Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

3196results about How to "Prevent freezing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

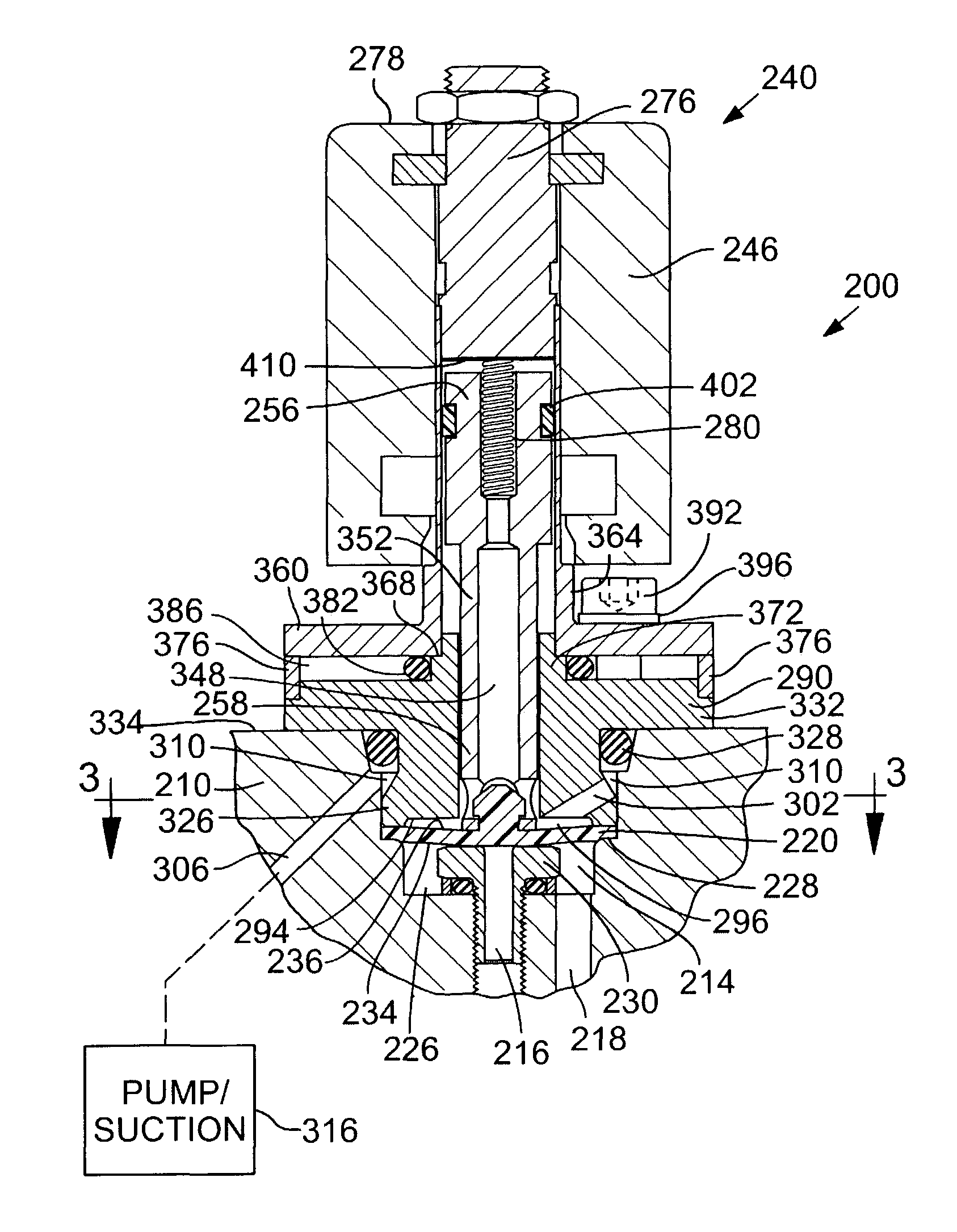

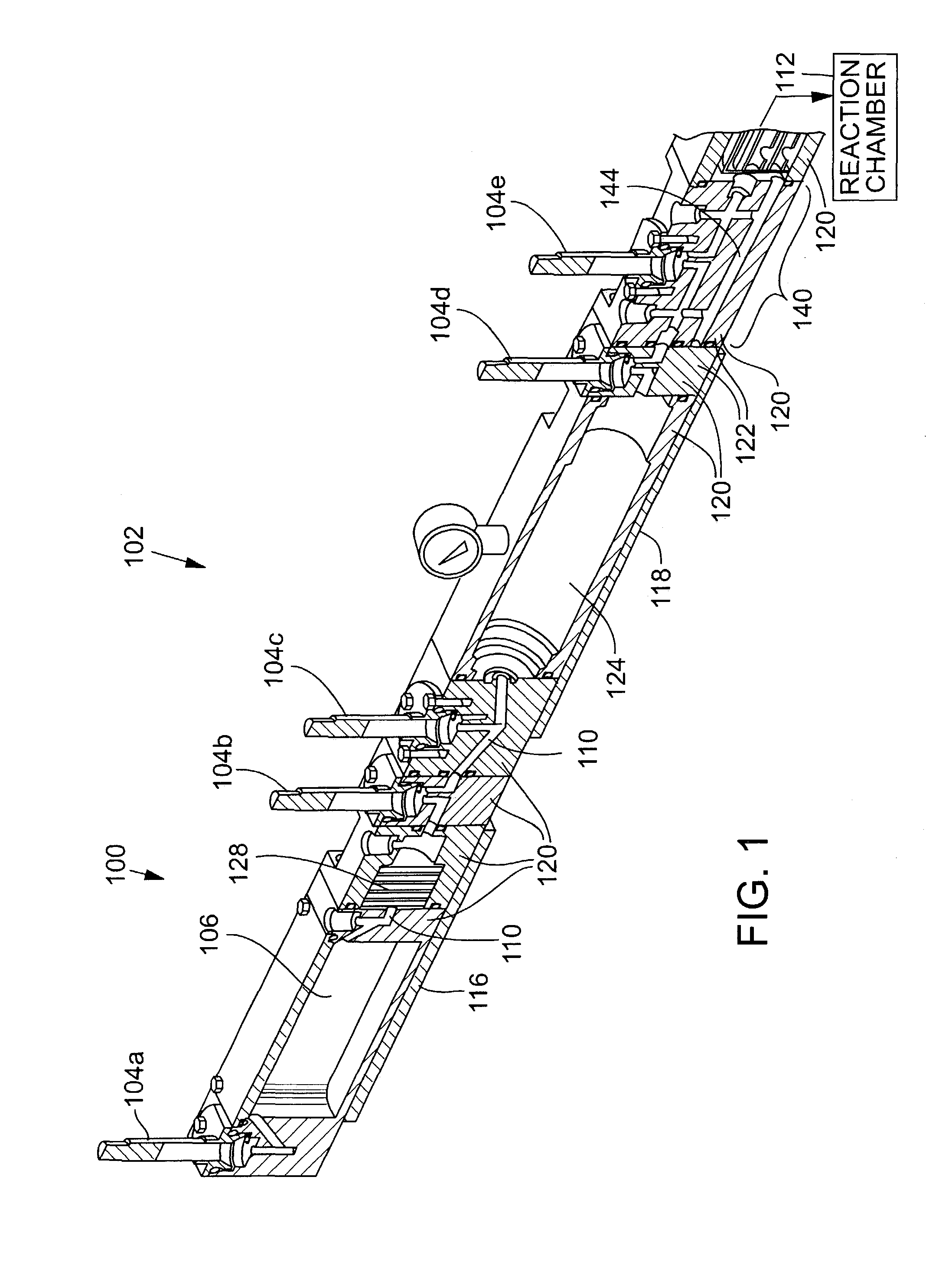

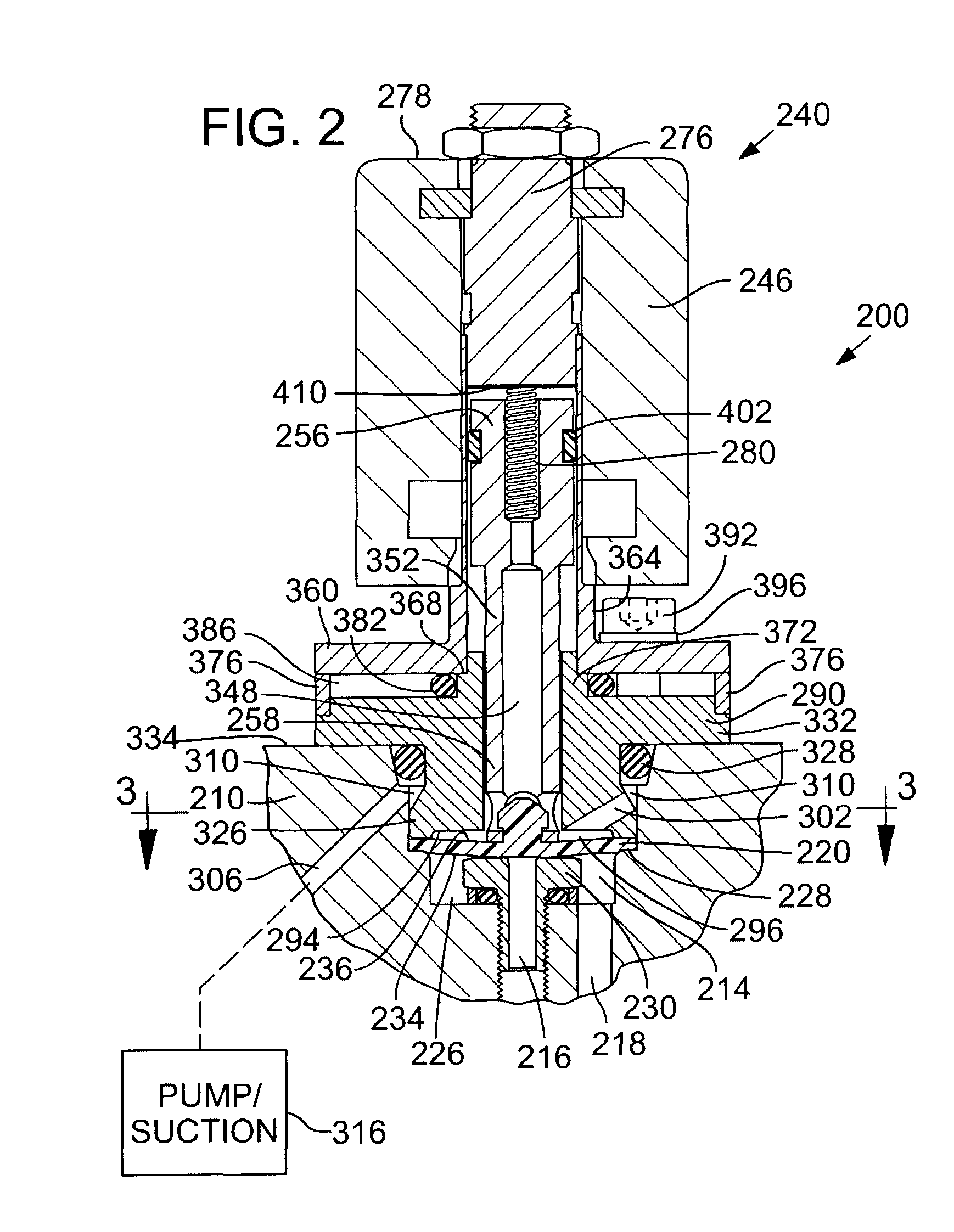

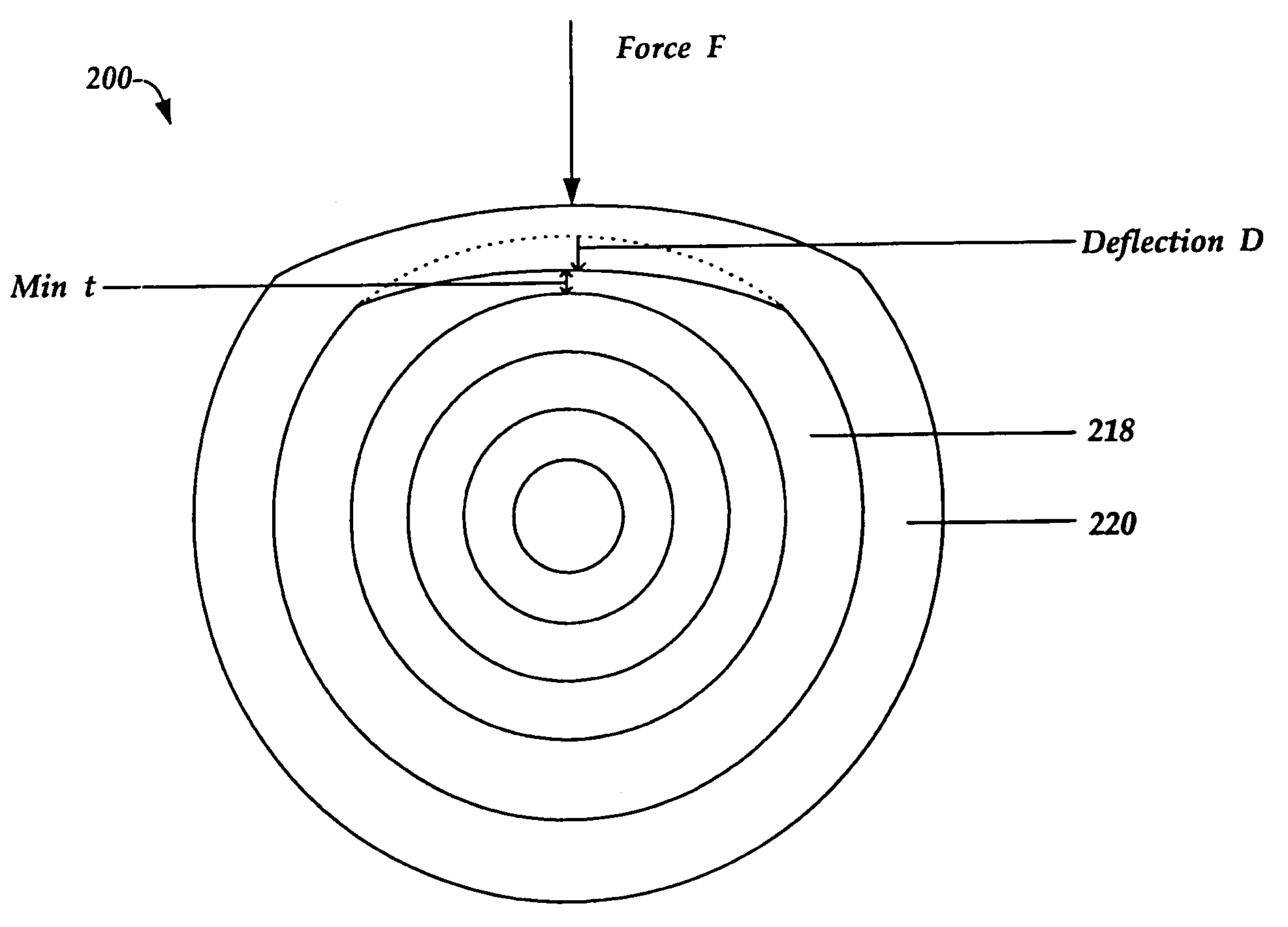

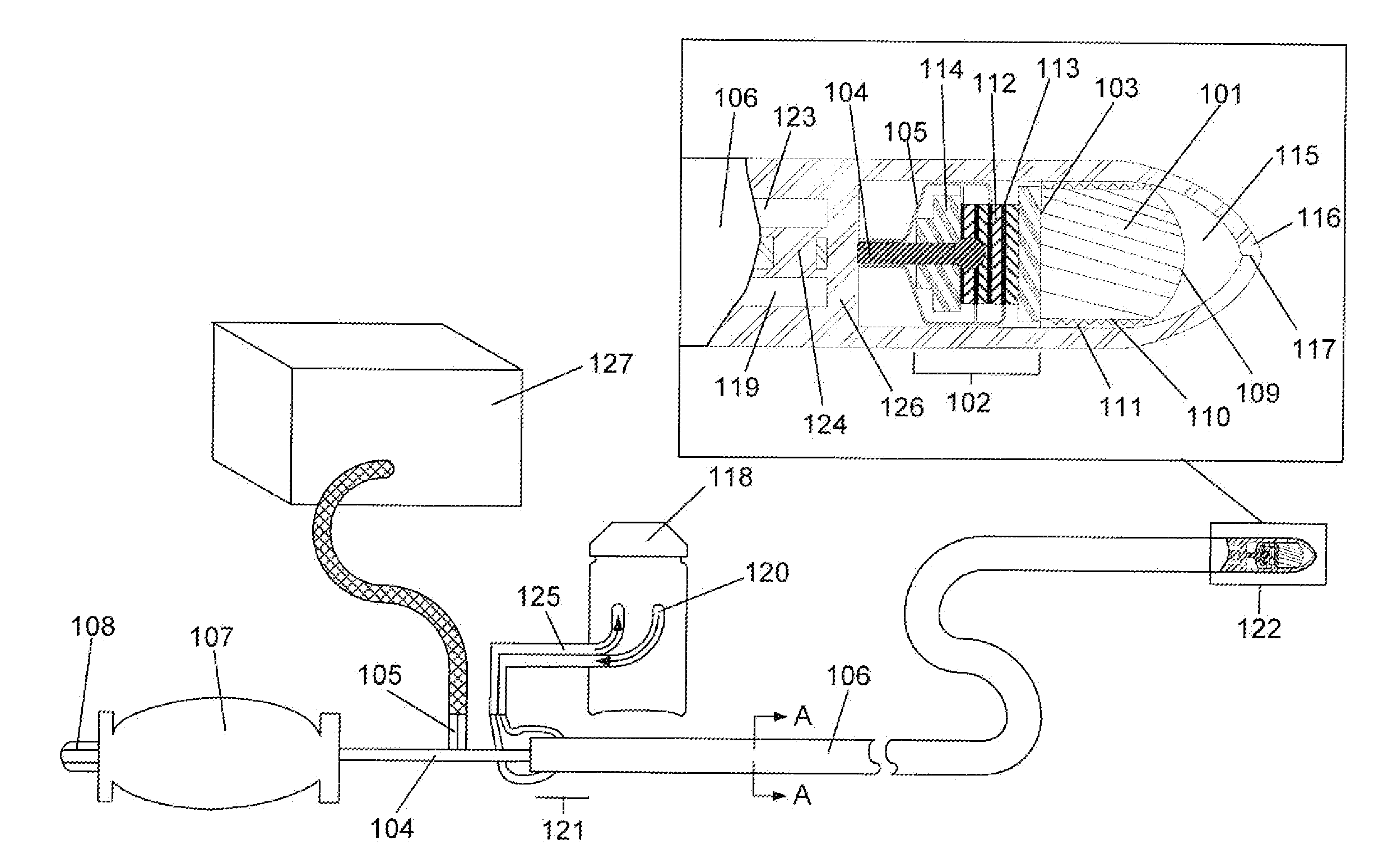

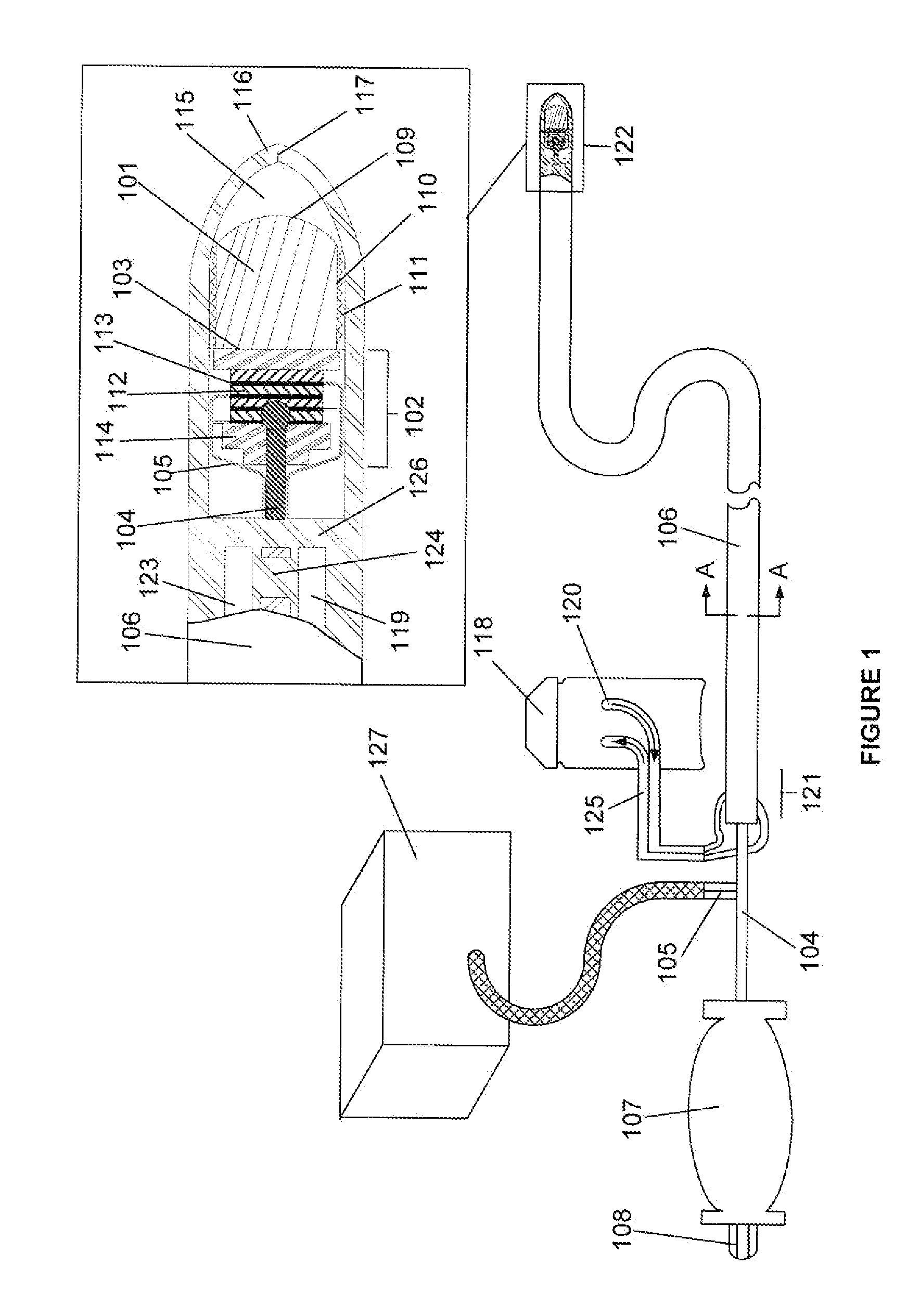

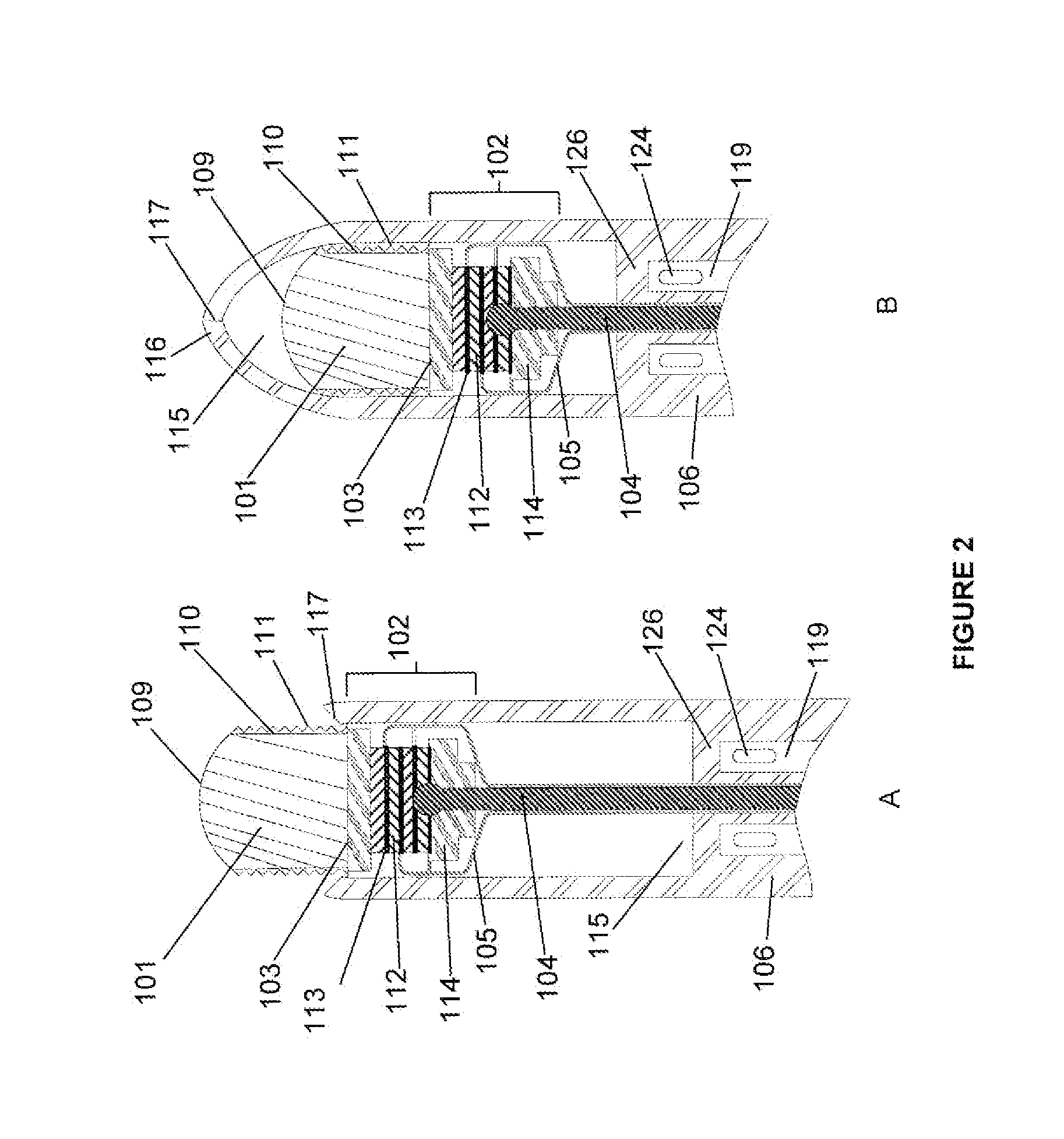

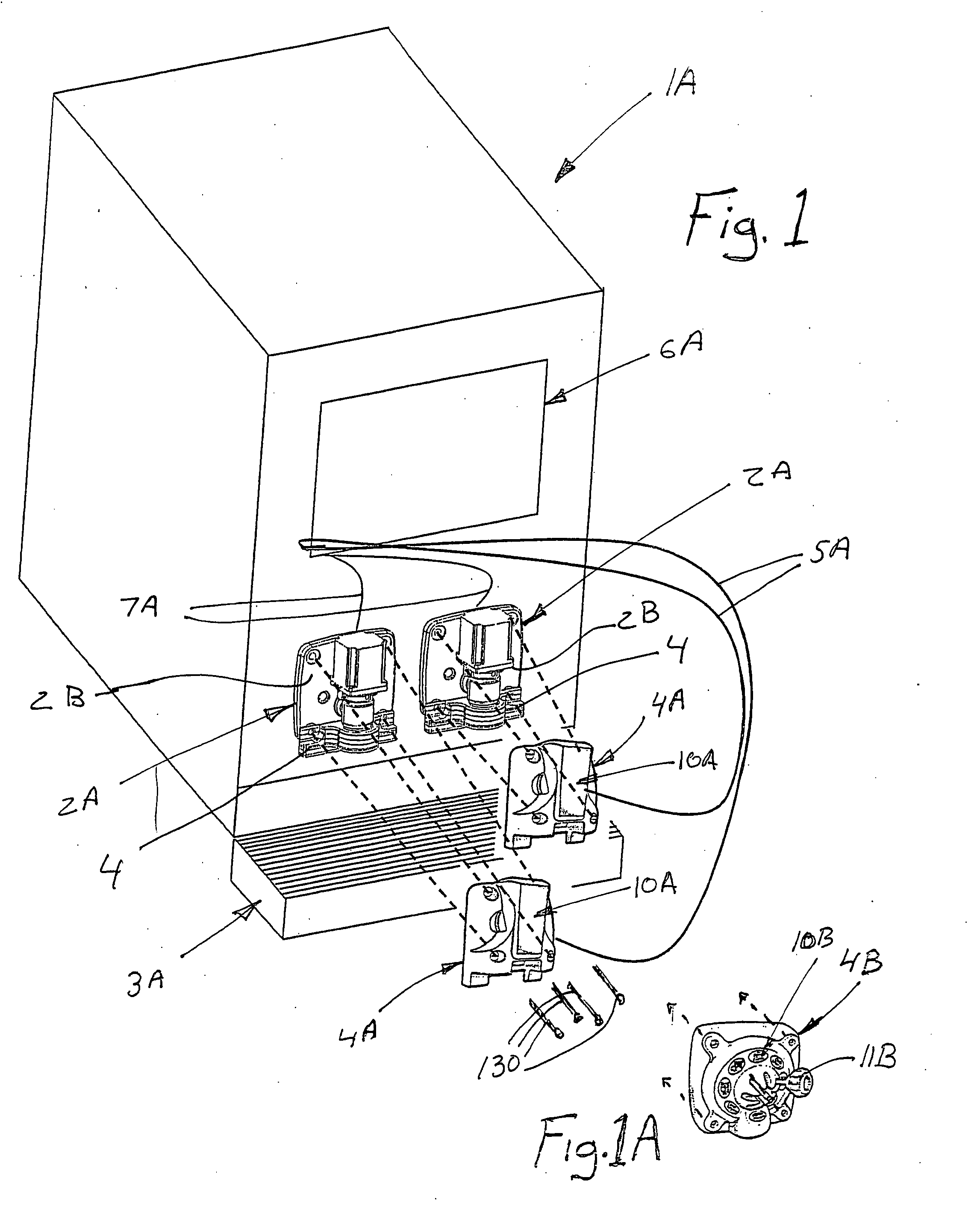

Diaphragm valve with reliability enhancements for atomic layer deposition

InactiveUS7021330B2Improve heat transfer performanceInhibiting condensingDiaphragm valvesOperating means/releasing devices for valvesEnhanced heat transferDiaphragm valve

A shut-off type diaphragm valve adapted for use in an atomic layer deposition system includes a valve seat having an annular seating surface that surrounds an inlet of the valve and extends radially therefrom. The seating surface contacts a substantial portion of the first side of a flexible diaphragm when the diaphragm is closed, to facilitate heat transfer and counteract dissipative cooling of the diaphragm, thereby inhibiting condensation of a medium flowing through the valve passage. The seating surface is preferably flat and smooth, to prevent shearing of an elastomeric diaphragm. For a plastic diaphragm, a ring-shaped seating ridge may extend from the seating surface to cause localized permanent deformation of the diaphragm and enhanced sealing, while still allowing a substantial portion of the diaphragm to contact the seating surface for enhanced heat transfer. Valve speed enhancements and other reliability enhancing features are also described.

Owner:BENEQ OY

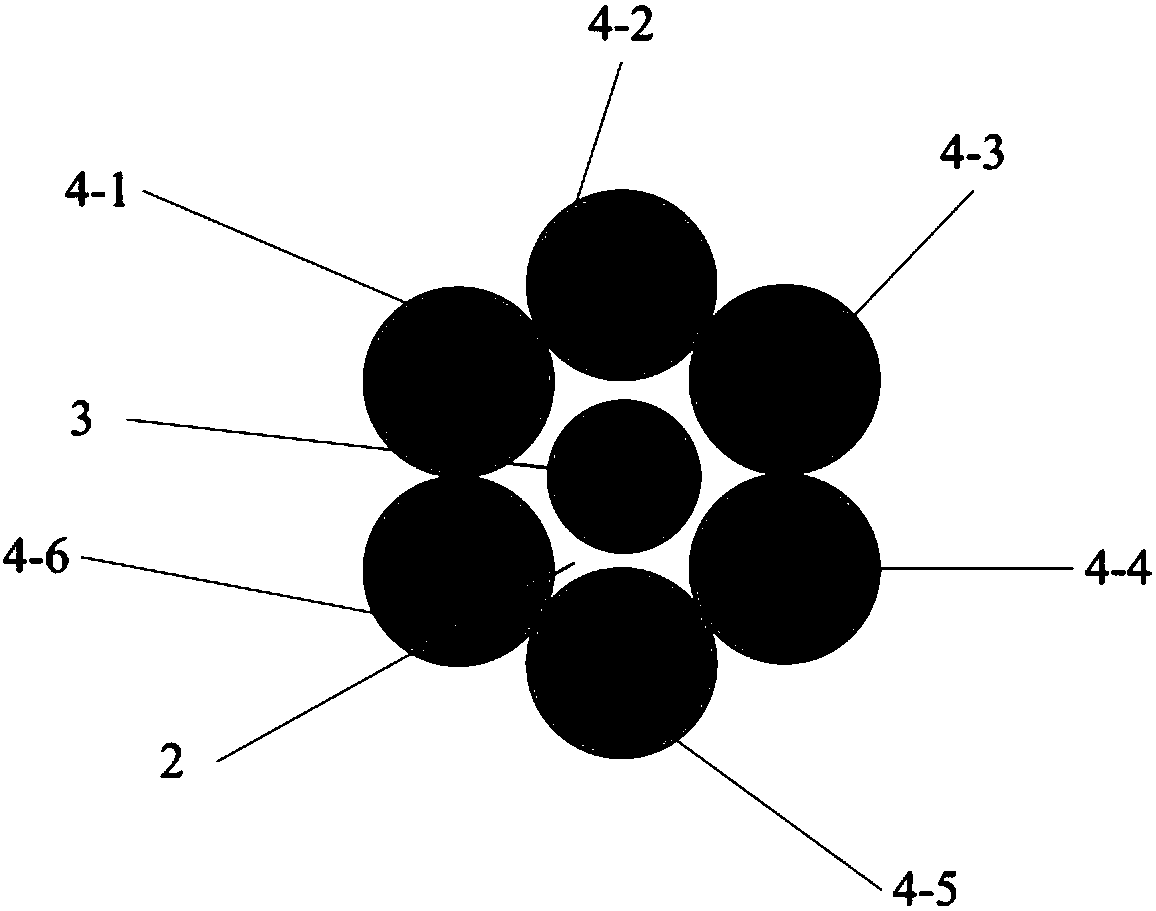

Compressible layer for fiber optic cable

InactiveUS7016585B2Avoid signal attenuationMaintain integrityOptical fibre with multilayer core/claddingFibre mechanical structuresAmbient waterEngineering

Owner:AT&T INTPROP I LP

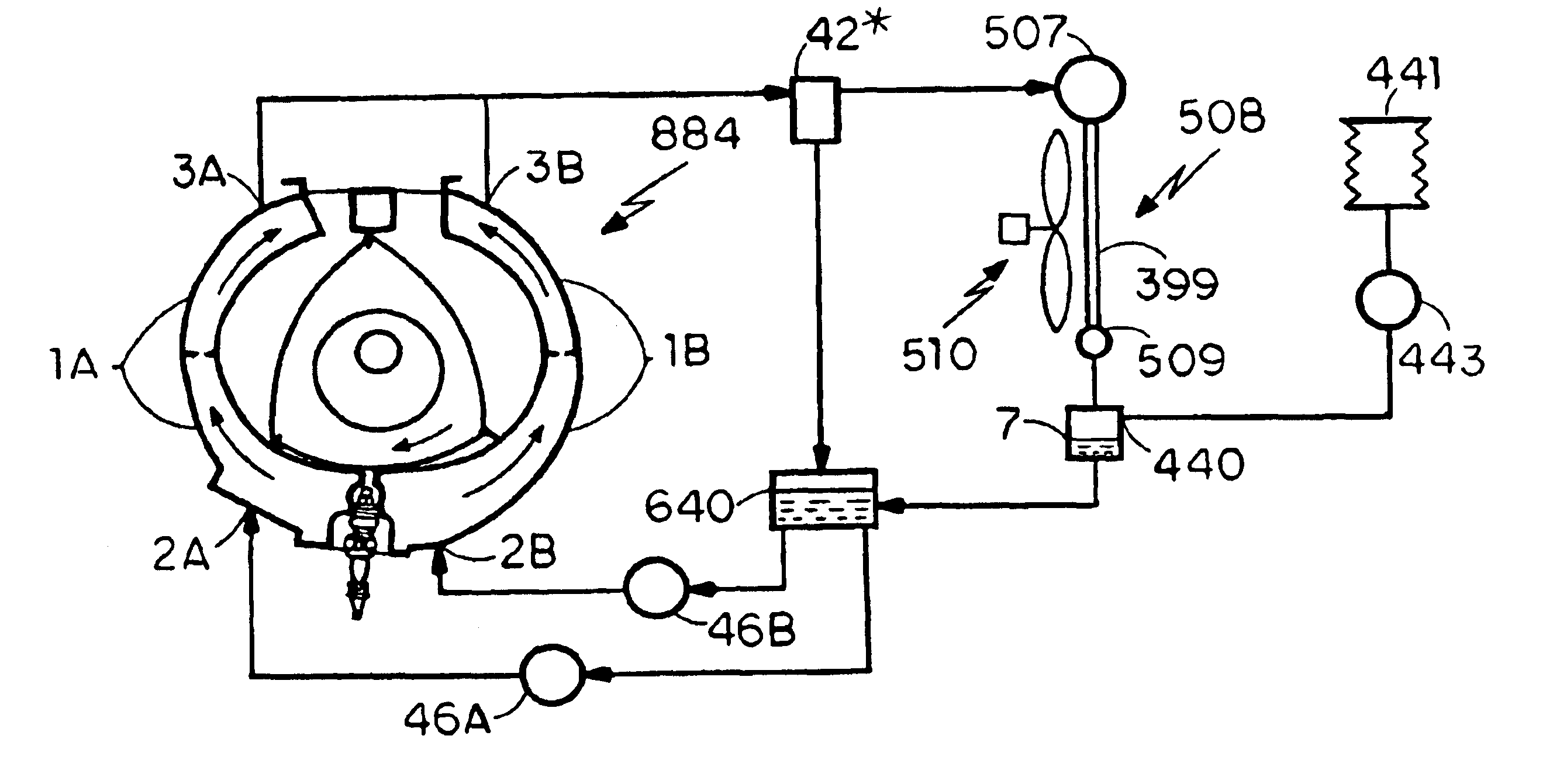

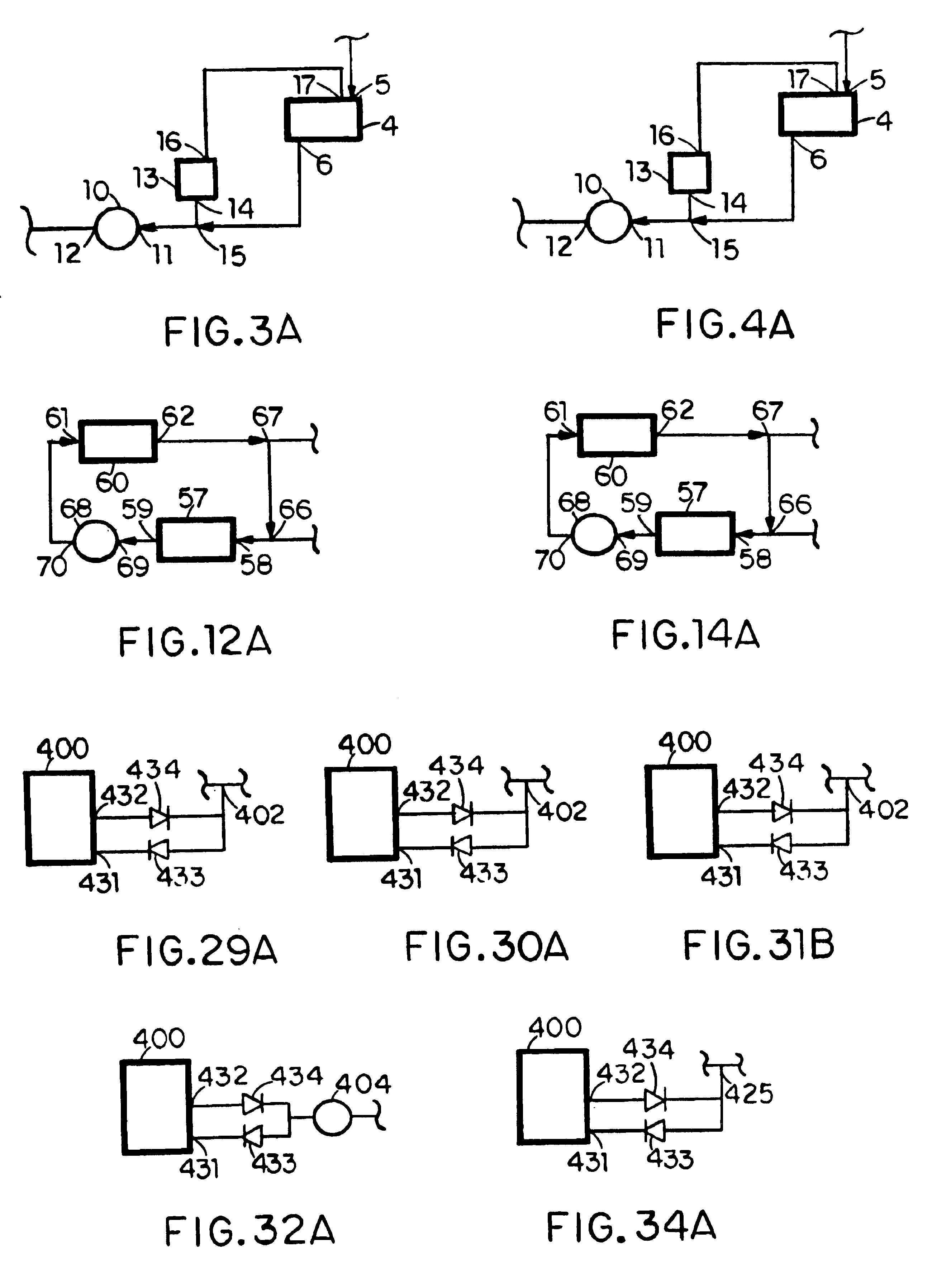

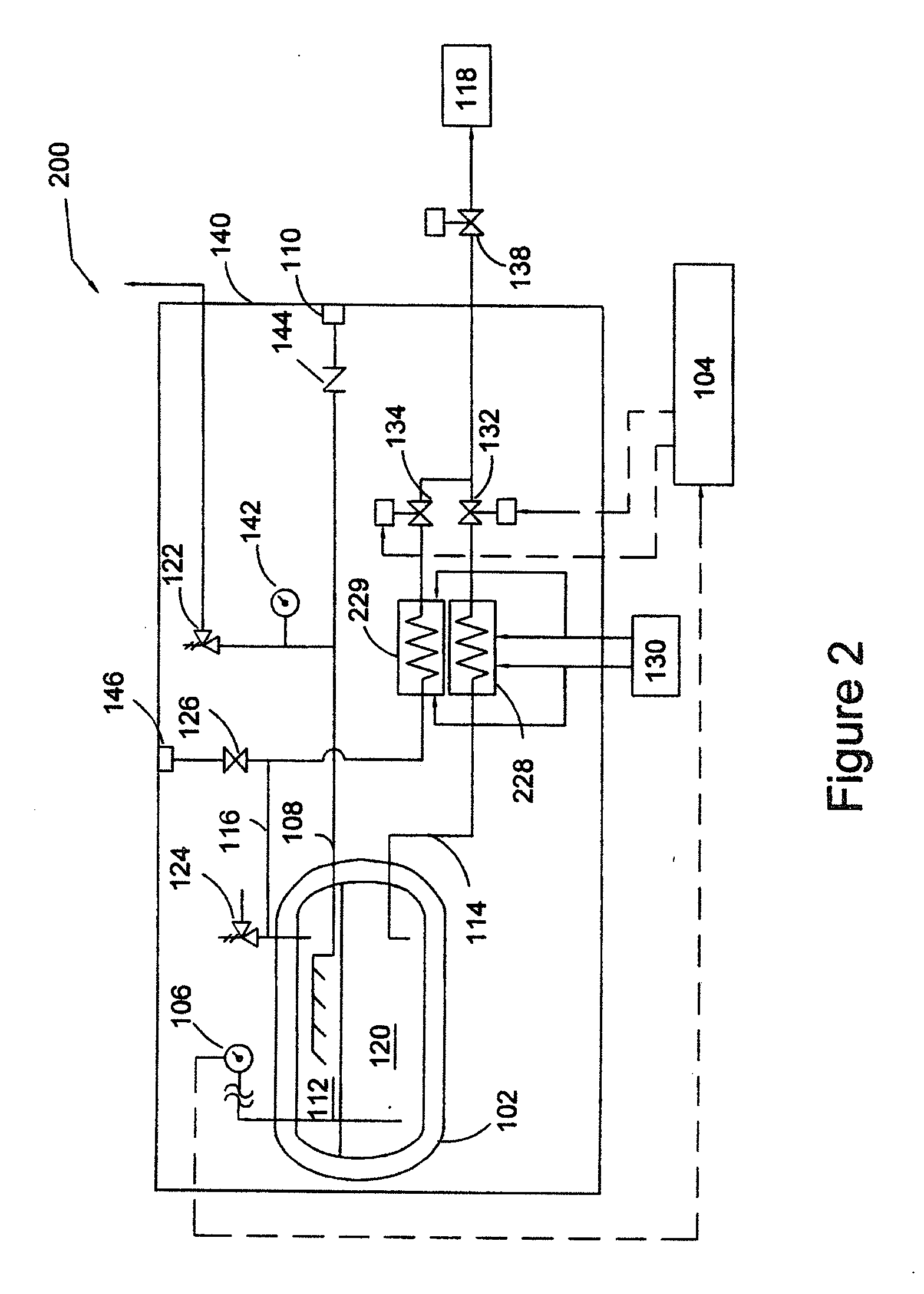

Two-phase heat-transfer systems

InactiveUS6866092B1Prevent freezingImprove the overall coefficientLiquid coolingCasingsLiquid jetInternal pressure

Various techniques are disclosed for improving airtight two-phase heat-transfer systems employing a fluid to transfer heat from a heat source to a heat sink while circulating around a fluid circuit, the maximum temperature of the heat sink not exceeding the maximum temperature of the heat source. The properties of those improved systems include (a) maintaining, while the systems are inactive, their internal pressure at a pressure above the saturated-vapor pressure of their heat-transfer fluid; and (b) cooling their internal evaporator surfaces with liquid jets. FIG. 43 illustrates the particular case where a heat-transfer system of the invention is used to cool a piston engine (500) by rejecting, with a condenser (508), heat to the ambient air; and where the system includes a heat-transfer fluid pump (10) and means (401-407) for achieving the former property.

Owner:MOLIVADAS STEPHEN

Ablative ultrasonic-cryogenic methods

InactiveUS20090221955A1Induced fastEasy to moveUltrasound therapyChiropractic devicesCardiac muscleTransducer

An ablative apparatus and associated methods that can be used to treat atrial fibrillation and other cardiac arryhythmias by ablating cardiac tissue is disclosed. When the distal end of the apparatus reaches the tissue to be ablated, an ablation probe driven by a transducer is vibrated. Scratching the tissue with abrasive members, the vibrating ablation probe is capable of mechanically ablating tissues. This mechanical ablation may be utilized to penetrate epicardial fat, thereby exposing the underlying myocardium. The ablative apparatus may then be used subject the exposed myocardium to mechanical ablation, cryoablation, ultrasonic ablation, and / or any combination thereof.

Owner:BACOUSTICS LLC

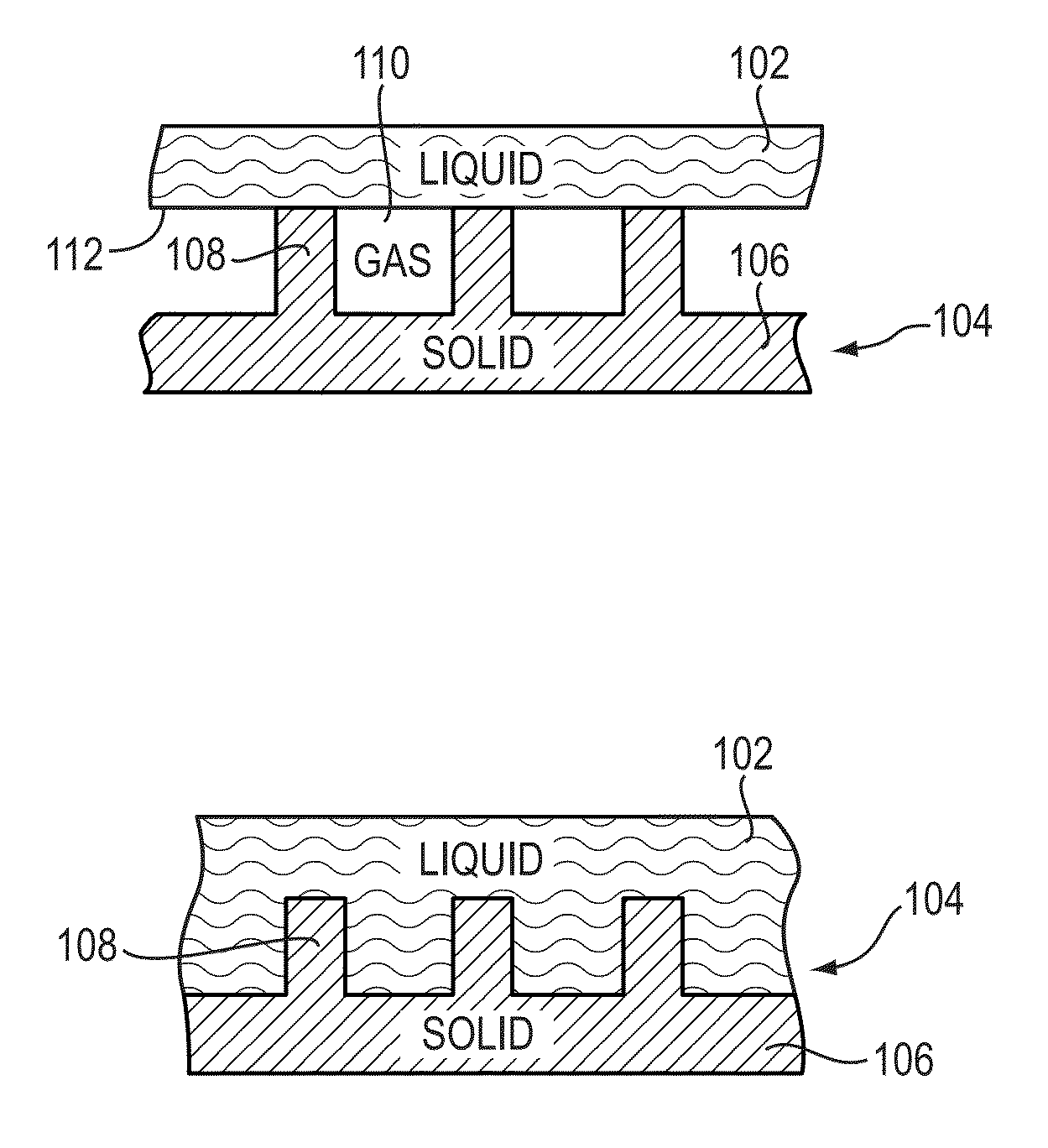

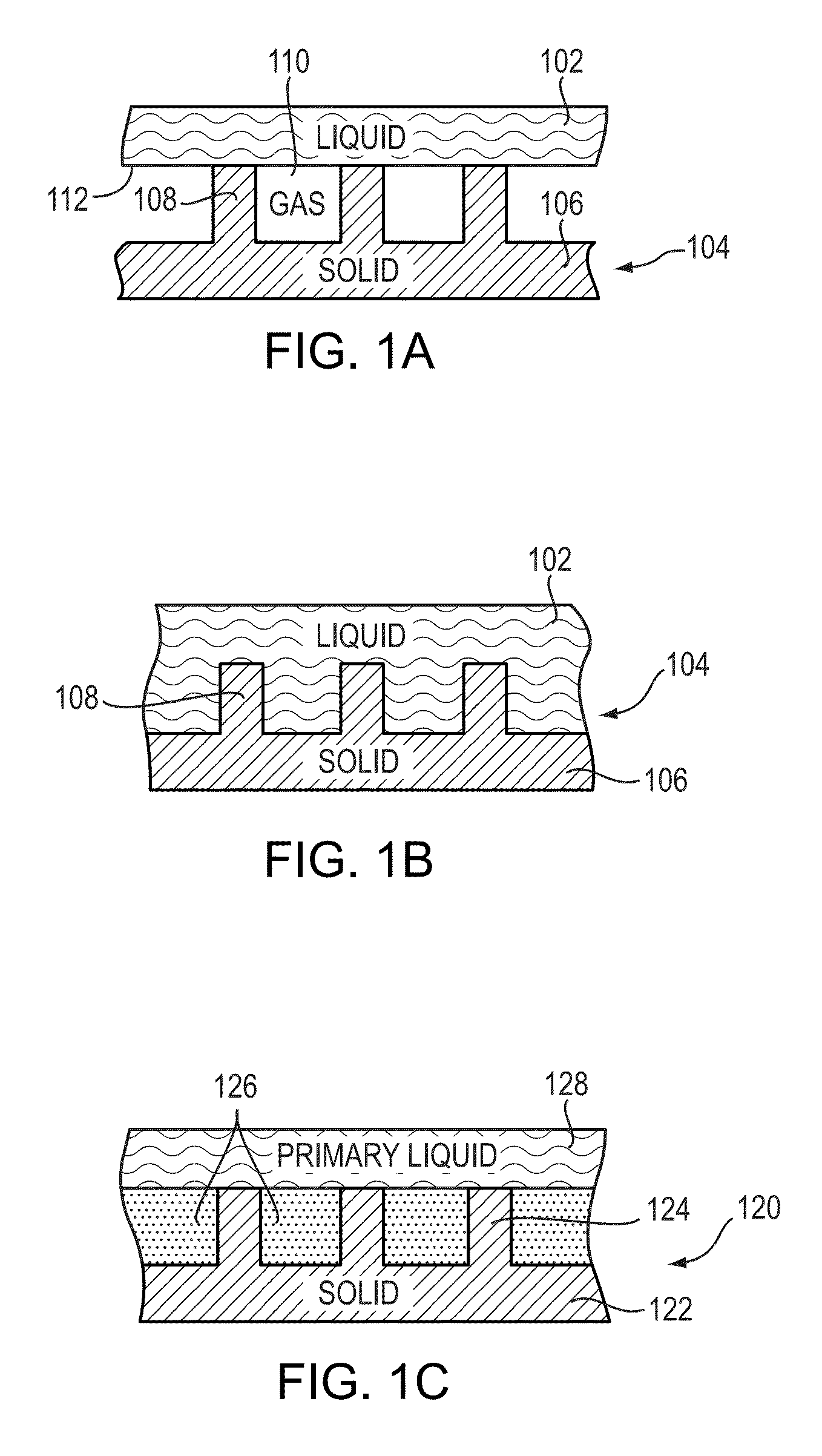

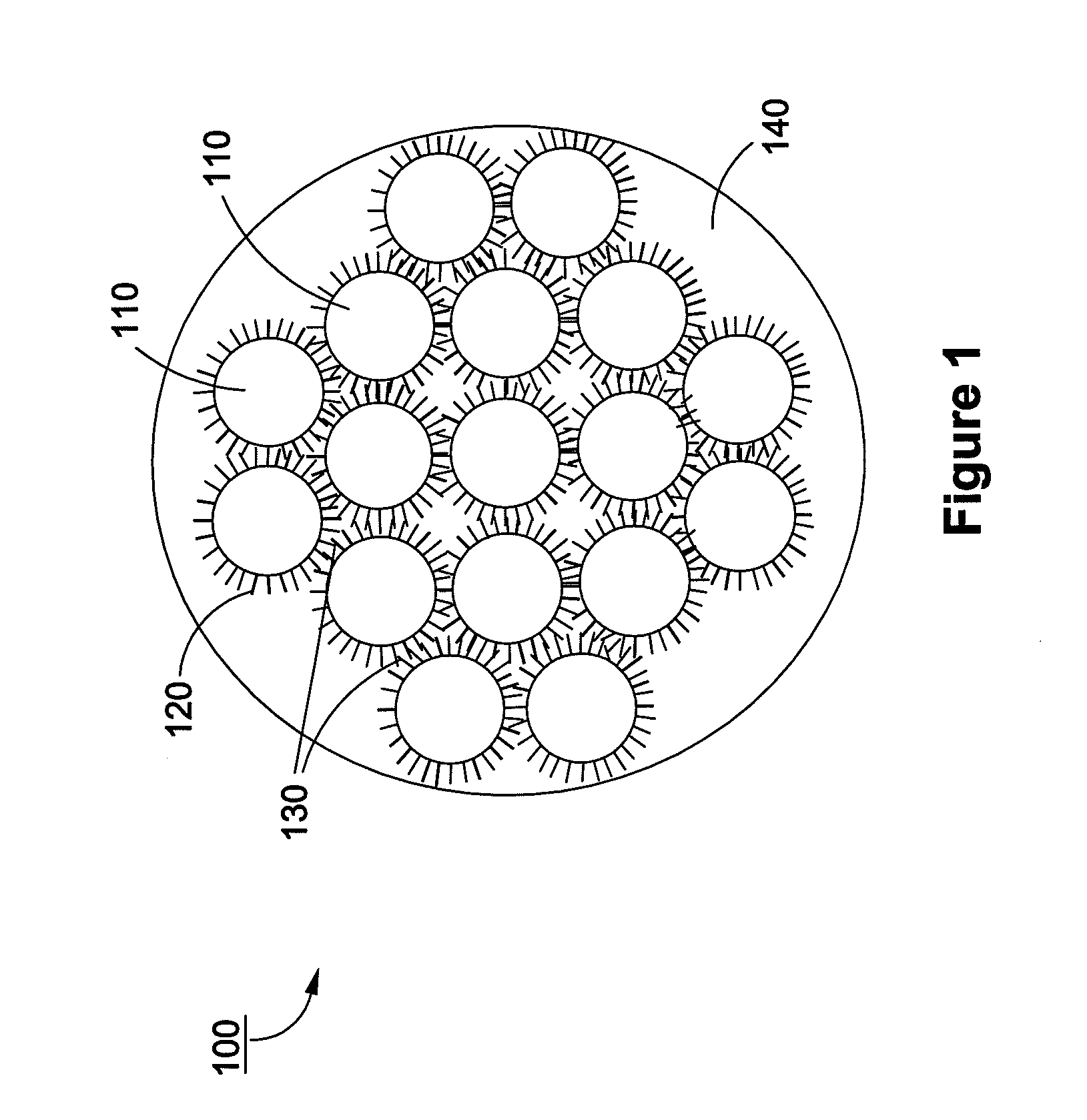

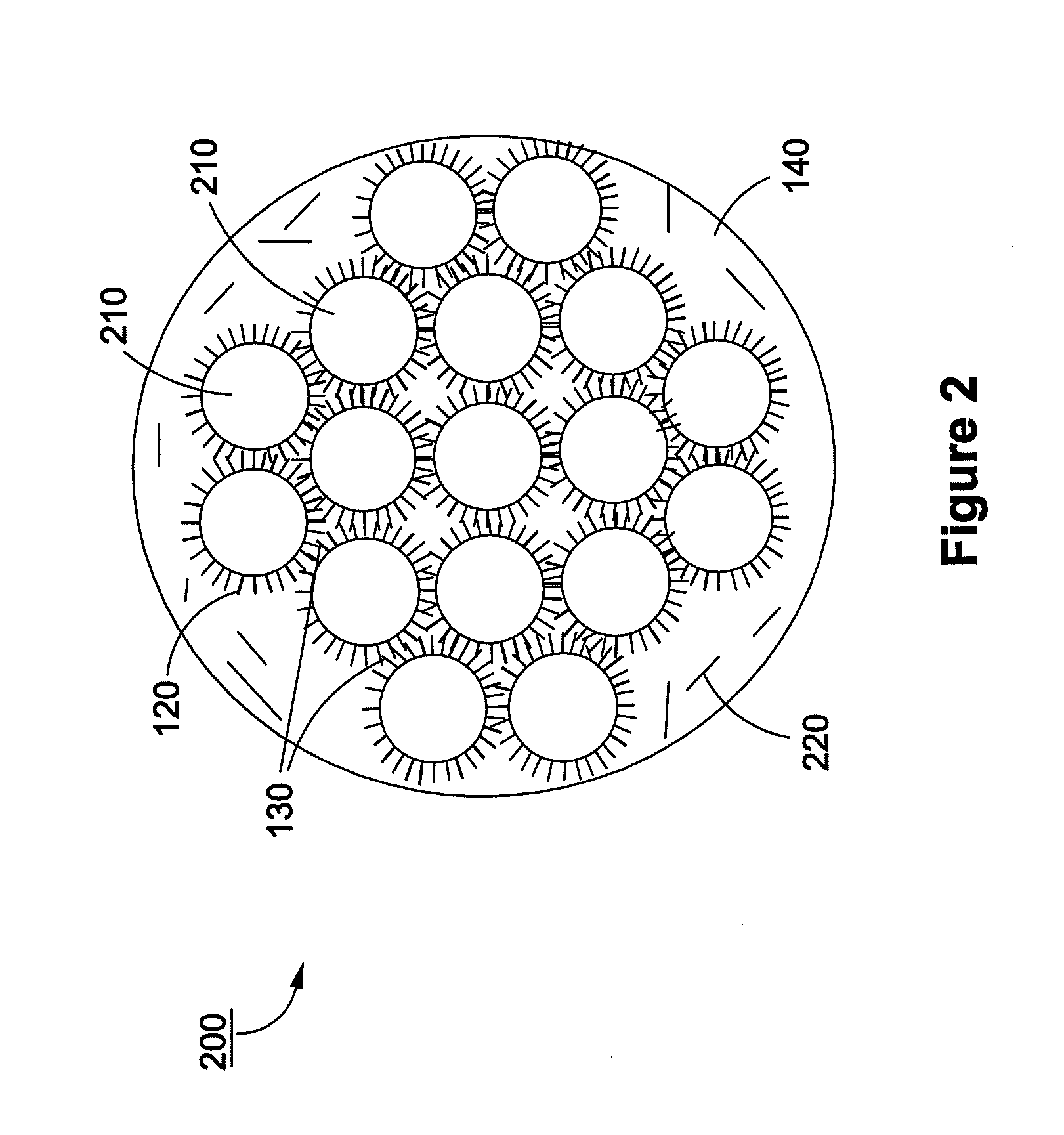

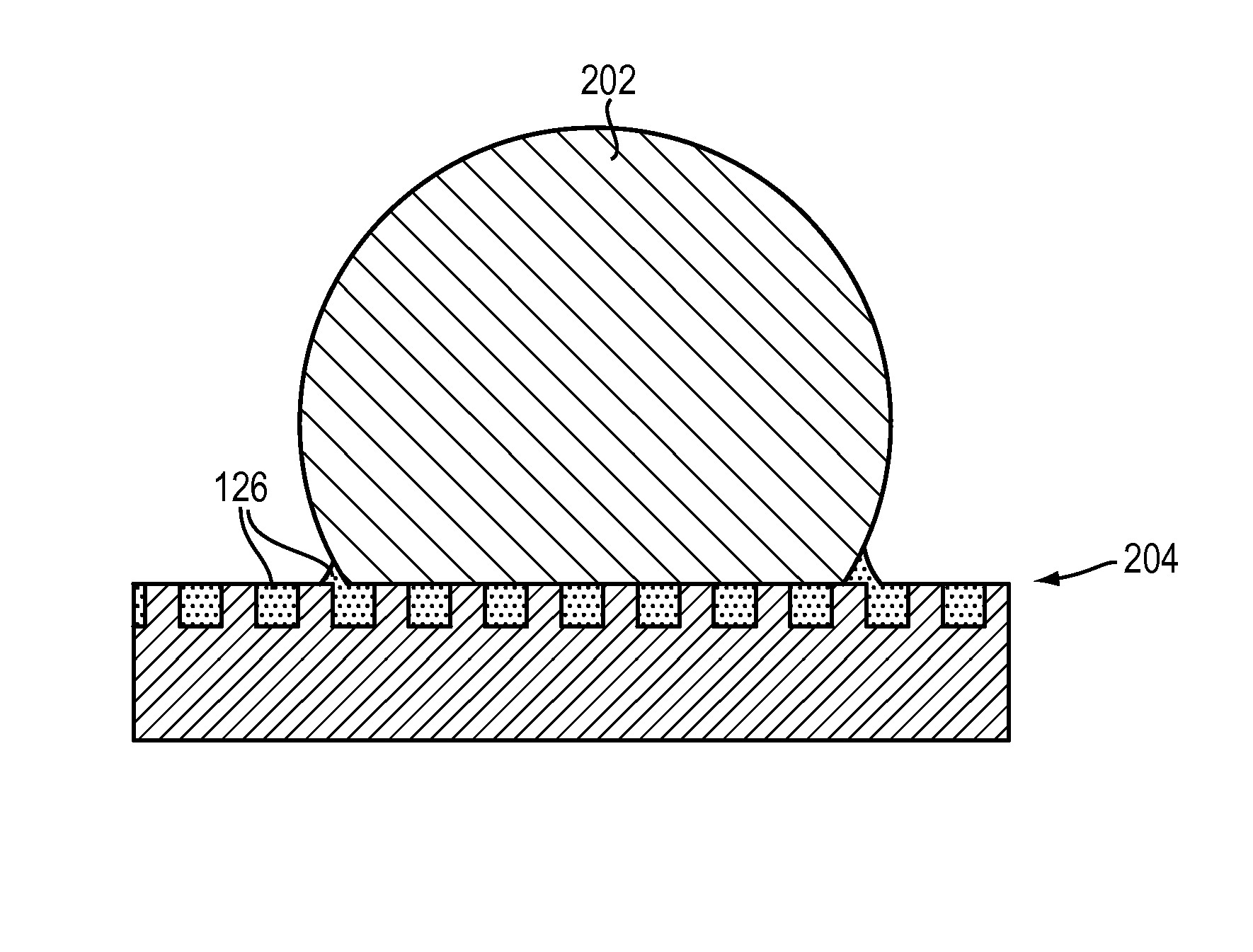

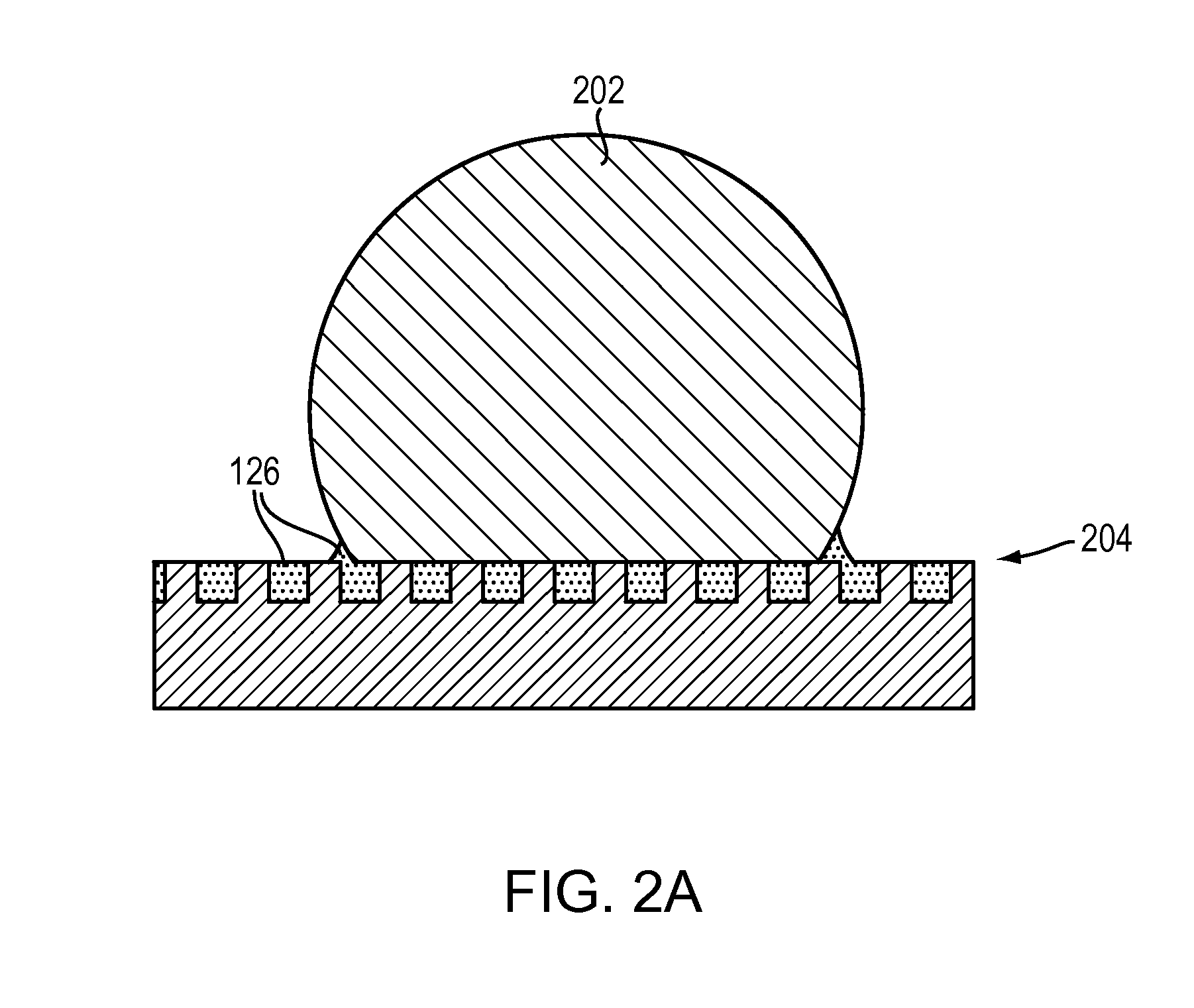

Liquid-Impregnated Surfaces, Methods of Making, and Devices Incorporating the Same

InactiveUS20130032316A1Improve skidReduce resistanceFouling preventionDe-icing equipmentsNon wettingFrost

The invention is directed to an article with a liquid-impregnated surface, the surface having a matrix of features thereupon, spaced sufficiently close to stably contain a liquid therebetween or therewithin, and preferable also a thin film thereupon. The surface provides the article with advantageous non-wetting properties. Compared to previous non-wetting surfaces, which include a gas (e.g., air) entrained within surface textures, these liquid-impregnated surfaces are resistant to impalement and frost formation, and are therefore more robust.

Owner:MASSACHUSETTS INST OF TECH

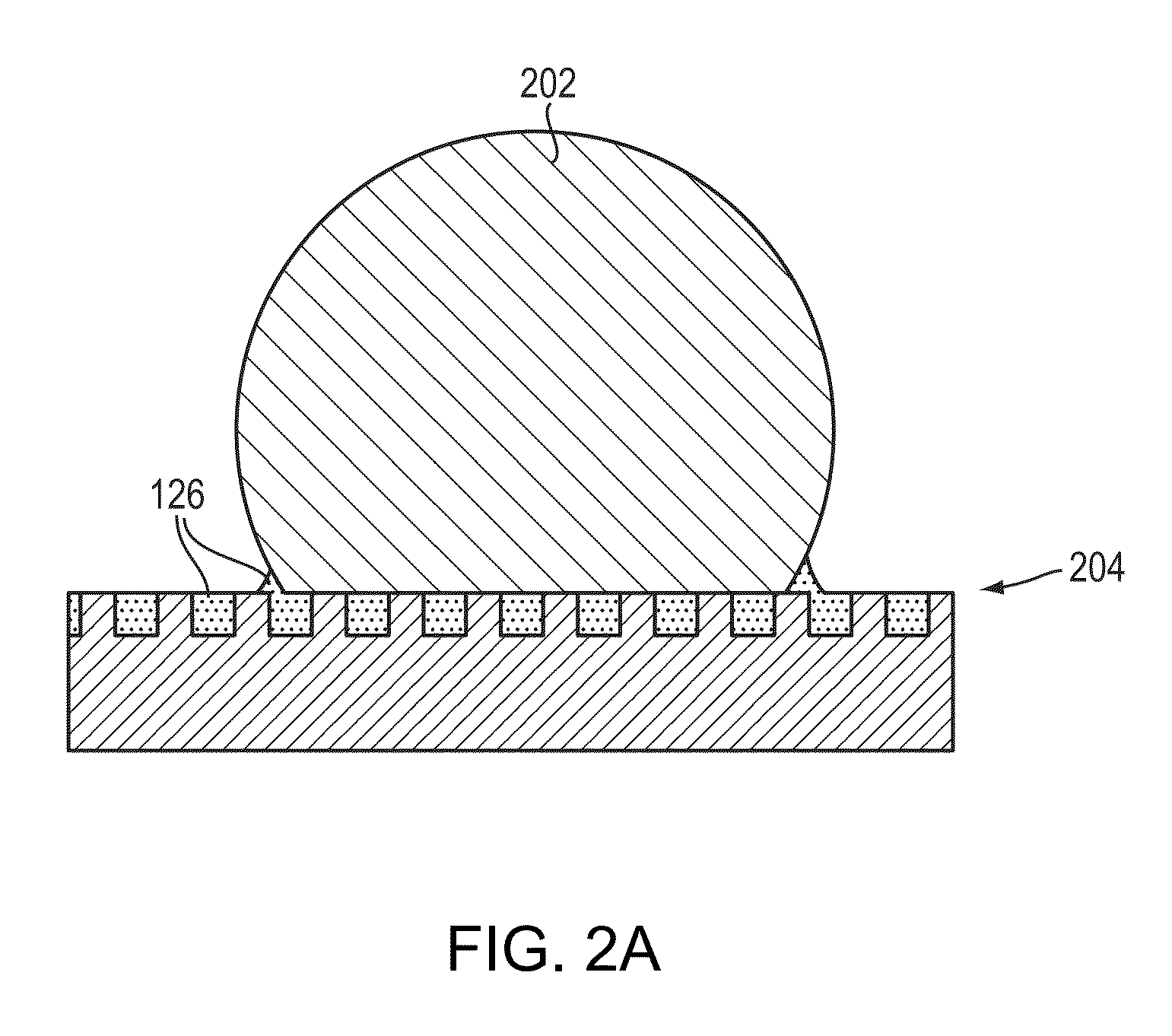

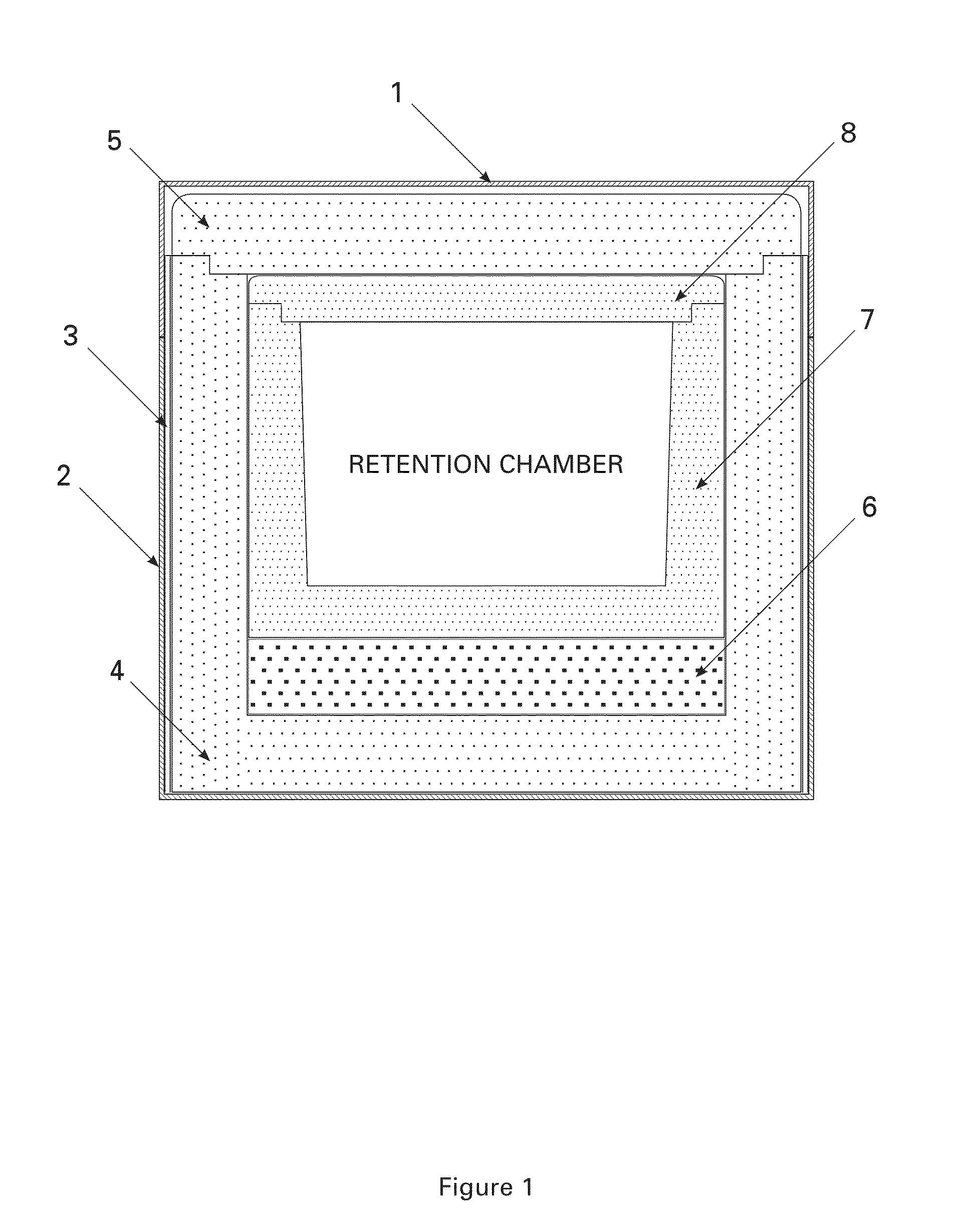

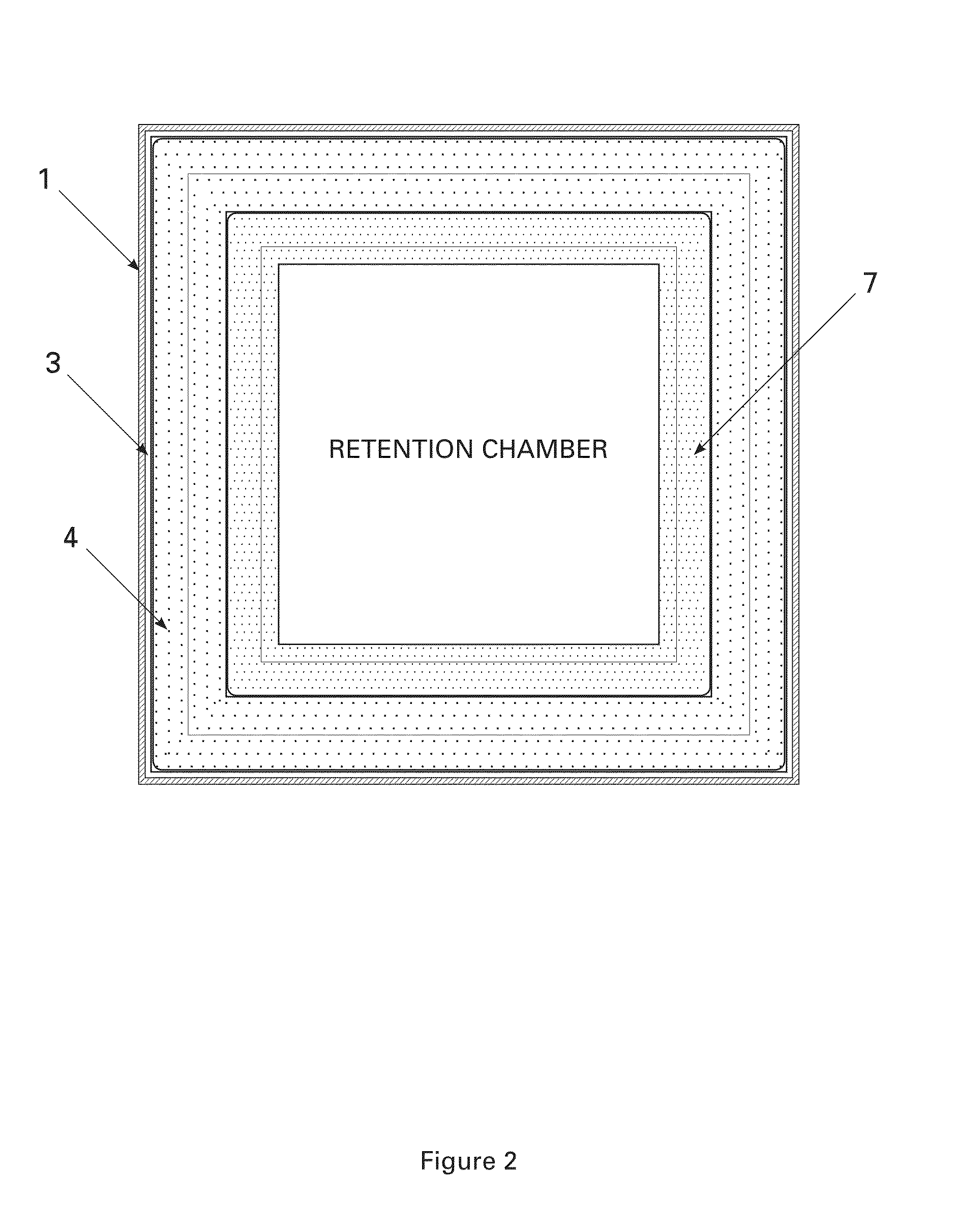

High-performance extended target temperature containers

InactiveUS20140021208A1Extends freezing temperature performanceGood temperature control effectDomestic cooling apparatusLighting and heating apparatusTemperature controlRefrigeration temperature

Reusable and recyclable target temperature storage and shipping containers designed to maintain the content therein within desired temperature levels for greatly extended periods of time are disclosed. A First species is customized to maintain refrigeration temperatures for extended periods of time and the Second species maintains freezing temperatures for extended periods of time. Both species models include containers having outer protective layers and inner insulating layers as well as a cavity for holding payload being stored or shipped, and one or more areas for holding passive coolants in a predetermined relationship to the products within specific target temperatures. The different species provide cold or freezing temperatures in reusable or disposable models for various applications. The main containers are substantially airtight when sealed for storage or shipping and includes an outer box, inner insulation, internal dividers, and different temperature controlling coolants designed for various temperature maintenance requirements of temperature-sensitive content.

Owner:ANTI ALEX N +1

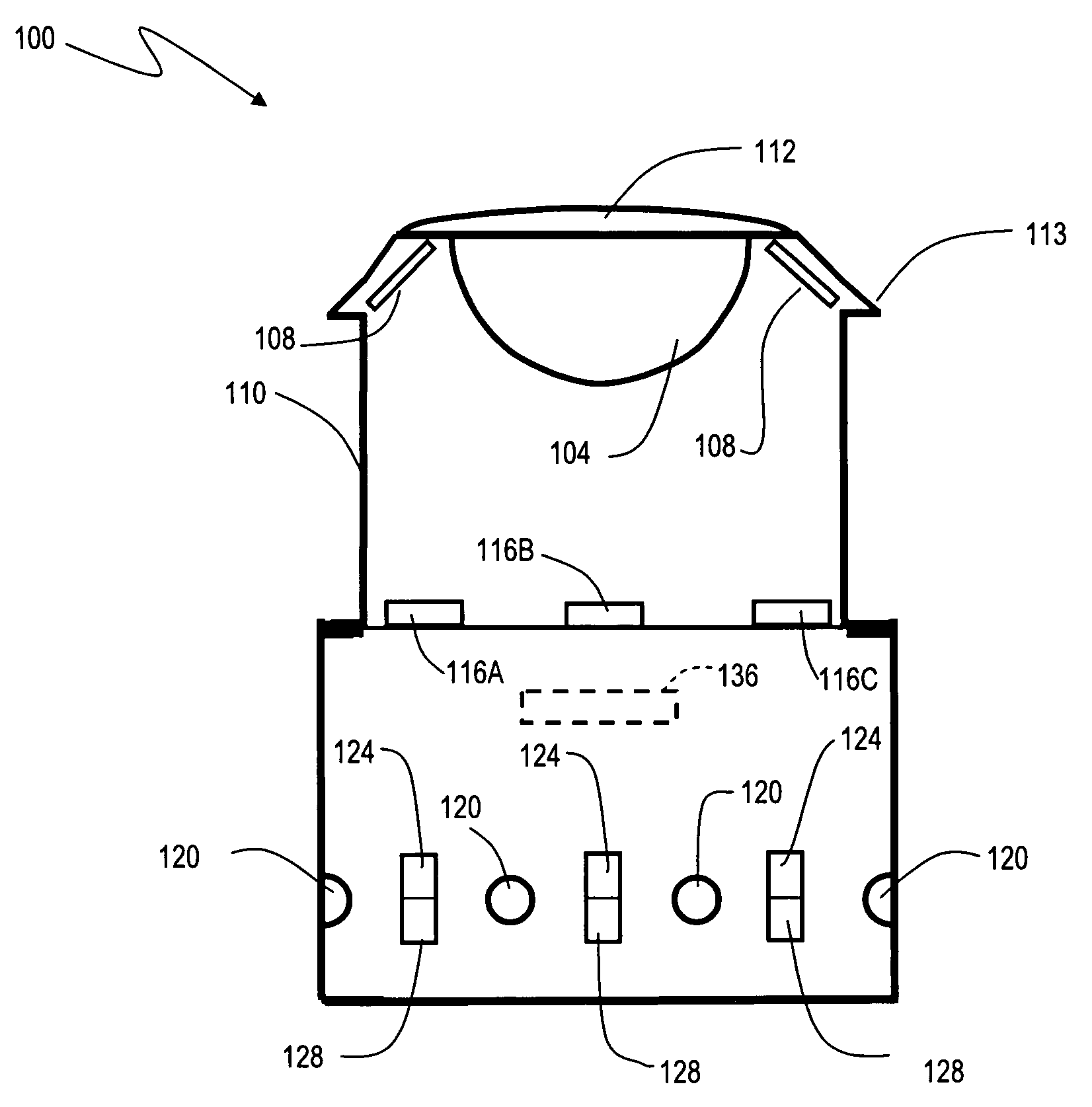

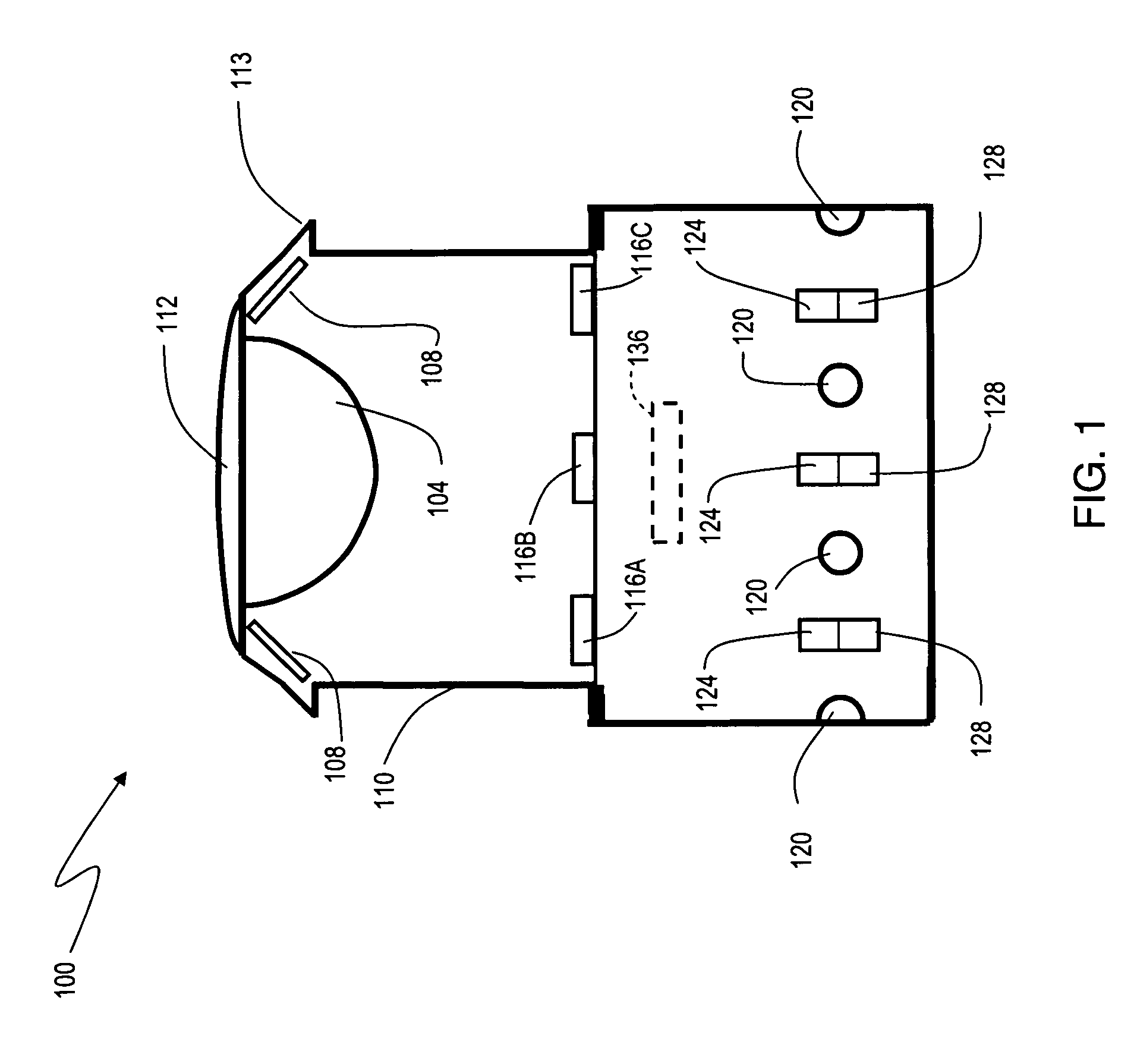

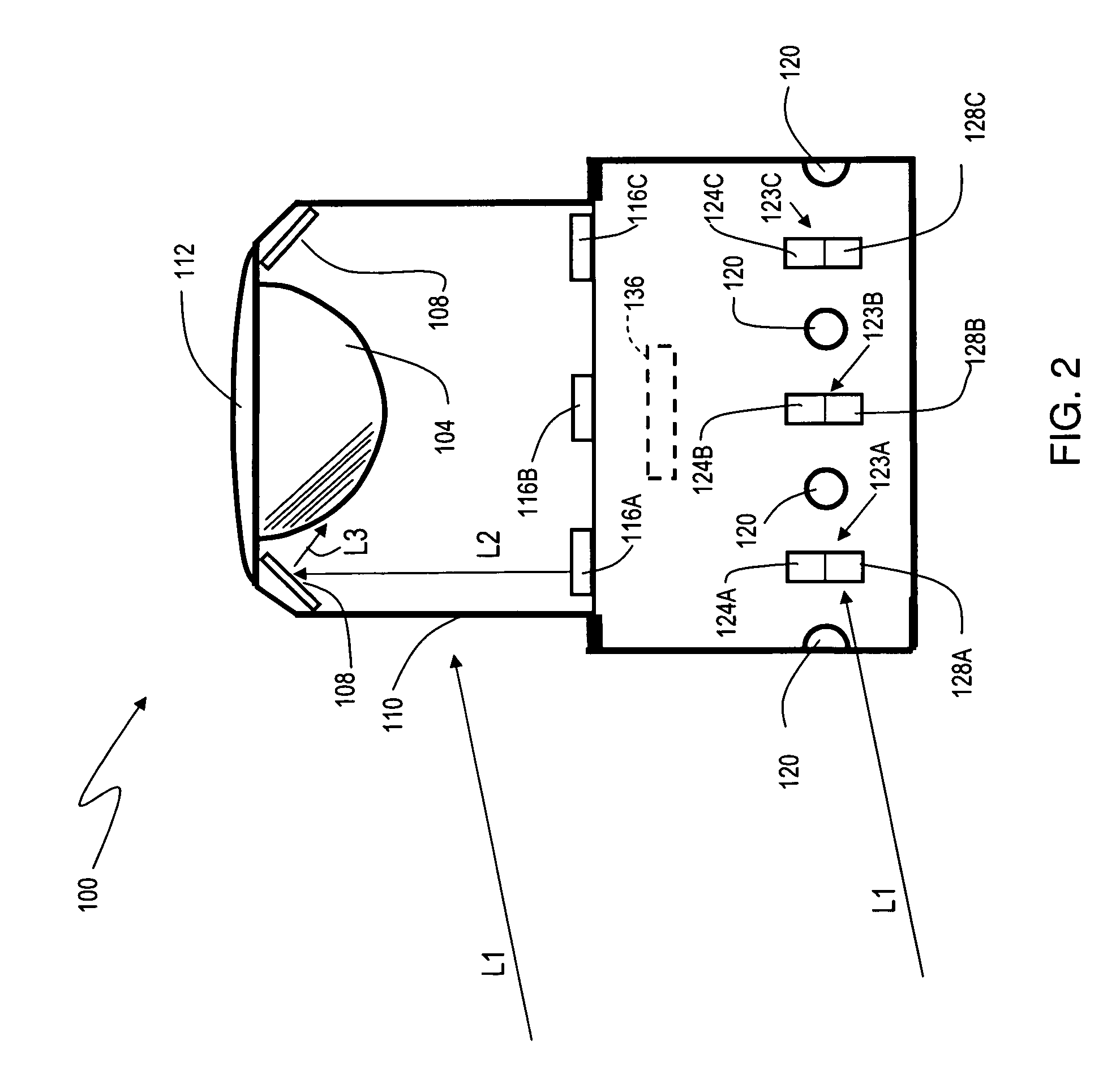

Panoramic camera

InactiveUS20090213208A1Maximize the effectStrong lightTelevision system detailsPanoramic photographyEffect lightImage capture

An improved camera for the acquisition of panoramic images is disclosed. The camera comprises a convex photochromic reflector directed towards an image capture element. Multiple incoming light sensors around the perimeter of the camera detect strong incoming light and cause the activation of a corresponding UV light. The UV light in turn activates the photochromic effect on a particular region of the photochromic reflector that corresponds to an area of strong incident light. The photochromic reflector then darkens in that area, providing compensation for a scene that has a wide range of lighting conditions. Therefore, the camera compensates for strong lighting indoors as well as outdoors.

Owner:GLATT OTTO GREGORY

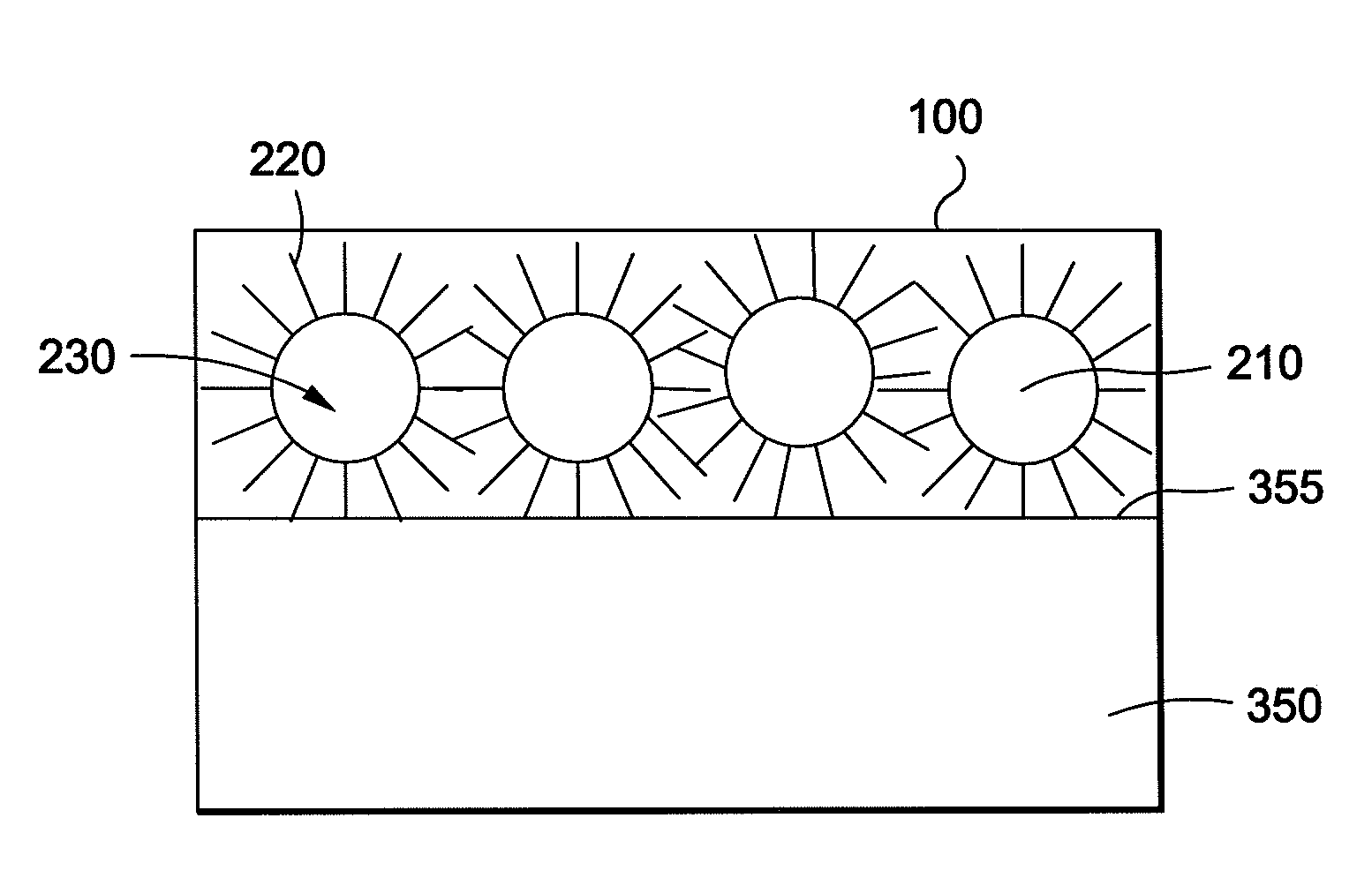

Cnt-based resistive heating for deicing composite structures

ActiveUS20110024409A1Prevent freezingInhibition formationMaterial nanotechnologyLayered productsFiberCarbon nanotube

A composite structure includes a matrix material and a carbon nanotube (CNT)-infused fiber material that includes a plurality of carbon nanotubes (CNTs) infused to a fiber material. The CNT-infused fiber material is disposed throughout a portion of the matrix material. The composite structure is adapted for application of a current through the CNT-infused fiber material to provide heating of the composite structure. A heating element includes a CNT-infused fiber material includes a plurality of CNTs infused to a fiber material. The CNT-infused fiber material is of sufficient proportions to provide heating to a structure in need thereof.

Owner:APPL NANOSTRUCTURED SOLUTIONS LLC

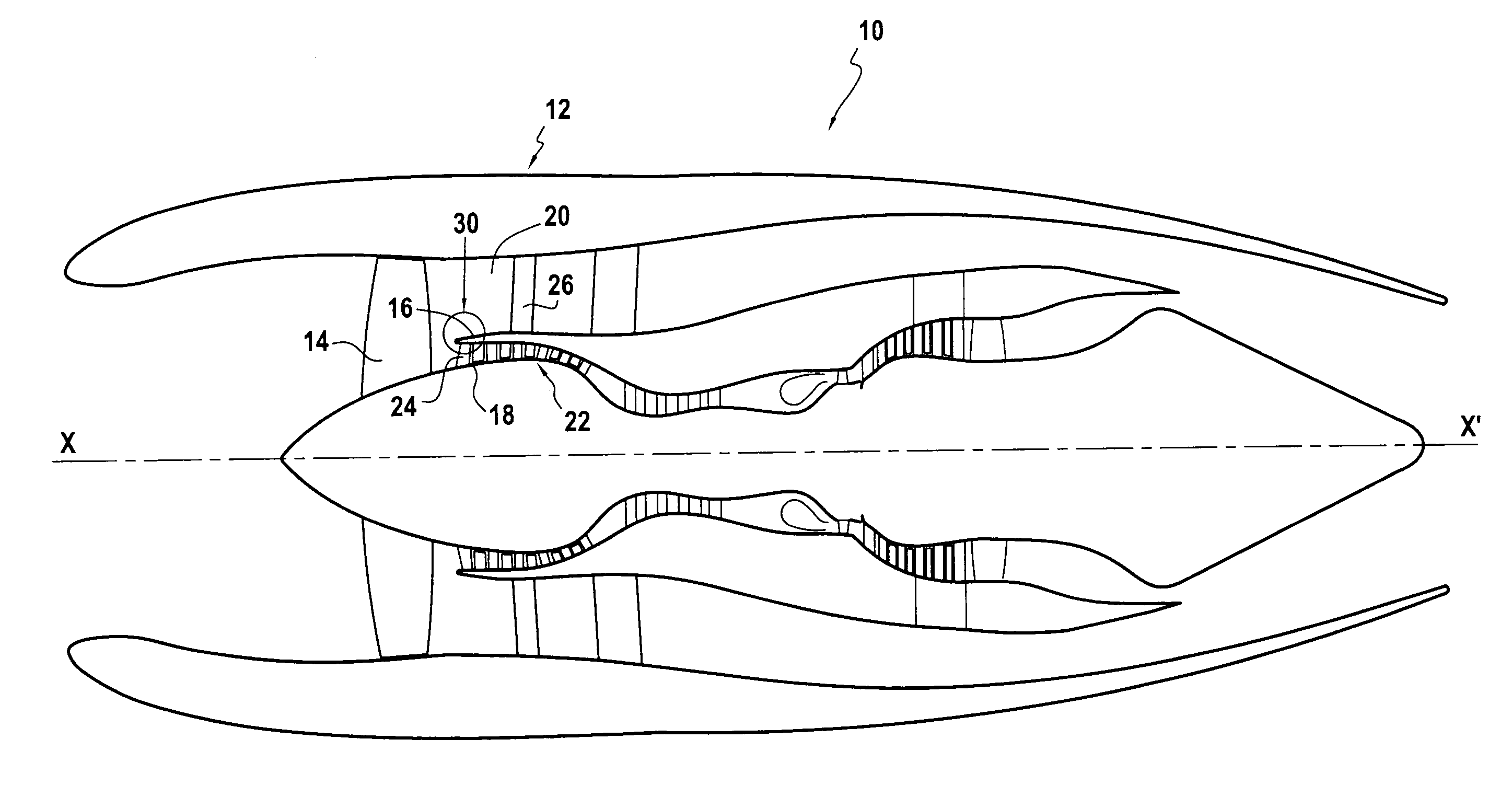

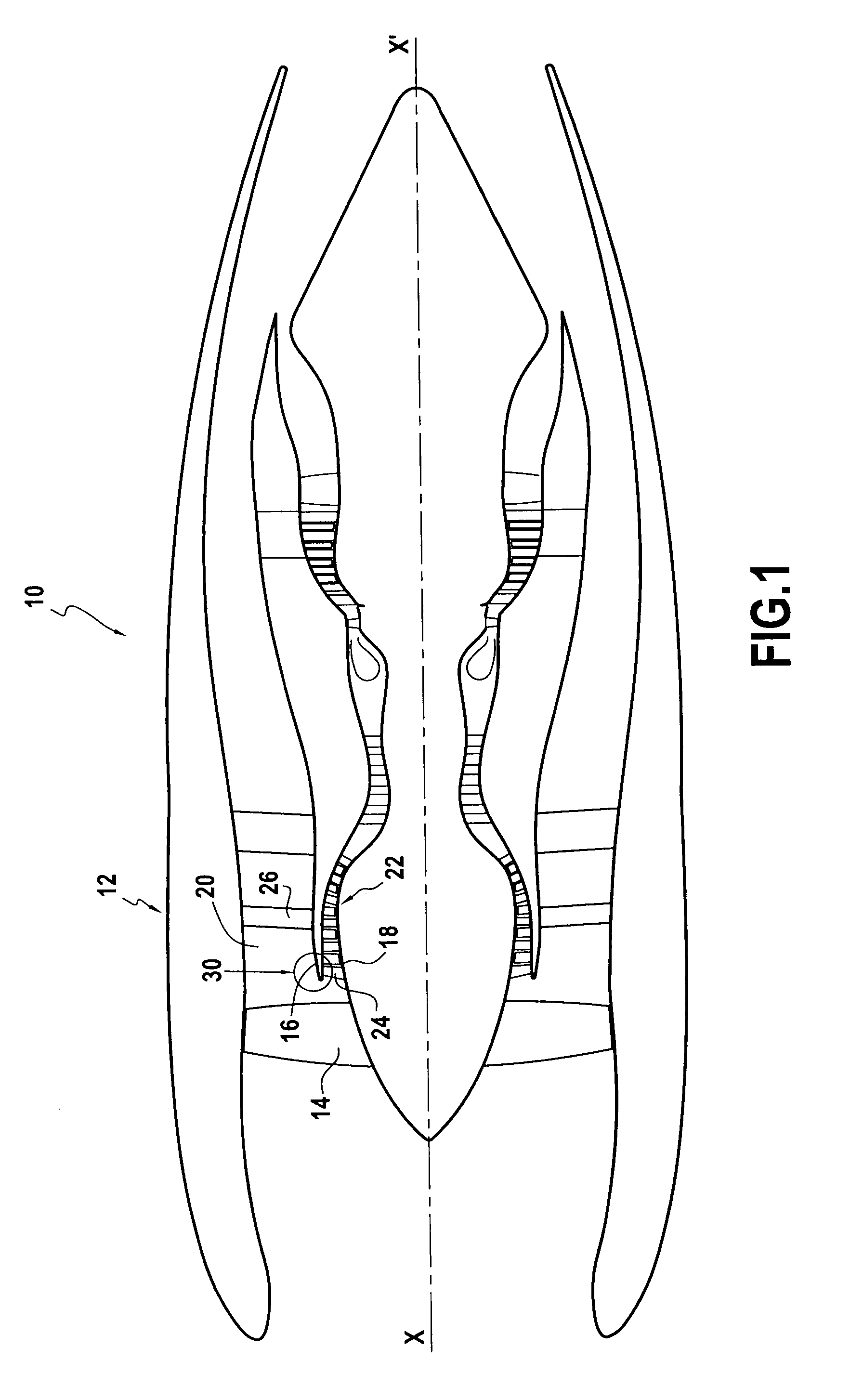

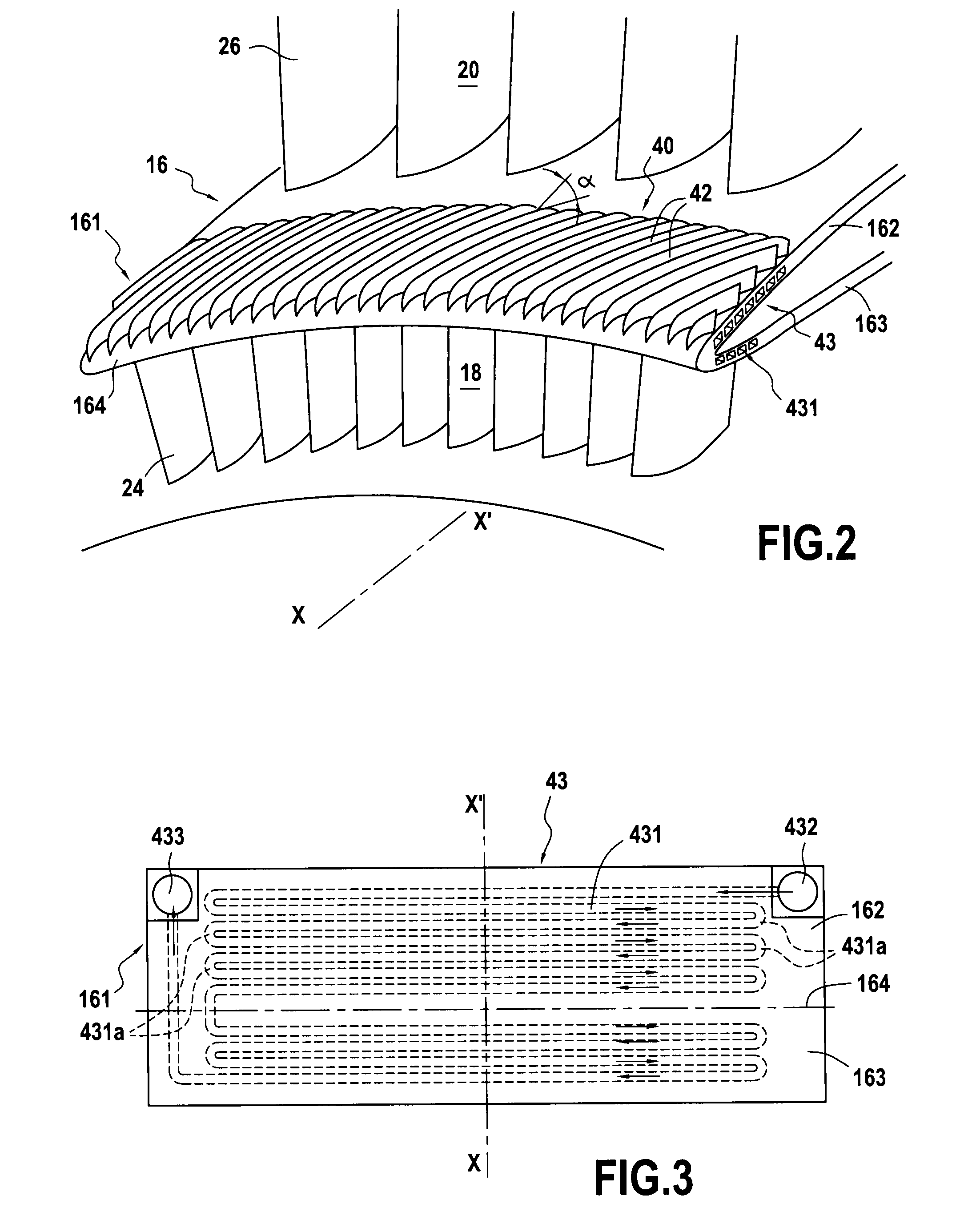

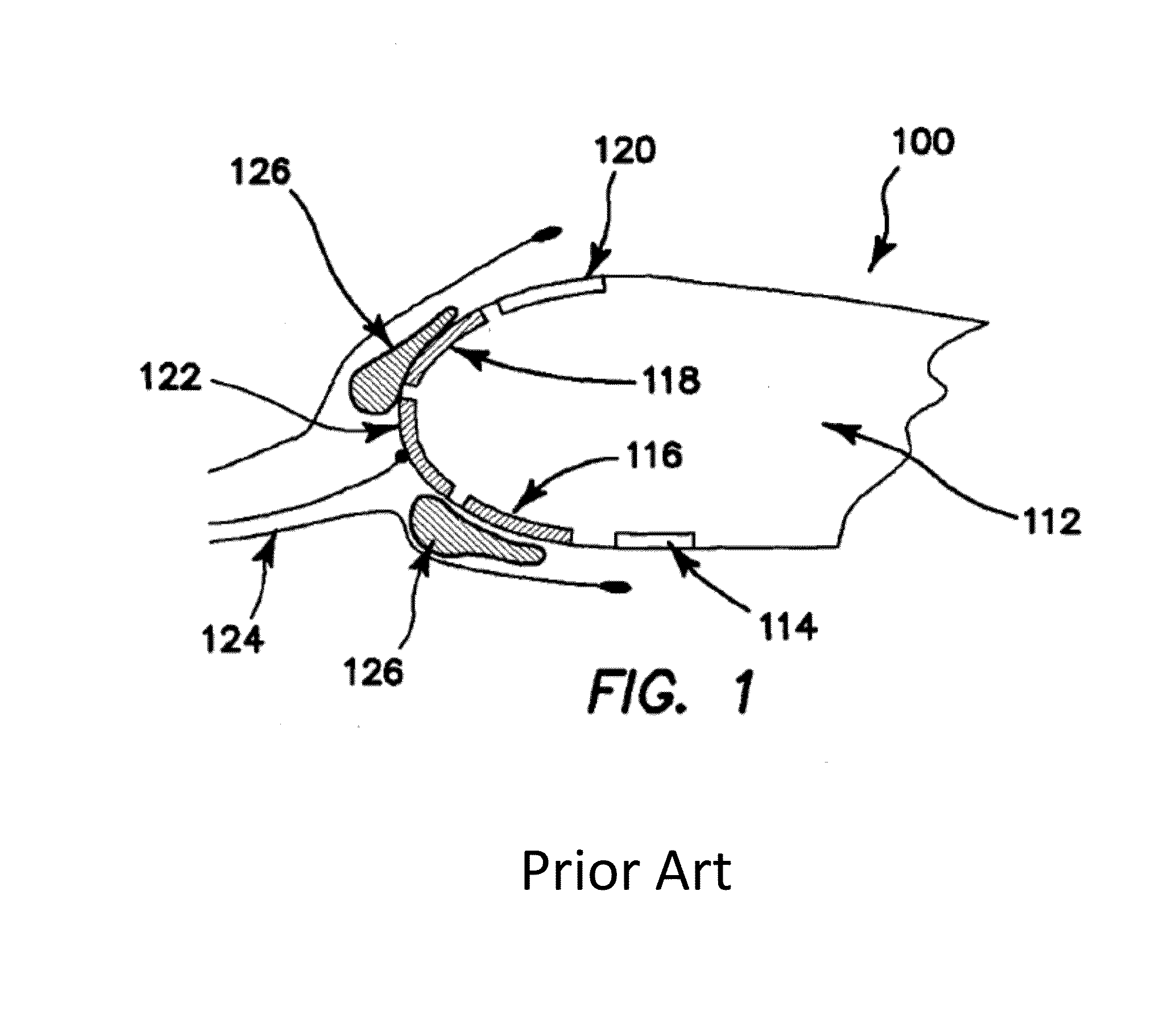

Air-oil heat exchanger placed at the location of the air separator nose of a turbojet, and a turbojet including such an air-oil heat exchanger

InactiveUS20090165995A1Prevent freezingWithout significantly disturbing the air streamExhaust apparatusTurbine/propulsion engine coolingLeading edgeJet engine

The invention relates to an air-oil heat exchanger located at the inner shroud of the secondary duct of a turbojet. In characteristic manner, it comprises an oil circuit placed inside the separator nose and fins placed outside the top wall of the separator nose, between the leading edge of the separator nose and the outlet guide vanes.

Owner:TECHSPACE AERO

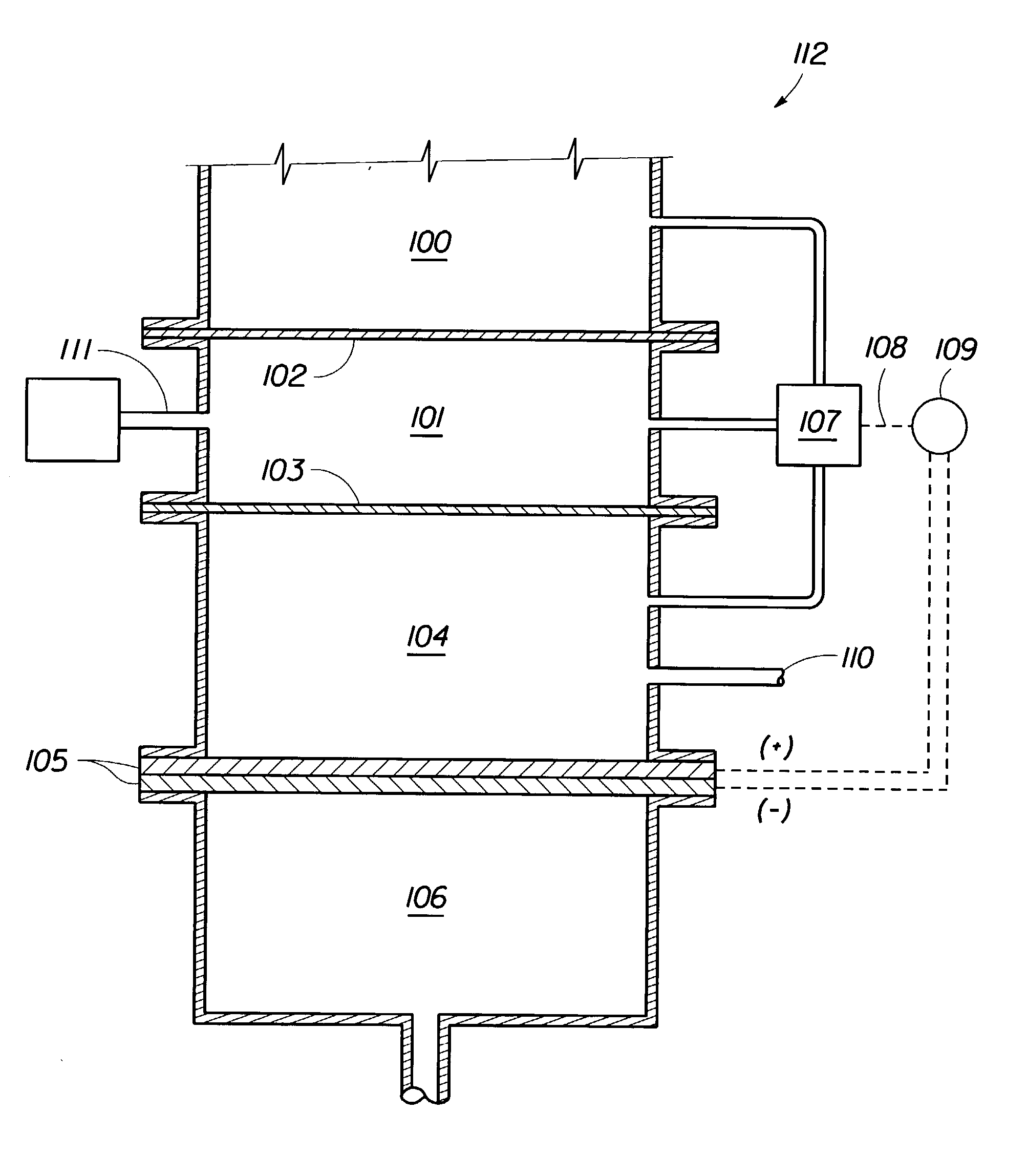

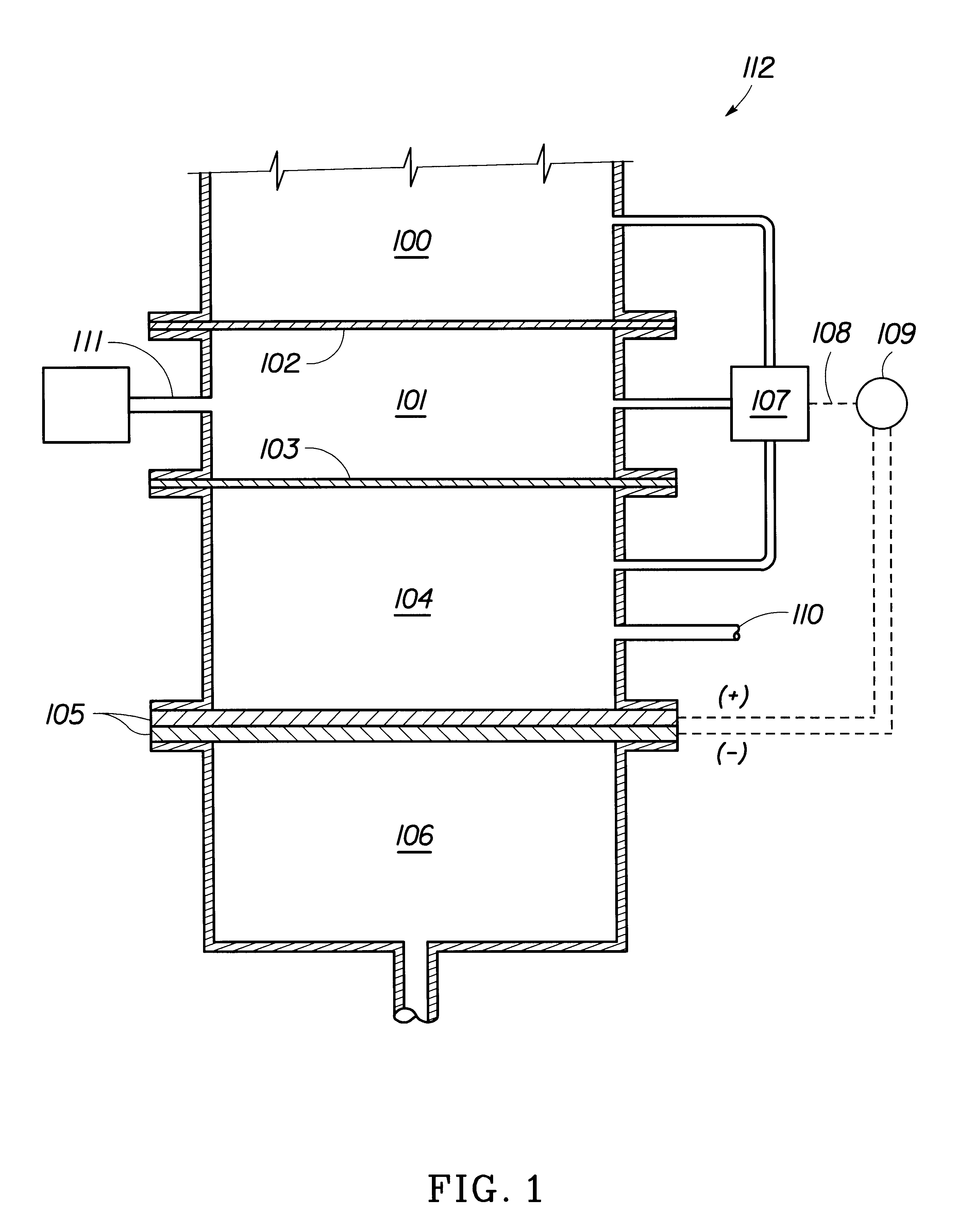

Microorganism control of point of use potable water sources

InactiveUS20030080467A1Keep it cleanPrevent freezingCellsSpecific water treatment objectivesMedical equipmentWater source

The present invention provides for the electrochemical generation of ozone for use in "point-of-use" applications. The electrochemical ozone generators or systems of the present invention may be used to provide disinfected water, ozone-containing water, and / or ozone gas. Disinfected water may be produced by introducing ozone gas into a potable or purified water source for the purpose of disinfecting or controlling the microorganisms in the water source. Ozonated water or ozone gas may be produced and provided for various anti-microbial and cleansing applications of the consumer, such as washing food, clothing, dishes, countertops, toys, sinks, bathroom surfaces, and the like. Furthermore, the ozone generator may be used to deliver a stream of ozone-containing water for the purpose of commercial or residential point-of-use washing, disinfecting, and sterilizing medical instruments and medical equipment. For example, the ozone-containing water may be used directly or used as a concentrated sterilant for the washing, disinfecting, and sterilizing of medical instruments or equipment. Ozone gas may also be used in many of the foregoing examples, as well as in the deodorization of air or various other applications. The invention allows the electrochemical ozone generator to operate in a nearly or entirely passive manner with simplicity of design.

Owner:LYNNTECH INT

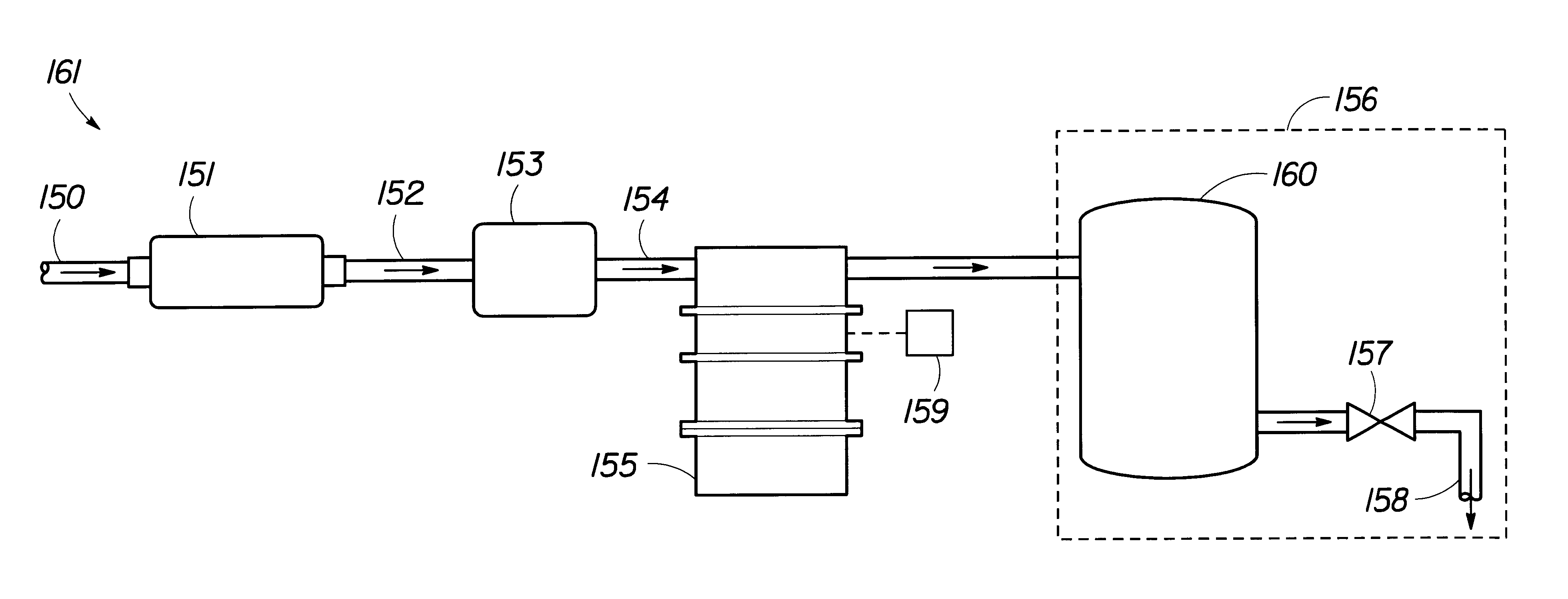

Pressure Control System And Method

ActiveUS20110314839A1Reduce pressurePrevent freezingInternal combustion piston enginesFuel supply apparatusProcess engineeringStreamflow

A pressure control system comprises separate conduits for supplying liquefied gas and vapor from a cryogen space defined by a cryogenic storage tank. A first conduit can deliver liquefied gas to a use device through a heater and then a first flow controller. A second conduit can deliver vapor to the use device with flow therethrough controlled by a second flow controller. The first flow controller is not exposed to liquefied gas at cryogenic temperatures because it is located downstream from the heater. For automatic operation a pressure sensor measures pressure inside the cryogen space and the first and second flow controllers are independently operable to maintain the pressure inside the cryogen space within a predetermined range. In a preferred embodiment the liquefied gas is a combustible fuel that is consumed by an internal combustion engine, which is the use device.

Owner:WESTPORT FUEL SYST CANADA INC

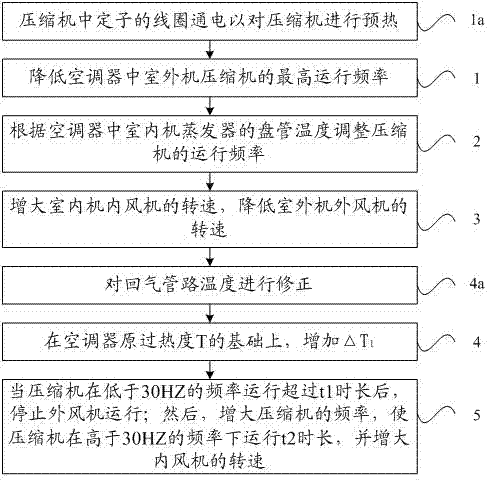

Refrigeration method of low temperature environment air conditioner

ActiveCN103115417AAchieve normal coolingAvoid frequent downtimeSpace heating and ventilation safety systemsSpace heating and ventilation control systemsEngineeringRefrigeration

The invention provides a refrigeration method of a low temperature environment air conditioner. When the air conditioner operates to refrigerate, the refrigeration method comprises the following steps of: step 1, reducing the topmost operating frequency of an outer door machine compressor in the air conditioner; step 2, adjusting the operating frequency of the compressor according to the temperature of a coil of an indoor machine evaporator in the air conditioner; and step 3, increasing the rotation speed of an inner fan of an indoor machine, and reducing the rotation speed of an outer door of an outdoor machine. The topmost operating frequency of the compressor is reduced, the compressor is frequently lifted frequency because of high frequency under the low temperature environment to be avoided, the frequency of the compressor is adjusted according to the temperature of the coil, and an evaporator is iced so that the compressor is stopped to be avoided; and the wind speed of the inner fan is increased, the evaporator and indoor heat transfer quantity is improved, the wind speed of the outer fan is reduced, the heat transfer quantity of a condenser is reduced, the air conditioner can normally refrigerate under the low temperature environment to be realized, and the refrigerating effect is optimized.

Owner:QINGDAO HAIER JIAOZHOU AIR CONDITIONER

Frozen carbonated modulating dispensing valve and/or flavor injection

InactiveUS20080073376A1Avoid residueAvoid pollutionFrozen sweetsLiquid flow controllersEngineeringFood flavor

This invention relates to a dispenser, for preferably Frozen Carbonate Beverage (FCB) product, having valves that can be manually or electrically operated in response to electronic controls. The valve has a jam dispensing position, and can be used with an additive, such as flavors, injector. A power failure back up is provided to close the valve, along with sanitation and optional purging cycles. Product dispense is provided only when sensed to have a desired consistency and / or in a condition to prevent splashing. Additive dispense is provided only when product is present. The dispenser can have a monitor and suitable controller to dispense strips or layers of different additives or flavors into the product.

Owner:IMI CORNELIUS

Liquid-impregnated surfaces, methods of making, and devices incorporating the same

ActiveUS8574704B2Reduce viscous dragMinimizes accumulationLayered productsDe-icing equipmentsNon wettingFrost

The invention is directed to an article with a liquid-impregnated surface, the surface having a matrix of features thereupon, spaced sufficiently close to stably contain a liquid therebetween or therewithin, and preferable also a thin film thereupon. The surface provides the article with advantageous non-wetting properties. Compared to previous non-wetting surfaces, which include a gas (e.g., air) entrained within surface textures, these liquid-impregnated surfaces are resistant to impalement and frost formation, and are therefore more robust.

Owner:MASSACHUSETTS INST OF TECH

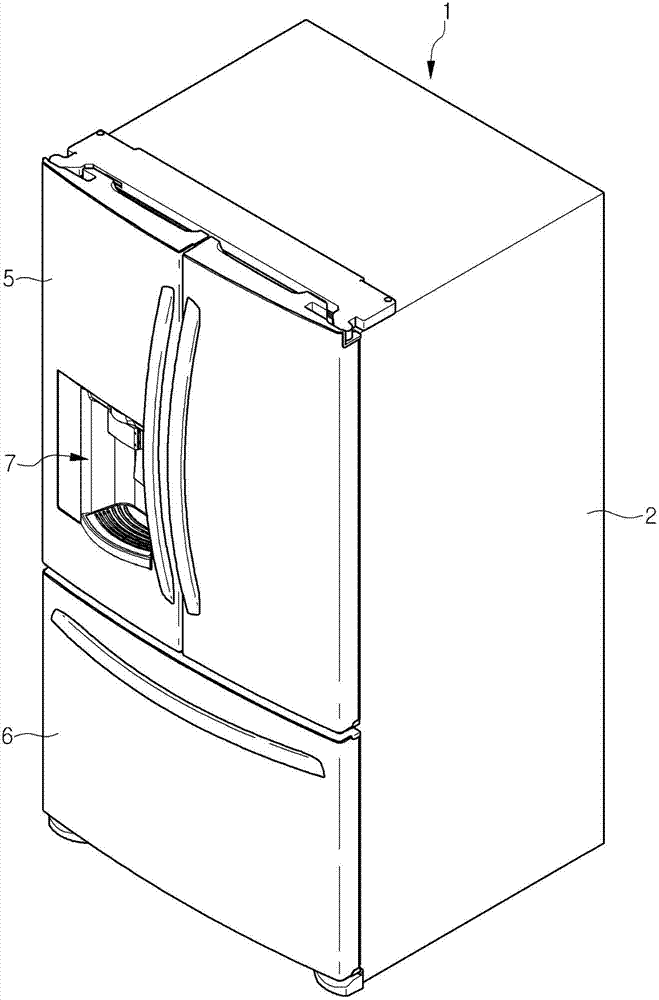

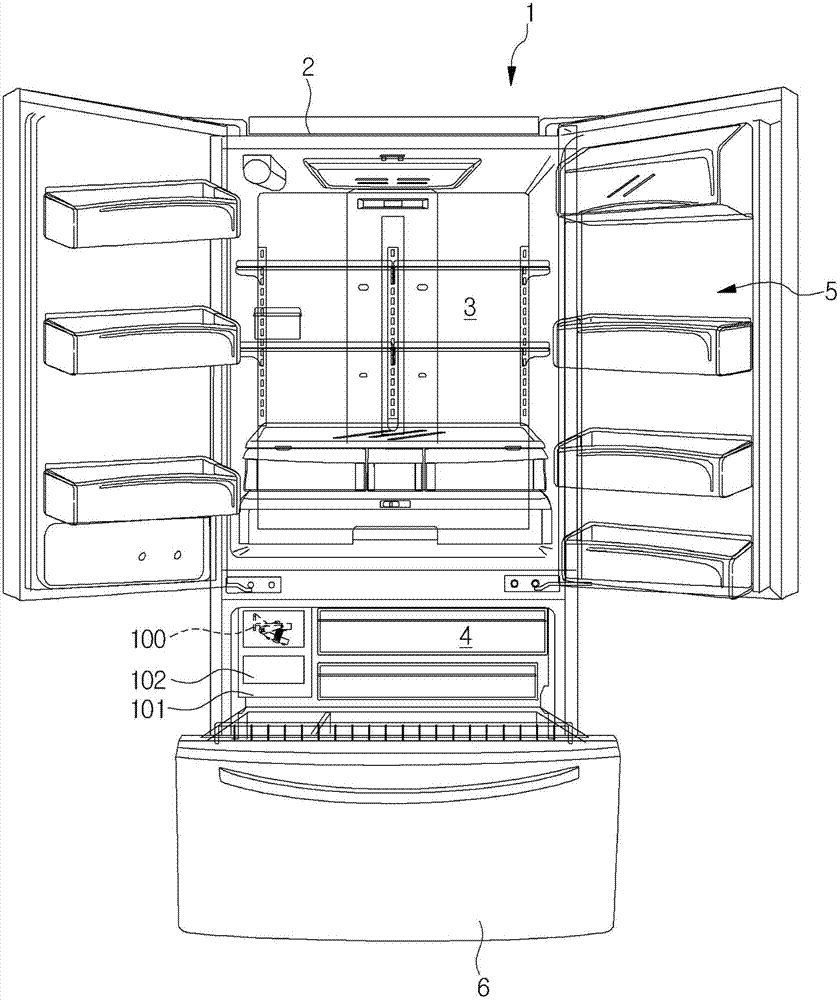

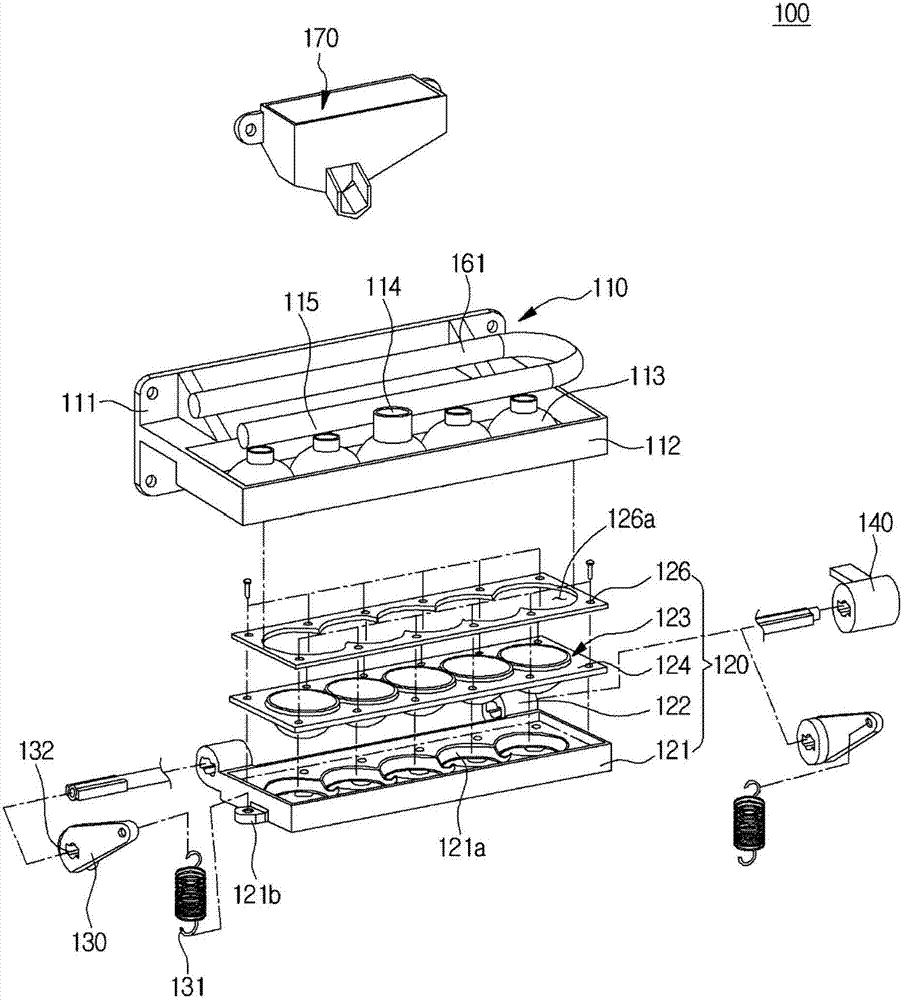

Ice maker

ActiveCN102878743APrevent freezing togetherPrevent freezingLighting and heating apparatusIce productionIcemakerWater supply

Provided is an ice maker. The ice maker includes an upper tray including a plurality of first recessed parts, each having a hemispherical shape, and a lower tray including a plurality of second recessed parts, each having a hemispherical shape. The ice maker also includes a driving unit that moves at least one of the upper tray and the lower tray to change between an attached orientation in which the upper tray is attached to the lower tray to define a plurality of spherical shells and a separated orientation in which the upper tray is separated from the lower tray. The ice maker further includes a water supply part configured to supply water into the shells and an ejecting unit disposed outside the shells and configured to facilitate separation of ice pieces made in the shells.

Owner:LG ELECTRONICS INC

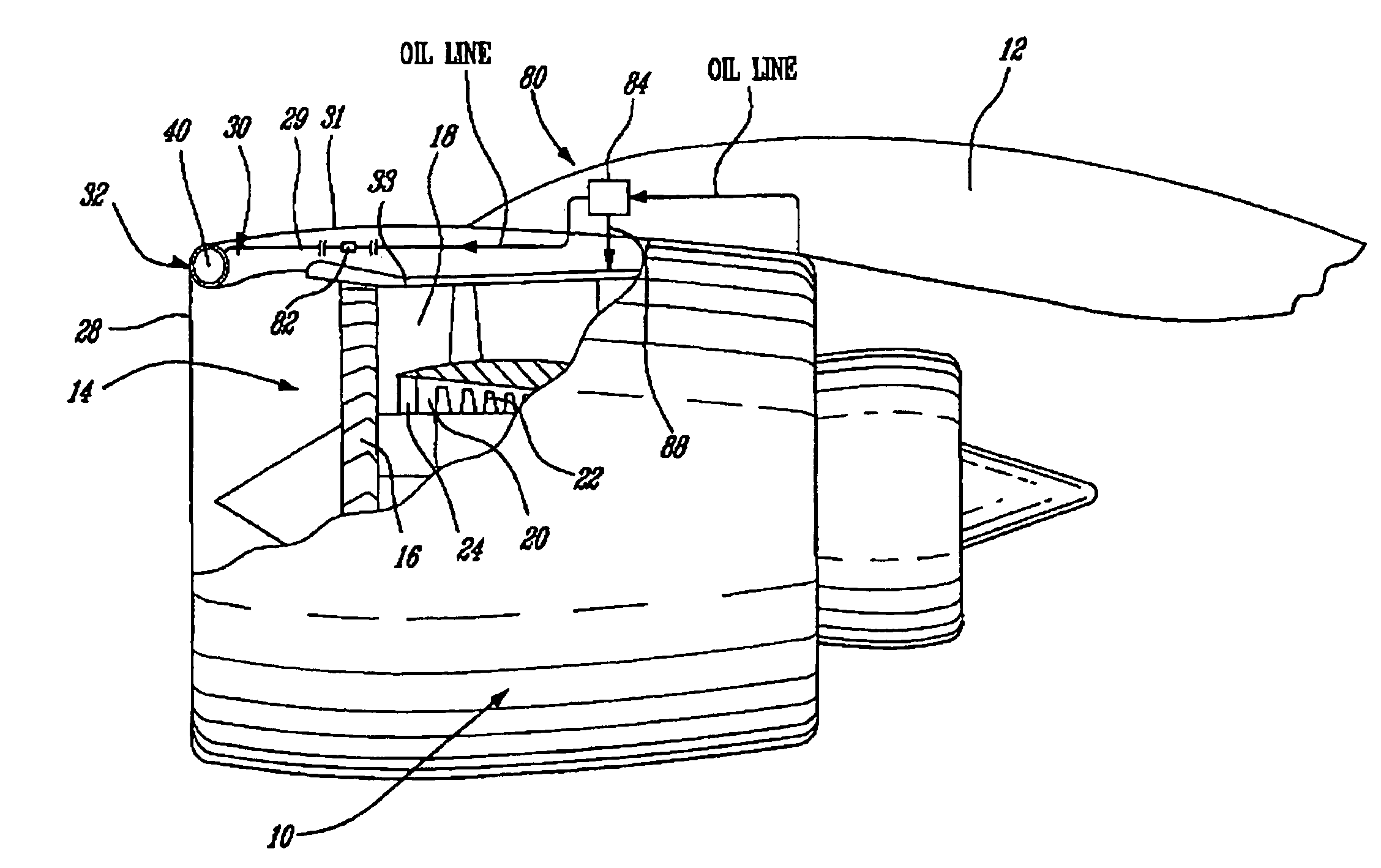

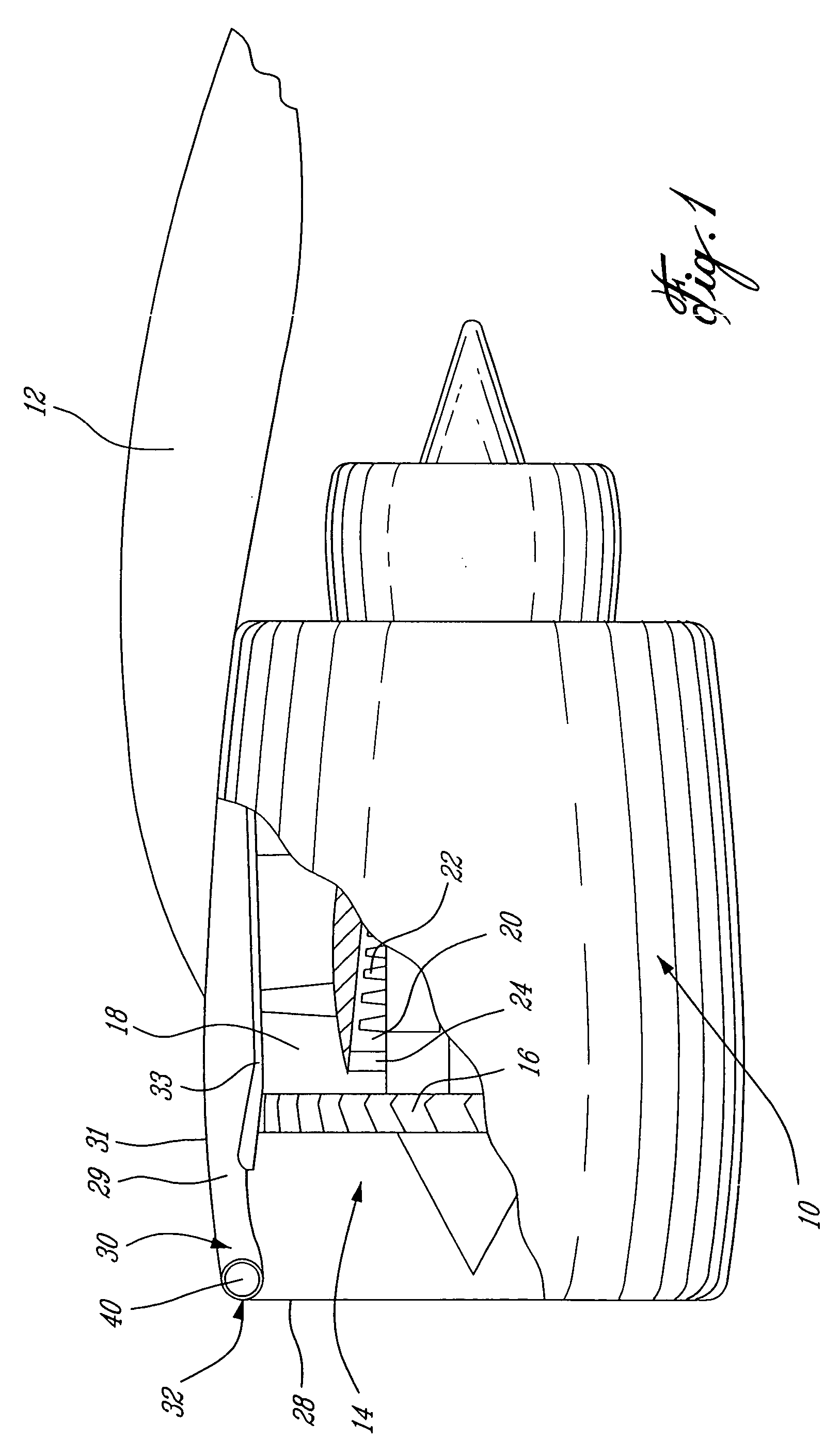

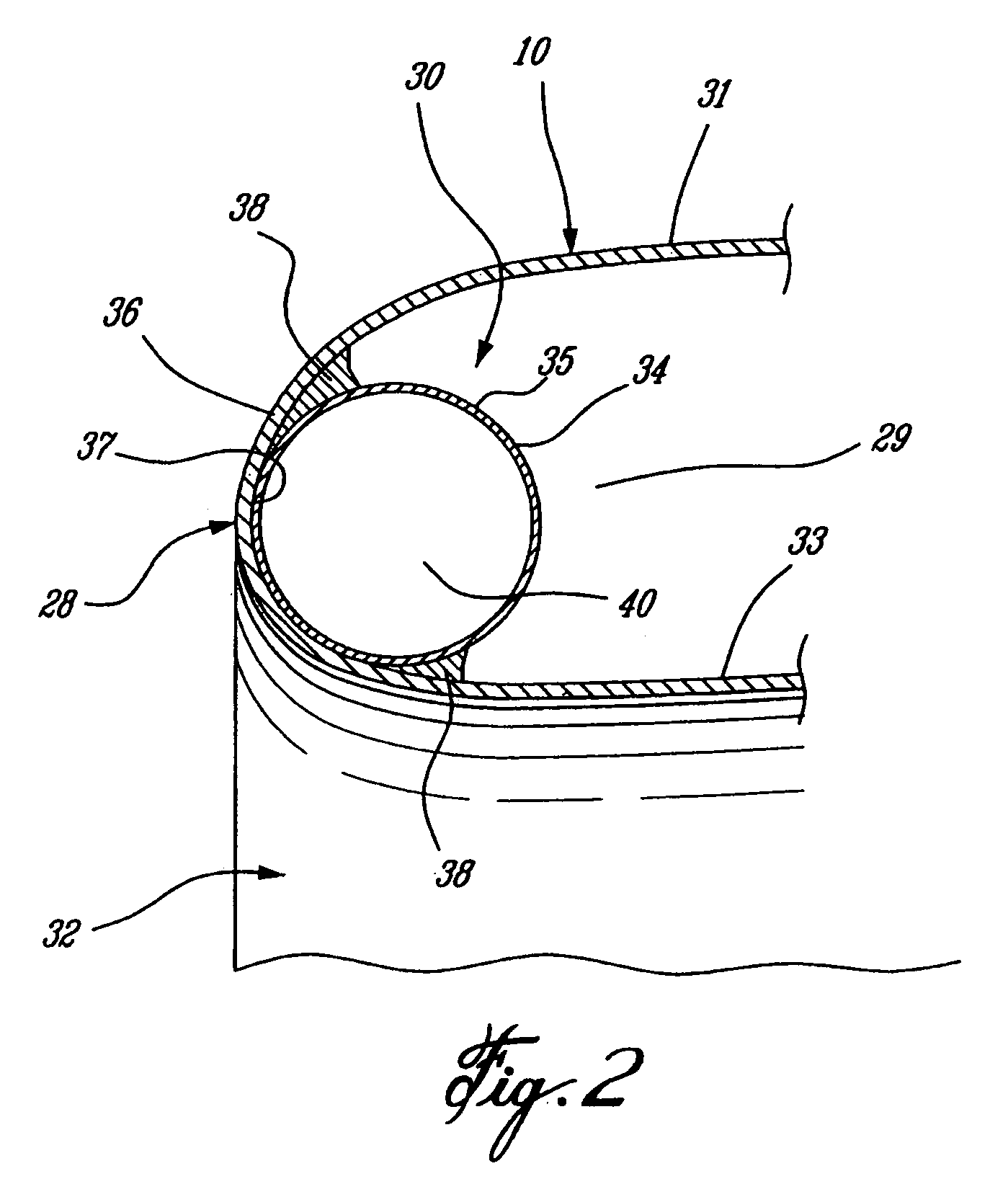

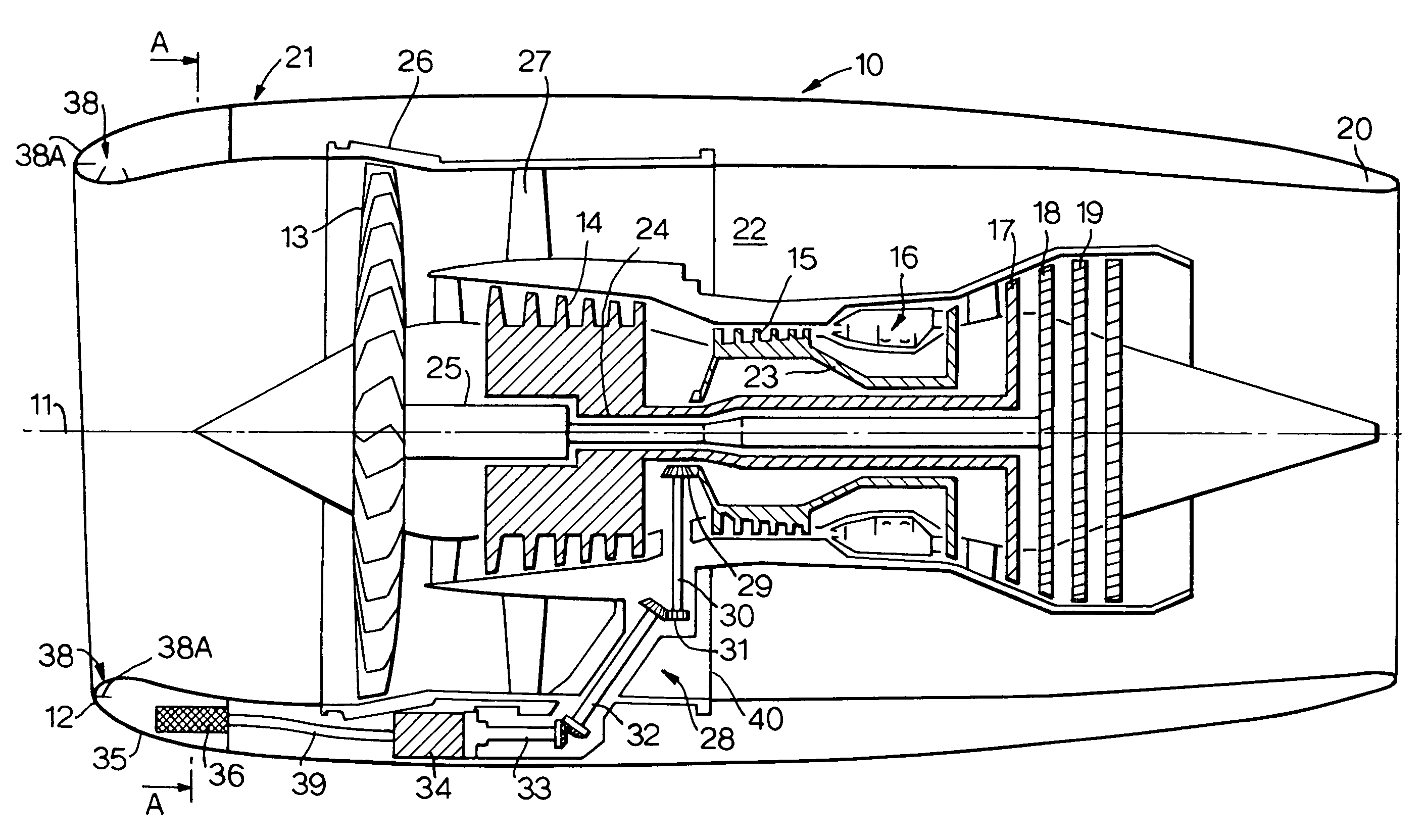

Nacelle inlet lip anti-icing with engine oil

InactiveUS7131612B2Inhibition formationPrevent freezingTurbine/propulsion engine coolingDe-icing equipmentsLeading edgeNacelle

A nacelle for housing a gas turbine engine having a pressurized oil system for lubricating components thereof comprises an inlet lip defining a leading edge of the nacelle, the inlet lip having a conduit therein in fluid flow communication with the pressurized oil system of the gas turbine engine and defining an oil passage for circulation of pressurized engine oil therethrough. The conduit is in heat transfer communication with an outer surface of the inlet lip.

Owner:PRATT & WHITNEY CANADA CORP

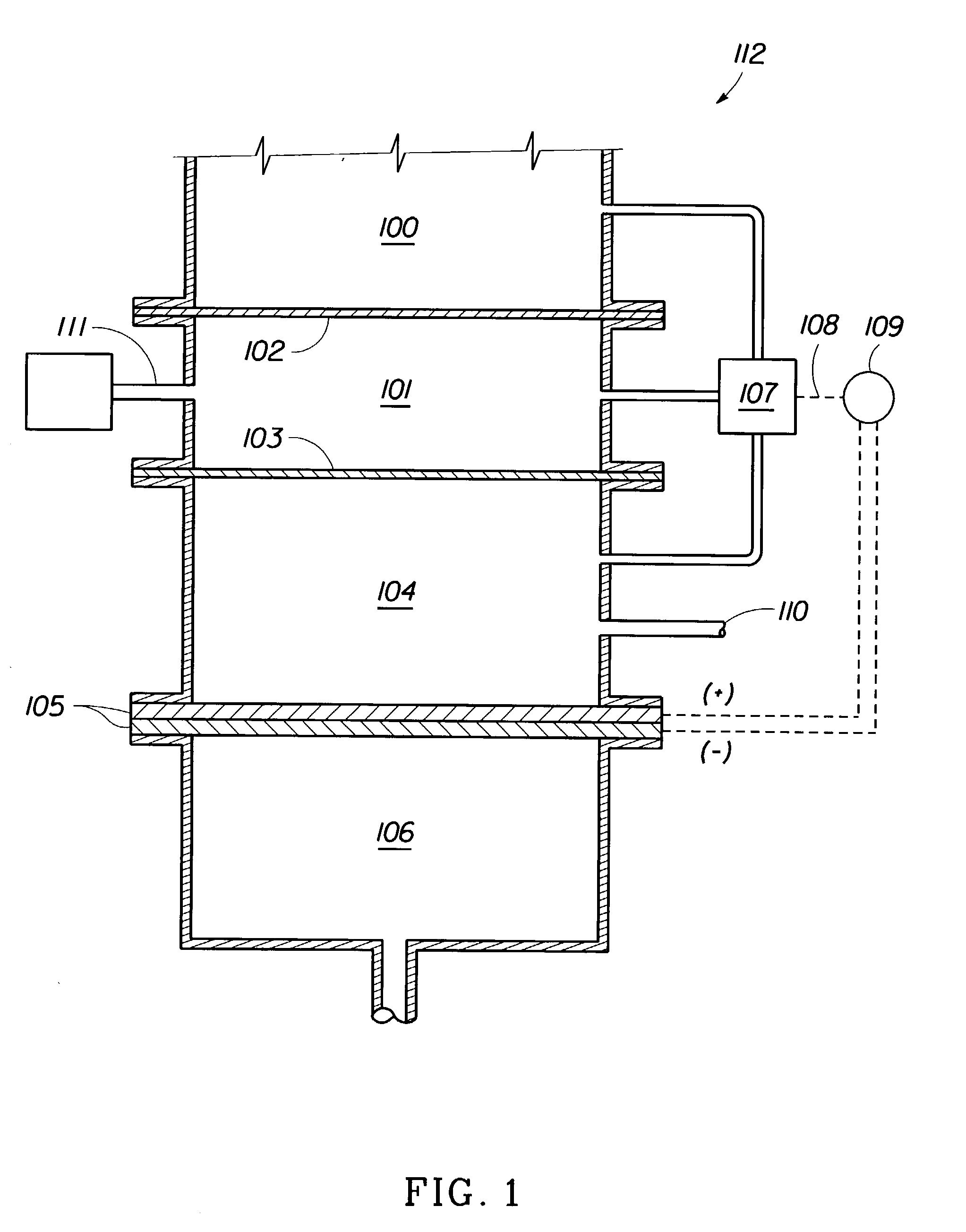

Microorganism control of point-of-use potable water sources

InactiveUS6458257B1Keep it cleanPrevent freezingCellsSpecific water treatment objectivesOzone generatorMedical equipment

The present invention provides for the electrochemical generation of ozone for use in "point-of-use" applications. The electrochemical ozone generators or systems of the present invention may be used to provide disinfected water, ozone-containing water, and / or ozone gas. Disinfected water may be produced by introducing ozone gas into a potable or purified water source for the purpose of disinfecting or controlling the microorganisms in the water source. Ozonated water or ozone gas may be produced and provided for various anti-microbial and cleansing applications of the consumer, such as washing food, clothing, dishes, countertops, toys, sinks, bathroom surfaces, and the like. Furthermore, the ozone generator may be used to deliver a stream of ozone-containing water for the purpose of commercial or residential point-of-use washing, disinfecting, and sterilizing medical instruments and medical equipment. For example, the ozone-containing water may be used directly or used as a concentrated sterilant for the washing, disinfecting, and sterilizing of medical instruments or equipment. Ozone gas may also be used in many of the foregoing examples, as well as in the deodorization of air or various other applications. The invention allows the electrochemical ozone generator to operate in a nearly or entirely passive manner with simplicity of design.

Owner:LYNNTECH INT

Environmentally benign anti-icing or deicing fluids

InactiveUS6843931B2Prevent reformationPrevent freezingOther chemical processesHeat-exchange elementsChemistryDeicing fluid

The present invention provides deicing compositions which are environmentally benign, a process for producing the composition from certain waste process streams, and methods of deicing and / or anti-icing.

Owner:MLI ASSOC

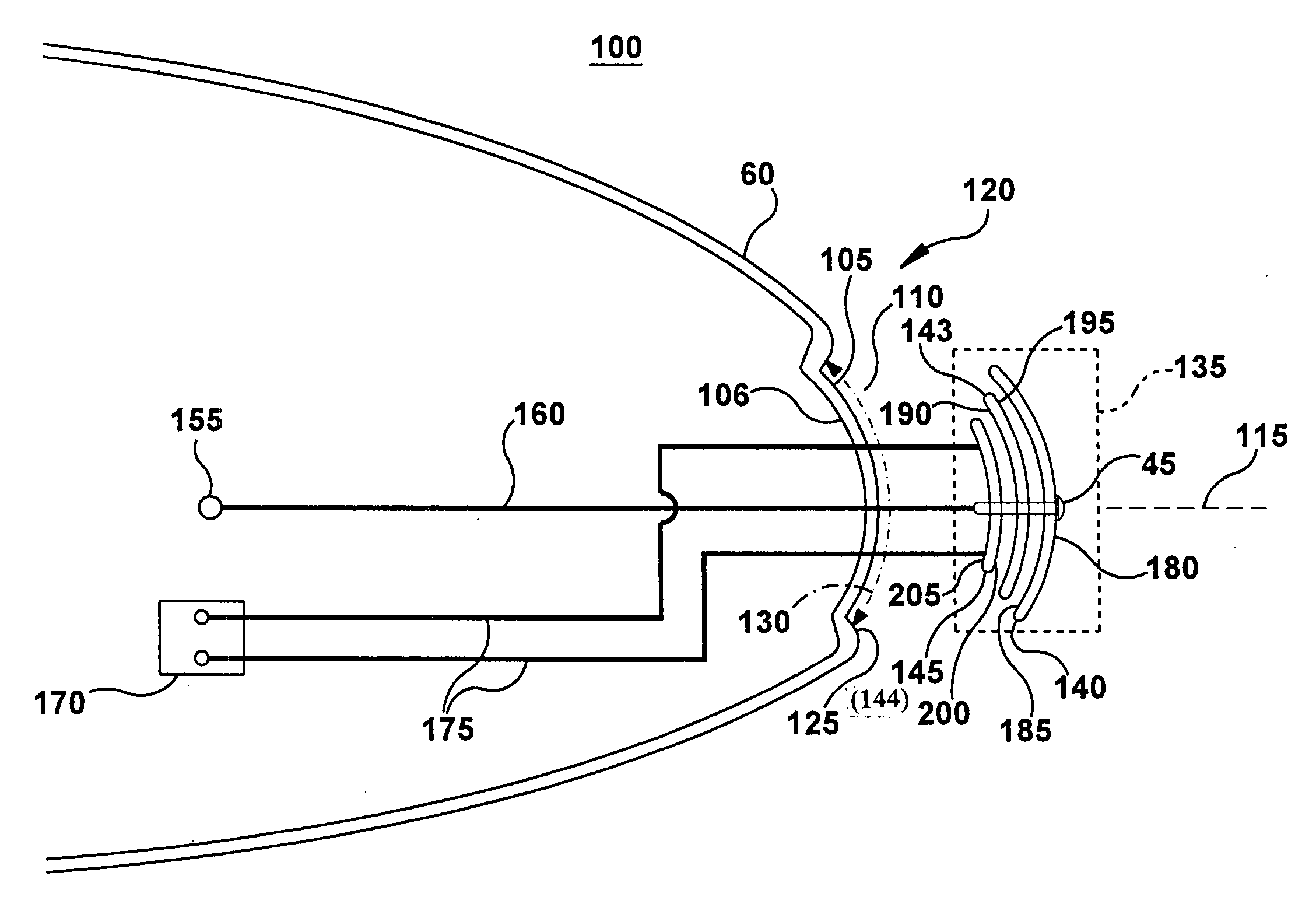

Integrated leading edge for wind turbine blade

A wind turbine blade that includes integrated erosion, lightning and icing protection for a leading edge. The leading edge includes a frontal surface with an erosion shield positioned external to the frontal surface. An internal lightning conveyance path is provided with an electrical connection from the erosion shield to the internal lightning conveyance path. A heat-generating element is positioned between the erosion shield and the frontal surface and a heat conduction path is provided from the heat-generating element to the erosion shield. Further, a structure is provided for connecting the heat-generating element to an energy source within the blade.

Owner:GENERAL ELECTRIC CO

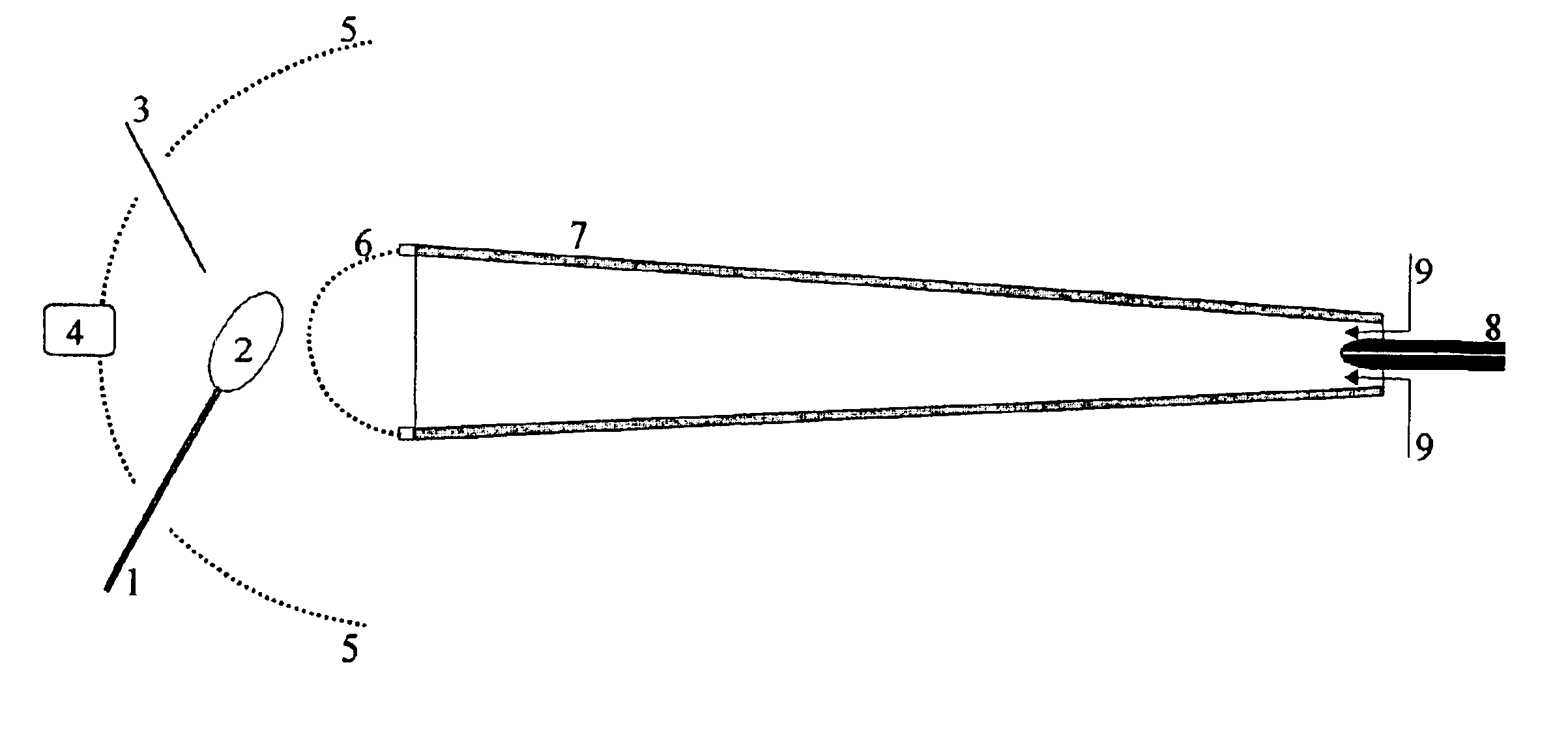

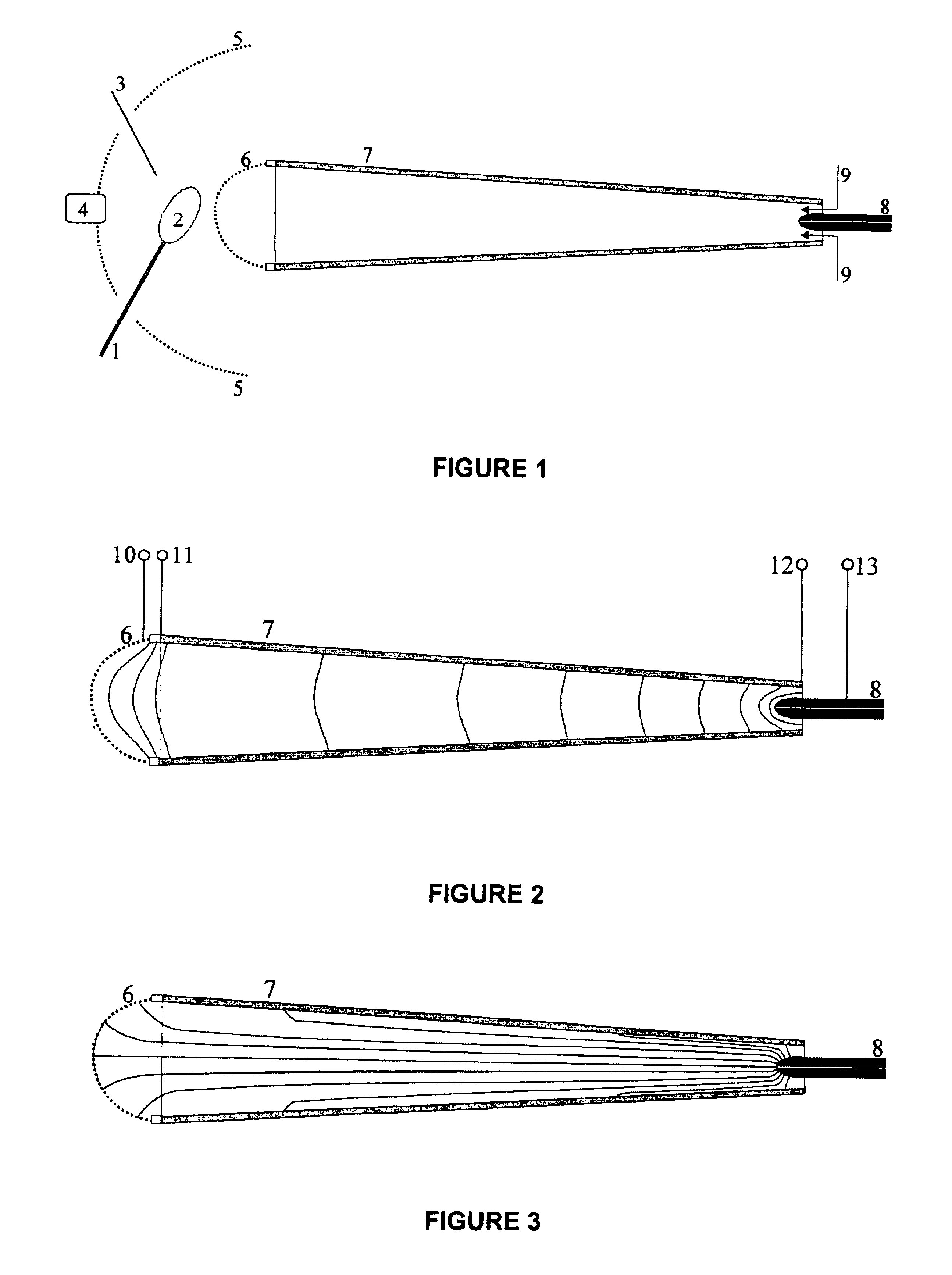

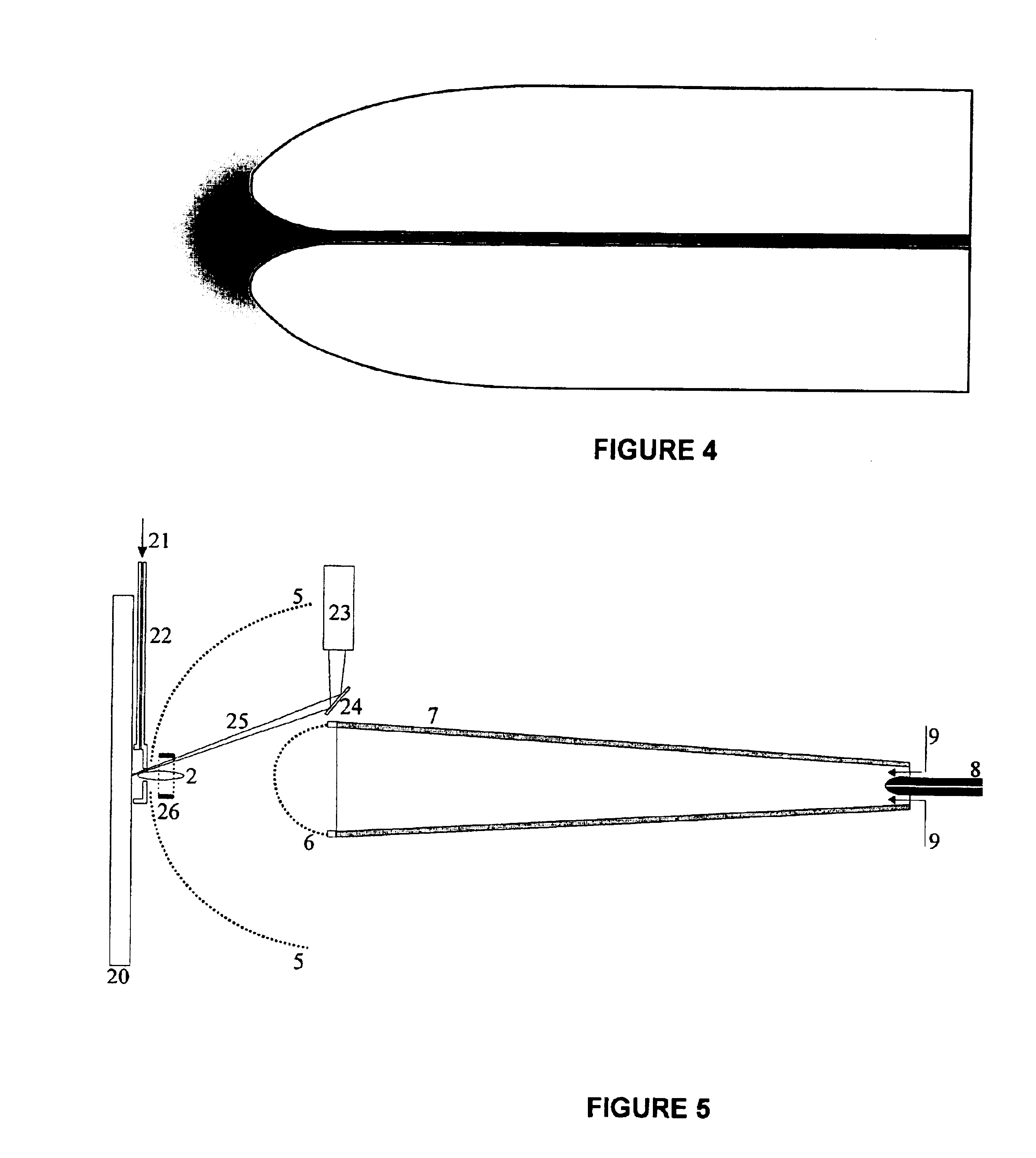

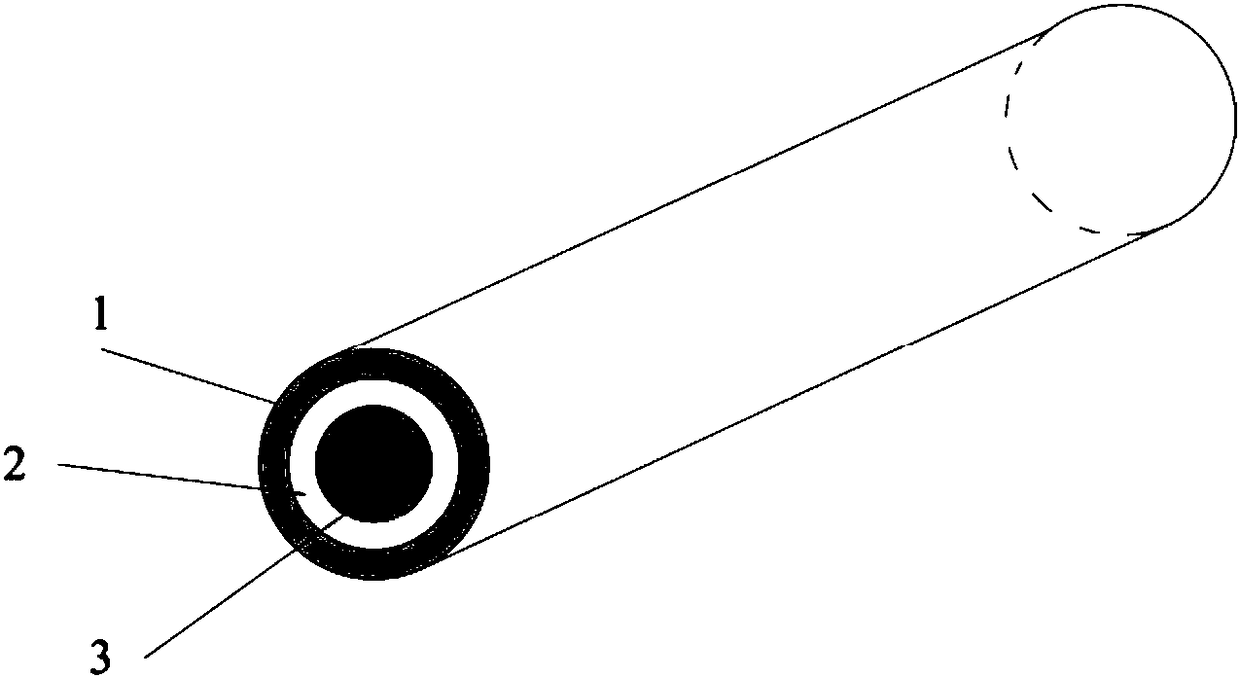

Ionization at atmospheric pressure for mass spectrometric analyses

InactiveUS6949739B2Avoid reactionPromote droplet evaporationSamples introduction/extractionIon sources/gunsAnalyteMass analyzer

The invention relates to the feeding of analyte ions, generated at atmospheric pressure, efficiently into the mass spectrometer. The invention provides a lengthy ion mobility drift tube with a focusing electric field inside to guide the ions from an ionization cloud generated at atmospheric pressure towards the entrance opening of the mass spectrometer, and to dry droplets which might occur in the ionization cloud by a hot drying gas flowing through the ion mobility drift tube towards the ionization cloud.

Owner:BRUKER DALTONIK GMBH & CO KG

Self-made heat conductor and heating equipment into which insulating heat conduction material is embedded and implementation method of self-made heat conductor and heating equipment

PendingCN108366442AHeating evenlyLow costOverhead installationHeating element shapesElectrical conductorEngineering

Owner:SICHUAN UNIV +1

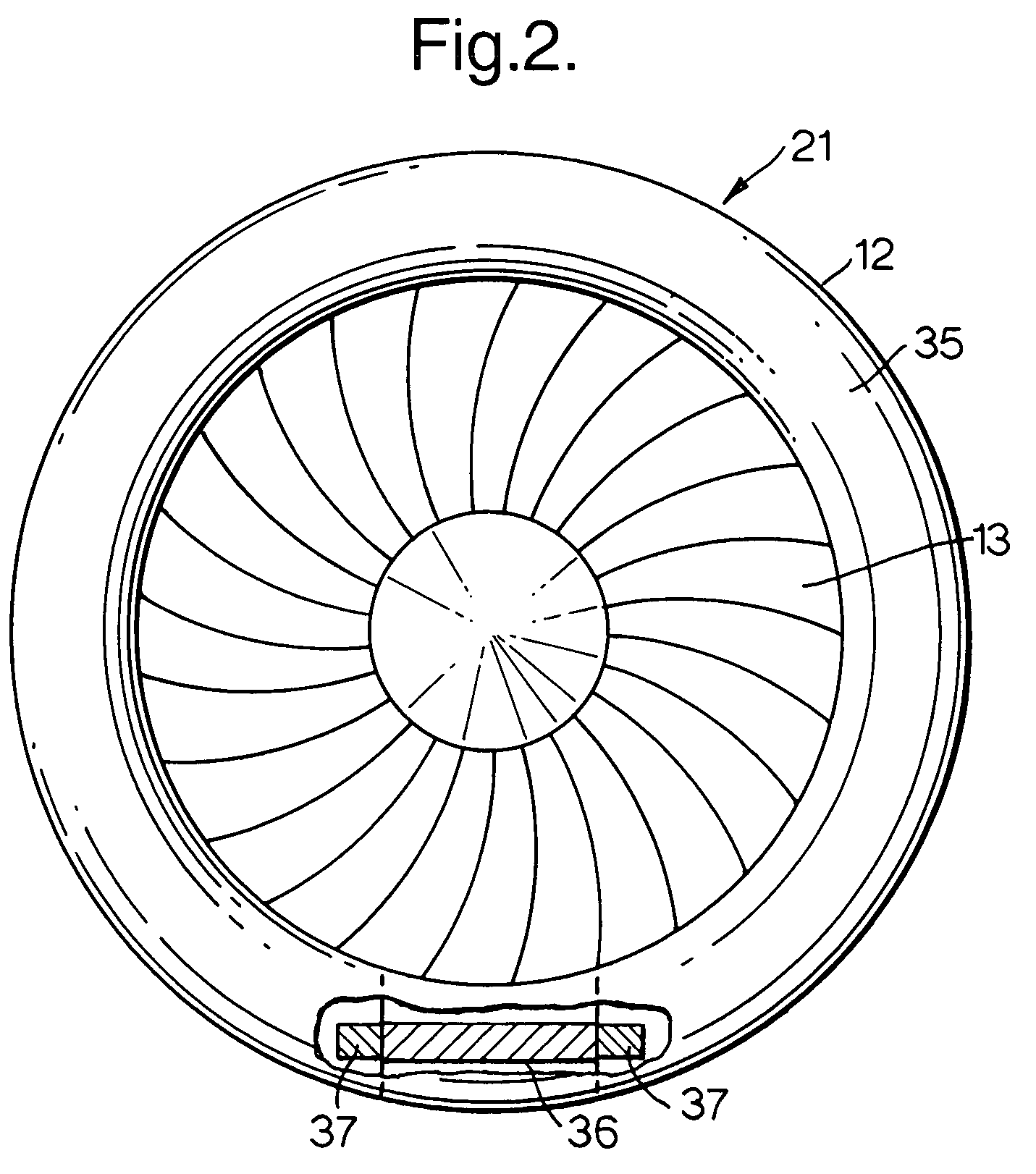

Aeroengine intake having a heat exchanger within an annular closed chamber

InactiveUS7398641B2Prevent freezingIncrease surface areaTurbine/propulsion engine coolingDe-icing equipmentsAviationNacelle

A gas turbine engine comprising a nacelle having an intake, the intake defining a generally annular chamber, an engine accessory and a heat exchanger for cooling a fluid of the accessory. The chamber is closed and the heat exchanger is disposed within the chamber operable to provide heat to prevent ice forming on the intake during engine operation.

Owner:ROLLS ROYCE PLC

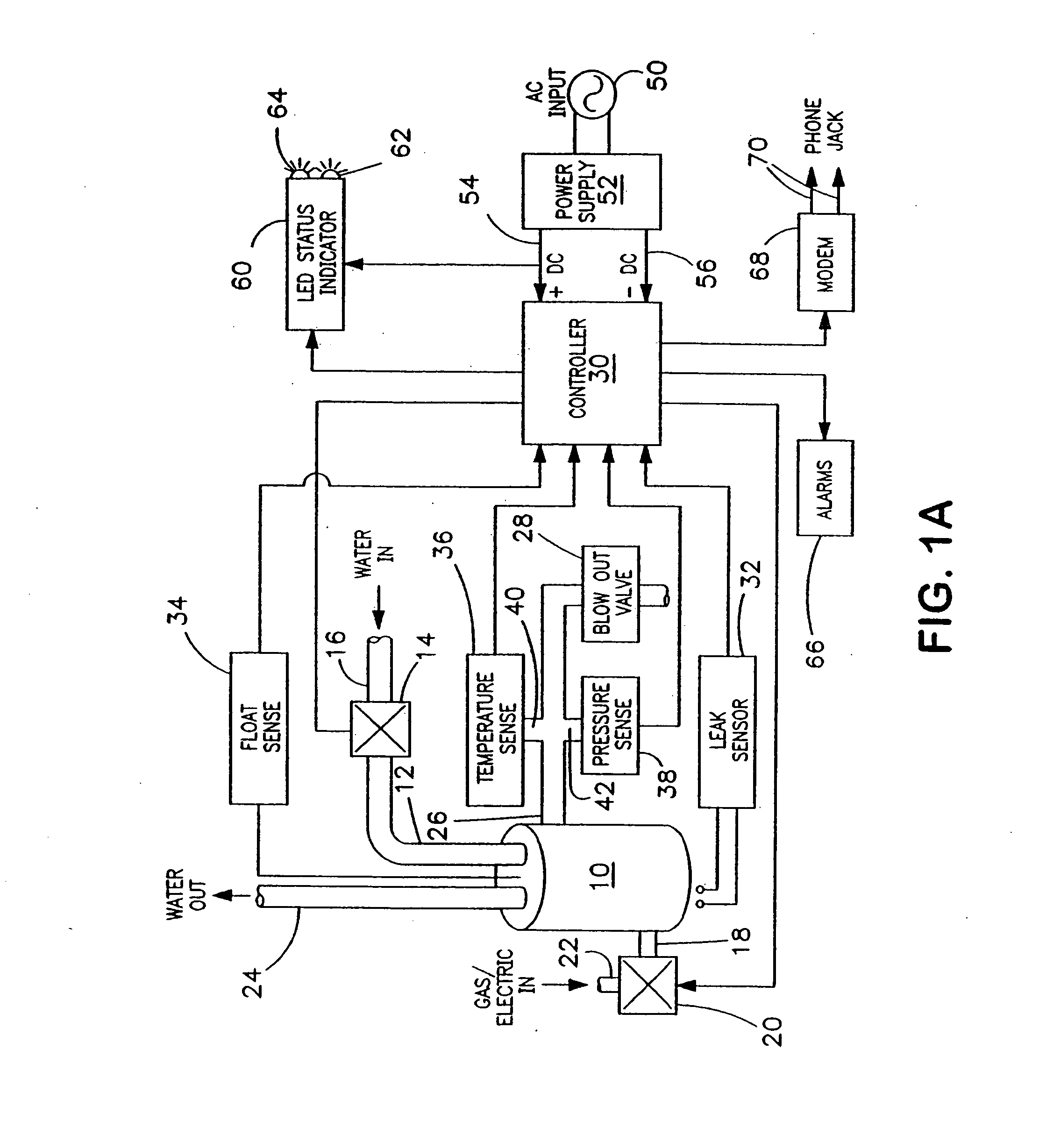

Systems and methods for monitoring and controlling fluid consumption

InactiveUS20060272704A1Save energyReduce energy costsLiquid fillingGeneral water supply conservationFluid controlControl signal

Systems and methods for monitoring and controlling fluid consumption in a fluid-supply system are disclosed using one or more sensors for generating signals indicative of the operation thereof. In one embodiment, a method of controlling gas flow in a conduit of a natural gas supply system comprises sensing a gas flow parameter related to the natural gas supply system; and if the sensed parameter satisfies a predetermined condition, sending, to at least one fluid control device interfaced with a conduit of the natural gas supply system, at least one control signal to impede a flow of gas through the conduit.

Owner:FIMA R GIOVANNI

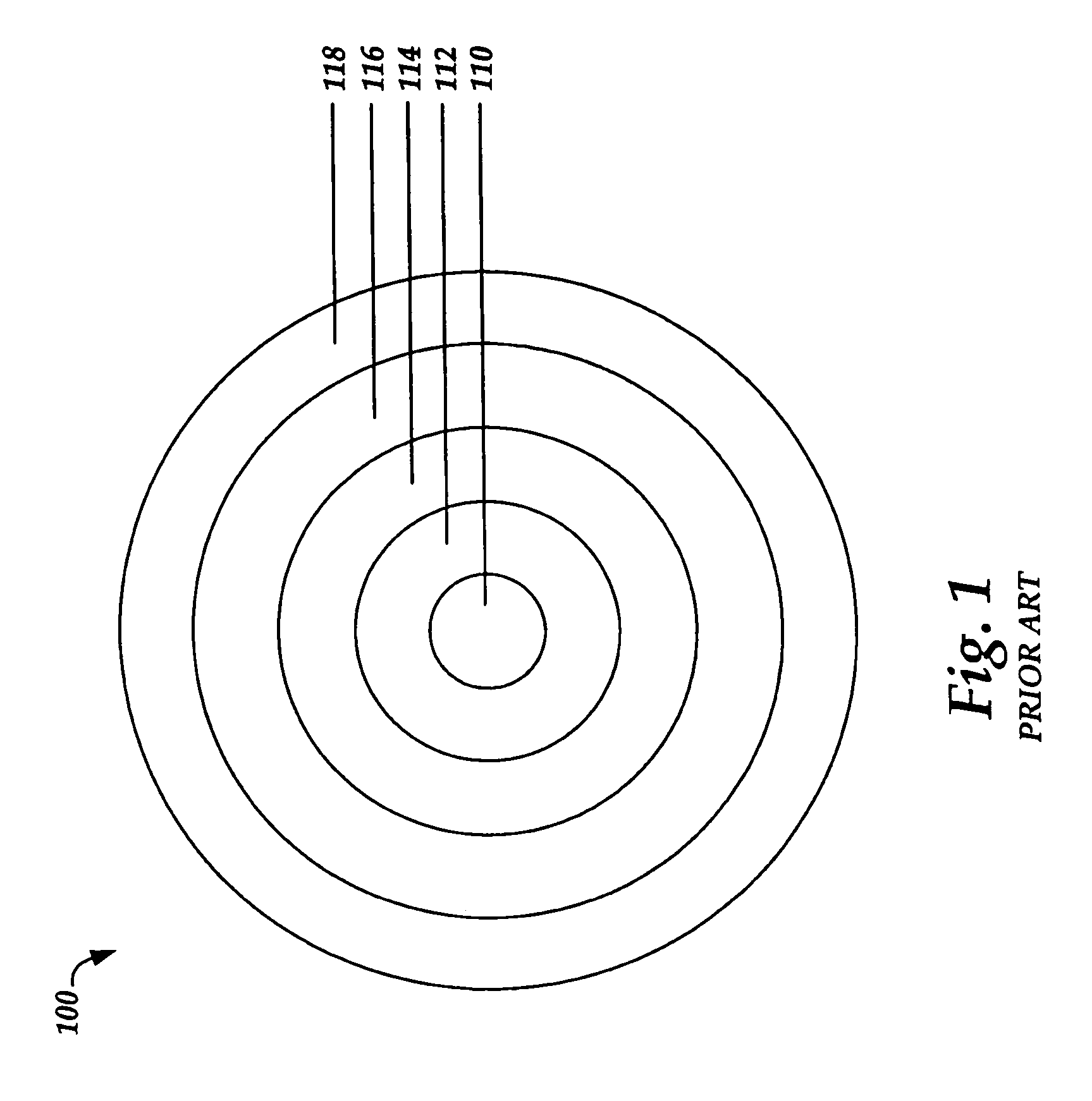

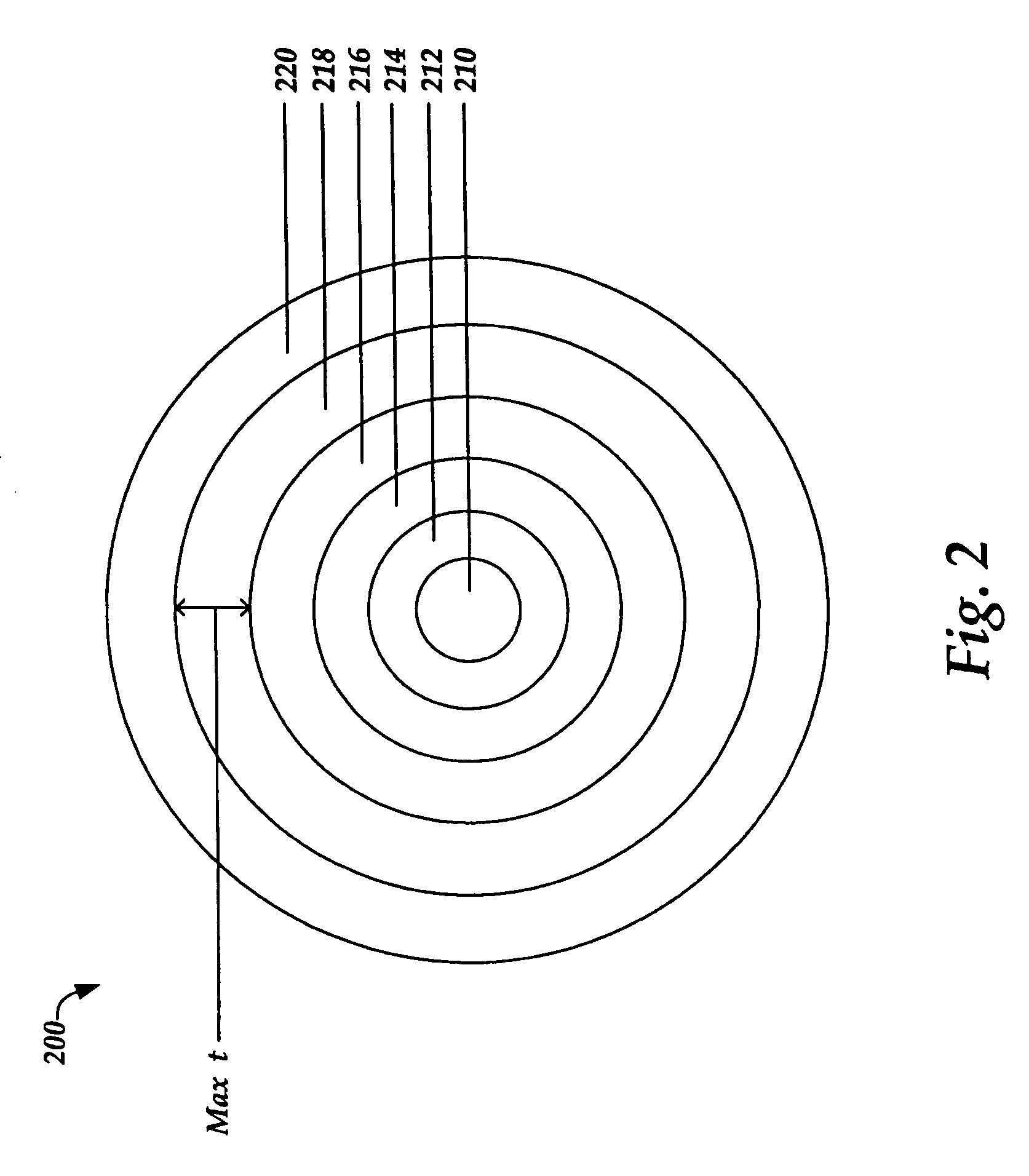

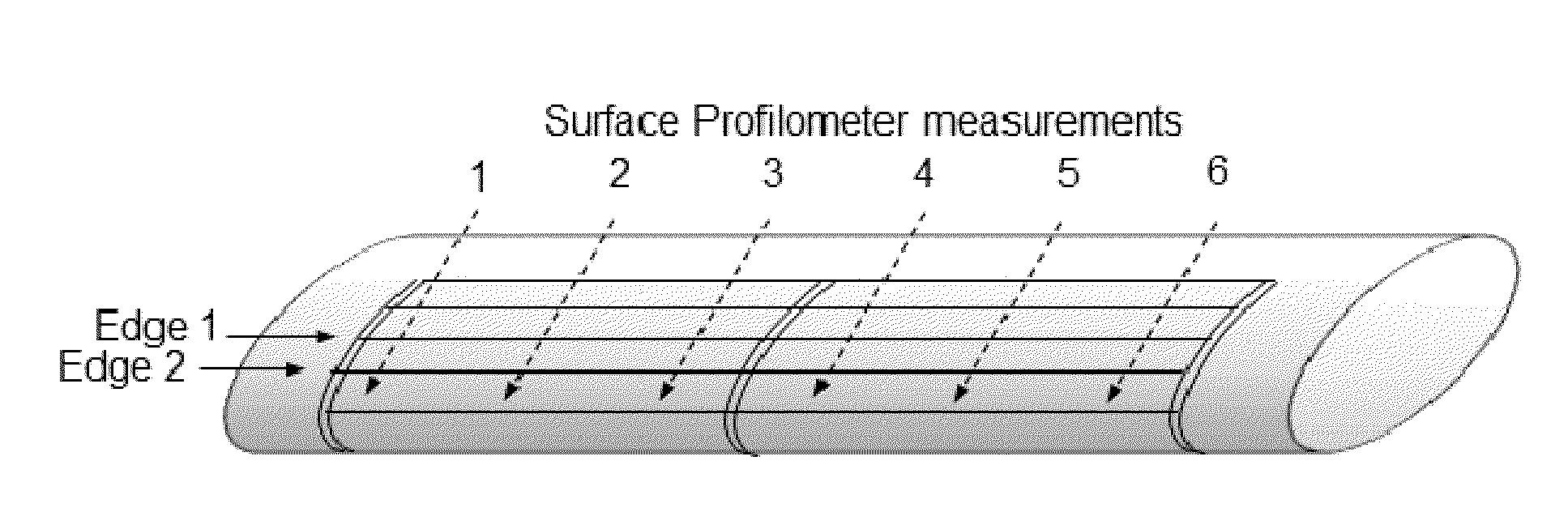

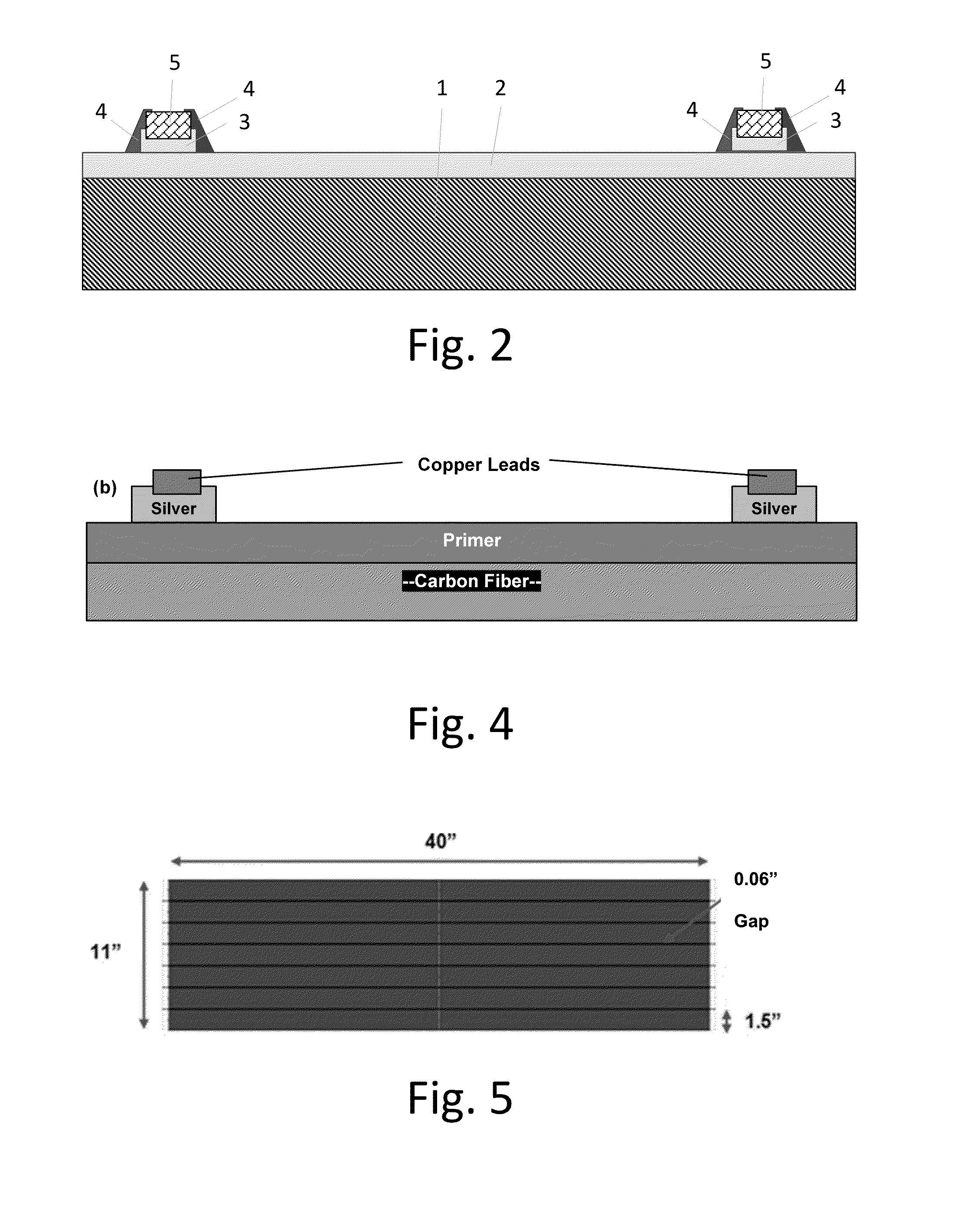

Uniform Heat Distribution in Resistive Heaters For Anti-Icing and De-Icing

ActiveUS20160221680A1Prevent freezingImprove protectionWindingsDe-icing equipmentsElectrical resistance and conductanceAdhesive

The concept of the present invention describes configurations to provide uniform heat distribution of resistive heaters. This configuration allows successful anti-icing and deicing with relatively low applied power. One aspect involves the use of a thin film heater applied just underneath the topcoat to efficiently direct all heat to the surface, allowing anti-icing and de-icing with minimal power. This can be accomplished by employing a hybrid electrode interface, using a metal foil or metal braid that is attached to the aircraft surface with a structural adhesive that has been smoothed along the edges with metal-filled adhesive. Another aspect of the present invention uses an array of heater cells created as a single sheet and a heat spreading material, provided underneath or overtop of the heater cells.

Owner:BATTELLE MEMORIAL INST

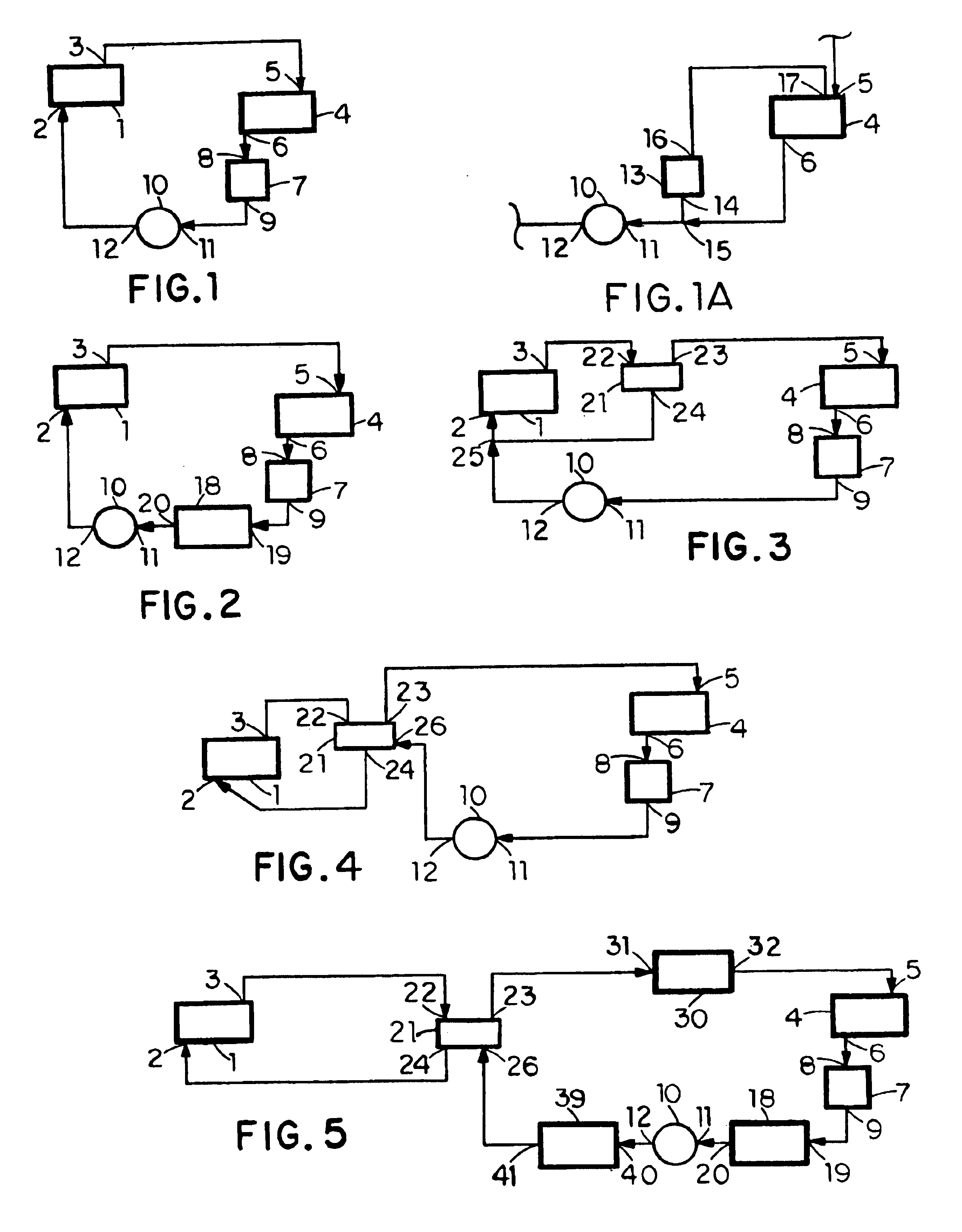

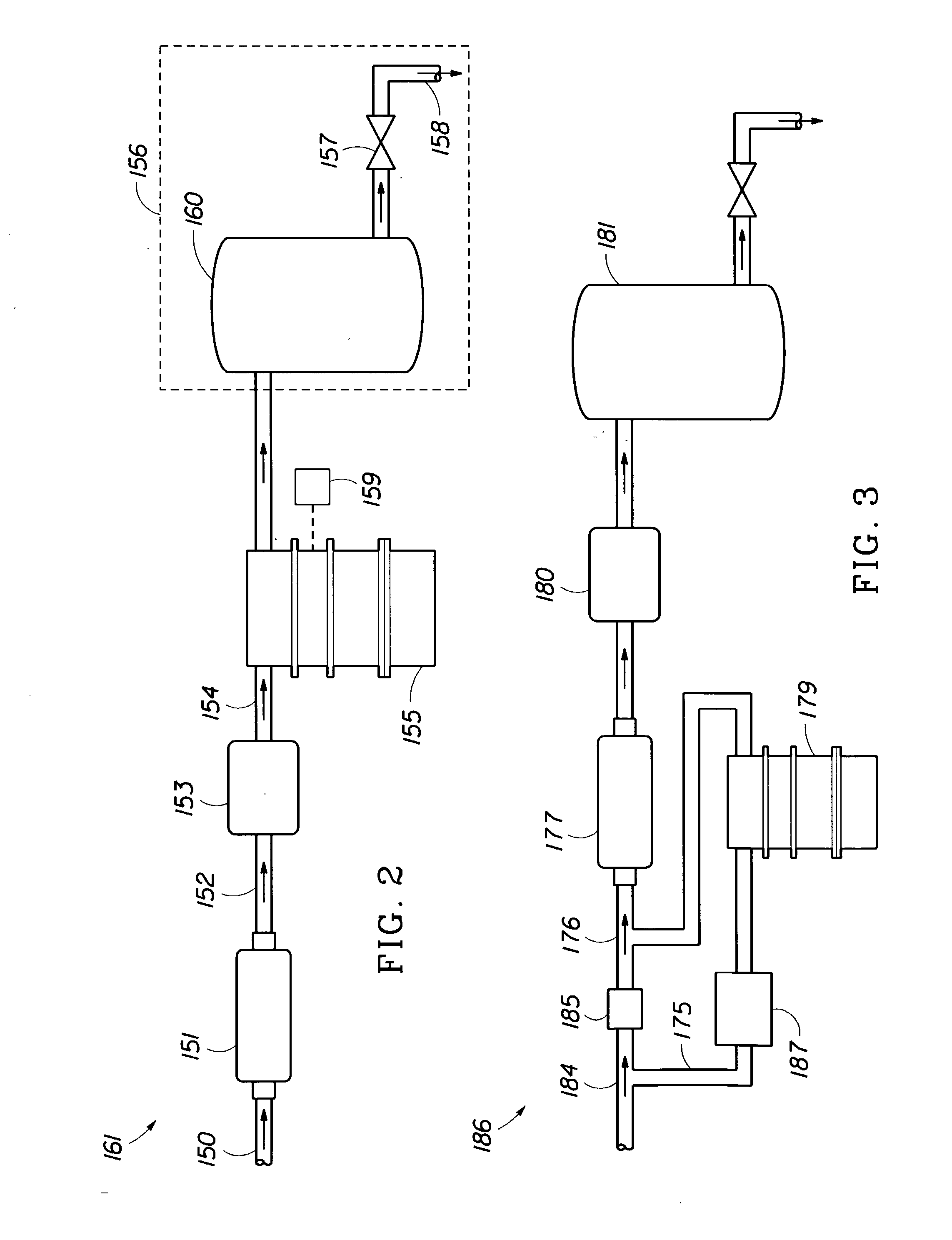

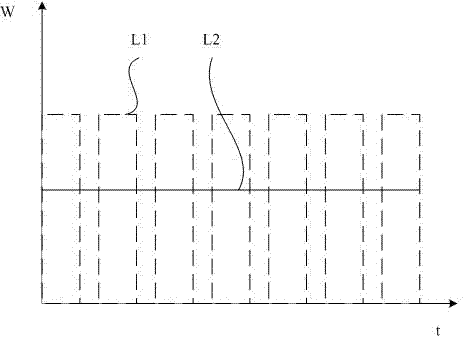

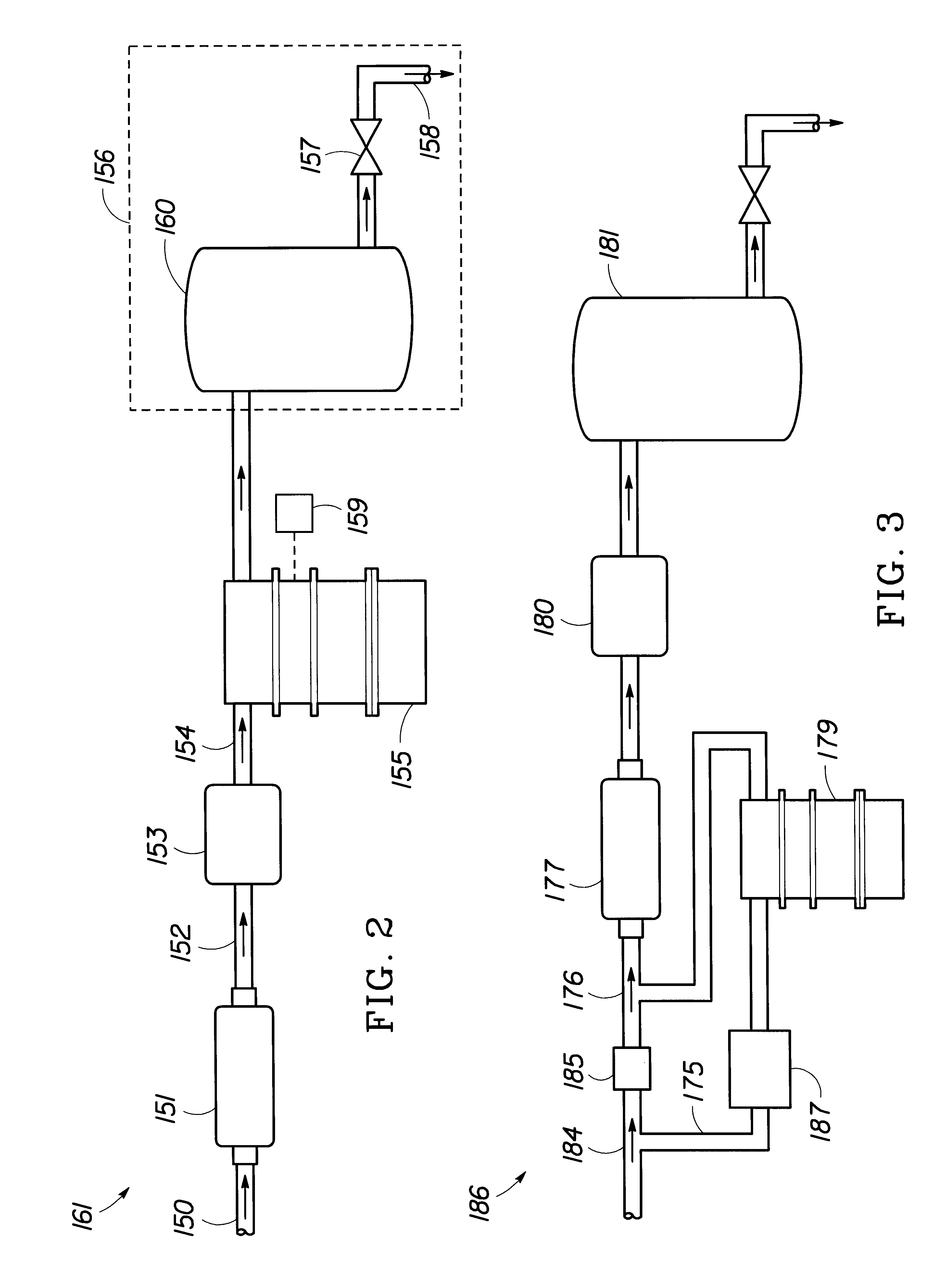

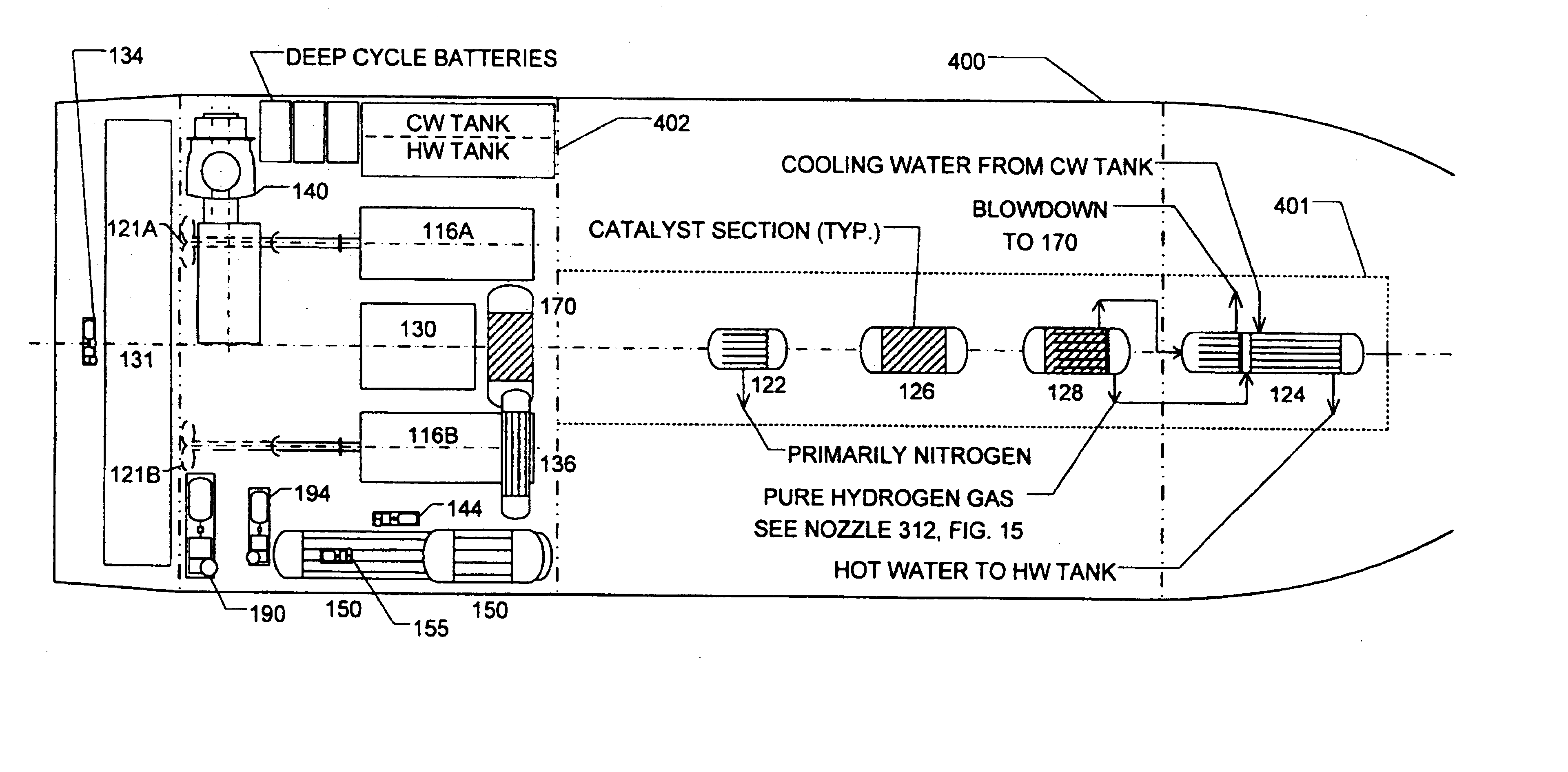

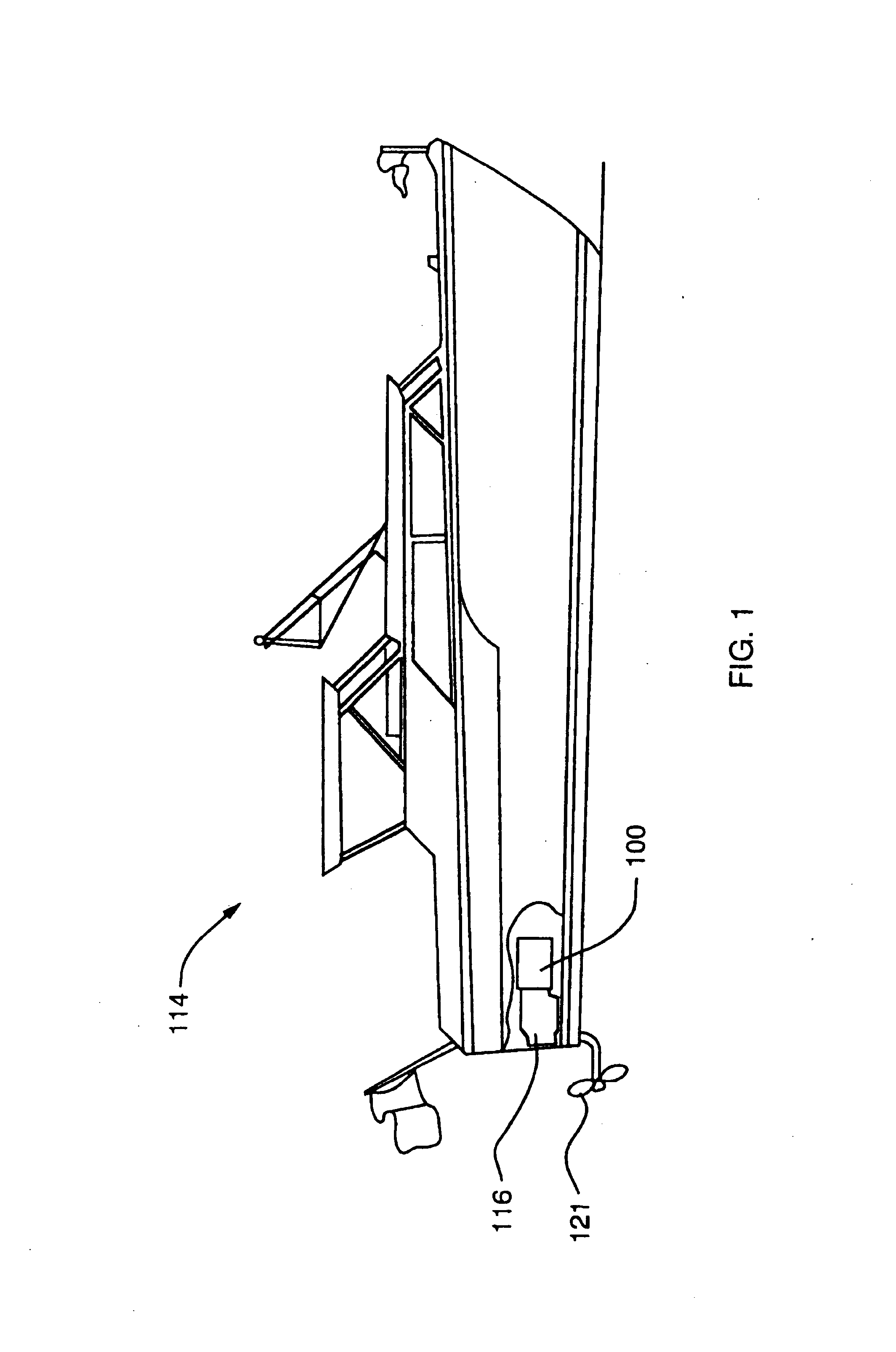

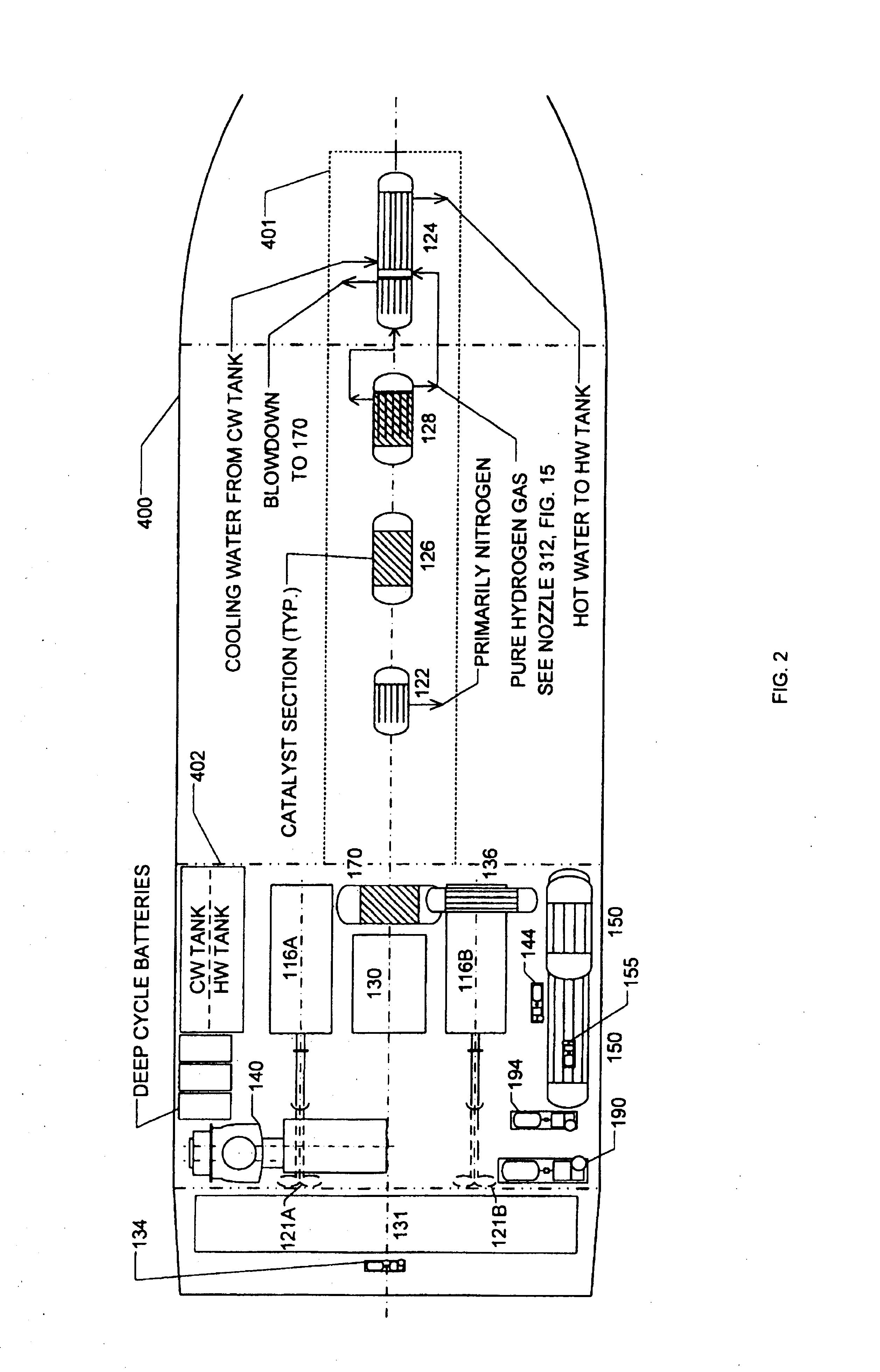

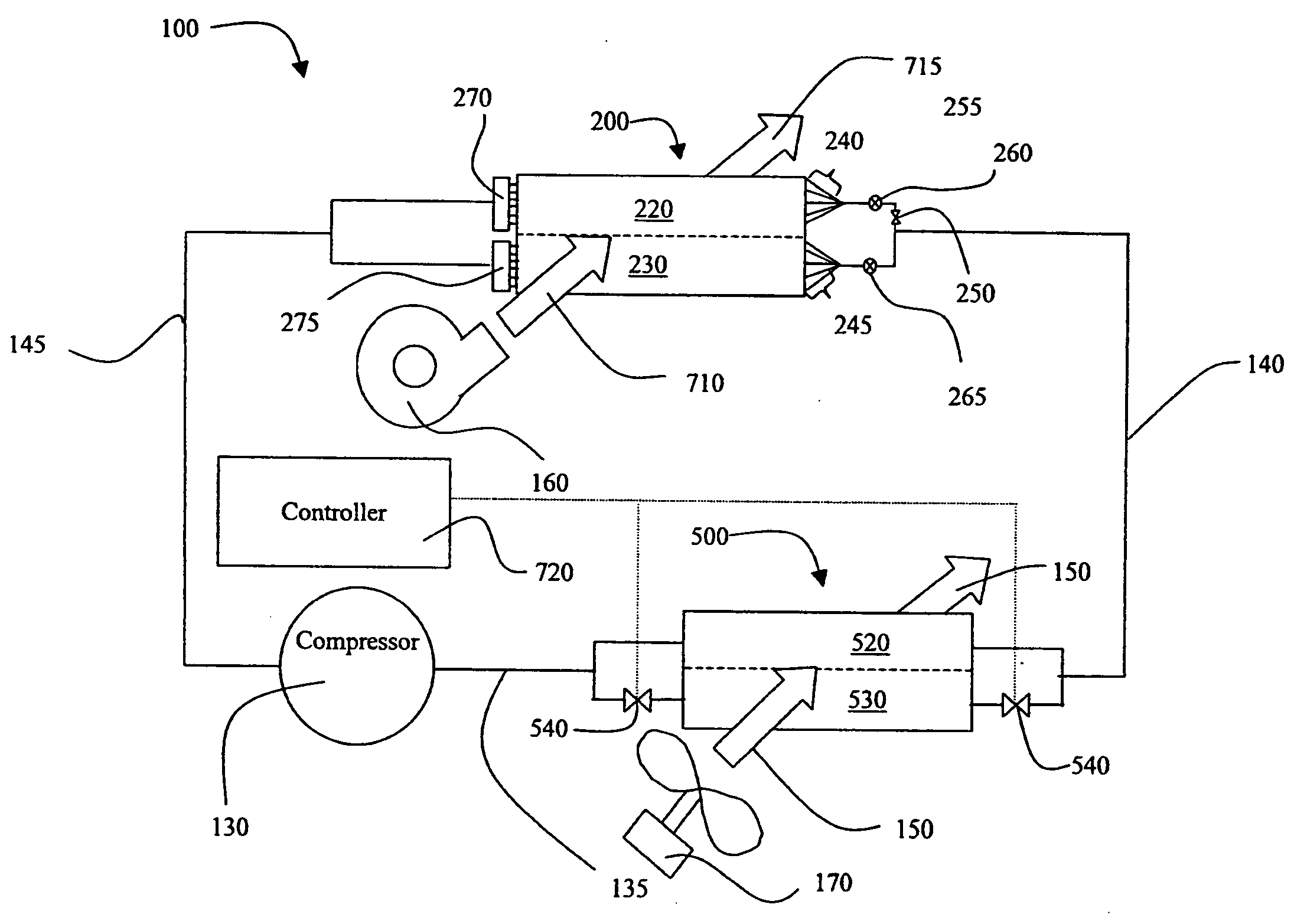

Fuel cell system with integrated fuel processor

InactiveUS20070122667A1MinimizesMaximize heat utilizationHydrogenOxygen/ozone/oxide/hydroxideBiodieselWater balance

A fuel cell system with fuel processor for integration with a marine vessel propulsion system. The system includes an auto thermal reactor that is the fuel processor for producing hydrogen from a fuel source. The fuel source is preferably ethanol or biodiesel or a mixture thereof, but can also be a sulfur containing fuel like petrodiesel of JP-8. The system further includes a gas-water shift reactor for further production and concentration of the hydrogen from the auto thermal reactor output. The system also includes a hydrogen permeable membrane separator for generating suitable quantities of essentially pure hydrogen to the fuel cell. The system also includes an oxygen permeable membrane separator for concentrating oxygen and reducing nitrogen to improve the partial pressure of hydrogen in subsequent fuel processing steps. The system contemplates the use of a Polymer Electrolyte Membrane (PEM) fuel cell. The system minimizes preheating of catalysts or other components to the extent just needed to initiate the fuel processor. To that end, heat sources and sinks of the system and associated usage systems are matched so as to minimize heat collection, storage and distribution systems. Water is recycled within the system to the extent necessary to maintain a water balance in the fuel processor and the fuel cell stack(s). The system includes cooling of the fuel cell stack(s) and integrated heat recovery with exothermic and endothermic catalysts. The fuel processor / fuel cell system components are configured to conform to and take advantage of the available space and limitations, such as the space constraints and opportunities associated with a marine vessel.

Owner:KELLEY RICHARD H

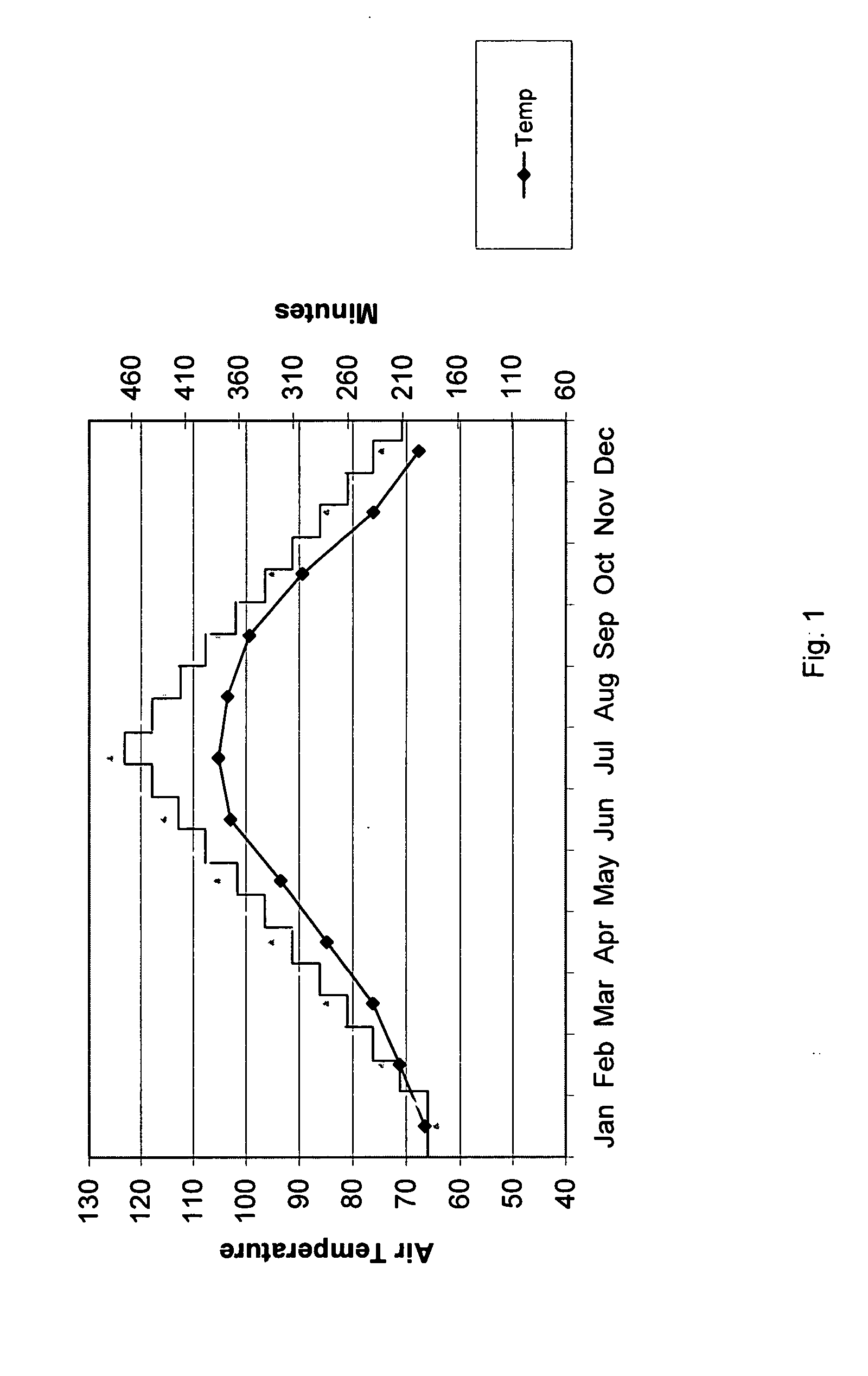

Electronic control for pool pump

An electronic pool pump timer that controls the run time of the pump for a period of time each day depending on the date. In the preferred embodiment, the user enters the historical daily maximum and minimum pump run times for the specific pool and the system calculates the required time the pump will run on a given day. The customized run time is thus calculated as a function of the date and the minimum and maximum run times for a given pool. The system then self-adjusts the run time each day as necessary. The device comprises a data input means, a display, memory, and a controller. It may also include a manual override to allow the user to turn the pump on at any time. The device is connected to the pump motor. The device is connected to a power supply and may also include a battery back-up in the event of a power outage. To prevent the pool from freezing, the system may also include an air temperature sensor that triggers pump operation when the ambient air is below a given temperature.

Owner:ALLEN STEPHEN D

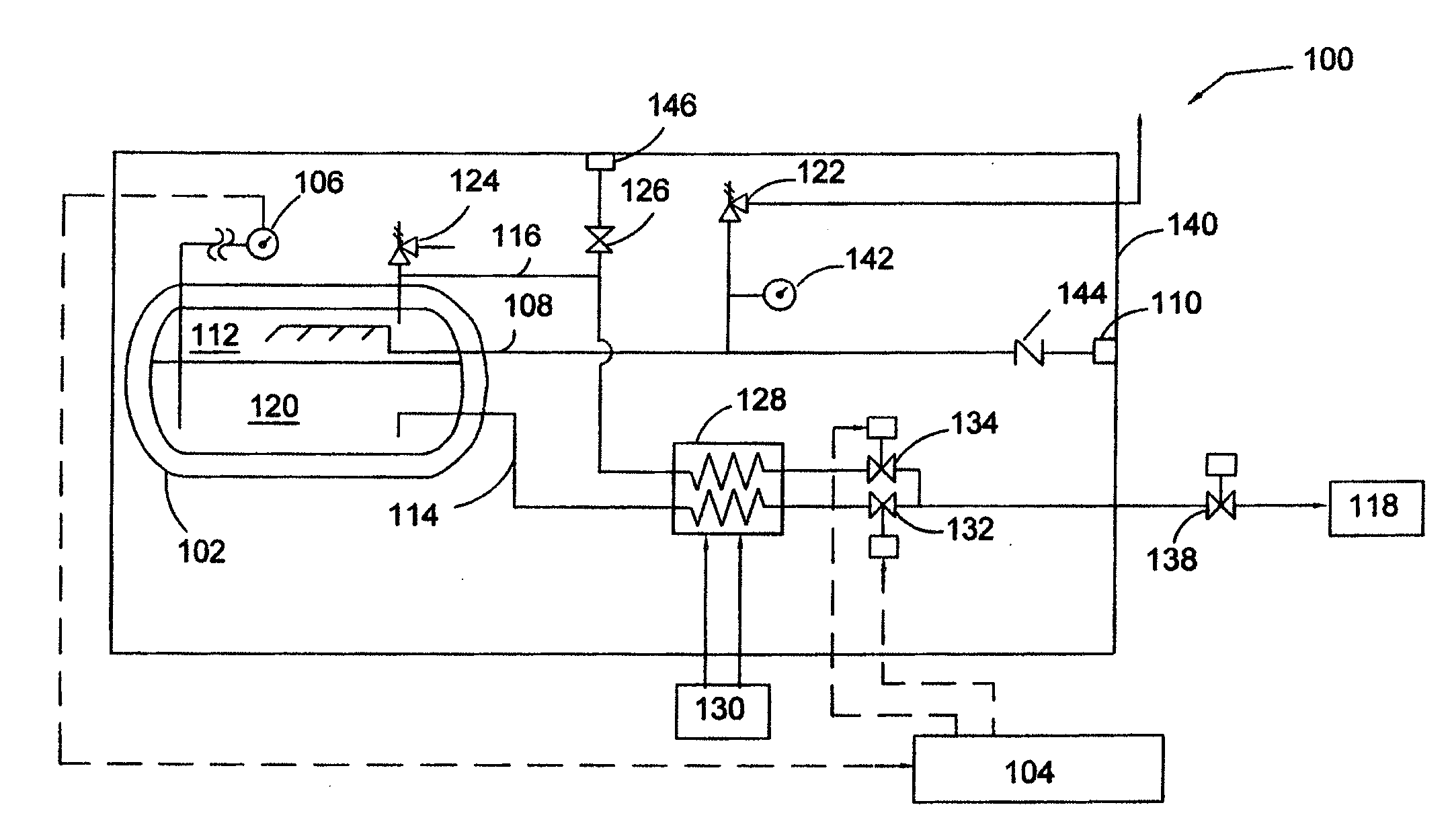

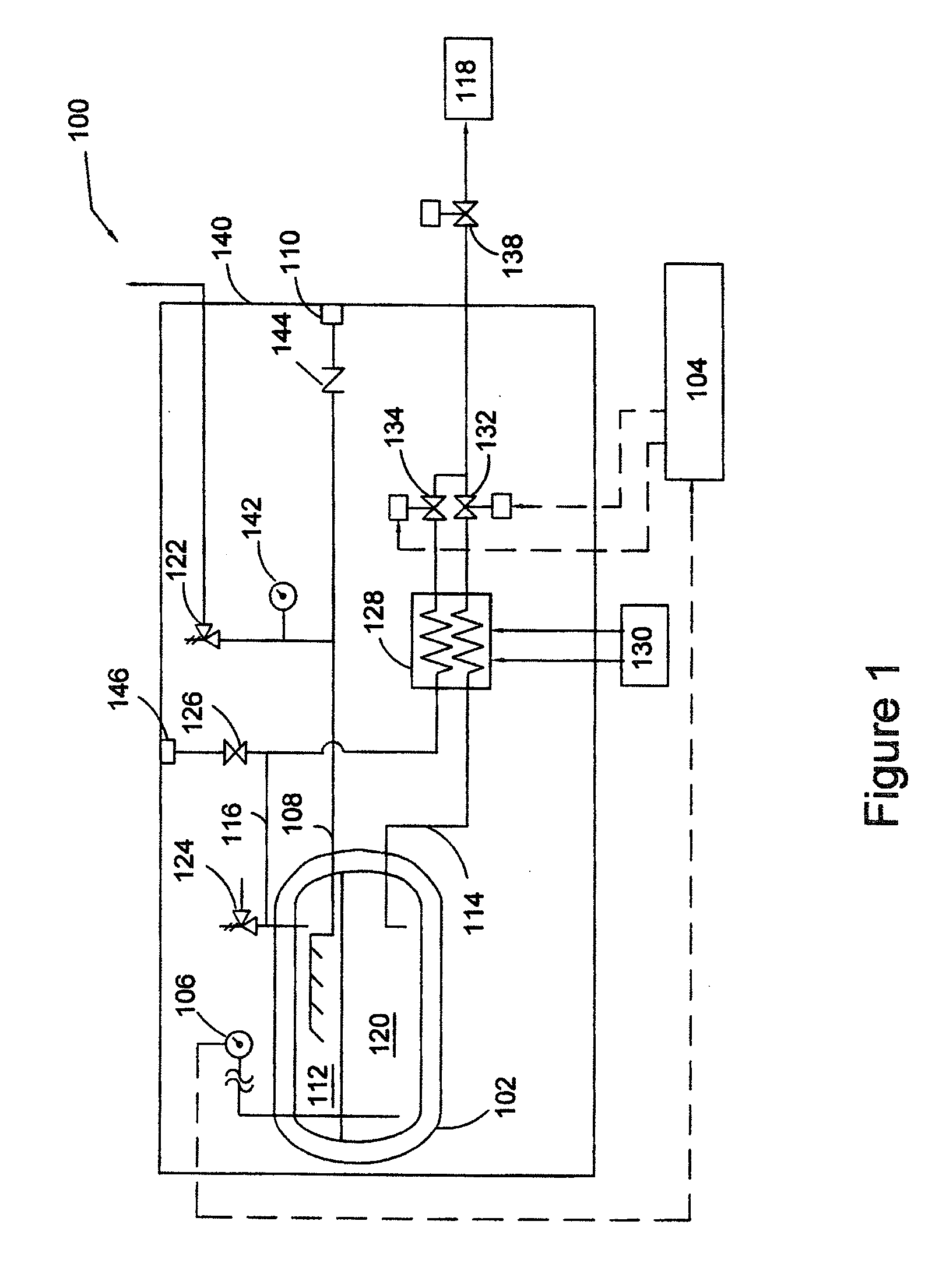

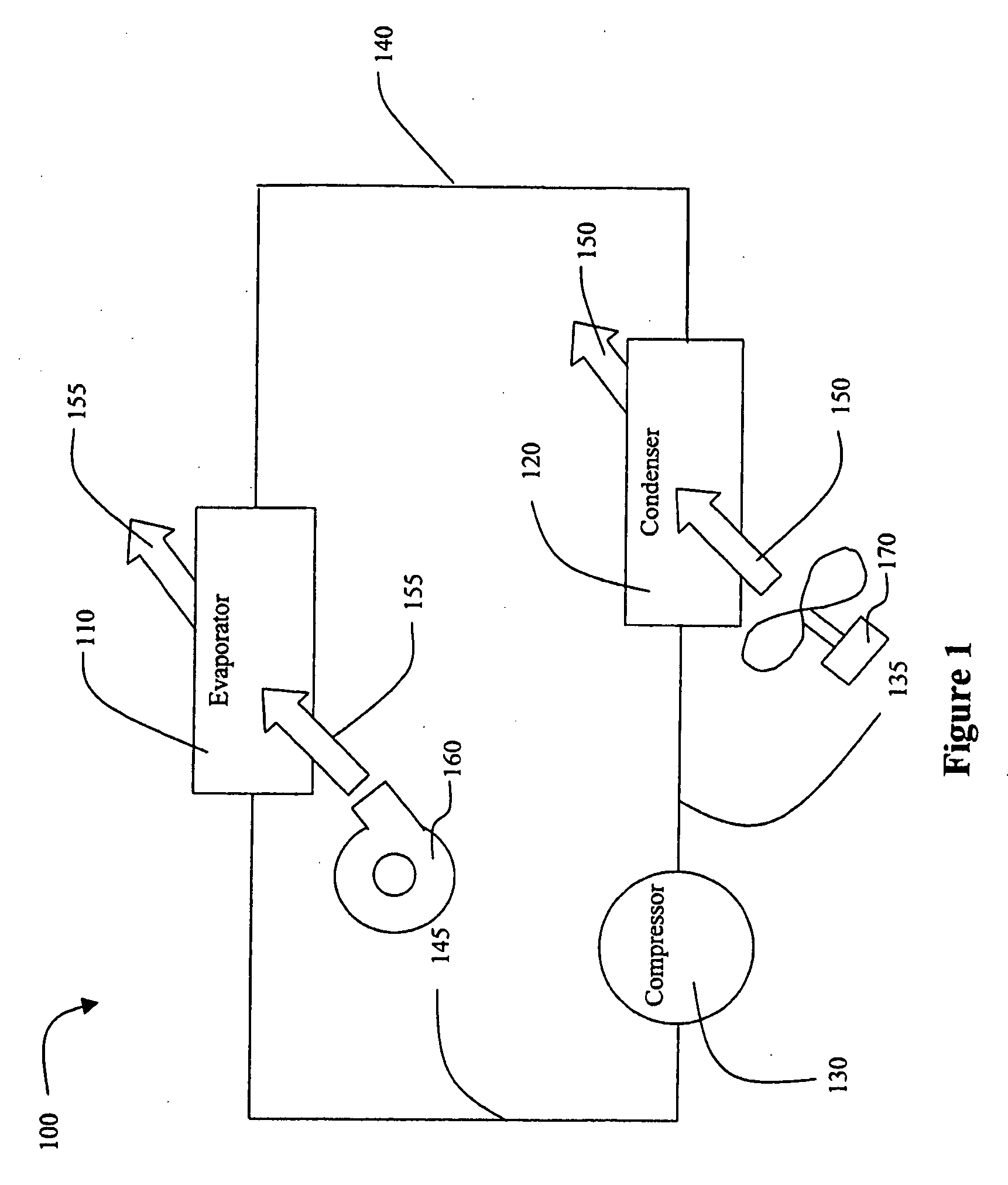

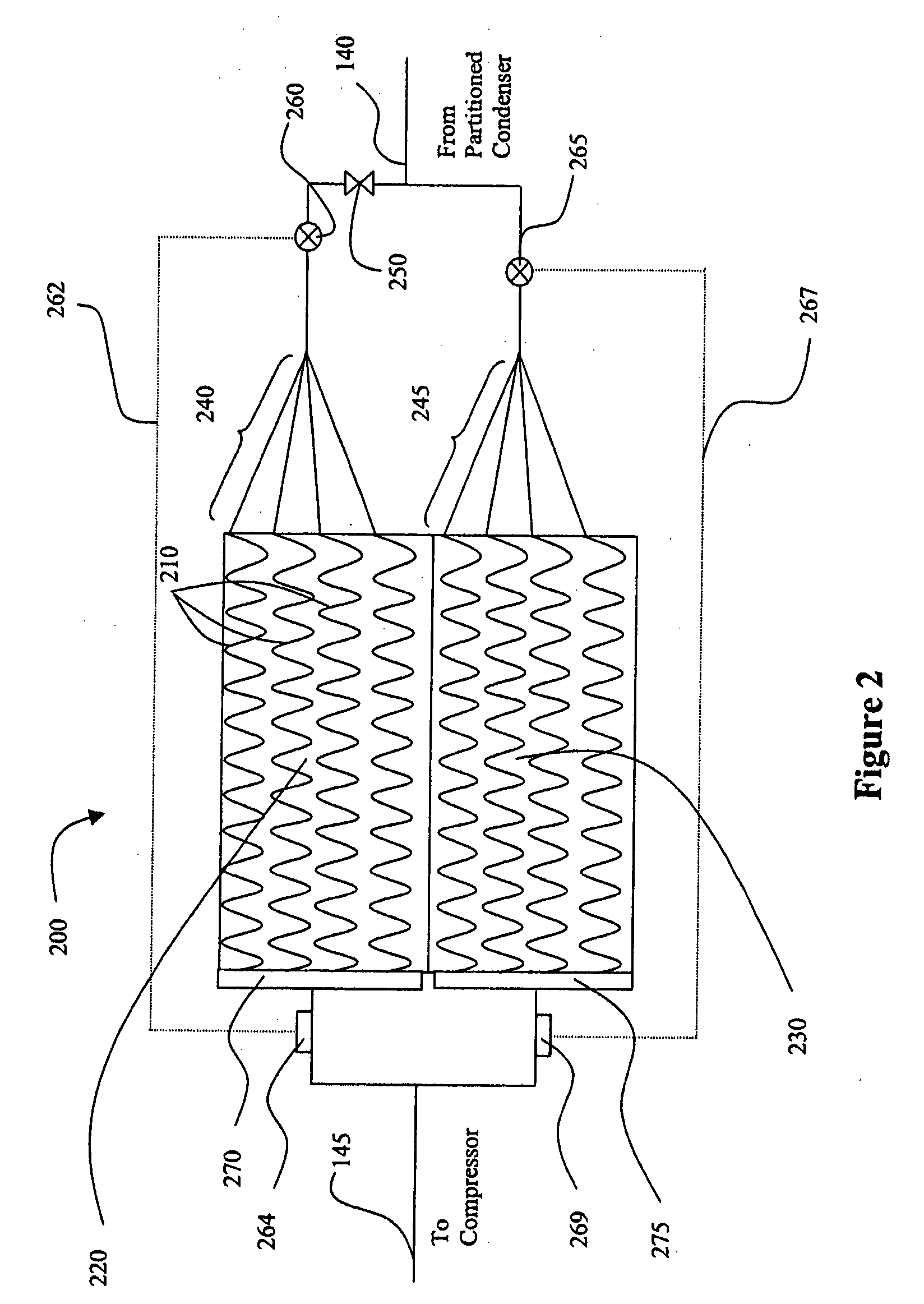

Method and system for dehumidification and refrigerant pressure control

InactiveUS20060288713A1Prevent freezingIncrease system pressureEvaporators/condensersCompression machines with several evaporatorsControl systemSystem pressure

A method for dehumidification and controlling system pressure in a refrigeration system includes providing a refrigeration system having a compressor, a condenser and an evaporator connected in a closed refrigerant loop. Each of the condenser and evaporator have a plurality of refrigerant circuits. A first heat transfer fluid is flowed over the condenser and a second heat transfer fluid is flowed over the evaporator. At least one of the refrigerant circuits of the condenser is isolated to provide a decreased amount of heat transfer area within the condenser and to increase the refrigerant pressure within the refrigeration system when the refrigerant pressure within the refrigeration system is at or below a predetermined pressure. At least one of the refrigerant circuits of the evaporator is isolated to dehumidify and maintain the temperature of the second heat transfer fluid at or above a predetermined temperature when dehumidification is required.

Owner:YORK INT CORP

Erosion resistant anti-icing coatings

InactiveUS20060281861A1Prevent freezingOvercomes shortcomingOther chemical processesAnti-corrosive paintsGas turbinesCorrosion resistant

Liquid and / or solid anti-icing fillers and / or oils are combined with erosion resistant silicone and / or fluorocarbon elastomeric materials to create erosion resistant anti-icing coatings. These coatings may be utilized to prevent ice build-up on various gas turbine engine components, aircraft components, watercrafts (i.e., boats and ships), power lines, telecommunication lines, etc.

Owner:UNITED TECH CORP

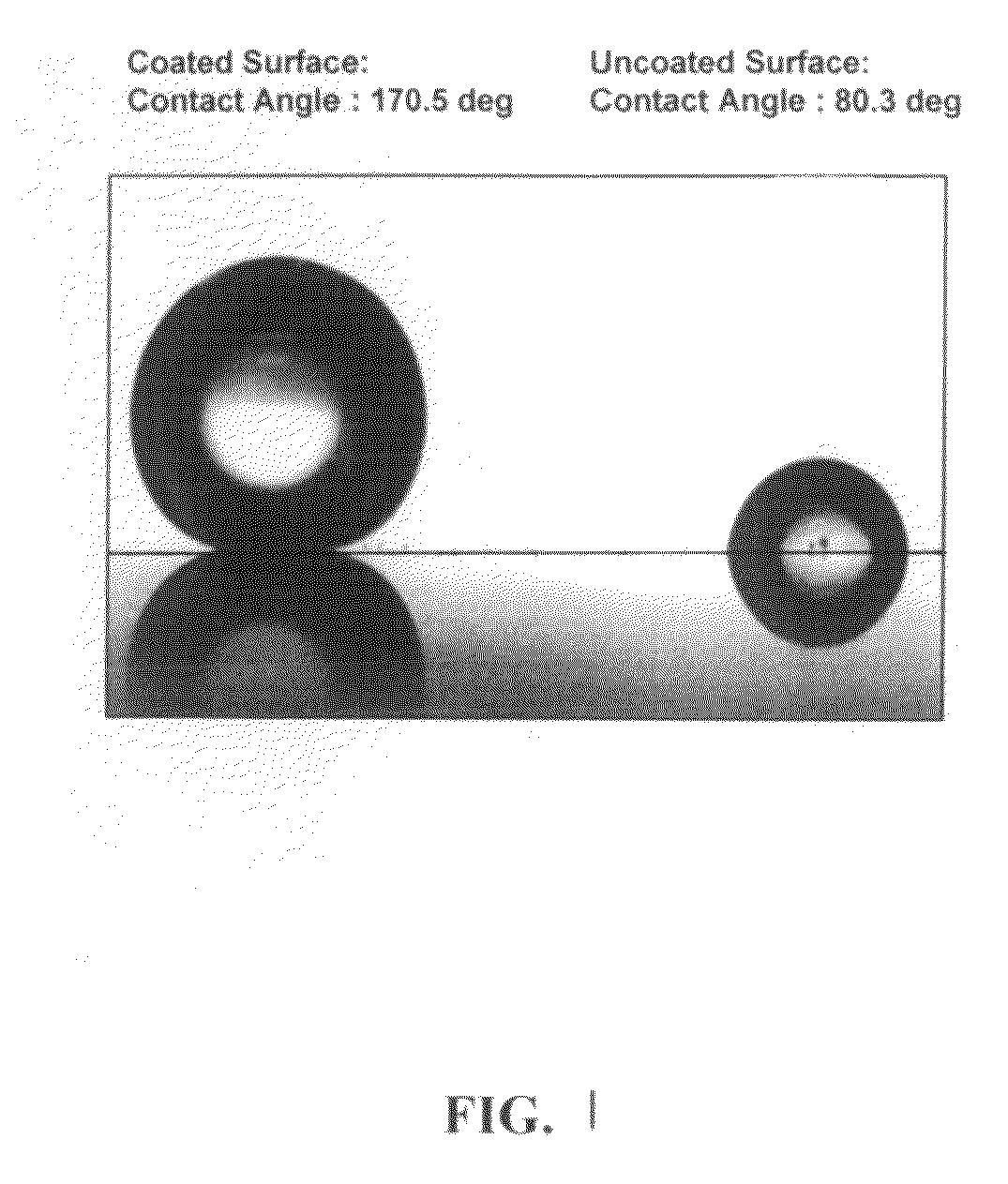

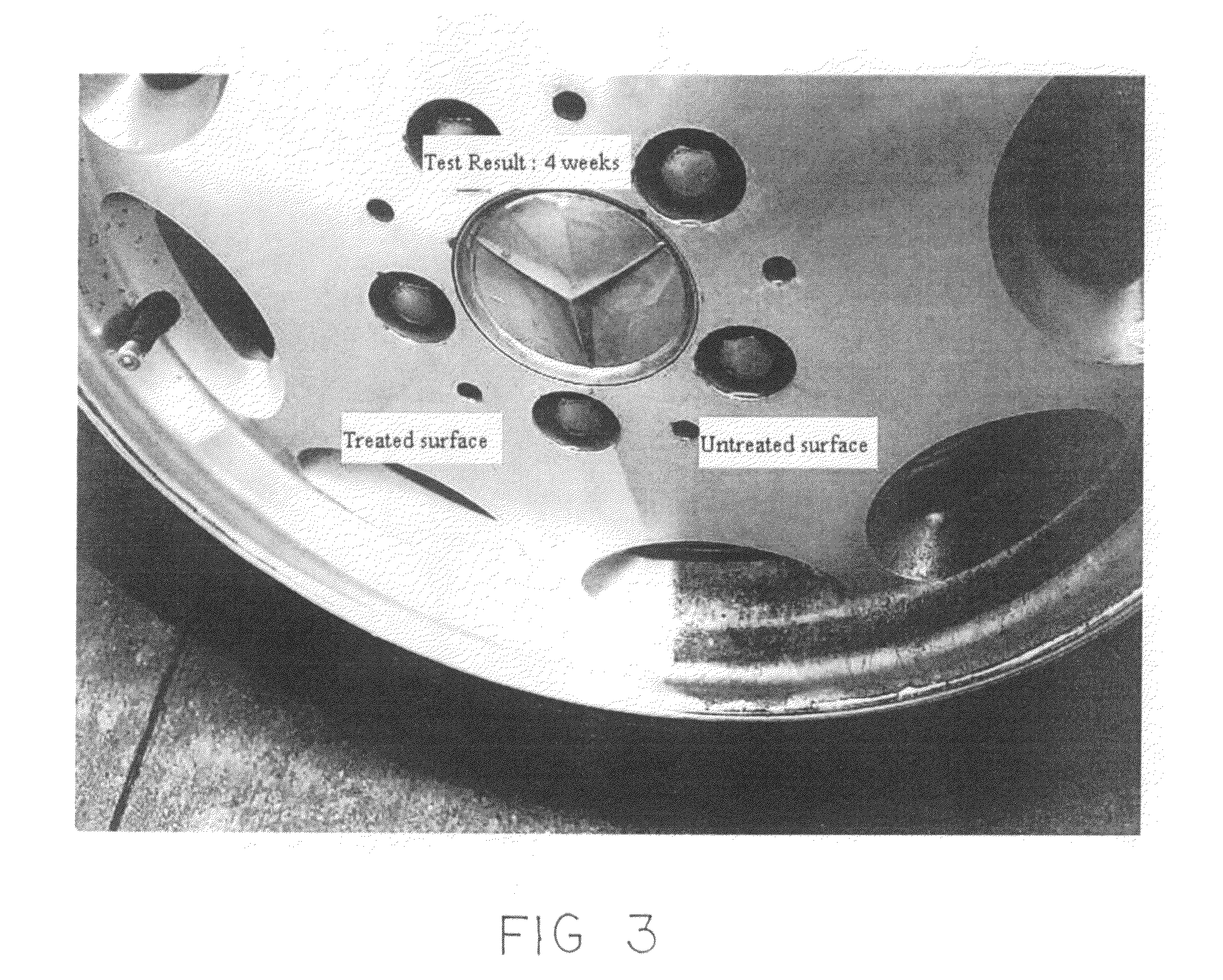

Hydrophobic coating compositions for drag reduction

Owner:VGP IPCO LLC

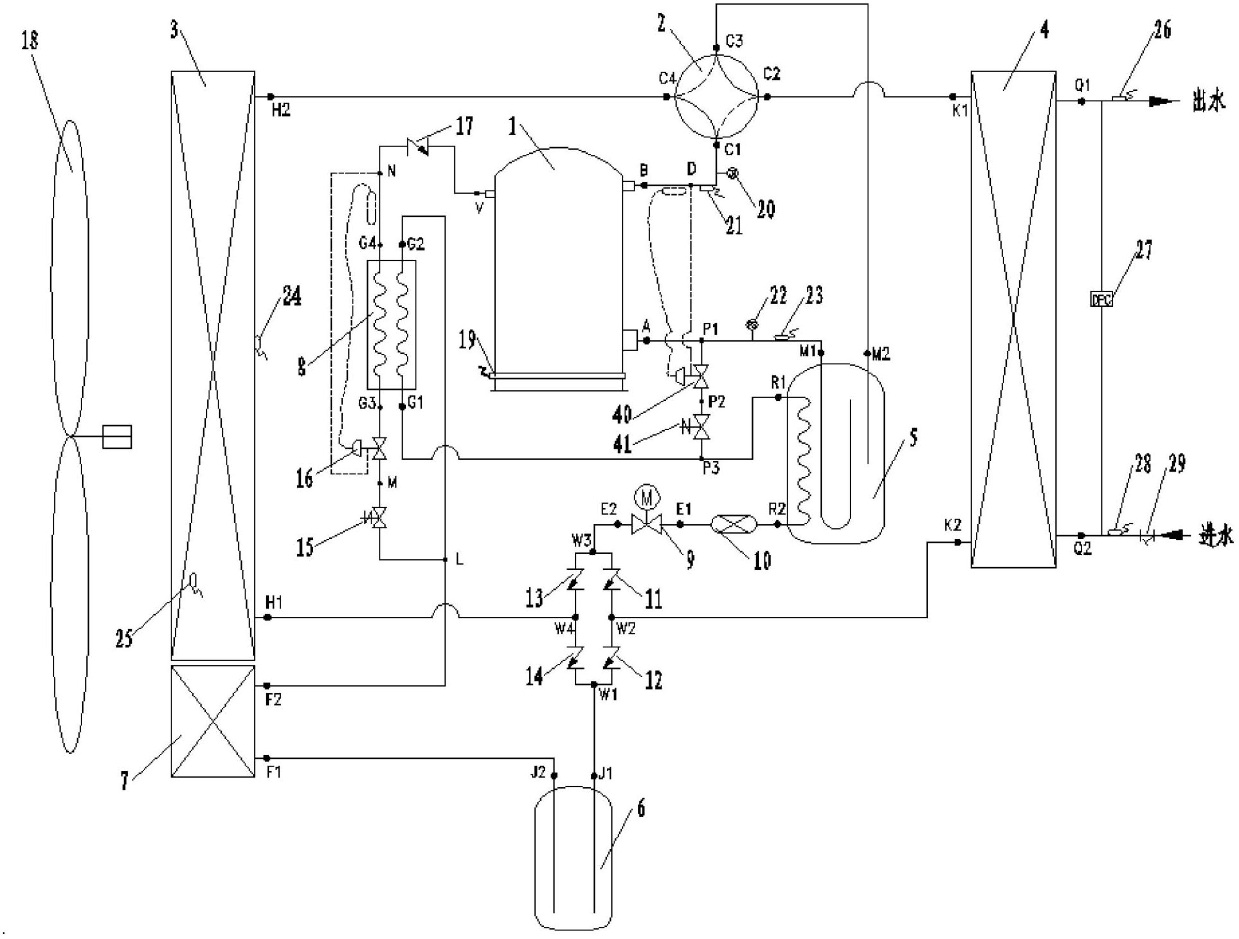

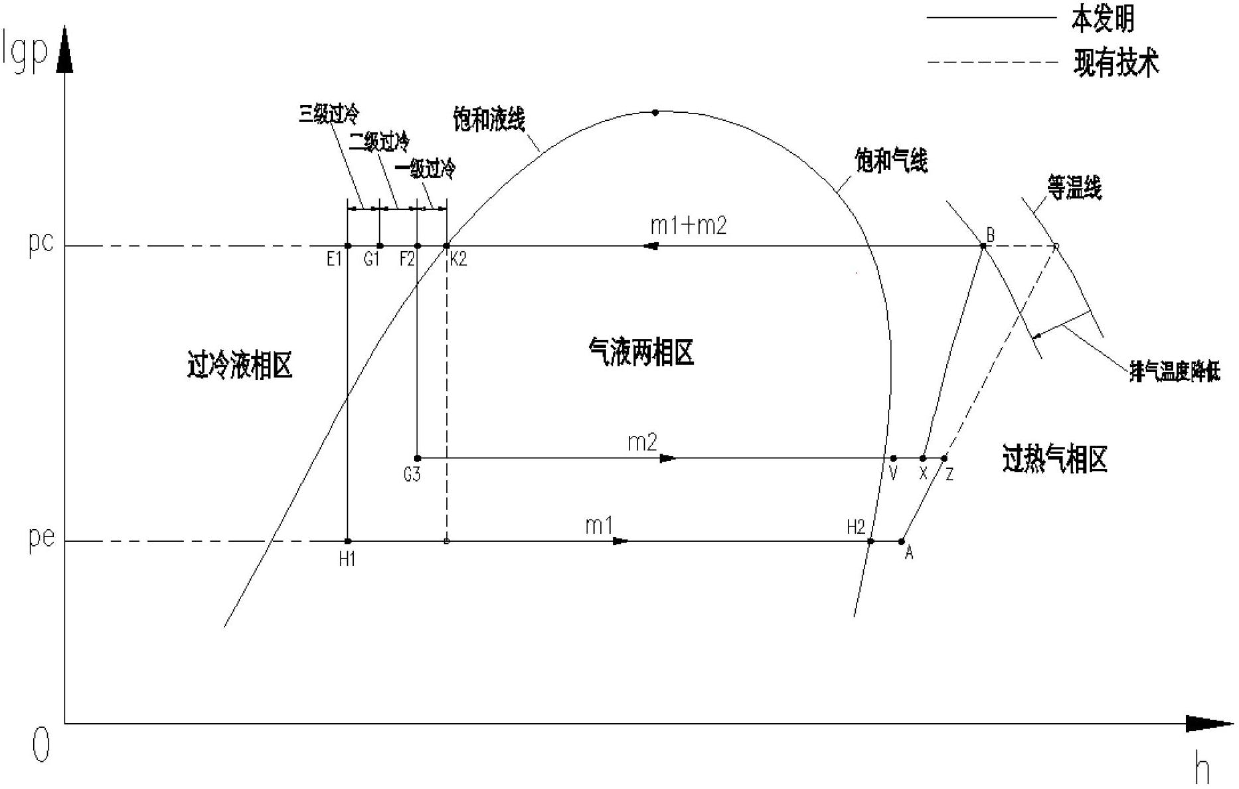

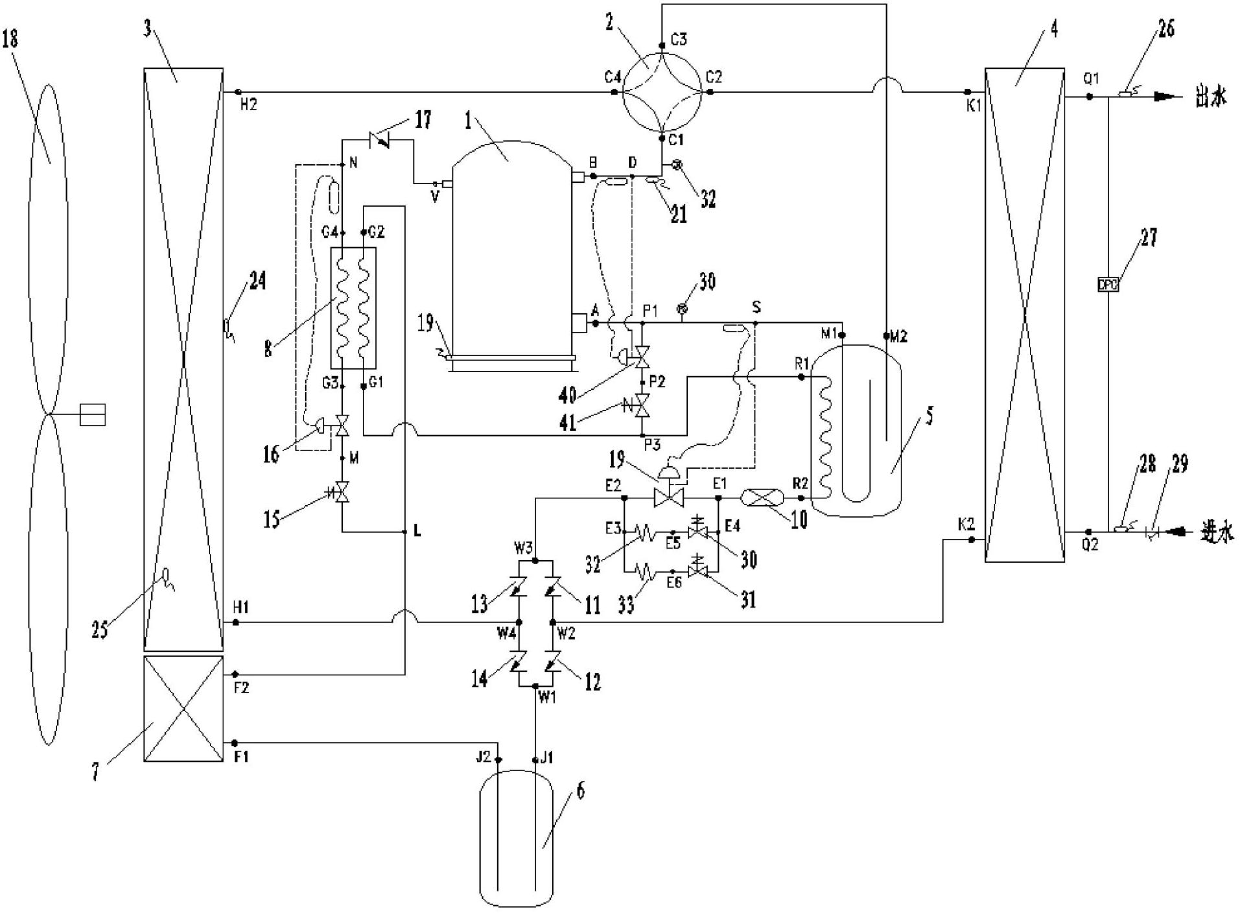

Air-cooled heat pump air conditioner

InactiveCN102679609AIncrease subcoolingLow heat recovery functionSubcoolersFluid circulation arrangementLiquid lineVapor–liquid separator

The invention discloses an air-cooled heat pump air conditioner which comprises a compressor, an outdoor coil, a heat exchanger, a main liquid line and supercooling devices, wherein the supercooling devices comprise two or three of a supercooling coil, an economizer and a liquid-vapor separator with a supercooling function, the supercooling devices are arranged on the main liquid line, and liquid state refrigerants which circulate in the main liquid line can achieve repeatedly the supercooling through the supercooling devices. According to the air-cooled heat pump air conditioner, the performance of cooling / heating circulation of the air-cooled heat pump air conditioner is effectively improved, so that the air-cooled heat pump air conditioner is stable and reliable in operation and energy saving in a low-temperature environment.

Owner:四川同达博尔置业有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com