Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

77 results about "Isothermal process" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

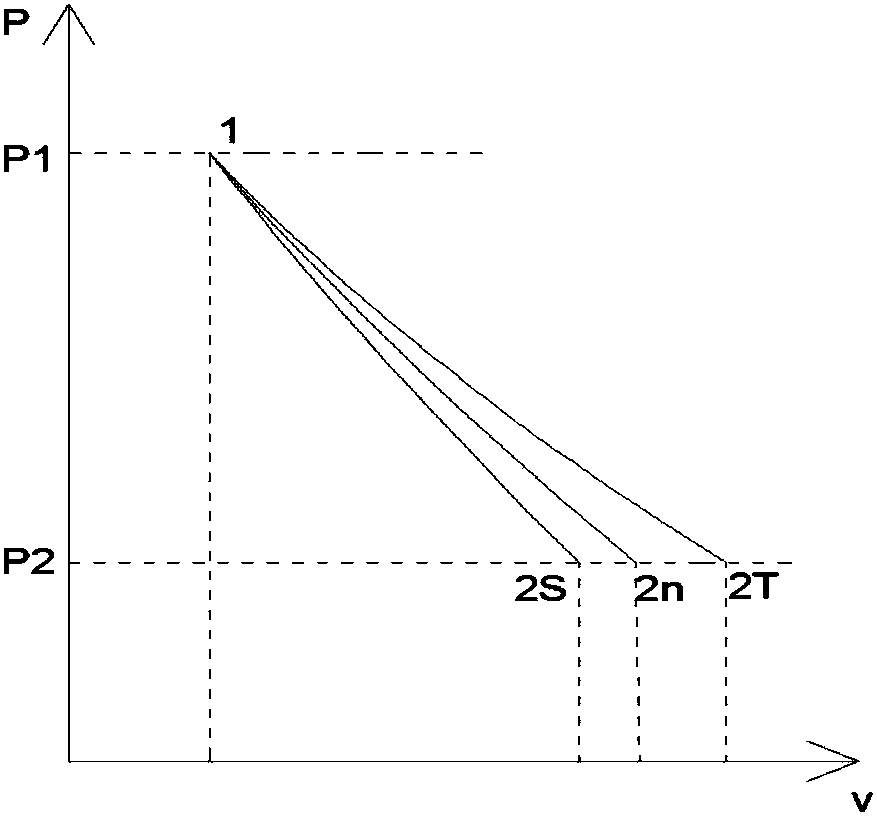

An isothermal process is a change of a system, in which the temperature remains constant: ΔT =0. This typically occurs when a system is in contact with an outside thermal reservoir (heat bath), and the change in the system will occur slowly enough to allow the system to continue to adjust to the temperature of the reservoir through heat exchange. In contrast, an adiabatic process is where a system exchanges no heat with its surroundings (Q = 0).

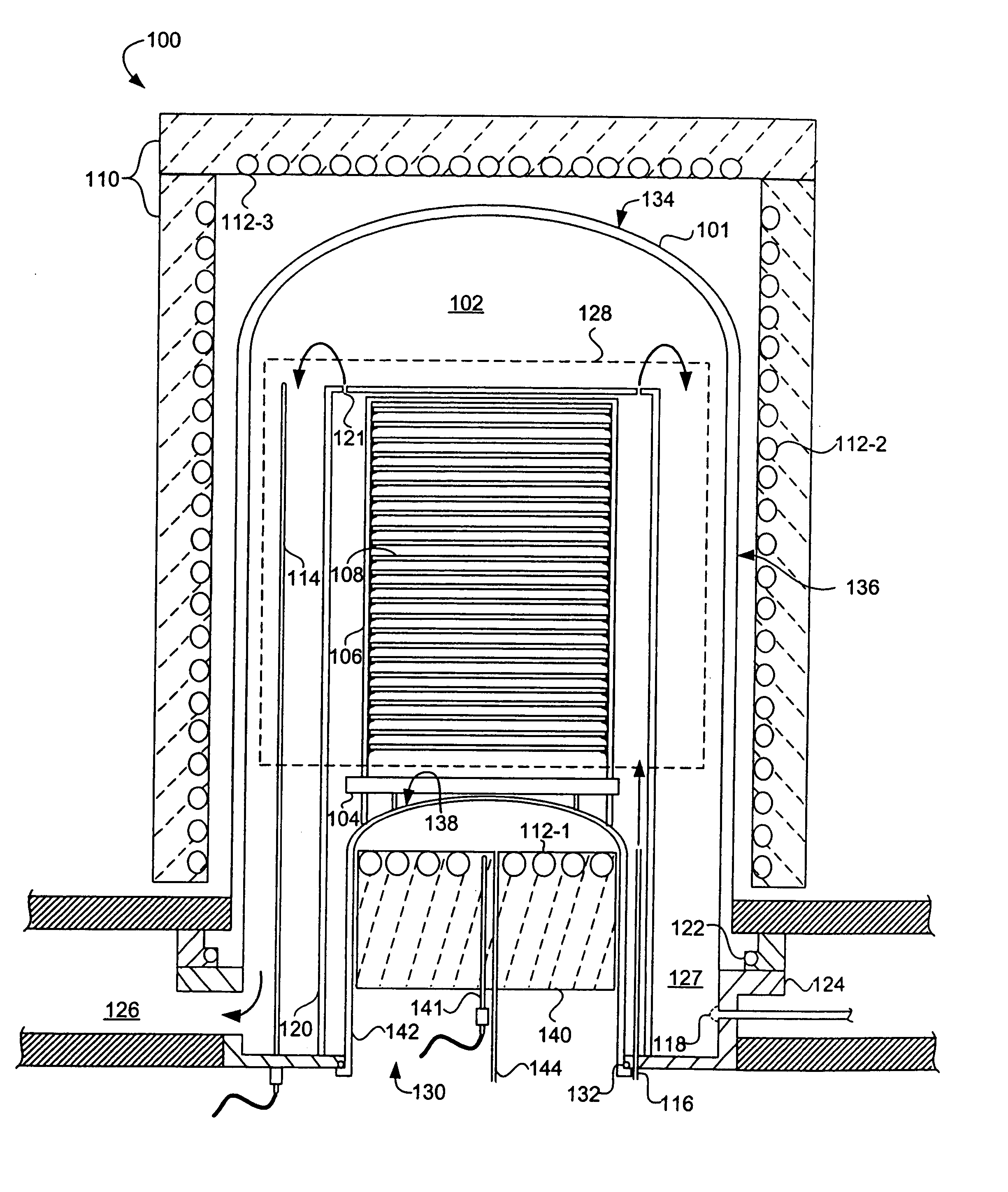

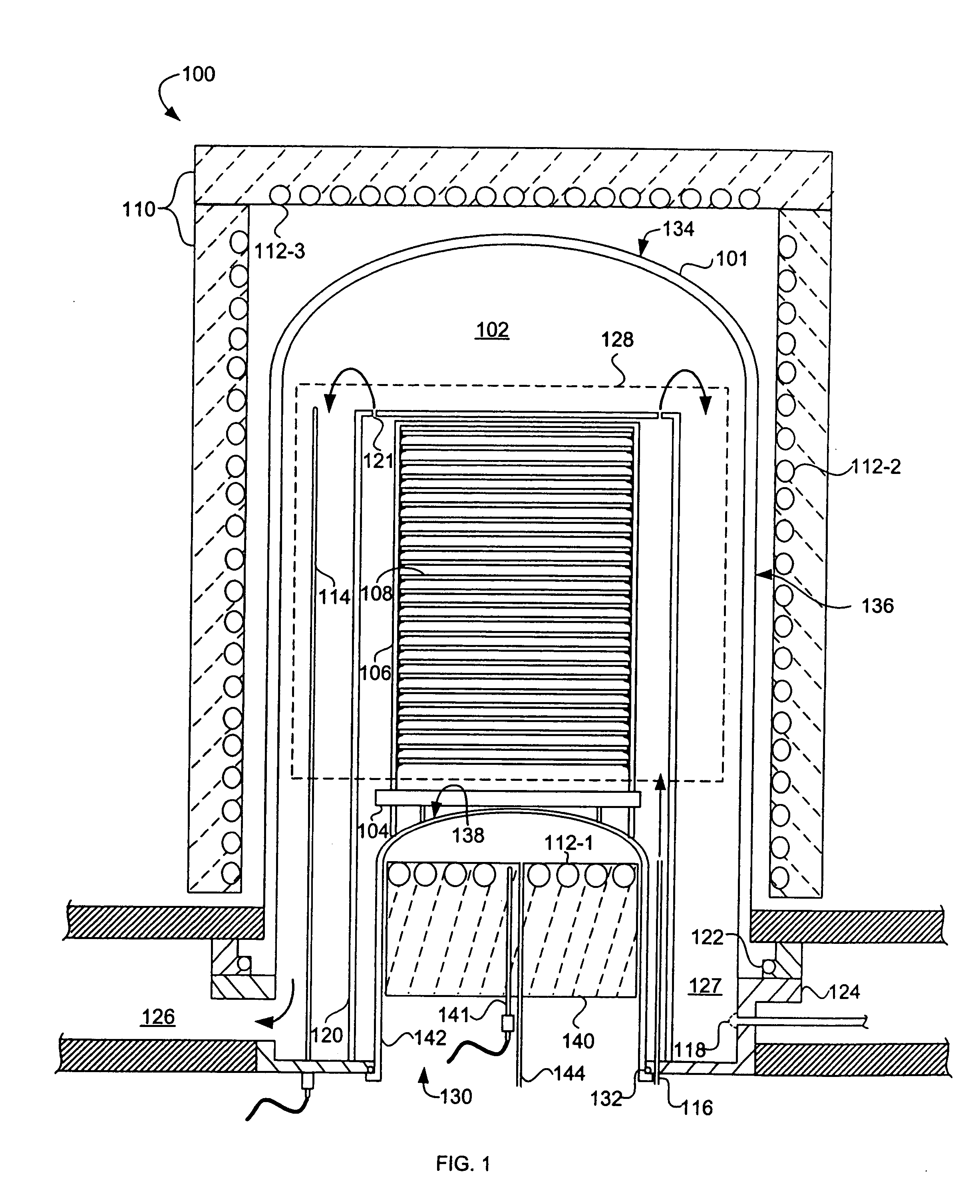

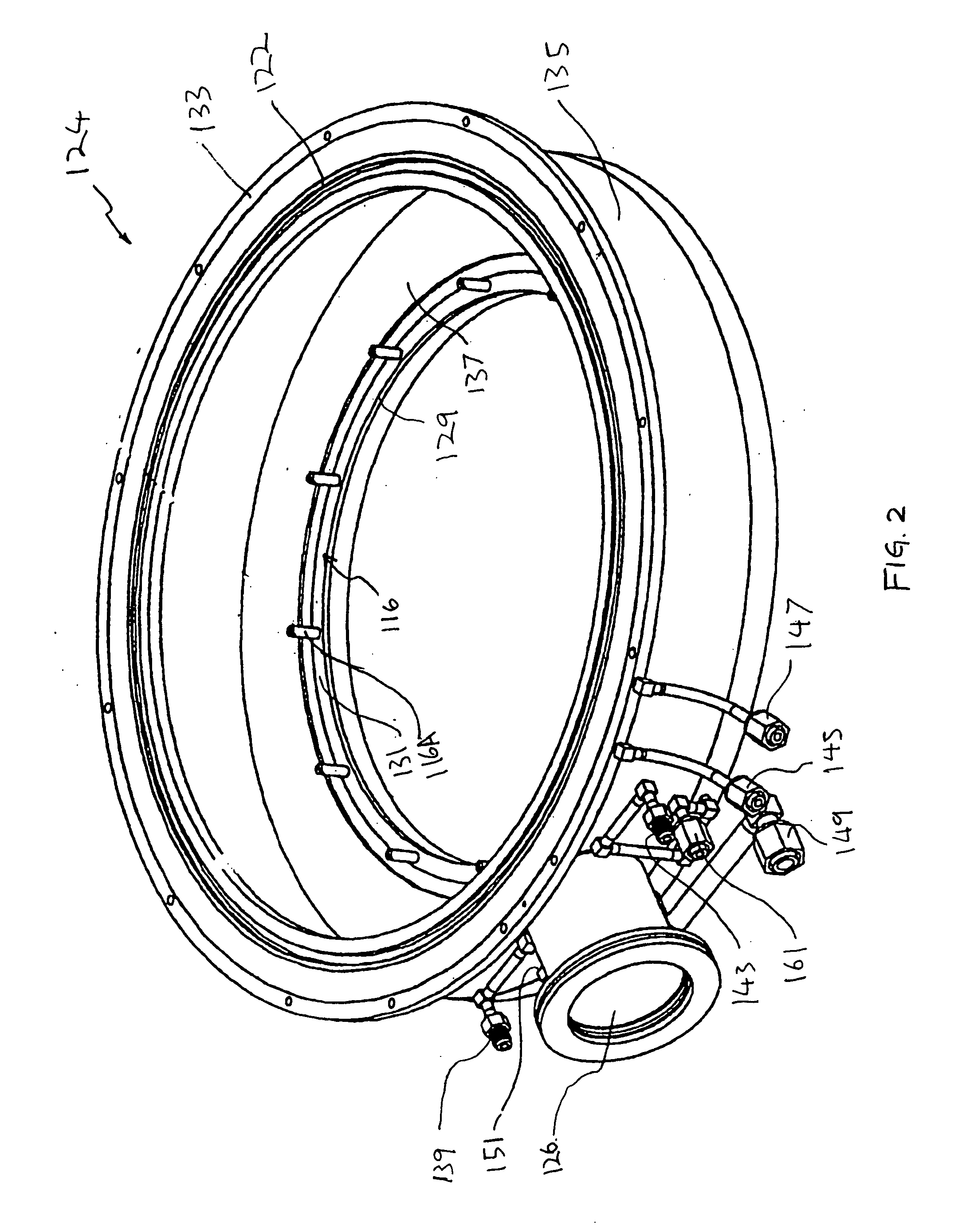

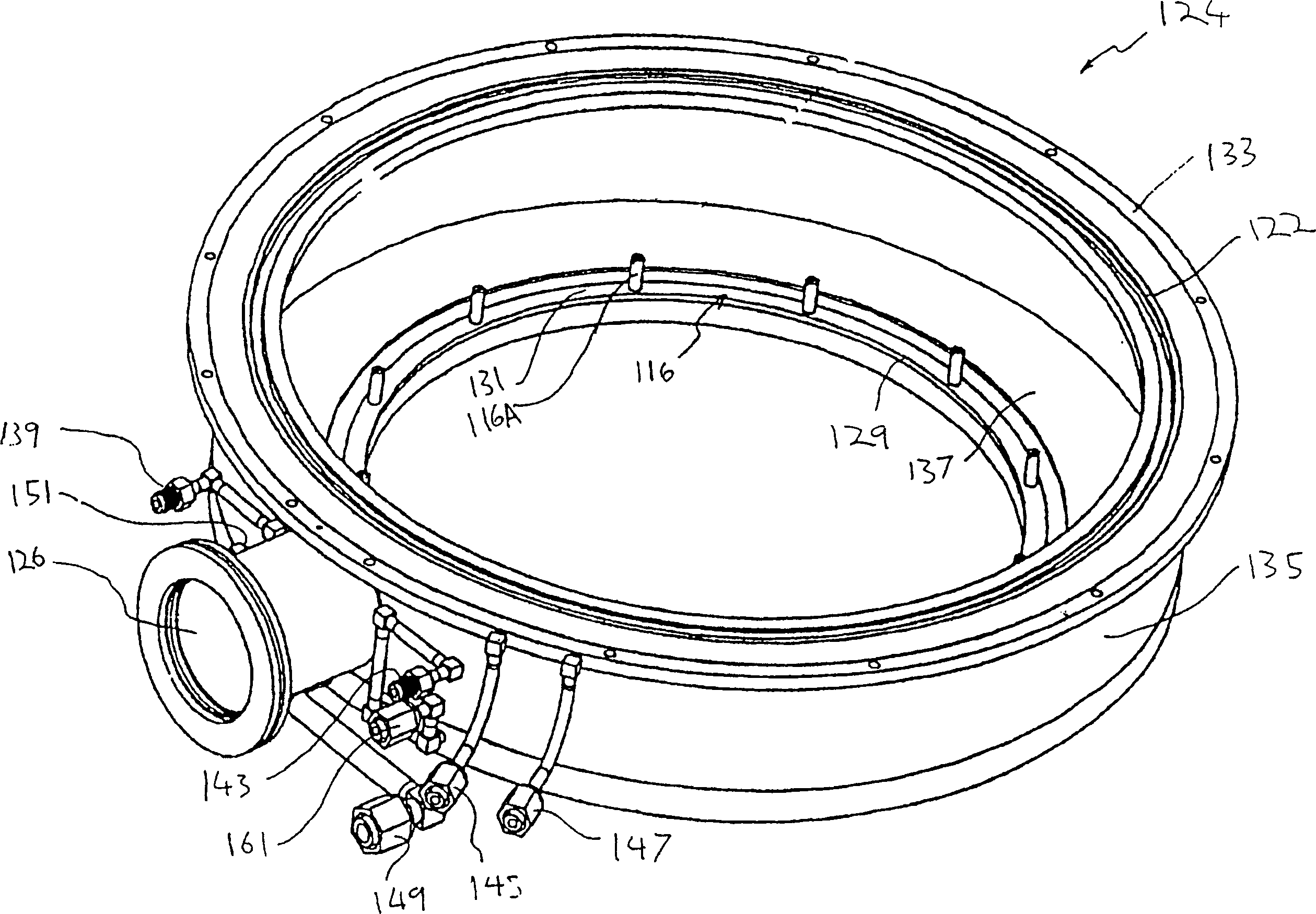

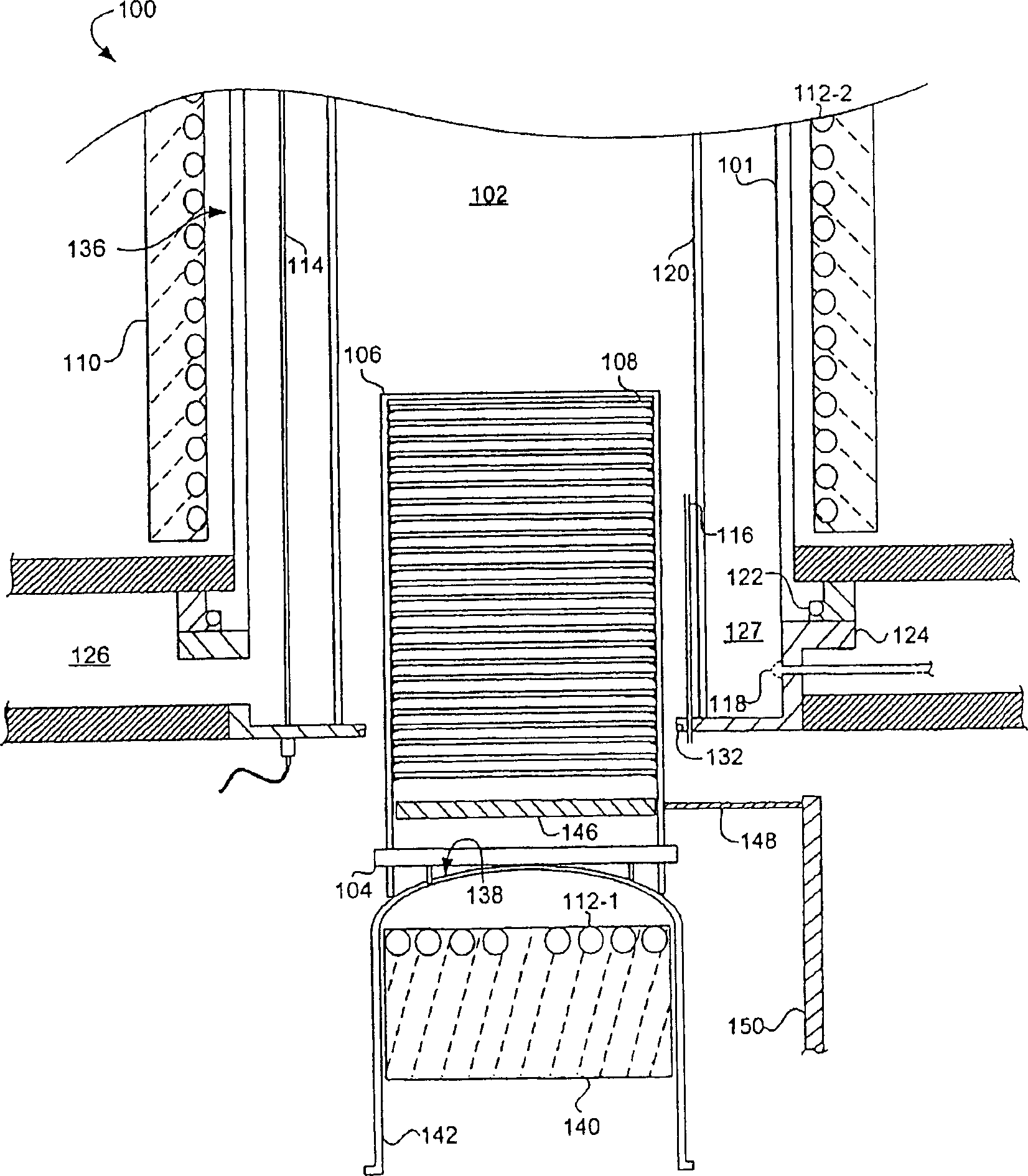

Thermal Processing System and Configurable Vertical Chamber

InactiveUS20070243317A1Semiconductor/solid-state device manufacturingLiquid/solution decomposition chemical coatingEngineeringIsothermal process

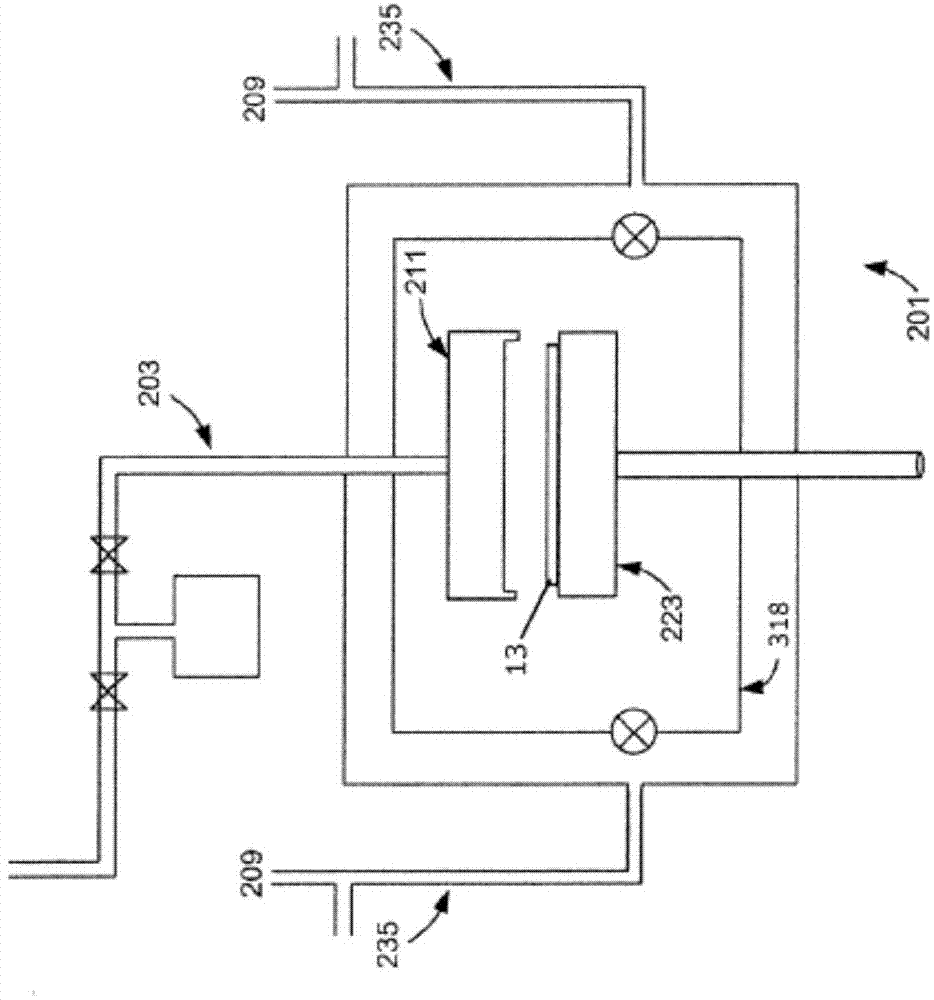

An apparatus (100) and method are provided for thermally processing substrates (108) held in a carrier (106). The apparatus (100) includes a vessel (101) having a top (134), side (136) and bottom (138), and a heat source (110) with heating elements (112-1, 112-2, 112-3) proximal thereto. The vessel (101) is sized to enclose a volume substantially no larger than necessary to accommodate the carrier (106), and to provide an isothermal process zone (128) extending throughout. In one embodiment, the bottom wall (138) includes a movable pedestal (140) with a bottom heating element therein (112-1), and the pedestal can be lowered and raised to insert the carrier (106) into the vessel (101). The apparatus (100) can include a movable shield (146) that is inserted between the pedestal (140) and the carrier (106) to shield the substrates (108) from the heating element (112-1) and to maintain pedestal temperature. A magnetically coupled repositioning system (162) repositions the carrier (106) during processing of the substrates (108) without use of a movable feedthrough into the volume enclosed by the vessel (101), and without moving the bottom heating element (112-1) in the pedestal (140).

Owner:DU BOIS DALE R +4

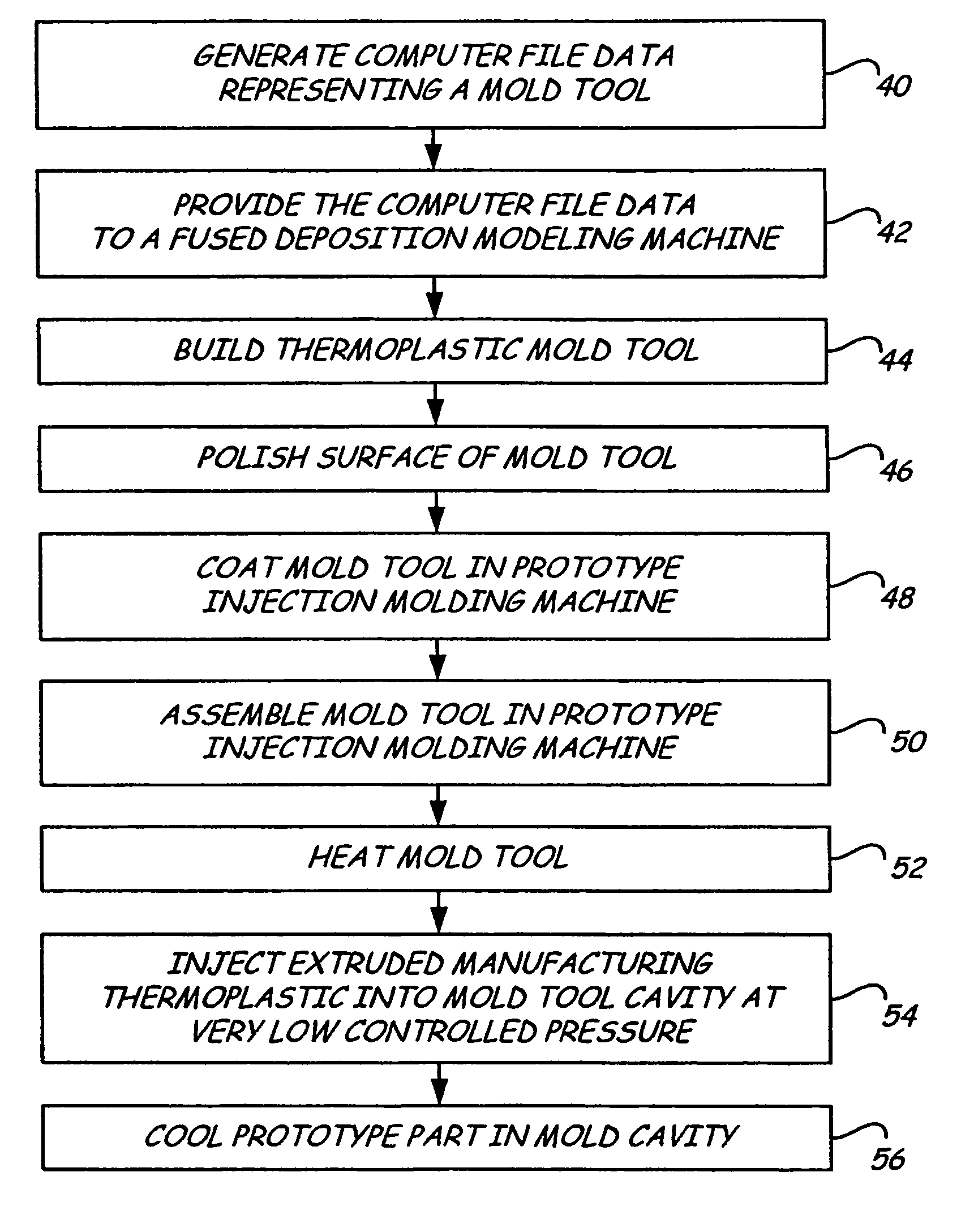

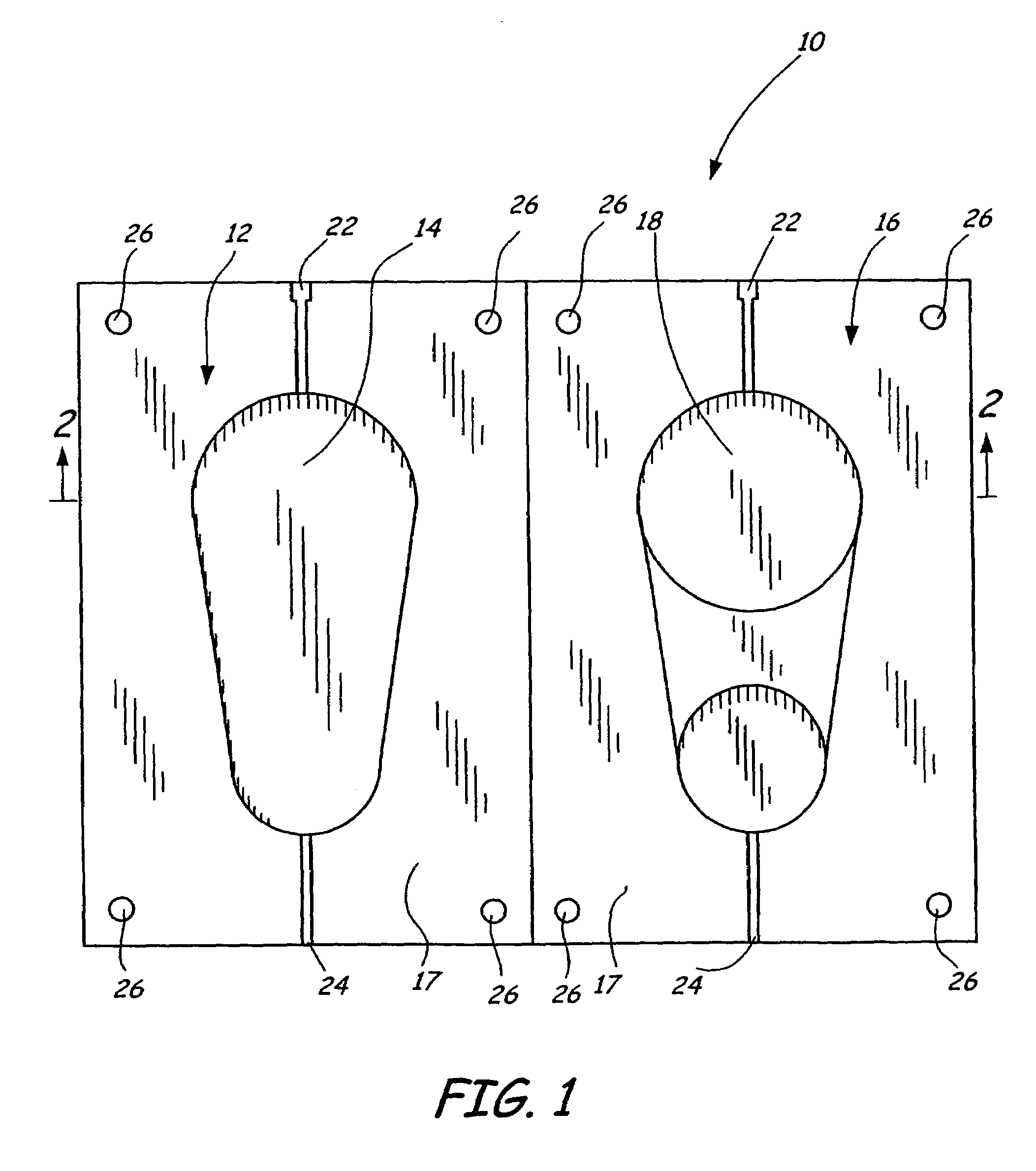

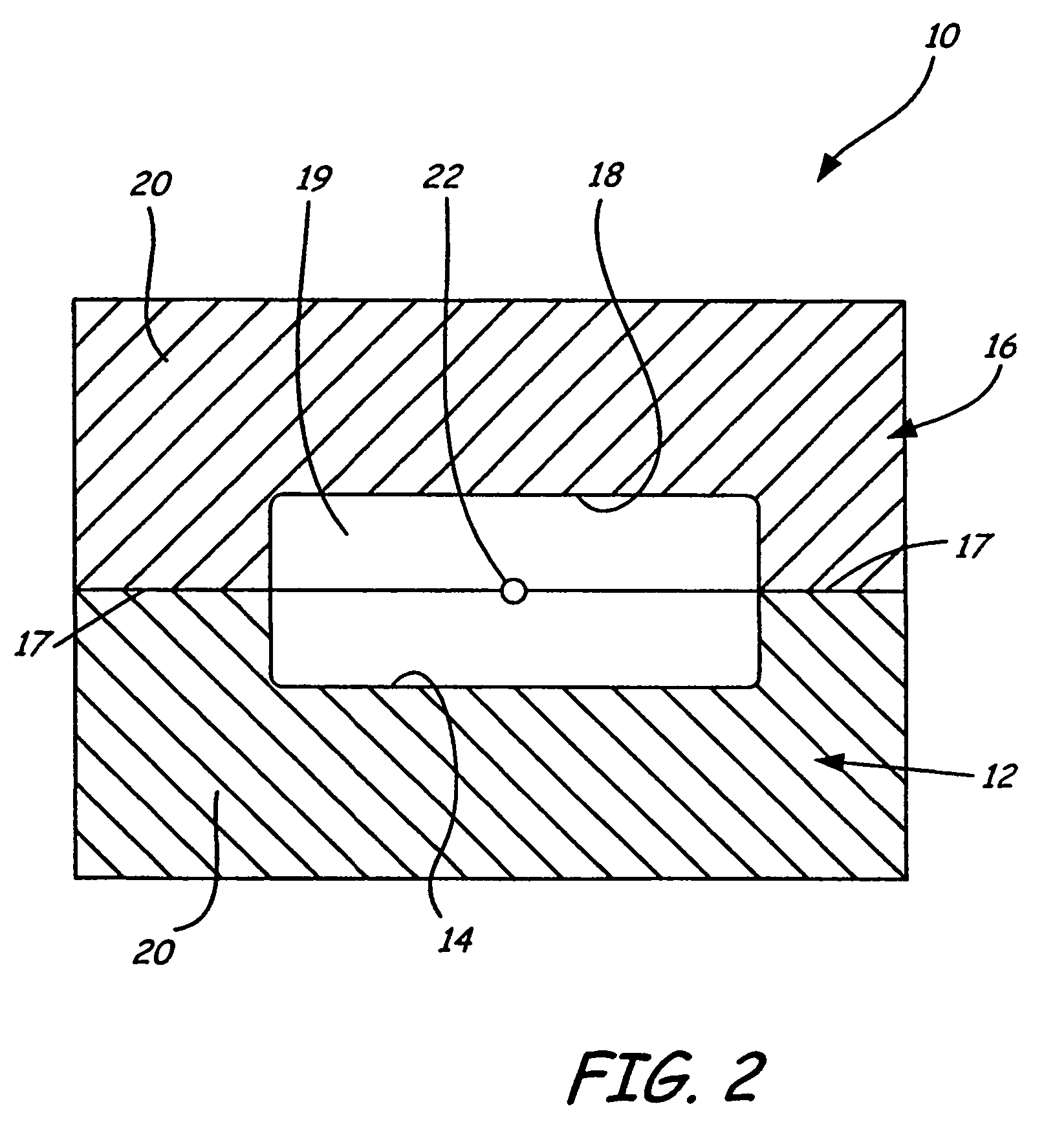

Rapid prototype injection molding

InactiveUS7125512B2Additive manufacturing apparatusMechanical vibrations separationInjection mouldingRapid prototyping

Owner:STRATSYS INC

Isothermal nucleic acid amplification

ActiveUS20110123991A1Easy to separateMicrobiological testing/measurementFermentationStrand invasionOligonucleotide

An isothermal process for amplifying a nucleic acid target molecule that relies on an upstream primer, a downstream primer, a strand invasion system and an oligonucleotide, wherein the upstream and downstream primers are not substrates for the strand invasion system during the amplification process and do not amplify the target molecule independently of the strand invasion system, wherein the oligonucleotide is a substrate for the strand invasion system.

Owner:GENEFORM TECH LTD

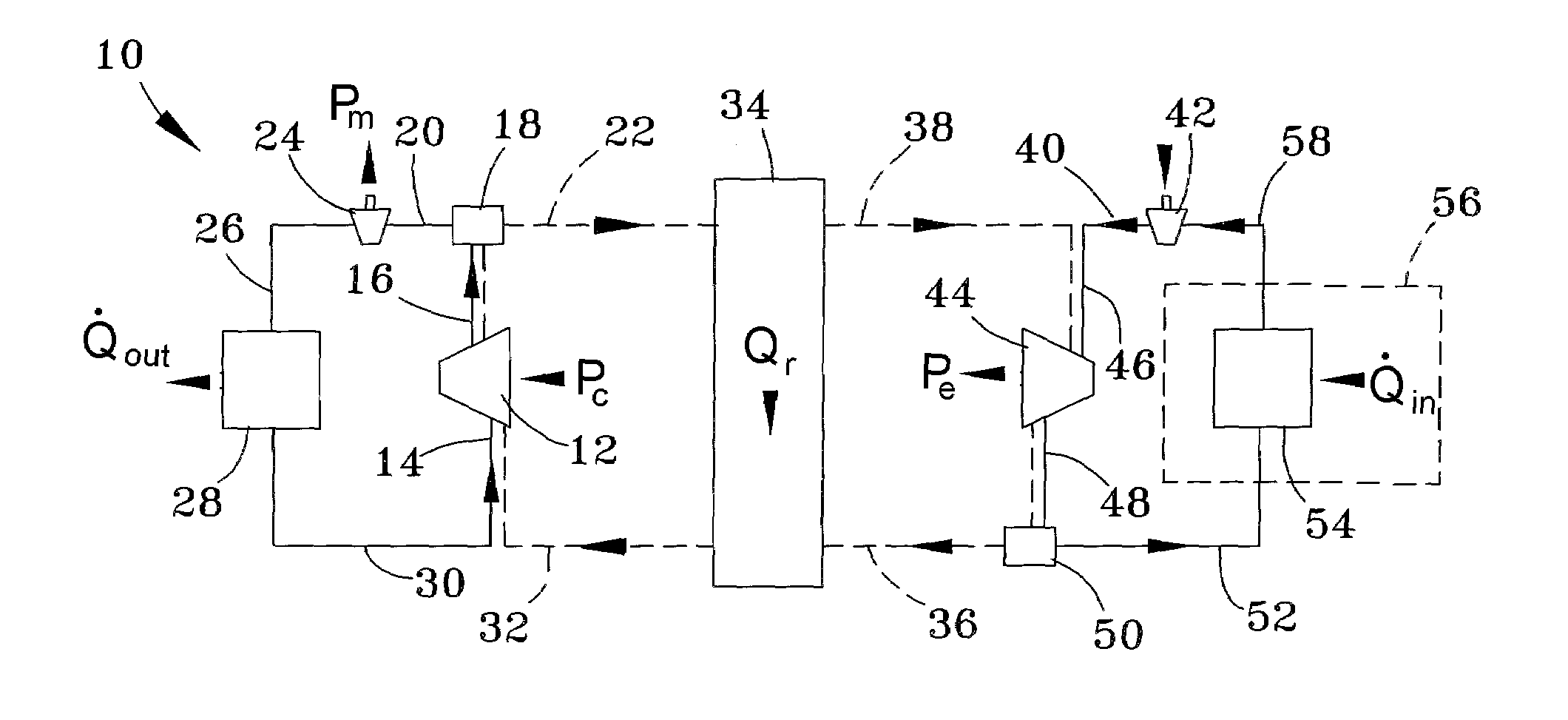

Isothermal power system

InactiveUS20090260361A1Increase in sizeMore energySteam engine plantsPlate heat exchangerCounter flow

This invention provides means for producing power by using isothermal compressors and isothermal expanders. One embodiment has an isothermal compressor that compresses air (or other gas), passes the air through a counter-flow heat exchanger, which heats the air, uses the heated air to drive an isothermal expander for power generation, and passes the expander exhaust back through the counter-flow heat exchanger to heat the input air to the expander. Another embodiment has a boiler that produces vapor that flows through a counter-flow heat exchanger to superheat the vapor. The vapor then flows through an isothermal expander for power generation. The exhaust from the isothermal expander flows back through the counter-flow heat exchanger to supply heat to super heat the vapor coming from the boiler. The description presents several devices that can perform at near isothermal conditions, including a modified Tesla turbine.

Owner:PRUEITT MELVIN L

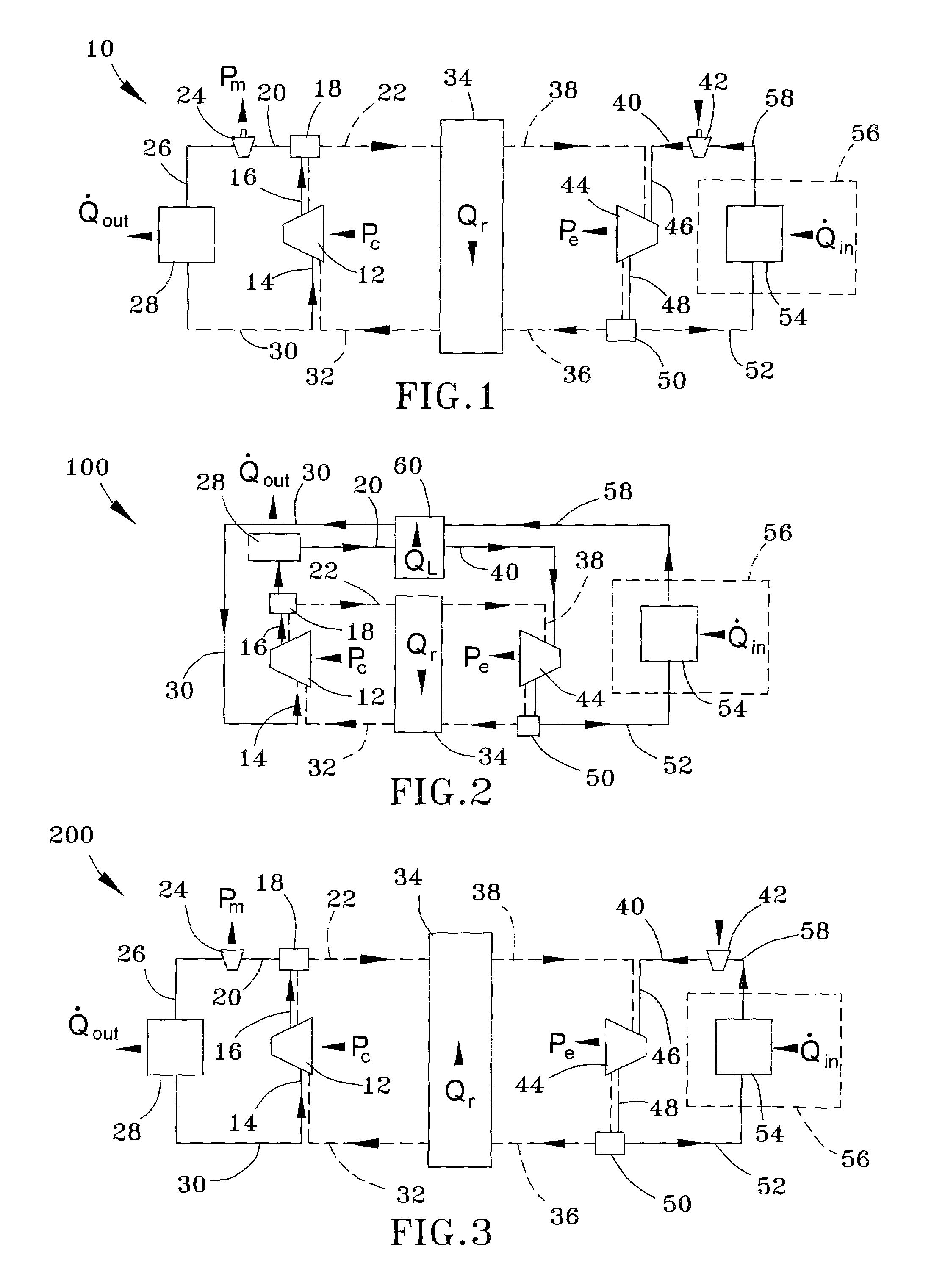

Thermodynamic systems operating with near-isothermal compression and expansion cycles

InactiveUS7401475B2Engine of arcuate-engagement typeCompression machines with non-reversible cycleBrayton cycleProduct gas

A thermodynamic system that can approximate the Ericsson or Brayton cycles and operated in reverse or forward modes to implement a cooler or engine, respectively. The thermodynamic system includes a device for compressing a first fluid stream containing a first gas-liquid mixture having a sufficient liquid content so that compression of the gas within the first gas-liquid mixture by the compressing device is nearly isothermal, and a device for expanding a second fluid stream containing a second gas-liquid mixture having a sufficient liquid content so that expansion of the gas within the second gas-liquid mixture by the expanding device is nearly isothermal. A heat sink is in thermal communication with at least the liquid of the first gas-liquid mixture for transferring heat therefrom, and a heat source is in thermal communication with at least the liquid of the second gas-liquid mixture for transferring heat thereto. A device is provided for transferring heat between at least the gas of the first gas-liquid mixture after the first fluid stream exits the compressing device and at least the gas of the second gas-liquid mixture after the second fluid stream exits the expanding device. The compressing and expanding devices are not liquid-ring compressors or expanders, but instead are devices that tolerate liquid flooding, such as scroll-type compressors and expanders.

Owner:PURDUE RES FOUND INC

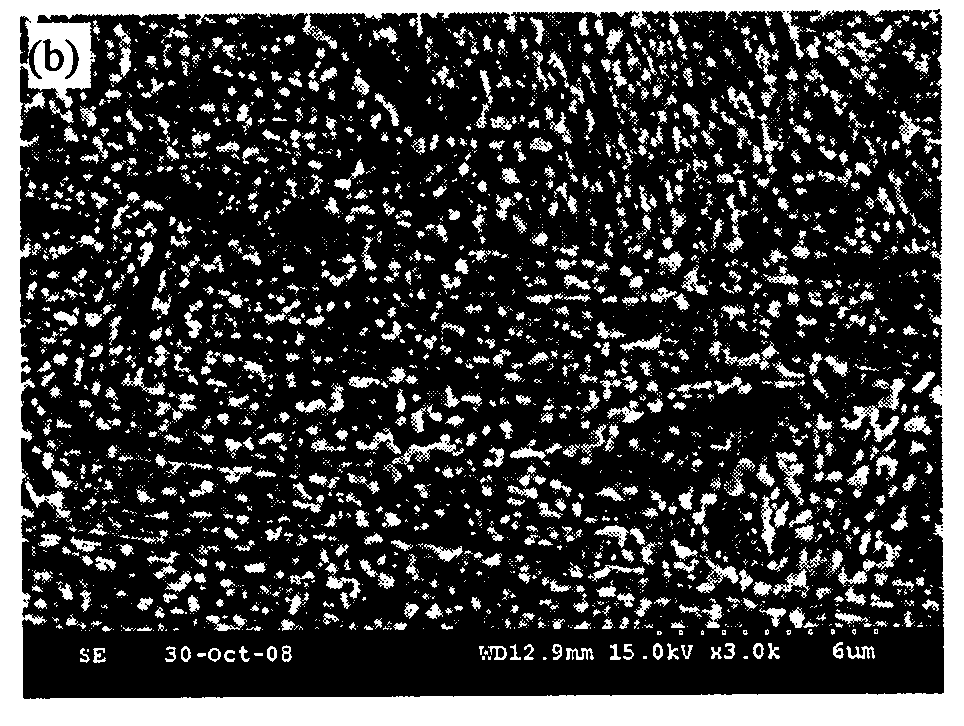

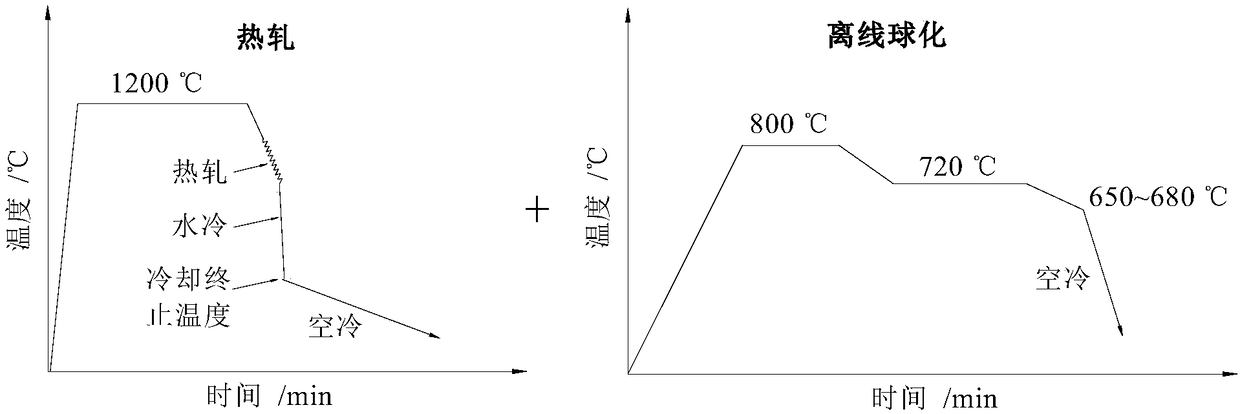

Medium carbon steel on-line balling rolling tech.

ActiveCN100999775AExcellent cold workabilityQuality improvementTemperature control deviceHeat treatment process controlMechanical componentsRoom temperature

The present invention discloses on-line medium carbon steel nodularizing and rolling process. The process includes low temperature finish rolling at 680-850 deg.c and accumulated cross section deformation of 50 %-80 %, controlled cooling after rolling at 3-15 deg.c / s to 660-720 deg.c, isothermal course, and naturally cooling to room temperature. The said technological scheme results in metallographic structure of the rolled piece with high ferrite component, less pearlite component, small and dispersed pearlite and granular cementite, lowered strength and hardness, raised plasticity and excellent cold machining performance.

Owner:MAANSHAN IRON & STEEL CO LTD

Method and device for on-line acoustic monitoring of foam and aerated fluid properties

InactiveUS20090006005A1Testing/calibration apparatusVibration measurement in fluidAdiabatic processElectronic form

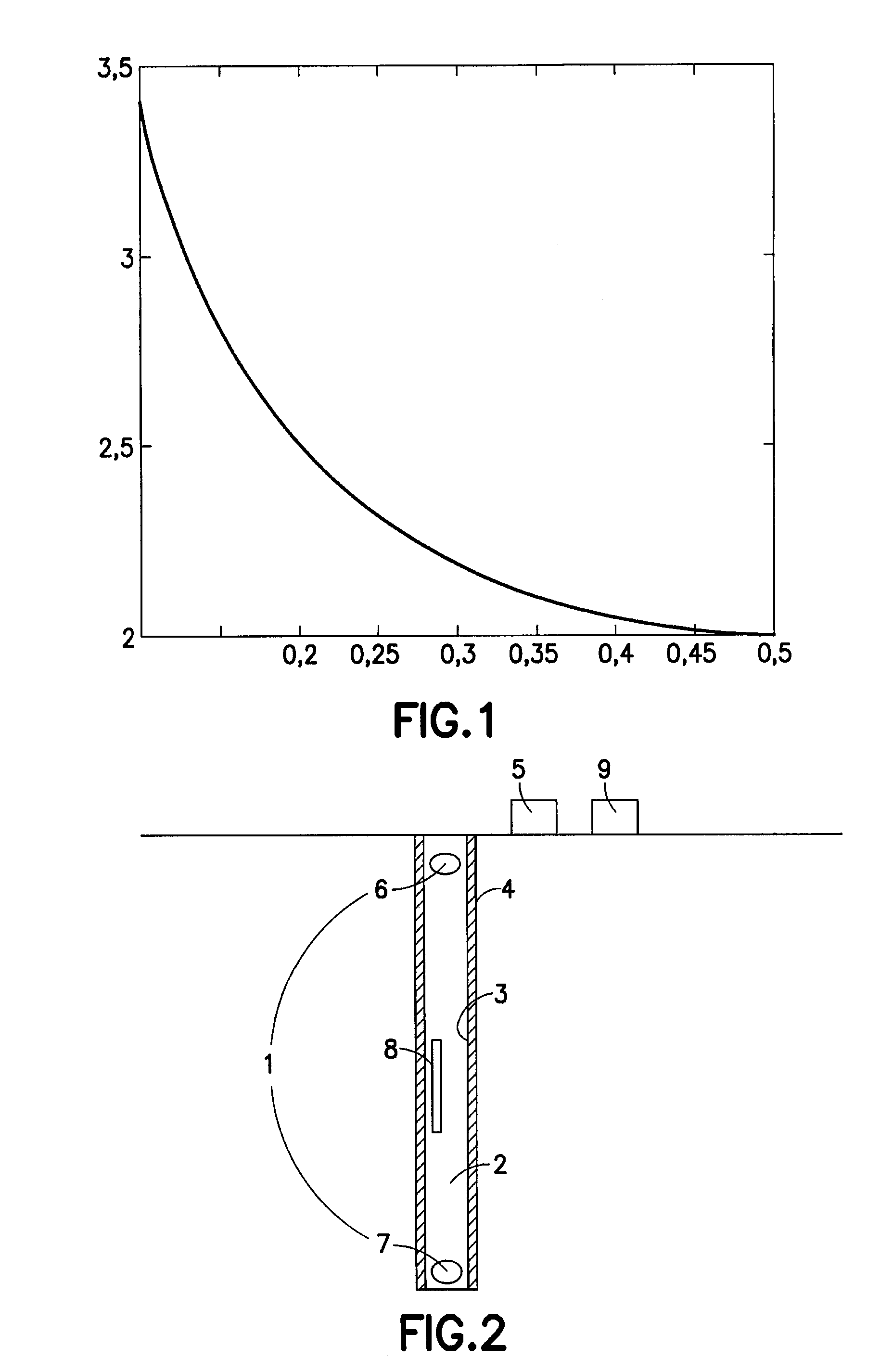

A method and device for on-line foam quality acoustic monitoring are suggested. As per the invention, the method provides for the following: at least one emitter / receiver pair is placed in a close vicinity to the foam flow; at least one acoustic pulse is emitted; time, within which the acoustic pulse overcomes the way from the emitter to the receiver, is recorded; acoustic pulse speed (sound speed) is determined by analyzing an acoustic response of the receiver. After that, pressure in the foam in the area between the emitter and receiver is defined and the foam quality Γ is calculated as per the equation:Γ=12±14-NρflpCfm2,where: Cfm—speed of sound in the foam, p—pressure, ρfl—fluid density, Γ—foam quality, N—polytrophic expansion coefficient (N=1 for isothermal process; N=1.4 for adiabatic process), in case of a foam composed of a perfect gas and a perfect fluid for cases, when the foam quality is supposedly much lower than ½ or much bigger than ½, the sign to be selected in the said formula is <<−>> and <<+>>, respectively; in cases when both values of Γ are near ½, the both quality values should be considered as a possible option, or in more complicated cases, it can be found from the Value Spreadsheet

Owner:SCHLUMBERGER TECH CORP

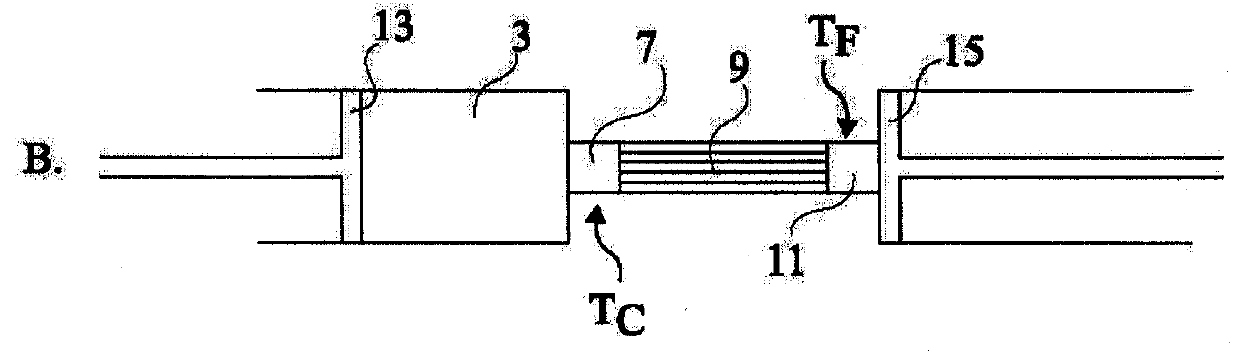

Near-isothermal compressor/expander

One aspect includes an isothermal compressor that includes an isothermal body, an isothermal cavity defined by the isothermal body, a compressible membrane heat exchanger disposed within the isothermal cavity that defines at least one first fluid chamber, and an actuating assembly configured to compress the membrane heat exchanger. A further aspect includes an isothermal engine that includes the isothermal compressor.

Owner:OTHER LAB

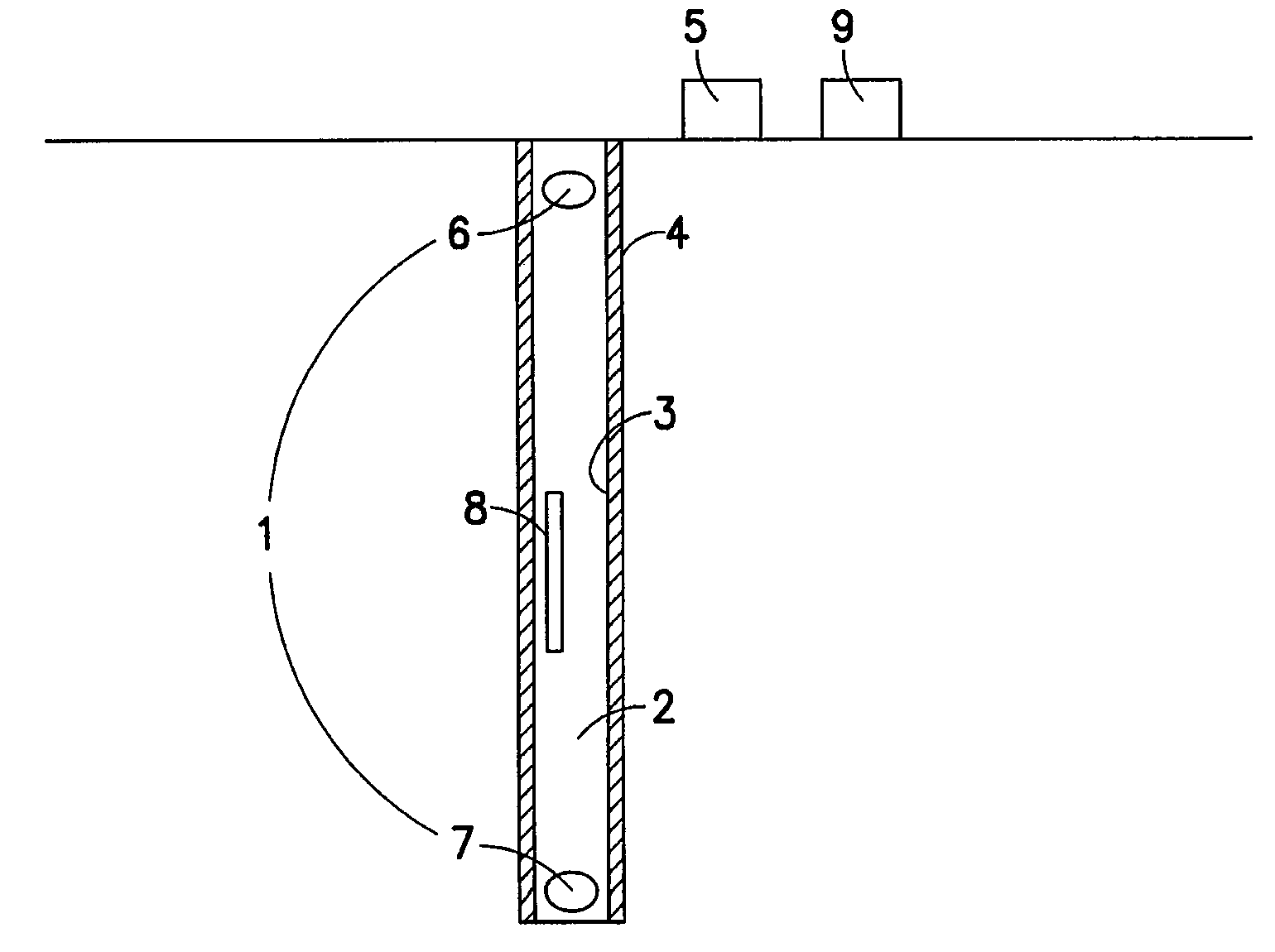

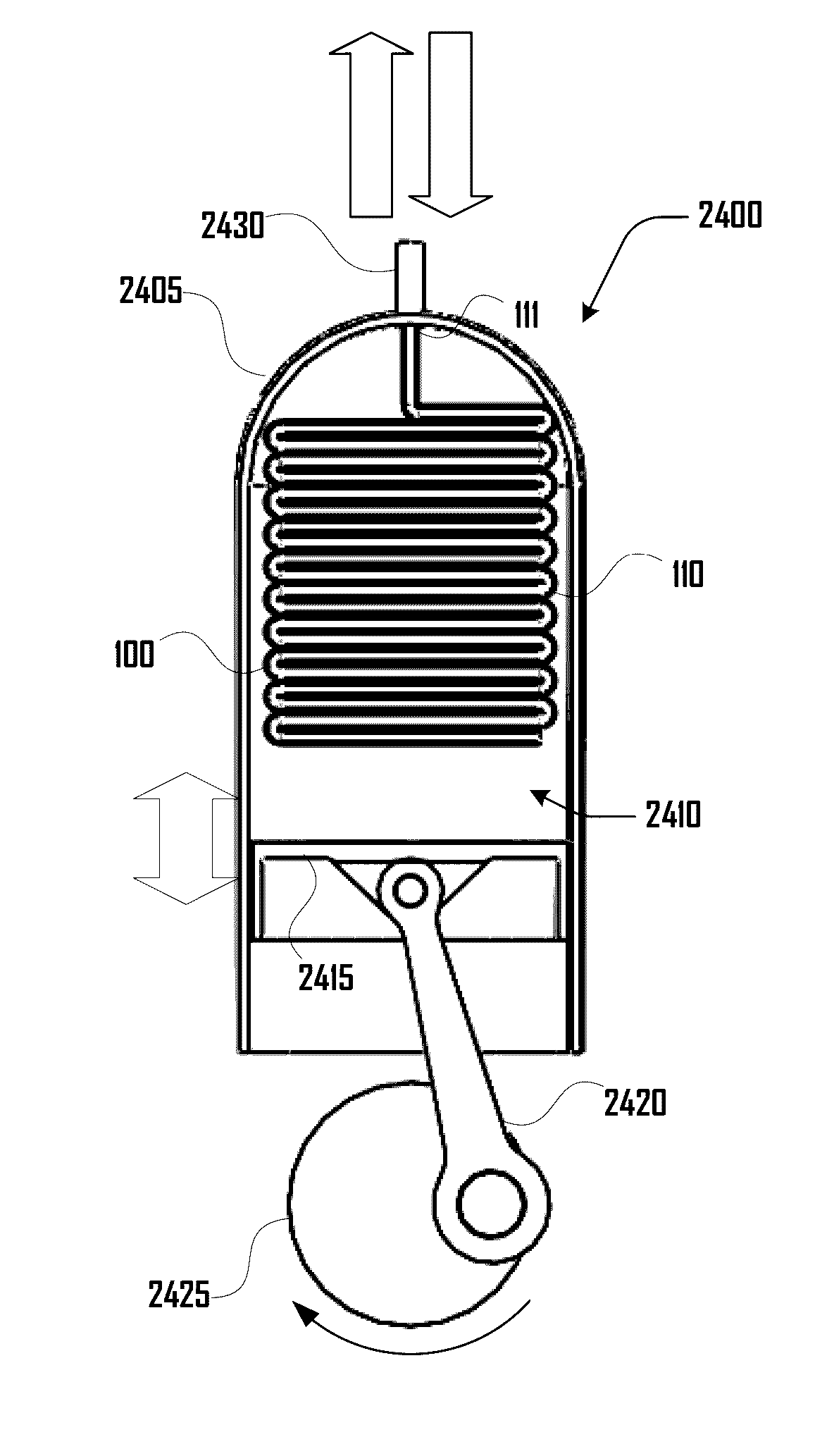

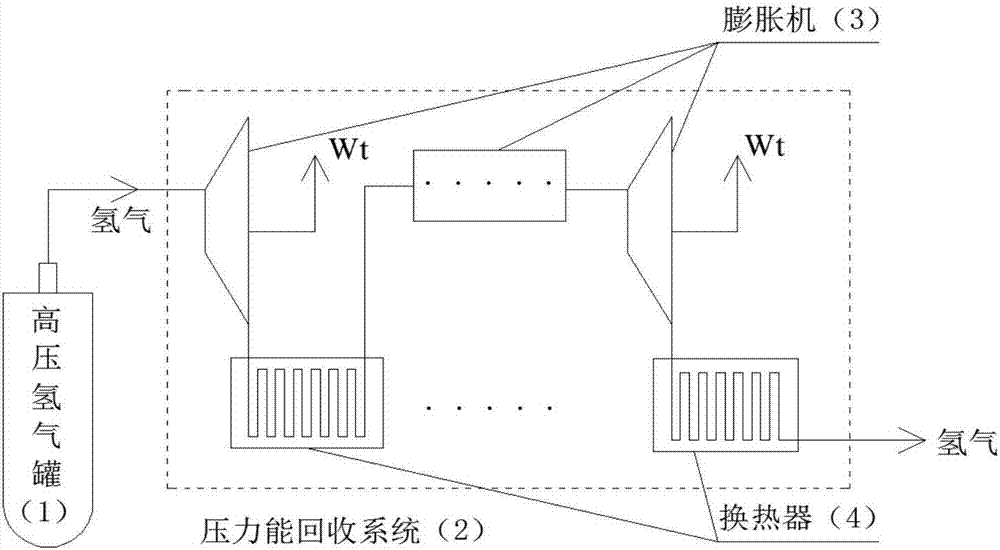

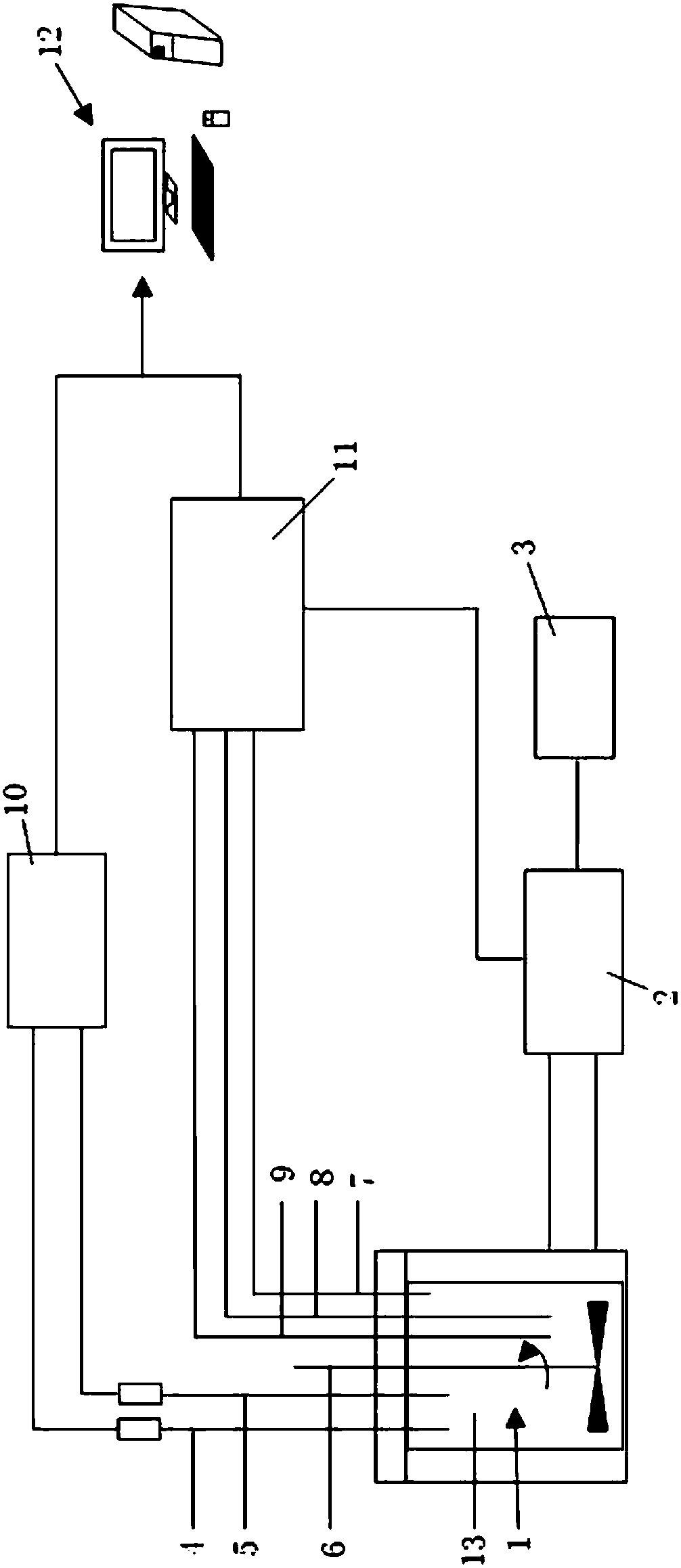

Pressure energy recycle device for high-pressure hydrogen storage tank of hydrogen fuel cell automobile

PendingCN107086319AReduce energy consumptionEasy to drive safelyFuel cell heat exchangeMotive system fuel cellsHigh pressure hydrogenWorking temperature

The invention provides a pressure energy recycle device for a high-pressure hydrogen storage tank of a hydrogen fuel cell automobile. The pressure energy recycle device comprises a high-pressure hydrogen tank (1) and a pressure energy recycle system (2), wherein the pressure energy recycle system (2) comprises a one-stage or multi-stage expansion system, each-stage expansion system comprises an expansion machine (3) and a heat exchanger (4), and high-pressure hydrogen flows out of the high-pressure hydrogen tank (1) and sequentially flows into each-stage expansion system; and in each-stage expansion system, temperature and pressure are reduced by the expansion machine (3), work is externally output and flows into the heat exchanger (4) for heat absorption and temperature rising, the working temperature is increased, so that the constant-temperature process is approximated during the expansion process of the pressure energy recycle device, and more expansion work is output. By the pressure energy recycle system (2), pressure energy in the high-pressure hydrogen tank is recycled, and the energy utilization ratio is improved.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

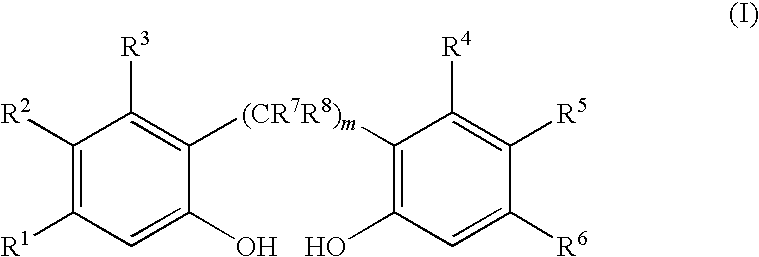

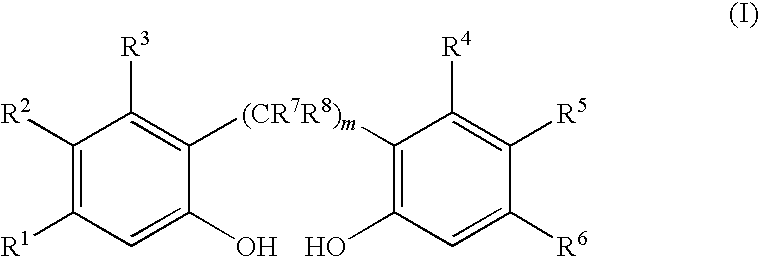

Isothermal process for phosphoromonochloridite synthesis

The present invention relates to a process for preparation of a phosphoromonochloridite in high yield by contacting phosphorus trichloride (PCl3) with an aromatic diol in a solution of one or more organic solvents under reaction conditions sufficient to produce the phosphoromonochloridite. The reaction is carried out by adding a feed solution containing the aromatic diol dissolved in a first organic solvent into a reaction zone containing PCl3, and optionally one or more second organic solvents, the addition being conducted so as to maintain substantially isothermal process conditions. The reaction solution comprises greater than 0.01 to less than 5 mole percent of a nitrogen base.

Owner:UNION CARBIDE CORP

Gear ring nitrogen protection continuous type normalizing process

InactiveCN101775478APrevent oxidative decarburizationImprove refinementFurnace typesHeat treatment furnacesNitrogenHearth

The invention relates to a normalizing process, in particular to a normalizing process under nitrogen protection atmosphere for a gear ring, which avoids the phenomena of easy oxidation and decarbonization in the traditional gear ring normalizing process, overcomes the defect of oxidation layers on gear blank surfaces and provides a gear ring nitrogen protection continuous type normalizing process. In the heating and insulating processes of normalizing heat treatment, high-purity nitrogen is led into a hearth so as to achieve the purposes of spacing and emptying oxygen in the hearth; oxidation and decarbonization on the surface of a material are suppressed, and before a workpiece is taken out of the furnace, quick cooling is carried out by utilizing a nitrogen cooling area at an outlet so as to be beneficial to fining and perfecting inner tissues of the material and obtaining good manufacturability and mechanical property indexes. In addition, the process omits the processes of water cooling and isothermy, realizes continuous production, effectively shortens the normalizing time, improves the production efficiency and realizes energy saving and emission reduction.

Owner:青岛奔达汽车配件有限公司

Manufacturing process method for increasing bearer ring performance

ActiveCN106467931AAchieve fragmentationIncrease dislocationFurnace typesQuenching agentsQuenchingMaterials science

The invention relates to a manufacturing process method for increasing bearer ring performance. The manufacturing process method comprises the following steps: S1) rolling a bearer ring blank on a cold ring-rolling mill for shaping; S2) heating the rolled bearer ring to the temperature of 800-900 DEG C, insulting the bearer ring for 10-20 min and austenitizing the bearer ring; placing the bearer ring in nitrate bath at the temperature of 150-250 DEG C for pre-quenching processing for 5-10 min; S3) heating the bearer ring after pre-quenching to the temperature of 200-300 DEG C, insulating the bearer ring for 15-25 min and performing isothermal quenching on the bearer ring, then performing isothermal processing on the bearer ring in quenching oil at temperature of 50-100 DEG C for 5-10 min; and S4) performing low-temperature tempering processing on the bearer ring after isothermal quenching for 1-2 hours, and then performing air cooling on the material. According to the invention, impact energy and fracture toughness of the bearer ring can be obviously increased through quenching, isothermal quenching and tempering processes.

Owner:WUHAN UNIV OF TECH

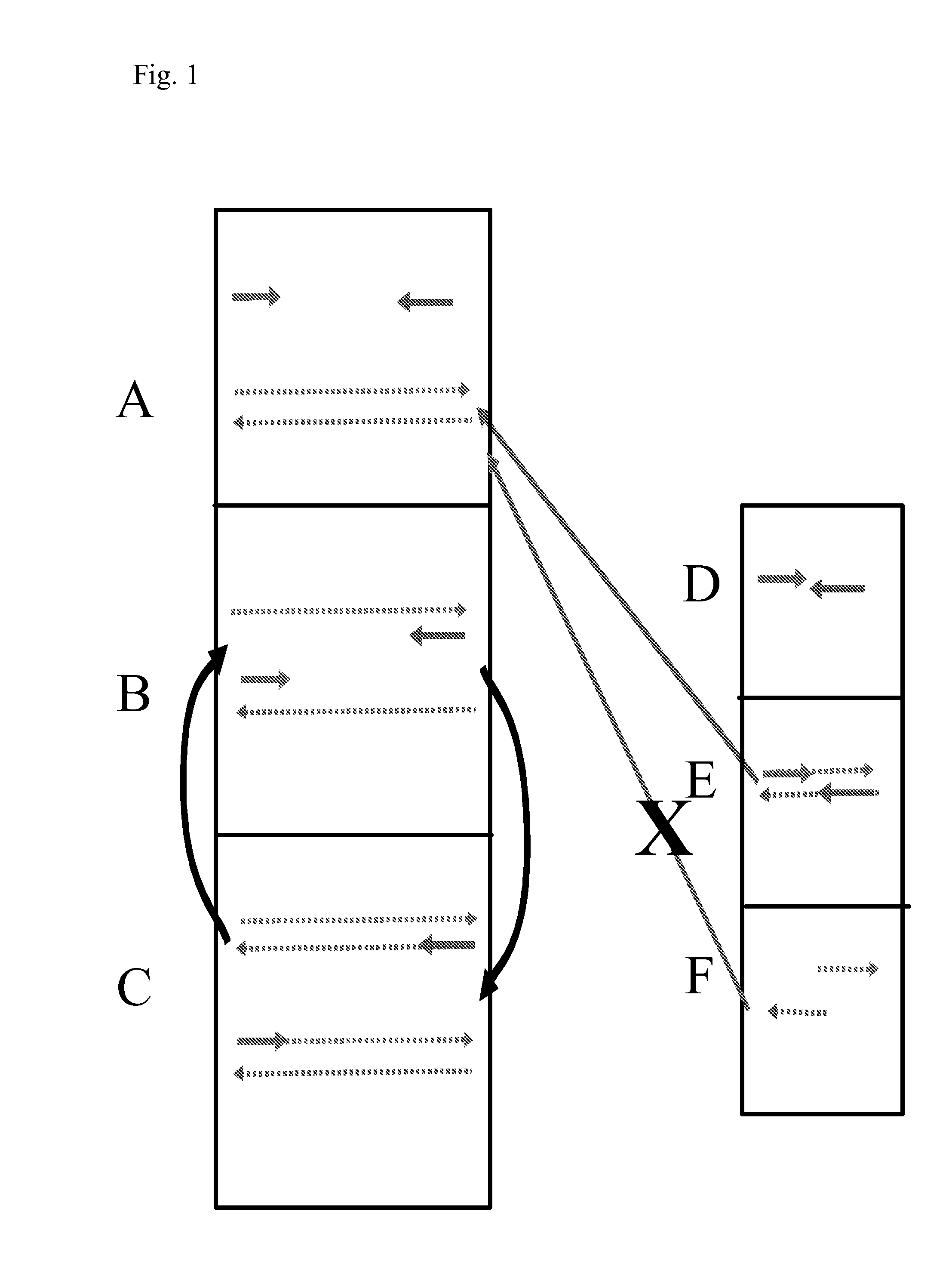

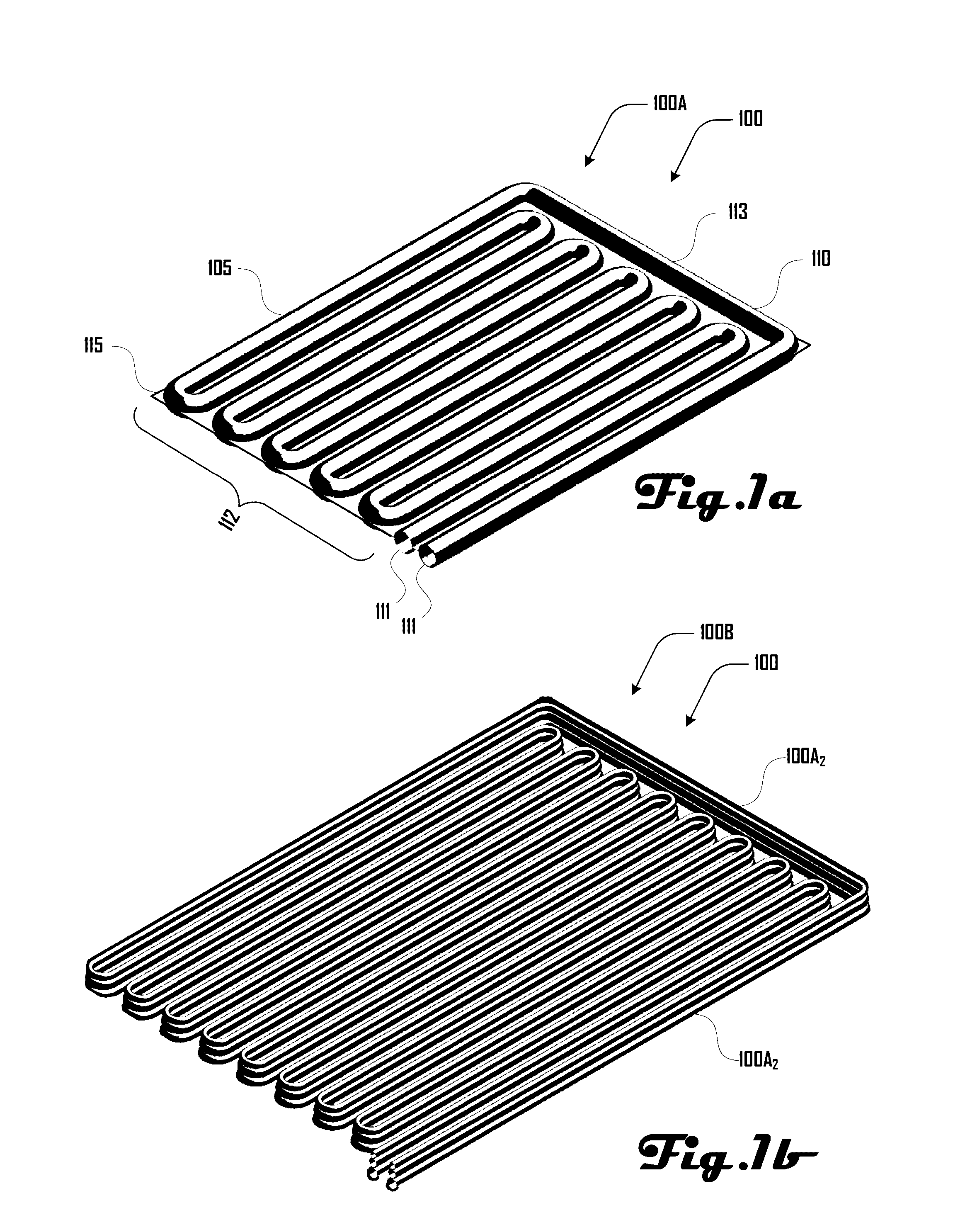

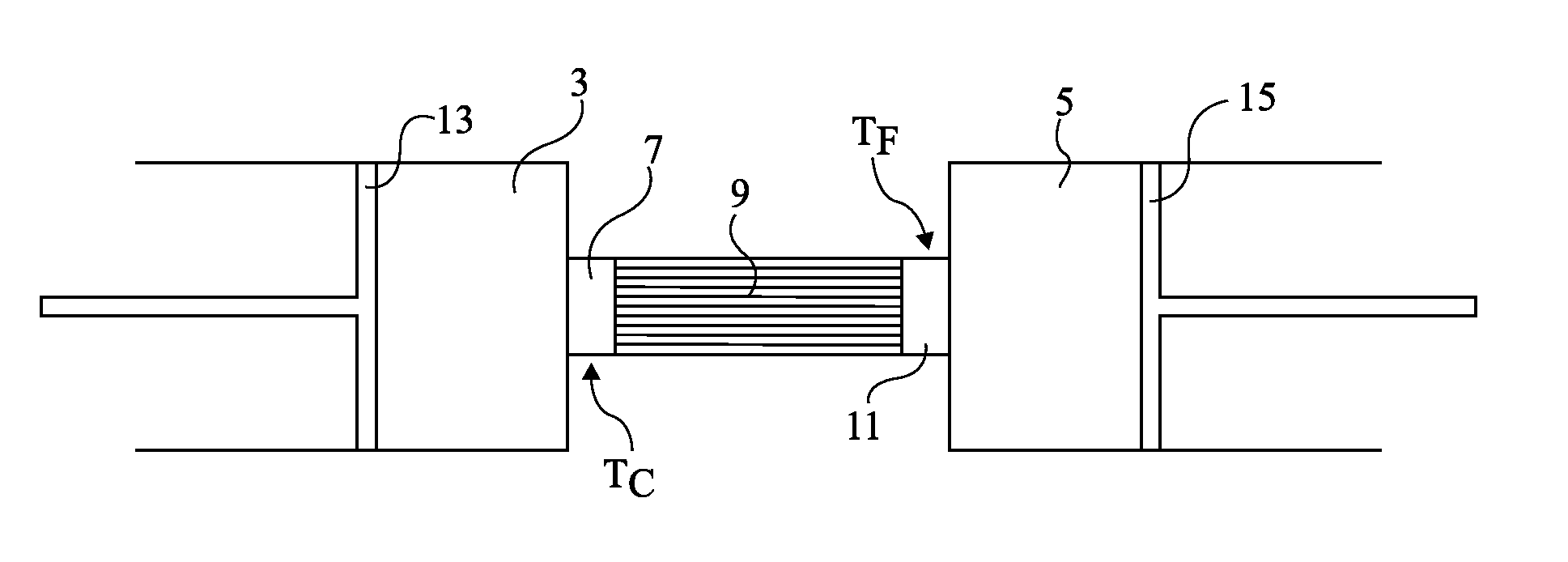

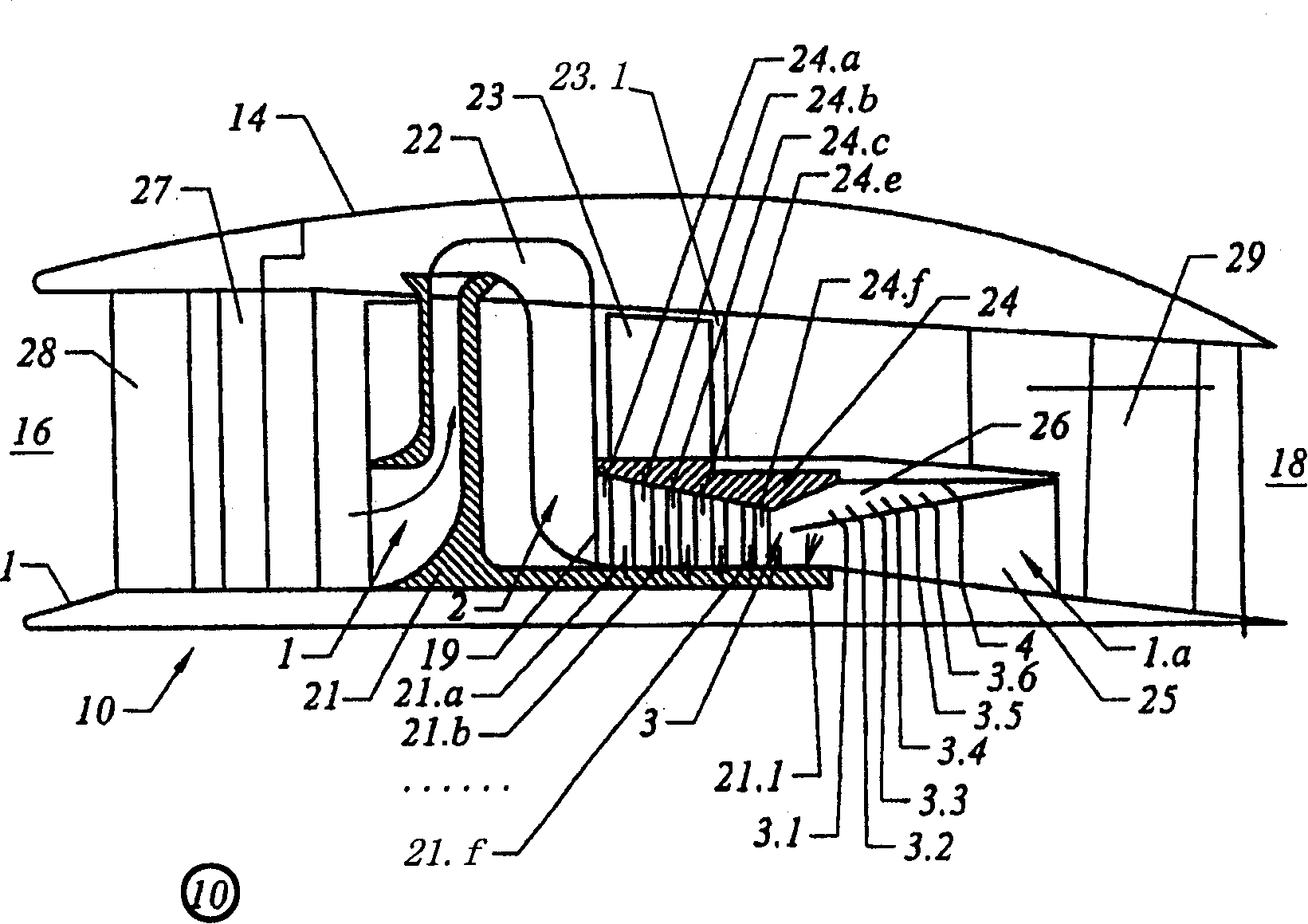

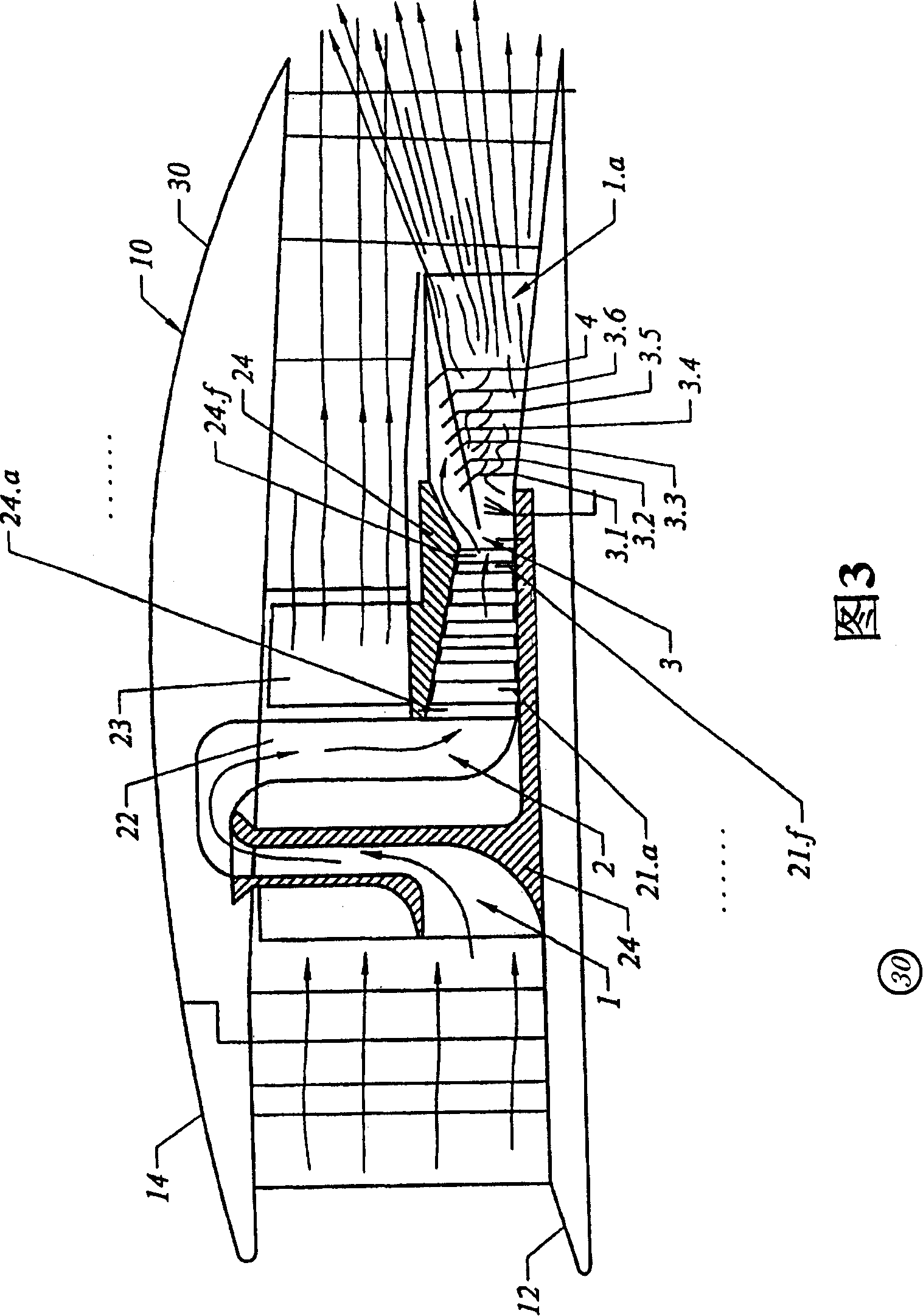

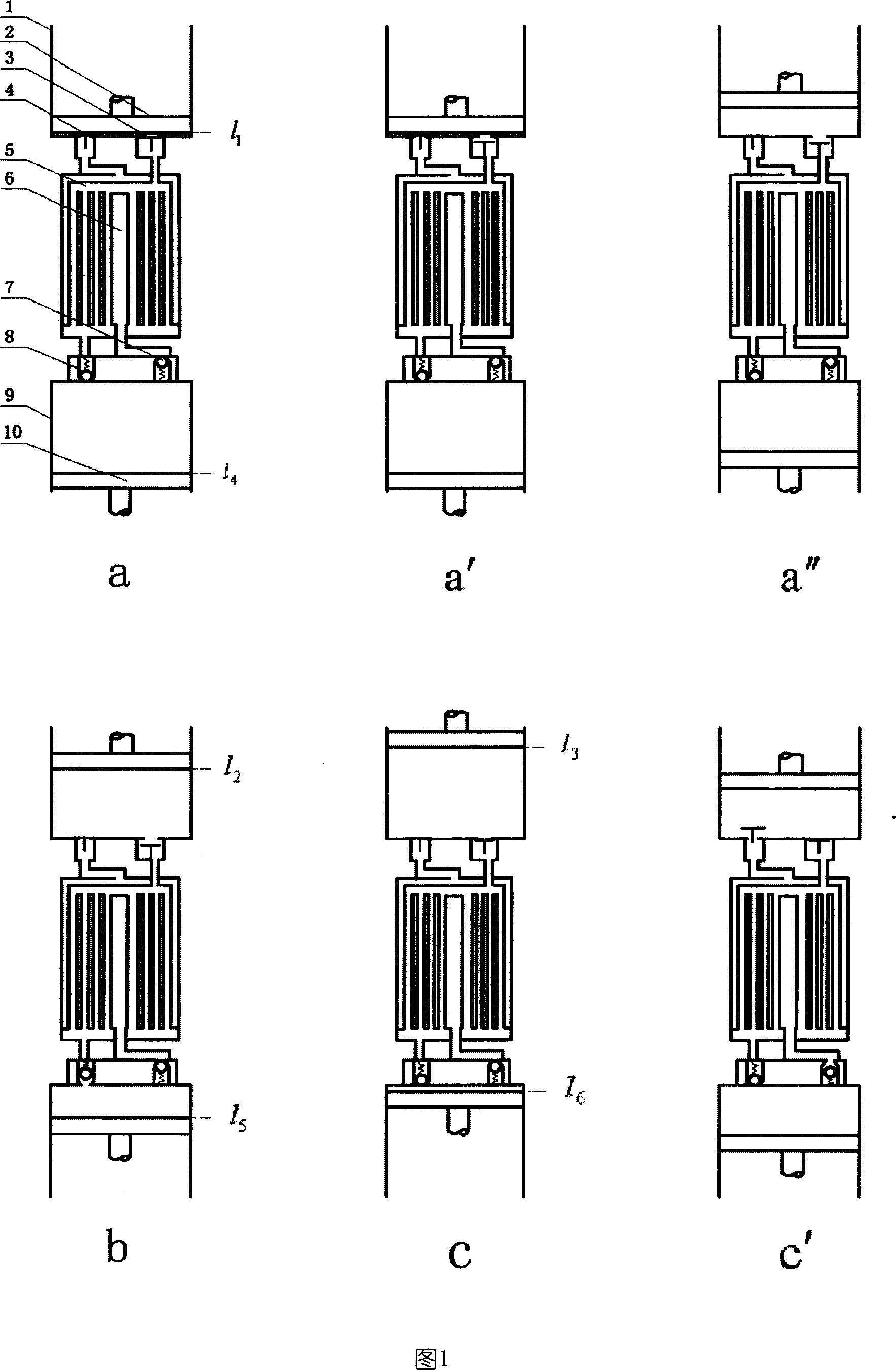

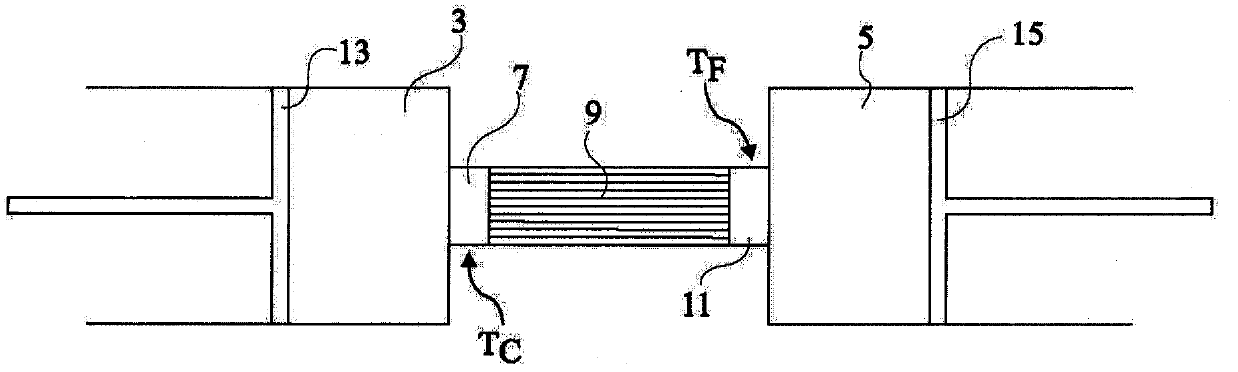

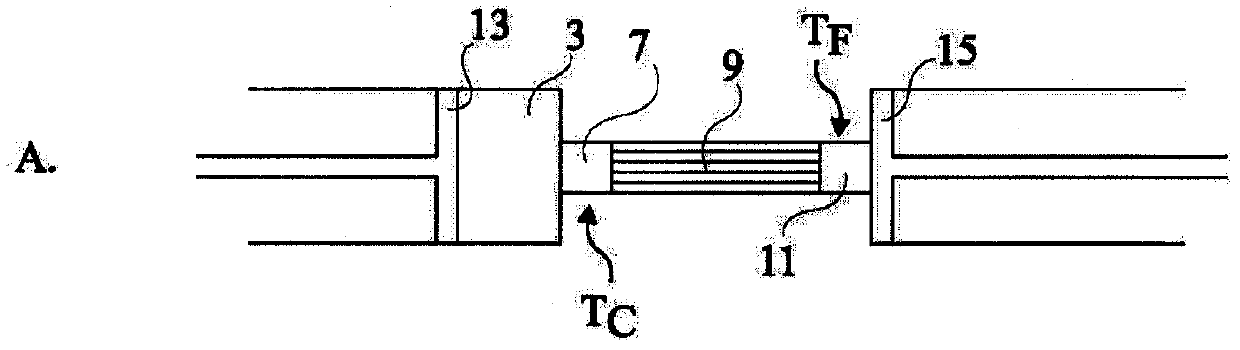

Heat exchanger structure and isothermal compression or expansion chamber

InactiveUS20110239640A1Reduce lossImprove efficiencyPistonsHeater tubesThermal diffusivityEngineering

A thermodynamic machine includes at least one chamber in which an isothermal expansion and / or compression is to be carried out, said chamber being longitudinally defined by first and second walls that are mobile relative to each other. The chamber is divided by partitions extending longitudinally from each of the first and second walls, the partitions being interleaved within each other, and the distance between the partitions extending from a same wall being such that the ratio between the distance squared and the cycle duration of the thermodynamic machine is lower than the average thermal diffusivity of the gas contained in the chamber.

Owner:STIRAL

Waste heat hardening and tempering process of motorcycle crank forged piece

InactiveCN101524813AUniform internal and external temperatureImprove quenching qualityOther manufacturing equipments/toolsQuenching agentsMedium frequencyHardness

The invention discloses a waste heat hardening and tempering process of motorcycle crank forged piece, comprising the working procedures like medium-frequency heating, extracting billet, blocking, precise forging, isothermal processing, quenching, tempering and the like. The process can obviously improve hardenability through forging waste heat hardening and tempering, ensure even distribution of tissues and hardness and ensure that the forged piece has the mechanical performance superior to that of the workpieces after conventional hardening and tempering. The workpieces undergoing finish forging adopt short isothermal processing to ensure the temperature of the workpieces to be uniform when entering quenching liquid, thus ensuring stable performance and excellent quality and realizing industrial production. Meanwhile, the short isothermal processing only consumes little electric energy, thus conforming to the requirement of the economical society.

Owner:重庆歇马机械曲轴有限公司

Method for manufacturing high carbon steel wheel

ActiveCN101818236AReduce hydrogen contentReduce difficultyFurnace typesHeat treatment furnacesHeating timeHigh carbon

The invention discloses a method for manufacturing a high carbon steel wheel. A preheating treatment process is set after a forging, stamping and rolling process and before an isothermal process. The process method comprises the following steps of: performing air cooling on the high carbon steel wheel workpiece after being subjected to high temperature forging, stamping and rolling to between 600 and 650 DEG C; heating the high carbon steel wheel workpiece, wherein the heating temperature is between 730 and 750 DEG C; and the heating time is 30 to 40 minutes; performing part of austenite transformation on a wheel rim; performing furnace cooling on the high carbon steel wheel workpiece to between 600 and 630 DEG C; and performing the isothermal process on the wheel workpiece. By adopting the technical scheme, the hydrogen content is reduced, and a hydrogen induced crack is inhibited; and the impact toughness of the high carbon steel wheel rim is effectively improved and the use safety of the product is ensured on the premise of ensuring the intensity and the rigidity of the high carbon steel wheel workpiece basically unchanged and a ferrite-pearlite microscopic structure.

Owner:MAANSHAN IRON & STEEL CO LTD

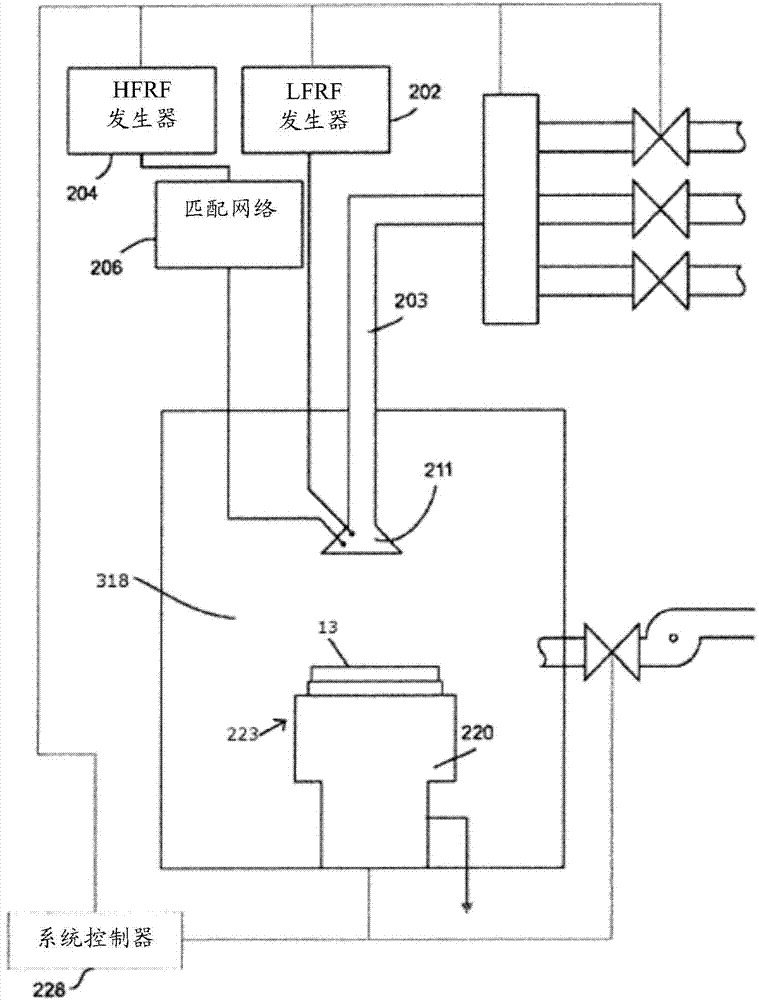

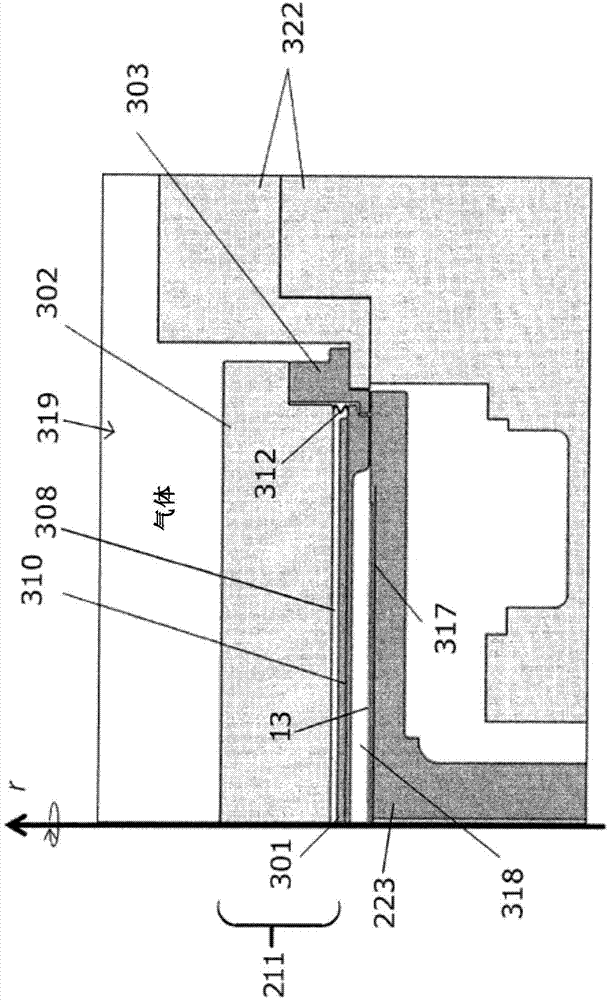

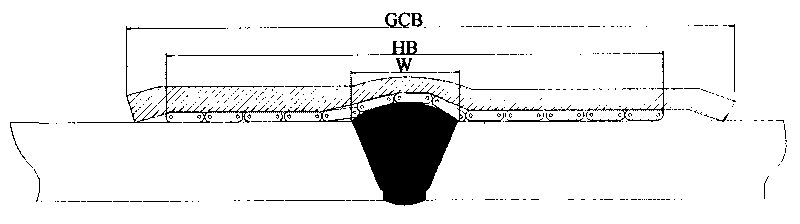

Plasma processing apparatus including an isothermal processing zone

ActiveCN104282530AElectric discharge tubesSemiconductor/solid-state device manufacturingProcess engineeringSemiconductor

A deposition apparatus for processing semiconductor substrates having an isothermal processing zone comprises a chemical isolation chamber in which semiconductor substrates are processed. A process gas source is in fluid communication with a showerhead module which delivers process gases from the process gas source to the isothermal processing zone wherein the showerhead module includes a faceplate wherein a lower surface of the faceplate forms an upper wall of a cavity defining the isothermal processing zone, a backing plate, and an isolation ring which surrounds the faceplate and the backing plate. At least one compression seal is compressed between the faceplate and the backing plate which forms a central gas plenum between the faceplate and the backing plate. A substrate pedestal module is configured to heat and support a semiconductor substrate wherein an upper surface of the pedestal module forms a lower wall of the cavity defining the isothermal processing zone within the chemical isolation chamber. A vacuum source is in fluid communication with the isothermal processing zone for evacuating process gas from the processing zone.

Owner:LAM RES CORP

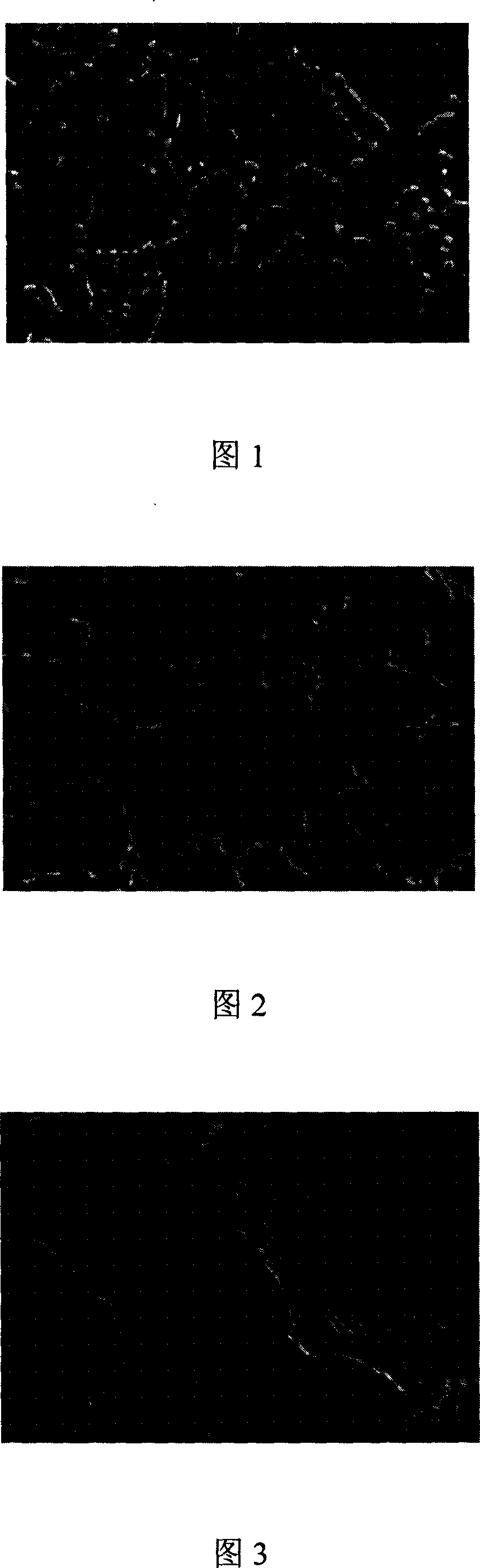

Pressure energy recovery device of high pressure hydrogen storage tank for hydrogen internal combustion engine automobile

InactiveCN108979771AReliable implementationImprove energy utilizationSteam engine plantsWorking temperatureEnergy recovery

The invention provides a pressure energy recovery device of a high pressure hydrogen storage tank for a hydrogen internal combustion engine automobile. The pressure energy recovery device of the highpressure hydrogen storage tank comprises a high pressure hydrogen tank (1) and a pressure energy recovery system (2), wherein the pressure energy recovery system (2) comprises one or multi stages of expansion systems, and each stage of expansion system includes an expansion machine (3) and a heat exchanger (4). High pressure hydrogen flows out from the high pressure hydrogen tank (1) and sequentially flows into all stages of expansion systems. In all stages of expansion systems, the high pressure hydrogen is first subjected to cooling and pressure reduction through the expansion machines (3),outputs work externally, and then flows into the heat exchangers (4) to absorb heat, the working temperature of the high pressure hydrogen is increased, and the expansion process of the high pressurehydrogen is enabled to be close to the isothermal process so as to output more expansion work. The pressure energy recovery device of the high pressure hydrogen storage tank for the hydrogen internalcombustion engine automobile recovers the pressure energy in the high pressure hydrogen tank through the pressure energy recovery system (2), thereby improving the energy utilization rate.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

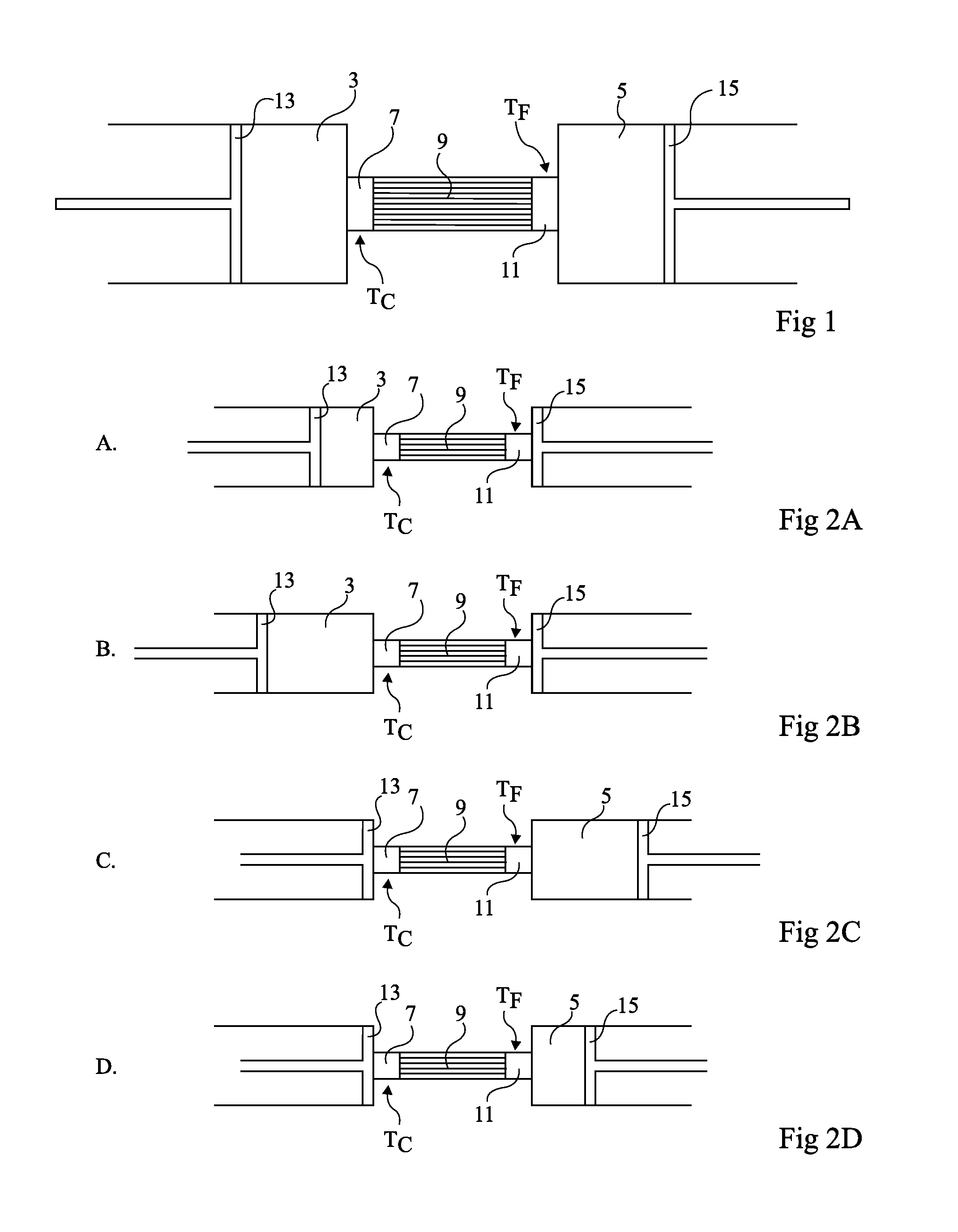

Heat treatment system and formable vertical chamber

An apparatus (100) and method are provided for thermally processing substrates (108) held in a carrier (106). The apparatus (100) includes a vessel (101) having a top (134), side (136) and bottom (138), and a heat source (110) with heating elements (112-1, 112-2, 112-3) proximal thereto. The vessel (101) is sized to enclose a volume substantially no larger than necessary to accommodate the carrier (106), and to provide an isothermal process zone (128) extending throughout. In one embodiment, the bottom wall (138) includes a movable pedestal (140) with a bottom heating element therein (112-1), and the pedestal can be lowered and raised to insert the carrier (106) into the vessel (101). The apparatus (100) can include a movable shield (146) that is inserted between the pedestal (140) and the carrier (106) to shield the substrates (108) from the heating element (112-1) and to maintain pedestal temperature. A magnetically coupled repositioning system (162) repositions the carrier (106) during processing of the substrates (108) without use of a movable feedthrough into the volume enclosed by the vessel (101), and without moving the bottom heating element (112-1) in the pedestal (140).

Owner:AVIZA TECHNOLOGY INC

Method for heat treatment of P92 steel

InactiveCN101724740AEasy to useReduce temperature difference between inner and outer wallsFurnace typesHeat treatment process controlElectrical resistance and conductanceInsulation layer

The invention discloses a method for the heat treatment of P92 steel. In the method, a flexible ceramic resistor heating heat treatment process is adopted; and in the arrangement of a heating zone and a heat insulation layer, an internal and external wall temperature difference in a isothermal process is made less than 30 DEG C by reasonably determining the width of a heater and a heat insulation cotton and controlling temperature rise speed and heat insulation time so as to ensure the impact performance of weld joints and improve the service performance of the material.

Owner:天津诚信达金属检测技术有限公司

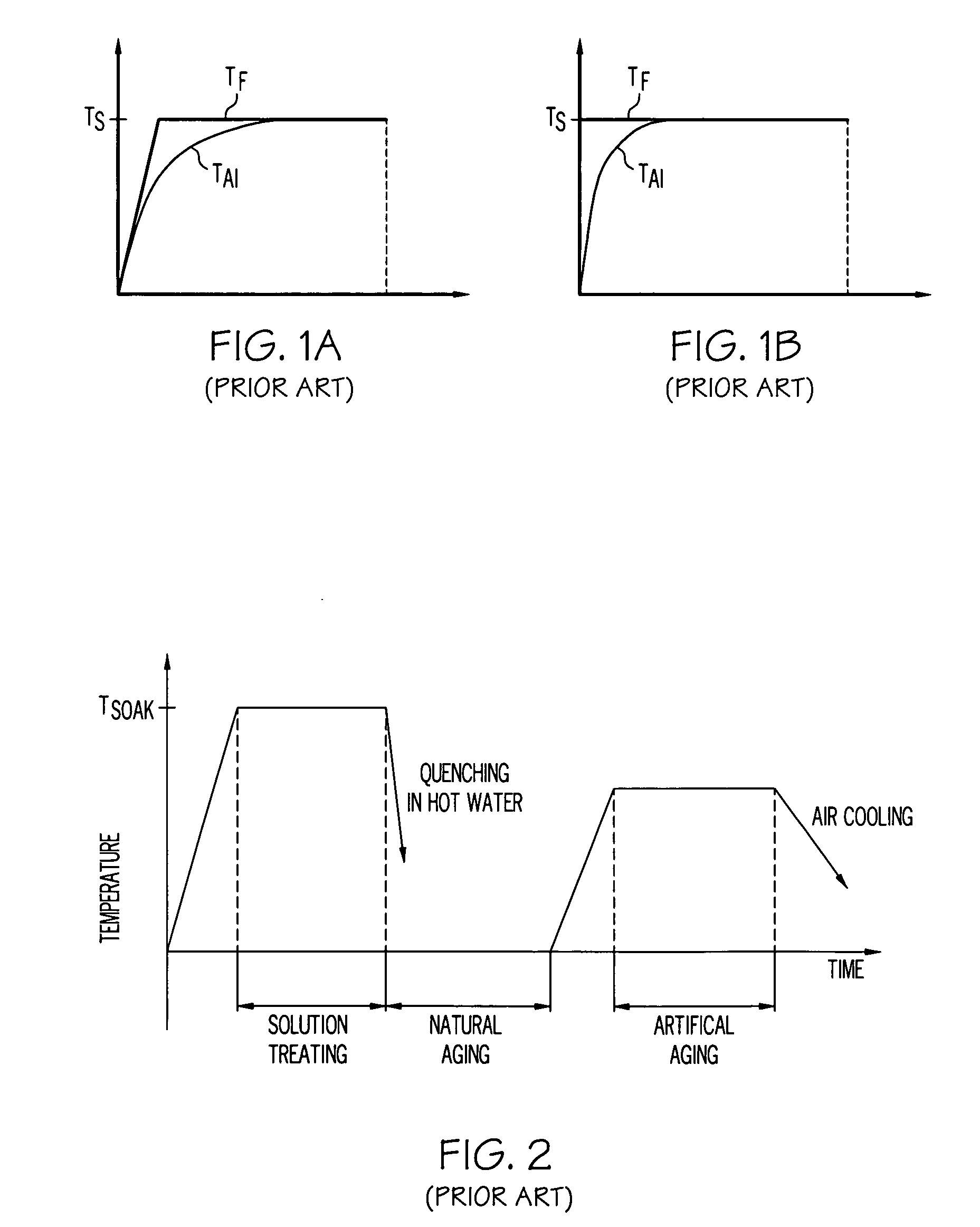

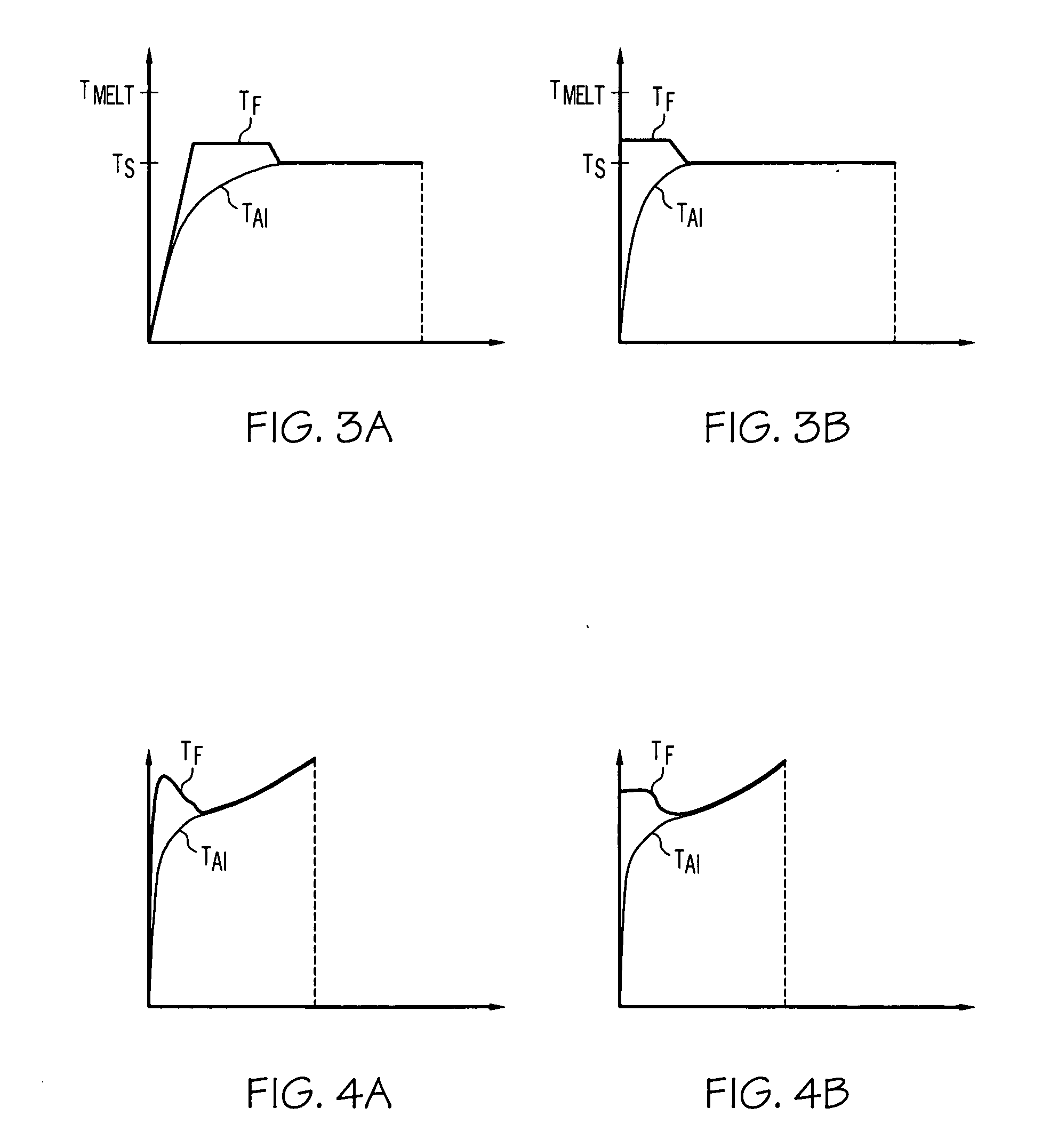

Accelerated solution treatment process for aluminum alloys

ActiveUS20090320963A1Heating fastImprove mechanical propertiesHeat treatment process controlAnalogue processes for specific applicationsSolution treatmentDissolution

A method of providing solution heat treatment to an aluminum alloy. A non-isothermal process is used to provide a faster heat treatment cycle time while maintaining or further improving the alloy mechanical properties after subsequent aging hardening. The process includes establishing a temperature inside a processing vessel that is greater than a soaking temperature but less than a liquidus temperature of the alloy, rapidly heating the alloy to the soaking temperature in a first heating operation, reducing the temperature inside of the processing vessel to the soaking temperature, then heating the alloy to a temperature above the soaking temperature through a gradually increasing temperature in a second heating operation. Protocols for the improved solution heat treatment may be based on one or more of computational thermodynamics, dissolution kinetics and coarsening kinetics.

Owner:GM GLOBAL TECH OPERATIONS LLC

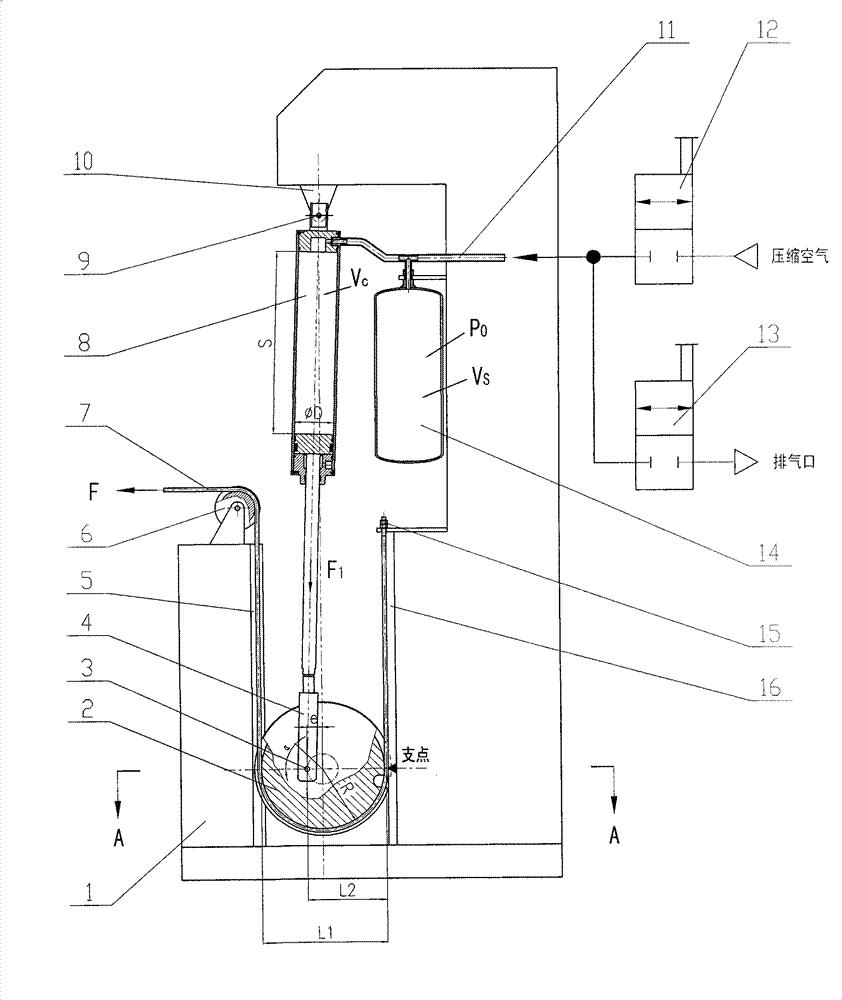

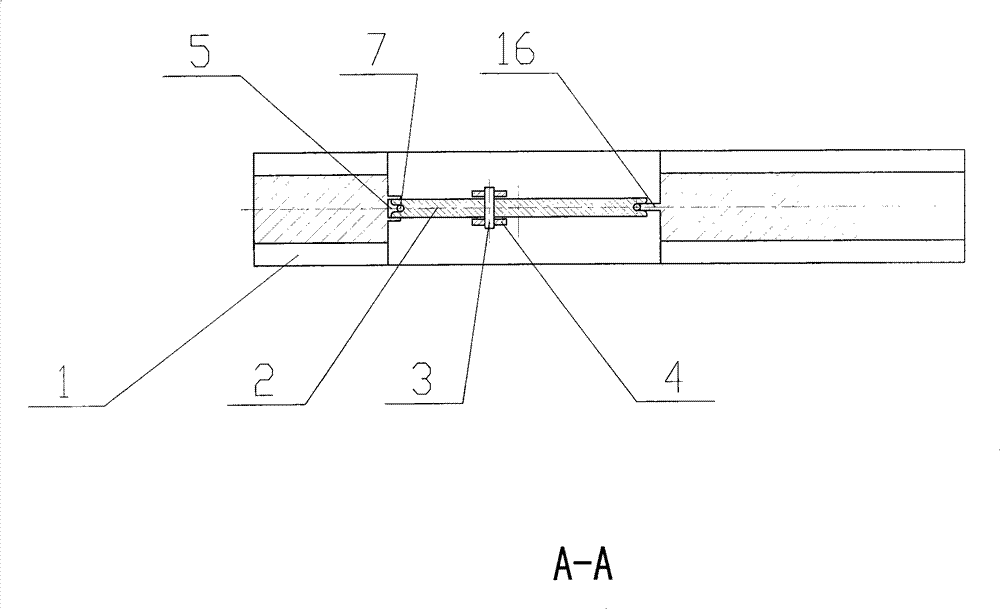

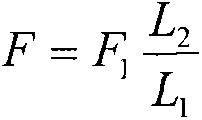

Air pressure stepless and adjustable constant-resistance health and fitness facility damper

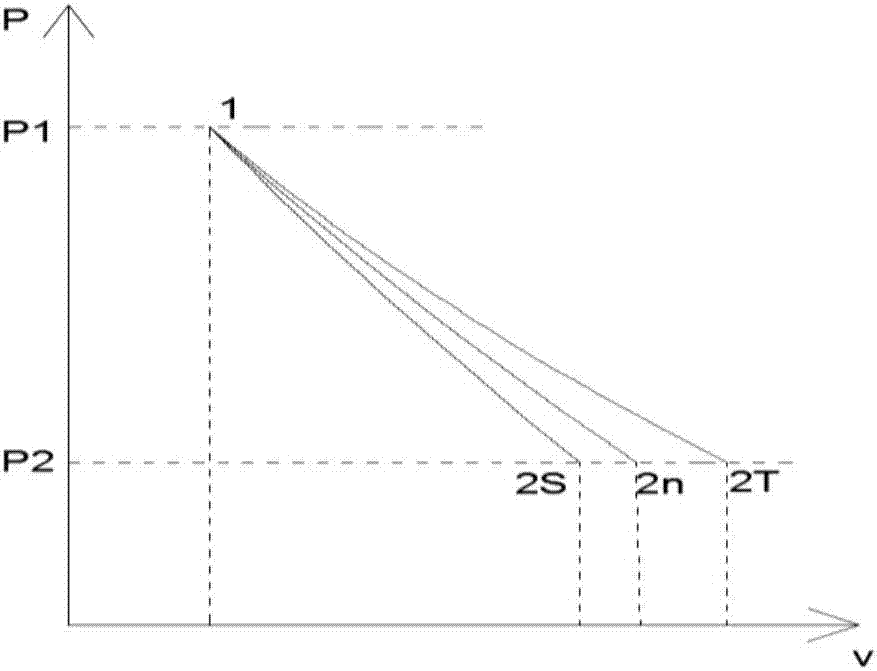

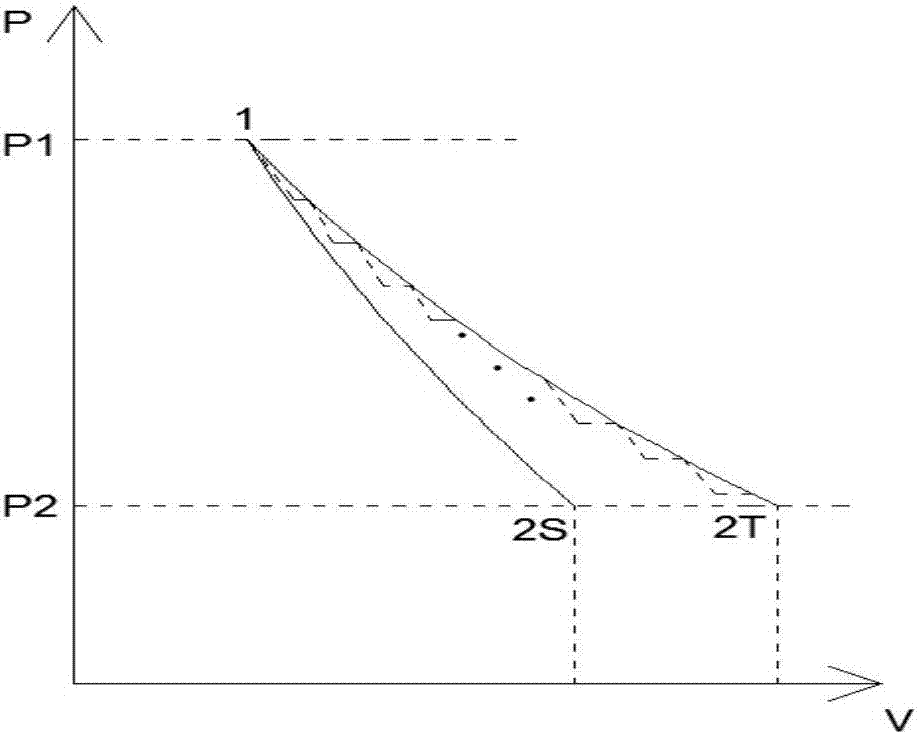

InactiveCN104707294ASuitable for training requirementsReduce weightMuscle exercising devicesEngineeringCompressibility

The invention provides an air pressure stepless and adjustable constant-resistance health and fitness facility damper which is used for replacing existing balance weight iron. The air compressibility is used, the pressure of air in a closed cavity with variable volume is adjusted to change resistance, and the air constant temperature process principle is used; the method that a specific value of a main force arm to an auxiliary force arm is changed to mend changes, generated by volume changes, of the pressure in a compressed cavity is used for achieving the constant-resistance output function; as the air pressure in the compressed cavity is continues and adjustable in a certain range, the generated resistance is continuous and adjustable. The air pressure stepless and adjustable constant-resistance health and fitness facility damper has the beneficial effects that the heavy balance weight iron is replaced with an air cylinder, and the device weight is effectively reduced; stepless and continuous adjustment on the resistance can be carried out through compressed air; and the air pressure stepless and adjustable constant-resistance health and fitness facility damper is more suitable for training requirements of professional athletes.

Owner:杨华平

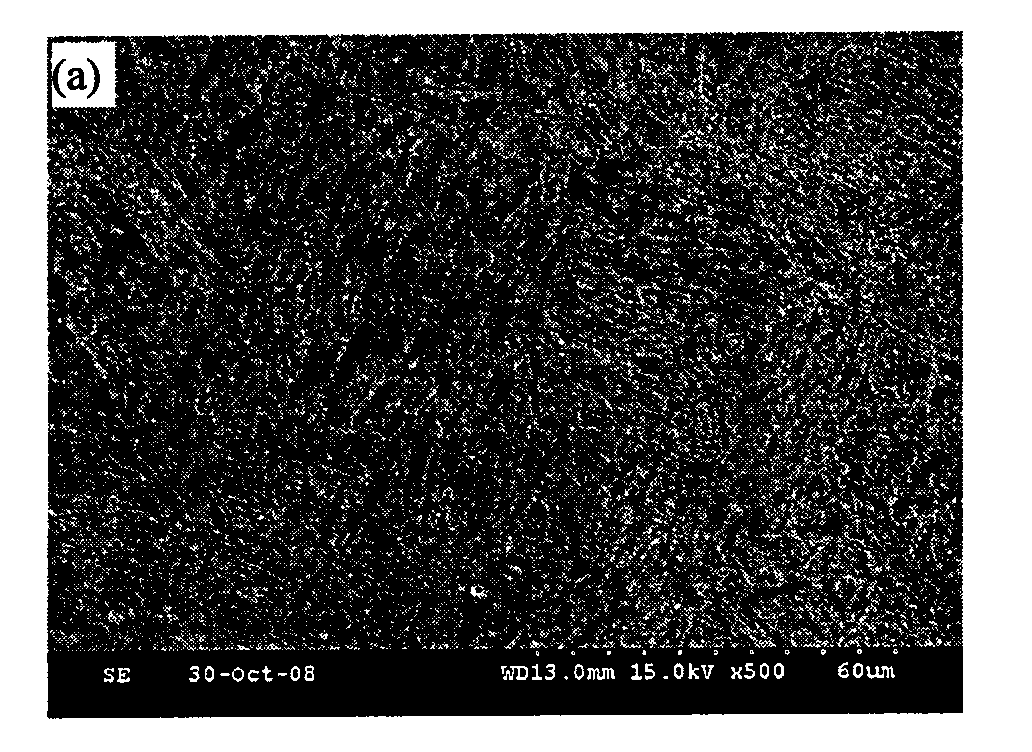

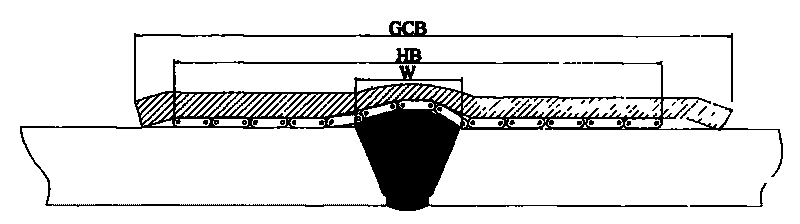

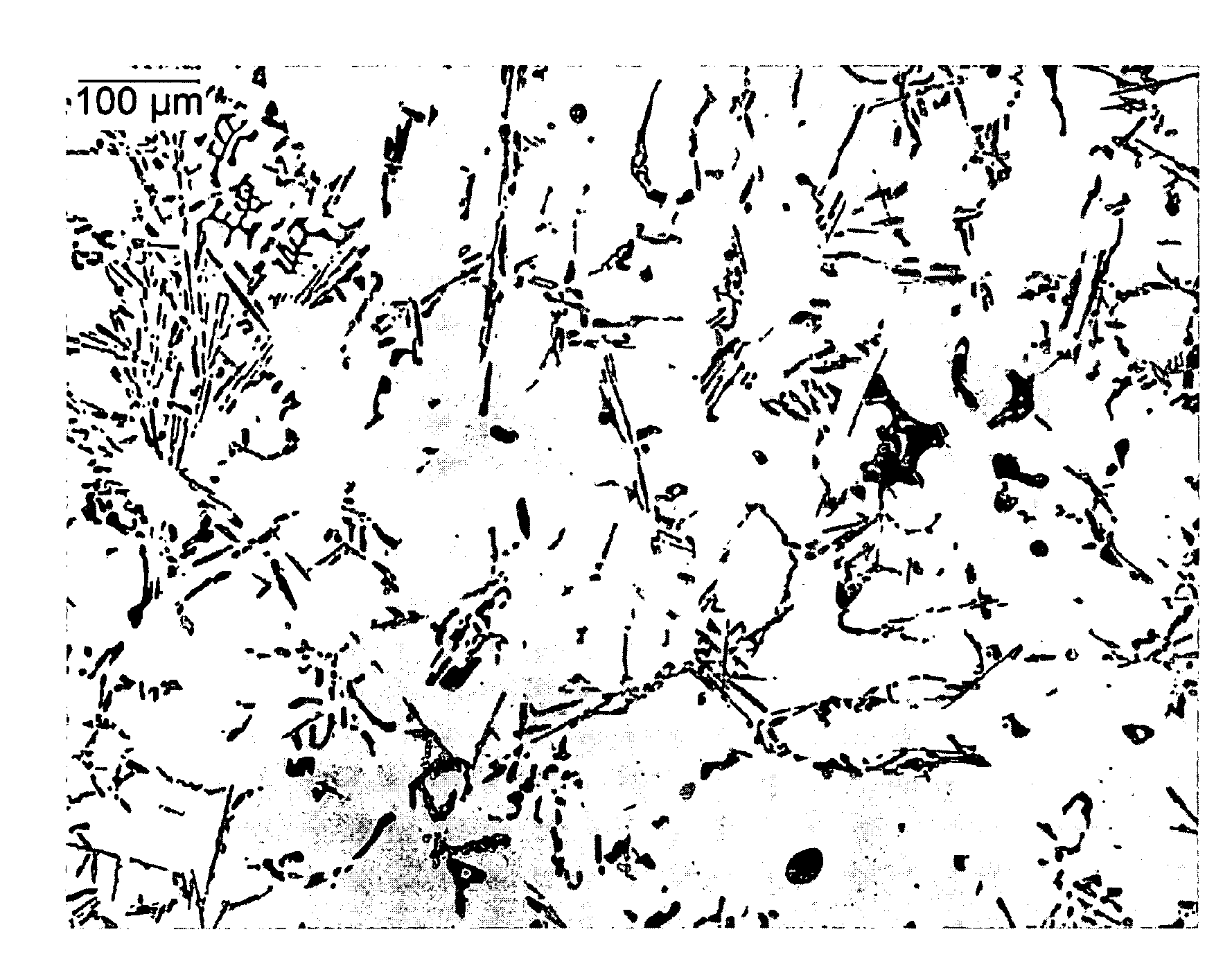

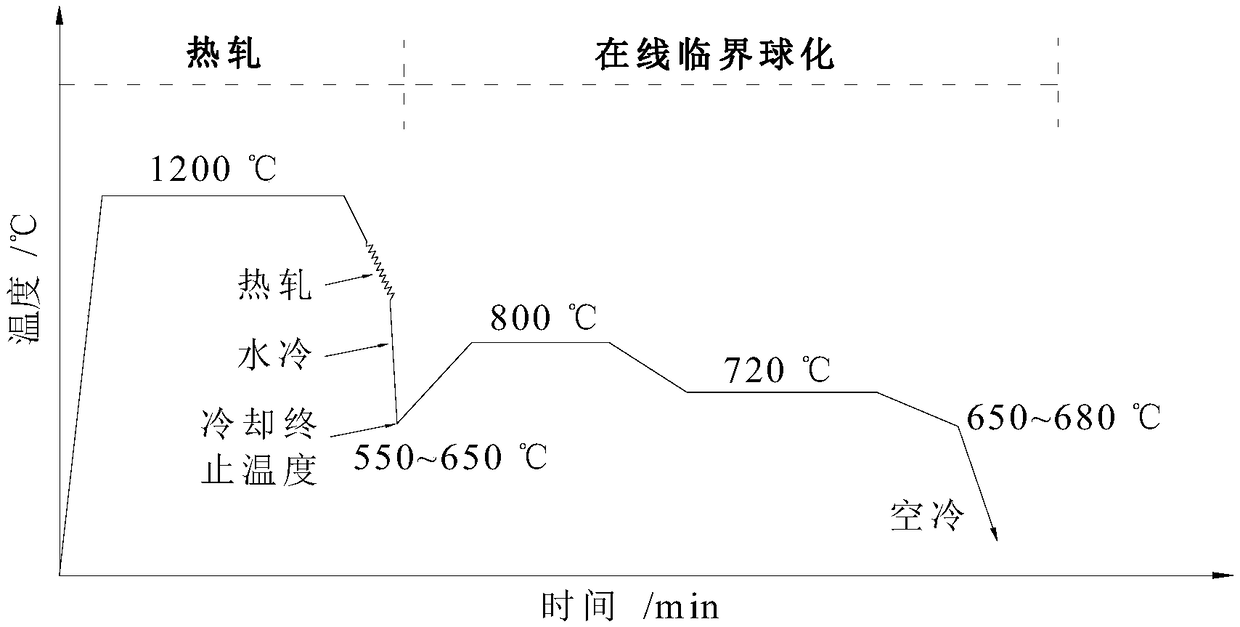

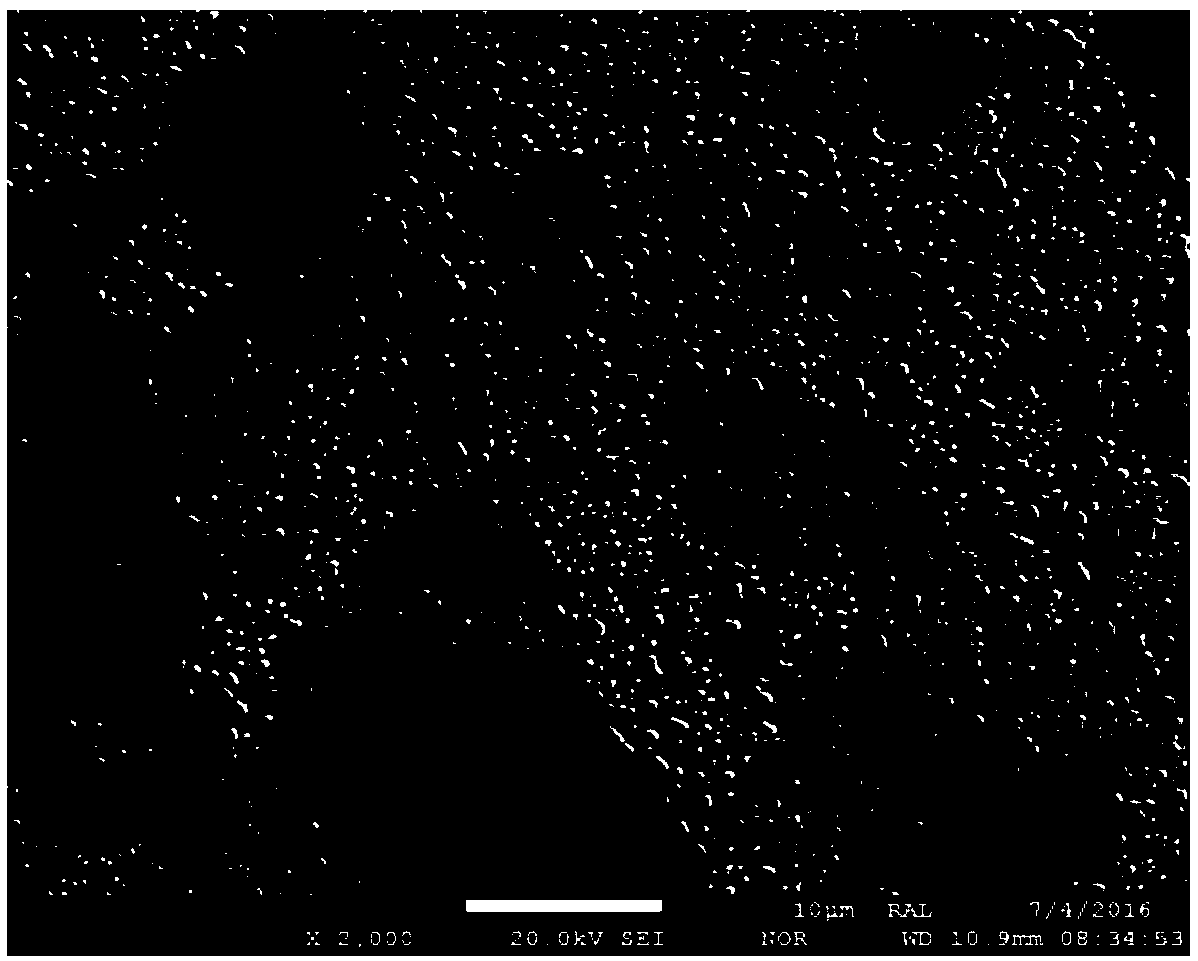

Online critical spheroidizing annealing method of GCr15 bearing steel

The invention relates to an online critical spheroidizing annealing method of GCr15 bearing steel and belongs to the field of metallurgical materials. According to the online critical spheroidizing annealing method of the GCr15 bearing steel, a steel rod after hot rolling is immediately water-cooled to 550 DEG C-650 DEG C at the speed of 10 DEG C / s-25 DEG C / s and then is heated to the critical temperature of 790 DEG C-800 DEG C at the speed of 5 DEG C / min-20 DEG C / min, heat preservation is conducted for 1h-3h, then, the steel rod is furnace-cooled to 710 DEG C-730 DEG C at the speed of 1 DEG C / min-3 DEG C / min, an isothermal process is carried out for 120 min, then the steel rod is furnace-cooled to 650 DEG C-680 DEG C at the speed of 0.5 DEG C / min-2.5 DEG C / min, and finally the steel rod is air cooled to the room temperature. A spheroidized structure obtained through the online critical spheroidizing annealing method is relatively close to a spheroidized structure obtained through a conventional offline spheroidizing annealing method, and the online critical spheroidizing annealing method can replace the conventional offline spheroidizing annealing method.

Owner:NORTHEASTERN UNIV

Supercritical carbon dioxide power generation system and method based on natural gas waste heat recovery

PendingCN109322743ARealize full captureThe actual compression work decreasesCarbon compoundsEnergy inputCyclic processExothermic process

The invention provides a supercritical carbon dioxide power generation system and method based on natural gas waste heat recovery. The supercritical carbon dioxide power generation system comprises anair separation device, a combustor, a carbon dioxide turbine, a heat regenerator, a water separator, a first carbon dioxide pressurization device, a carbon dioxide recovery device, a waste-heat-recovery heat exchanger, a Kalina turbine, a Kalina heat regenerator, a first mixer, an ammonia separator, a second mixer, a high-pressure condenser and a gas-liquid separator. According to the supercritical carbon dioxide power generation system, natural gas is taken as fuel, and the full capture of carbon dioxide is achieved by adopting an oxygen-enriched combustion method; in the carbon dioxide turbine, carbon dioxide expands to the subcritical state and achieves a higher expansion ratio than that the supercritical carbon dioxide Brayton cycle, so that the carbon dioxide turbine can do more workand the cycle efficiency can be improved; and during the bottom cycle, waste heat of the supercritical carbon dioxide cycle is recovered by adopting the Kalina cycle, and the concentration of a working medium changes in the working medium phase-change non-isothermal process and cycle process, so that the vaporization process and the heat-source heat release process can be matched well, the irreversible loss in the heat exchange process can be reduced, and the waste heat utilization efficiency can be improved.

Owner:HUANENG CLEAN ENERGY RES INST

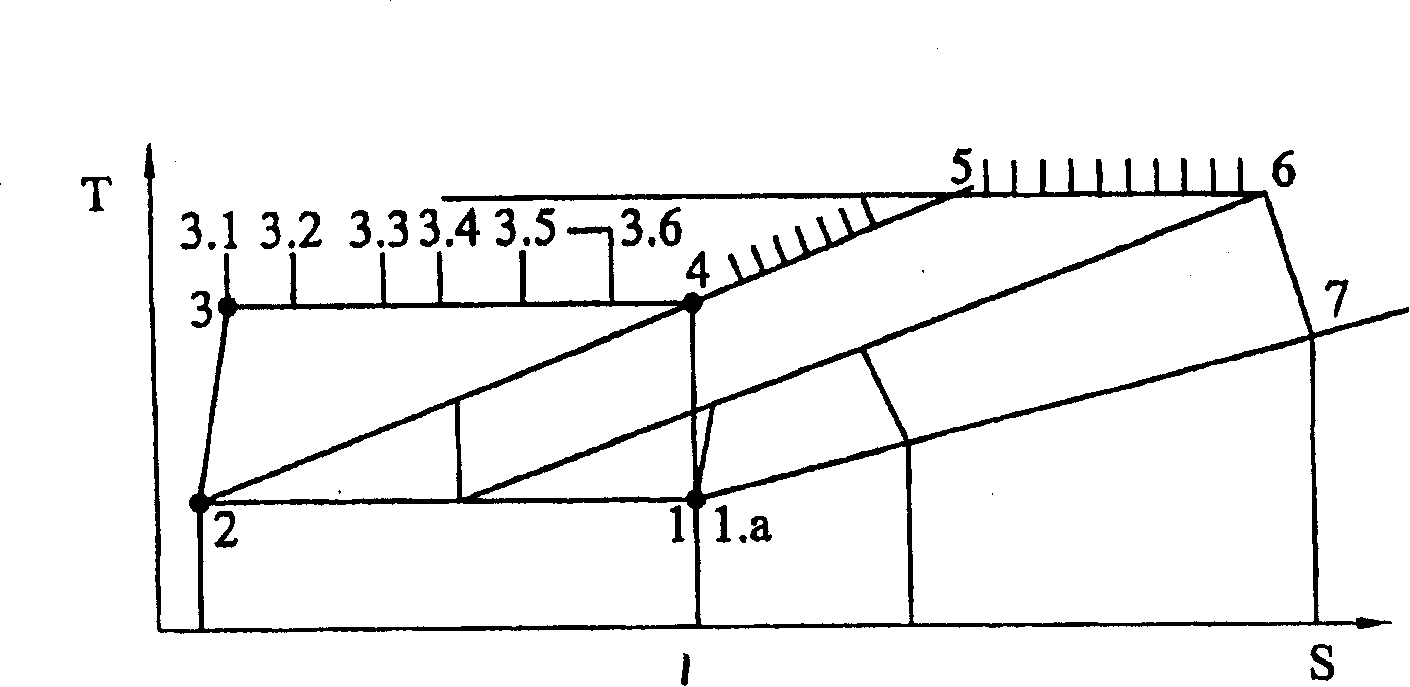

Turbo rocket with real Carnot cycle

Owner:马里厄斯・A・保罗

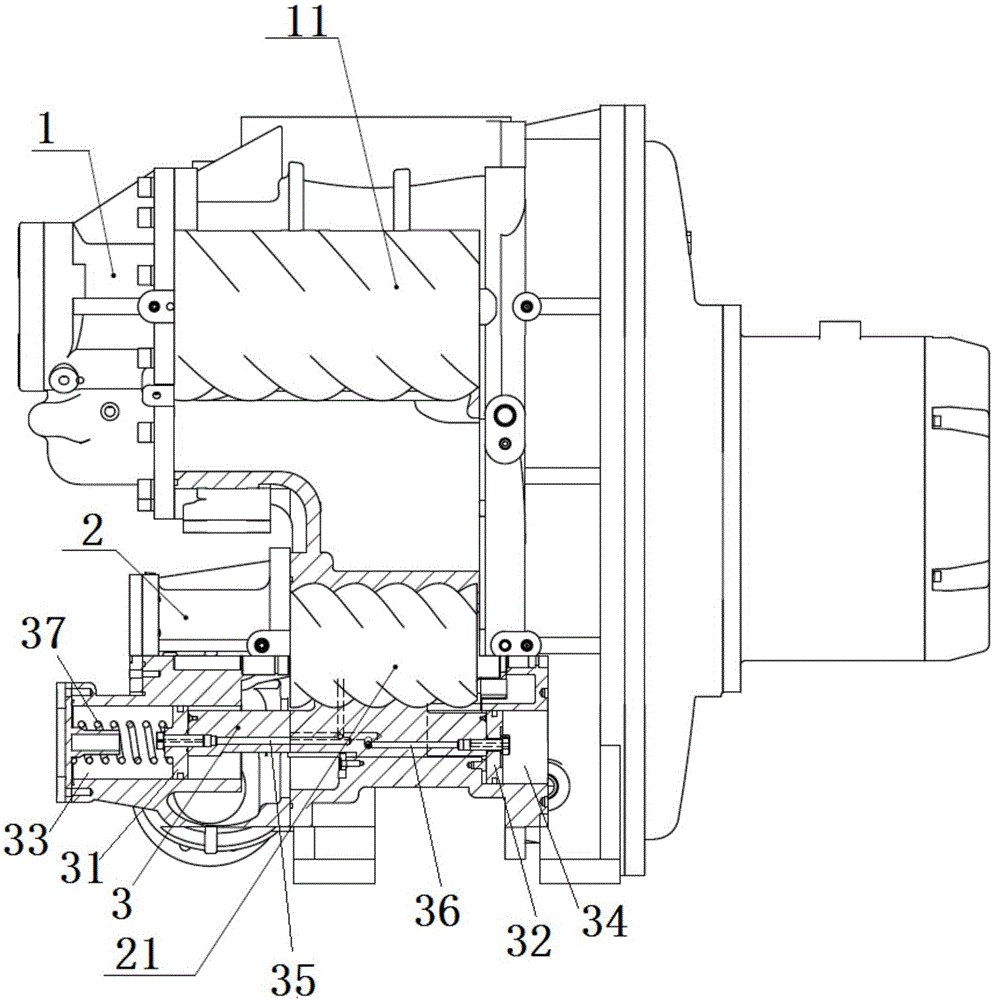

Two-grade screw rod compressor with flexible slide valve

InactiveCN105715548AIncreased operating lifeSimple designRotary piston pumpsRotary piston liquid enginesDischarge pressureMechanical engineering

The invention discloses a two-grade screw rod compressor with a flexible slide valve. The two-grade screw rod compressor comprises a first-grade compression mechanism, a second-grade compression mechanism, a transmission mechanism, the slide valve, a first cylinder and a second cylinder; the slide valve is arranged on the second-grade compression mechanism between the first cylinder and the second cylinder, and includes a slide valve body; the two ends of the slide valve body are respectively a first end surface and a second end surface; the first end surface and the second end surface respectively seal the first cylinder and the second cylinder; and the slide valve searches the balance under the driving of pressure in the first cylinder and the second cylinder. The two-grade screw rod compressor adopts a working mode of two-grade compression and interstage cooling, so that the compression process is closer to isothermal compression, and the efficiency is higher; and a compression ratio is reasonably distributed, and the bearing design is optimized, so that a host machine is longer in service life. The second-grade compression mechanism is provided with the slide valve, and an exhaust hole is automatically adjusted according to exhaust pressure needed by a user terminal, so that the two-grade screw rod compressor compresses the matching between ending pressure and the pressure needed by the user terminal, and the operation efficiency of the compressor is the highest.

Owner:浙江开山凯文螺杆机械有限公司

Isothermal process for phosphoromonochloridite synthesis

The present invention relates to a process for preparation of a phosphoromonochloridite in high yield by contacting phosphorus trichloride (PCl3) with an aromatic diol in a solution of one or more organic solvents under reaction conditions sufficient to produce the phosphoromonochloridite. The reaction is carried out by adding a feed solution containing the aromatic diol dissolved in a first organic solvent into a reaction zone containing PCl3, and optionally one or more second organic solvents, the addition being conducted so as to maintain substantially isothermal process conditions. The reaction solution comprises greater than 0.01 to less than 5 mole percent of a nitrogen base.

Owner:UNION CARBIDE CORP

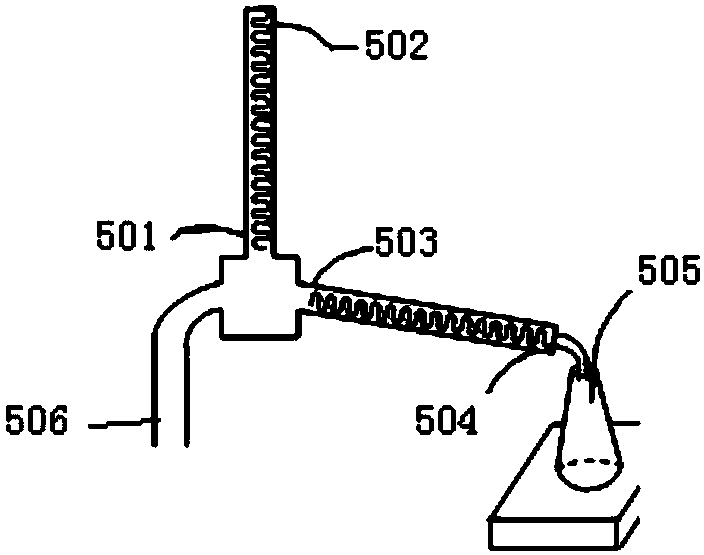

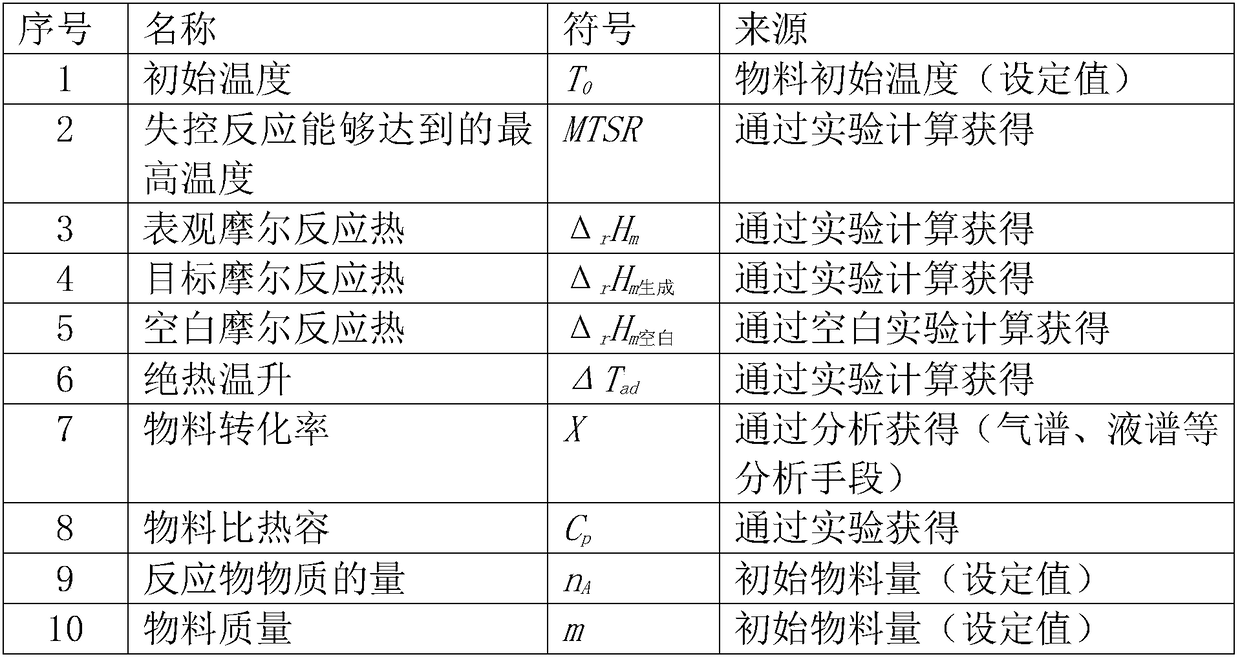

Method and device for measuring calorimetry of non-isothermal reaction process

PendingCN108535315AThe results of the study are close toThe research results are closer to the actual production conditionsMaterial heat developmentChemical safetyHeat flow

The invention belongs to the field of chemical safety technology and engineering, and relates to a method and a device for measuring calorimetry of a non-isothermal reaction process. Reaction temperature gradients T1, T2, T3 to Tn are set according to the non-isothermal reaction, initial acquisition temperature T0 is obtained, and generation reaction heat DELTArHm (generation) is calculated and obtained; according to the non-isothermal reaction, blank experimental reaction heat DELTArHm (blank) is obtained; according to the generation reaction heat DELTArHm (generation) and the blank experimental reaction heat DELTArHm (blank), heat effect caused by temperature rise during the reaction calorimetry process is obtained and deducted, and target reaction heat DELTArHm is obtained. The method adopts a non-isothermal heat flow mode to carry out the reaction calorimetry to realize real-time collection of various heat data in the reaction process and risk assessment on the non-isothermal reaction.

Owner:SHENYANG RES INST OF CHEM IND

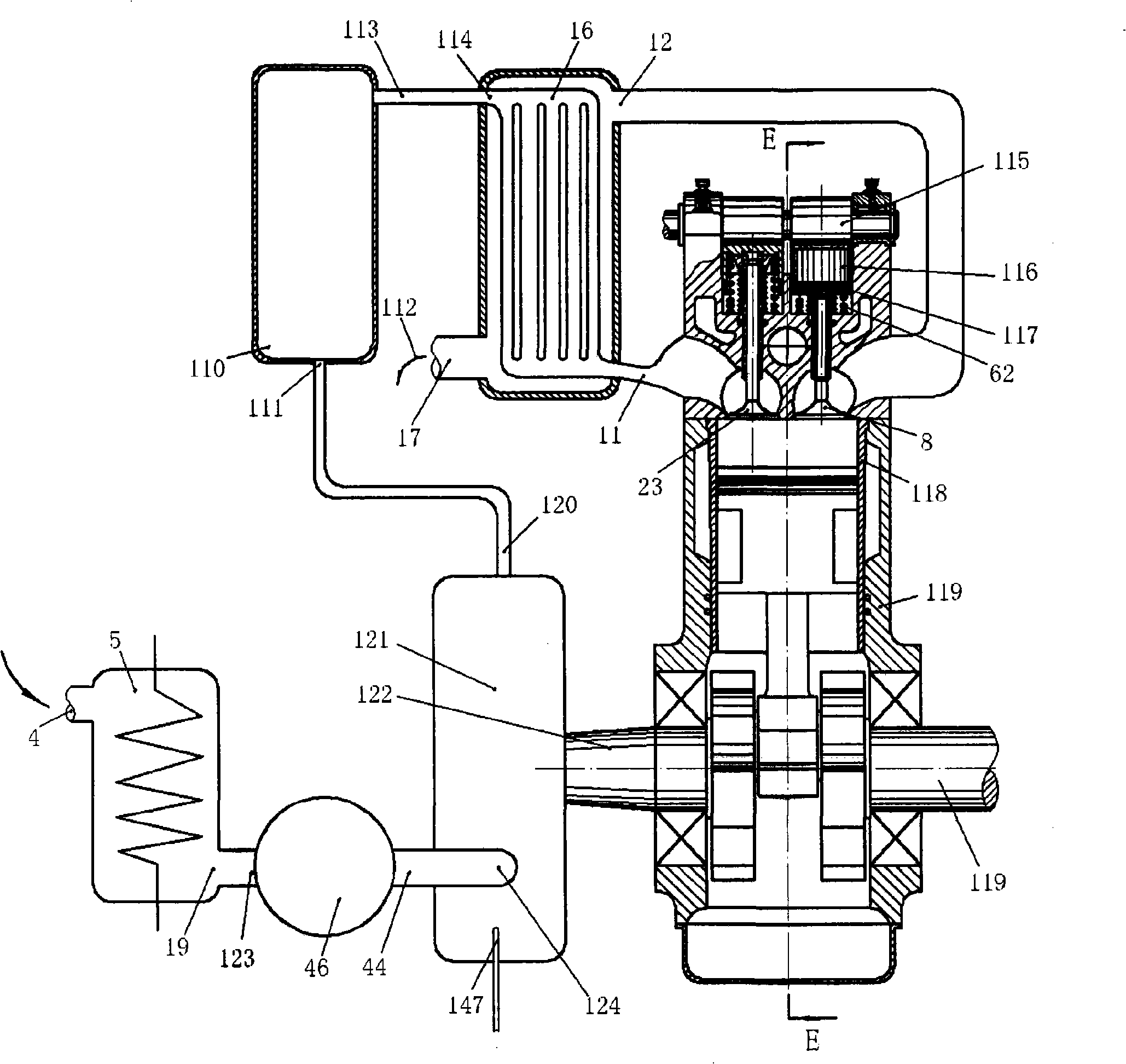

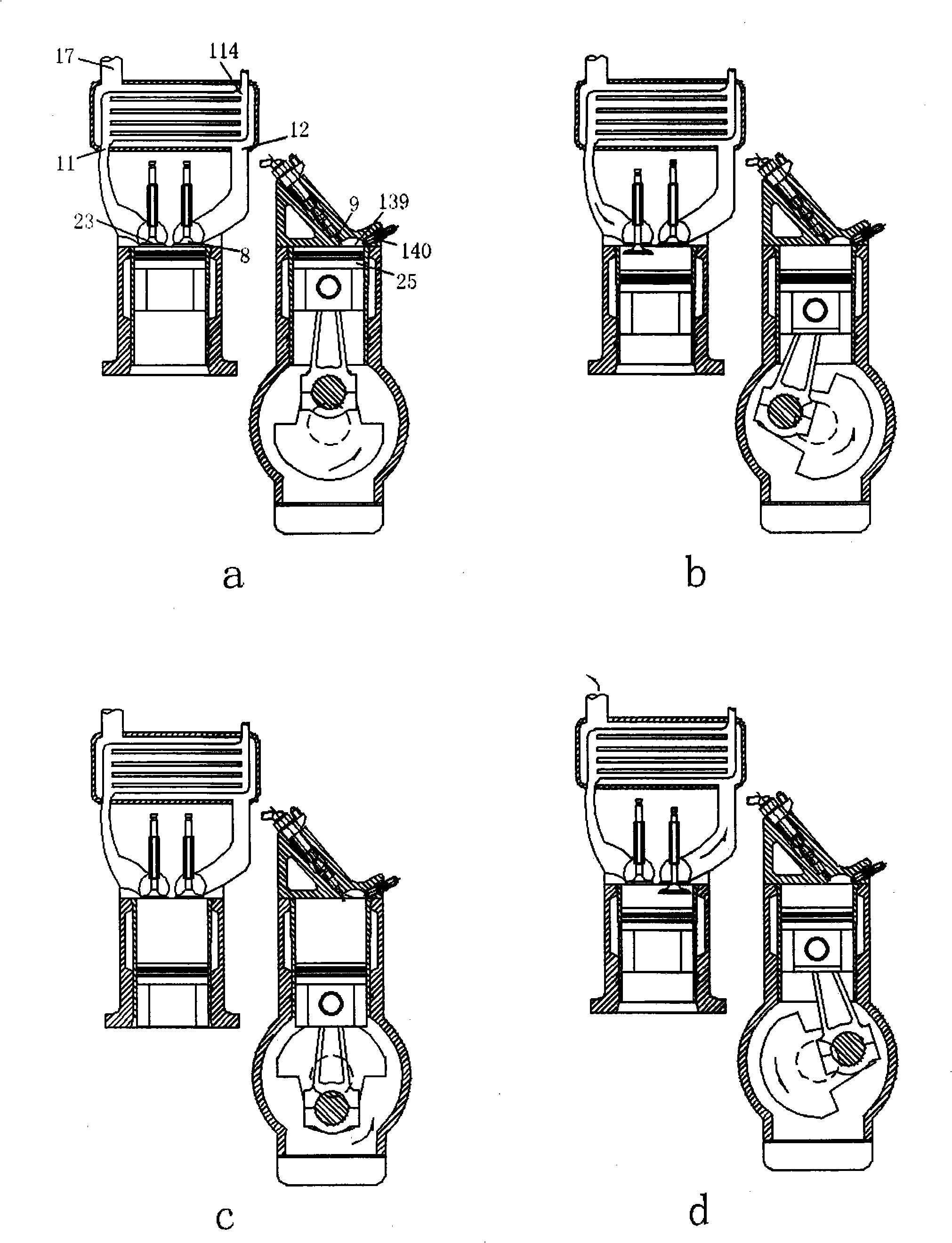

Internal-burning type gas-heating machine

InactiveCN101270702AIncrease output powerIncrease powerOpen-cycle gas positive displacement engine plantInlet channelCombustion chamber

An internal combustion type heat engine mainly consists of a cylinder, a cylinder cover, a compressor, a heat exchanger, a valve actuating mechanism, a power transmission mechanism and a heater. The heater consists of an oil atomizer, a heater plug and the combustion chamber with changeable cubage. The heat engine is a novel circulating working engine established on the basis of the circulation formed by two isothermal processes and two isopiestic processes. Under the action of the valve actuating mechanism and the power transmission mechanism, a piston inside the heat engine runs discontinuously. The air inlet channel of the heat engine is provided with a cooling mechanism and a water fog generator, thus when the compressor in the heat engine compresses the mixture of low-temperature air and the water fog by low proportion, no high temperature is produced, which helps to improve the operation rate. The heat engine burns and works inside the cylinder like an internal combustion engine, and a majority of the parts of the heat engine are the same as the prior internal combustion engine.

Owner:赛星嘎

Air supplemental heat transfer engine

InactiveCN101012785ASmooth output rotationImprove powerOpen-cycle gas positive displacement engine plantExternal combustion engineCarnot cycle

The invention discloses an air storing and heat exchanging engine, mainly comprising hot air cylinder, heater, air storing room I, compressor and air storing room II. The compressor is connected with the cooling system. When the engine works, the high-temperature heat source transfers heat to the air in inner cavity of heater pipes and on the cover of heat cylinder there is a microcomputer control valve mechanism. The theoretical cycle of engine comprises two equal temperature processes, two equal cubage processes and a moving process. In the moving process energies can not be exchanged in system and the work that the outside puts to system is zero. So the cycling efficiency is equal to carnot cycle efficiency. Compared with the linkage-crank internal combustion engine the open engine, which works in the cycle, can save energy by more than 10%. Compared with prior stirling engine the transmission structure of closed engine is simple.

Owner:赛星嘎

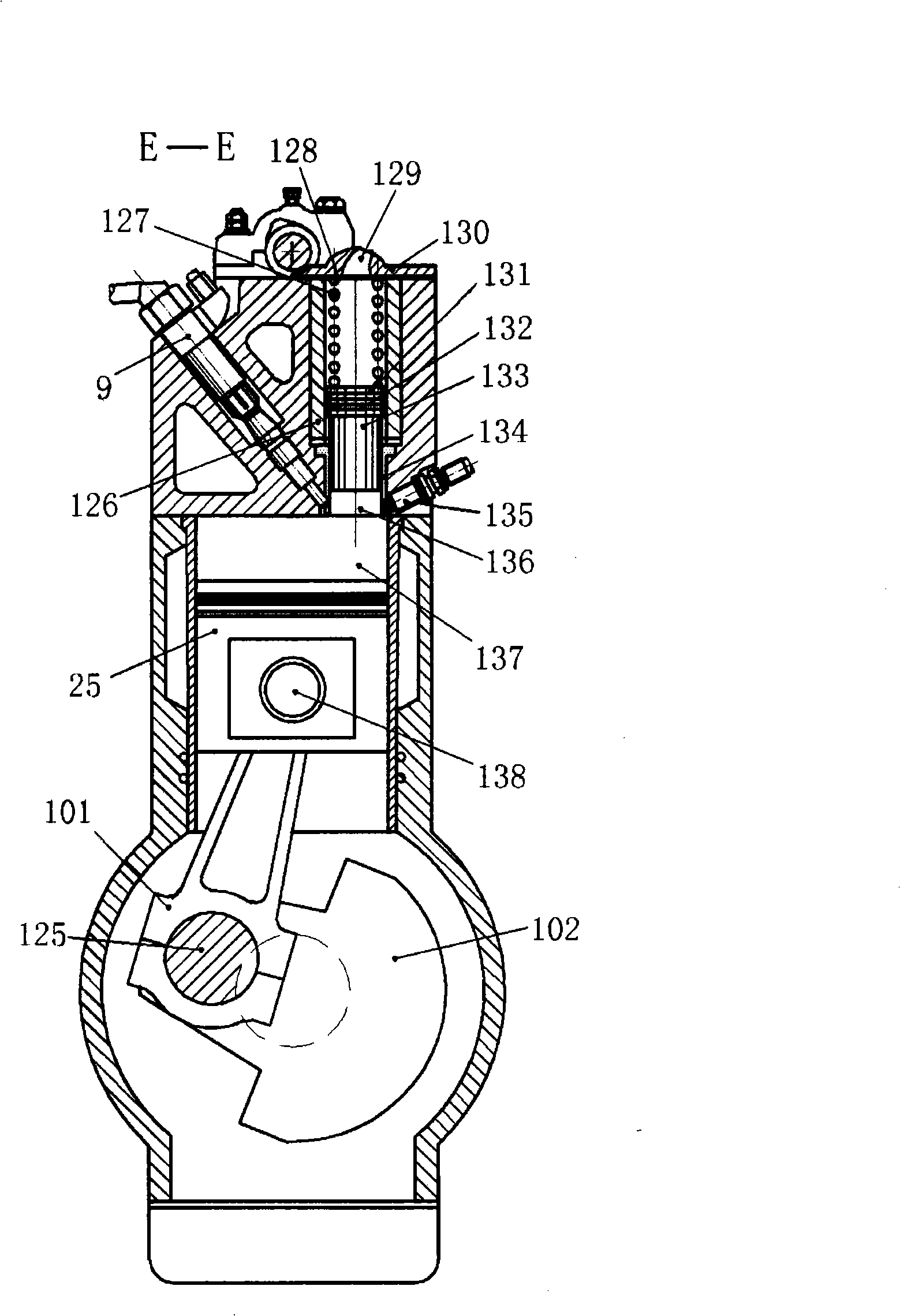

Heat exchanger structure and isothermal compression or expansion chamber

The invention relates to a thermodynamic machine that includes at least one chamber (21) in which an isothermal expansion and / or compression is to be carried out, said chamber being longitudinally defined by first and second walls (23, 25) that are mobile relative to each other. The chamber (21) is divided by partitions (31, 33) extending longitudinally from each of the first and second walls, the partitions being interleaved within each other, and the distance between the partitions extending from a same wall being such that the ratio between the distance squared and the cycle duration of the thermodynamic machine is lower than the average thermal diffusivity of the gas contained in the chamber.

Owner:思迪莱尔(简易有限公司)

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com