Clamping and positing device capable of automatically aligning center and using method thereof

A clamping positioning and automatic technology, applied in workpiece clamping devices, manufacturing tools, etc., can solve problems such as the inability to guarantee the constant reference position of the center of the part, the inability to solve quality problems, and the troubled production of enterprises. It is easy to process, assemble, eliminate Position offset, the effect of improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

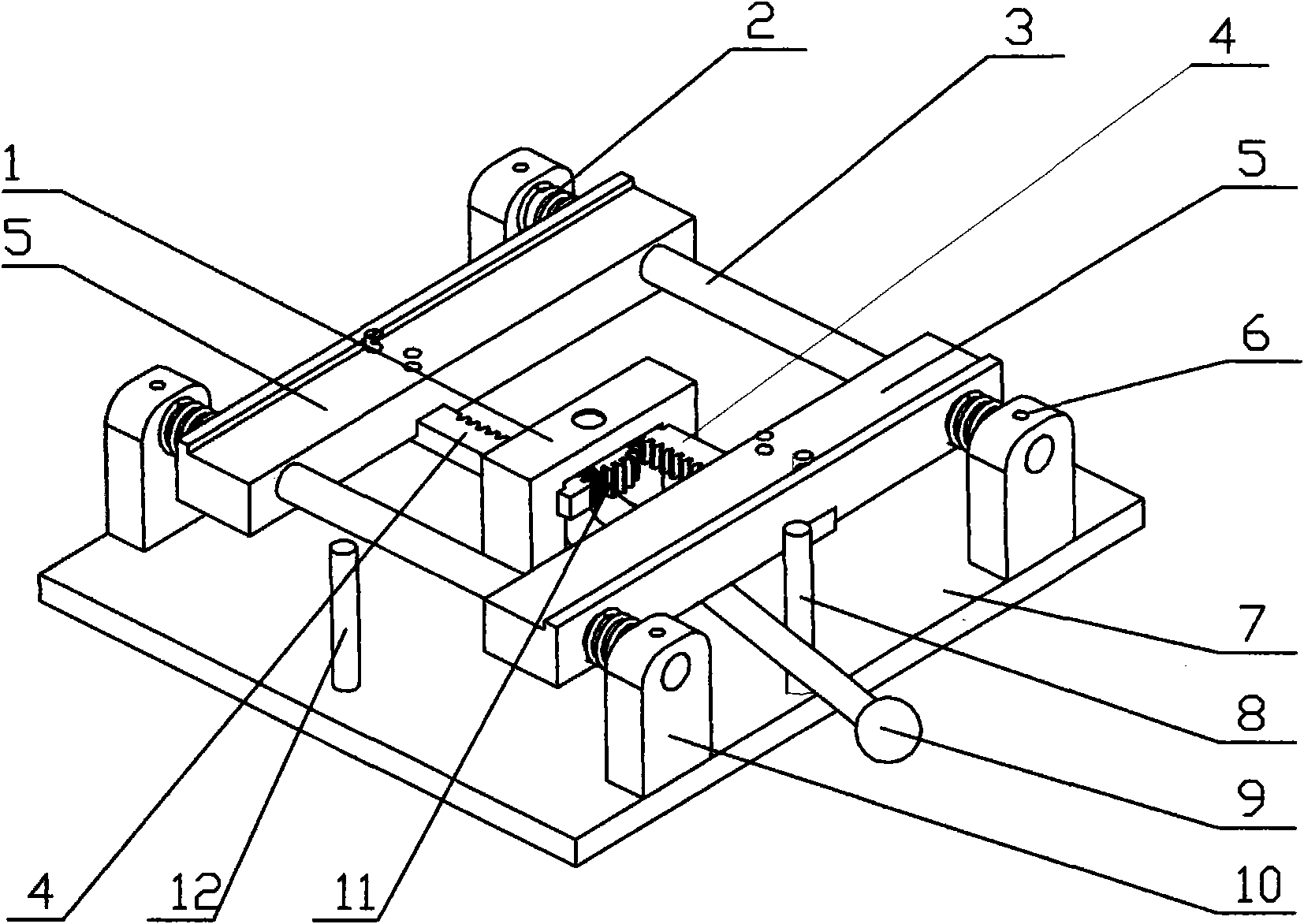

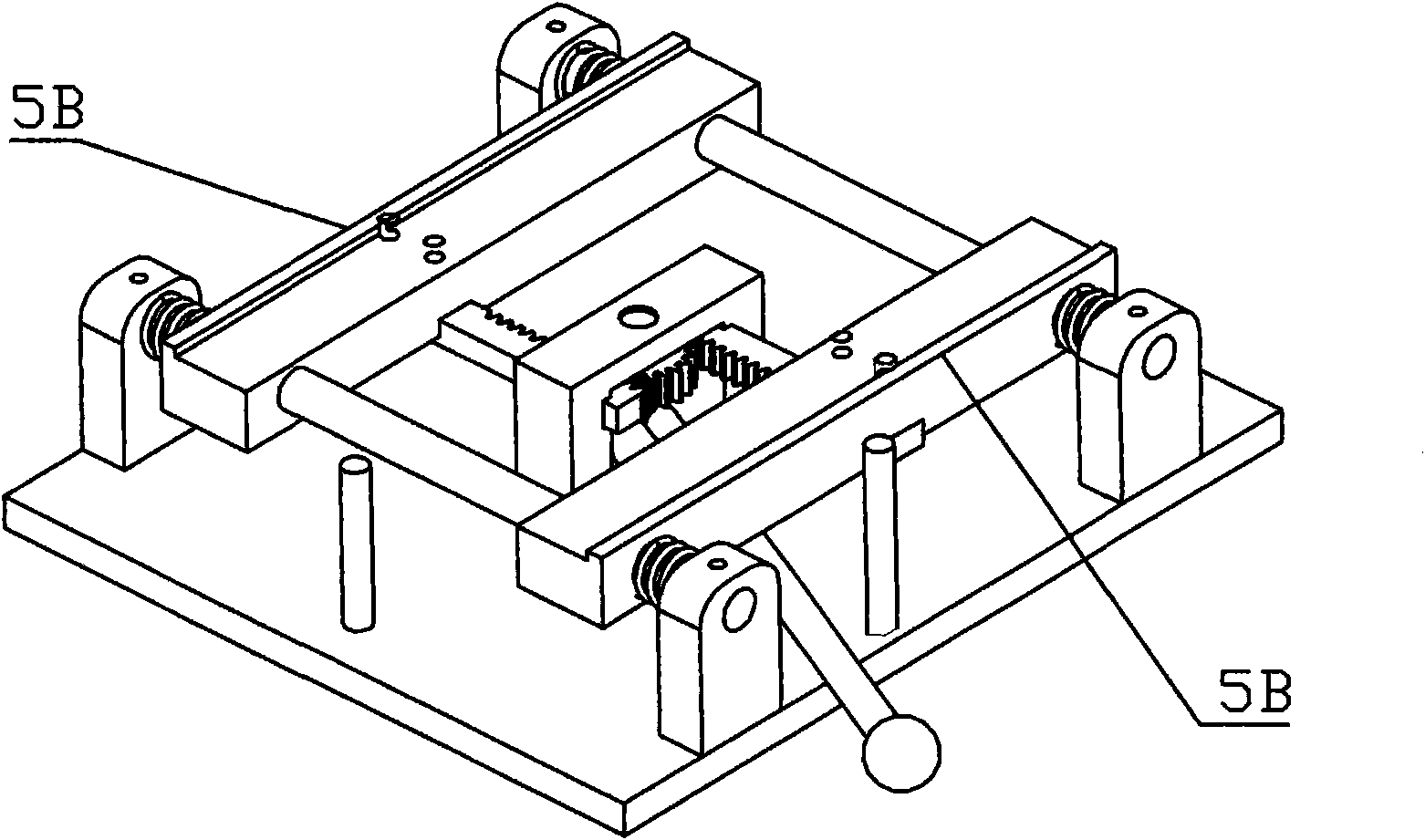

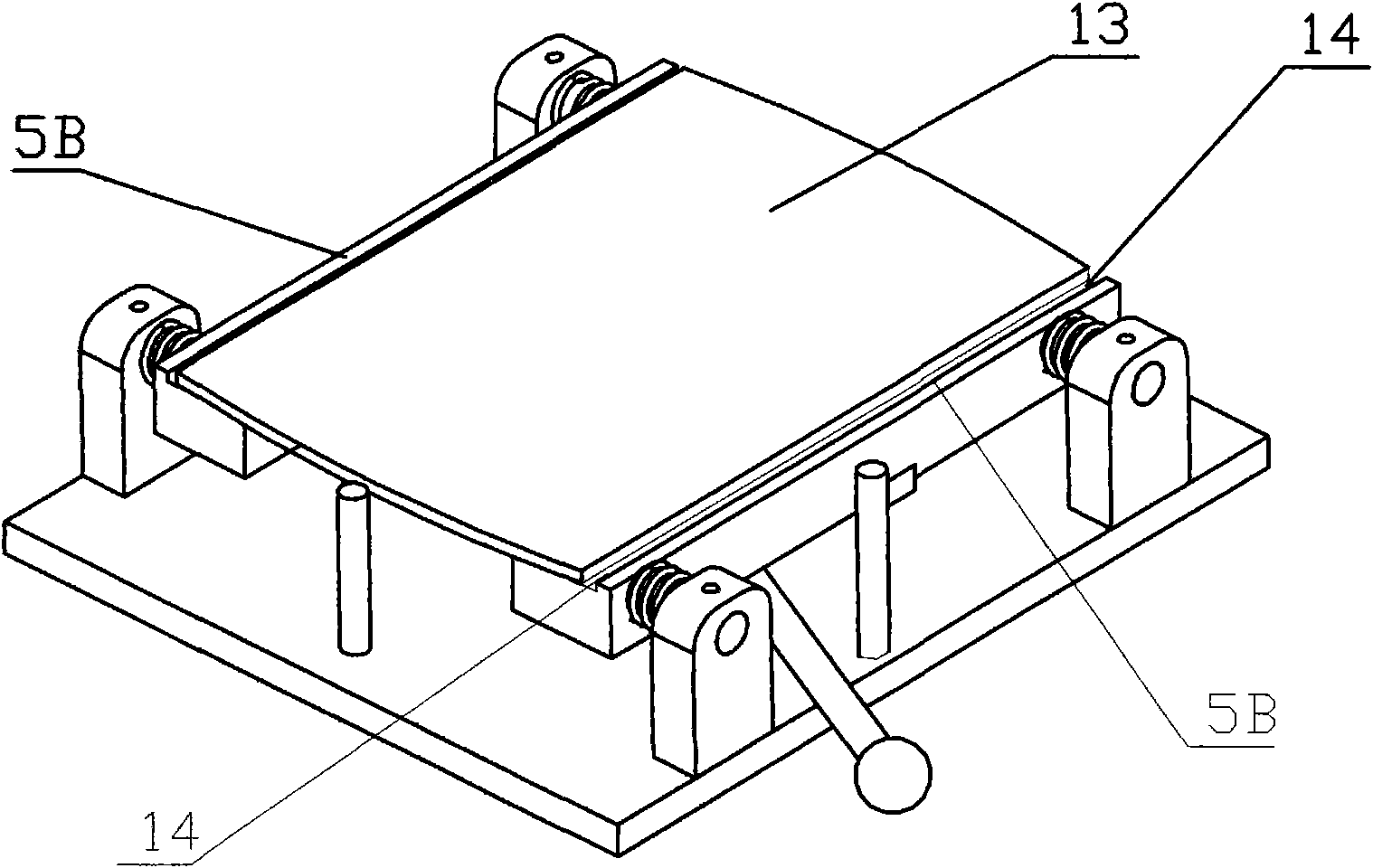

[0033] 1. The clamping and positioning device that can automatically align the center is characterized in that it includes a driving mechanism, a clamping mechanism, a guiding mechanism and a supporting mechanism. The driving mechanism includes a driving device and a driving force transmission device. The clamping mechanism includes a positioning plate 5, a guide The mechanism includes a guide column 3, the supporting mechanism includes a base 7, a fixed seat 10, the driving mechanism, the clamping mechanism and the guiding mechanism are supported by the supporting mechanism, the driving mechanism drives the positioning plate 5, and the guiding mechanism makes the positioning plate 5 move according to the guided moving route. Move, thereby, the positioning plate 5 can clamp the workpiece 13 to be processed, and make the center reference position of the workpiece 13 to be automatically located at the station positioned to the center (center line or center point).

[0034] 2. As ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com