Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

29105results about "Dynamo-electric converter control" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

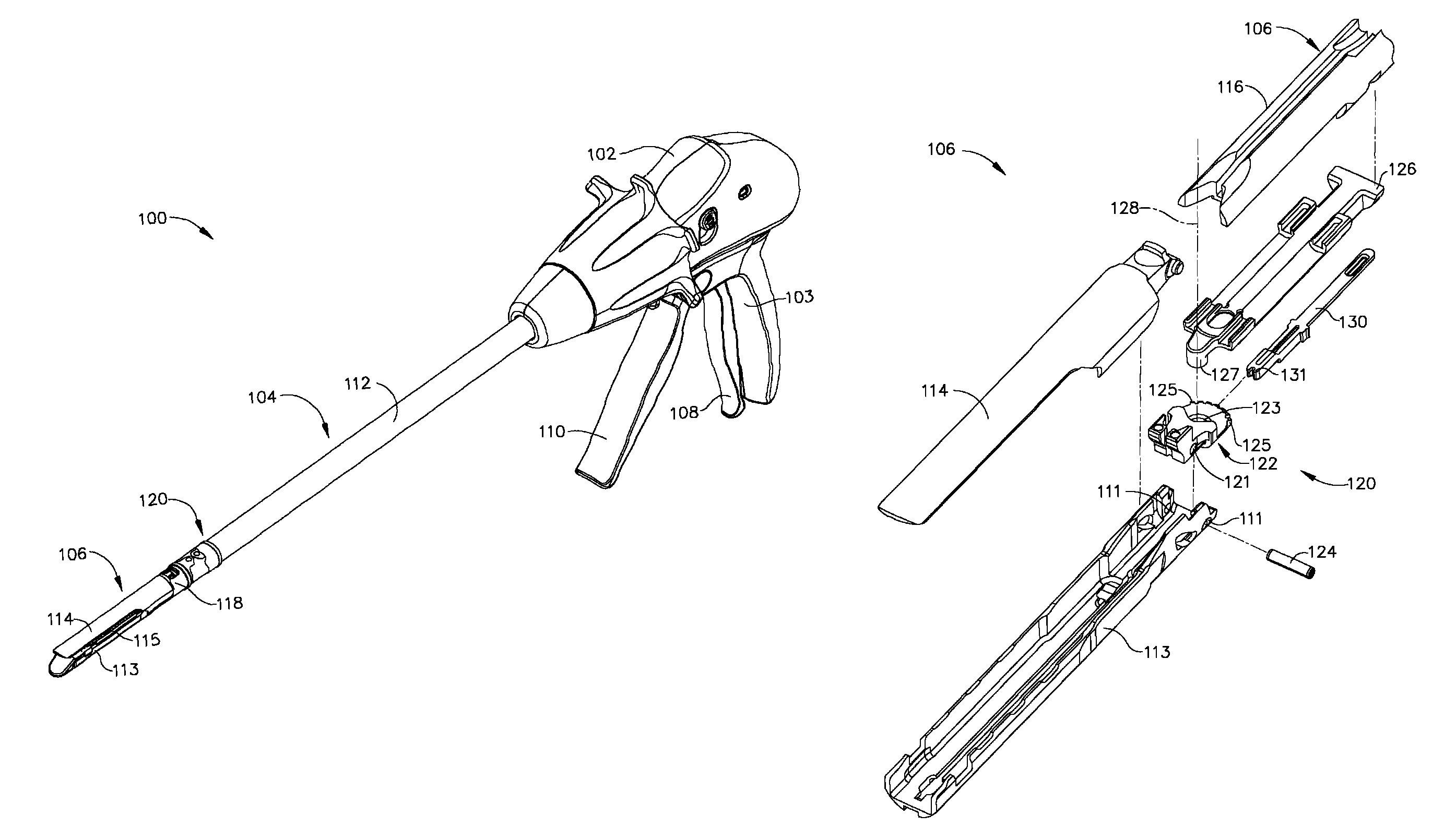

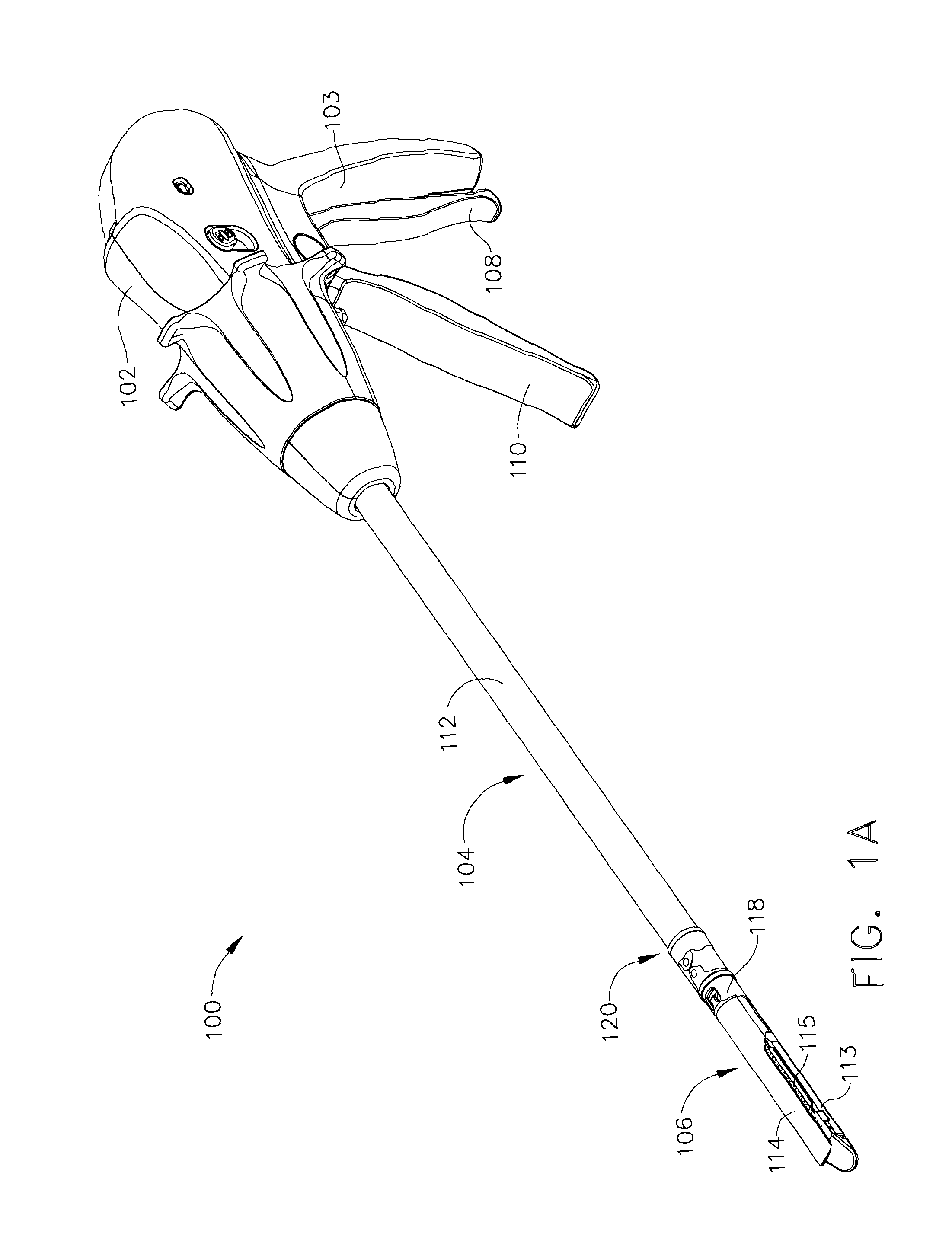

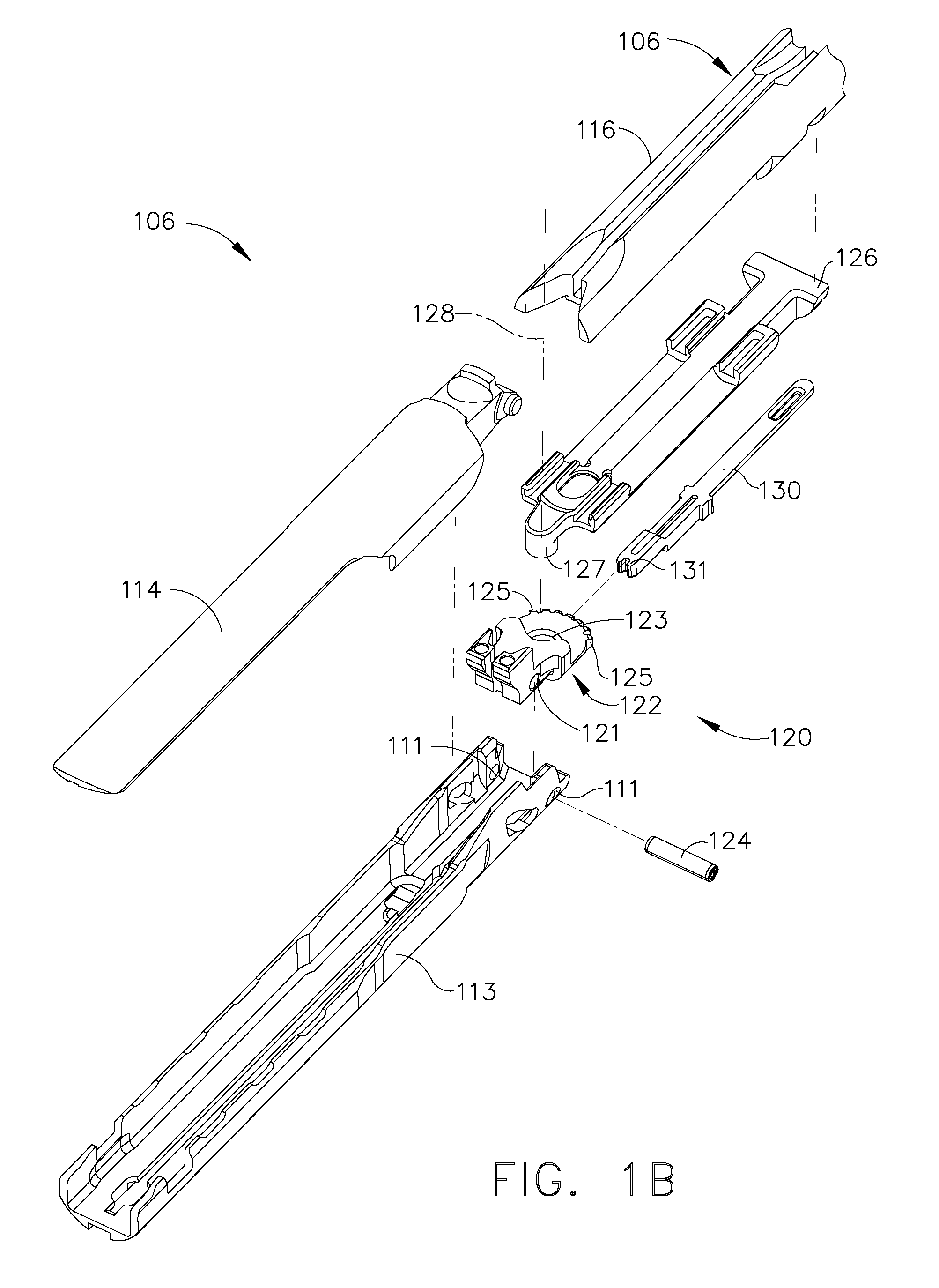

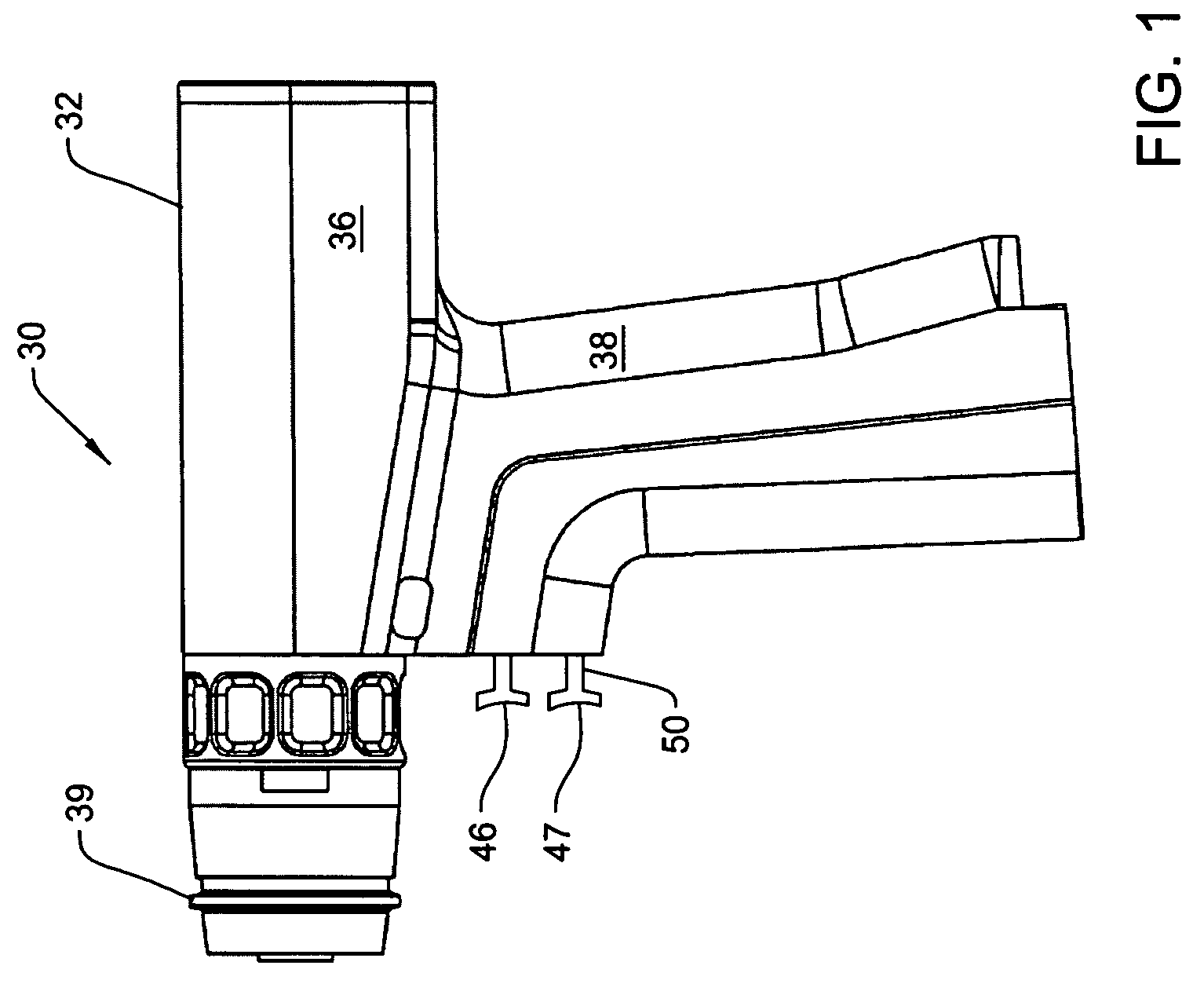

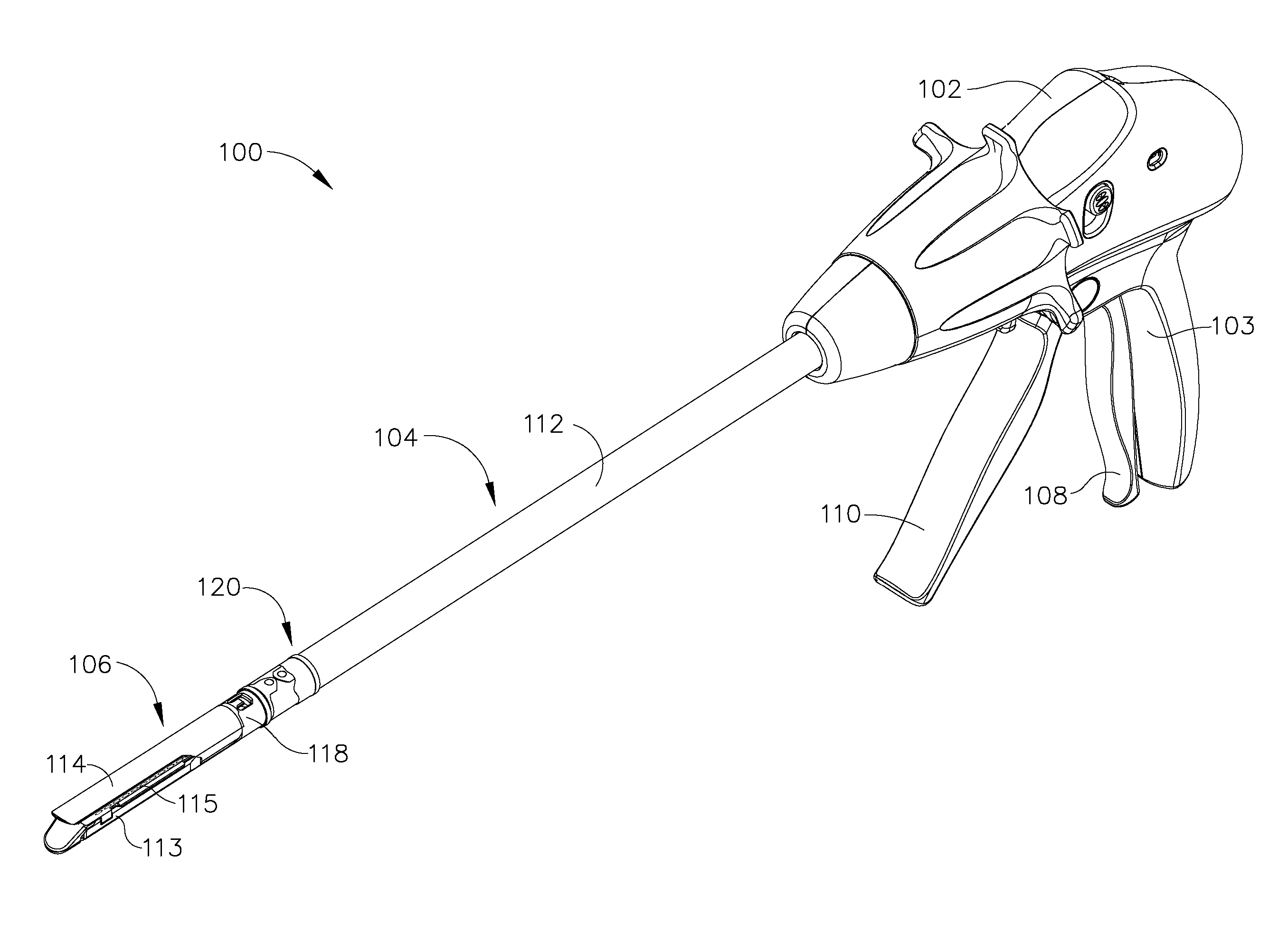

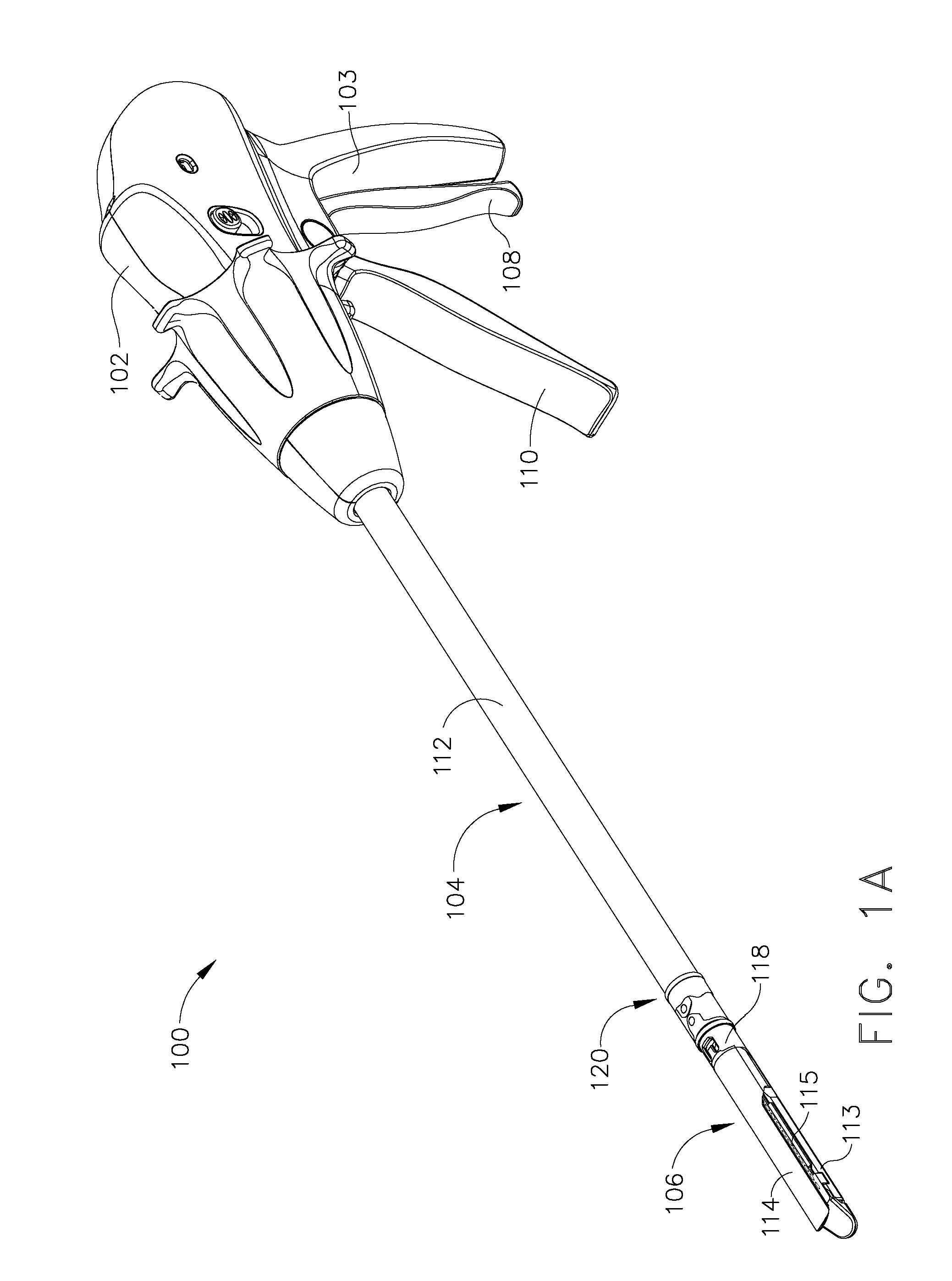

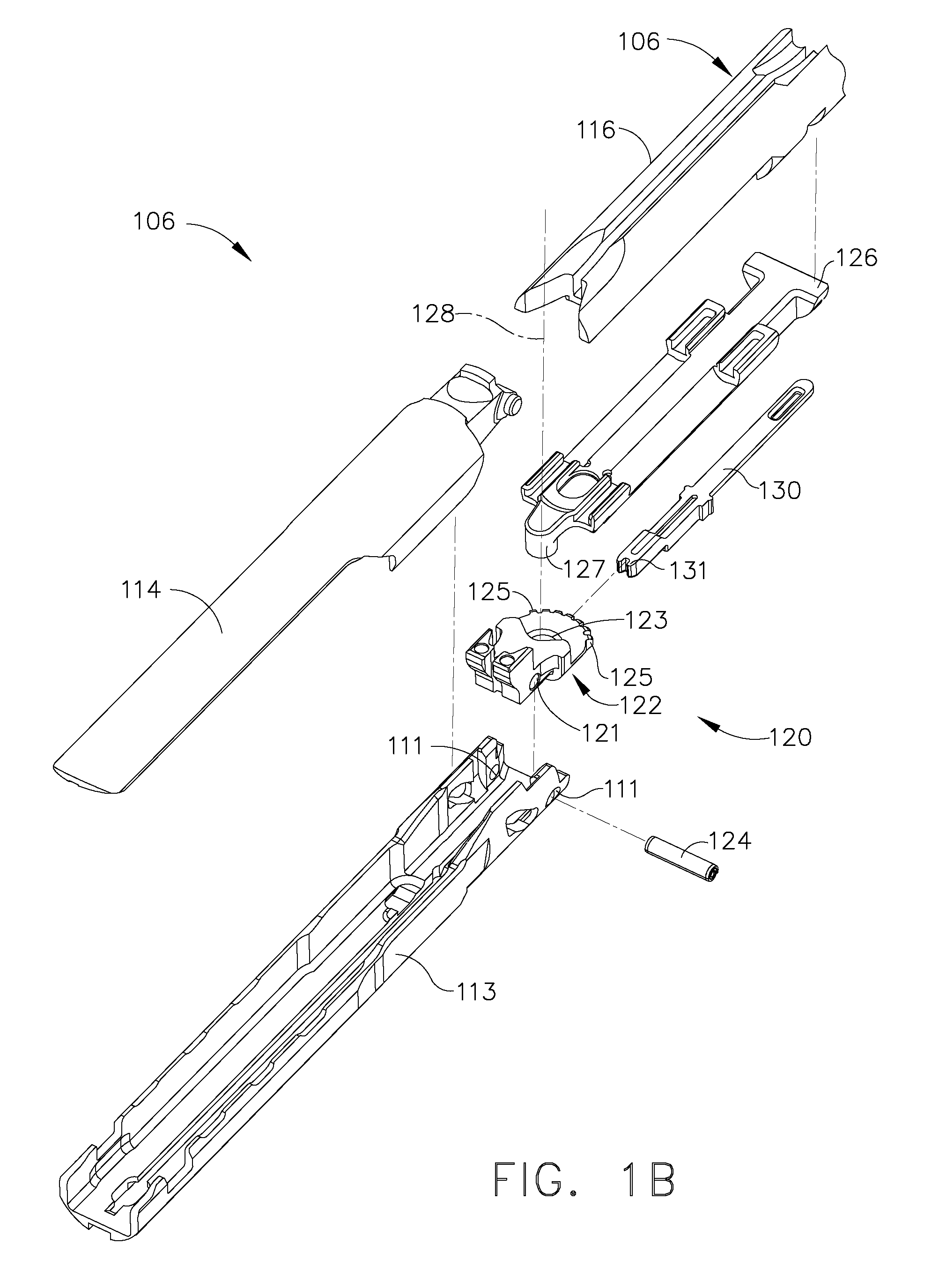

Surgical stapling instrument comprising a magnetic element driver

In various embodiments, a surgical stapling instrument can comprise a plurality of magnetic elements configured to articulate an end effector of the surgical instrument. The surgical instrument can comprise at least one electromagnet which can be selectively activated, or polarized, to generate a magnetic field sufficient to motivate a second magnetic element, such as a permanent magnet and / or an iron core, for example, mounted to the end effector. In certain embodiments, a surgical stapling instrument can comprise a plurality of magnetic elements configured to open and / or close an end effector of the surgical instrument. In at least one embodiment, a surgical stapling instrument can comprise a plurality of magnetic elements configured to advance and / or retract a firing bar, cutting member, and / or staple sled within the surgical instrument in order to incise and / or staple tissue positioned within an end effector of the surgical instrument.

Owner:CILAG GMBH INT

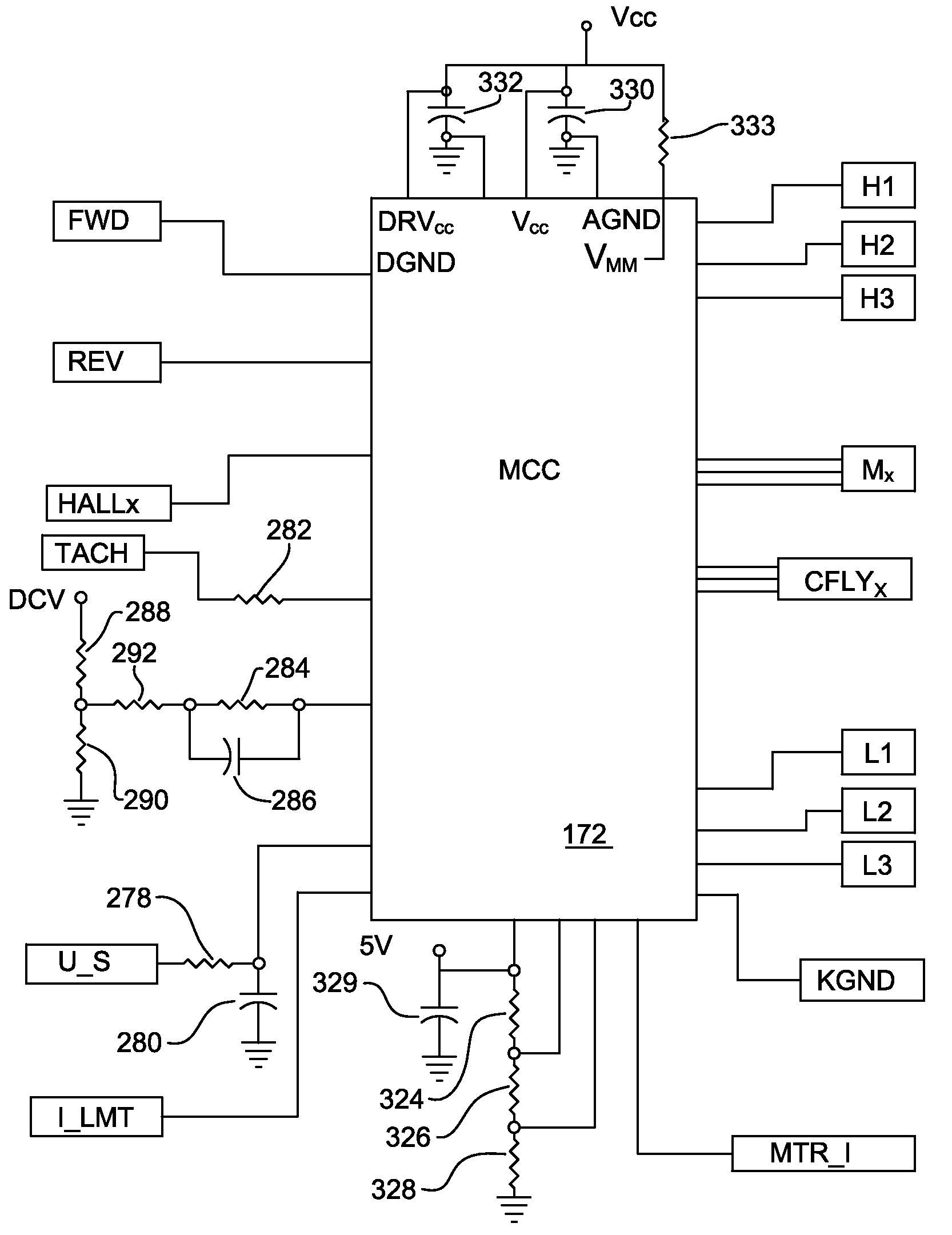

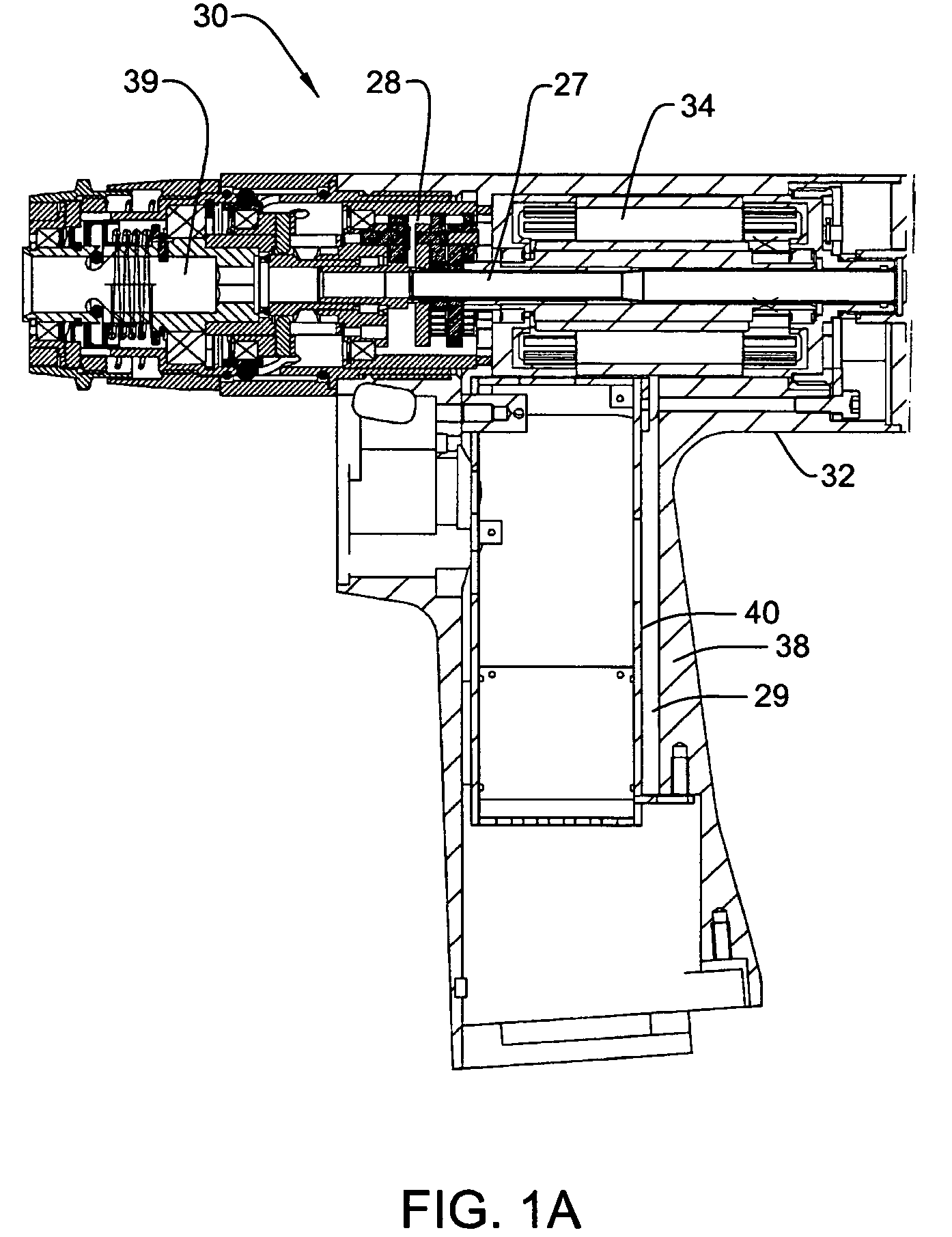

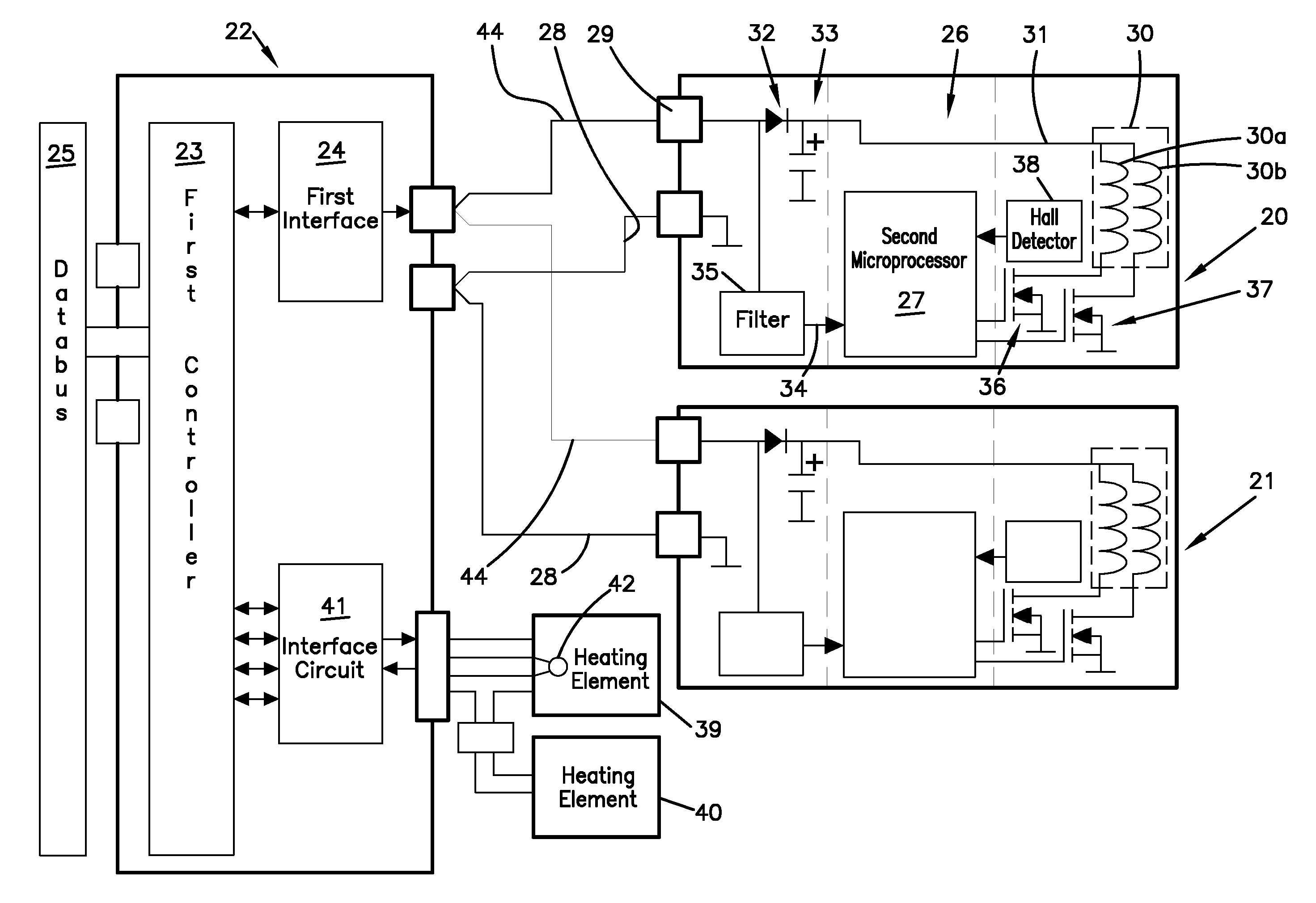

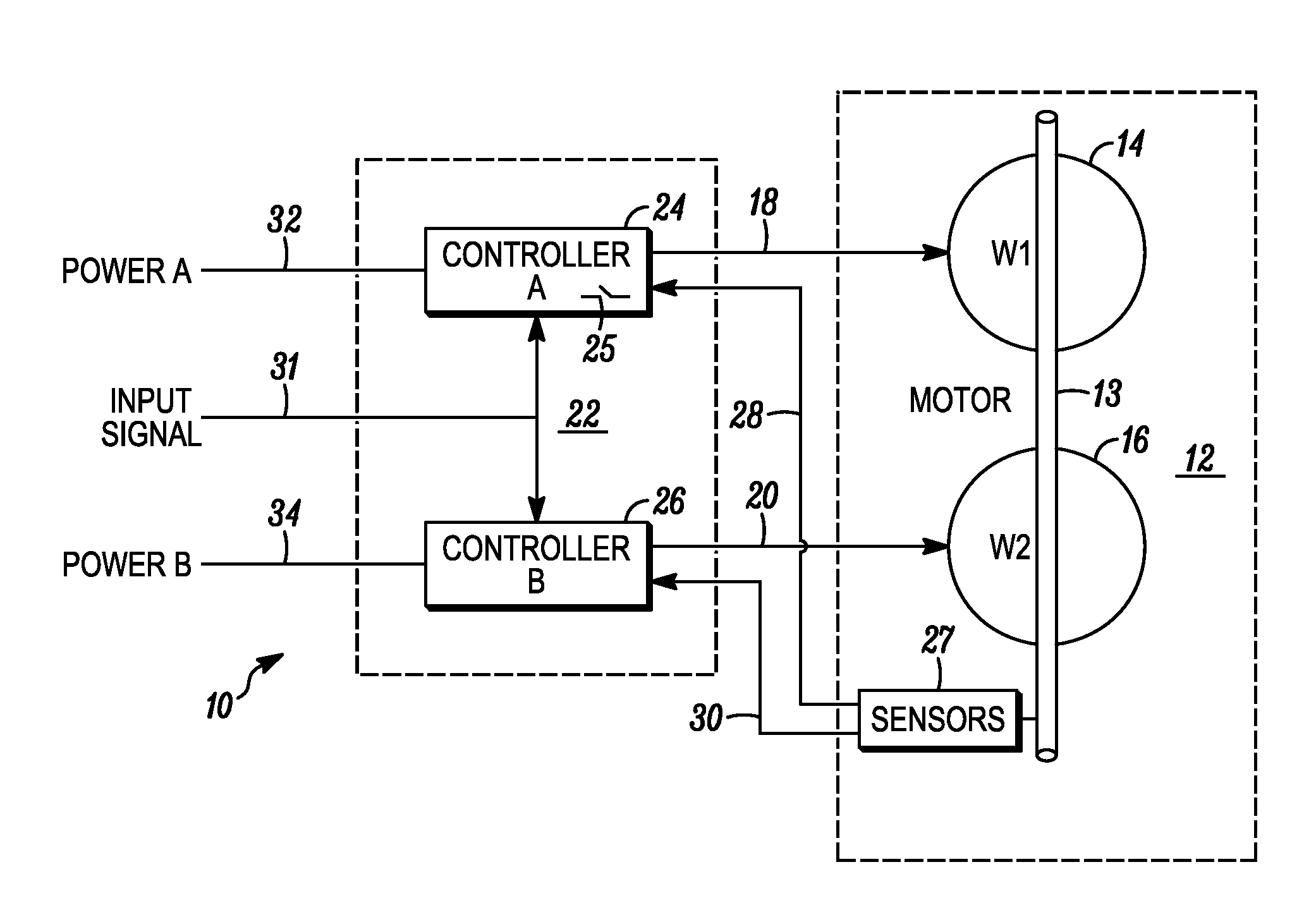

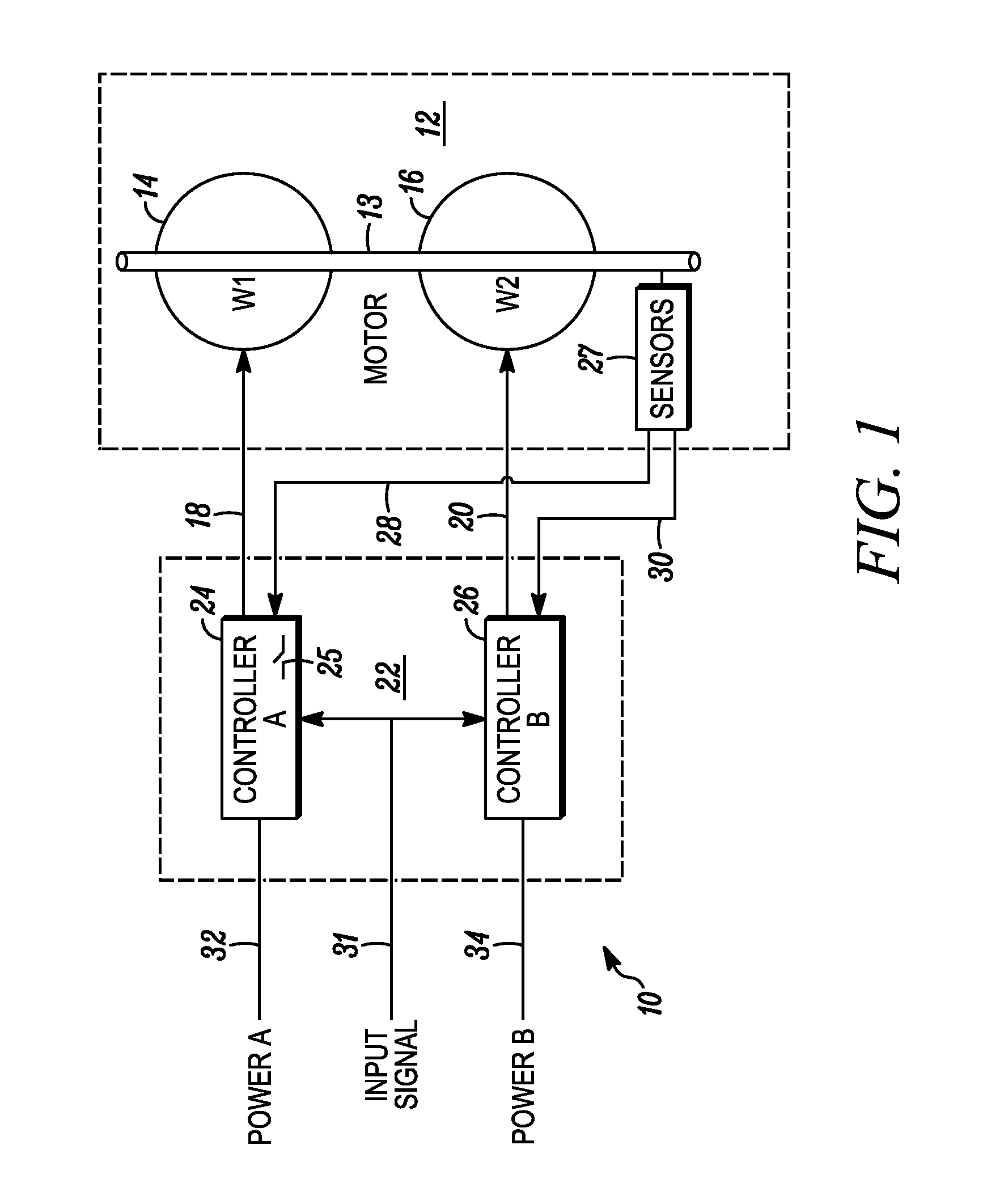

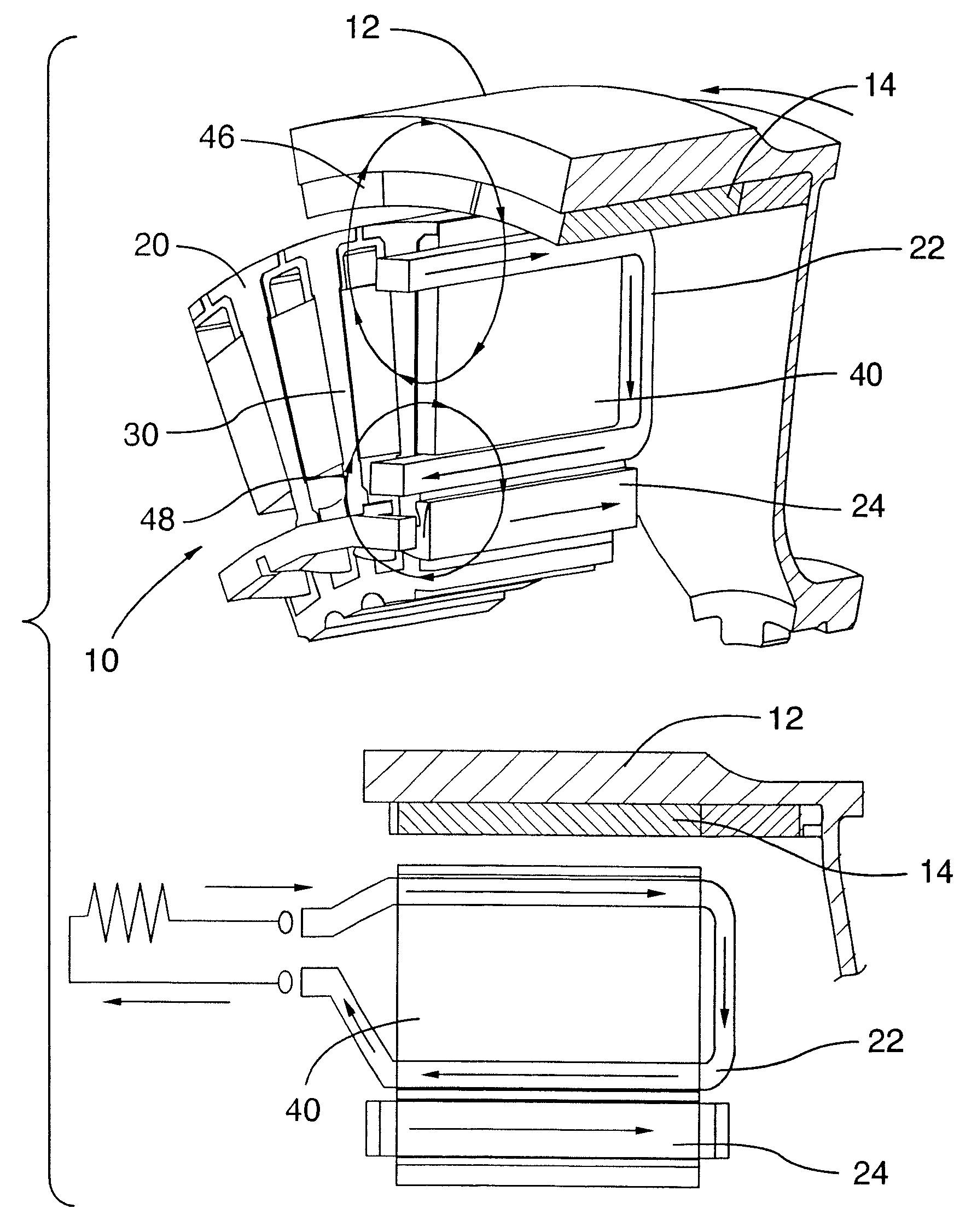

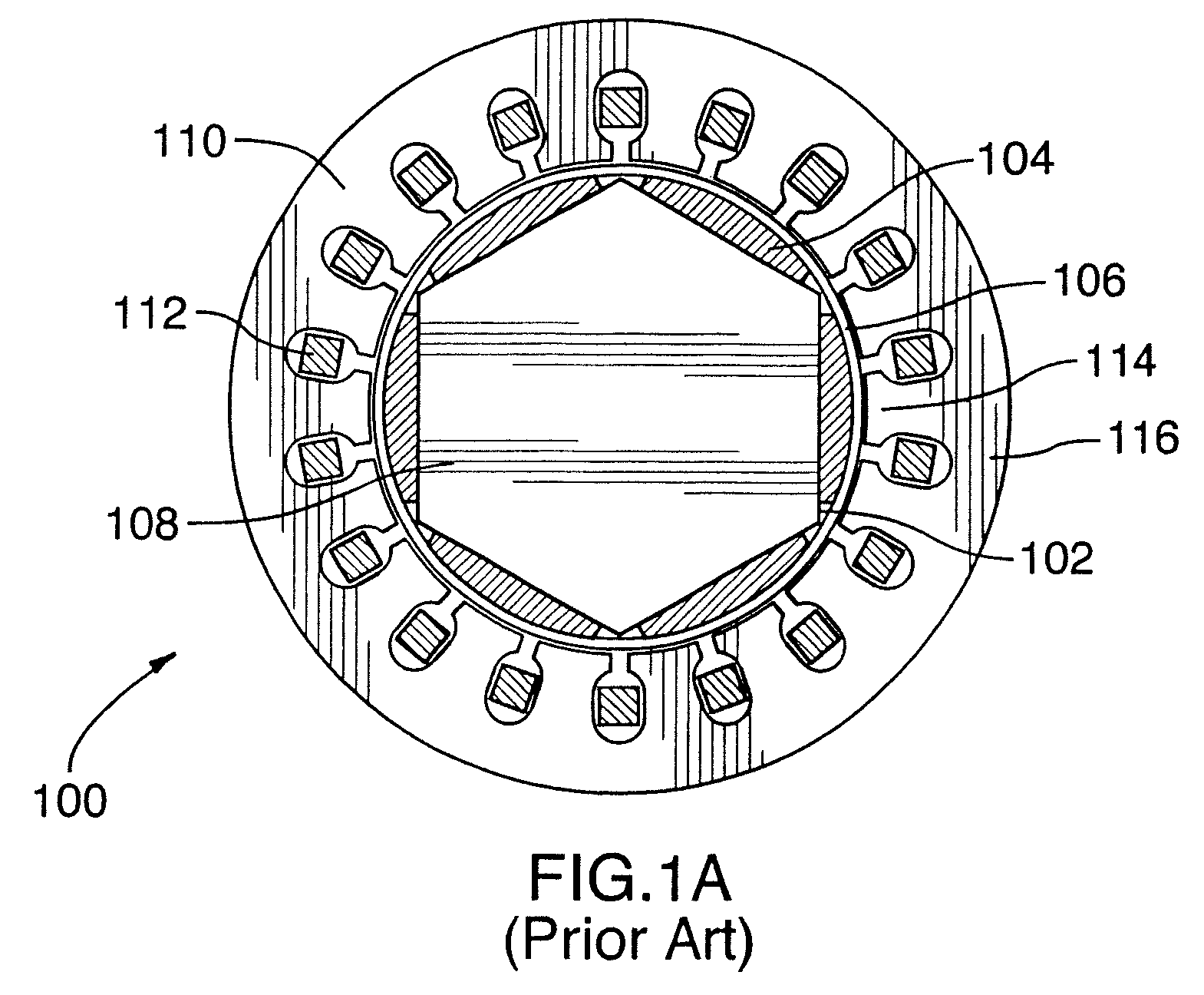

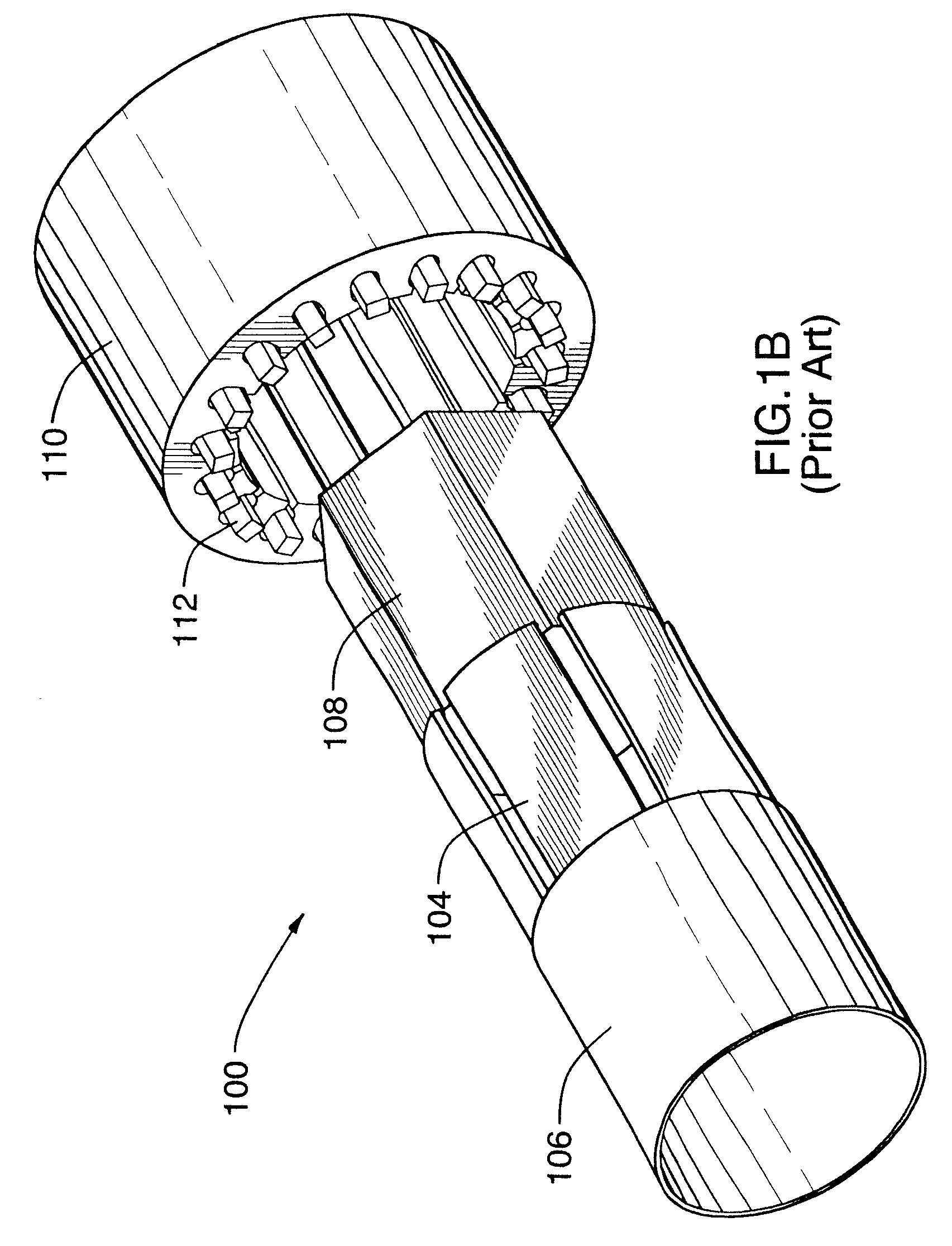

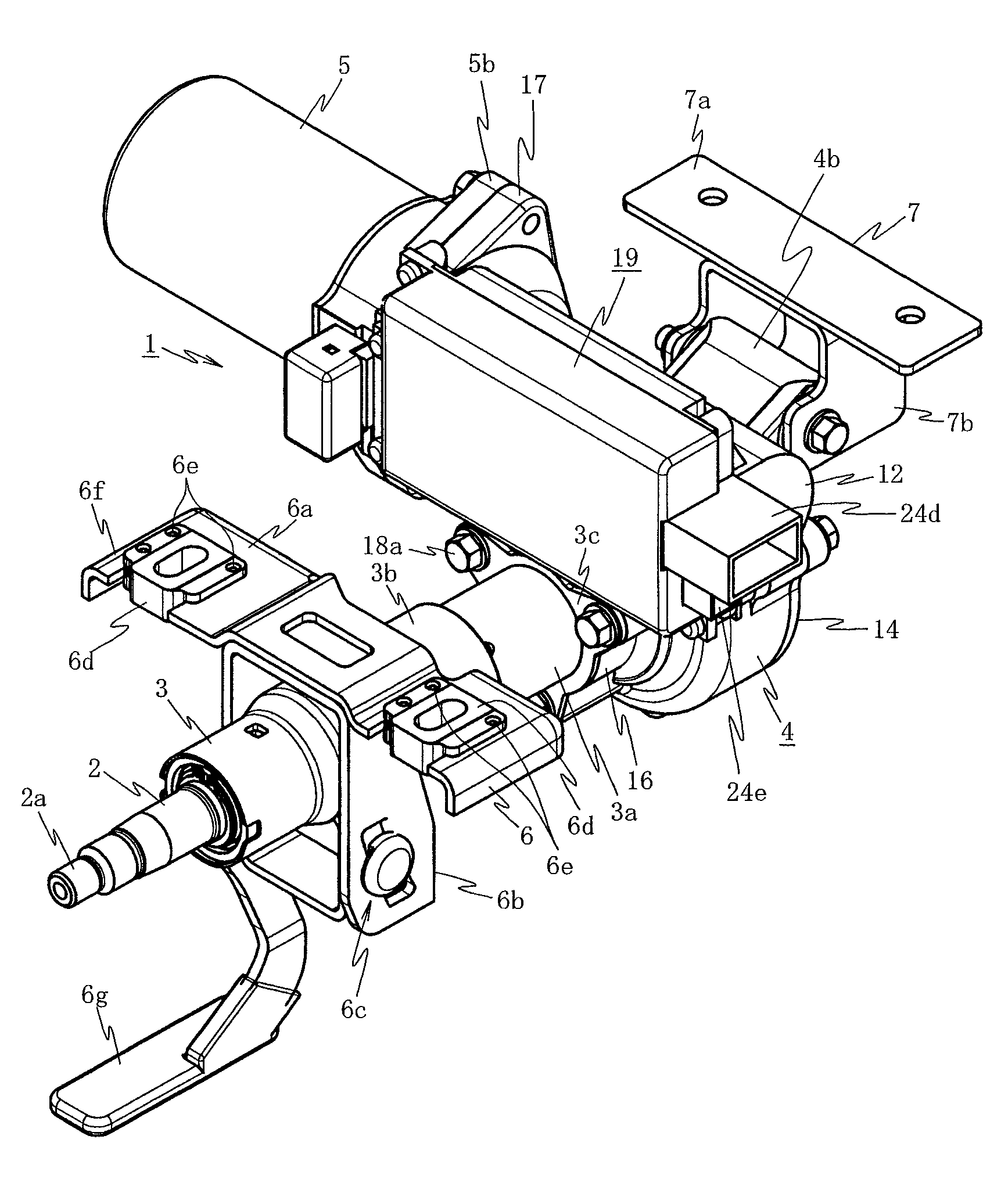

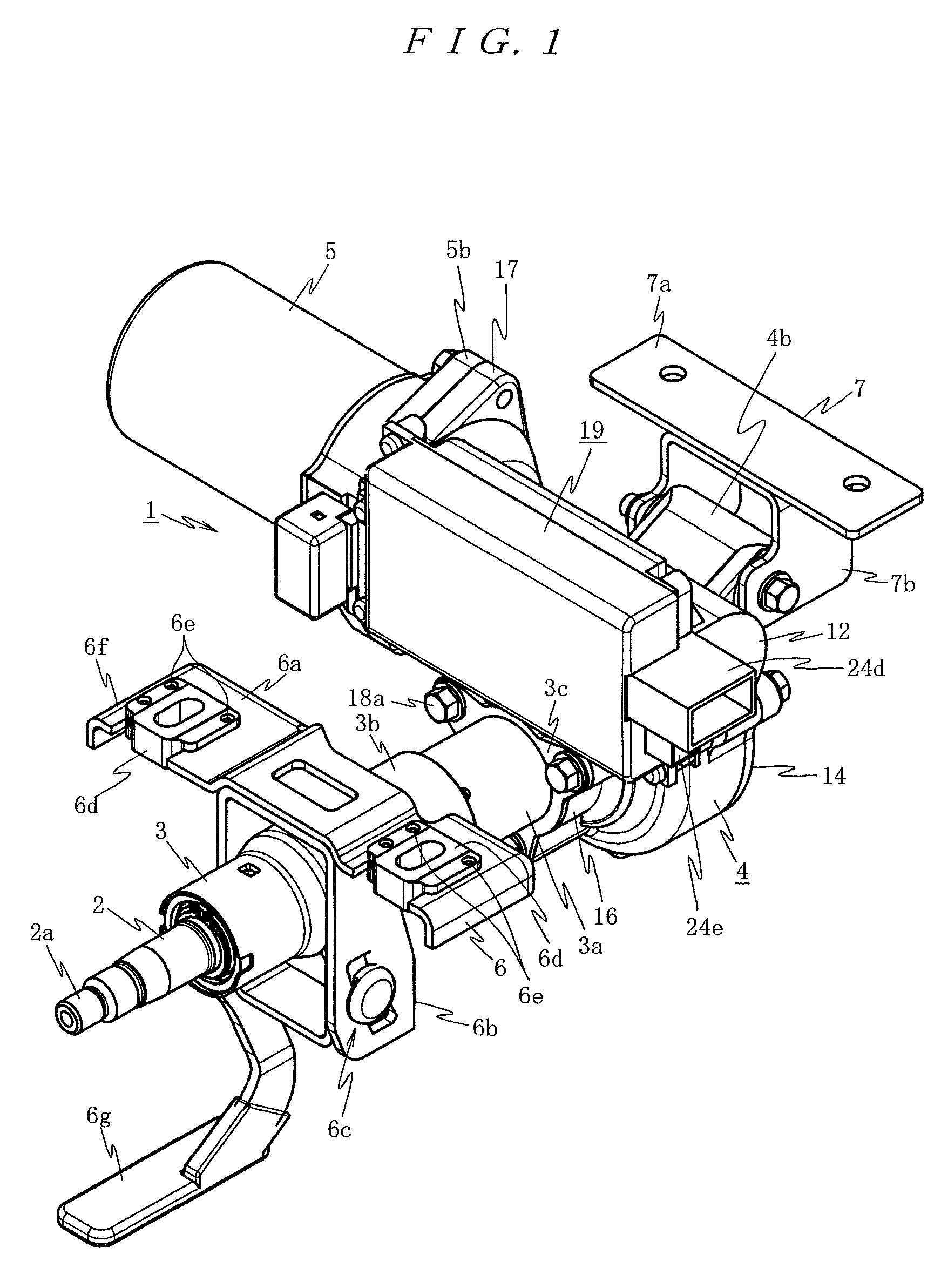

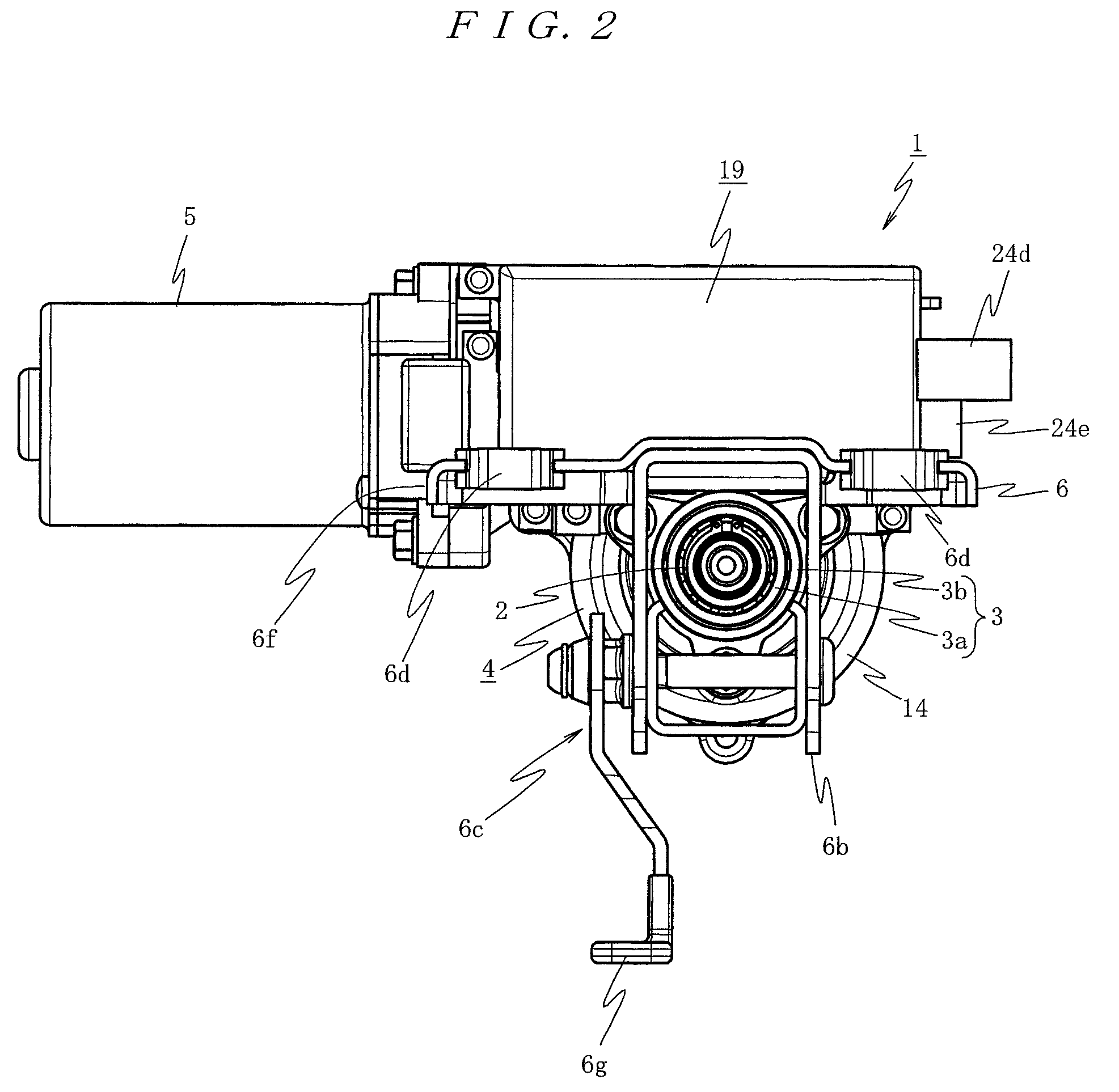

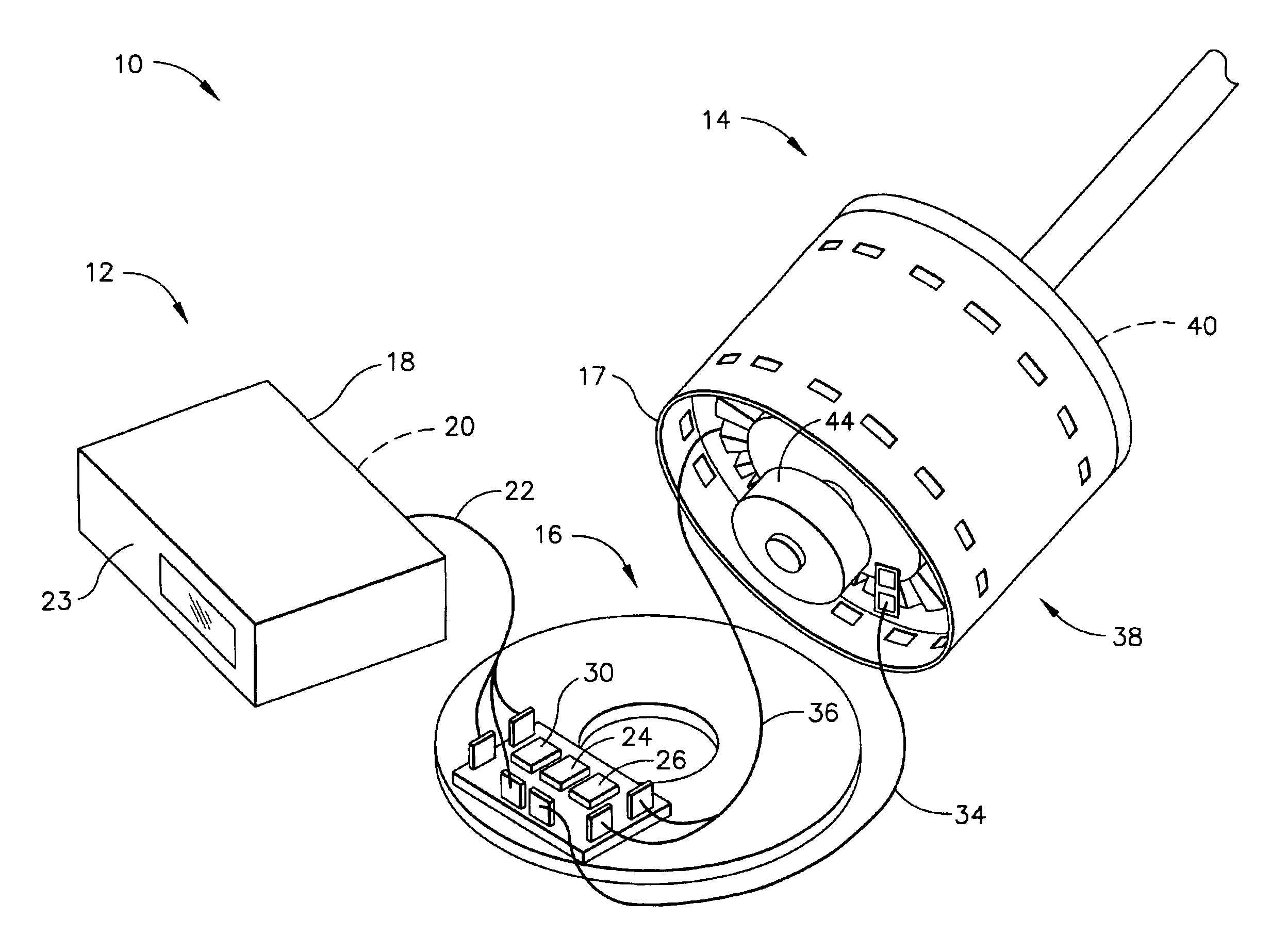

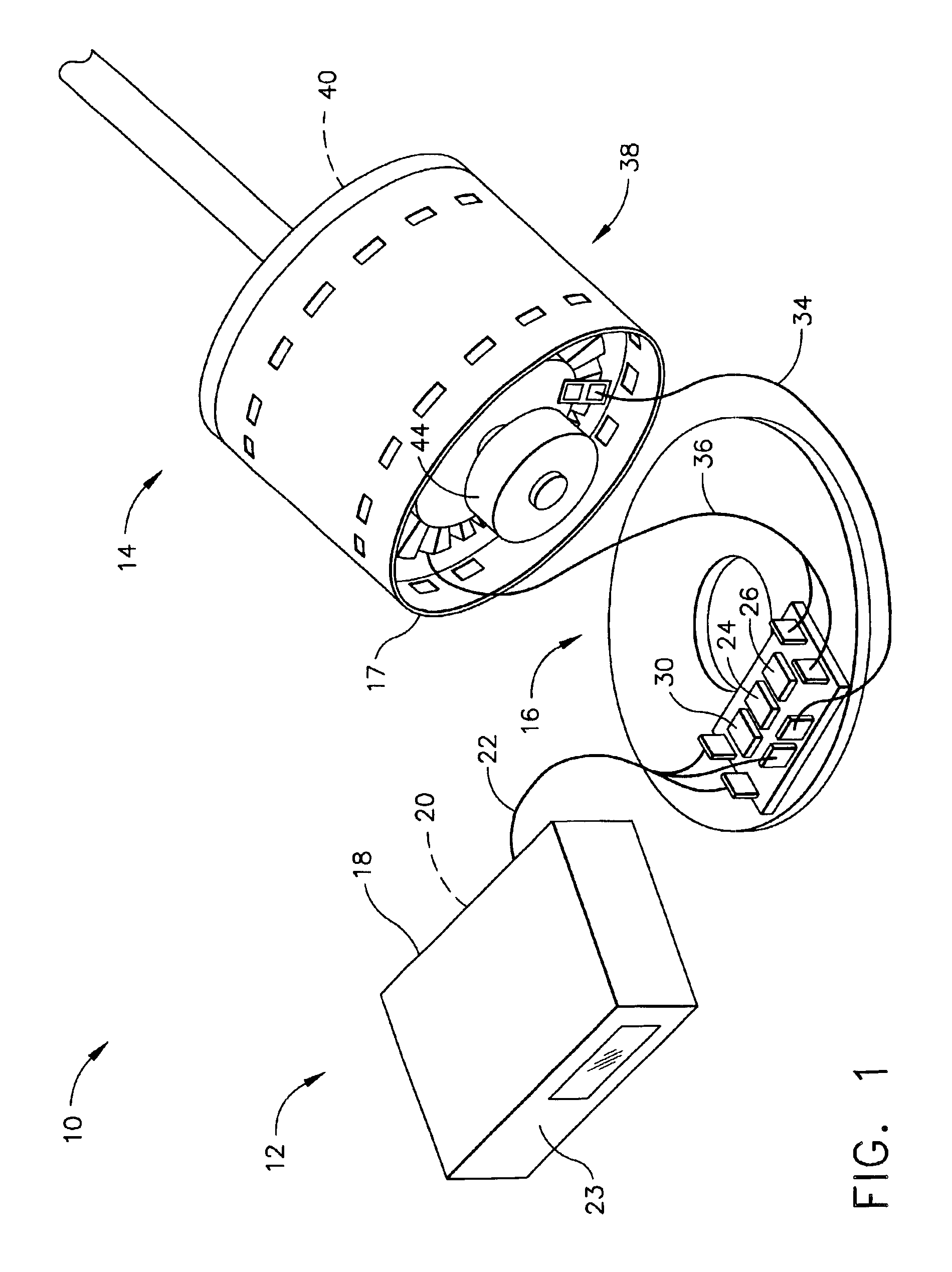

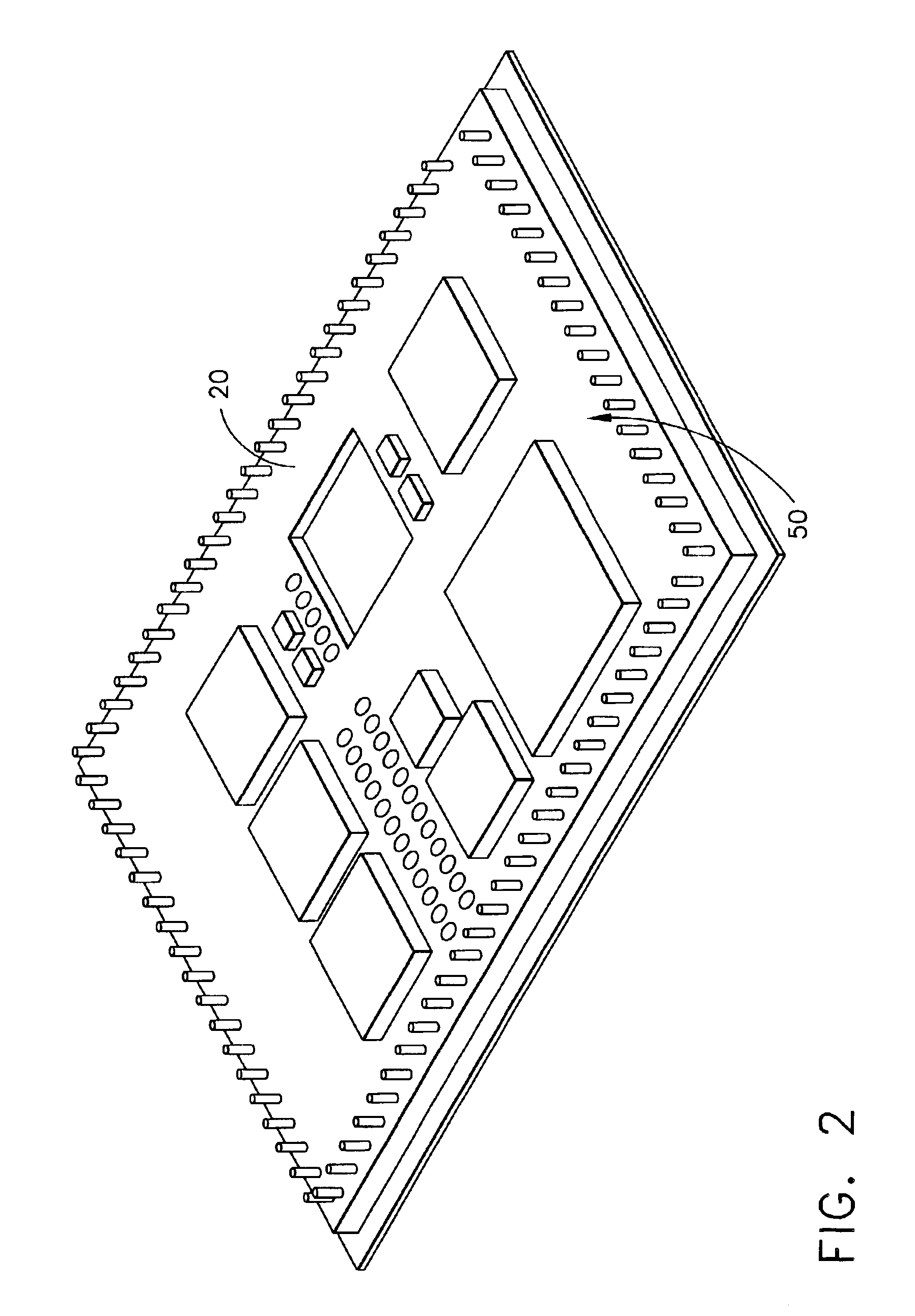

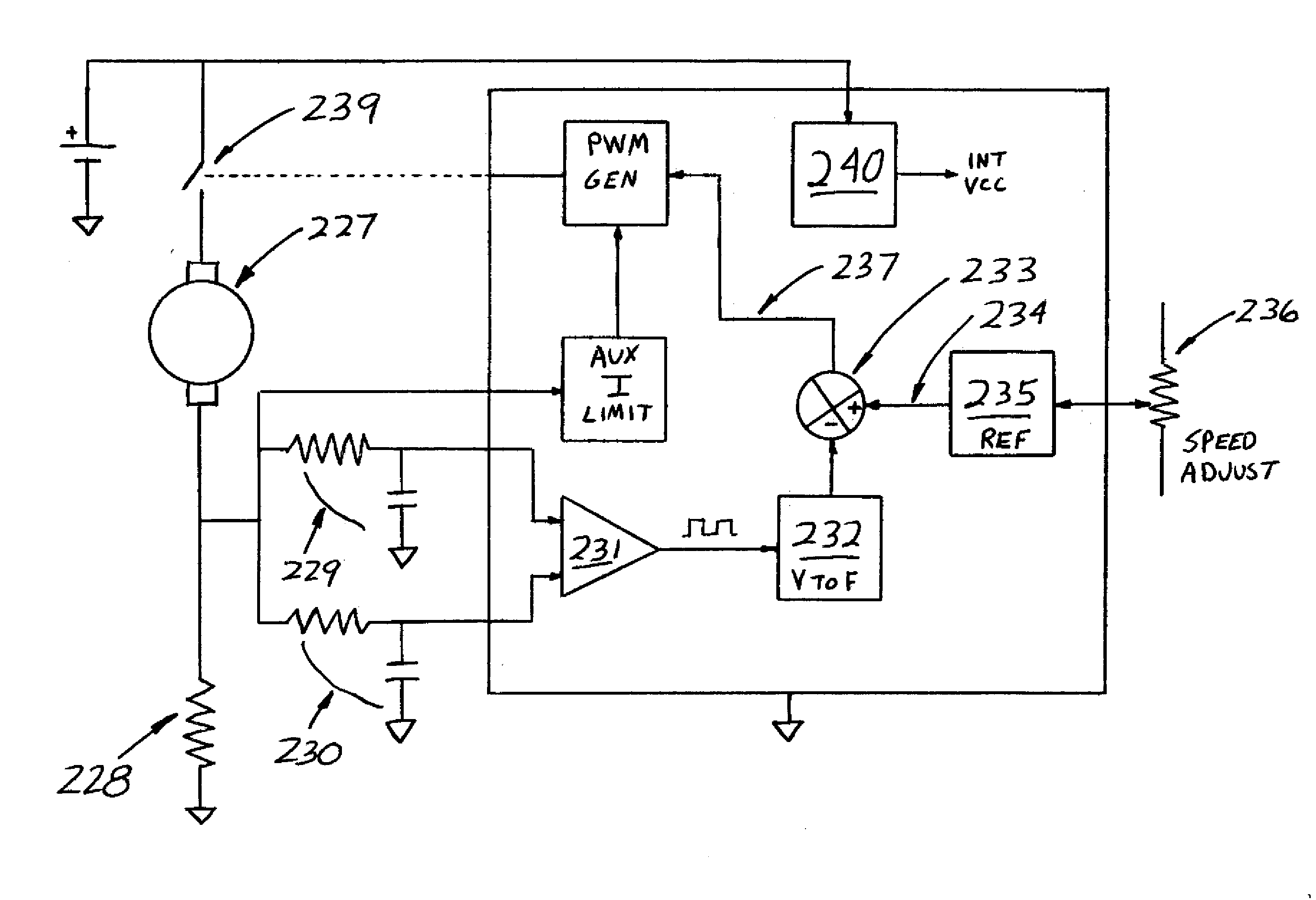

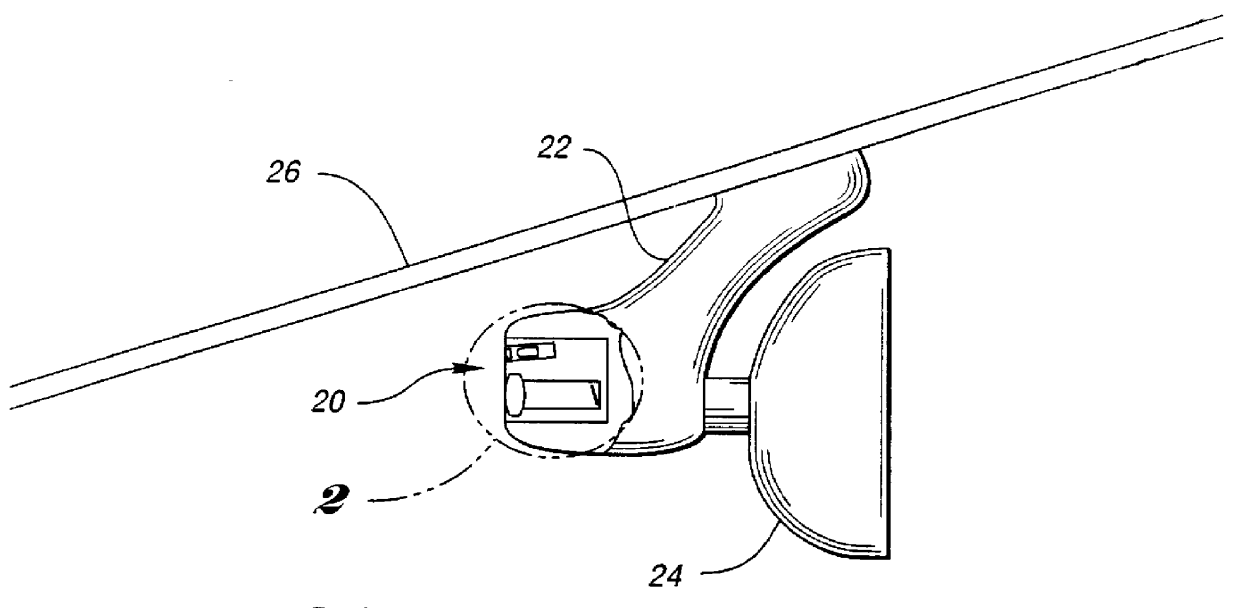

Powered surgical tool with control module that contains a sensor for remotely monitoring the tool power generating unit

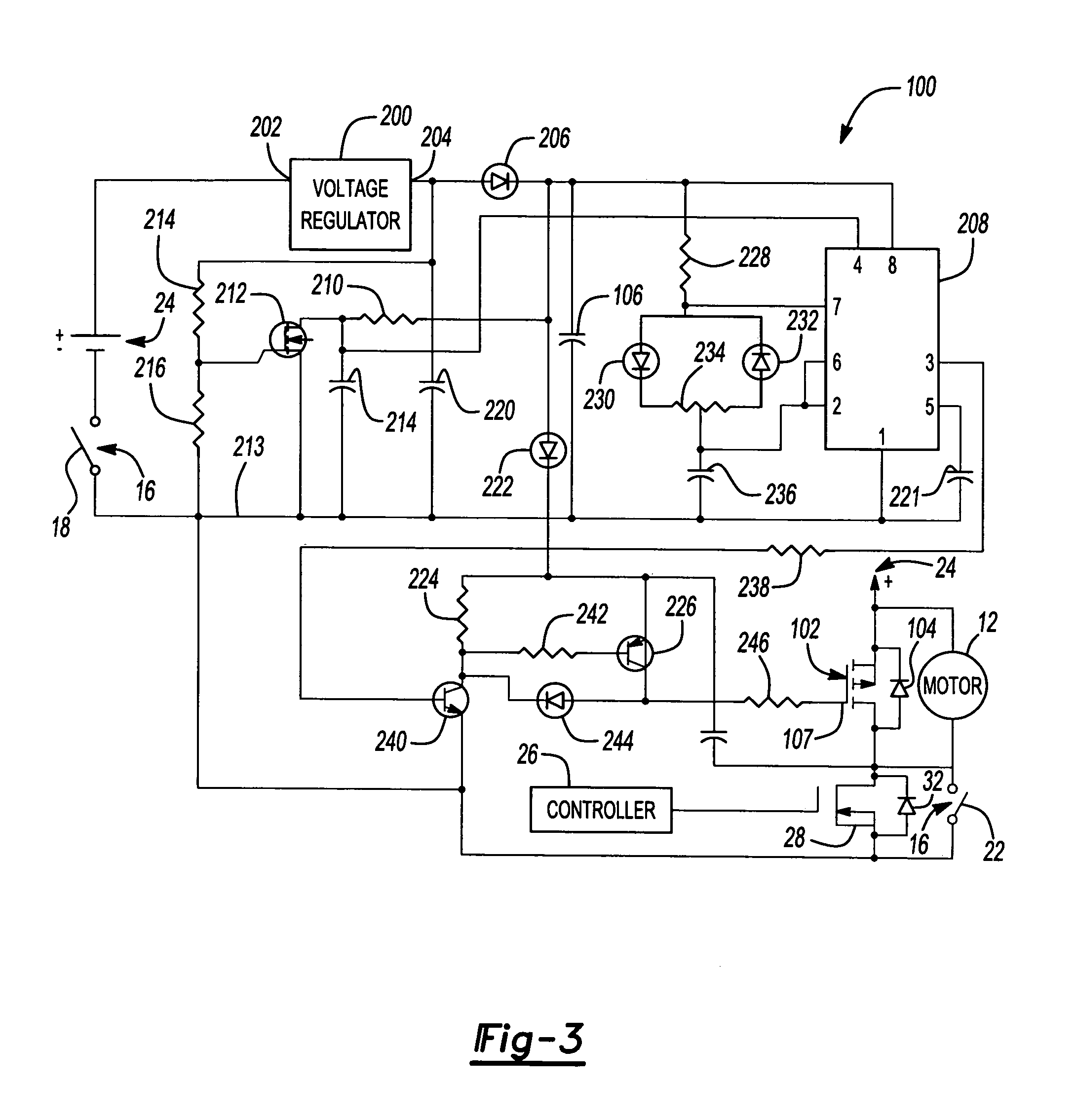

ActiveUS7638958B2Shaking/oscillating/vibrating mixersTransportation and packagingEngineeringControl circuit

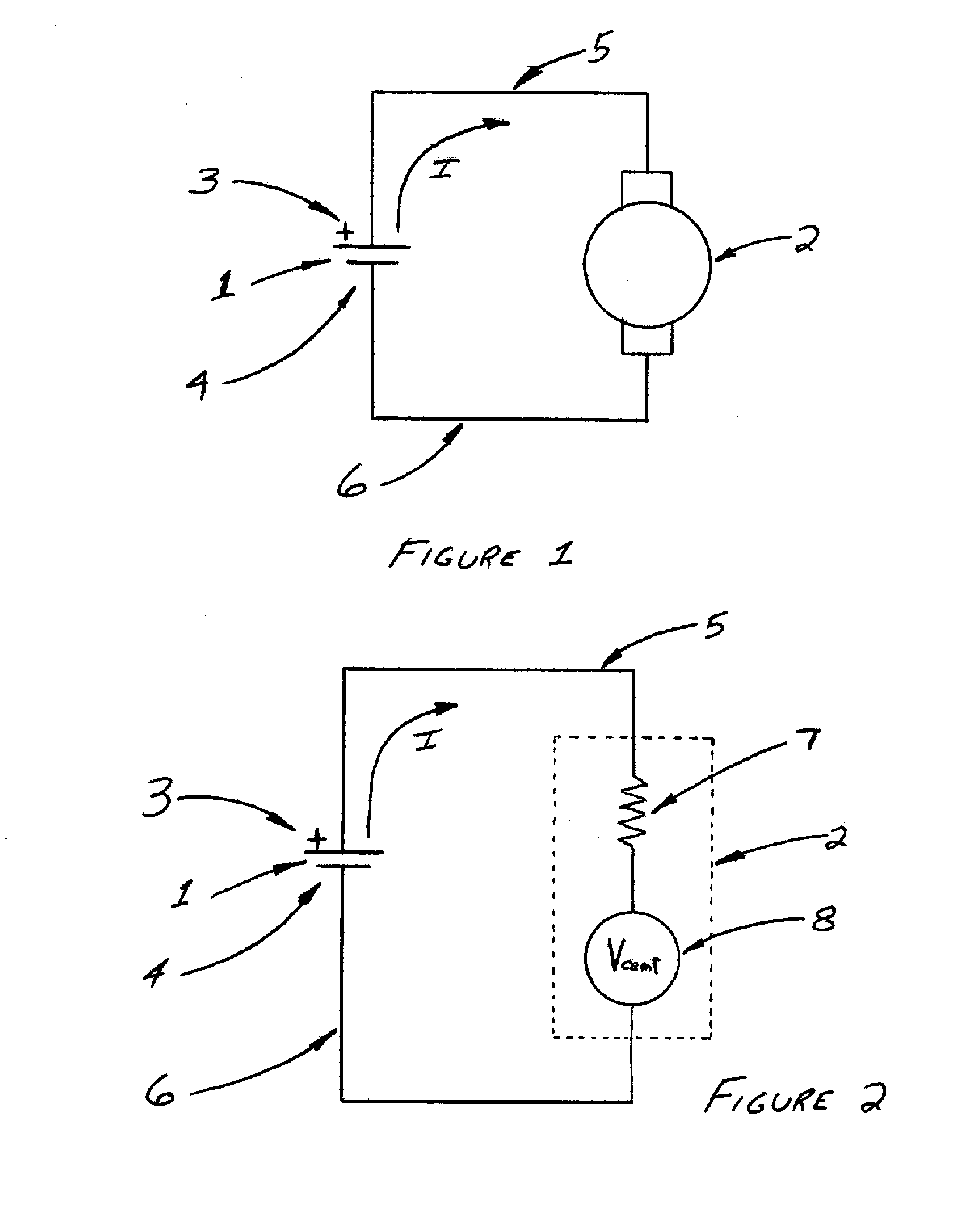

A powered surgical tool with a housing that contains a power generating unit such as a motor. A control module is disposed in a shell that is mounted in the housing. The control module contains a control circuit for regulating the actuation of the power generating unit. The power generating unit emits a signal representative of the operating state of the unit that is transmitted through the structural material forming the shell. Also internal to the control module shell is a sensor that monitors the signal emitted by the power generating unit. This signal output by the sensor is applied to the control circuit. The control circuit, based on the sensor signal regulates actuation of the power generating unit. Wherein the power generating unit is a motor, the signal emitted is the magnetic field that varies with rotor position. The sensor monitors the strength of this field.

Owner:STRYKER CORP

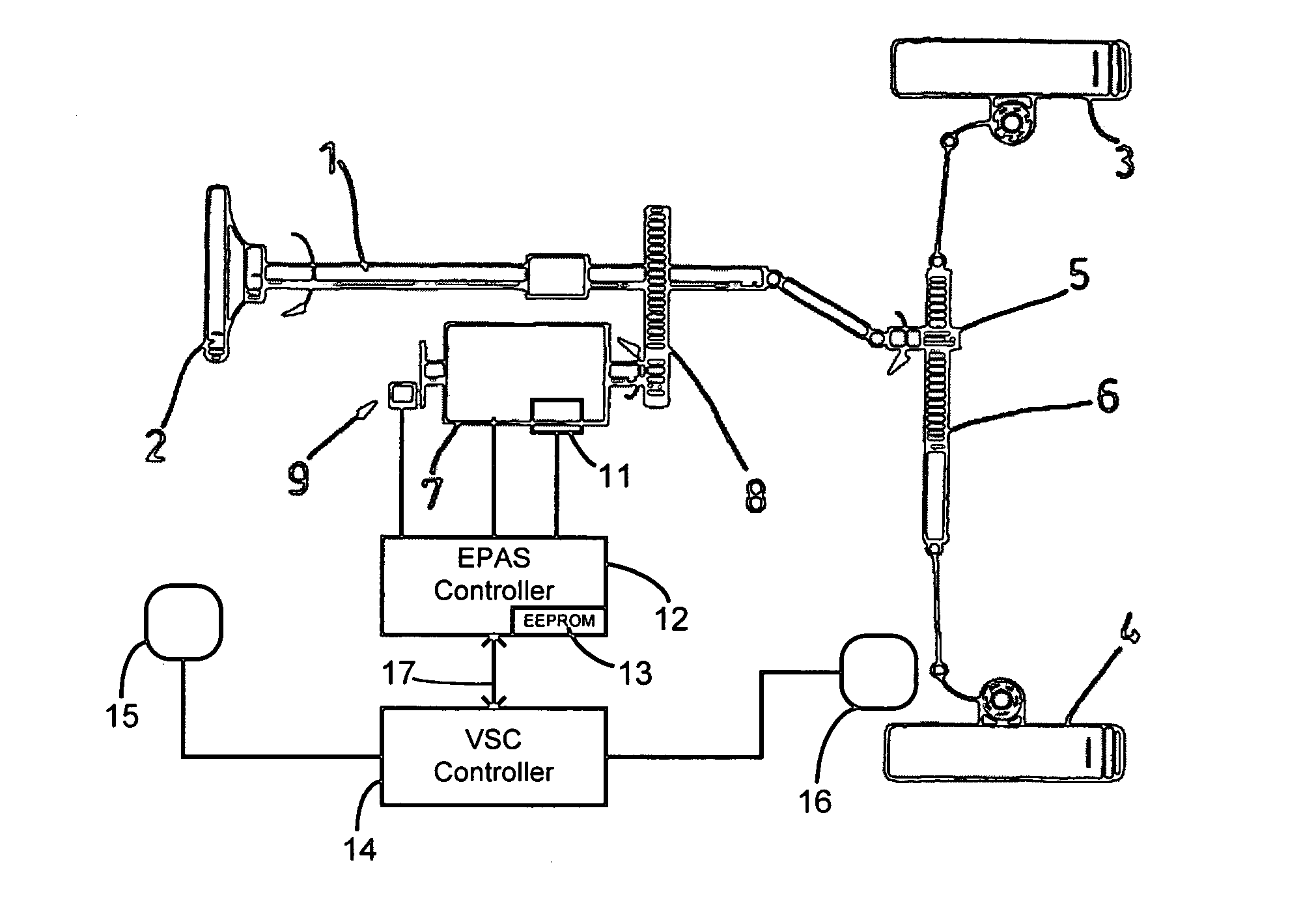

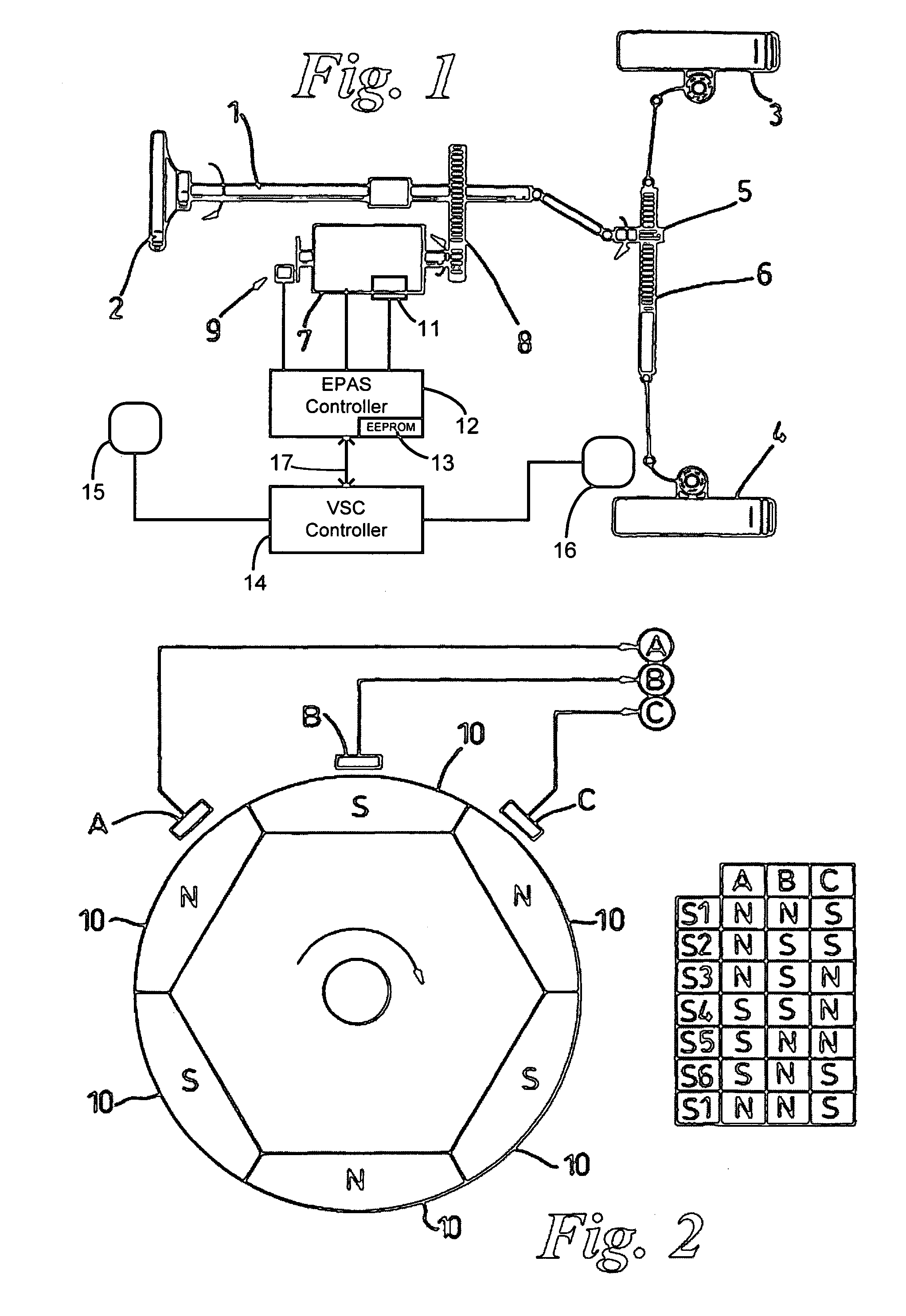

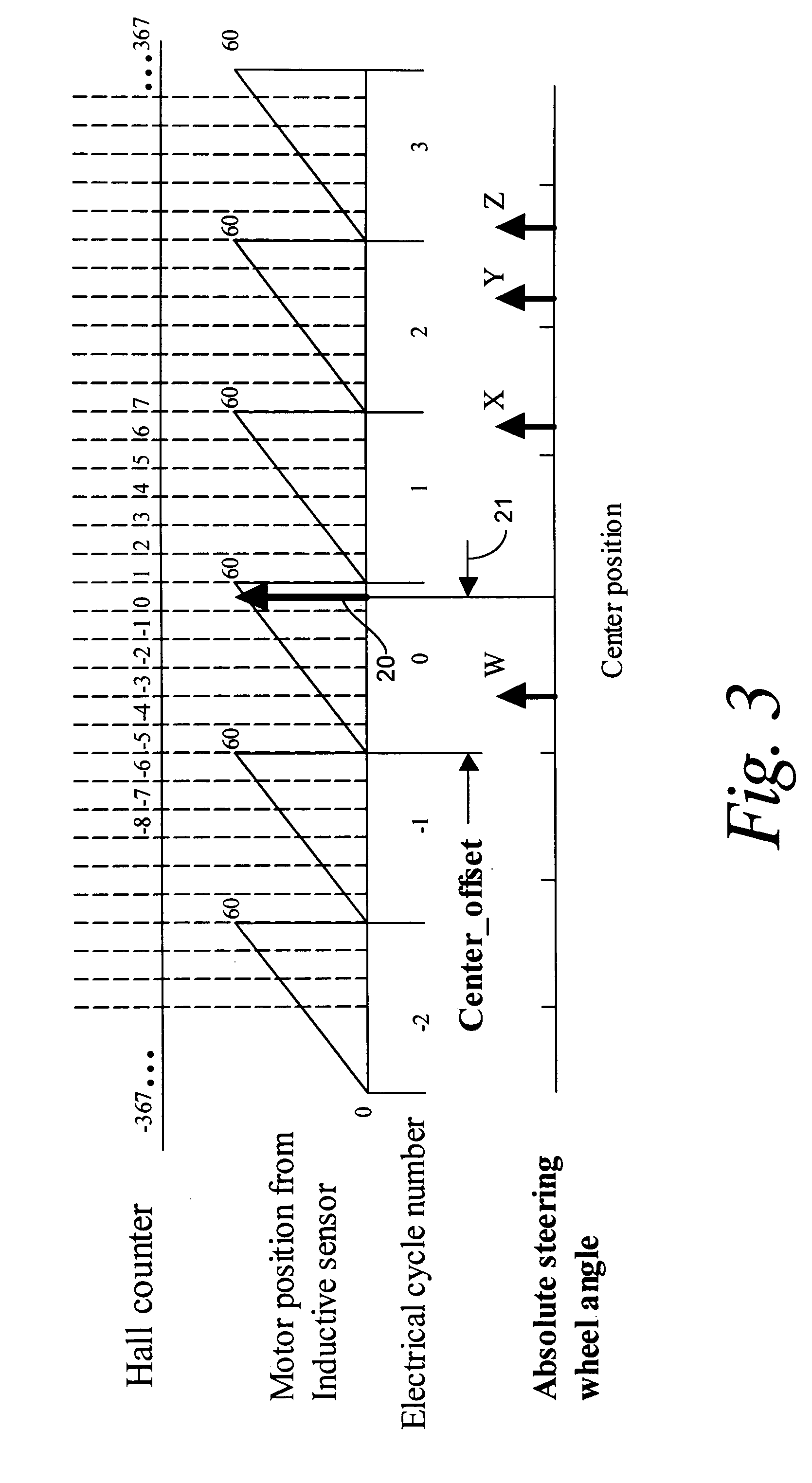

Recovery of calibrated center steering position after loss of battery power

ActiveUS7295907B2Accurate absolute steering angleAvoid the needDigital data processing detailsOptical signallingElectric power steeringSteering angle

The steering angle of a vehicle is monitored using position sensors of an electric motor of an electric power assisted steering (EPAS) system. A position of the electric motor corresponding to the straight-ahead, center position of the steering system is stored in non-volatile memory during a steering calibration procedure, such as an end-of-line calibration in a vehicle assembly plant. Following power loss due to a dead battery, a steering angle zeroing procedure performed in a vehicle stability control (VSC) system generates a center position with enough accuracy to be within one electrical cycle of the motor. The pre-stored electric motor position is then used to determine the electrical cycle where the center position was located, and accurate monitoring of steering angle is resumed.

Owner:TRW AUTOMOTIVE US LLC

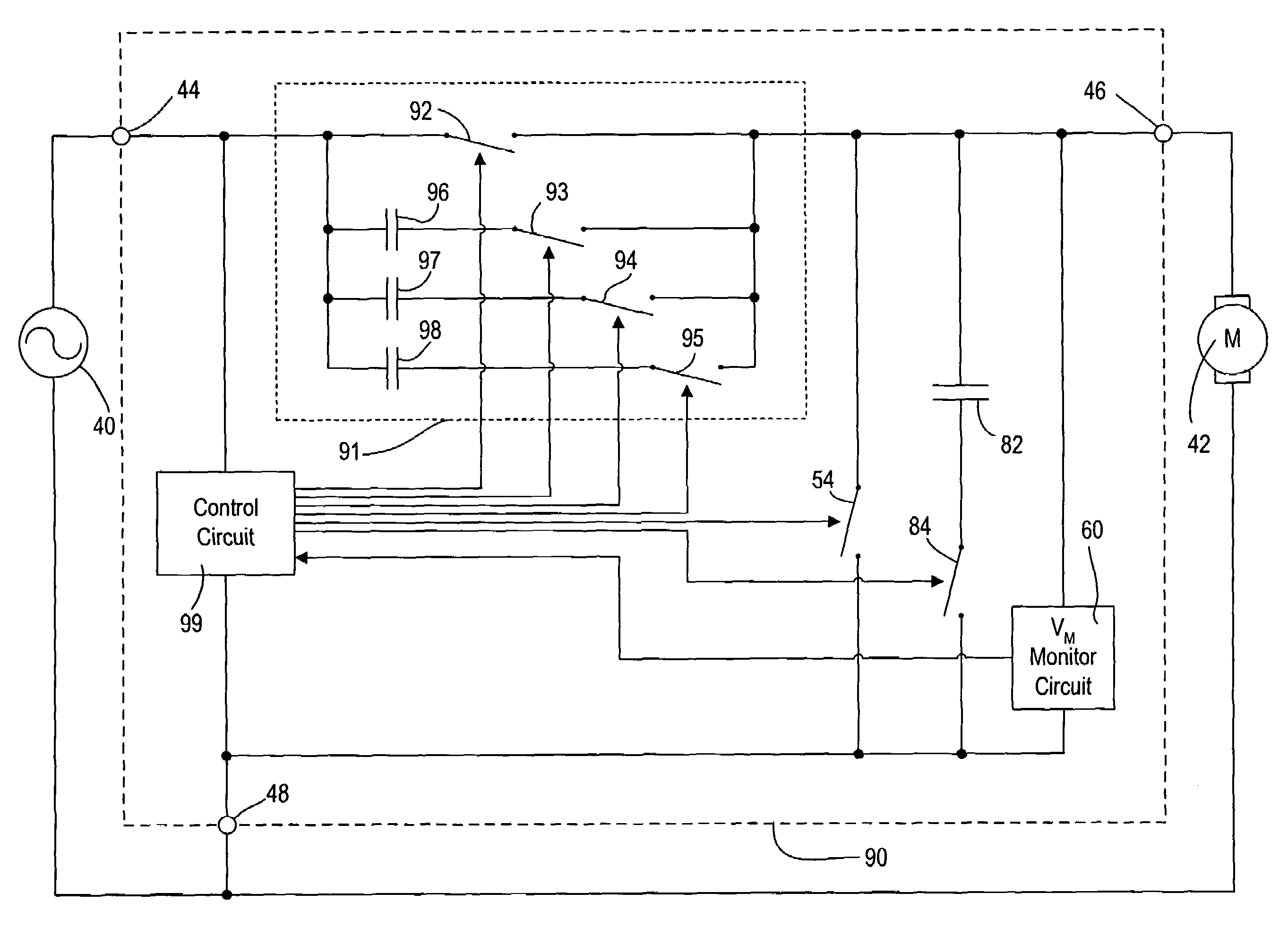

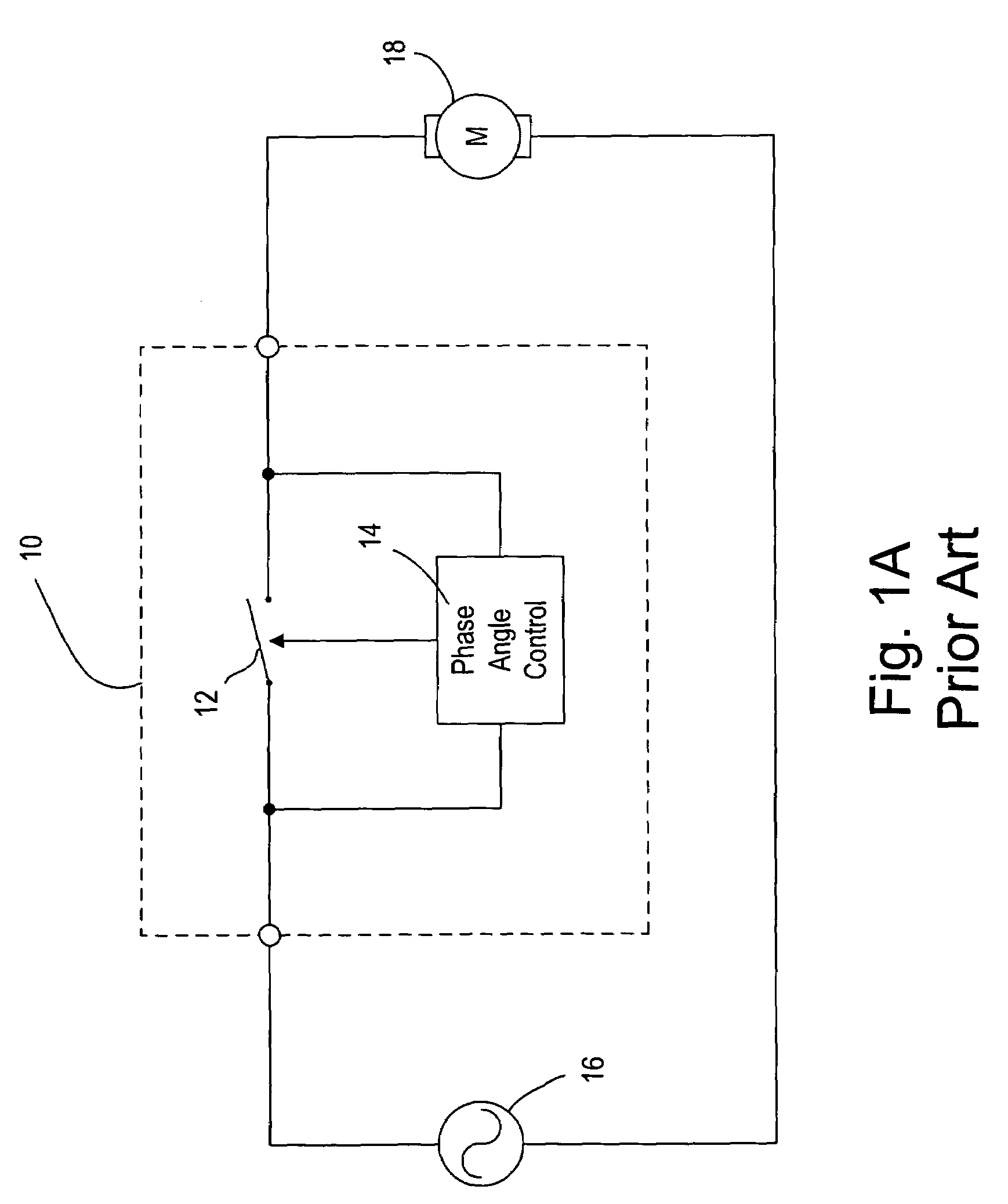

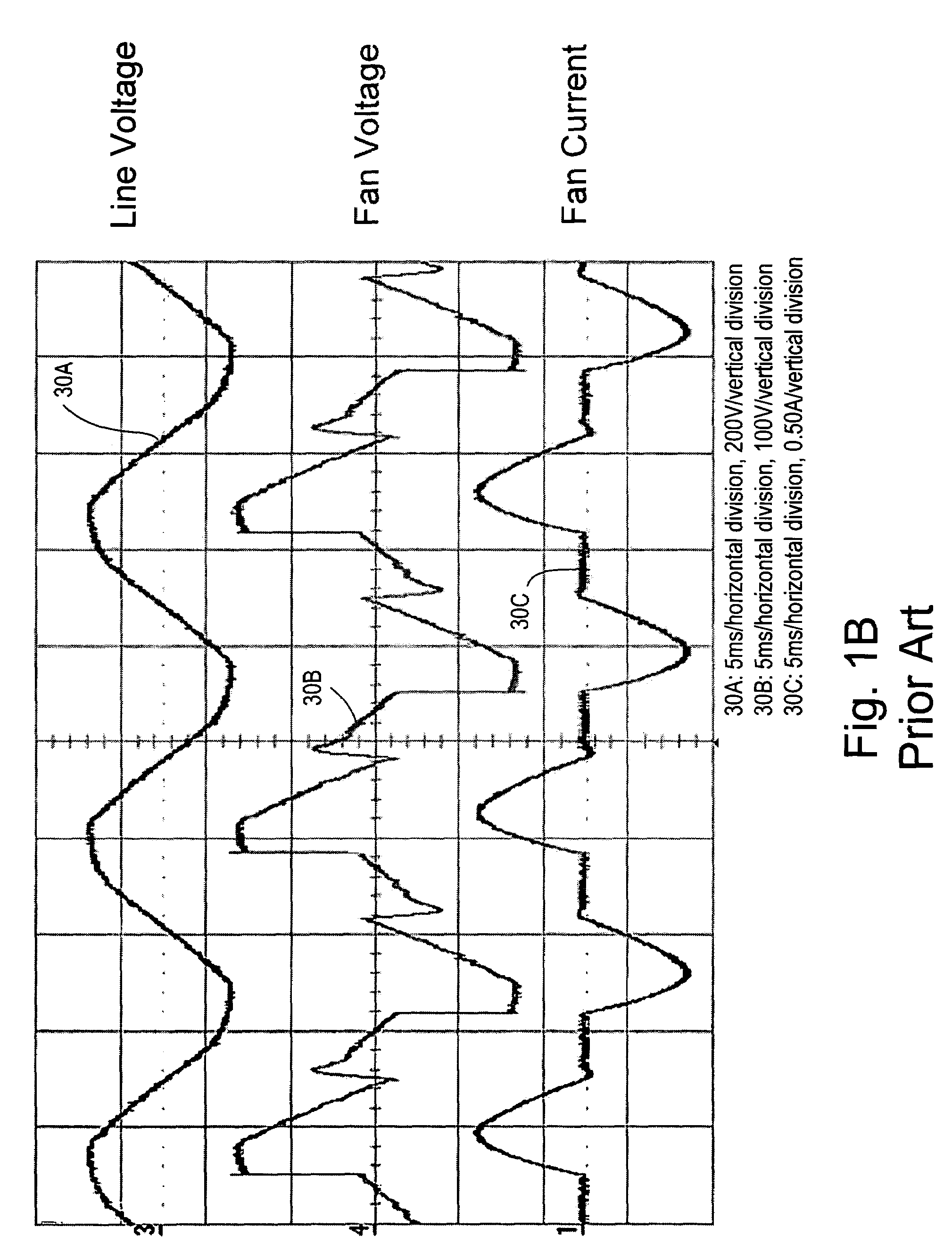

Method and apparatus for quiet variable motor speed control

ActiveUS7330004B2Single-phase induction motor startersMotor/generator/converter stoppersMotor speedEngineering

An apparatus for controlling the speed of an AC motor comprising a switch adapted to be coupled in parallel with power terminals for the AC motor; a capacitor coupled in series with the parallel combination of the switch and the motor; the capacitor adapted to provide an AC supply voltage from an AC source to the parallel circuit comprising the motor and the switch; and a control circuit for controlling the conduction time of the switch in order to vary the speed of the motor. The switch is preferably pulse-width modulated at a frequency twice the line frequency of the AC supply voltage, and the switch is turned on when the voltage across the AC motor is zero volts. The apparatus is operable to provide for continuously variable control of the motor speed while minimizing acoustic noise in the motor.

Owner:LUTRON TECH CO LLC

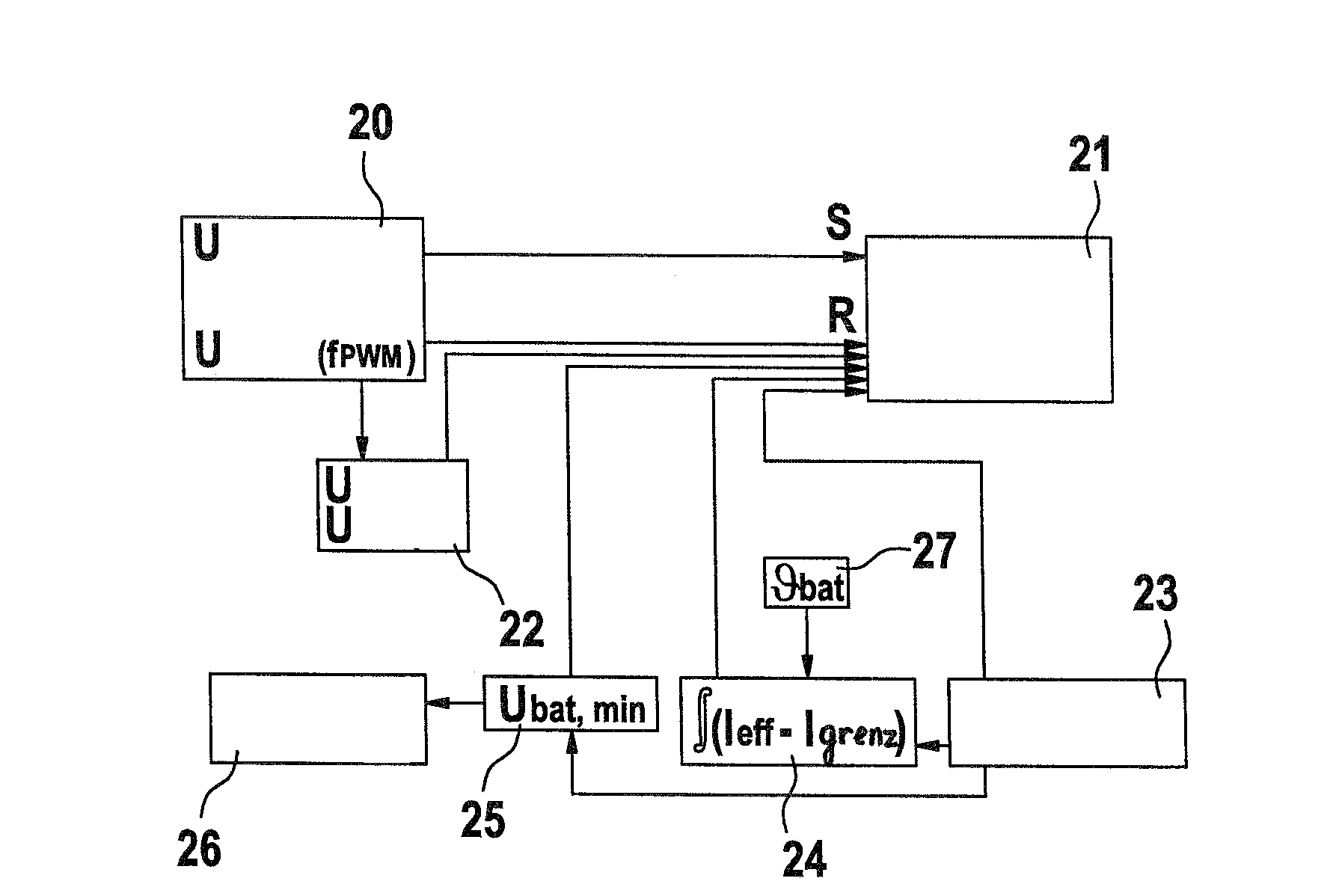

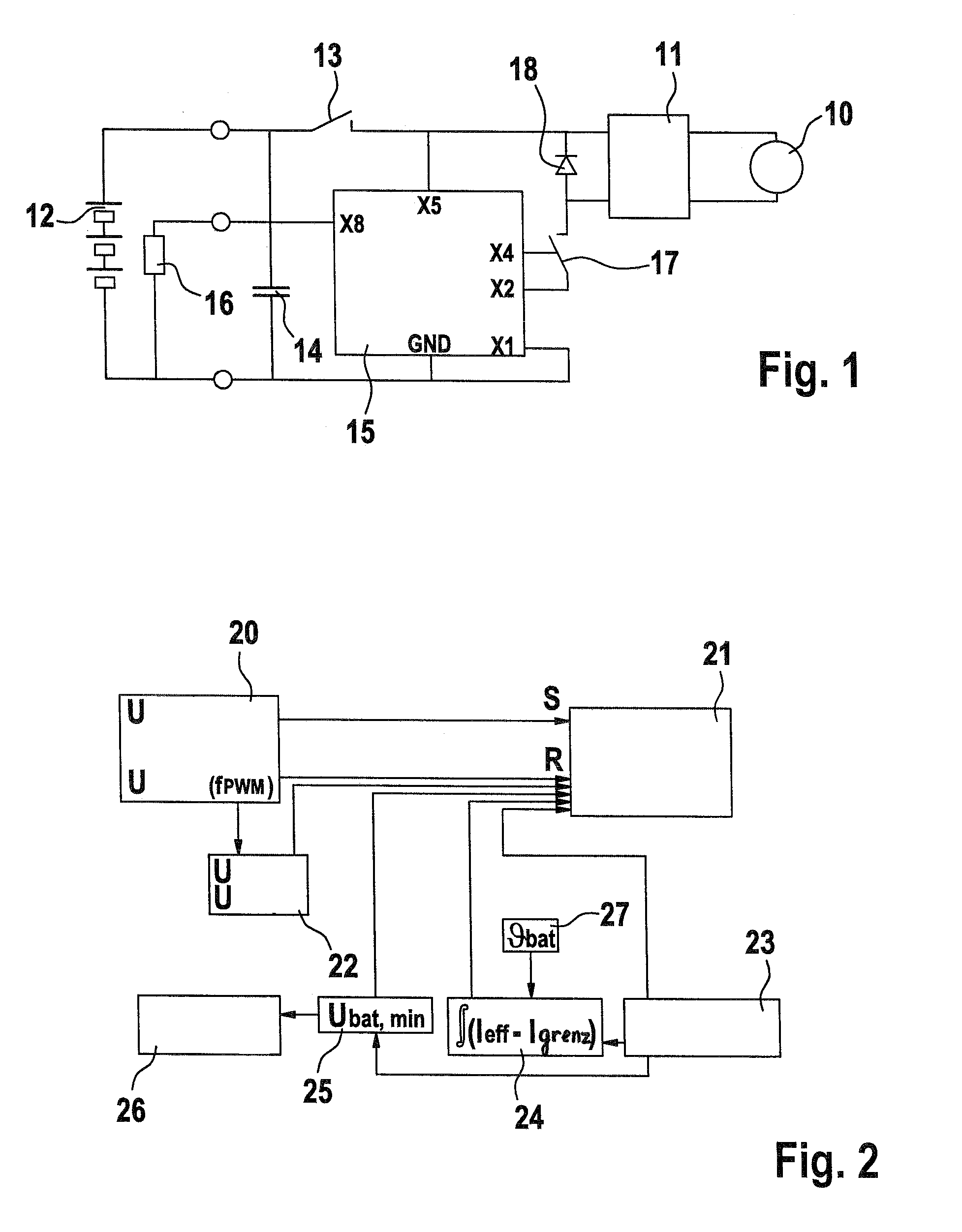

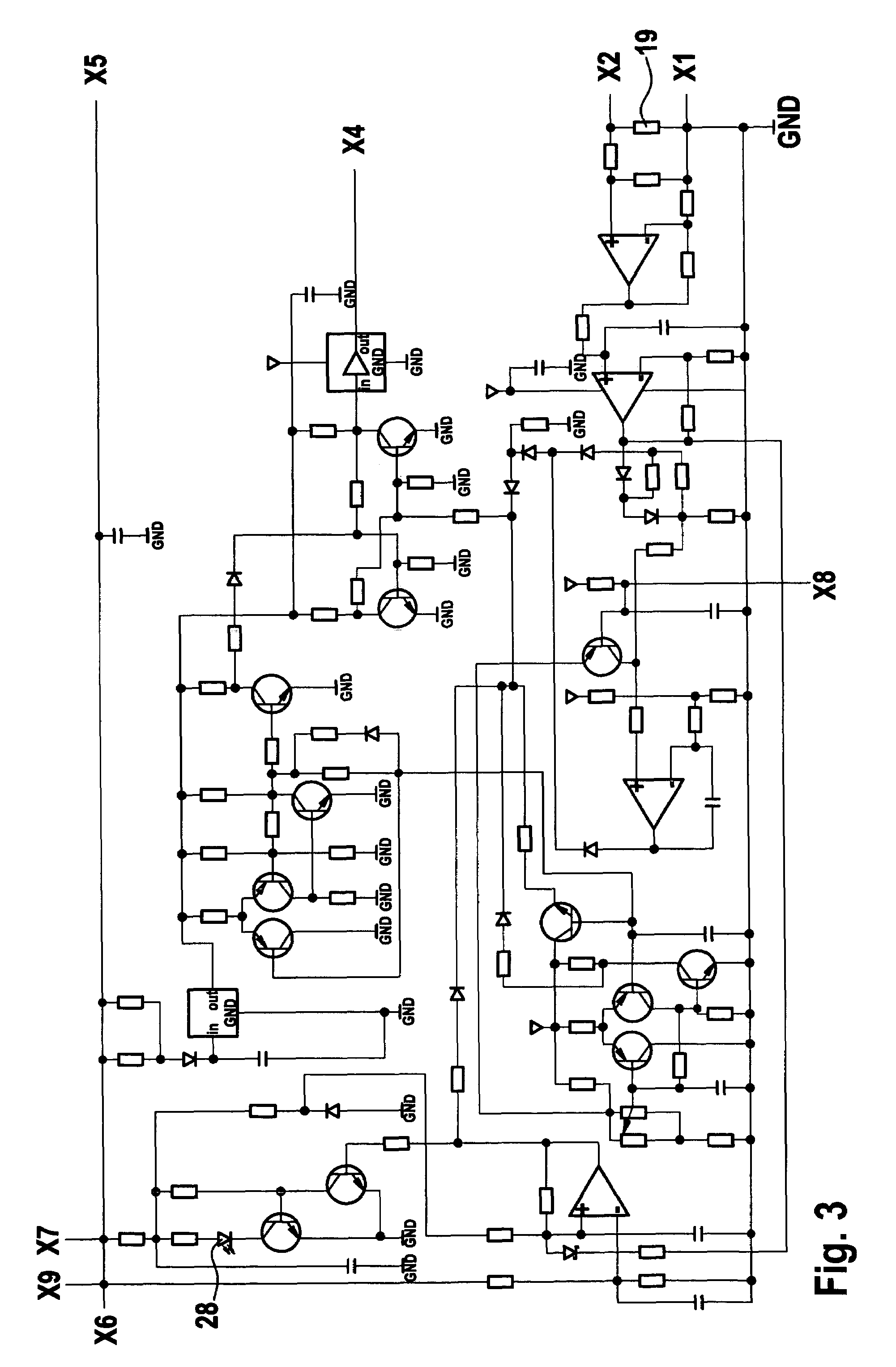

Method for operating a power tool

ActiveUS7336048B2Maintain good propertiesReduce widthTemperatue controlEmergency protective arrangements for automatic disconnectionMOSFETElectricity

In a method for operating a power tool with an energy accumulator, in particular a rechargeable energy accumulator, which supplies power to an electric drive motor, a clock frequency is generated by an electronic unit, with which a gate of a MOSFET—which supplies operating voltage to the drive motor—is switched on with each cycle, and a switching-off of the MOSFET is carried out within one cycle using different signals, as a function of operating parameters.

Owner:ROBERT BOSCH GMBH

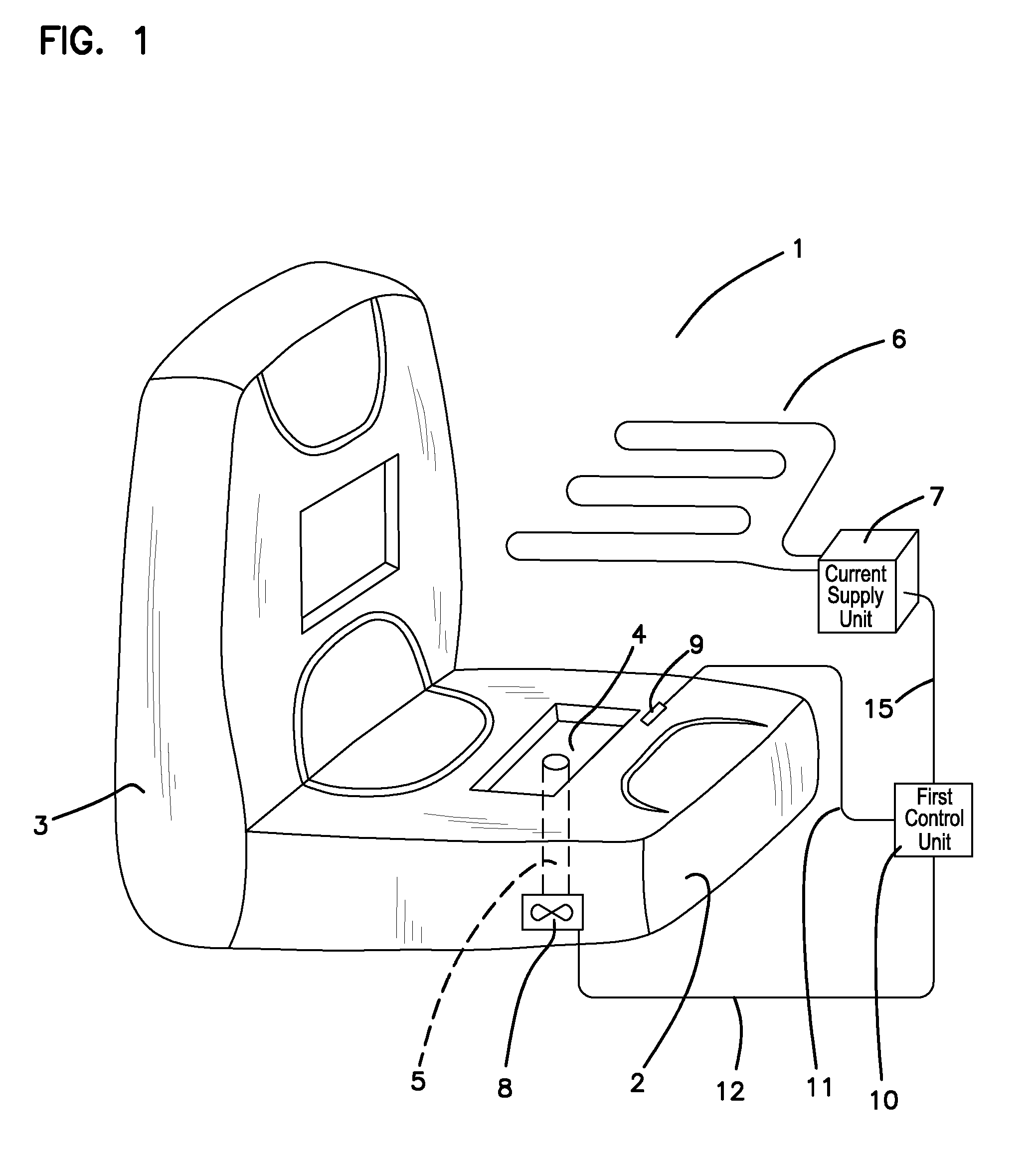

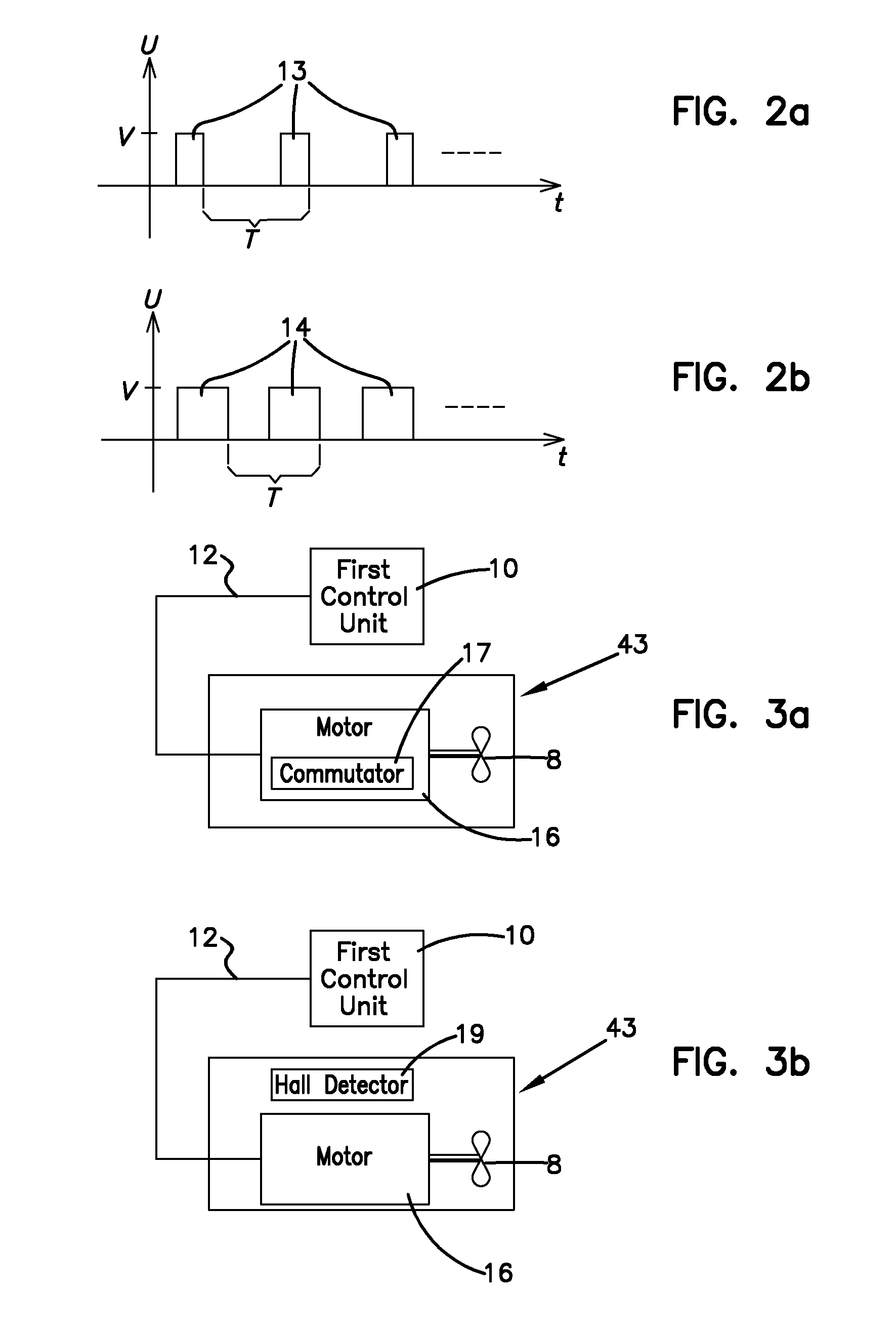

Method and arrangement for control of direct current motor

InactiveUS7567045B2Efficient coordinationLow costVehicle seatsMultiple motor speed/torque controlTelecommunications linkControl signal

Owner:KONGSBERG AUTOMOTIVE AB (SE)

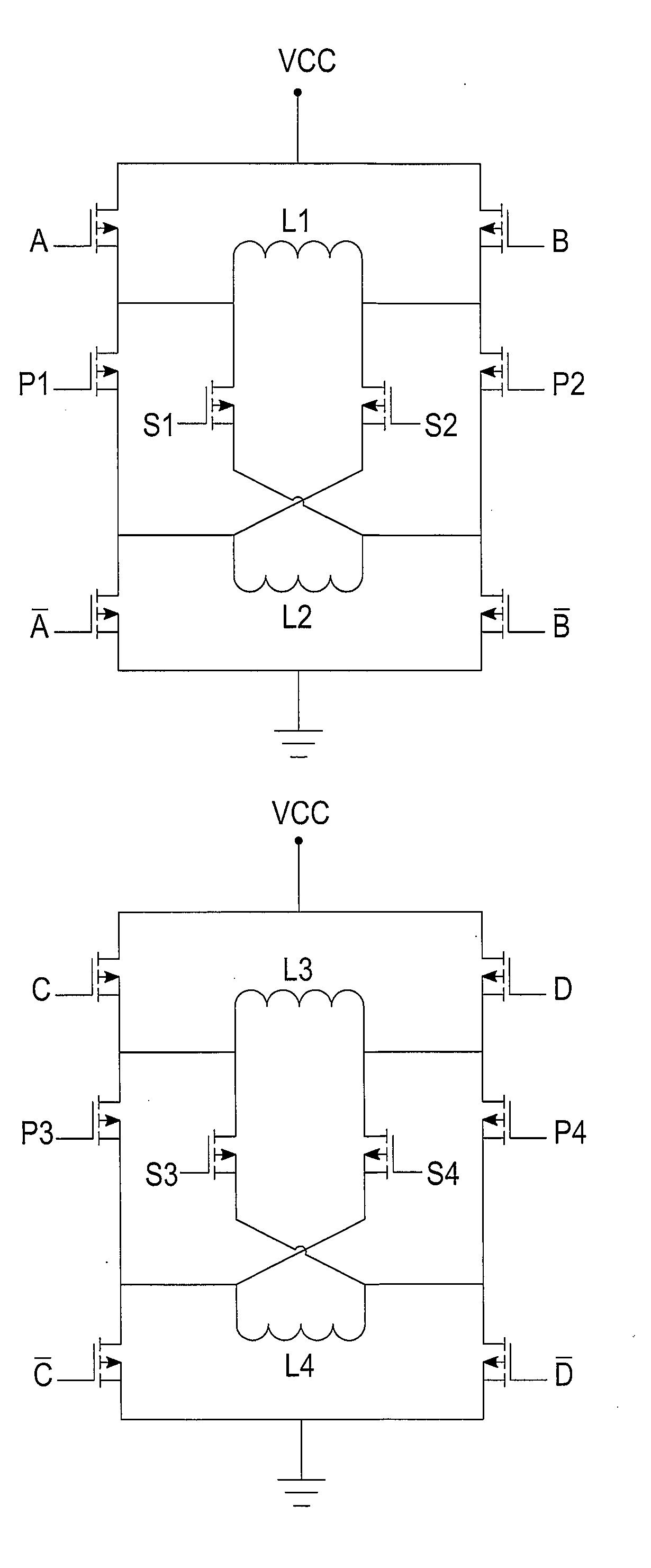

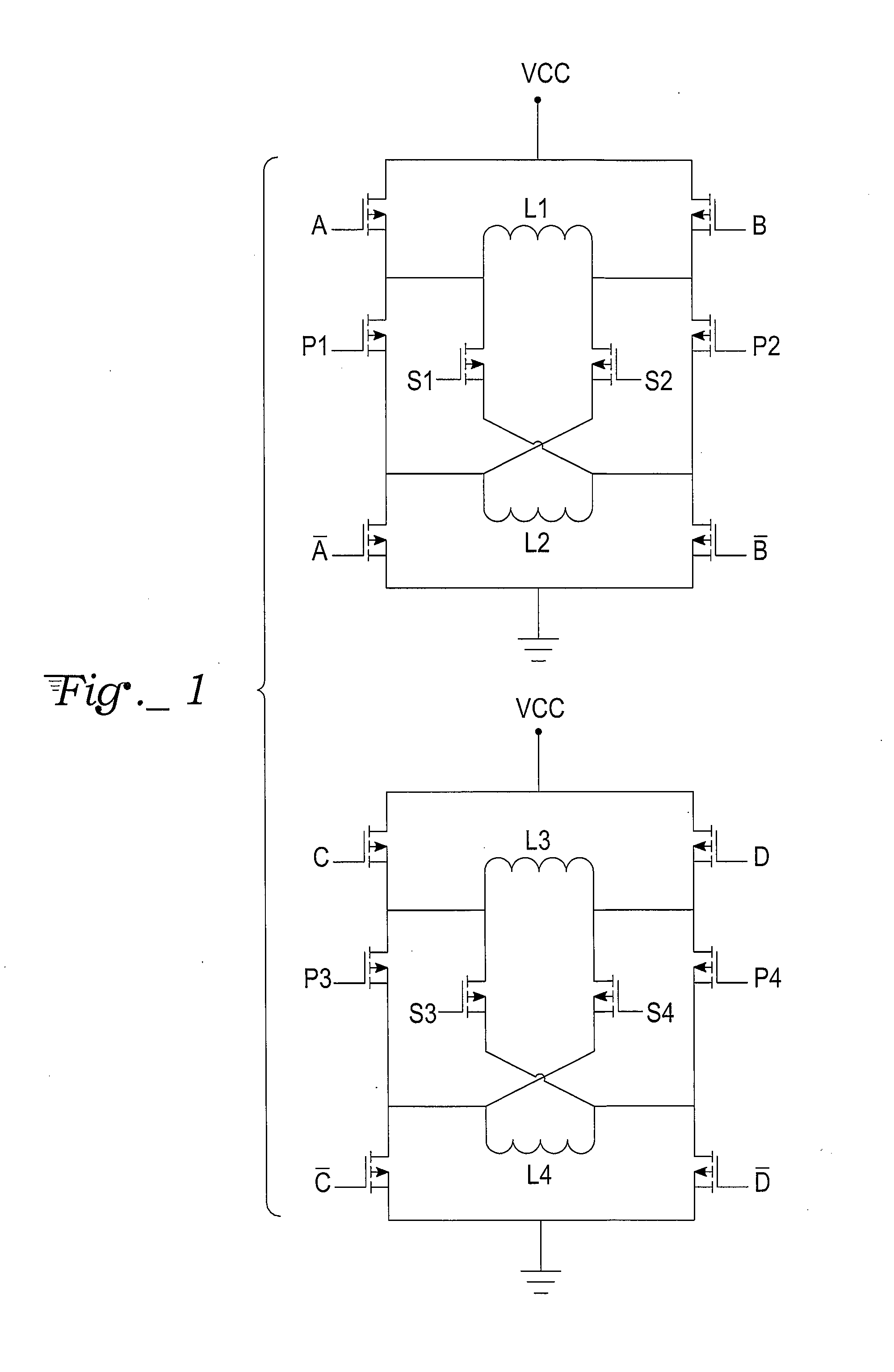

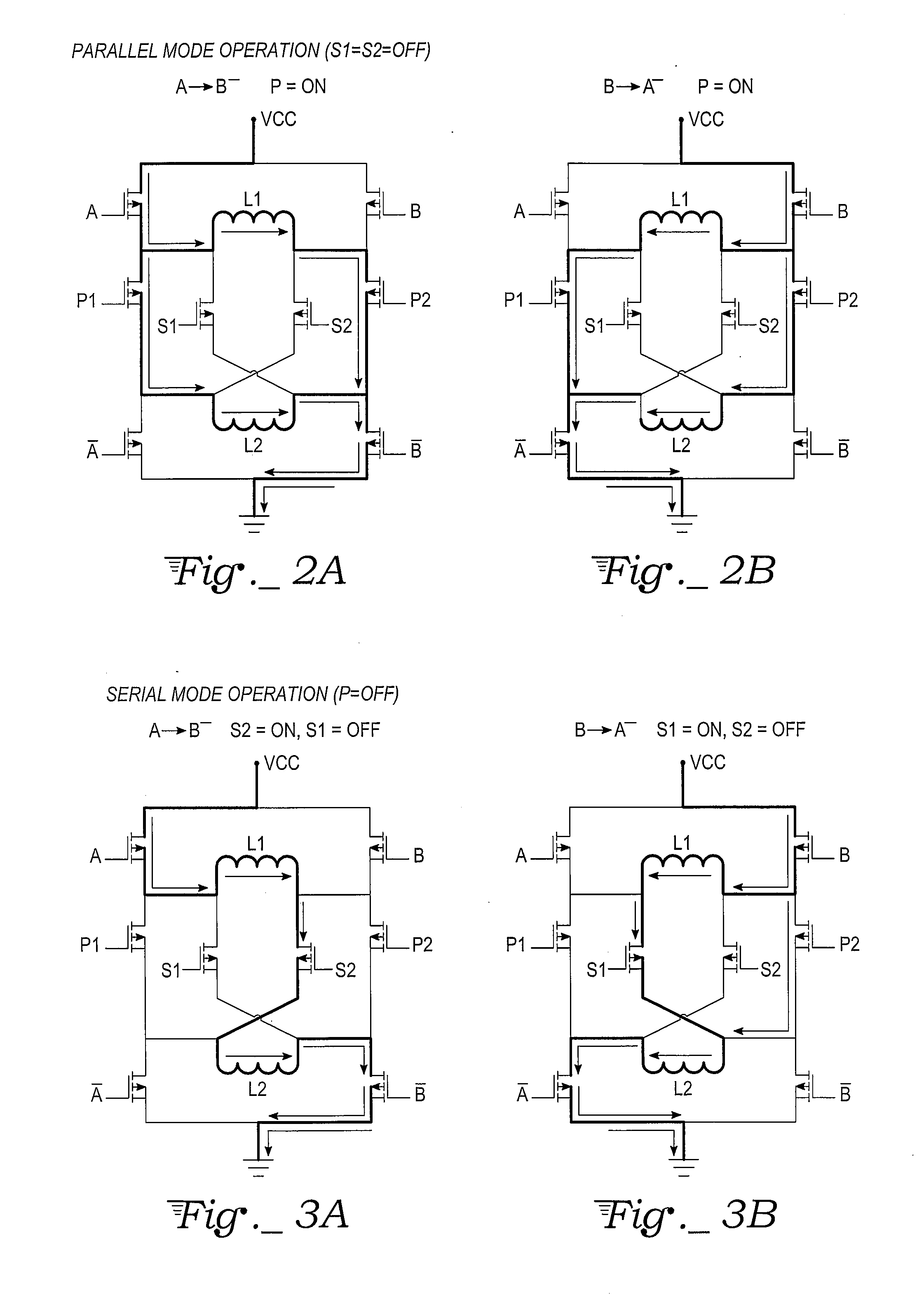

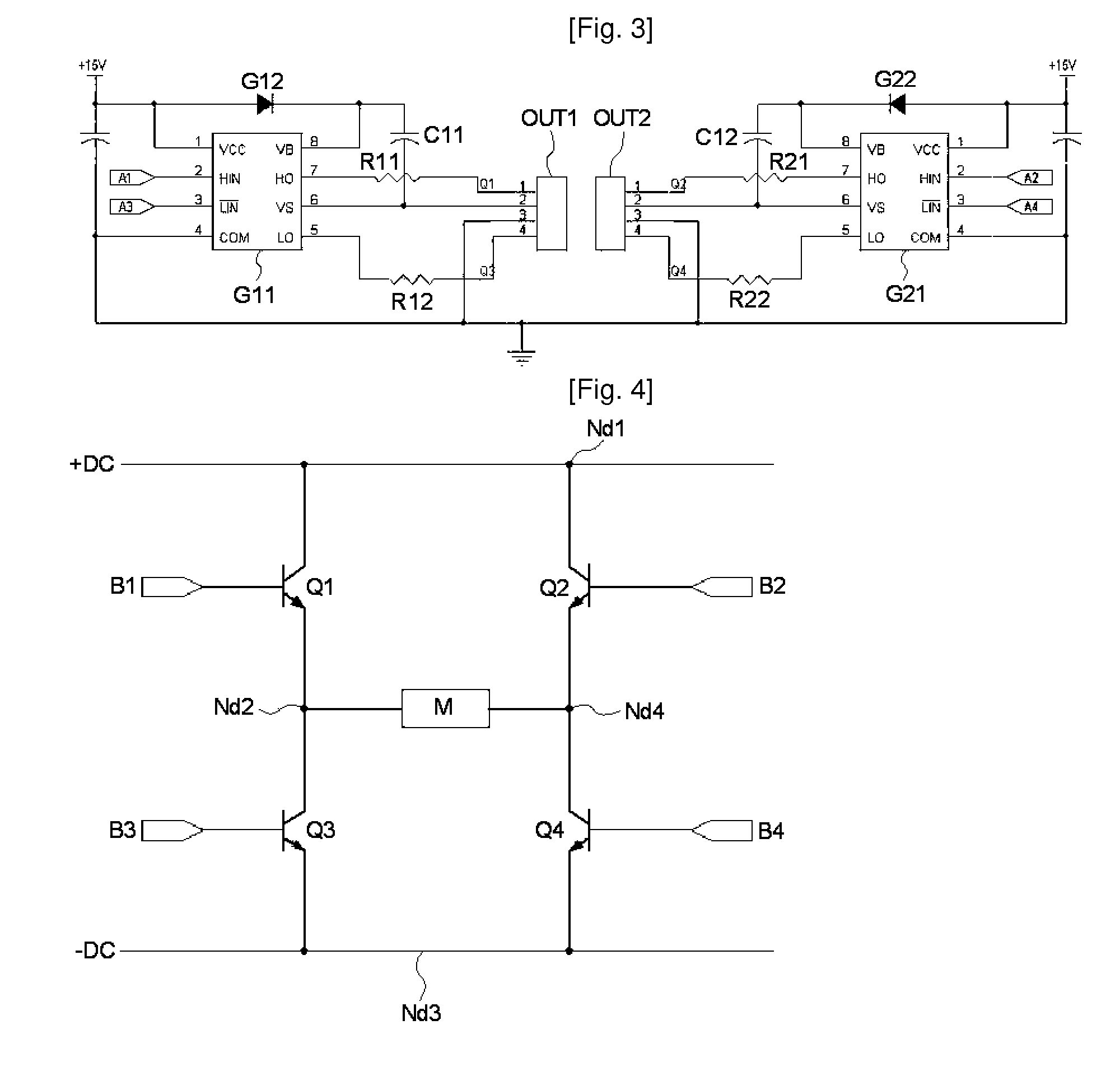

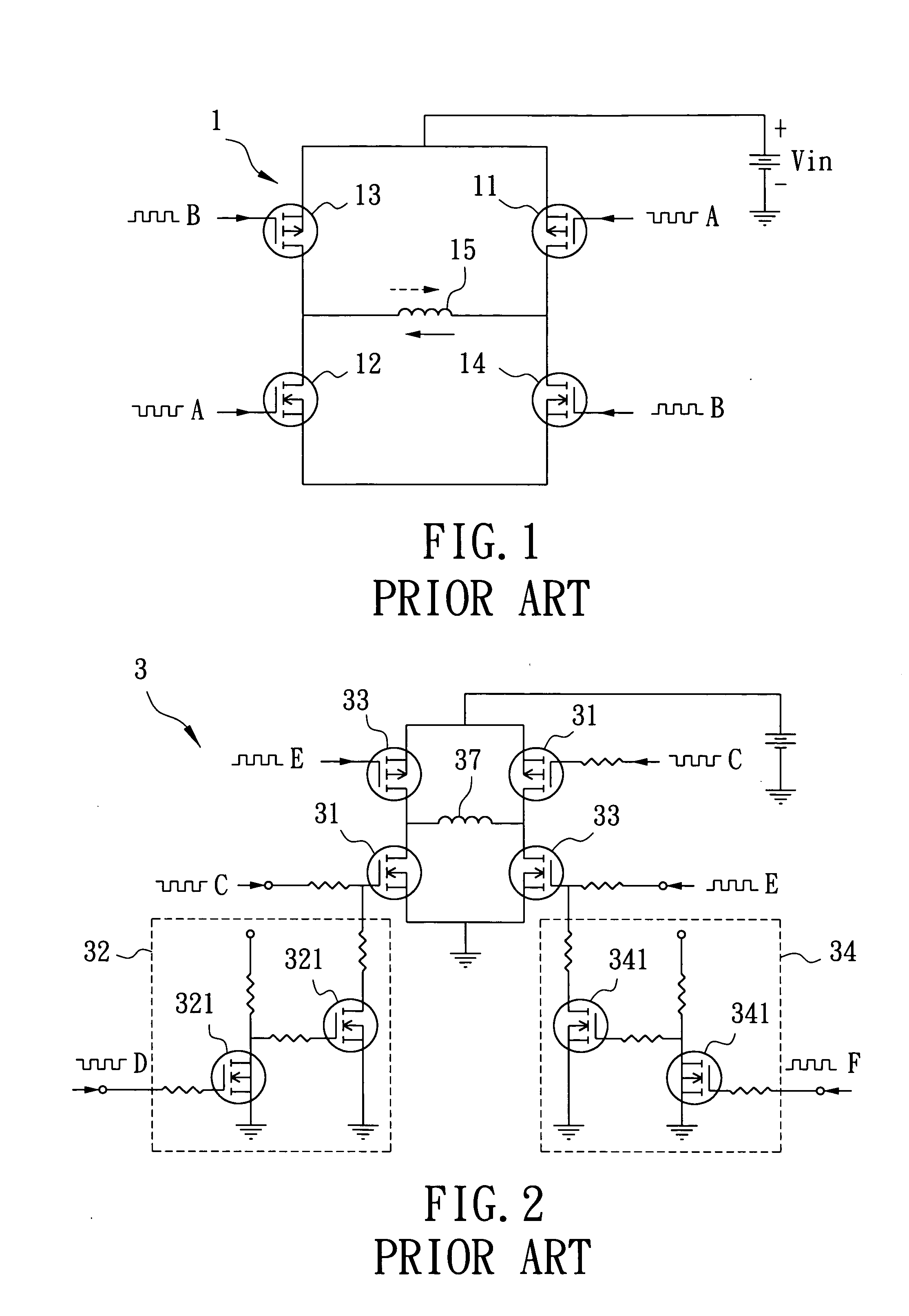

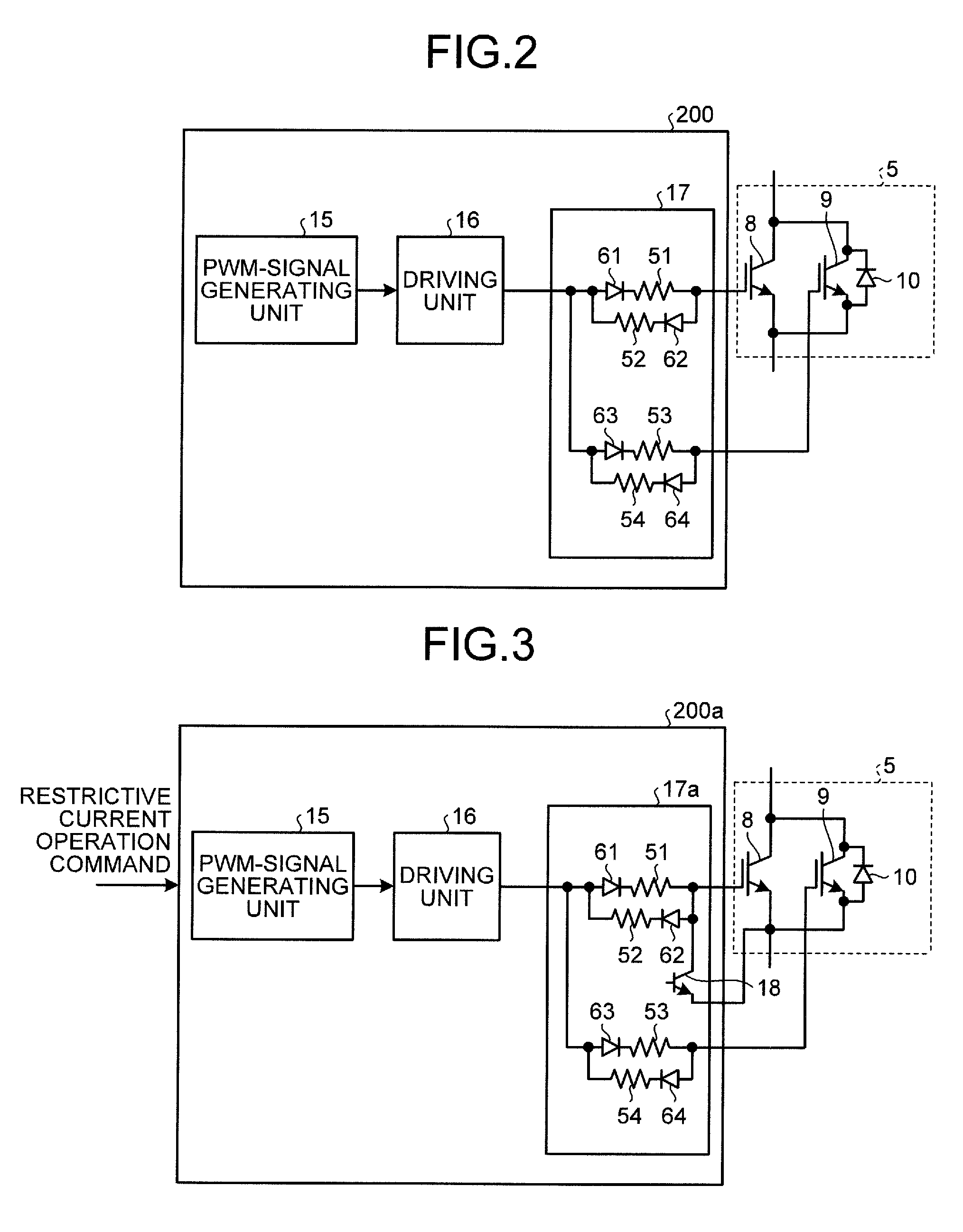

H-bridge drive circuit for step motor control

InactiveUS20110241597A1Improve stand-alone performanceEasy to implementDynamo-electric converter controlMotor speedDriving current

A drive circuit for step motors with bifilar windings is provided in which both parallel and series winding configurations for the stator coils are selectable by a motor controller based on the motor speed. For low speeds a series configuration is selected, while for higher speeds a parallel configuration is selected. Dynamic torque is optimized by the selection for more efficient motor operation with less drive current.

Owner:LIN ENG INC

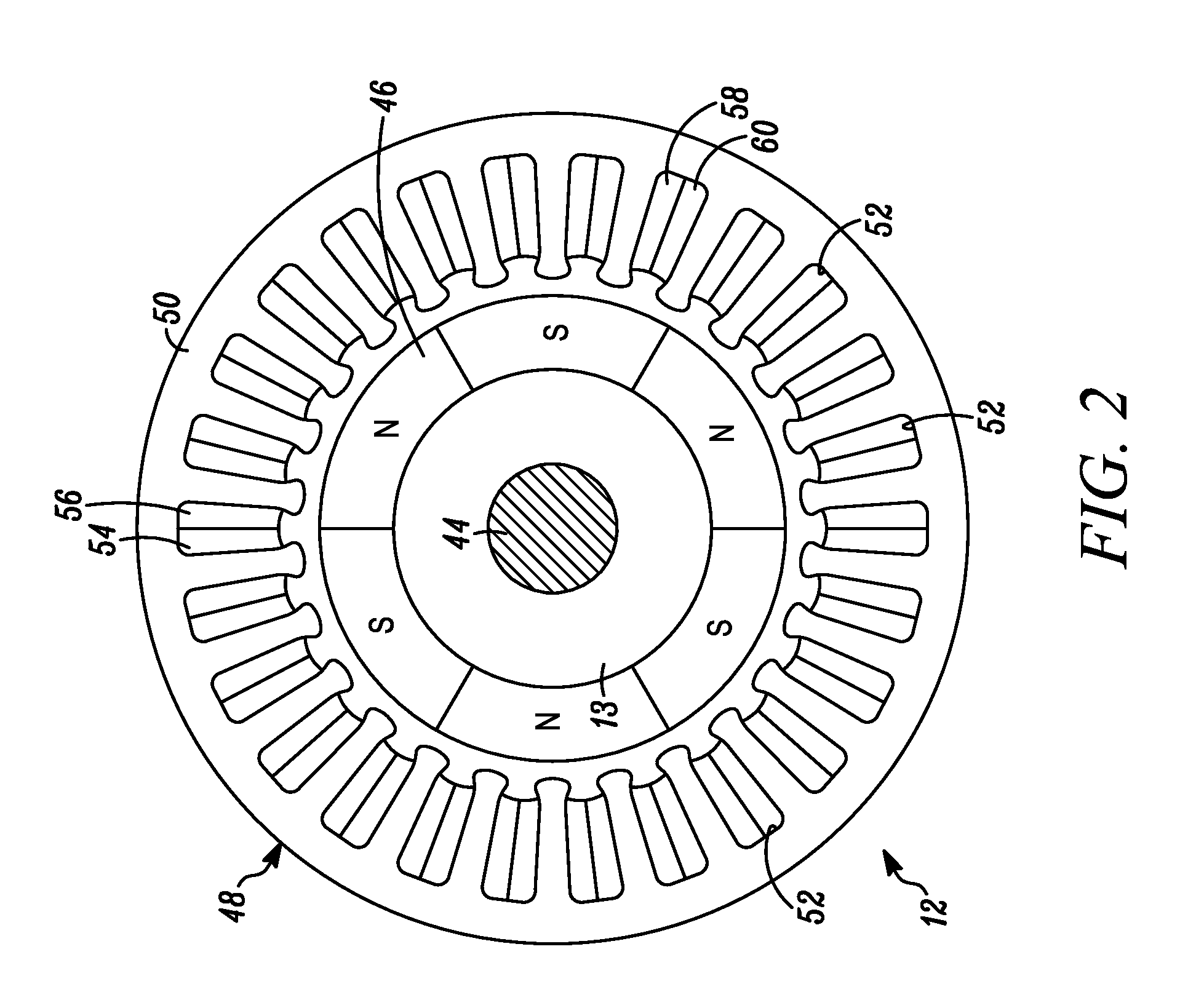

Motor having controllable torque

InactiveUS8125168B2Single-phase induction motor startersCommutation monitoringMotor controlElectric motor

A controllable motor includes a rotor. A first stator winding set is operable, upon being energized, to generate and apply a first torque to the rotor. A second stator winding set independent of the first stator winding set is operable, upon being energized, to generate and apply a second torque to the rotor. A motor control is coupled to the first and second stator winding sets. The motor control is operable to selectively energize one of the first or second stator winding sets to thereby generate and apply one of the first or second torques to the rotor, and simultaneously energize both the first and second stator winding sets to thereby generate and apply a third torque greater than the first or the second torque.

Owner:HONEYWELL INT INC

Architecture for electric machine

InactiveUS7583063B2Magnetic circuitEmergency protective circuit arrangementsElectricityElectric machine

The invention includes an electric machine having a rotor, stator and at least one winding in the stator adapted to conduct a current, and a secondary winding, electrically isolated from the first winding and inductively coupled to the first winding, which may be used to control at least one of the output voltage and current of the first winding.

Owner:PRATT & WHITNEY CANADA CORP

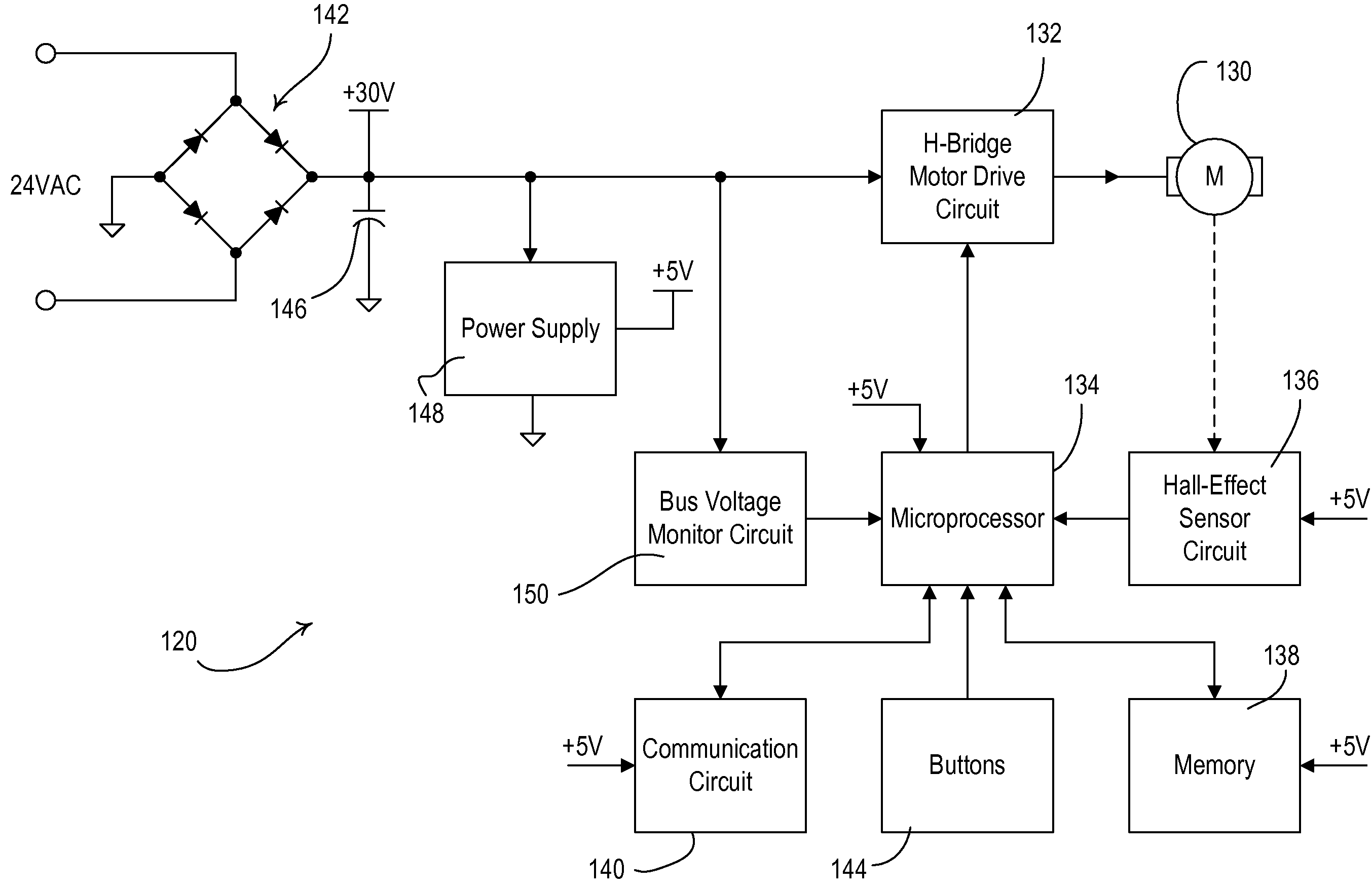

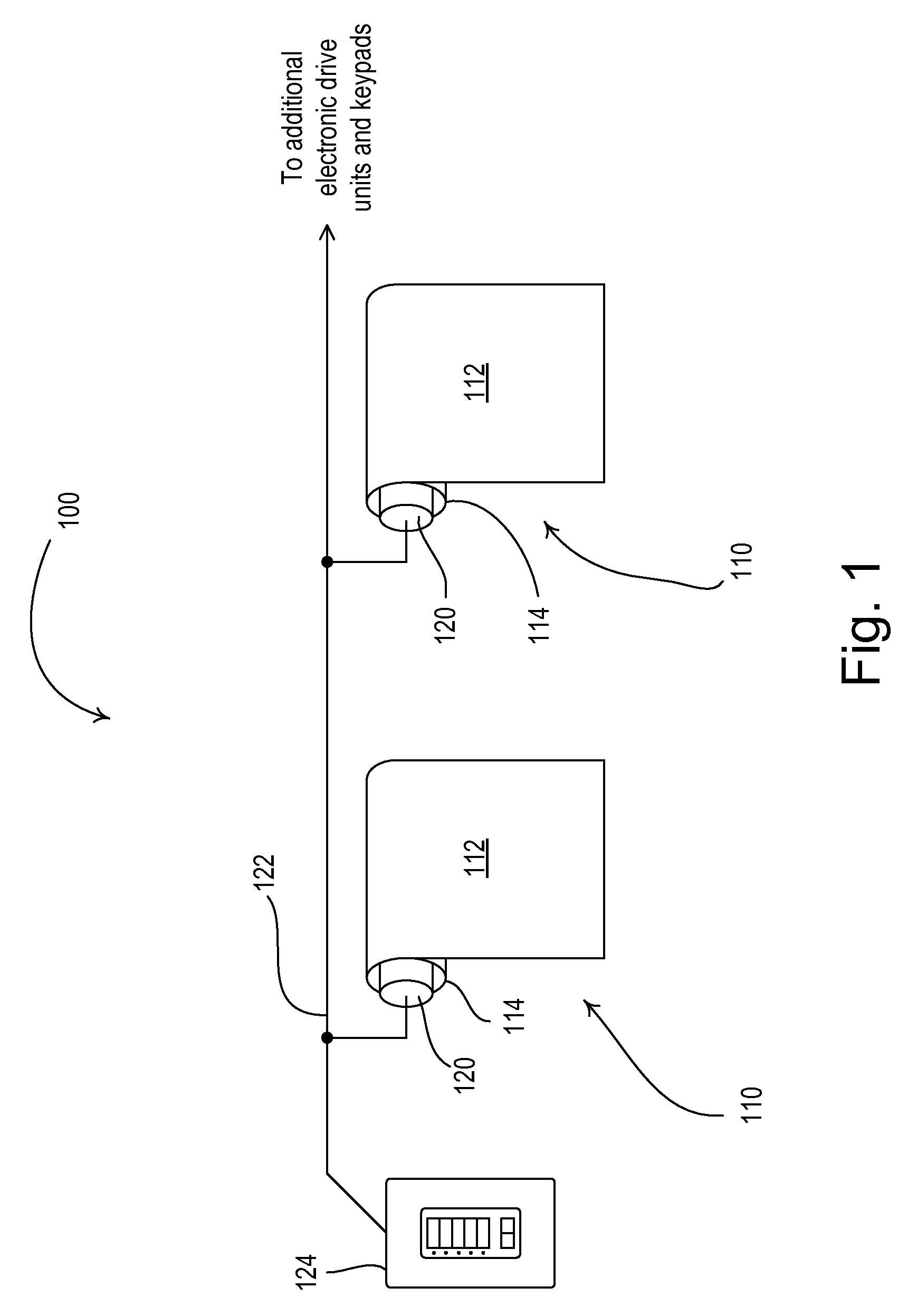

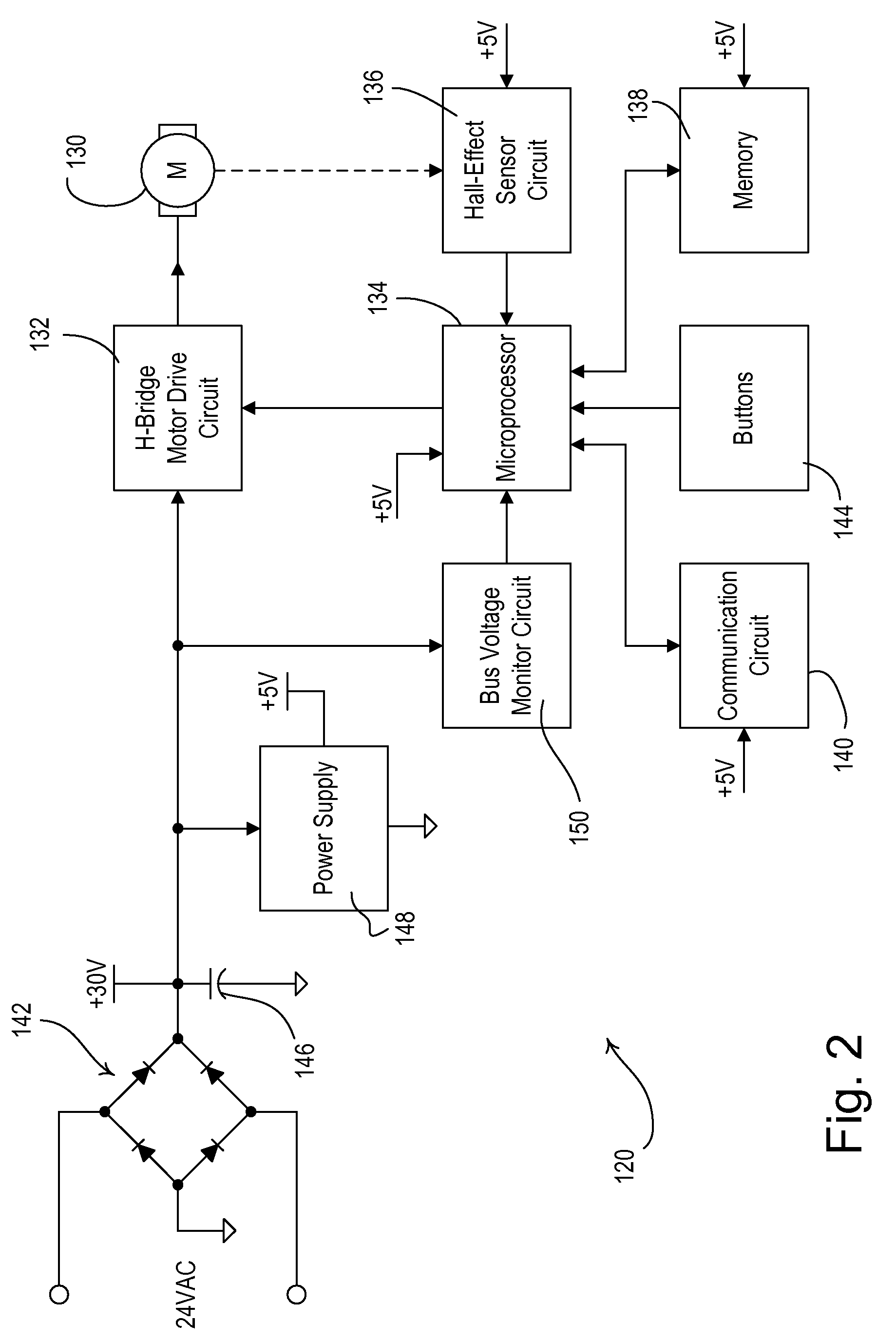

Method of controlling a motorized window treatment

ActiveUS7839109B2Motor/generator/converter stoppersDoor/window protective devicesMotor driveControl theory

A method of controlling a motorized window treatment provides for continued operation of the motorized window treatment during an overload or low-line condition. The motorized window treatment is driven by an electronic drive unit having a motor, a motor drive circuit, and a controller. The controller controls the motor drive circuit to drive the motor with a pulse-width modulated signal generated from a bus voltage. The controller is operable to monitor the magnitude of the bus voltage. If the bus voltage drops below a first voltage threshold, the controller stops the motor or reduces the duty cycle of the pulse-width modulated signal to allow the bus voltage to increase to an acceptable magnitude. When the bus voltage rises above a second voltage threshold, the controller begins driving the motor normally once again. During an overload or low-line condition, the controller is prevented from resetting, while driving the motor with minimal interruption to the movement of the motorized window treatment.

Owner:LUTRON TECH CO LLC

Method and device for braking a motor

InactiveUS7023159B2Eliminate needAC motor controlDC motor speed/torque controlPower switchingConductor Coil

A method and apparatus for braking a motor has a braking power switching device coupled across windings of the motor. To brake the motor, the braking power switching device is cycled on and off.

Owner:BLACK & DECKER INC

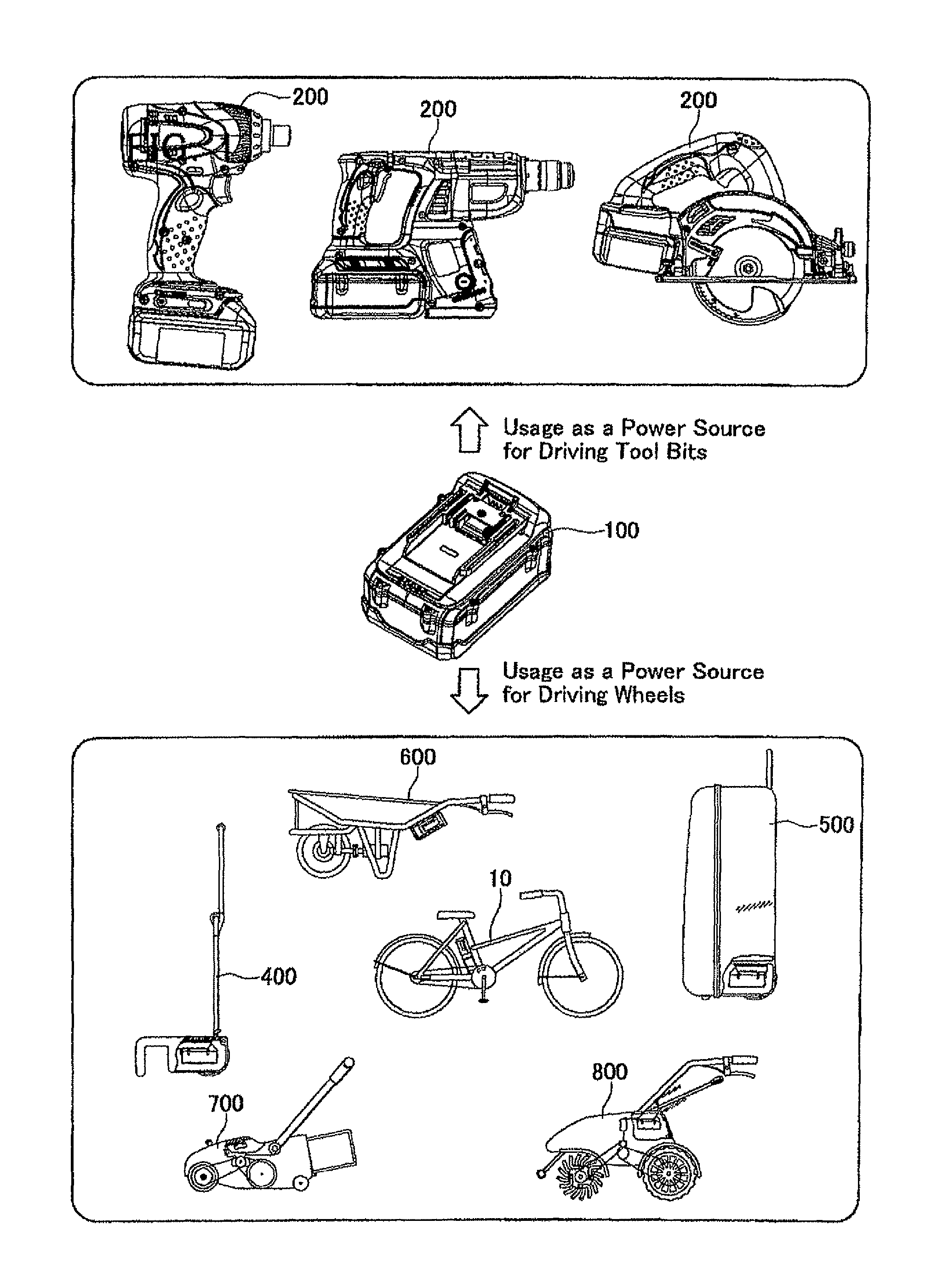

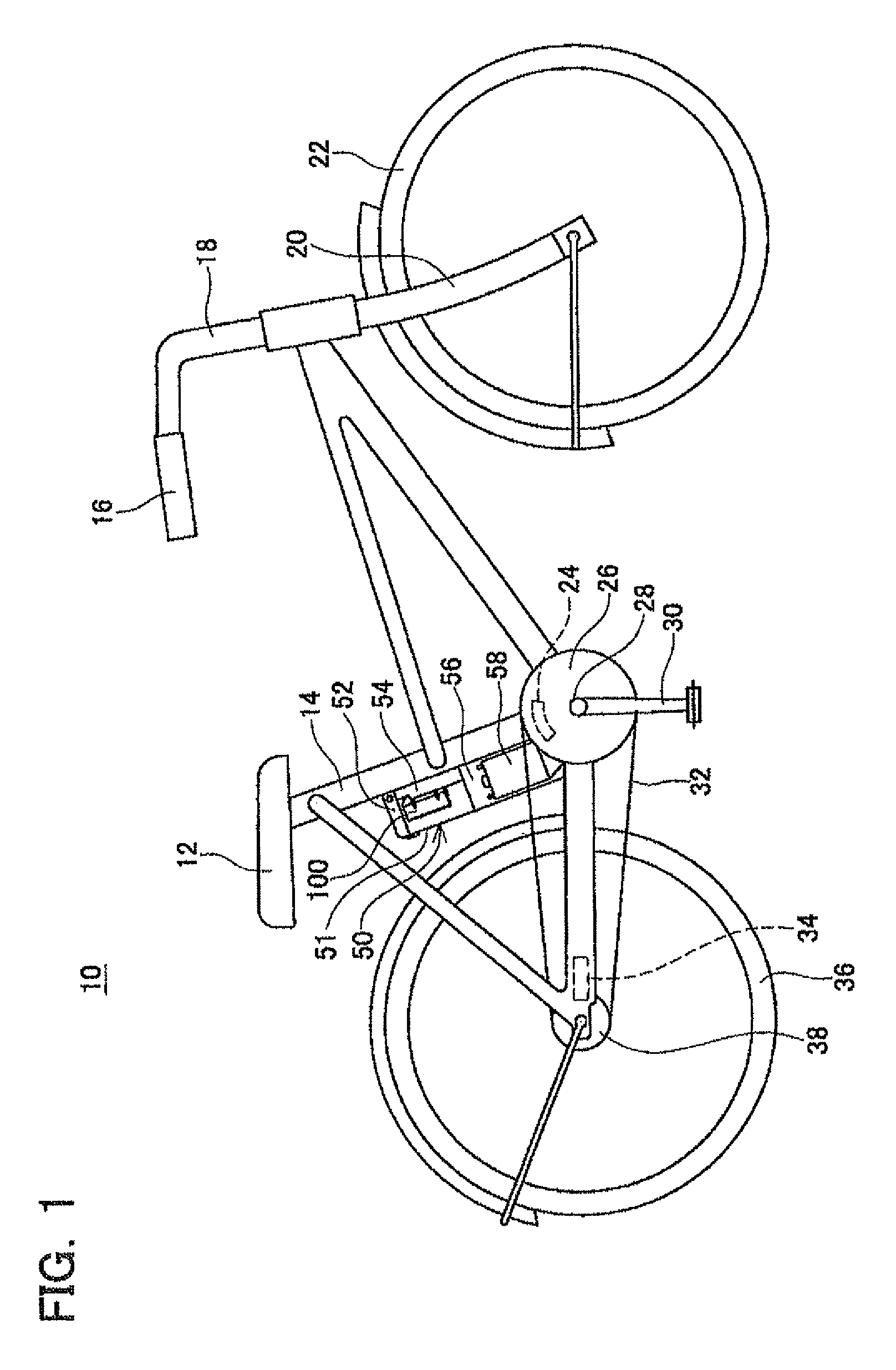

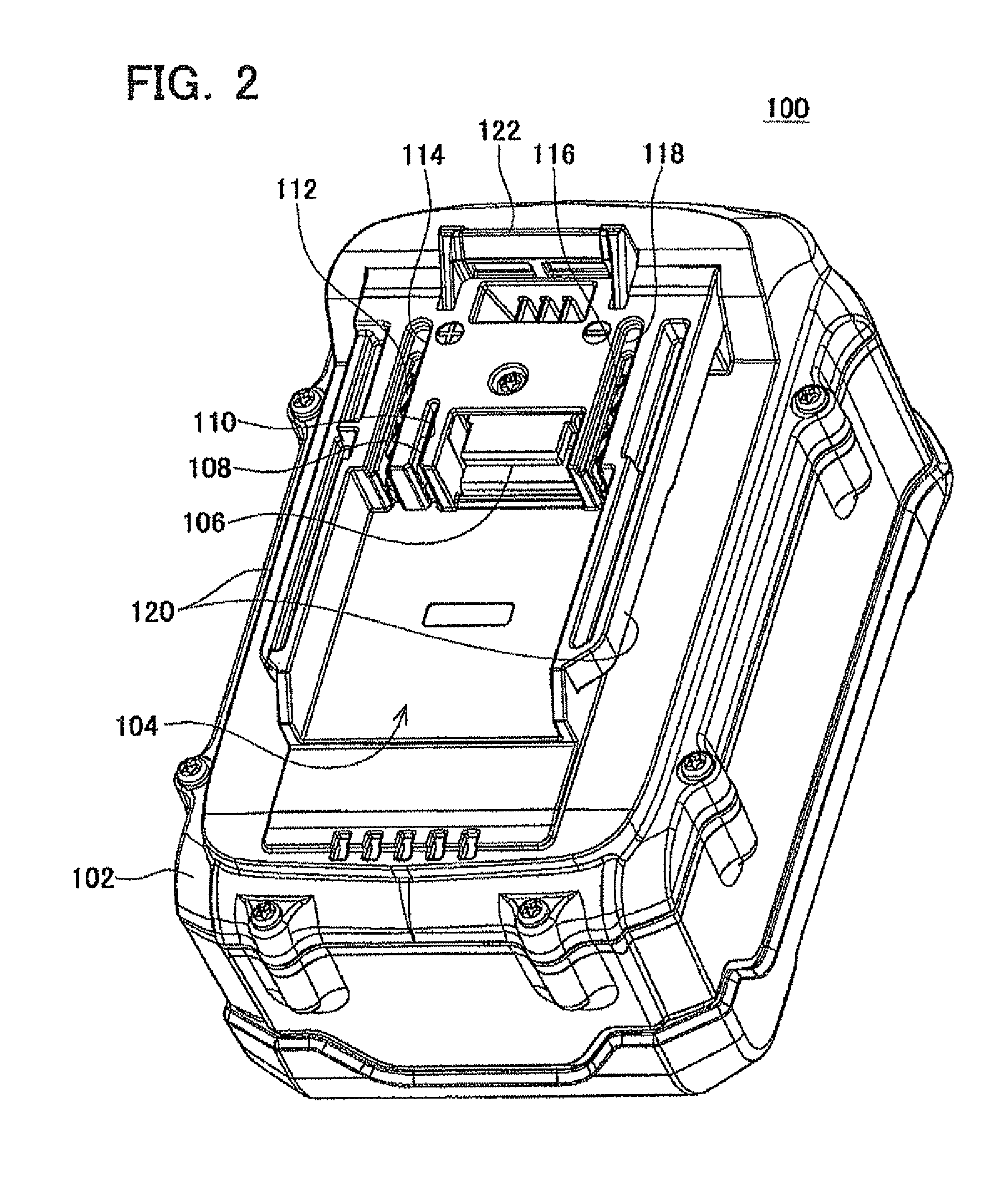

Electric wheeled apparatus

ActiveUS8851215B2Increase the output voltageLarge capacityMowersTilling equipmentsElectricityElectric power system

Owner:MAKITA CORP

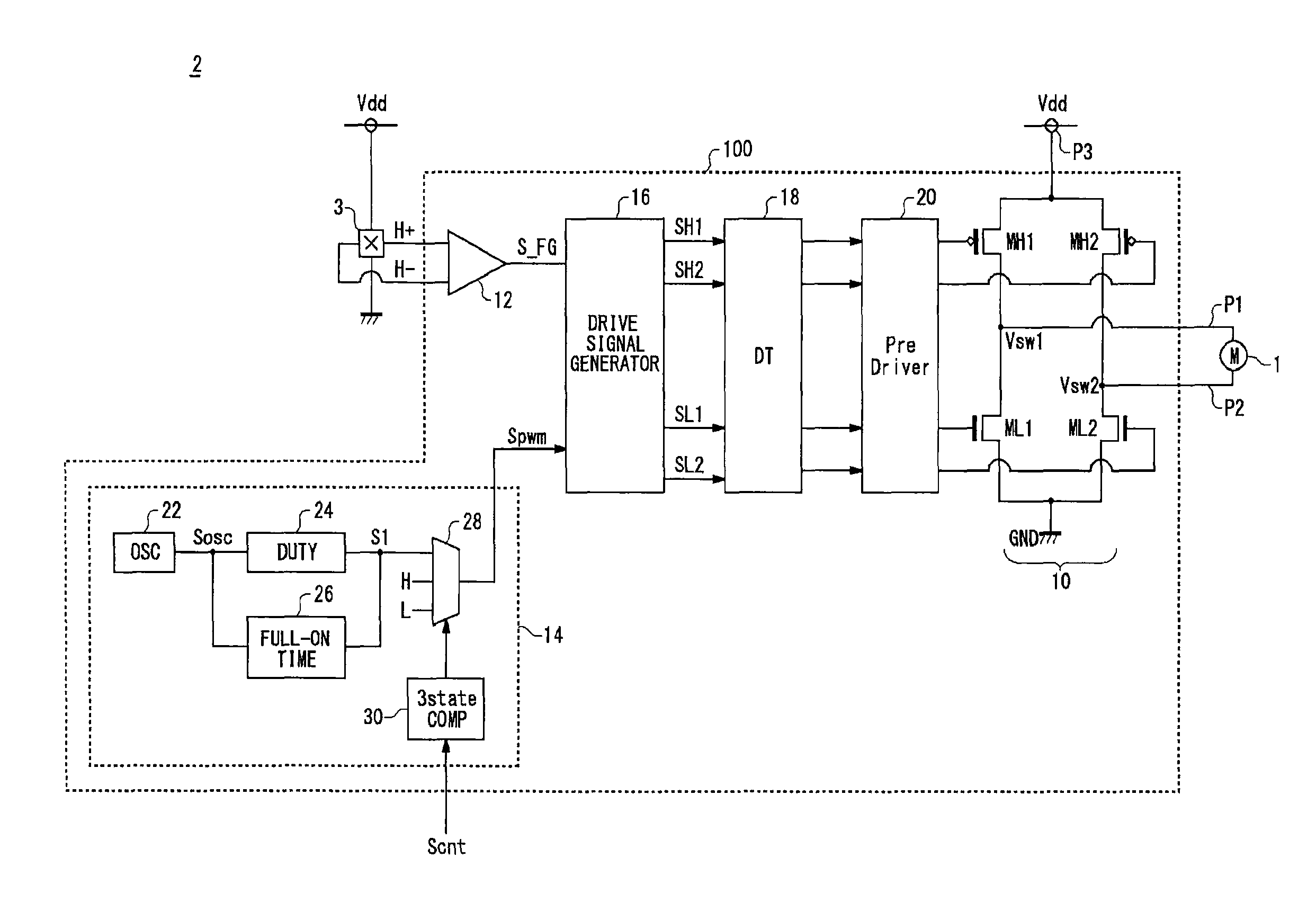

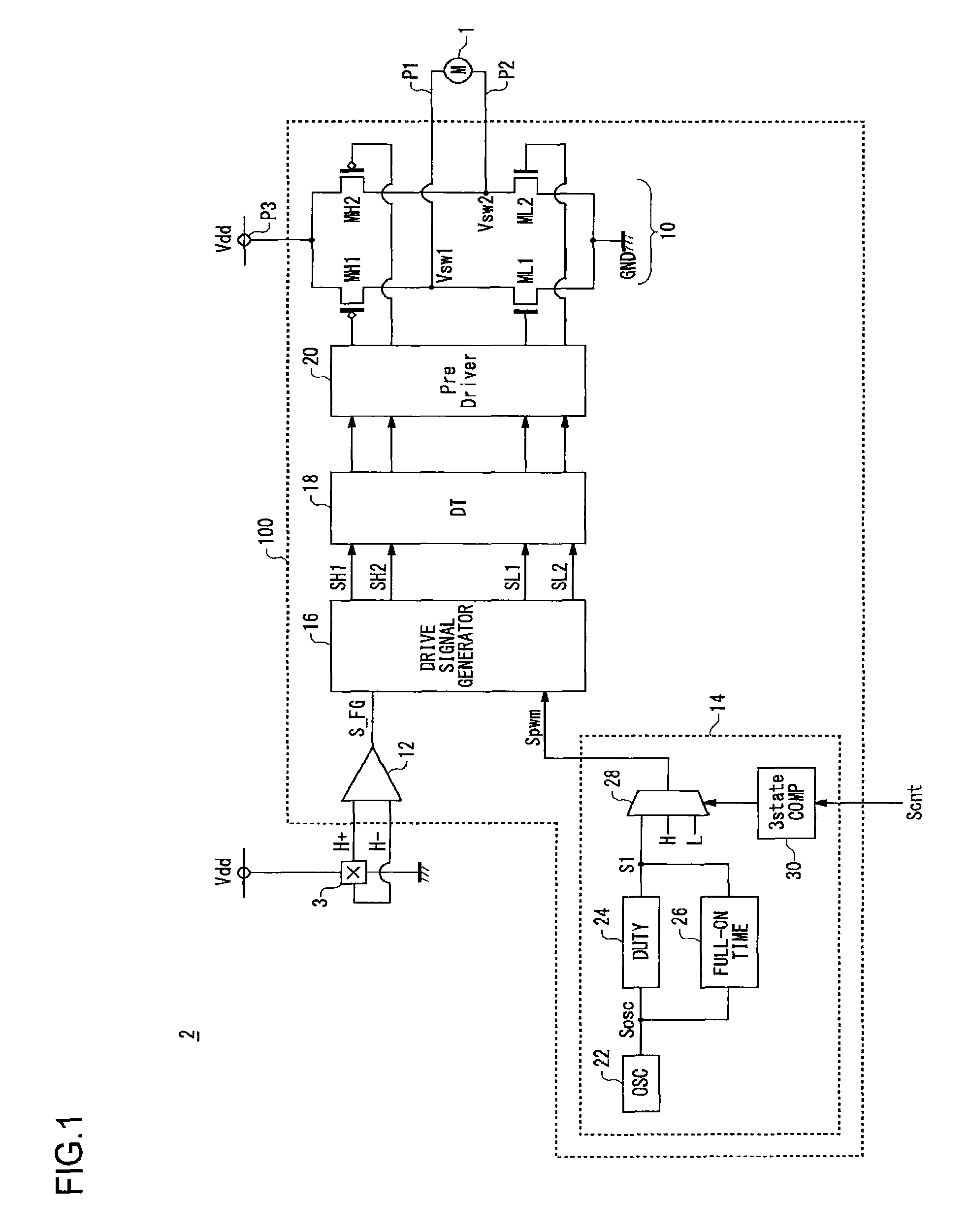

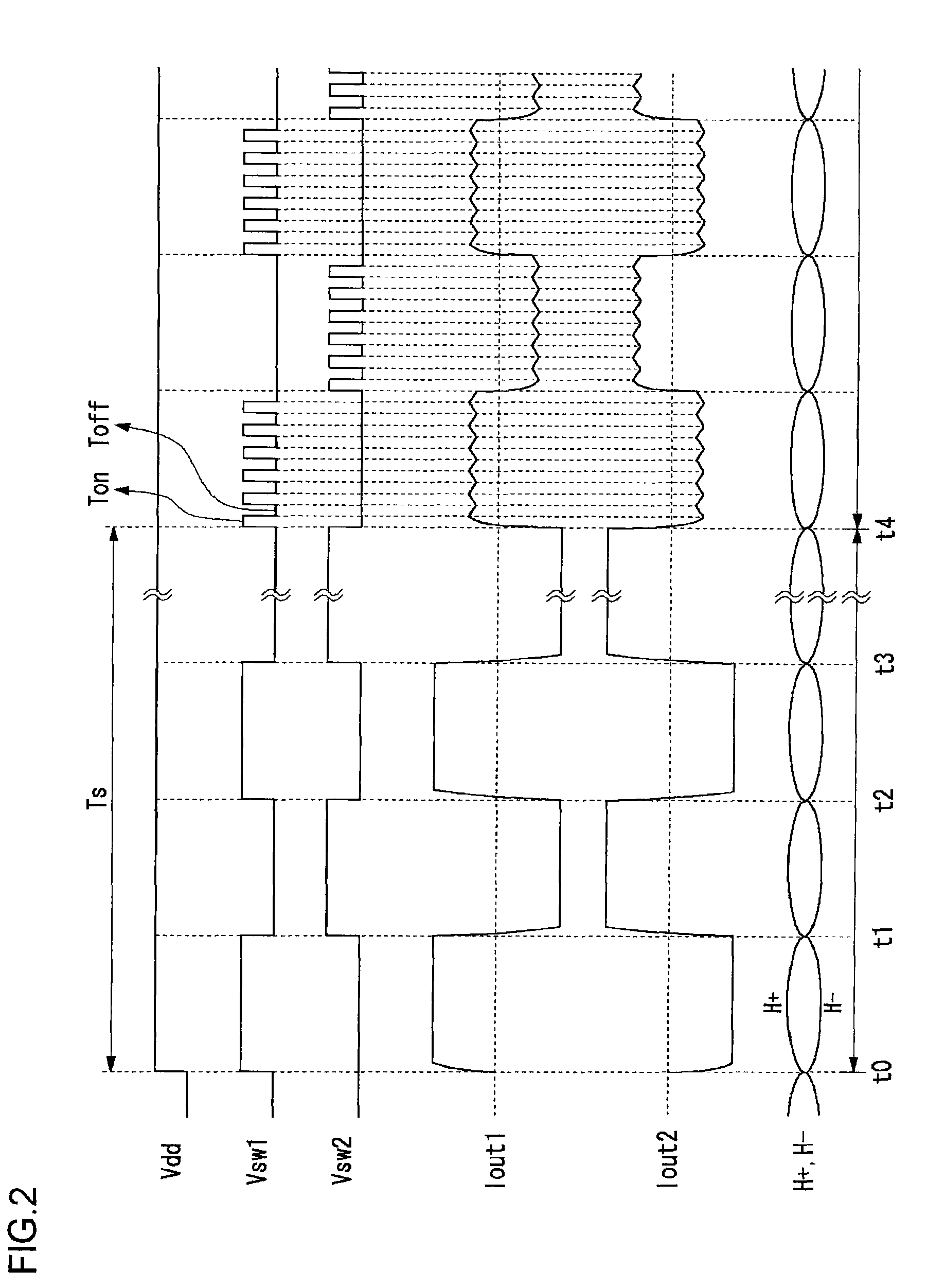

Motor drive circuit with short startup time

An H-bridge circuit is connected to a coil of the vibration motor that is to be driven. A comparator receives Hall signals indicating position information of a rotor of the vibration motor, and converts to an FG signal. A pulse width modulator generates a pulse-modulated pulse signal specifying energization time of the coil of the vibration motor. The pulse width modulator, in a first mode, after commencing start-up of the vibration motor, sets a duty ratio of the pulse signal to 100%, and after that, switches the duty ratio to a predetermined value in accordance with rotational frequency of the motor. In a second mode, the duty ratio of the pulse signal continues to be set to 100%. In a third mode, frequency and the duty ratio of the pulse signal are set based on a control signal of a pulse form inputted from outside. The control signal is used also in switching mode.

Owner:ROHM CO LTD

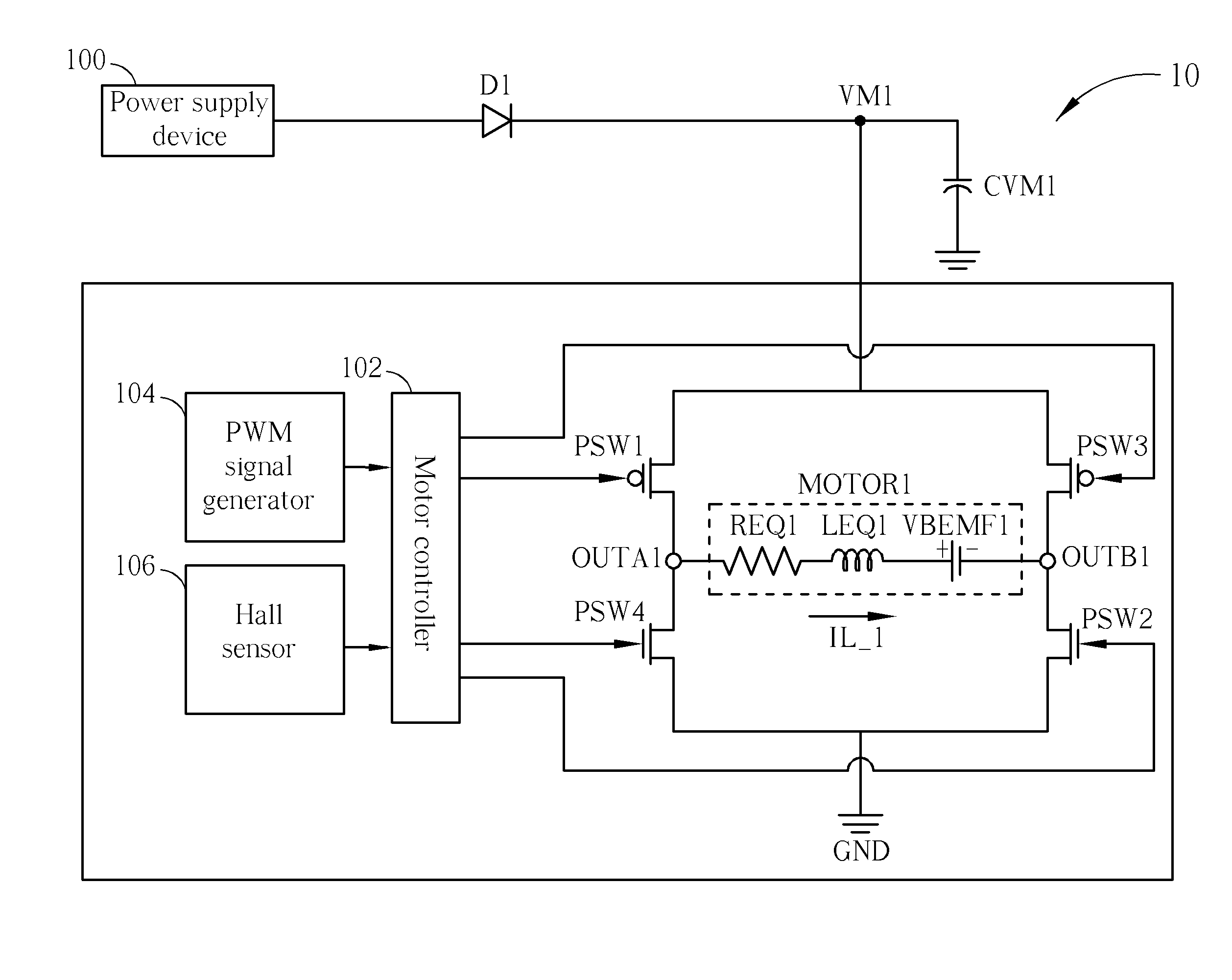

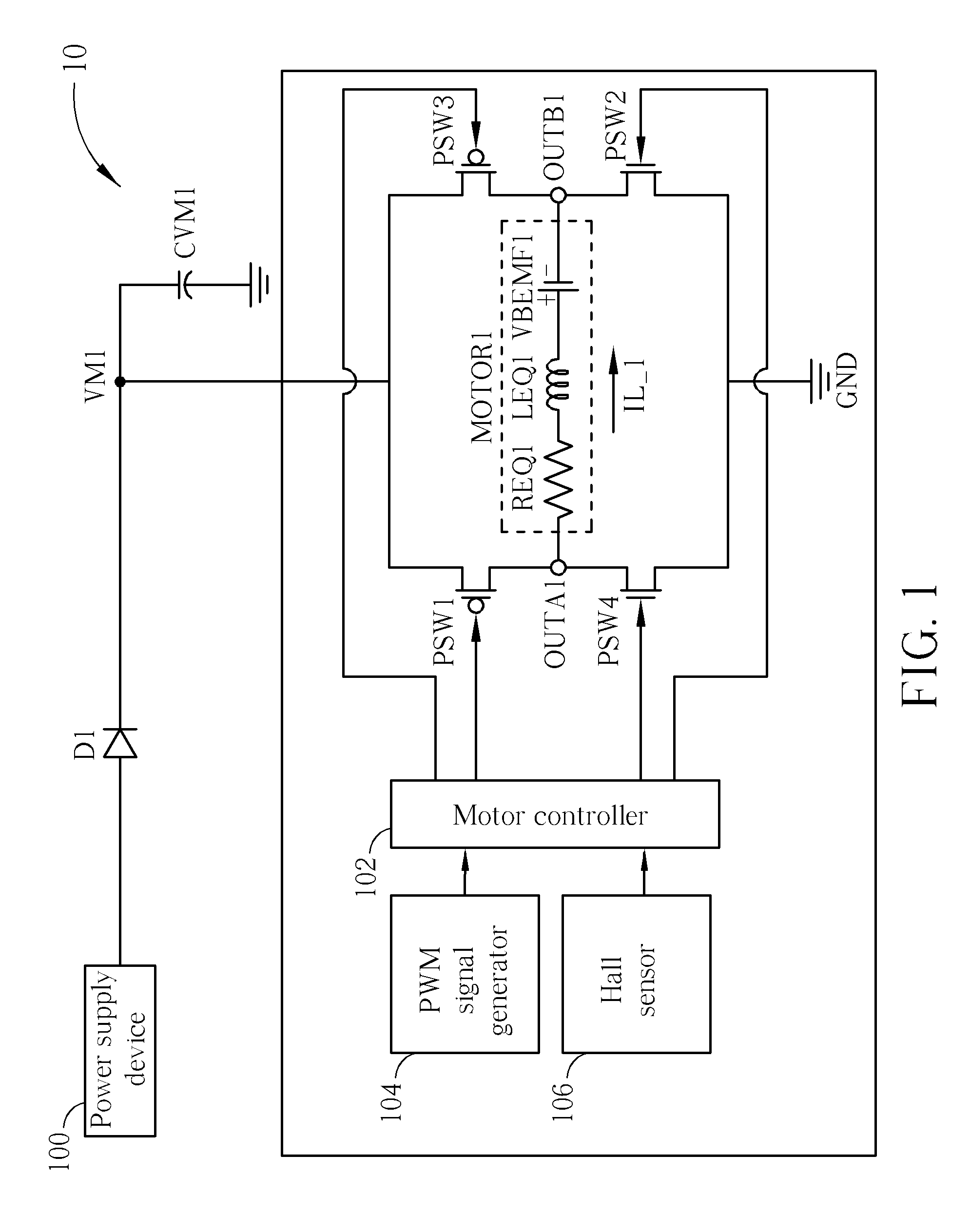

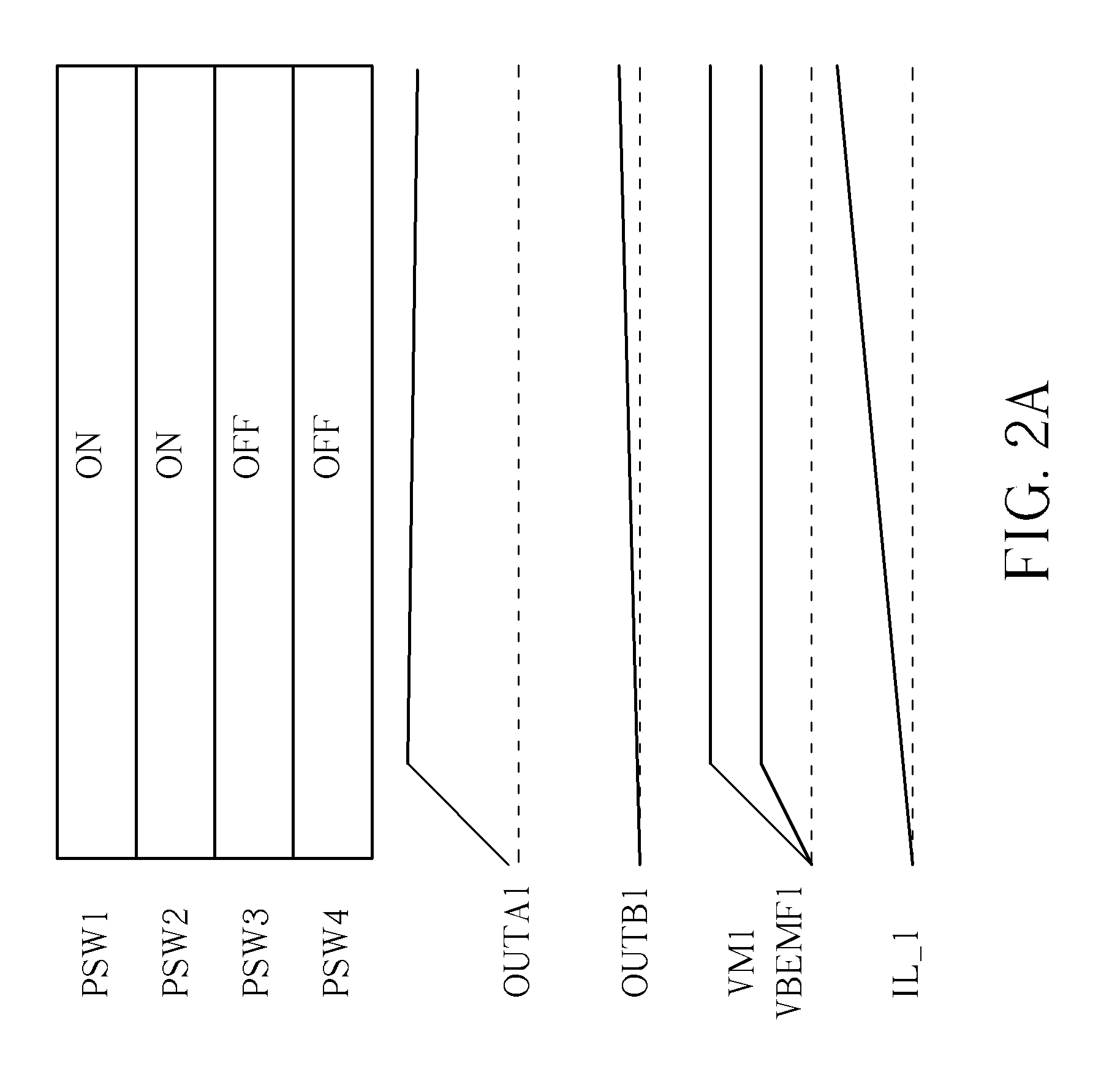

Method of driving DC motor and related circuit for avoiding reverse current

ActiveUS8183807B2Avoid it happening againMotor/generator/converter stoppersAC motor controlDriver circuitPower flow

Owner:ANPEC ELECTRONICS CORPORATION

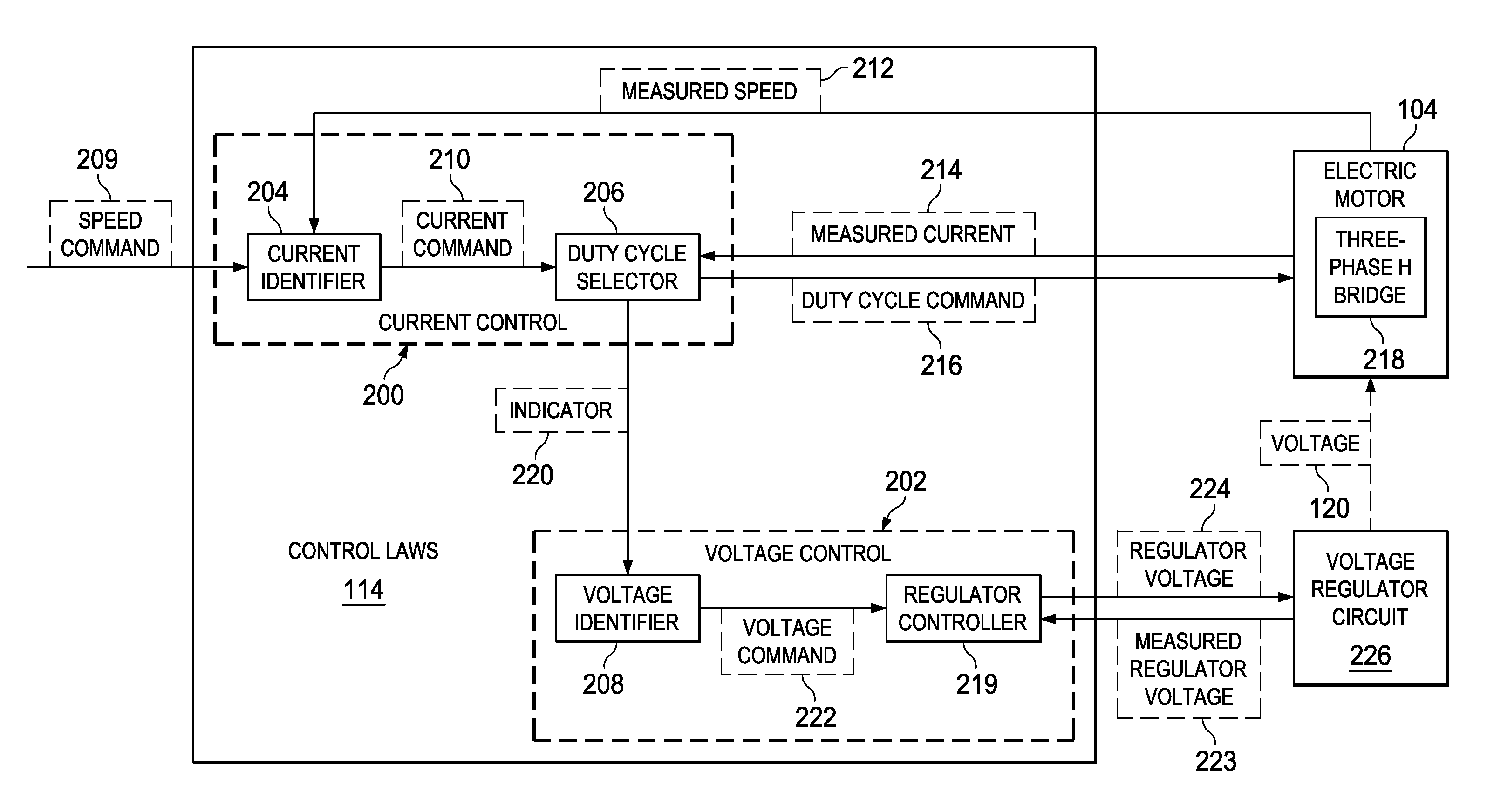

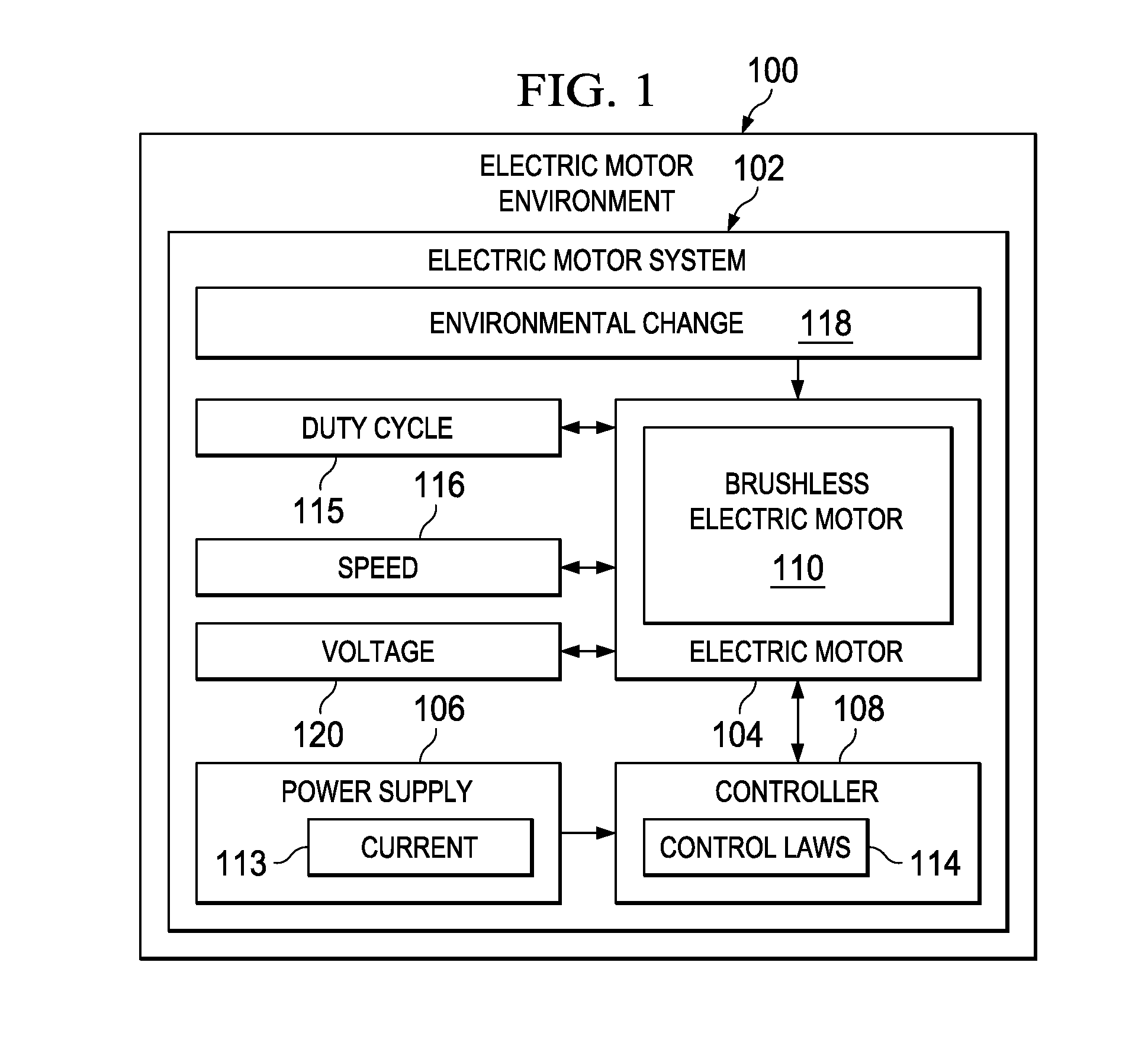

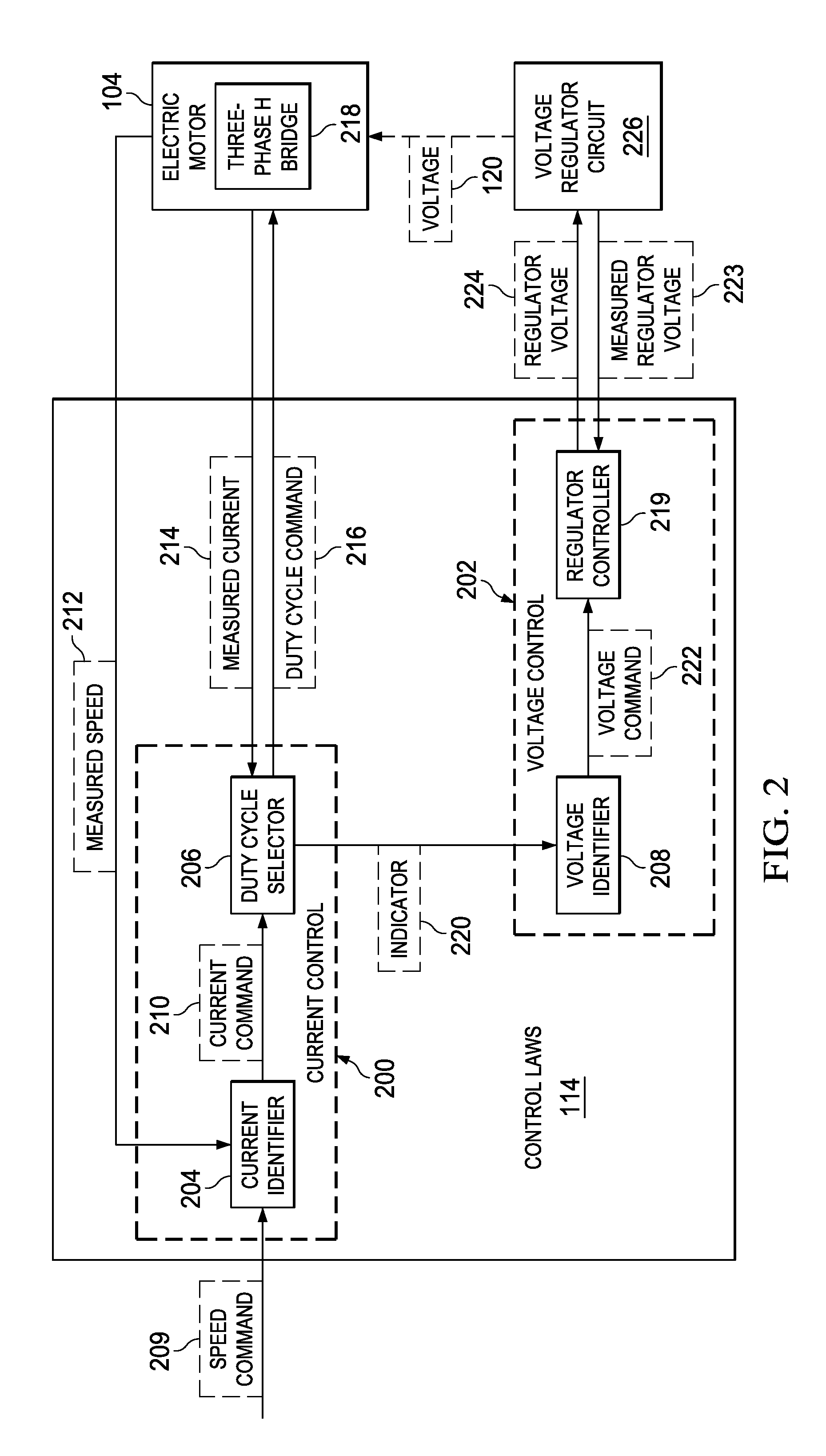

Active voltage controller for an electric motor

A method for controlling an electric motor. A desired speed is identified for the electric motor during operation of the electric motor. A voltage is identified to cause the electric motor to turn at the desired speed. The voltage is applied to the electric motor and actively controlled during operation of the electric motor.

Owner:THE BOEING CO

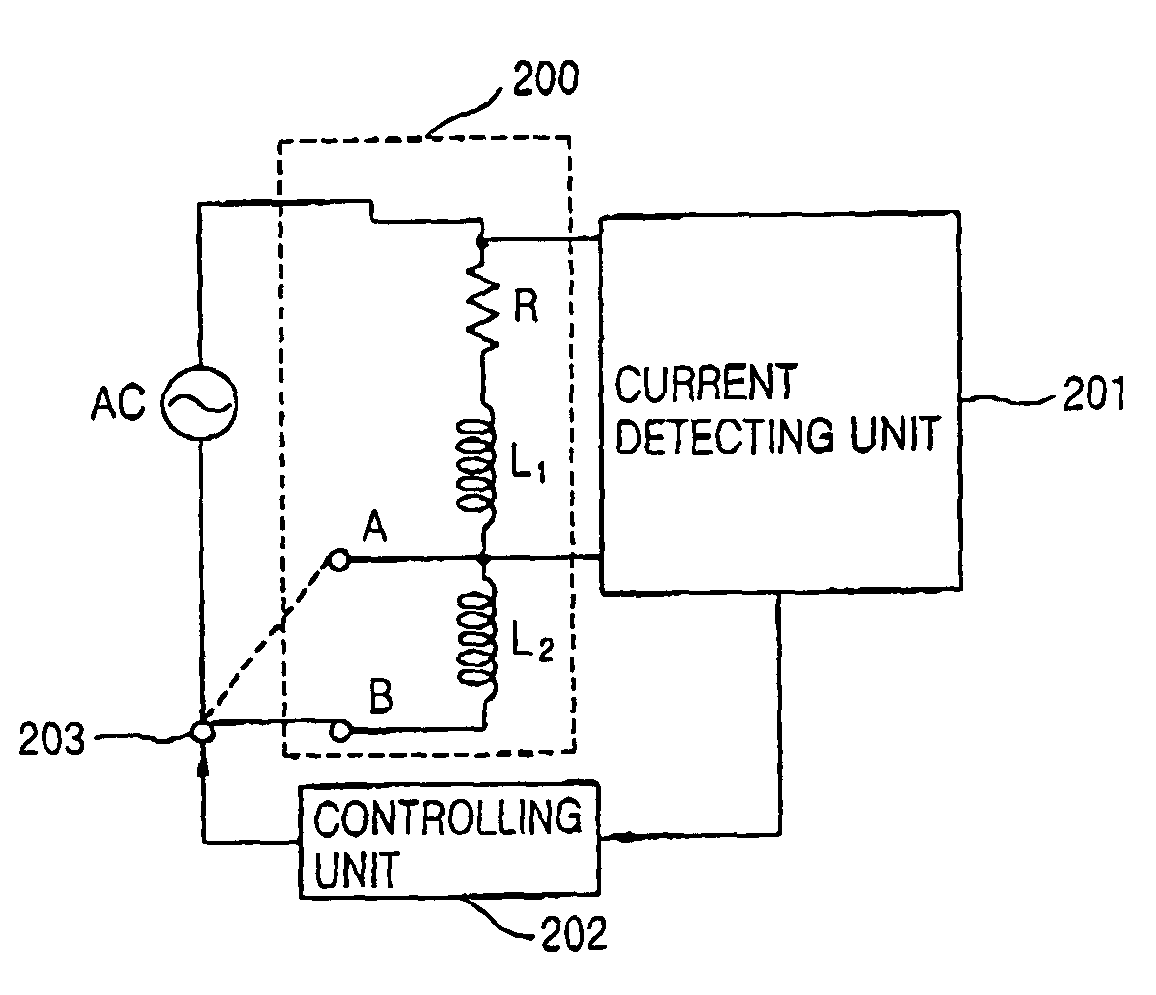

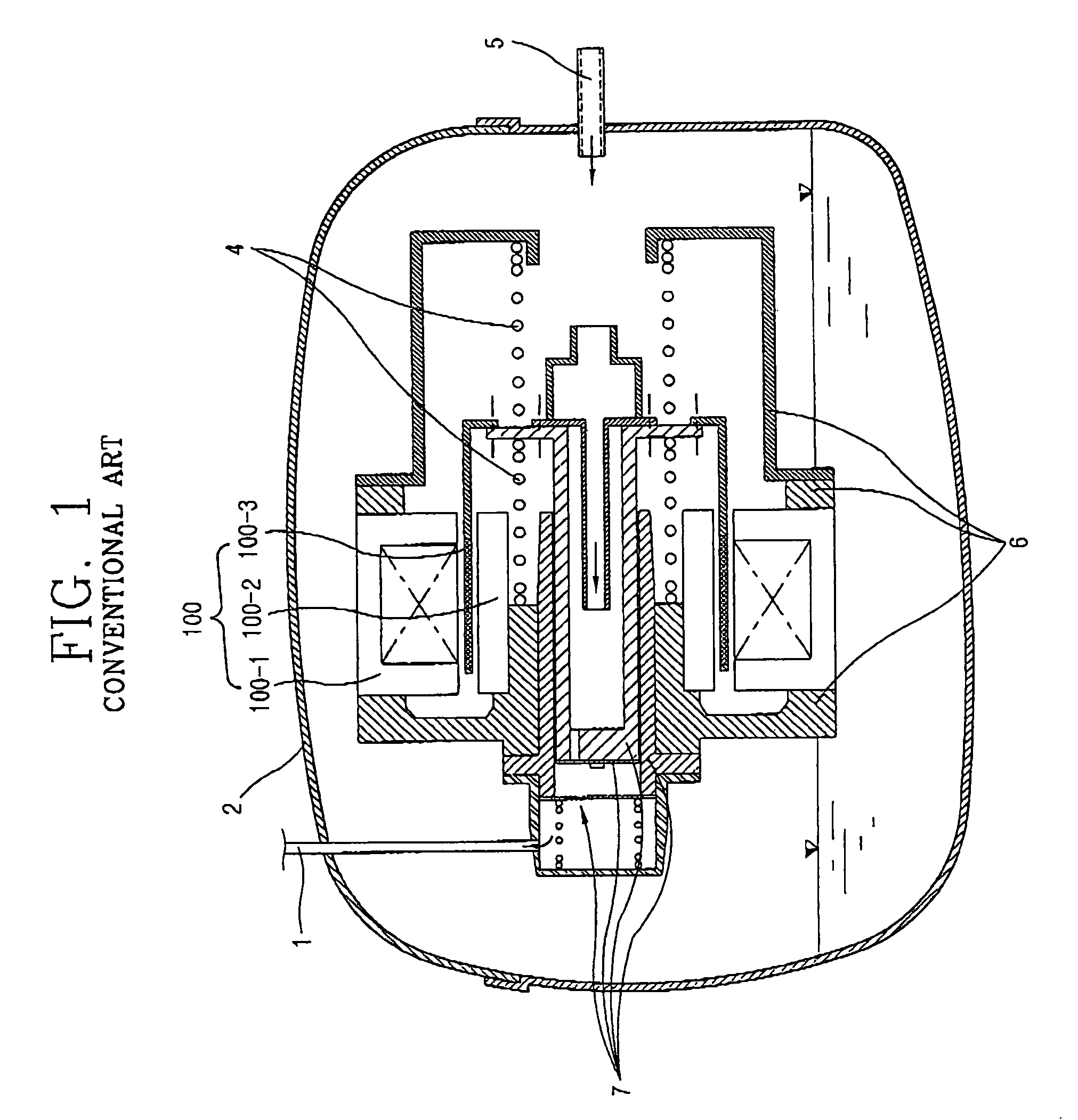

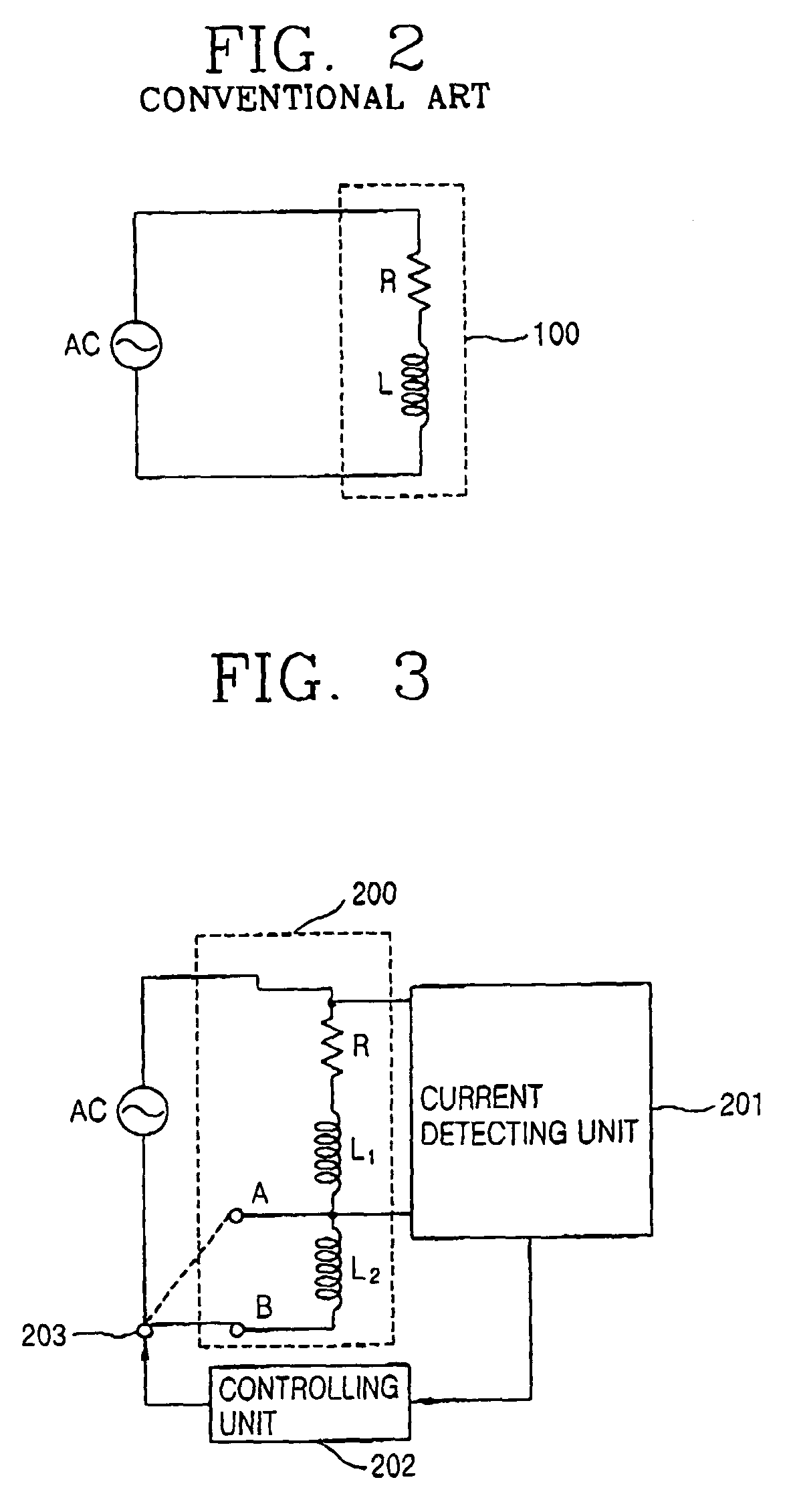

Apparatus and method for controlling driving of linear motor

InactiveUS6998736B2Increase efficiency of linearMotor/generator/converter stoppersDC motor speed/torque controlControl signalLinear compressor

Owner:LG ELECTRONICS INC

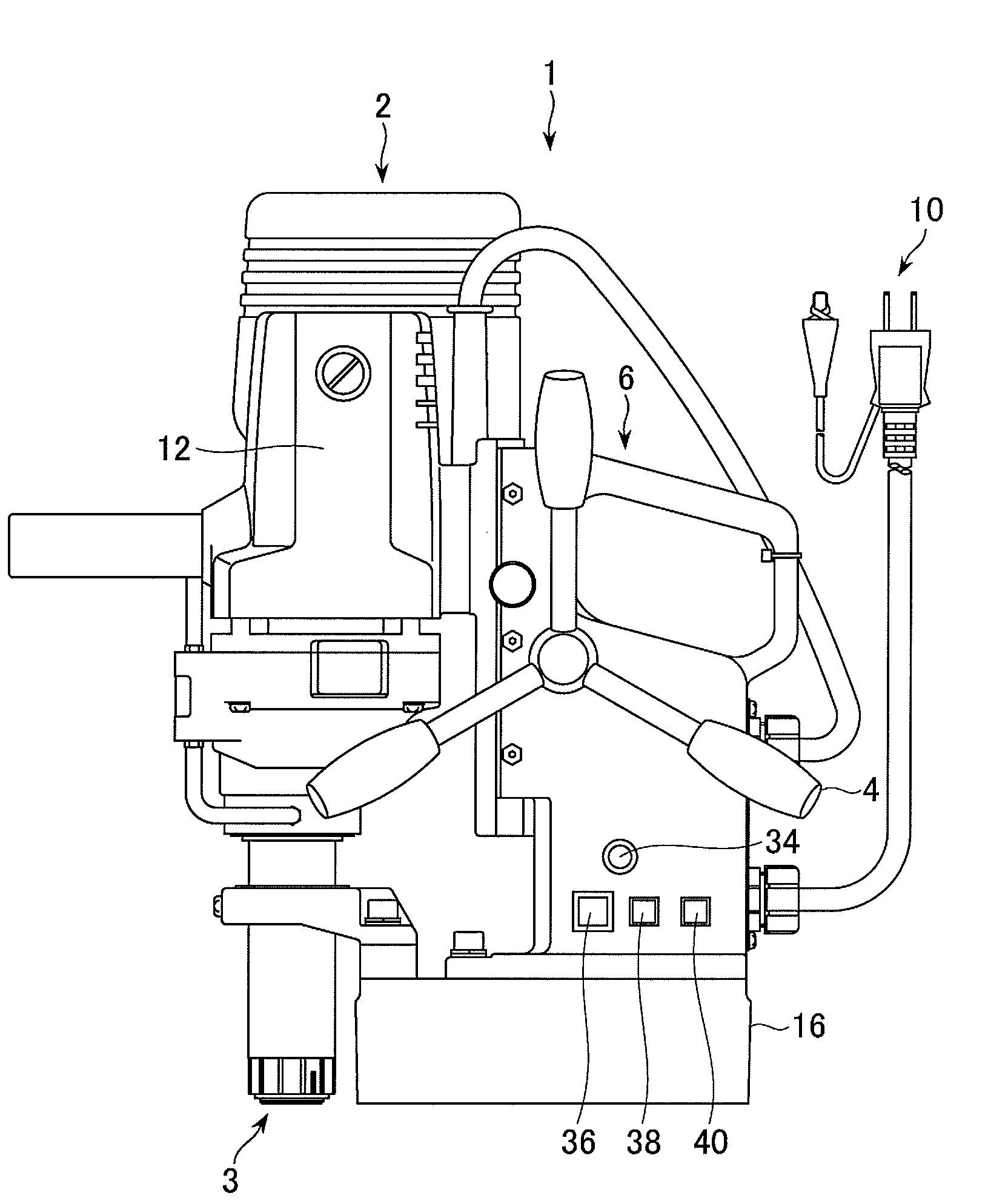

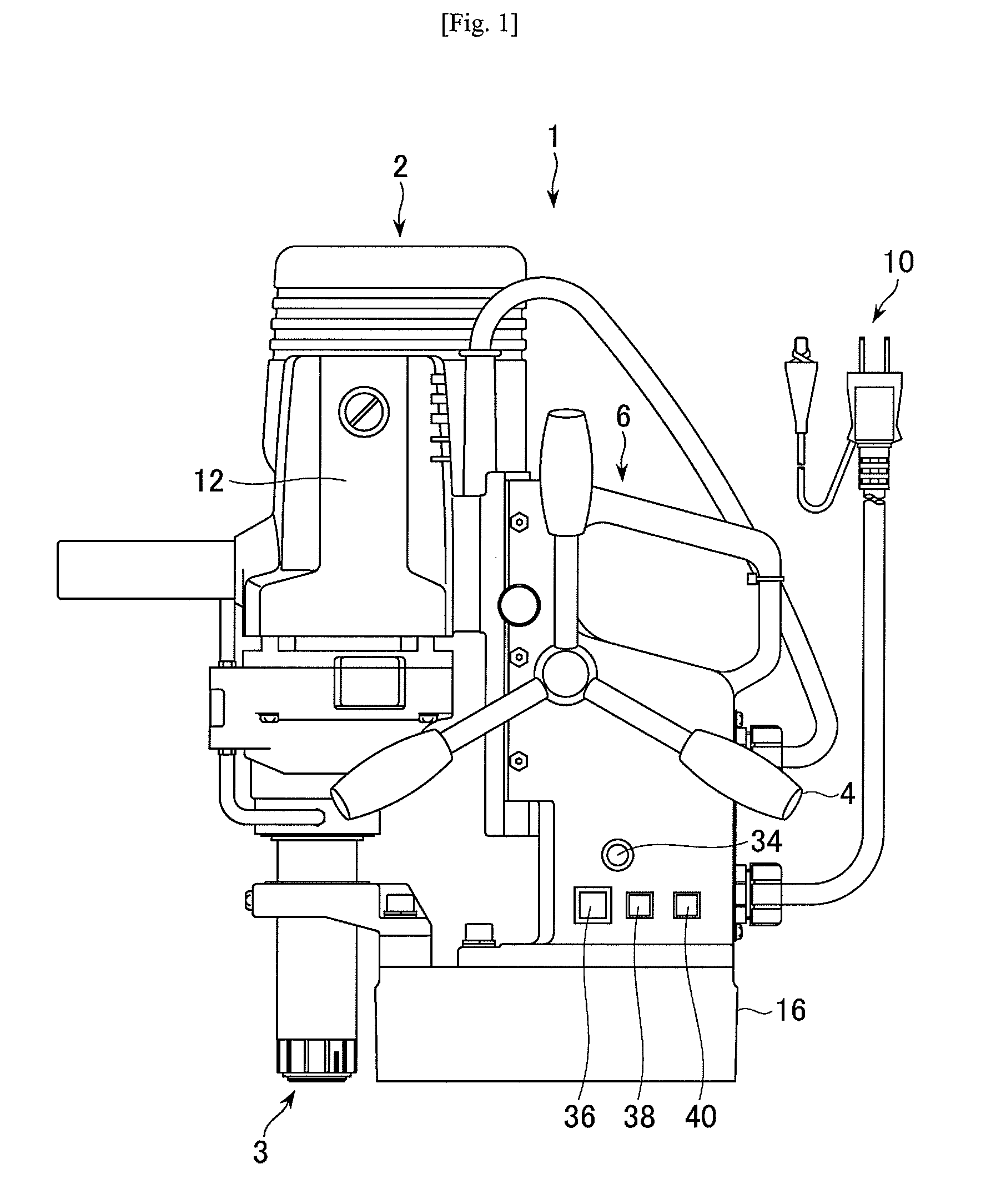

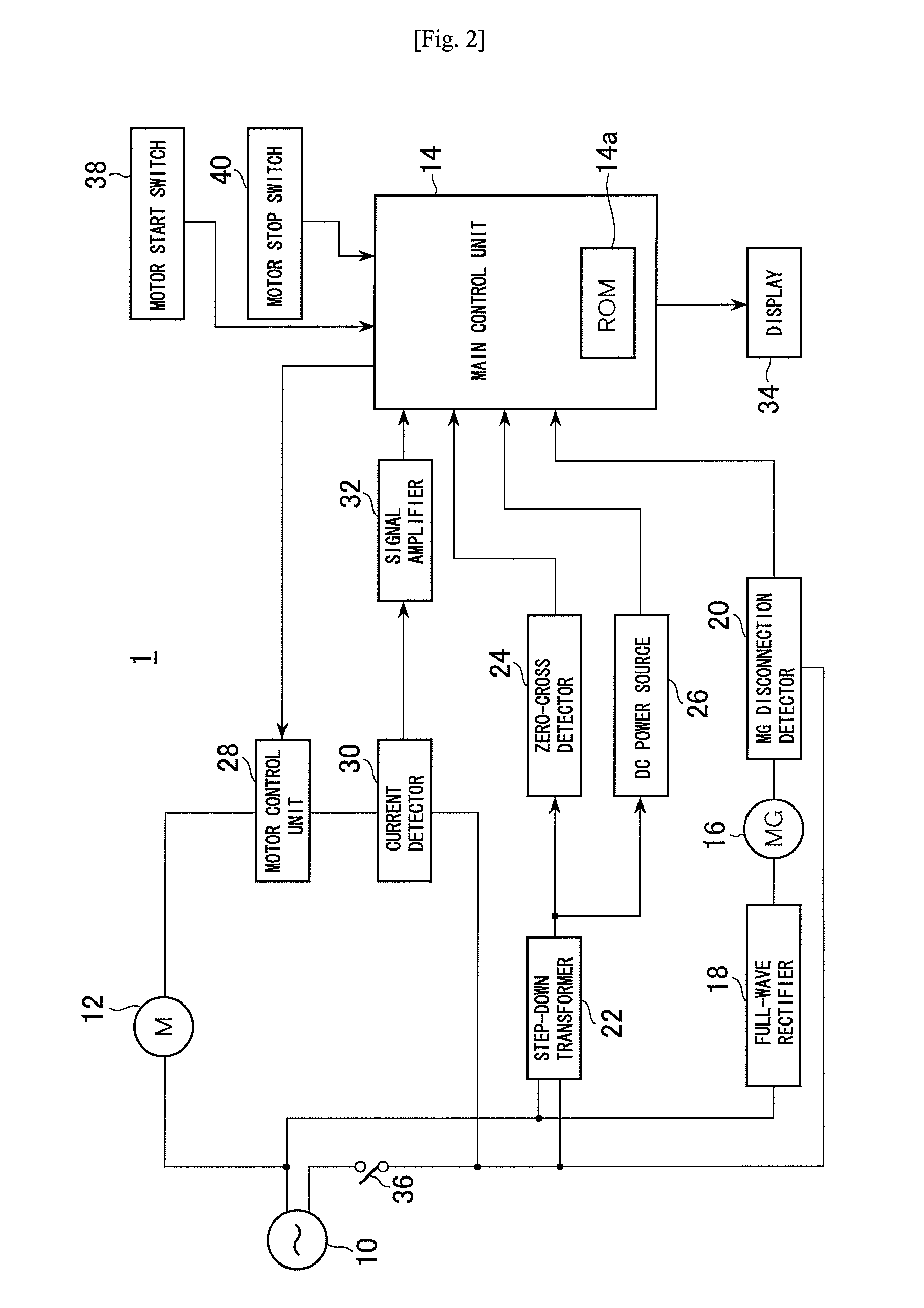

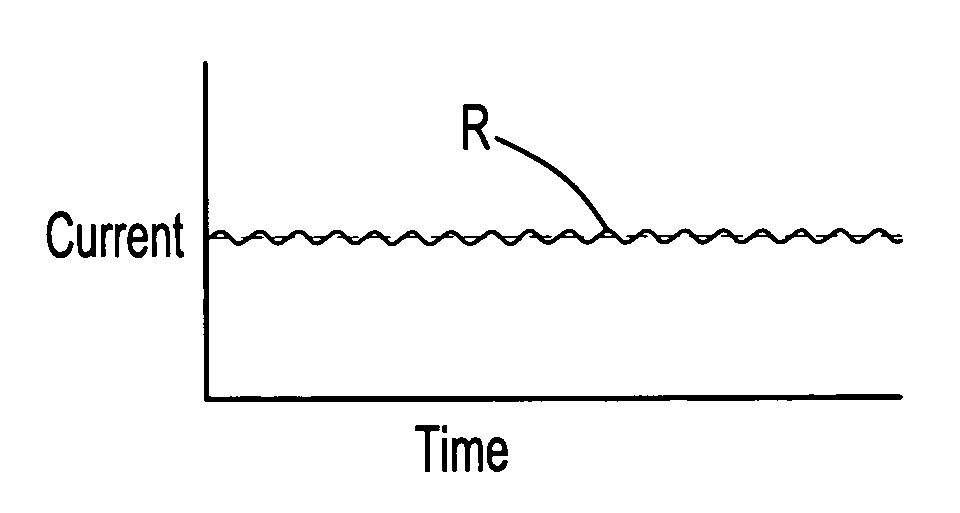

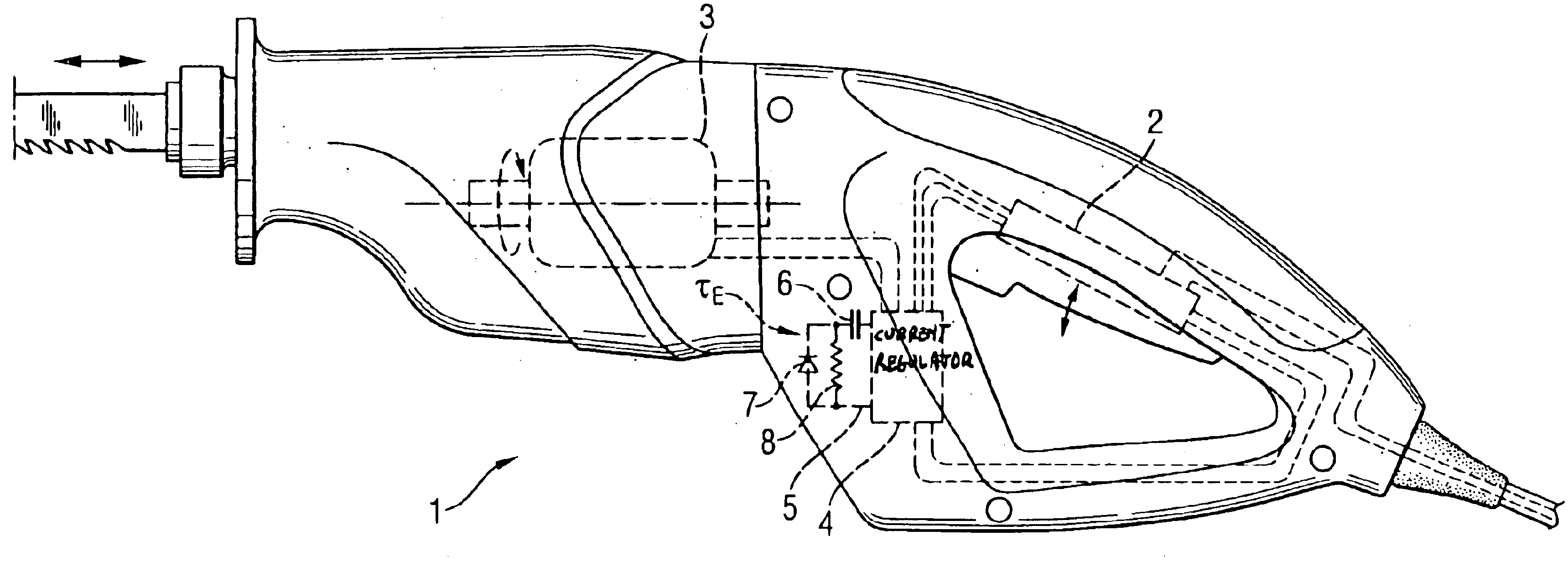

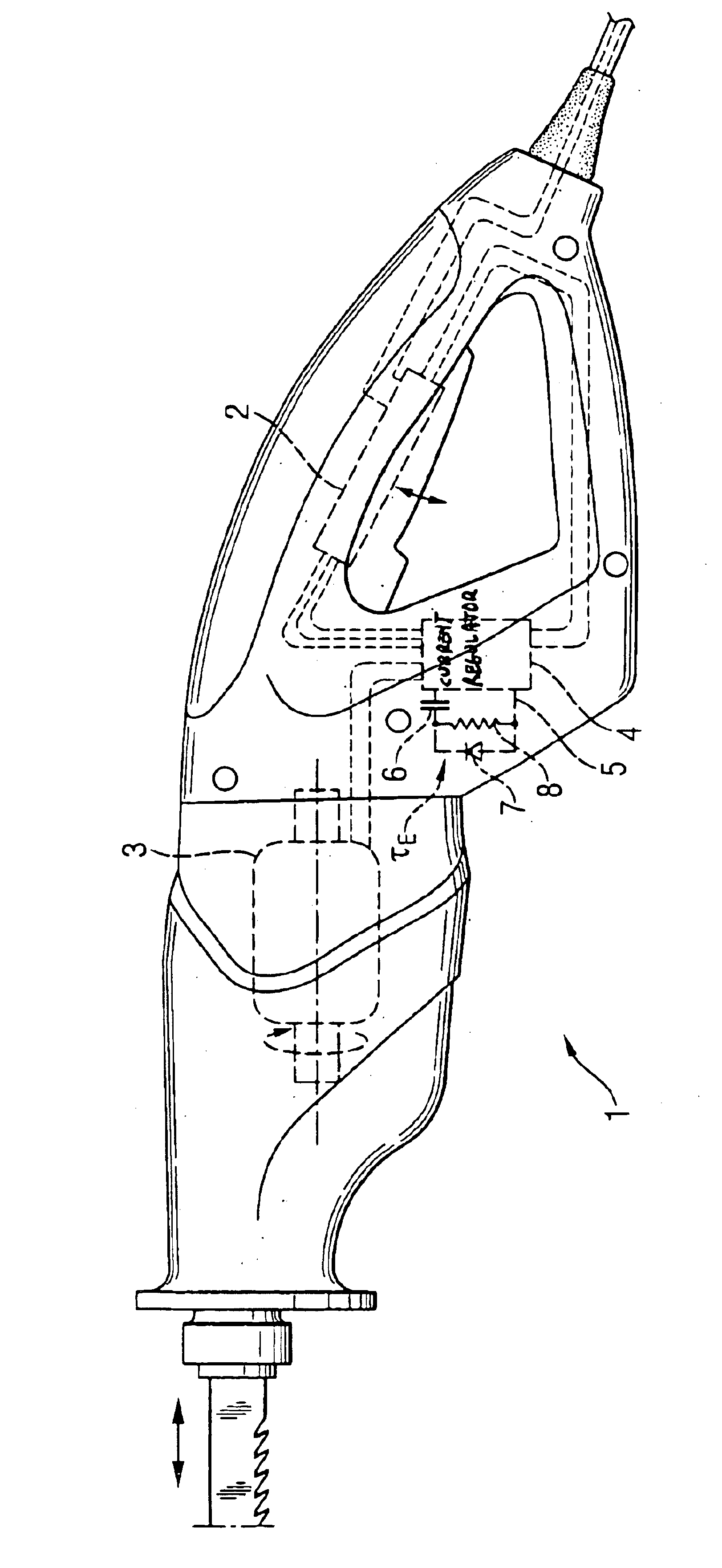

Portable drilling device

ActiveUS7936142B2Easy to operateImprove securityAC motor controlDC motor speed/torque controlFull waveEngineering

A drilling device prevents recurrence of an overload condition after occurrence of the overload condition, thereby improving operability and safety in the drilling device. A motor for rotating a drill is connected to an AC power source through a motor control unit, a current detector, and a power switch. A magnet is also connected to the AC power source through the power switch and a full-wave rectifier. The motor control unit rotationally drives the motor on the basis of a signal sent from a main control unit according to a state in which a motor start switch is on. The main control unit controls the motor control unit to gradually reduce a supply voltage to the motor when the motor becomes overloaded, to gradually increase the voltage to the normal power supply condition when the overload condition is vanished, and to stop power supply to the motor if the overload condition continues for a predetermined period.

Owner:NITTO KOHKI CO LTD

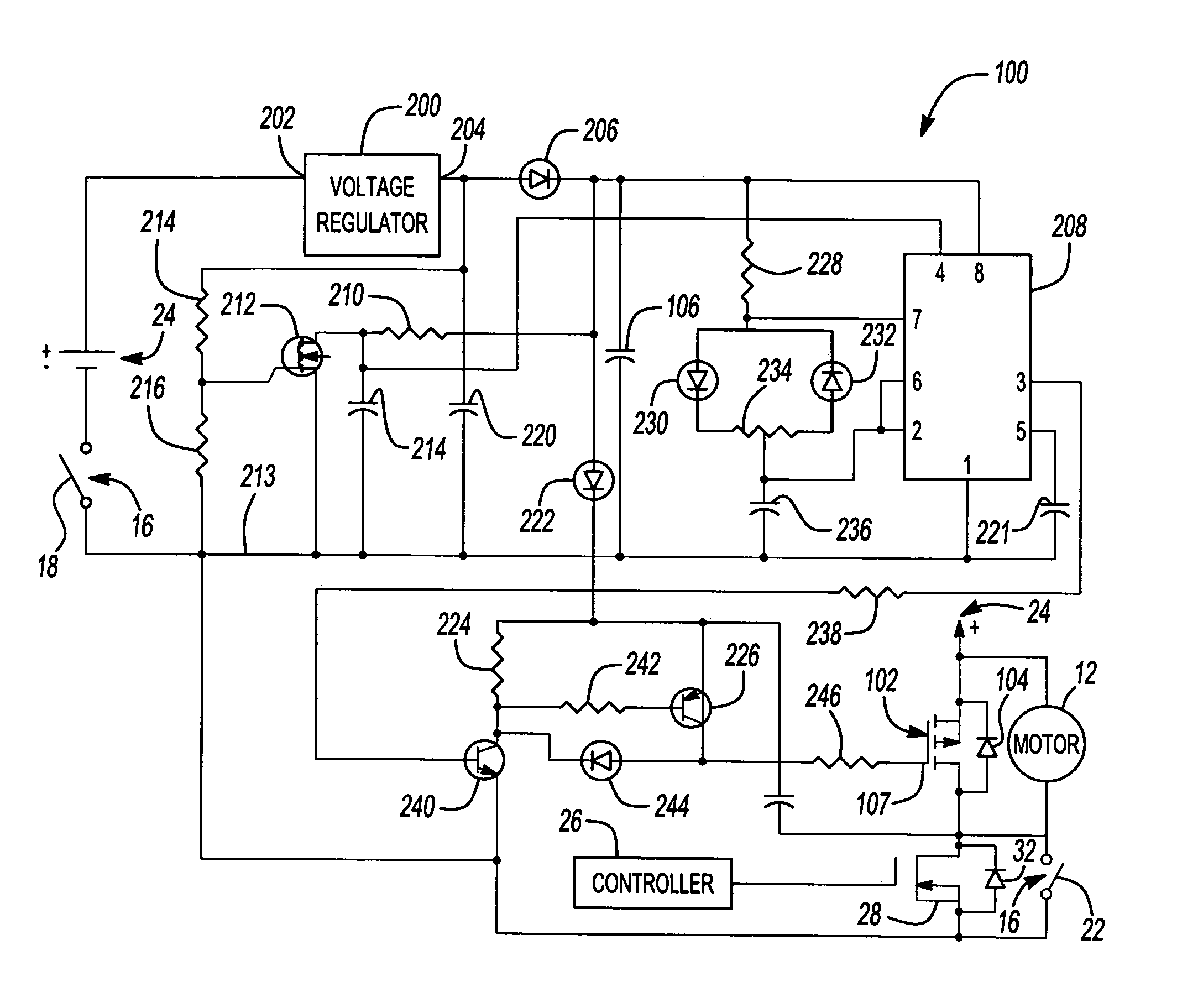

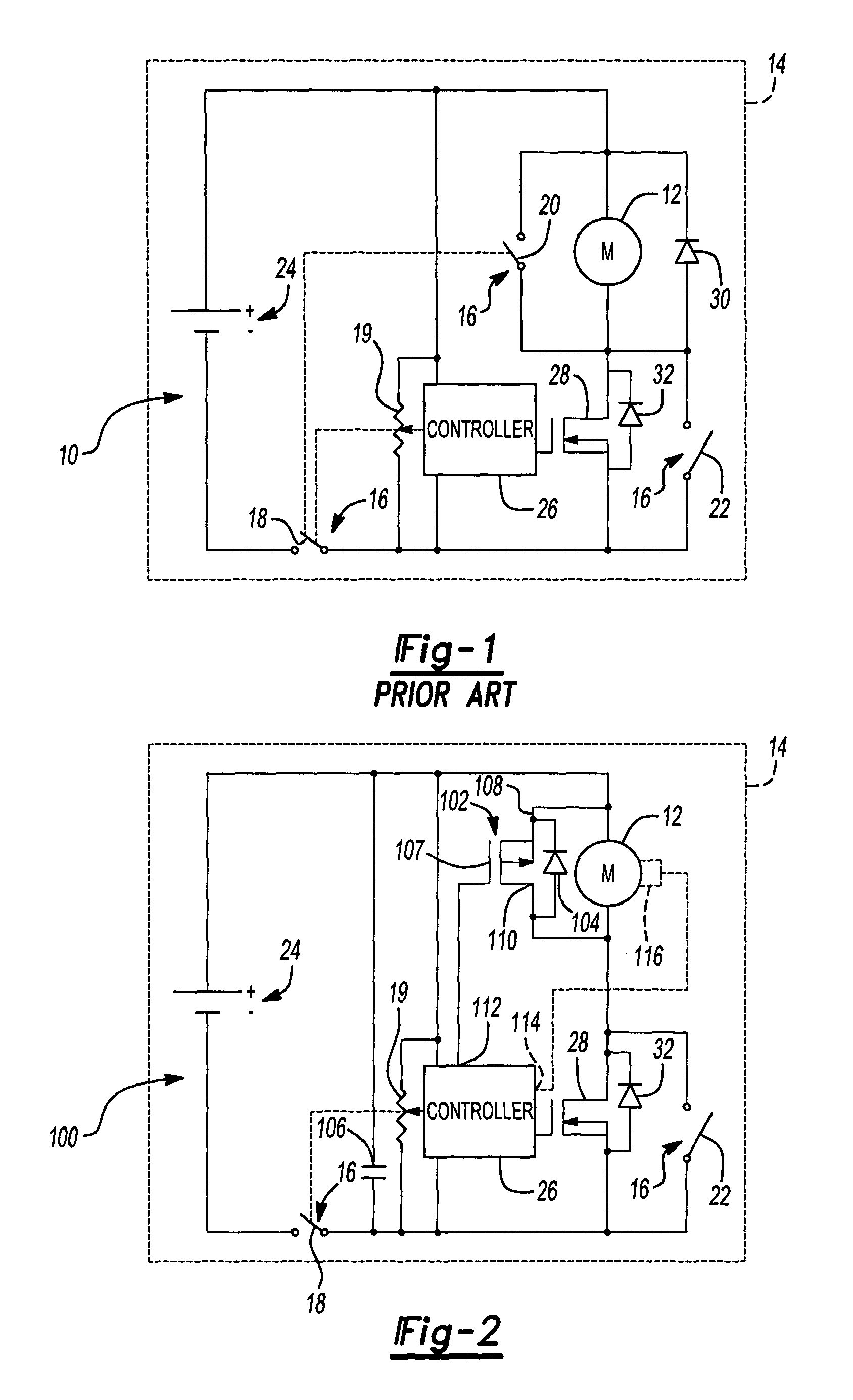

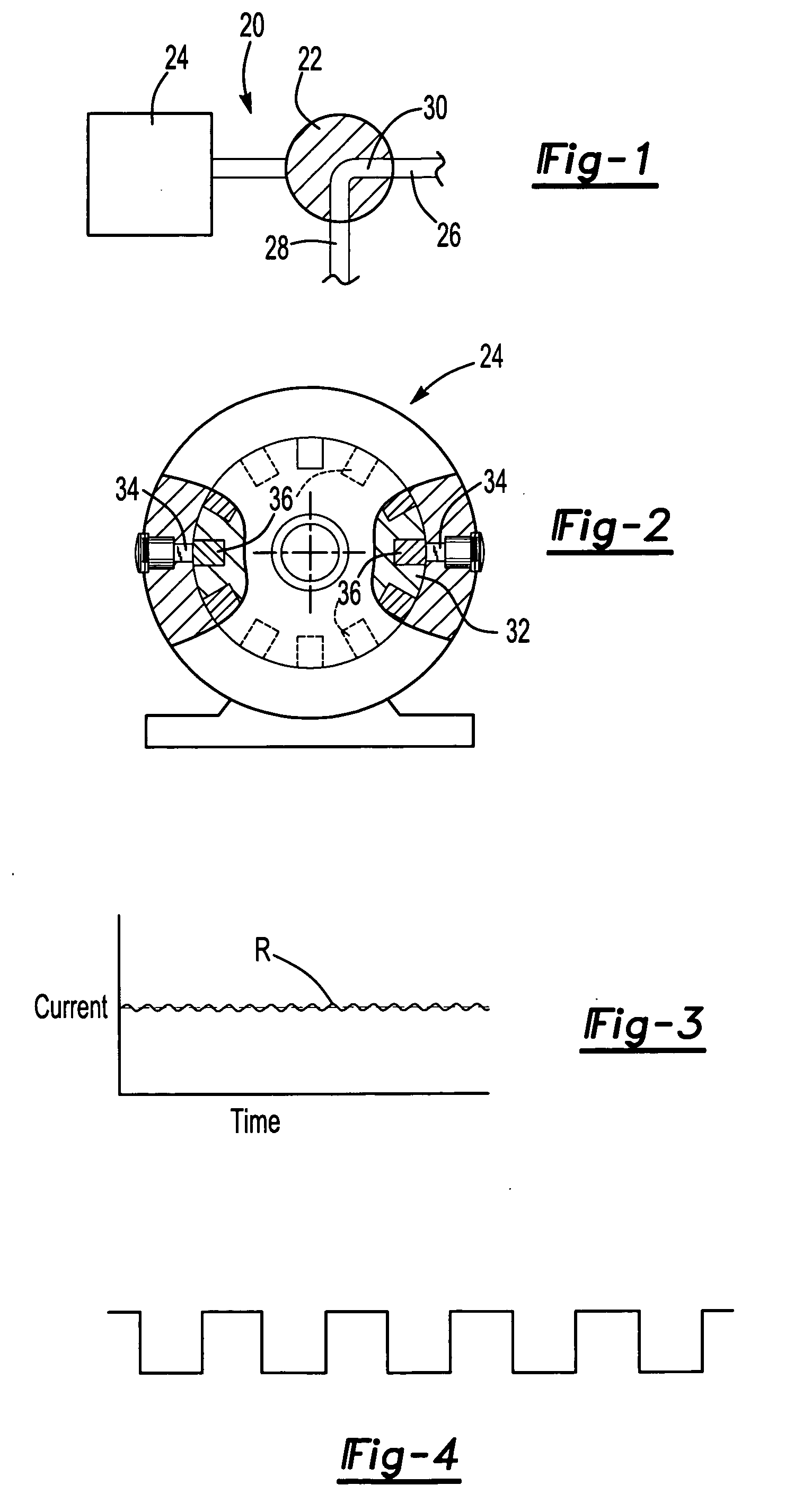

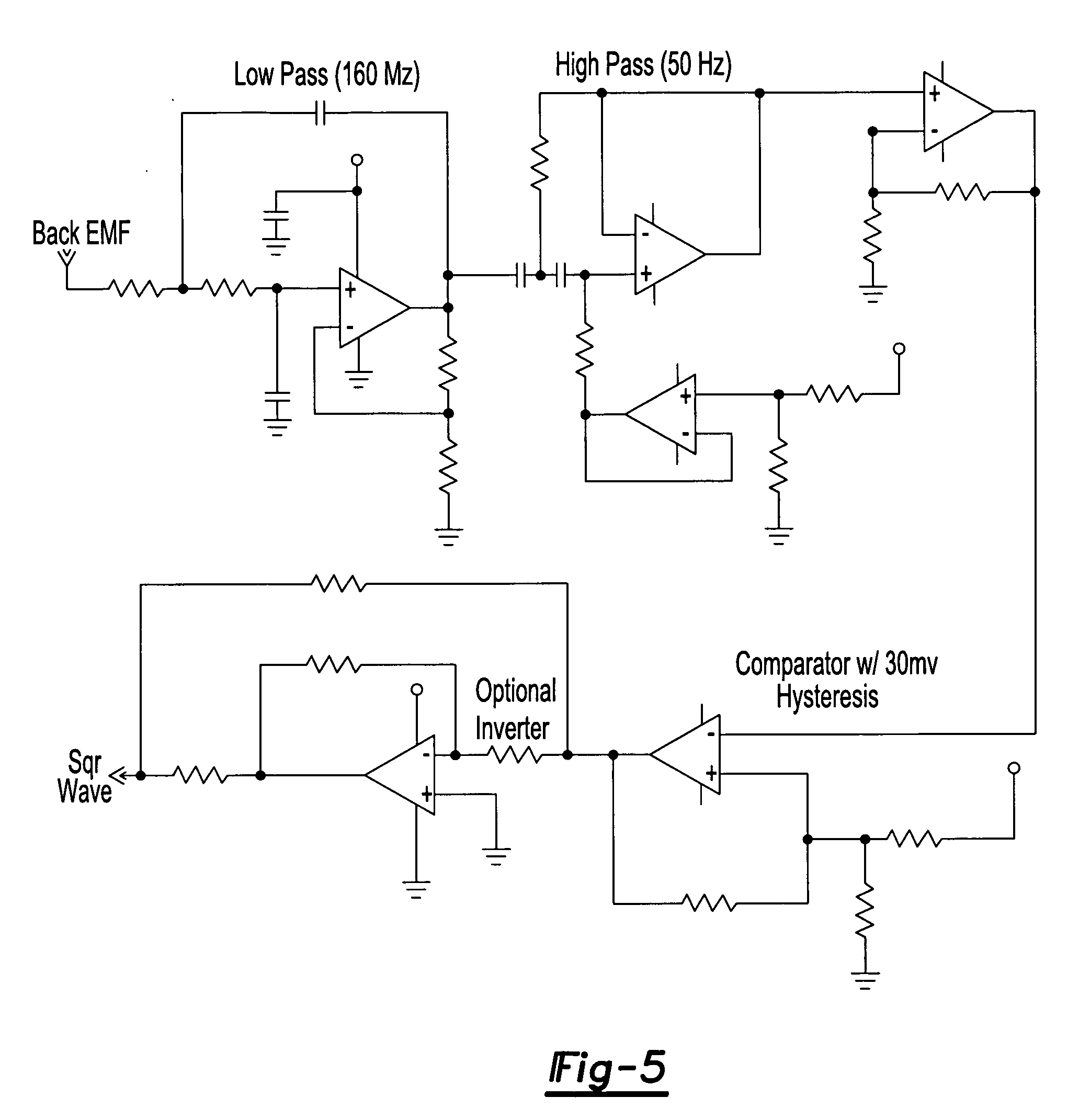

Brushed motor position control based upon back current detection

InactiveUS20060261763A1Exact numberStop preciseElectronic commutation motor controlMotor/generator/converter stoppersReverse currentEngineering

Owner:MASCO CORP

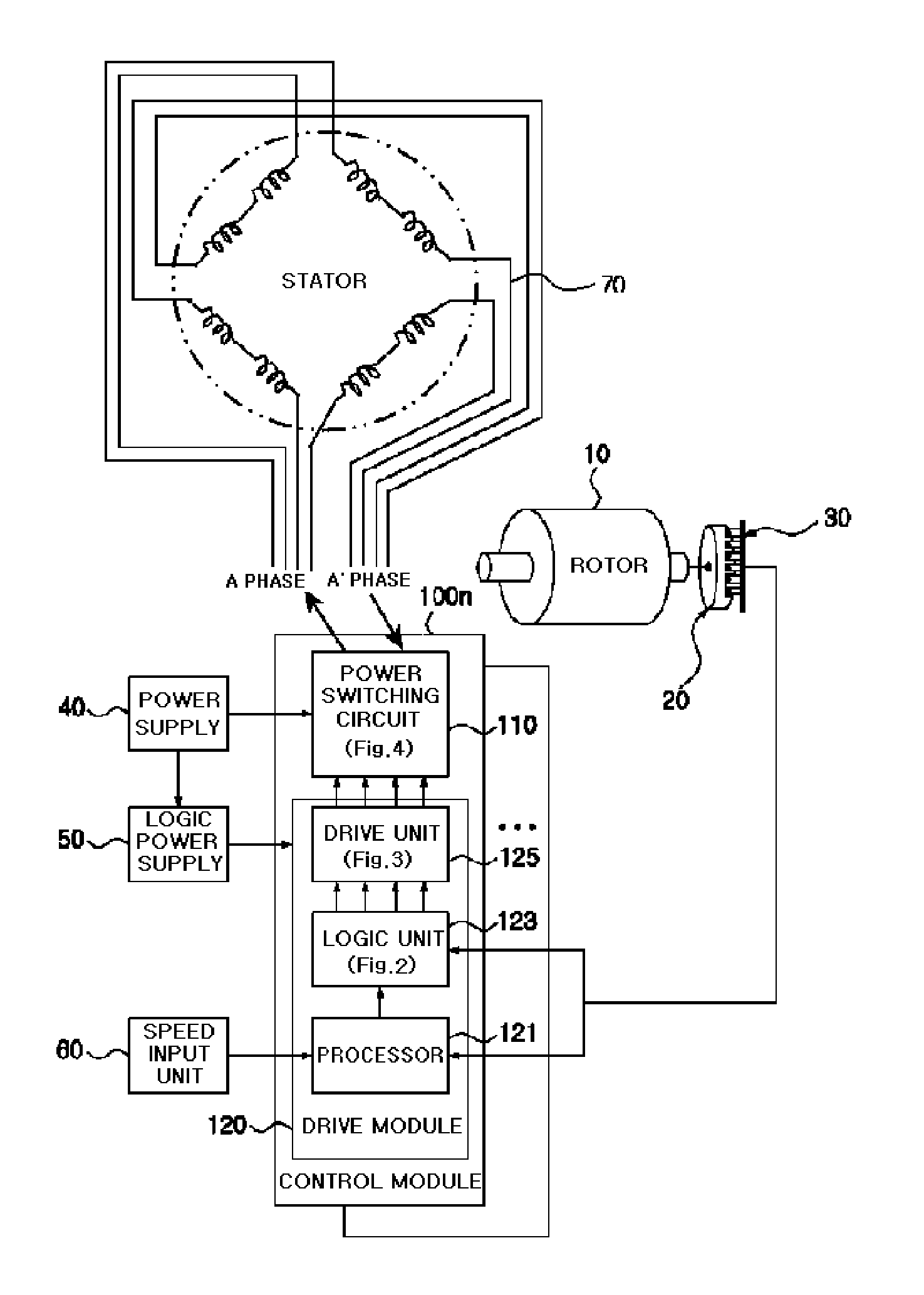

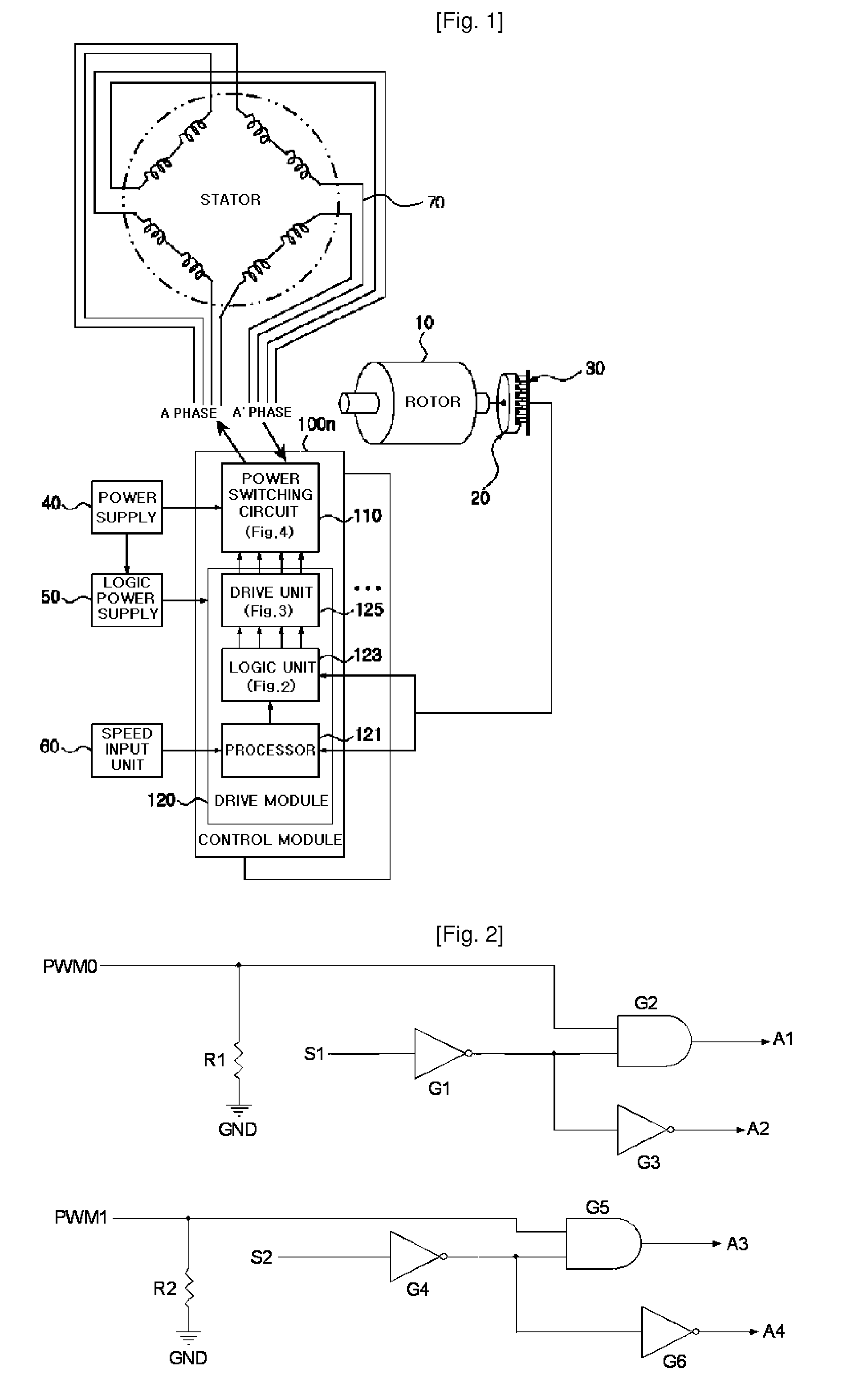

Apparatus and method for controlling hybrid motor

ActiveUS8228020B2Reduce capacityReduce electricity loadSingle-phase induction motor startersWindingsDriver circuitPower switching

An apparatus and method for controlling a hybrid motor, The hybrid motor, uses a permanent magnet instead of a field coil for a rotor, winds a coil round a stator in a multi-phase independent parallel manner, fixes a rectifying type encoder to the rotor and connects a sensor to a driving circuit. The apparatus comprises: an encoder attached to a rotor in cooperation with a pole sensor a speed input unit for generating a speed instruction signal a power switching circuit to generate motor driving signals; a drive module receiving the speed instruction signal and the sensor signal and outputting the speed instruction signal synchronized with the sensor signal as a driving motor signal; a power supply for applying a DC voltage to the power switching circuit; A logic power supply for converting the DC voltage into a logic voltage, and applying logic voltage to the drive module. The motor has n phases, n power switching circuits and n drive modules.

Owner:NAMYANG NEXMO CO LTD

Electric power steering apparatus and method of assembling the same

ActiveUS8102138B2Large massDC motor speed/torque controlElement comparisonElectricityElectric power steering

A motor control apparatus includes a steering column having inserted therein a steering shaft to which steering torque is transmitted, a reduction gear box coupled to the steering shaft, and an electric motor that transmits a steering assisting force to the steering shaft via a reduction mechanism in the reduction gear box. The electric motor and its control unit including a control board mounted with a control circuit, are provided side by side in the reduction gear box. A connection terminal of the electric motor is electrically connected to the control unit directly. This minimizes a connection distance between the control unit and the electric motor.

Owner:NSK LTD

Method and apparatus for controlling electronically commutated motor operating characteristics

InactiveUS6895176B2Operation controlSingle-phase induction motor startersAC motor controlBrushless motorsControl electronics

A permanent magnet DC brushless motor control assembly permits a user to select the permanent magnet DC brushless motor operating characteristics by selecting appropriate control circuits to interface with the motor. The assembly includes a permanent magnet DC brushless motor, a commutator electrically coupled to the motor, and at least one control module electrically coupled to the commutator, to control operating characteristics of the permanent magnet DC brushless motor.

Owner:REGAL BELOIT AMERICA

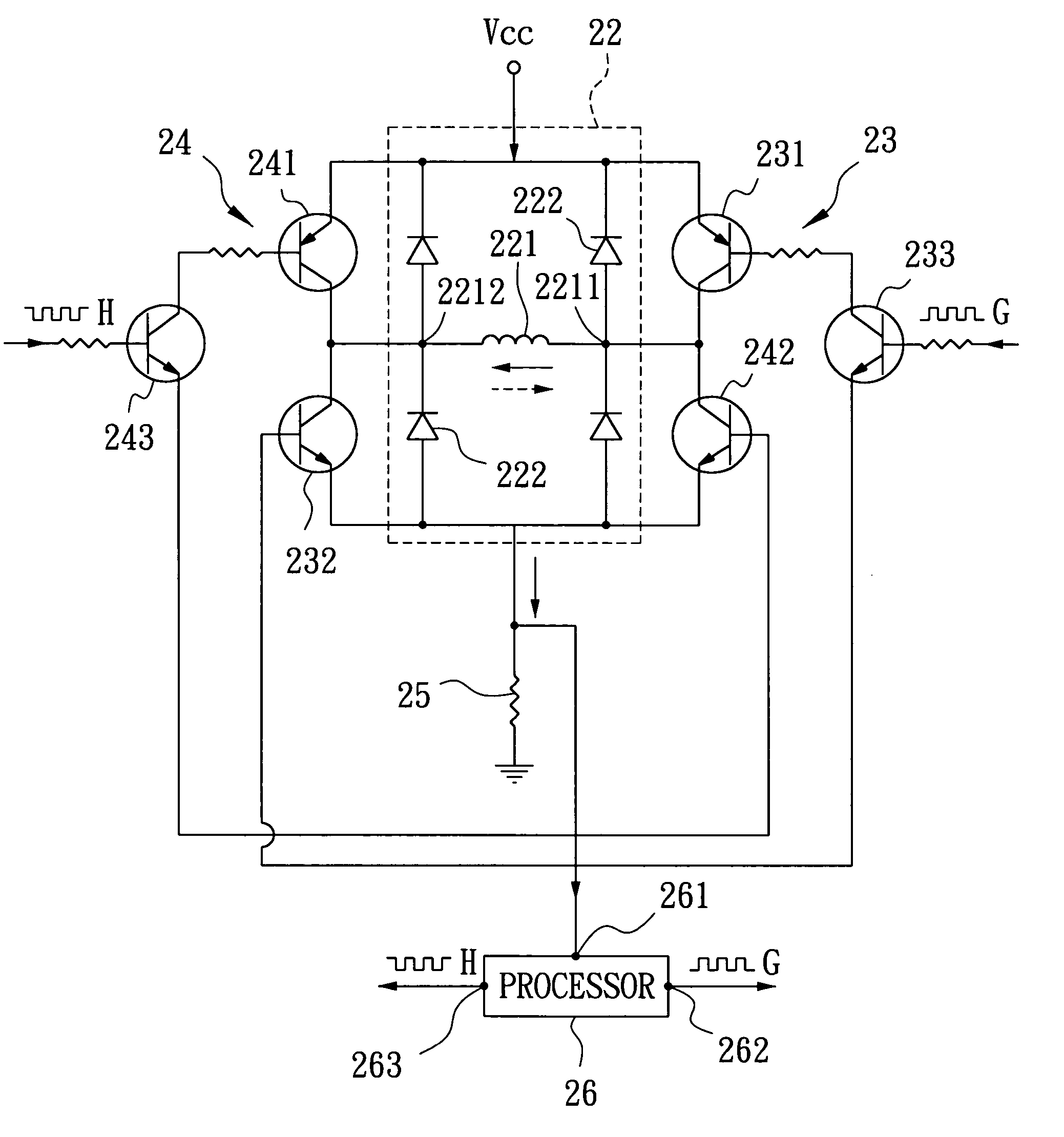

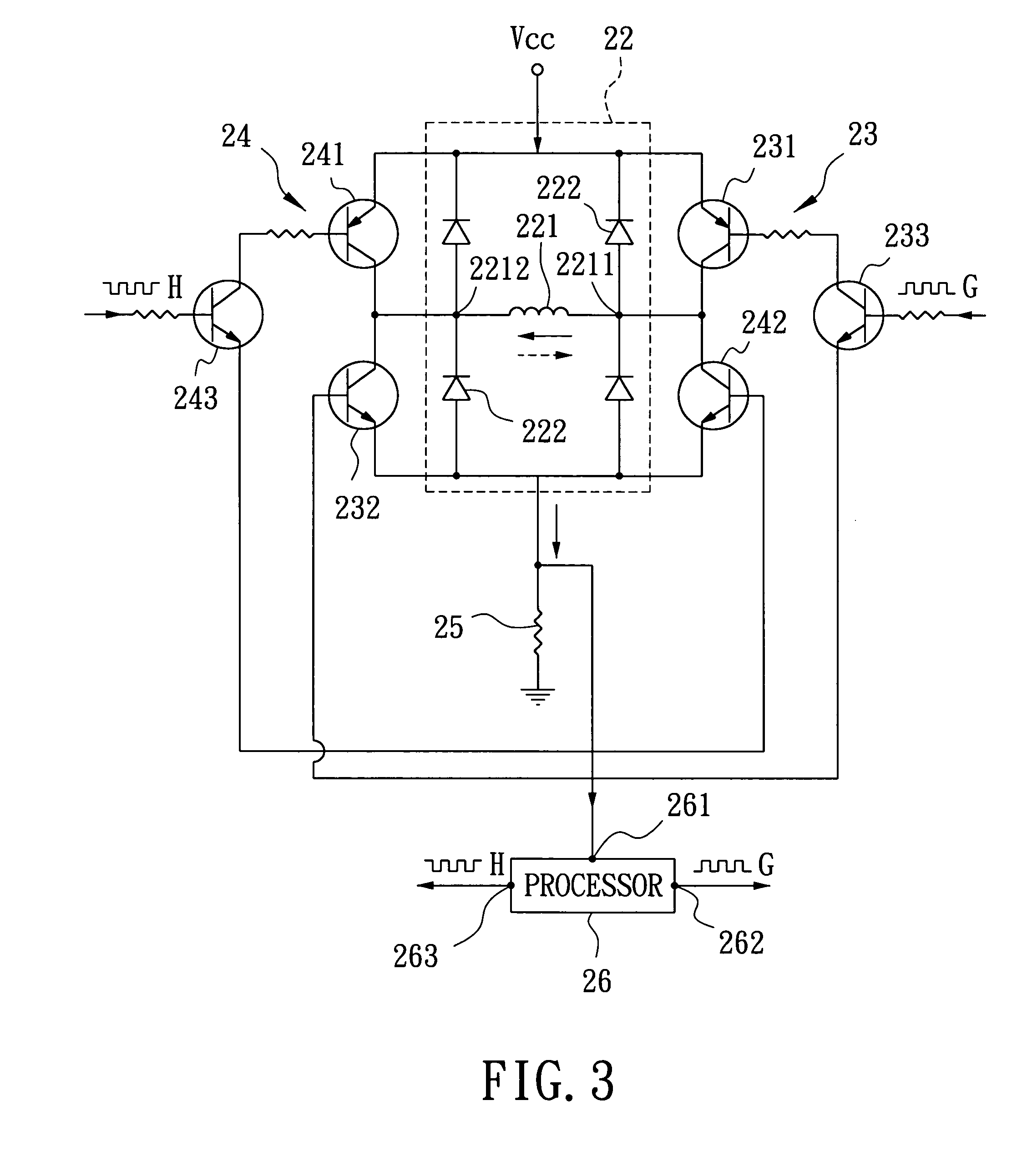

Motor controller

InactiveUS20070152612A1Accurate speed regulationAccurately control conduction and non-conduction of transistorsSingle motor speed/torque controlDynamo-electric converter controlElectricityVoltage drop

A motor controller includes a power source unit providing a direct current output, a drive unit including a drive coil, first and second transistor units, a voltage drop component, and a processor. The transistor units are coupled to the power source unit and the drive unit, and enable electricity to flow through the drive coil in a first direction when the first and the second transistor units are in conducting and non-conducting states respectively, and in an opposite second direction when the first and the second transistor units are in non-conducting and conducting states respectively. The voltage drop component has a first end coupled to the drive unit and a grounded second end. The processor is coupled to a junction of the drive unit and the voltage drop component, and provides first and second pulse-width-modulated signals to the first and second transistor units, respectively.

Owner:YEN SUN TECH CORP

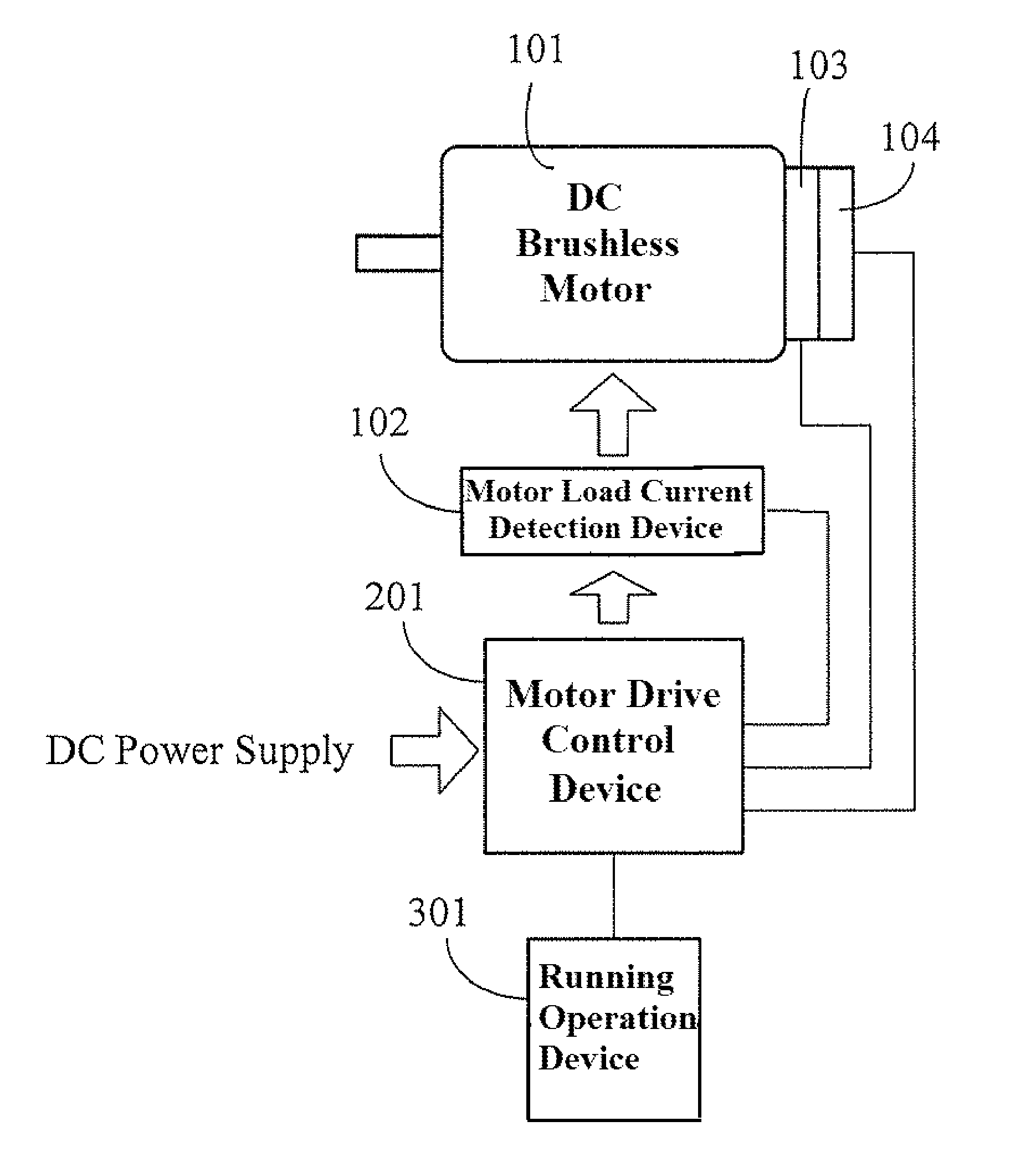

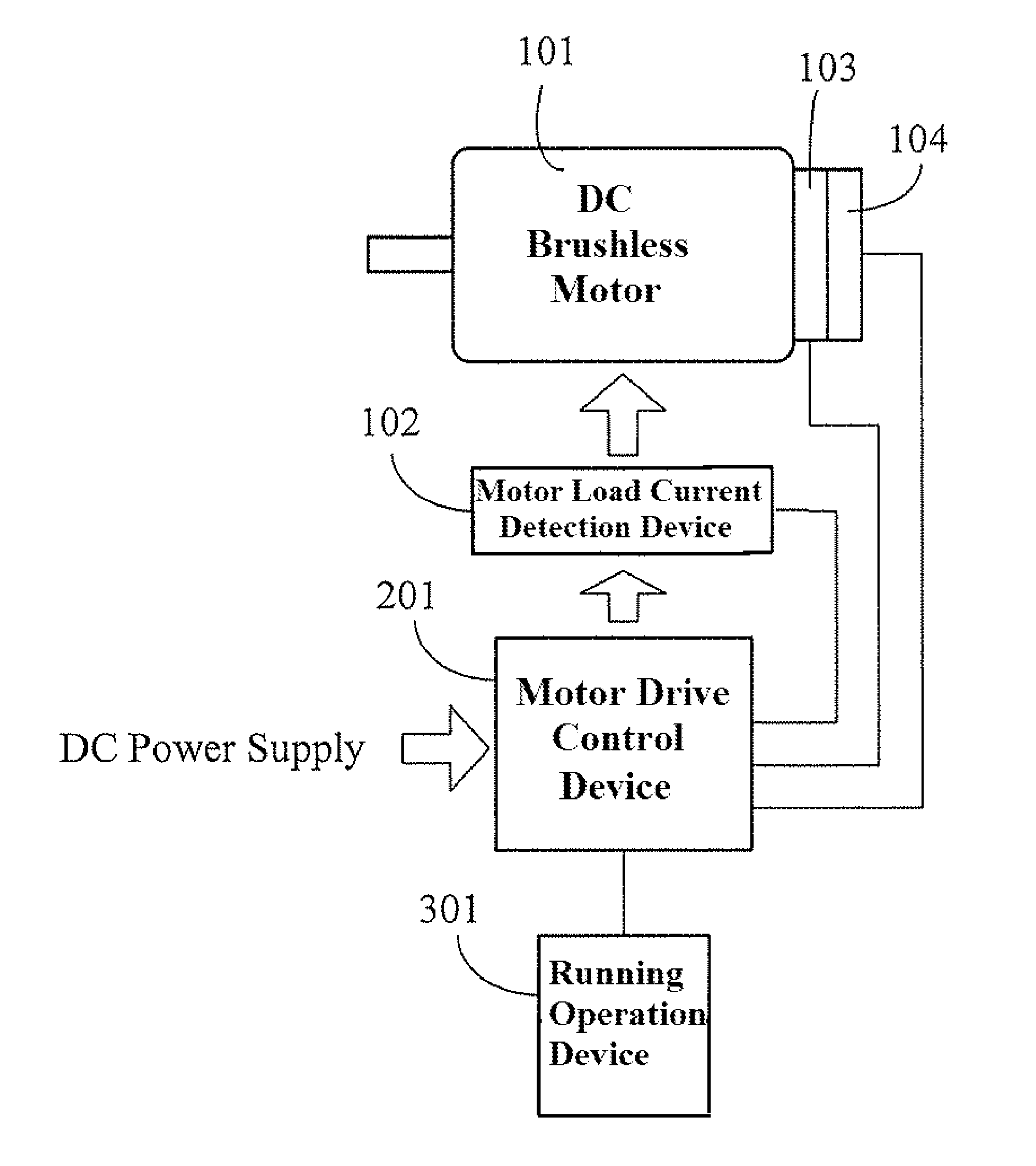

DC brushless motor drive circuit with speed variable-voltage

ActiveUS8288984B2Increase inputOvercome increased inductive impedanceTorque ripple controlMotor/generator/converter stoppersBrushless motorsMotor drive

For the present invention, under various running speeds statuses, the voltage supplied to the DC brushless motor is relatively increased or decreased on the basis of the internal setting of the motor drive control device according to the increased or decreased rotational output speed, so as to prevent the shortcoming of too much variation of the input impedance caused by the inductive reactance of the winding accordingly changed when the speed of the DC brushless motor is changed, specifically, to prevent the shortcoming of unable producing required torque resulting from the increased inductive reactance caused by increasing the rotational speed which makes the current value become too low when input by the original working voltage.

Owner:YANG TAI HER

Surgical stapling instrument comprising a magnetic element driver

In various embodiments, a surgical stapling instrument can comprise a plurality of magnetic elements configured to articulate an end effector of the surgical instrument. The surgical instrument can comprise at least one electromagnet which can be selectively activated, or polarized, to generate a magnetic field sufficient to motivate a second magnetic element, such as a permanent magnet and / or an iron core, for example, mounted to the end effector. In certain embodiments, a surgical stapling instrument can comprise a plurality of magnetic elements configured to open and / or close an end effector of the surgical instrument. In at least one embodiment, a surgical stapling instrument can comprise a plurality of magnetic elements configured to advance and / or retract a firing bar, cutting member, and / or staple sled within the surgical instrument in order to incise and / or staple tissue positioned within an end effector of the surgical instrument.

Owner:CILAG GMBH INT

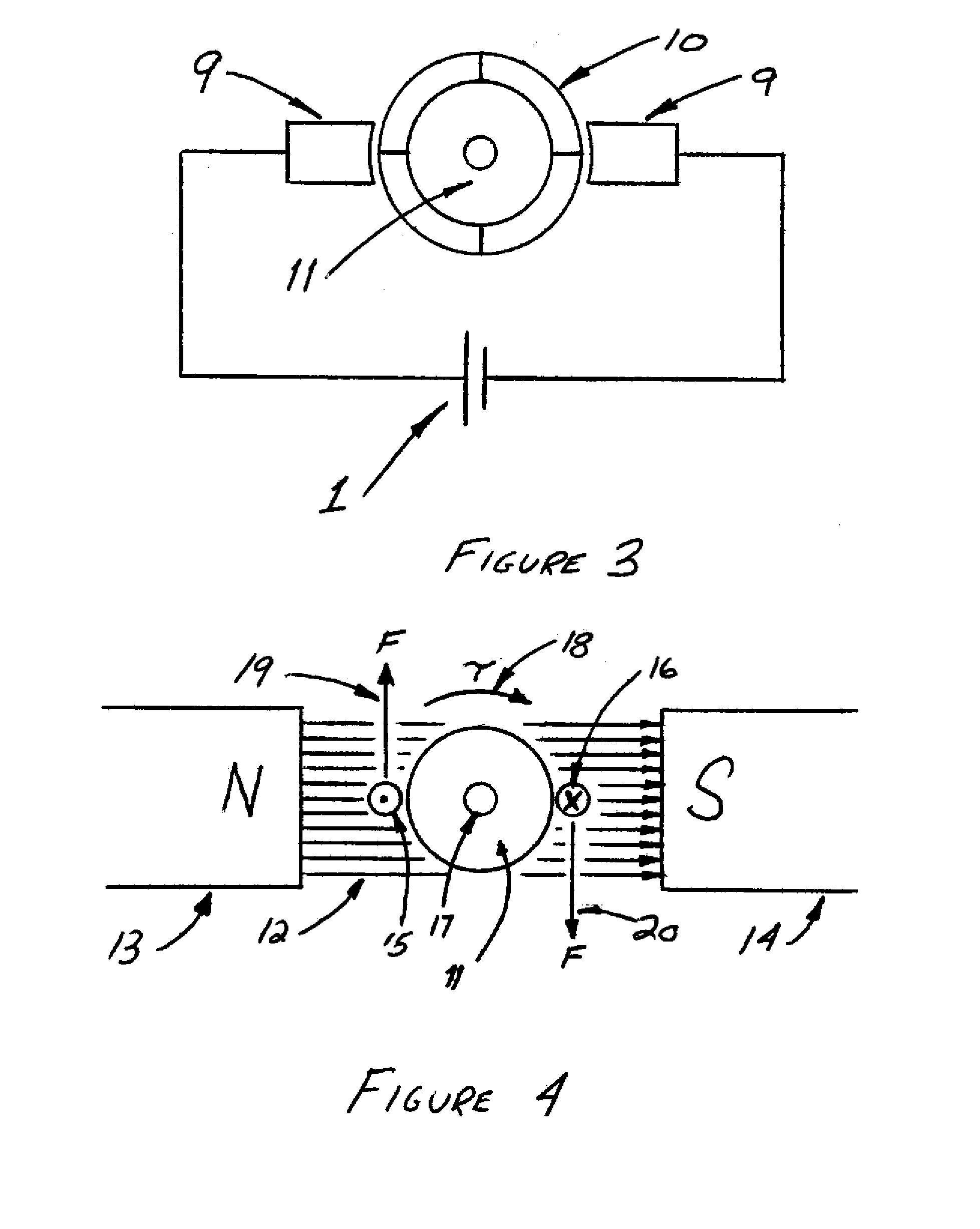

Method of Sensing Speed of Electric Motors and Generators

InactiveUS20080298784A1Simple and inexpensiveLow costMotor/generator/converter stoppersField or armature current controlMotor speedMotor control

A method and circuit for determining the speed and / or counting the revolutions of brush and commutator motors is described. The method and circuitry detects signals present on the windings of the motor due to commutation that occurs at the brushes and commutator of the motor. This method can be used to simply monitor & indicate the motor speed and revolutions or to form the basis of a motor control.

Owner:KASTNER MARK ALLEN

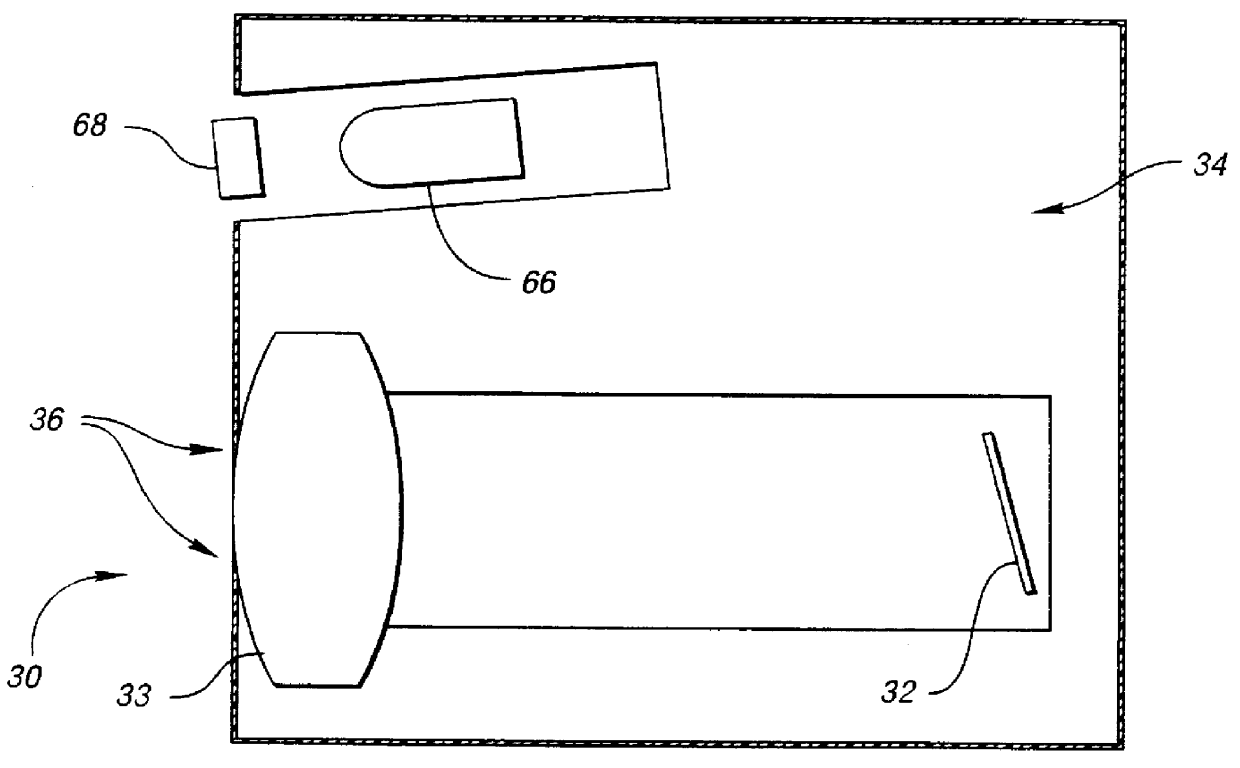

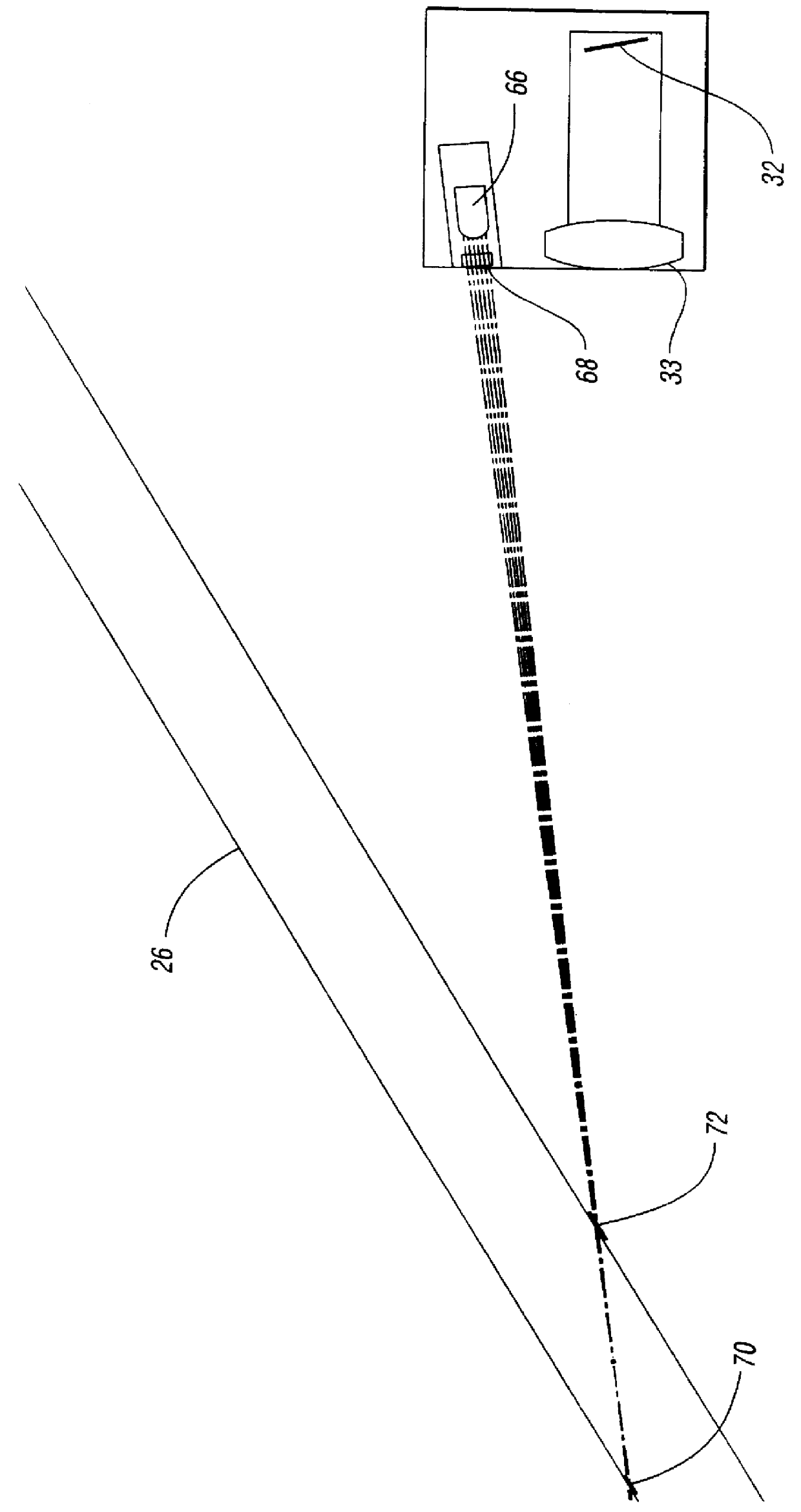

Moisture sensor and windshield fog detector

InactiveUS6097024AAutomatic detectionLower performance requirementsTelevision system detailsImage enhancementControl signalEngineering

A control system for automatically detecting moisture on the windshield of a vehicle. The automatic moisture detecting system includes an optical system for imaging a portion of the windshield on to an image array sensor, such as a CMOS active pixel sensor. The voltages of each of the pixels which represents the illumination level is converted to a corresponding gray scale value by an analog digital converter. The gray scale values corresponding to the image are stored in memory. The spatial frequency composition of the gray scale values are analyzed to determine the amount of rain present. In order to provide a control signal to control the operation of the windshield wipers of the vehicle as a function of the amount of moisture present. The system is also adapted to detect the level of fog both on the interior of the windshield as well as the exterior of the windshield. By providing a system for automatically detecting the presence of fog on the interior and exterior of the windshield, serious performance limitations of known automatic rain sensors are eliminated.

Owner:GENTEX CORP

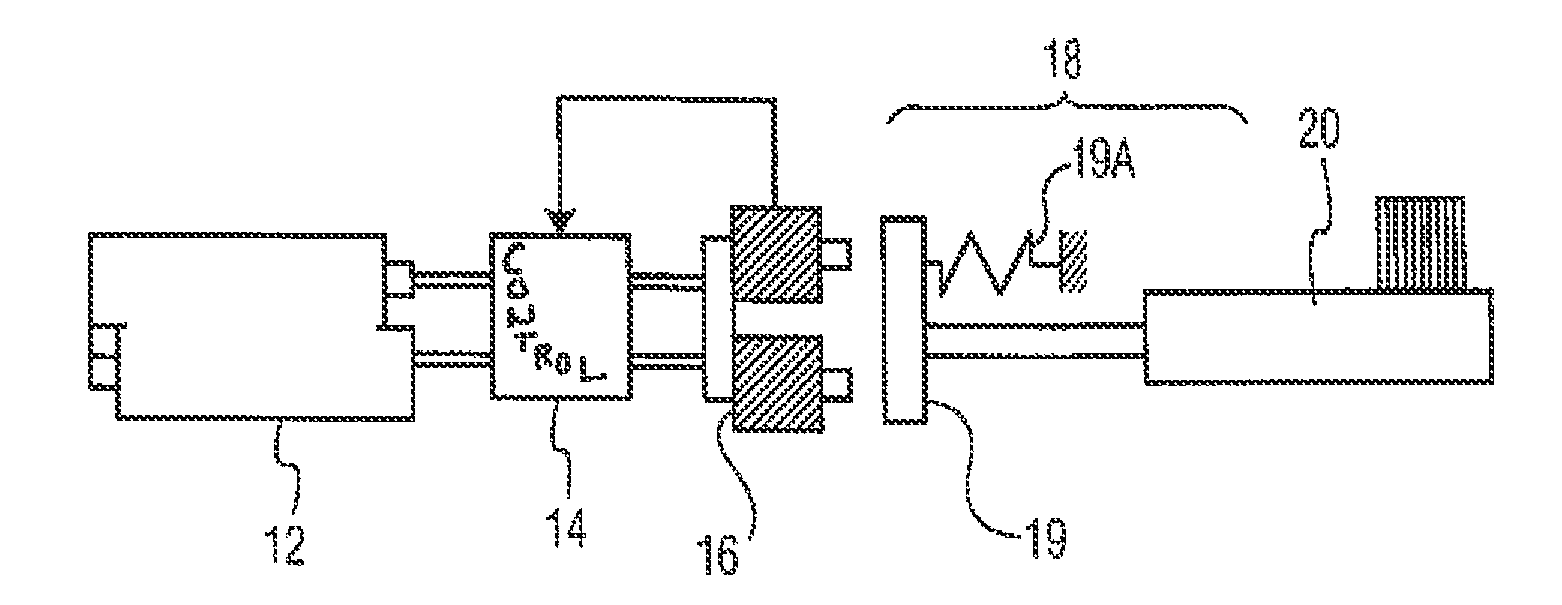

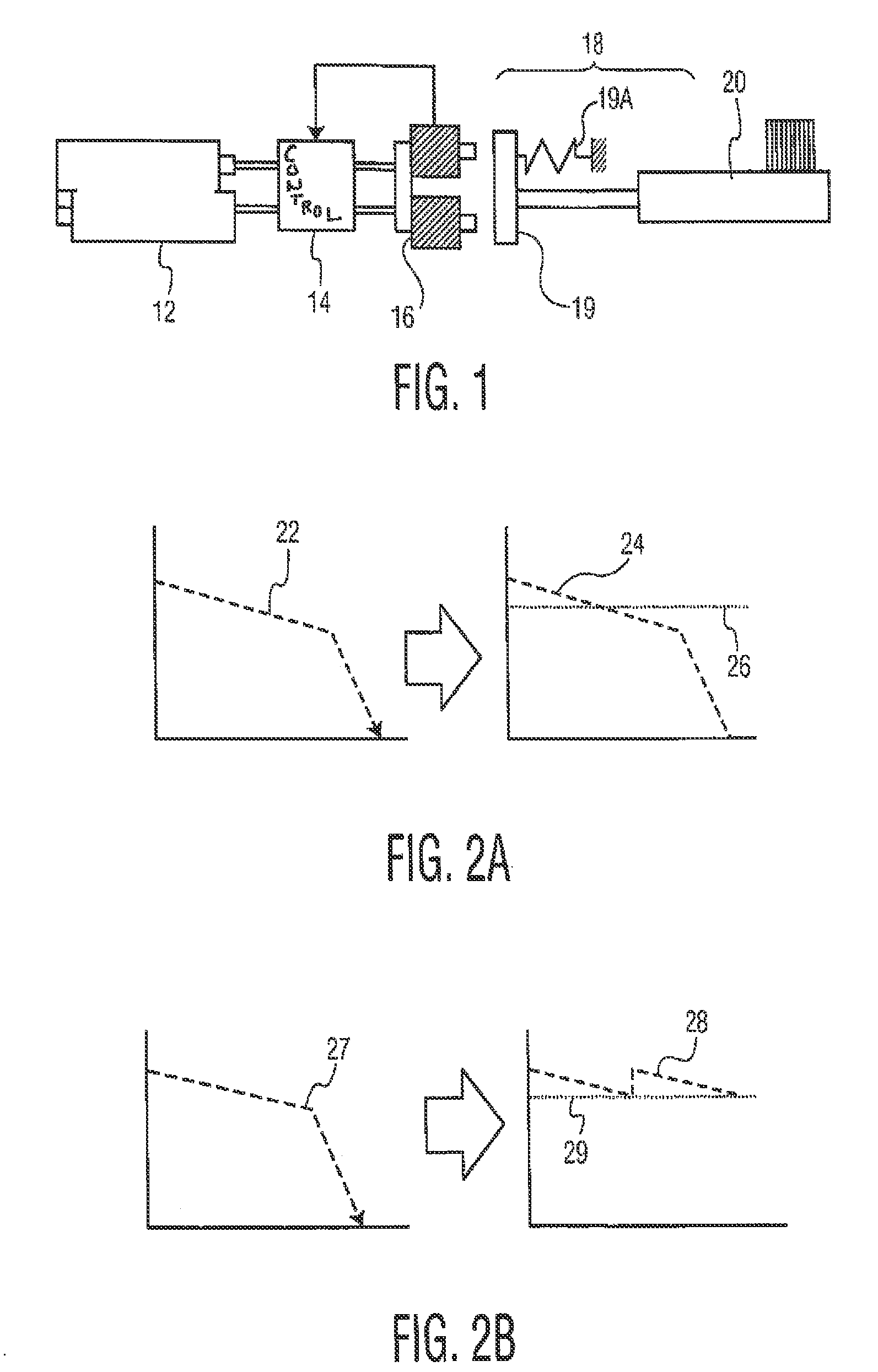

System and method for maintaining performance of battery-operated toothbrushes

ActiveUS8368327B2Maintain performanceIncrease range of motionMotor/generator/converter stoppersDC motor speed/torque controlVoltage dropEngineering

The system periodically measures the battery voltage of the toothbrush and the current in a stator portion of the motor for the appliance. The amplitude of movement of the toothbrush workpiece is determined from the measured stator current. A circuit / control program changes the duty cycle or pulse width of the drive signal from the motor if the battery voltage drops below a first threshold value and a circuit or control program changes the drive frequency of the appliance if the amplitude of the workpiece movement falls below a first threshold value. A circuit / control program terminates the operation of the toothbrush if the voltage drops below a second threshold value or if the amplitude drops below a second threshold value, both of which are less than the respective first thresholds.

Owner:KONINKLIJKE PHILIPS ELECTRONICS NV

Electrical hand tool machine with soft-start

An electrical hand tool machine (1) having a motor switch (2) configured as a button and a current regulator (4) disposed in the current circuit of an electrical motor (3), having a soft-start input (5), in whose branch current a timing capacitor (6) is arranged. A current-direction-dependent element (7) is arranged between the soft-start input (5) and the capacitor (6).

Owner:HILTI ELLSCHAFAT

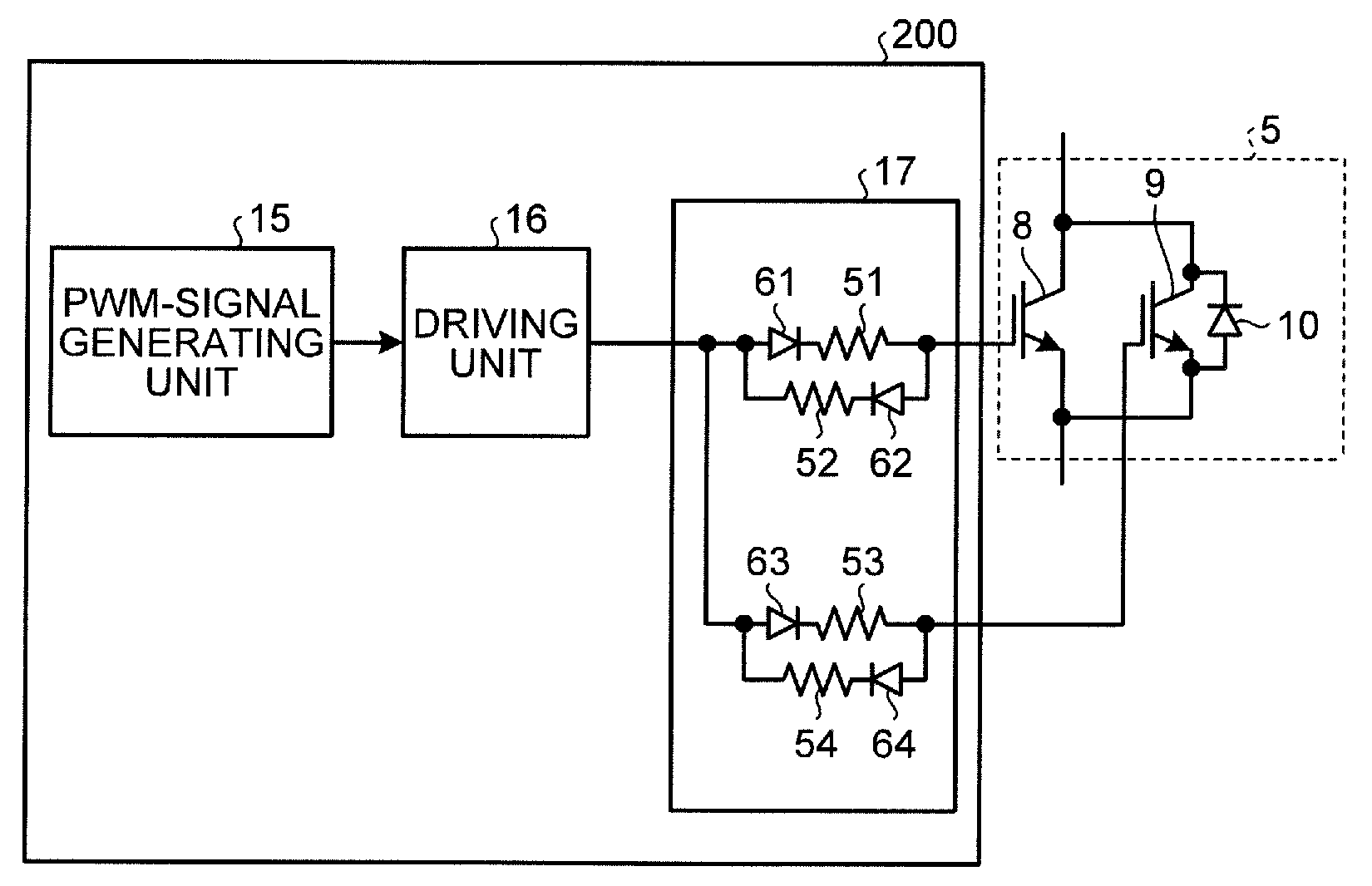

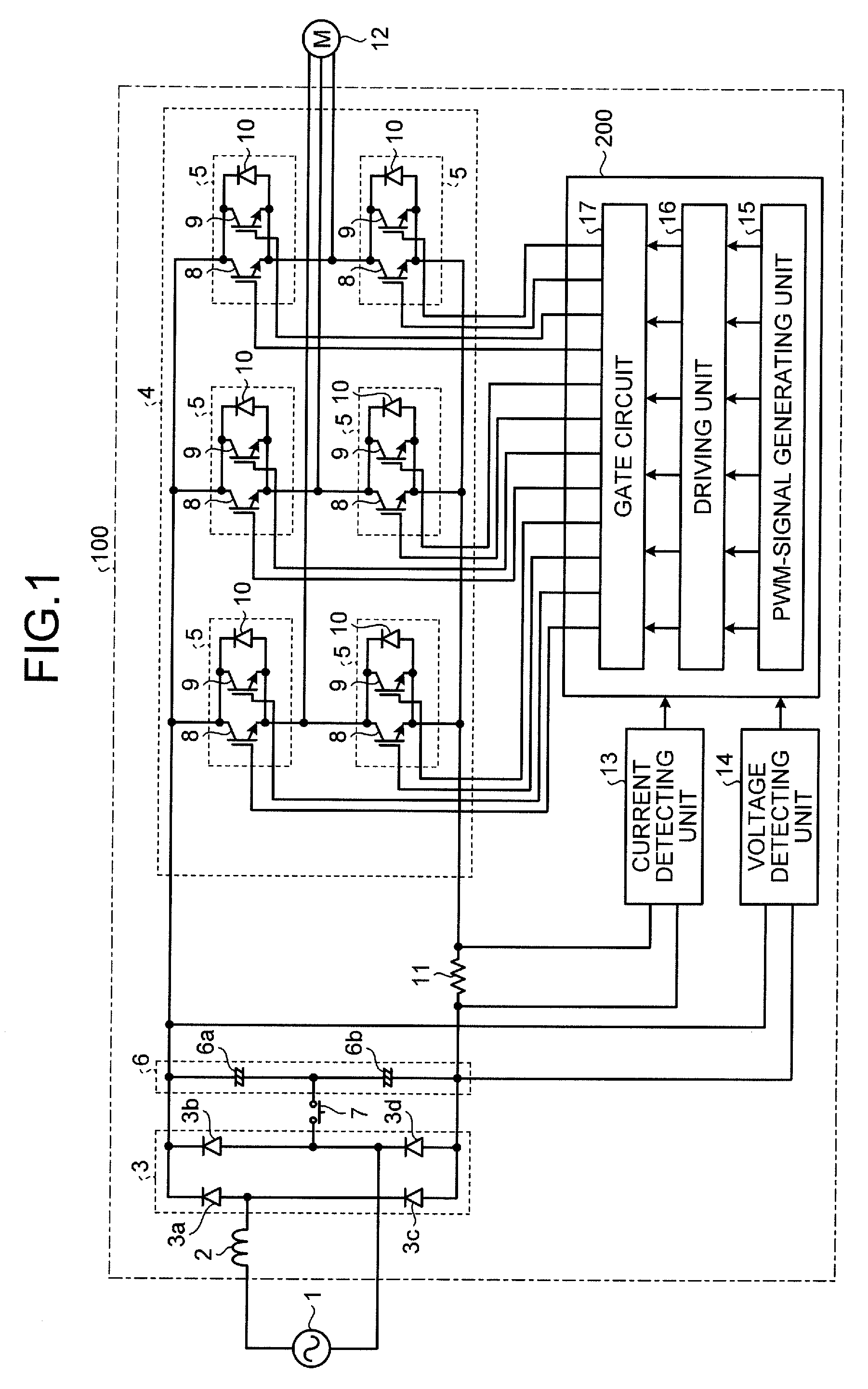

Inverter device and air conditioner including the same

Owner:MITSUBISHI ELECTRIC CORP

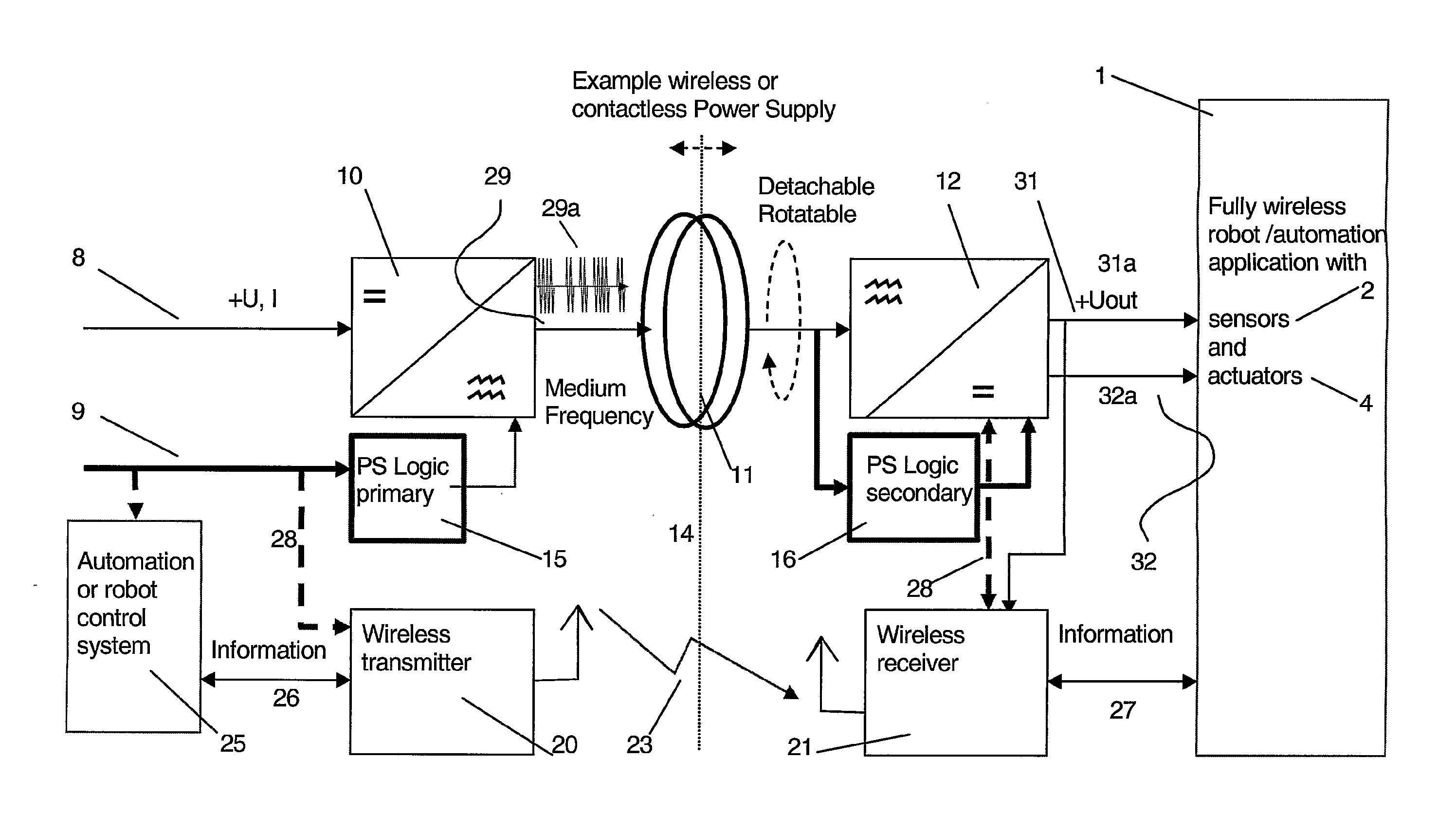

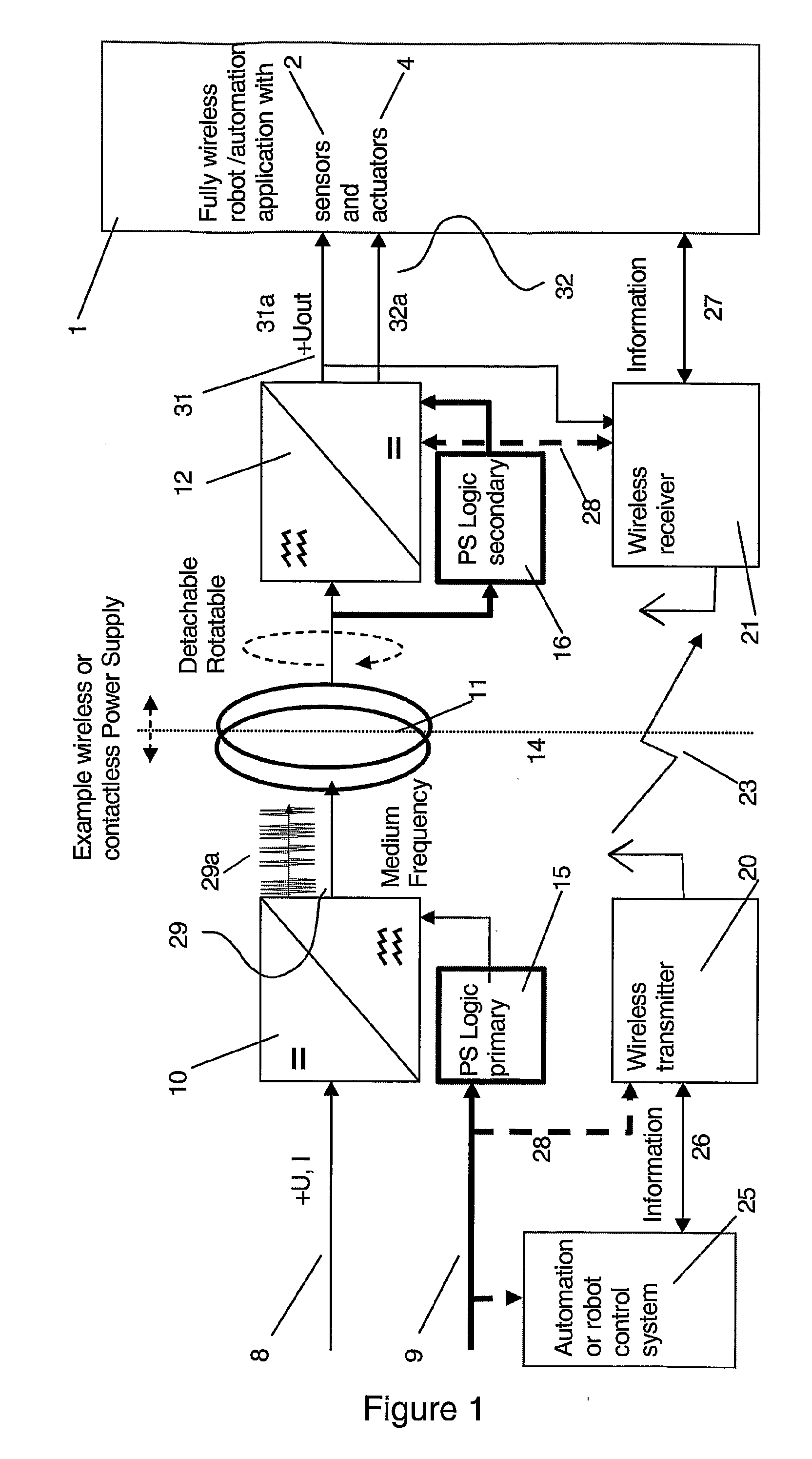

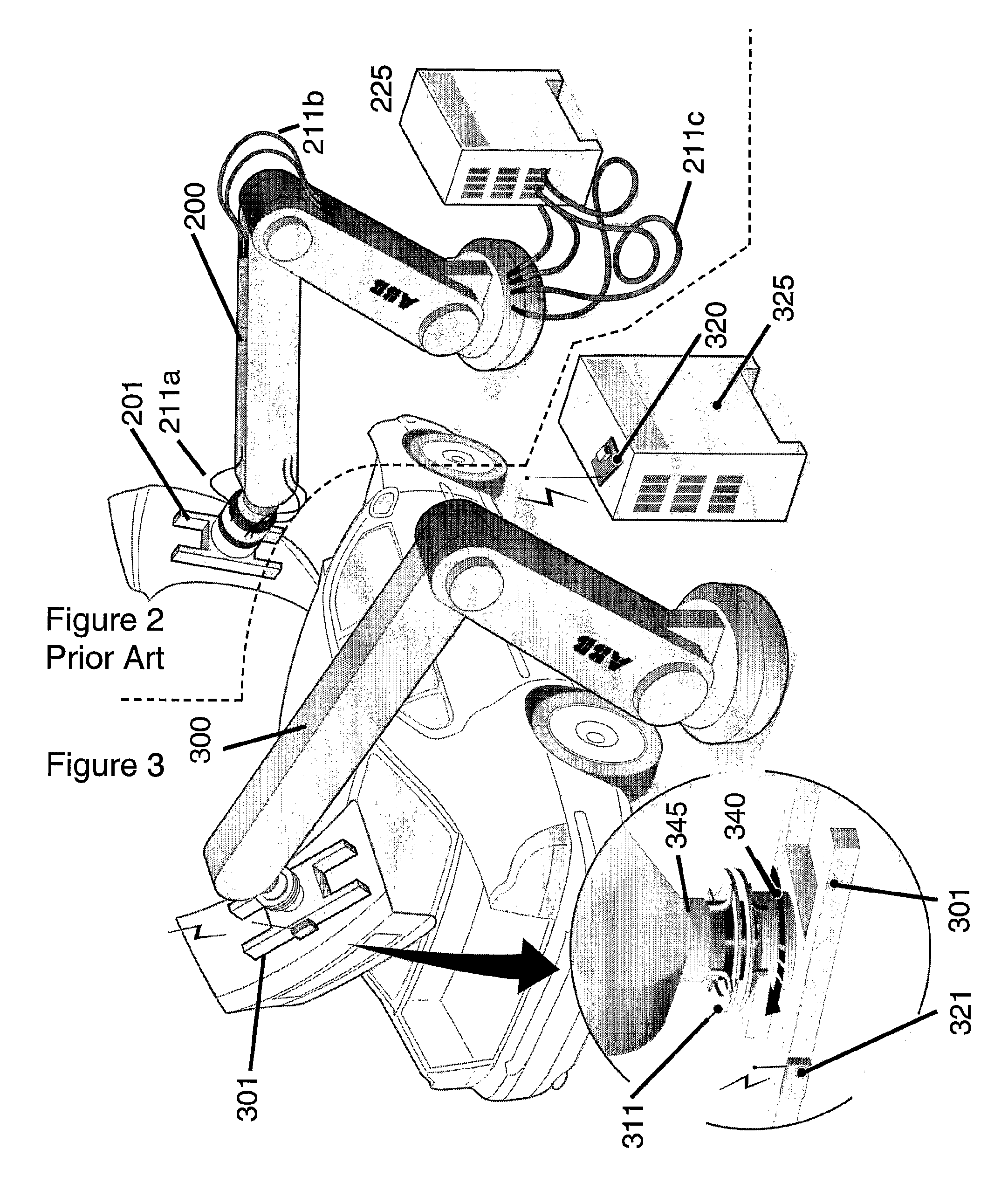

Tool for an Industrial Robot

InactiveUS20070276538A1Speeding up changeReduce downtimeSingle-phase induction motor startersProgramme-controlled manipulatorWireless controlIndustrial robotics

A robot or manipulator including a wireless power supply and a wireless communication device. One or more actuators on the robot tool may be wirelessly powered and wirelessly controlled. The robot tool may have one or more wireless communication members for transmission of data from sensors on the tool. The power supply includes a primary power supply member and secondary power supply member. Tool changes may be carried out automatically by the robot. In other aspects of the invention a method, a control system and a computer program for carrying out the method are described.

Owner:ABB RES LTD

Popular searches

Dynamo-electric brakes/clutches Piezoelectric/electrostriction/magnetostriction machines Joint implants Staples Electric motor speed/torque regulation Mechanical energy handling Dynamo-electric brake control Electric/dynamo-electric converter starters Surgical staples Synchronous machines with stationary armatures and rotating magnets

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com