Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

22089results about How to "Improve pass rate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

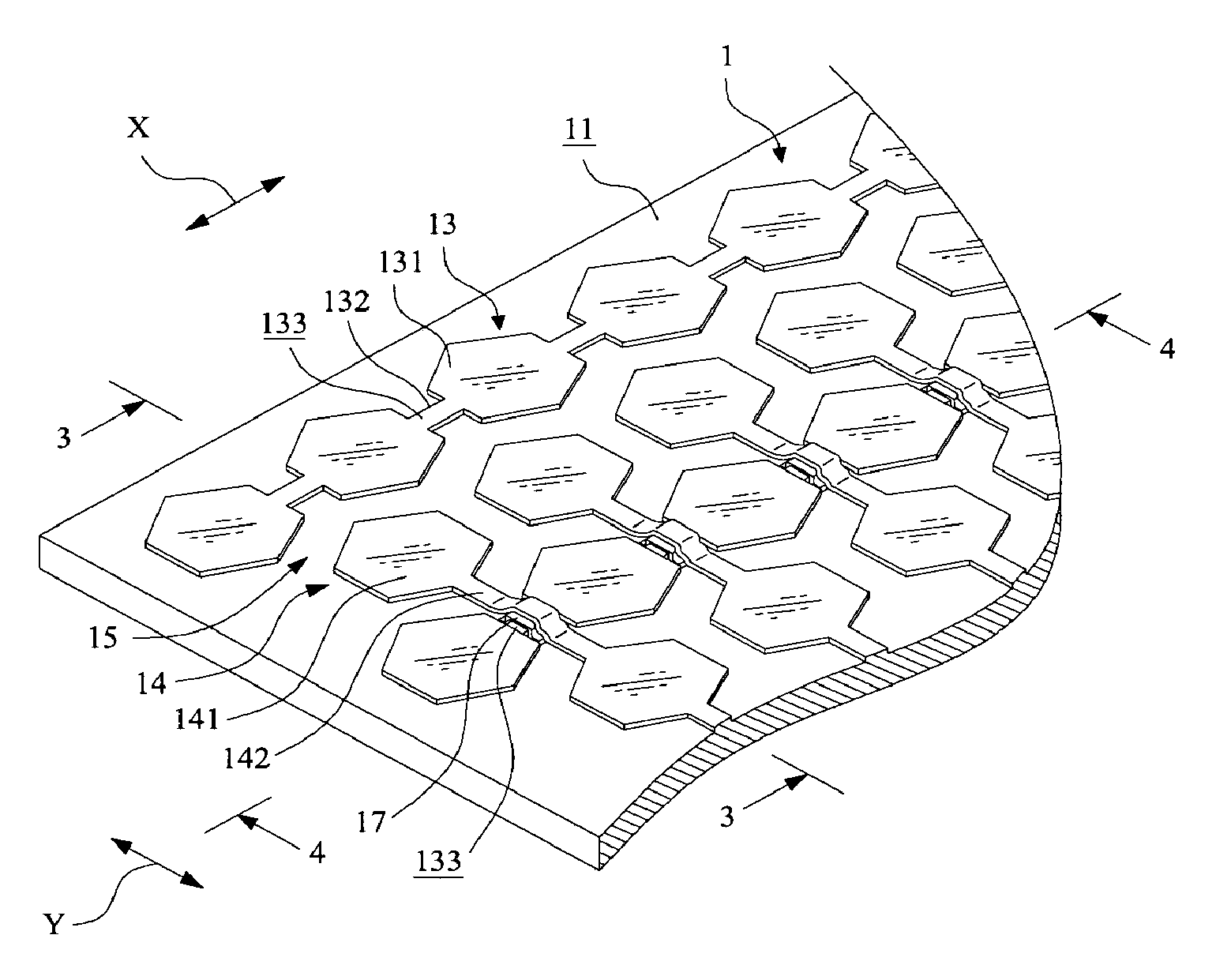

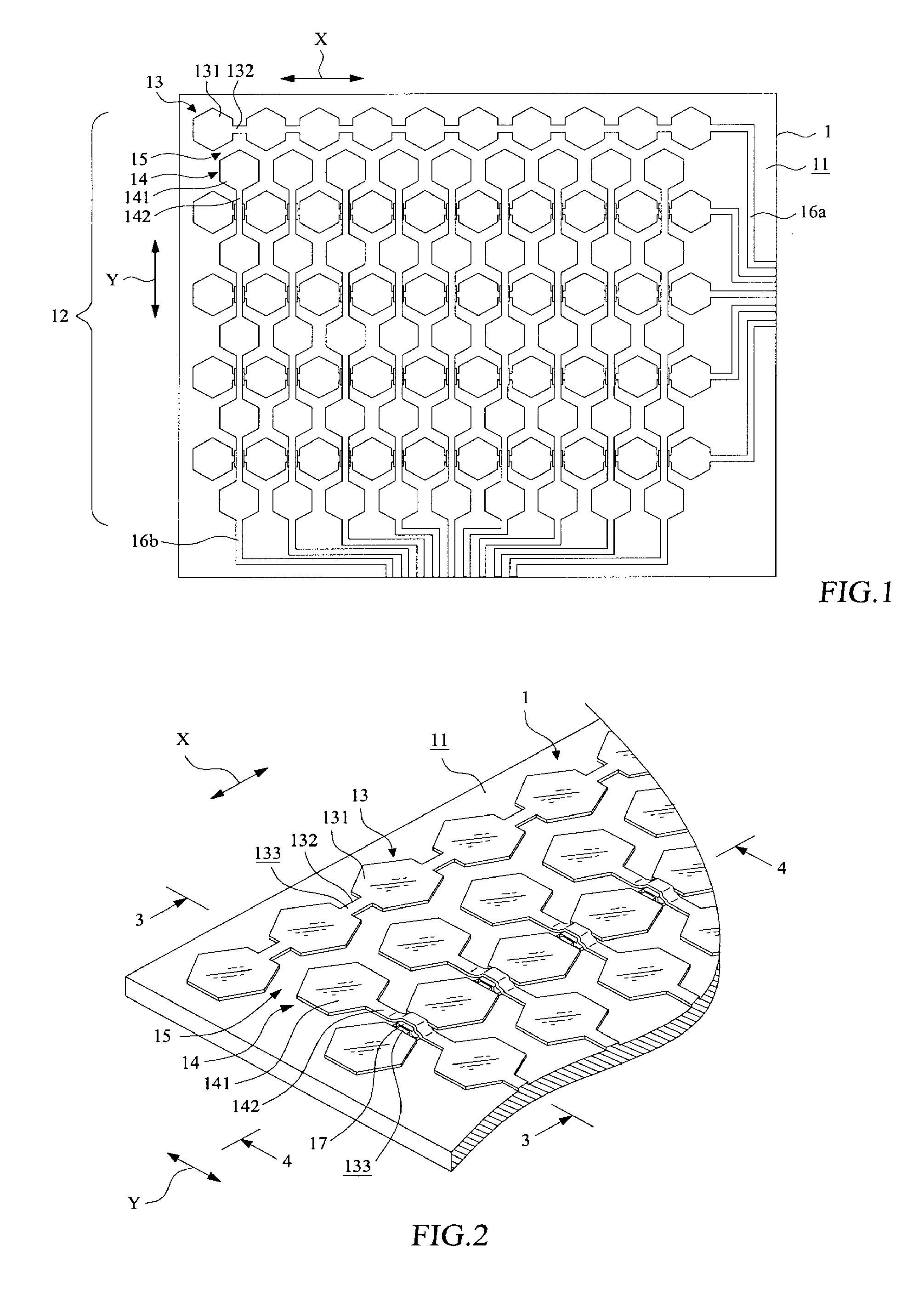

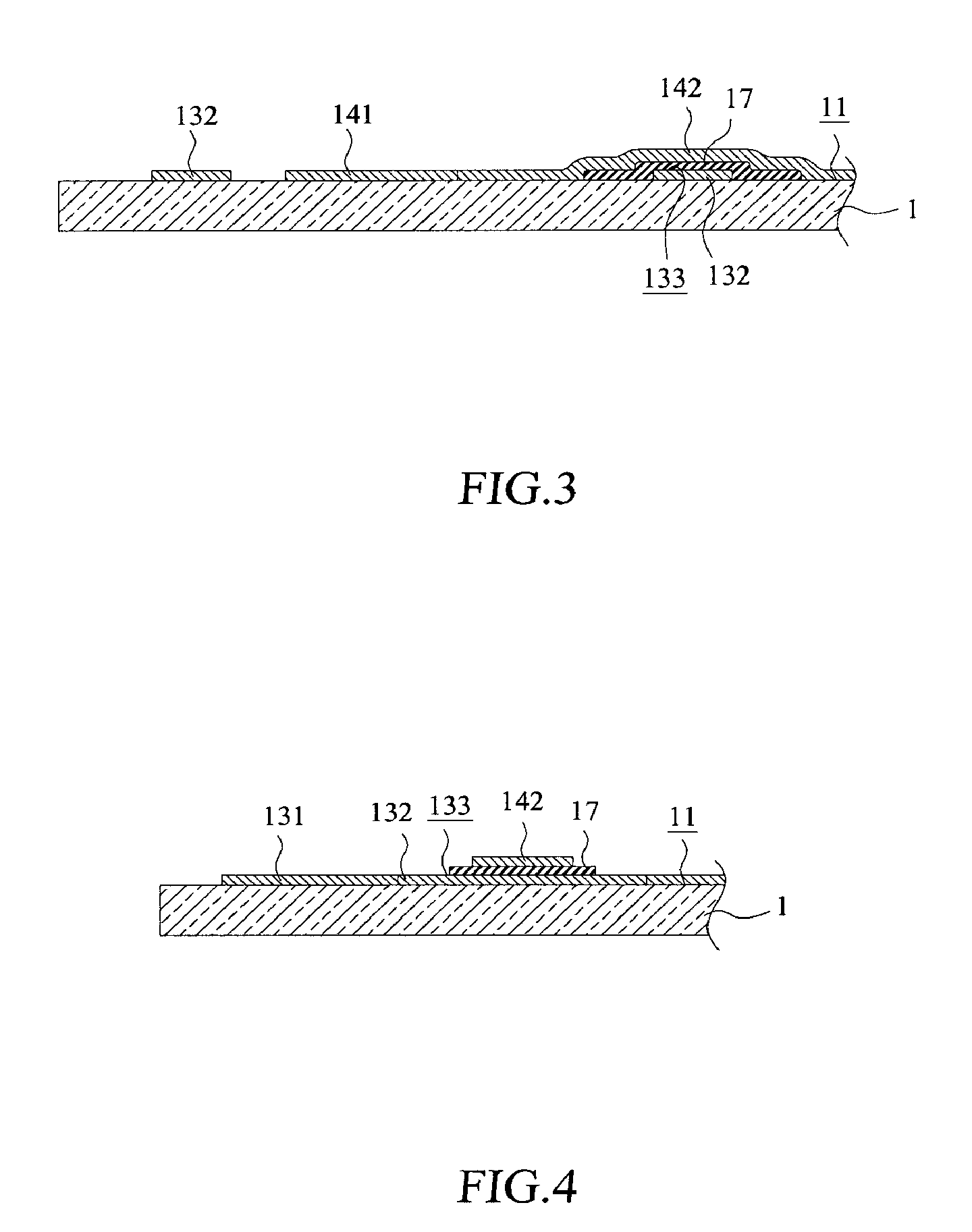

Conductor pattern structure of capacitive touch panel

ActiveUS20080264699A1Simple structureReduce the thickness of the structureTransmission systemsResistance/reactance/impedenceElectrical conductorEngineering

Disclosed is a conductor pattern structure of a capacitive touch panel. First-axis conductor assemblies and second-axis conductor assemblies are formed on a surface of a substrate. Each first-axis conductor assembly includes a plurality of first-axis conductor cells that are interconnected by first-axis conduction lines. An insulation layer is formed on a surface of each first-axis conduction line. Each second-axis conductor assembly includes a plurality of second-axis conductor cells that are interconnected by second-axis conduction lines. Each second-axis conduction line extends across the insulation layer of the associated first-axis conduction line.

Owner:TRENDON TOUCH TECHNOLOGY CORPORATION

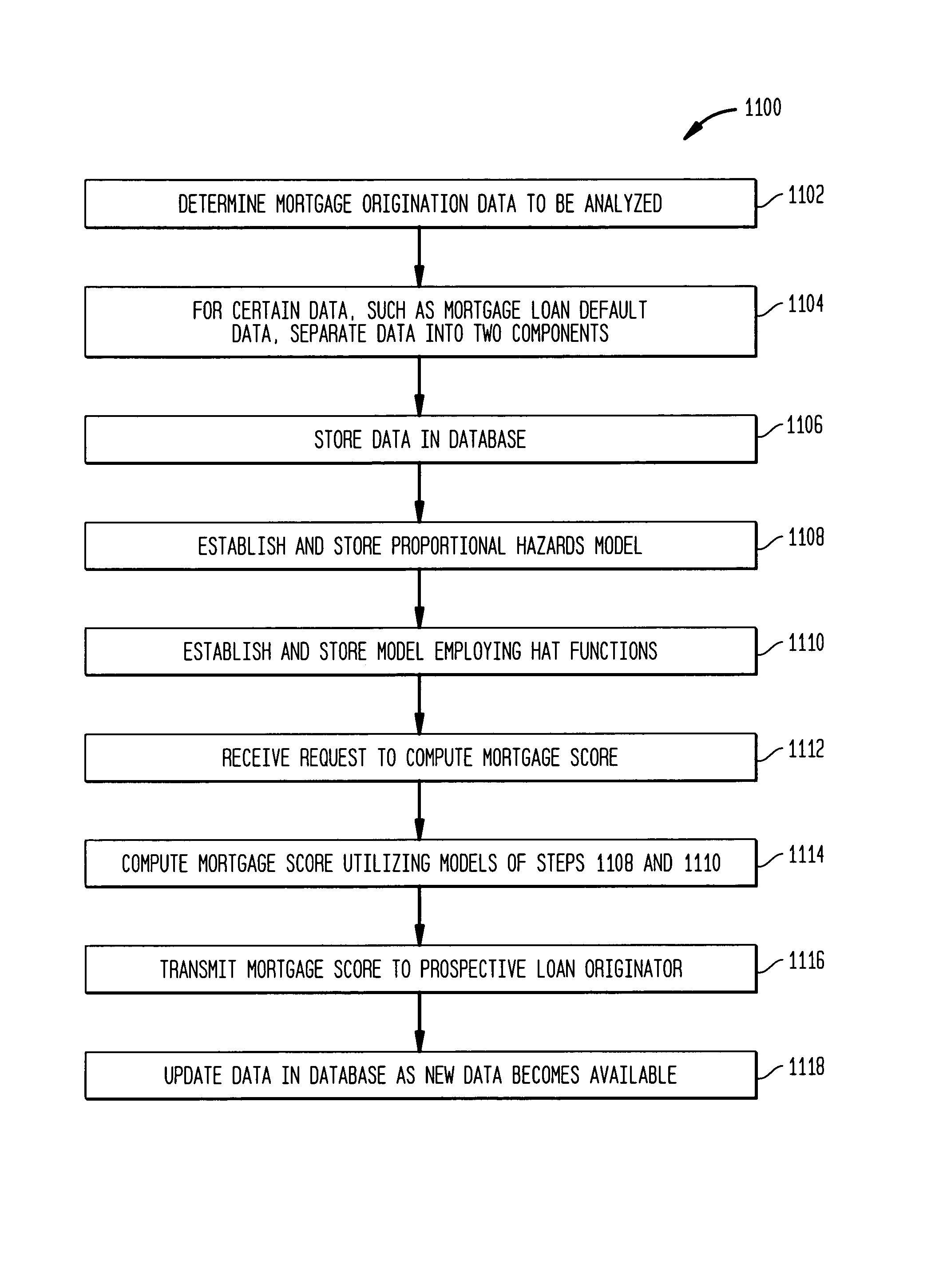

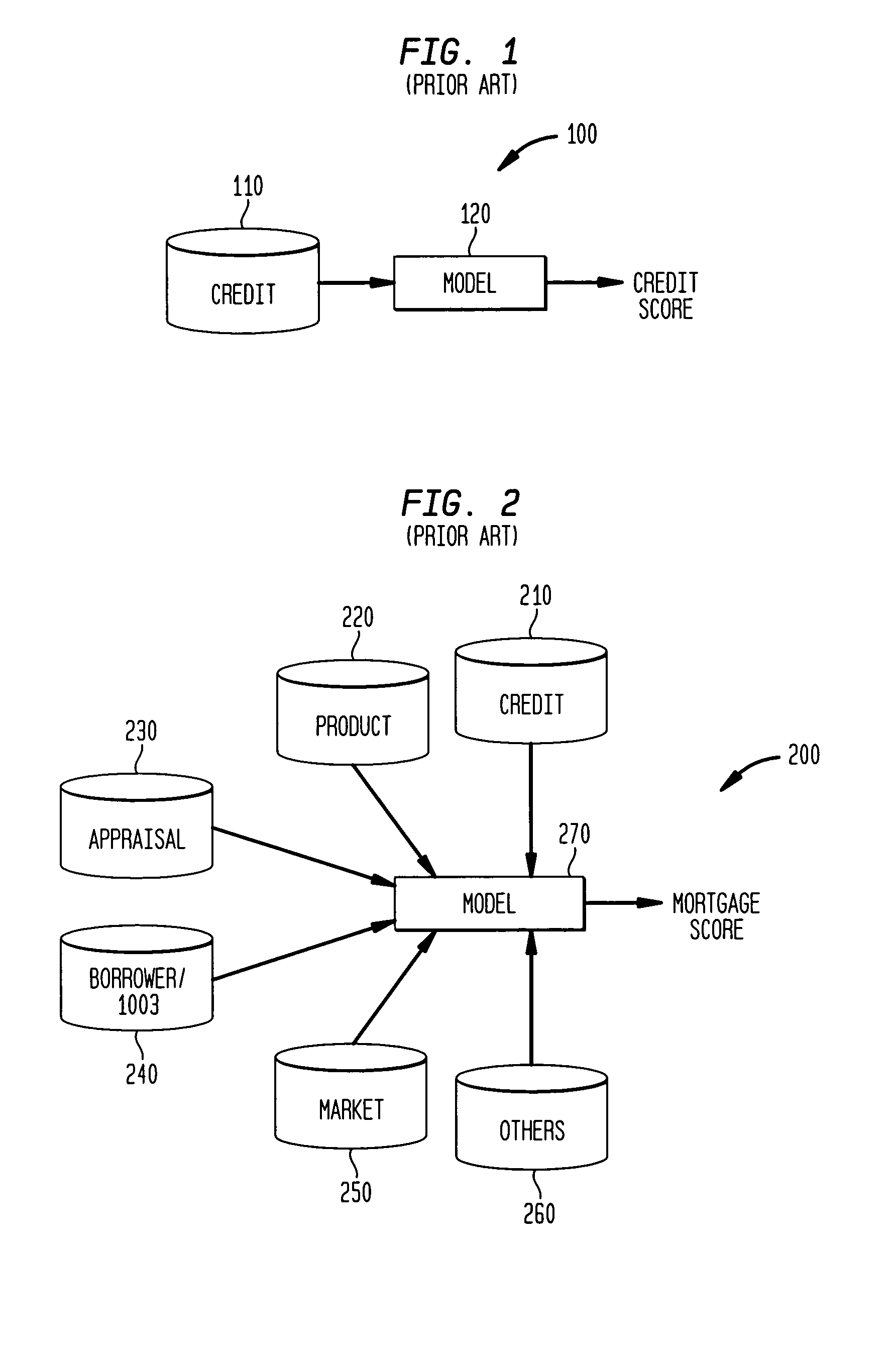

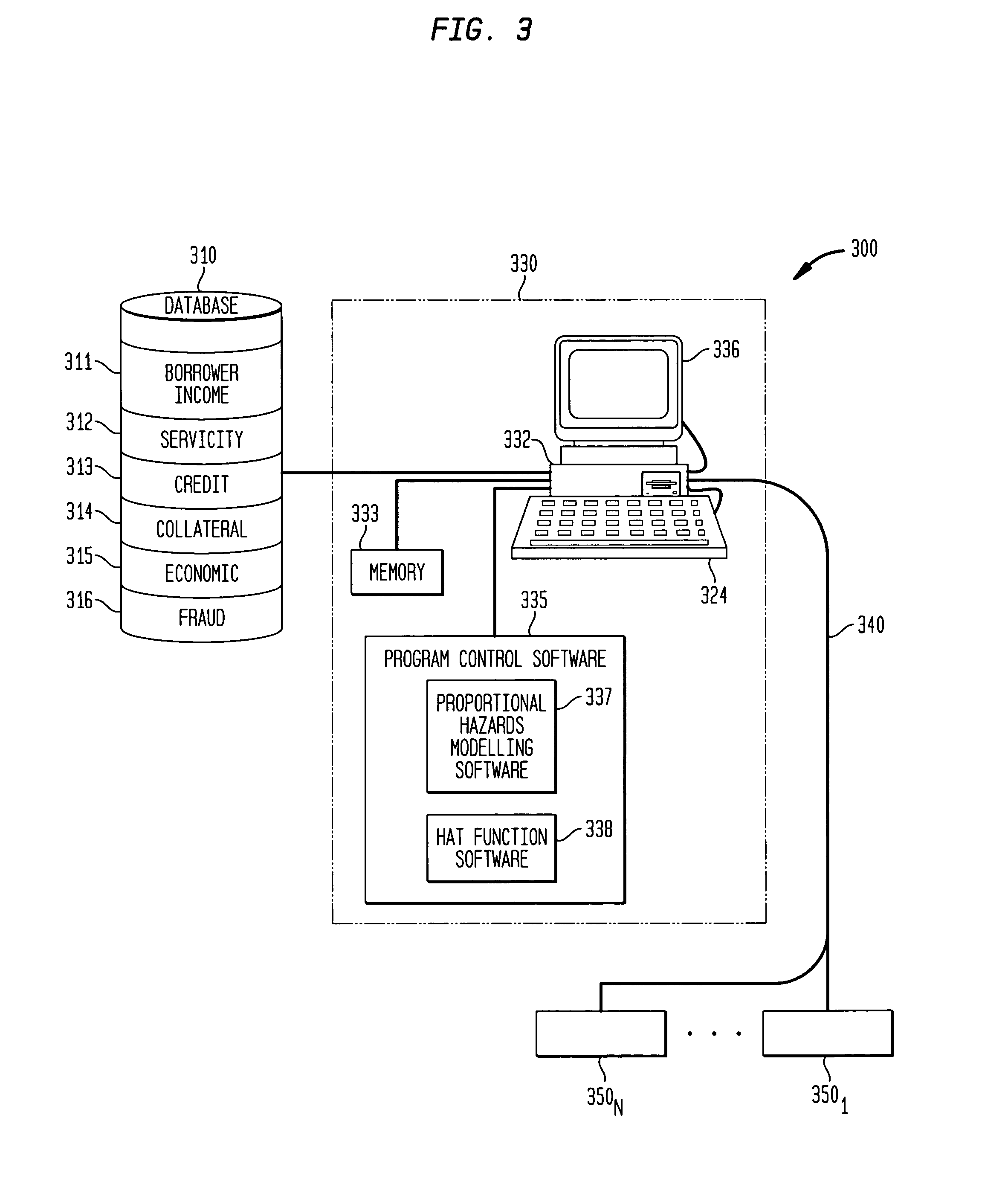

Methods and apparatus for utilizing a proportional hazards model to evaluate loan risk

InactiveUS7392216B1Increase valueAccurate identificationFinanceProportional hazards modelErrors and residuals

Systems and processes for more accurate mortgage scoring are described. A proportional hazards model is employed in which not only the occurrence of an event, but also the time to an event such as default of a loan, is considered. In this approach, a hazard rate can be viewed as the chance that an observation will experience an event in the next instant. There are two components to the response, and a binary variable is utilized to indicate whether the event was observed or not, and a time variable. As a result, the number of loans used for modeling is greatly increased, and the time it takes to observe the event, a valuable piece of information in itself, is included in the process. In addition, nonlinear effects are advantageously modeled in a continuous fashion using hat functions to map a series of independent variables. This approach typically yields smaller prediction errors near boundary points.

Owner:GE MORTGAGE HLDG

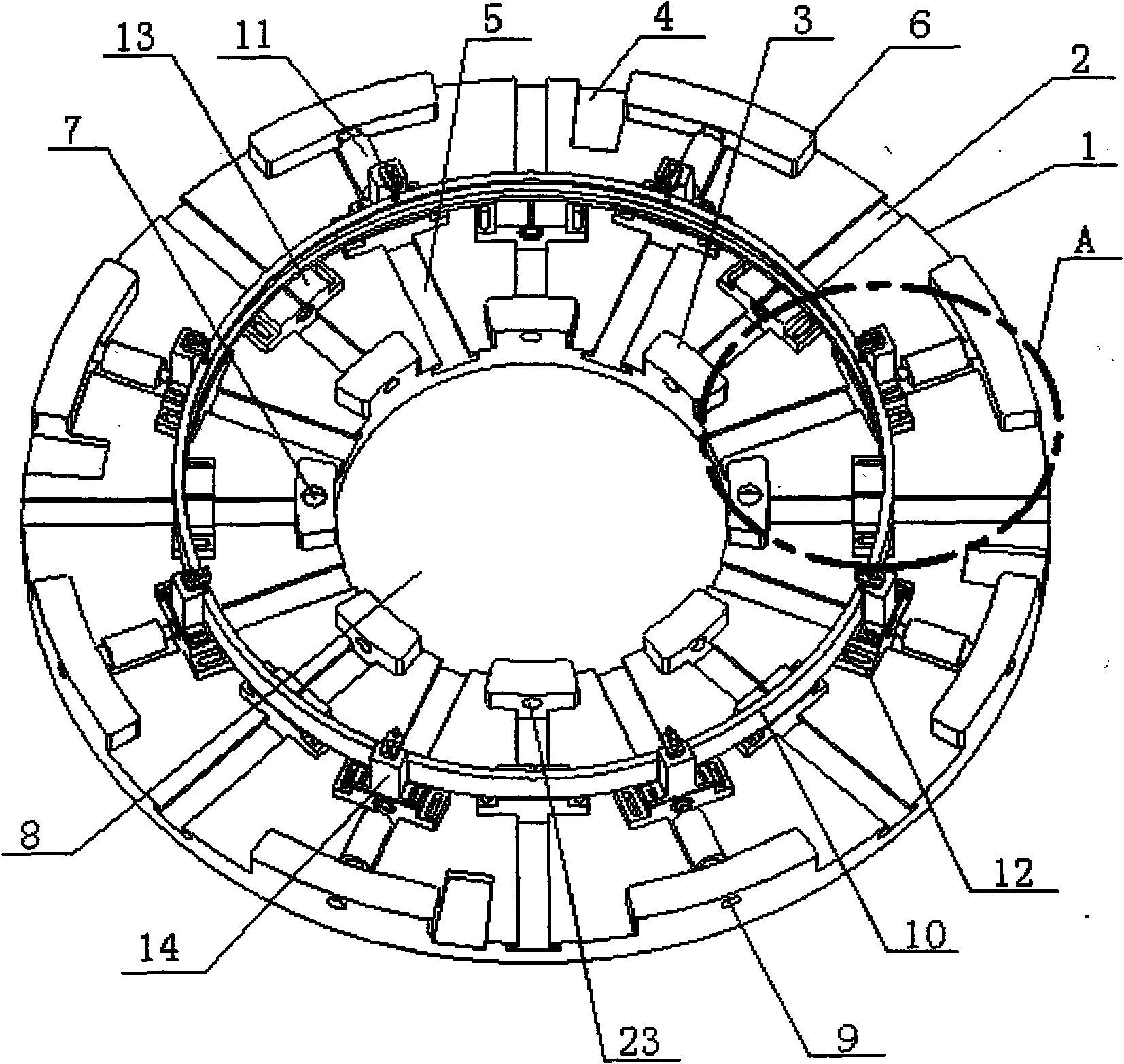

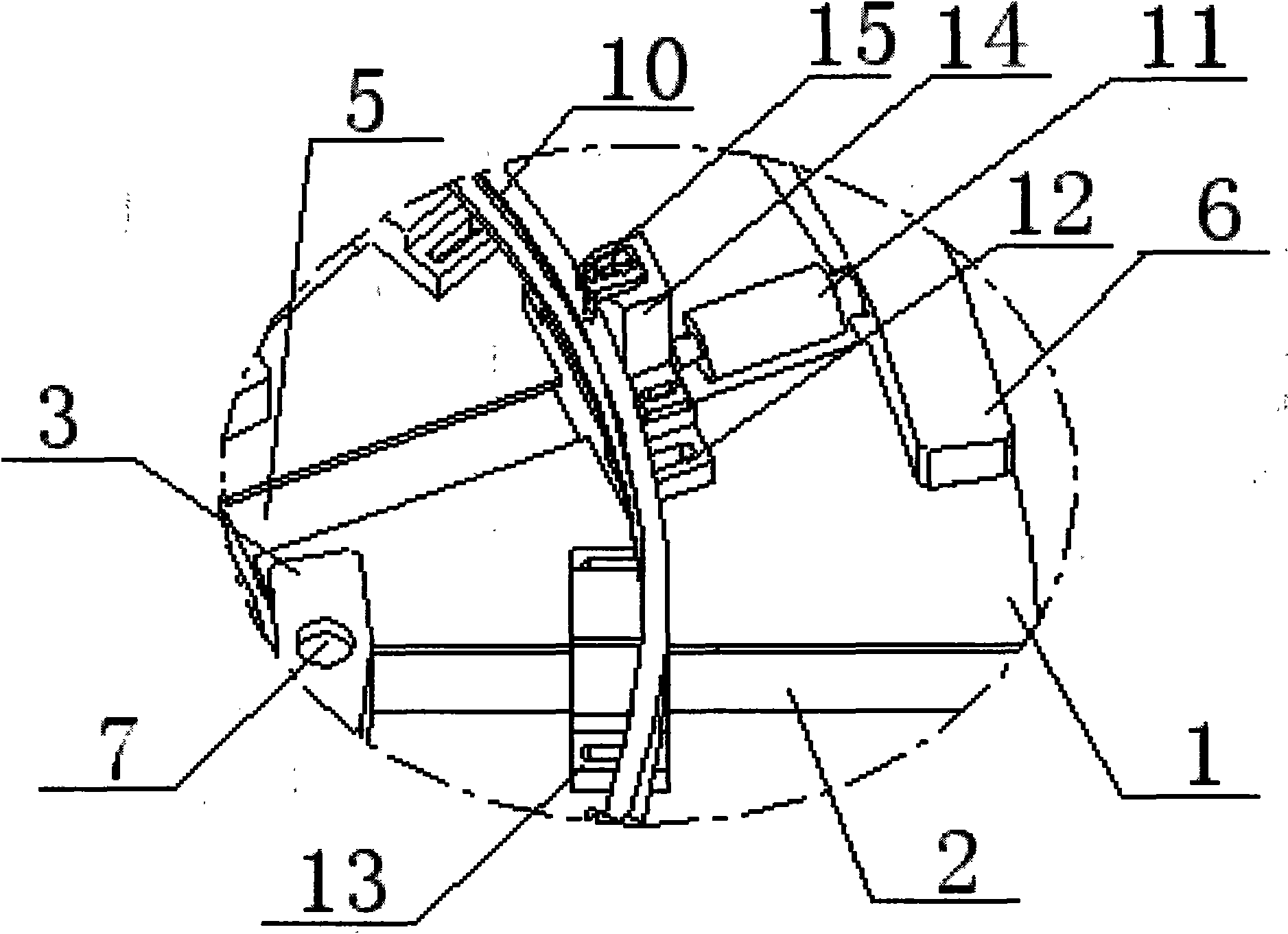

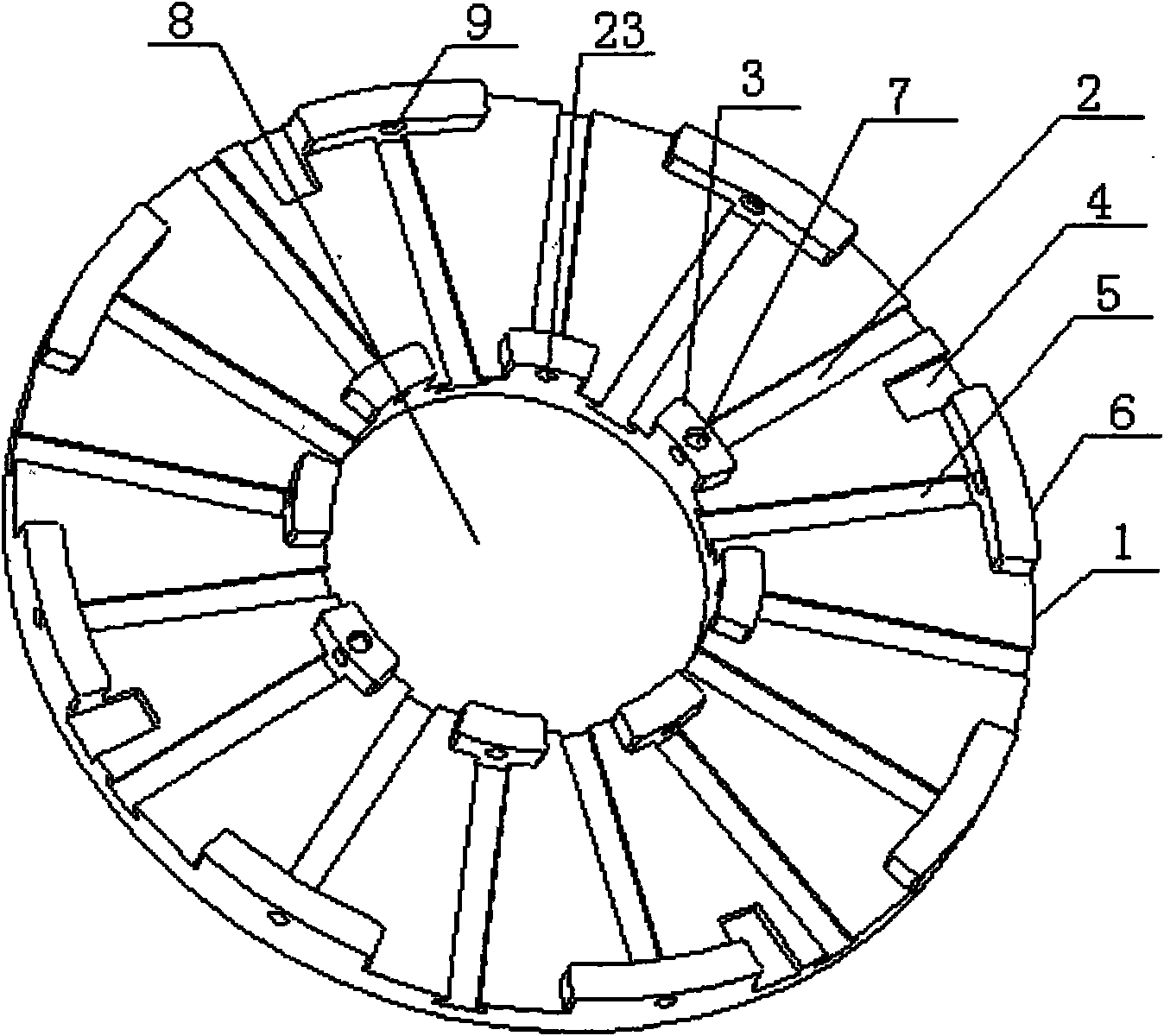

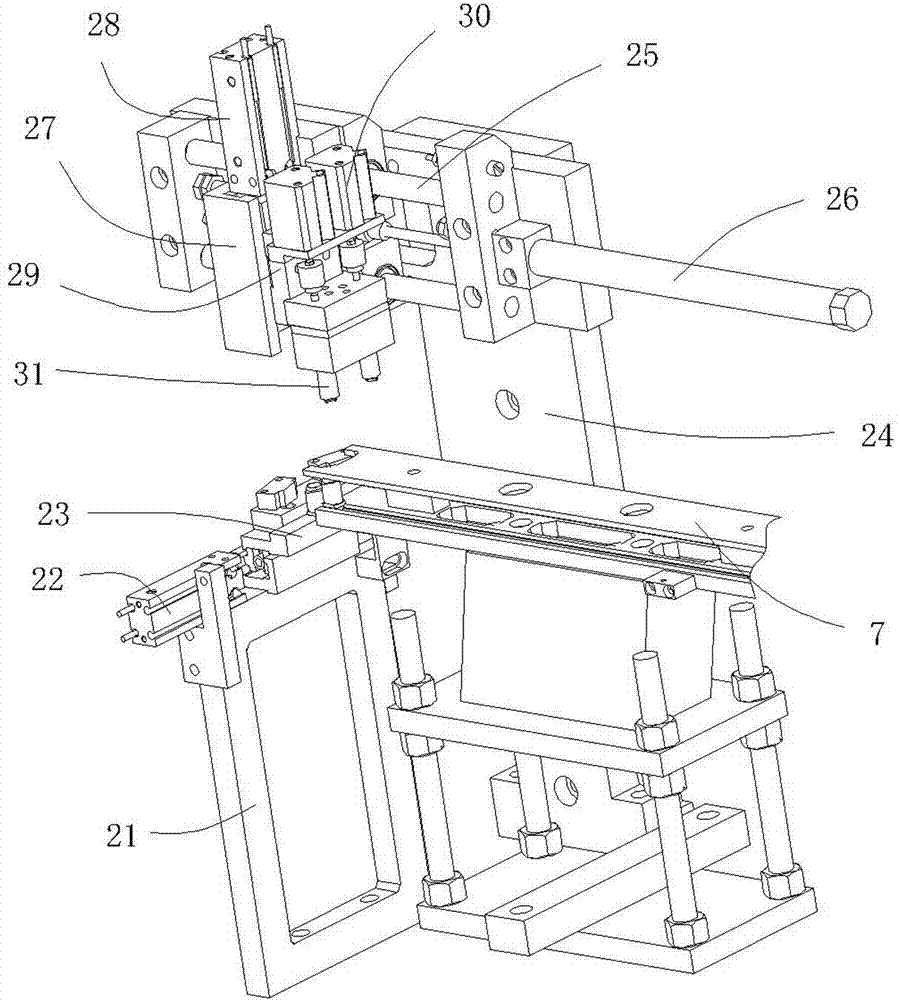

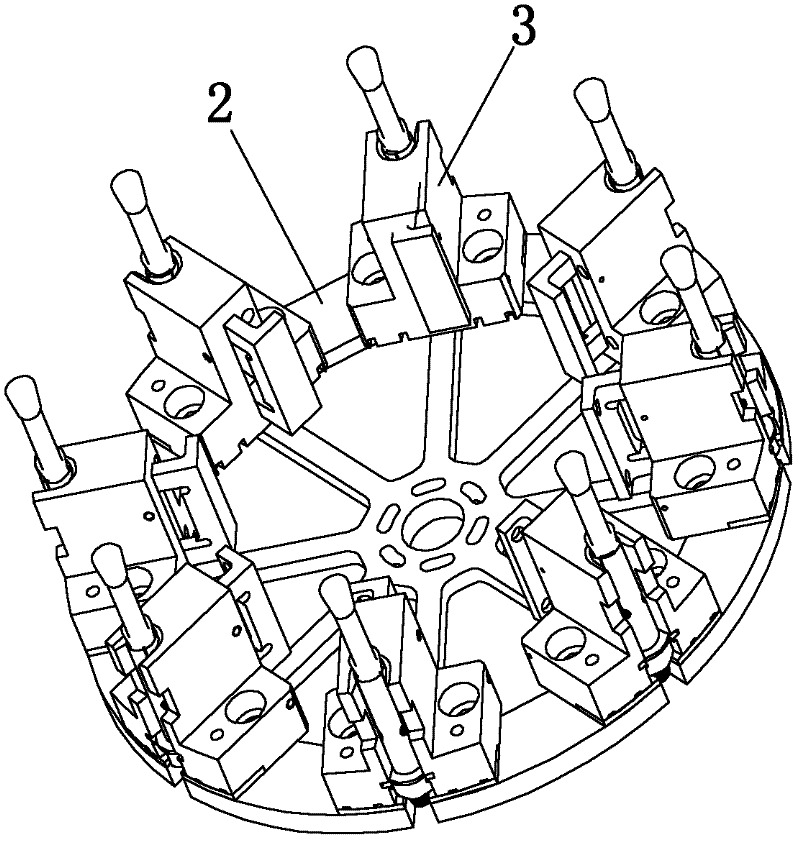

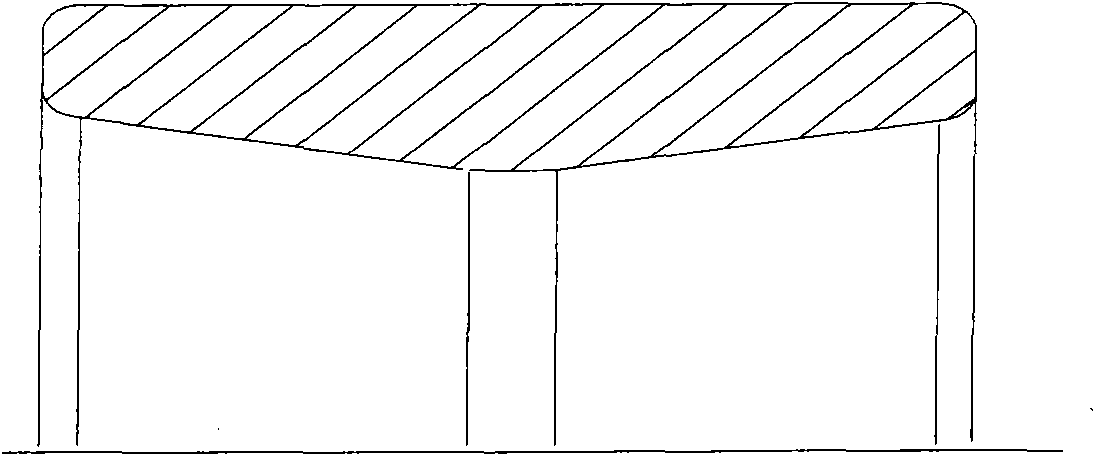

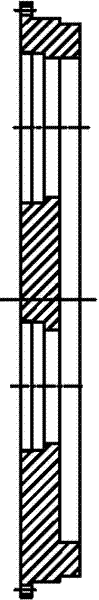

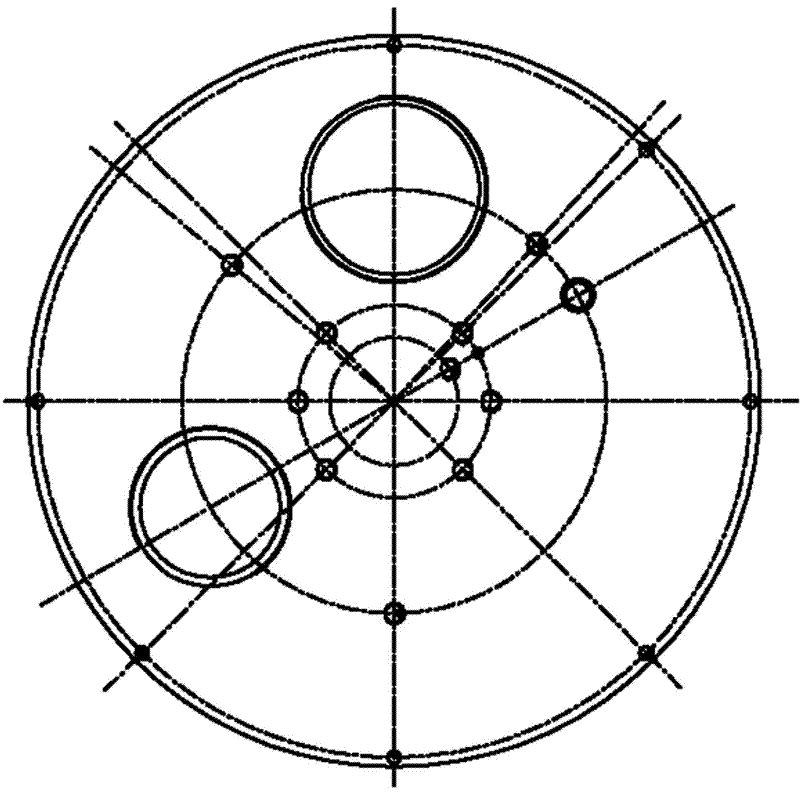

Annular thin-wall article clamping device and using method thereof

ActiveCN101954604AGuaranteed accuracyReduce labor intensityAutomatic conveying/guiding stockPositioning apparatusEngineeringThin walled

The invention provides an annular thin-wall article clamping device and a using method of the device. The clamping device comprises an annular chassis; the chassis is provided with a radial regulation mechanism of a locating workpiece; the radial regulation mechanism is divided into an inner radial regulation mechanism and an outer radial mechanism; two radial regulation mechanisms position workpiece respectively from the inner side or the outer side of the workpiece; the chassis is respectively provided with track-directed sliding grooves for the two radial adjustment mechanisms; the inner end of the sliding groove of the inner radial regulation mechanism is provided with a stopping block; the outer end of the sliding groove of the outer radial regulation mechanism is provided with the stopping block; the sliding grooves of the two groups of radial regulation mechanisms are disposed at intervals; one of the two groups of radial regulation mechanisms is provided with an axial compacting mechanism for fixing the workpiece; and the axial compacting mechanism is displaced alternatively between the two groups of radial regulation mechanisms when turning the workpiece. The clamping device can realize the processing of two side walls of the workpiece by clamping the workpiece once, and is fit for the clamping of the workpieces with different specifications. The device has the characteristics of high use rate, strong practical applicability, good generality, time saving and labor saving, light labor intensity, high production efficiency and the like.

Owner:DONGFANG TURBINE CO LTD

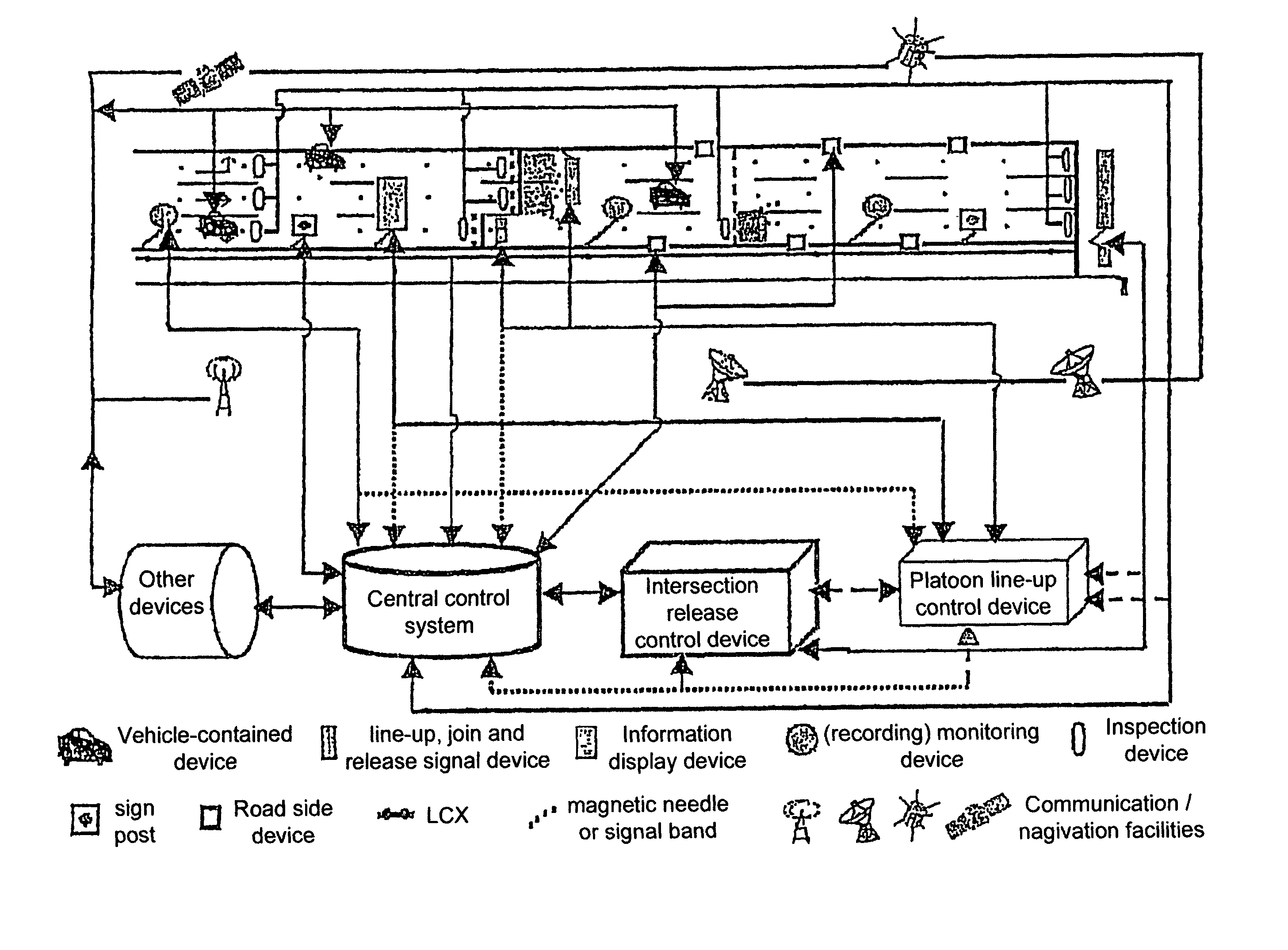

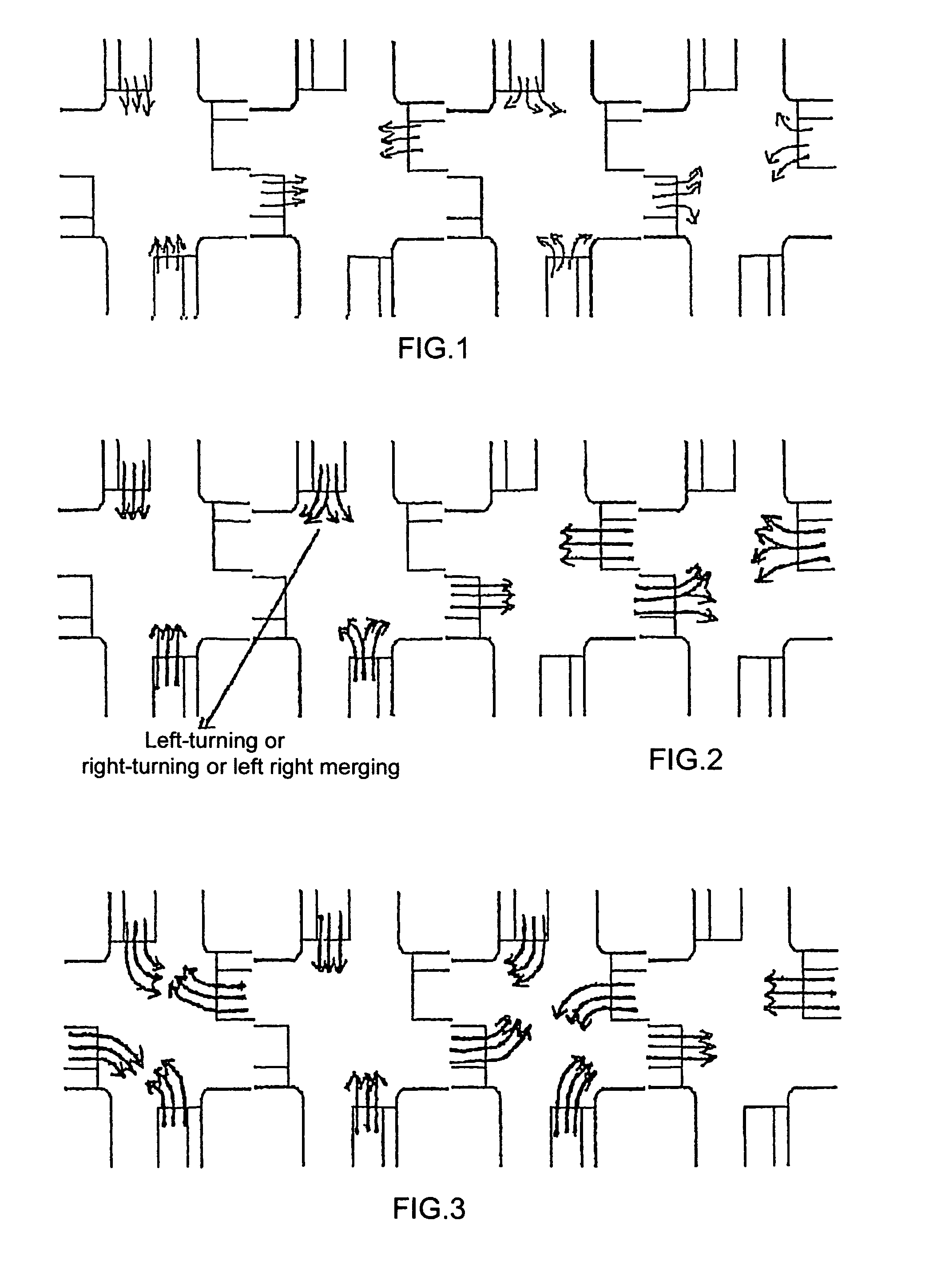

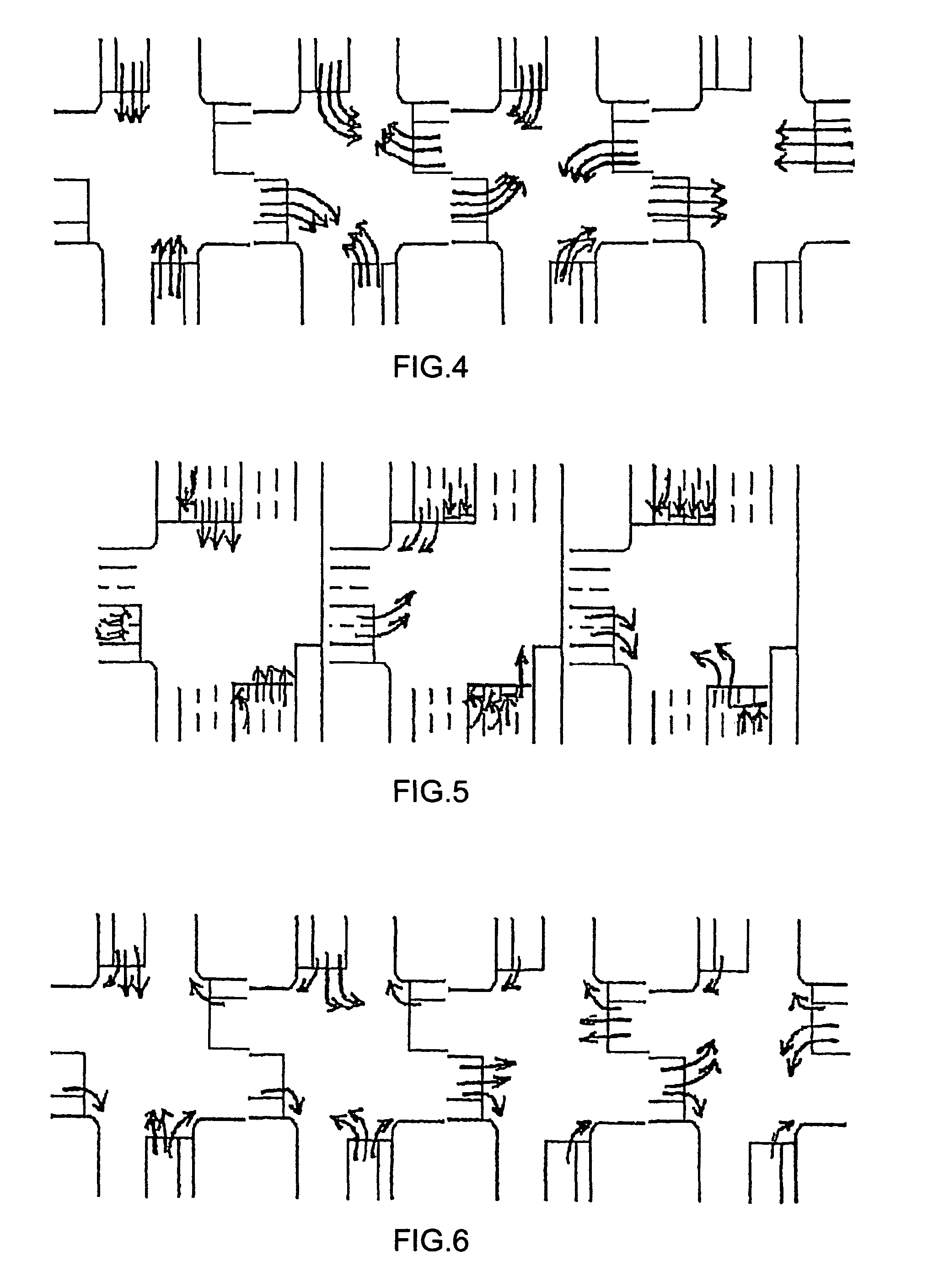

Road traffic control method and traffic facilities

InactiveUS7860639B2Improve pass rateHigh trafficControlling traffic signalsAnalogue computers for vehiclesRoad traffic controlEngineering

Owner:SHENZHEN ZHONGSHUNZHITONG INTELLIGENT TRANSPORTATION TECH CO LTD

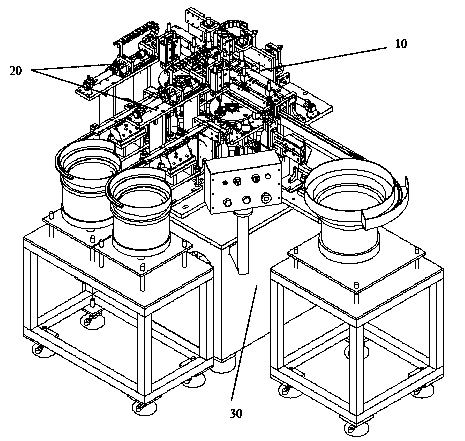

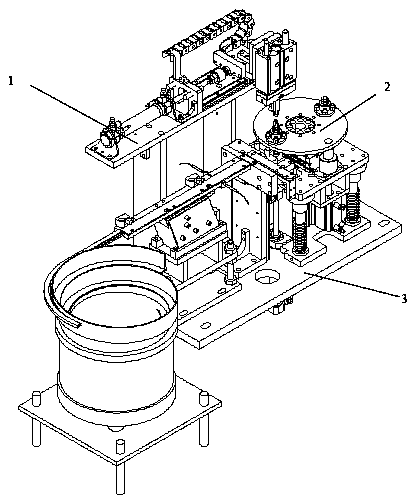

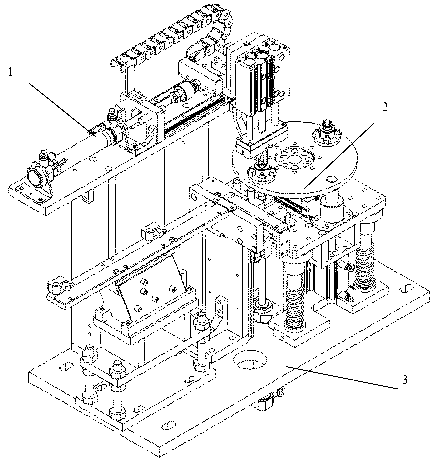

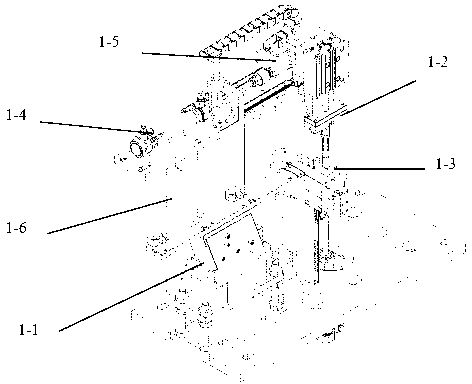

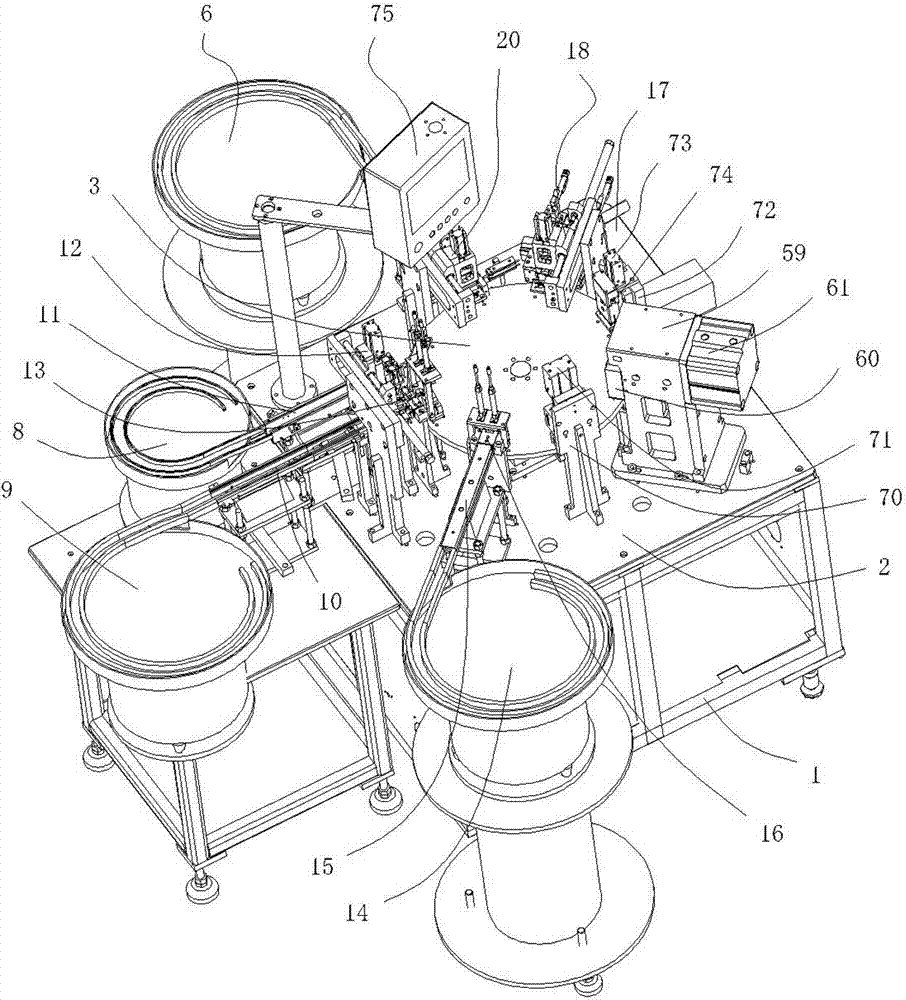

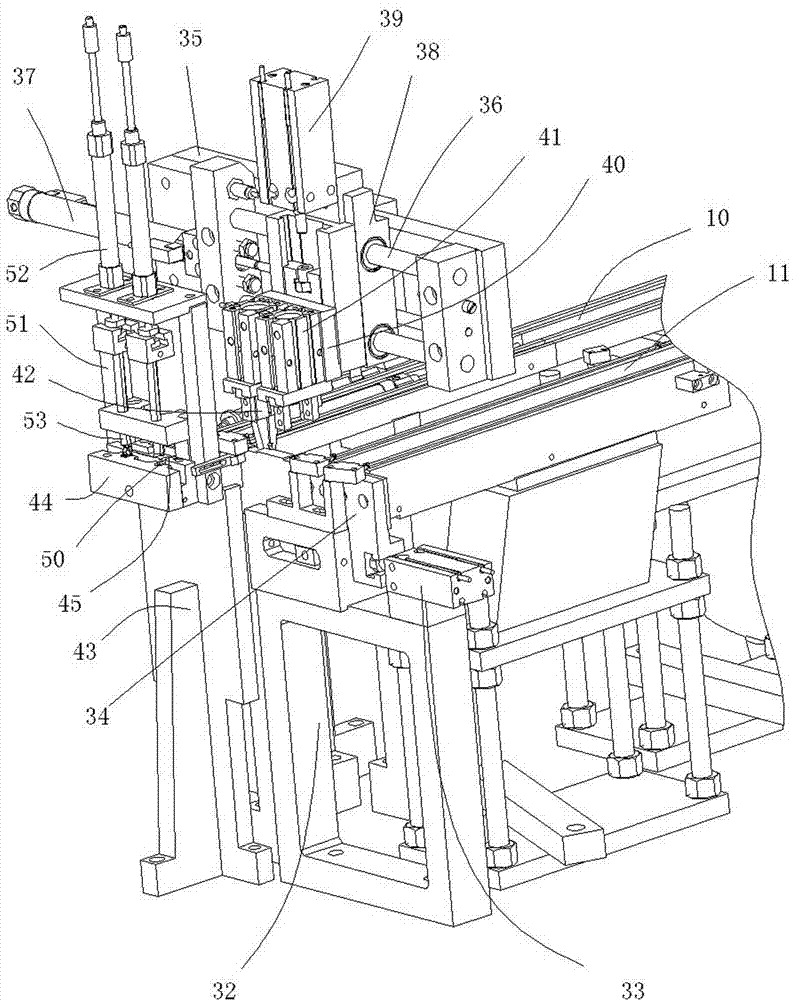

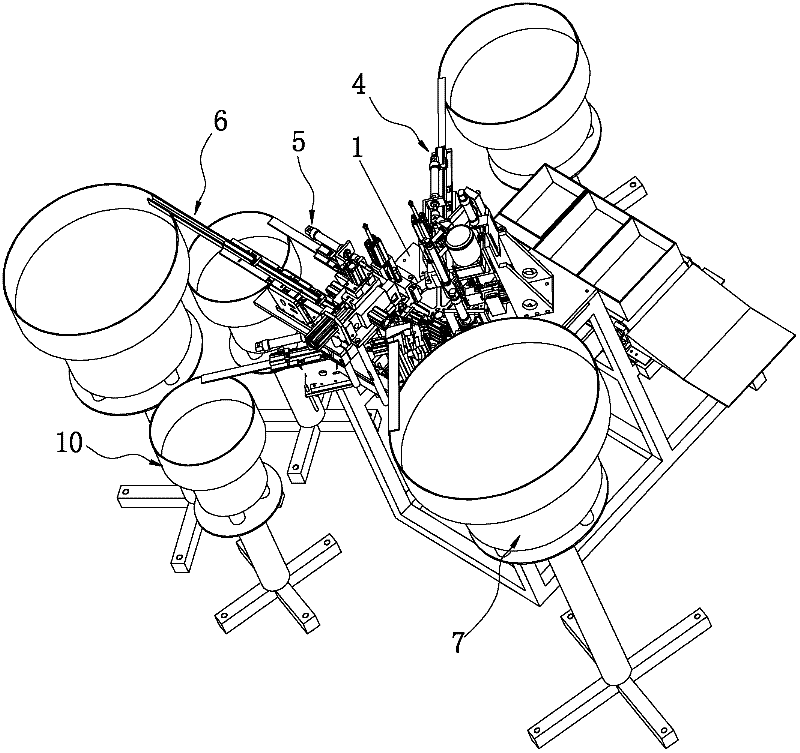

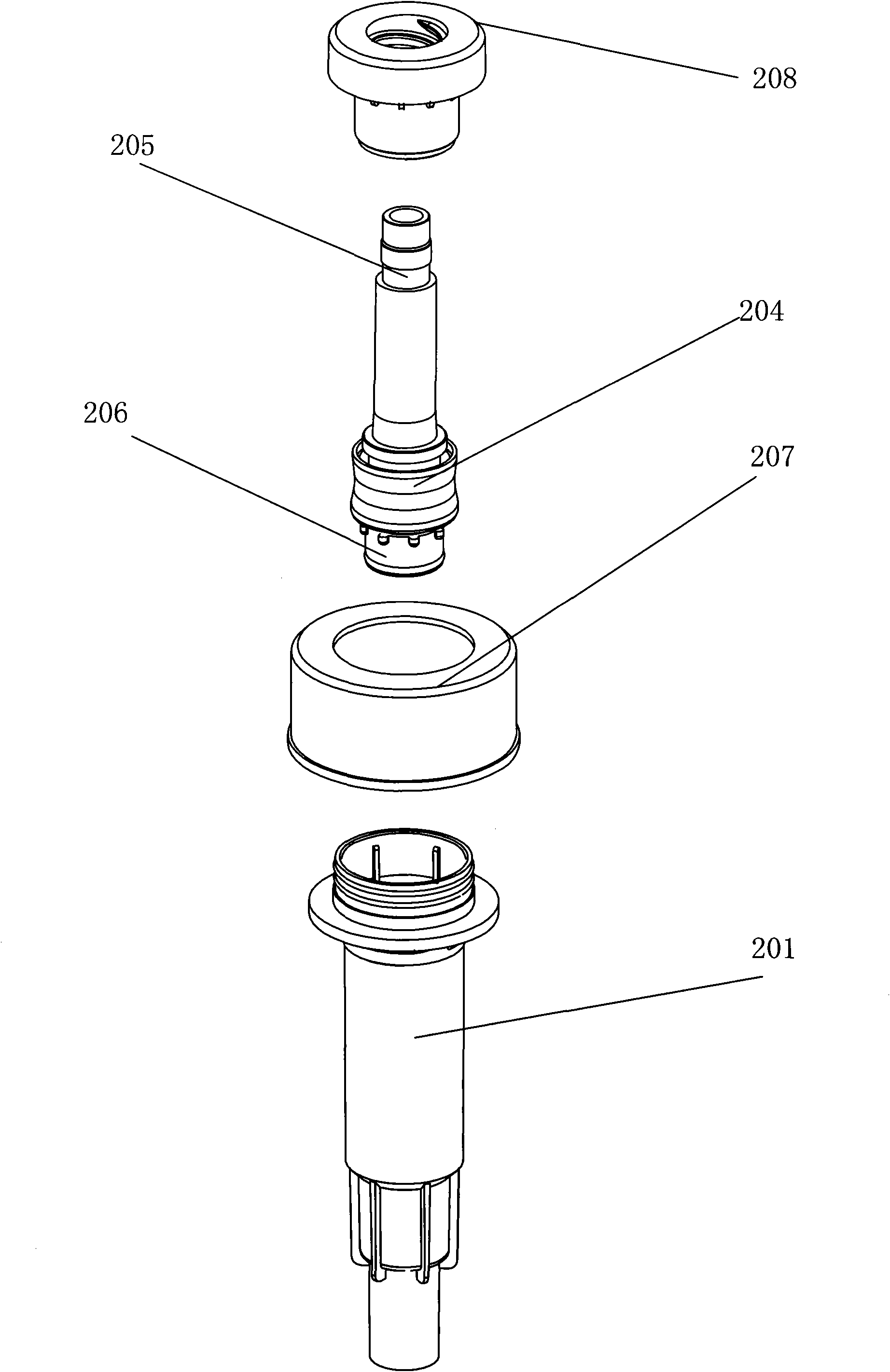

Automatic assembling device and assembling method for valve rod sealing rings

InactiveCN103465005ASmall support ringImprove assembly efficiencyMetal working apparatusEngineeringAssembly automation

The invention discloses an automatic assembling device for valve rod sealing rings. The automatic assembling device comprises an automatic valve rod feeding device and two sets of automatic sealing ring assembling devices, wherein the automatic valve rod feeding device sequentially moves valve rods to positions to be assembled for realizing the automatic feeding of the valve rods; after the automatic valve rod feeding device positions the valve rods and tightly presses the valve rods, the automatic feeding and ring supporting actions of O-shaped sealing rings are respectively completed by the two sets of automatic sealing ring assembling devices, in addition, the supported O-shaped sealing rings are pushed into grooves of the valve rods in the two positions to be assembled of the valve rods, and the automatic assembly of the two sealing rings is completed; finally, the assembled valve rods are conveyed and discharged. The automatic assembling device has the advantages that the assembly automation of the valve rod sealing rings can be realized, the defects of low assembly speed and automation assembly adaption difficulty of manual operation can be overcome, the product qualification rate and the assembly efficiency are greatly improved, and in addition, the work intensity, the labor and the production cost are reduced. The invention also discloses an automatic assembling method for the valve rod sealing rings.

Owner:TAIZHOU LIANFANG ELECTROMECHANICAL TECH

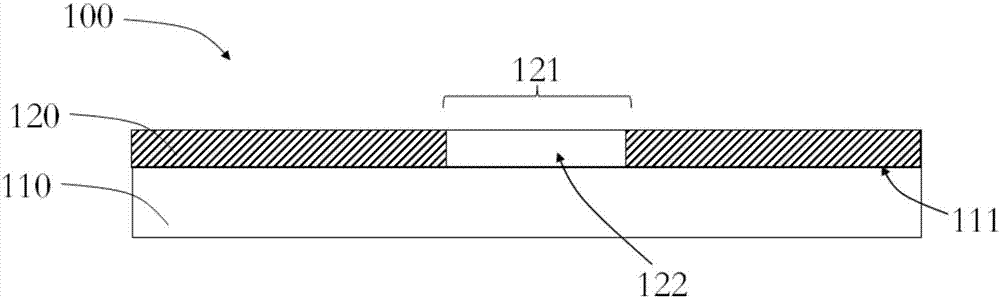

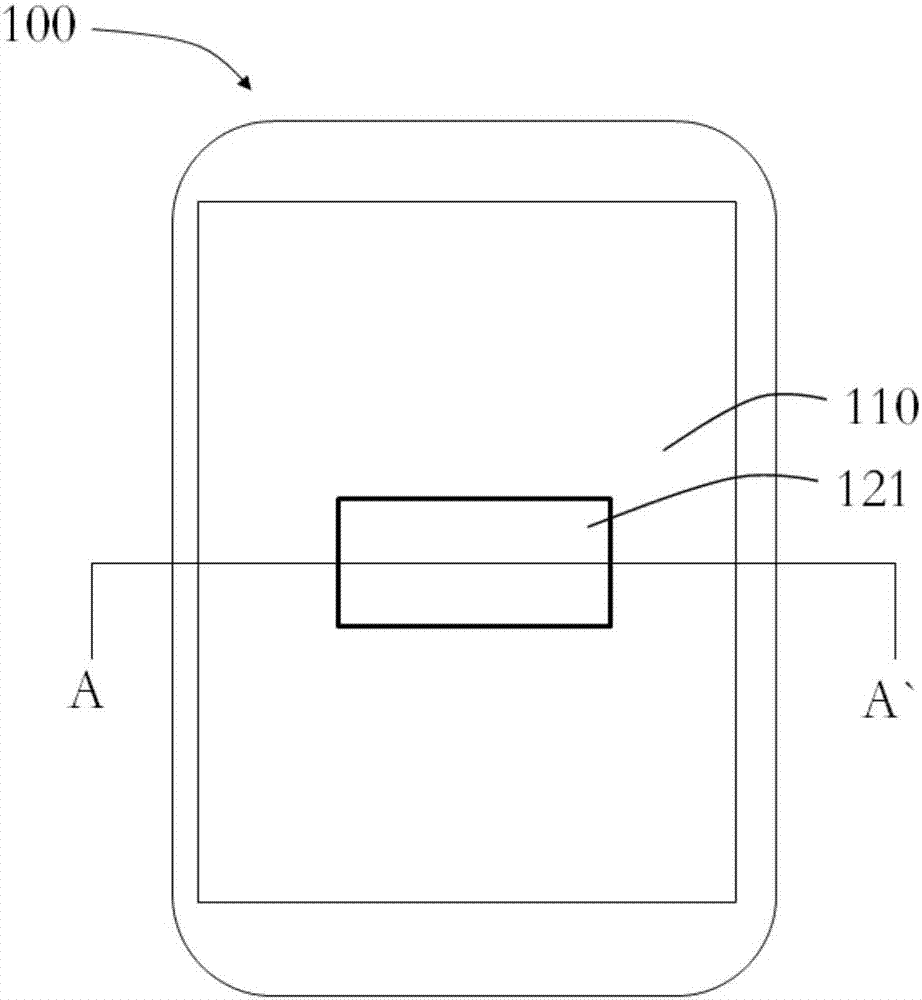

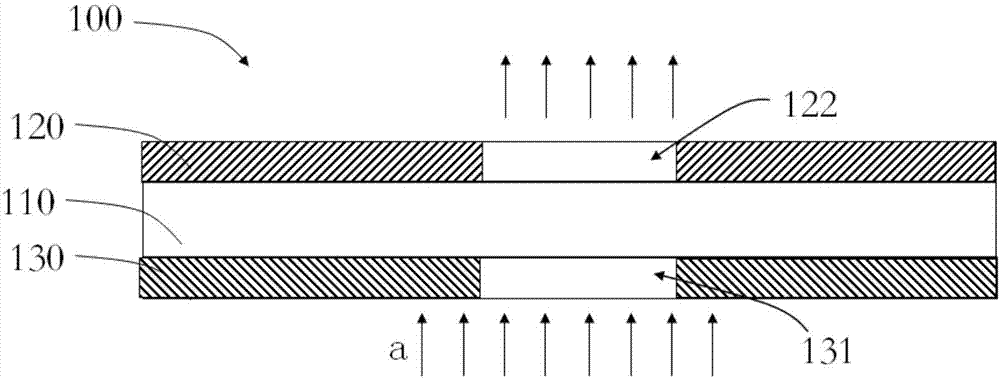

Display screen, display device and mobile terminal

ActiveCN107102693AImprove collection efficiencyImprove recognition efficiencyDigital data processing detailsPrint image acquisitionDisplay deviceInductor

The invention provides a display screen. The display screen comprises a display layer and a blocking layer, wherein the display layer is provided with a displaying face facing a user, the blocking layer is arranged on the displaying face in a stacked mode, the blocking layer comprises a fingerprint recognition region, the fingerprint recognition region comprises at least one first through hole, and the first through holes are used for transmitting induction signals transmitted and received by a fingerprint module below a display screen. The invention provides a display device, the display device comprises a display screen and an optical fingerprint module, and the optical fingerprint module is arranged at the side, away from the blocking layer, of the display layer and is located at the position corresponding to the optical fingerprint recognition region. The fingerprint module comprises an optical transmitting device and an optical inductor, and light signals transmitted by the optical transmitting device are conveyed to the fingerprint lines through the first through holes and are received by the optical inductor through the first through holes after being reflected by the fingerprint lines. The invention further provides a mobile terminal, and the recognition efficiency of the optical fingerprint module is improved.

Owner:GUANGDONG OPPO MOBILE TELECOMM CORP LTD

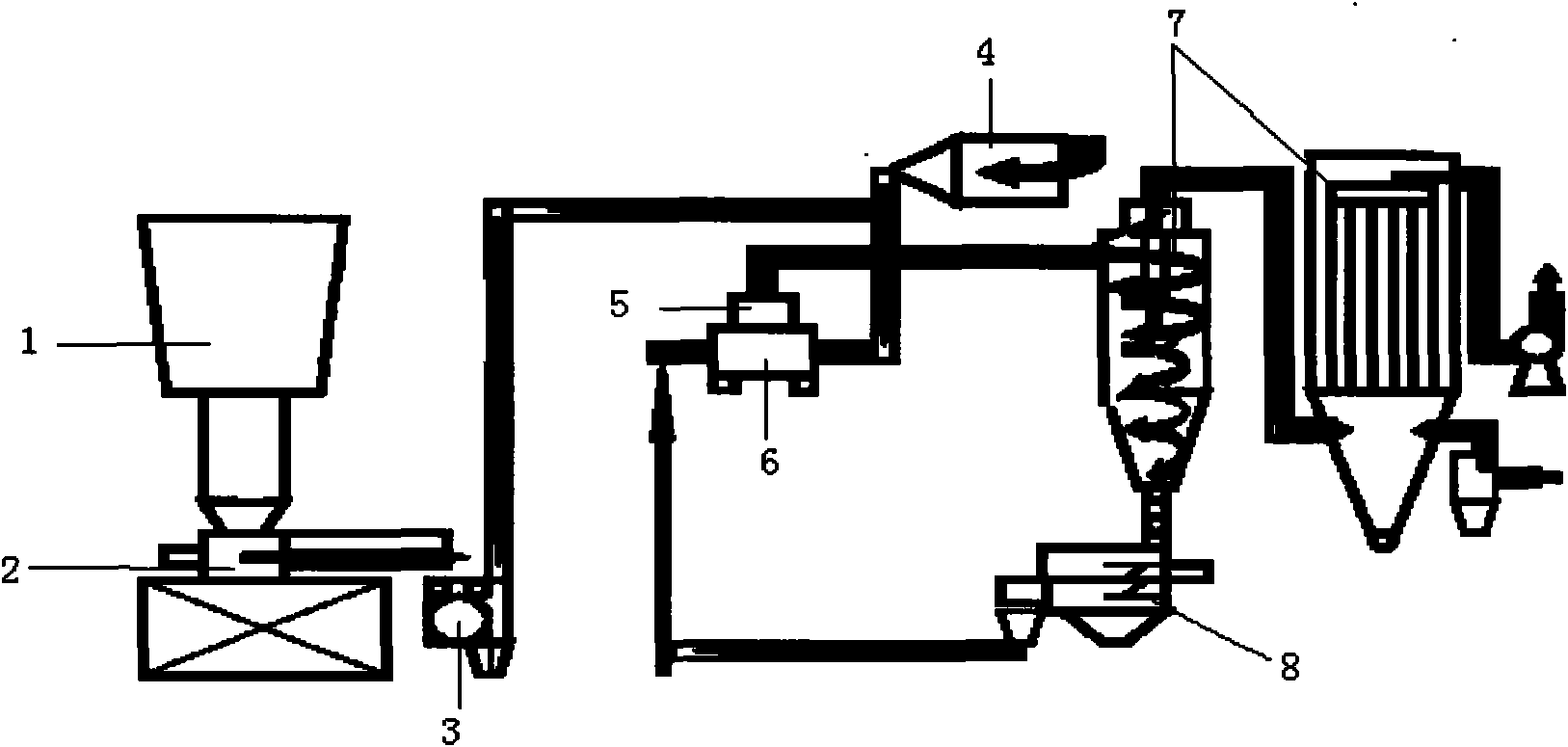

Preparation method of high-tensile high-model heterocycle aramid fiber

ActiveCN101787582ALess fuzz on the surfaceImprove pass rateFibre typesMonocomponent copolyamides artificial filamentDiaminePolyamide

The invention relates to a preparation method of a high-tensile high-model heterocycle aramid fiber, which comprises an integrated production method from polymerization, spinning to post-process. By optimizing the molar ratio of two diamine monomers, the invention prepares heterocycle polyamide solution polymer of which the diamine proportional distribution is narrower, the polymer solid content is 2-8%, and the dynamic viscosity is 5-3 million centipoise; and the heterocycle polyamide solution is subjected to deaeration, filtration and wet spinning, and can prepare the high-tensile high-model heterocycle aramid fiber with narrower diamine proportional distribution through spinning process control, wherein the breaking strength is 27-33cN / dtex, the modulus of elasticity is 950-1,200cN / dtex, and the elongation at break is 2.5-3.8%.

Owner:CHINA BLUESTAR CHENGRAND CO LTD

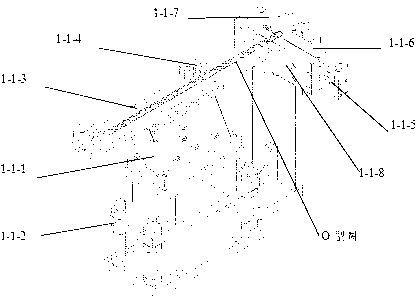

Automatic assembly device and method of O-type sealing ring

InactiveCN103317336ANo damageSmall support ringMetal working apparatusEngineeringUltimate tensile strength

The invention discloses an automatic assembly device of an O-type sealing ring. The automatic assembly device comprises a ring loading and supporting module and a ring moving and releasing module. The ring loading and supporting module forms a feeding station and a ring supporting station, and when a loading device of the O-type sealing ring is located at the feeding station, the O-type sealing ring is delivered to the loading device of the O-type sealing ring by a feeding device of the O-type sealing ring. A loading needle-shaped air cylinder drives the loading device of the O-type sealing ring to move to the ring supporting station, the ring supporting motion is carried out on the O-type sealing ring by a ring supporting device, the O-type sealing ring is delivered to the ring moving and releasing module by the ring supporting device, the ring moving and releasing module enables the supported O-type sealing ring to be delivered to a ring releasing station from the ring supporting station, the ring moving and releasing module breaks away from the supported O-type sealing ring, the supported O-type sealing ring is sleeved at the position of a groove of a workpiece to be assembled, and automatic assembly between the workpiece and the O-type sealing ring is achieved. According to the automatic assembly device, assembly automation of the O-type sealing ring can be achieved, the qualified rate and the assembly efficiency of products are greatly improved, the labor strength is relieved, and the production cost is reduced. The invention further discloses an automatic assembly method of the O-type sealing ring.

Owner:TAIZHOU LIANFANG ELECTROMECHANICAL TECH

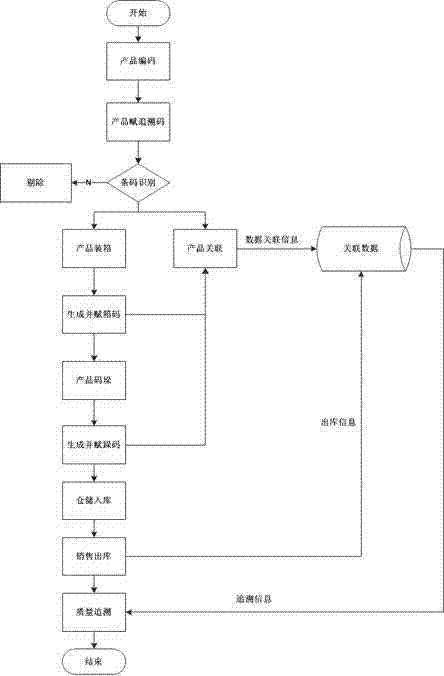

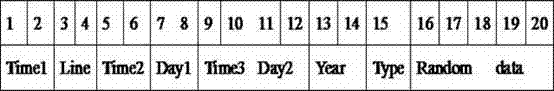

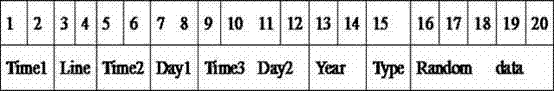

Quality safety tracing method for food processing enterprises

InactiveCN103761546ANo repeated codes appearMeet randomnessCo-operative working arrangementsDebit schemesProduction lineRelational database

The invention discloses a quality safety tracing method for food processing enterprises. The quality safety tracing method includes the steps that a laser coder generates random tracing codes according to a coding rule when a laser marking machine in a production line device is dynamically read in an on-line tagging mode; the laser marking machine carries out tracing mode marking on products on a production line, and two-dimension codes and plain codes are all marked on packages; a fixed reader is used for scanning and reading designated tagged code portions of the products; the two-dimension codes are successfully scanned and read, the tracing codes are recorded, and relevance between the tracing codes and commodity attribute information is completed; if the two-dimension codes fail to be scanned, the two-dimension codes will be removed through a removing device; the commodity tracing code information and the commodity attribute information are recorded into a relational database; after the products are packaged, package code data and product tracing code data are related; the products are stacked, stacking codes and tagged stacking codes are generated, and the stacking codes and the product package code data are related; the stacking codes are scanned, storage of the products is completed, delivery orders and the stacking codes are scanned to complete delivery, and the database records delivery information.

Owner:武汉华工赛百数据系统有限公司

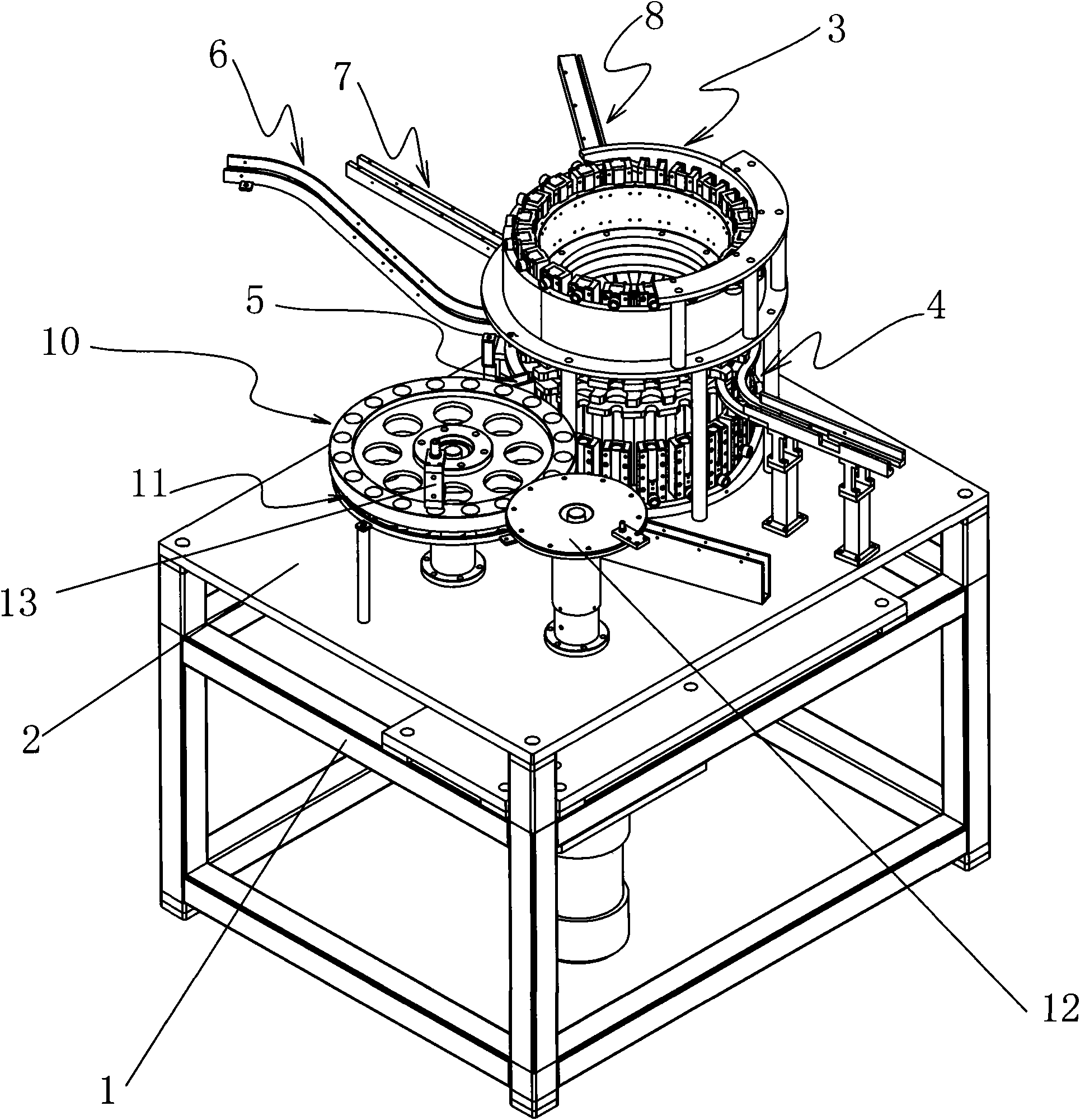

Automatic assembling machine for female joint of television signal line

ActiveCN103481060ARealize automated assemblyIncrease productivityAssembly machinesWork in processEngineering

The invention relates to an automatic assembling machine for a female joint of a television signal line. The automatic assembling machine comprises a frame, a working platform and a multi-station turnplate. A plurality of locating modules are uniformly distributed on the multi-station turnplate, and locating slots are concavely arranged on the positioning modules. An upper shell station, an upper semi-finished product station, an upper insulating sleeve station, a riveting station and a discharge station are uniformly and sequentially distributed above the multi-station turnplate. A shell feed vibrating plate and a shell feed mechanism are arranged outside the upper shell station. A socket spring plate feed vibrating plate, an insulating seat feed vibrating plate, a semi-finished product assembling mechanism and a semi-finished product feed mechanism are arranged outside the upper semi-finished product station. An insulating sleeve feed vibrating plate and an insulating sleeve feed mechanism are arranged outside the upper insulating sleeve station. A riveting mechanism is arranged above the riveting station. A discharge channel and a discharge mechanism are arranged outside the discharge station. With the above structure, automatic assembly of the female joint of the television signal line can be achieved, and the assembling machine is high in production efficiency, low in labor intensity and high in qualification rate.

Owner:NINGBO XINGRUI ELECTRONICS TECH

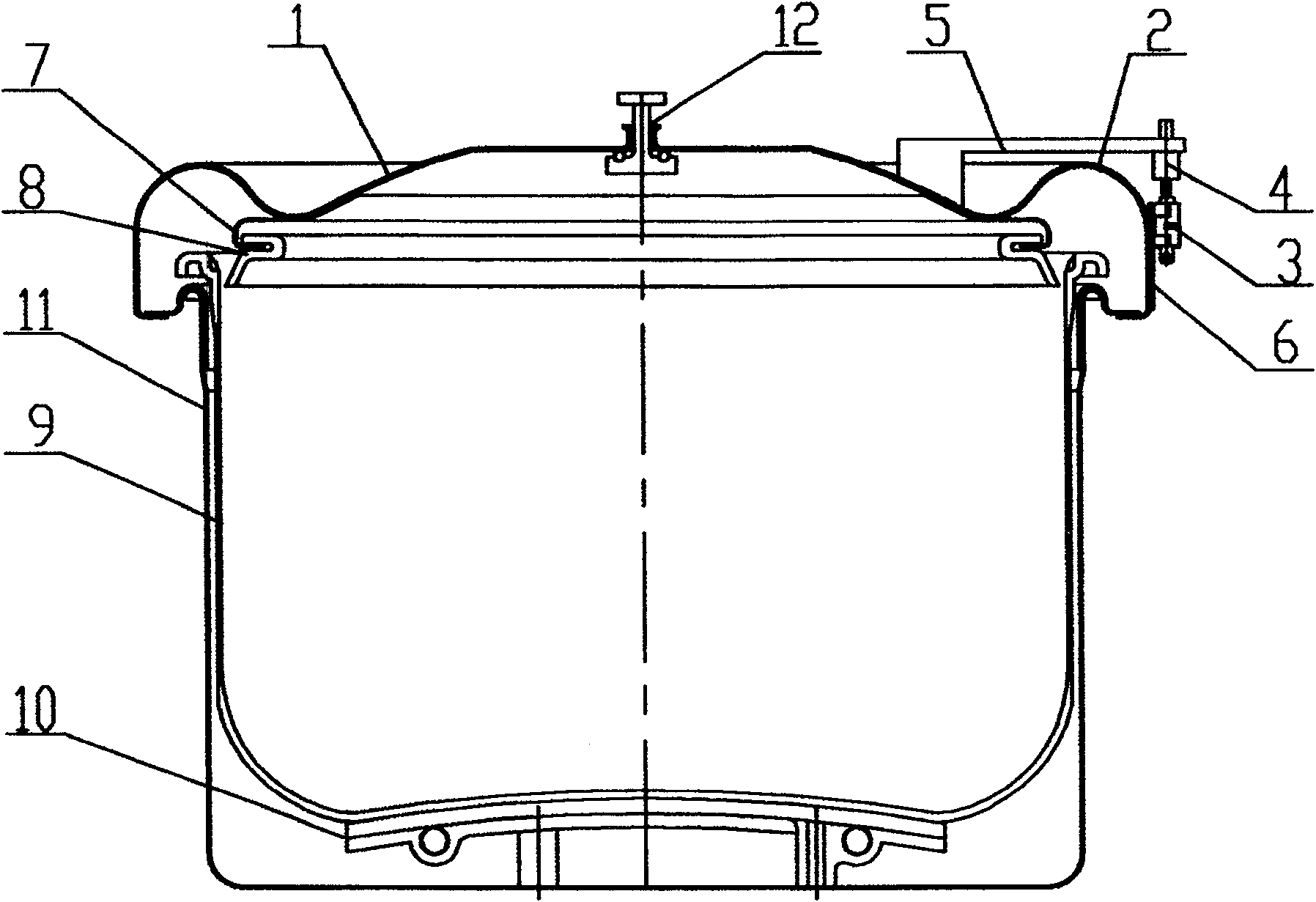

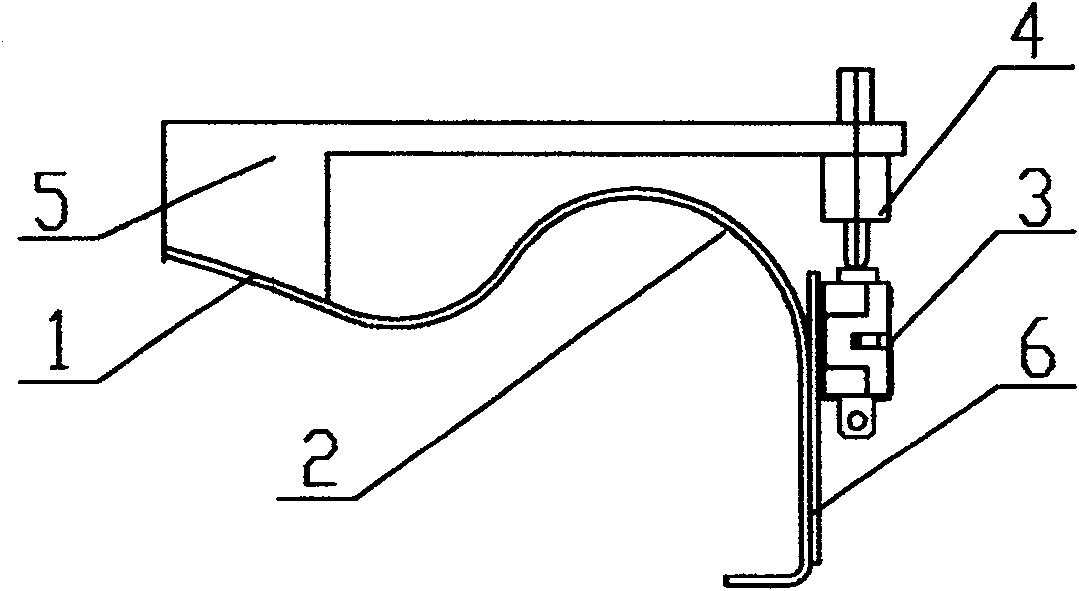

Moving-cover type electric pressure cooker

The invention relates to a movable cover electric pressure cooker, which belongs to kitchen electric appliances, and is a patented technology of electric rice cooker pressurization that controls and limits the pressure inside the cooker through an elastic cooker cover. It includes a pot cover, an elastic element, a switch, a sealing ring, an inner pot, an electric heater, and an outer pot; the edge of the inner pot sits on the edge of the outer pot; The outer pot is movable and rigidly connected; the elastic element controls the on-off of the switch by the elastic displacement generated under the pressure in the pot, and the elastic displacement is transmitted to the corresponding device through the transmission part arranged at the displacement or static position of the elastic element. on the switch. The invention can solve the problems in the integrated design and mechanical connection of the elastic element and other parts in the prior art, improve the utilization rate of materials, simplify the production process and reduce the production cost.

Owner:王永光

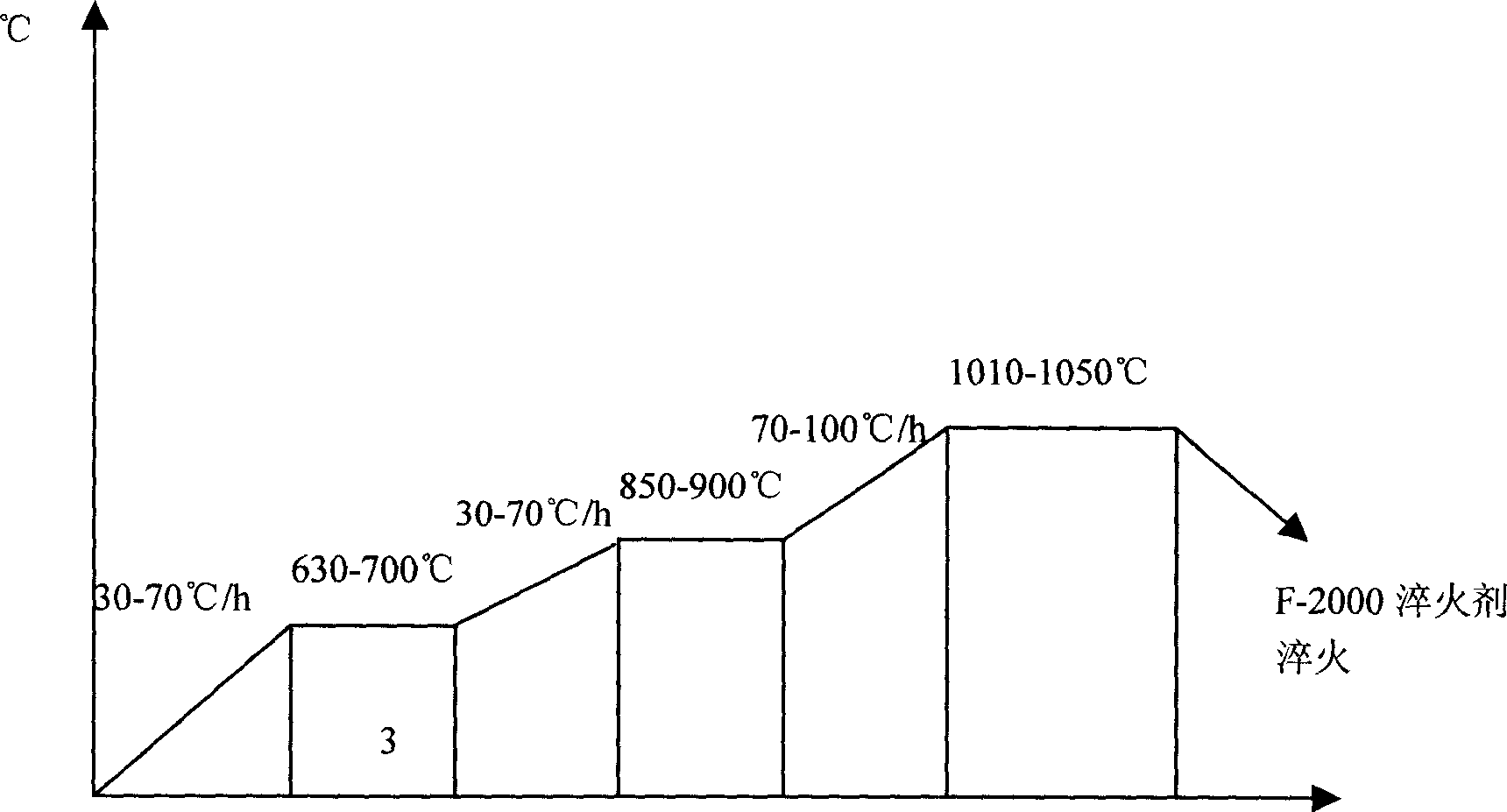

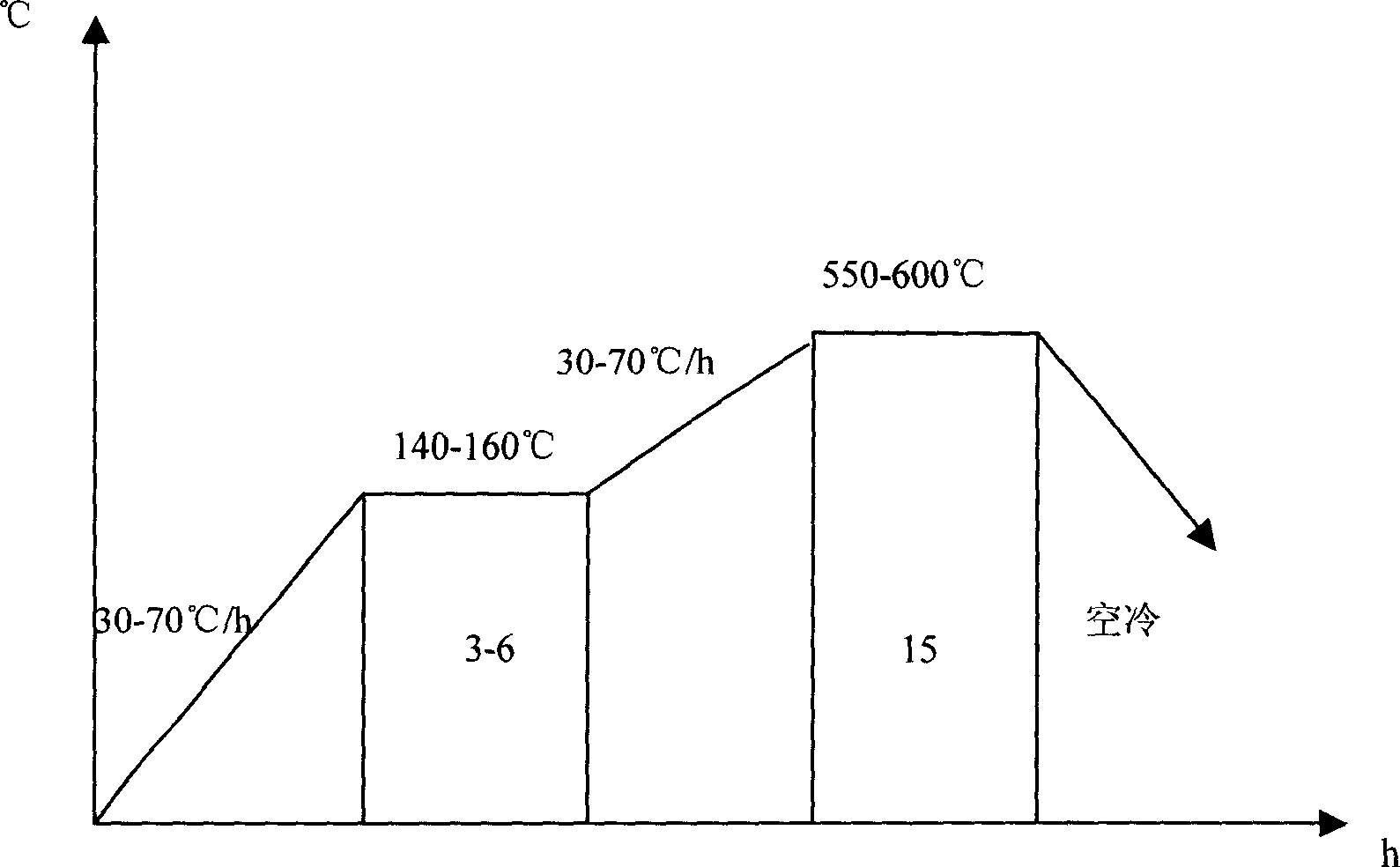

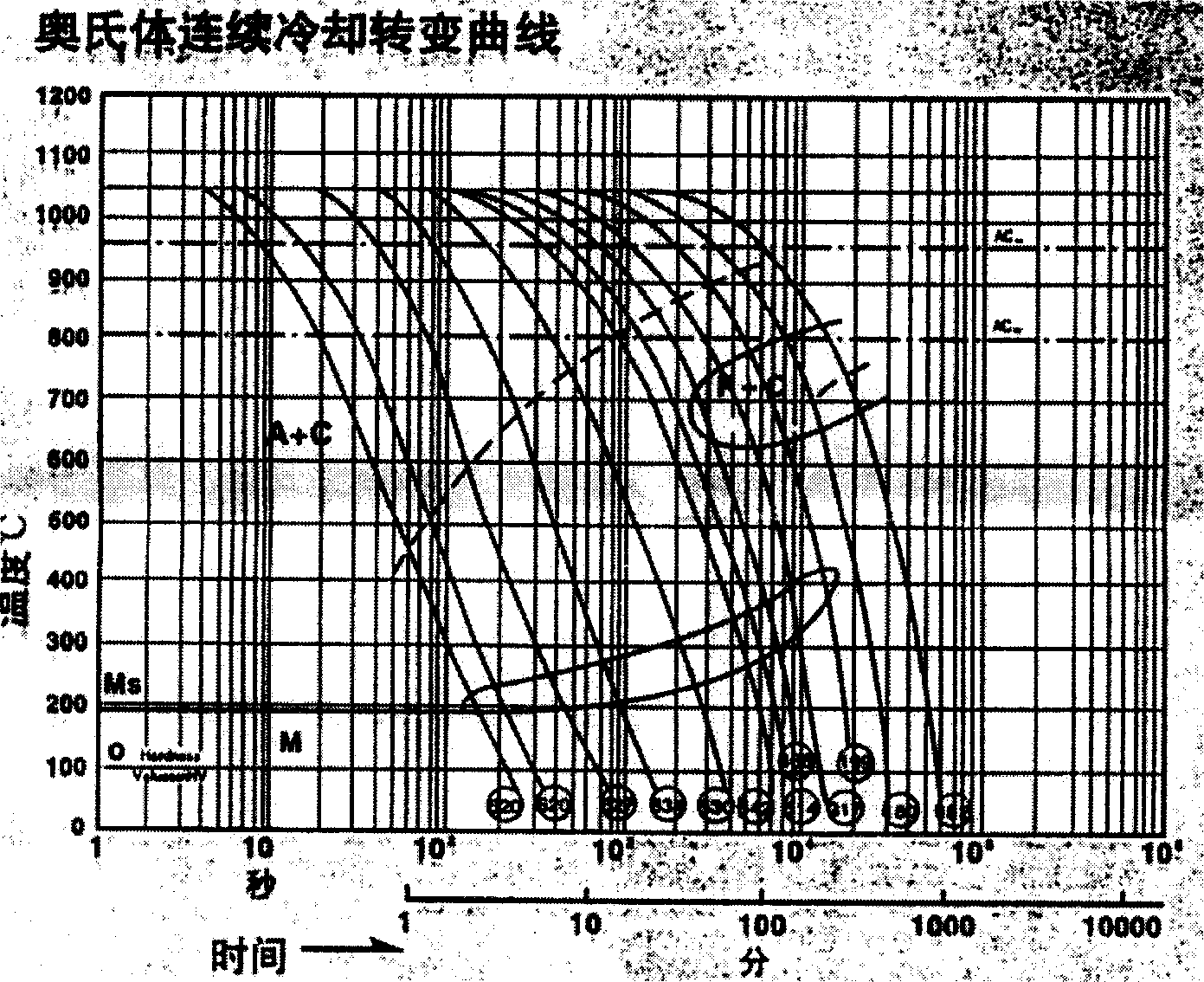

Anticorrosion, wear-resistant plastic die steel 4Cr16Mo and its mirror large-die-block preparing and producing method

ActiveCN1676653AImprove lateral performanceMeet mirror polishing requirementsHeat treatment process controlProcess efficiency improvementChemical compositionWear resistant

It is a new preparation and production method of corrosion-resistant and anti-abrasive plastic die steel 4Cr16Mo and its big mirror module. The characteristic is about its chemical composition. There are 0.33-0.43%C, 0.30-1.00%Mn, 0.30-1.00%Si, less than 0.045%S, less than 0.045%P, 14-18%Cr, 0.10-1.00%Ni, 0.80-1.50%Mo besides Fe. The method includes double refinement consisting of the primer smelting in electric furnace and vacuum handling outside the furnace and electroslag remelting, and necessary stress relieving annealing static ingot and electroslag ingot to refine electroslag ingot of component-uniform. After that, it uses hot machining forging technology and necessary stress relieving annealing of module to make the electroslag ingot into big module (thickness: 500mm, width:1200mm, length: 2500mm). At last, special heat-treat module modified treatment technology is used to bring out big highly corrosion-resistant and highly anti-abrasive plastic die steel module. This kind of module has stable quality and the nature reaching the standard(dirty component A<=2.0, B<=2.0, C thinness<=2.0, C thickness<=1.5, D<=2.0). To sum up, it has significant economic and social efficiency.

Owner:宝武特种冶金有限公司

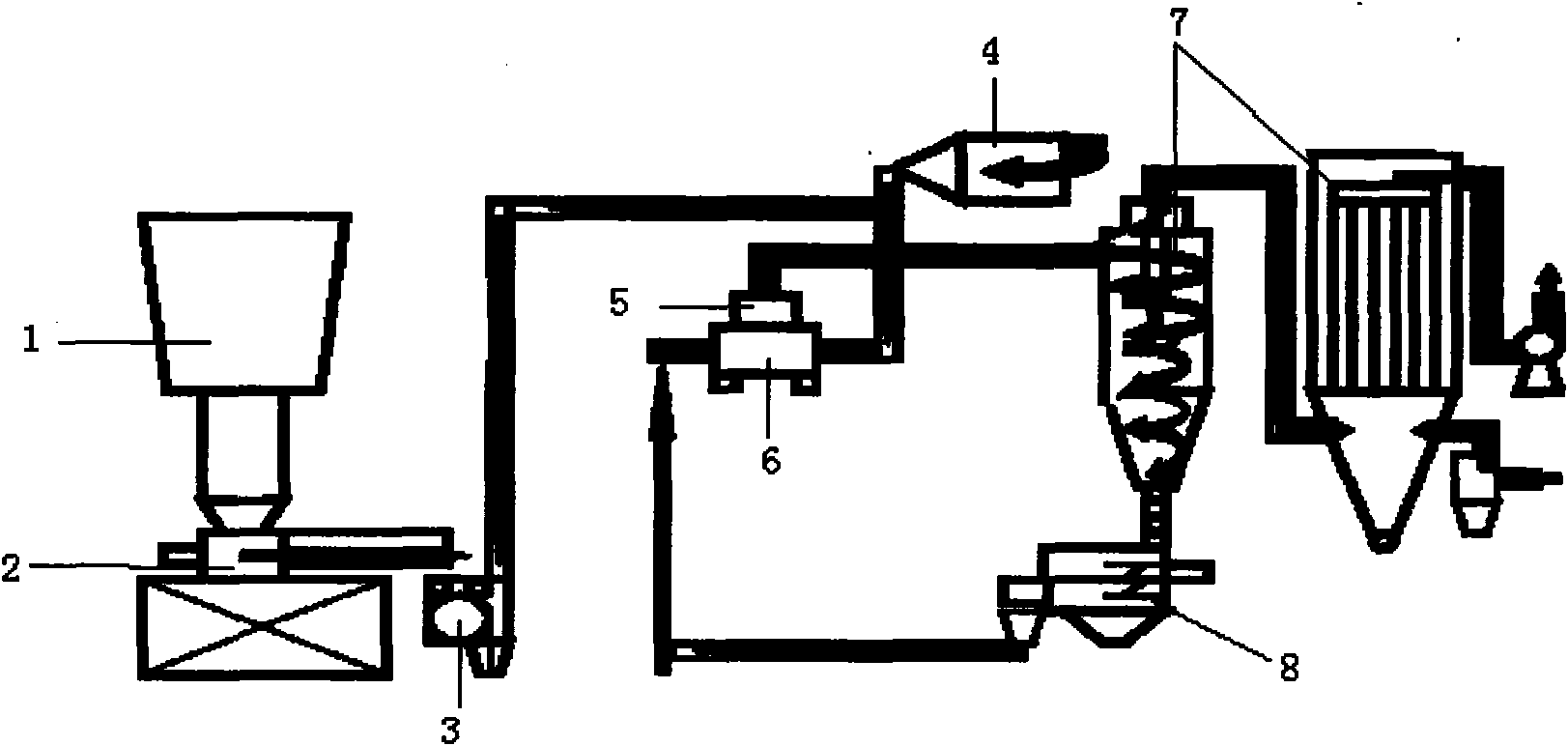

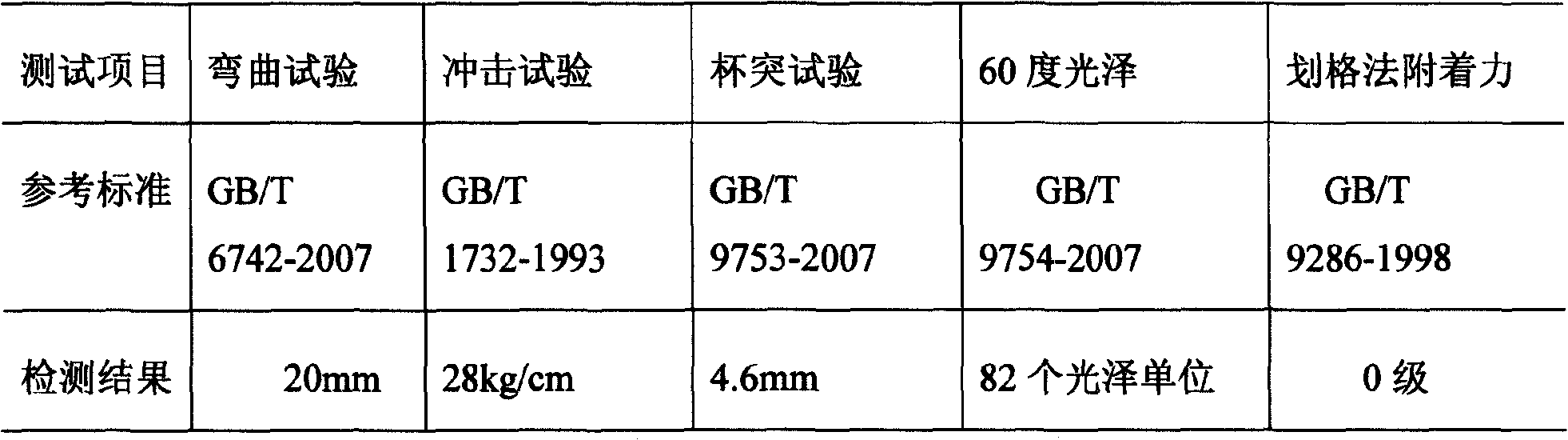

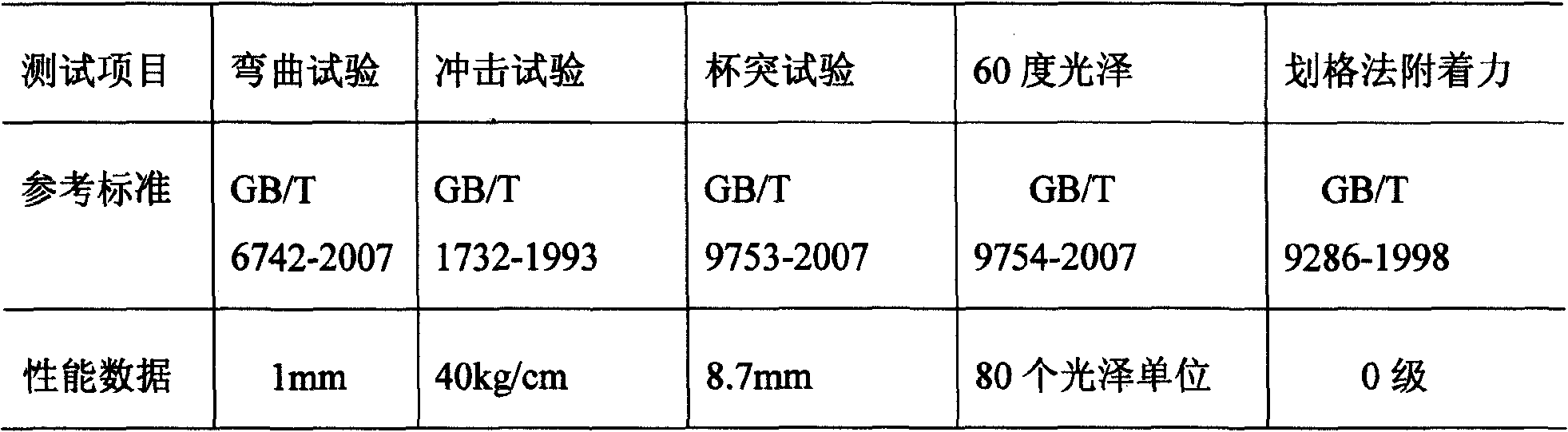

Powder coating with super-weathering resistance, preparation method and application thereof

InactiveCN101671518AWith super weather resistanceThe ratio is scientific and reasonablePowdery paintsPolyester coatingsPliabilityUltraviolet

The invention discloses powder coating with super-weathering resistance, a preparation method and an application thereof. The powder coating comprises the following raw materials in parts by weight: 40-90 parts of weather-resistant polyester resin, 3-30 parts of thermosetting fluorocarbon resin, 4-50 parts of curing agent, 0.1-1.5 parts of flatting agent, 0.2-0.8 part of degasifying agent, 0-4.5 parts of defoaming agent and 4-45 parts of pigment and filler. The powder coating with super-weathering resistance provided by the invention has scientific and reasonable proportioning in the aspects of raw material composition and raw materials, fine comprehensive properties such as flexibility, hardness, adhesive force and the like, stable chemical property, easy storage, performances of acid rain, ozone, ultraviolet ray and chemical medicine resistance and the like in long-term outdoor use, environment protection and wide application range. The preparation method provided by the invention has reasonable processes, strong operability, high qualified rate of finished products and capability of realizing industrialized production.

Owner:TIGER DRYLAC TAICANG

Biomass wood-plastic composite material for 3D (three-dimensional) printing and preparation method for biomass wood-plastic composite material

InactiveCN104356618AStrong self-lubrication and melt fluidityImprove work efficiencyBiomassWeather resistance

The invention provides a biomass wood-plastic composite material for 3D (three-dimensional) printing. The composite material is characterized by comprising the following components in parts by mass: 30 to 60 parts of PLA (poly lactic acid), 6 to 10 parts of UHMWPE (ultrahigh molecular weight polyethylene), 10 to 40 parts of wood dust, bamboo powder or rice hull powder, 10 to 20 parts of paper pulp, 1 to 4 parts of a compatilizer, 1 to 3 parts of a coupling agent, 5 to 10 parts of hollow microspheres, 1 to 3 parts of a lubricant, 0.5 to 2 parts of an antioxidant and 1 to 3 parts of a toughening agent. The composite material is low-carbon, environment-friendly, high in stability, free of hole plugging and warping, can be completely recycled, has the natural friendliness of wood, and has low requirements for machining conditions, and a product has higher physical and mechanical performance and higher weather resistance such as acid and alkali resistance, mothproof performance and ultraviolet resistance.

Owner:QUZHOU UNIV +1

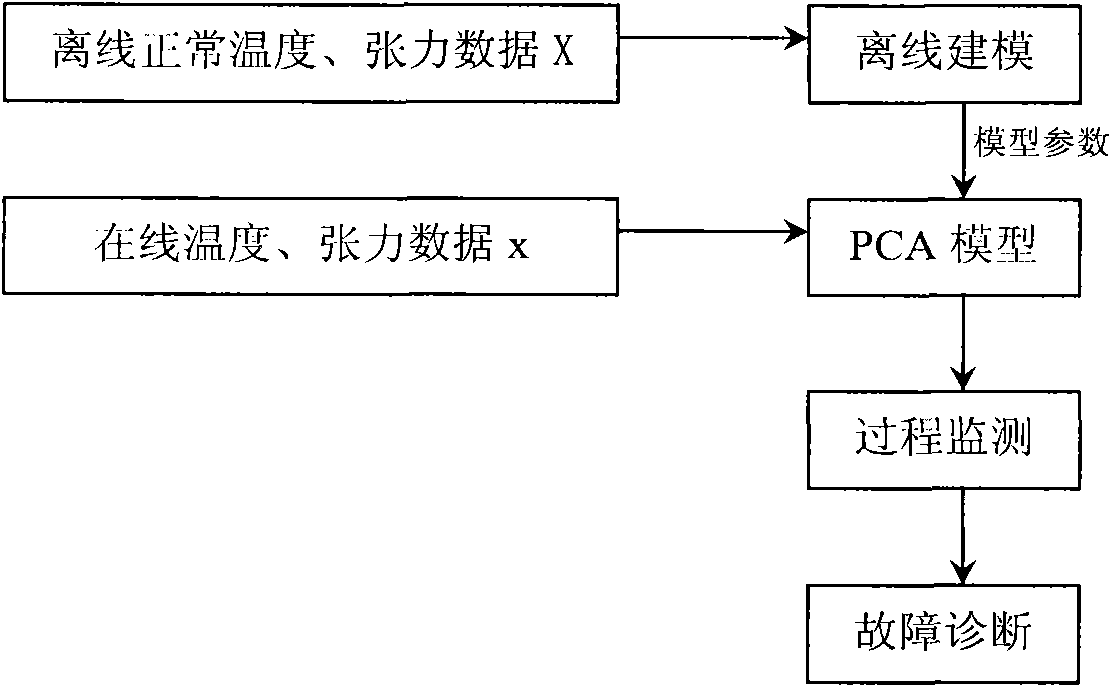

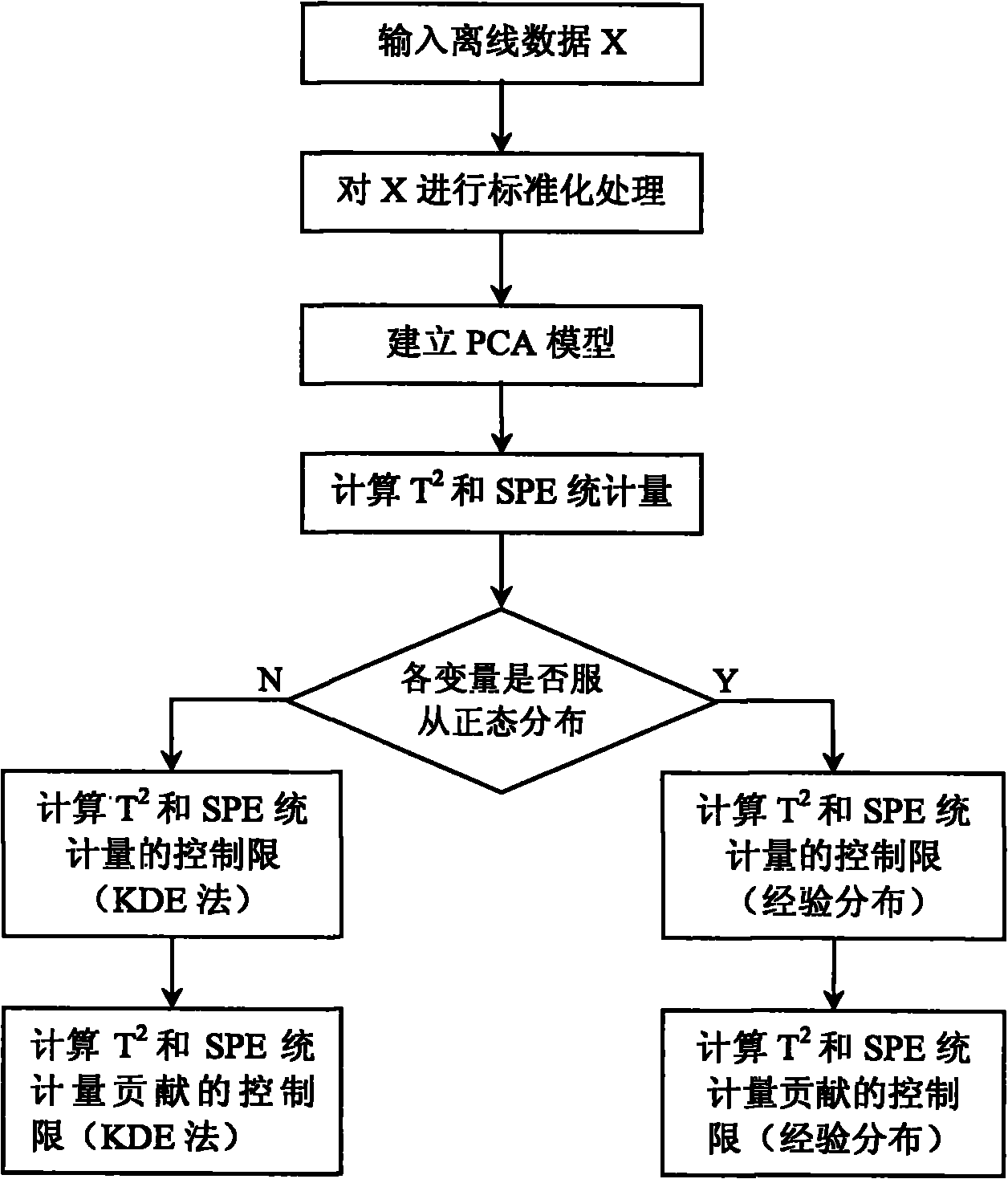

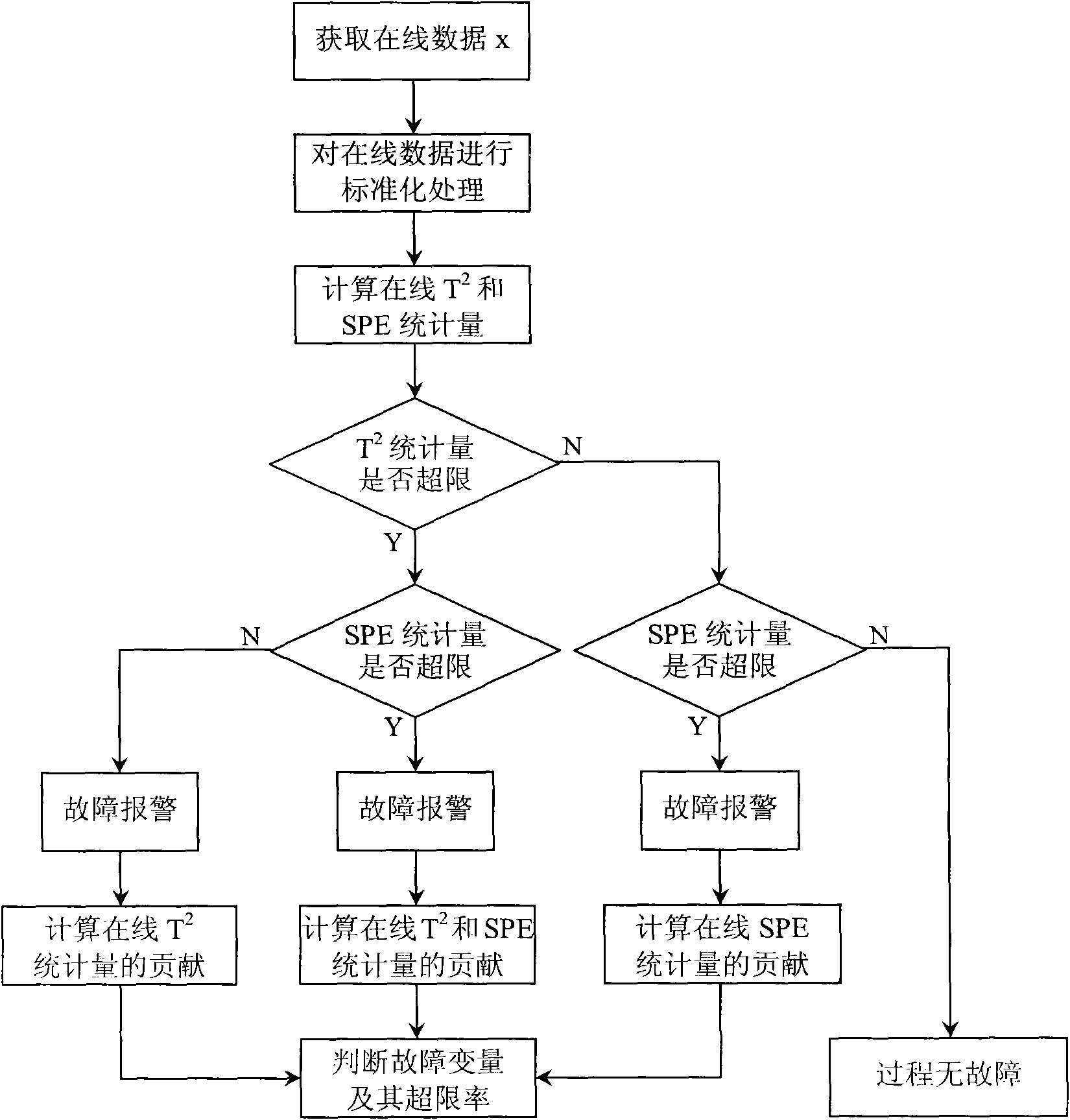

PCA (Principle Component Analysis) model based furnace temperature and tension monitoring and fault tracing method of continuous annealing unit

InactiveCN101899563AClear structureClear relationshipHeat treatment process controlFurnace temperatureOnline model

The invention relates to a fault monitor and diagnosis method of a continuous annealing unit, in particular to a PCA (Principle Component Analysis) model based furnace temperature and tension monitoring of a continuous annealing unit, mainly comprising the following steps of firstly, according to process variable data obtained in the field, and establishing a temperature and tension monitor modelby utilizing a principle component analysis PCA method; secondly, establishing an off-line model and calculating the T2 statistics quantity and the SPE statistics quantity as well as contributed control limits thereof by utilizing the data, obtained in step one, when process variable is in a normal work condition; thirdly, applying an on-line model, calculating the T2 statistics quantity and the SPE statistics quantity of current data, monitoring whether a current state is normal or not according to information supplied by the off-line model, and giving alarm signals if abnormal; fourthly, determining a leading variable which causes a fault by utilizing contribution of the T2 statistics quantity and contribution of the SPE statistics quantity. The invention monitors the furnace temperature and tension in real time in the production process and traces back a fault reason for leading to system abnormality when the abnormality occurs.

Owner:SHANGHAI BAOSTEEL IND TECHNOLOGICAL SERVICE +1

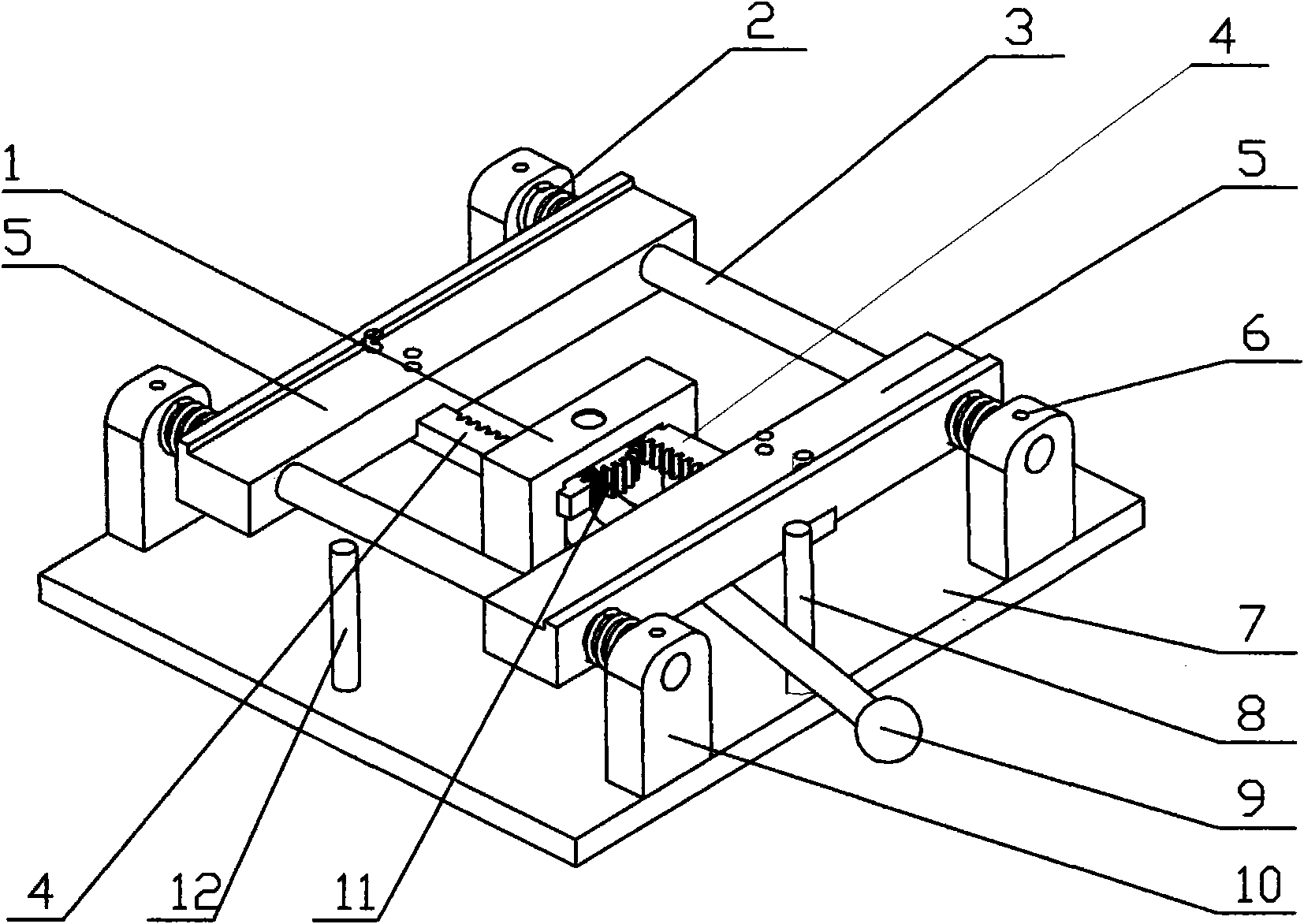

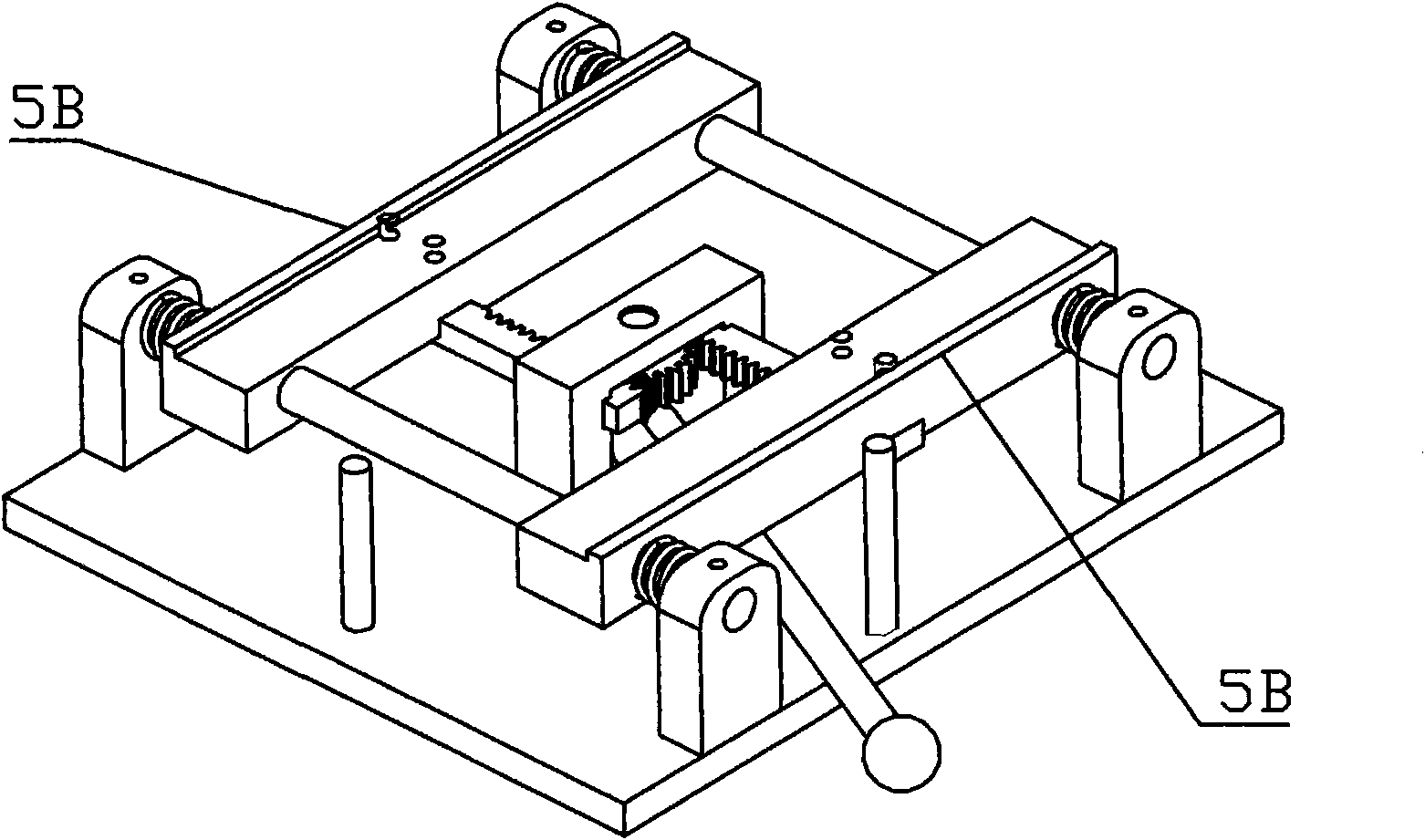

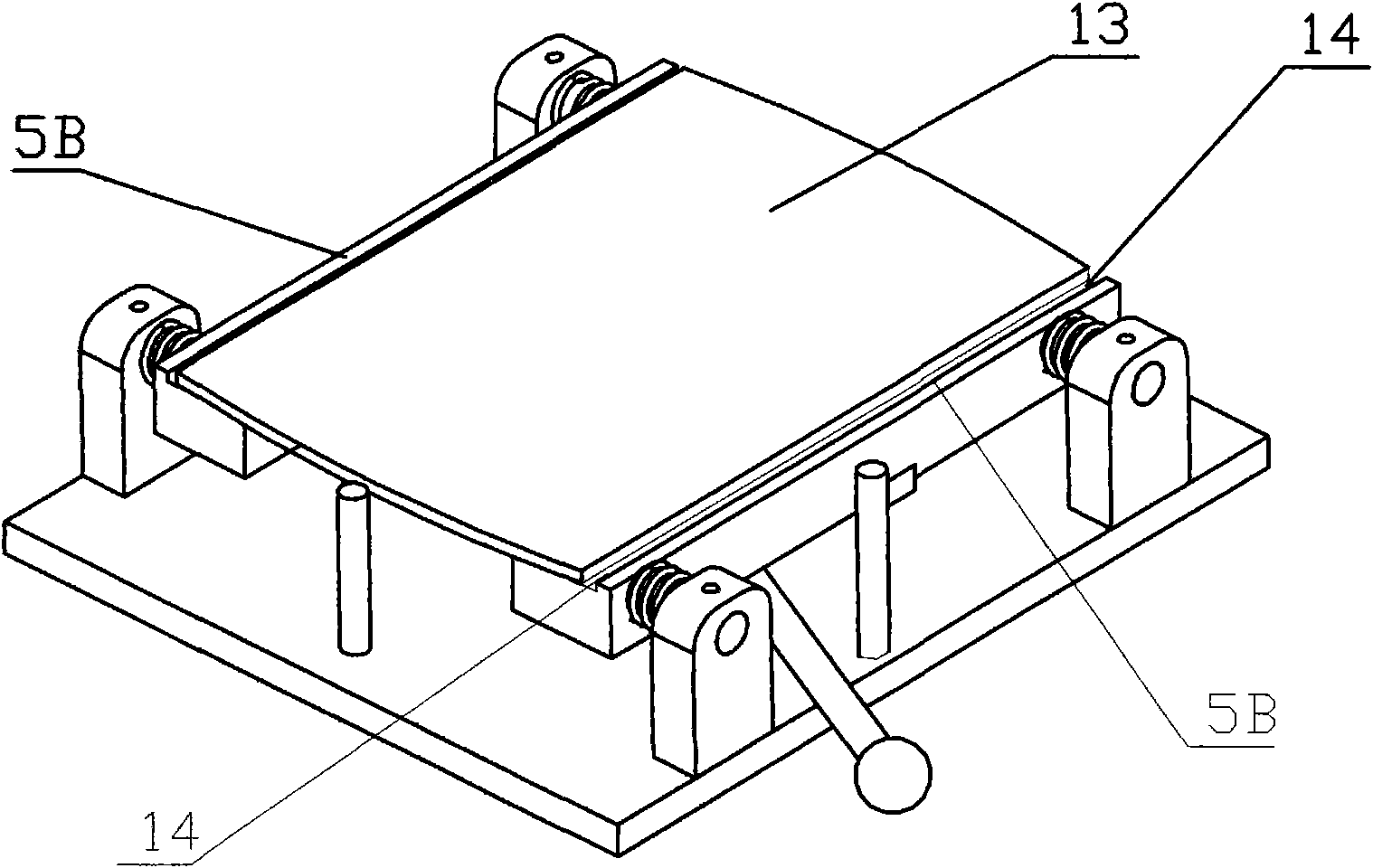

Clamping and positing device capable of automatically aligning center and using method thereof

The invention provides a clamping and positing device capable of automatically aligning center and a using method thereof, relating to a tooling clamp capable of automatically aligning center and being used in a plurality of fields of mechanical manufacture, printing, surface coating, electronic assembly and the like. The device comprises a driving mechanism, a clamping mechanism, a guiding mechanism and a supporting mechanism, wherein, the driving mechanism comprises a driving device and a driving force transmission device; the clamping mechanism comprises a positioning board (5); the supporting mechanism comprises a base (7) and a fixed seat (10); the driving mechanism, the clamping mechanism and the guiding mechanism are supported by the supporting mechanism; the driving mechanism drives the positioning board (5); the guiding mechanism ensures that the positioning board (5) moves according to a guided movement route; thus, the positioning board (5) can clamp a piece (13) to be processed, and the central reference position of the piece (13) to be processed is automatically positioned on the station for positioning a centre (central line or central point). The device can automatically align center and eliminate central line / point position offset.

Owner:李梓鸿 +1

Expansion bolt automatic assembly machine

The invention discloses an automatic expansion bolt assembling machine, comprising a rack and a cam divider rotary table which is arranged on the rack and provided with a plurality of fixtures at intervals. The automatic expansion bolt assembling machine also comprises a nut feeding device, a shim feeding device, an expansion tube feeding device, a bolt feeding device, a rotary assembling device and a finished product discharging device which are all arranged on the rack, wherein the nut feeding device is used for feeding nuts into the fixtures; the shim feeding device is used for feeding shims into the fixtures; the expansion tube feeding device is used for feeding expansion tubes into the fixtures; the bolt feeding device is used for feeding bolts into the fixture; the rotary assemblingdevice is used for assembling the nuts, the shims, the expansion tubes and the bolts which are fed into the fixture; and the finished production discharging device is used for unloading an assembled finished product; and the automatic expansion bolt assembling machine also comprises a spring shim feeding device which is arranged between the shim feeding device and the expansion tube feeding device on the rack and is used for feeding spring shims into the fixtures. Therefore, all the components of an expansion bolt are automatically assembled into the expansion bolt; and the automatic expansion bolt assembling machine has the advantages of high assembling efficiency, stable product quality and the capability of effectively improving the product percent of pass.

Owner:DONGGUAN YIXIN AUTOMATION EQUIP

Ventilated polyurethane plastic race-track surface layer cementing material

ActiveCN103666233AGuaranteed bonding strengthGood weather resistanceNon-macromolecular adhesive additivesPolyureas/polyurethane adhesivesMass ratioEnd-group

The invention discloses a ventilated polyurethane plastic race-track surface layer cementing material, and belongs to the technical field of race-track construction. The ventilated polyurethane plastic race-track surface layer cementing material consists of a component I and a component II at the mass ratio of 1:(3-4), wherein the component I is prepolymer containing isocyanate end group prepared from environment-friendly polyisocyanate, polyether glycol and an addition agent by reacting in a reaction kettle for 3 to 4 hours at the temperature of 70 to 80 DEG C, and the component II comprises polyether glycol with three functionalities, inorganic filler, pigment, a plasticizing agent, a curing agent, an antioxygen, an ultraviolet light absorber and the like. The obtained plastic race-track has the advantages that surface particles are not easy to fall out, the surface is smooth, the quality of the plastic race-track is improved, the service life of the plastic race-track is prolonged, the qualification rate of the plastic race-track is increased to more than 95% as compared with the conventional 82%, the production cost and the use cost are reduced. Moreover all of the used raw materials are environmental protection materials, and belongs to environment friendly materials, the environmental pollution is avoided, and security is provided for the health safety of sporters.

Owner:金华市一家建设工程有限公司

Powder coating with antibacterial function and preparation method and application thereof

InactiveCN101665652AHas antibacterial functionThe ratio is scientific and reasonableAntifouling/underwater paintsPaints with biocidesThermal stabilityInhibitory effect

The invention discloses a powder coating with an antibacterial function and a preparation method and an application thereof. The powder coating comprises the following raw materials in the parts by weight: 60-90 parts of resin, 2-40 parts of curing agent, 1.5-10 parts of antibacterial agent color concentrate, 0.5-2 parts of flatting agent, 0-4.5 parts of defoaming agent, 4-30 parts of pigments andfillers and 0-15 parts of other auxiliary agents. The powder coating provided by the invention has the functions of bacterium resistance and broad spectrum and has strong functions of sterilizing andinhibiting various bacteria and mould fungi; the heat resistant temperature of the inorganic antibacterial agent can reach 500 DEG C, and the inorganic antibacterial agent has good heat stability; and the inorganic antibacterial agent is a silver ion antibacterial agent using glass as a carrier, has good transparency and can be made into a transparent antibacterial powder coating which has the advantages of safety and wide application range. The preparation method provided by the invention has reasonable processes, strong operability and high qualified rate of the prepared finished products and can realize industrial production in a large batch.

Owner:TIGER DRYLAC TAICANG

Low temperature sintered 99 aluminium oxide ceramic and its production method and use

InactiveCN1533999AImprove product qualityAvoid pollutionSemiconductor/solid-state device detailsSolid-state devicesSiliconAlumina ceramic

A low-temp sintered alumina ceramics having 99% or 99.6% of alumina is prepared from alumina particles (2.0-2.5 microns), and sintering aid chosen from Y2O5, ZrO2 and MgO throgh shaping by doctor blading process or die pressing, degumming, and sintering in tunnel kiln at temp C04B 35 / 10 C04B 35 / 119 C04B 35 / 622 C04B 35 / 64 C04B 35 / 63 H01L 23 / 15 0 5 3 2003 / 4 / 2 1533999 2004 / 10 / 6 000000000 Yueke Qinghua Electronic Ceramic Co., Ltd., Zhuhai Guangdong 519015 Zhou Heping Wu Chongjuan Dang Guibin

Owner:珠海粤科京华电子陶瓷有限公司

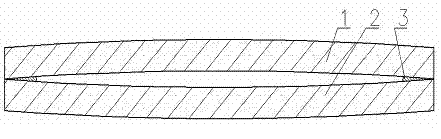

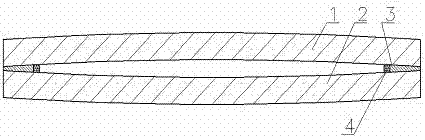

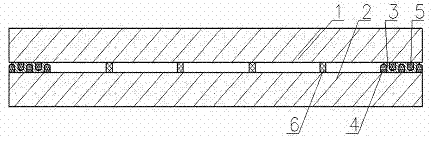

Convex-sided vacuum heat-insulating board, flattened vacuum heat-insulating board and preparation methods thereof

InactiveCN102953441AHigh compressive strengthSimple manufacturing processClimate change adaptationInsulation improvementConvex sideEngineering

The invention provides a vacuum heat-insulating board which comprises an upper heat-insulating board and a lower heat-insulating board, wherein the peripheries of the upper heat-insulating board and the lower heat-insulating board are welded together through using a welding flux, a closed vacuum layer is formed between the upper heat-insulating board and the lower heat-insulating board, the upper heat-insulating board and the lower heat-insulating board are flattened heat-insulating boards or convex-sided heat-insulating boards, and the convex side of each convex-sided heat-insulating board faces outwards. The production method of the vacuum heat-insulating board provided by the invention is simple in process, and the prepared vacuum heat-insulating board overcomes the defects of the existing heat-insulating board, so that the tightness of a vacuum layer of the vacuum heat-insulating board can be effectively guaranteed, the service life of the vacuum heat-insulating board is prolonged, and the strength and heat insulation, sound insulation and fire prevention properties of the vacuum heat-insulating board can be increased.

Owner:戴长虹

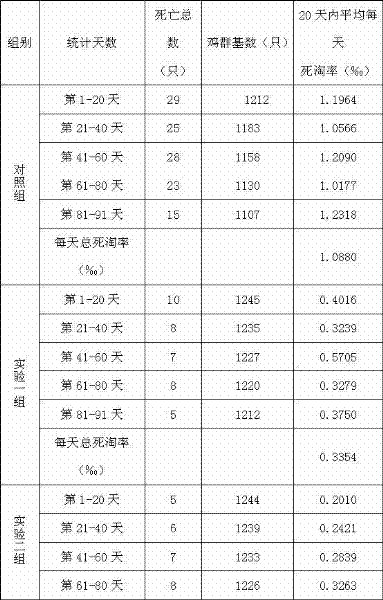

Fermented feed additive, preparation method and application

ActiveCN102550815ASlow down digestionPromote digestion and decompositionFood processingAnimal feeding stuffMonosodium glutamateBacillus licheniformis

The invention discloses a fermented feed additive, a preparation method and application thereof. The fermented feed additive is prepared by fermenting mixed strains and mixed auxiliary materials consisting of monosodium glutamate protein, bean pulp, bran, cottonseed meal, corn fibers, rice bran and powdered rice hulls, wherein the mixed strains are obtained by mixing activated strains of lactobacillus acidophilus, lactobacillus planetarium, lactobacillus casei, saccharomyces cerevisiae, bacillus subtilis and bacillus licheniformis in a proportion of (1-5): (1-5): (1-5): (1-5): (1-5): (1-5); and the dosage of the fermented feed additive is 5 to 100 percent of the weight of the animal feed when used for the animal feed. According to the fermented feed additive, the bean pulp, the bran, the cottonseed meal and other raw auxiliary materials are sufficiently utilized, so that the food consumption in the animal feeding process is reduced; the fermented feed additive can be used to partiallyor completely replace the animal feed, and antibiotic medicaments can be reduced or prevented from being used; and no medicament is left, so that the feeding cost of farmers is reduced.

Owner:WEIFANG ZHONGKEJIAYI BIO FODDER TECH

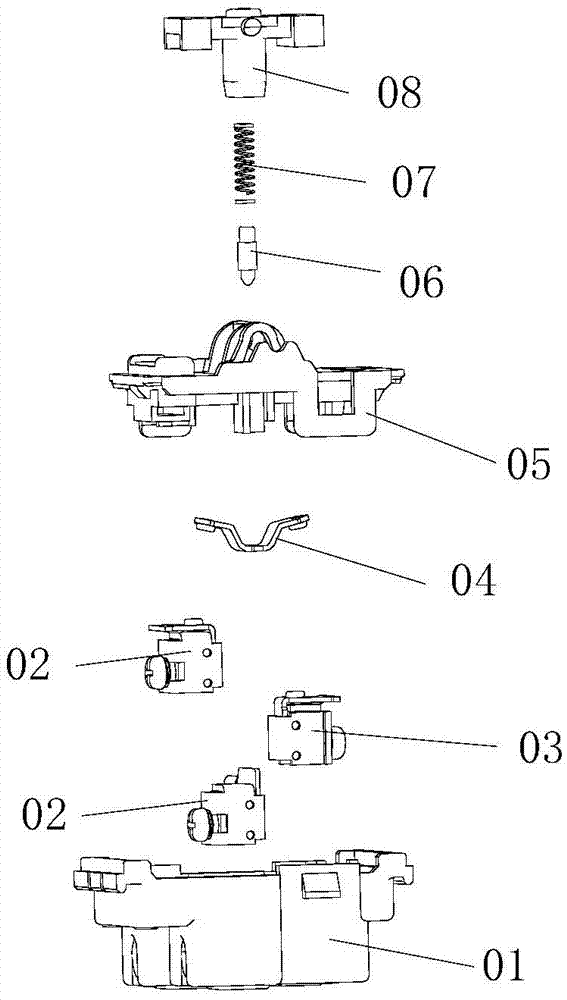

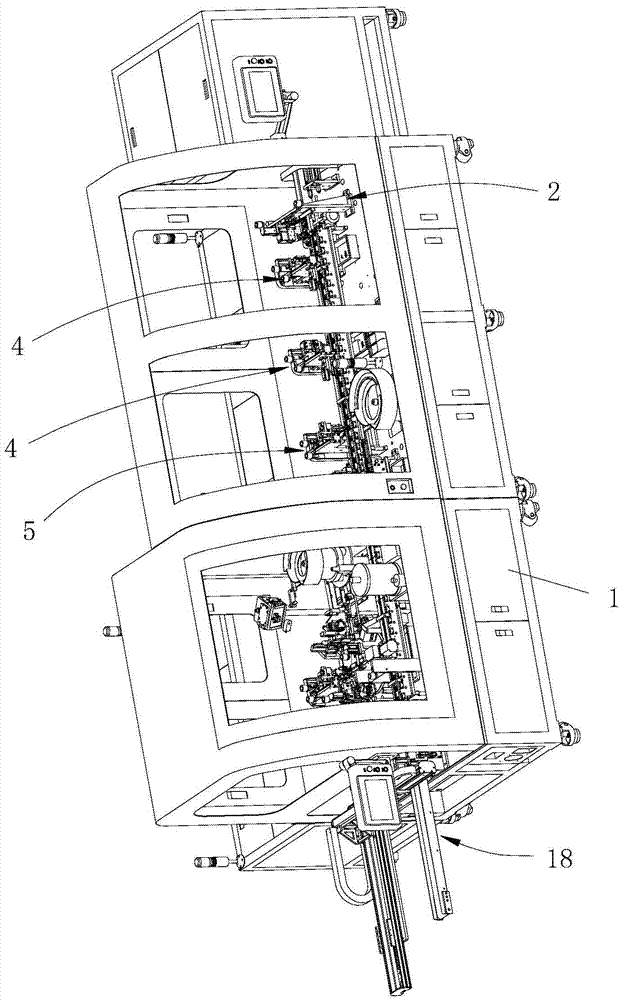

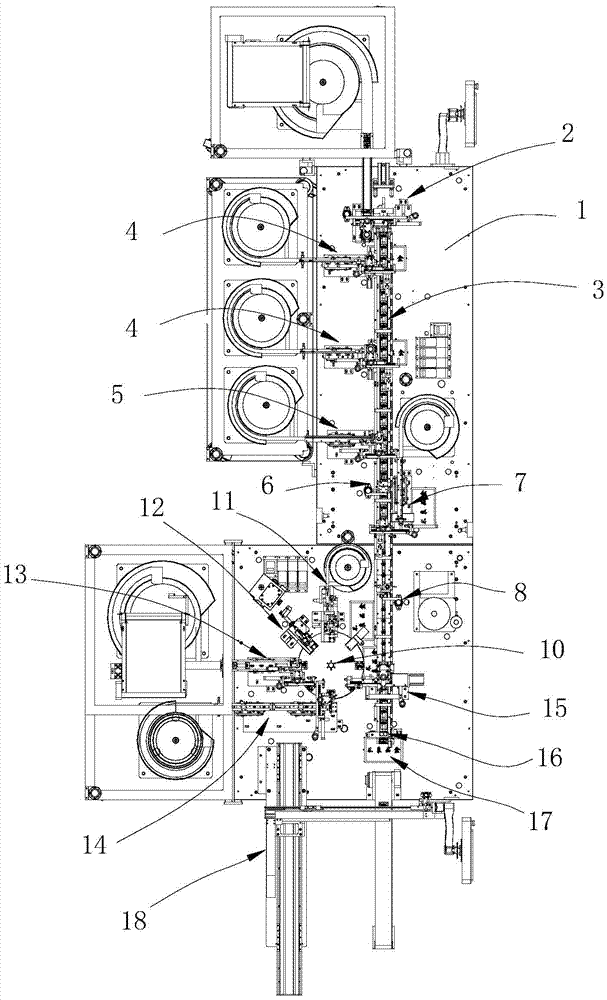

Automatic assembly machine for wall control switch

ActiveCN105448562AHigh degree of automationImprove assembly efficiencyAssembly machinesElectric switchesEngineeringControl switch

The invention discloses an automatic assembly machine for a wall control switch. The automatic assembly machine comprises a rack, a trough conveyer device, a base feeding mechanism, a side terminal feeding assembly mechanism, a medium terminal feeding assembly mechanism, a terminal missing detection mechanism, a wane feeding assembly mechanism, an oil adding mechanism, a rotary plate mechanism, a bullet feeding mechanism, a spring feeding assembly mechanism, a pressure plate feeding assembly mechanism, a transition part feeding assembly mechanism, a transition part component assembly mechanism, a switch conduction detection mechanism, a defective product discharge mechanism and a finished product discharge mechanism, wherein the trough conveyer device, the base feeding mechanism, the side terminal feeding assembly mechanism, the medium terminal feeding assembly mechanism, the terminal missing detection mechanism, the wane feeding assembly mechanism, the oil adding mechanism, the rotary plate mechanism, the bullet feeding mechanism, the spring feeding assembly mechanism, the pressure plate feeding assembly mechanism, the transition part feeding assembly mechanism, the transition part component assembly mechanism, the switch conduction detection mechanism, the defective product discharge mechanism and the finished product discharge mechanism are arranged on the rack. According to the automatic assembly machine for the wall control switch, various components of the wall control switch can be automatically assembled into a finished product of the wall control switch; the automatic degree and the assembly efficiency are high; the quality of the product is stable; and the qualified rate of the product can be effectively improved.

Owner:DONGGUAN YI CHENG AUTOMATIC EQUIP

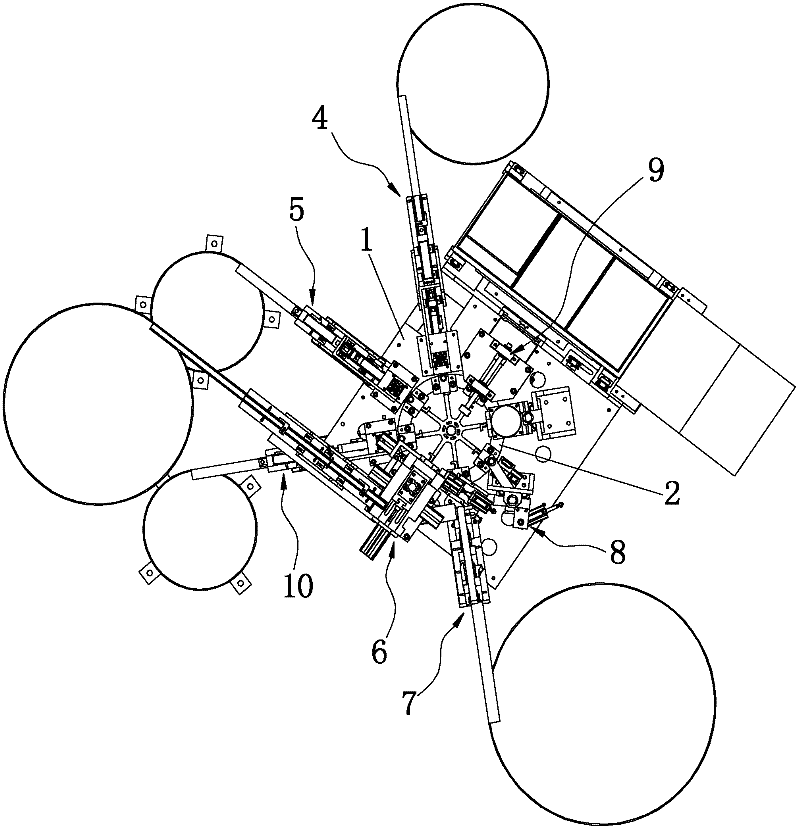

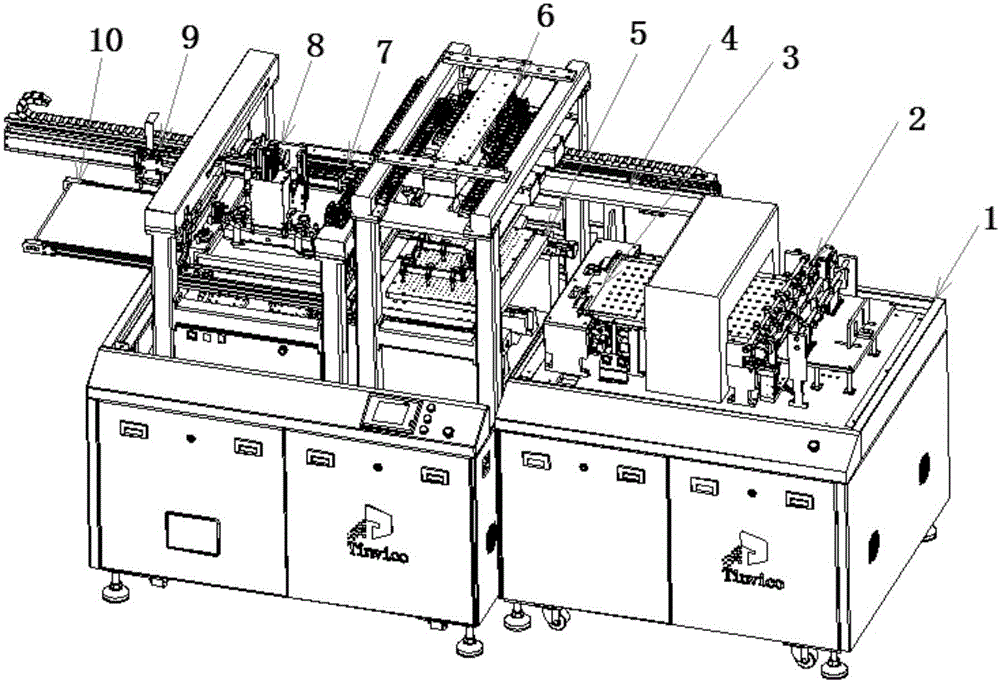

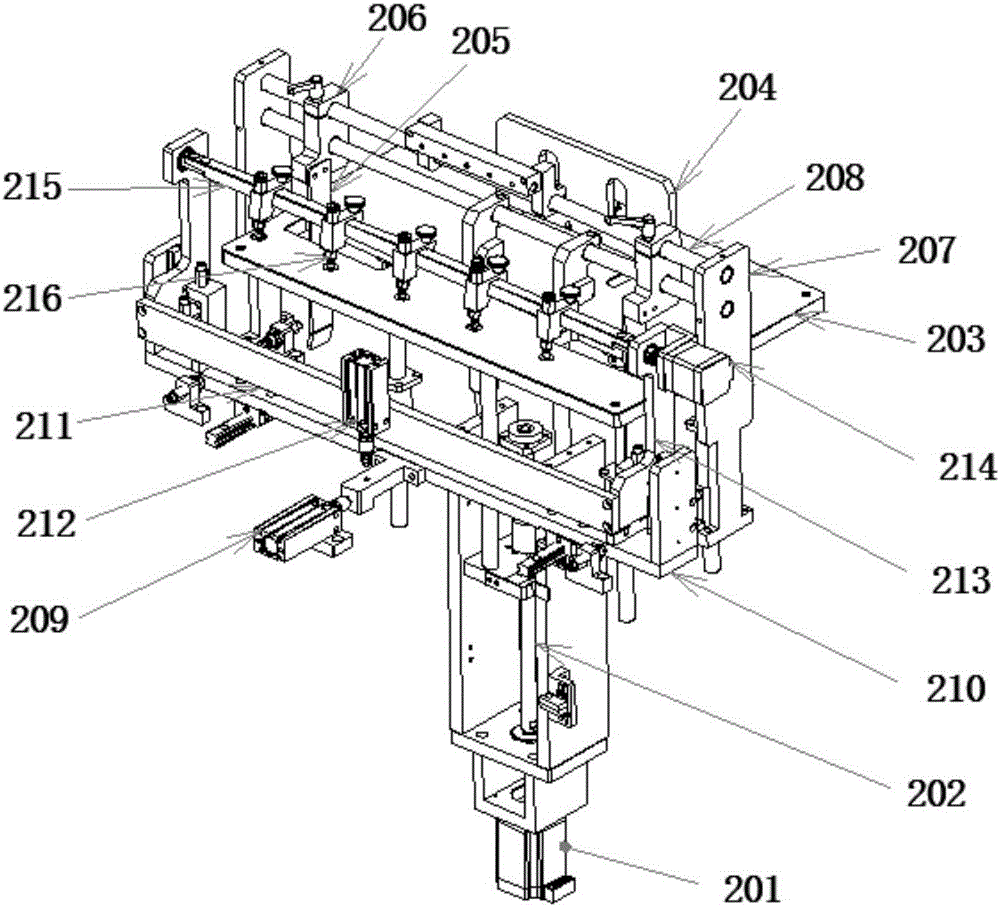

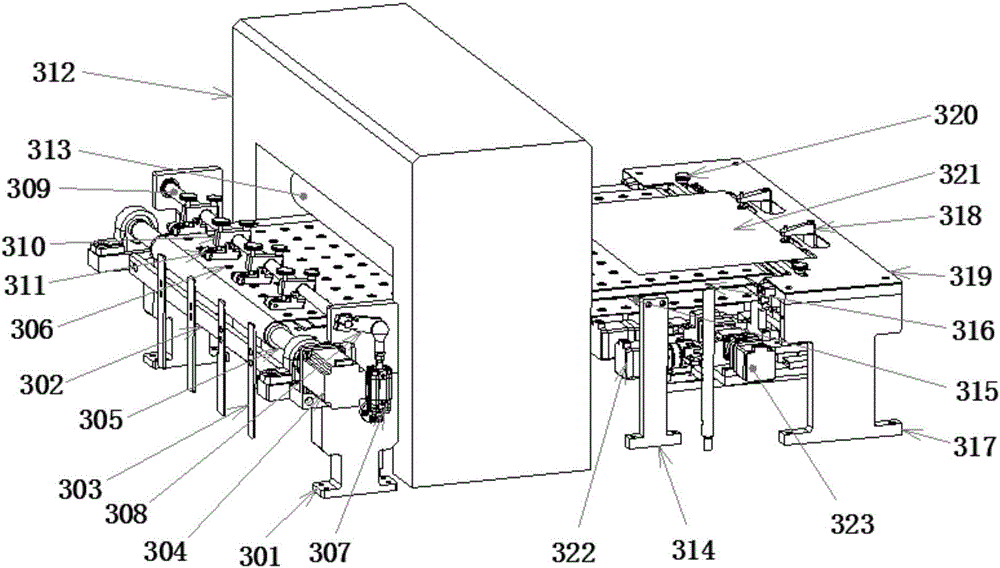

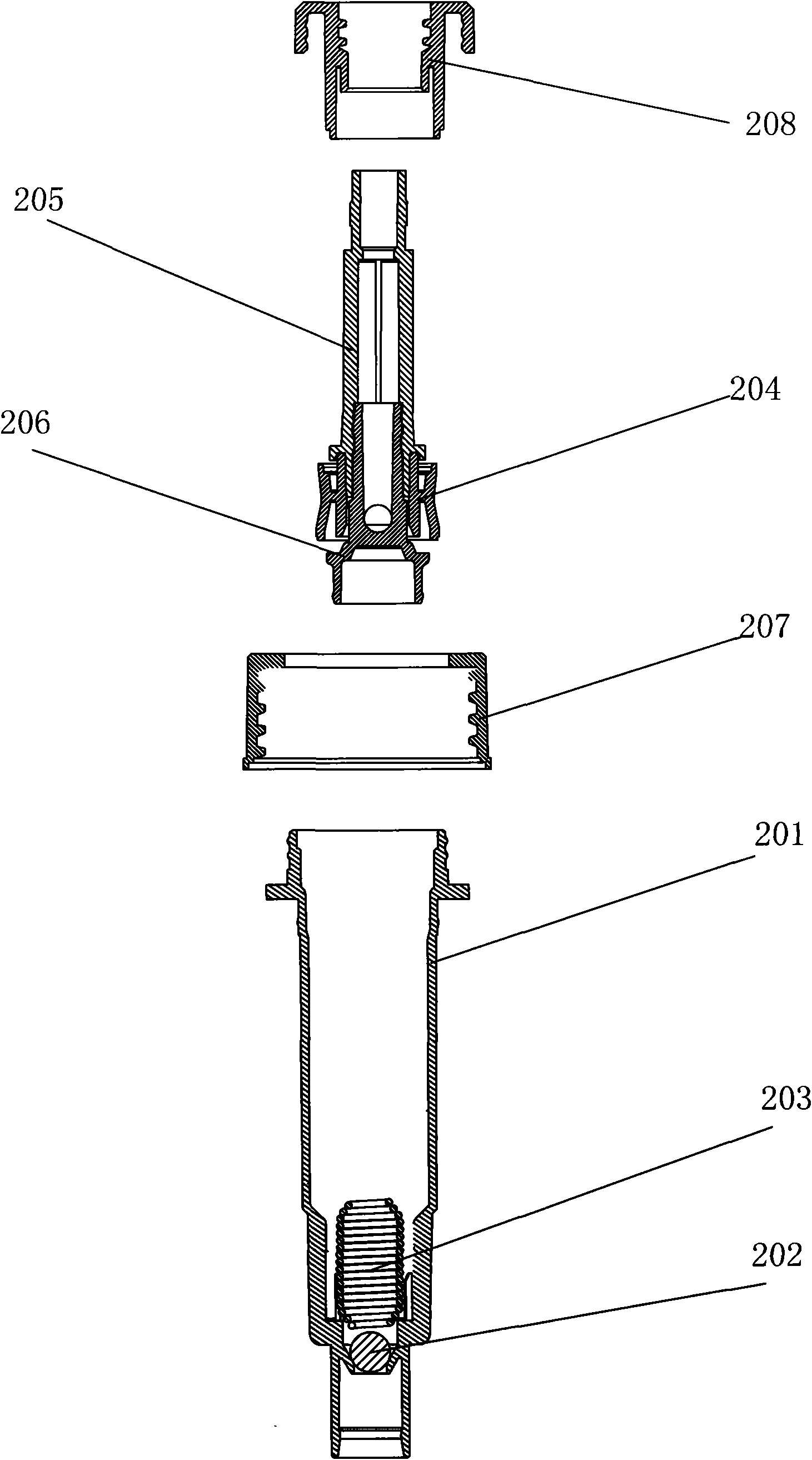

Full-automatic high-precision double-printing-platform screen printing machine

InactiveCN106671579ASolve the problem of manual loading and unloadingReasonable layoutScreen printersConveyor partsEngineeringPrinting press

The invention discloses a full-automatic high-precision double-printing-platform screen printing machine. The full-automatic high-precision double-printing-platform screen printing machine comprises a machine frame, material conveying mechanism, a screen printing plate mounting and alignment mechanism and a screen printing mechanism and further comprises a double-printing-platform transfer assembly located on the machine frame, wherein the material conveying mechanism is located on the machine frame; the double-printing-platform transfer assembly comprises a positioning position, a printing position, a lifting printing platform and a printing platform, the lifting printing platform and the printing platform are located in the positioning position or the printing position alternately and switched between the positioning position or the printing position; the material conveying mechanism is used for conveying to-be-printed materials to the positioning position; and the screen printing plate mounting and alignment mechanism and the screen printing mechanism are arranged above the printing position for printing the to-be-printed materials located in the printing position. By means of the full-automatic high-precision double-printing-platform screen printing machine, while one to-be-printed material is printed, another to-be-printed material is automatically fed onto the printing platform and photographed and positioned, and the technical problems that most of existing full-automatic flexible-plate screen printing machine adopts single-platform linear material conveying, and consequently the system efficiency is low are solved.

Owner:SHENZHEN TINVICO TECH CO LTD

Automatic assembling machine for lotion pump

The invention discloses an automatic assembling machine for a lotion pump, which can assemble a pump ball, a spring, a suction plug, an upper pump rod, a lower pump rod, a bottle-locking cap and a locking cap on a pump case. The automatic assembling machine comprises a frame and a workbench arranged on the frame, wherein, the workbench is equipped with an upper press mounting device and a lower press mounting device; a discharge device for the pump case, a discharge device for the bottle-locking cap, a discharge device for the suction plug, a discharge device for the locking cap and a discharge channel for the finished lotion pump product are arranged between the upper press mounting device and the lower press mounting device, wherein, the discharge device for the pump case is internally equipped with the pump ball and the spring; the discharge device for the bottle-locking cap is used for covering the bottle-locking cap on the pump case; the discharge device for the suction plug is used for placing the suction plug with the upper pump rod and the lower pump rod into the pump case; and the discharge device for the locking cap is used for covering the locking cap on the bottle-locking cap and the pump case. The automatic assembling machine for the lotion pump provided by the invention has high production efficiency and high processing precision.

Owner:ZHONGSHAN MEIJIESHI PACKAGING PROD

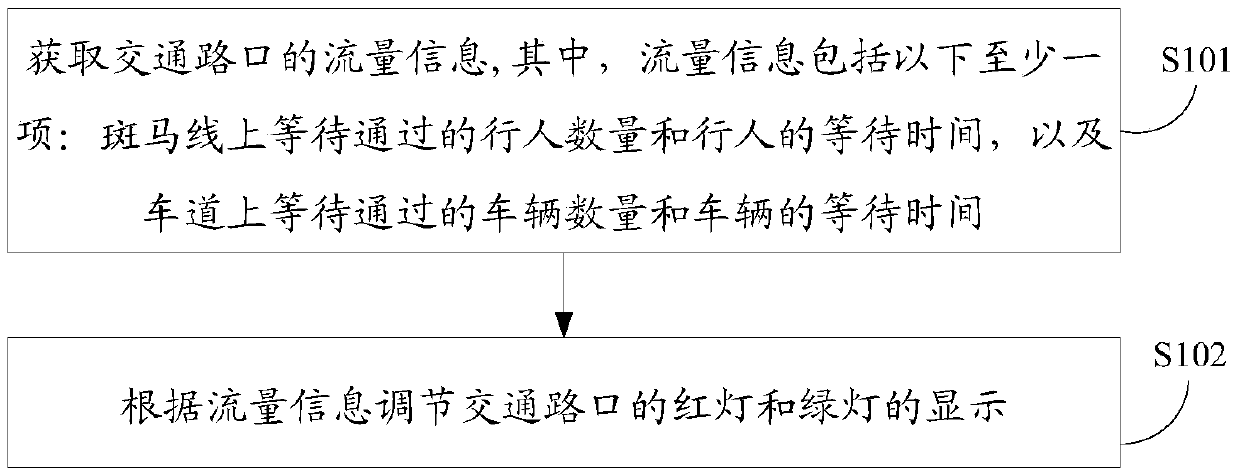

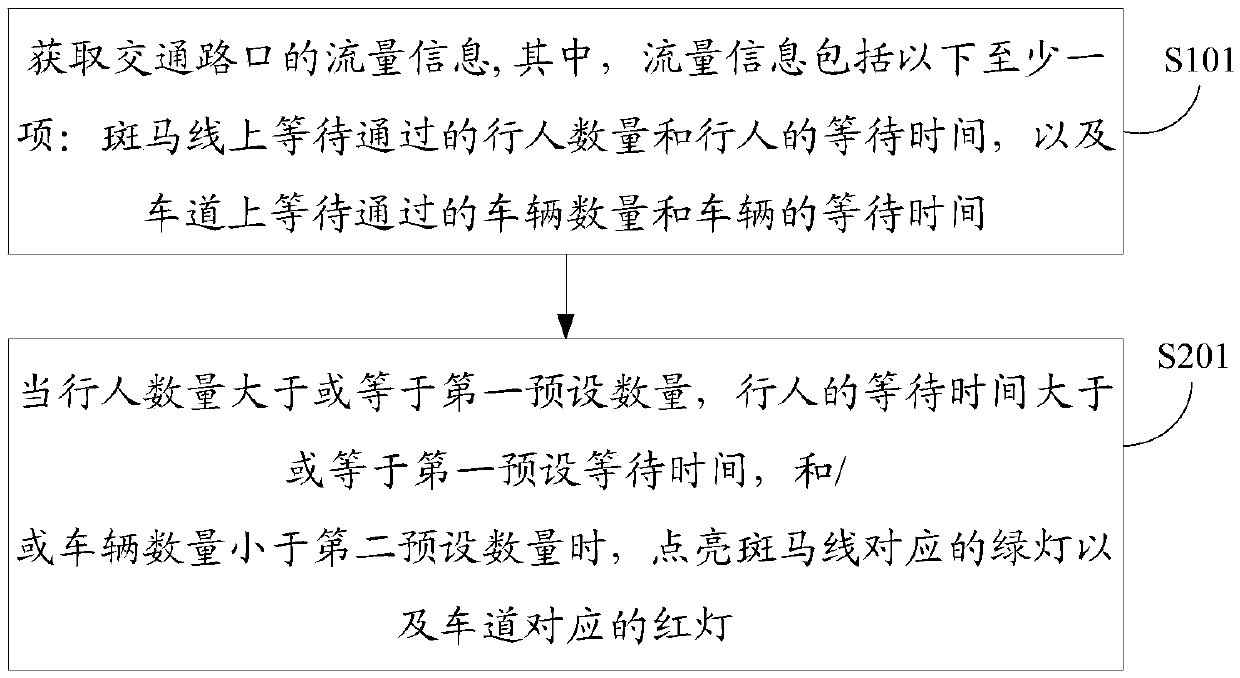

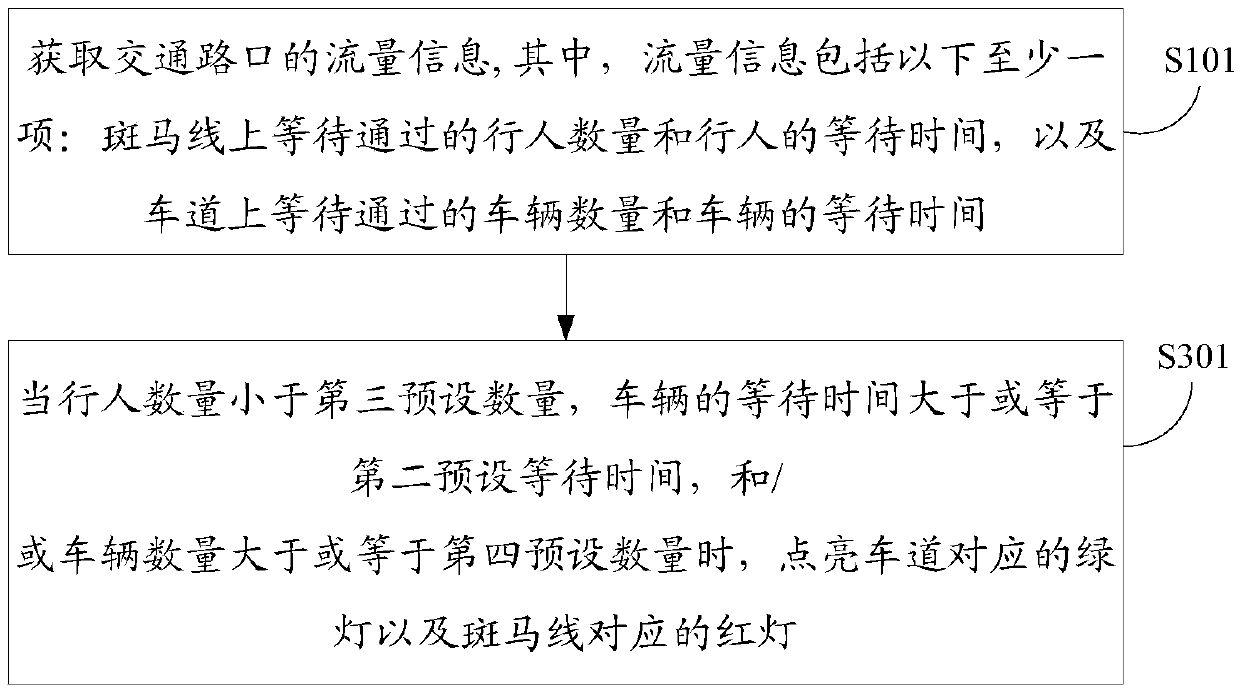

Traffic light adjustment method and device

InactiveCN105513376AReduce waiting timeImprove pass rateControlling traffic signalsPass rateGreen-light

The invention relates to a traffic light adjustment method and device, and the method comprises the steps: obtaining the flow information of a traffic intersection, wherein the flow information comprises at least one of the number of pedestrians waiting to pass at a zebra crossing, the waiting time of the pedestrians, the number of vehicles waiting to pass on lanes, and the waiting time of the vehicles; and adjusting the display of the red and green lights of the traffic intersection according to the flow information. Through the technical scheme of the invention, the method and device adjust the red and green lights according to the number of pedestrians and the number of vehicles, can reduce the waiting time of the pedestrians and vehicles, improve the passing rate of the pedestrians and vehicles, and improve the user experience.

Owner:XIAOMI INC

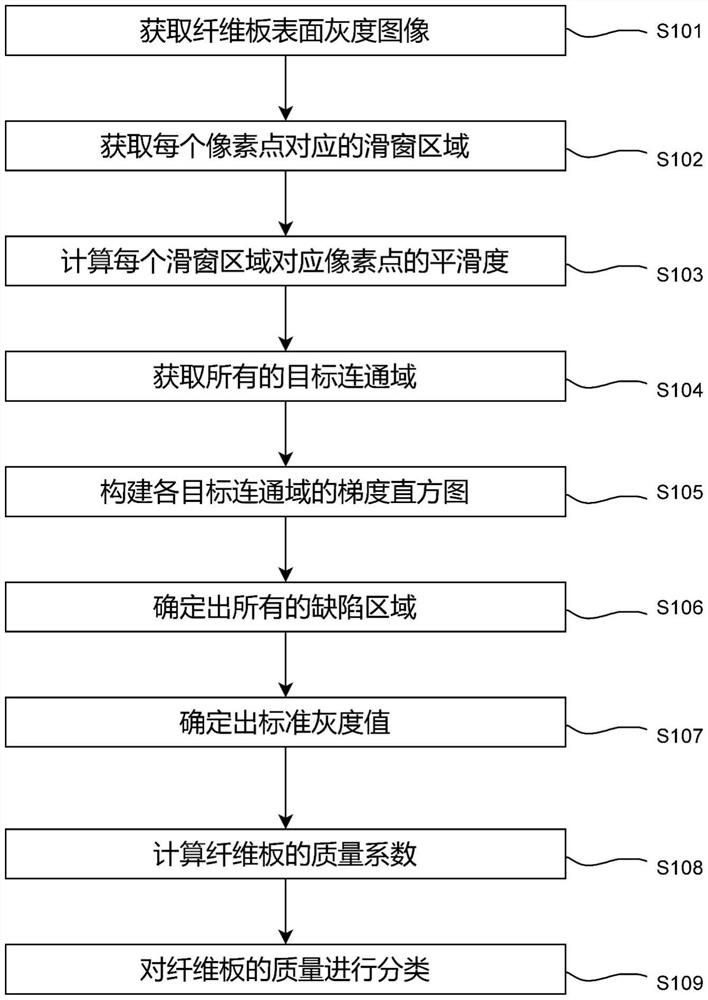

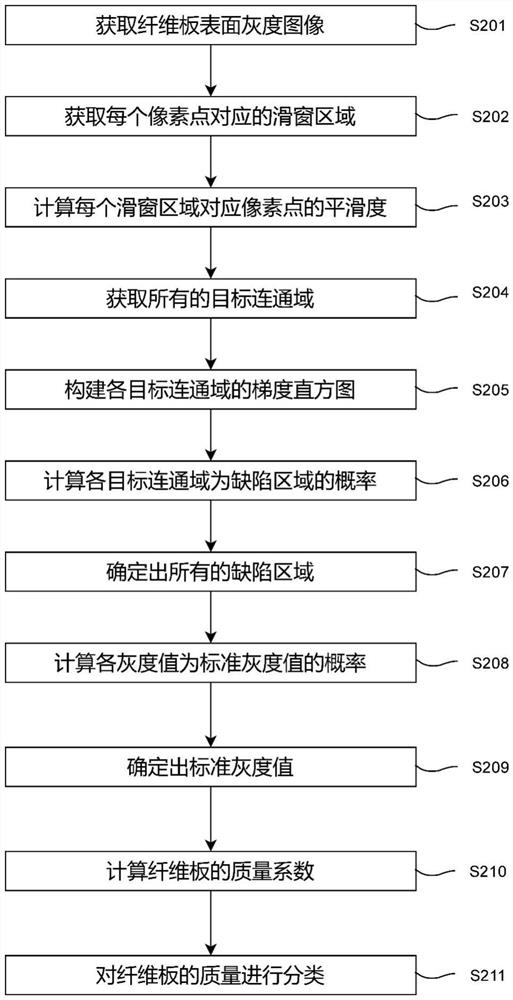

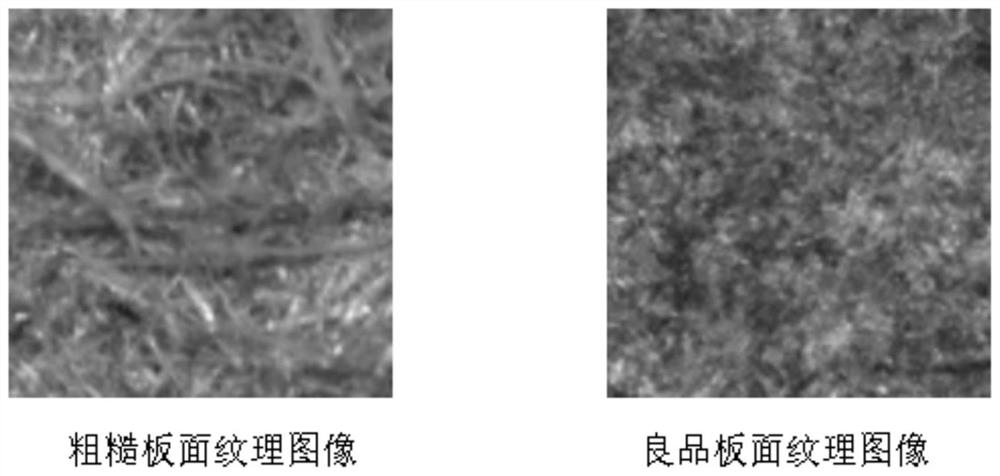

Fiberboard quality classification method based on machine vision

InactiveCN114445387AThe test result is accurateImprove accuracyImage enhancementImage analysisHistogramEngineering

The invention relates to the field of artificial intelligence, in particular to a fiberboard quality classification method based on machine vision. The method includes: acquiring a fiberboard surface grayscale image; performing sliding window processing on the grey-scale map on the surface of the fiberboard to obtain a plurality of sliding window areas; calculating the smoothness of a central pixel point of the sliding window; taking the pixel point corresponding to the minimum smoothness as a target pixel point, and obtaining a plurality of target connected domains; obtaining gradient amplitudes of pixel points in each target connected domain to construct a corresponding gradient histogram, calculating the probability that each target connected domain is a defect area, and determining all defect areas; calculating the probability of each gray value as a standard gray value, and determining the standard gray value; and calculating the quality coefficient of the fiberboard according to the gray average value of each defect area, and classifying the quality of the fiberboard. By analyzing the glossiness of the surface image of the fiberboard, the defect that the spatial domain feature is not obvious can be detected, so that the detection result is more accurate, and the product classification accuracy and the repair timeliness are improved; and the production efficiency is effectively improved.

Owner:泗阳富艺木业股份有限公司

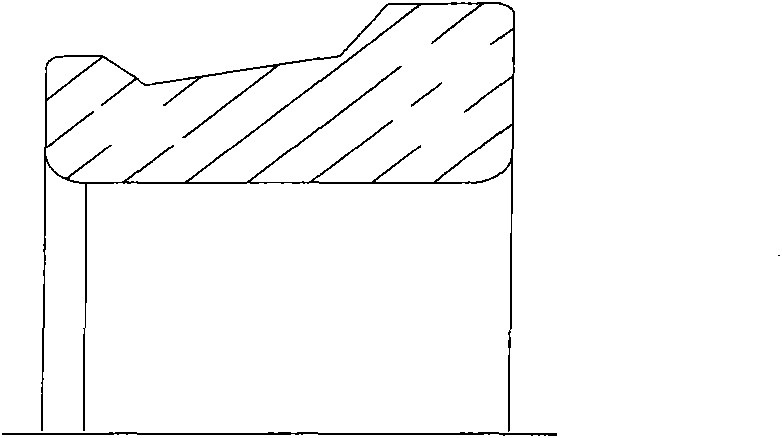

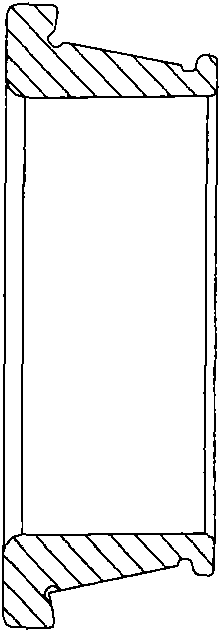

Composite machining process for inner and outer rings of narrow-series thin-walled high-precision conical thin-walled bearings

The invention discloses a composite machining process for inner and outer rings of narrow-series thin-walled high-precision conical thin-walled bearings, belongs to the technical field of forging, turning, heating and grinding machining of the inner and outer rings of bearing components, and mainly solves the problems of low production efficiency and high rejection rate in a conventional machining method. The composite machining process is mainly characterized by comprising the following steps of: (1) cutting bar stock into straight material sections; (2) after heating, forming a single-forged inner ring and double combined-forged outer rings by using a pressing machine; (3) spheroidizing and annealing; (4) performing shot blasting to remove surface oxide scales; (5) after cutting the double outer rings, performing rough turning and soft grinding; (6) performing additional tempering; (7) performing the soft grinding on the outside diameter of the outer rings, and performing finish turning and rolling; (8) performing heat treatment in quenching and tempering furnaces, and performing shot blasting again; and (9) performing rough grinding machining, the additional tempering, finish grinding machining, super-finishing, cleaning and assembling. The composite machining process has the characteristics of great improvement on product qualification rate and production efficiency, and suitability for batch production on the premise of no increase of equipment investment, and is mainly used for machining the inner and outer rings of the narrow-series thin-walled high-precision conical thin-walled bearings.

Owner:XIANGYANG AUTOMOBILE BEARING CO LTD

Sintered water permeable brick and preparation method thereof

ActiveCN106087631AImprove water permeabilityLittle tortuousnessSingle unit pavingsPaving detailsBiomass fuelsSurface layer

The invention discloses a sintered water permeable brick and a preparation method thereof, and belongs to the technical field of sintered ceramics. According to the water permeable brick, structural pug in a surface layer is composed of, by weight, 45-65% of structural fine aggregates, 20-30% of plastic high-temperature binders and 15-25% of water, pore forming pug in the surface layer is composed of, by weight, 20-50% of pore forming agent aggregates, 45-80% of plastic pore adding binders and 0-5% of biomass fuel internal combustion catalysts, and a blank of a secondary surface layer is composed of, by weight, 70-75% of coarse structural aggregates, 10-15% of plastic high-temperature binders, 0-5% of pore adding agent coarse aggregates and 10-15% of water. A blank of the surface layer and the blank of the secondary surface layer are prepared firstly, the blank of the surface layer contains the orderly distributed structural pug and the pore forming pug, and then single-shaft extrusion forming, drying and sintering are conducted to obtain the water permeable brick. The water permeable brick has high water permeable rate, high strength, high abrasion resistance and durability and is a paving material with excellent ecological and environmental functions.

Owner:四川绿岛环境工程有限公司

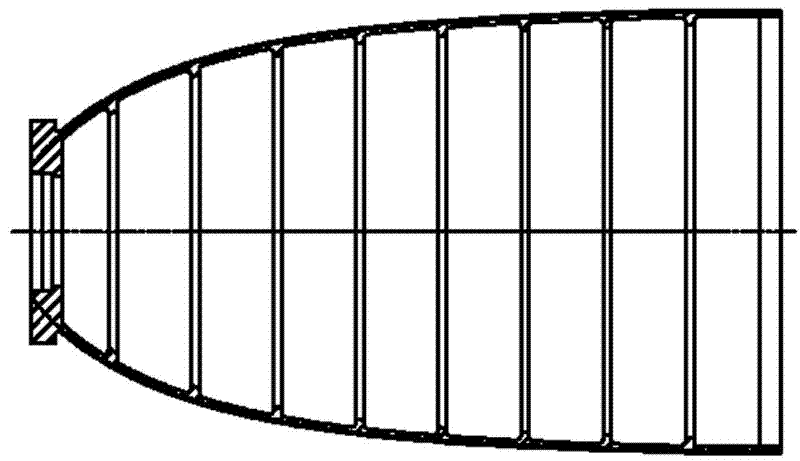

Processing method of thin and long aluminium alloy thin-walled cylinder

ActiveCN102513785AHigh material utilizationShort processing cycleNon-electric welding apparatusWeld seamThin walled cylinder

The invention provides a processing method of a thin and long aluminium alloy thin-walled cylinder and belongs to a mechanical processing method of a slewing structure, and the processing method is used for carrying out friction stir welding on a shell blank so as to process and mold the shell blank into a bent generatrix thin-walled cylinder shell. The method provided by the invention can be used for solving the problems of poor shell generatrix displacement, poor shell roundness, uneven wall thickness, clearance at welding seams, unqualified performance detection and incapability of ensuring use requirements in the existing processing method. The method comprises a part manufacturing step, a matching step, a caustic washing step, a trial assembly step, a positioned welding step, a friction stir welding step, a welding seam polishing step, a stress-relief annealing step, an X-ray detection step, a shape processing step, a ultrasonic flaw detection step and an end face hole processingstep. The method provided by the invention can be used for solving the problems of poor shell roundness, uneven wall thickness, clearances at the welding seams and unqualified performance detection in the existing processing method, improving the shell processing precision and reliably ensuring the product quality.

Owner:HUBEI SANJIANG AEROSPACE GRP HONGYANG ELECTROMECHANICAL

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com