Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

189results about How to "Increase plasma density" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Gas separation type showerhead

InactiveUS20070163440A1Minimize hydrogen contentIncrease diversityElectric discharge tubesExternal electric electrostatic seperatorEngineeringProcess engineering

Provided is a gas separation type showerhead for effective energy supply. The gas separation type showerhead includes: a gas supply module to which a first gas and a second gas are separately supplied; a gas separation module in which the supplied first and second gases are separately dispersed; and a gas injection module which is a multi-hollow cathode having a plurality of holes and in which the first and second gases separately dispersed are ionized in the holes to be commonly dispersed.

Owner:ATO

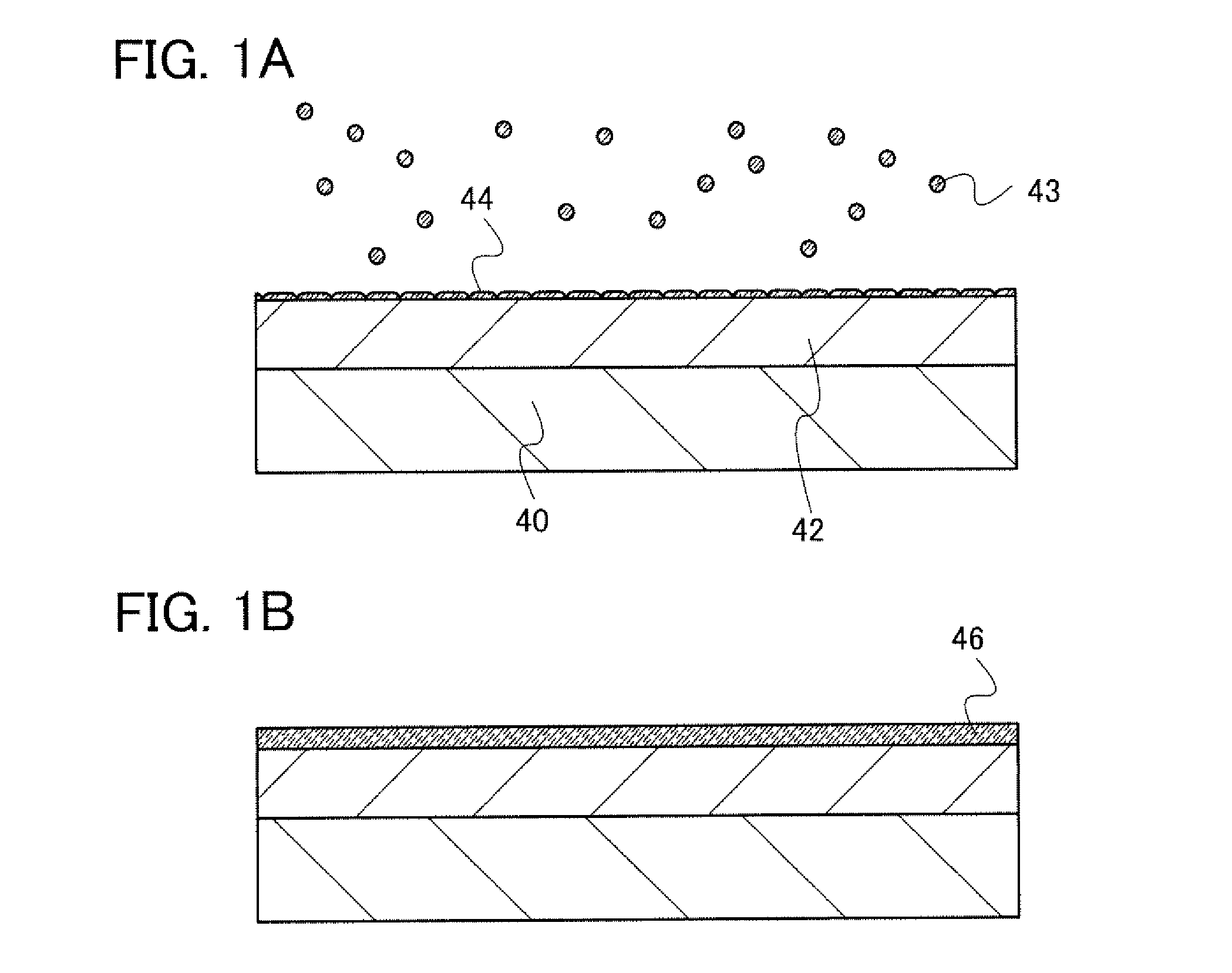

Method for manufacturing photoelectric conversion device

InactiveUS20090029503A1Quality improvementReduce deterioration rateFinal product manufactureSemiconductor/solid-state device manufacturingProduction rateMicrowave

To form a microcrystalline semiconductor with high quality which can be directly formed at equal to or less than 500° C. over a large substrate with high productivity without decreasing a deposition rate. In addition, to provide a photoelectric conversion device which employs the microcrystalline semiconductor as a photoelectric conversion layer. A reactive gas containing helium is supplied to a treatment chamber which is surrounded by a plurality of juxtaposed waveguides and a wall, the pressure in the treatment chamber is maintained at an atmospheric pressure or a subatmospheric pressure, microwave is supplied to a space sandwiched between the juxtaposed waveguides to generate plasma, and a photoelectric conversion layer of a microcrystalline semiconductor is deposited over a substrate which is placed in the treatment chamber.

Owner:SEMICON ENERGY LAB CO LTD

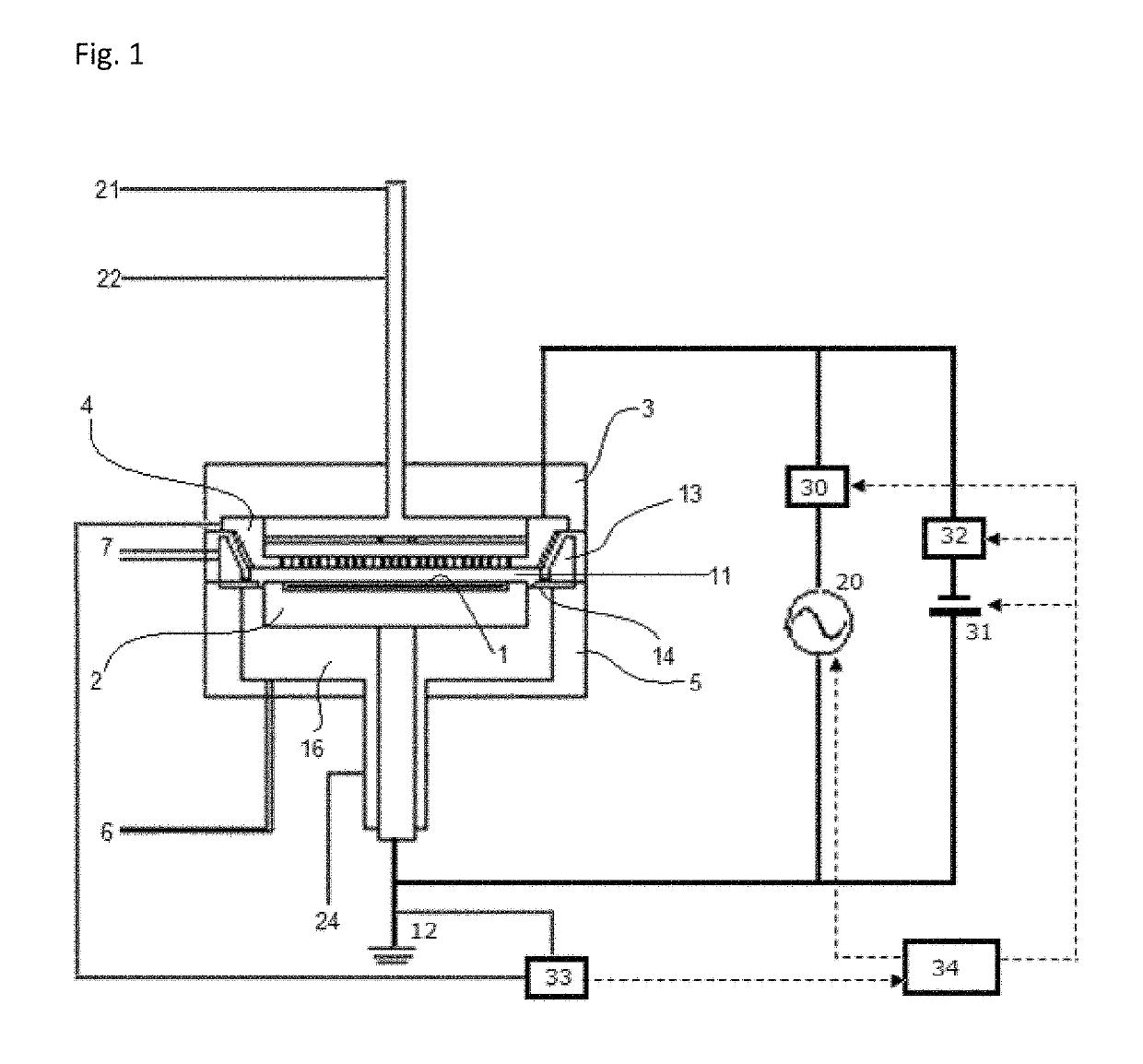

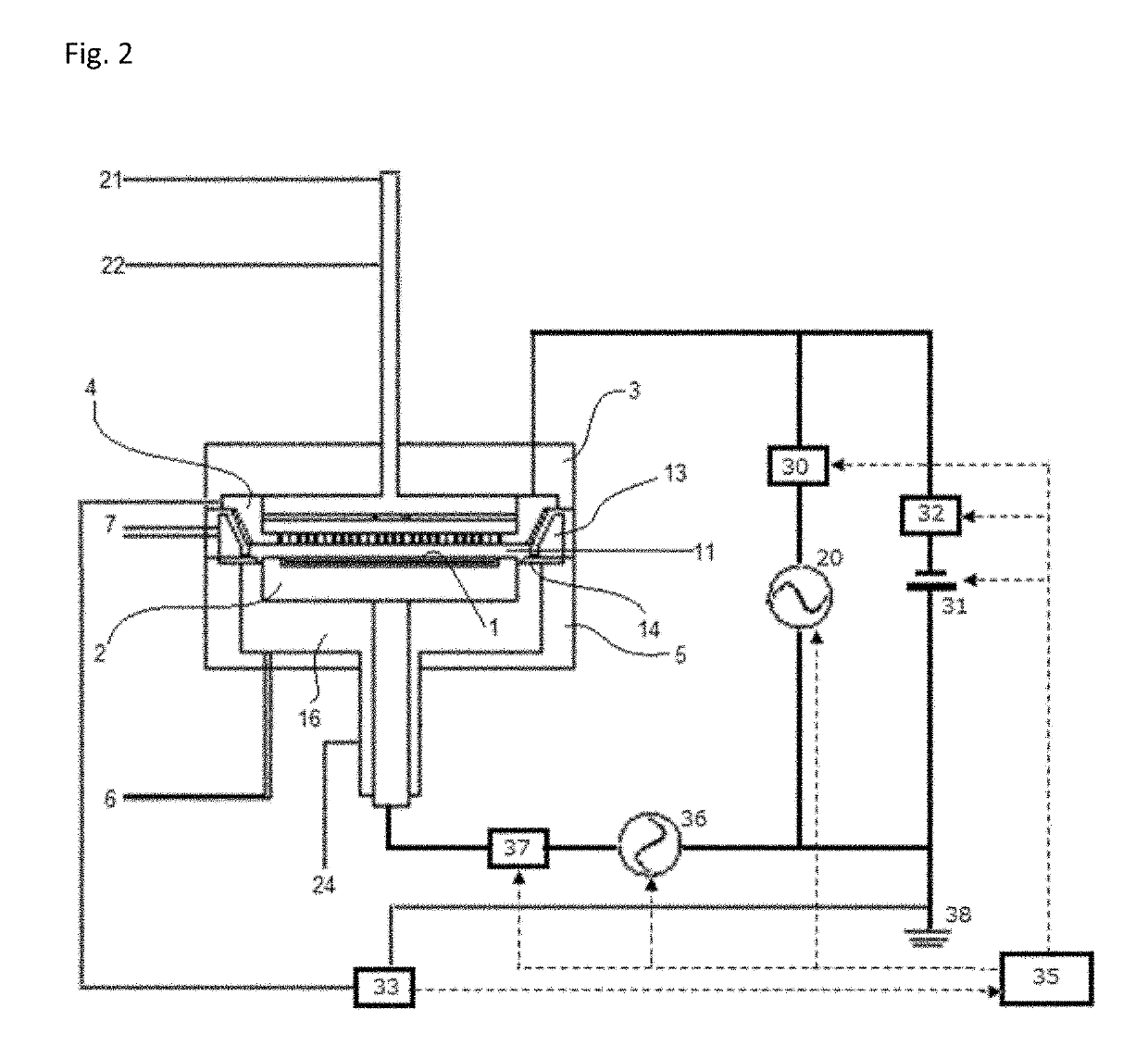

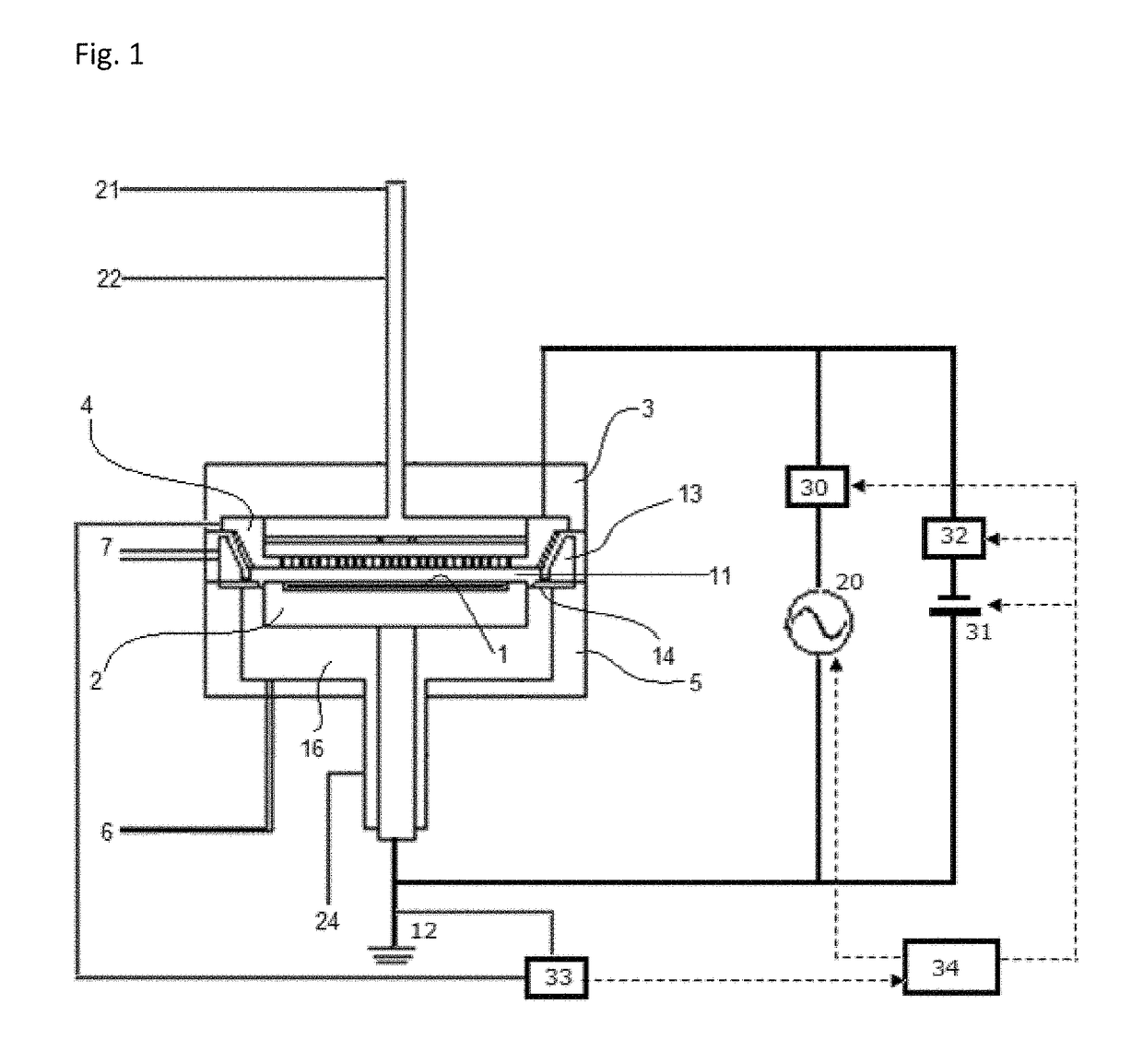

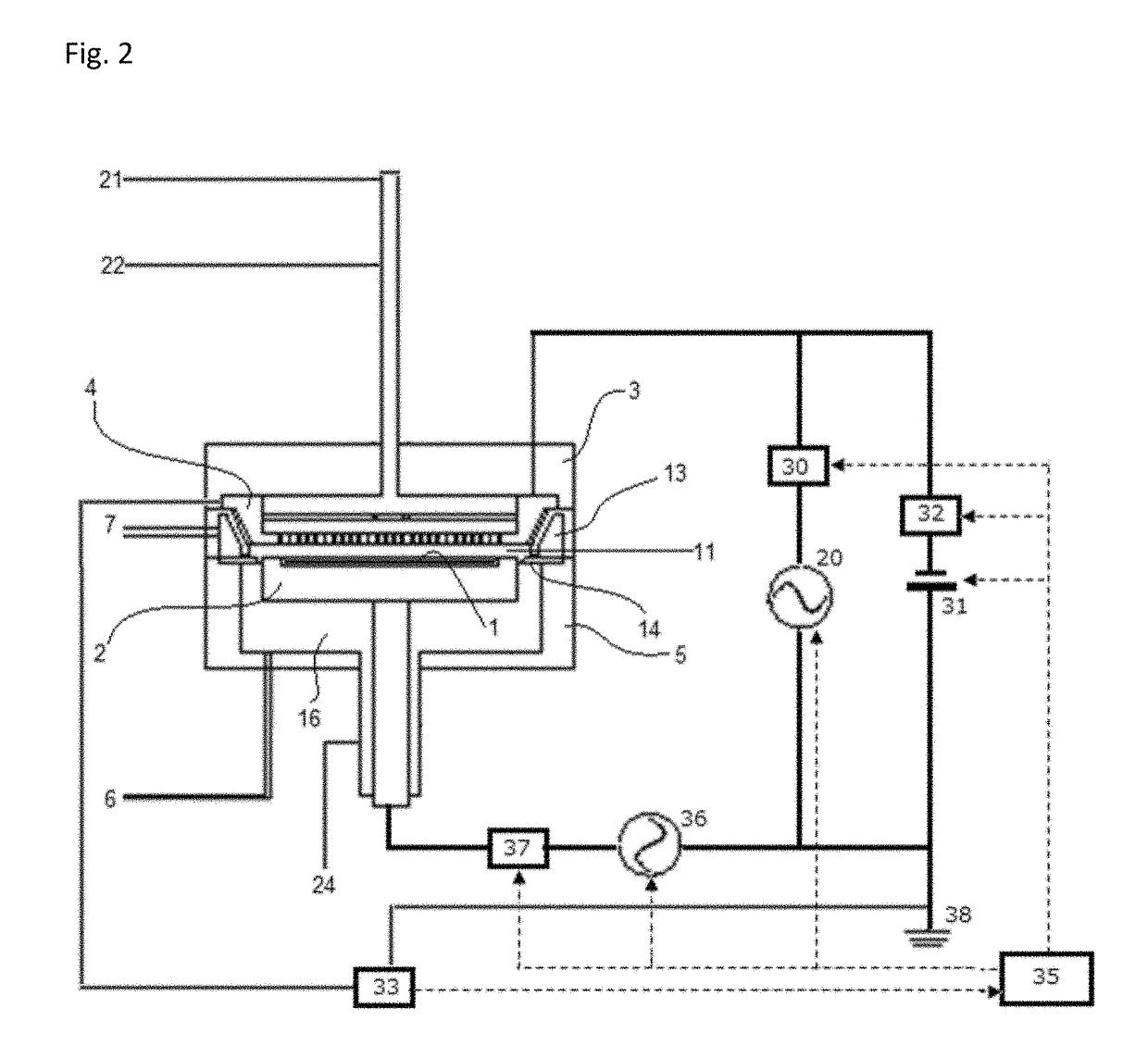

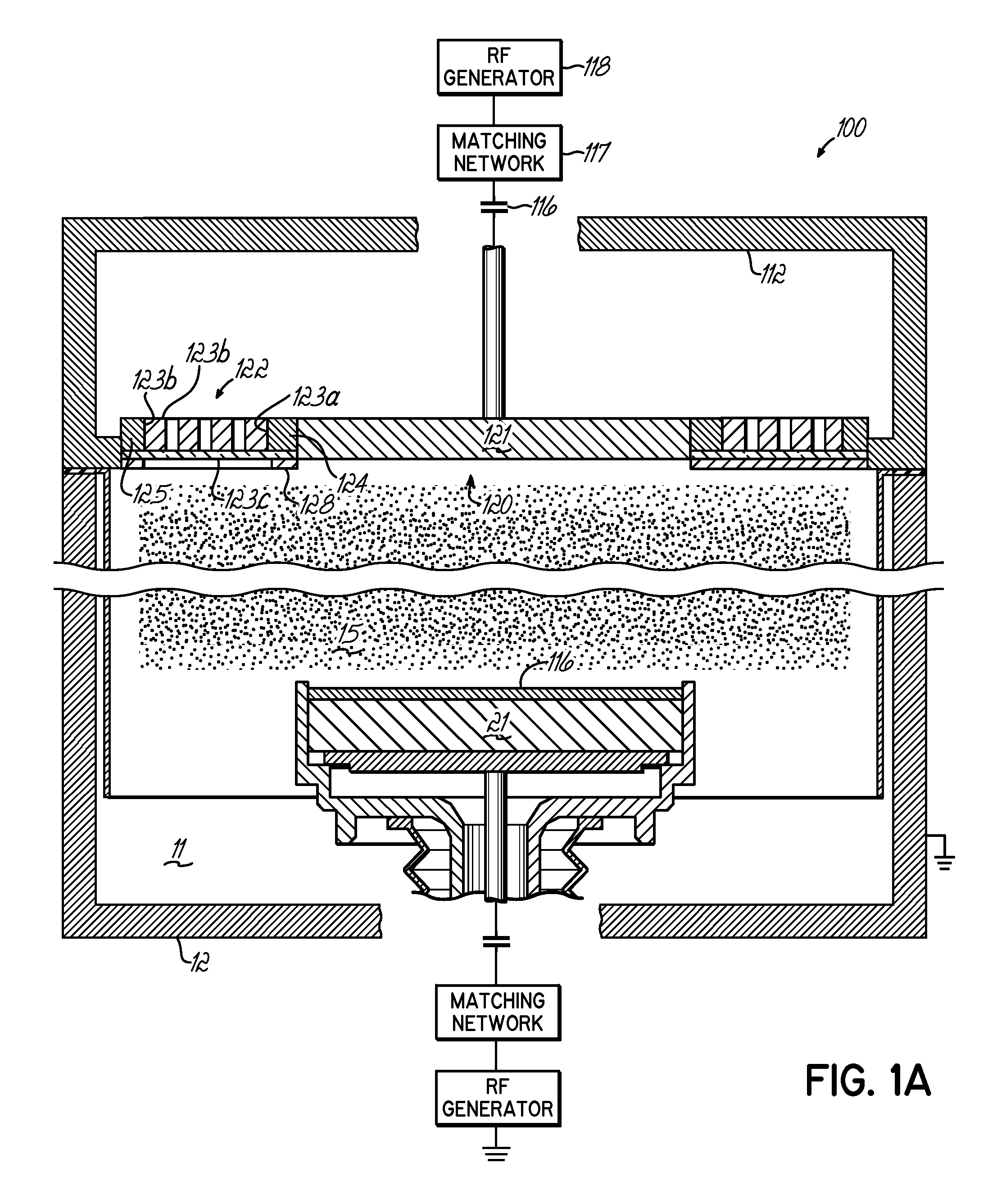

Method of depositing film by PEALD using negative bias

ActiveUS10312055B2Less particle generationLower average energyElectric discharge tubesSemiconductor/solid-state device manufacturingPhysical chemistryThin membrane

A method of forming a film on a substrate by PEALD includes deposition cycles, each including (i) feeding a precursor in a pulse to a reaction space to adsorb a precursor on a surface of a substrate; (ii) after step (i), applying RF power to a second electrode to generate in the reaction space a plasma to which the precursor-adsorbed surface is exposed, thereby forming a sublayer on the surface; and (iii) applying a bias voltage to the second electrode while applying RF power in step (ii), which bias voltage is negative with reference to a potential on a surface of the first electrode, wherein the cycle is repeated to deposit multiple sublayers until a film constituted by the sublayers has a desired thickness.

Owner:ASM IP HLDG BV

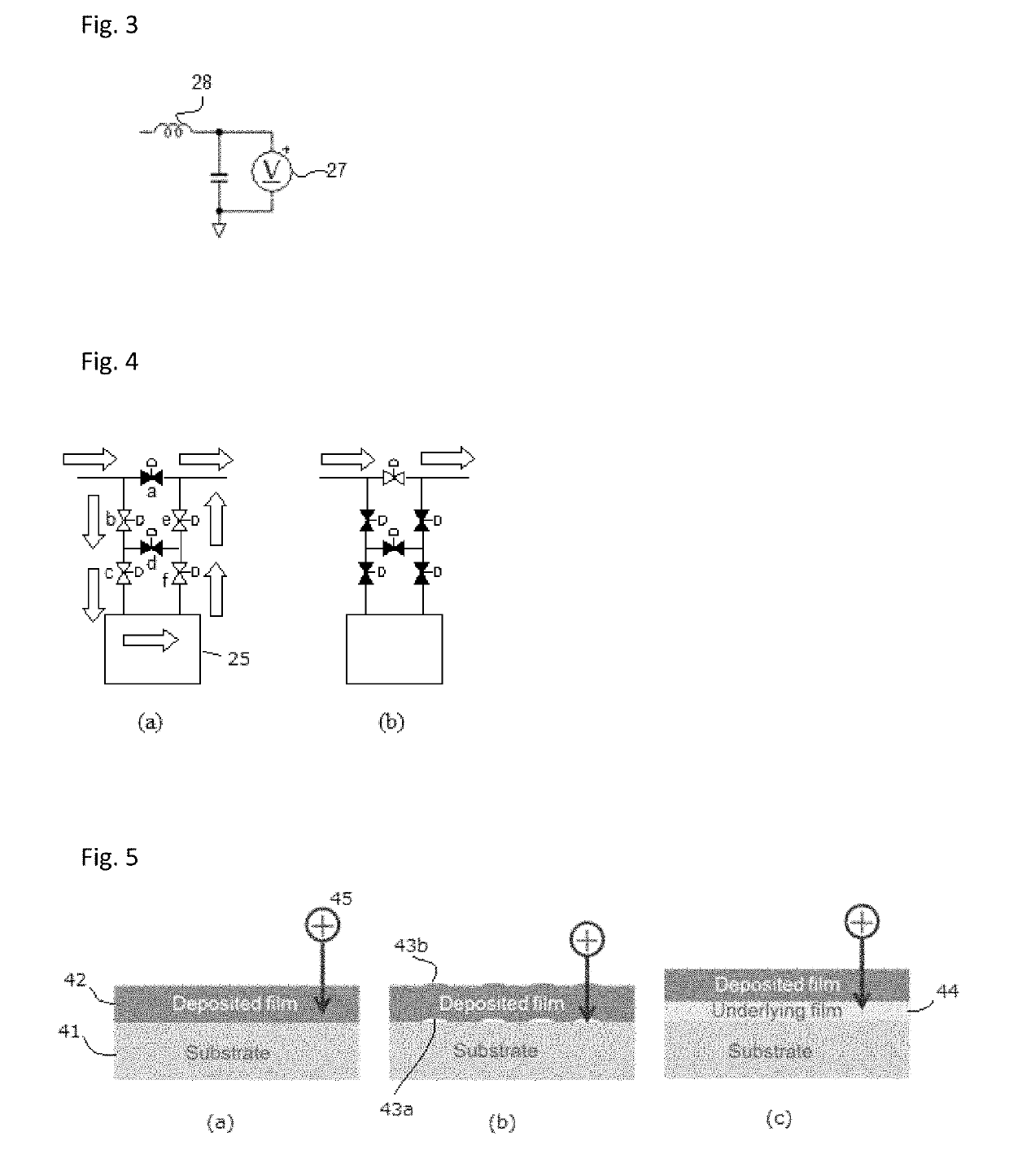

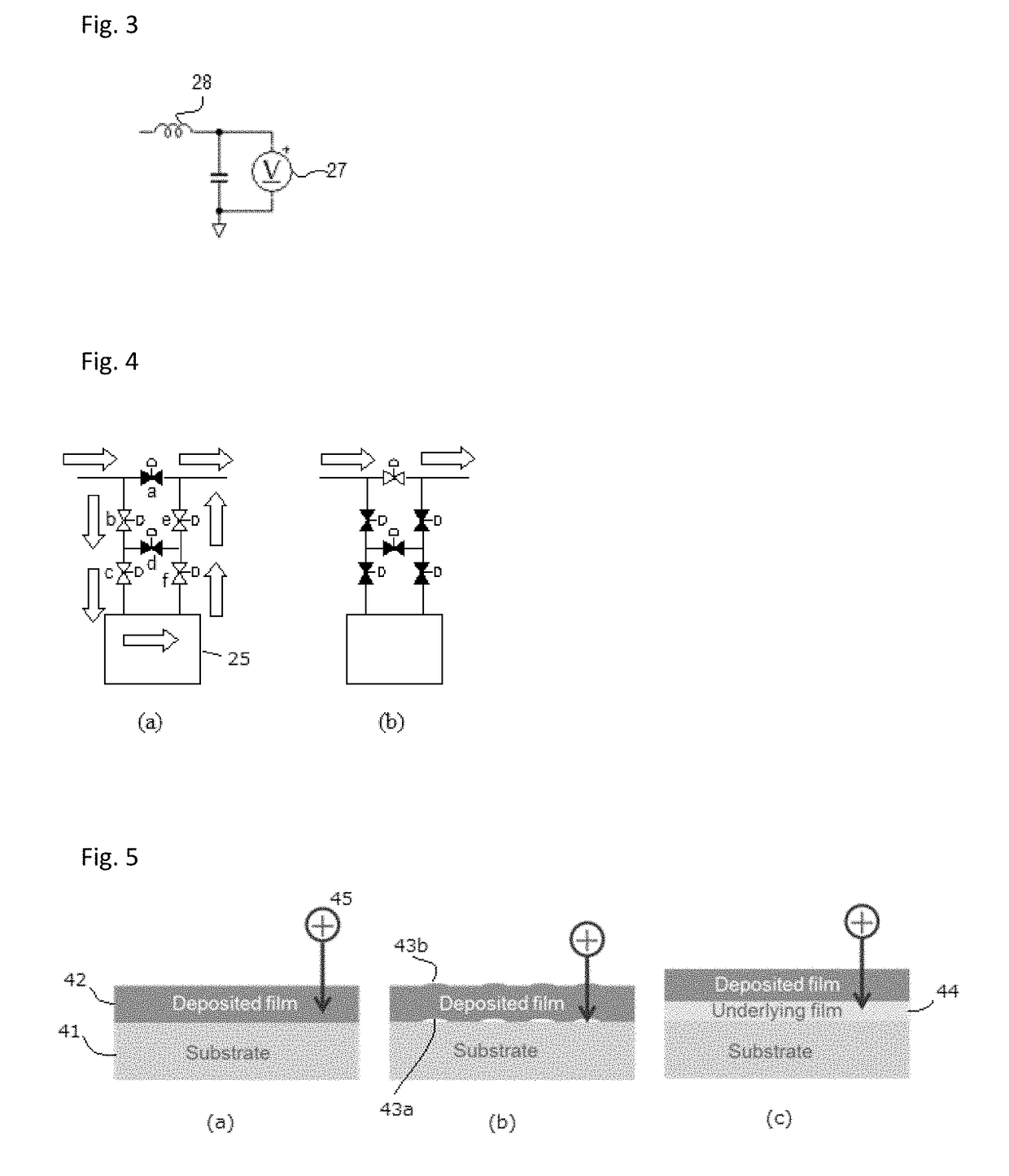

Method of depositing film by peald using negative bias

ActiveUS20190035605A1Low ion energyHigh throughputElectric discharge tubesSemiconductor/solid-state device manufacturingEngineeringNegative bias

A method of forming a film on a substrate by PEALD includes deposition cycles, each including (i) feeding a precursor in a pulse to a reaction space to adsorb a precursor on a surface of a substrate; (ii) after step (i), applying RF power to a second electrode to generate in the reaction space a plasma to which the precursor-adsorbed surface is exposed, thereby forming a sublayer on the surface; and (iii) applying a bias voltage to the second electrode while applying RF power in step (ii), which bias voltage is negative with reference to a potential on a surface of the first electrode, wherein the cycle is repeated to deposit multiple sublayers until a film constituted by the sublayers has a desired thickness.

Owner:ASM IP HLDG BV

Capacitively coupled remote plasma source with large operating pressure range

InactiveUS20100101727A1System costExtension of timeElectric discharge tubesSemiconductor/solid-state device manufacturingCapacitanceRadio frequency

A radio frequency (RF) coaxial resonator feeding a saltshaker-like gas distributing electrode assembly forms a capacitively coupled plasma source. This apparatus can generate plasma of high density over a wide pressure range and large process window. The system may be used as a remote radical-rich plasma source for materials surface processing.

Owner:JI HELIN

Capacitive-coupled plasma processing apparatus and method for processing substrate

ActiveUS20130032574A1Adjust electric field strengthIncrease the electric field strengthElectric discharge tubesDecorative surface effectsCapacitanceHigh pressure

The present invention relates to a capacitive-coupled plasma processing apparatus, wherein an electric field regulating element, i.e., an “electric field lens”, is arranged in the reaction chamber to generate a regenerated electric field in a direction opposite to that of the original radio frequency electric field in the reaction chamber, so that the non-uniformity of etching rate on the surface of the substrate of the plasma incurred by the original radio frequency electric field is decreased; and the electric field regulating element, i.e., the “electric field lens”, further decreases the equivalent quality factor Q value of the reaction chamber, expands the radio frequency band, and prevents high-voltage electric arcing. The present invention further provides a method for processing the substrate using the processing apparatus.

Owner:ADVANCED MICRO FAB EQUIP INC CHINA

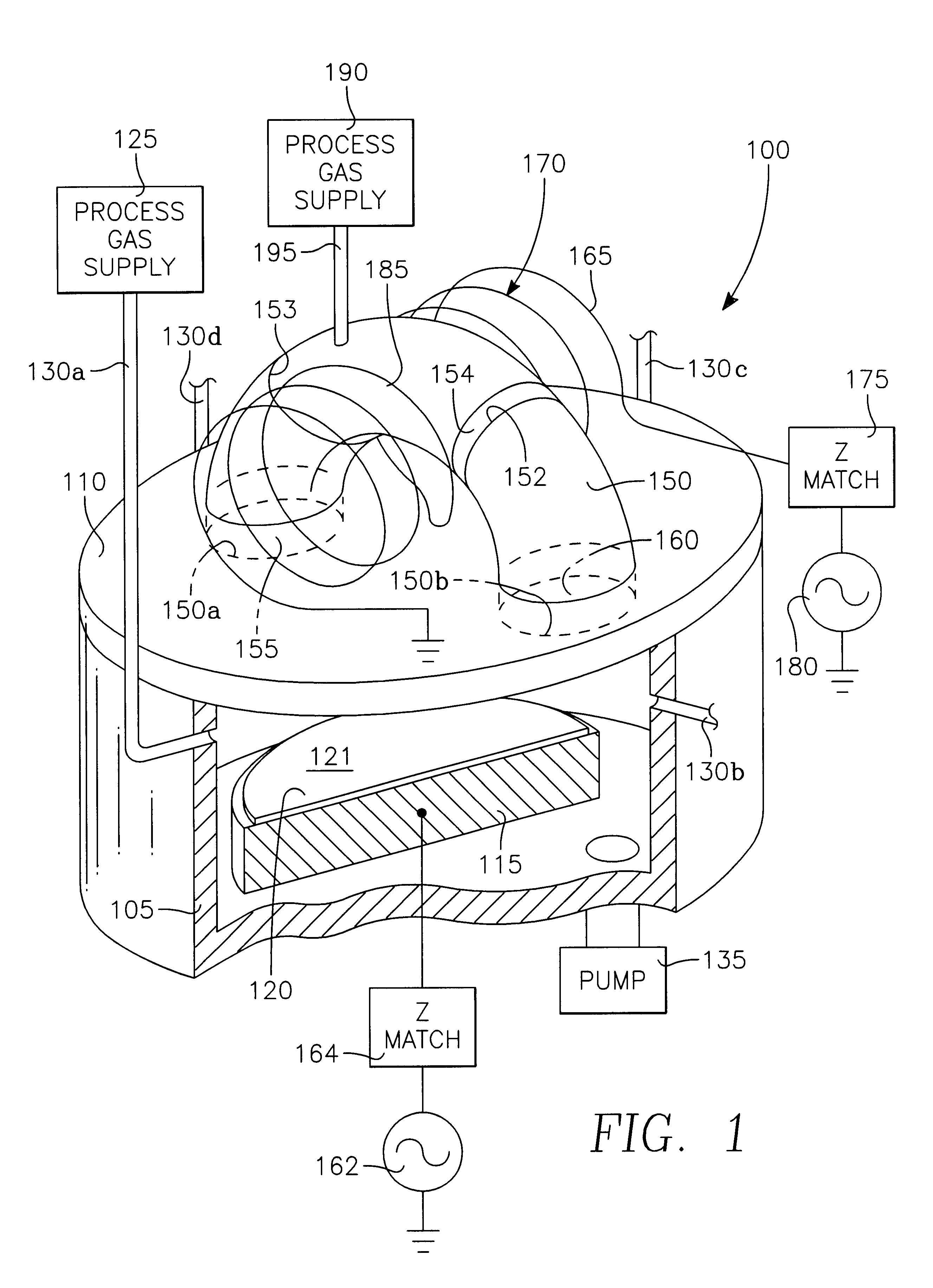

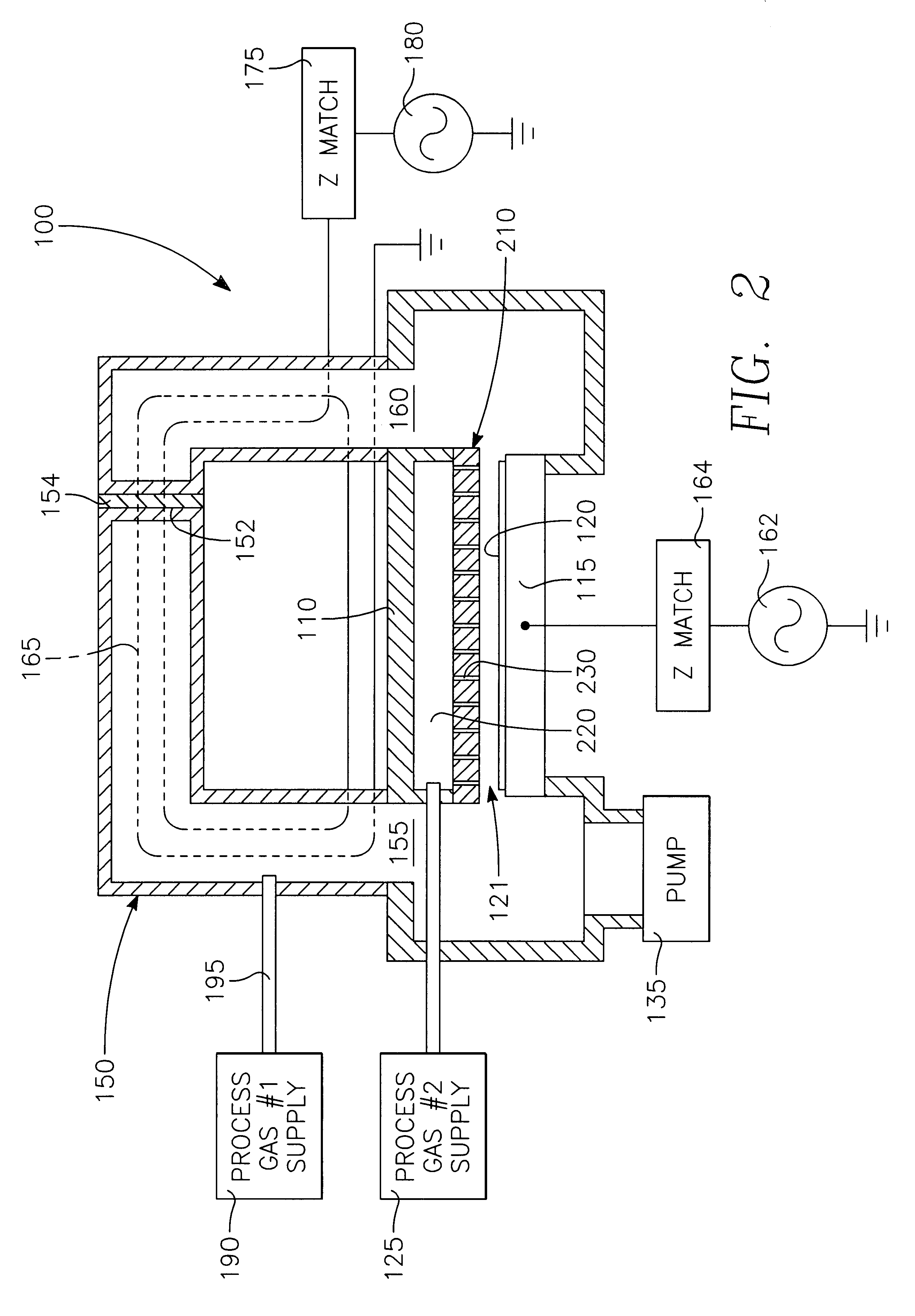

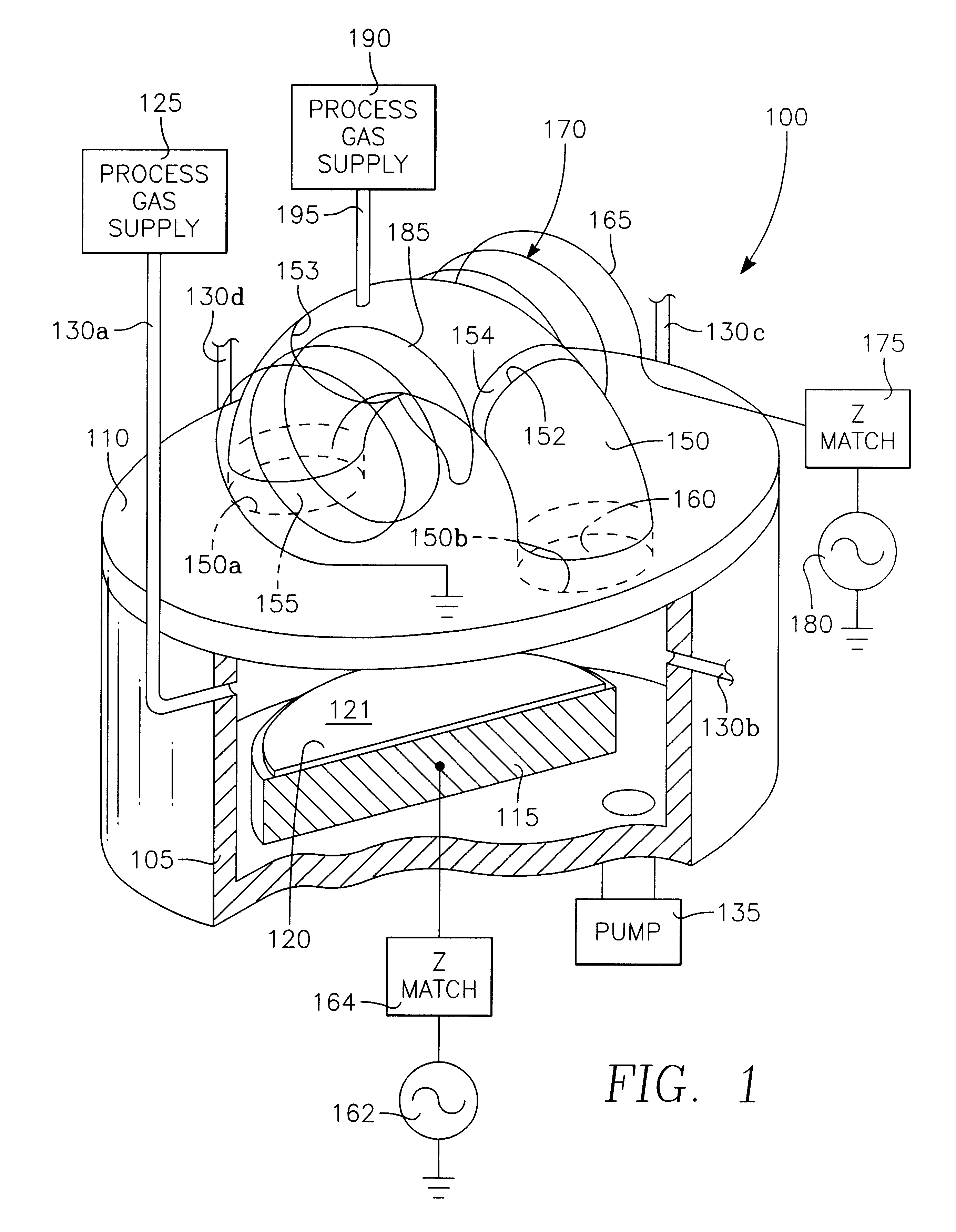

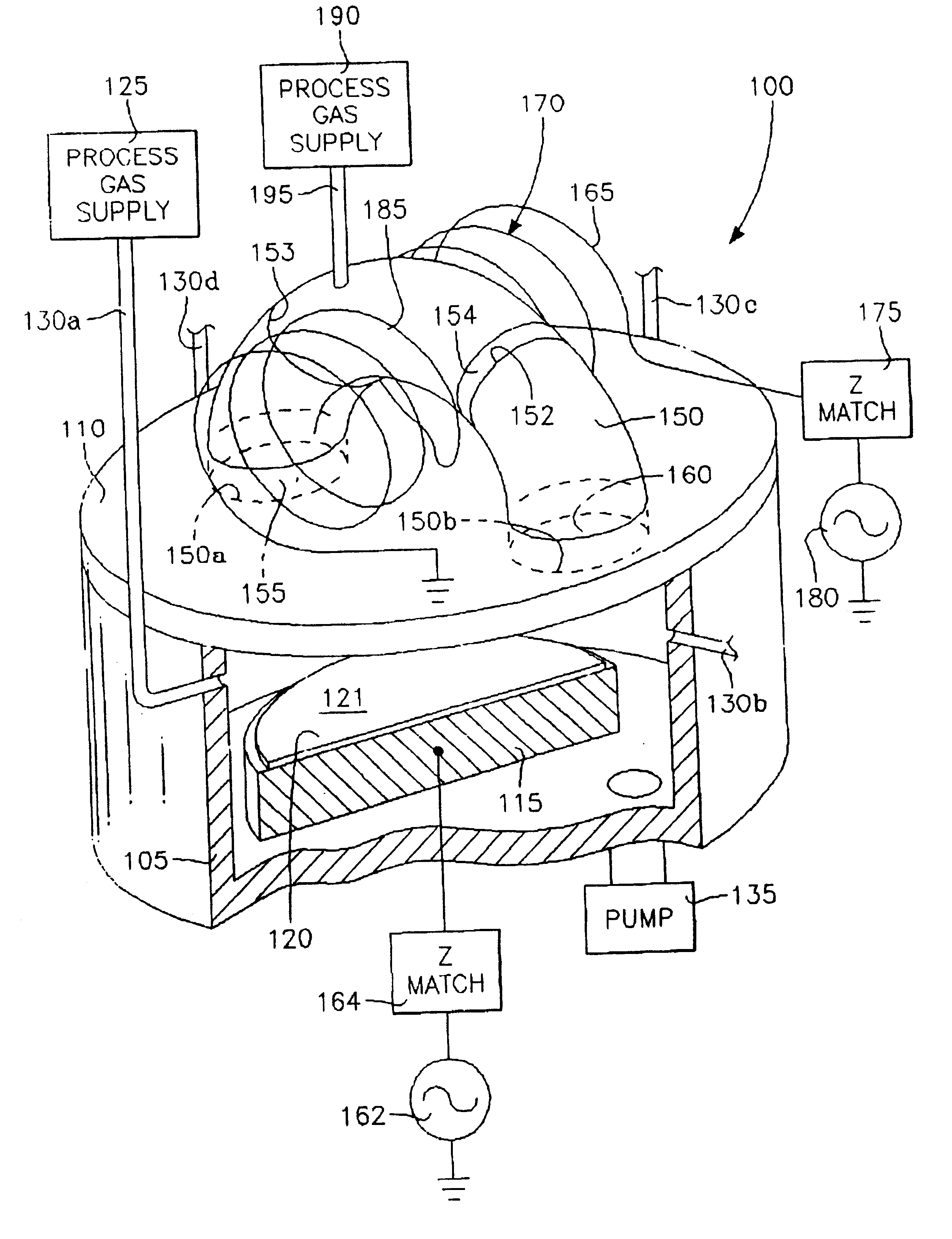

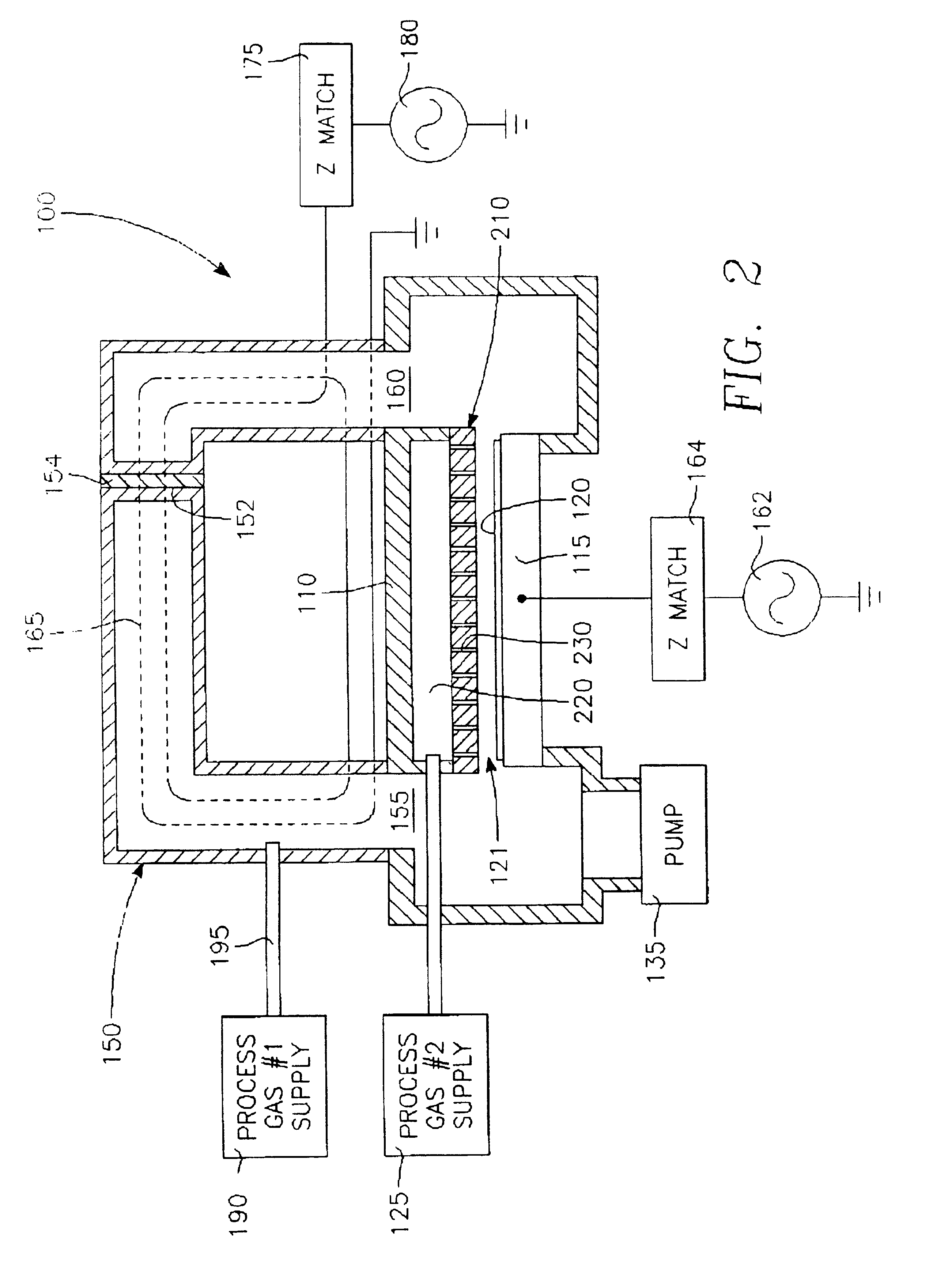

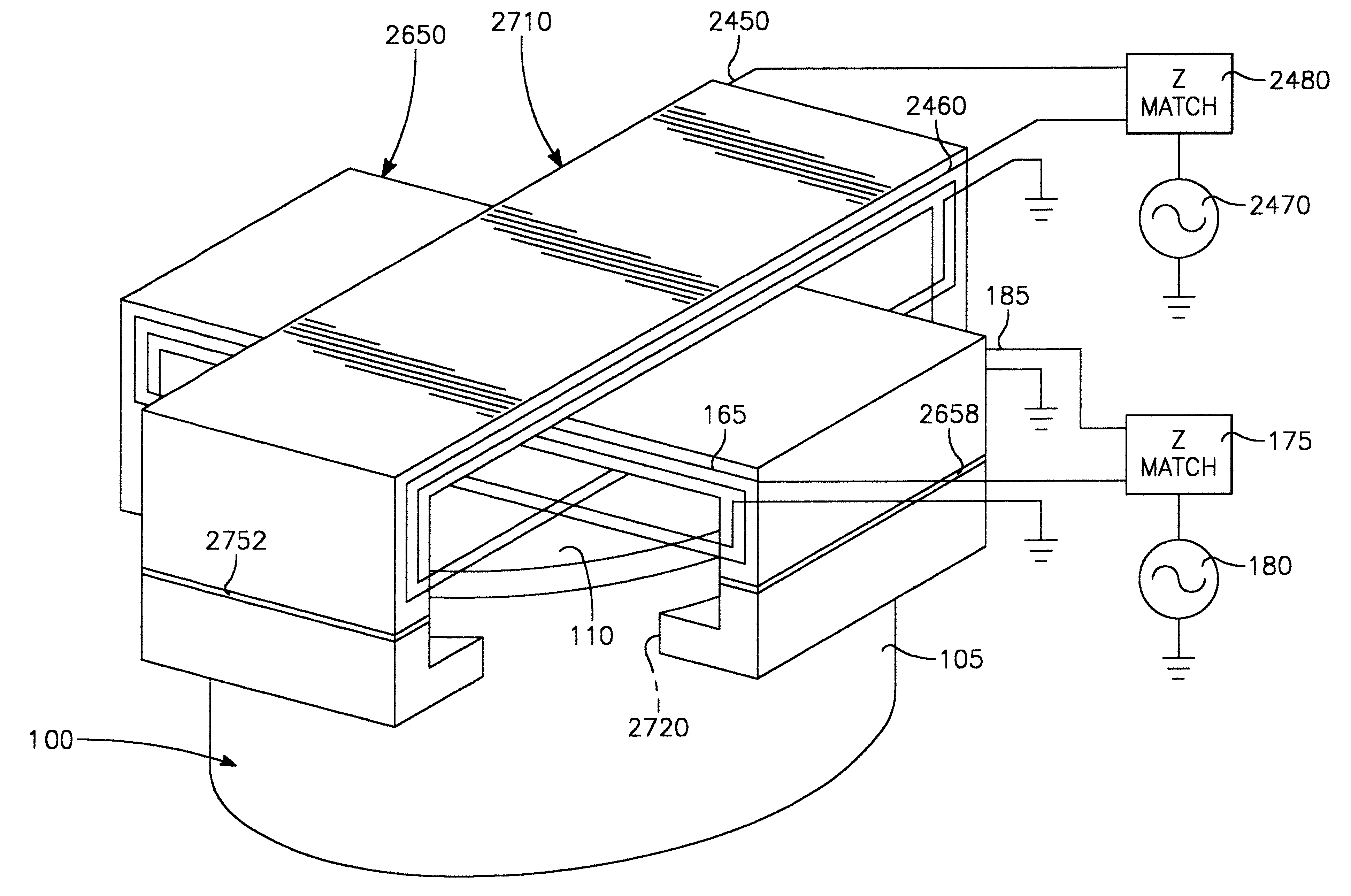

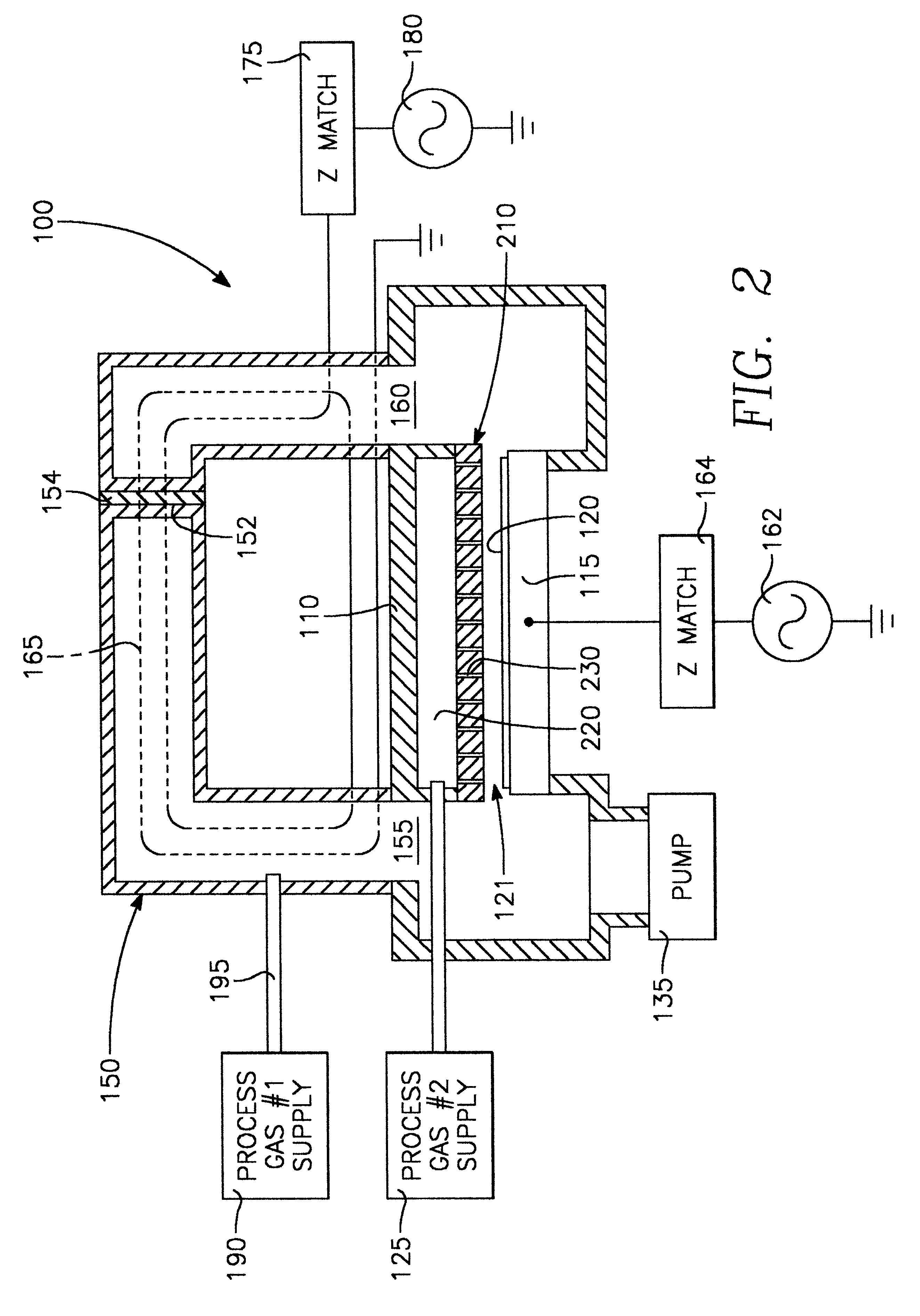

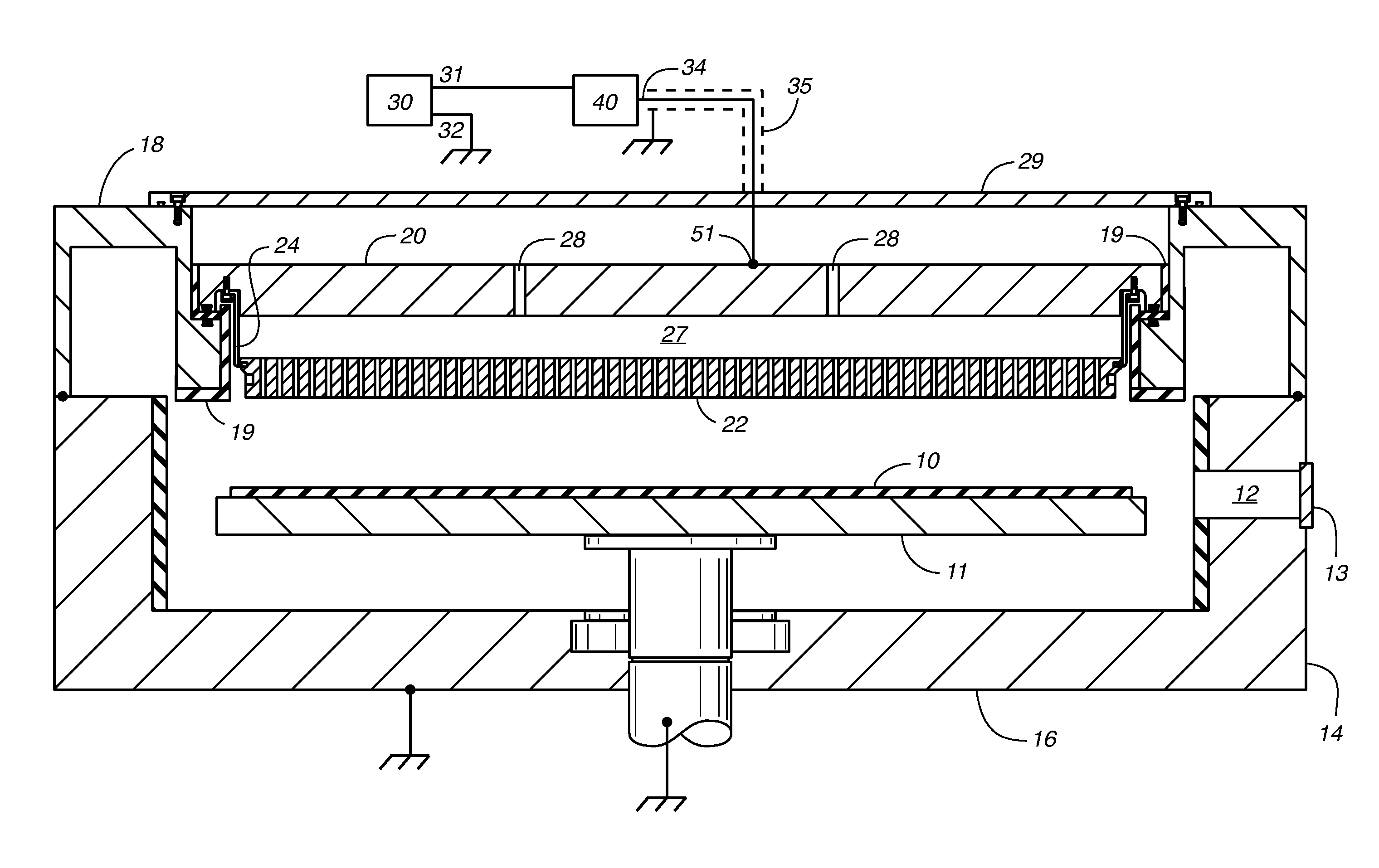

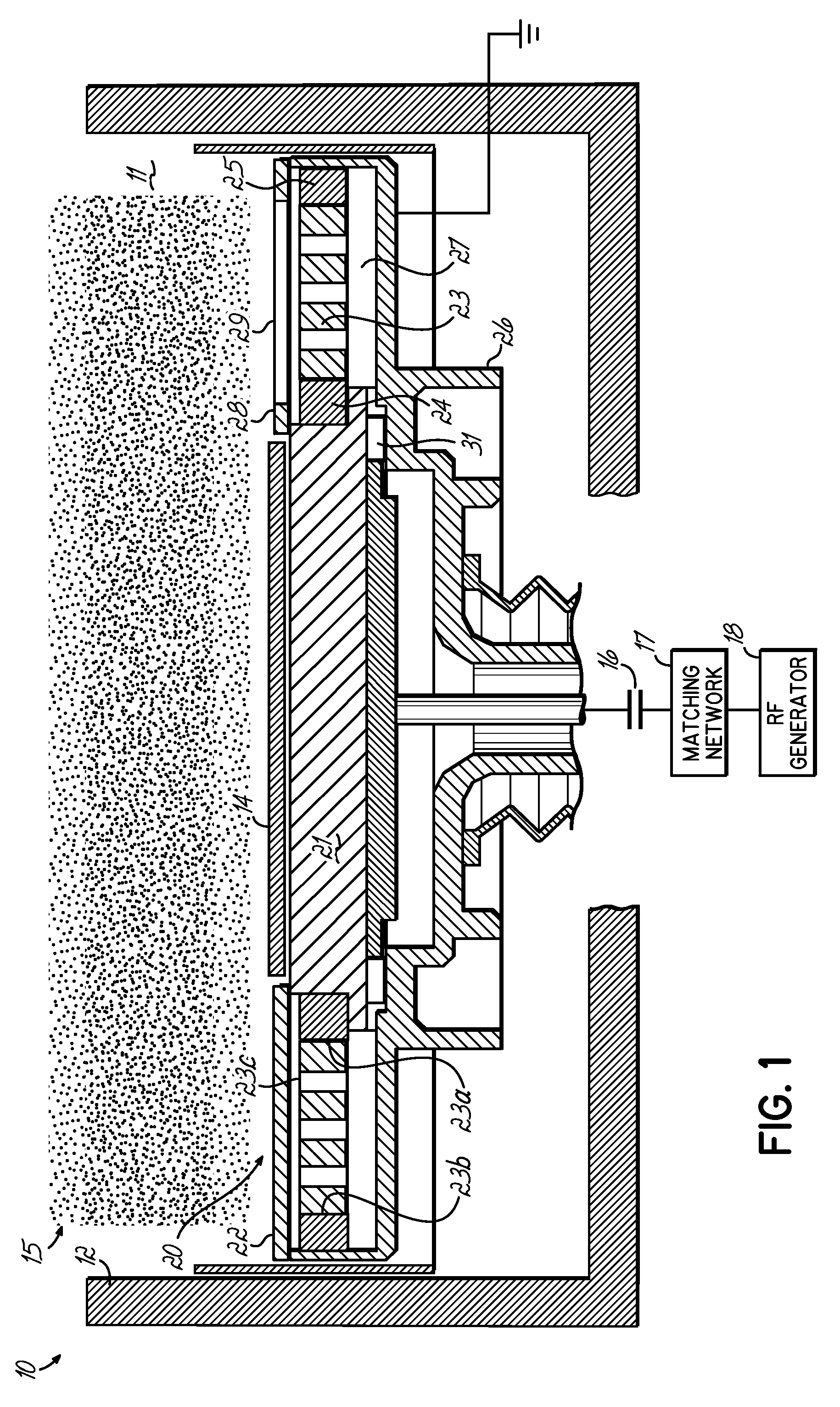

Externally excited torroidal plasma source

InactiveUS6348126B1Increase plasma densityImprove etch selectivityElectric discharge tubesSemiconductor/solid-state device manufacturingEnergy applicatorEngineering

A plasma reactor for processing a workpiece includes a chamber adapted to accept processing gases in an evacuated environment including a workpiece support, a hollow conduit defining a wall of the chamber, and having respective ends opening adjacent opposite sides of the workpiece support, and a chamber wall portion in facing relationship to the workpiece support and defining a workpiece processing zone therebetween, the processing zone and the interior of the conduit forming a torroidal interior path, and an RF energy applicator irradiating gas within the chamber to maintain a plasma within the torroidal interior path.

Owner:APPLIED MATERIALS INC

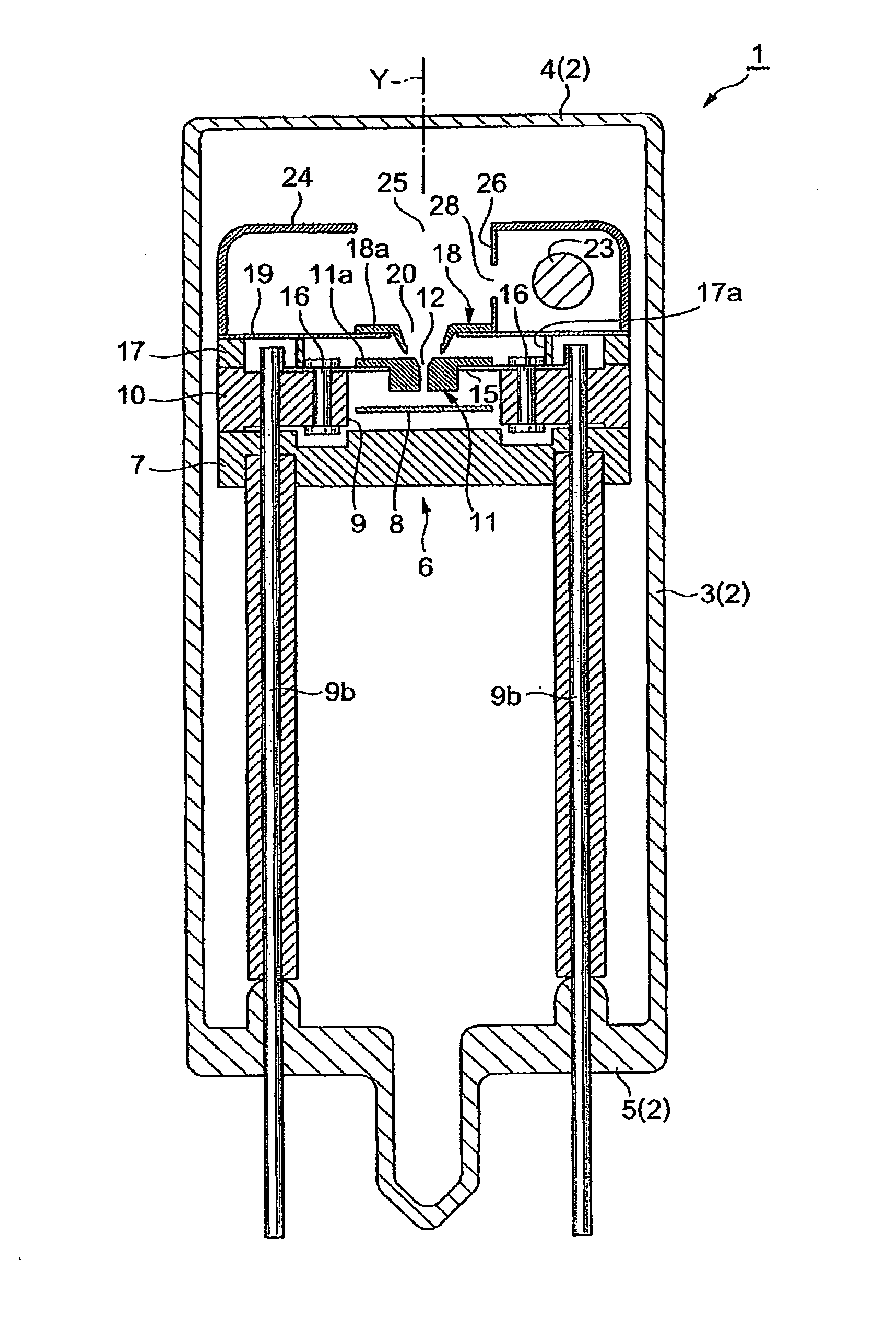

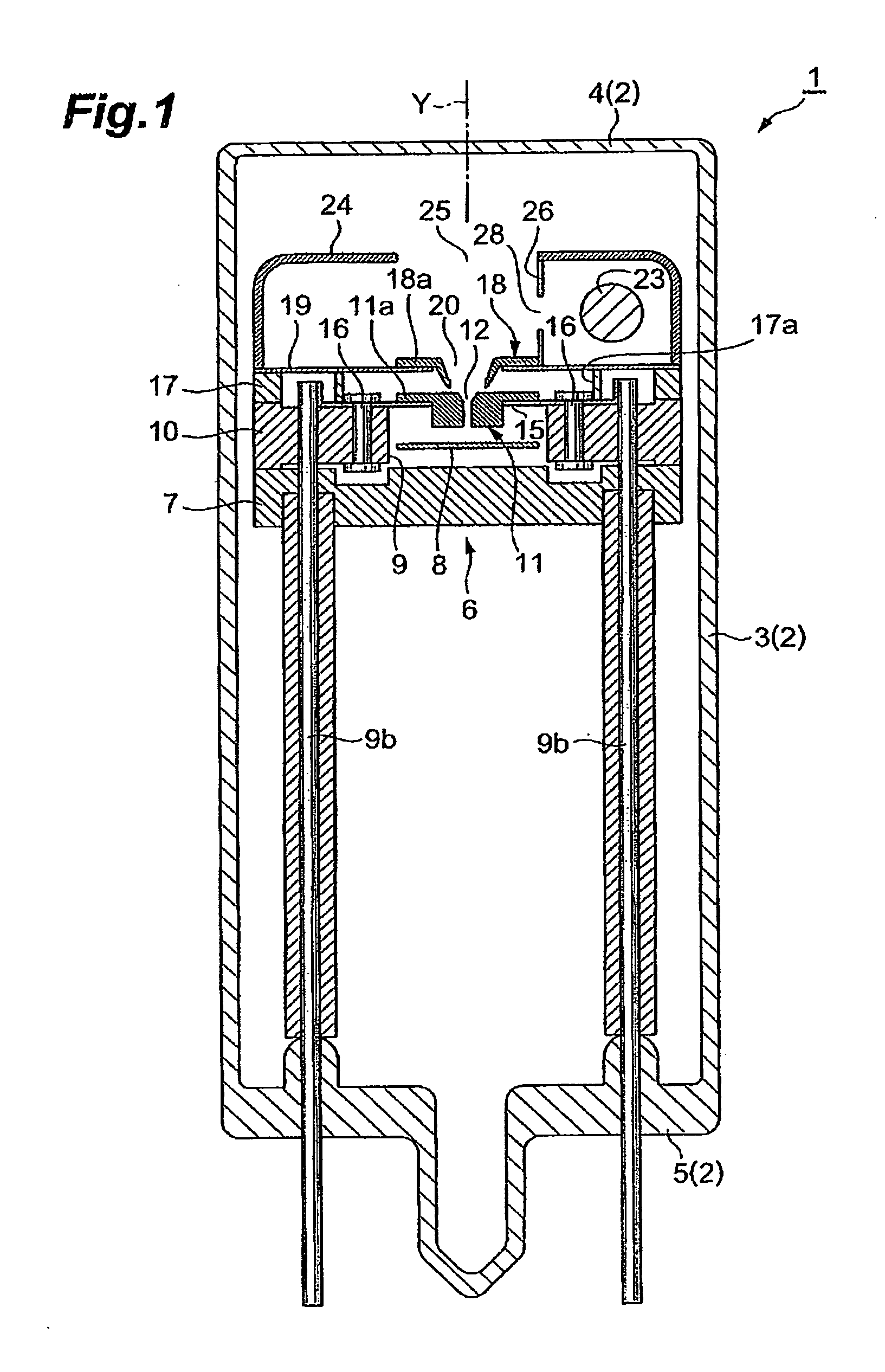

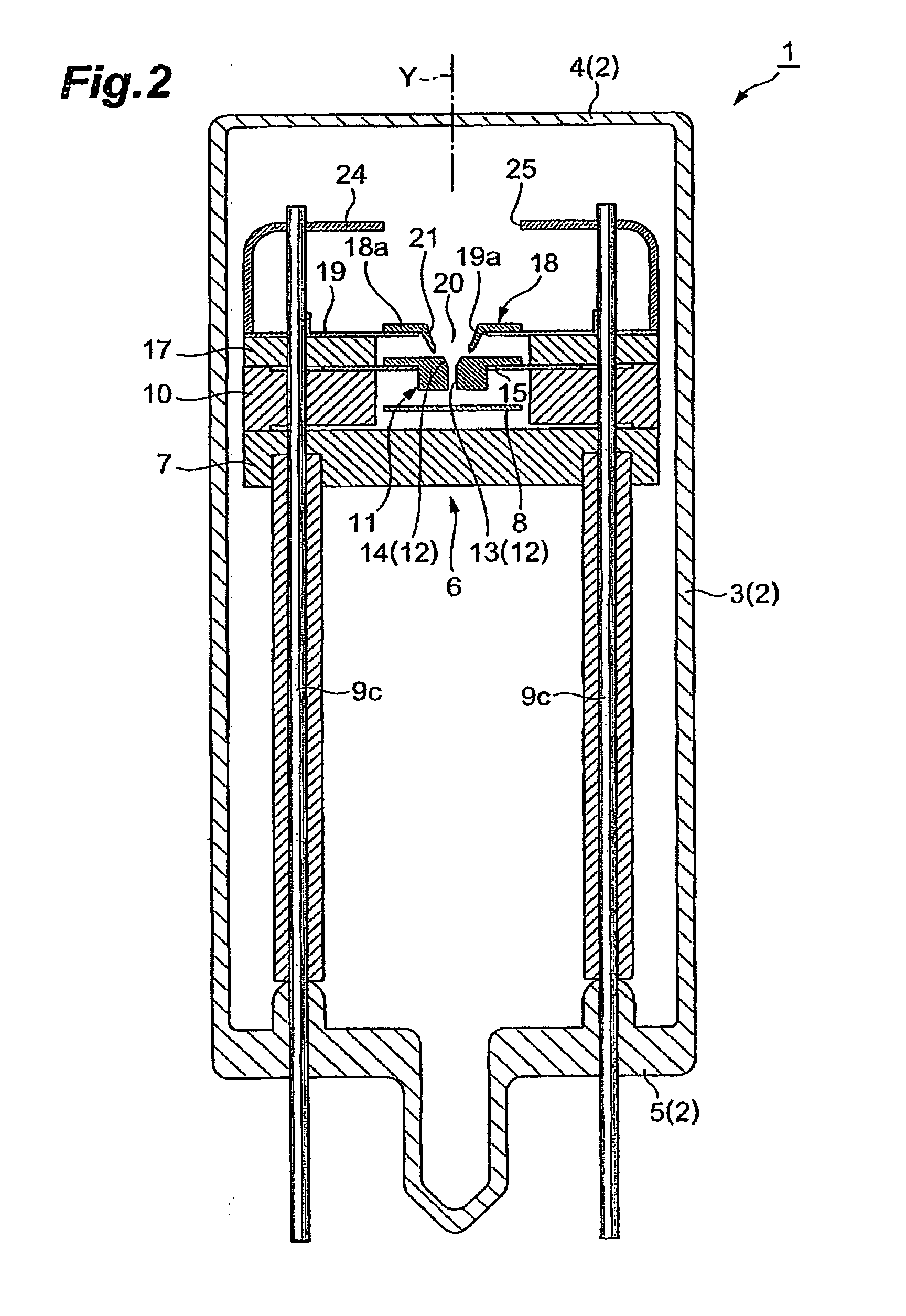

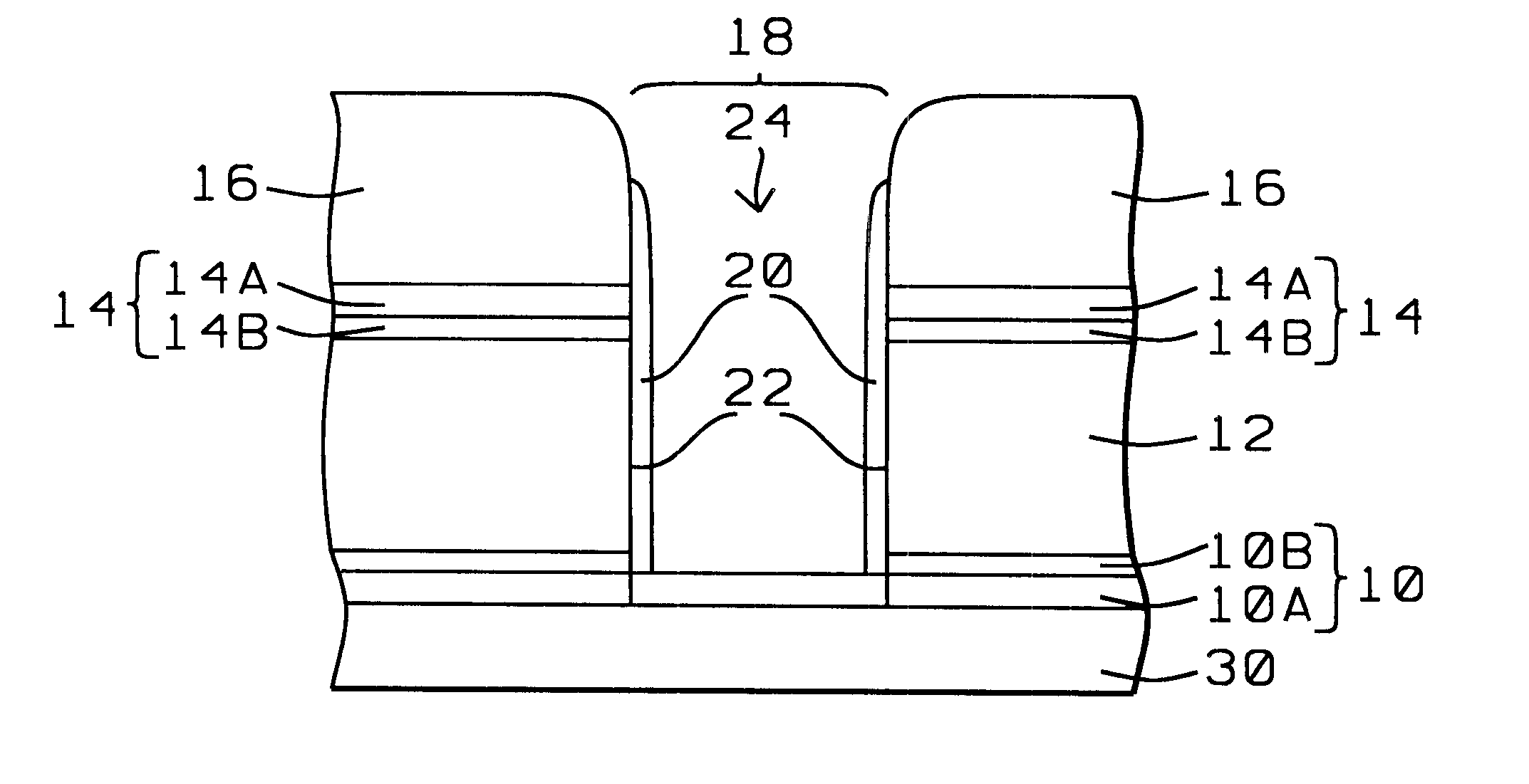

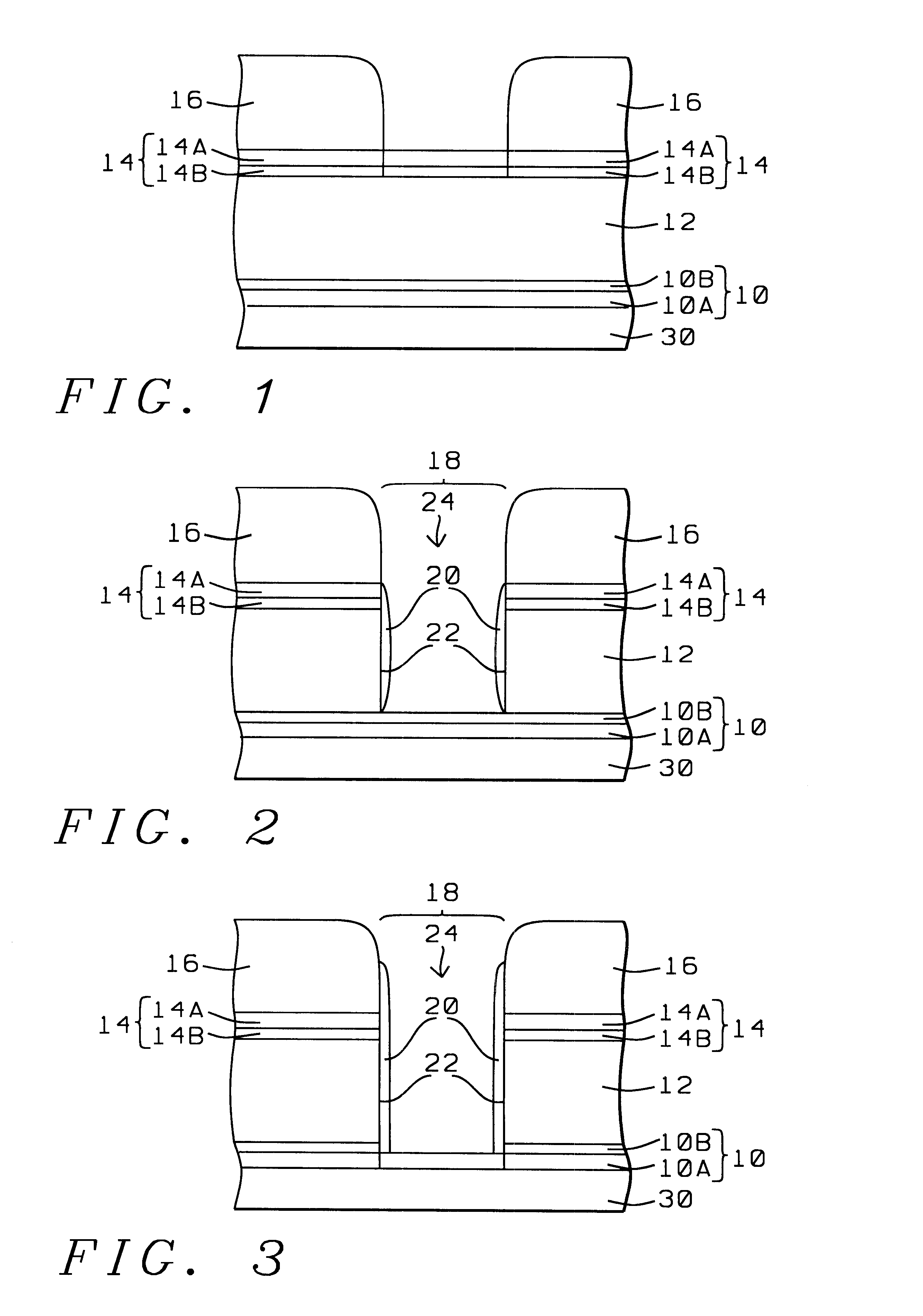

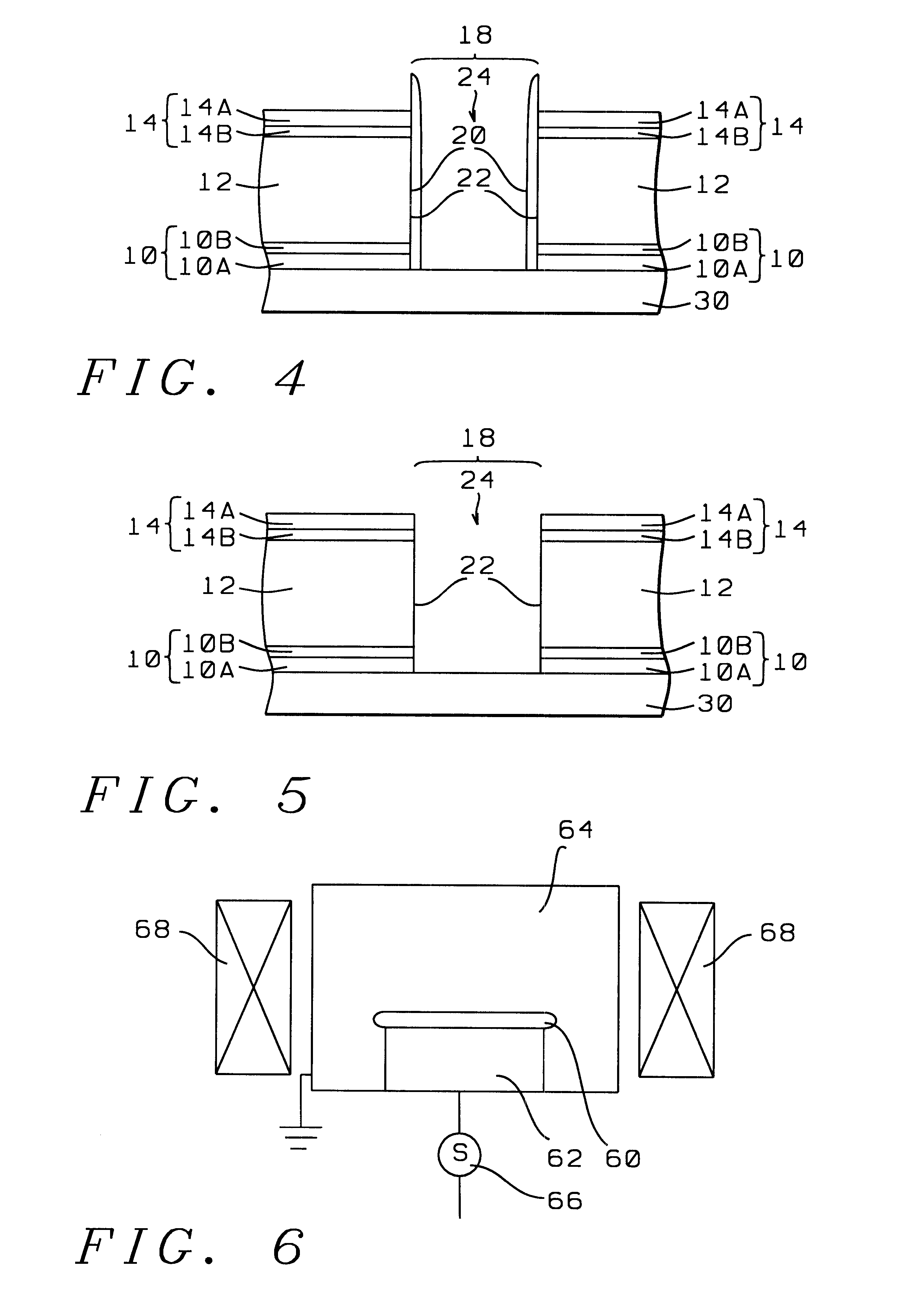

Gas discharge tube

ActiveUS20050231119A1Improvement of start propertyIncrease plasma densitySolid cathode detailsGas discharge lamp detailsStart timeHigh luminance

In the gas discharge tube according to the present invention, there is carried out narrowing of the discharge path with cooperation of the first opening 20 and the second opening 12 in order to obtain higher luminance of light. Further, in order to maintain excellent starting-properties of a lamp even if the discharge path is narrowed, a predetermined voltage is applied to a second discharge path limit portion 11 externally. Thereby, a positive or active starting discharge is produced in such a manner as to pass through the first opening 20. Further, the second opening 12 is comprised of not only a straight section 13 extending in a direction of an optical axis Y, but also a spread section 14 extending from an end portion of the straight section 13 toward the first opening 20. The spread section 14 has a function of improving the starting properties of the lamp and forms an arc ball, and the straight section has a function of improving a plasma density. Thereby, discharge at a starting time is made easy to pass through the second discharge path limit portion 11. As a result, a rapid start of discharge between a cathode 23 and an anode portion 8 is achieved in the second discharge path limit portion 11, and that contributes to proper generation of an arc ball after lighting.

Owner:HAMAMATSU PHOTONICS KK

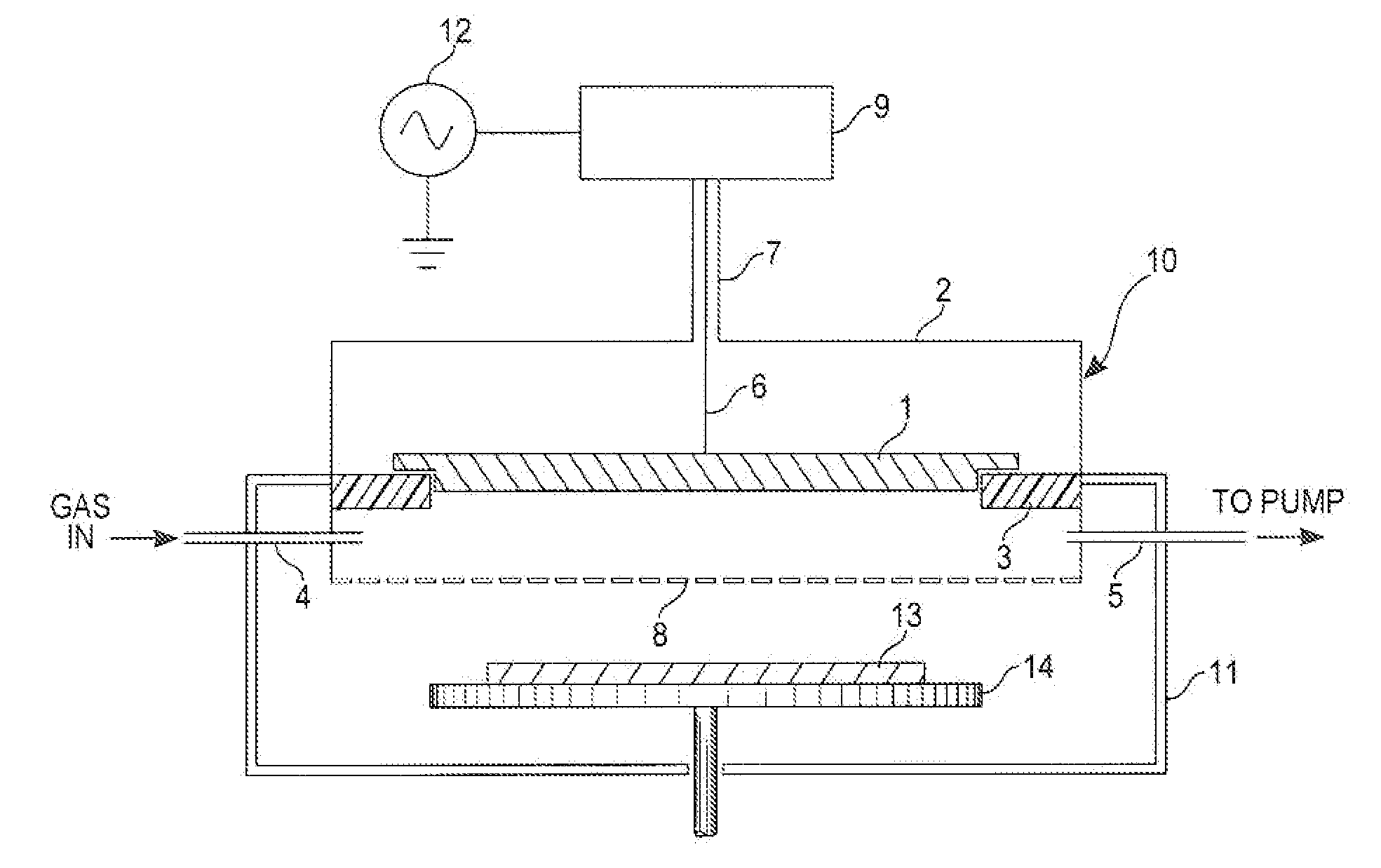

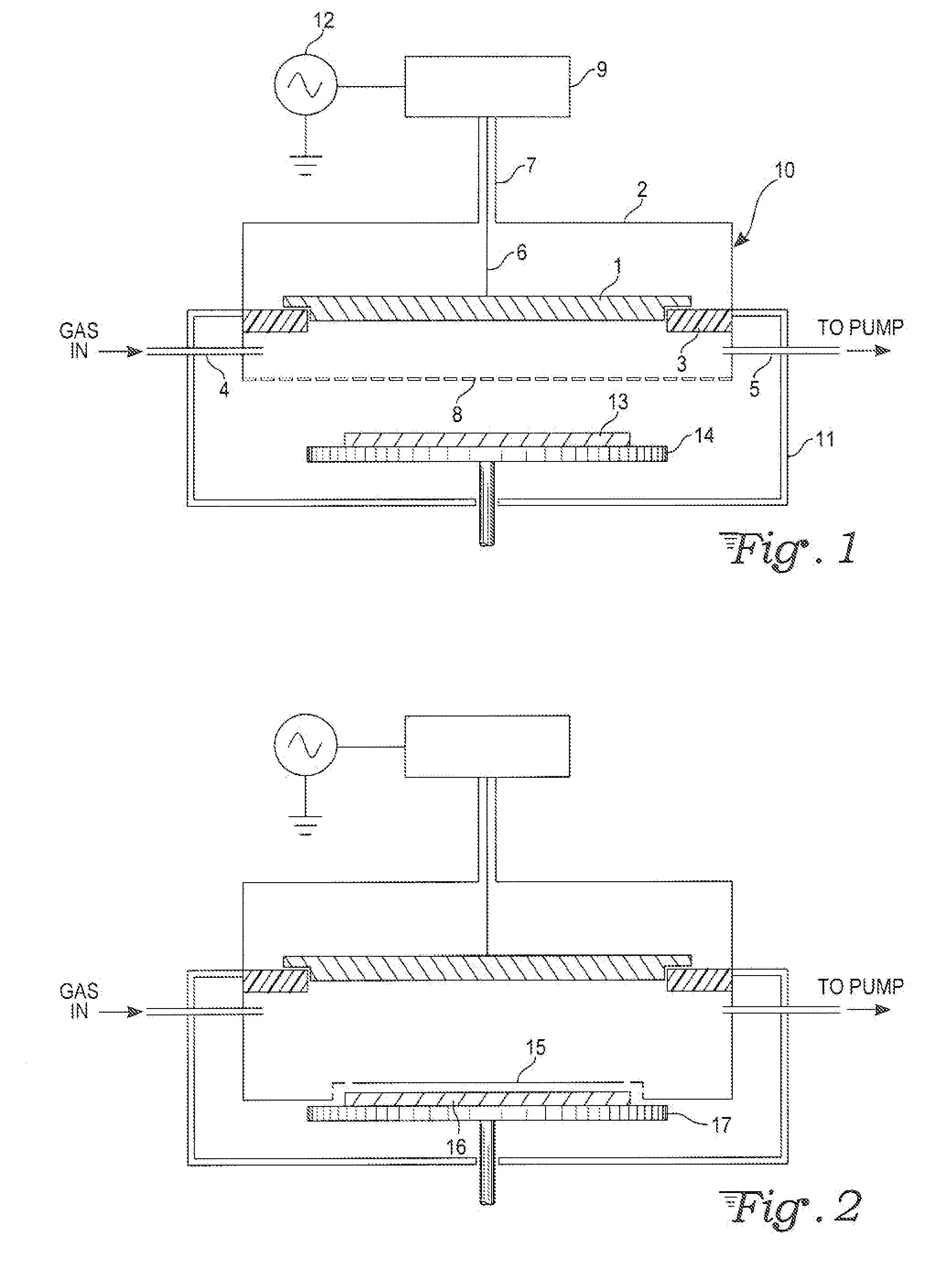

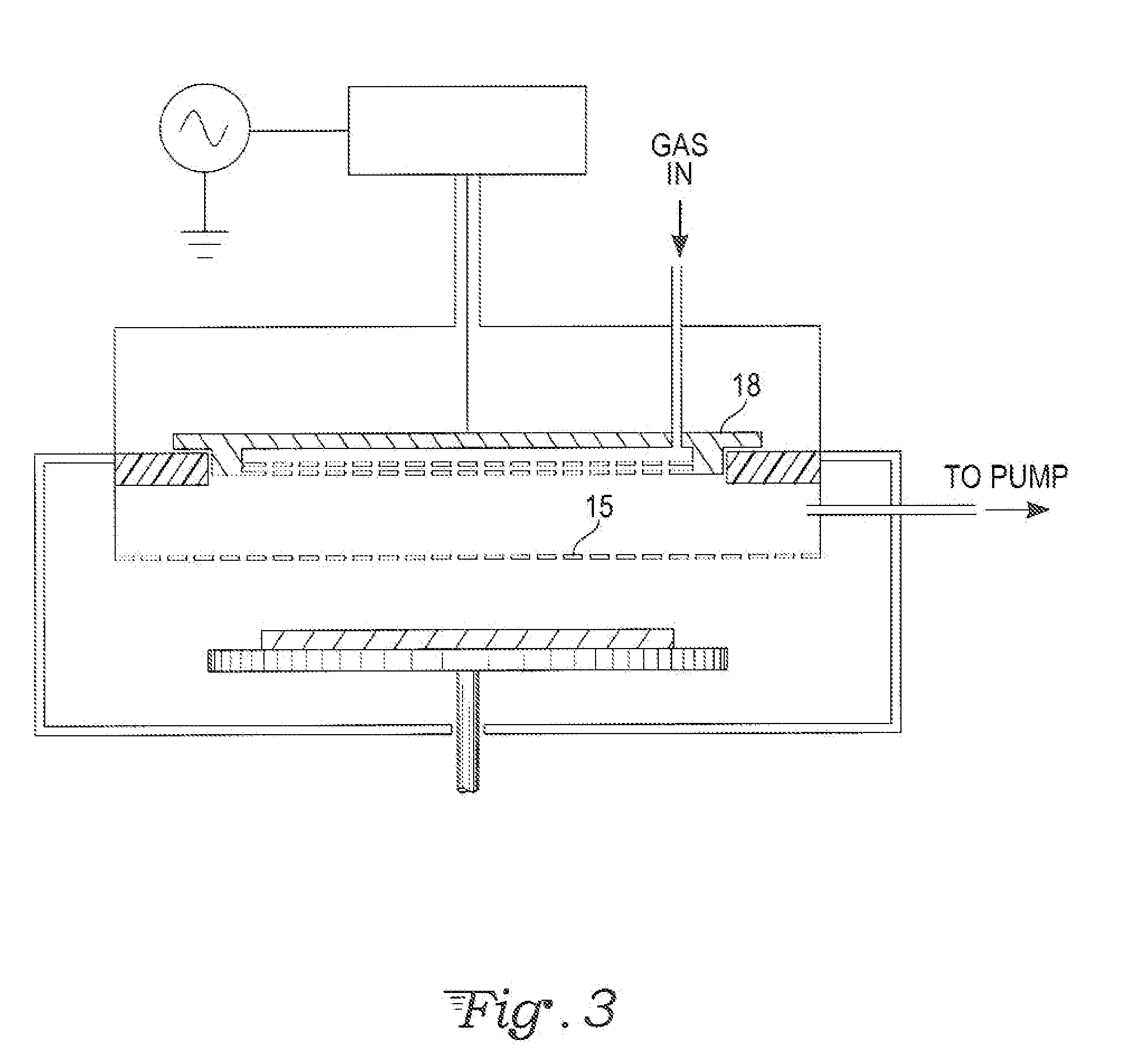

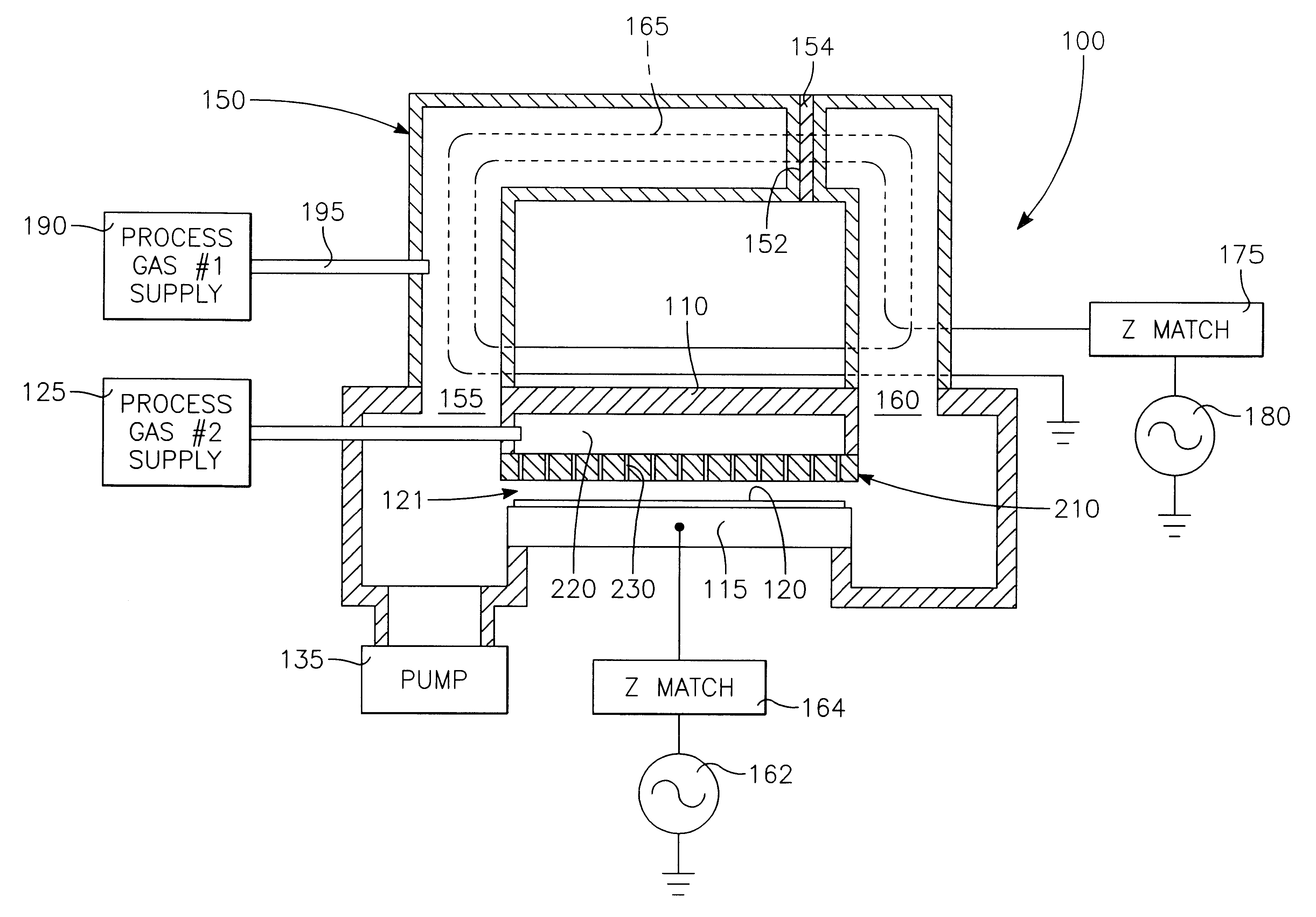

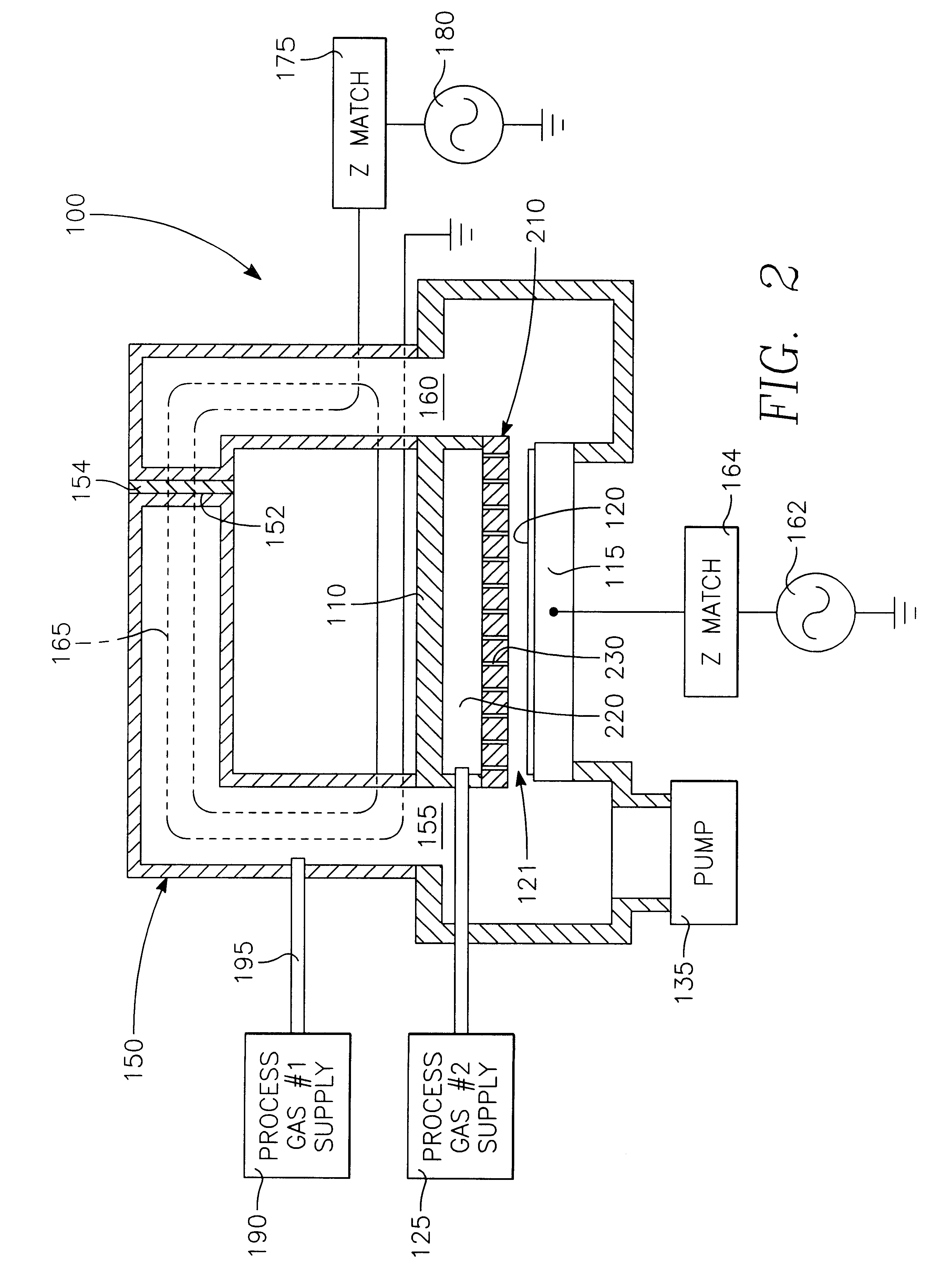

Externally excited torroidal plasma source with a gas distribution plate

InactiveUS6551446B1Increase plasma densitySimple materialElectric discharge tubesSemiconductor/solid-state device manufacturingInjection portProcess region

A plasma reactor for processing a workpiece includes a vacuum enclosure, including a wall, defining a vacuum chamber, the vacuum chamber having a main chamber portion on one side of the wall and a plenum on another side of the wall, the plenum communicating with the chamber portion through at least one opening in the wall, a workpiece support within the main chamber portion and facing the wall. A gas distribution plate is adjacent the wall and faces the workpiece support and is coupled to a reactive process gas supply for injecting reactive process gases directly into a process region adjacent the workpiece support. A gas injection port at the plenum is coupled to a diluent gas supply for injecting diluent gases into the plenum. A coil antenna adapted to accept RF power is inductively coupled to the interior of said plenum, and is capable of maintaining a plasma in a reentrant path through the plenum and across the process region.

Owner:APPLIED MATERIALS INC

Method of processing a workpiece using an externally excited torroidal plasma source

InactiveUS6410449B1Increase ion densityIncrease plasma densityElectric discharge tubesSemiconductor/solid-state device manufacturingPlasma currentIon density

A method of processing a workpiece in a plasma reactor includes establishing a torroidal path for a plasma current to flow that passes near and transverse to the surface of said workpiece, maintaining a plasma current in the torroidal path by applying RF power to a portion of the torroidal path away from the surface of the workpiece, and increasing the ion density of the plasma current in the vicinity of the workpiece by constricting the area of a portion of the torroidal path overlying the workpiece.

Owner:APPLIED MATERIALS INC

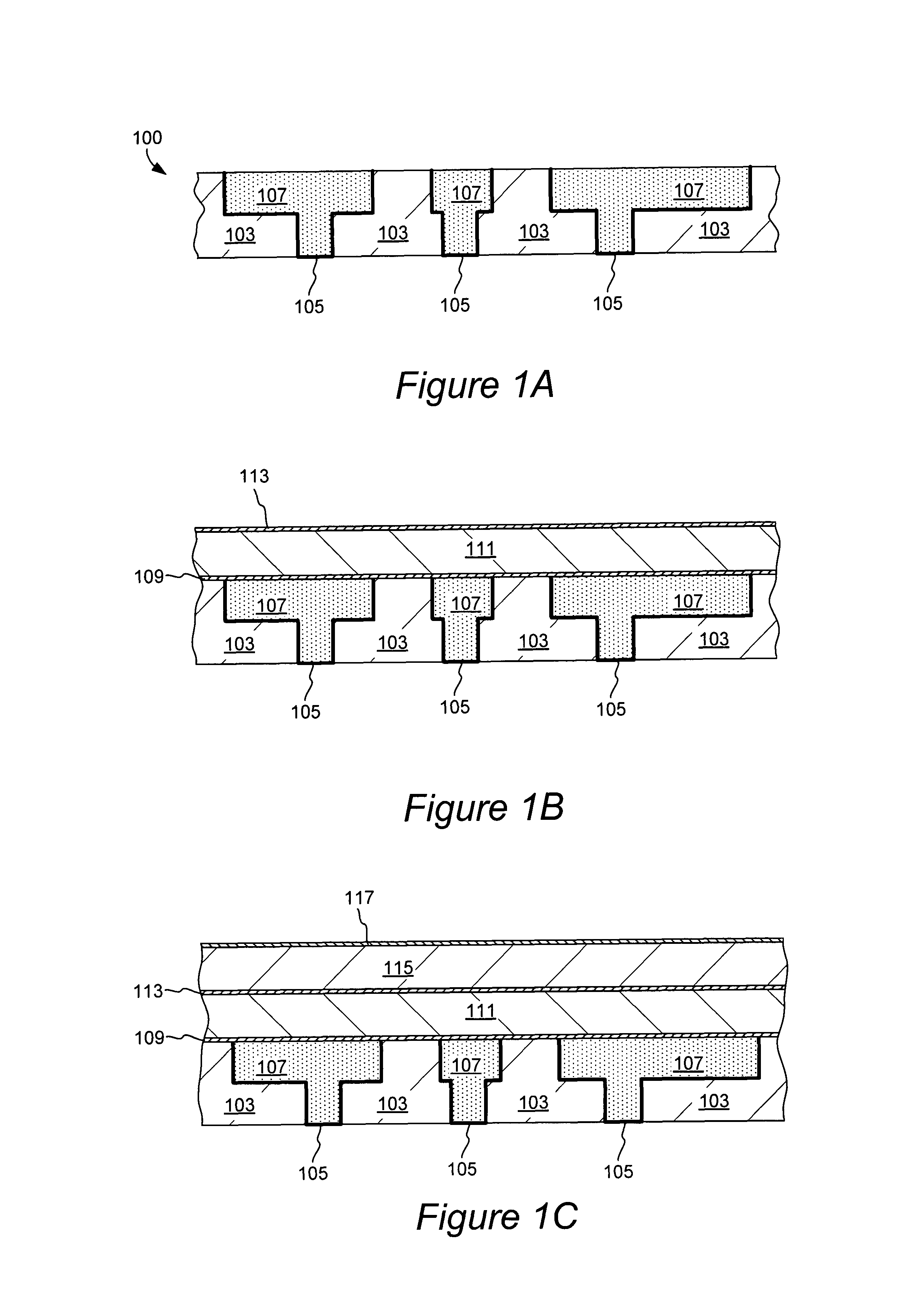

Dry clean method instead of traditional wet clean after metal etch

InactiveUS6526996B1Increase plasma densityIncrease ion accelerationDecorative surface effectsSemiconductor/solid-state device manufacturingChemistryMicrowave

A dry cleaning method for use in semiconductor fabrication, including the following steps. An etched metallization structure is provided and placed in a processing chamber. The etched metallization structure is cleaned by introducing a fluorine containing gas / oxygen containing gas mixture into the processing chamber proximate the etched metallization structure without the use of a downstream microwave while applying a magnetic field proximate the etched metallization structure and maintaining a pressure of less than about 50 millitorr within the processing chamber for a predetermined time.

Owner:PROMOS TECH INC +2

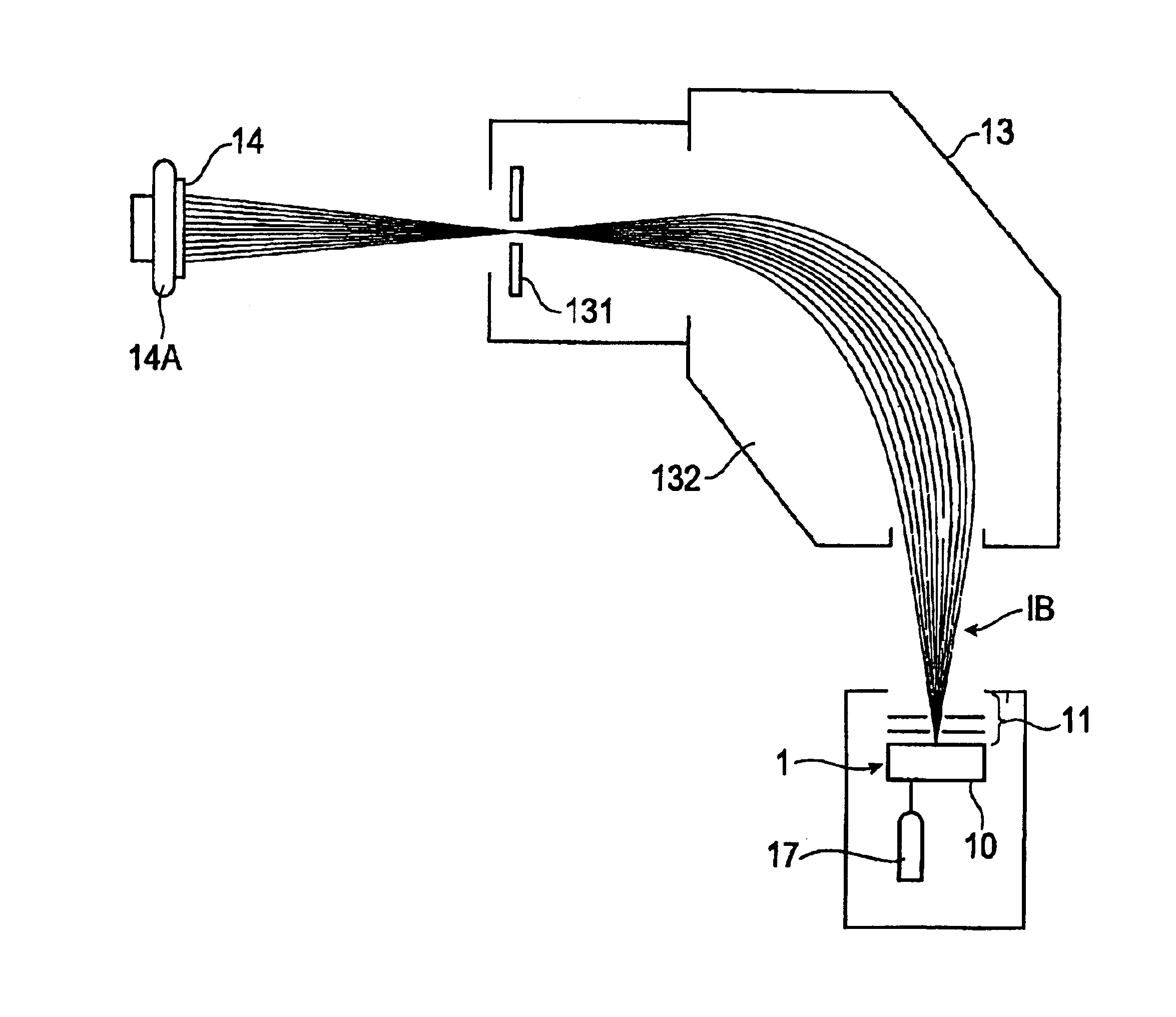

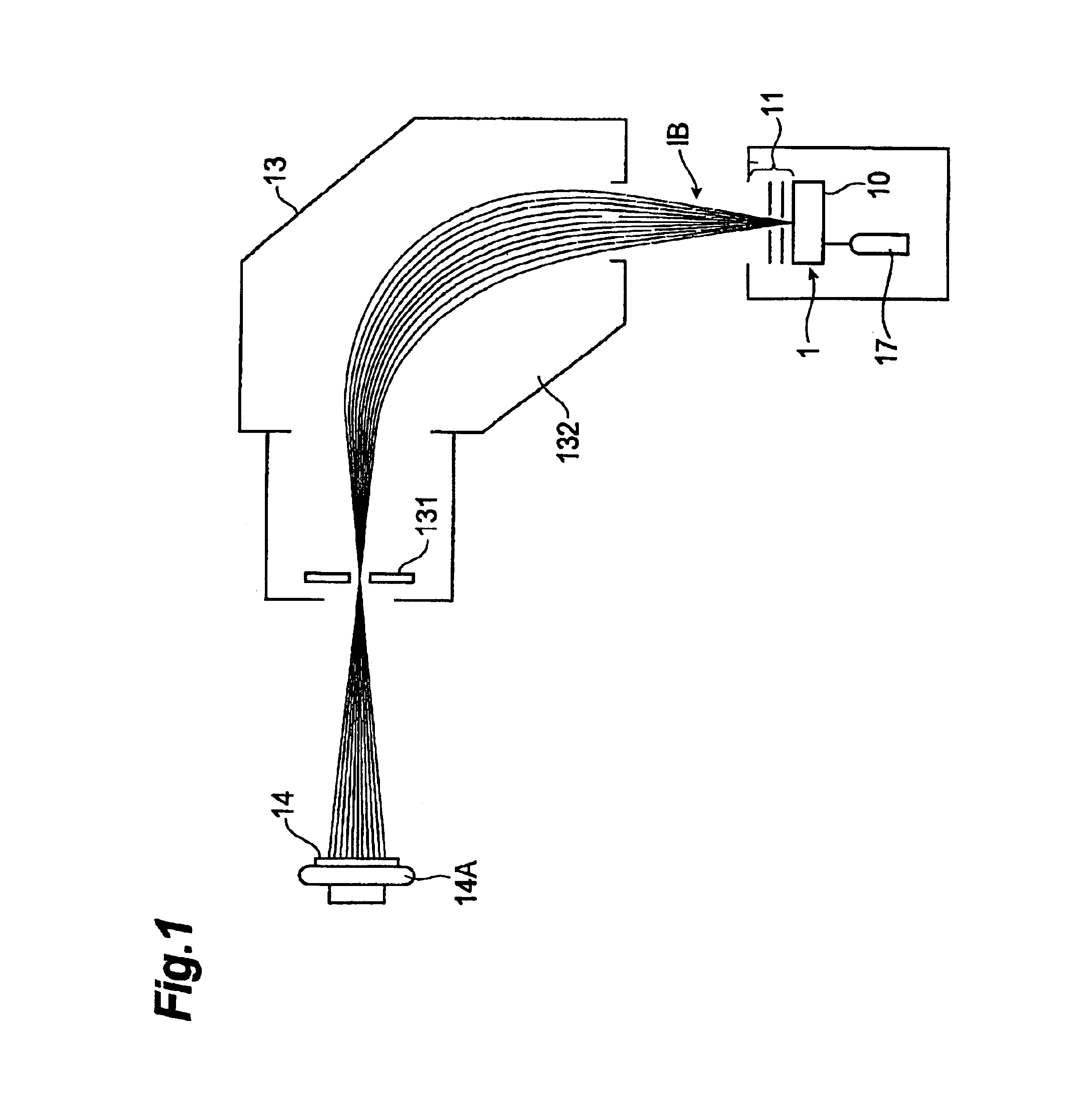

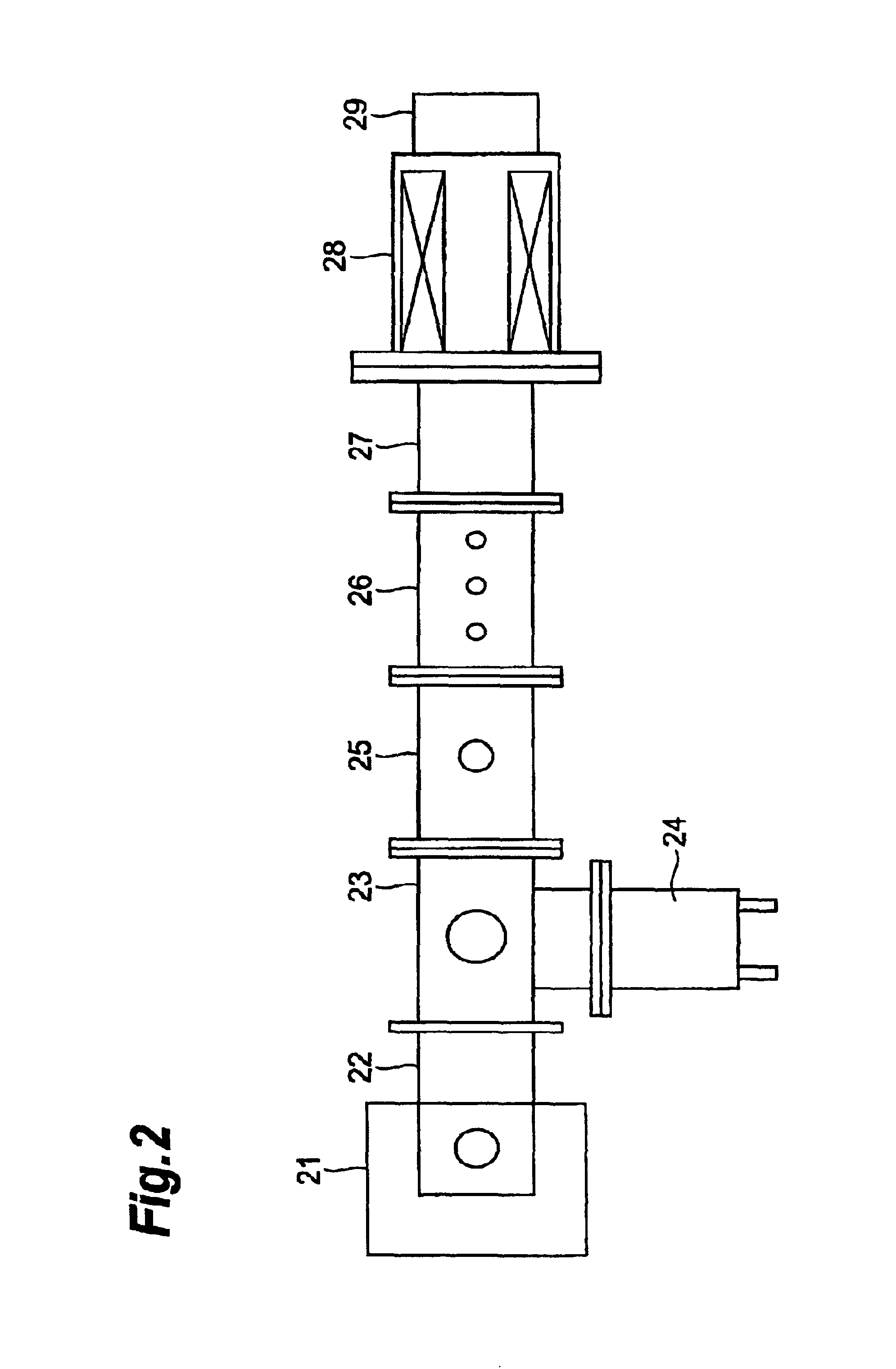

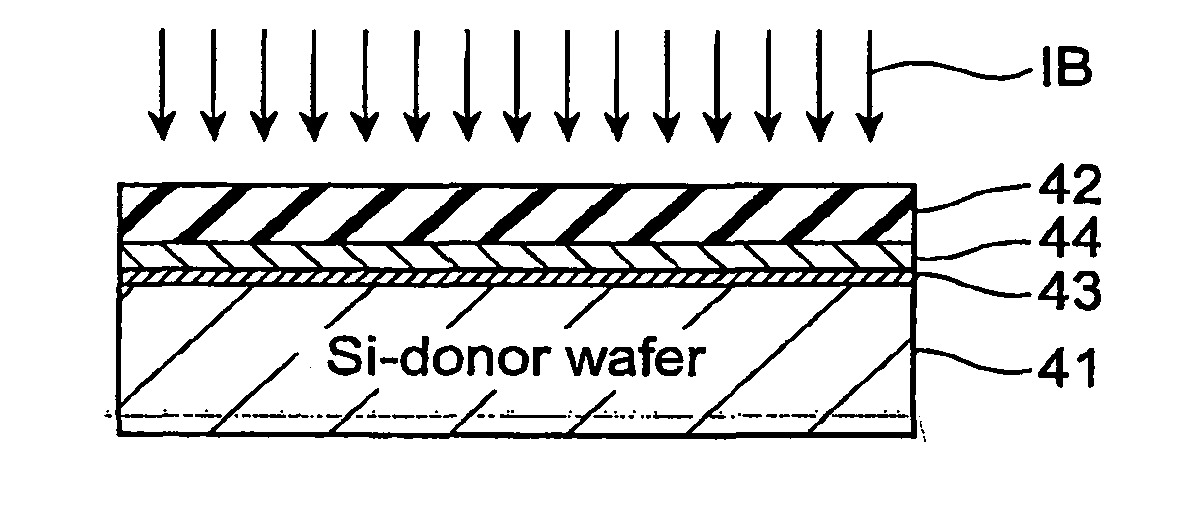

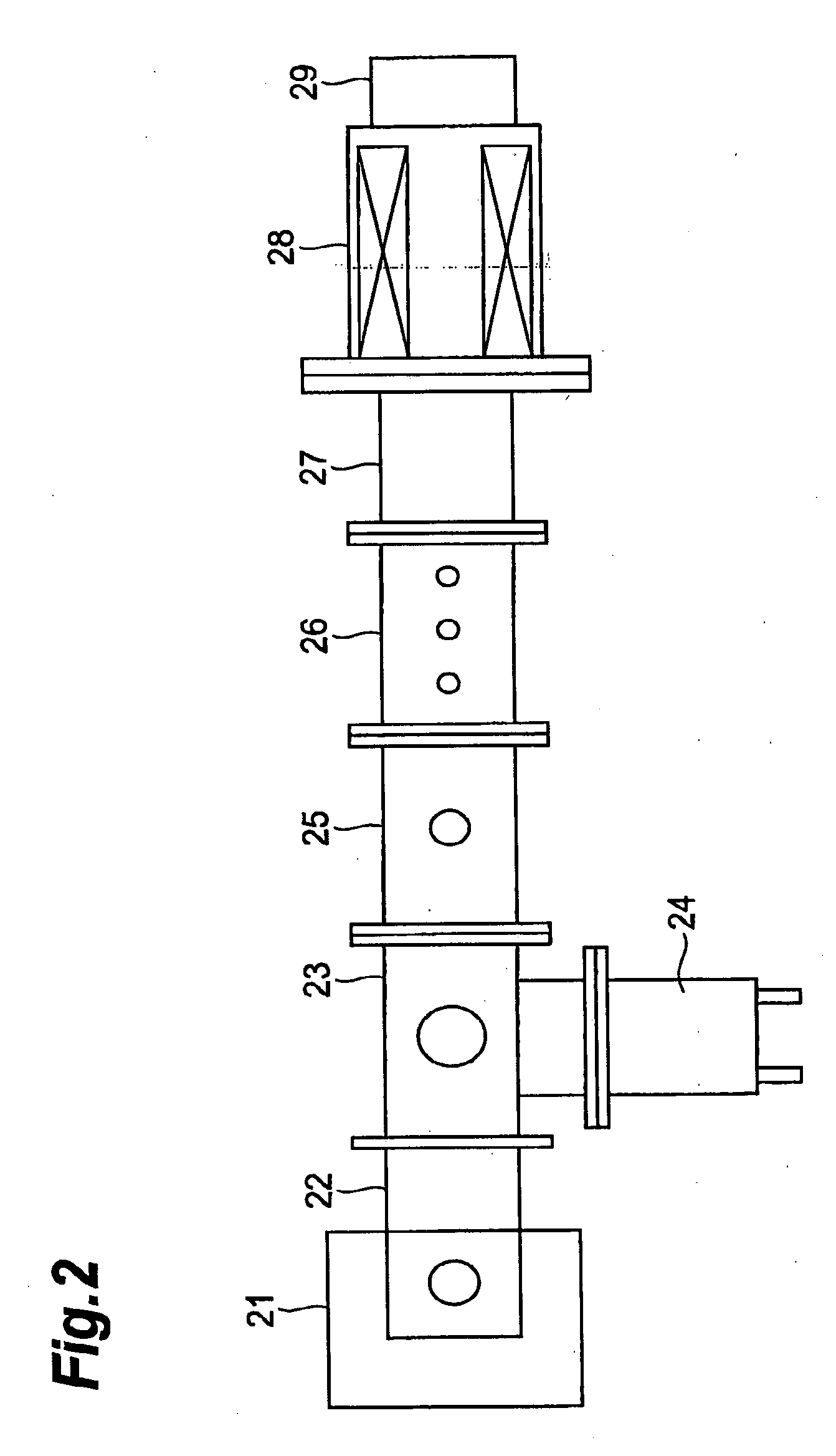

Ion implantation method and method for manufacturing SOI wafer

ActiveUS6927148B2Increase generationIncrease plasma densitySolid-state devicesVacuum evaporation coatingInternal pressureMicrowave

Disclosed are an ion implantation method capable of dramatically increasing an implantation rate of hydrogen ions into a semiconductor substrate and a method for manufacturing an SOI wafer, in which manufacturing efficiency of the SOI wafer is sufficiently high. When the hydrogen ions are implanted to a predetermined depth of the semiconductor substrate, hydrogen gas is introduced into a chamber where an inner pressure is reduced and a predetermined magnetic field is formed, plasma is generated by introducing a microwave into the magnetic field, hydrogen ion beams containing hydrogen molecule ions is extracted from the plasma, and the hydrogen molecule ions are irradiated and implanted onto the semiconductor substrate. Thus, a throughput in the hydrogen ion implantation is improved, thus making it possible to enhance the manufacturing efficiency of the SOI wafer.

Owner:APPLIED MATERIALS INC

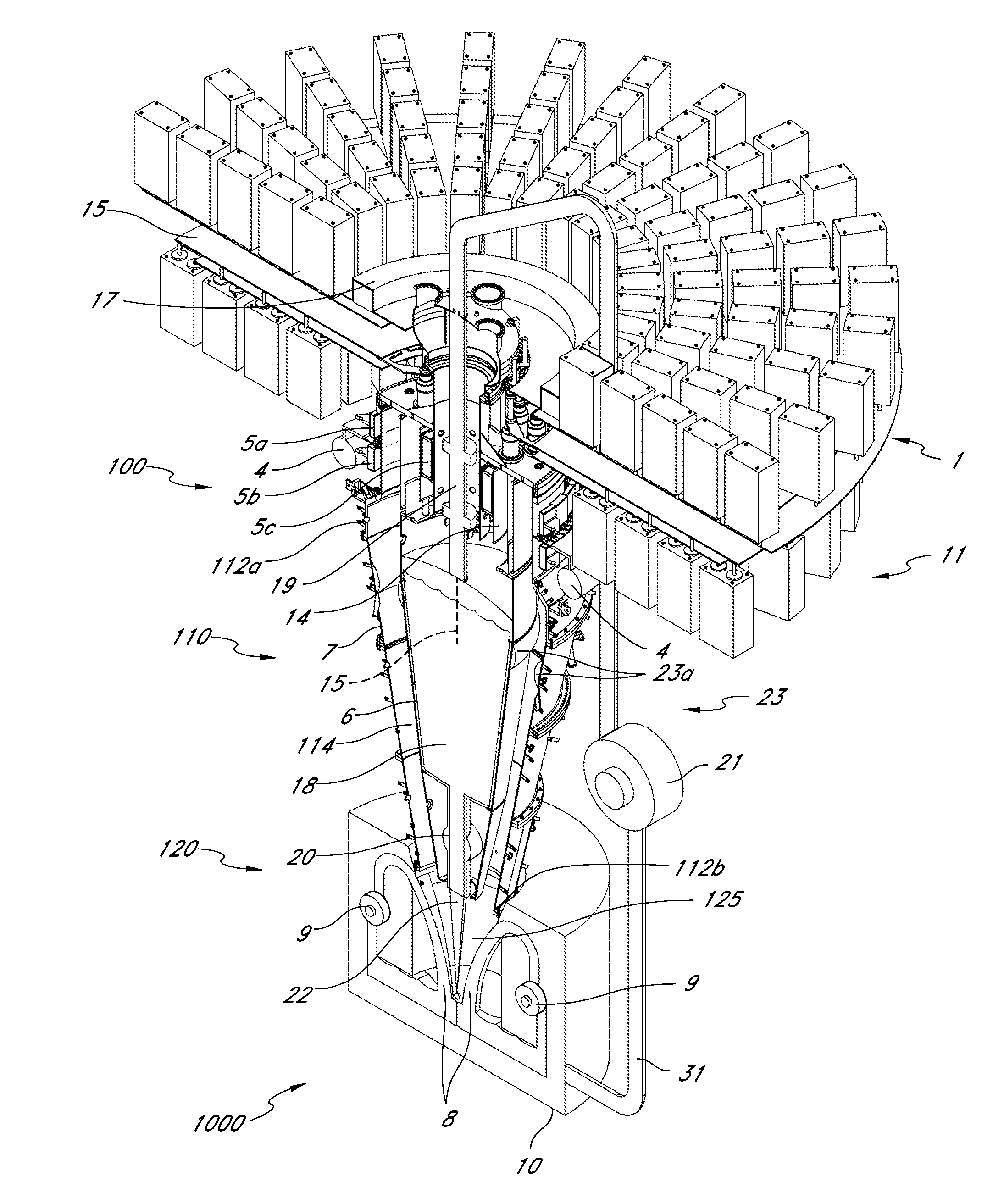

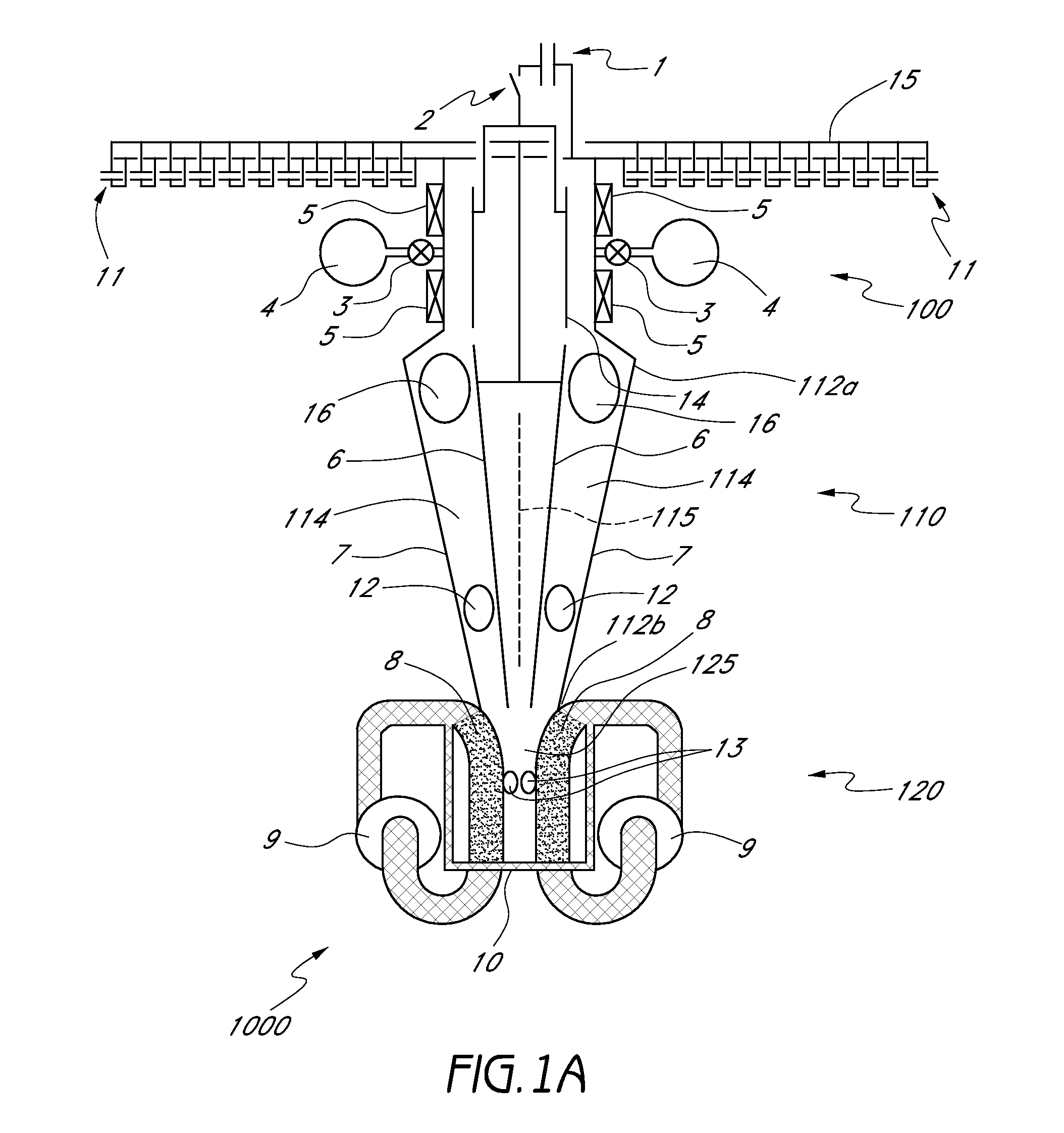

Systems and methods for compressing plasma

ActiveUS20110026657A1Sufficient reactionIncrease plasma densityNuclear energy generationLow temperature fusion reactorLiquid metalBreaking point

Embodiments of systems and methods for compressing plasma are described in which plasma pressures above the breaking point of solid material can be achieved by injecting a plasma into a funnel of liquid metal in which the plasma is compressed and / or heated.

Owner:GENERAL FUSION INC

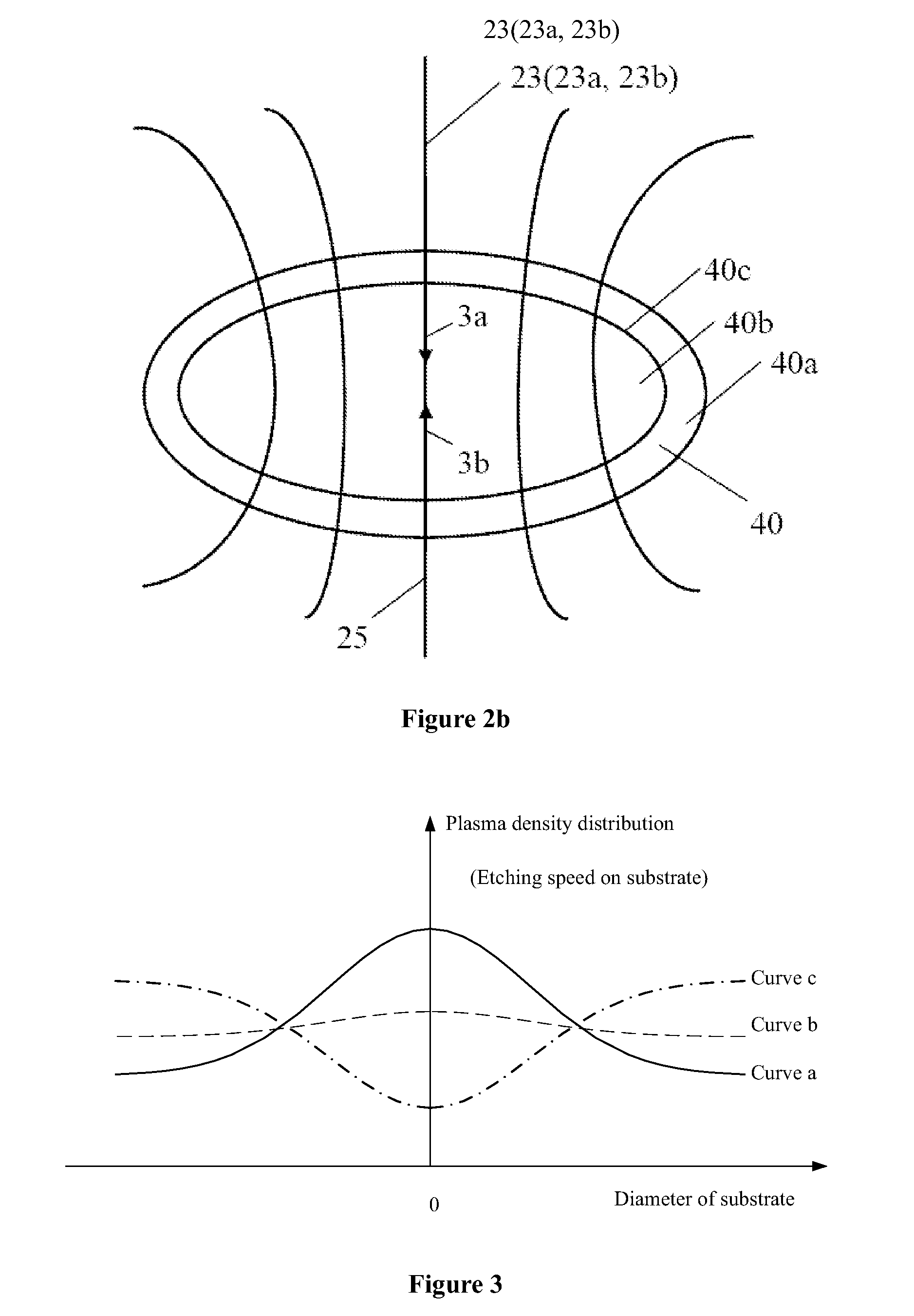

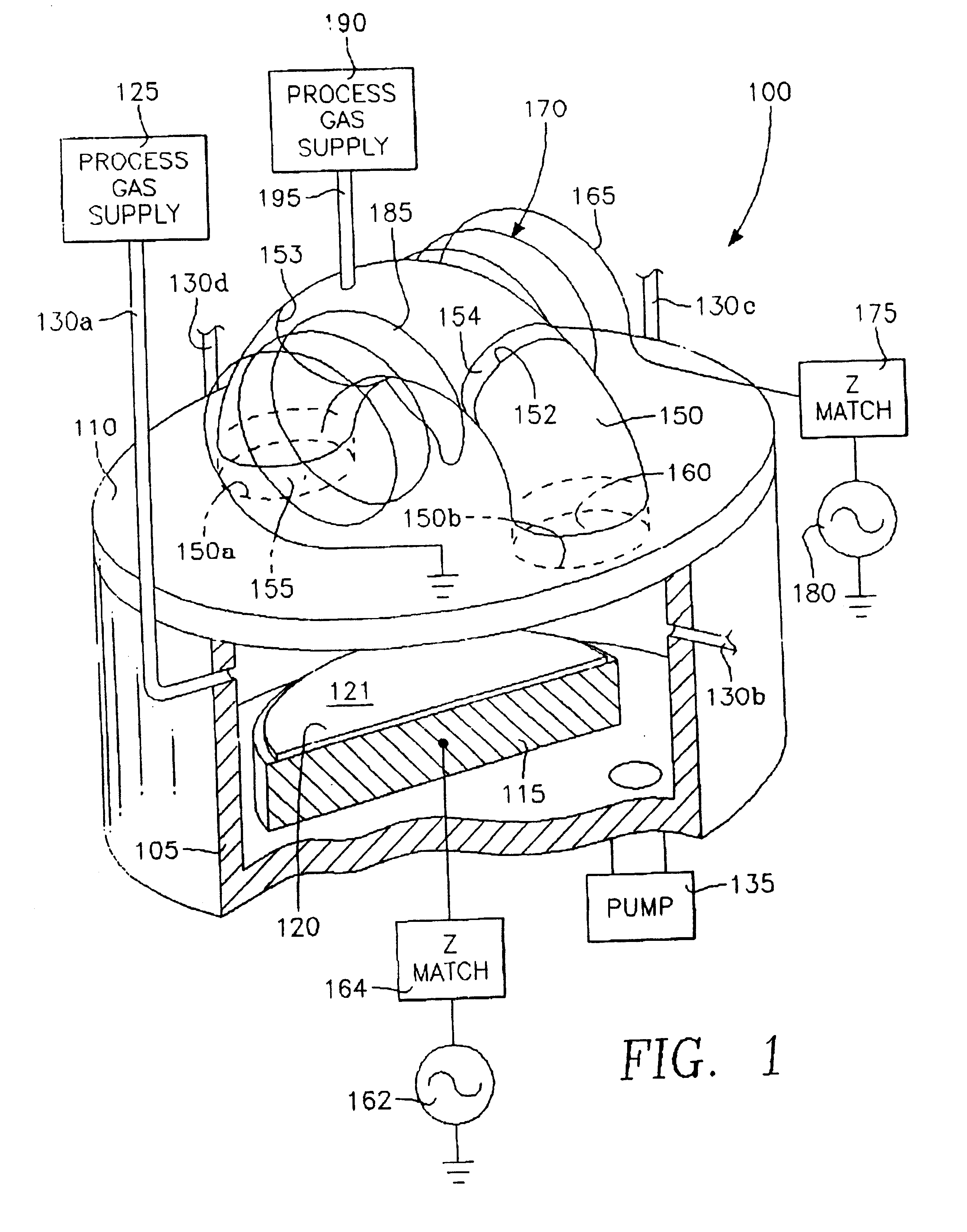

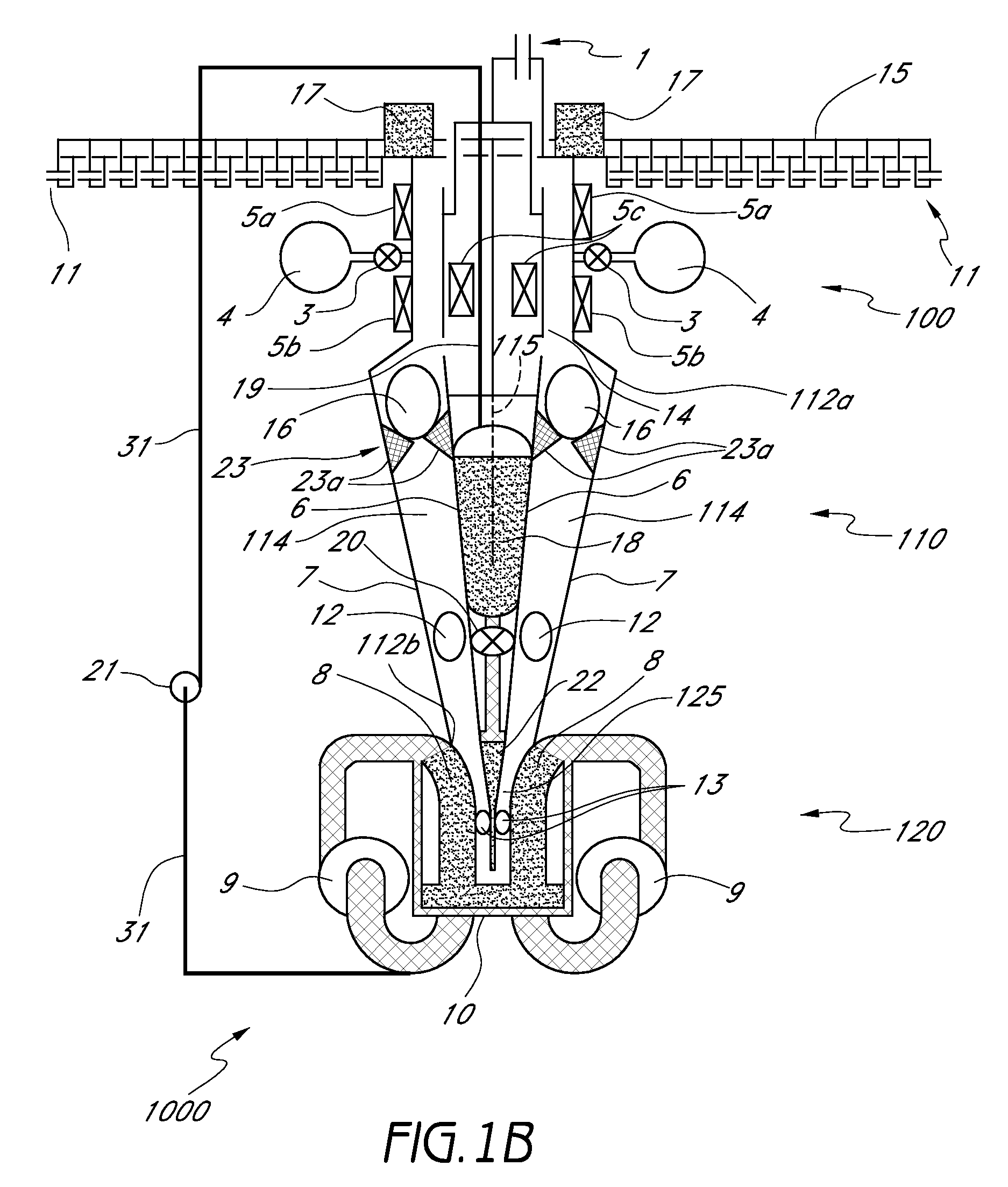

Externally excited multiple torroidal plasma source

InactiveUS6494986B1Increase plasma densityImprove etch selectivityElectric discharge tubesSemiconductor/solid-state device manufacturingEngineeringVacuum chamber

A plasma reactor for processing a workpiece, including an enclosure defining a vacuum chamber, a workpiece support within the enclosure facing an overlying portion of the enclosure, the enclosure having at least first and second pairs of openings therethrough near generally opposite sides of the workpiece support. At least first and second hollow conduits are connected to respective pairs of the openings to provide at least first and second closed torroidal paths through the respective conduits and extending between respective pairs of the openings across the wafer surface. A process gas supply is coupled to the interior of the chamber for supplying process gas to the torroidal paths. Coil antennas are coupled to RF power sources and inductively coupled to the interior of the hollow conduits and capable of maintaining a plasma in the torroidal paths.

Owner:APPLIED MATERIALS INC

Method and apparatus for increasing local plasma density in magnetically confined plasma

ActiveUS7922880B1Easily damagedLow reliabilityCellsElectric discharge tubesPlasma densityHigh density

Local plasma density, e.g., the plasma density in the vicinity of the substrate, is increased by providing an ion extractor configured to transfer ions and electrons from a first region of magnetically confined plasma (typically a region of higher density plasma) to a second region of plasma (typically a region of lower density plasma). The second region of plasma is preferably also magnetically shaped or confined and resides between the first region of plasma and the substrate. A positively biased conductive member positioned proximate the second region of plasma serves as an ion extractor. A positive bias of about 50-300 V is applied to the ion extractor causing electrons and subsequently ions to be transferred from the first region of plasma to the vicinity of the substrate, thereby forming higher density plasma. Provided methods and apparatus are used for deposition and resputtering.

Owner:NOVELLUS SYSTEMS

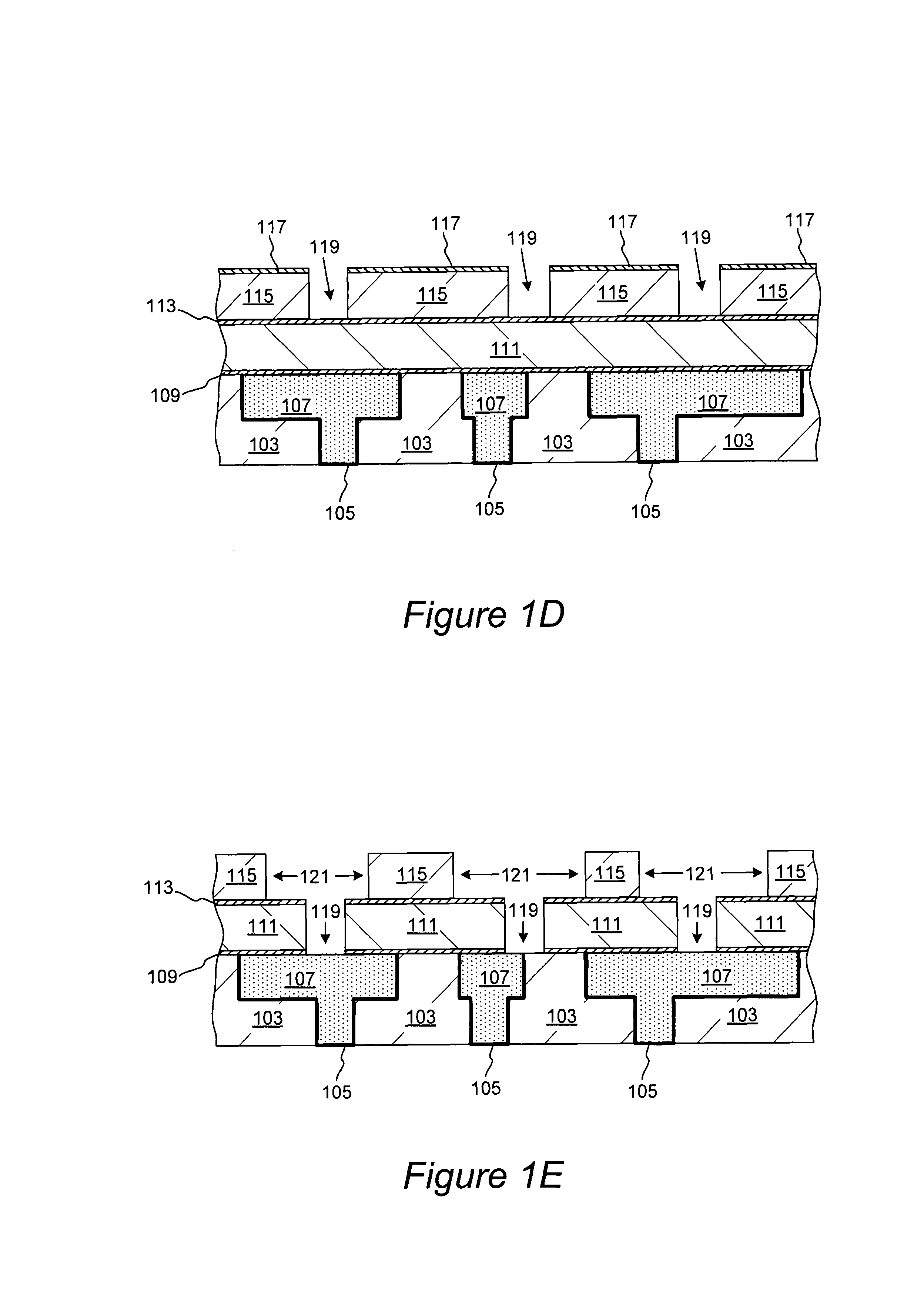

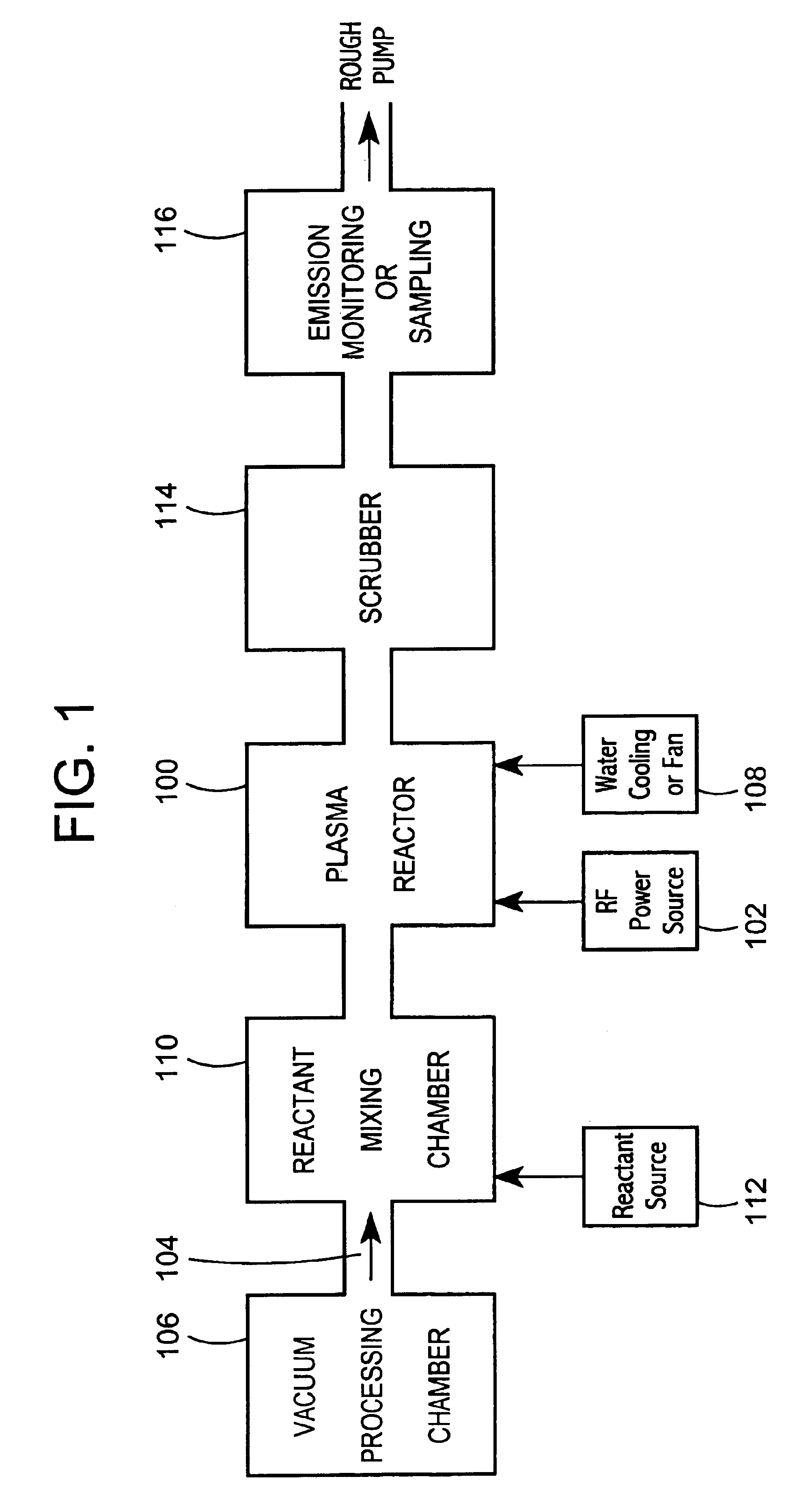

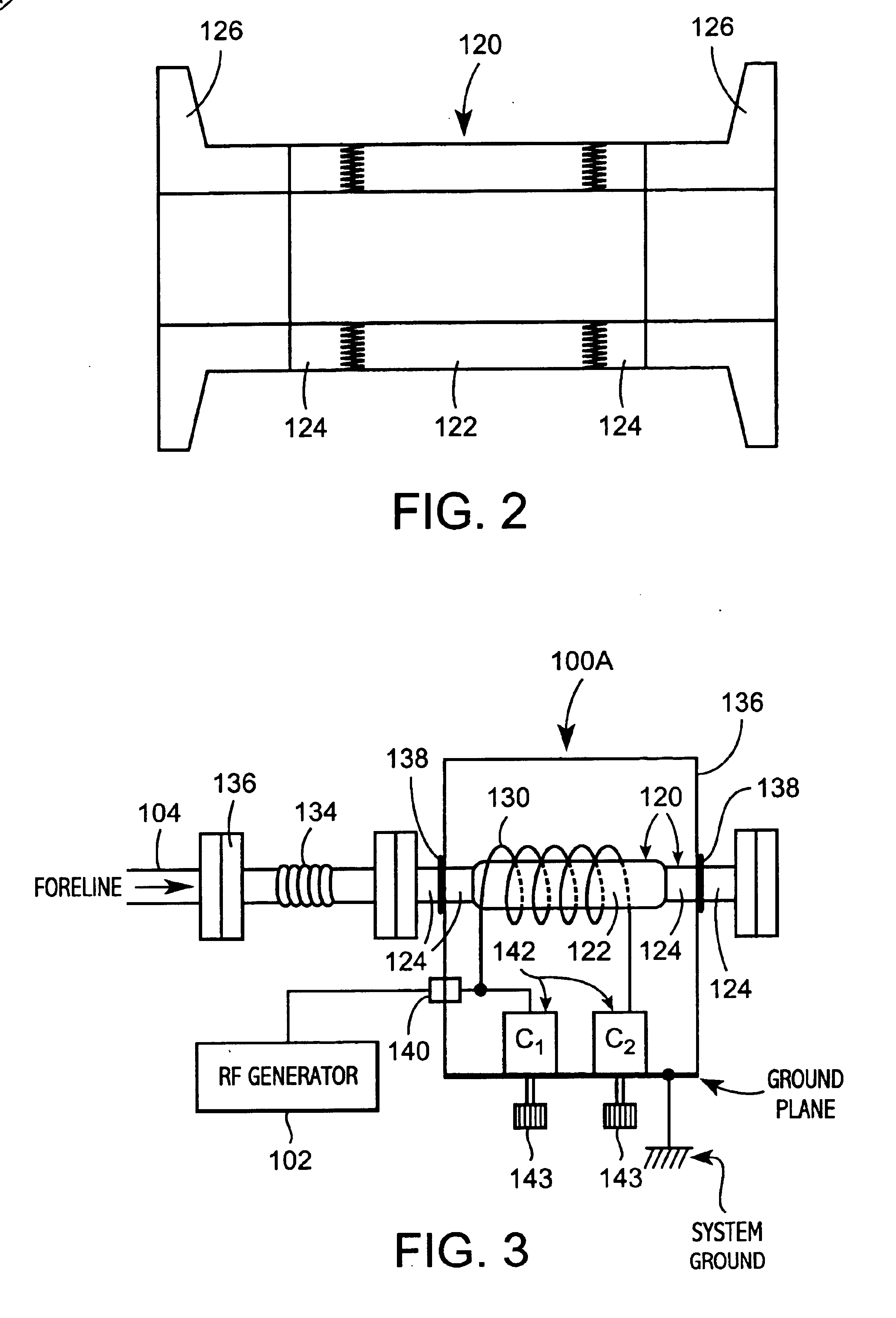

Method and apparatus for abatement of reaction products from a vacuum processing chamber

InactiveUS6888040B1Increase plasma densityHigh operating requirementsGas treatmentUsing liquid separation agentHydrofluorocarbonReaction chamber

An exemplary method and apparatus for abating reaction products from a vacuum processing chamber includes a reaction chamber in fluid communication with the vacuum processing chamber, a coil disposed about the reaction chamber, and a power source for supplying RF energy to the coil. The coil creates a plasma in the reaction chamber which effectively breaks down stable reaction products from the vacuum processing chamber such as perfluorocarbons (PFCs) and hydrofluorocarbons (HFCs) which significantly contribute to global warming. According to alternative embodiments, the plasma may be generated with grids or coils disposed in the reaction chamber perpendicular to the flow of reaction products from the vacuum processing chamber.

Owner:LAM RES CORP

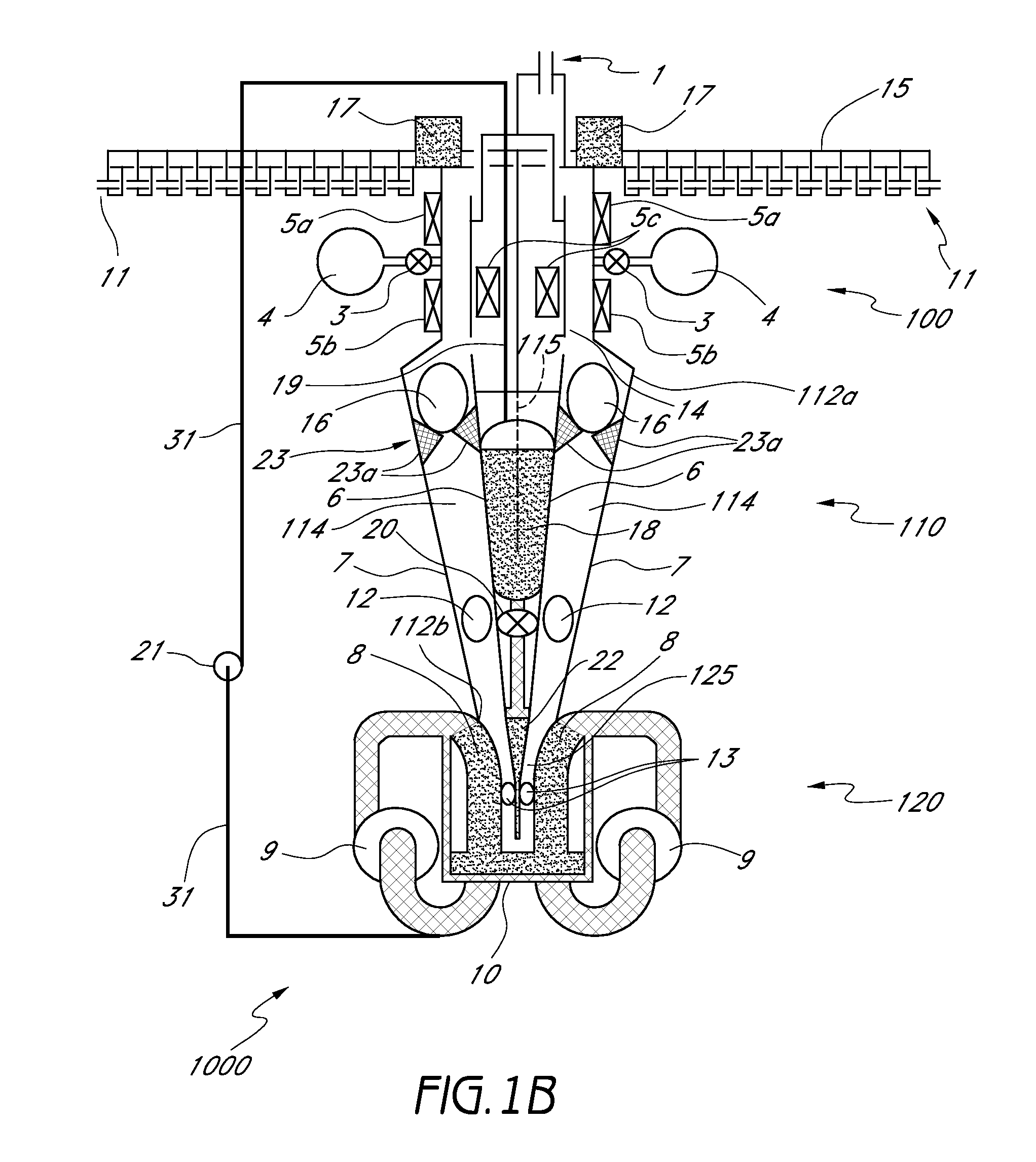

Phase-Modulated RF Power for Plasma Chamber Electrode

InactiveUS20110192349A1Increase plasma densityElectric discharge tubesChemical vapor deposition coatingTime functionEngineering

A plurality of RF power signals have the same RF frequency as a reference RF signal and are coupled to respective RF connection points on an electrode of a plasma chamber. At least three of the RF connection points are not collinear. At least two of the RF power signals have time-varying phase offsets relative to the reference RF signal that are distinct functions of time. Such time-varying phase offsets can produce a spatial distribution of plasma in the plasma chamber having better time-averaged uniformity than the uniformity of the spatial distribution at any instant in time.

Owner:APPLIED MATERIALS INC

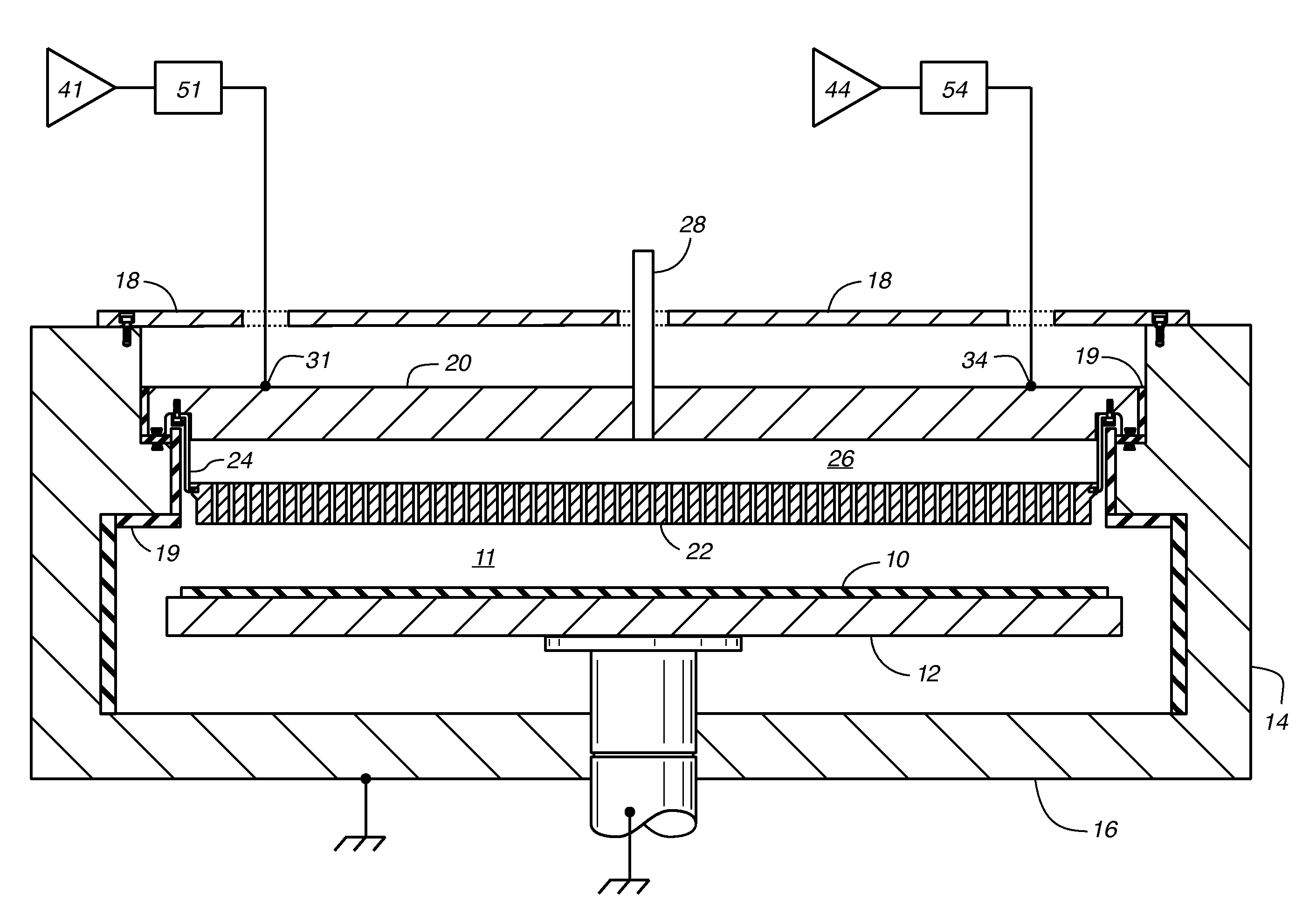

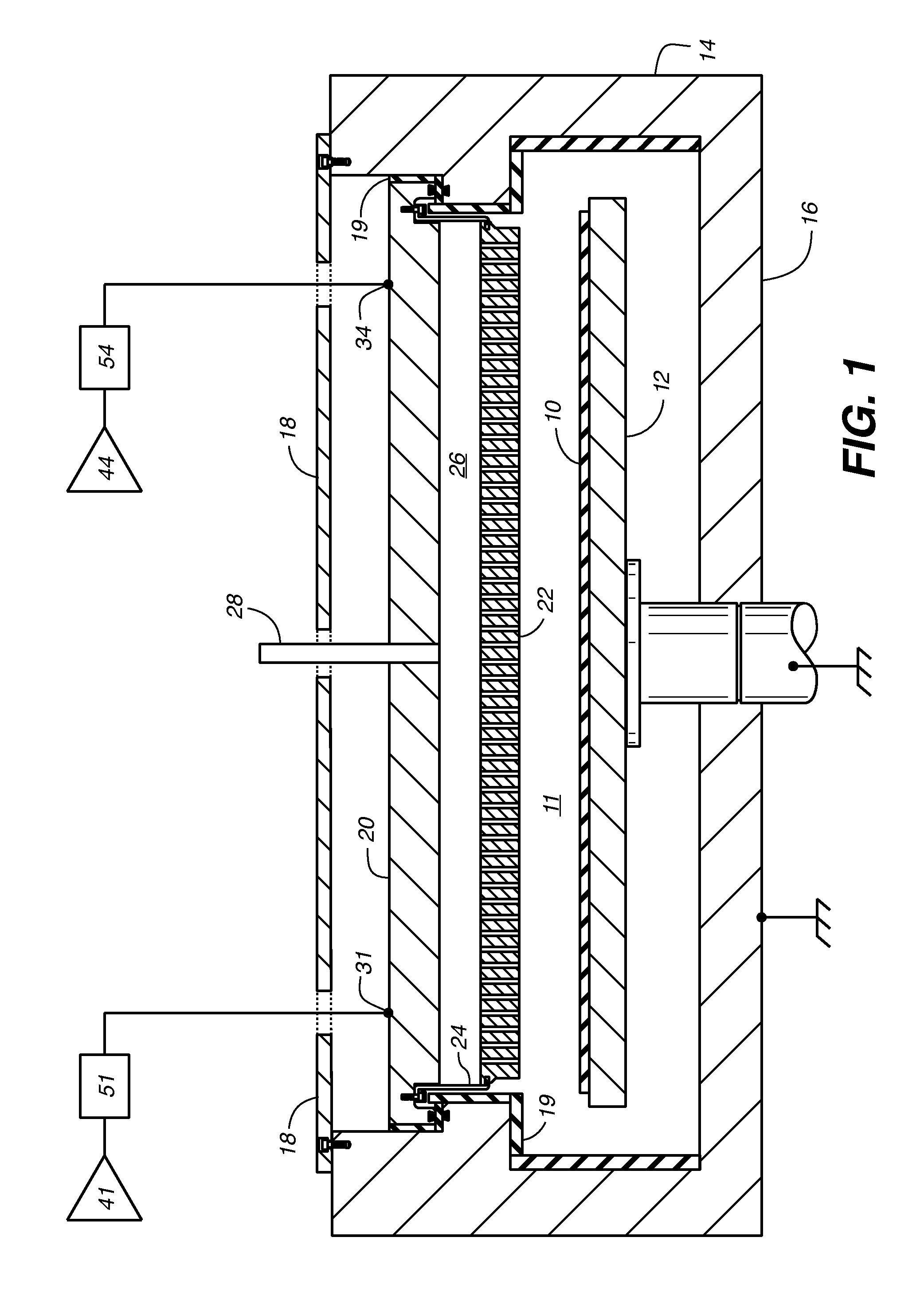

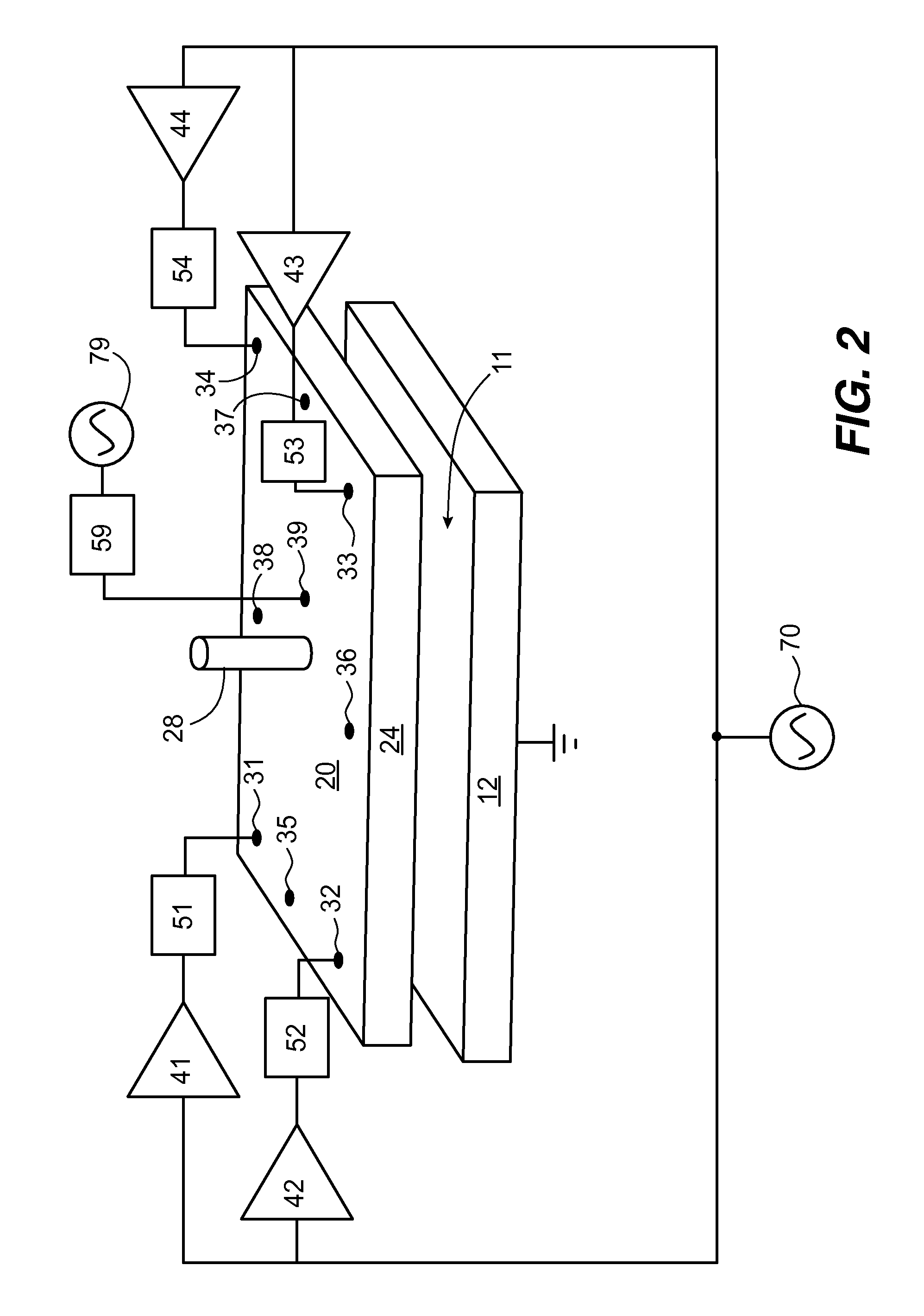

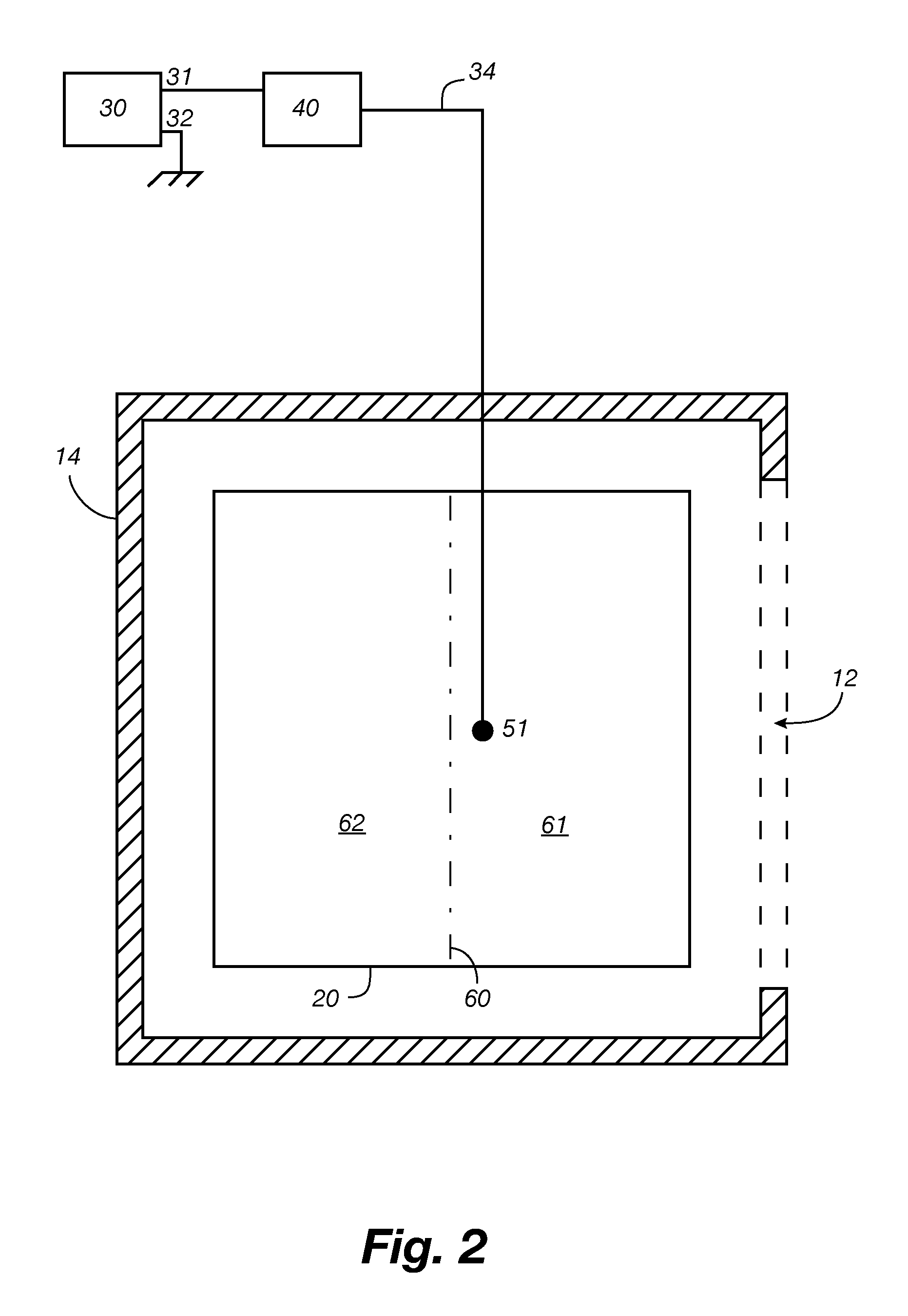

Asymmetrical RF Drive for Electrode of Plasma Chamber

ActiveUS20090159423A1Increase plasma densityDrop in plasma densityElectric discharge tubesDecorative surface effectsPlasma densityEngineering

RF power is coupled to one or more RF drive points (50-56) on an electrode (20-28) of a plasma chamber such that the level of RF power coupled to the RF drive points (51-52, 55-56) on the half (61) of the electrode that is closer to the workpiece passageway (12) exceeds the level of RF power coupled to the RF drive points (53-54), if any, on the other half (62) of the electrode. Alternatively, RF power is coupled to one or more RF drive points on an electrode of a plasma chamber such that the weighted mean of the drive point positions is between the center (60) of the electrode and the workpiece passageway. The weighted mean is based on weighting each drive point position by the time-averaged level of RF power coupled to that drive point position. The invention offsets an increase in plasma density that otherwise would exist adjacent the end of the electrode closest to the passageway.

Owner:APPLIED MATERIALS INC

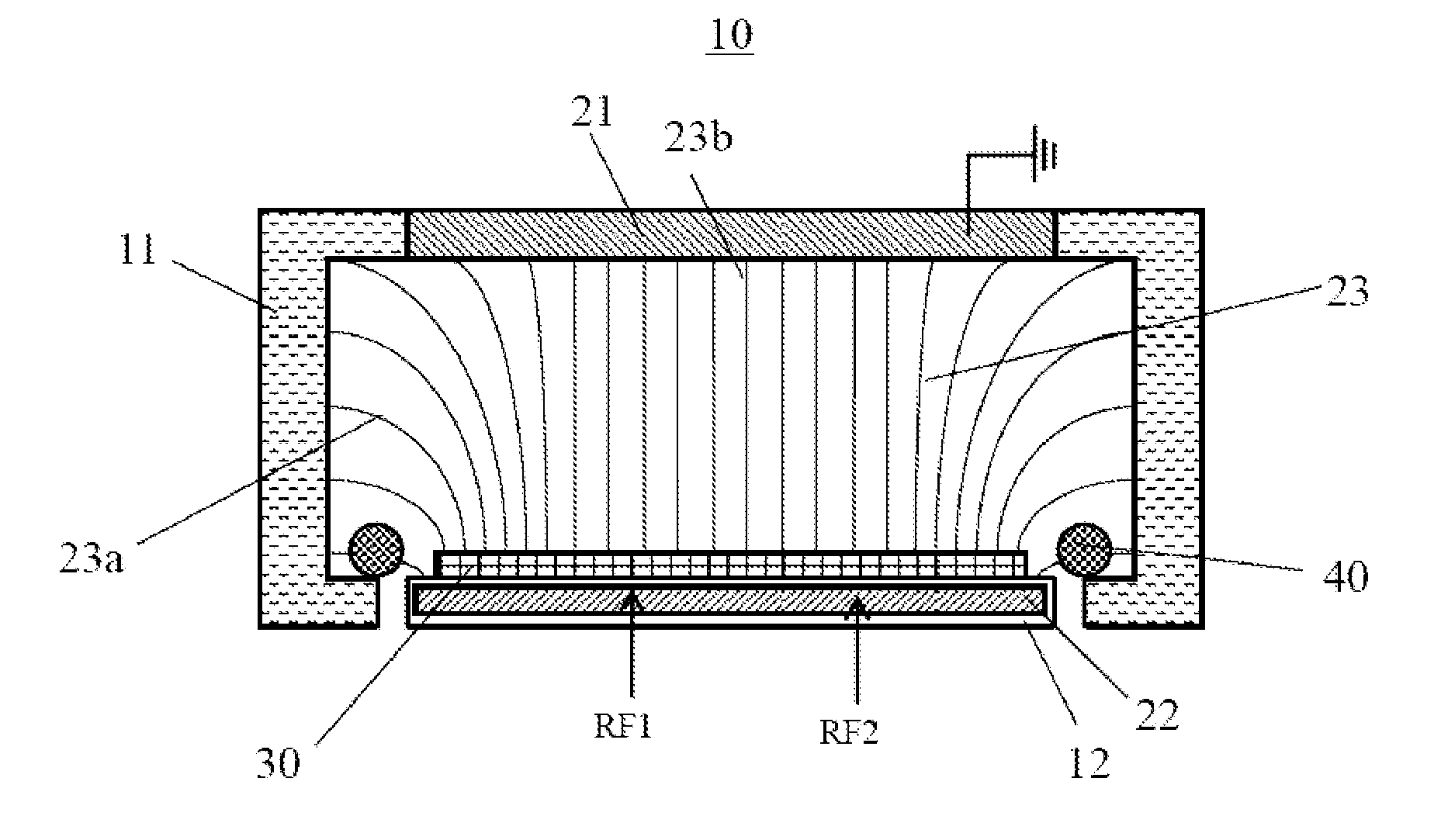

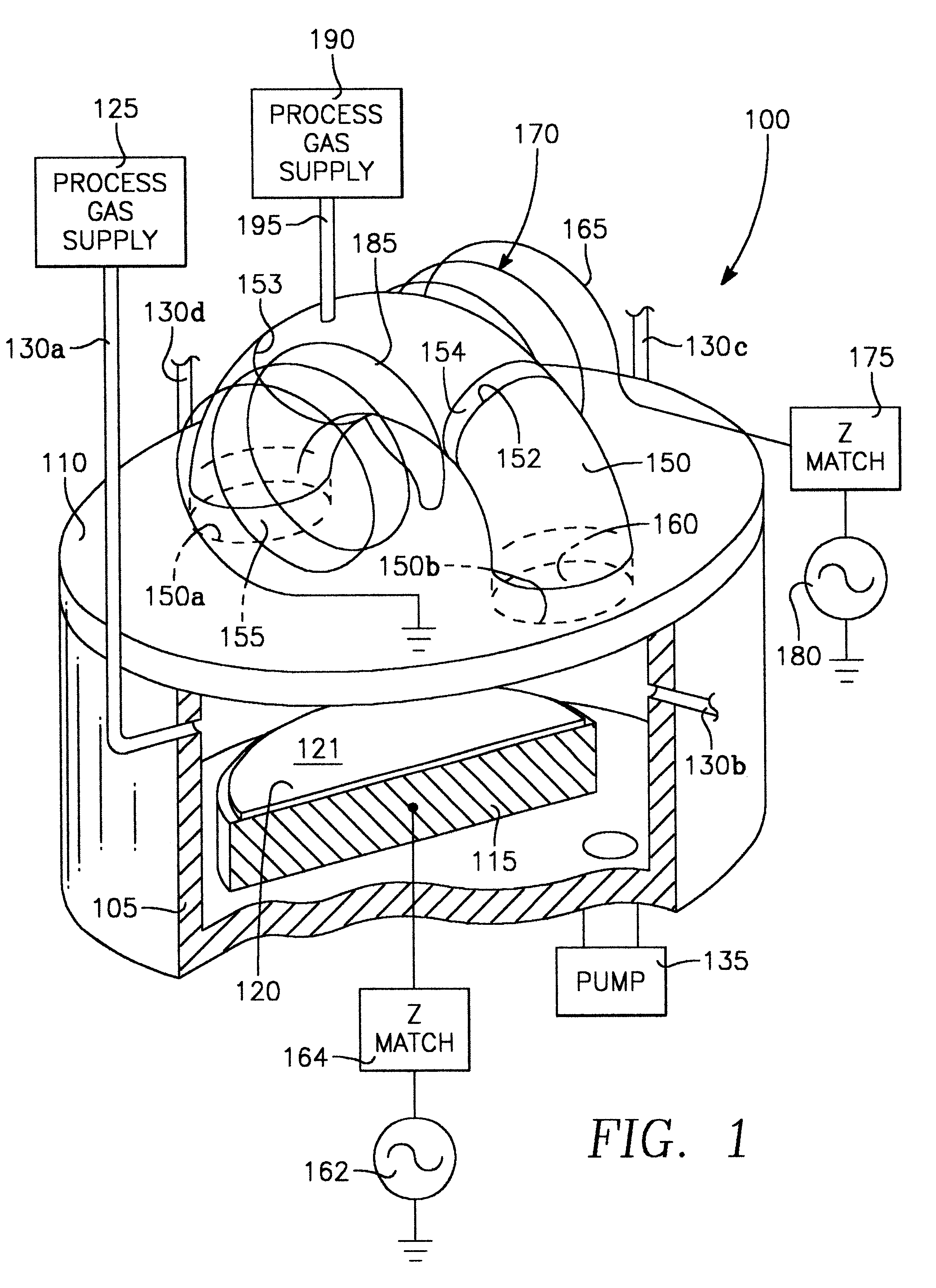

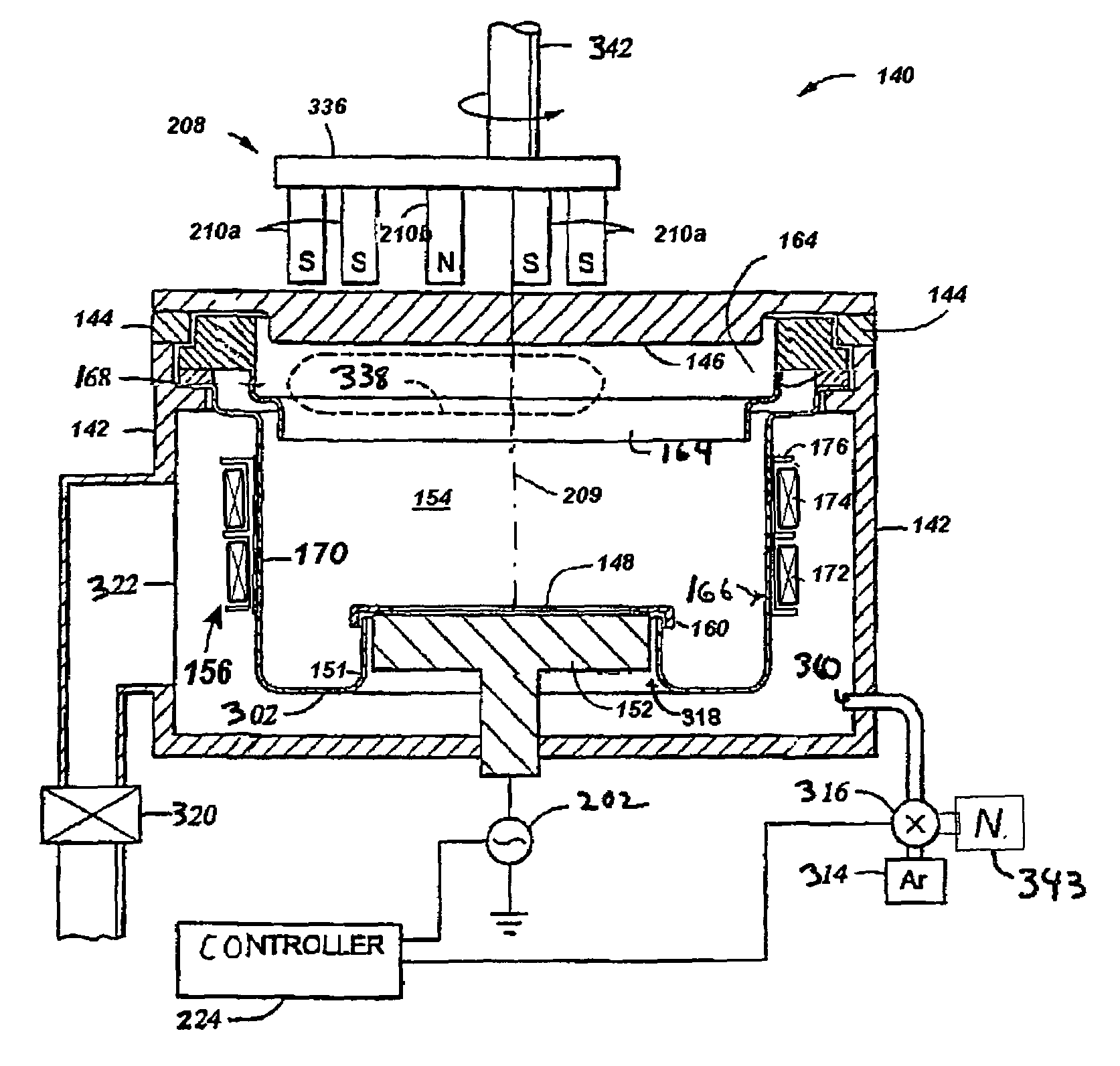

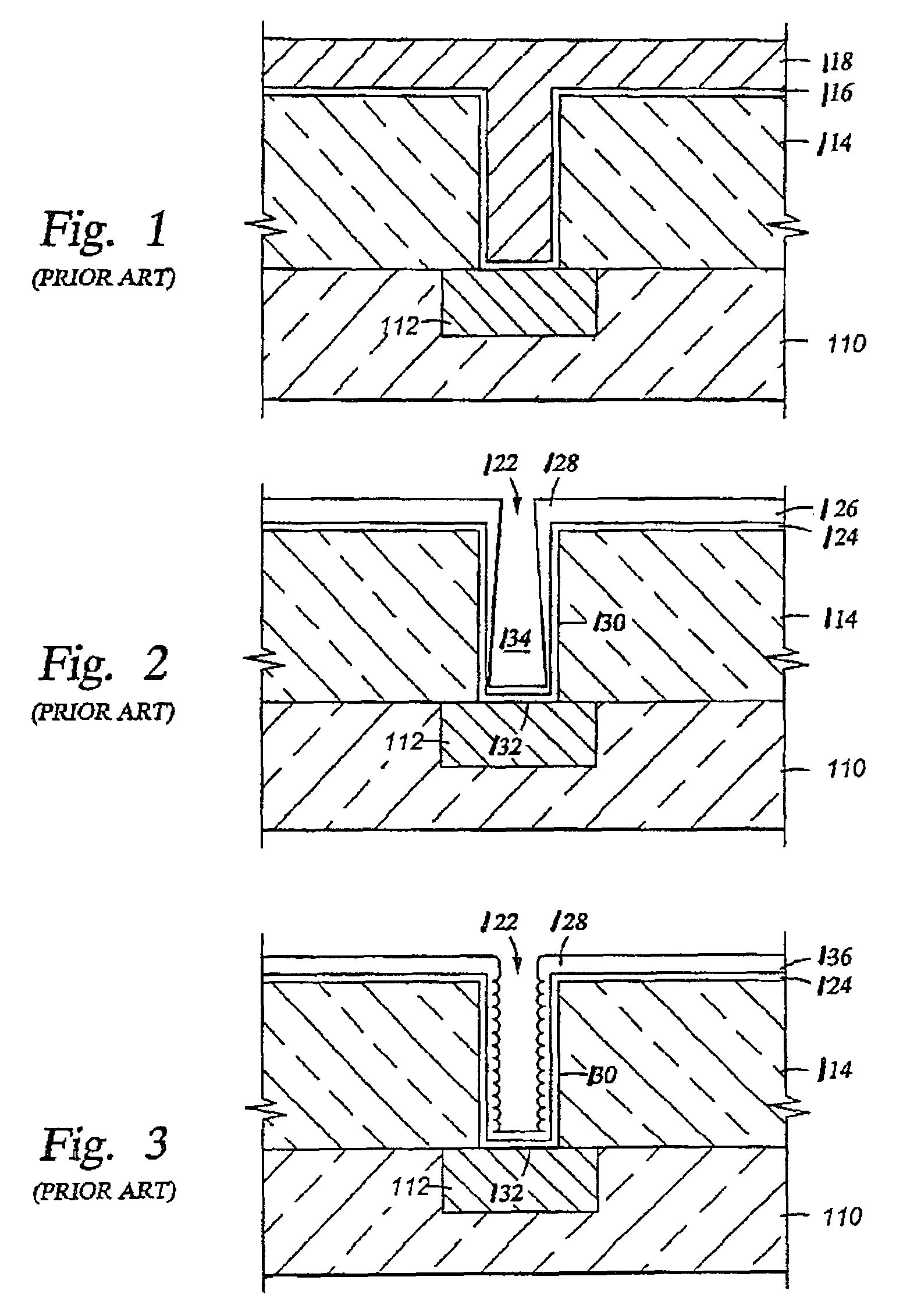

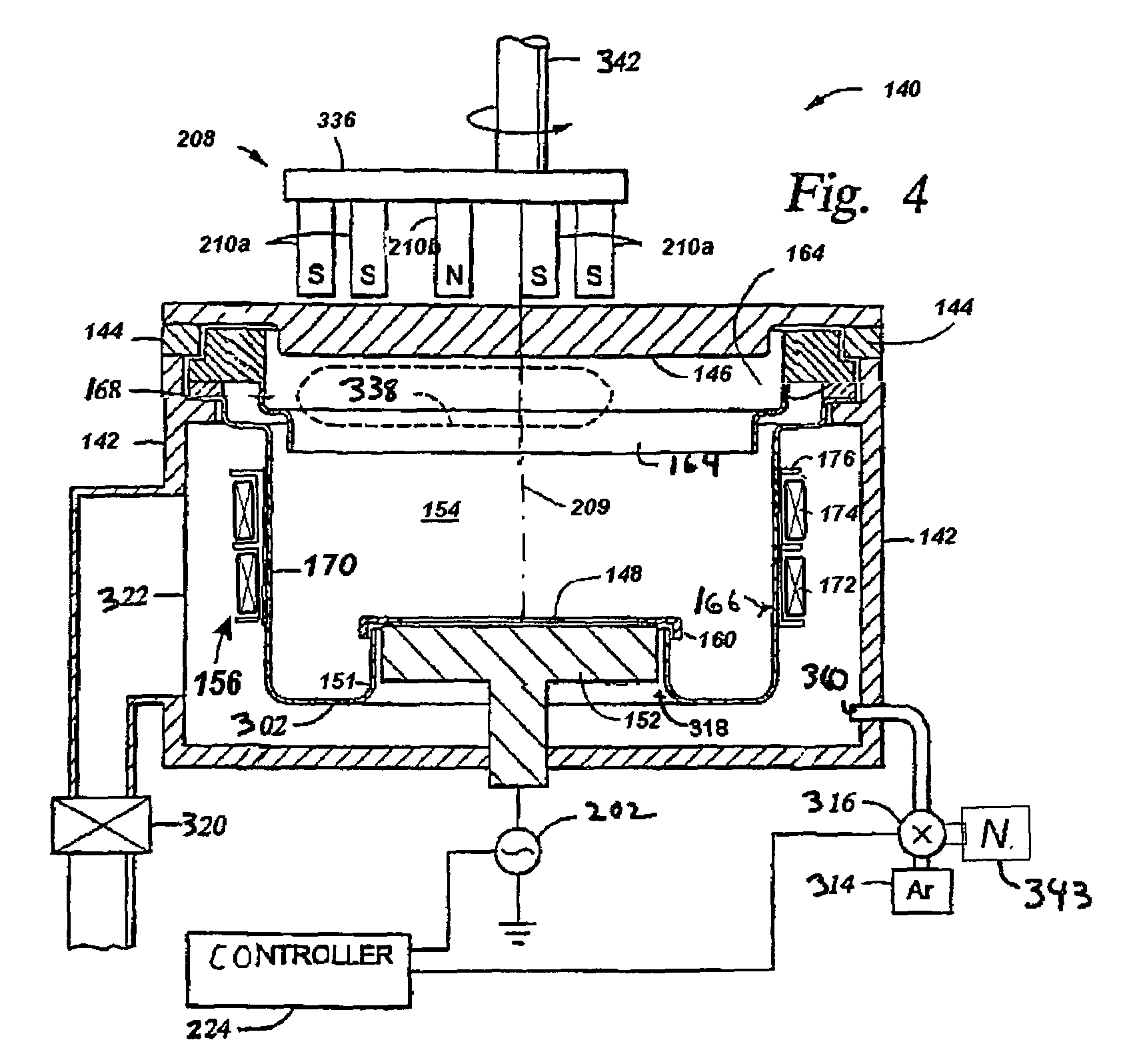

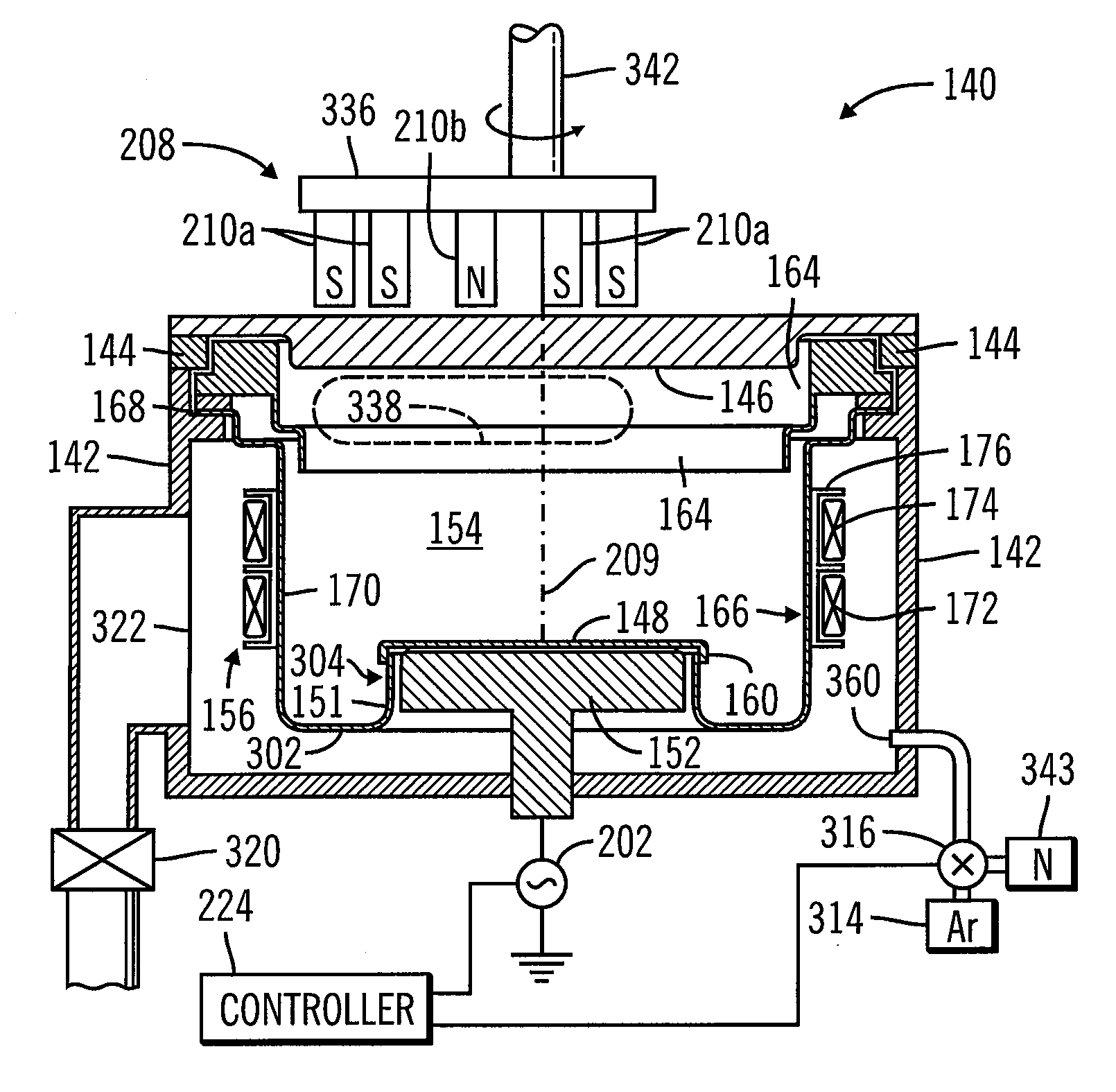

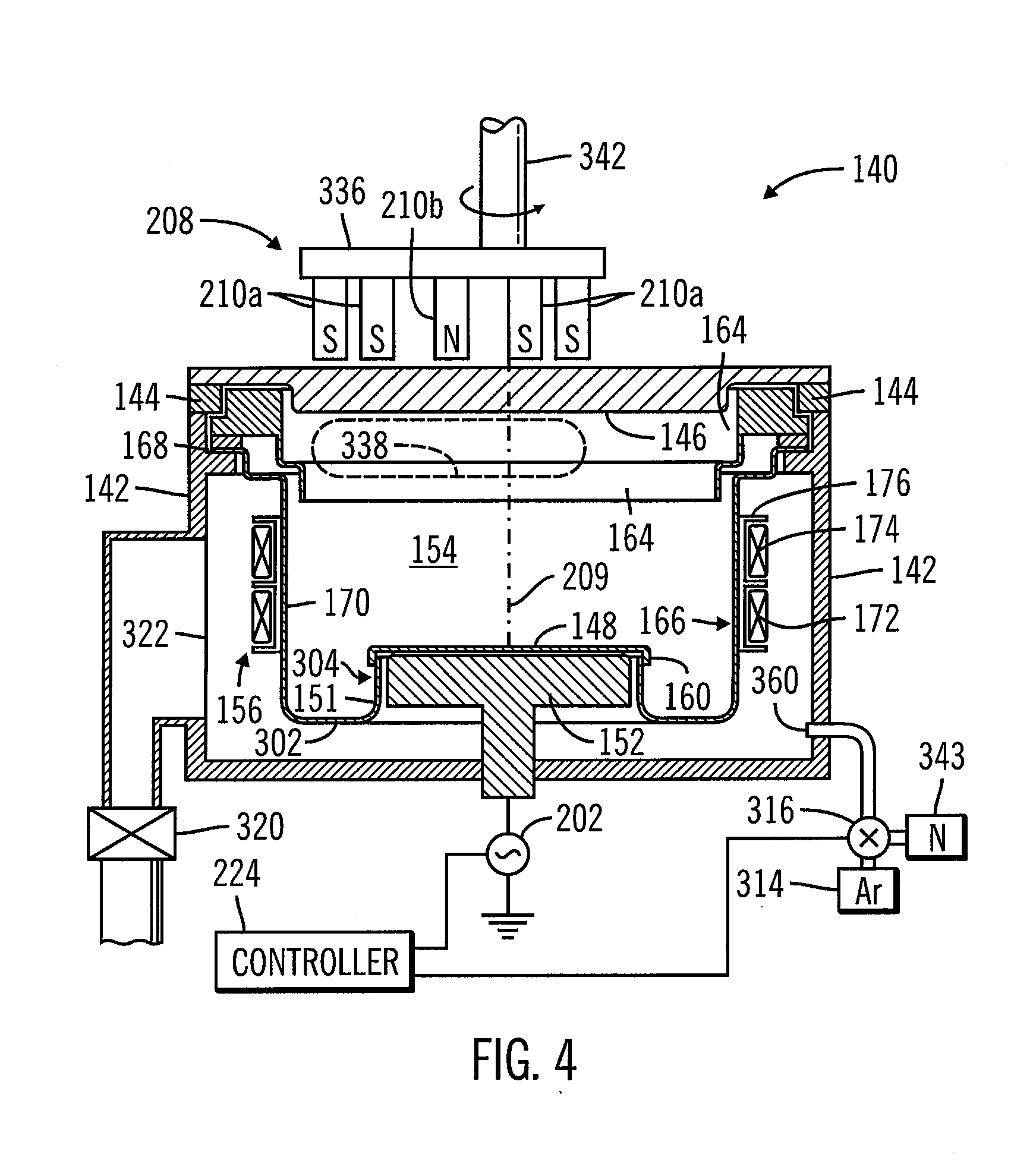

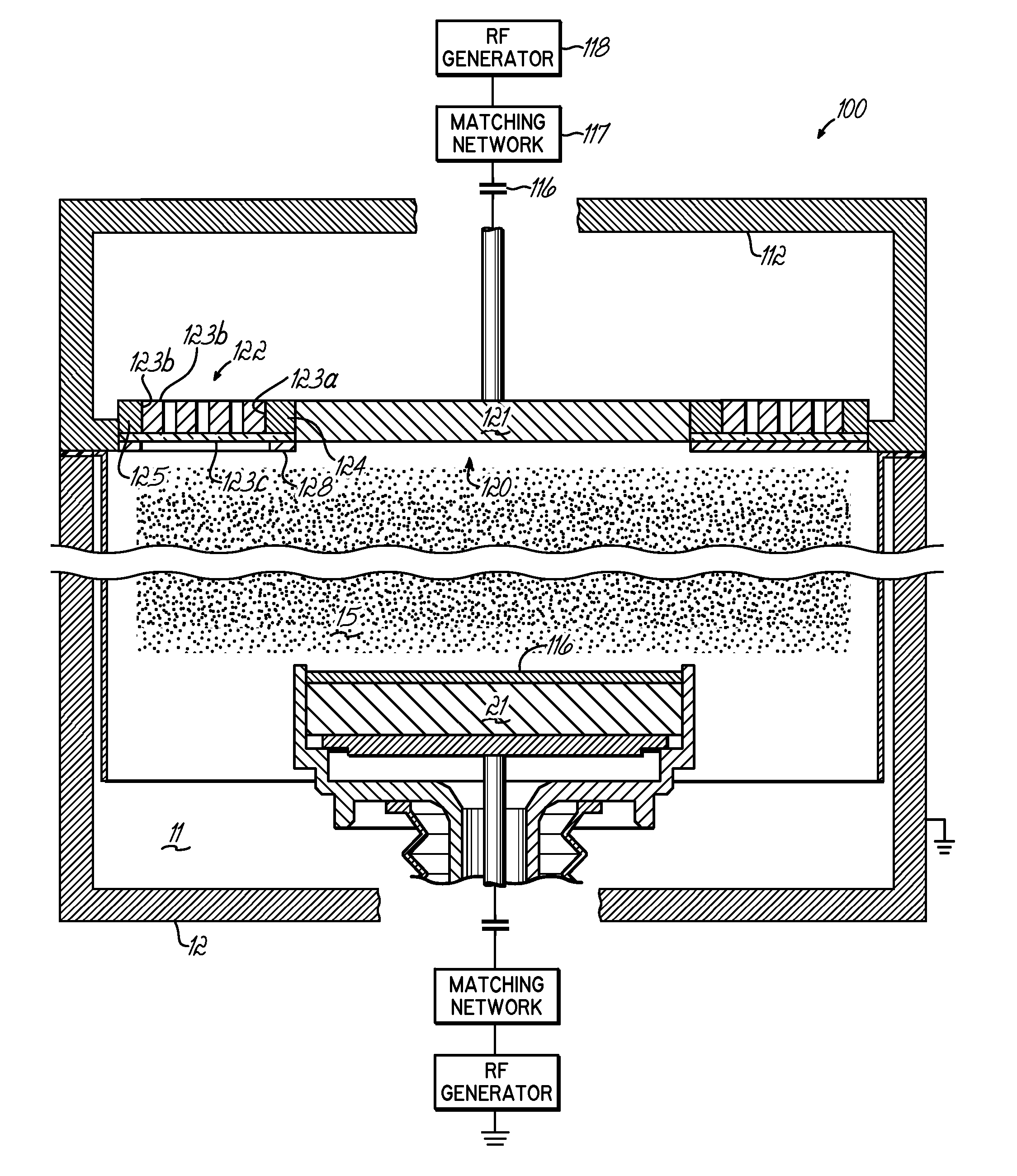

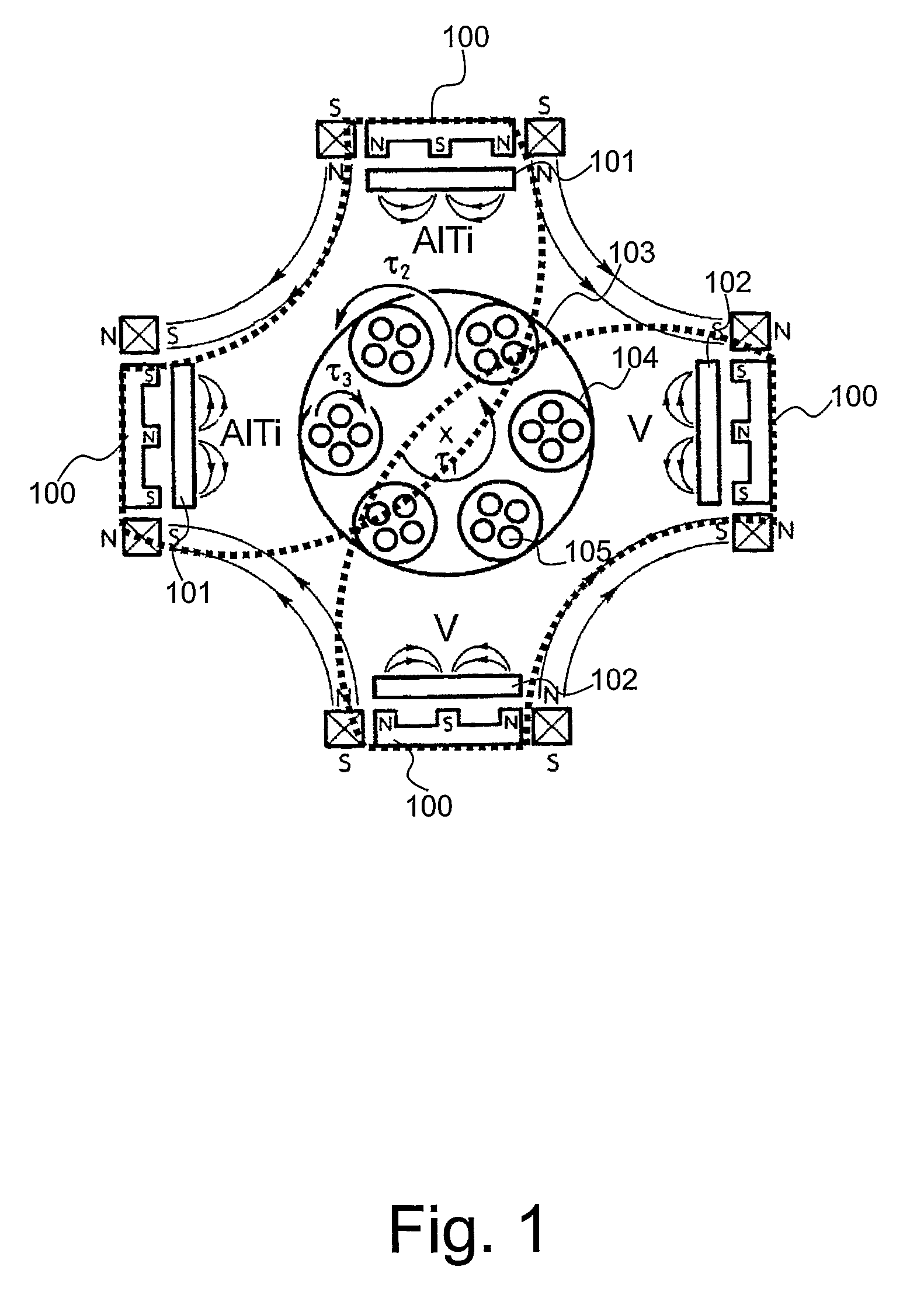

Self-ionized and capacitively-coupled plasma for sputtering and resputtering

InactiveUS7504006B2Raise the ratioIncrease plasma densityCellsElectric discharge tubesCapacitanceTantalum nitride

A DC magnetron sputter reactor for sputtering deposition materials such as tantalum and tantalum nitride, for example, and its method of use, in which self-ionized plasma (SIP) sputtering and capacitively coupled plasma (CCP) sputtering are promoted, either together or alternately, in the same chamber. Also, bottom coverage may be thinned or eliminated by inductively-coupled plasma (ICP) resputtering. SIP is promoted by a small magnetron having poles of unequal magnetic strength and a high power applied to the target during sputtering. CCP is provided by a pedestal electrode which capacitively couples RF energy into a plasma. The CCP plasma is preferably enhanced by a magnetic field generated by electromagnetic coils surrounding the pedestal which act to confine the CCP plasma and increase its density.

Owner:APPLIED MATERIALS INC

Systems and methods for compressing plasma

ActiveUS8537958B2Increase plasma densityNuclear energy generationLow temperature fusion reactorLiquid metalBreaking point

Embodiments of systems and methods for compressing plasma are described in which plasma pressures above the breaking point of solid material can be achieved by injecting a plasma into a funnel of liquid metal in which the plasma is compressed and / or heated.

Owner:GENERAL FUSION INC

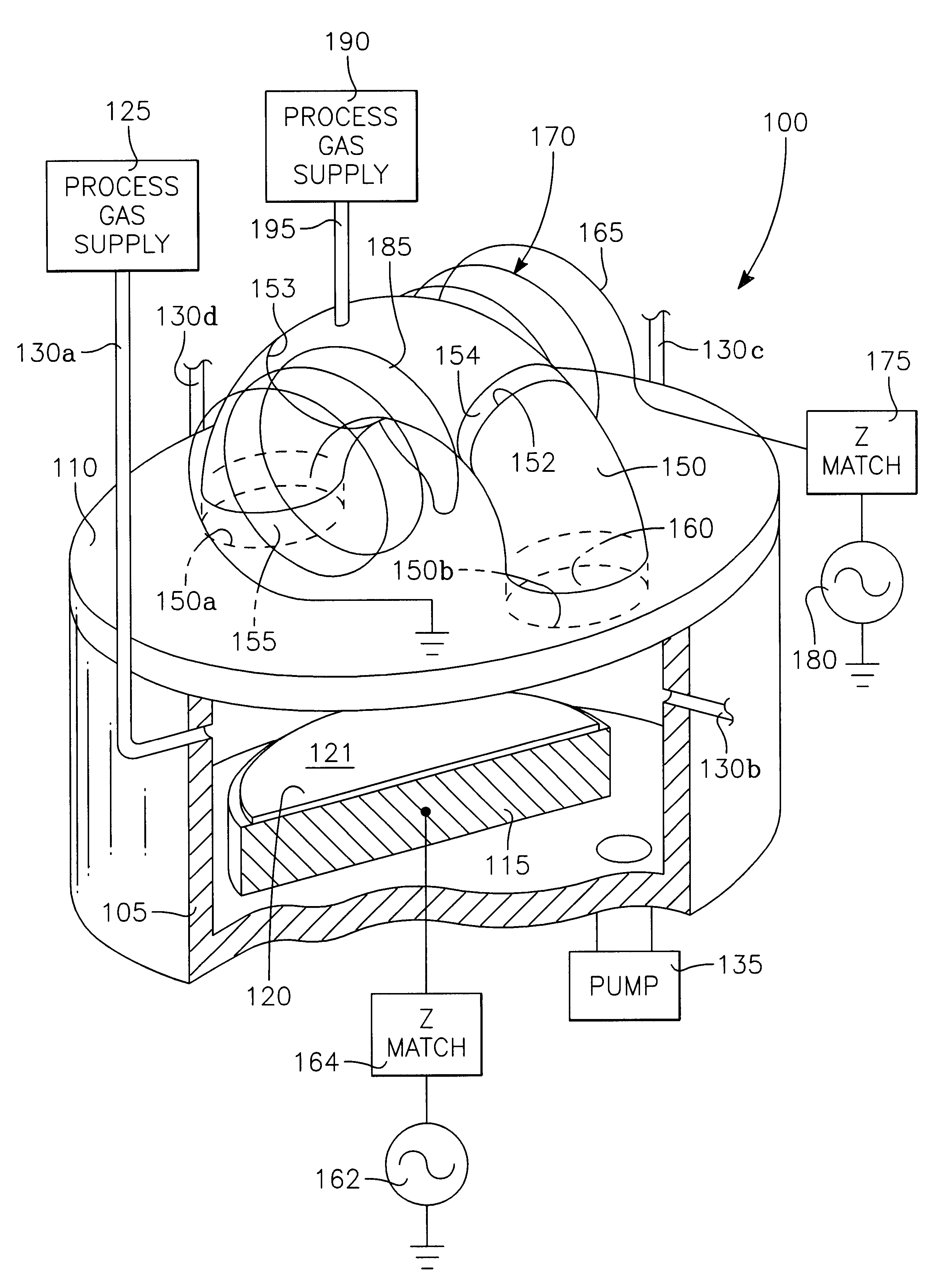

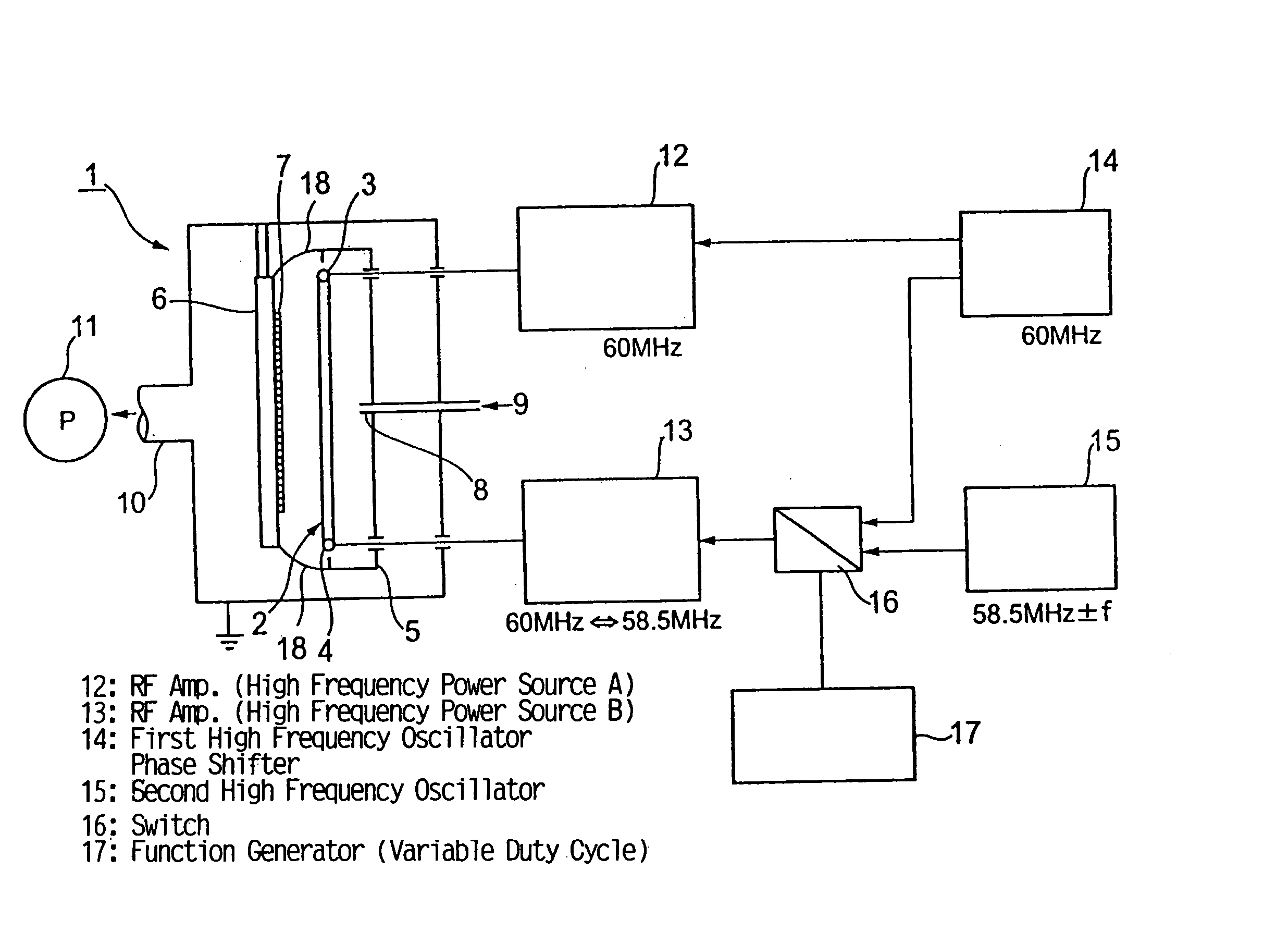

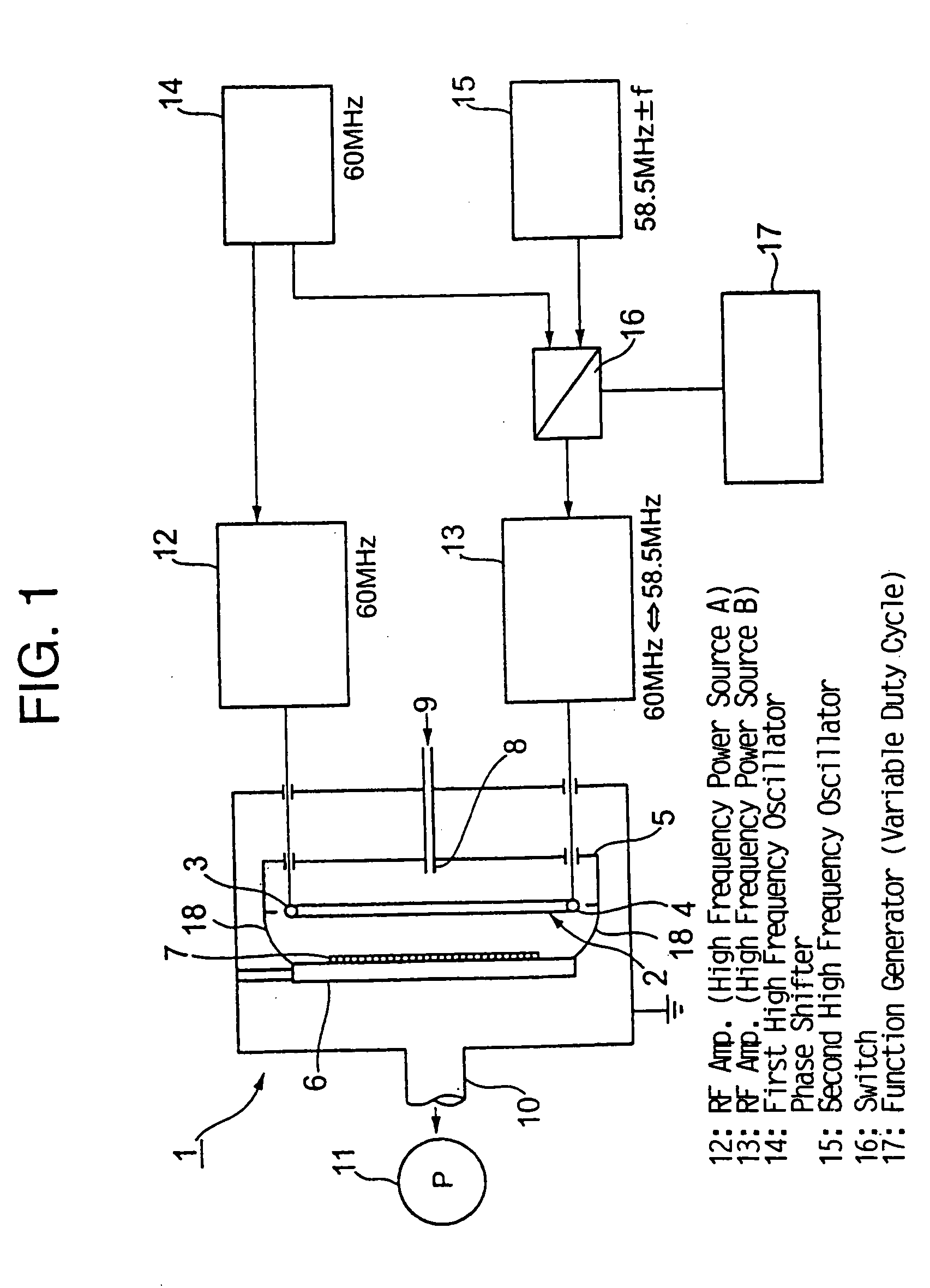

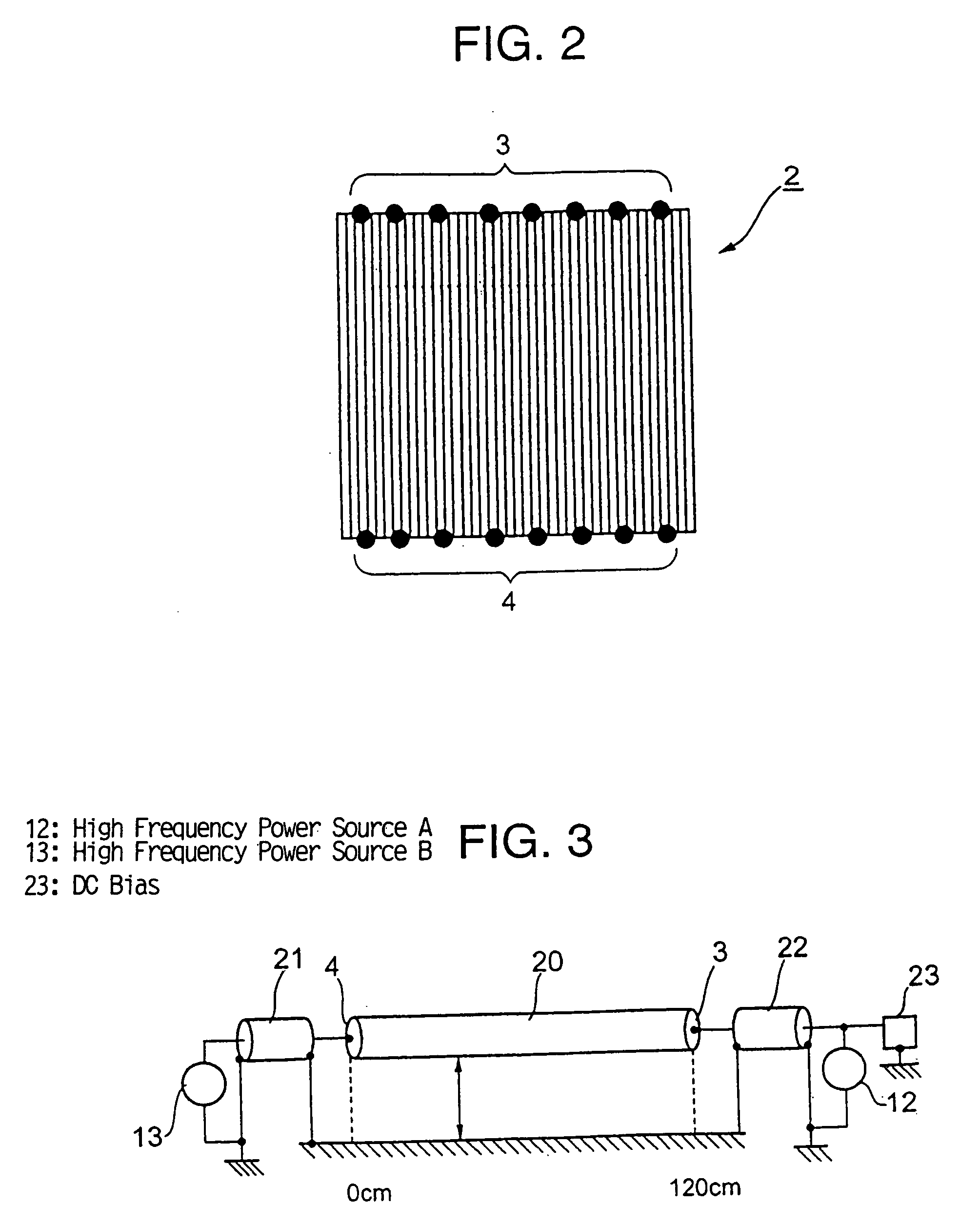

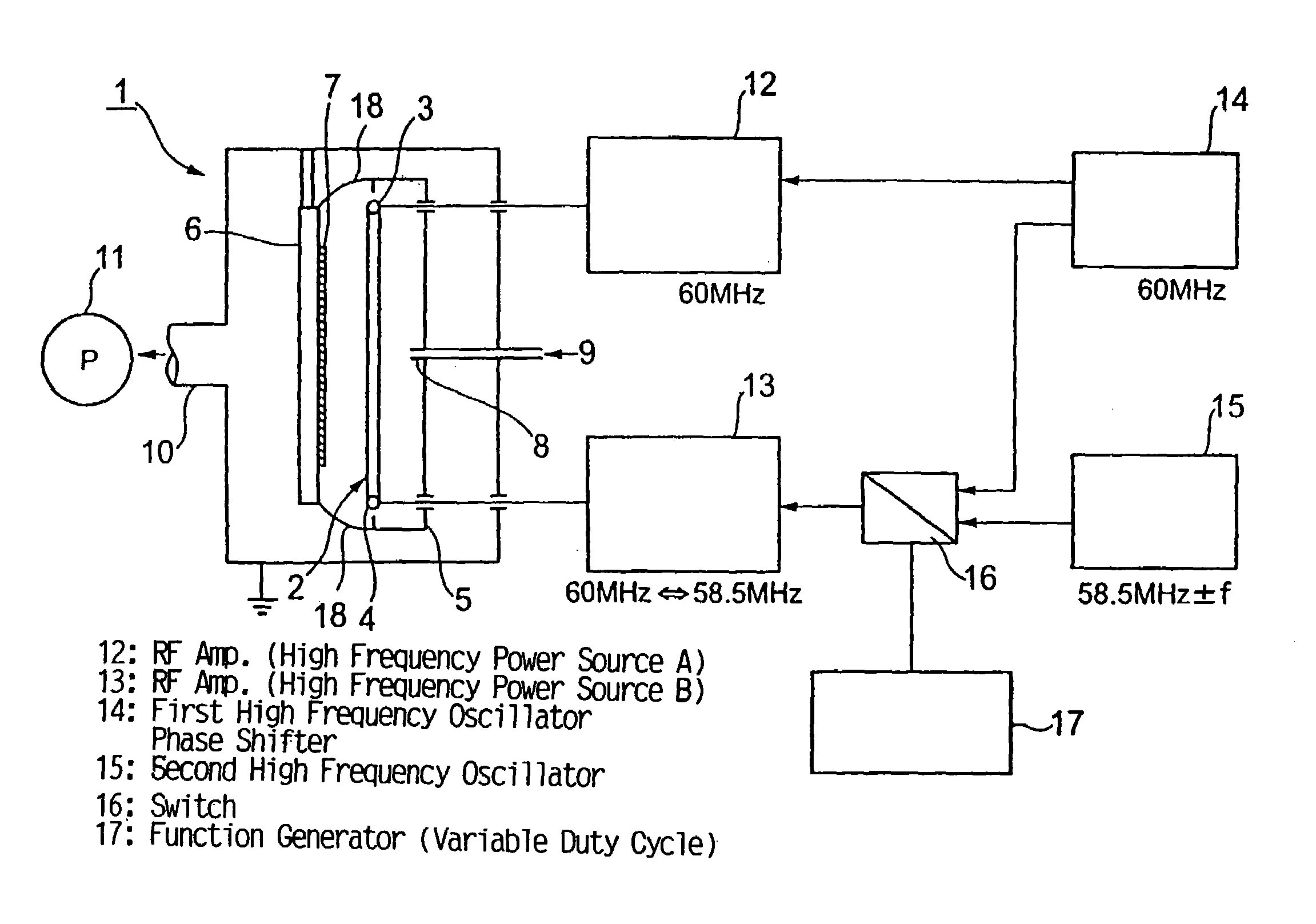

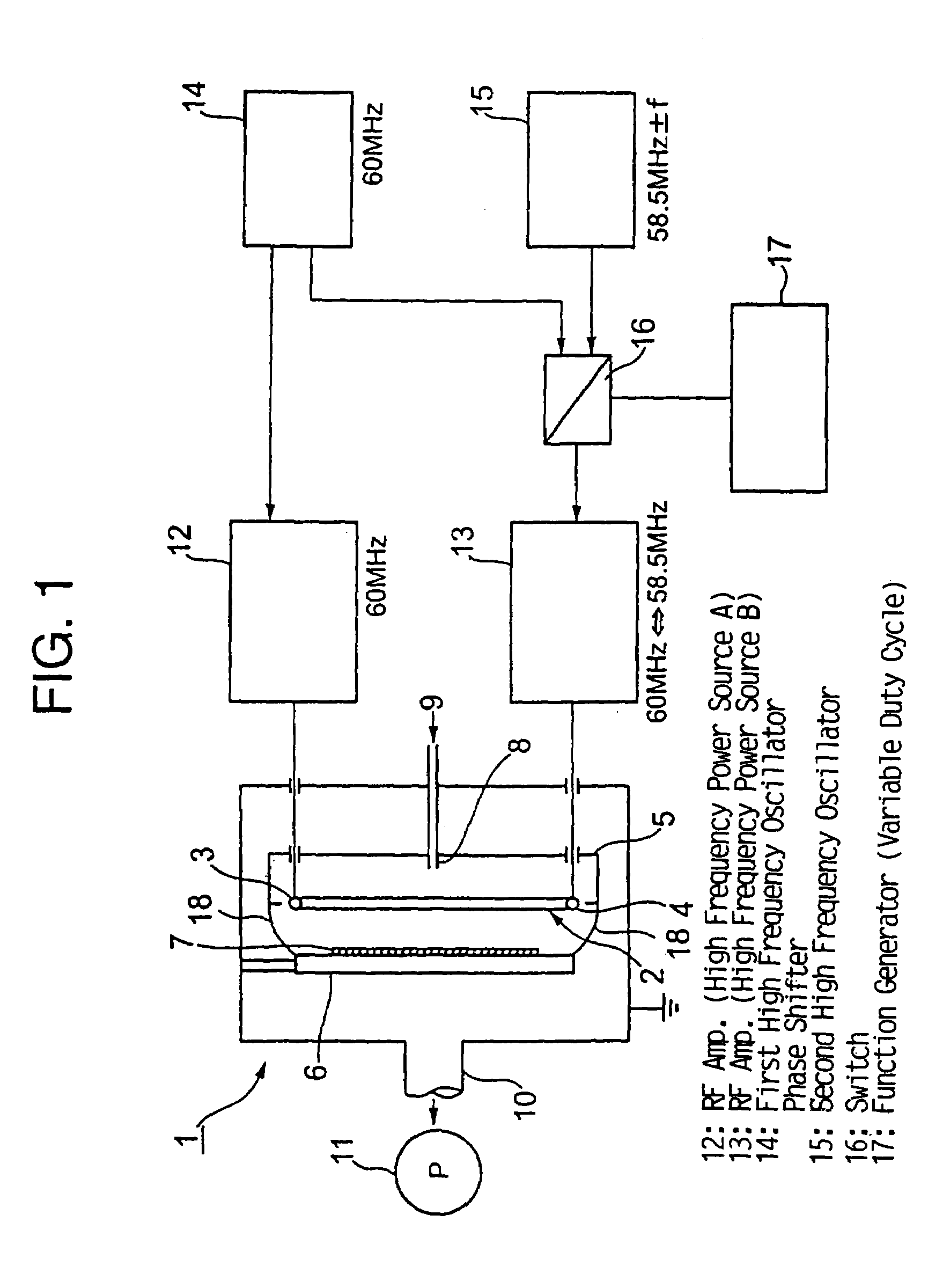

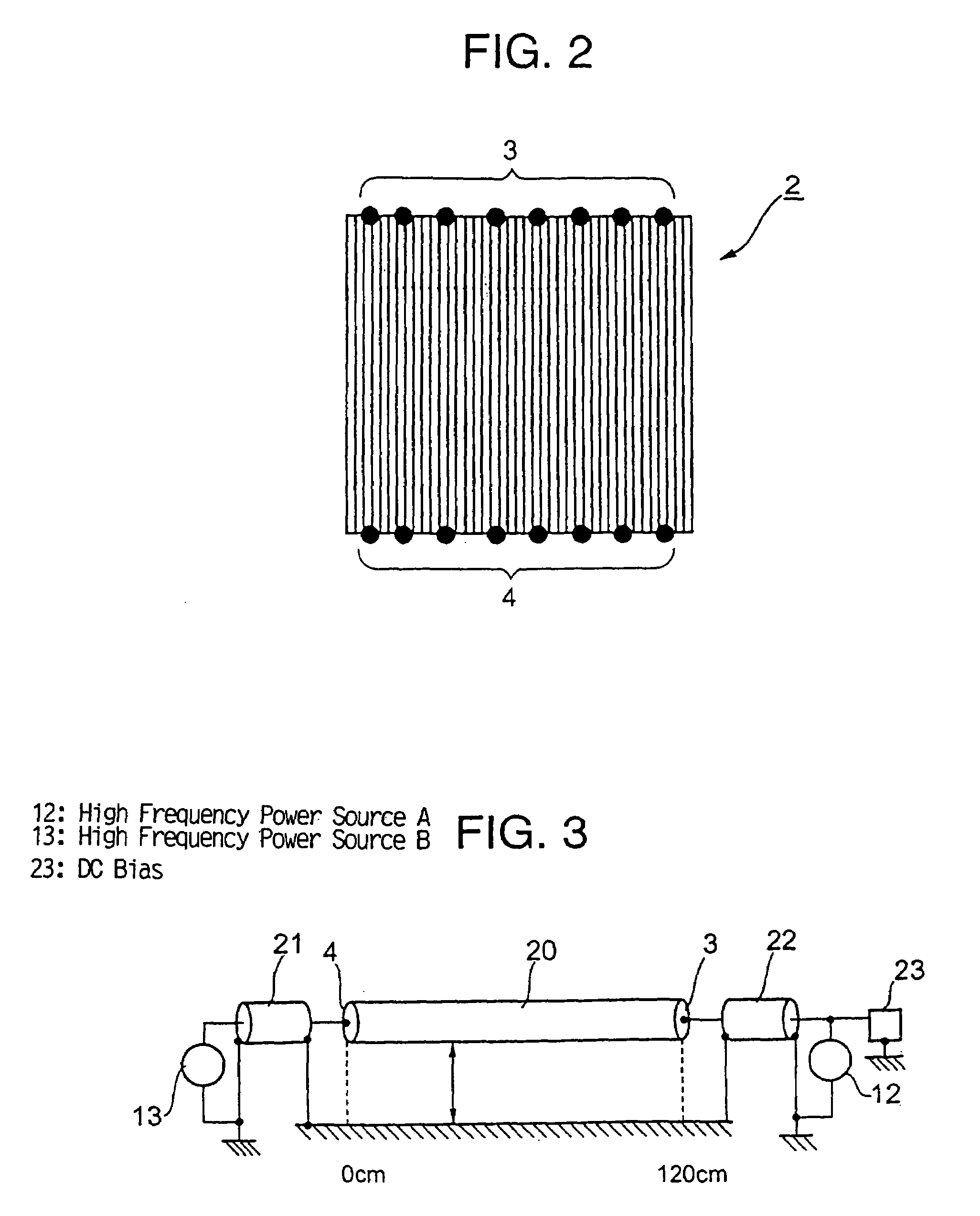

Method and device for generating uniform high-frequency plasma over large surface area used for plasma chemical vapor deposition apparatus

InactiveUS20050255255A1Reduce power lossIncrease rangeElectric discharge tubesChemical vapor deposition coatingPhysicsVery high frequency

This invention relates a plasma generation device for generating plasma uniformly over a large surface area by very high frequency (VHF), which is installed in a plasma chemical vapor deposition apparatus. The present invention installs a first and a second power supply section on both ends of the discharge electrode installed in plasma chemical vapor deposition apparatus, which are supplied with alternate cycles: the first cycle wherein the first and second power supply sections receive high frequency waves at the same frequency, and a second cycle wherein different high frequency waves are received. In this manner, the state of plasma generation may be varied in each cycle, and when averaged over time, it makes possible uniform plasma generation over a large surface area.

Owner:MITSUBISHI HEAVY IND LTD

Self-ionized and capacitively-coupled plasma for sputtering and resputtering

ActiveUS20080142359A1Raise the ratioIncrease plasma densityCellsElectric discharge tubesIonizationSputter deposition

A DC magnetron sputter reactor for sputtering deposition materials such as tantalum and tantalum nitride, for example, and its method of use, in which self-ionized plasma (SIP) sputtering and capacitively coupled plasma (CCP) sputtering are promoted, either together or alternately, in the same chamber. Also, bottom coverage may be thinned or eliminated by inductively-coupled plasma (ICP) resputtering. SIP is promoted by a small magnetron having poles of unequal magnetic strength and a high power applied to the target during sputtering. CCP is provided by a pedestal electrode which capacitively couples RF energy into a plasma. The CCP plasma is preferably enhanced by a magnetic field generated by electromagnetic coils surrounding the pedestal which act to confine the CCP plasma and increase its density.

Owner:APPLIED MATERIALS INC

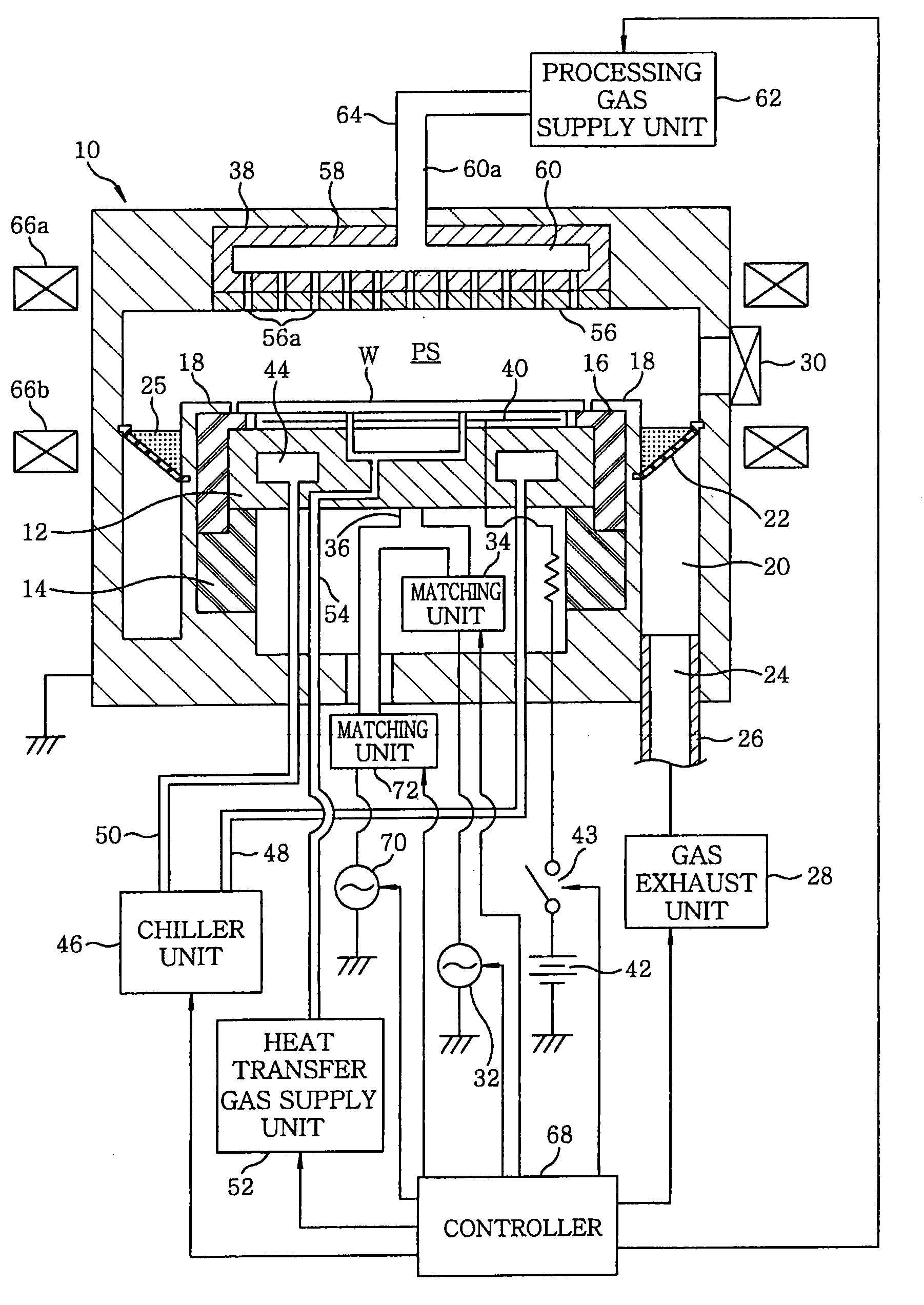

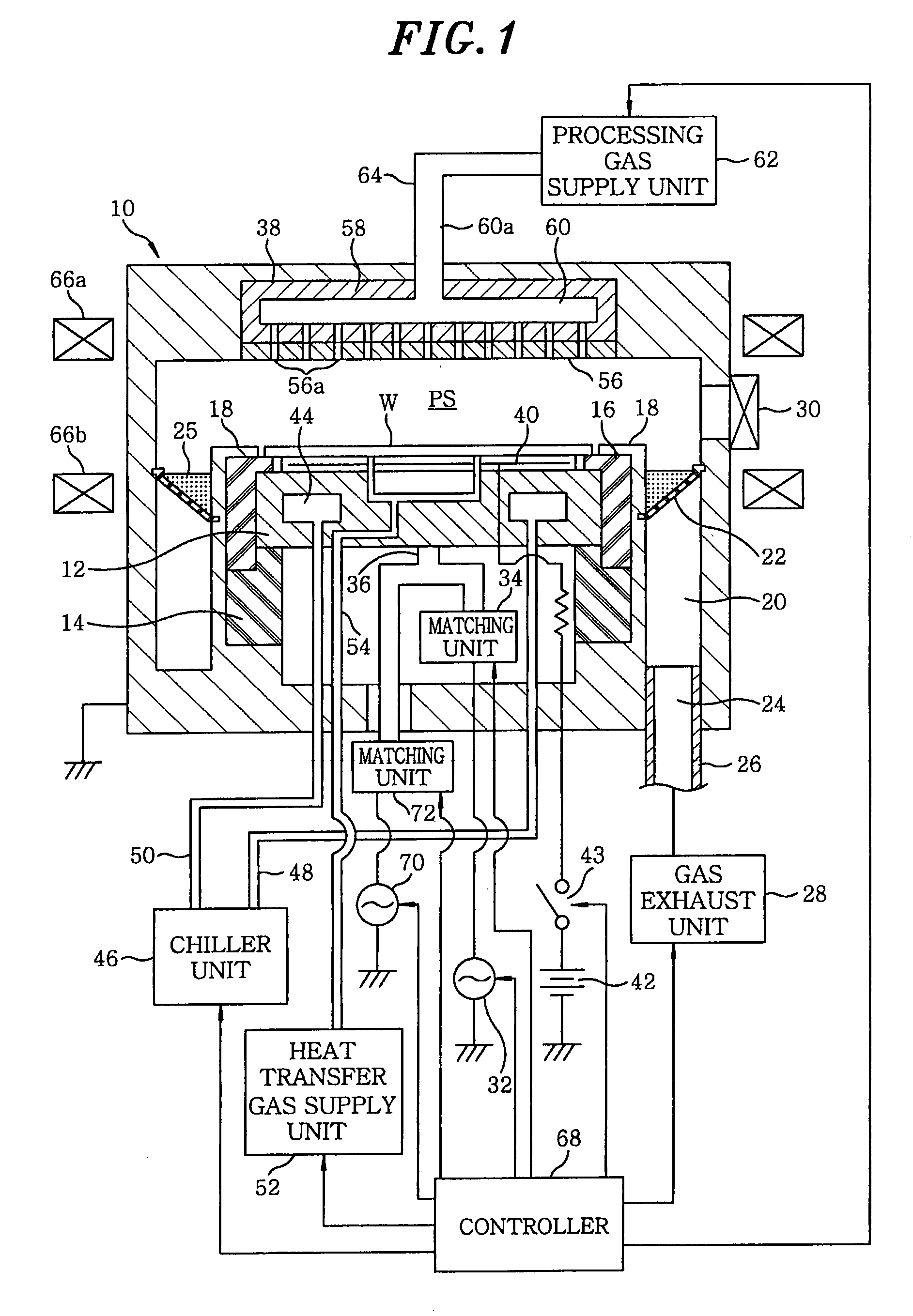

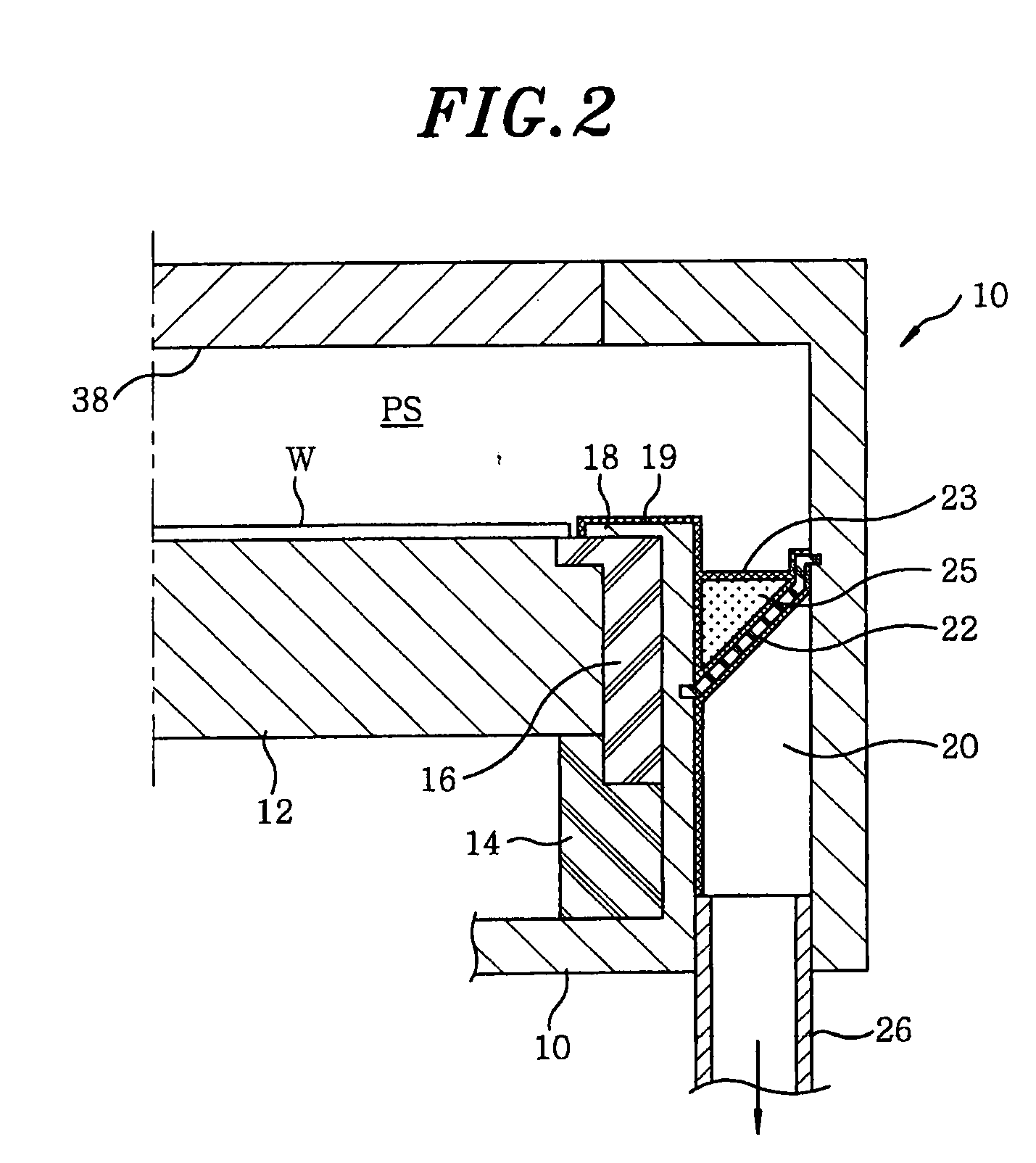

Plasma processing apparatus

InactiveUS20090236043A1Improve in-plane uniformityWide power rangeCellsElectric discharge tubesRf dischargeRadio frequency

A plasma processing apparatus includes a processing gas supplying unit for supplying a desired processing gas to a processing space between an upper electrode and a lower electrode which are disposed facing each other in an evacuable processing chamber. The plasma processing apparatus further includes a radio frequency (RF) power supply unit for applying an RF power to one of the lower and the upper electrode to generate plasma of the processing gas by RF discharge and an electrically conductive RF ground member which covers a periphery portion of the electrode to which the RF power is applied to receive RF power emitted outwardly in radial directions from the periphery portion of the electrode to which the RF power is applied and send the received RF power to a ground line.

Owner:TOKYO ELECTRON LTD

Method and device for generating uniform high-frequency plasma over large surface area used for plasma chemical vapor deposition apparatus

InactiveUS7205034B2Increase plasma densityLow densityElectric discharge tubesChemical vapor deposition coatingEngineeringChemical vapor deposition

A plasma generation device for generating plasma uniformly over a large surface area by very high frequency (VHF), which is installed in a plasma chemical vapor deposition apparatus. A first and a second power supply section are installed on both ends of the discharge electrode installed in a plasma chemical vapor deposition apparatus, and are supplied with alternate cycles: the first cycle wherein the first and second power supply sections receive high frequency waves at the same frequency, and a second cycle wherein different high frequency waves are received. In this manner, the state of plasma generation may be varied in each cycle, and when averaged over time, it makes possible uniform plasma generation over a large surface area.

Owner:MITSUBISHI HEAVY IND LTD

Etch system with integrated inductive coupling

InactiveUS20070113981A1Highly effectiveLow costElectric discharge tubesElectric arc lampsCapacitancePlasma density

An integrated capacitively-coupled and inductively-coupled device is provided for plasma etching that may be used as a primary or secondary source for generating a plasma to etch substrates. The device is practical for processing advanced semiconductor devices and integrated circuits that require uniform and dense plasma. The invention may be embodied in an apparatus that contains a substrate support, typically including an electrostatic chuck, that controls ion energy by capacitively coupling RF power to the plasma and generating voltage bias on the wafer relative to the plasma potential. An etching electrode is provided opposite the substrate support. An integrated inductive coupling element is provided at the perimeter of the etching electrode that increases plasma density at the perimeter of the wafer, compensating for the radial loss of charged particles toward chamber walls, to produce uniform plasma density above the processed wafer. The device has a capacitive coupling zone in its center for energizing etching ions and an inductive coupling zone at its perimeter of the wafer. Both zones together with plasma create a resonant circuit with the plasma.

Owner:TOKYO ELECTRON LTD

Ion implantation method and method for manufacturing SOI wafer

ActiveUS20040038504A1Increase generationIncrease plasma densitySolid-state devicesVacuum evaporation coatingInternal pressureMicrowave

Disclosed are an ion implantation method capable of dramatically increasing an implantation rate of hydrogen ions into a semiconductor substrate and a method for manufacturing an SOI wafer, in which manufacturing efficiency of the SOI wafer is sufficiently high. When the hydrogen ions are implanted to a predetermined depth of the semiconductor substrate, hydrogen gas is introduced into a chamber where an inner pressure is reduced and a predetermined magnetic field is formed, plasma is generated by introducing a microwave into the magnetic field, hydrogen ion beams containing hydrogen molecule ions is extracted from the plasma, and the hydrogen molecule ions are irradiated and implanted onto the semiconductor substrate. Thus, a throughput in the hydrogen ion implantation is improved, thus making it possible to enhance the manufacturing efficiency of the SOI wafer.

Owner:APPLIED MATERIALS INC

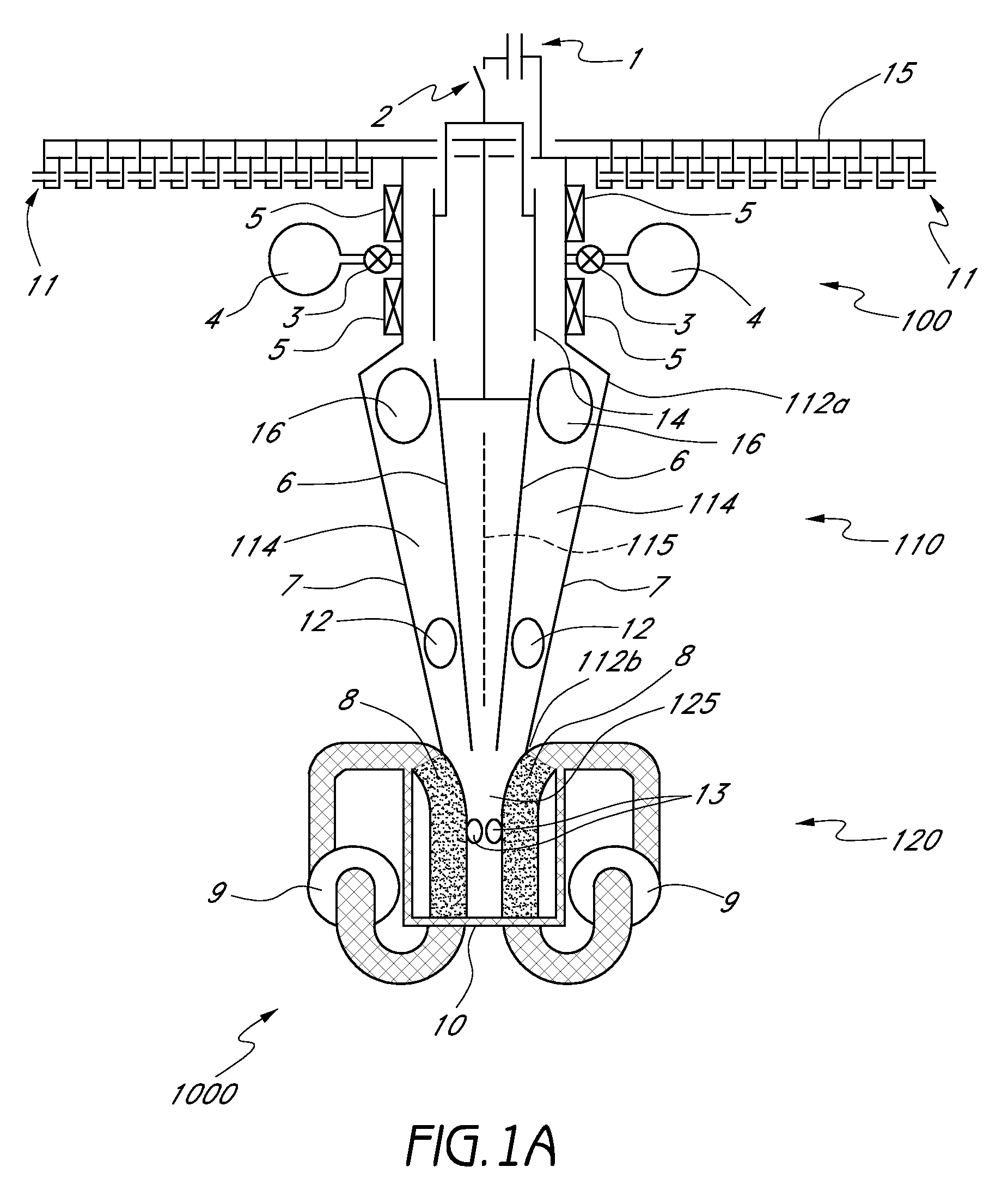

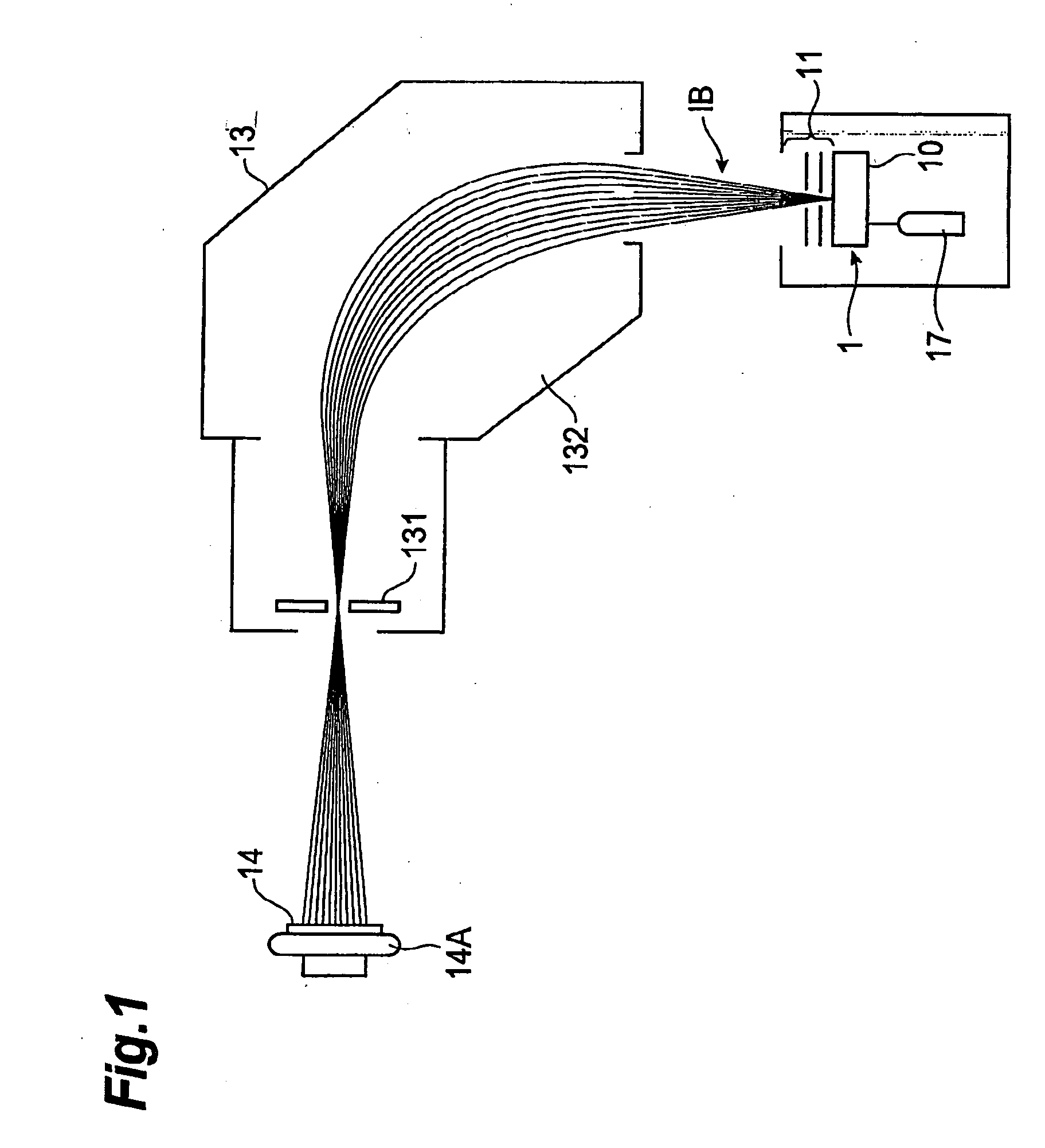

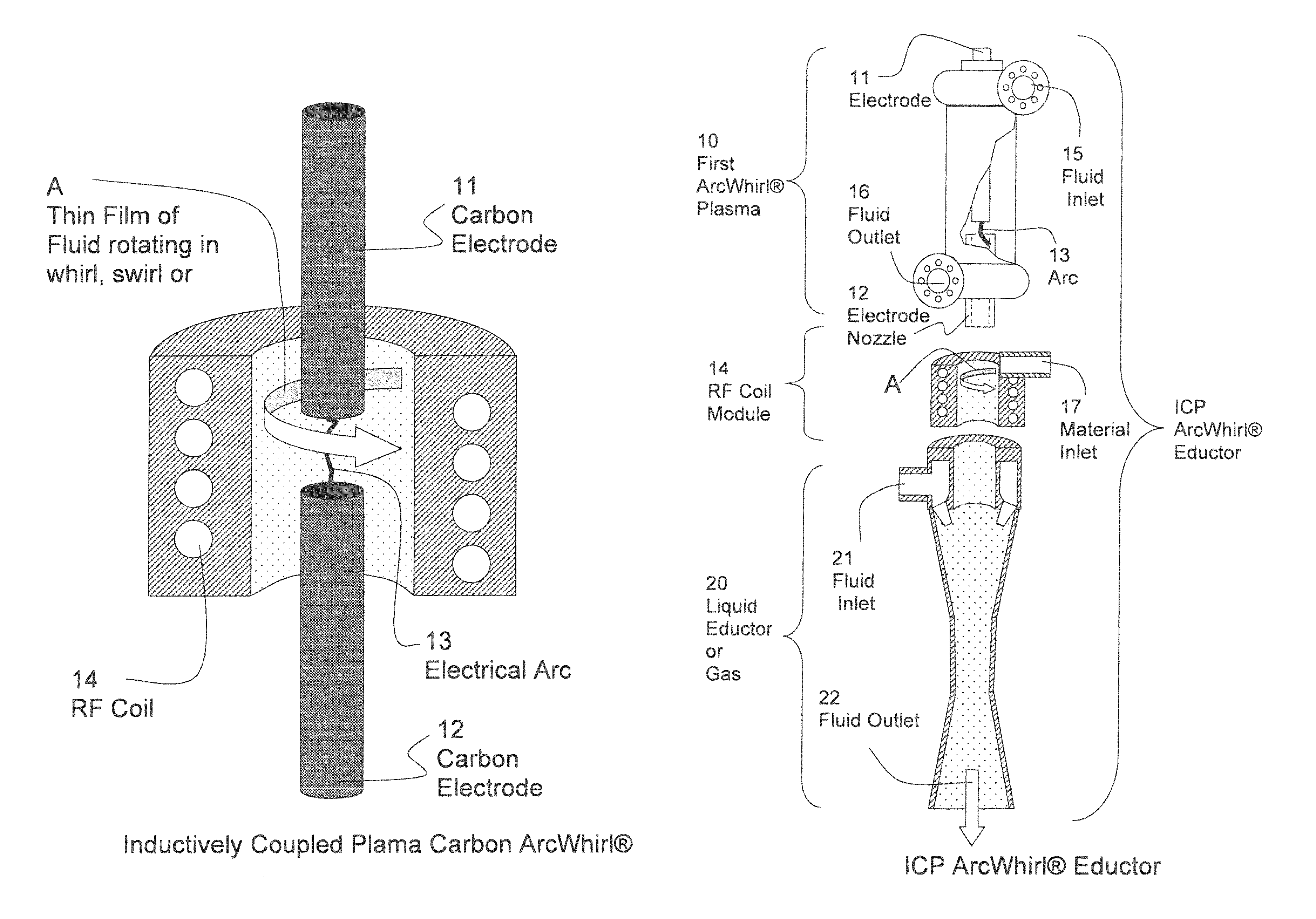

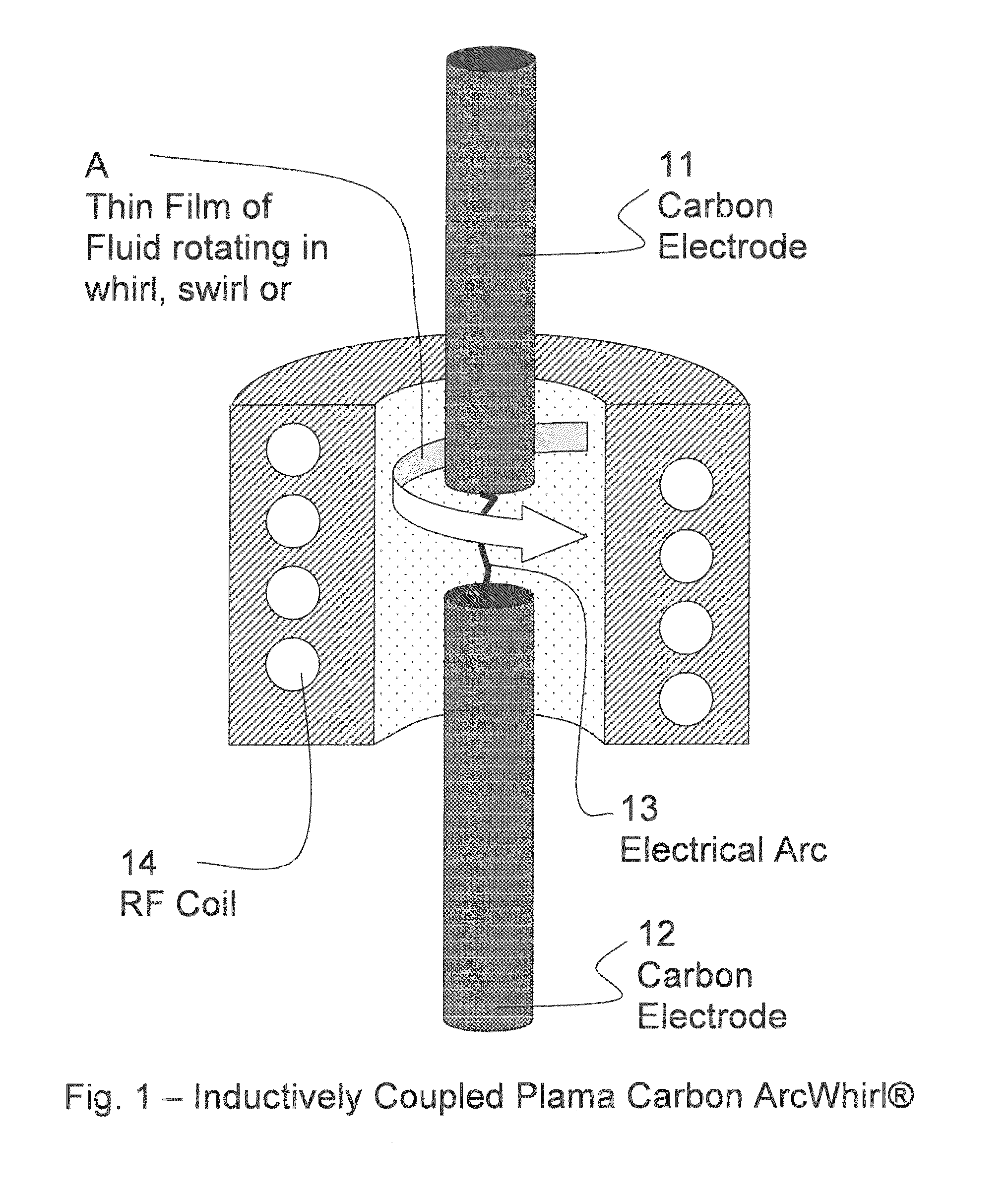

Plasma whirl reactor apparatus and methods of use

ActiveUS9445488B2Maximize anisotropyDecrease productivityGas-gas reaction as plasma stateElectron beam welding apparatusEngineeringPlasma arc welding

A plasma system includes a plasma arc torch, a cylindrical tube and an eductor. The plasma arc torch includes a cylindrical vessel having a first end and a second end, a first tangential inlet / outlet connected to or proximate to the first end, a second tangential inlet / outlet connected to or proximate to the second end, an electrode housing connected to the first end such that a first electrode is (a) aligned with a longitudinal axis of the cylindrical vessel, and (b) extends into the cylindrical vessel, and a hollow electrode nozzle connected to the second end of the cylindrical vessel. The cylindrical tube is attached to the hollow electrode nozzle and aligned with the longitudinal axis, the cylindrical tube having a side inlet and a radio frequency coil disposed around or embedded within the cylindrical tube. The eductor is attached to the cylindrical tube and aligned with the longitudinal axis.

Owner:FORET PLASMA LABS

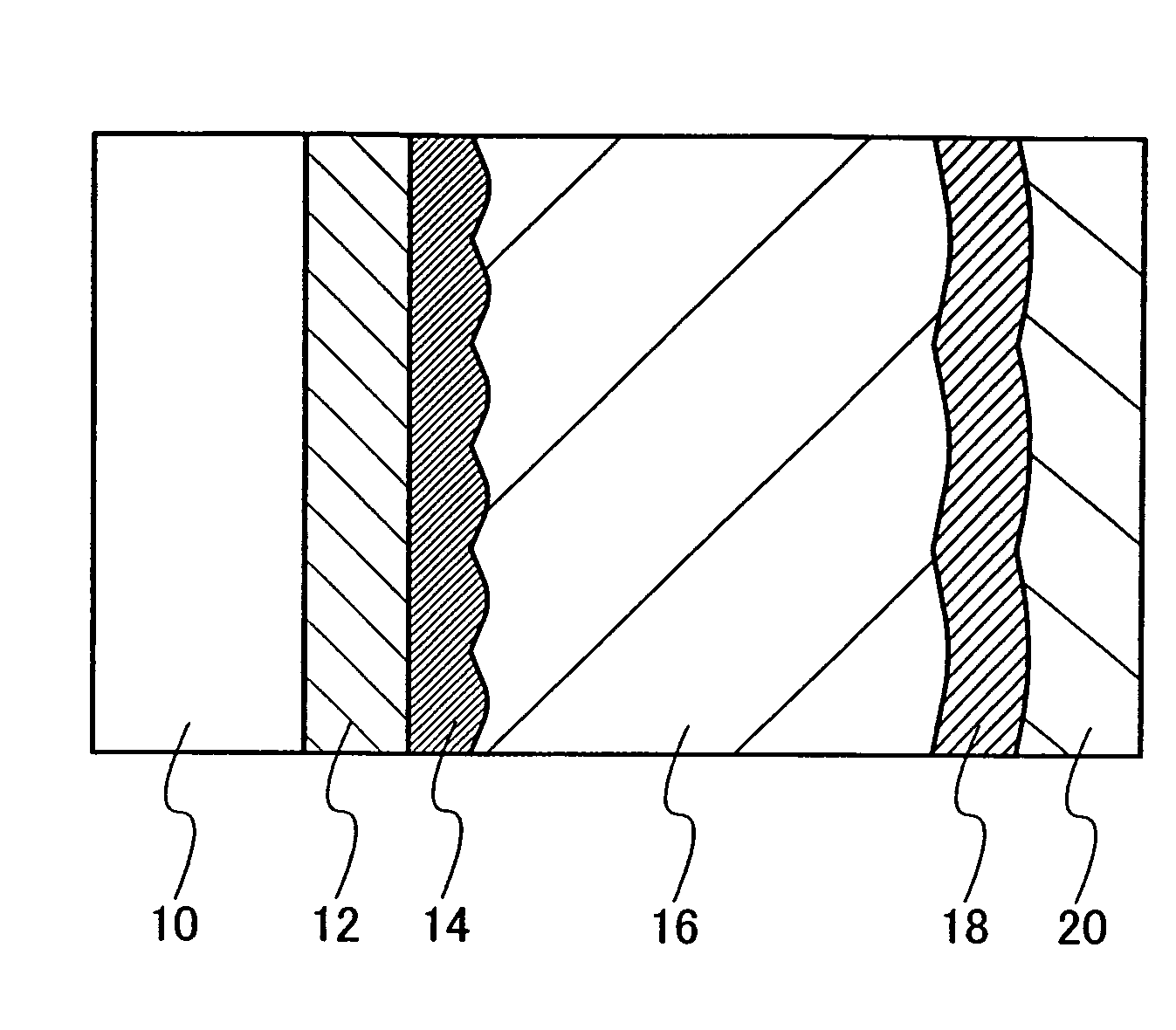

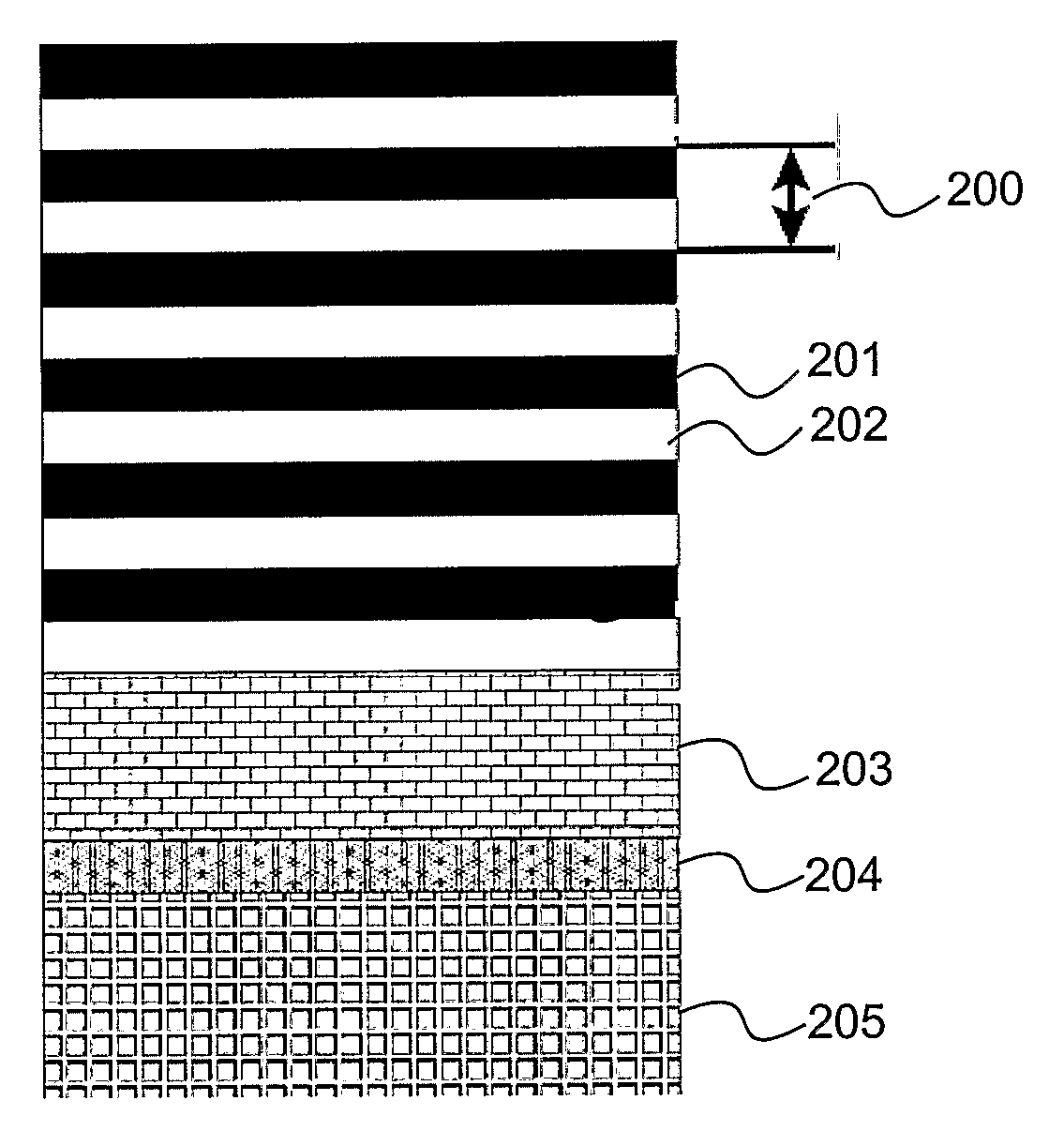

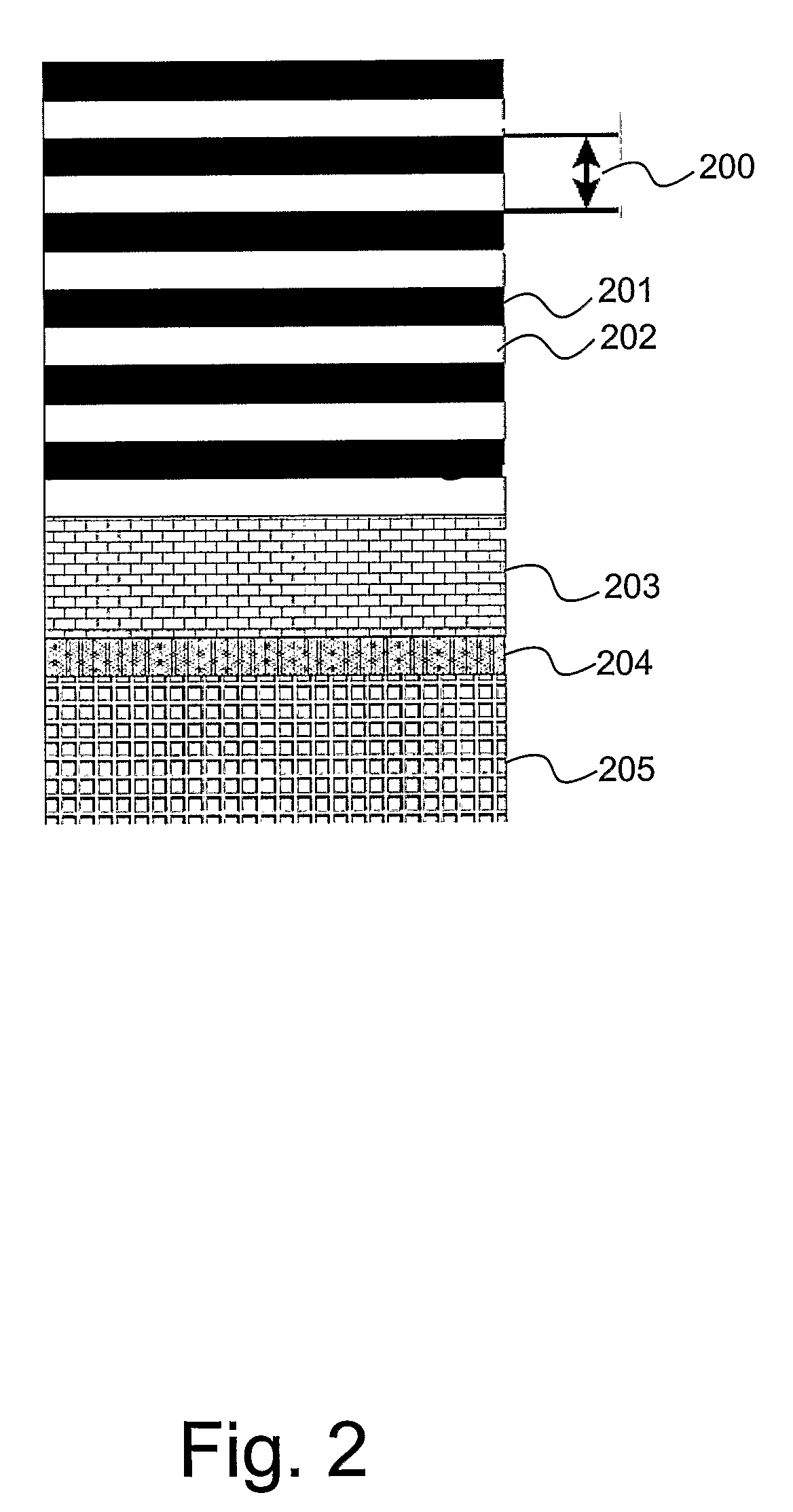

Pvd Coated Substrate

InactiveUS20080260478A1High hardnessReduce coefficient of frictionPigmenting treatmentVacuum evaporation coatingMetal alloyHardness

A PVD coating is disclosed, and in particular a nanoscale multilayer superlattice PVD coating comprising high hardness, a low friction coefficient and increased chemical inertness. The multilayer coating comprises a repeating bilayer represented by (VxMe(i-x))CyN(i-y) / (MezV(1-z))CyN(i-y) where 0.1≦x≦0.9; 0.01<y<0.99 and 0.1≦z≦0.9 and Me is a substantially pure metal or a metal alloy. The composition of the coating through the layers alternates from layer to layer according to a V-rich layer and a Me-rich layer modulated sequence. Vanadium is incorporated within the layer composition and has been found to act as a lubricating agent during sliding wear. Carbon, also incorporated within the coating, serves to further stabilise the friction coefficient thereby increasing the chemical inertness between cutting tool and workpiece material.

Owner:SHEFFIELD HALLAM UNIVERSITY

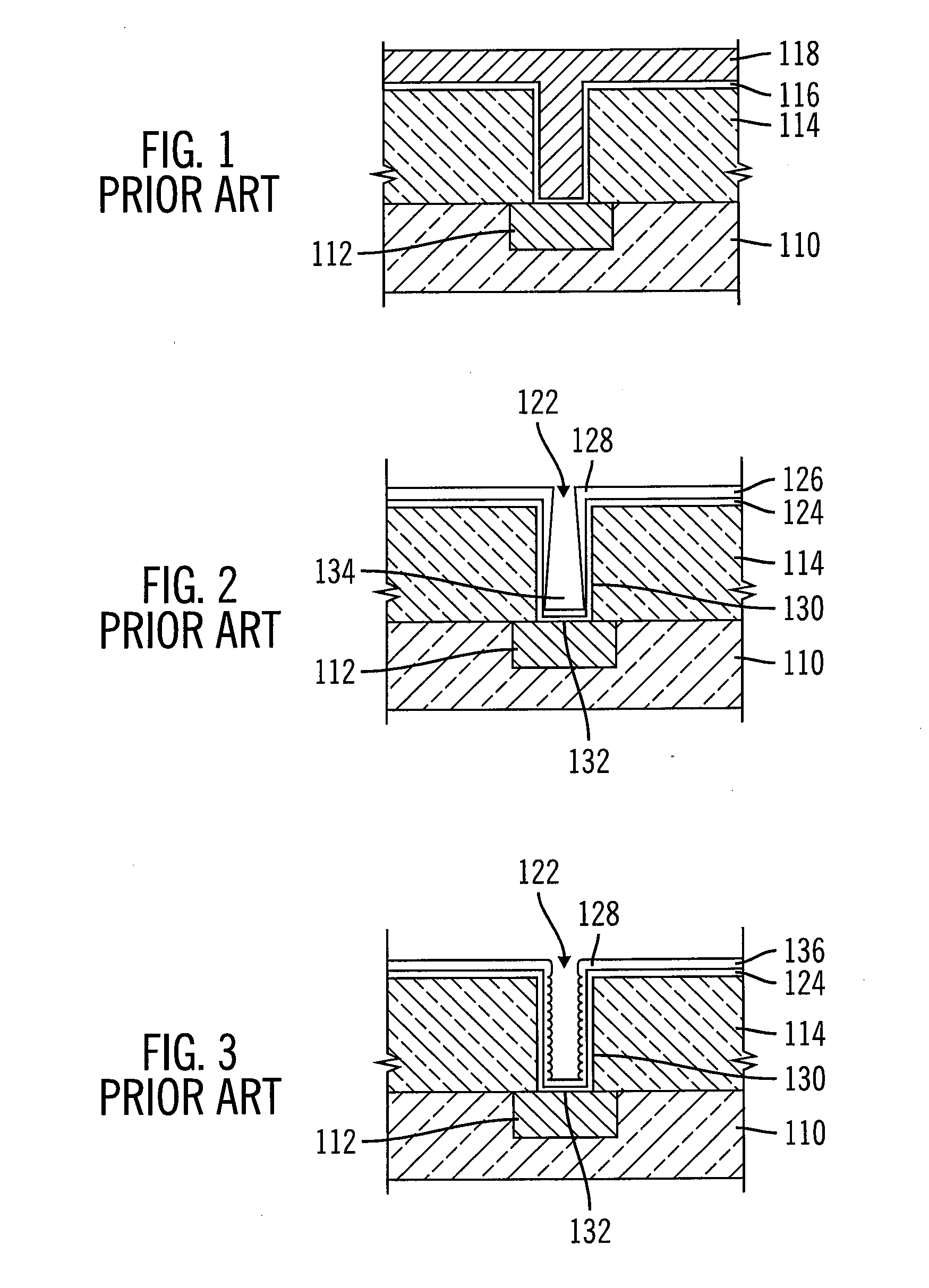

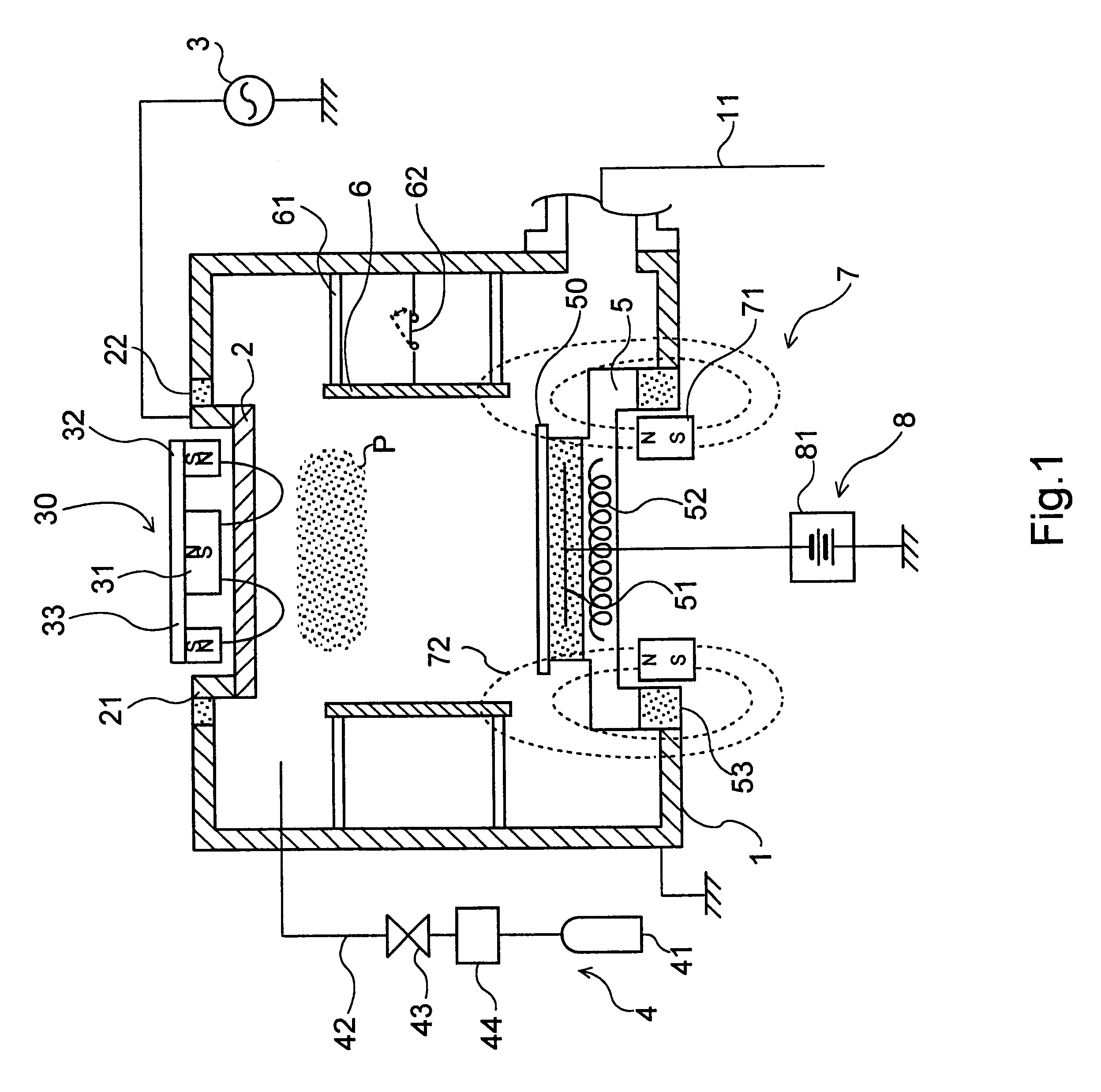

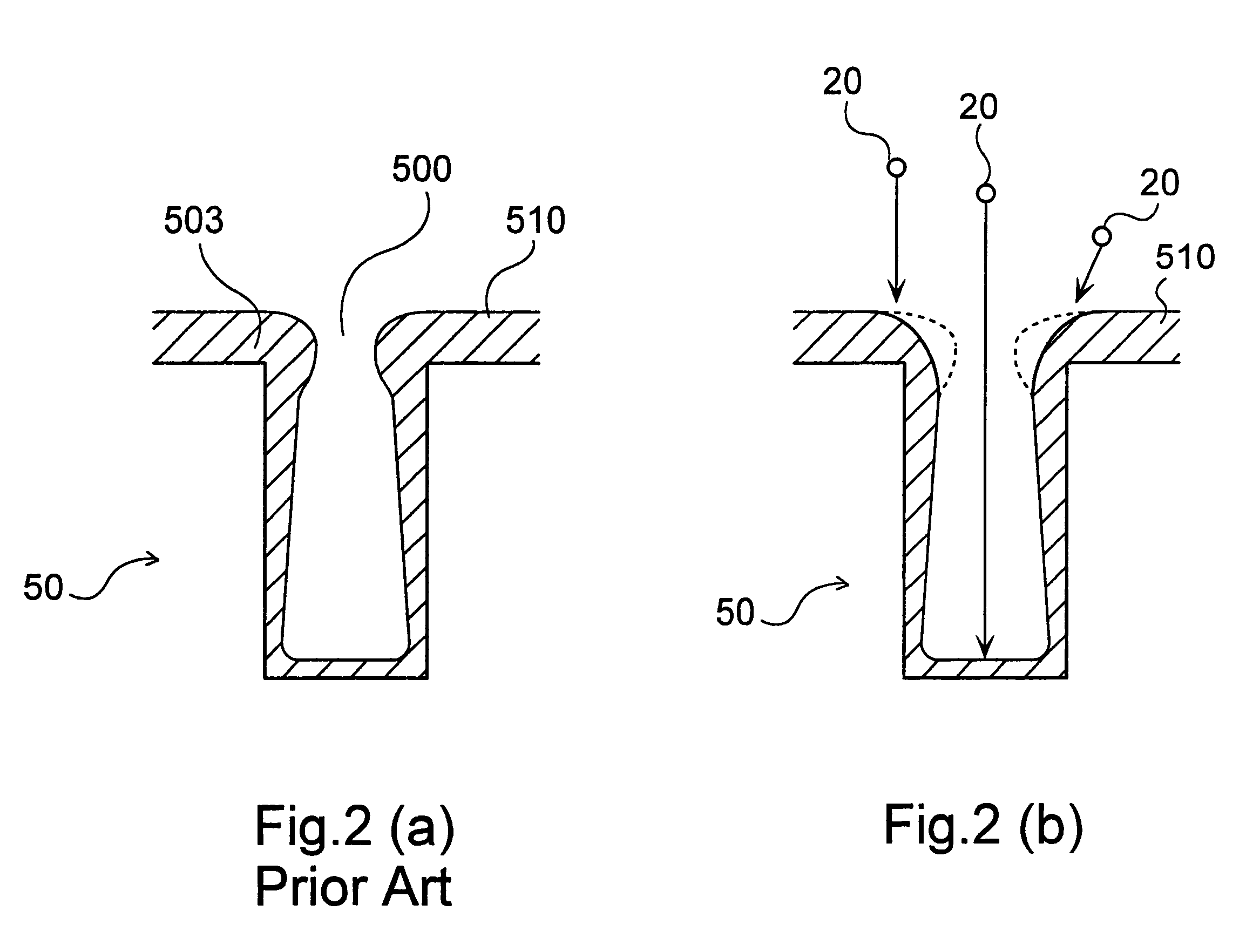

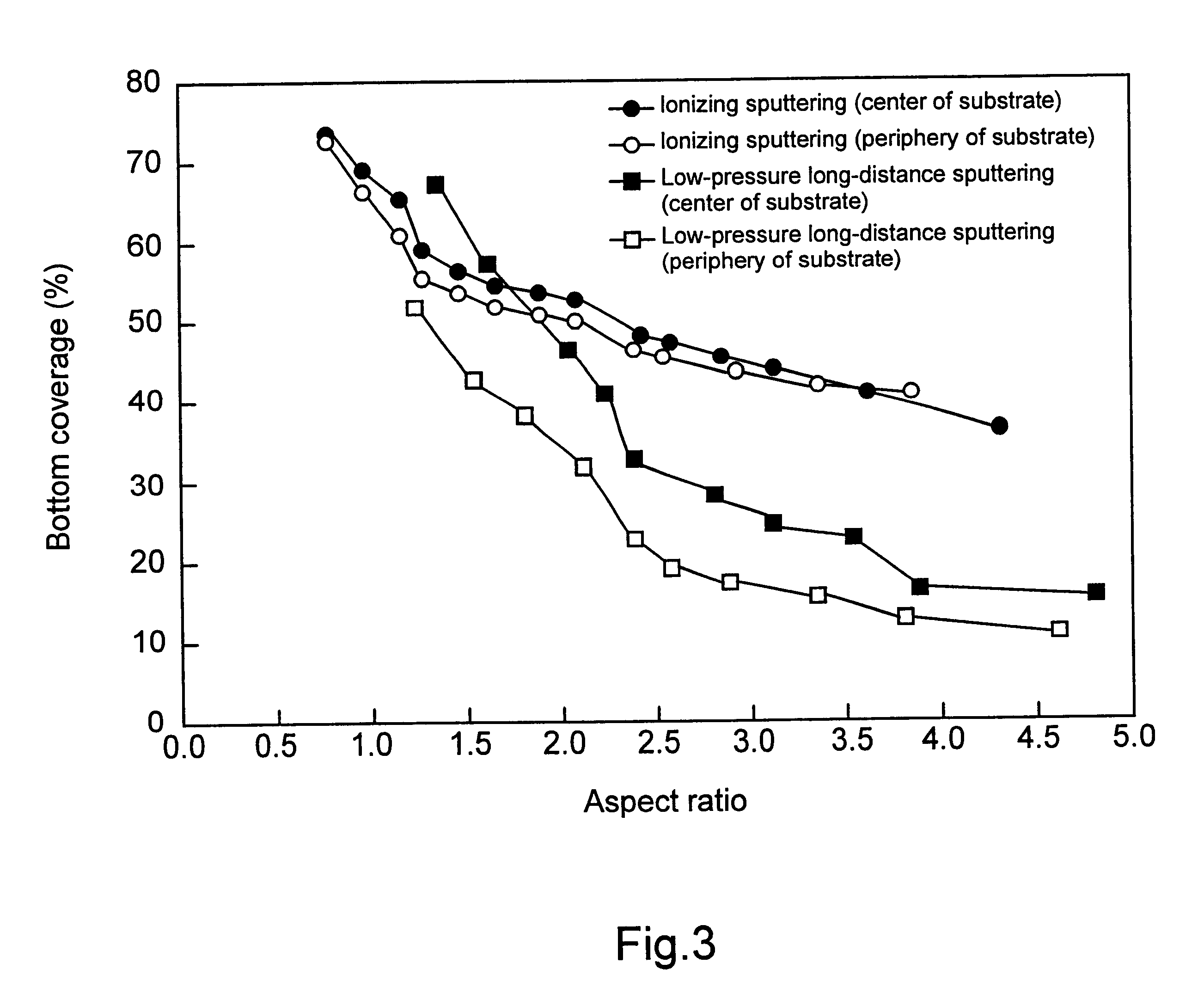

Ionizing sputtering method

InactiveUS6444099B1Less generation of particulateBottom coverage is improvedElectric discharge tubesVacuum evaporation coatingSputteringEngineering

To form a film by ionized sputtering with good bottom coverage for holes with a high aspect ratio, and to simplify the structure inside and out of the sputter chamber, a target 2 is provided inside a sputter chamber 1 equipped with an exhaust system 11 and is sputtered by a sputtering power source 3. The released sputter particles are made to arrive at a substrate 50 to form a film. The sputtering power source 3 sends electric power of at least 5 W / cm2 to a target 2, and the sputter particles are ionized in a plasma formed by this electric power alone. A cylindrical shield 6 may be provided between the target 2 and the substrate holder 5 to restrict the plasma formation space, and an electric field establishment means 8 may set up an electric field for extracting the ionized sputter particles from the plasma P and directing them at the substrate 50.

Owner:ANELVA CORP

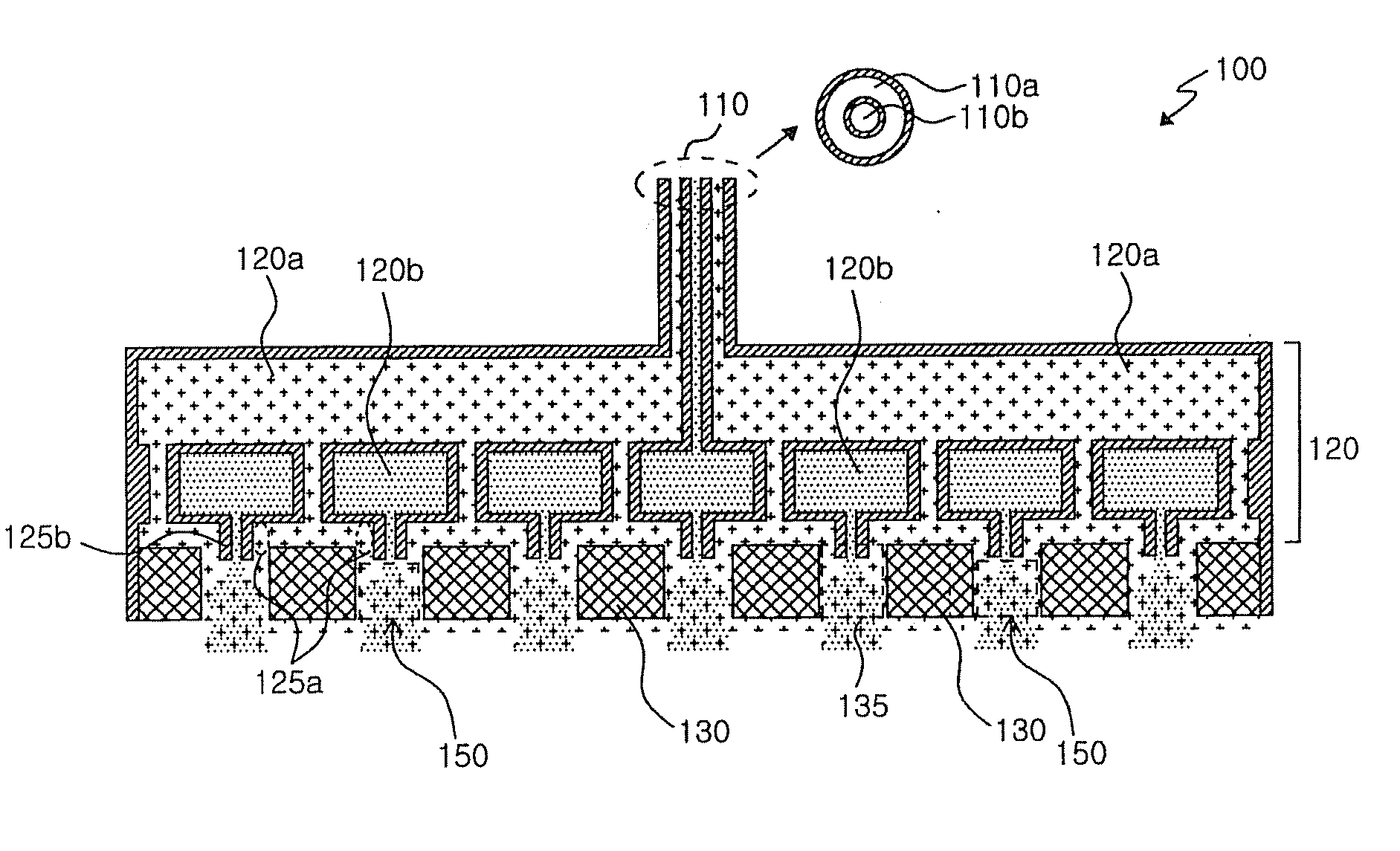

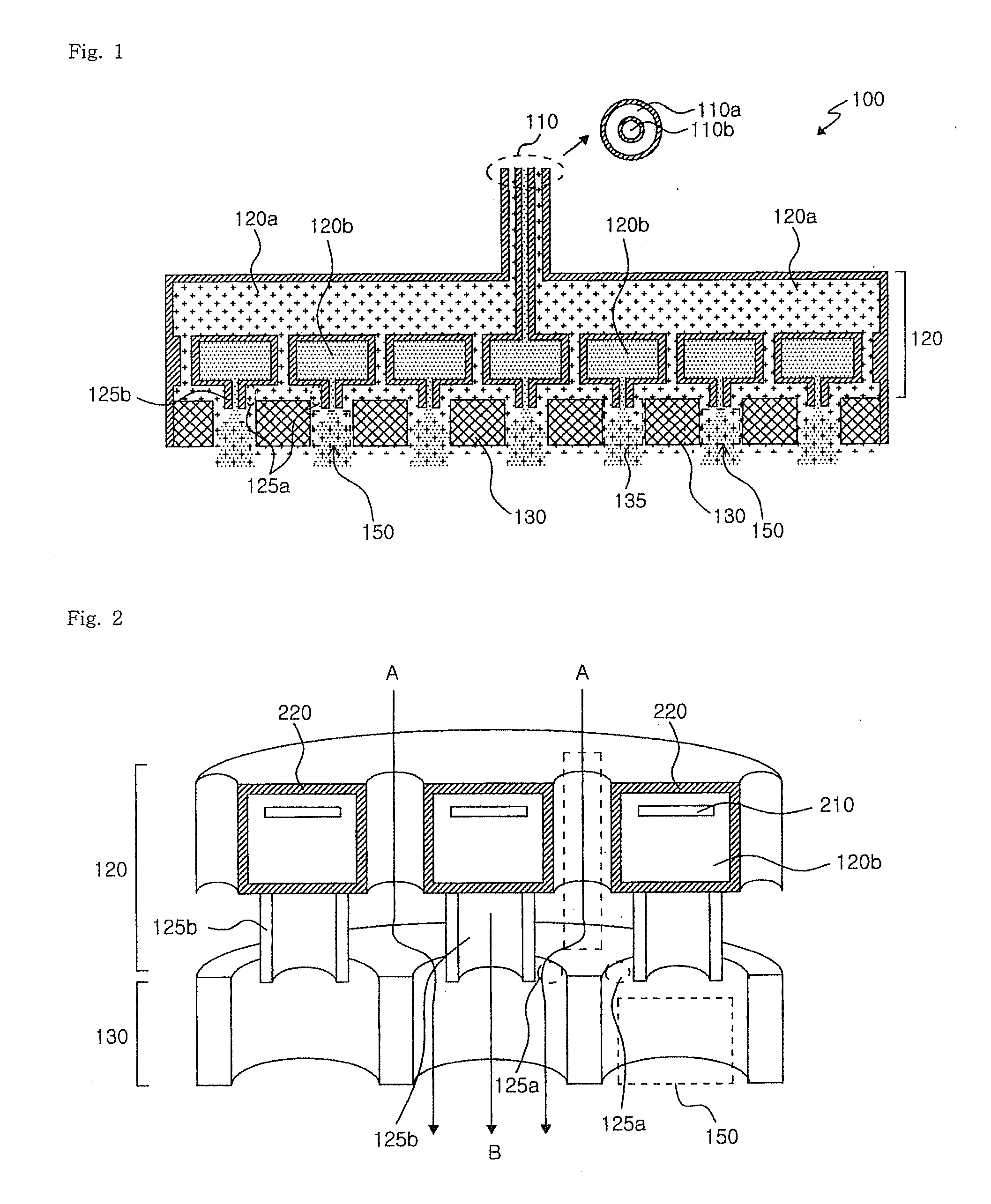

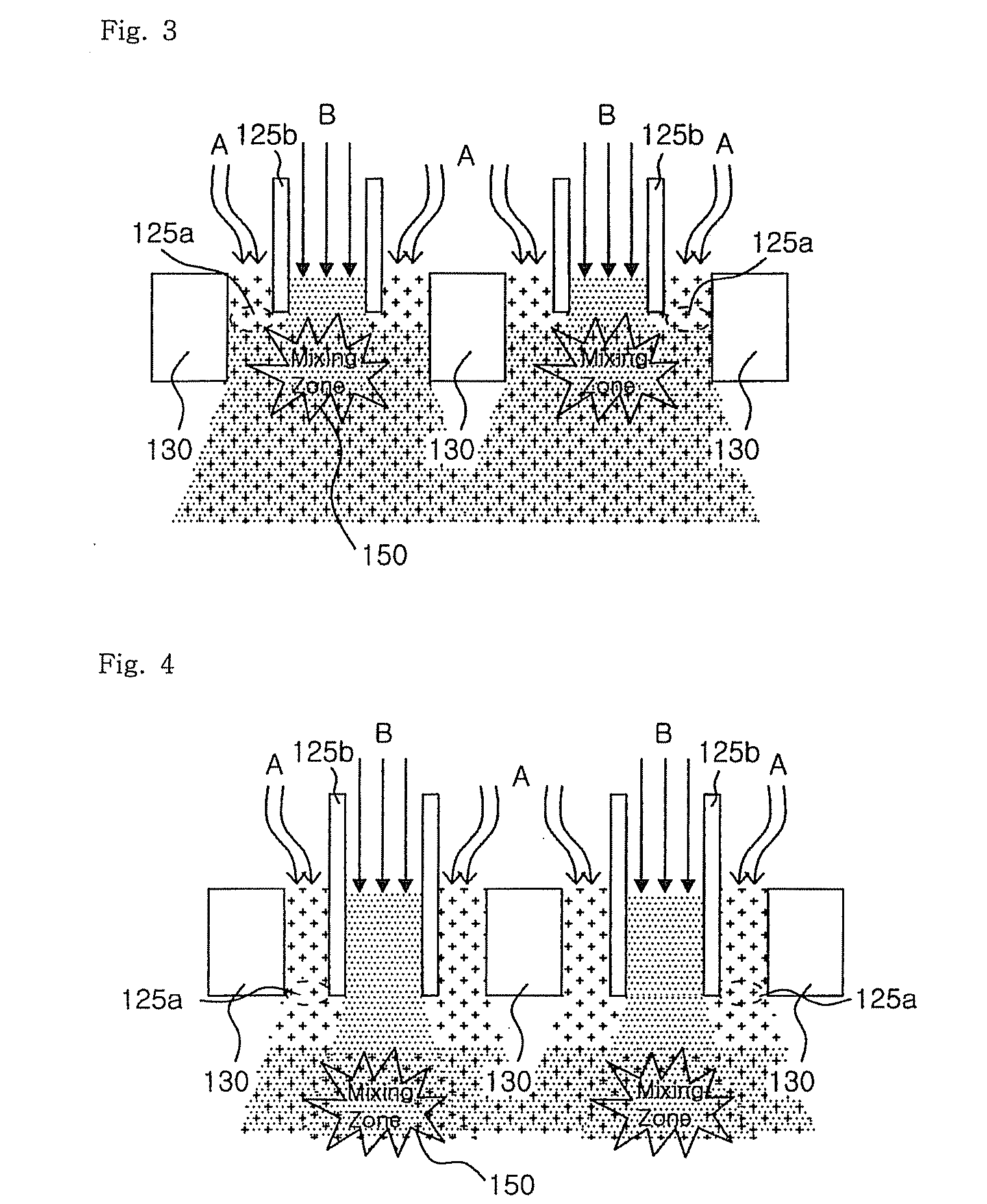

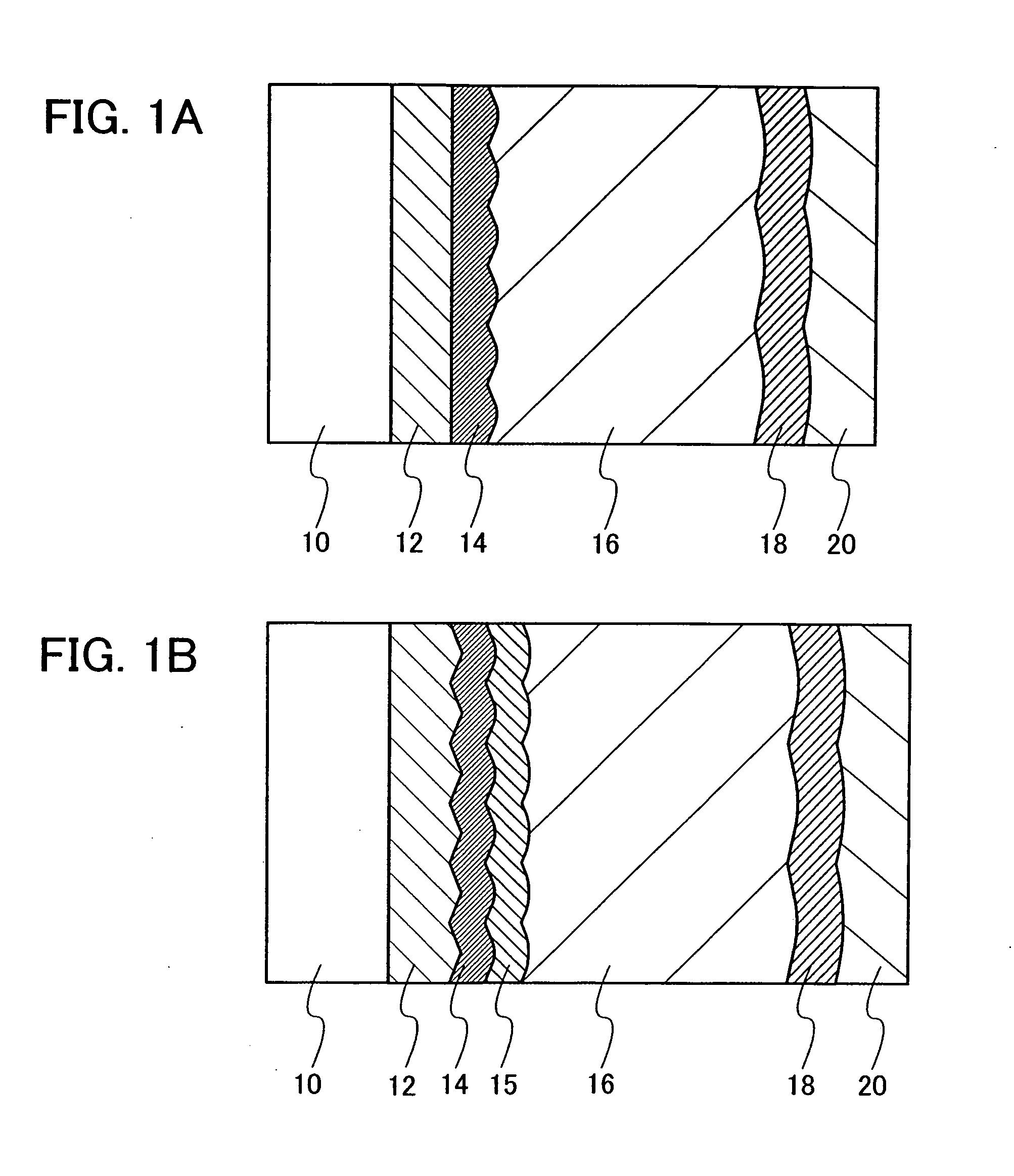

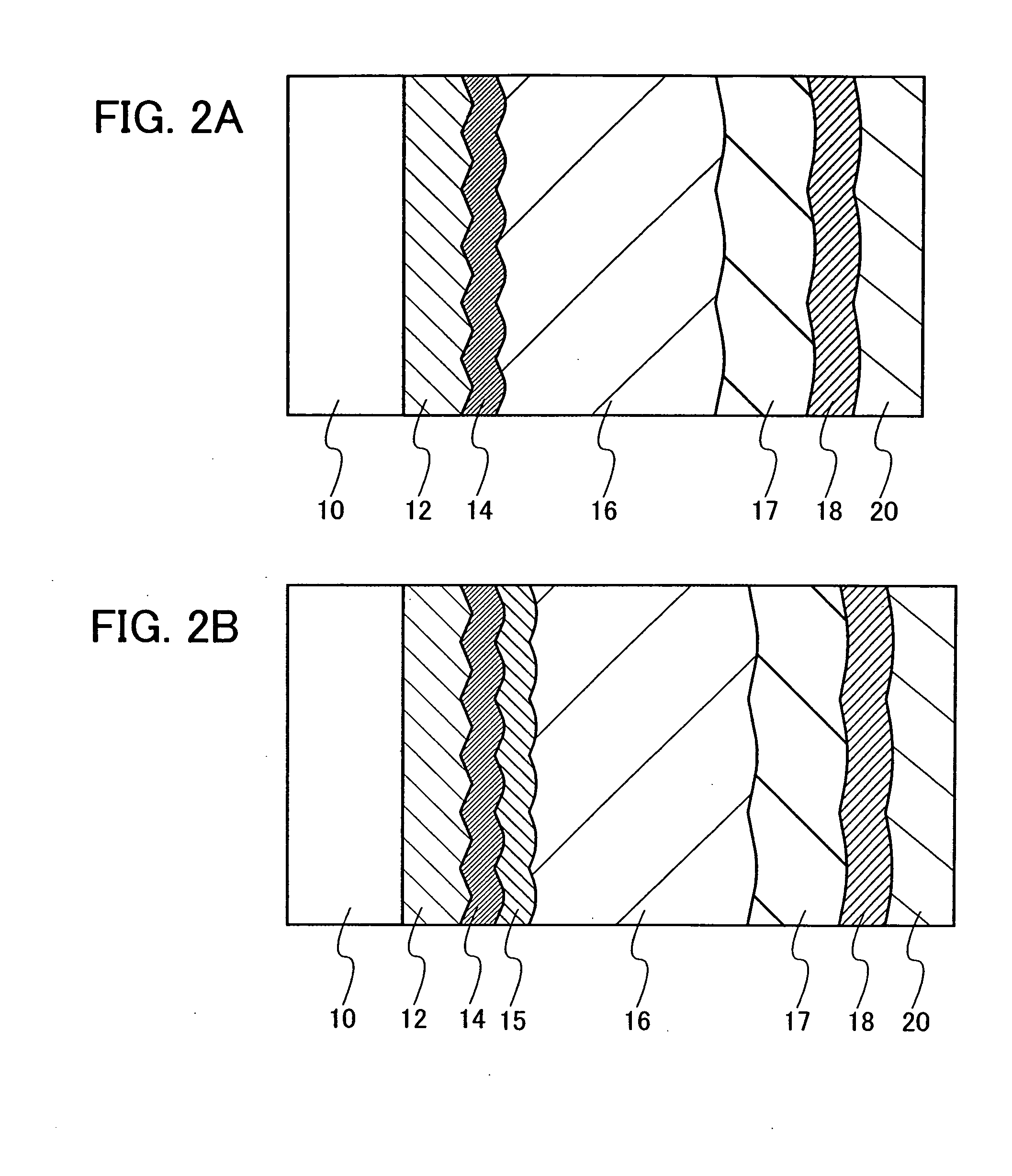

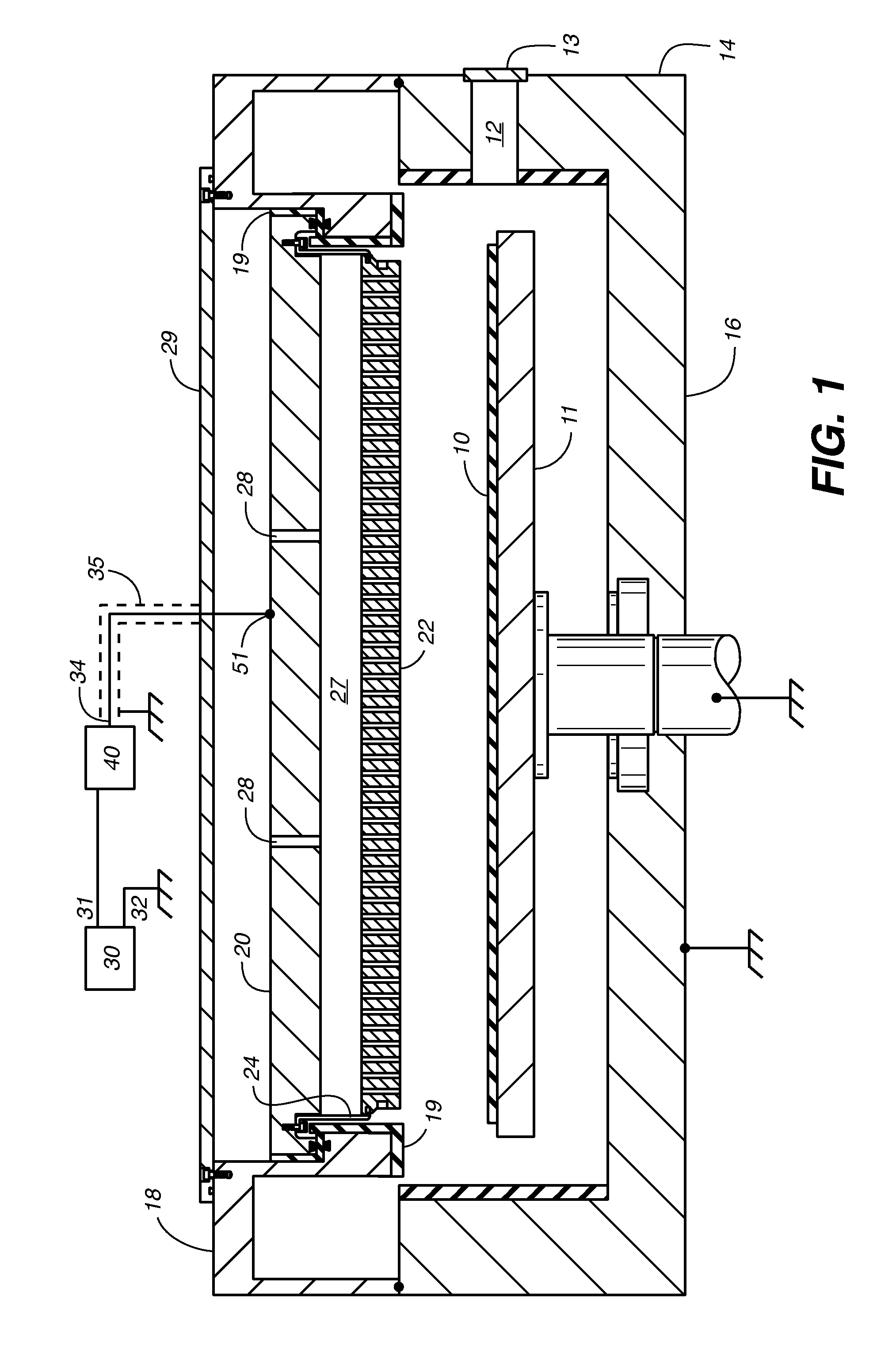

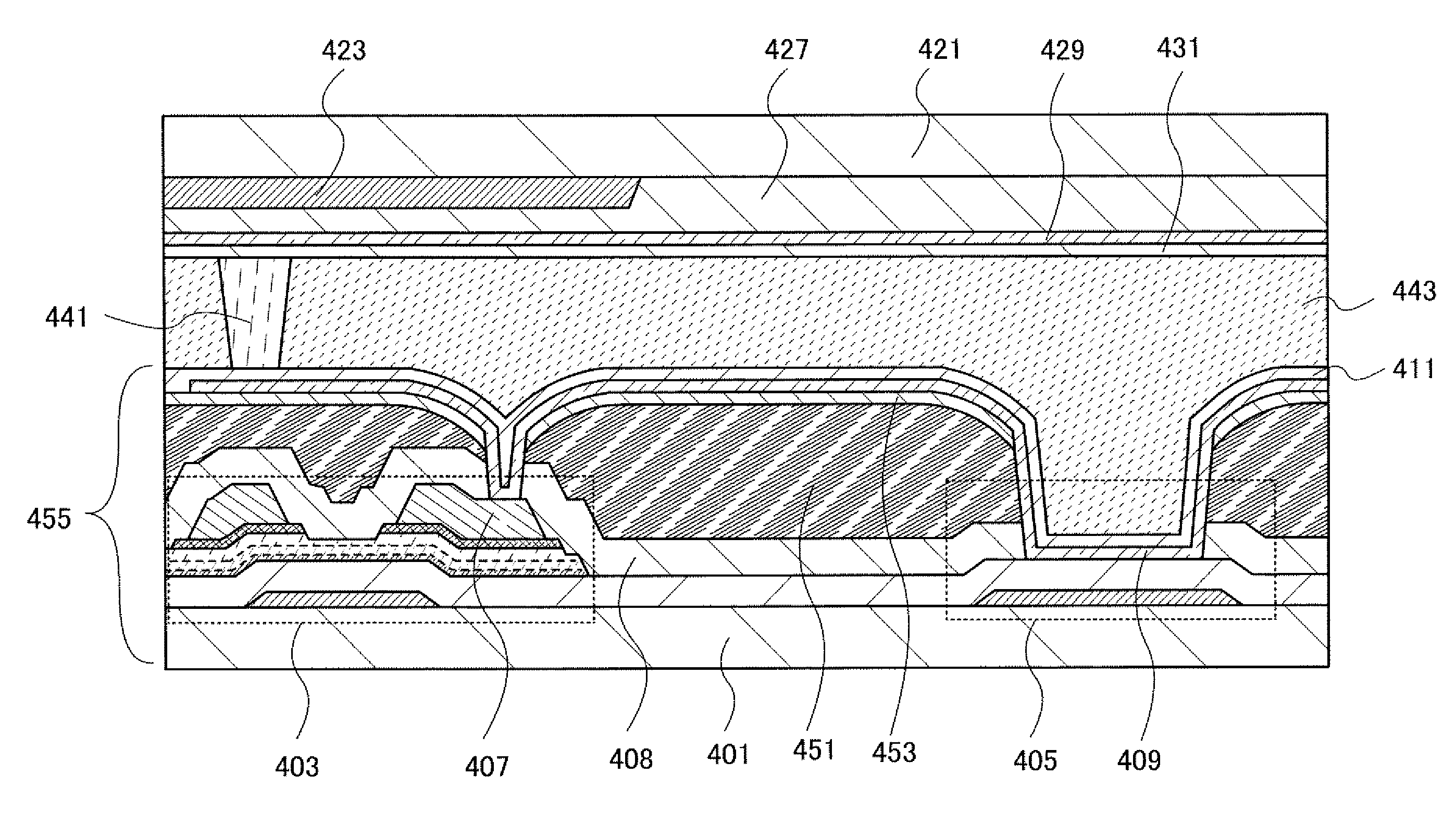

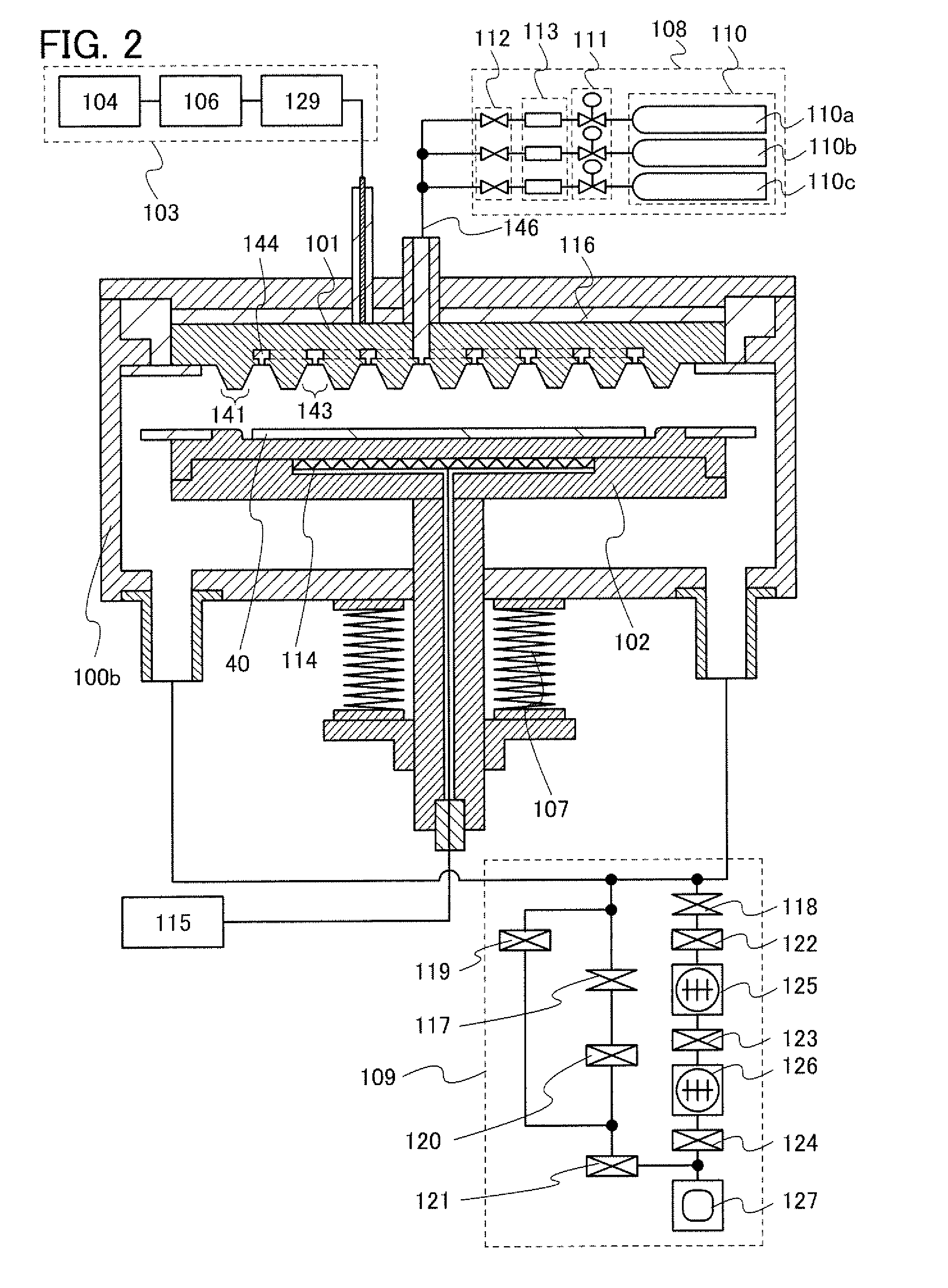

Plasma CVD apparatus, method for forming microcrystalline semiconductor film and method for manufacturing semiconductor device

ActiveUS20110053357A1Reduce in quantityReduce componentsElectric discharge tubesSemiconductor/solid-state device manufacturingGas supplyCrystalline semiconductor

A structure of a plasma CVD apparatus for forming a dense semiconductor film is provided. Further, a technique for forming a dense crystalline semiconductor film (e.g., a microcrystalline semiconductor film) without a cavity between crystal grains is provided. An electrode supplied with electric power for generating plasma is included in a reaction chamber of the plasma CVD apparatus. This electrode has a common plane on a surface opposite to a substrate, and the common plane is provided with depressed openings. Gas supply ports are provided on the bottom of the depressed openings or on the common plane of the electrode. The depressed openings are provided in isolation from one another.

Owner:SEMICON ENERGY LAB CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com