Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

5386results about "Windings" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

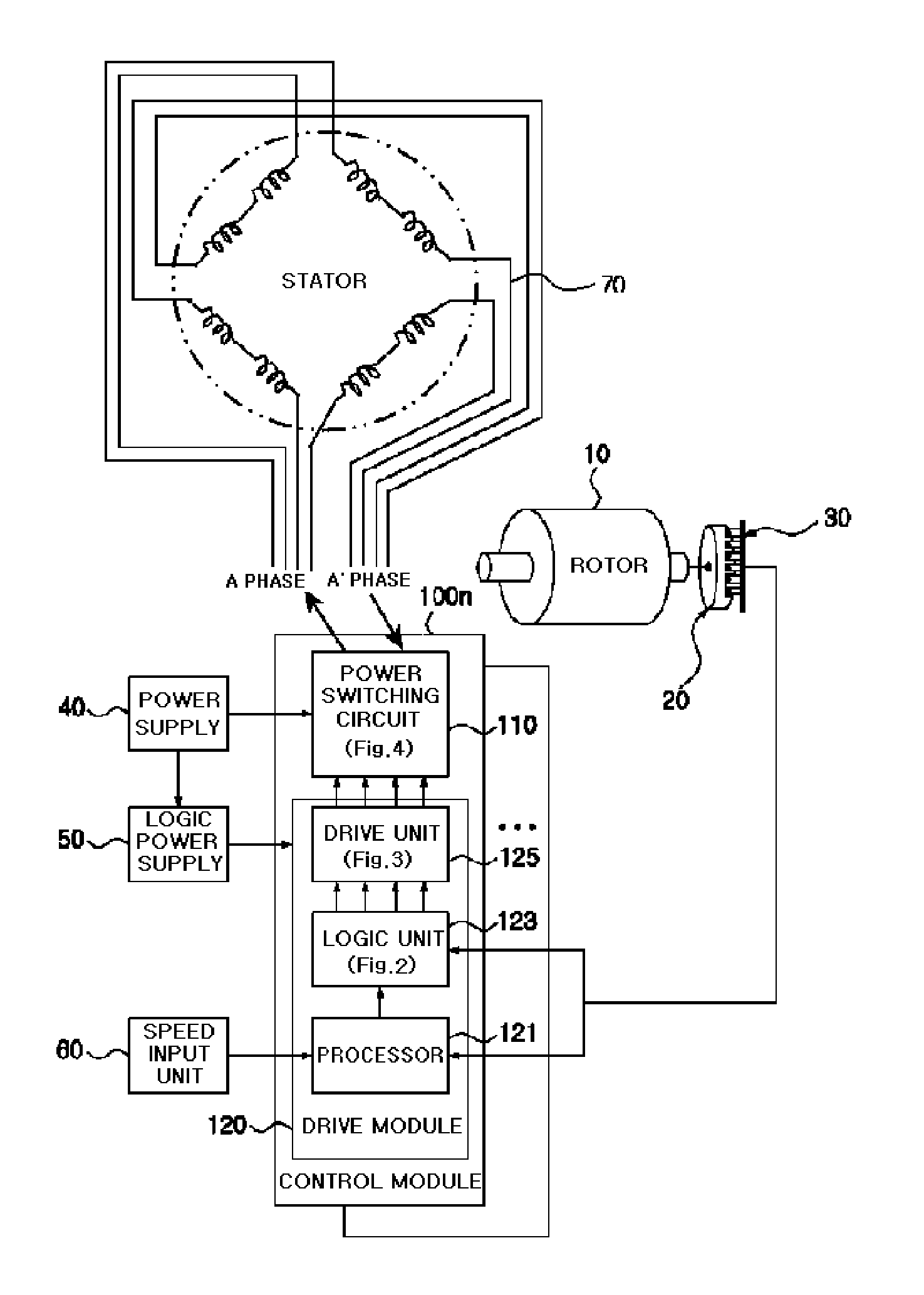

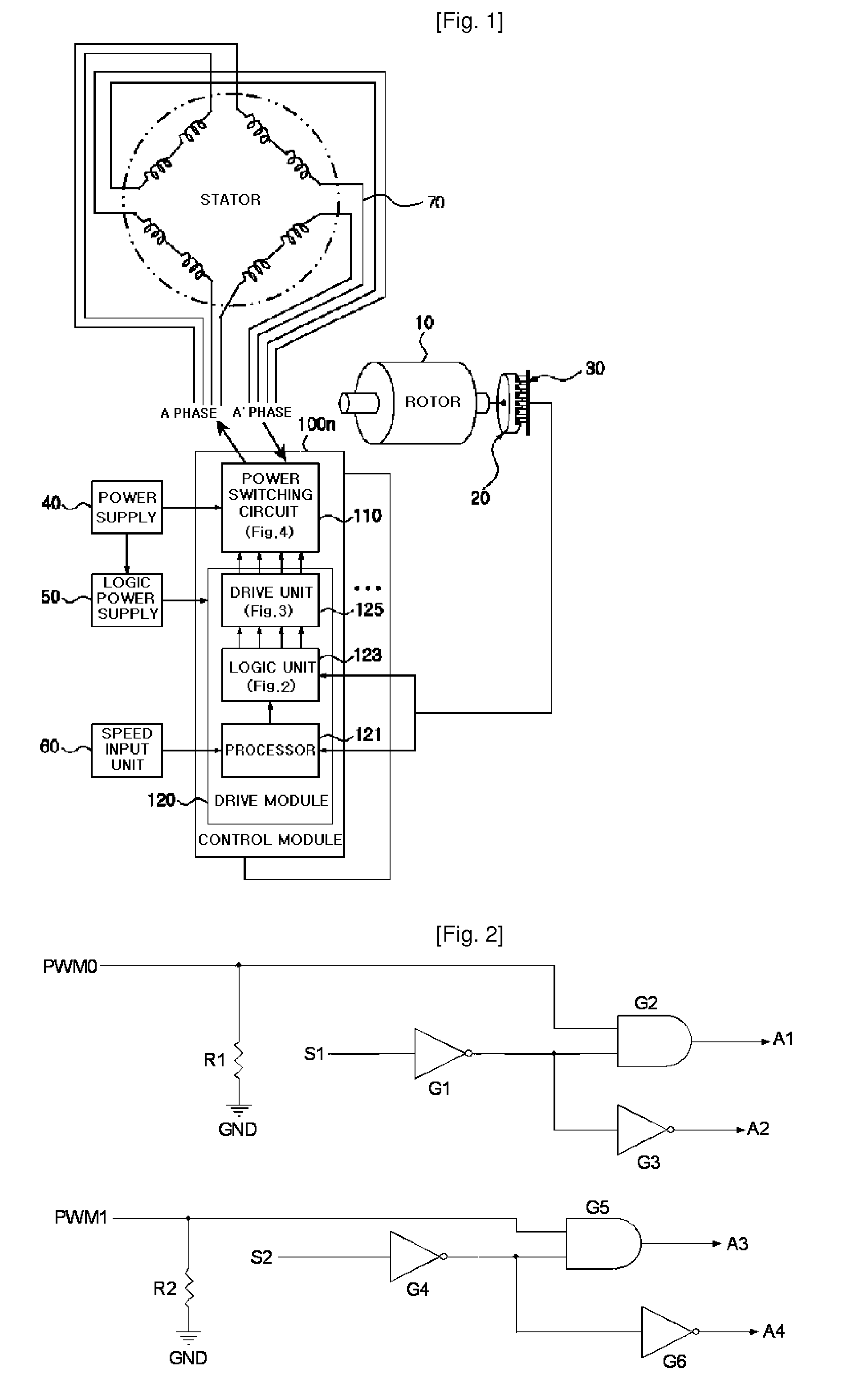

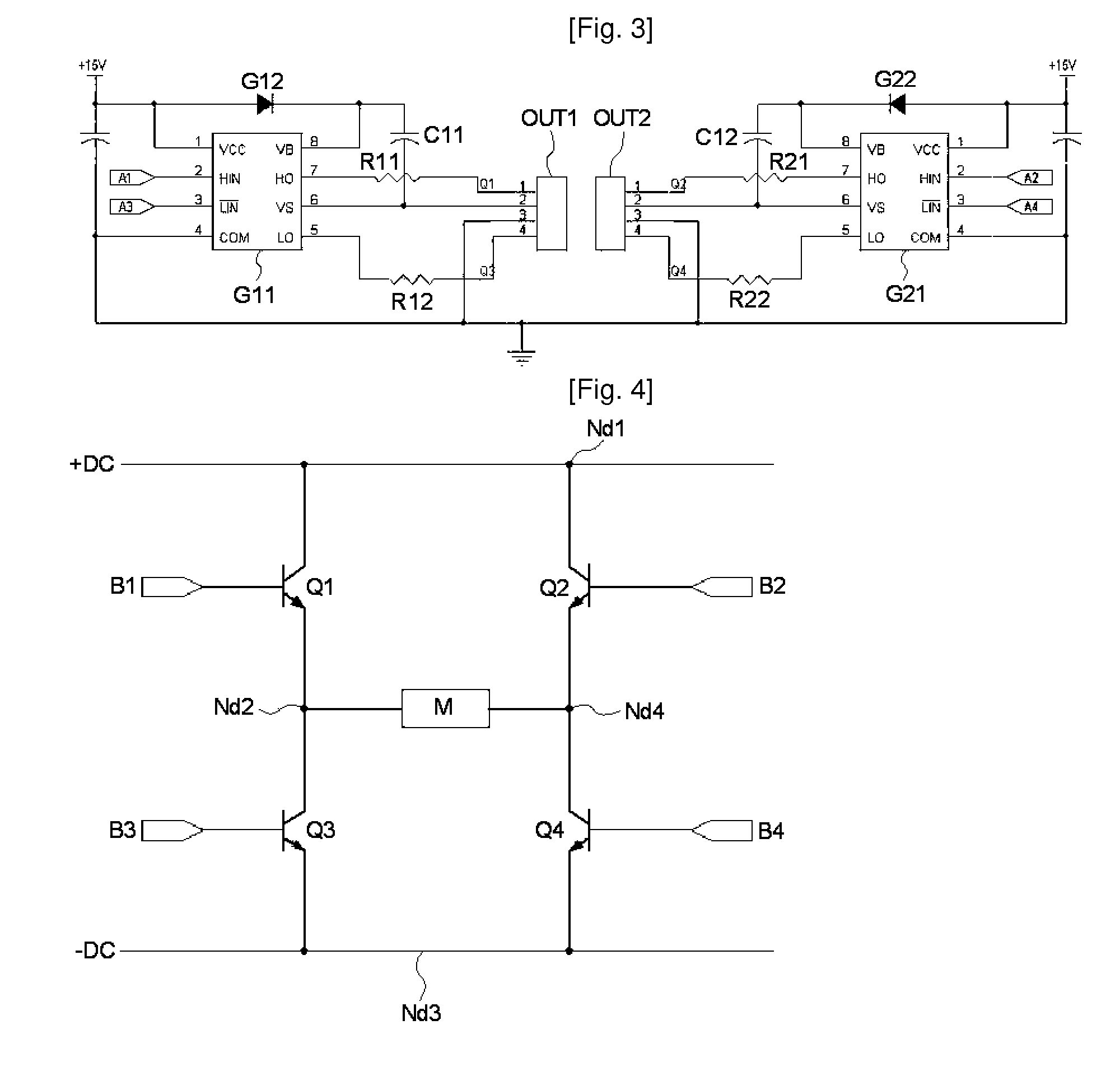

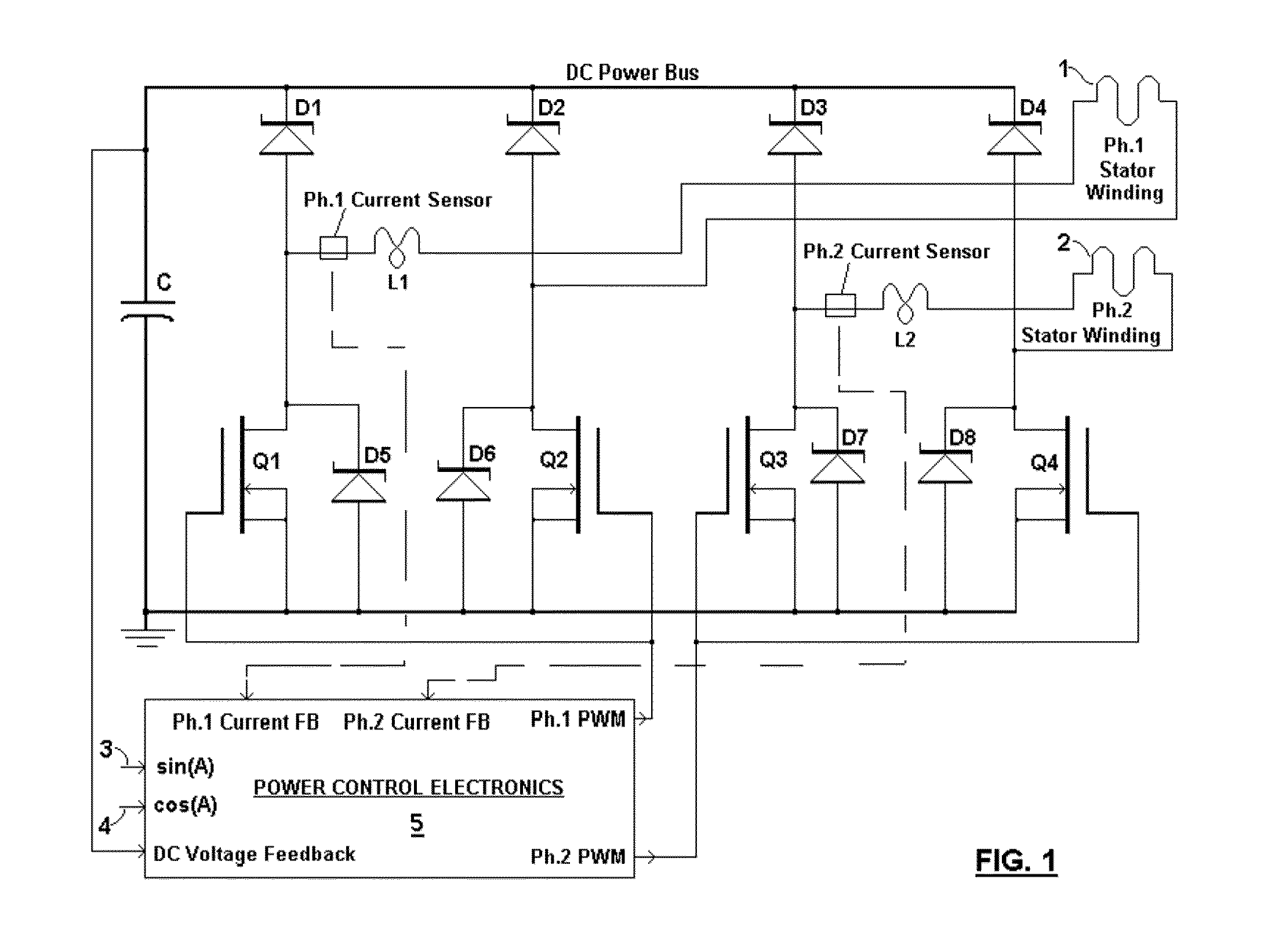

Apparatus and method for controlling hybrid motor

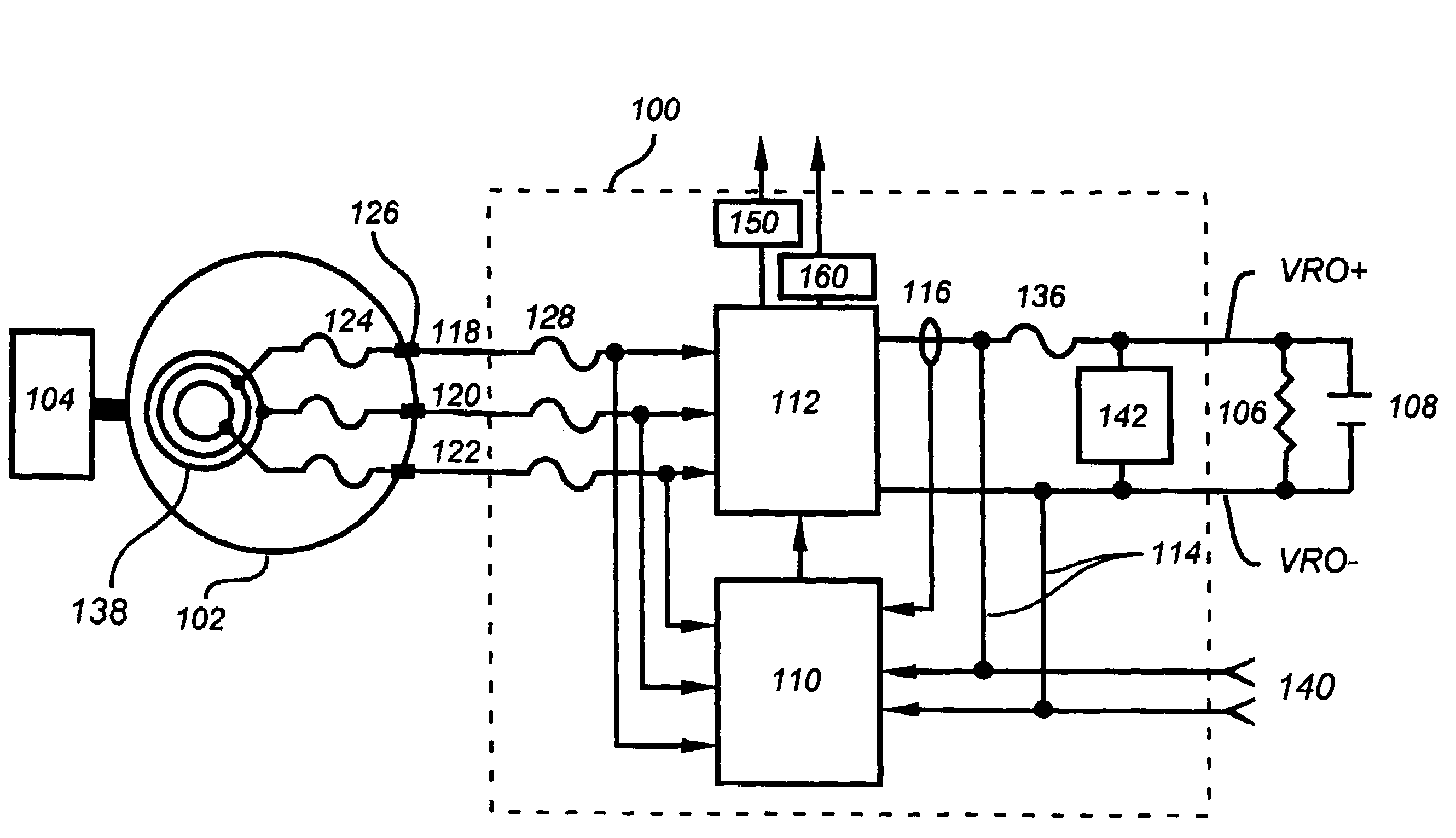

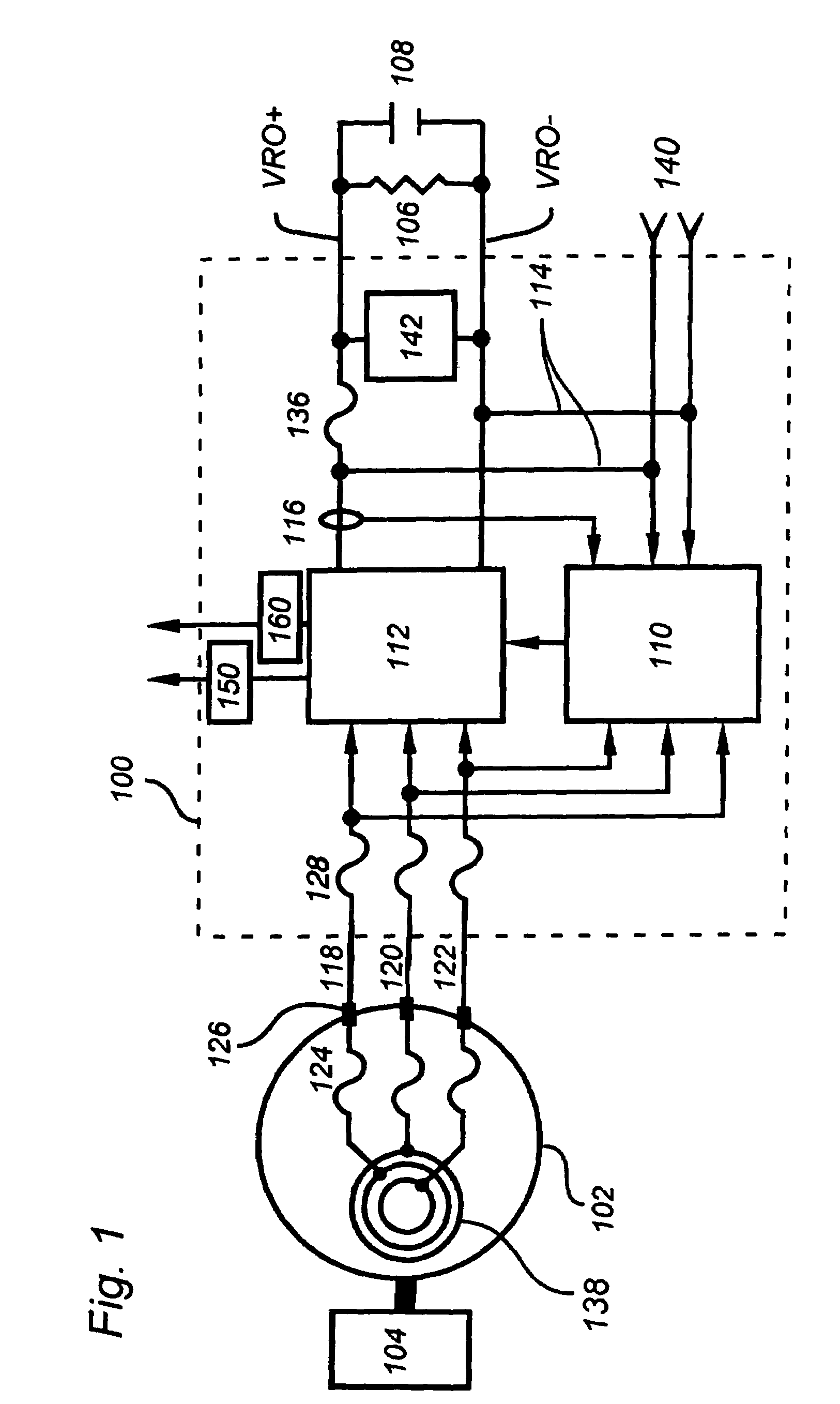

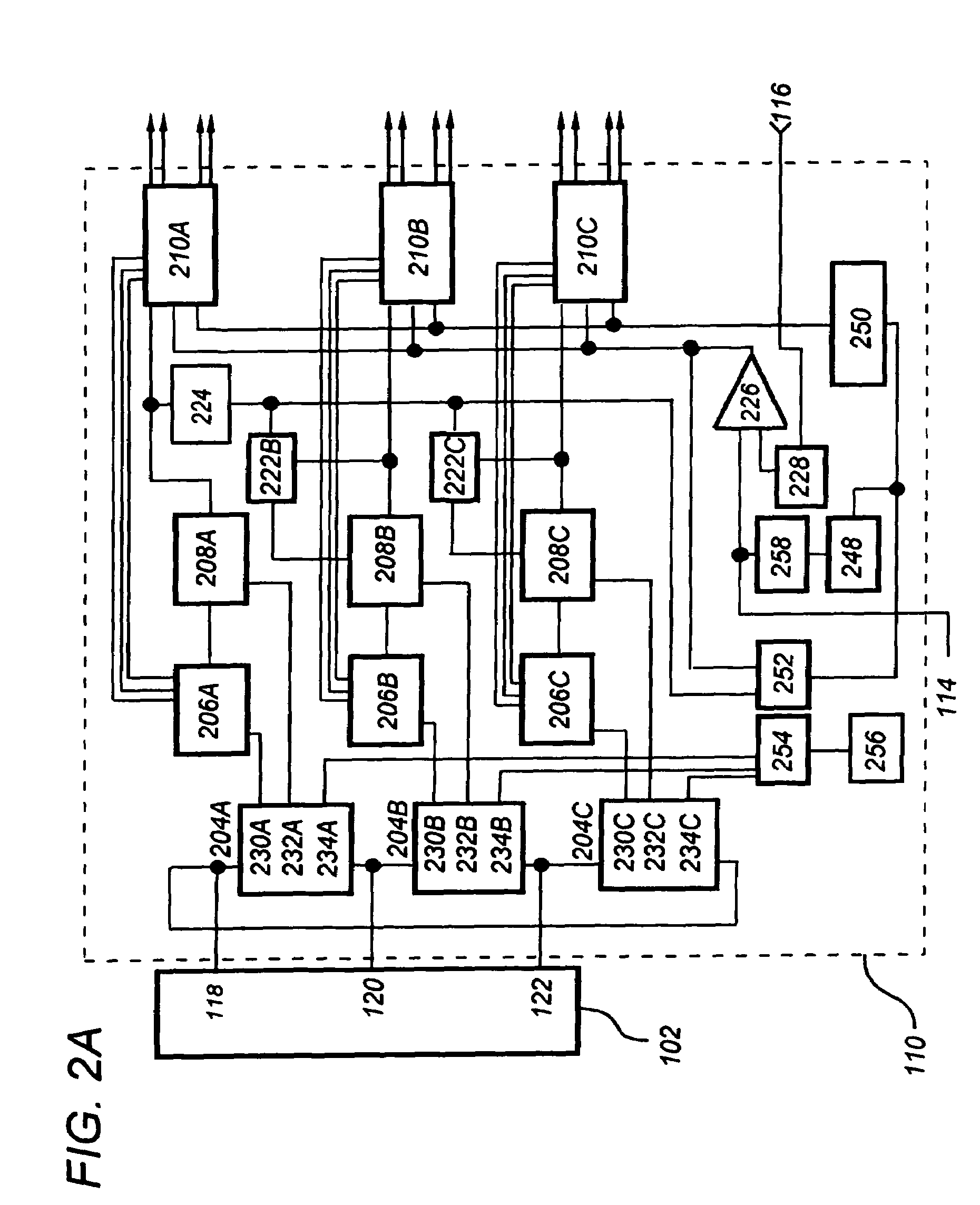

ActiveUS8228020B2Reduce capacityReduce electricity loadSingle-phase induction motor startersWindingsDriver circuitPower switching

An apparatus and method for controlling a hybrid motor, The hybrid motor, uses a permanent magnet instead of a field coil for a rotor, winds a coil round a stator in a multi-phase independent parallel manner, fixes a rectifying type encoder to the rotor and connects a sensor to a driving circuit. The apparatus comprises: an encoder attached to a rotor in cooperation with a pole sensor a speed input unit for generating a speed instruction signal a power switching circuit to generate motor driving signals; a drive module receiving the speed instruction signal and the sensor signal and outputting the speed instruction signal synchronized with the sensor signal as a driving motor signal; a power supply for applying a DC voltage to the power switching circuit; A logic power supply for converting the DC voltage into a logic voltage, and applying logic voltage to the drive module. The motor has n phases, n power switching circuits and n drive modules.

Owner:NAMYANG NEXMO CO LTD

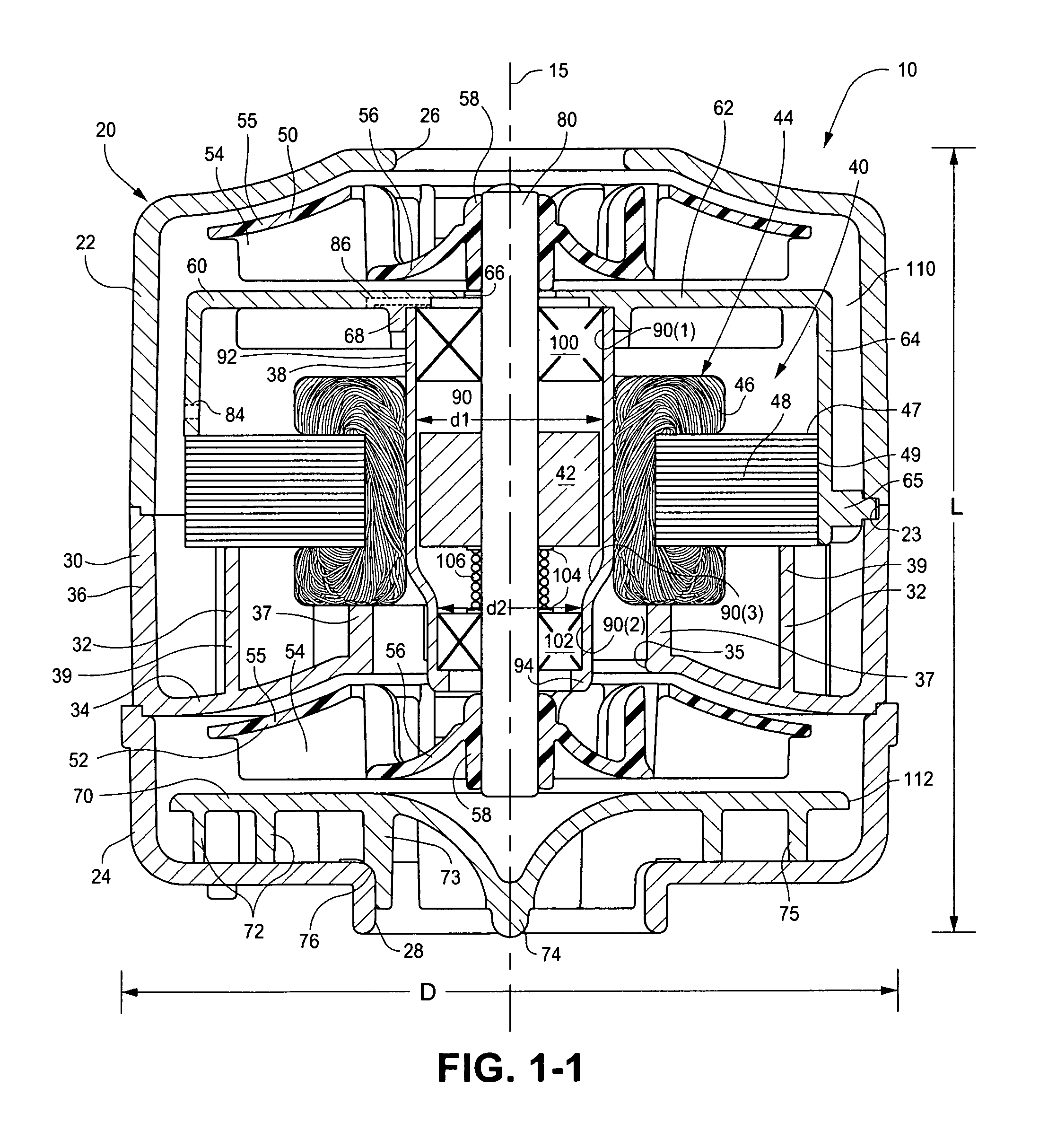

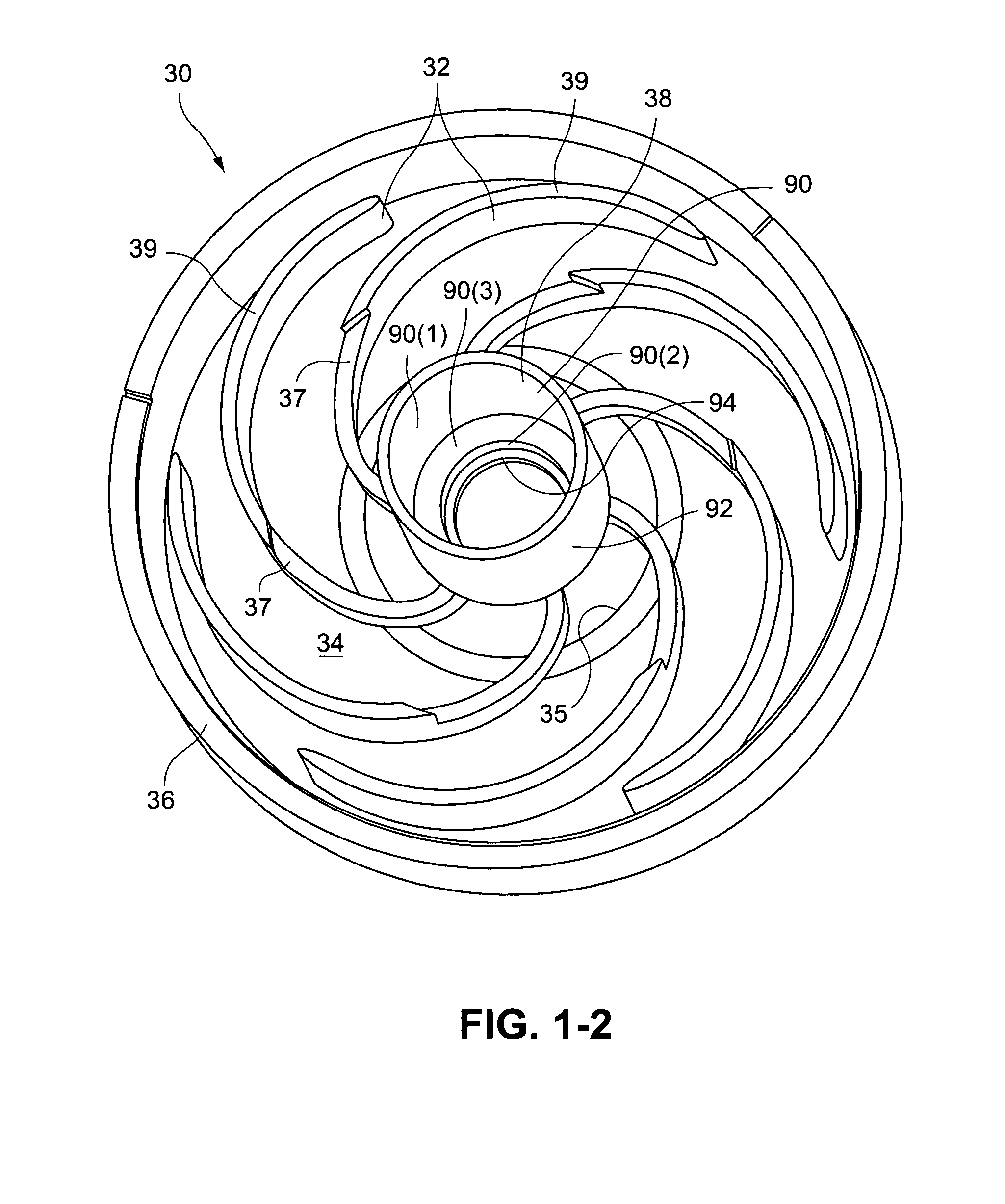

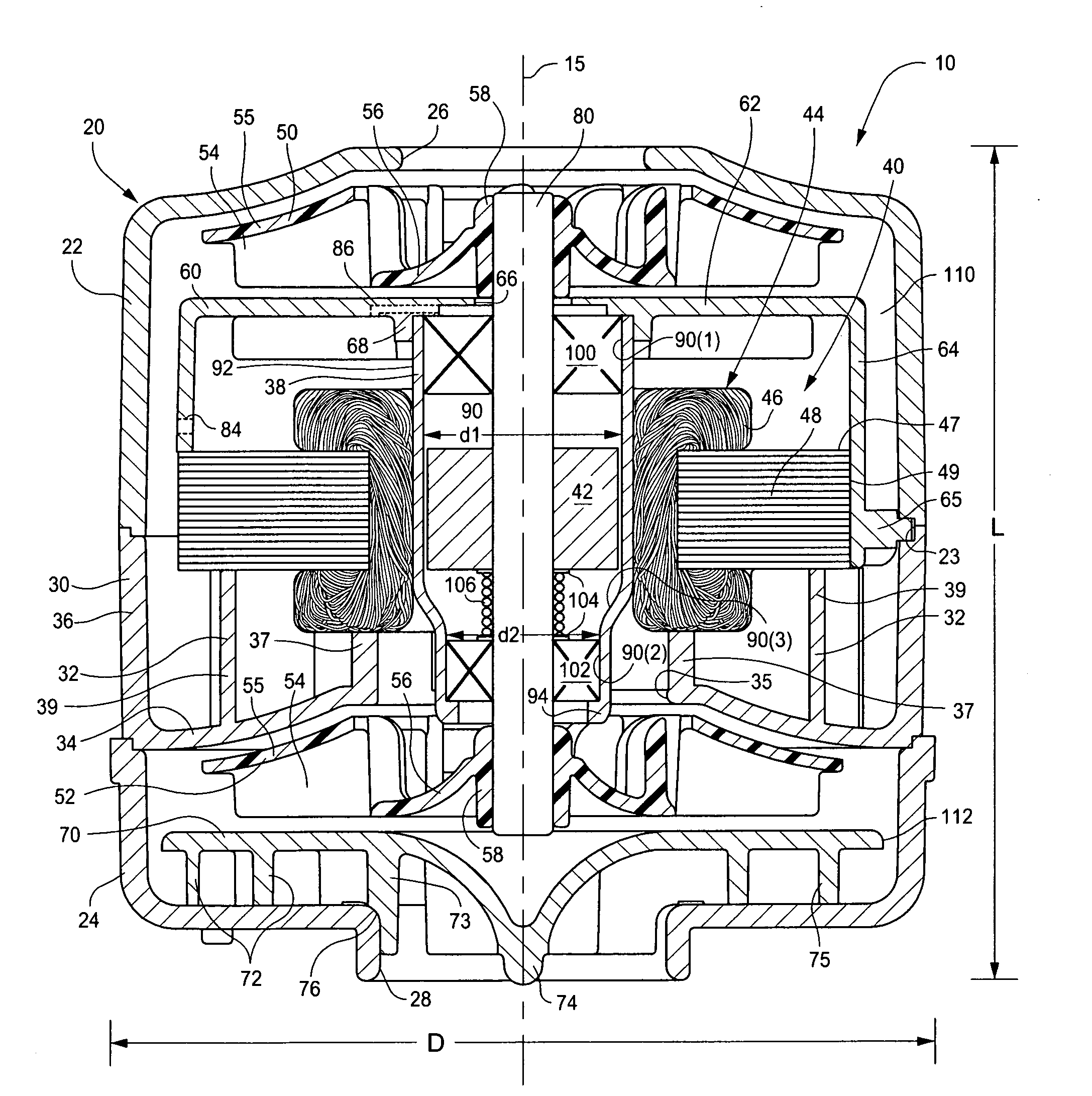

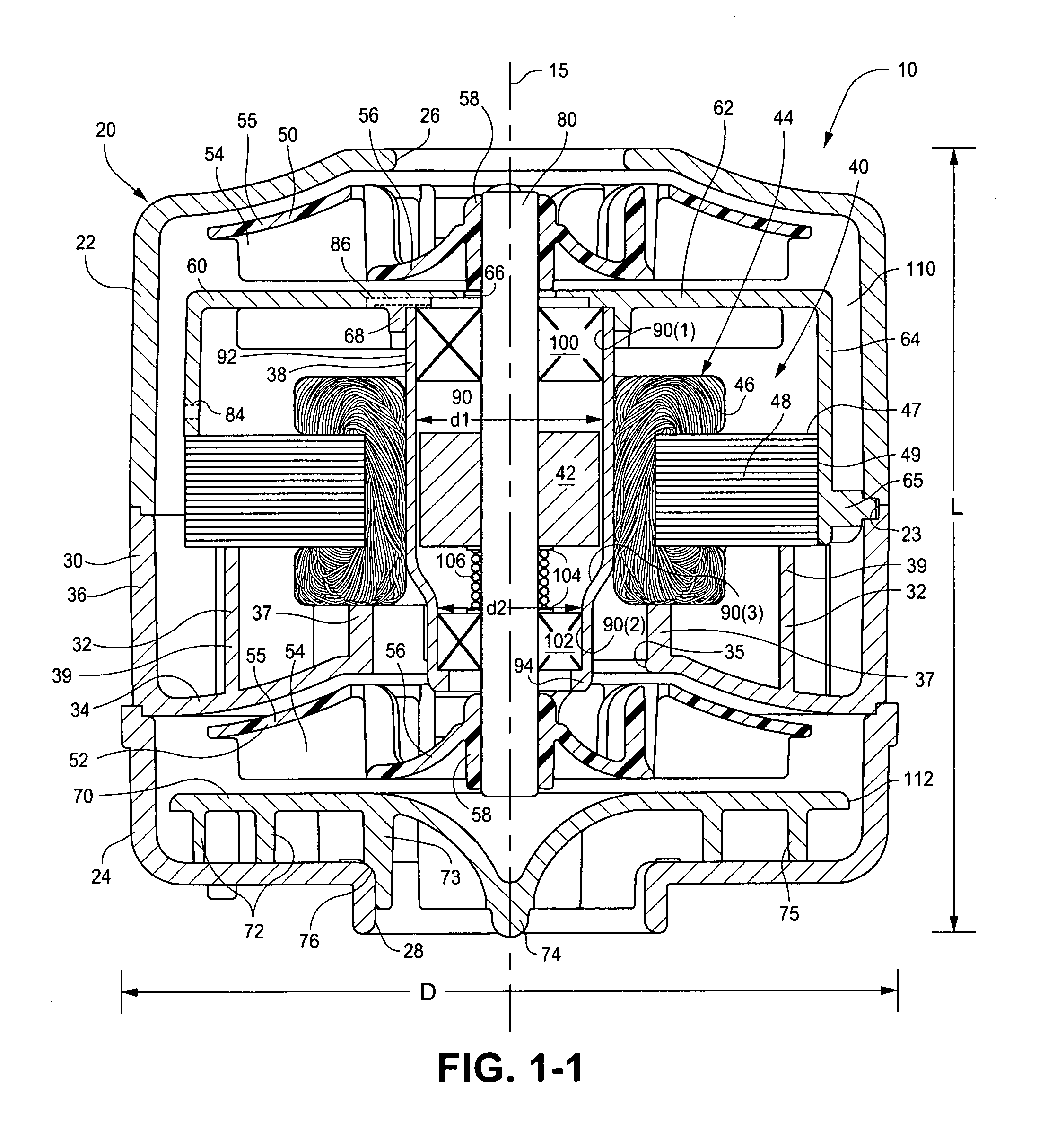

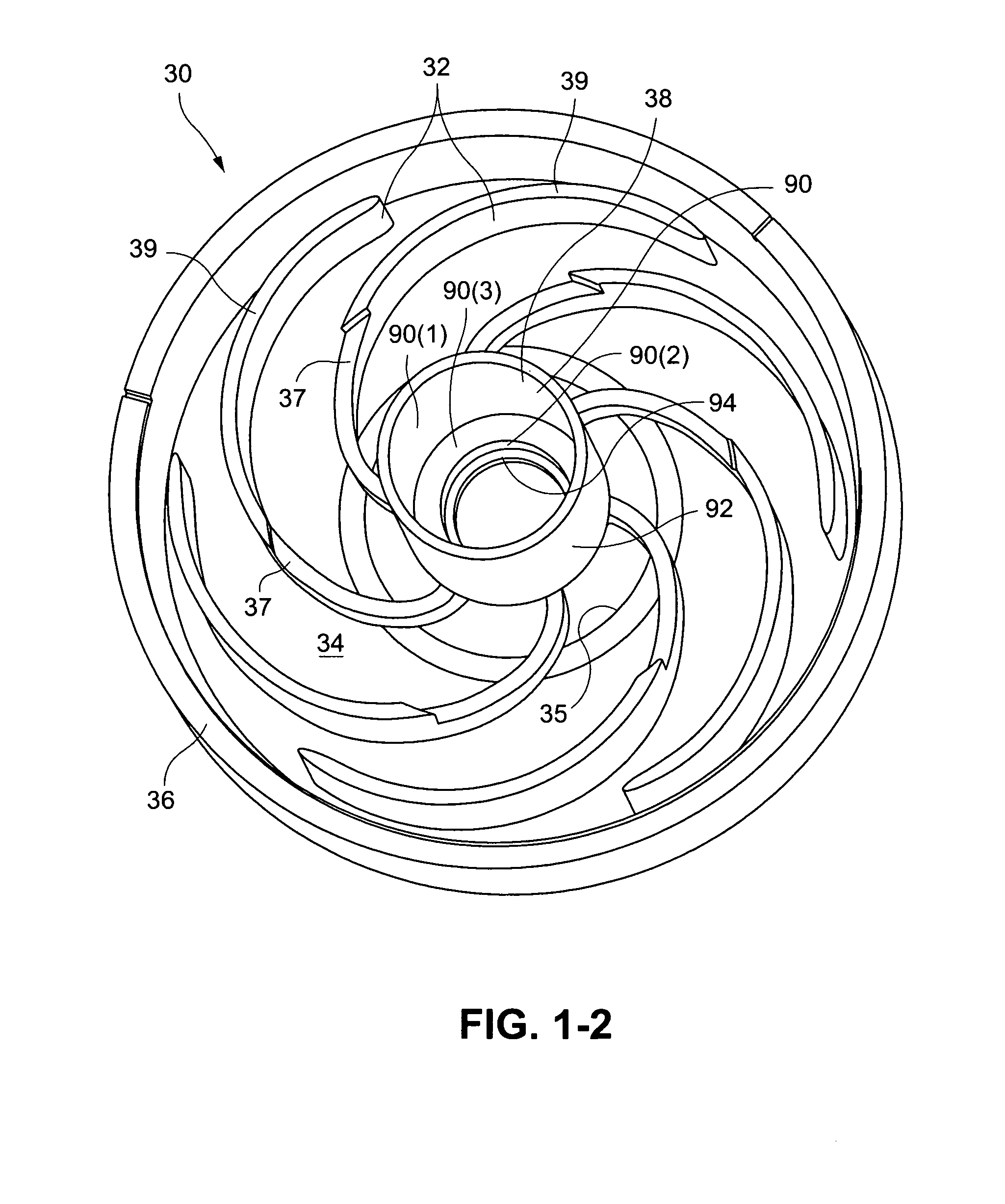

Blower with bearing tube

Owner:RESMED MOTOR TECH

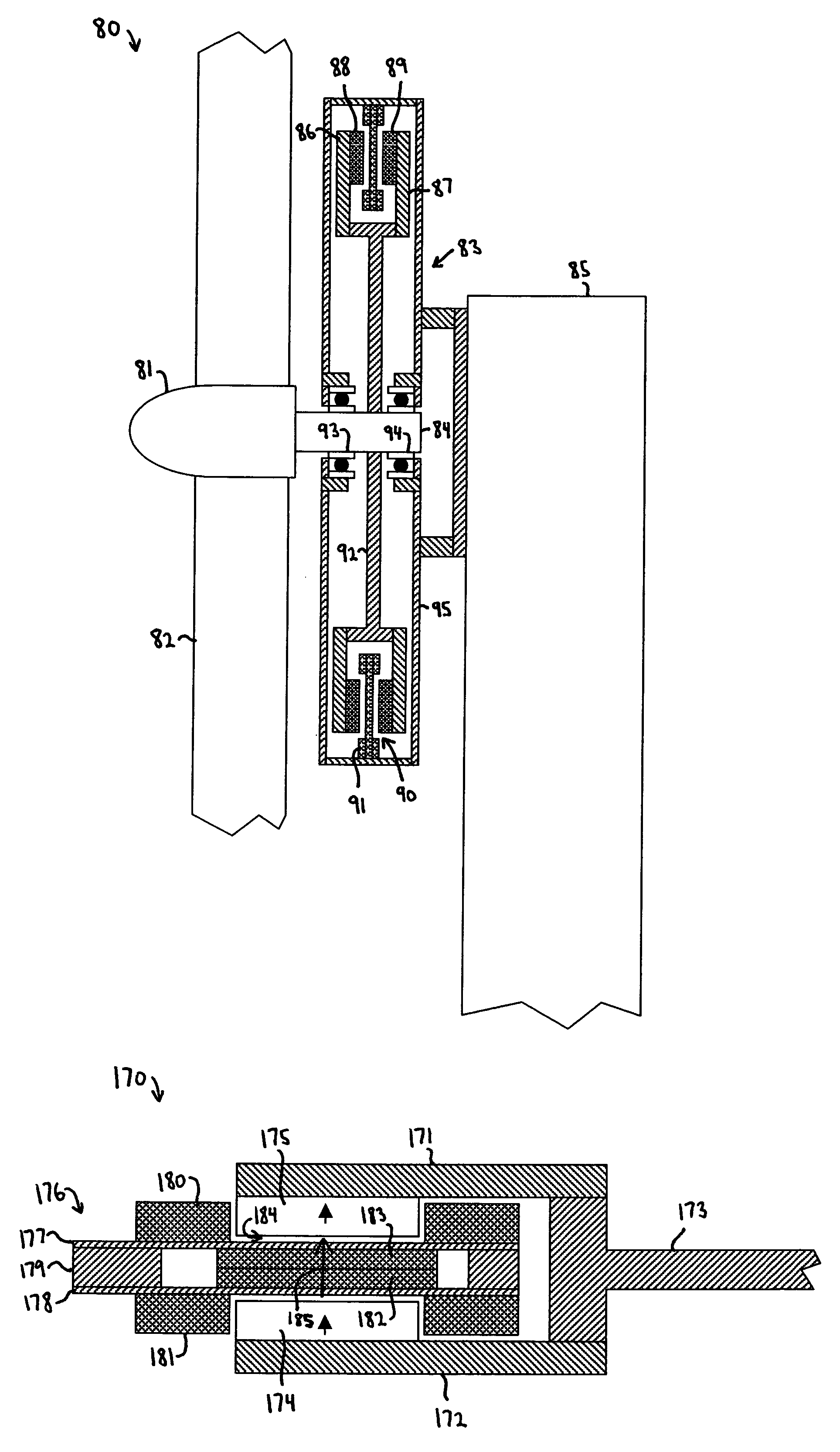

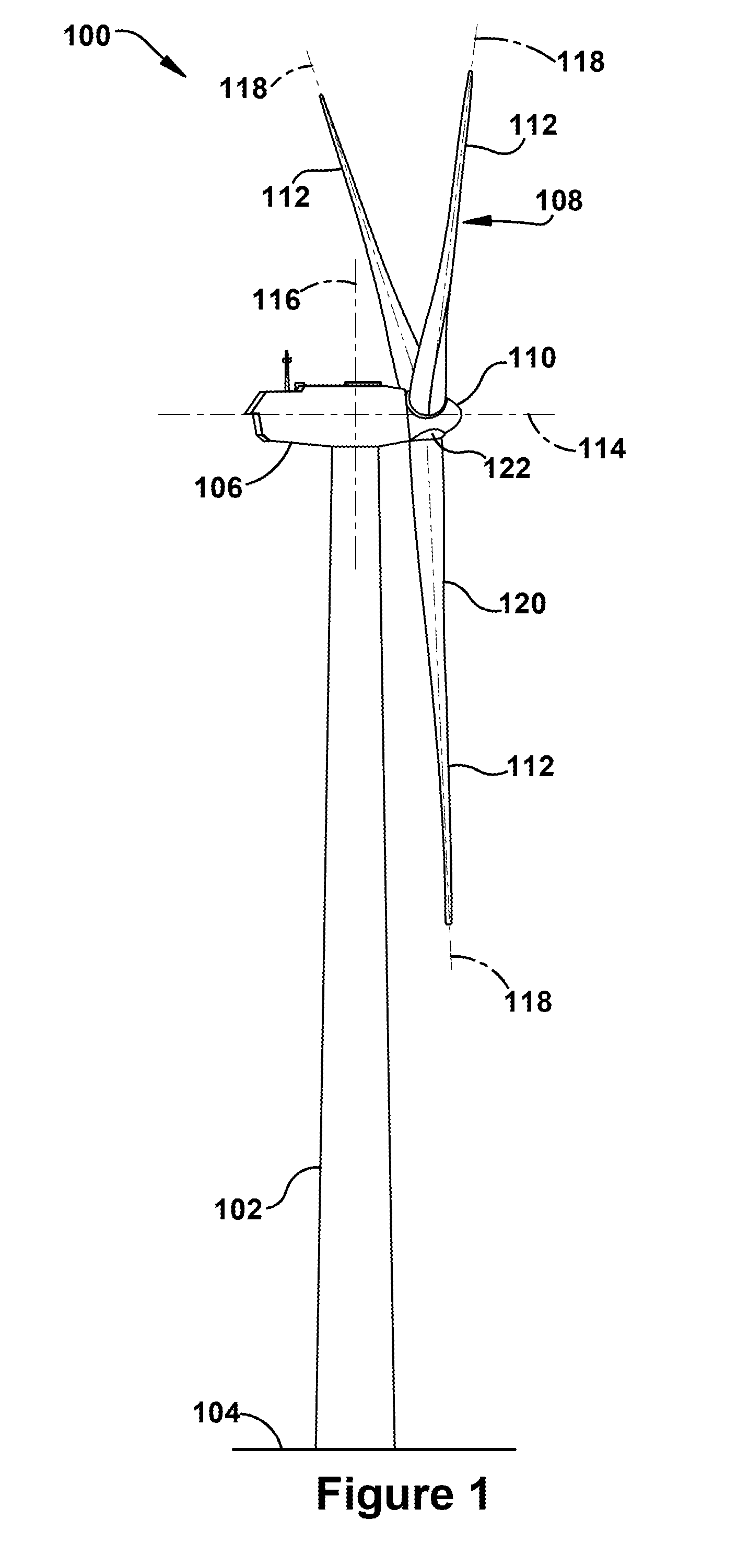

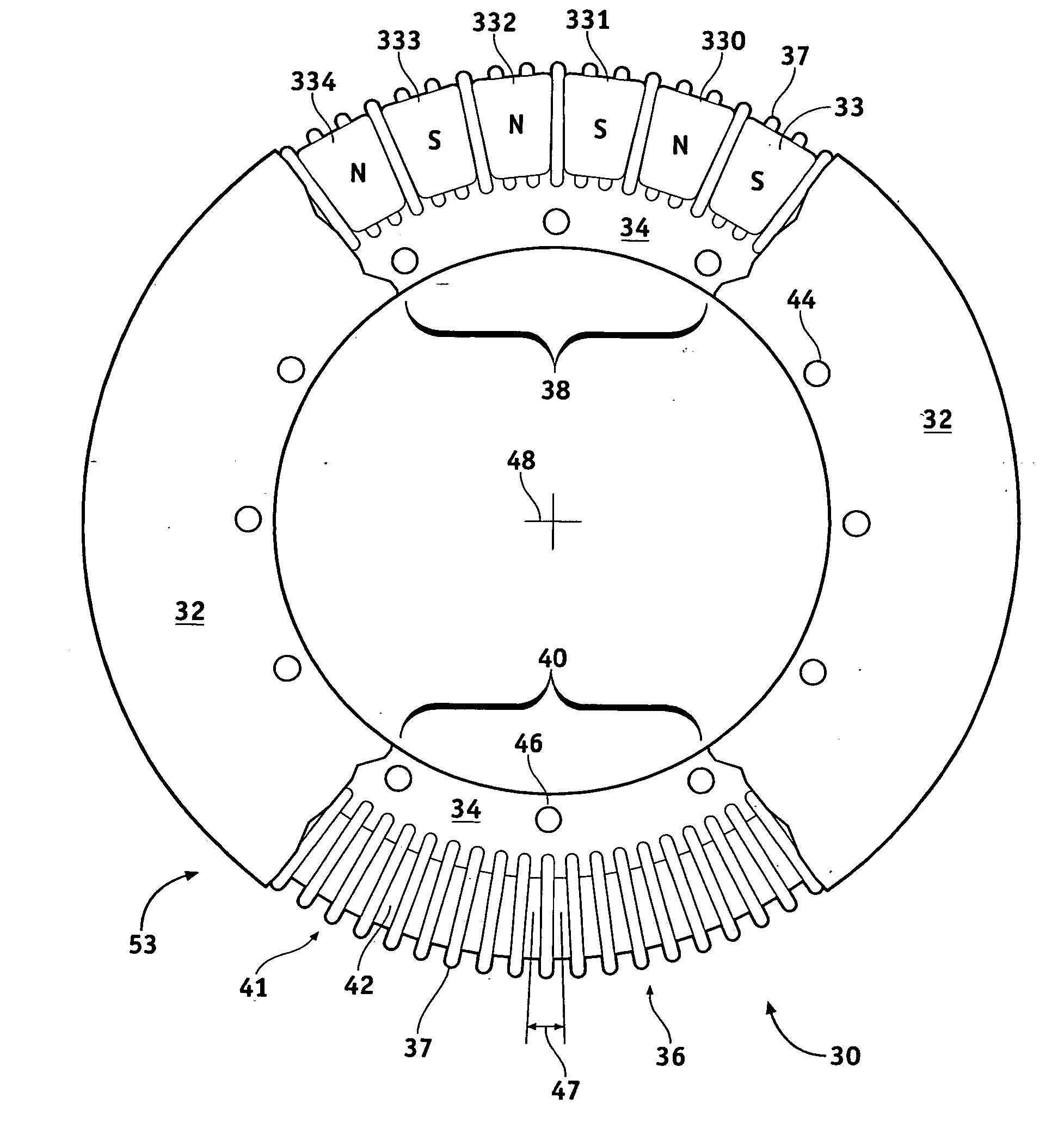

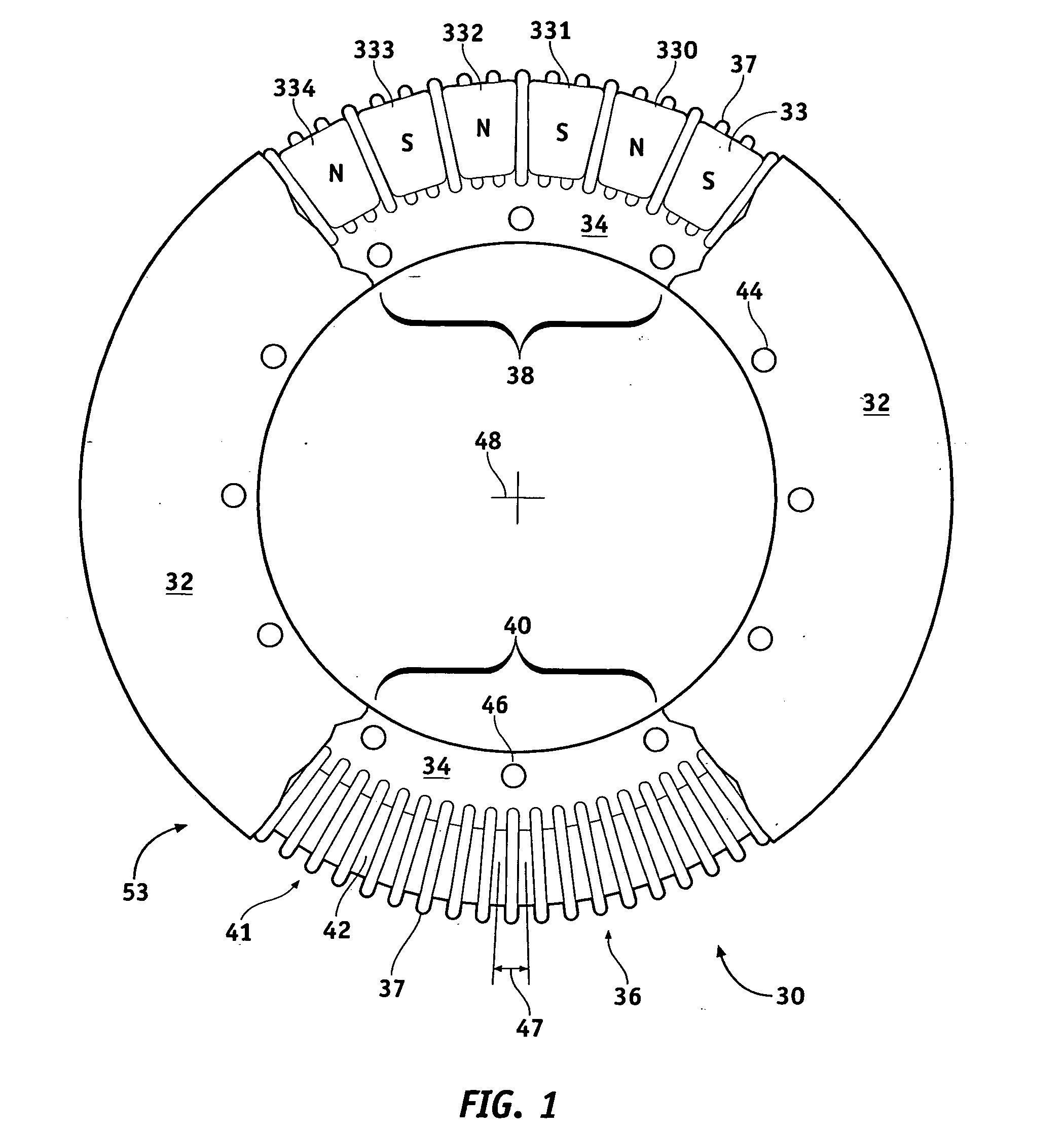

Wind turbine

InactiveUS7042109B2Improve efficiencyCost per unit power generationWindingsWind motor controlRotational energyAir core

A wind turbine for generating electrical power from wind energy includes a turbine rotor mounted for rotation in wind, and having multiple blades for converting energy in the wind into rotational energy. A generator is coupled with said turbine rotor such that said turbine rotor drives said generator. The generator has a stationary air core armature that is located in a magnetic airgap between two generator rotor portions. The generator rotor portions have circumferential arrays of multiple alternating polarity permanent magnets attached to ferromagnetic back irons such that the permanent magnets drive magnetic flux back and forth between each rotor portion and through the stationary air core armature. The stationary air core armature has multiple phase windings of multiple individually insulated strand conductor wire that is wound with two separate portions including an active length portion and an end turn portion. The end turn portion is located outside the magnetic airgap and traverses predominately circumferentially, and the active length portion is located in the magnetic airgap and traverses predominately non-circumferentially and perpendicular to the direction of the magnetic airgap. The end turn portion has a thickness that is greater than the thickness of said active length portion in the direction of said magnetic airgap. AC voltage is induced in the multiple phase windings as the turbine rotor rotates.

Owner:MARIAH POWER

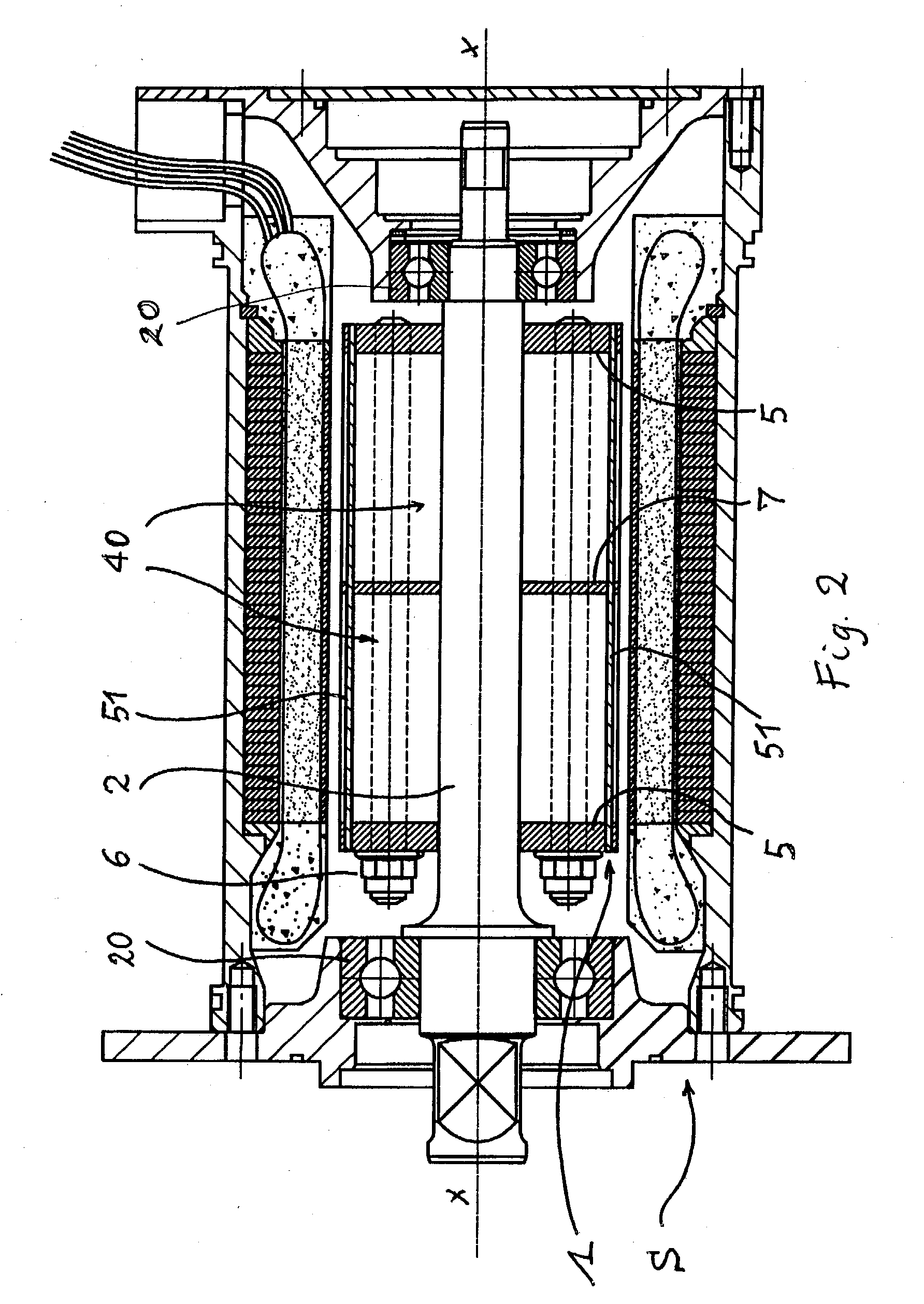

Blower with bearing tube

A blower includes a stationary portion including an inlet and an outlet, a rotating portion provided to the stationary portion, and a motor adapted to drive the rotating portion. The inlet and outlet are co-axially aligned. The stationary portion includes a housing, a stator component provided to the housing, and a tube providing an interior surface. The rotating portion includes one or more bearings that are provided along the interior surface of the tube to support a rotor within the tube. In an embodiment, the blower is structured to supply air at positive pressure.

Owner:RESMED MOTOR TECH

Controller for hybrid vehicle

InactiveUS6018694AGreat torque balanceStable vehicle behaviorWindingsPlural diverse prime-mover propulsion mountingElectricityControl system

A gas-sparing vehicle is achieved by a control system for a hybrid vehicle equipped at least with: a hybrid engine which includes at least a first rotary electric unit for deciding the rpm of the engine and a second rotary electric unit for deciding the driving force of the vehicle and which has power converting means connected to the output shaft of the engine; and electricity storing means. In one embodiment, a hybrid controller 16 controls the drive of a first rotary electric unit 2000 according to a startup torque command value which is decided based on the rpm of an engine at the time of engine startup and which decreases as the rpm increases; it also determines that the complete explosion in an engine 1 has occurred when the startup torque command value falls below a predetermined complete explosion judgment value.

Owner:DENSO CORP

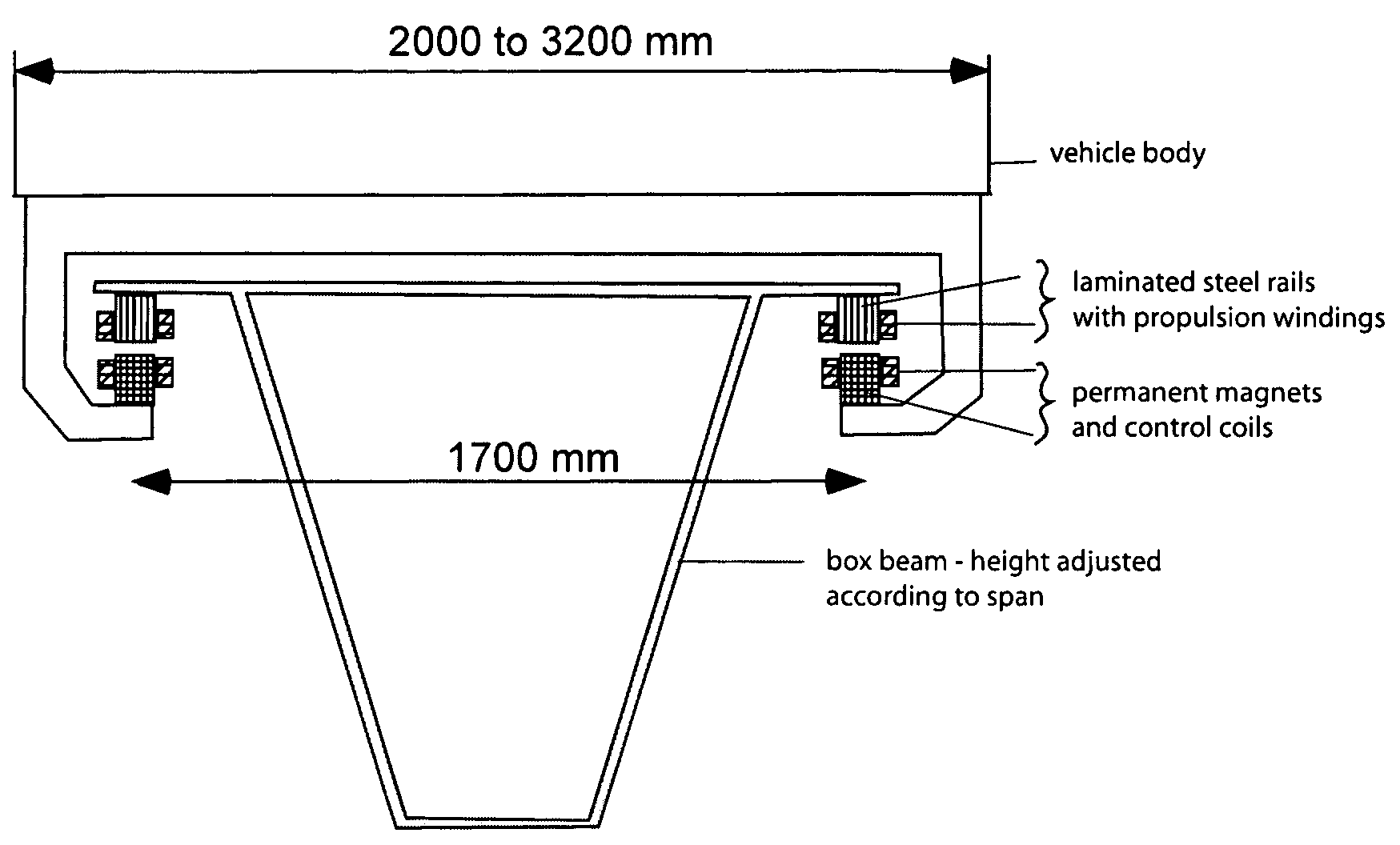

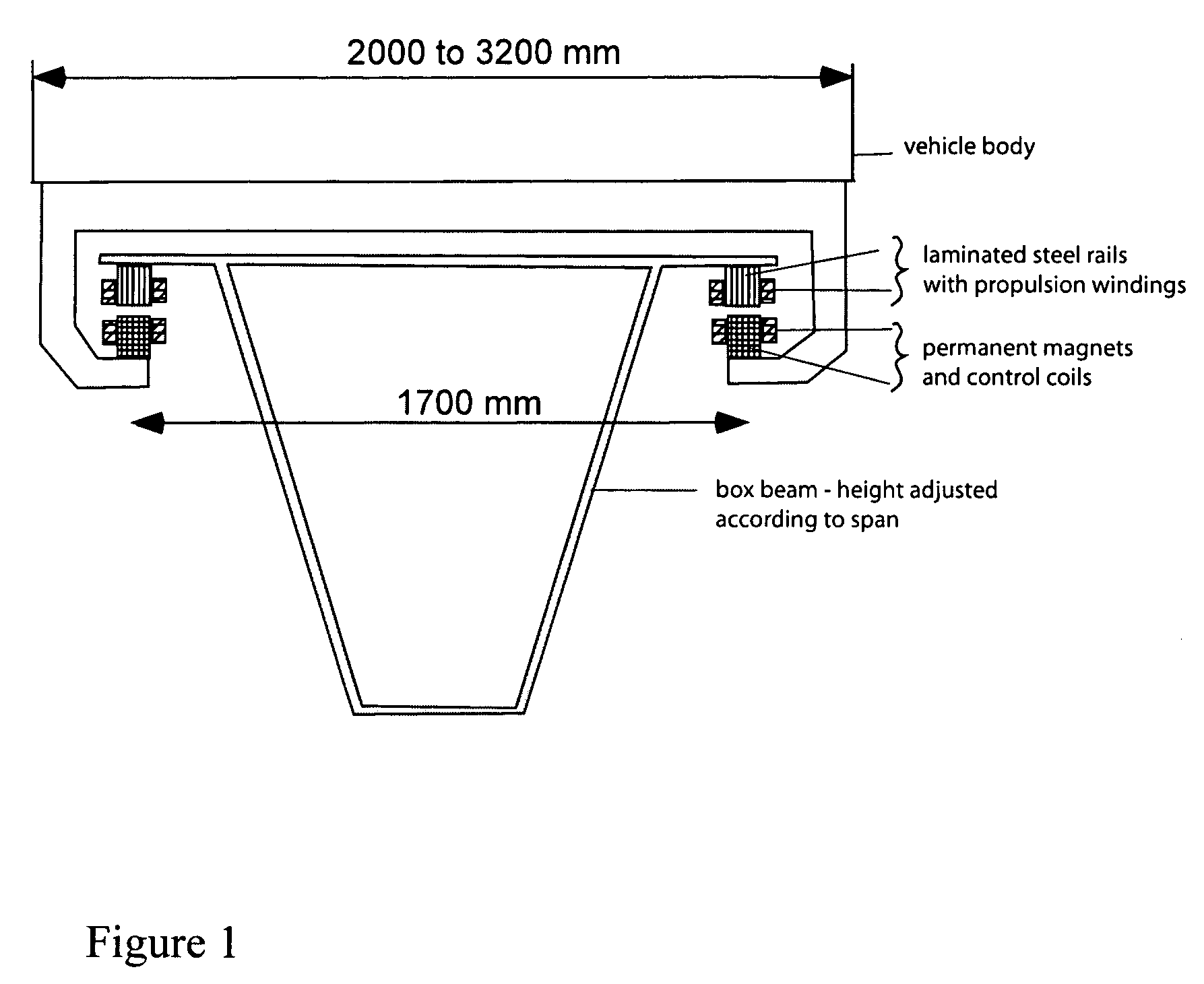

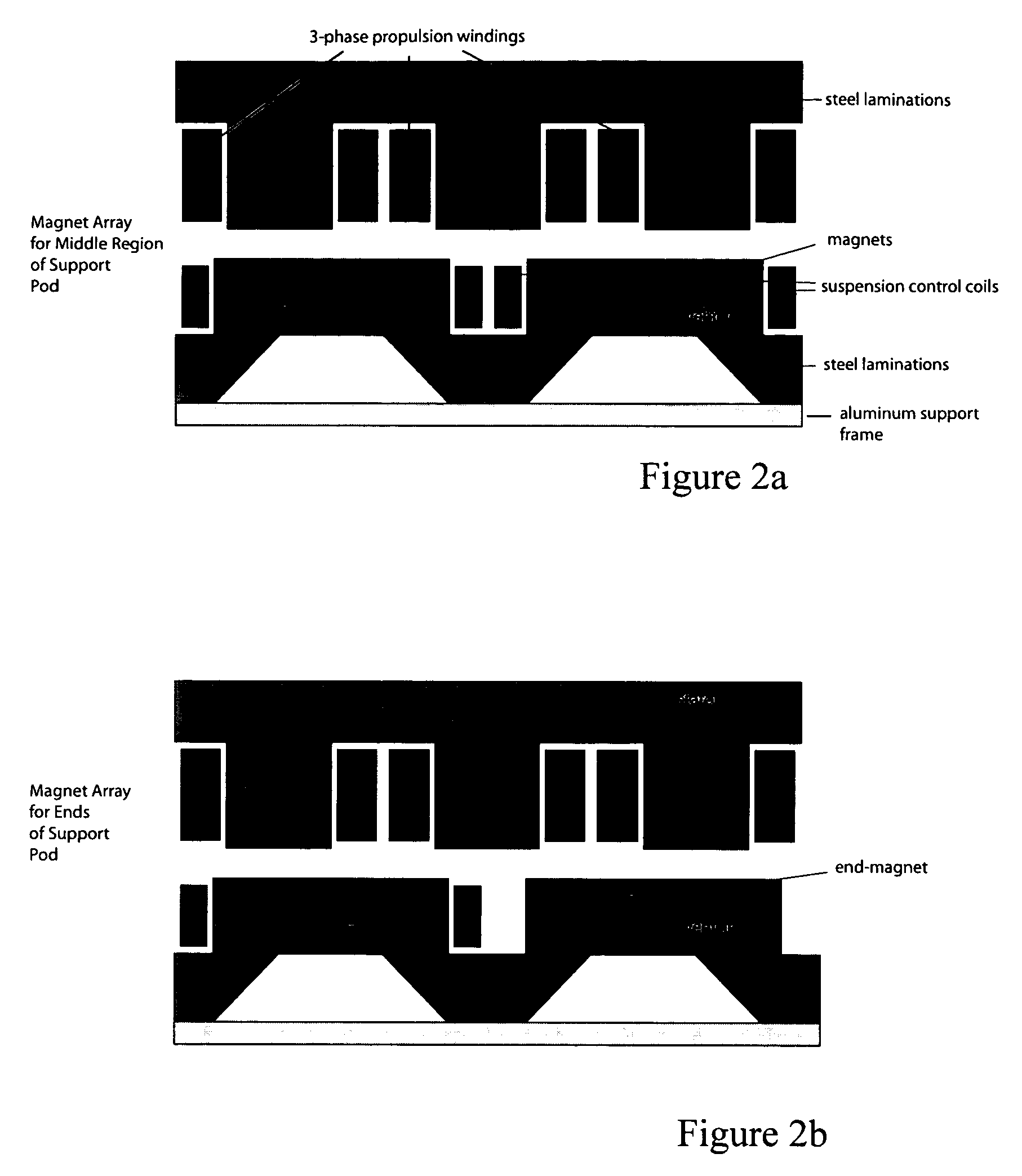

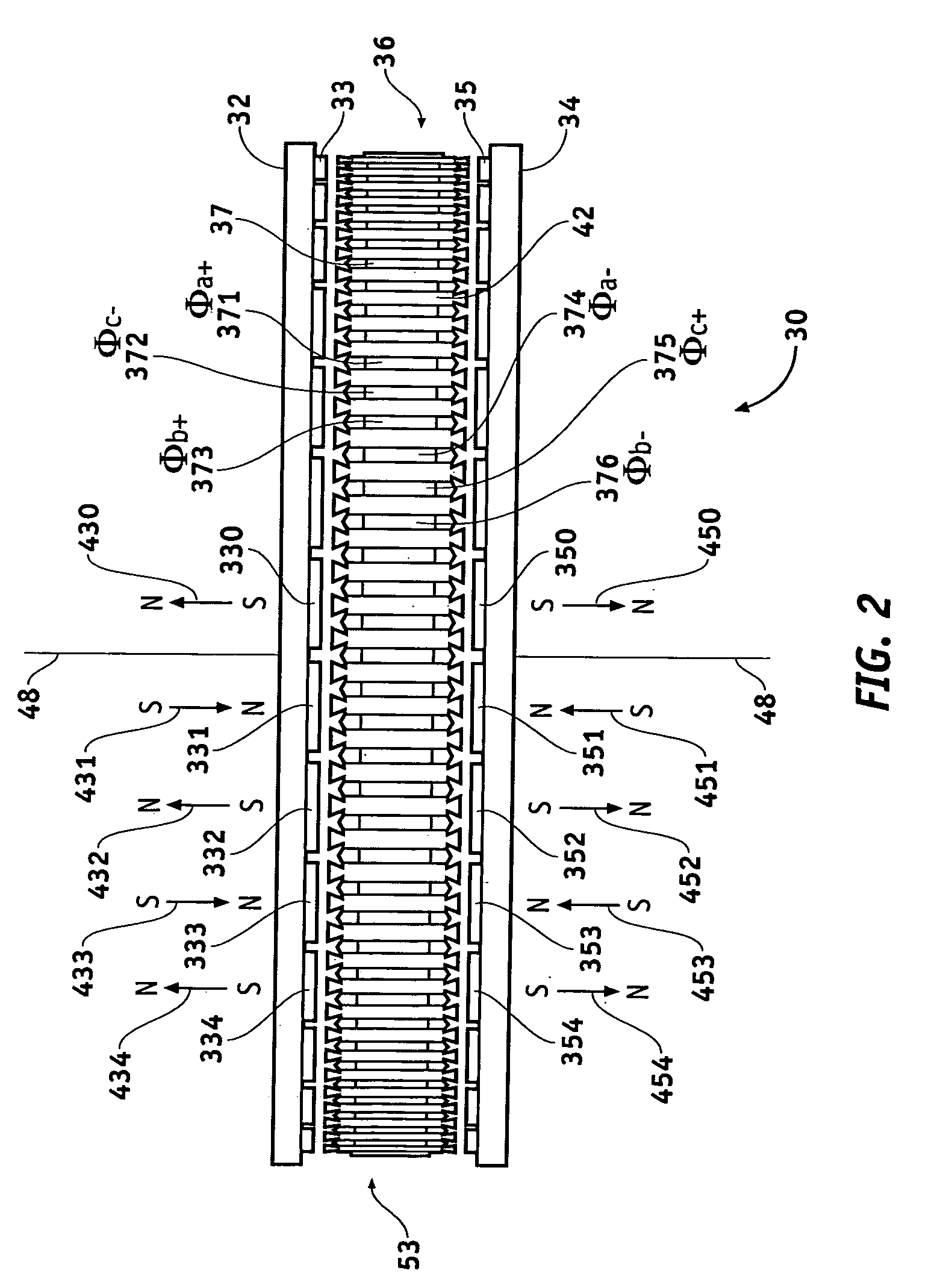

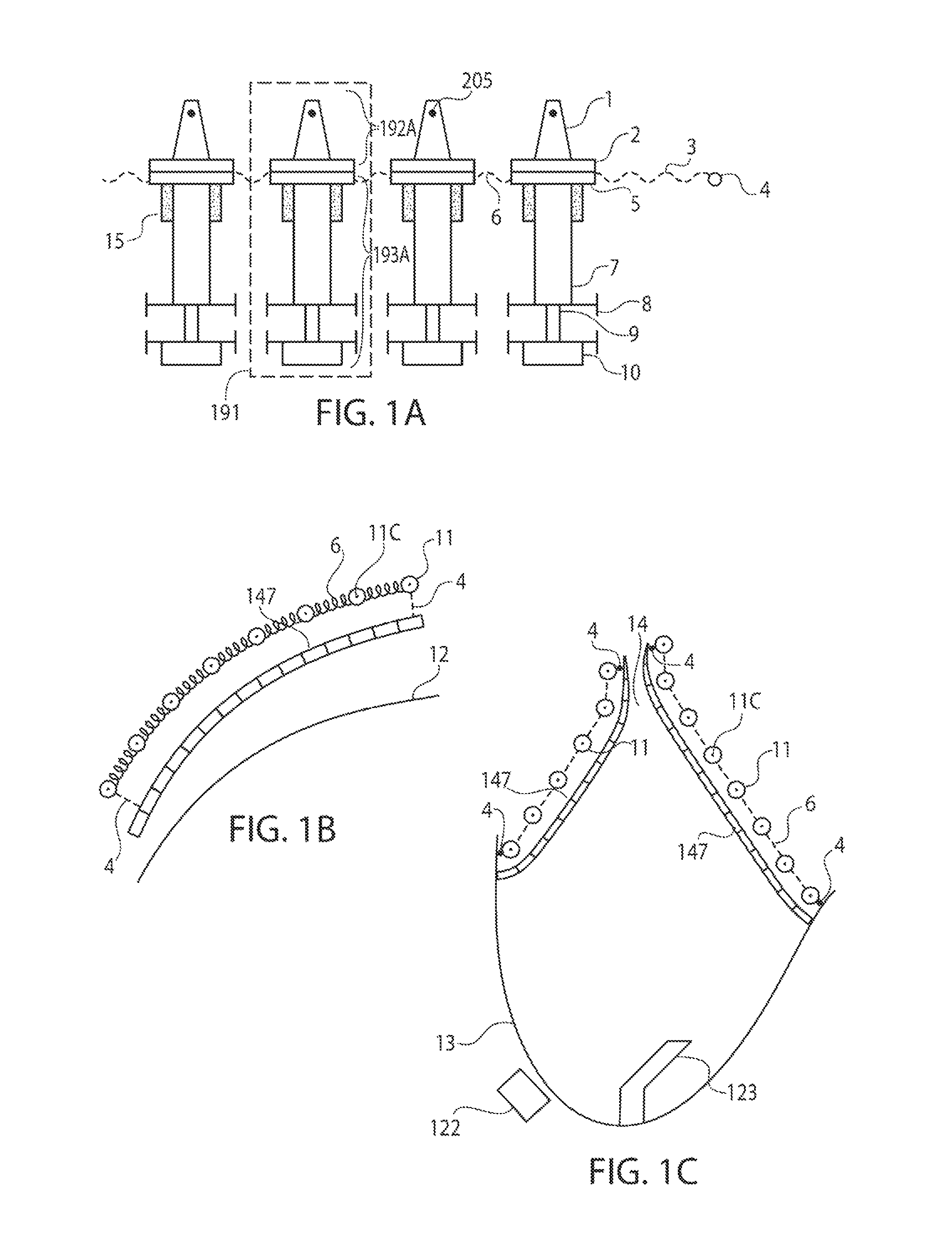

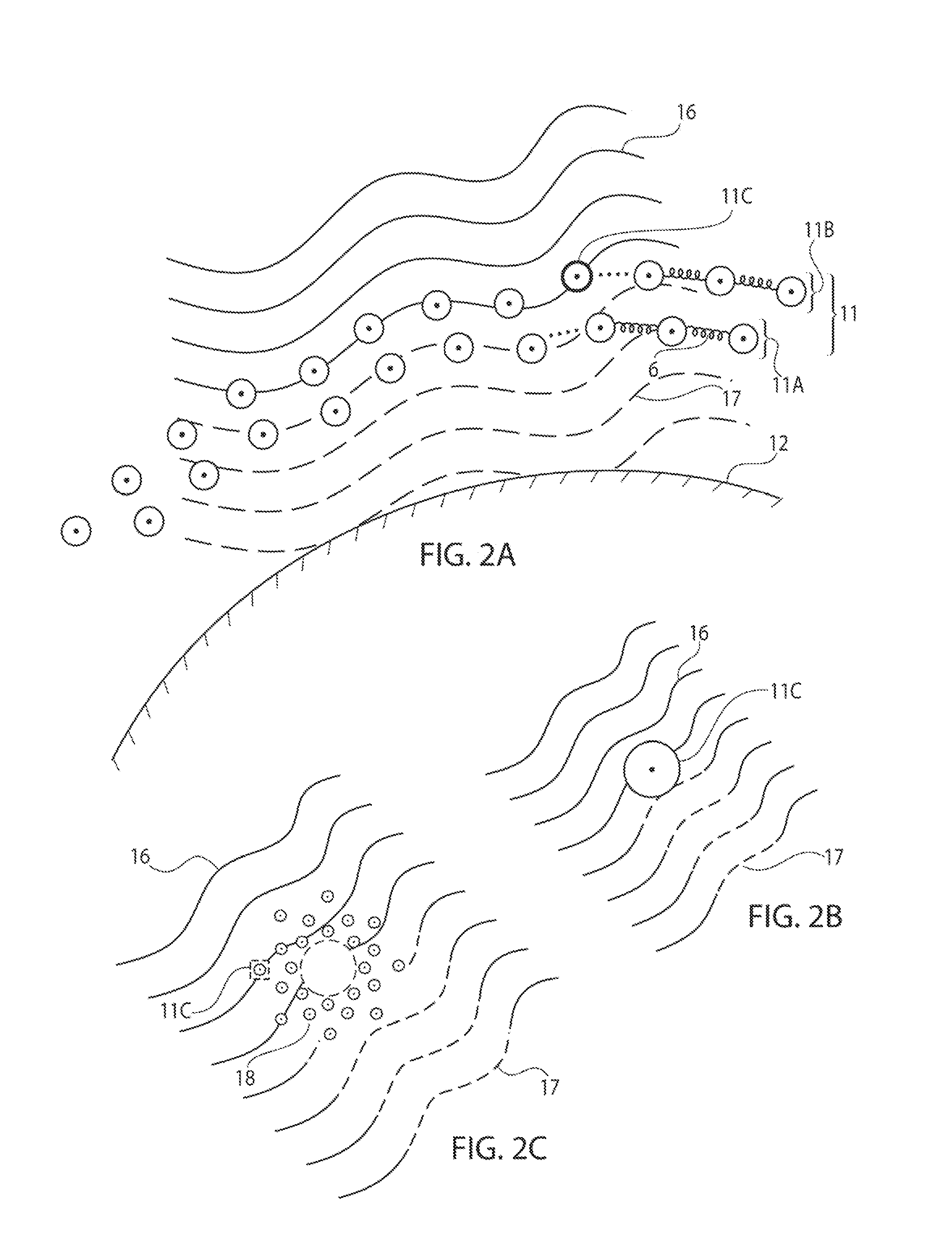

Suspending, guiding and propelling vehicles using magnetic forces

InactiveUS6983701B2Increase heightIncrease computing speedSynchronous generatorsWindingsMagnetic tension forceSuperconducting Coils

Magnetic levitation methods and apparatus use arrays of vehicle magnets to provide three forces: suspension, guidance and propulsion. The magnets, which can be permanent magnets or superconducting magnets operating in the persistent current mode, have associated control coils that allow the magnets to provide a controllable attractive force to a laminated steel rail. The control coils adjust the gap between the magnets and the rails so as to be in stable equilibrium without requiring significant power dissipation in the control coils. These same magnets and steel rails also provide lateral guidance to keep the vehicle on the track and steer the vehicle on turns. The suspension control coils can provide lateral damping by means of offset magnets in the suspension arrays. Windings in transverse slots in the steel rails are excited with currents that react against the field produced by the vehicle magnets to create vehicle propulsion. The magnet size is adjusted to provide negligible cogging force even when there are as few as three winding slots per wavelength along the rail. Means are used to mitigate end effects so that a multiplicity of magnet pods can be used to support the vehicle.

Owner:MAGNEMOTION INC

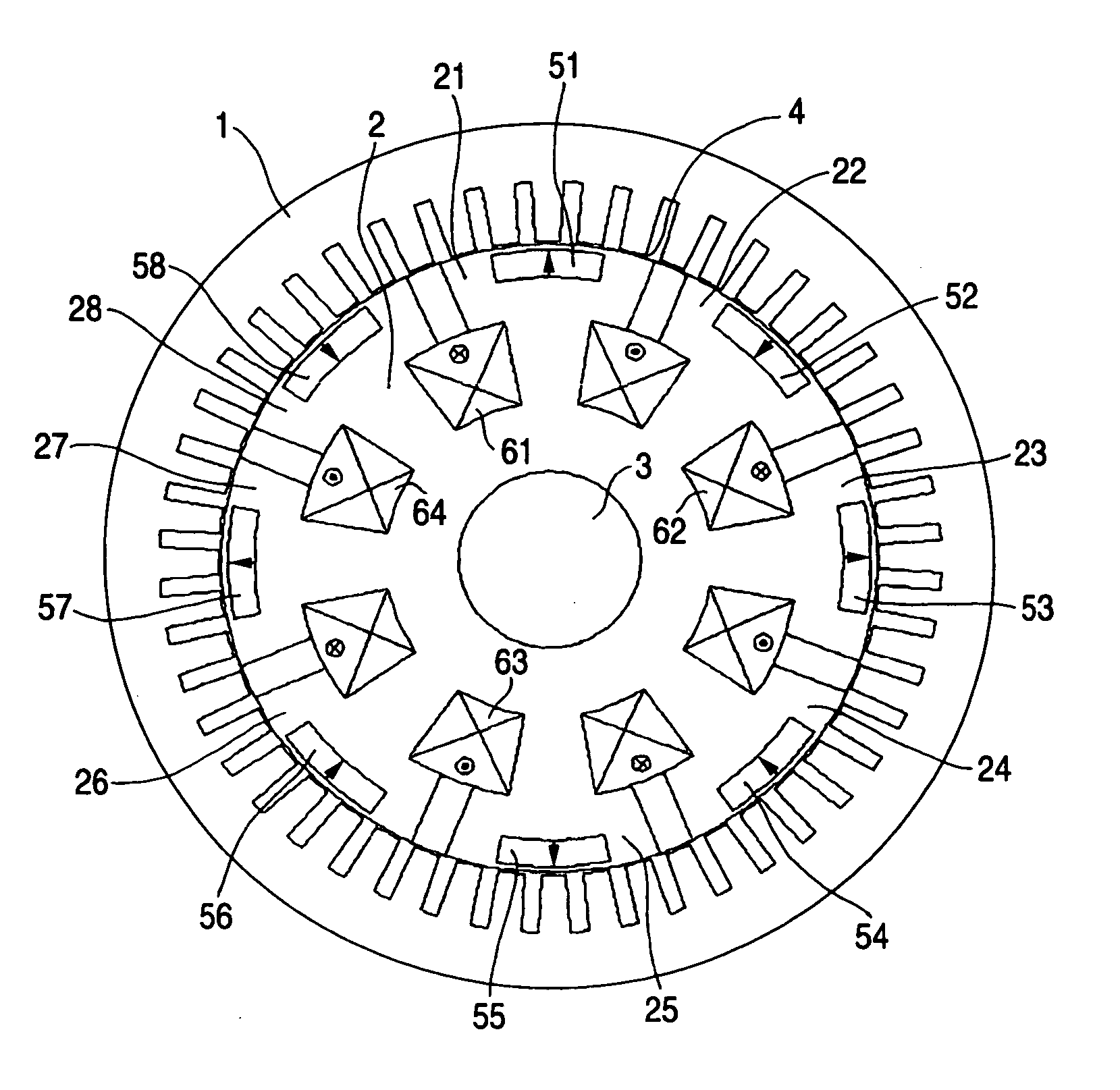

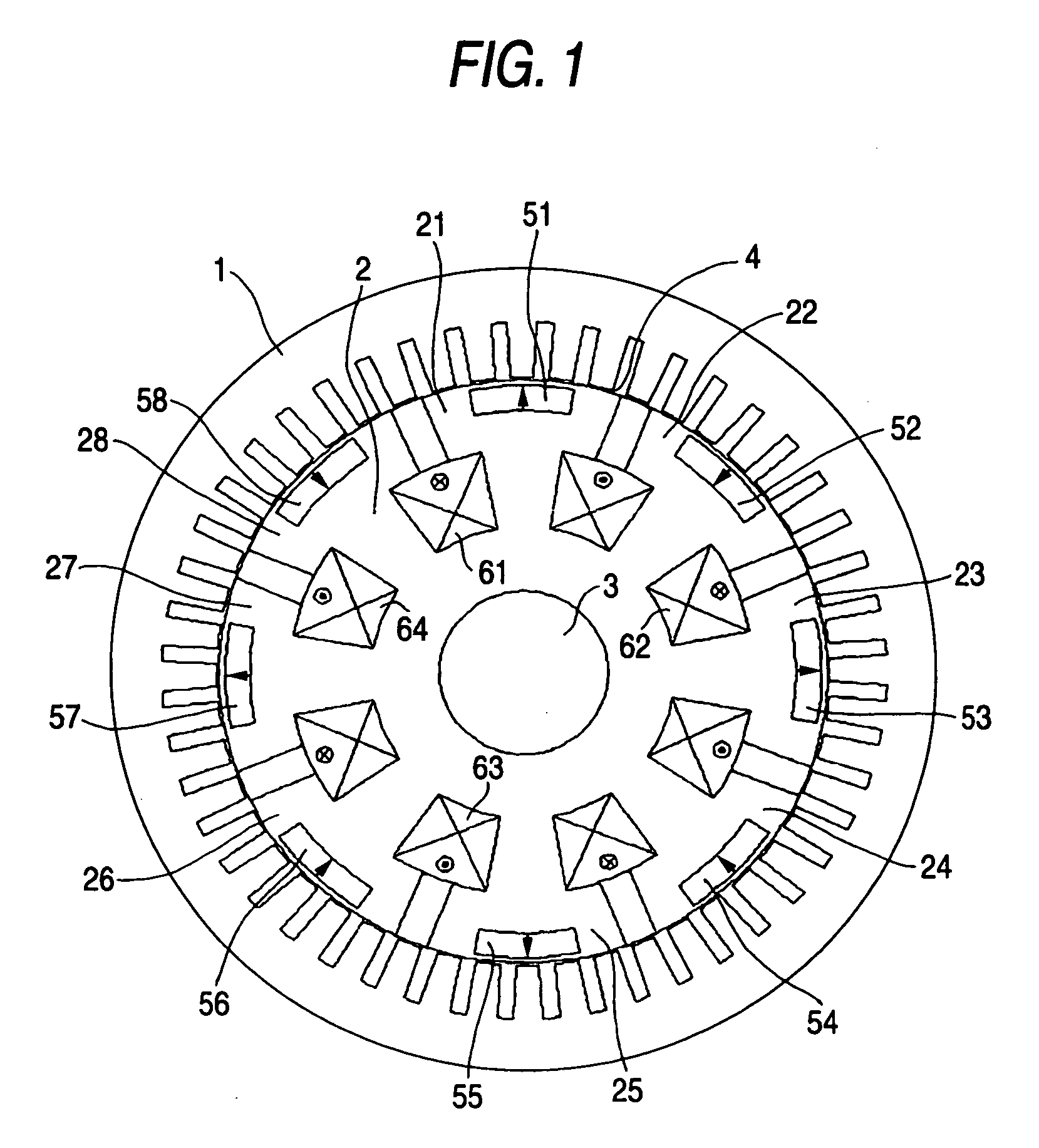

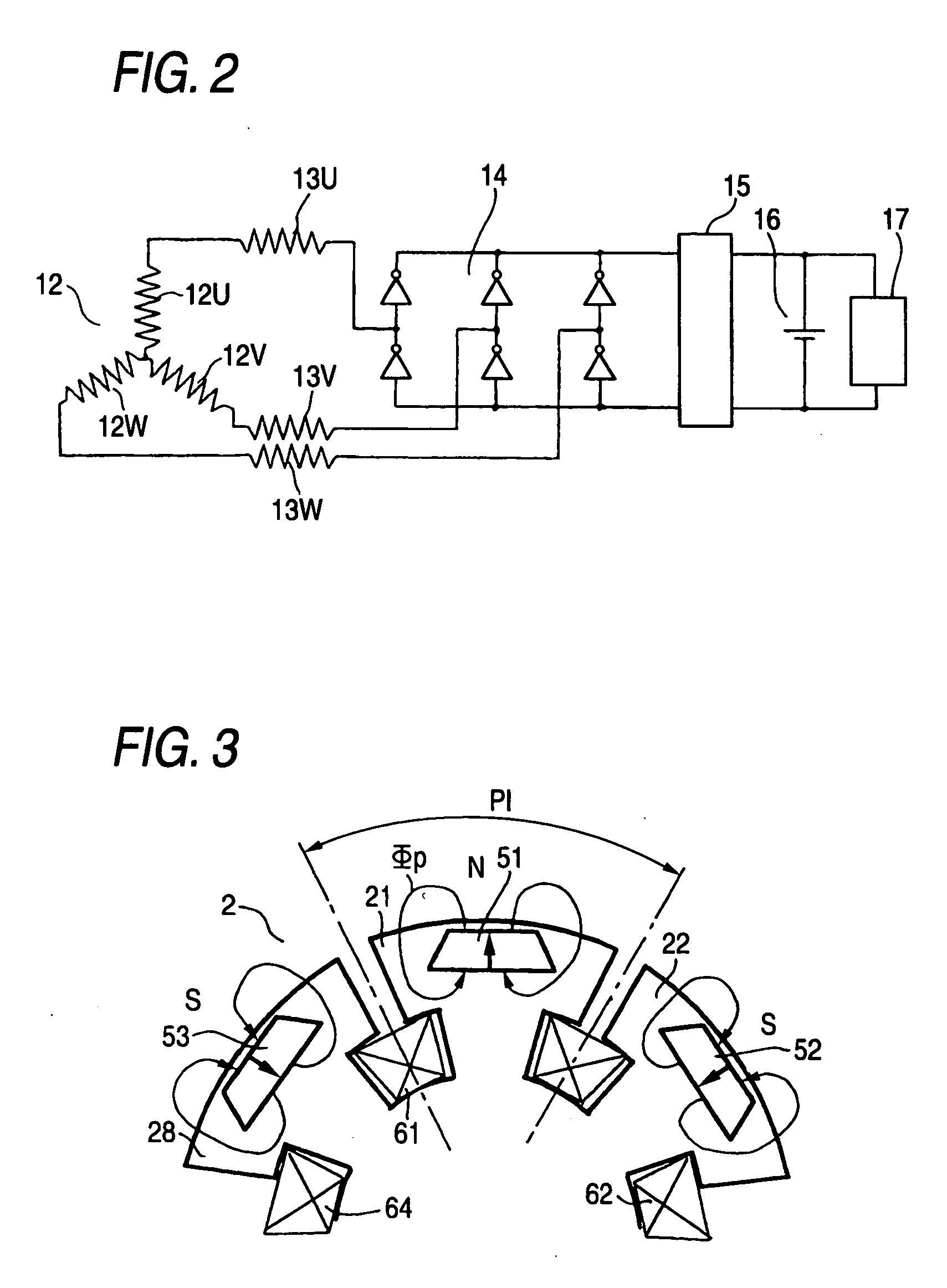

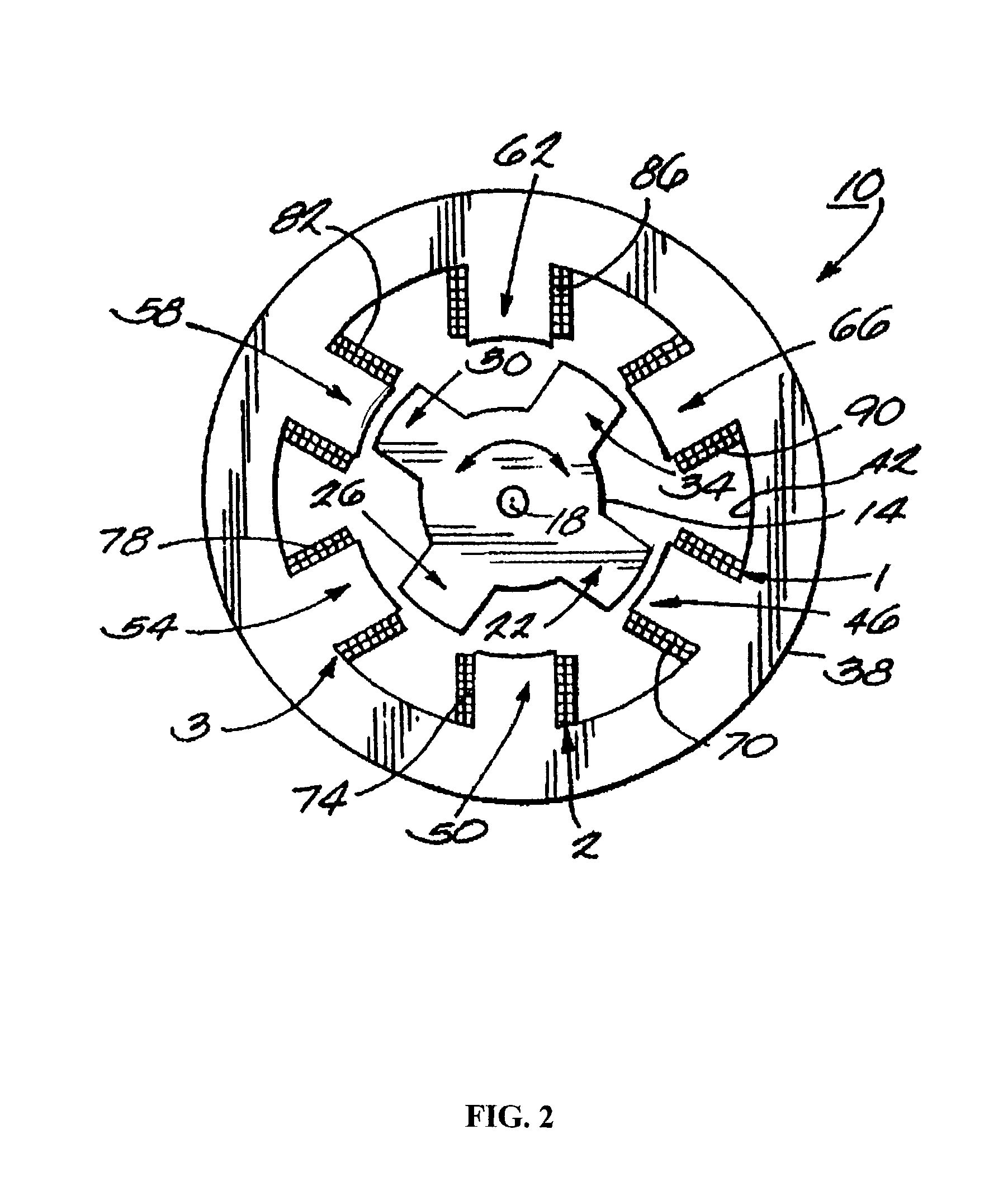

Hybrid-excited rotating machine, and vehicle with the hybrid-excited rotating machine

ActiveUS20070090713A1Increase total magnetic fluxIncrease torqueSynchronous generatorsWindingsEngineeringConductor Coil

A hybrid-excited rotating machine comprising: a stator winding 12 of a multi-phase Y-connection; a plurality of rotor magnetic poles 21, 22, 23, 24, 25, 26, 27, 28 fixed on a rotor shaft 3 at a predetermined spacing in the circumferential direction and confronting the inner circumference of said stator 1 through a air gap; a plurality of permanent magnets 51, 52, 53, 54, 55, 56, 57, 58 fixed at substantially central portions of said circumferential direction of said individual rotor magnetic poles and magnetized in the radial direction of said rotor shaft; and a plurality of field windings 61, 62, 63, 64, 65, 66, 67, 68 wound individually on said rotor magnetic poles.

Owner:MITSUBISHI ELECTRIC CORP

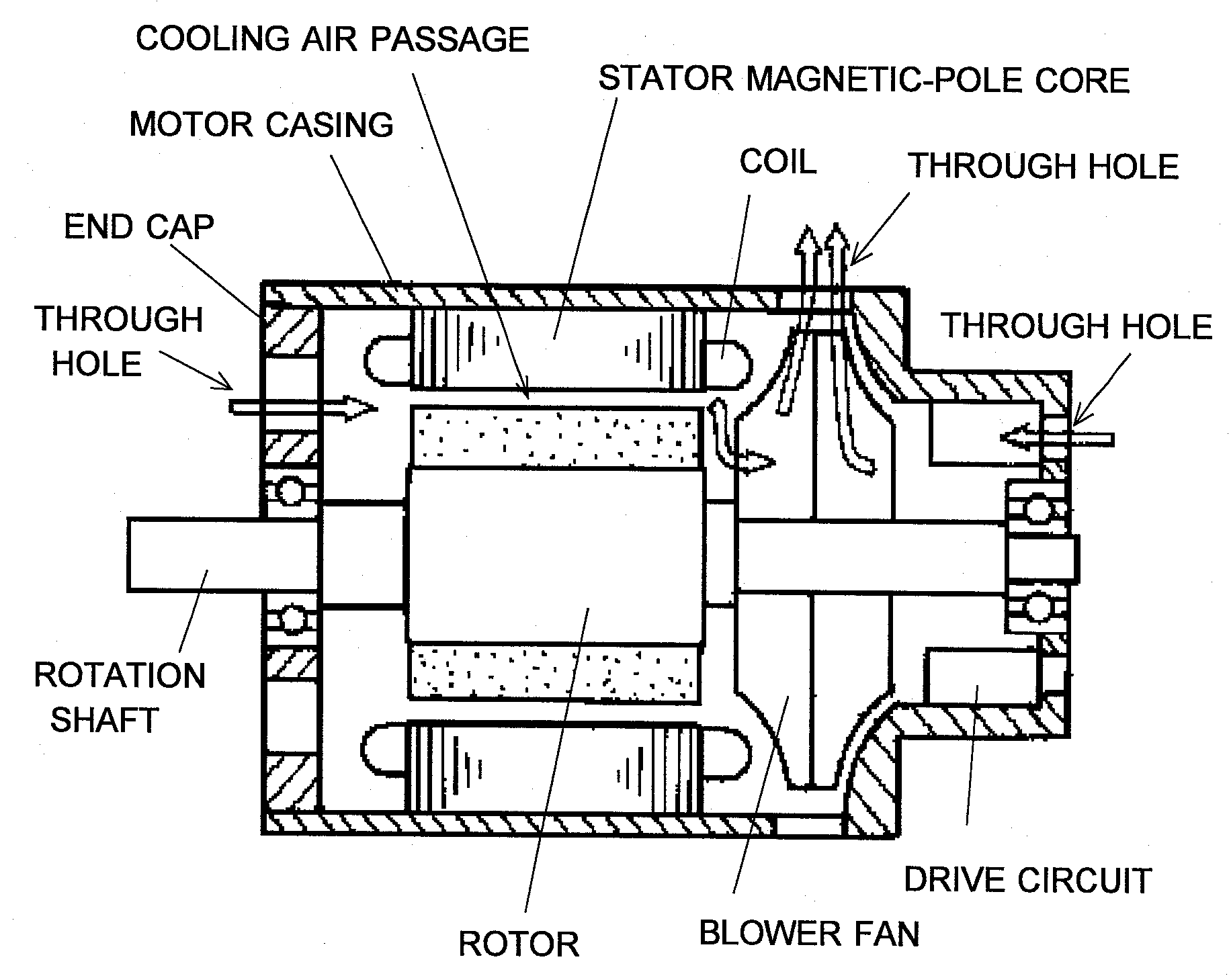

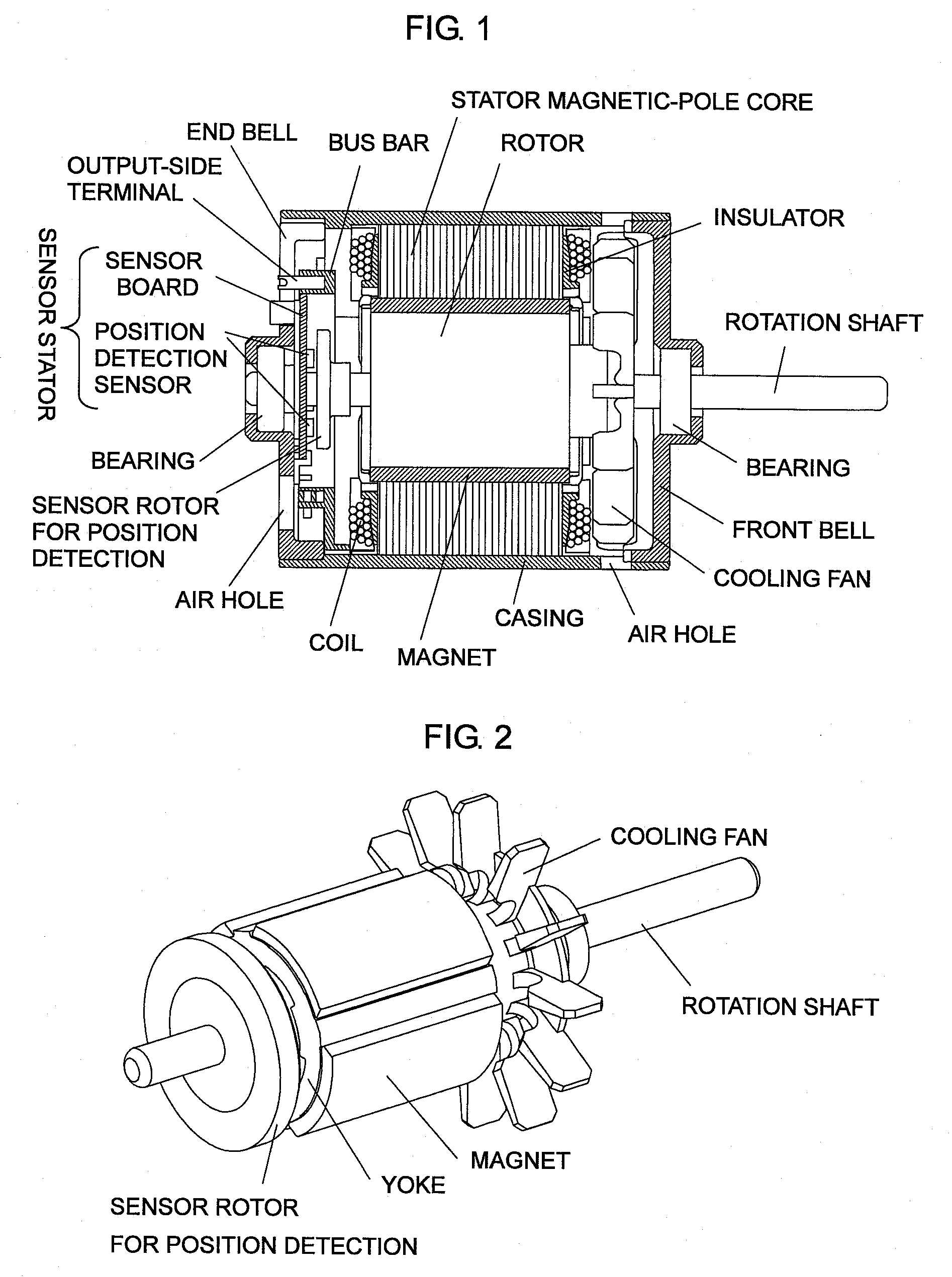

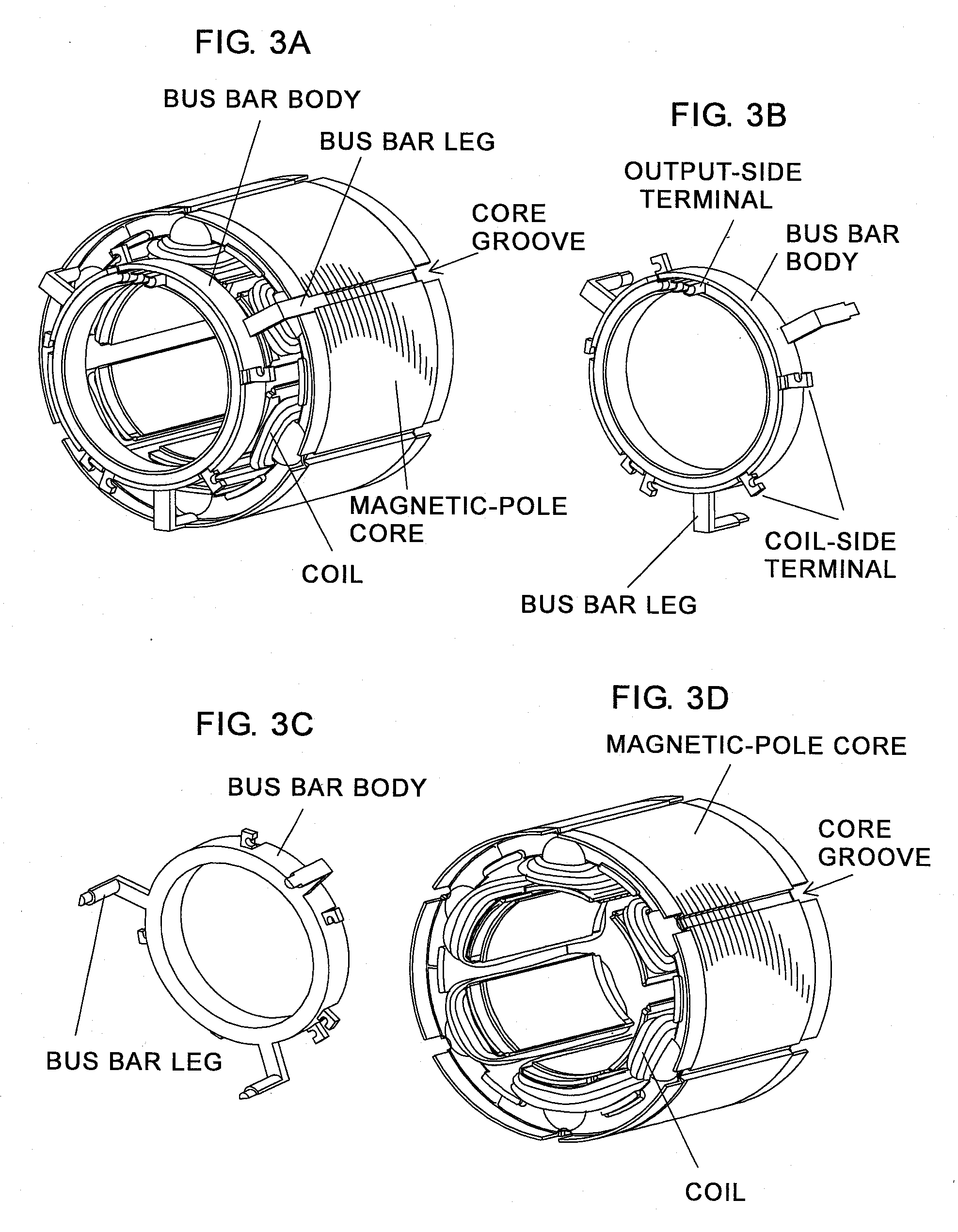

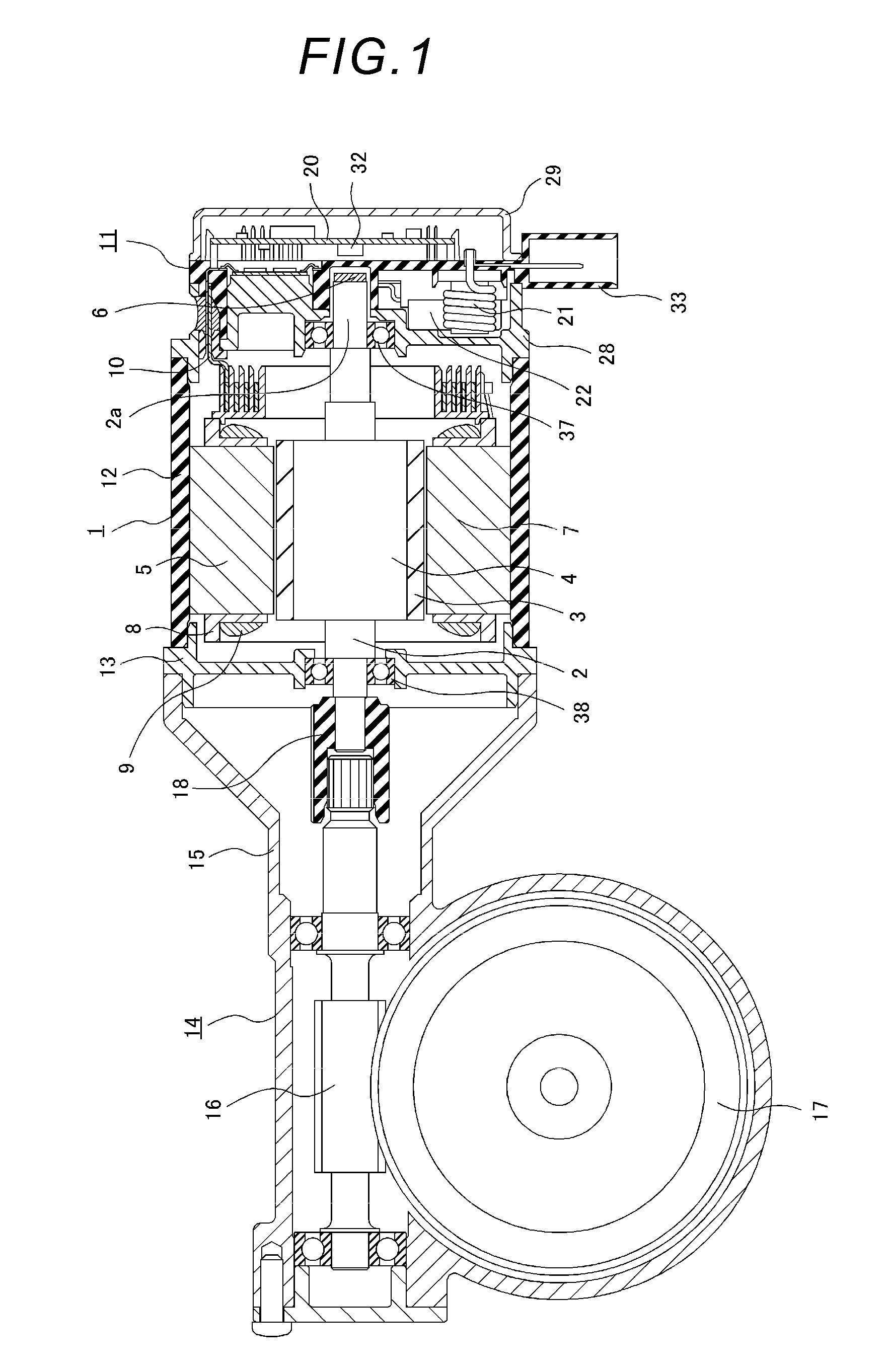

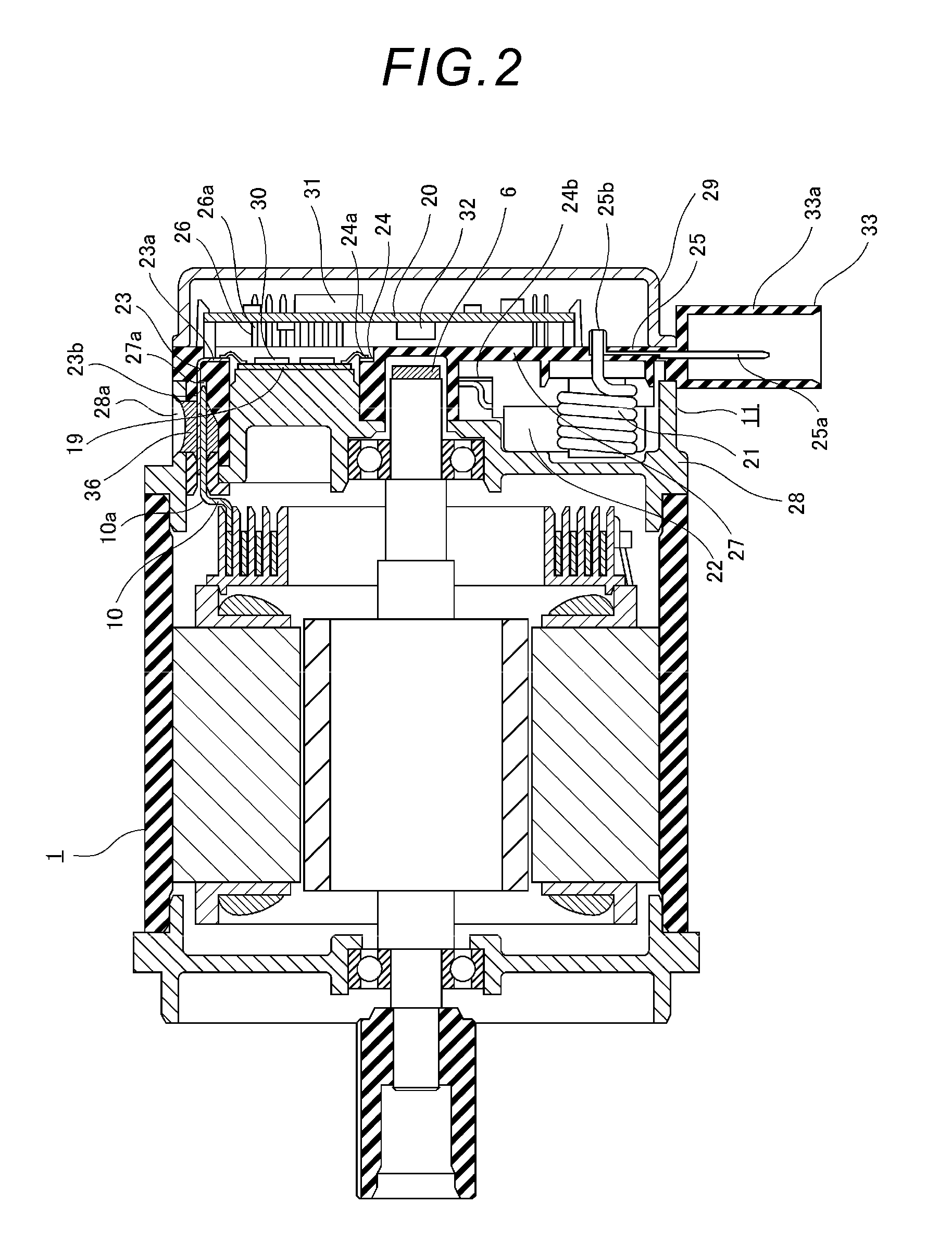

Brushless motor

InactiveUS20070273221A1Improve cooling efficiencyIncrease airflowWindingsDC commutatorBrushless motorsMagnetic poles

A plurality of coils wound around a stator magnetic-pole core are connected together and connected to output wires by use of a bus bar. The bus bar having a generally cylindrical body portion is disposed at one axial end of the stator magnetic-pole core, around which the coils are wound such that clearances are formed within magnetic-pole core slots, with an axial clearance formed between the bus bar and the coils. The body portion has such a radial dimension that at least a portion of the clearances within the magnetic-pole core slots is left uncovered. Air holes are formed in the motor housing on opposite sides of the stator magnetic-pole core to thereby form cooling air passages extending through the magnetic-pole core slots.

Owner:MABUCHI MOTOR

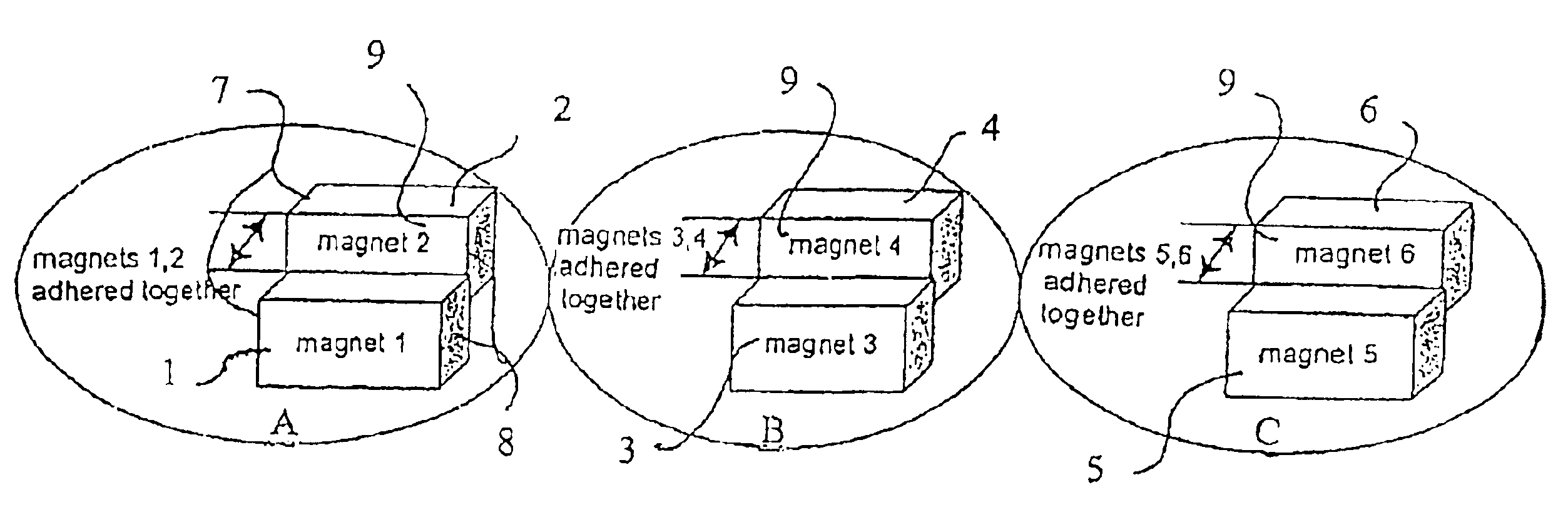

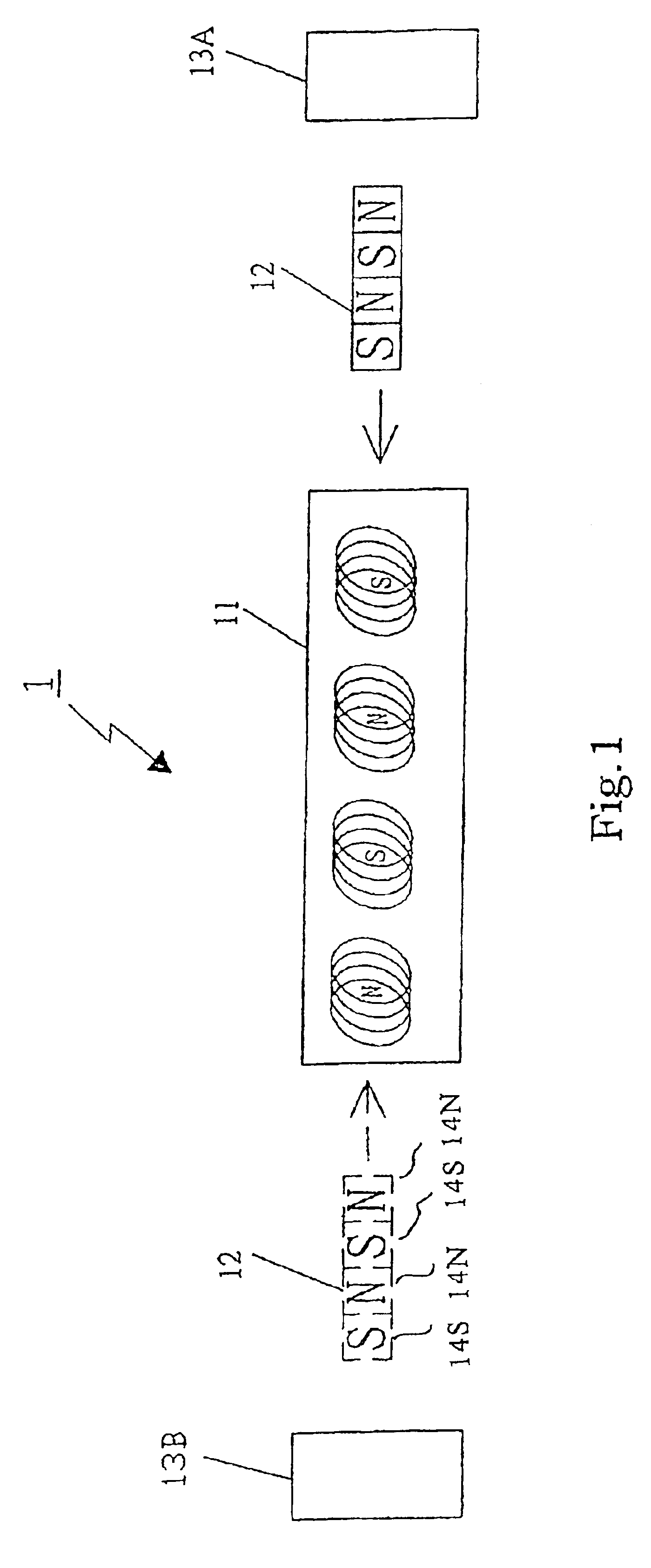

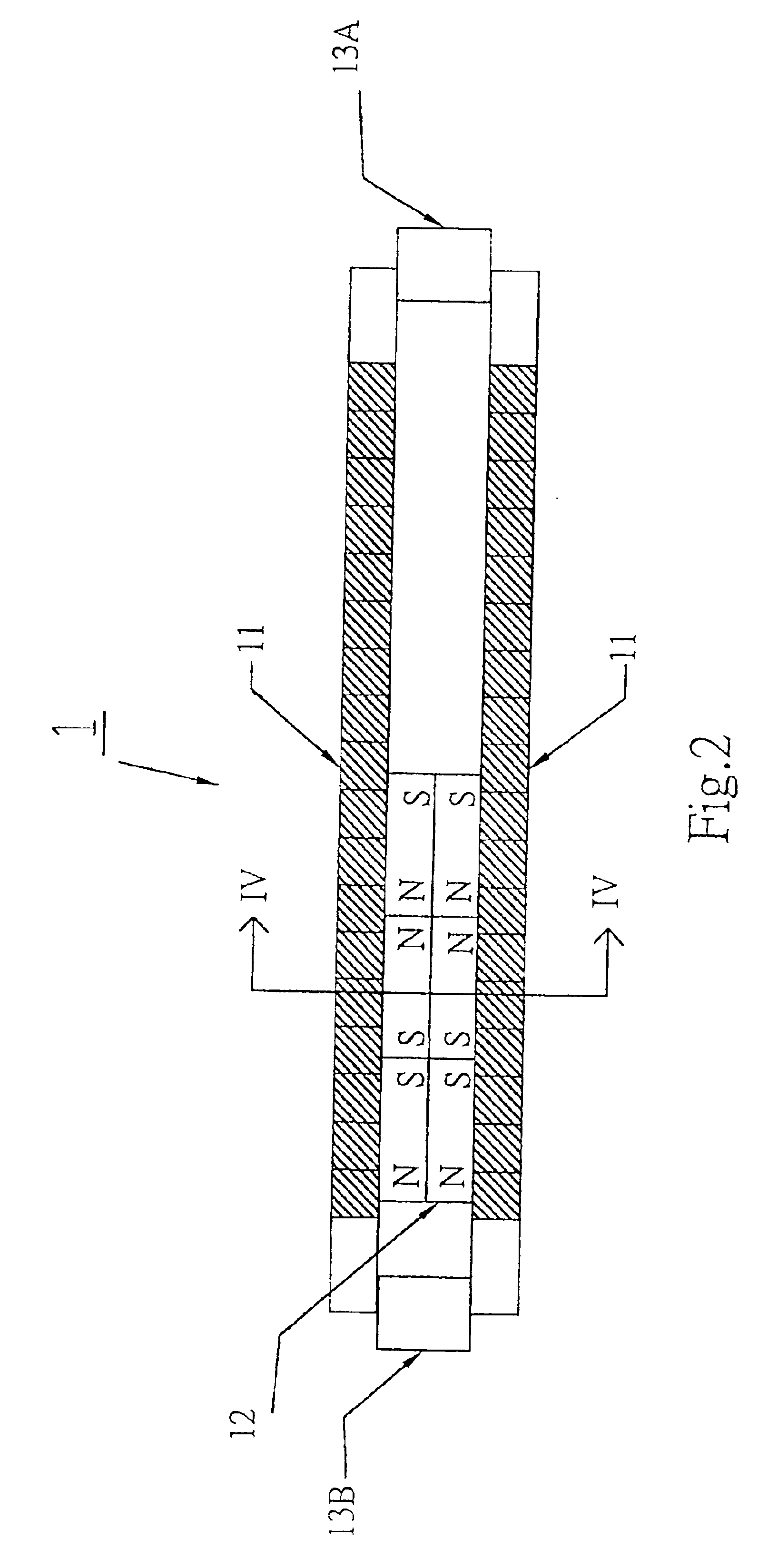

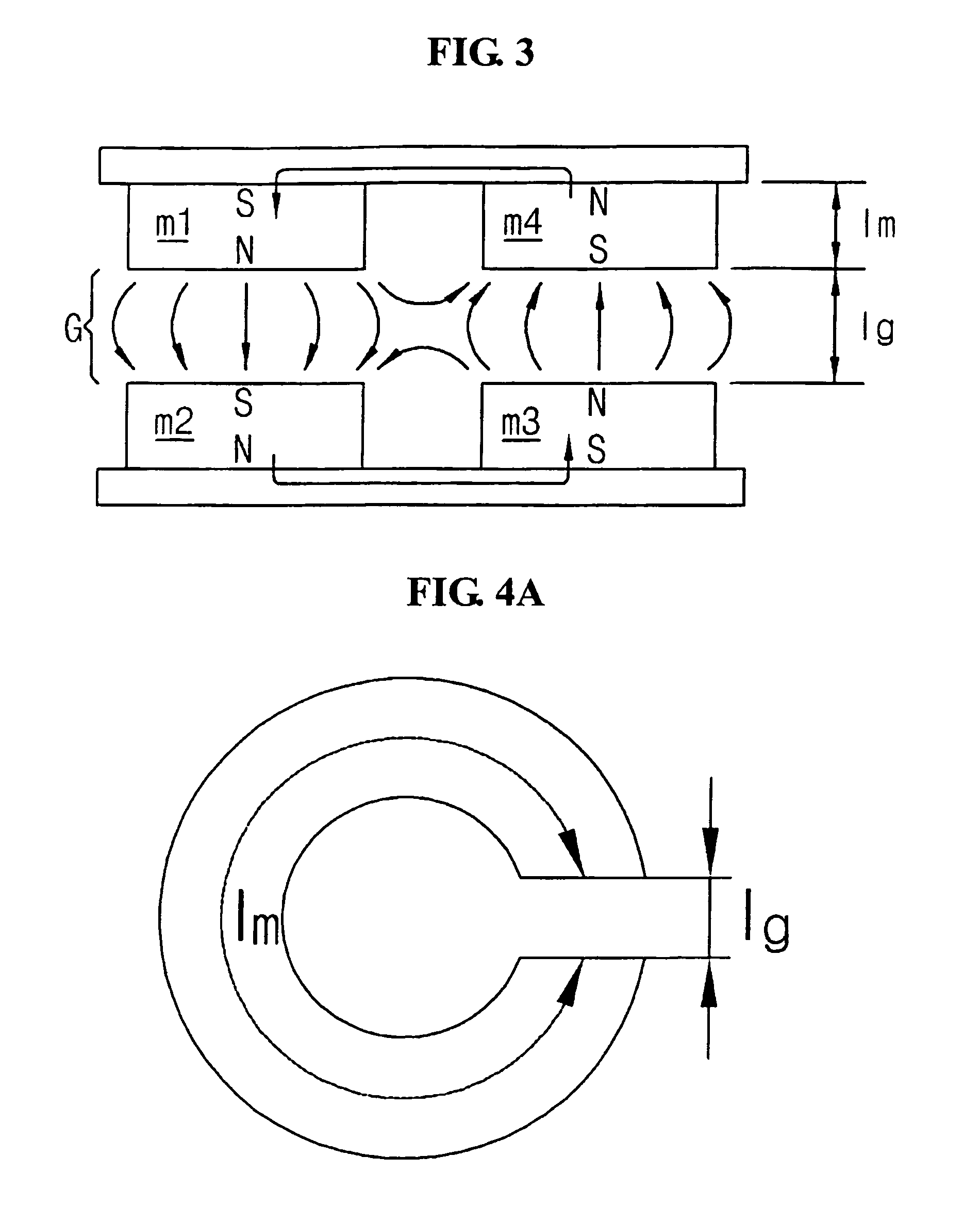

Linear electric generator having an improved magnet and coil structure, and method of manufacture

InactiveUS6936937B2Reduce demandIncrease demandWindingsMagnetic circuitReciprocating motionElectrical polarity

Linear electric generators include stationary windings and armature magnets arranged to reciprocate axially relative to the windings, or stationary magnet structures and movable windings arranged to reciprocate relative to the stationary magnet structures. The armature magnets or stationary magnet structures are in the form of multiple pole magnets made up of a plurality of individual pole structures, each pole structure including a pair of magnets joined to each other with facing poles of like polarity. In addition, the windings may be in the form of a double winding structure including at least one first clockwise winding and at least one second counterclockwise winding arranged in a multi-layered stacked arrangement.

Owner:SUNYEN CO LTD

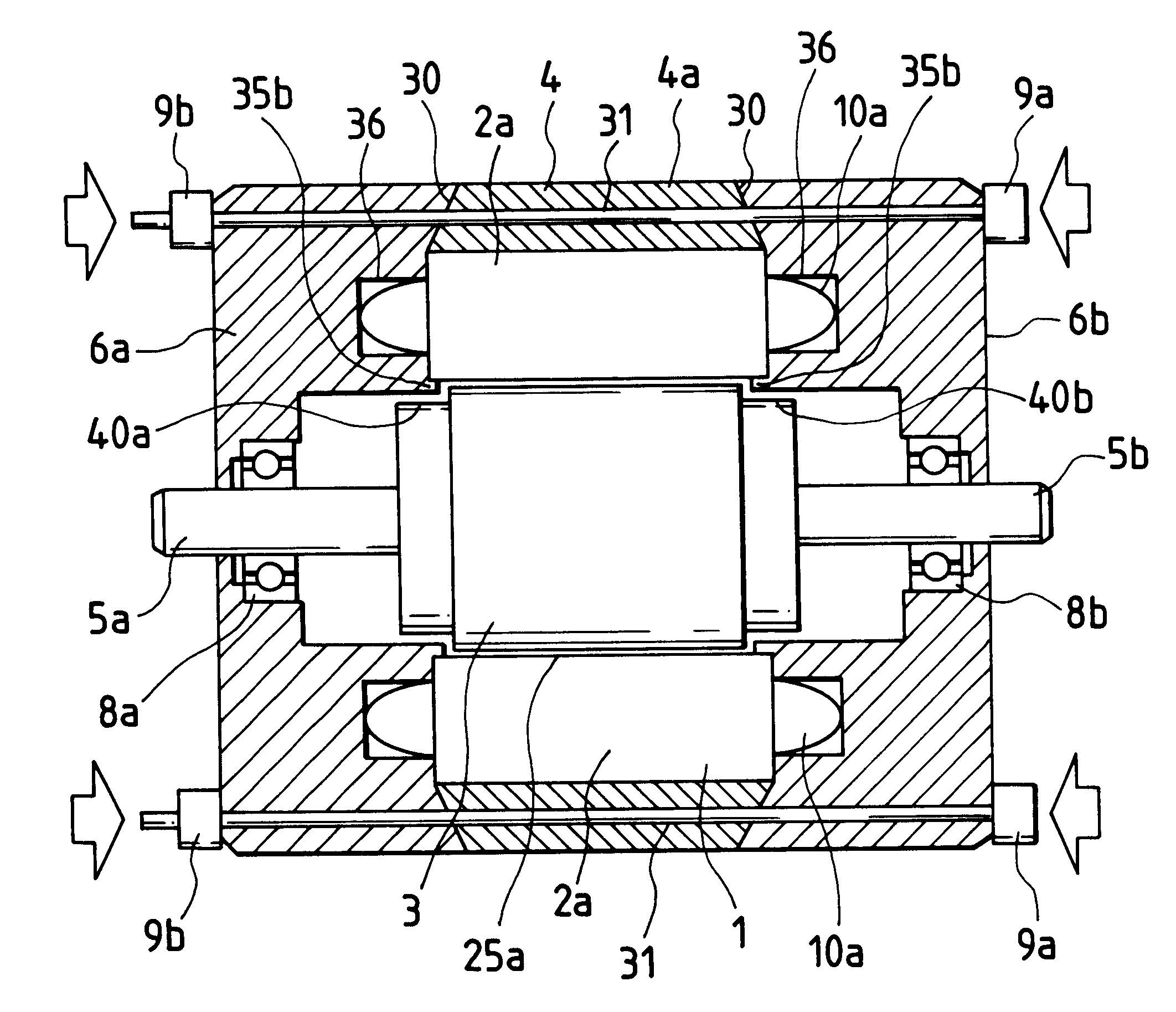

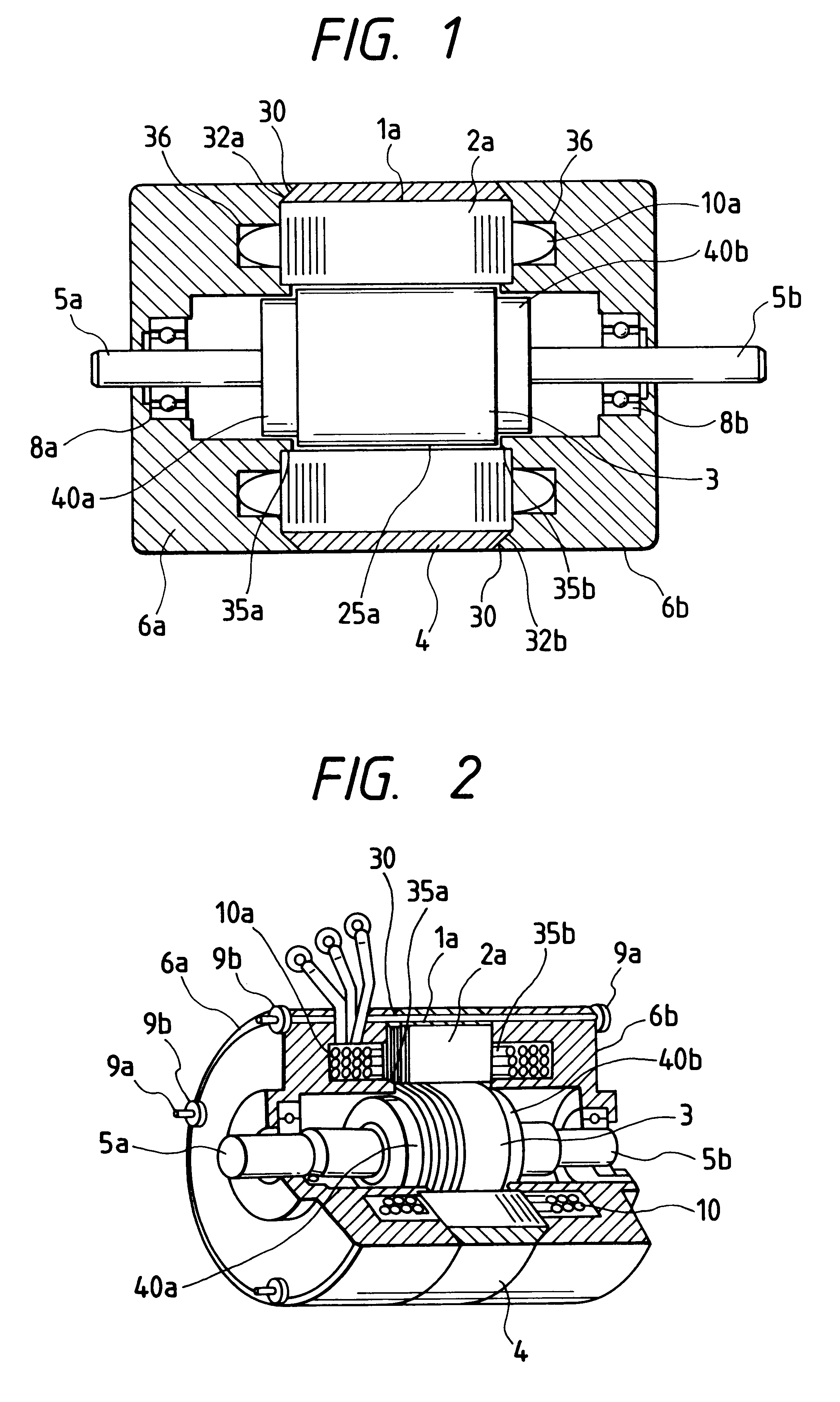

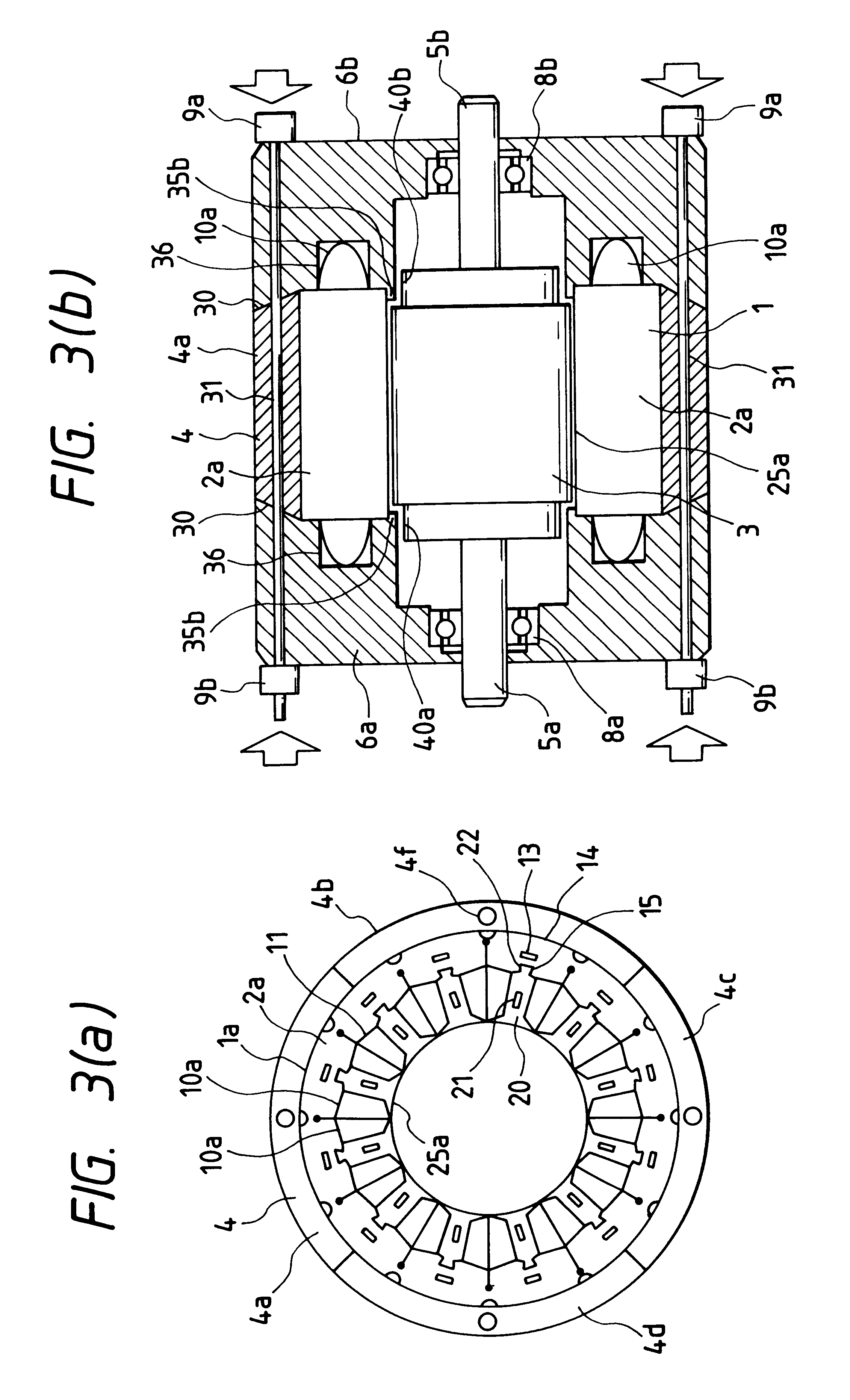

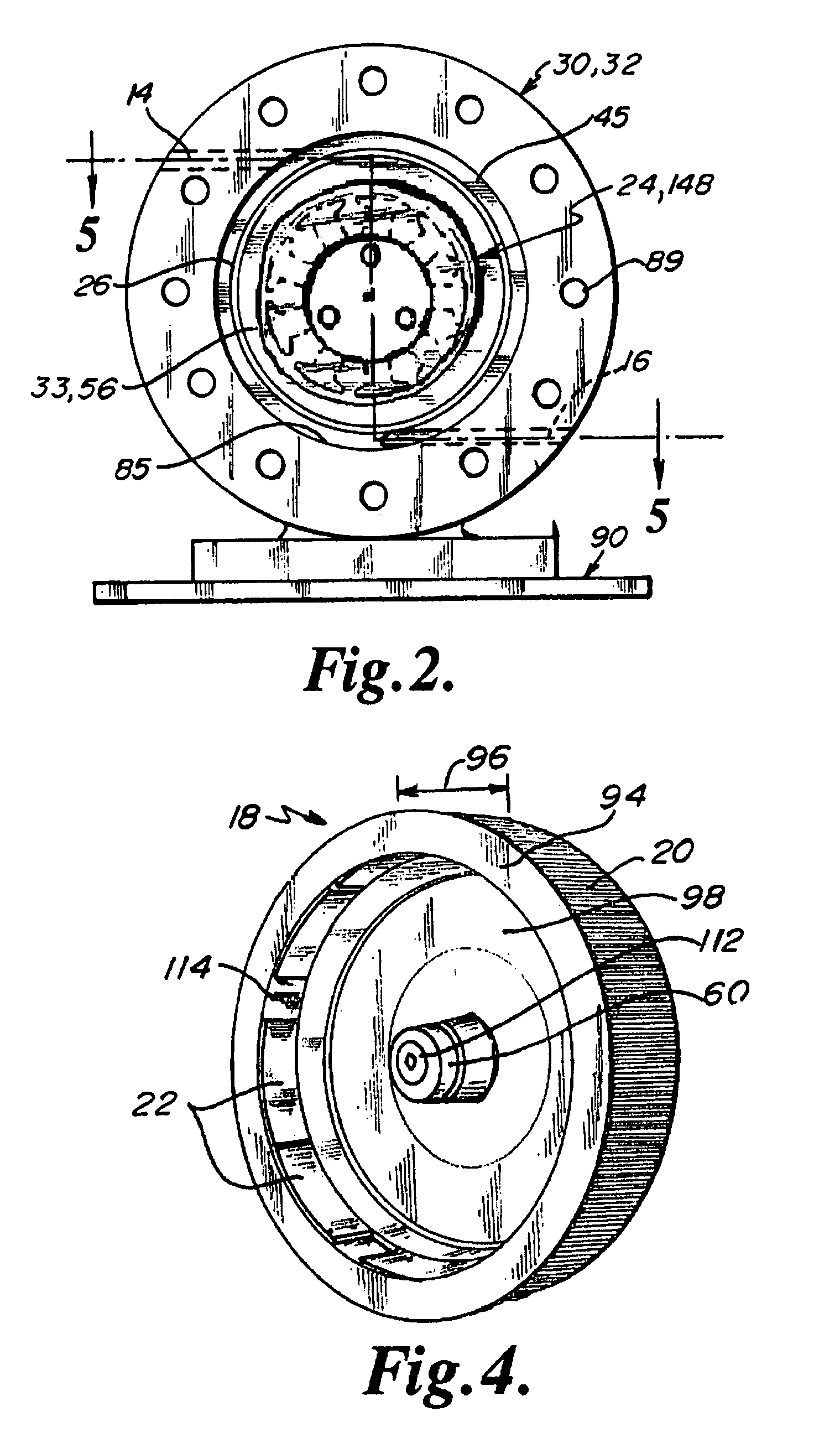

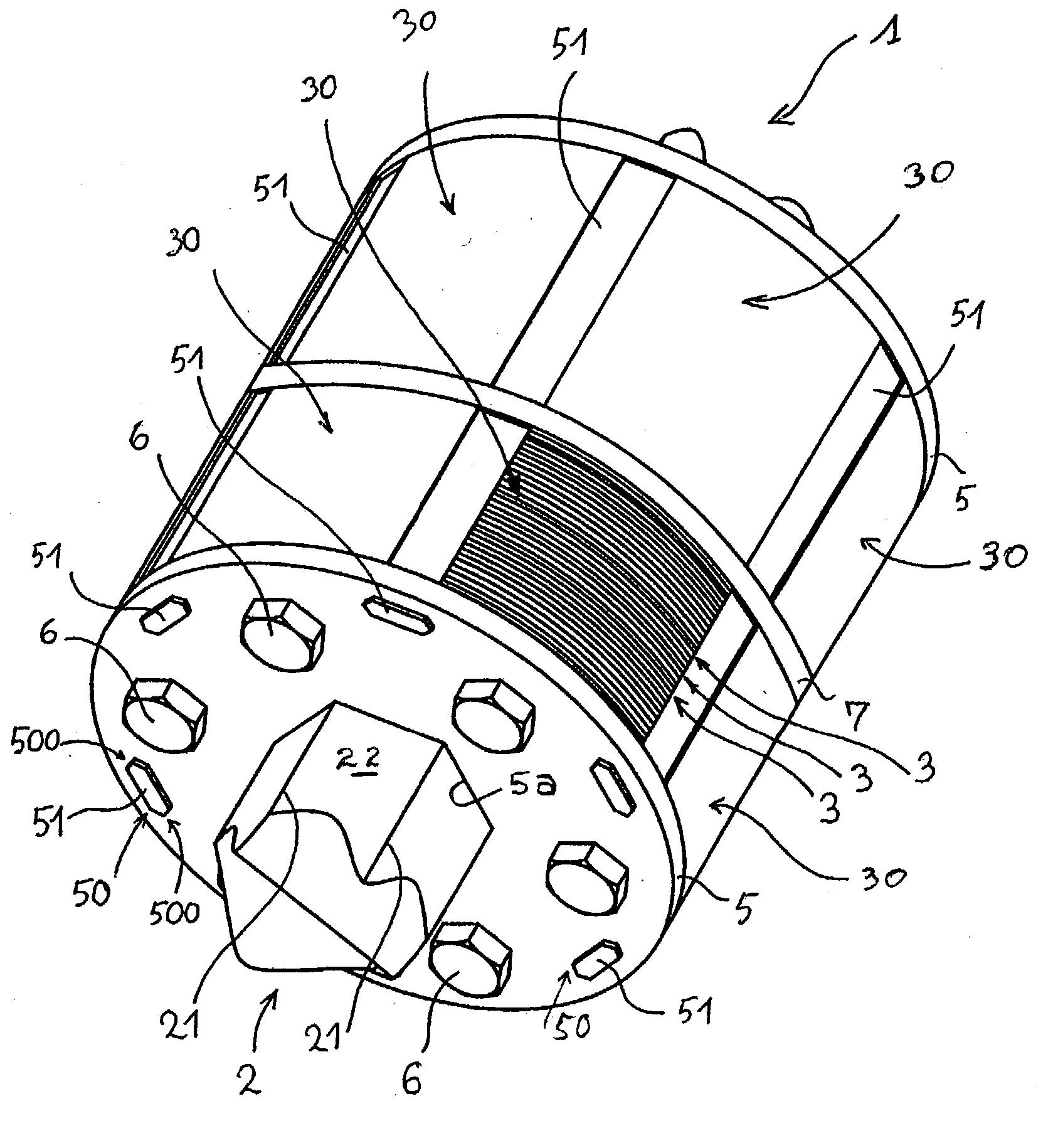

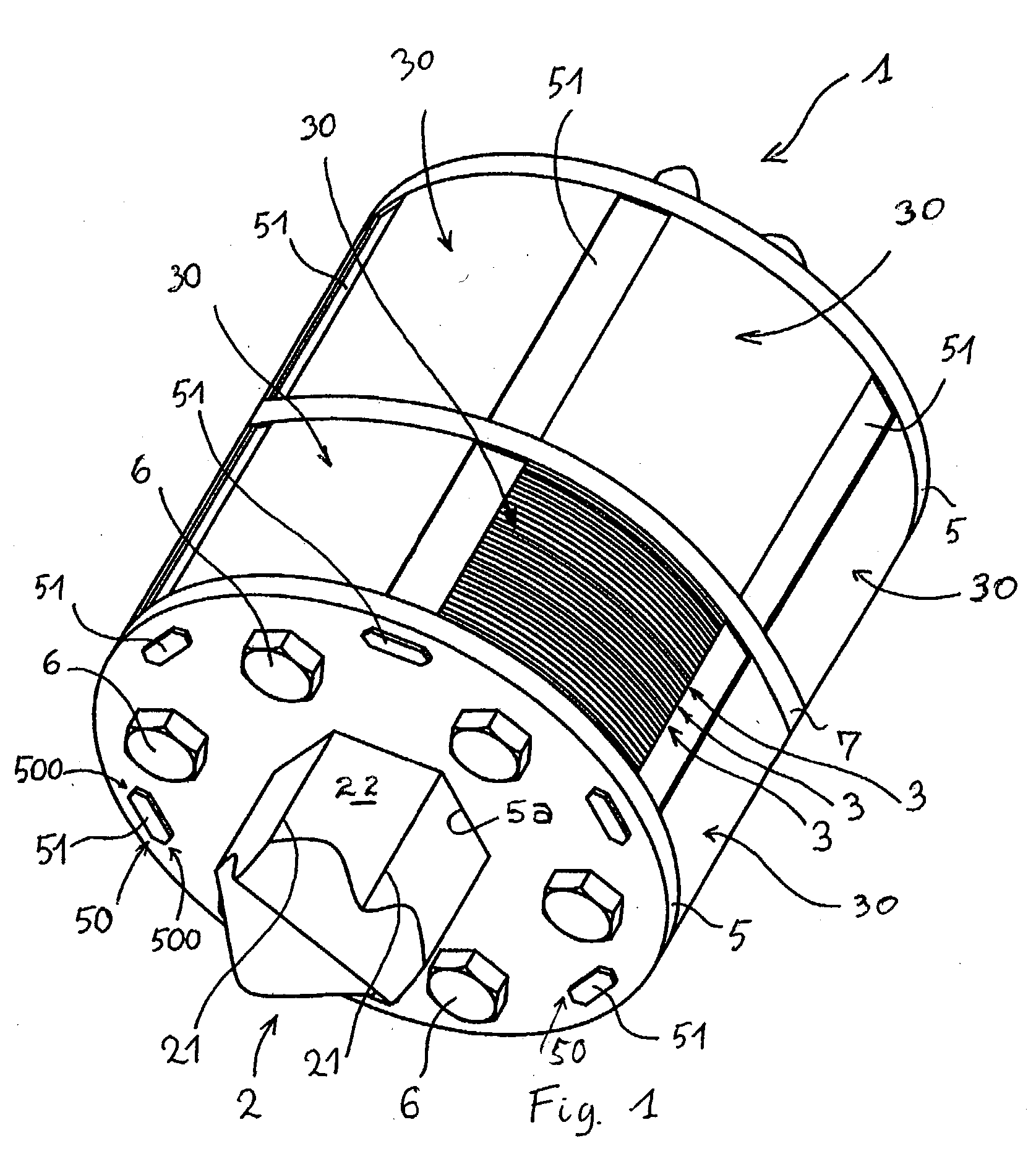

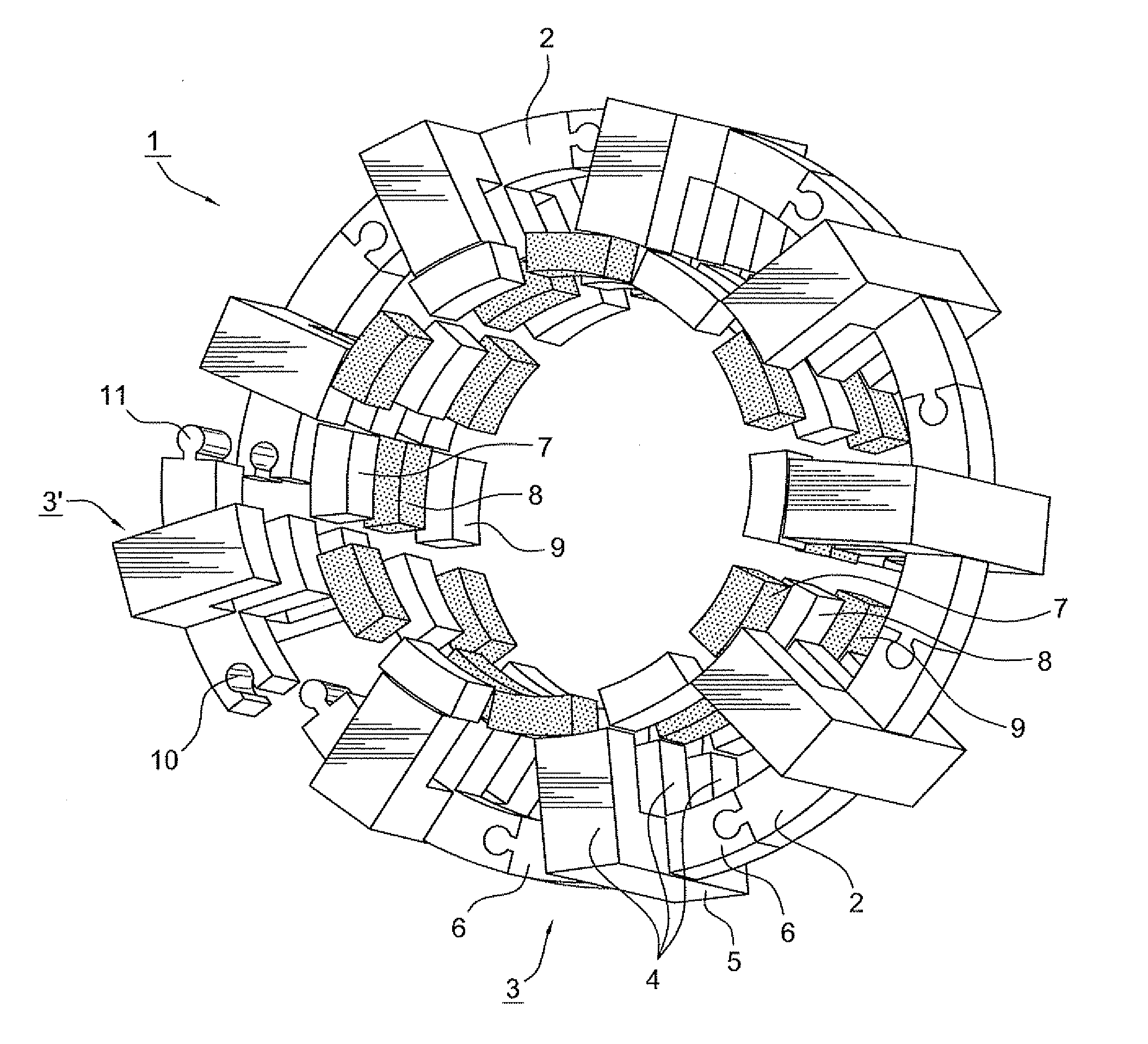

Electric rotating machine

For achieving small-sizing and high efficiency by improving heat radiation of coils, and further for simple-construction to be easily disassembled, thereby being environment-friendly from a view point of recycling, an electric rotating machine comprising: a stator 1a being constructed by inserting coils 10a into slots 11 of a stator core 2a; an outer frame 4 being divided into a plurality thereof, so as to cover periphery of the stator core of said stator; a pair of bearing holder portions 6a and 6b, each having a fitting portion 35a or 35b to be fitted into an inner diameter reference surface 25a at both end portions of said stator and being provided with a bearing 8a or 8b at an axial center portion thereof, and being attached at both sides of said stator core so as to cover coil end portions dropping out at both sides of said stator; a squeezing mechanism (30, 32a, 32b, 6a, 6b) fixing the outer frame at an outer periphery of the stator core, by a wedge function between each of the bearing holder portions and the outer frame due to a squeezing function of attaching the each of said pair of bearing holder portions at both sides of said stator core; and a rotor 3 being formed with an escaping portion for escaping from an outer diameter of a portion opposing to a fitting portion of each of said bearing holder portion, rotatably positioned within said stator core.

Owner:HITACHI LTD

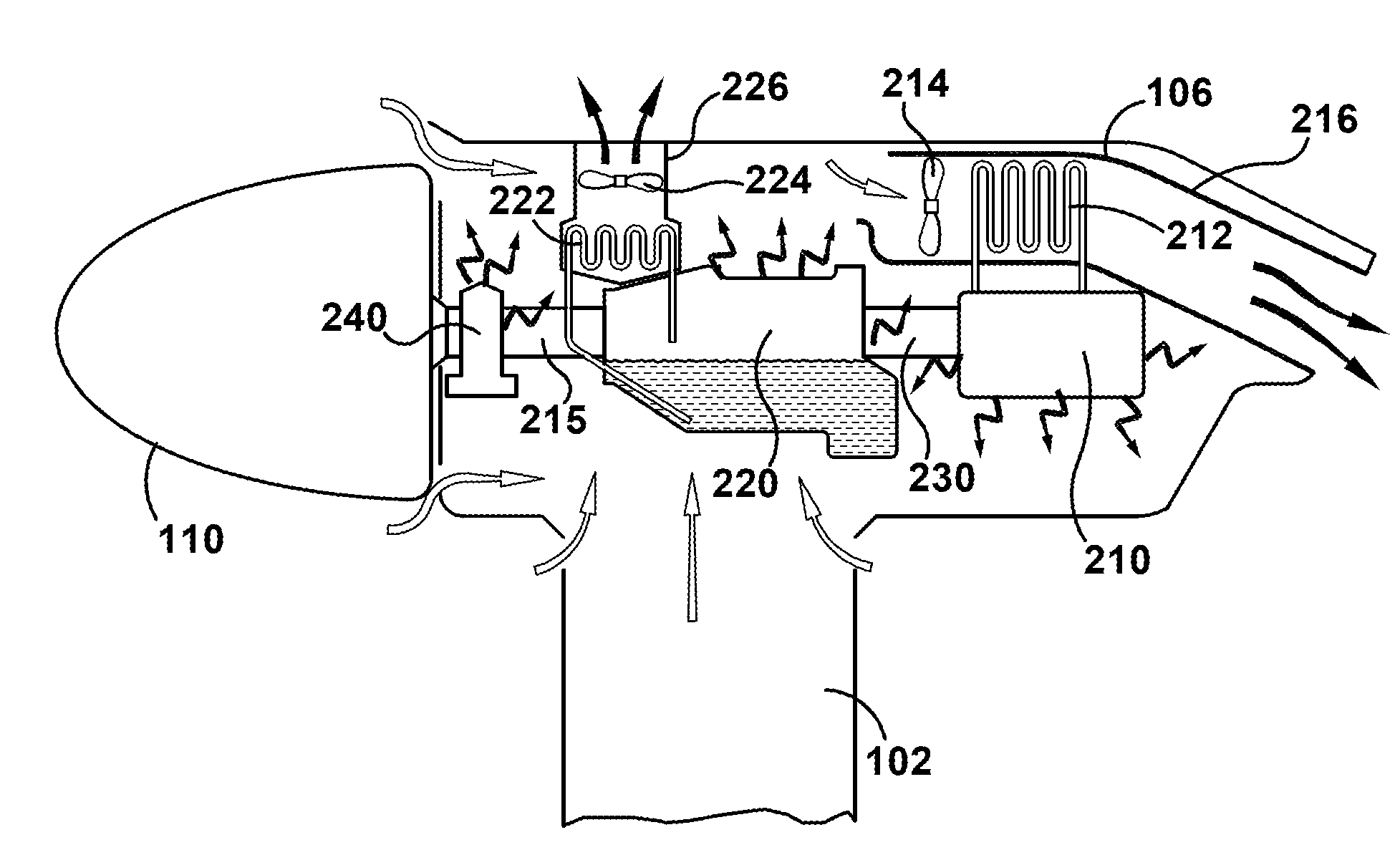

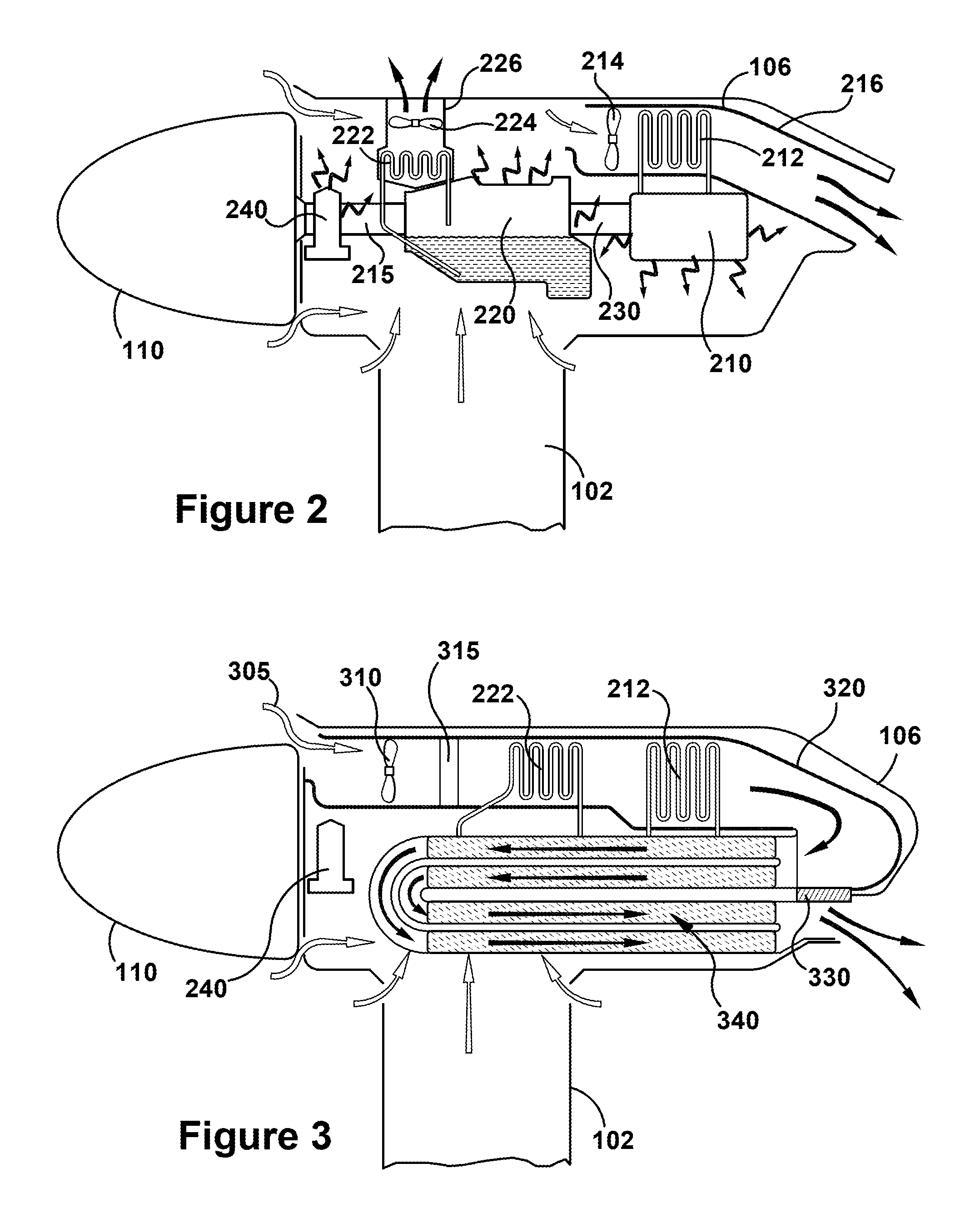

System for heating and cooling wind turbine components

A heating and cooling system for a wind turbine is provided and includes a gearbox, gearbox heat exchanger, generator, generator heat exchanger, and a cooling duct. The cooling duct is connected to the gearbox and generator heat exchangers, and is used to transport air across both heat exchangers to cool the gearbox and generator.

Owner:GENERAL ELECTRIC CO

Gearless wheel motor drive system

Methods and apparatus are provided for an electric vehicle embodying an axial flux traction motor directly coupled to a wheel thereof. The traction motor comprises a stator having coils for producing a magnetic field, an annular rotor magnetically coupled to the stator and mechanically to an output shaft. Permanent magnets of alternating polarity are mounted on the annular rotor. Magnetic shunts bridge a portion of the stator slots above the coils. The magnets are arranged in groups with group-to-group spacing exceeding magnet-to-magnet spacing. Adjacent edges of the magnets diverge. The method comprises, looking up d- and q-axis currents to provide the requested torque and motor speed for the available DC voltage, combining at least one of the d- and q-axis currents with a field weakening correction term, converting the result from synchronous to stationary frame and operating an inverter therewith to provide current to the coils of the motor.

Owner:GM GLOBAL TECH OPERATIONS LLC

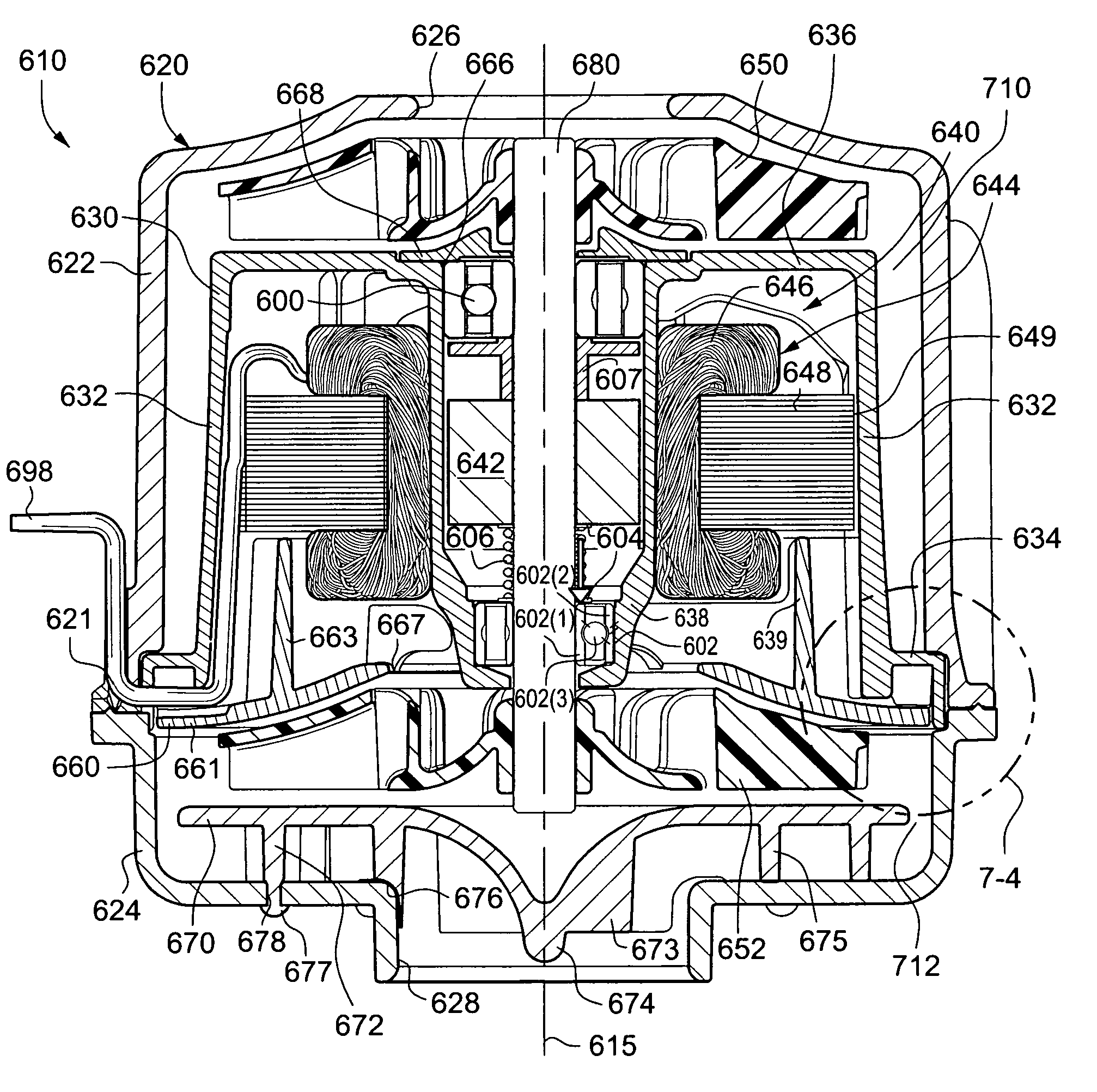

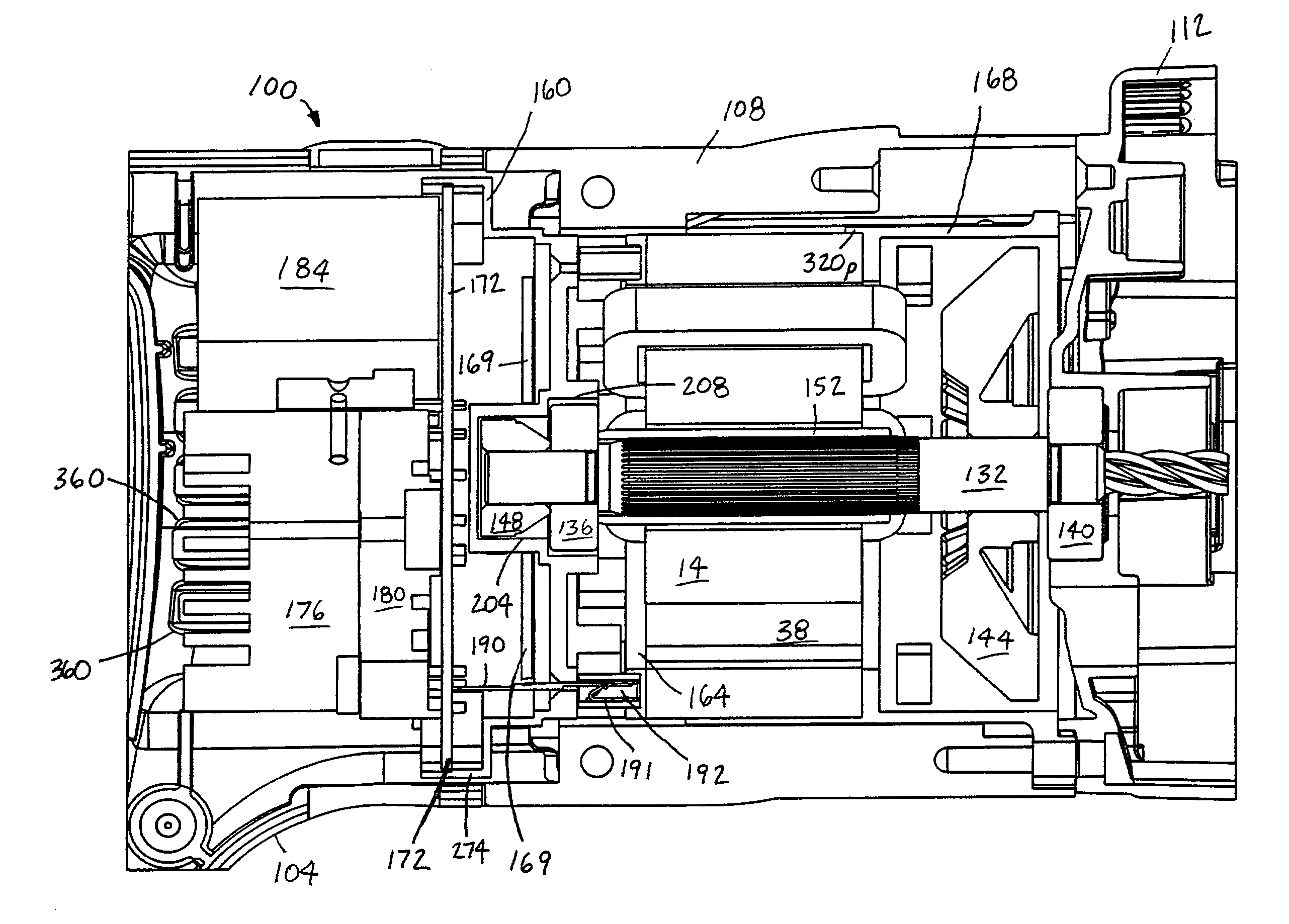

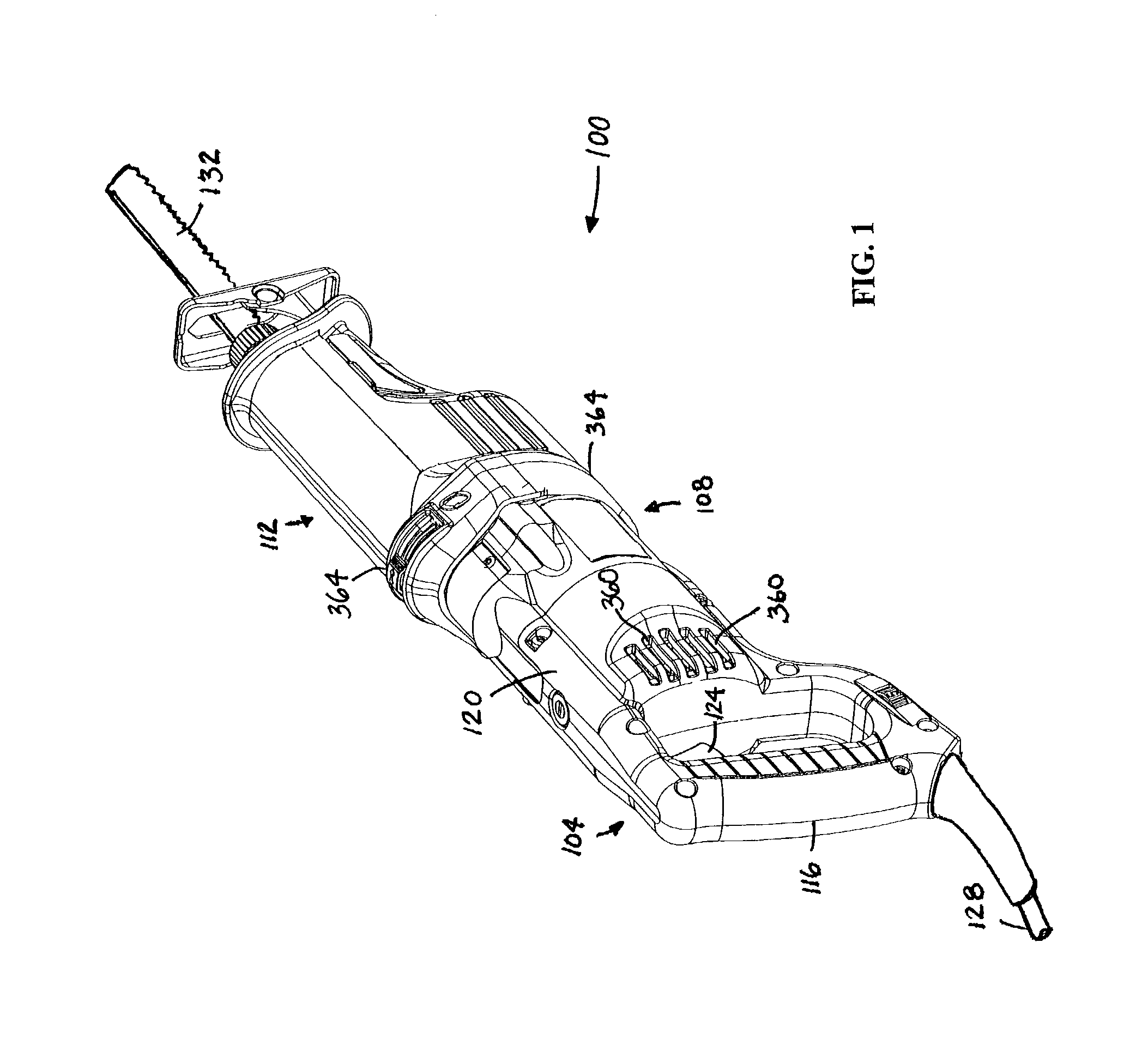

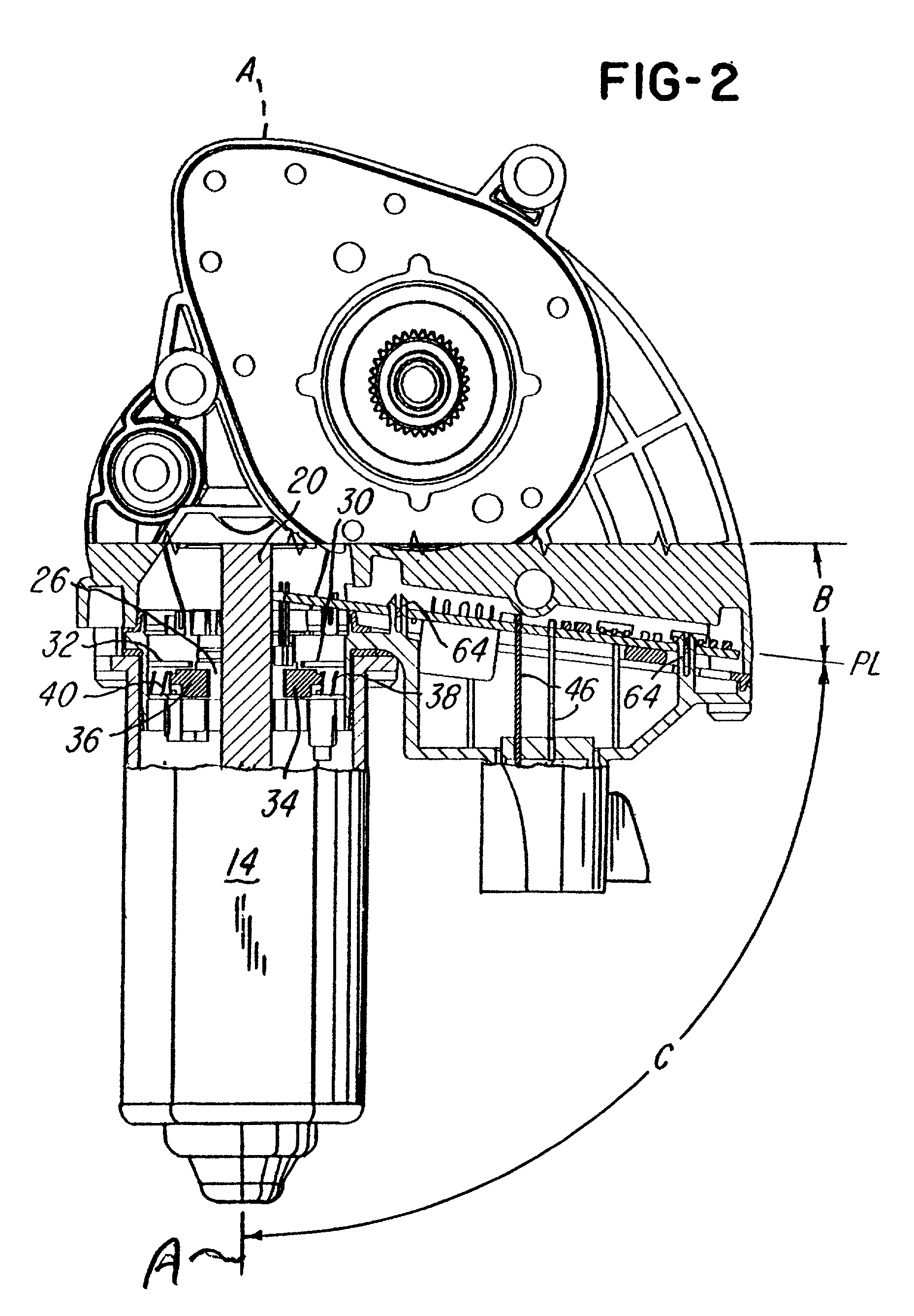

Power tools with switched reluctance motor

InactiveUS7064462B2Reduce Tolerance StackupImprove cooling effectAC motor controlWindingsHand heldMotor control

A method of assembling a power tool, a power tool, a method of assembling an electrical device, and an electrical device includes a switched reluctance motor. The electrical device is preferably a hand-held power tool, however, any type of electrical device that includes a switched reluctance motor may benefit from any number of aspects of the invention. In one independent aspect, the invention provides a construction that reduces tolerance stack-up. In another independent aspect, the invention provides a self-contained electronics package that plugs into a switched reluctance motor to provide control operation of the switched reluctance motor. In another independent aspect, the invention provides enhanced cooling that increases the efficiency of the electrical device using a switched reluctance motor. In another independent aspect, the invention provides an encapsulated magnet that allows for contaminant free motor control over the life of the SR motor. In another independent aspect, the invention provides an apparatus and a method for aligning magnets of a magnet hub with respect to the rotor poles the magnet poles represent.

Owner:MILWAUKEE ELECTRIC TOOL CORP

Natural gas turbine generator

ActiveUS7683499B2Minimize explosion hazardEliminating carbon bridging between connectionsMotor/generator/converter stoppersWindingsElectricityMomentum

A turbine generator utilizing a passive high pressure fluid source such as a natural gas well head. The generator includes a core and lead wires encapsulated in a dielectric medium to isolate current-bearing components from the motivating fluid, thereby preventing carbon bridging and reducing the explosion hazard when the motivating fluid is a hydrocarbon. The turbine generator includes a rotor that utilizes the full length as an impingement surface for imparting momentum to the rotor, thereby maintaining a compact design that reduces the overall footprint of the turbine generator. Fluid exits the generator via horizontal passages that penetrate the lower extremities of the turbine generator, preventing the buildup of condensation in the unit.

Owner:REVOLUTION TURBINE TECH LLC

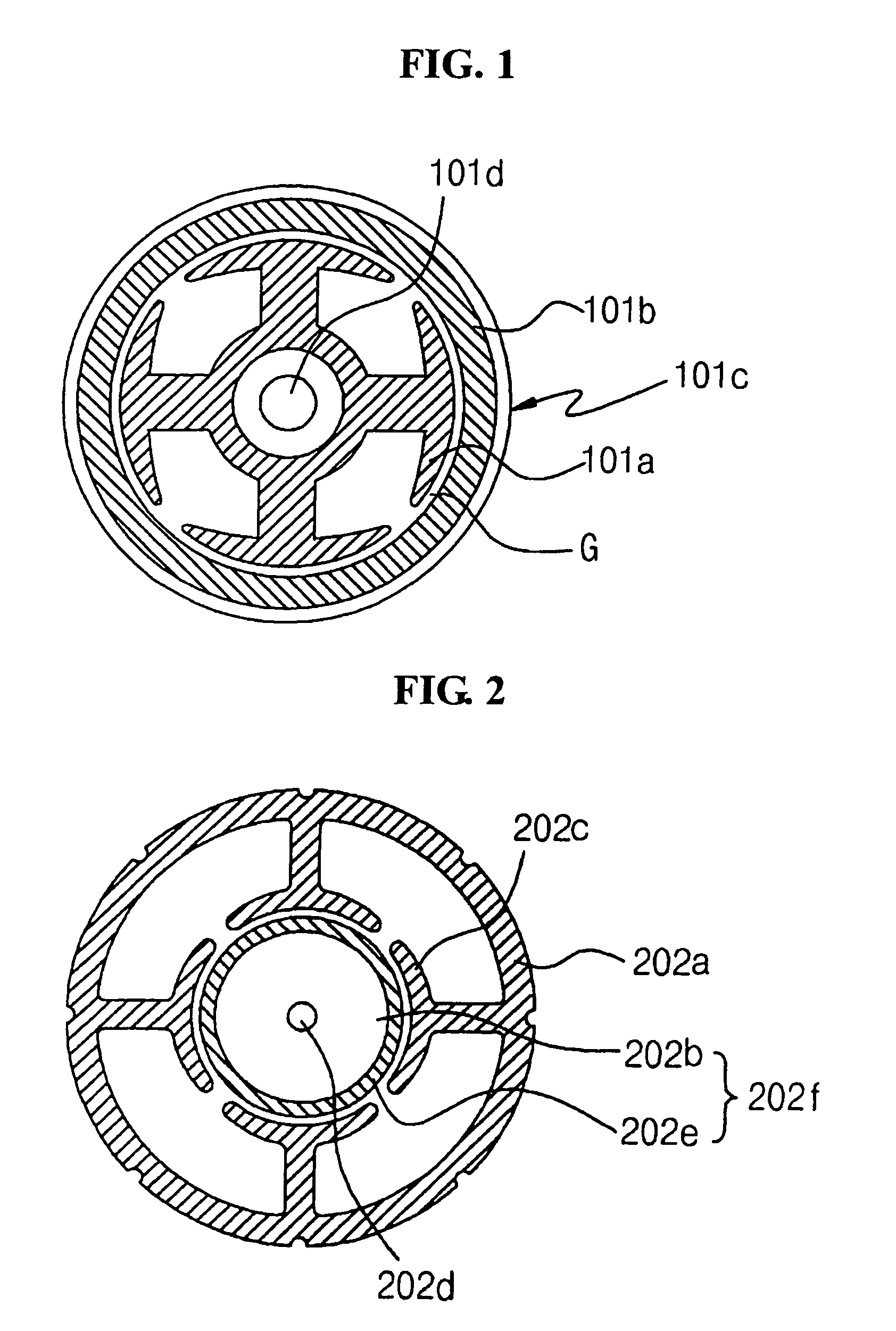

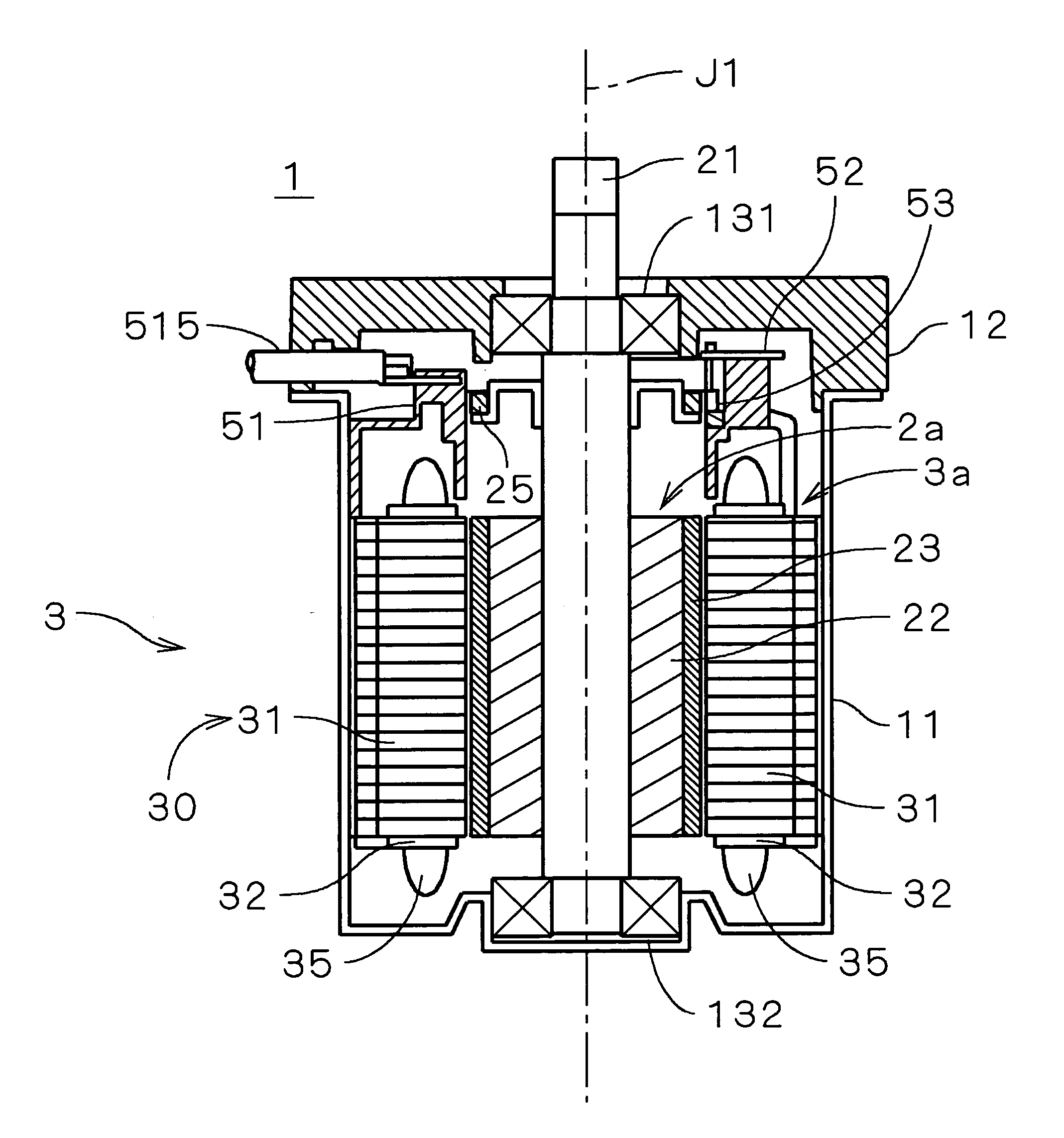

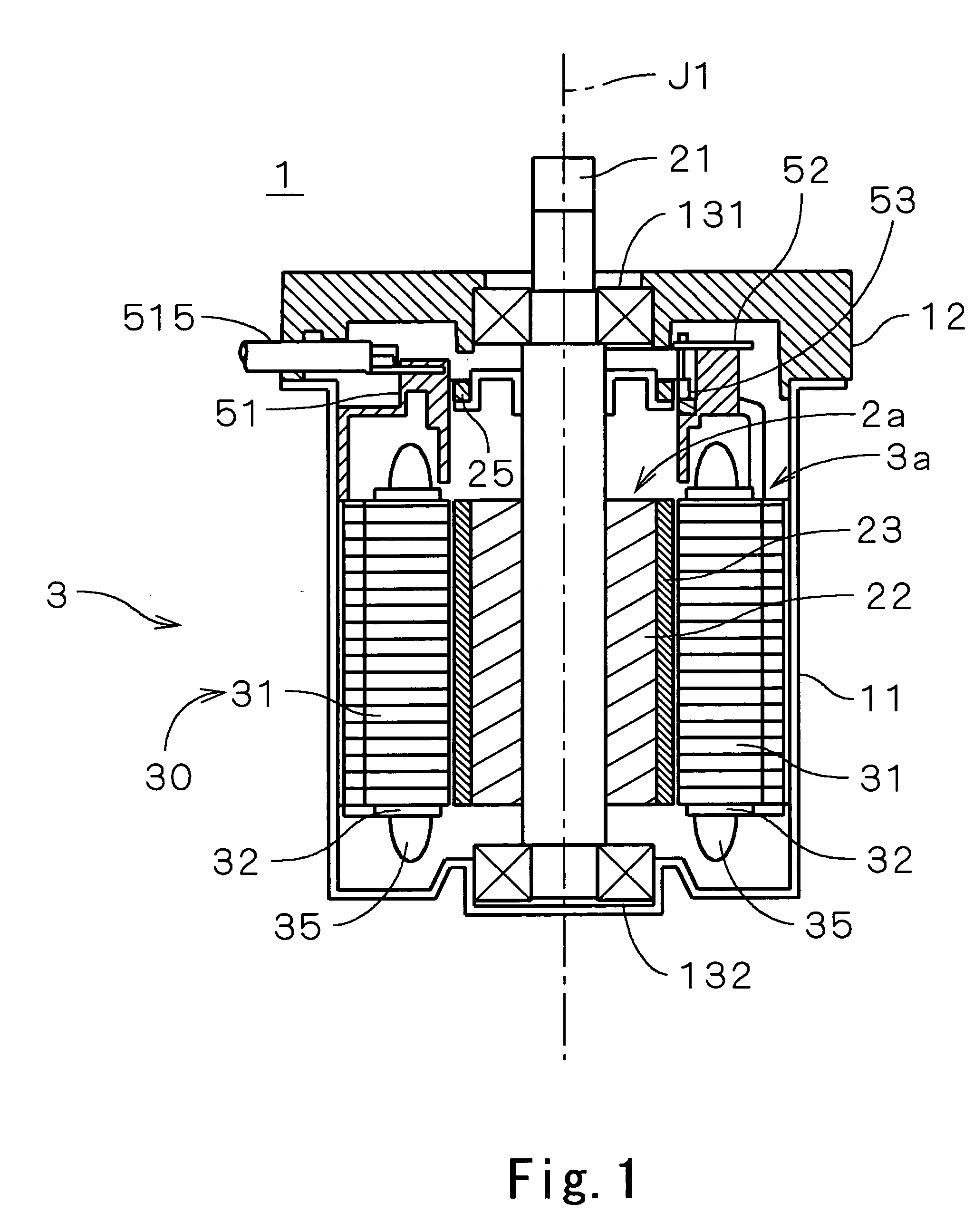

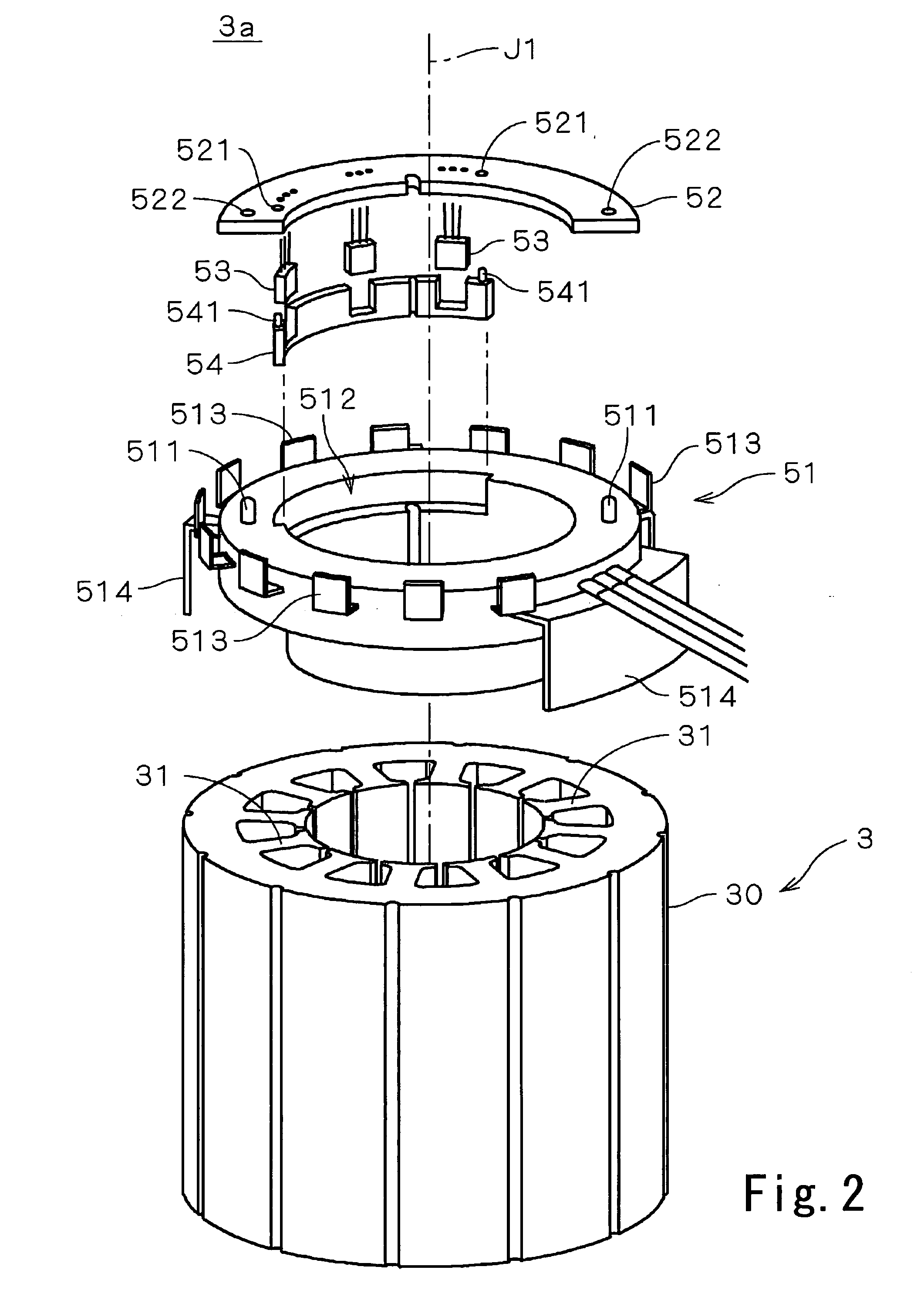

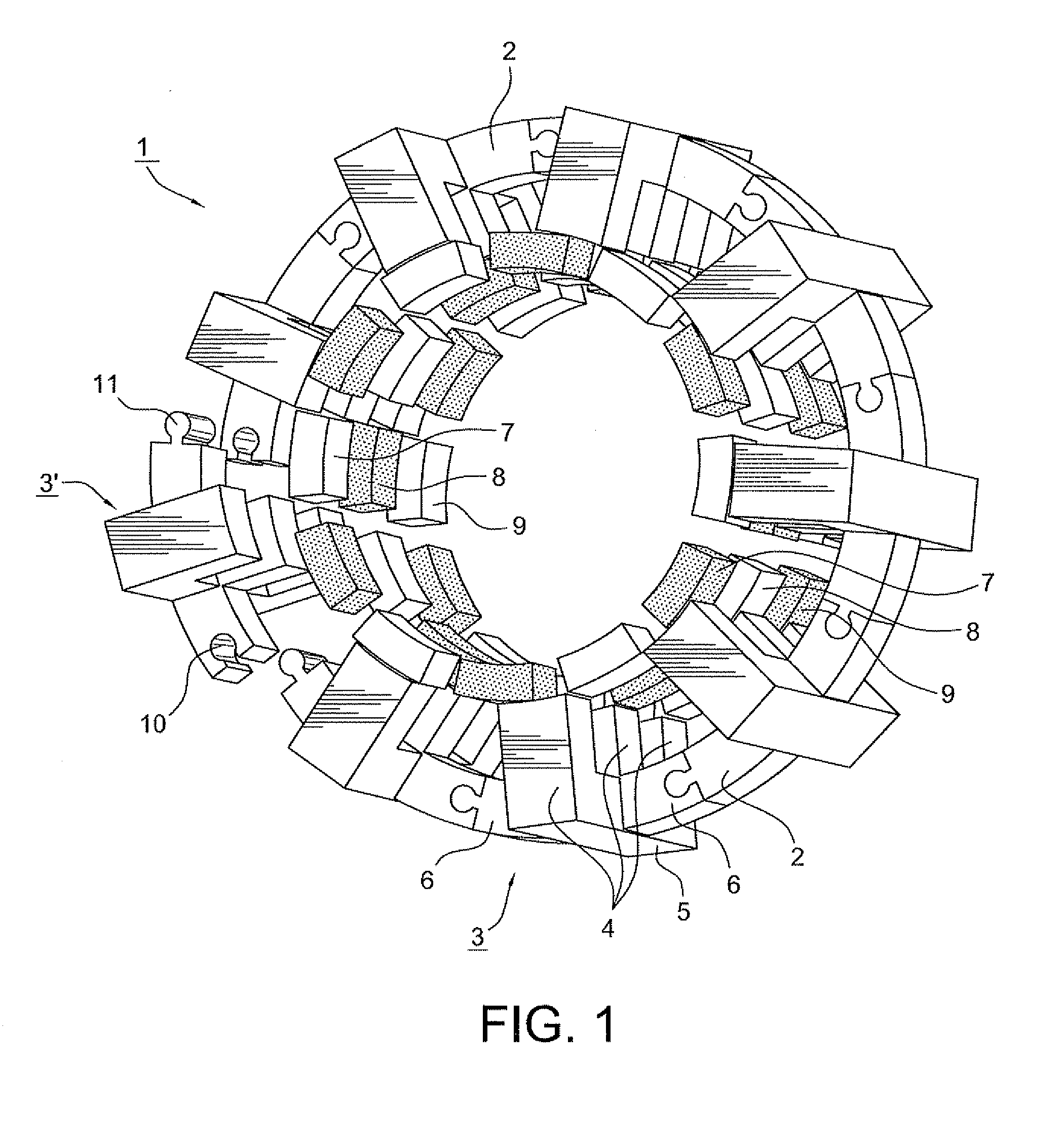

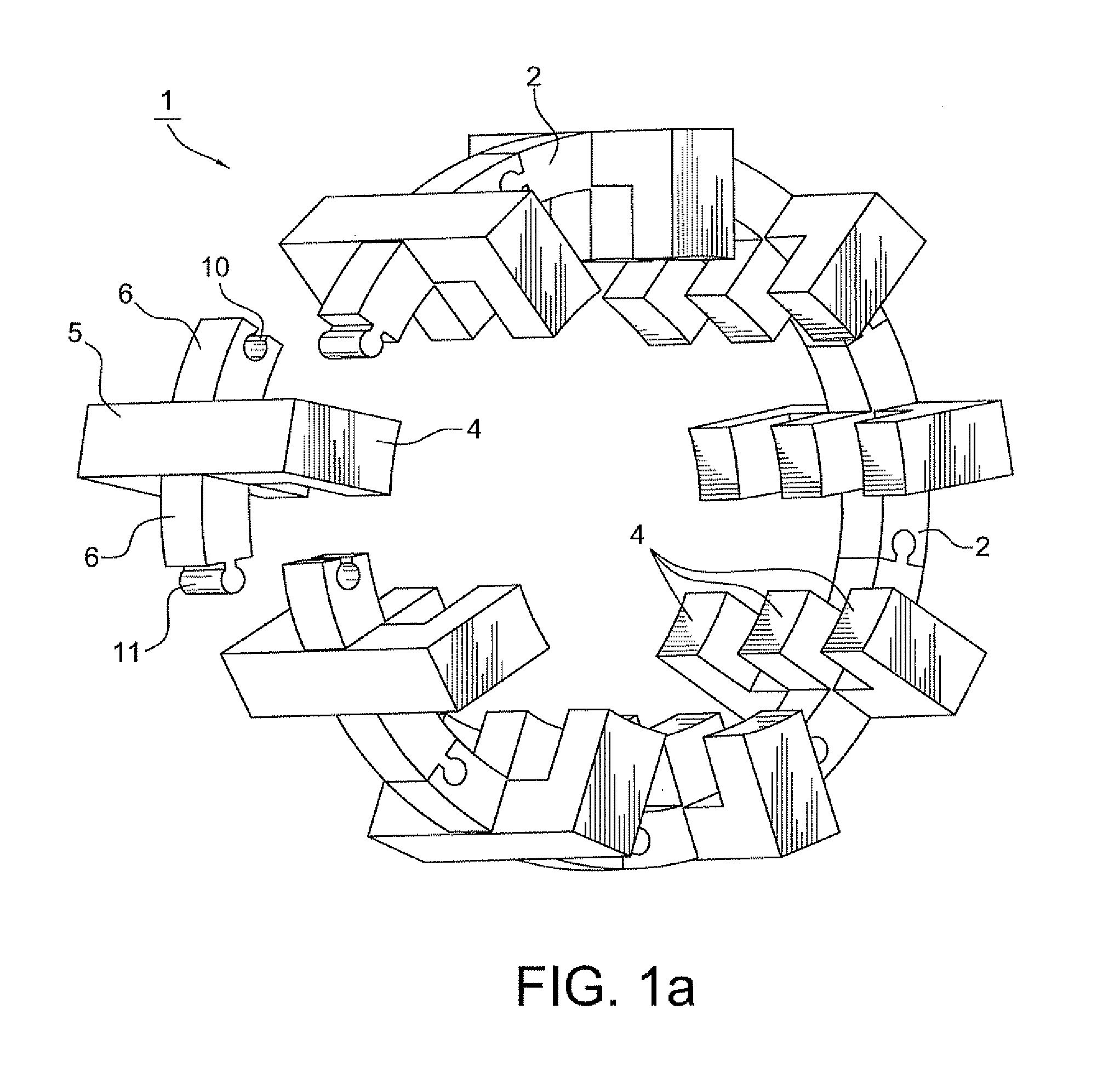

Brushless direct-current motor of radial core type having a structure of double rotors and method for making the same

InactiveUS6992419B2Improve productivityImprove shortcomingsWindingsMagnetic circuit rotating partsElectrical polarityEngineering

A radial core type double rotor brushless direct-current motor is provided in which a double rotor structure is employed with inner and outer rotors which are doubly disposed and thus a stator core is completely divided. The motor includes a rotational shaft which is rotatably mounted on a housing of an apparatus, cylindrical inner and outer yokes which are rotatably mounted on the center of the housing, inner and outer rotors including a number of magnets which are mounted with the opposing polarities on the outer surface of the inner yoke and the inner surface of the outer yoke, and a number of cores assemblies which are installed between the inner and outer rotors in which a number of coils are wound around a number of division type cores, respectively.

Owner:AMOTECH

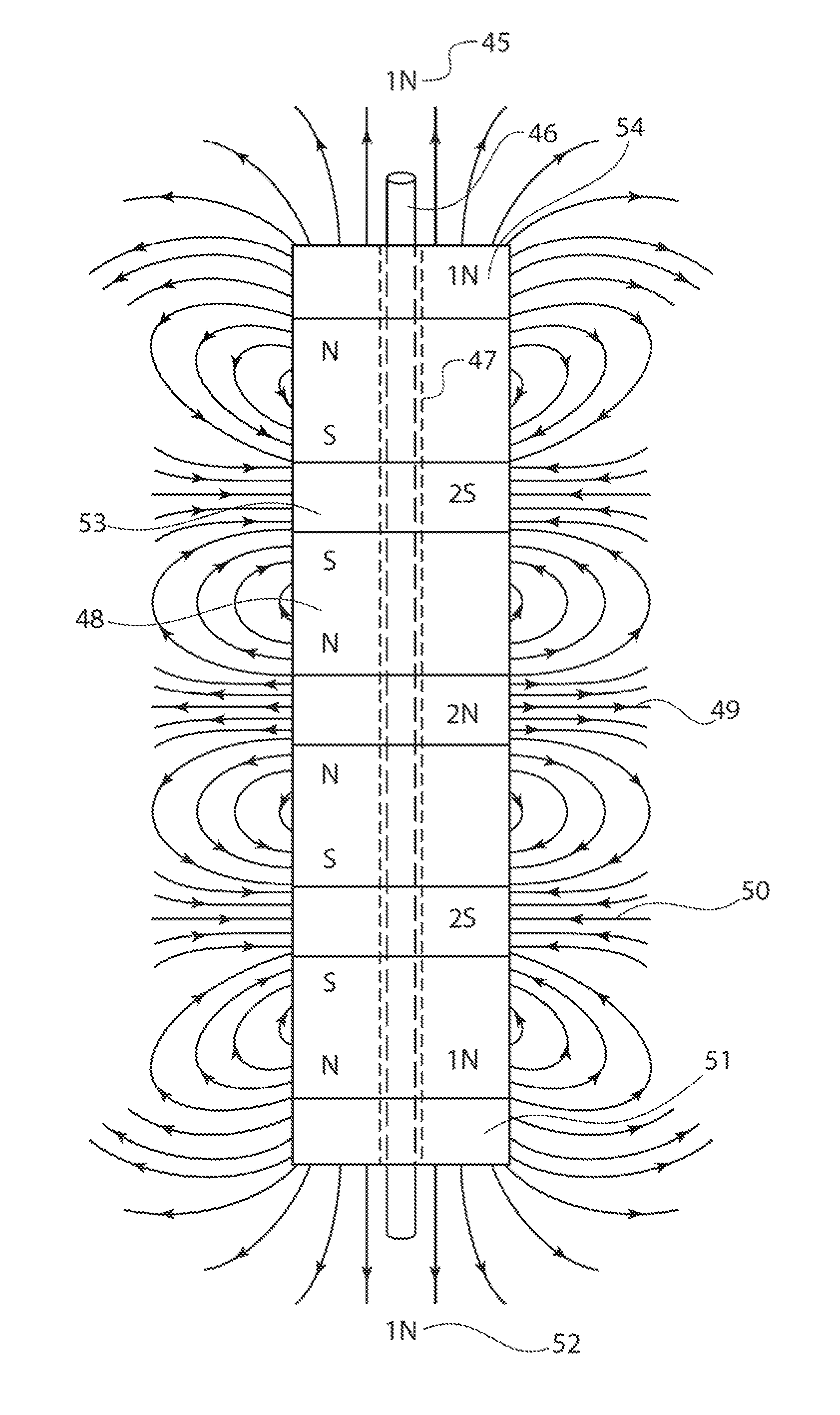

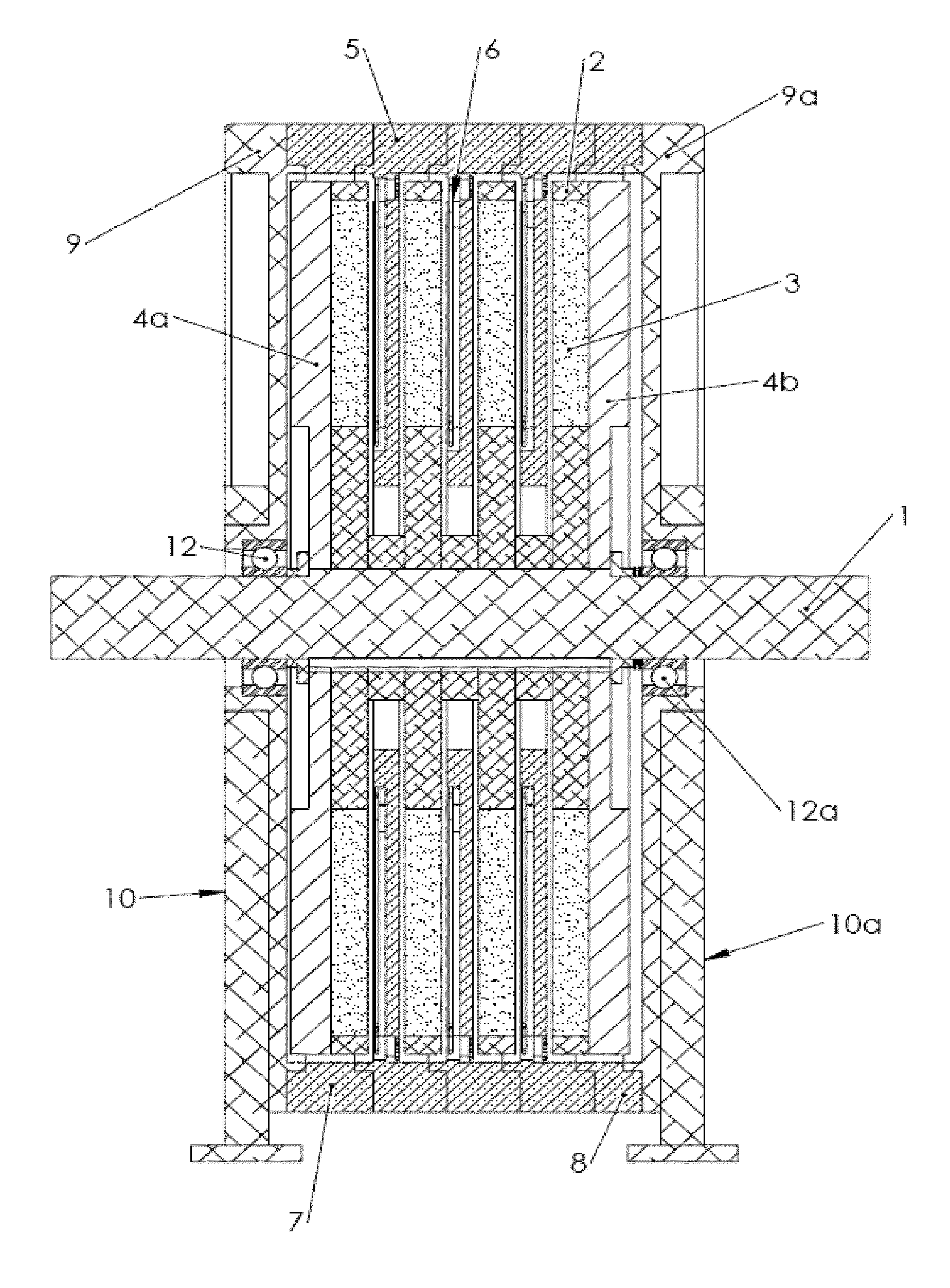

Linear faraday induction generator for the generation of electrical power from ocean wave kinetic energy and arrangements thereof

ActiveUS8629572B1Dissipates wave energyDissipate energyWindingsAc-dc conversionCoil arrayElectrical polarity

Various embodiments of linear electric generators and arrangements thereof are disclosed. One such generator includes a permanent magnetic array with magnets that are oriented such that like poles of the magnets are disposed adjacently to concentrate a magnetic field through a coil array. To enhance the magnetic field distribution, the magnets are affixed under a compressive strain due to repulsive forces resulting from proximity of the like poles. According to another aspect, a plurality of vibrational linear electric generators (VLEGs) can be arranged so that magnets of different VLEGs are oriented so that poles of opposite polarity are disposed adjacently to further enhance magnetic field concentration through coil arrays. In addition, a plurality of wave energy converters can be arranged in very close proximity, at most 8 times a height of a buoyant portion of the converters, to act as a seawall and thereby protect various structures from ocean waves.

Owner:SLP CONSULTANTS INC

Brushless motor for vehicle air conditioner

InactiveUS6333576B1Control failureAssociation with control/drive circuitsAir-treating devicesBrushless motorsEngineering

A brushless motor for a vehicle air conditioner has a motor holder having an accommodation portion, a stator having a center piece fastened to a bottom of the accommodation portion and a core on which a winding is wound, and an exciting circuit disposed below the bottom to supply an exciting current to the winding. A terminal of the exciting circuit is upwardly extended to an upper side of the core through a through hole formed in the bottom and a terminal accommodation hole formed in the center piece to be connected to the winding. Liquid having entered the accommodation portion is restricted from falling through the through hole of the bottom by an O-ring disposed to surround the through hole and is drained through a drain opening formed in the bottom. As a result, a connection portion between the terminal and the winding and the exciting circuit are restricted from making contact with liquid.

Owner:ASMO CO LTD

Interconnecting ring and wire guide

InactiveUS6856055B2Low costReduced characteristicsWindingsMagnetic circuit stationary partsElectric machineDetent

An interconnecting ring and wire guide for an electric machine includes an annular radial ring having a radially inner edge and a radially outer edge. An axial ring projects axially from the radially inner edge of the annular radial ring. A guide positioner positions the annular radial ring and the axial ring relative to the electric machine. Wire dividers are located on a radially outer surface of the radial ring. The wire dividers include a plurality of circumferential projections that are formed on the radially outer surface of the radial ring. A plurality of wire guides are located adjacent to a radially outer edge of the annular radial ring. Indicia on an outer surface of the annular radial ring identifies at least one of a mounting position for the interconnecting ring and wire guide and a wiring schematic for phases wiring of the electric machine.

Owner:NIDEC MOTOR CORP

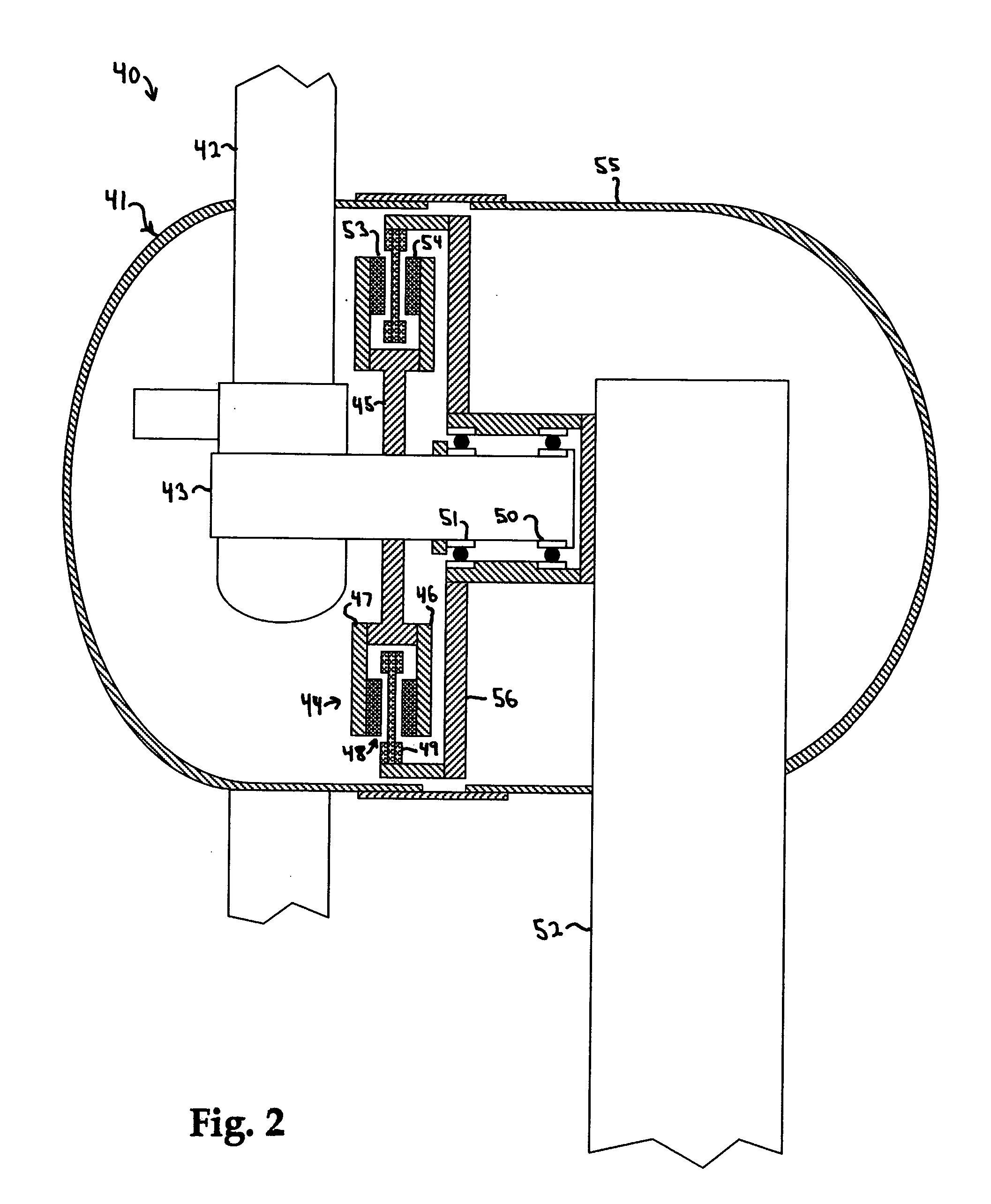

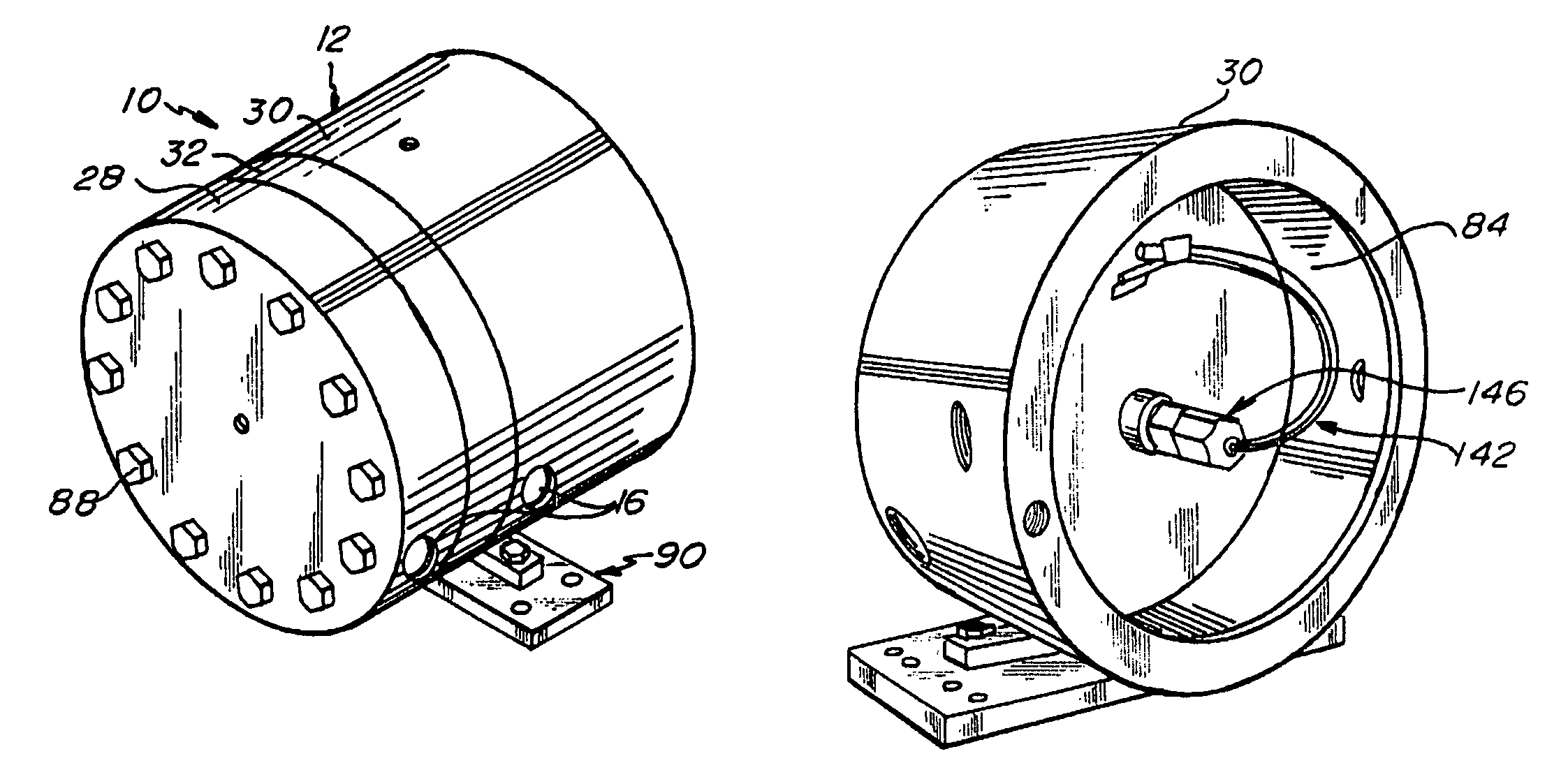

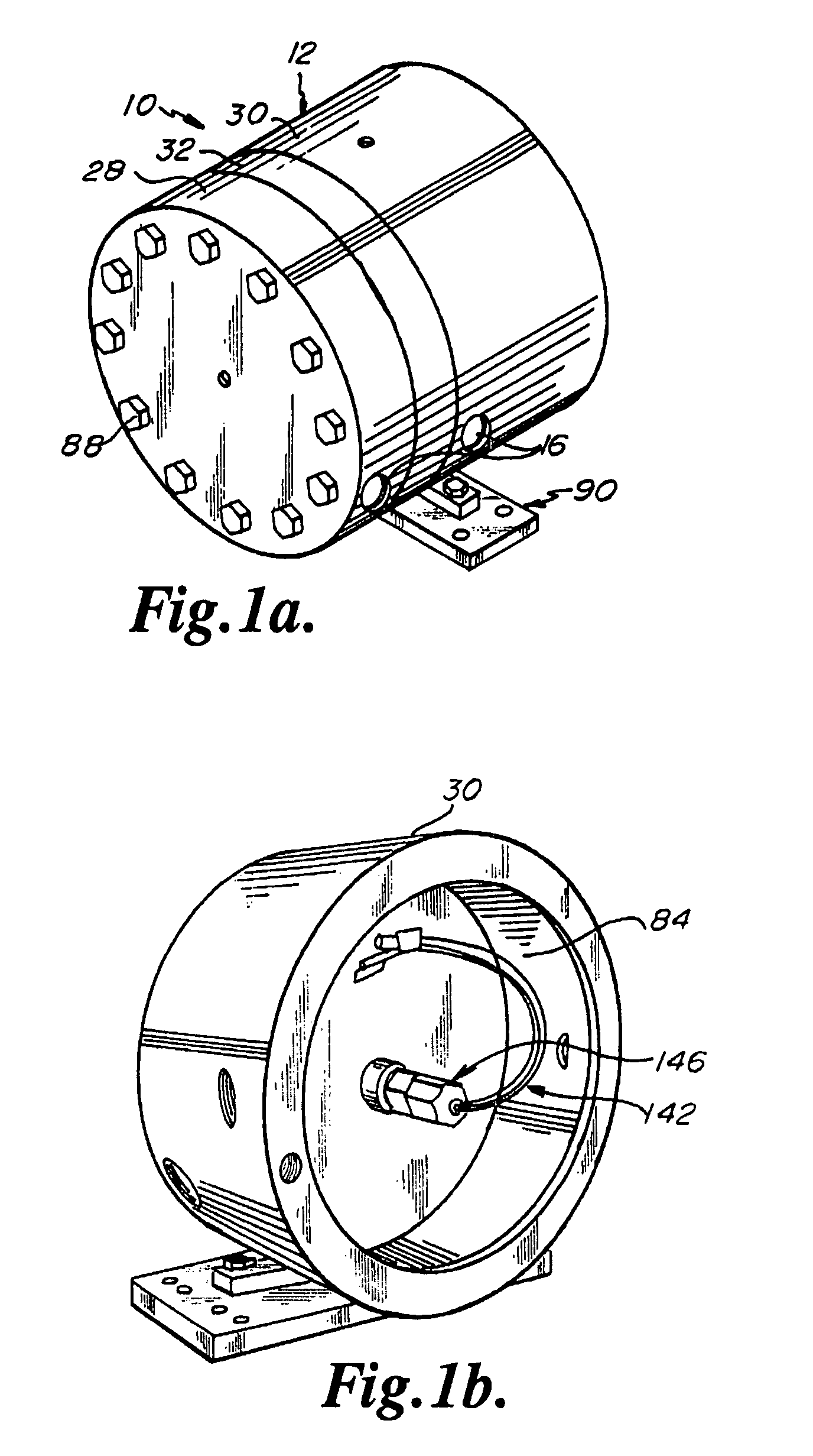

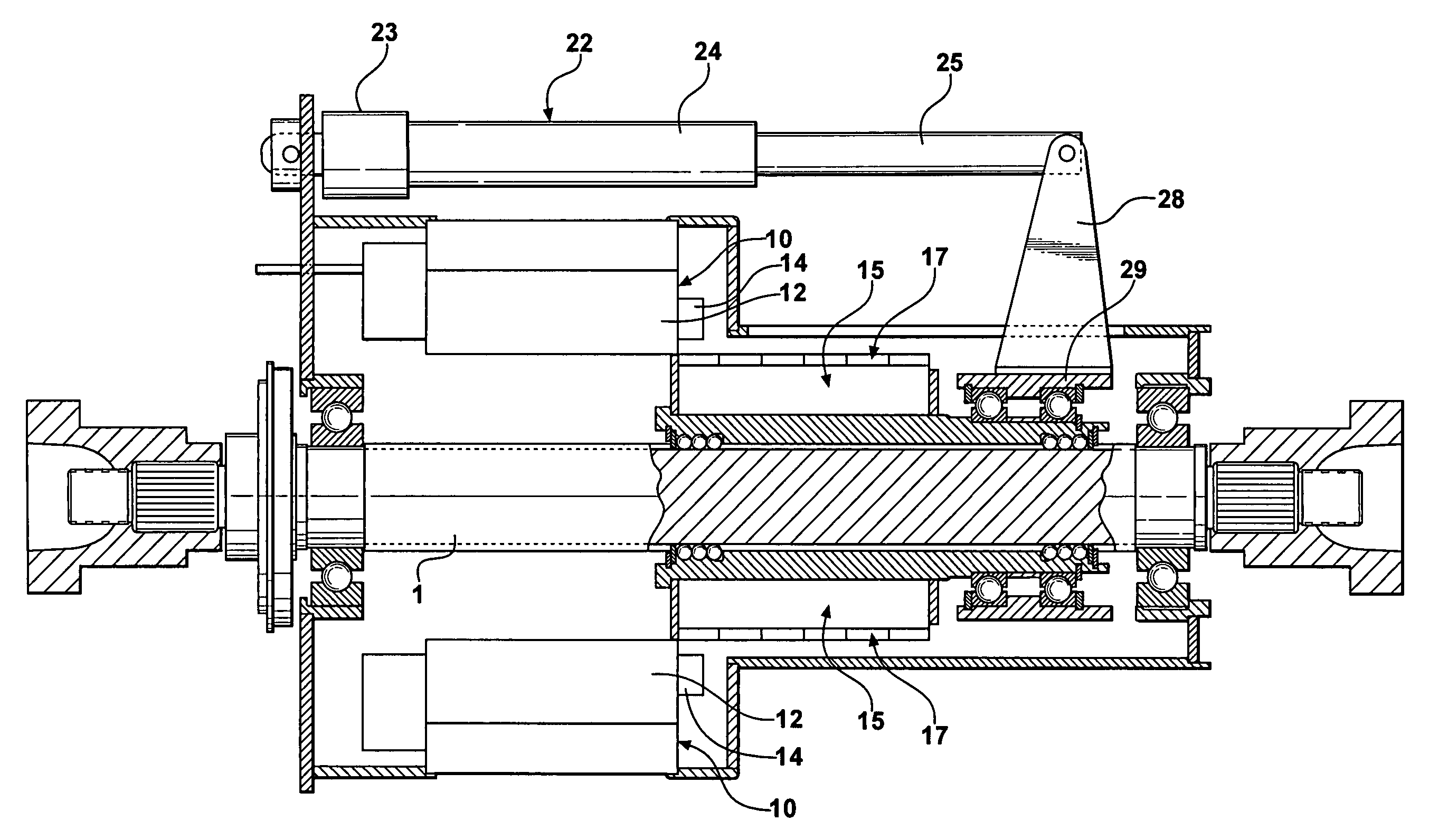

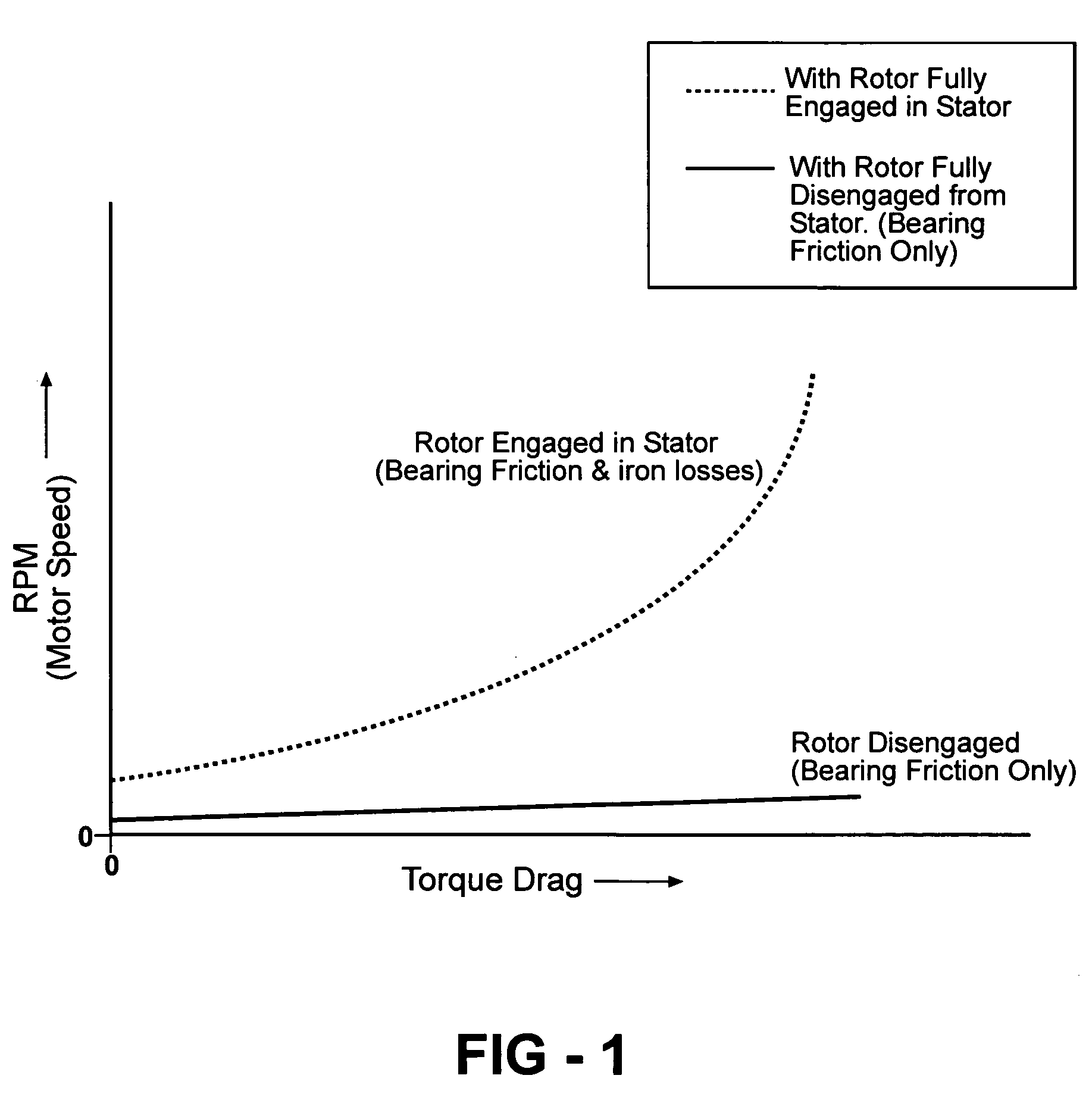

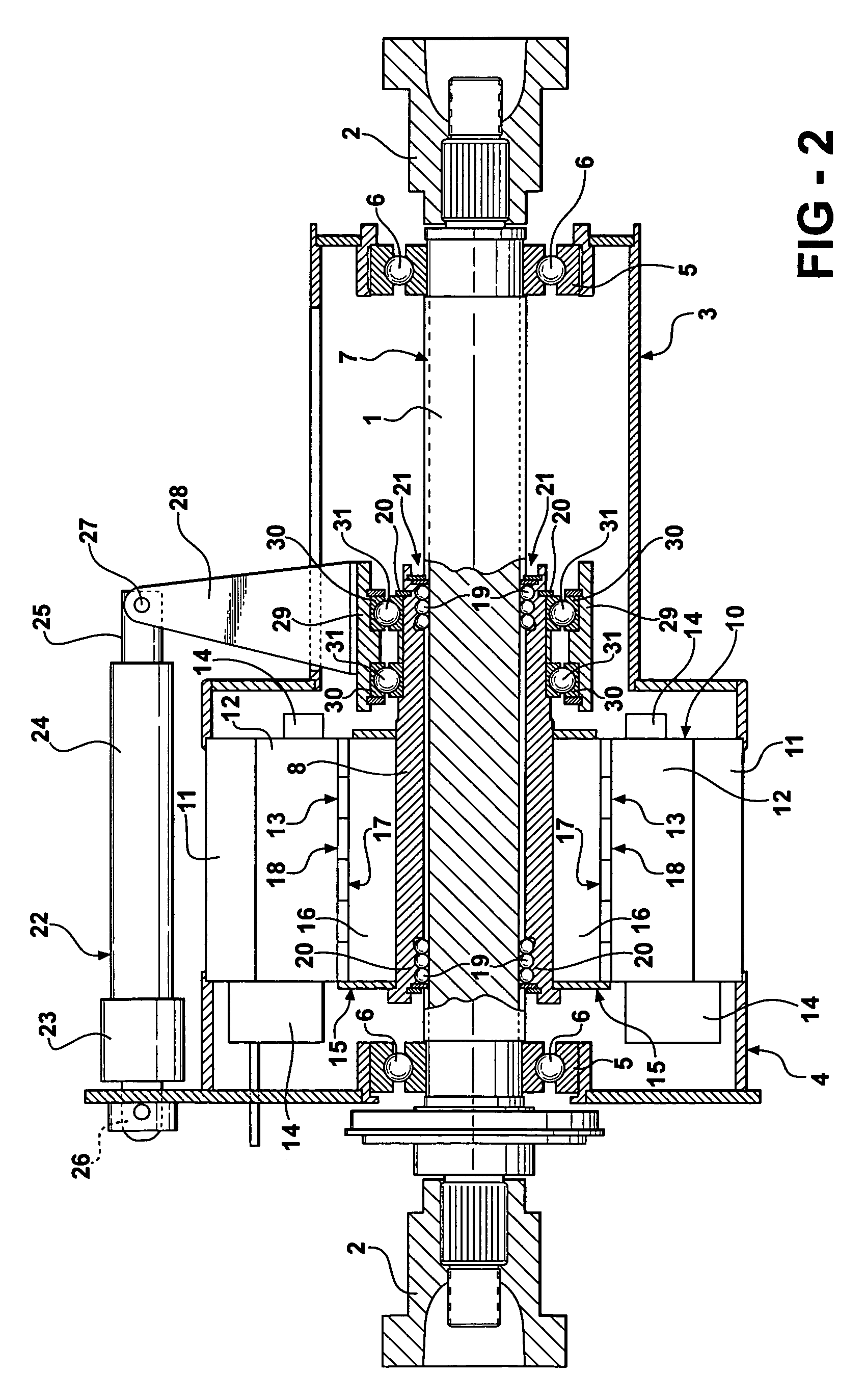

Brushless permanent magnet motor/generator with axial rotor decoupling to eliminate magnet induced torque losses

ActiveUS7863789B2Eliminate magnet induced torque dragSynchronous generatorsWindingsEngineeringPermanent magnet motor

A permanent magnet motor / generator that includes a stator, a rotor provided with a plurality of permanent magnets at a peripheral surface thereof and having a central axis which coincides with the central axis of the stator, a rotatable shaft upon which the rotor is coupled, and an actuator for moving the rotor with respect to the stator axially along the rotatable shaft a sufficient distance to completely decouple the rotor from the stator so as to eliminate magnet induced torque drag. When the permanent magnet / generator is used in parallel hybrid vehicles, the ability to completely decouple the rotor from the stator greatly improves range and efficiency. In addition, by progressively engaging the rotor with the stator a desired voltage output can be obtained upon deceleration.

Owner:DURA TRAC MOTORS INC

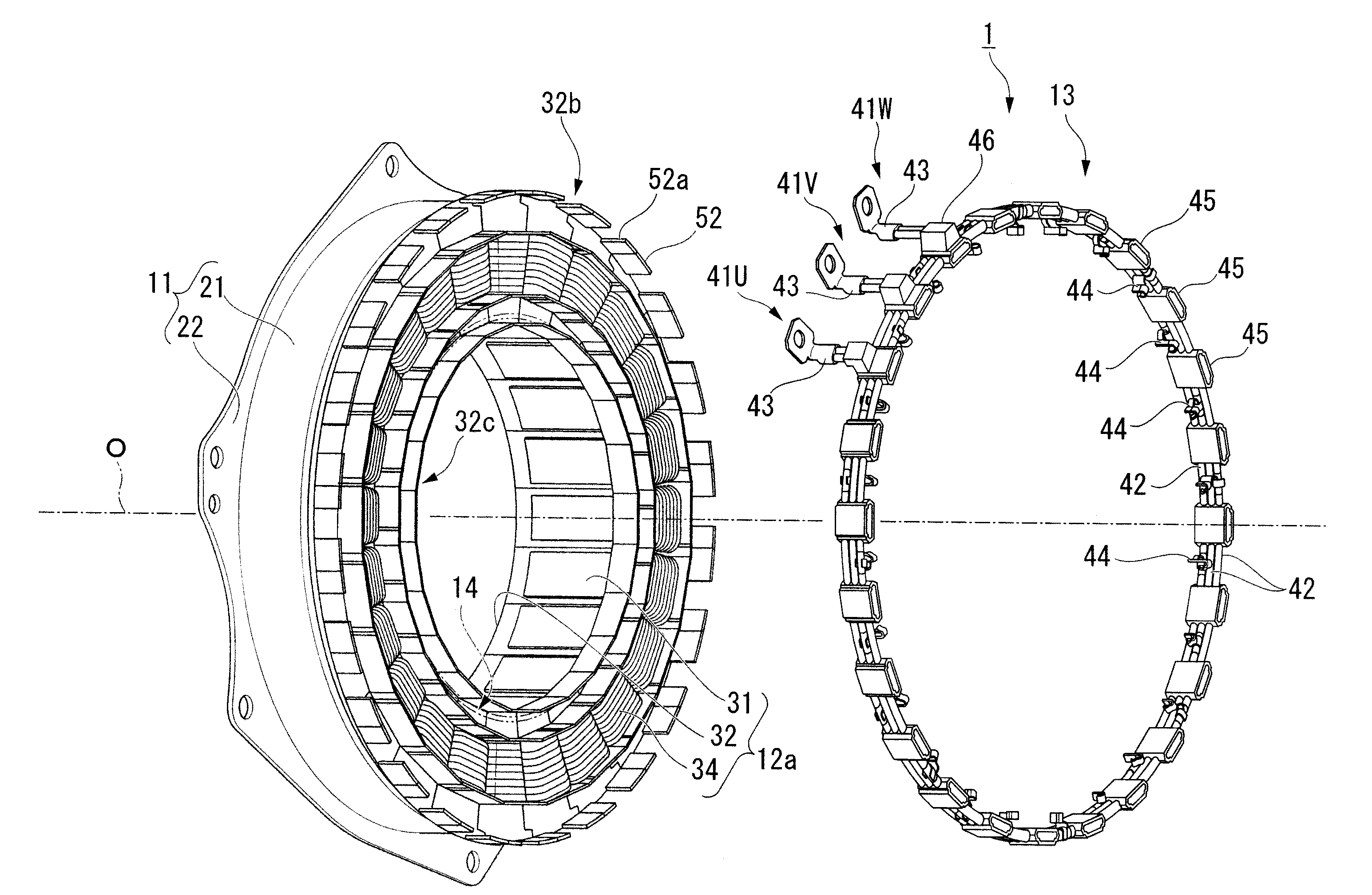

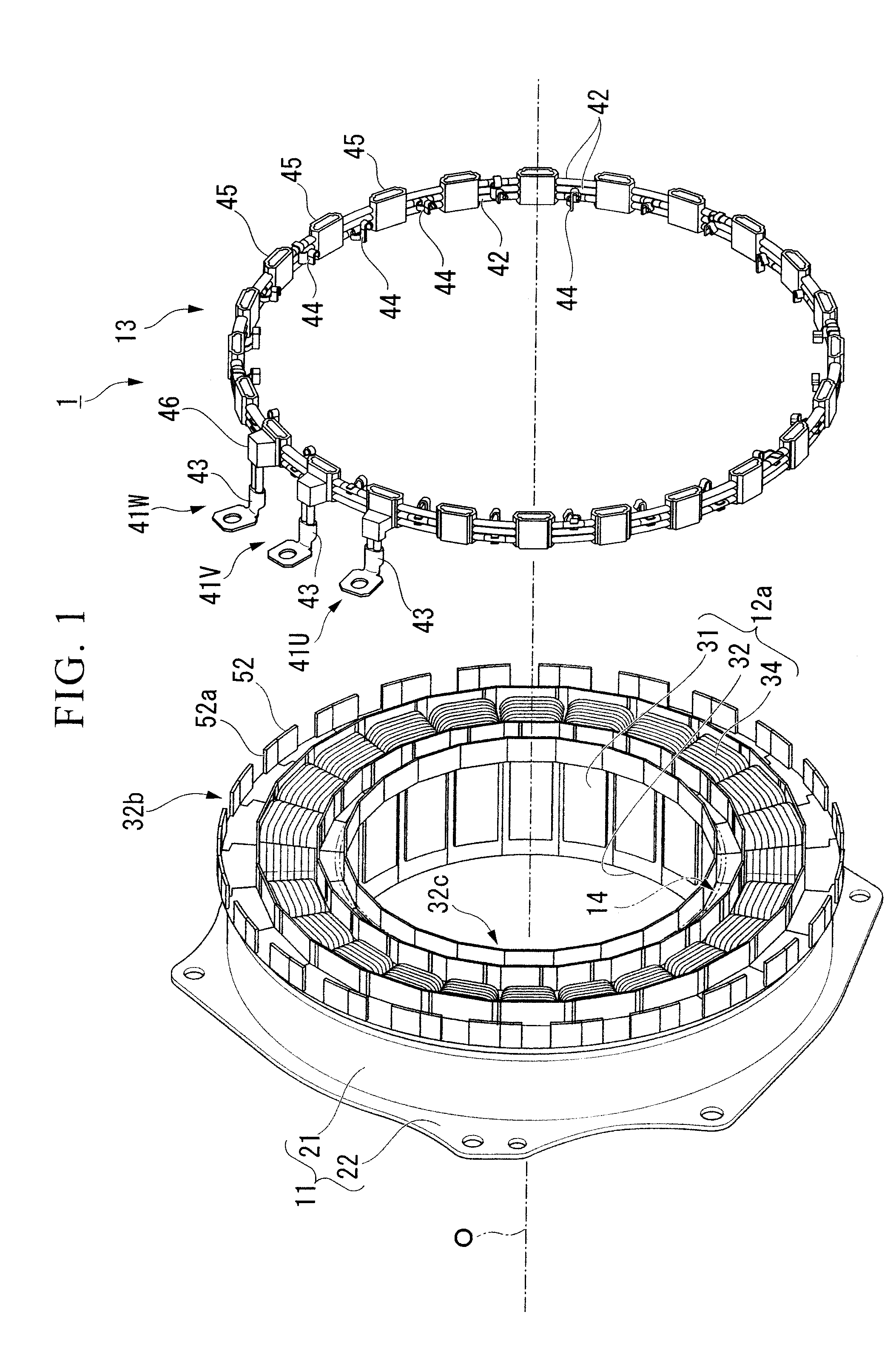

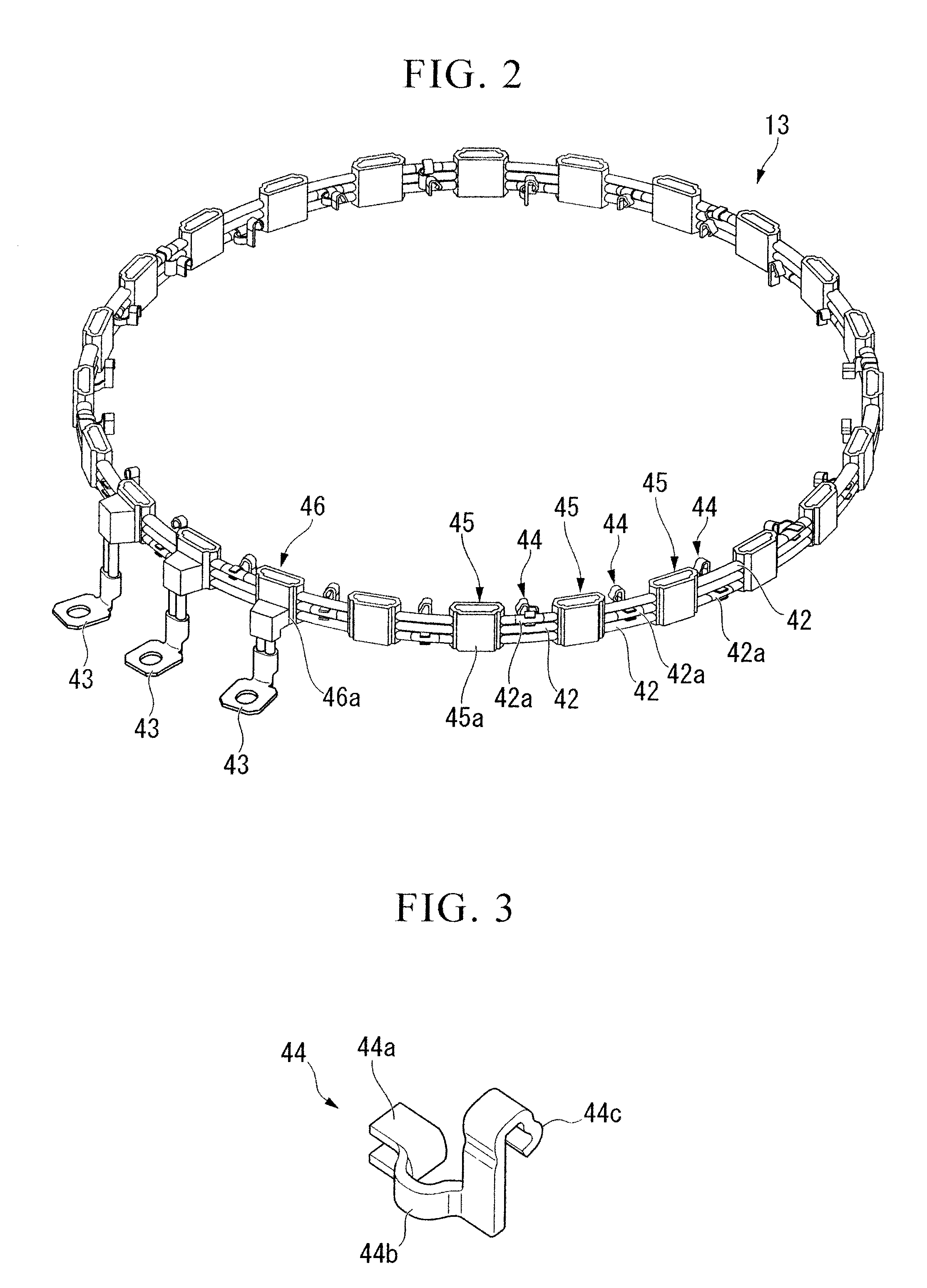

Electric power collection/distribution ring of rotary electric machine

An electric power collection / distribution ring of a rotary electric machine including: a plurality of ring shaped bus rings each of which is to be connected to one of a plurality of coils provided in the rotary electric machine, the coils each corresponding to phases of the rotary electric machine; a plurality of fixing member which are fixed to the bus rings and arranged along the circumferential direction thereof; and a plurality of connection terminals which are fixed to the bus rings and arranged along said circumferential direction, and which can be connected with one of leader line sections of the coils.

Owner:HONDA MOTOR CO LTD

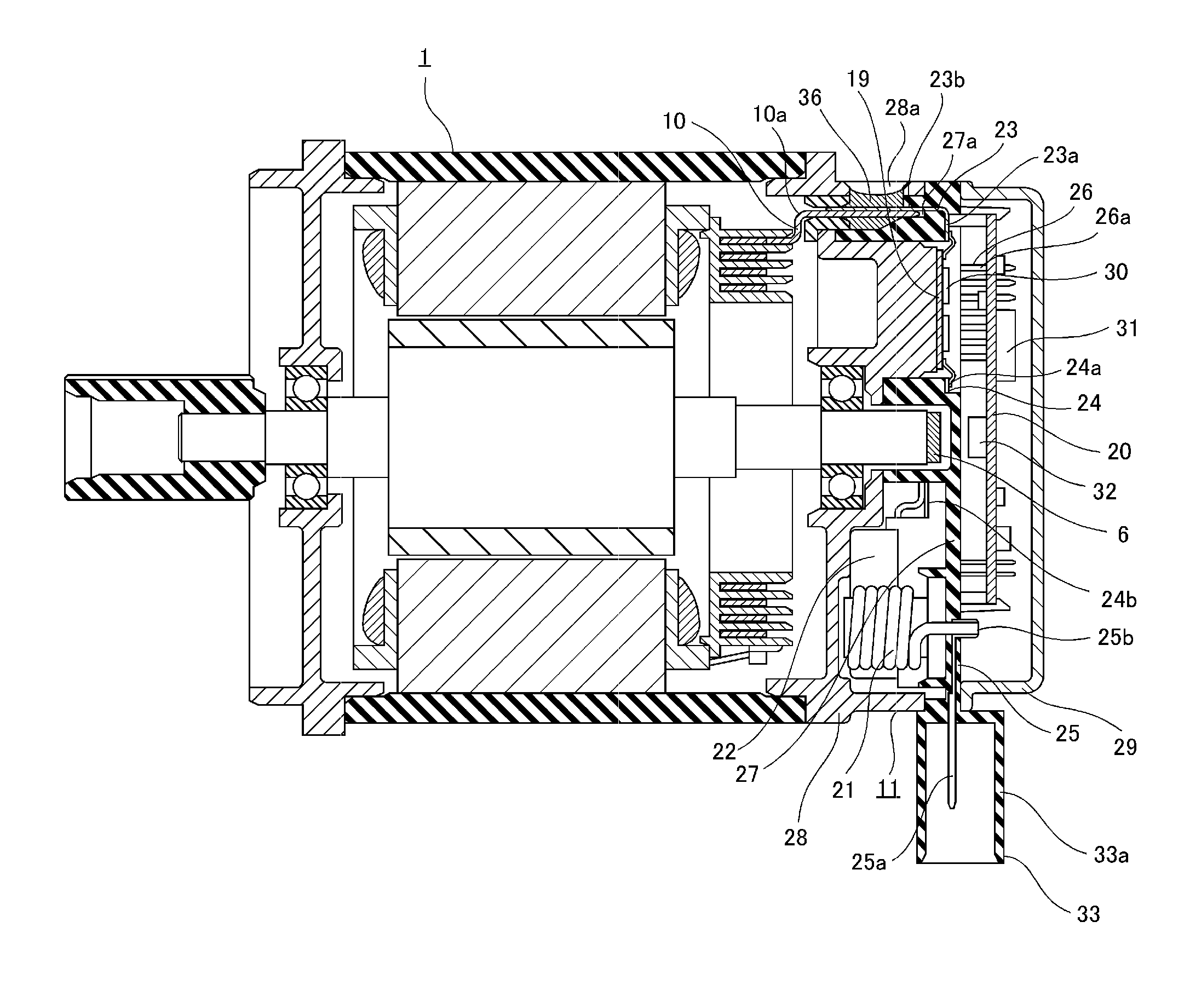

Electric driving device and electric power steering apparatus equipped with the same

ActiveUS20120229005A1Low costSmall sizeAssociation with control/drive circuitsWindingsElectric power steeringElectricity

Reduction in costs and size of an electric driving device is achieved and reliability of electrical connection thereof is enhanced. The device comprises: an electric motor; a controller that is disposed coaxially with the axis of the electric motor rotation shaft and takes control of driving the electric motor; a motor terminal whose end extends from the electric motor toward the controller; and an output terminal whose end extends from the controller toward the electric motor; wherein a portion of the motor terminal including the end thereof and that of the output terminal including the end thereof each are formed to extend in parallel to an axial direction of the electric motor, and overlappingly connected with each other.

Owner:MITSUBISHI ELECTRIC CORP

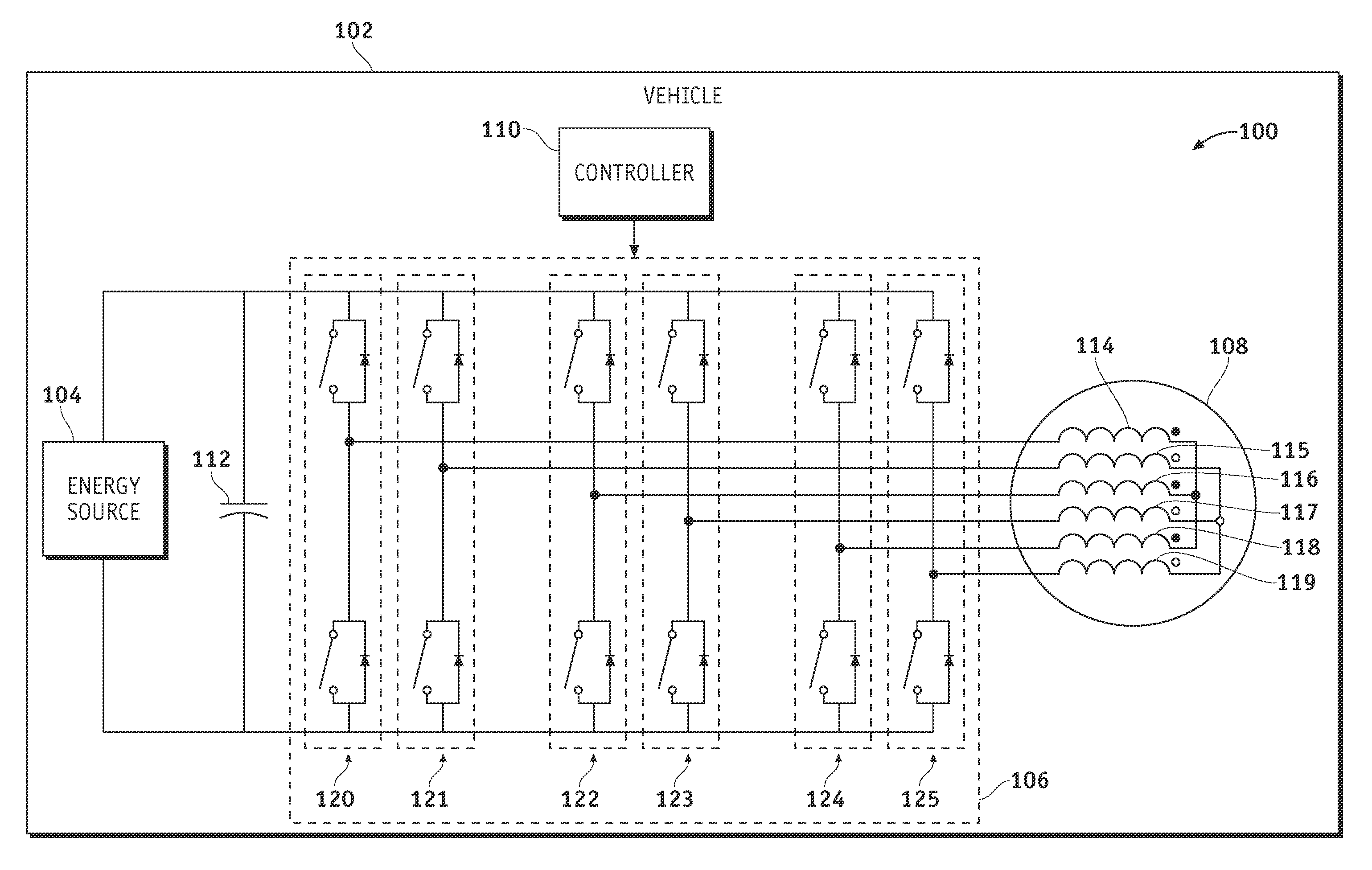

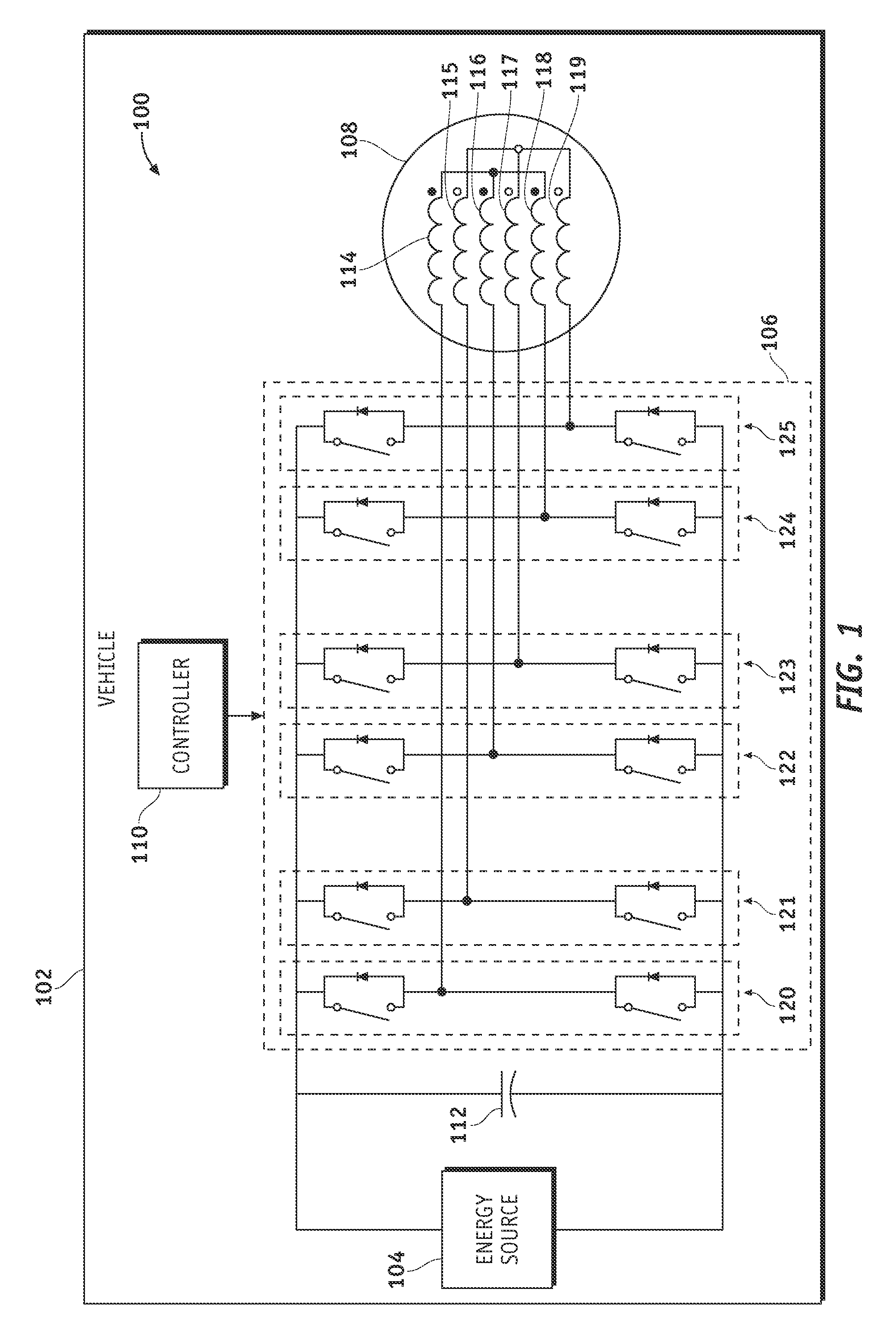

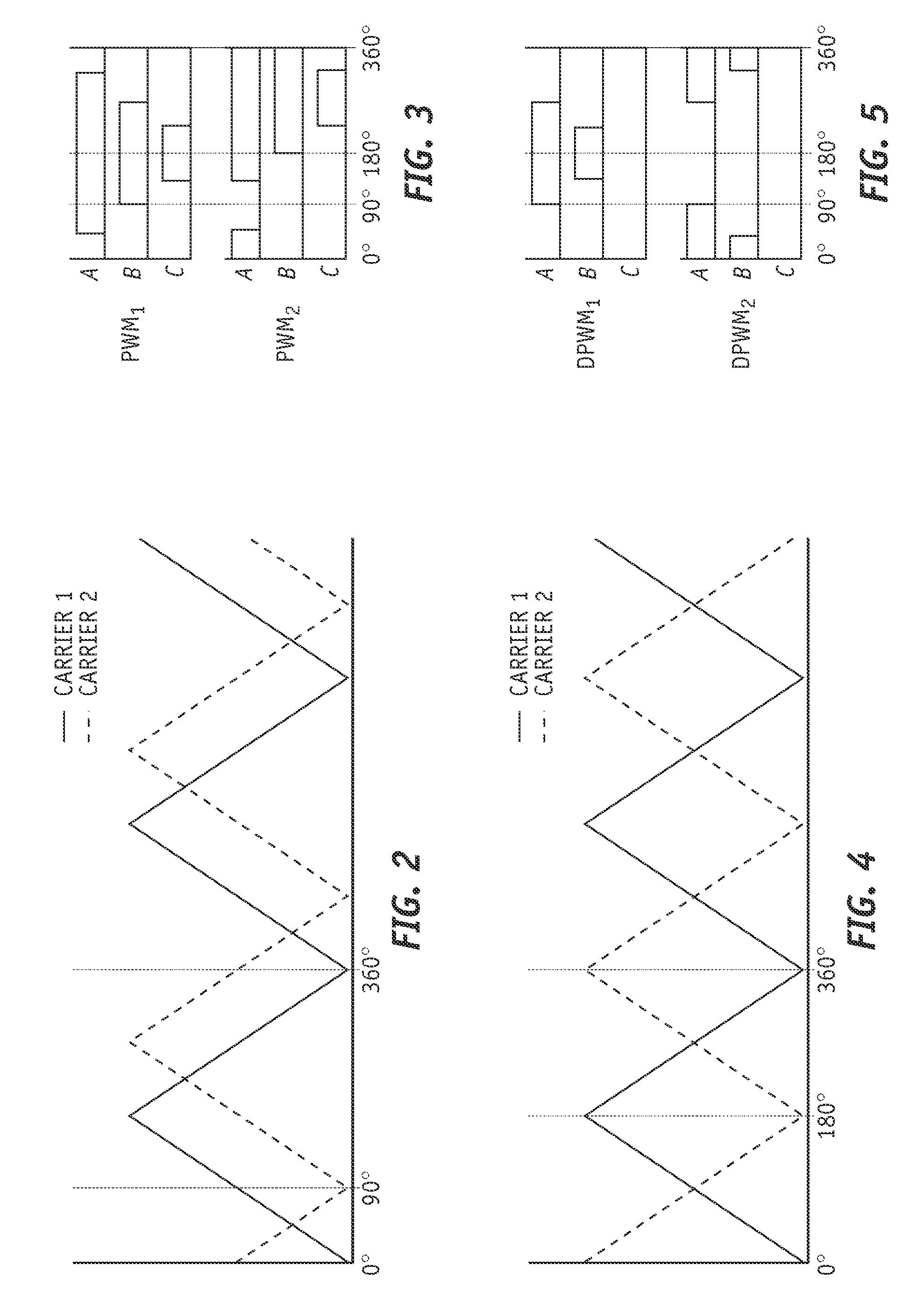

Electrical system using phase-shifted carrier signals and related operating methods

An automotive drive system and methods for making the same are provided. The system includes a three-phase motor and an inverter module. The three-phase motor includes a first set of windings each having a first magnetic polarity; and a second set of windings each having a second magnetic polarity that is opposite the first magnetic polarity. The first set of windings being electrically isolated from the second set of windings. The inverter module includes a first set of phase legs and a second set of phase legs. Each one of the first set of phase legs is coupled to a corresponding phase of the first set of windings, and each one of the second set of phase legs is coupled to a corresponding phase of the second set of windings.

Owner:GM GLOBAL TECH OPERATIONS LLC

Electrical machine having a rotor specially adapted to high speeds

InactiveUS20040004407A1Increase speedWindingsMagnetic circuit rotating partsElectric machinePole piece

An electrical rotating machine having a rotor comprising a shaft made from nonmagnetic material, a plurality of pole pieces made from magnetic material and surrounding the shaft, with permanent magnets fixed in receivers by wedges cooperating with the pole pieces to block radially outward movement of the magnets.

Owner:CONCEPTION & DEV MICHELIN SA

Motor

ActiveUS20070278876A1Reliable motorReduce axial heightWindingsMagnetic circuit stationary partsEngineeringElectric motor

A motor includes a stator and a bus bar supported axially above the stator. The bus bar includes a concave portion arranged in a lower surface thereof facing toward coils of the stator. In a gap defined between the coil and the concave portion, a portion of the wire extracted from the coil and wound in the circumferential direction (i.e., a crossover wire portion) is accommodated. The bus bar includes a wire-positioning hole through which the wire is led to a terminal to be connected with the wire.

Owner:NIPPON DENSAN CORP

Motor and bus bar

ActiveUS20060068617A1Easy to fillWindingsManufacturing dynamo-electric machinesShell moldingEngineering

A bus bar secured to a stator in an electric motor in a preferred embodiment according to the invention includes four wiring boards, which are arranged perpendicularly to a center axis at intervals in a direction toward the center axis, and a resin portion for covering the surroundings of the four wiring boards by injection molding. Resin passing holes, through which a resin flows when the resin portion is molded, are formed at each of the wiring boards. When the bus bar is molded, the resin is injected into a resin molding die in a state in which the four wiring boards are supported by supporting pins disposed inside of the die. The resin flows to and fro between a space defined between the die and the wiring board and a space defined between the adjacent wiring boards.

Owner:NIDEC CORP

High efficiency magnetic core electrical machines

InactiveUS20130154397A1Increase powerImprove utilizationWindingsMagnetic circuit rotating partsBobbinElectric machine

A high efficiency magnetic core electrical machine includes magnet and coil assemblies that may be axially stacked to form modules. The magnet sub-assemblies include magnet locators on which multiple permanent magnets are arranged, and the coil sub-assembly includes a pair of bobbin holders supporting multiple bobbins and magnetic cores that extend through the bobbins and through openings in the bobbin holders to form magnetic poles that face the permanent magnets. The permanent magnets and magnetic poles may be arranged in various zero-cogging configurations, including one in which the permanent magnets on opposite sides of the coil assembly are skewed relative to each other to cause cogging force cancellation. In addition, a power matching circuit may be used to optimize the output power of the electrical machine to rotor speed when the electrical machine is used as a generator.

Owner:SULLIVAN JOHN T

Broad speed range generator

InactiveUS20100283252A1Harvest sustainable mechanical powerWide speed rangeWindingsMagnetic circuitPower qualityDc current

A brushless generator with permanent-magnet multi-pole rotor disks and coreless stator winding disks includes integral electronics to efficiently generate regulated DC current and voltage from shaft input power over a broad speed range. Its power rating is scalable, and it incurs no cogging torque, or friction from gearing. Integral power control electronics includes high-frequency pulse-width-modulated boost regulation, which provides regulated current at requisite voltage over its broad speed range. A main embodiment to produce DC power at widely variable speeds includes signal processing so output power varies according to the third power of speed. A version for use with vertical-axis wind turbines has a relatively large diameter to facilitate a large number of poles. Combined boost-regulation, zero cogging torque, and no gearing, enable a wide speed range, for better power quality and higher wind energy yields. An alternate embodiment is intended to produce DC power from a variety of shaft drive sources, with selectable shaft torque.

Owner:FRADELLA RICHARD B

Controller for AC generator

InactiveUS7327123B2Uniform phase rippleWide variationWindingsEmergency protective circuit arrangementsAlternatorControl system

A control system that can accommodate the wide variations in the output of a generator, such as a permanent magnet alternator, while providing an output with relatively uniform phase ripple. The control system includes a zero crossing detector and variable ramp generator for generating control signals to a switching rectifier to generate a regulated DC signal.

Owner:MAGNETIC APPL

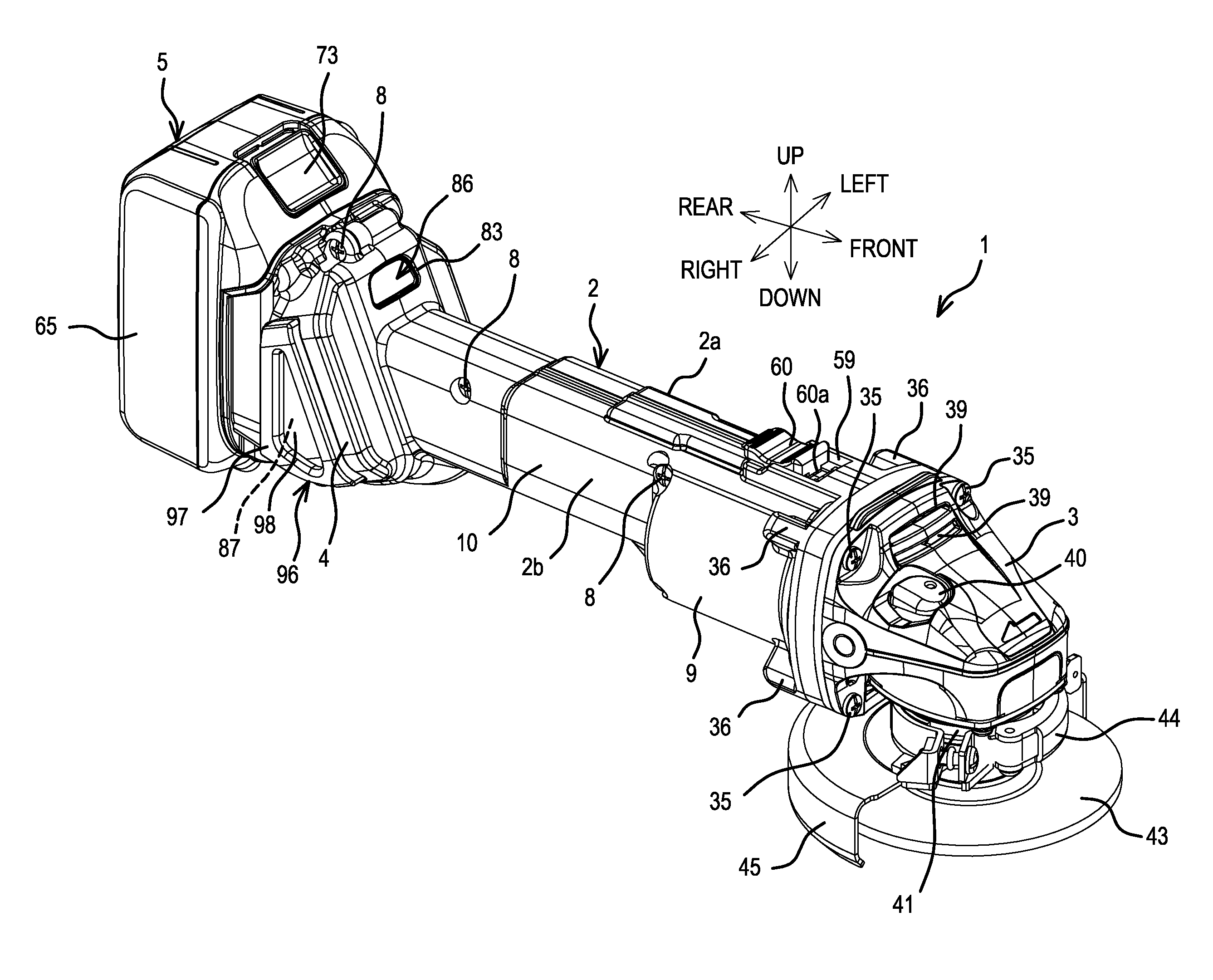

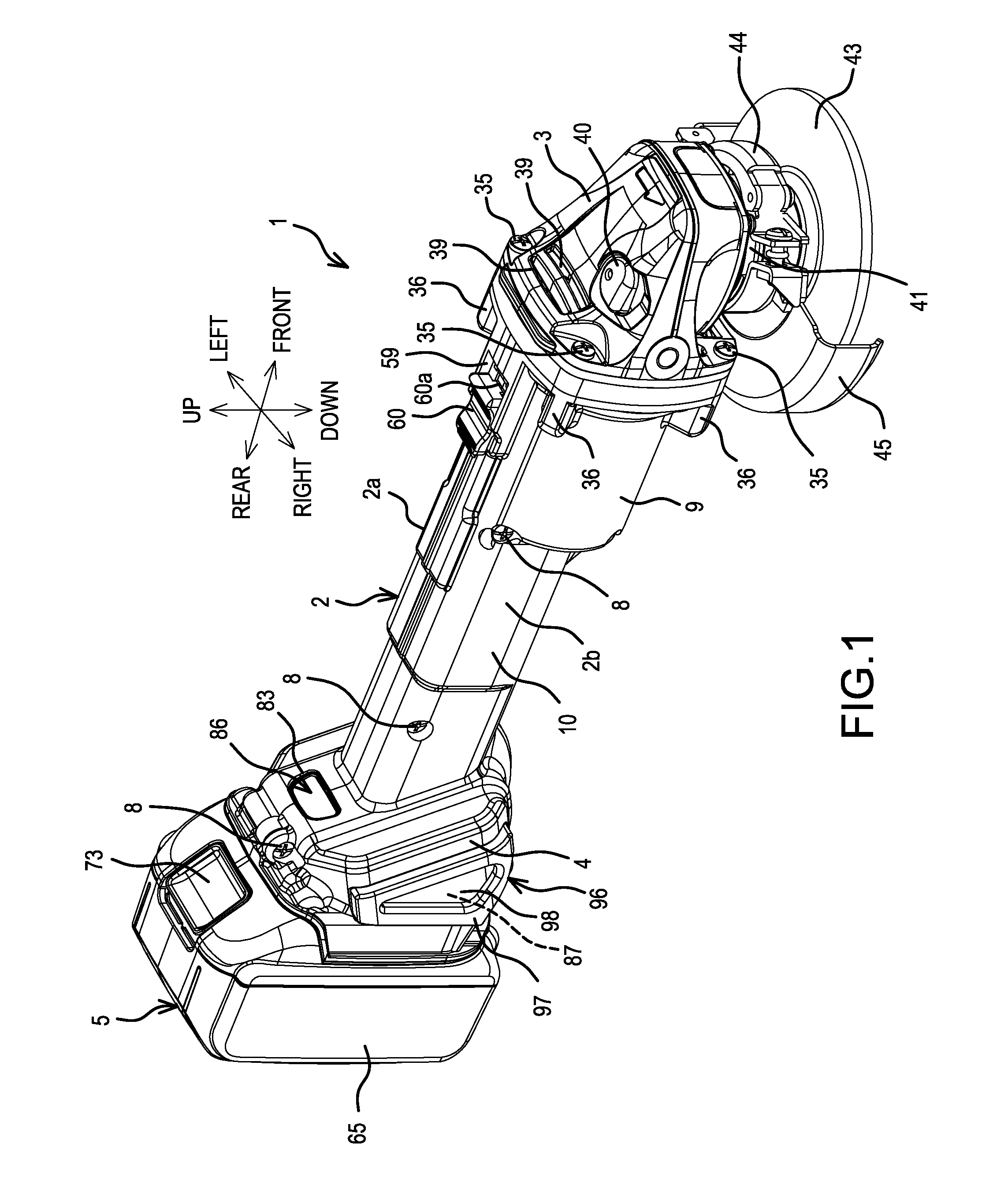

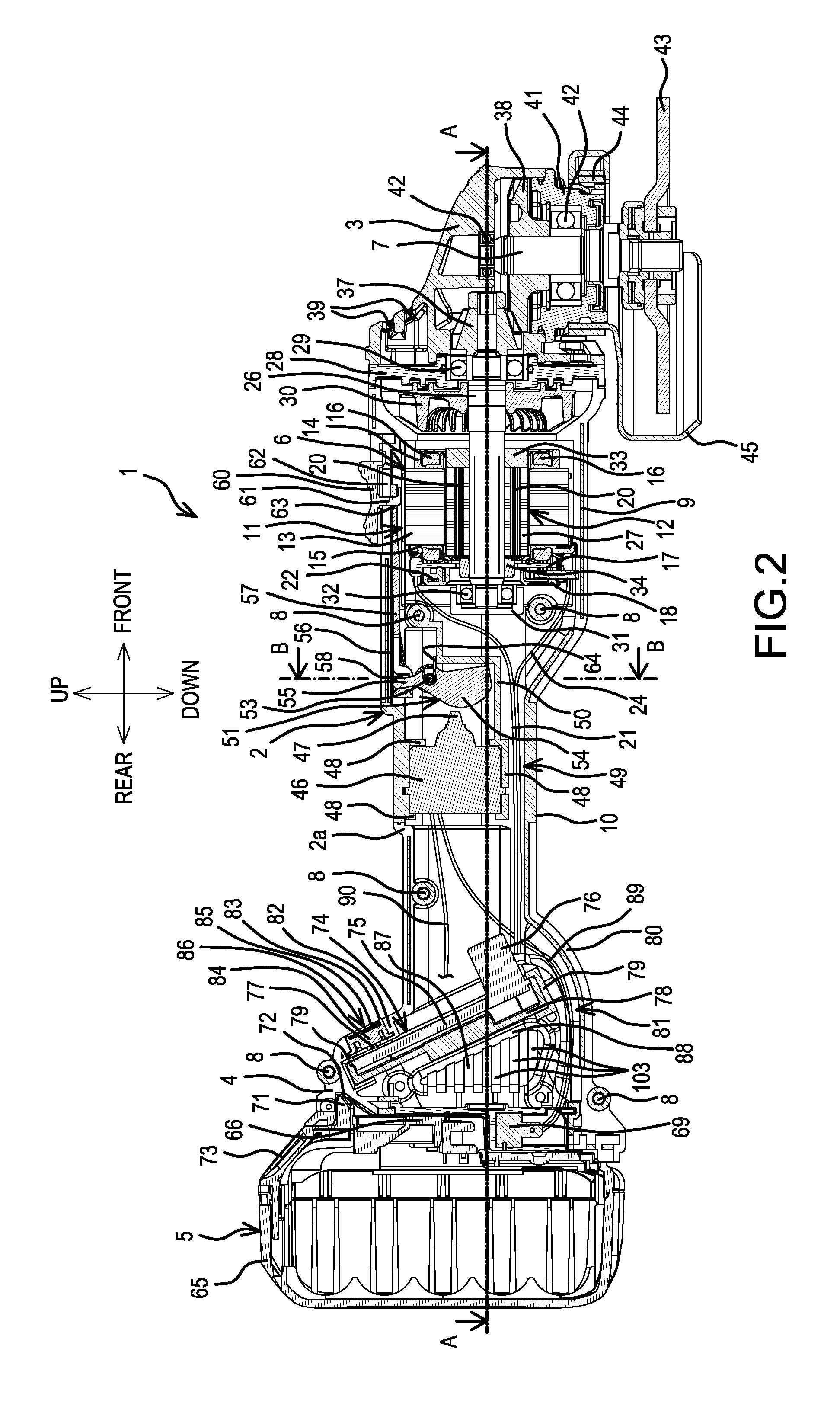

Power tool

ActiveUS20150263592A1Comfortable to holdImprove cooling effectWindingsPortable grinding machinesBrushless motorsEngineering

A power tool includes a brushless motor having a stator and a rotor, which includes a rotary shaft extending in a front-rear direction of the power tool. The rotary shaft rotates a spindle that extends in an up-down direction of the power tool. A fan is fixedly coupled to the rotary shaft and rotates therewith. A switch is disposed rearward of the brushless motor and a controller is disposed rearward of the switch in the front-rear direction. A battery pack is disposed rearward of the controller. A main-body housing houses the brushless motor, the switch and the controller. The main-body housing includes a first tubular part, which houses the brushless motor, and a second tubular part, which houses the switch. The diameter of the second tubular part is smaller than the diameter of the first tubular part.

Owner:MAKITA CORP

Electric motor drive system and method

InactiveUS20030137202A1Synchronous generatorsAssociation with control/drive circuitsAcute angleEngineering

An electric motor system and method are shown having a circuit board arranged in a plane that lies in a predetermined angle relative to an axis to an armature of the electric motor. In one embodiment the predetermined angle is an acute angle and the plane is not perpendicular to an axis of an armature of the motor 10. Brushes are located remotely from the board.

Owner:VALEO ELECTRICAL SYST

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com