Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

2211 results about "Maximum temperature" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

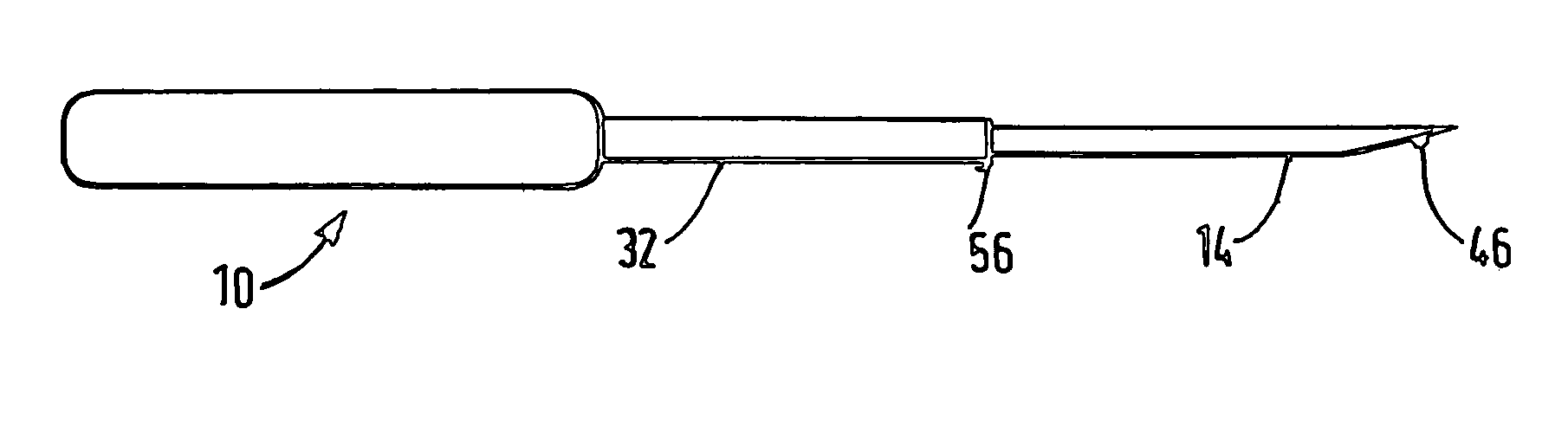

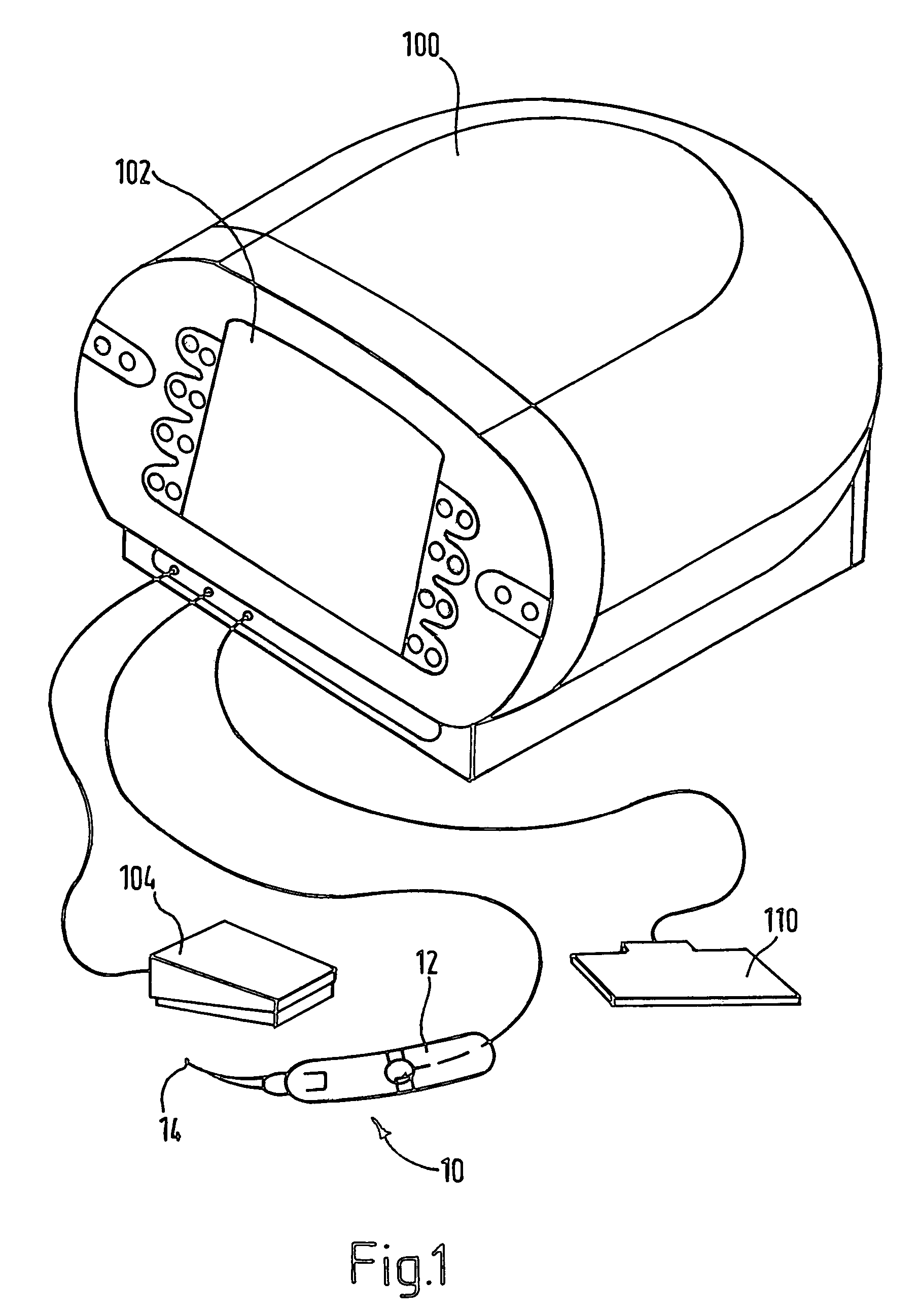

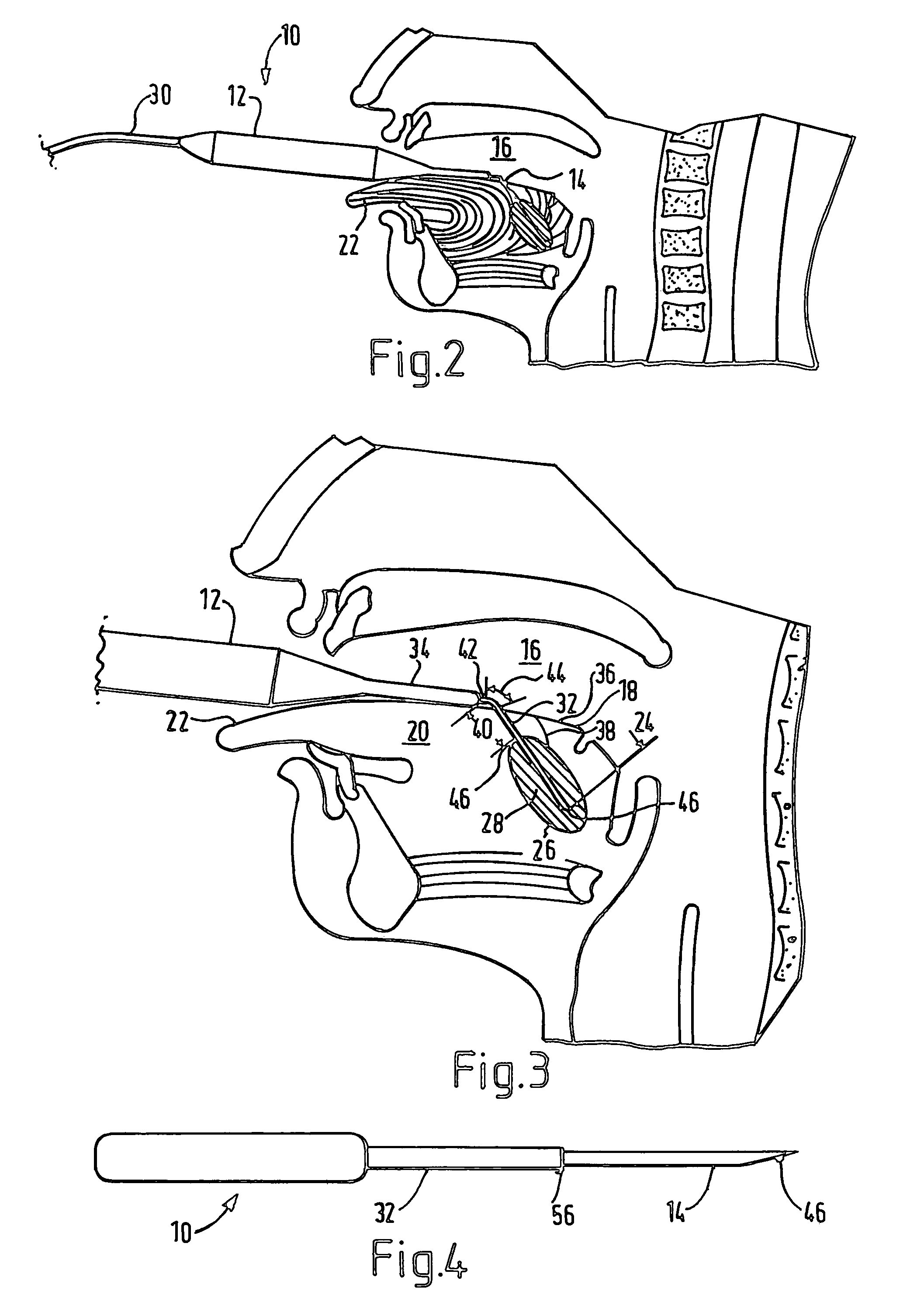

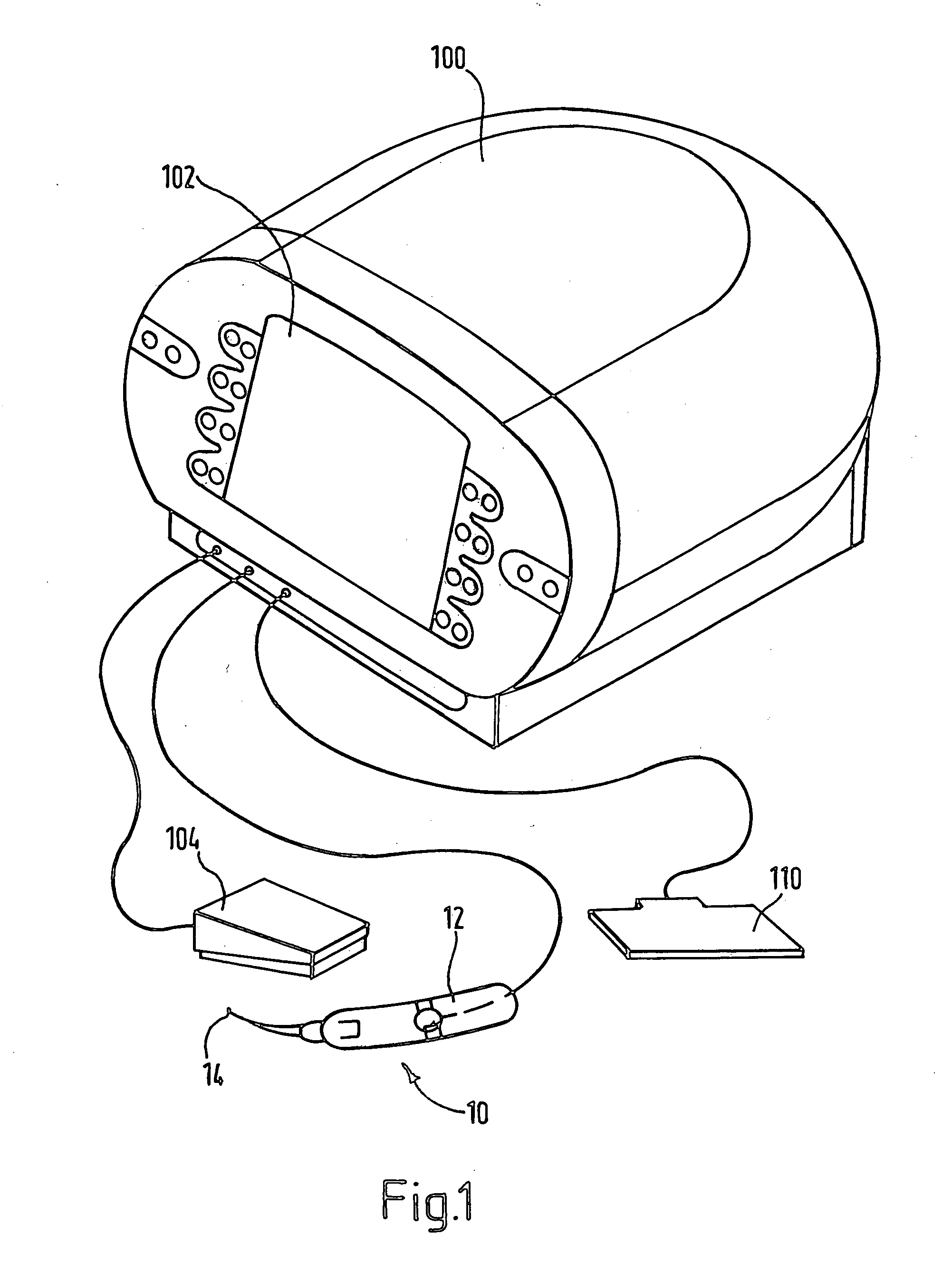

Electrosurgical method and apparatus

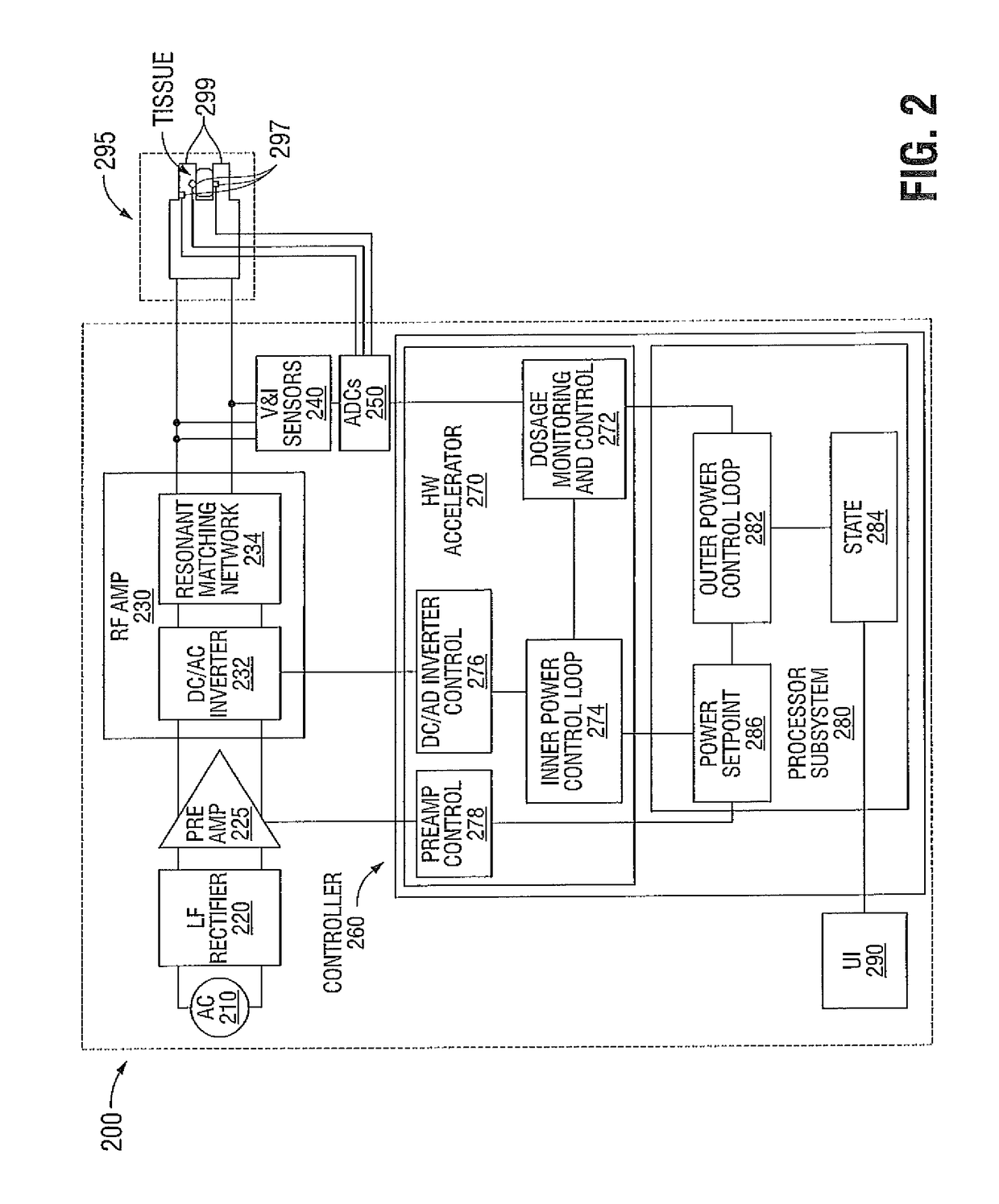

ActiveUS7377918B2Compensation delayIncrease temperatureSurgical needlesSurgical instruments for heatingThreshold temperatureRadio frequency

Owner:GYRUS ENT

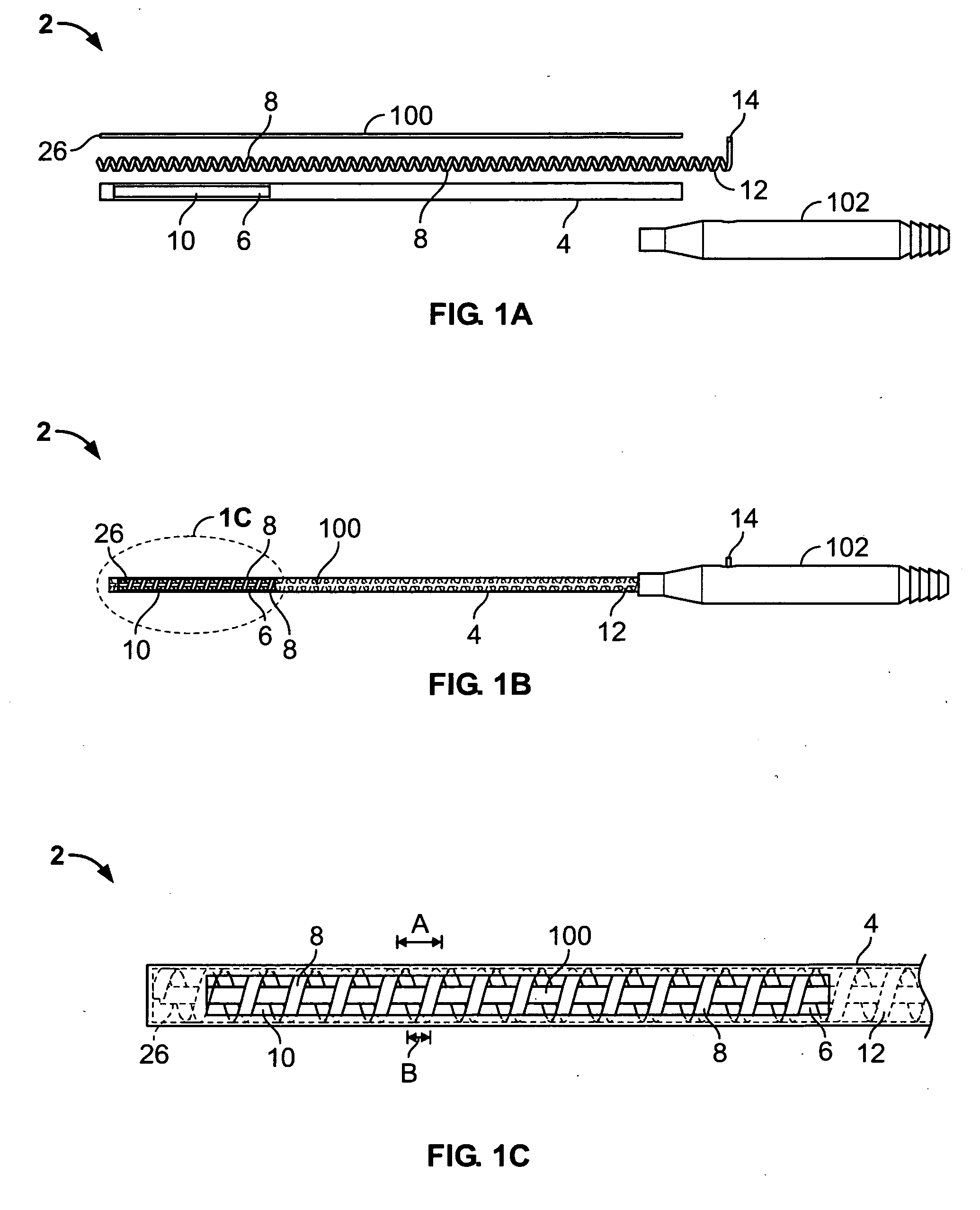

Electrosurgical method and apparatus

ActiveUS20050251128A1Compensation delayIncrease temperatureSurgical needlesSurgical instruments for heatingEngineeringRadio frequency

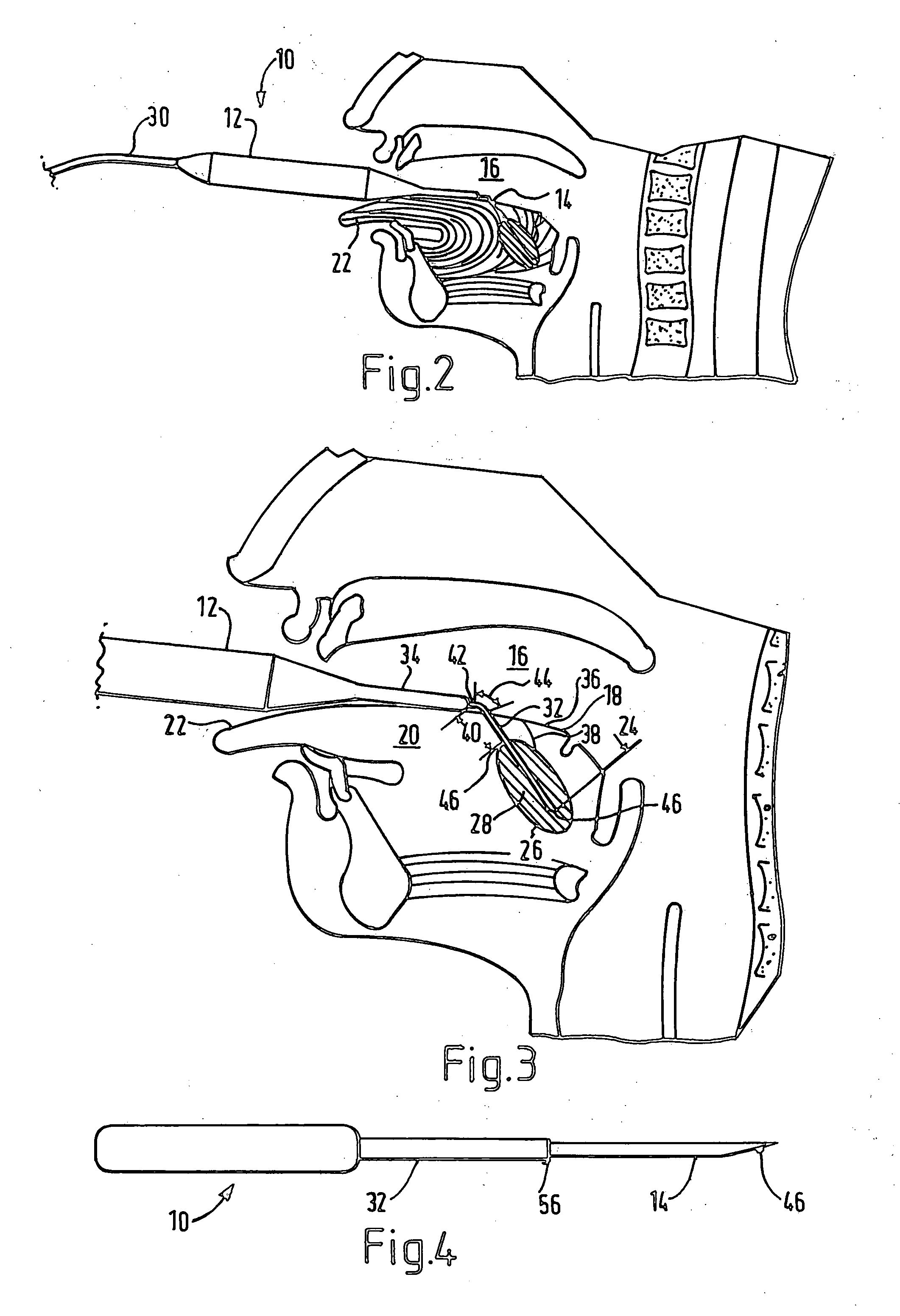

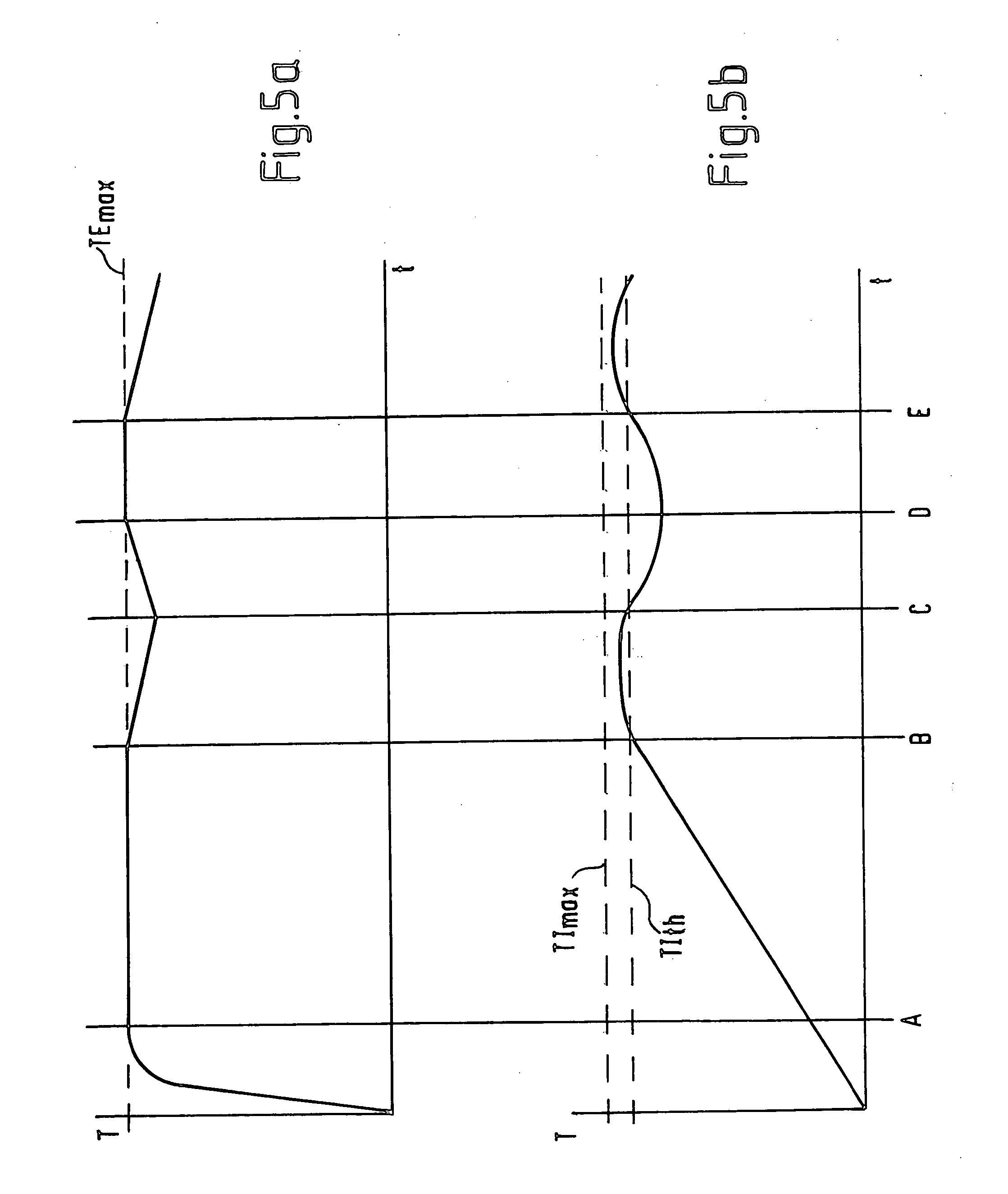

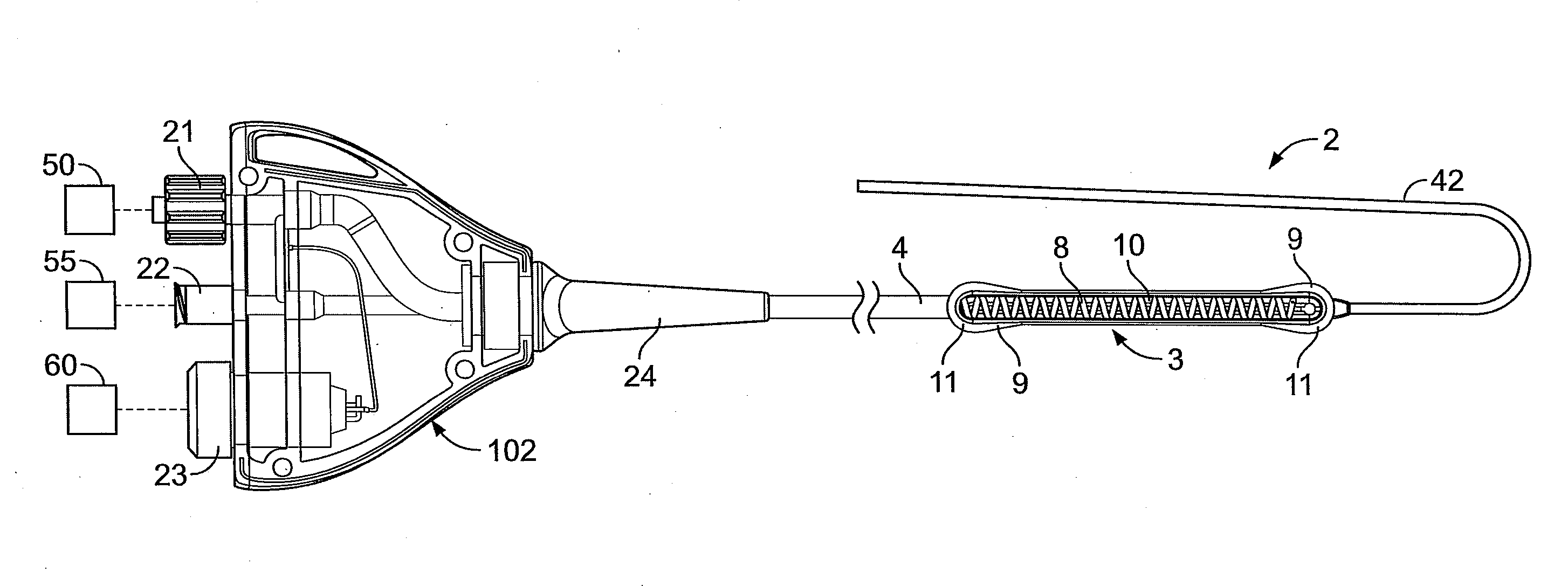

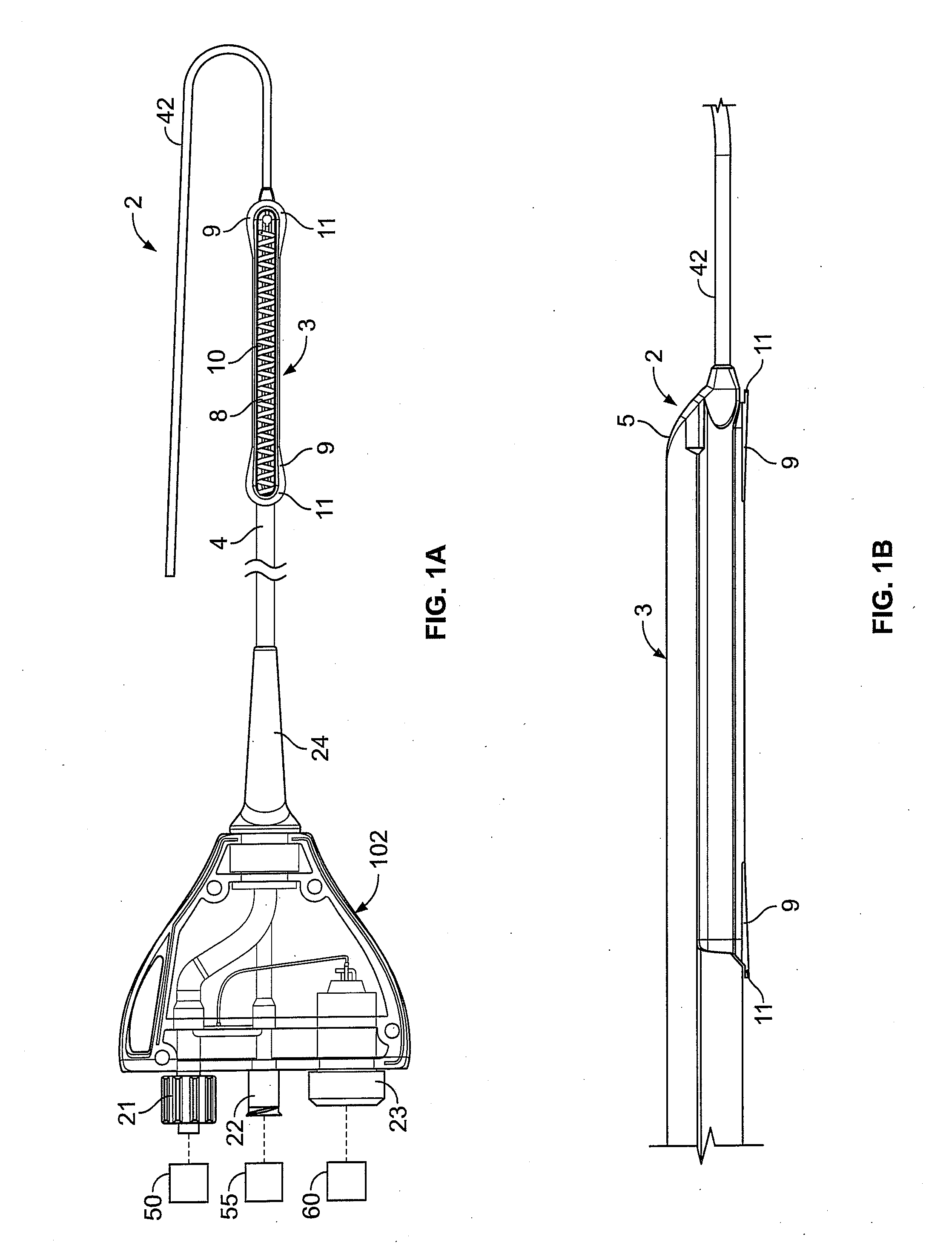

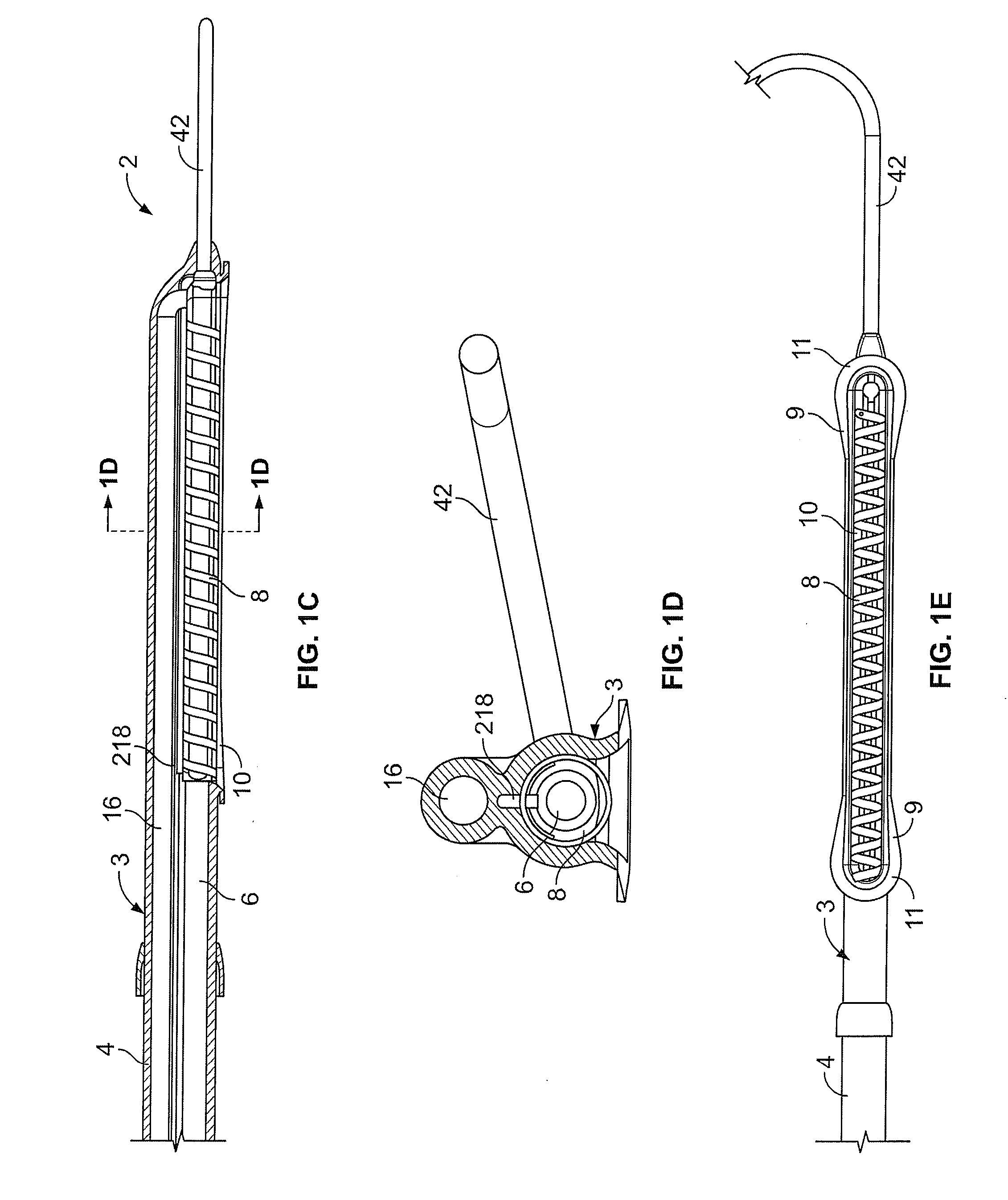

Apparatus for forming a lesion in body tissue includes a probe having an active region with an electrode for contacting tissue to be treated, and an inactive region including an insulative sleeve around a portion of the electrode. The temperature of the inactive region is monitored using a temperature sensor. A controller supplies radio frequency energy to the electrode and samples signals from the temperature sensor. By performing a calculation using the sampled signals and a predetermined inactive region threshold temperature, and by adjusting the supplied radio frequency power, the inactive region of the probe can be maintained at or below an inactive region maximum temperature whilst the controller continues to supply radio frequency energy to the electrode. The probe has a second temperature sensor, mounted at a distal end of the electrode, the controller being configured to reduce the supplied radio frequency power when the electrode temperature reaches a predetermined maximum electrode temperature.

Owner:GYRUS ENT

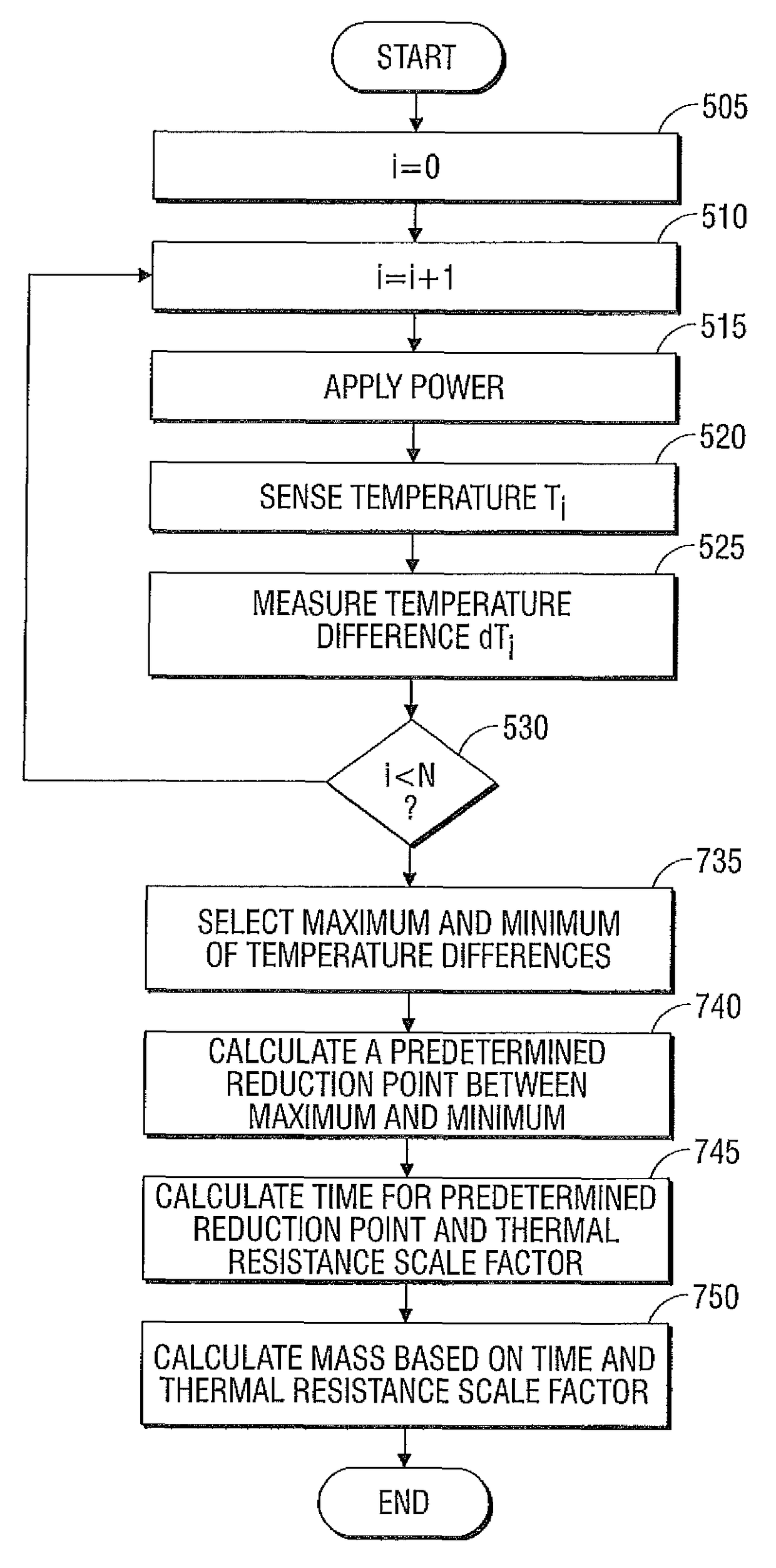

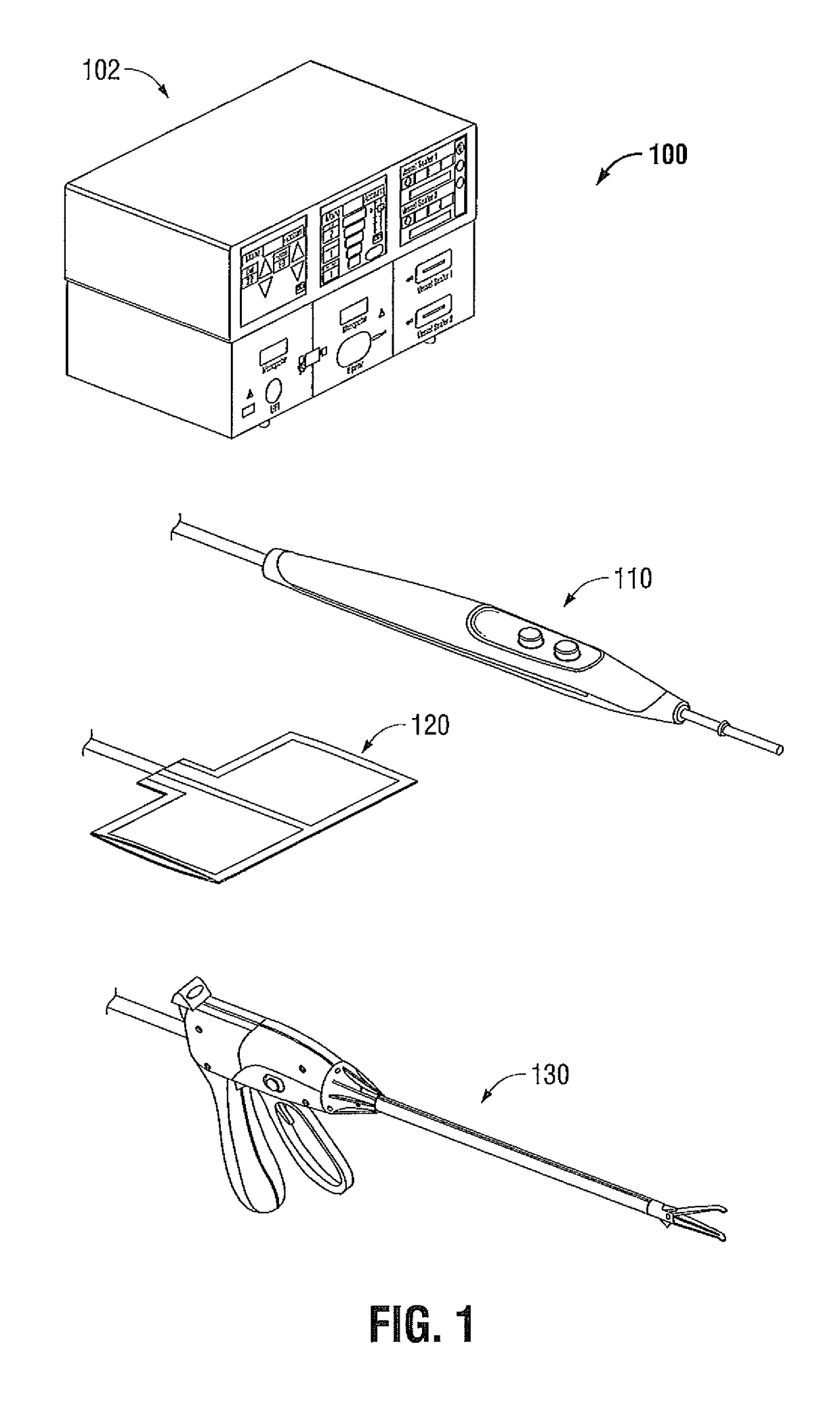

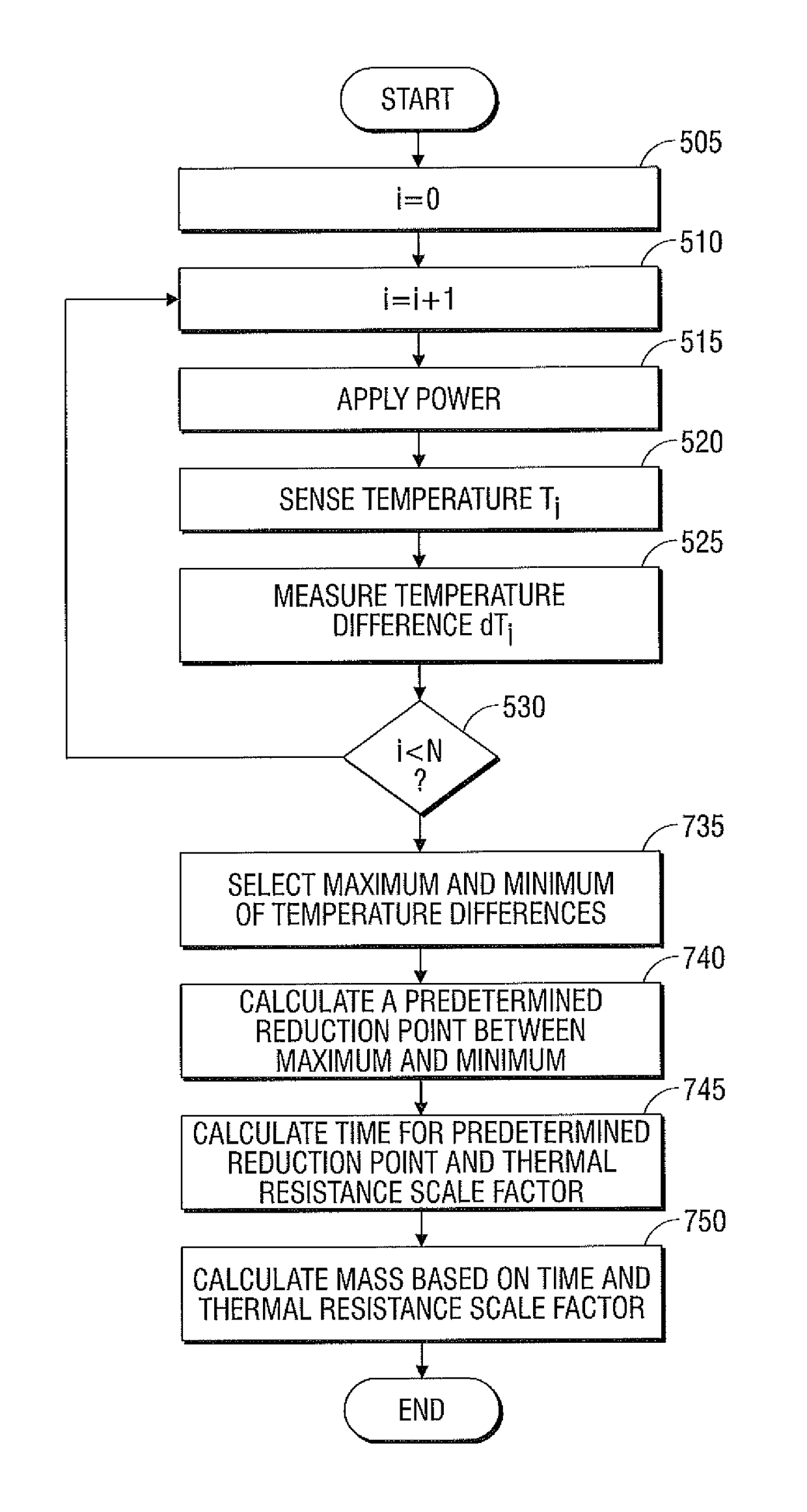

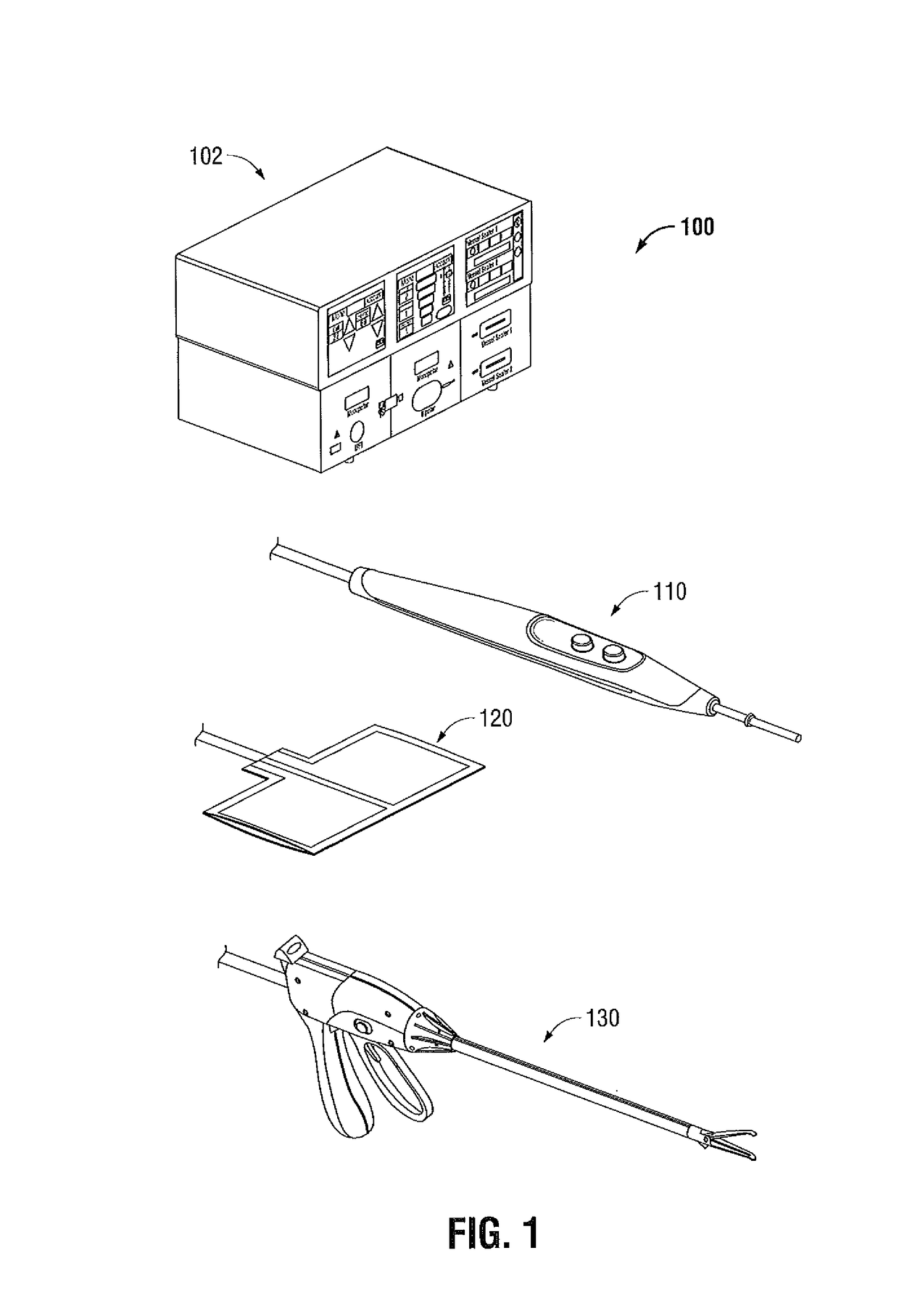

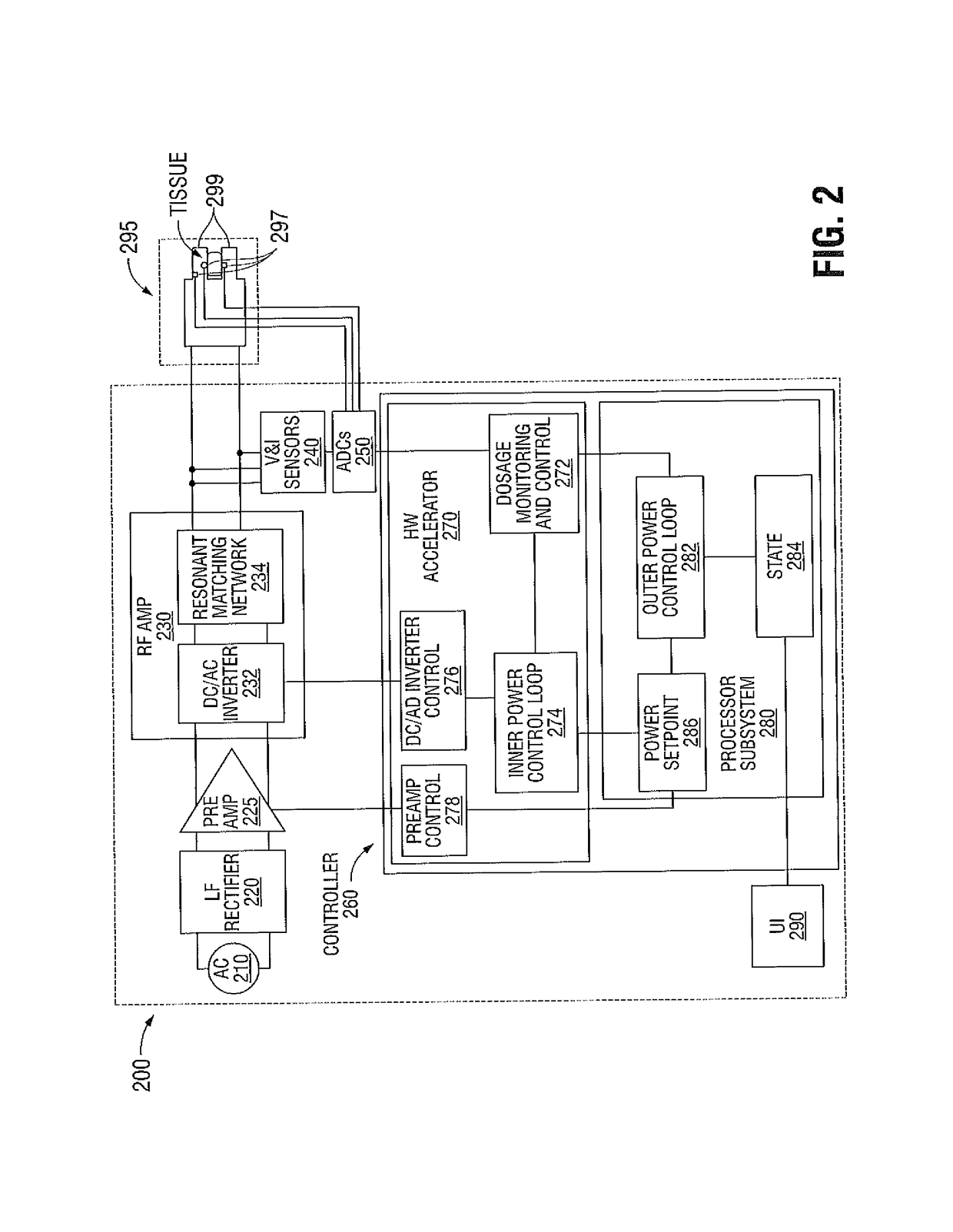

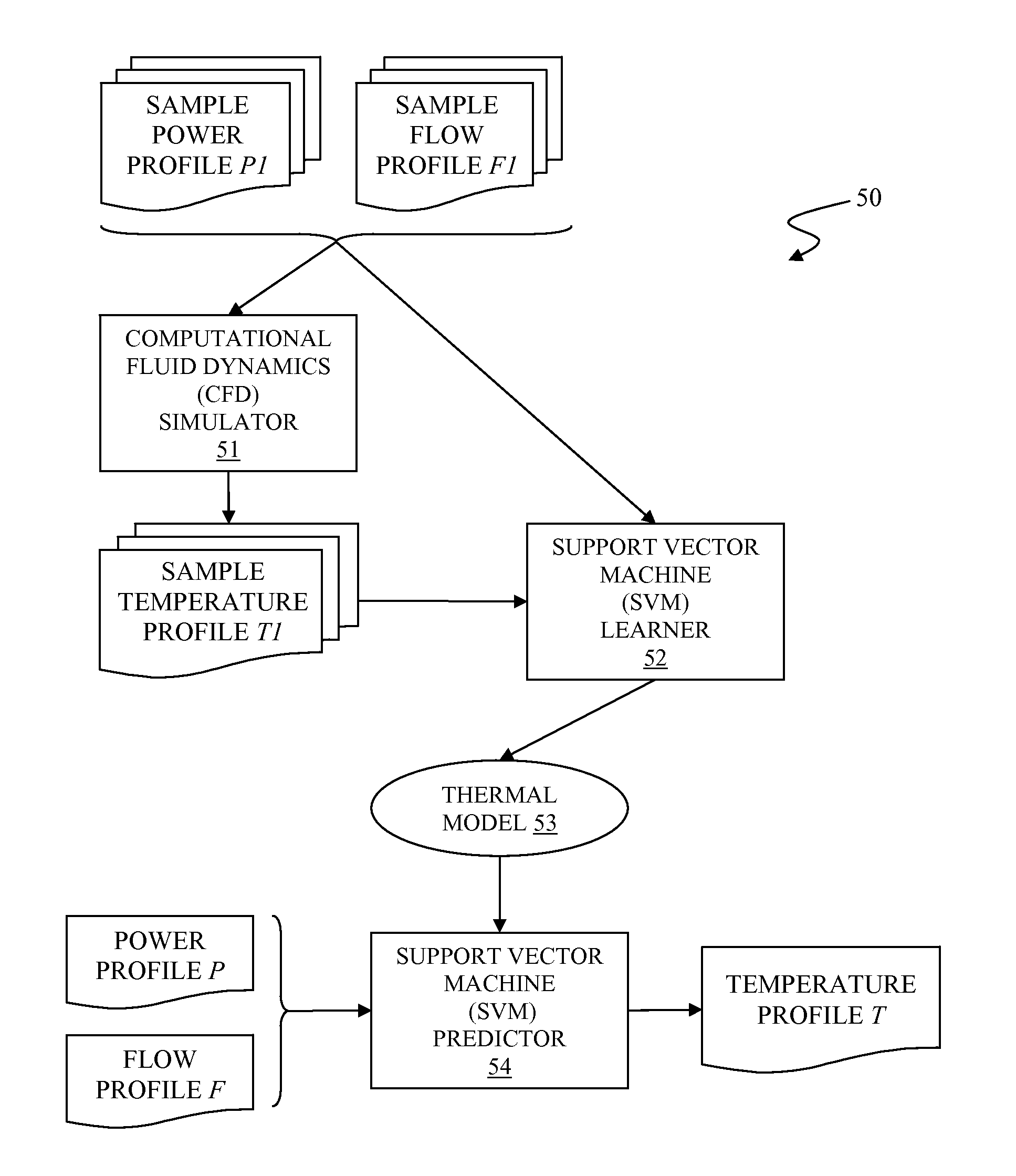

Systems and methods for estimating tissue parameters using surgical devices

Systems and methods for estimating tissue parameters, including mass of tissue to be treated and a thermal resistance scale factor between the tissue and an electrode of an energy delivery device, are disclosed. The method includes sensing tissue temperatures, estimating a mass of the tissue and a thermal resistance scale factor between the tissue and an electrode, and controlling an electrosurgical generator based on the estimated mass and the estimated thermal resistance scale factor. The method may be performed iteratively and non-iteratively. The iterative method may employ a gradient descent algorithm that iteratively adds a derivative step to the estimates of the mass and thermal resistance scale factor until a condition is met. The non-iterative method includes selecting maximum and minimum temperature differences and estimating the mass and the thermal resistance scale factor based on a predetermined reduction point from the maximum temperature difference to the minimum temperature difference.

Owner:COVIDIEN LP

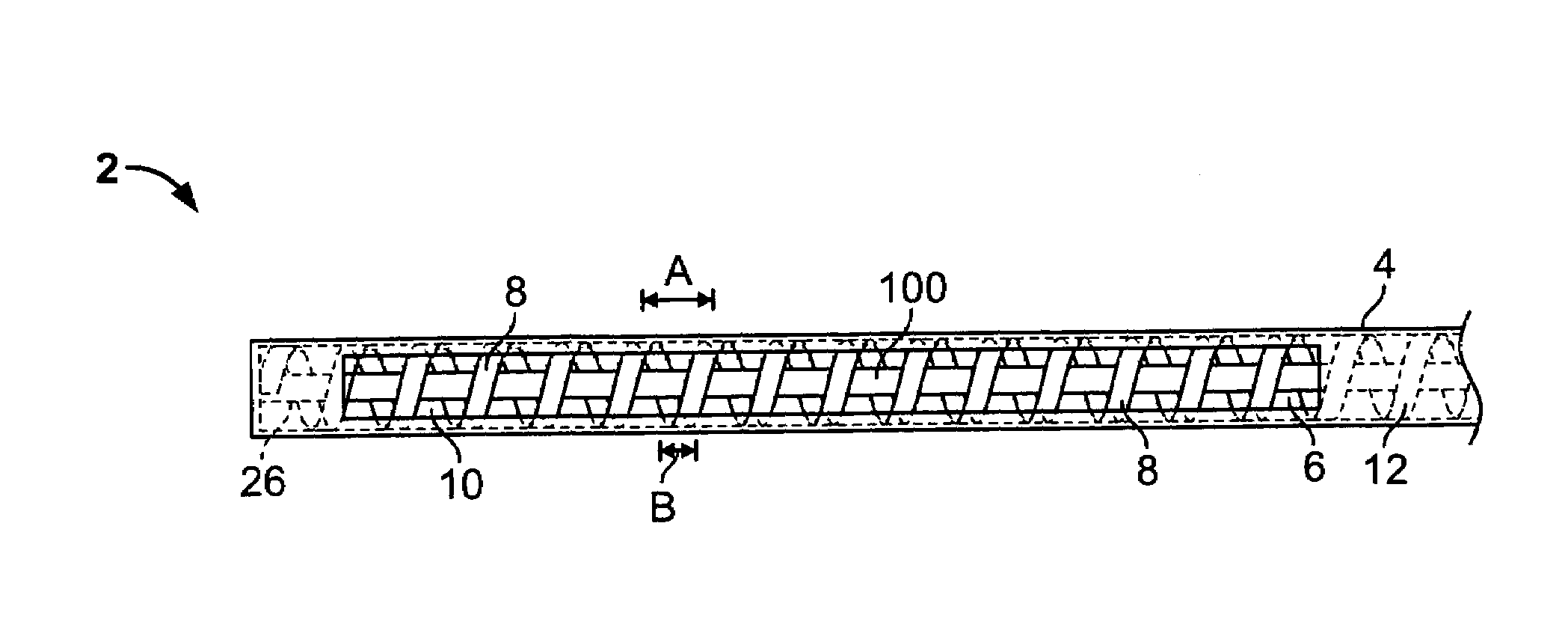

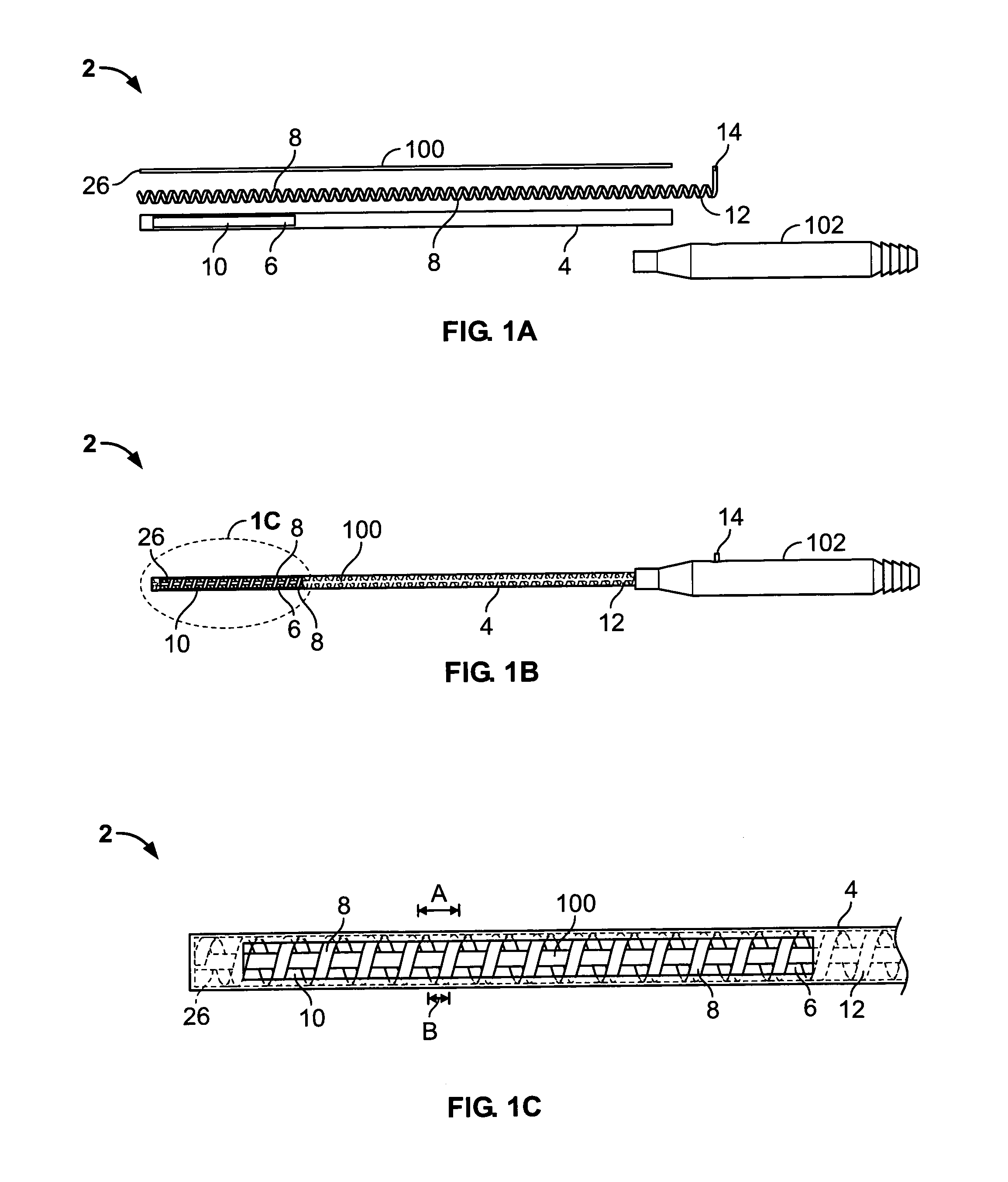

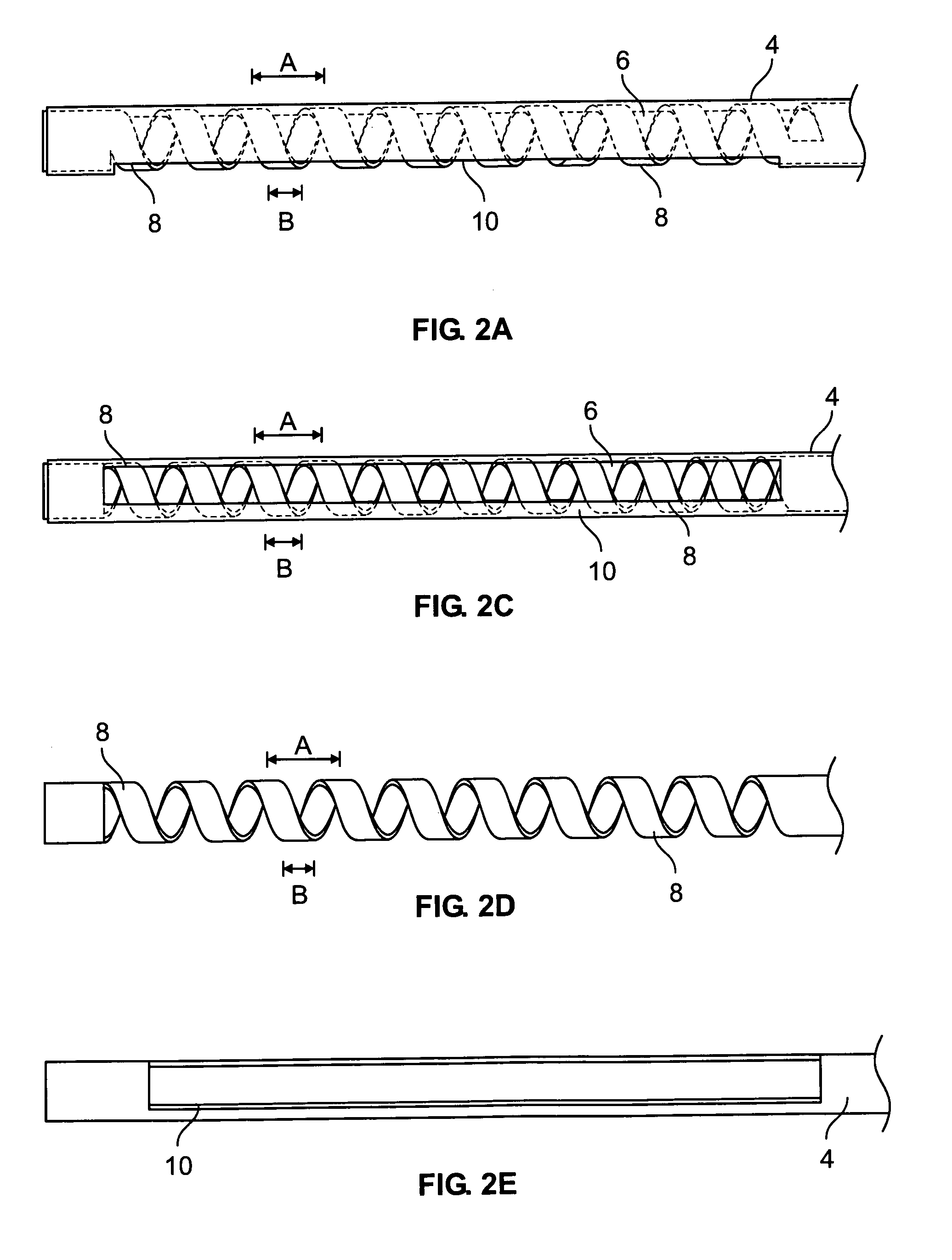

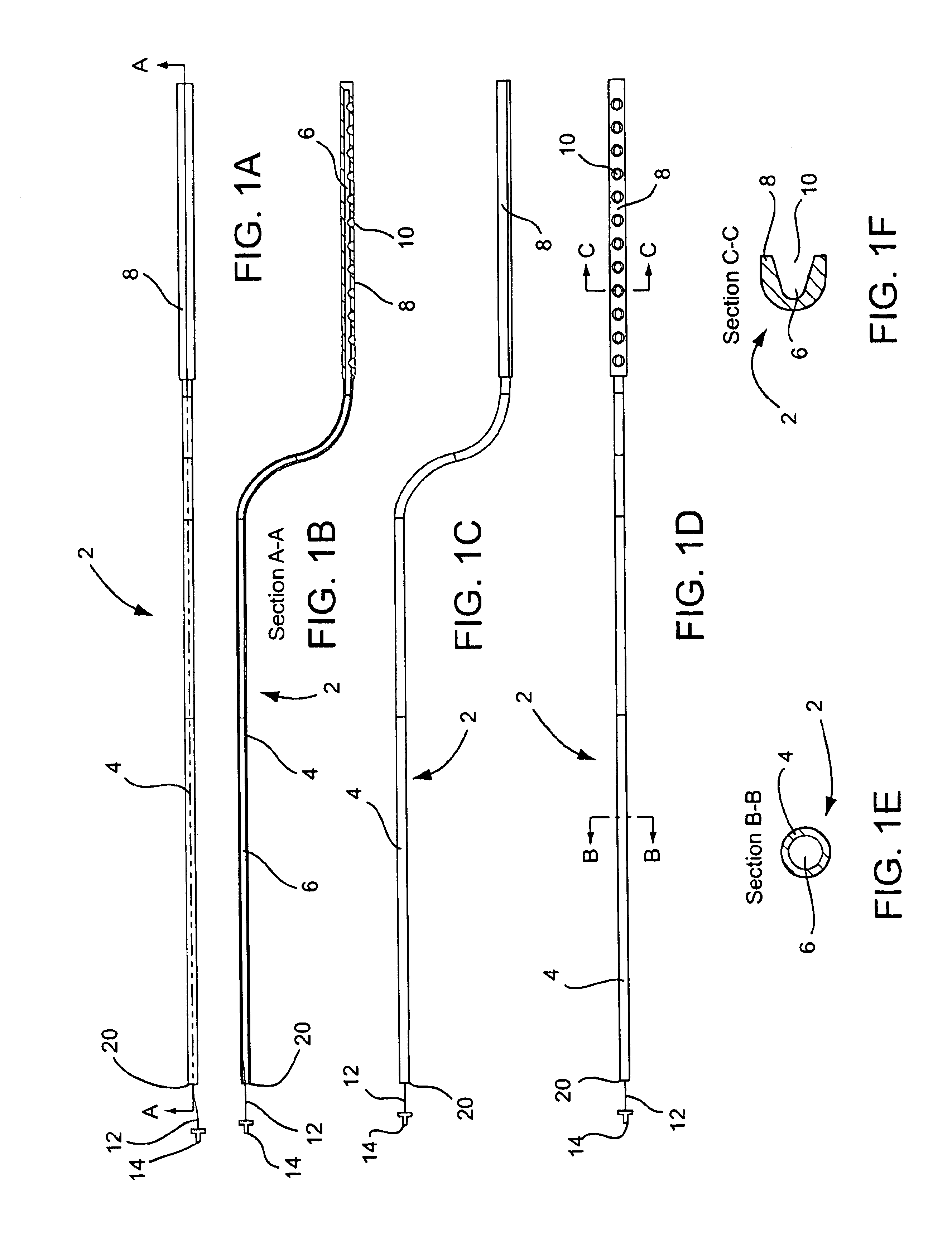

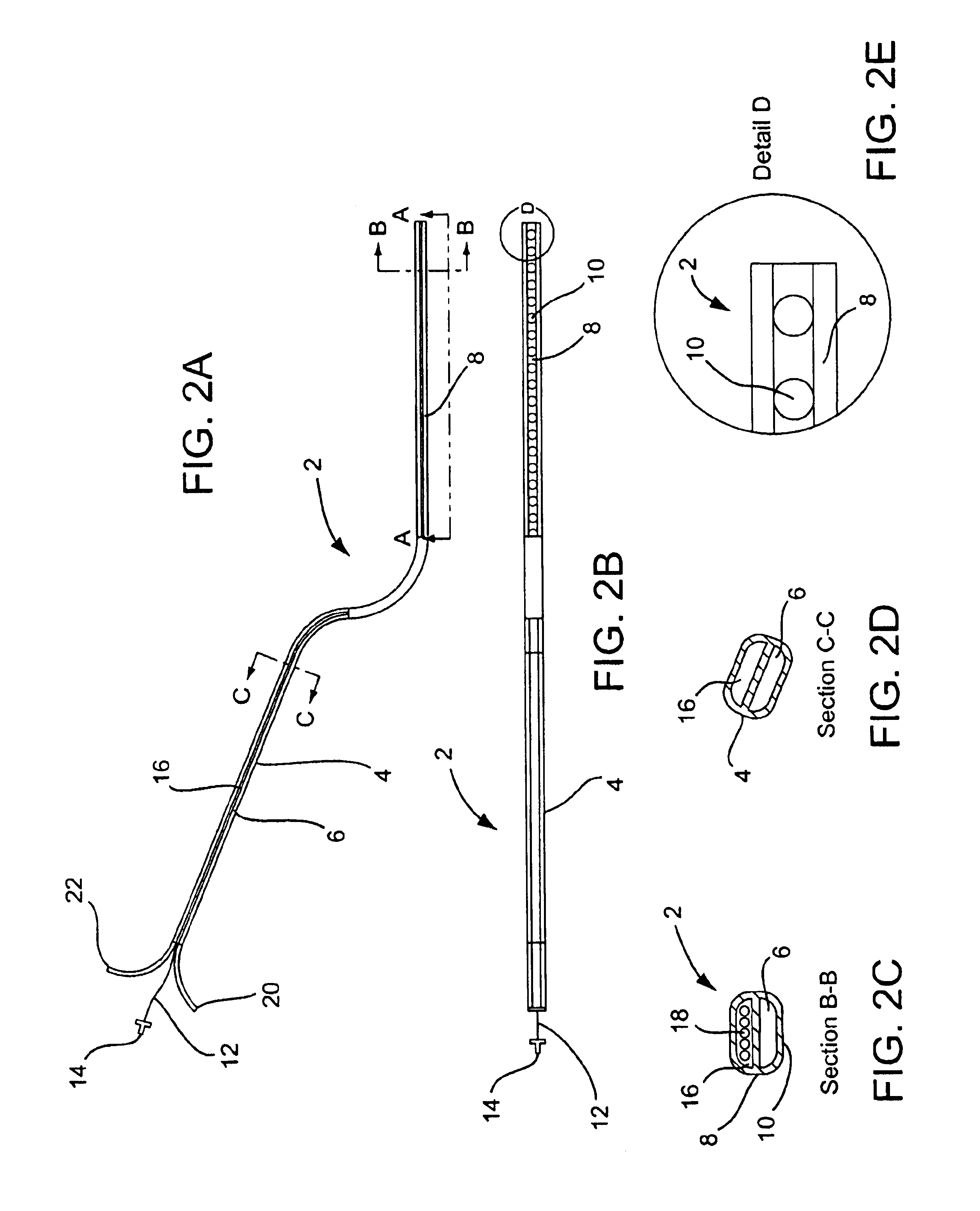

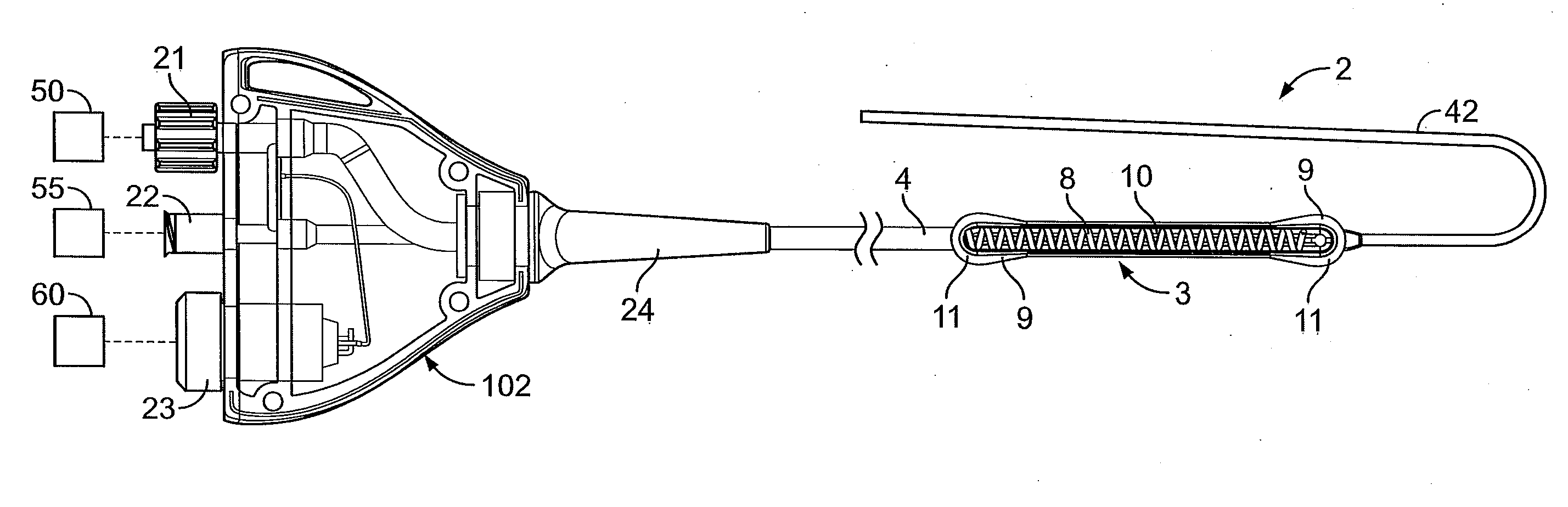

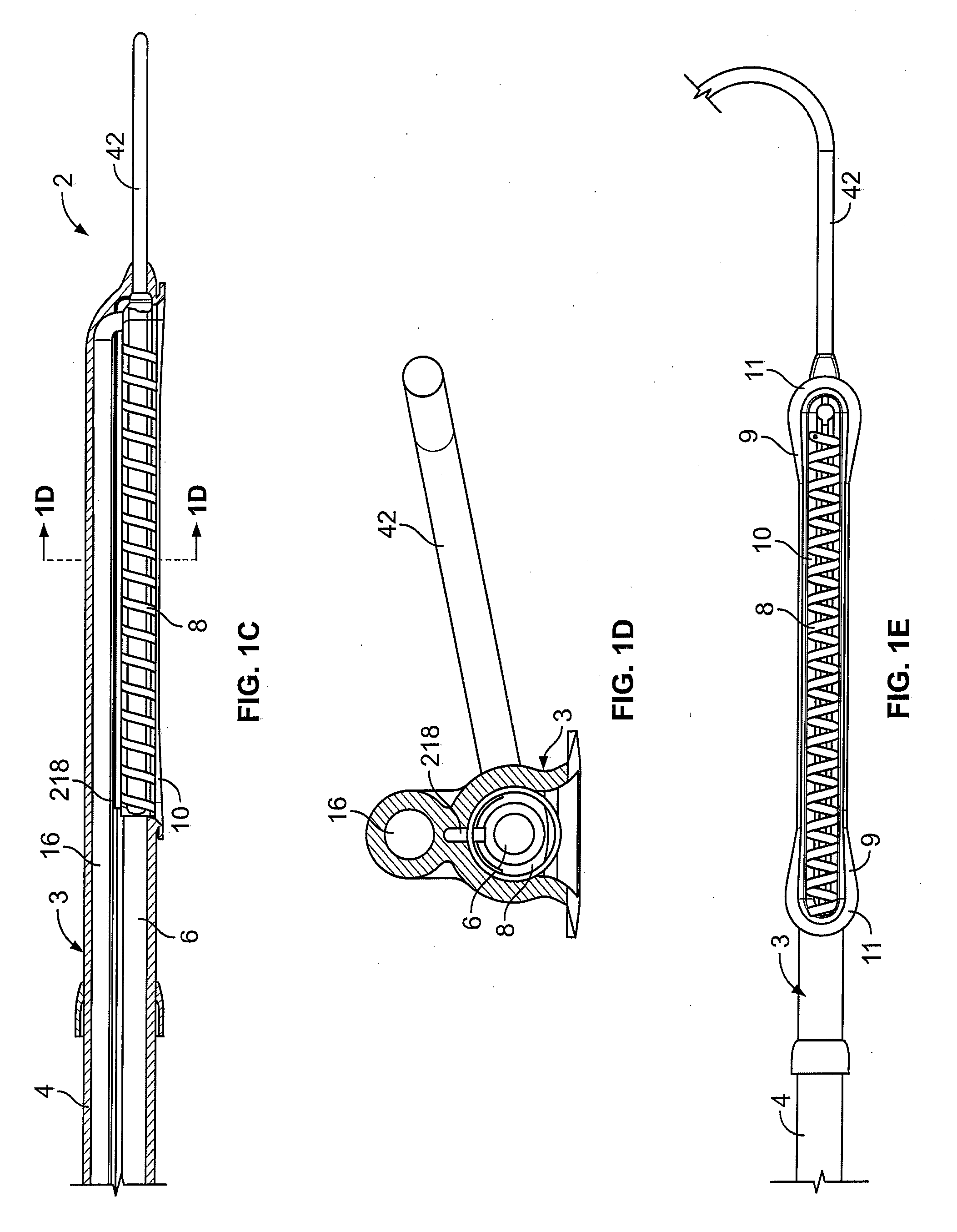

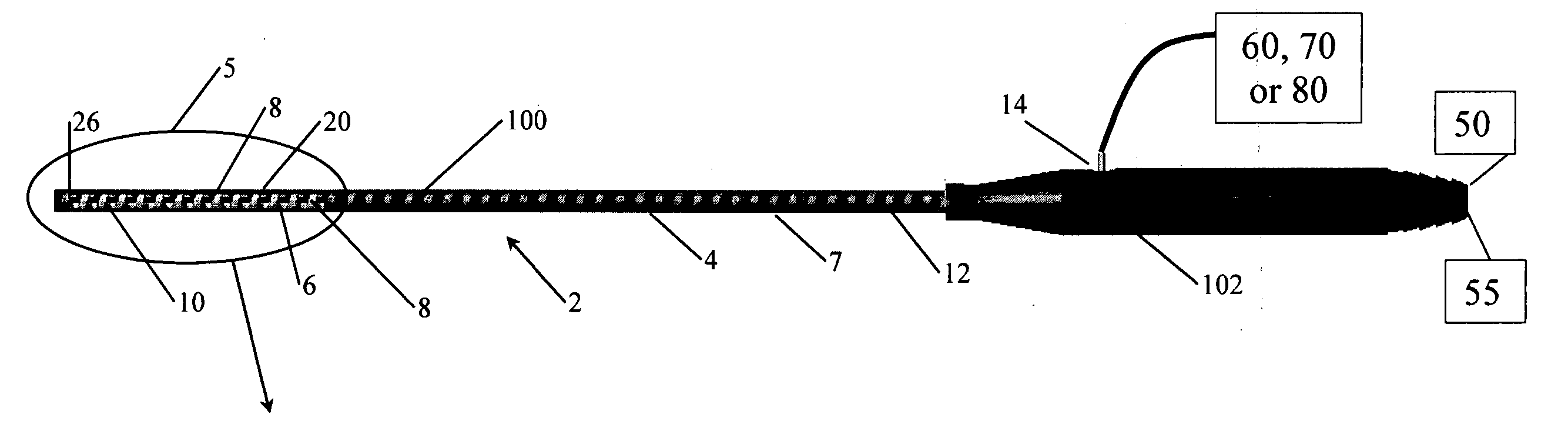

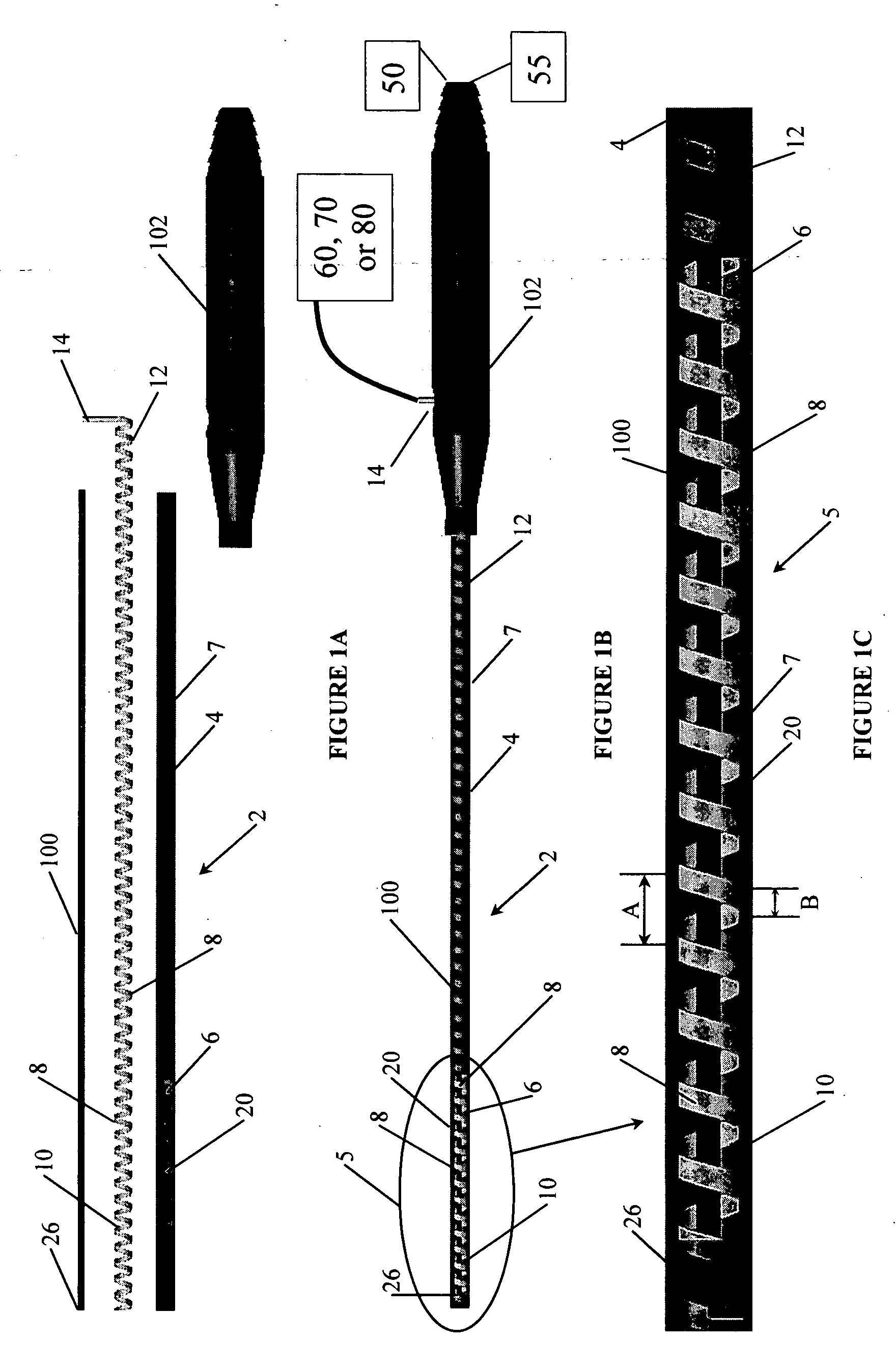

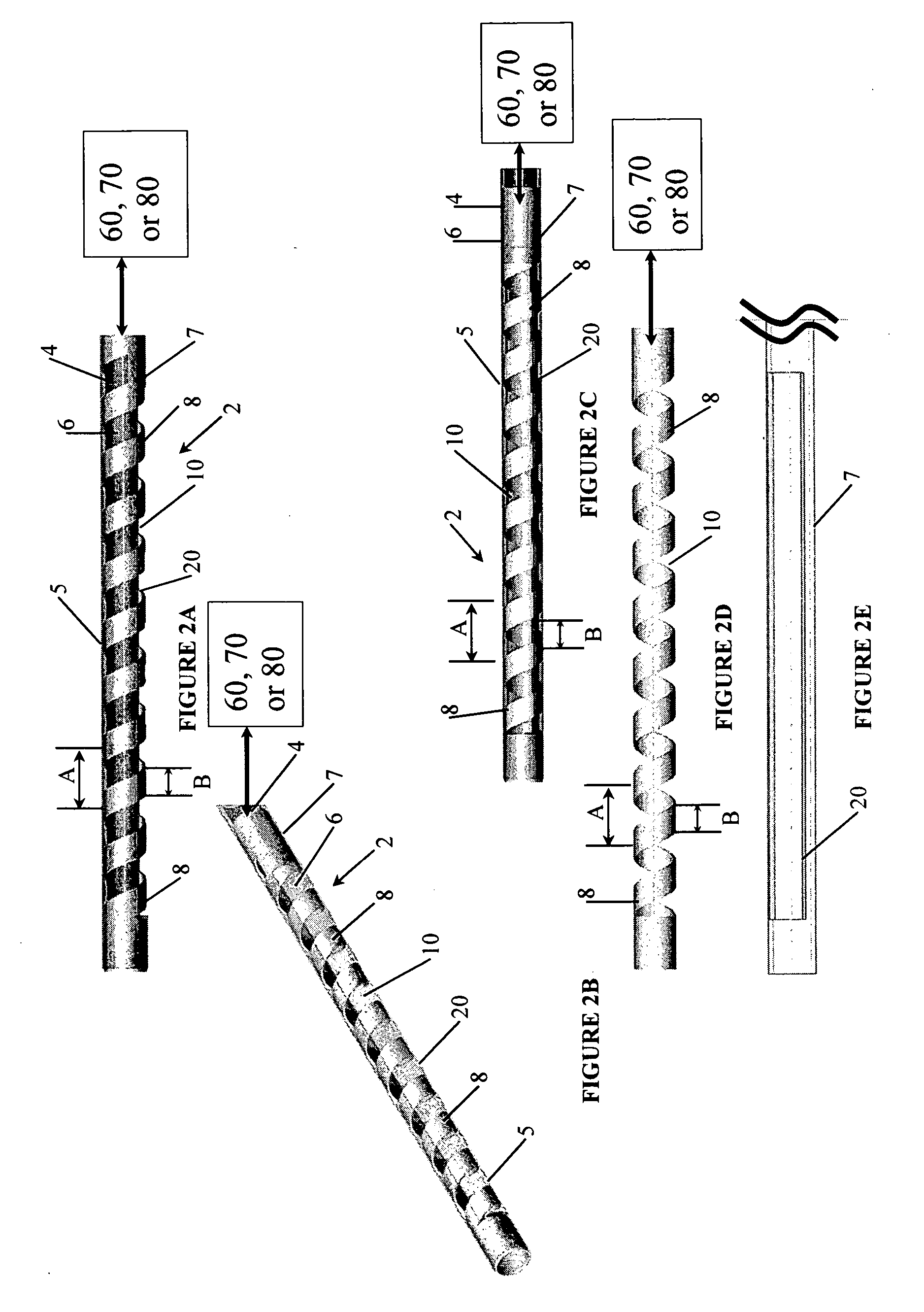

Vacuum coagulation probes

InactiveUS7063698B2Surgical instruments for heatingSurgical instruments for aspiration of substancesRadio frequencyArticular cartilage

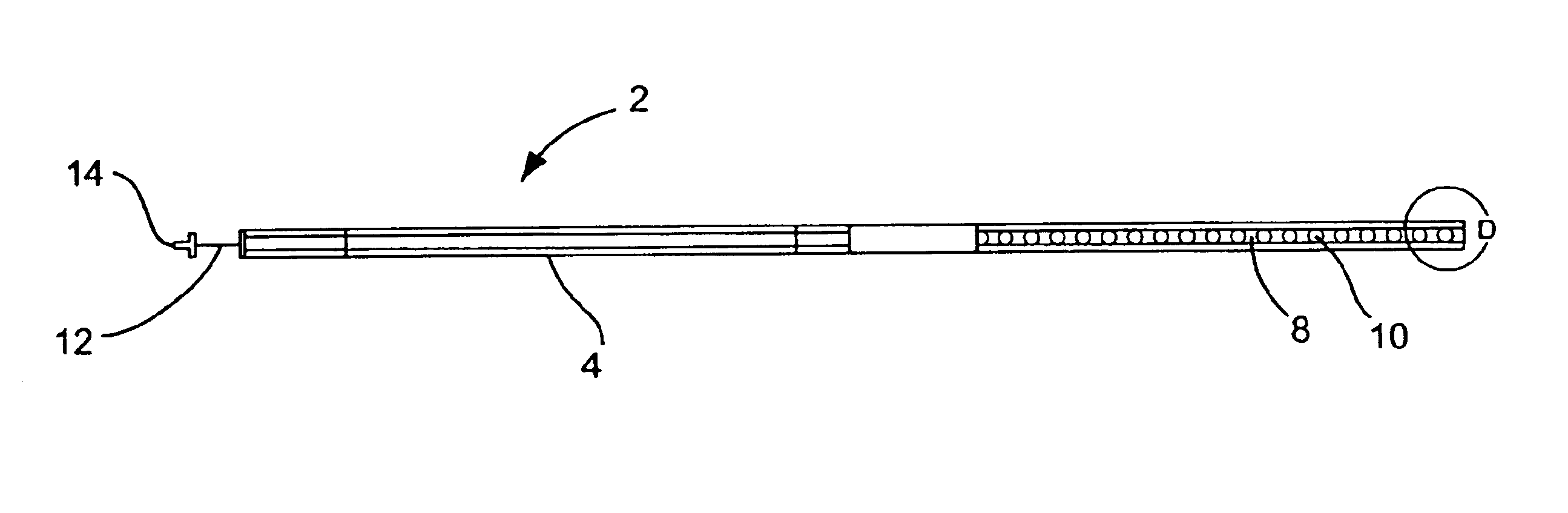

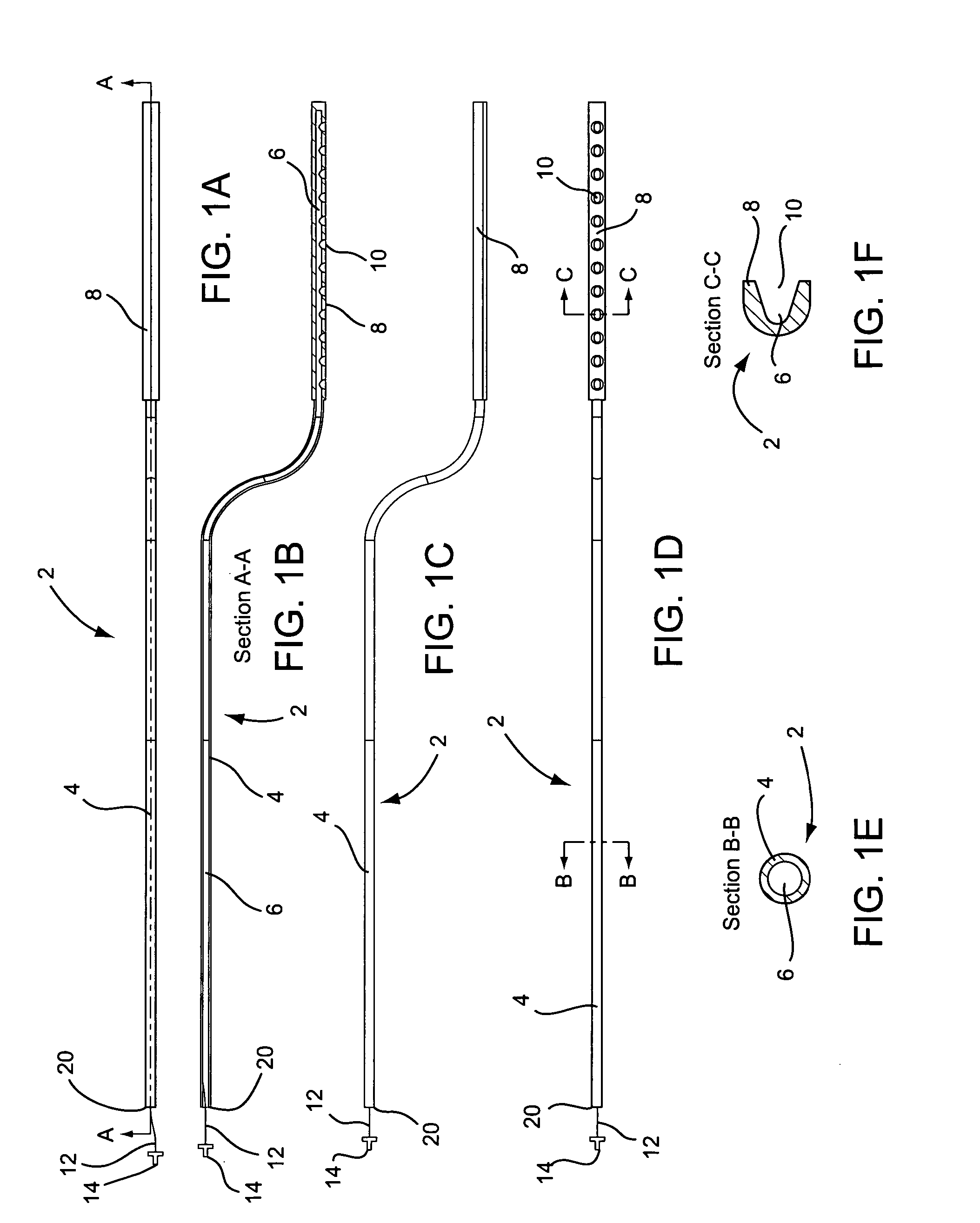

An embodiment of the invention includes a surgical device for coagulating soft tissue such as atrial tissue in the treatment of atrial fibrillation, atrial flutter, and atrial tachycardia; tendon or ligament shrinkage; or articular cartilage removal. The surgical device integrates a suction mechanism with the coagulation mechanism improving the lesion creation capabilities of the device. The surgical device comprises an elongate member having an insulative covering attached about conductive elements capable of coagulating soft tissue when radiofrequency or direct current energy is transmitted to the conductive elements. Openings through the insulative covering expose regions of the conductive elements and are coupled to lumens in the elongate member which are routed to a vacuum source. Suction causes the soft tissue to actively engage the opening thus the integrated, exposed conductive elements to facilitate the coagulation process and ensure the lesions created are consistent, continuous, and transmural. The embodiments of the invention can also incorporate cooling mechanisms associated with the conductive elements and coupled to a fluid source to passively transport fluid along the contacted soft tissue surface to cool thus pushing the maximum temperature deeper into tissue.

Owner:ATRICURE

Two-phase heat-transfer systems

InactiveUS6866092B1Prevent freezingImprove the overall coefficientLiquid coolingCasingsLiquid jetInternal pressure

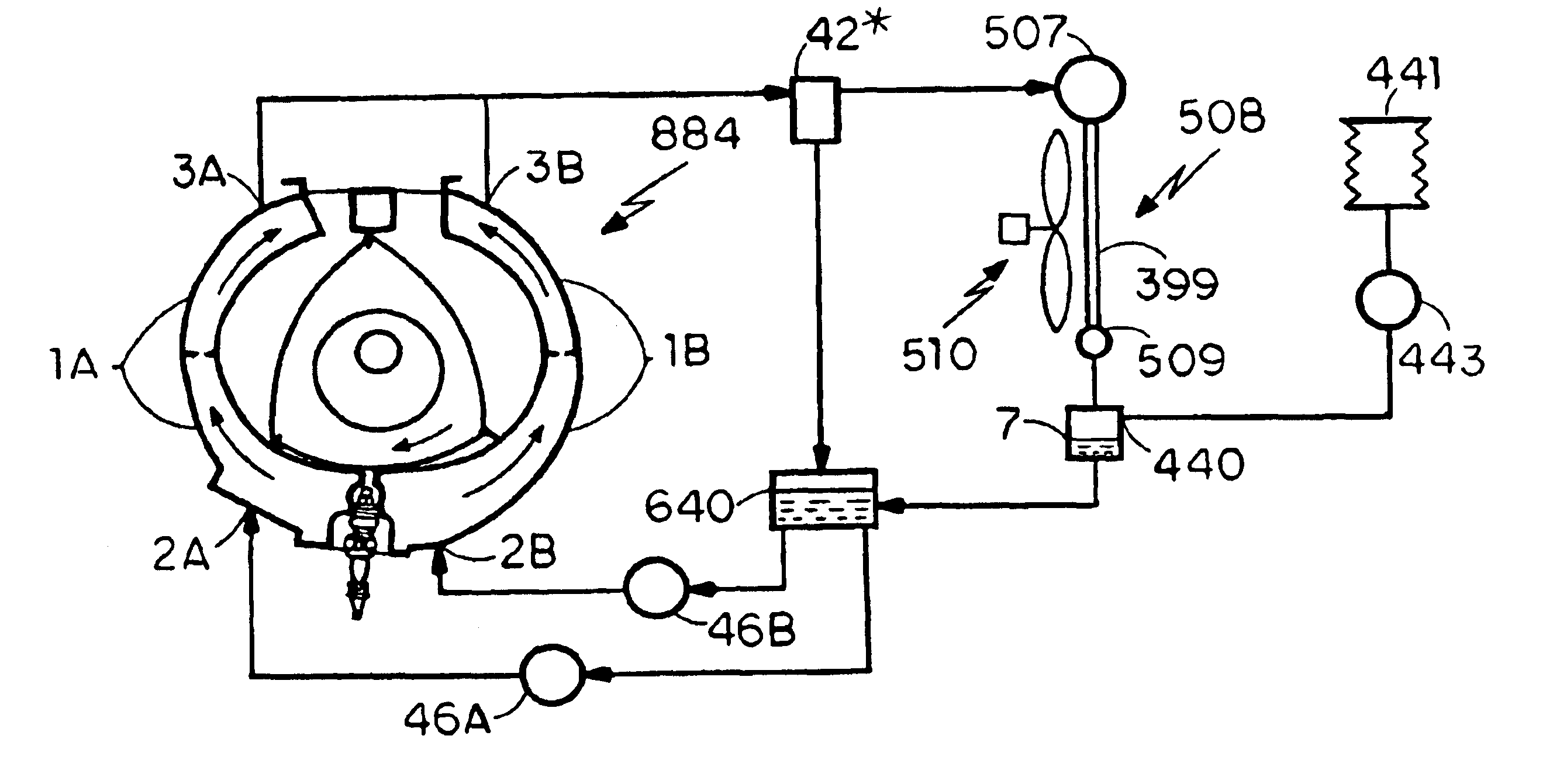

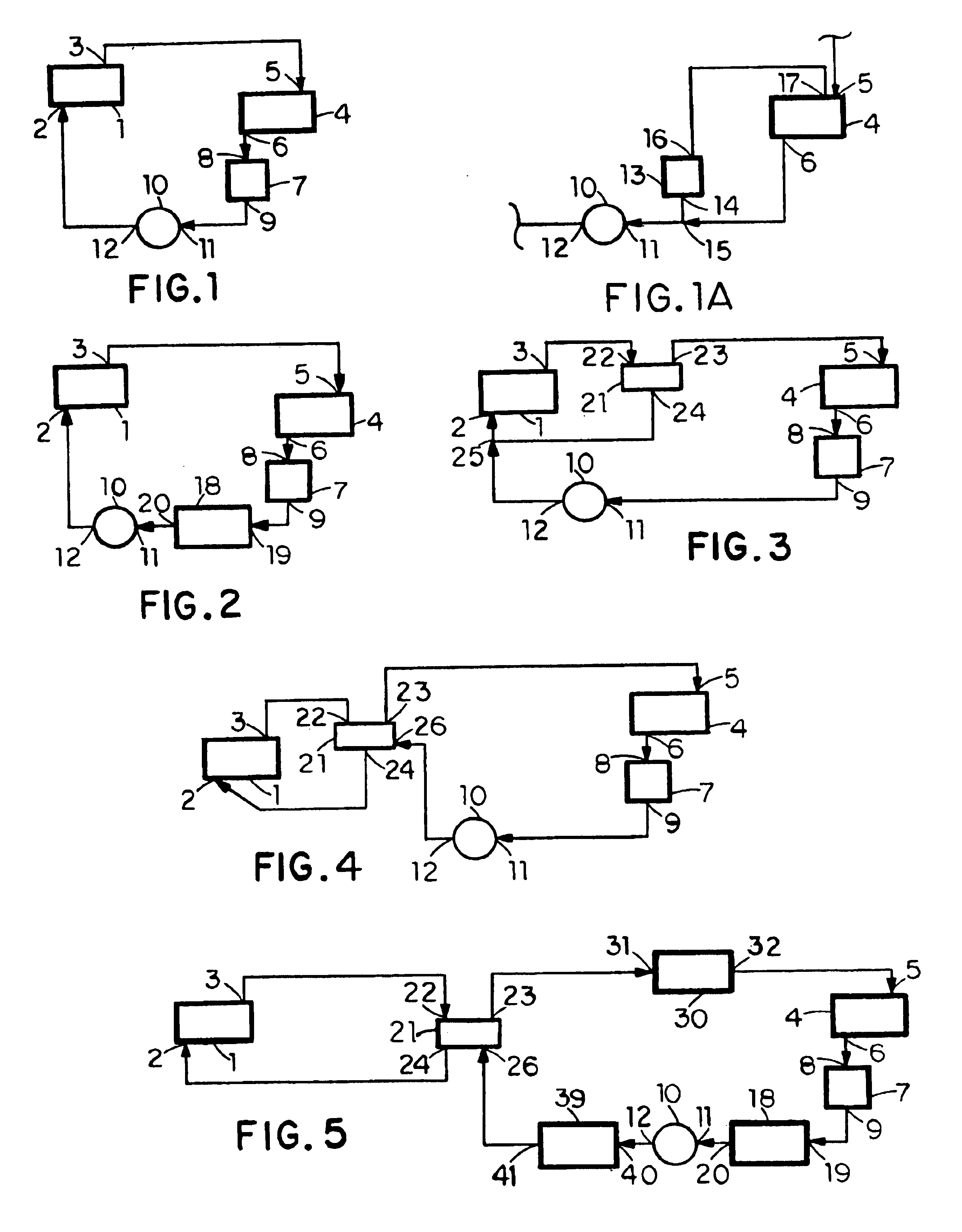

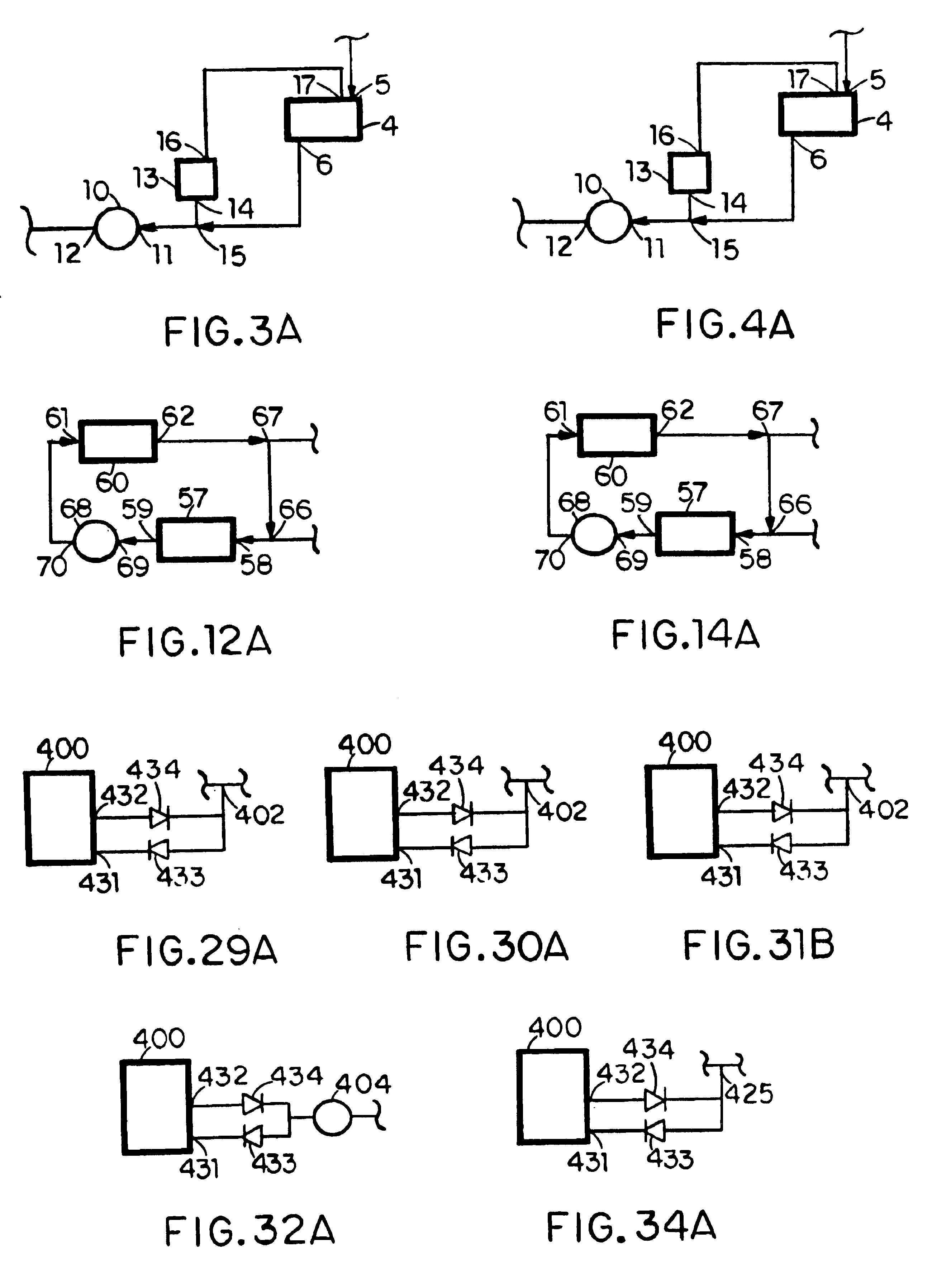

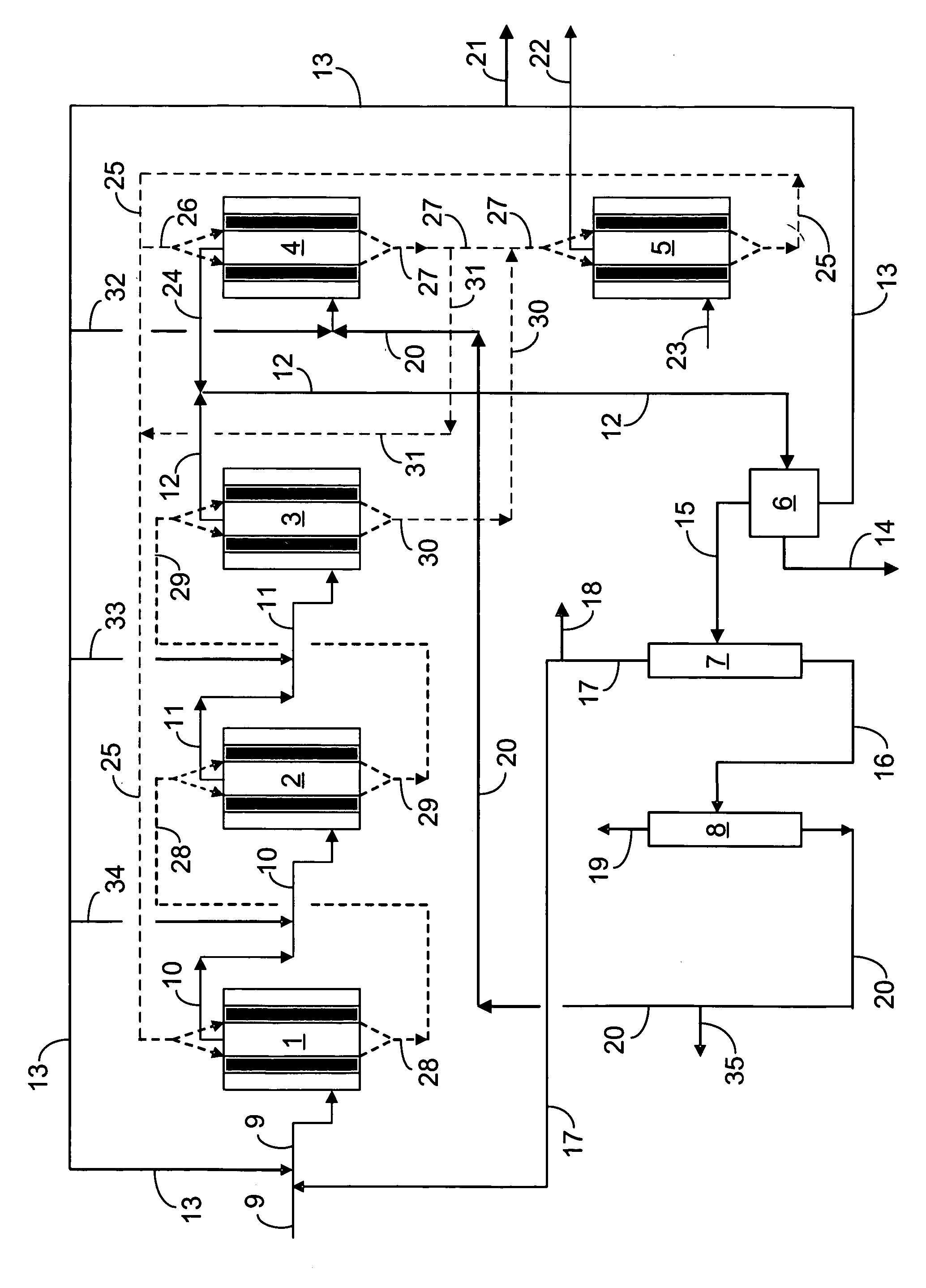

Various techniques are disclosed for improving airtight two-phase heat-transfer systems employing a fluid to transfer heat from a heat source to a heat sink while circulating around a fluid circuit, the maximum temperature of the heat sink not exceeding the maximum temperature of the heat source. The properties of those improved systems include (a) maintaining, while the systems are inactive, their internal pressure at a pressure above the saturated-vapor pressure of their heat-transfer fluid; and (b) cooling their internal evaporator surfaces with liquid jets. FIG. 43 illustrates the particular case where a heat-transfer system of the invention is used to cool a piston engine (500) by rejecting, with a condenser (508), heat to the ambient air; and where the system includes a heat-transfer fluid pump (10) and means (401-407) for achieving the former property.

Owner:MOLIVADAS STEPHEN

Vacuum coagulation probe for atrial fibrillation treatment

InactiveUS6893442B2Surgical instruments for heatingSurgical instruments for aspiration of substancesLess invasiveRadio frequency

An embodiment of the invention includes a surgical device for coagulating soft tissue such as atrial tissue in the treatment of atrial fibrillation, atrial flutter, and atrial tachycardia. The surgical device can include at least one elongate member comprising conductive elements adapted to coagulate soft tissue when radiofrequency or direct current energy is transmitted to the conductive elements. Openings through said conductive elements are routed through lumens in the elongate member to a vacuum source to actively engage the soft tissue surface intended to coagulate into intimate contact with the conductive elements to facilitate the coagulation process and ensure the lesions created are consistent, contiguous, and transmural. The embodiments of the invention can also incorporate cooling openings positioned near the conductive elements and coupled with a vacuum source or an injection source to transport fluid through the cooling openings causing the soft tissue surface to cool thus pushing the maximum temperature deeper into tissue. The embodiments of the invention can also incorporate features to tunnel between anatomic structures or dissect around the desired tissue surface to coagulate thereby enabling less invasive positioning of the soft tissue coagulating device and ensuring reliable and consistent heating of the soft tissue.

Owner:ATRICURE

Water-absorbing resin and method for manufacturing the same

The present invention provides a highly productive method for manufacturing a water-absorbing resin, the amounts of fine powder and dust of which are small, the amount of residual monomer of which is small, and whose absorption rate is high. That is, the method for manufacturing the water-absorbing resin of the present invention is a method for crosslinking and polymerizing an aqueous solution of an acid-group containing unsaturated monomer, and is characterized in that stationary polymerization is carried out in such a manner that a solid matter is added to the monomer aqueous solution, and an initiation temperature of the polymerization is adjusted to 40° C. or more or a maximum temperature of the polymerization is adjusted to 100° C. or more.

Owner:NIPPON SHOKUBAI CO LTD

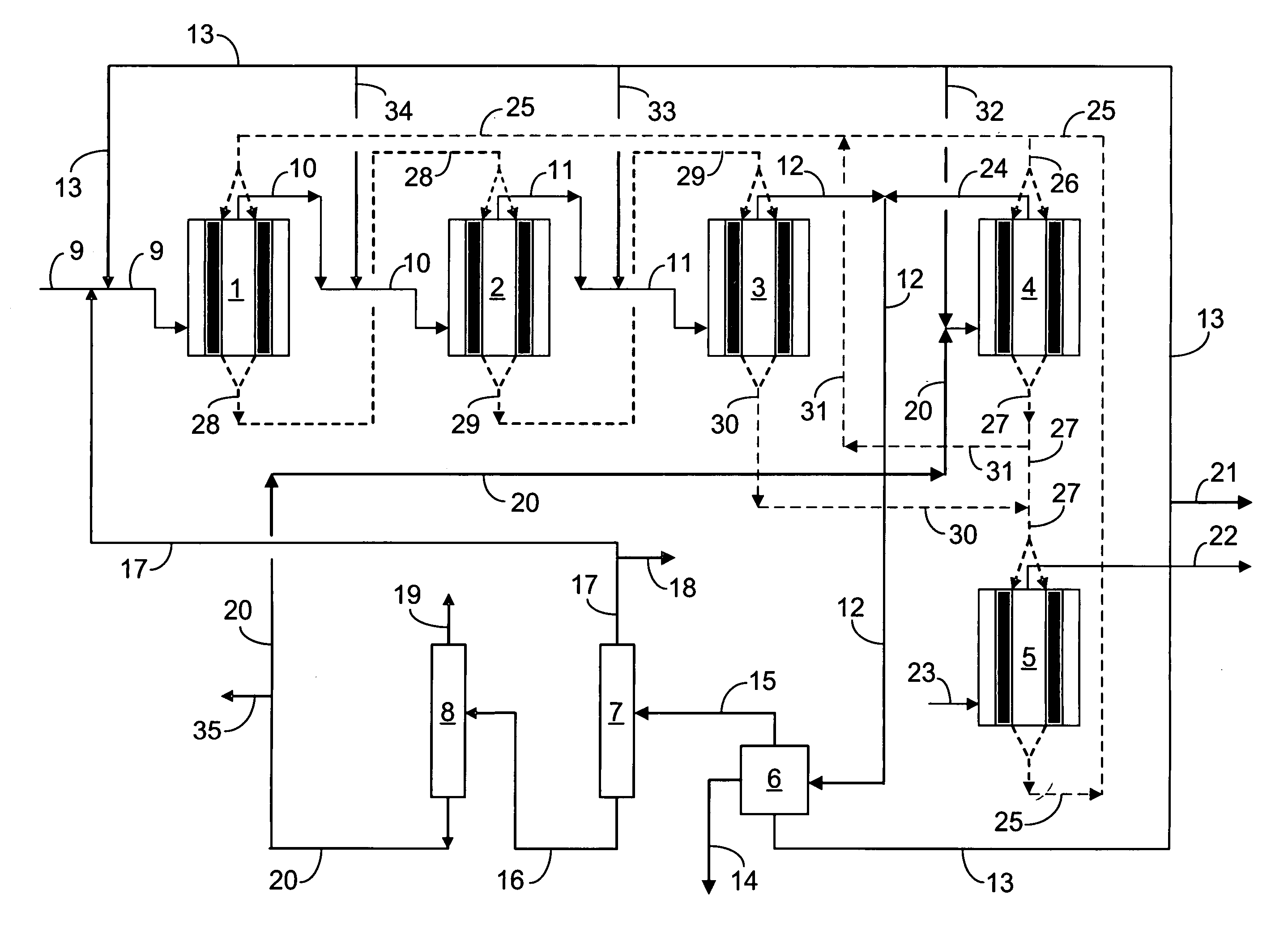

Conversion of oxygenate to propylene using moving bed technology and a separate heavy olefin interconversion step

ActiveUS20060161035A1Improve economyEfficient OTP processMolecular sieve catalystCatalystsFixed bedOxygenate

The average propylene cycle yield of an oxygenate to propylene (OTP) process using a dual-function oxygenate conversion catalyst is substantially enhanced by the use of a combination of: 1) moving bed reactor technology in the catalytic OTP reaction step in lieu of the fixed bed technology of the prior art; 2) a separate heavy olefin interconversion step using moving bed technology and operating at an inlet temperature at least 15° C. higher than the maximum temperature utilized in the OTP reaction step; 3) C2 olefin recycle to the OTP reaction step; and 4) a catalyst on-stream cycle time of 700 hours or less. These provisions hold the build-up of coke deposits on the catalyst to a level which does not substantially degrade dual-function catalyst activity, oxygenate conversion and propylene selectivity, thereby enabling maintenance of average propylene cycle yield for each cycle near or at essentially start-of-cycle levels.

Owner:UOP LLC

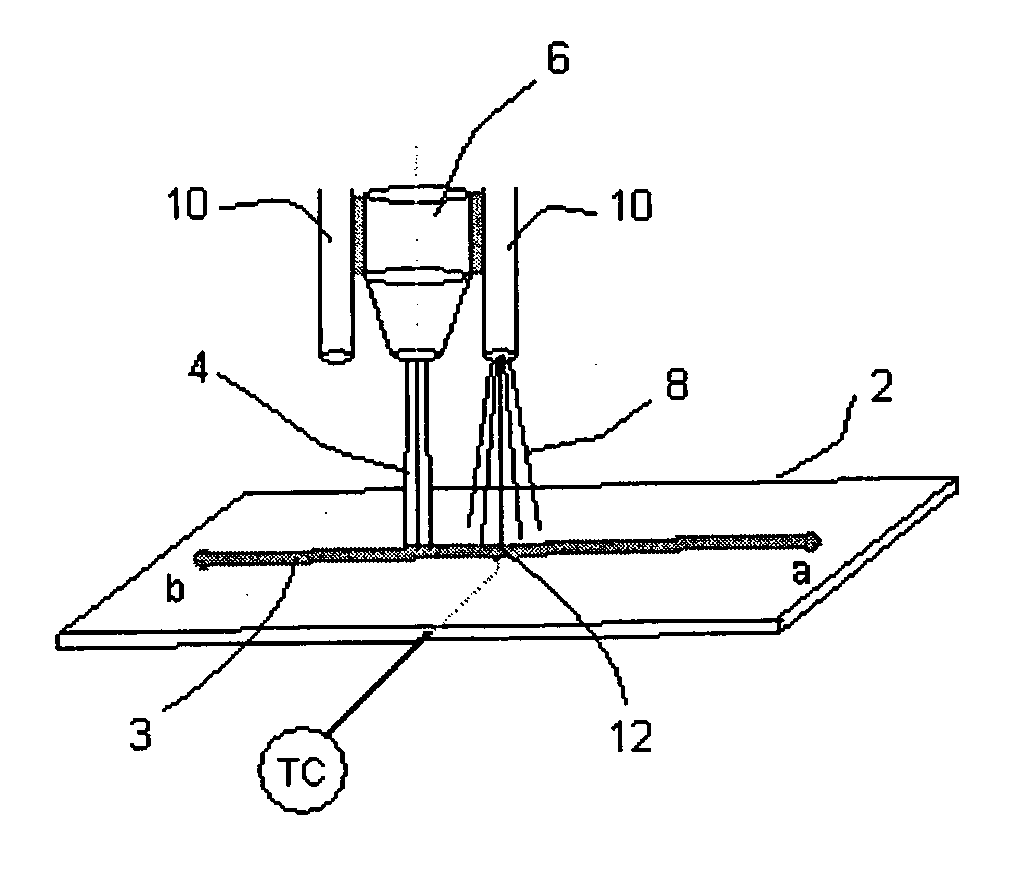

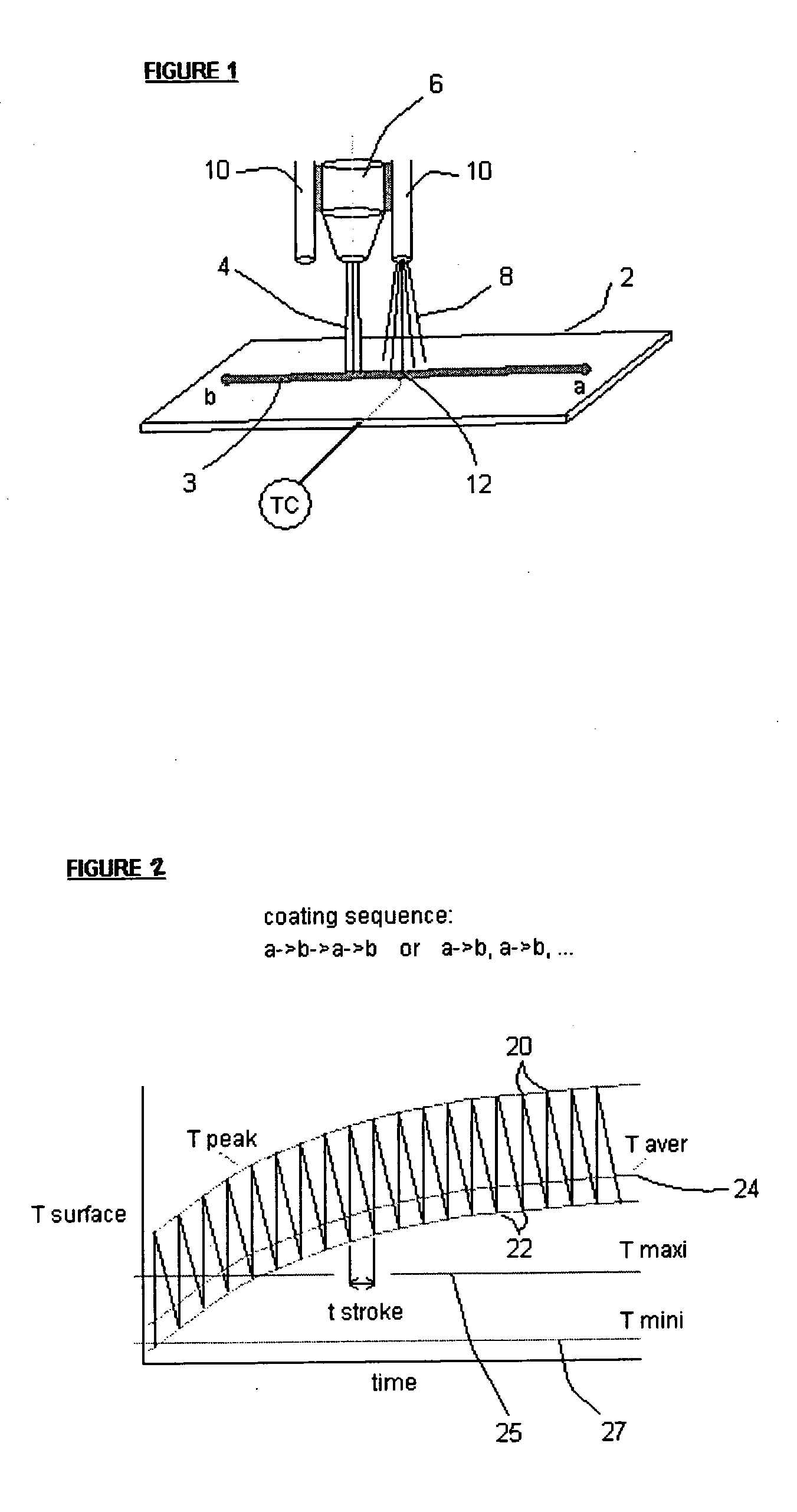

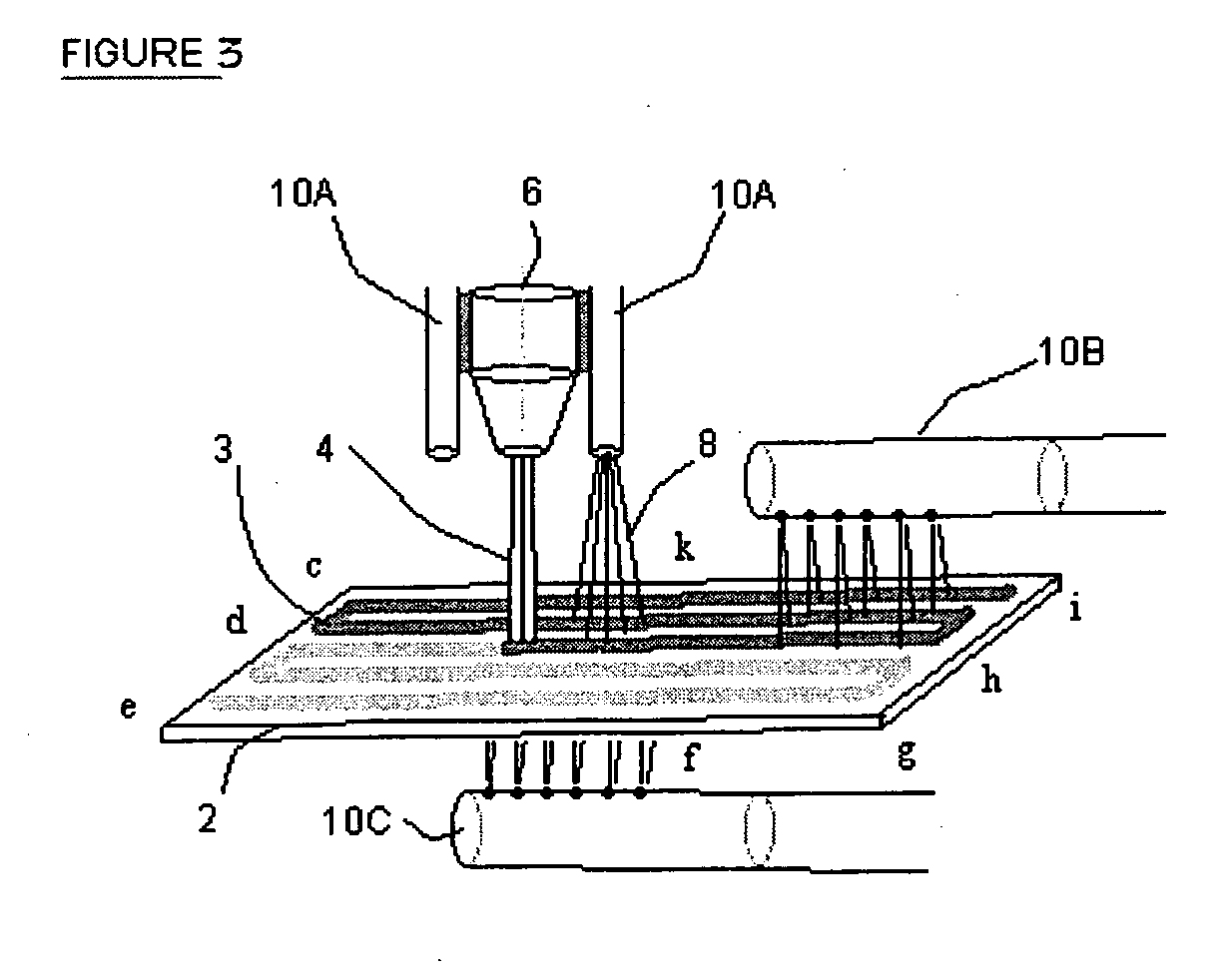

Thermal deposition coating method

ActiveUS20060228465A1Excellent coating production rateDamaging internal stressLiquid surface applicatorsMolten spray coatingThermal depositionRelative motion

A process for the thermal deposition coating of a workpiece, said process comprising the steps of: (c) thermally depositing a coating on a metallic surface of a workpiece from a deposition head wherein at least one condition selected from the group of: coating deposition rate onto said surface, relative motion between the surface and said deposition head, and cryogenic coolant application rate onto said workpiece is controllable; (d) substantially simultaneously measuring temperatures at a plurality of locations over the metallic surface of the workpiece; (c) determining an average temperature of the temperatures measured in step (b); (d) comparing the average temperature to a preselected minimum temperature and a preselected maximum temperature for the workpiece; and (e) adjusting at least one of the controllable conditions if said average temperature is not between the preselected minimum temperature and the preselected maximum temperature for the workpiece. Standard deviations of all temperature readings and controlling the relative motion speed between the thermal coating deposition head and the workpiece provide another improvement for obtaining temperature uniformity over the workpiece surface.

Owner:AIR PROD & CHEM INC

Vacuum coagulation probe for atrial fibrillation treatment

InactiveUS20060009762A1Surgical instruments for heatingSurgical instruments for aspiration of substancesAnatomical structuresLess invasive

An embodiment of the invention includes a surgical device for coagulating soft tissue such as atrial tissue in the treatment of atrial fibrillation, atrial flutter, and atrial tachycardia. The surgical device can include at least one elongate member comprising conductive elements adapted to coagulate soft tissue when radiofrequency or direct current energy is transmitted to the conductive elements. Openings through said conductive elements are routed through lumens in the elongate member to a vacuum source to actively engage the soft tissue surface intended to coagulate into intimate contact with the conductive elements to facilitate the coagulation process and ensure the lesions created are consistent, contiguous, and transmural. The embodiments of the invention can also incorporate cooling openings positioned near the conductive elements and coupled with a vacuum source or an injection source to transport fluid through the cooling openings causing the soft tissue surface to cool thus pushing the maximum temperature deeper into tissue. The embodiments of the invention can also incorporate features to tunnel between anatomic structures or dissect around the desired tissue surface to coagulate thereby enabling less invasive positioning of the soft tissue coagulating device and ensuring reliable and consistent heating of the soft tissue.

Owner:ATRICURE

Systems and methods for estimating tissue parameters using surgical devices

Systems and methods for estimating tissue parameters, including mass of tissue to be treated and a thermal resistance scale factor between the tissue and an electrode of an energy delivery device, are disclosed. The method includes sensing tissue temperatures, estimating a mass of the tissue and a thermal resistance scale factor between the tissue and an electrode, and controlling an electrosurgical generator based on the estimated mass and the estimated thermal resistance scale factor. The method may be performed iteratively and non-iteratively. The iterative method may employ a gradient descent algorithm that iteratively adds a derivative step to the estimates of the mass and thermal resistance scale factor until a condition is met. The non-iterative method includes selecting maximum and minimum temperature differences and estimating the mass and the thermal resistance scale factor based on a predetermined reduction point from the maximum temperature difference to the minimum temperature difference.

Owner:TYCO HEALTHCARE GRP LP

Vacuum coagulation probes

InactiveUS20080114354A1Less invasive treatmentImprove efficiencySurgical instruments for heatingSurgical instruments for aspiration of substancesLesionMaximum temperature

A surgical device integrating a suction mechanism with a coagulation mechanism is provided for improving lesion creation capabilities. The device comprises an elongate member having an insulative covering attached about means for coagulating soft tissue. Openings through the covering expose regions of the coagulation-causing elements and are coupled to lumens in the elongate member which are routed to a vacuum source. A fluid source to passively transport fluid along the contacted soft tissue surface may be provided in order to push the maximum temperature deeper into tissue.

Owner:ATRICURE

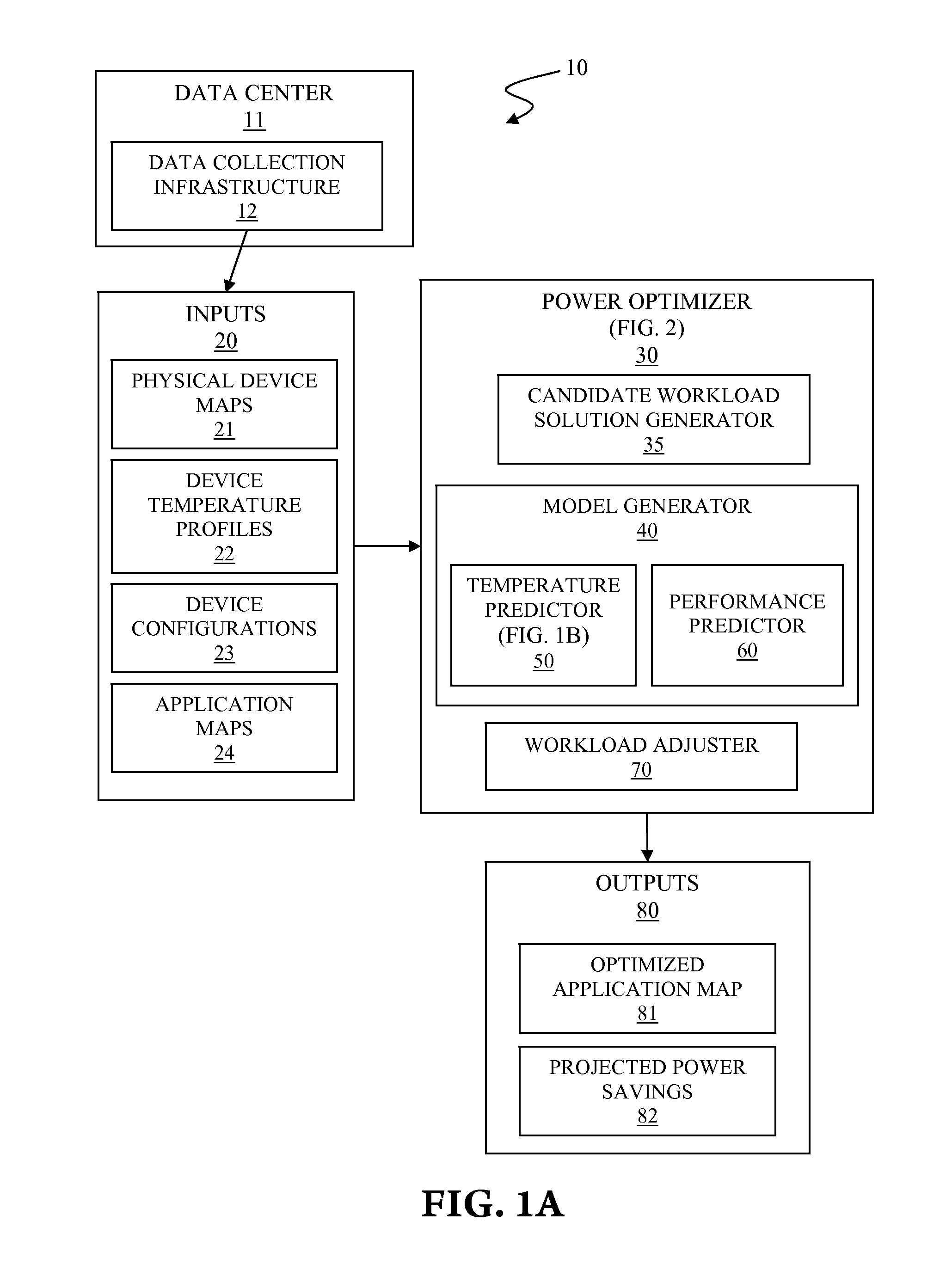

Optimizing power consumption by dynamic workload adjustment

InactiveUS20110213508A1Increase power consumptionEnergy efficient ICTMechanical power/torque controlData centerParallel computing

A system and associated method for optimizing power consumption of a data center by dynamic workload adjustment. A current workload distribution of the data center is shifted to an optimal workload solution that provides acceptable level of service with the least amount of power consumption. The sum of power cost and migration cost that corresponds to the optimal workload solution is the lowest among all sums that correspond to respective candidate workload solutions. The power cost is determined by a maximum temperature of the data center and accompanying cooling cost for each candidate workload solution. The migration cost is determined by performance degradation that occurs during shifting a workload distribution of the data center from the current workload distribution to each candidate workload solution.

Owner:KYNDRYL INC

Vacuum coagulation probes

InactiveUS20070043351A1Improve efficiencyIncrease contactSurgical instruments for heatingSurgical instruments for aspiration of substancesLesionMaximum temperature

A surgical device integrating a suction mechanism with a coagulation mechanism is provided for improving lesion creation capabilities. The device comprises an elongate member having an insulative covering attached about means for coagulating soft tissue. Openings through the covering expose regions of the coagulation-causing elements and are coupled to lumens in the elongate member which are routed to a vacuum source. A fluid source to passively transport fluid along the contacted soft tissue surface may be provided in order to push the maximum temperature deeper into tissue.

Owner:ATRICURE

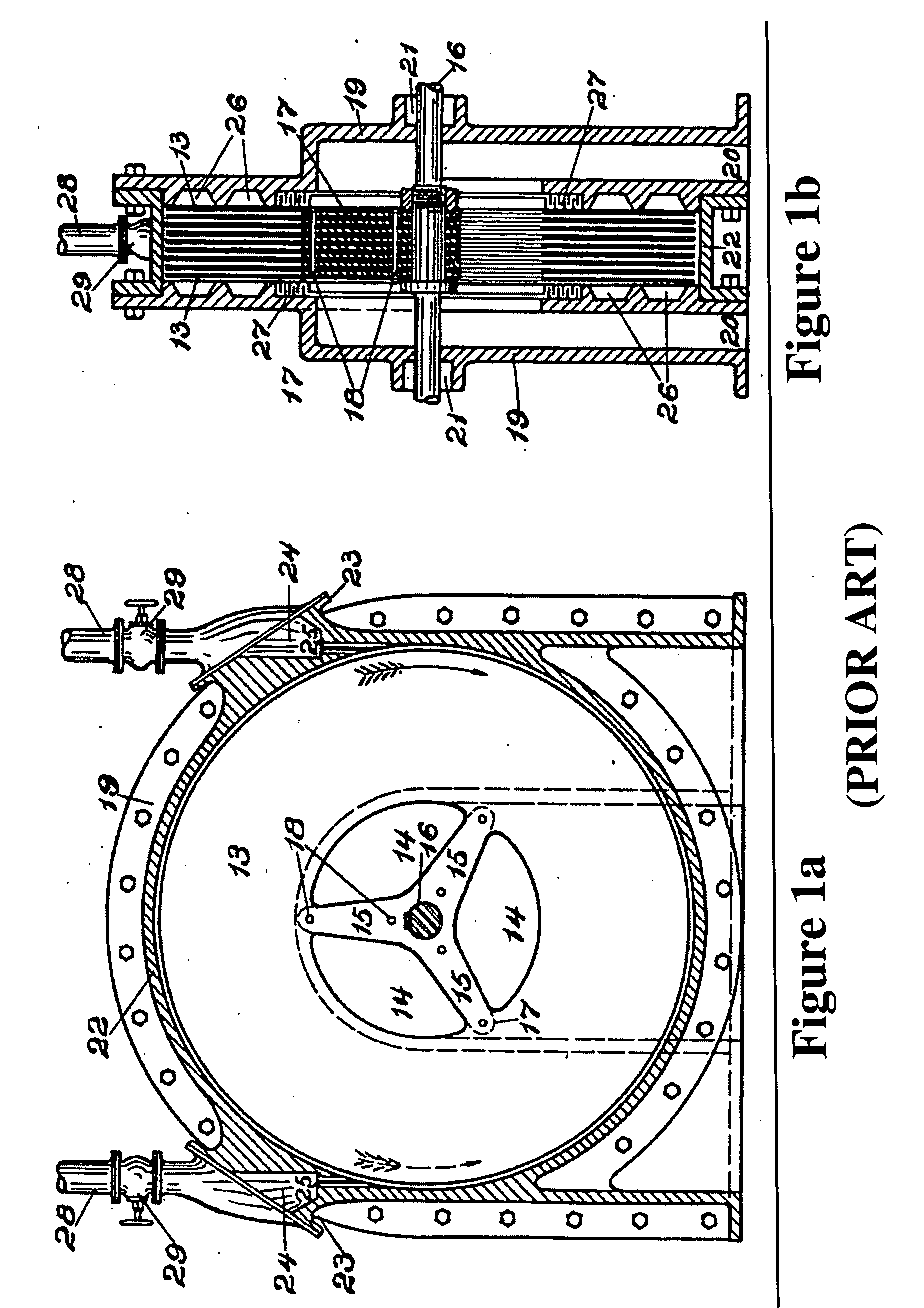

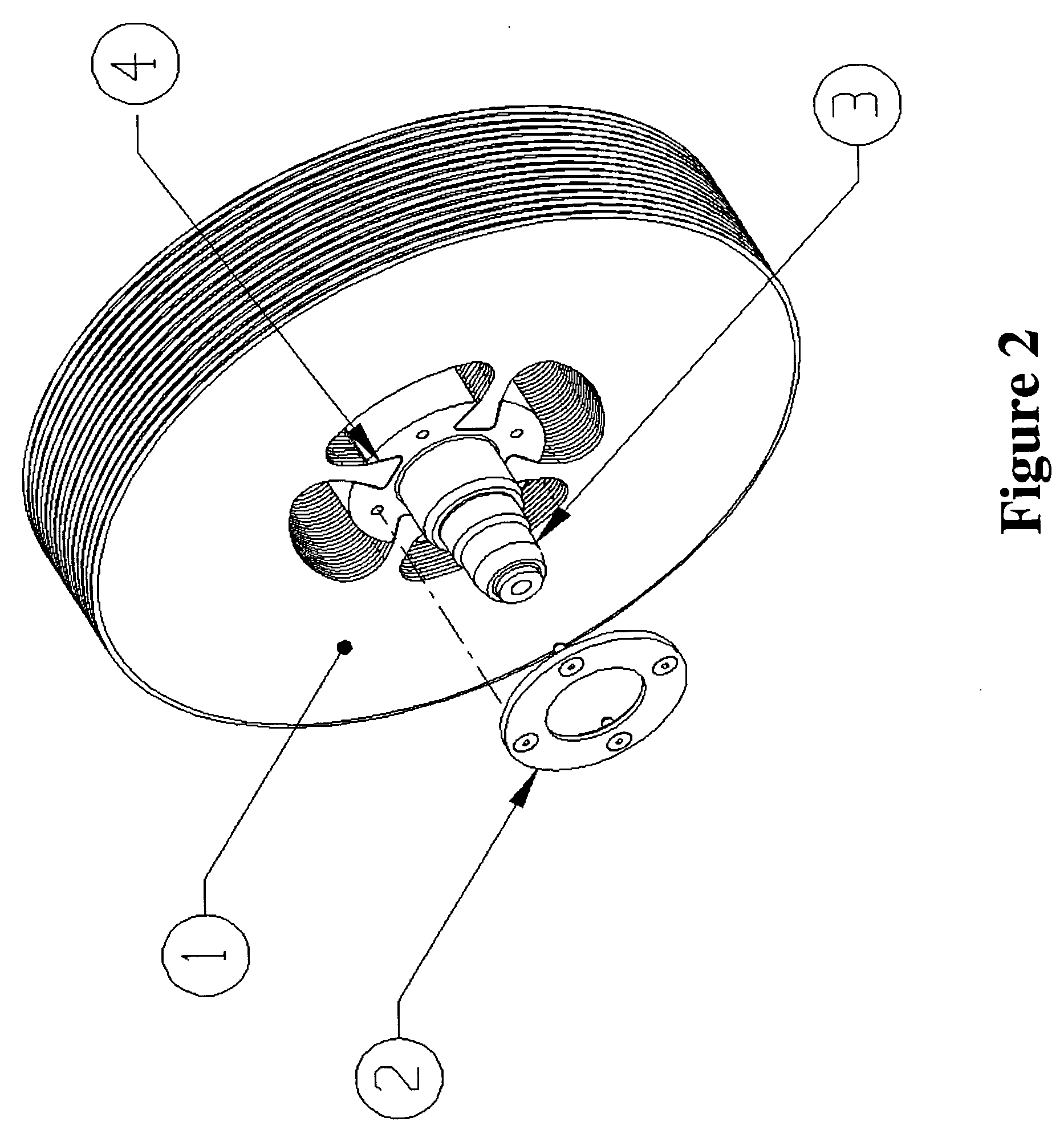

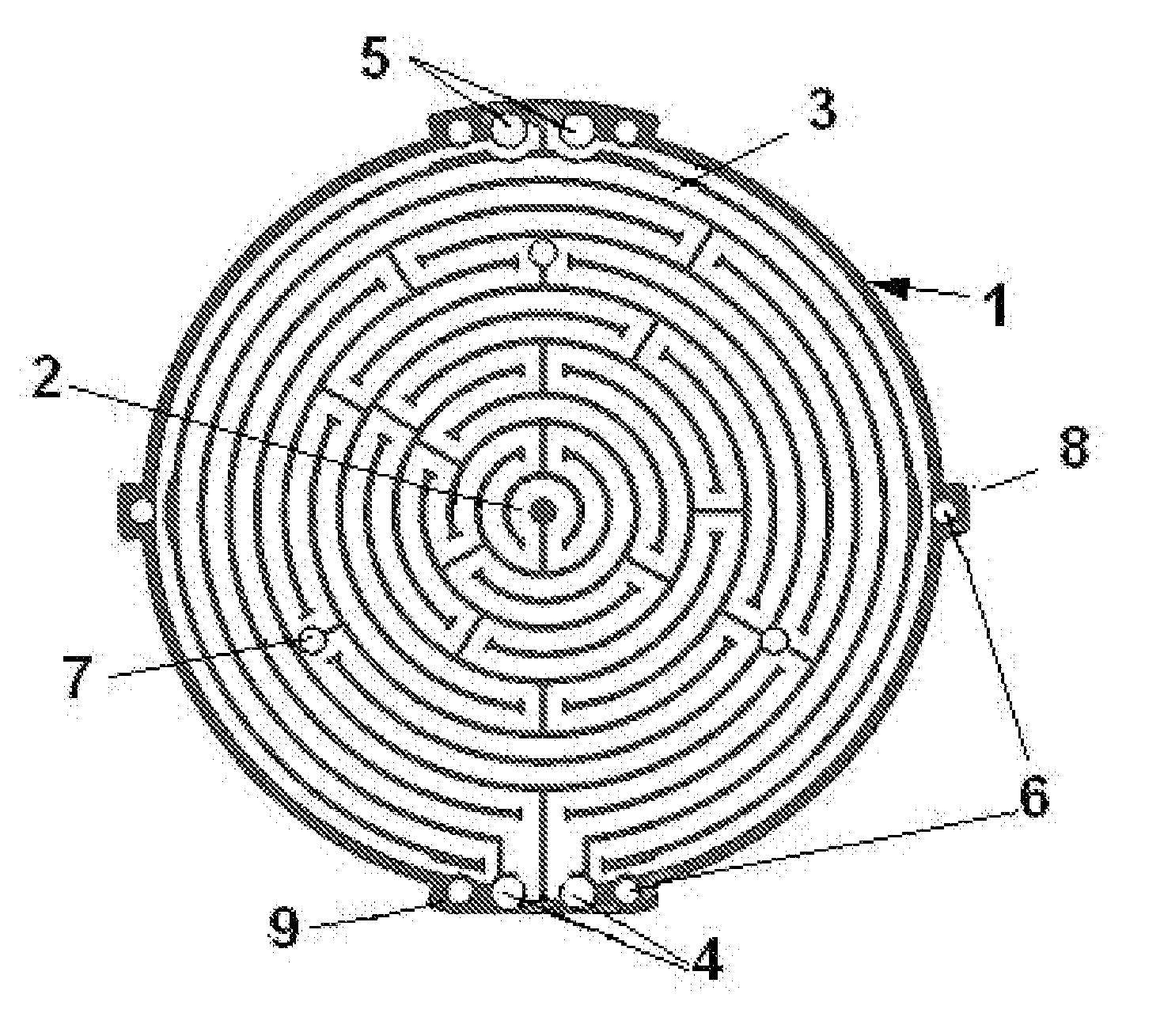

Method of and apparatus for a multi-stage boundary layer engine and process cell

InactiveUS20050169743A1Improve turbine efficiencyIncrease efficiency and reliability and flexibilityMaterial nanotechnologyInfluencers using Magnus effectCombustion chamberClosed loop

A multi-staged boundary layer engine and process cell, (based on the effect known as adhesion and viscosity) which achieves high thermal efficiencies and high mechanical power output for use in the power generation, geothermal, energy recovery, solar, transportation, hydrogen production, desalinating water and hydroelectric fields. The design is novel with a dovetail attachment of the disc packs, allowing lower stress and allowing the use of next generation materials such as ceramics, composites and nanocomposites to improve the maximum temperature and the maximum RPM of the engine, thereby producing more horsepower and torque. In addition, this invention includes multi-stage vacuum, an external combustion chamber and condenser stages to improve the vortex flow through the primary disc pack cell. This engine will also encompass a closed loop cycle for ultimate efficiencies. This invention will also include the use of catalysts and / or electrical polarities applied to the disc pack and the disc pack / casing respectively to achieve low NOx and also to achieve process cell capability for applications such as desalinization and hydrogen generation.

Owner:CENTRIPETAL DYNAMICS

Vacuum coagulation & dissection probes

ActiveUS20060293646A1Reduce wall thicknessImprove efficiencySurgical instruments for heatingSurgical instruments for aspiration of substancesDissectionMaximum temperature

A surgical device integrating a suction mechanism with a coagulation mechanism is provided for improving lesion creation capabilities. The device comprises an elongate member having an insulative covering attached about means for coagulating soft tissue. Openings through the covering expose regions of the coagulation-causing elements and are coupled to lumens in the elongate member which are routed to a vacuum source. A fluid source to passively transport fluid along the contacted soft tissue surface may be provided in order to push the maximum temperature deeper into tissue.

Owner:ATRICURE

Extruded gluten based pet chew bodies

InactiveUS20050214349A1Facilitate easeEasy to storeAnimal feeding stuffAccessory food factorsFiberAdditive ingredient

A method of forming solid gluten-based pet chew is provided wherein a gluten mixture is heated to a maximum temperature of up to about 80° C. to create a substantially homogeneous and flowable mixture under extrusion processing conditions. The formulation includes from about 40-90% by weight of grain protein, from about 10-40% by weight plasticizer, and at least about 0.01 by weight of a reducing agent such as sodium bisulfite for cleaving disulfide bonds present in the grain protein. Dental health agents including an acidulent and a chelator are added to promote good dental health. Optional ingredients such as fillers, fiber, lubricant / mold release agents and colorants can also be used. The formulations can be processed in extrusion or injection molding equipment.

Owner:DERMAPET

Optically transitioning thermal detector structures

ActiveUS20110266445A1Good effectHeat dissipationPhotometrySolid-state devicesMaximum temperatureTemperature sensitive

A thermal absorption structure of a radiation thermal detector element may include an optically transitioning material configured such that optical conductivity of the thermal absorption structure is temperature sensitive and such that the detector element absorbs radiation less efficiently as its temperature increases, thus reducing its ultimate maximum temperature.

Owner:DRS NETWORK & IMAGING SYST

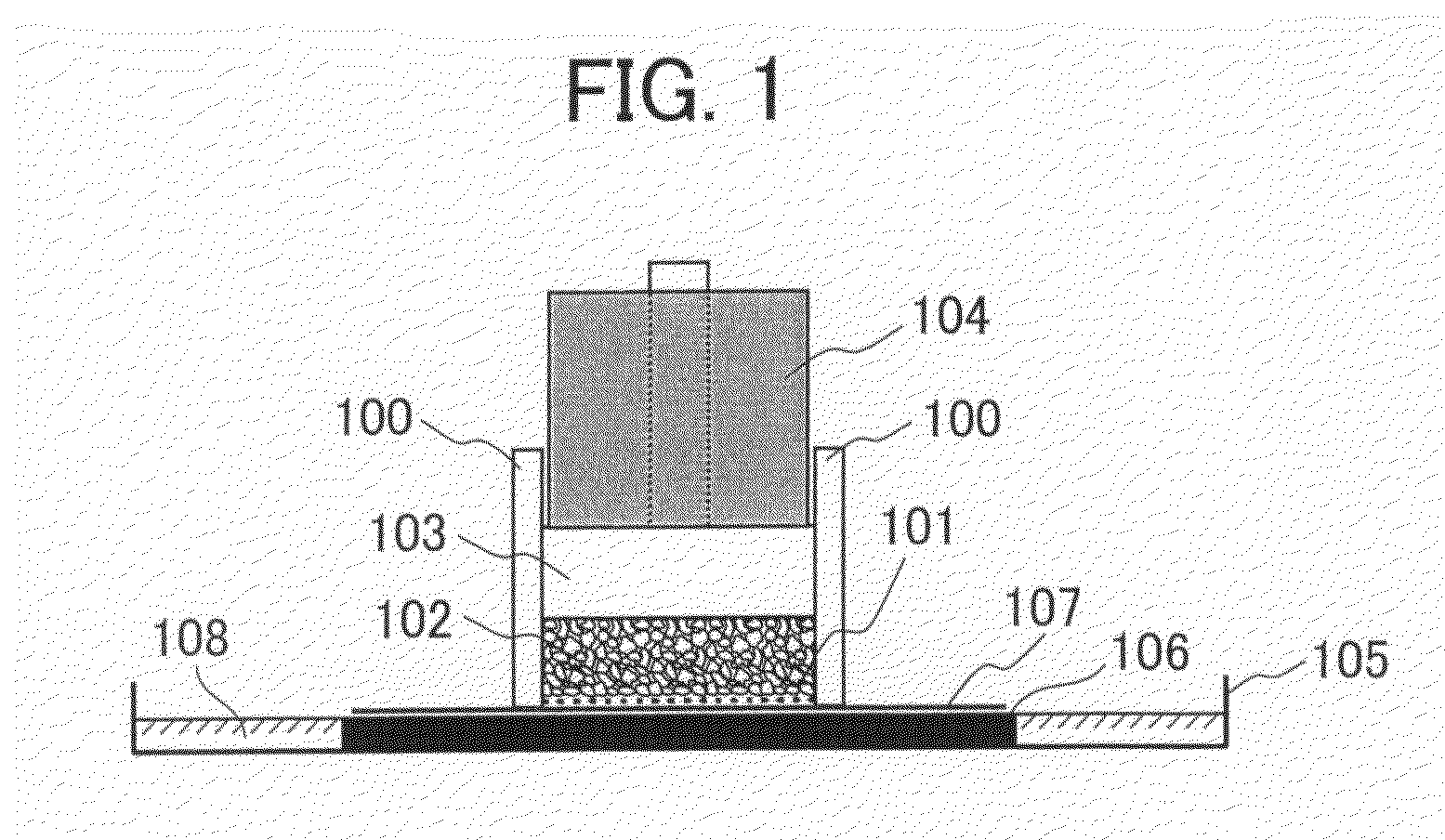

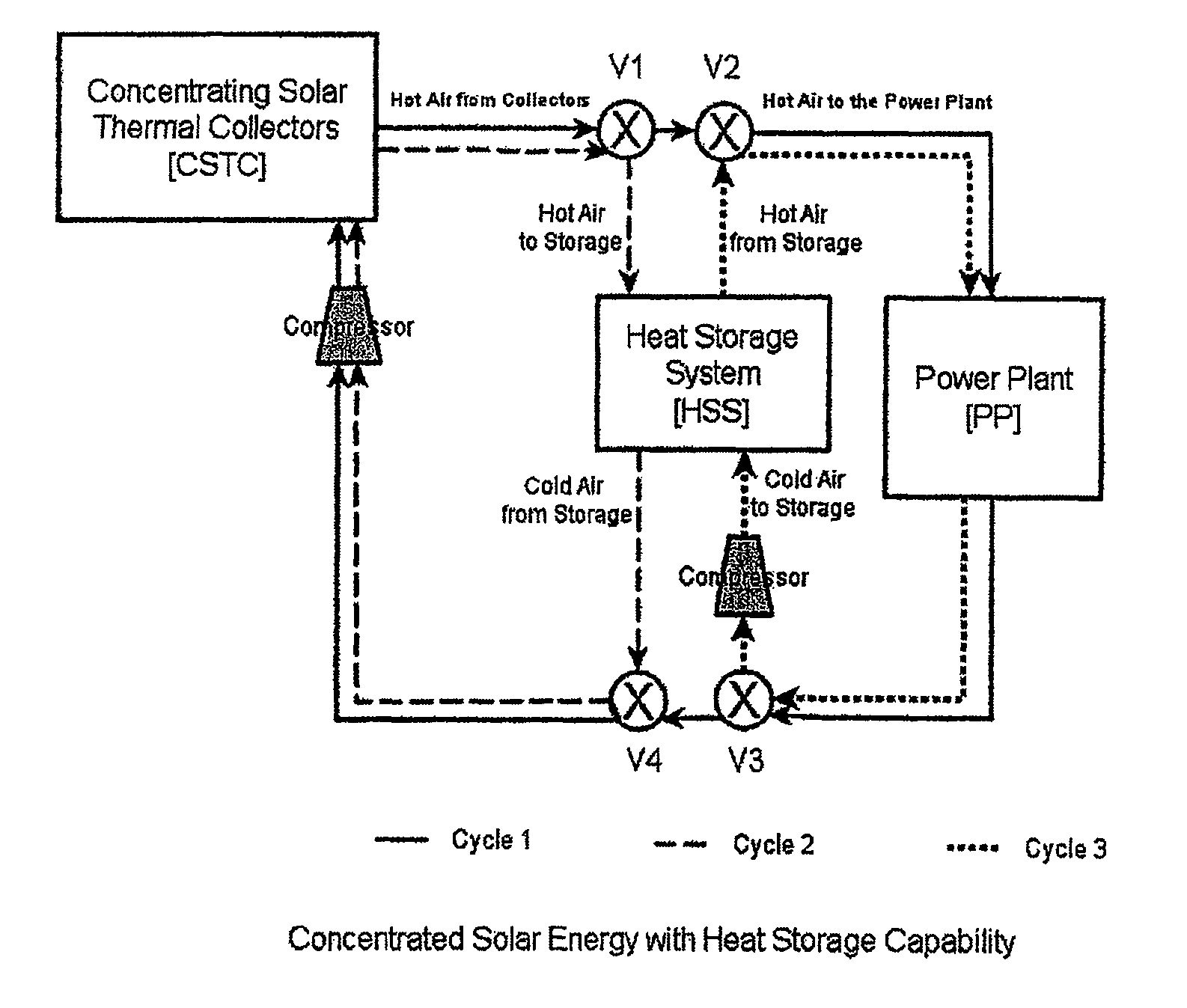

Solar power plant and method and/or system of storing energy in a concentrated solar power plant

ActiveUS7954321B2Big advantageLower energy requirementsSolar heating energyAuxillary drivesPower stationEngineering

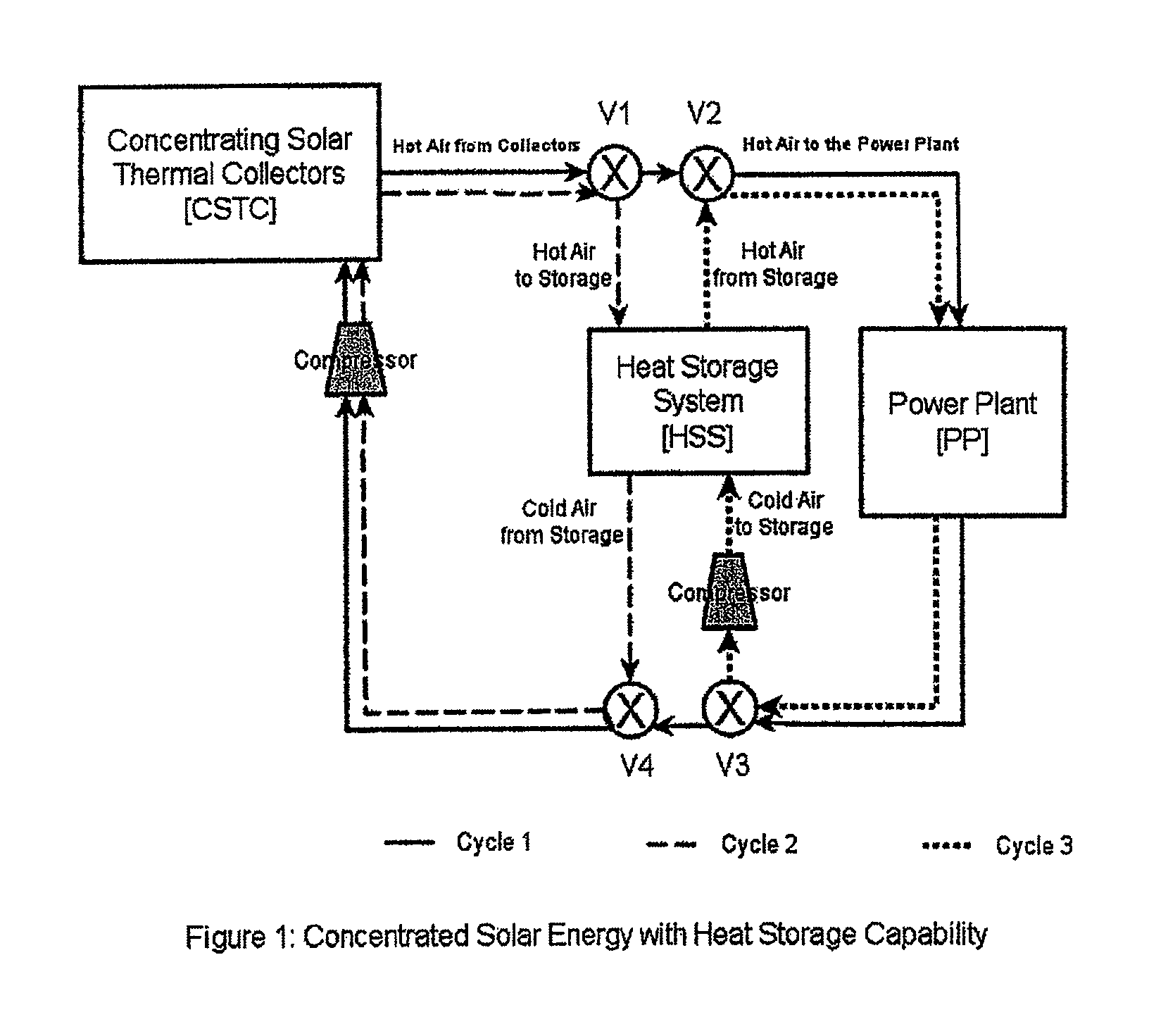

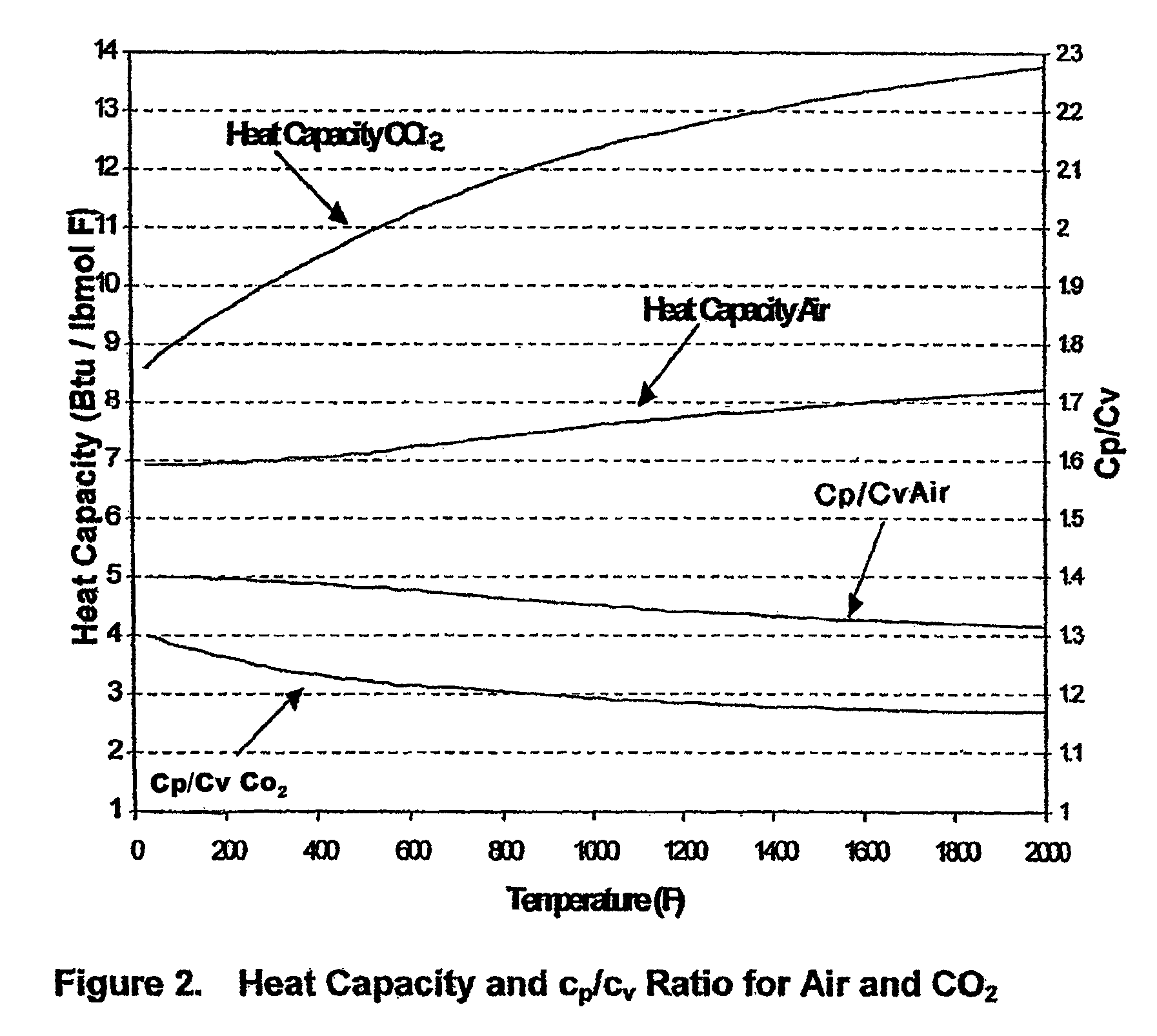

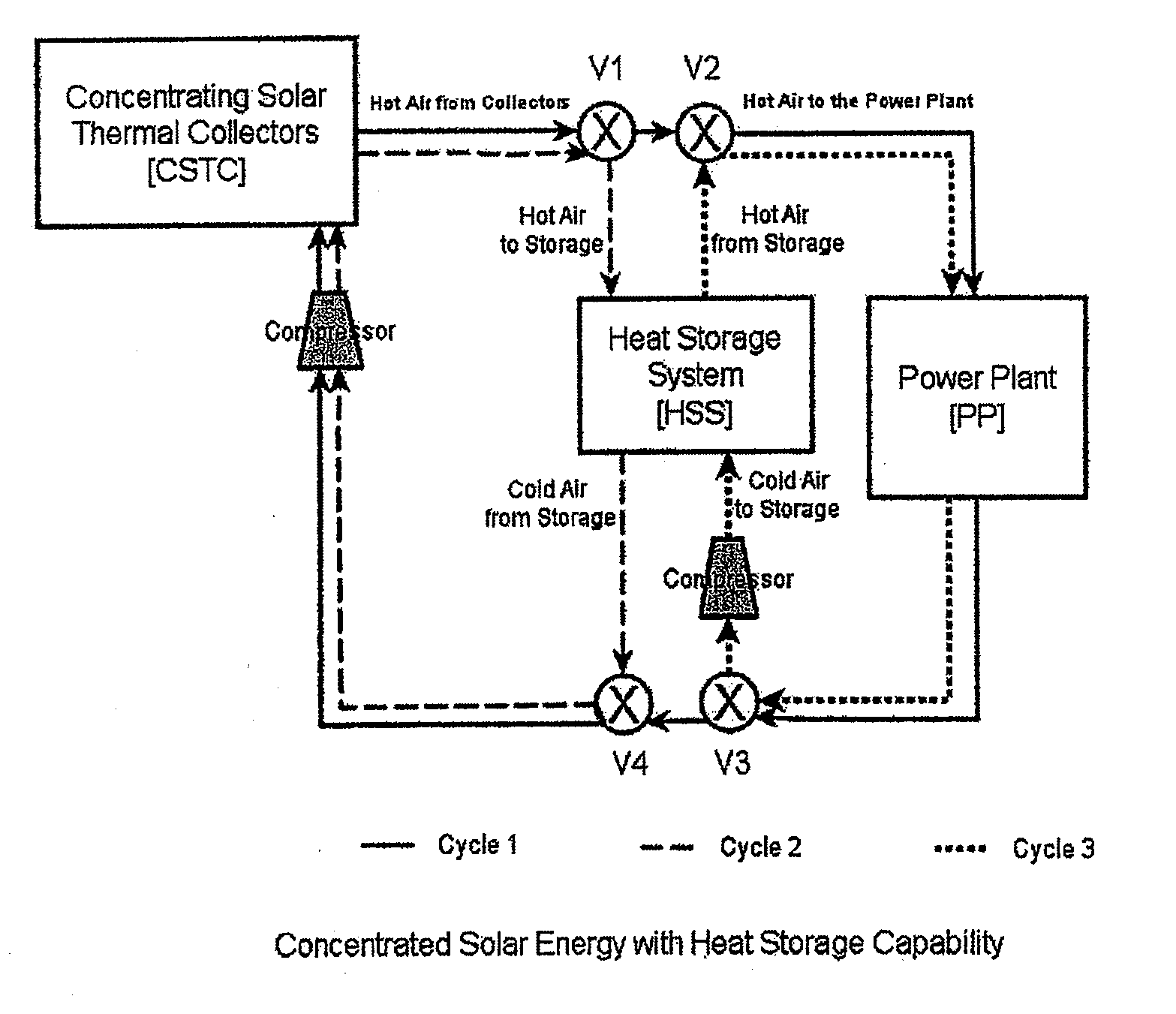

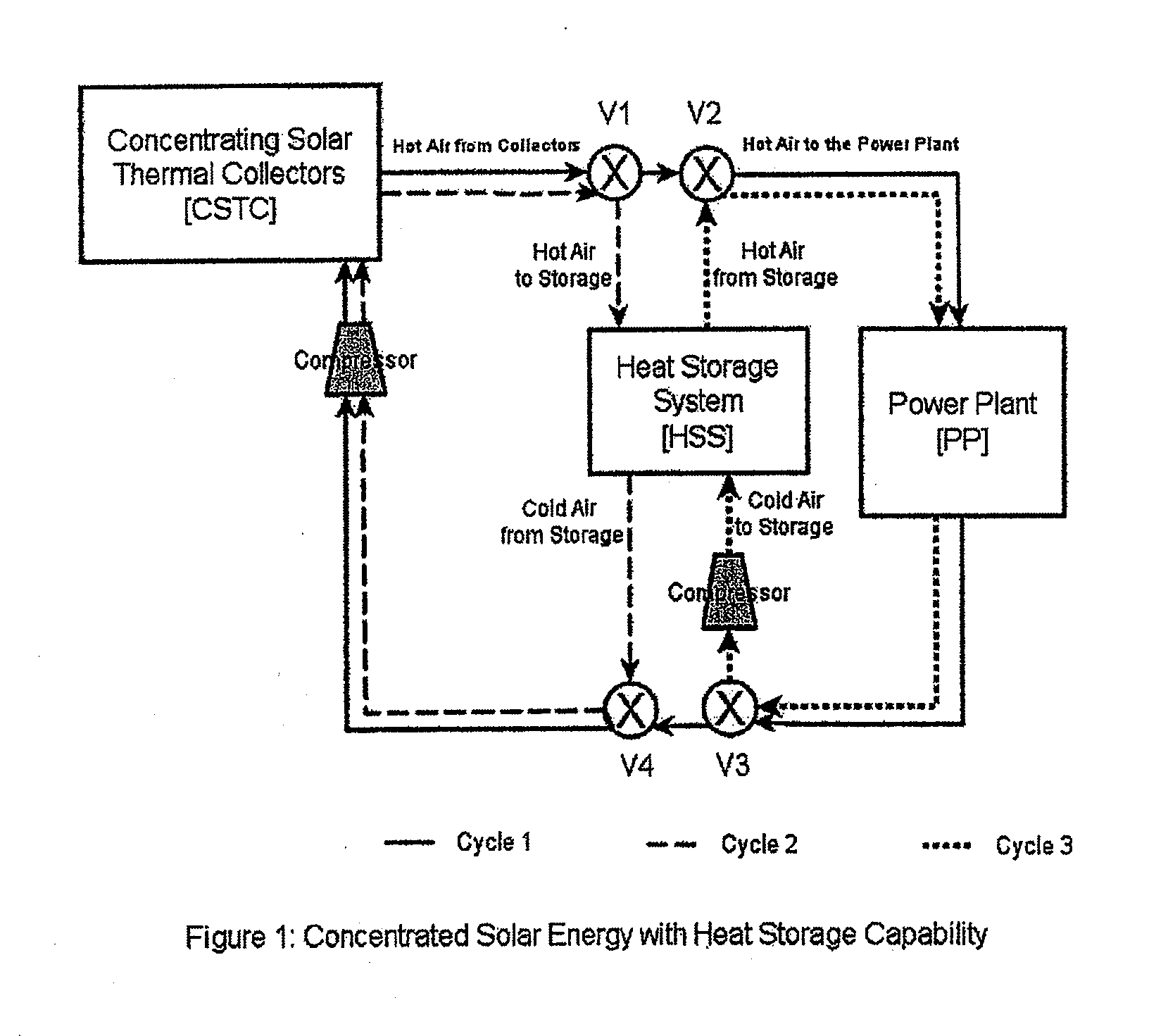

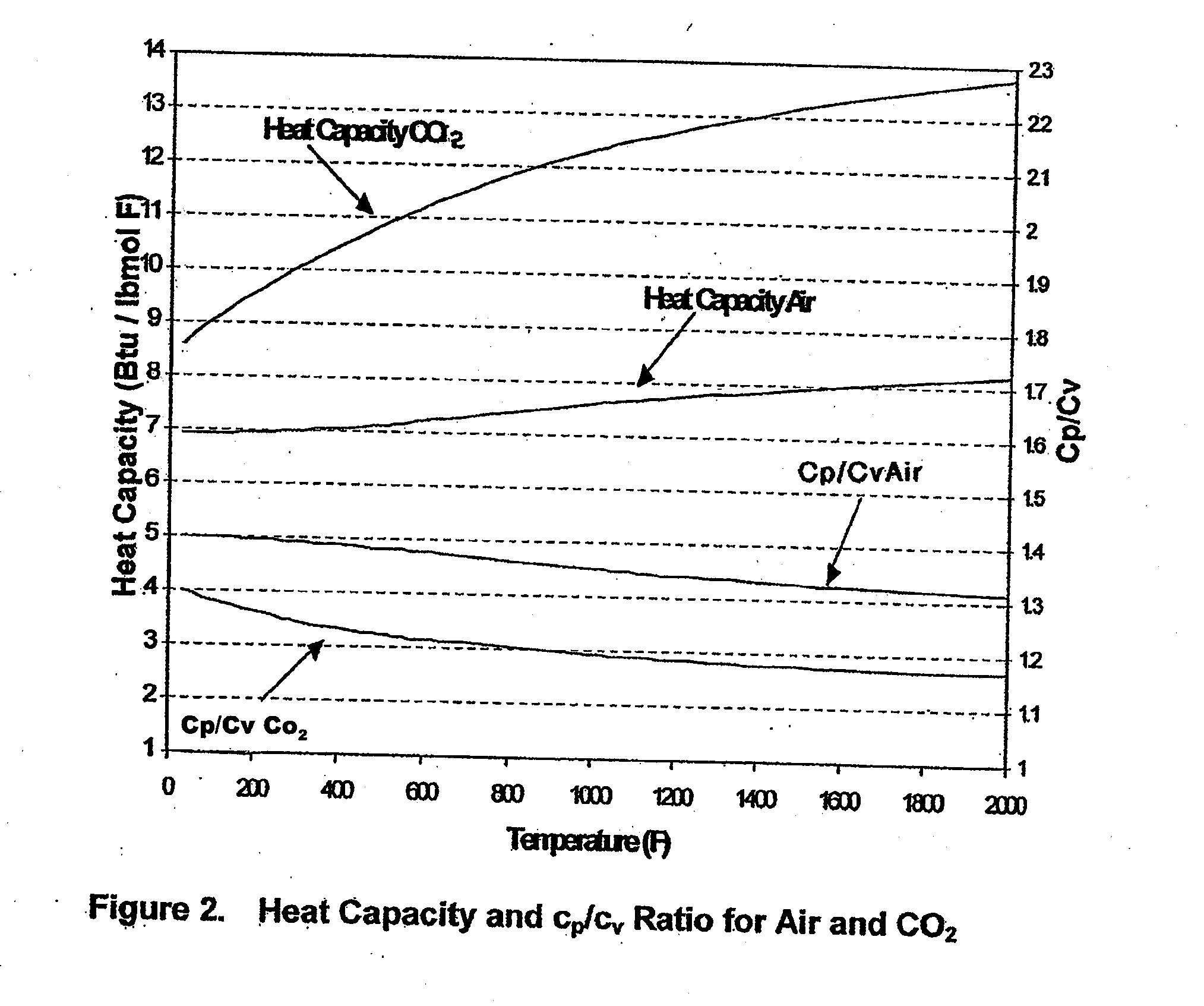

A method for storing heat from a solar collector CSTC in Concentrating Solar Power plants and delivering the heat to the power plant PP when needed. The method uses a compressed gas such as carbon dioxide or air as a heat transfer medium in the collectors CSTC and transferring the heat by depositing it on a bed of heat-resistant solids and later, recovering the heat by a second circuit of the same compressed gas. The storage system HSS is designed to allow the heat to be recovered at a high efficiency with practically no reduction in temperature. Unlike liquid heat transfer media, our storage method itself can operate at very high temperatures, up to 3000° F., a capability which can lead to greater efficiency. Due to material constraints and cost considerations in the rest of the system the maximum temperature is presently limited to between 1700° F. and 2000° F. The method can be applied to all current solar collector designs. This Abstract is not intended to define the invention disclosed in the specification, nor intended to limit the scope of the invention in any way.

Owner:RES FOUND THE CITY UNIV OF NEW YORK

Solar power plant and method and/or system of storing energy in a concentrated solar power plant

ActiveUS20100176602A1Big advantageLower energy requirementsSolar heating energyAuxillary drivesPower stationEngineering

A method for storing heat from a solar collector CSTC in Concentrating Solar Power plants and delivering the heat to the power plant PP when needed. The method uses a compressed gas such as carbon dioxide or air as a heat transfer medium in the collectors CSTC and transferring the heat by depositing it on a bed of heat-resistant solids and later, recovering the heat by a second circuit of the same compressed gas. The storage system HSS is designed to allow the heat to be recovered at a high efficiency with practically no reduction in temperature. Unlike liquid heat transfer media, our storage method itself can operate at very high temperatures, up to 3000° F., a capability which can lead to greater efficiency. Due to material constraints and cost considerations in the rest of the system the maximum temperature is presently limited to between 1700° F. and 2000° F. The method can be applied to all current solar collector designs. This Abstract is not intended to define the invention disclosed in the specification, nor intended to limit the scope of the invention in any way.

Owner:RES FOUND THE CITY UNIV OF NEW YORK

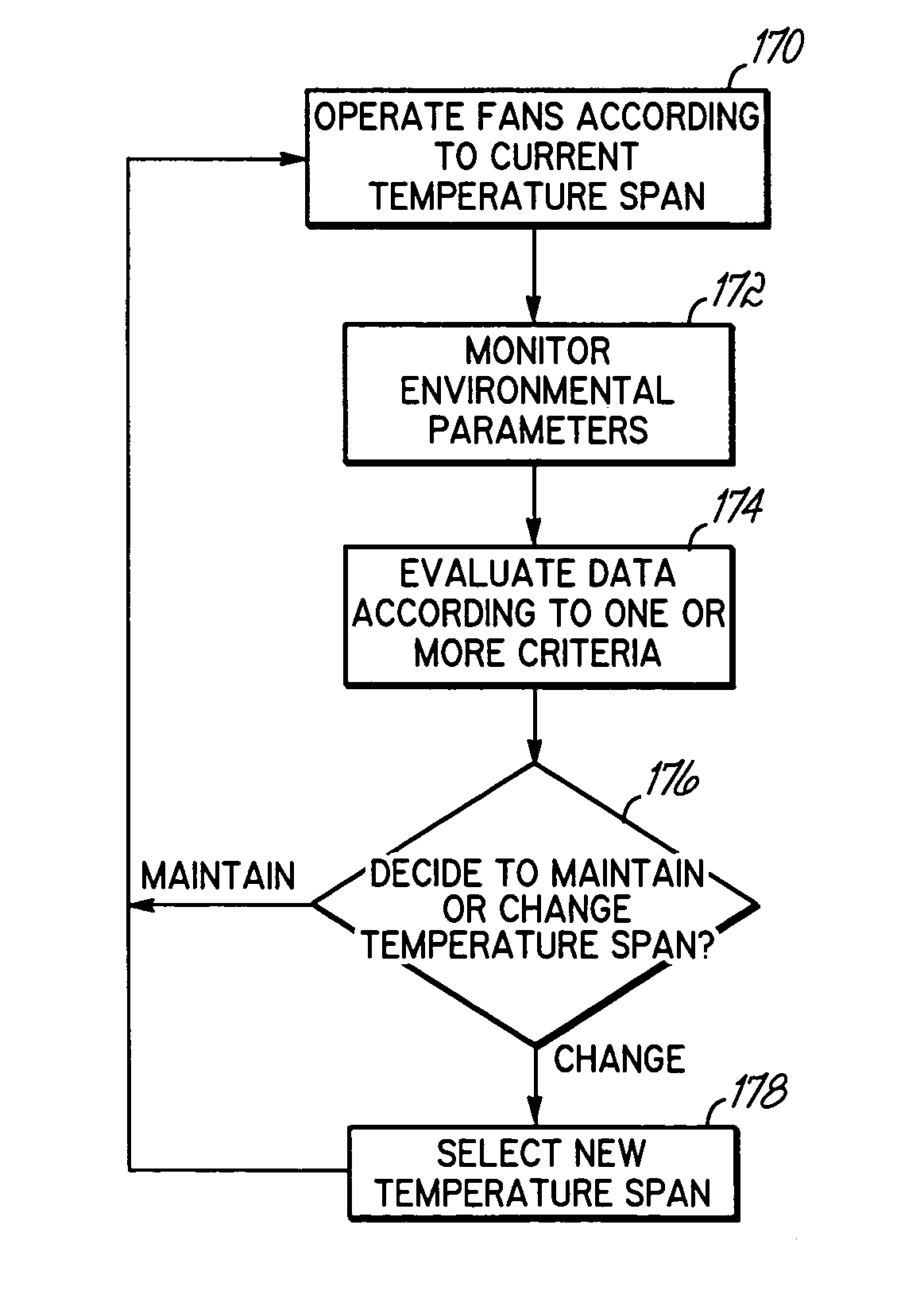

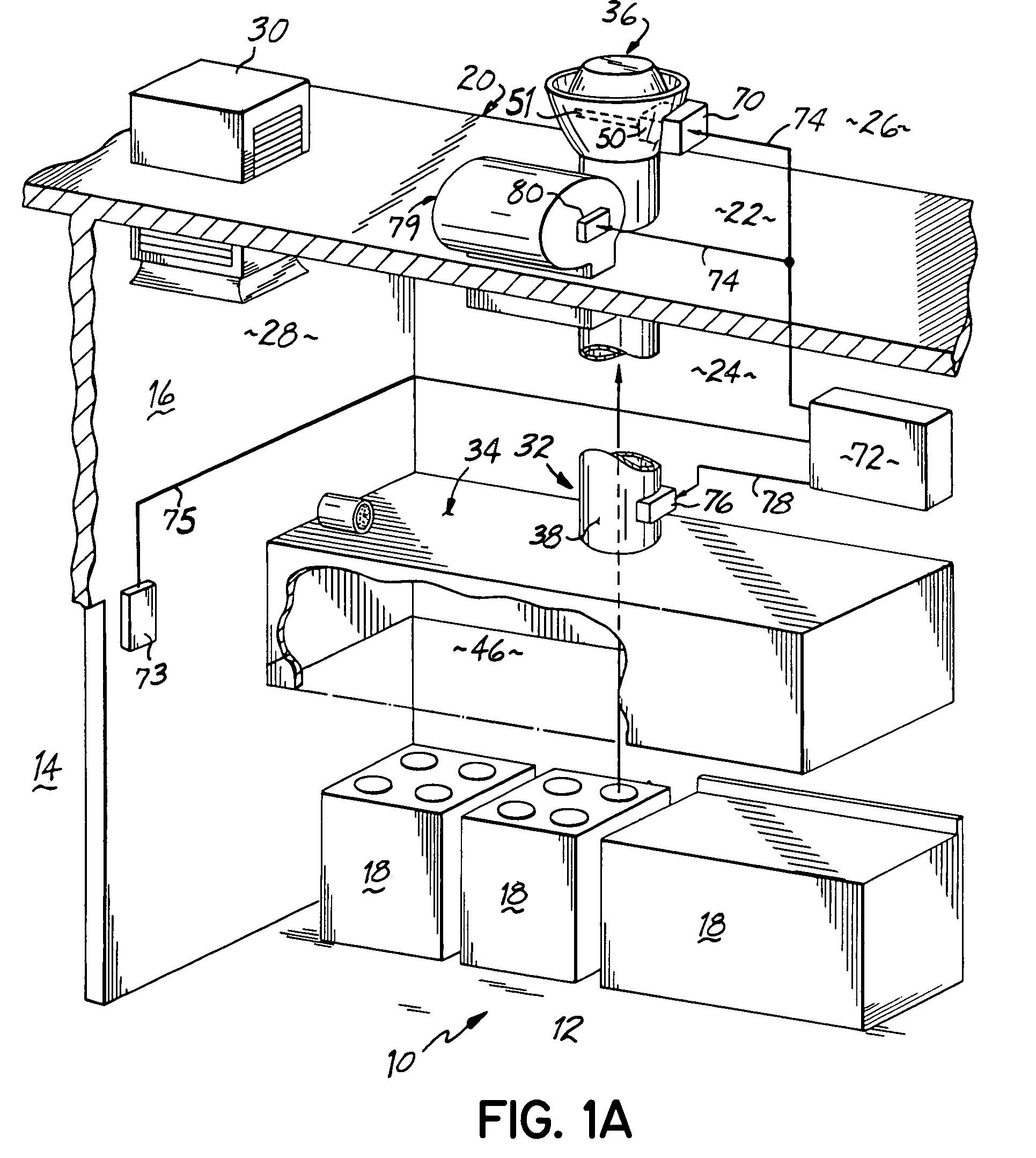

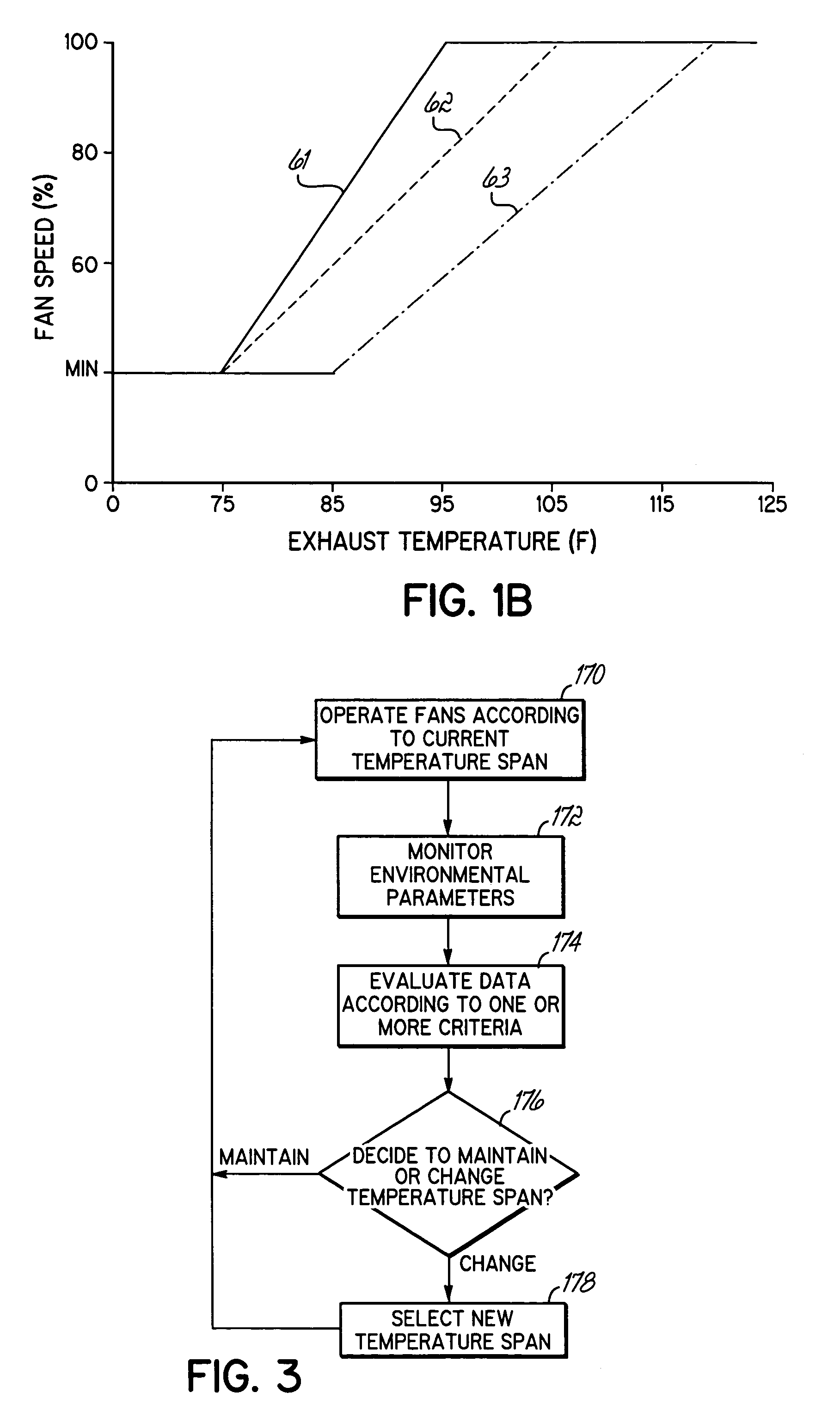

Kitchen exhaust optimal temperature span system and method

ActiveUS7048199B2Optimal exhausting conditionMechanical apparatusDomestic stoves or rangesControl systemProcess engineering

An exhaust control system (72) for a commercial or institutional kitchen exhaust system (32) is disclosed in which the exhaust fan speed is optimized for the amount of cooking heat and cooking by-product generated by the cooking units, as well as for comfort in the kitchen (12). Kitchen comfort is determined by sensing temperature, humidity, noxious gases, smoke, odor, or some combination thereof. In particular, exhaust air temperature can be used by the control system (72) to modulate fan speed from a minimum value to a maximum value based on the minimum and maximum temperatures that define a particular temperature span. During operation, the control system (72) continues to monitor environmental parameters of the kitchen (12) to determine if the current temperature span provides optimal performance. Upon determining that the current temperature span is no longer the optimal one, the control system (72) operates the exhaust system (32) according to a different temperature span.

Owner:MELINK CORP

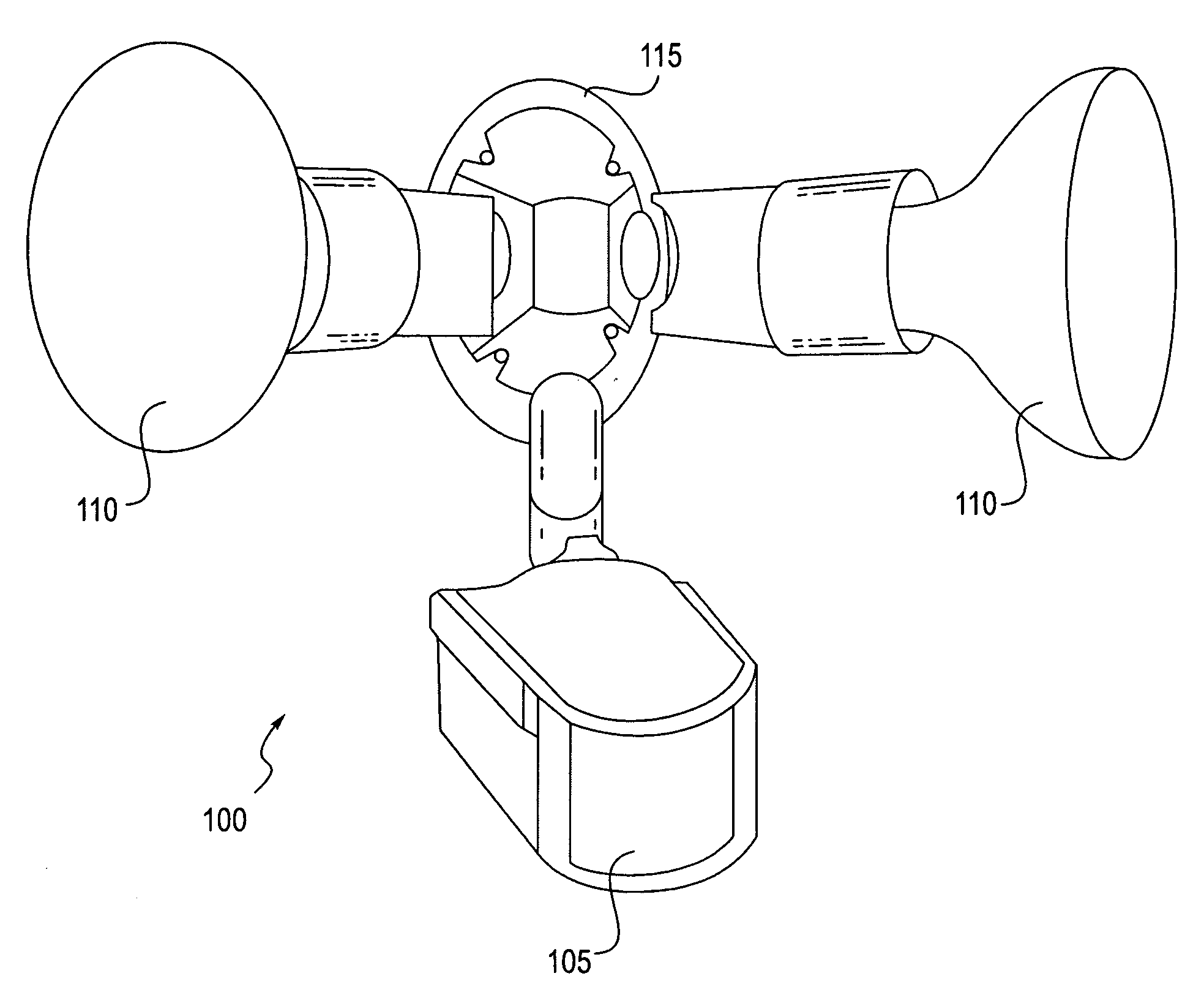

Multifunctional lighting system

The teachings herein generally relate to a single unit, energy efficient, lighting and safety system and a security surveillance system that includes the lighting and safety system. The lighting and safety system that includes an enclosed housing having a lens, a fitting configured to connect to a standard receptacle, and a sensor that can be activated upon detection of sound, heat, or motion; an illumination source disposed within the housing and creating a maximum temperature of less than 70° C. in the atmosphere that is in contact with the illumination source; and a current control engine that is disposed within the housing and coupled to the sensor and illumination source to control current to the illumination source upon activation of the sensor.

Owner:M I D ENTERPRISES

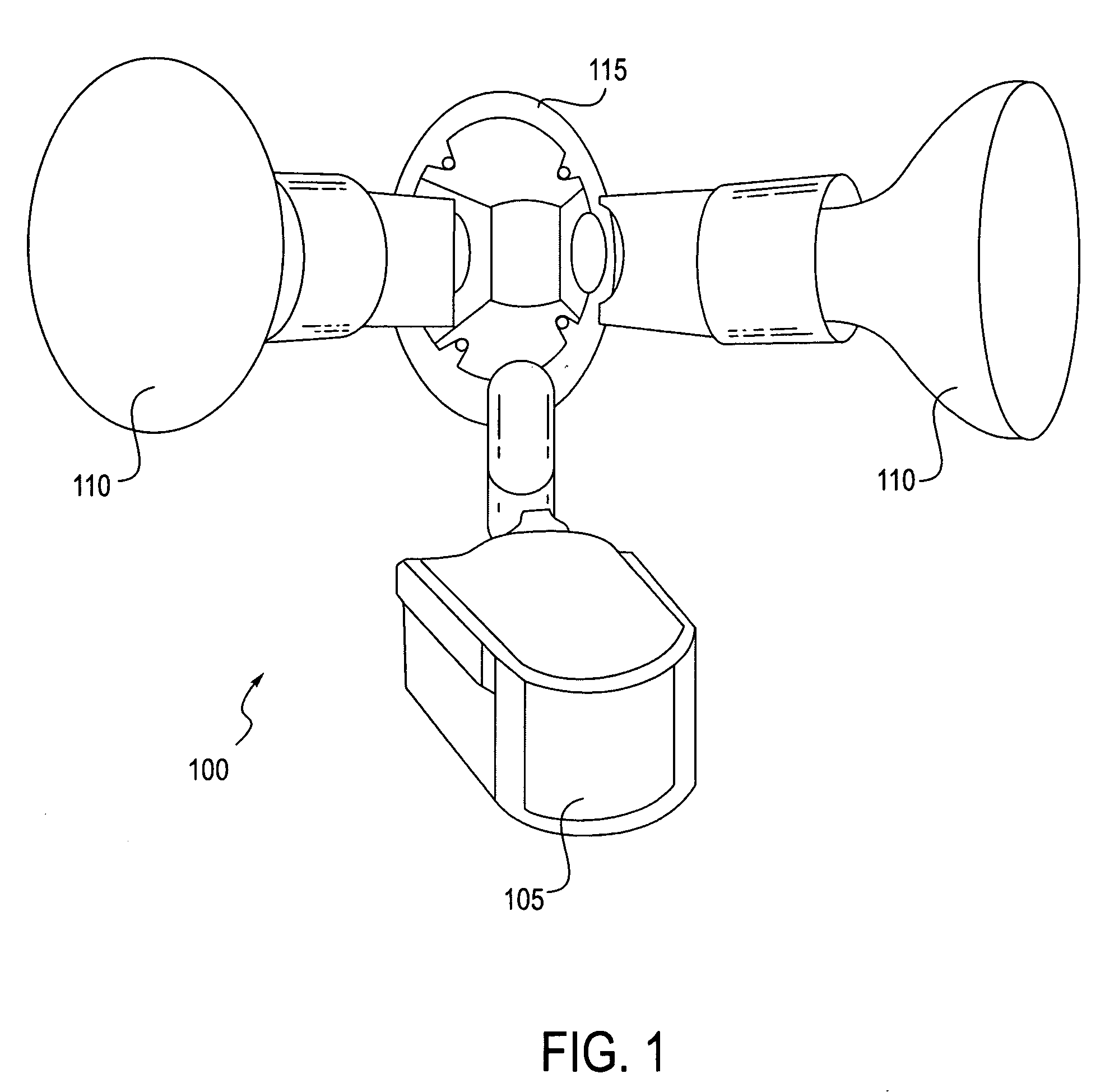

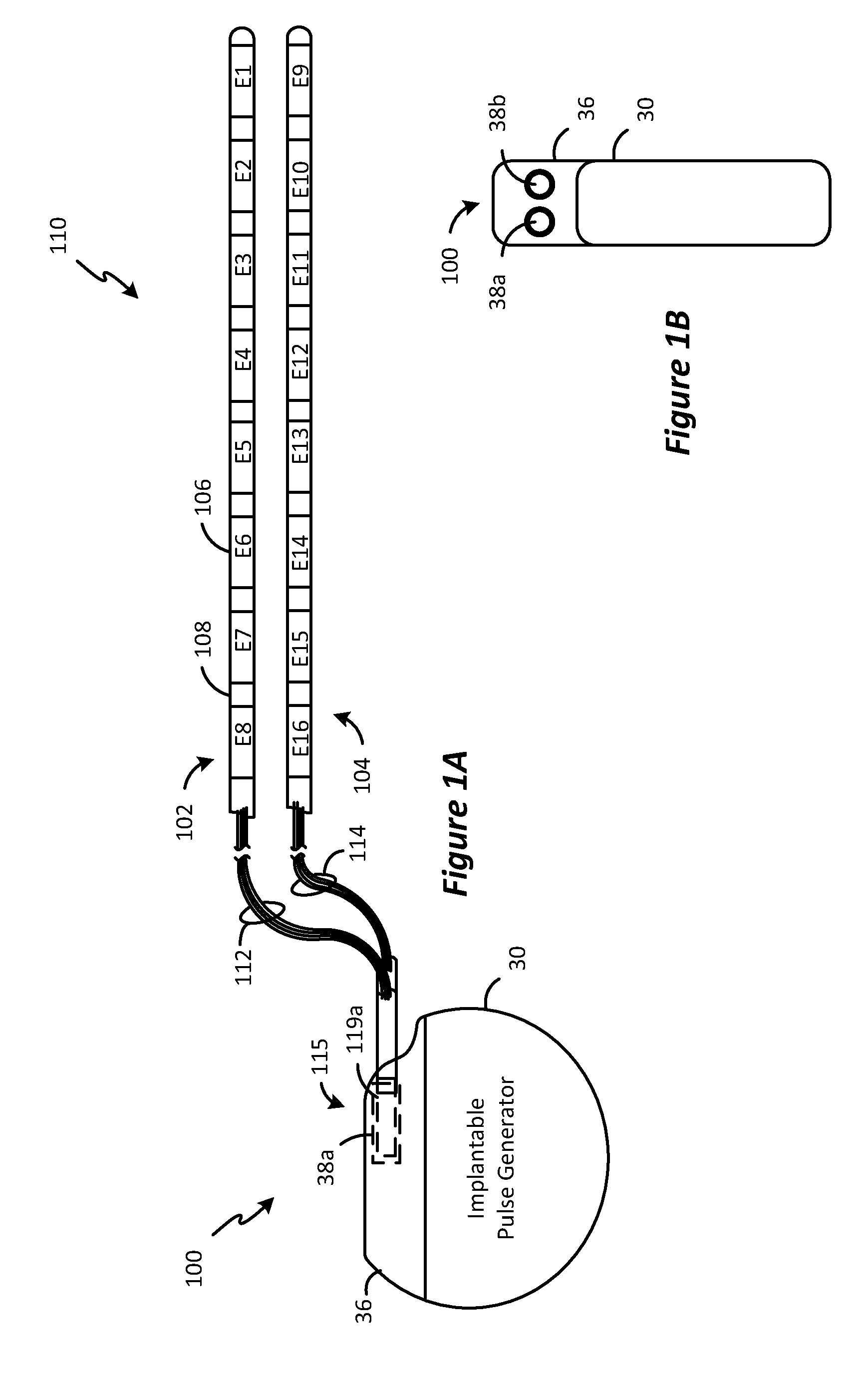

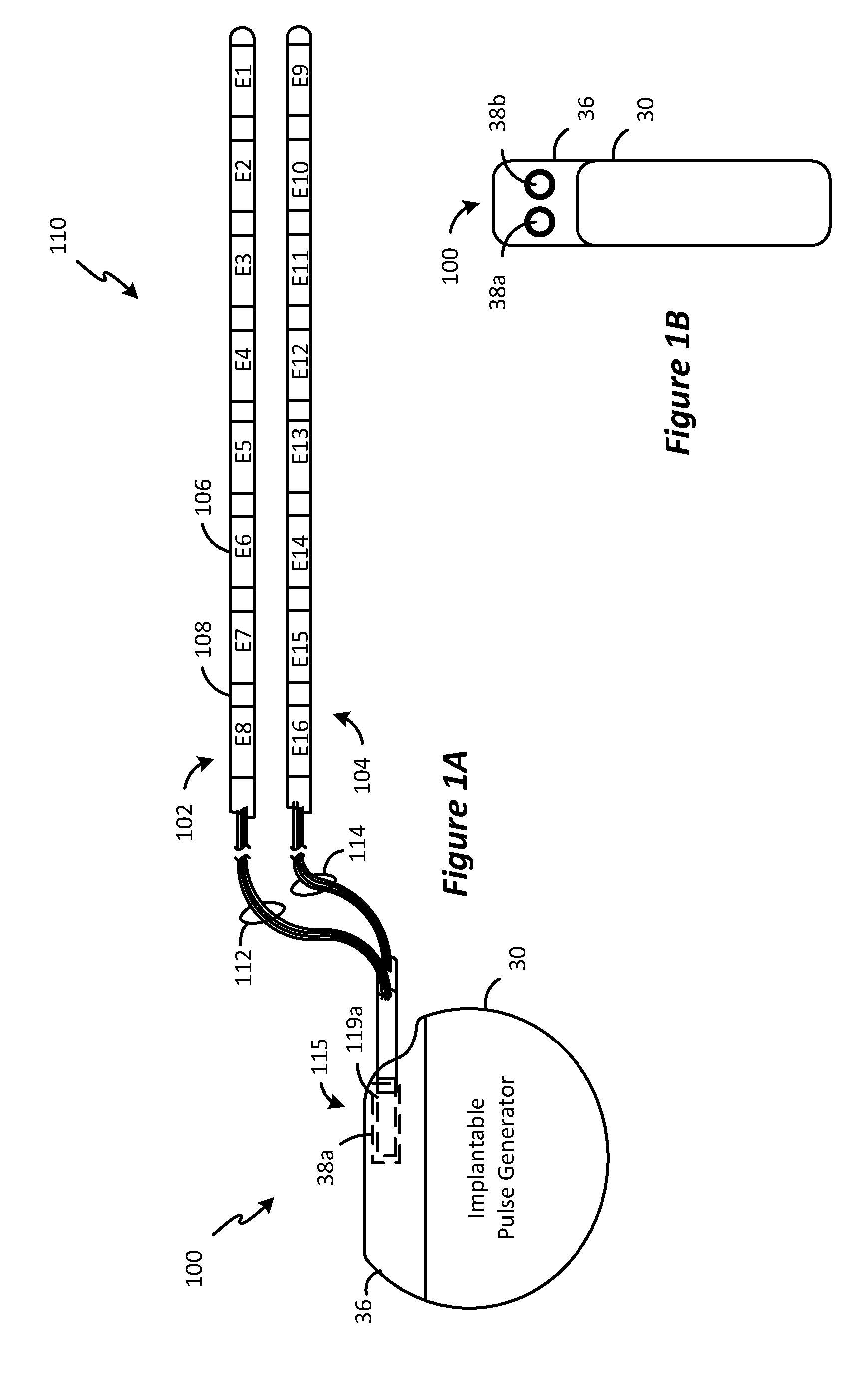

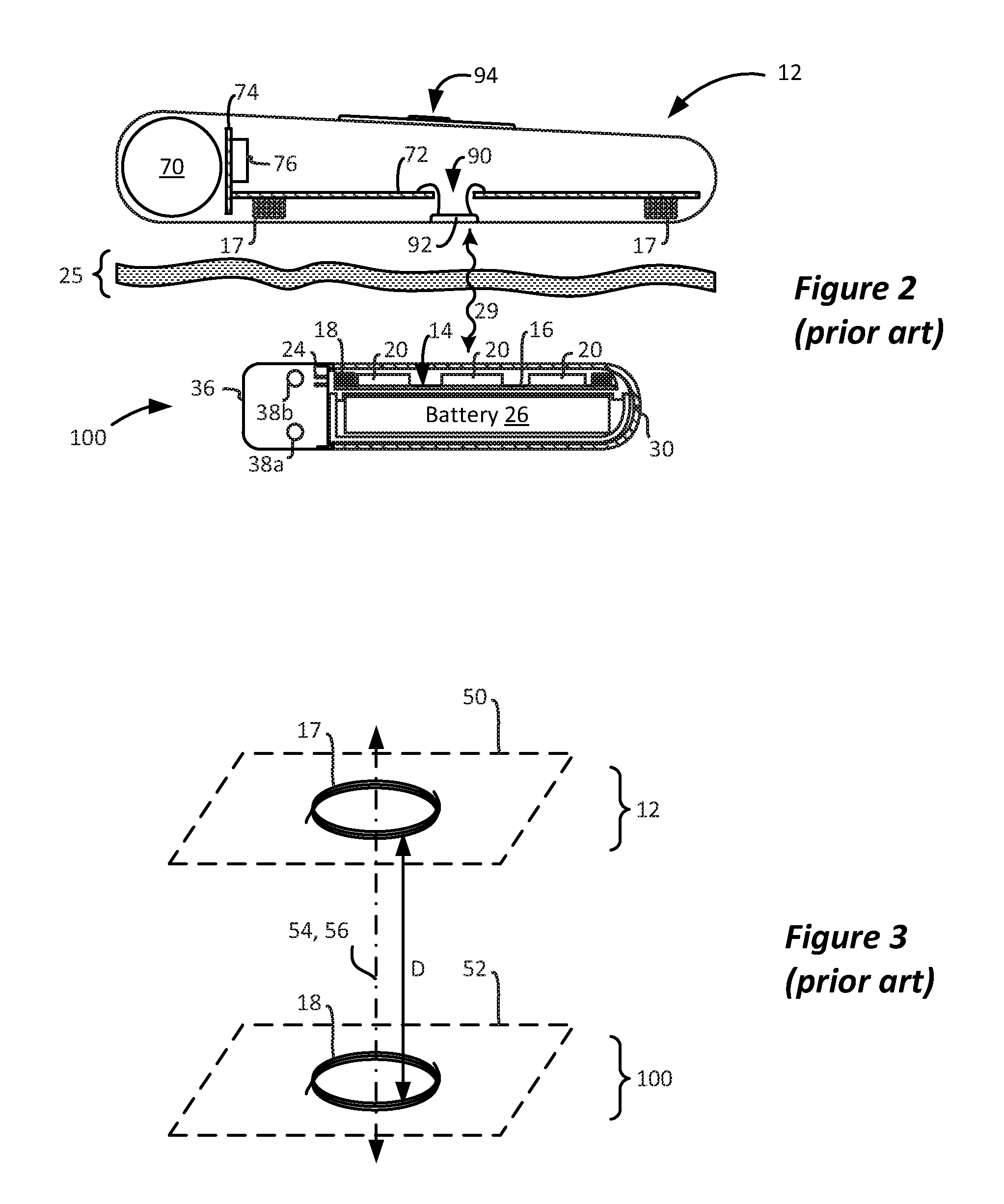

External Charger Usable with an Implantable Medical Device Having a Programmable or Time-Varying Temperature Set Point

An improved external charger for charging the battery within or providing power to an implantable medical device is disclosed. The improved external charger includes circuitry for detecting the temperature of the external charger and for controlling charging to prevent exceeding a maximum temperature. The external charger in some embodiments includes a user interface for allowing a patient to set the external charger's maximum temperature. The user interface can be used to select either constant maximum temperatures, or can allow the user to choose from a number of stored charging programs, which programs can control the maximum temperature to vary over time. Alternatively, a charging program in the external charger can vary the maximum temperature set point automatically. By controlling the maximum temperature of the external charger during charging in these manners, the time needed to charge can be minimized while still ensuring a temperature that is comfortable for that patient.

Owner:BOSTON SCI NEUROMODULATION CORP

Methods of coagulating tissue

InactiveUS20060206113A1Surgical instruments for heatingSurgical instruments for aspiration of substancesRadio frequencyLesion

An embodiment of the invention includes a surgical device for coagulating soft tissue such as atrial tissue in the treatment of atrial fibrillation, atrial flutter, and atrial tachycardia; tendon or ligament shrinkage; or articular cartilage removal. The surgical device integrates a suction mechanism with the coagulation mechanism improving the lesion creation capabilities of the device. The surgical device comprises an elongate member having an insulative covering attached about conductive elements capable of coagulating soft tissue when radiofrequency or direct current energy is transmitted to the conductive elements. Openings through the insulative covering expose regions of the conductive elements and are coupled to lumens in the elongate member which are routed to a vacuum source. Suction causes the soft tissue to actively engage the opening thus the integrated, exposed conductive elements to facilitate the coagulation process and ensure the lesions created are consistent, continuous, and transmural. The embodiments of the invention can also incorporate cooling mechanisms associated with the conductive elements and coupled to a fluid source to passively transport fluid along the contacted soft tissue surface to cool thus pushing the maximum temperature deeper into tissue.

Owner:ATRICURE

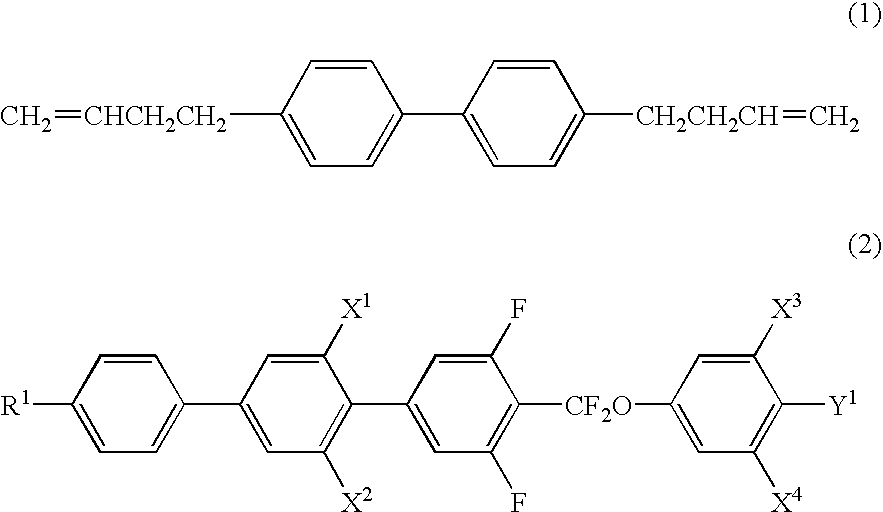

Liquid crystal composition and liquid crystal display device

InactiveUS20090091703A1Liquid crystal compositionsThin material handlingElectricityDielectric anisotropy

A liquid crystal composition is provided that satisfies at least one characteristic among the characteristics such as a high maximum temperature of a nematic phase, a low minimum temperature of a nematic phase, a small viscosity, a large optical anisotropy, a large dielectric anisotropy, a large specific resistance, a high stability to ultraviolet light and a high stability to heat, or is properly balanced regarding at least two characteristics. An AM device is provided that has a short response time, a large voltage holding ratio, a large contrast ratio, a long service life and so forth. The liquid crystal composition contains a specific tricyclic compound having a large optical anisotropy as the first component and a specific tetracyclic compound having a large dielectric anisotropy as the second component, and may contain a specific bicyclic compound having a particularly small viscosity as the third component. The liquid crystal composition has a nematic phase. The liquid crystal display device contains the liquid crystal composition.

Owner:JNC PETROCHEM +1

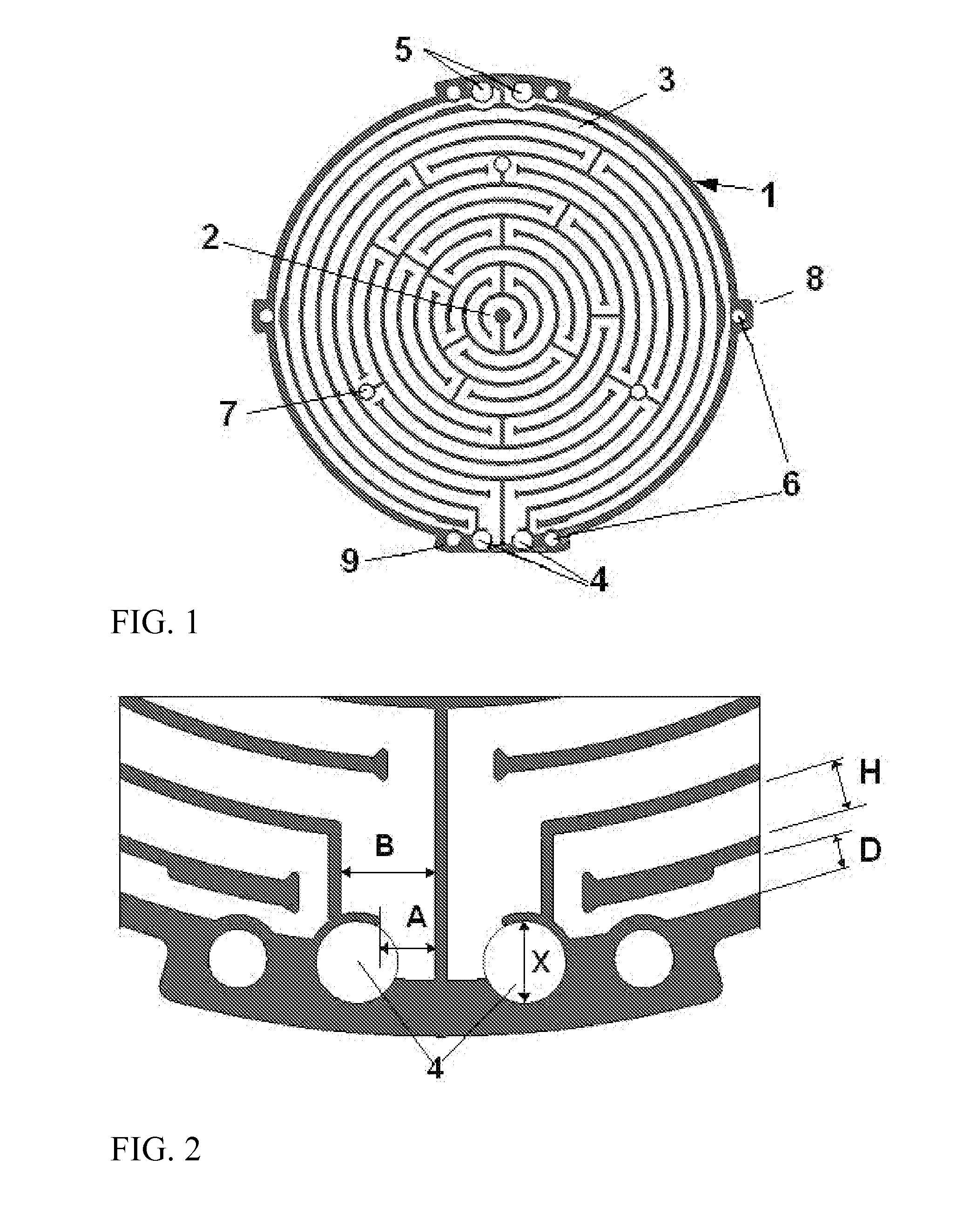

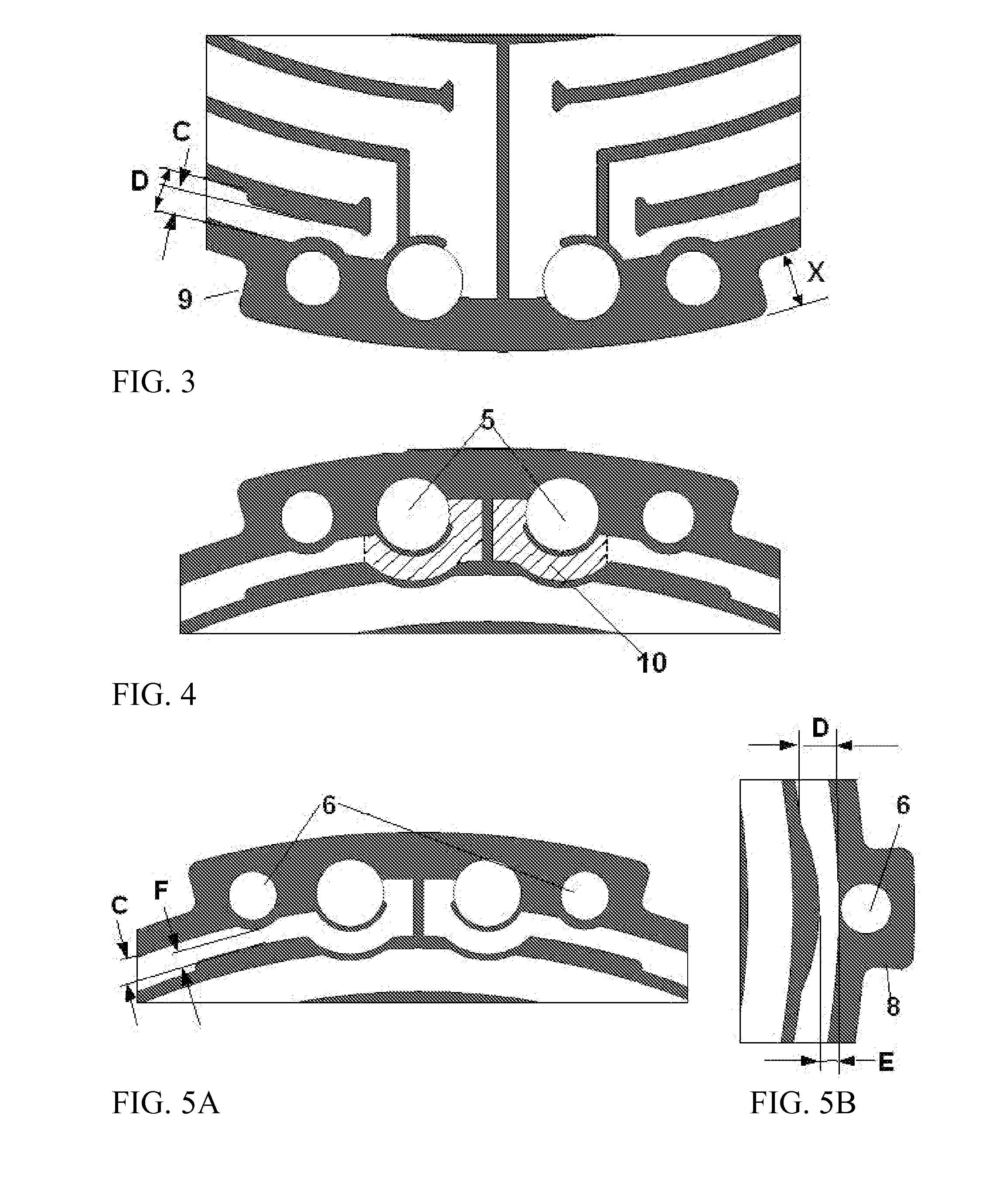

Electrode Pattern For Resistance Heating Element and Wafer processing Apparatus

ActiveUS20080029195A1Uniform temperature distributionImprove heat lossWorkpiece holdersCellsElectrical resistance and conductanceElectrical connection

There is disclosed a wafer processing apparatus having optimized electrode patterns for its resistive heating element. The optimized electrode pattern is designed to compensate for the heat loss around contact areas, electrical connections, and through-holes, etc., by generating more heat near or around those areas, providing maximum temperature uniformity. In another embodiment of the optimized design of the invention, the resistance of heating element closely matches the impedance of the power supply for higher efficiency, especially when higher operating temperature or higher electrical power is required.

Owner:GENERAL ELECTRIC CO

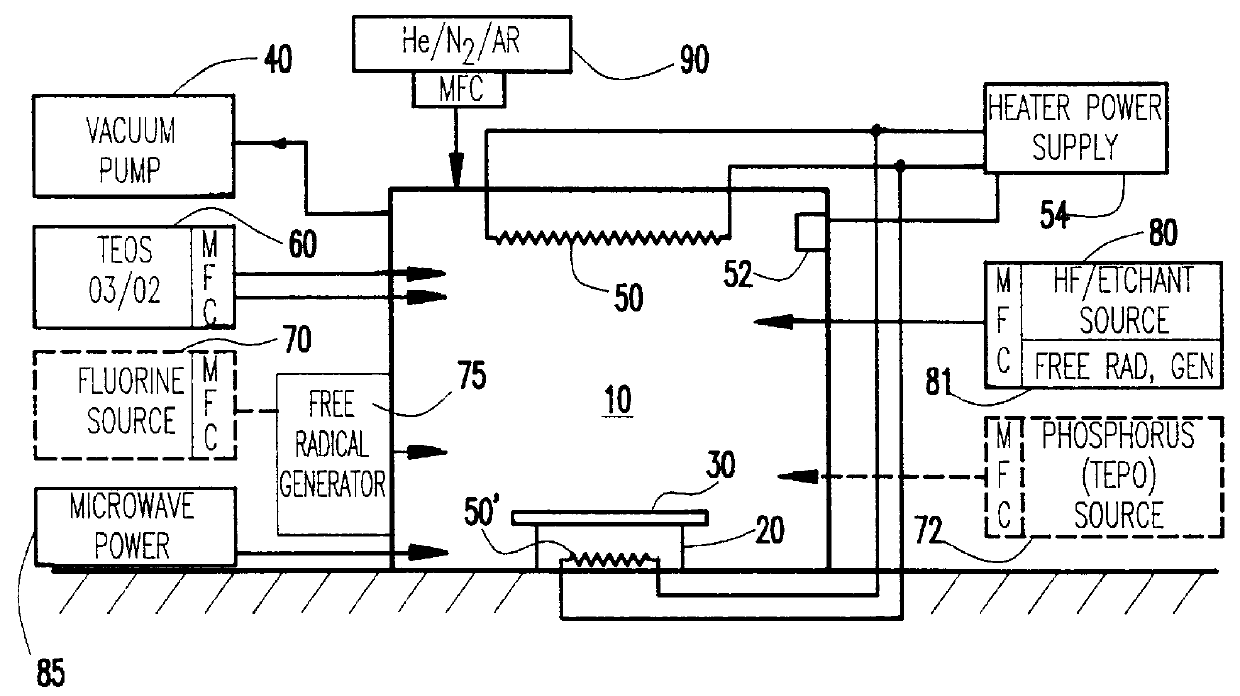

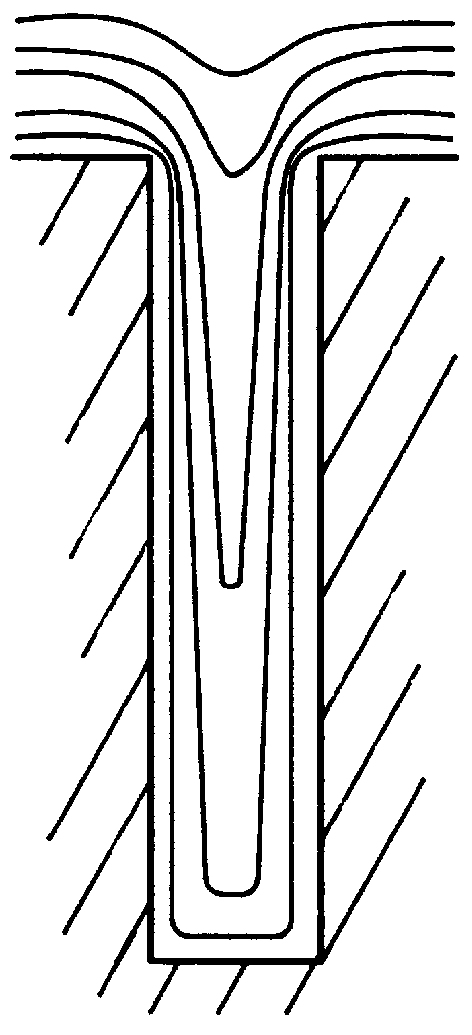

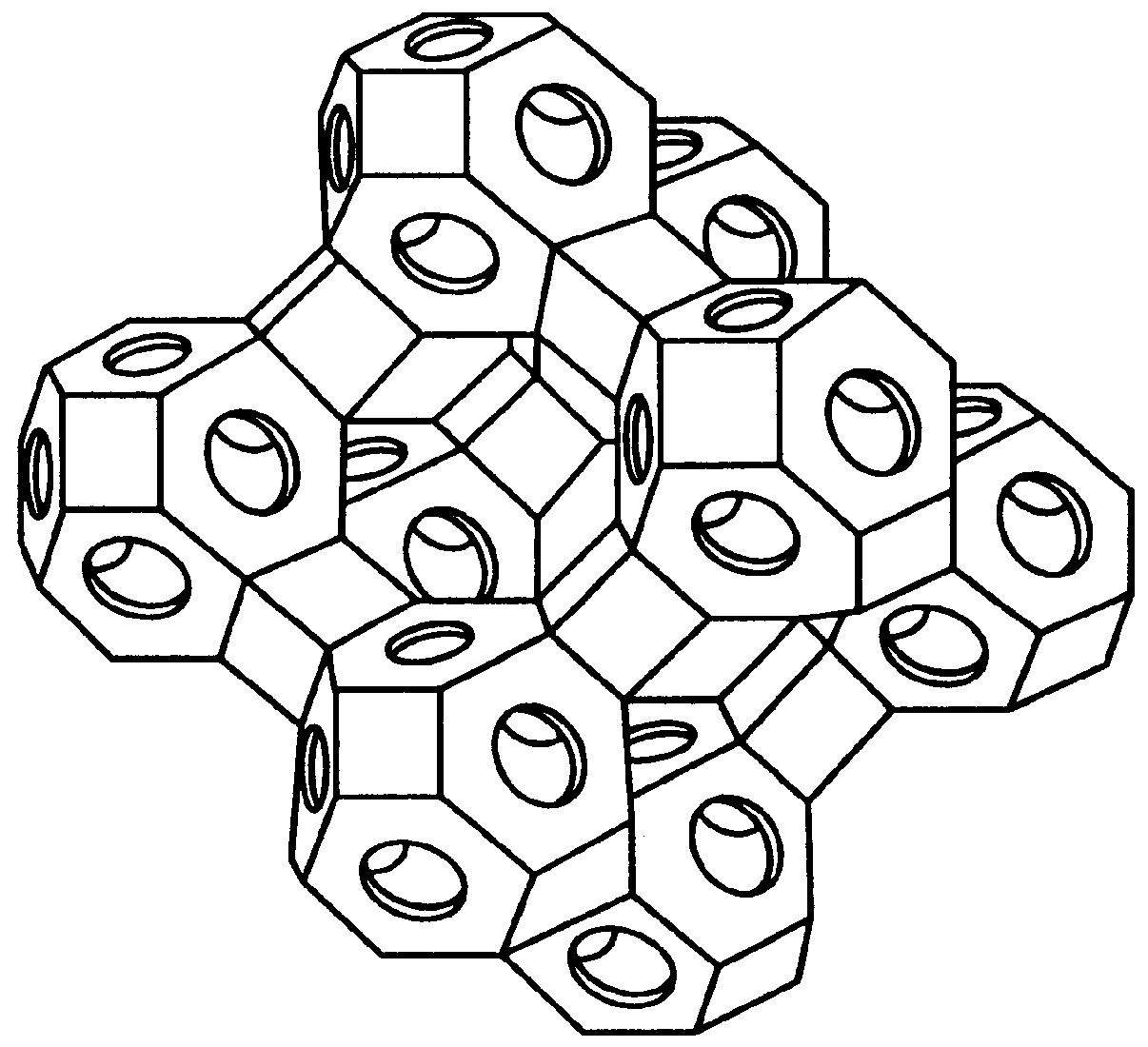

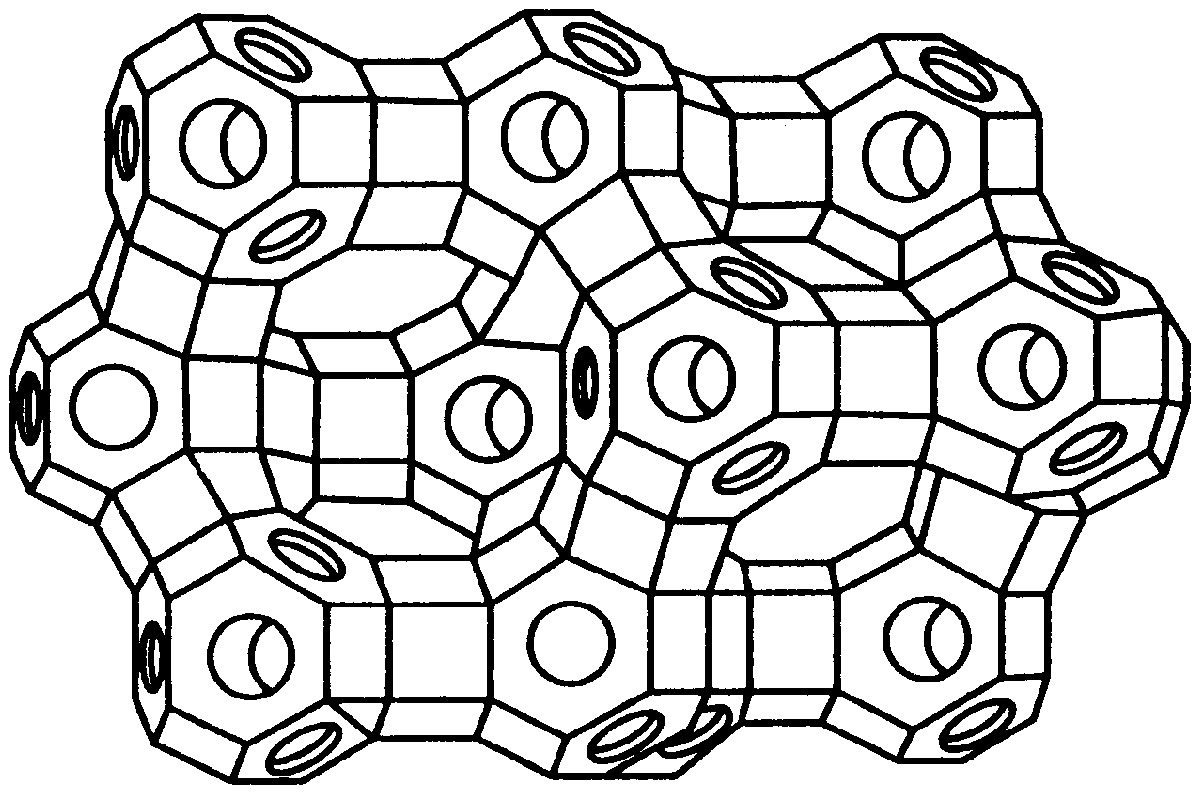

Methods and apparatus for filling high aspect ratio structures with silicate glass

InactiveUS6077786ADecorative surface effectsSemiconductor/solid-state device manufacturingGas phaseDeposition rate

Filling of narrow and / or high aspect ratio gaps and trenches with silicate glass is accomplished at reduced temperatures and without reflow by etching the glass concurrently with thermal chemical vapor deposition of the glass such that the deposition rate will exceed the etching rate by a relatively small net deposition rate near the surface with the excess deposition rate increasing over the depth of the trench or gap. The as-deposited glass film is made dense and stable by carrying out the concurrent etch and deposition process at an elevated temperature but which is within the maximum temperature and heat budget which can be tolerated by structures formed by previously performed processes. Fluorine can be incorporated in the silicate glass film as a dopant in sufficient concentration to reduce dielectric constant of the film. Phosphorus and / or boron can be incorporated into the film, as well, and may enhance void-free filling of trenches and gaps.

Owner:IBM CORP

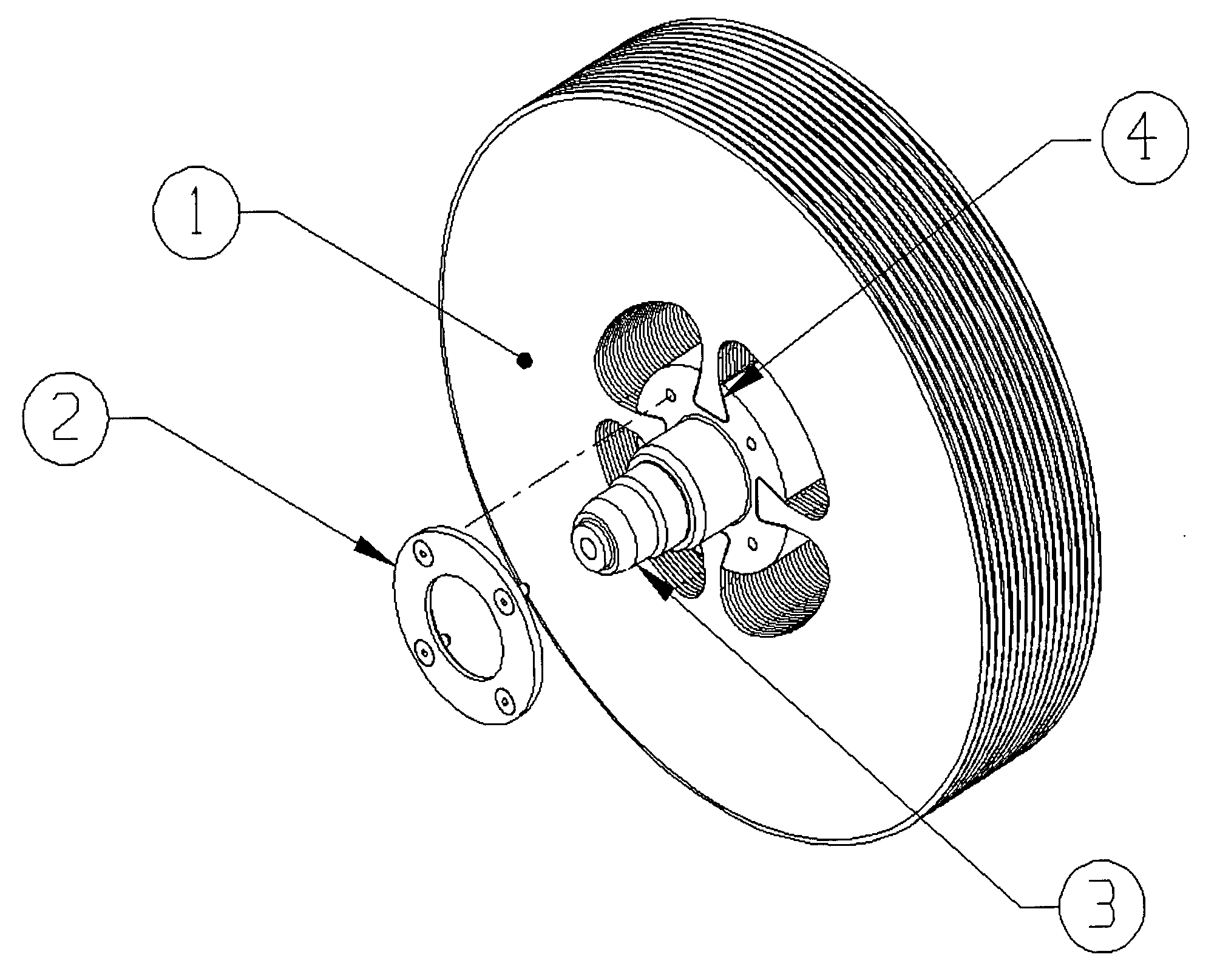

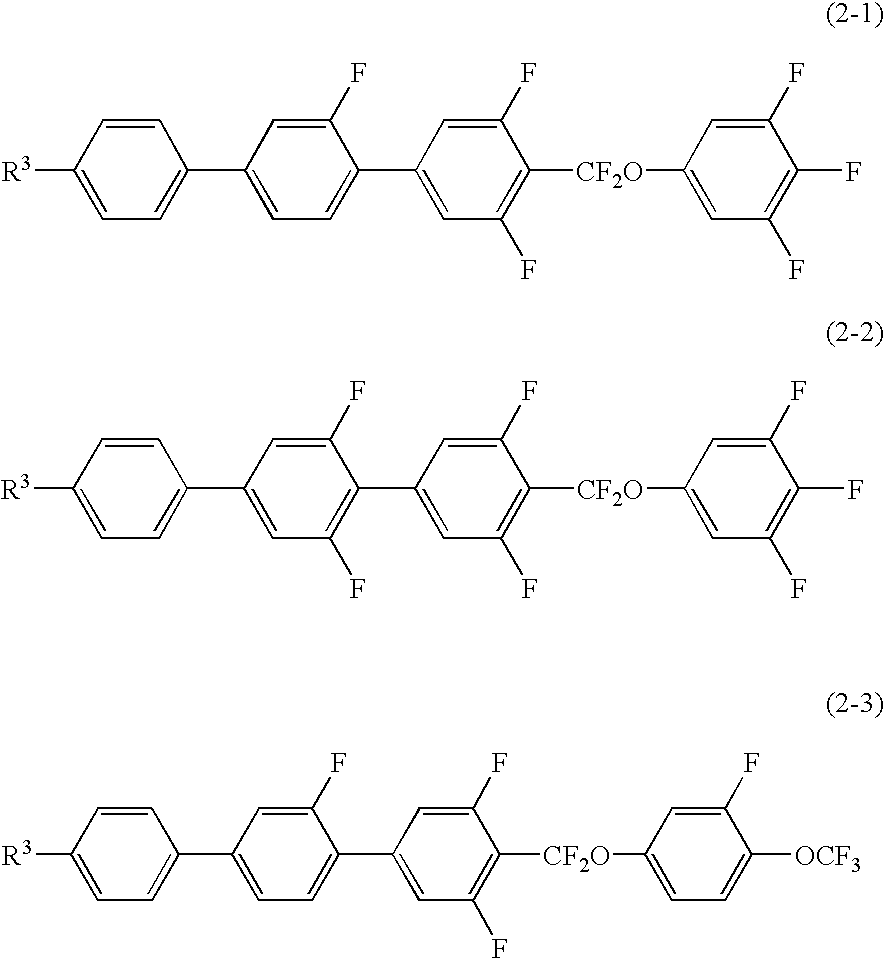

Method and apparatus for extinguishing fires

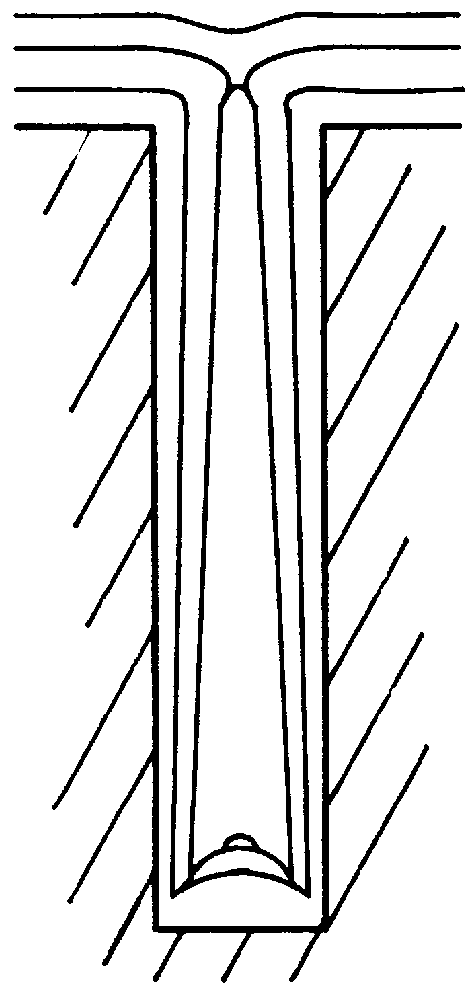

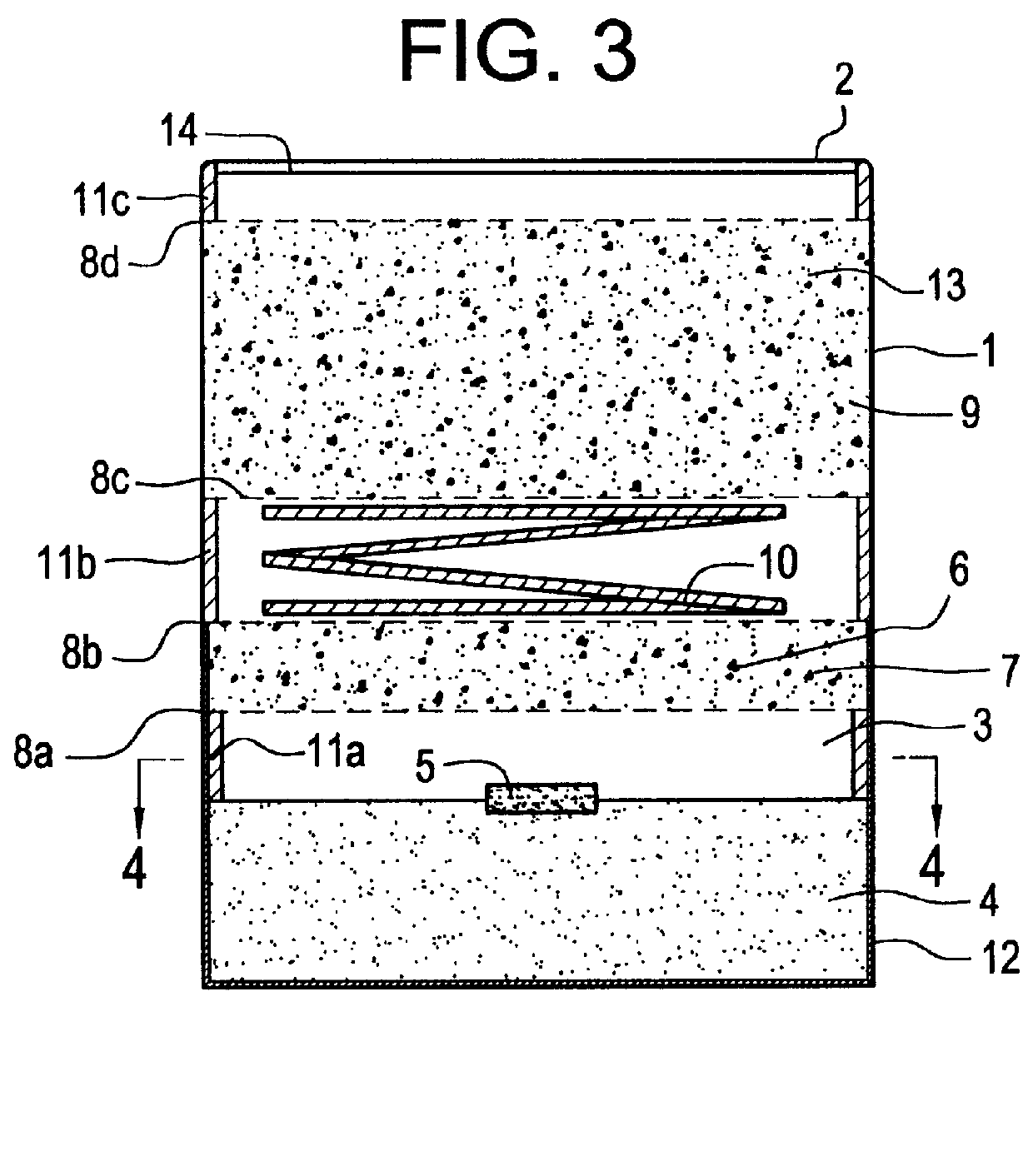

A method for extinguishing fire, wherein a gas an aerosol mixture is fed into a space includes steps of igniting a pyrotechnic composition that ensures a predetermined temperature profile during burning and a predetermined composition of the gas and aerosol mixture completely oxidizing the combustion products of incomplete combustion of the pyrotechnic composition by causing them to pass through a bed of catalytically active substances, which is located in the zone of the maximum temperature of the temperature profile of combustion of the pyrotechnic composition, with the temperature remaining constant by redistribution of said profile; cooling the combustion products and completely oxidizing them by reacting with substances having high heat absorbing capacity, concurrently with the filtering of the combustion products according to composition of the gas phase and particle size of the aerosol phase. An apparatus for extinguishing fire, having a casing (1) that has a discharge port (2), a combustion chamber (3) that is accommodated in the casing (1) and heat insulated from the walls of the casing (1), a pyrotechnic composition (4) and an igniter (5) that are received in the combustion chamber, a cooling section (9) and a complete catalytic oxidation section (6) that has a pair of spaced metal gratings (8a, 8b) between which a catalytically active substance is placed and that is located at a fixed distance from the pyrotechnic composition (4). A compensation device (10) is provided for maintaining the above-mentioned fixed distance during the burning of the pyrotechnic composition (4).

Owner:R AMTECH INT

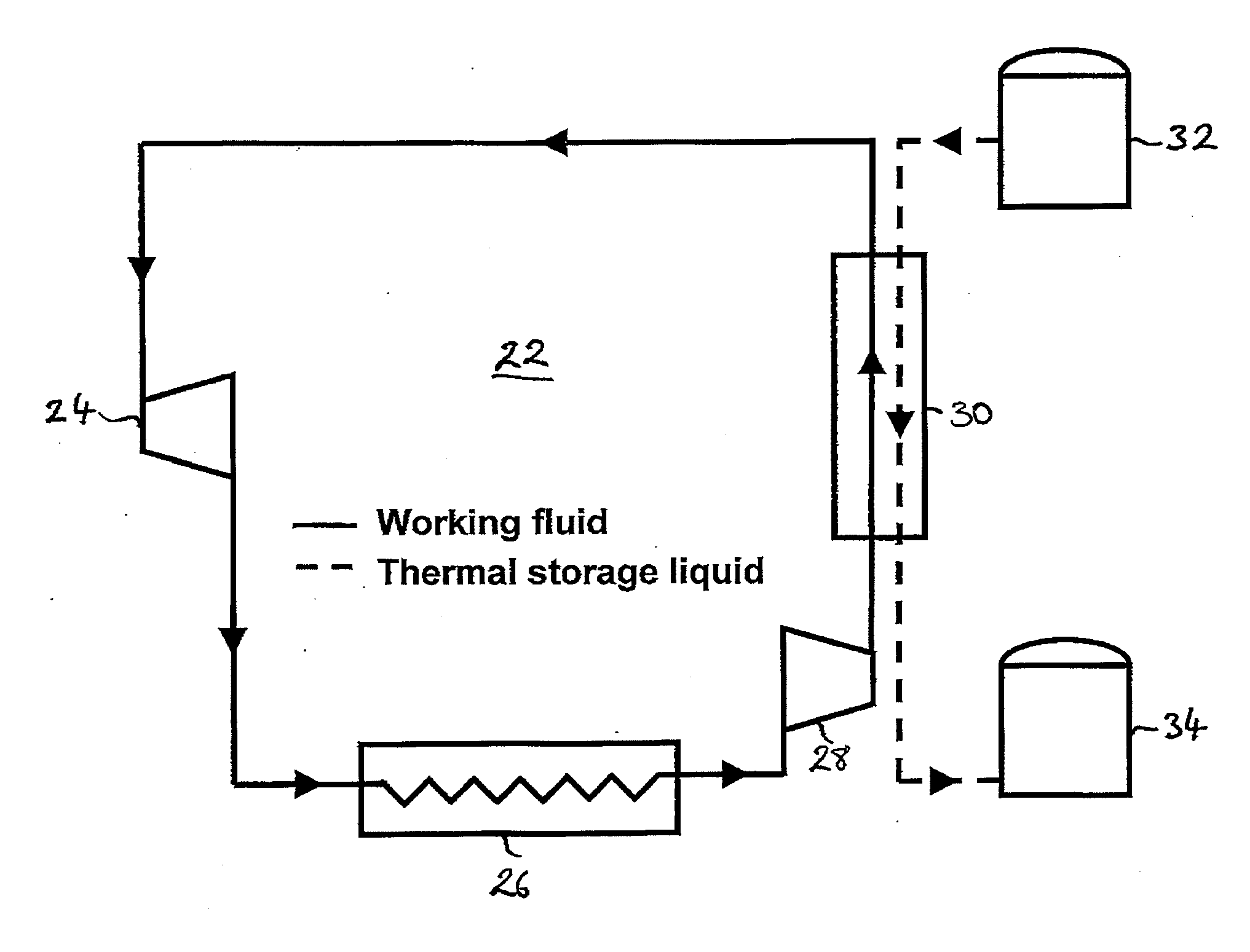

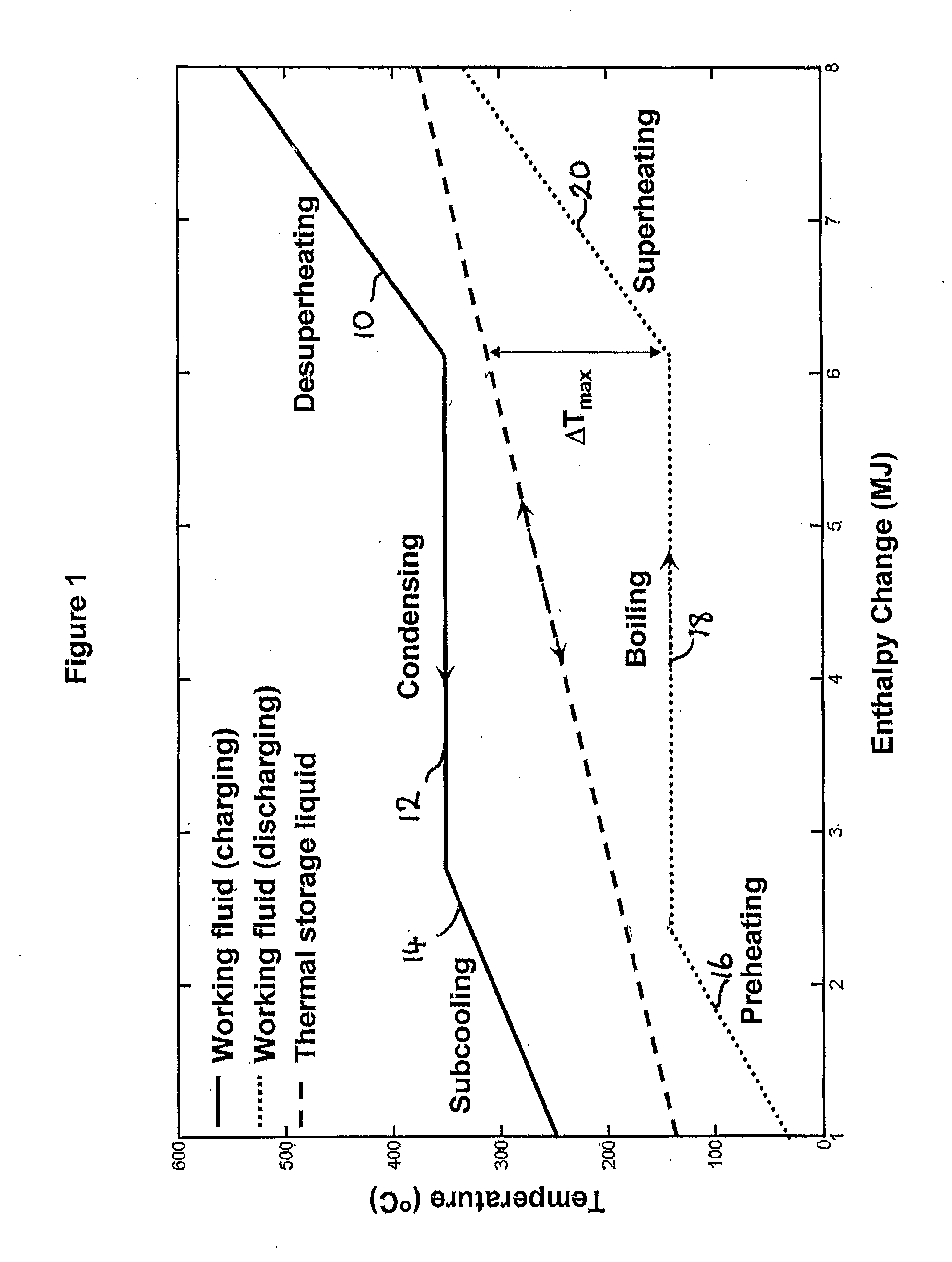

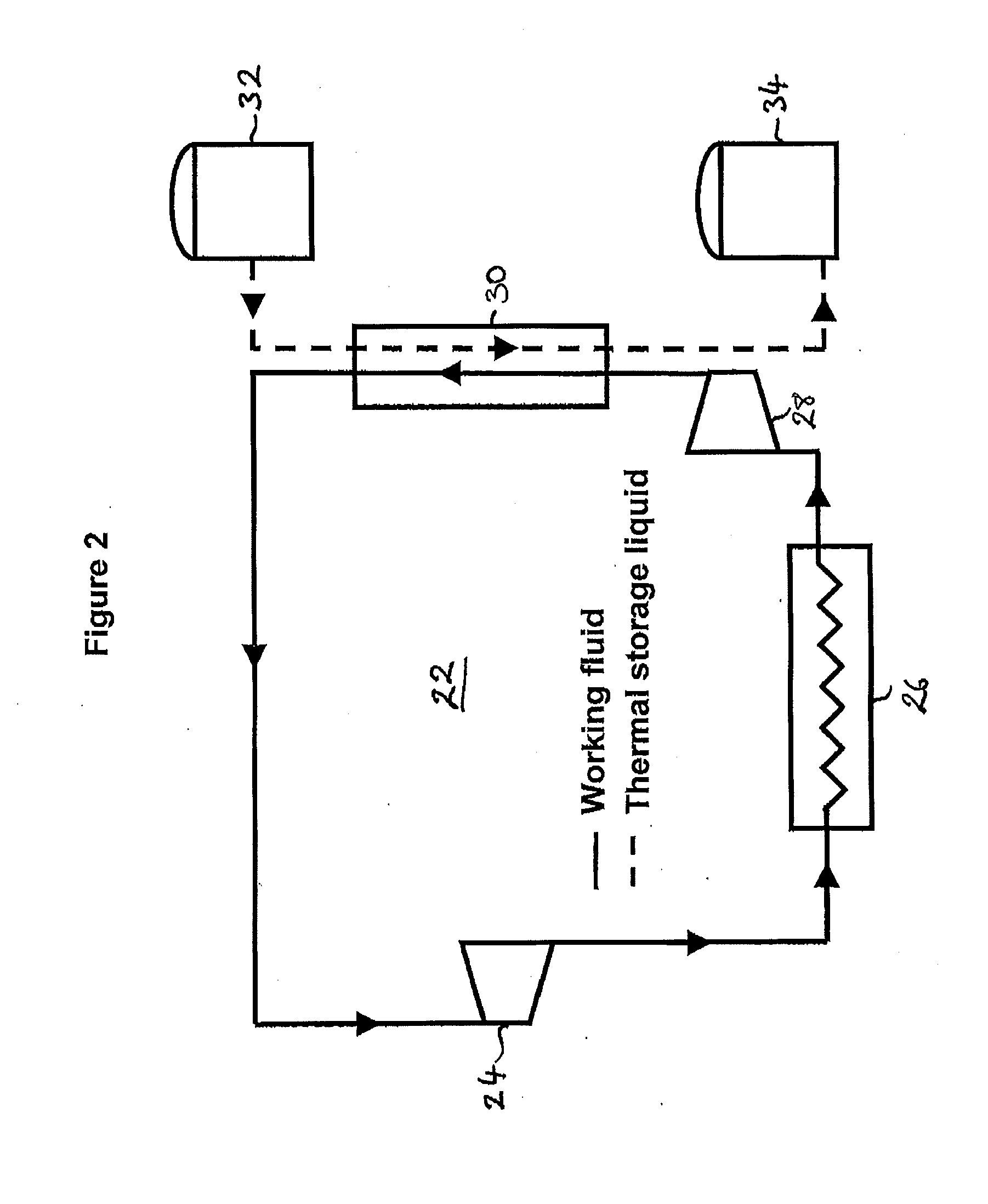

Thermoelectric energy storage system and method for storing thermoelectric energy

InactiveUS20110139407A1Suitable for storageIndirect heat exchangersHeat-exchange elementsWorking fluidThermal energy storage

A system and method for thermoelectric energy storage are disclosed. A thermoelectric energy storage system can include a heat exchanger which contains a thermal storage medium, and a working fluid circuit for circulating a working fluid through the heat exchanger for heat transfer with the thermal storage medium. The working fluid undergoes transcritical cooling during the charging and transcritical heating during the discharging cycle as it exchanges heat with the thermal storage medium. Improved roundtrip efficiency can be achieved through minimizing the maximum temperature difference (ΔTmax) between the working fluid and the thermal storage medium during operating cycles.

Owner:ABB RES LTD

External charger usable with an implantable medical device having a programmable or time-varying temperature set point

An improved external charger for charging the battery within or providing power to an implantable medical device is disclosed. The improved external charger includes circuitry for detecting the temperature of the external charger and for controlling charging to prevent exceeding a maximum temperature. The external charger in some embodiments includes a user interface for allowing a patient to set the external charger's maximum temperature. The user interface can be used to select either constant maximum temperatures, or can allow the user to choose from a number of stored charging programs, which programs can control the maximum temperature to vary over time. Alternatively, a charging program in the external charger can vary the maximum temperature set point automatically. By controlling the maximum temperature of the external charger during charging in these manners, the time needed to charge can be minimized while still ensuring a temperature that is comfortable for that patient.

Owner:BOSTON SCI NEUROMODULATION CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com