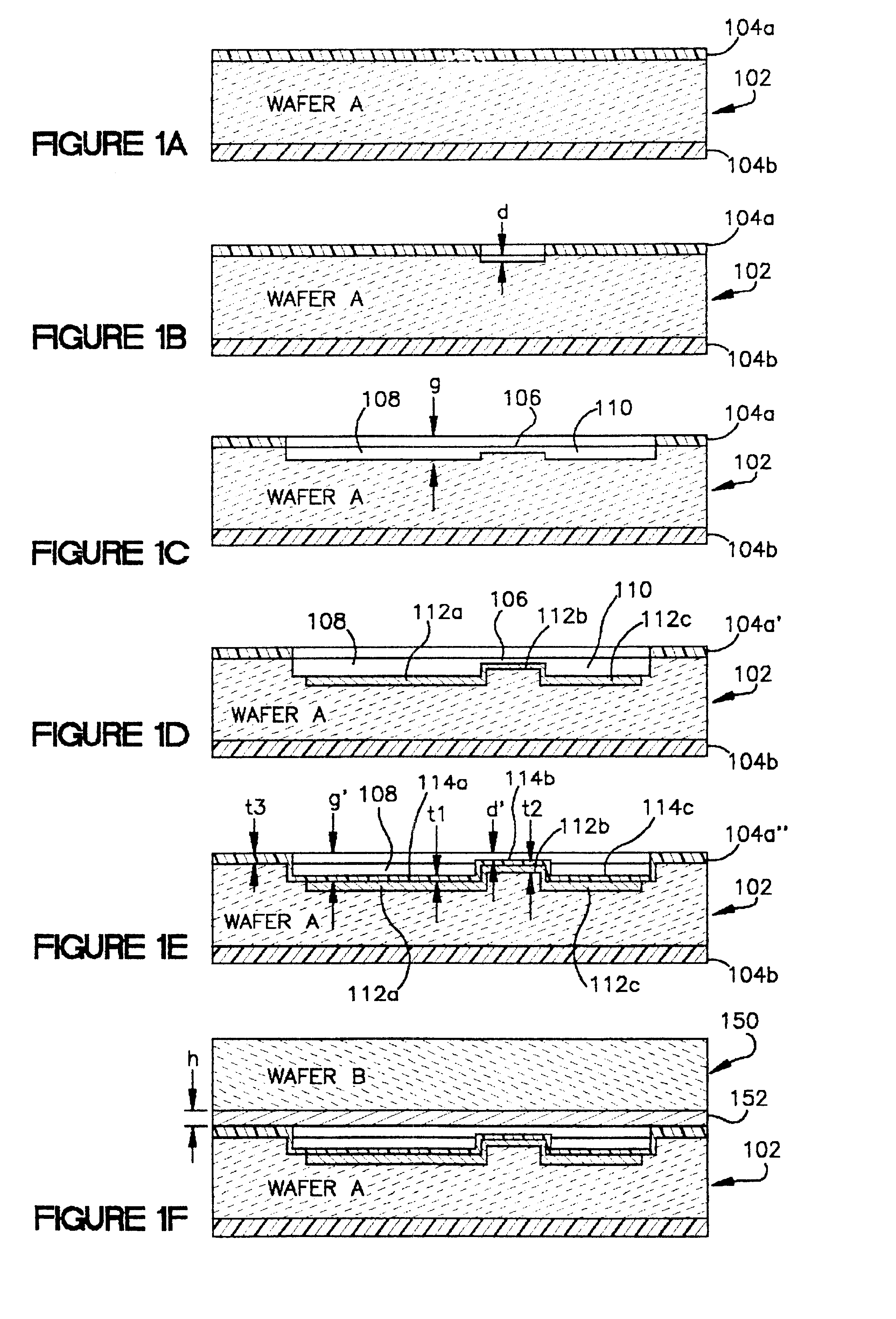

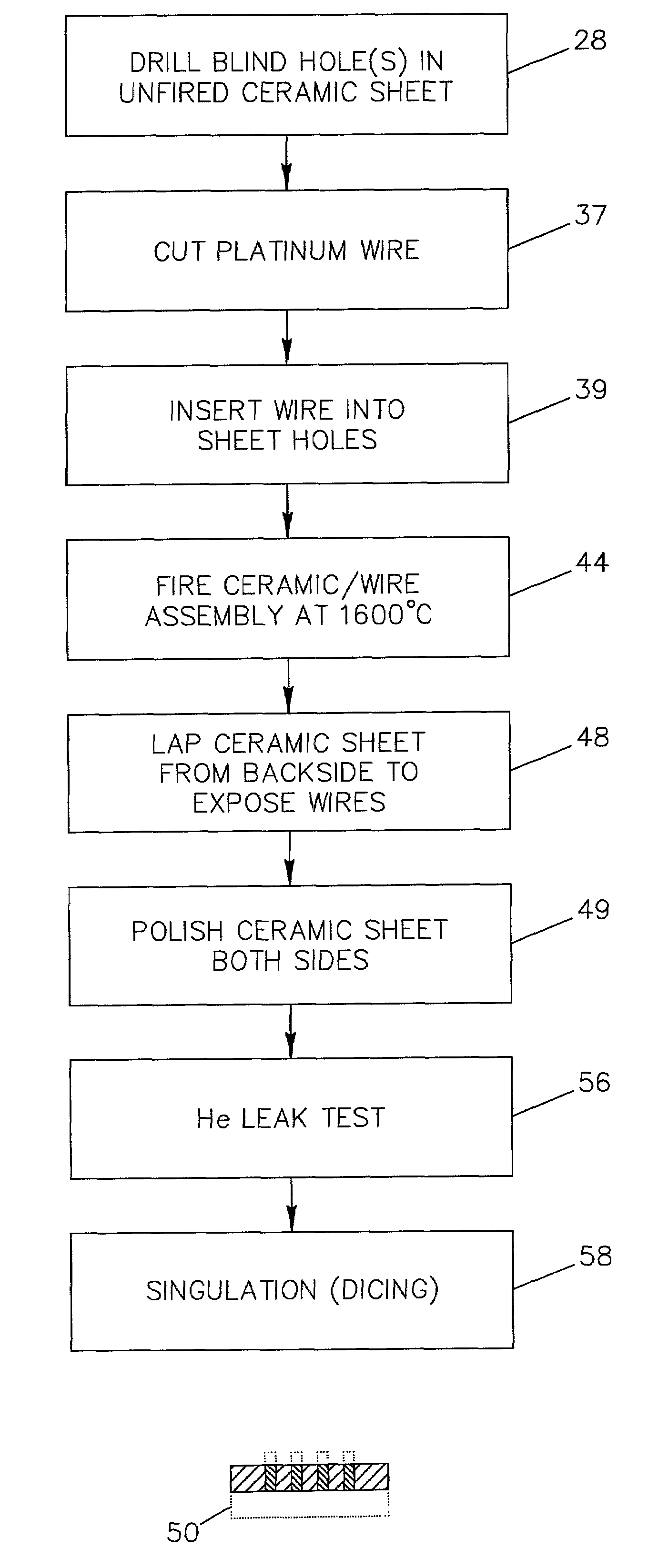

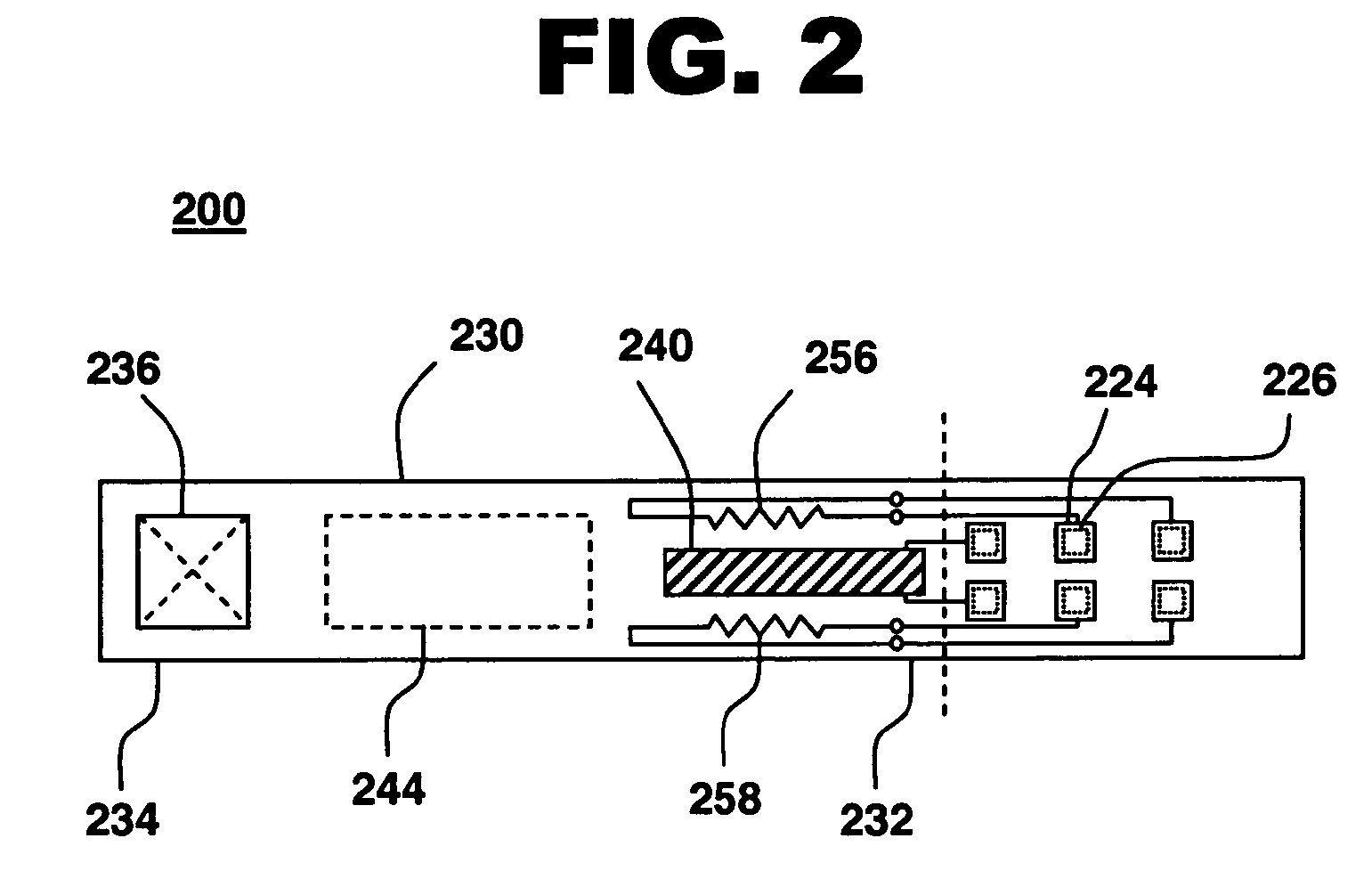

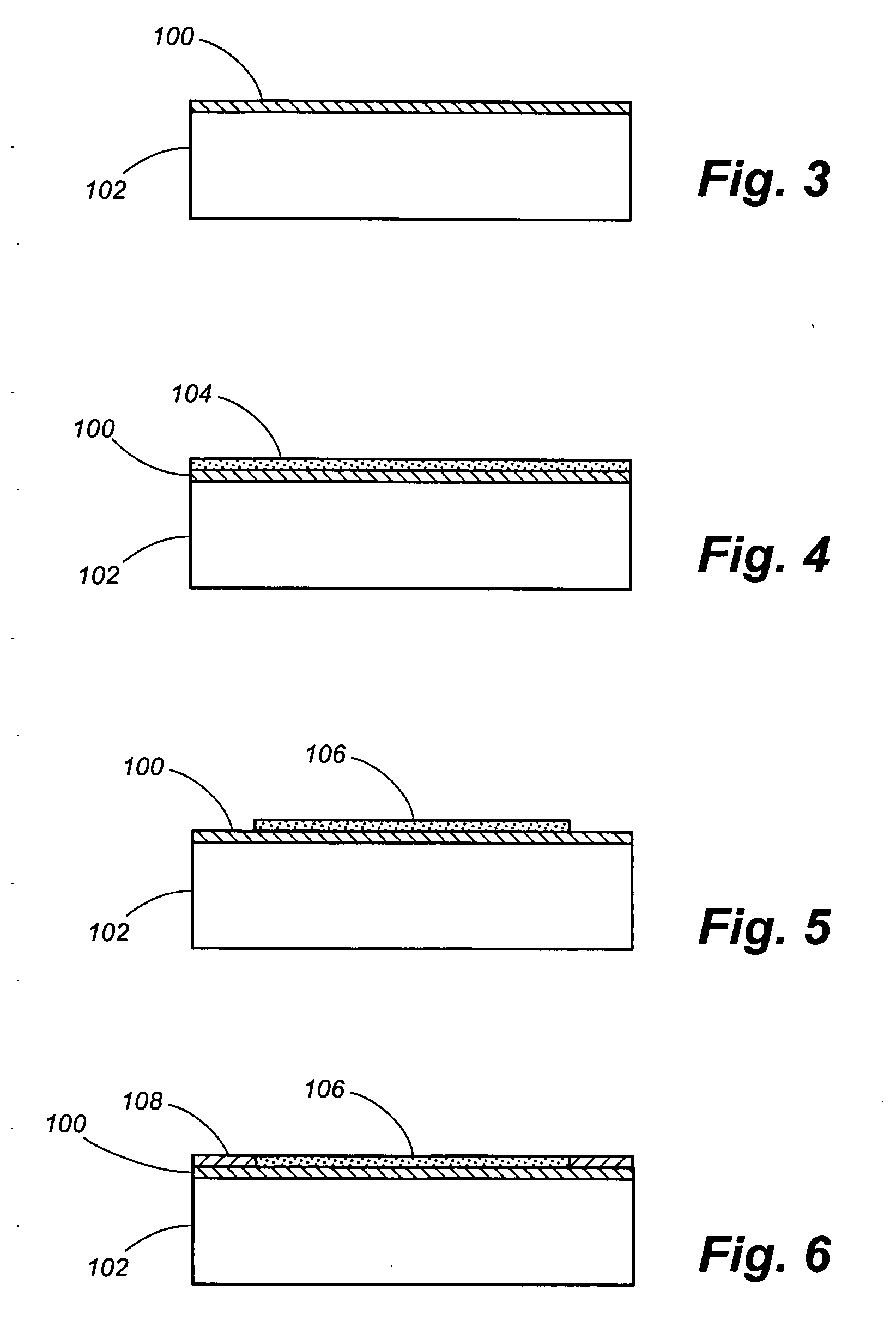

Method of fabricating silicon capacitive sensor

InactiveUS6465271B1Good linear sensitivityLong-term stabilityInflated body pressure measurementSemiconductor/solid-state device manufacturingCapacitive pressure sensorDiffusion

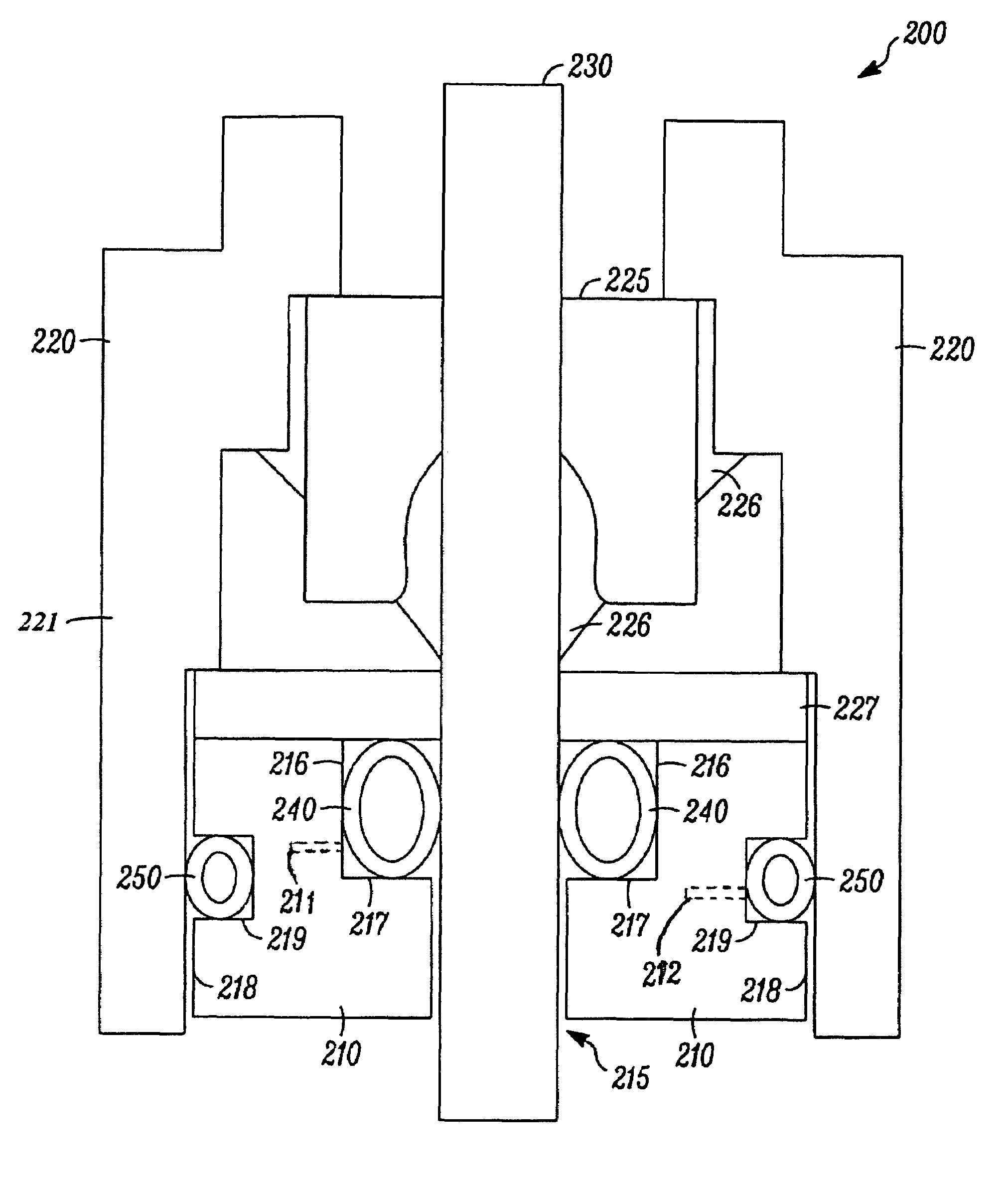

Manufacturing all-silicon force sensors, such as capacitive pressure sensors (100, 200) that have long term stability and good linear sensitivity, and can be built into of a pneumatic tire. The sensors include buried electrical feedthrough (112b) to provide an electrical connection into a sealed silicon cavity (108). The buried feedthrough consists of a conductor (112b) in a shallow groove (106) in a substrate (102), communicating between the sensing cavity (108) and an external contact area (110). The sensor designs also feature a method for forming a silicon-to-silicon fusion bond (SFB) wherein at least one of the two surfaces (152, 252) to be has a tough silicon surface unsuitable for good SFB joints because it was bonded heavily boron-doped by means of diffusion. The method of this invention includes preparing each doped surface (152, 252) for SFB by polishing the surface with a Chemical-Mechanical Polishing (CMP) process. The sensor designs can also include optional reference capacitors (141, 241) on the same chip (100, 200) as the sensing capacitor (140, 240). The reference capacitors (141, 241) are insensitive to pressure (force), but respond to ambient temperature changes in the same way as the sensing capacitor. Suitable external interface circuits can utilize the reference capacitors (141, 241) to pull out the majority of ambient temperature effects.

Owner:CASE WESTERN RESERVE UNIV

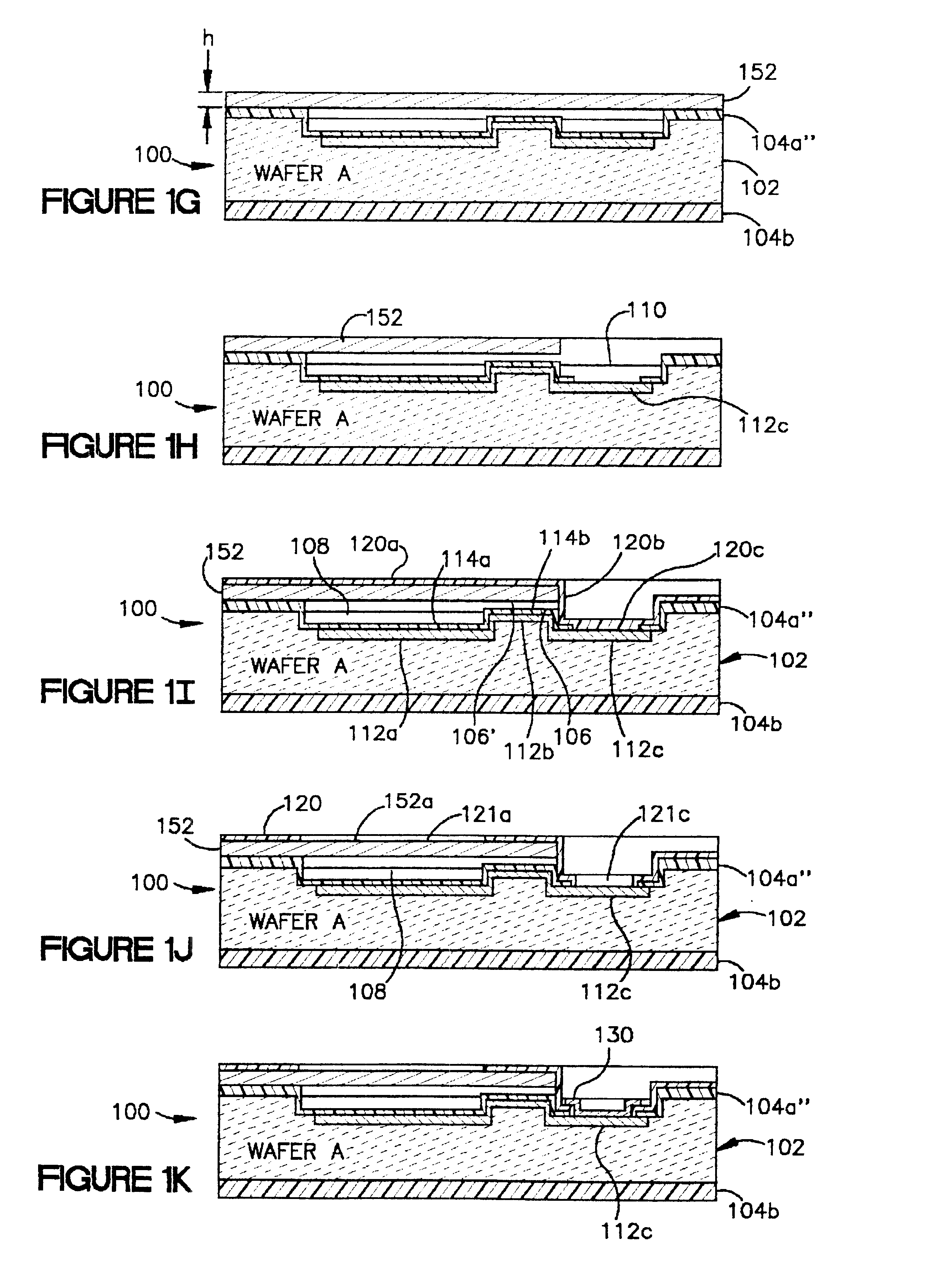

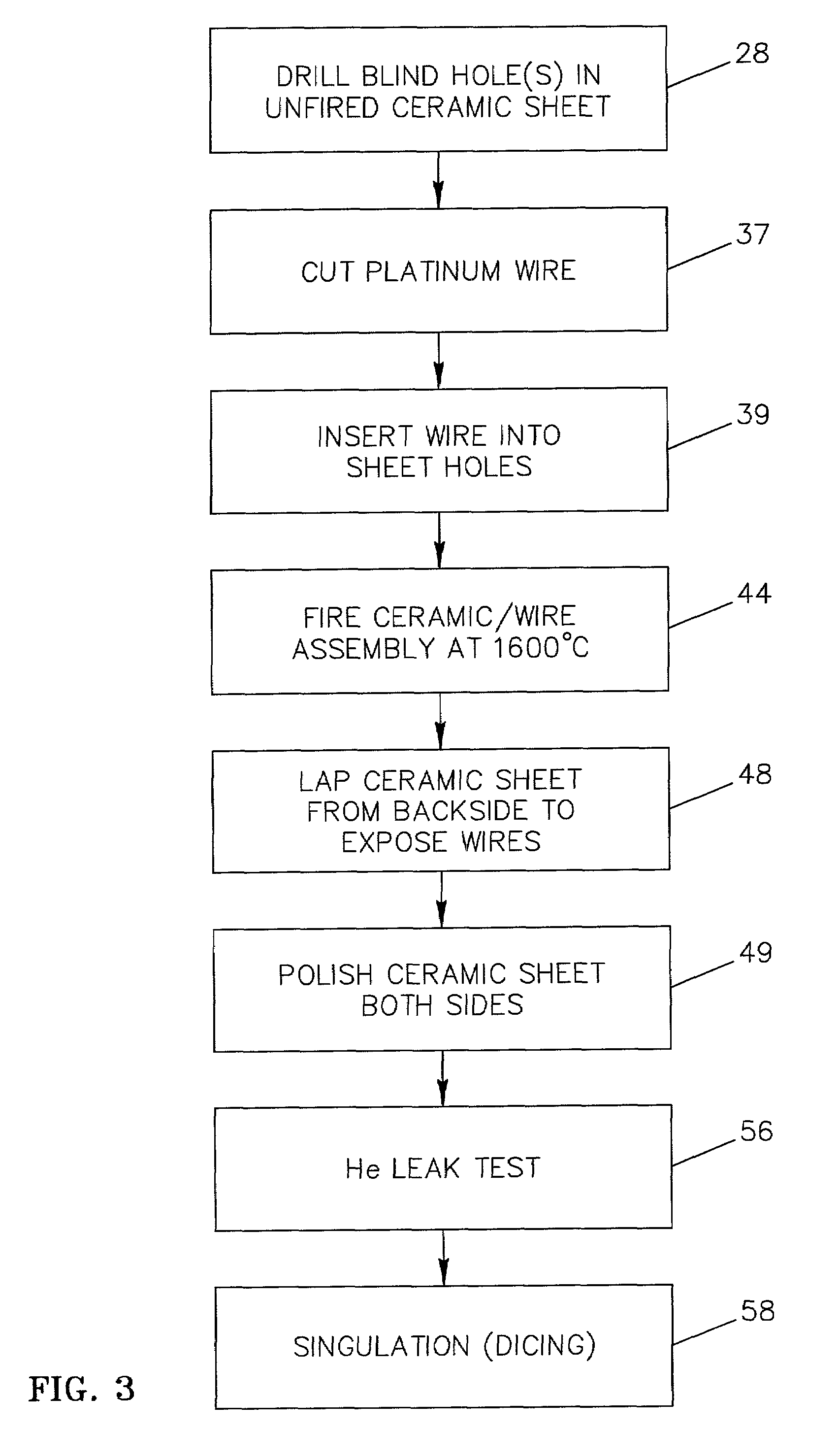

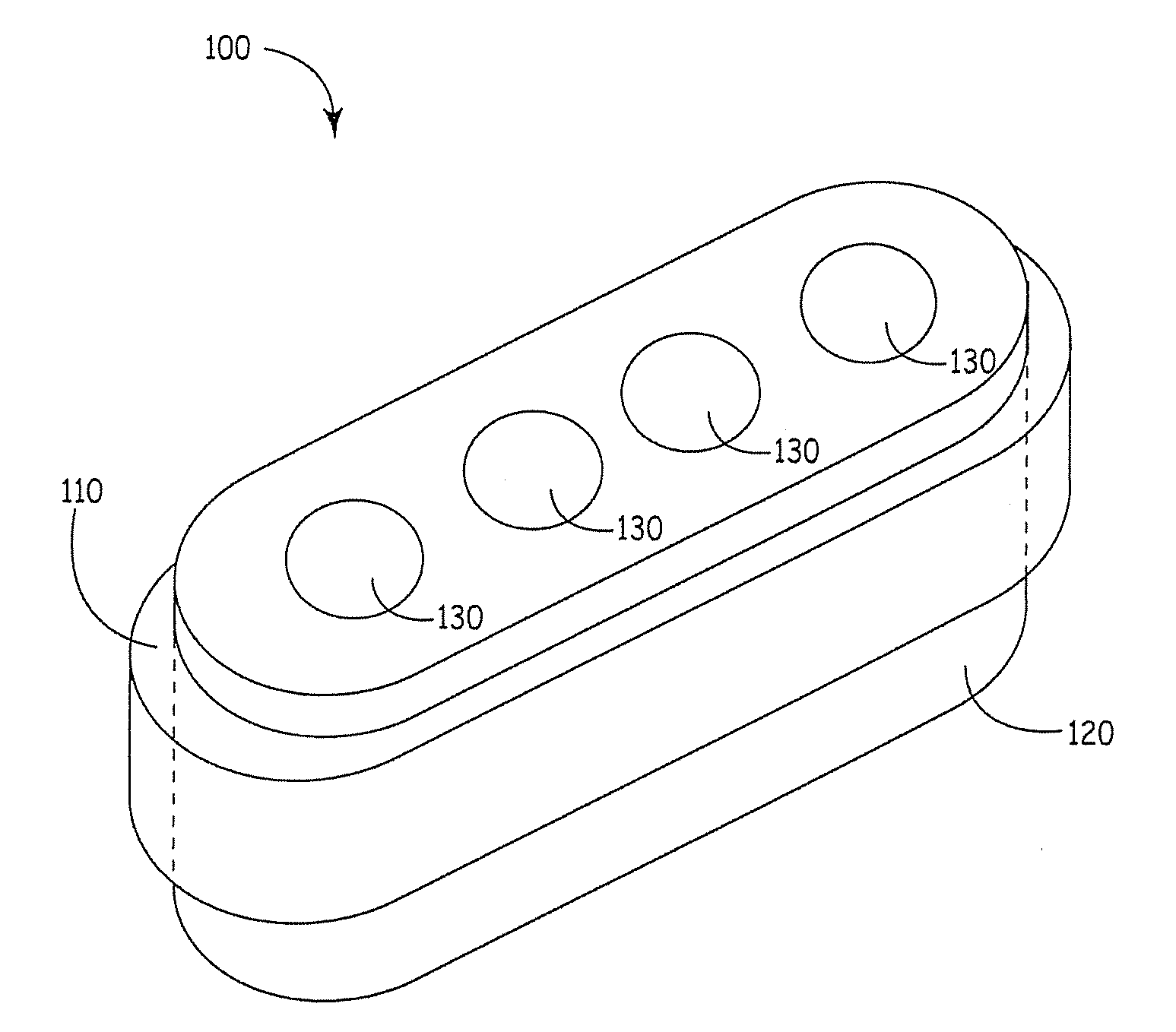

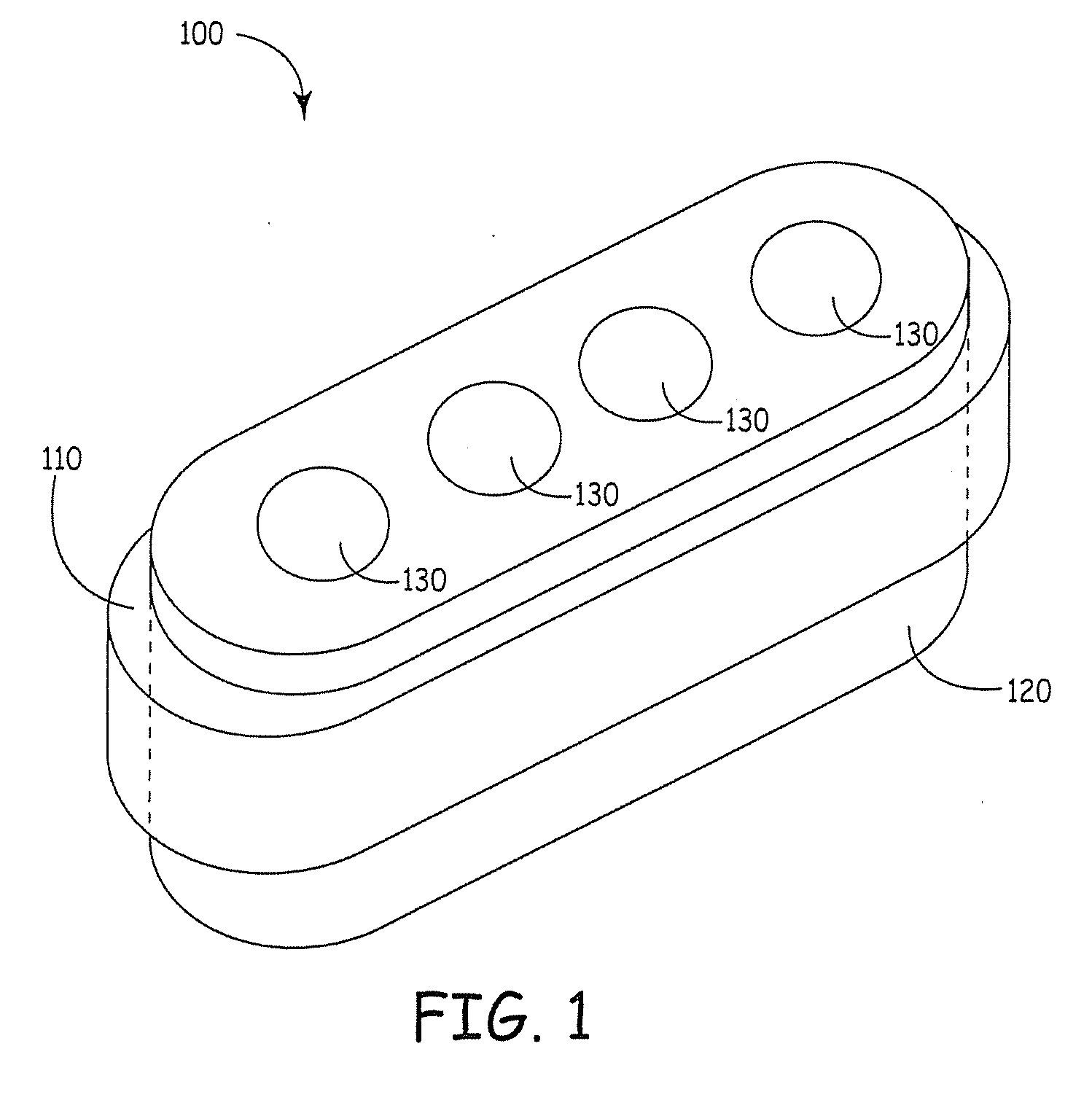

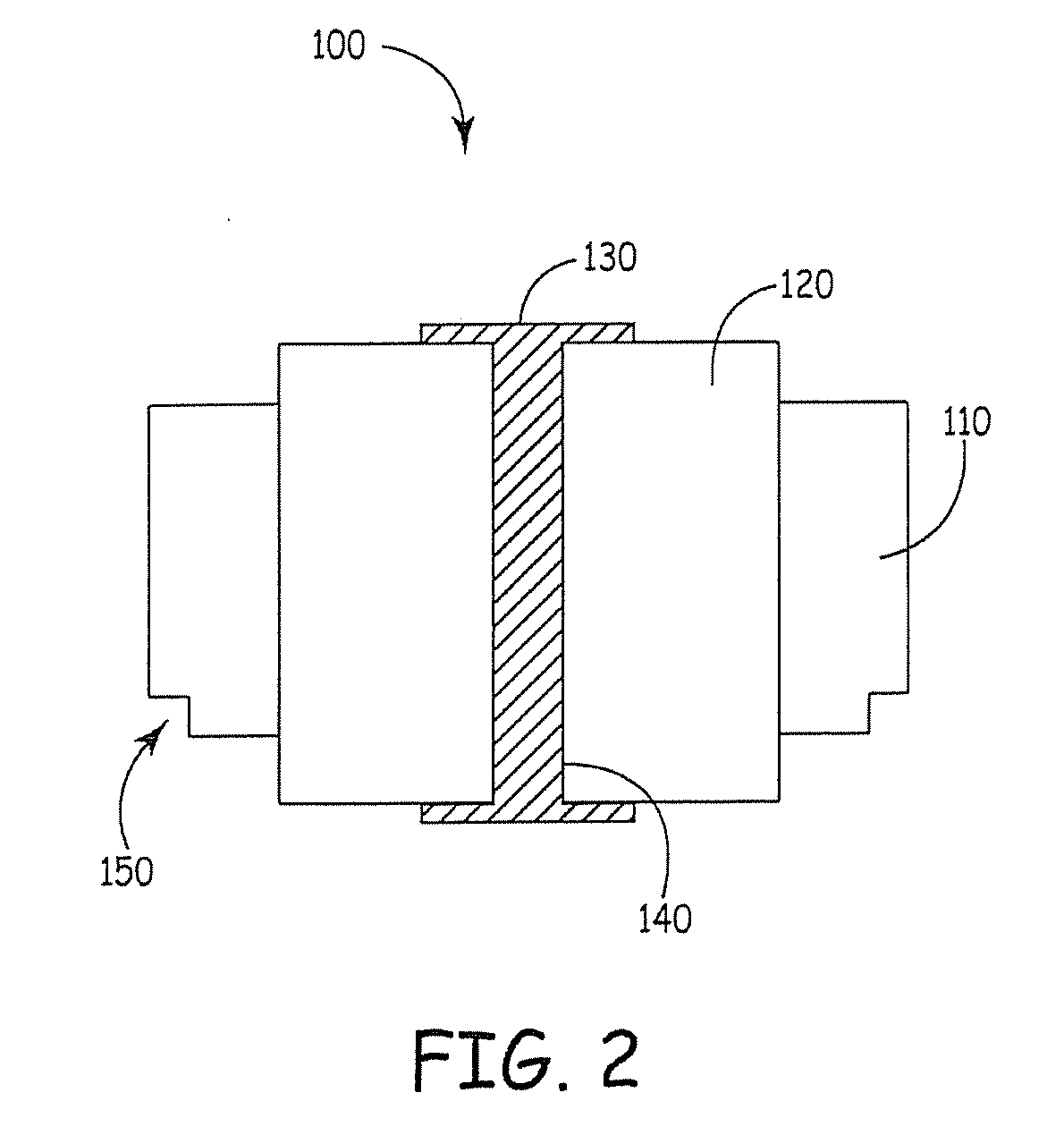

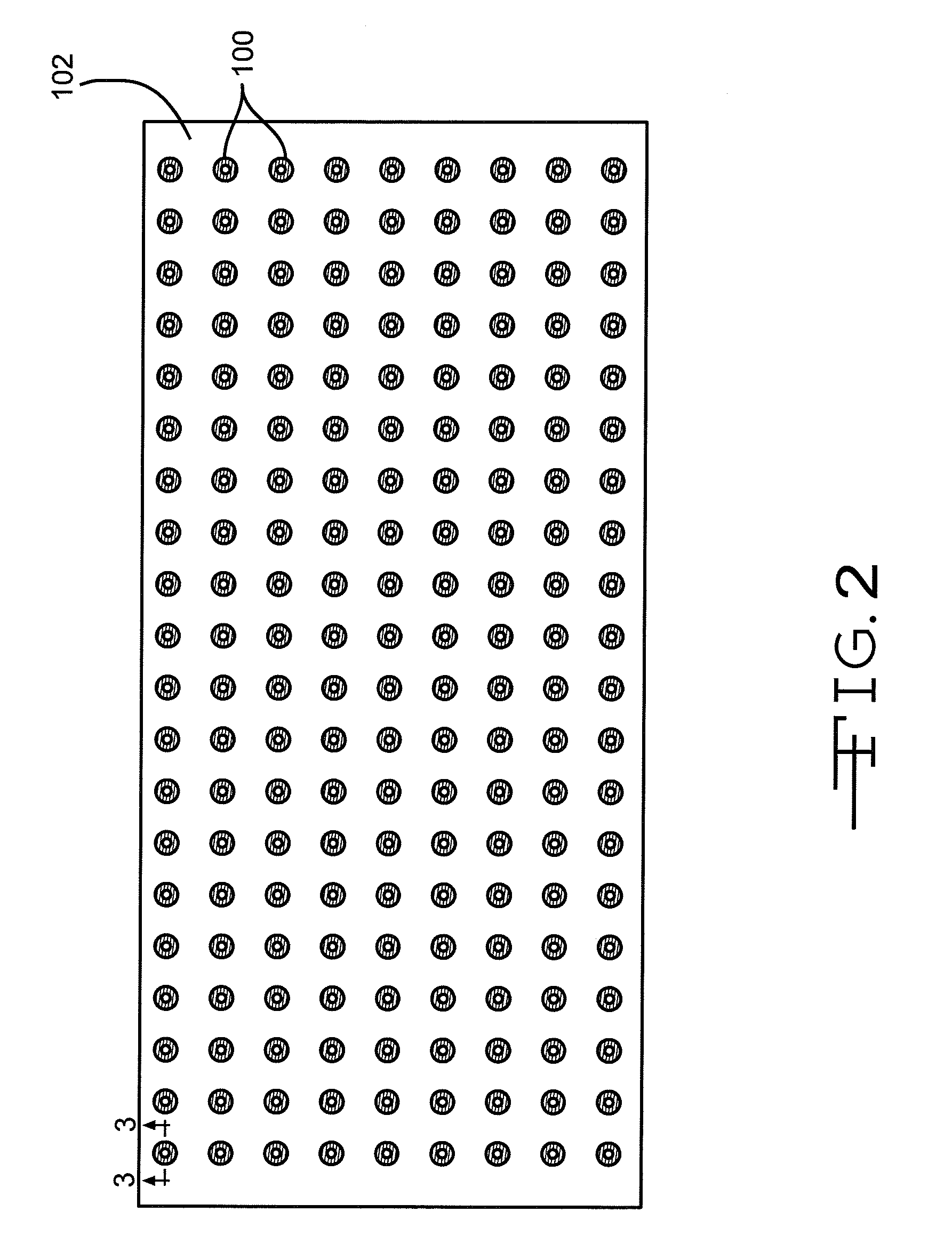

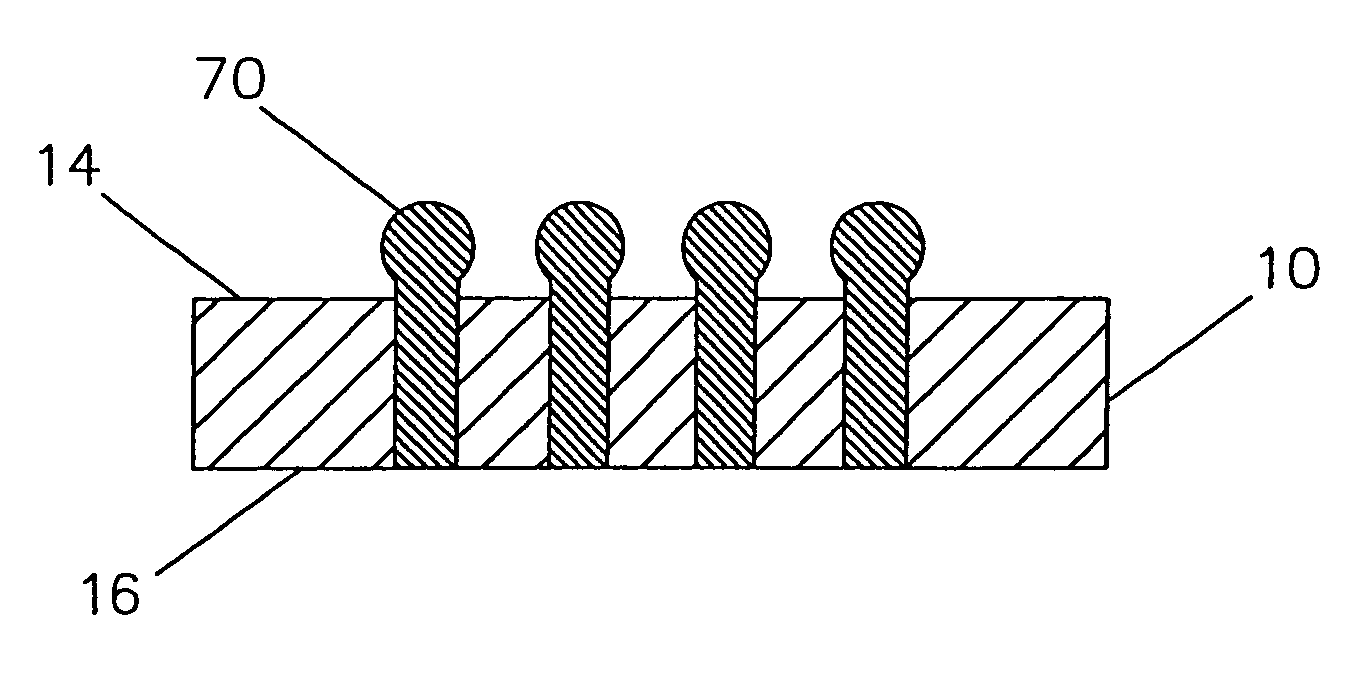

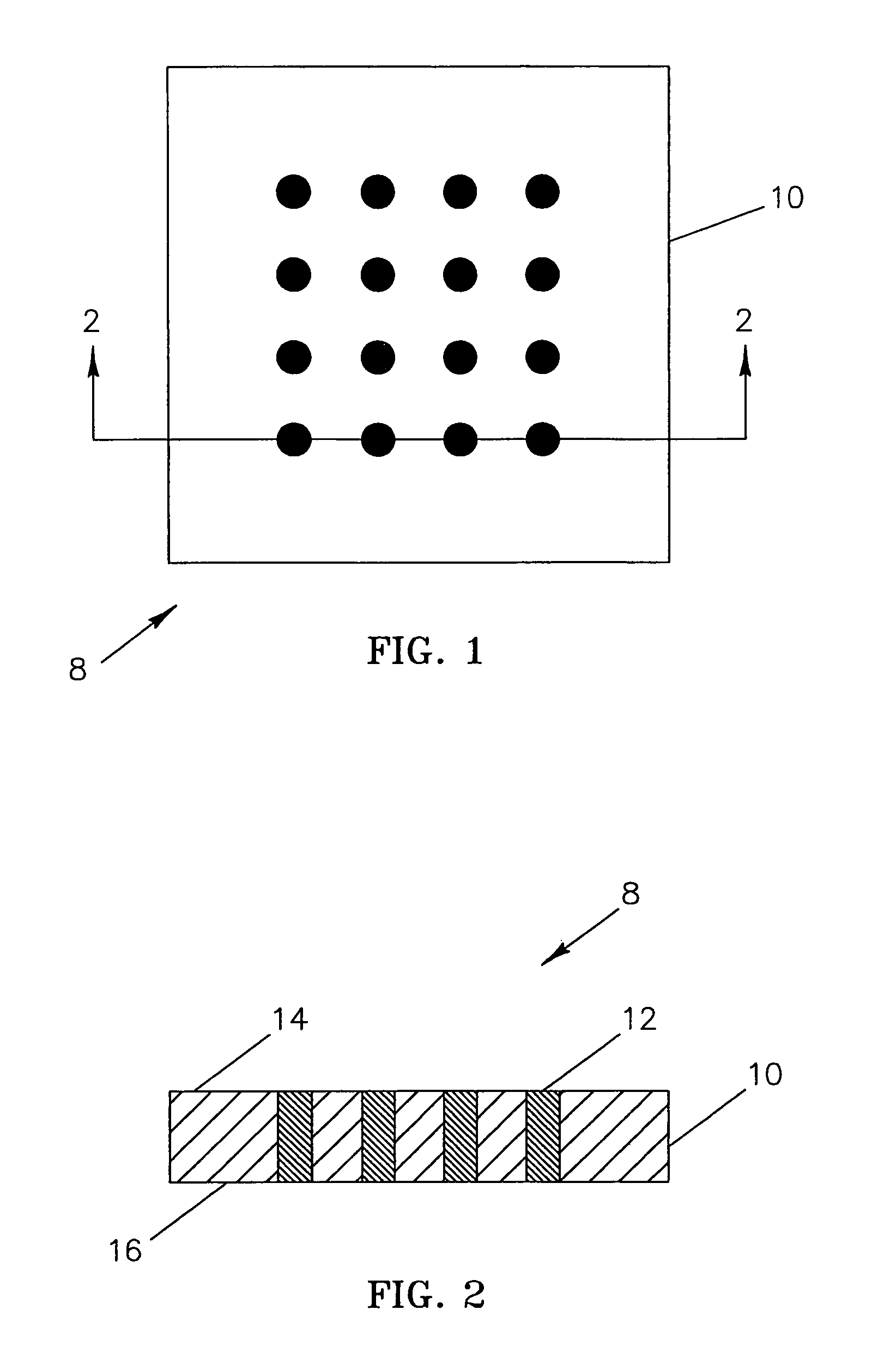

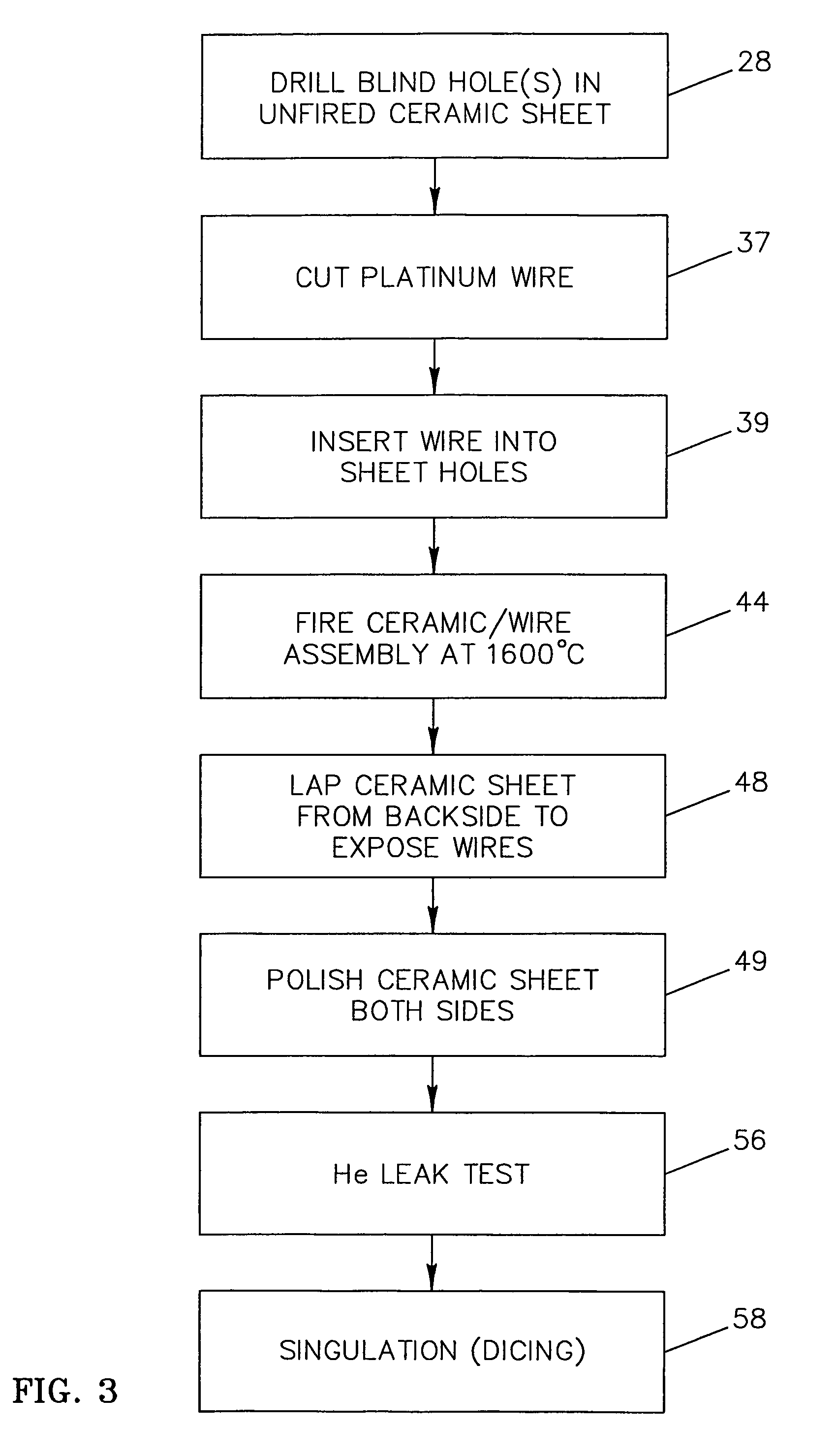

Method and apparatus for providing hermetic electrical feedthrough

A method and apparatus suitable for forming hermetic electrical feedthroughs in a ceramic sheet having a thickness of ≦40 mils. More particularly, the method yields an apparatus including a hermetic electrical feedthrough which is both biocompatible and electrochemically stable and suitable for implantation in a patient's body. The method involves:(a) providing an unfired, ceramic sheet having a thickness of ≦40 mils and preferably comprising >99% aluminum oxide;(b) forming multiple blind holes in said sheet;(c) inserting solid wires, preferably of platinum, in said holes;(d) firing the assembly of sheet and wires to a temperature sufficient to sinter the sheet material but insufficient to melt the wires; and(e) removing sufficient material from the sheet lower surface so that the lower ends of said wires are flush with the finished sheet lower surface.

Owner:SECOND SIGHT MEDICAL PRODS

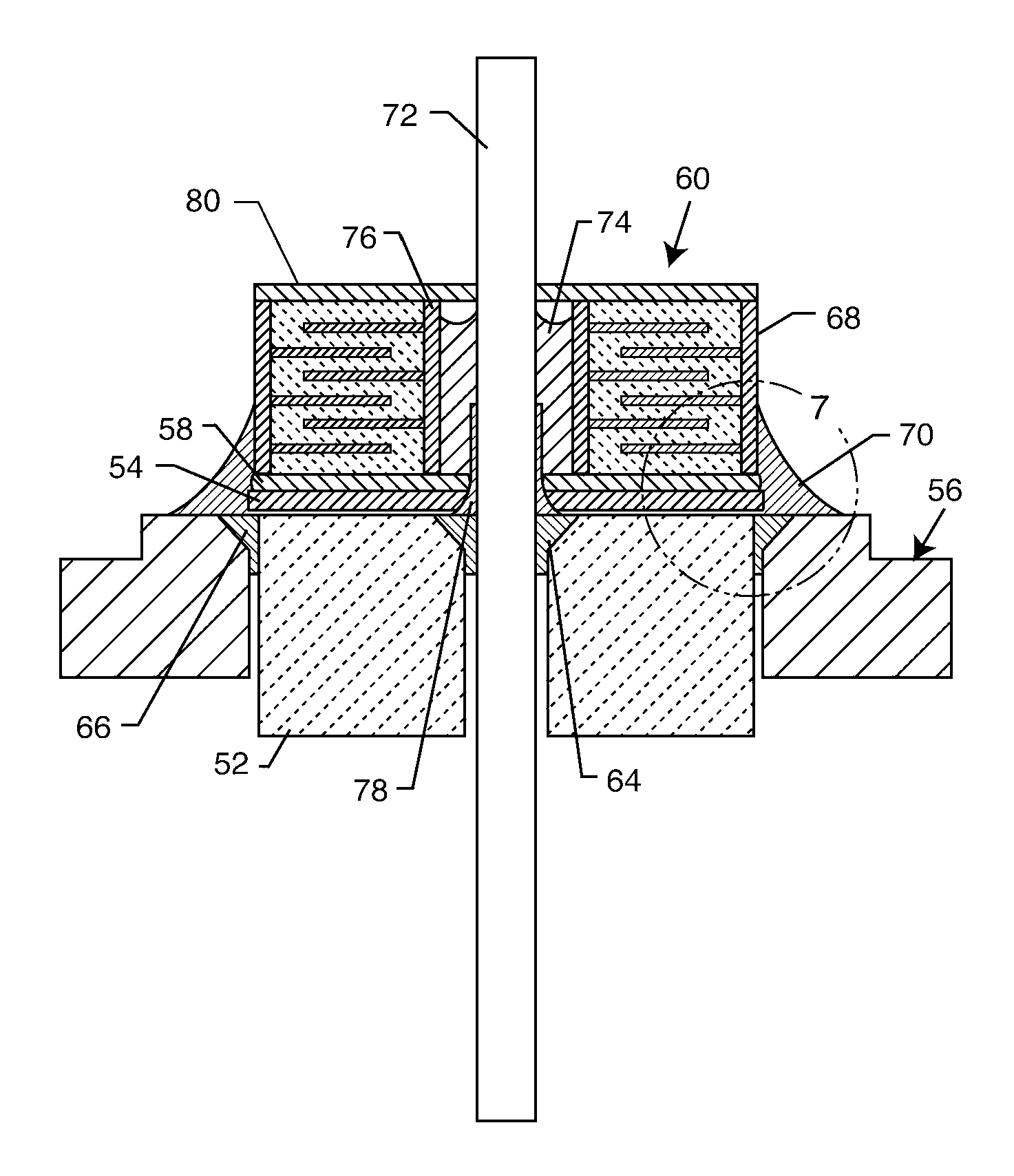

Injection molded ferrule for cofired feedthroughs

InactiveUS20110048770A1Low bulk permeabilityElectrotherapyElectric discharge tubesHermetic sealTitanium

Feedthrough assemblies and methods of manufacturing feedthrough assemblies are provided. Methods include molding a ferrule comprising titanium using metal injection molding and positioning the ferrule about at least a portion of an insulator, the insulator comprising alumina. Methods also include overmolding a ferrule about at least a portion of an insulator using metal injection molding, the ferrule comprising titanium and the insulator comprising alumina. Sintering densifies the ferrule and provides a hermetic seal between the ferrule and insulator. The insulator may be fired or unfired prior to sintering of the ferrule.

Owner:MEDTRONIC INC

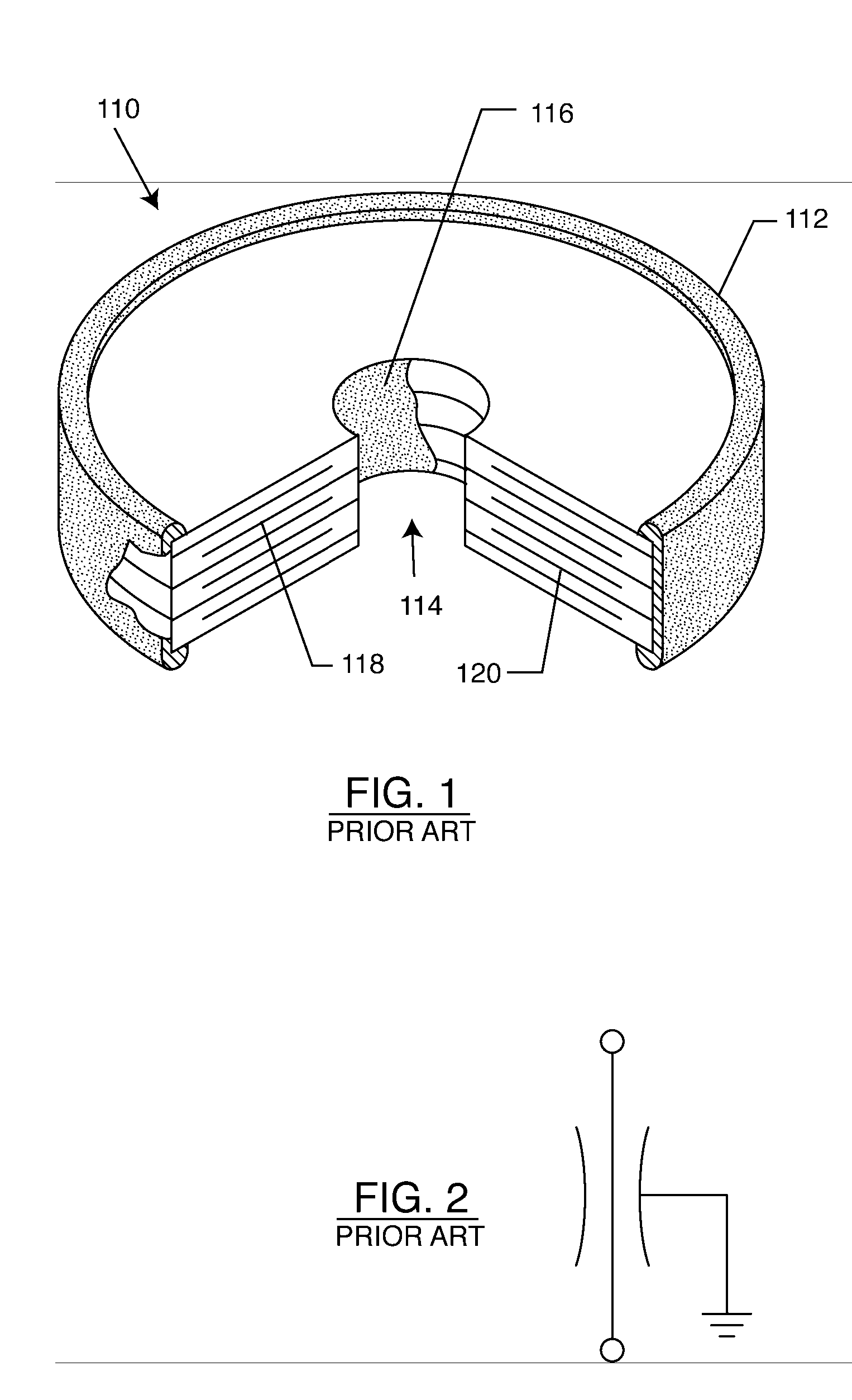

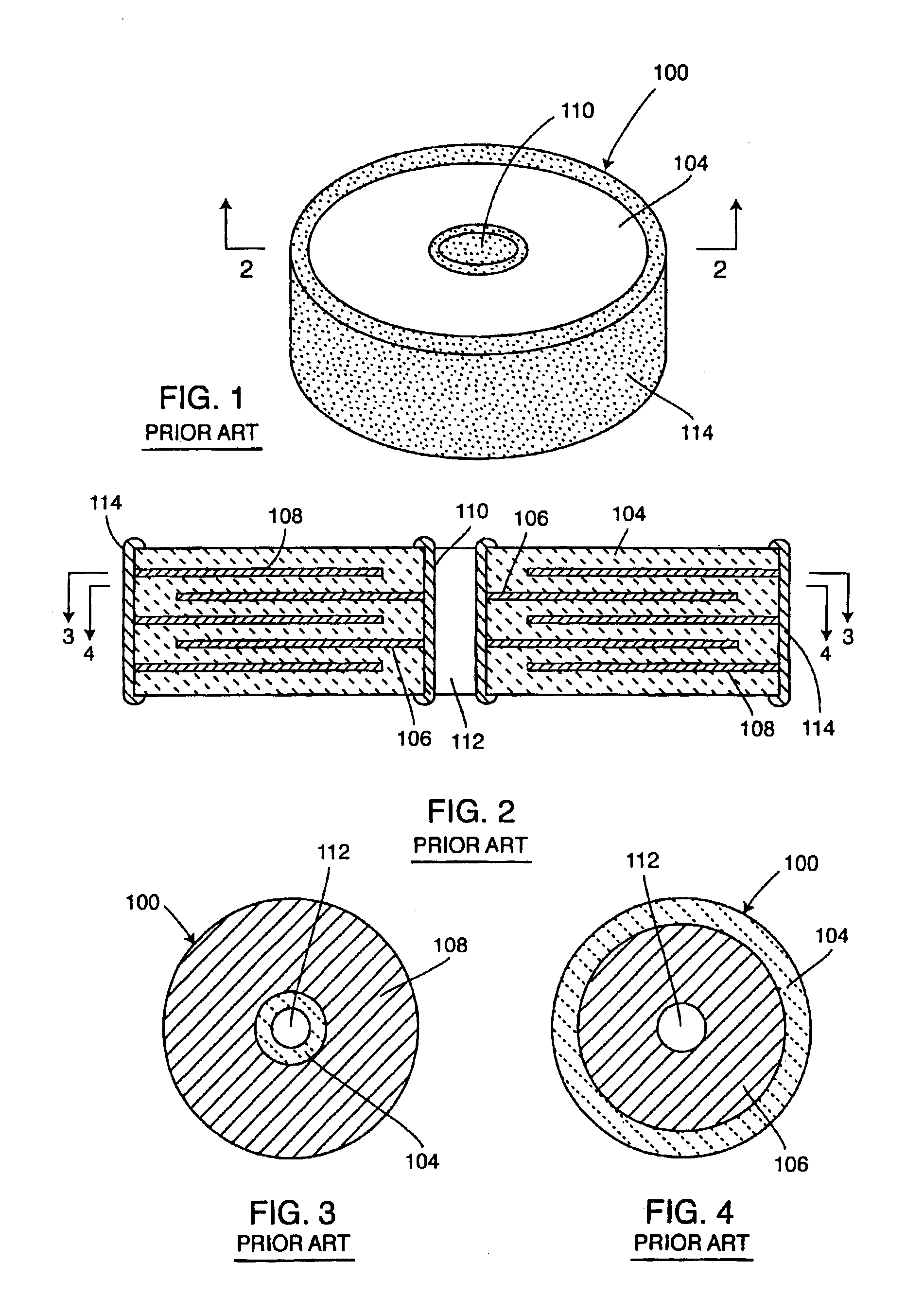

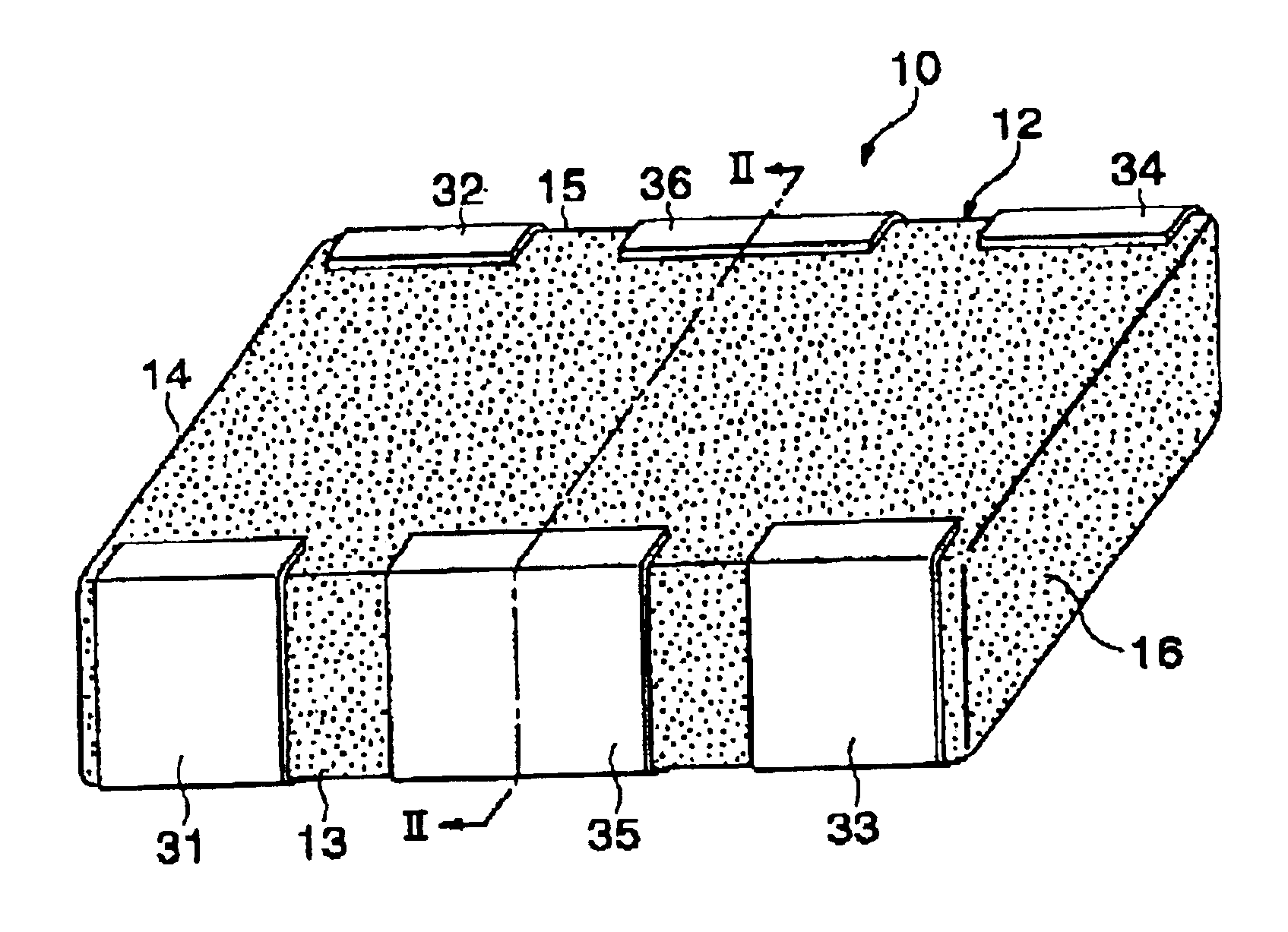

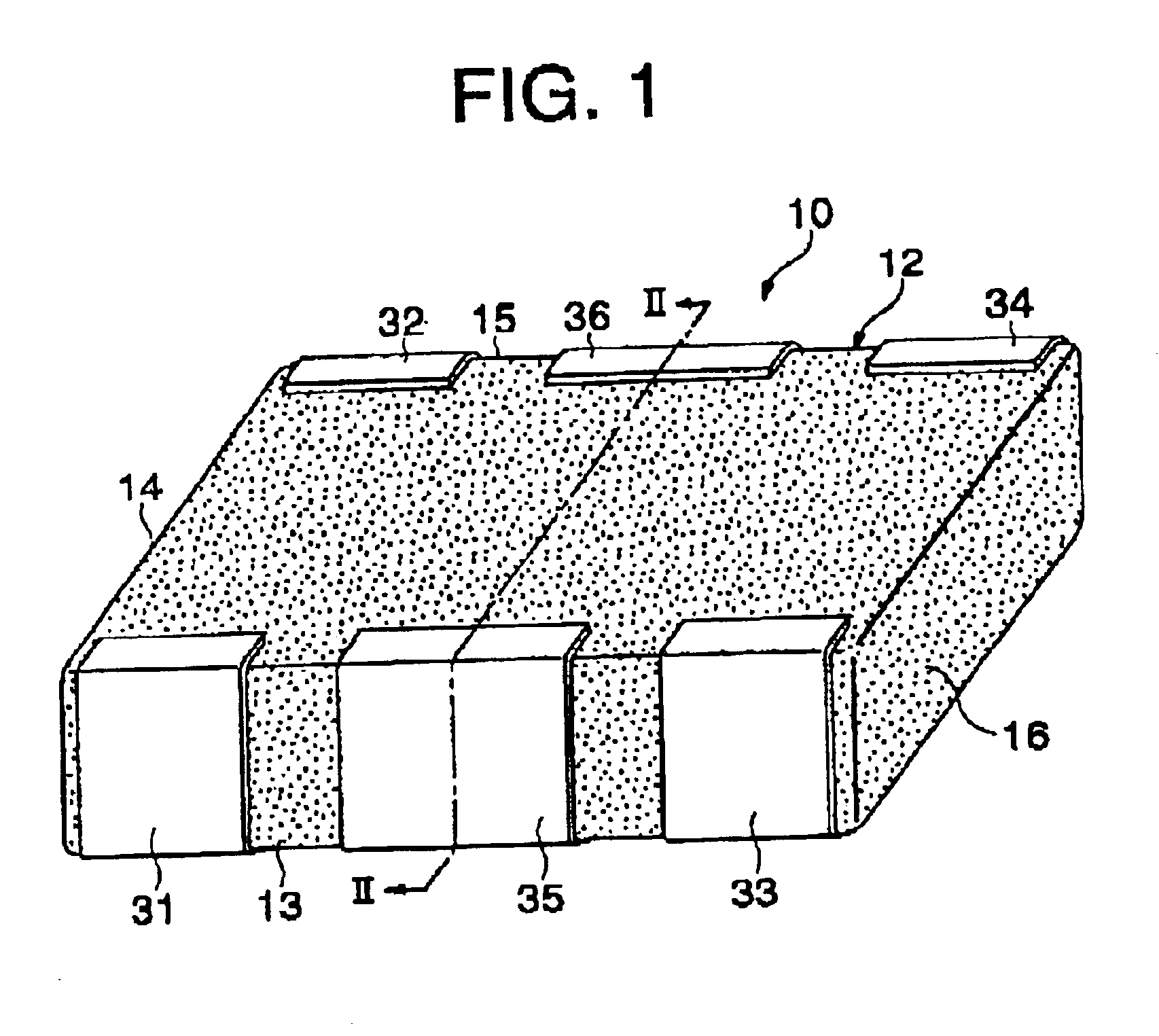

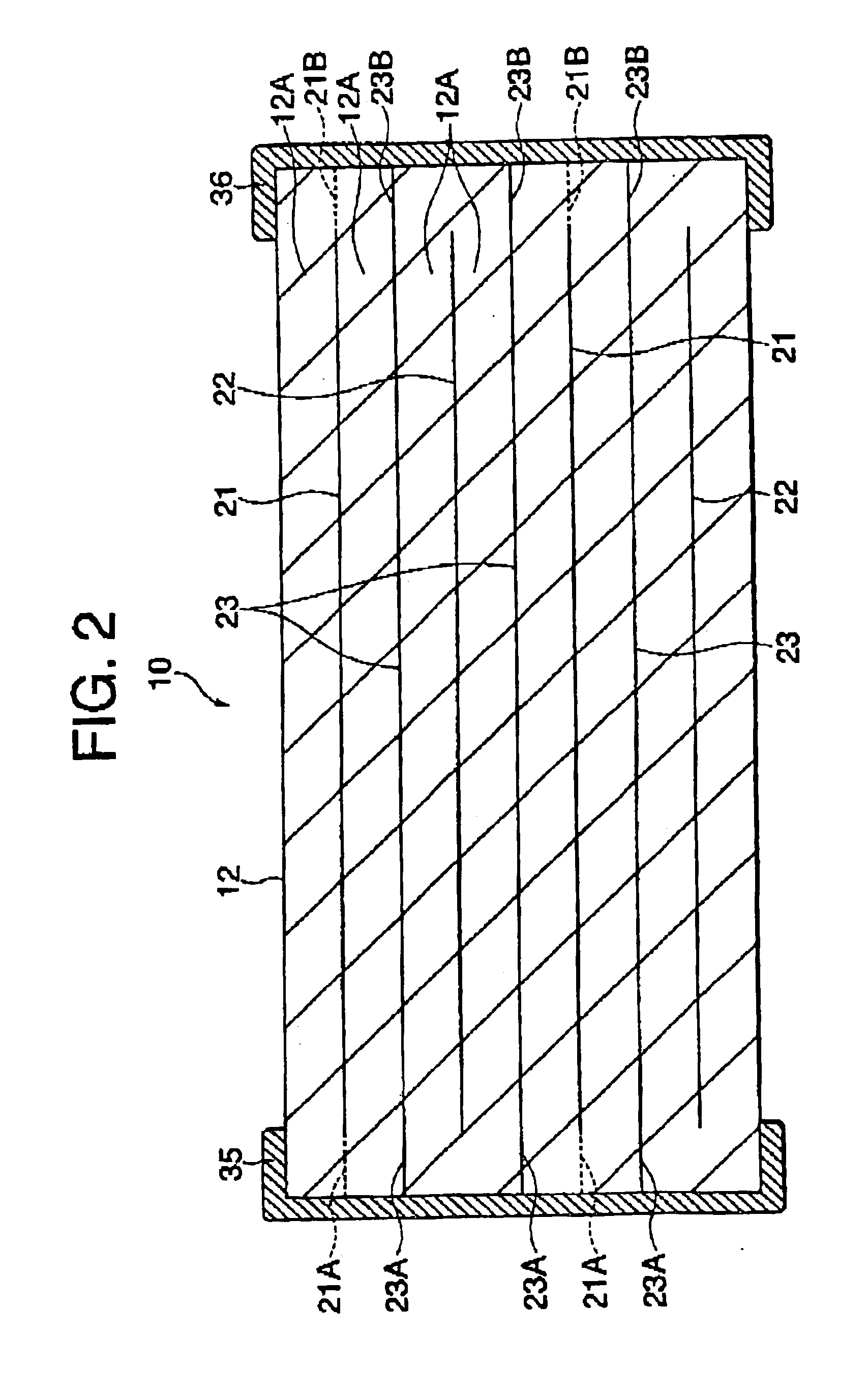

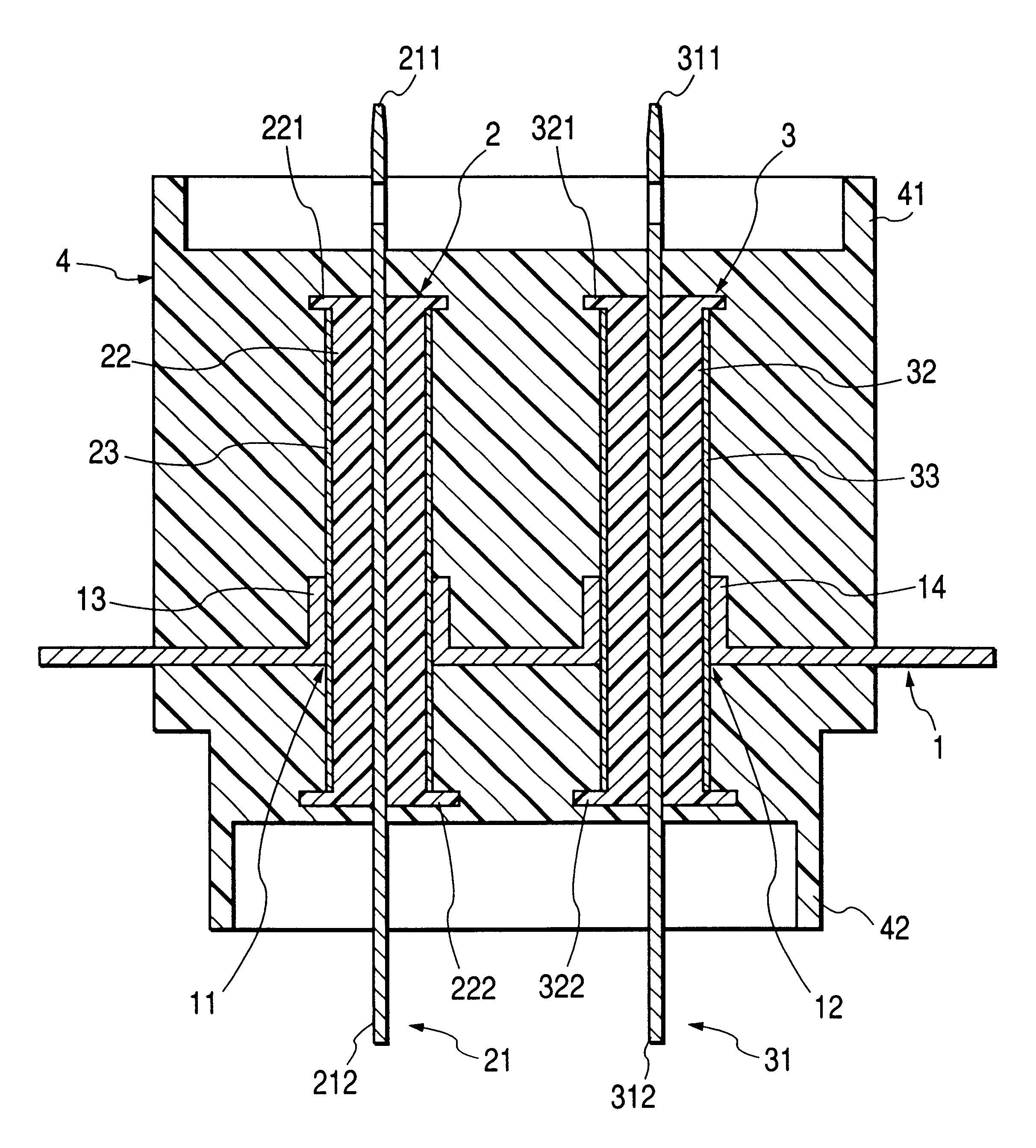

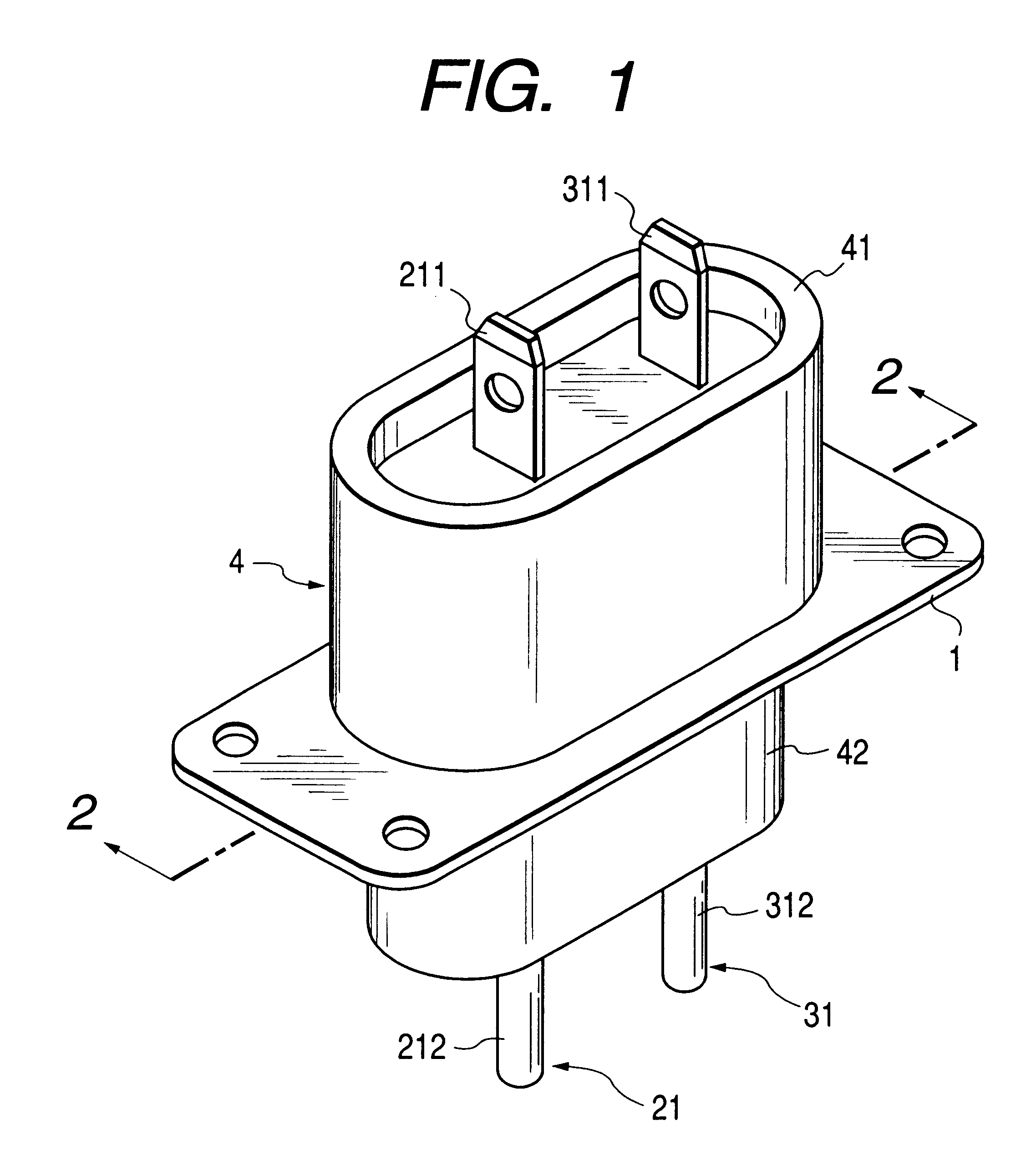

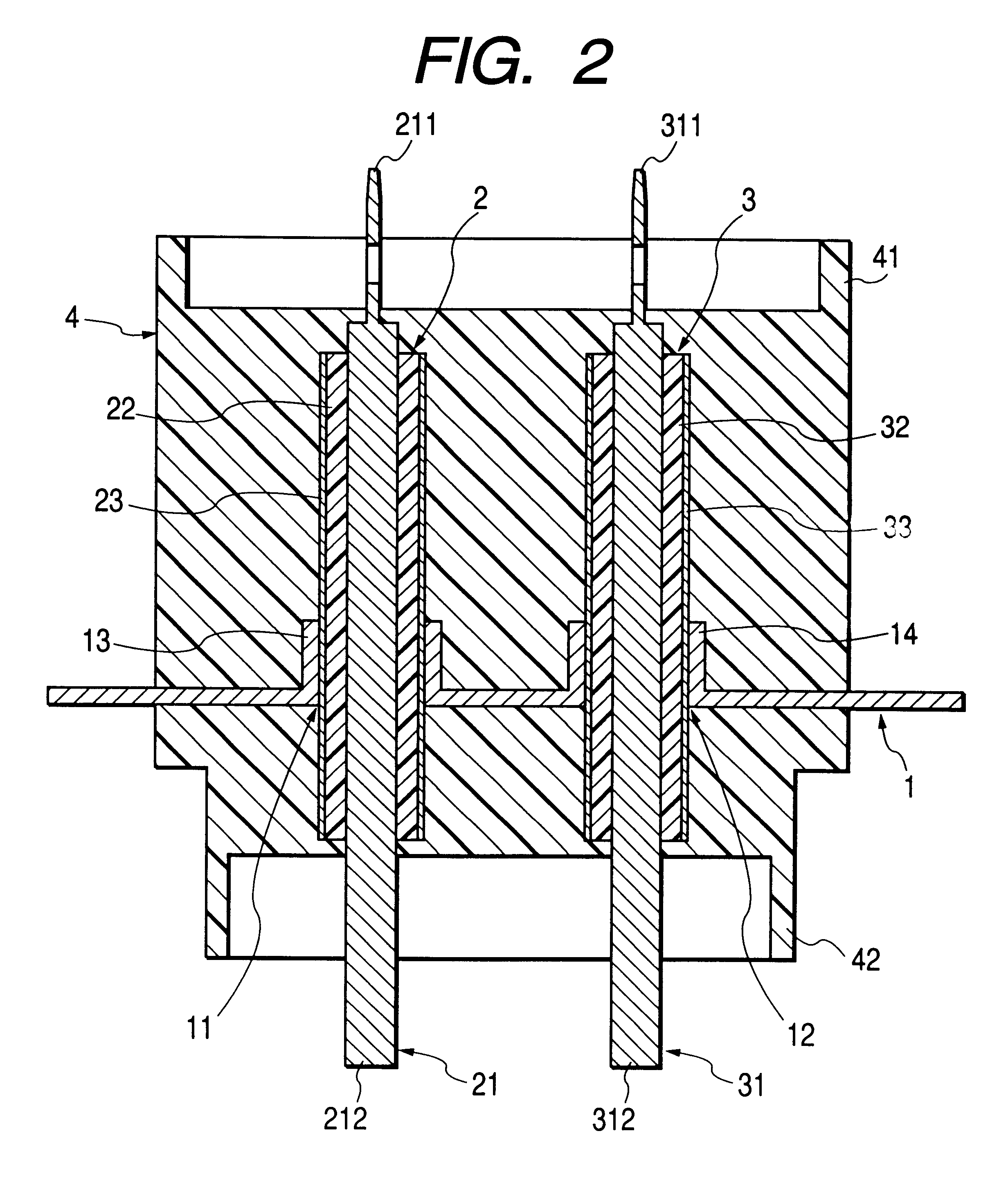

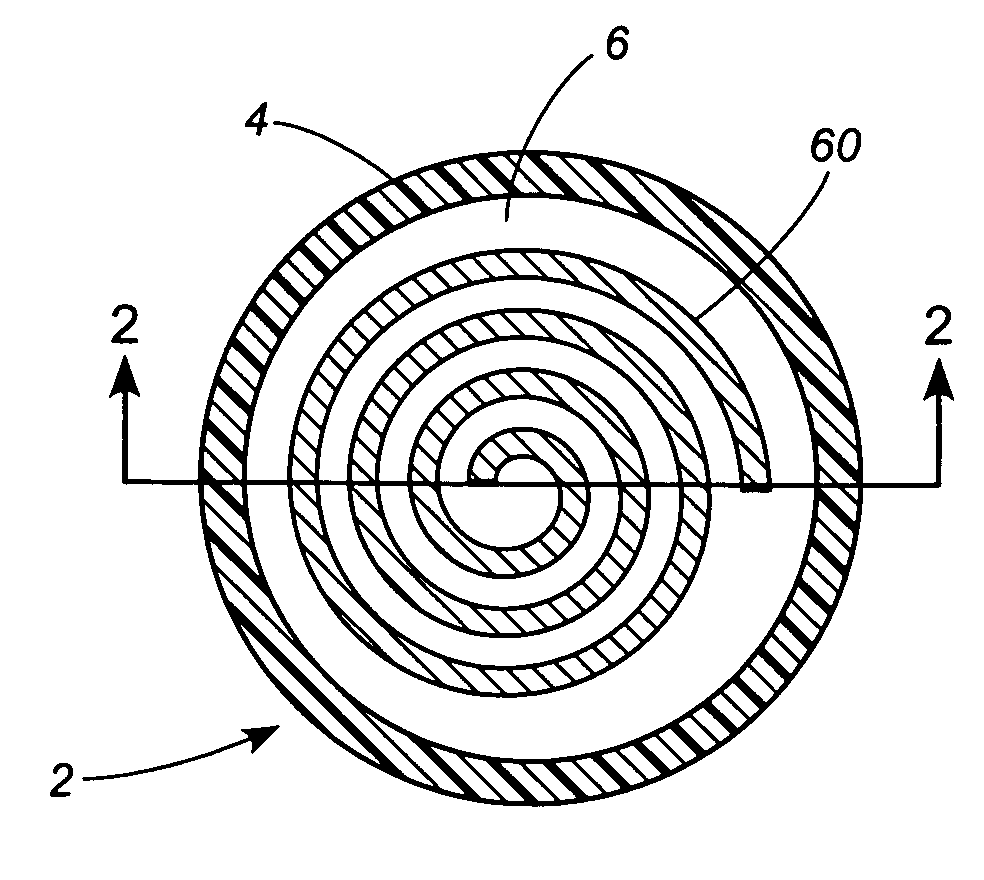

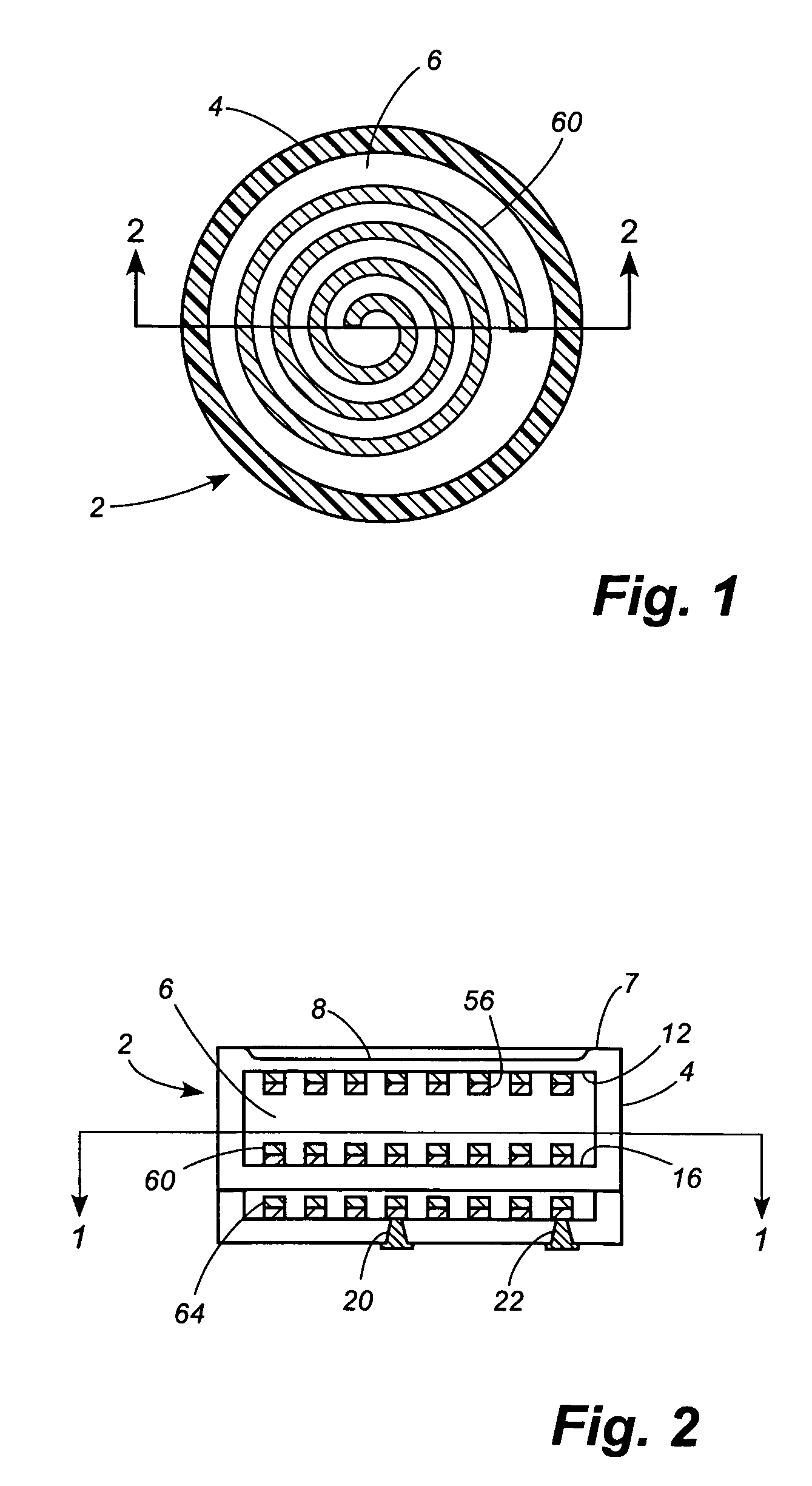

Multilayer feedthrough capacitor

InactiveUS6768630B2Reduce common mode noiseESL is further reducedAnti-noise capacitorsFixed capacitor electrodesElectrical conductorEngineering

A multilayer feedthrough capacitor having a first internal conductor arranged in a dielectric body, an intermediate internal conductor arranged in the dielectric body and stacked with the first internal conductor via a ceramic layer, a second internal conductor arranged in the dielectric body and stacked with the intermediate internal conductor via a ceramic layer, a first terminal electrode formed at an outside surface of the dielectric body and connected to the first internal conductor, a second terminal electrode formed at the outside surface of the dielectric body and connected to the second internal conductor, and an intermediate terminal electrode formed at the outside surface of the dielectric body and connected to the intermediate internal conductor. The intermediate terminal electrode is connected to the ground, while the first terminal electrode and the second terminal electrode are connected to paths for transmitting signals. The first internal conductor and the second internal conductor have currents flowing through them in opposite directions.

Owner:TDK CORPARATION

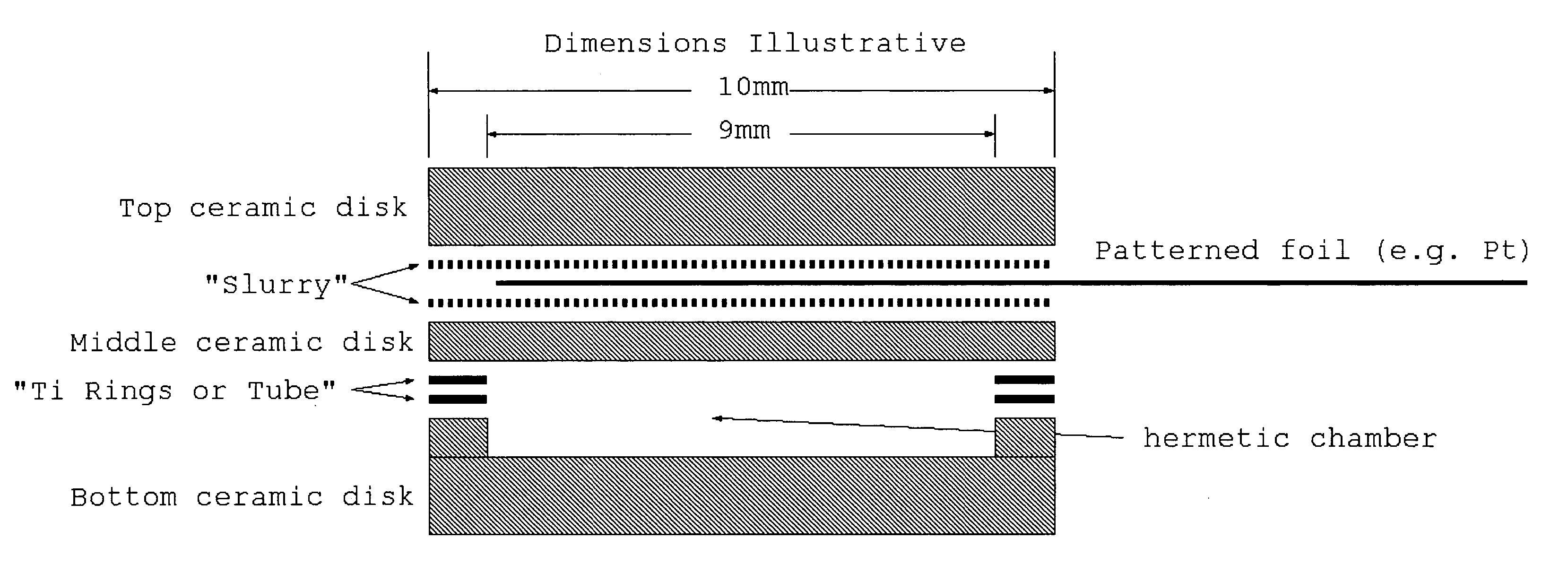

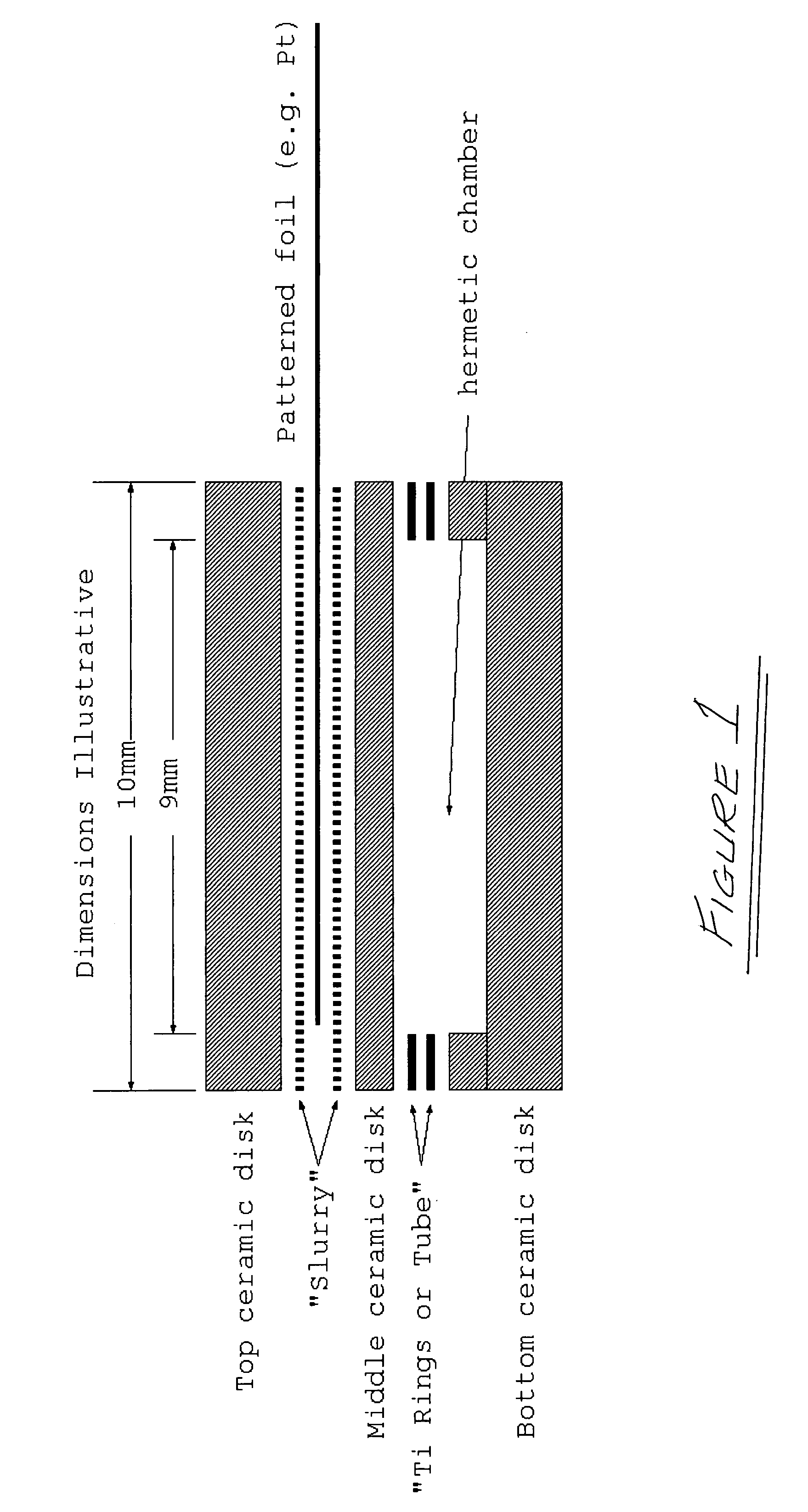

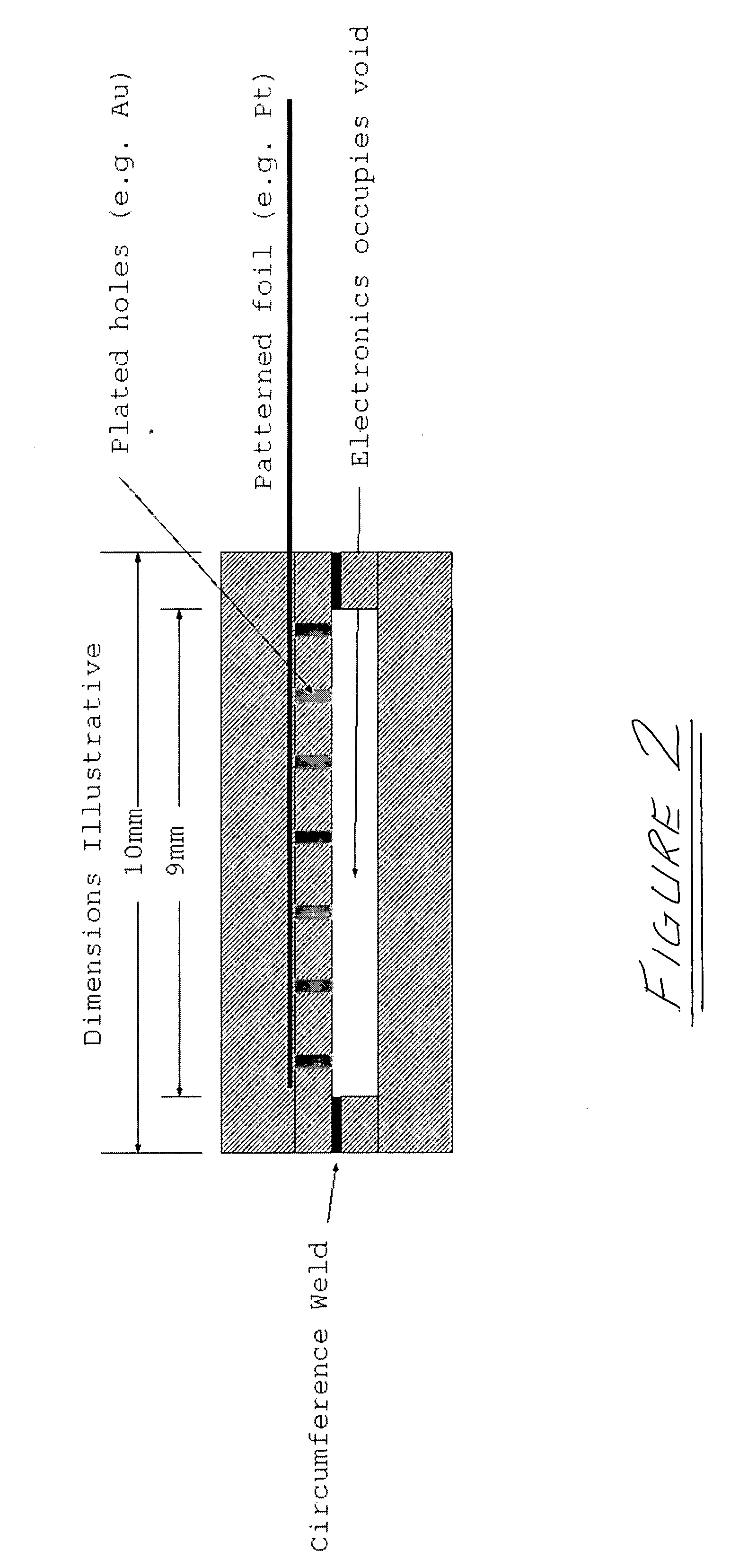

Method for fabrication of hermetic electrical conductor feedthroughs

InactiveUS20070277374A1High bonding strengthComplicated in fabrication procedurePrinted circuit assemblingLine/current collector detailsOxide ceramicPlatinum

A method is disclosed for the fabrication of feedthrough devices that can transmit a single or plurality of electrical signal(s) to or from within a leak-tight (hermetic) chamber from or to the outside of said leak-tight (hermetic) chamber. The invention allows materials known to be well-tolerated within the human body such as alumina-oxide ceramic and platinum to be used as raw materials in the fabrication of body-compatible, single or multi-channel leak-tight (hermetic) feedthroughs.

Owner:NEWSOUTH INNOVATIONS PTY LTD

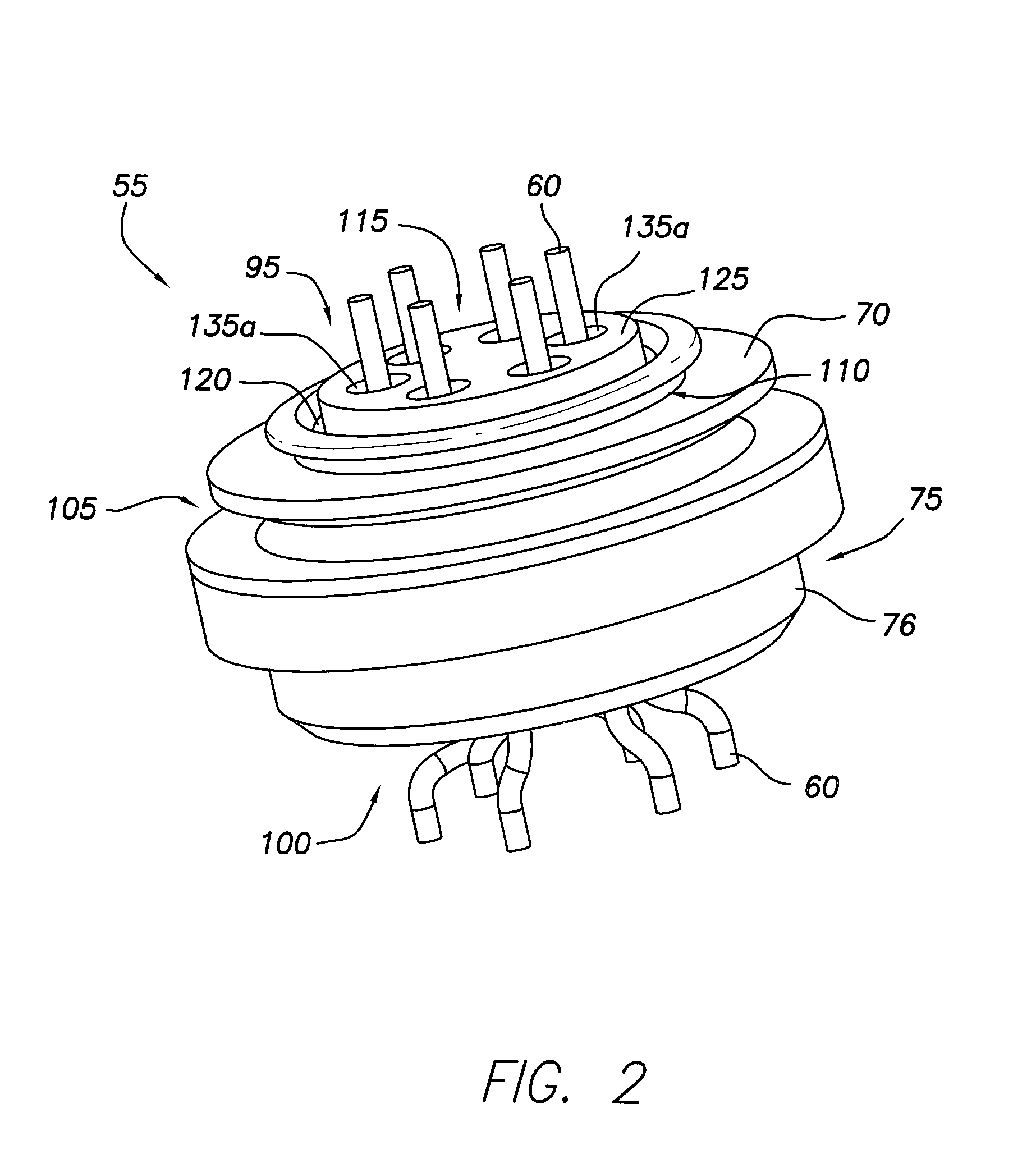

Filtering capacitor feedthrough assembly

A filtering capacitor feedthrough assembly for an implantable active medical device is disclosed. The filtering capacitor feedthrough assembly includes a capacitor having an aperture, the capacitor is electrically grounded to an electrically conductive feedthrough ferrule or housing of the implantable active medical device. A terminal pin extends into the aperture and an electrically conductive continuous coil is disposed within the aperture and between the terminal pin and the capacitor. The electrically conductive continuous coil mechanically secures and electrically couples the terminal pin to the capacitor.

Owner:MEDTRONIC INC

Integrated Filter Feedthrough Assemblies Made From Low Temperature Co-Fired (LTCC) Tape

InactiveUS20070217121A1Prevent leakageAvoid spreadingAnti-noise capacitorsElectrotherapyScreen printingState of art

A filter capacitor comprising a substrate of at least one layer of a low temperature co-fires ceramic (LTCC) tape supporting alternating active and ground electrode layers segregated by a dielectric layer is described. The substrate is preferably a laminate of three LTCC tapes pieces that are heated under pressure and at a relatively low temperature to become a laminate that maintains its shape and structure dimensions even after undergoing numerous sintering steps. Consequently, relatively thin active and ground electrode layers along with the intermediate dielectric layer can be laid down or deposited on the LTCC substrate by a screen-printing technique. A second laminate of LTCC tapes is positioned on top of the active / dielectric / ground layers to finish the capacitor. Consequently, a significant amount of space is saved in comparison to a comparably rated capacitor or, a capacitor of a higher rating can be provided in the same size as a conventional prior art capacitor.

Owner:WILSON GREATBATCH LTD

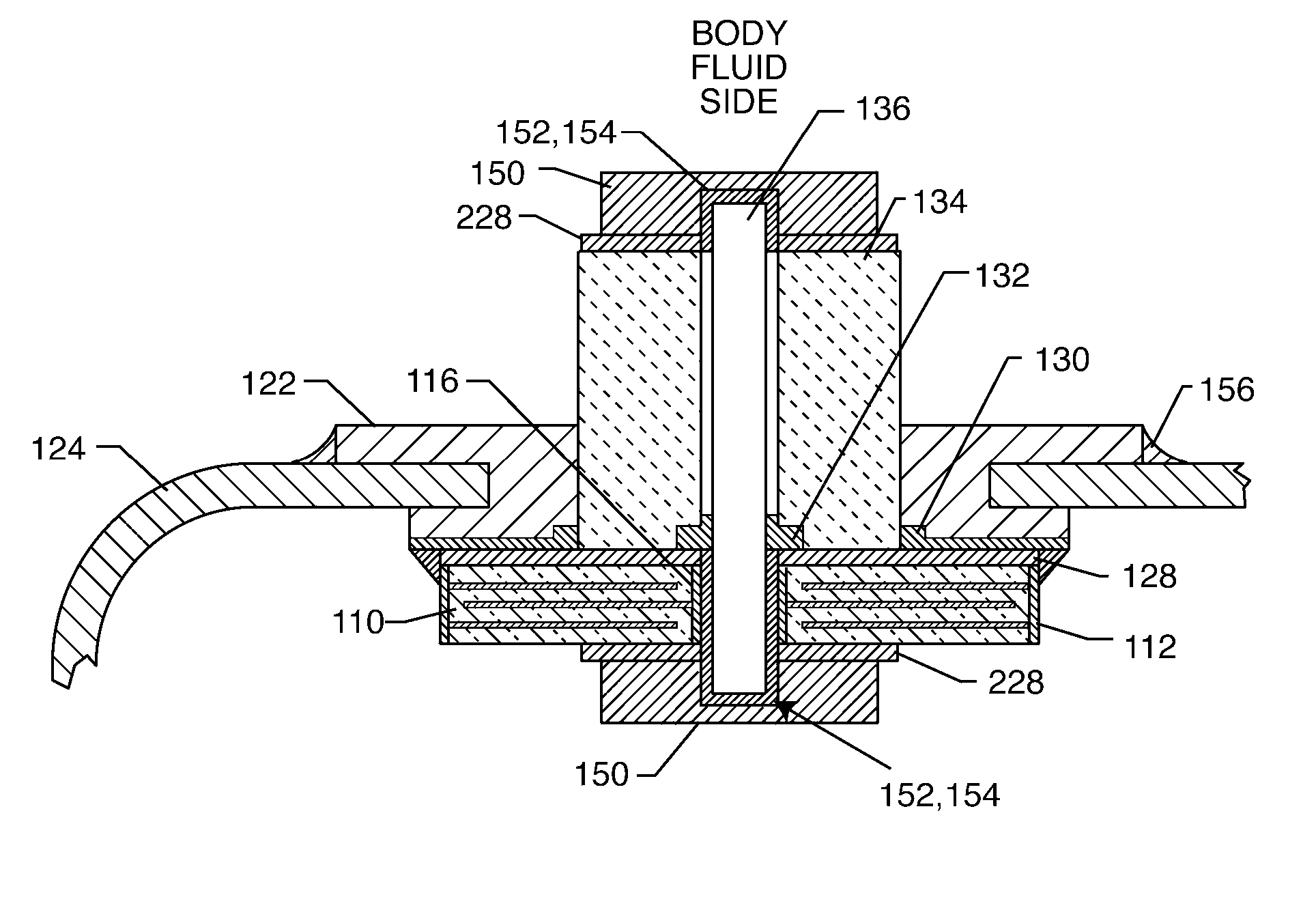

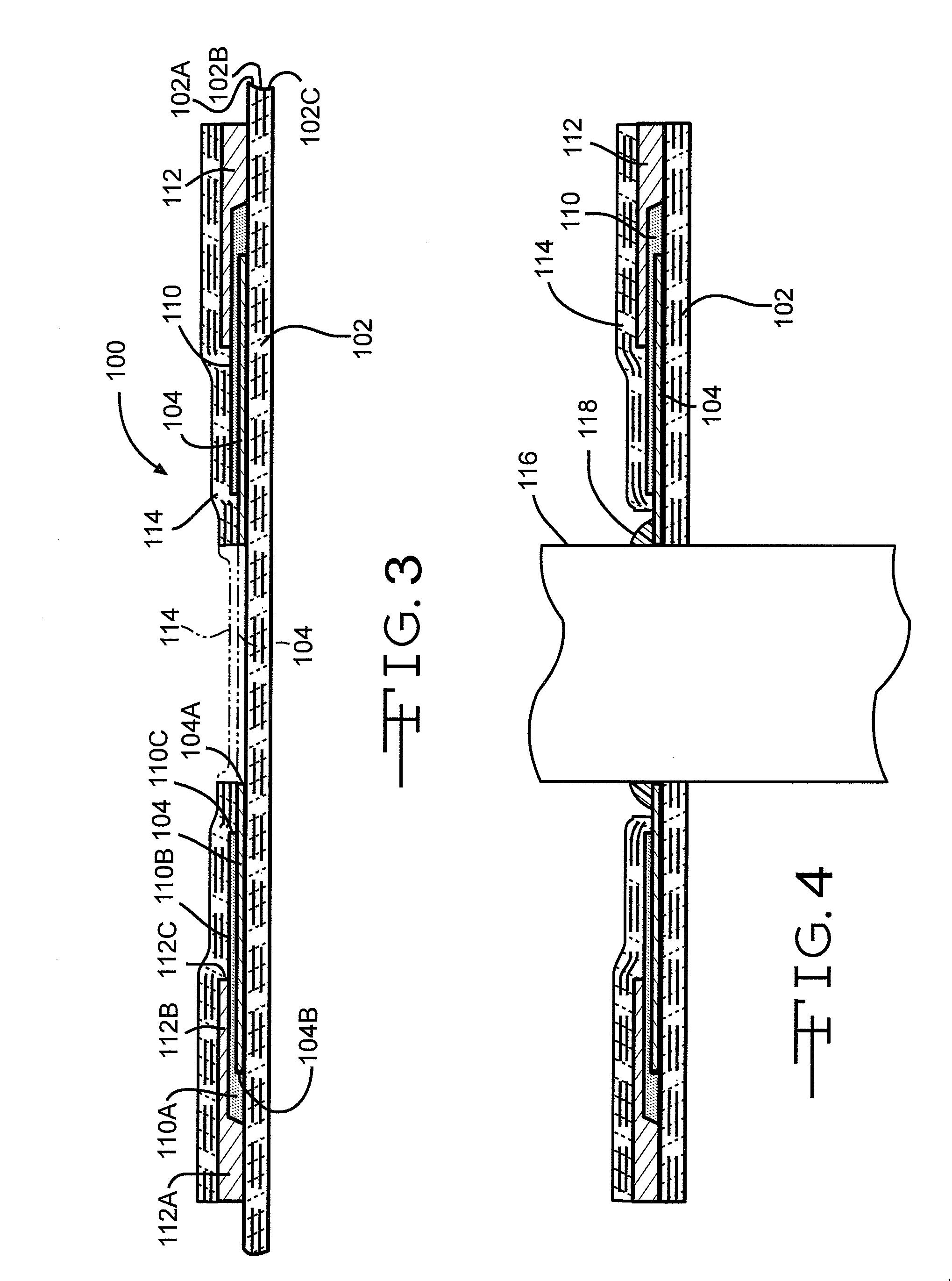

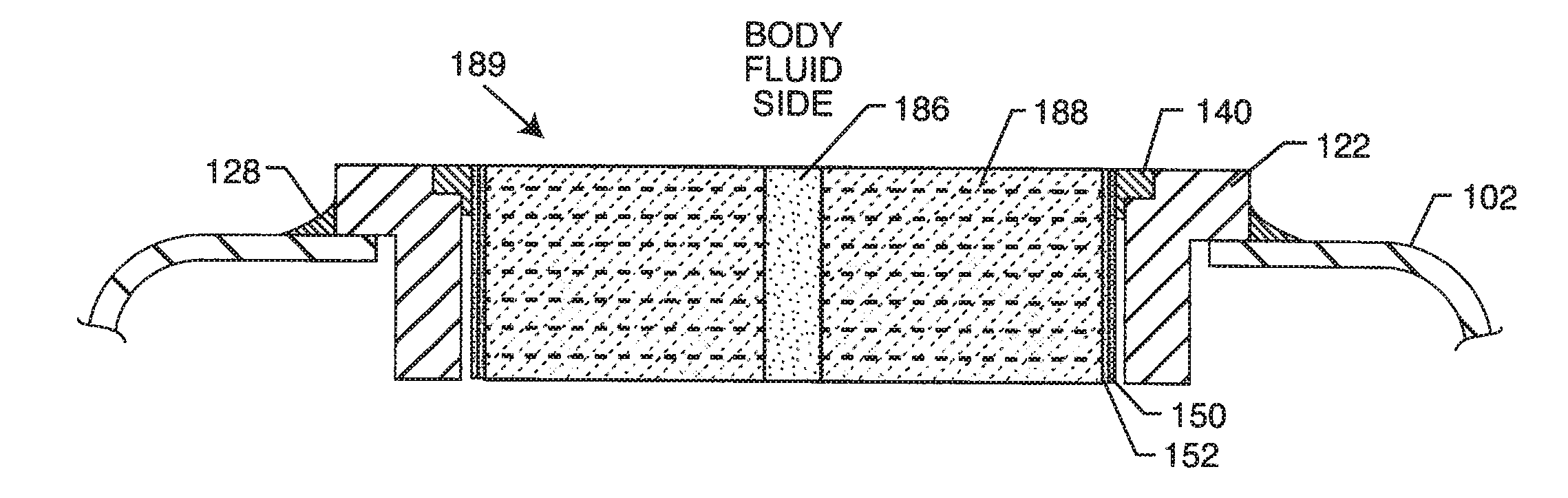

Elevated Hermetic Feedthrough Insulator Adapted for Side Attachment of Electrical Conductors on the Body Fluid Side of an Active Implantable Medical Device

ActiveUS20130184796A1Minimizes damaging tensile stressTensile stress is particularly damagingAnti-noise capacitorsLine/current collector detailsElectricityElectrical conductor

An elevated feedthrough is attachable to a top or a side of an active implantable medical device. The feedthrough includes a conductive ferrule and a dielectric substrate. The dielectric substrate is defined as comprising a body fluid side and a device side disposed within the conductive ferrule. The dielectric substrate includes a body fluid side elevated portion generally raised above the conductive ferrule. At least one via hole is disposed through the dielectric substrate from the body fluid side to the device side. A conductive fill is disposed within the at least one via hole forming a hermetic seal and electrically conductive between the body fluid side and the device side. A leadwire connection feature is on the body fluid side electrically coupled to the conductive fill and disposed adjacent to the elevated portion of the dielectric substrate.

Owner:WILSON GREATBATCH LTD

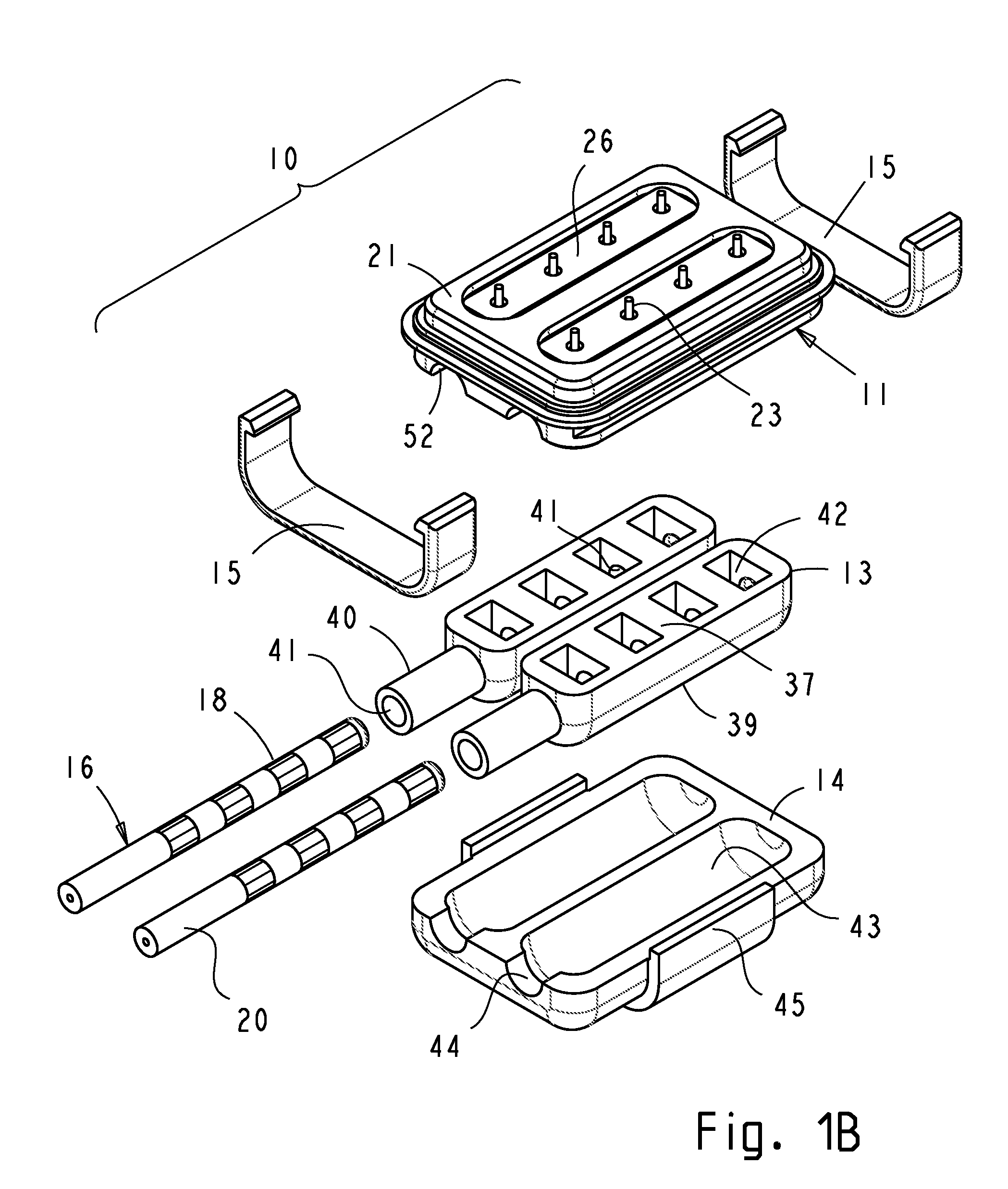

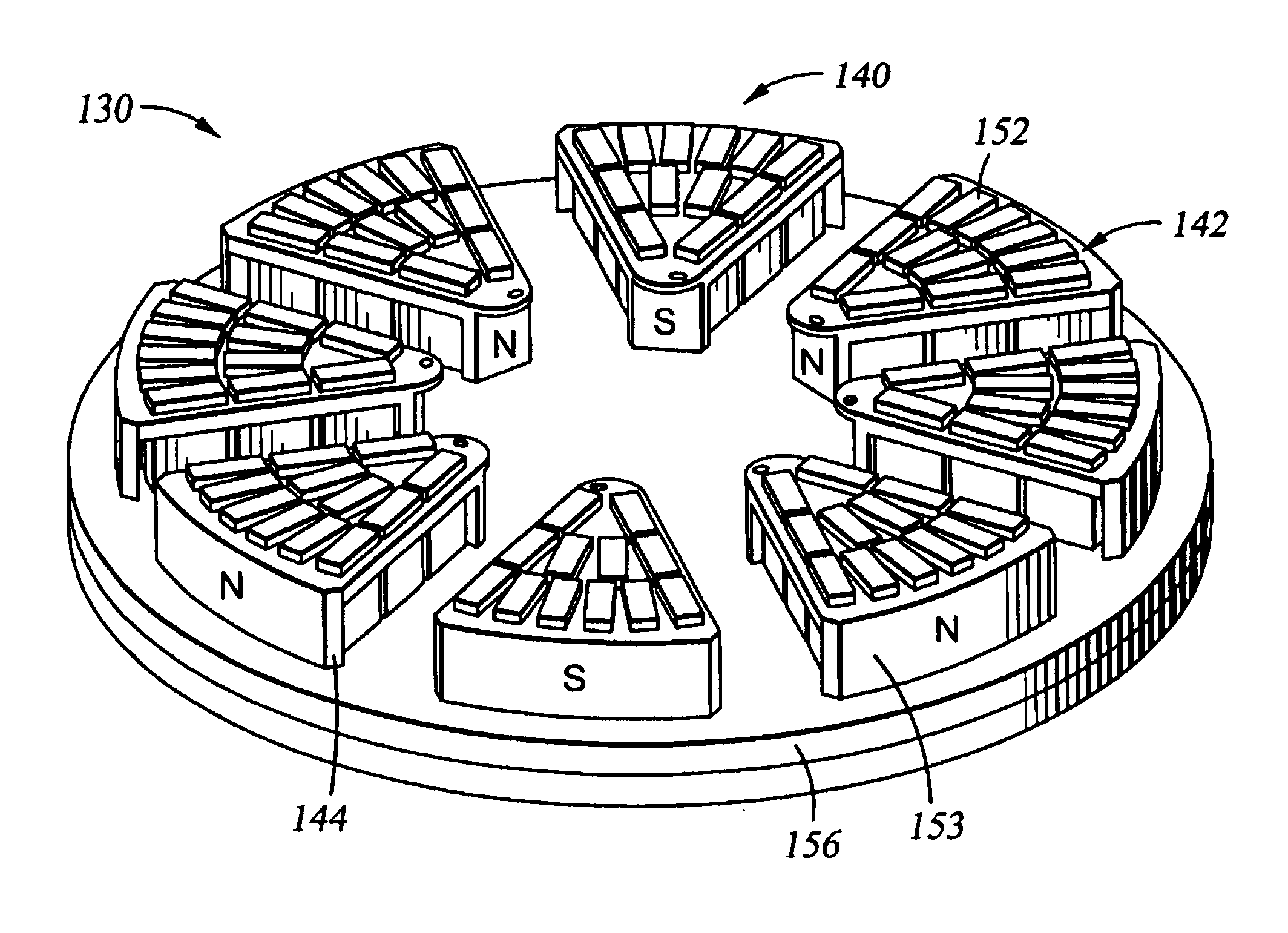

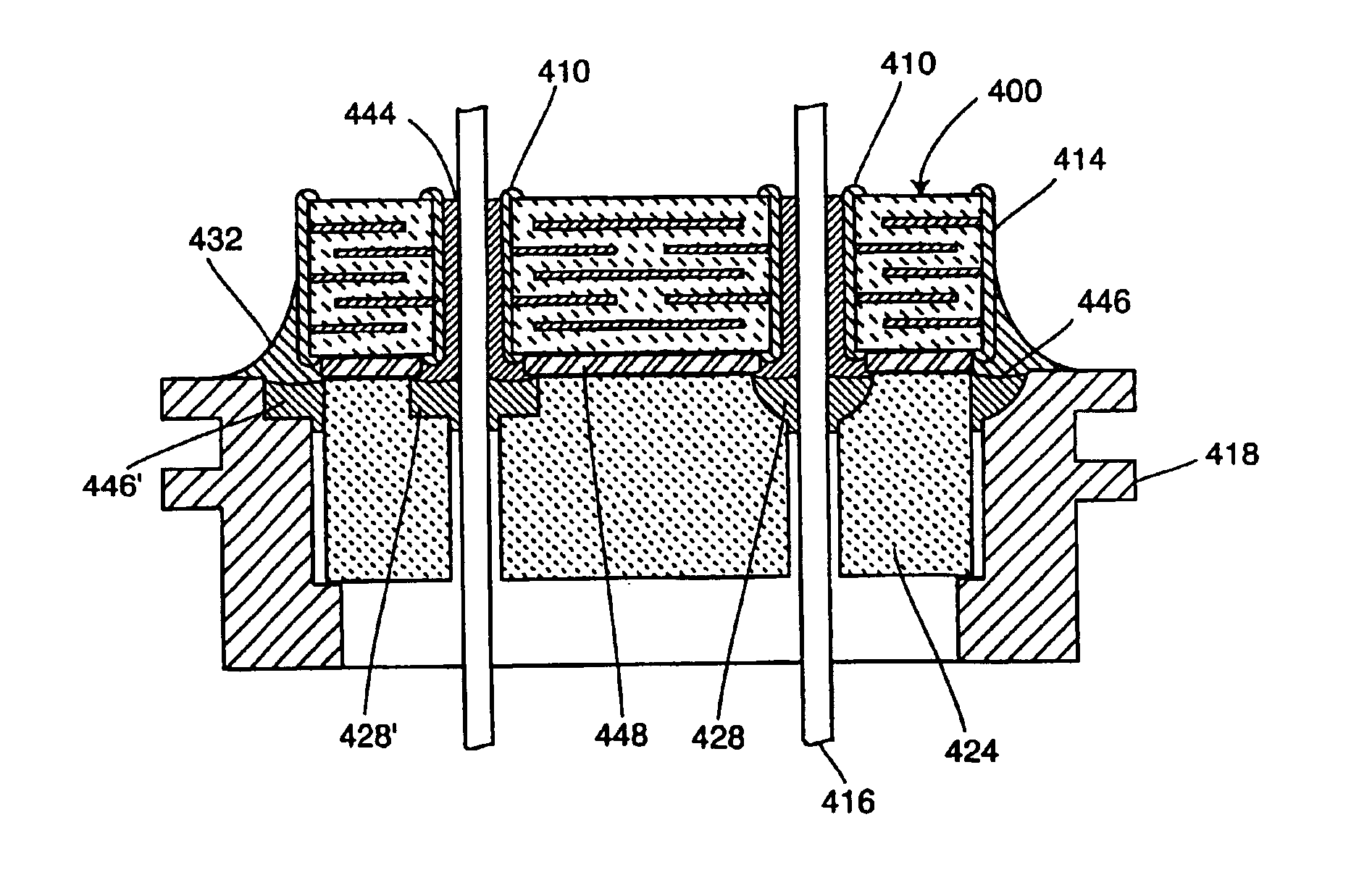

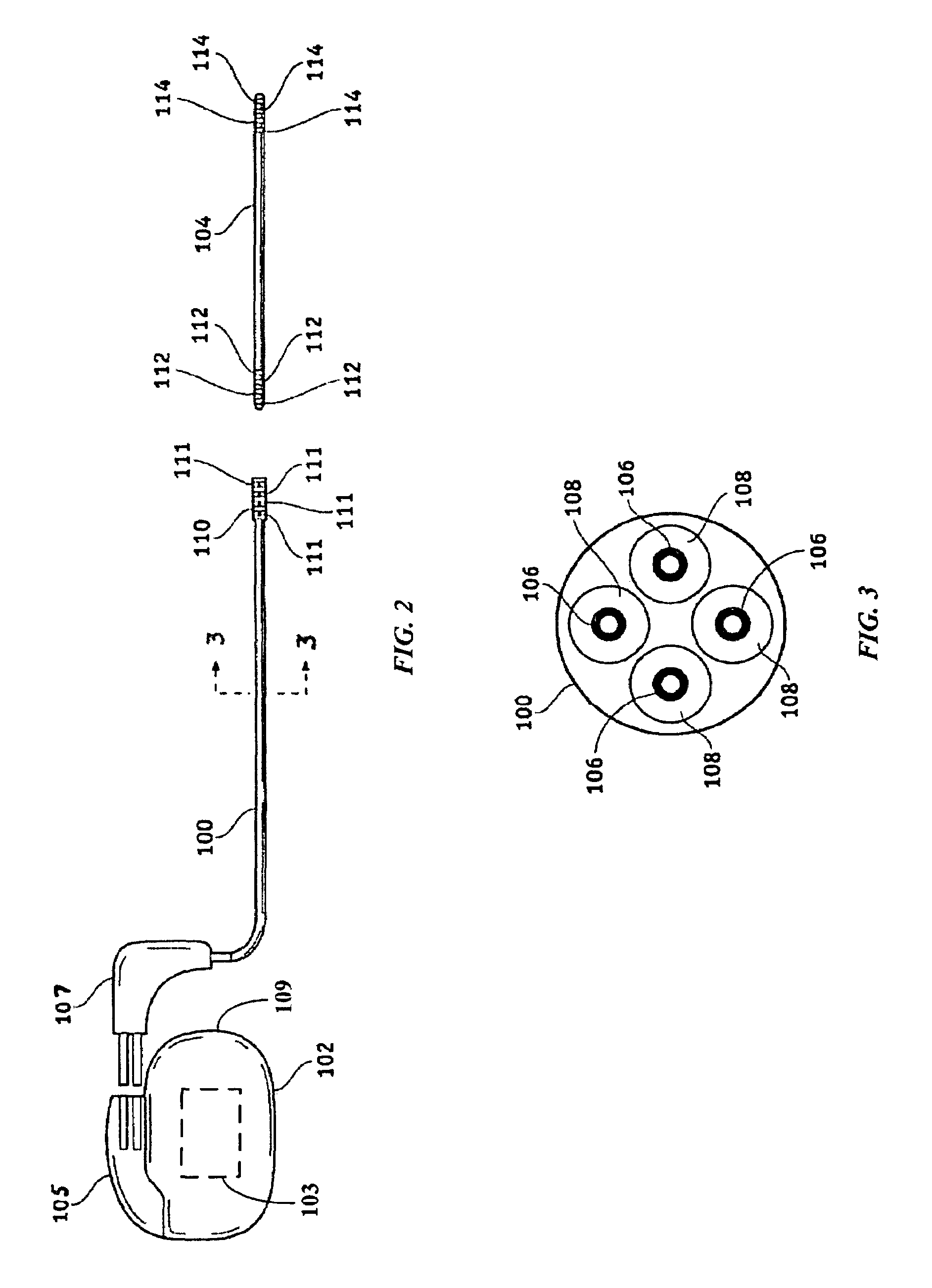

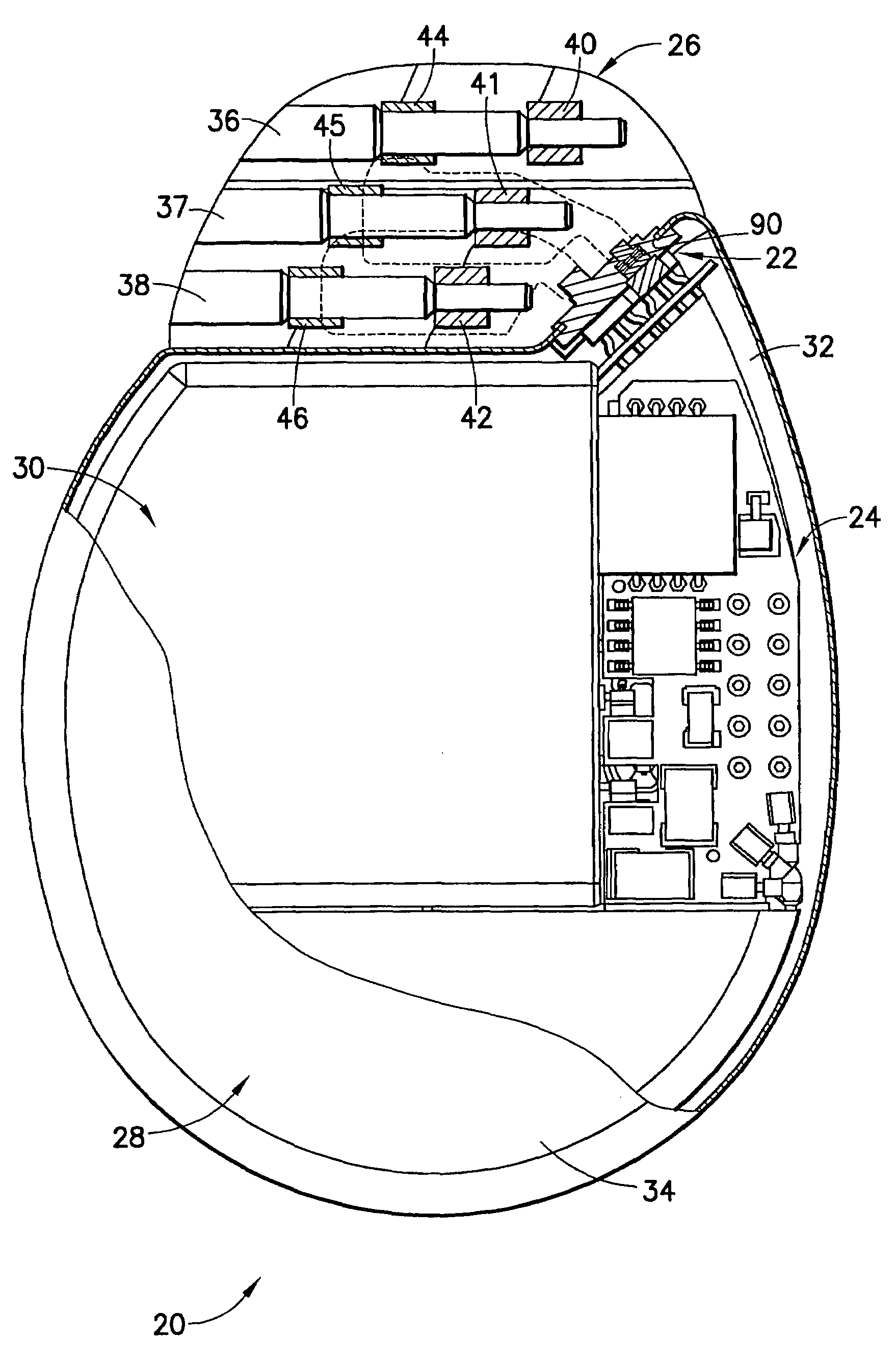

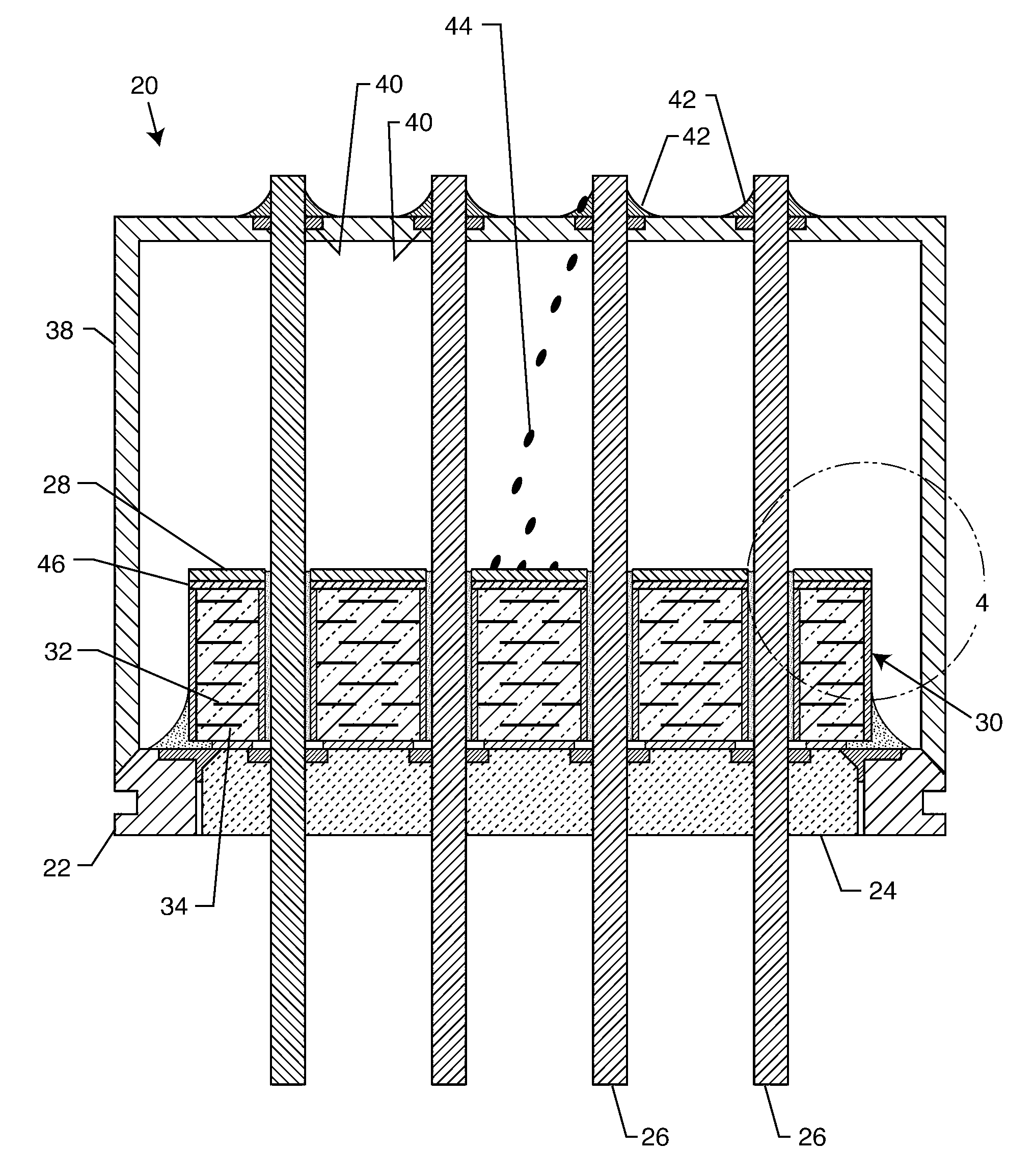

Integrated 8-pole filtered feedthrough with backfill tube for implantable medical devices

ActiveUS7260434B1Save additional assembly stepMinimize functional impactElectrotherapyElectricityEngineering

A feedthrough apparatus for a implantable medical device having a casing includes a conductive housing having an outer side, an inner side, and a peripheral surface with a continuous assembly groove therein for mounting on the casing of the implantable medical device. The conductive housing has first and second through bores extending between the outer side and the inner side in spaced apart, generally parallel, relationship. First and second filtered feedthrough assemblies are received, respectively, in the first and second through bores. Each filtered feedthrough assembly includes an insulative terminal, a filter capacitor, and a plurality of lead wires electrically isolated from the conductive housing supported on and extending through the insulative terminal and through the filter capacitor in conductive relation therewith. Also, a backfill port is provided on the conductive housing and has a passageway extending between the inner side and the outer side.

Owner:PACESETTER INC

Device to protect an active implantable medical device feedthrough capacitor from stray laser weld strikes, and related manufacturing process

An insulative shield is co-bonded to the top of a ceramic capacitor in a feedthrough terminal assembly on an active implantable medical device. The insulative shield is a thin substrate that provides protection against damage and degradation of the feedthrough capacitor and / or its conformal coating from heat, splatter or debris resulting from the electromechanical connection of components during construction of the assembly. Laser welding, thermal or ultrasonic bonding, soldering, brazing or related lead attachment techniques can create such heat, splatter or debris. In a preferred embodiment, the insulative shield is co-bonded using the capacitor's own conformal coating.

Owner:WILSON GREATBATCH LTD

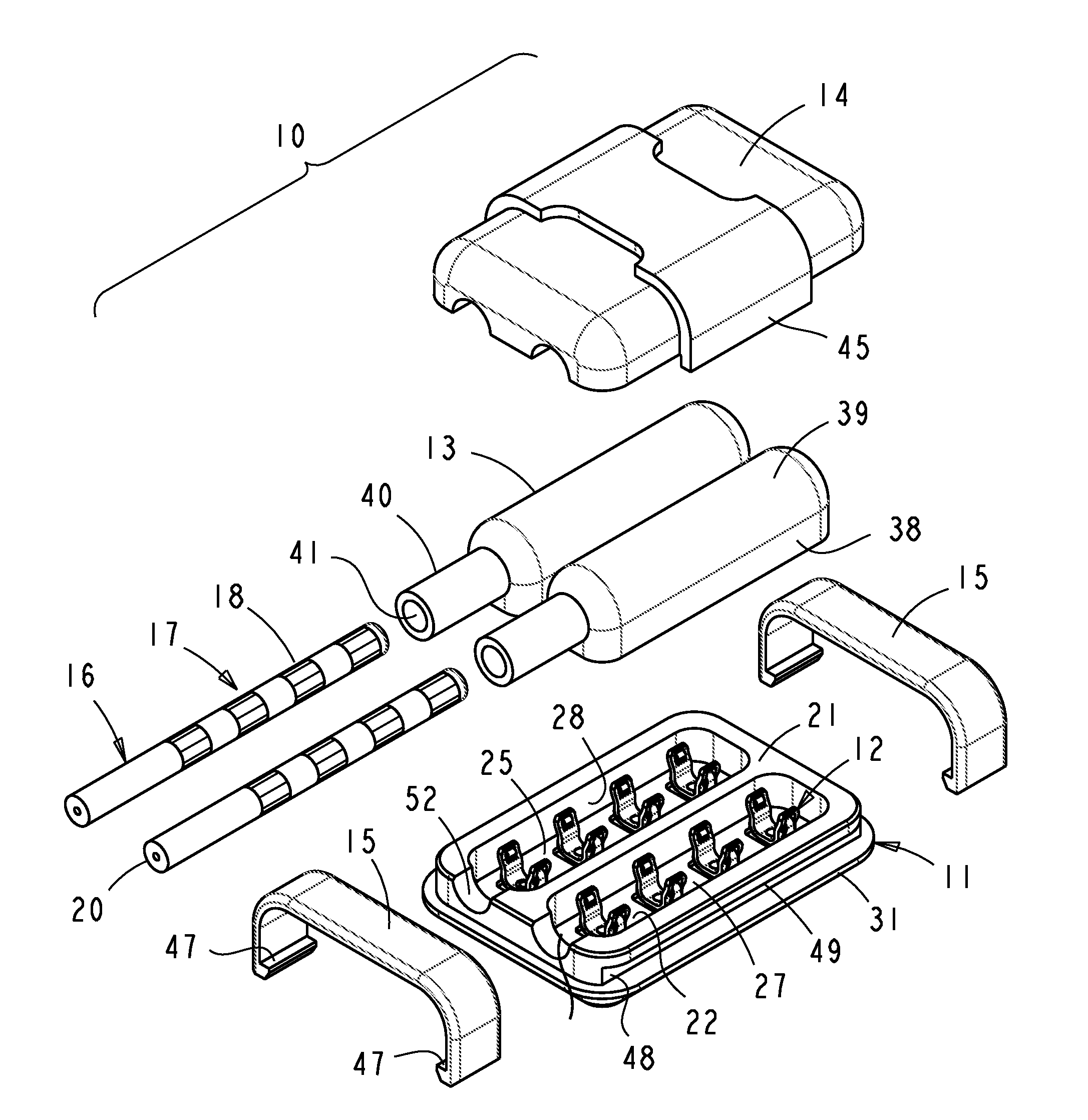

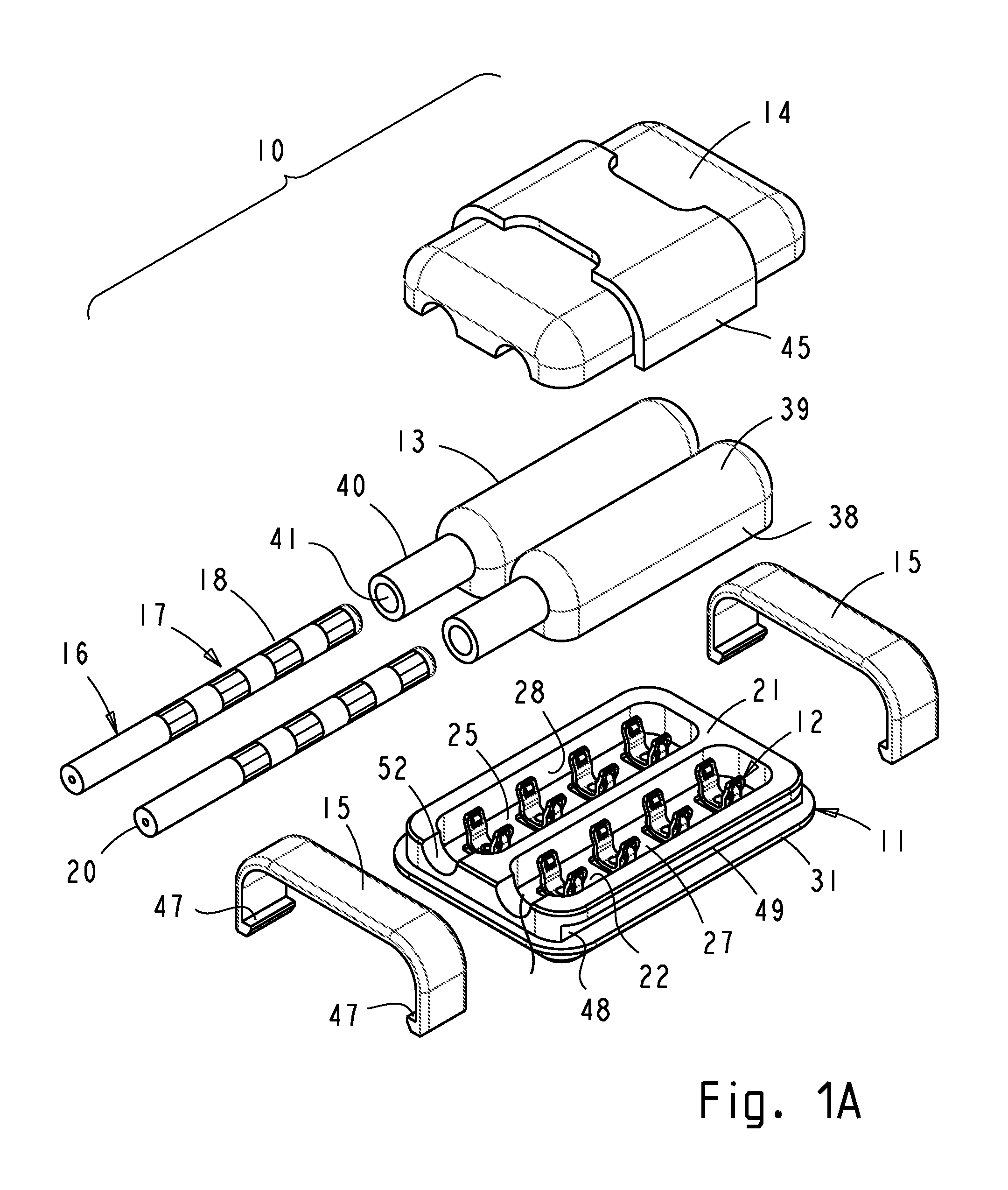

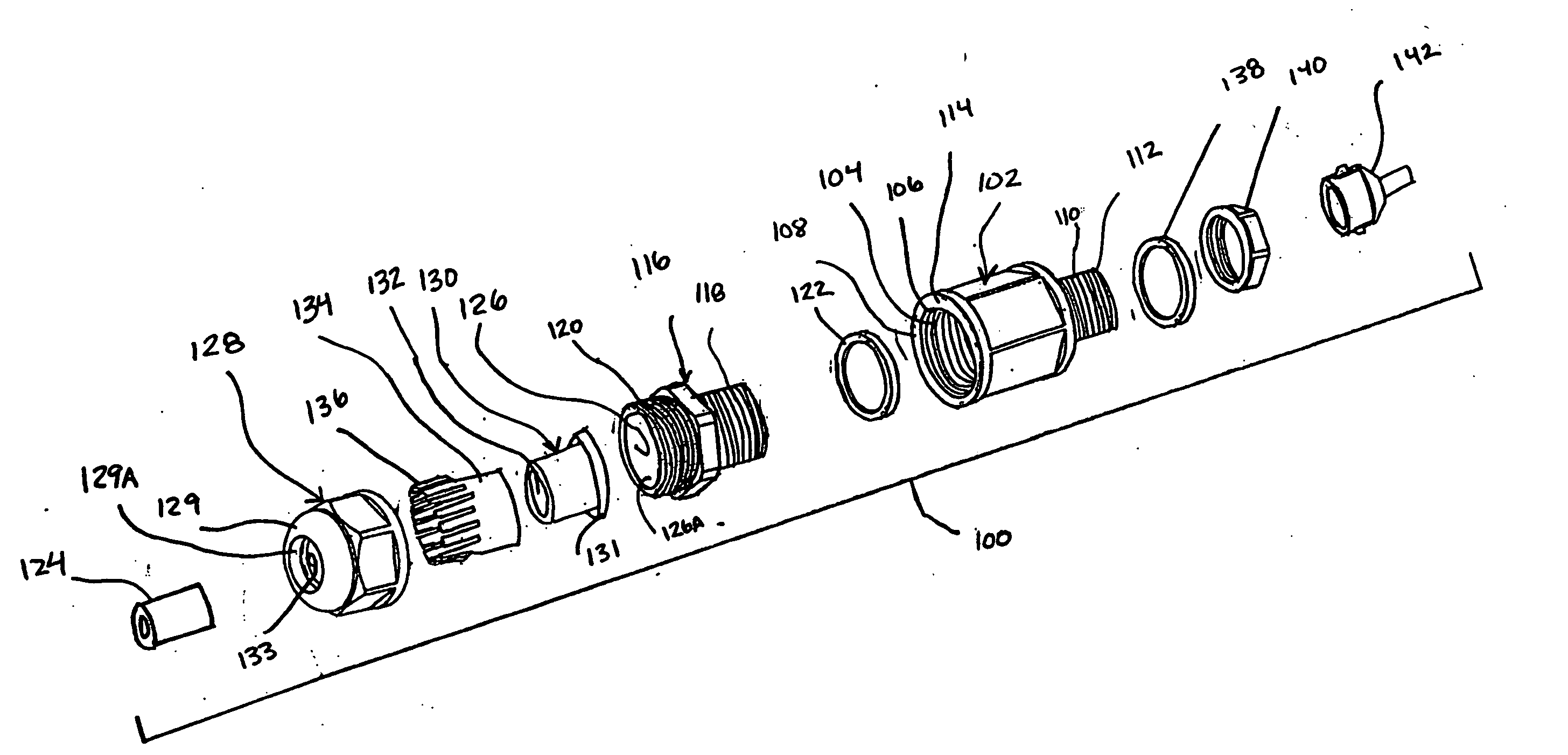

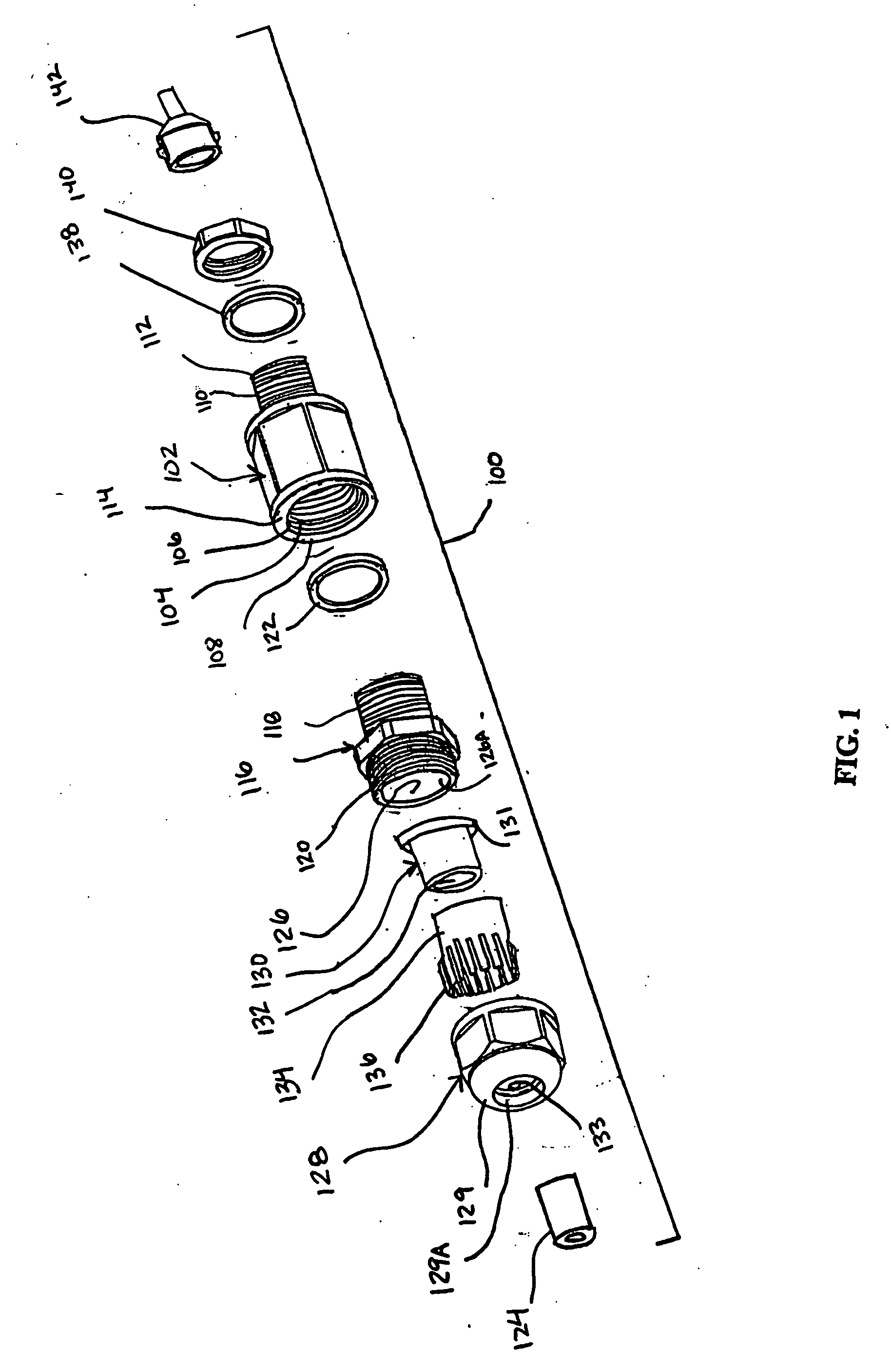

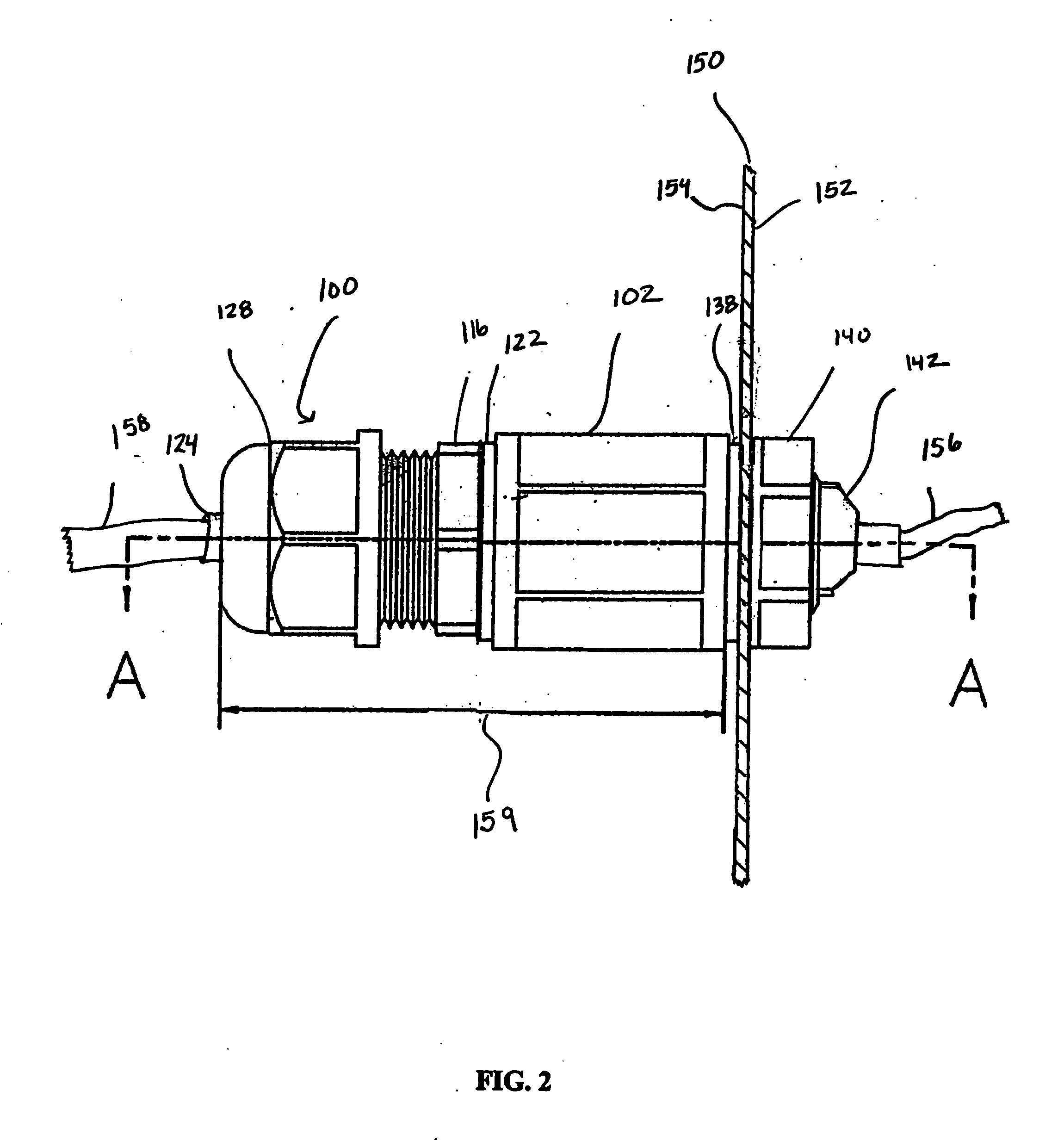

Low-cost weatherproof cable feedthrough

ActiveUS20060172578A1Electrically conductive connectionsRelieving strain on wire connectionOff the shelfMechanical engineering

An assembly for providing a weatherproof feedthrough for data communications cables into a structure. The assembly includes a unique housing having a cavity for removably receiving a connector attached to a terminal end of a cable in a fixed orientation. The cable attached to the connector in the cavity exits the assembly into a protected side of the structure. A cable from the unprotected side of the structure enters the assembly such that a connector disposed on its terminal end may be connected to the connector in the cavity. The assembly is particularly suited to allow off the shelf connectors to be used within the housing. The assembly may include strain relief devices for protecting the cables attached to the connectors.

Owner:TYCO ELECTRONICS LOGISTICS AG (CH)

Method and apparatus for providing hermetic electrical feedthrough

A method and apparatus suitable for forming hermetic electrical feedthroughs in a ceramic sheet having a thickness of ≦40 mils. More particularly, the method yields an apparatus including a hermetic electrical feedthrough which is both biocompatible and electrochemically stable and suitable for implantation in a patient's body. The method involves: (a) providing an unfired, ceramic sheet having a thickness of ≦40 mils and preferably comprising ≧99% aluminum oxide; (b) forming multiple blind holes in said sheet; (c) inserting solid wires, preferably of platinum, in said holes; (d) firing the assembly of sheet and wires to a temperature sufficient to sinter the sheet material but insufficient to melt the wires; and (e) removing sufficient material from the sheet lower surface so that the lower ends of said wires are flush with the finished sheet lower surface.

Owner:SECOND SIGHT MEDICAL PRODS

Liquid cell and passivated probe for atomic force microscopy and chemical sensing

ActiveUS20050199047A1Material analysis using sonic/ultrasonic/infrasonic wavesSurface/boundary effectAtomic force microscopyLiquid medium

The invention provides a liquid cell for an atomic force microscope. The liquid cell includes a liquid cell housing with an internal cavity to contain a fluid, a plurality of conductive feedthroughs traversing the liquid cell housing between the internal cavity and a dry side of the liquid cell, a cantilevered probe coupled to the liquid cell housing, and a piezoelectric drive element disposed on the cantilevered probe. The cantilevered probe is actuated when a drive voltage is applied to the piezoelectric drive element through at least one of the conductive feedthroughs. A method of imaging an object in a liquid medium and a method of sensing a target species with the liquid cell are also disclosed.

Owner:BOARD OF RGT NEVADA SYST OF HIGHER EDUCATION ON BEHALF OF THE UNIV OF NEVADA RENO

Feedthrough capacitor filter assemblies with laminar flow delaminations for helium leak detection

A feedthrough filter capacitor assembly includes a capacitor having first and second sets of conductive electrode plates embedded within a dielectric body and mounted to the hermetic terminal of an implantable medical device. A laminar delamination gap is provided between the capacitor sealing materials and the hermetic terminal assembly to facilitate helium leak detection. At least one feedthrough terminal pin extends through the capacitor in conductive relation with the first set of electrode plates, and an outer ferrule is mounted about the capacitor in conductive relation with the second set of electrode plates. The mounting washer is spaced against the hermetic seal and is adhesively connected to the feedthrough capacitor. The mounting washer forms a laminar flow delamination through which helium molecules can flow during a helium leak detection test. Provision is made for a pre-connection to the gold braze so that the capacitor inside diameter termination is not electrically isolated from the lead wire.

Owner:WILSON GREATBATCH LTD

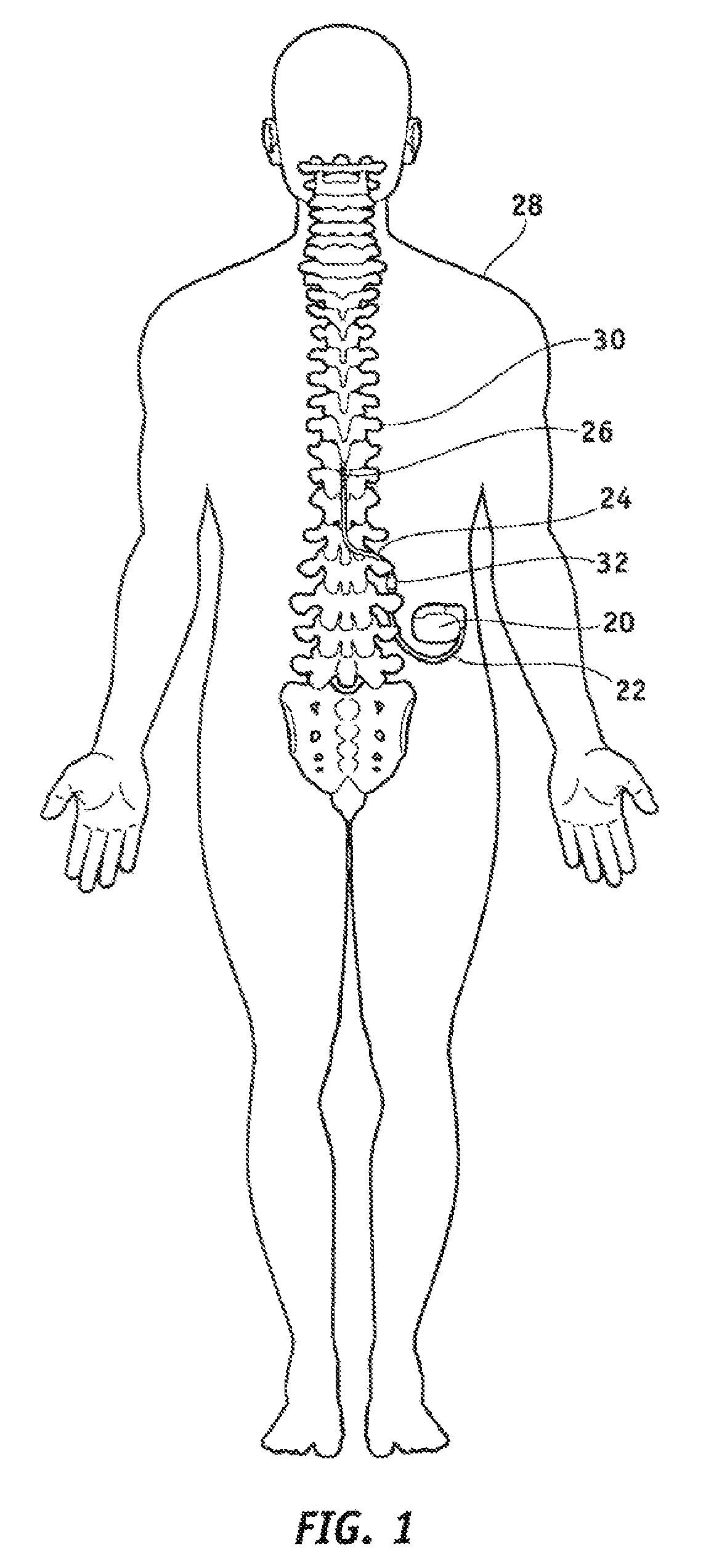

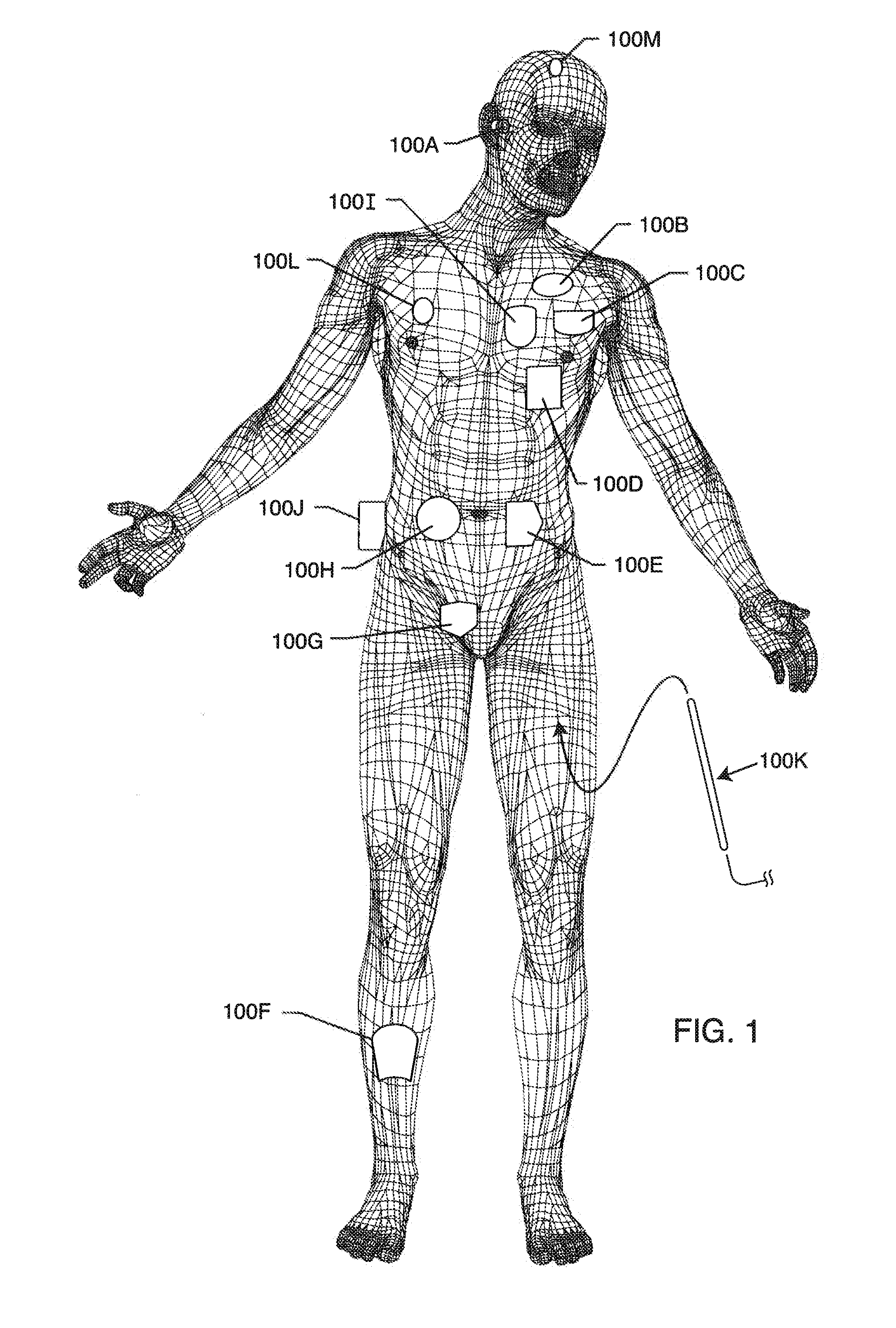

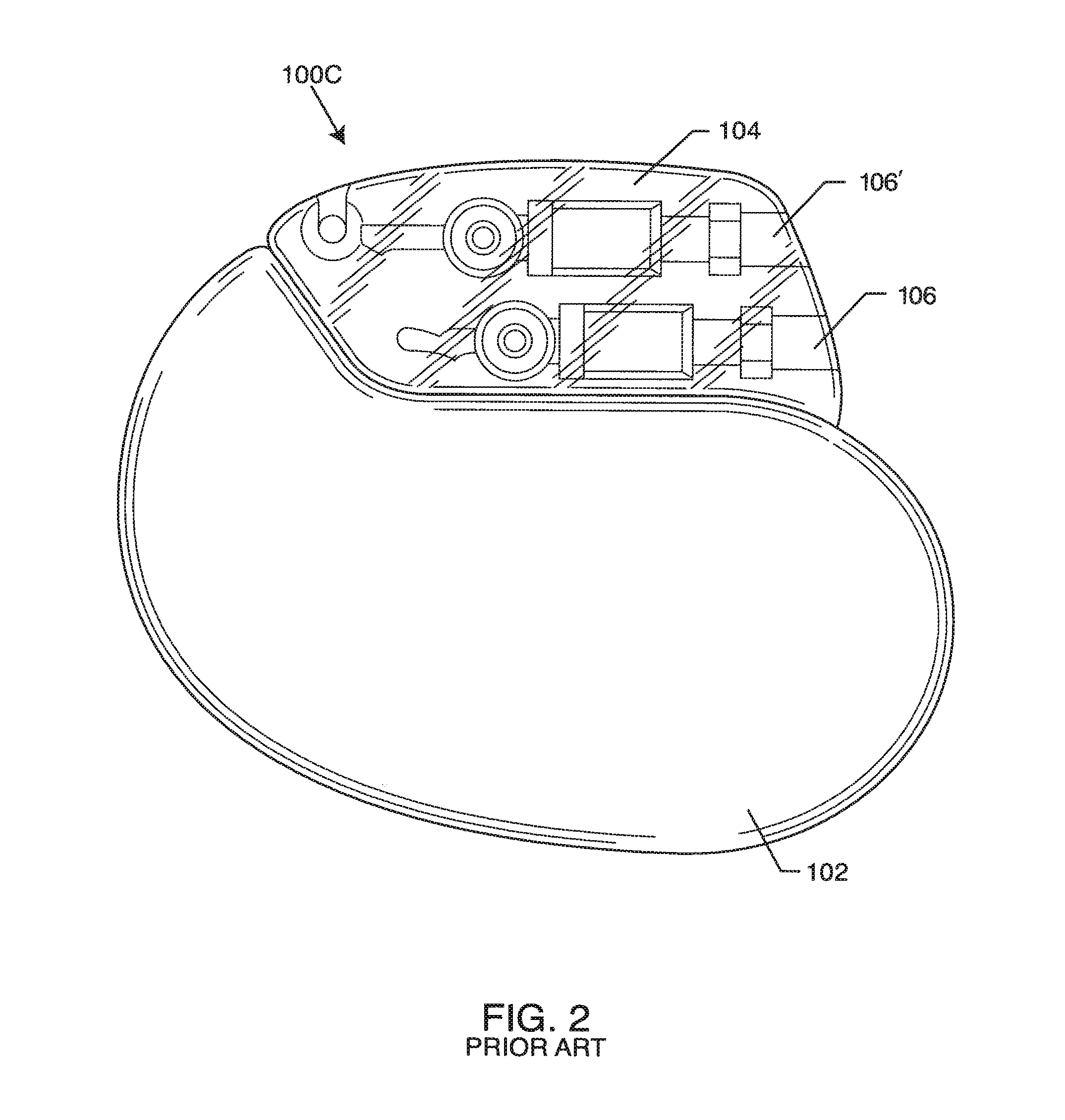

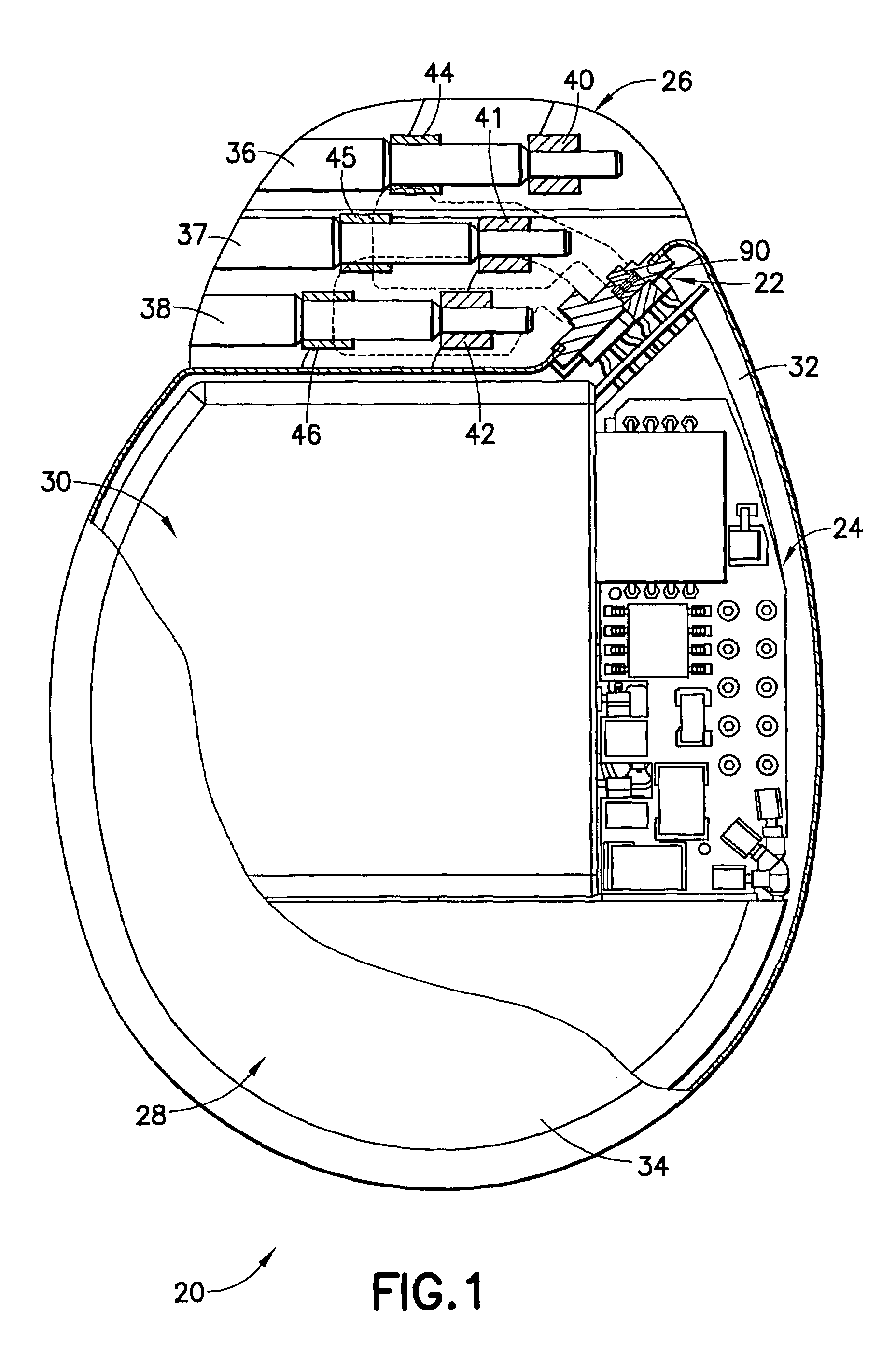

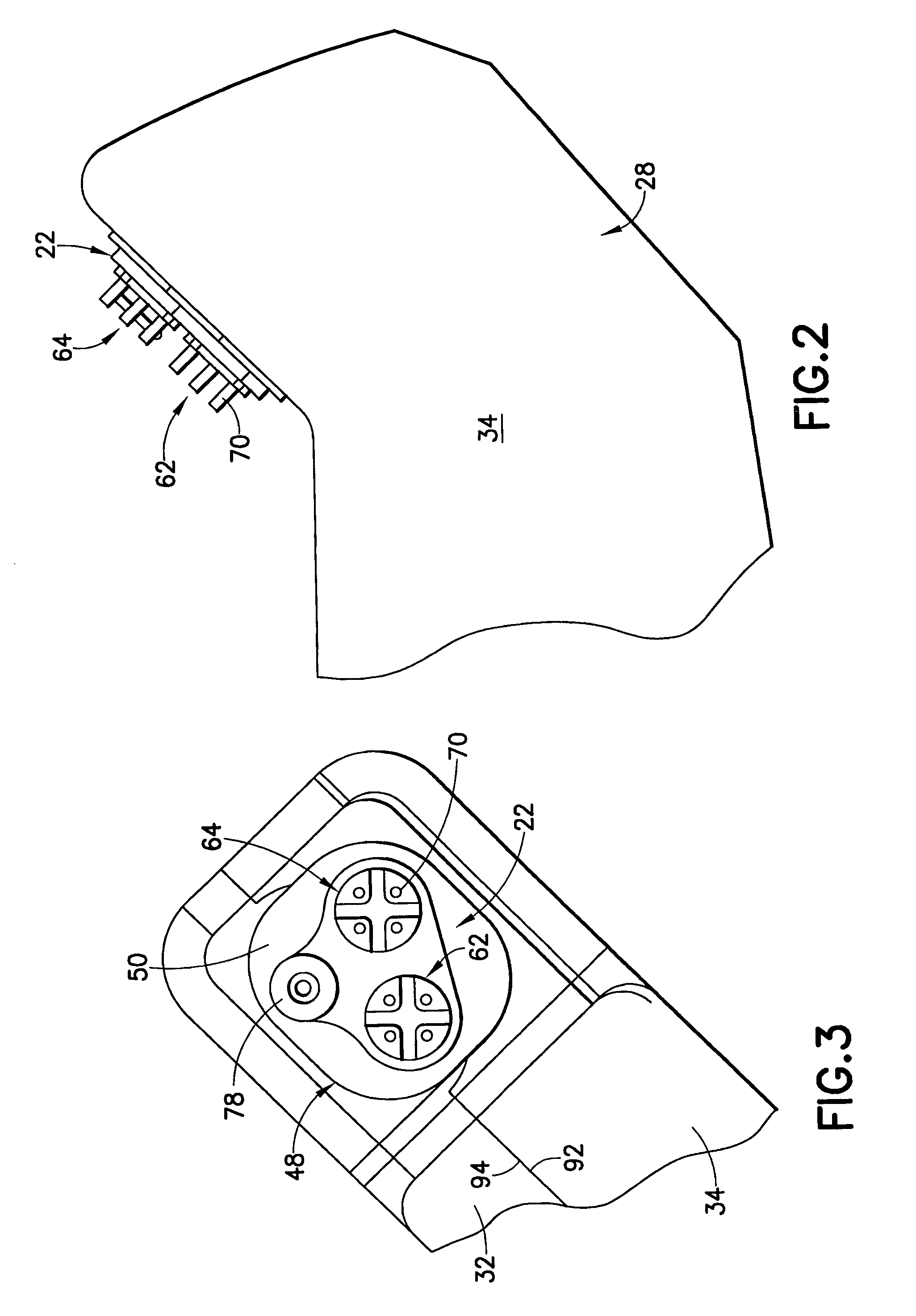

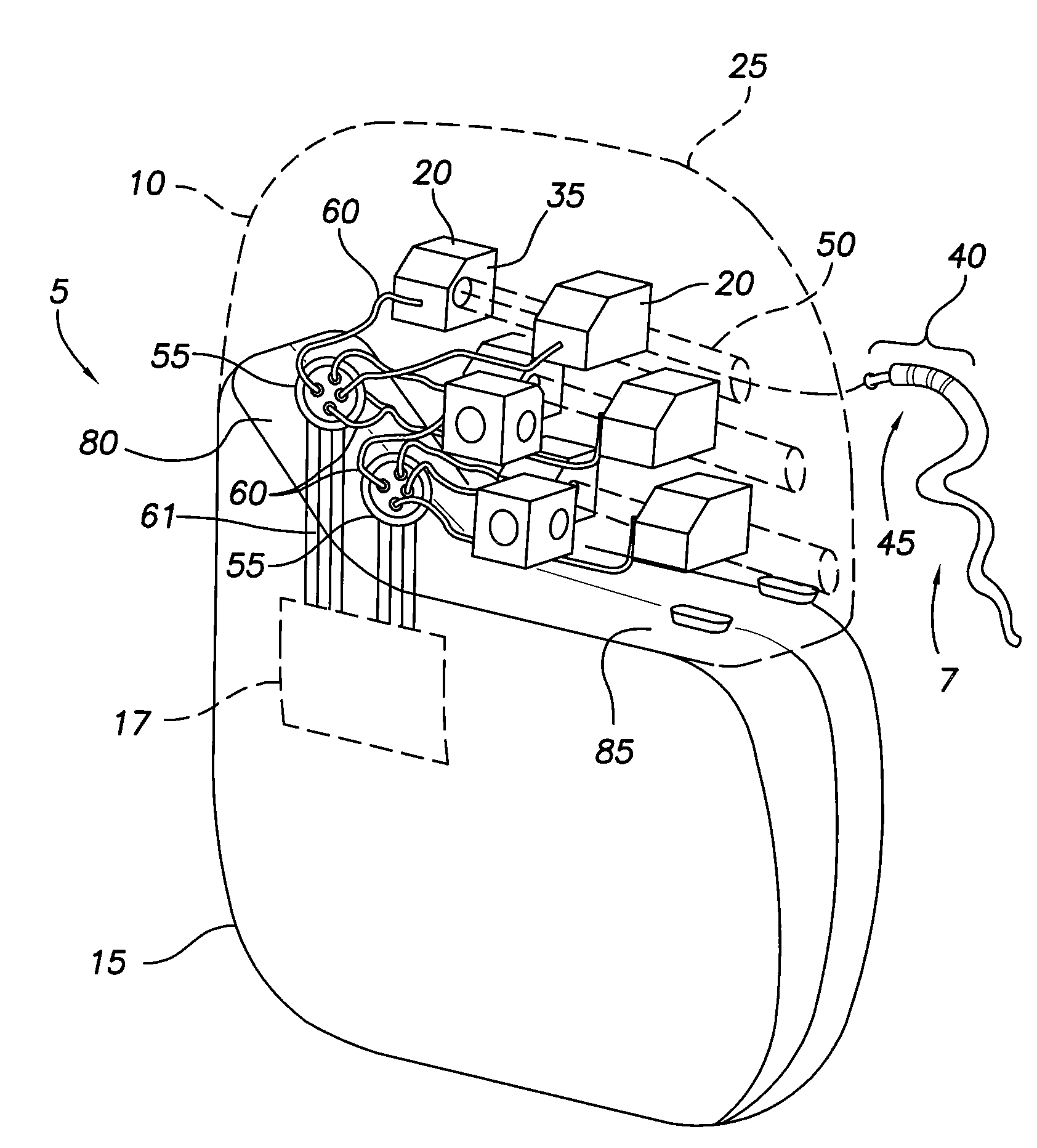

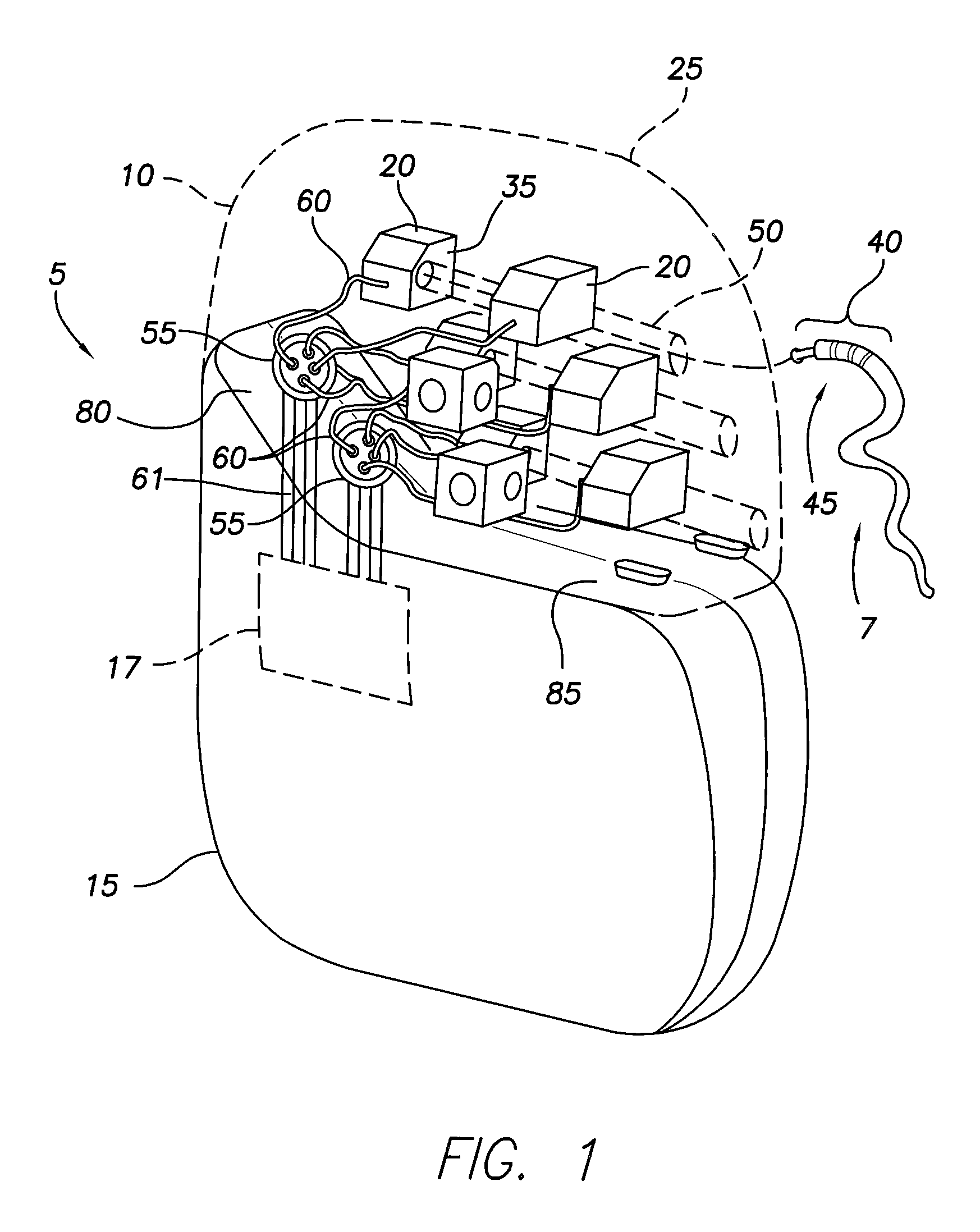

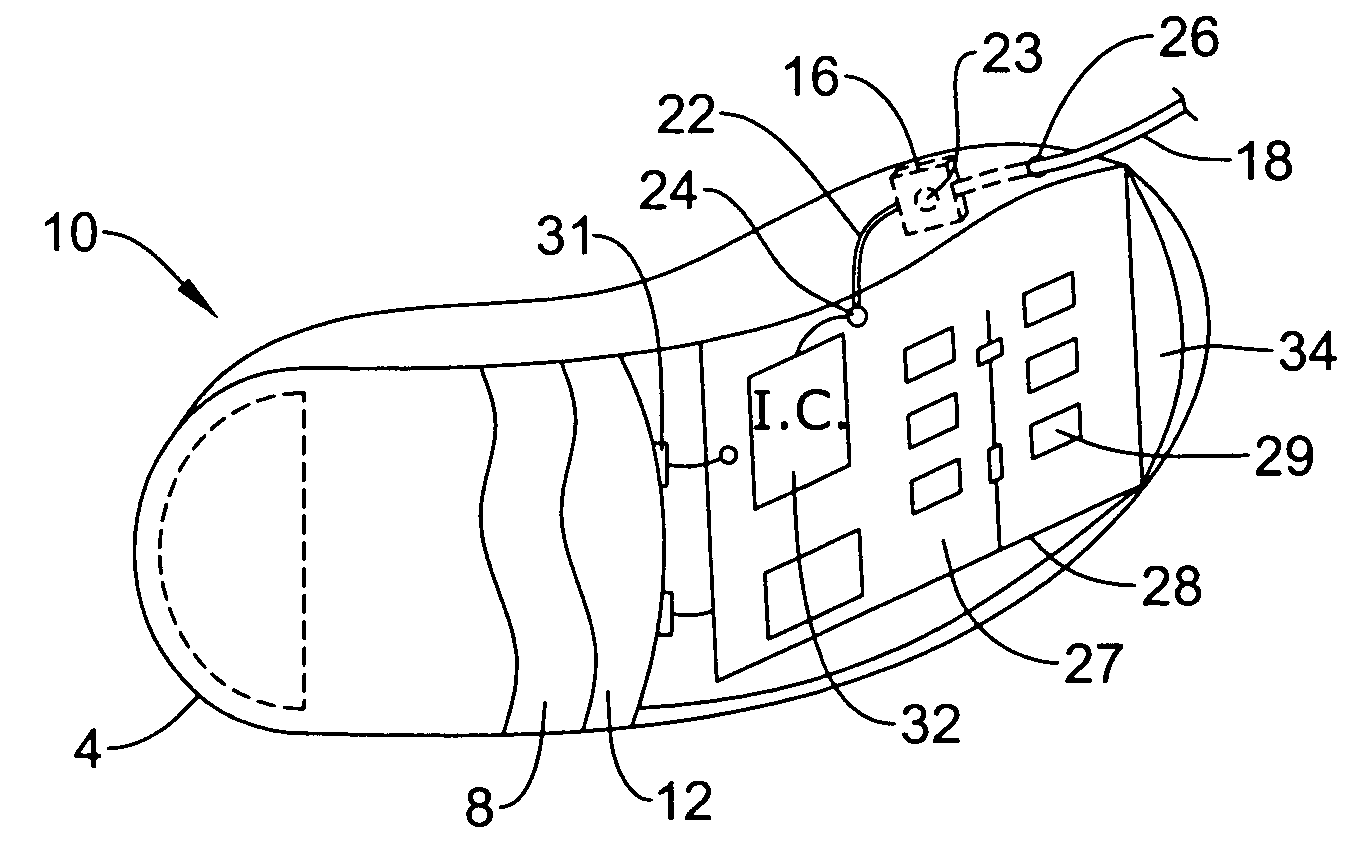

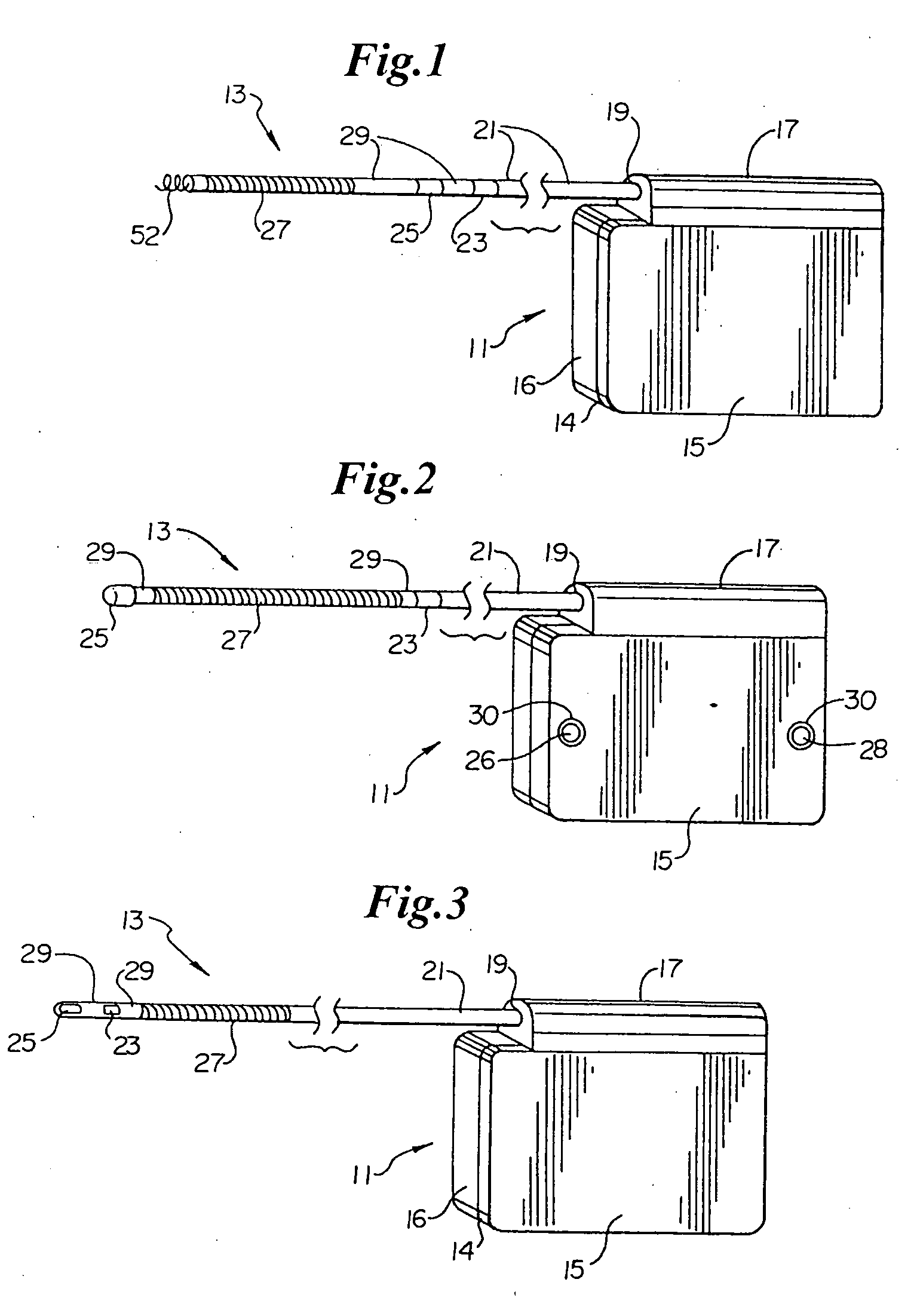

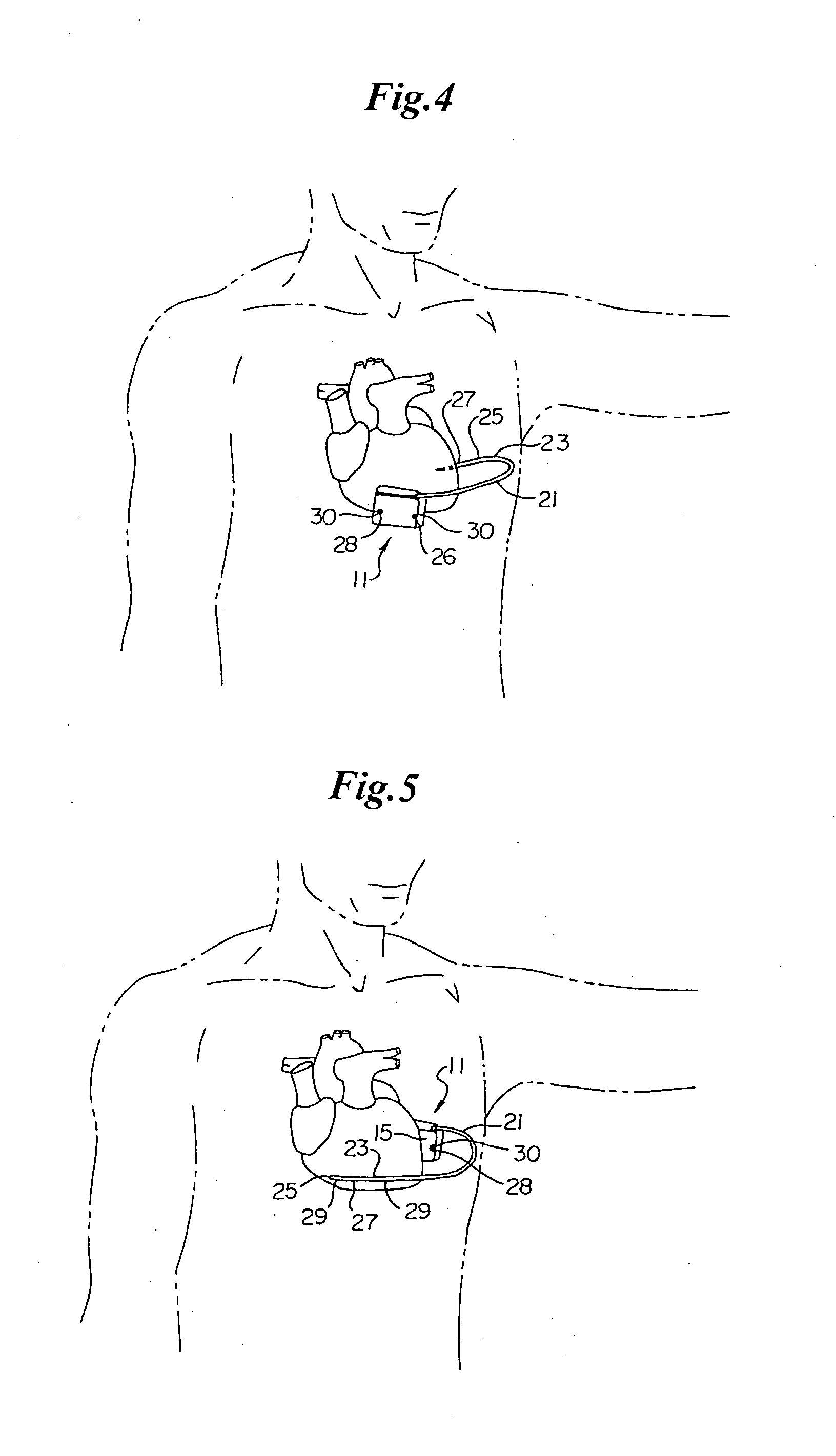

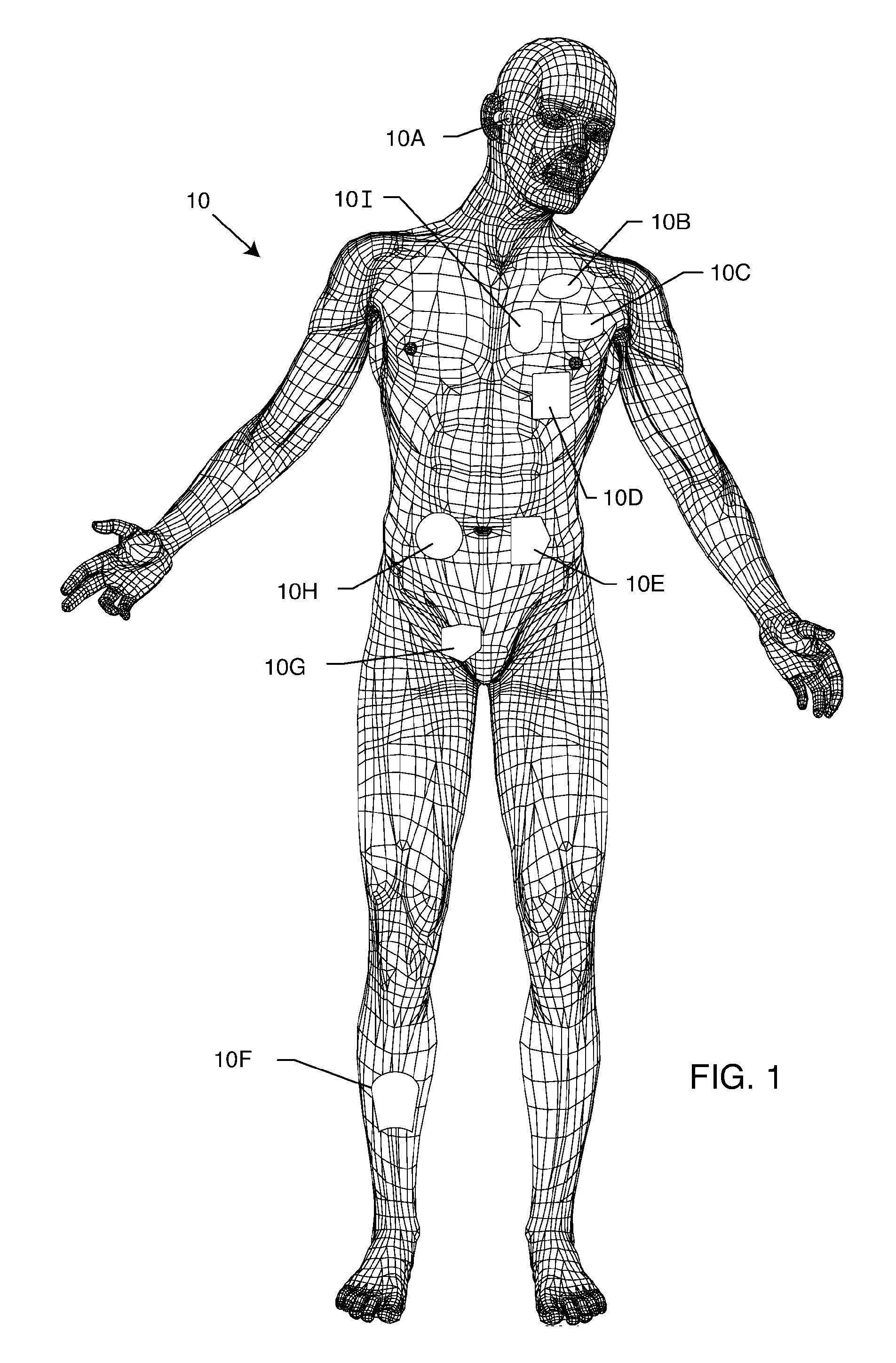

Packaging technology for non-transvenous cardioverter/defibrillator devices

Packaging techniques for a non-transvenous implantable cardioverter / defibrillator include a housing and a frame within the housing for holding electronic components. A header is disposed on the housing and includes at least one feedthrough extending through the housing for providing electrical communication to and from the electronic components within the housing.

Owner:CAMERON HEALTH

Filter feedthrough for implants

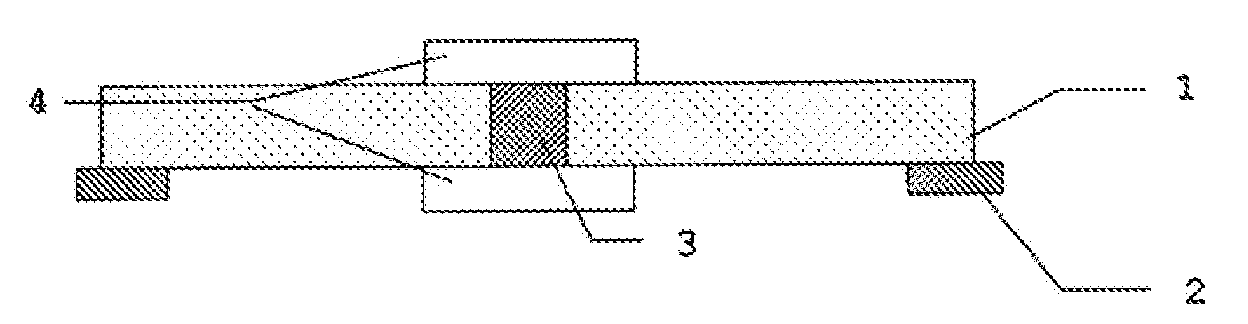

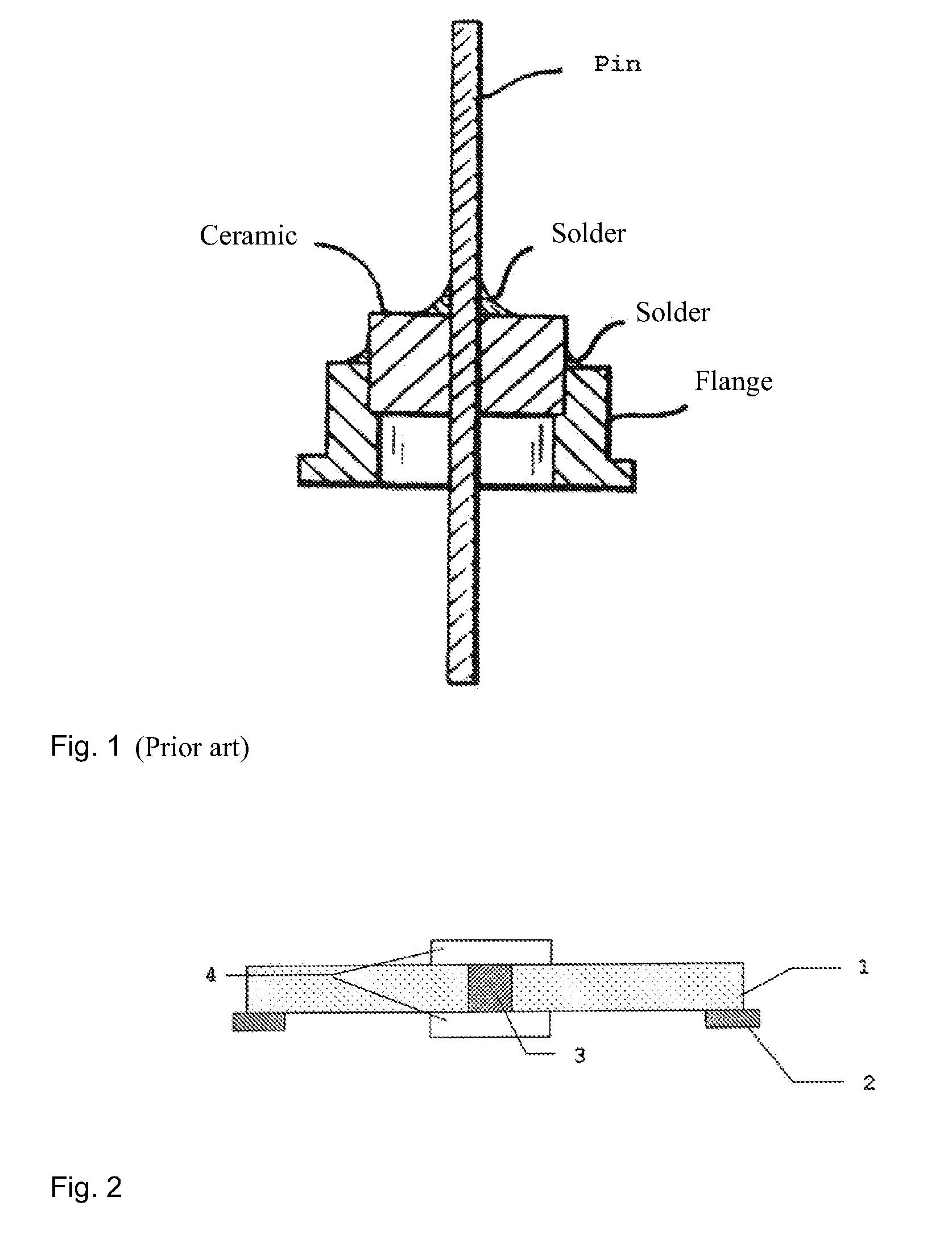

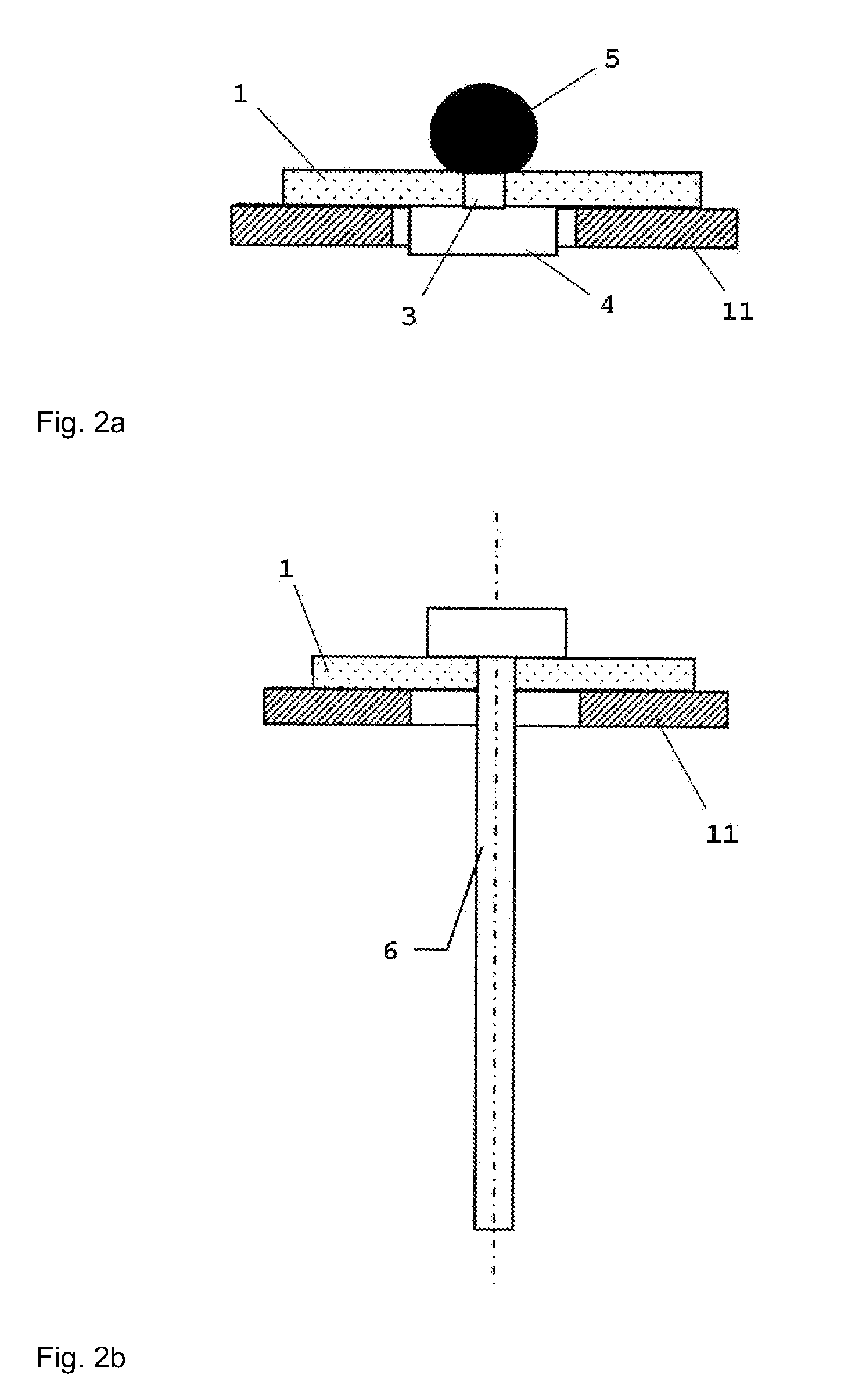

A new hermetically-sealed contact feedthrough for cardiac pacemakers and defibrillators for the connection between internal device electronics and external components, a flat ceramic disk (1) being used as an insulating main carrier, in which openings (3) are situated, into which various electrode embodiments (4, 5, 6, 7) may be inserted as through contacts. Using a metal flange or metal-plated vapor deposition zone (2), the ceramic disk may be soldered directly onto the implant housing (11). In addition, active and passive auxiliary components (8) may be applied directly to the ceramic. The main carrier may be implemented as a multilayer ceramic (9), so that rewiring levels and shielding components (10) may be integrated in the feedthrough. The feedthrough according to the present invention allows novel construction variants, above all things having orientation to multipolar systems, through use of standardized ceramic semifinished products.

Owner:BIOTRONIK SE & CO KG

Device to protect an active implantable medical device feedthrough capacitor from stray laser weld strikes, and related manufacturing process

InactiveUS20060028784A1Protect the surfaceAnti-noise capacitorsElectrotherapyManufacturing technologyCeramic capacitor

An insulative shield is co-bonded to the top of a ceramic capacitor in a feedthrough terminal assembly on an active implantable medical device. The insulative shield is a thin substrate that provides protection against damage and degradation of the feedthrough capacitor and / or its conformal coating from heat, splatter or debris resulting from the electromechanical connection of components during construction of the assembly. Laser welding, thermal or ultrasonic bonding, soldering, brazing or related lead attachment techniques can create such heat, splatter or debris. In a preferred embodiment, the insulative shield is co-bonded using the capacitor's own conformal coating.

Owner:WILSON GREATBATCH LTD

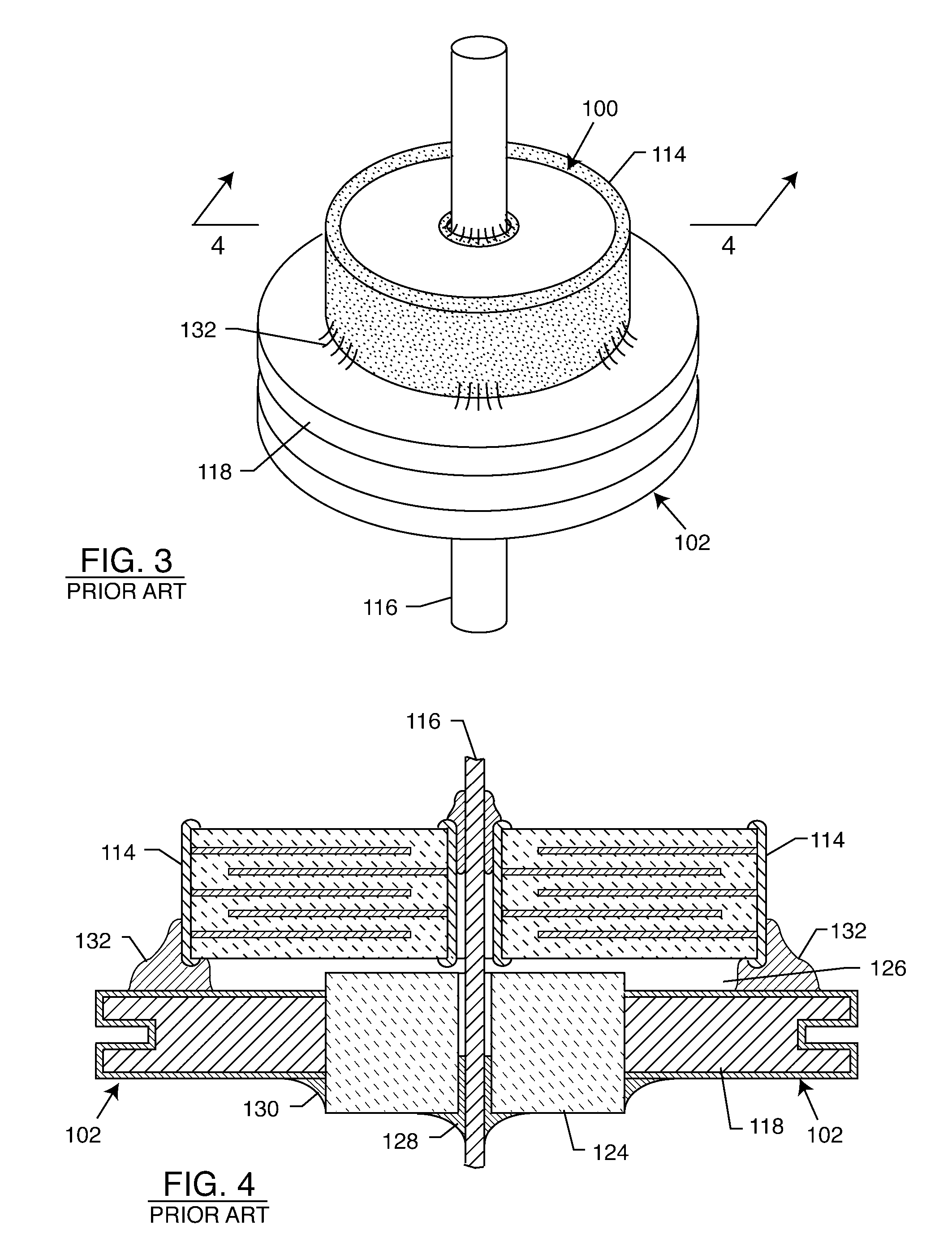

High-voltage feedthrough capacitor

InactiveUS6510038B1Increase capacitanceImprove filtering effectAnti-noise capacitorsTransit-tube leading-in arrangementsElectrical conductorEngineering

In a high-voltage feedthrough capacitor, a grounding member has two through-holes spaced away from each other. Feedthrough capacitors each has one central conductor, a dielectric layer, and an electrode. The periphery of the central conductor is respectively covered with the dielectric layer, and the surface of the dielectric layer is respectively covered with the electrode. The feedthrough capacitor extends respectively through the through-hole, and has been fitted to the grounding member. The electrode has been bonded to the grounding member. An armoring insulator covers the peripheries of the feedthrough capacitors and the periphery of the grounding member.

Owner:TDK CORPARATION

Electromagnetically coupled hermetic chamber

ActiveUS20060241354A1Reduce sensitivityReducing drift and instabilityFluid pressure measurement by electric/magnetic elementsEvaluation of blood vesselsElectromagnetic couplingElectronics

An electromagnetically coupled hermetic chamber includes a body defining a hermetic chamber. A first conductive structure is disposed within the hermetic chamber, and a second conductive structure is attached to the body outside of the hermetic chamber. The first conductive structure is electromagnetically coupled to the second conductive structure without direct electrical paths connecting the first and second conductive structures. Thus the first conductive structure can be coupled to external electronics without the need for electrical feedthroughs or vias that could compromise the integrity of the hermetic chamber.

Owner:ST JUDE MEDICAL LUXEMBOURG HLDG II S A R L SJM LUX II

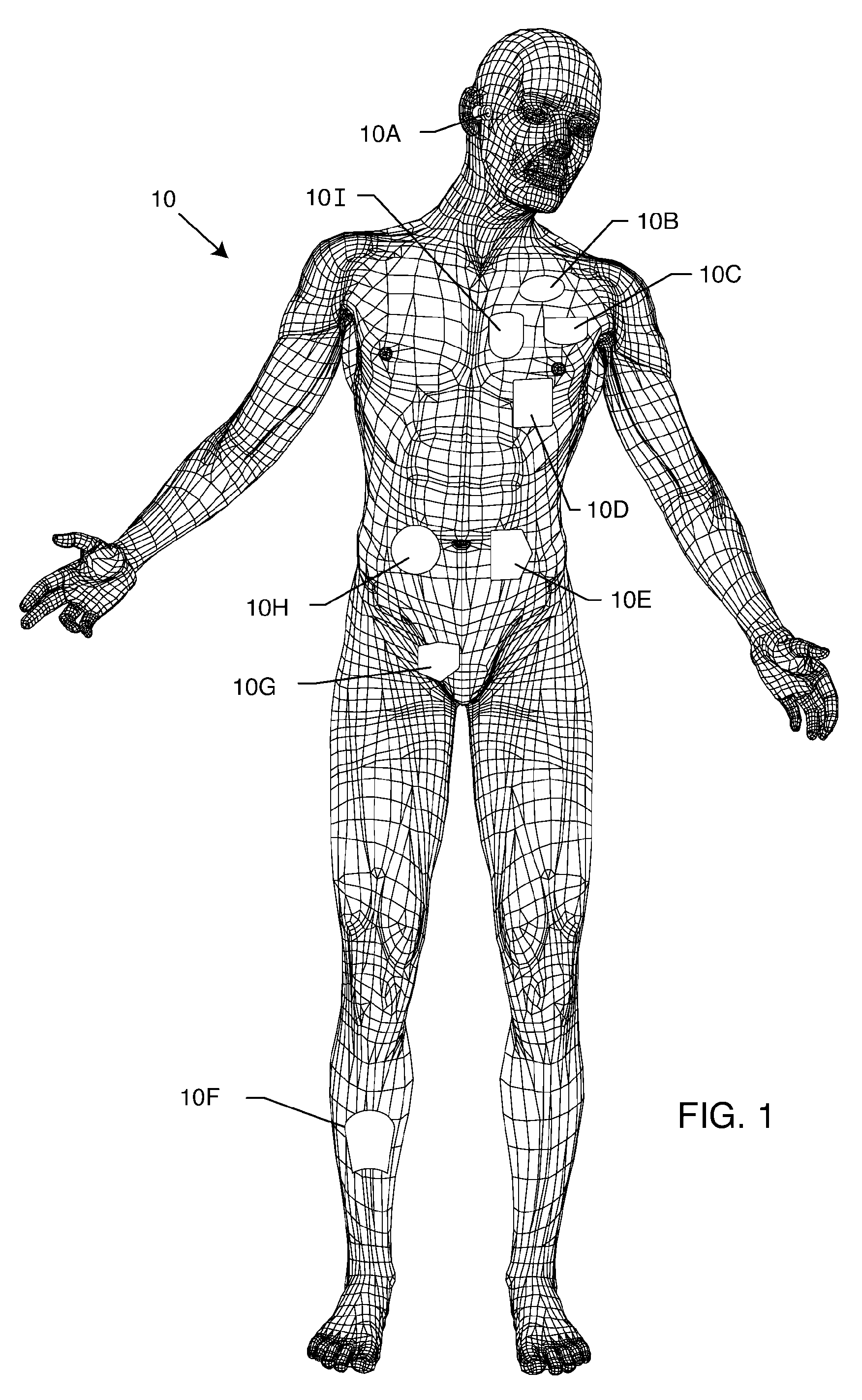

Implantable biocompatible component integrating an active sensor for measurement of a physiological parameter, a micro-electromechanical system or an integrated circuit

ActiveUS20080102096A1Reduce manufacturing costDiagnostic recording/measuringSensorsElectricityIntegrated electronics

An implantable biocompatible component (10) integrating an active element of the type of a sensor for the measurement of a physiologic parameter, a micro-electromechanical system and an integrated electronic circuit. This component (10) has a substrate (12) and a lid (22) in silicon or quartz. The substrate (12) integrates the active element (14) and biocompatible metallic pads (16), electrically connected to the active element. The lid (22) encompasses and peripherally closes the substrate in a hermetic manner, level with the face integrating the active element. This component is void of metallic case for insulation between the active element and outside environment, and of insulative feedthrough for electrical connection to the active element. The substrate and lid can be directly welded to each other through their faces in vis-à-vis, or by interpositioning a sealing ring made of a biocompatible material.

Owner:SORIN CRM

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com