Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

2410results about "Quenching agents" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

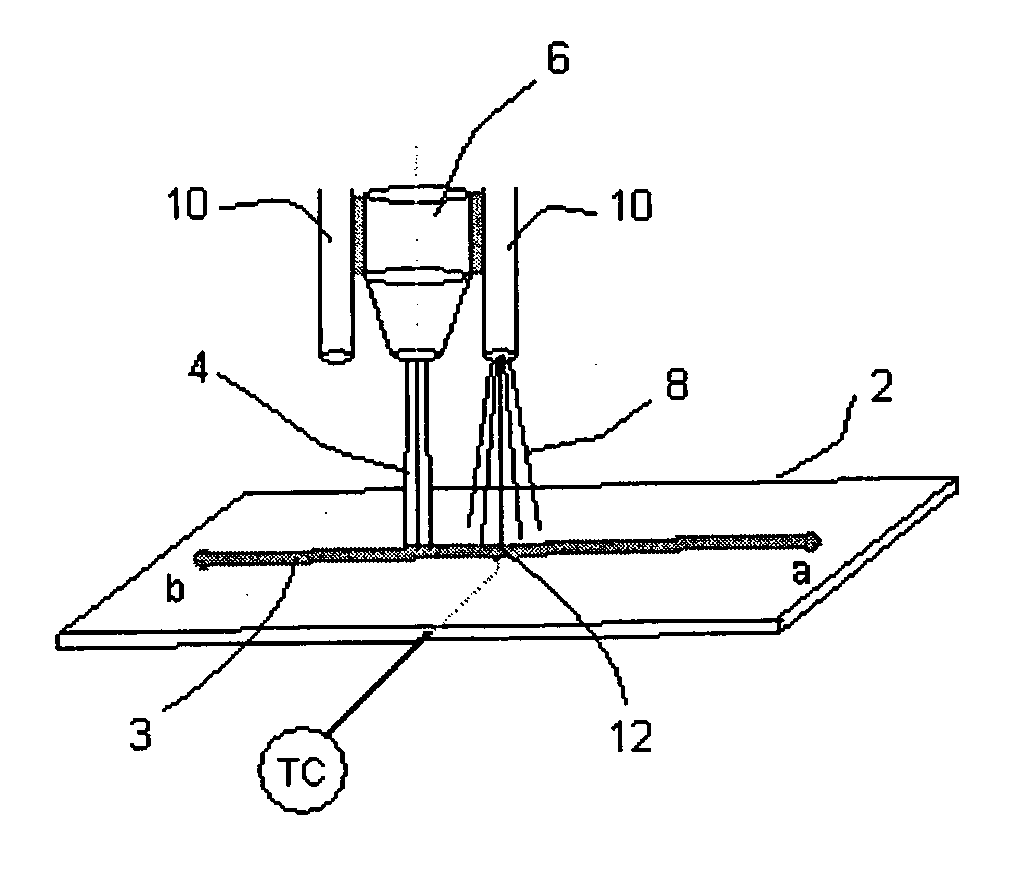

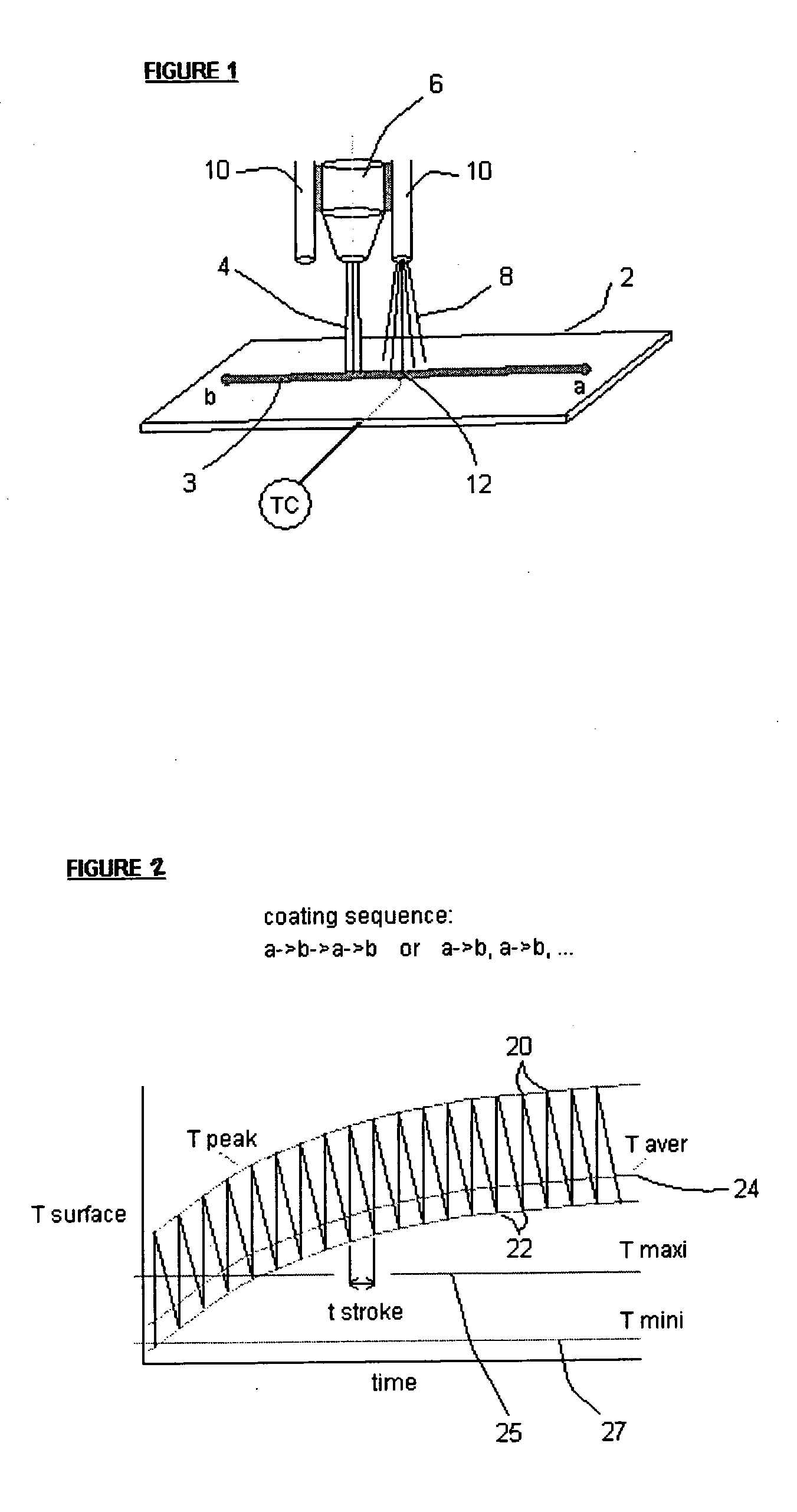

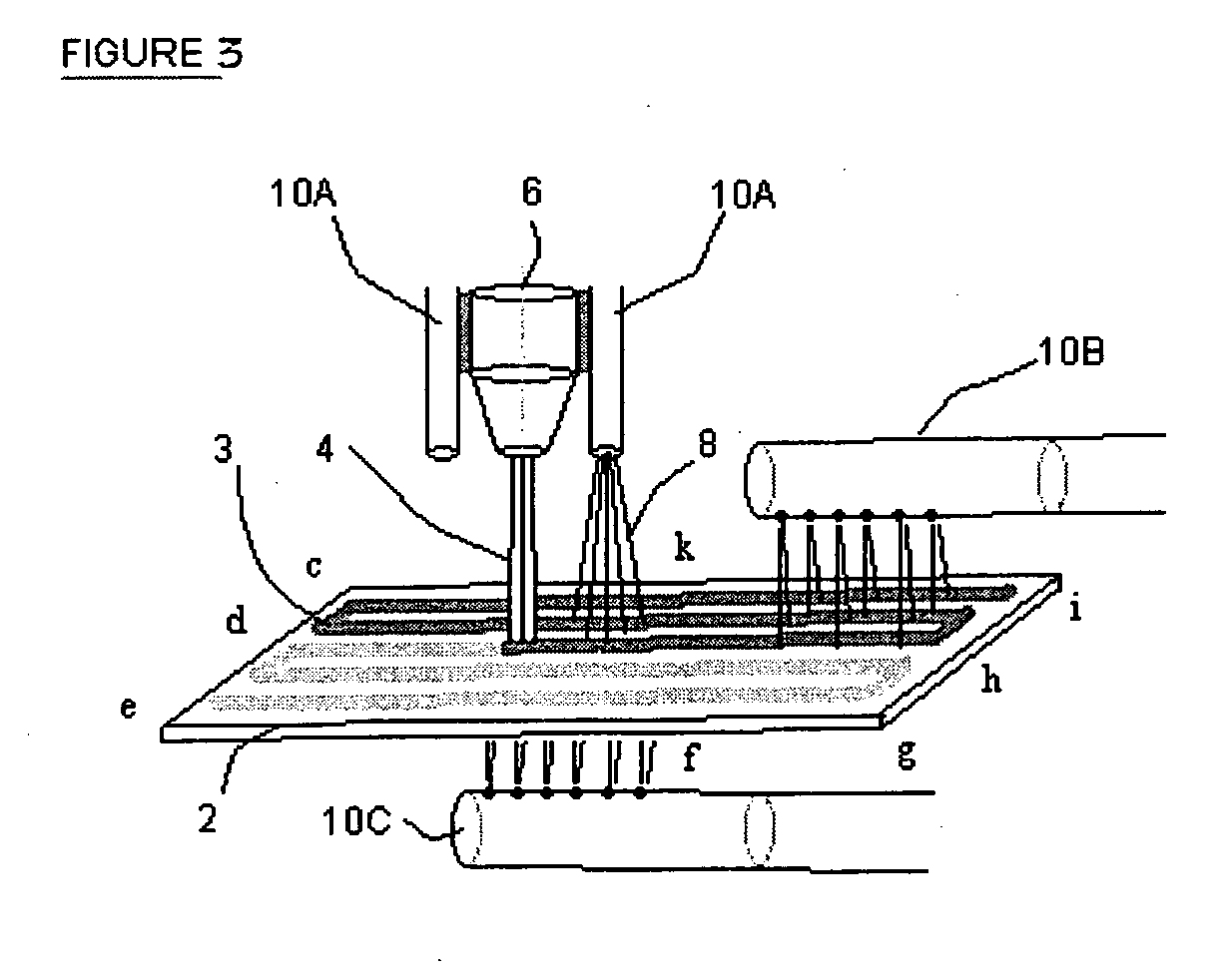

Thermal deposition coating method

ActiveUS20060228465A1Excellent coating production rateDamaging internal stressLiquid surface applicatorsMolten spray coatingThermal depositionRelative motion

A process for the thermal deposition coating of a workpiece, said process comprising the steps of: (c) thermally depositing a coating on a metallic surface of a workpiece from a deposition head wherein at least one condition selected from the group of: coating deposition rate onto said surface, relative motion between the surface and said deposition head, and cryogenic coolant application rate onto said workpiece is controllable; (d) substantially simultaneously measuring temperatures at a plurality of locations over the metallic surface of the workpiece; (c) determining an average temperature of the temperatures measured in step (b); (d) comparing the average temperature to a preselected minimum temperature and a preselected maximum temperature for the workpiece; and (e) adjusting at least one of the controllable conditions if said average temperature is not between the preselected minimum temperature and the preselected maximum temperature for the workpiece. Standard deviations of all temperature readings and controlling the relative motion speed between the thermal coating deposition head and the workpiece provide another improvement for obtaining temperature uniformity over the workpiece surface.

Owner:AIR PROD & CHEM INC

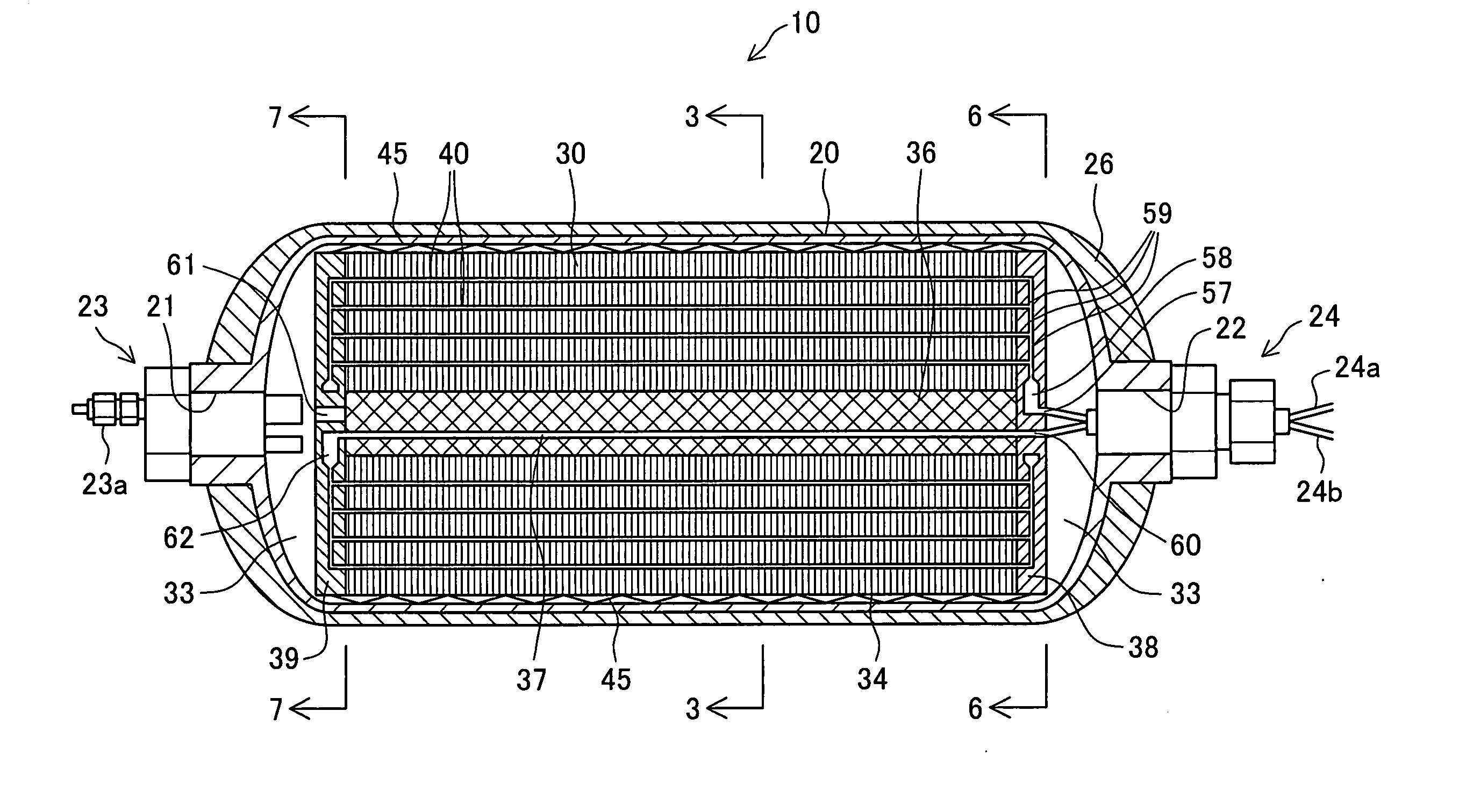

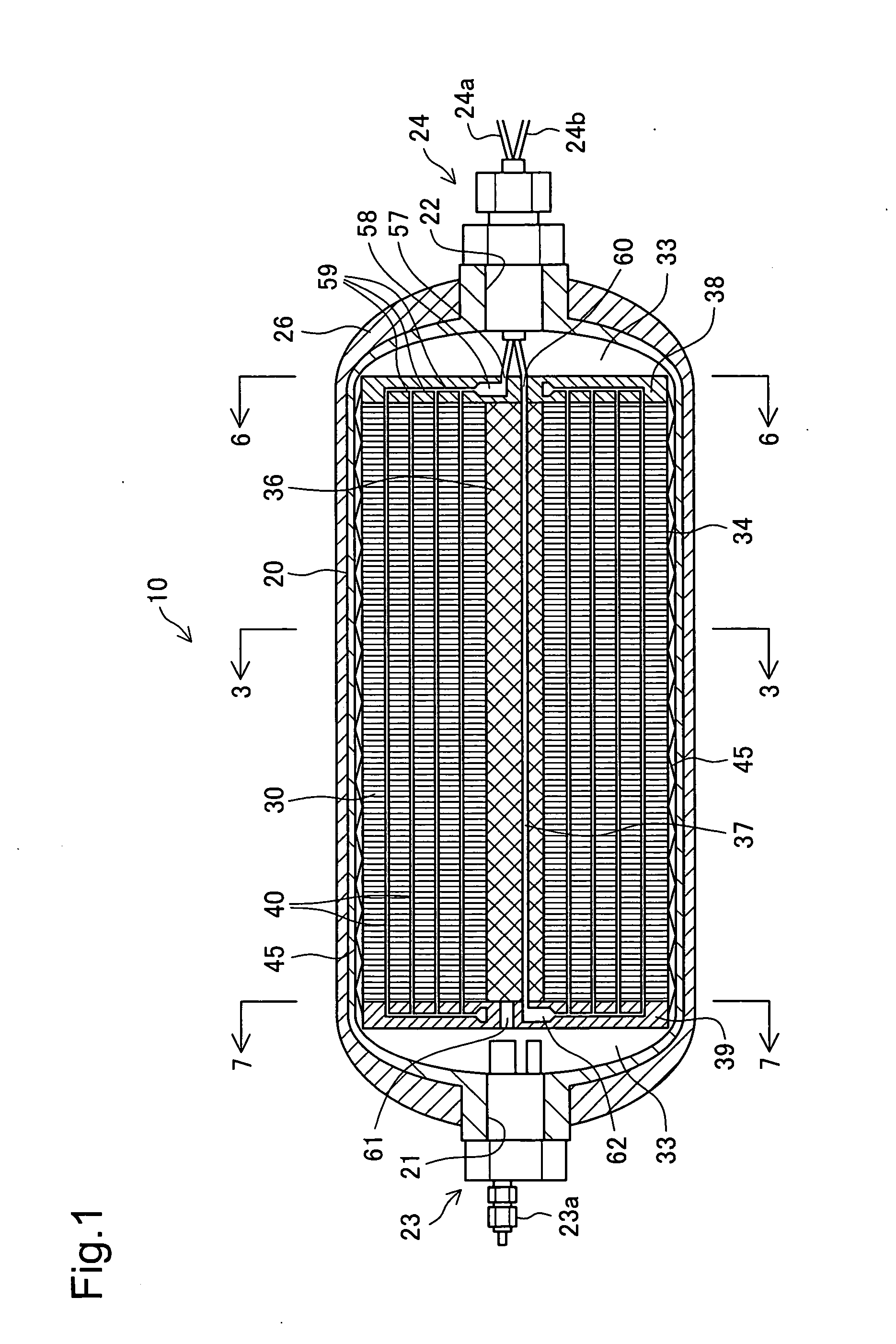

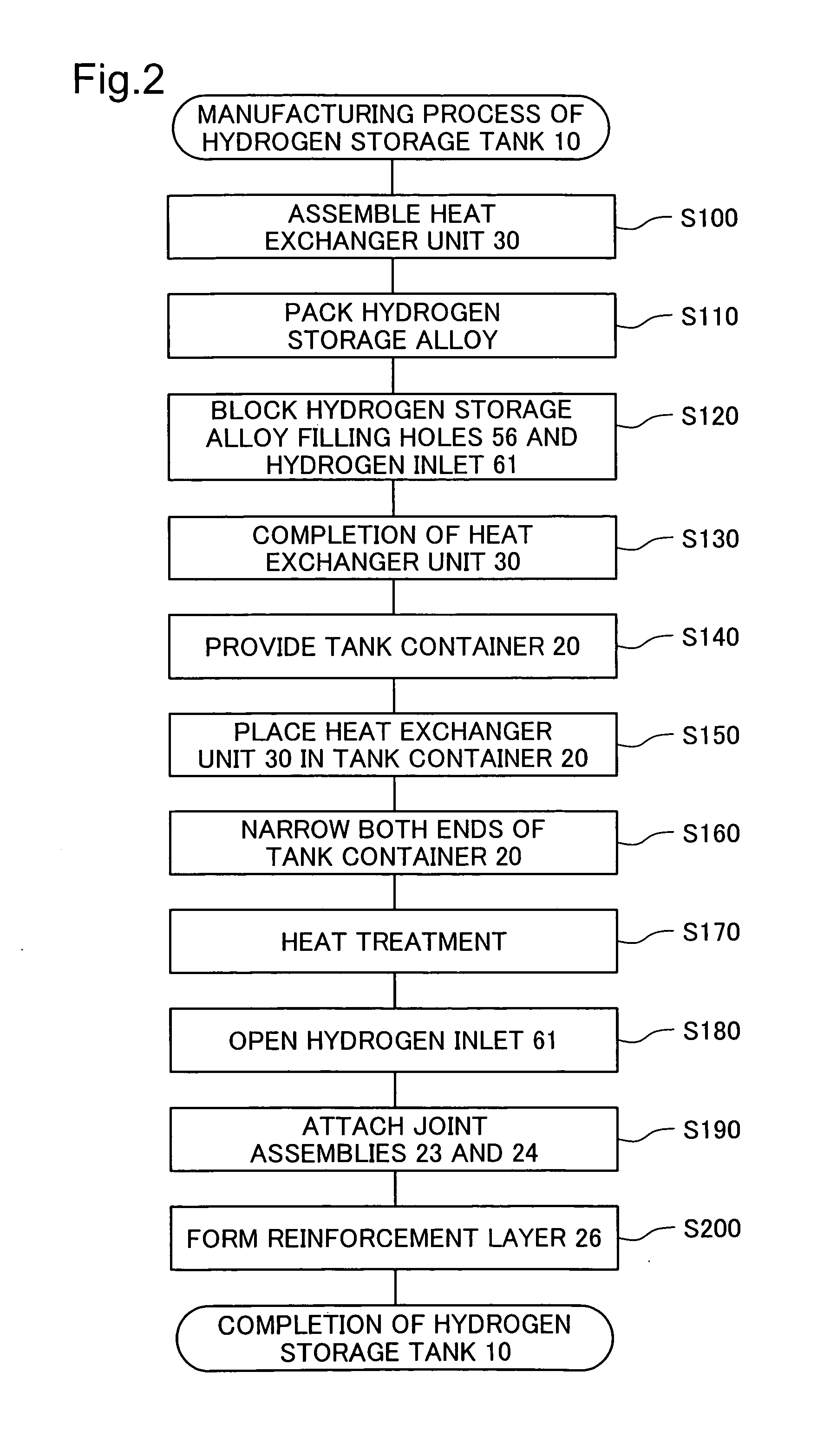

Gas storage tank and method of manufacturing the same

InactiveUS20050000970A1Drawback can be obviatedSufficient performanceReversible hydrogen uptakeCombustion enginesWater coolingHigh pressure

The technique of the invention manufactures a gas storage tank, which includes a gas absorbent / adsorbent and is capable of storing a high-pressure gas. The manufacturing process of a hydrogen storage tank first assembles a heat exchanger unit and packs the particles of hydrogen storage alloy into the heat exchanger unit. The manufacturing process then blocks hydrogen storage alloy filling holes used for packing the hydrogen storage alloy in the heat exchanger unit and attaches a detachable cover member to a hydrogen inlet. The manufacturing process subsequently locates the heat exchange unit filled with the hydrogen storage alloy in a cylindrical tank and narrows both ends of the tank to form joint openings. The manufacturing process then heat-treating the tank under water cooling and detaches the cover member. The manufacturing process attaches joint assemblies to the joint openings and forms a reinforcement layer around the outer circumference of the tank to complete the hydrogen storage tank.

Owner:TOYOTA JIDOSHA KK +1

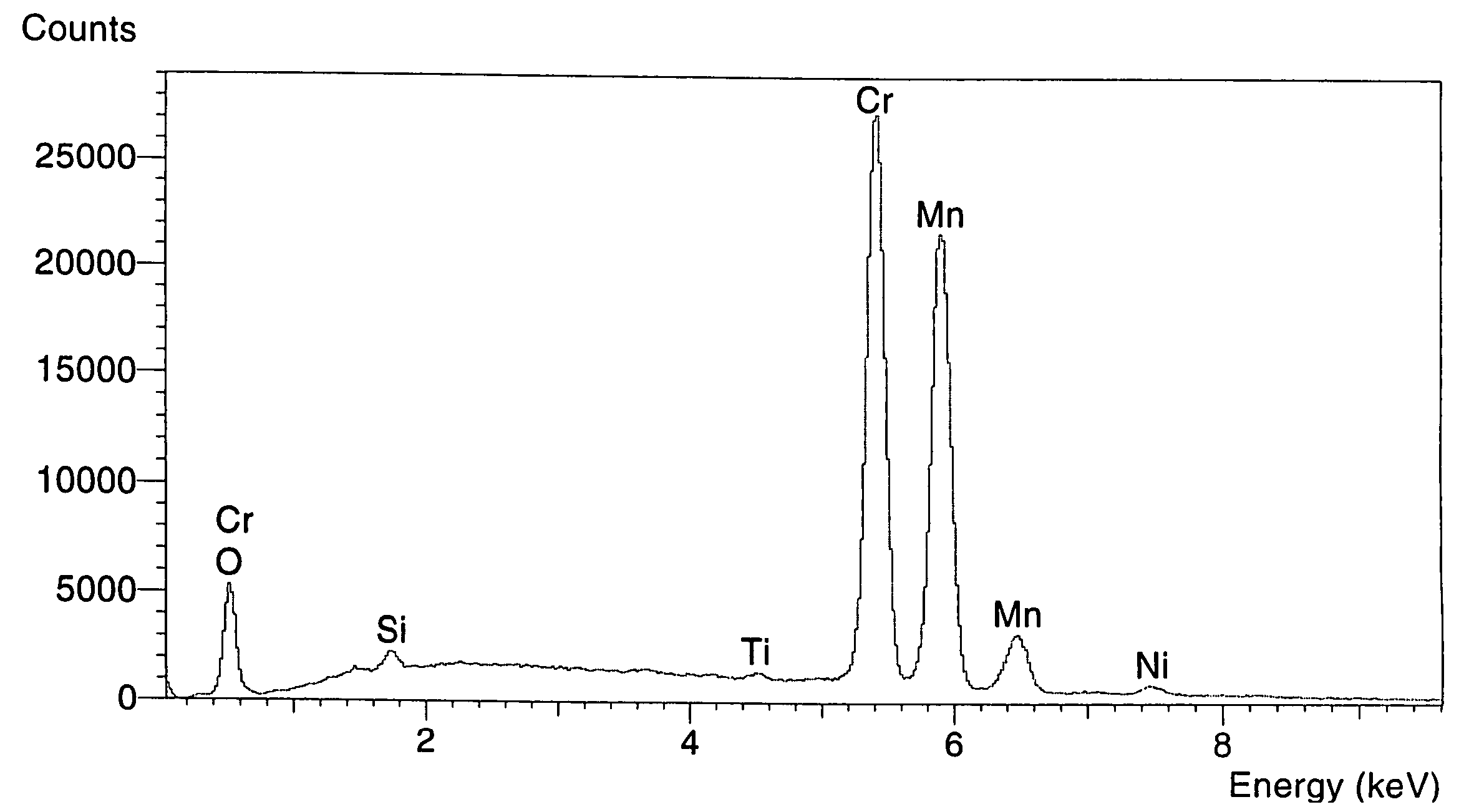

Surface on a stainless steel matrix

InactiveUS7488392B2Not to damage surfaceSolid state diffusion coatingQuenching agentsChemical reactionSpinel

A stainless steel comprising at least 20 weight % of chromium and at least 1.0 weight % of manganese is adapted to support an overcoating having a thickness from 1 to 10 microns of a spinel of the formula MnxCr3−xO4 wherein x is from 0.5 to 2. Preferably the overcoating is on chromia and has stability against chemical reaction at temperatures at least 25° C. higher than the uncoated chromia.

Owner:NOVA CHEM (INT) SA

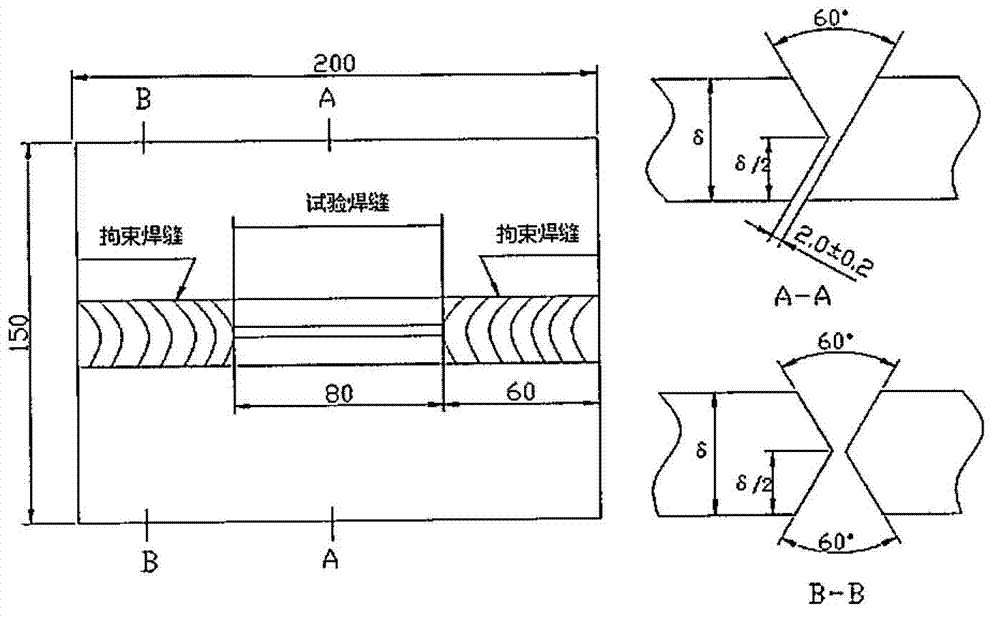

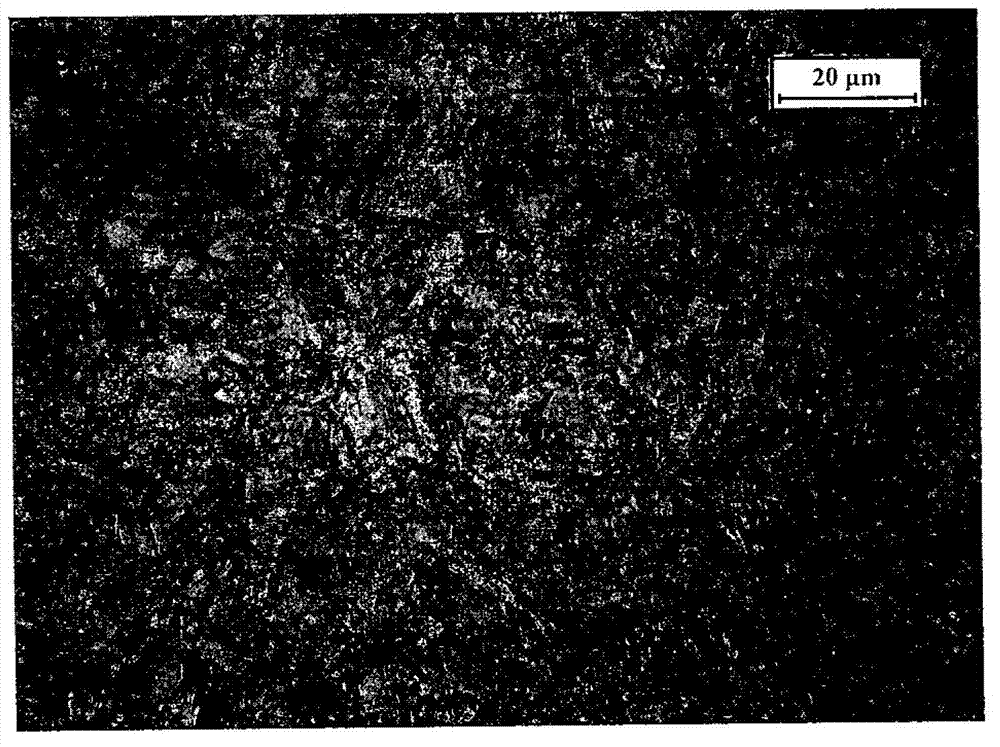

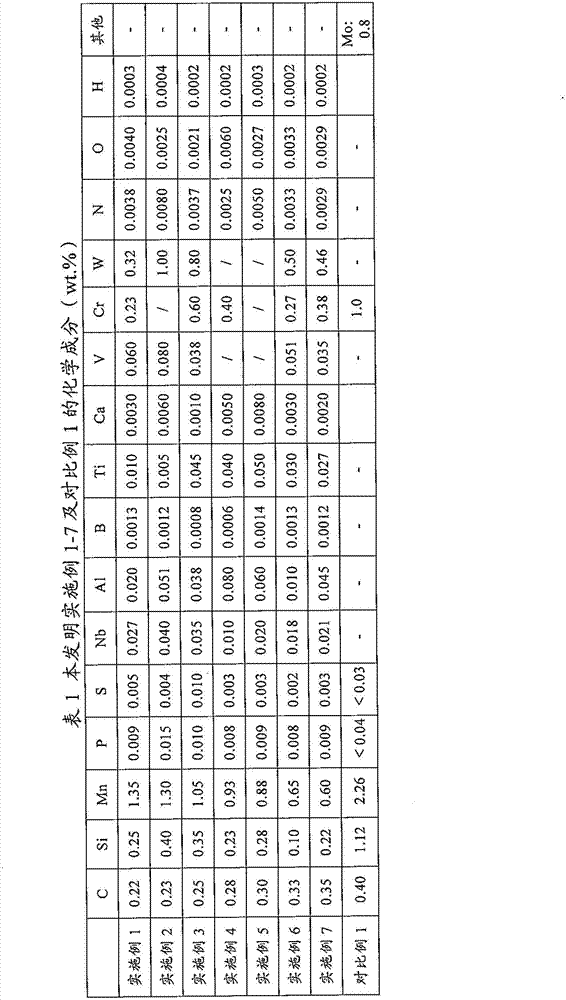

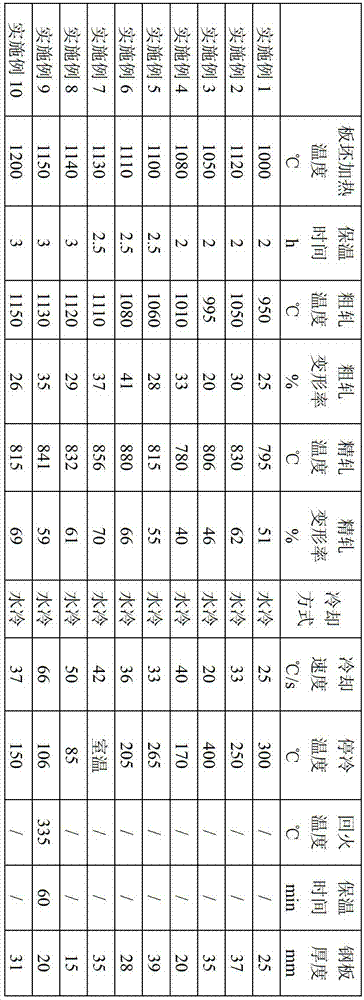

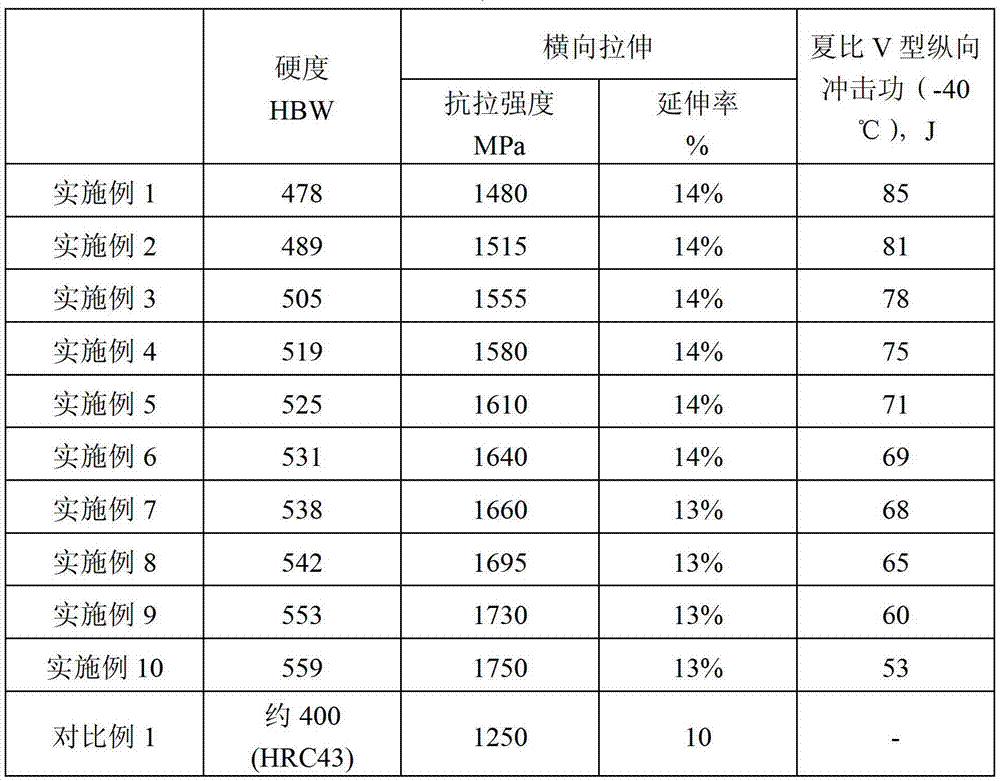

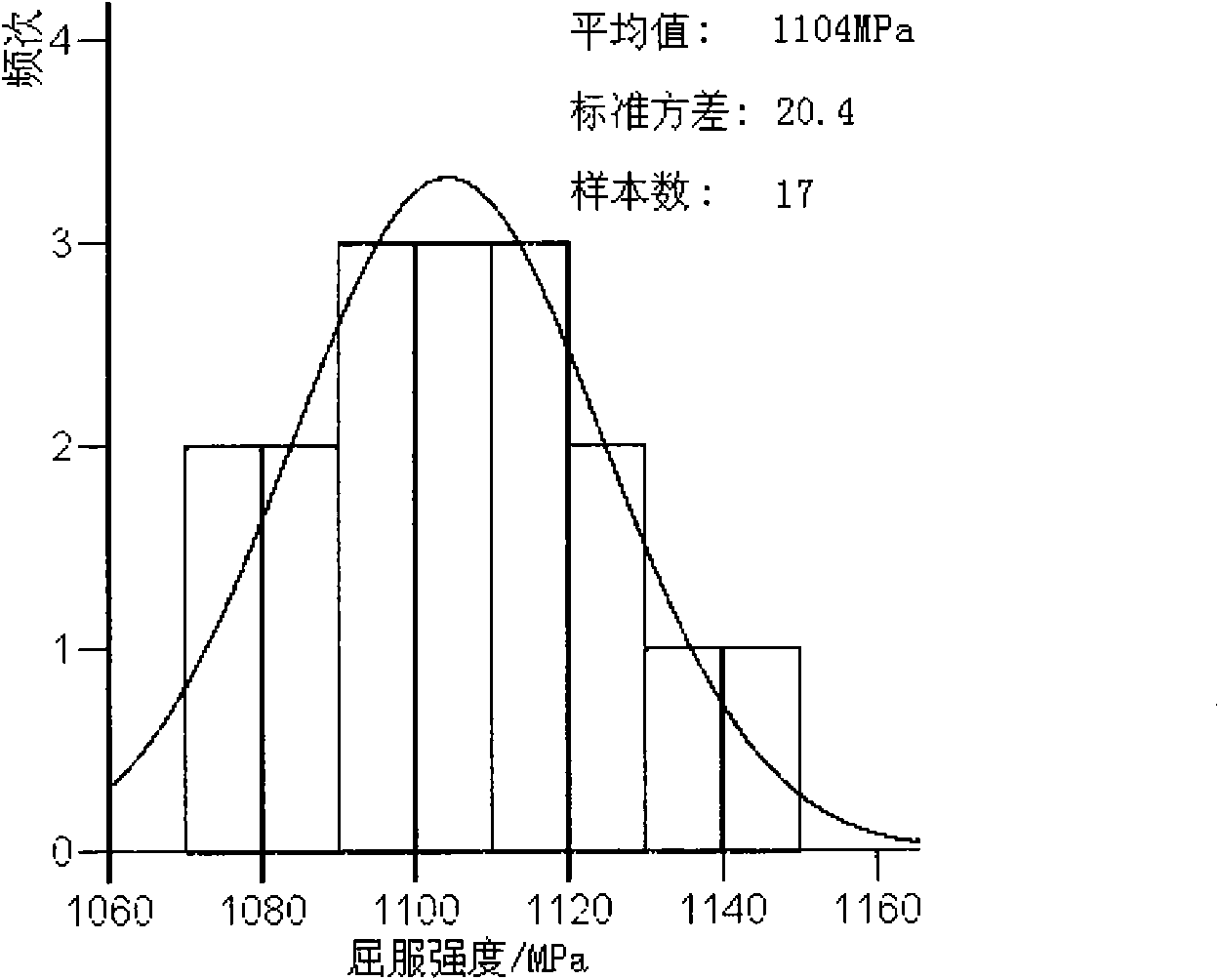

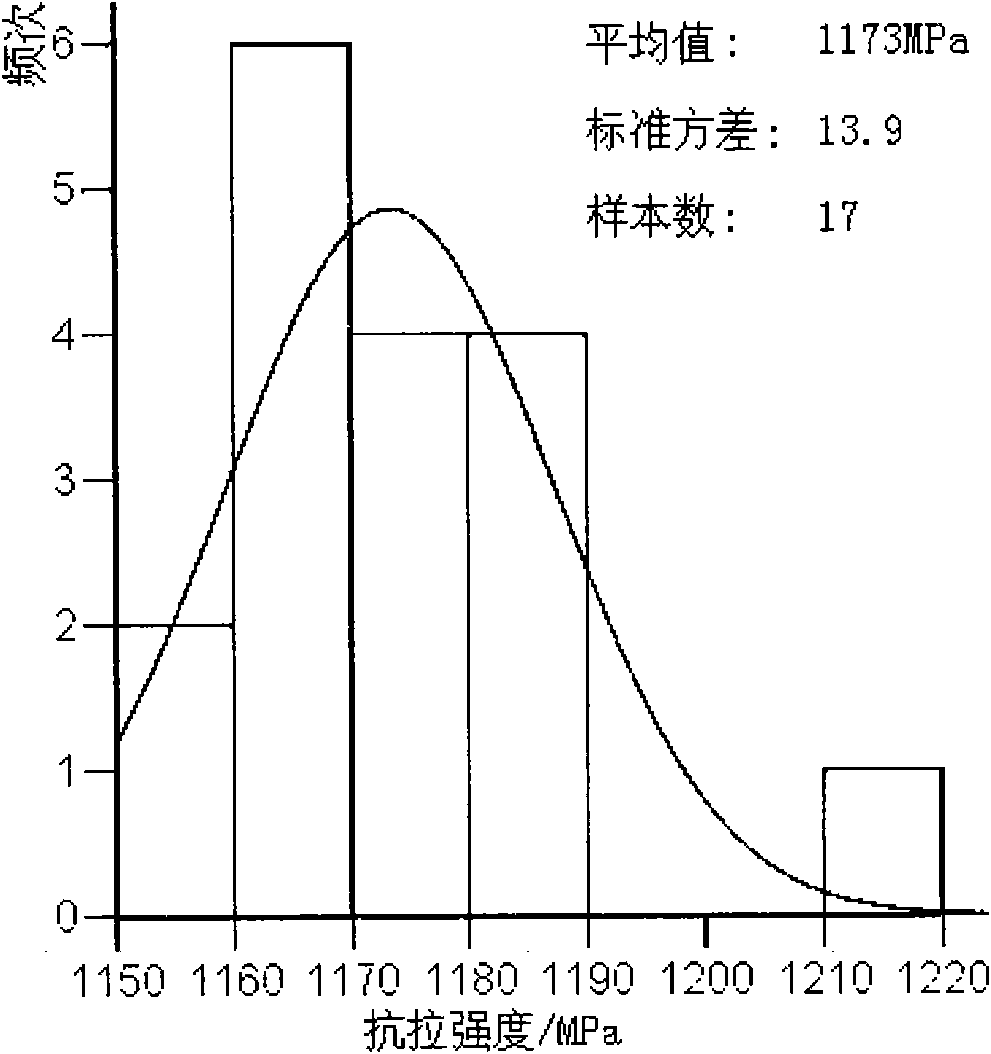

Super-strength high-toughness wear resistant steel plate and production method thereof

ActiveCN102876969AStrong mechanical propertiesGood mechanical propertiesFurnace typesQuenching agentsWear resistantHigh intensity

The invention provides a wear resistant steel plate, comprising the following chemical components (wt%): 0.22-0.35% of C, 0.10-0.40% of Si, 0.60-1.35% of Mn, not more than 0.015% of P, not more than 0.010% of S, 0.010-0.040% of Nb, 0.010-0.080% of Al, 0.0006-0.0014% of B, 0.005-0.050% of Ti, 0.0010-0.0080 wt% of Ca, not more than 0.080% of V, not more than 0.60% of Cr, not more than 1.00 wt% of W, not more than 0.0080% N, not more than 0.0060% of O, not more than 0.0004% of H and the balance of Fe and inevitable impurities, wherein Nb+Ti is not less than 0.025% and not more than 0.080%, and Al+Ti is not less than 0.030% and not more than 0.12%. The production method of the wear resistant steel plate comprises the steps of smelting, casting, rolling and directly cooling after rolling. The wear resistant steel plate obtained through the components and the process has the advantages of high intensity, good low temperature toughness, and excellent mechanical processing performance, and is suitable for easily abrasive devices in engineering and mine machinery, such as a grab bucket, a scraper conveyer and the like.

Owner:BAOSHAN IRON & STEEL CO LTD

Machinable austempered cast iron article having improved machinability, fatigue performance, and resistance to environmental cracking and a method of making the same

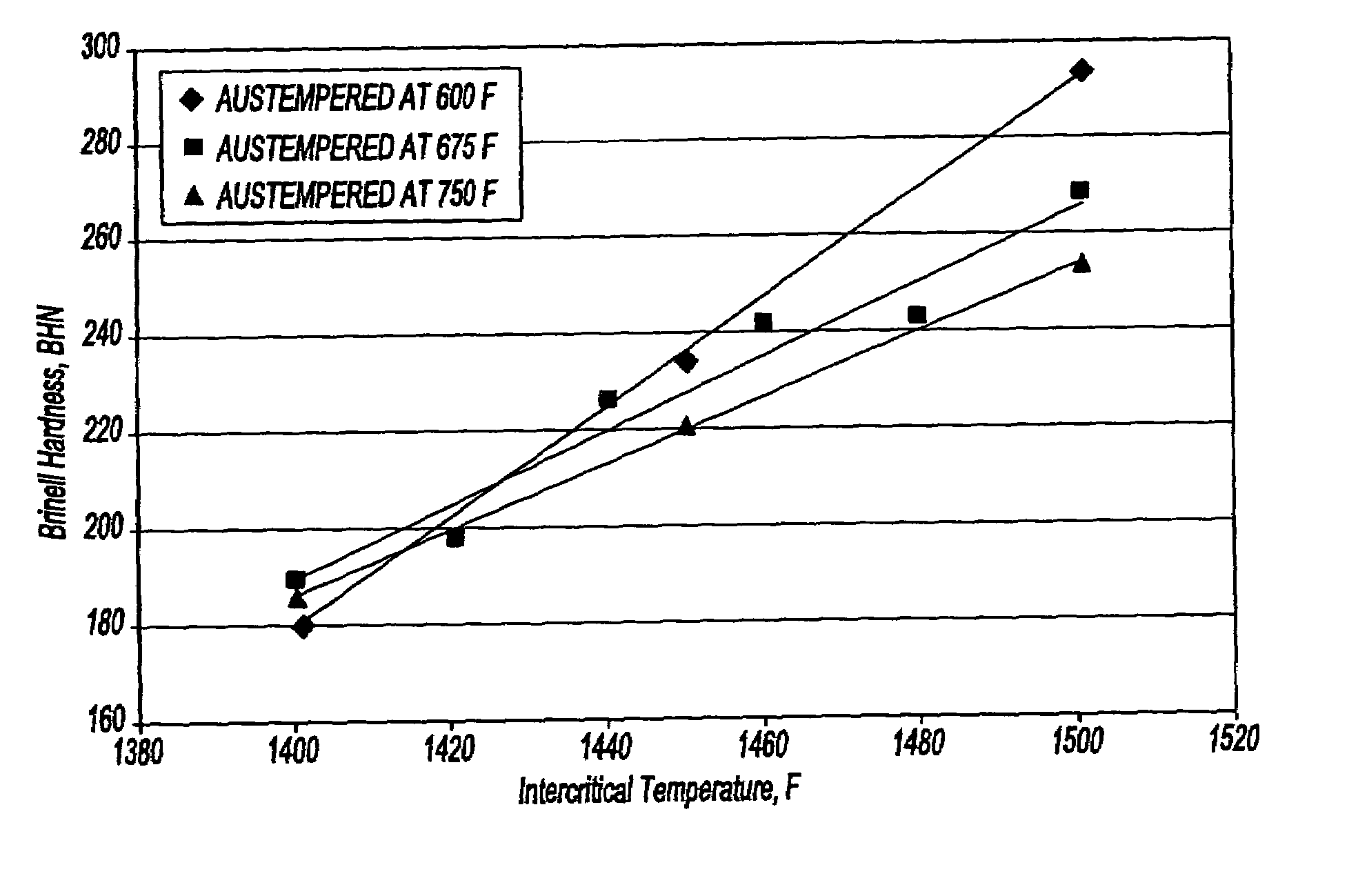

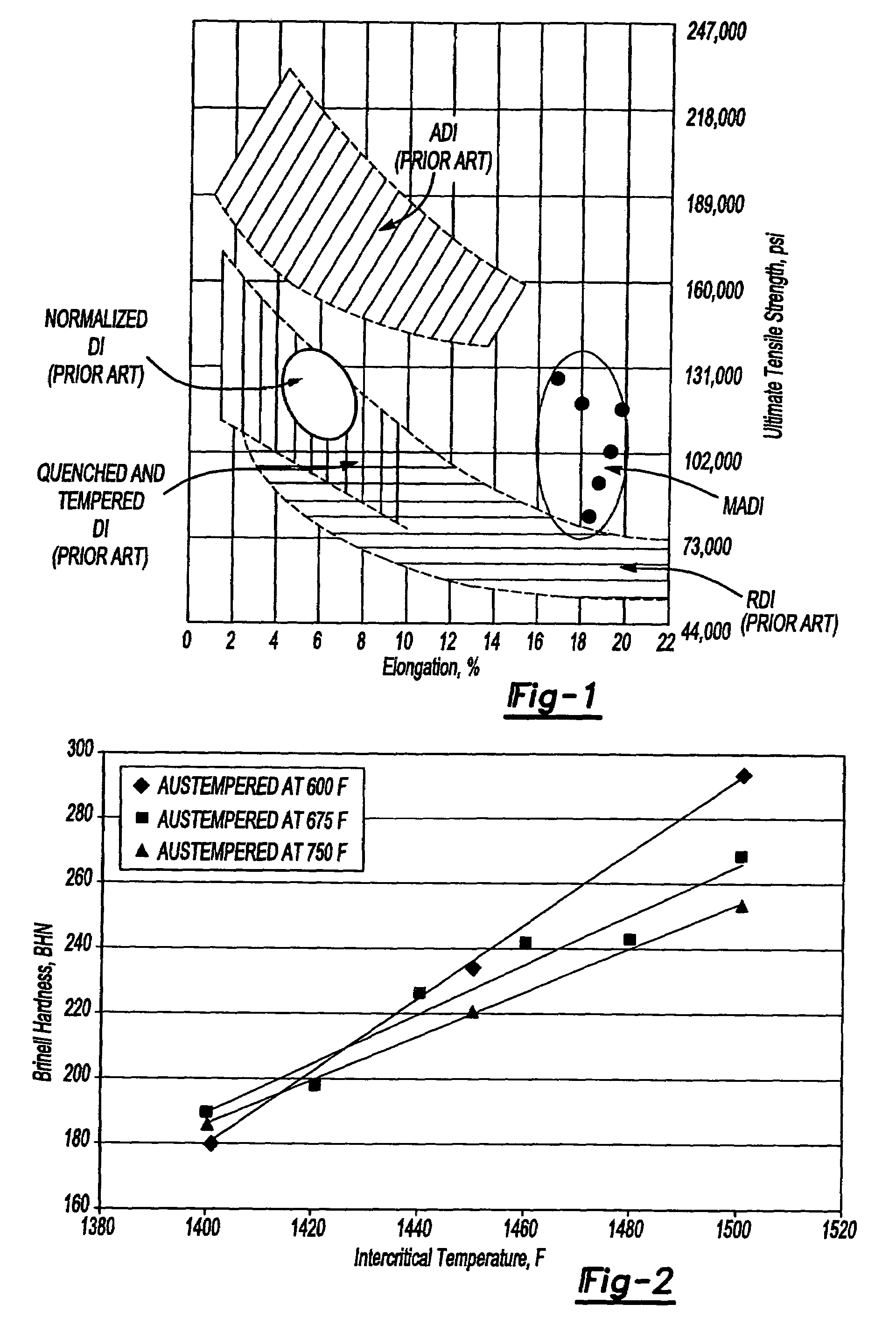

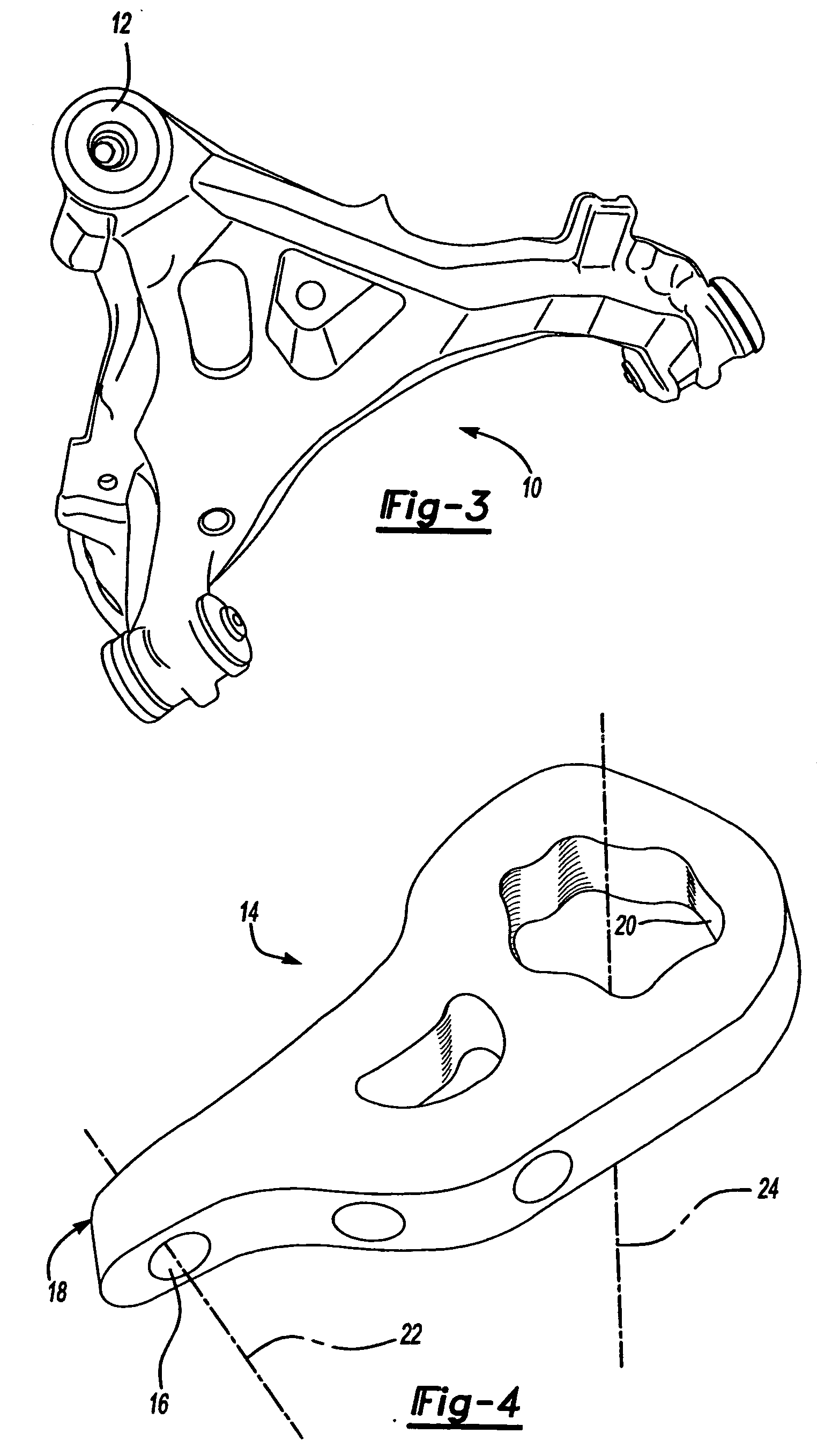

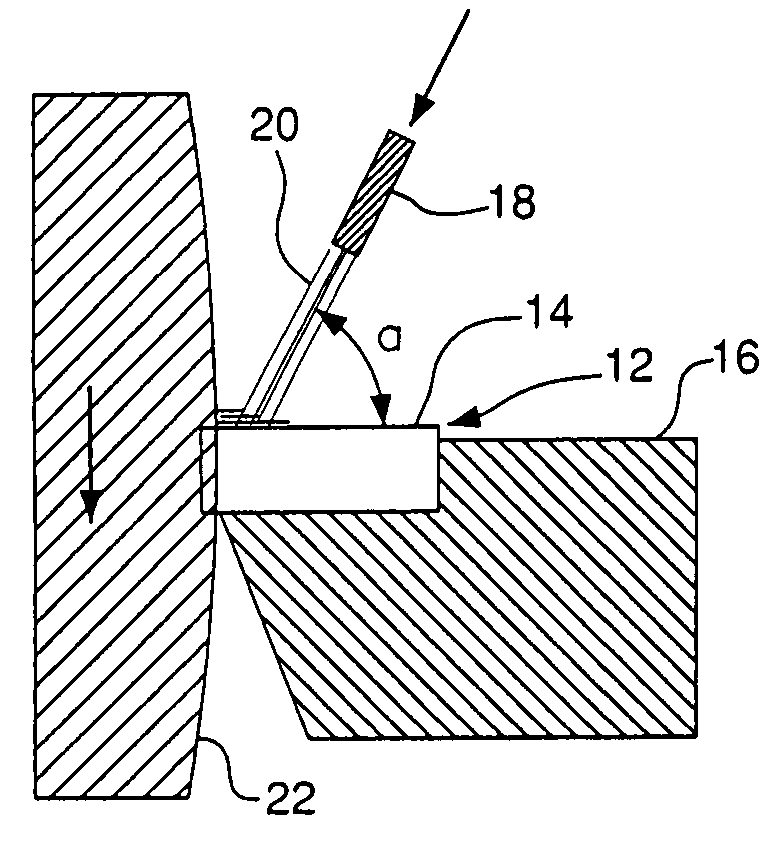

InactiveUS7070666B2Extension of timeInhibition formationFurnace typesQuenching agentsPearliteUltimate tensile strength

A machinable austempered cast iron article has improved strength, machinability, fatigue performance, and resistance to environmental cracking. A method of making the machinable austempered cast iron article includes austenitizing an iron composition having a substantially pearlitic microstructure in an intercritical temperature range of between 1380° F. and 1500° F. This produces a ferritic plus austenitic microstructure. The ferritic plus austenitic microstructure is quenched into an austempering temperature range of between 575° F. and 750° F. within 3 minutes to prevent formation of pearlite. The ferritic plus austenitic microstructure is then austempered in the austempering temperature range of between 575° F. and 750° F. to produce a microstructure of a continuous matrix of equiaxed ferrite with islands of austenite. Finally, the microstructure of the continuous matrix of equiaxed ferrite with islands of austenite is cooled to ambient temperature to produce the machinable austempered cast iron article.

Owner:INTERMET CORP

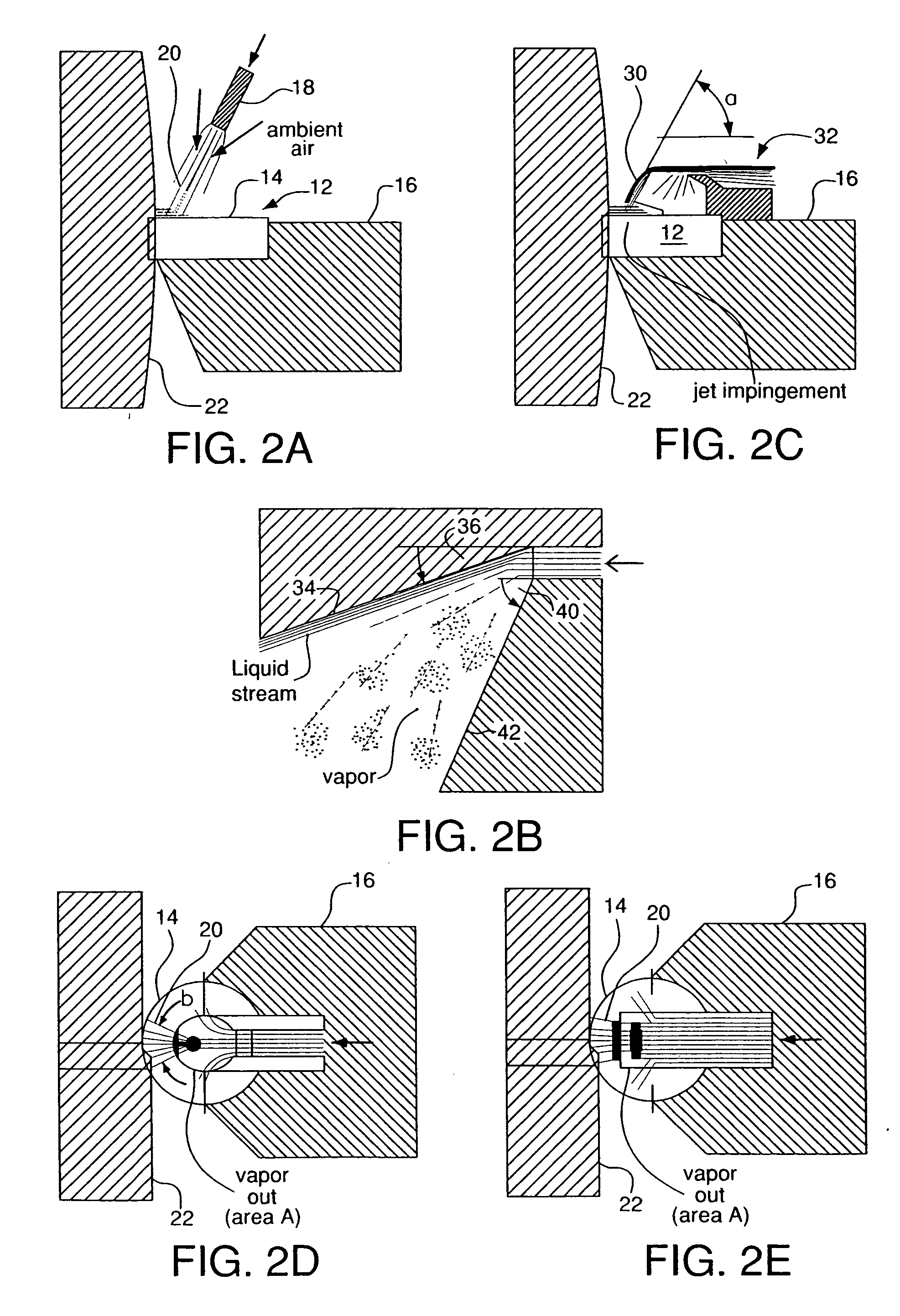

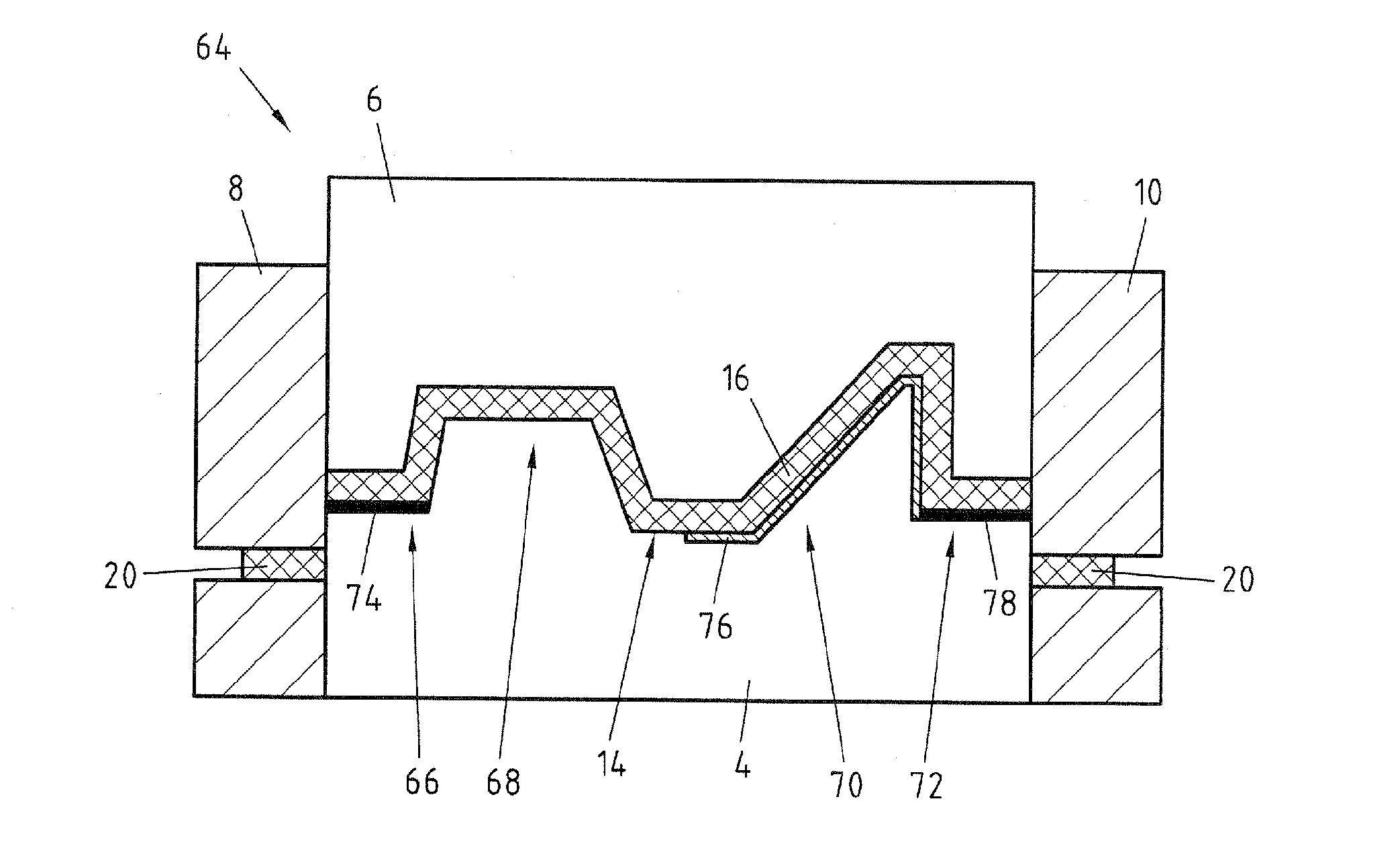

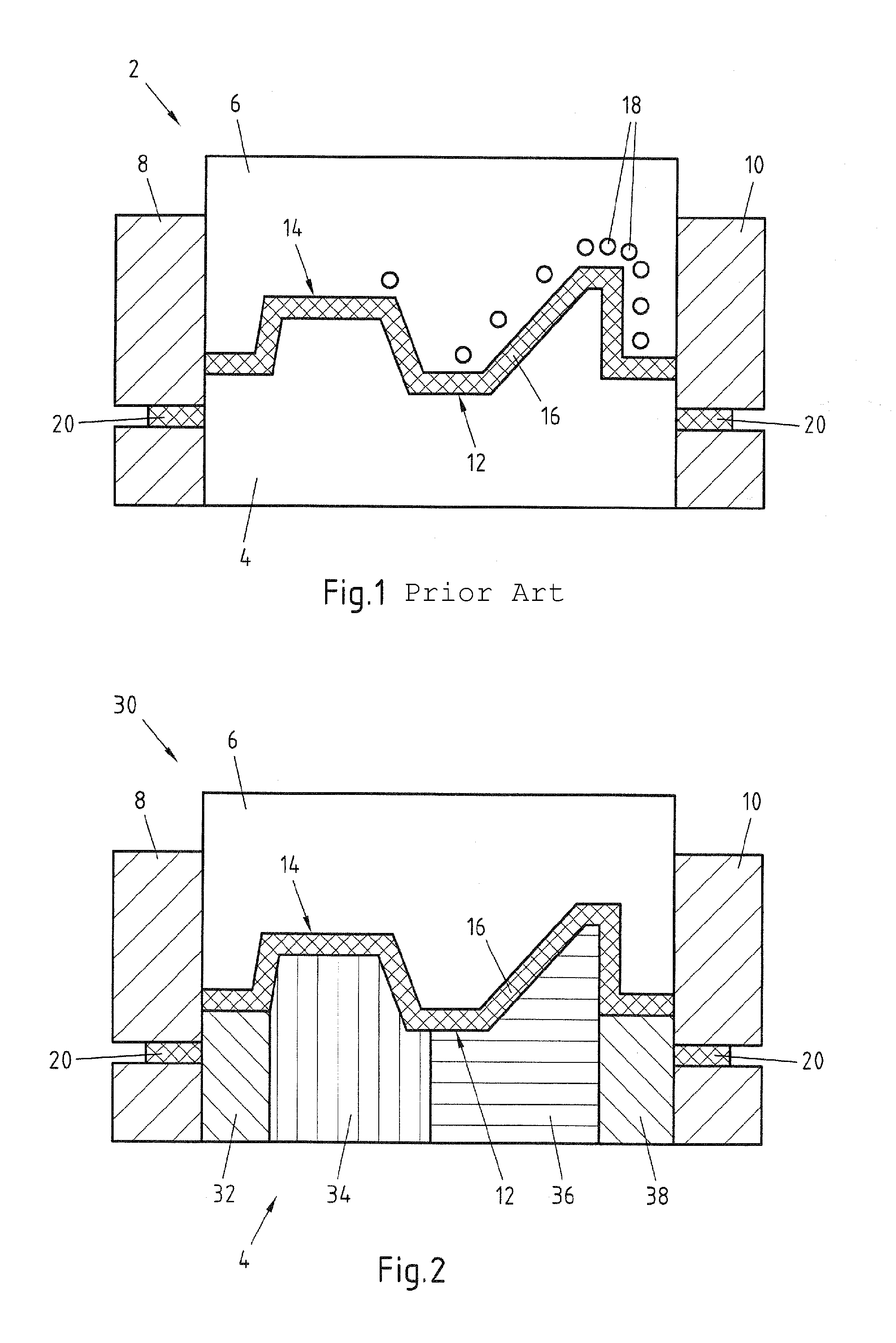

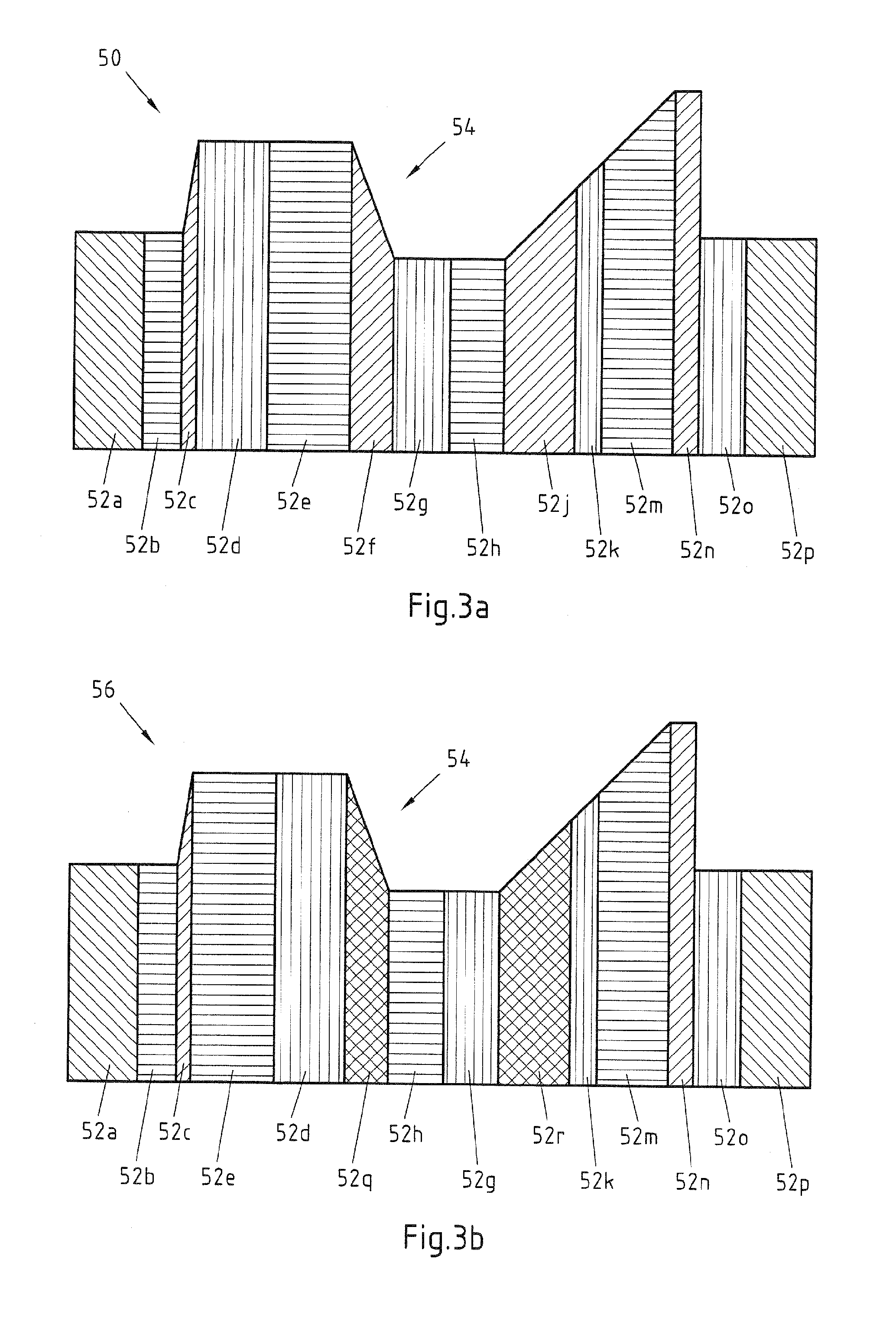

Apparatus and method for improving work surface during forming and shaping of materials

ActiveUS20050211029A1High surface finishImprove surface integrityLiquid surface applicatorsFurnace typesSurface finishHardness

A method and apparatus for improving the surface finish and / or surface integrity of a workpiece formed or shaped with a tool increase the surface hardness of the workpiece during forming or shaping of the workpiece. A method and apparatus for forming or shaping a workpiece also increase the surface hardness of the workpiece during forming or shaping of the workpiece with a tool, as do a method and apparatus for manufacturing a finished part or product from a workpiece. In some embodiments, an expanding jet of cryogen may be jetted to a surface of a workpiece and a tool from a nozzle, wherein the cryogen is at least partially separated into a condensed phase portion and a vapor portion within a downstream portion of the nozzle.

Owner:AIR PROD & CHEM INC

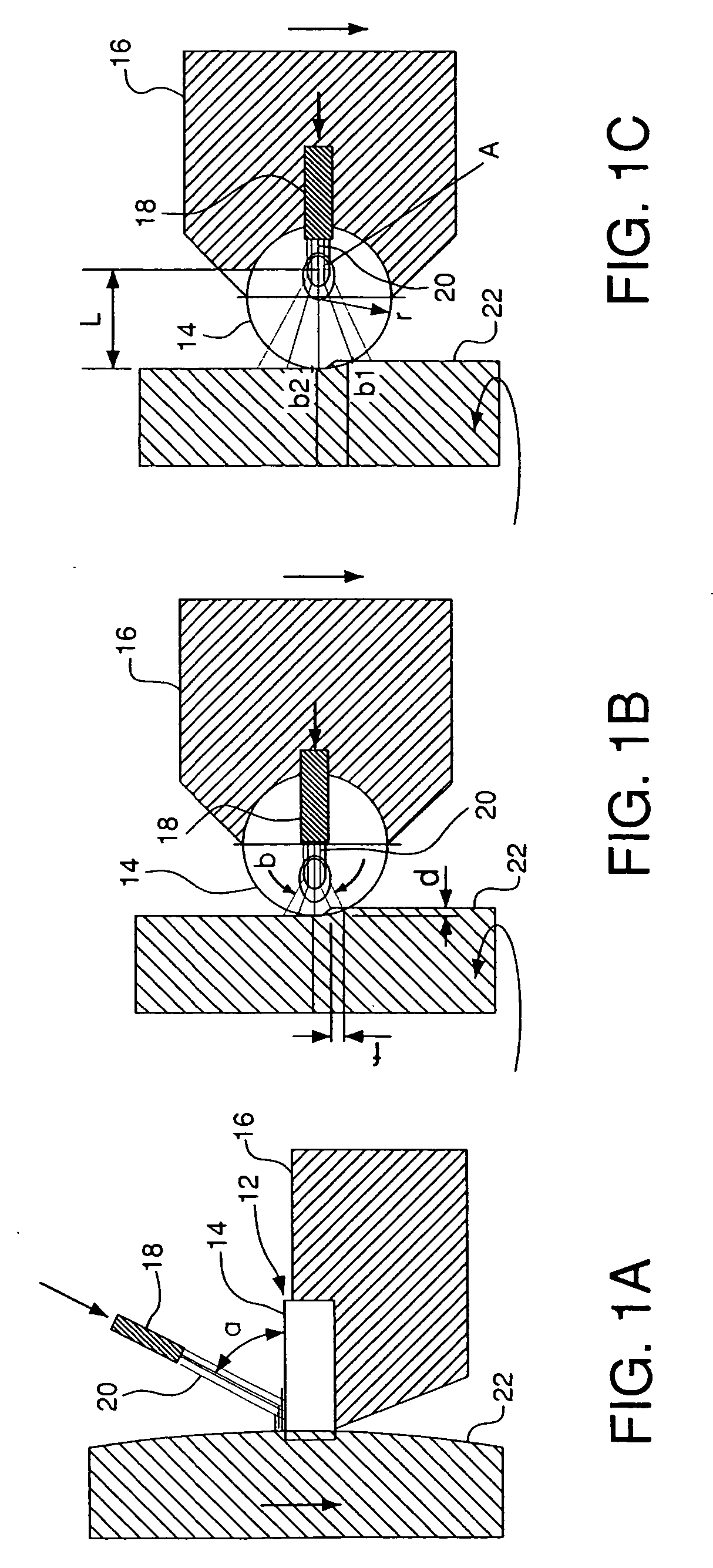

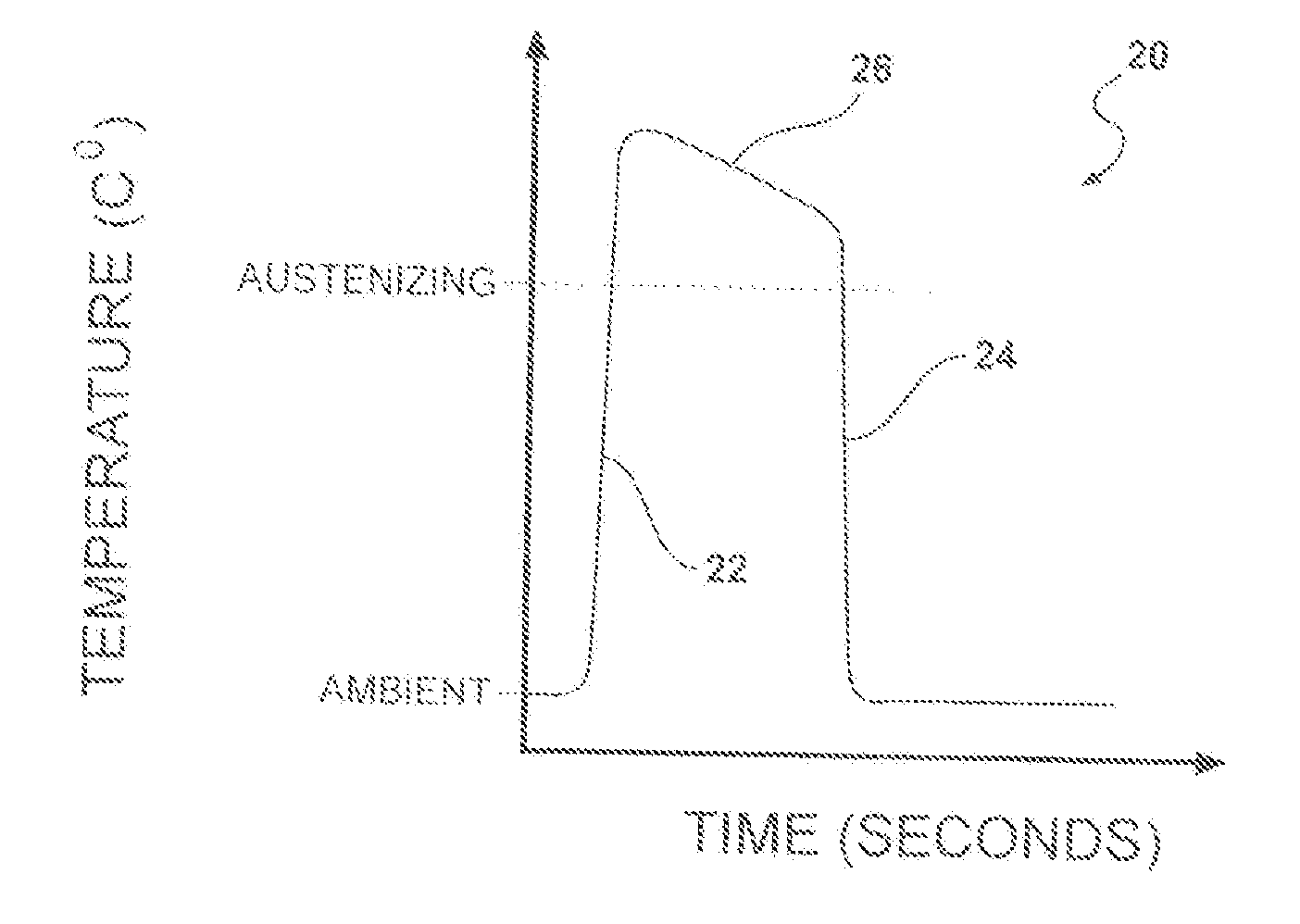

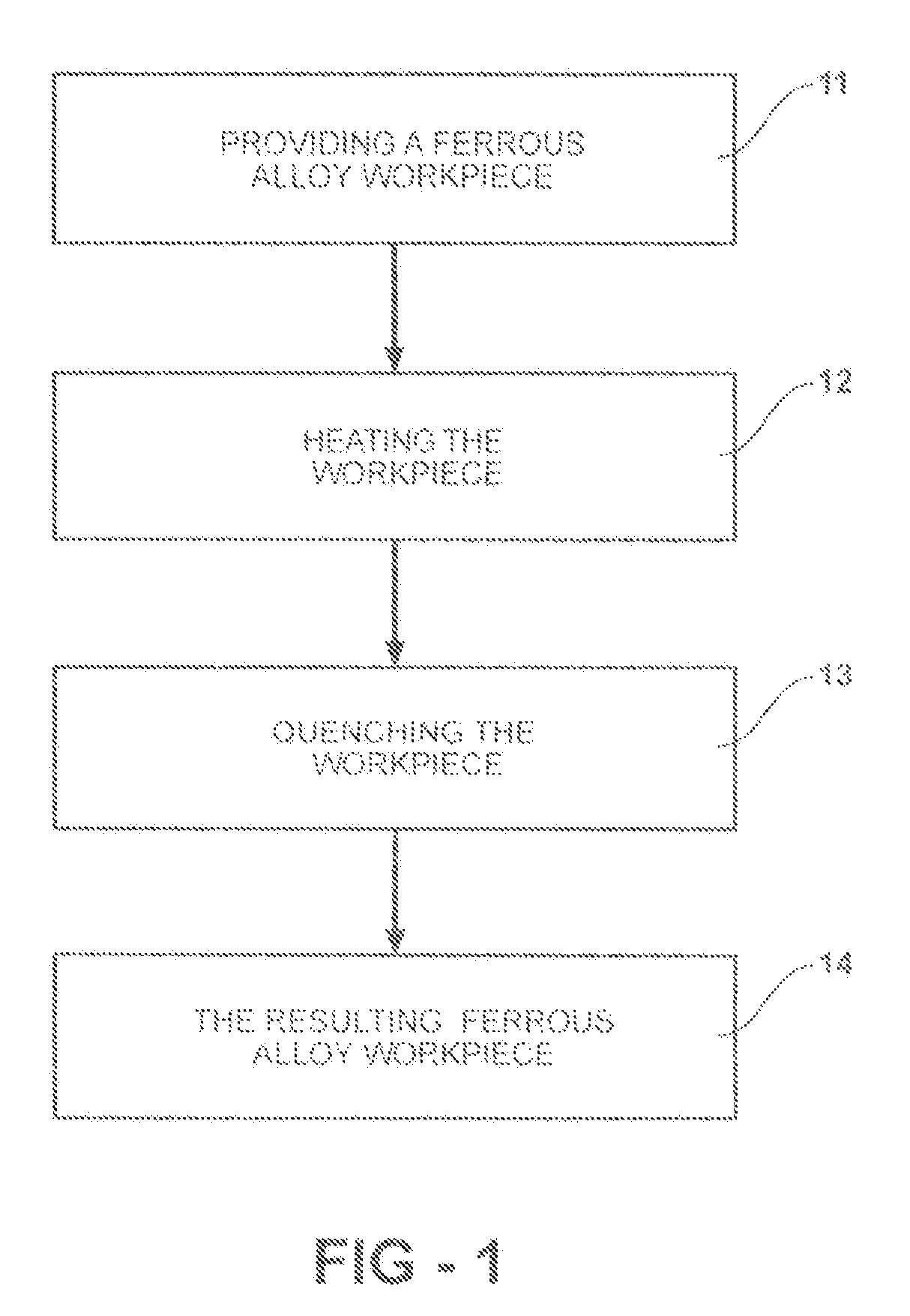

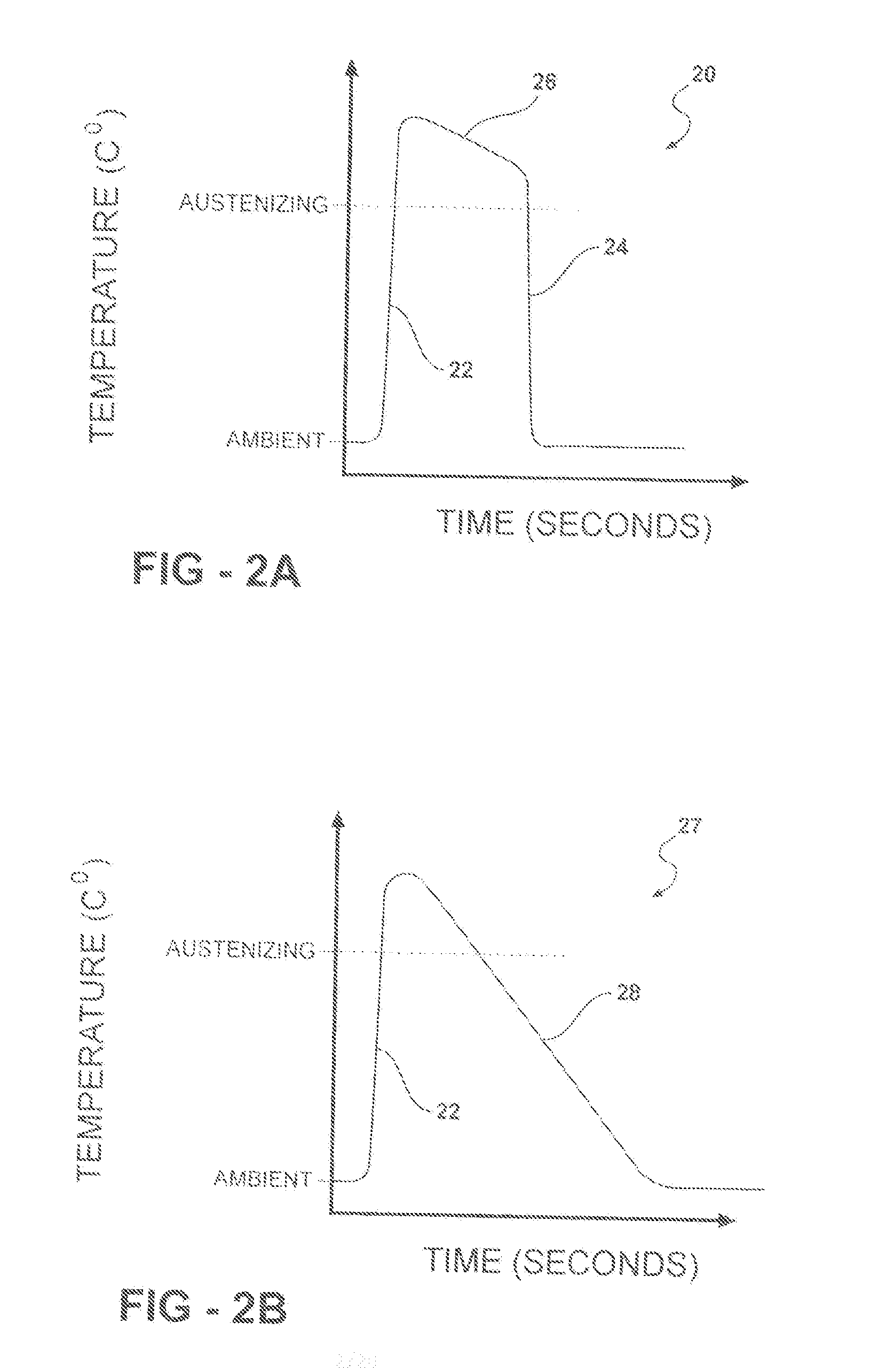

Microtreatment of Iron-Based Alloy, Apparatus and Method Therefor, and Articles Resulting Therefrom

ActiveUS20100132854A1Minimum of costMinimum of timeFurnace typesIncreasing energy efficiencyHigh carbonQuenching

Iron-based alloys and articles in strips, sheets, workpieces and the like are converted into high strength steel with a minimum of cost, time and effort, including producing dual phase materials. This is achievable by extremely rapid micro-treating of low, medium, and high carbon iron-based alloys and articles by rapid heating and rapid cooling at least a portion of the alloy / article. This heating step involves nearly immediately heating the iron-based alloy to a selected temperature above its austenite conversion temperature. Then, the alloy is immediately quenched, also at an extremely fast rate, on at least a portion of the iron-based alloy in a quenching unit adjacent the heating unit. This procedure forms high strength alloy in a desired area, depending upon where the treatment was performed.

Owner:COLA JR GARY M

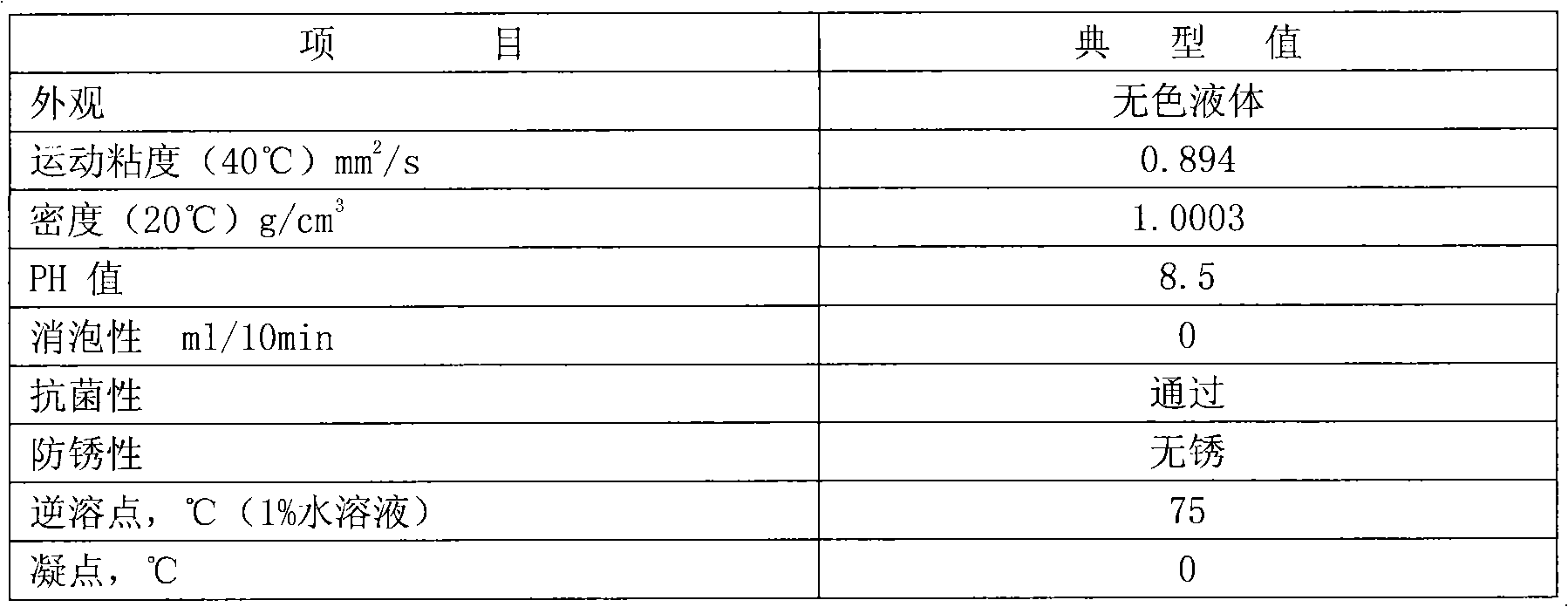

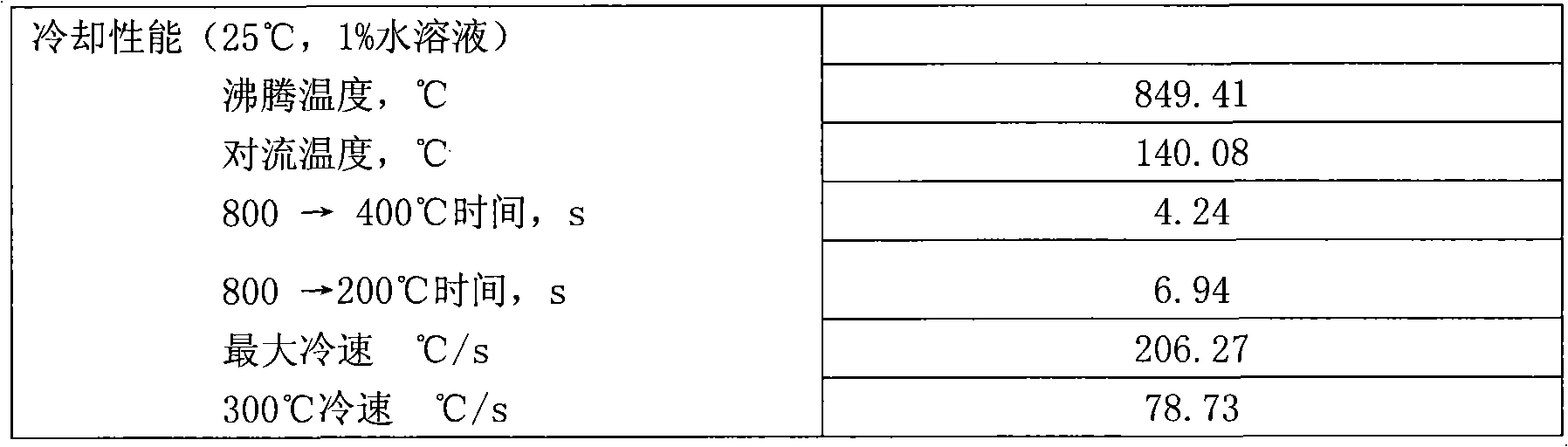

Water soluble polyether quenching medium

ActiveCN101660027AOvercome the easy-to-growth bacteria fromOvercome the smelly problemQuenching agentsQuenchingDefoaming Agents

The invention relates to a water soluble polyether quenching medium for quenching a metal material, which comprises the following components in percentage by weight: 1 to 30 percent of water soluble polyether, 0.1 to 1.0 percent of antirusting agent, 100 to 500ppm of defoaming agent, 0.1 to 1.0 percent of composite germicide, 0.2 to 2 percent of pH regulator and the balance of water, wherein the water soluble polyether is a condensation compound of ethylene oxide and propylene epoxide and a number-average molecular weight is less than 20,000. The water soluble polyether quenching medium is characterized by solving the problems of insufficient hardness of oil quenched workpieces and cracking and deformation of water quenched workpieces, reducing fire hazards in quenching, improving production safety, avoiding oily fume discharge, reducing environment pollution, improving working environment, contributing to the body and mind health of workers, along with readily available raw materials,simple production process, low price, excellent antirusting, defoaming and antibacterial performance, wide quenching cooling speed range and cooling speed ranging from oil quenching cooling speed andwater quenching cooling speed.

Owner:PETROCHINA CO LTD

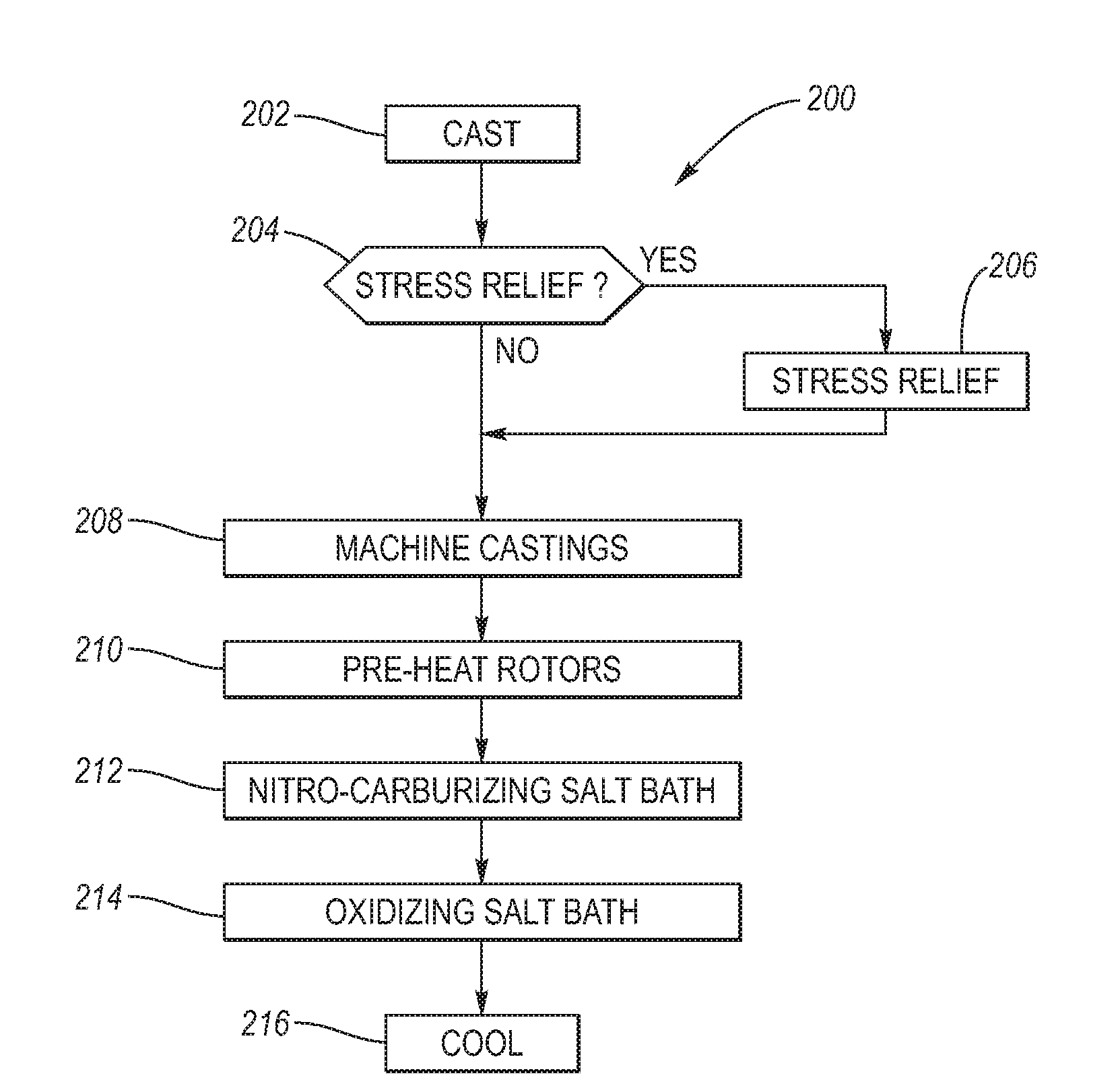

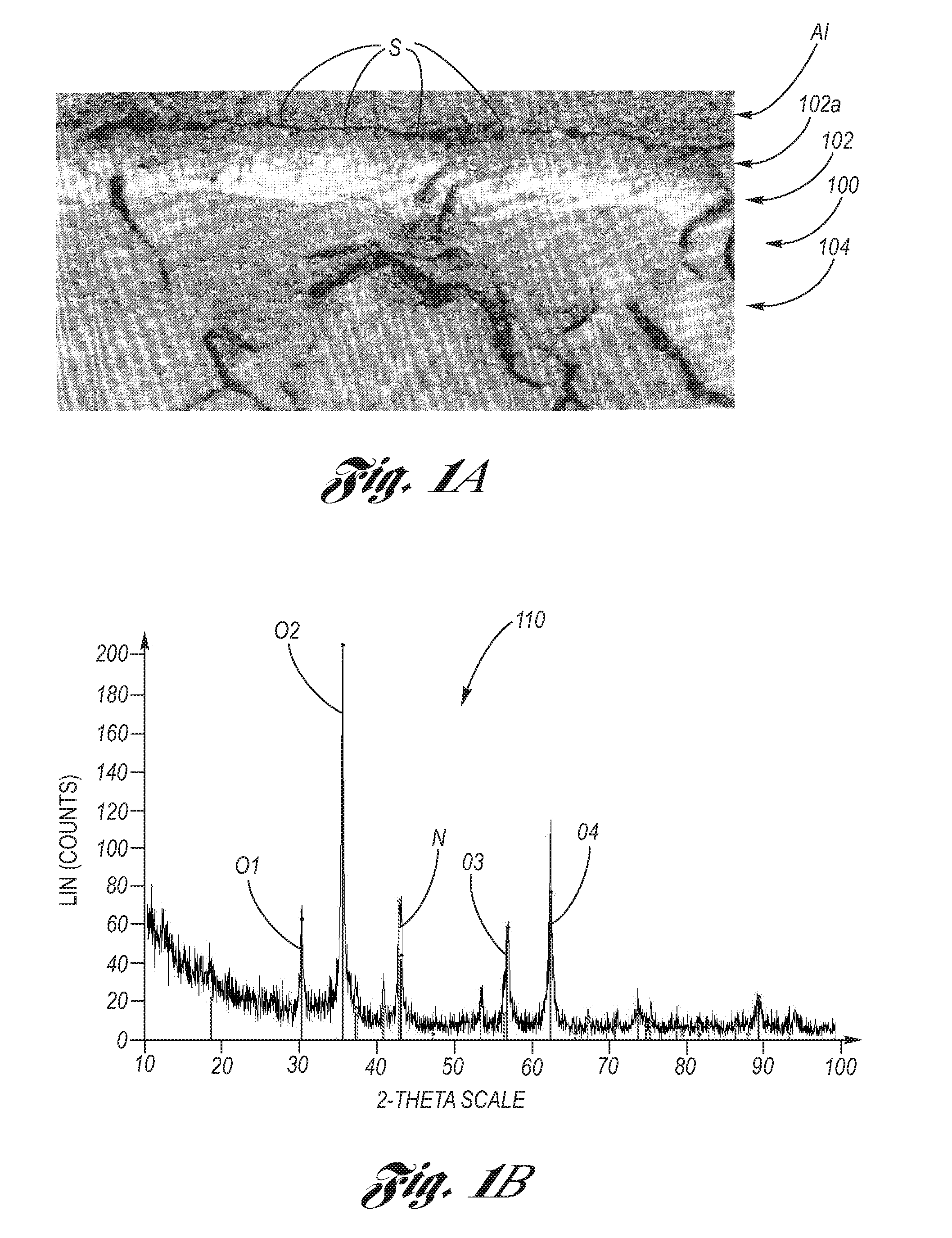

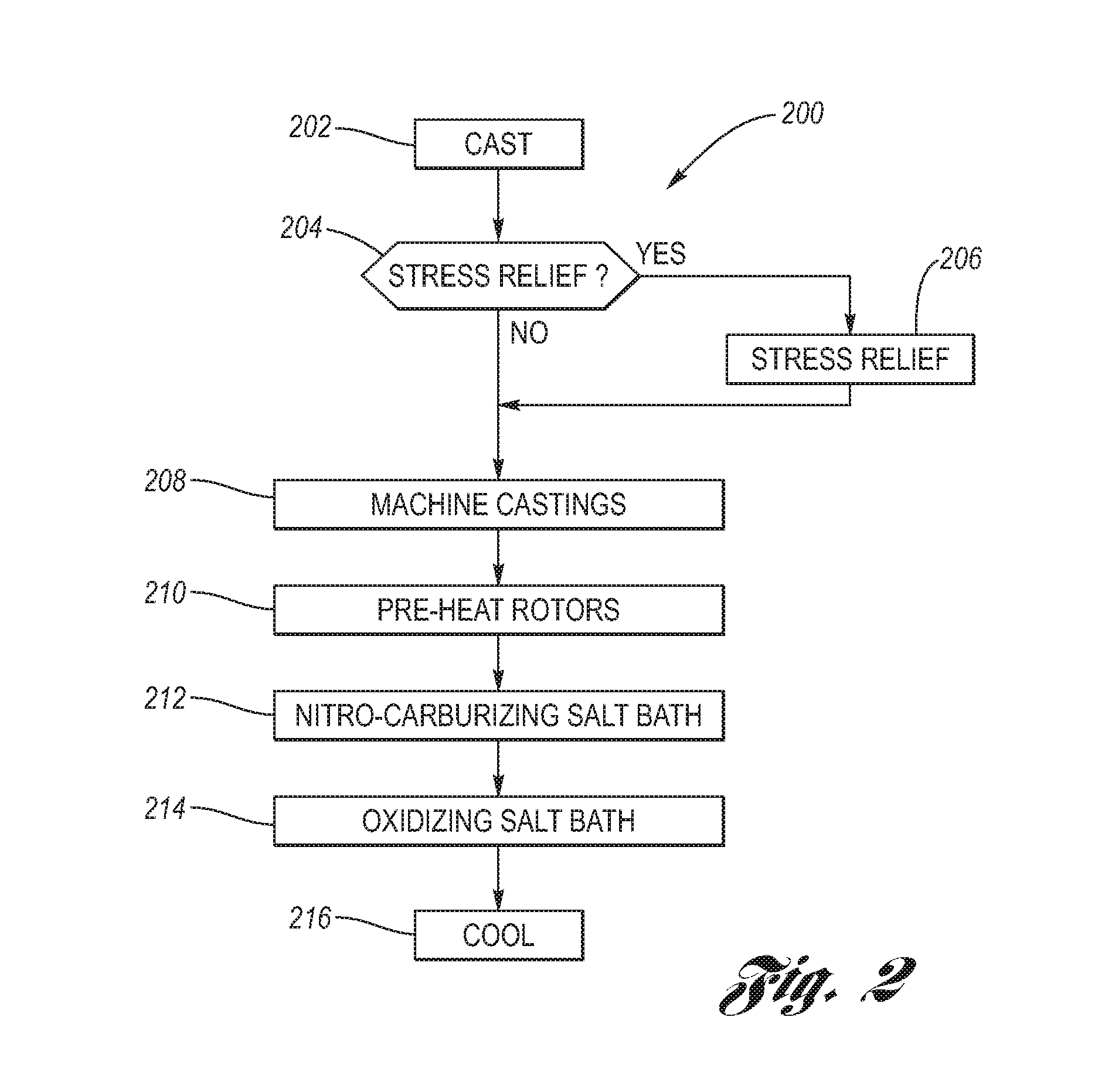

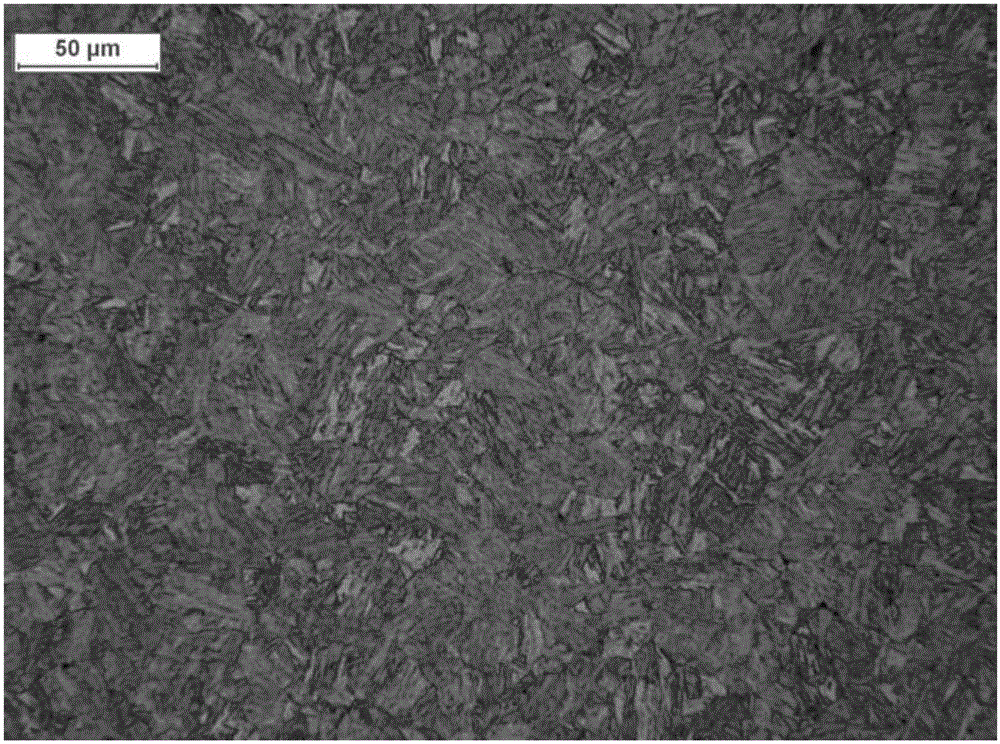

Salt Bath Ferritic Nitrocarburizing of Brake Rotors

ActiveUS20080000550A1Absence of distortionProvide resistanceBraking discsSolid state diffusion coatingRoom temperatureNitrogen

Ferritic nitrocarburized surface treatment of cast iron brake rotors providing oxidation resistance, good braking performance and absence of distortion. Machined brake rotors are pre-heated, then immersed into a high temperature molten nitrocarburizing salt bath for a first predetermined dwell time. After removing the brake rotors from the nitrocarburizing salt bath, the brake rotors are directly immersed into an oxidizing salt bath at a lower temperature than the nitrocarburizing salt bath so that the brake rotors are thermally quenched. After a predetermined second dwell time in the oxidizing salt bath, the brake rotors are removed therefrom and further cooled to room temperature, either by water application thermal quenching or slow cooling in air. A fixture provides stable holding the brake rotors with a minimum of contact during placement in the salt baths.

Owner:KOLENE +1

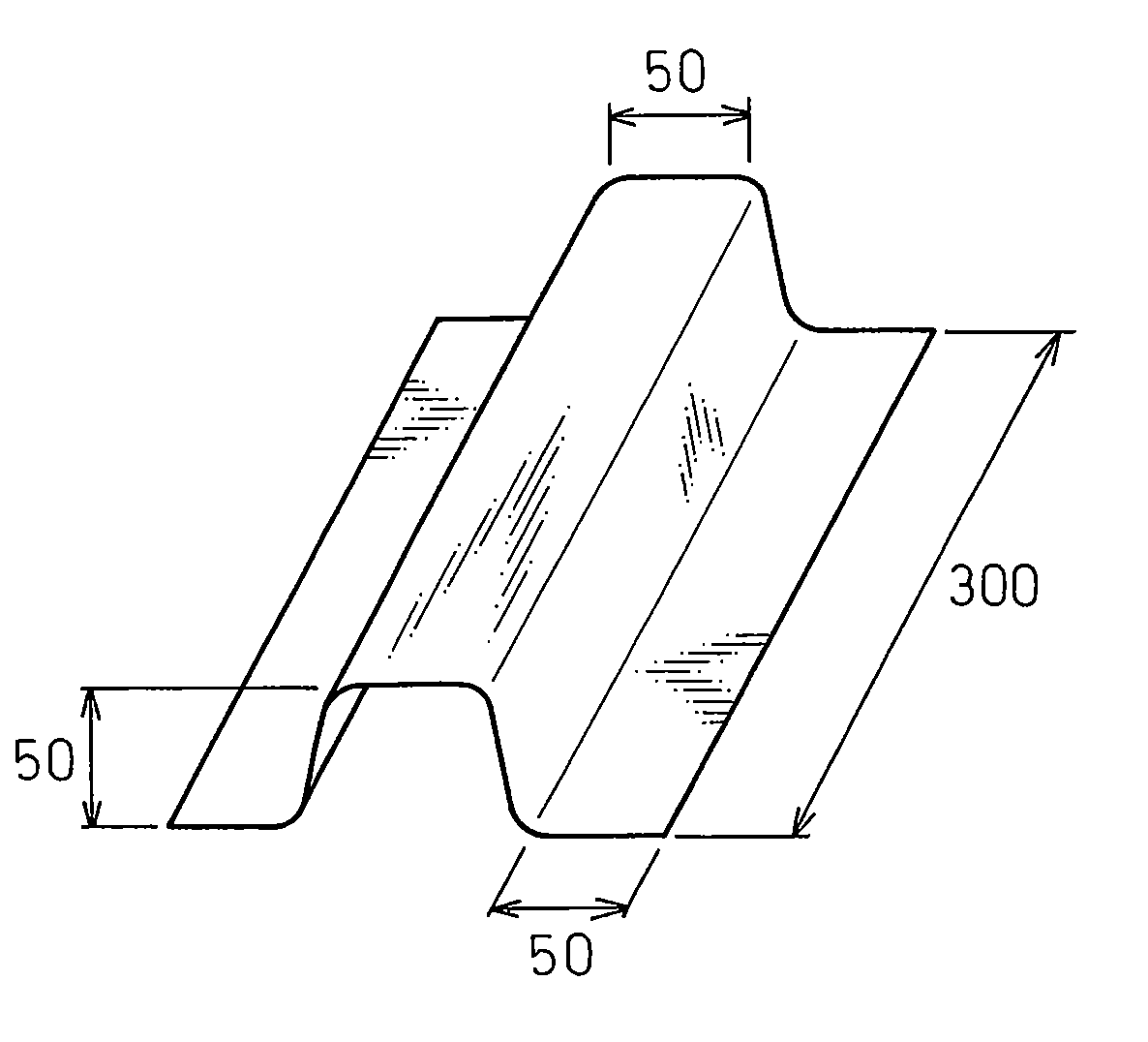

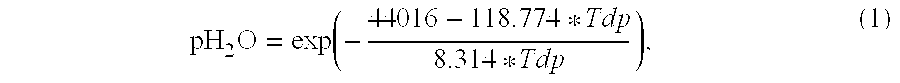

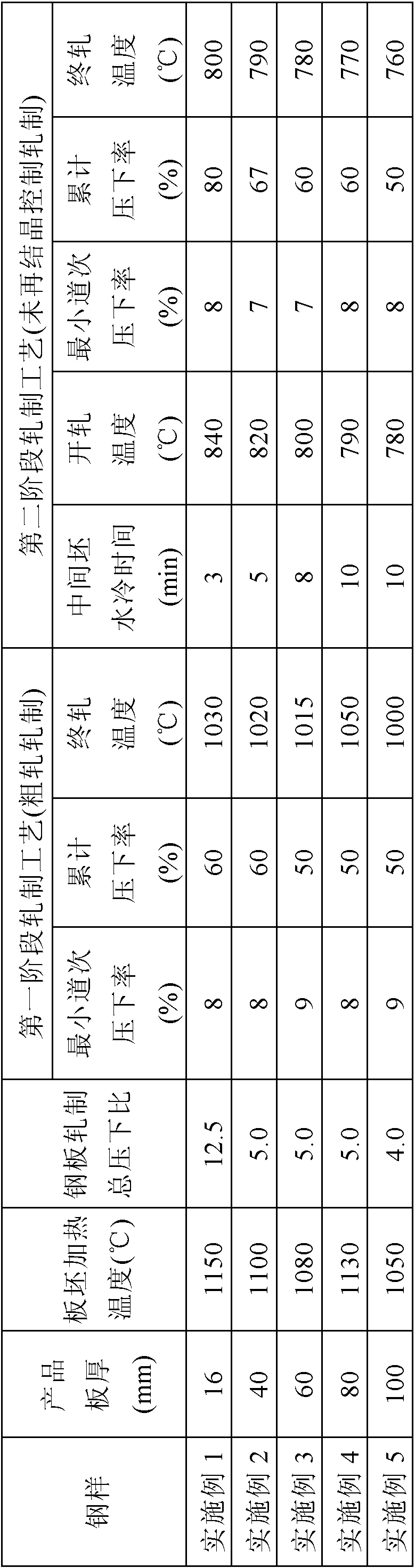

Low-alloy high-toughness wear resistant steel plate and manufacturing method thereof

ActiveCN103146997AGood mechanical propertiesHigh strengthFurnace typesQuenching agentsChemical compositionWear resistant

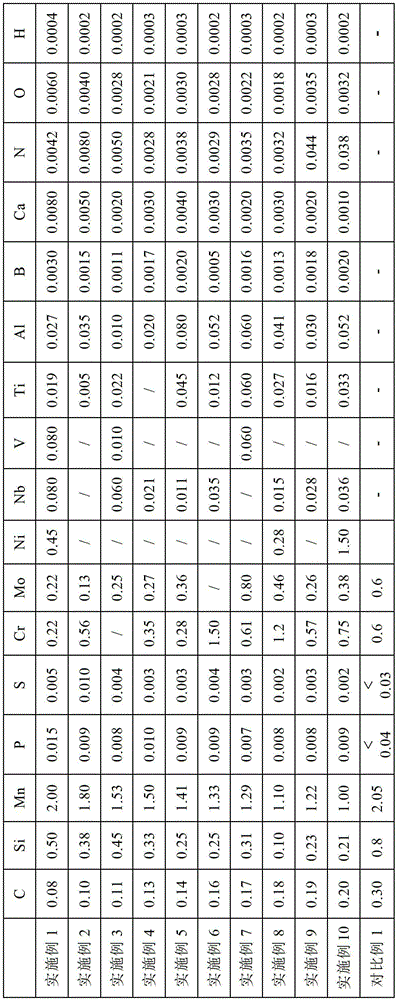

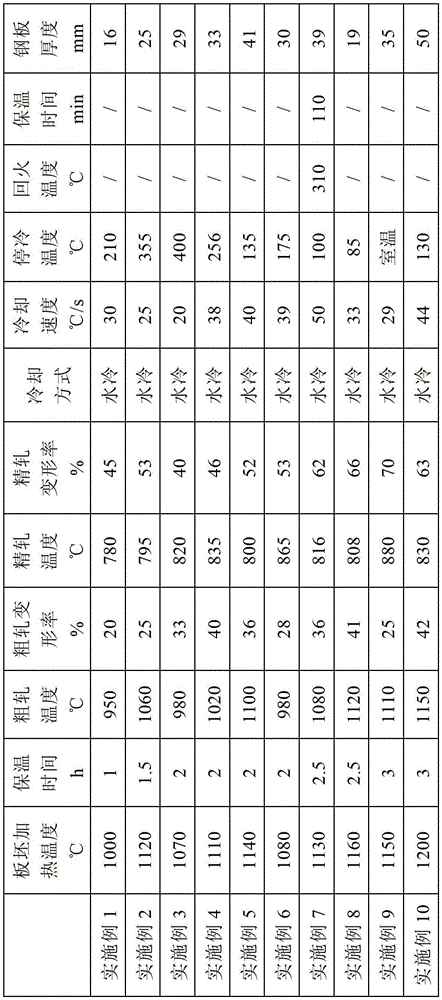

The invention relates to a low-alloy high-toughness wear resistant steel plate and a manufacturing method thereof. The steel plate contains the following chemical components (wt%): C: 0.08-0.20%, Si: 0.10-0.60%, Mn: 1.00-2.00%, B: 0.0005-0.0040%, Cr<=1.50%, Mo<=0.80%, Ni<=1.50%, Nb<=0.080%, V<=0.080%, Ti<=0.060%, Al: 0.010-0.080%, Ca: 0.0010-0.0080%, N<=0.0080%, O<=0.0080%, H<=0.0004%, P<=0.0015% and S<=0.010%, wherein the following relationships are satisfied: 0.20%<=(Cr / 5+Mn / 6+50 B)<=0.55%, 0.02%<=(Mo / 3+Ni / 5+2Nb)<=0.45%, and 0.01%<=(Al+Ti)<=0.13%; and the balance of Fe and inevitable impurities. The contents of both carbon and alloy elements are reduced, the characteristics of refining, strengthening and the like of micro-alloy elements such as Nb and Ti are fully utilized, and a TMCP (thermal mechanical control processing) technology is adopted, so that the wear resistant steel plate is high in hardness, good in toughness, easy to weld, perfect in wear resistance, and applicable to easily-worn components in various types of mechanical equipment.

Owner:BAOSHAN IRON & STEEL CO LTD

High Strength Low Alloy Steel and Method of Manufacturing

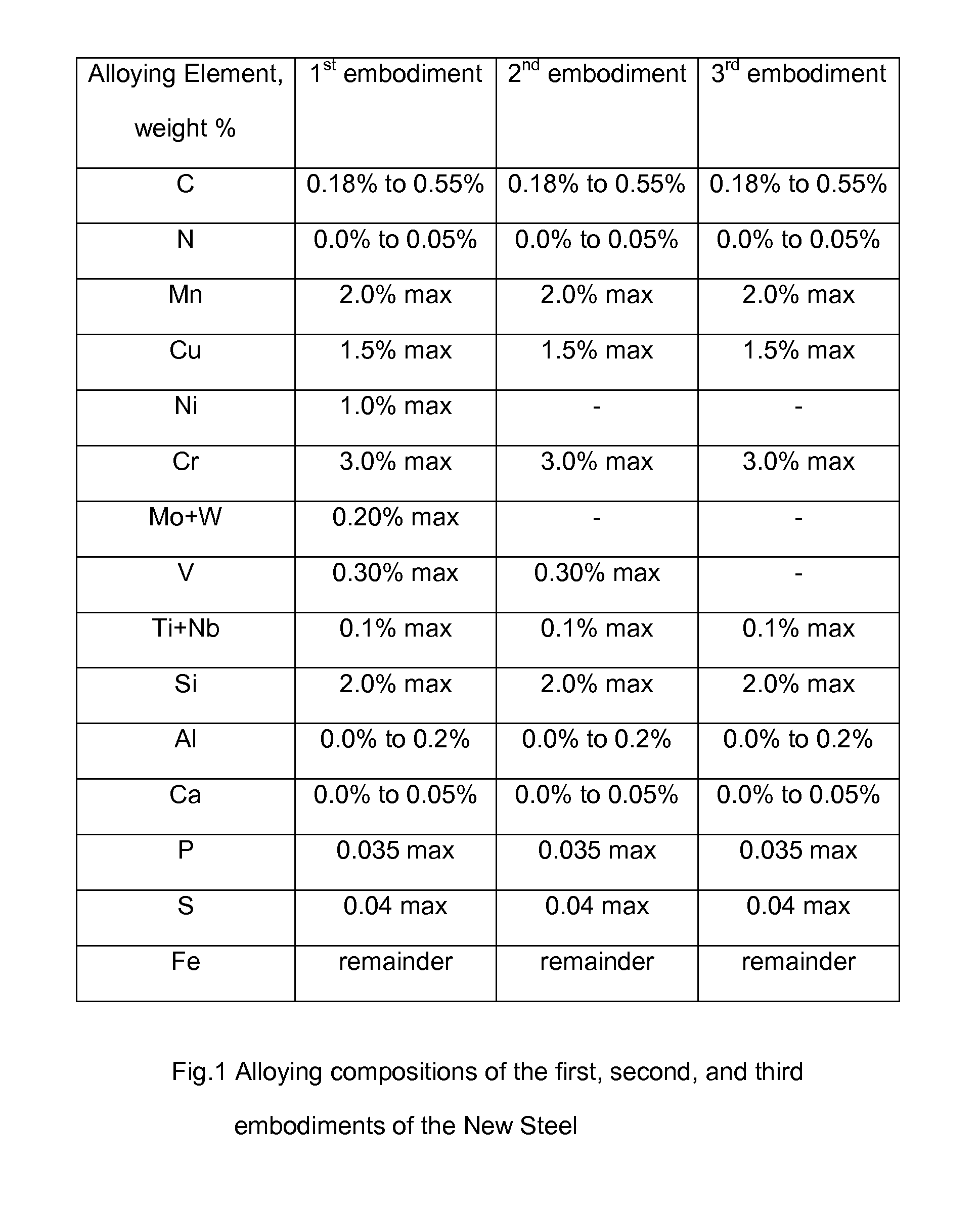

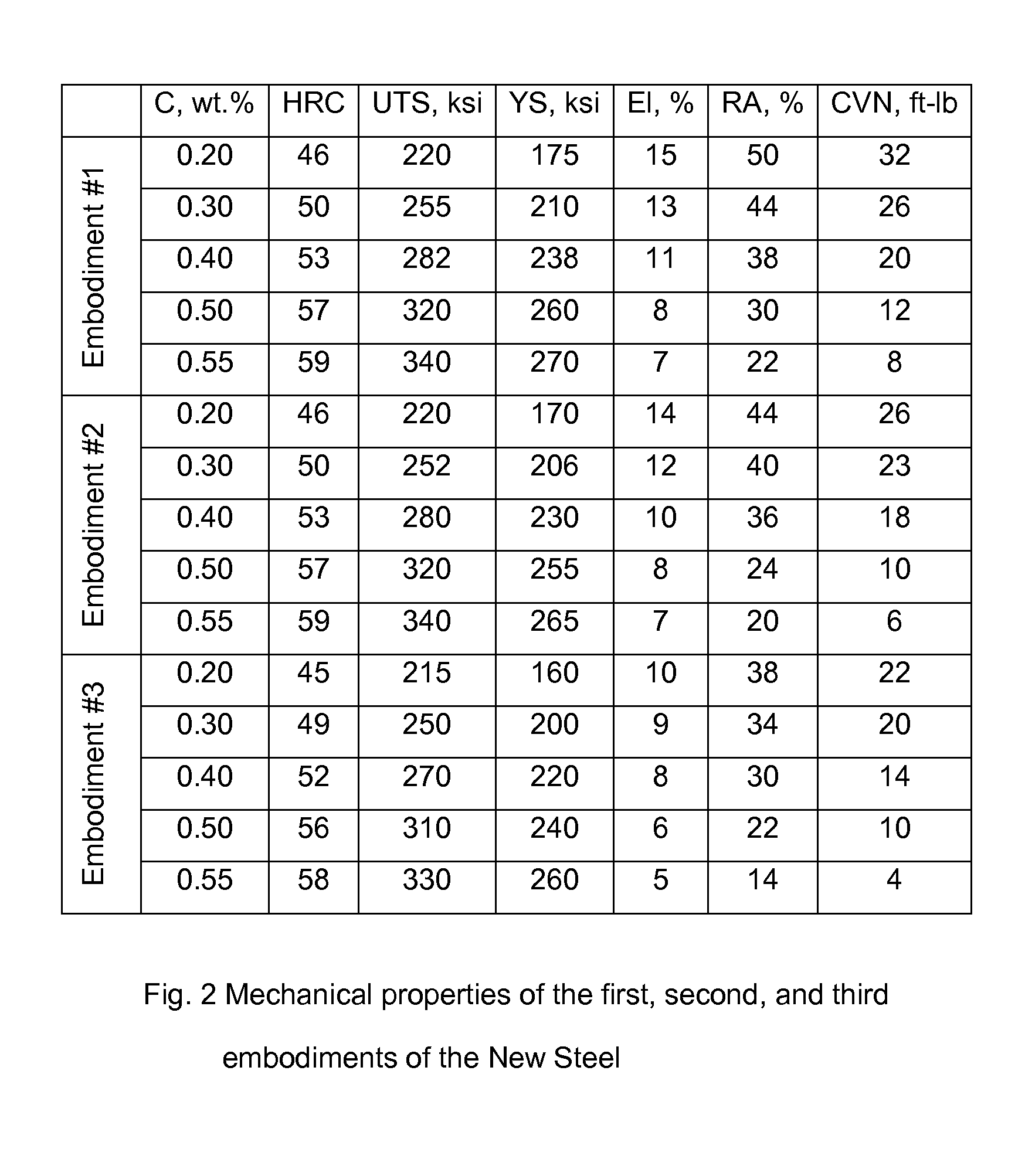

The present invention relates to a wrought, quenched and tempered, fine-grained, with deep hardenability, high strength and low alloy steel having a sum of the alloying elements: nickel, molybdenum, tungsten, vanadium, titanium, and niobium in weight percentage of 1.60% maximum in the first embodiment; vanadium, titanium, and niobium in weight percentage of 0.40% maximum in the second embodiment; titanium and niobium in weight percentage of 0.10% in the third embodiment. The air melted and hot forged steel of the first embodiment has hardness of HRC 55, an ultimate tensile strength of 300 ksi, a yield strength of 257 ksi, a total elongation of 9%, a reduction of area of 32%, and Charpy v-notch impact toughness energy of 15 ft-lb after normalizing, gas quenching, and tempering at 450° F.

Owner:VARTANOV GREGORY

Method and Device for Producing a Metal Component

The invention relates to a method for producing a metal structural component, in particular a vehicle structural component, in which a steel part is hot formed and is hardened at least over sections by contact with a tool surface, in which the steel part is during the hardening cooled in at least two partial regions at different cooling rates, so that the partial regions after the hardening differ in their microstructure, wherein the cooling rates differing from one another are produced by sections of the tool surface corresponding to the partial regions of the steel part, which differ from one another as regards their thermal conductivities. The invention also relates to a further method for producing a metal structural component, as well as a tool and a batch furnace.

Owner:THYSSENKRUPP STEEL EURO AG

Method for manufacturing high-vanadium, high-cobalt high speed steel

ActiveCN101153376ALow priceSimple processHeat treatment process controlQuenching agentsNumerical controlMilling cutter

The invention provides a manufacturing method of high-vanadium high-cobalt high-speed steel, wherein, the composition weight percent of the high-speed steel is as follows: 1.1 percent to 2.18 percent of C, 5.0 percent to 8.0 percent of W, 4.0 percent to 6.0 percent of Mo, 3.0 percent to 5.0 percent of Cr, 1.2 percent to 8.3 percent of V, 6.5 percent to 11.5 percent of Co and the rest, Fe; the process steps of the high-speed steel includes master alloy preparation, spray forming, hot forging, quench tempering treatment, turning, milling and grinding or TiN / AlTiN coating treatment. The invention omits working procedures such as powder sieving, blending, encapsulation and cold and hot isostatic pressing, etc. and does not need costly equipment investment; moreover, the performance of the invention reaches to or even exceeds that of powder high-speed steel, thereby saving process cost and reducing the applied cost of the high-speed steel. The invention can be widely used in various cutters such as cutting tools for making difficult-to-machining material, and is particularly suitable to make cutters with quick-cutting, high hot hardness and long service life such as large-size broaching tool, gear shaver, hob and gear shaping tool for machining gear and various milling cutters used in digital control machine tool, etc.; moreover, the invention also can be used in making mould, etc.

Owner:BAOSHAN IRON & STEEL CO LTD +1

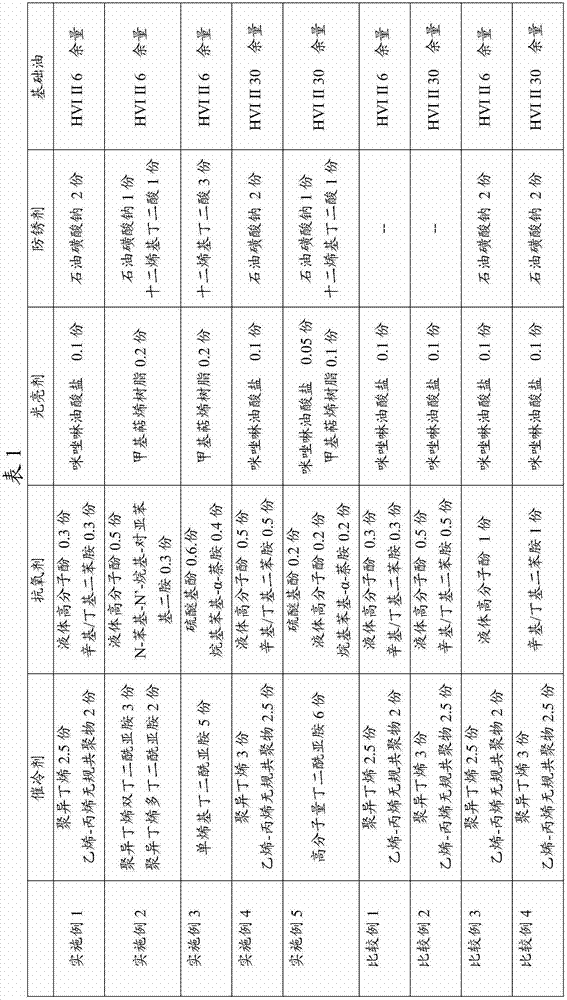

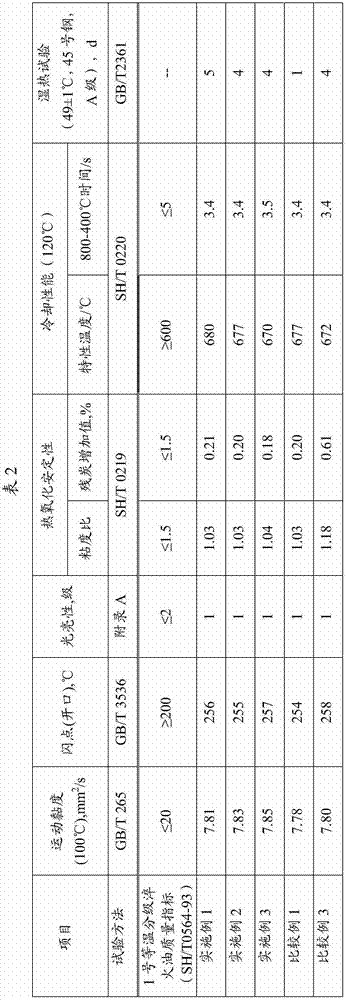

Isothermal graded quenching oil composition and uses thereof

ActiveCN103710083ABright surfaceMeet the requirements of high temperature quenchingQuenching agentsLubricant compositionPhenolic antioxidantSteel ball

The invention relates to an isothermal graded quenching oil composition and uses thereof, mainly aims at further improvement of cooling performances, thermal oxidation stability and brightness of isothermal graded quenching oil in the prior art, and solves the problem that the isothermal graded quenching oil has no corrosion resistant performance on workpieces after quenching. The isothermal graded quenching oil composition comprises the following components: by weight, a) 0.3 to 8 parts of a cooling accelerant; b) 0.1 to 3 parts of an antioxidant; c) 0.001 to 1 part of a brightener; d) 0.03 to 5 parts of an anti rust agent; and e ) 78 to 98 parts of base oil; in the technical scheme, the antioxidant is selected from a phenolic antioxidant or a mixture of amine antioxidants, the technical scheme can well solve the problem, and the isothermal graded quenching oil composition can be used for quenching of wearable steel balls, saw blade, auto gearbox gears, gear rings, gear sleeves, shafts and other precision parts.

Owner:CHINA PETROLEUM & CHEM CORP +1

Low-alloy high-performance wear-resistant steel plate and manufacturing method thereof

ActiveCN103205627AImprove performanceHigh hardnessFurnace typesQuenching agentsChemical compositionWear resistant

The present invention provides a low-alloy high-performance wear-resistant steel plate and a manufacturing method thereof. The steel plate comprises the following chemical compositions (wt%) of 0.21-0.32% of C, 0.10-0.50% of Si, 0.60-1.60% of Mn, 0.0005-0.0040% of B, 0-1.50% of Cr, 0-0.80% of Mo, 0-1.50% of Ni, 0-0.080% of Nb, 0-0.080% of V, 0-0.060% of Ti, 0.010-0.080% of Al, 0.0010-0.0080% of Ca, 0-0.0080% of N, 0-0.0080% of O, 0-0.0004% of H, 0-0.015% of P, and 0-0.010% of S, wherein the following relationships are satisfied: 0.20%<=(Cr / 5+Mn / 6+50B)<=0.55%, 0.02%<=(Mo / 3+Ni / 5+2Nb)<=0.45%, 0.01%<=(Al+Ti)<=0.13%, and the balance is Fe and inevitable impurities. The low-alloy high-performance wear-resistant steel plate manufactured by the above compositions and through a TMCP process has high strength and hardness, good toughness and excellent wear resistance, and is suitable for easy-to-wear parts in various mechanical equipments.

Owner:BAOSHAN IRON & STEEL CO LTD

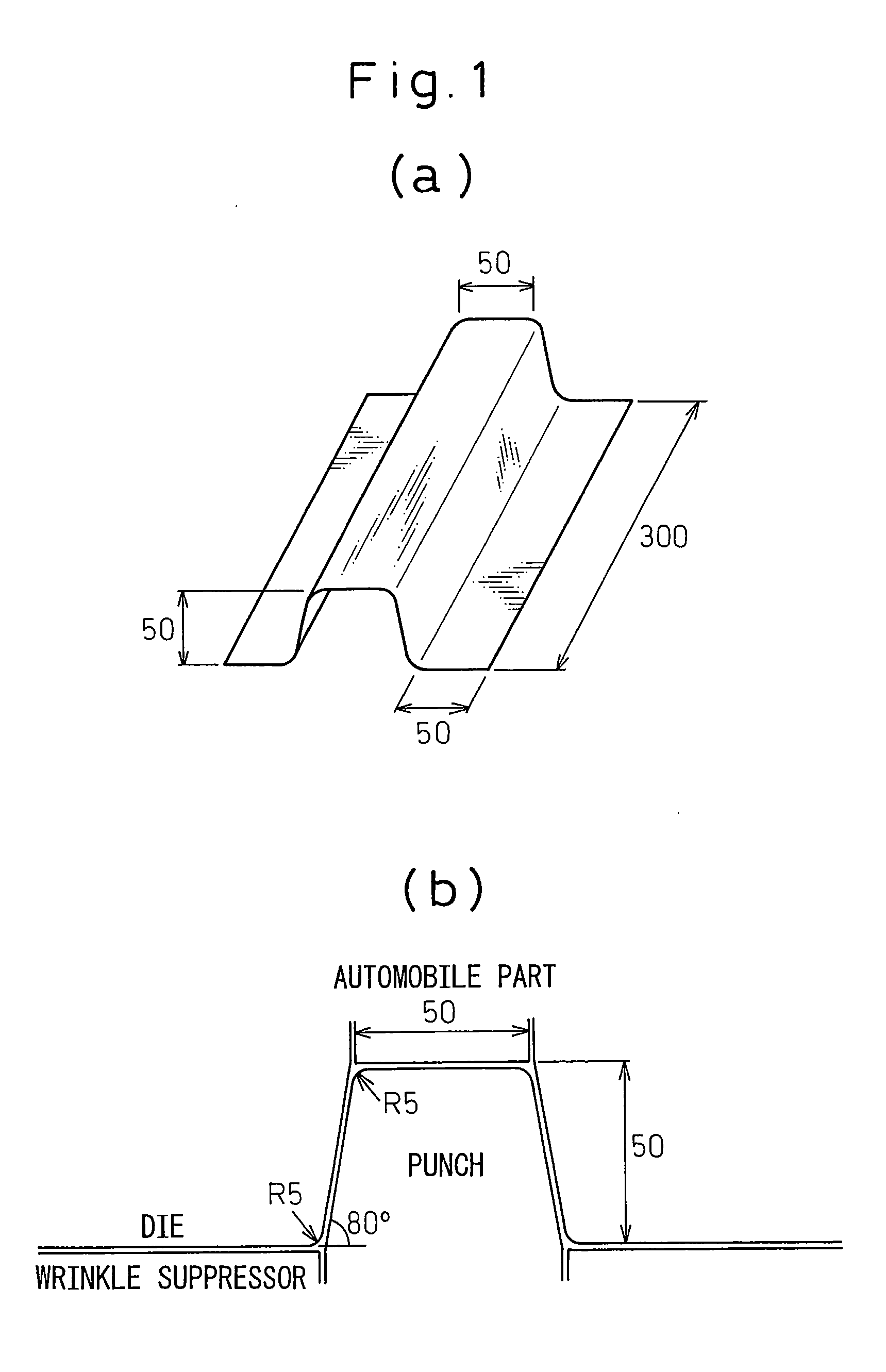

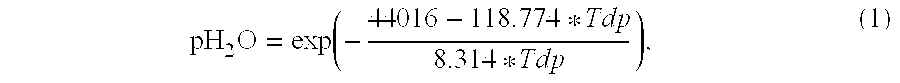

Hot pressing method for high strength member using steel sheet and hot pressed parts

ActiveUS20070163685A1Little riskImprove hydrogen embrittlement resistanceHot-dipping/immersion processesThin material handlingHydrogen concentrationHigh intensity

The present invention provides a method of hot pressing using hot rolled and cold rolled steel sheet or Al-based plated steel sheet or Zn-based plated steel sheet enabling a strength of at least 1200 MPa to be obtained after high temperature forming and with extremely little possibility of hydrogen embrittlement and such hot pressed parts, that is, a method of hot pressing a high strength automobile parts comprising using steel sheet containing as steel compositions by wt % C:0.05 to 0.5% or steel sheet plated mainly with Al or Zn to produce automobile members by hot pressing during which making the heating temperature before pressing Ac3 or more to 1100° C. or less, making the hydrogen concentration in the heating atmosphere 6 vol % or less, and making the dew point 10° C. or less and such hot pressed parts.

Owner:NIPPON STEEL CORP +1

HT550 steel plate with ultrahigh toughness and excellent weldability and manufacture method thereof

ActiveCN103320692AImprove performanceShorten the manufacturing cycleFurnace typesQuenching agentsSheet steelYield ratio

Owner:BAOSHAN IRON & STEEL CO LTD

Seamless steel pipe for line pipe and method for producing the same

ActiveUS20160161028A1Excellent SSC resistanceHigh hardnessFurnace typesRigid pipesChemical compositionLine tubing

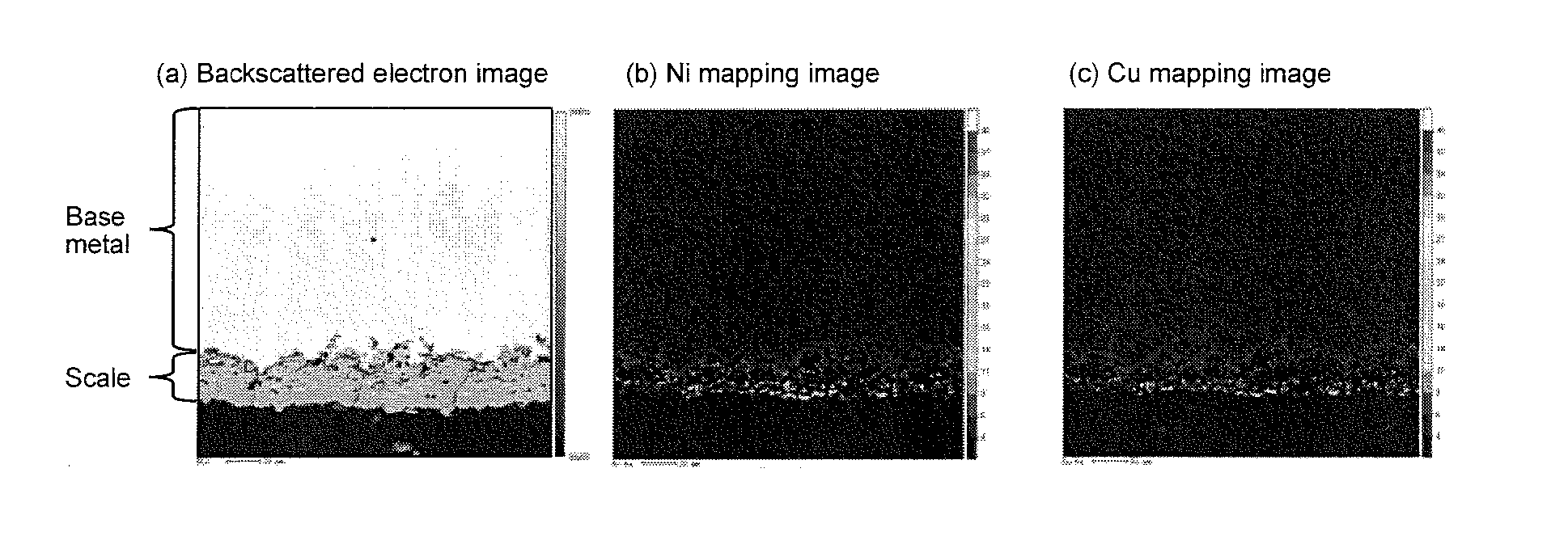

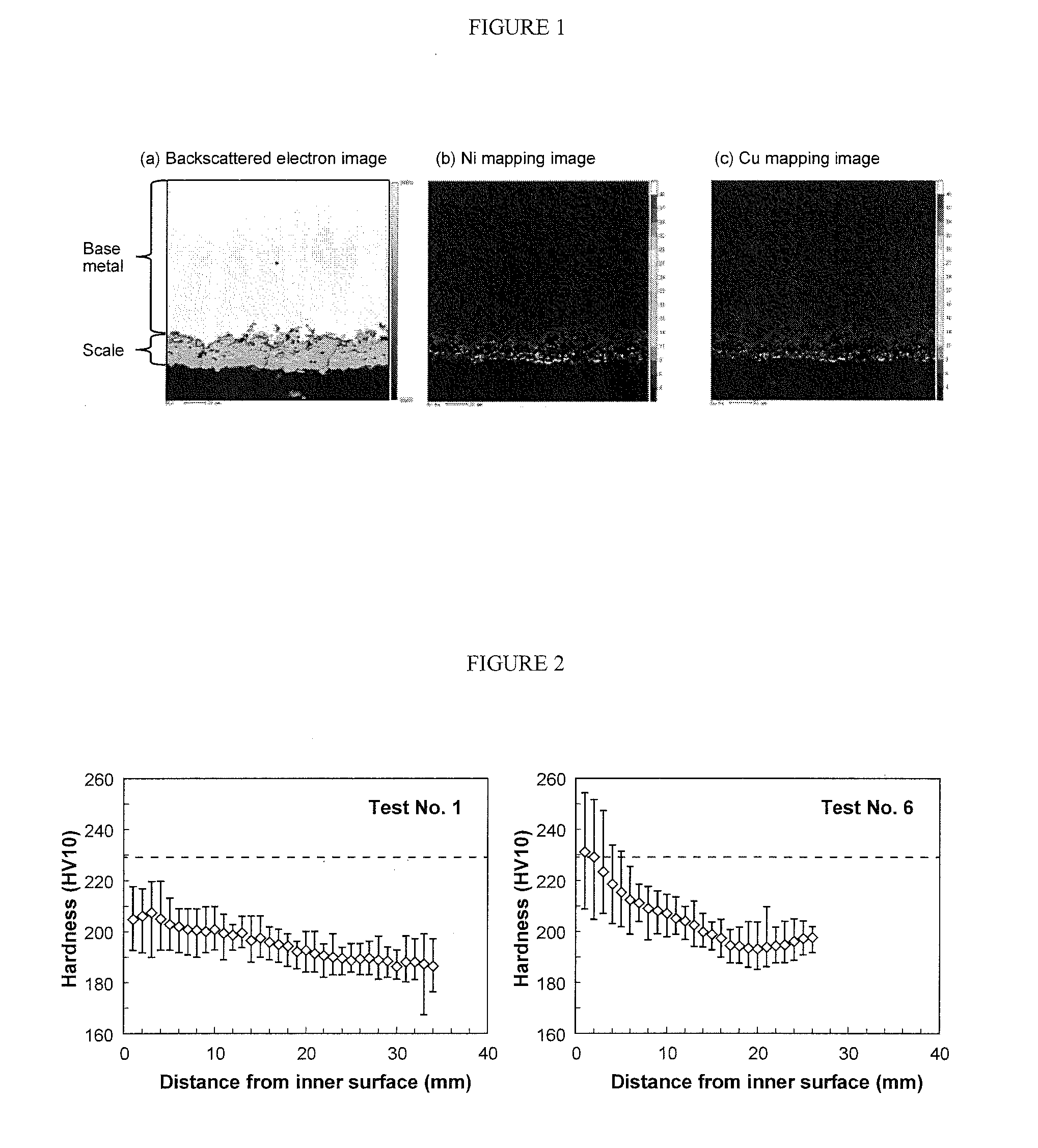

There is provided a seamless steel pipe for line pipe, wherein a chemical composition consists, by mass percent, of C: 0.03-0.10%, Si: ≦0.50%, Mn: 1.0-2.0%, P: ≦0.050%, S: ≦0.005%, Cr: 0.05-1.0%, Mo: 0.01-0.30%, Al: 0.001-0.10%, N: ≦0.01%, Ni: 0.04-2.0%, Ca: 0.0005-0.0050%, Cu: 0-2.0%, Ti: 0-0.05%, Nb: 0-0.05%, V: 0-0.10%, the balance: Fe and impurities, and satisfies the conditions of Cu+Ni: ≧0.10%, and Mo+V: ≦0.30%, wherein in a scale formed on the surface of the steel pipe, metal particles consisting mainly of Ni or Cu having an average circle-equivalent diameter of 0.1-5 μm exist, and a distance from a boundary between the base metal of the steel pipe and the scale to a region in which the metal particles do not exist is 20 μm or longer.

Owner:NIPPON STEEL CORP

High carbon hot-rolled steel sheet and method for manufacturing the same

InactiveUS20050199322A1High tensile strengthImprove ductilityQuenching agentsMetal rolling arrangementsHigh carbonCarbide

The high carbon hot-rolled steel sheet contains, in terms of percentages of mass, 0.10 to 0.7% C, 2.0% or less Si, 0.20 to 2.0% Mn, 0.03% or less P, 0.03% or less S, 0.1% or less Sol.Al, 0.01% or less N, and the balance being Fe and inevitable impurities, and has a structure of ferrite having 6 μm or less average grain size and carbide having 0.10 μm or more and less than 1.2 μm of average grain size. The volume ratio of the carbide having 2.0 μm or more of grain size is 10% or less. The volume ratio of the ferrite containing no carbide is 5% or less. The manufacturing method thereof has the steps of hot-rolling, primary cooling, holding, coiling, acid washing, and annealing. The primary cooling step is to cool the hot-rolled steel sheet down to cooling termination temperatures ranging from 450° C. to 600° C. at cooling rates of higher than 120° C. / sec. The holding step is to apply secondary cooling to hold the primarily cooled hot-rolled steel sheet at a temperature range from 450° C. to 650° C. until coiling.

Owner:JFE STEEL CORP

Ultra quick quenching oil and preparation method thereof

InactiveCN102212662AFast coolingFast medium temperature cooling speedQuenching agentsPolybutyleneAntioxidant

The invention relates to ultra quick quenching oil and a preparation method thereof. The ultra quick quenching oil comprises the following raw materials in percentage by weight: 80 to 97 percent of refined mineral oil, 1 to 10 percent of cooling catalyst, 1 to 5 percent of antioxidant and 1 to 6 percent of anionic surfactant. The kinematic viscosity of the refined mineral oil at the temperature of 40 DEG C is 6 to 9 mm<2> / s; the cooling catalyst is a mixture of oily phenolic resin and polybutylene; the antioxidant is alkylated diphenylamine; and the anionic surfactant is petroleum sodium sulfonate. The preparation method of the ultra quick quenching oil is simple and convenient; the obtained quenching oil has the advantages of ultra high cooling speed, good thermal oxidation stability, long service life and continuous and stable property retention; little peculiar smell, smog and carbon deposit are produced, and the take-out consumption of a workpiece is low; and after the workpiece is quenched by adopting the quenching oil, the workpiece has the advantages of high and uniform surface hardness, deep quenching layer, low deformation, metallographic structure, good mechanical property and good brightness, the surface of the workpiece does not become black, and the workpiece is easily cleaned.

Owner:上海德润宝特种润滑剂有限公司

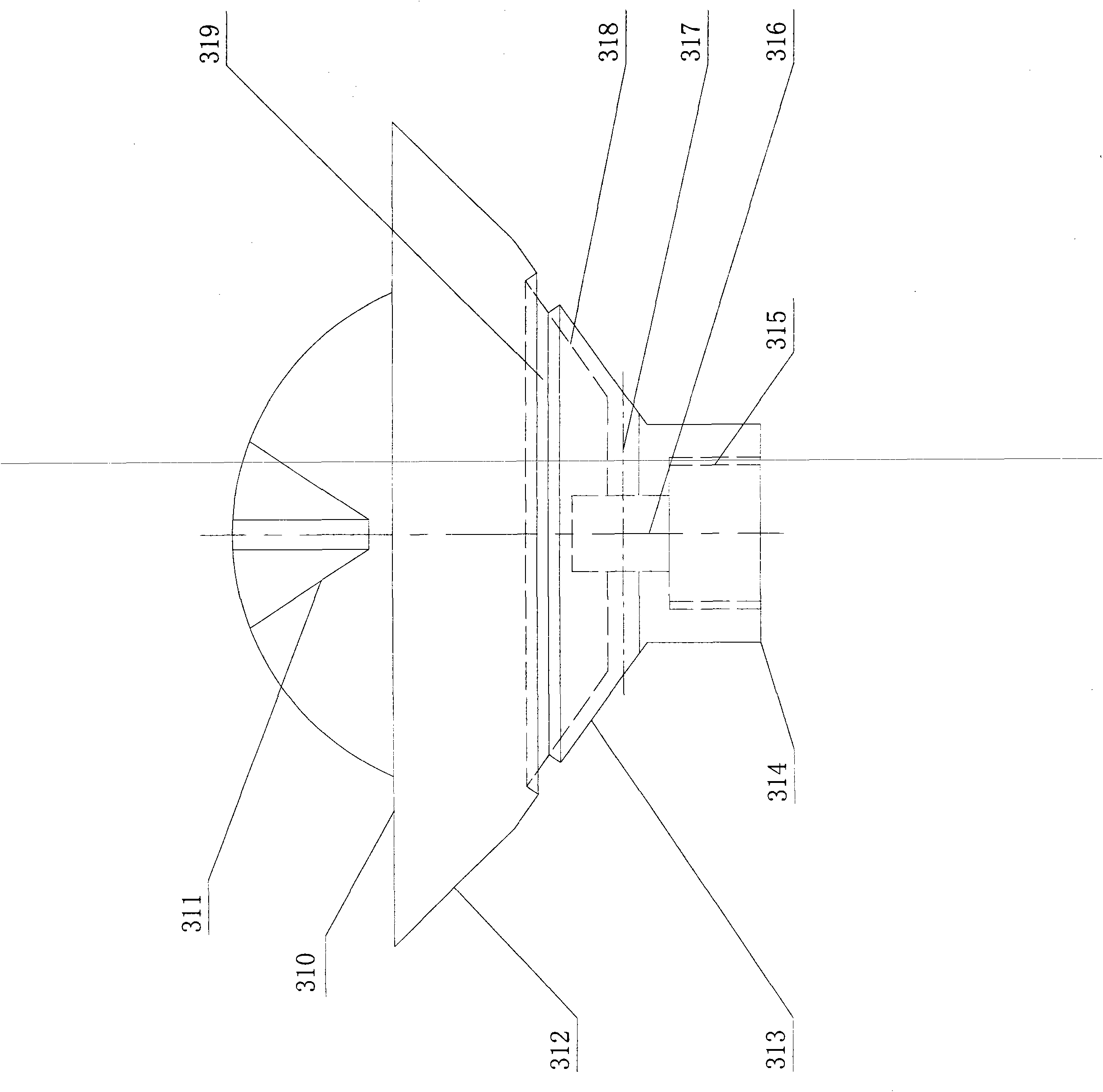

Conical-face spray nozzle without blockage or air resistance and method for forming conical-face aerial fog

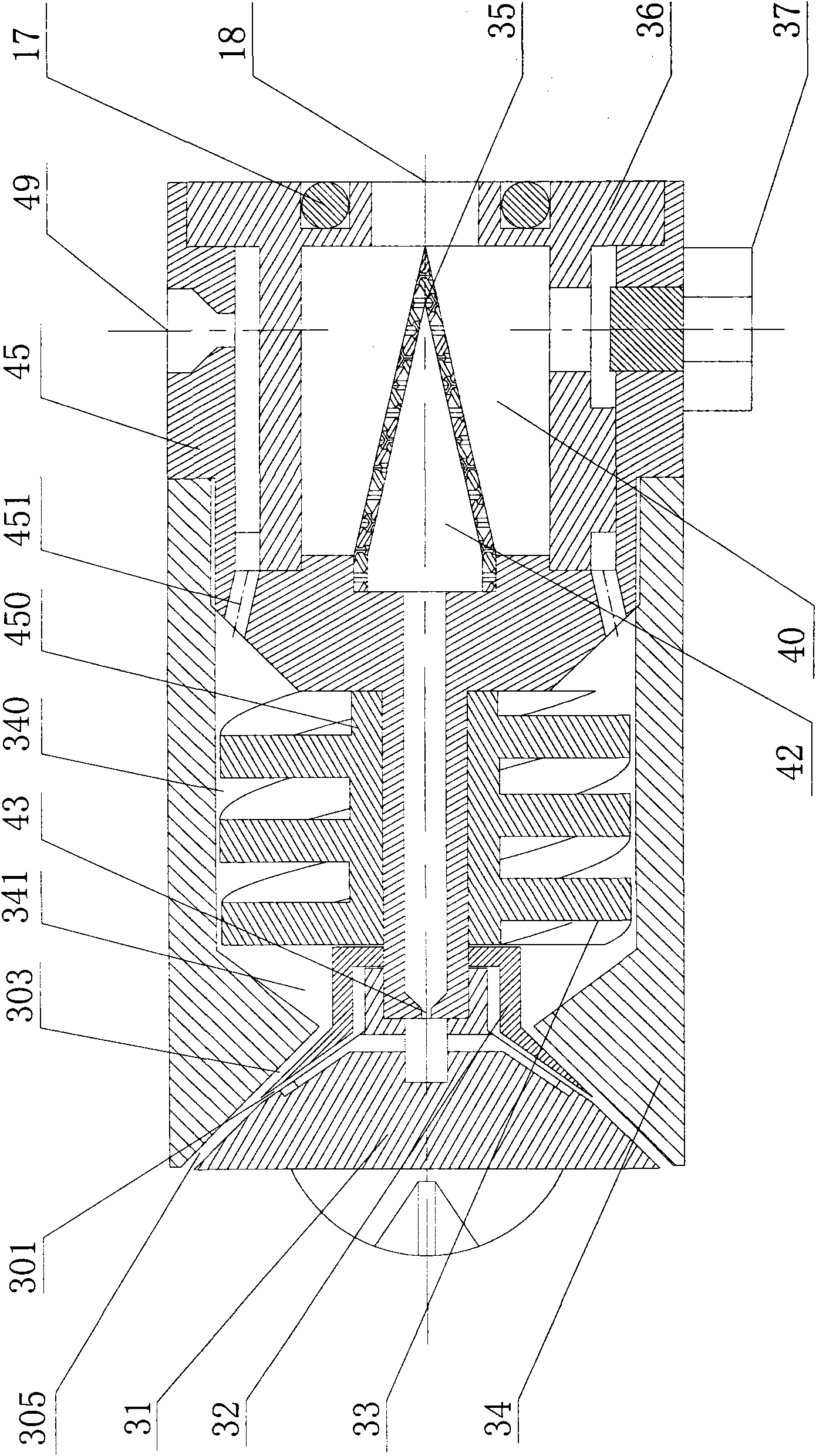

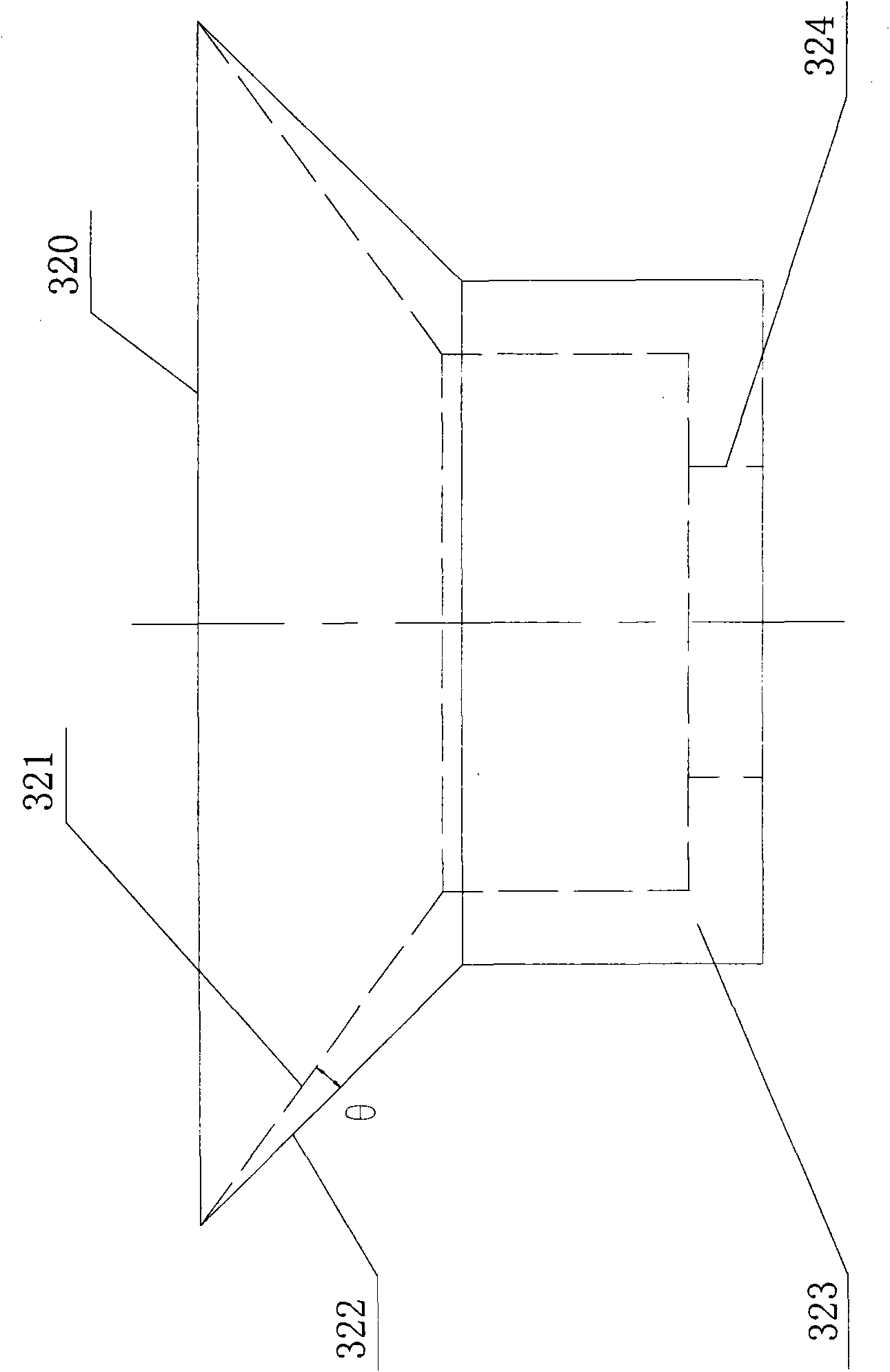

ActiveCN101884962ANo air lockWell mixedSpray nozzlesLiquid spraying apparatusSpray nozzleEngineering

The invention relates to a conical-face spray nozzle without blockage or air resistance and a method for forming conical-face aerial fog. The conical-face spray nozzle comprises a fluid mixing ejector, wherein the ejector is provided with a first conical-face fluid slit, a second conical-face fluid slit and a conical-face mixing ejection slit; the first fluid slit and the second fluid slit are partitioned with a certain angle and converged into the mixing ejection slit at the tail end; first fluid and second fluid which are converged into the mixing ejection slit by the first fluid slit and the second fluid slit are fully mixed and atomized by the mechanical synergism of a floating ring machine rotating at high speed and ejected in a conical face along the mixing ejection slit; and accordingly, the conical-face spray nozzle of the invention prevents an ejecting shape and angle of an ejecting medium from the influence of air pressure and flow and can eject according to the design shapeand angle.

Owner:MCC CAPITAL ENGINEERING & RESEARCH

Technology for processing high strength large hexagon-headed bolt used for steel structure

InactiveCN101934466AImprove heating uniformityFast heatingBoltsFurnace typesHigh intensityElectrical current

The invention provides a technology for processing high strength large hexagon-headed bolt used for steel structure. The invention relates to a technology for processing high strength connecting piece. High frequency induction current hot forging and cold extruding are adopted, so as to produce a bolt. The invention is on the basis of patent application with patent application number of 200810020090.5, high frequency induction heating is adopted in hot forging, frequency thereof is controlled to be 20000-50000Hz, and the advantages of high frequency induction heating that speed is fast and heating is uniform are utilized, so that work piece surface can obtain uniform tissue and properties from center part to the surface, heating uniformity of work piece is improved, better crystal phase structure can be obtained, and high strength bolt with better property can be obtained.

Owner:扬州狮鹤高强度螺栓有限公司

Processing technology for high-strength large hexagon head bolt used for steel structure

InactiveCN101549449AHigh strengthExtended service lifeBoltsFurnace typesFatigue fracturesHigh intensity

The invention discloses a processing technology for a high-strength large hexagon head bolt used for a steel structure and belongs to a processing technology for a high-strength connecting piece. The high-strength large hexagon head bolt is processed by less or non cutting including one time of hot forging forming and three times of cold extrusion forming, wherein the hot forging forming is bolt rail forming. The first time of cold extrusion forming is screw forming, the second time of cold extrusion forming is upper screw thread section forming, and the third time of cold extrusion forming is thread forming. The invention mainly adopts the cold extrusion process for bolt production, improves the strength of the bolt, optimizes the production process of the bolt, overcomes the delay fracture and fatigue fracture of the high-strength bolt, ensures that the bolt is not easy to fracture in the use process and reliably connected, prolongs the service life of the bolt and can more meet the use requirement for the high-strength large hexagon head bolt used for the steel net frame bolt ball node in modern society.

Owner:扬州狮鹤高强度螺栓有限公司

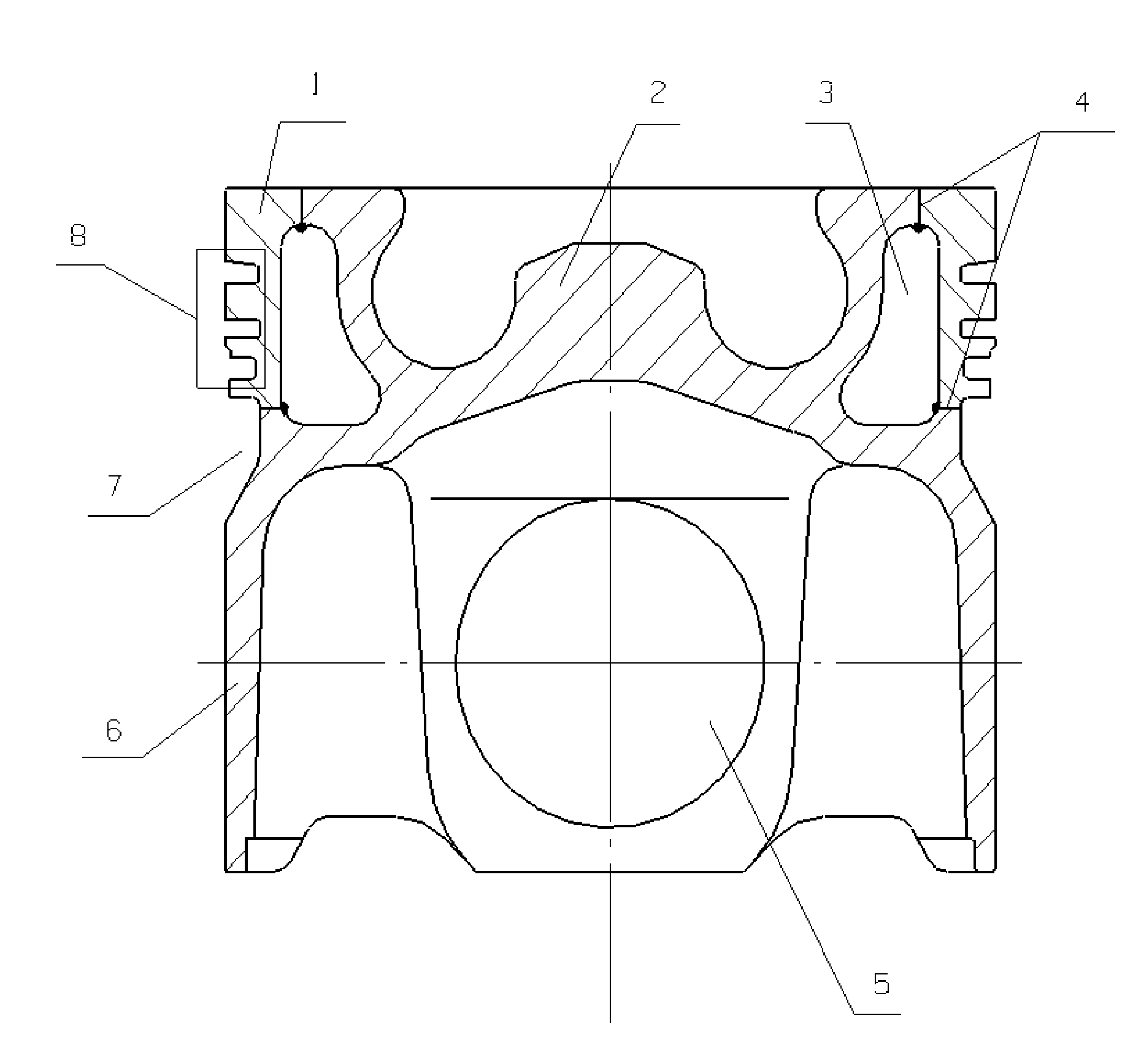

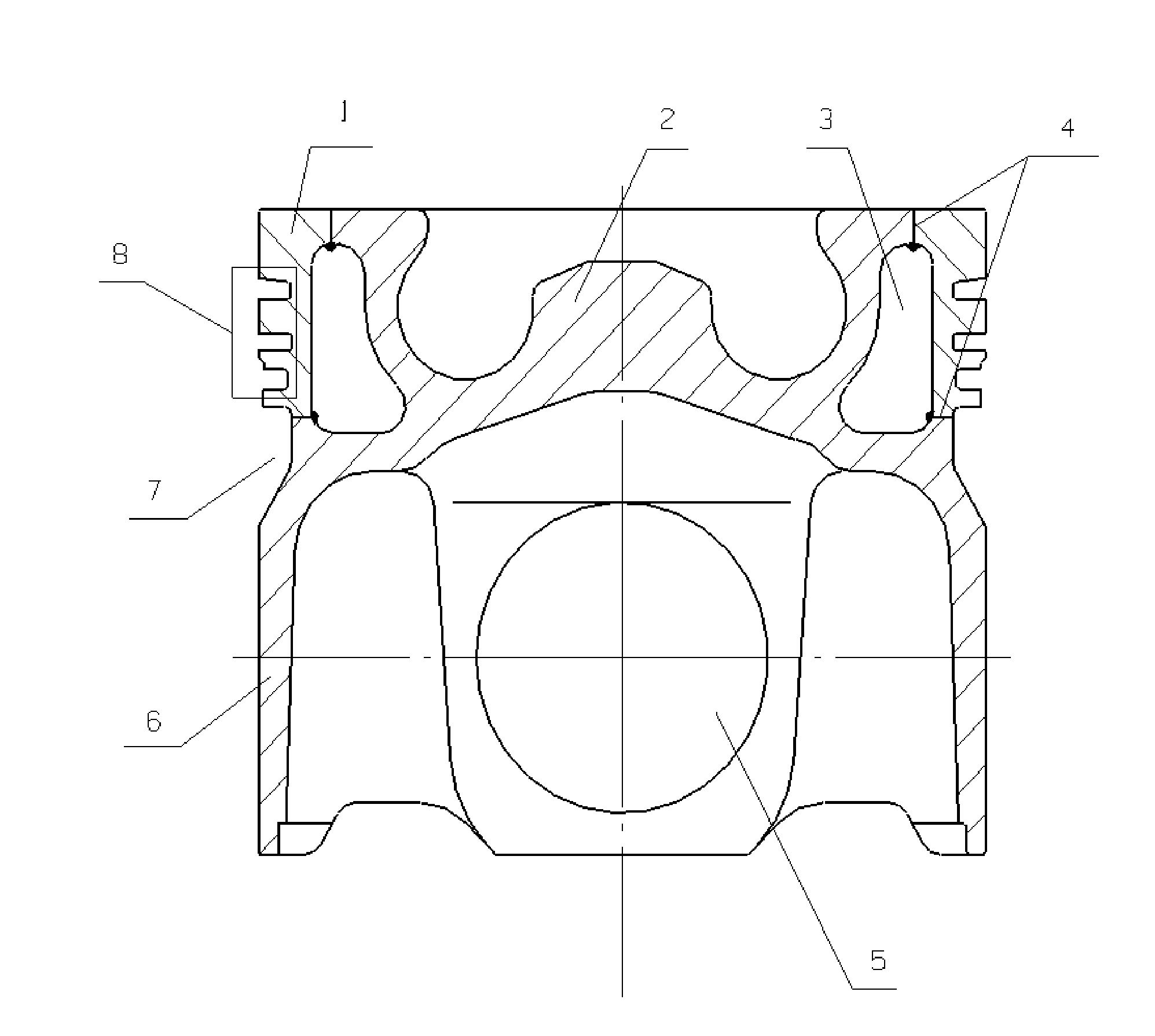

Single-piece forged-steel piston with inner oil cooling chamber and a method for manufacturing thereof

InactiveUS20090020007A1Simple structureEasy to makeValve arrangementsPlungersPiston ringCooling chamber

A laser-welded single-piece forged-steel piston with an enclosed inner oil cooling chamber having the advantages of simple structure and easy manufacturing process, and capable of satisfying the requirement of engines for high power, high rigidity, and low discharge development, and its manufacturing process. The laser-welded single-piece forged-steel piston of the invention comprises a piston body member and a piston ring member, wherein the piston body member is welded together with the piston ring member through laser welding procedure, an enclosed inner oil cooling chamber is formed between the piston body member and the piston ring member, and is connected with the piston inner cavity by means of at least two oil inlet / outlet holes, and a pin hole is opened at the lower portion of the piston body member.

Owner:LIN FENGHUA +3

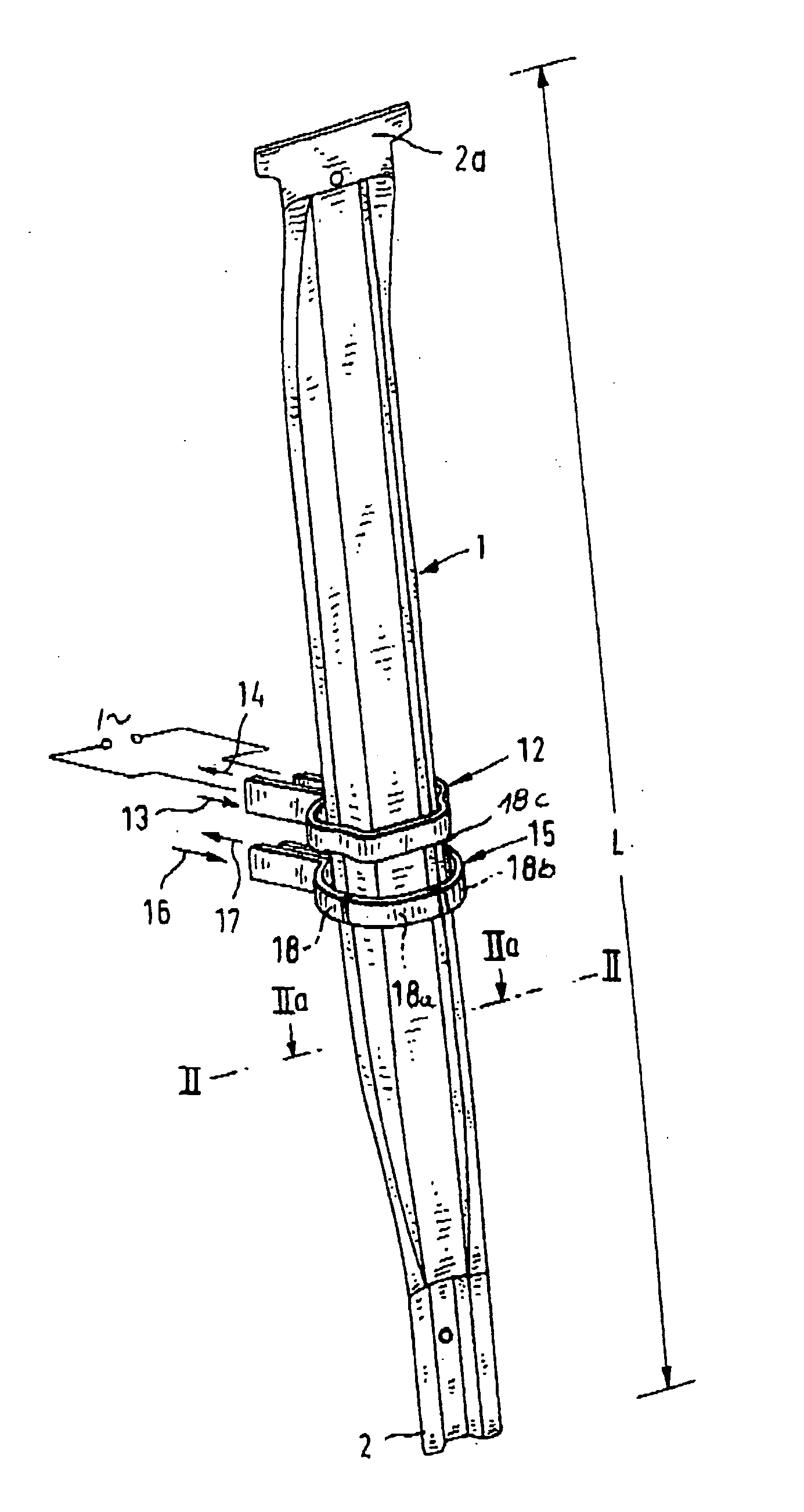

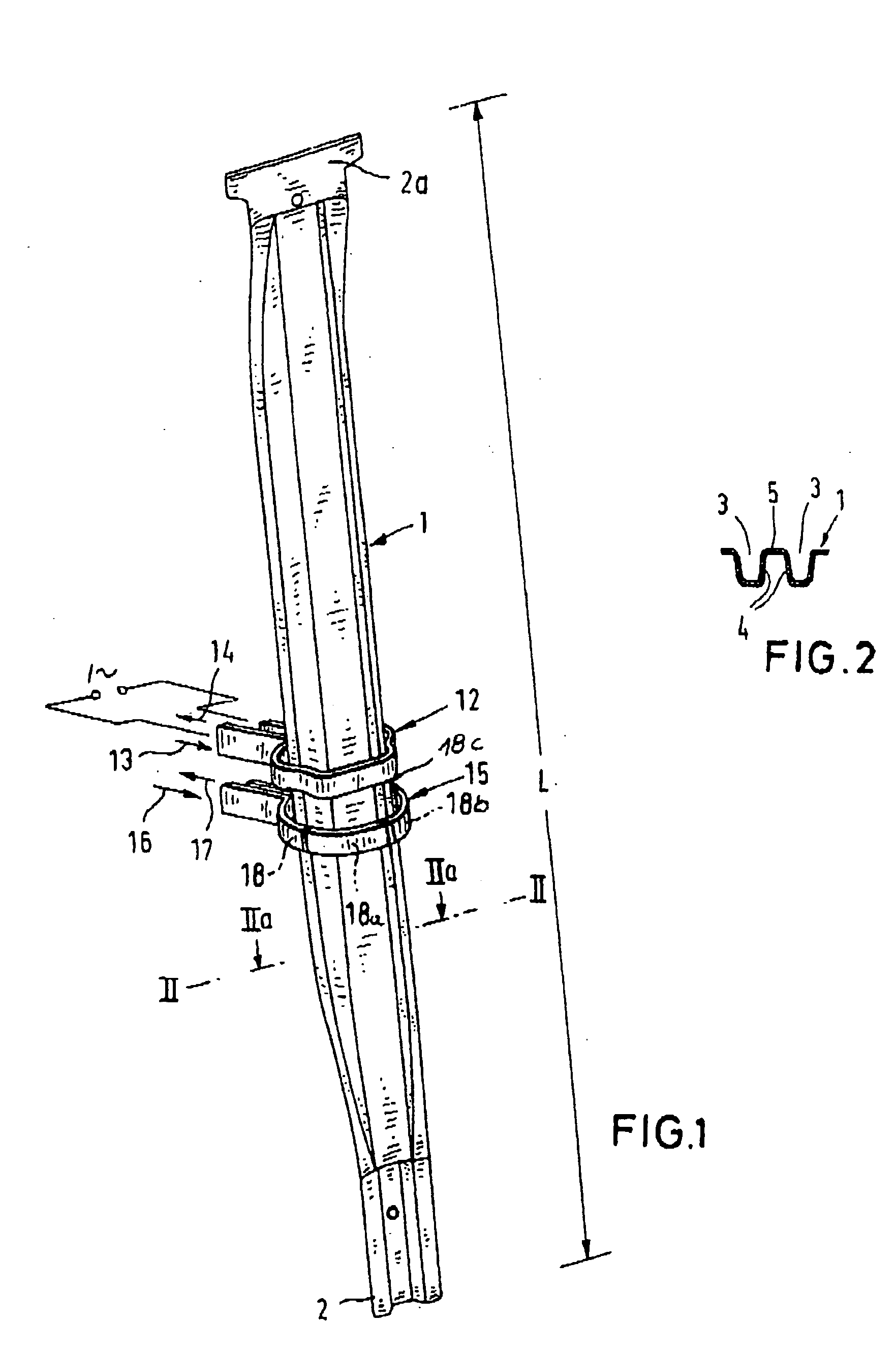

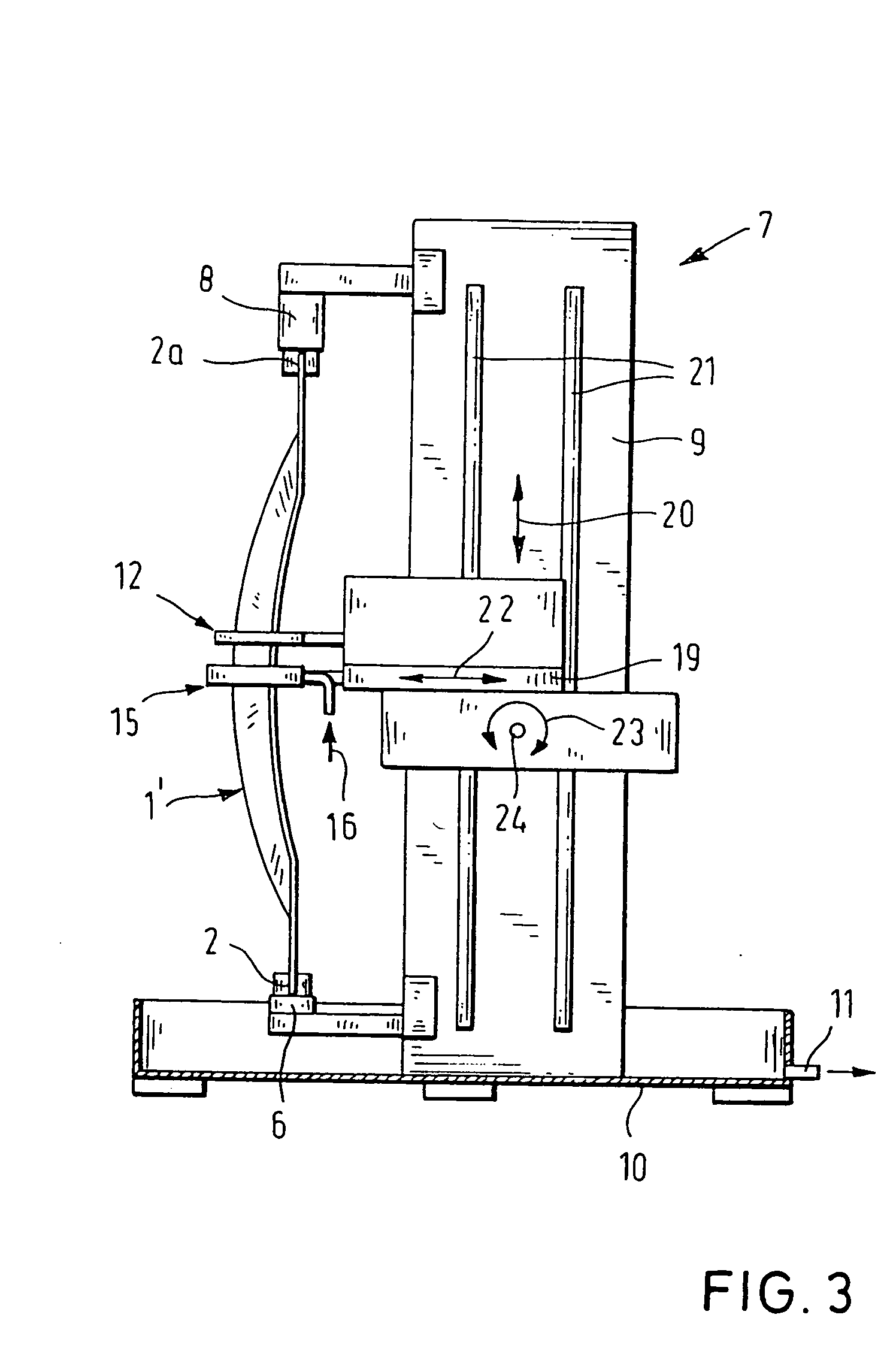

Apparatus for heat treatment of structural body parts in the automobile industry

InactiveUS20050006828A1Reduce maintenanceReduce wearFurnace typesIncreasing energy efficiencySheet steelHorizontal axis

Apparatus for heat-treating an elongate structural body part made from a blank compressed while being soft or from steel strip of hardenable 22 Mn B5 mod. steel sheet with a thickness of 1 mm to 3 mm, includes an apparatus for positioning the structural body part in substantially upright disposition. Placed in surrounding relationship to the structural body part is an induction element which can move from bottom to top, thereby being able to follow a contour of the structural body part and allowing to at least partially heat the structural body part to an austenitizing temperature suitable for hardening. Disposed adjacent to the induction element is a cooling unit which follows the induction element in movement direction. The induction element and the cooling unit are moveable relative to one another and connected to a tool carriage which is mounted to a column for movement in a vertical direction, in a transverse direction to the column and about a horizontal axis.

Owner:BENTELER AKTIENGES

Steel pipe for borehole operation of 150ksi steel grade high toughness oil and gas well and production method thereof

ActiveCN101613829AImprove the level of toughnessExcellent physical and chemical propertiesElectric furnaceProcess efficiency improvementElectric arc furnaceHigh density

The invention provides a steel pipe for borehole operation of 150ksi steel grade high toughness oil and gas well and a production method thereof. The components of the steel pipe are as follows by weight percentage: 0.22%-0.26% of C, 0.15%-0.35% of Si, 0.40%-0.60% of Mn, less than or equal to 0.010% of P, less than or equal to 0.005% of S, 0.90%-1.10% of Cr, 0.70%-0.80% of Mo, 0.10%-0.15% of V, and the balance being Fe. The production method of the invention utilizes scrap steel and sponge iron or molten iron as steelmaking raw materials, after going through electric arc furnace smelting, external refining and vacuum degassing, continuous casting is carried out on the raw materials to mold round billets, and then high-precision hot rolling is carried out on the round billets to mold seamless steel pipes for quenching and heat treatment, finally the hollow plain end seamless steel pipes are obtained. The product has the beneficial effects that the steel pipe features good physical and chemical properties, can be applied to borehole testing of the oil and gas well with high density of rock and increasing production operations such as perforation, fracturing and the like, and 150ksi grade steel pipe strength and toughness matched thereof ensures the security of the whole borehole operation system in the situation.

Owner:TIANJIN STEEL PIPE MFG CO LTD

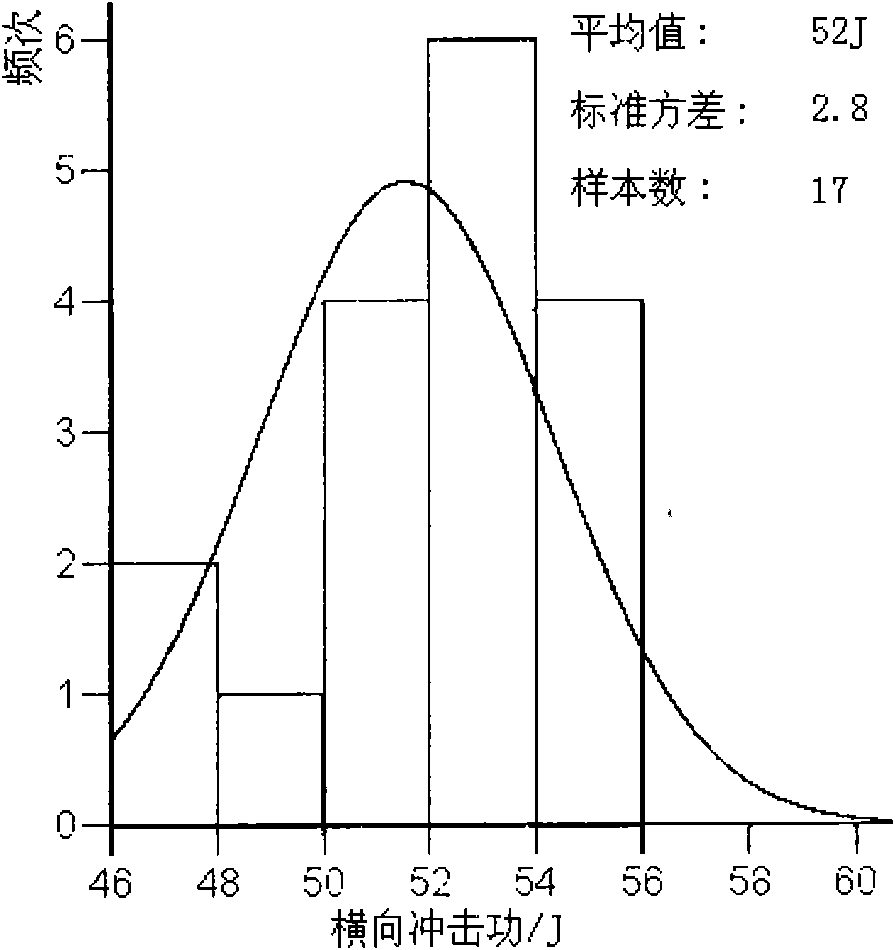

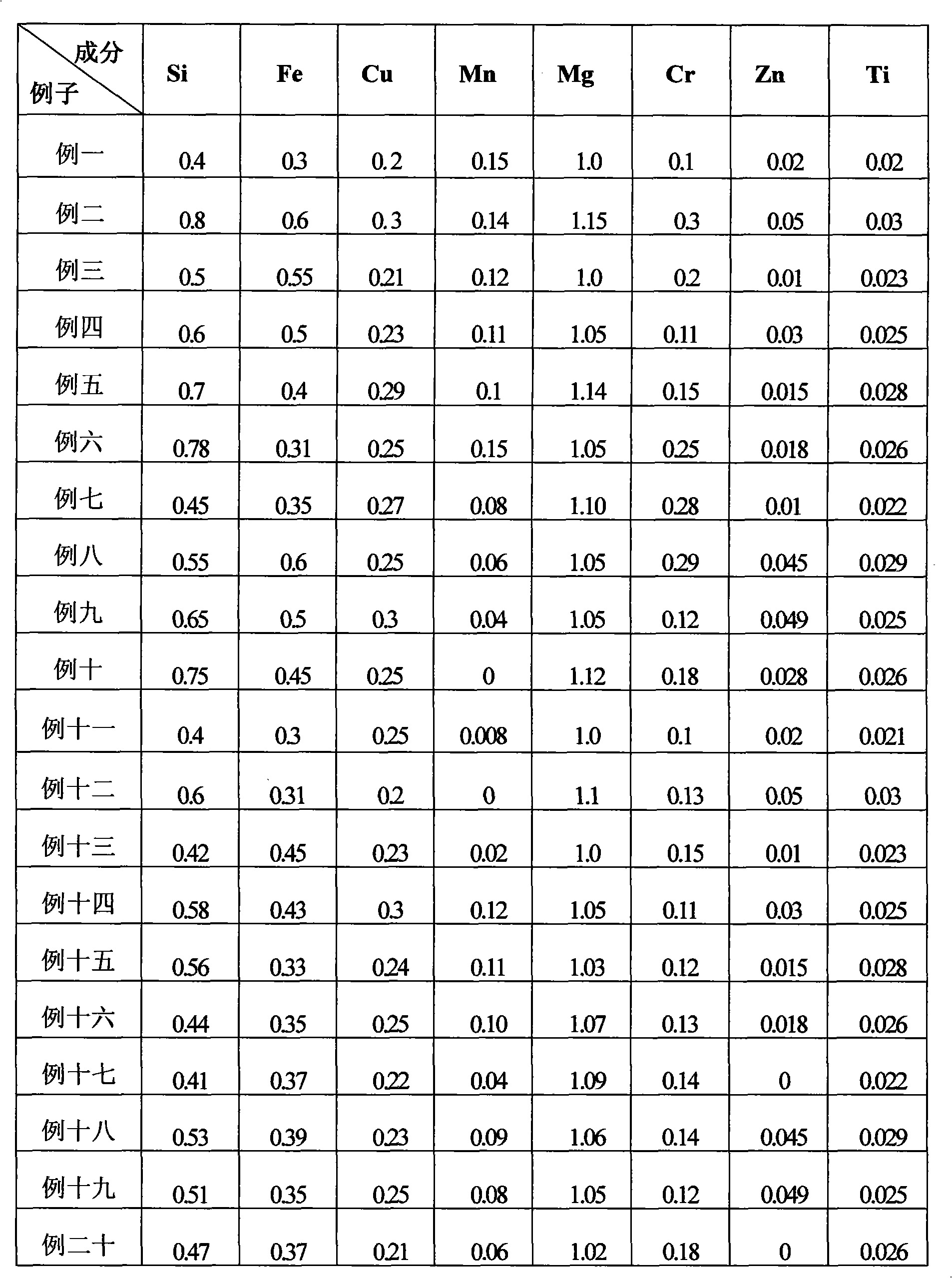

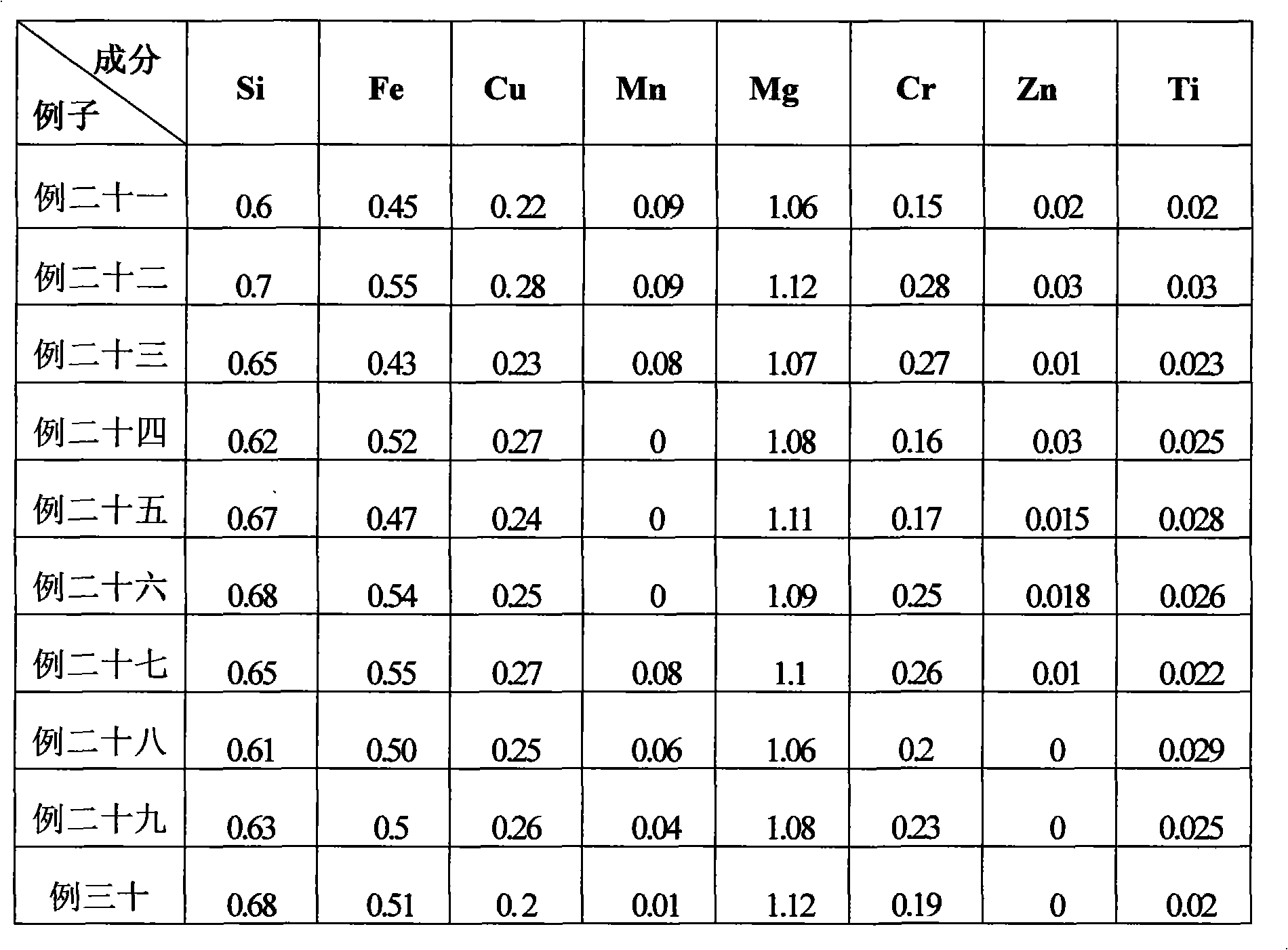

High-strength aluminium alloy plate and production method thereof

ActiveCN101649406AHigh strengthAccelerated corrosionQuenching agentsMetal rolling arrangementsHigh intensityQuenching

The invention relates to a high-strength aluminium alloy plate and a production method thereof. The high-strength aluminium alloy plate is made from the components in parts by weight: 0.4-0.8 part ofSi, 0.3-0.6 part of Fe, 0.2-0.3 part of Cu, not more than 0.15 part of Mn, 1.0-1.15 parts of Mg, 0.1-0.3 part of Cr, not more than 0.05 part of Zn, 0.02-0.03 part of Ti, not more than 0.01 part of other impurities and the balance of Al, wherein the total amount is 100 parts. The production method comprises following steps: smelting, refining, stewing, casting, face milling, hot rough rolling, hotprecision rolling, cold rolling and online continuous quenching, wherein furnace temperature is 590-610 DEG C, and the quenching speed is 0.7-2.0m / min; and then carrying out secondary cold rolling till a aluminium alloy platen is rolled to be 0.8-10mm; and finally obtaining a finished product through finishing and artificial ageing treatment. The plate has the advantages of high strength, corrosion resistance, good welding performance and the like; the adopted hot rolling method is a continuous quenching process, thereby realizing the rapidity and the continuity of uncoiling quenching and shortening the production cycle, therefore being beneficial to energy saving and consumption reducing and popularization and application.

Owner:河南明晟新材料科技有限公司

Polymeric quenchant, manufacture thereof, and method for quenching steel

A polymeric quenchant. The polymeric quenchant comprises an inorganic nanoparticle, a water-soluble polymer, and water, wherein a weight ratio of the inorganic nanoparticle, water-soluble polymer and water is about 0.05-5:1-5:100. The cooling rate of steel during a quenching process can be adjusted by regulating the components and ratios of the adjusted by regulating the components and ratios of the polymeric quenchant to achieve desirable steel properties.

Owner:IND TECH RES INST

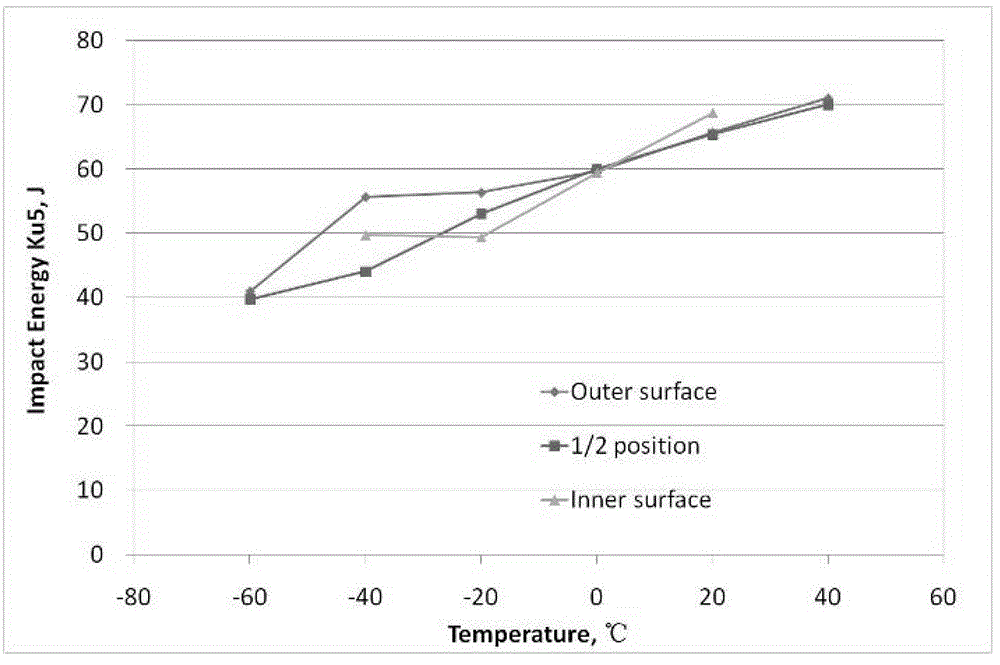

Heat treatment method of novel alloy steel hollow car axle material

ActiveCN102876860AGood mechanical propertiesWide range of water temperature allowedQuenching agentsPre treatmentPassenger train

The invention belongs to the technical field of heat treatment processes of alloy steel hollow car axle materials for high-speed passenger trains and particularly relates to a heat treatment method of a novel alloy steel hollow car axle material. The heat treatment method is characterized by pre-heating novel alloy steel with shaft blank sizes at the temperature of 910-950 DEG C, quenching the novel alloy steel at the temperature of 900-940 DEG and tempering the novel alloy steel at the temperature of 620-670 DEG C. The heat treatment method has the advantages that the developed novel alloy steel hollow car axle material for the high-speed passenger trains is domestically and independently developed, mechanical properties of axles which are treated by a heat treatment process matched with the material all exceed requirements of the European hollow car axle standard EN13261, the axles are good in obdurability matching, especially, high in smooth specimen fatigue strength and notch specimen fatigue strength and excellent in low temperature impact toughness, so that the axles can be used under various domestic weather conditions. According to the heat treatment method of the novel alloy steel hollow car axle material, heat treatment process technical assurance is provided for finally producing novel alloy steel hollow car axles at the speed of 200km / h-350km / h.

Owner:TSINGHUA UNIV +1

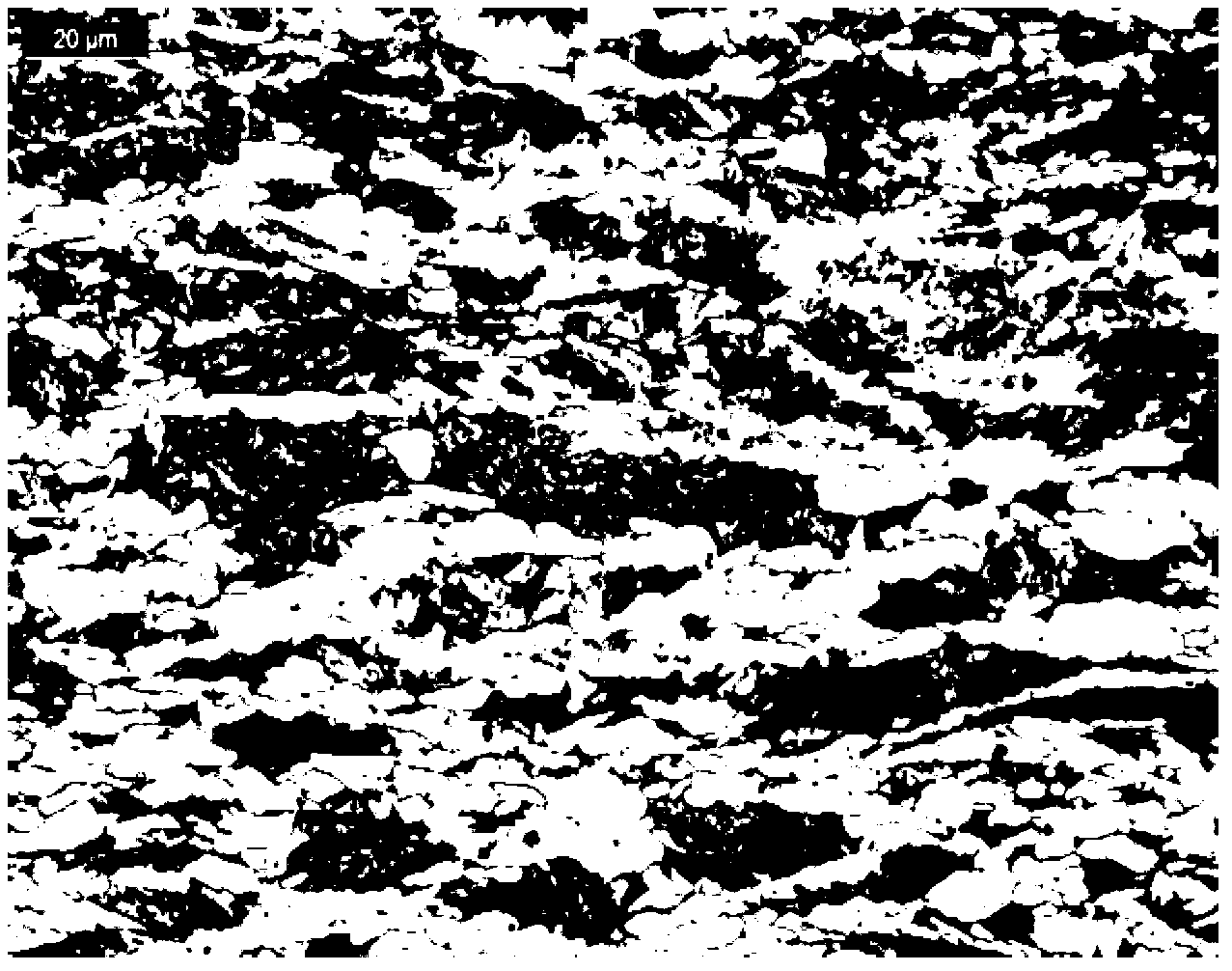

Hot pressing method for high strength member using steel sheet and hot pressed parts

ActiveUS7867344B2Little riskImprove hydrogen embrittlement resistanceHot-dipping/immersion processesQuenching agentsSheet steelHigh intensity

A method is proved for hot pressing hot rolled steel sheet, cold rolled steel sheet, Al-based plated steel sheet or Zn-based plated steel sheet, where the hot pressed sheet can exhibit a strength of at least about 1200 Mpa, and my be prevented from exhibiting hydrogen embrittlement. The steel sheet may include between about 0.05 to 0.5 wt % C, and / or it may be plated with an Al-based or Zn-based plating material. The steel sheet may be heating to a temperature greater than an Ac3 temperature and not more than about 1100° C. before pressing. An atmosphere can be provided during heating which contains not more than about 6 vol % of hydrogen and a dew point of not more than about 10° C. The exemplary methods may be used to form high strength parts which may be used, e.g., in automobiles.

Owner:NIPPON STEEL CORP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com