Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

445results about "Temperature control using plurality of sensors" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

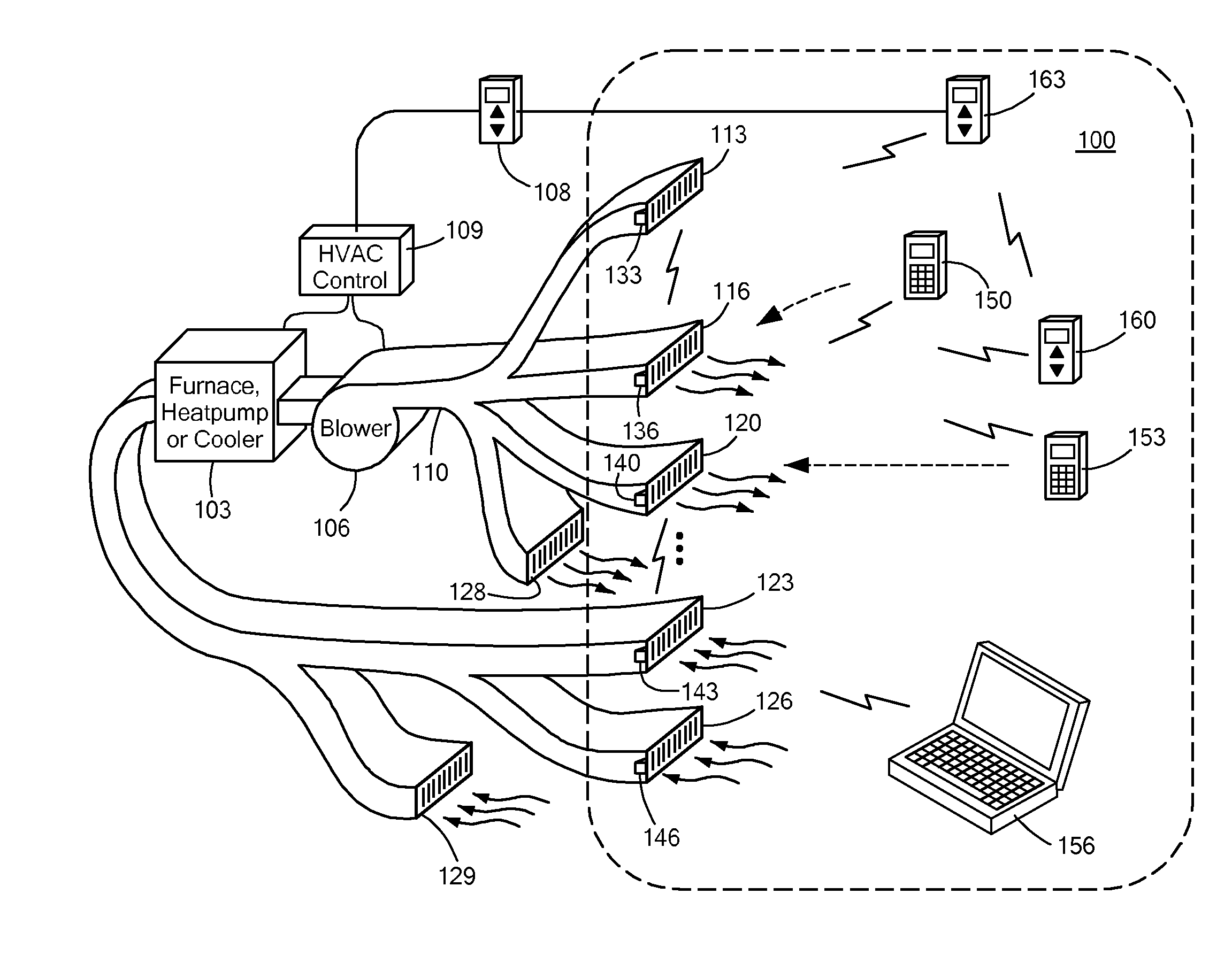

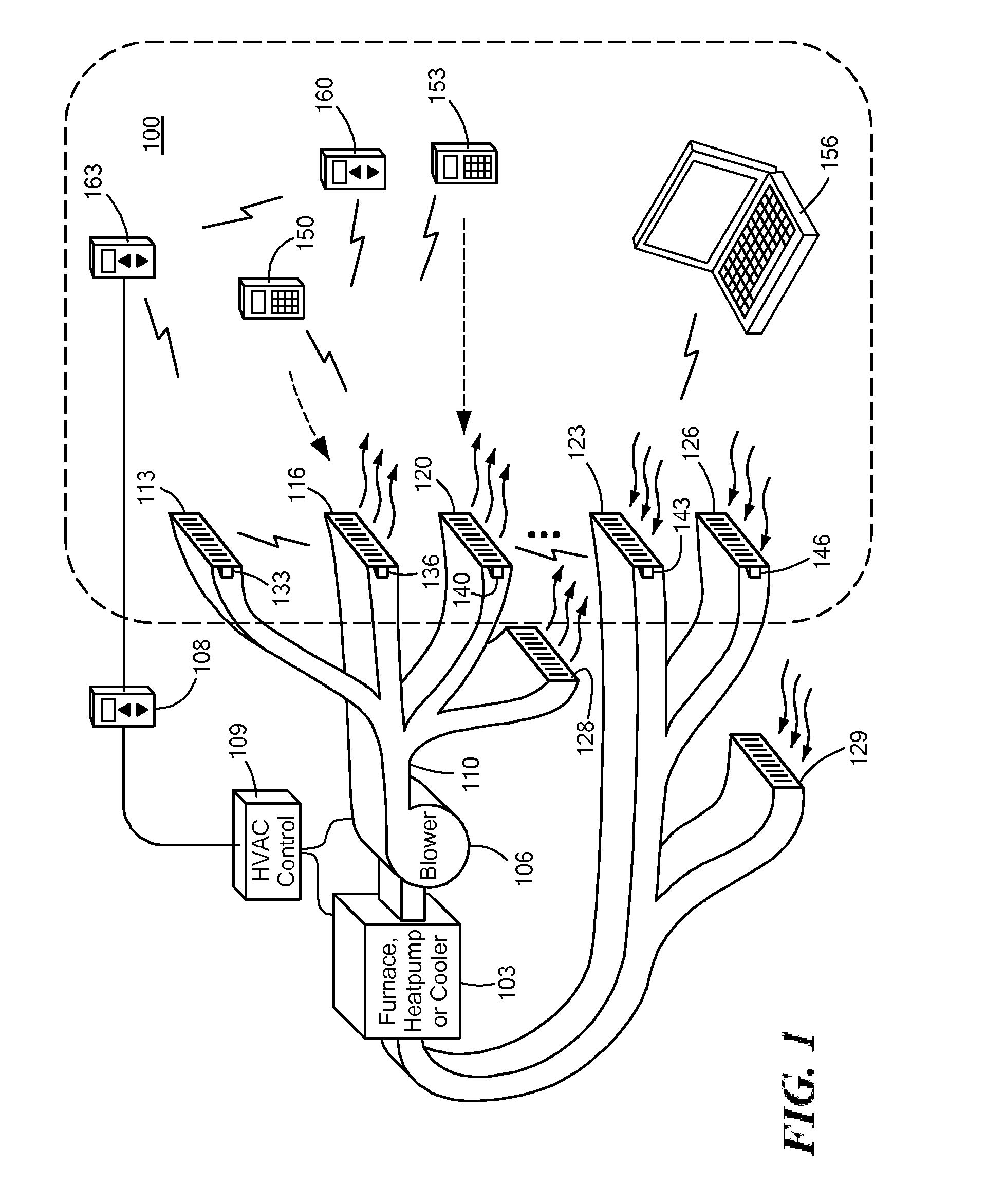

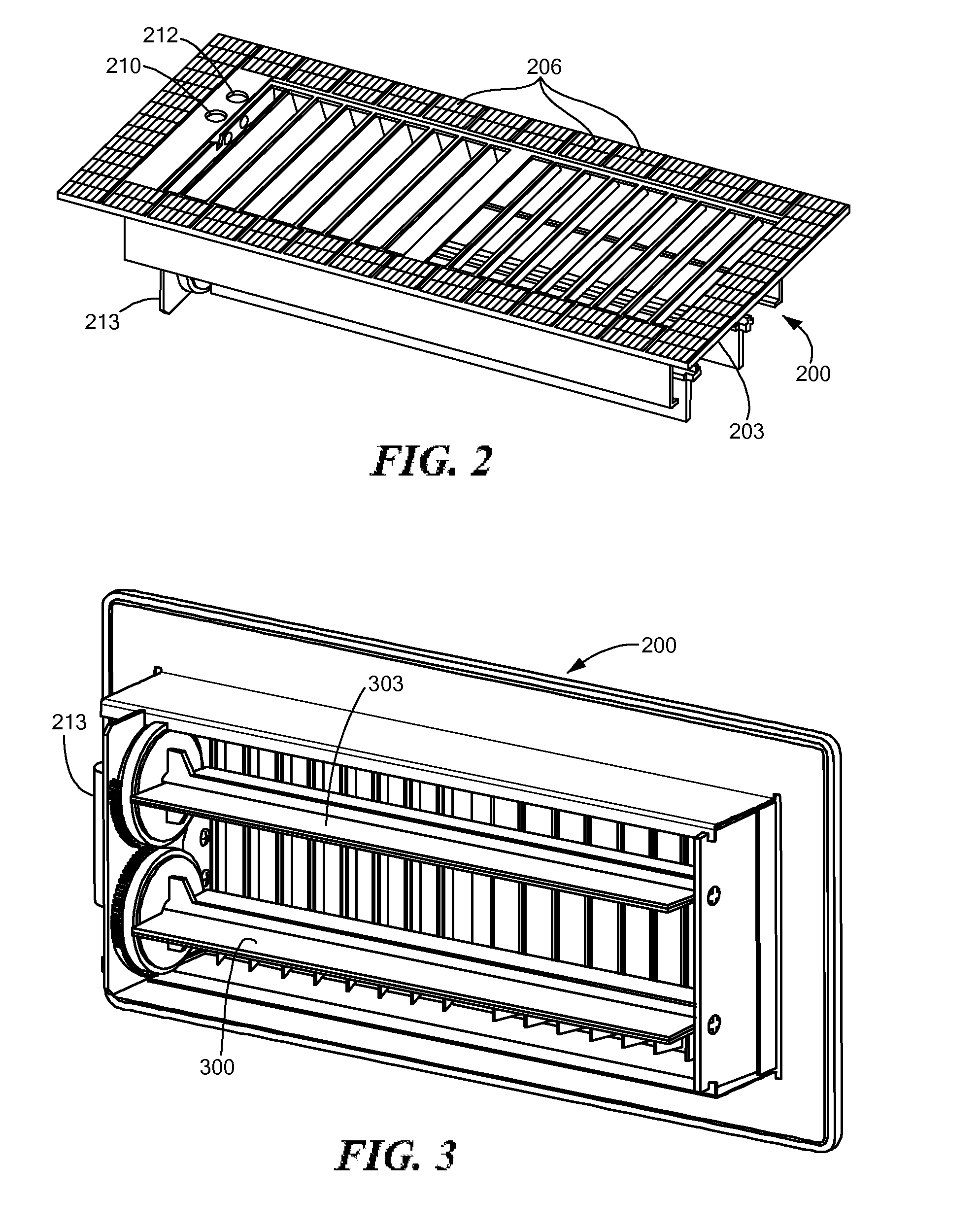

Automatically Balancing Register for HVAC Systems

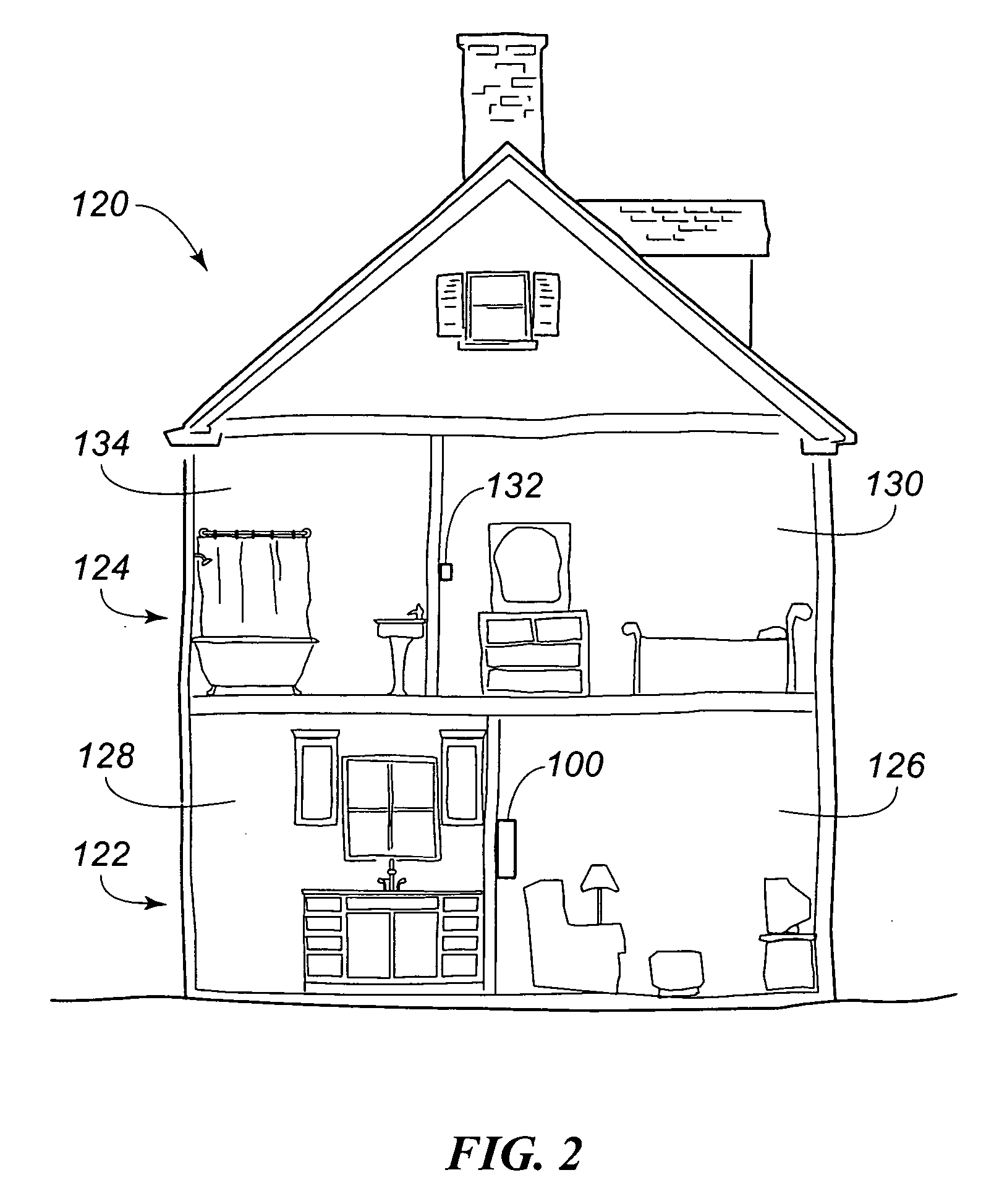

Distributed nodes, such as intelligent register controllers, of a heating, ventilating and / or air conditioning (HVAC) system wirelessly communicate with each other on a peer-to-peer basis, forming a network, and collectively control the HVAC system, without a central controller. The intelligent register controllers collectively control the amount of conditioned air introduced into each region. Each node may base its operation at least in part on information about one or more (ideally all) of the other nodes. Each intelligent register controller automatically determines how much conditioned air to allow into its region, or how much return air to allow to be withdrawn from its region, based on information collected by the register controller, such as: current temperature of the region; desired temperature of the region; calculated amount of conditioned air required to change the region's temperature to the desired temperature; temperature of conditioned air begin supplied by a duct to the register; current time, day of week, vacation or other schedule data; temperatures of other regions and their respective desired temperatures; calculated amounts of air required to be supplied or withdrawn by the other controlled registers to change their respective regions' temperatures to their desired temperatures; or combinations thereof. Each register controller automatically determines when and to what extent to operate its respective controllable damper.

Owner:ZONER

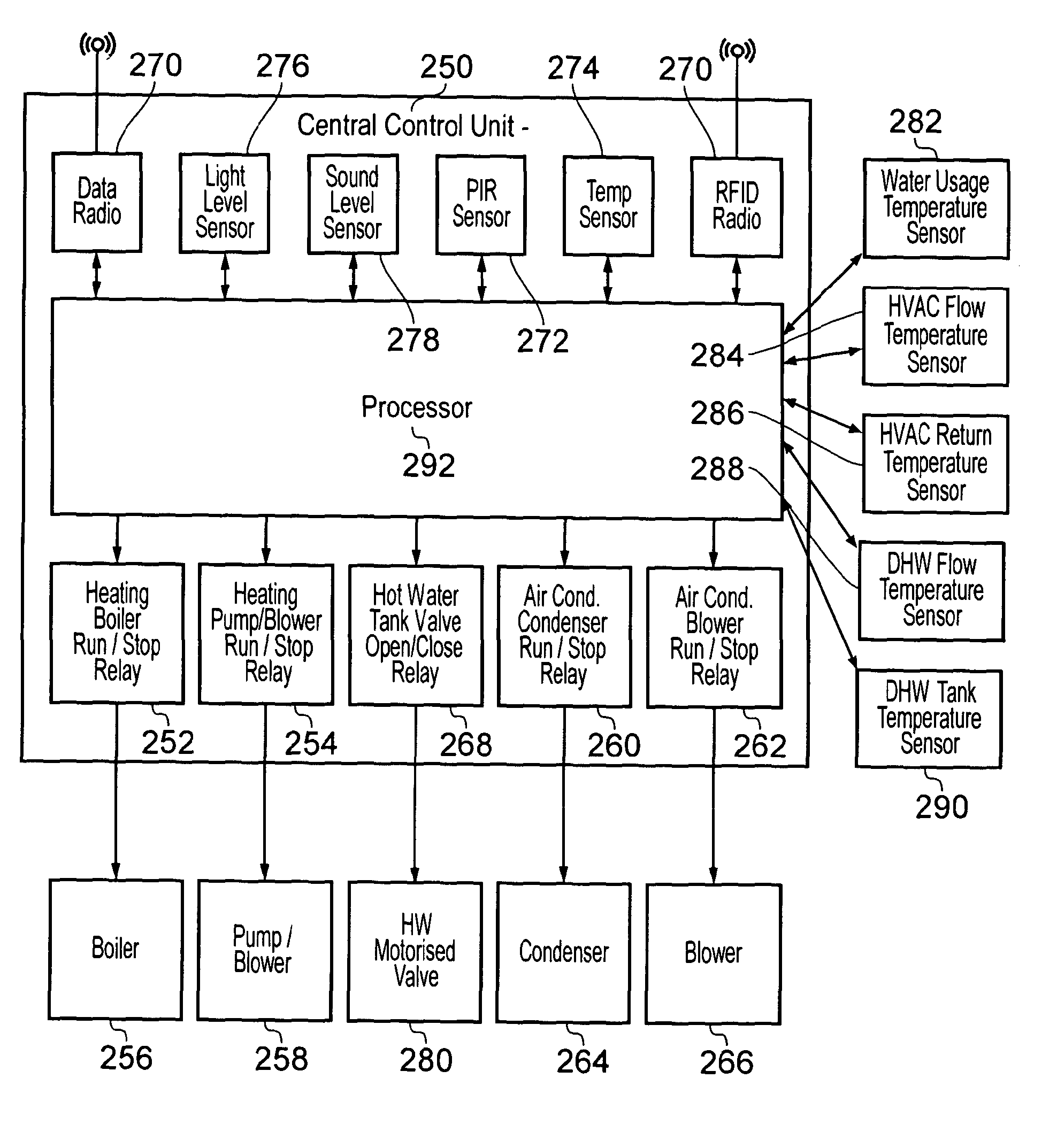

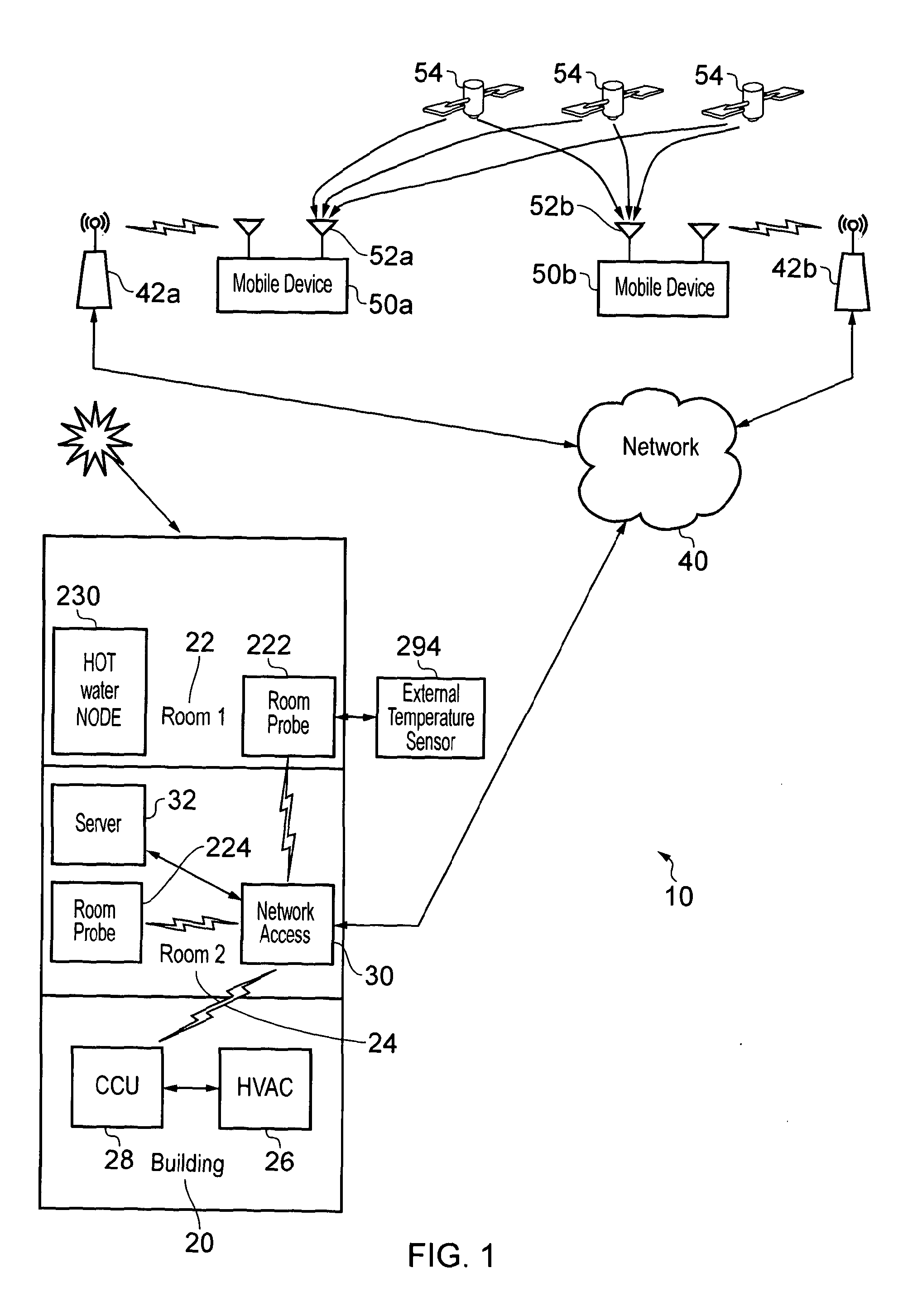

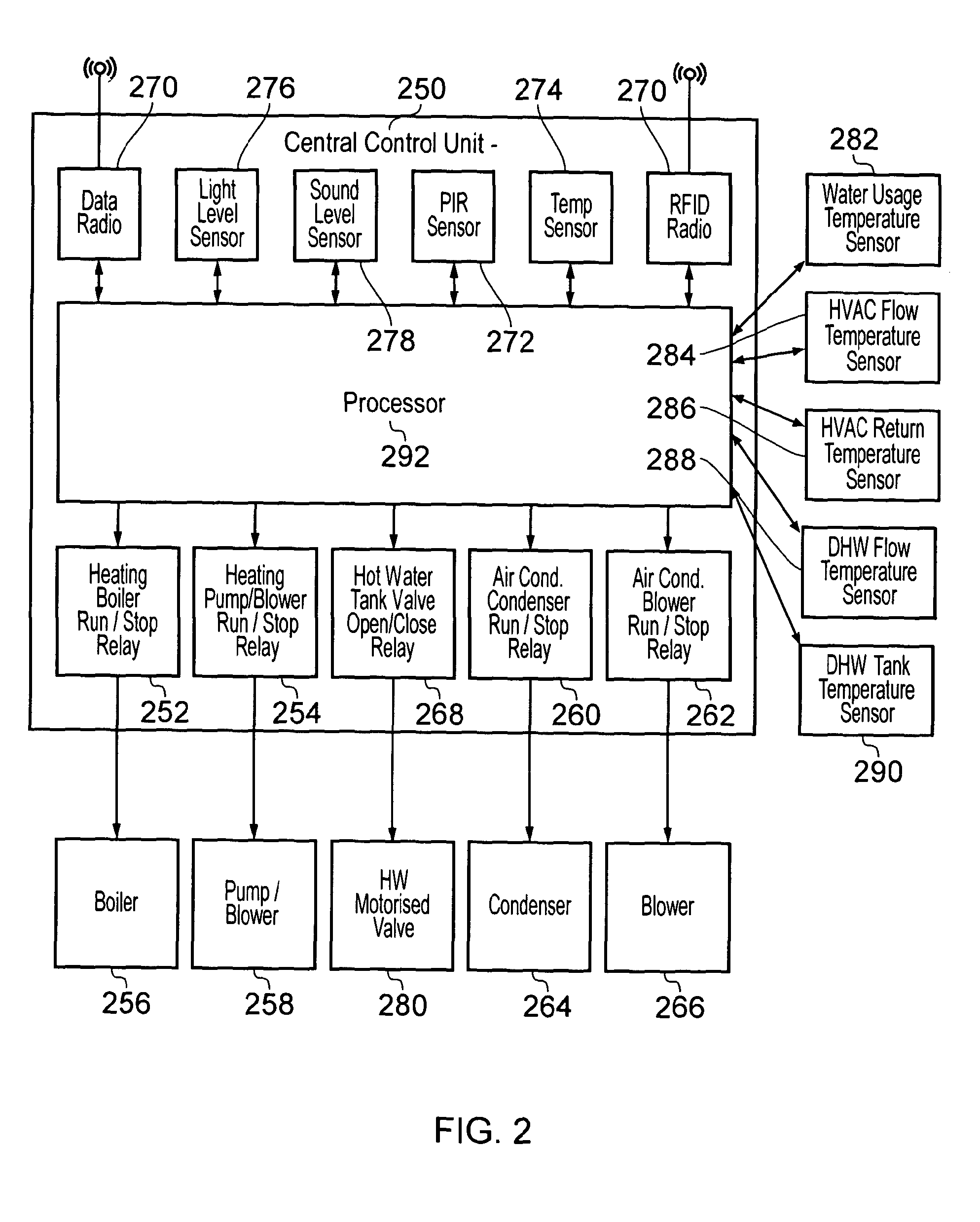

Building occupancy dependent control system

InactiveUS20130073094A1Low production costQuick installationProgramme controlSampled-variable control systemsHuman–machine interfaceControl system

An HVAC control system is described comprising: a server (32) having planned information, a man-machine interface (50) capable of communication with the server (32) to provide dynamic information about building occupancy based on a change in cold water in a mains riser. A central control unit (28) which can communicate with the server (32), and a room node (22, 24) for providing information about conditions within the room whereby, the information about room conditions is compared to planned information and / or dynamic information and adjustments made accordingly. The room node (22, 24) may comprise sensors (276, 278, 272, 274) which provide information about conditions in the room. Dynamic information can include changes to planned occupancy, the effect of solar heating and weather conditions. Changes to planned occupancy can be established through detecting location (internally or externally) or destination of a user; and calculating estimated time of arrival of a user.

Owner:TELEPURE

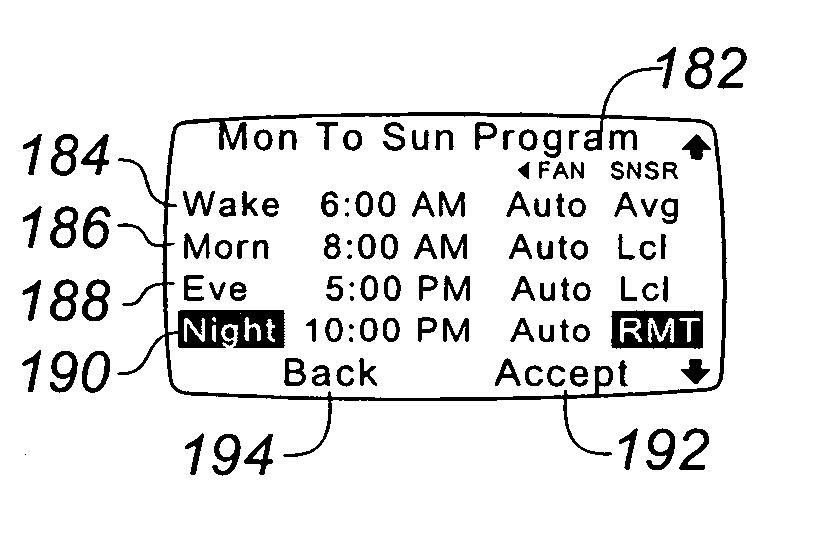

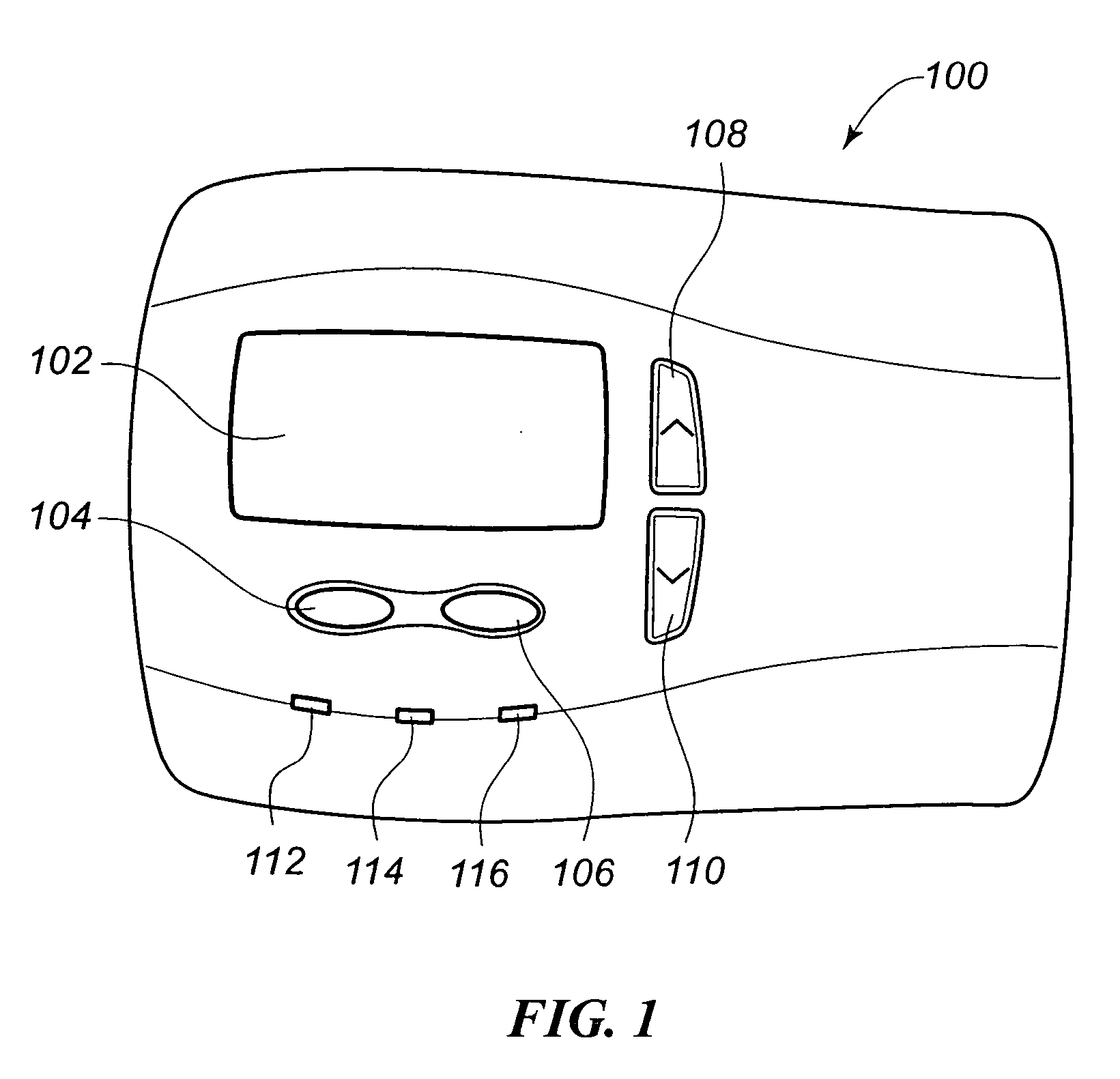

Time of day zoning climate control system and method

InactiveUS20070045429A1Easy to superviseImprove overall occupant comfortTemperature control without auxillary powerMechanical apparatusControl systemMultiple sensor

A time of day zoning control system for a heating, ventilating, and air conditioning system is provided. The system utilizes a programmable thermostat and a number of temperature sensors to control the HVAC system to regulate the temperature in a particular location within a dwelling or structure based on consumer preferences. The regulation control will utilize a temperature sensed by a particular temperature sensor at different times throughout the day to control the temperature in that zone to ensure occupant comfort. A single temperature sensor may be selected to control the HVAC system during these different periods, or multiple sensors may be utilized during the same period. When multiple sensors are used, a weighting factor may be used.

Owner:RANCO OF DELAWARE

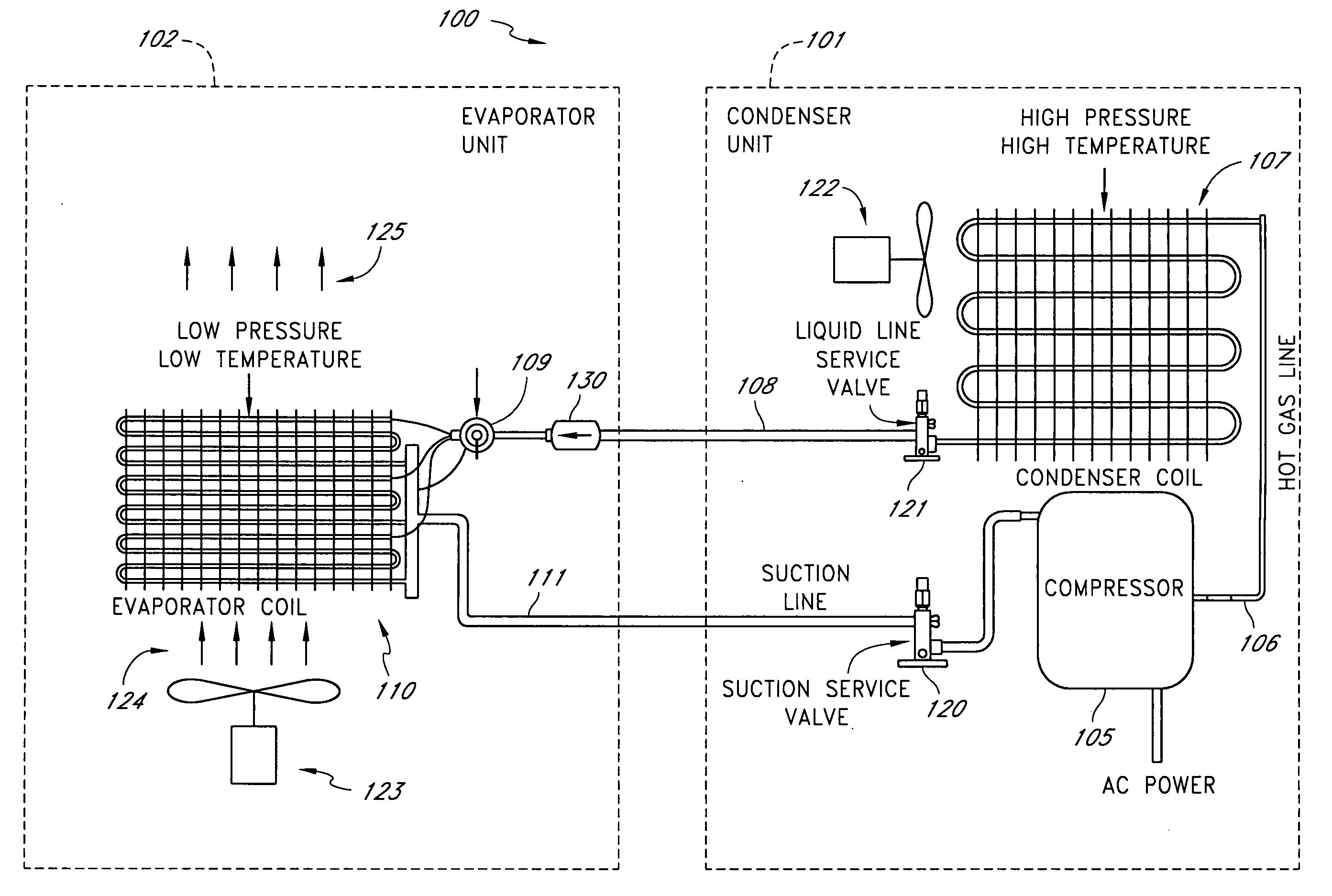

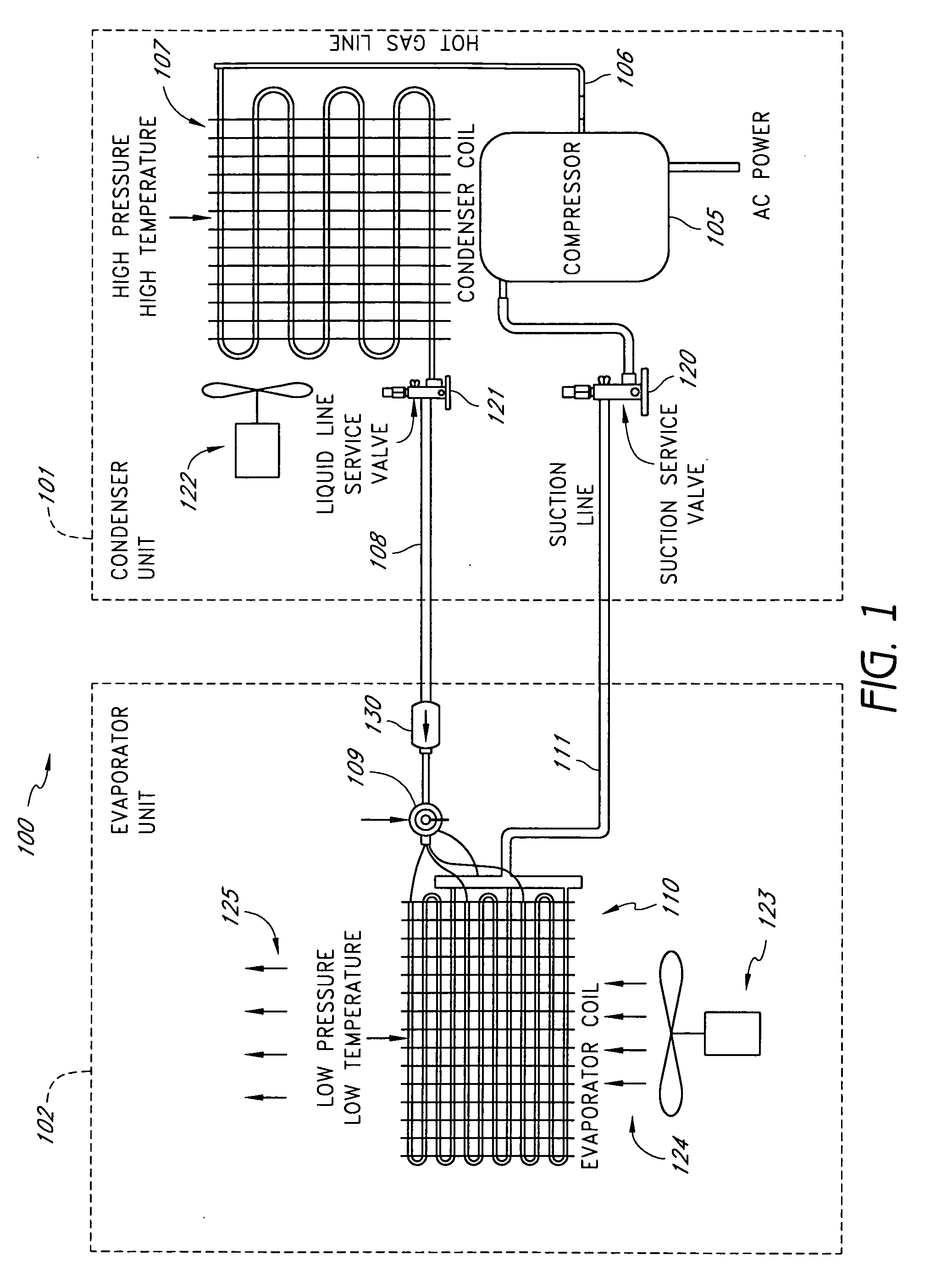

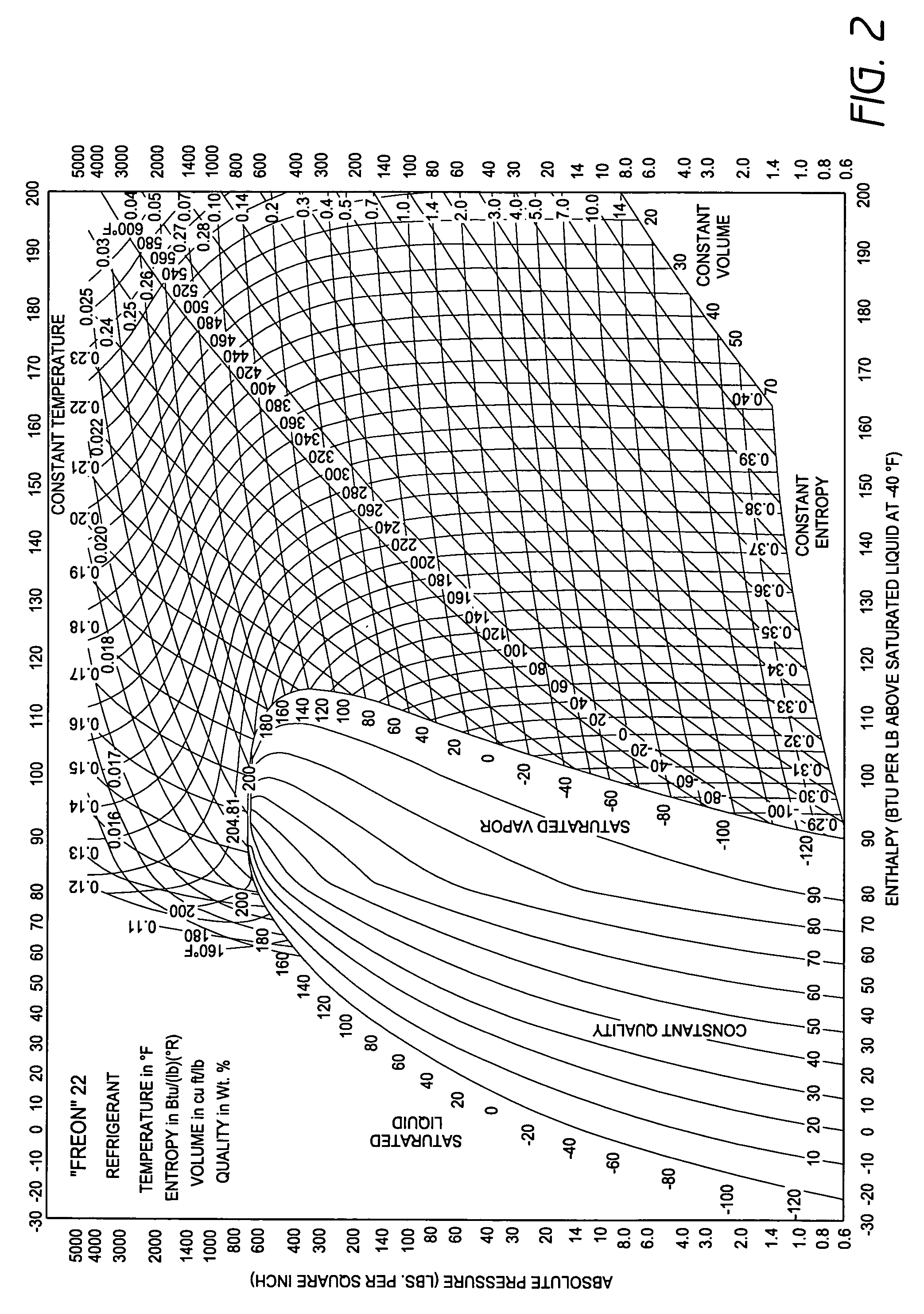

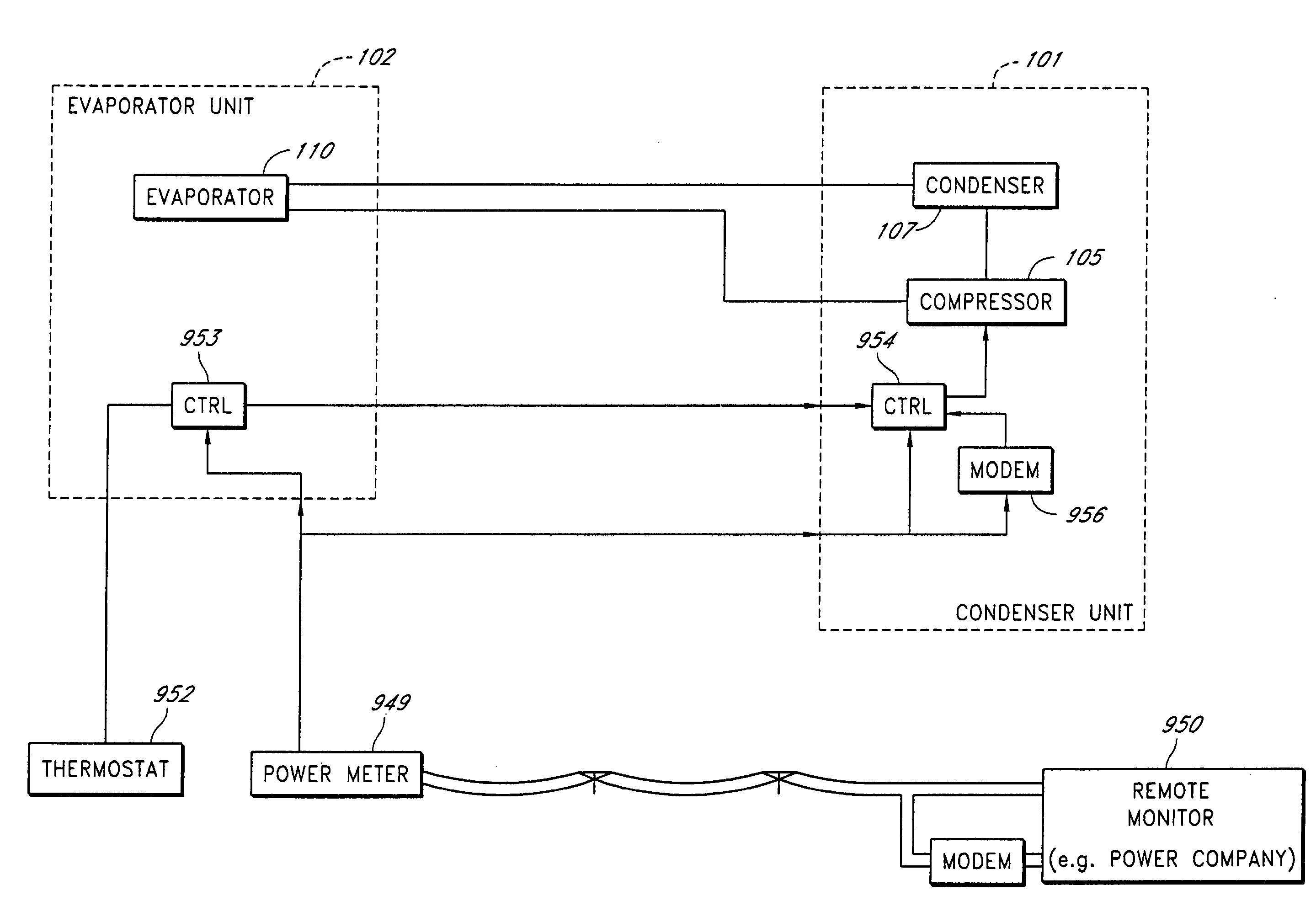

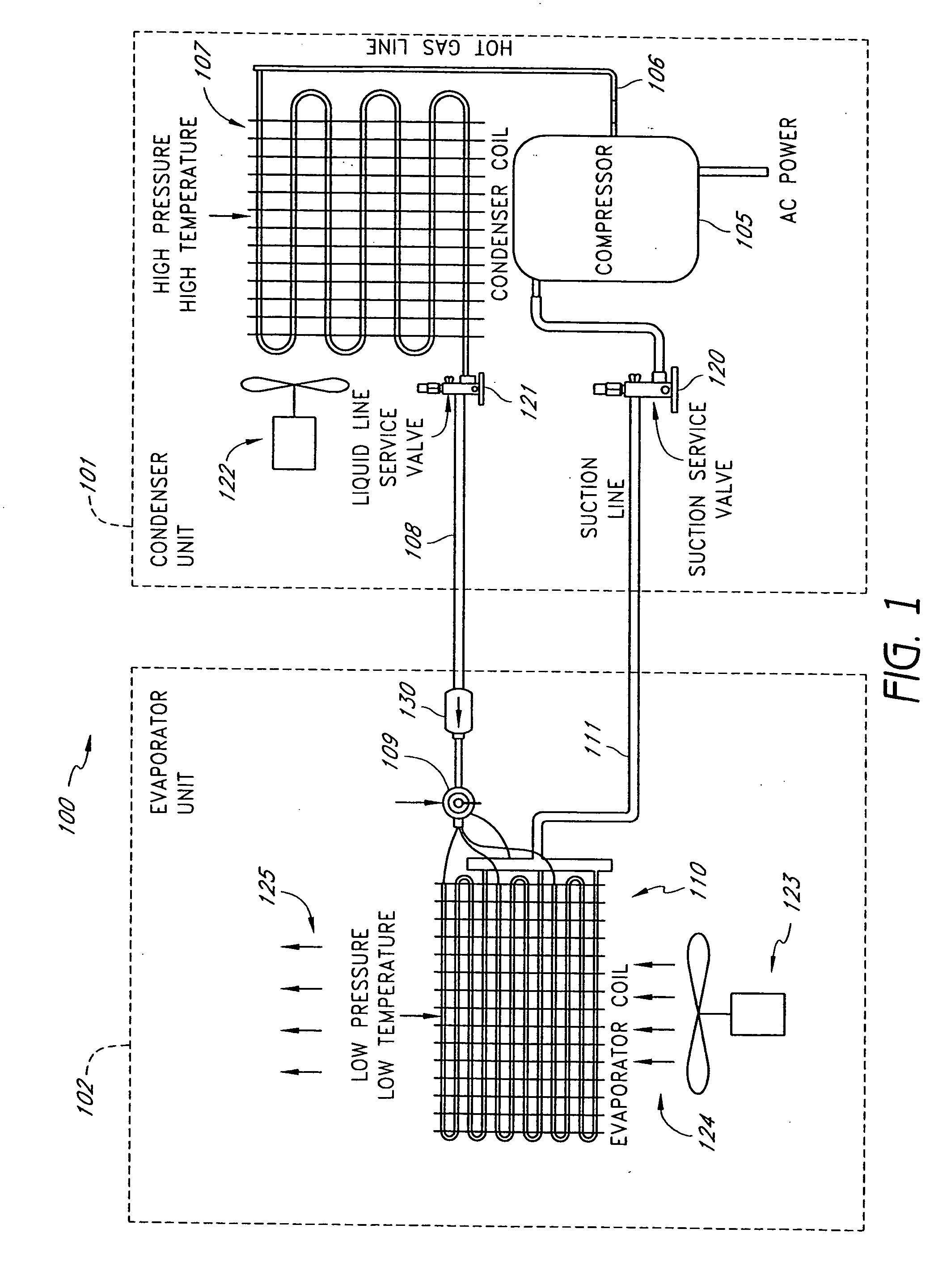

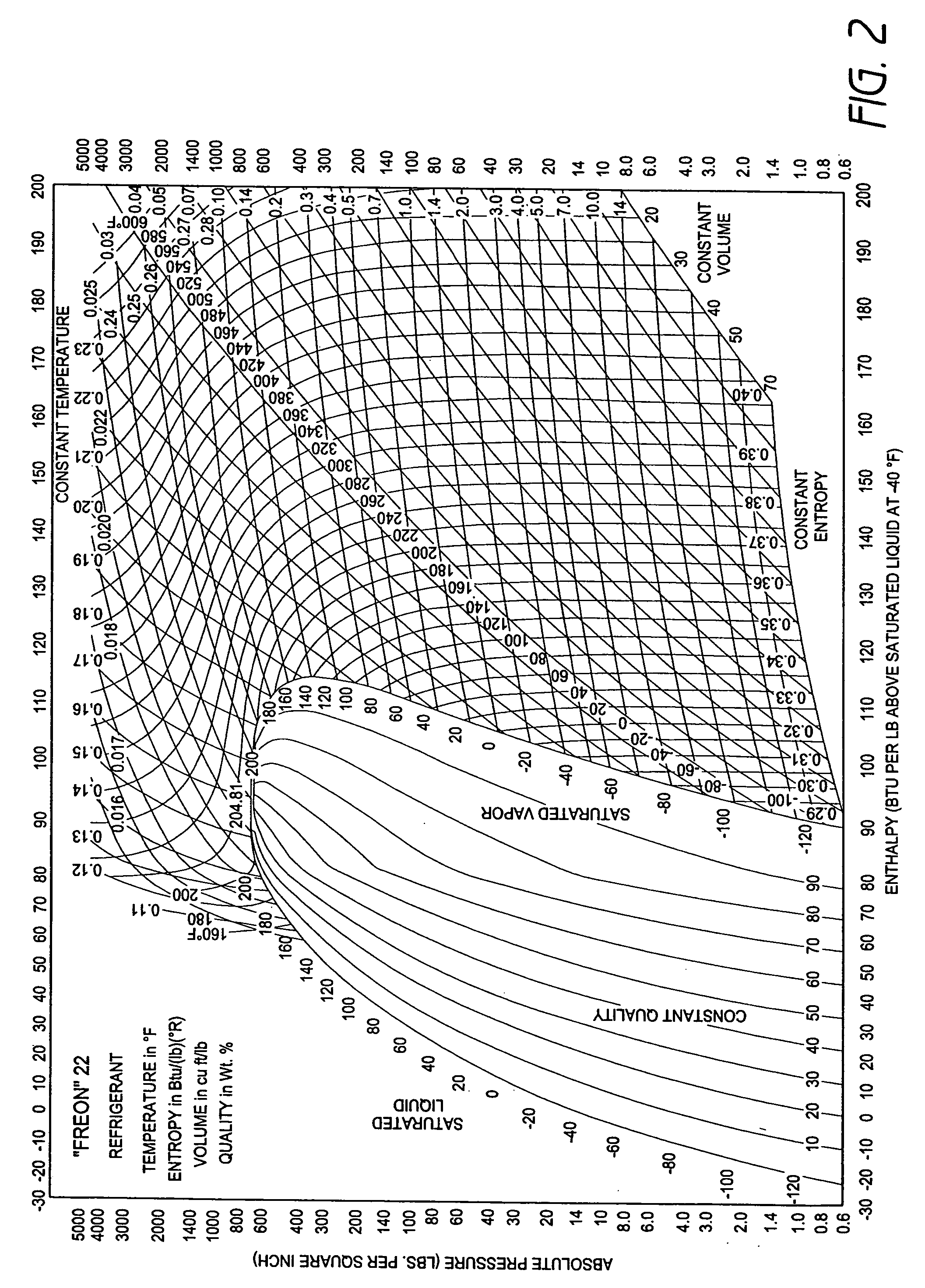

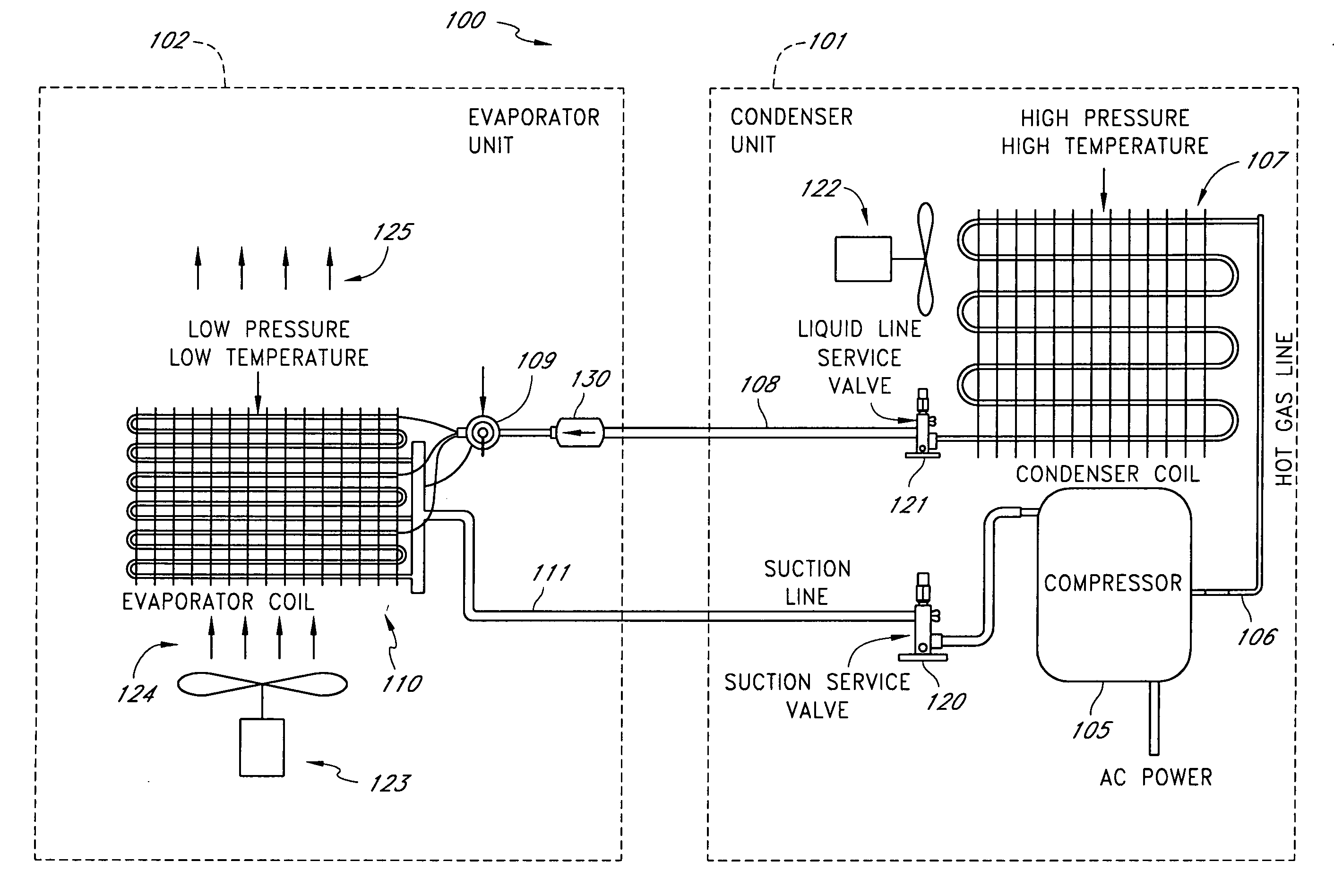

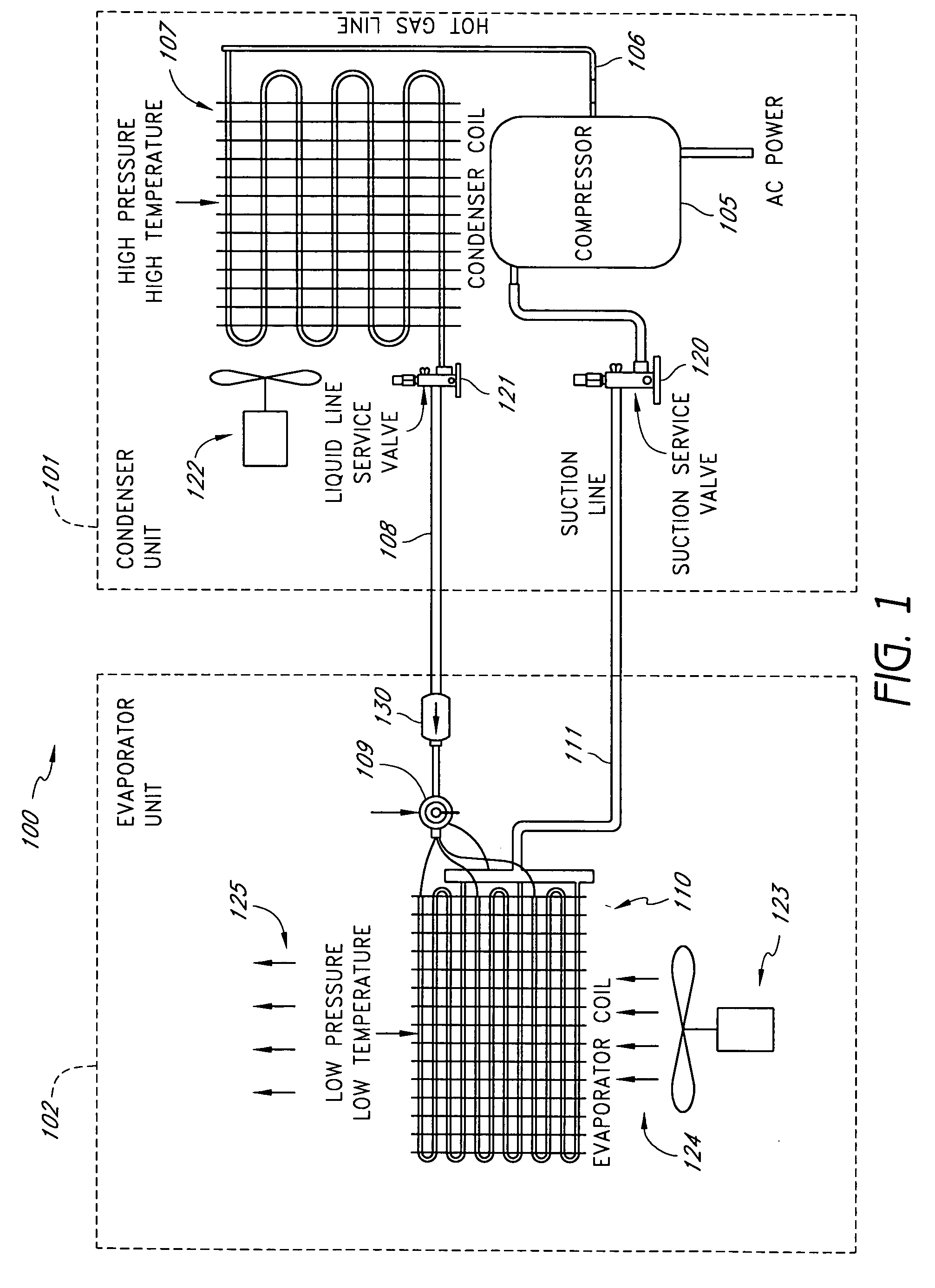

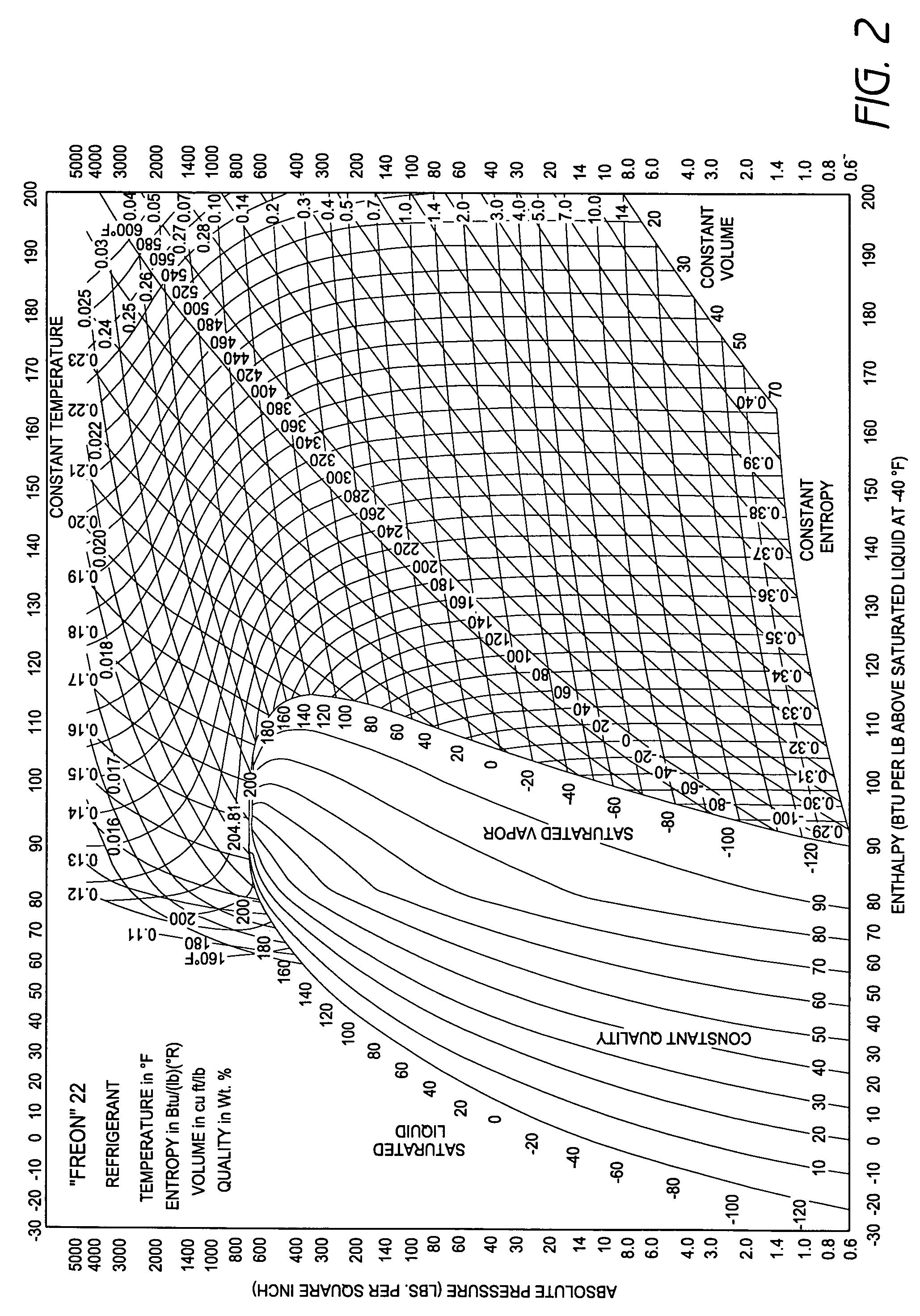

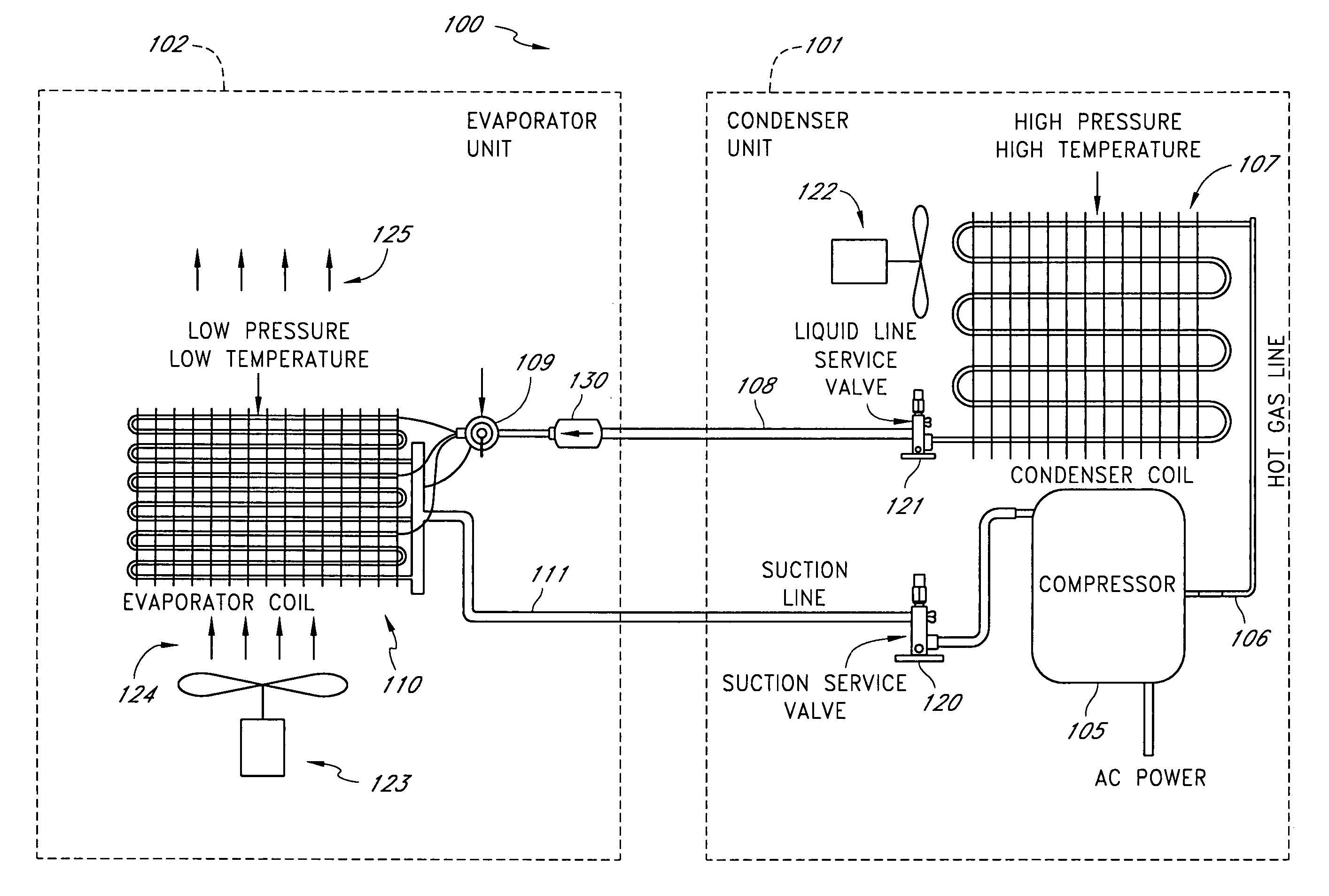

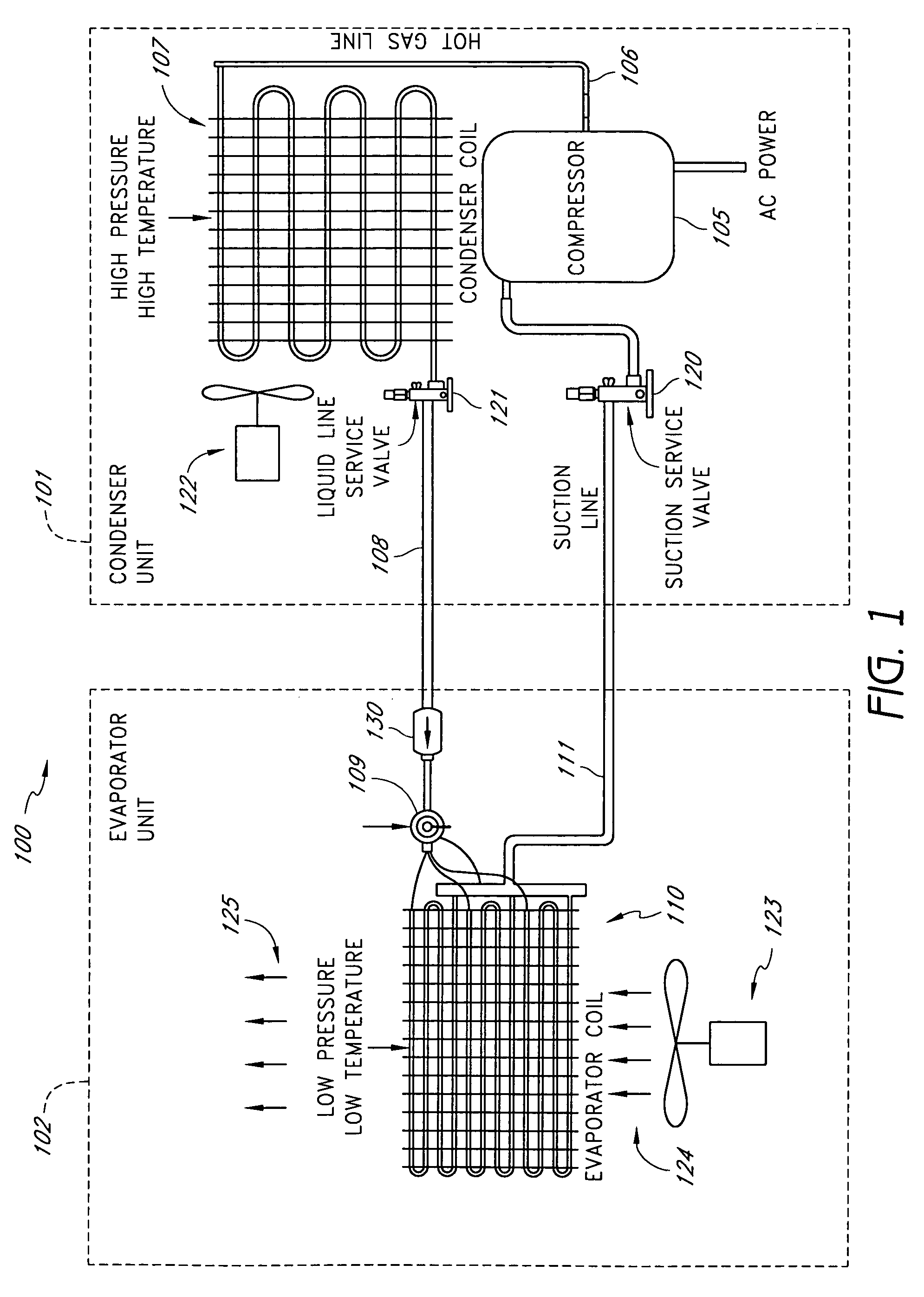

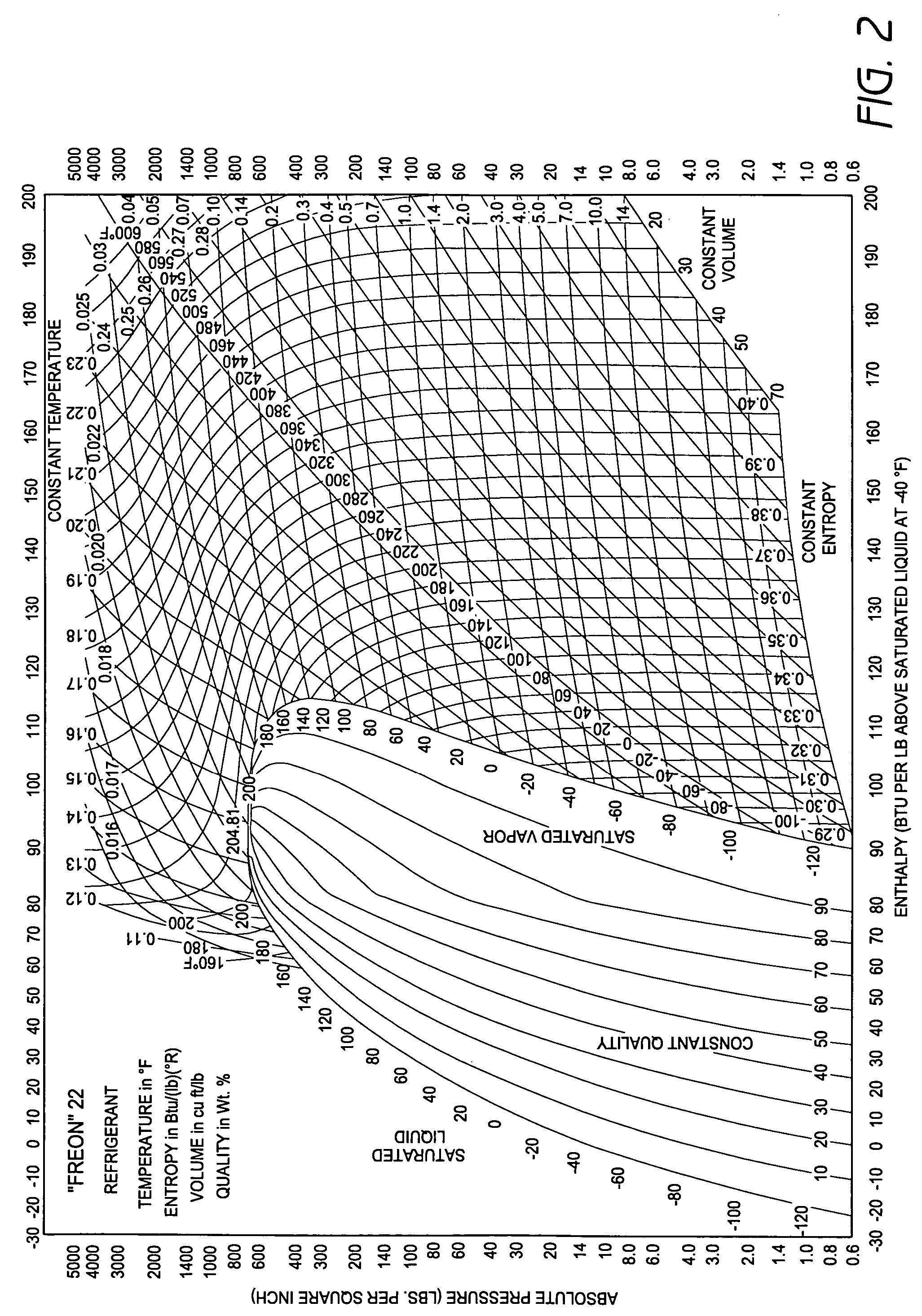

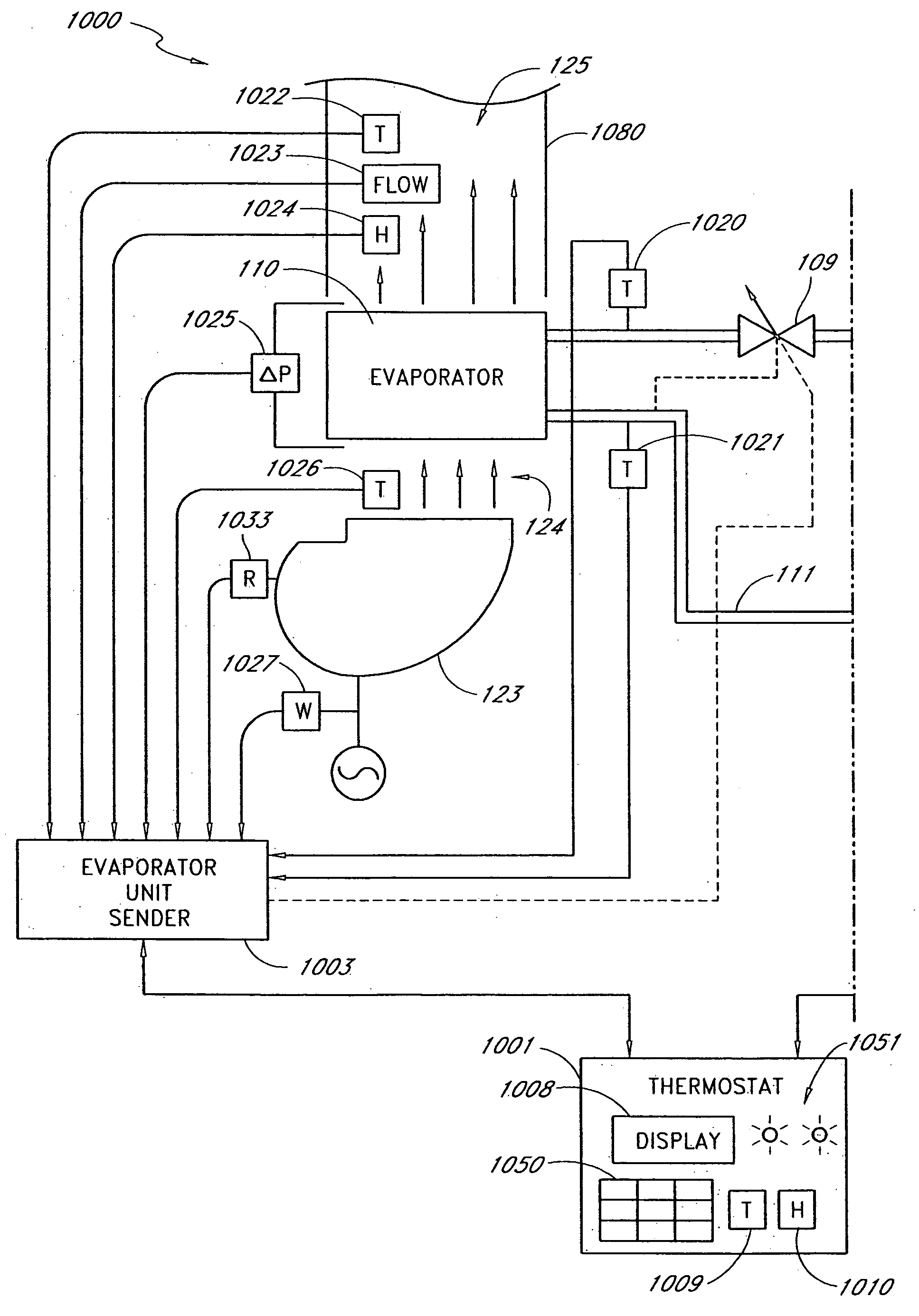

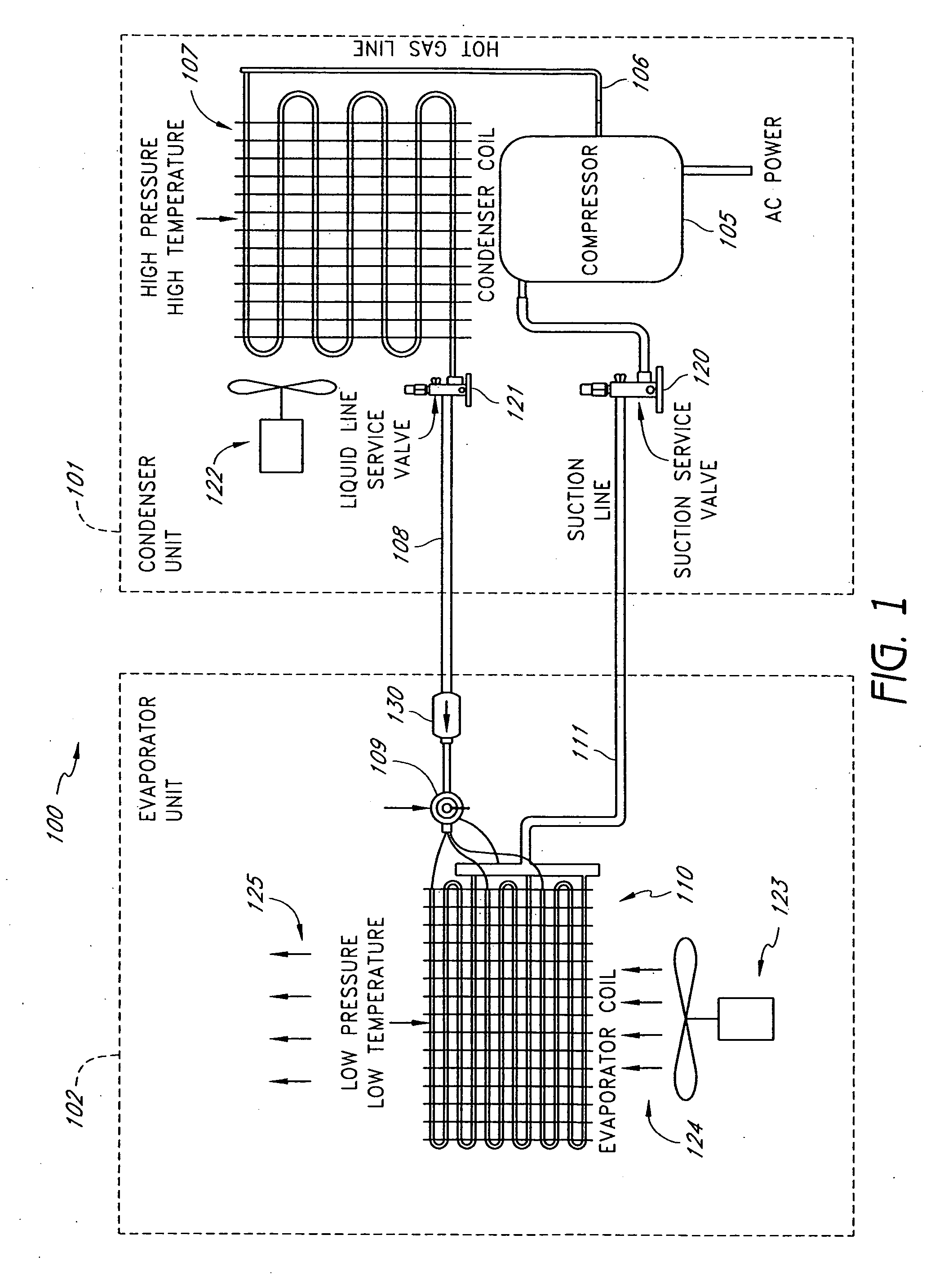

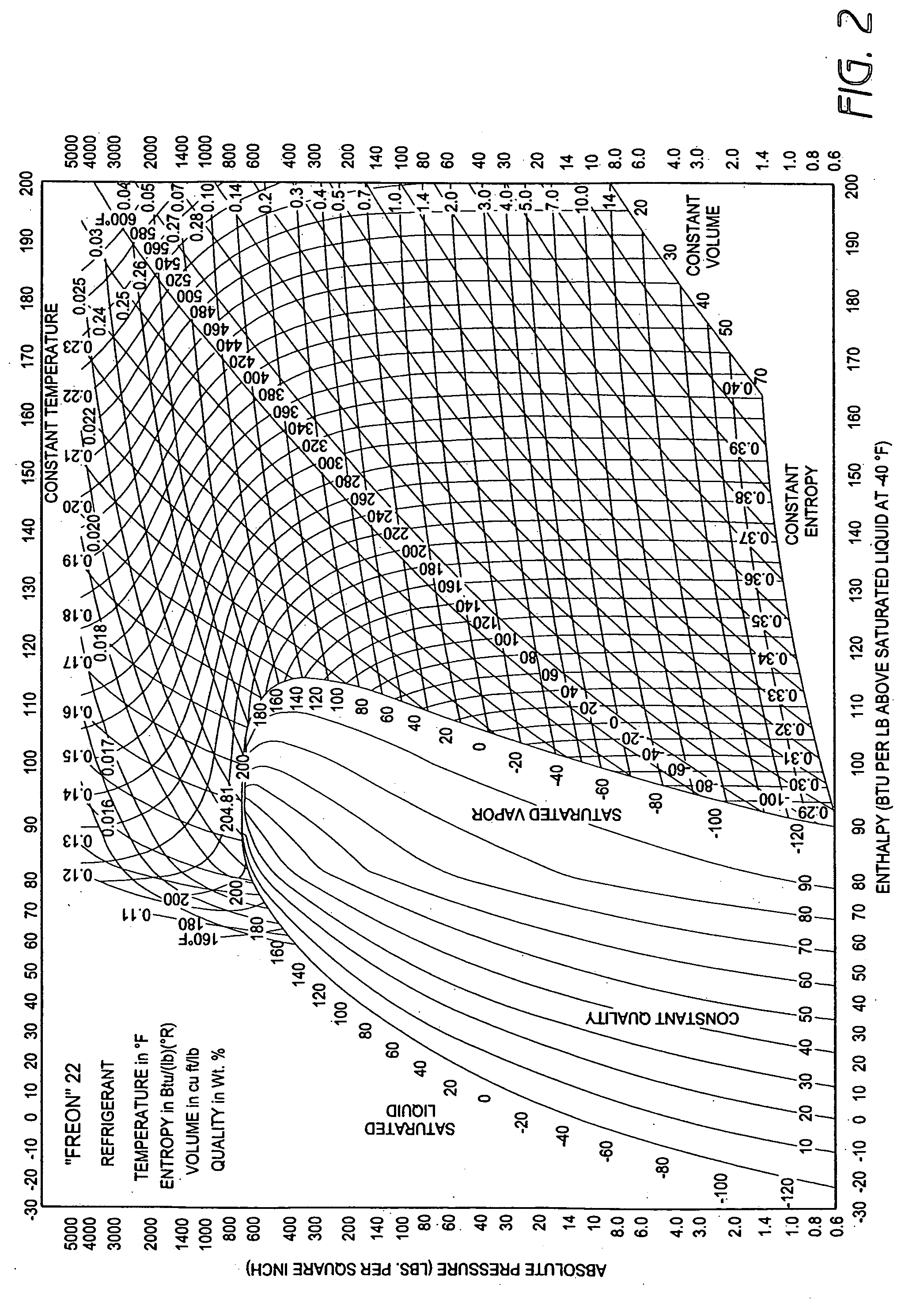

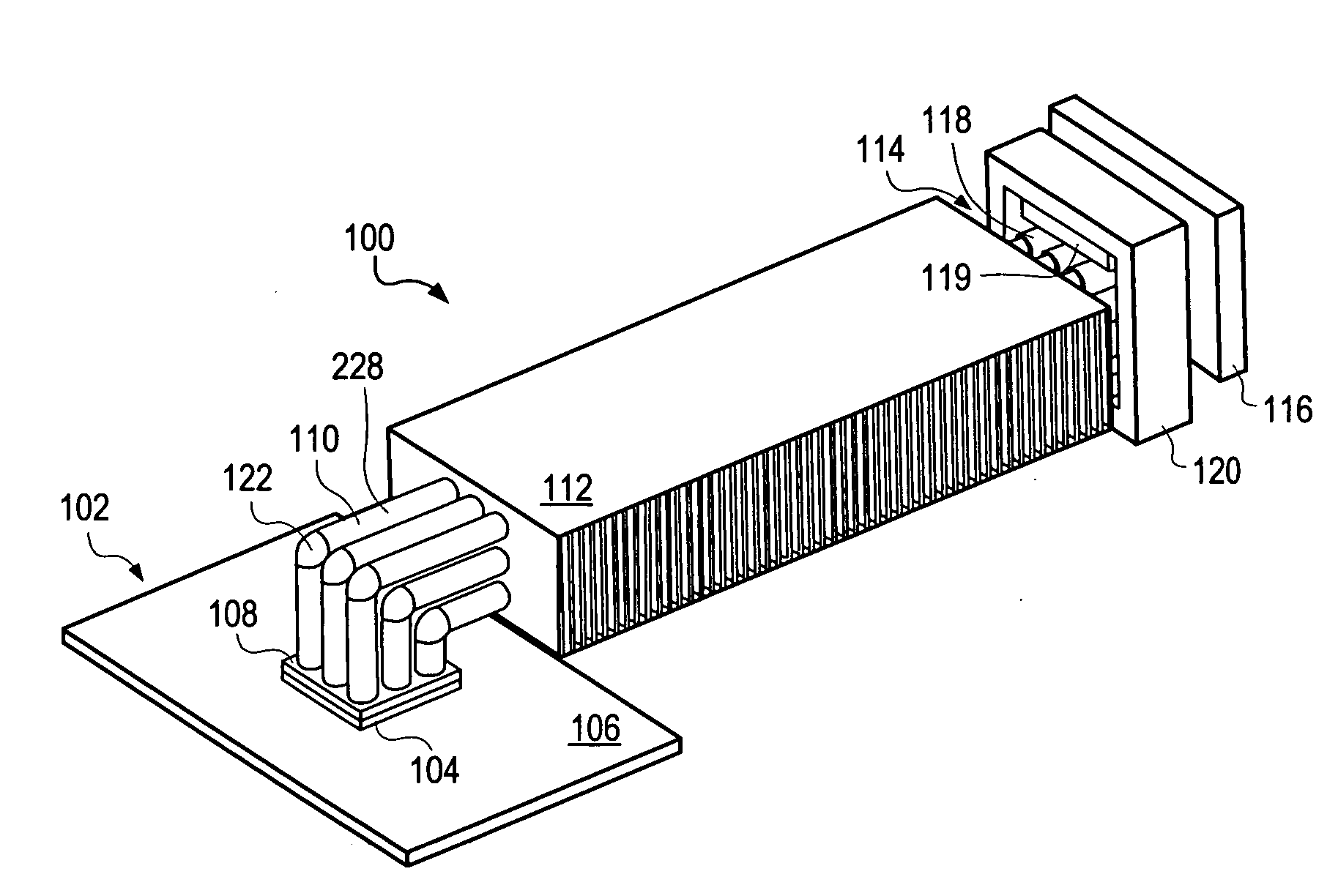

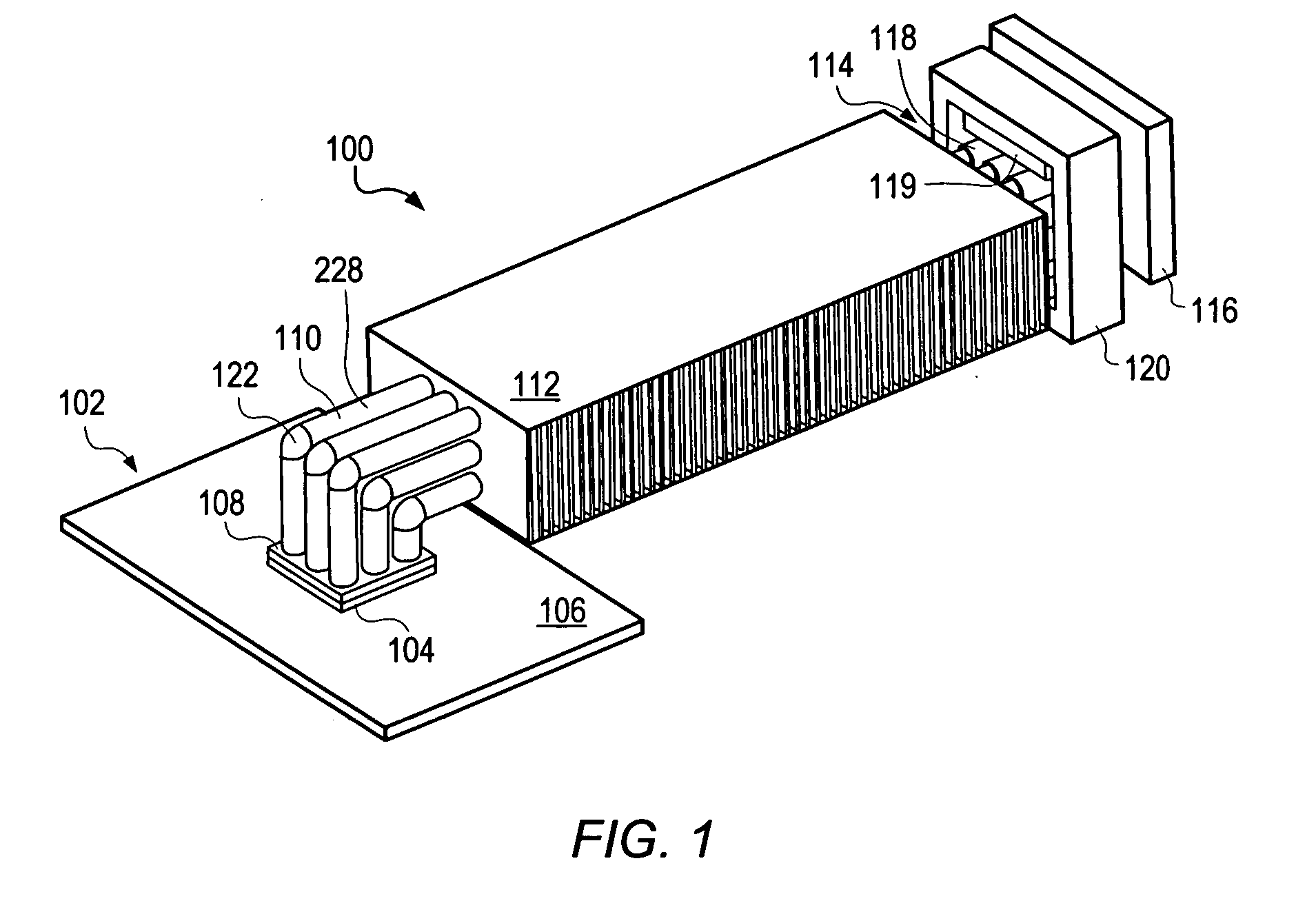

Method and apparatus for monitoring refrigerant-cycle systems

ActiveUS20060032245A1Mechanical apparatusTemperature measurement in air-conditioning systemsDifferential pressureEngineering

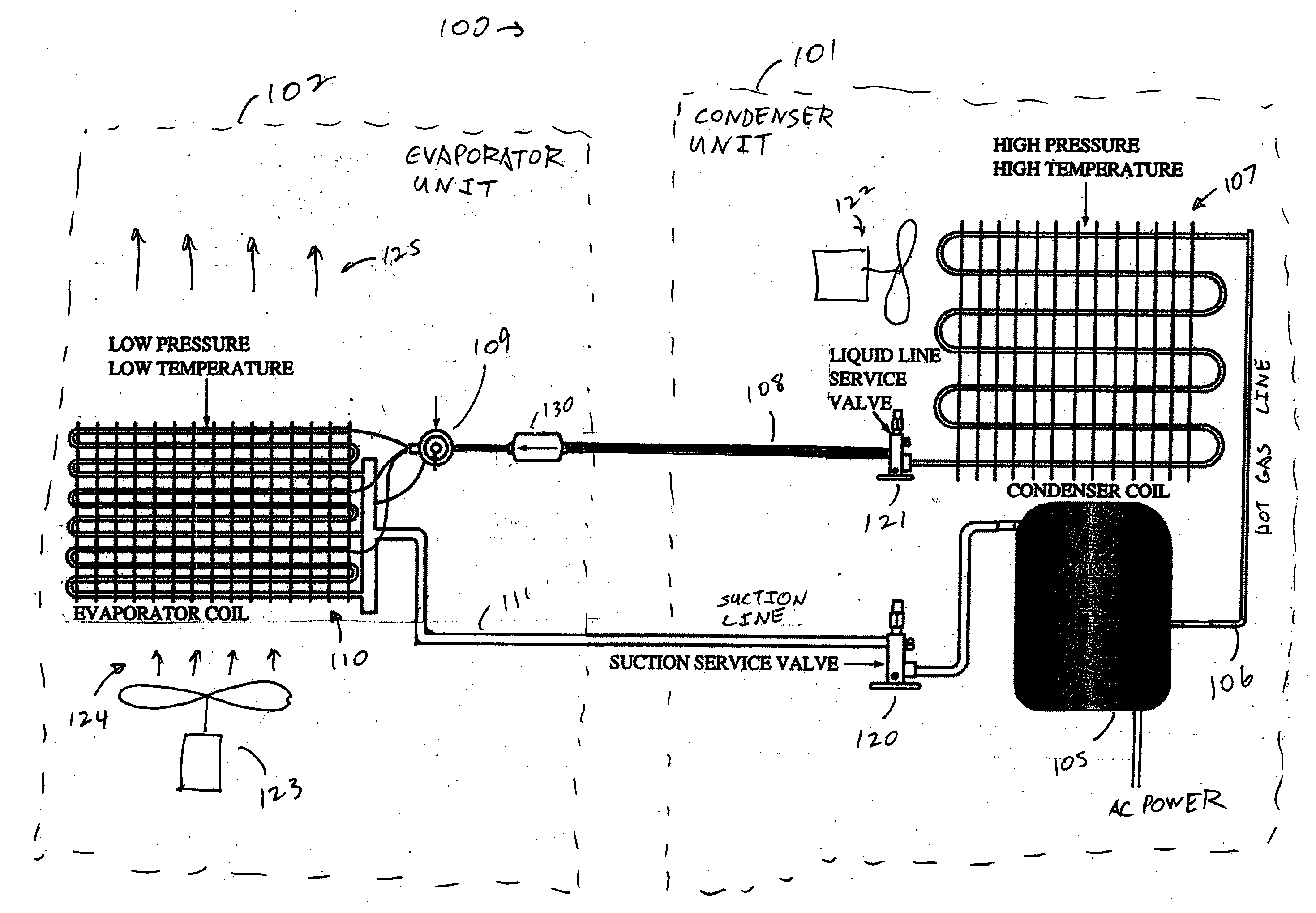

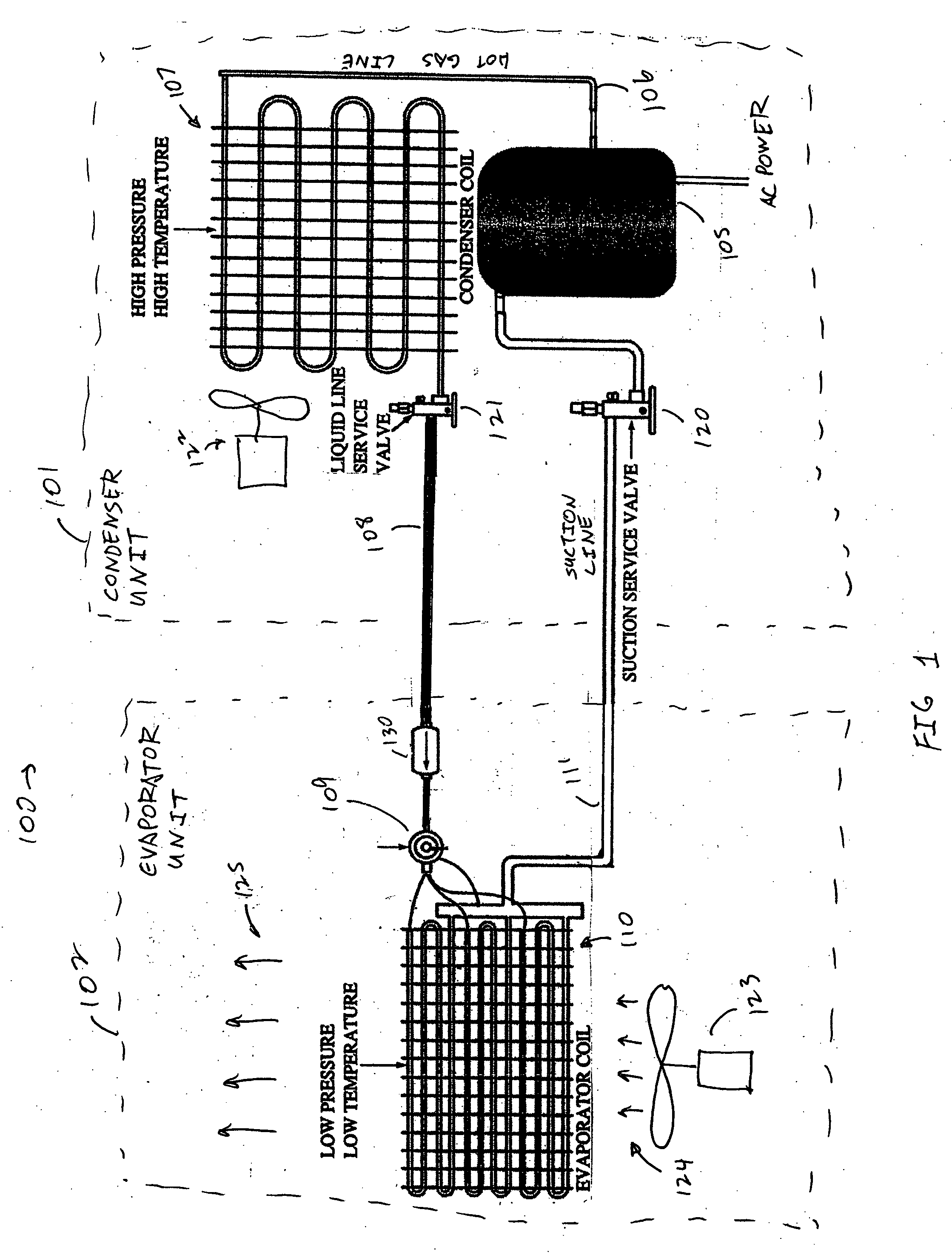

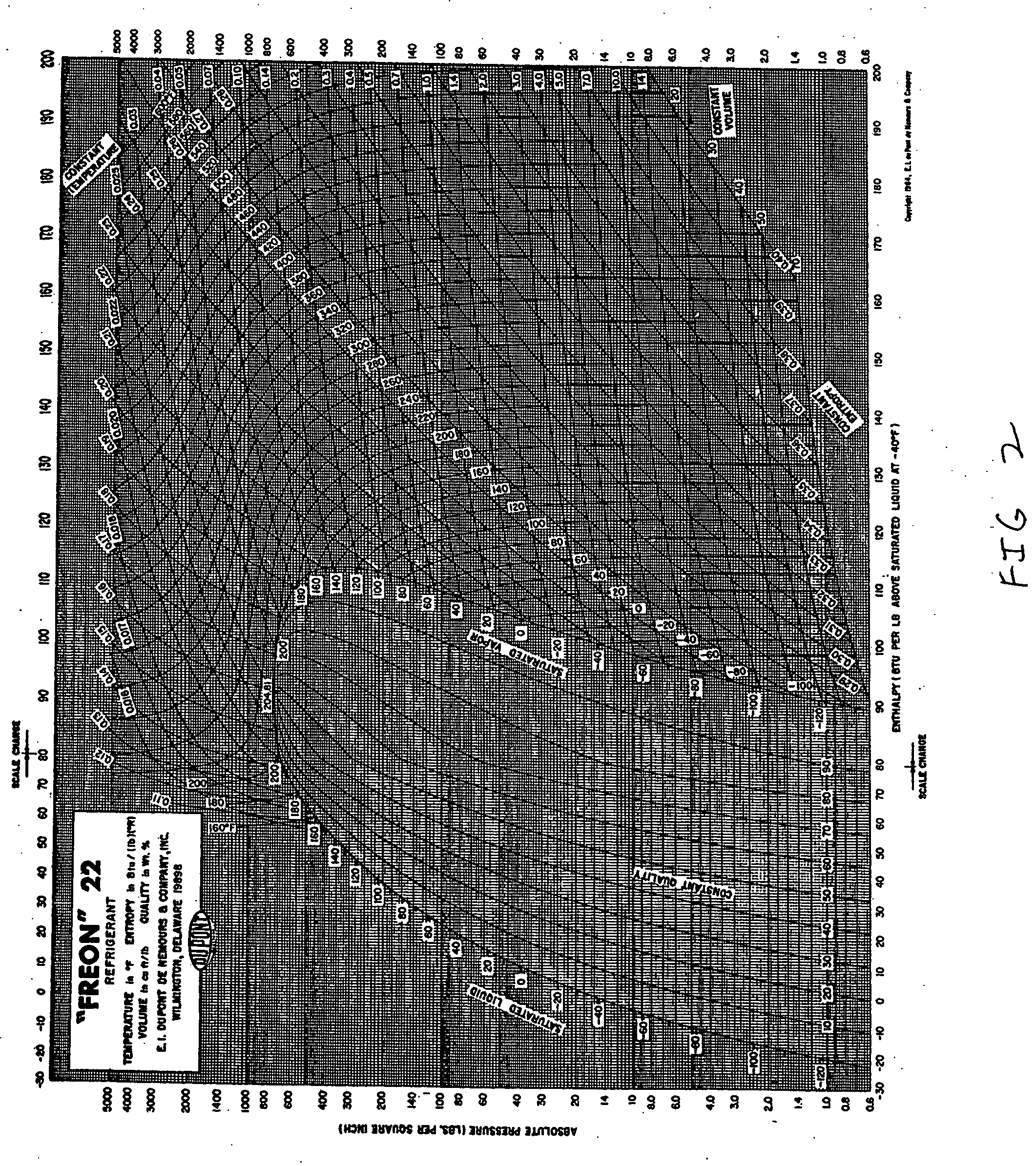

A real-time monitoring system that monitors various aspects of the operation of a refrigerant-cycle system is described. In one embodiment, the system includes a processor that measures power provided to the refrigerant-cycle system and that gathers data from one or more sensors and uses the sensor data to calculate a figure of merit related to the efficiency of the system. In one embodiment, the sensors include one or more of the following sensors: a suction line temperature sensor, a suction line pressure sensor, a suction line flow sensor, a hot gas line temperature sensor, a hot gas line pressure sensor, a hot gas line flow sensor, a liquid line temperature sensor, a liquid line pressure sensor, a liquid line flow sensor. In one embodiment, the sensors include one or more of an evaporator air temperature input sensor, an evaporator air temperature output sensor, an evaporator air flow sensor, an evaporator air humidity sensor, and a differential pressure sensor. In one embodiment, the sensors include one or more of a condenser air temperature input sensor, a condenser air temperature output sensor, and a condenser air flow sensor, an evaporator air humidity sensor. In one embodiment, the sensors include one or more of an ambient air sensor and an ambient humidity sensor.

Owner:COPELAND LP

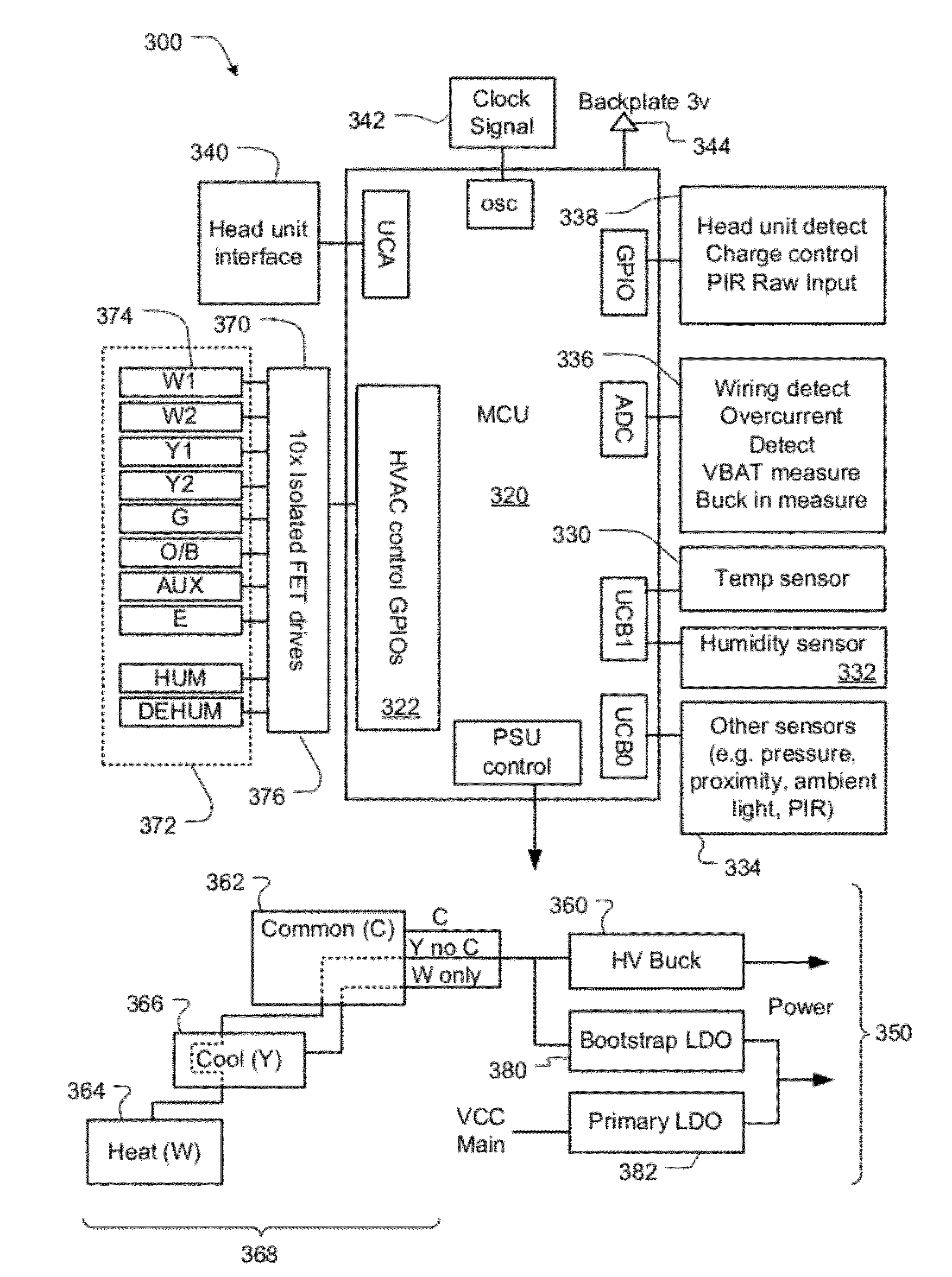

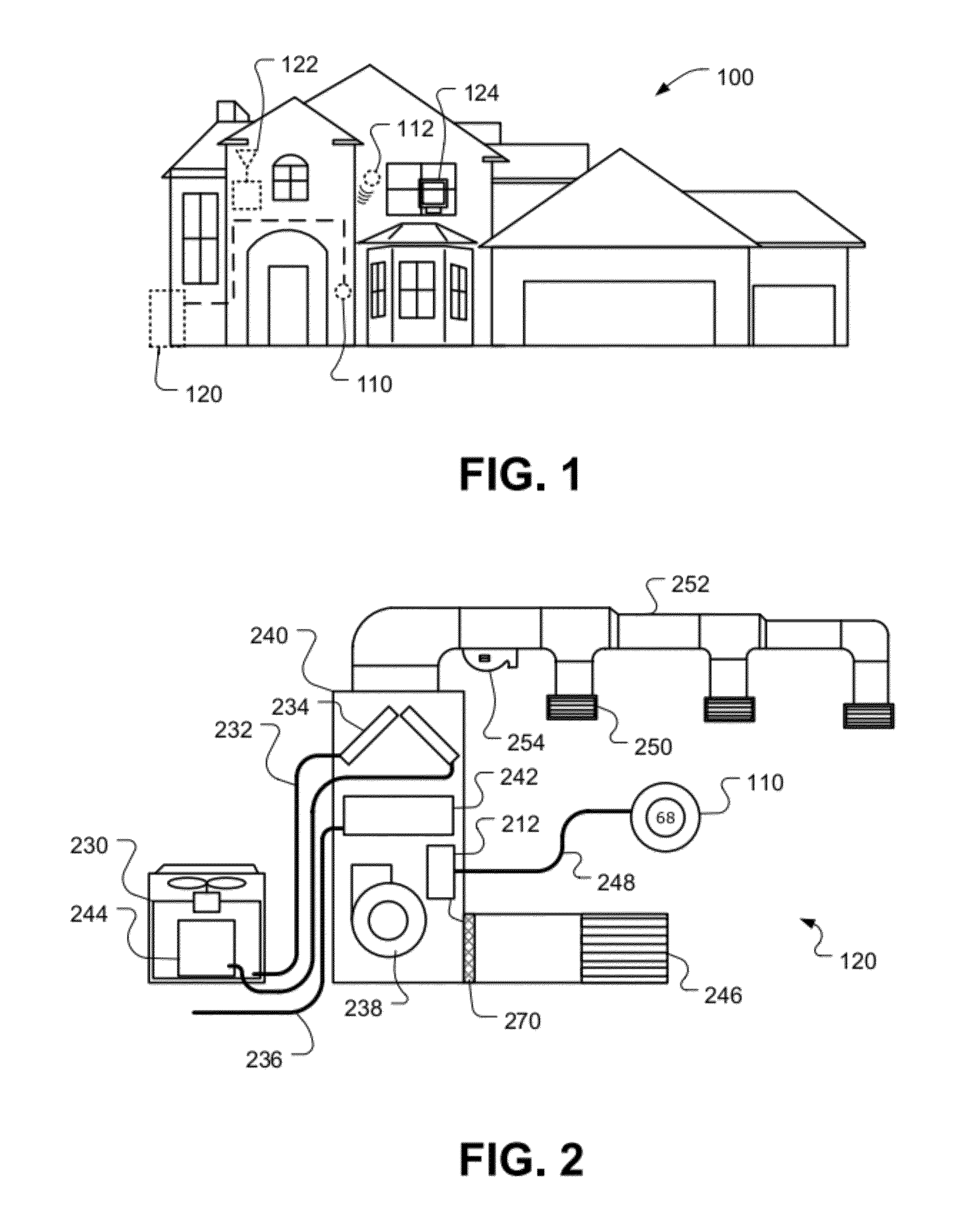

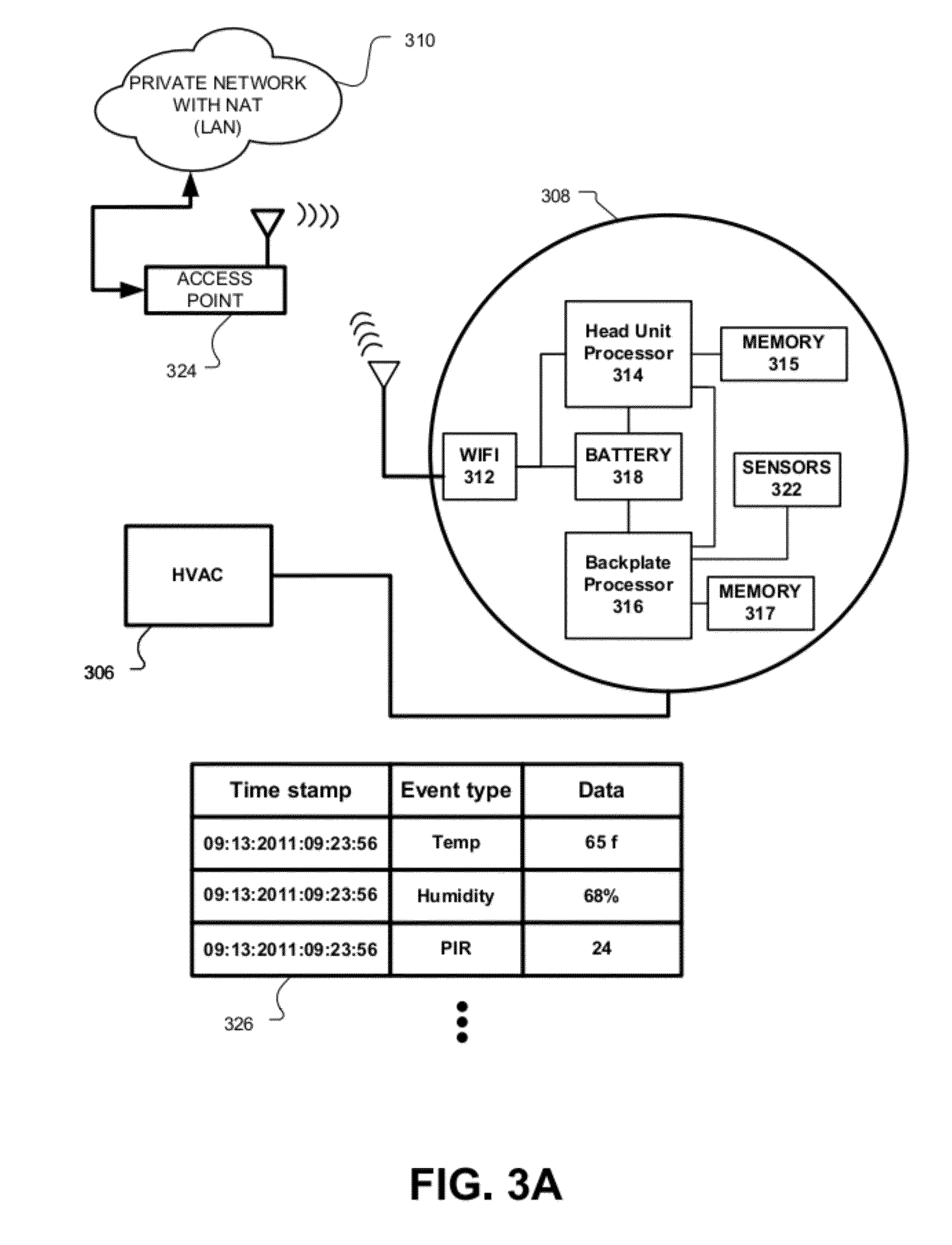

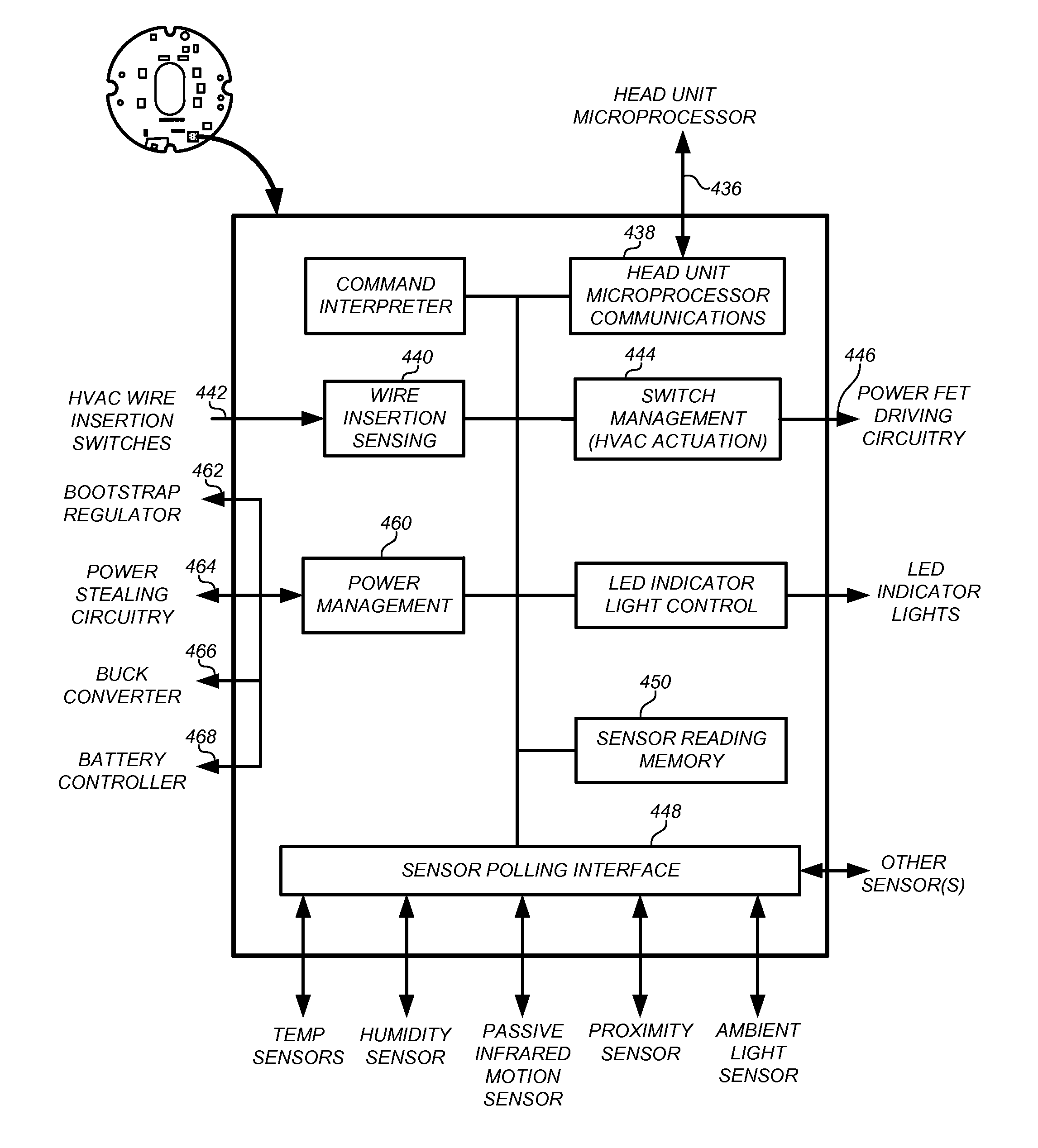

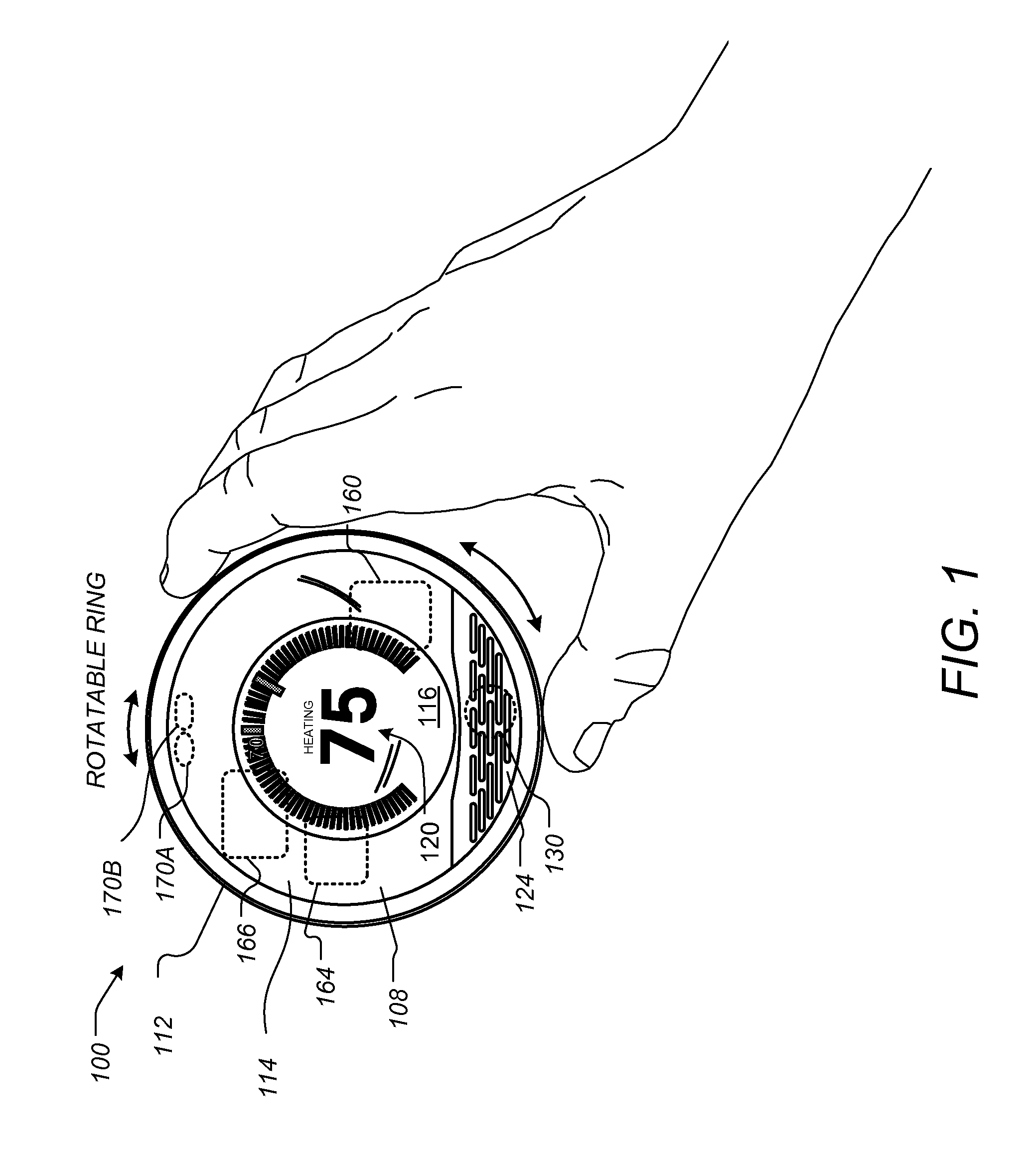

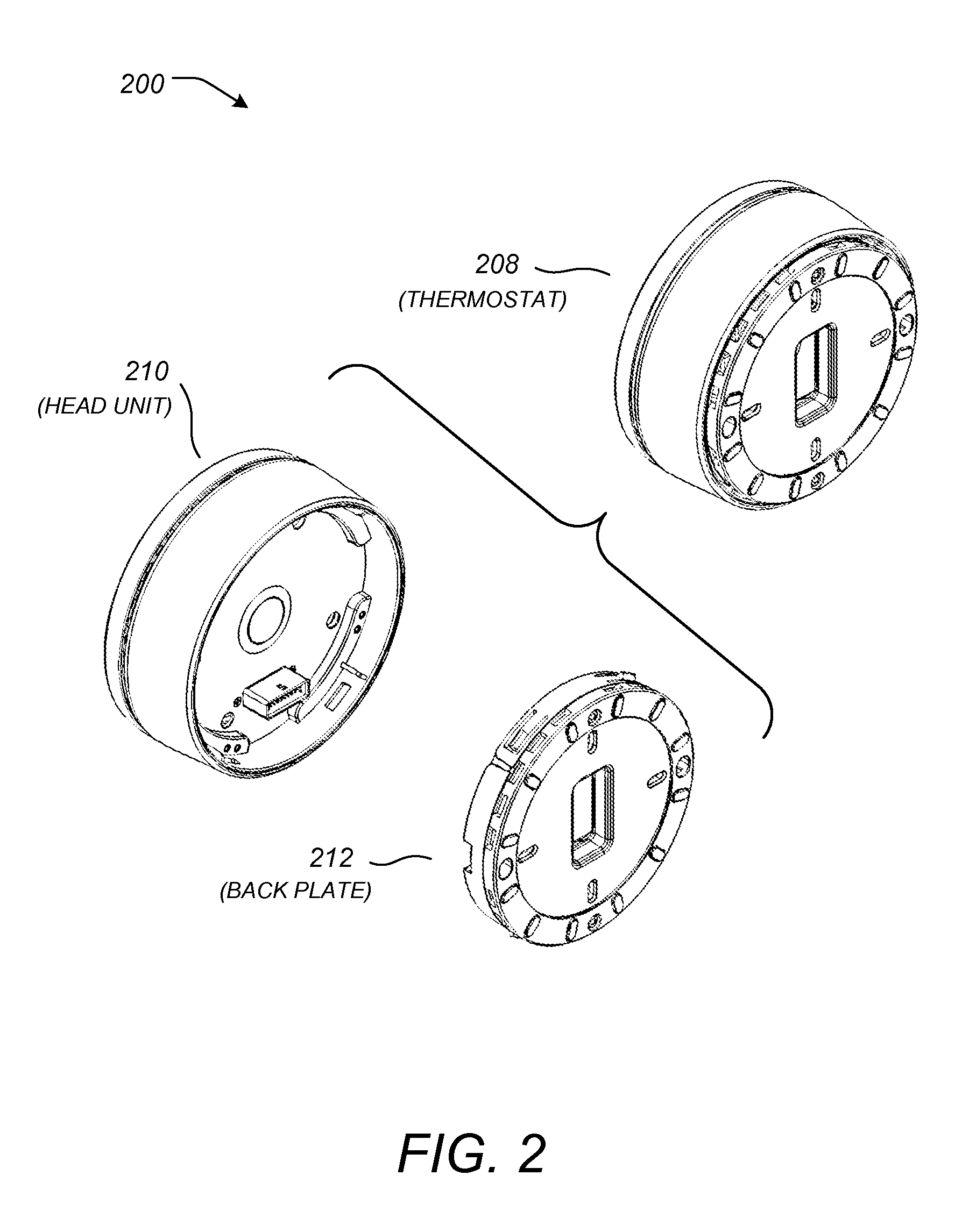

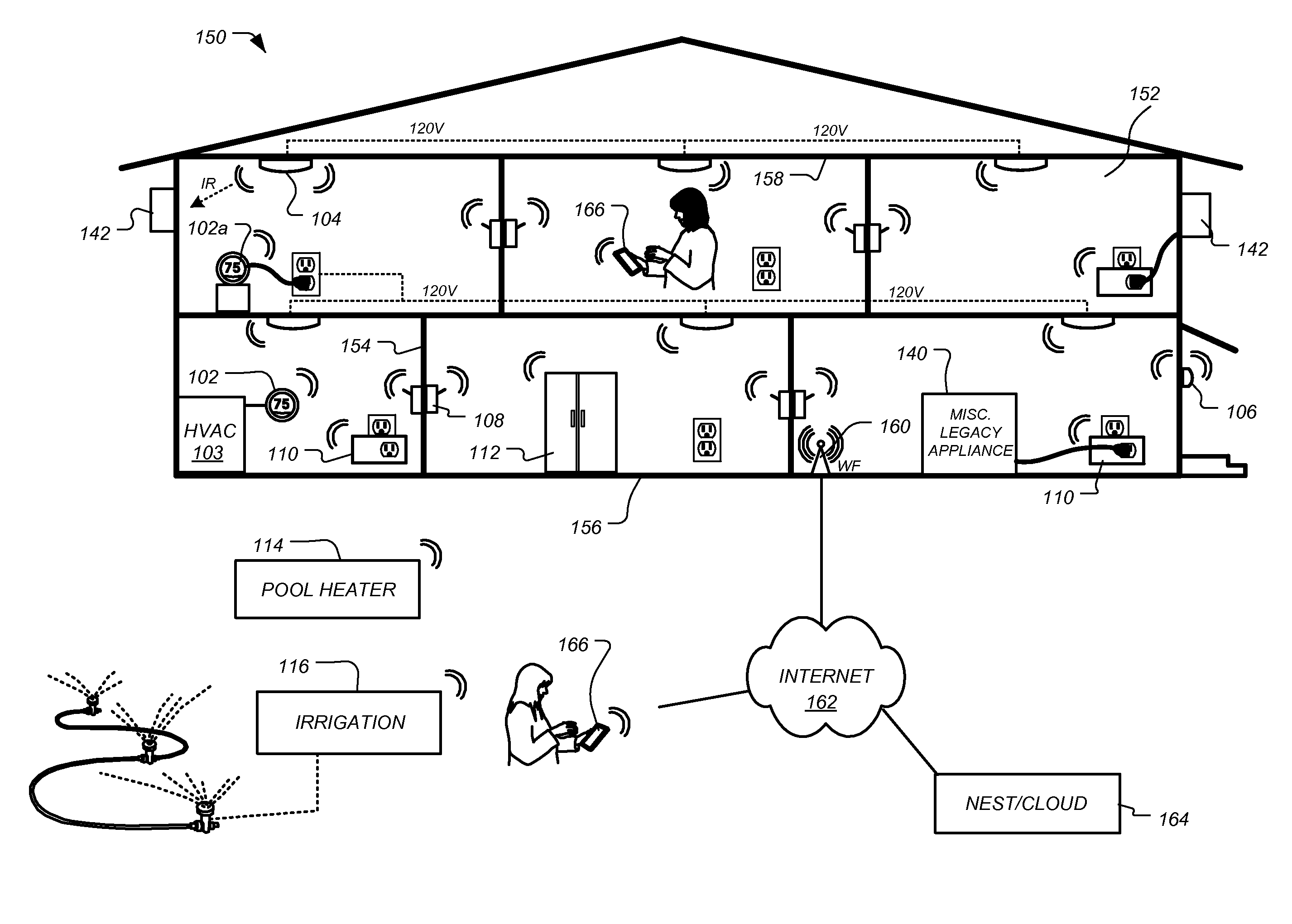

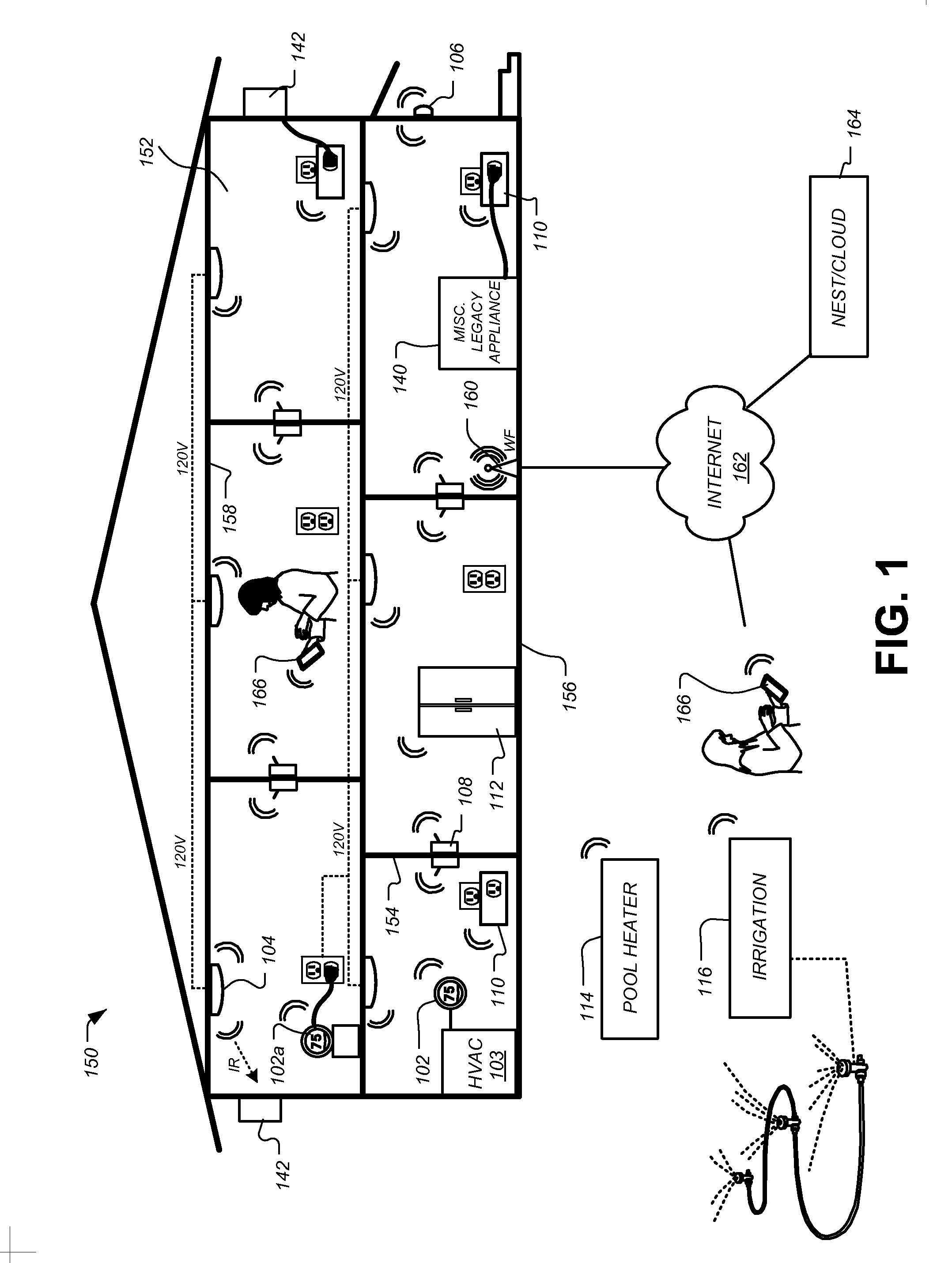

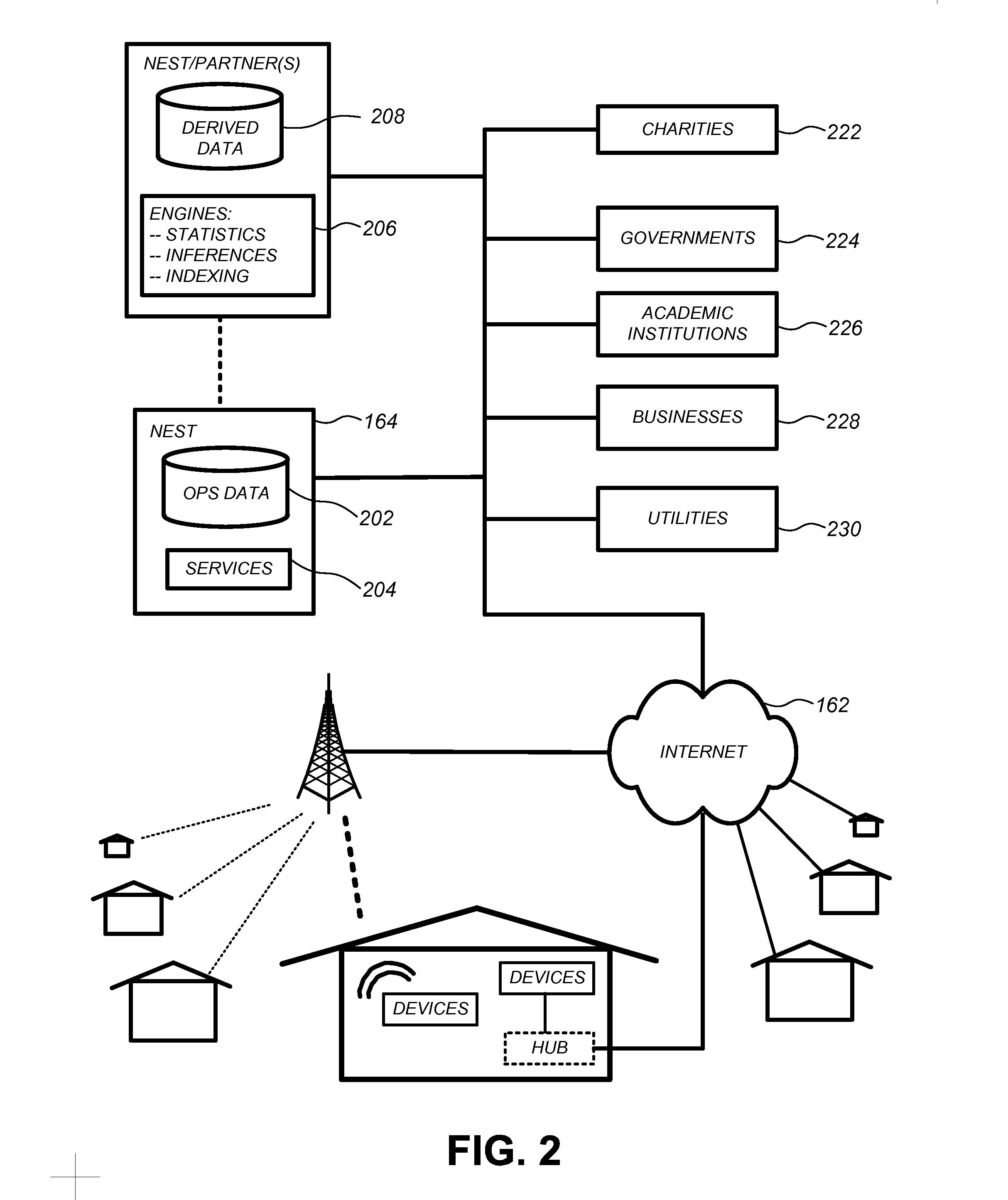

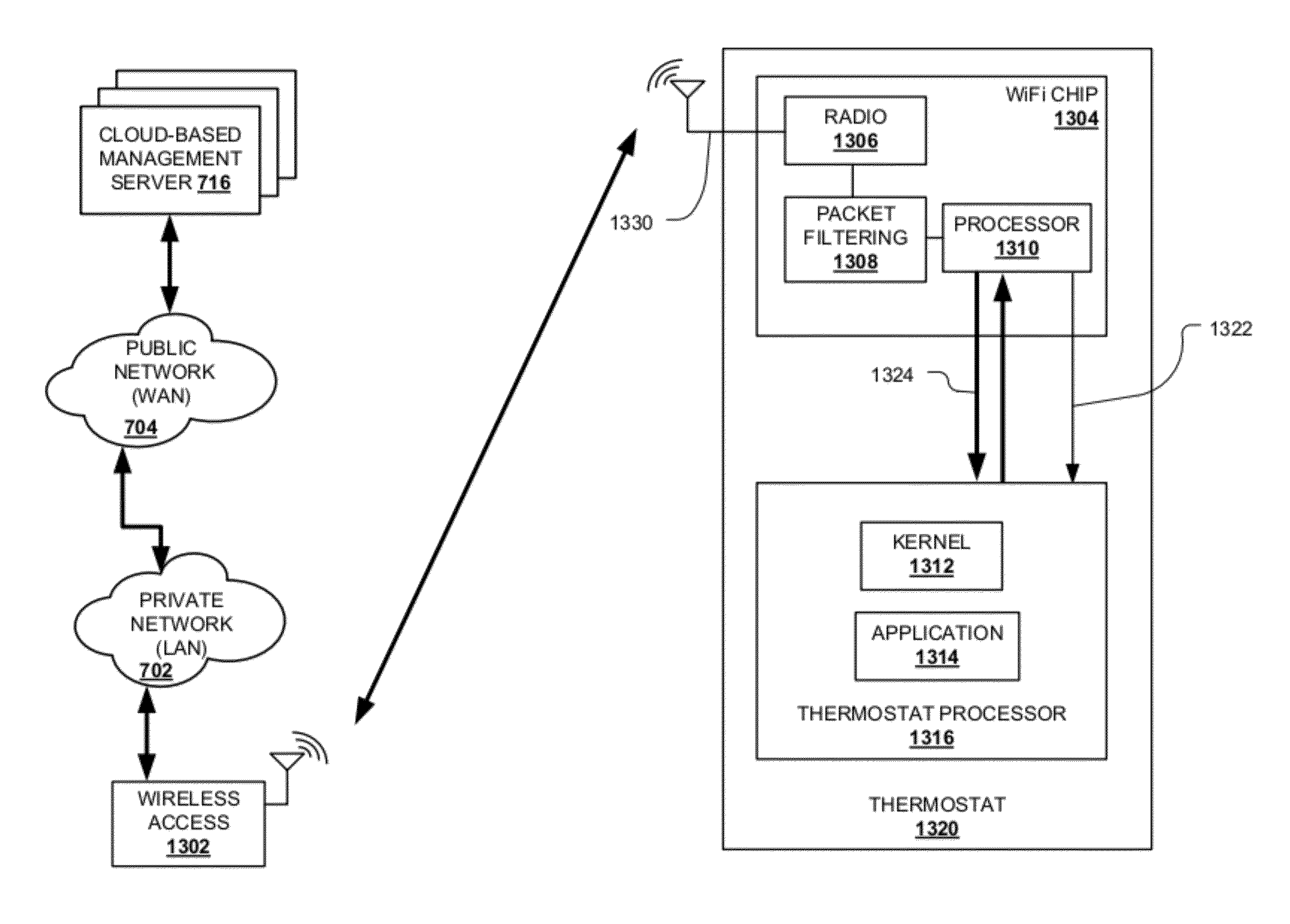

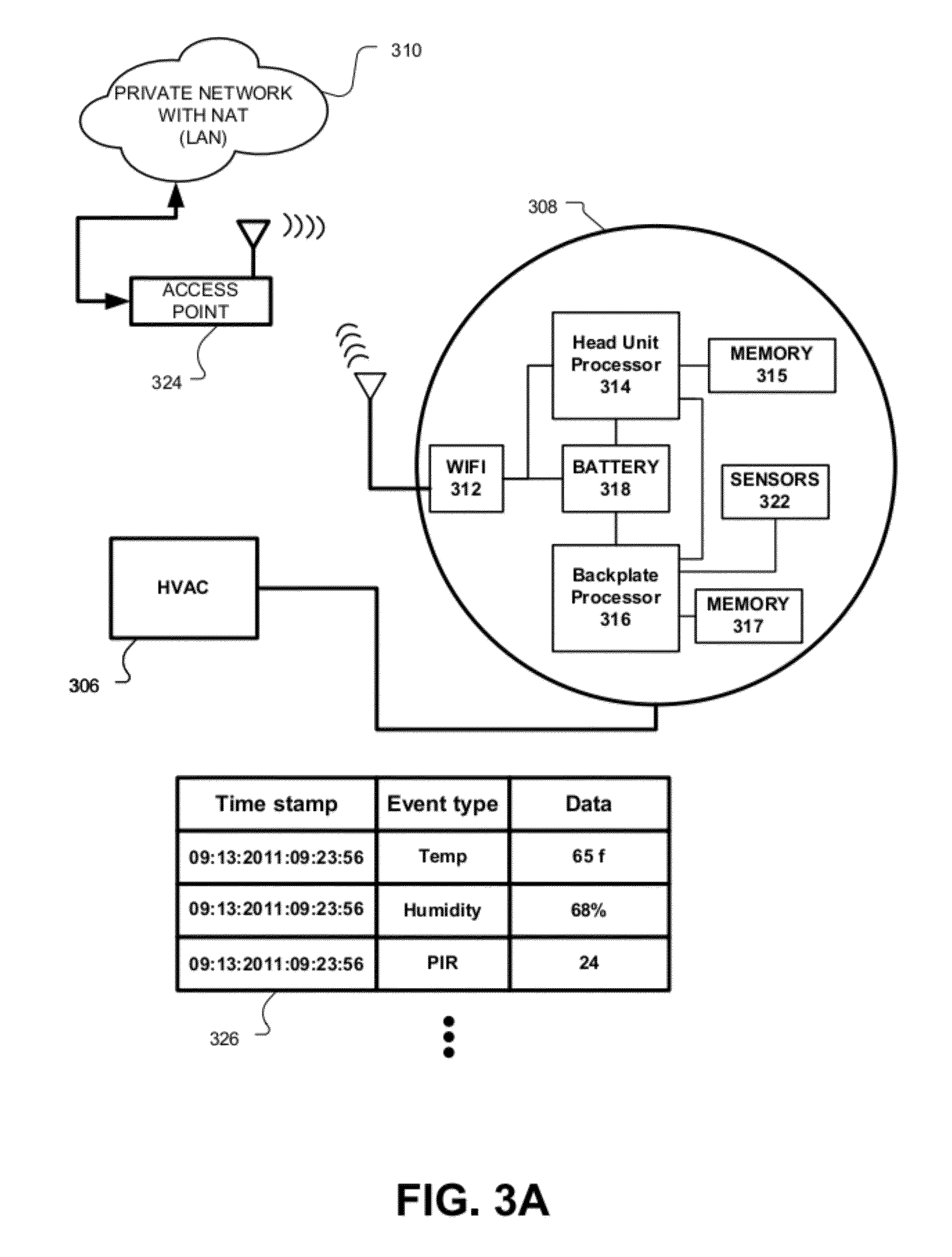

Power-preserving communications architecture with long-polling persistent cloud channel for wireless network-connected thermostat

ActiveUS20120256009A1Reduce total powerReduced serviceEnergy efficient ICTTemperature control without auxillary powerElectrical batteryCloud base

Provided according to one or more embodiments herein are methods, systems and related architectures for facilitating network communications between a wireless network-connected thermostat and a cloud-based management server in a manner that promotes reduced power usage and extended service life of a rechargeable battery of the thermostat, while at the same time accomplishing timely data transfer between the thermostat and the cloud-based management server for suitable and time-appropriate control of an HVAC system. The thermostat further comprises powering circuitry configured to: extract electrical power from one or more HVAC control wires in a manner that does not require a “common” wire; supply electrical power for thermostat operation; recharge the rechargeable battery (if needed) using any surplus extracted power; and discharge the rechargeable battery to assist in supplying electrical power for thermostat operation during intervals in which the extracted power alone is insufficient for thermostat operation.

Owner:GOOGLE LLC

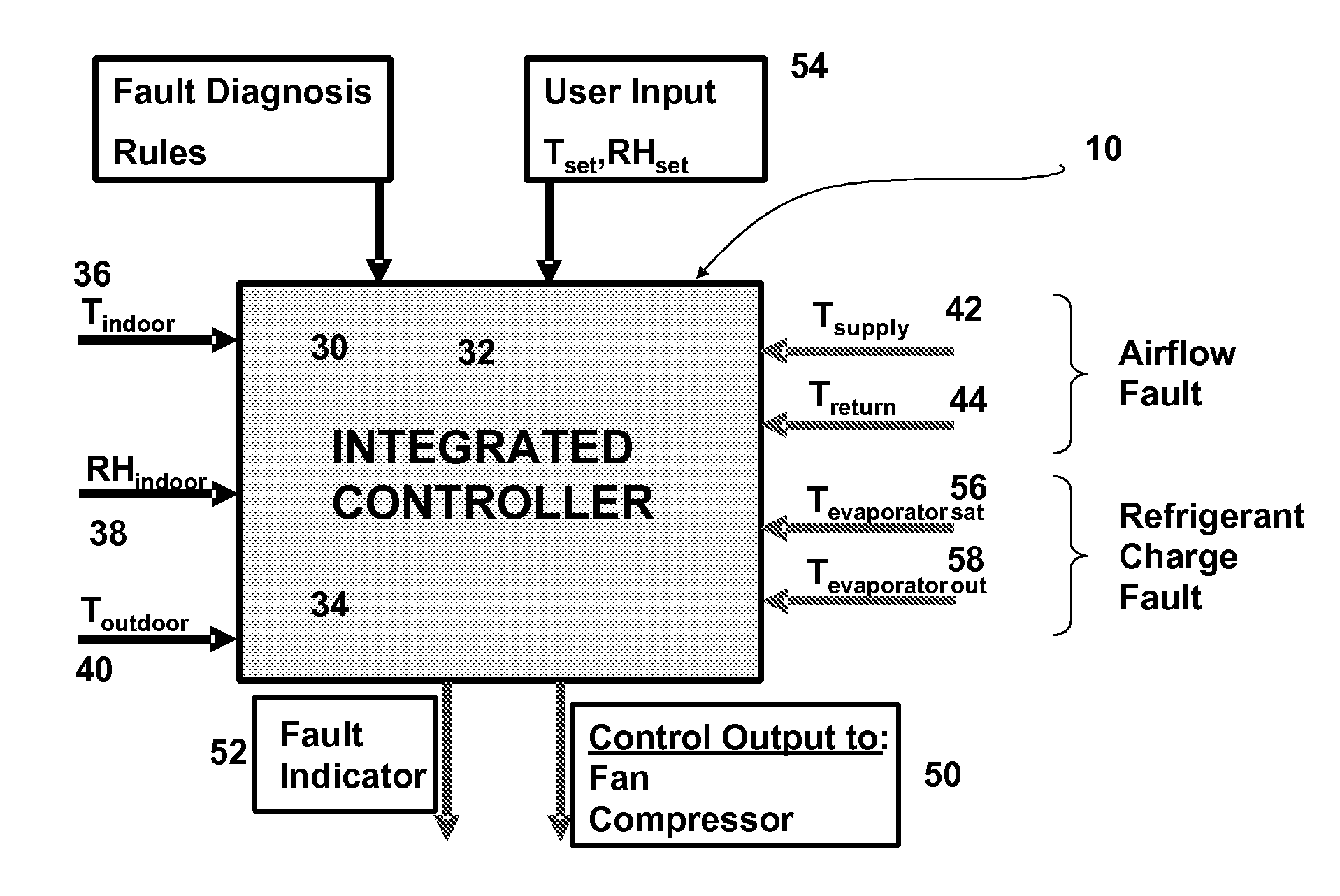

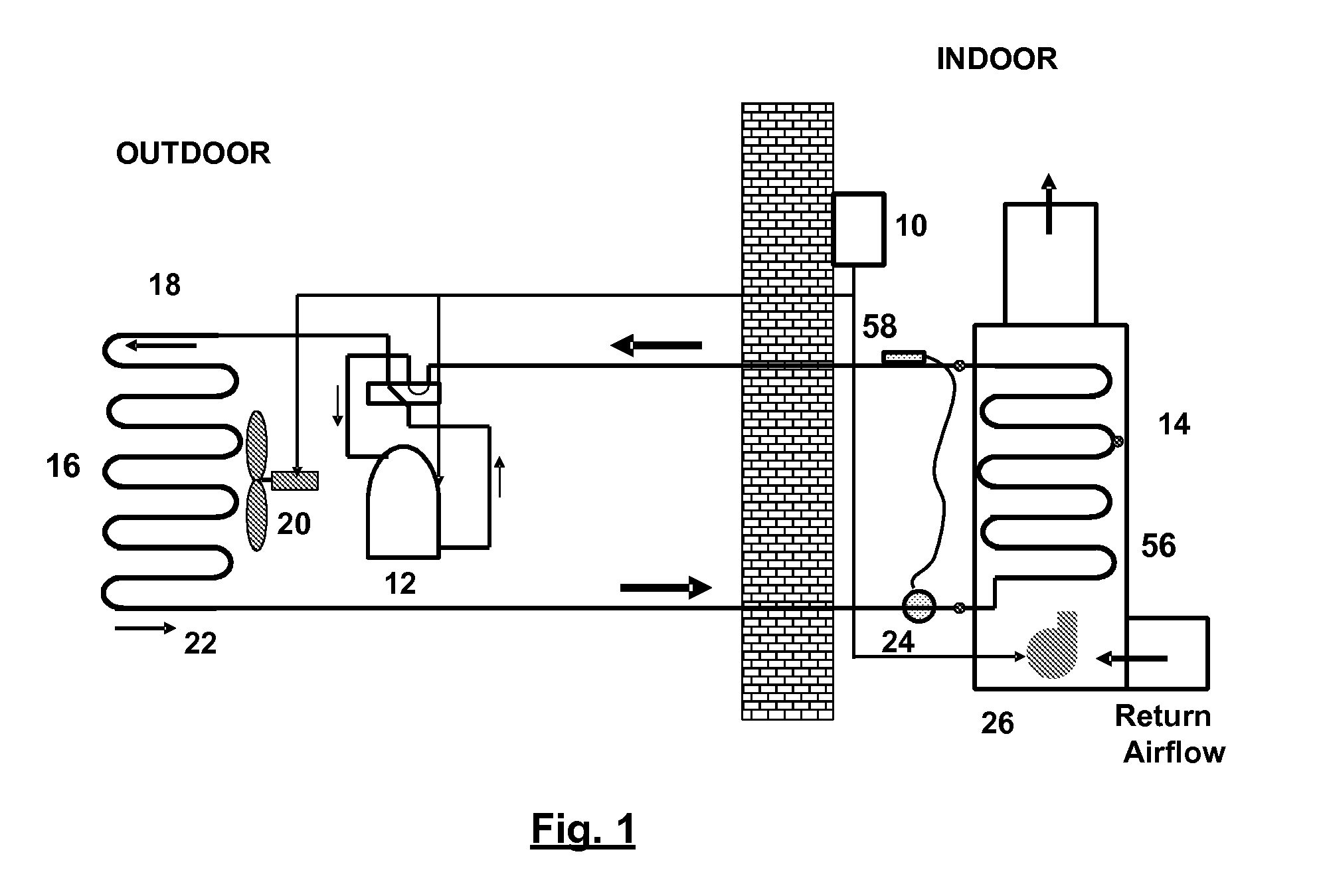

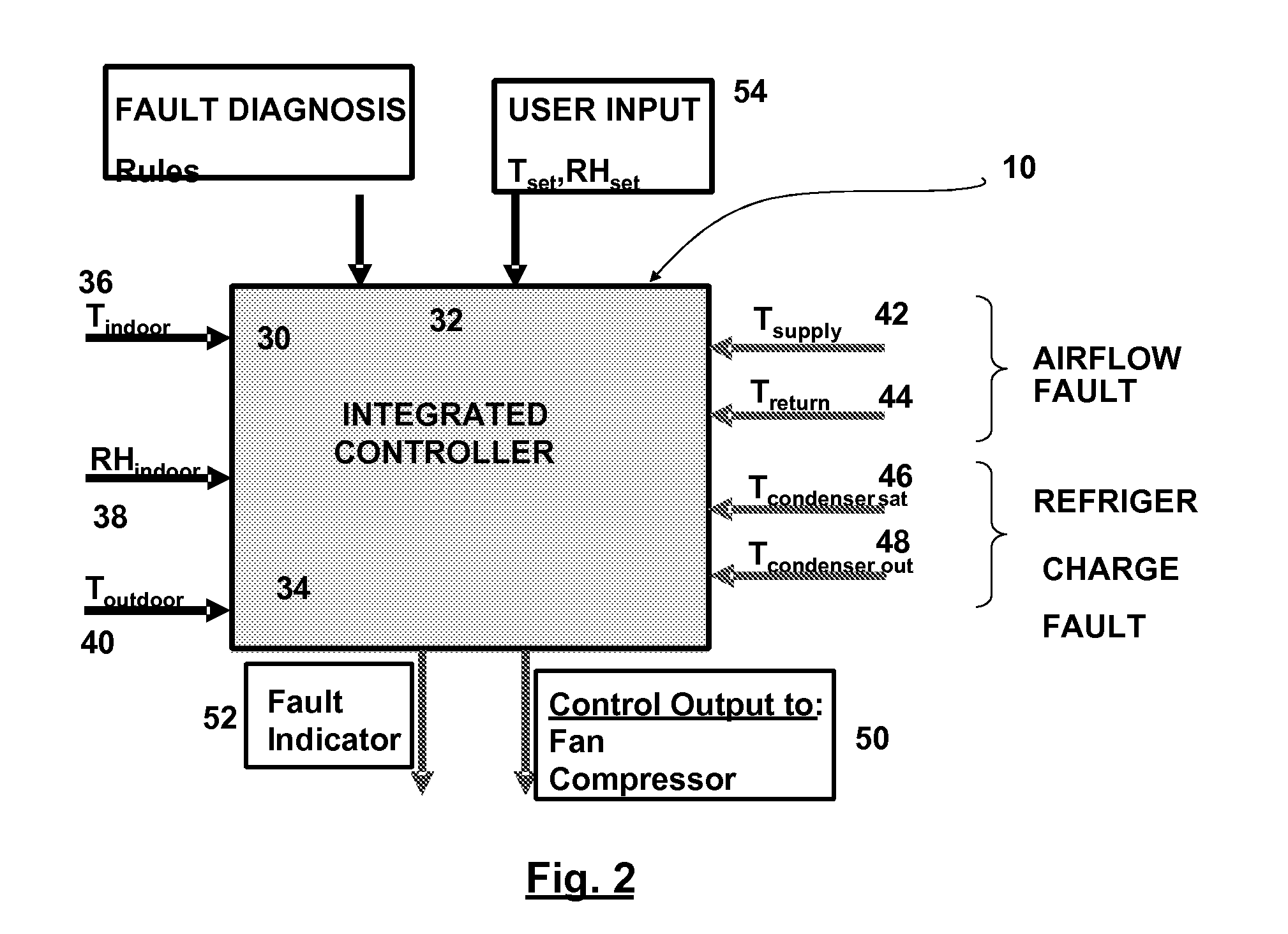

Integrated Controller And Fault Indicator For Heating And Cooling Systems

InactiveUS20080315000A1Promote mold growthShorten speedTemperature control using plurality of sensorsTesting/monitoring control systemsFault indicatorEngineering

An integrated controller for controlling a vapor compression based heating and cooling system. The integrated controller includes modules for independently controlling dry bulb temperature, humidity level, and incorporating a fault detection module therewith. The fault detection module being capable of detecting abnormal refrigerant levels using only temperature sensors on the condenser with thermal expansion valve or evaporator with fixed orifice type of expansion valve.

Owner:HOME AUTOMATION INC

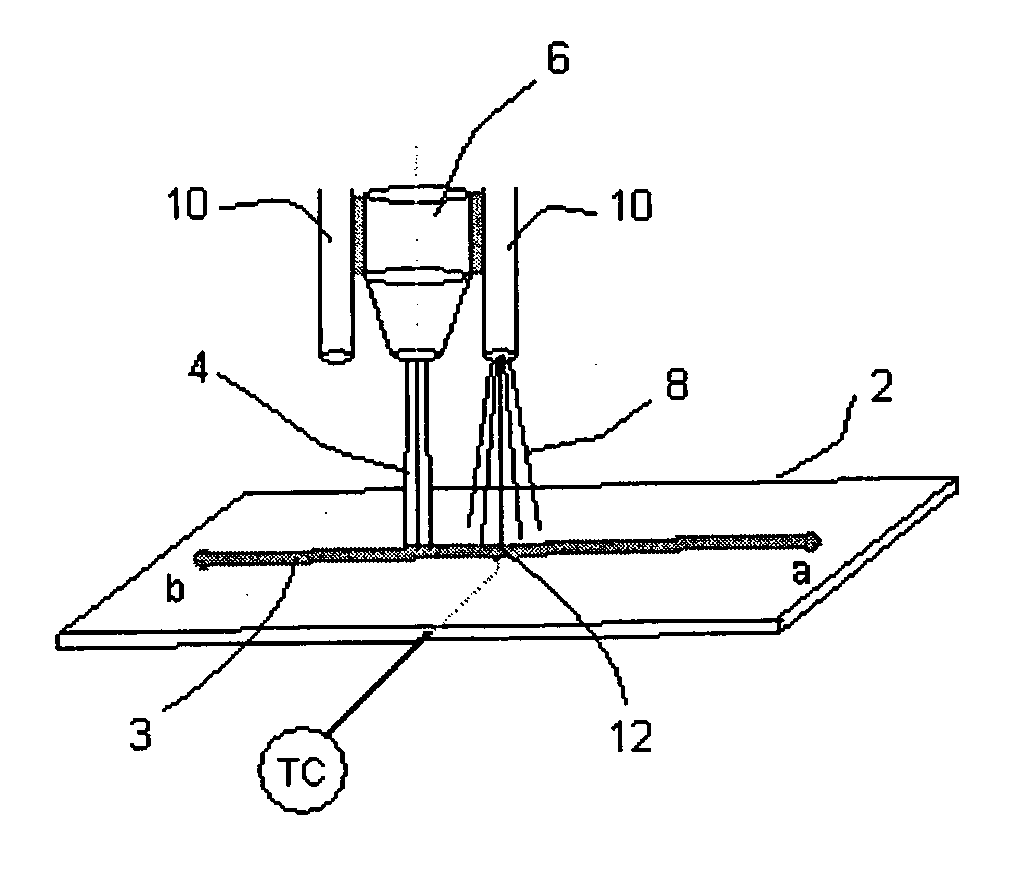

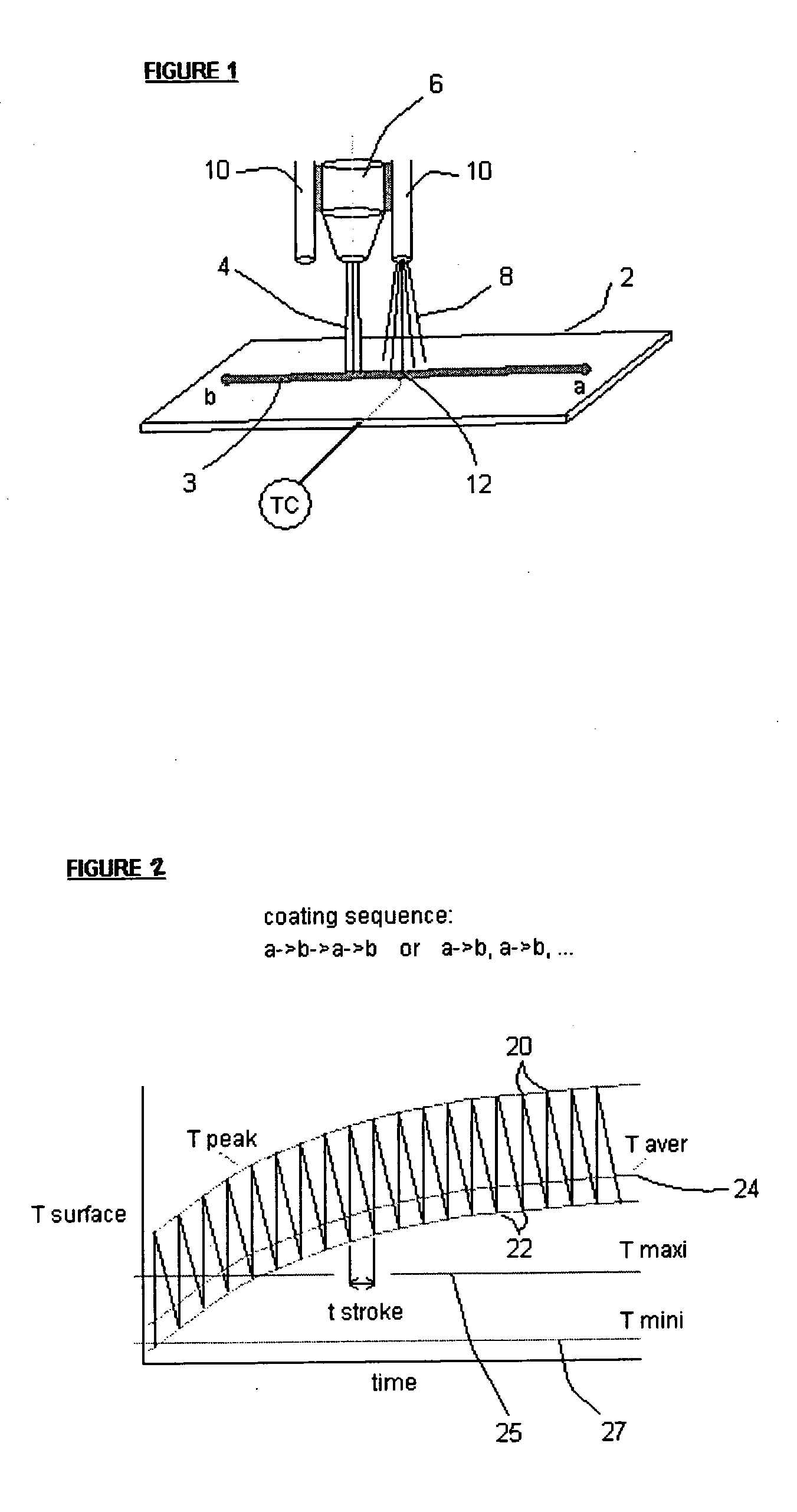

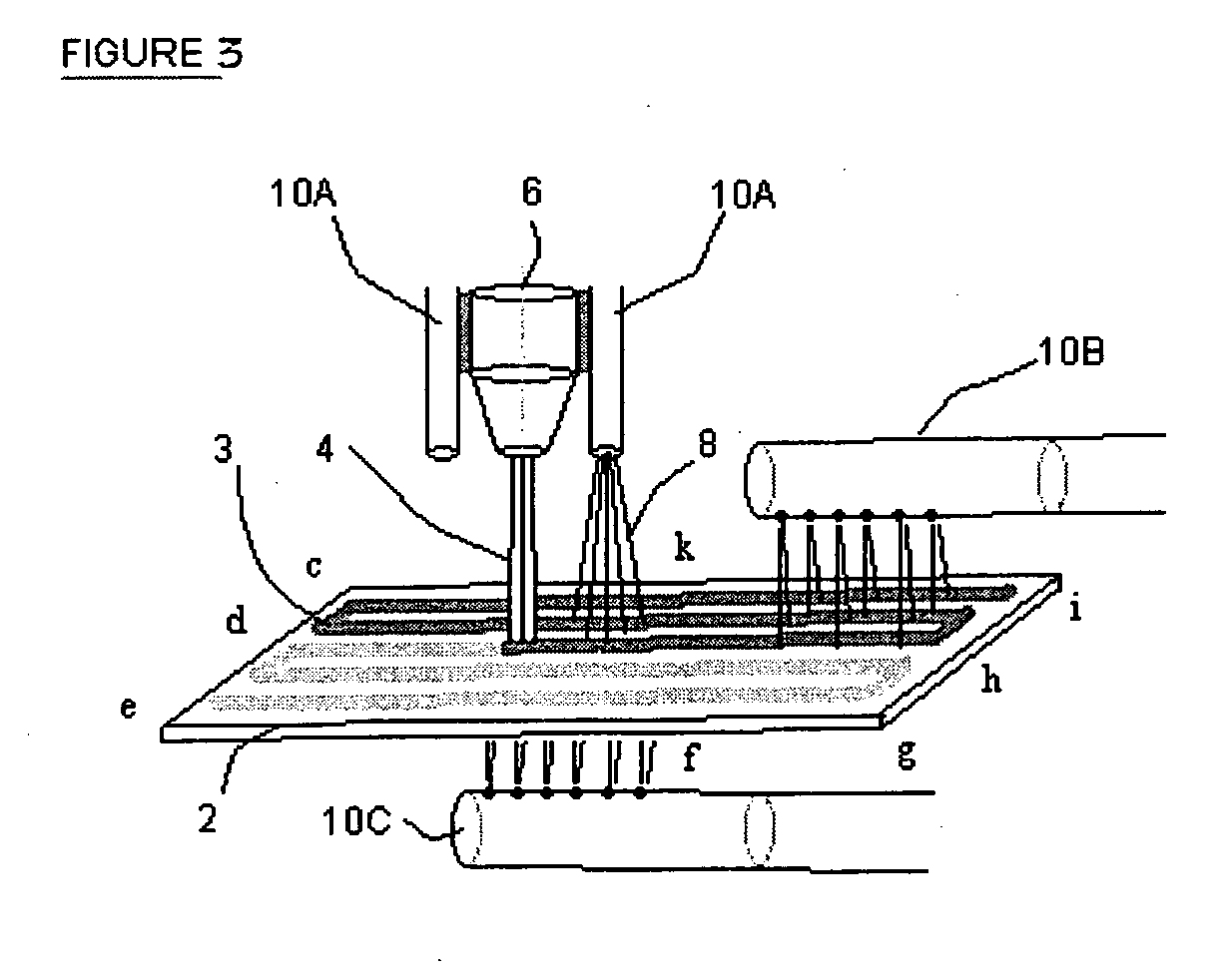

Thermal deposition coating method

ActiveUS20060228465A1Excellent coating production rateDamaging internal stressLiquid surface applicatorsMolten spray coatingThermal depositionRelative motion

A process for the thermal deposition coating of a workpiece, said process comprising the steps of: (c) thermally depositing a coating on a metallic surface of a workpiece from a deposition head wherein at least one condition selected from the group of: coating deposition rate onto said surface, relative motion between the surface and said deposition head, and cryogenic coolant application rate onto said workpiece is controllable; (d) substantially simultaneously measuring temperatures at a plurality of locations over the metallic surface of the workpiece; (c) determining an average temperature of the temperatures measured in step (b); (d) comparing the average temperature to a preselected minimum temperature and a preselected maximum temperature for the workpiece; and (e) adjusting at least one of the controllable conditions if said average temperature is not between the preselected minimum temperature and the preselected maximum temperature for the workpiece. Standard deviations of all temperature readings and controlling the relative motion speed between the thermal coating deposition head and the workpiece provide another improvement for obtaining temperature uniformity over the workpiece surface.

Owner:AIR PROD & CHEM INC

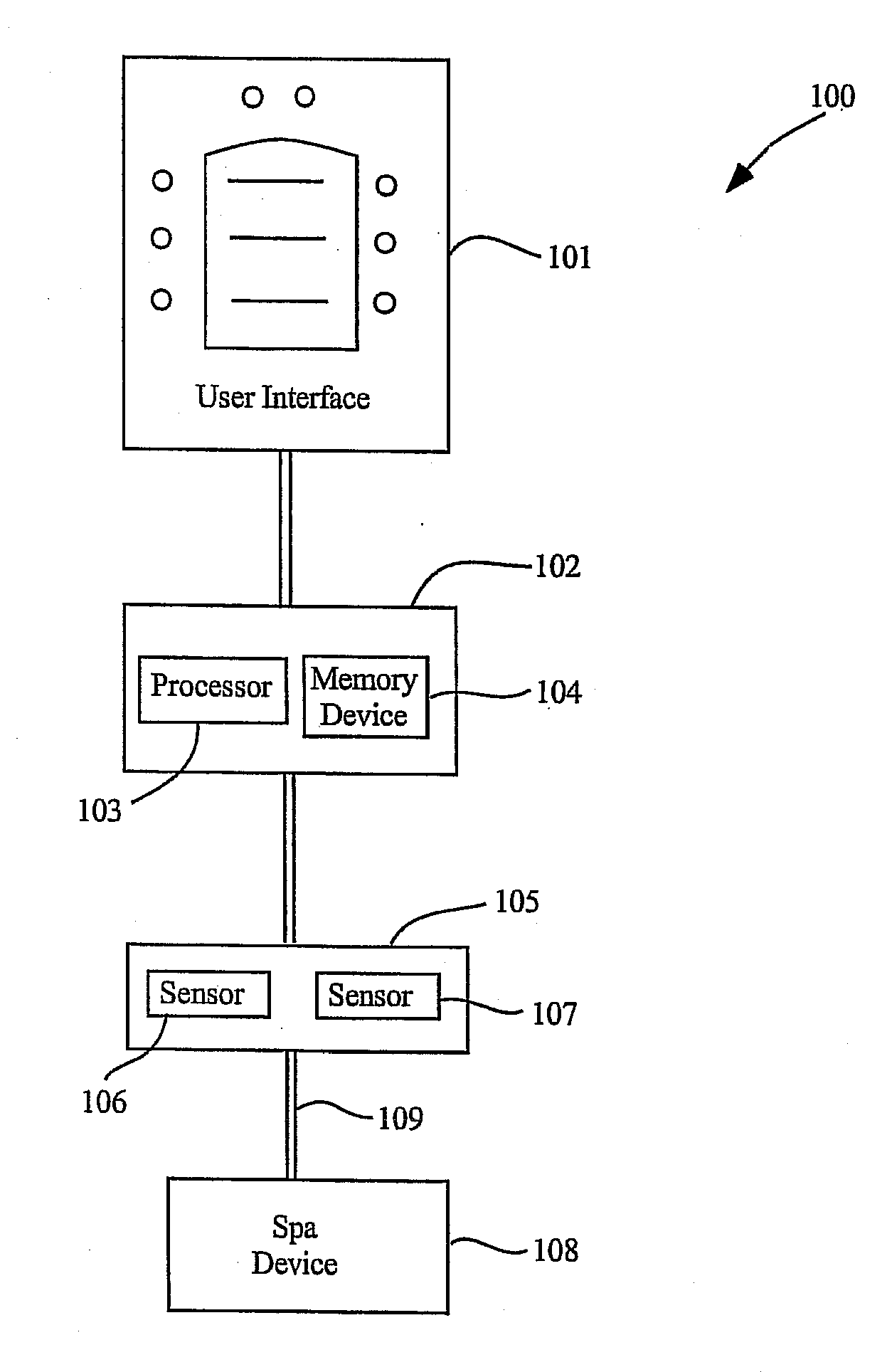

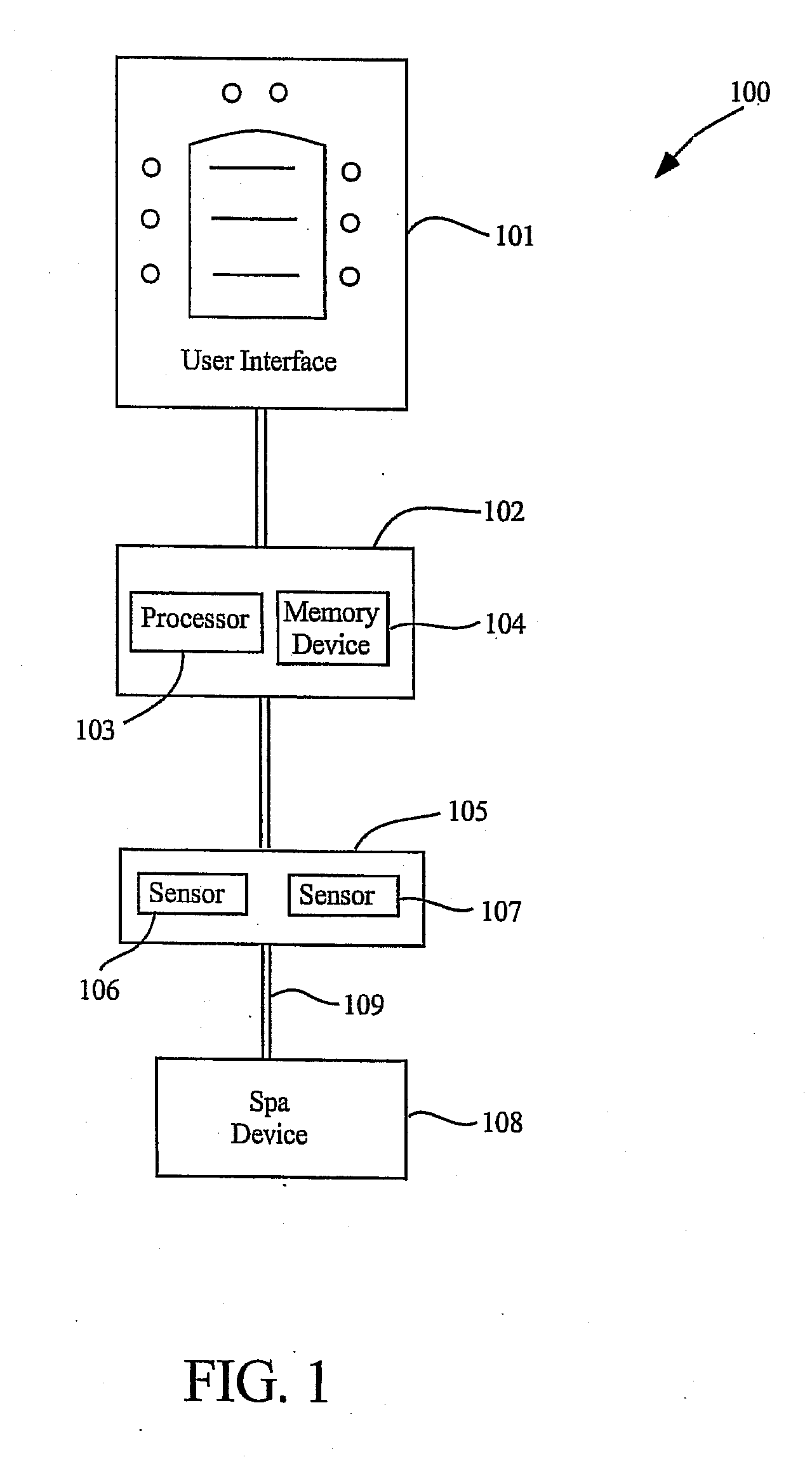

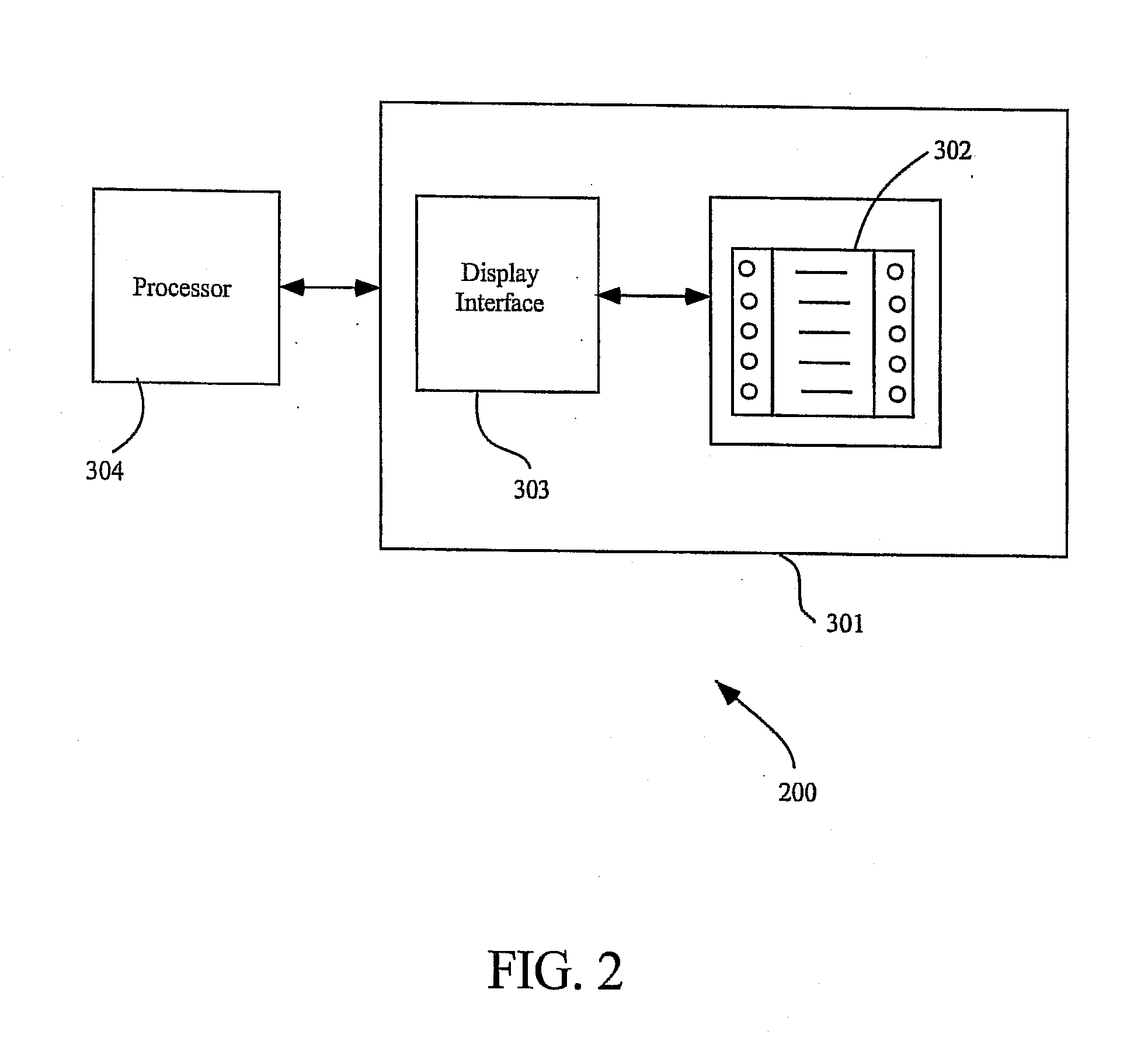

Controlling spas

InactiveUS20070061051A1Temperature control using plurality of sensorsComputer controlComputer hardwareControl system

A spa control system, the spa control system comprising a processor, wherein the processor is adapted to provide a signal to a user interface representing a spa operation. The user interface coupled to the processor, the user interface comprising a display, wherein the display can comprise of various display technology and is adapted to provide a user understandable data representing the spa operation. The spa control system utilizing electrical current sensors and temperature sensors to operate spa functions.

Owner:MADDOX HAROLD

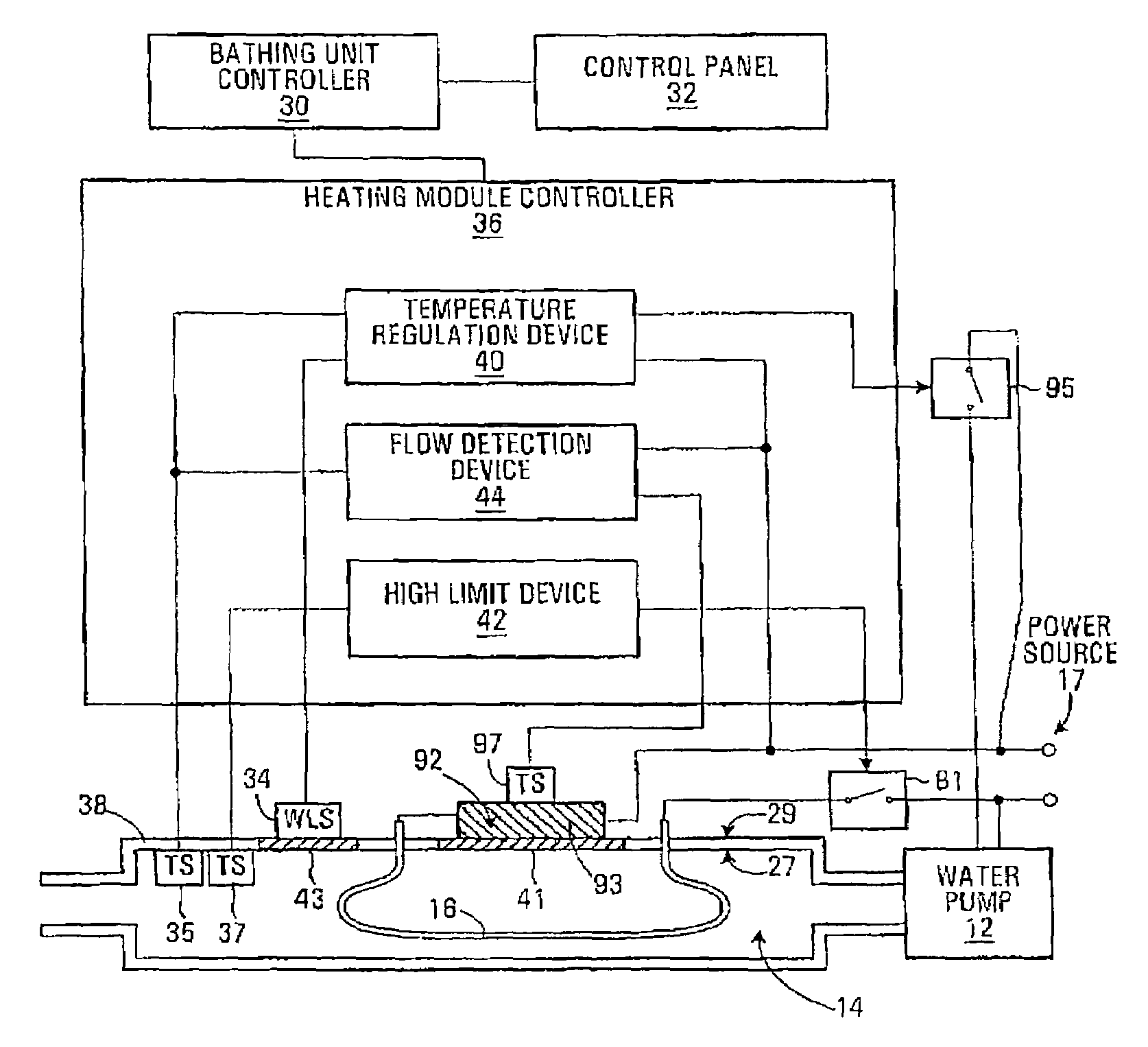

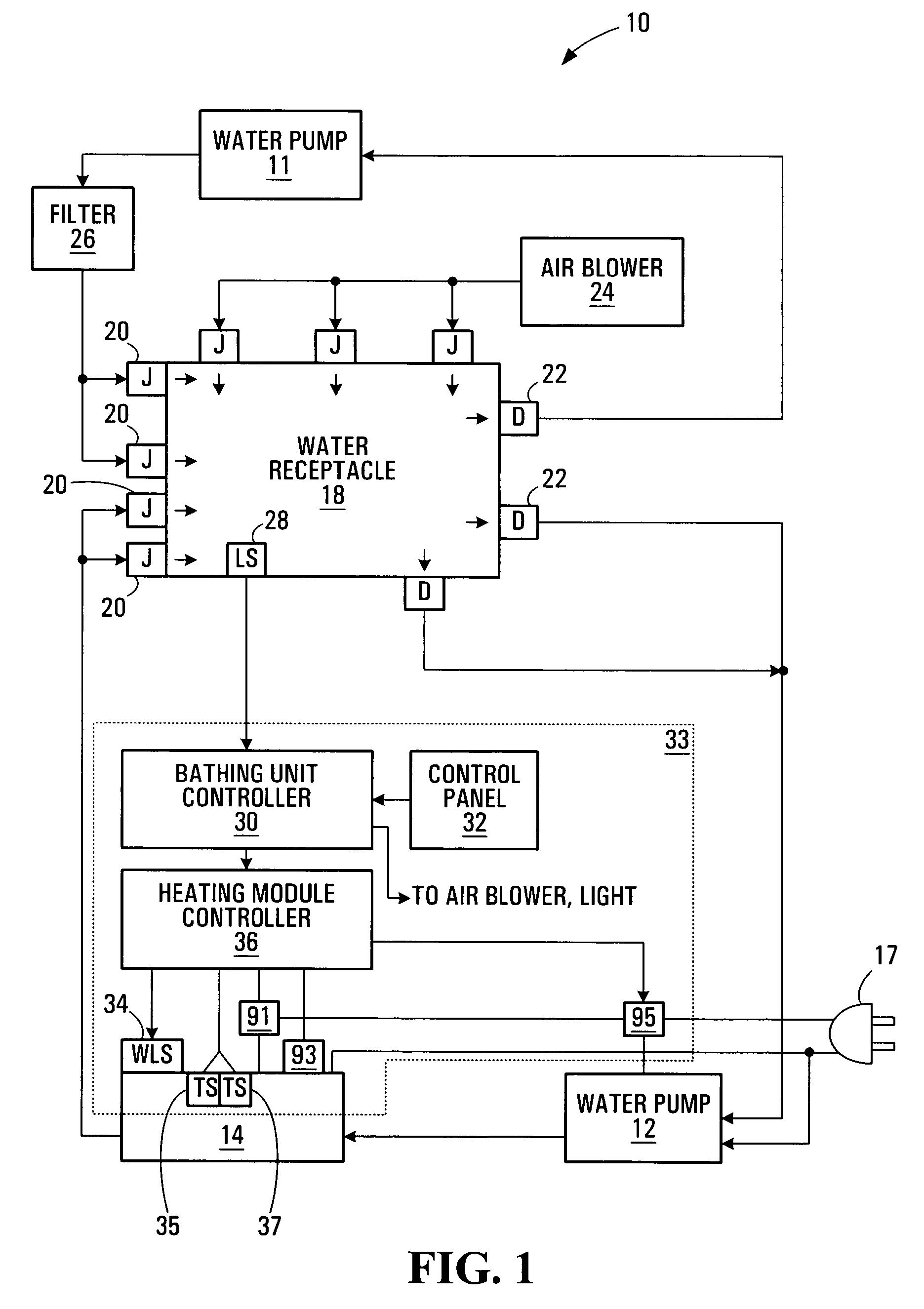

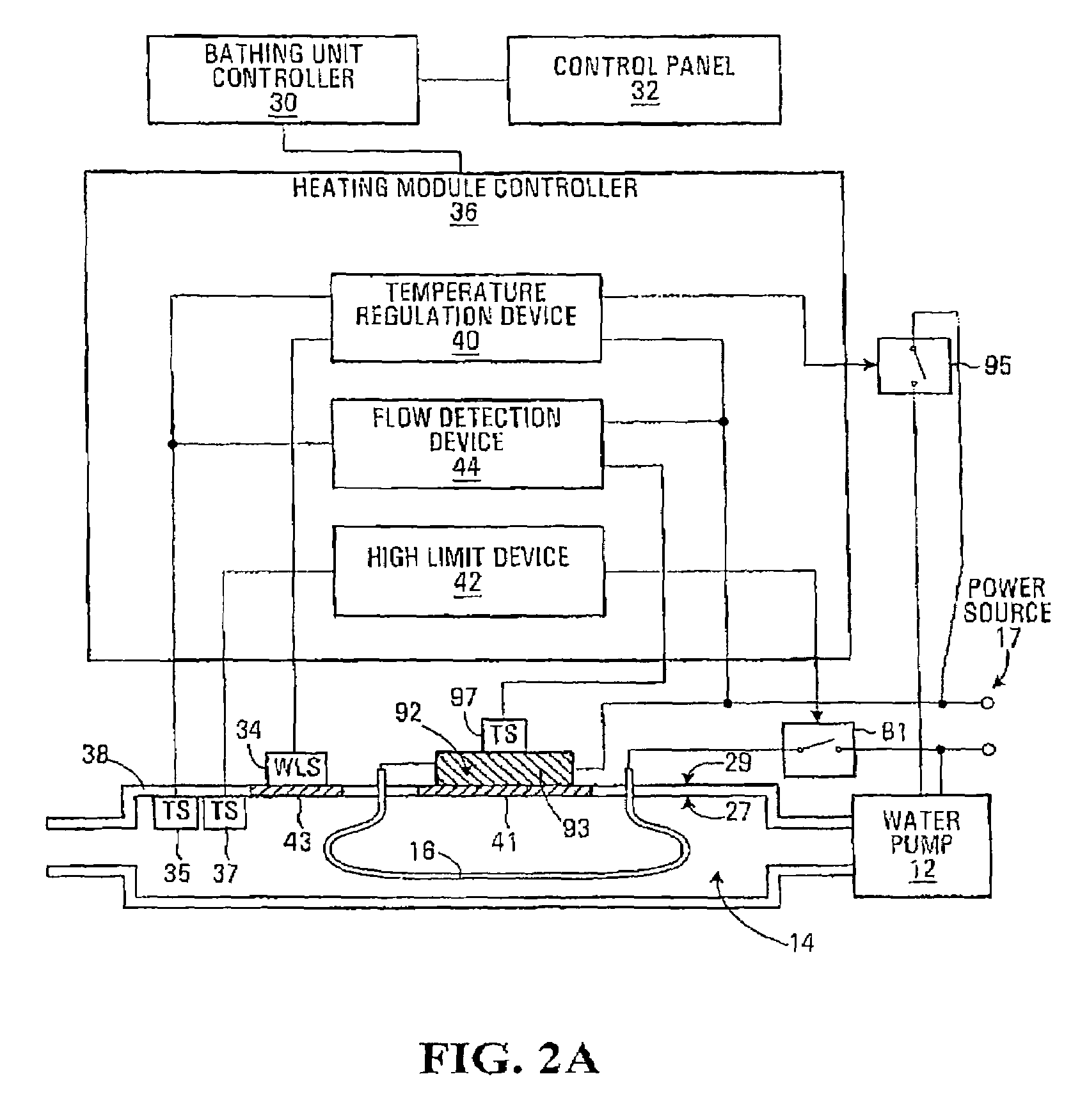

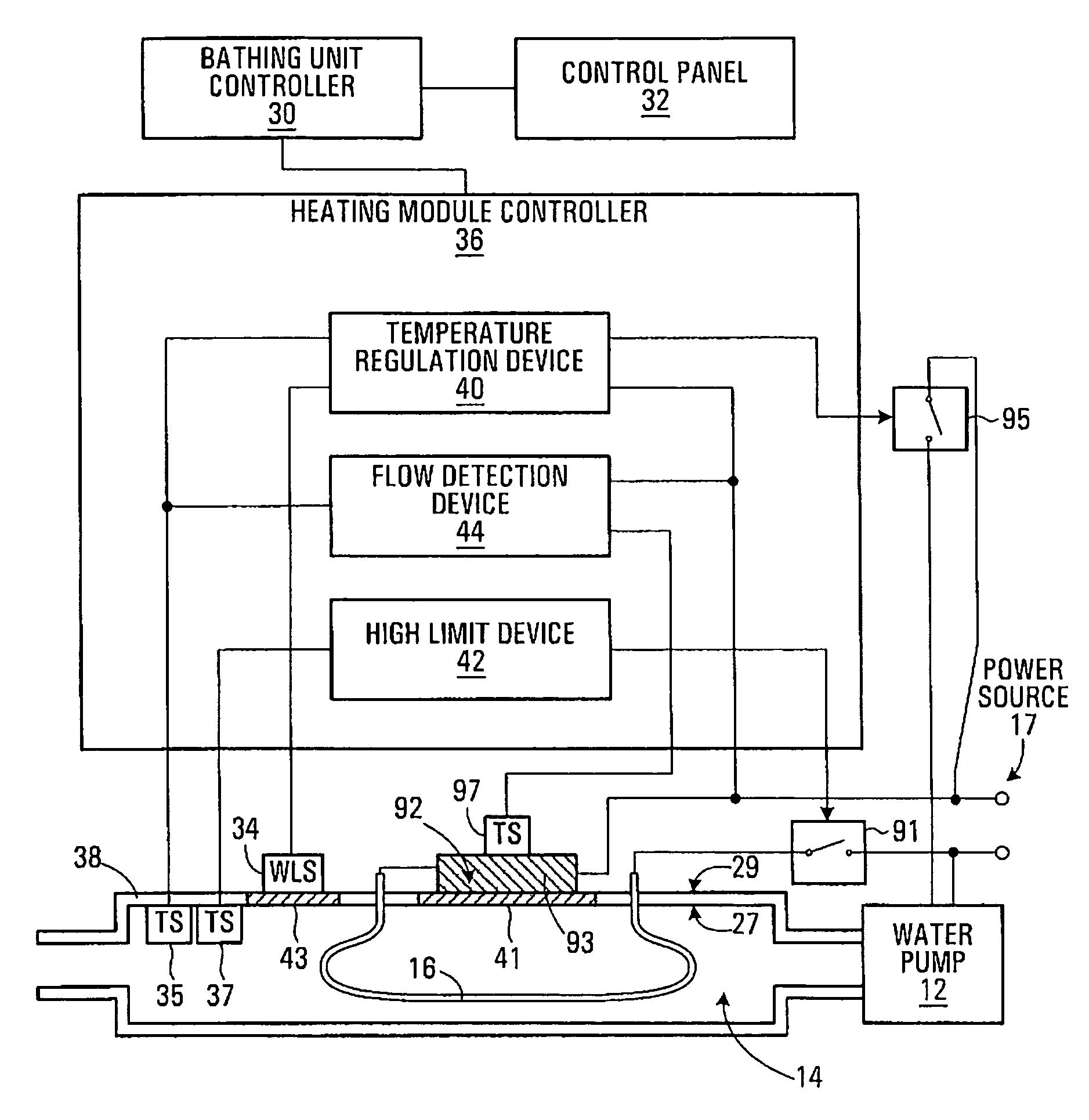

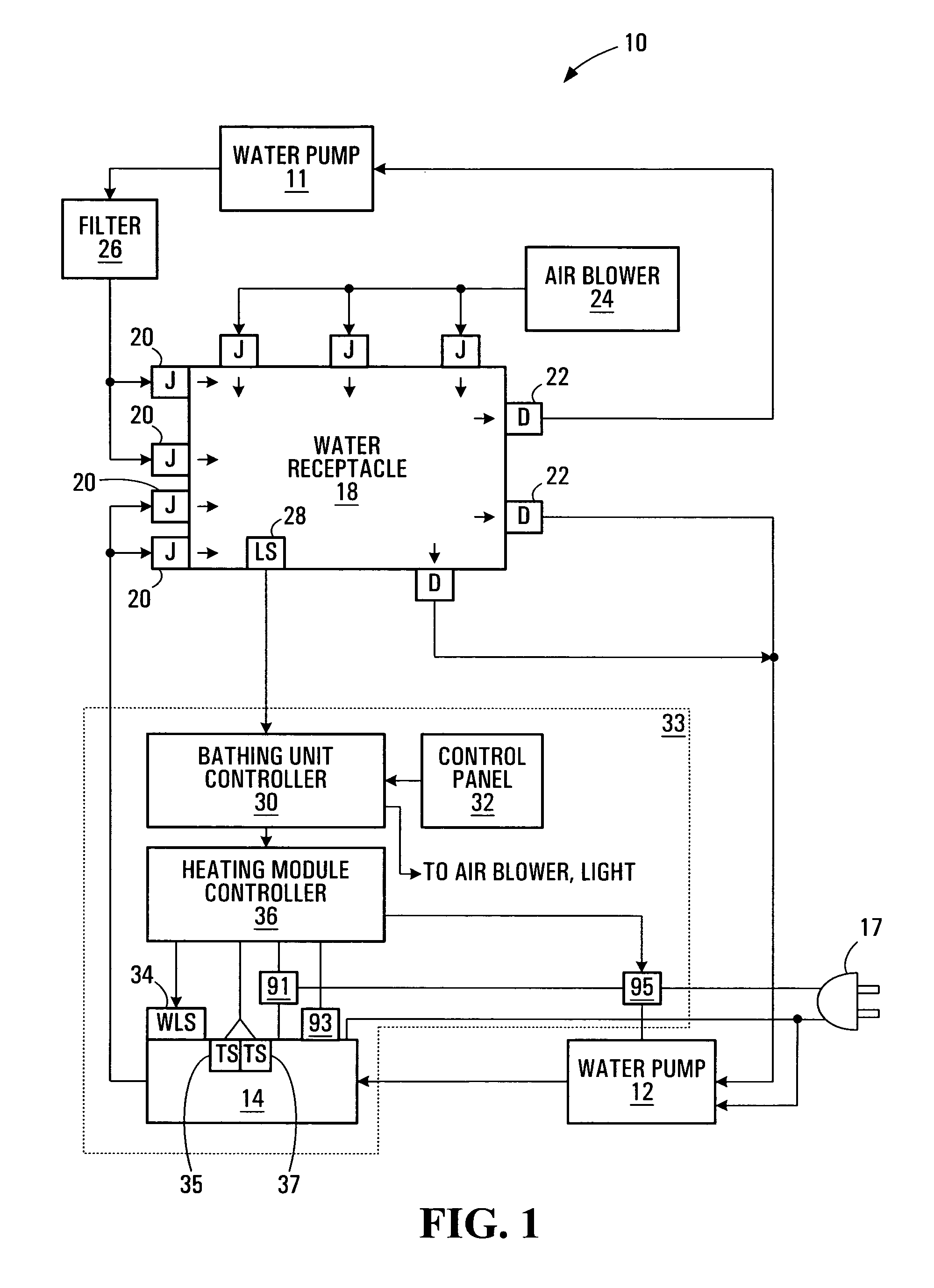

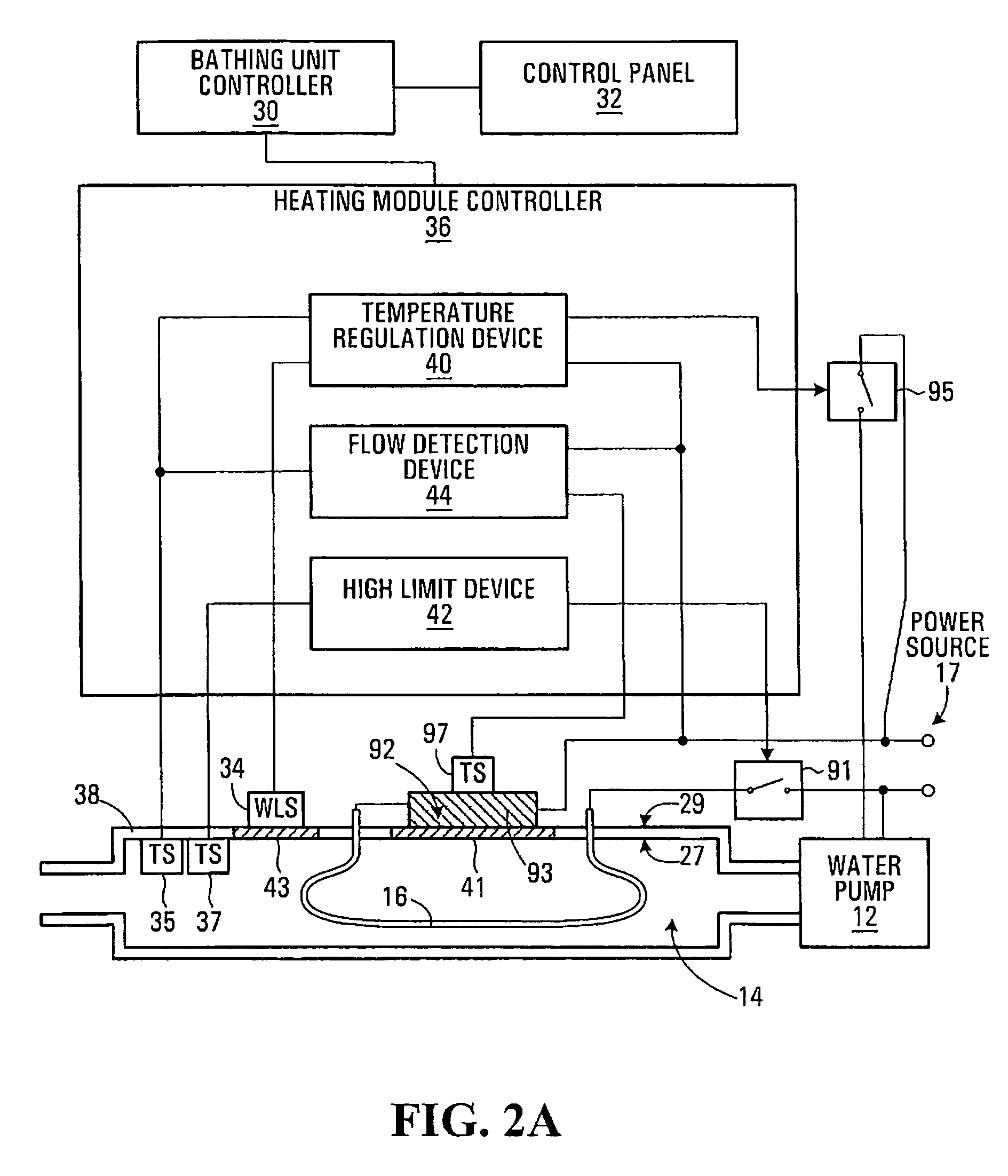

Water flow detection system for a bathing unit

ActiveUS7593789B2Inhibition of activationReduce usageMechanical apparatusBaking ovenControl systemWater flow

The present invention provides a control system for a bathing unit that comprises a heating module, a temperature sensing entity and a heating module controller. The heating module includes a body that defines a passage through which water can flow, that has an inner surface and an outer surface. The heating module further includes a heating device that is operative for heating the water that flows through the body. The temperature sensing entity is mounted to the outer surface of the body such that the temperature sensing entity is in thermally conductive communication with water flowing through the body. The heating module controller is operative for obtaining temperature information associated with the temperature sensing entity for detecting at least in part on the basis of the temperature information the sufficiency of water flow through the body.

Owner:GECKO ALLIANCE GROUP

Method and apparatus for monitoring air-exchange evaporation in a refrigerant-cycle system

ActiveUS20060032248A1Mechanical apparatusTemperature measurement in air-conditioning systemsDifferential pressureEvaporation

A real-time monitoring system that monitors various aspects of the operation of a refrigerant-cycle system is described. In one embodiment, the system includes a processor that measures power provided to the refrigerant-cycle system and that gathers data from one or more sensors and uses the sensor data to calculate a figure of merit related to the efficiency of the system. In one embodiment, the sensors include one or more of the following sensors: a suction line temperature sensor, a suction line pressure sensor, a suction line flow sensor, a hot gas line temperature sensor, a hot gas line pressure sensor, a hot gas line flow sensor, a liquid line temperature sensor, a liquid line pressure sensor, a liquid line flow sensor. In one embodiment, the sensors include one or more of an evaporator air temperature input sensor, an evaporator air temperature output sensor, an evaporator air flow sensor, an evaporator air humidity sensor, and a differential pressure sensor. In one embodiment, the sensors include one or more of a condenser air temperature input sensor, a condenser air temperature output sensor, and a condenser air flow sensor, an evaporator air humidity sensor. In one embodiment, the sensors include one or more of an ambient air sensor and an ambient humidity sensor.

Owner:COPELAND LP

Method and device for controlling the thermal balance in buildings

InactiveUS20050234596A1Easy to implementEasy to integrateSampled-variable control systemsTemperature control using plurality of sensorsHeat flowOperating energy

A method for controlling thermal flows in at least one building, according to which a mechanism for influencing the temperature within the building is controlled based on a plurality of input parameters. Controlling can be done in the most economical manner by triggering the mechanism that regulates the temperature of a specific monitored space or the at least one area of a specific space by using a) at least one target value, especially the desired temperature of the specific space, b) at least one general parameter characteristic of at least one variable inside and / or outside the building, which at least indirectly influences the temperature within the specific space, and c) at least one special parameter characteristic of the specific thermal flow conditions of the specific monitored space or the area of the specific space, as input parameters, and calculating the controlling of the mechanism from the input parameters in a control unit.

Owner:BARIX

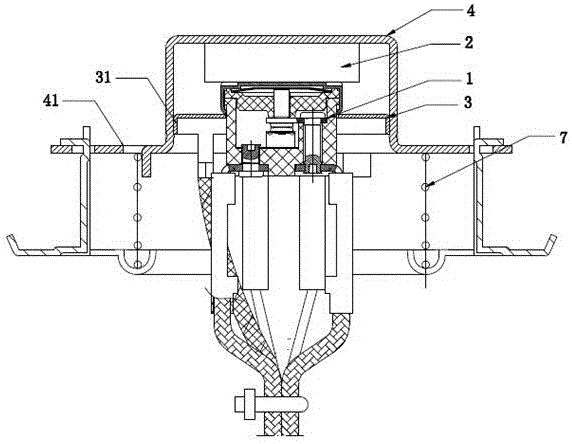

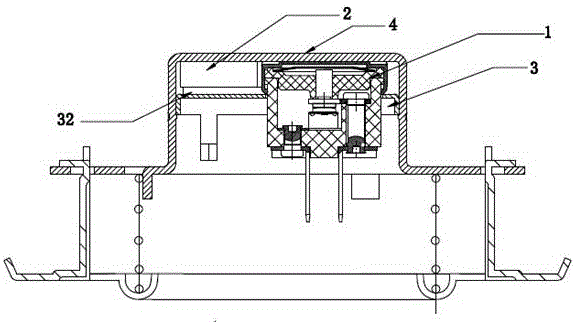

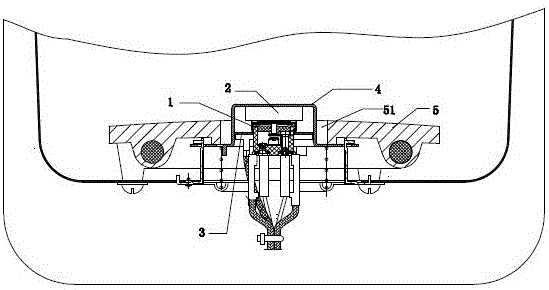

Novel electric cooker temperature control assembly and electric cooker using same

InactiveCN105662112ARealize the insulation functionRealize anti-dry functionTemperature control using plurality of sensorsVessels with intergral heatingTemperature controlThermal insulation

The invention provides a novel electric cooker temperature control assembly which is high in PTC heater heat transfer efficiency and stable in performance.The temperature control assembly comprises a kick type temperature controller, a PTC heater, a support and a heat conduction cover, wherein the upper heat dissipation surface of the PTC heater is tightly attached to the inner top surface of the heat conduction cover, and the kick type temperature controller and the PTC heater are pressed and fixed into the heat conduction cover through the support.The invention further provides an electric cooker using the temperature control assembly.The electric cooker further comprises a heating disc and a liner.A skirt extends outwards from the open portion of the heat conduction cover, an elastic component is arranged on the lower portion of the heat conduction cover, the heating disc is provided with a heat conduction cover installation hole, the heat conduction cover upwards penetrates through the heat conduction cover installation hole, the skirt of the heat conduction cover is sustained by the elastic component so as to be in close contact with the heating disc, and the PTC heater and the kick type temperature controller are connected in parallel and then connected with the heating disc in a power circuit of the electric cooker in series.The electric cooker adopting the temperature control assembly can achieve automatic temperature limitation, heat insulation and dry heating prevention.

Owner:梁炜畅 +1

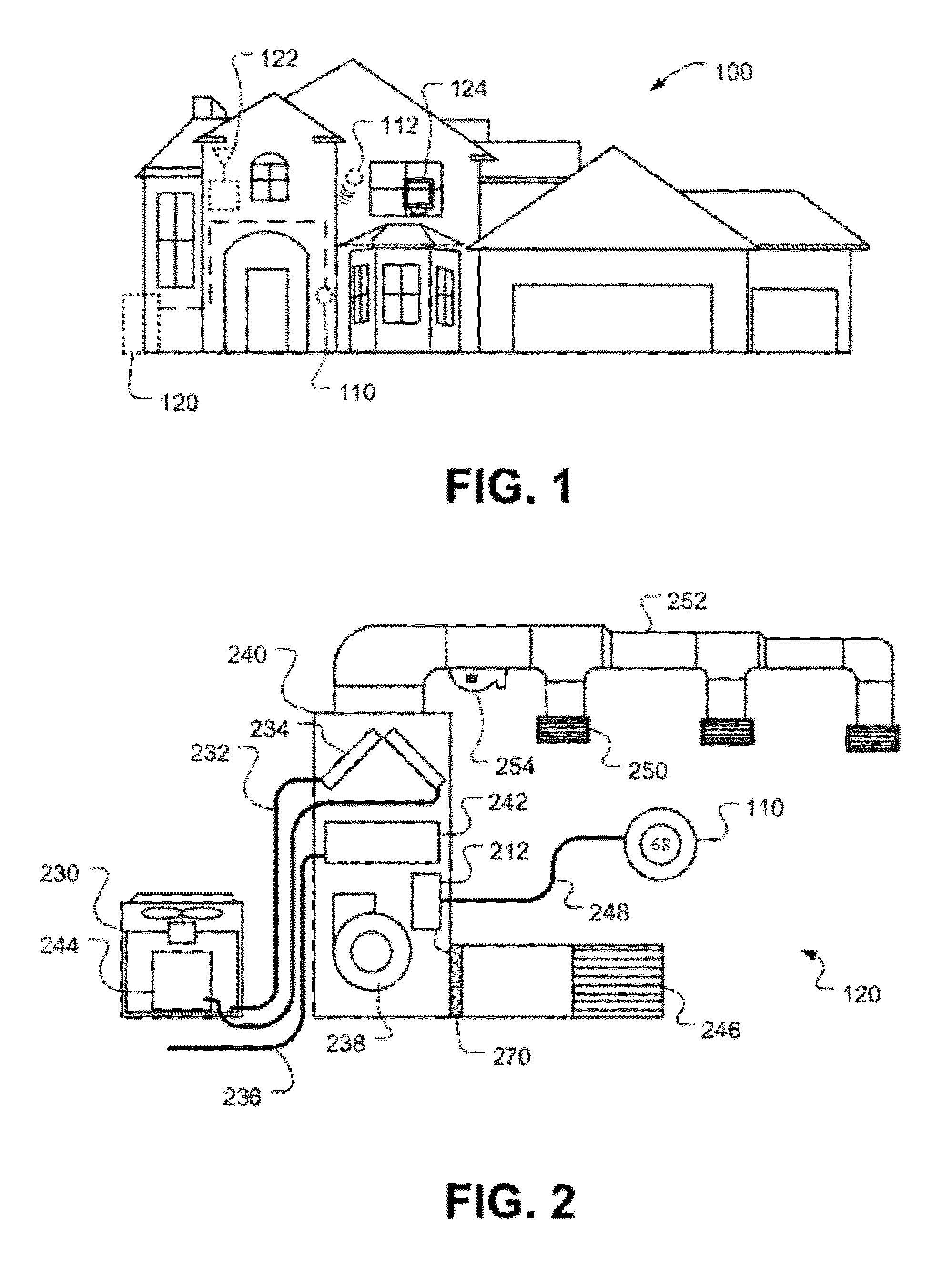

HVAC controller configurations that compensate for heating caused by direct sunlight

A thermostat may include a housing, a user interface, temperature sensors providing temperature sensor measurements, and a processing system configured to control an HVAC system based on a comparison of a determined ambient temperature and a setpoint temperature. The thermostat may (i) determine time intervals in which direct sunlight is incident on the thermostat; (ii) during time intervals in which direct sunlight is not incident on the thermostat, process the temperature sensor measurements according to a first ambient temperature determination algorithm to compute the determined ambient temperature; and (iii) during time intervals in which it is determined that direct sunlight is incident on the thermostat, process the temperature sensor measurements according to a second ambient temperature determination algorithm to compute the determined ambient temperature that compensates for a heating of the thermostat caused by the direct sunlight.

Owner:GOOGLE LLC

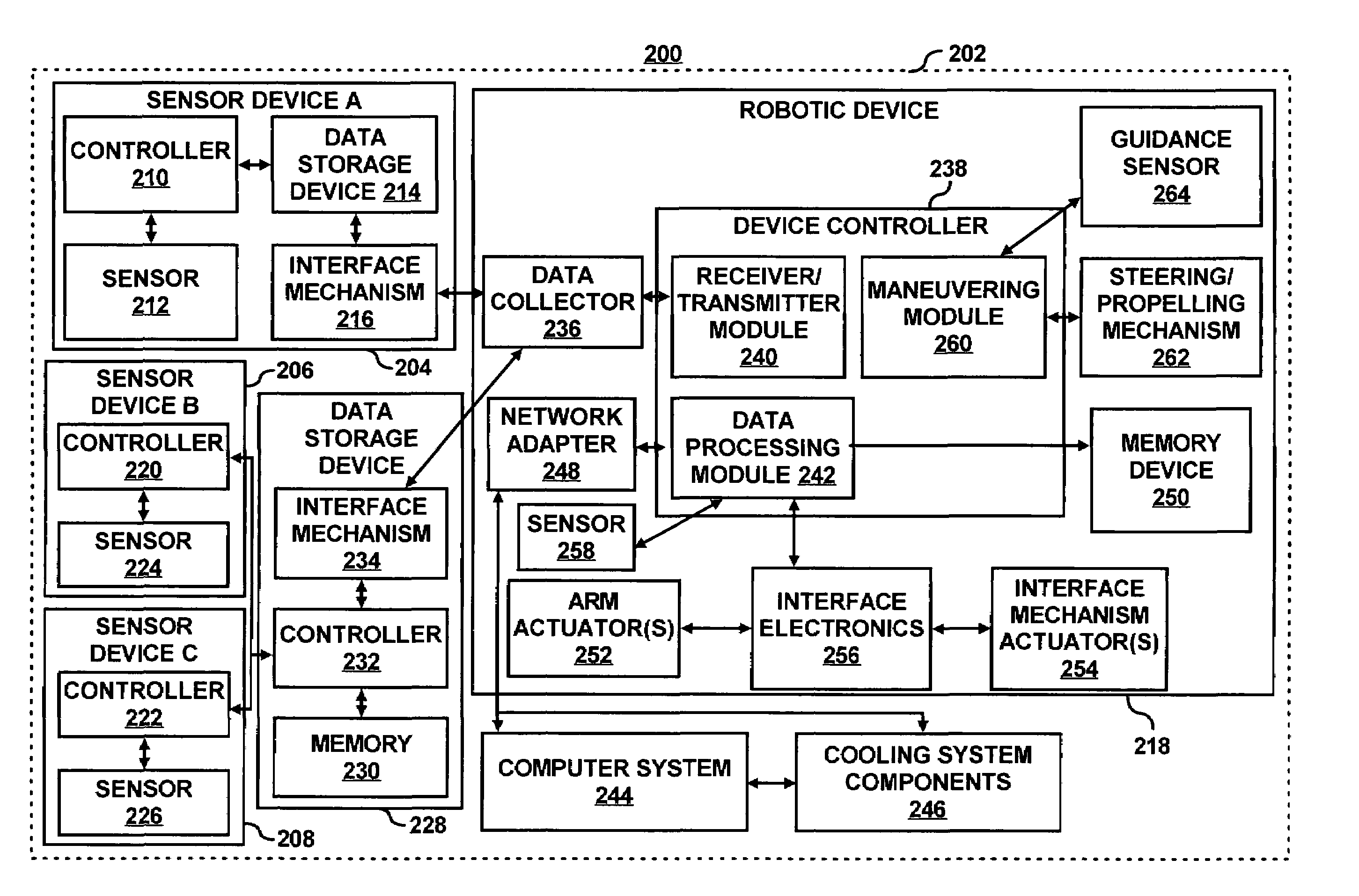

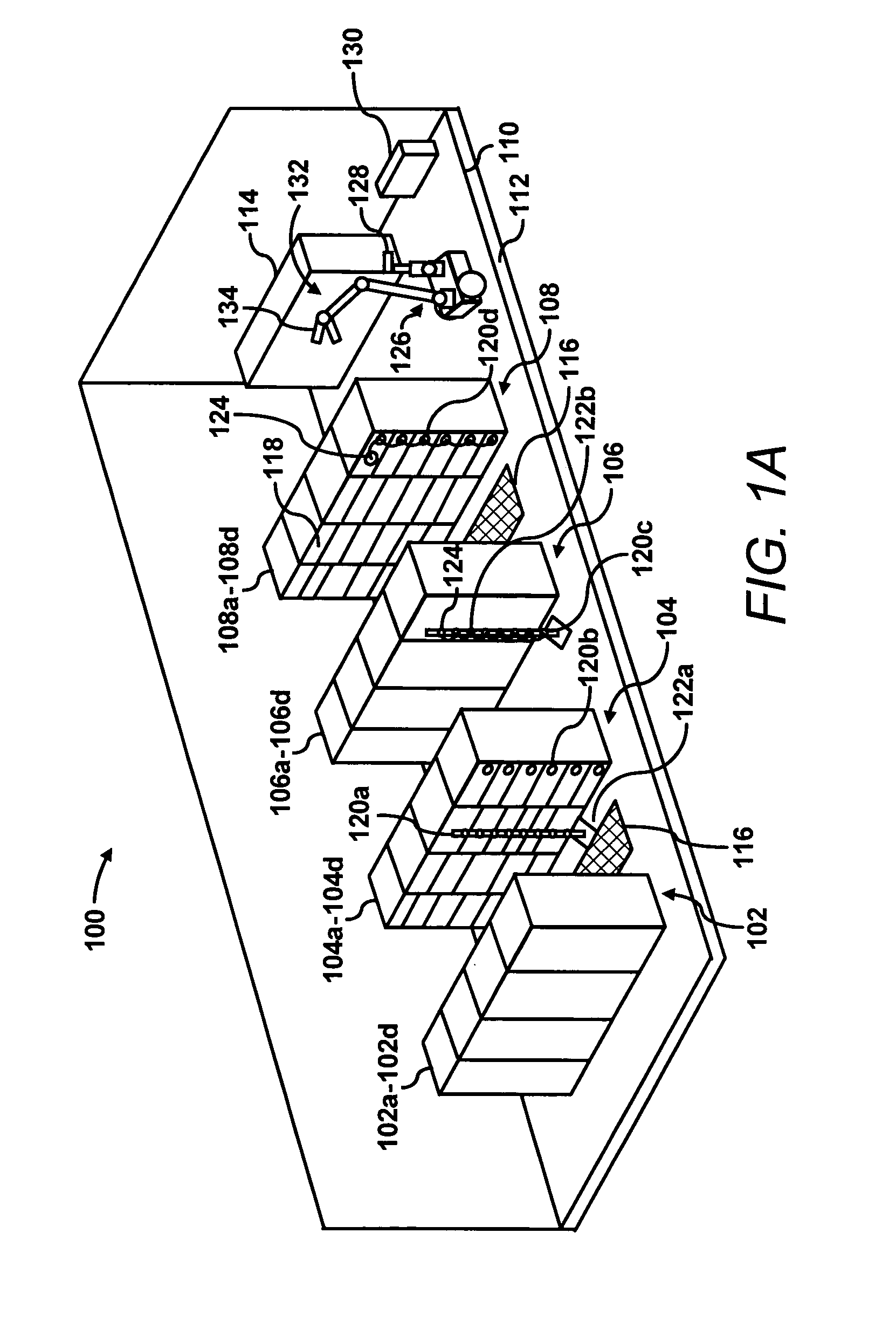

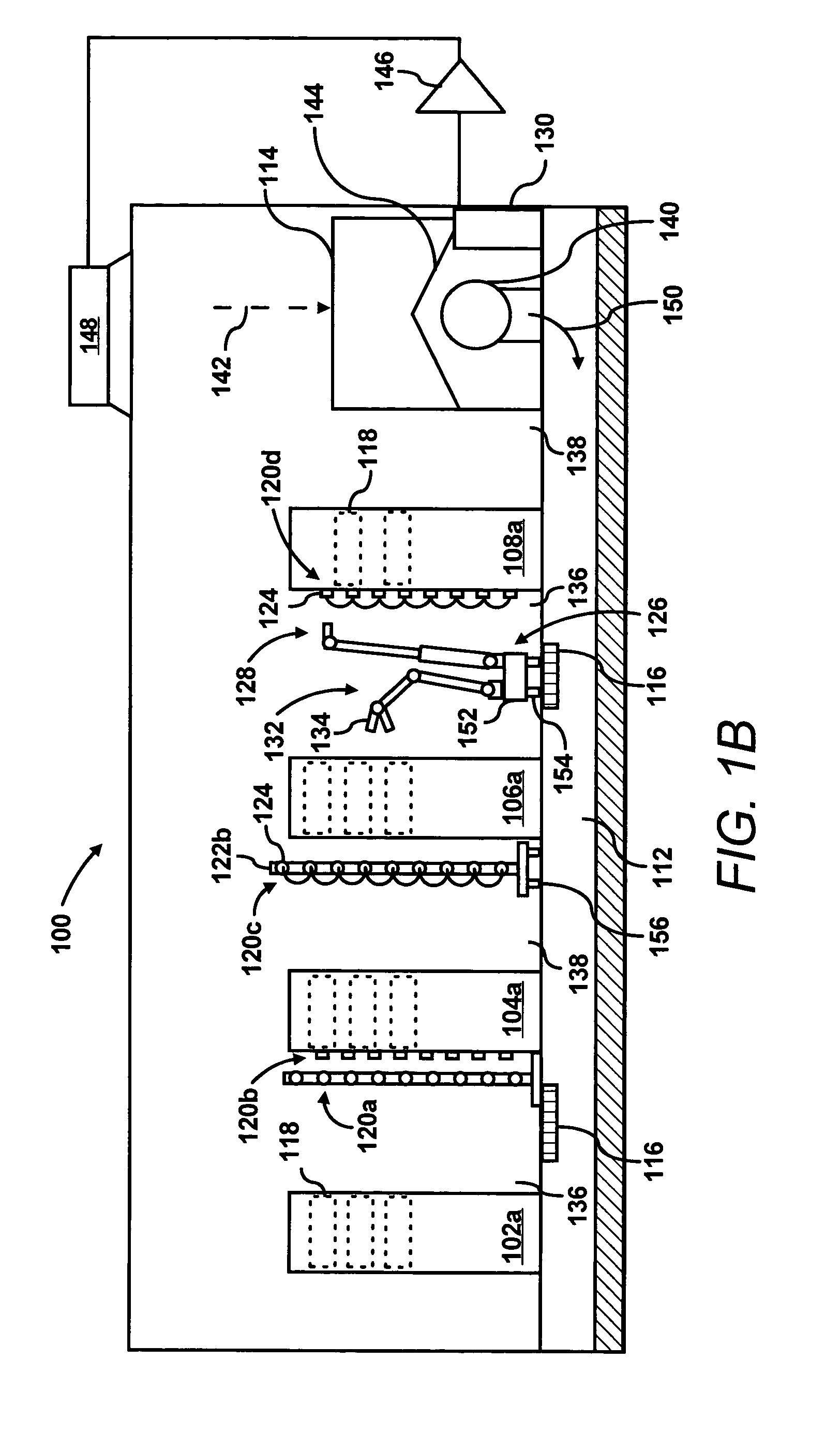

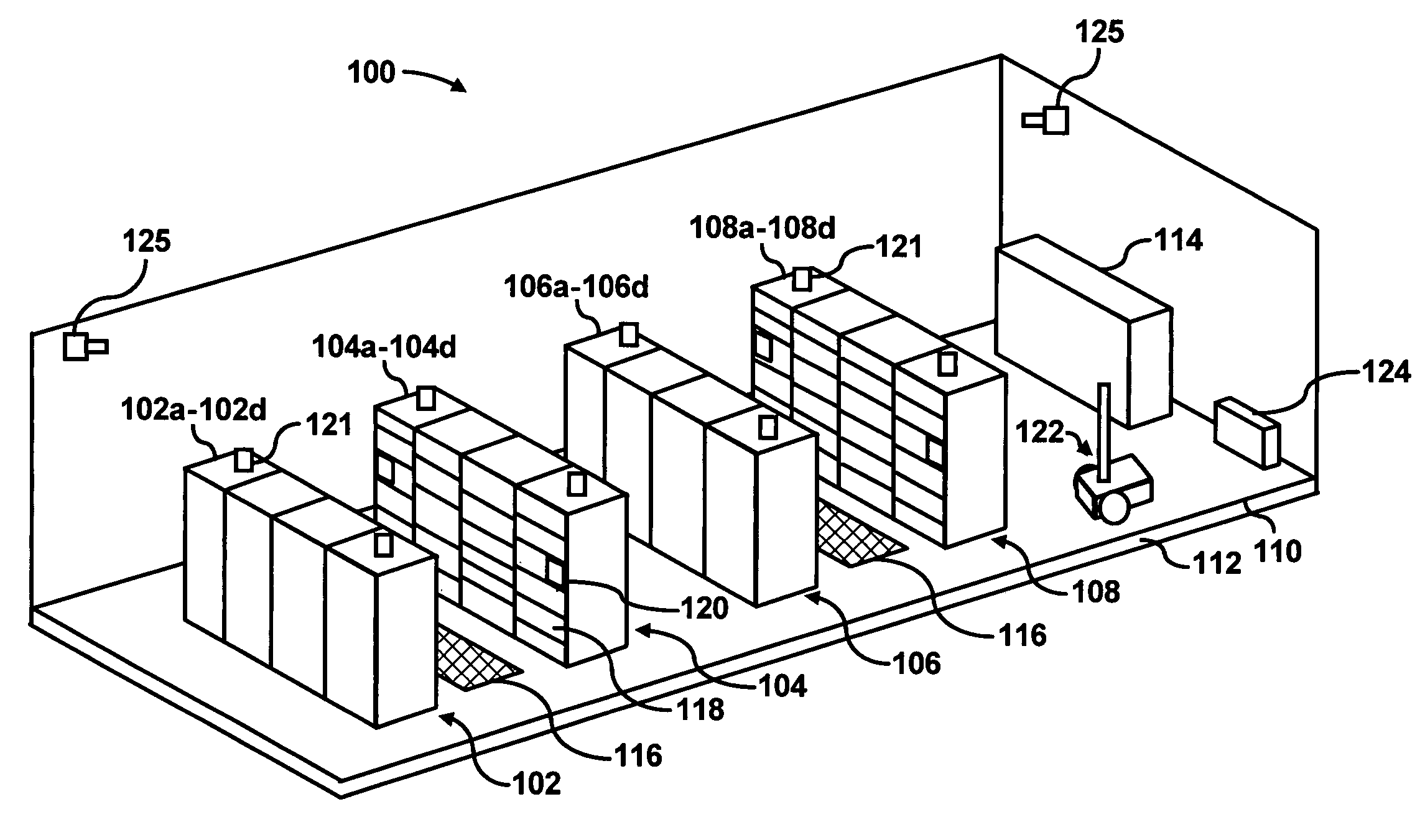

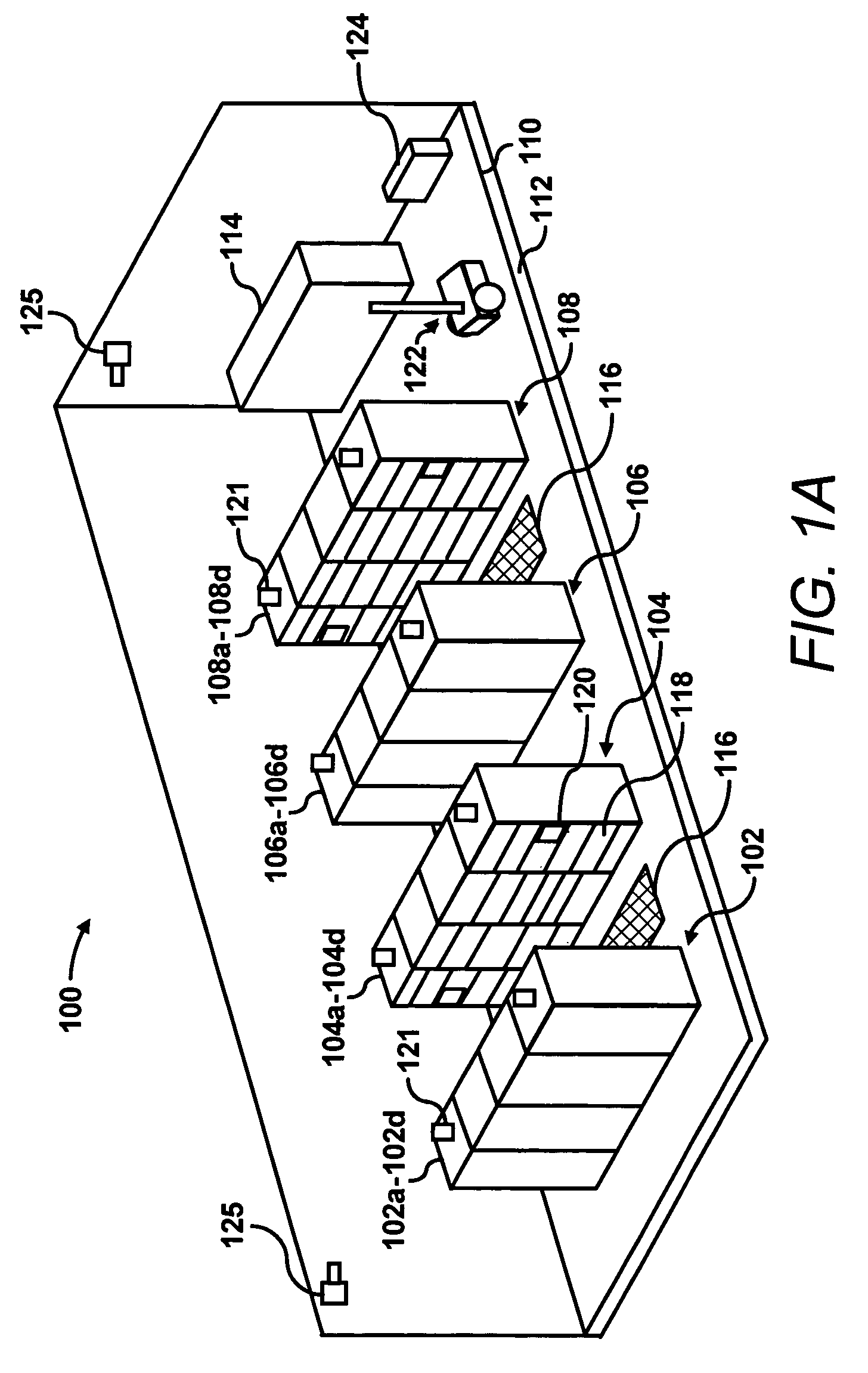

Data collection system having a data collector

ActiveUS7086603B2Temperature control using plurality of sensorsLighting and heating apparatusComputer hardwareData store

A system for collecting data in a room. The system includes a plurality of sensor devices positioned at various locations in the room. The sensor devices include a sensor configured to detect at least one condition and a controller configured to control the sensor. The system also includes at least one data storage device configured to store the detected at least one condition and an interface mechanism for enabling communication of the stored at least one condition. The system further includes a data collector for interfacing with the interface mechanism to receive the stored at least one condition from the at least one data storage device.

Owner:HEWLETT-PACKARD ENTERPRISE DEV LP

Intelligent thermostat system for load monitoring a refrigerant-cycle apparatus

ActiveUS20060196197A1Mechanical apparatusTemperature measurement in air-conditioning systemsDifferential pressureEngineering

A real-time monitoring system that monitors various aspects of the operation of a refrigerant-cycle system is described. In one embodiment, the system includes a processor that measures power provided to the refrigerant-cycle system and that gathers data from one or more sensors and uses the sensor data to calculate a figure of merit related to the efficiency of the system. In one embodiment, the sensors include one or more of the following sensors: a suction line temperature sensor, a suction line pressure sensor, a suction line flow sensor, a hot gas line temperature sensor, a hot gas line pressure sensor, a hot gas line flow sensor, a liquid line temperature sensor, a liquid line pressure sensor, a liquid line flow sensor. In one embodiment, the sensors include one or more of an evaporator air temperature input sensor, an evaporator air temperature output sensor, an evaporator air flow sensor, an evaporator air humidity sensor, and a differential pressure sensor. In one embodiment, the sensors include one or more of a condenser air temperature input sensor, a condenser air temperature output sensor, and a condenser air flow sensor, an evaporator air humidity sensor. In one embodiment, the sensors include one or more of an ambient air sensor and an ambient humidity sensor.

Owner:COPELAND LP

Intelligent thermostat system for monitoring a refrigerant-cycle apparatus

ActiveUS20060032246A1Mechanical apparatusTemperature measurement in air-conditioning systemsDifferential pressureThermostat

A real-time monitoring system that monitors various aspects of the operation of a refrigerant-cycle system is described. In one embodiment, the system includes a processor that measures power provided to the refrigerant-cycle system and that gathers data from one or more sensors and uses the sensor data to calculate a figure of merit related to the efficiency of the system. In one embodiment, the sensors include one or more of the following sensors: a suction line temperature sensor, a suction line pressure sensor, a suction line flow sensor, a hot gas line temperature sensor, a hot gas line pressure sensor, a hot gas line flow sensor, a liquid line temperature sensor, a liquid line pressure sensor, a liquid line flow sensor. In one embodiment, the sensors include one or more of an evaporator air temperature input sensor, an evaporator air temperature output sensor, an evaporator air flow sensor, an evaporator air humidity sensor, and a differential pressure sensor. In one embodiment, the sensors include one or more of a condenser air temperature input sensor, a condenser air temperature output sensor, and a condenser air flow sensor, an evaporator air humidity sensor. In one embodiment, the sensors include one or more of an ambient air sensor and an ambient humidity sensor.

Owner:COPELAND LP

Method and apparatus for monitoring a condenser unit in a refrigerant-cycle system

ActiveUS20060032247A1Mechanical apparatusTemperature measurement in air-conditioning systemsDifferential pressureEngineering

A real-time monitoring system that monitors various aspects of the operation of a refrigerant-cycle system is described. In one embodiment, the system includes a processor that measures power provided to the refrigerant-cycle system and that gathers data from one or more sensors and uses the sensor data to calculate a figure of merit related to the efficiency of the system. In one embodiment, the sensors include one or more of the following sensors: a suction line temperature sensor, a suction line pressure sensor, a suction line flow sensor, a hot gas line temperature sensor, a hot gas line pressure sensor, a hot gas line flow sensor, a liquid line temperature sensor, a liquid line pressure sensor, a liquid line flow sensor. In one embodiment, the sensors include one or more of an evaporator air temperature input sensor, an evaporator air temperature output sensor, an evaporator air flow sensor, an evaporator air humidity sensor, and a differential pressure sensor. In one embodiment, the sensors include one or more of a condenser air temperature input sensor, a condenser air temperature output sensor, and a condenser air flow sensor, an evaporator air humidity sensor. In one embodiment, the sensors include one or more of an ambient air sensor and an ambient humidity sensor.

Owner:COPELAND LP

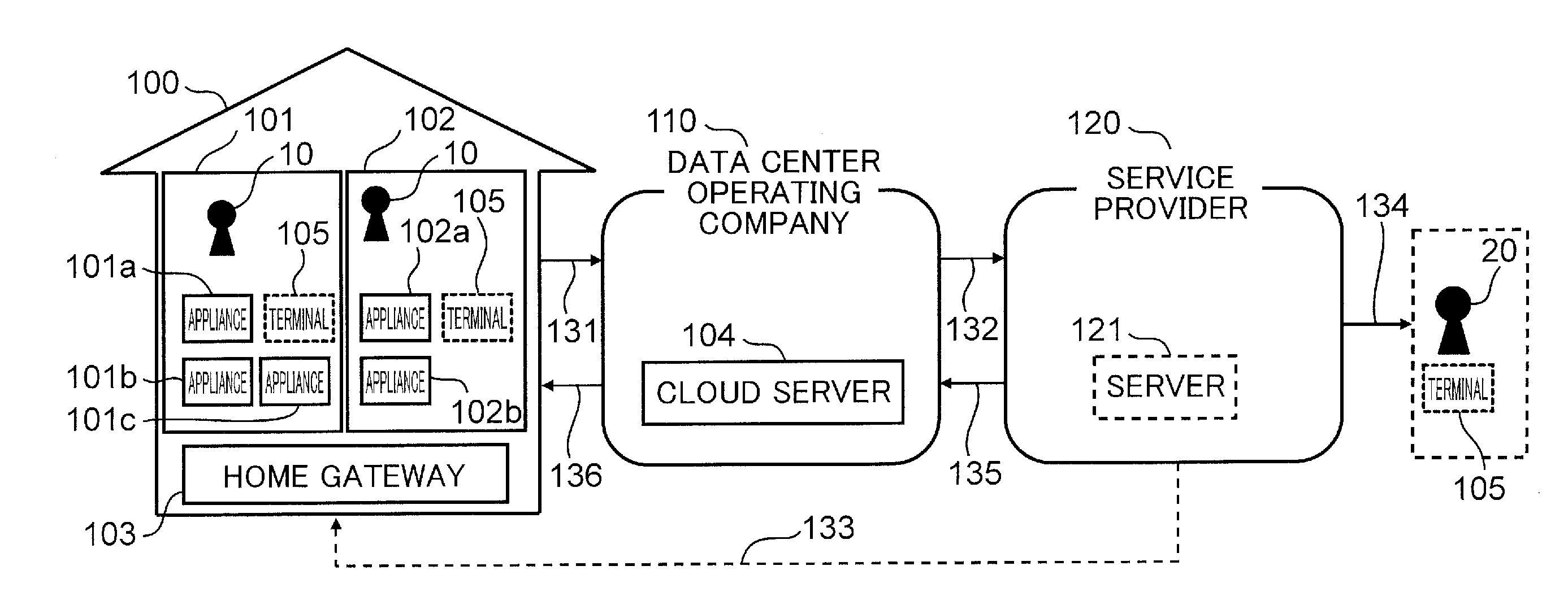

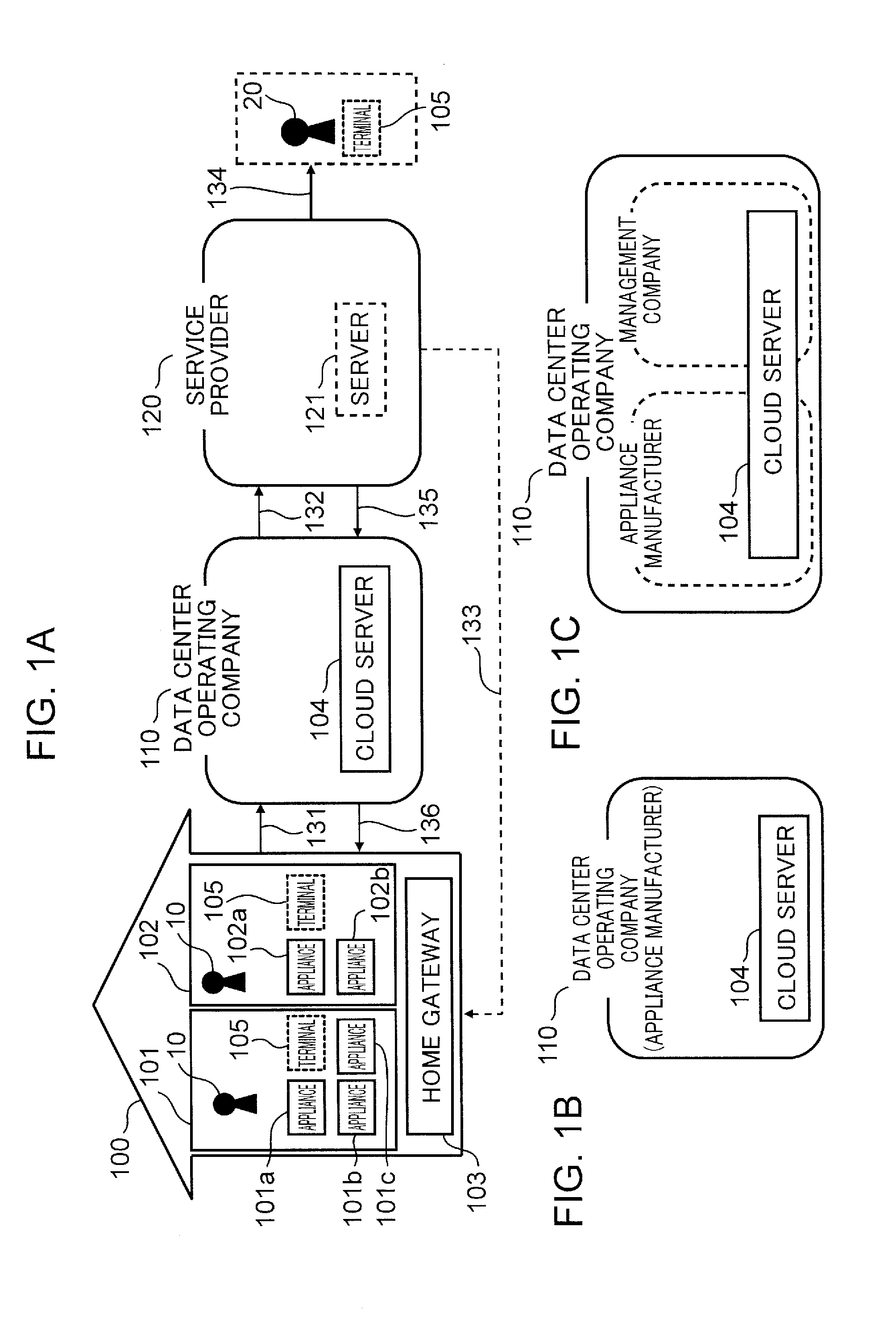

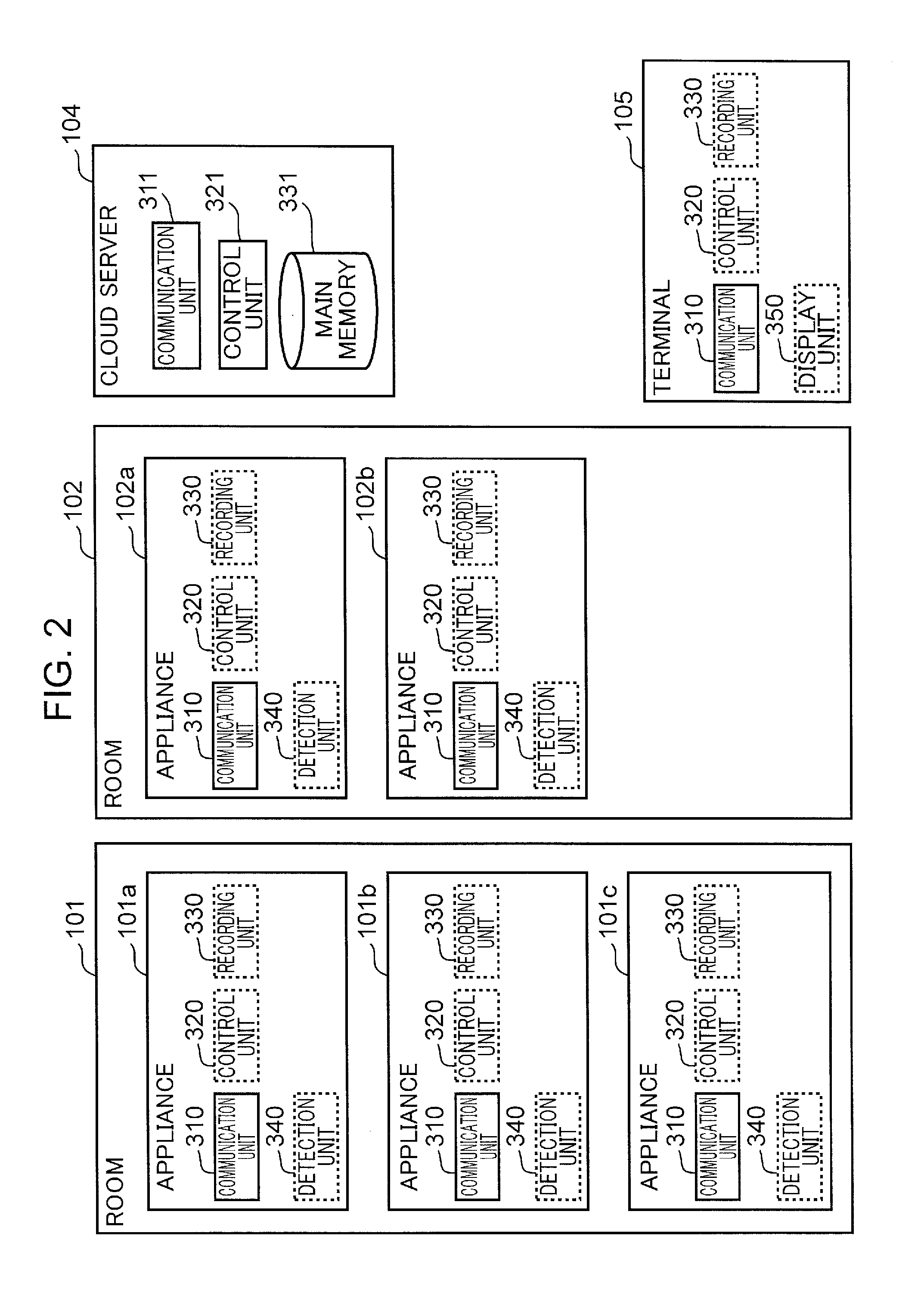

Information providing method and information providing apparatus

ActiveUS20140365018A1Improve user friendlinessSampled-variable control systemsTemperature control using digital meansOperating systemCloud server

A cloud server (104) receives environmental information of respective installation sites of a plurality of appliances (101a, 101b, 101c, 102a, 102b) via a network (1000), and determines one or more appliances that are installed in a same room among the plurality of appliances (101a, 101b, 101c, 102a, 102b), based on the received environmental information.

Owner:PANASONIC INTELLECTUAL PROPERTY CORP OF AMERICA

Method and apparatus for airflow monitoring refrigerant-cycle systems

InactiveUS20060196196A1Mechanical apparatusTemperature measurement in air-conditioning systemsDifferential pressureEngineering

A real-time monitoring system that monitors various aspects of the operation of a refrigerant-cycle system is described. In one embodiment, the system includes a processor that measures power provided to the refrigerant-cycle system and that gathers data from one or more sensors and uses the sensor data to calculate a figure of merit related to the efficiency of the system. In one embodiment, the sensors include one or more of the following sensors: a suction line temperature sensor, a suction line pressure sensor, a suction line flow sensor, a hot gas line temperature sensor, a hot gas line pressure sensor, a hot gas line flow sensor, a liquid line temperature sensor, a liquid line pressure sensor, a liquid line flow sensor. In one embodiment, the sensors include one or more of an evaporator air temperature input sensor, an evaporator air temperature output sensor, an evaporator air flow sensor, an evaporator air humidity sensor, and a differential pressure sensor. In one embodiment, the sensors include one or more of a condenser air temperature input sensor, a condenser air temperature output sensor, and a condenser air flow sensor, an evaporator air humidity sensor. In one embodiment, the sensors include one or more of an ambient air sensor and an ambient humidity sensor.

Owner:KATES LAWRENCE

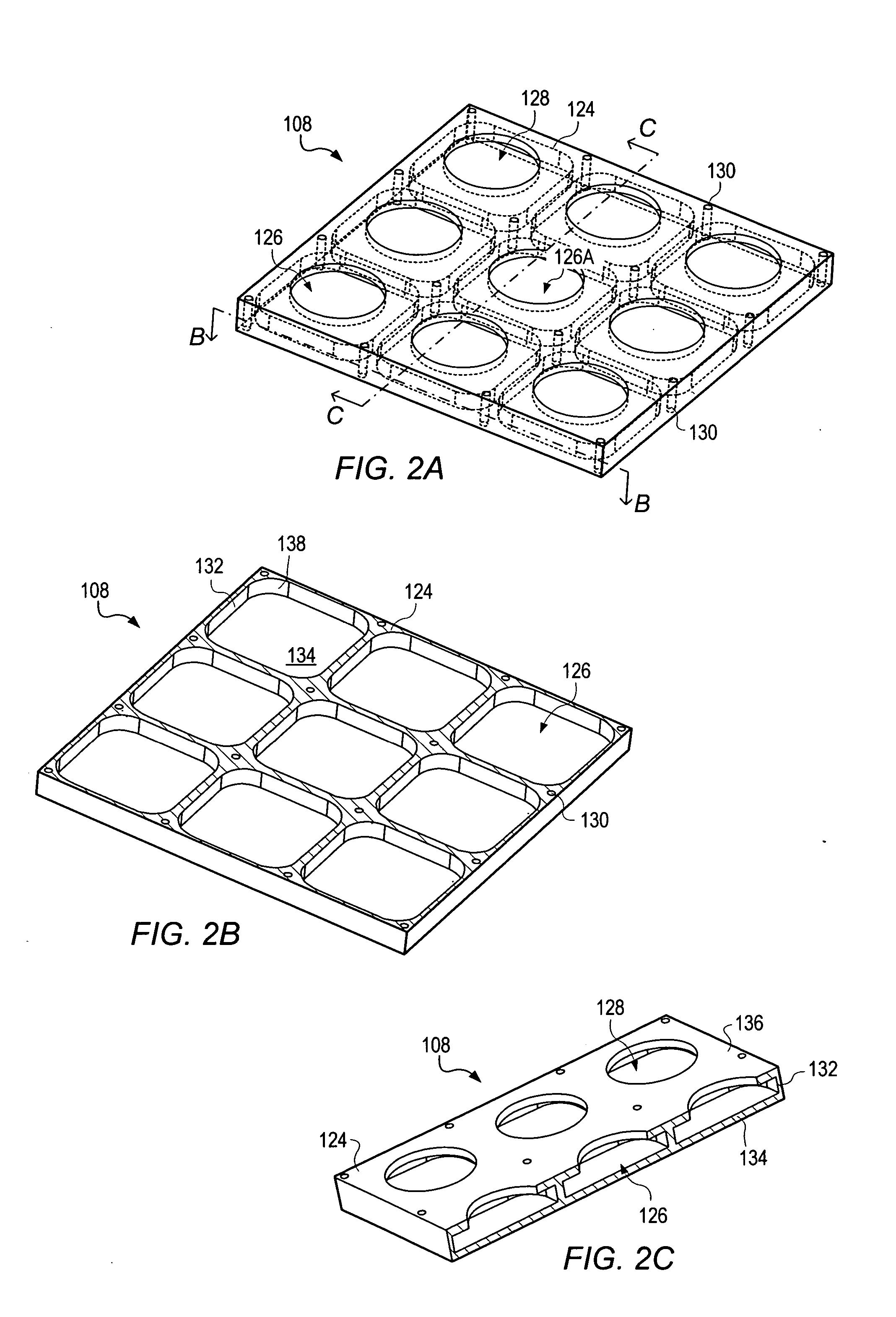

Multichannel cooling system with magnetohydrodynamic pump

ActiveUS20070235180A1Temperature control using plurality of sensorsSemiconductor/solid-state device detailsMagneto hydrodynamicEngineering

A cooling device includes a base having cells. A pipe is coupled to the base for each of the cells. The pipes include passages that carry fluid toward the cell and away from the cell. A magnetohydrodynamic pump system coupled to the pipe circulates an electrically conductive cooling fluid within the passages and the cell. An orifice may emits jets of fluid into the cells. A controller coupled to the cooling device may independently control flow rates in two or more cells of the cooling device. The controller may receive information from the temperature sensors on the base of the cooling device for use in controlling the flow rates in the cells.

Owner:ORACLE INT CORP

Water flow detection system for a bathing unit

The present invention provides a control system for a bathing unit that comprises a heating module, a thermal element and a heating module controller. The heating module includes a body that defines a passage through which water can flow, that has an inner surface and an outer surface. The heating module further includes a heating device that is operative for heating the water that flows through the body. The thermal element is mounted to the outer surface of the body such that the thermal element is in thermally conductive communication with water flowing through the body. The heating module controller is operative for obtaining temperature information associated with the thermal element for detecting at least in part on the basis of the temperature information the sufficiency of water flow through the body.

Owner:GECKO ALLIANCE GROUP

Smart thermostat robust against adverse effects from internal heat-generating components

ActiveUS20170059190A1Error minimizationMinimize changesThermometer detailsMechanical apparatusThermostatEngineering

A thermostat may include a plurality of heat-generating components; a plurality of first temperature sensors, each of the plurality of first temperature sensors being disposed next to a corresponding one of the plurality of heat-generating components; a second temperature sensor that is disposed away from the plurality of heat-generating components; and a memory device storing a coefficient matrix. The thermostat may also include one or more processors that combine a plurality of inputs to calculate an ambient temperature for an enclosure in which the thermostat is installed, the plurality of inputs including readings from the plurality of first temperature sensors, readings from the second temperature sensor, and the coefficient matrix.

Owner:GOOGLE LLC

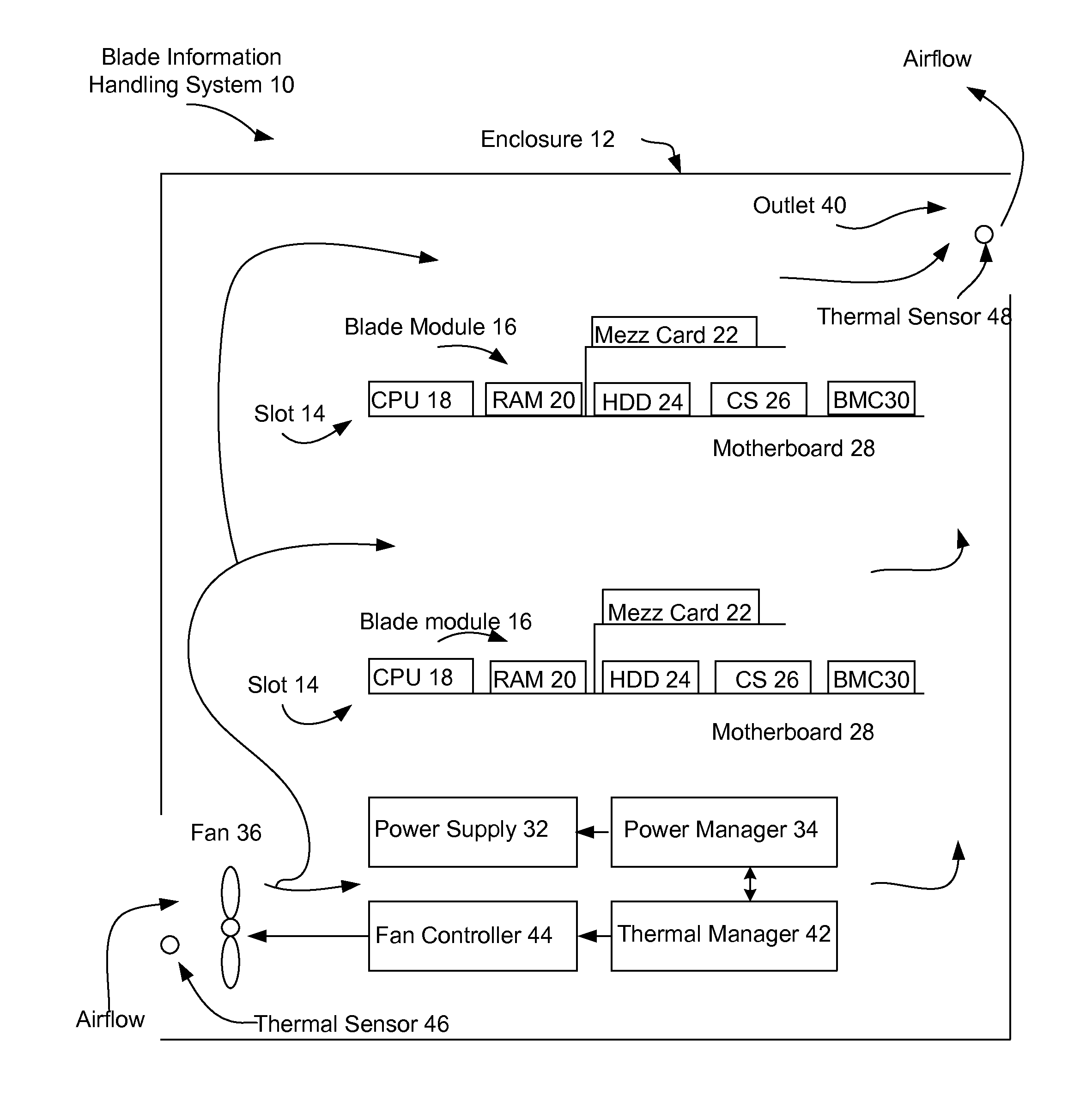

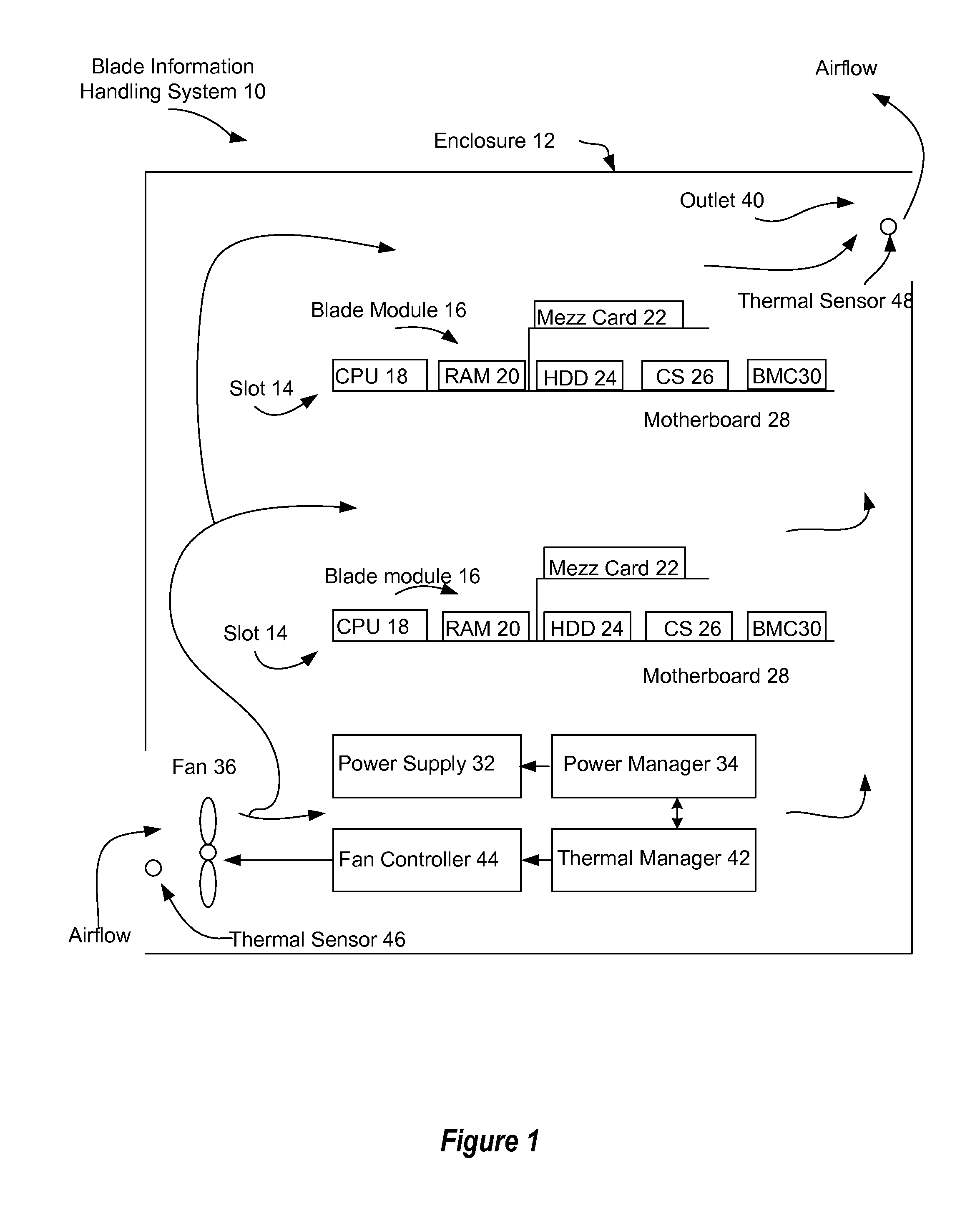

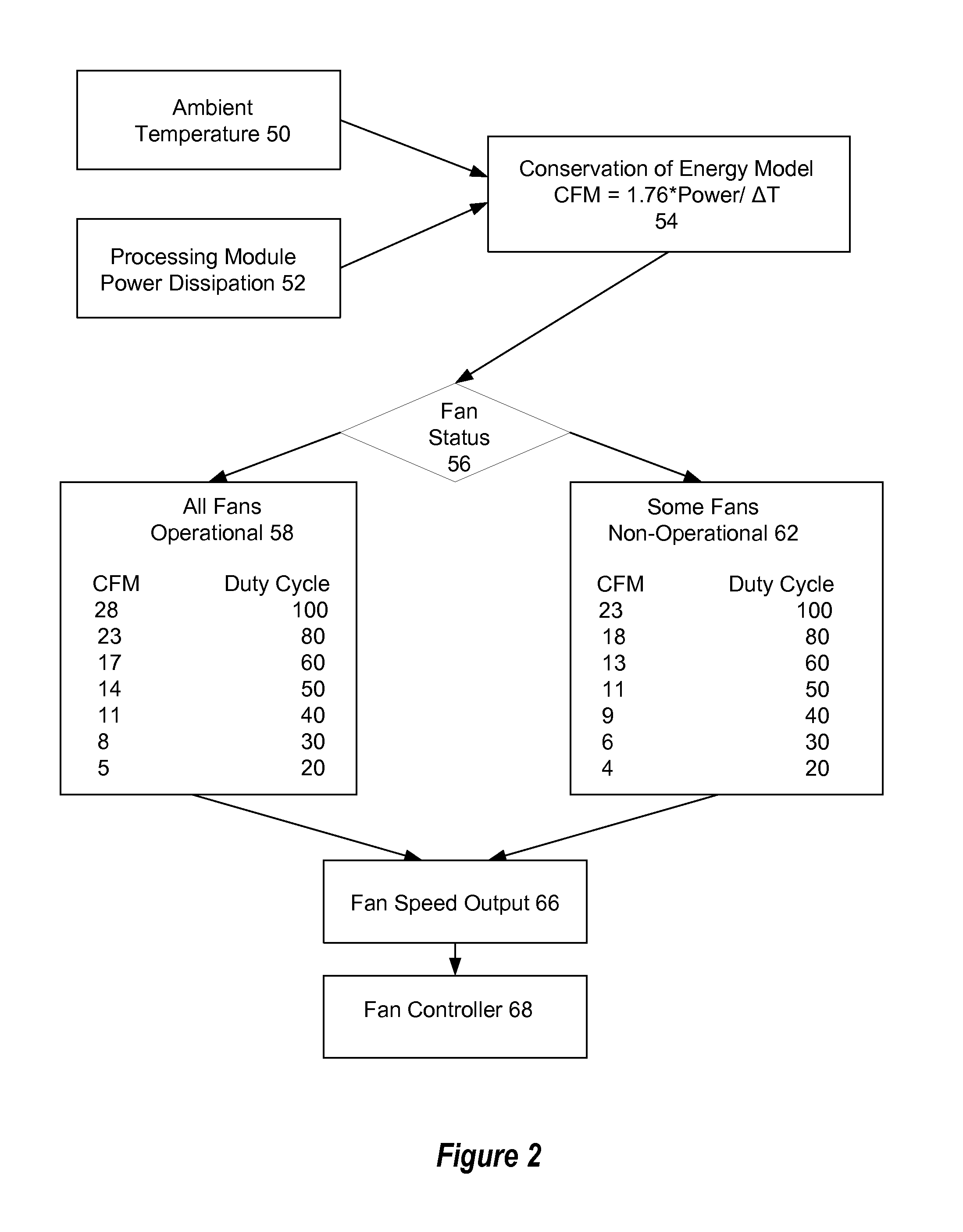

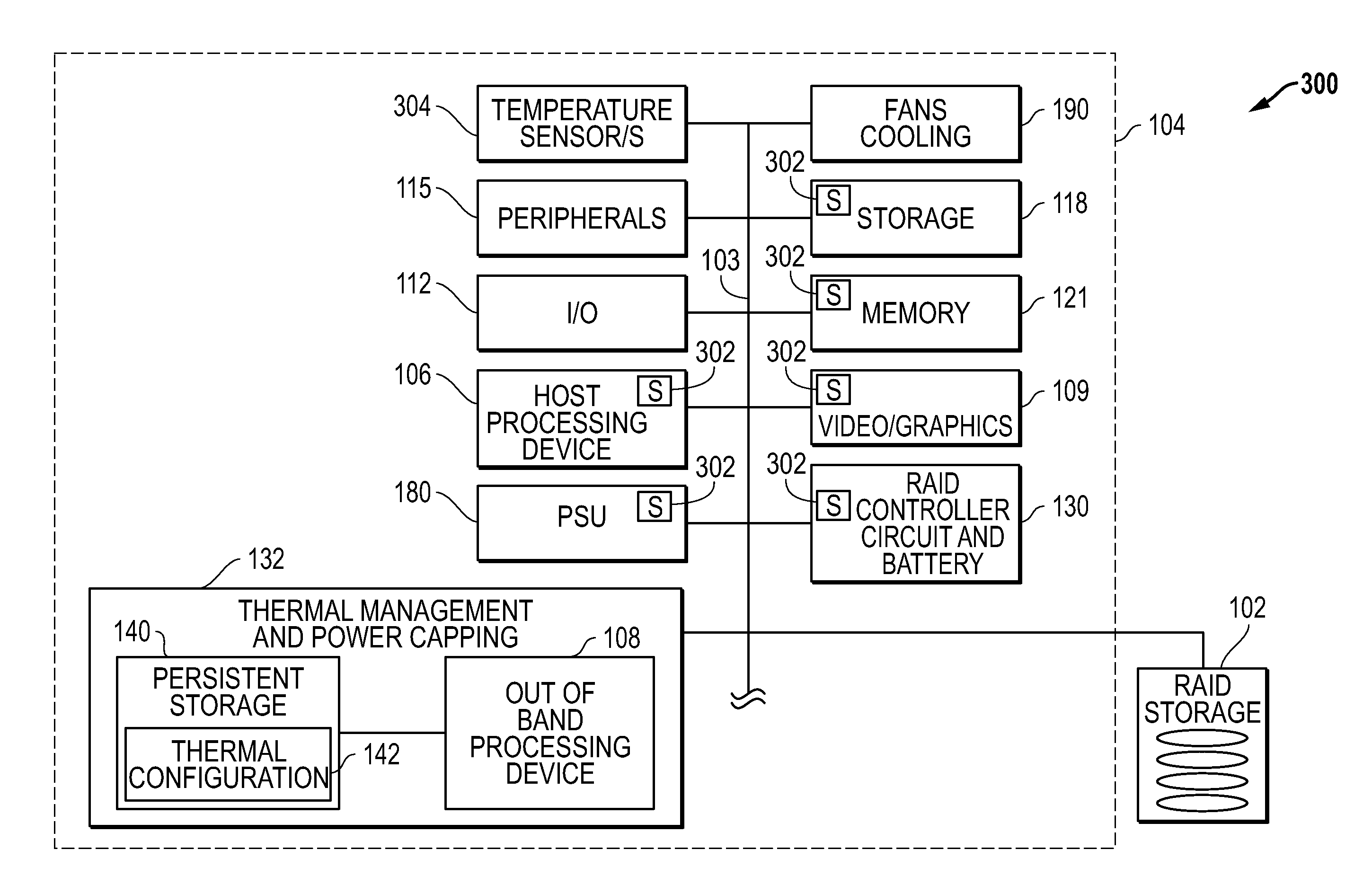

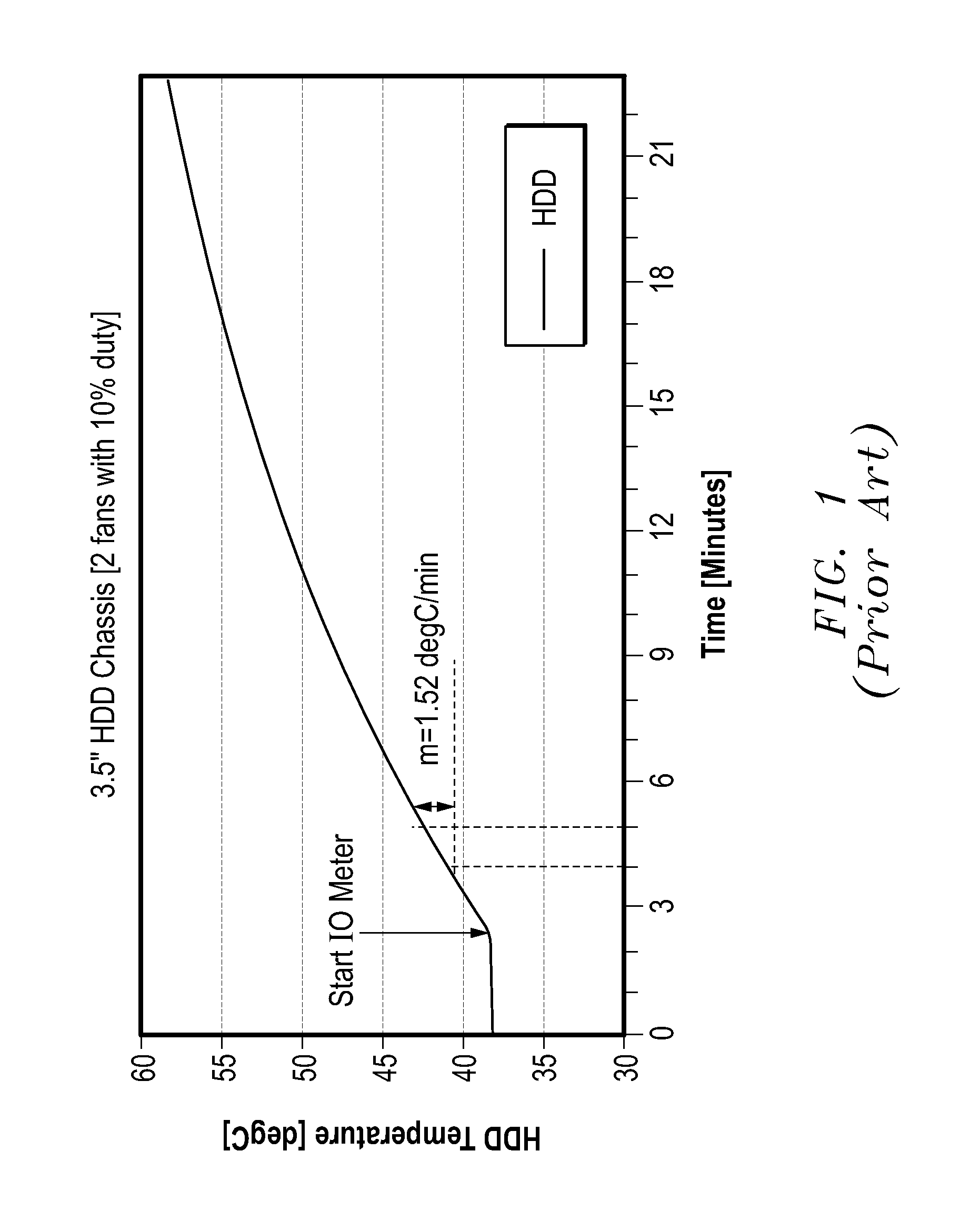

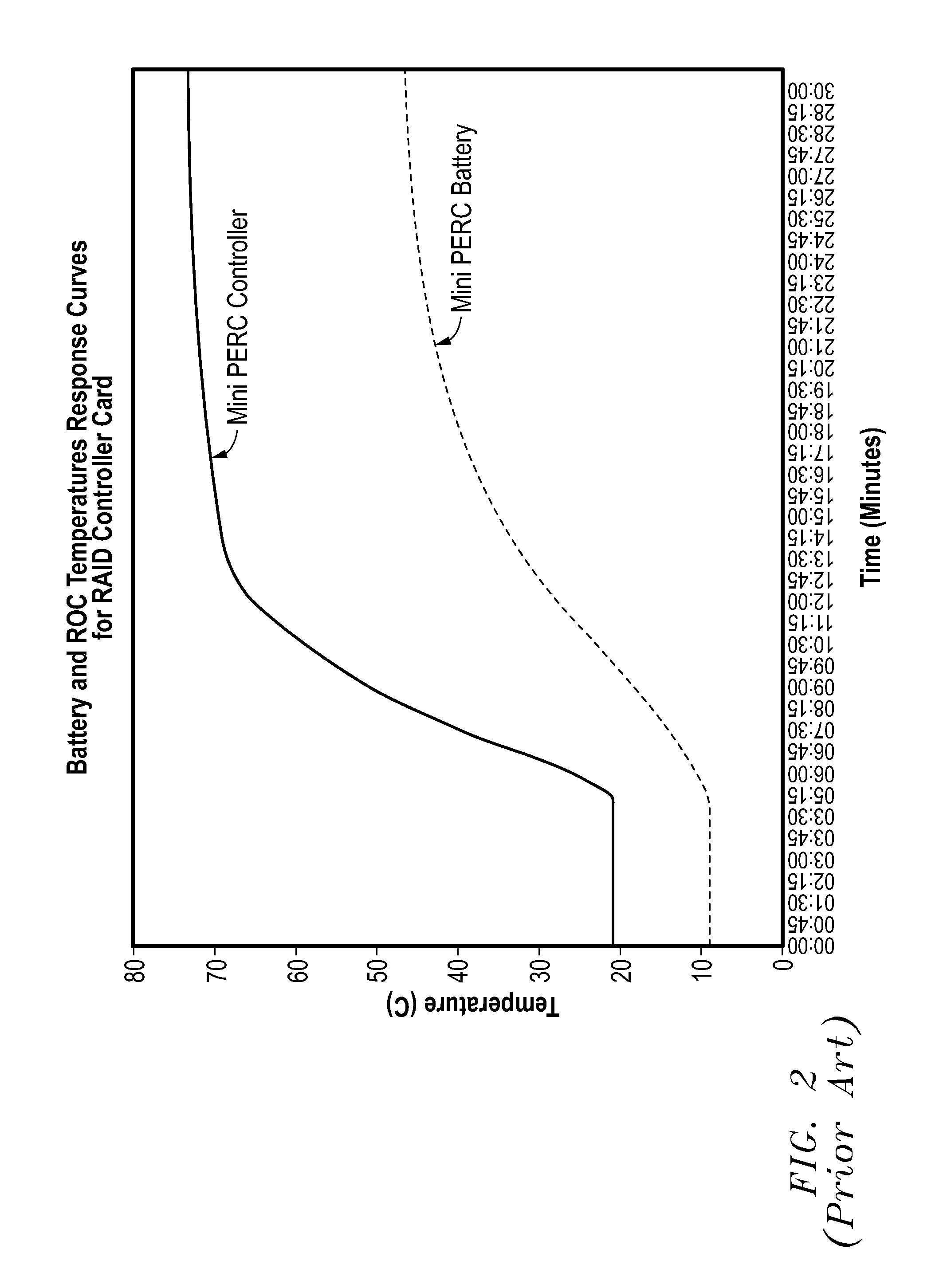

Information Handling System Thermal Control By Energy Conservation

ActiveUS20130258582A1Reduce disadvantagesReduce problemsEnergy efficient ICTTemperature control using plurality of sensorsThermal energyThermal state

A thermal state within an information handling system enclosure is managed within predetermined constraints by estimating thermal energy introduced to the enclosure by power dissipation to electronic components and thermal energy removed from the enclosure by a cooling airflow generated by a fan. A desired bulk temperature of a cooling airflow is attained at a predetermined position in an enclosure by selecting a fan speed and power allocation to the components that conserves energy within the enclosure at a predetermined thermal state.

Owner:DELL PROD LP

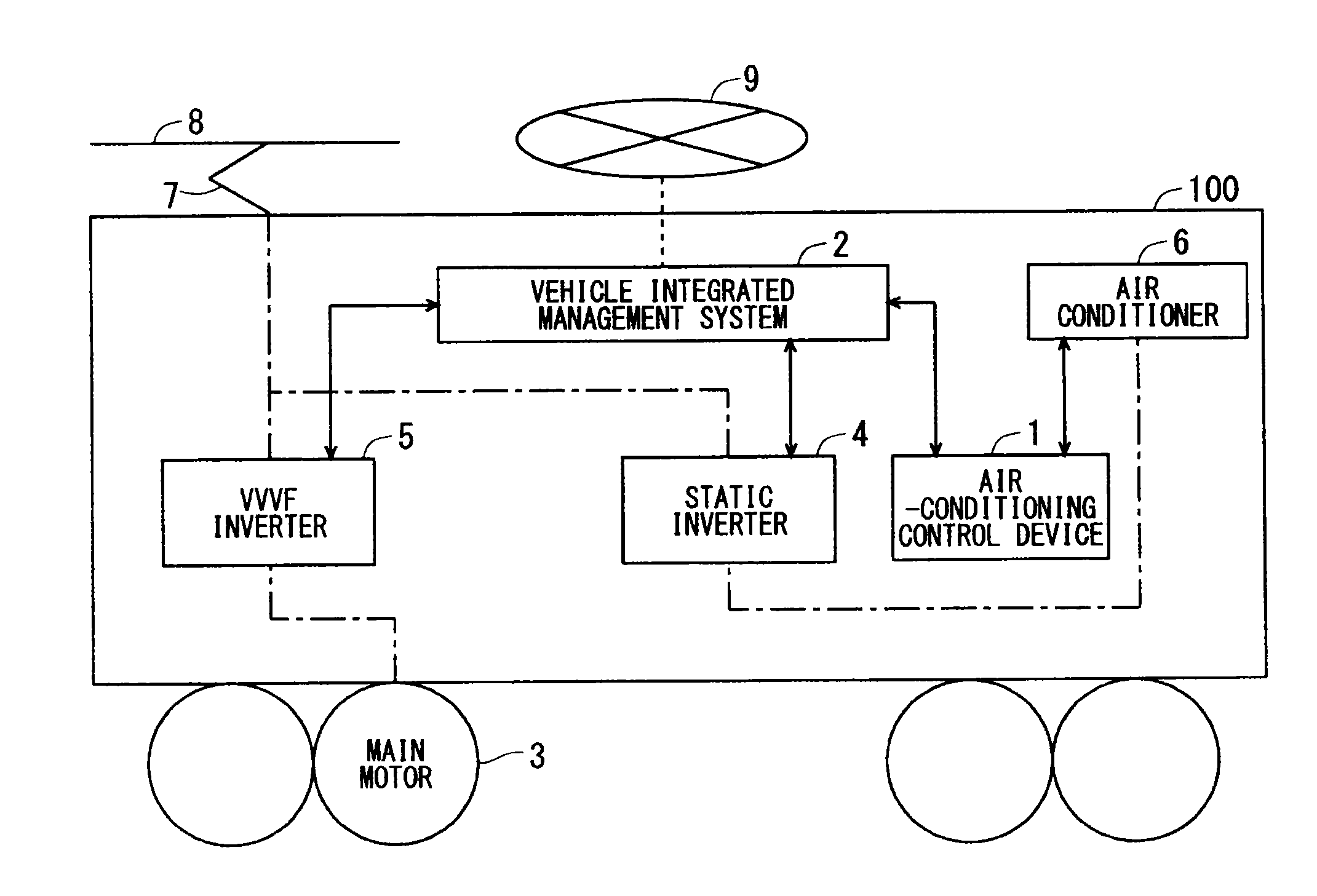

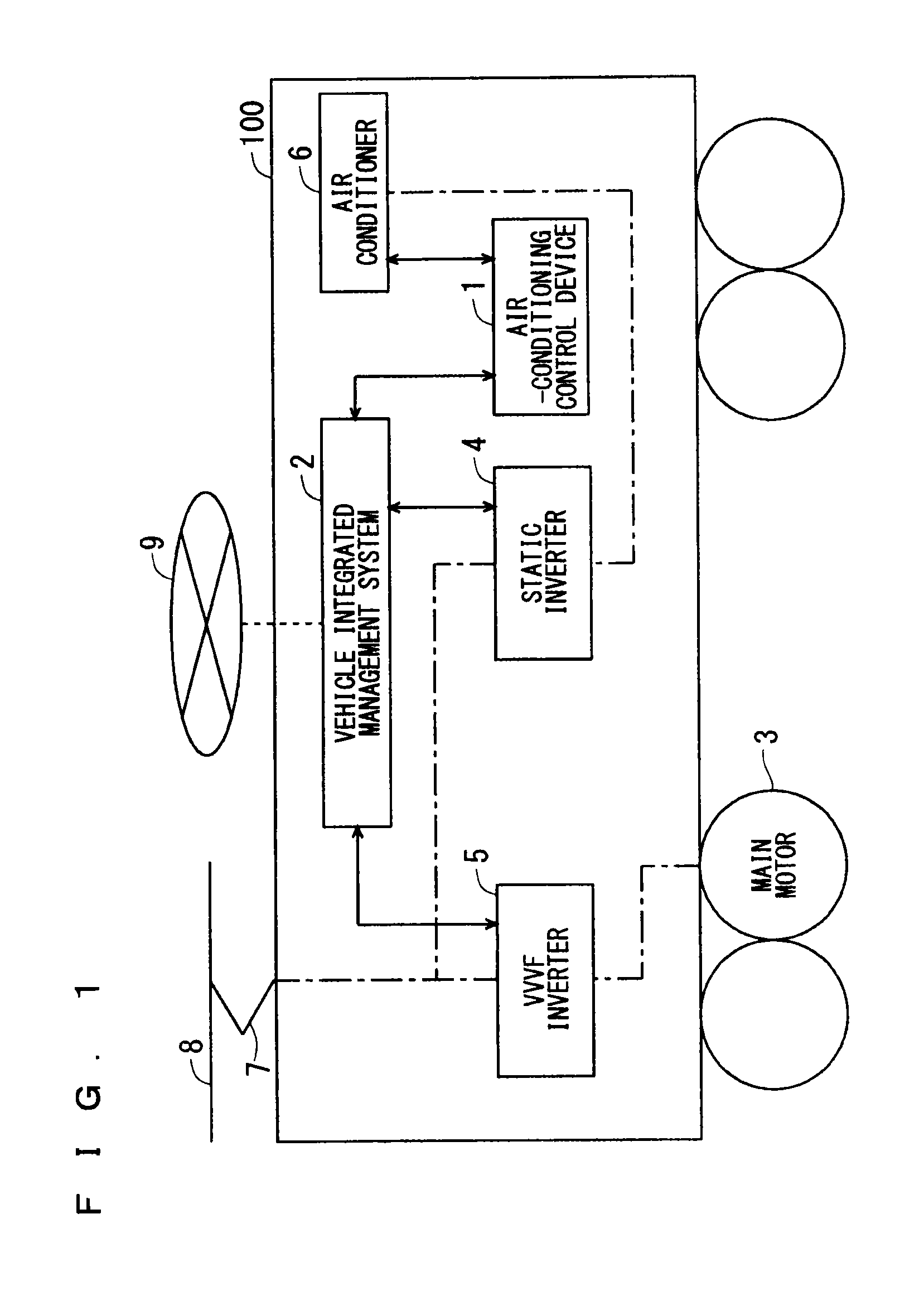

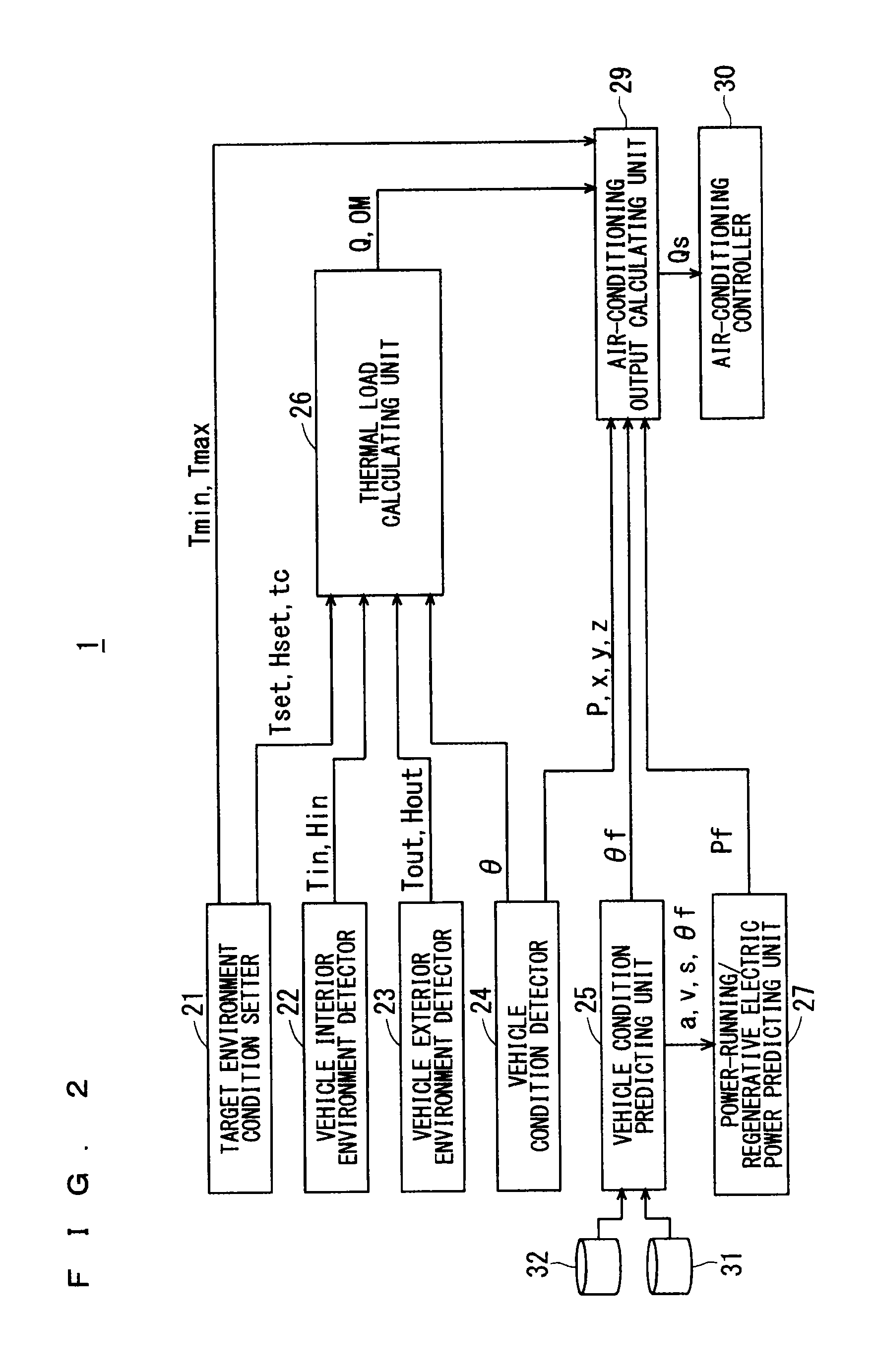

Vehicle air conditioning control device

ActiveUS20150306937A1Addressing Insufficient ControlVehicle interior comfortAir-treating devicesTemperature control using digital meansLower limitEngineering

A vehicle air conditioning control device calculates, through a thermal load calculating unit, a vehicle interior thermal load Q on the basis of, for example, a vehicle interior temperature Tin, a vehicle interior humidity Hin, a vehicle exterior temperature Tout, a passenger load factor θ, and a vehicle-interior-temperature set value Tset. Through an air conditioning output calculating unit, the vehicle air conditioning control device calculates an output command value for an air conditioner on the basis of a vehicle-interior-temperature upper-limit value Tmax, a vehicle-interior-temperature lower-limit value Tmin, the thermal load Q, power-running / regenerative electric power P, and then, corrects the calculated output command value for the air conditioner on the basis of power-running / regenerative electric power Pf at or after a prediction time point and of a passenger load factor Of at or after the prediction time point.

Owner:MITSUBISHI ELECTRIC CORP

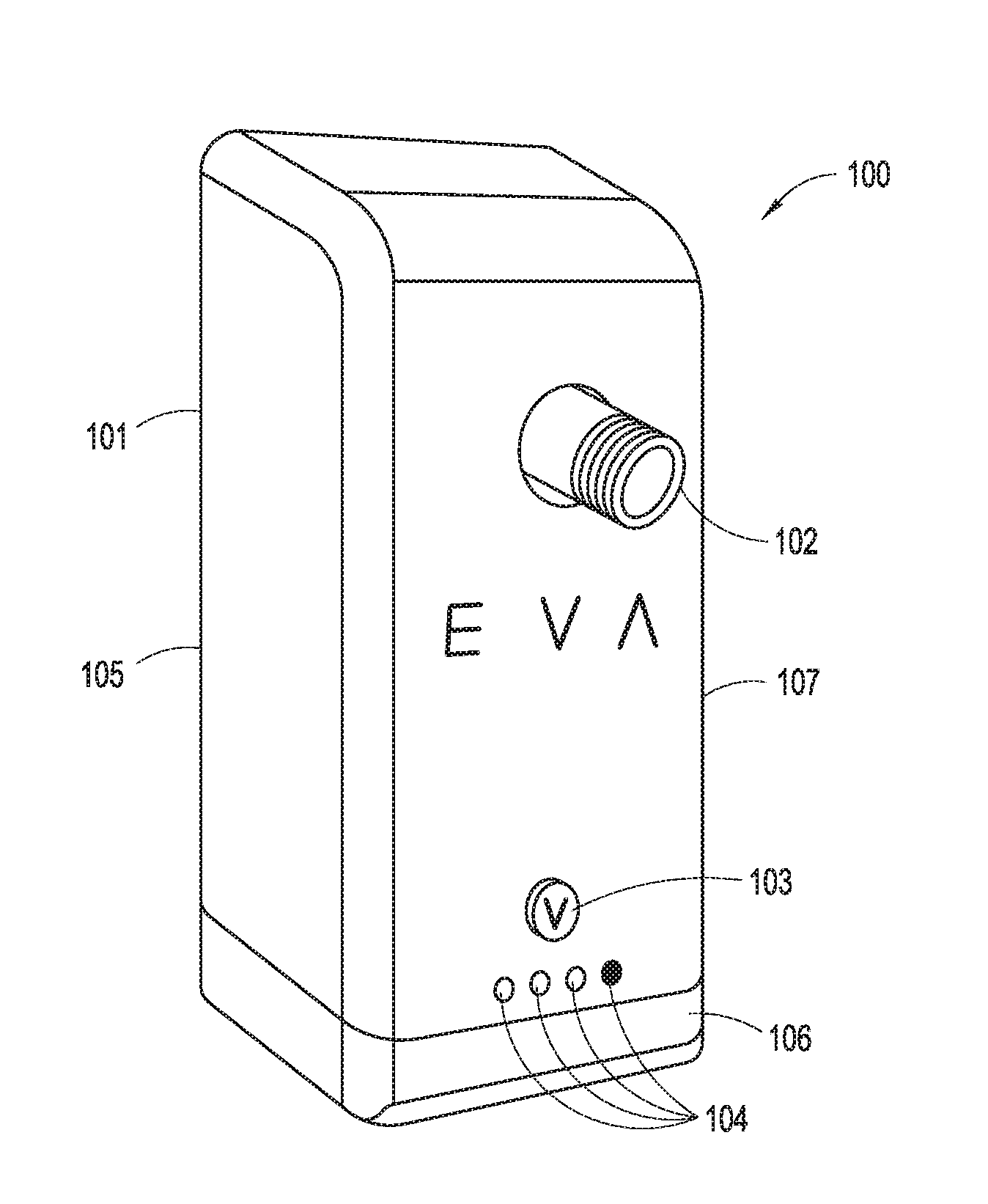

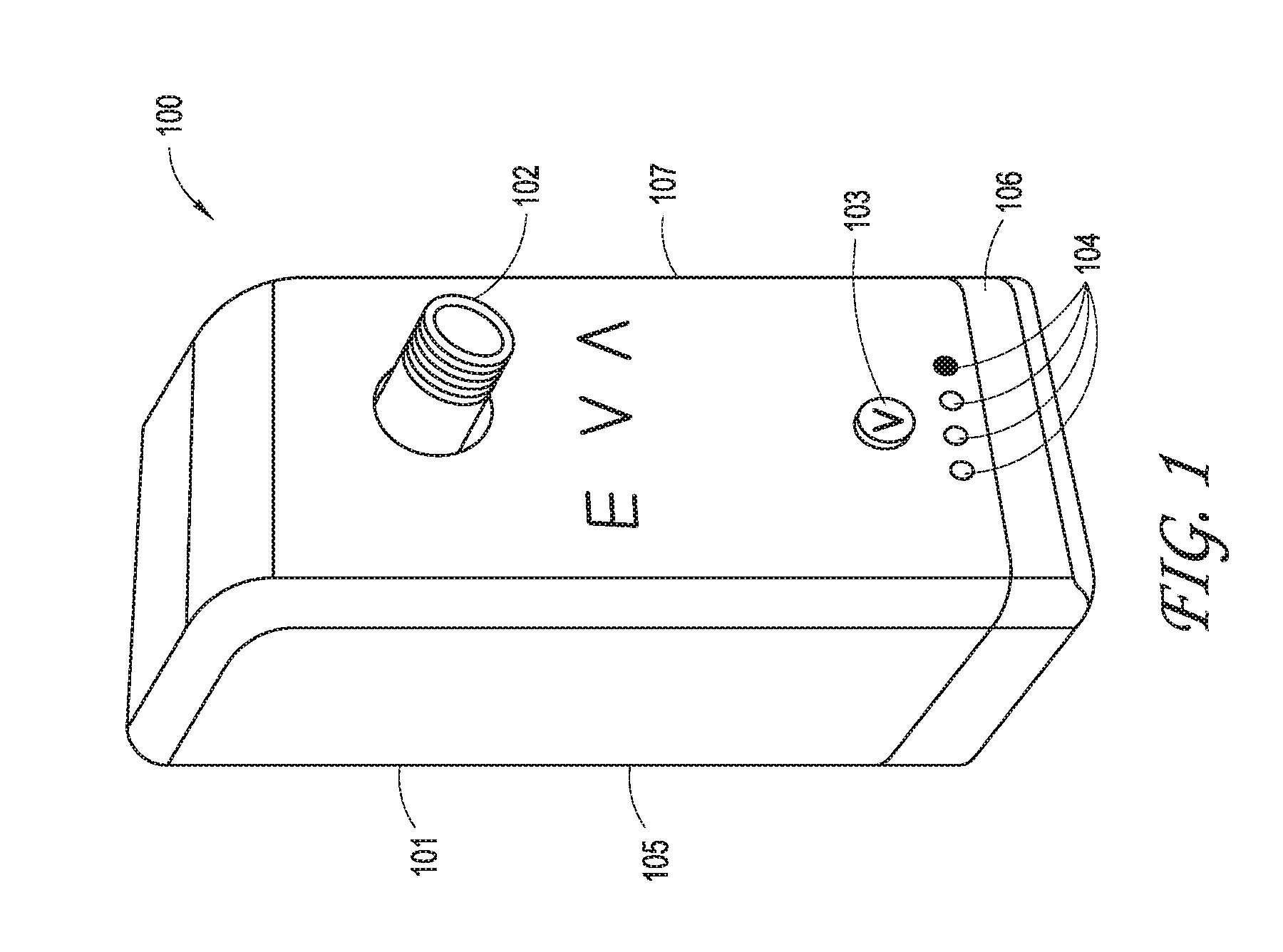

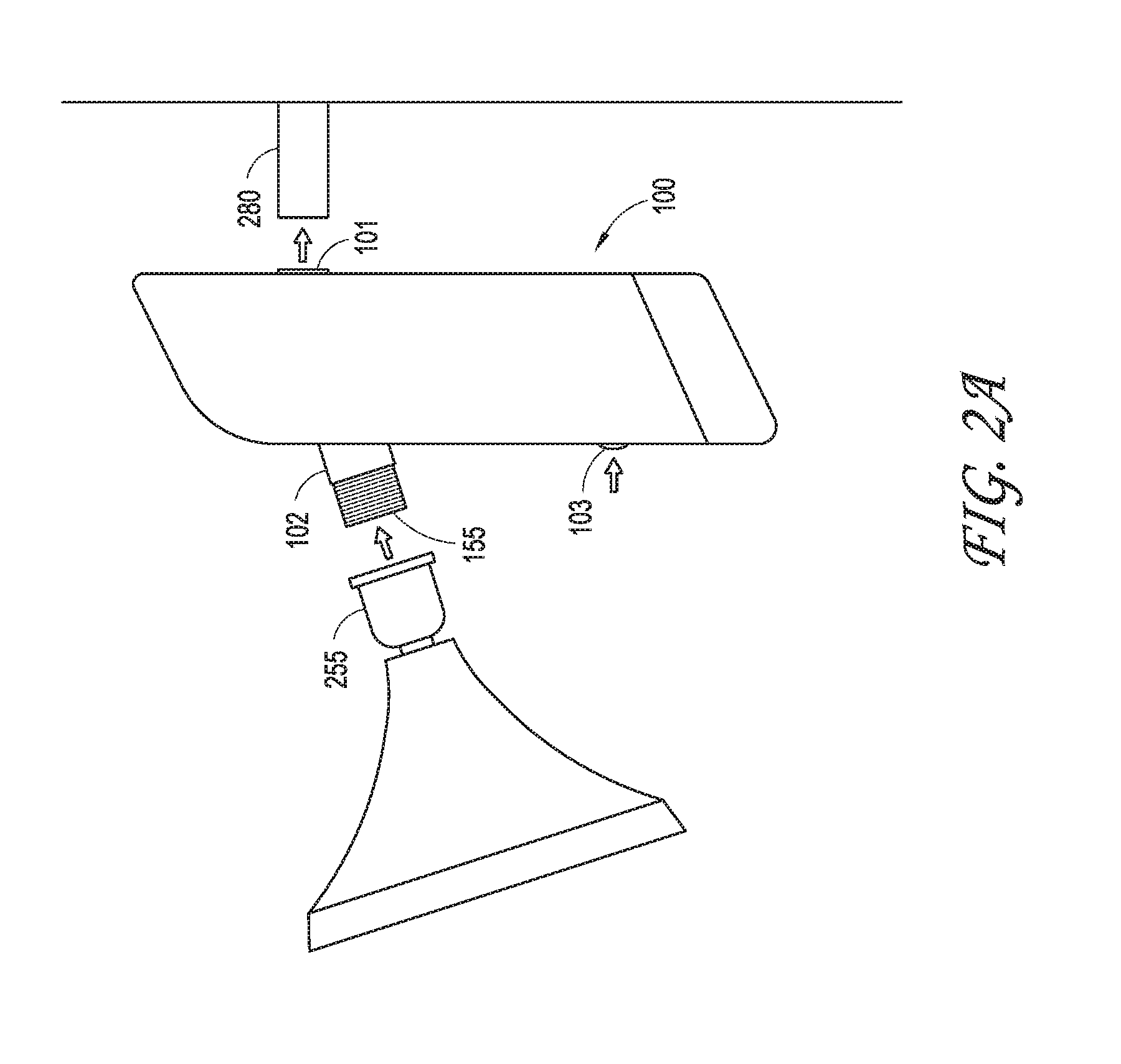

Systems and methods for controlling water flow

ActiveUS20160258144A1Temperature control using plurality of sensorsComputer controlProximity sensorSmart water

Smart water conservation systems are described herein, as are methods of using the same. In some embodiments, the systems can comprise a flow assembly configured to discharge fluid received from a fluid source to a shower area at a variable flow rate, the flow assembly comprising a flow path and one or more valves positioned along the flow path. In some embodiments, the systems can comprise a proximity sensor system comprising one or more proximity sensors, the proximity sensor system being configured to detect a person's proximity to the smart water conservation system. In some embodiments, the systems can comprise a controller configured to control operation of the smart water conservation system based at least in part on signals received from the proximity sensor system. In some embodiments, the controller can be configured to adjust the one or more valves in response to signals received from the proximity sensor system to vary the flowrate at which fluid is discharged from an output of the smart water conservation system.

Owner:EVA SMART SHOWER LLC

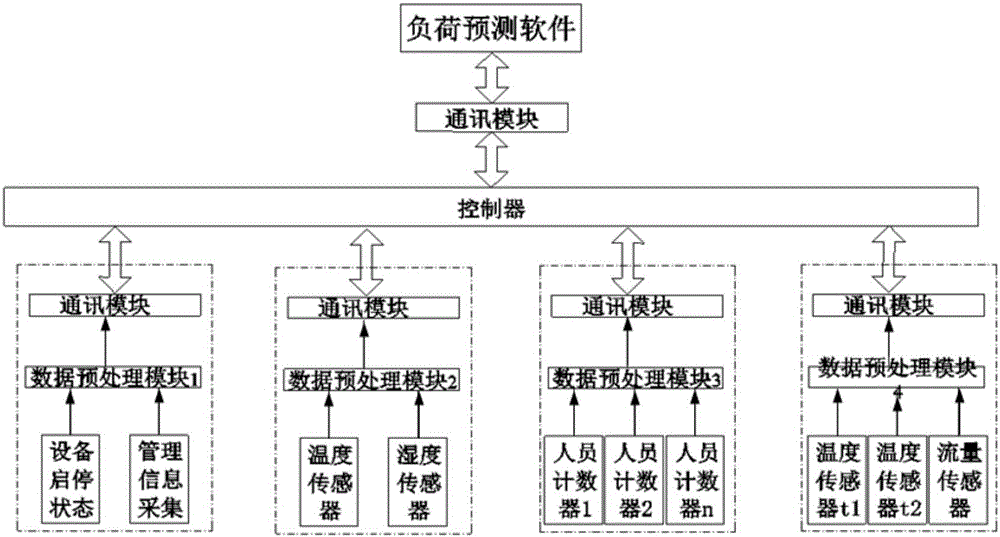

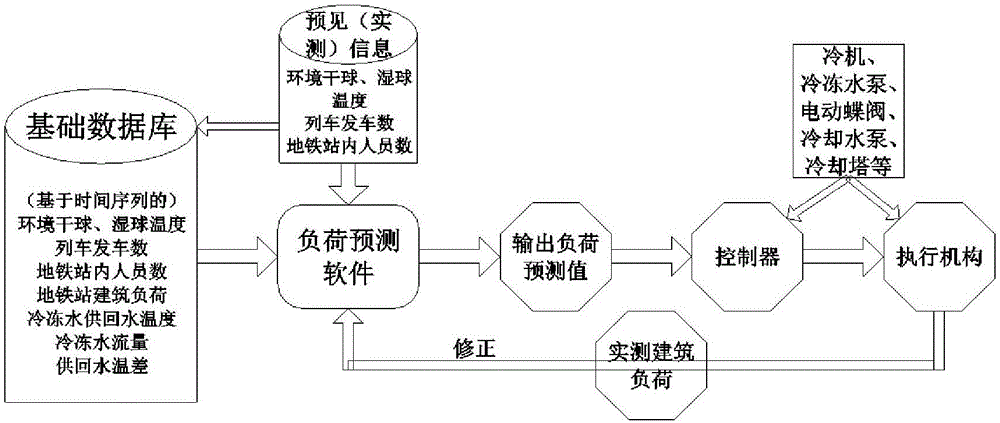

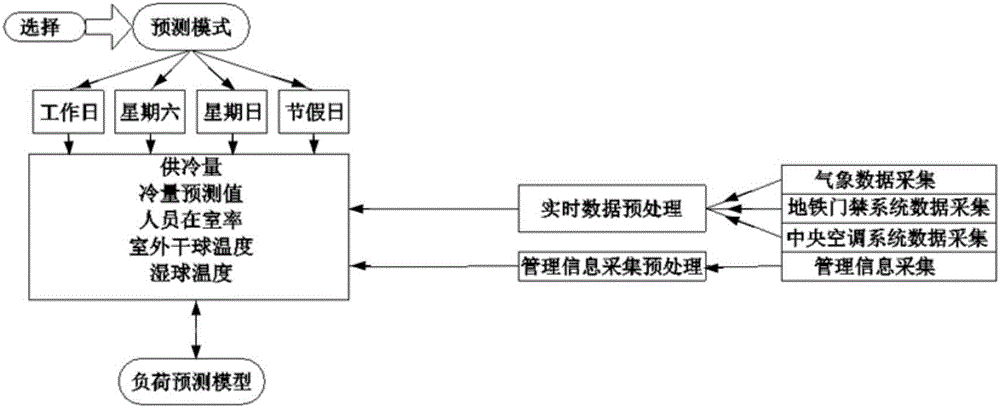

Load forecast and control system and method for metro heat ventilation and air-conditioning system

ActiveCN106338127AImprove global control effectGood energy saving effectProgramme controlMechanical apparatusLoad forecastingControl system

The invention relates to a load forecast and control system and method for a metro heat ventilation and air-conditioning system. In one respect, the load forecast and control system for the metro ventilation and air-conditioning system is provided. The system comprises a basic database, a sensing system, a load forecast part and a controller. The basic database stores historical data. The sensing system provides measured data. The load forecast part works out the forecast load value of the metro heat ventilation and air-conditioning system based on the historical data and the measured data and transmits the forecast load value to the controller. The controller gives out a control command to control operation of the metro heat ventilation and air-conditioning system based on the forecast load value. The historical data and the measured data comprise strong time-variable data. According to the load forecast and control system, the problems that according to traditional load forecast, the precision is poor, and control over the air-conditioning system is not ideal enough are solved; and the load forecast and control system and method have the advantages that initial investment is reduced, operation is reliable, the energy saving effect of the heat ventilation and air-conditioning system is improved, stored data of the database are reduced, a load forecast model is simple, and the practicability is high.

Owner:GREE ELECTRIC APPLIANCE INC OF ZHUHAI

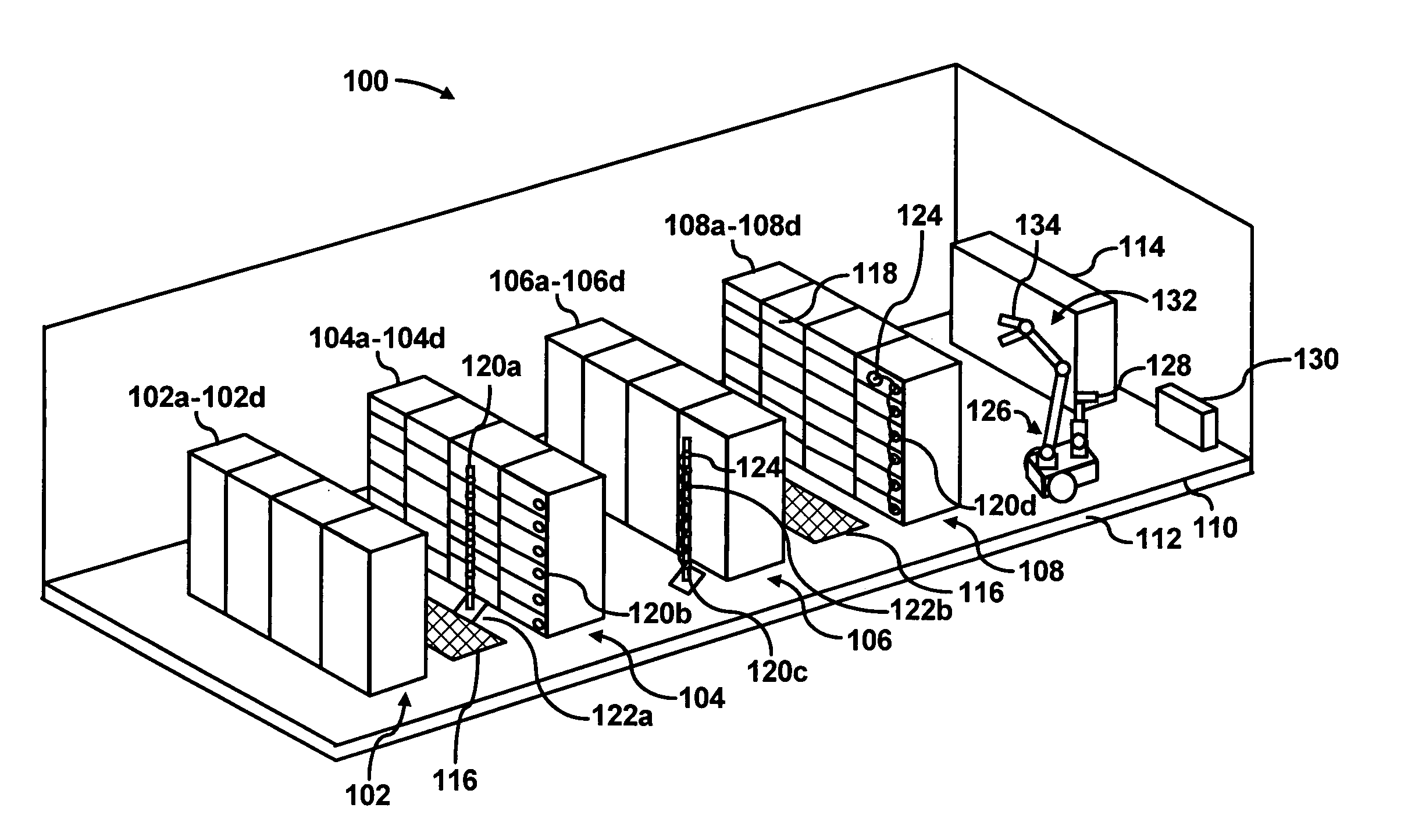

Data collection system having a data collector

ActiveUS20050173549A1Temperature control using plurality of sensorsPosition/course control in two dimensionsComputer scienceData store

A system for collecting data in a room. The system includes a plurality of sensor devices positioned at various locations in the room. The sensor devices include a sensor configured to detect at least one condition and a controller configured to control the sensor. The system also includes at least one data storage device configured to store the detected at least one condition and an interface mechanism for enabling communication of the stored at least one condition. The system further includes a data collector for interfacing with the interface mechanism to receive the stored at least one condition from the at least one data storage device.

Owner:HEWLETT-PACKARD ENTERPRISE DEV LP

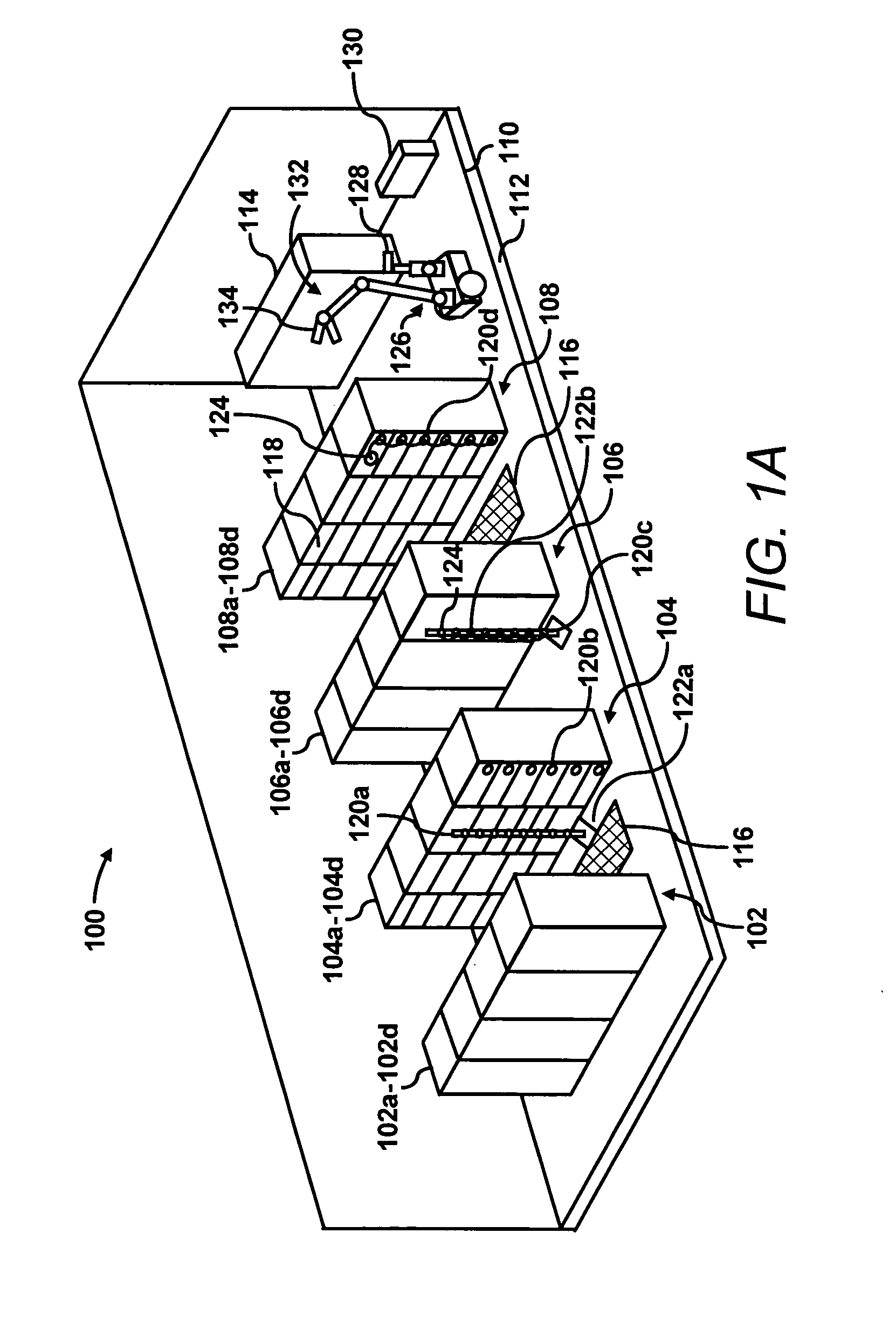

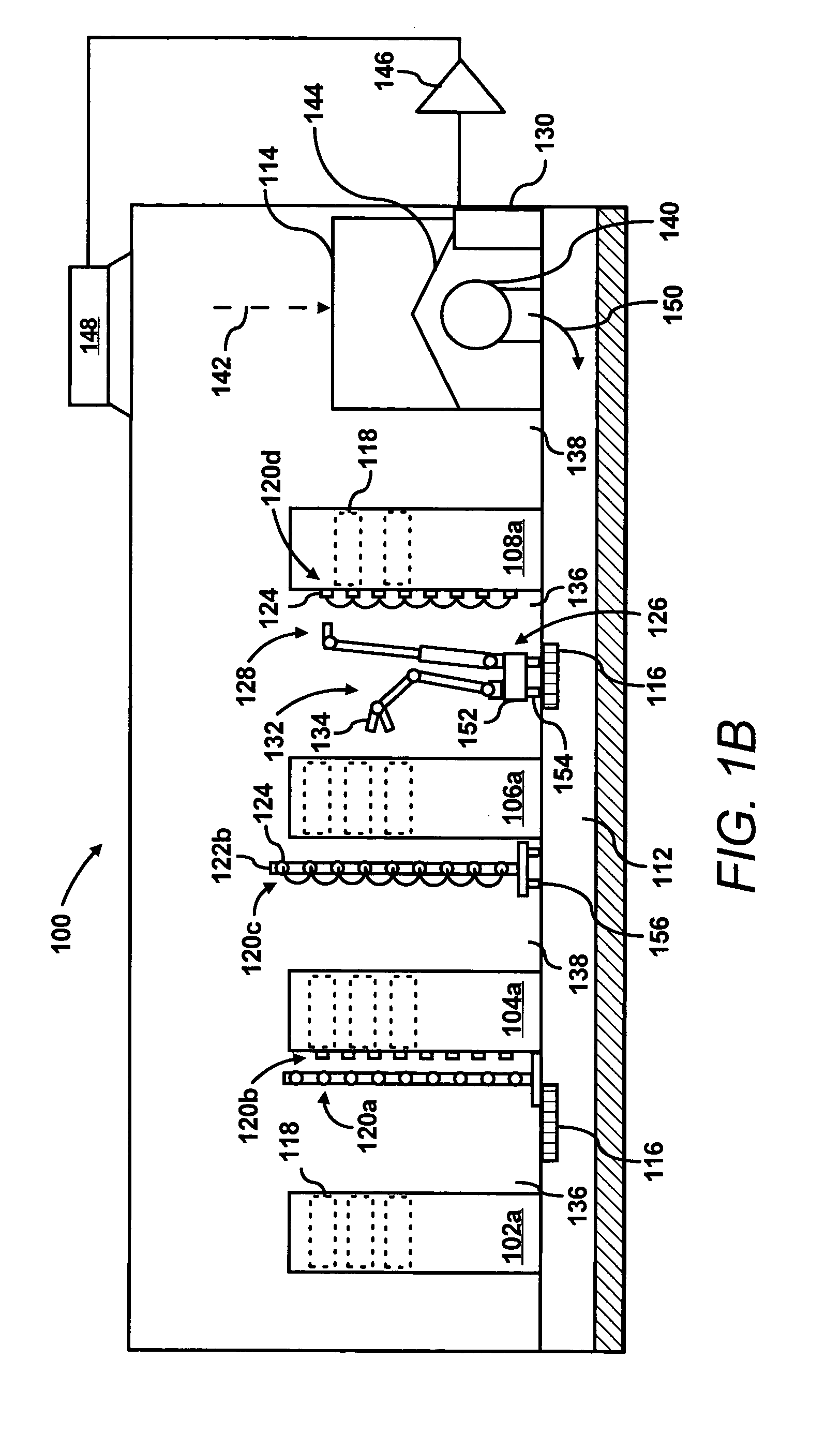

Thermal control systems and methods for information handling systems

ActiveUS20140032011A1Large temperature requirementImprove stabilityTemperature control using plurality of sensorsDigital data processing detailsComputer control systemClosed loop

Systems and methods are provided for information handling system thermal control that employ configuration-based temperature feedback, e.g., by using configuration-based fan speed control based on real time individual measured component temperatures. In one example, the disclosed systems and methods may be implemented to allow inputs from one or more hardware temperature sensors to set cooling fan speeds and / or power capping levels in a closed loop fashion, rather than relying solely (or at all) on system inlet ambient temperature.

Owner:DELL PROD LP

Power-preserving communications architecture with long-polling persistent cloud channel for wireless network-connected thermostat

ActiveUS8627127B2Reduce total powerReduced serviceEnergy efficient ICTMechanical apparatusElectrical batteryCloud base

Provided according to one or more embodiments herein are methods, systems and related architectures for facilitating network communications between a wireless network-connected thermostat and a cloud-based management server in a manner that promotes reduced power usage and extended service life of a rechargeable battery of the thermostat, while at the same time accomplishing timely data transfer between the thermostat and the cloud-based management server for suitable and time-appropriate control of an HVAC system. The thermostat further comprises powering circuitry configured to: extract electrical power from one or more HVAC control wires in a manner that does not require a “common” wire; supply electrical power for thermostat operation; recharge the rechargeable battery (if needed) using any surplus extracted power; and discharge the rechargeable battery to assist in supplying electrical power for thermostat operation during intervals in which the extracted power alone is insufficient for thermostat operation.

Owner:GOOGLE LLC

Data connectivity with a robotic device

ActiveUS7313461B2Programme-controlled manipulatorDigital data processing detailsData connectionEngineering

A method for data connectivity in a room with a robotic device. In the method, at least one condition is detected with a plurality of sensors and the detected at least one condition is communicated from the sensors to associated access points. One or more of the access points are selected and the robotic device is maneuvered to a location in a vicinity of one or more of the selected access points. The detected at least one condition is communicated from one or more of the selected access points to the robotic device. In addition, the robotic device is maneuvered to a location in a vicinity of a base station and the detected at least one condition is communicated from the robotic device to the base station.

Owner:HEWLETT-PACKARD ENTERPRISE DEV LP

Popular searches

Space heating and ventilation safety systems Space heating and ventilation control systems Static/dynamic balance measurement Space heating and ventilation details Air conditioning systems Adaptive control Ventilation systems Control inputs involving users/components Control inputs involving air properties Temperature control with auxillary non-electric power

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com