Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

7384 results about "Vibration motor" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

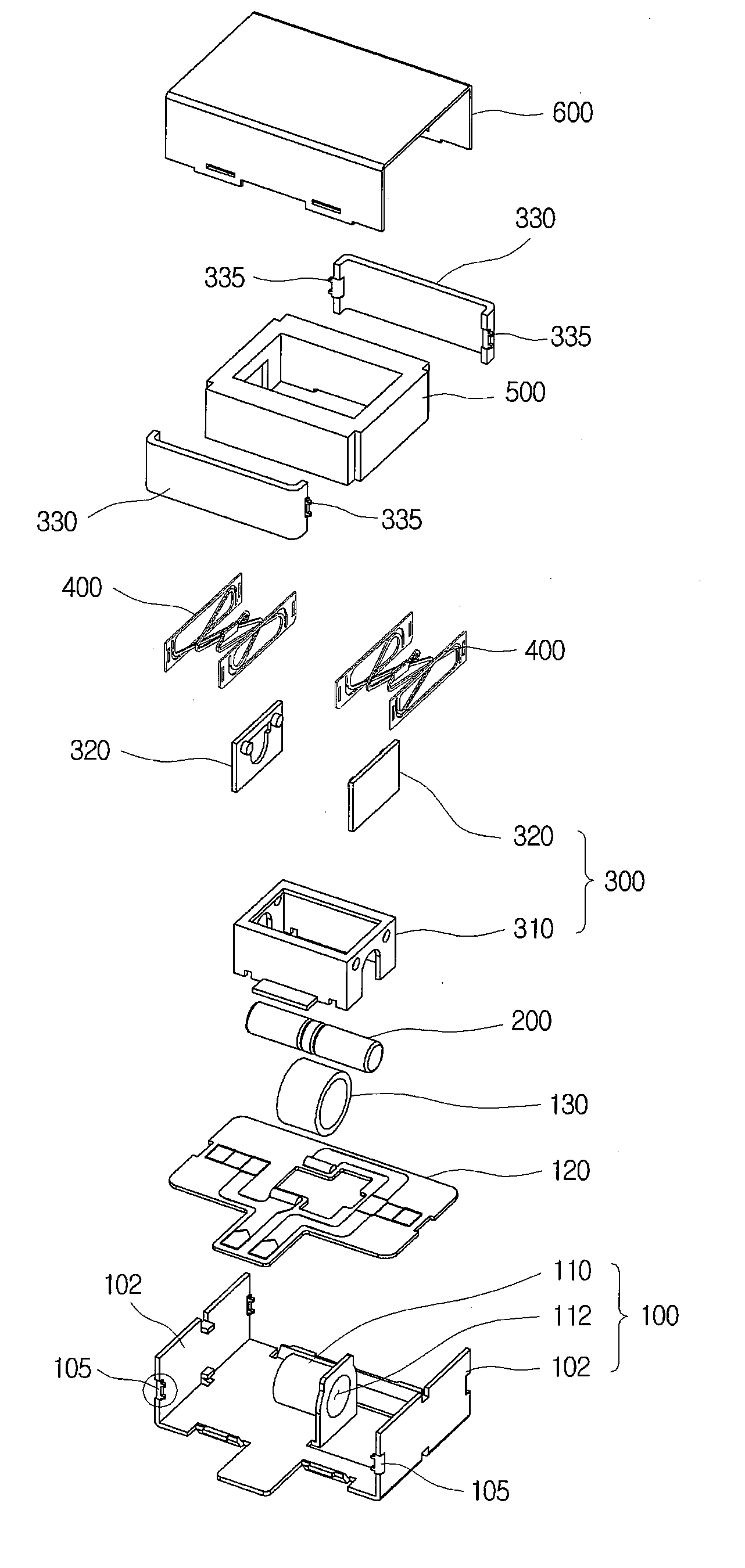

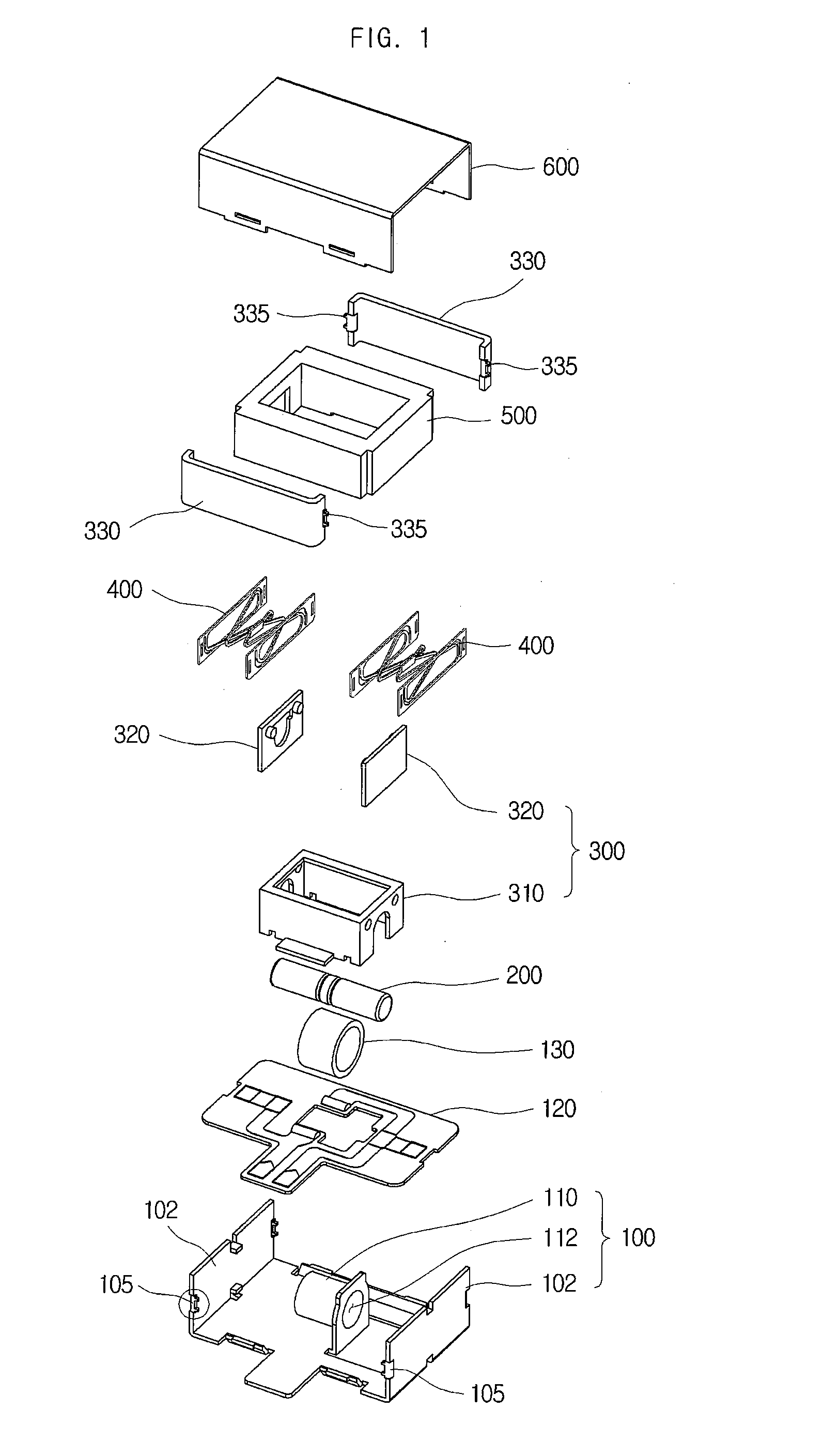

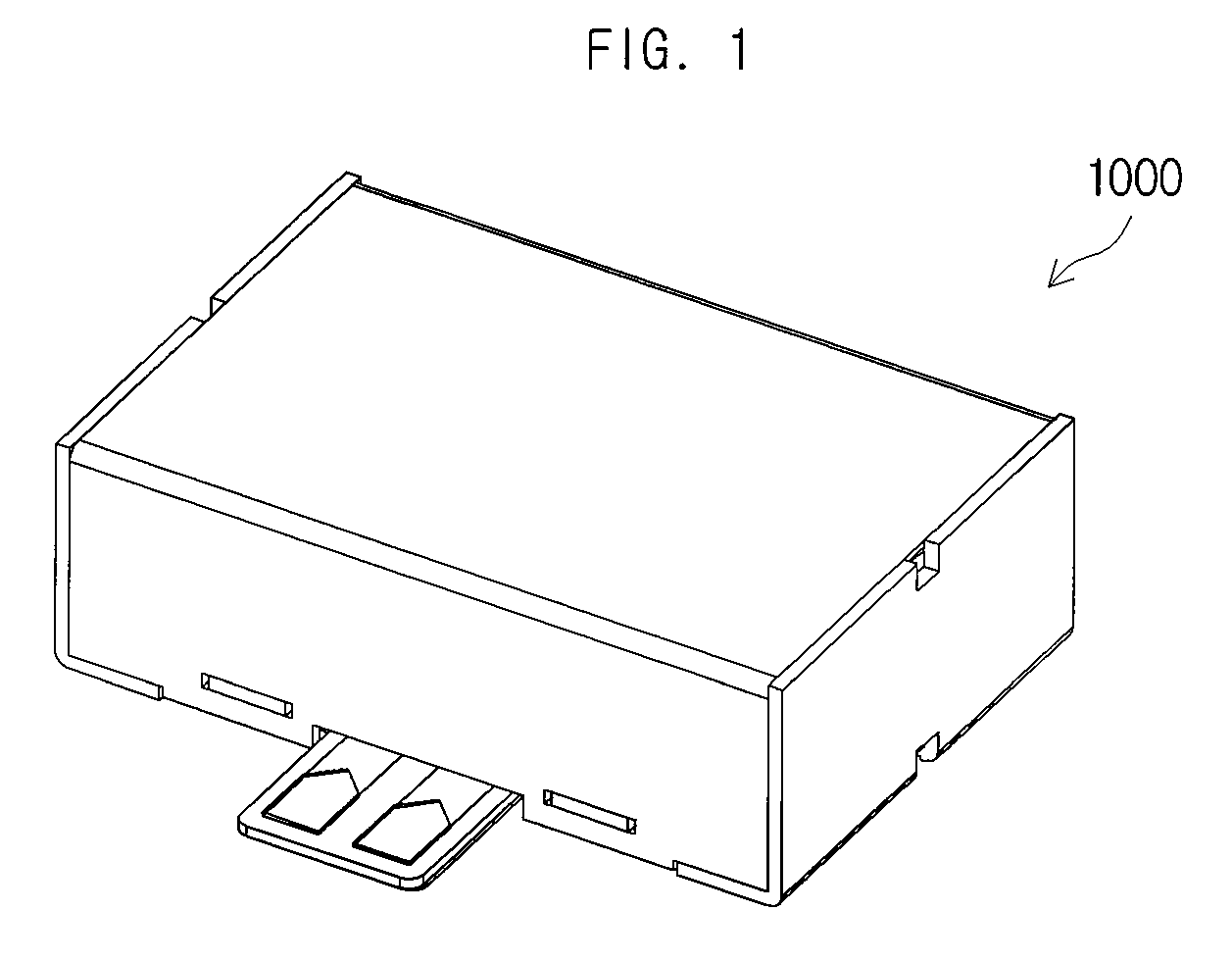

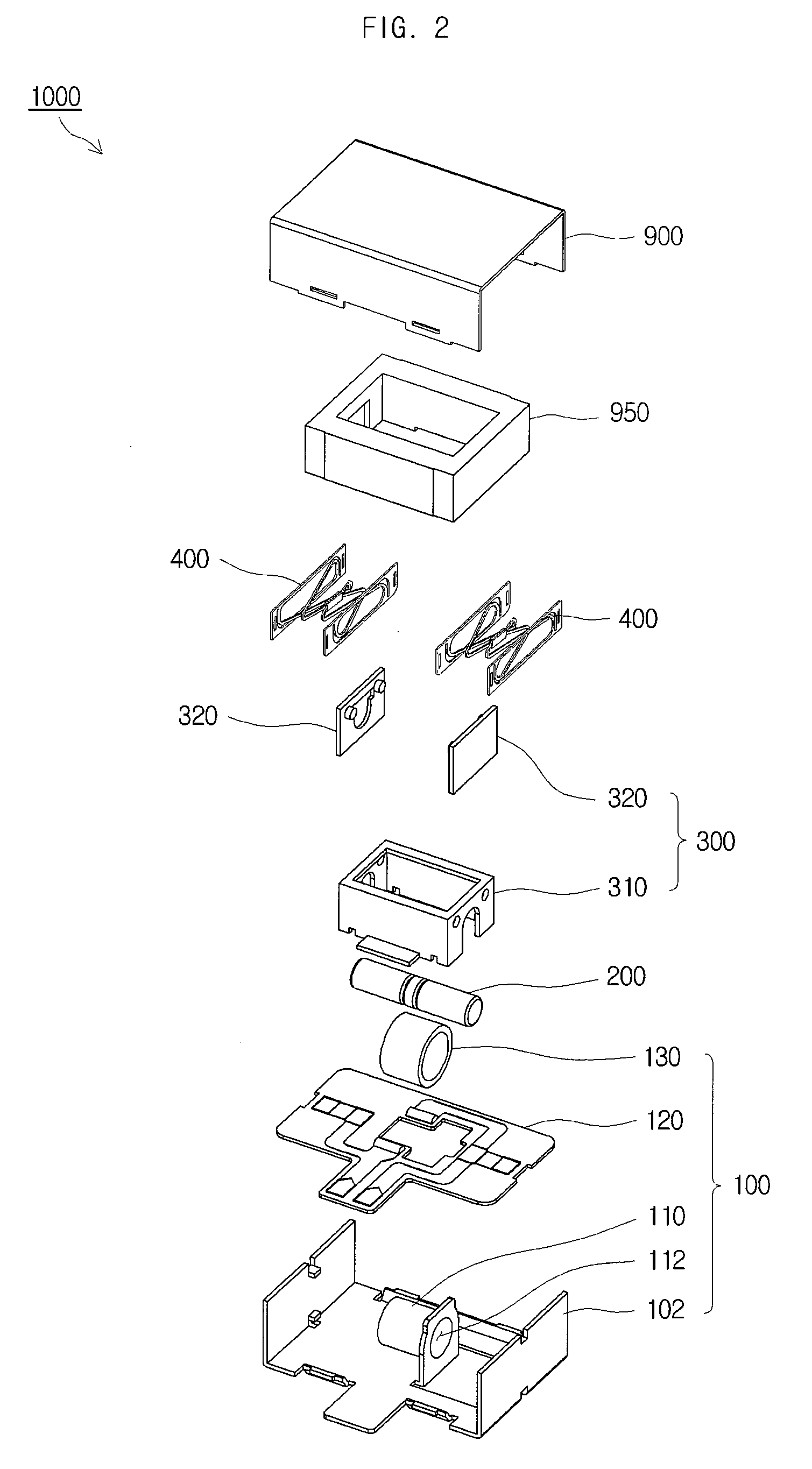

Flat type vibration motor

InactiveUS8227946B2Increase connection forceReduce noiseMechanical energy handlingSupports/enclosures/casingsElectricityEngineering

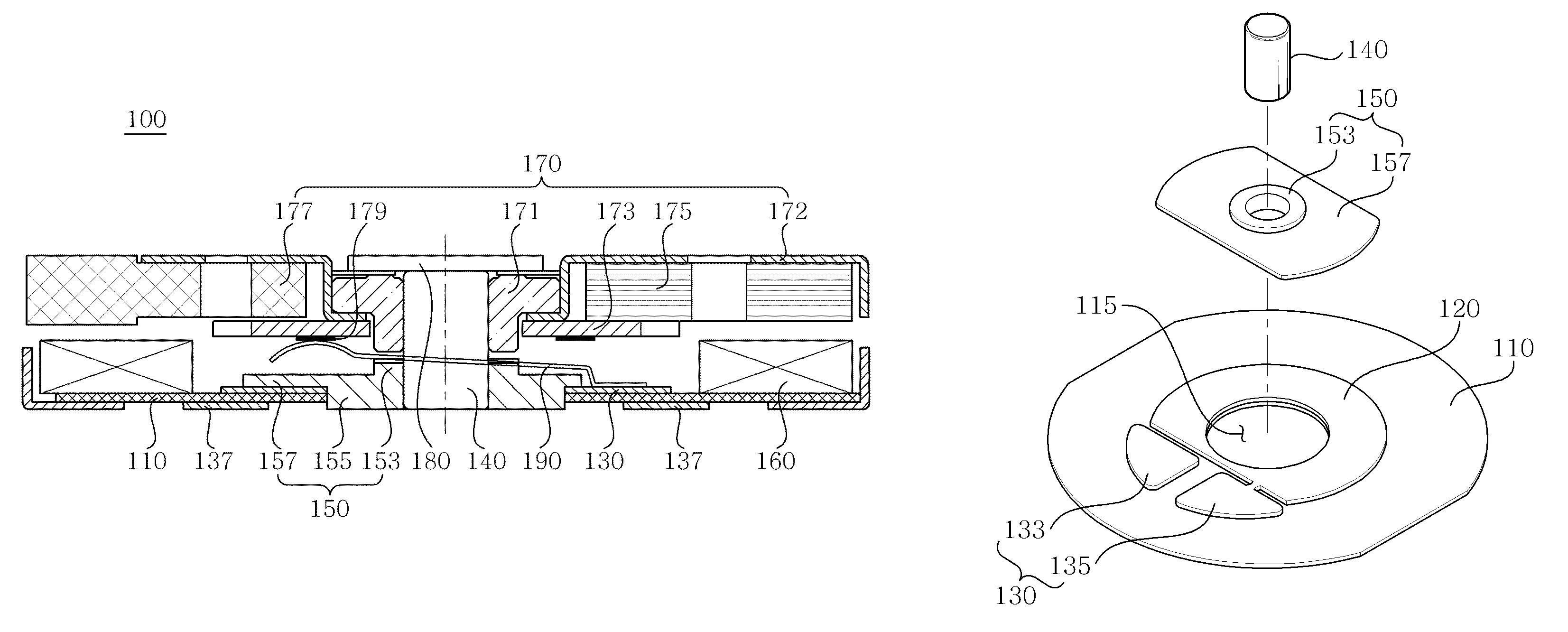

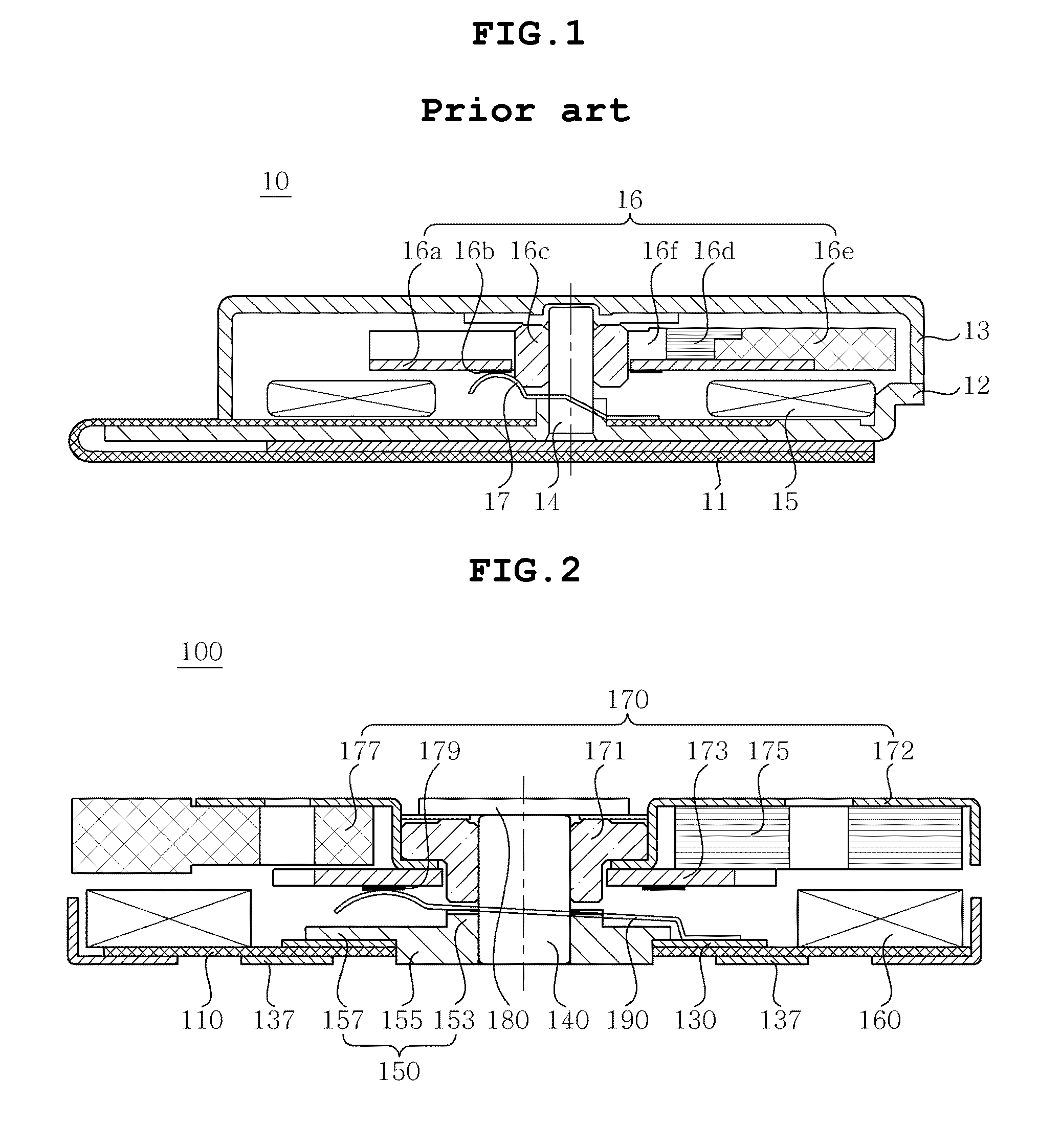

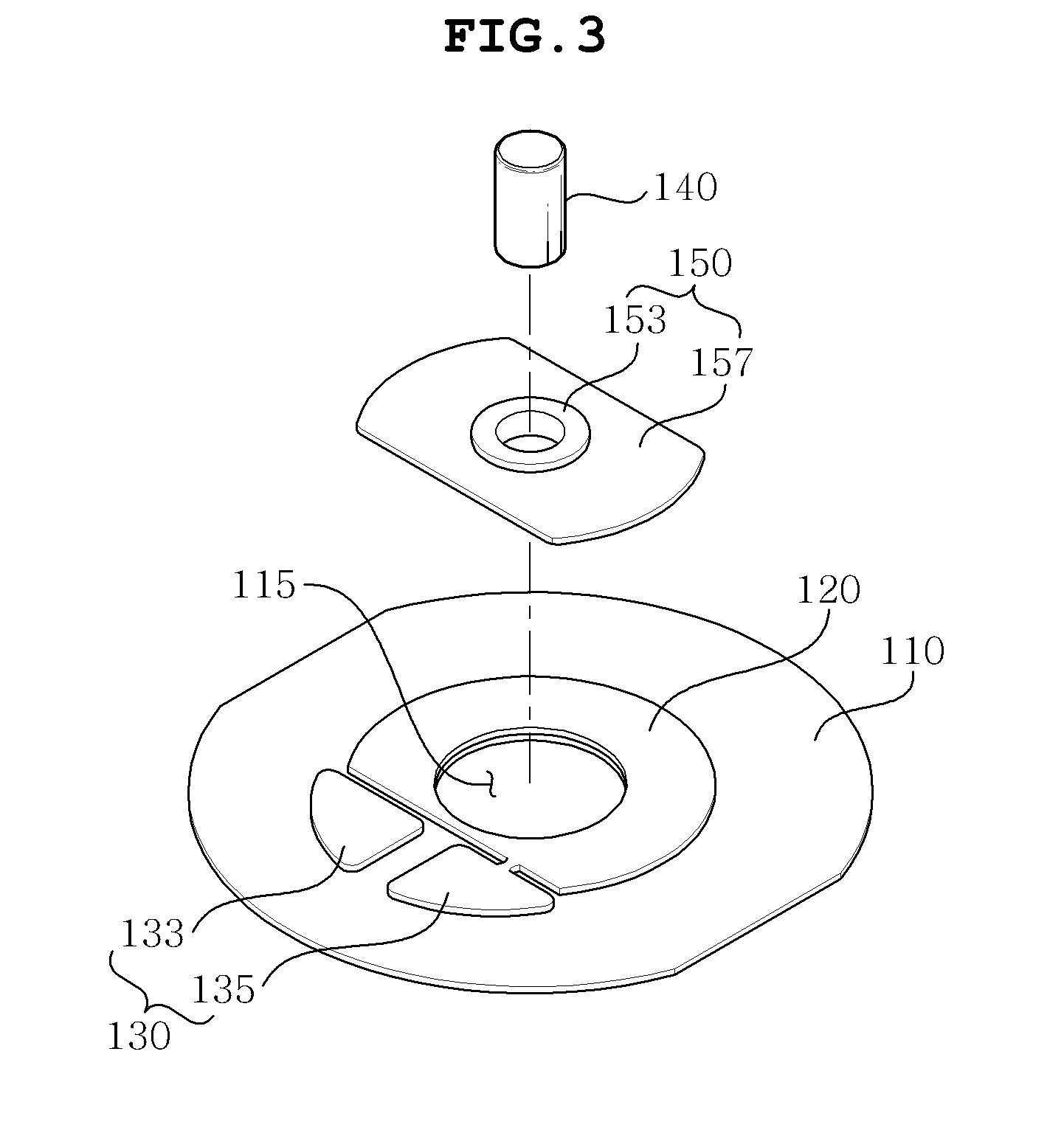

There is provided a flat type vibration motor 100 that includes a bracket 150 with a shaft 140 of which one end is inserted into and fixed to the center thereof, a printed circuit board 110 having a terminal portion 130 receiving external electricity and disposed on the side of the bracket 150, a stator disposed on the top of the printed circuit board 110, a rotor 170 rotatably installed in the shaft 140 and generating vibration while rotating by interaction with the stator 160, and a stopper 180 installed at the other end of the shaft 140. The bracket 150 and the shaft 140 are electrically connected with the terminal portion 130. Further, it is possible to use the bracket or a shaft as an external power connection terminal by electrically connecting a negative terminal to the bracket and the shaft through the contact portion.

Owner:MPLUS

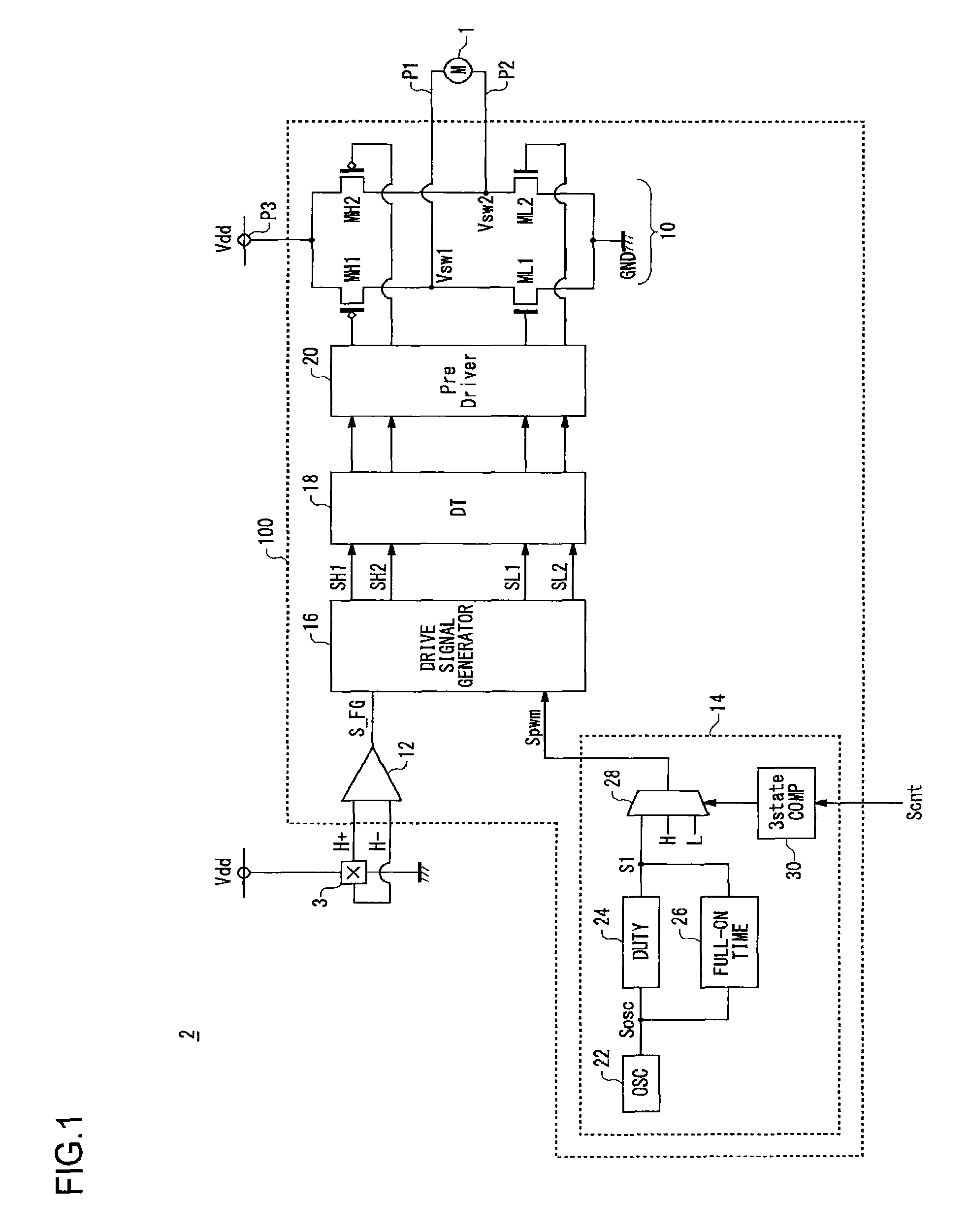

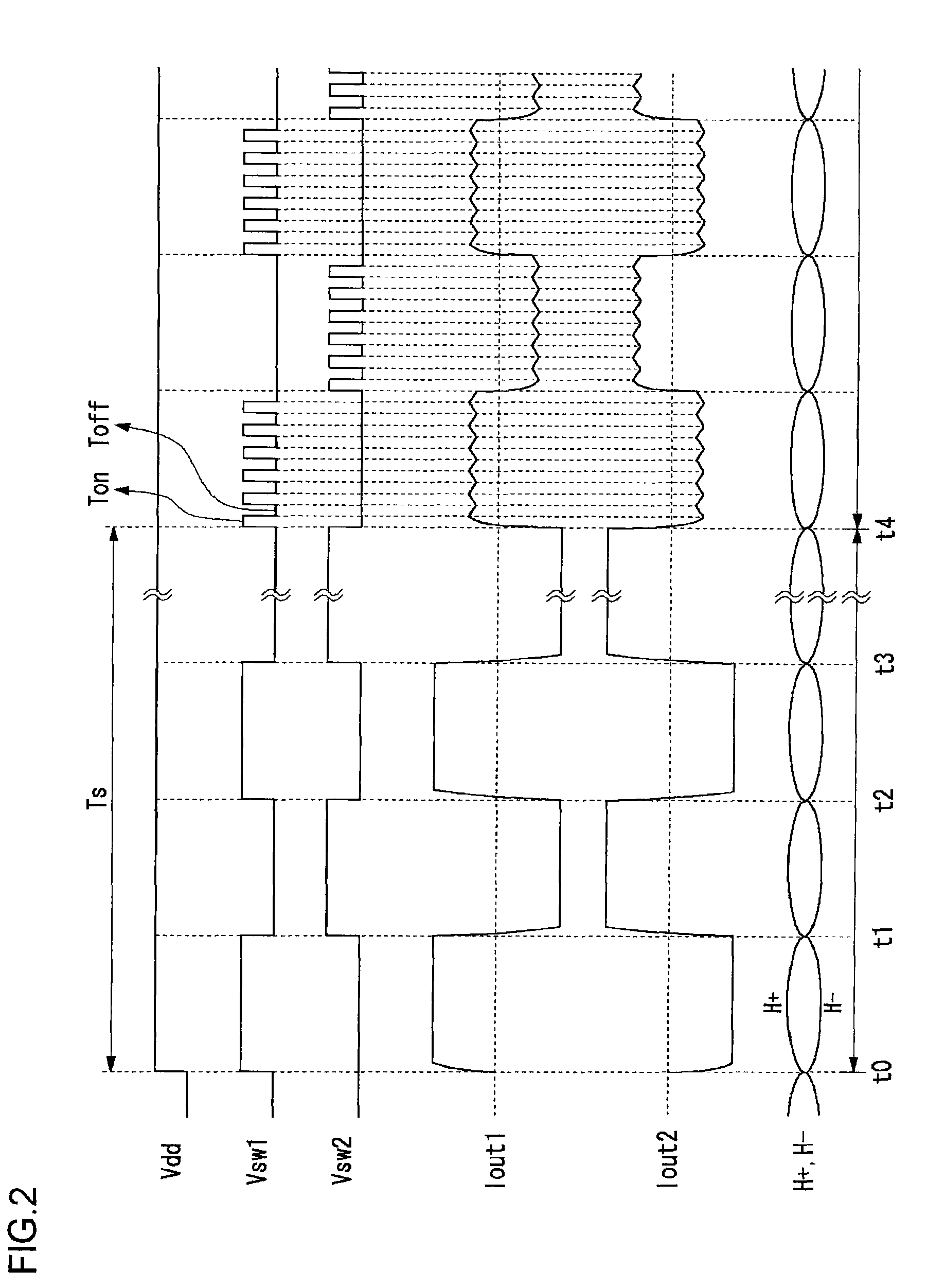

Motor drive circuit with short startup time

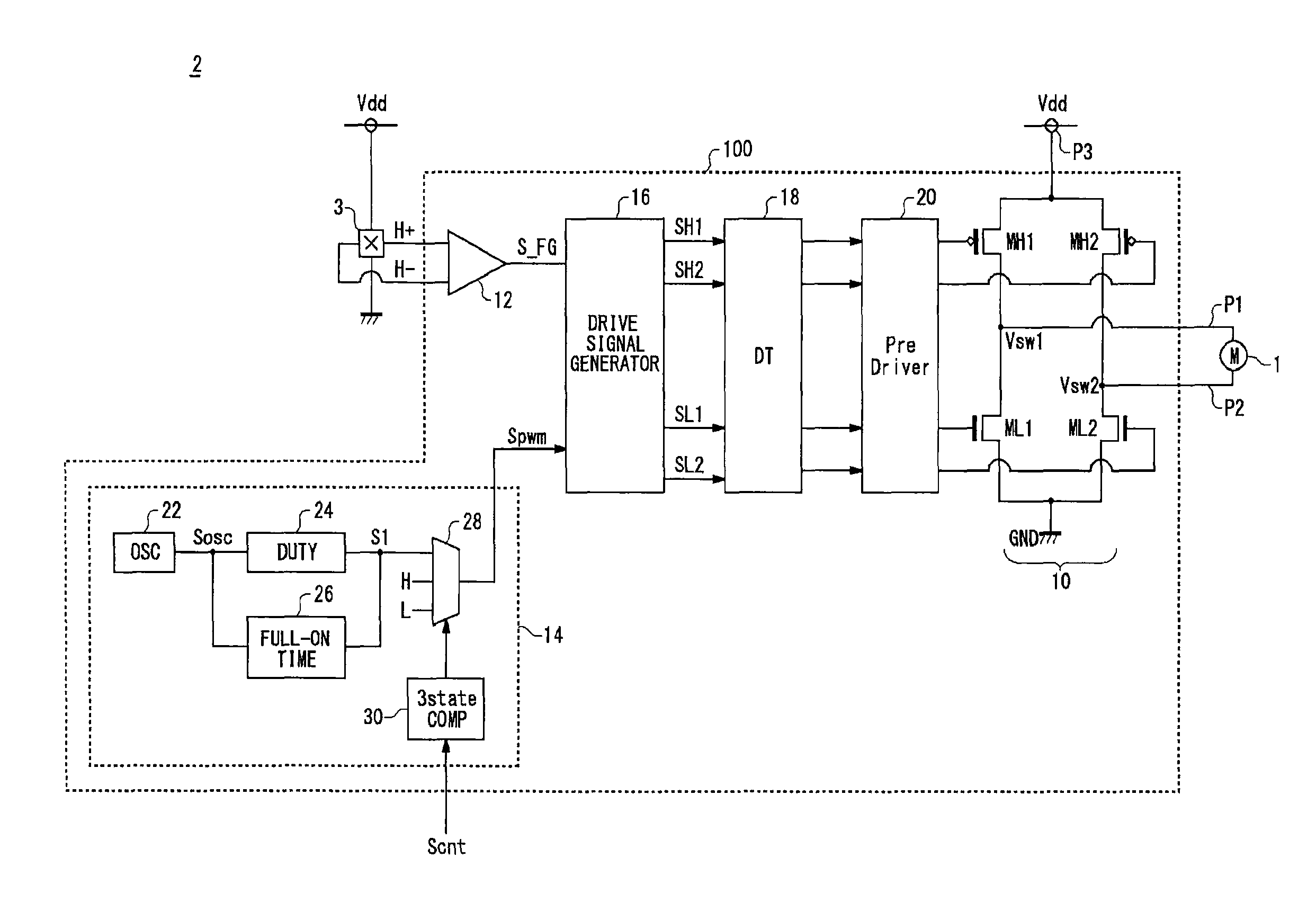

An H-bridge circuit is connected to a coil of the vibration motor that is to be driven. A comparator receives Hall signals indicating position information of a rotor of the vibration motor, and converts to an FG signal. A pulse width modulator generates a pulse-modulated pulse signal specifying energization time of the coil of the vibration motor. The pulse width modulator, in a first mode, after commencing start-up of the vibration motor, sets a duty ratio of the pulse signal to 100%, and after that, switches the duty ratio to a predetermined value in accordance with rotational frequency of the motor. In a second mode, the duty ratio of the pulse signal continues to be set to 100%. In a third mode, frequency and the duty ratio of the pulse signal are set based on a control signal of a pulse form inputted from outside. The control signal is used also in switching mode.

Owner:ROHM CO LTD

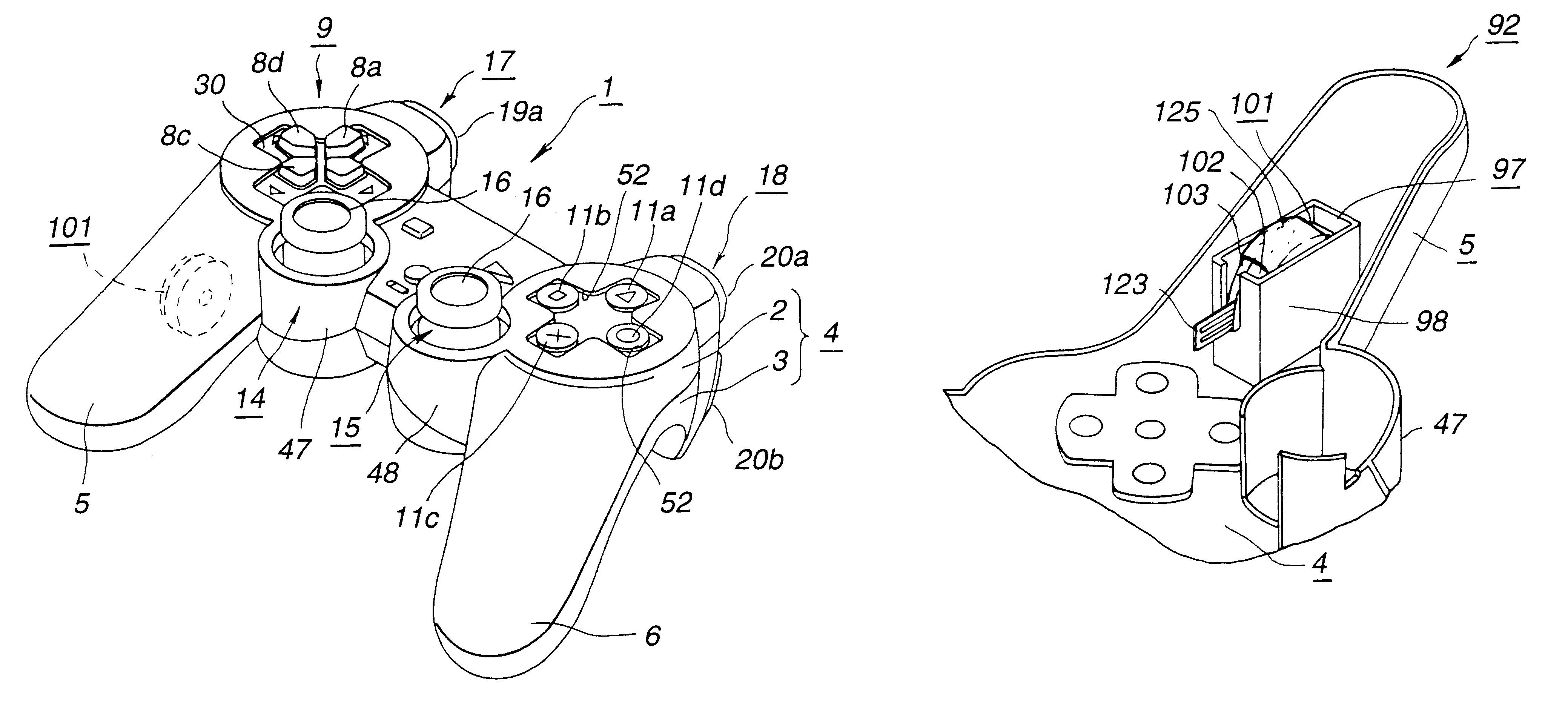

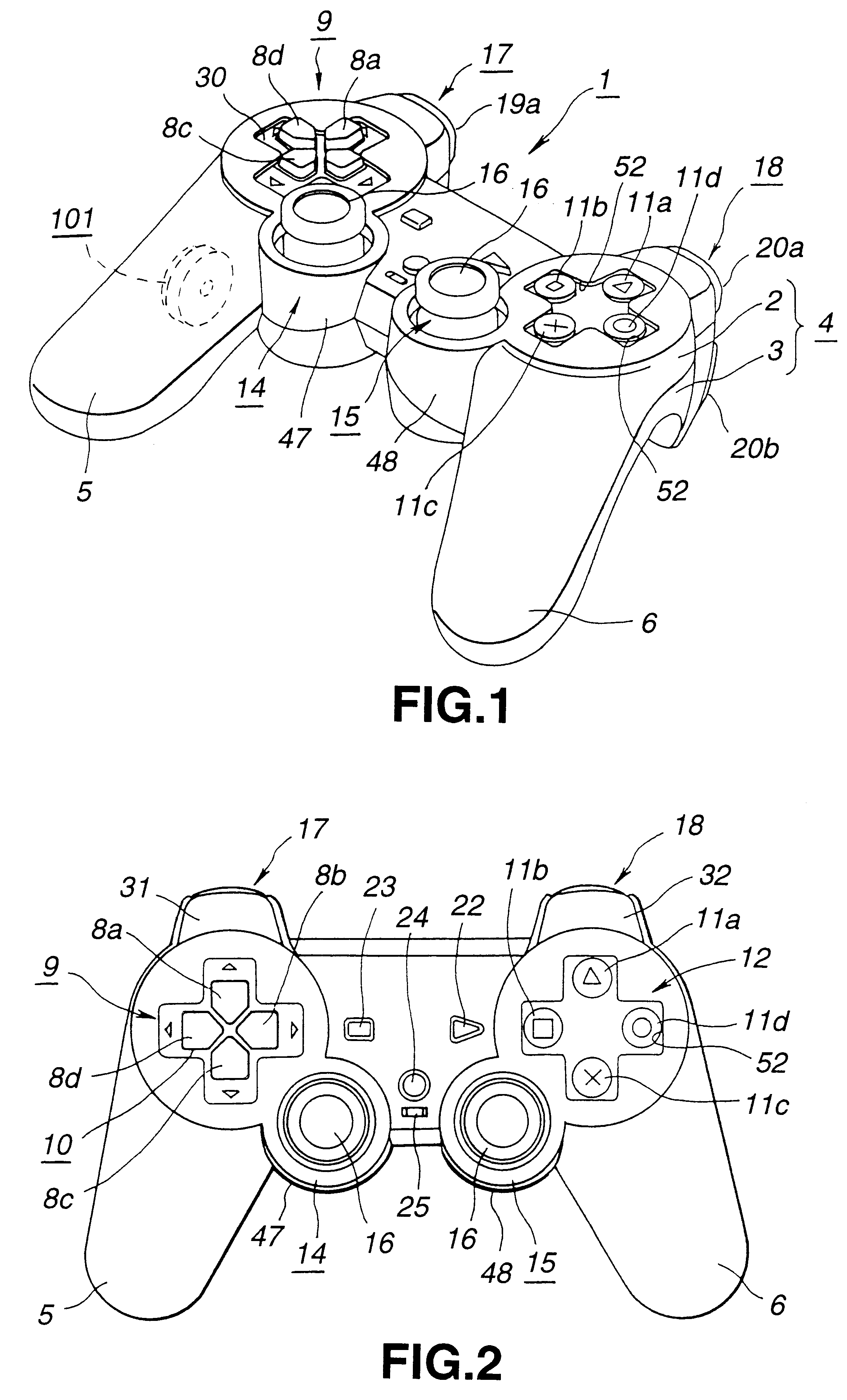

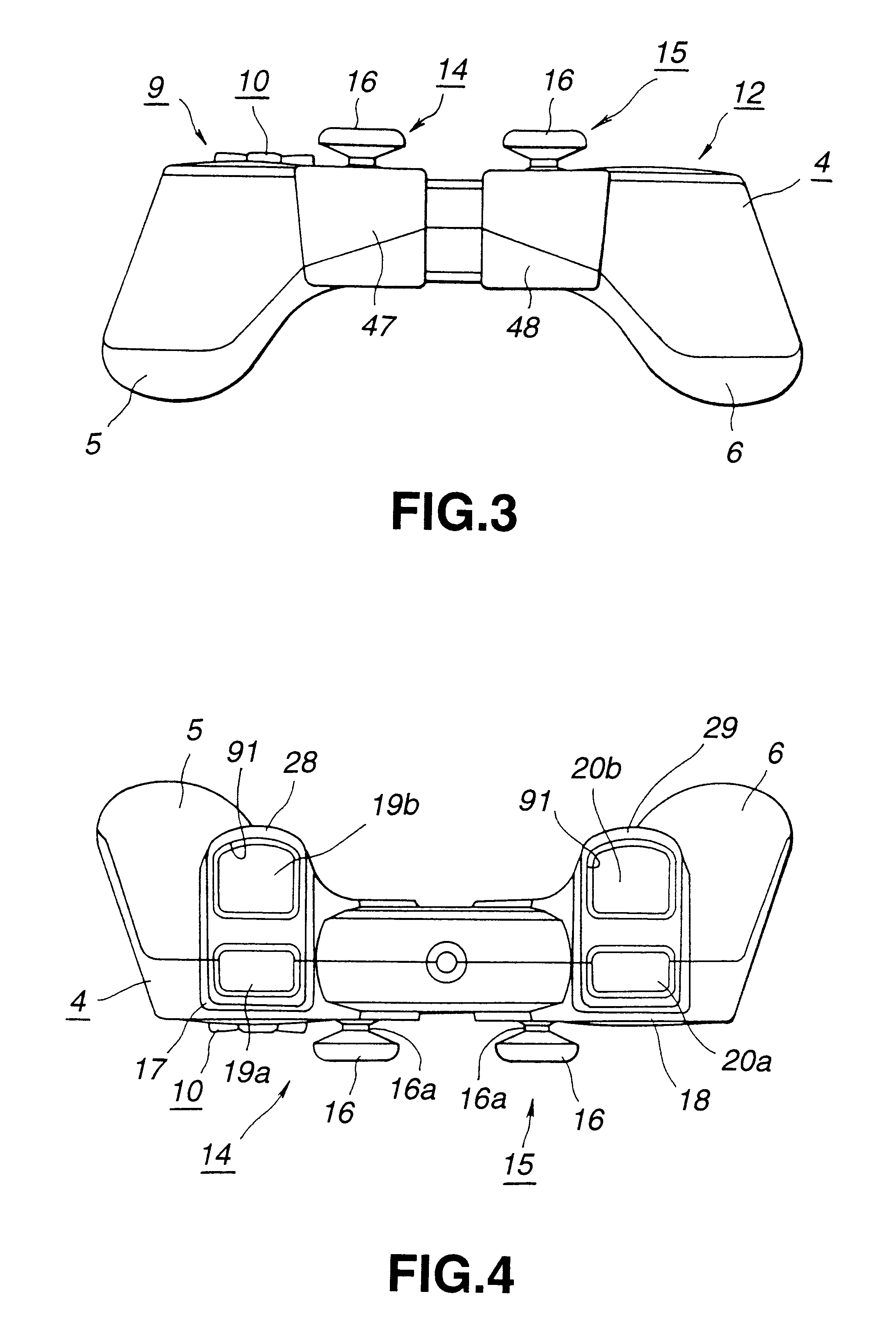

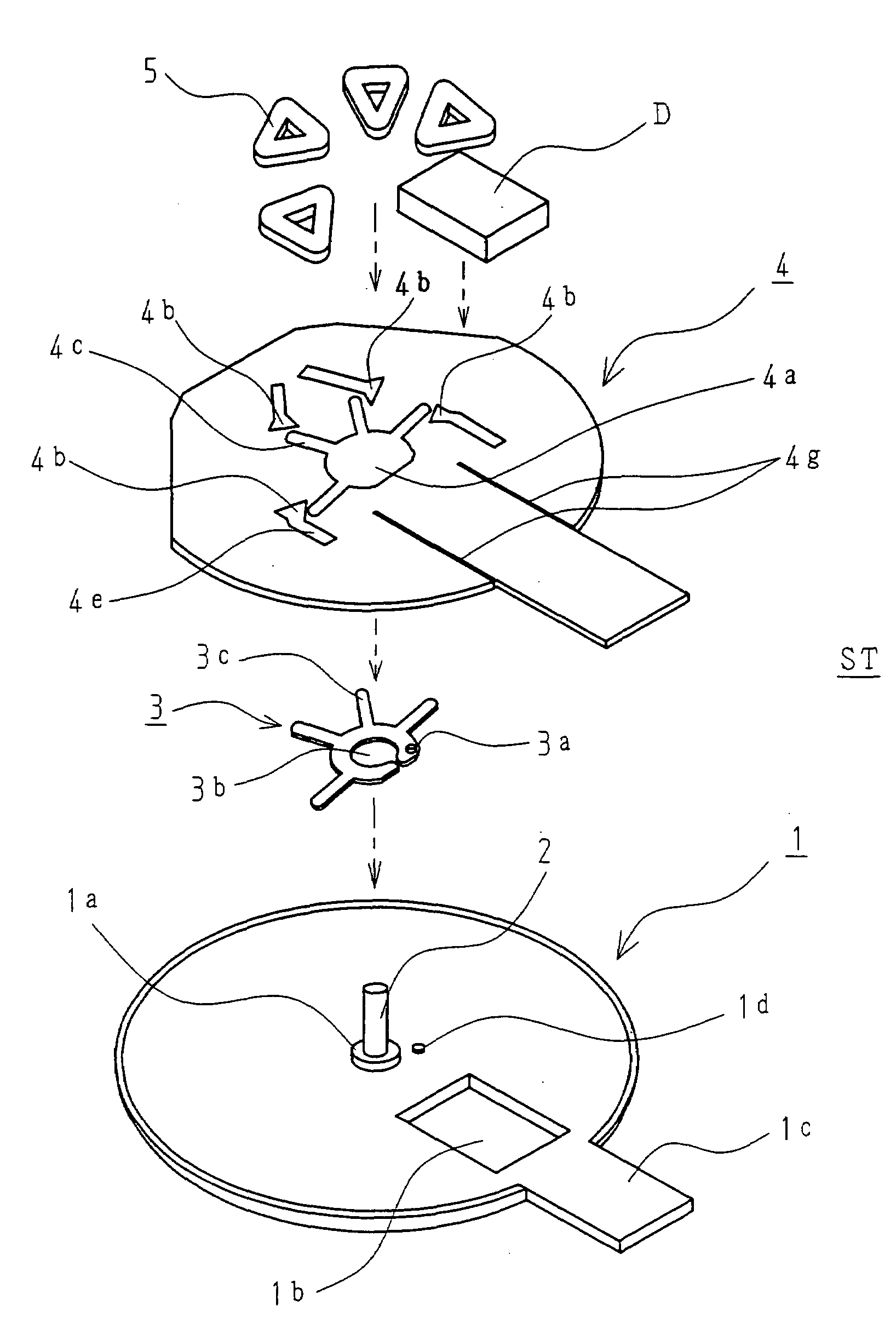

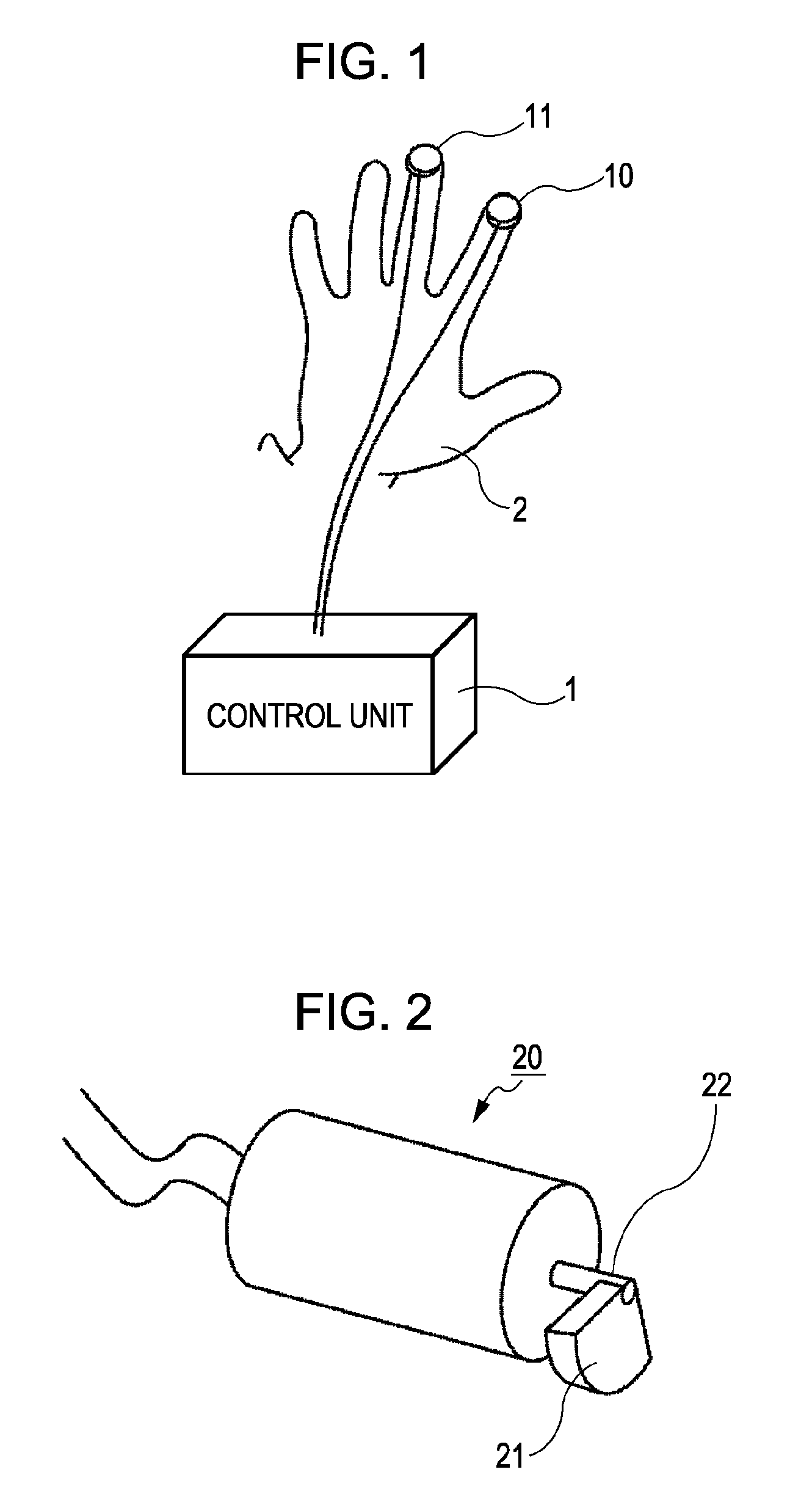

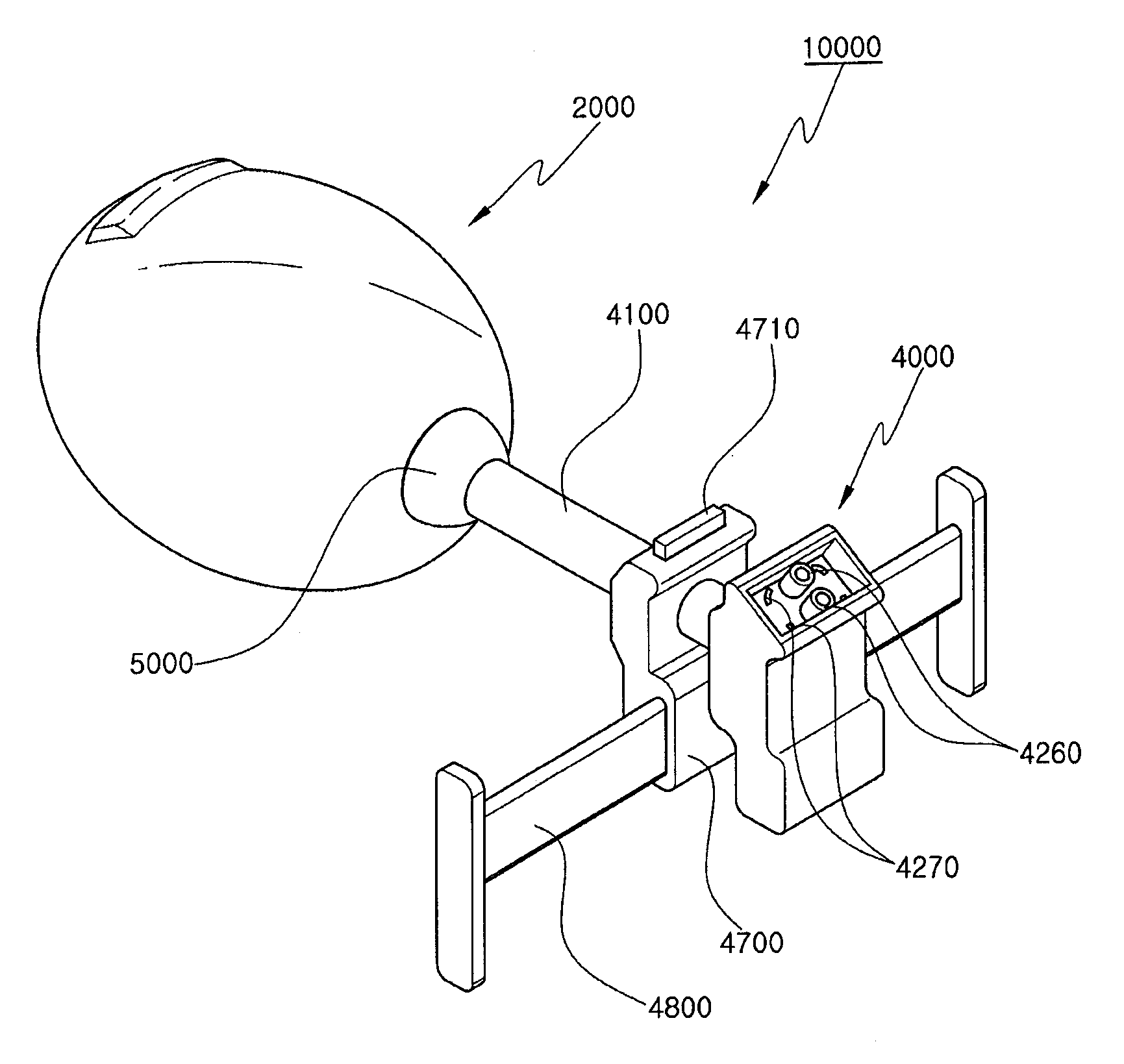

Actuating device and system exploiting the actuating device

InactiveUS6171191B1Good simulated presence feelingGuaranteed normal transmissionInput/output for user-computer interactionCathode-ray tube indicatorsDriving currentElectric machine

A system having a machine having the function of reproducing an information recording medium, in which the system executes a program recorded on the recording medium by sending a machine actuating command signal to the machine by user actuation and by receiving signals from the machine. The system includes a main body portion of a machine, and a control unit for controlling the machine connected to the main body portion of the machine. The control unit has a housing, a plurality of control sections mounted on the housing actuated by the user with fingers, and a vibration motor mounted via a vibration motor mounting portion provided in the housing. The vibration motor includes a motor casing, a shaft rotatably supported by the motor casing, and an eccentric member mounted on the shaft. The eccentric member has a rotor and a plurality of coils mounted on the rotor which is mounted on the shaft. The vibration motor also includes a magnet mounted on the casing for facing the eccentric member, and a supplying member for supplying the driving current to each coil. The eccentric member is rotated when the driving current is supplied to each coil to cause vibrations of the vibration motor itself, with the vibrations being supplied via the housing to the user. This permits the vibrations to be felt by the user to make possible execution of the program excellent in simulated presence feeling.

Owner:SONY COMPUTER ENTERTAINMENT INC

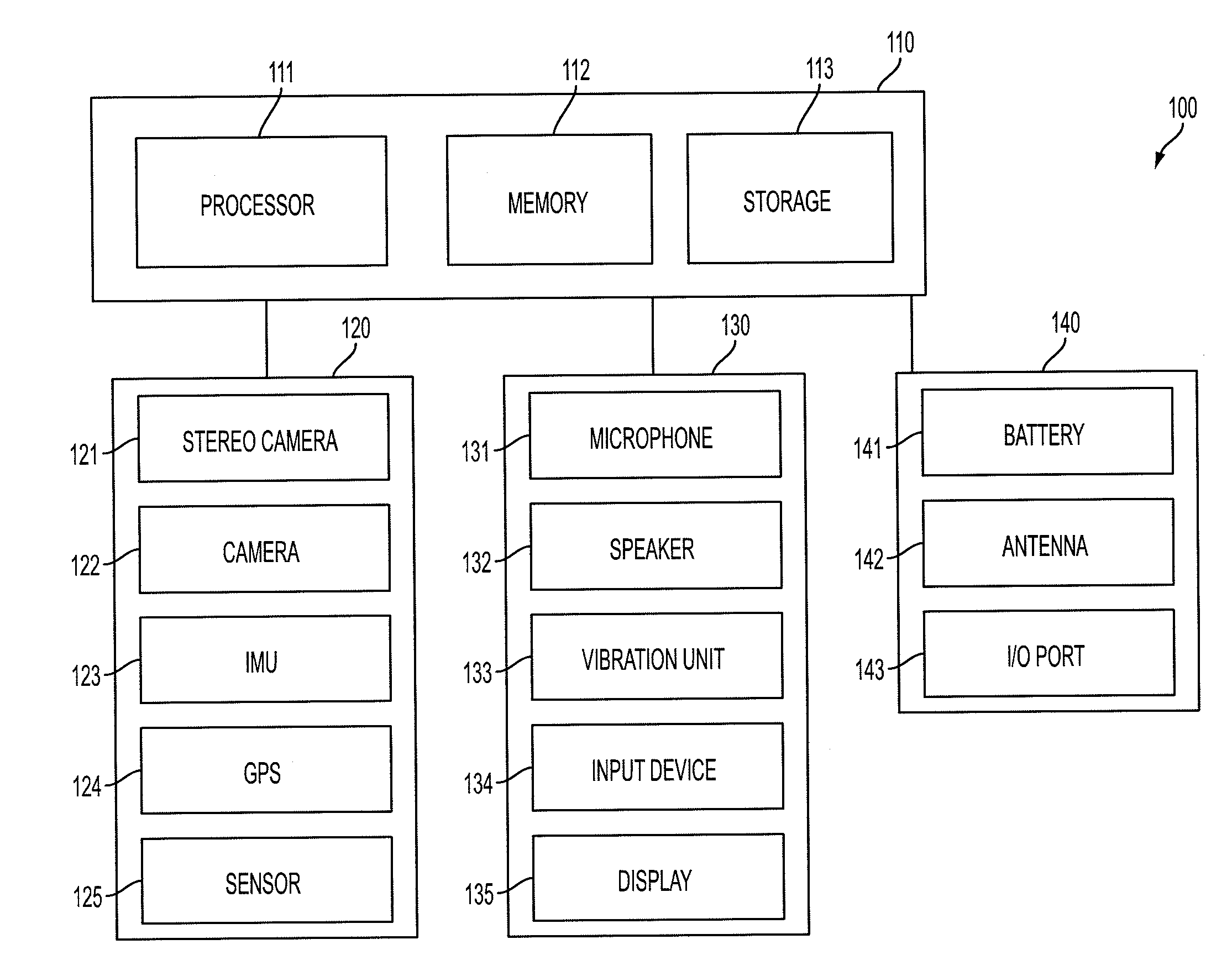

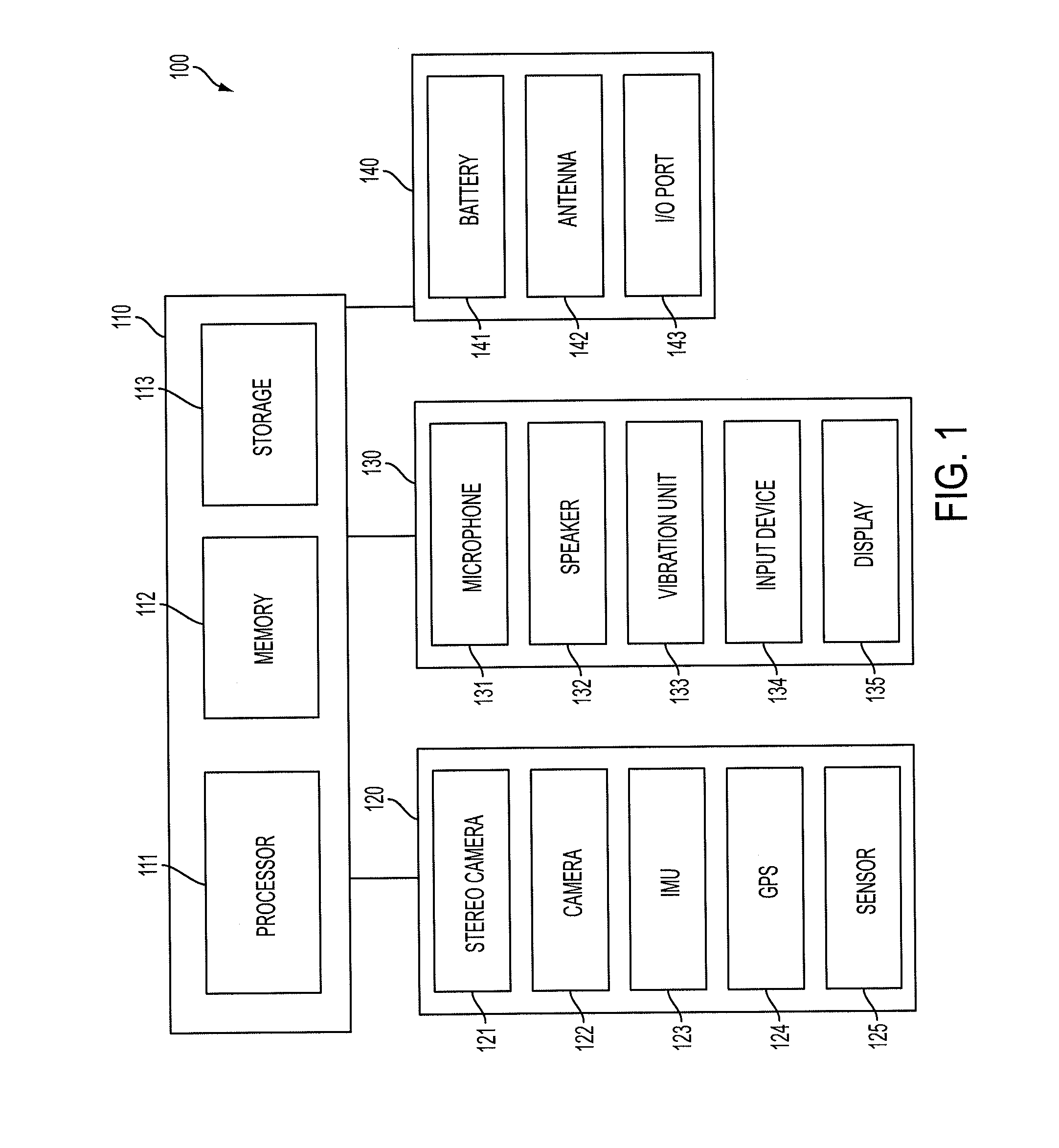

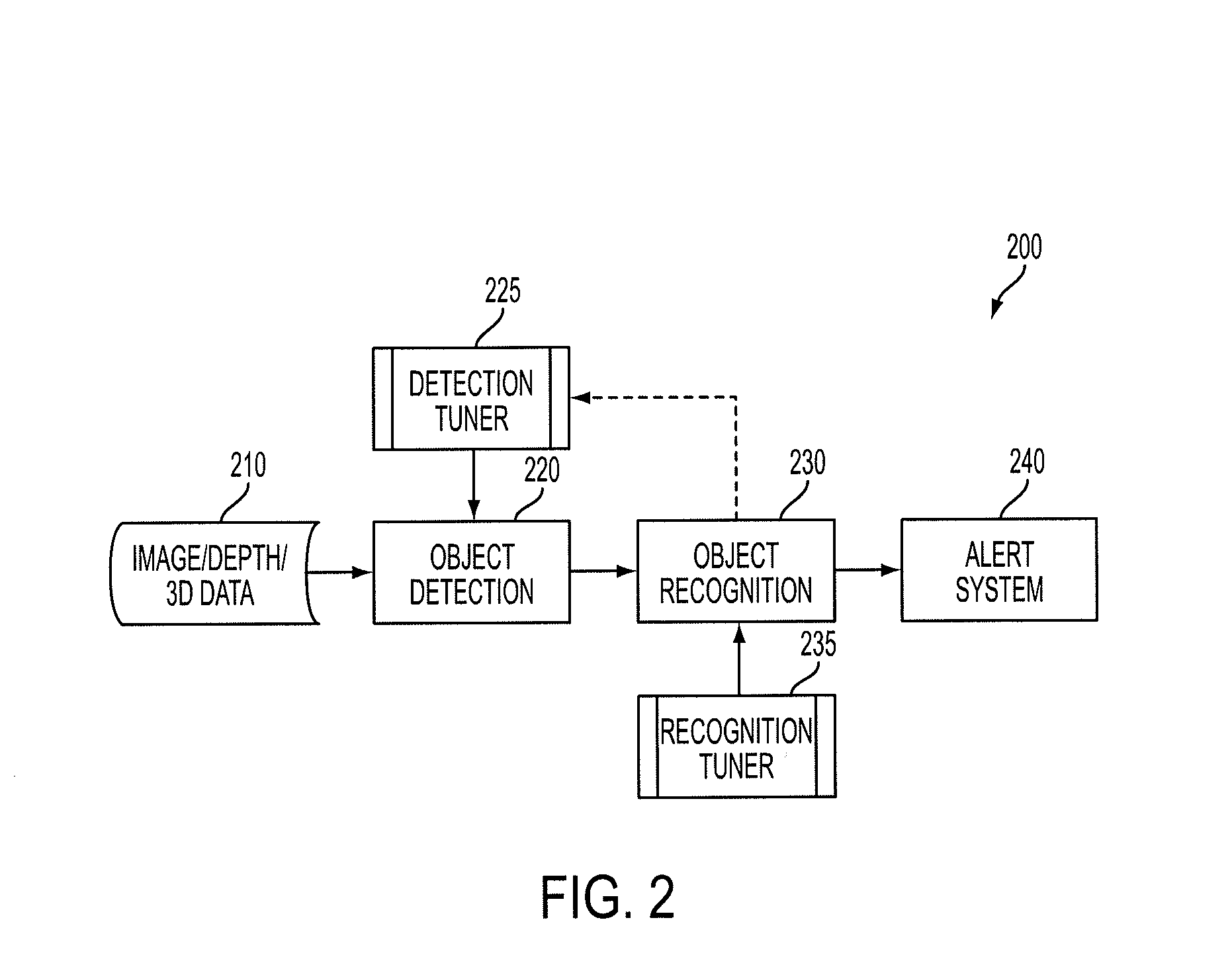

Smart necklace with stereo vision and onboard processing

ActiveUS20150201181A1Enhance environmental awarenessIncreased obstacle avoidanceInput/output for user-computer interactionImage enhancementTouch PerceptionStereo camera

A wearable neck device for providing environmental awareness to a user, the wearable neck device includes a flexible tube. A first stereo pair of cameras is encased in a left portion of the flexible tube and a second stereo pair of cameras is encased in a right portion of the flexible tube. A vibration motor within the flexible tube provides haptic and audio feedback to the user. A processor in the flexible tube recognizes objects from the first stereo pair of cameras and the second stereo pair of cameras. The vibration motor provides haptic and audio feedback of the items or points of interest to the user.

Owner:TOYOTA JIDOSHA KK

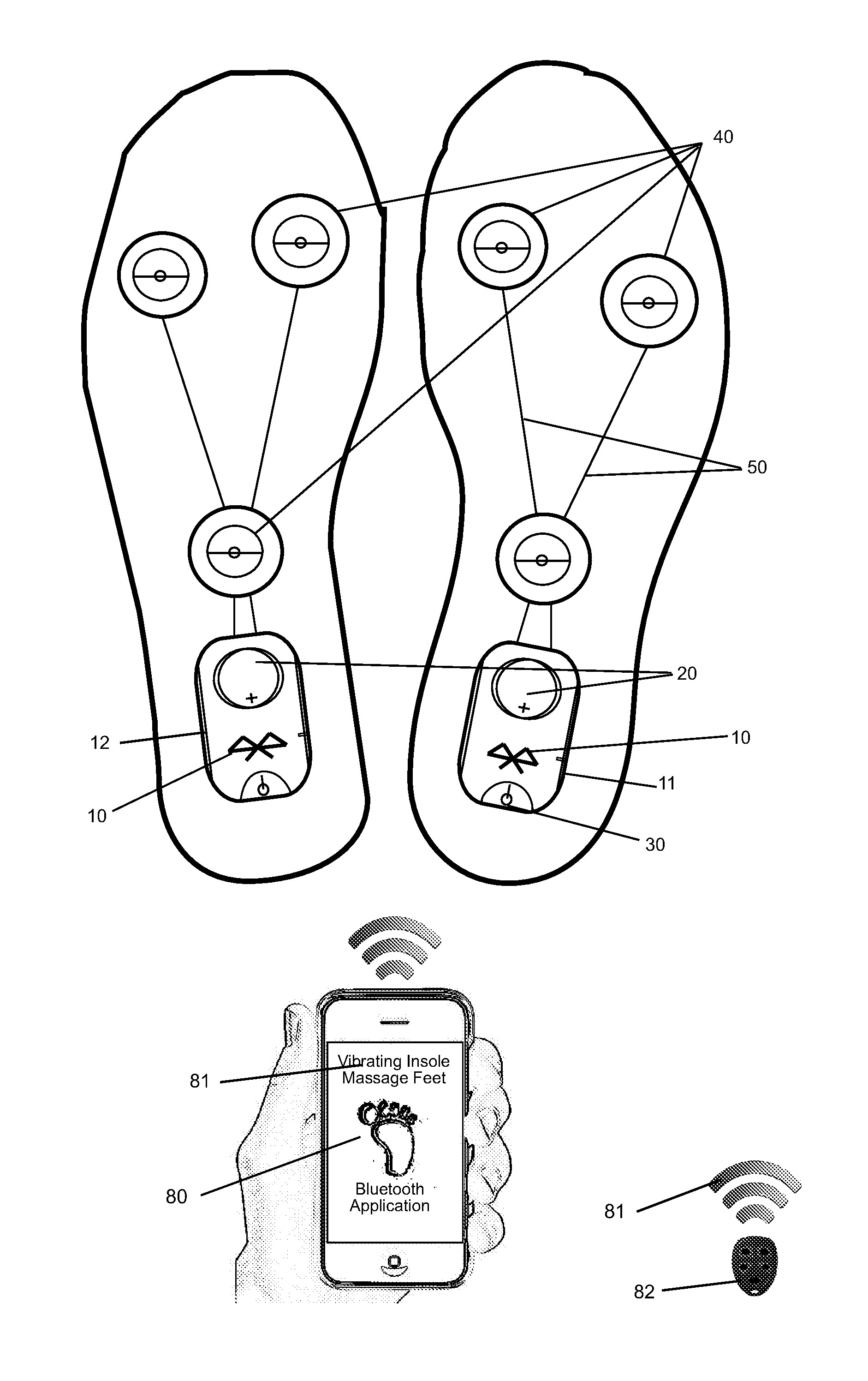

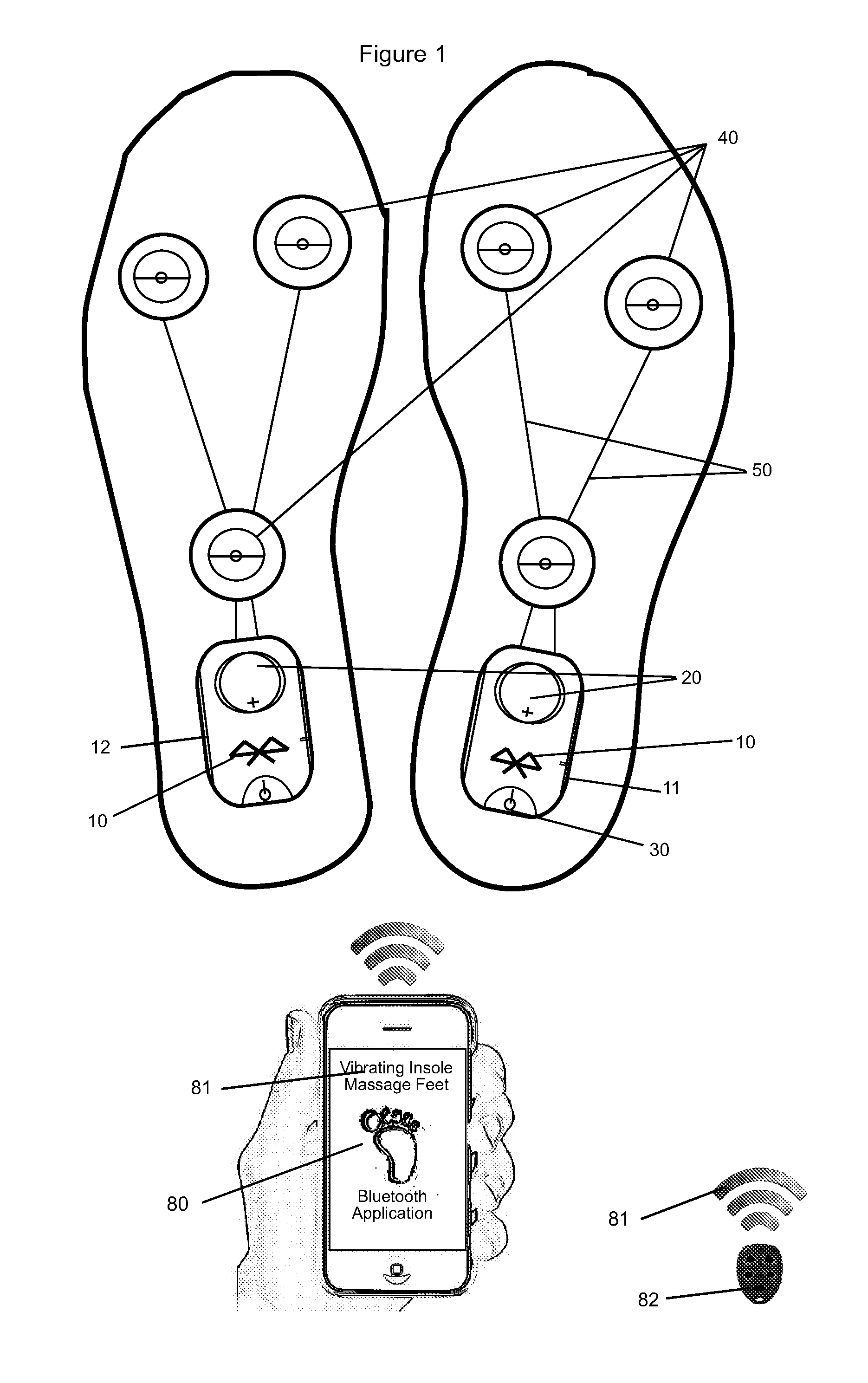

Vibrating insole with Bluetooth wireless, rechargeable battery, and vibrate motors integrated

A vibrating insoles with Bluetooth wireless components, vibrate motors, and built in rechargeable battery all integrated in the insole. Slip on insoles that vibrate the feet and are remotely activated via Bluetooth wireless cell phone application. The vibrate motors oscillate and uses vibration to massage the feet. A remote control application from a cell phone uses Bluetooth wireless technology to power on the vibrating motors of the insoles. Vibrate motors get electricity from rechargeable battery that is inside the insoles. Bluetooth wireless activates the vibrate motors and insoles continues vibrating to massage and relax the feet while wearing shoes. Vibrating insole can be used with any shoe allowing user with Bluetooth wireless cell phone to remote control the massaging motion of the vibrating insoles to massage the feet anywhere on the go. Vibrating insole can be slipped into any shoe allow users to remote activate via Bluetooth wireless or wireless radio frequency that powers on the vibrating motors to massages the feet while walking. Portable cordless shoe insole that vibrates and massage the feet inside the shoe.

Owner:SANCHEZ ROY C

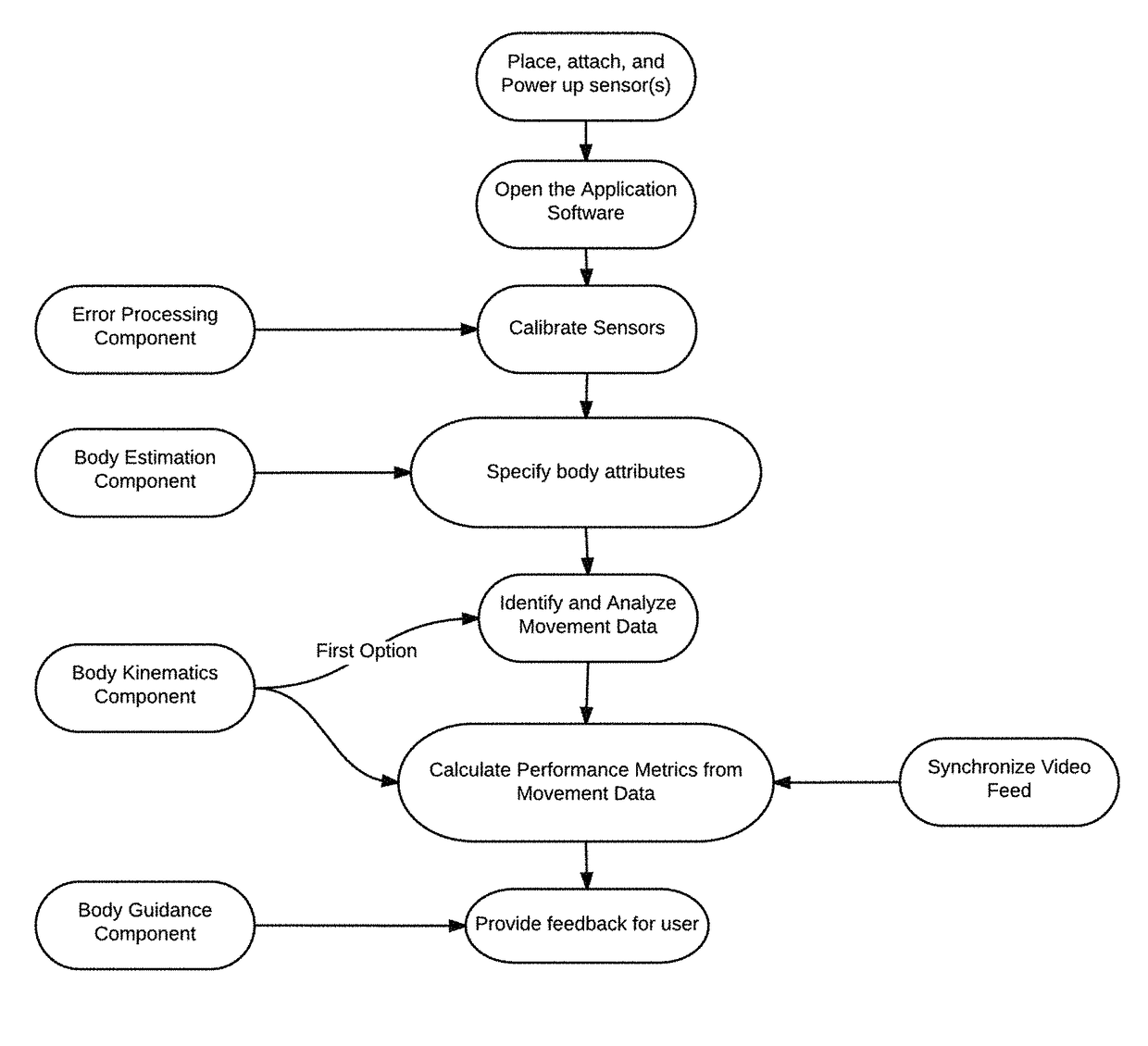

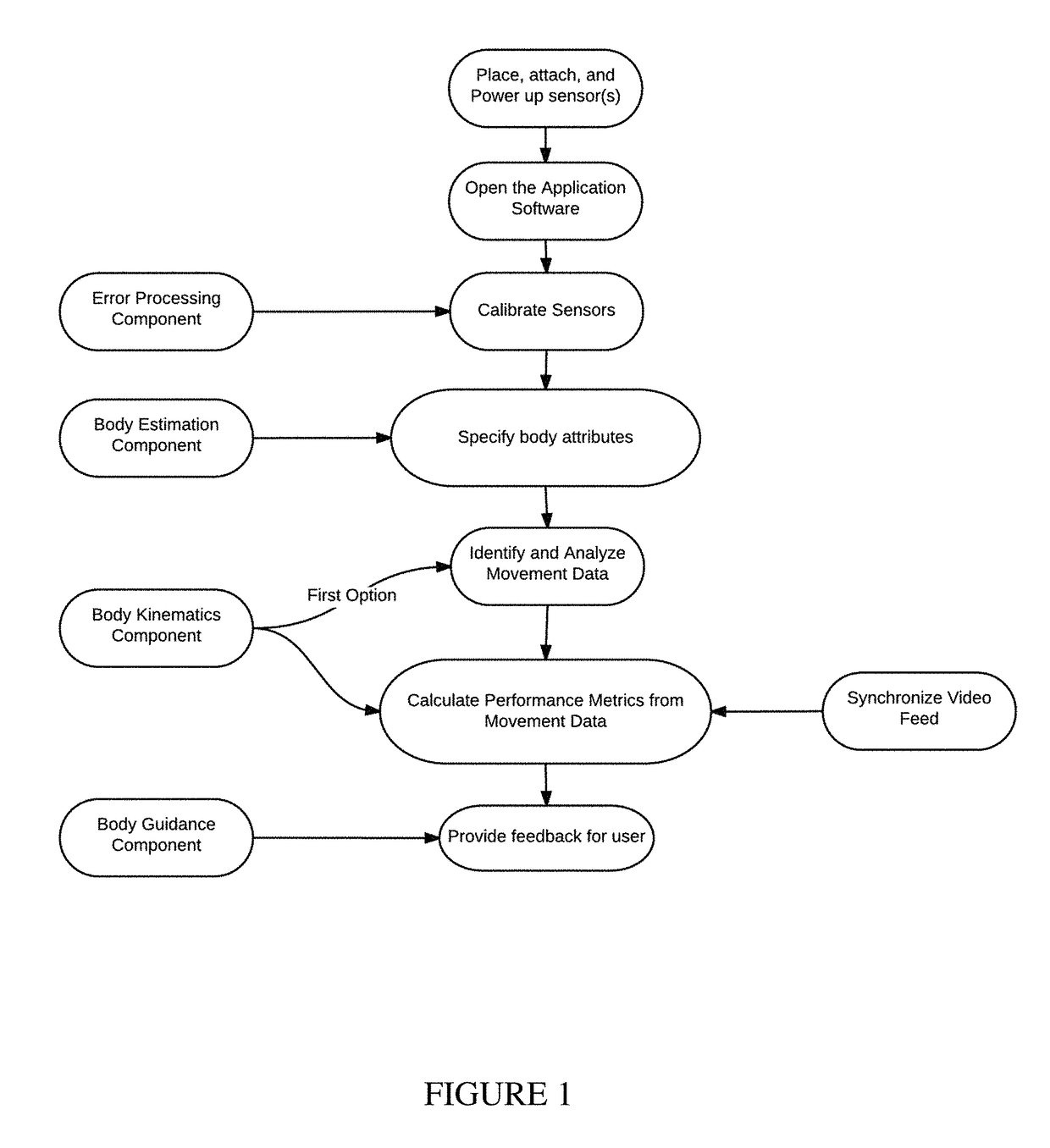

Training systems with wearable sensors for providing users with feedback

InactiveUS10065074B1Accelerated trainingEnhance coachingPhysical therapies and activitiesHealth-index calculationMultiple sensorHuman motion

A training system based on mobile technology and kinematics of human motion characterizes, analyzes, and supplies feedback to a user based on the user's movements. The training system includes a garment having a sensor control module connected to multiple sensor nodes via electrically-conductive fabric running along parts portions of the garment. The sensor module / nodes can communicate through the conductive fabric. The sensor nodes acquire motion and / or physiologic readings that are wirelessly transmitted to a mobile computing device that runs an application that analyzes the data and provides visual (e.g., graphs, 3D avatar) and audio feedback (e.g., voice prompts). Vibration motors and LEDs / electroluminescent fabric in the garment also provide notifications and alerts. The triple layer of garment, conductive fabric, and sensor module / sensor node are sealed against contaminants, allowing the garment to be washable.

Owner:ENFLUX INC

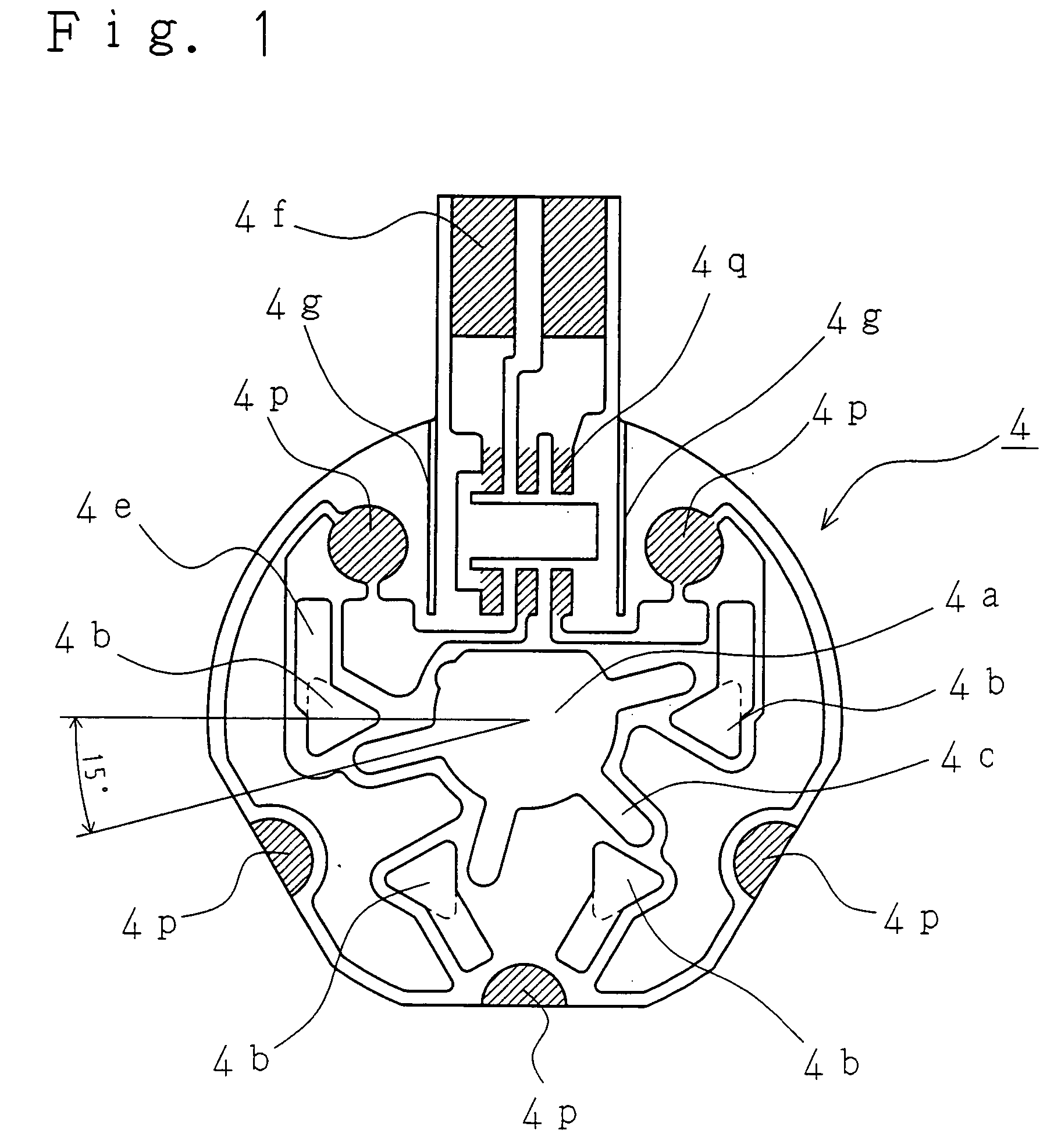

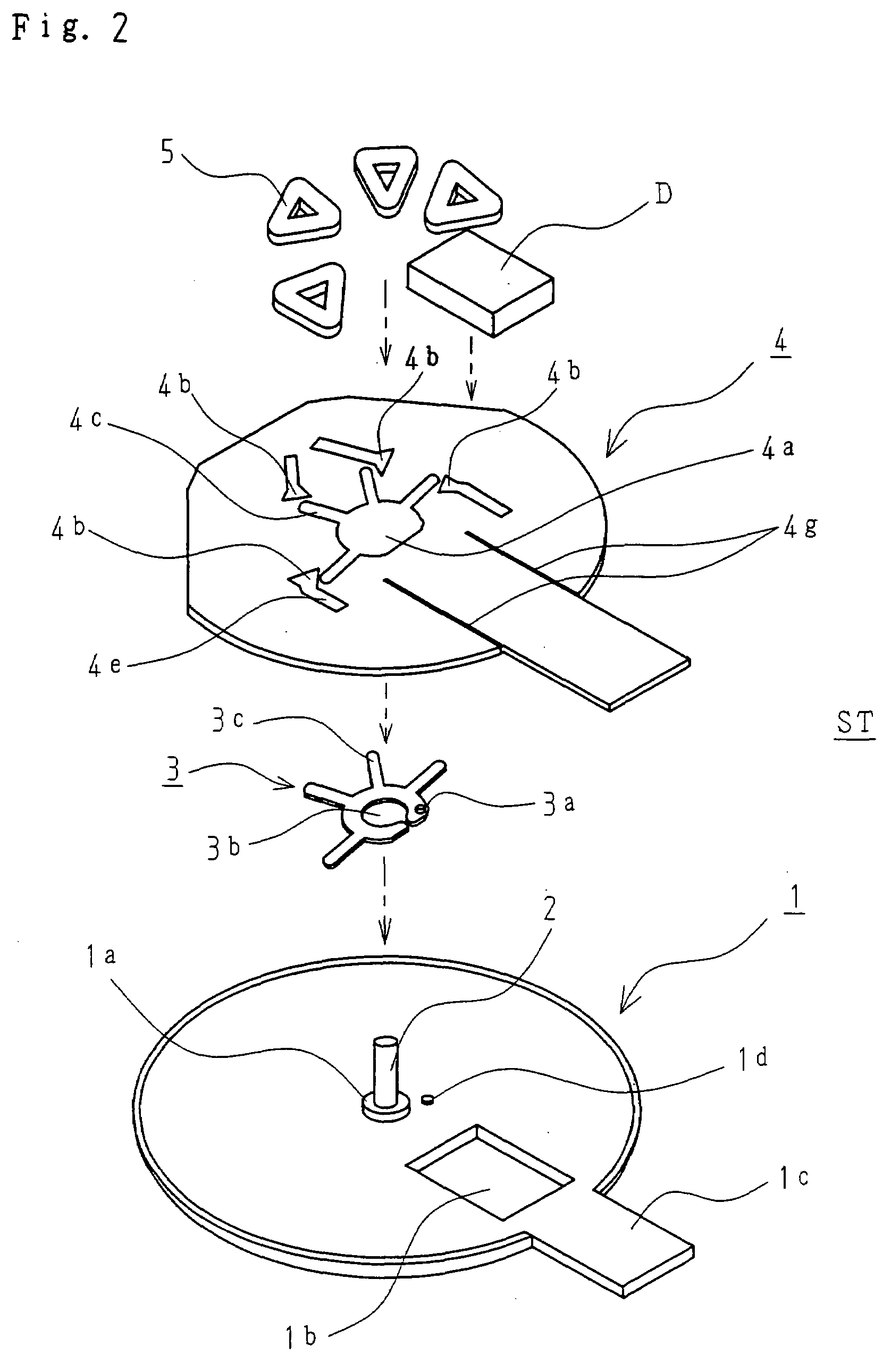

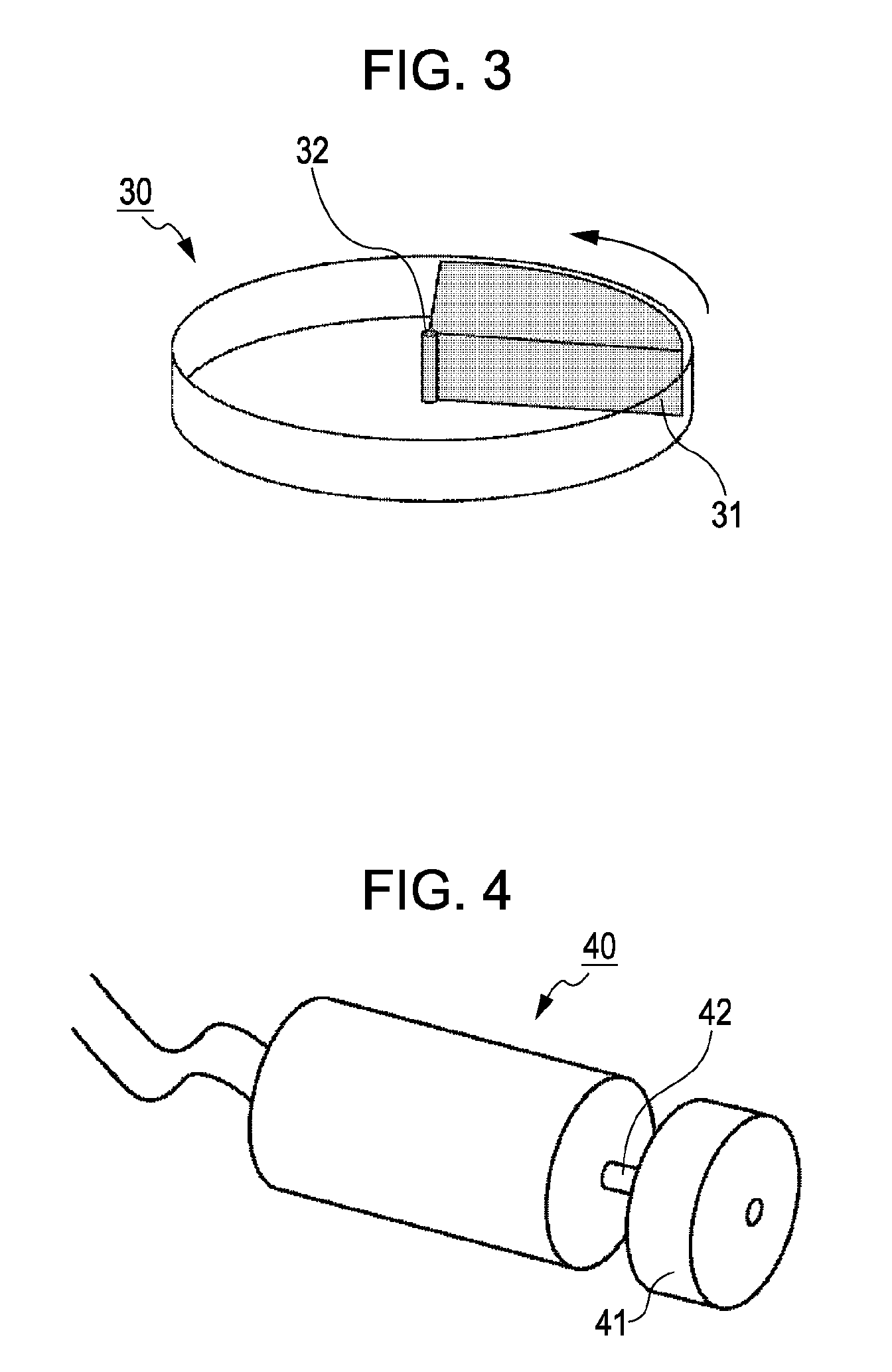

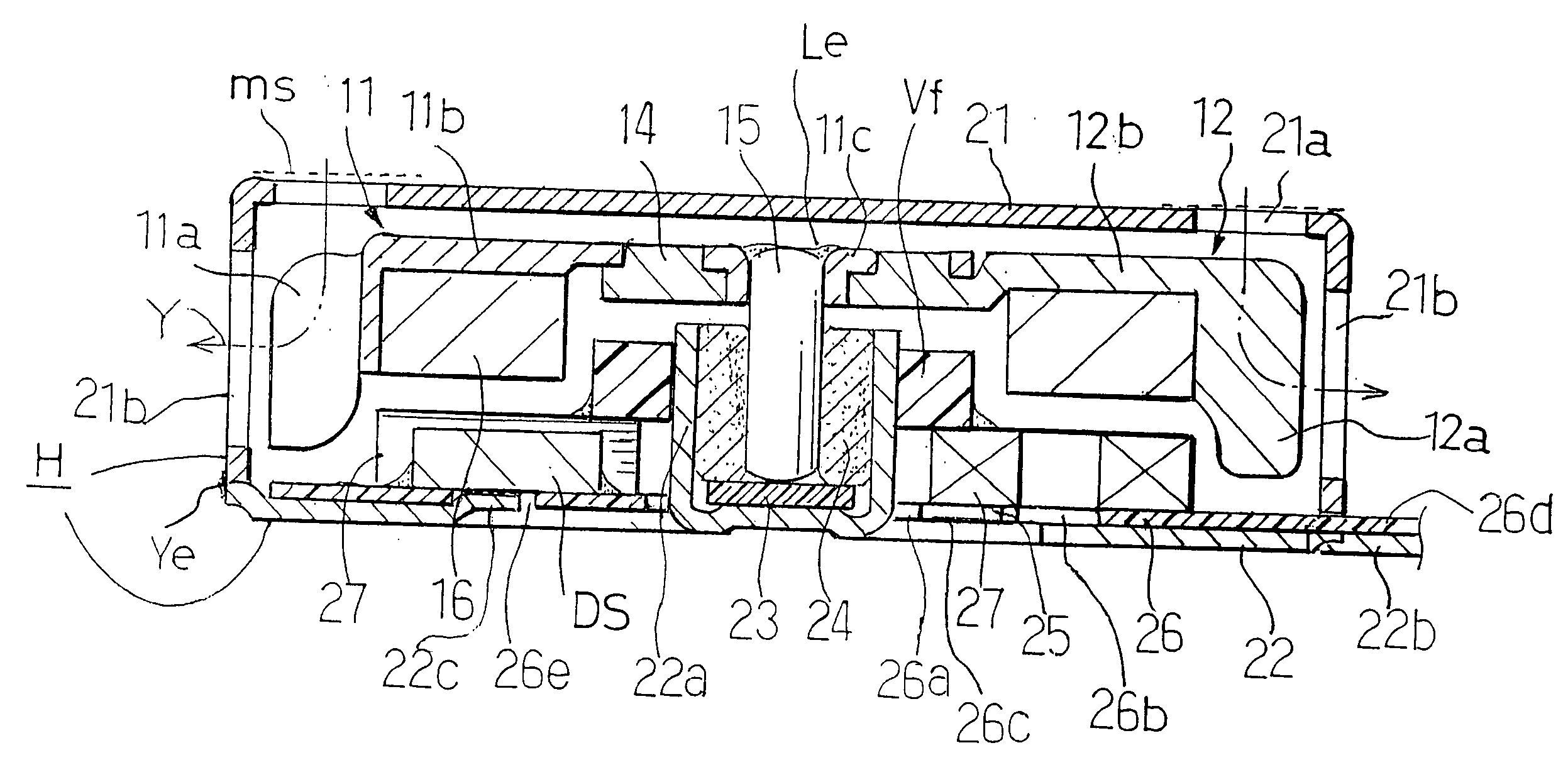

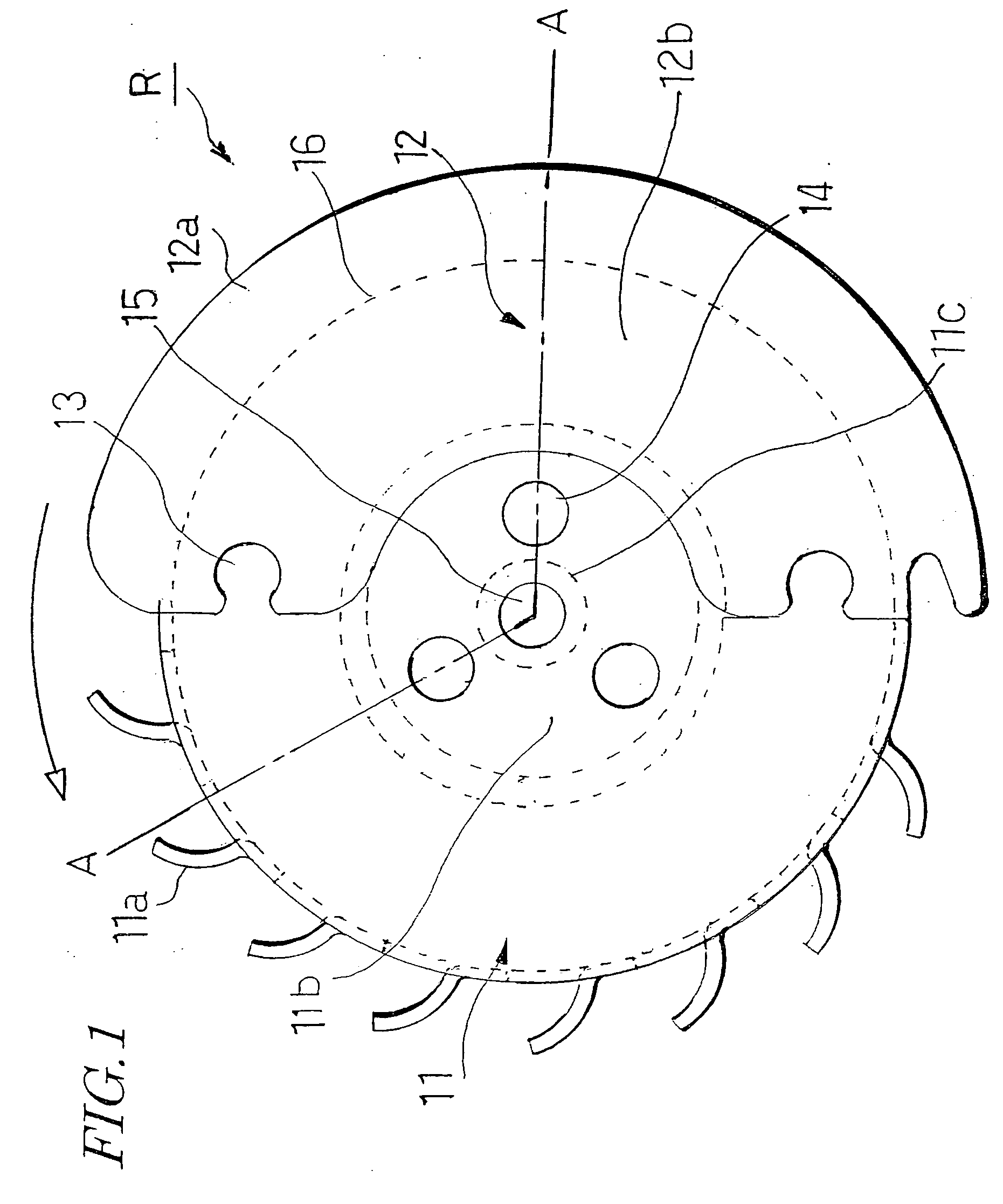

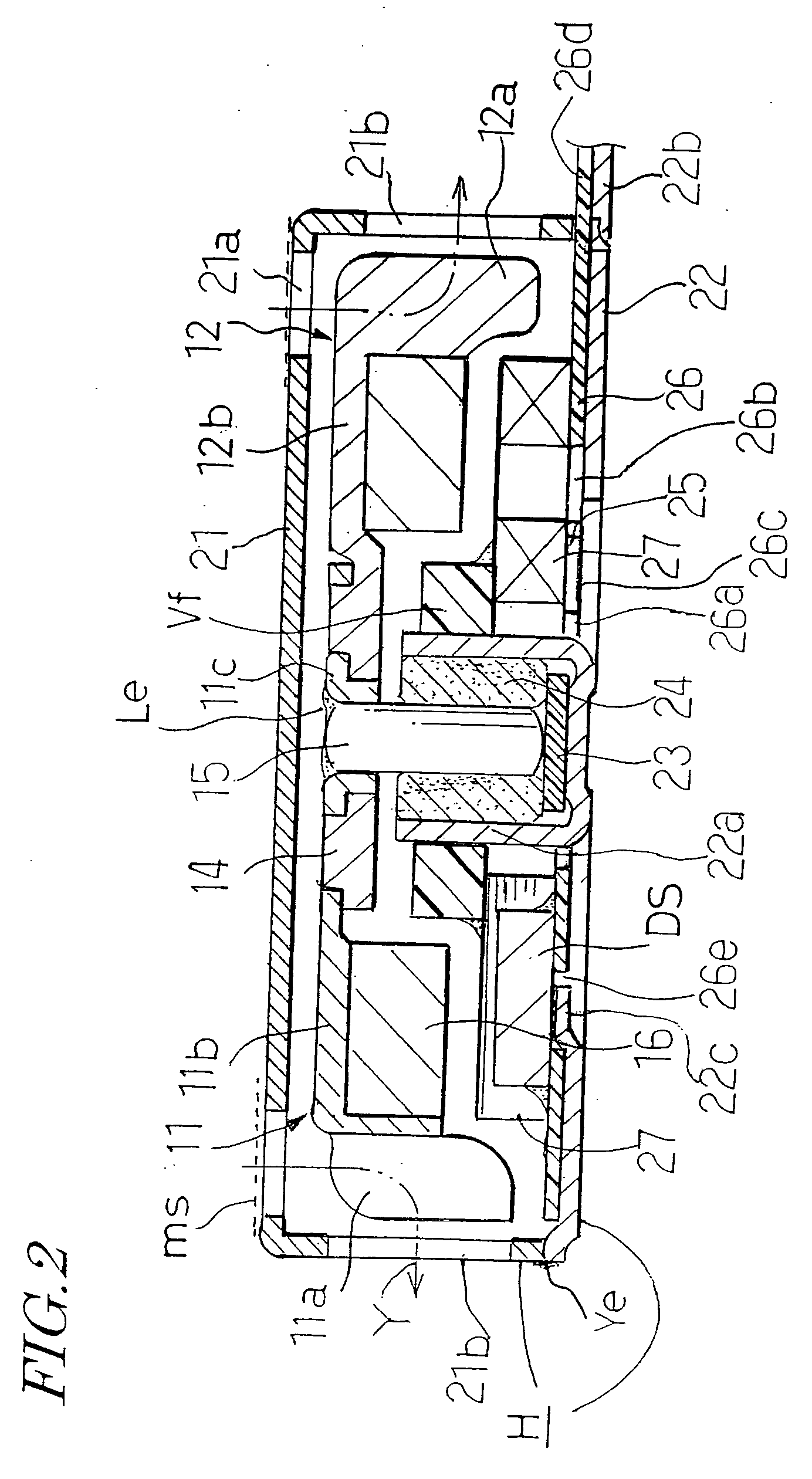

Thin stator, eccentric motor and axial air-gap brushless vibration motor equipped with the same

InactiveUS20080018187A1Sufficient starting torqueInfluence of bracket magnetic force can be suppressedMagnetic circuit stationary partsMechanical energy handlingDetentAir core

A stator includes a bracket having a shaft bearing portion at a center, a stator base including a flexible printed wiring board outwardly attached to the shaft bearing portion, single-phase air-armature coils disposed on the stator base, and a drive circuit member disposed on the stator base so as not to overlap with the single-phase air-core armature coils. The bracket has a through hole at the section corresponding to the bottom of the drive circuit member. The stator base is embedded at least partly in the thickness direction in the through hole and fixed using a resin, and a detent torque generation member is contained in, and is no thicker than, the stator base.

Owner:TOKYO PARTS IND CO LTD

Method for abruptly stopping a linear vibration motor in portable communication device

InactiveUS20070178942A1Quick stopFrequency-division multiplex detailsPrinted circuit aspectsTransducerEngineering

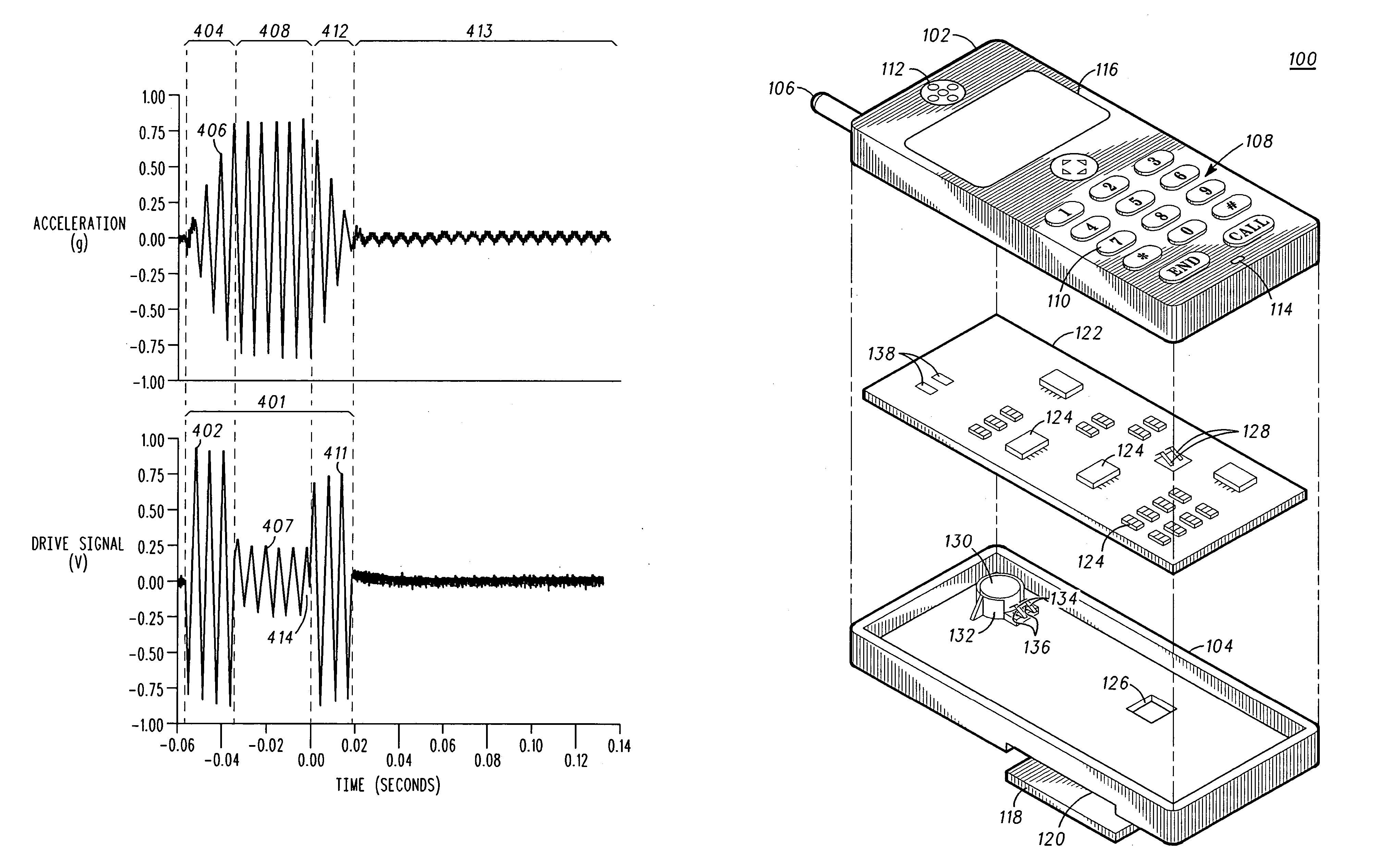

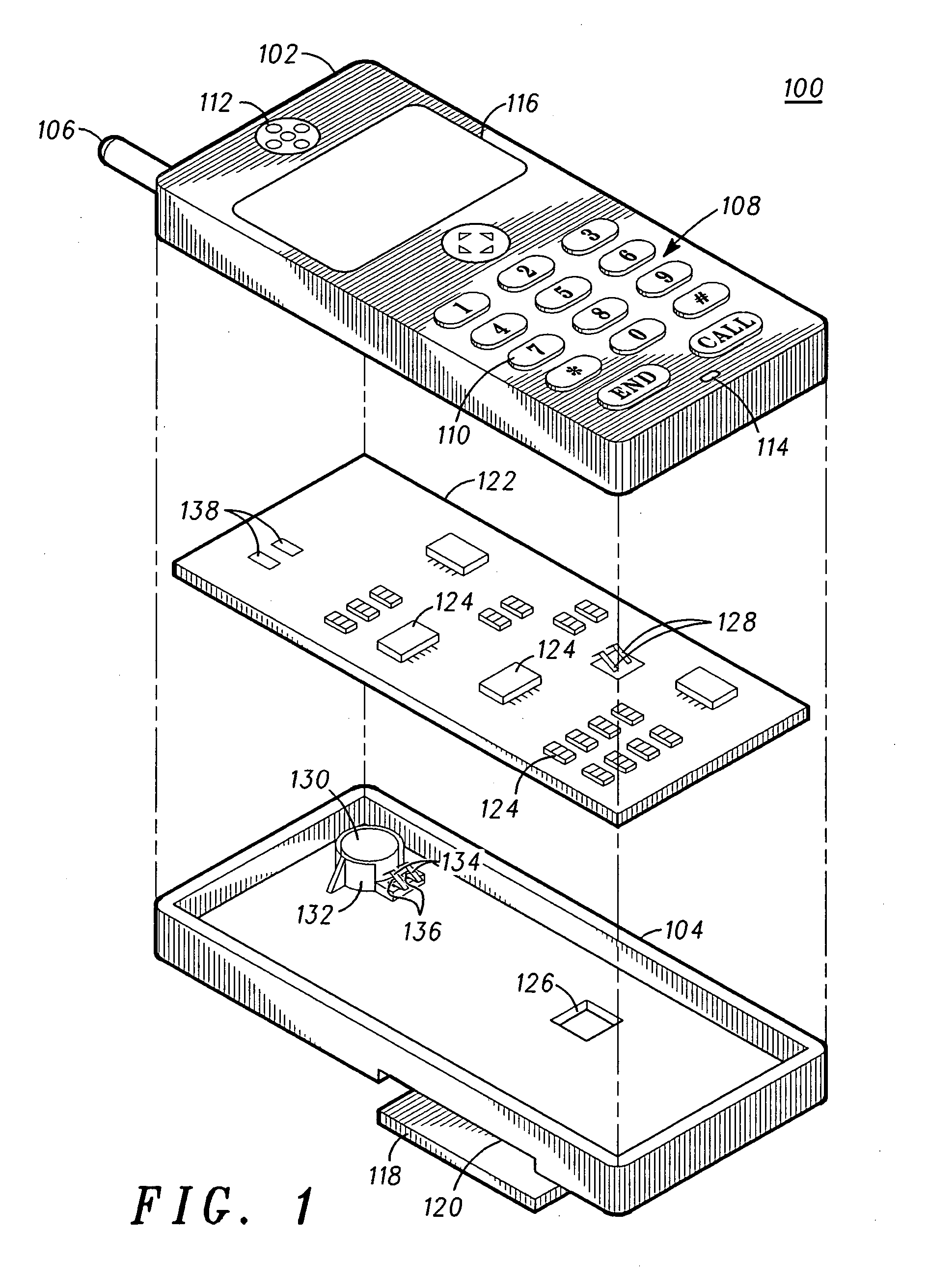

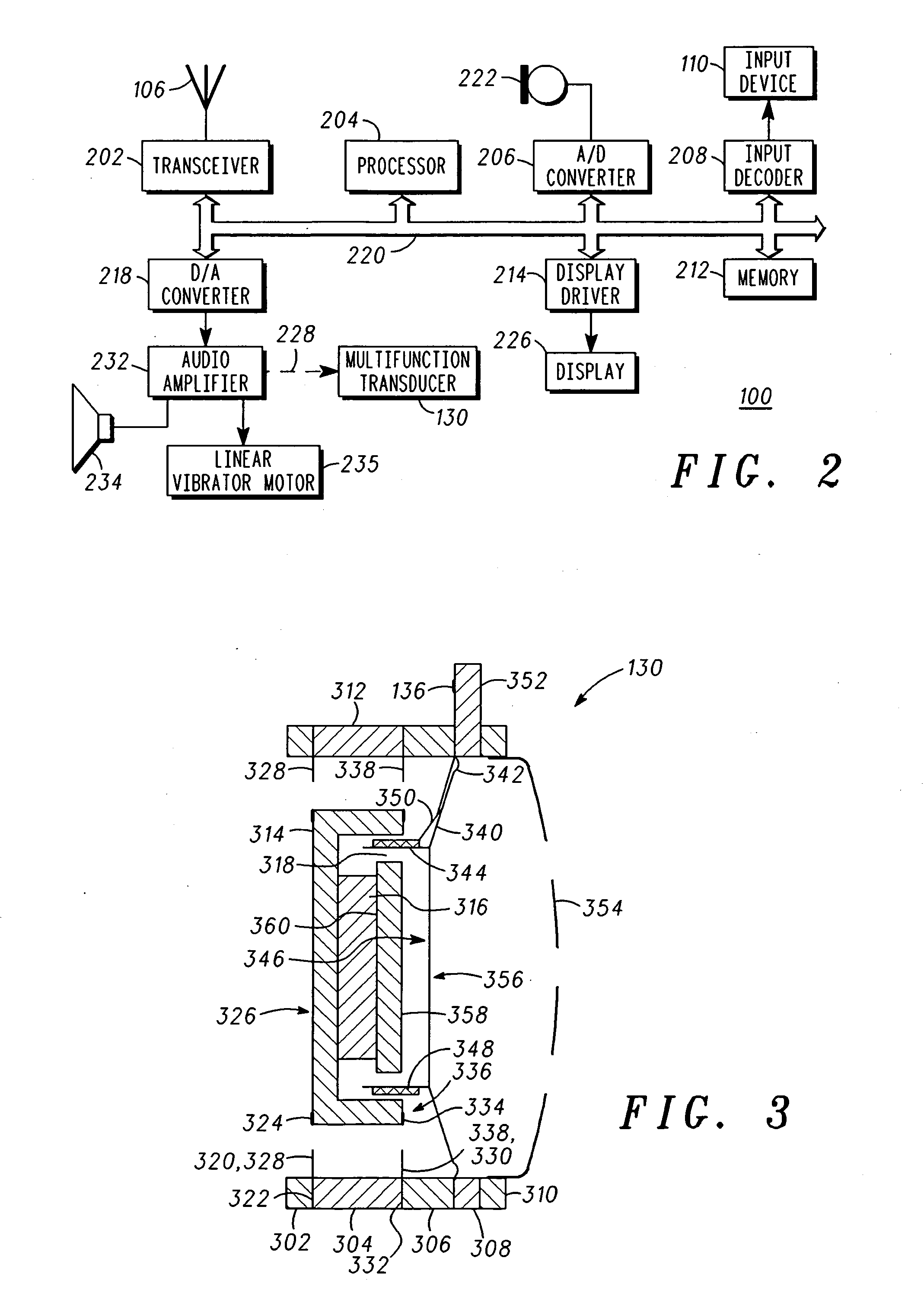

A method is provided for abruptly stopping a vibration motor providing tactile feedback (406) to the user of a portable communication device (100). The method comprises providing a drive waveform (401) including an attack signal (402), and a stop signal (411) out of phase with the attack signal (402), to one of the vibration motor (235) or the multi-function transducer (130) to quickly stop the vibration. The drive waveform may include an optional sustain signal (407) subsequent to the attack signal (402) and prior to the stop signal (411). A file stored in memory (212) is accessed to provide the drive waveform (401).

Owner:MOTOROLA INC

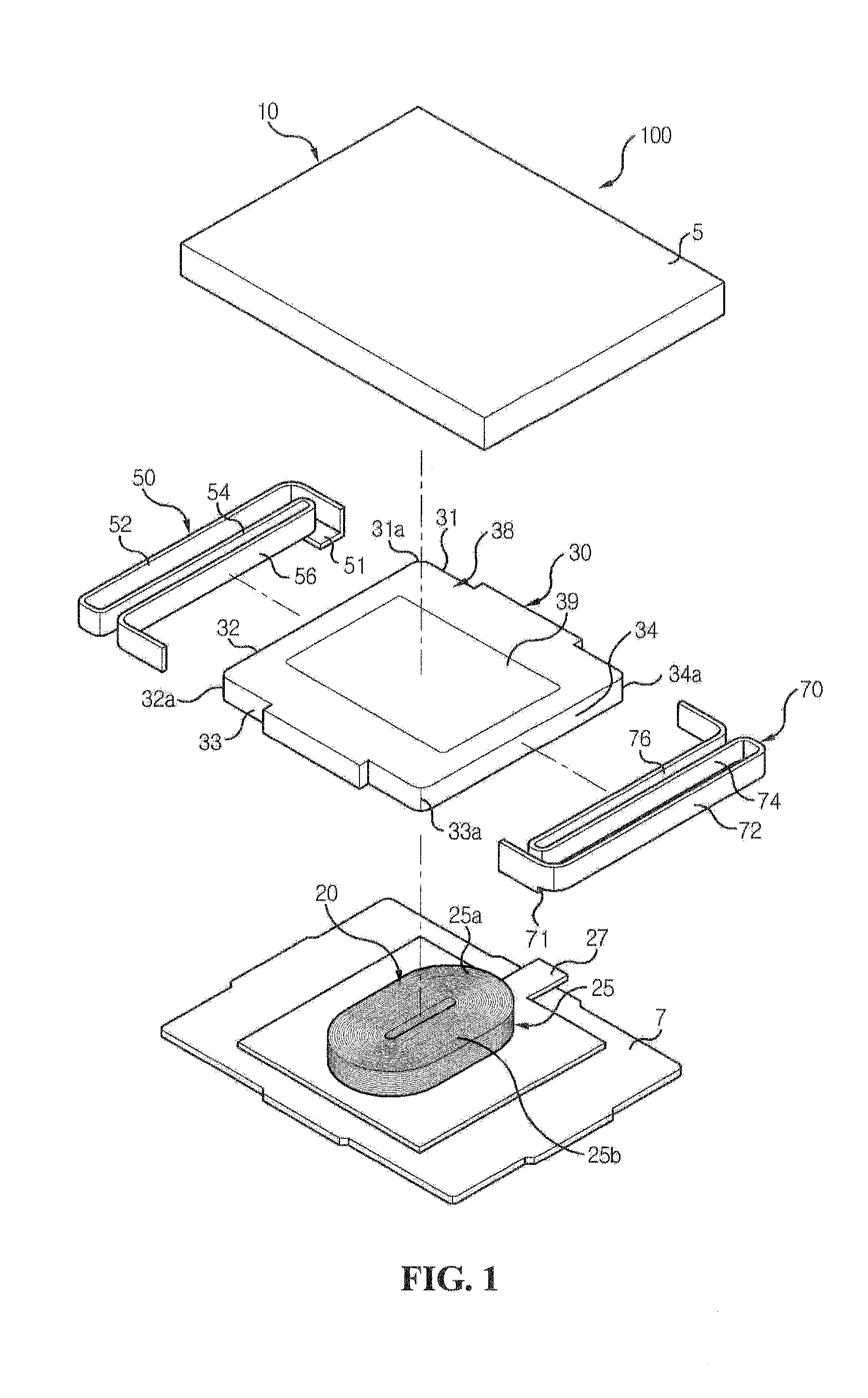

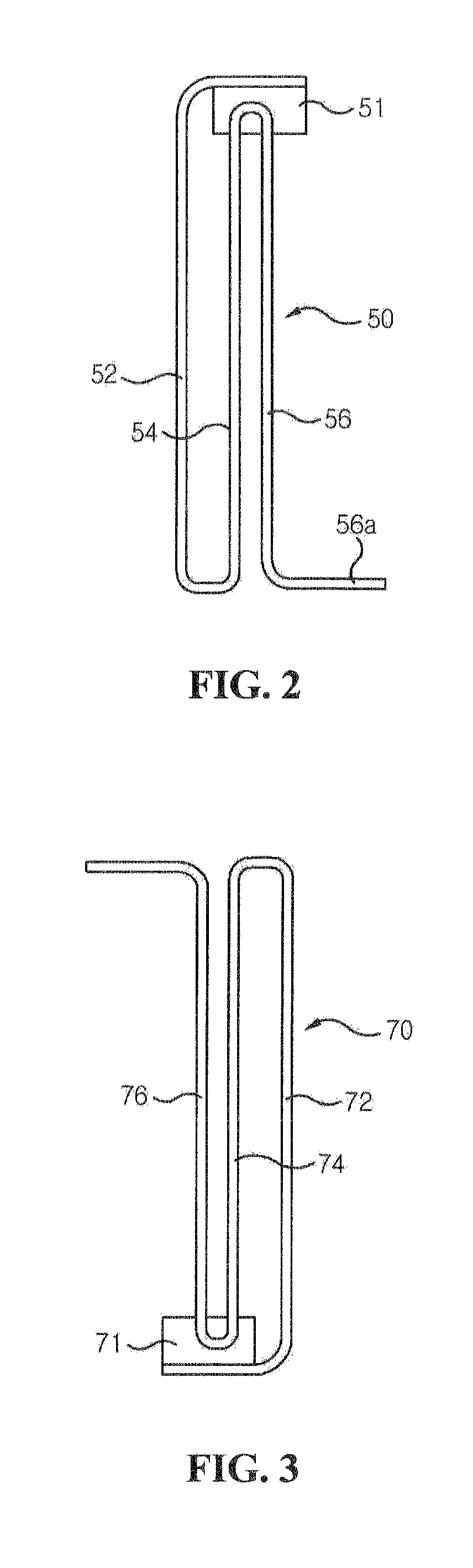

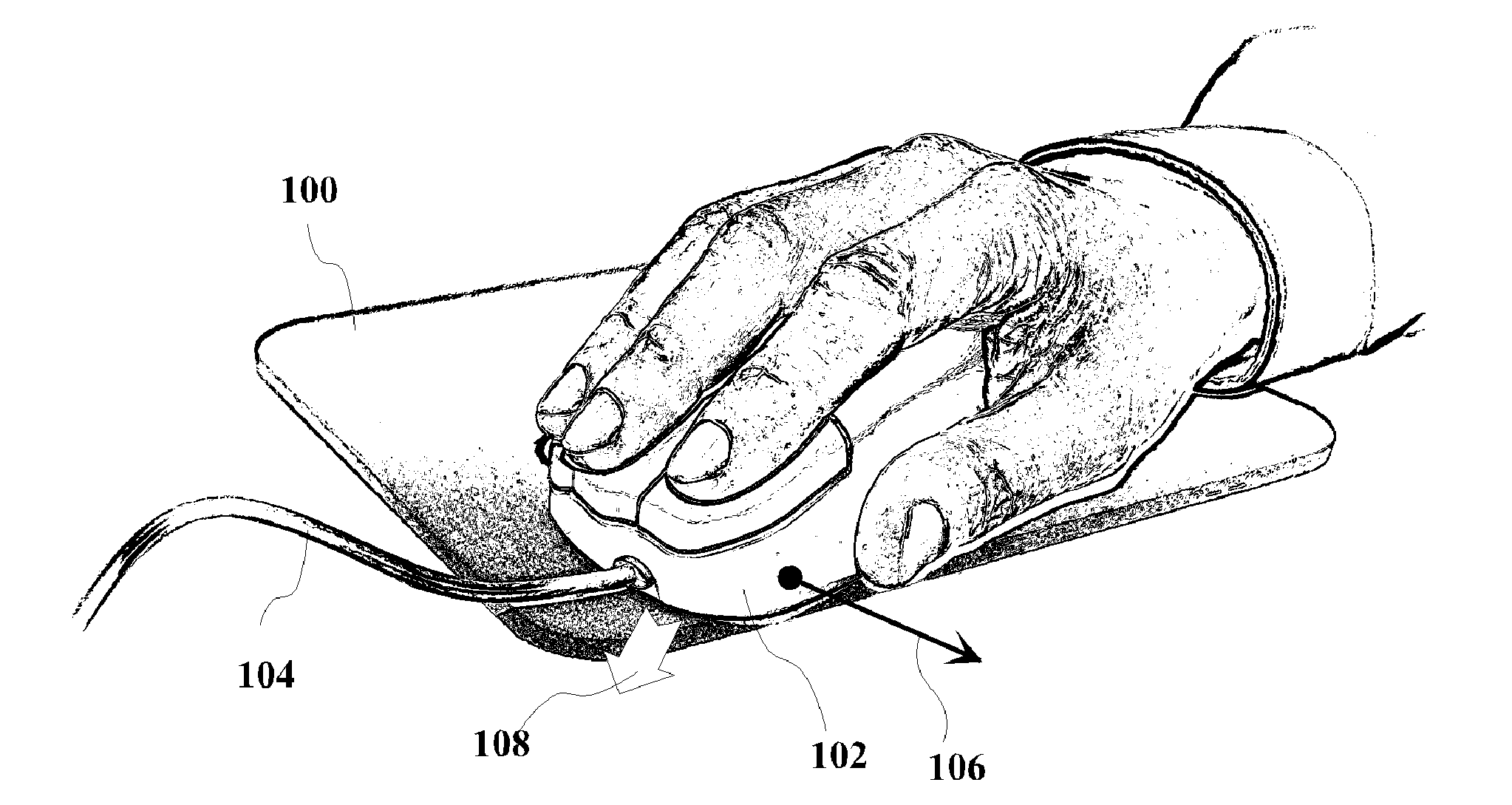

Horizontal vibration motor

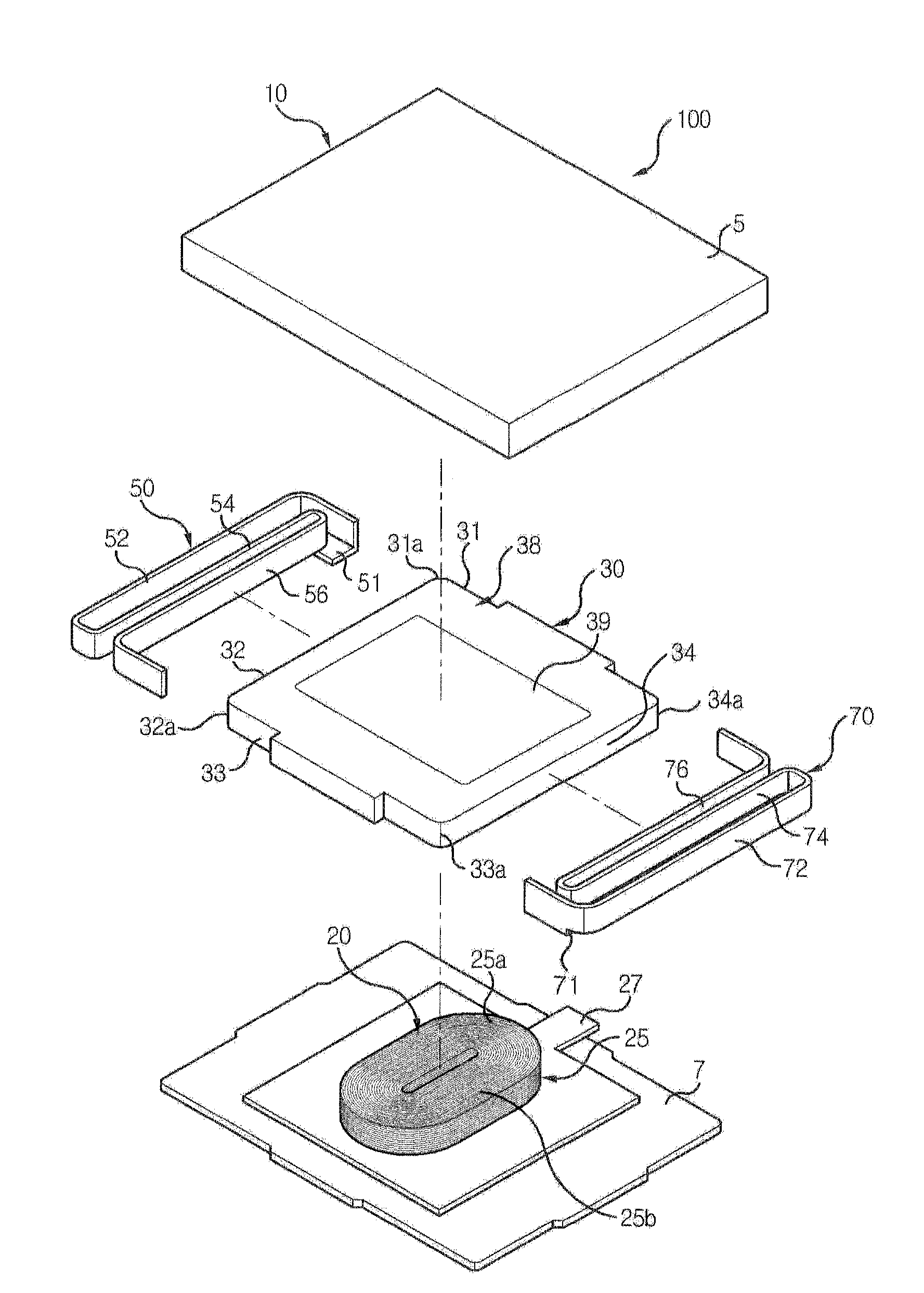

ActiveUS20120049660A1Reduce volumeReduce thicknessMechanical vibrations separationDynamo-electric machinesEngineeringMagnet

Disclosed is a horizontal vibration motor, the motor including a stator having a coil block secured to a bottom plate of a case, a vibrator having magnets placed above the coil block and a weight holding the magnets, a first elastic member having a first elastic plate secured to portion of the case corresponding to a first corner of the weight, a second elastic plate bent inwards from the first elastic plate, and a third elastic plate bent outwards from the second elastic plate and secured to portion around a second corner, and a second elastic member having a fourth elastic plate secured to portion of the bottom plate corresponding to a third corner, a fifth elastic plate bent inwards from the fourth elastic plate, and a sixth elastic plate bent outwards from the fifth elastic plate and secured to a fourth corner.

Owner:EM TECHNOLOGY CO LTD

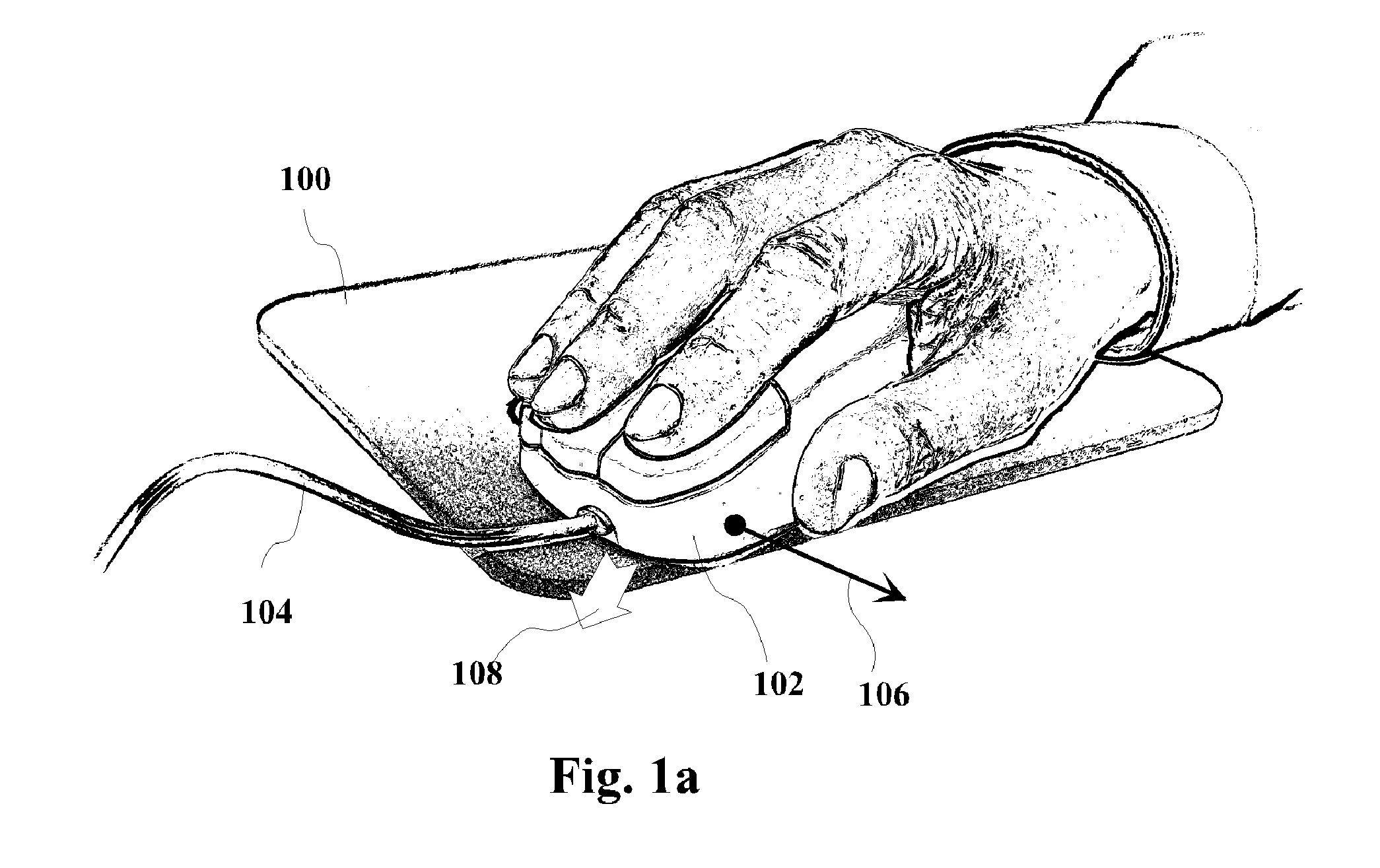

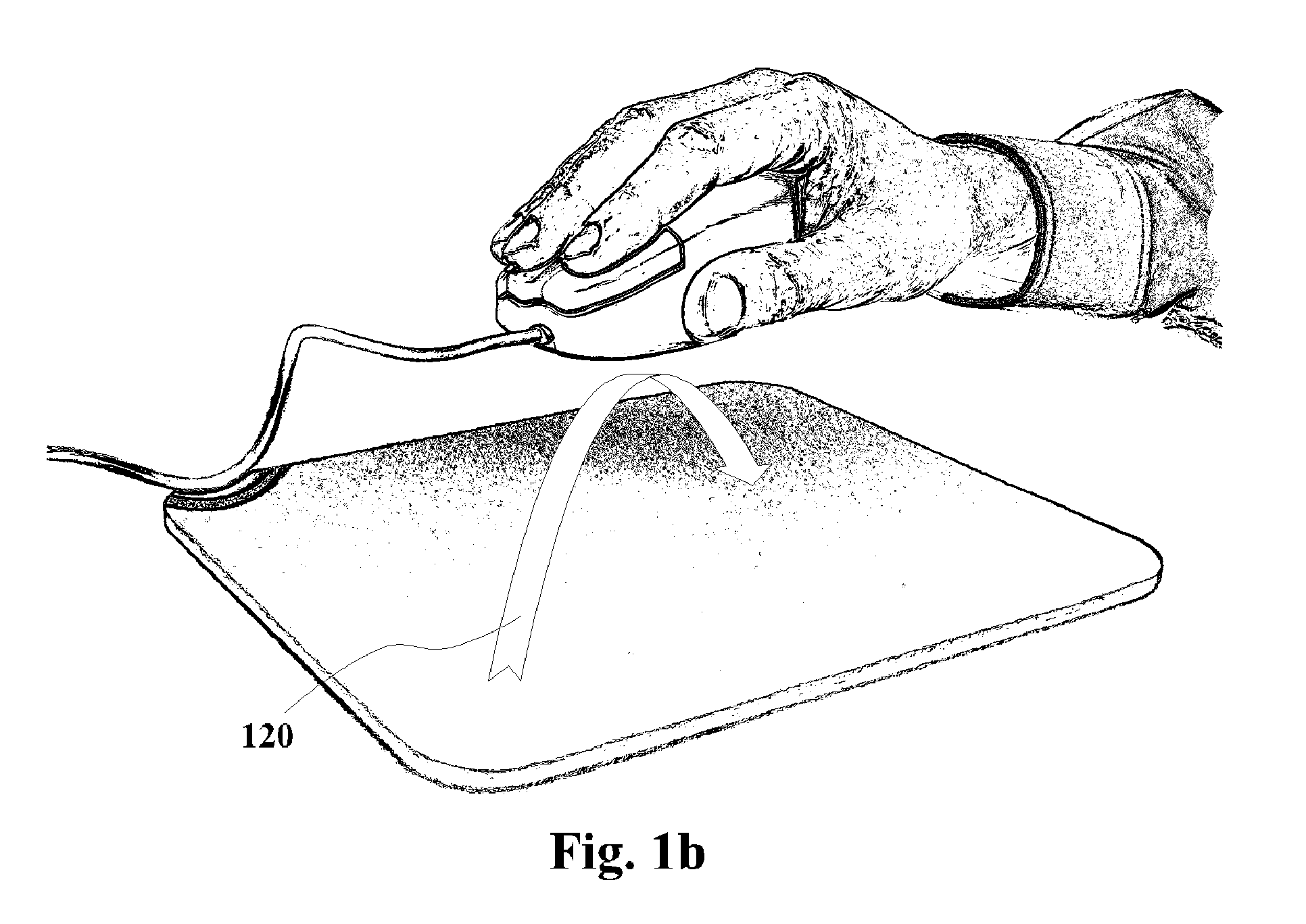

Self-propelled haptic mouse system

InactiveUS20080111791A1Cathode-ray tube indicatorsInput/output processes for data processingComputerized systemDrive motor

A haptic mouse system, comprising a self-propelled mouse (102) and a mouse pad (100), is intended for use as a mouse pointing device in a computer system. The haptic mouse system can provide directional force feedback to a user in response to commands from the host computer. The self-propelled mouse (102) is moveable over the mouse pad (100) and is separable therefrom, thus allowing the user to operate the device in multiple strokes like a regular mouse. The self-propelled mouse (102) includes a control circuit and a two-dimensionally driving motor having multiple drive elements. The motor can interact with the mouse pad (100) and produce a horizontal propelling force (106), perceptible to the user as a haptic feedback, when the drive elements are activated in a predetermined pattern and only when the self-propelled mouse (102) is placed on the mouse pad (100). The control circuit responds to commands from the host computer by varying the activation pattern in order to control direction and magnitude of the propelling force (106). Several preferred embodiments describe two-dimensionally driving motors of various design and principle of operation, including planar and spherical dynamoelectric motors, friction drives, and different types of vibration motors.

Owner:NIKITTIN ALEX SASHA

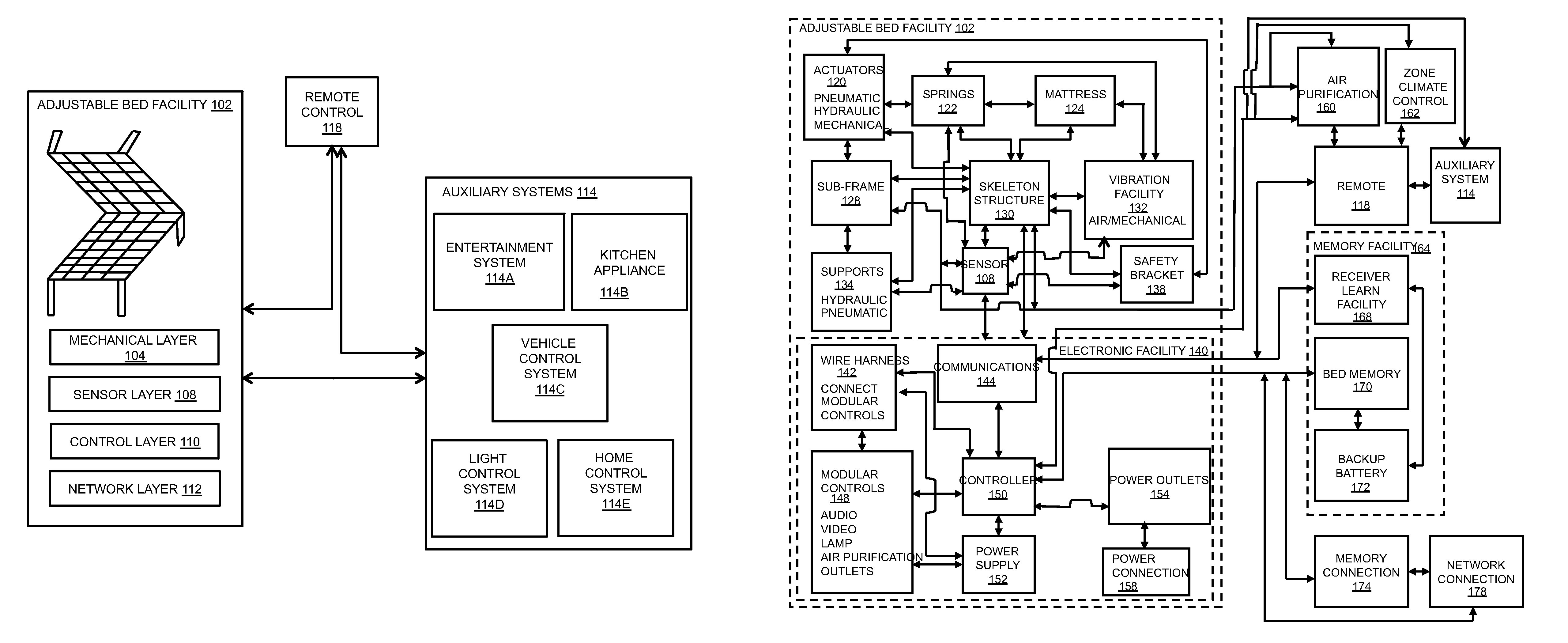

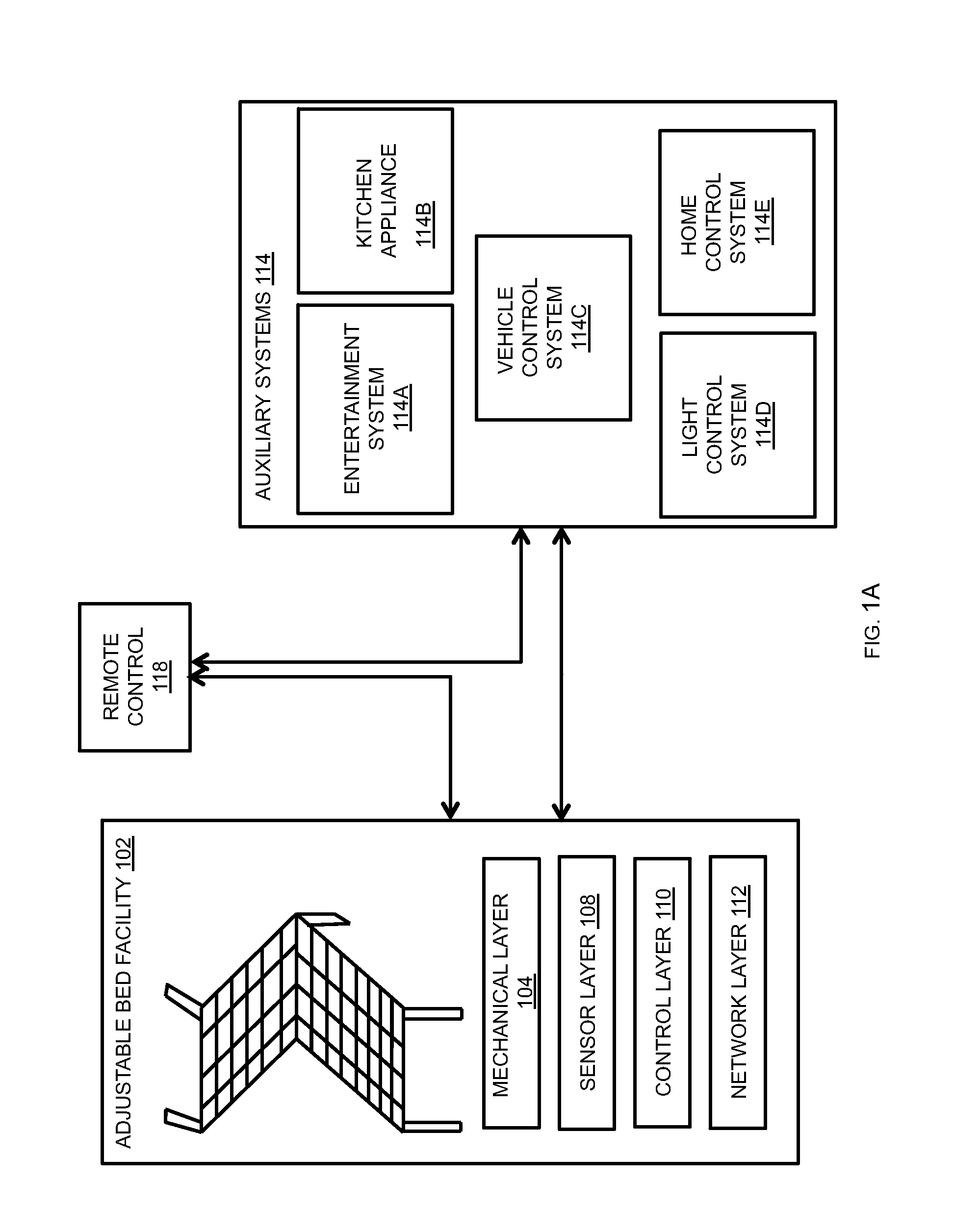

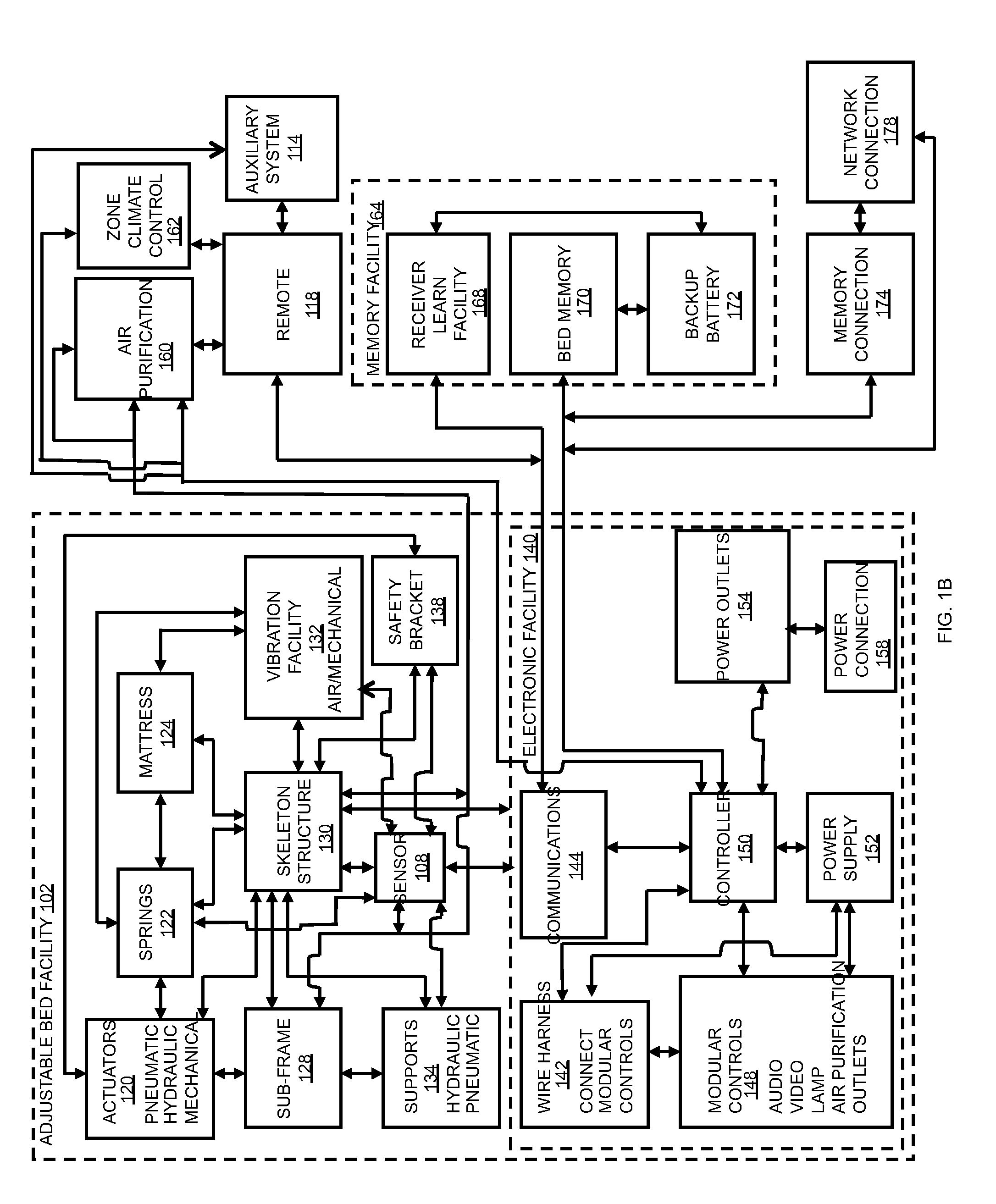

System and method of an adjustable bed with a vibration motor

The present disclosure concerns an adjustable bed facility including a system for executing a computer-based safety-action during a motor-actuated adjustable bed position adjustment, comprising an adjustable bed facility comprising a computer-based controller, an actuator, and a sensor, the computer-based controller providing control of adjustable bed position adjustments, the actuator configured to adjust a height of the adjustable bed facility upon receiving a height-adjustment command from the computer-based controller, and the sensor for determining an actuator action parameter measured value of the actuator, the computer-based controller in communicative connection with the sensor to monitor and compare the motor action parameter measured value to an actuator action parameter normal operation value range, and when the controller determines the monitored motor action parameter measured value is outside the range of the actuator action parameter normal operation value range the controller sends a safety-action command to the actuator.

Owner:RAWLS MEEHAN MARTIN B

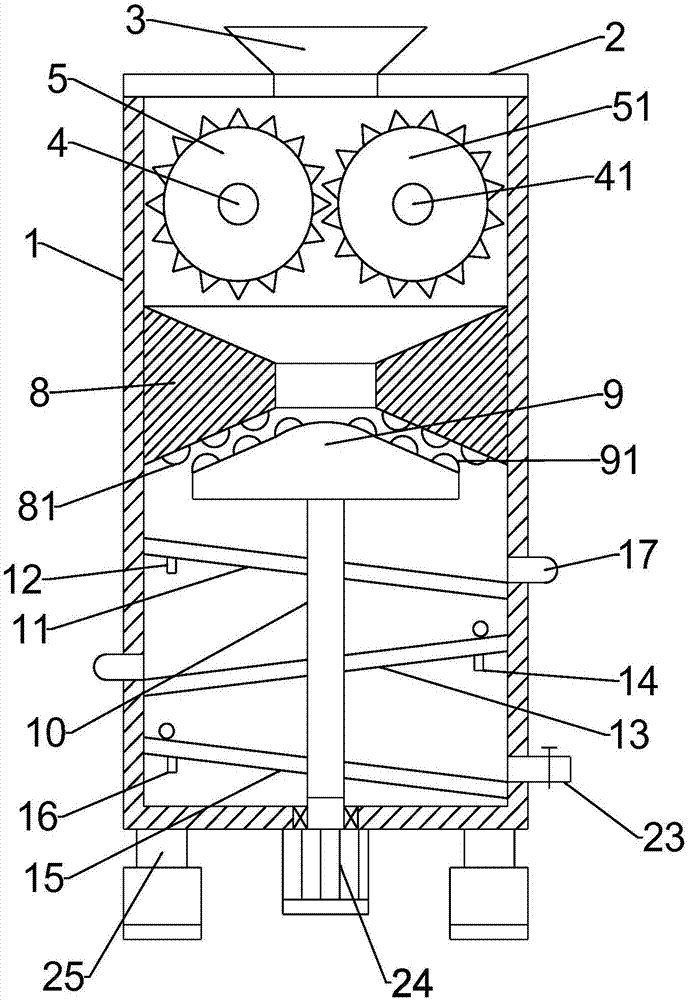

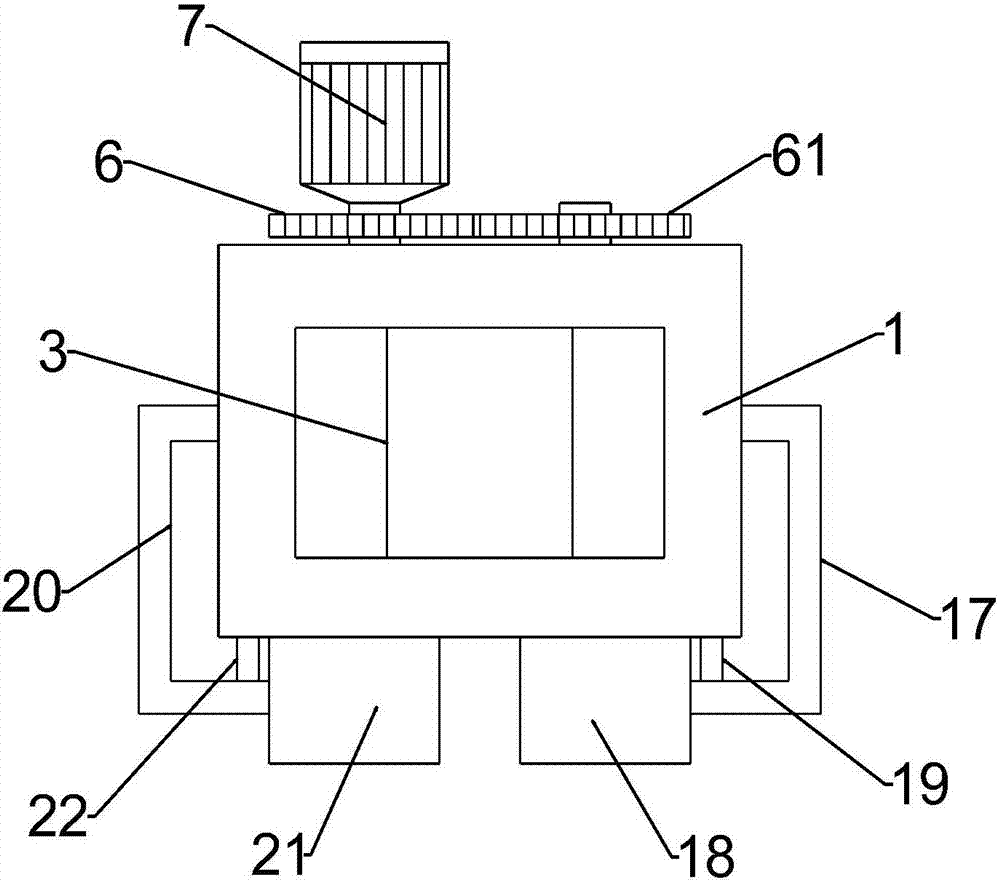

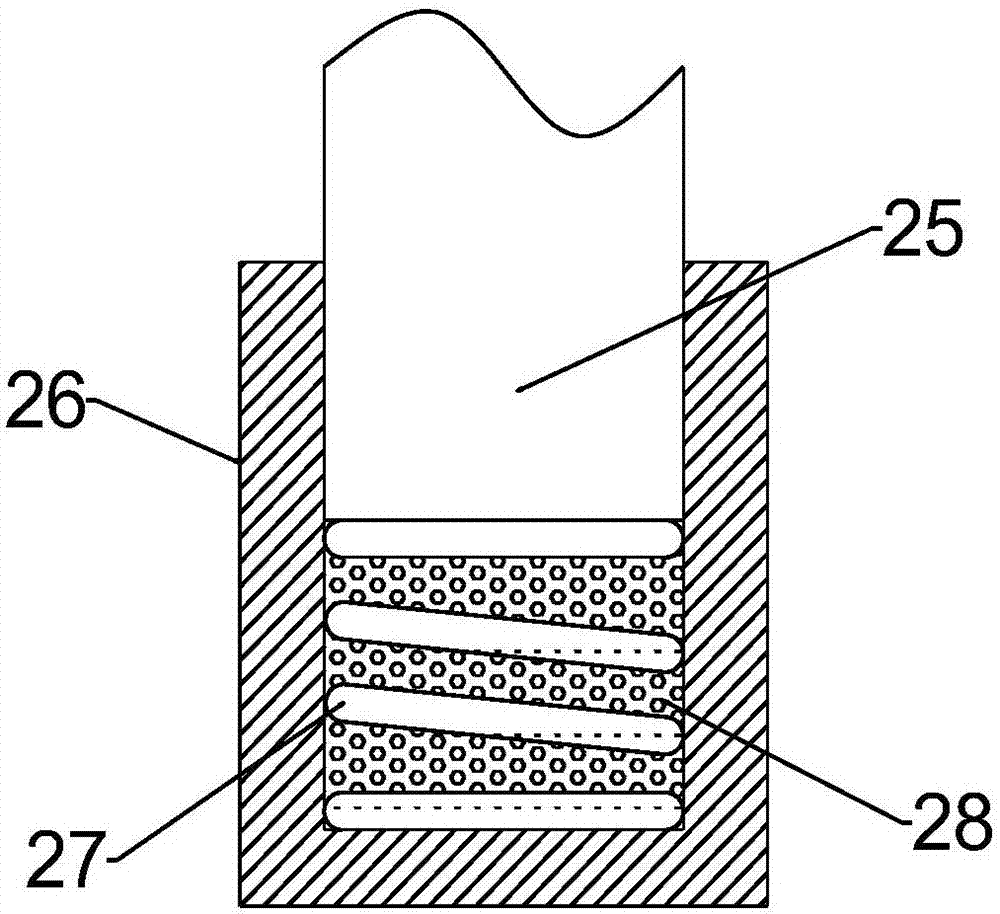

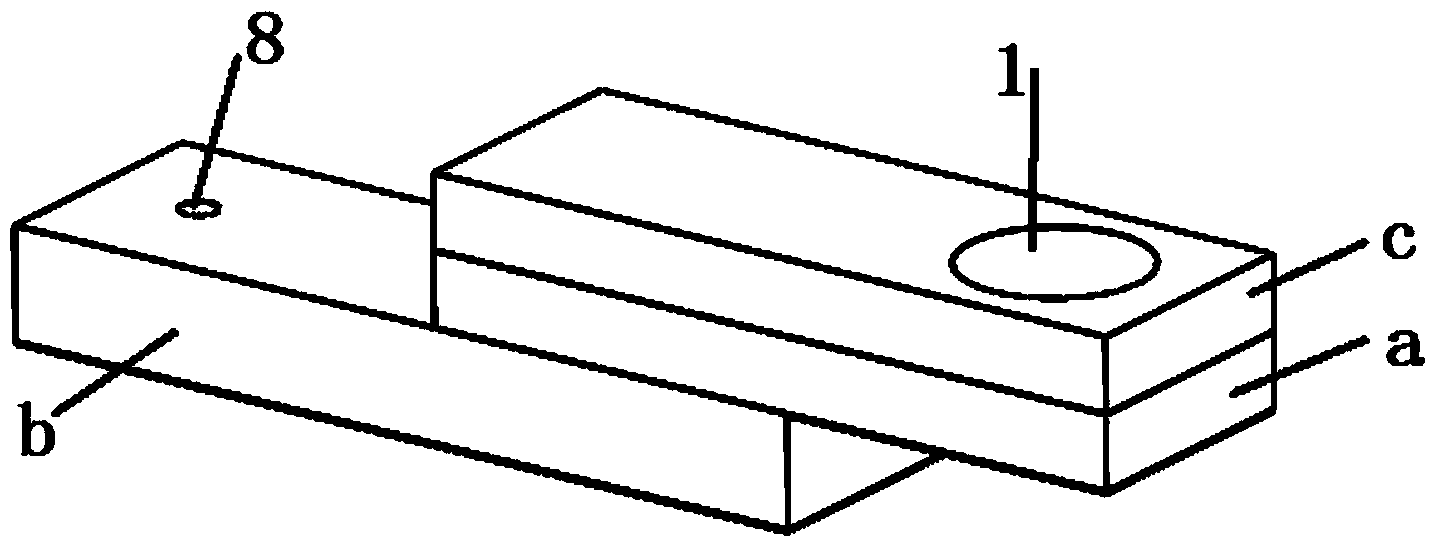

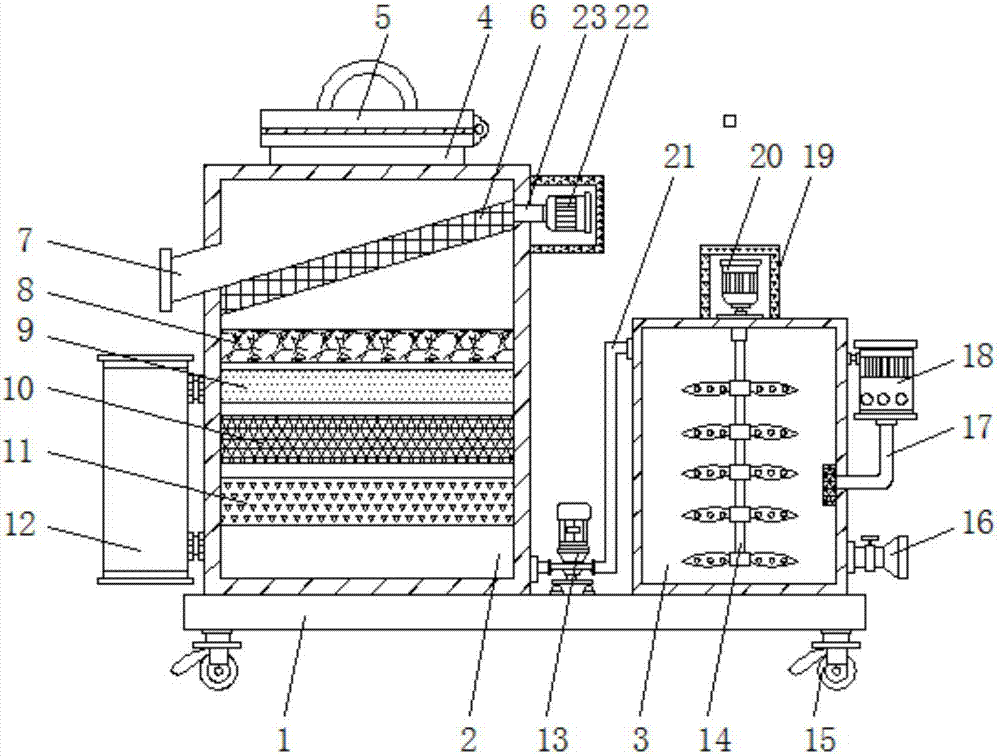

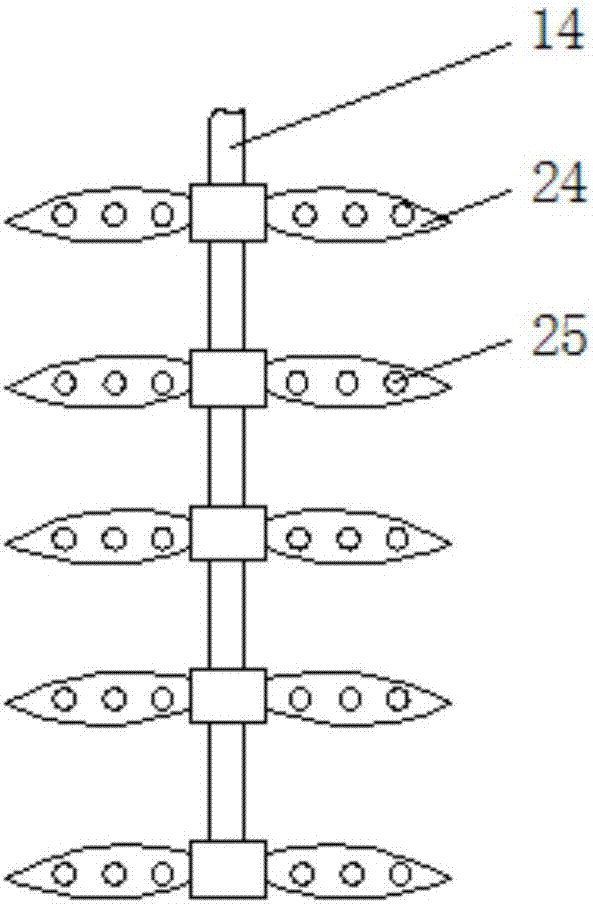

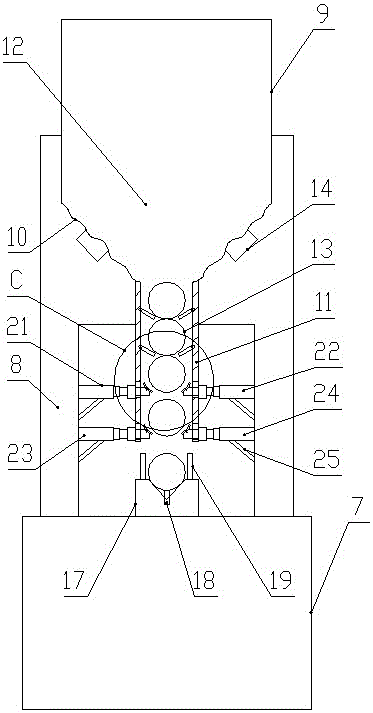

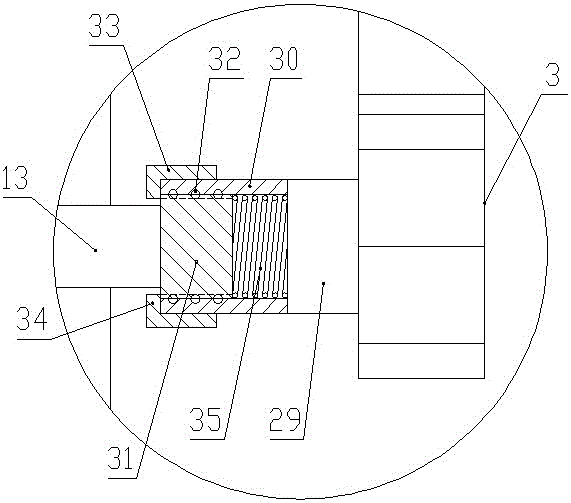

Smashing, classifying and separating device for kaolin raw ore

InactiveCN107309020AAvoid accidental adulterationStable design structureSievingScreeningGear wheelKaolin clay

The invention discloses a crushing, grading and separating device for kaolin raw ore, which comprises a casing, the upper end of the casing is provided with an upper cover, the middle part of the upper cover is provided with a feeding hopper, and the casing is provided with a left rotating shaft, a right rotating shaft, and a left crushing wheel. , right crushing wheel, concentrated guide plate, fixed grinding protrusion, grinding disc, rotating protrusion, vertical shaft, primary screen filter, first vibration motor, fine screen filter, second vibration motor, tailing deflector, The third vibrating motor is provided with a driving gear and a driven gear on the periphery of the left and right shafts, a first motor is provided at the end of the left shaft, and the right wall of the housing is provided with a primary sieve discharge pipe, a primary sieve collection box, a first return pipe and The tailings discharge pipe, the left wall of the shell is provided with a fine sieve discharge pipe, a fine sieve collection box and a second return pipe, and the lower end of the shell is riveted with a second motor, a support rod, a support sleeve, a damping spring and a shock absorber filling. The invention can efficiently grind and pulverize the kaolin and sieve and classify it.

Owner:CHANGSHA KEYUE ENTERPRISE MANAGEMENT CONSULTING CO LTD

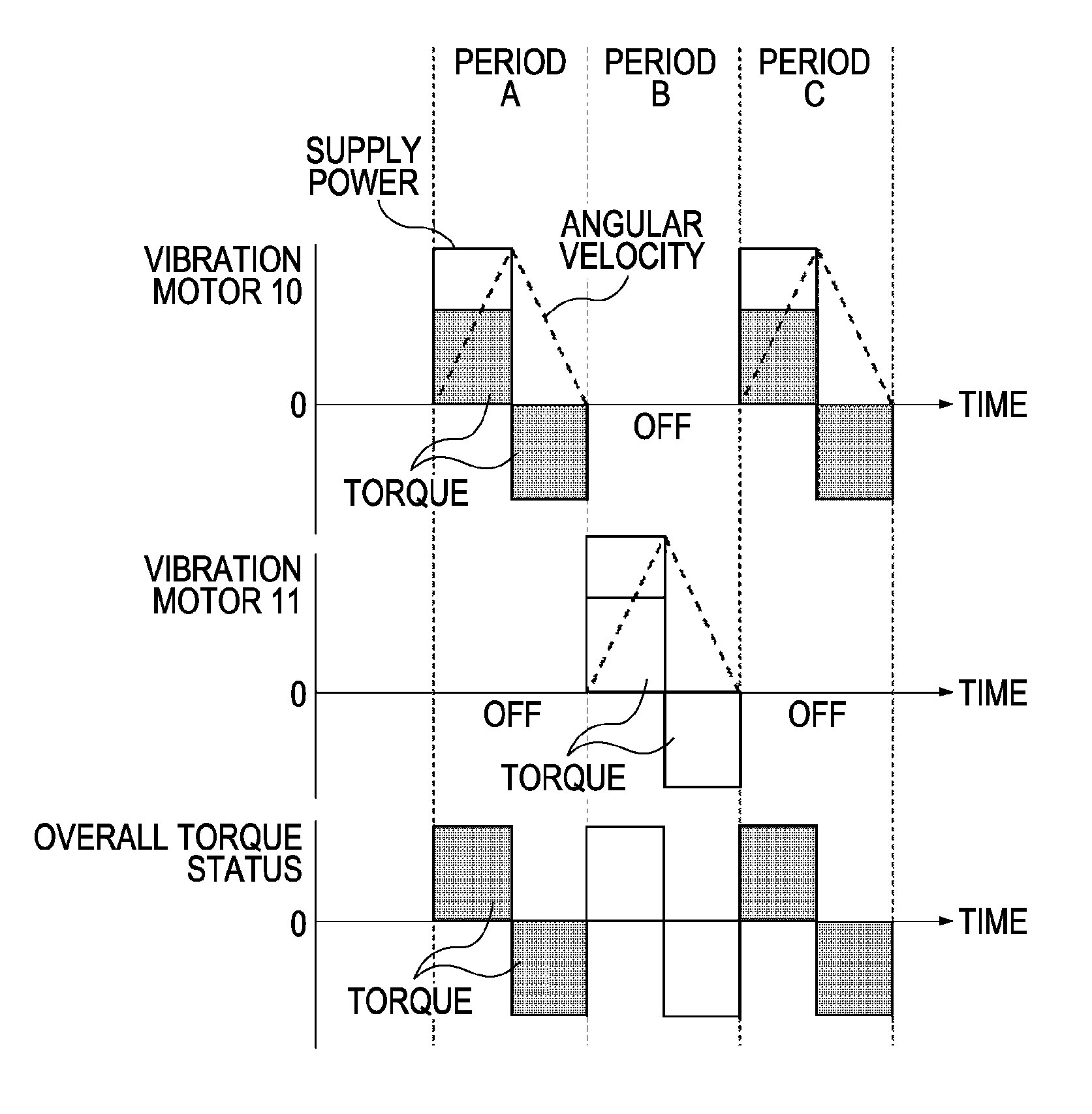

Feel presenting device and method

InactiveUS20070290988A1Increasing its expressive powerIncrease powerCathode-ray tube indicatorsInput/output processes for data processingHuman bodySkin surface

The present invention provides a device configured to present the feel of a plane or an object surface to a user using equipment configured to generate physical vibration such as a vibration motor or the like. A plurality of vibration motors including an eccentric rotor are put on a human body, and torque generated at the vibration motor along with an angular velocity fluctuation is provided to a skin surface in the horizontal direction with a different timing. Alternately generating torque by the plurality of vibration motors enables the user to perceive a plane or an object surface.

Owner:CANON KK

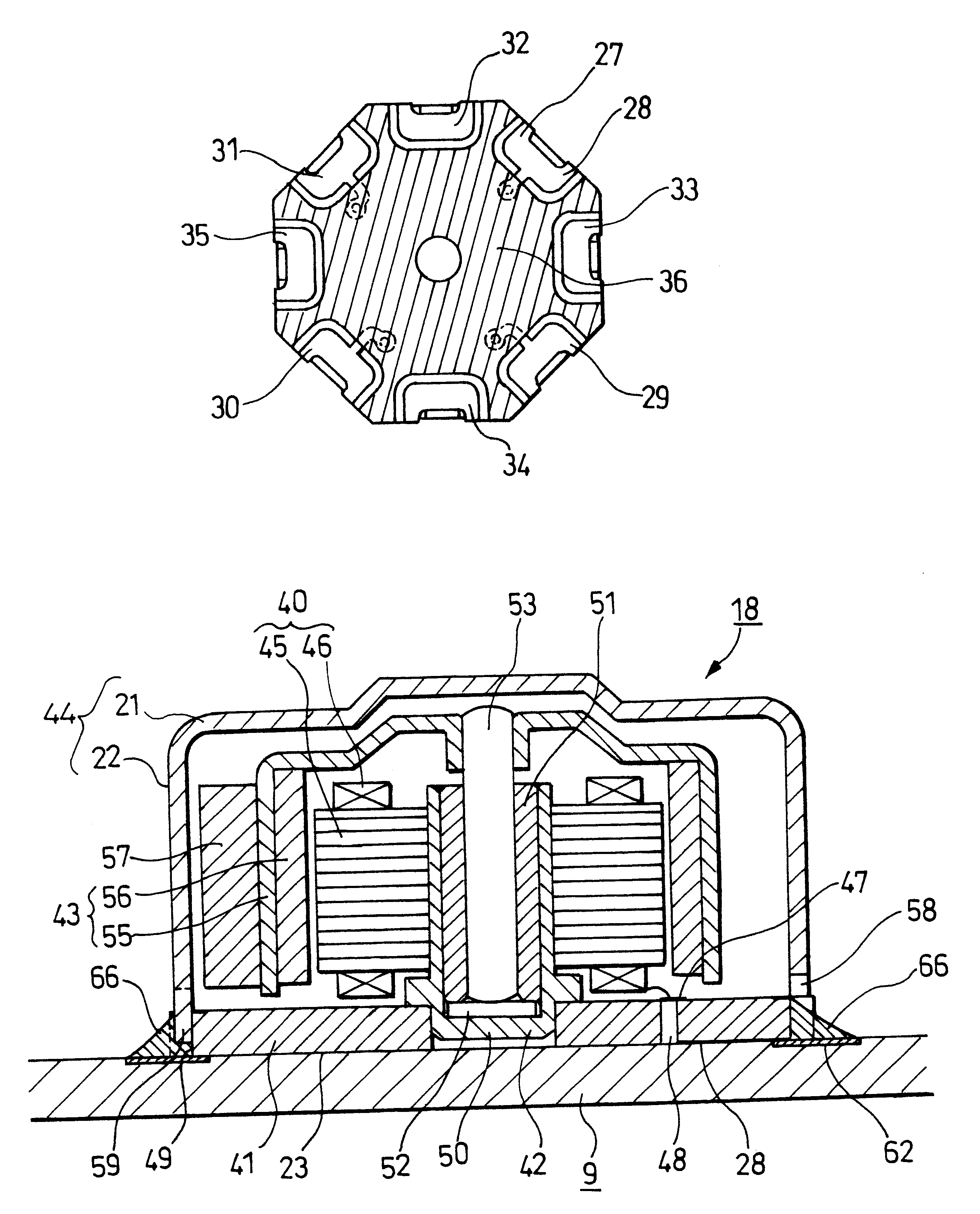

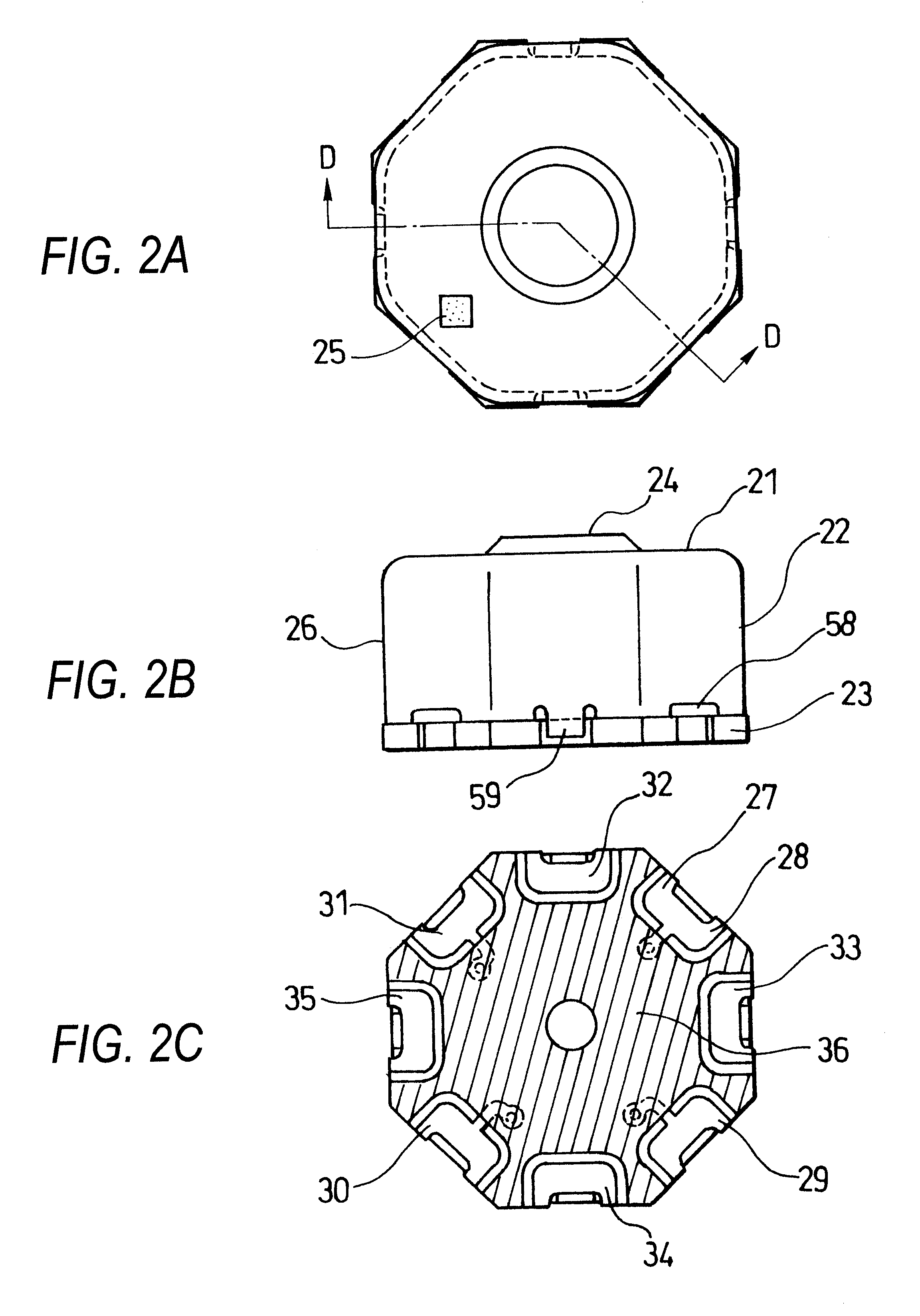

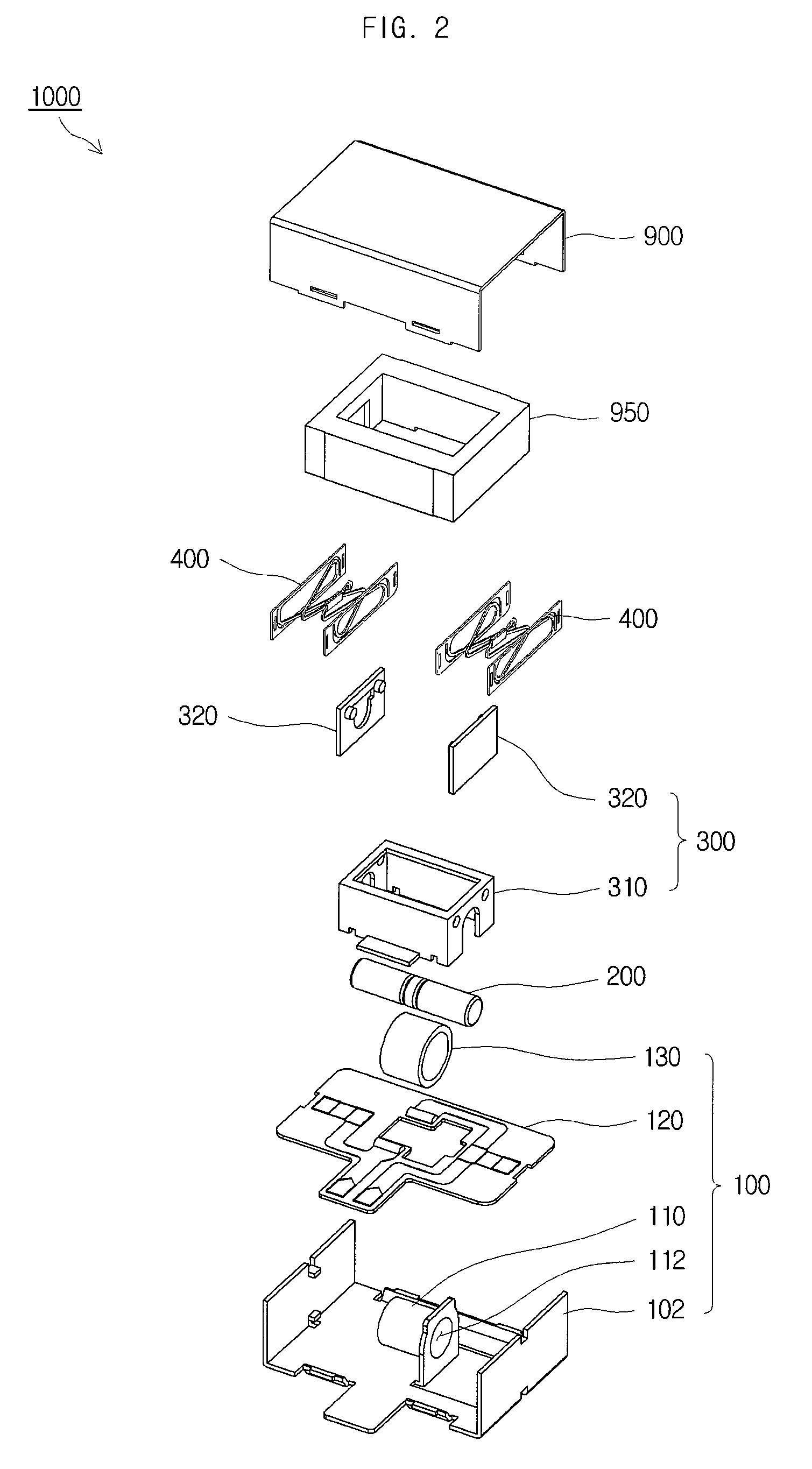

Vibration motor holding apparatus and portable electronic equipment having the same

InactiveUS6274955B1Easy to identifyConvenient inspectionMagnetic/electric field screeningMechanical vibrations separationElectronic equipmentVibration motor

A vibration motor 18 constituted by a motor provided with a weight 57 is covered with a cover 44 having a flat portion for making the cover 44 be sucked easily and a marking for positioning, and this vibration motor is mounted on a main-body printed board 9. In this main-body printed board, line lands and main-body lands also having a function for identification are provided outside the outline of the mounted vibration motor, so that a displacement of the mounting position can be easily detected even visually.

Owner:PANASONIC CORP

Vibration motor

InactiveUS7911098B2Increase volumeSimple structureMechanical vibrations separationStructural associationLinear vibrationMagnet

A linear vibrator is disclosed. The linear vibrator includes a base, a coil unit, which is coupled to the base, a magnet, which is coupled to the coil unit such that the magnet can move relatively, and a plurality of leaf springs, which are interposed between the magnet and the base. Here, the plurality of leaf springs face one another and are coupled to one another Thus, the linear vibrator can increase the range of vibration displacement in a structure and increase the amount of vibration in the linear vibrator. Also, even though the linear vibrator becomes thinner, the range of displacement can be increased because the weight is vibrated horizontally.

Owner:MPLUS

Flat eccentric rotor equipped with a fan and flat vibration motor equipped with a fan comprising same rotor

InactiveUS20070104593A1Increase the differenceIncrease the amount of vibrationPump componentsPiston pumpsImpellerEngineering

An eccentric rotor equipped with a fan is included in an axial gap micro-fan motor for generating vibrations and cooling. The rotor has a first impeller section having a low specific gravity and a second impeller section having a high specific gravity. Each fan comprises a flat section at an upper surface of an axial gap magnet and an impeller section at a side of the magnet. The fans are assembled by concave-convex mating sections at the flat sections and are also bonded to and held by the axial gap magnet. Impeller blades of the fans are optionally formed as backward vanes.

Owner:TOKYO PARTS IND CO LTD

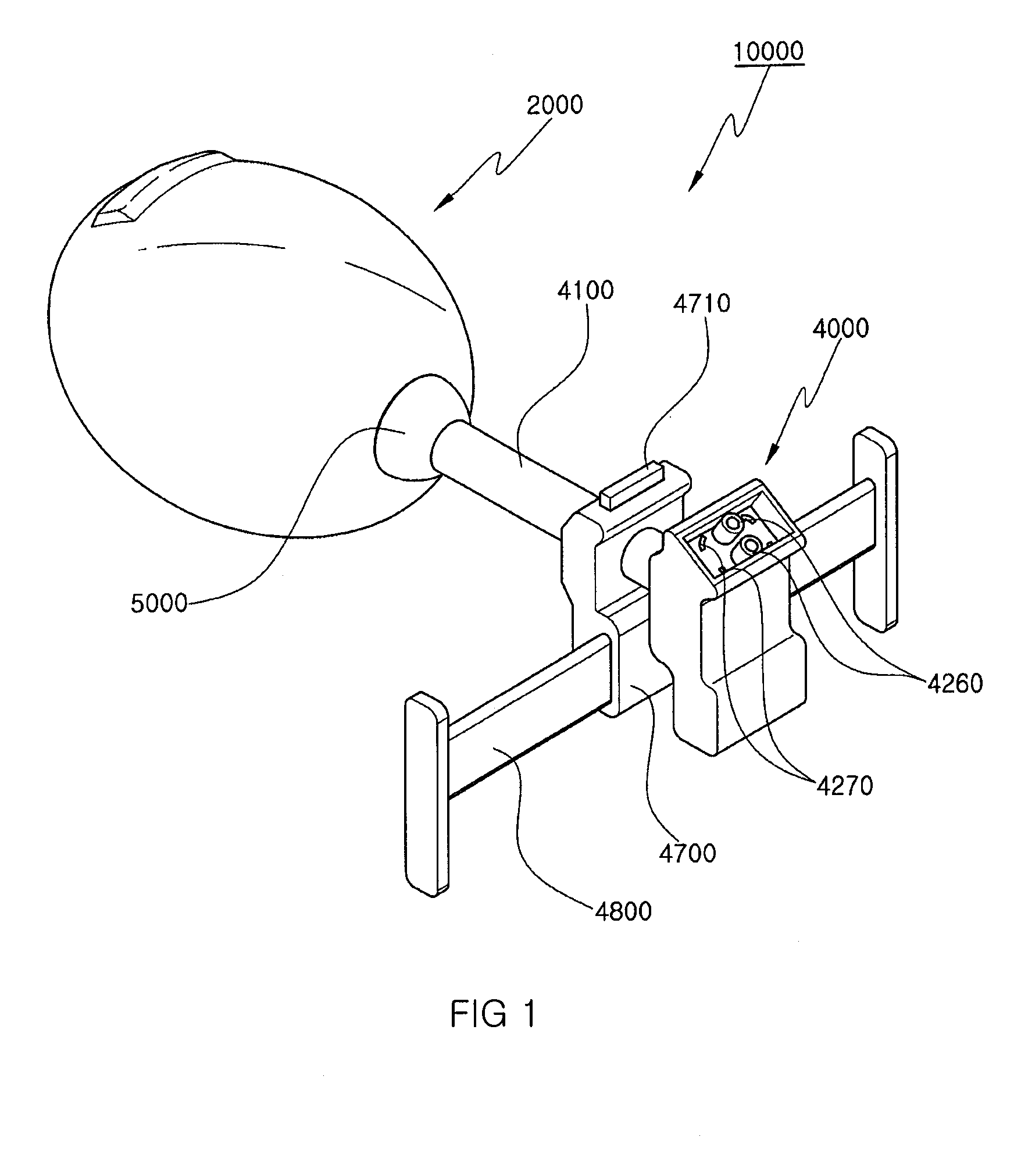

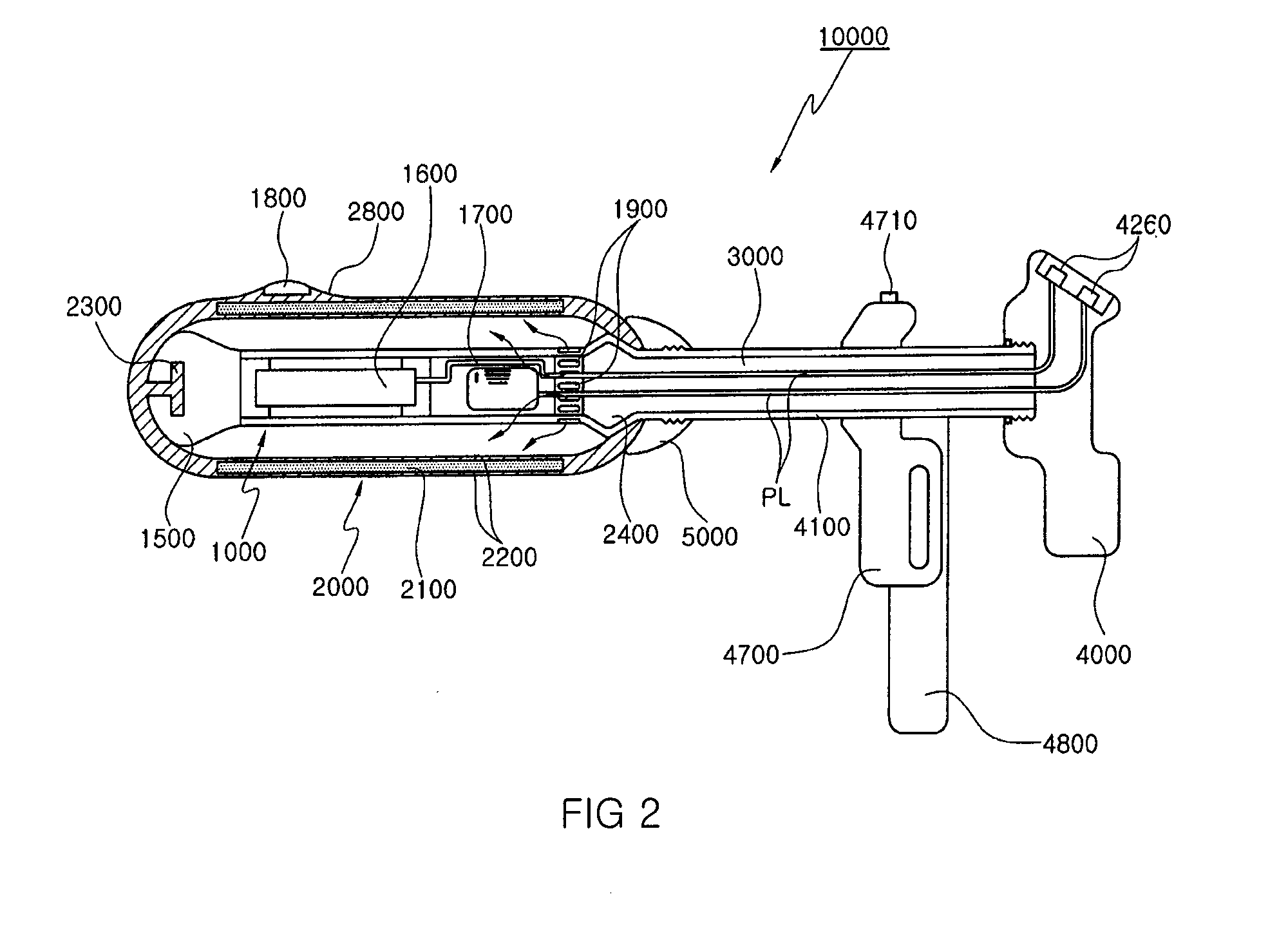

Apparatus For Examining and Curing Urinary Incontinence, and For Exercising Bio-Feedback of Women Vagina Muscles

ActiveUS20080139876A1Simple treatmentReadily treat urinaryPerson identificationGenitals massagePelvic diaphragm muscleAir pump

An apparatus for examining and curing urinary incontinence and exercising the pelvic floor muscles and vaginal muscles using bio-feedback including a controller main body, a probe, and a bio-feedback device. The probe includes: an insert frame extending in a longitudinal direction thereof, an insert expansion part surrounding adjacent to a front end of the insert frame and expandable therearound; an air supply path connected to the interior of the insert expansion part to supply air; a handle engaged with the insert frame; a fixing means for fixing the insert expansion part to the insert frame or the handle; a valve installed at the air supply path; and a PTC ceramic heater and a vibration motor installed at the insert frame. An elastic member includes a magnet, an insertion depth adjustment part, and leg support parts installed at the insertion depth adjustment part. The bio-feedback device includes a sound generating means, and an image display means. The main body includes a controller for controlling each component, a motorized air pump, an air flow detection sensor, a pressure detection sensor, a spring air cylinder, a solenoid air injection valve, an air tank, etc. Therefore, it is possible for a user to readily perform examination and treatment of urinary incontinence and pelvic floor muscle (vagina muscle) reinforcement exercise using bio-feedback.

Owner:APIMEDS

Vibration motor

InactiveUS20110101797A1Avoid concentrated stressAvoid a damage caused by the stressMagnetic circuit stationary partsReciprocating motionLeaf spring

A vibration motor is disclosed. In accordance with an embodiment of the present invention, the vibration motor includes a base, a vibrator, which reciprocates, a coupling part, which is protruded on at least one of the base and the vibrator, and a leaf spring, which includes a frame and an elastic part. Here, the frame is coupled to the coupling part and disposed apart from the base or the vibrator in which the coupling part is formed, and the elastic part is extended from the frame and elastically supports the vibrator. Thus, the leaf spring can be prevented from having concentrated stress and damage occurred, thereby improving the lifetime of the leaf spring.

Owner:SAMSUNG ELECTRO MECHANICS CO LTD

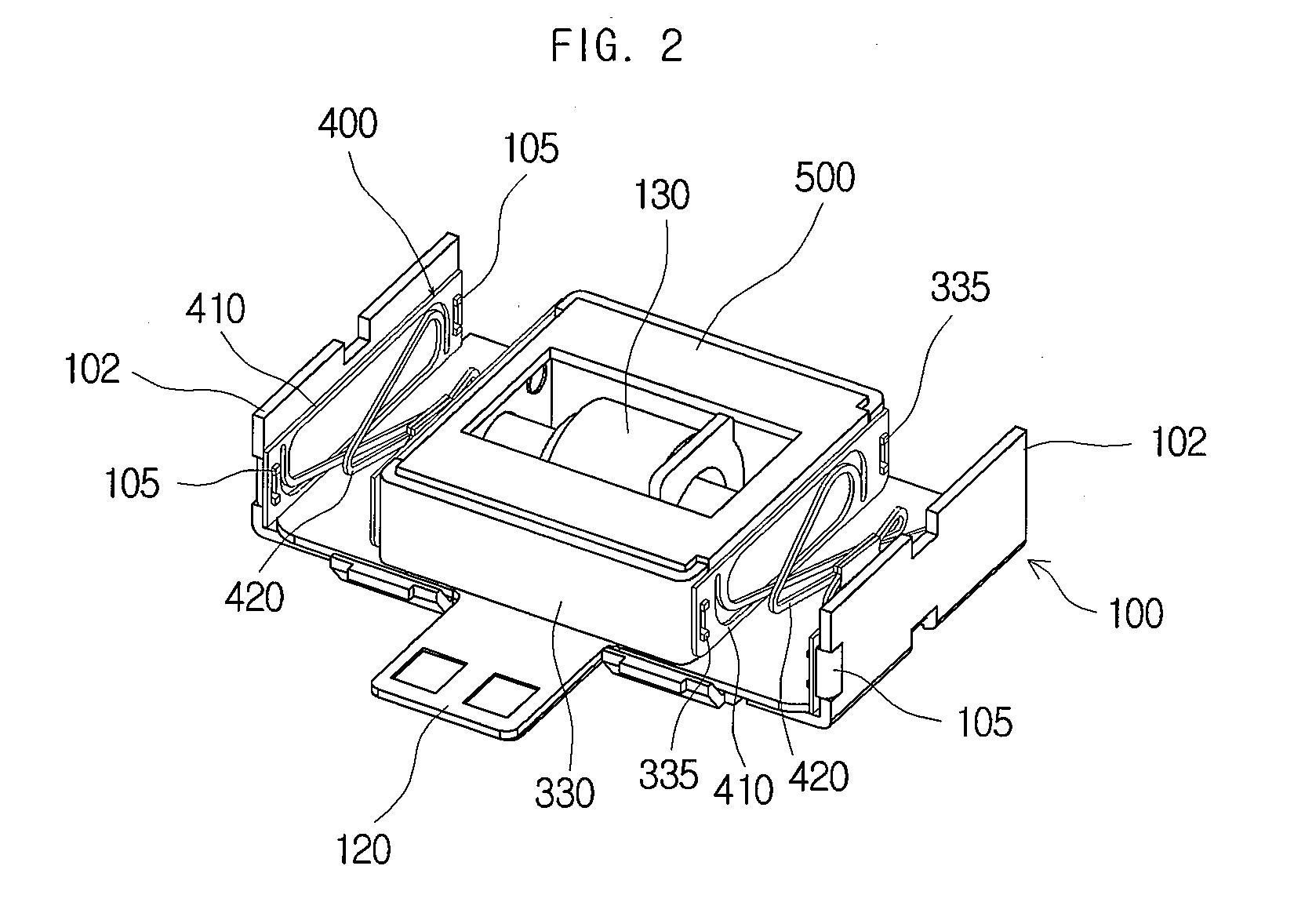

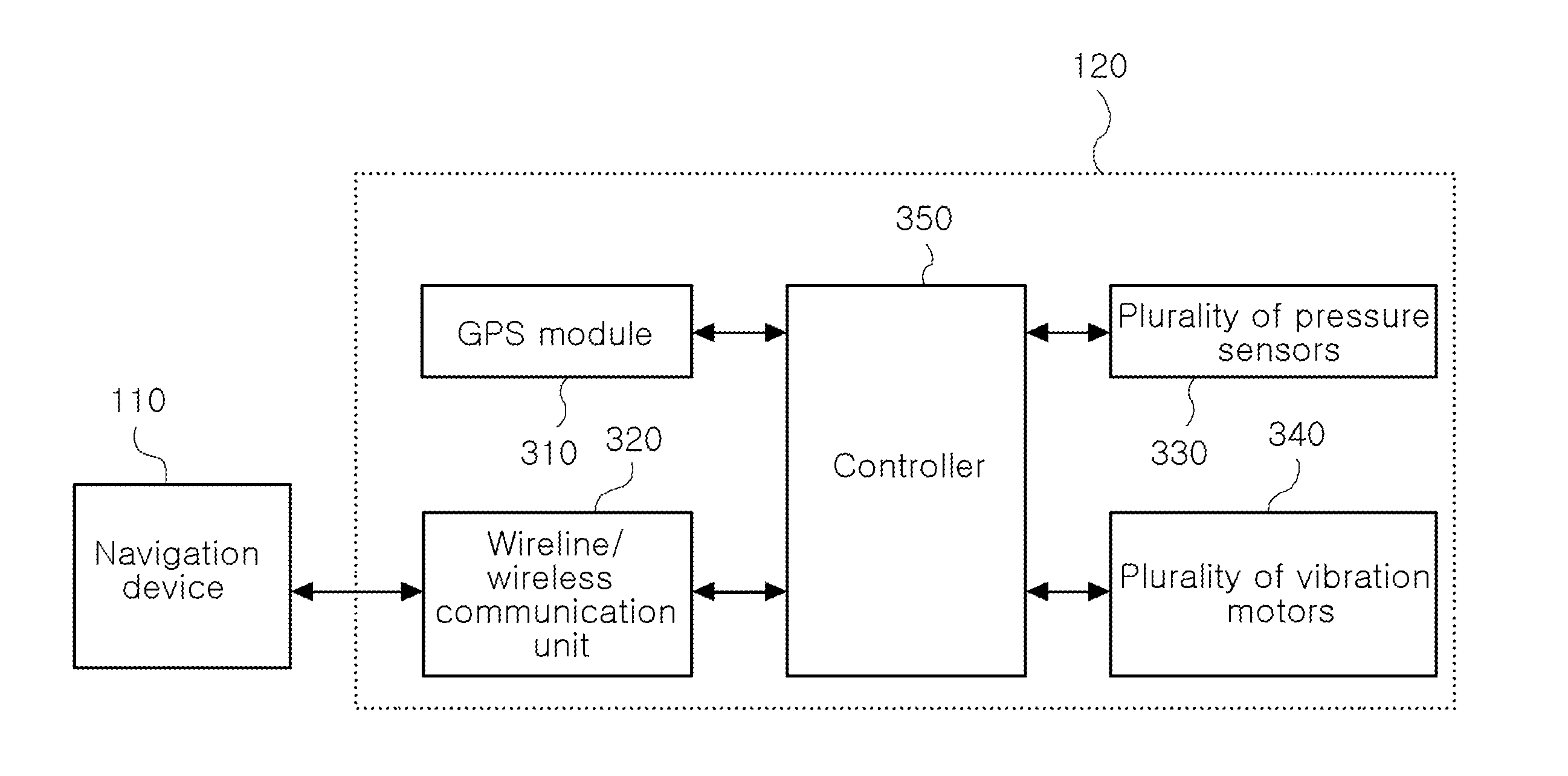

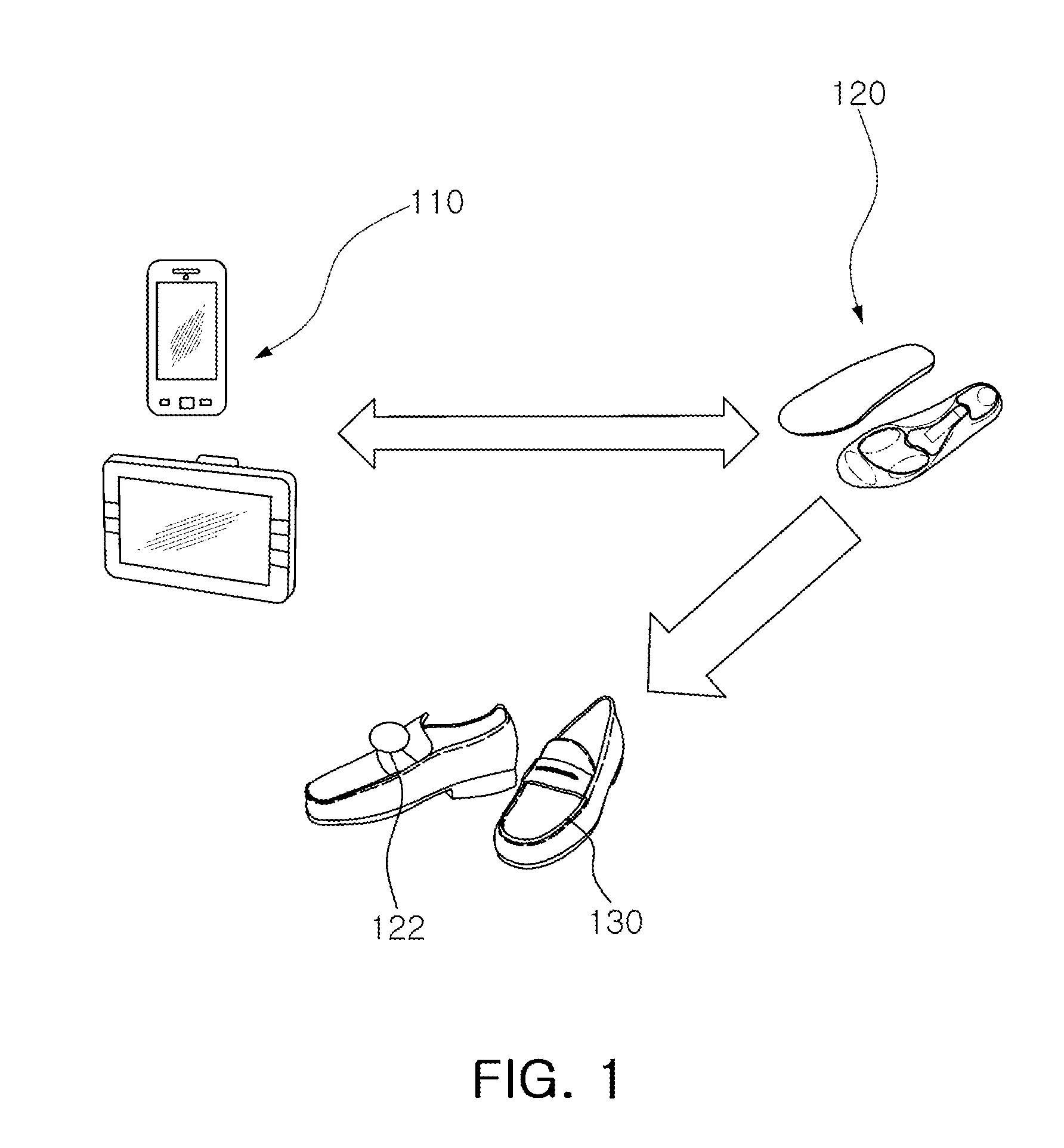

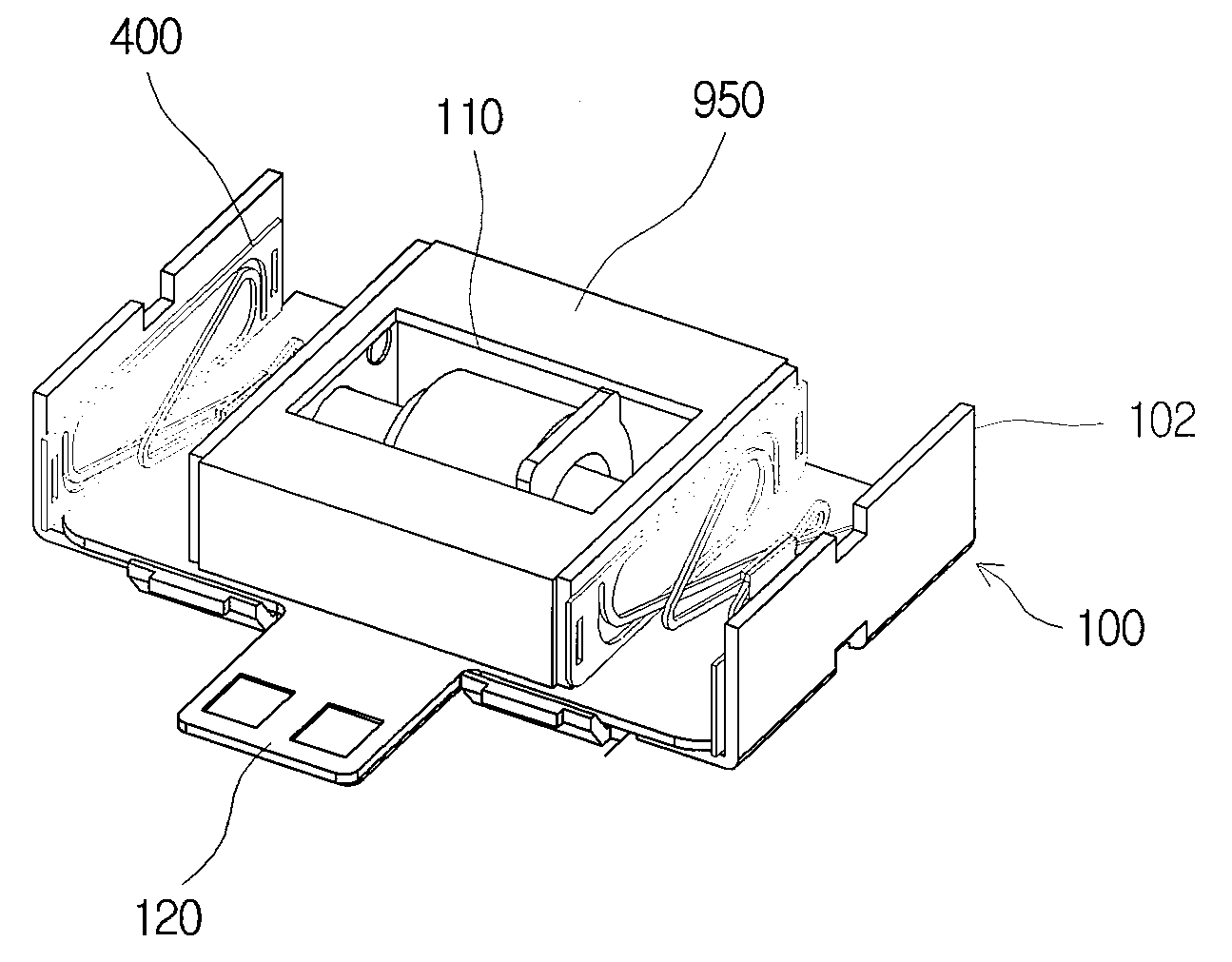

Insole type navigation apparatus and operation method thereof

InactiveUS20110153197A1Maximizing user convenienceEasy to useInstruments for road network navigationInflated body pressure measurementEngineeringVibration motor

Owner:ELECTRONICS & TELECOMM RES INST

Vibration motor

InactiveUS20110006618A1Increase volumeSimple structureMechanical vibrations separationMechanical energy handlingEngineeringLinear vibration

A linear vibrator is disclosed. The linear vibrator includes a base, a coil unit, which is coupled to the base, a magnet, which is coupled to the coil unit such that the magnet can move relatively, and a plurality of leaf springs, which are interposed between the magnet and the base. Here, the plurality of leaf springs face one another and are coupled to one another Thus, the linear vibrator can increase the range of vibration displacement in a structure and increase the amount of vibration in the linear vibrator. Also, even though the linear vibrator becomes thinner, the range of displacement can be increased because the weight is vibrated horizontally.

Owner:MPLUS

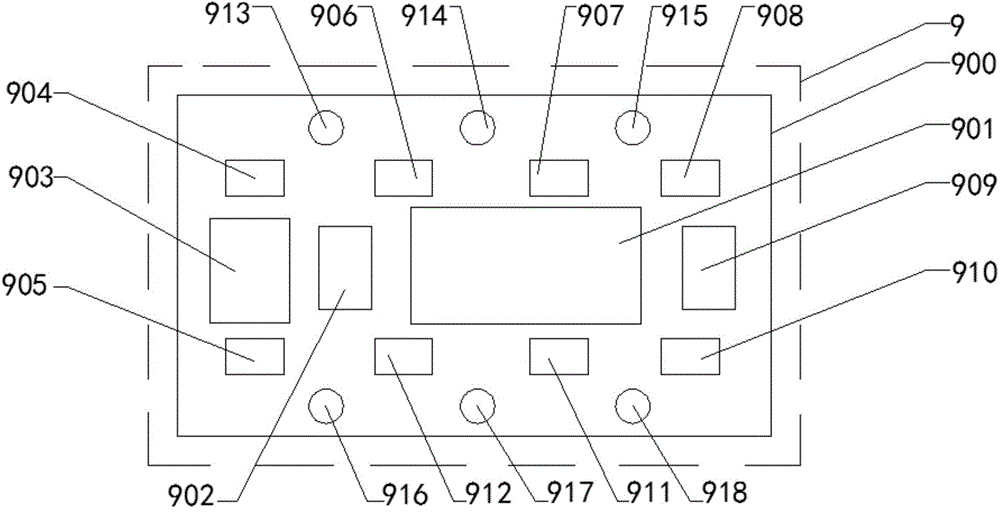

Magnetic bead-based sample treatment and nucleic acid automatic extraction system

InactiveCN104232469AImplement automatic removalEasy to operateBioreactor/fermenter combinationsBiological substance pretreatmentsSiphonPeriodic alternating

The invention discloses a magnetic bead-based sample treatment and nucleic acid automatic extraction system, comprising a micro-fluidic chip and a micro motor drive device, wherein the micro-fluidic chip comprises a layer of cover plate, two layers of bottom plates and two layers of structure plates, wherein the chip can automatically finish the operation processes such as cell lysis, nucleic acid purification, nucleic acid eluting and the like, and finally a nucleic acid sample is obtained. Based on siphon principle or micro-fluidic surface tension properties, a driven drive pump without external drive force is designed by the chip, so as to achieve flowing and transferring of a detection sample, a reaction reagent and reaction liquid waste. Under mixed hardening of a micro vibration motor, through a periodic alternating magnetic field and a constant magnetic field provided by an external magnet, effective mixing between the magnetic bead and the reaction sample and the reaction reagent in a reaction cavity, and fixing of the magnetic bead in the liquid waste discharge process are achieved; and the chip is matched with a full-automatic micro motor drive device to automatically finish a plurality of reaction steps, so that a high-purity nucleic acid sample template is provided for gene amplification reaction.

Owner:BEIJING UNIV OF CHEM TECH +1

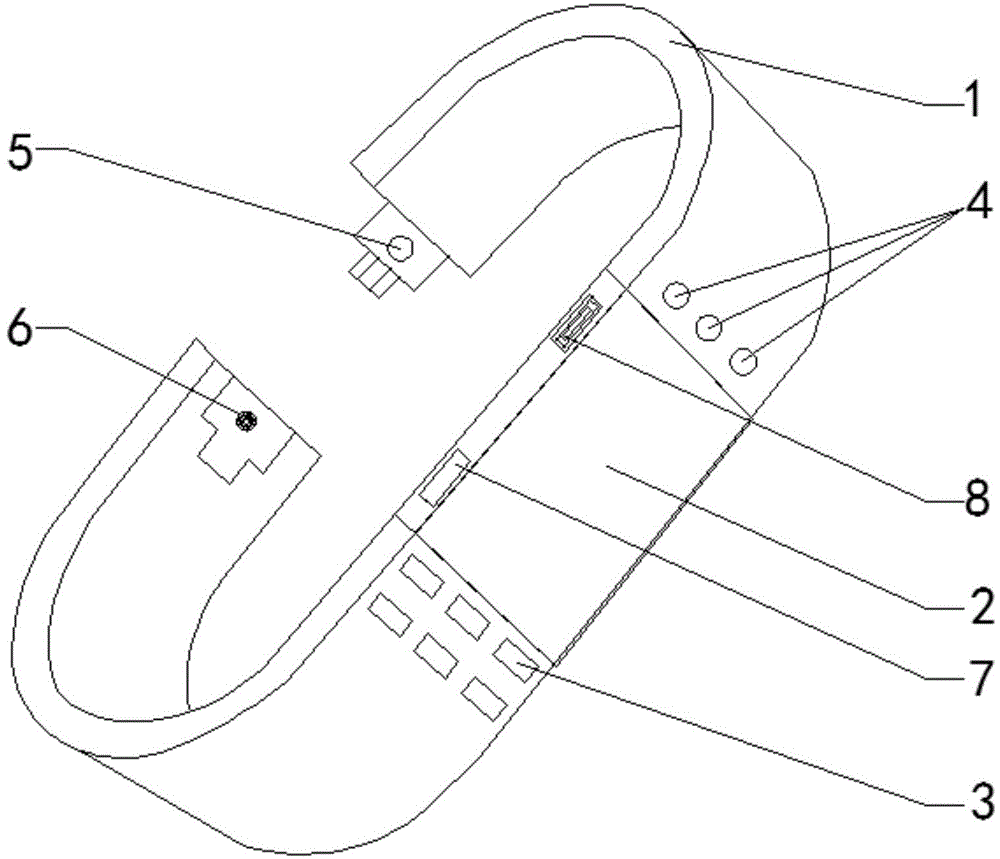

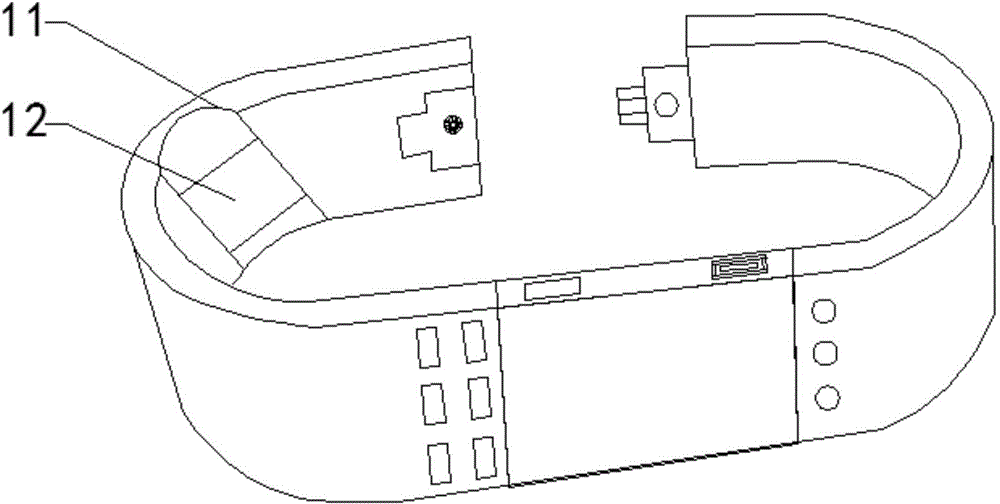

Intelligent sports healthcare bracelet

ActiveCN104522945AImprove the decorative effectHumanized designDiagnostic recording/measuringBraceletsYounger peopleEngineering

The invention discloses an intelligent sports healthcare bracelet which comprises a bracelet belt, a lock head and a lock hole. A control unit is arranged in the bracelet belt and comprises a printed circuit mainboard. A central processor, an analog signal processing chip, sensors, a power module, a voice module, a time control module, a Bluetooth module, a key input module, a timing vibration motor and a storage device are arranged on the printed circuit mainboard. The sensors comprise the electrocardio sensor and the skin impedance sensor. Electrode wires for releasing detection current are arranged on the electrocardio sensor and the skin impedance sensor. The sensor is electrically connected with the central processor through the analog signal processing module, and the power module, an electric quantity detection module, the voice module, the time control module, the Bluetooth module, the key input module, the timing vibration motor and the storage device are electrically connected with the central processor. The intelligent sports healthcare bracelet is practical in design, user-friendly, close to daily life and suitable for young people and the aged.

Owner:CHENGDU ICARETECH

Lost foam casting vibration clotting method

The invention relates to a vibration solidification method of lost mold casting, pertaining to the precision casting field, which aims at fining the organization of castings of the lost mold casting, reducing the cost and enhancing the performance of castings. The invention comprises three steps of: production of foamy mold, imbedding the foamy mold into a casting box for filling and compacting sand as well as casting of molten metal; the invention is characterized in that: before and during the period of casting molten metal, during the solidification period, or the solidification period after the period of casting molten metal, casting box filled with foamy mold and scattered sand is vibrated at the frequency ranging from 10 to 100Hz and the amplitude ranging from 0.1 to 3.0mm, and rotation speed of a vibration motor that drives the vibration is 750 to 3000 rpm, and the vibration is stopped after the solidification of casting is completed. The invention has the advantages of low cost, easy operation and control, obvious fining effect of casting organizations, greatly improving performance and no environmental pollution, which is both suitable for the casting of the lost molds of nonferrous metals components, such as aluminum alloy, magnesium alloy, copper alloy, etc., and is also suitable for the casting of the lost mold of ferrous metal components, such as cast iron, cast steel and so on.

Owner:HUAZHONG UNIV OF SCI & TECH

Efficient domestic sewage treatment device

InactiveCN107032527AEffective filtration to removeEfficient removalTreatment involving filtrationWater/sewage treatment bu osmosis/dialysisActivated carbonOzone generator

The invention discloses a high-efficiency domestic sewage treatment device, which comprises a base, a purification box and a storage box. Rollers are installed at four corners of the bottom of the base, and a vibrating vibration device arranged obliquely is arranged on the upper part of the inner cavity of the purification box. Grille, the side wall of the purification box close to the lower end of the vibration grid is provided with a sewage outlet, the side wall of the purification box close to the higher end of the vibration grid is provided with an excitation motor, and the inner cavity of the purification box The lower part is provided with a quartz sand filter material layer, a PP cotton layer, an activated carbon adsorption layer and a biological filter membrane layer in sequence from top to bottom. An ozone generator is installed on the side wall of the storage box, and the ozone generator passes through the gas pipeline. Connected to the storage box. The present invention can effectively remove various impurities in the sewage through the multi-layer treatment of the sewage, has good sewage treatment effect, more thorough purification, simple structure, multiple functions, convenient use and strong practicability.

Owner:盐城百利豪环保机械制造有限公司

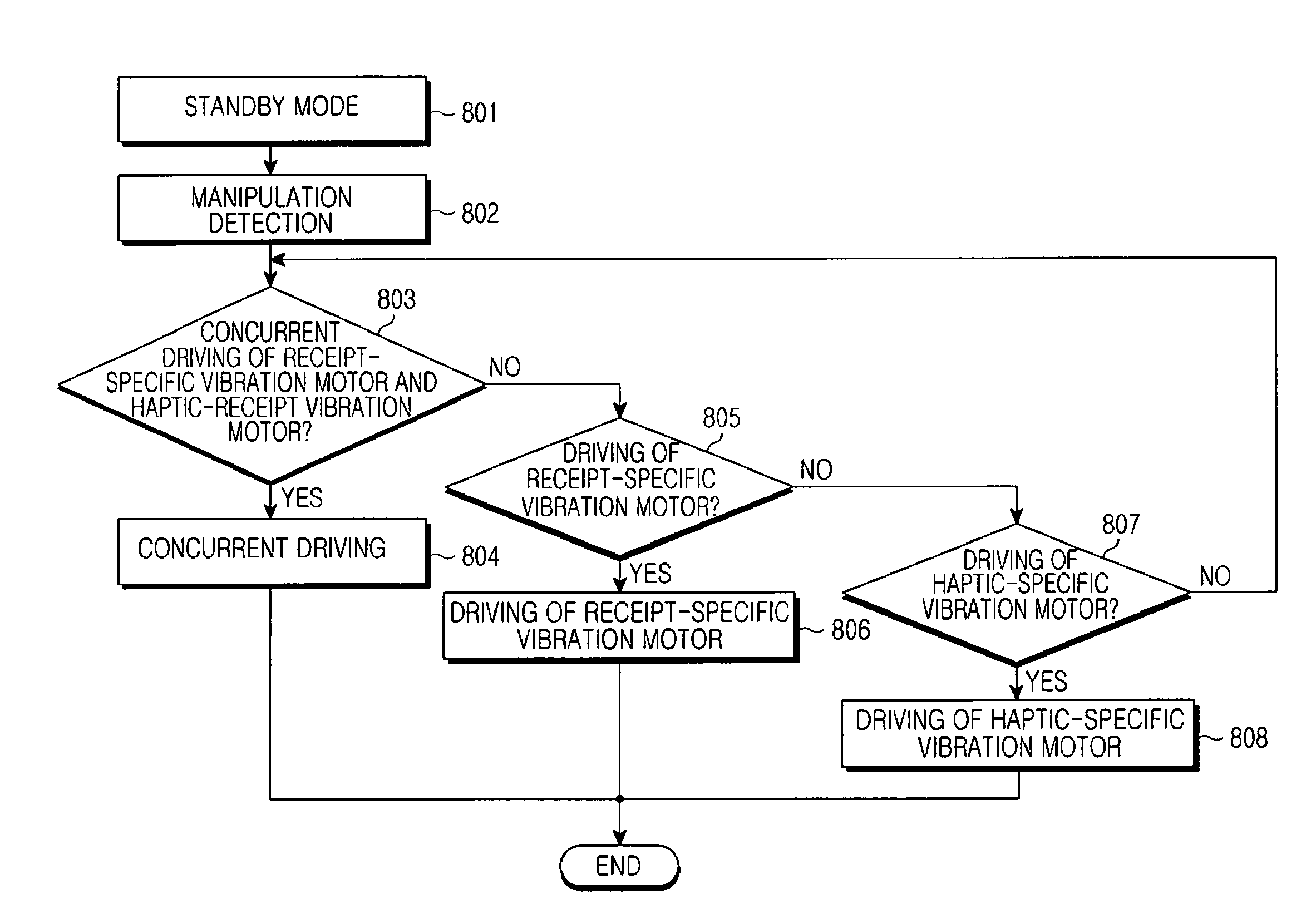

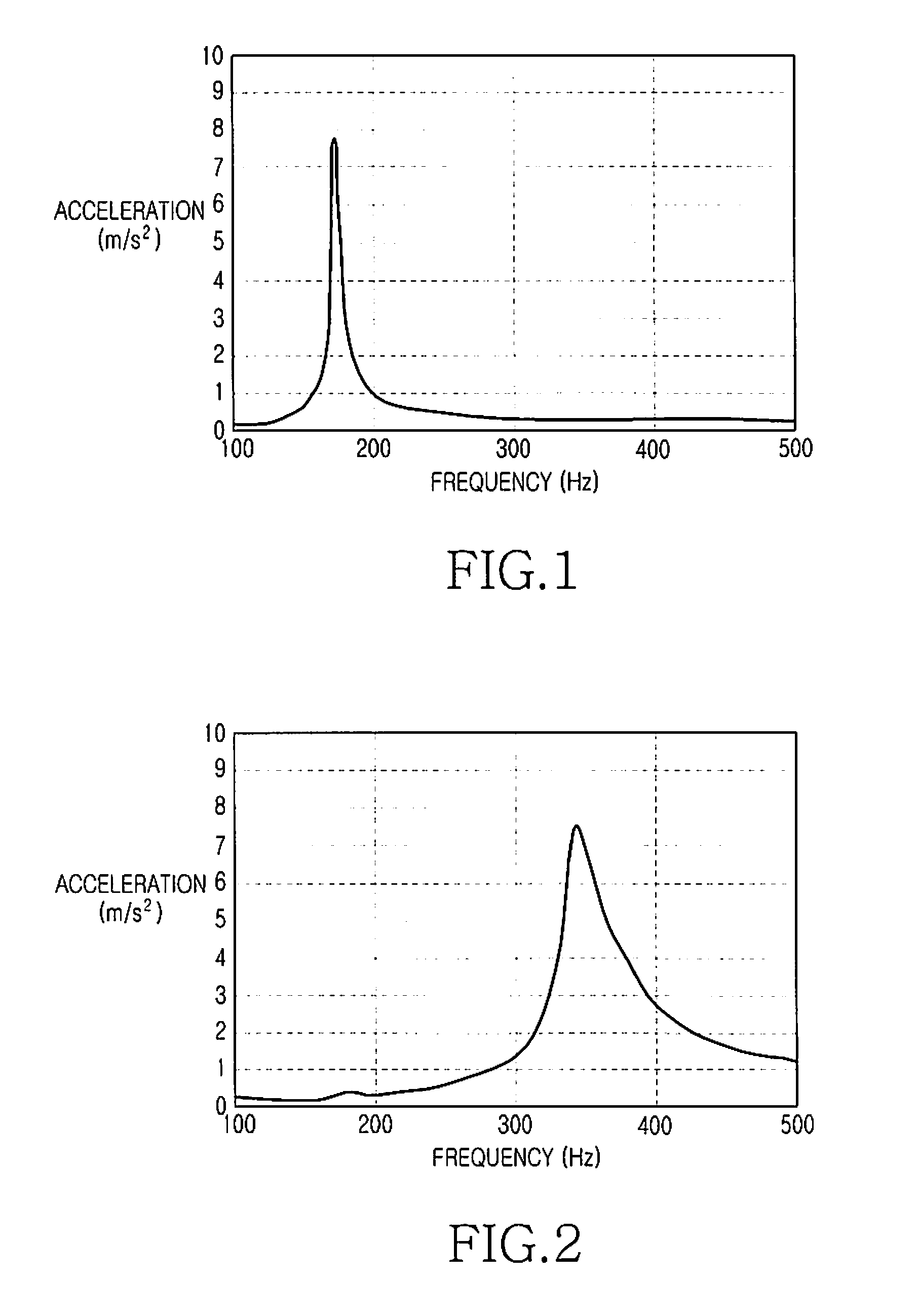

Haptic function control method for portable terminals

InactiveUS20100148944A1Piezoelectric/electrostriction/magnetostriction machinesRepeater circuitsPhysical medicine and rehabilitationPhysical therapy

A haptic function control method for a portable terminal including a receipt-specific vibration motor that vibrates in a first frequency band and a haptic-specific vibration motor that vibrates in a second frequency band. At least one of the receipt-specific vibration motor and the haptic-specific vibration motor is driven based on a drive sampling frequency signal. The drive sampling frequency signal that vibrates the receipt-specific vibration motor and the haptic-specific vibration motor is determined from the first frequency band and the second frequency band.

Owner:SAMSUNG ELECTRONICS CO LTD

Digital controlled lathe capable of conducting automatic loading and suitable for shaft parts

InactiveCN105798330AAvoid shockPrevent flying outTurning machinesMetal working apparatusEngineeringExpansion joint

The invention discloses a digital controlled lathe capable of conducting automatic loading and suitable for shaft parts. The digital controlled lathe comprises a lathe body, wherein the lathe body is provided with a hollow spindle, a sliding rail is arranged on the lathe body in the front and back horizontal direction, a knife rest is arranged on the sliding rail in a slidable manner, the front end of the hollow spindle is coaxially and fixedly connected with a hollow chuck, the knife rest is provided with an electromagnetic attraction mechanism, and an automatic loading device is arranged behind the lathe body; and the automatic loading device comprises a work bin base, the work bin base is fixedly connected with a work bin support, the work bin support is fixedly connected with a storage box, a corrugated pipe expansion joint and an unloading box from top to bottom in sequence, one vibration motor is arranged on the left outer wall of the corrugated pipe expansion joint, one vibration motor is arranged on the right outer wall of the corrugated pipe expansion joint, a stock stop is arranged on the lower portion of the unloading box, and the upper surface of the work bin base is fixedly connected with a material pushing base located under the unloading box. The digital controlled lathe is easy and convenient to operate, high in automation degree and stable in work, and can achieve automatic loading, effectively shorten the auxiliary time and improve the working efficiency.

Owner:HUANGHE S & T COLLEGE

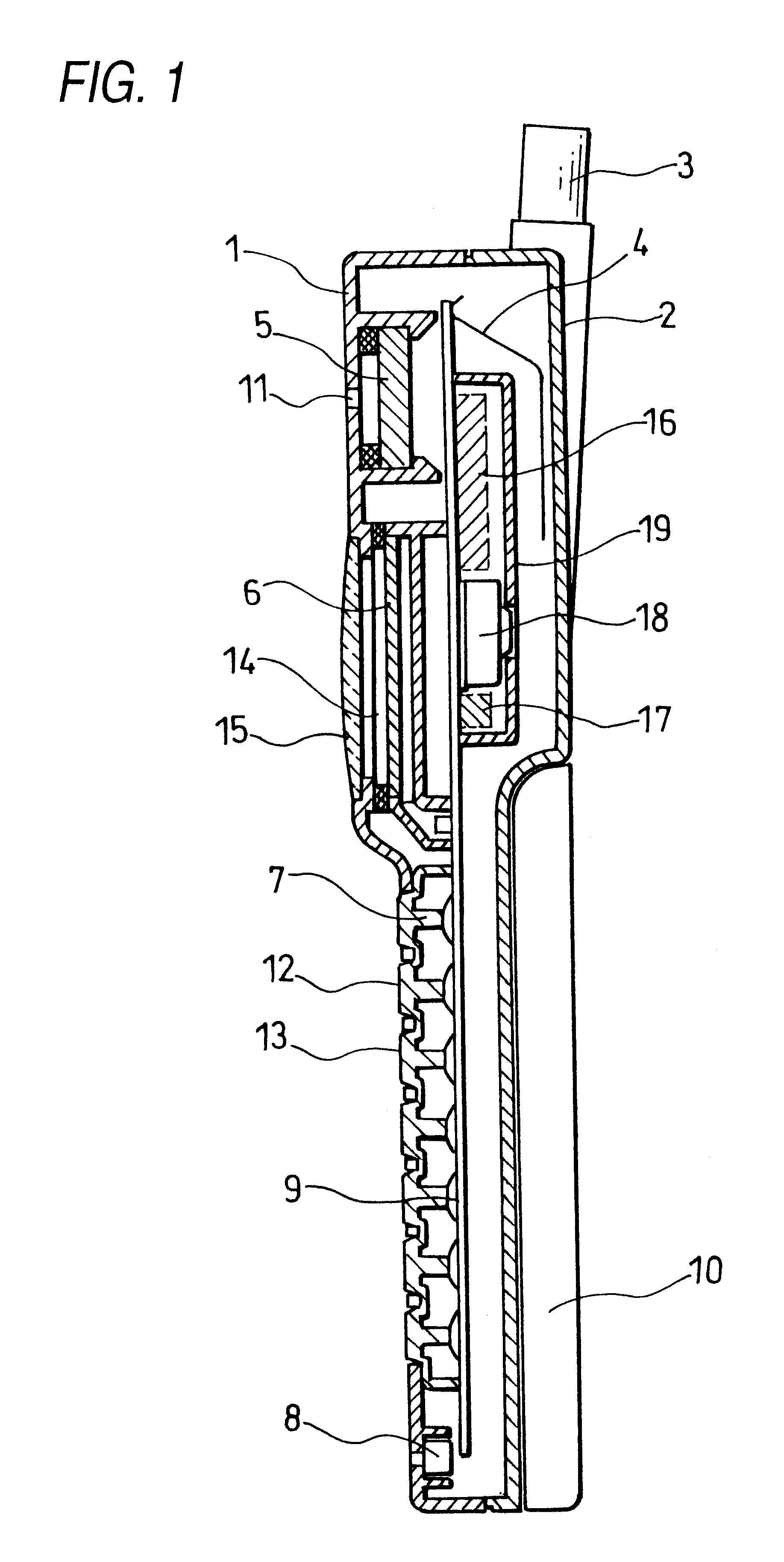

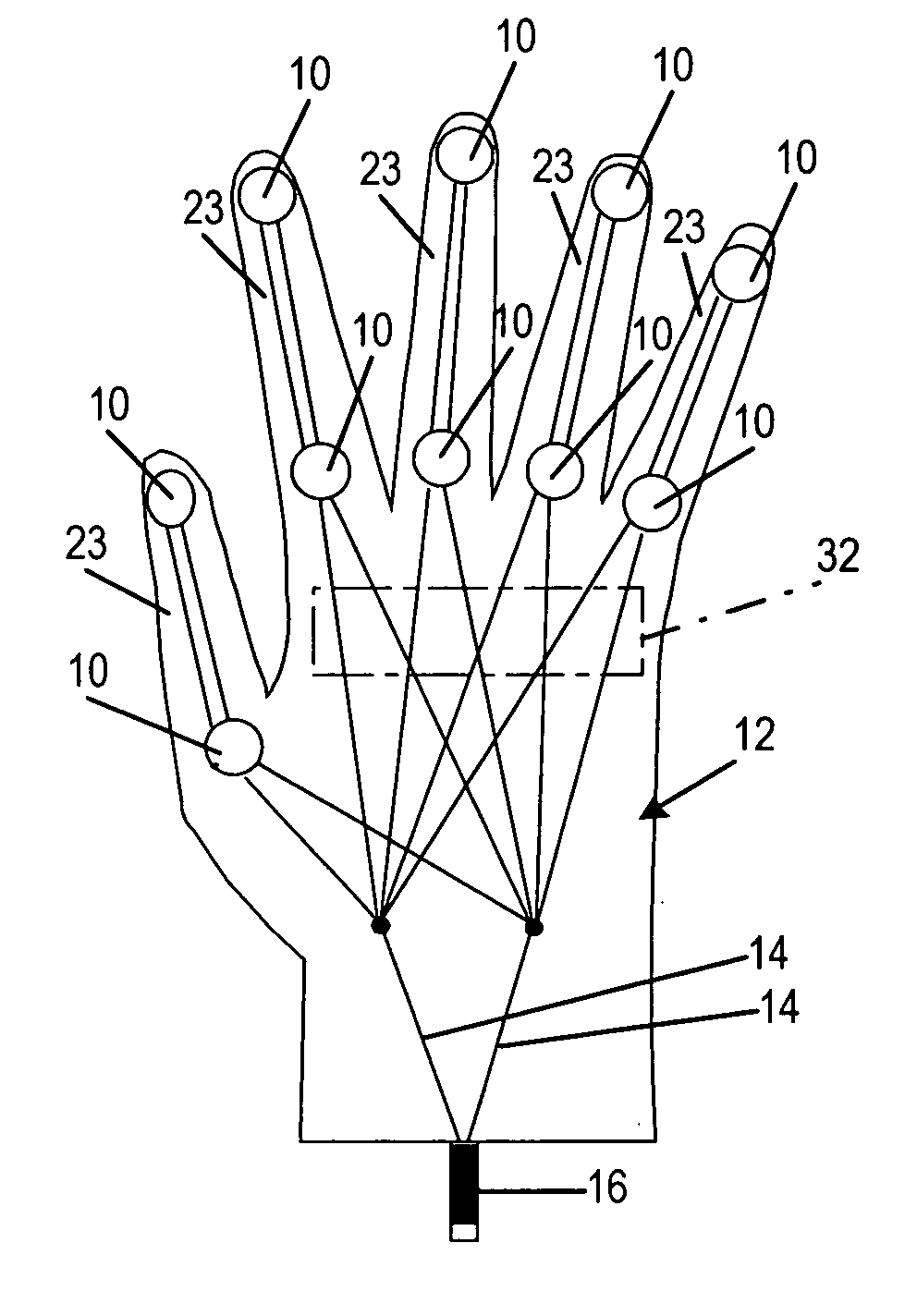

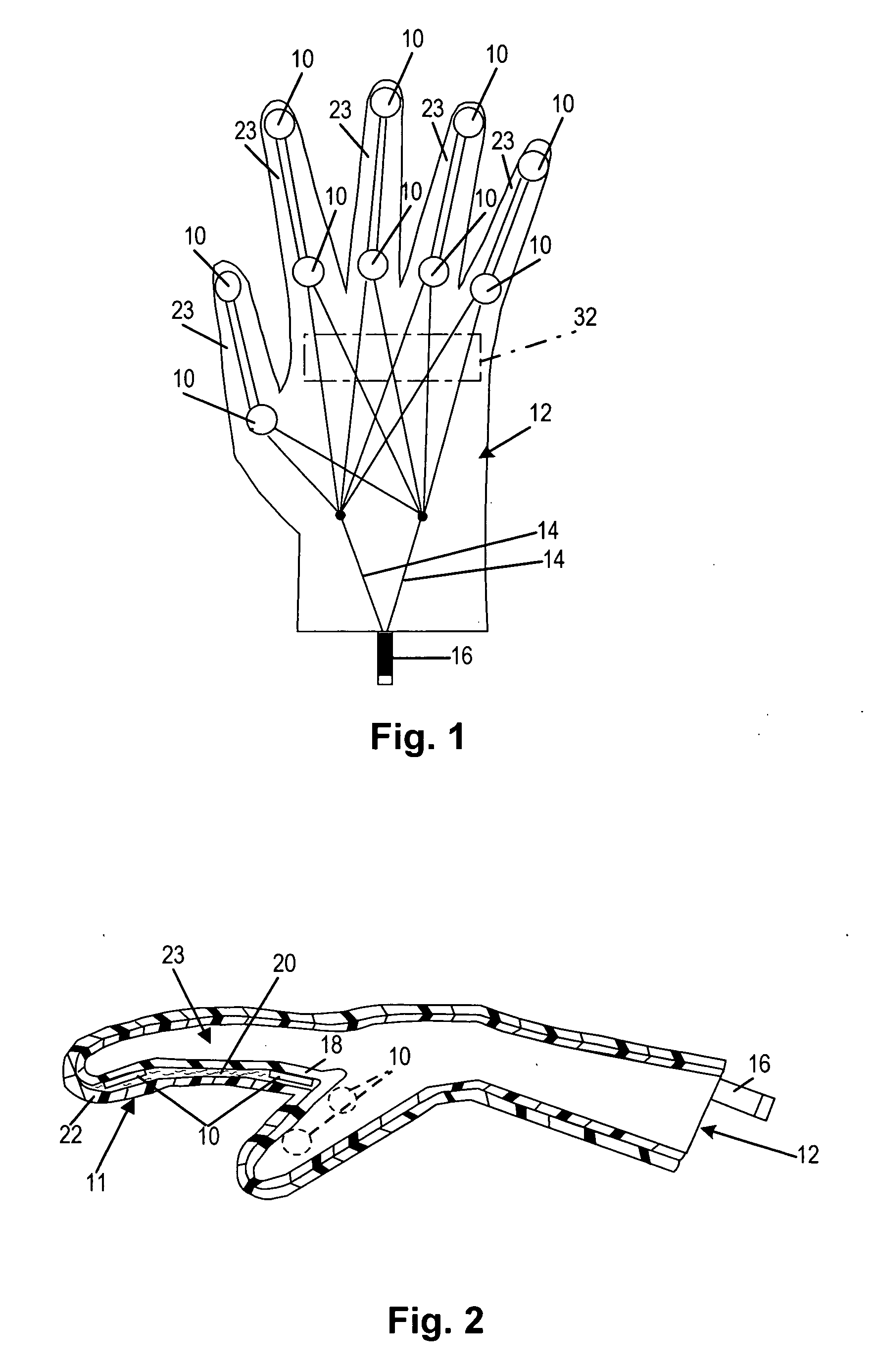

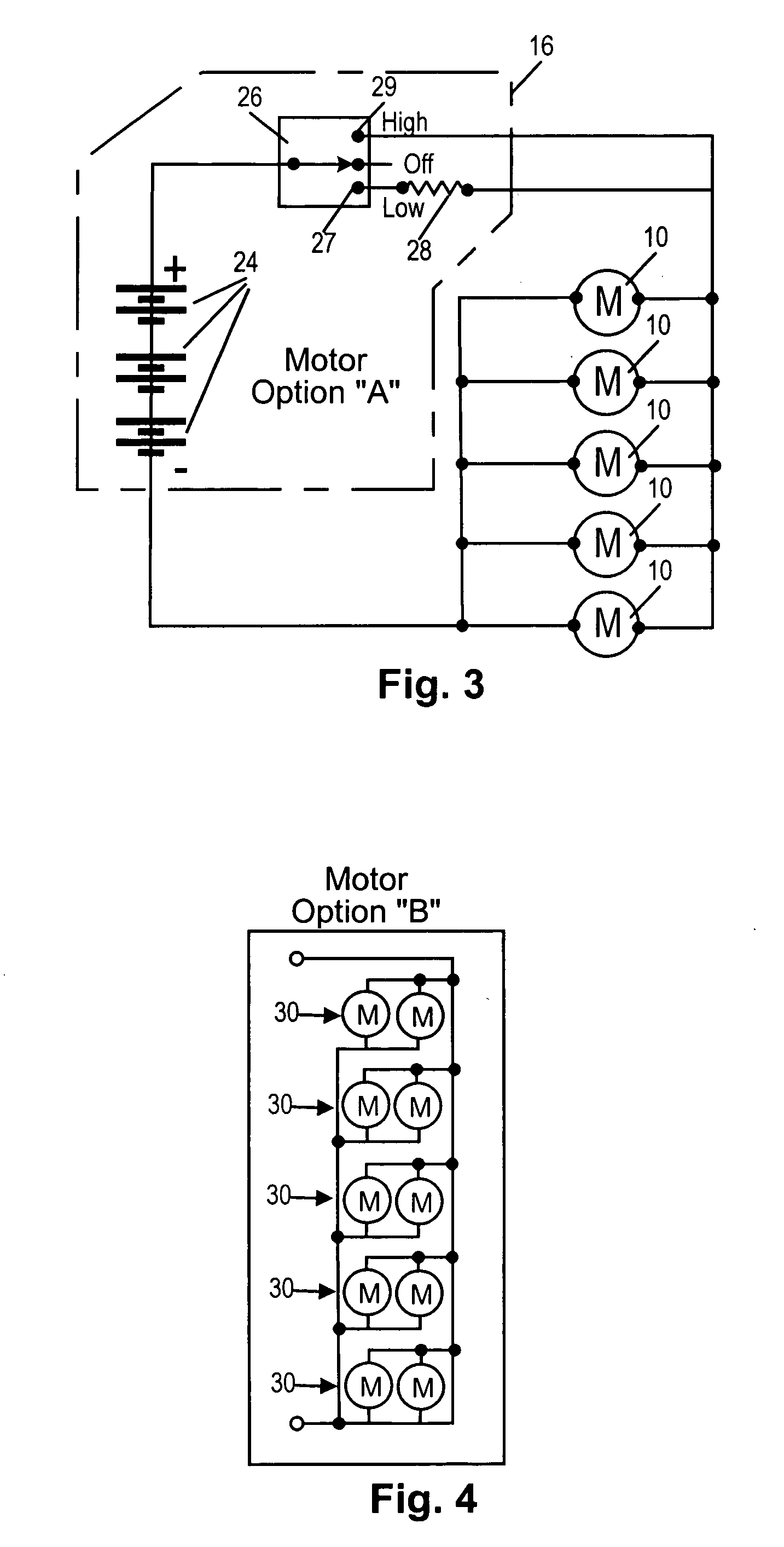

Massage glove

InactiveUS20050143679A1Avoid harsh engagementHarmful and unpleasant engagementChiropractic devicesVibration massageHand palmsHeating element

A massage glove having a plurality of vibratory motors secured within it on the palm side. The glove employs small vibrator motors located within the glove fingers. The motors are of a size and weight such that ordinary movement of the therapist's fingers within the glove in traditional massaging movements is not hampered. A heating element may be included in the glove for applying heat in addition to the vibration and the more traditional massage.

Owner:GELBER MITCHELL L +1

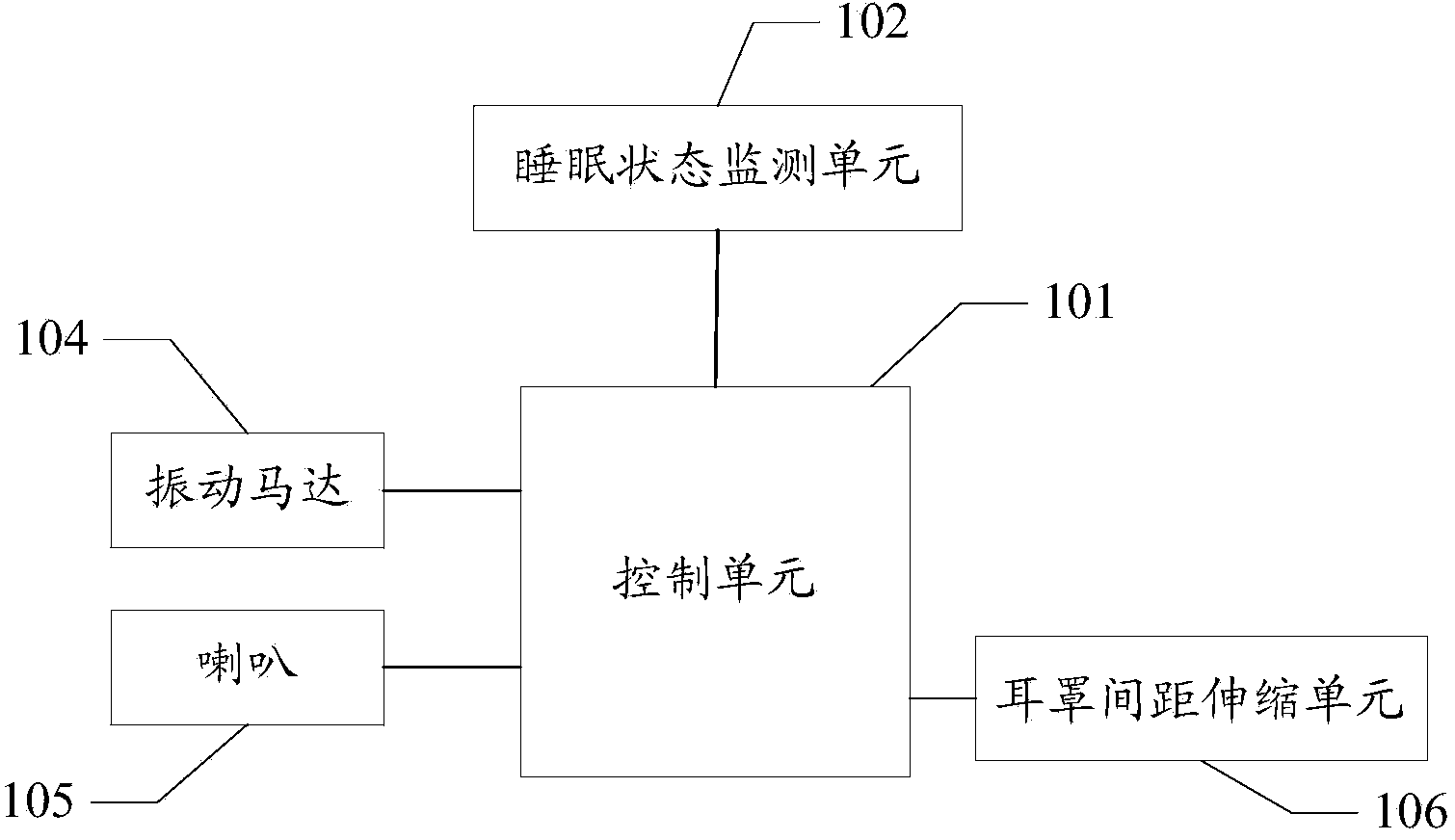

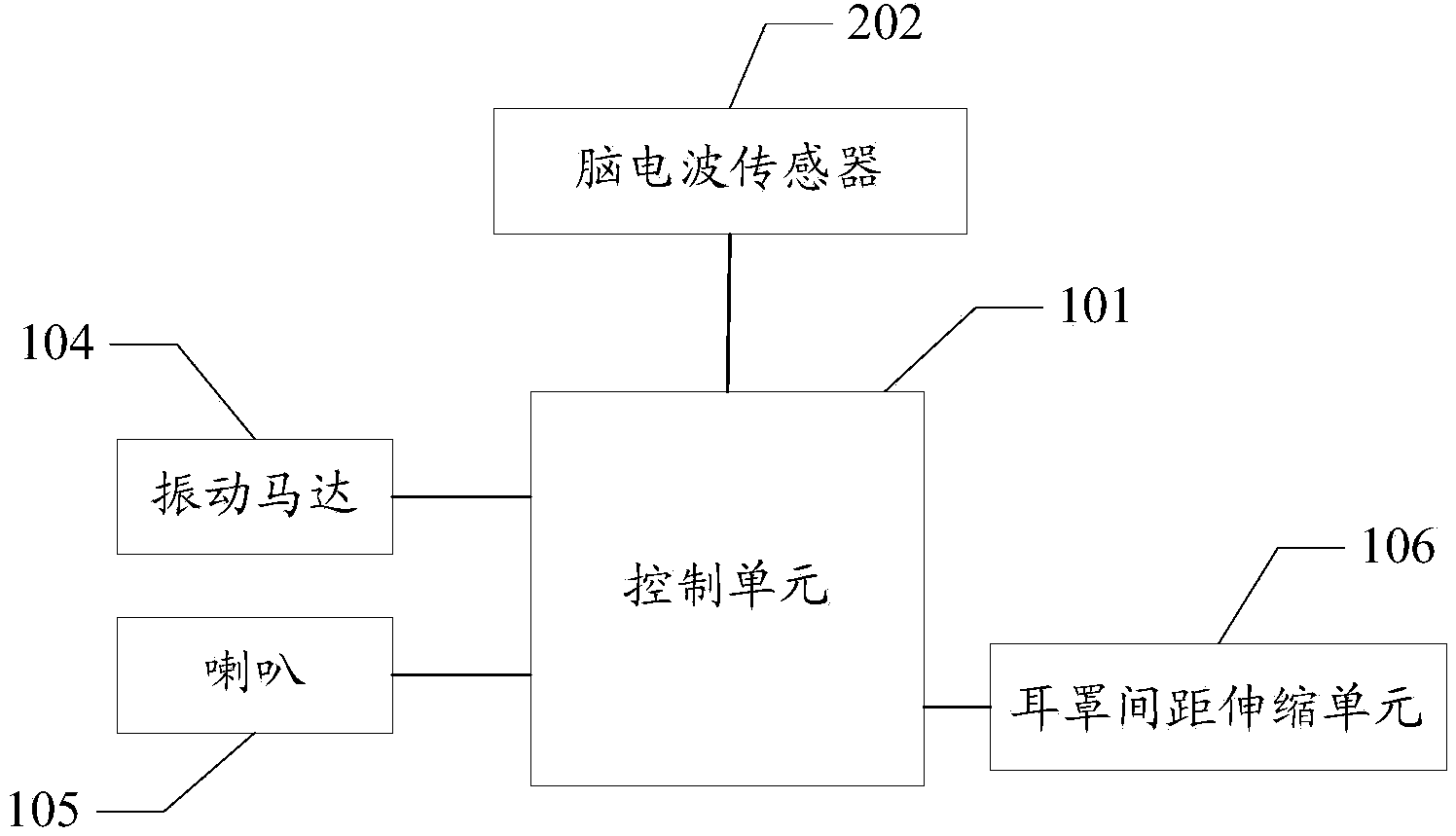

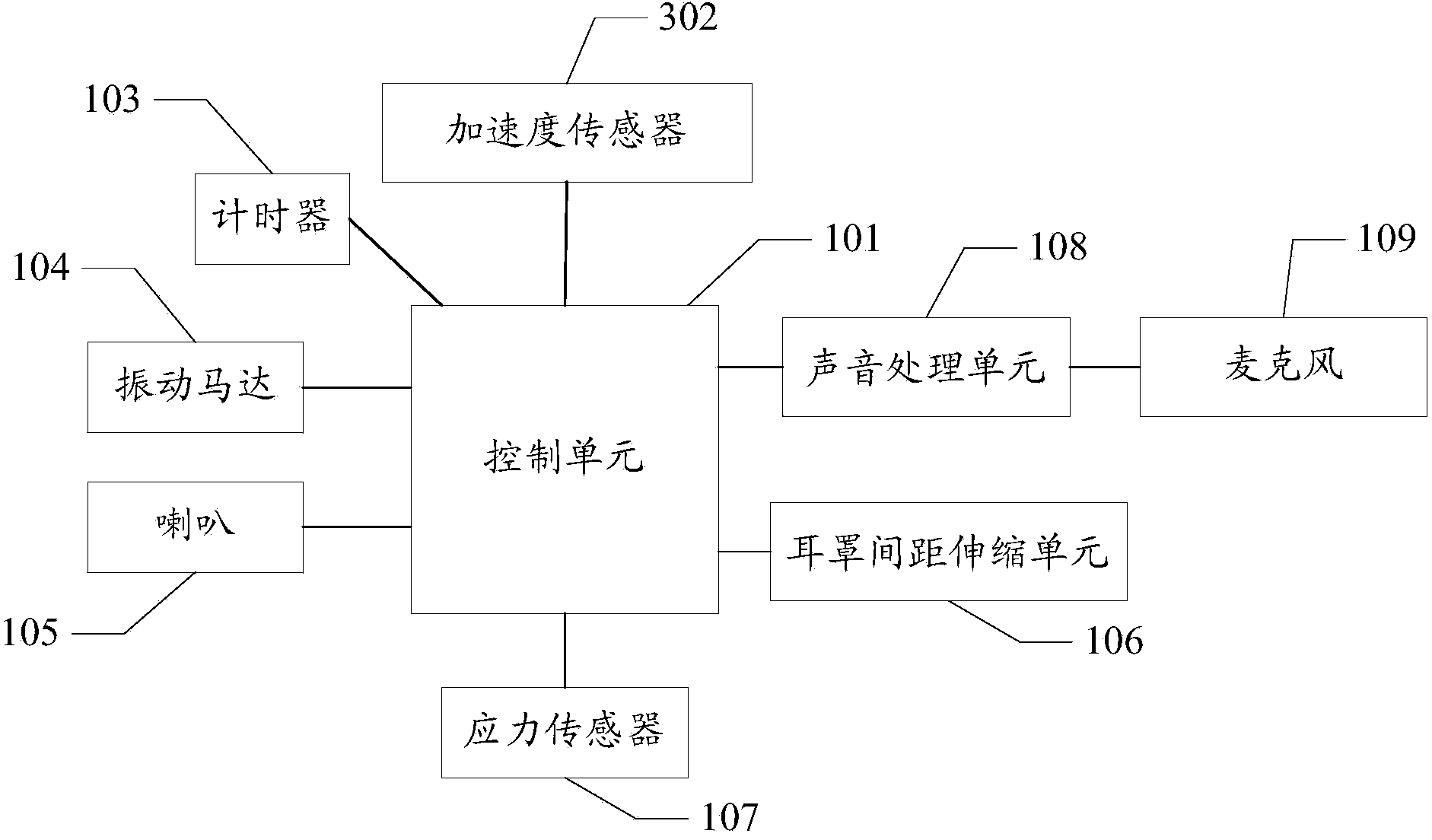

Headset

ActiveCN103475971AControls the output volume of the speaker by reducing the rotation speedOutput volume downEarpiece/earphone attachmentsSleep stateLight sleep

The invention discloses a headset. The headset comprises a left earmuff, a right earmuff, a head band portion, two horns, a vibration motor, a sleep state monitoring unit, a control unit and an earmuff distance telescopic unit. The sleep state monitoring unit is used for monitoring different sleep states of a user of the headset and sending a monitoring result to the control unit. The control unit is used for controlling the output volume of the horns to be lowered when the monitoring result of the sleep state monitoring unit is light sleep; the control unit is used for sending a distance increasing signal to the earmuff distance telescopic unit when the monitoring result of the sleep state monitoring unit is deep sleep. The earmuff distance telescopic unit is used for increasing the distance between the left earmuff and the right earmuff when the distance increasing signal sent by the control unit is received. The headset can solve the problems that an existing headset can work after the user falls asleep so that hearing impairment can be caused easily.

Owner:QINGDAO GOERTEK

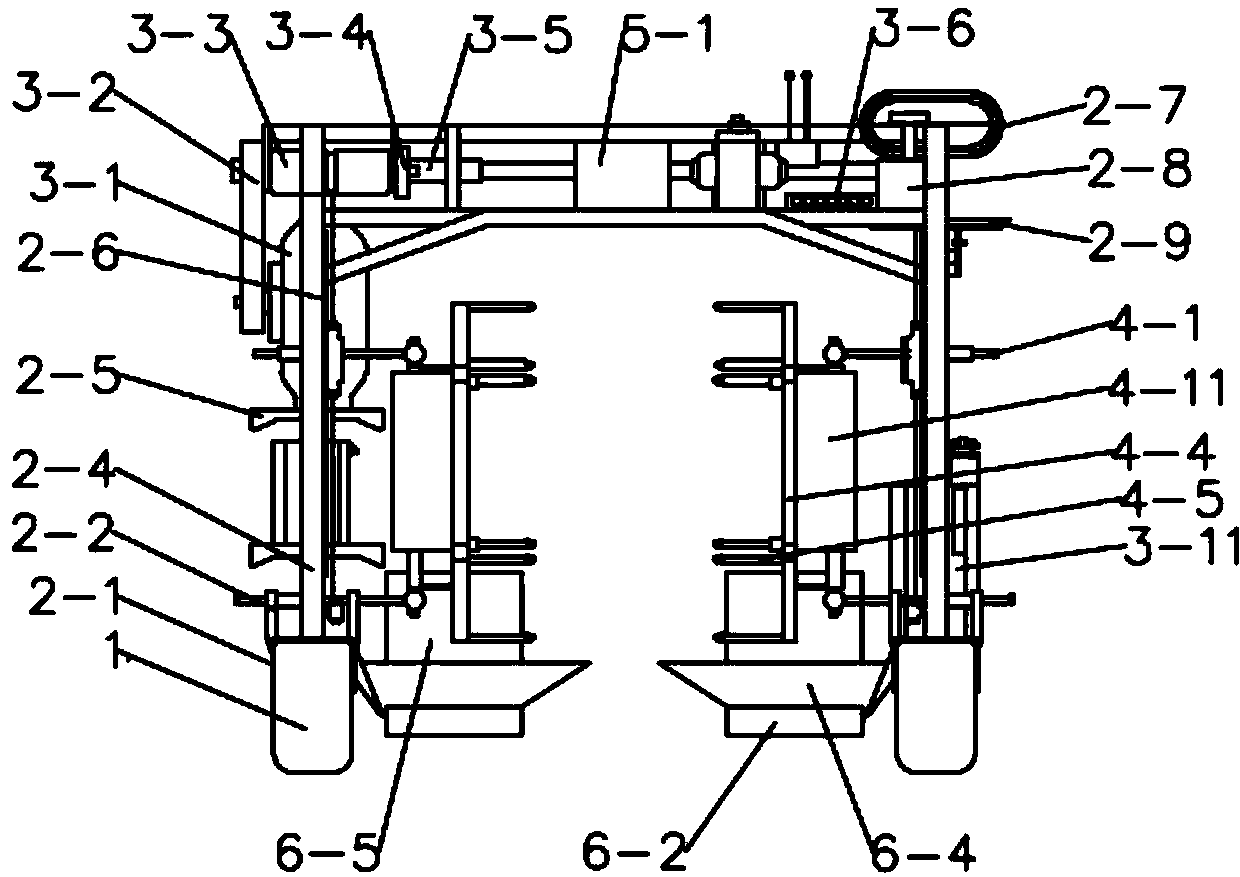

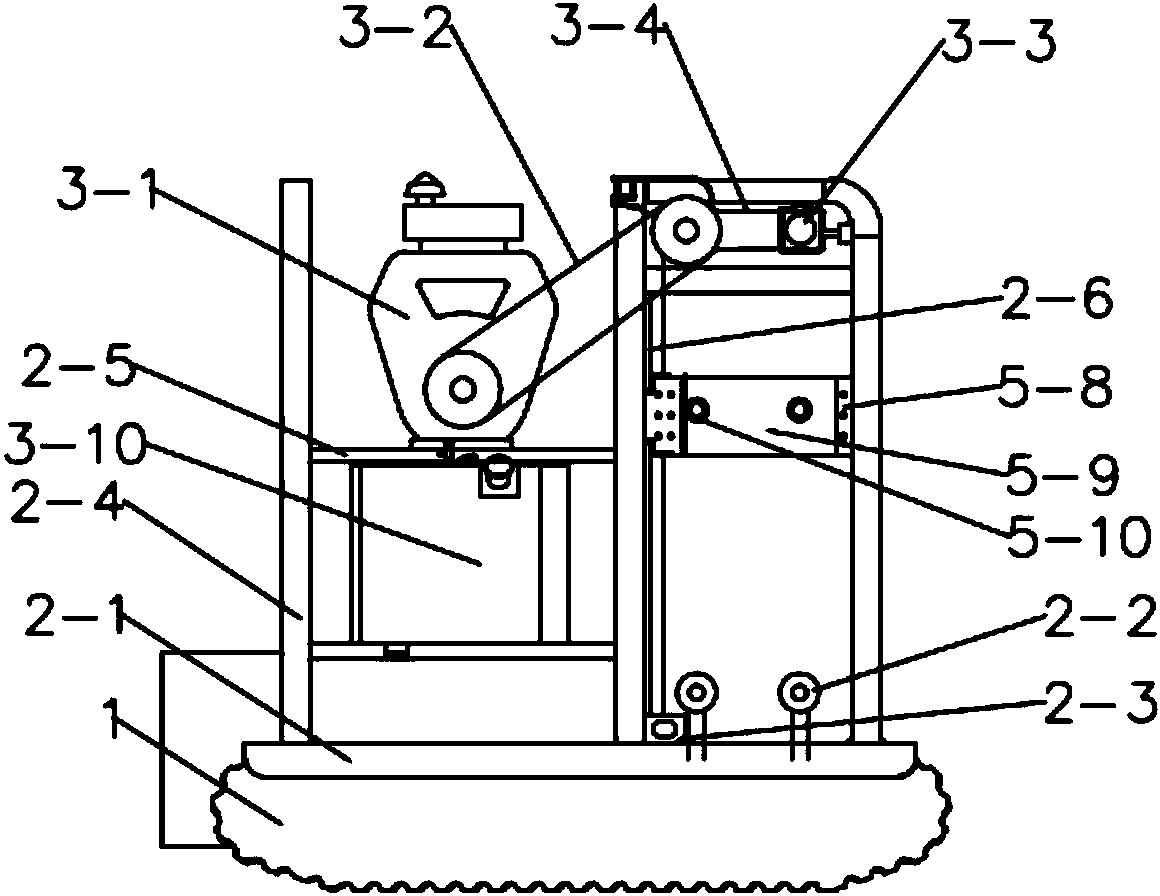

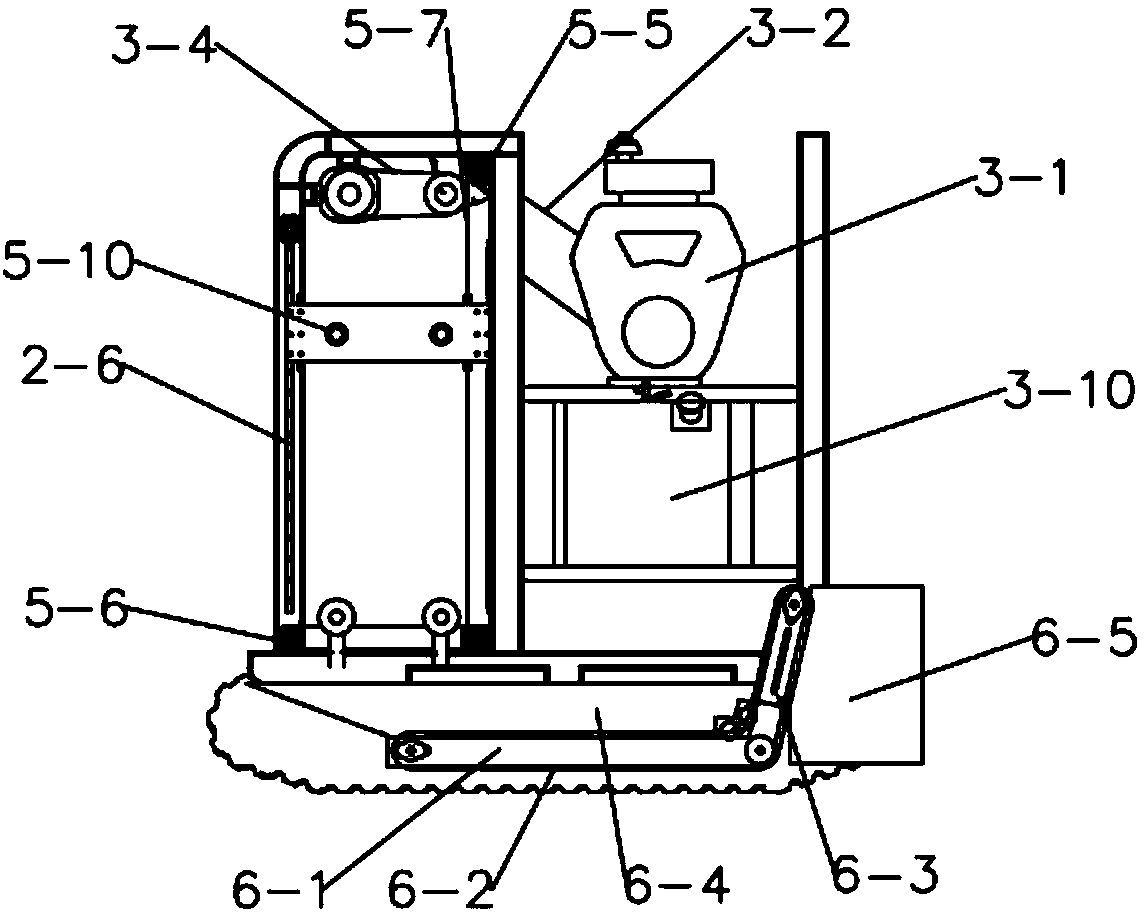

Medlar harvesting machine

The invention relates to a medlar harvesting machine and belongs to the technical field of agricultural machinery. The machine is mounted on a door-shaped framework on a walking mechanism and is provided with a vertical slide rail; the vertical slide rail is provided with a hoisting sliding plate and a vibration assembly; a collection assembly is mounted under the vibration assembly; a hoisting plate is mounted at the upper part of the hoisting sliding plate; the upper and lower ends of a fixed bracket of the vibration assembly are hinged to one end of an upper sliding rod and one end of a lower sliding rod respectively; the other end of the upper sliding rod penetrates through a horizontal perforated hole of the hoisting plate to form a lockable movable pair and the other end of the lower sliding rod penetrates through a sliding rod support at the lower part of the hoisting sliding plate to form a lockable movable pair; a frame-shaped vibration tooth bracket is mounted on the inner side of the fixed bracket and a horizontal movable pair is composed of the frame-shaped vibration tooth bracket and the fixed bracket; horizontal vibration teeth which are distributed at intervals are arranged on the inner side of the vibration tooth bracket by extending; a vibration motor is in transmission connection with the vibration tooth bracket through an eccentric wheel mechanism. The medlar harvesting machine can avoid a branch breaking phenomenon and is conveniently wound on a tree shed so that the movement of the medlar harvesting machine is not influenced by the impeding of branches, and medlar branches can be further prevented from being damaged.

Owner:NANJING AGRI MECHANIZATION INST MIN OF AGRI

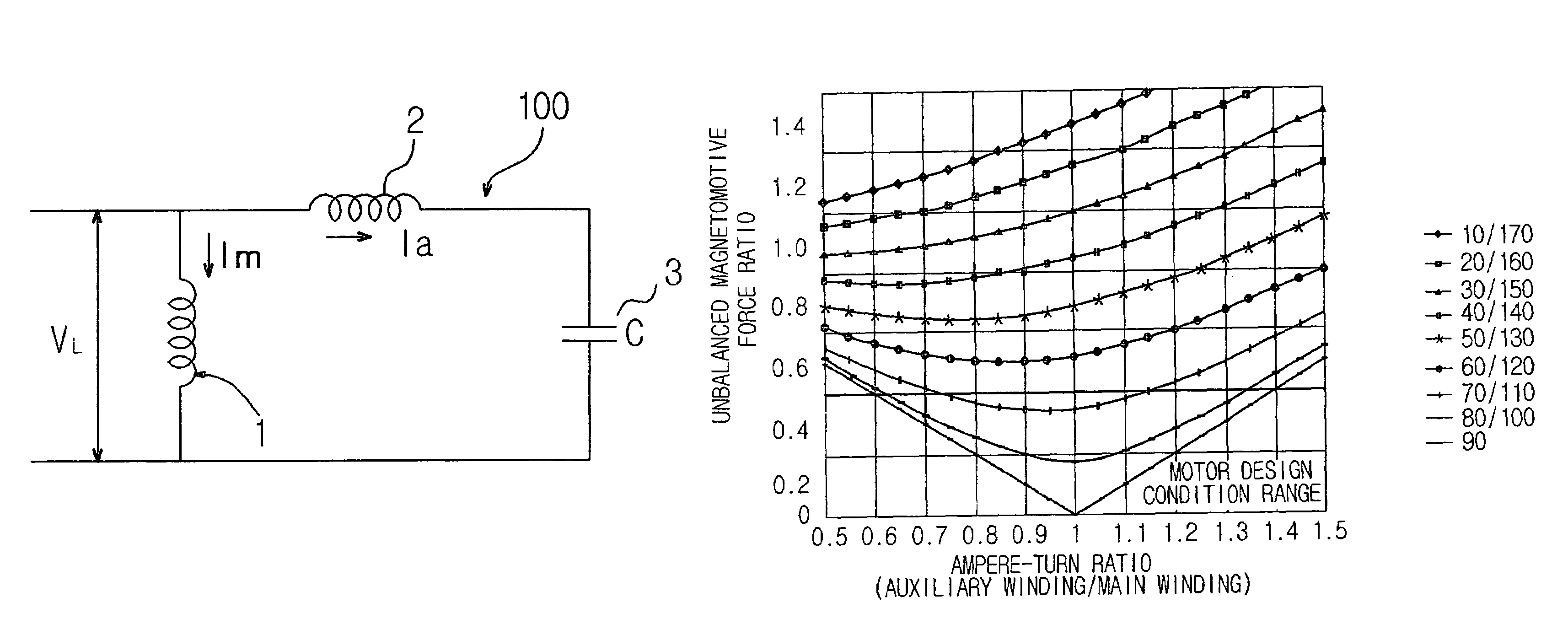

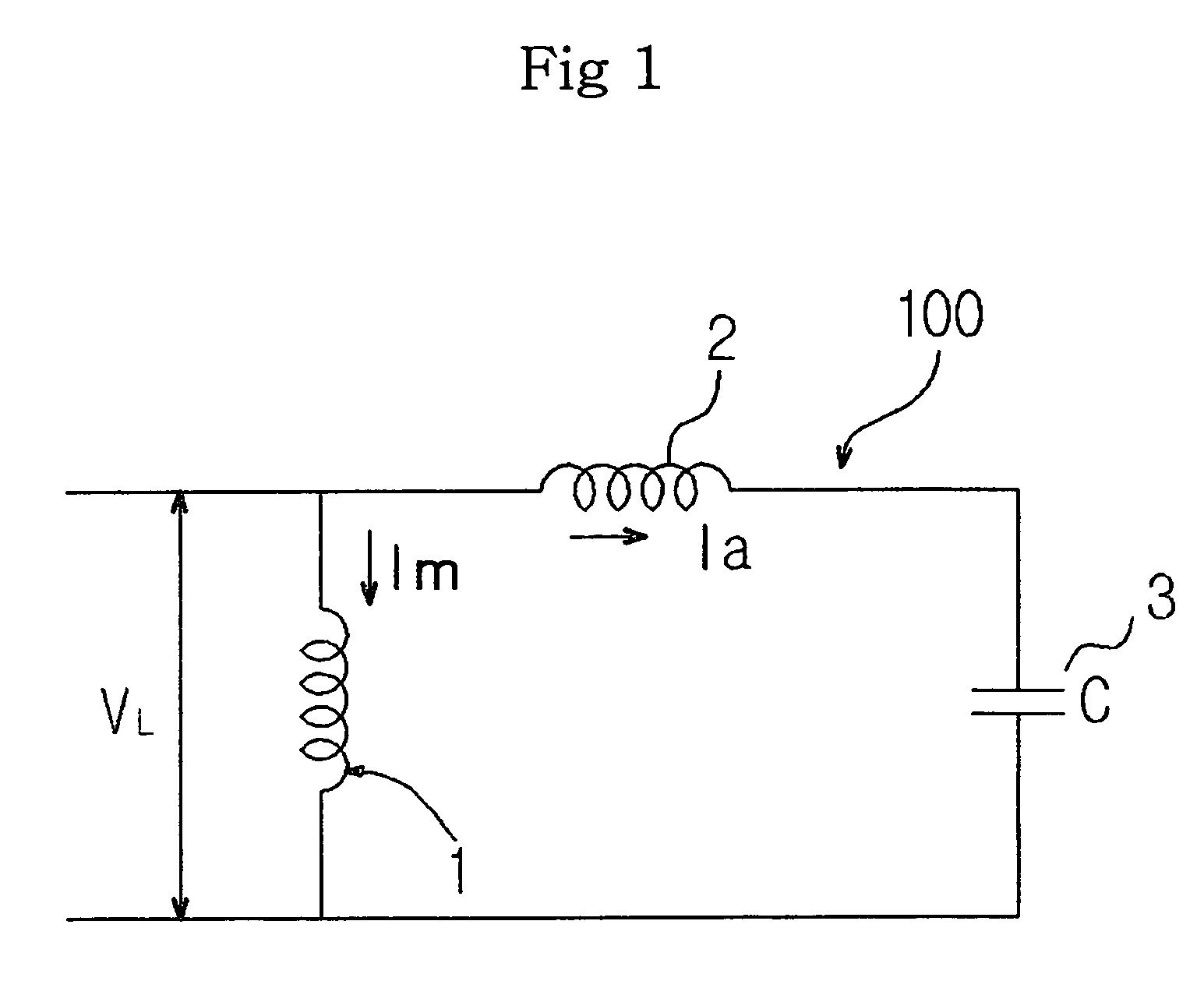

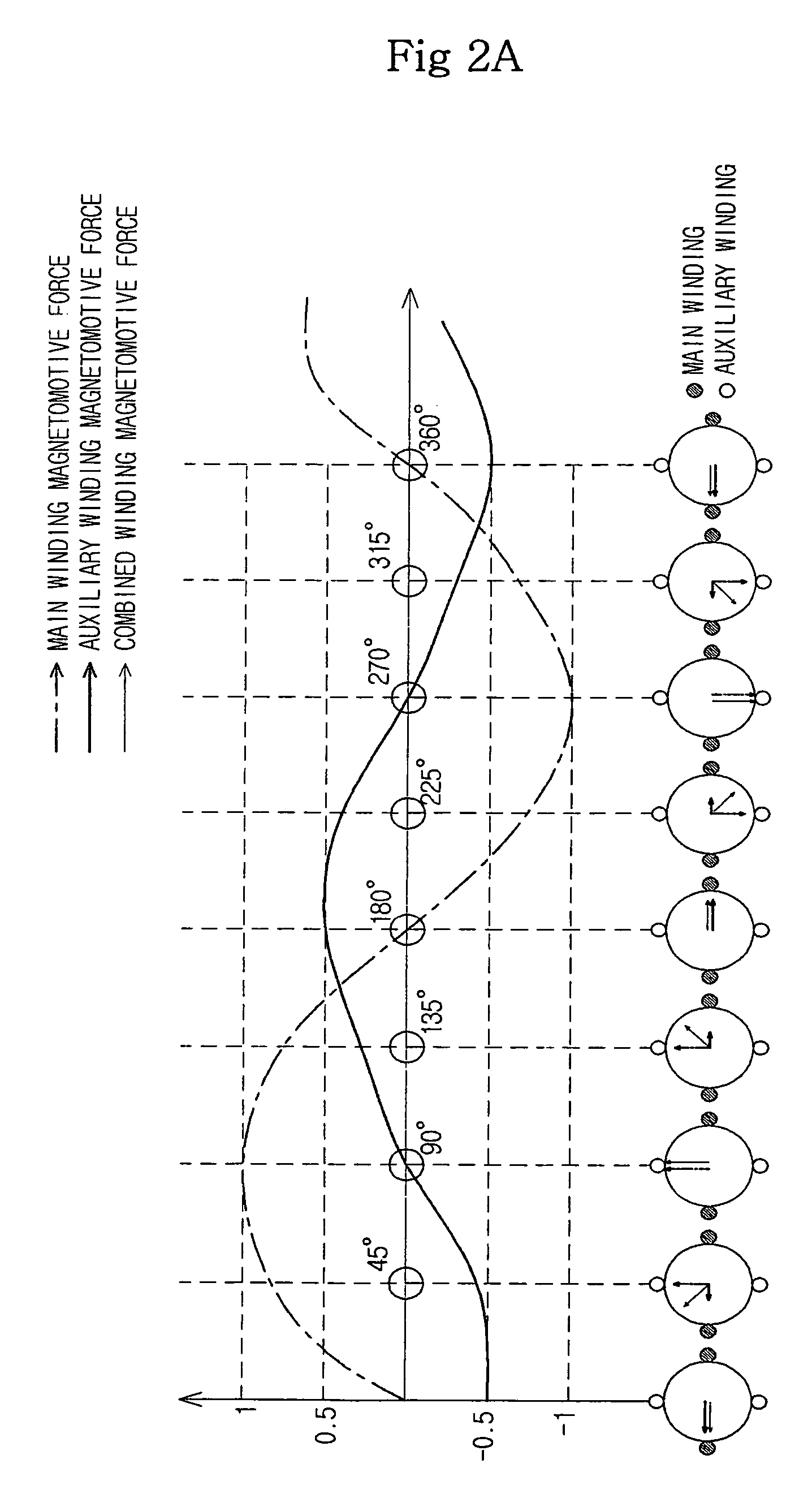

Single-phase induction motor and method for reducing noise in the same

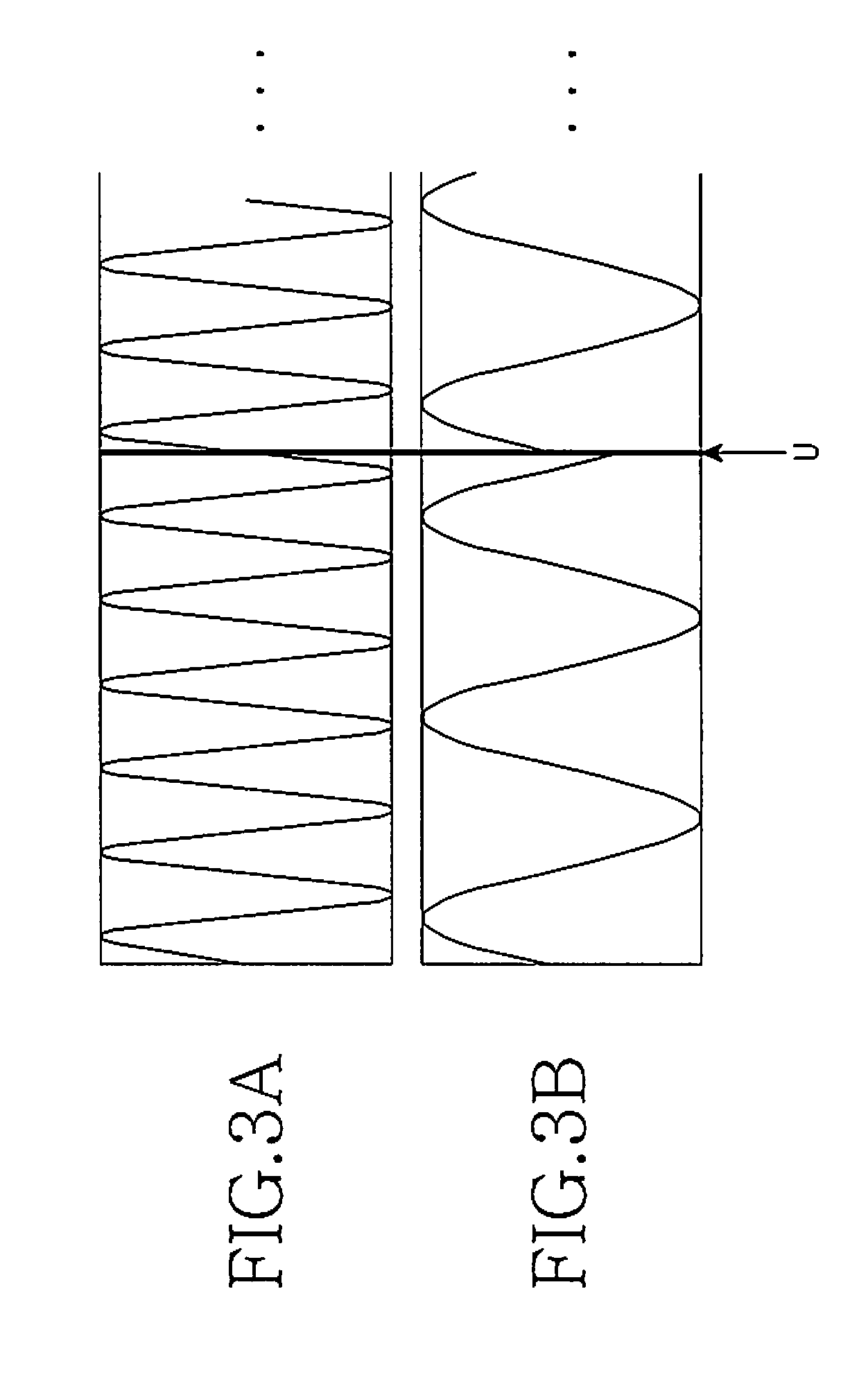

ActiveUS7245105B2Reduce noiseReduce vibrationSingle-phase induction motor startersSynchronous motors startersLow noiseMagnetomotive force

A single-phase induction motor and a method for reducing noise in the same, which can eliminate unbalance between magnetomotive forces of main and auxiliary windings in a stator of the motor, thereby implementing a low noise, low vibration motor, and can also achieve balance between the magnetomotive forces of the stator windings in the entire running range of the motor, and can further achieve balance between the magnetomotive forces of the stator windings on the basis of temperature increase of the motor as it runs. The amplitude of a main-winding current flowing through the main winding in the stator is controlled to be equal to the amplitude of an auxiliary-winding current flowing through the auxiliary winding in the stator, and the phase difference between the main-winding and auxiliary-winding currents is controlled to be maintained at a predetermined value.

Owner:SAMSUNG ELECTRONICS CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com