Processing method of thin and long aluminium alloy thin-walled cylinder

A technology of thin-walled cylinders and processing methods, applied in metal processing equipment, manufacturing tools, non-electric welding equipment, etc., can solve the problems of large aspect ratio of the shell, difficult to coordinate processing, and thin walls, etc., to achieve high material utilization and improve Machining accuracy, the effect of ensuring product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0045] Embodiment 1, the processing method of aluminum alloy slender and thin-walled cylinder, comprises sequentially:

[0046] 1) Manufacturing steps of semi-finished parts:

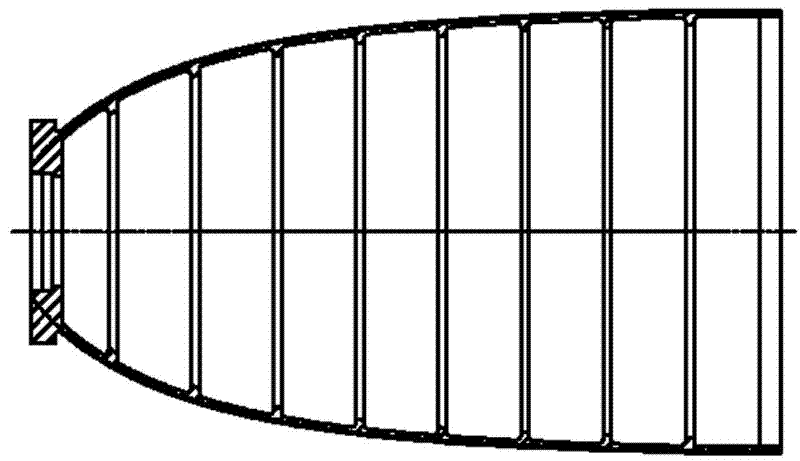

[0047] like figure 1 As shown, the shape of the molding shell 1 is a slender thin-walled cylinder with a curved shape, forming a semi-finished product 1;

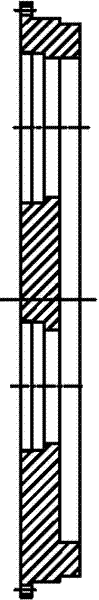

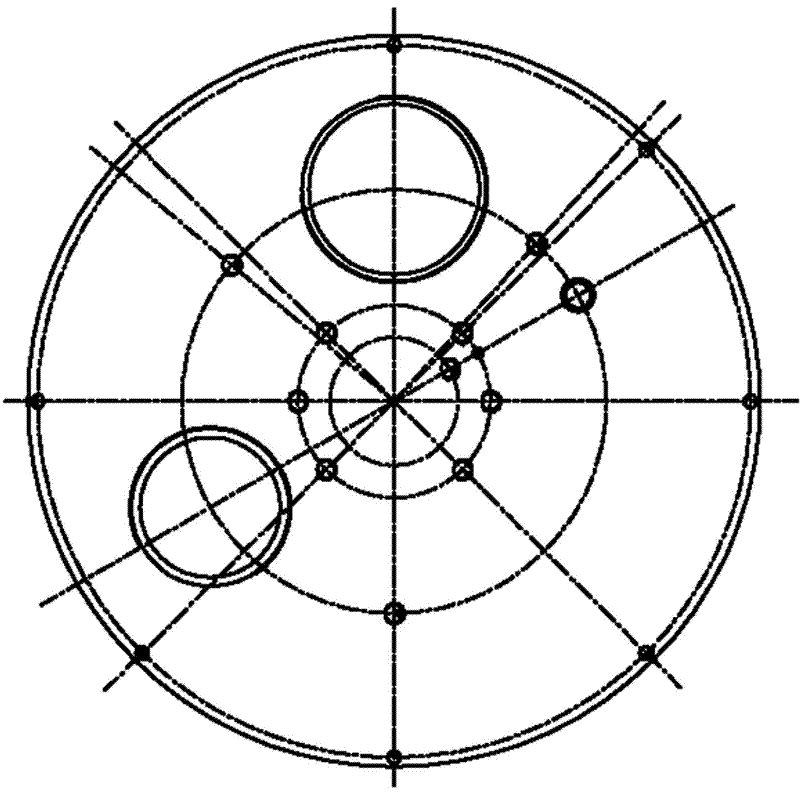

[0048] like figure 2 , image 3 As shown, the shape of the forming end frame 2 is a circular plate, and a plurality of holes with different diameters are processed on the end surface to form a semi-finished product 2;

[0049] 2) Supporting steps:

[0050] Complete set of shell 1 and end frame 2;

[0051] 3) Alkaline washing steps:

[0052] Clean the supporting parts;

[0053] 4) Trial installation steps, the sequence includes the following process:

[0054] 4.1 Use acetone or alcohol to clean the fitting surface and accessory area of the parts;

[0055] 4.2 Measure the inner diameter D1 of shell 1 and the fit surface size and interferenc...

Embodiment 2

[0082] Embodiment 2, the processing method of aluminum alloy slender and thin-walled cylinder, comprises:

[0083] 1) Manufacturing steps of semi-finished parts:

[0084] like figure 1 As shown, the shape of the molding shell 1 is a slender thin-walled cylinder with a curved shape, forming a semi-finished product 1;

[0085] like figure 2 , image 3 As shown, the shape of the forming end frame 2 is a circular plate, and a plurality of holes with different diameters are processed on the end surface to form a semi-finished product 2;

[0086] 2) Matching steps: complete set of shell 1 and end frame 2;

[0087] 3) Alkaline washing steps:

[0088] Clean the supporting parts;

[0089] 4) Trial installation steps, the sequence includes the following process:

[0090] 4.1 Use acetone or alcohol to clean the fitting surface and accessory area of the parts;

[0091] 4.2 Measure the inner diameter D1 of shell 1 and the fit surface size and interference of end frame 2 respecti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Roundness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com