Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

727 results about "Grind" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A blade's grind is its cross-sectional shape in a plane normal to the edge. Grind differs from blade profile, which is the blade's cross-sectional shape in the plane containing the blade's edge and the centre contour of the blade's back.

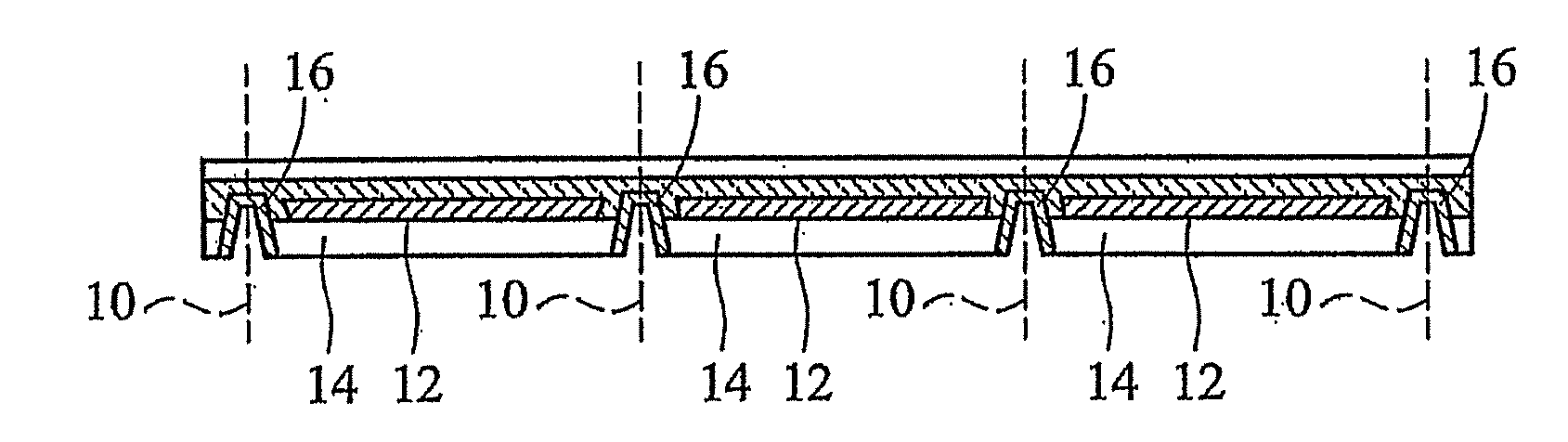

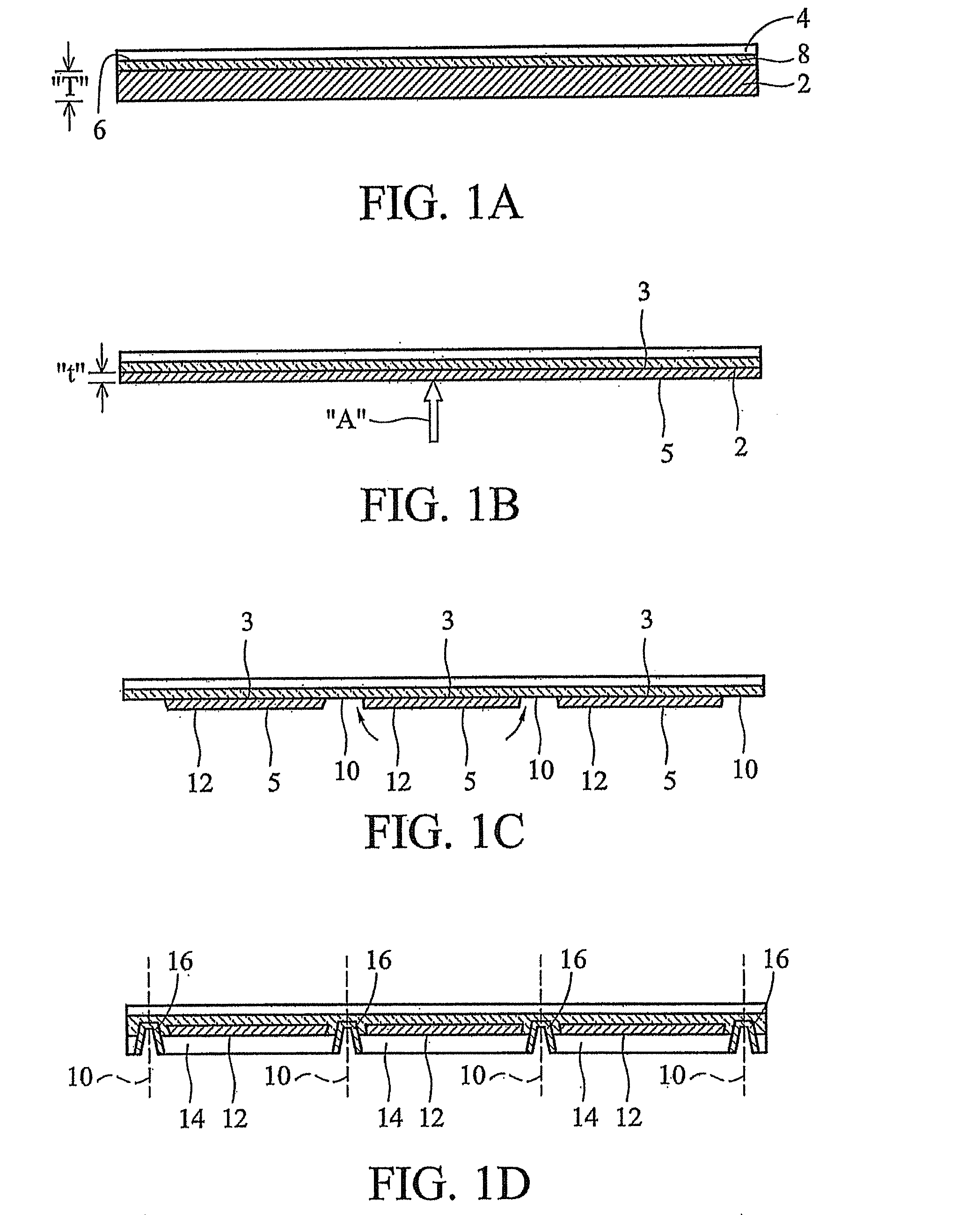

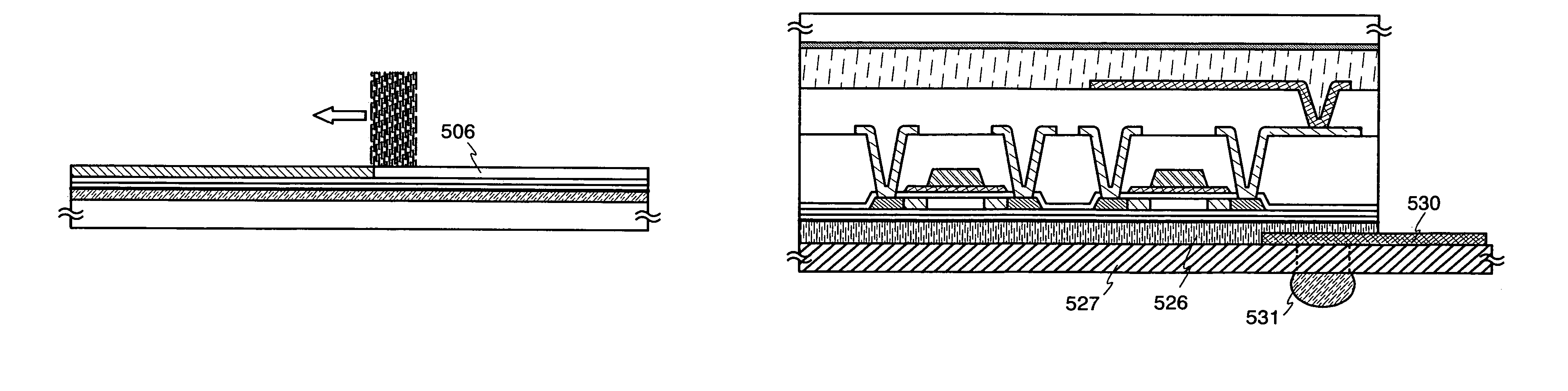

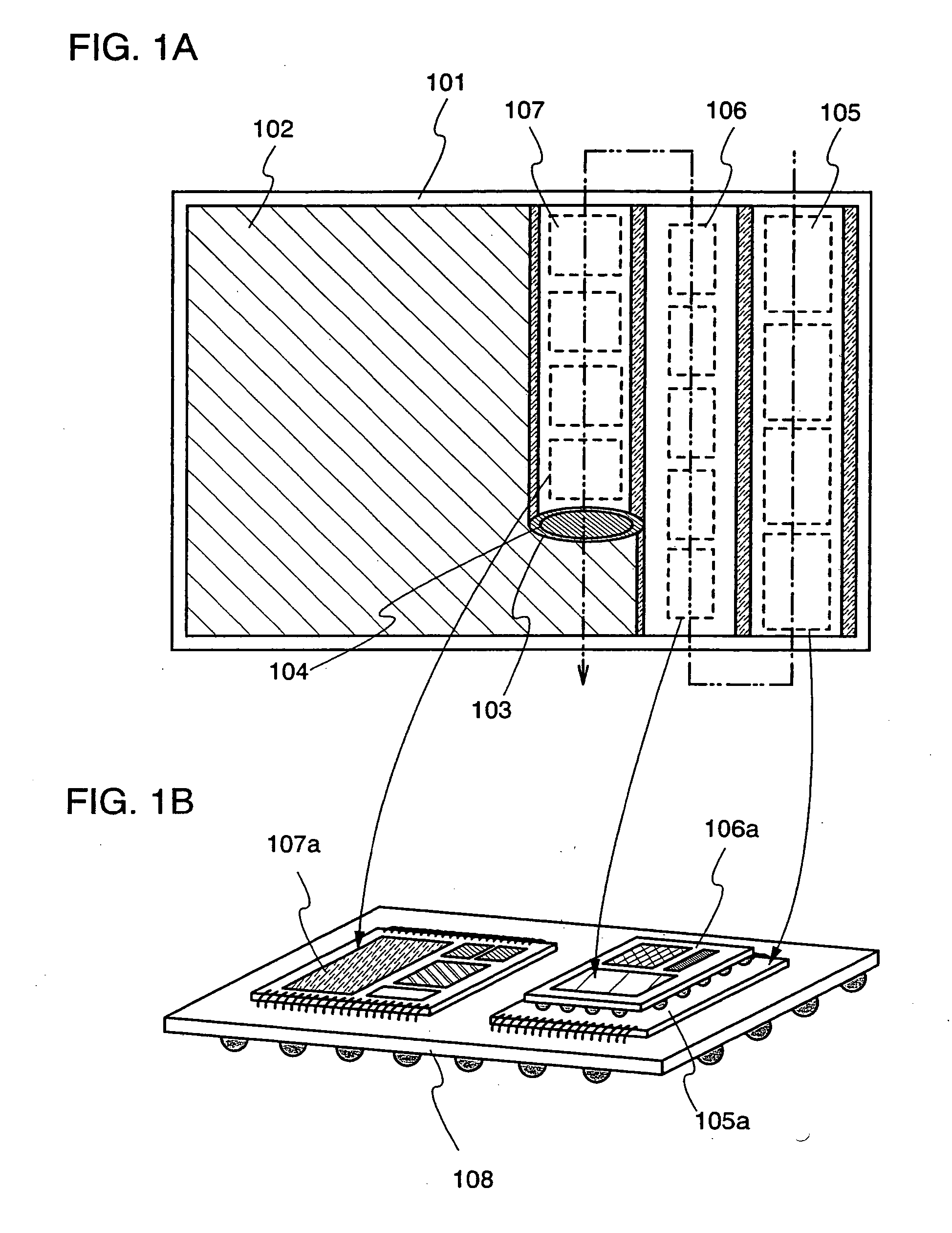

Methods of avoiding wafer breakage during manufacture of backside illuminated image sensors

InactiveUS20080044984A1Wafer thickness reductionReduce thicknessSolid-state devicesSemiconductor/solid-state device manufacturingGrindImage sensor

A process for forming backside illuminated devices is disclosed. Specifically, the process reduces processing damage to wafers caused by poor bond quality at the wafer edge ring. In one embodiment, a wafer edge trimming step is implemented prior to bonding the wafer to the substrate. A pre-grind blade is used to create a straight edge around the wafer perimeter, eliminating any sharp edges. In another embodiment, edge trimming is performed after the wafer has been bonded to the substrate, and a pre-grind blade is used to remove portion of the wafer edge ring subject to poor bonding quality before grinding. The final thickness of the ground wafer is about 50 microns in either case.

Owner:TAIWAN SEMICON MFG CO LTD

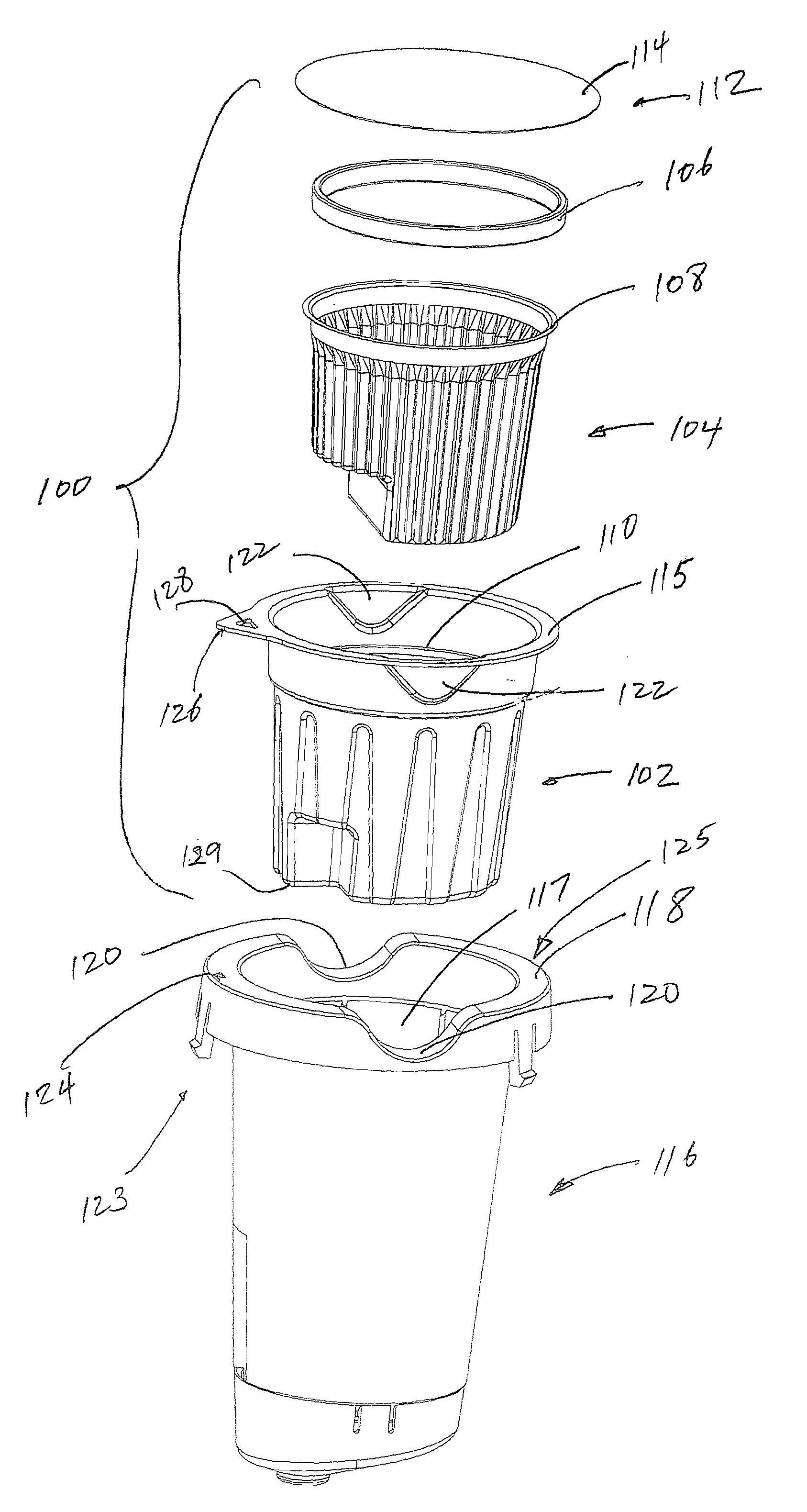

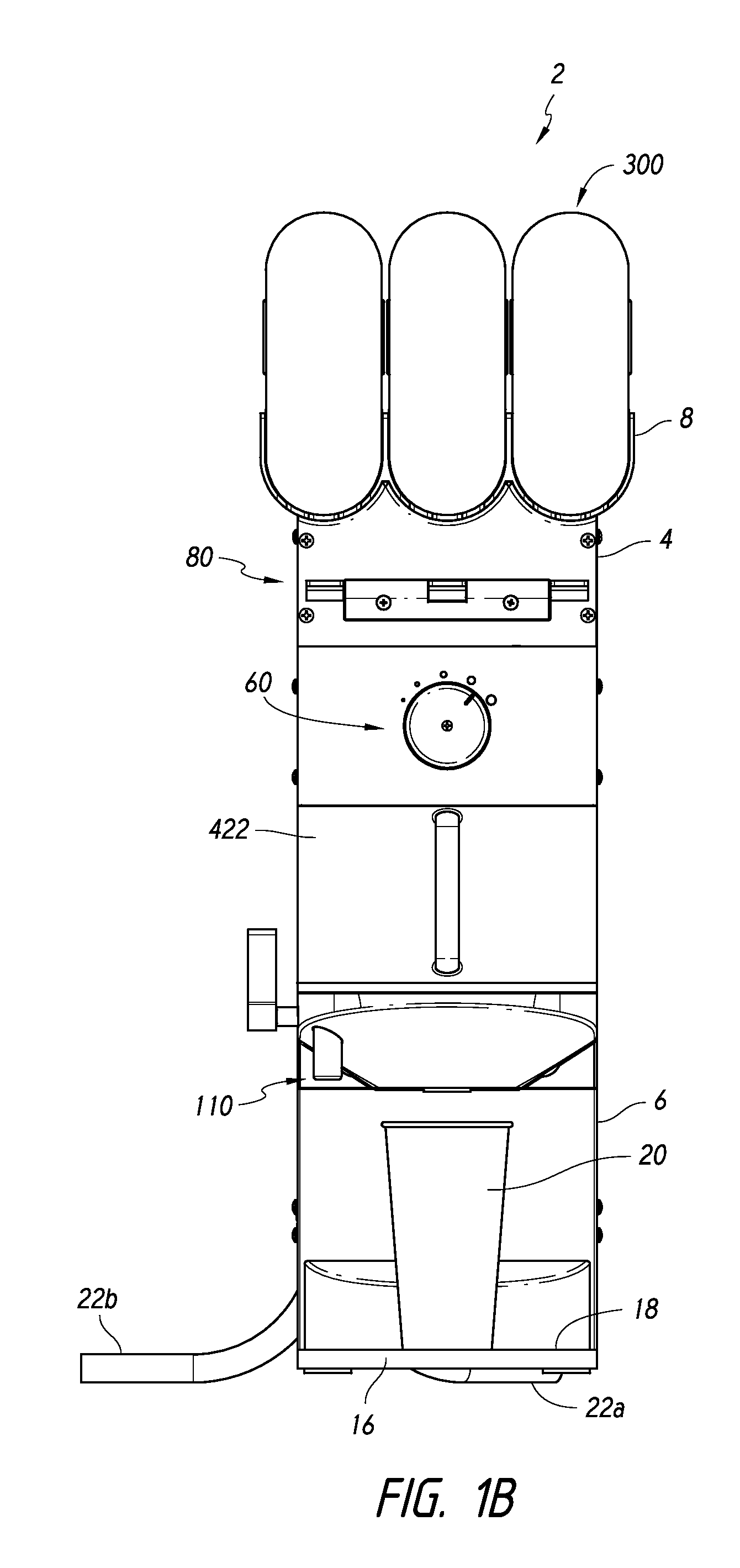

Beverage brewing system

InactiveUS20130340626A1Convenient amountSmooth tasteReady-for-oven doughsContainer decorationsGrindBiomedical engineering

A beverage cartridge system is adapted to brew a beverage through a brewer having a holder adapted to receive the cartridge system. The holder may have a deep well with one or more needles therewithin to pierce through the bottom of the cartridge system when inserted into the well. The cartridge system may include a short cup and a tall cup, where the tall cup is taller than the short cup to pack more beverage grind. The cartridge system may include a filter within an outer cup. The bottom of the filter may be deep enough to be juxtaposed to the bottom of the cup. The filter may be formed from a material that is substantially resistant to piercing by the needle within the holder such that when the outlet needle pierces through the bottom of the cup, the outlet needle raises the filter at a point of contact, and the filter substantially resists the outlet needle from piercing through the filter during a brewing process.

Owner:TOUCH COFFEE & BEVERA

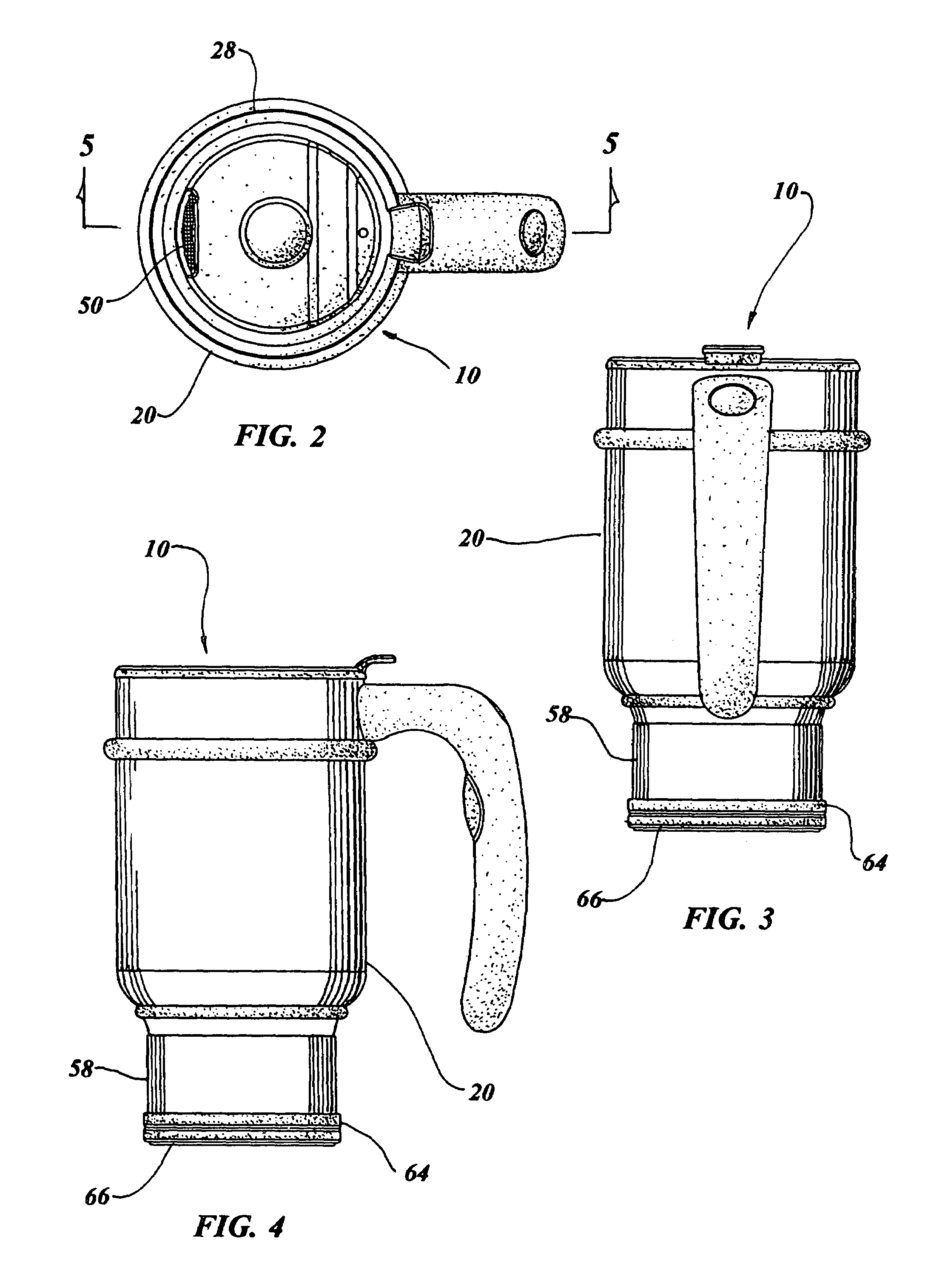

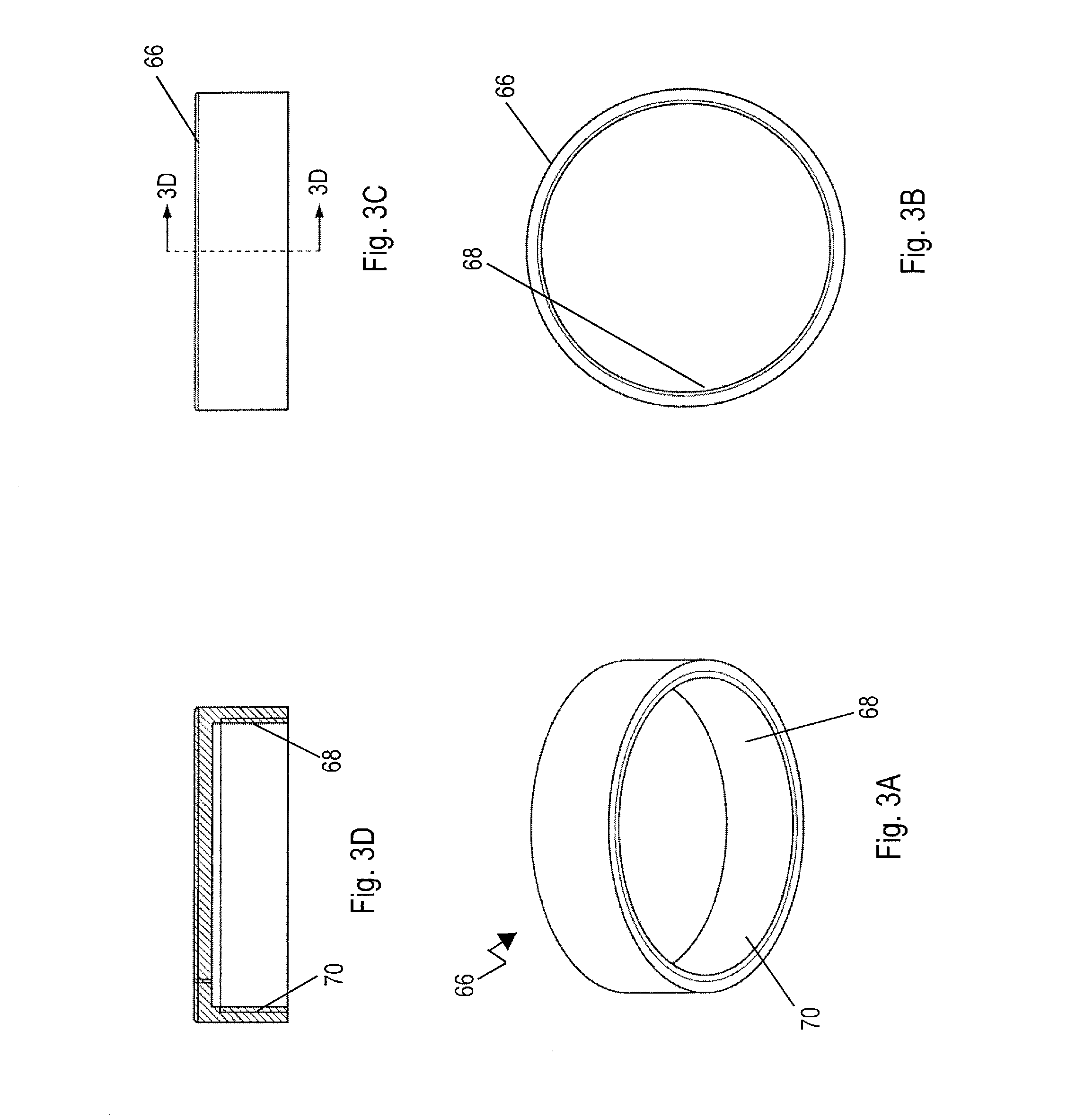

Beverage press mug with storage container

InactiveUS7194951B1Tight actionPrevent leakageBeverage vesselsRigid containersSugarMechanical engineering

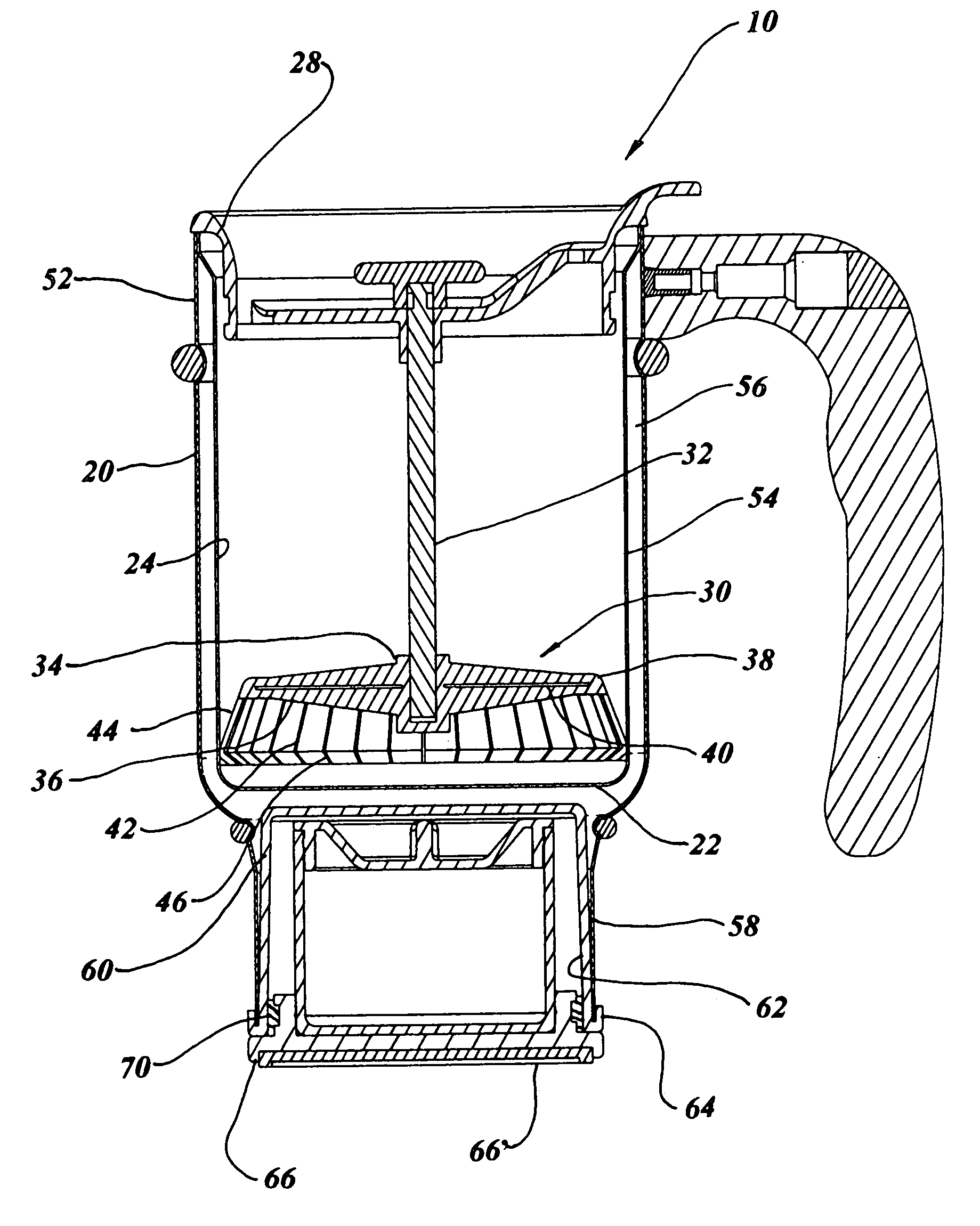

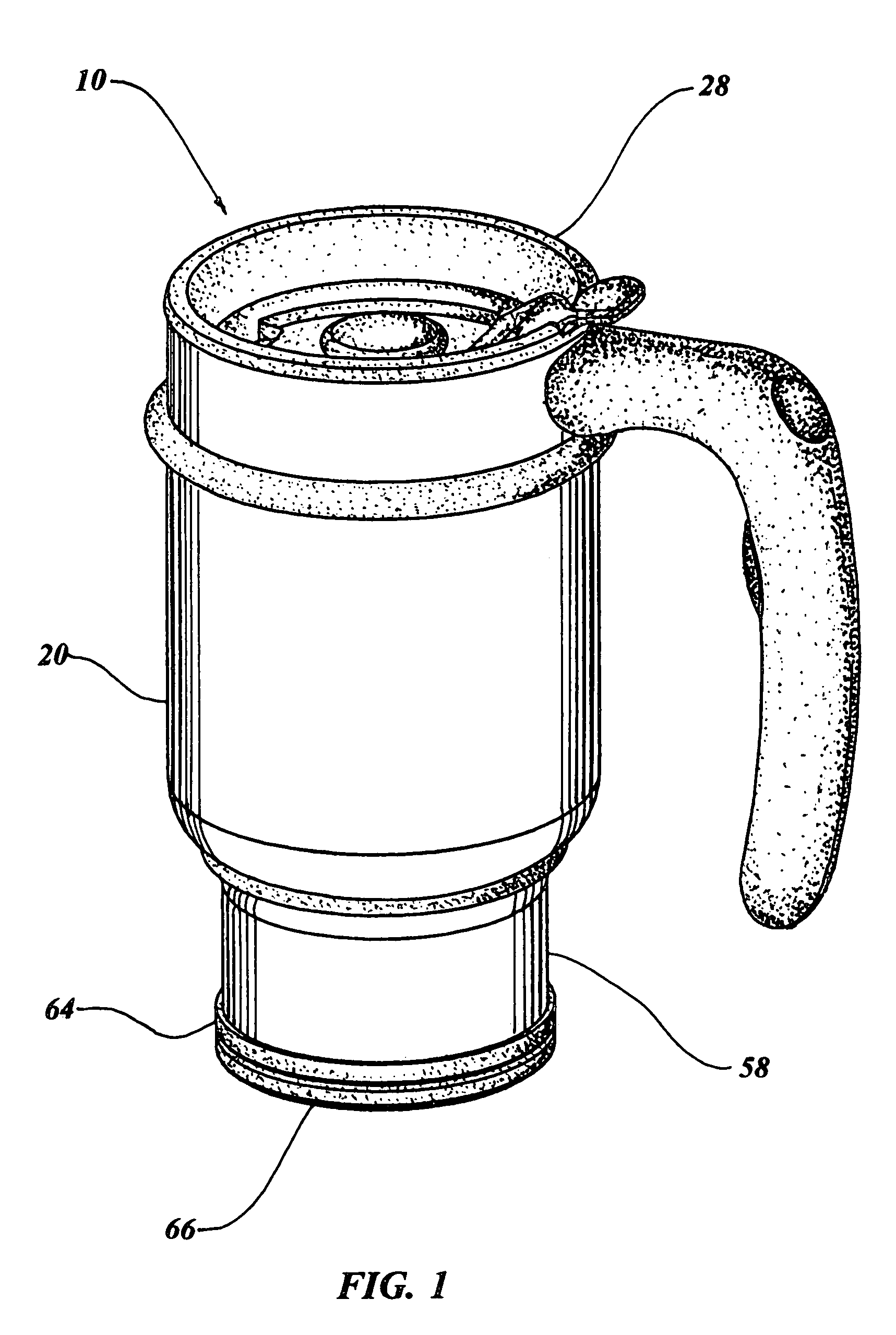

A mug (10), specifically a vessel (20) incorporating a plunger assembly (30), that includes a number of fingers (42), is improved by positioning the fingers downwardly to contact the side wall of the vessel. The improvement also includes the following; a minor diameter portion (58) of the vessel sized to fit a motor vehicle cup holder. An open distal ended liner (62) intimately embracing a storage container compartment (60) formed on an inside surface of the outer shell minor diameter portion of the vessel. A closure base (66) removably engages the liner and encloses the bottom of the vessels storage container compartment. The closure base includes a number of inwardly facing spacer legs (68) that removably retain a storage container (72) including a detachable lid (74). The storage container provides a receptacle for such items as coffee grinds, tea leaves, sugar and creamer etc. such that the items may be conveniently available with the mug.

Owner:RATTLER HLDG LLC

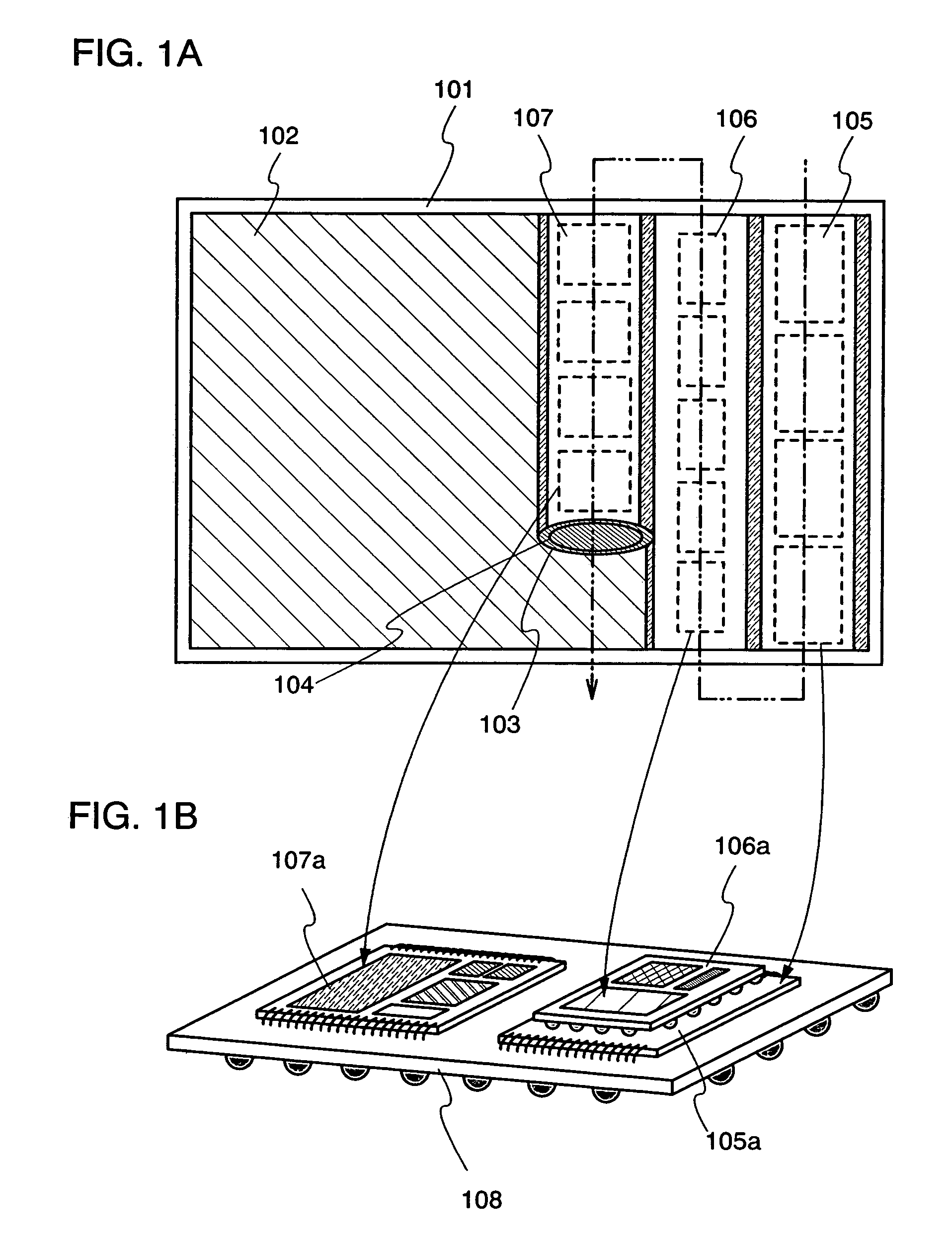

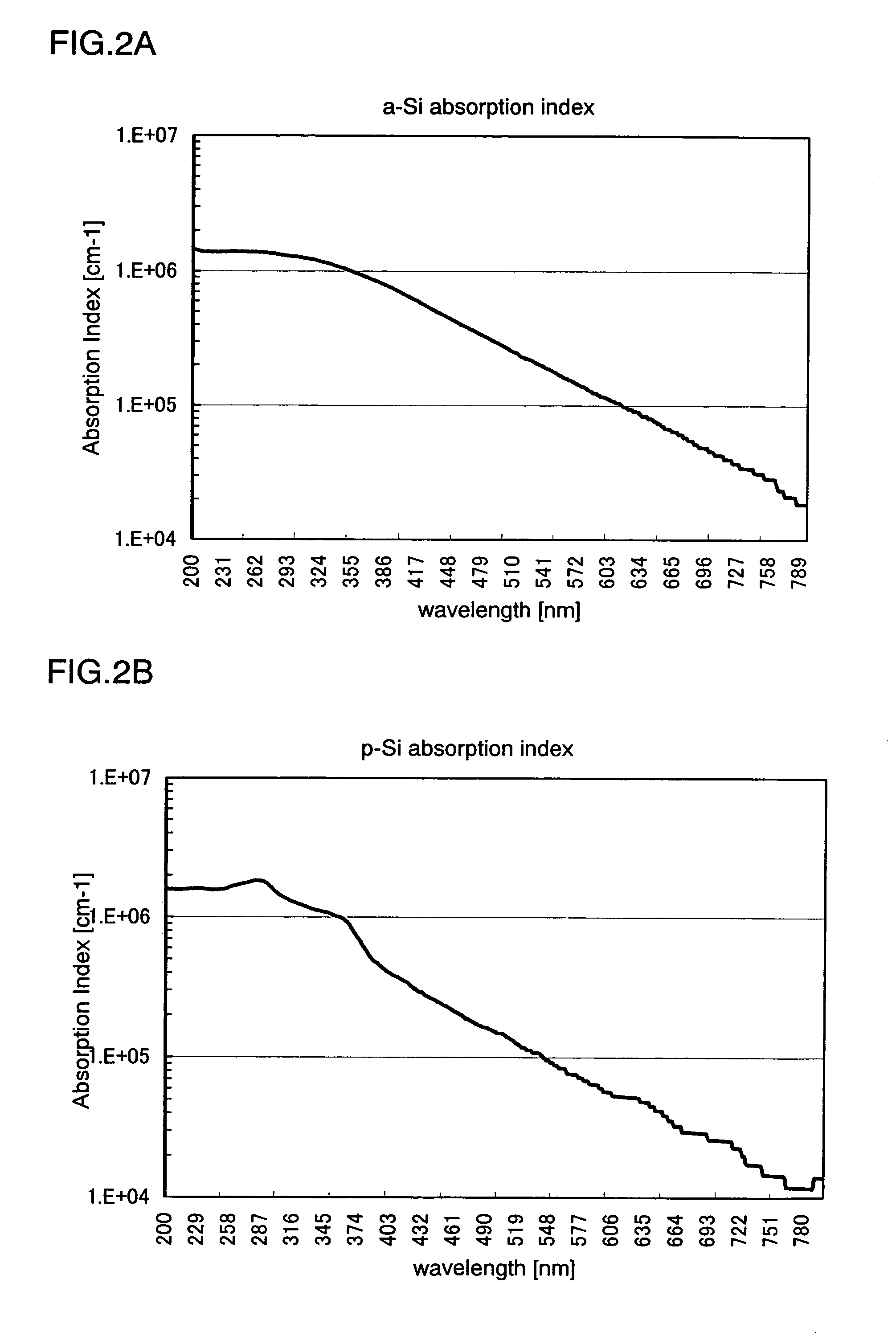

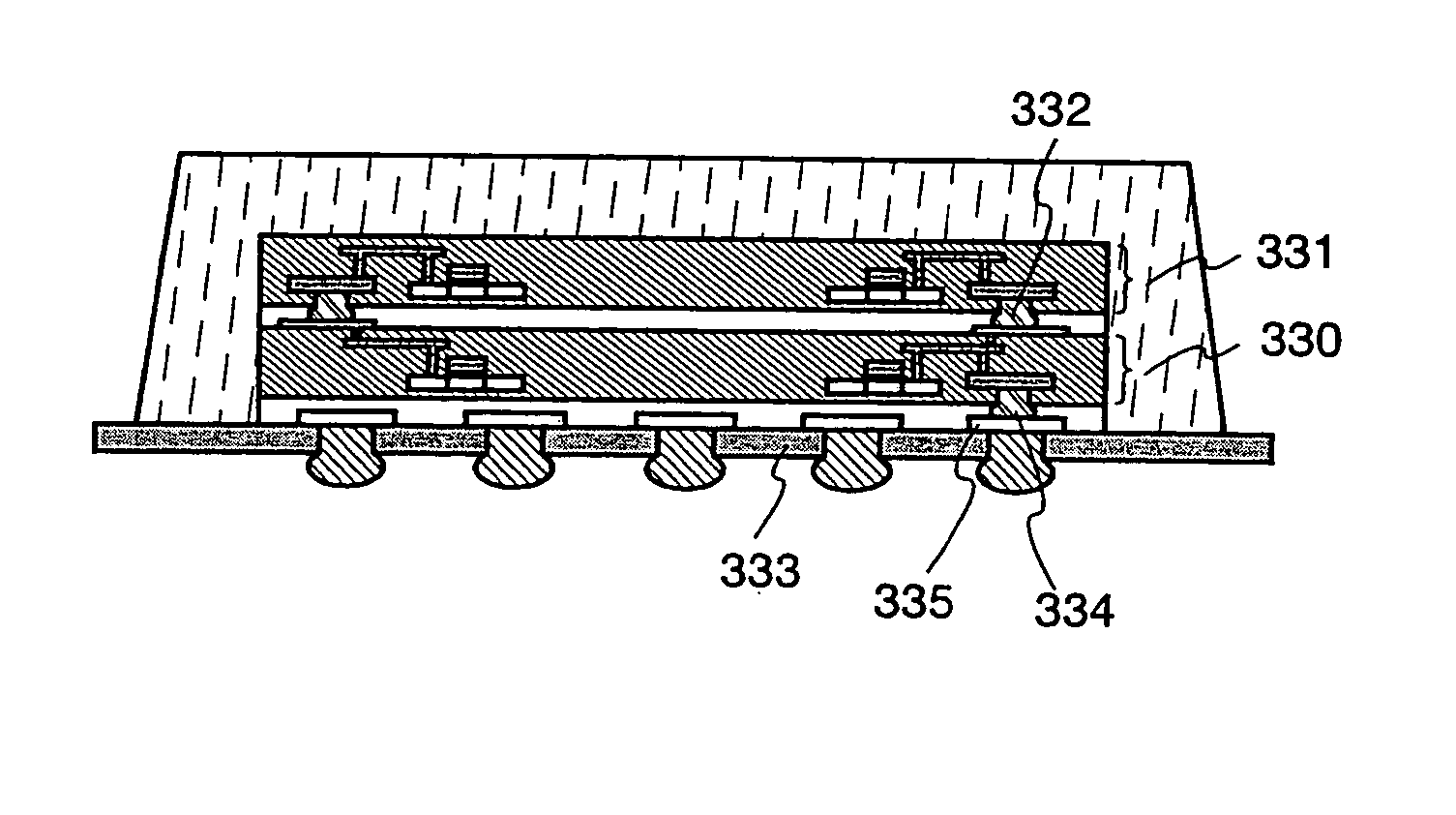

Method for manufacturing semiconductor apparatus, and semiconductor apparatus and electric appliance

ActiveUS7056810B2Low costImprove throughputPolycrystalline material growthSemiconductor/solid-state device detailsEngineeringCw laser

According to the package and the method for manufacturing the package of the present invention, a chip can be formed extremely to be thin, and manufactured at lower cost and higher throughput, and the variations of a chip thickness can be reduced without back grind that causes cracks or polishing marks. In the present invention, a semiconductor film with a thickness of at most 500 μm deposited over a substrate serving as a support medium is crystallized with a CW laser light, and a chip having a semiconductor device is formed to have a total thickness of 5 μm, preferably at most 2 μm by using the crystallized semiconductor film. Consequently, the chip is mounted on an interposer after separating a substrate.

Owner:SEMICON ENERGY LAB CO LTD

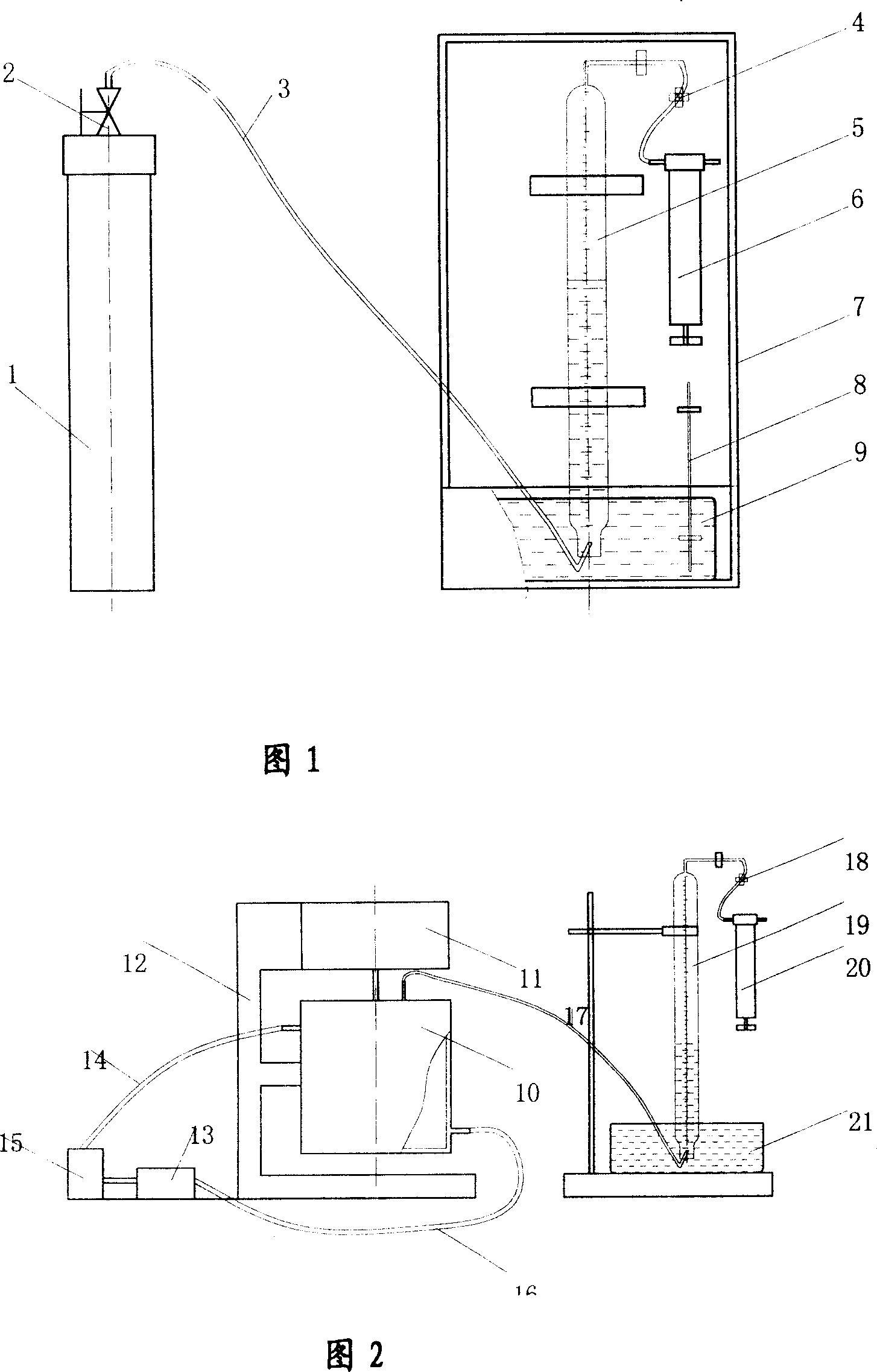

Direct rapid measuring method capable of desorbing mash gas content with coal seam

ActiveCN101135621AThe amount of measurement work is smallLow assay costWithdrawing sample devicesPreparing sample for investigationDesorptionGrind

The method comprises: sampling coal core from underground mining; at underground mining, measuring and calculating the gas loss quantity of coal core; at the ground, measuring and calculating the desorption of the coal mining gas; measuring and calculation the grind gas desorption of partial coal core; calculating the content of gas capable of being desorbed.

Owner:CHINA COAL TECH ENG GRP CHONGQING RES INST

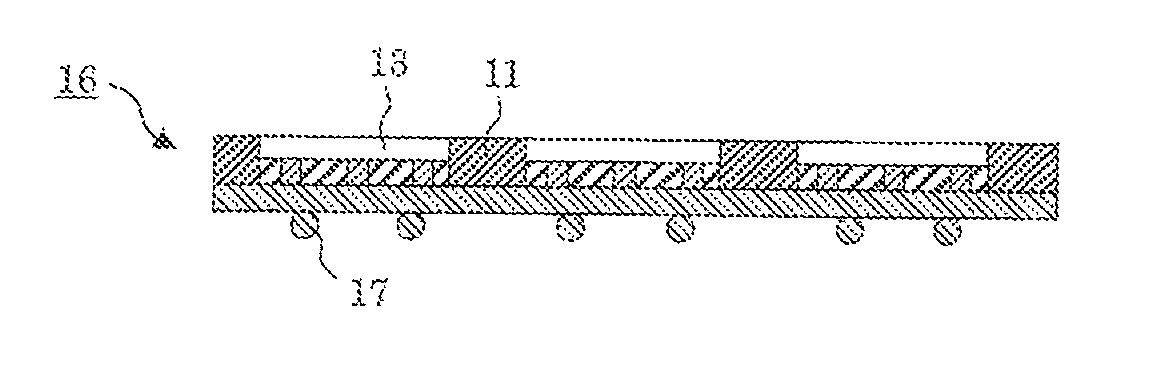

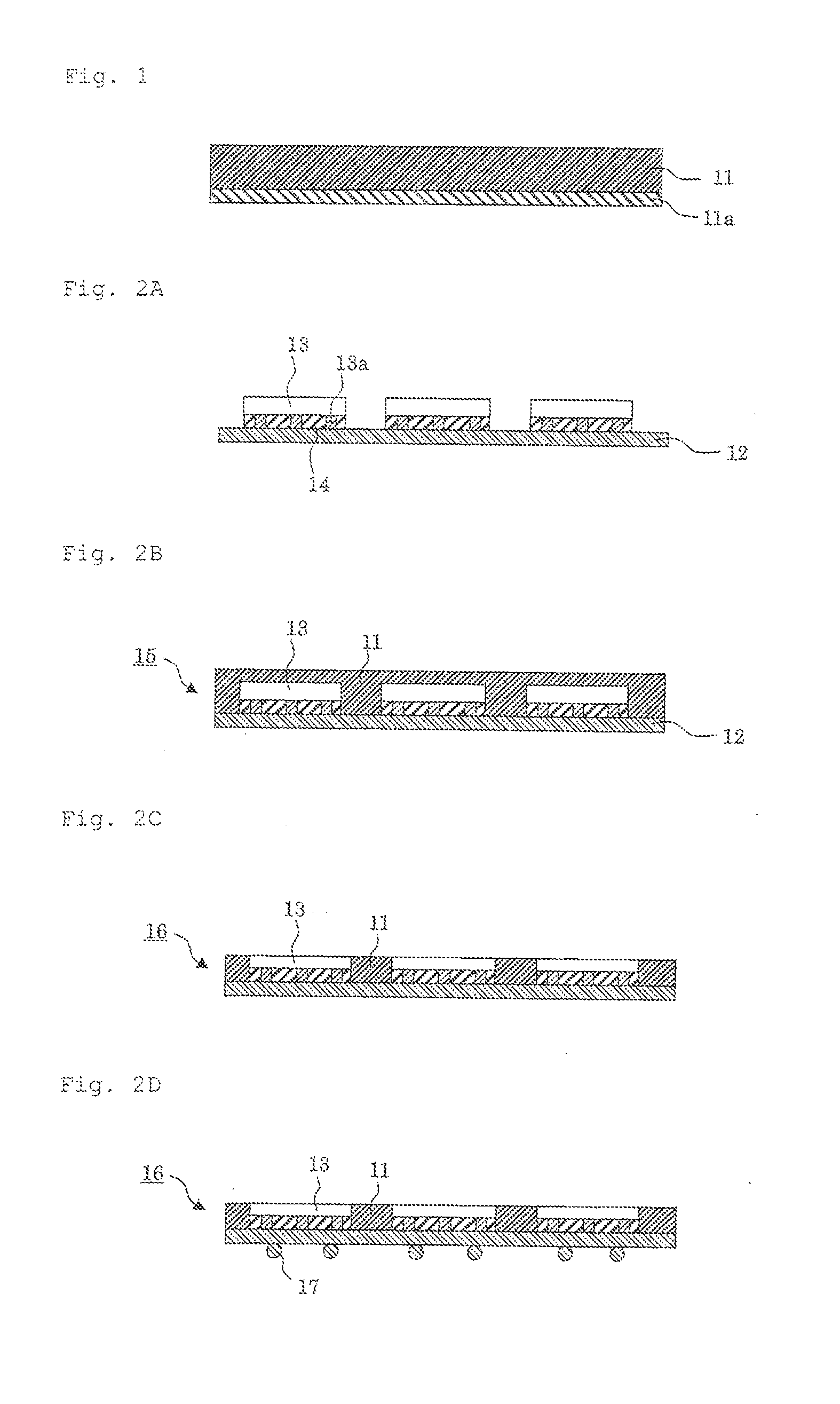

Method for manufacturing semiconductor apparatus, and semiconductor apparatus and electric appliance

ActiveUS20060220211A1Thickness drasticallyLow costPolycrystalline material growthSemiconductor/solid-state device detailsCrazingDevice material

According to the package and the method for manufacturing the package of the present invention, a chip can be formed extremely to be thin, and manufactured at lower cost and higher throughput, and the variations of a chip thickness can be reduced without back grind that causes cracks or polishing marks. In the present invention, a semiconductor film with a thickness of at most 500 μm deposited over a substrate serving as a support medium is crystallized with a CW laser light, and a chip having a semiconductor device is formed to have a total thickness of 5 μm, preferably at most 2 μm by using the crystallized semiconductor film. Consequently, the chip is mounted on an interposer after separating a substrate.

Owner:SEMICON ENERGY LAB CO LTD

Negative-electrode active material for lithium secondary battery, negative electrode for lithium secondary battery, and lithium secondary battery

ActiveUS20060035146A1Reduce thicknessProlong lifeSecondary cellsNon-aqueous electrolyte accumulator electrodesLithiumCarboxymethyl cellulose

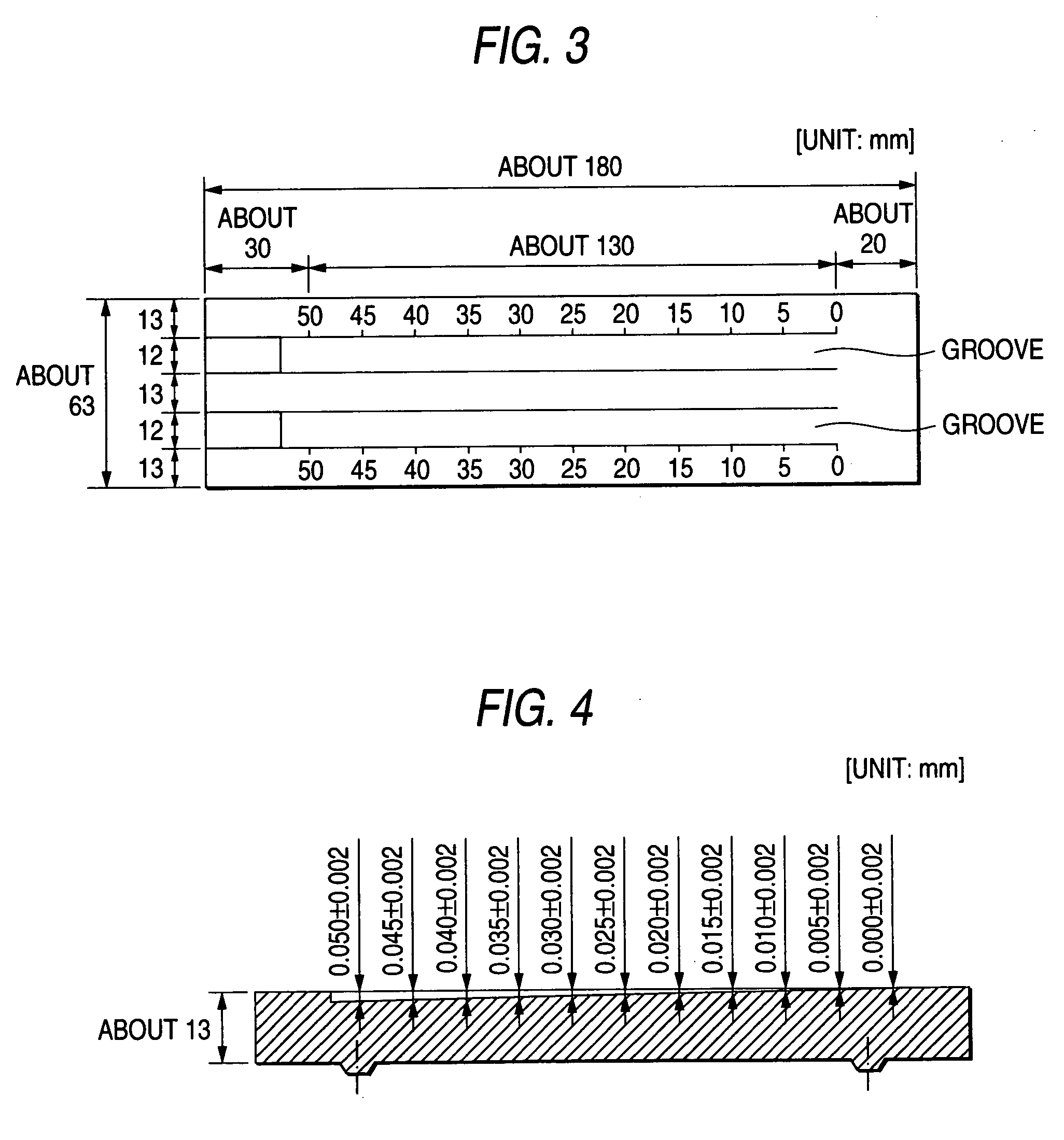

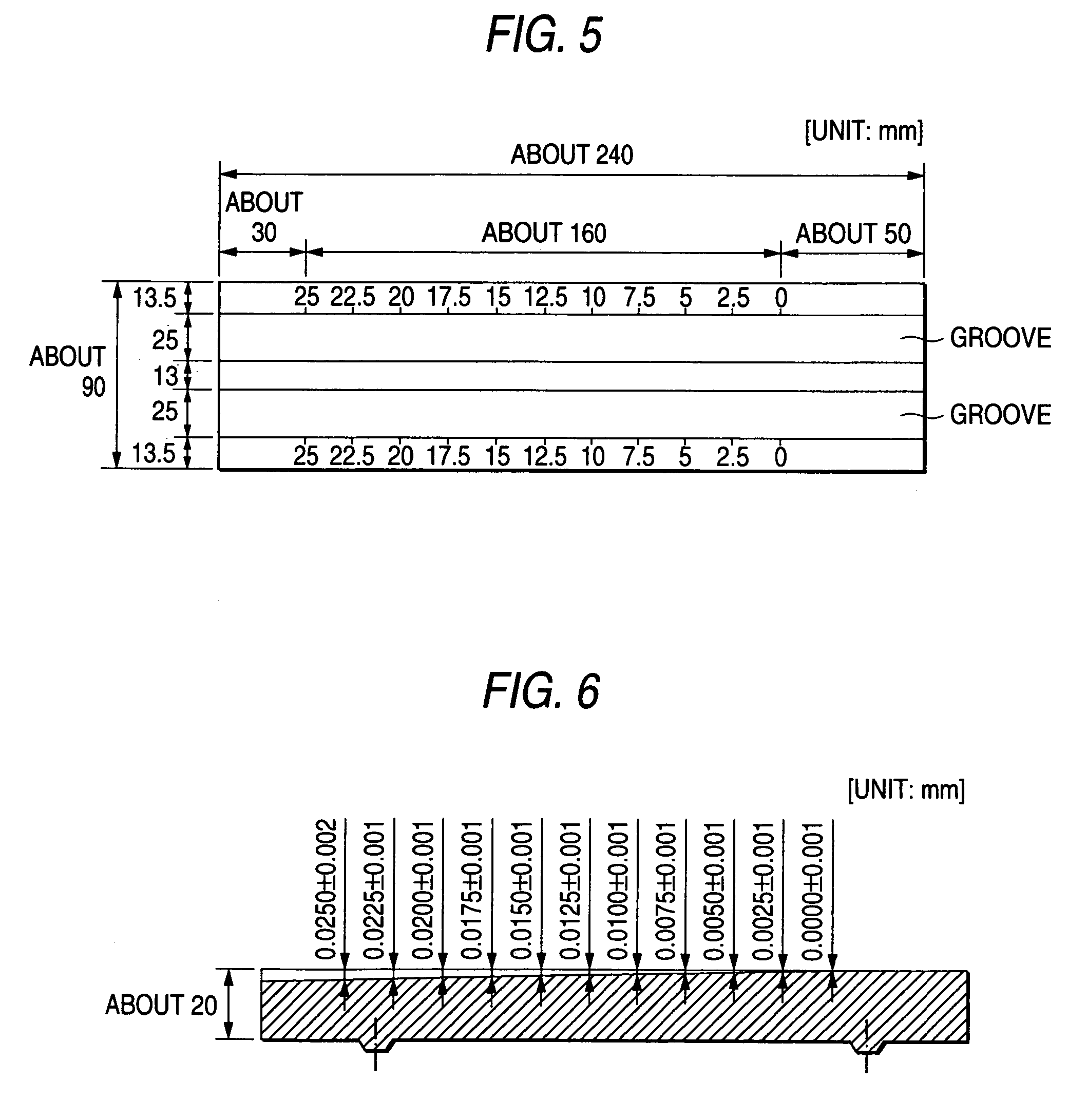

A subject for the invention is to provide a lithium secondary battery which can be improved in high-output / high-input characteristics based on a reduction in the thickness of an active material layer, has a long life, and is highly safe. The invention relates to: a negative-electrode active material for lithium secondary battery, which is in a carbonaceous powder form and in which when a dispersion prepared by dispersing 100 g of the active-material powder in 200 g of water together with 2 g of carboxymethyl cellulose is examined by the grind gauge method for determining the degree of dispersion in accordance with JIS K5400, the particle diameter at which particles begin to appear is 50 μm or smaller; a negative electrode for lithium secondary battery which comprises a current collector having provided thereon an active material layer comprising an active material and an organic material having binding and thickening effects, wherein the active material layer has a thickness of 50 μm or smaller and an arithmetic mean roughness (Ra) as measured in accordance with JIS B0601 of 5 μm or smaller; and a lithium secondary battery employing the negative electrode.

Owner:MITSUBISHI CHEM CORP

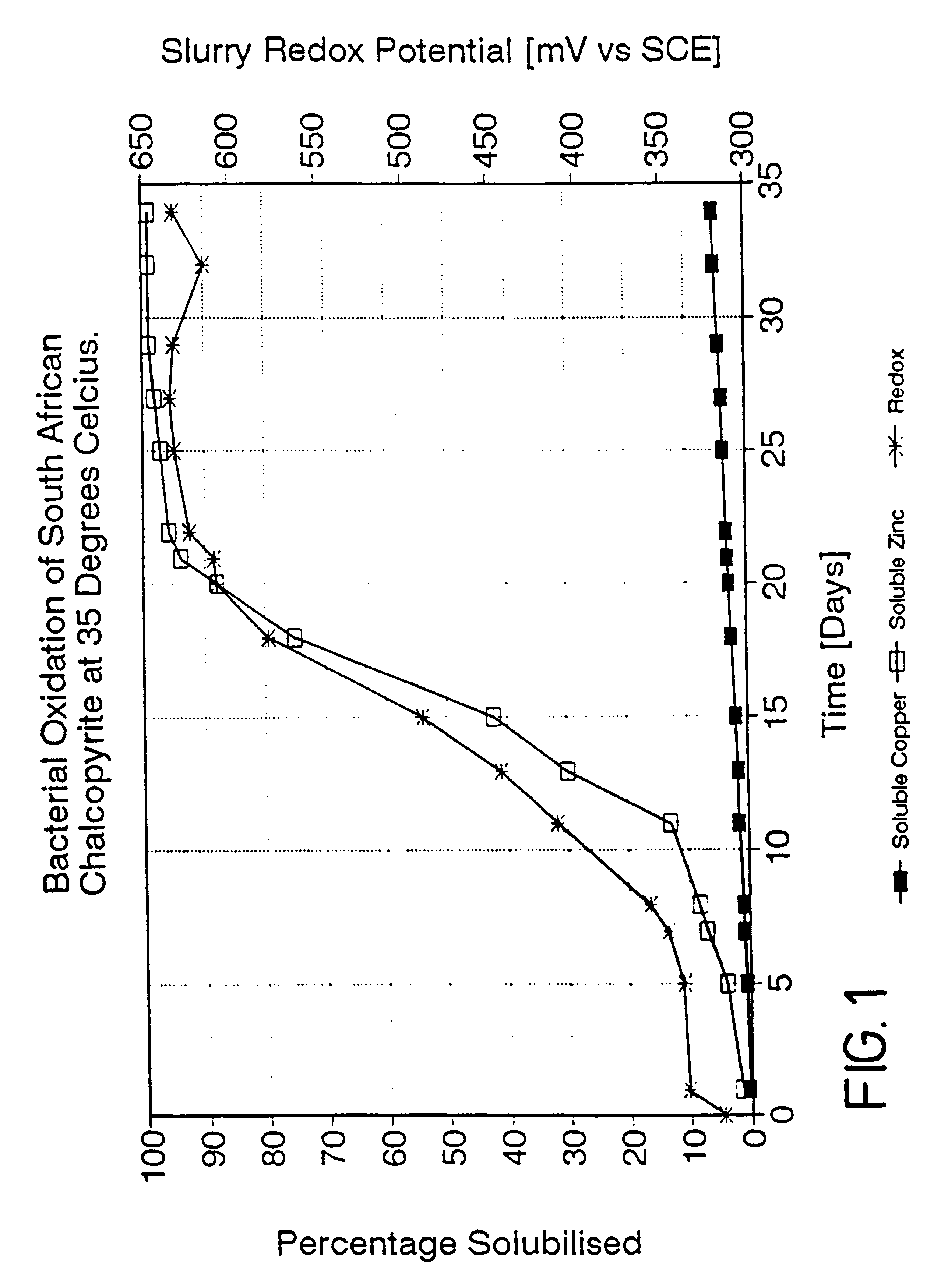

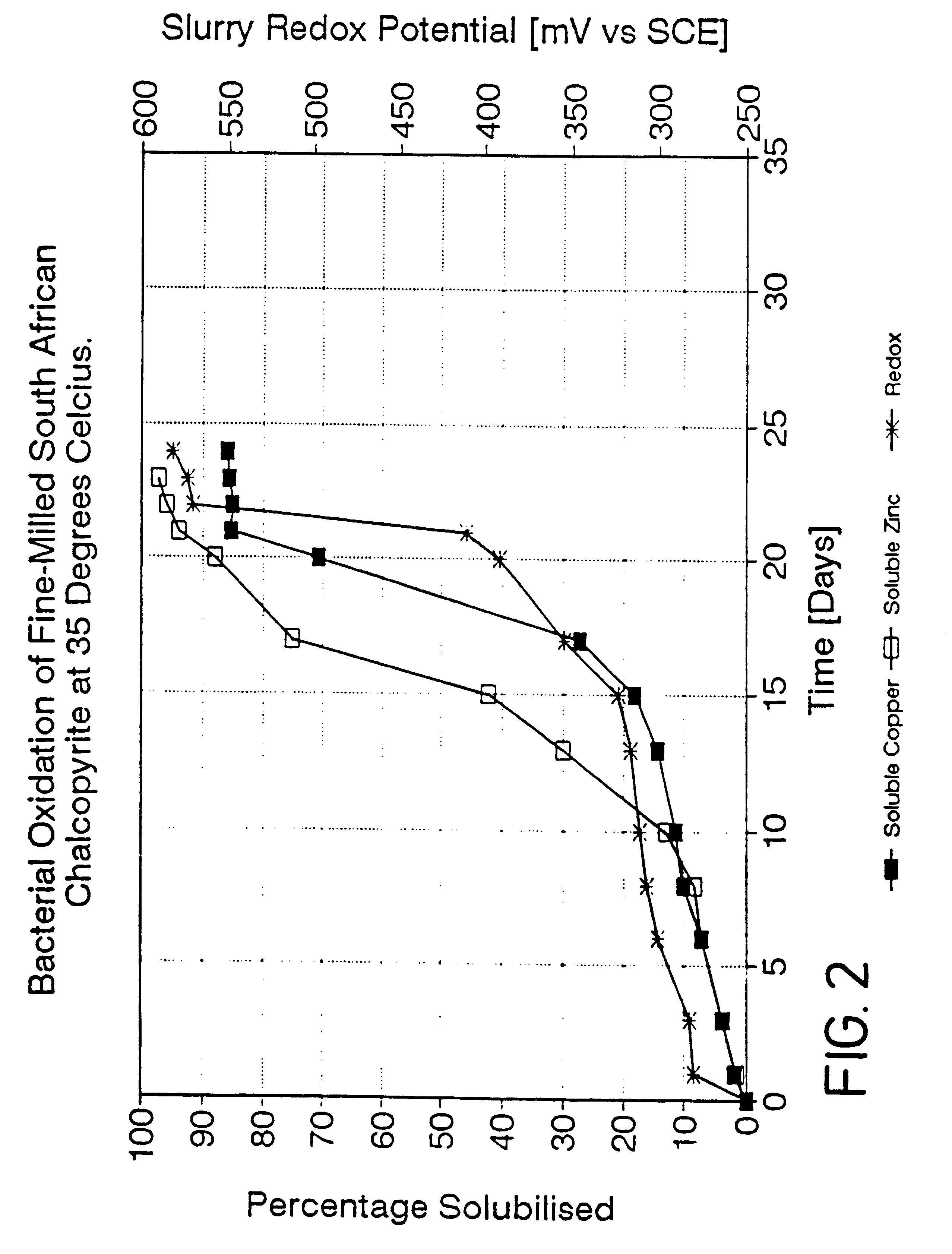

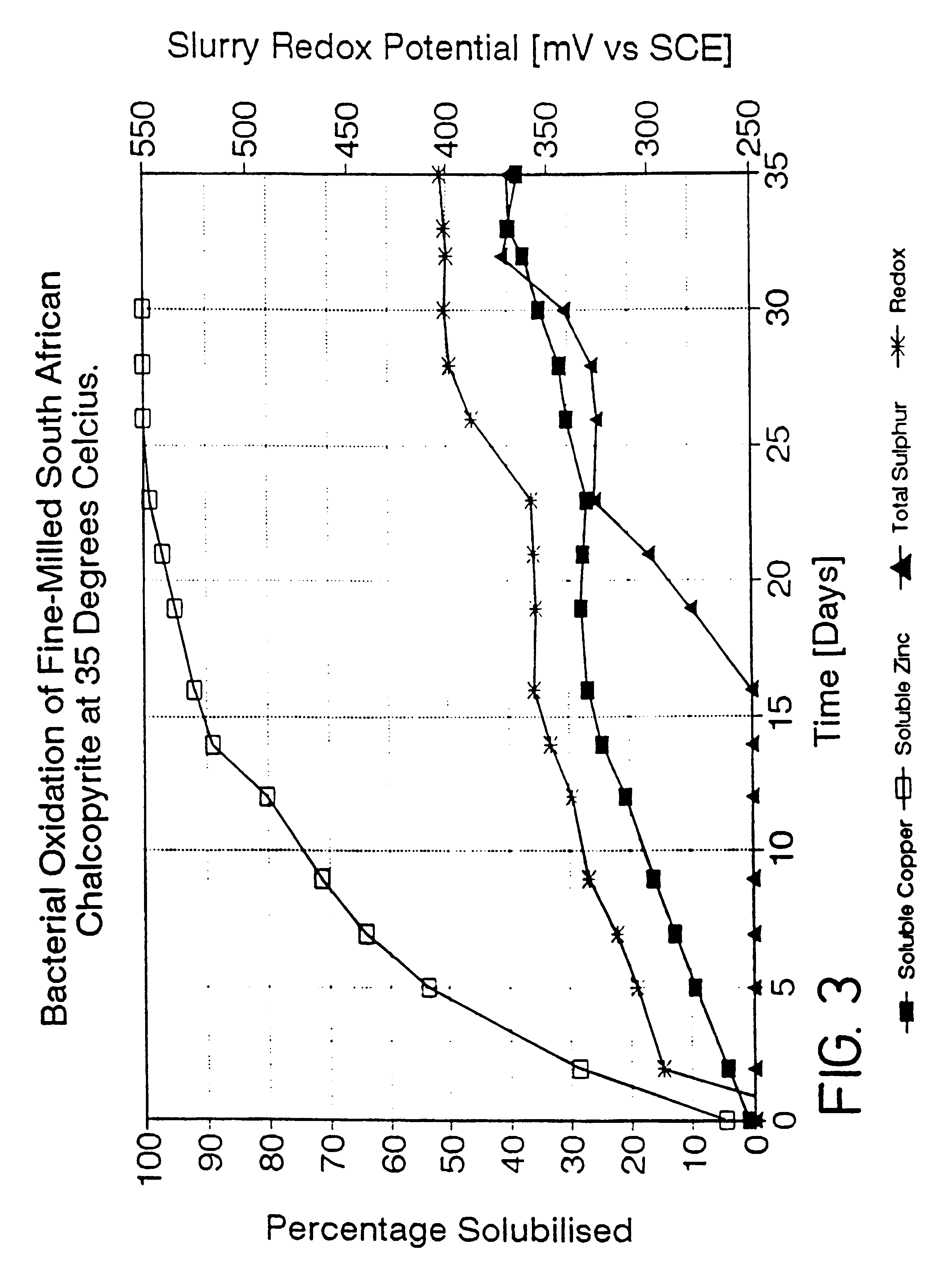

Process for the rapid leaching of chalcopyrite in the absence of catalysts

InactiveUS6277341B1Increase surface areaImprove misalignmentSolvent extractionGold compoundsPregnant leach solutionChalcopyrite

Owner:MINTEK

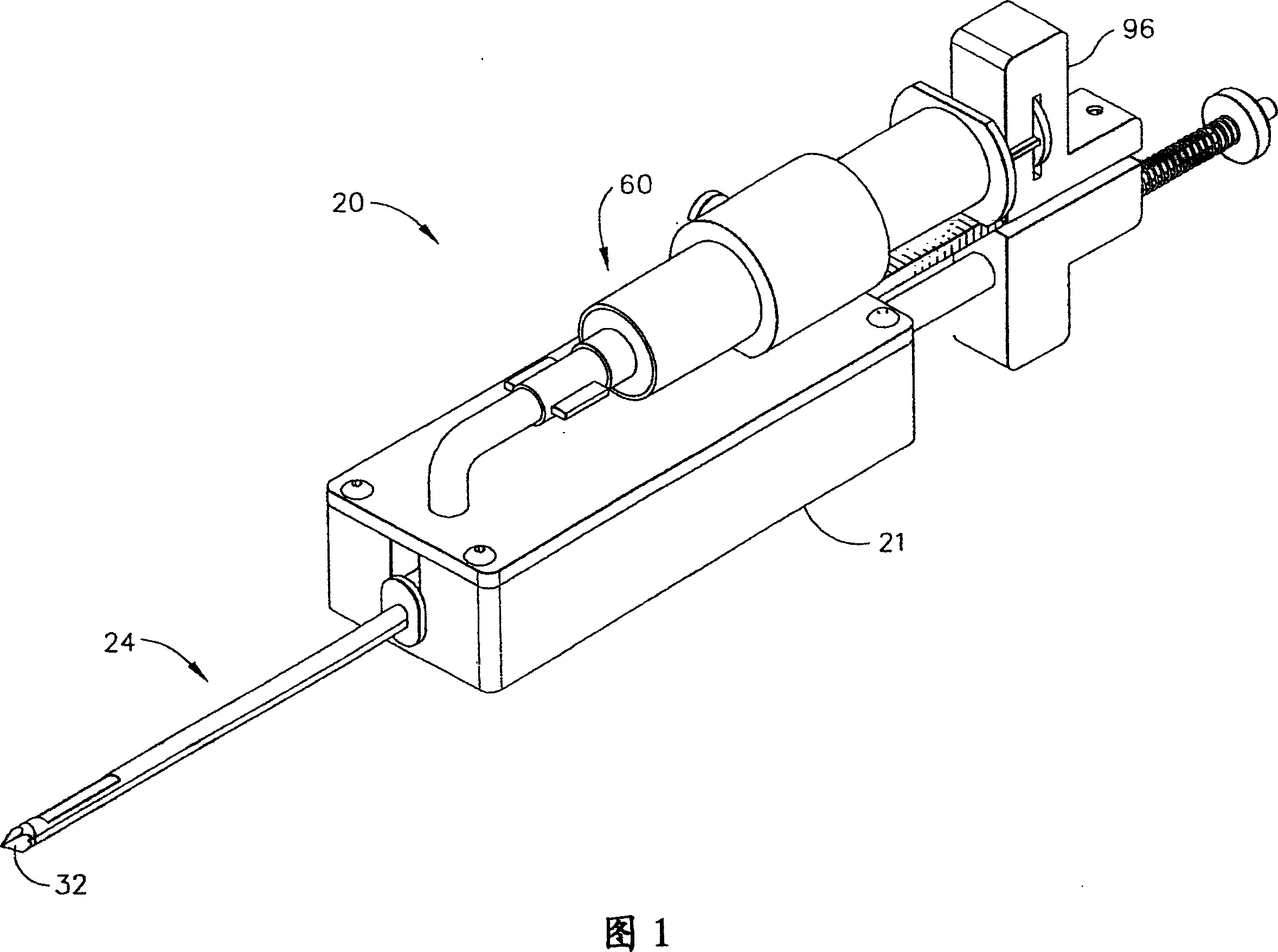

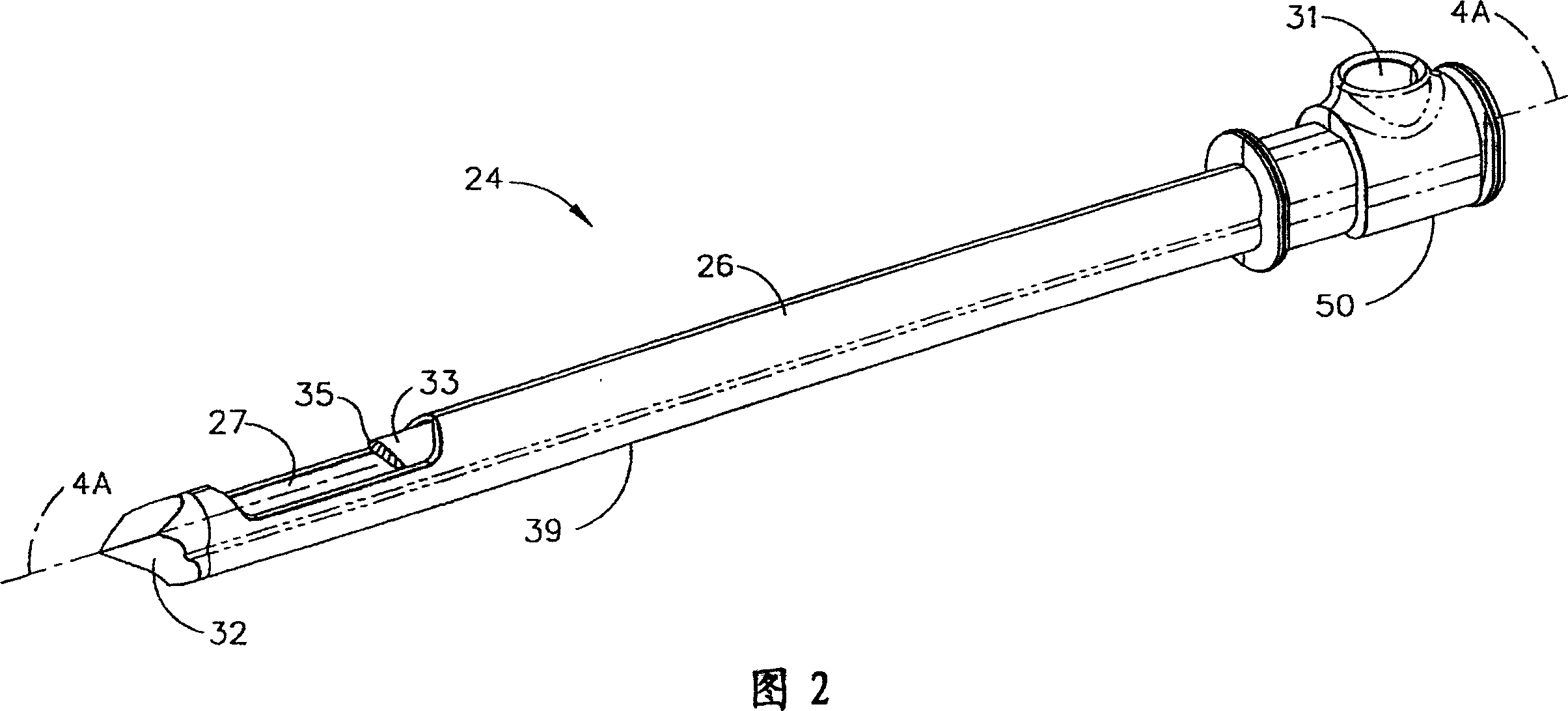

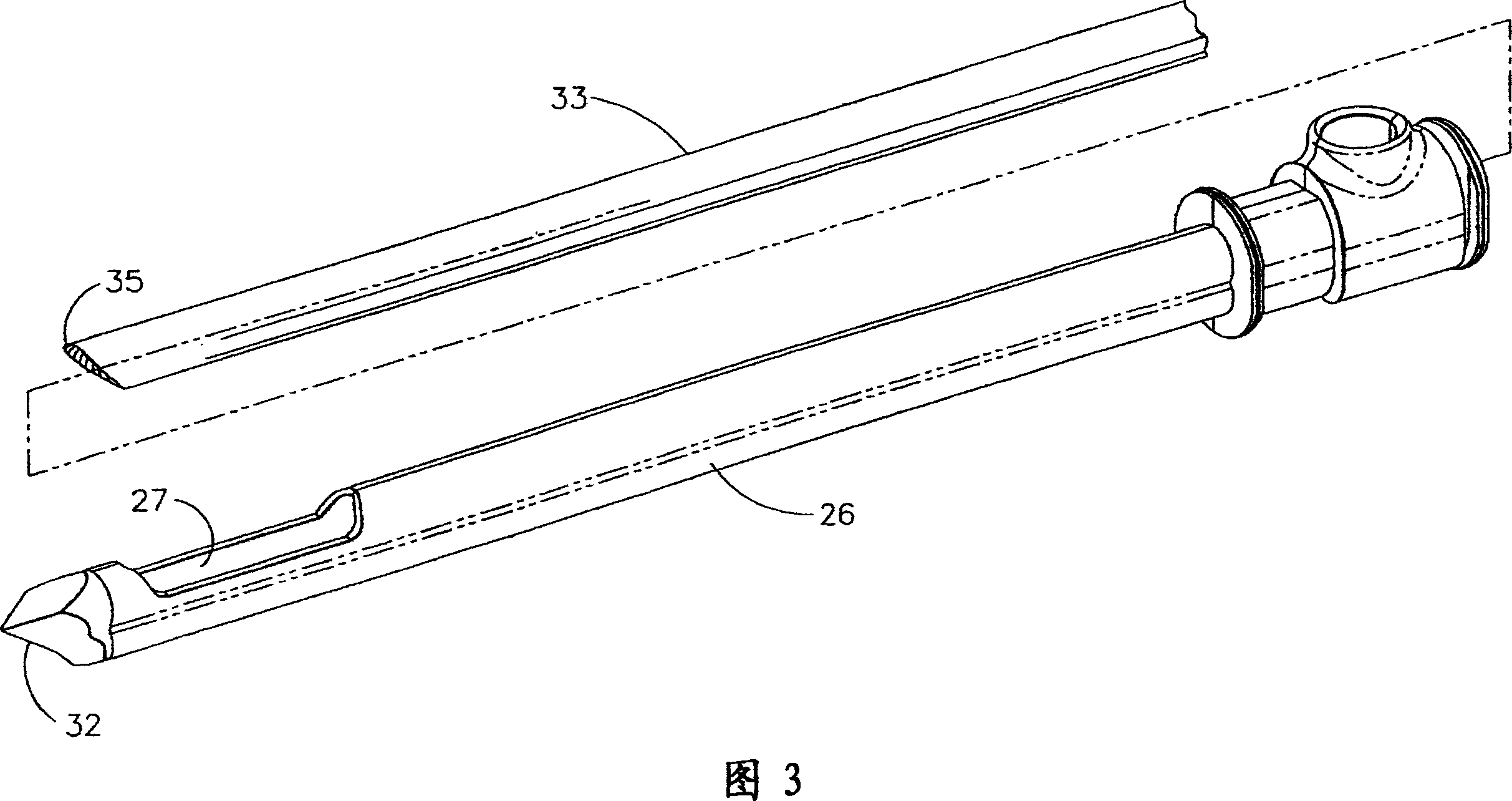

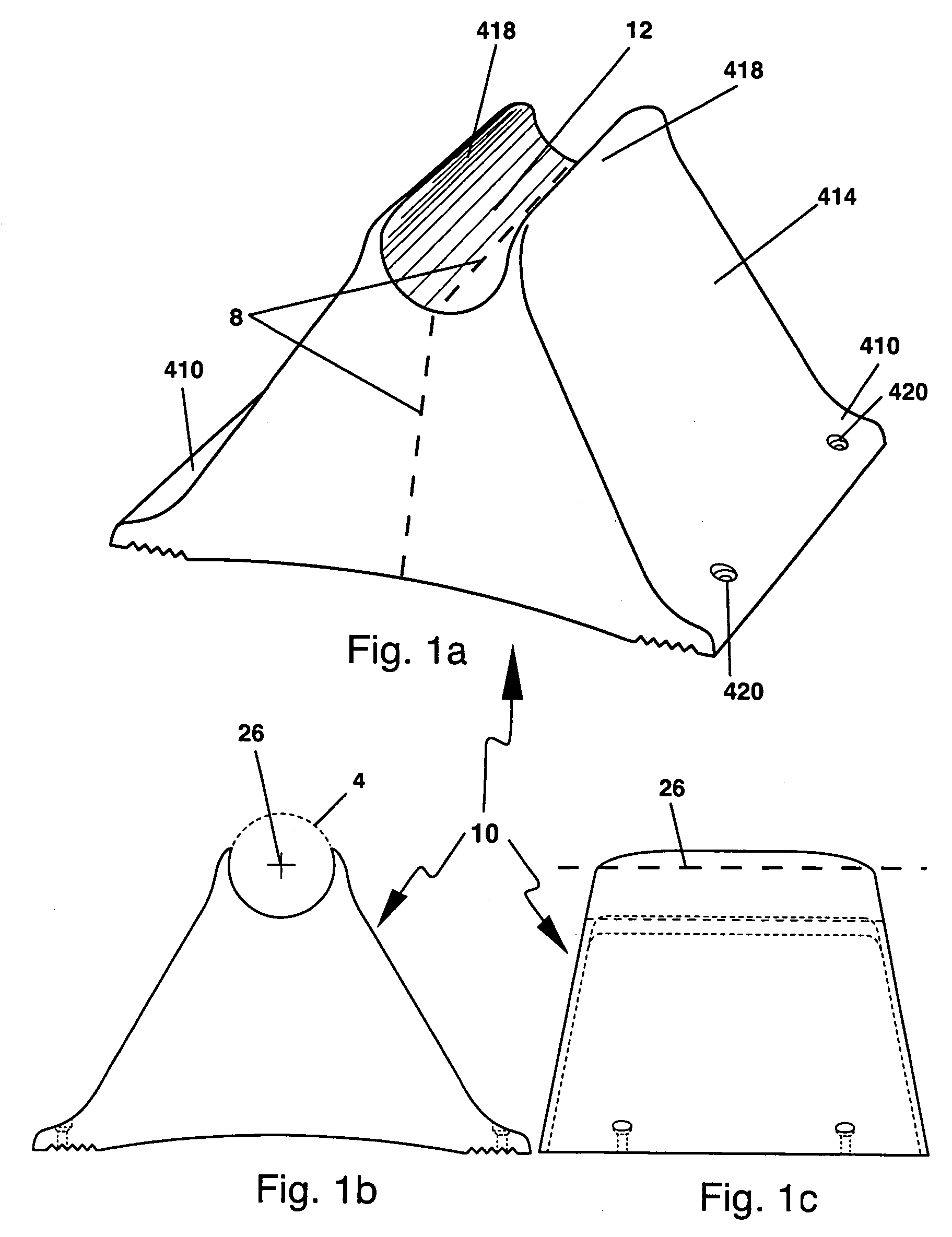

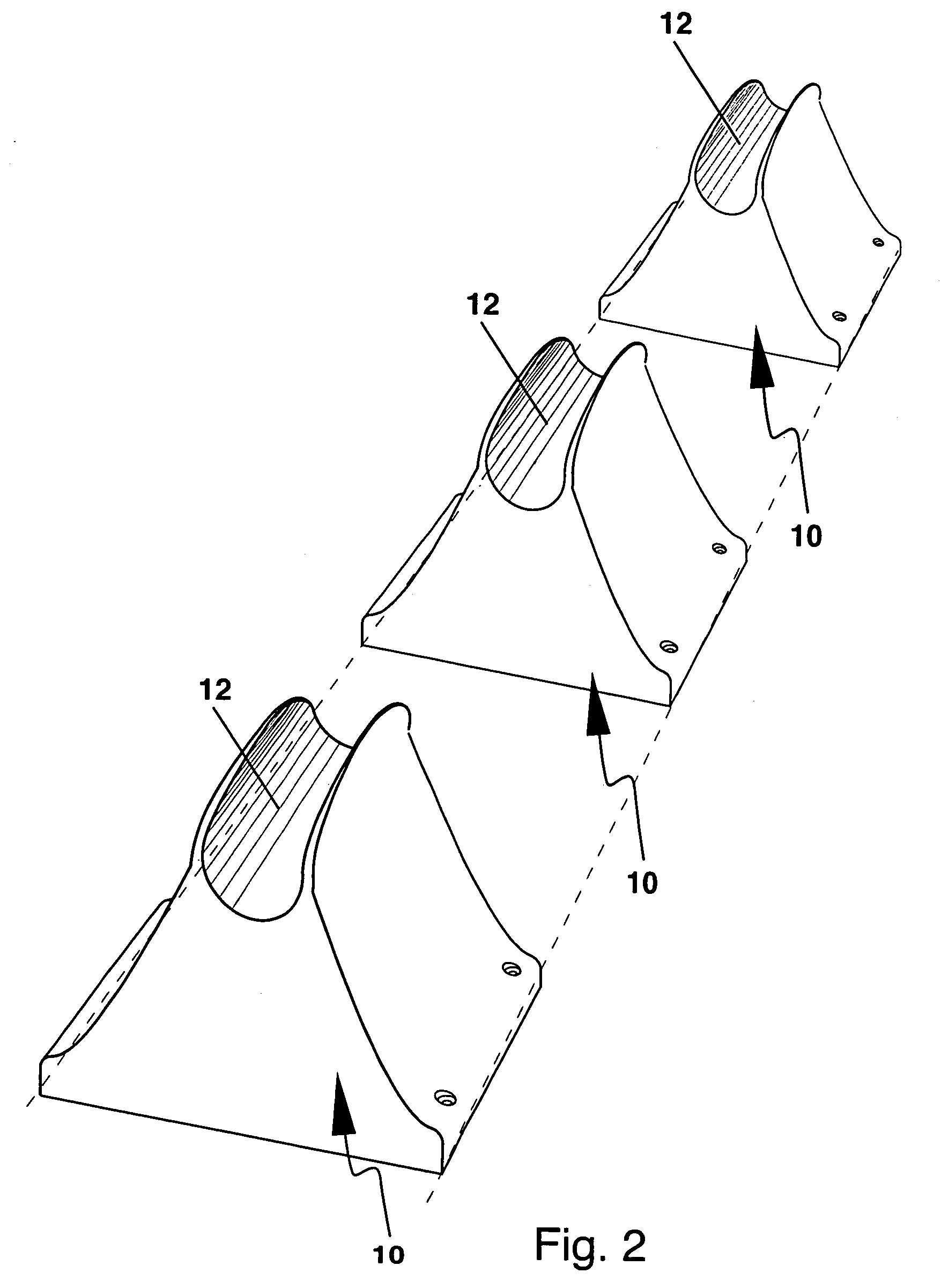

Device for minimally invasive internal tissue removal

A medical device for severing and removing small amounts of internal tissue for biopsy sampling or other purposes is disclosed. Versions of the device may include a hollow probe having a piecing tip, a tissue receiving aperture and a vacuum lumen; a cutter within the probe having a cutting edge that moves past the tissue receiving aperture, and a cutter driver mechanism. A cutter for use with versions disclosed herein may include an angled cutting tip and a cutting edge having a concave grind. Versions of the device also may include an aspirator fluidly connected to the vacuum lumen, coordinated operation of the aspirator and the cutter driver mechanism, and a fluid management system. Versions described may be used for removing multiple samples of tissue during a single insertion of the probe proximate to a target tissue mass.

Owner:ETHICON ENDO SURGERY INC

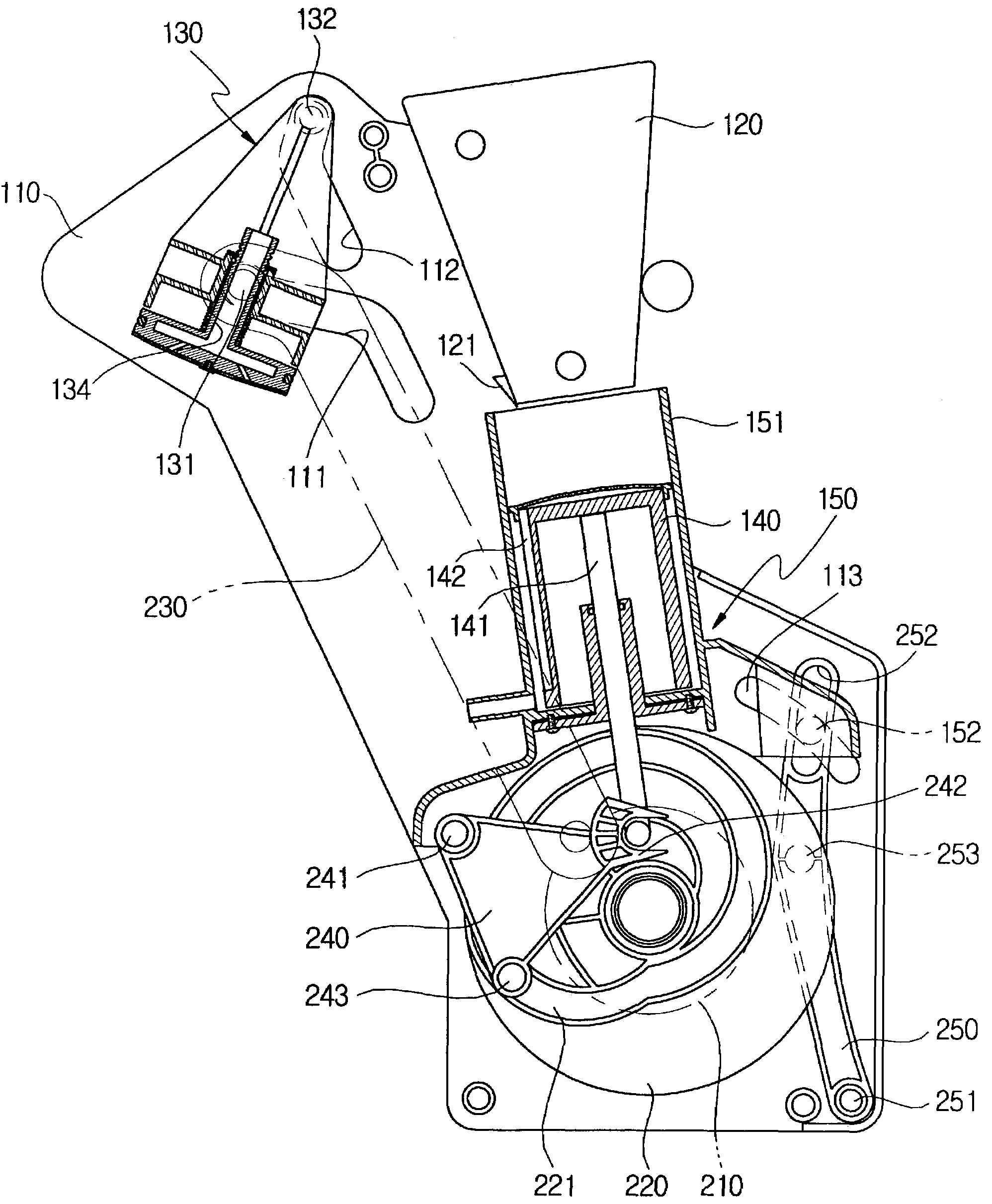

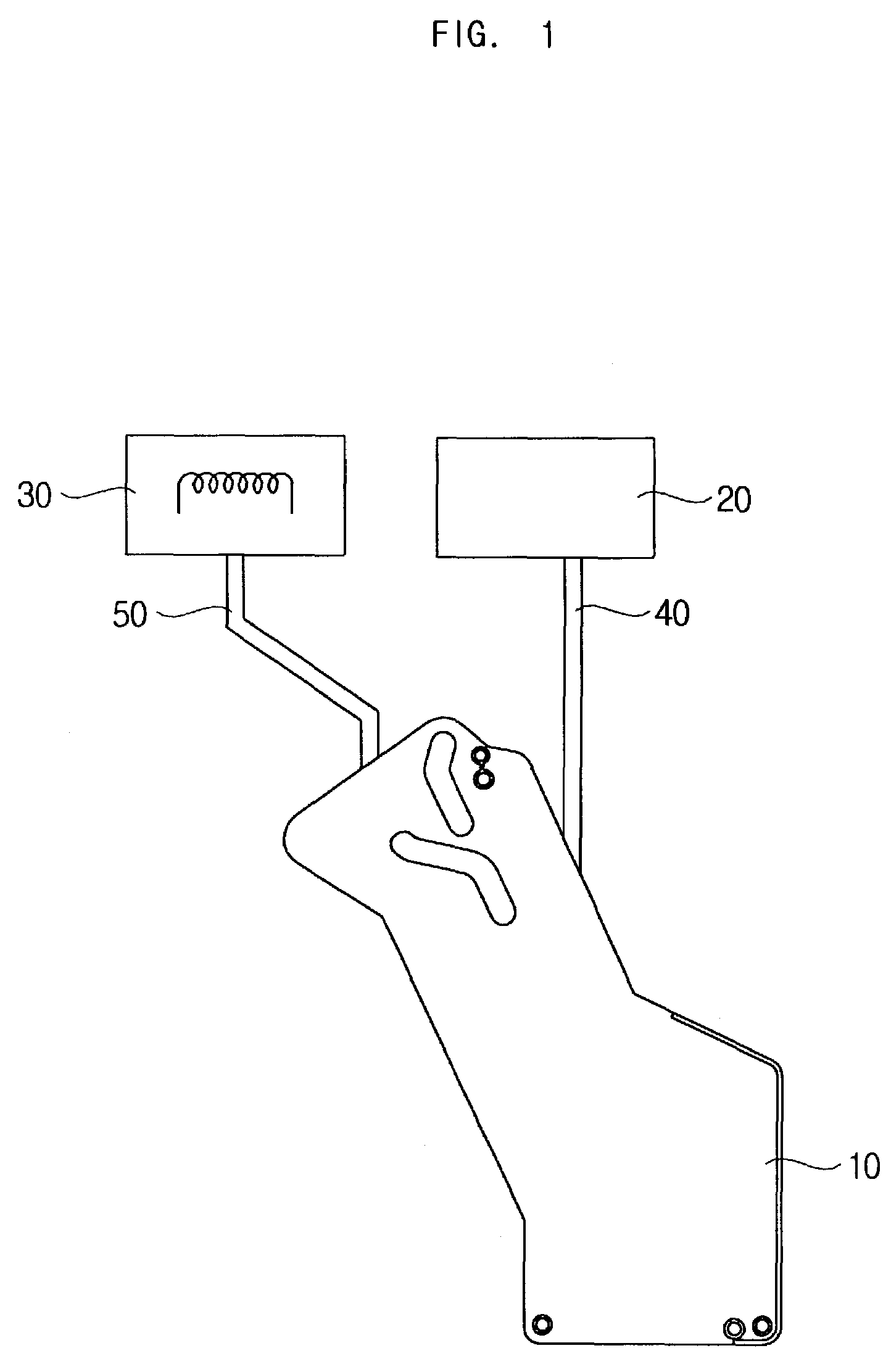

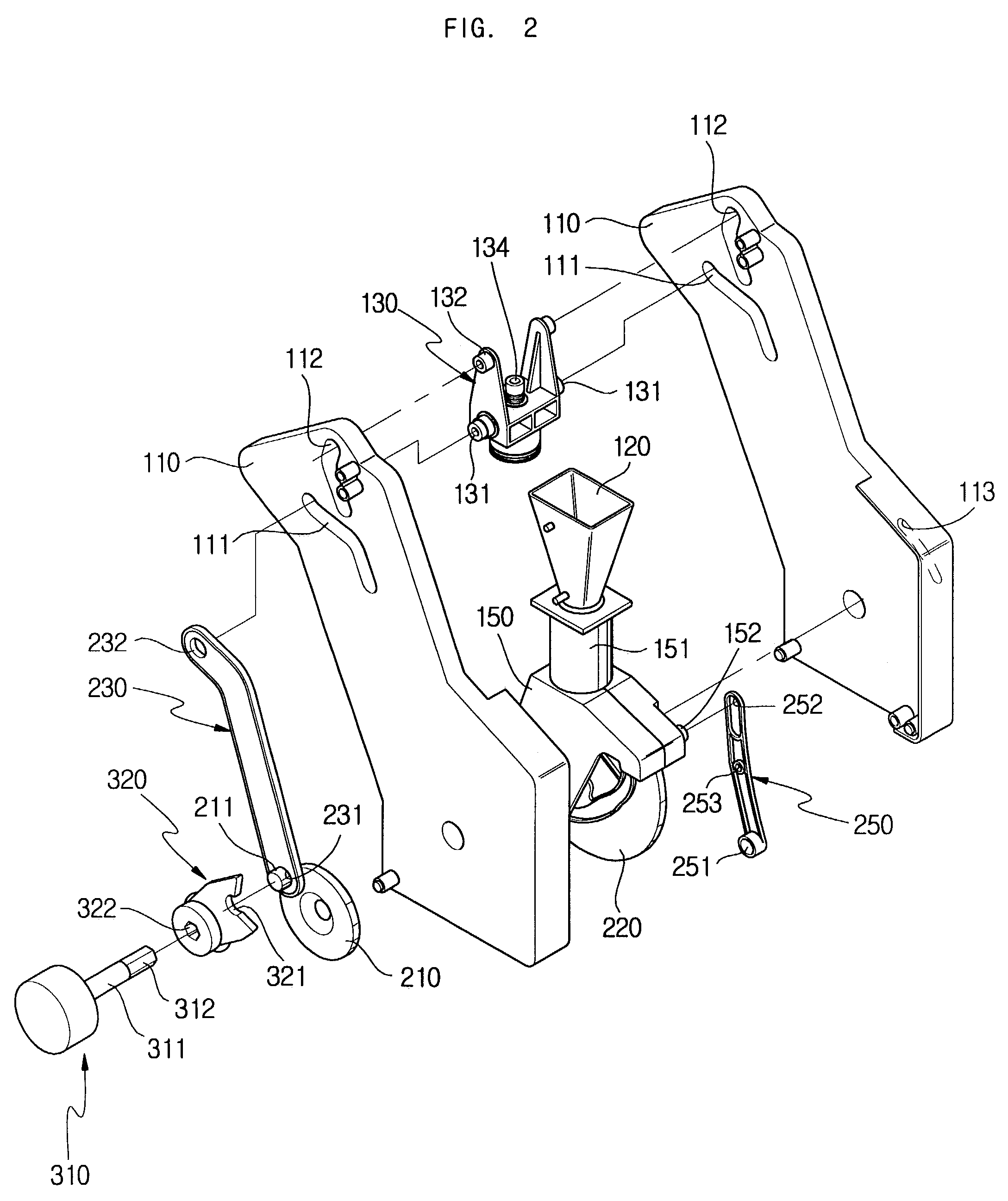

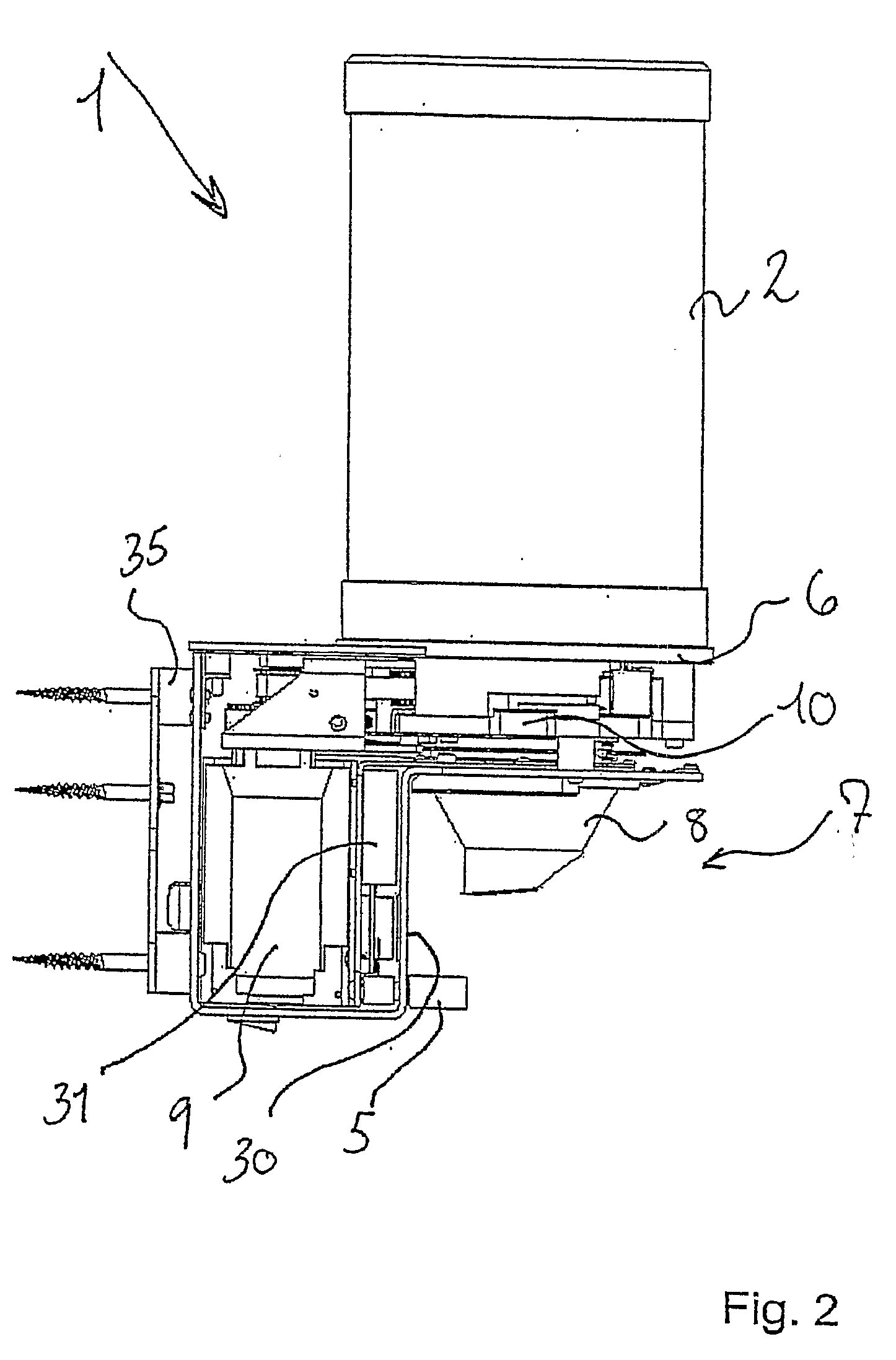

Coffee extracting apparatus for a coffee machine

A coffee extracting apparatus for a coffee machine, which allows easy extraction of coffee liquid and easy removal of coffee grinds, is disclosed. The coffee extracting apparatus includes a machine case, a hopper receiving coffee grinds, a cylinder unit disposed below the hopper and rotated within a certain angle range, a upper piston movably inserted in the cylinder unit and having a hot water path therein, a lower piston inserted in the cylinder unit to press coffee grinds against the upper piston and having coffee discharge paths therein, cam and link members to guide movement of the cylinder, the upper piston and the lower piston, and a drive unit mounted on the machine case to supply driving force to the cam members. The coffee extracting apparatus is easily removed from the coffee machine. A unit amount of coffee liquid is extracted every revolution of the drive unit. Since hot water to be mixed with coffee grinds is supplied to the lower piston from the upper piston, adhesion of coffee grinds on a bottom surface of the upper piston is avoided.

Owner:LOTTE ENG & MACHINERY MFG

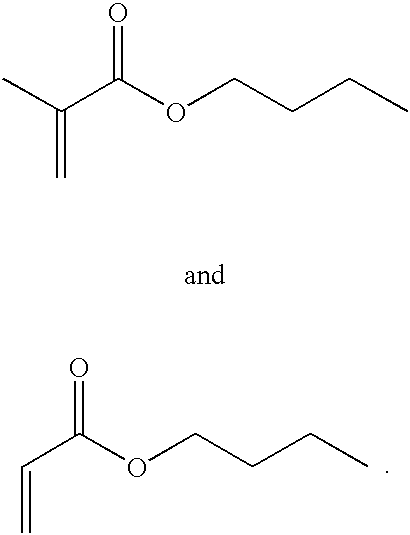

Water-based acrylic emulsion dispersants utilized as grind resins for pigments and method of preparing the same

The present invention is directed to a water-based acrylic emulsion dispersant to be used as a grind resin to incorporate inorganic pigment into a pigment dispersion for a coating composition. The acrylic emulsion dispersant is the reaction product of butyl methacrylate, butyl acrylate, styrene, methyl ether polyethylene glycol methacrylate, polyethylene glycol methacrylate, and polyphosphoric acid. The present invention is also directed to a method of preparing the acrylic emulsion dispersant. In this method, the butyl methacrylate, butyl acrylate, and styrene are combined with water to establish a first reaction blend. Similarly, the methyl ether polyethylene glycol methacrylate and the polyethylene glycol methacrylate are combined with water to establish a second reaction blend. Next, the first and second reaction blends are polymerized to form an intermediate emulsion polymer containing a hydroxyl group from the functionality of the polyethylene glycol methacrylate. Finally, the hydroxyl group from the polyethylene glycol methacrylate is reacted with polyphosphoric acid to form the acrylic emulsion dispersant which is utilized for efficient wetting and grinding of the pigment.

Owner:BASF CORP

Negative electrode for lithium secondary battery and lithium secondary battery

InactiveUS20060147799A1Excellent high-output/high-input characteristicProlong lifeNon-aqueous electrolyte accumulatorsNon-aqueous electrolyte accumulator electrodesLithiumCarboxymethyl cellulose

A subject for the invention is to provide a lithium secondary battery which can be improved in high-output / high-input characteristics based on a reduction in the thickness of an active material layer, has a long life, and is highly safe. The invention relates to: a negative electrode for lithium secondary battery which comprises a current collector having provided thereon an active material layer comprising an active material and an organic material having binding and thickening effects, wherein the active material is a powdery active material comprising an amorphous-material-coated graphite, and when a dispersion prepared by dispersing 100 g of the active-material powder in 200 g of water together with 2 g of carboxymethyl cellulose is examined by the grind gauge method for determining the degree of dispersion in accordance with JIS K5400, the particle diameter at which particles begin to appear is 50 μm or smaller; and a lithium secondary battery employing the negative electrode.

Owner:MITSUBISHI CHEM CORP +1

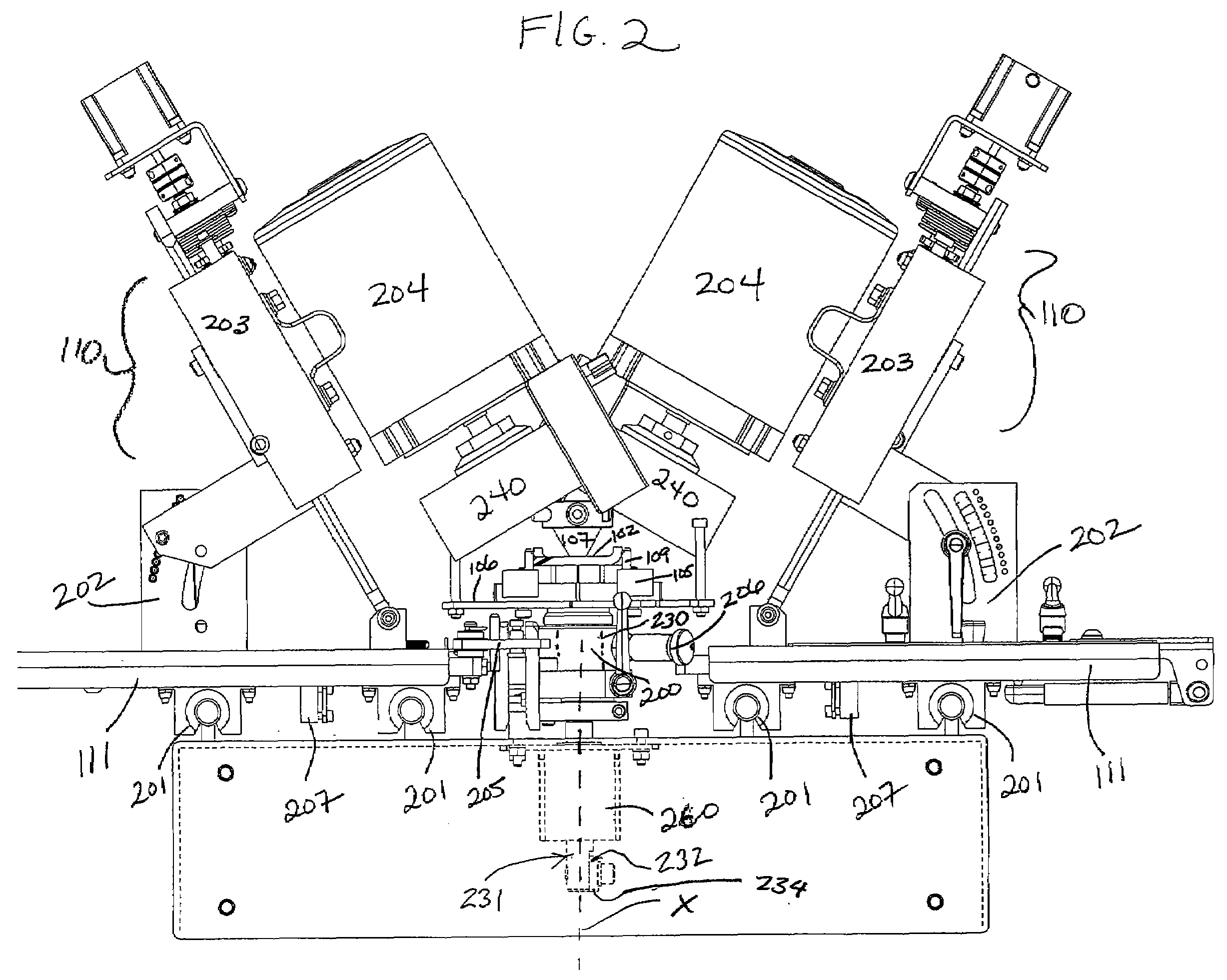

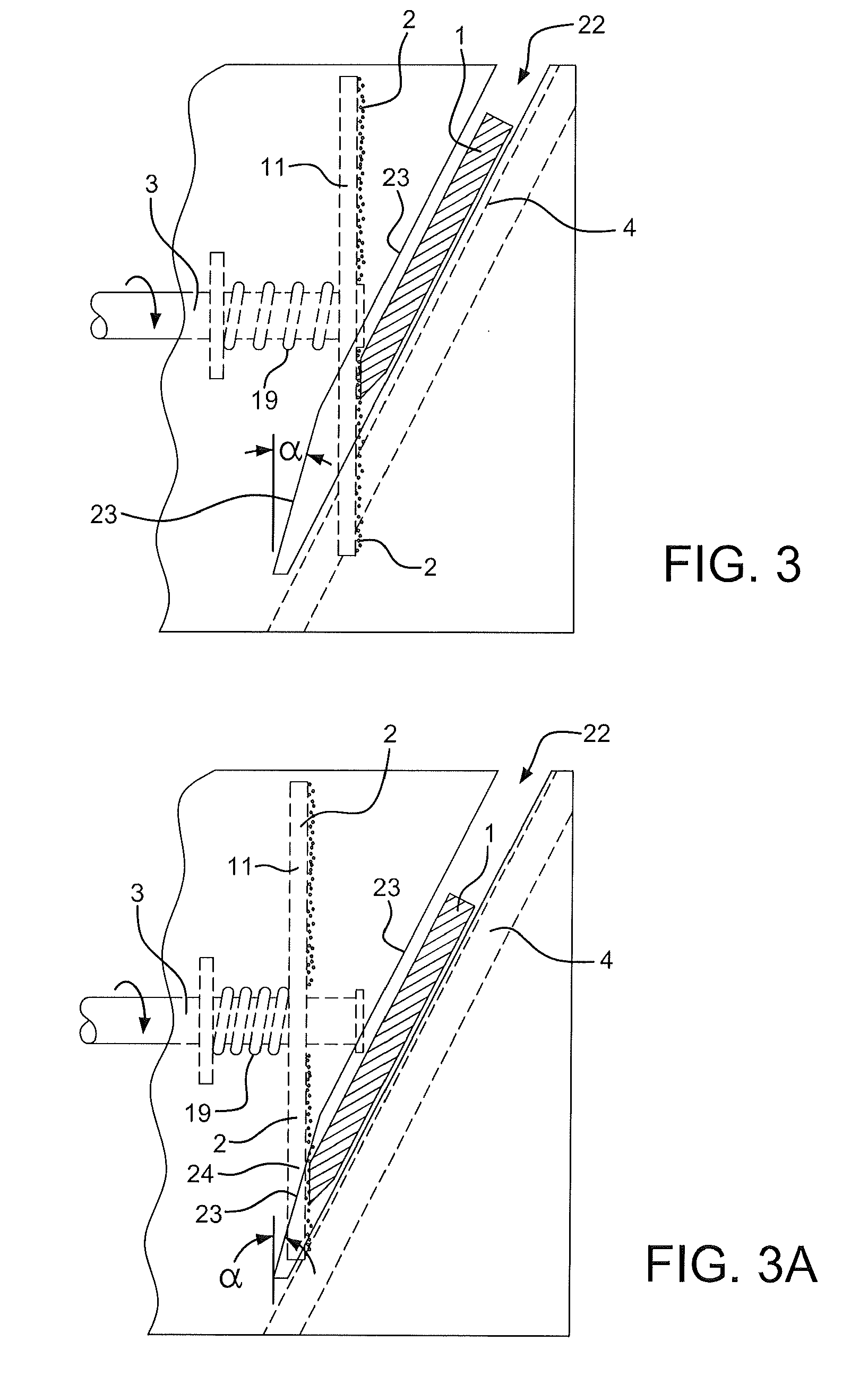

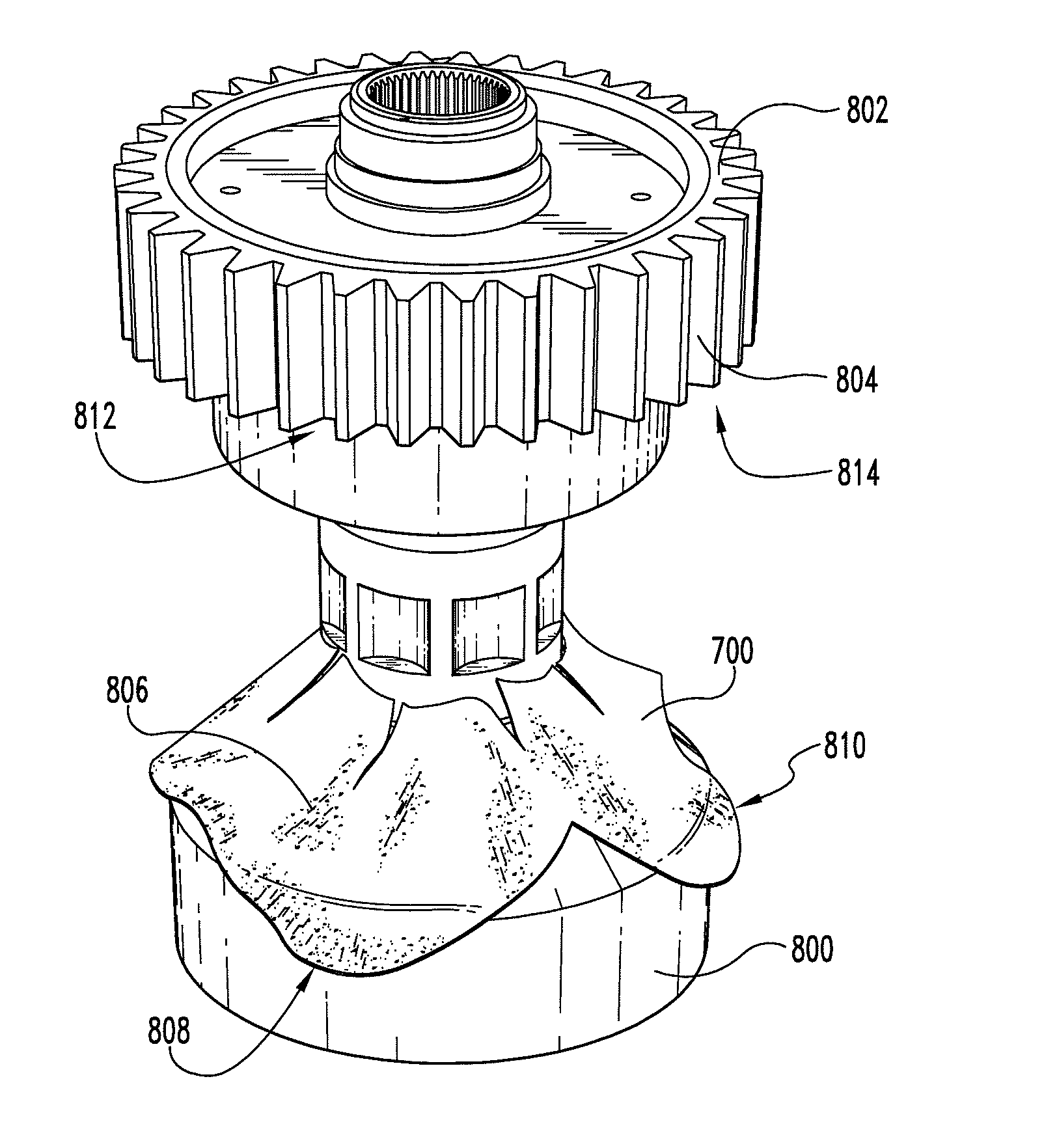

Apparatus and method for precision grinding face gear

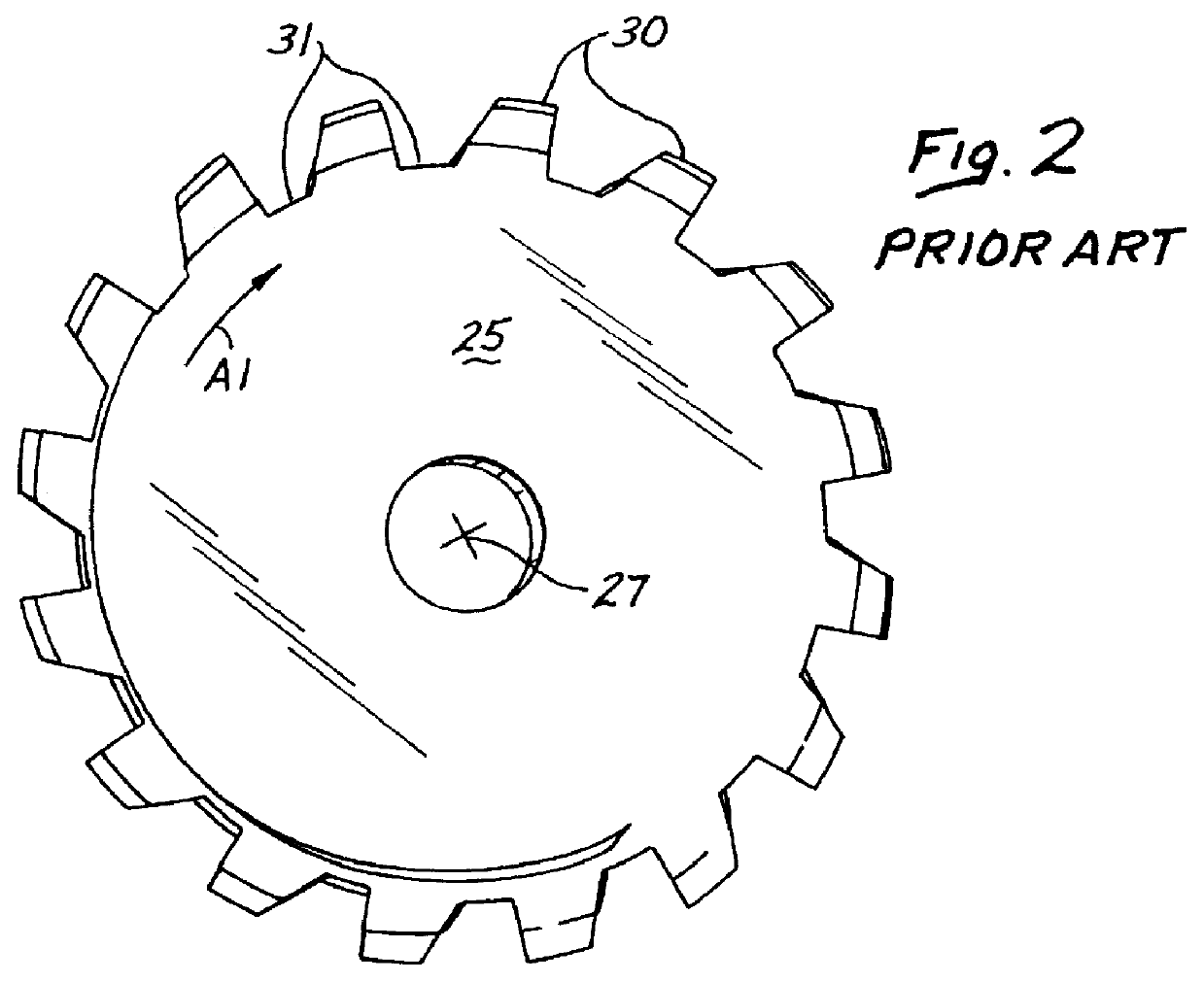

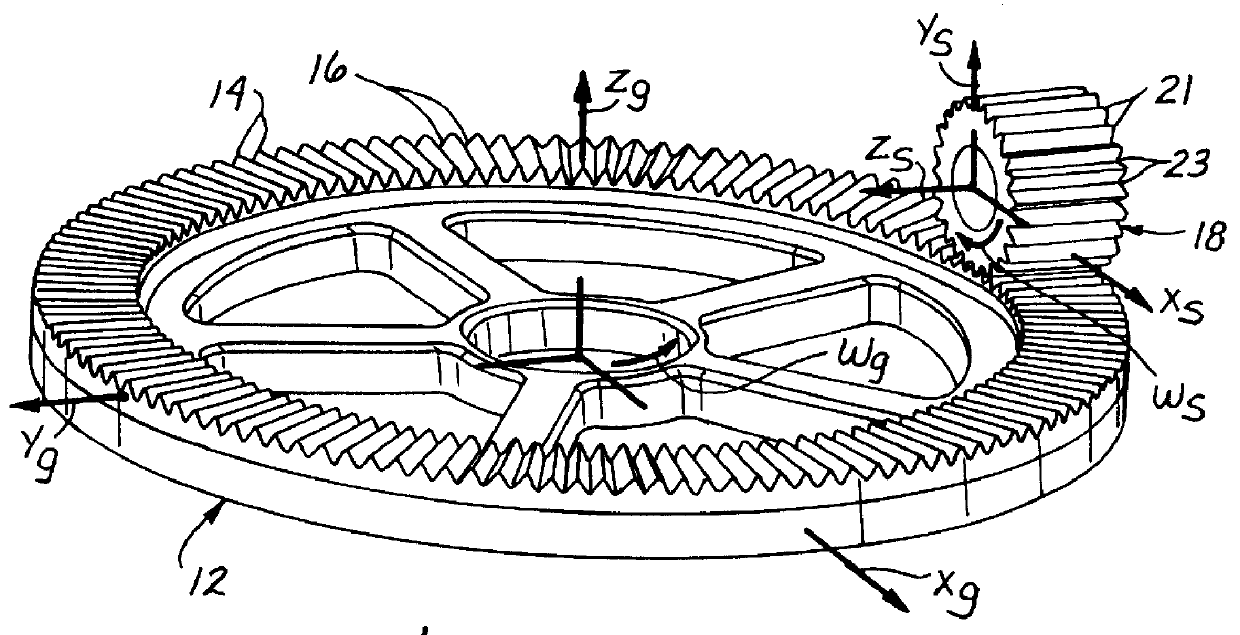

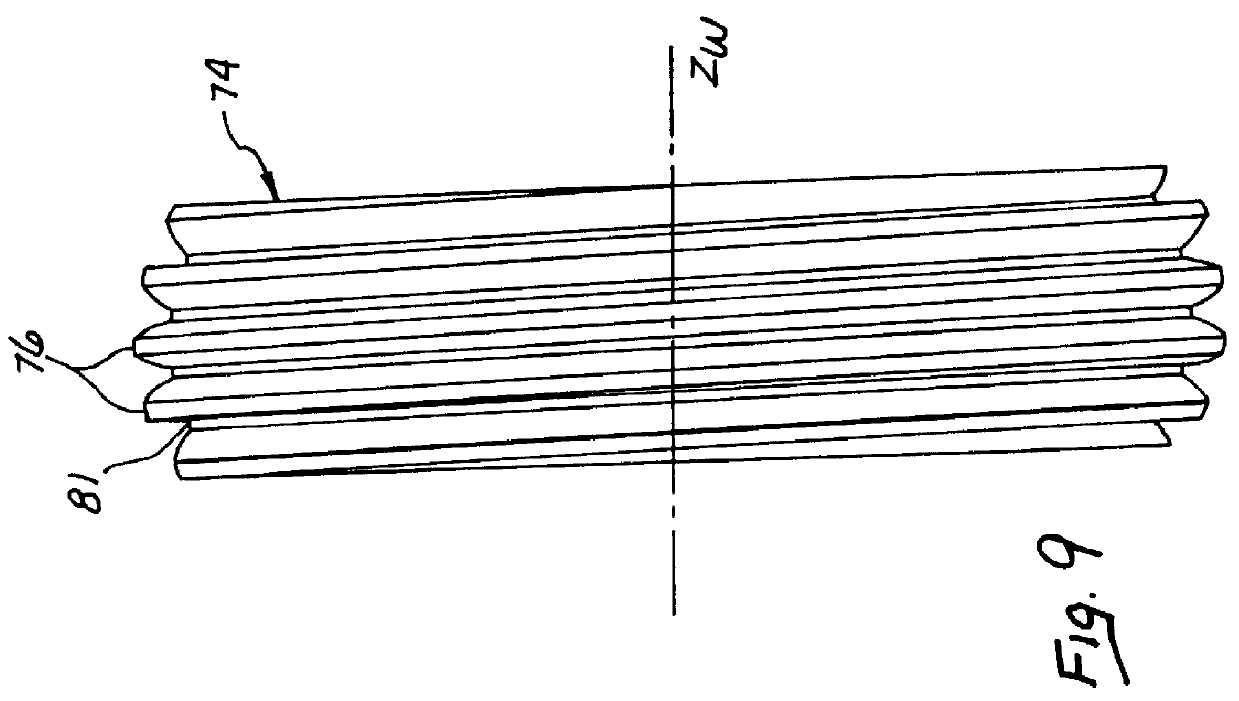

InactiveUS6146253AAbrasive surface conditioning devicesGear-cutting machinesGear wheelCase hardening

A precision grinding apparatus includes a grinding worm for precision grinding a case-hardened face gear. A shaper is first placed into contact with a face gear, to thereby shape a surface of the face gear into a plurality of face gear teeth. The shaper is then removed, and the face gear is case hardened. The grinding worm is disposed in a normal orientation to the case-hardened face gear and includes a spiral tooth extending along a perimeter of the grinding worm. The spiral tooth of the grinding worm is adapted to contact and precision grind the case-hardened gear. A dressing tool includes a protrusion for contacting the spiral tooth of the grinding worm, as the spiral tooth contacts and precision grinds the case-hardened face gear. The dressing tool thus maintains the shape of the grinding worm to within a desired tolerance range.

Owner:THE BOARD OF TRUSTEES OF THE UNIV OF ILLINOIS

System for varying coffee intensity

A coffee pod with varying intensity. The coffee pod includes a substantially rigid sidewall, a substantially rigid base, and coffee grinds positioned therein. More than about seventy percent (70%) of the coffee grinds may include a particle size distribution of between about 200 to about 300 microns. The coffee grinds may have a weight of the about five (5) to about eight (8) grams.

Owner:THE COCA-COLA CO

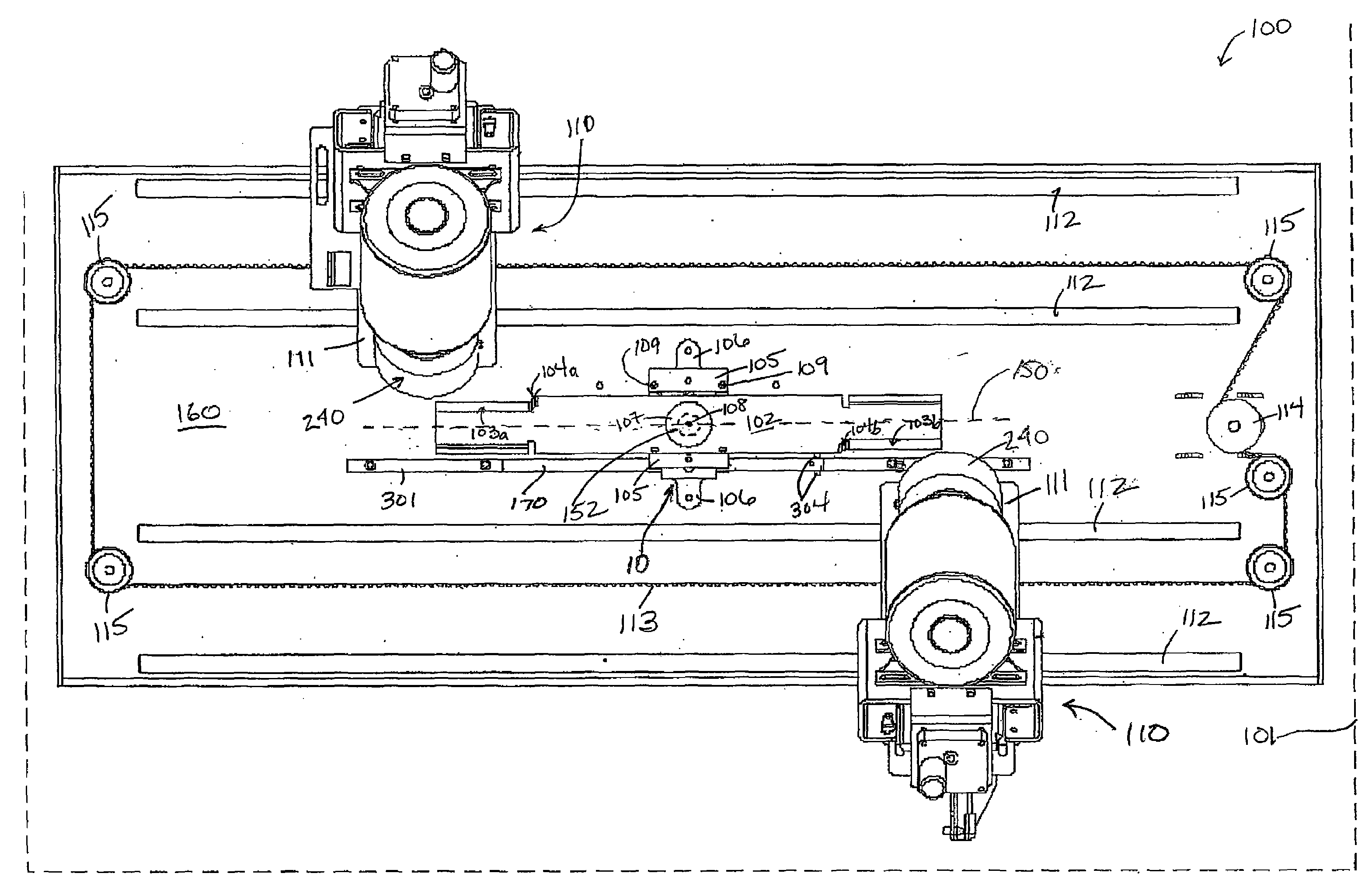

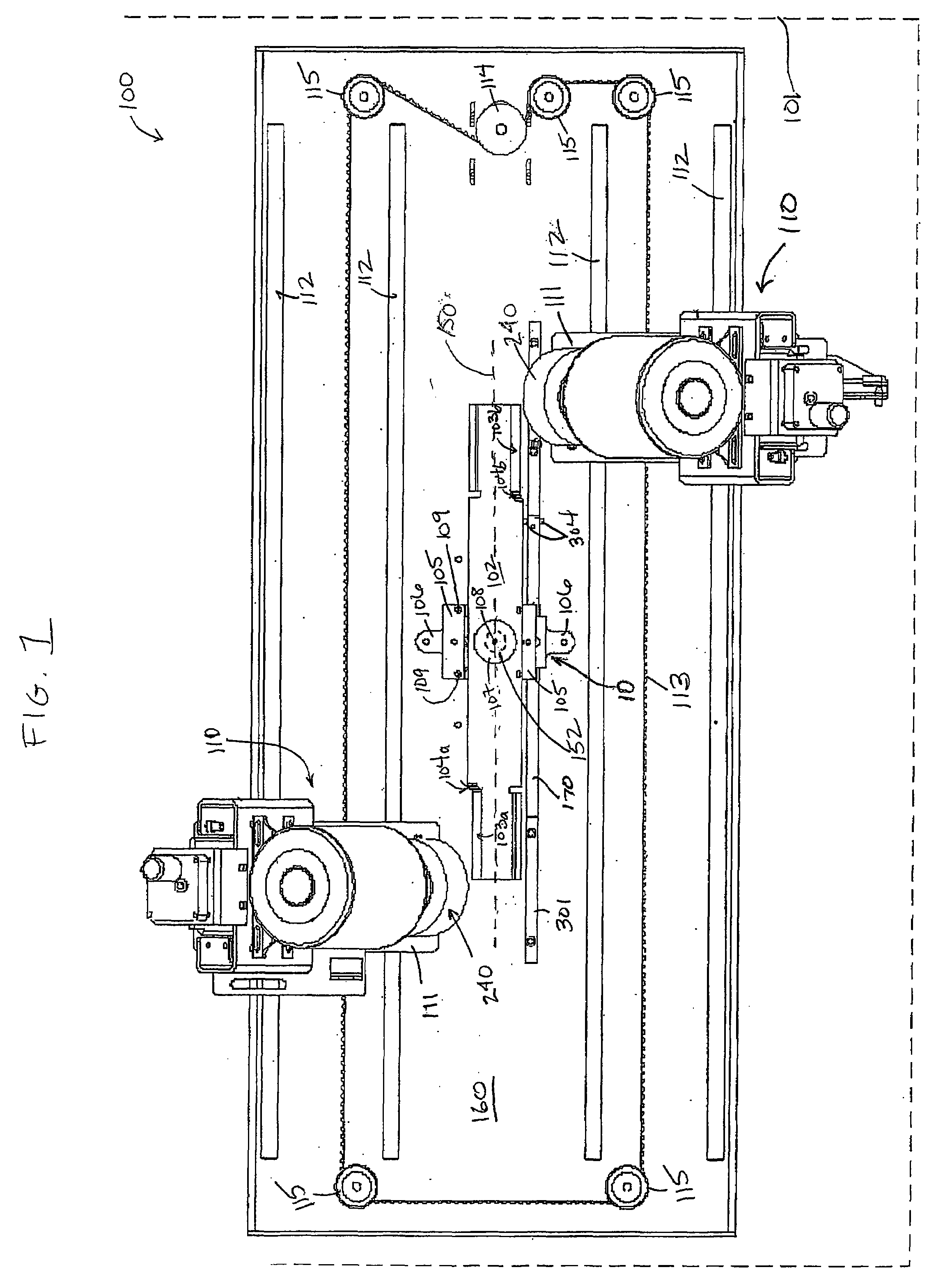

Rotary Mower Blade Sharpener Having Movable Griding Wheels

ActiveUS20070184756A1Simple methodEdge grinding machinesRevolution surface grinding machinesControl systemKnife blades

A device and method for sharpening a mower blade are provided, in which a mounting device for mounting a rotary blade having two opposite cutting edges to be sharpened, wherein the mounting device is capable of positioning the blade in a first fixed state and a second, axially pivoting state. One or more grinding head assemblies are each positioned on an opposite end of the blade, wherein the grinding head assemblies respectively grind the two opposite cutting edges to be sharpened. A control system controls movement of the two grinding head assemblies. The mounting device positions the blade in the first fixed state to enable the two grinding head assemblies to grind the cutting edges in a direction substantially parallel to the cutting edges of the blade to perform a straight grind, and then may position the blade in the second axially pivoting state to enable the blade to pivot around its blade rotation axis away from the grinding head assemblies upon completion of the straight grind, thereby forming a curve at the end of each cutting edge. The mounting assembly also holds the blade in a third, freely rotating state in which the blade may substantially freely rotate around its blade rotation axis to enable balancing of the blade after sharpening.

Owner:FOLEY BELSAW

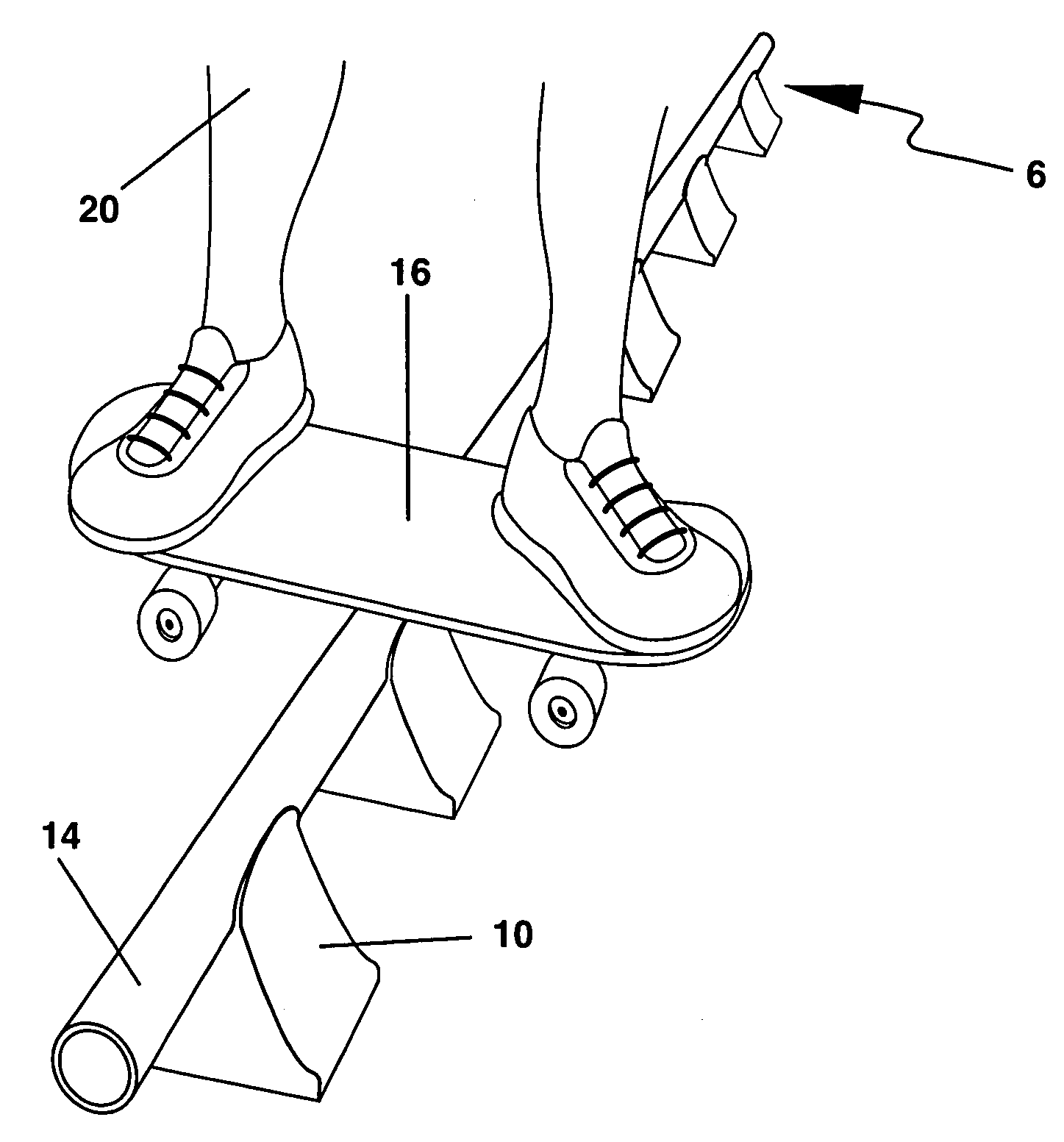

Skate activities rail support

InactiveUS7007978B1Unwanted braking forceEffective supportPipe supportsSnowboard bindingsEngineeringMechanical engineering

Owner:PURDOM ERIK

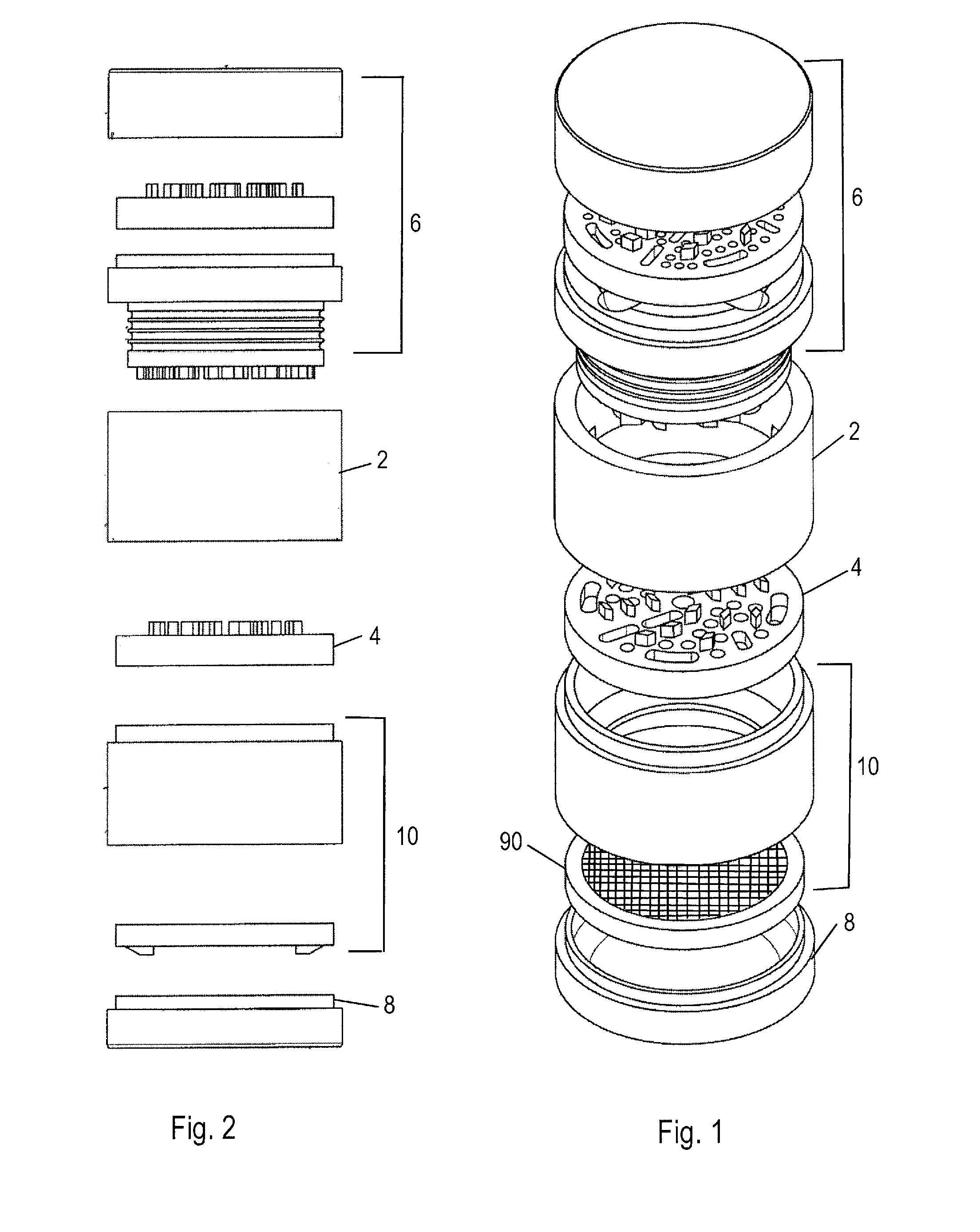

Herb grinder system

ActiveUS20160100715A1Easy and fast assemblySatisfies needCoffee millsSpice millsLeading edgeEngineering

The present invention involves a system and method for grinding herbs, tobacco, marijuana and the like. The herb grinder system herein includes interchangeable and replaceable lower grinder plates that are secured in place with threading, bayonet mounts or the like. The upper and lower grinding plates are provided with blades having a modified diamond shape which provides extremely sharp leading edges regardless of which direction the grip assembly of the grinder housing is rotated. The lower plates are also provided with variations in the size, shape and arrangement of hole sizes through which the ground material is allowed to pass through. This construction provides the user with the ability to control his / her grind size mixture, which may be consistent sized grinds or a mixture of different sized grinds.

Owner:VOLO TRADE

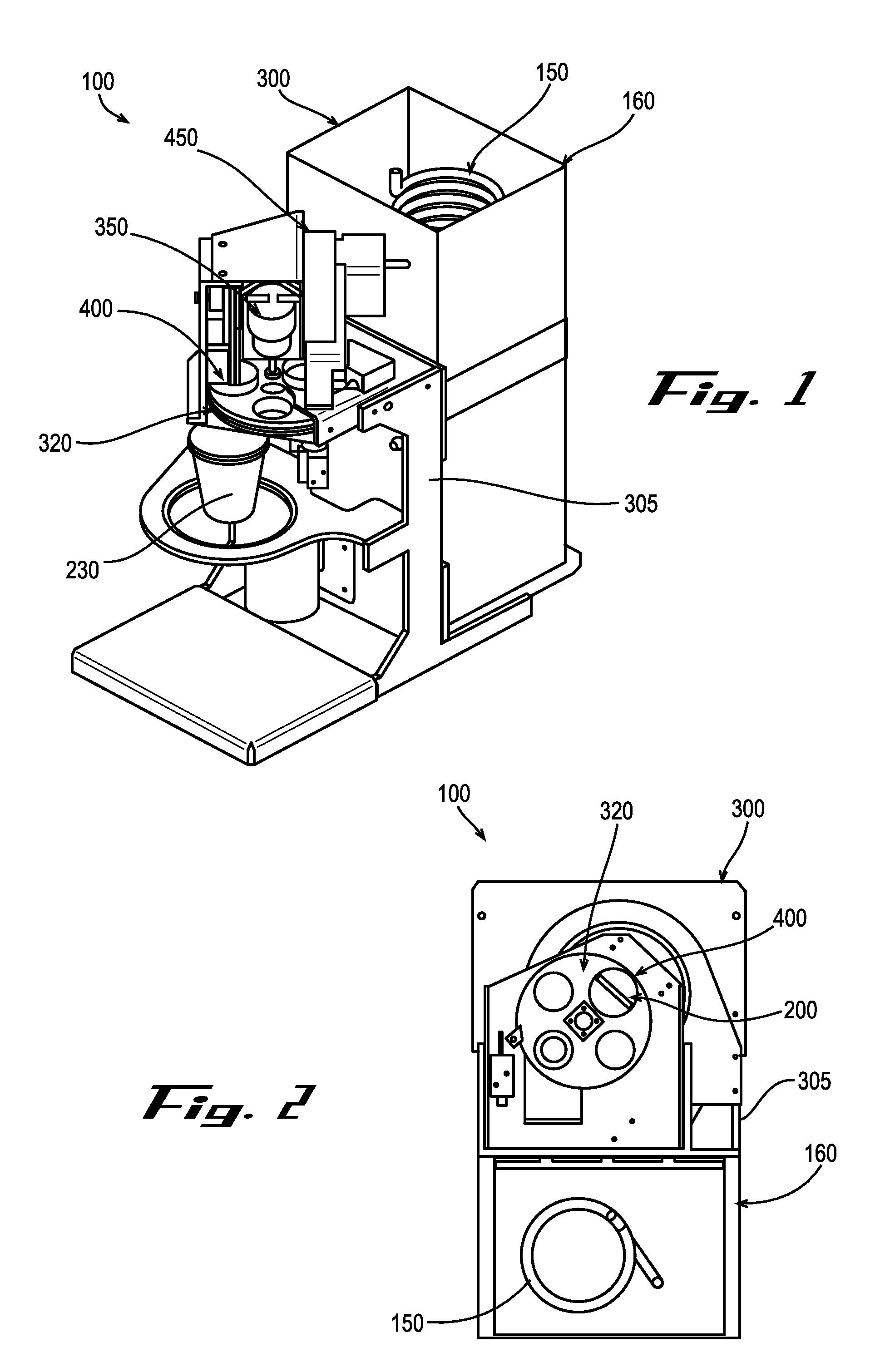

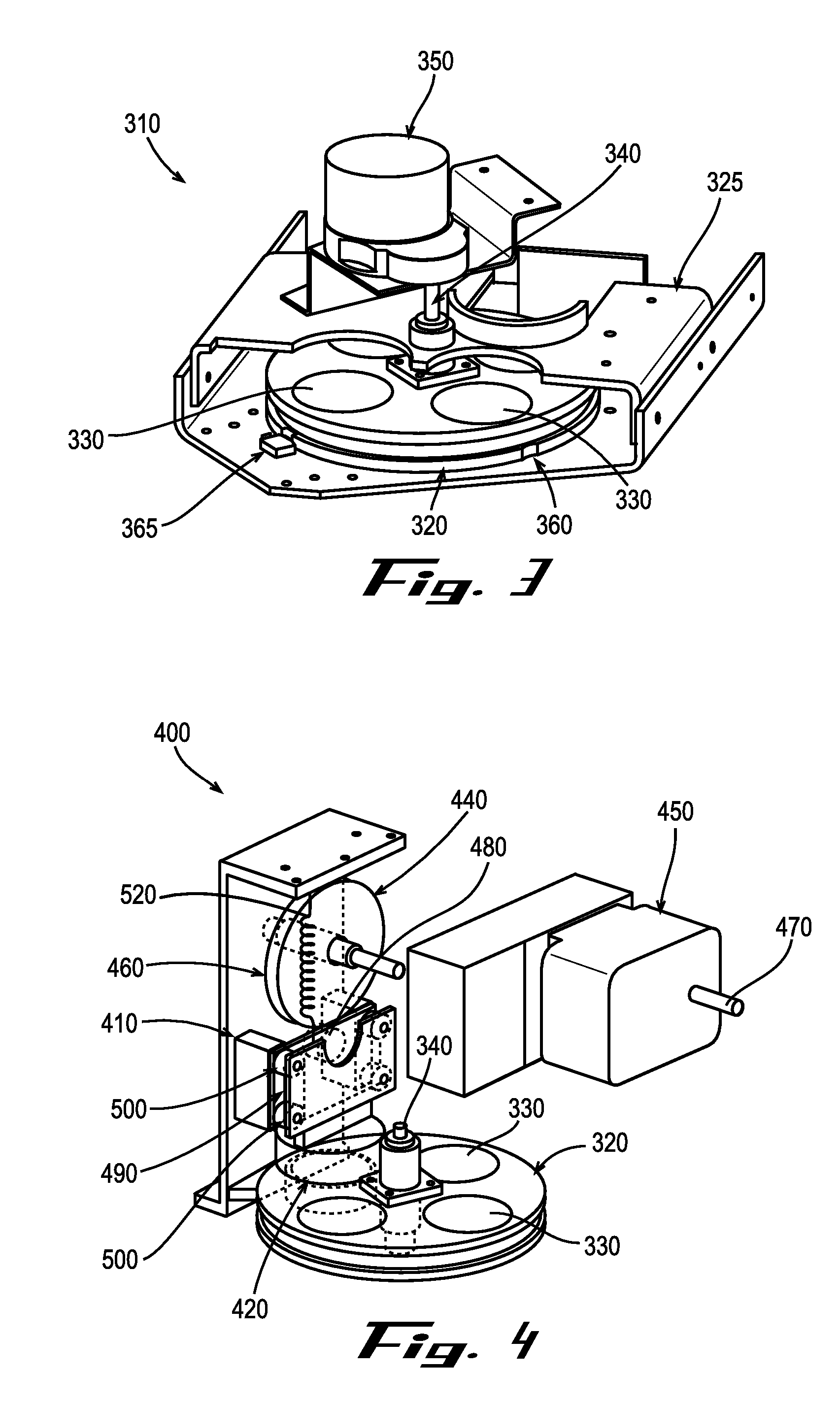

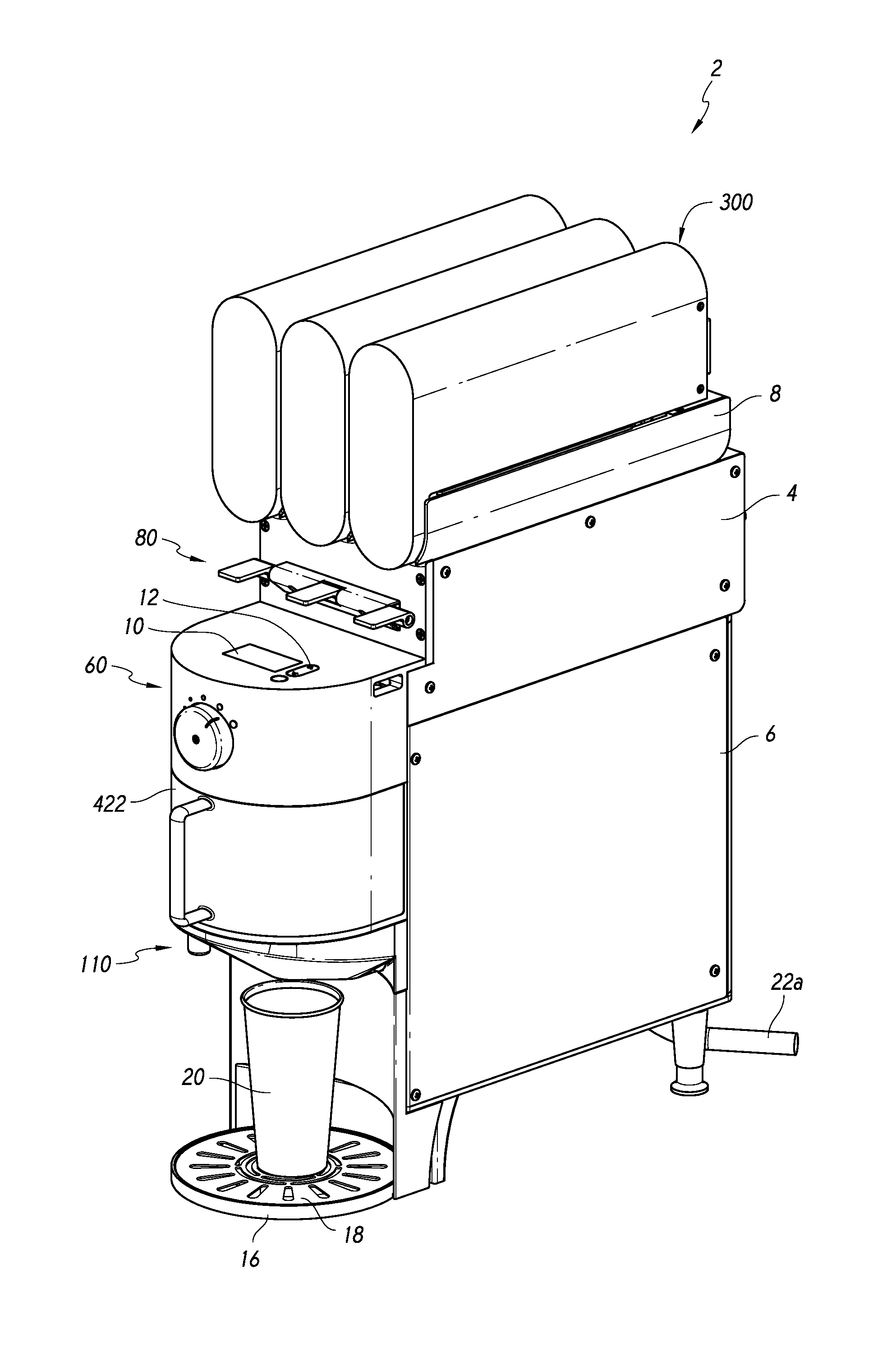

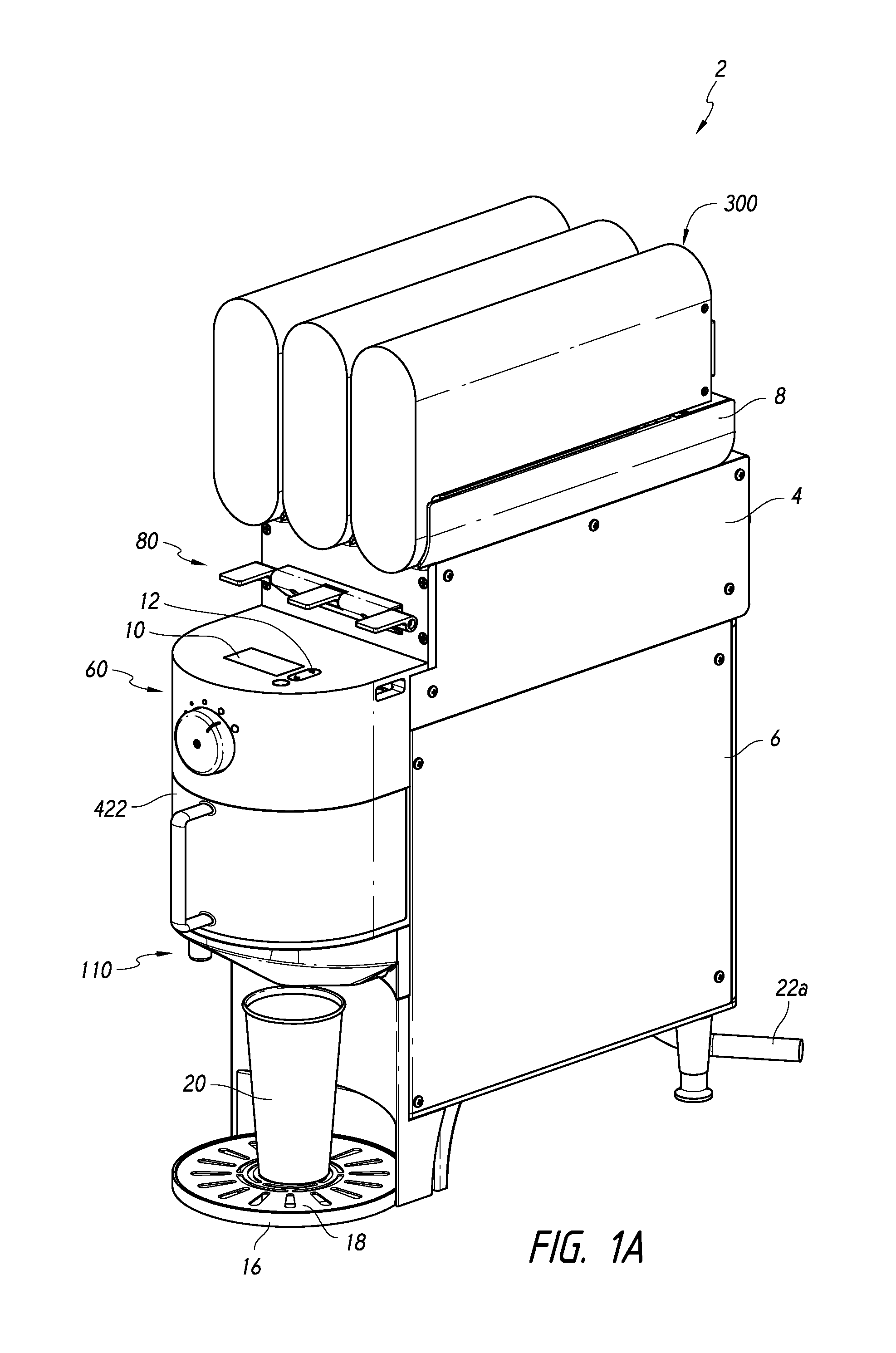

Apparatuses, systems, and methods for brewing a beverage

ActiveUS20150135966A1Shorten brewing timeReduce corrosionCoffee millsSpice millsEngineeringMechanical engineering

Apparatuses, systems, and methods for brewing a desired portion of a beverage, such as a single-cup portion of coffee, are provided. The system can include one or more hopper assemblies configured to provide a controlled dose of beverage material to a brew chamber. The system can also include a water input system configured to wet the ground beverage material as the grinds enter the brew chamber and substantially prevent steam from reaching grinder components of the system. Further, the system can include an automatic cleaning mechanism such that a user does not need to manually clean components of a brewing machine between brew cycles.

Owner:STARBUCKS

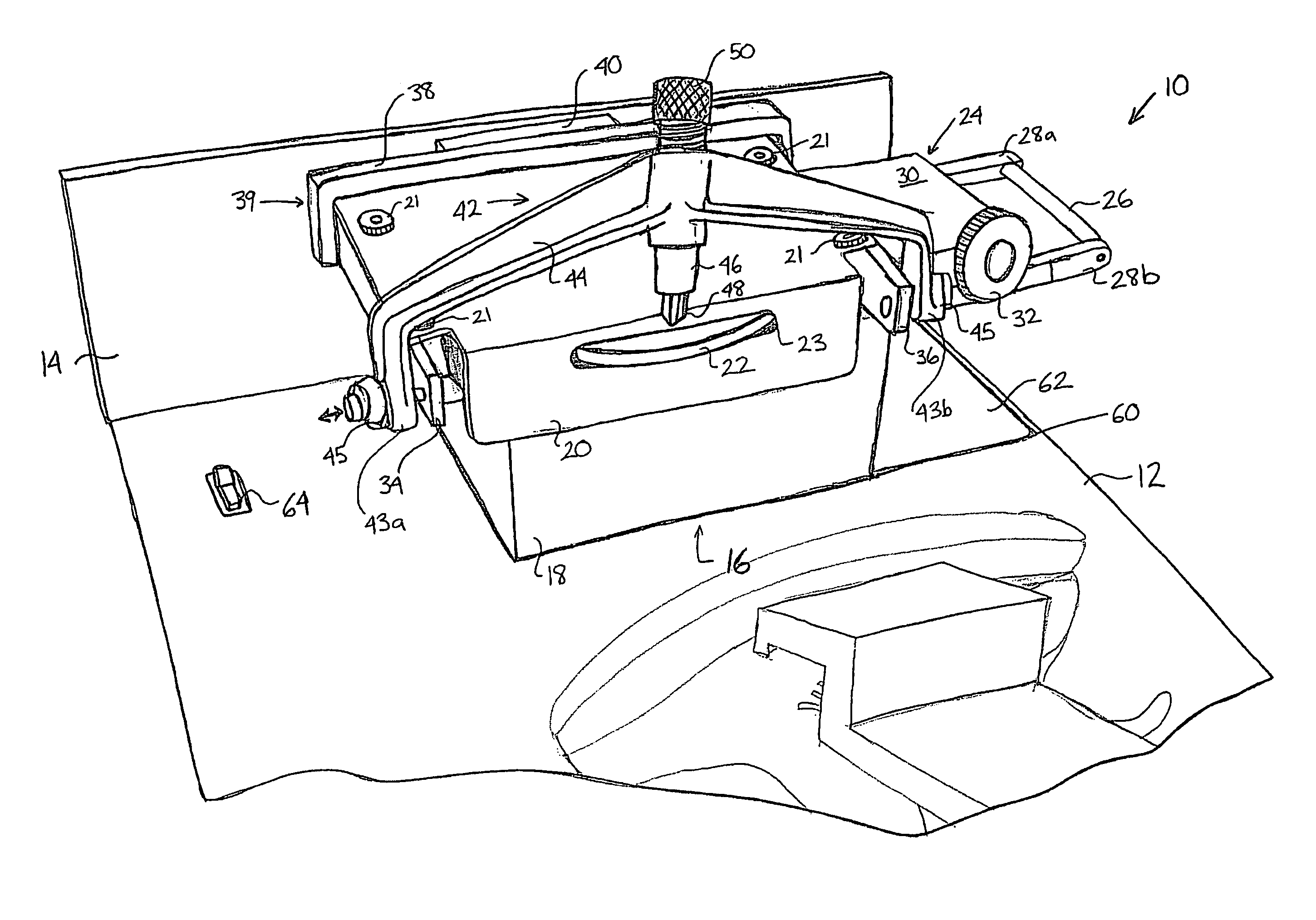

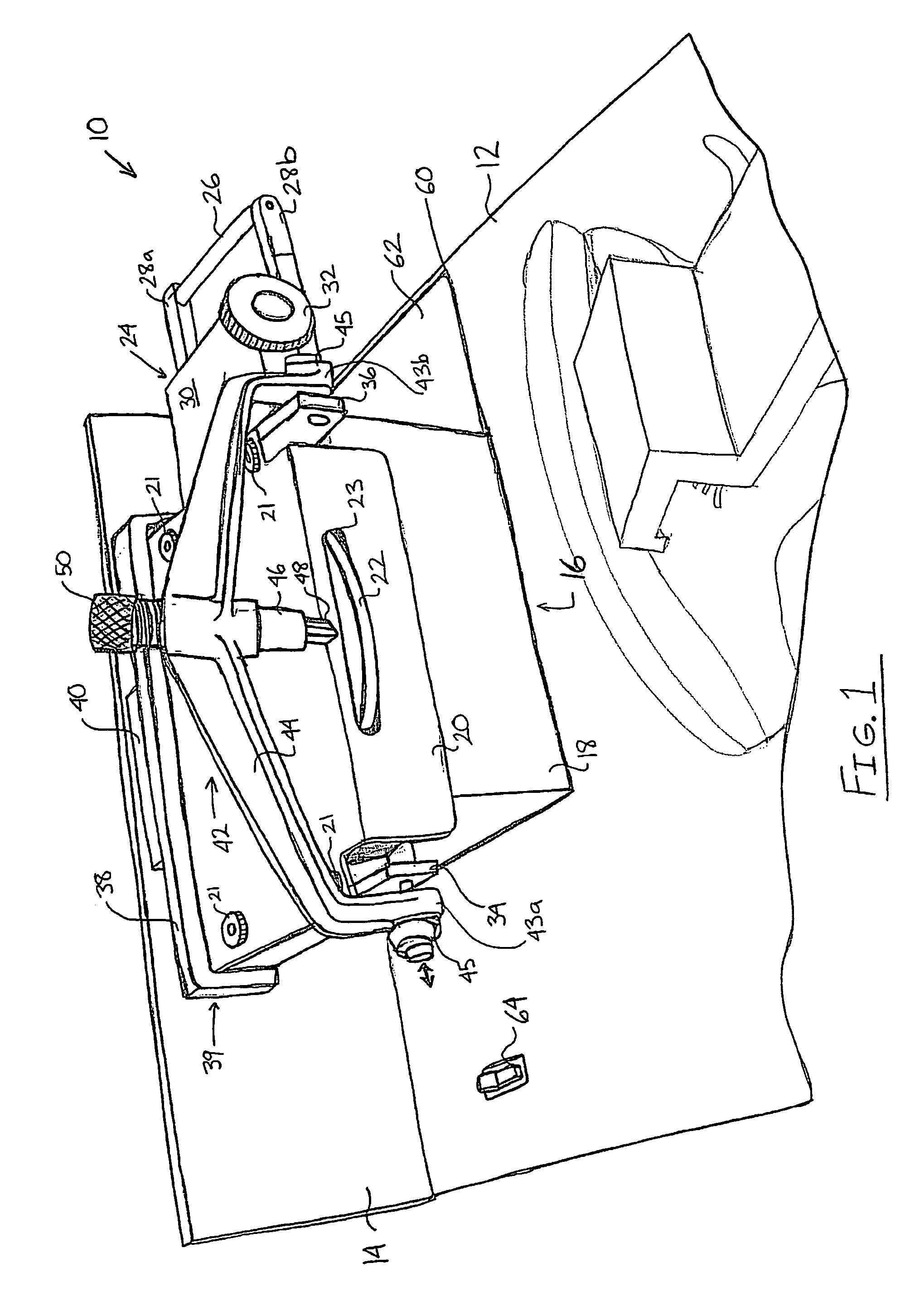

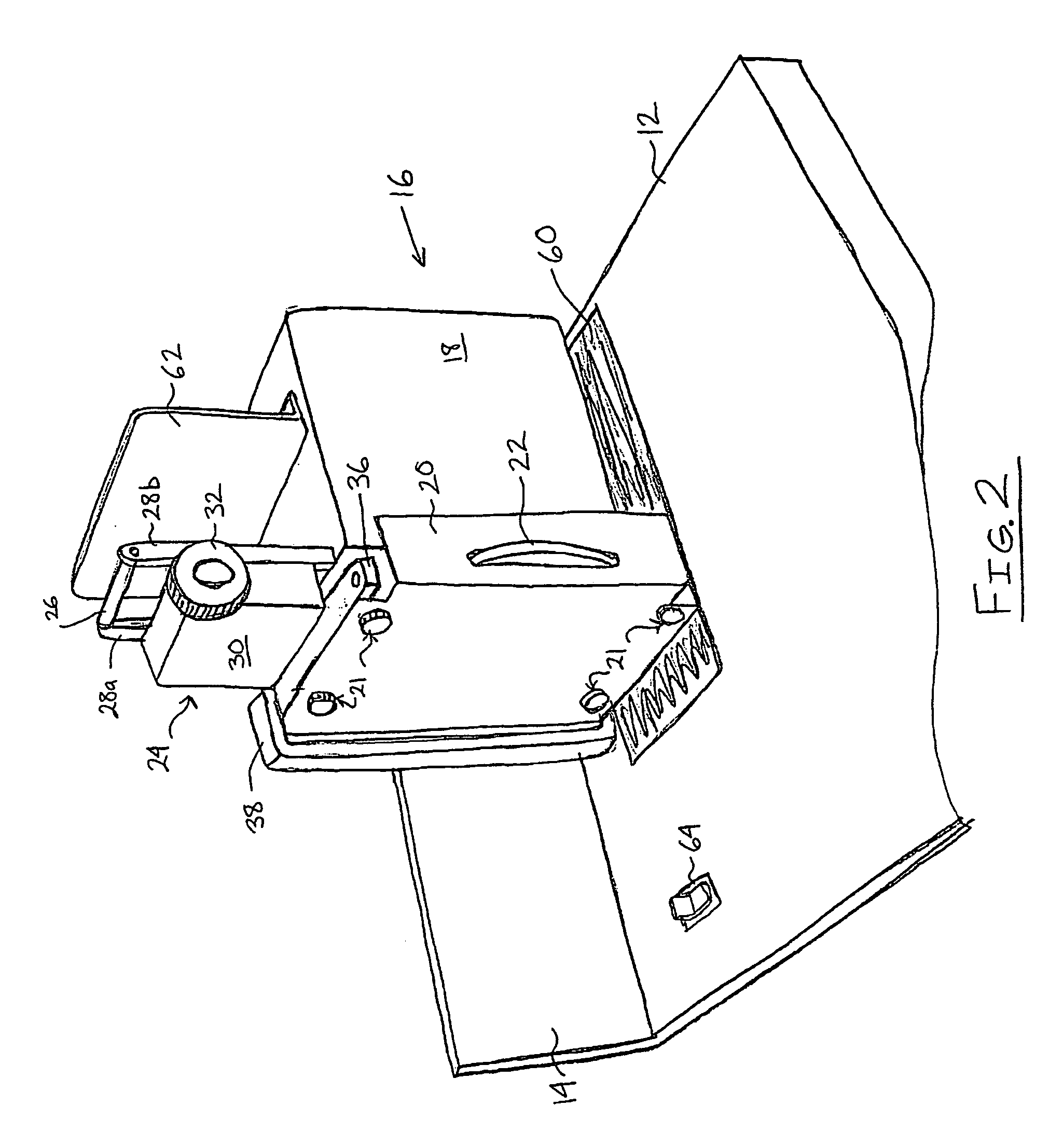

Portable skate sharpener

A skate sharpening device is provided which allows a grinding device to rotate with respect to a working surface of the device in both a cross grind configuration and a finish grind configuration. The grinding device pivots about a pin and is guided by a threaded stud protruding through an arcuate slot and securable using a flared, hand operated nut. A slidable rack attached to the grinding device is moveable in fore and aft directions relative thereto. A dressing tool may be attached to the rack and its forward position is governed by an actuating system. The actuating system allows a user to selectively inhibit forward movement of the rack to position the dressing tool at a suitable position to allow a dressing bit to contact a grinding wheel attached to and powered by the grinding device to dress the grinding wheel.

Owner:GUSPRO

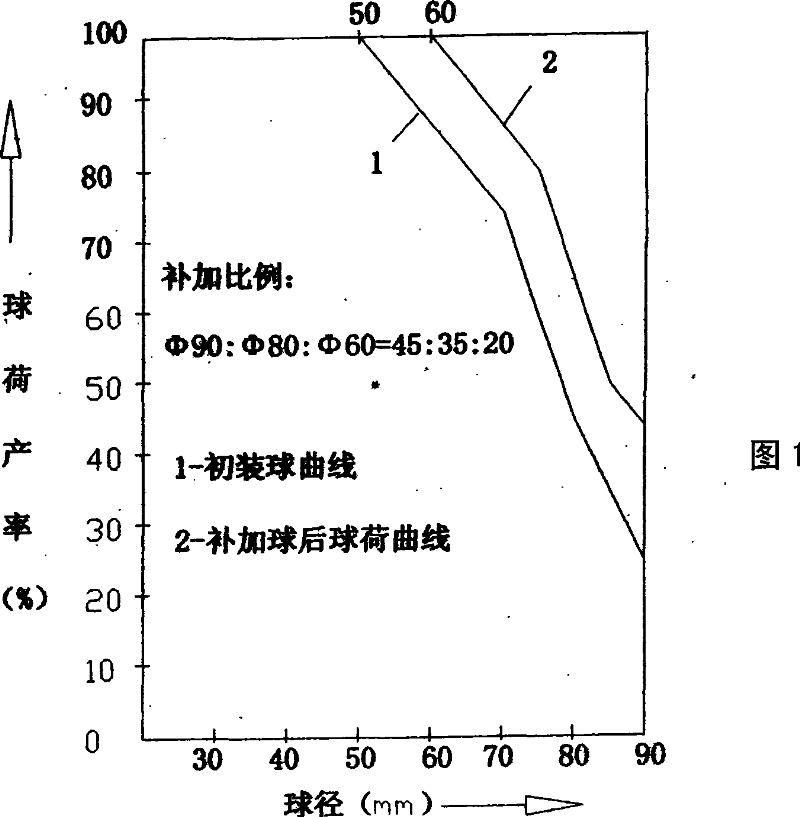

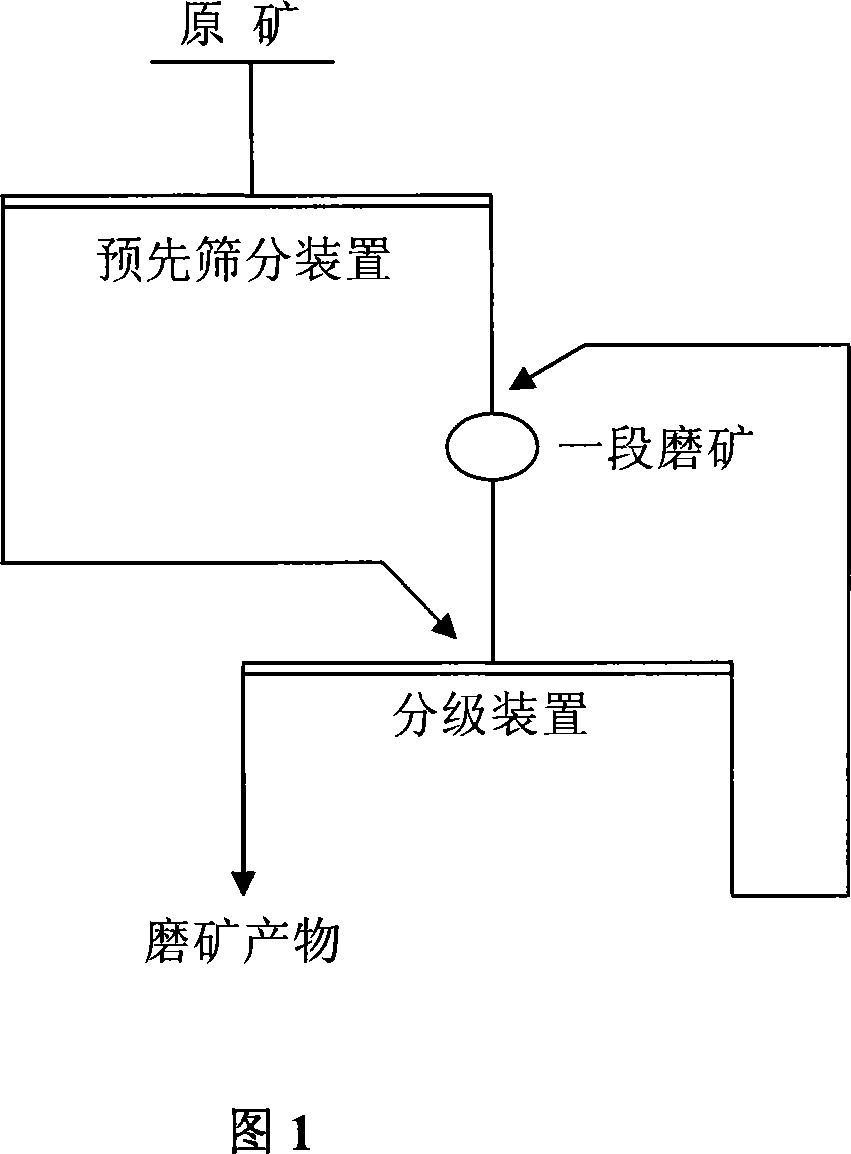

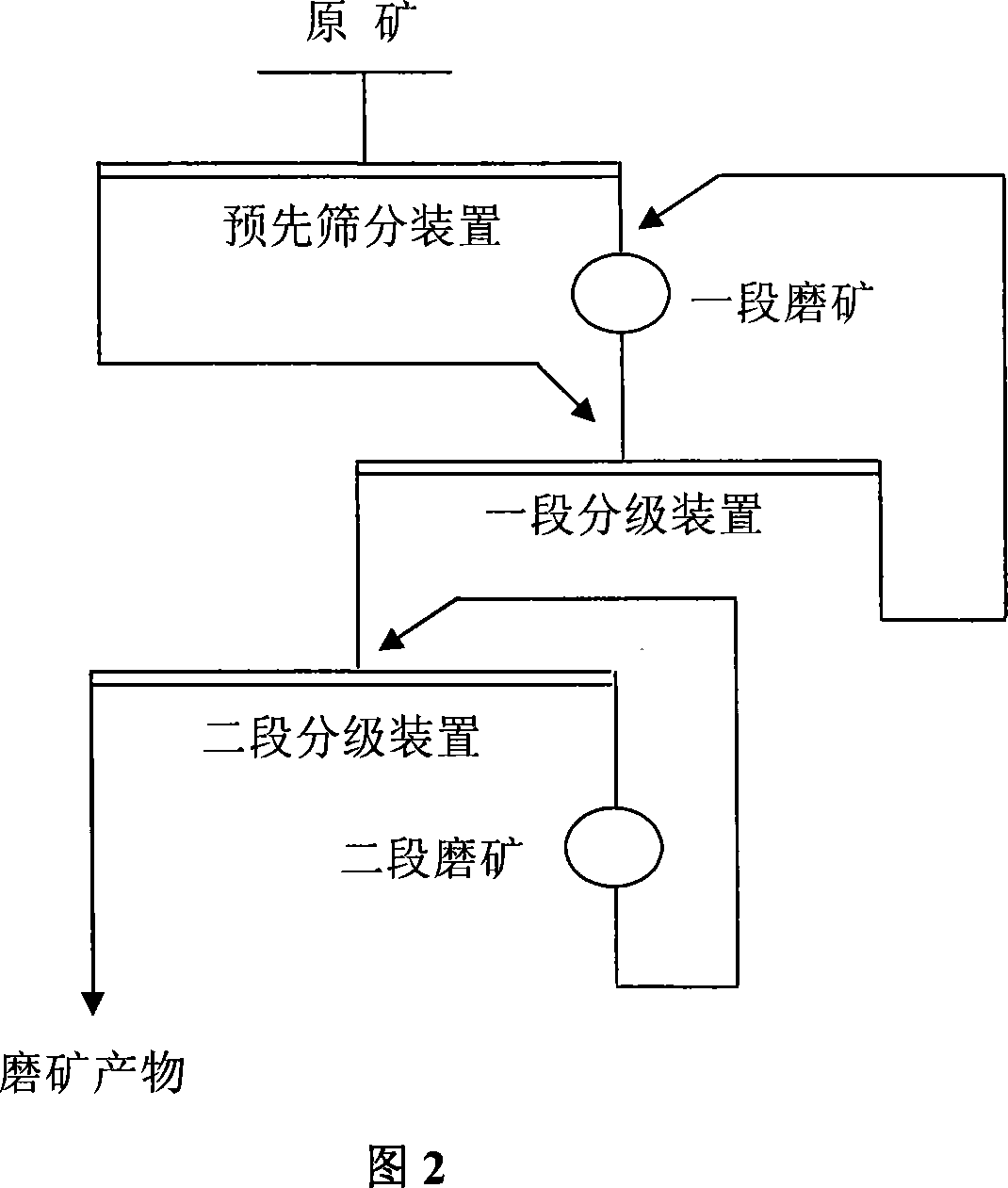

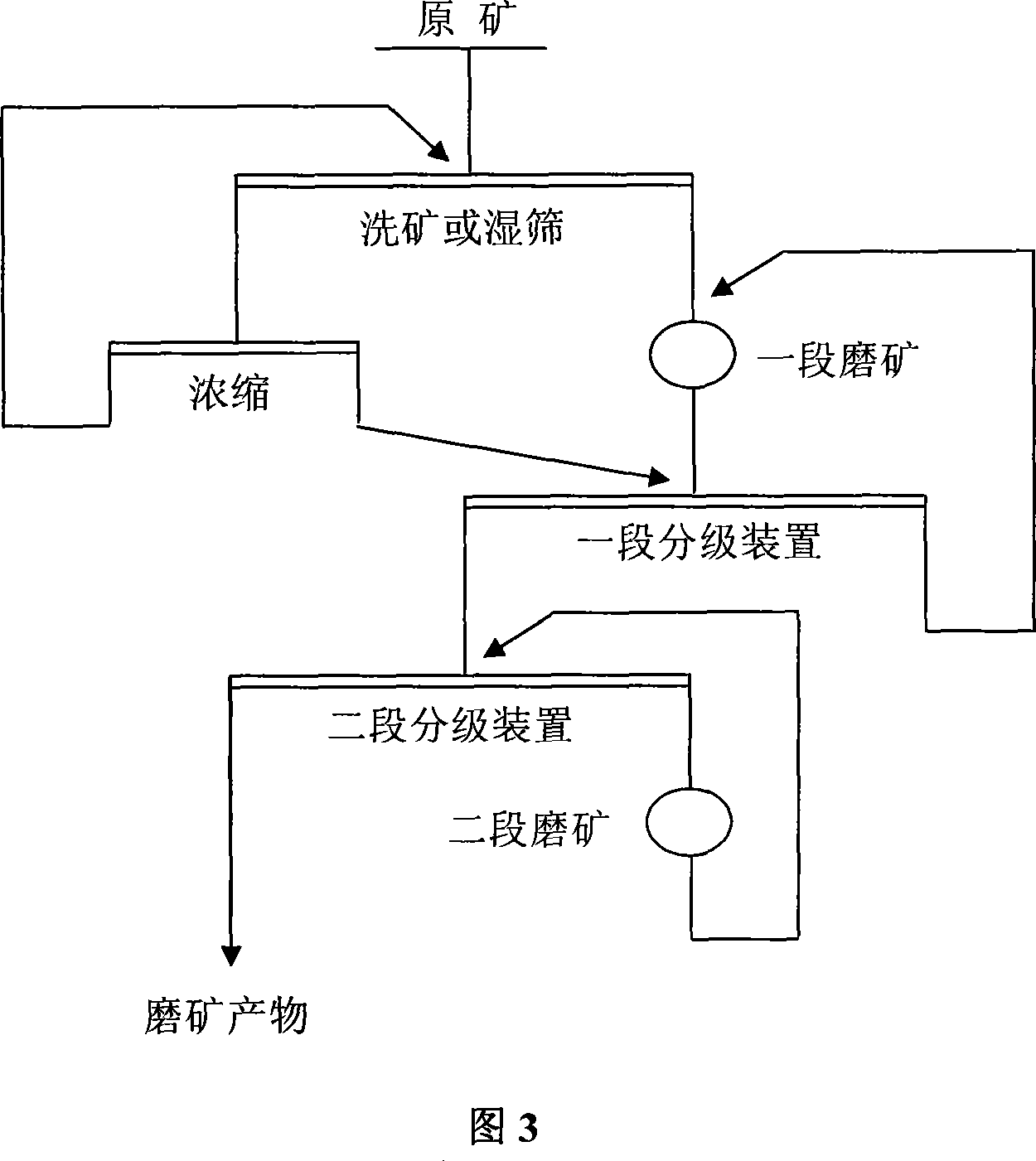

The method of accurate loading-and-filling ball of two sections of milling mine

The invention relates to a precise remedy method for two sections of grind, belonging to the ore crash, the mill technical field in the method of preparation. The newly feeding ore with the largest size 25-15 mm is ground to the size smaller than 0.15 mm for two sections, wherein the size smaller than 0.074 mm reaches 70 wt% or thinner product fineness. According to the requirement, the precise makeup remedy method in two sections of grinding suggested in the invention mills the newly feeding mineral grain to the largest size 2-3 mm, wherein the size smaller than 0.074 mm is 20-30wt%, in the second grinding, the size is then ground to smaller than 0.15 mm, wherein the size smaller than 0.074 reaches beyond 70%, to replace the experience remedy method with rude and bad effect in the existing production. The invention not only used in the two section grinding circuit, but also is fit for the three-section grinding circuit, which has good product size characteristic, high sizing index, and can be applied in the grinding technology of the different ore rigidity, different mill specification, different rotating speed mill and different character of ore.

Owner:KUNMING UNIV OF SCI & TECH +1

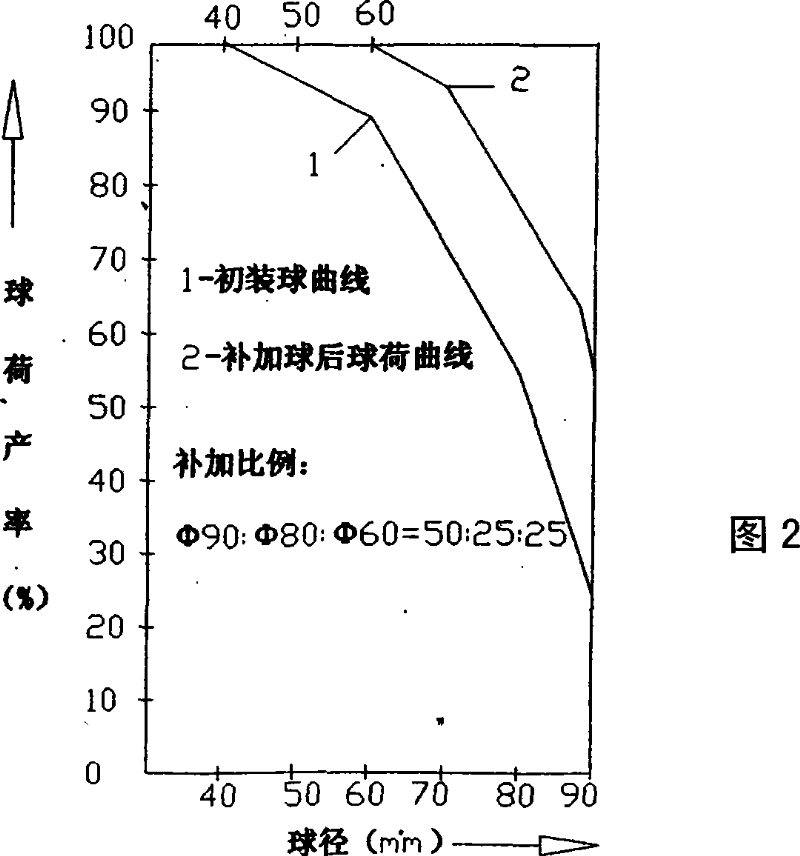

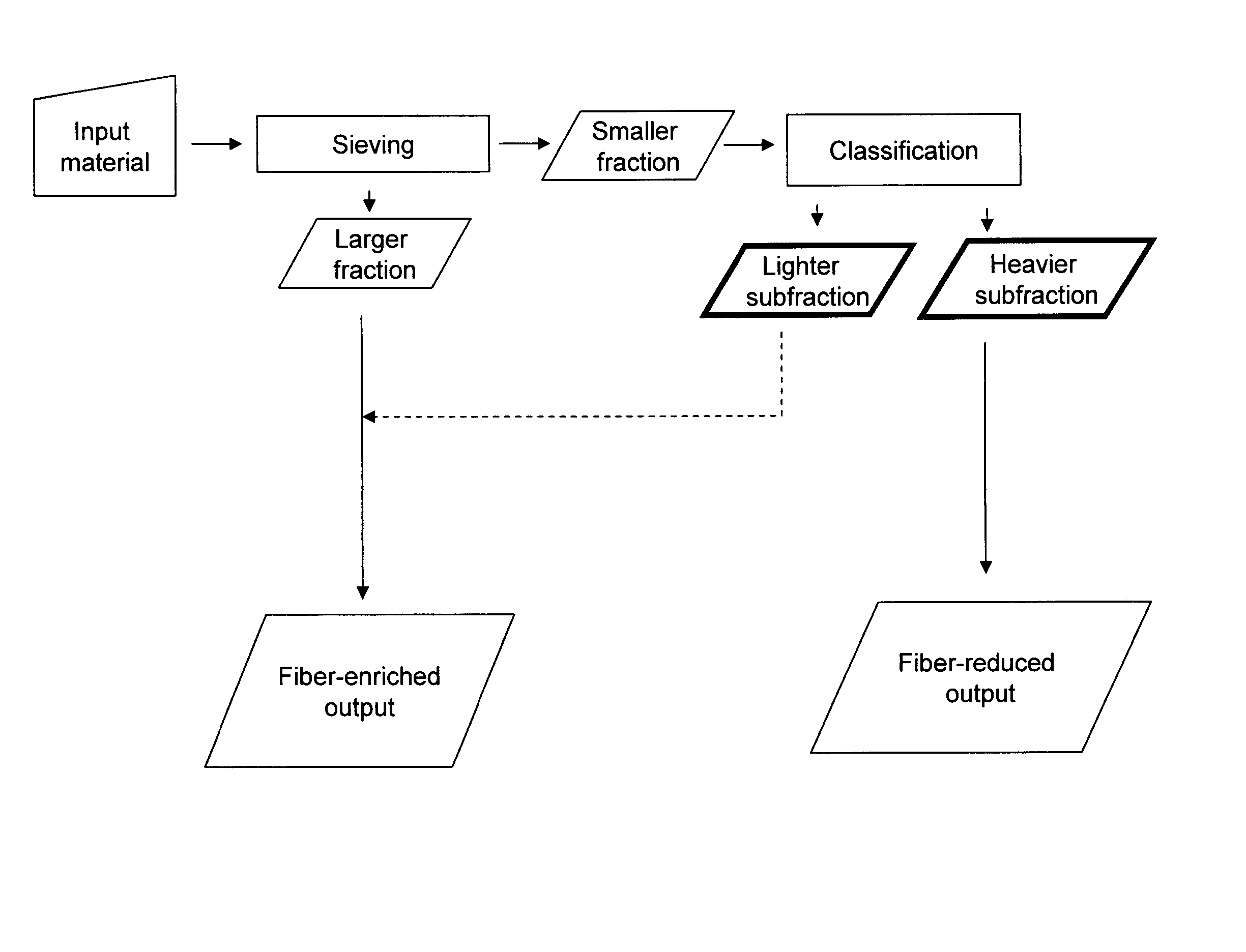

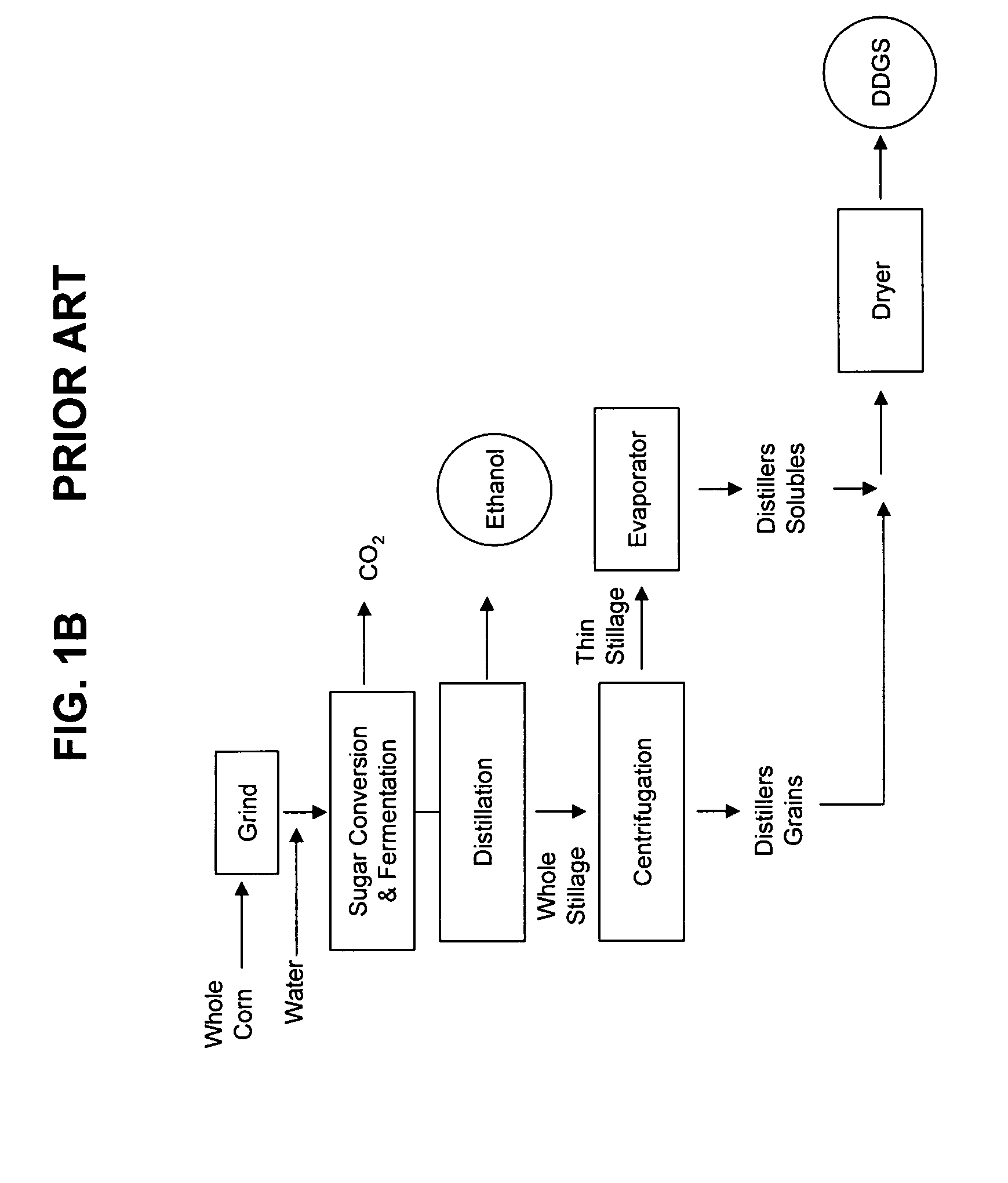

Removal of fiber from grain products including distillers dried grains with solubles

Methods, devices, and compositions relating to processed grain products are disclosed. An exemplary method disclosed is a fiber separation process for the ethanol industry corn products of Distillers Dried Grains (DDG) and Distillers Dried Grains with Solubles (DDGS) resulting from the widely used dry grind technology. A disclosed process and apparatus allows the removal and separate recovery of fiber-reduced DDG or DDGS products with expanded potential for use as a non-ruminant feed product in addition to the removal and separate recovery of a fiber-enriched product. The specific processes, devices, and compositions disclosed are readily adaptable to modern ethanol production plants.

Owner:MISSISSIPPI STATE UNIV RES TECH

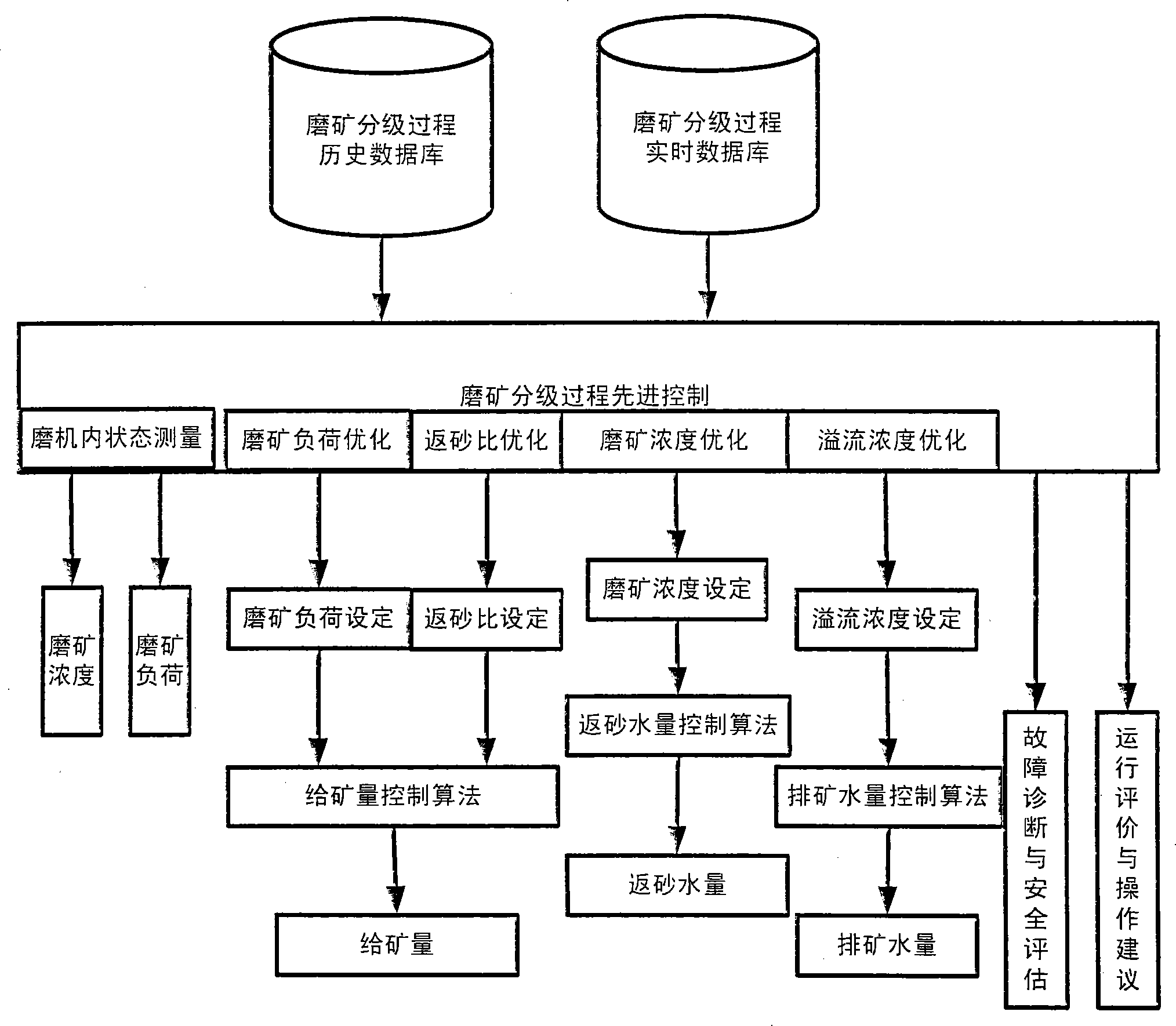

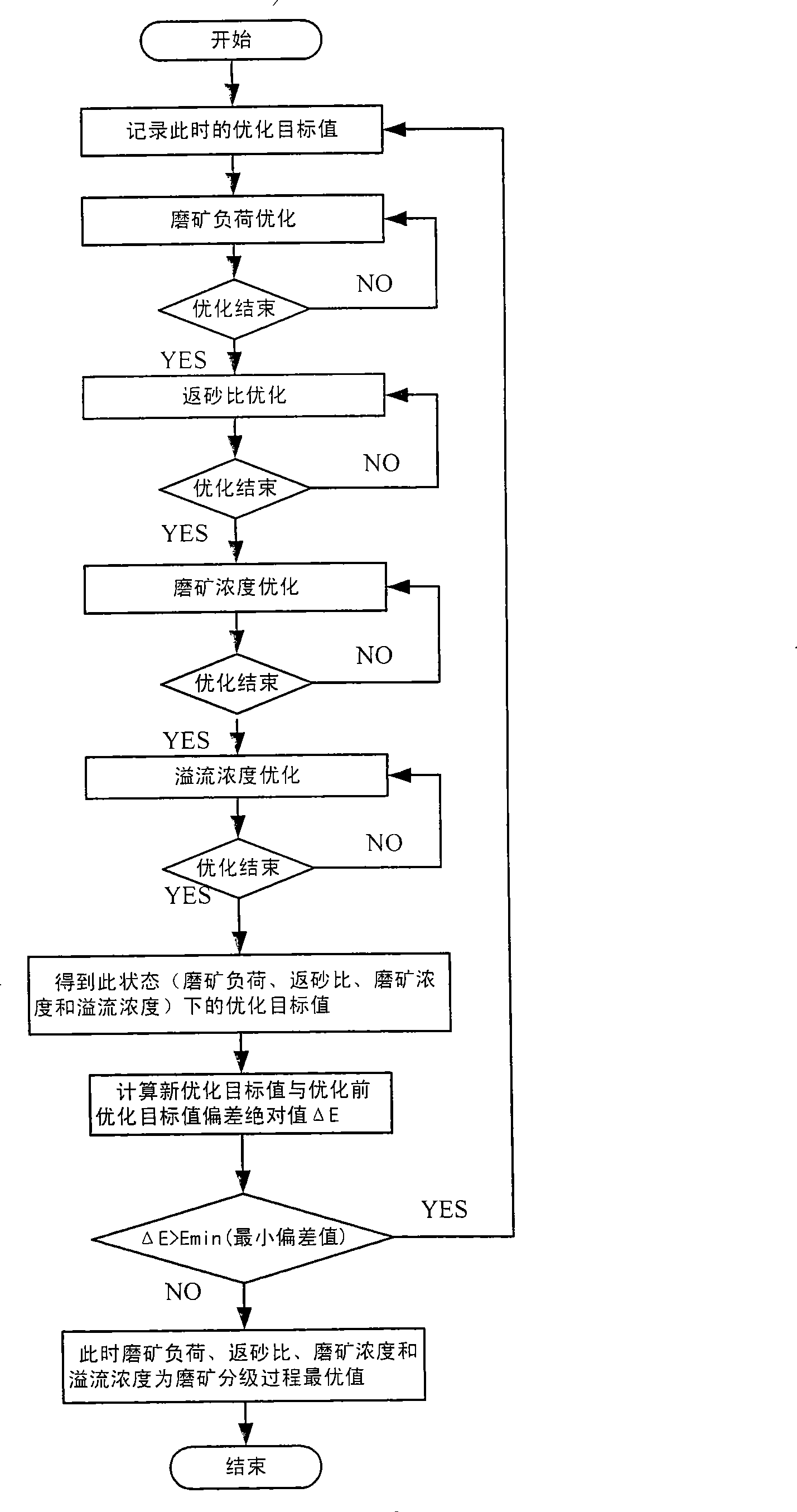

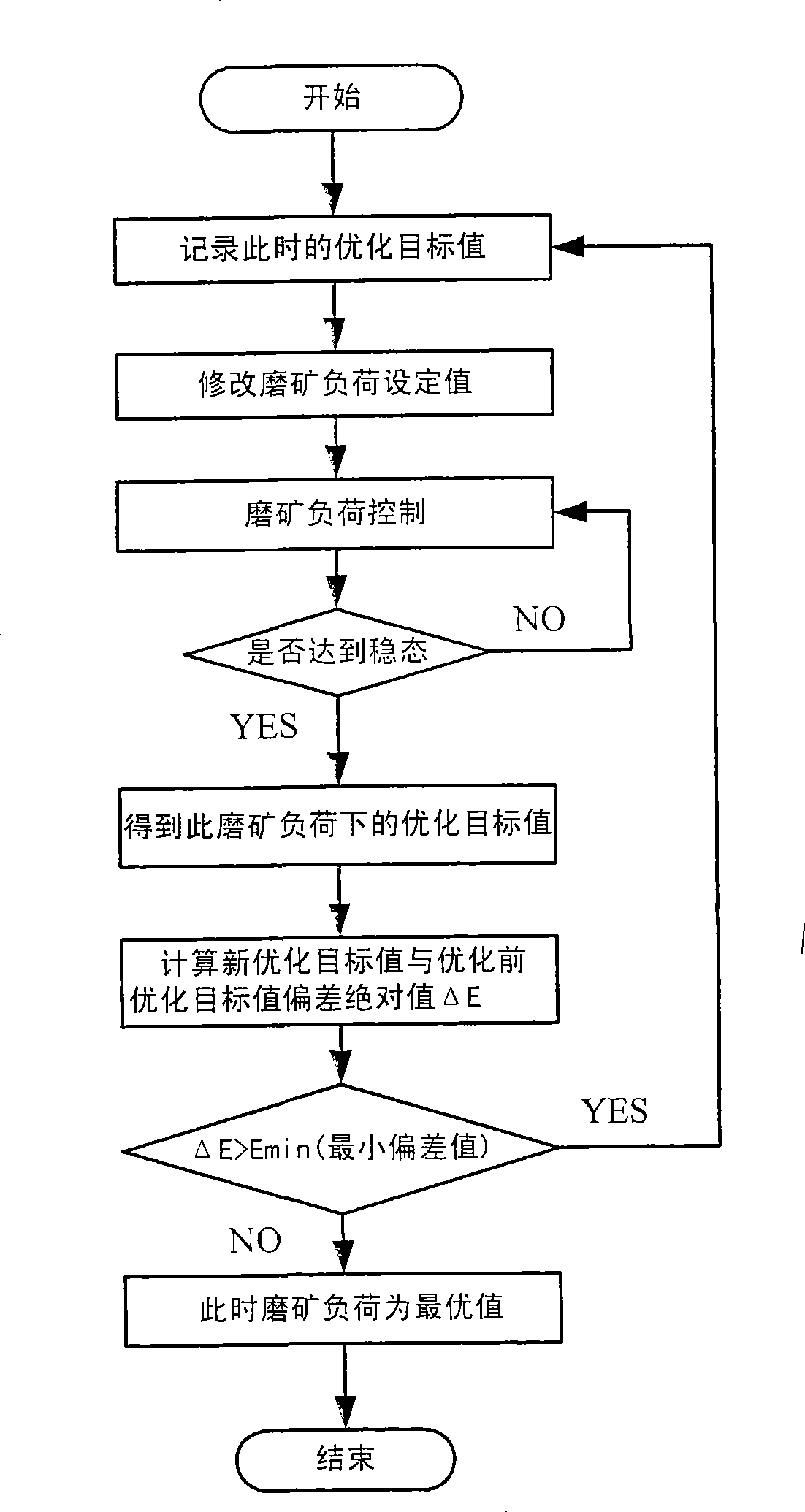

Optimization control method for grind grading process

InactiveCN101244403ARealize online measurementImprove pass rateElectric testing/monitoringGrain treatmentsComing outWater volume

The invention discloses an optimal control method for grinding and grading mineral powder, which is characterized in that: the grinding load and grinding concentration is obtained by sampling grinding-grading process signal, with the help of the advanced control and through testing the state in the grinder; the optimal grinding load, the optimal sand-returning ratio, the optimal grinding concentration and the optimal overflow concentration are obtained through the grinding load optimization, the sand-returning ratio optimization, the grinding concentration optimization and the overflow concentration optimization; the feeding quantity is obtained through the control algorithm of the feeding quantity ; the sand-returning water volume is obtained through the control algorithm of the sand-returning water volume; the discharging water volume is obtained through the control algorithm of the discharging water volume. The optimal control method has advantages that: the global optimization to the grinding-grading process is realized; and meanwhile the diagnosis is done to reveal the fault of the grinding-grading process; the appraisal and analysis is executed in the grinding-grading process; reasonable advice is come out; continuous, stable, safe and economic running is ensured; so the method is widely used in the grinding-grading process and similar wet milling process in other industry crafts.

Owner:徐宝平

Method for preparing powdered test sample for transmission electron microscope

InactiveCN102200497AExtend deposition timeIncrease sample preparation costPreparing sample for investigationVacuum evaporation coatingConventional transmission electron microscopeTest sample

The invention relates to a method for preparing a powdered test sample for a transmission electron microscope. The method comprises the following steps of: cutting a crystal with a flat and neat surface from a soluble monocrystalline material according to a cleavage surface of the soluble monocrystalline material; placing an electron microscope carrying net onto the cut crystal block; ultrasonically dispersing the powdered sample to be observed by using absolute ethanol, dropping a proper amount of dispersed liquid onto the carrying net and naturally drying in the air; sputtering and depositing a layer of metal thin film by adopting a magnetron sputtering technology, and wrapping and fixing particles to be analyzed onto the carrying net by using the deposited thin film; after sputtering, shearing off a sputtered thin film along the edge of the carrying net; placing the carrying net with the fixed particles to be analyzed into an ion milling for milling until leakage; and taking down the sample and placing into the electron microscope for observation after the center of the sample is punctured. By the method, the problems that a plurality of powdered samples which have large particle size and complicated structure and are hard to smash or grind are hard to prepare, and an observation area is limited and the sample is easy to pollute can be solved; and the method is a sample preparation method with high sample preparation success rate and high suitability.

Owner:CHINA NAT ACAD NANOTECH & ENG

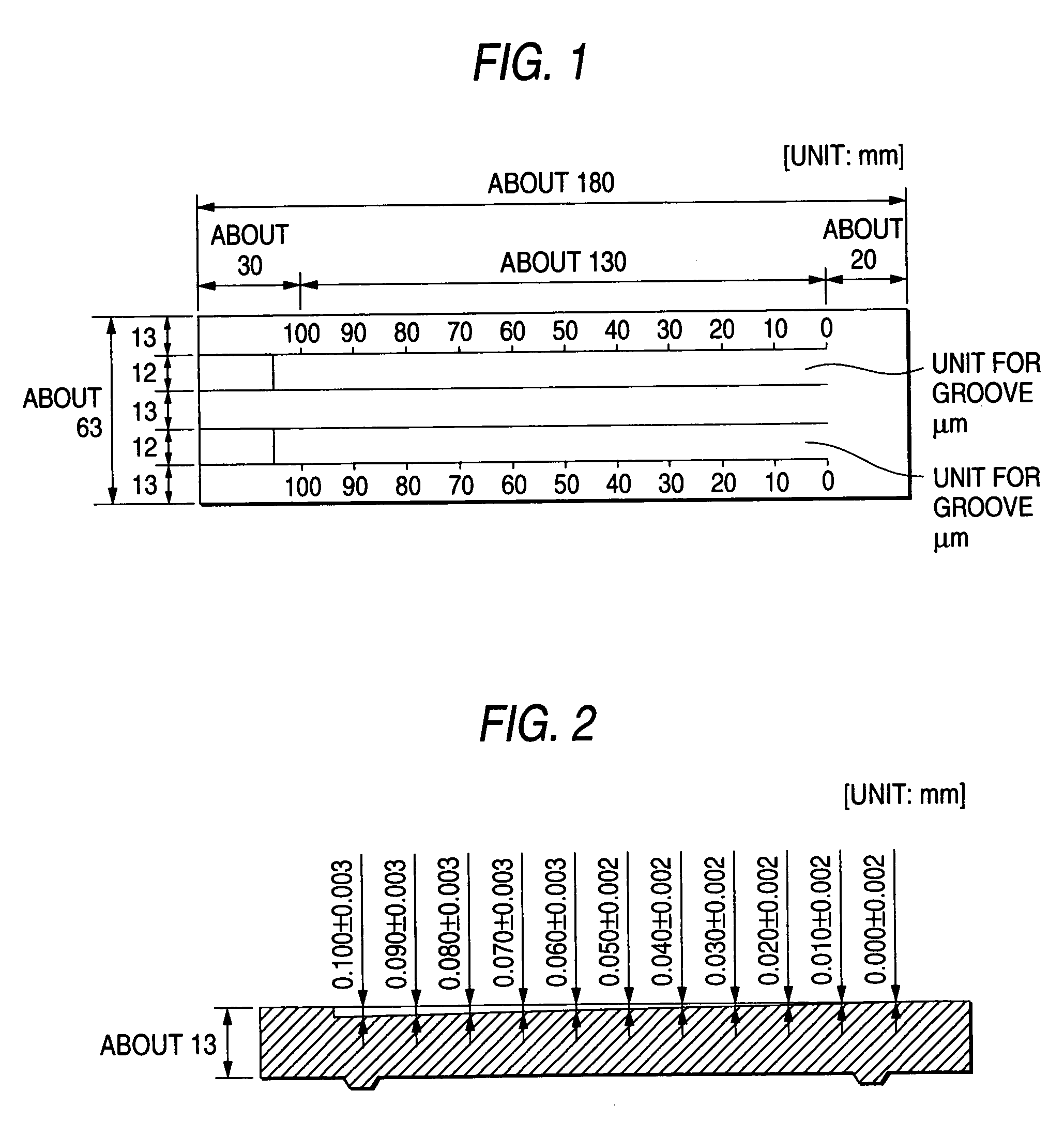

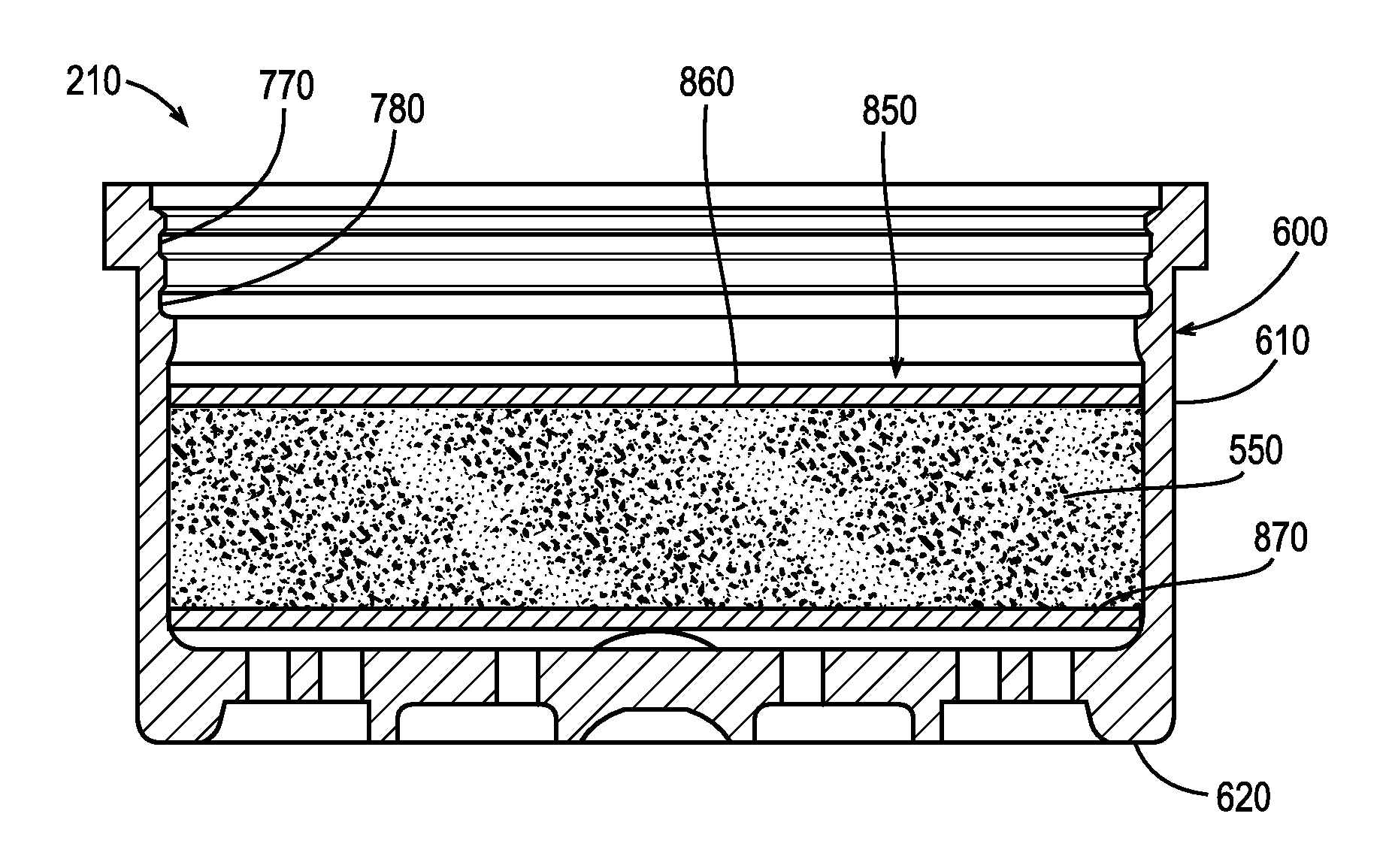

Sealing resin sheet, method for producing electronic component package and electronic component package

InactiveUS20140008821A1Semiconductor/solid-state device detailsSolid-state devicesSurface roughnessHardness

Provided are a sealing resin sheet, wherein a clean, smooth and flat ground surface is obtained by grinding after resin sealing, a method for producing an electronic component package using the same, and an electronic component package obtained by the production method. The present invention provides a sealing resin sheet, wherein a ground surface has a mean surface roughness Ra of 1 μm or less when grinding is performed under conditions of a grind bite peripheral velocity of 1000 m / minute, a feed pitch of 100 μm and a cut depth of 10 μm after a heat curing treatment is performed at 180° C. for 1 hour; and a Shore D hardness at 100° C. after the heat curing treatment is 70 or more.

Owner:NITTO DENKO CORP

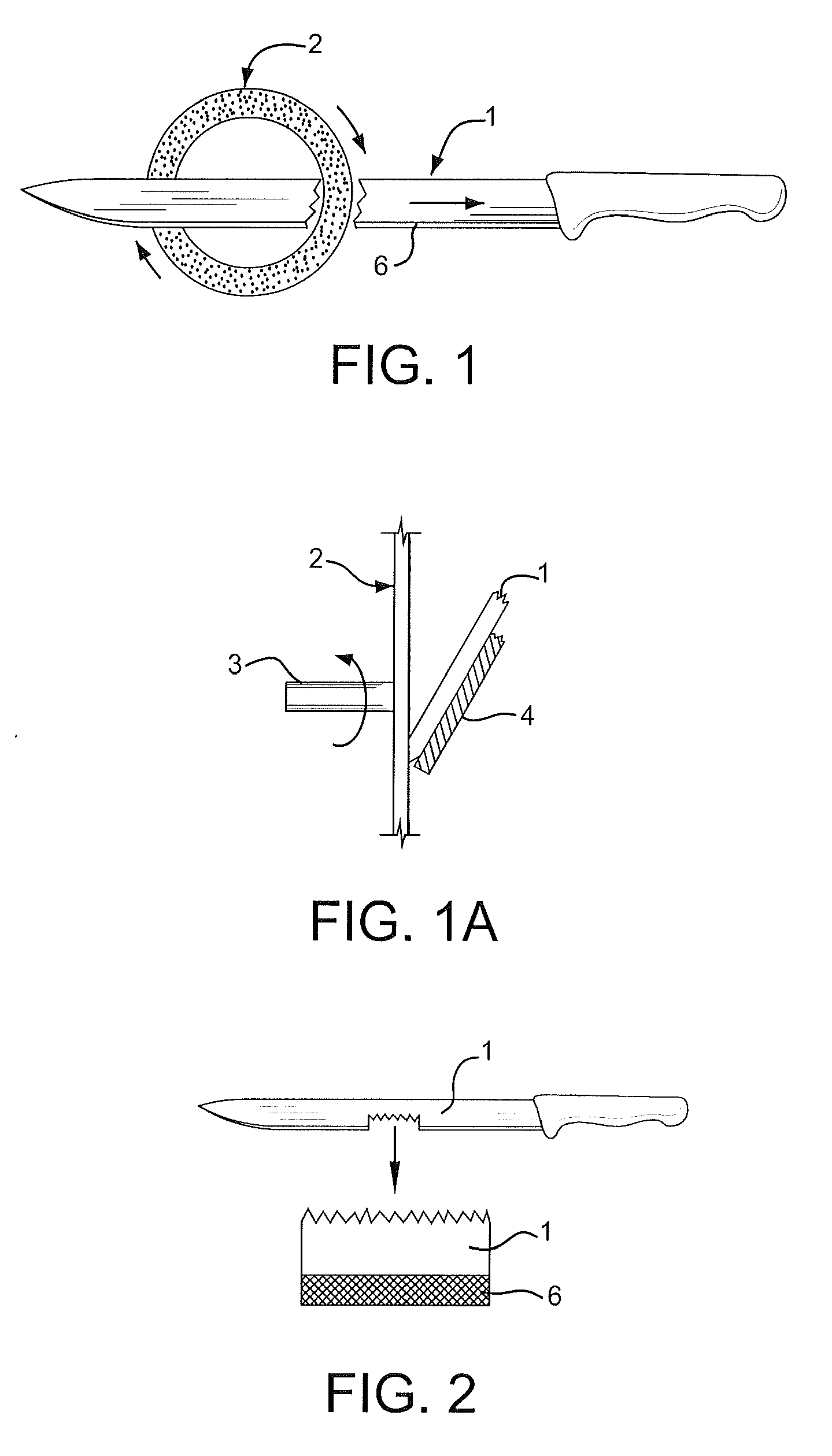

Novel sharpeners to create cross-grind knife edges

ActiveUS20110034111A1Highly effectiveSmall sizeEdge grinding machinesRevolution surface grinding machinesCircular discEngineering

A sharpener for creating cross-grind knife edges includes a nominally flat annular abrasive sharpening member which could be a ring or a disk and is rotated about its center and held against a moving knife edge facet to simultaneously and sequentially abrade the knife edge at multiple locations on the abrasive member. The disk may be slidably mounted on a shaft in opposition to a spring restraining force. The disk is nominally disposed in a vertical orientation. The sharpener may include multiple stages including a manual stage having a pair of off axis conical shaped rotatable abrasive coated disks which have abrading lines on opposing facets which are not parallel but cross and intersect in a crossing pattern at the blade edge.

Owner:EDGECRAFT

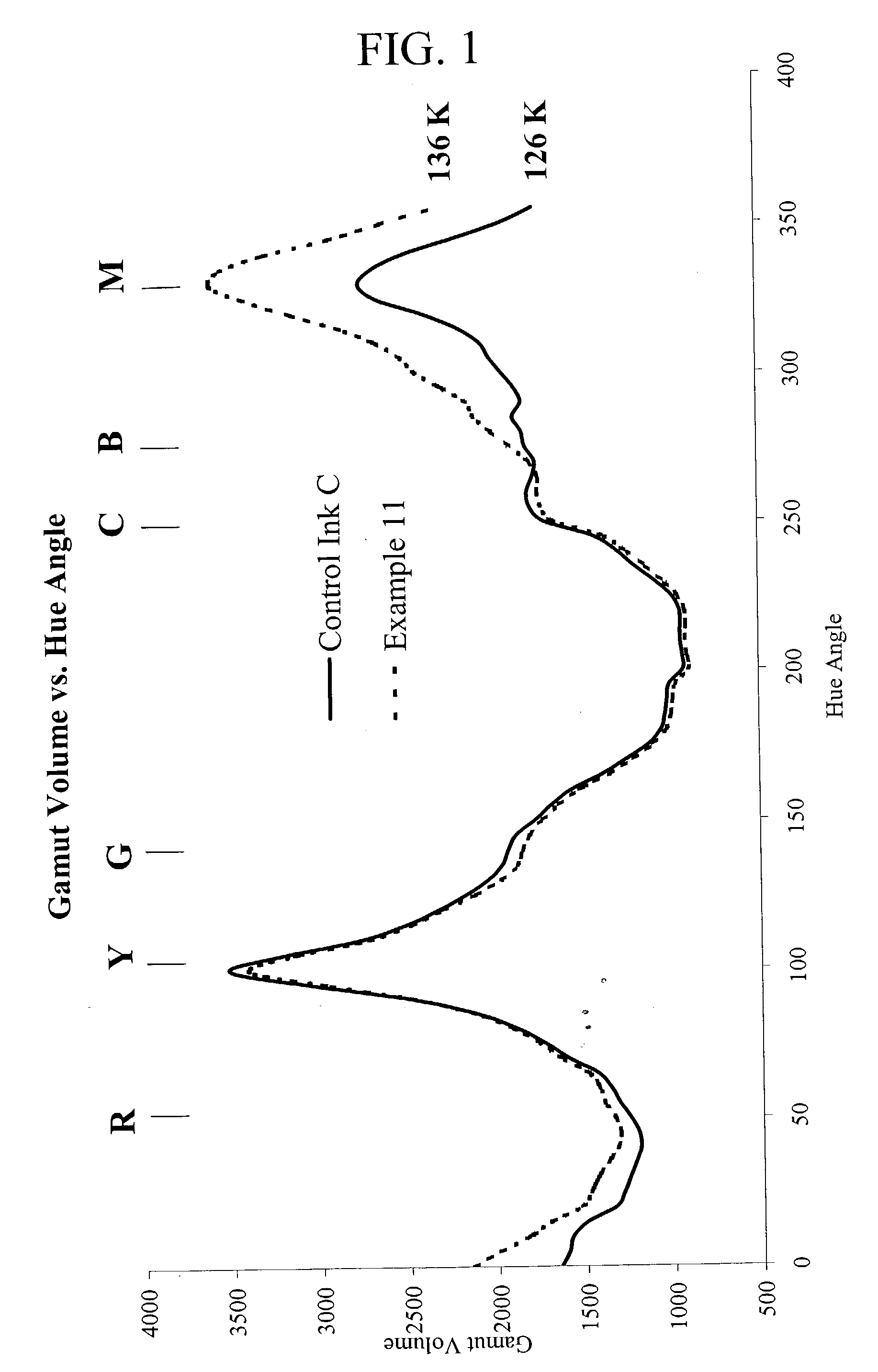

Pigmented inks and methods to improve ink performance

InactiveUS20040127619A1Improve reliabilityGood chromaMeasurement apparatus componentsInksPigment dispersionGrind

The present invention relates to a pigment dispersion and a method of producing a pigment dispersion by grinding a grind mixture comprising a pigment, a humectant, water, and a polymeric dispersant. The invention also relates to an ink composition comprising an aqueous carrier and a pigment dispersion produced by grinding a grind mixture comprising a pigment, a humectant, water, and a polymeric dispersant. The invention also relates to an ink composition comprising a pigment, a polymeric dispersant, a humectant, a basic dye, an aqueous carrier, wherein the pH of the ink composition is less than or equal to 7.

Owner:FUNAI ELECTRIC CO LTD

Mine milling method for improving particles size distribution of bauxite mine milling products

The invention relates to a grinding method to improve aluminum ore grinding particle distribution. It screens or separates the fine aluminum ore or paste, with thick particles or block ore for grinding. Using quick grinding, forced ore extraction and highly efficient leveling technique, it reduces the regrinding for acceptable grain product, reducing pelitization or overgrinding, especially fine level content, with -200 being 85%, reducing -400 content lower than 40%, significantly improving grain distribution of the grind ore and reduced grinding energy consumption.

Owner:GUIZHOU BRANCH CHINA ALUMINUM IND

Automatic dosage unit

Automatic dosage unit for dosage of a product into a collecting unit, said dosage unit comprising a grinding device, which is arranged to prepare, e.g. grind or mill, a product, and an identification device. The collecting unit comprises a handle, which is adapted to hold a container, such as a bag, and an adjustable part, and in that the identification device is arranged to identify a setting of the adjustable part of the collecting unit and on the basis of this setting dose a predetermined amount of the product into the container.

Owner:MALYKKE TORBEN

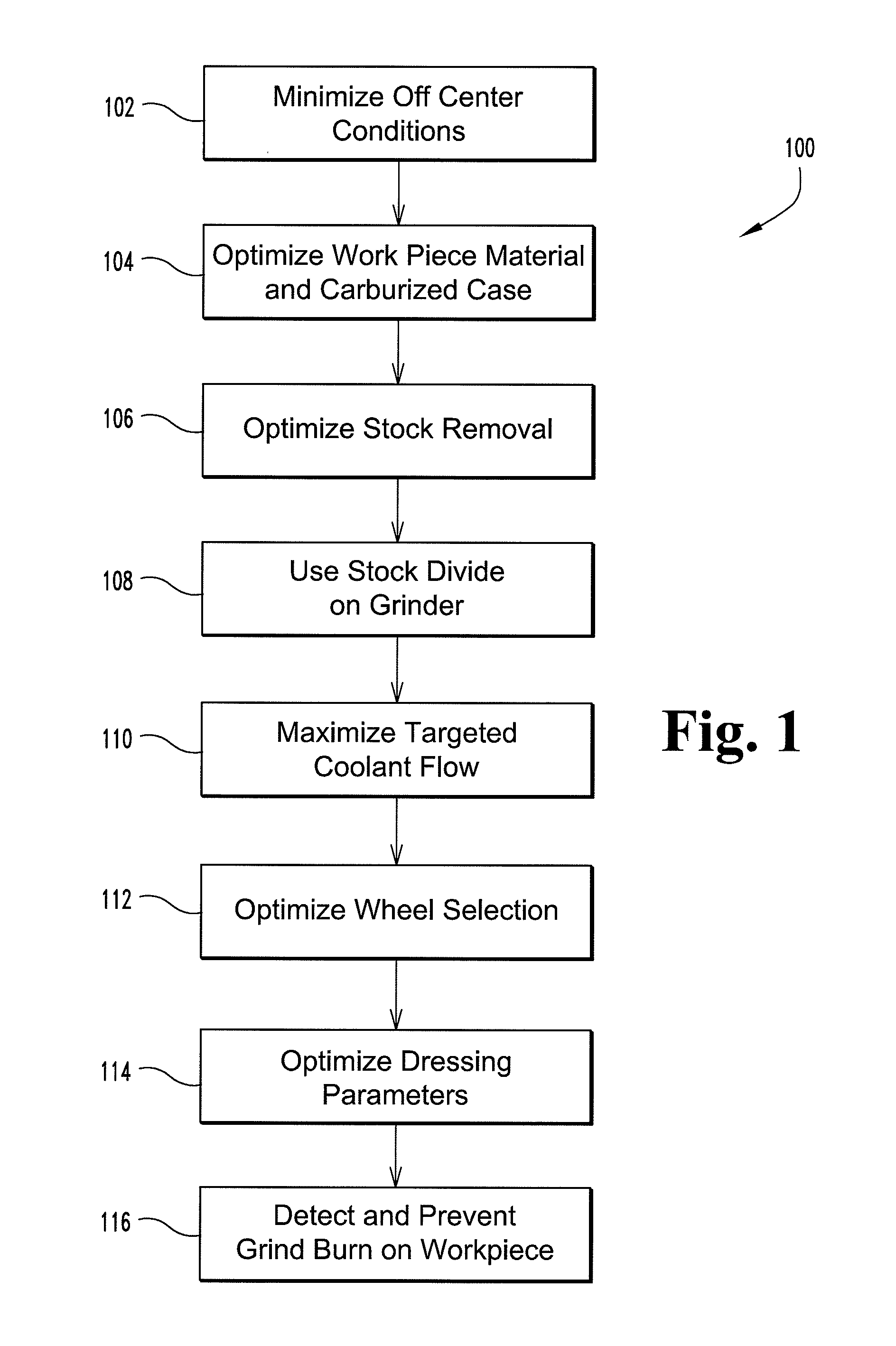

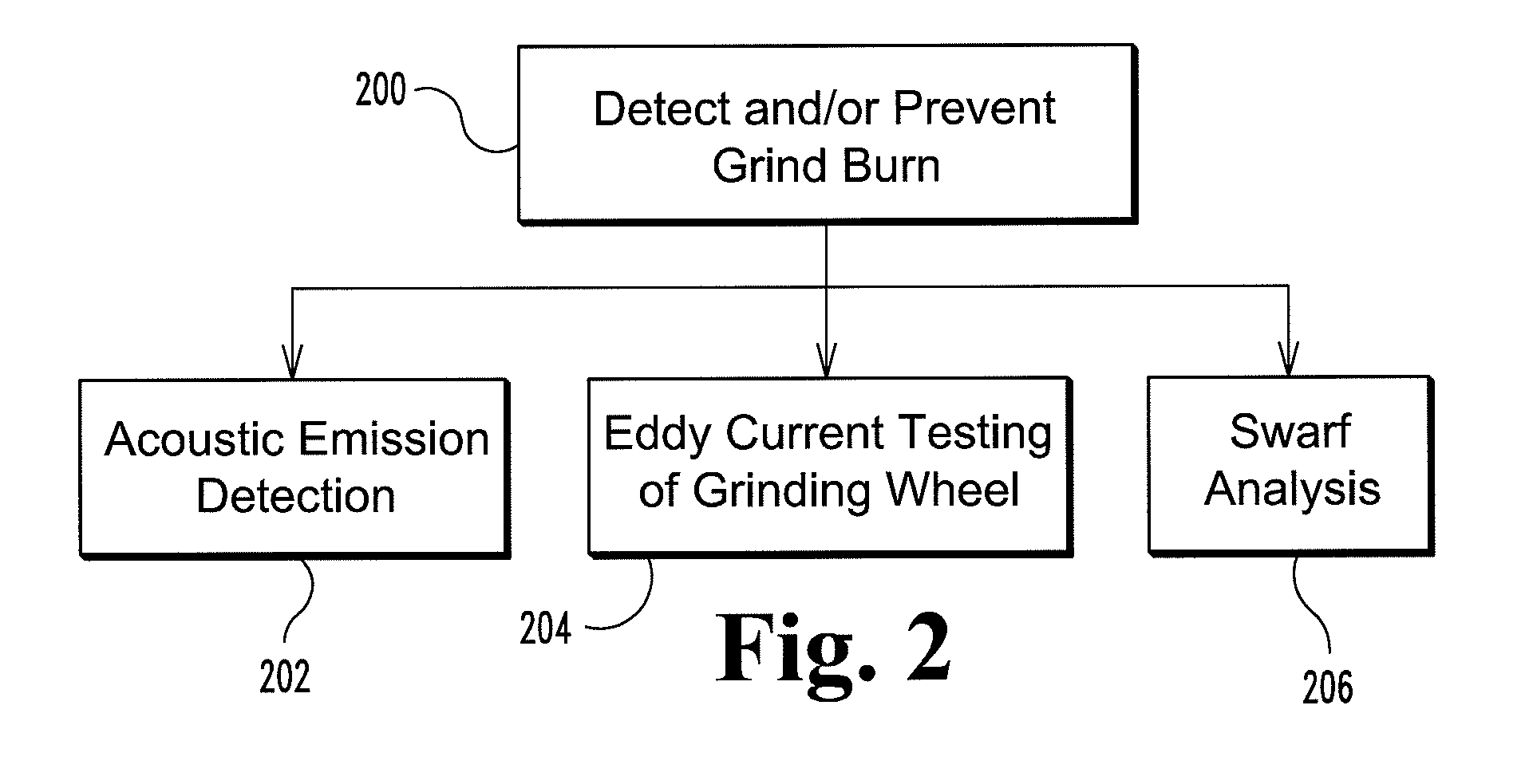

Method for detecting and/or preventing grind burn

ActiveUS20110136408A1Low costThe test result is moreGrinding feed controlAbrasive surface conditioning devicesAcoustic emissionEngineering

The present invention provides a method of detecting and preventing grind burn from developing on a gear. The method includes performing acoustic emission testing while the gear is being ground during a grinding operation. The grinding wheel is evaluated during an eddy current test to detect material buildup on the grinding wheel which could cause grind burn. In addition, the method includes collecting swarf from the gear during the grinding operation and inspecting the swarf for an indication of grind burn.

Owner:ALLISON TRANSMISSION INC

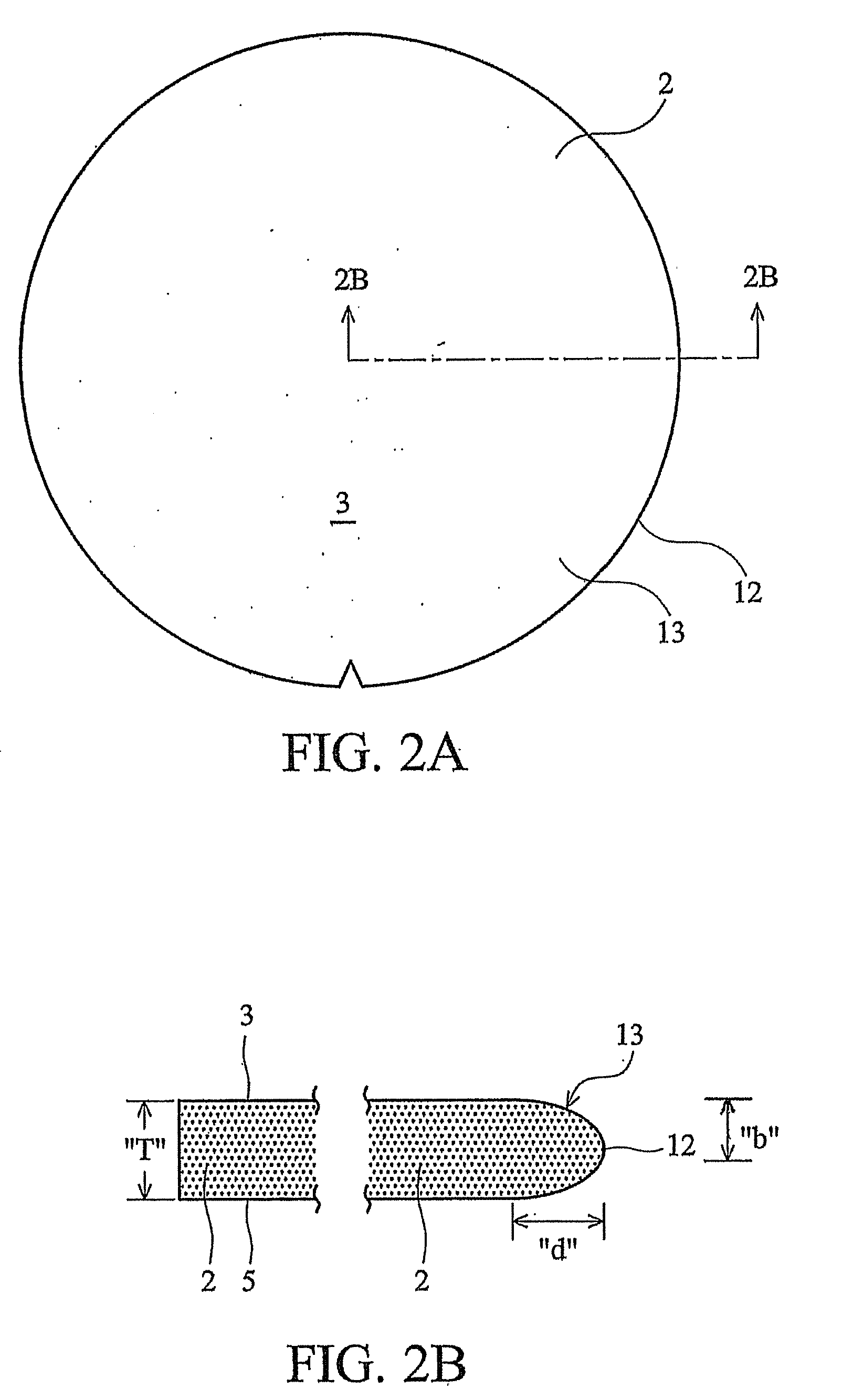

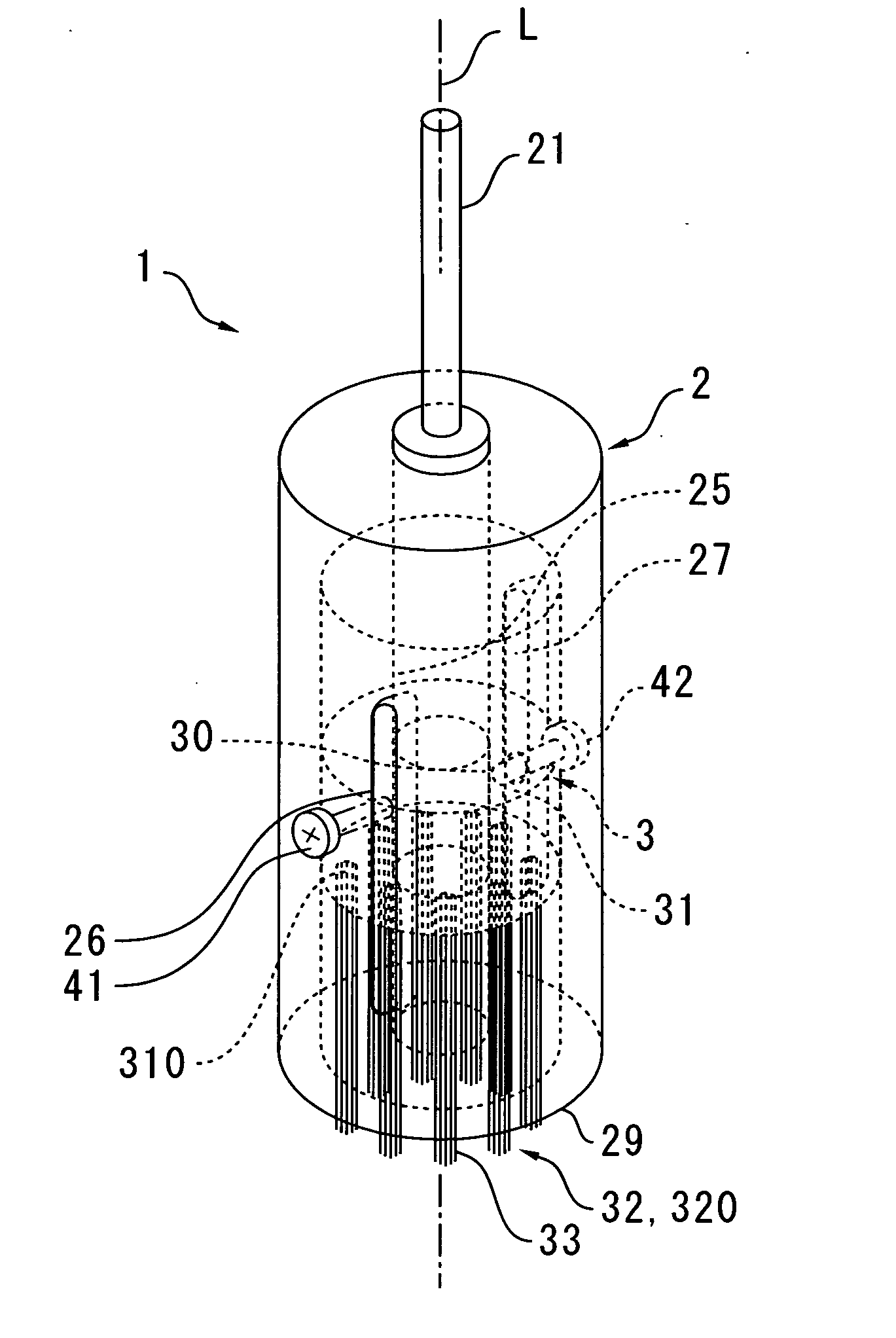

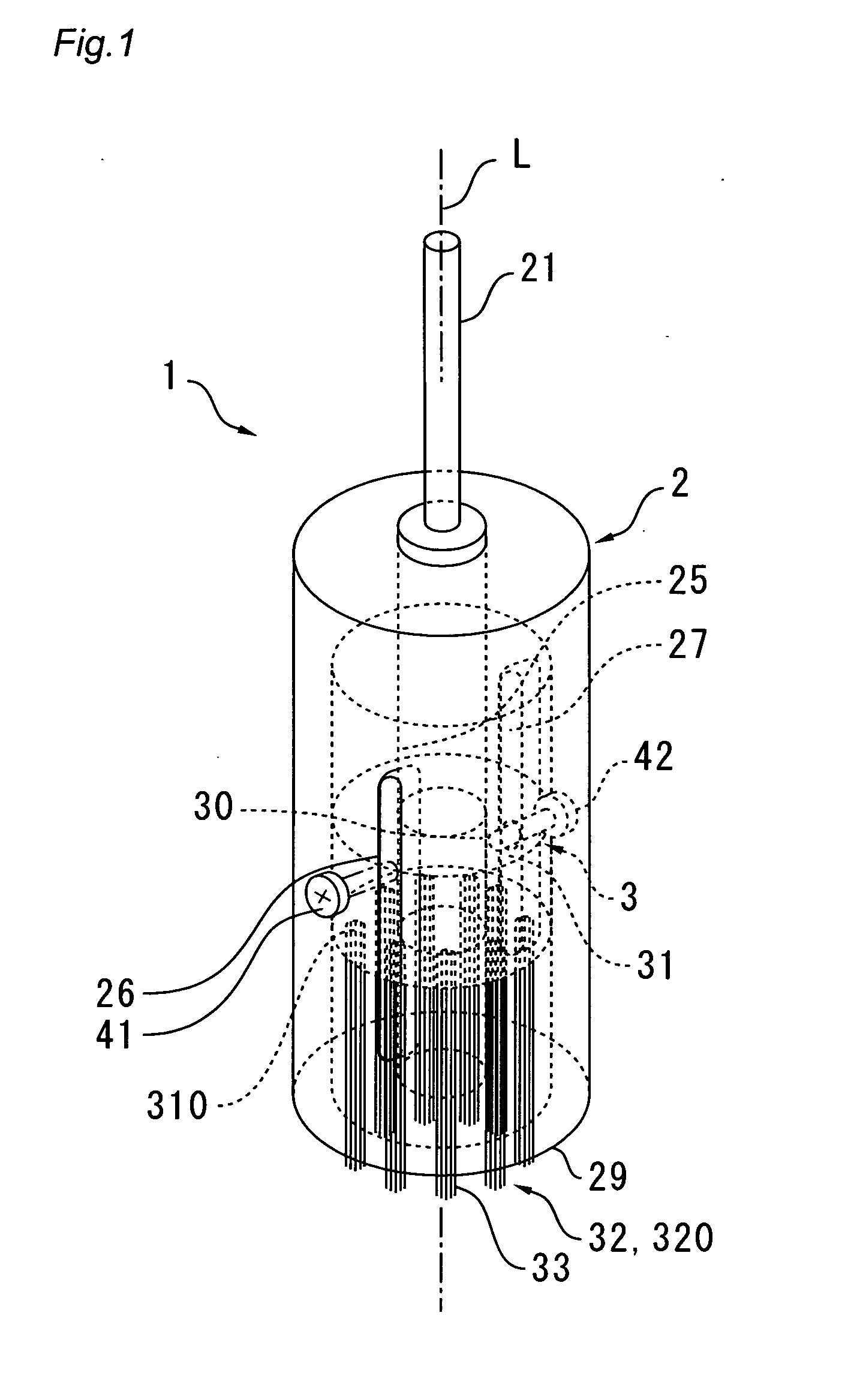

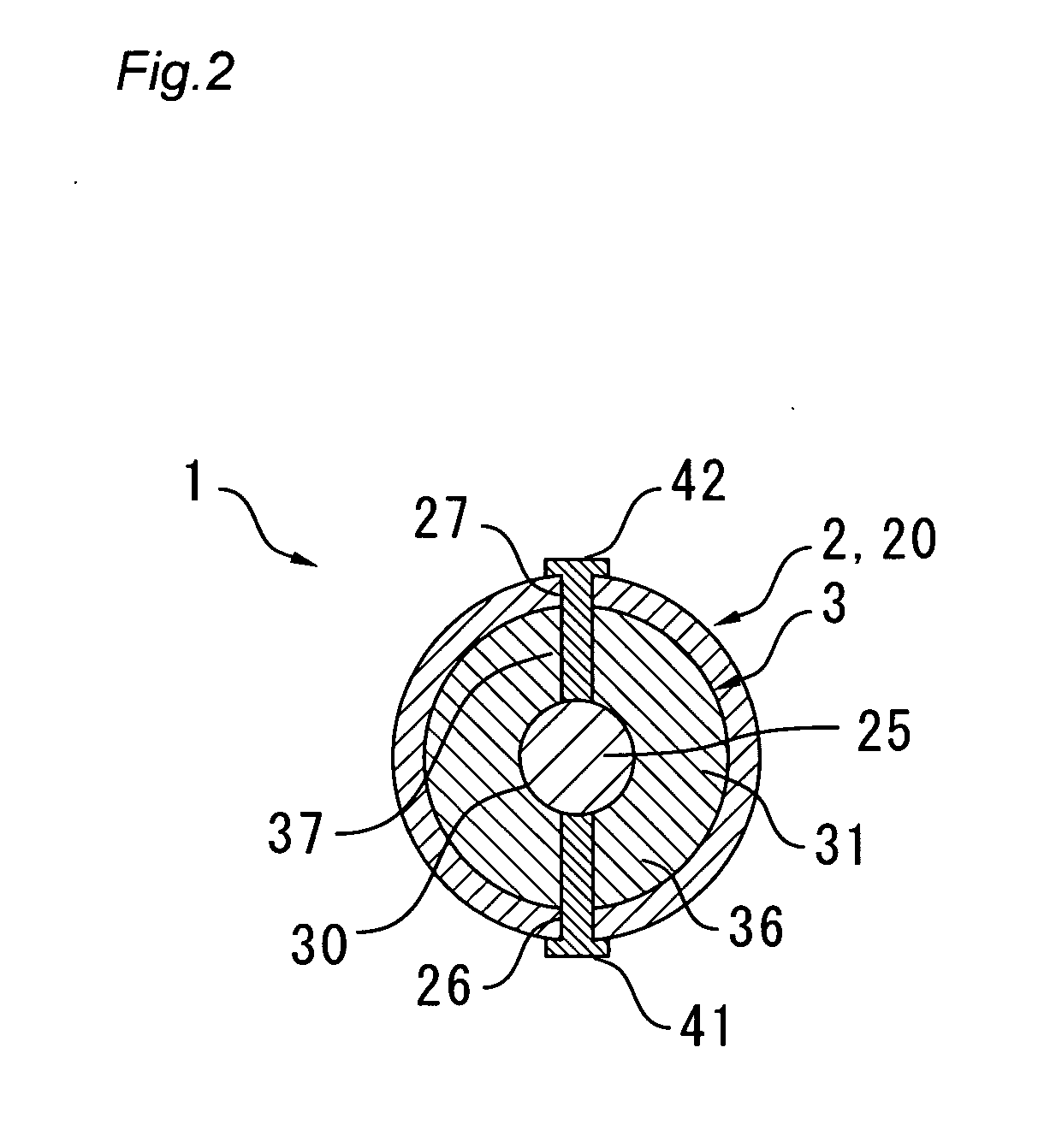

Method of producing brush-like grind stone, the brush-like grind stone, and brush for grind machine

In the manufacture of a brush-shaped grindstone (3), embedding holes (310) are formed in a grinding element holding surface (311) of a holder (31) in mutually separated positions. A base end side of a plurality of wire-shaped grinding elements (32), formed such that a composite yarn composed of inorganic filaments is impregnated and hardened with a resin, is aligned, and rod assemblies (320) are thereafter formed by fixing the base end side of the plurality of wire-shaped grinding elements (32) with adhesive (71) in holes (60) of a die material (6), which is formed to have substantially the same size as the embedding holes (310) of the holder (31). The rod assemblies (320) are thereafter embedded in the embedding holes (310) of the holder (32), and fixed with adhesive (72). Whereby, removing burrs from a precision work component, performing polishing, and the like can be carried out with good efficiency and high precision.

Owner:XEBEC TECH CO LTD +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com