Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

1459 results about "Sputter deposition" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Sputter deposition is a physical vapor deposition (PVD) method of thin film deposition by sputtering. This involves ejecting material from a "target" that is a source onto a "substrate" such as a silicon wafer. Resputtering is re-emission of the deposited material during the deposition process by ion or atom bombardment. Sputtered atoms ejected from the target have a wide energy distribution, typically up to tens of eV (100,000 K). The sputtered ions (typically only a small fraction of the ejected particles are ionized — on the order of 1 percent) can ballistically fly from the target in straight lines and impact energetically on the substrates or vacuum chamber (causing resputtering). Alternatively, at higher gas pressures, the ions collide with the gas atoms that act as a moderator and move diffusively, reaching the substrates or vacuum chamber wall and condensing after undergoing a random walk. The entire range from high-energy ballistic impact to low-energy thermalized motion is accessible by changing the background gas pressure. The sputtering gas is often an inert gas such as argon. For efficient momentum transfer, the atomic weight of the sputtering gas should be close to the atomic weight of the target, so for sputtering light elements neon is preferable, while for heavy elements krypton or xenon are used. Reactive gases can also be used to sputter compounds. The compound can be formed on the target surface, in-flight or on the substrate depending on the process parameters. The availability of many parameters that control sputter deposition make it a complex process, but also allow experts a large degree of control over the growth and microstructure of the film.

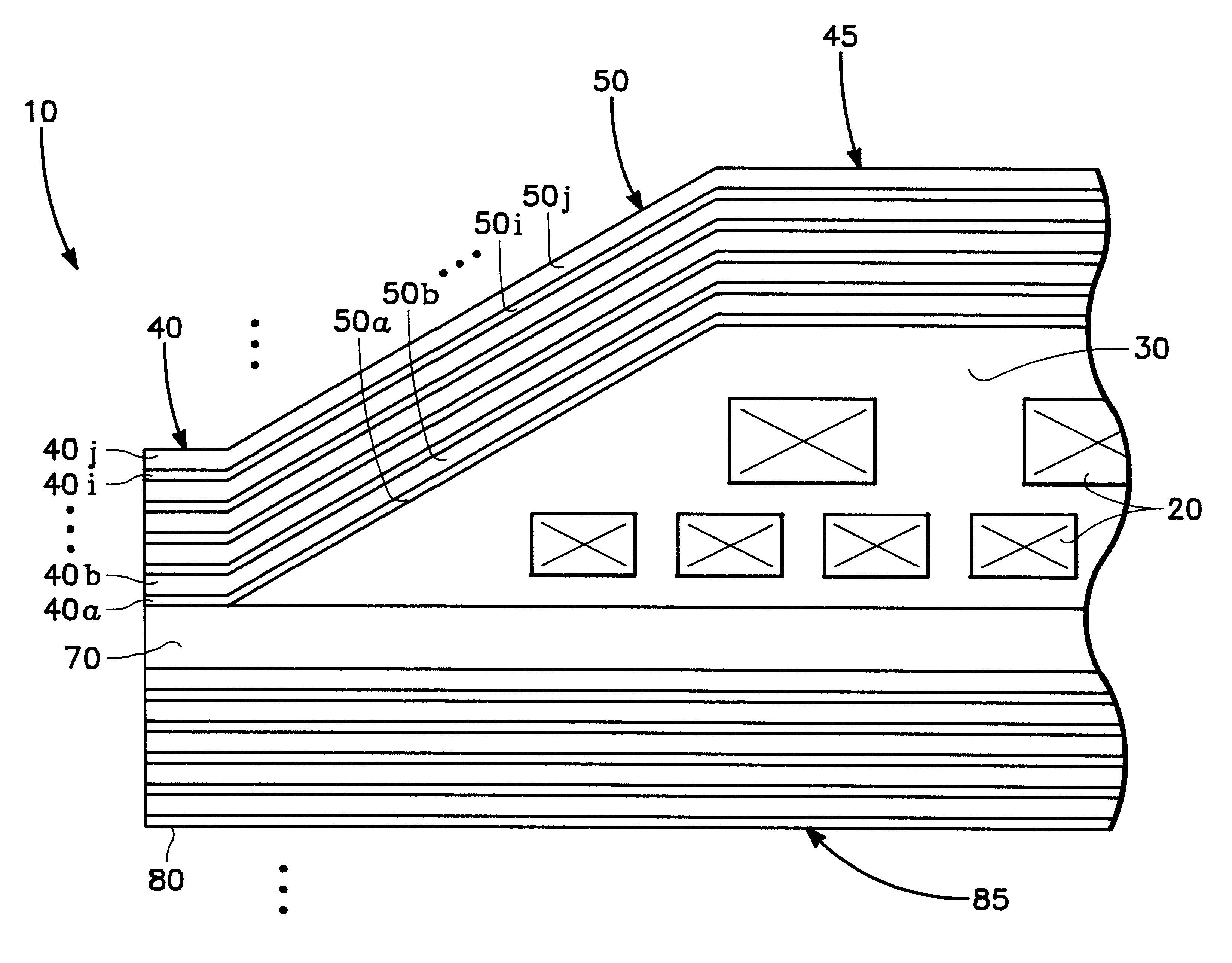

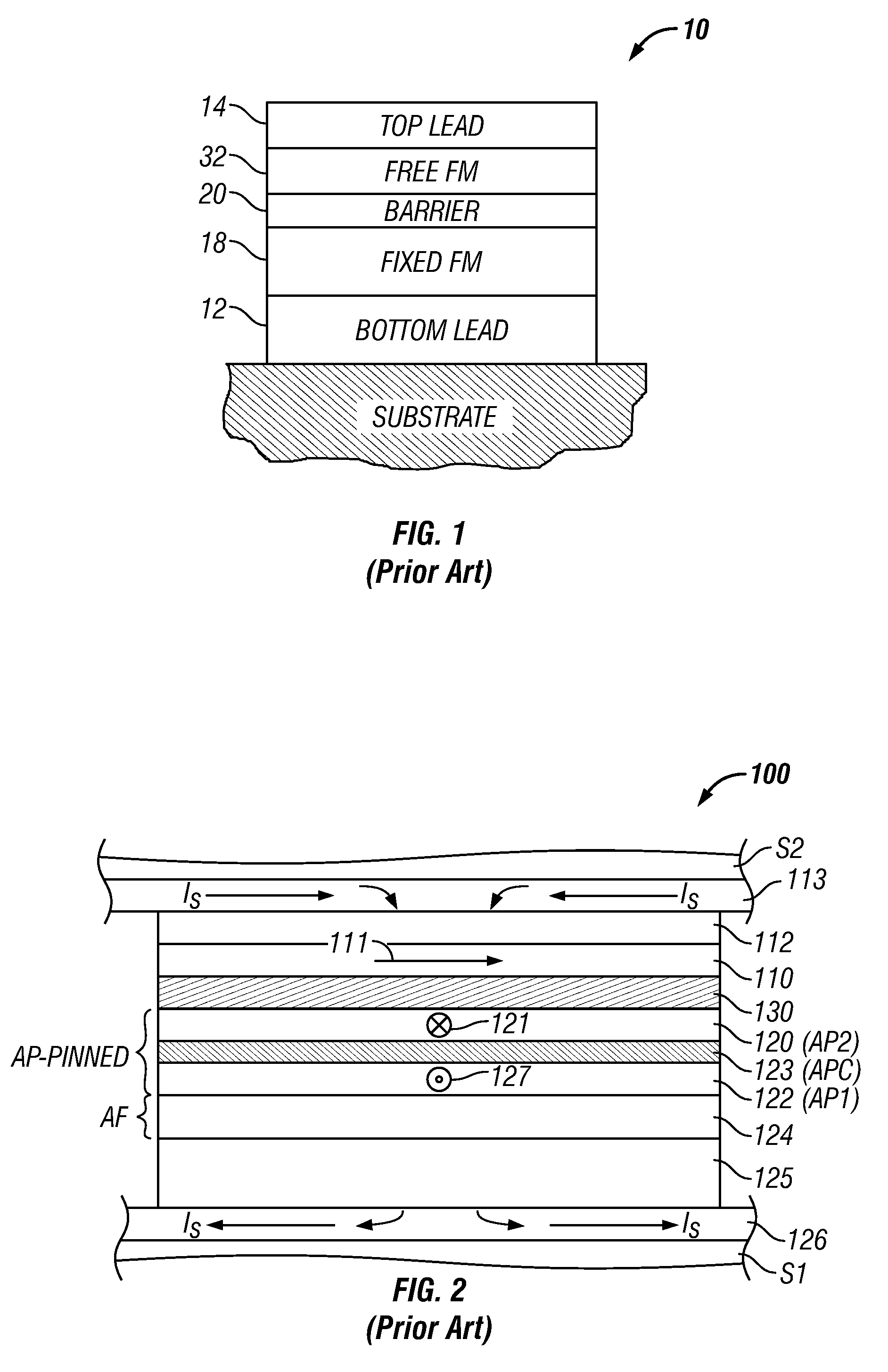

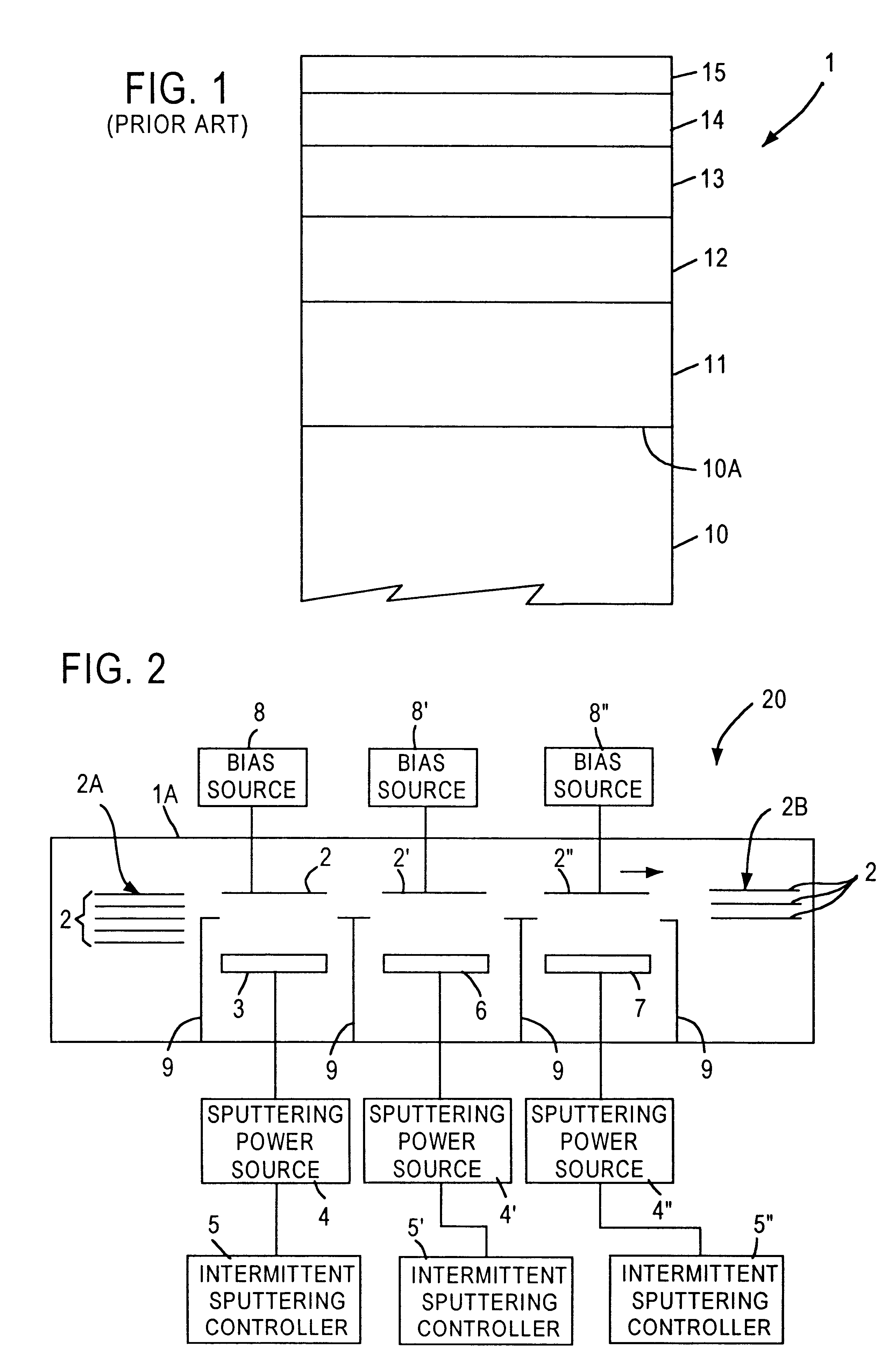

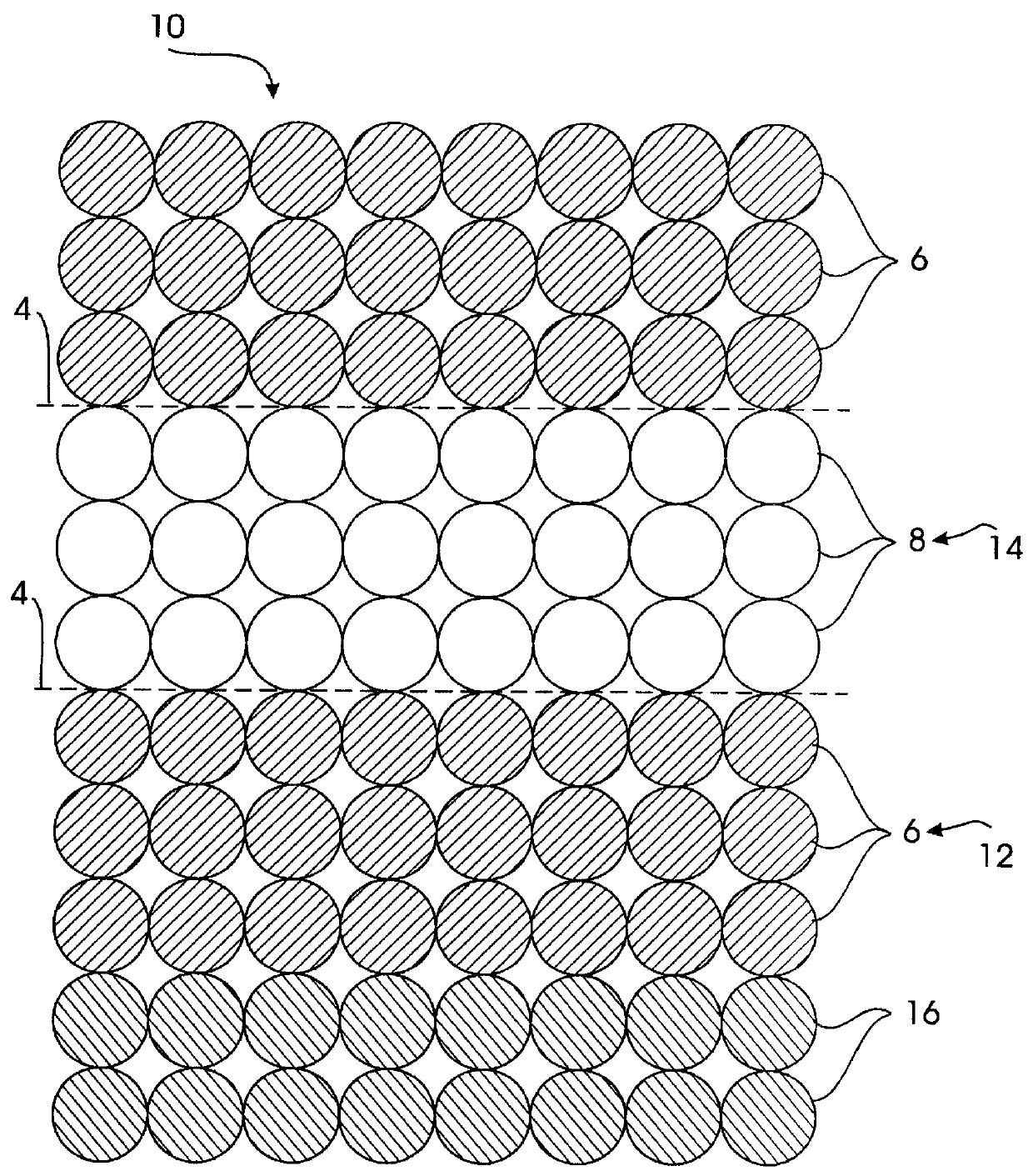

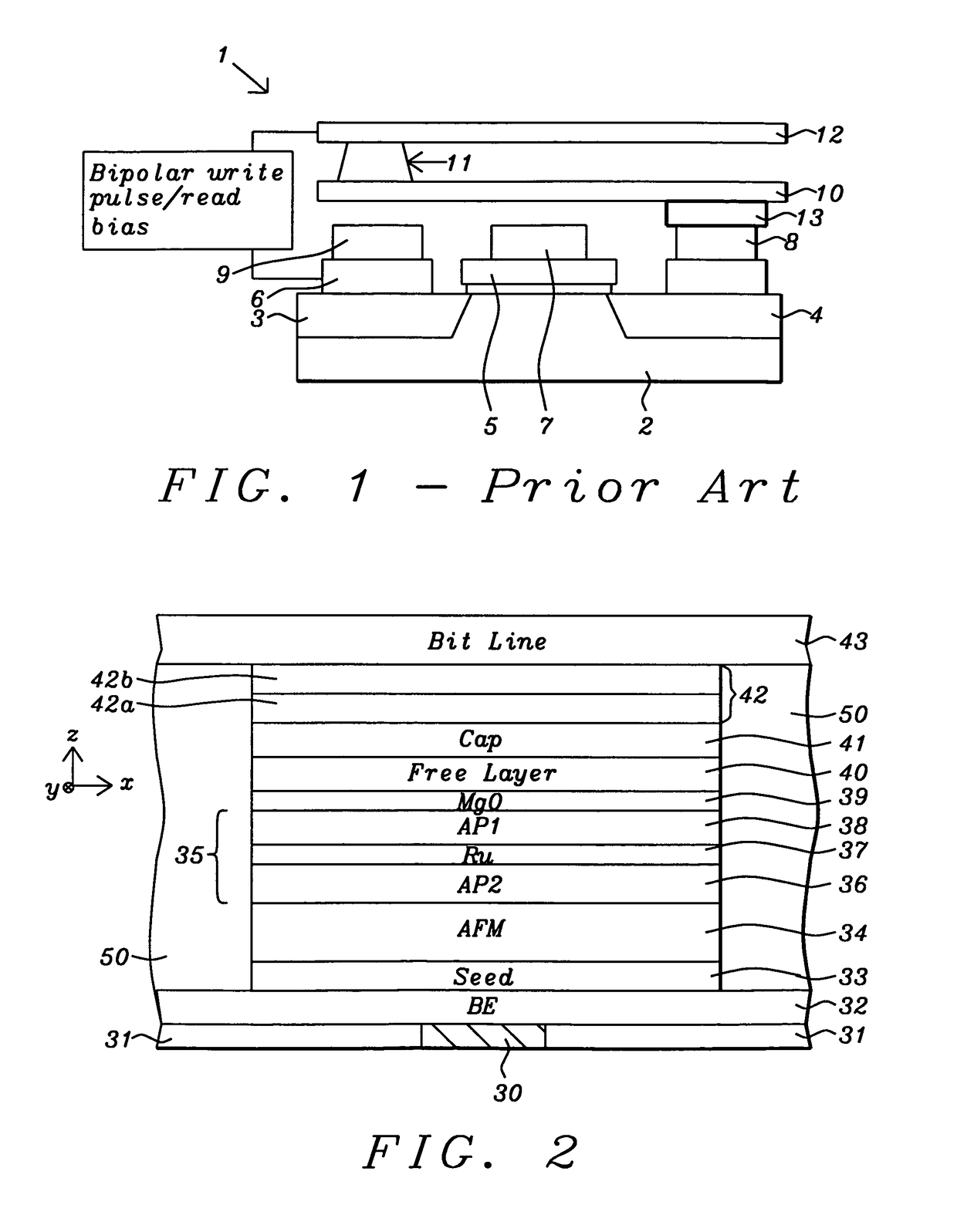

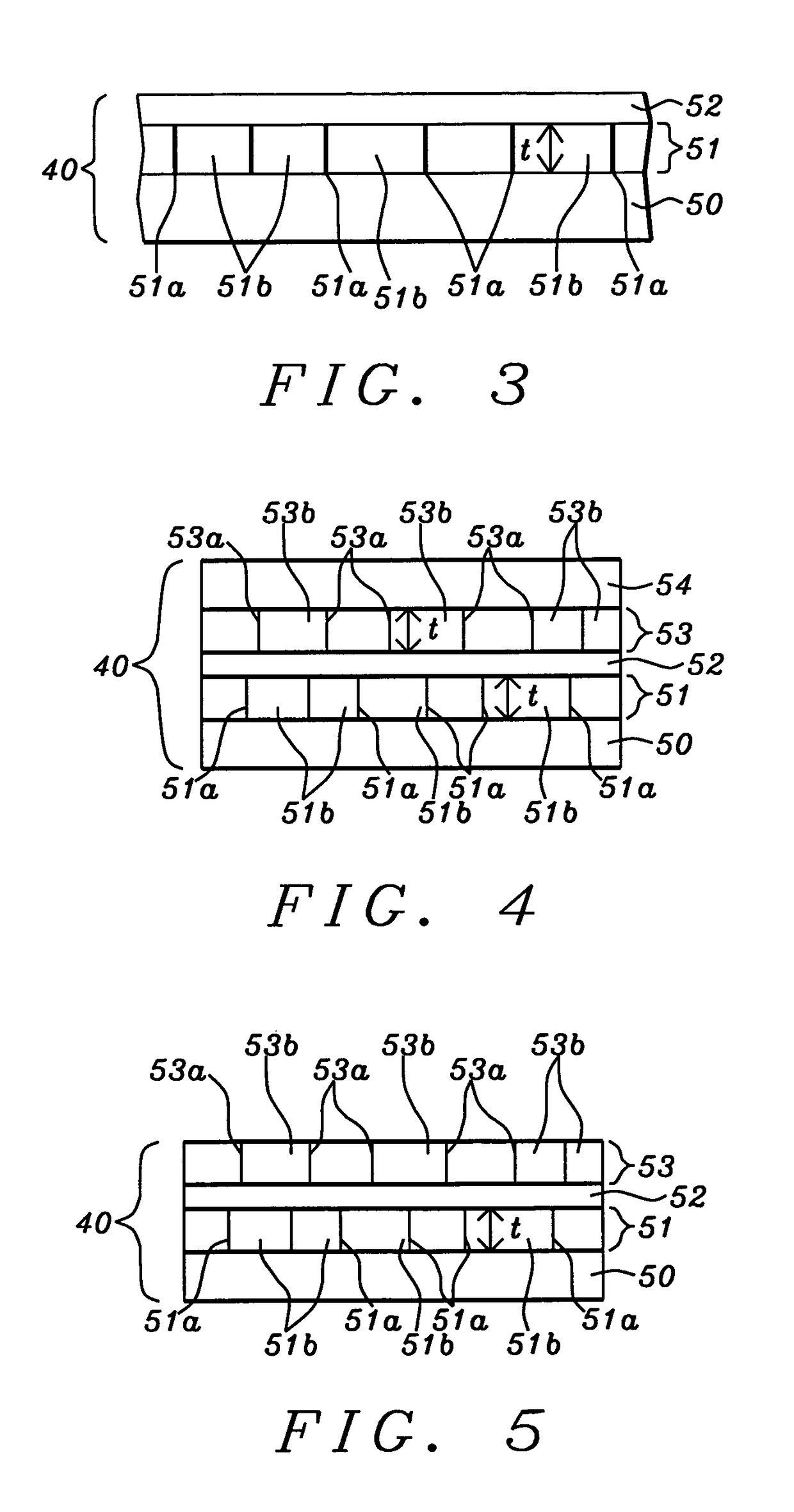

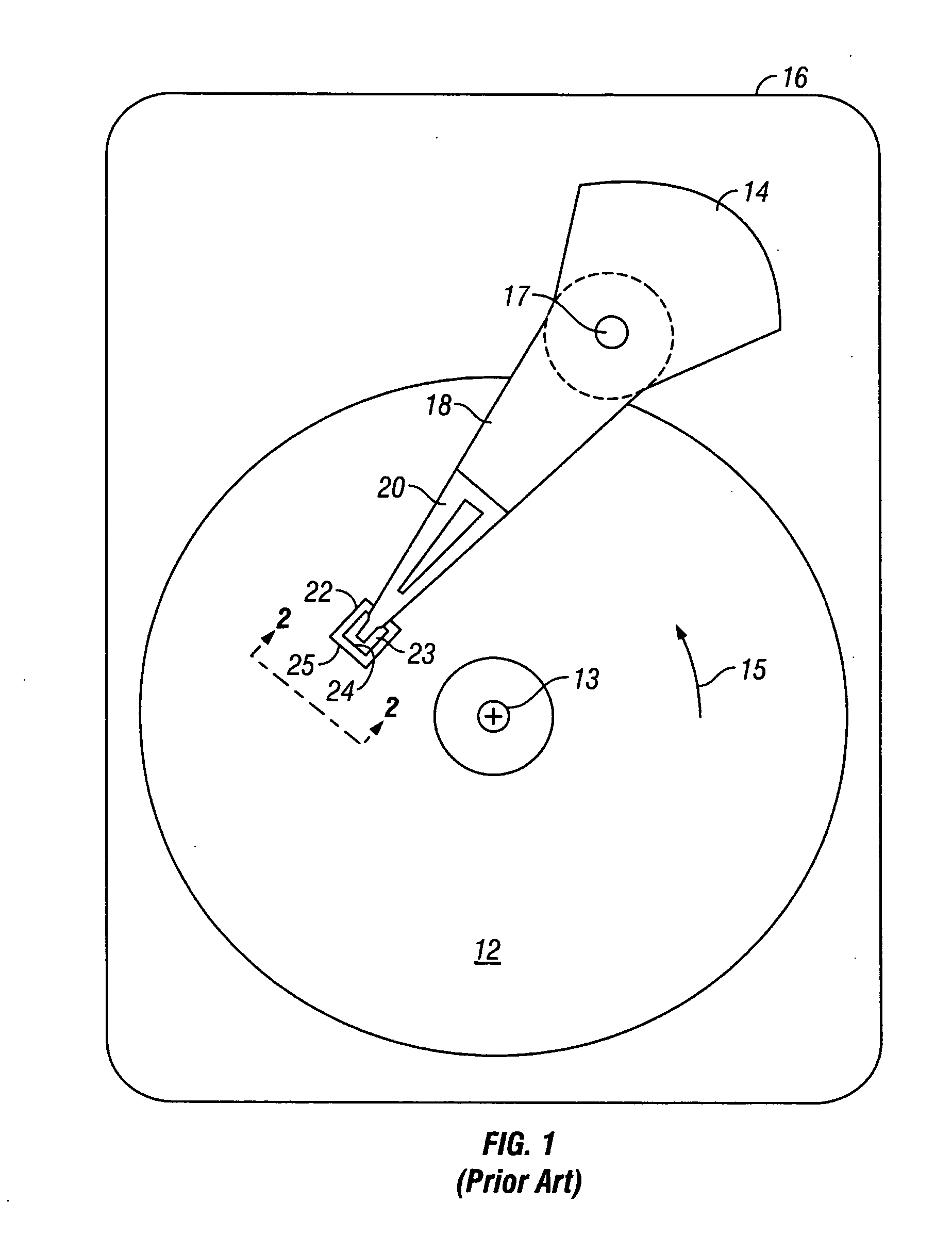

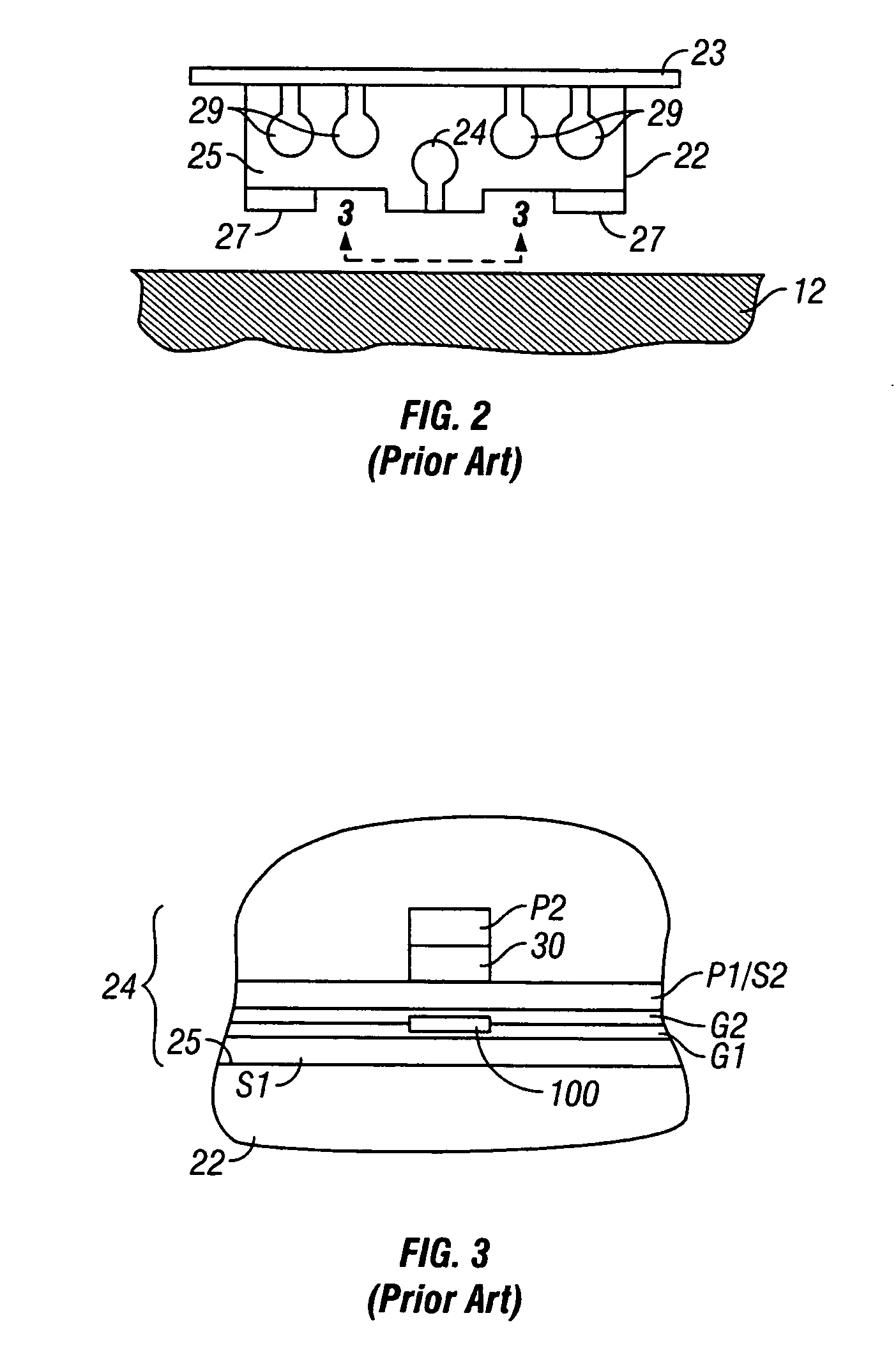

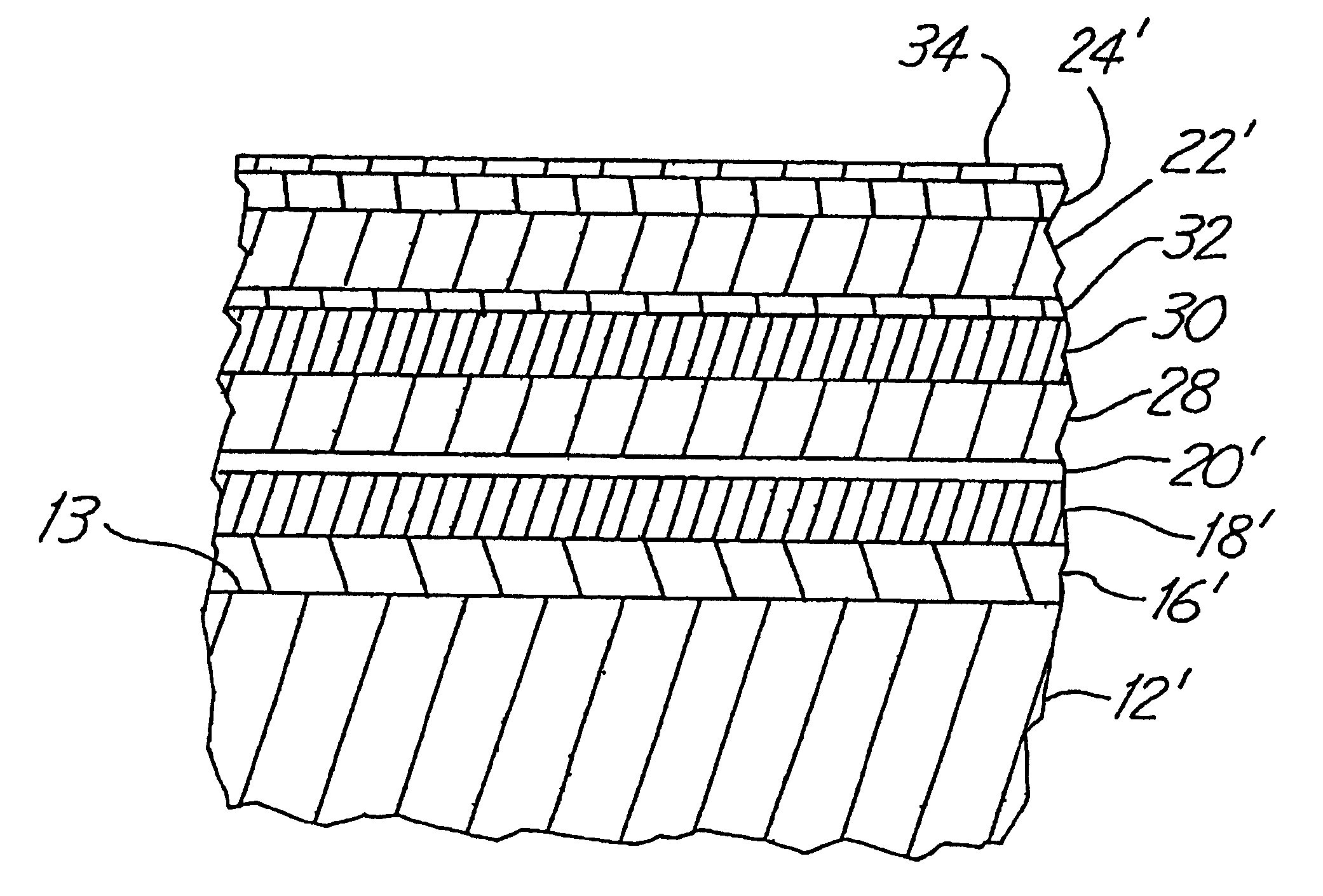

Thin film write head with improved laminated flux carrying structure and method of fabrication

InactiveUS6233116B1High resistivityExcellent soft magnetic propertiesConstruction of head windingsHeads using thin filmsLower poleHigh resistivity

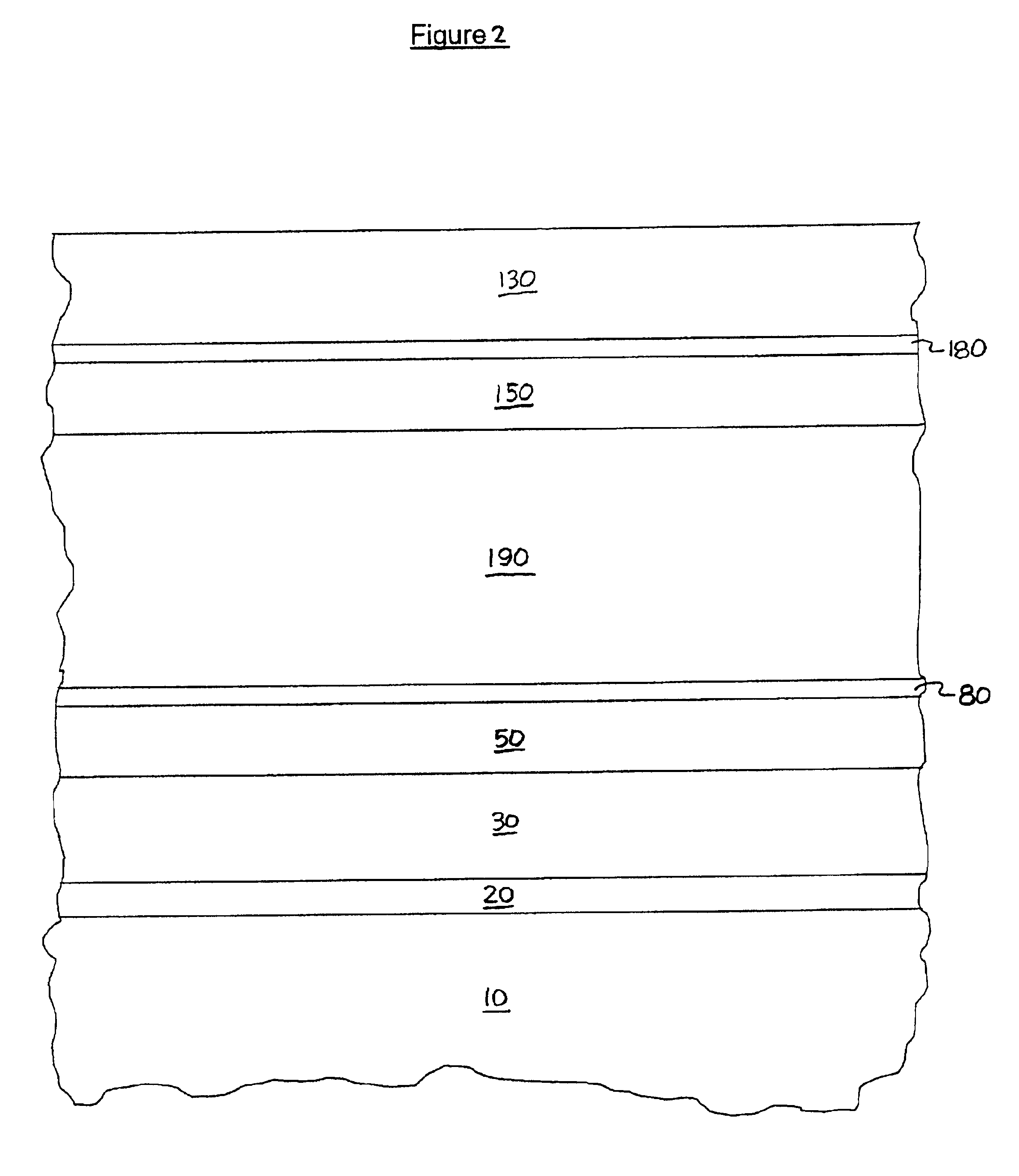

The present invention provides a thin film write head having an improved laminated flux carrying structure and method of fabrication. The preferred embodiment provides laminated layers of: high moment magnetic material, and easily aligned high resistivity magnetic material. In the preferred embodiment, the easily aligned laminating layer induces uniaxial anisotropy, by exchange coupling, to improve uniaxial anisotropy in the high moment material. This allows deposition induced uniaxial anisotropy by DC magnetron sputtering and also provides improved post deposition annealing, if desired. It is preferred to laminate FeXN, such as FeRhN, or other crystalline structure material, with an amorphous alloy material, preferably Co based, such as CoZrCr. In the preferred embodiment, upper and lower pole structures may both be laminated as discussed above. Such laminated structures have higher Bs than structures with insulative laminates, and yokes and pole tips and may be integrally formed, if desired, because flux may travel along or across the laminating layers. The preferred embodiment of the present invention improves soft magnetic properties, reduces eddy currents, improves hard axis alignment while not deleteriously affecting the coercivity, permeability, and magnetostriction of the structure, thus allowing for improved high frequency operation.

Owner:WESTERN DIGITAL TECH INC +1

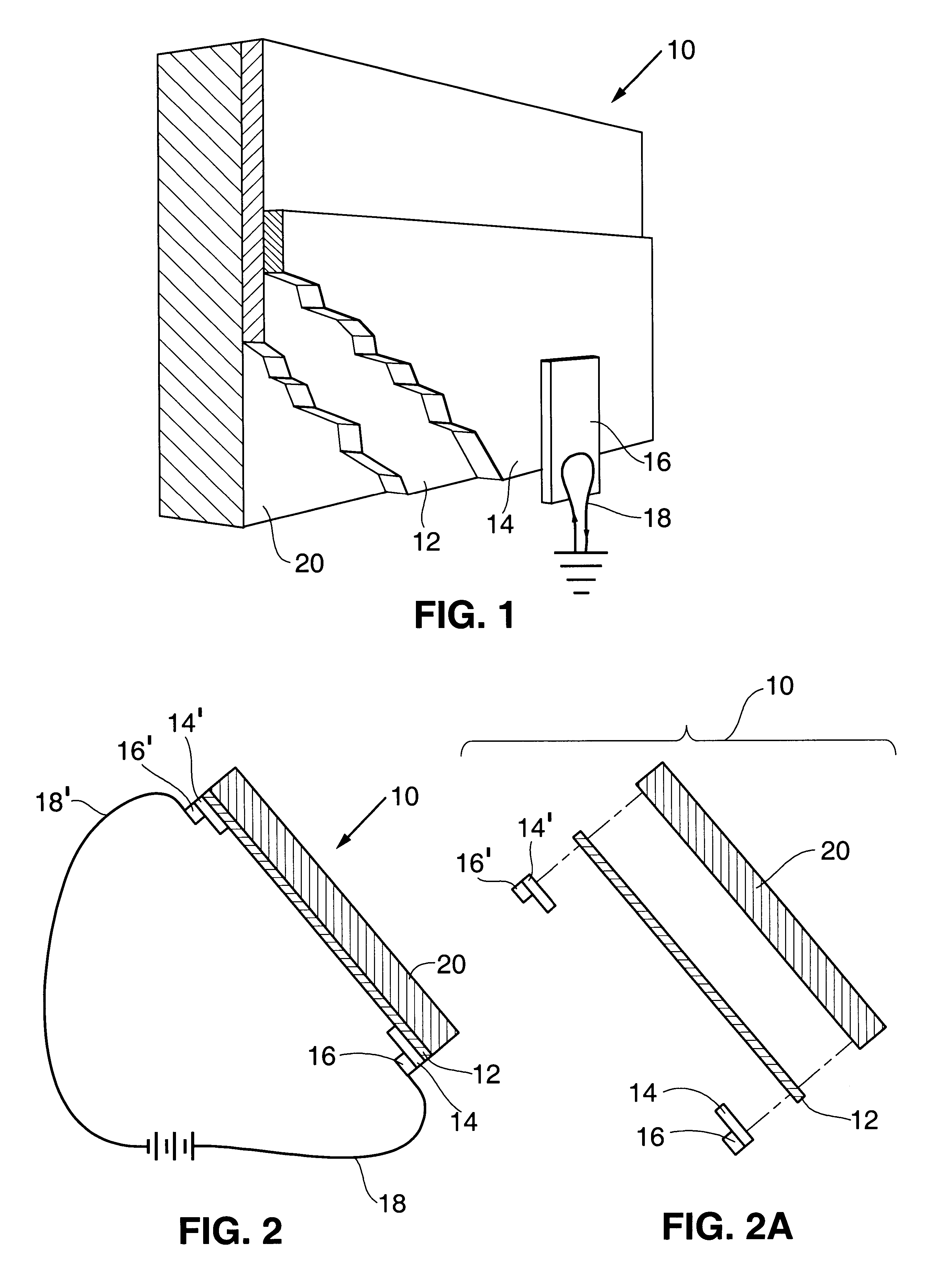

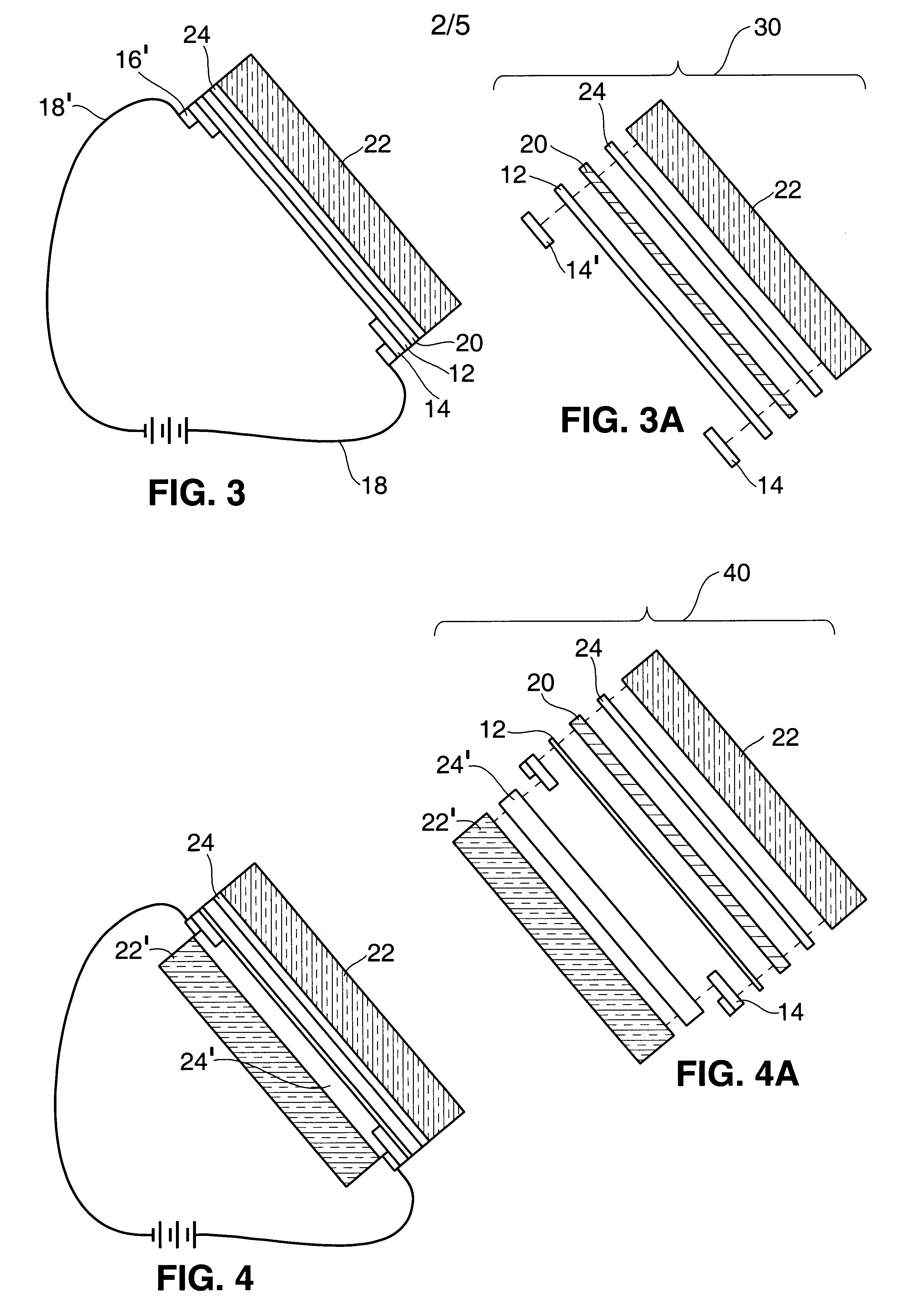

Vacuum deposition of bus bars onto conductive transparent films

InactiveUS6204480B1Suitable for processingWindowsConductive layers on insulating-supportsElectrical resistance and conductanceElectrical connection

Vacuum deposition processes such as sputter-depositing are employed to deposit electrically conductive bus bars onto thin film transparent conductor sheets. These assemblies provide efficient and durable electrical connections to the conductor sheets which can be laminated into glazing structures such as automotive windshields to provide resistance heating for defogging and deicing or the provide an electrical connection for in-window antennas and in window radiation shields.

Owner:SOUTHWALL TECH INC

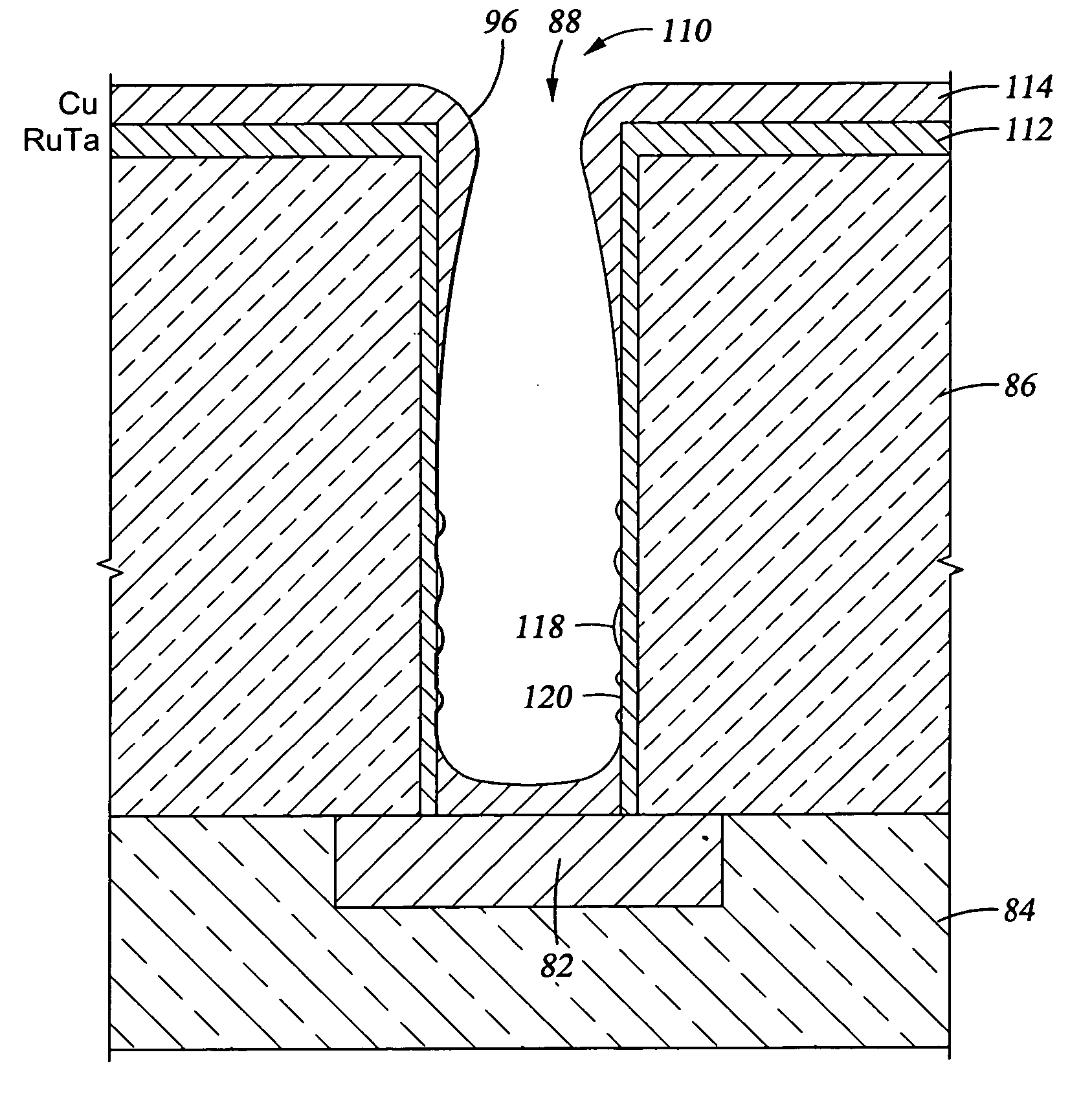

Integrated process for sputter deposition of a conductive barrier layer, especially an alloy of ruthenium and tantalum, underlying copper or copper alloy seed layer

InactiveUS20070059502A1Effective interfacial barrierGood suitSemiconductor/solid-state device detailsVacuum evaporation coatingMoisture barrierRefractory metals

A fabrication method and a product for the deposition of a conductive barrier or other liner layer in a vertical electrical interconnect structure. One embodiment includes within a a hole through a dielectric layer a barrier layer of RuTaN, an adhesion layer of RuTa, and a copper seed layer forming a liner for electroplating of copper. The ruthenium content is preferably greater than 50 at % and more preferably at least 80 at % but less than 95 at %. The barrier and adhesion layers may both be sputter deposited. Other platinum-group elements substitute for the ruthenium and other refractory metals substitute for the tantalum. Aluminum alloying into RuTa when annealed presents a moisture barrier. Copper contacts include different alloying fractions of RuTa to shift the work function to the doping type.

Owner:APPLIED MATERIALS INC

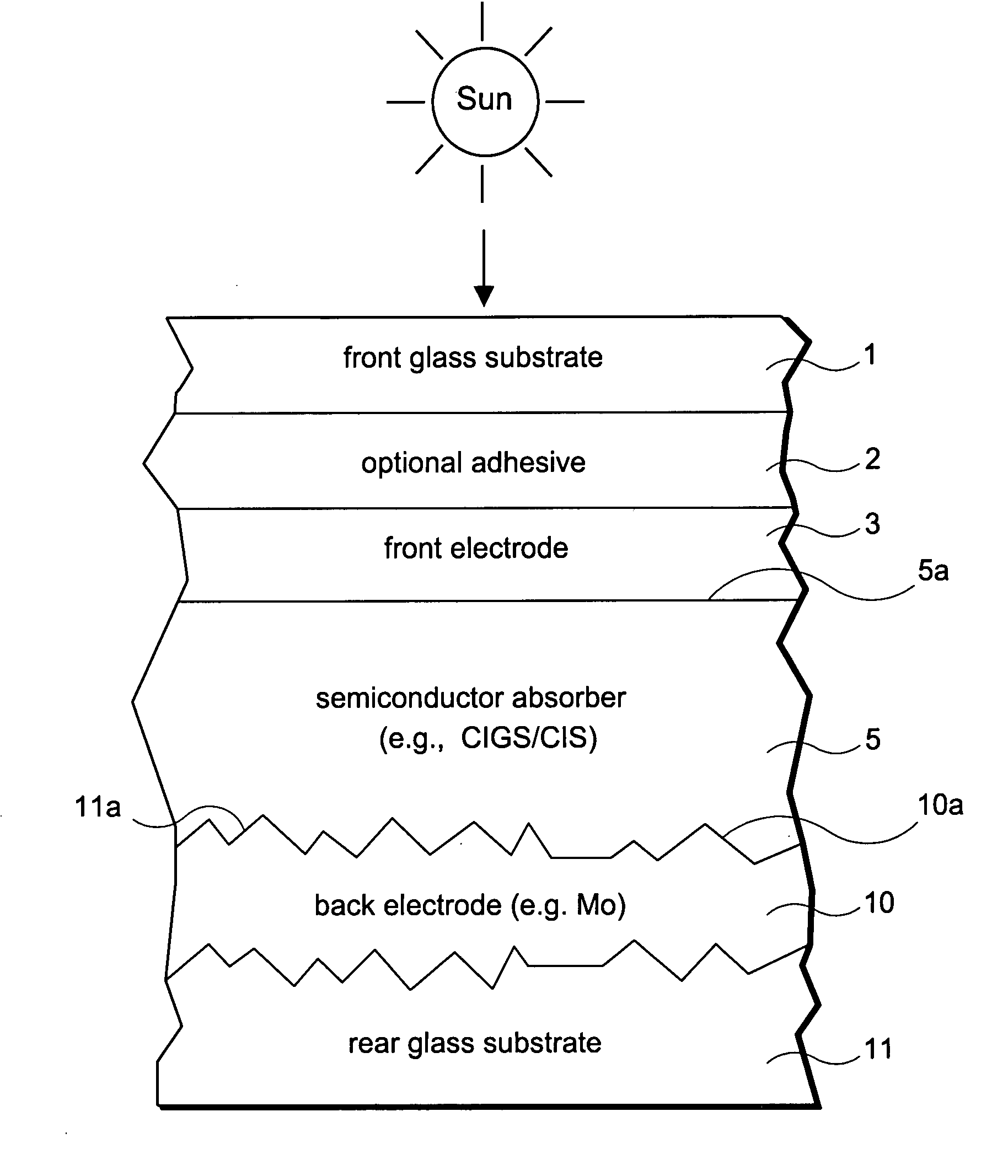

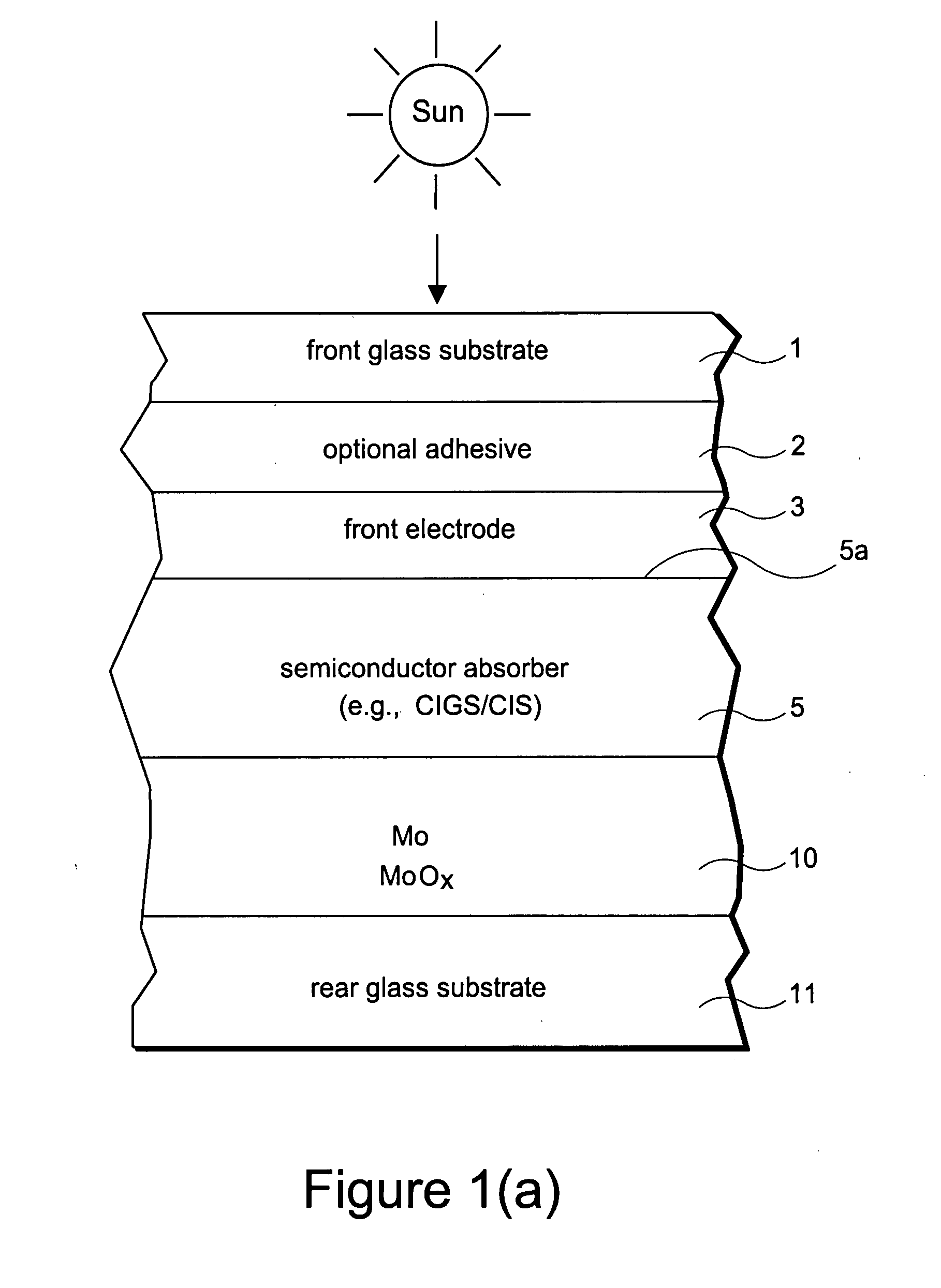

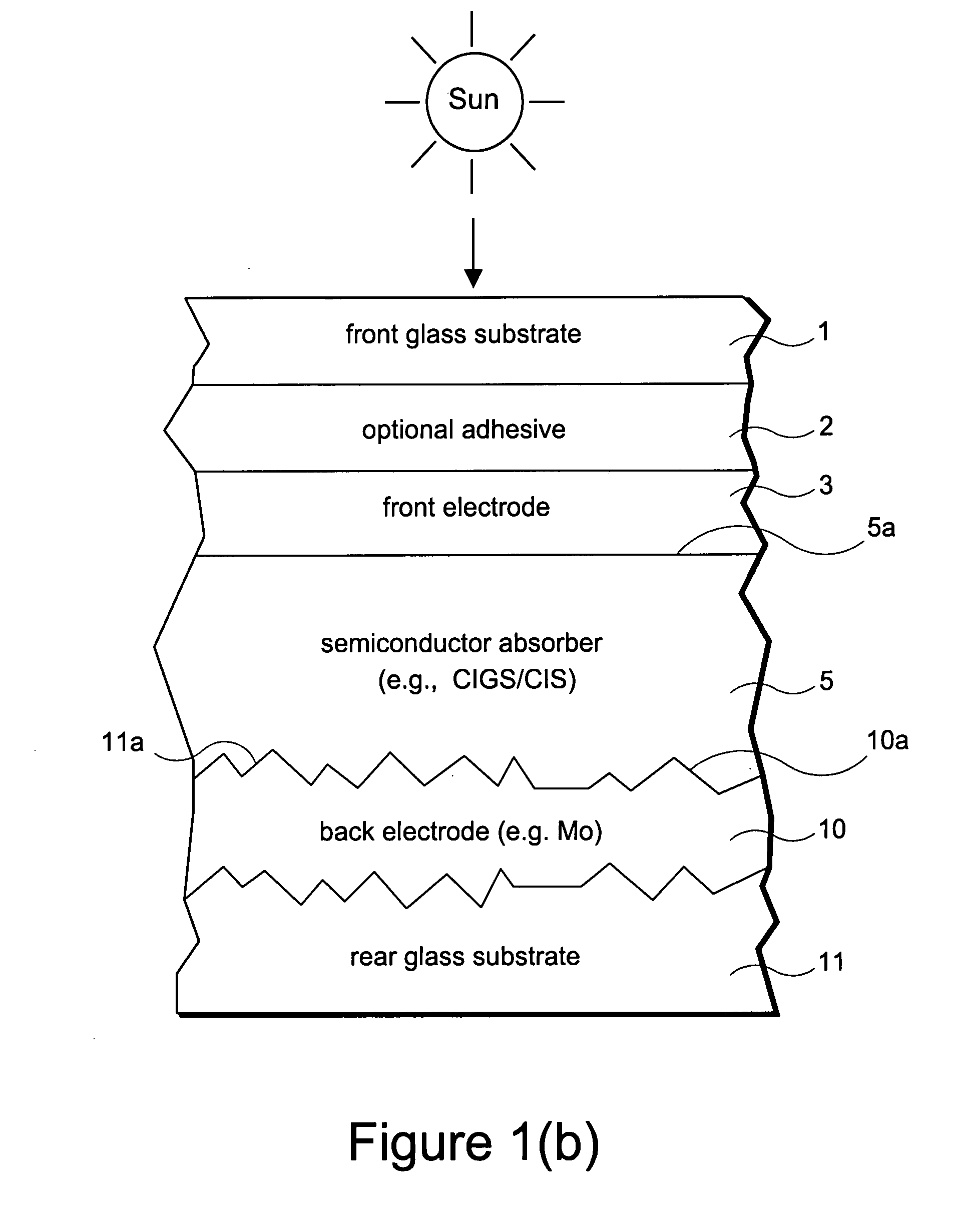

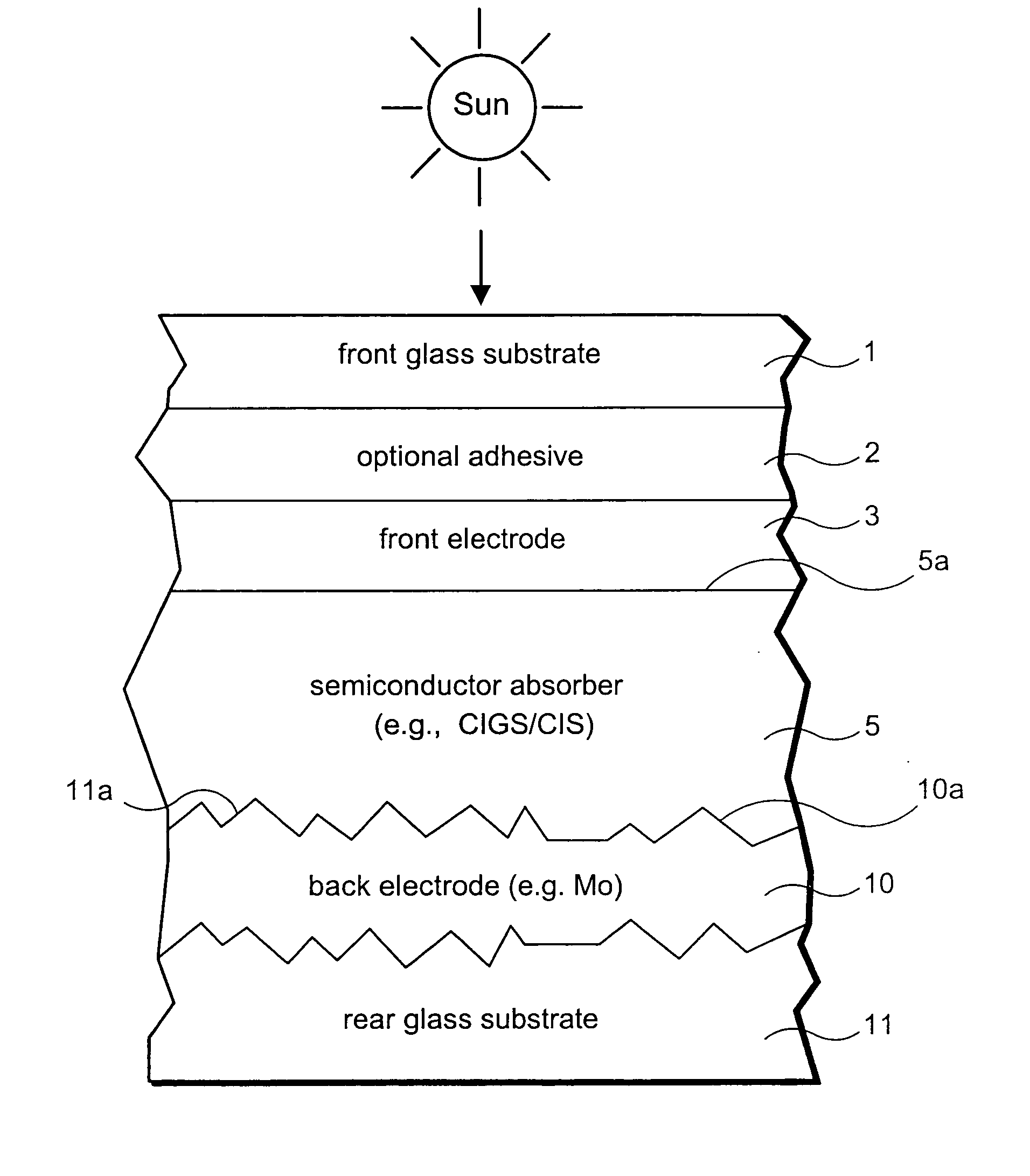

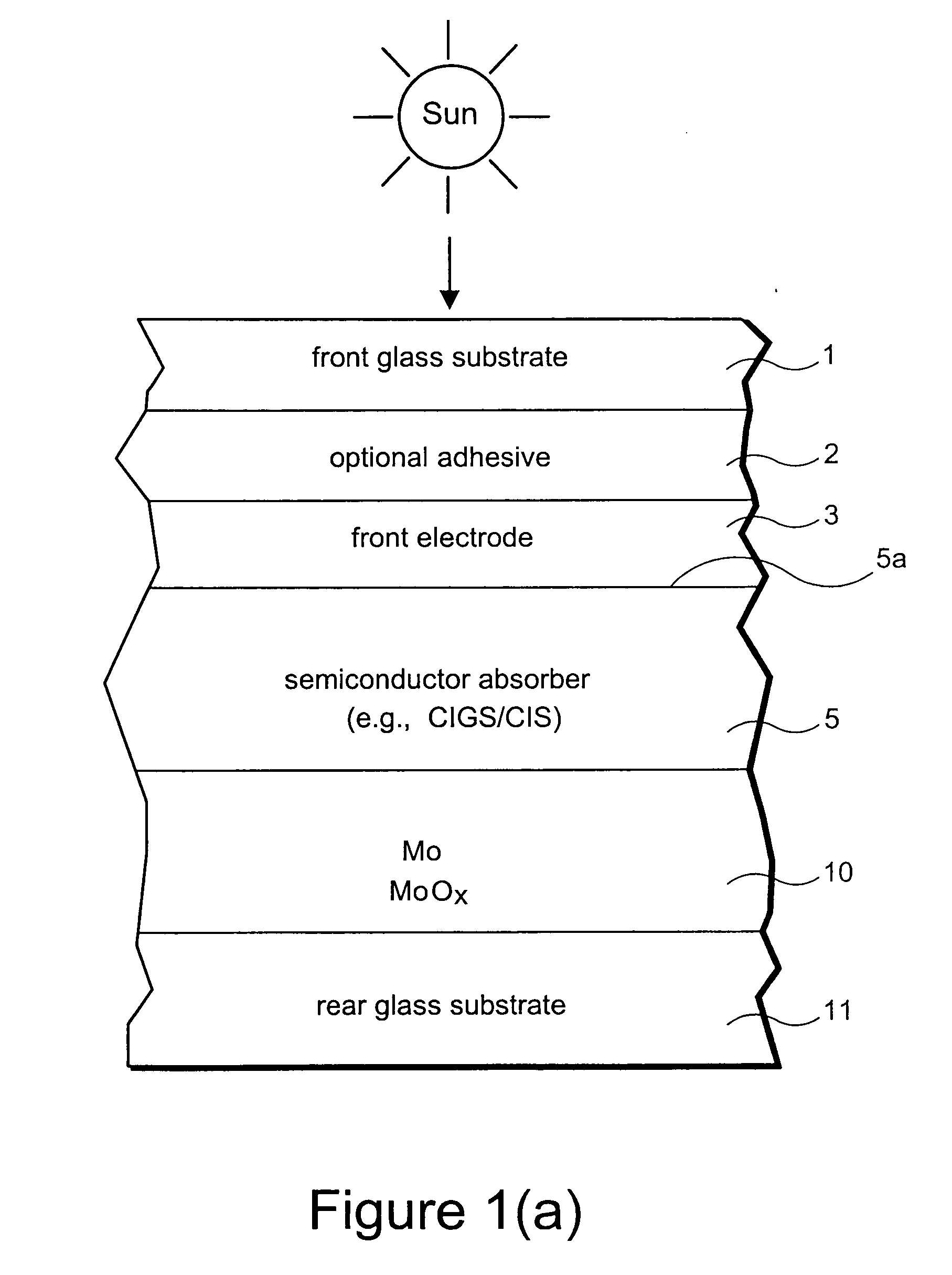

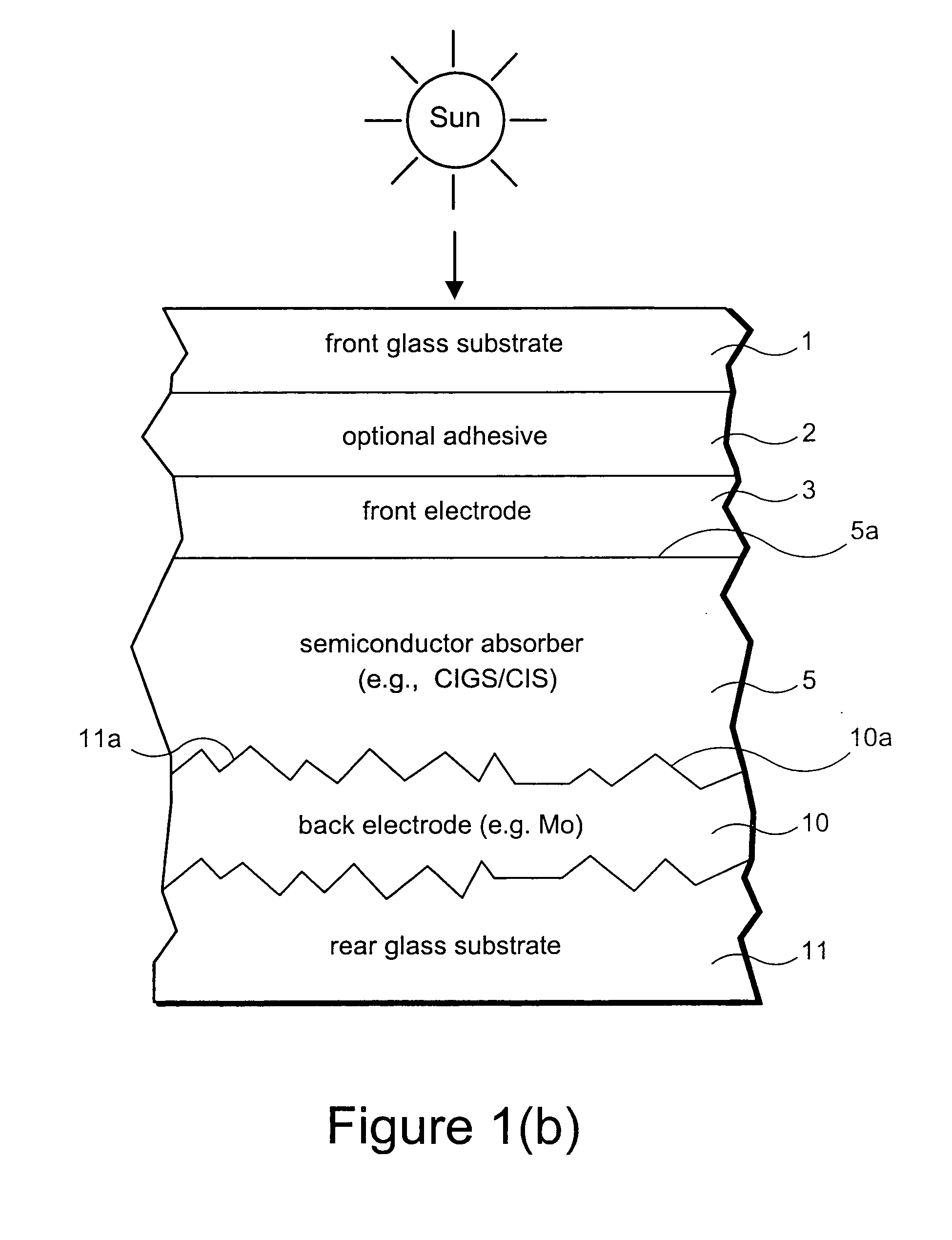

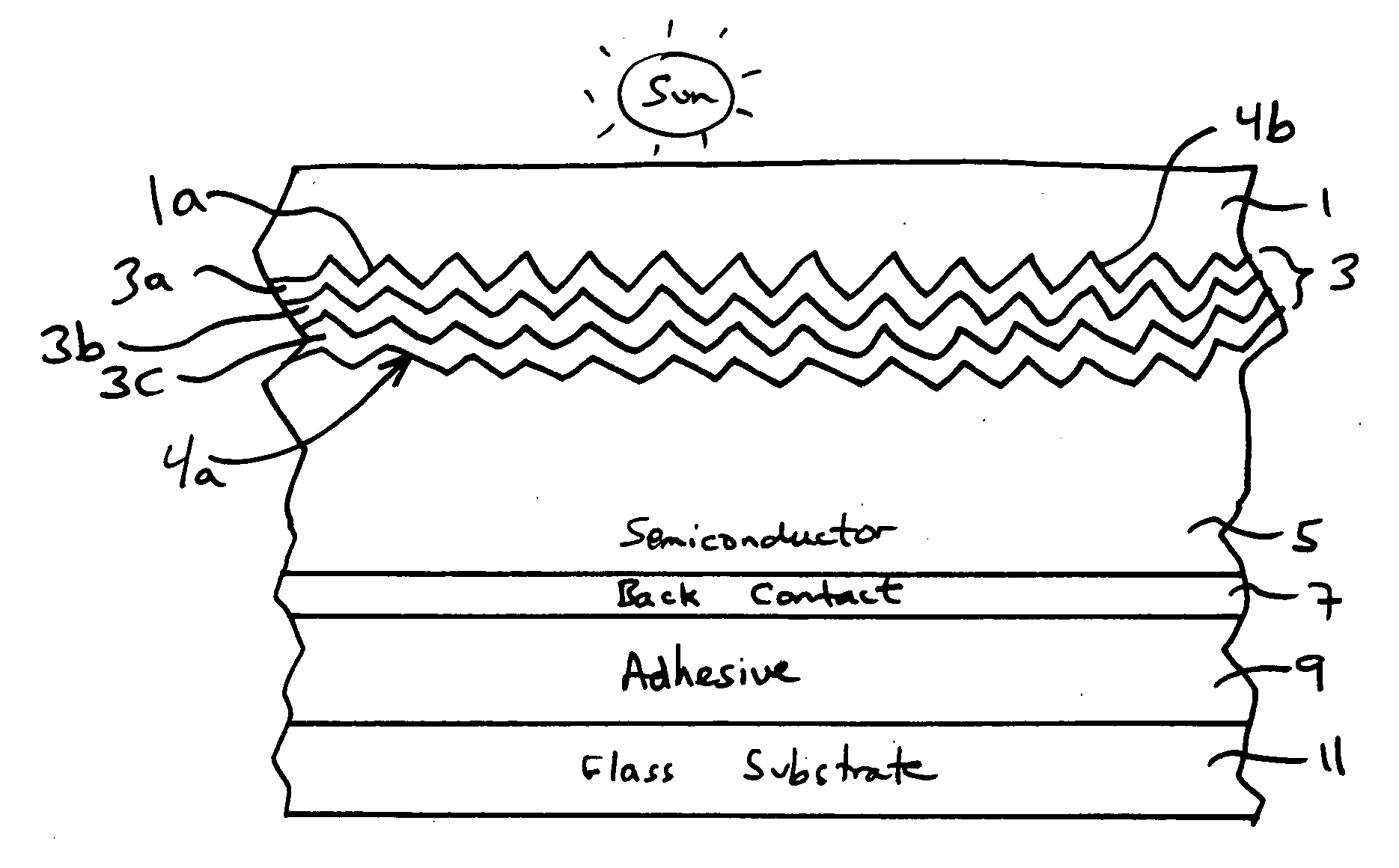

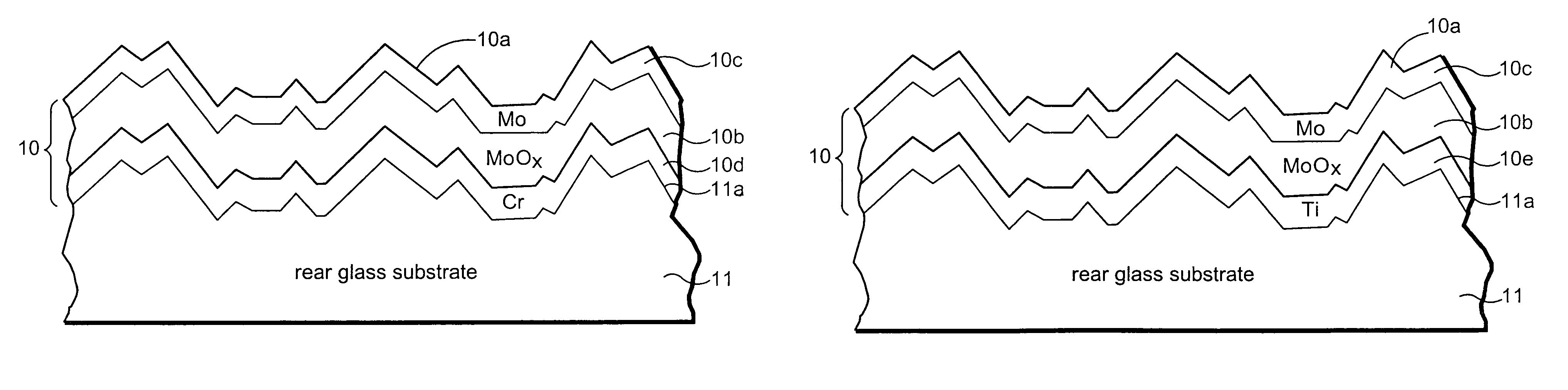

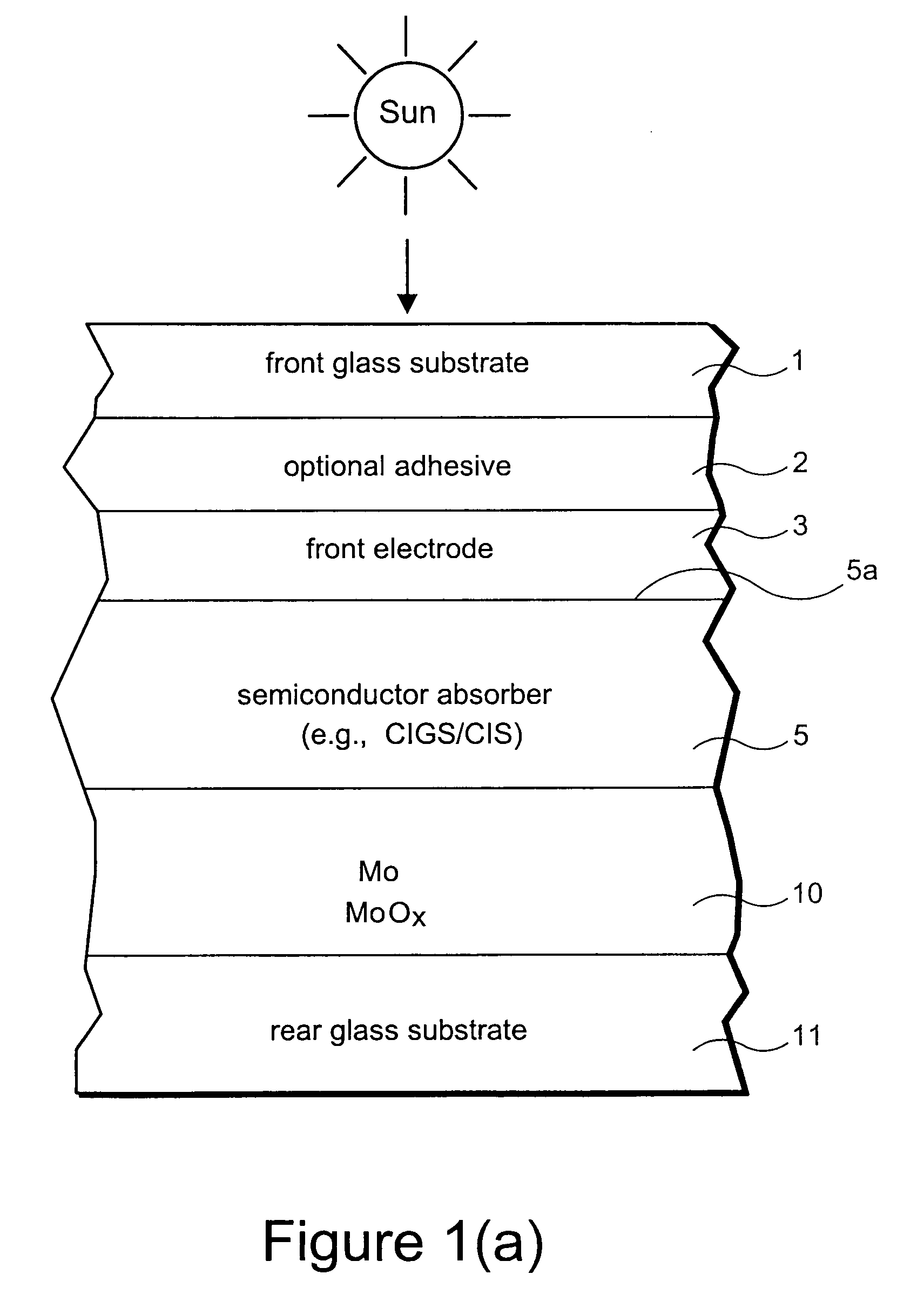

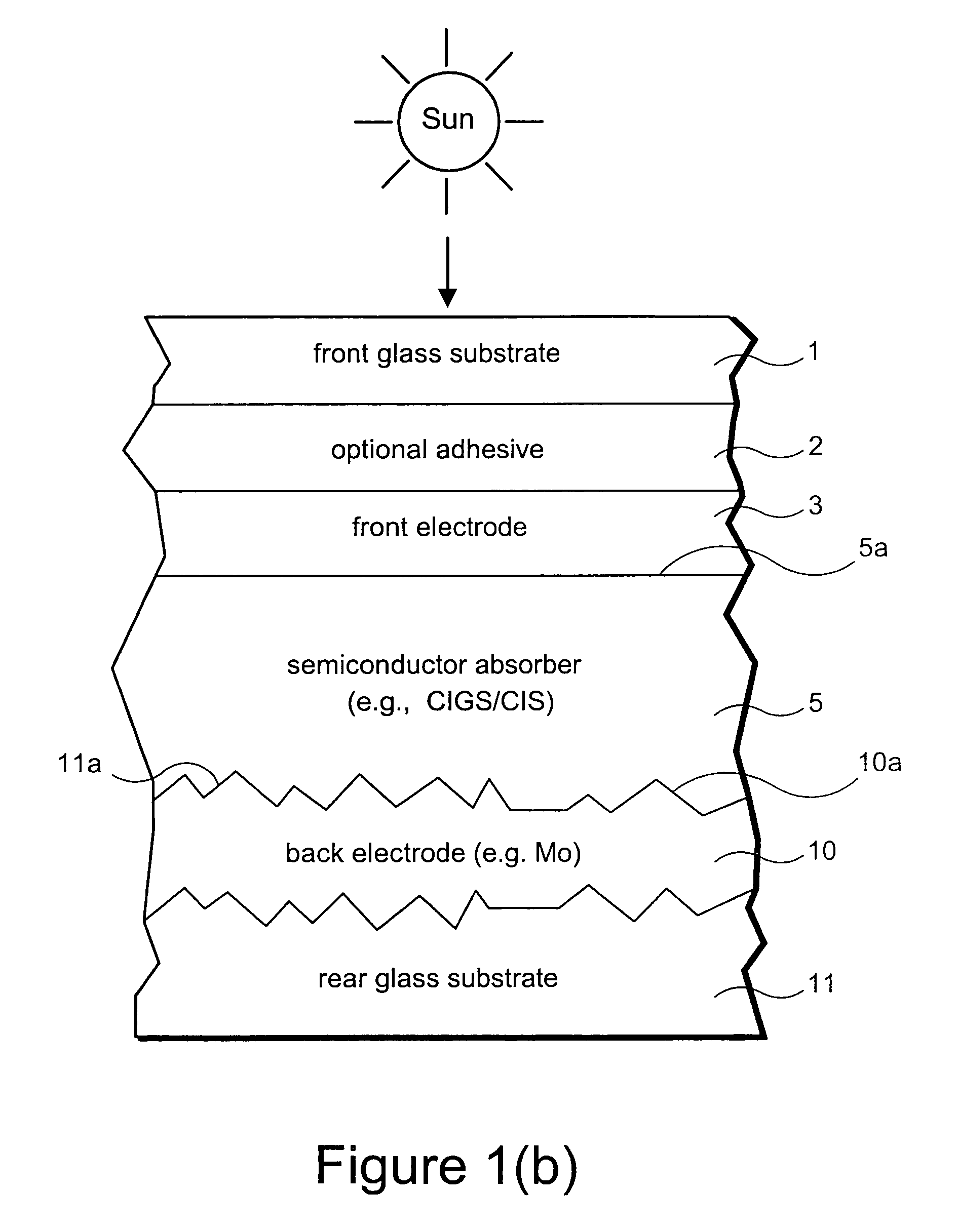

Rear electrode structure for use in photovoltaic device such as CIGS/CIS photovoltaic device and method of making same

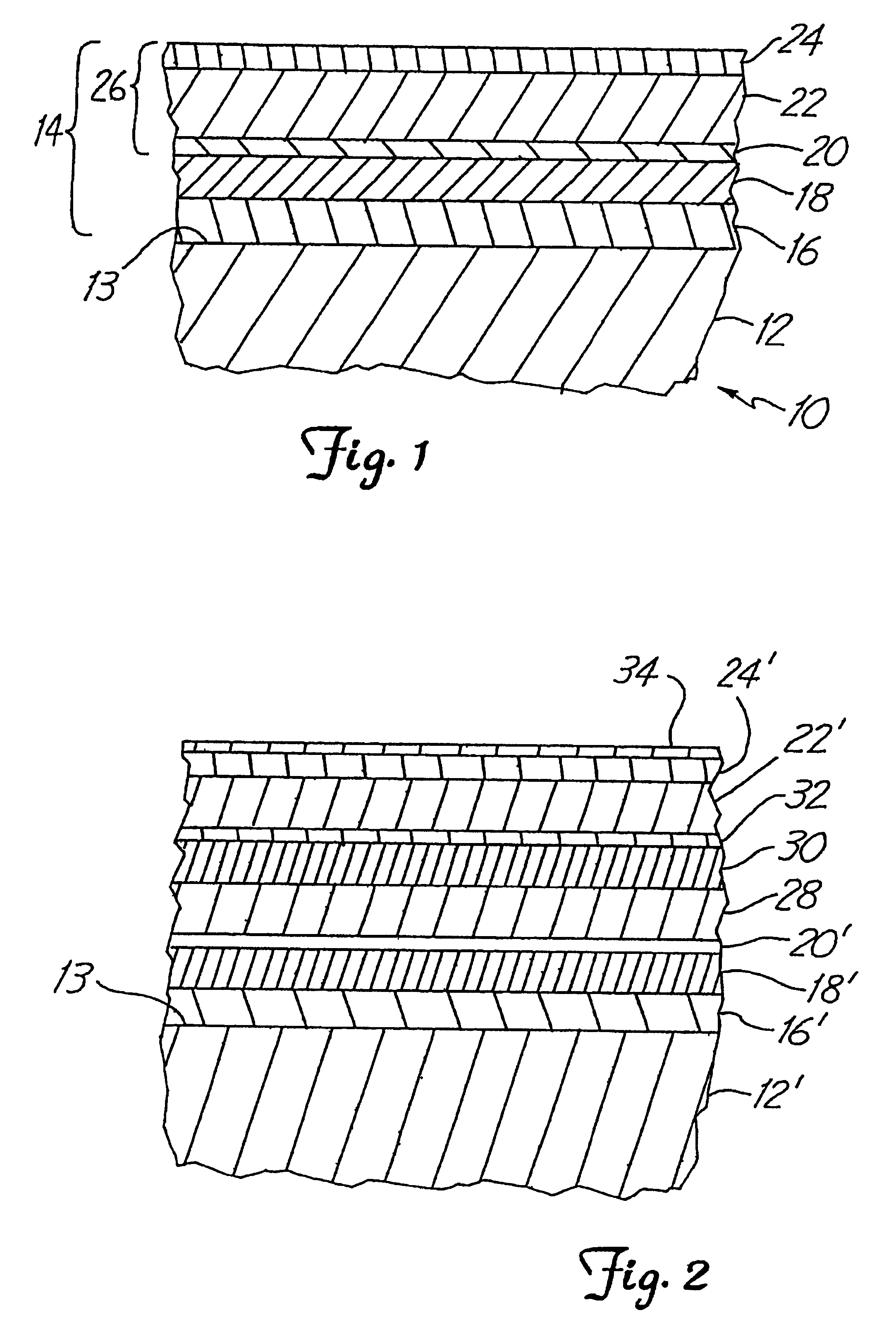

InactiveUS20080308147A1Improve adhesionImprove efficiencyFinal product manufacturePretreated surfacesEngineeringSputter deposition

A photovoltaic device including a rear electrode which may also function as a rear reflector. In certain example embodiments of this invention, the rear electrode includes a metallic based reflective film that is oxidation graded, so as to be more oxided closer to a rear substrate (e.g., glass substrate) supporting the electrode than at a location further from the rear substrate. In other words, the rear electrode is oxidation graded so as to be less oxided closer to a semiconductor absorber of the photovoltaic device than at a location further from the semiconductor absorber in certain example embodiments. In certain example embodiments, the interior surface of the rear substrate may optionally be textured so that the rear electrode deposited thereon is also textured so as to provide desirable electrical and reflective characteristics. In certain example embodiments, the rear electrode may be of or include Mo and / or MoOx, and may be sputter-deposited using a combination of MoOx and Mo sputtering targets.

Owner:GUARDIAN GLASS LLC

Rear electrode structure for use in photovoltaic device such as CIGS/CIS photovoltaic device and method of making same

InactiveUS20090020157A1Improve adhesionImprove efficiencyFinal product manufactureVacuum evaporation coatingSputter depositionEngineering

A photovoltaic device including a rear electrode which may also function as a rear reflector. In certain example embodiments of this invention, the rear electrode includes a metallic based reflective film that is oxidation graded, so as to be more oxided closer to a rear substrate (e.g., glass substrate) supporting the electrode than at a location further from the rear substrate. In other words, the rear electrode is oxidation graded so as to be less oxided closer to a semiconductor absorber of the photovoltaic device than at a location further from the semiconductor absorber in certain example embodiments. In certain example embodiments, the interior surface of the rear substrate may optionally be textured so that the rear electrode deposited thereon is also textured so as to provide desirable electrical and reflective characteristics. In certain example embodiments, the rear electrode may be of or include Mo and / or MoOx, and may be sputter-deposited using a combination of MoOx and Mo sputtering targets.

Owner:GUARDIAN GLASS LLC

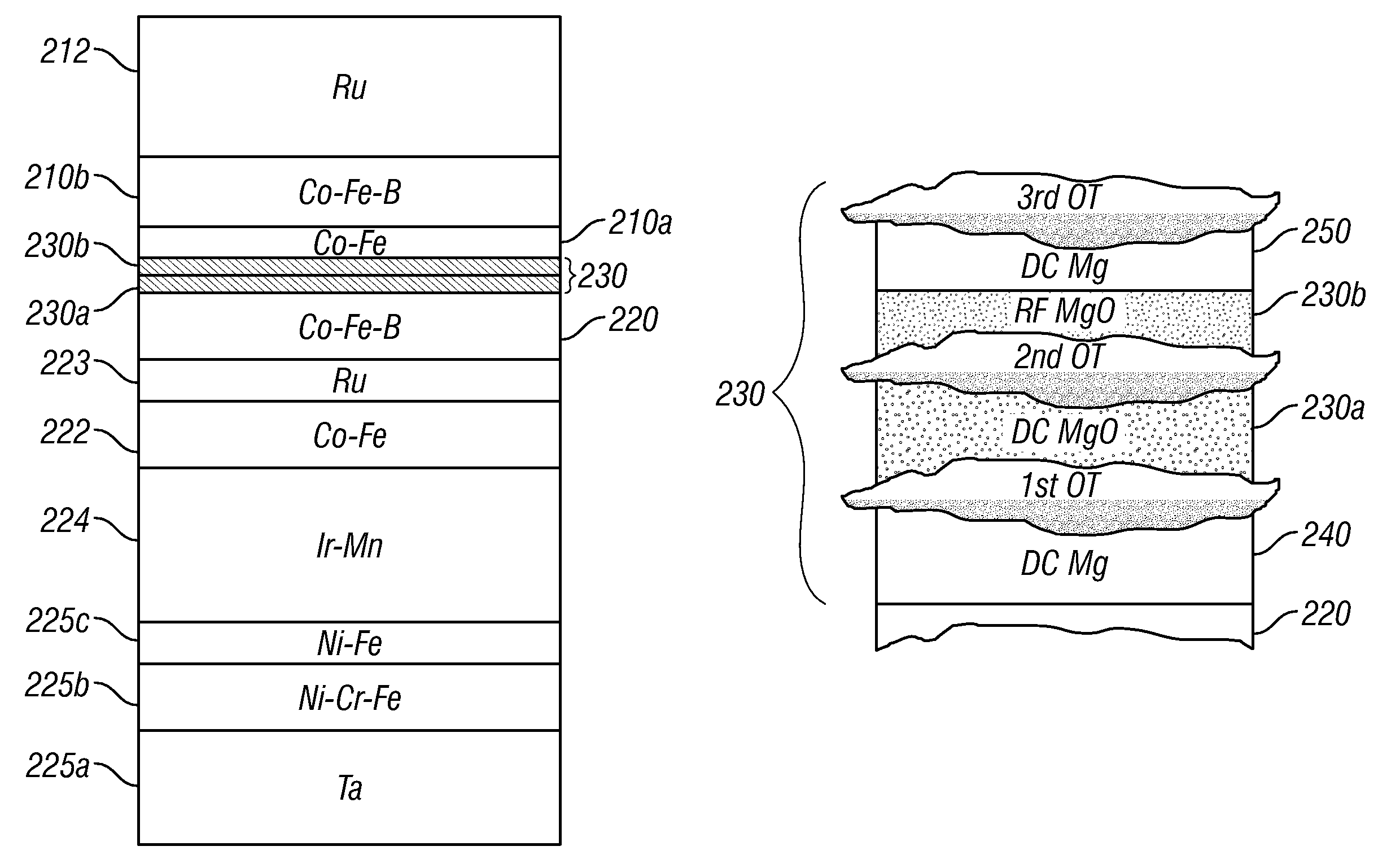

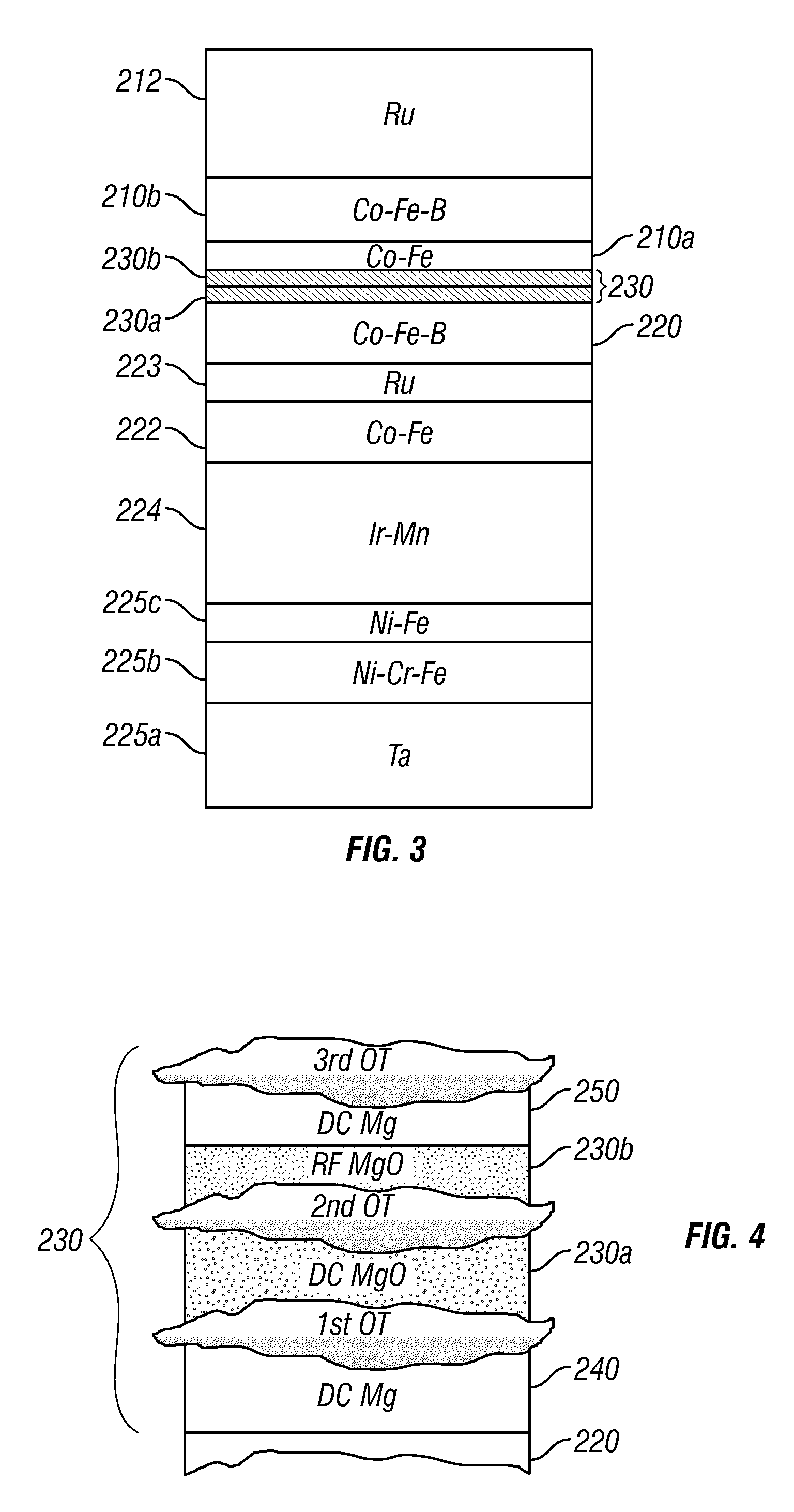

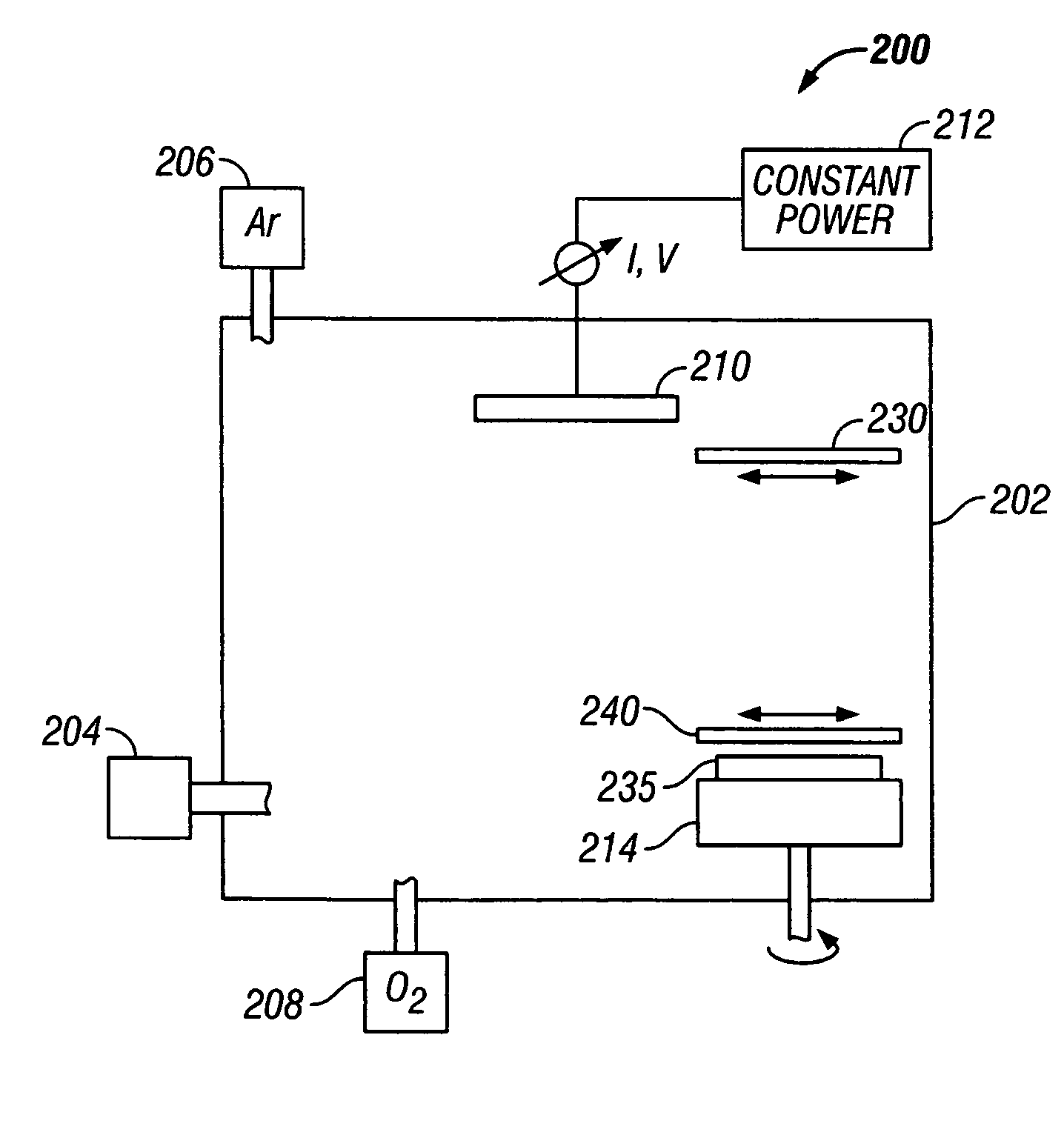

Method for forming an MgO barrier layer in a tunneling magnetoresistive (TMR) device

A method of forming a barrier layer of a tunneling magnetoresistive (TMR) device by forming first and second MgO barrier layers by different sputtering methods, but in the same sputtering system module. A first magnesium-oxide (MgO) barrier layer is formed over one of the TMR device's ferromagnetic layers by a DC magnetron sputter deposition from an Mg target in an oxygen environment. In the same module, a second MgO barrier layer is formed over the first MgO film by an RF sputter deposition from an MgO target and in an environment free of oxygen. Prior to the formation of the first MgO barrier layer, an optional Mg protection layer can be deposited on the ferromagnetic layer and oxidized by a first optional oxygen treatment. After deposition of the first MgO barrier layer, a second optional oxygen treatment may be conducted. After deposition of the second MgO barrier layer, a second Mg protection layer may be deposited by DC sputter deposition, followed by an optional third oxygen treatment.

Owner:WESTERN DIGITAL TECH INC

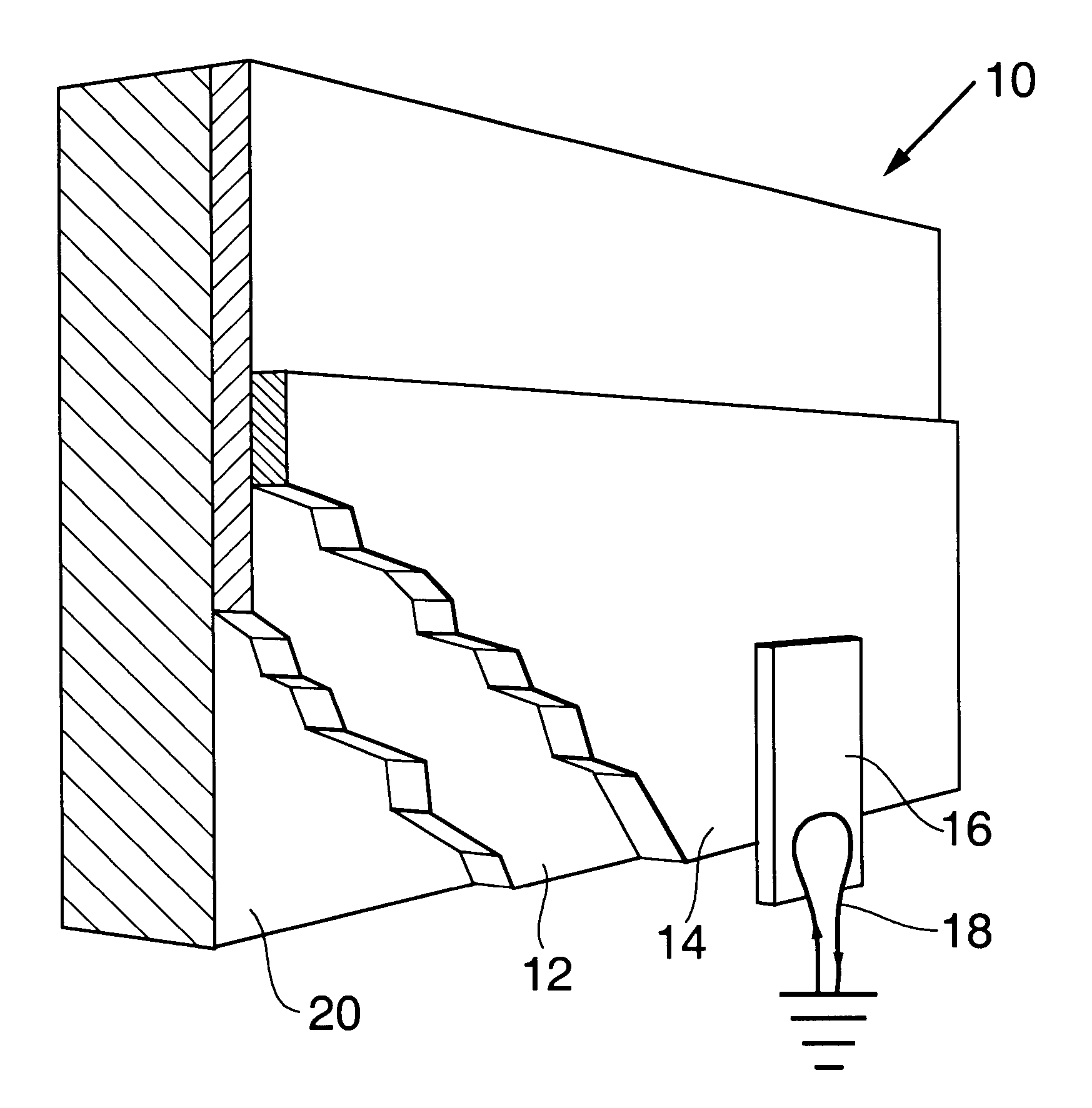

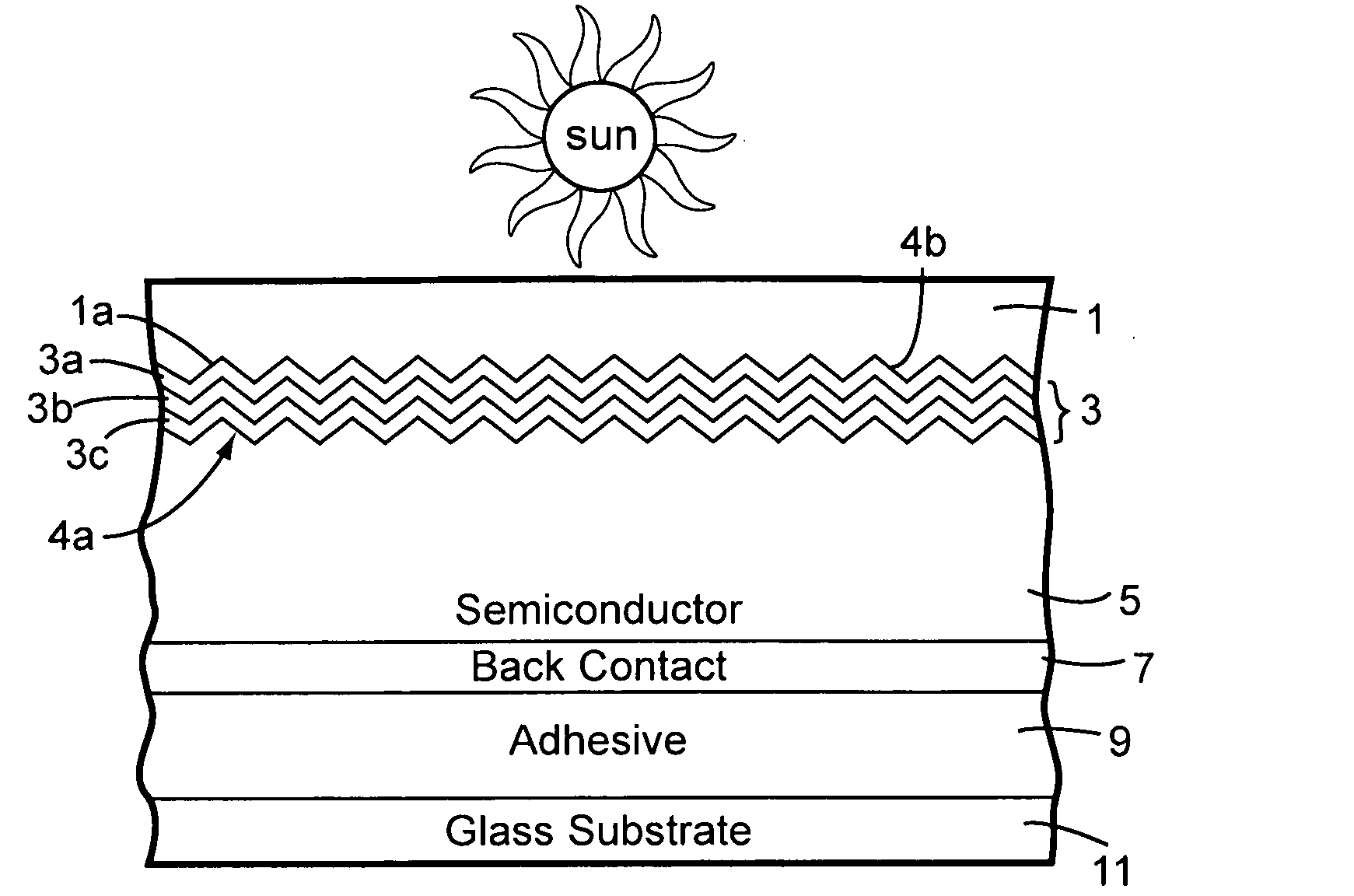

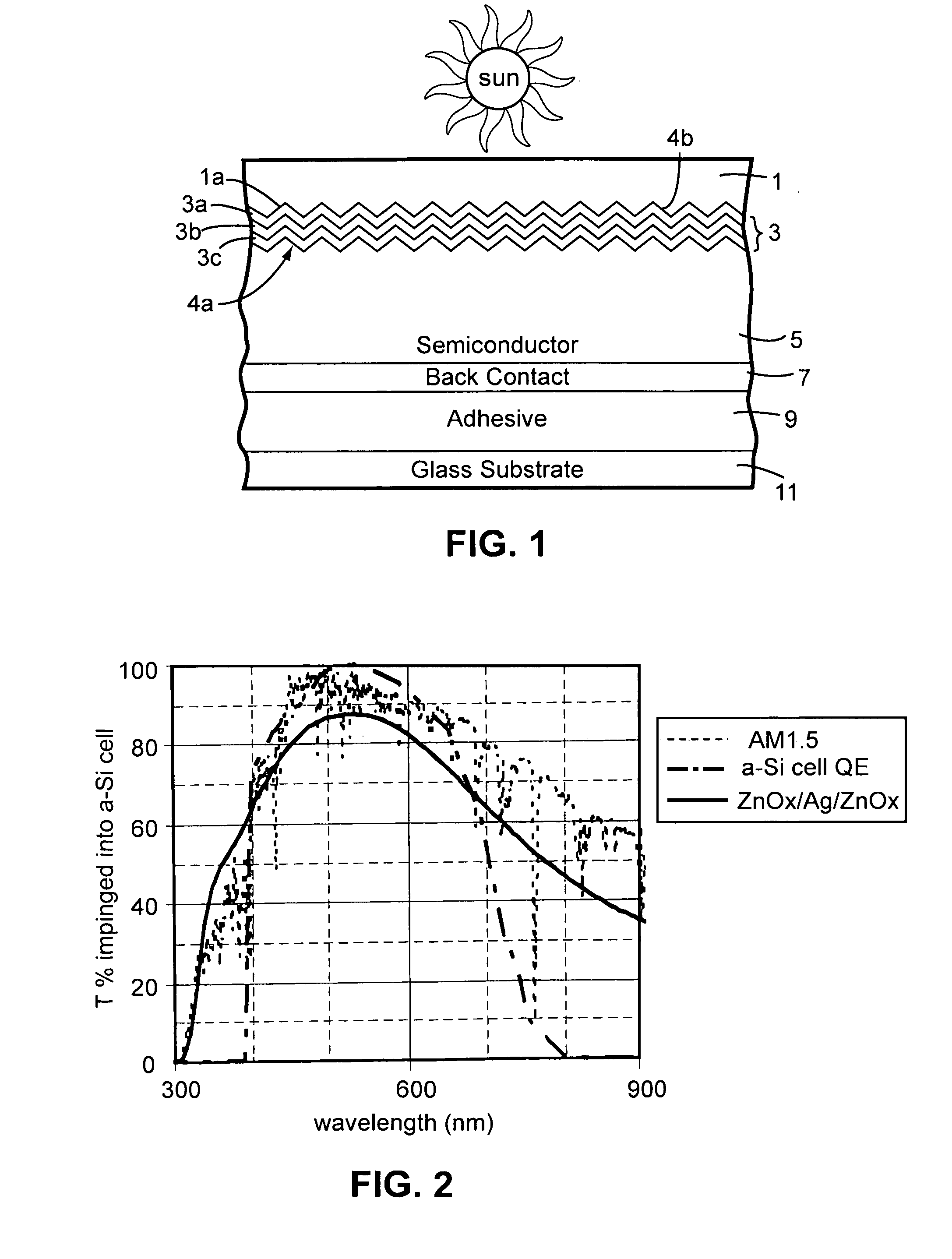

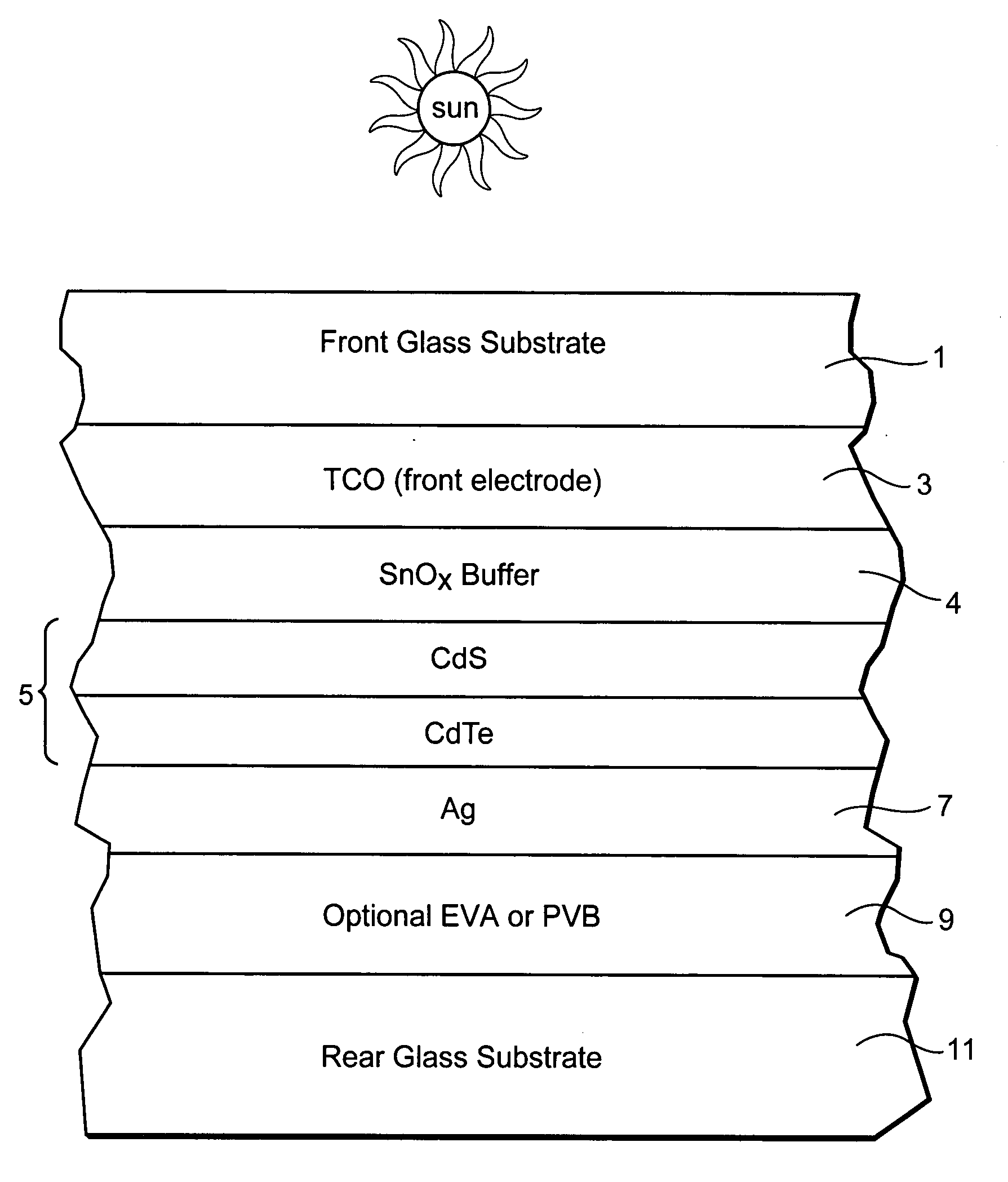

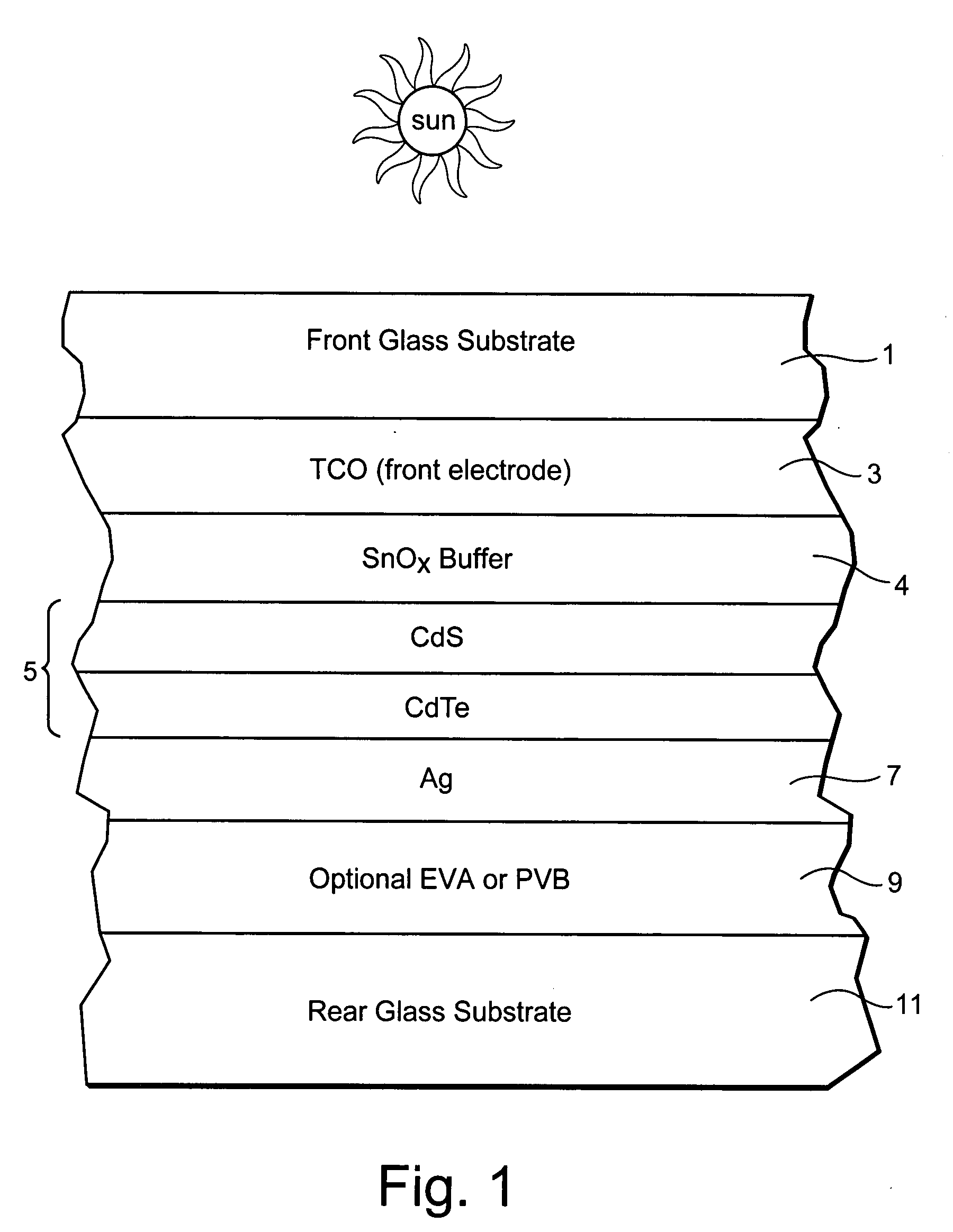

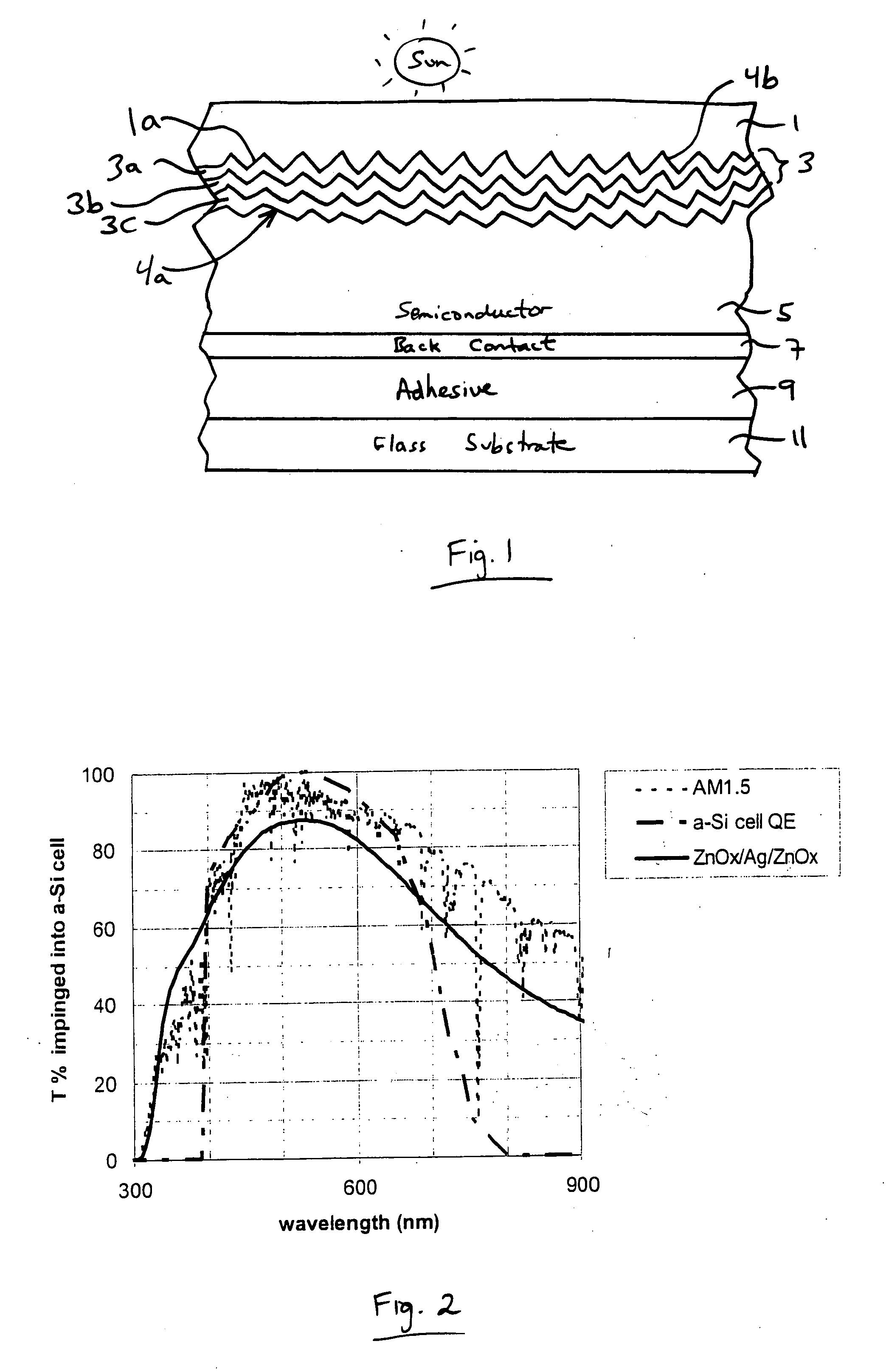

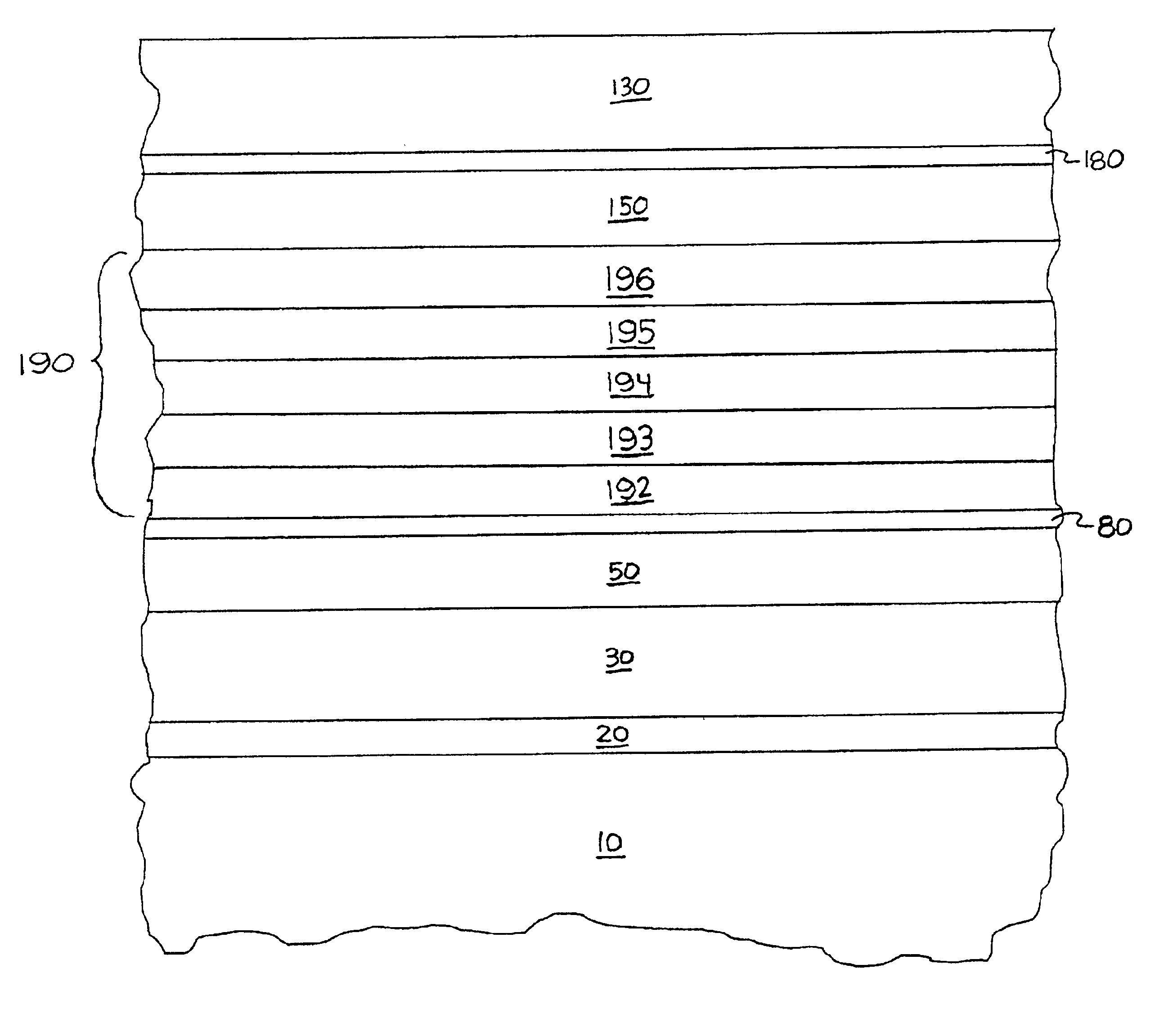

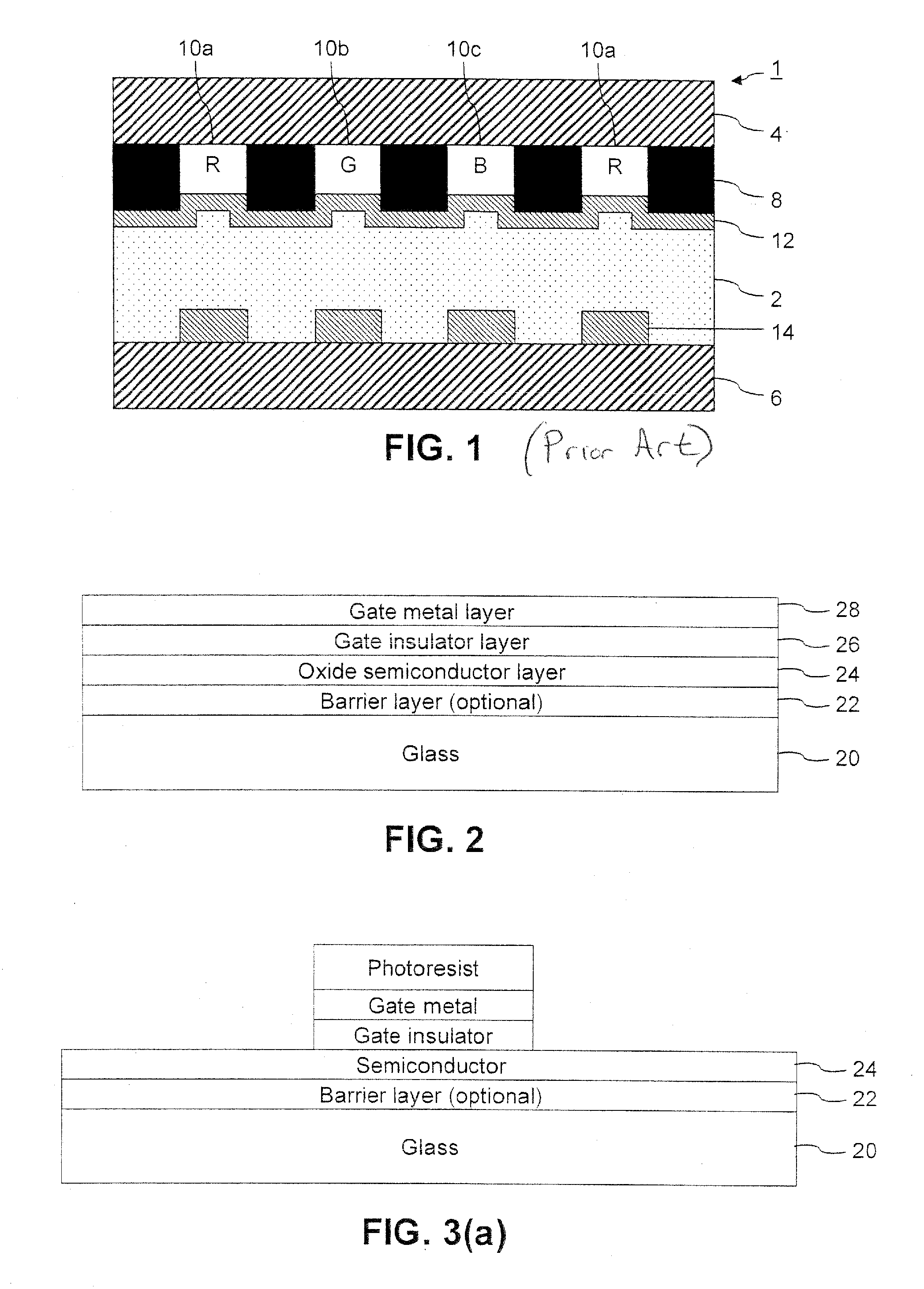

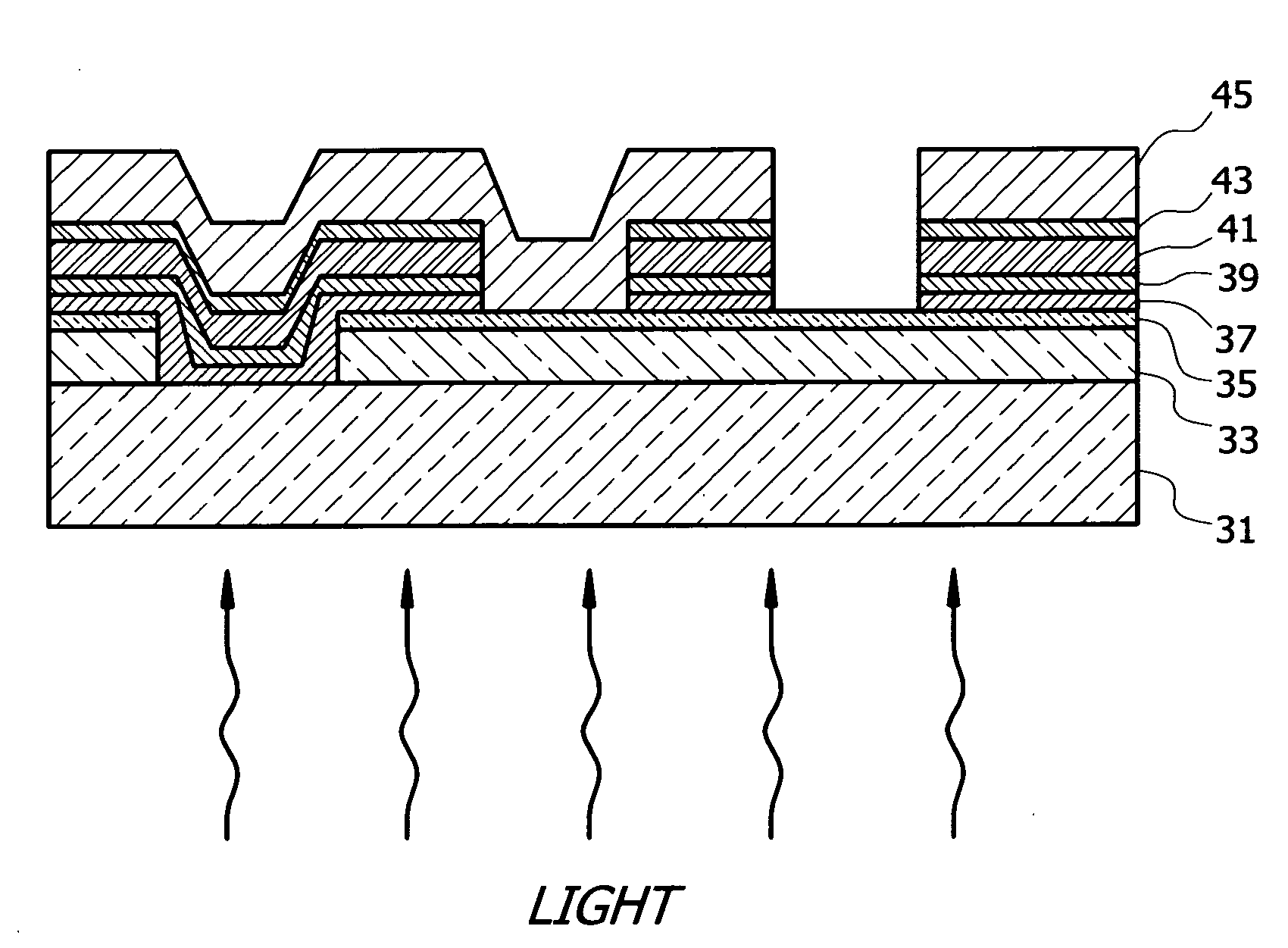

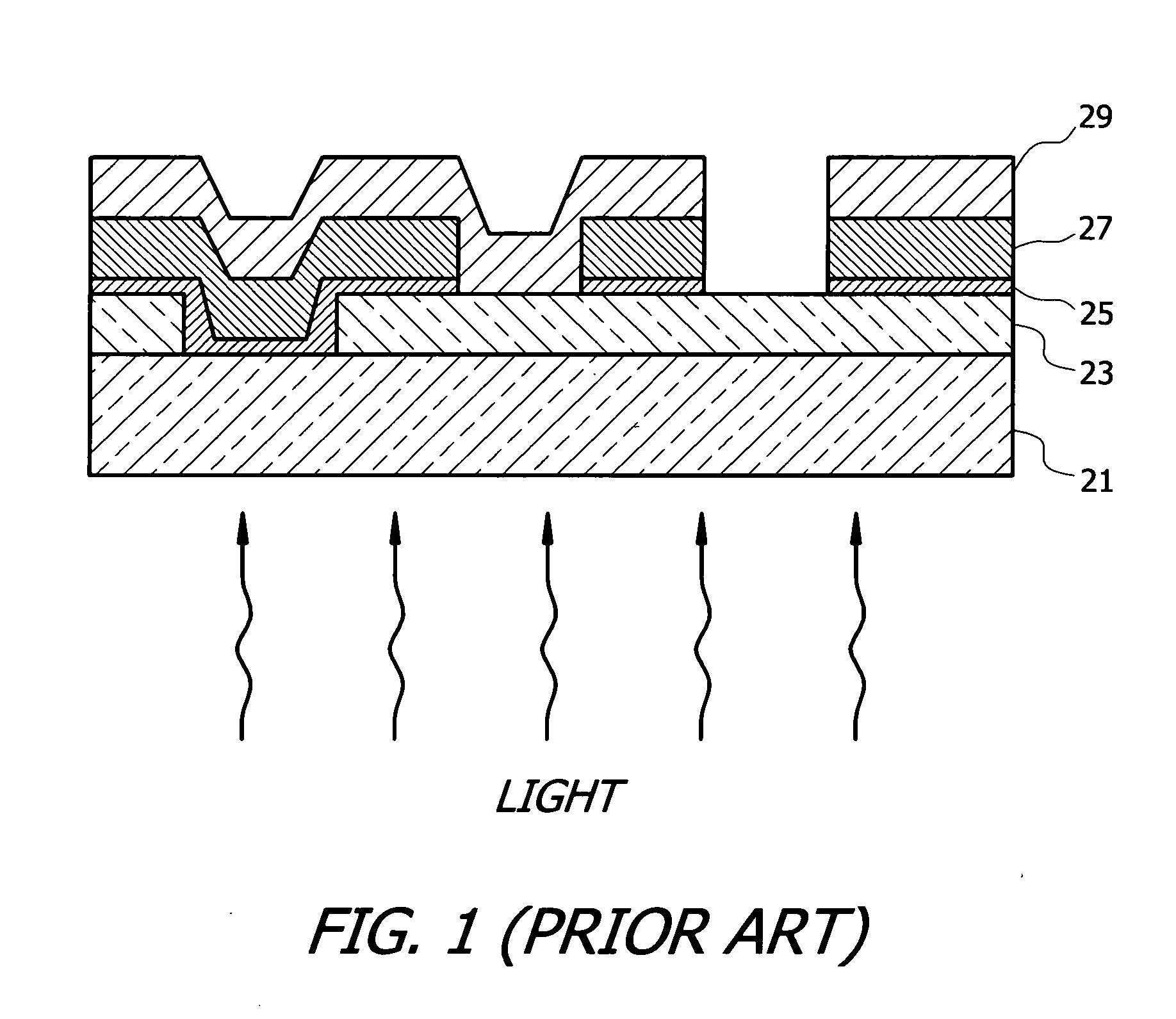

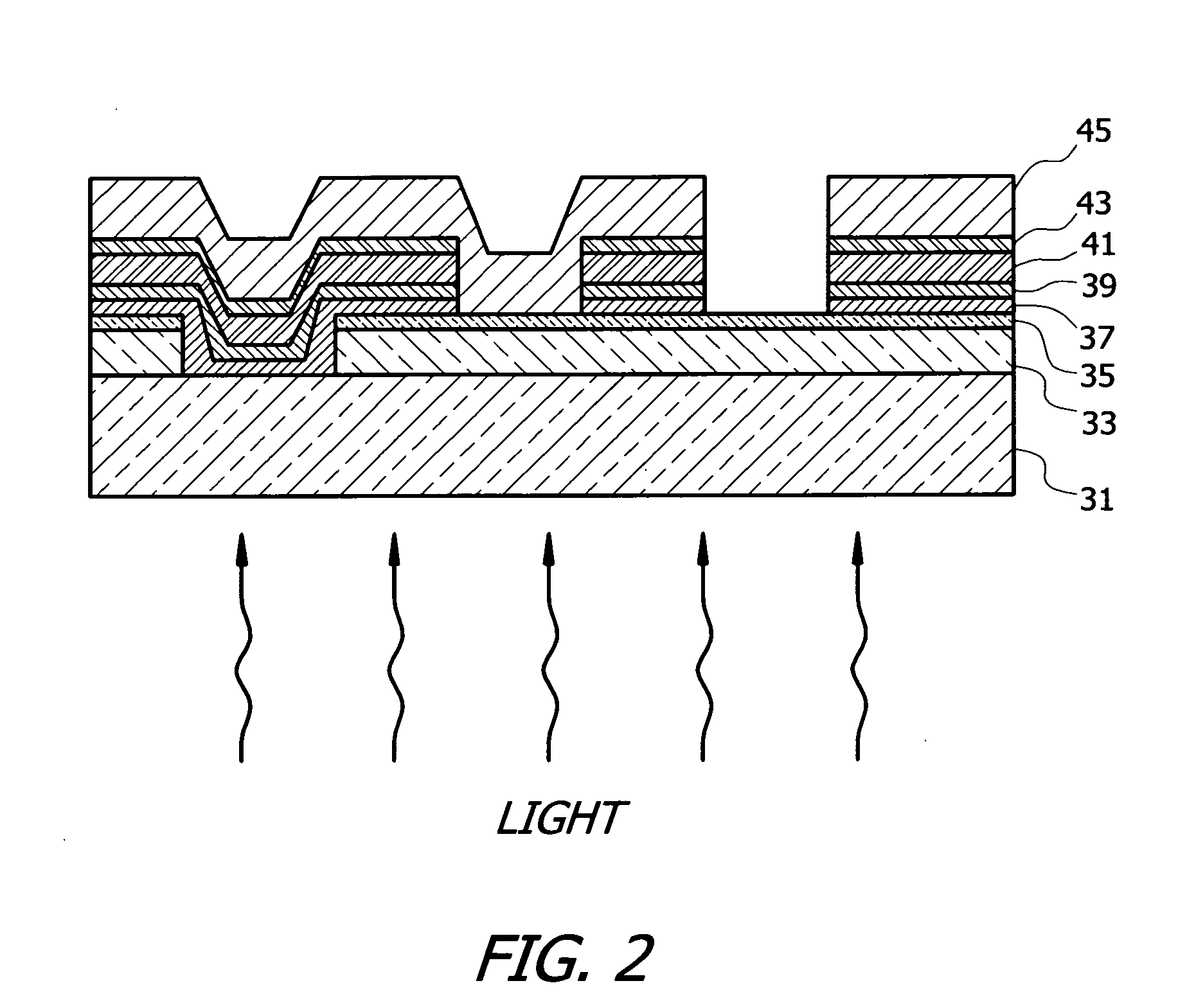

Front electrode including transparent conductive coating on patterned glass substrate for use in photovoltaic device and method of making same

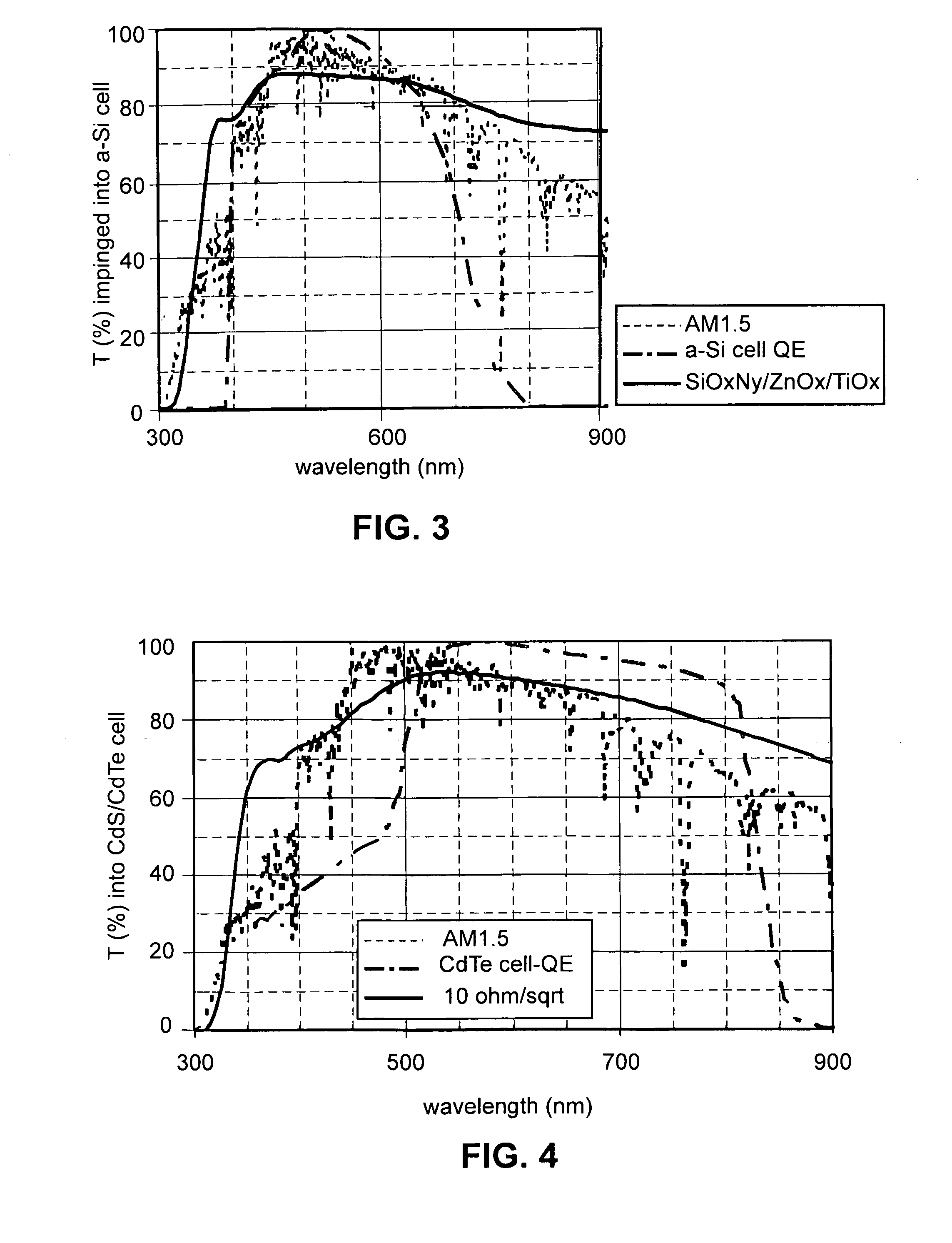

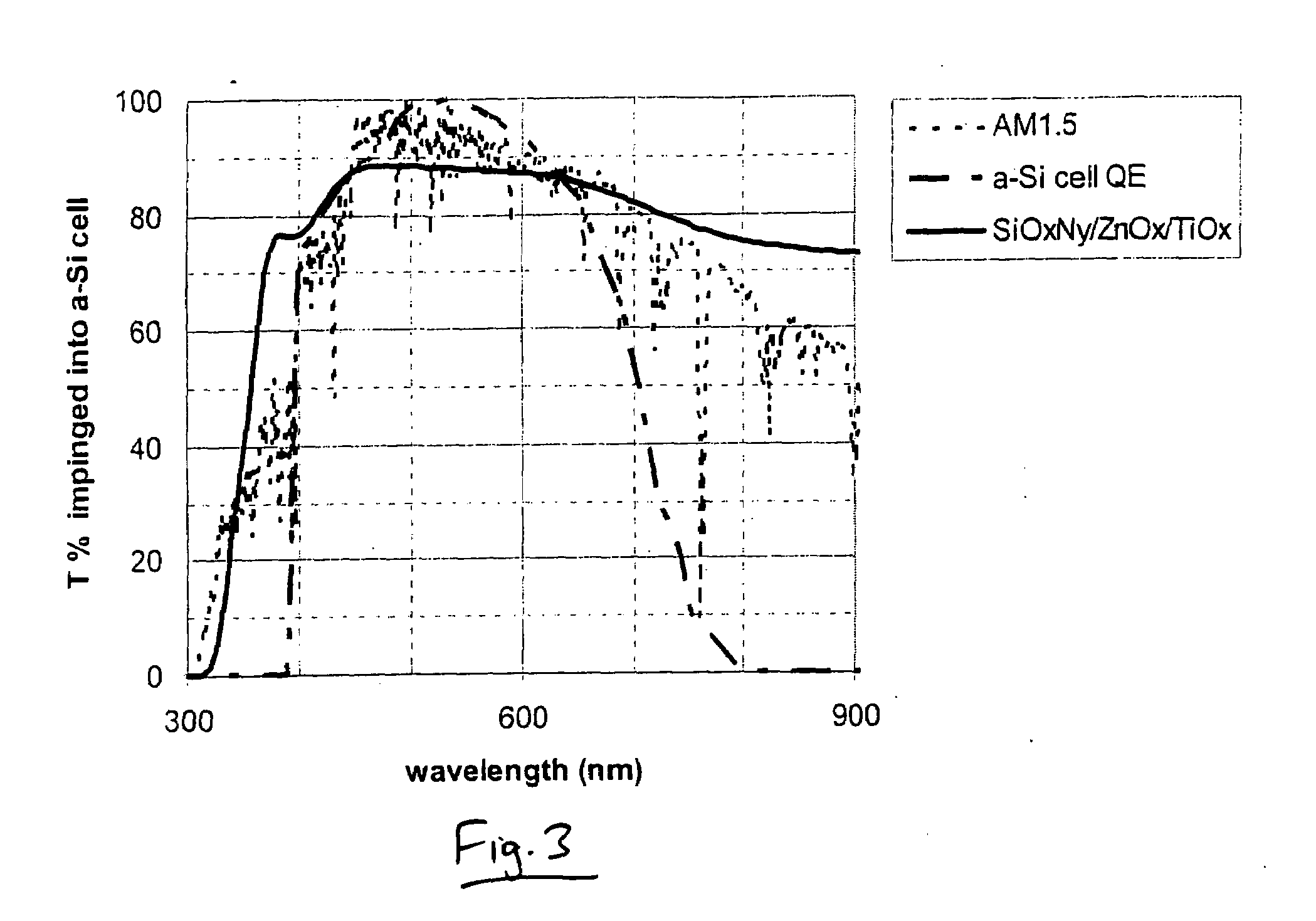

InactiveUS20080178932A1Reduced visible light reflectionImprove conductivitySemiconductor/solid-state device manufacturingPhotovoltaic energy generationPeak valuePeak area

This invention relates to a photovoltaic device including an electrode such as a front electrode / contact. In certain example embodiments, the front electrode of the photovoltaic device includes a multi-layered transparent conductive coating which is sputter-deposited on a textured surface of a patterned glass substrate. In certain example embodiments, a maximum transmission area of the substantially transparent conductive front electrode is located under a peak area of a quantum efficiency (QE) and / or QEx (photon flux of solar radiation) curve of the photovoltaic device and a light source spectrum used to power the photovoltaic device. In certain example embodiments, the front electrode includes a transparent conductive layer of or including one or more of (i) titanium zinc oxide doped with aluminum and / or niobium, and / or (ii) titanium niobium oxide.

Owner:GUARDIAN GLASS LLC

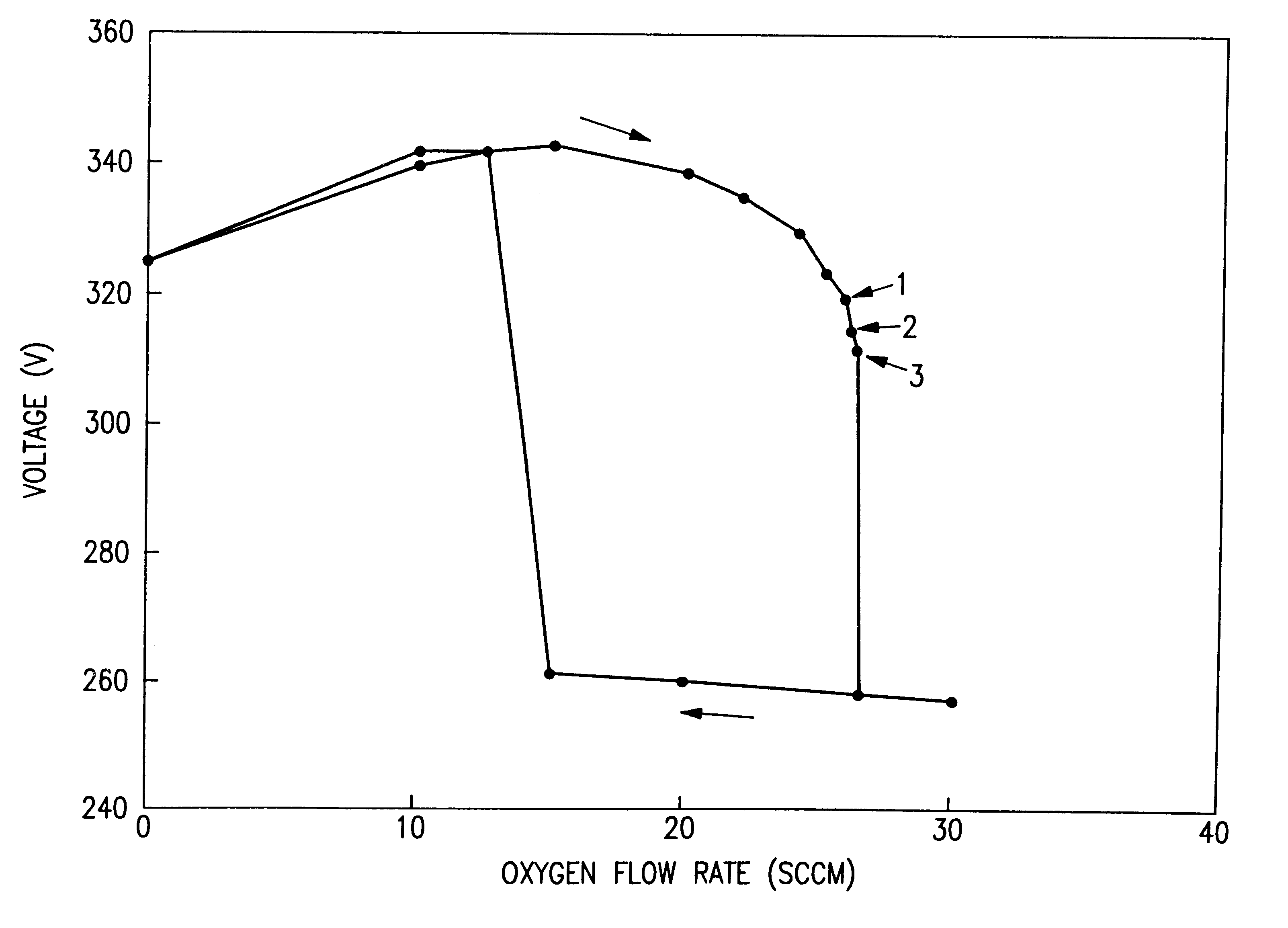

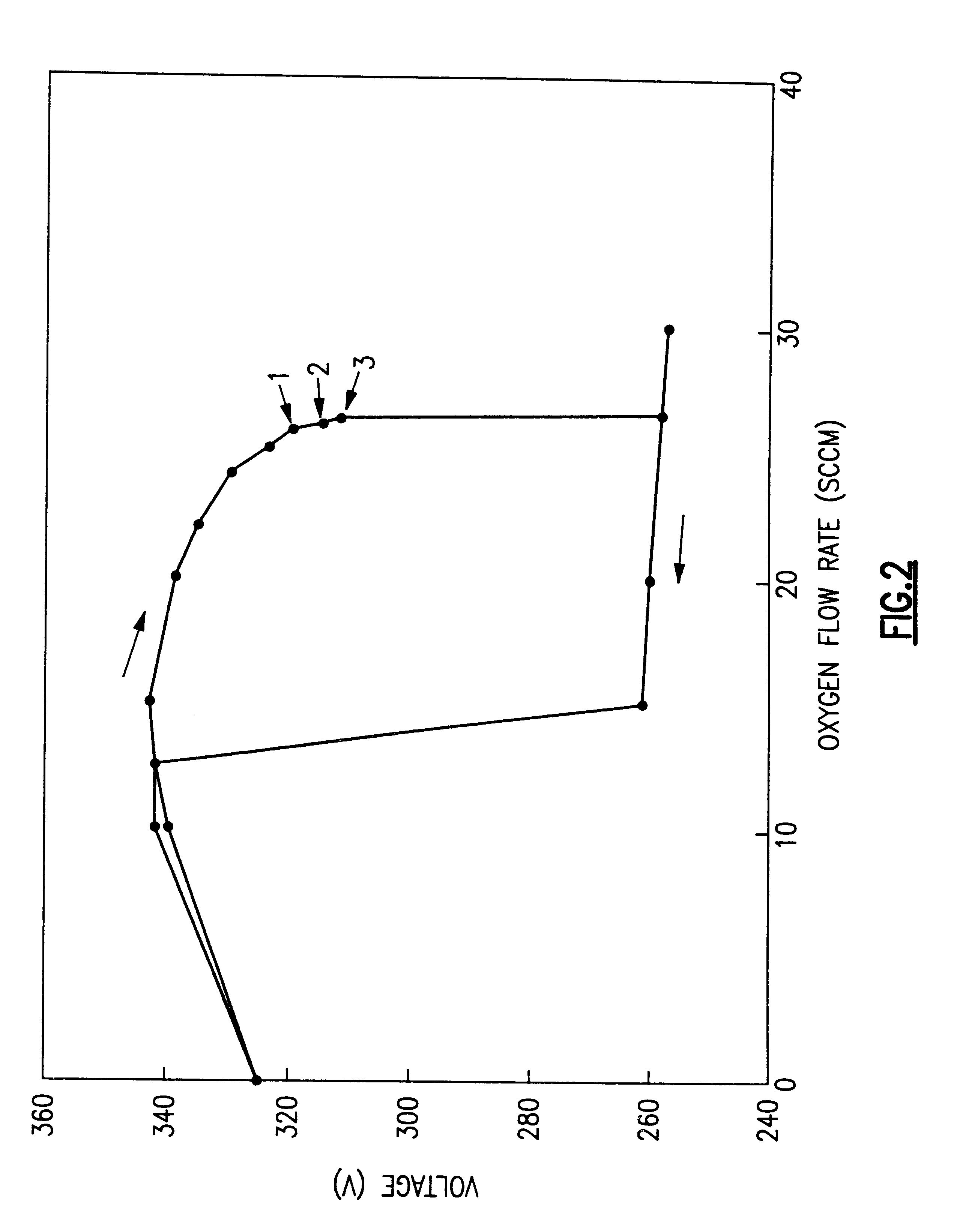

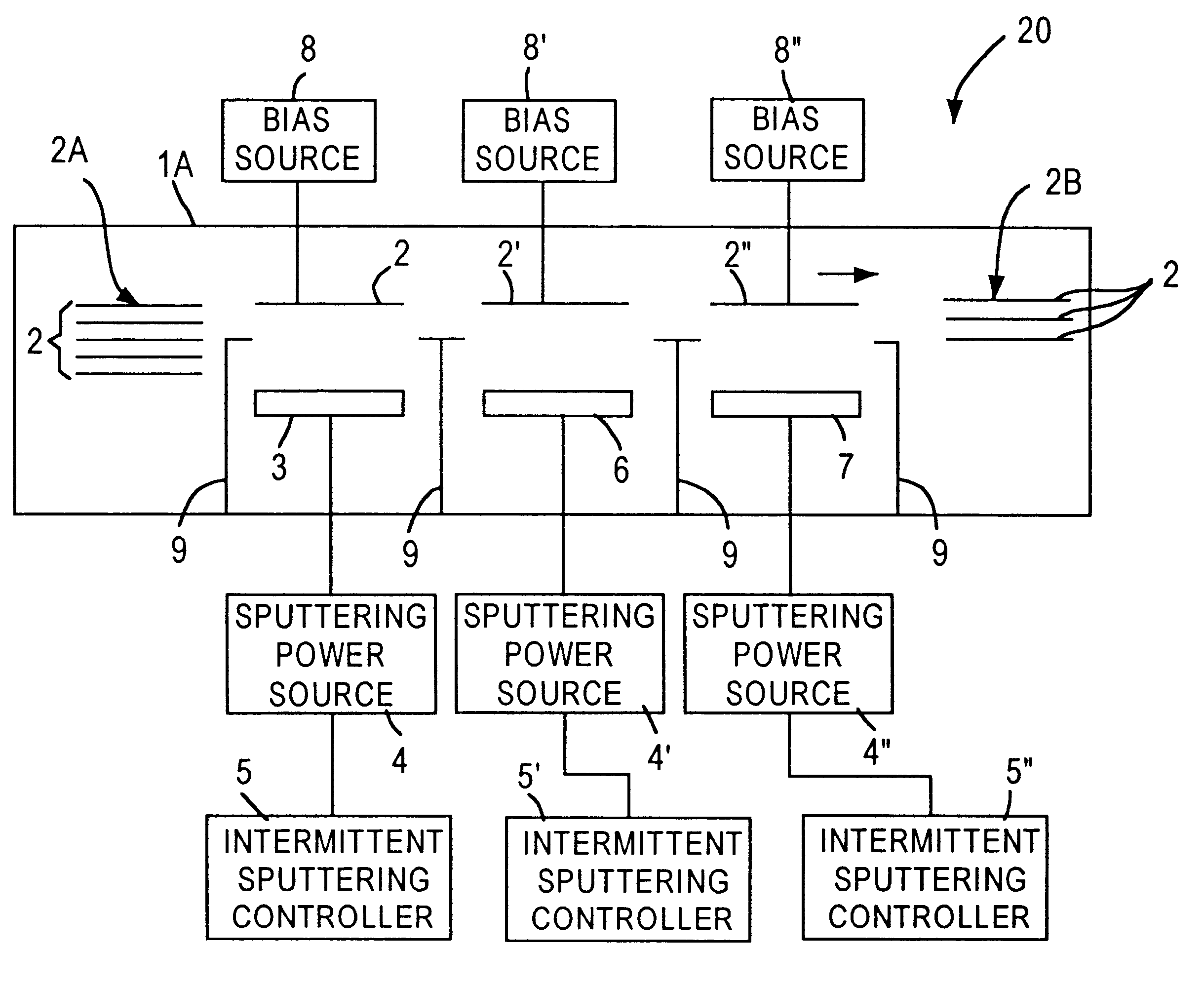

Stable high rate reactive sputtering

A method and apparatus for monitoring and controlling reactive sputter deposition, particularly useful for depositing insulating compounds (e.g., metal-oxides, metal-nitrides, etc.). For a given nominal cathode power level, target material, and source gases, the power supplied to the cathode (target) is controlled to stabilize the cathode (target) voltage at a specified value or within a specified range corresponding to a partial pressure or relative flow rate value or range of the reactive gas. Such an operating point or range, characterized by a specified voltage value or range and corresponding reactive gas relative-flow / partial-pressure value or range, may be determined empirically based on measuring the cathode voltage as a function of reactive gas relative-flow / partial-pressure for the given nominal power. This relationship is typically a hysteresis curve, and preferably the operation point is selected at or near the hysteresis transition edge to provide high rate deposition of high quality films, including insulating or dielectric films using a metallic target.

Owner:VEECO INSTR

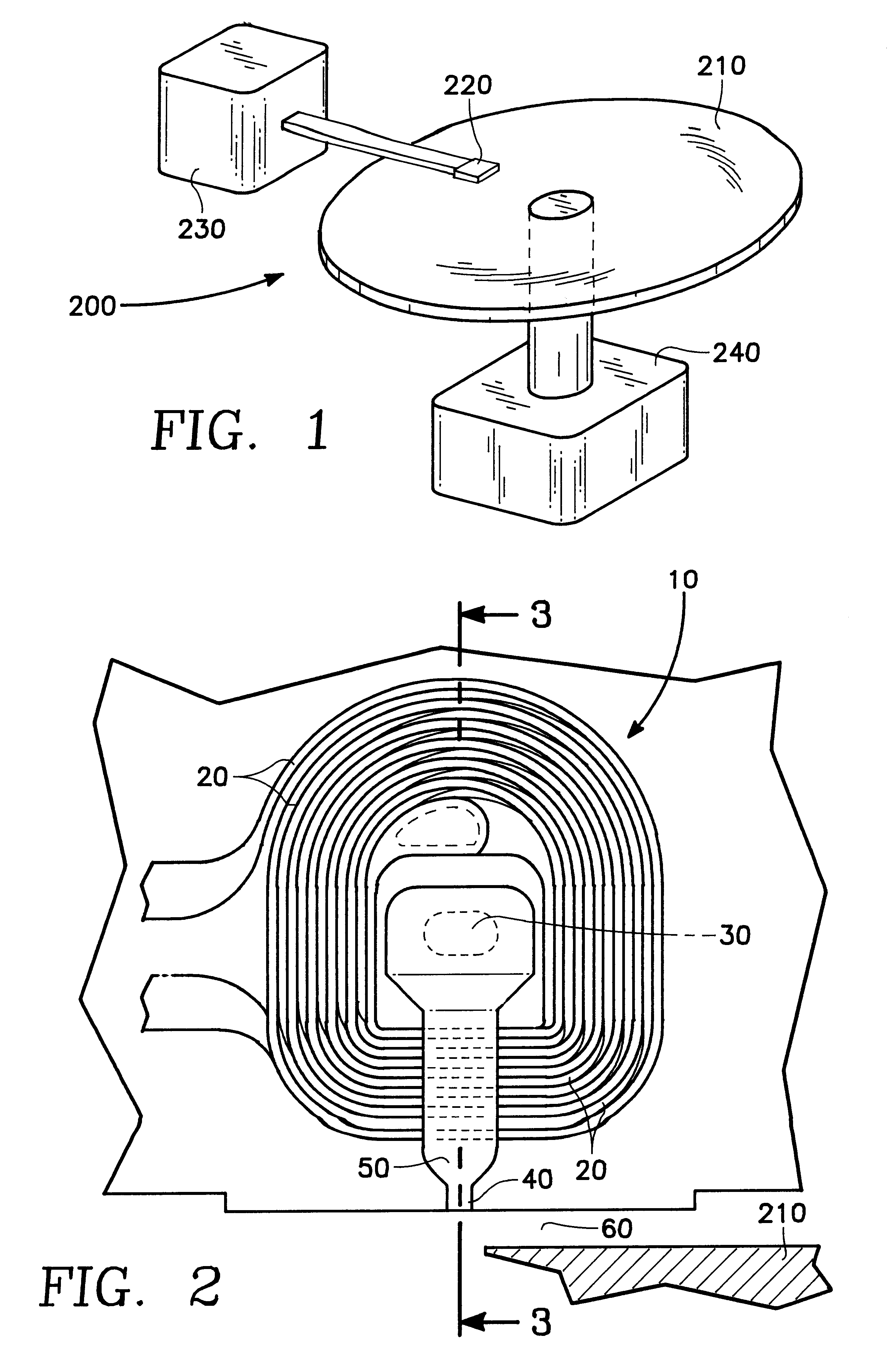

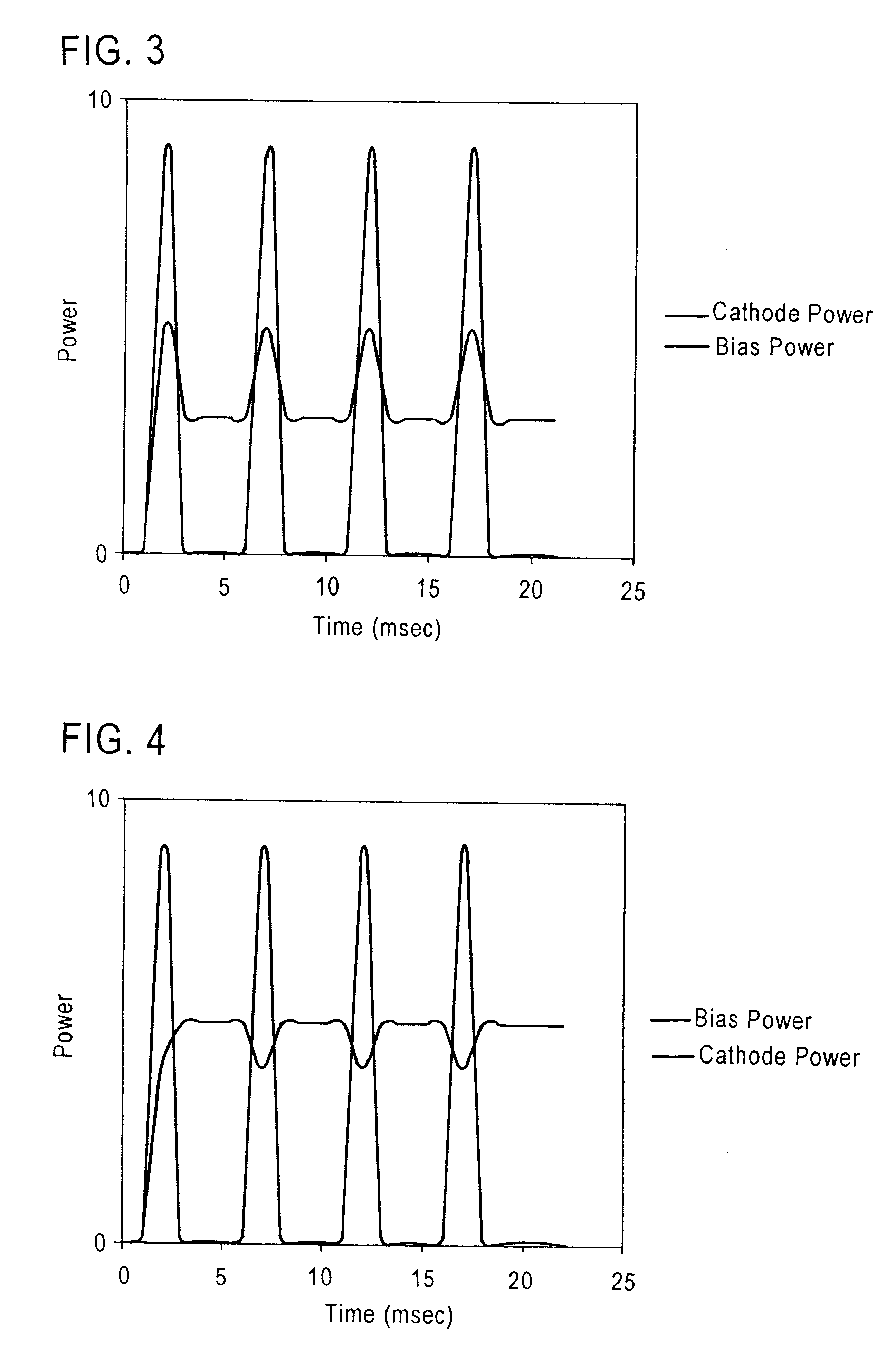

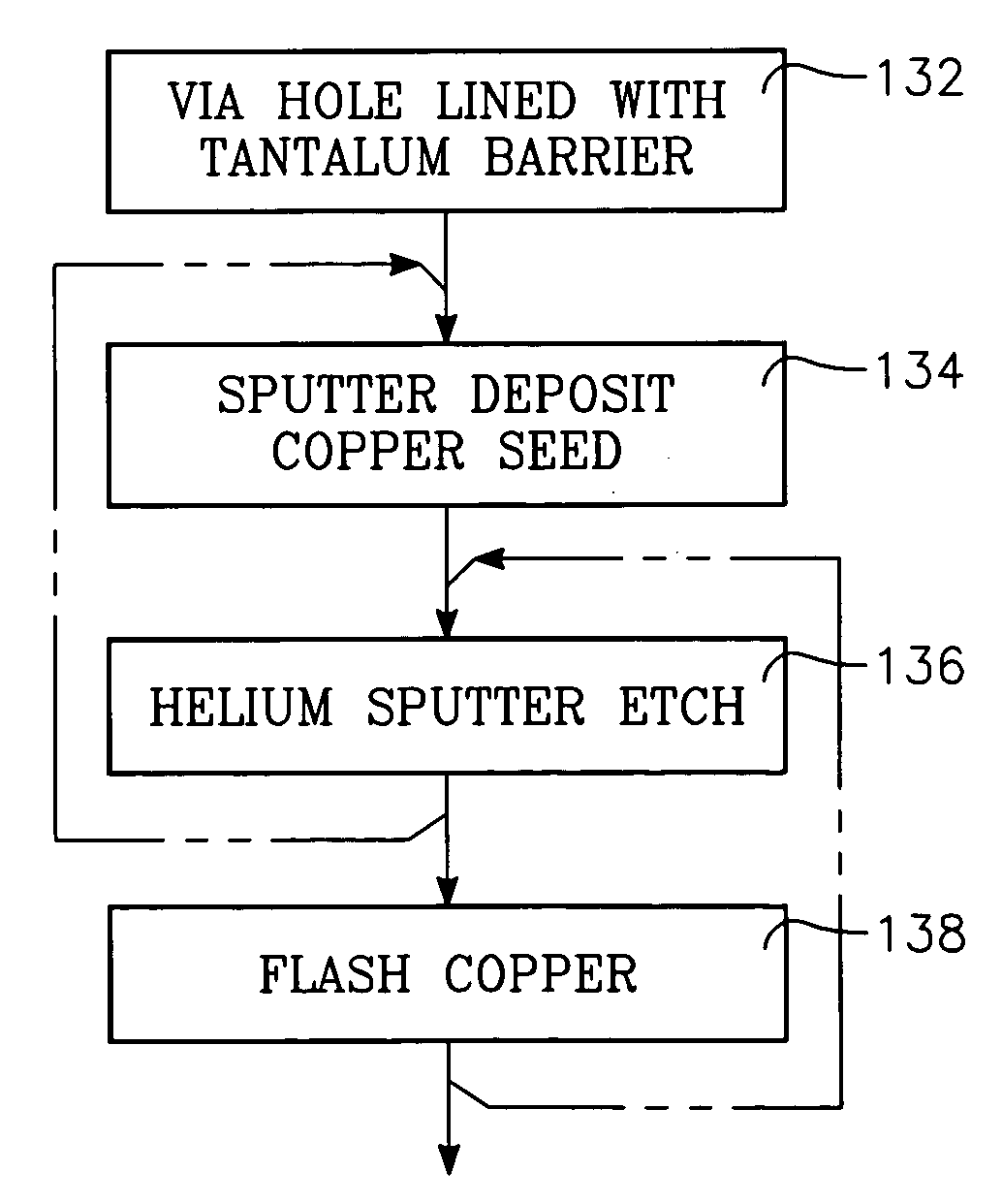

Sputter deposition utilizing pulsed cathode and substrate bias power

InactiveUS6290821B1Simple methodVacuum evaporation coatingSputtering coatingOptoelectronicsSubstrate bias voltage

A method for depositing on a substrate surface a thin film layer comprising a target material comprises providing a cathode including a target having a sputtering surface comprised of the target material, with the target sputtering surface facing the substrate surface with a space therebetween, and sputtering the target material onto the substrate surface by applying a plurality of negative voltage pulses to the cathode while simultaneously applying a bias voltage to the substrate. Embodiments include depositing thin film layers onto static or moving substrates and application of constant or time-varying substrate bias voltage. The invention finds particular utility in the formation of high purity layers in the automated manufacture of magnetic data / information storage and retrieval media.

Owner:SEAGATE TECH LLC

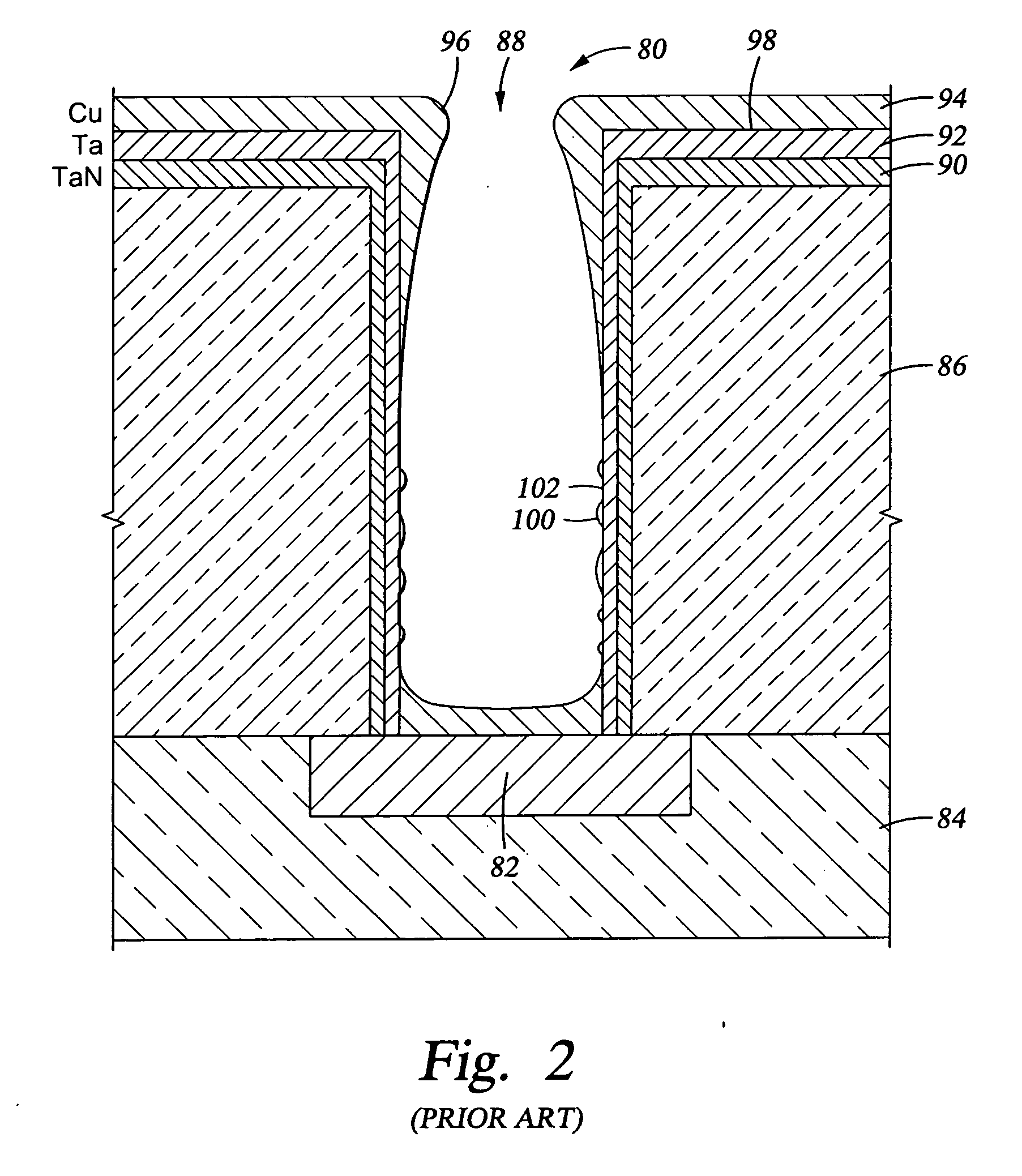

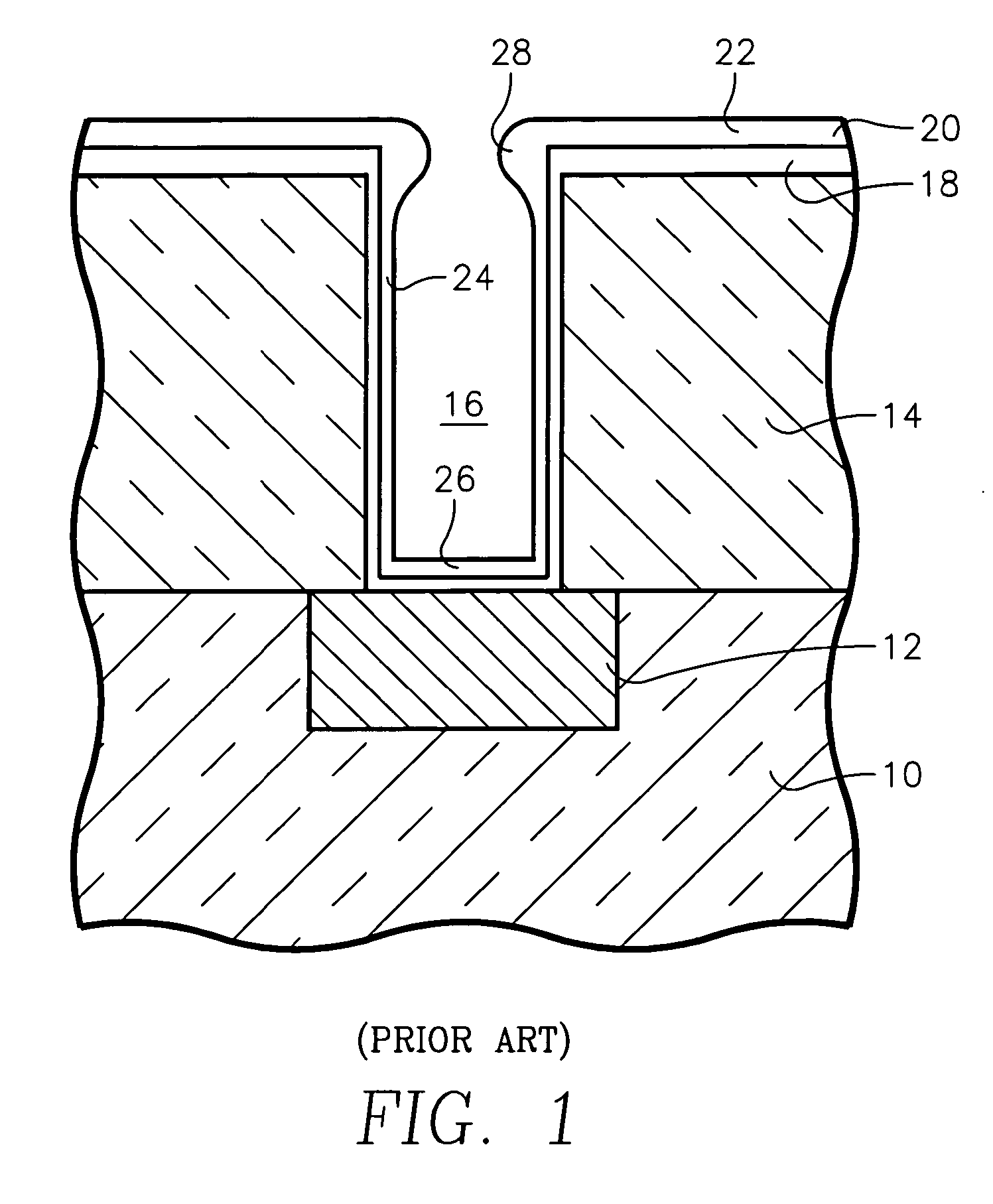

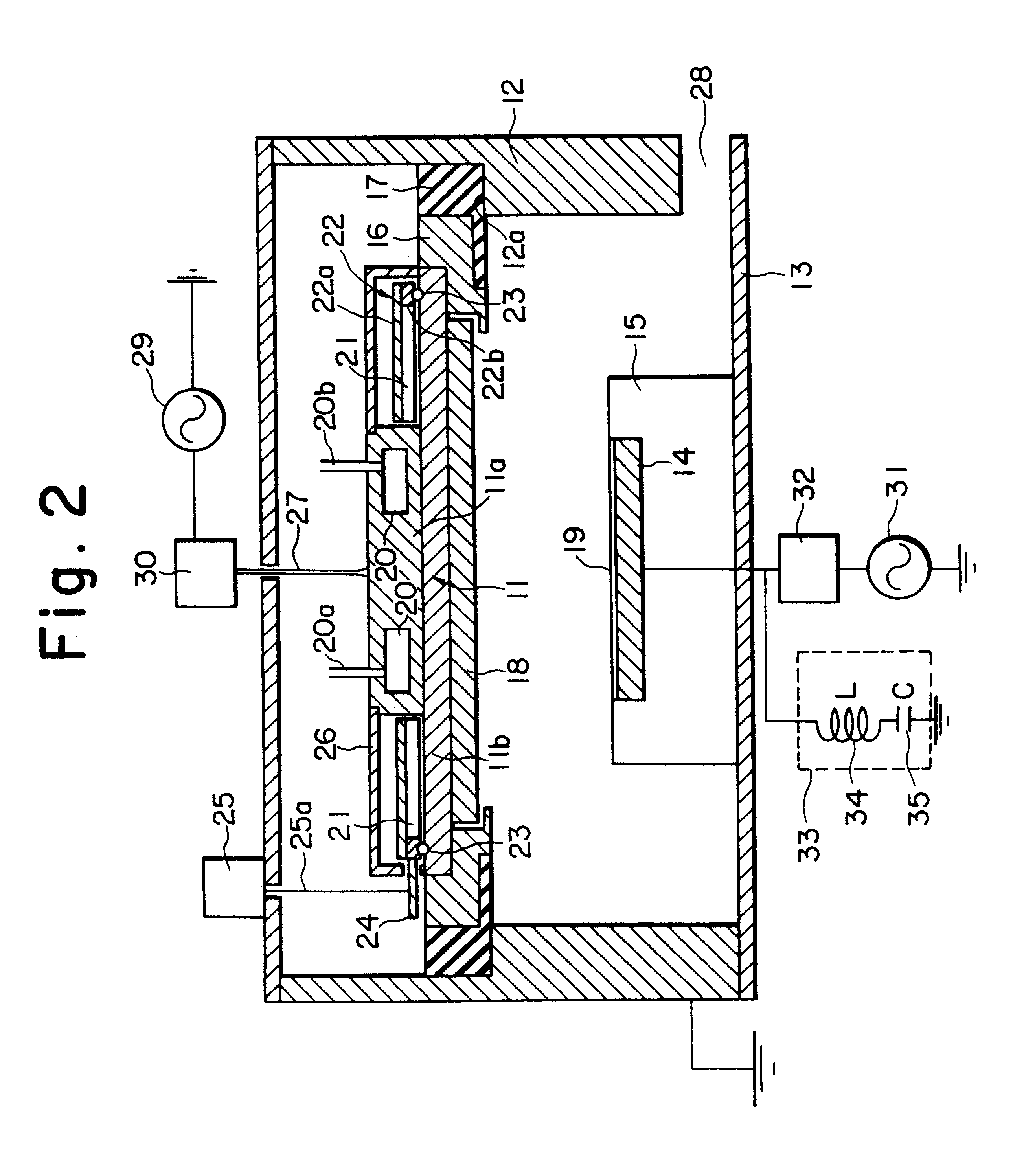

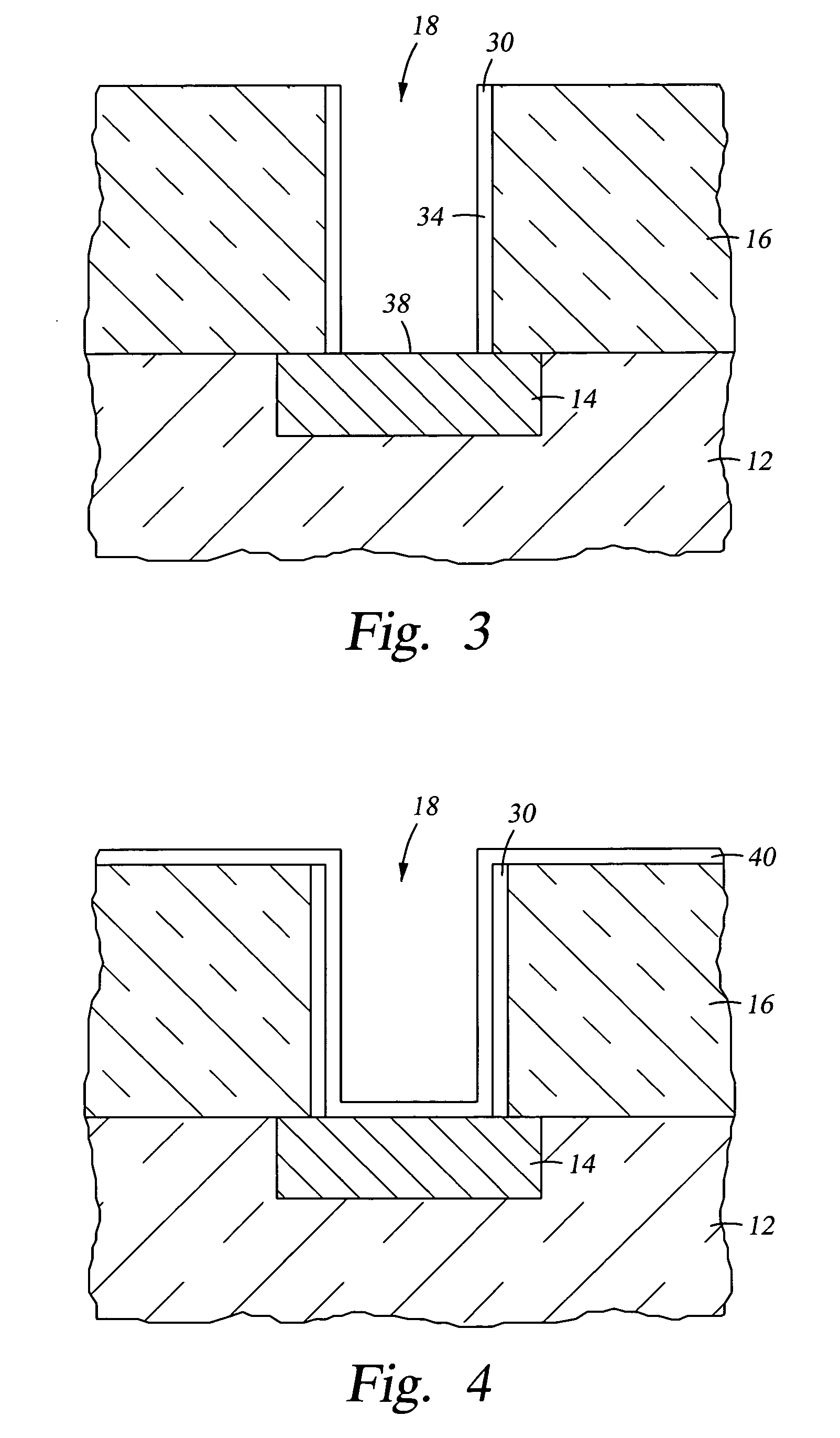

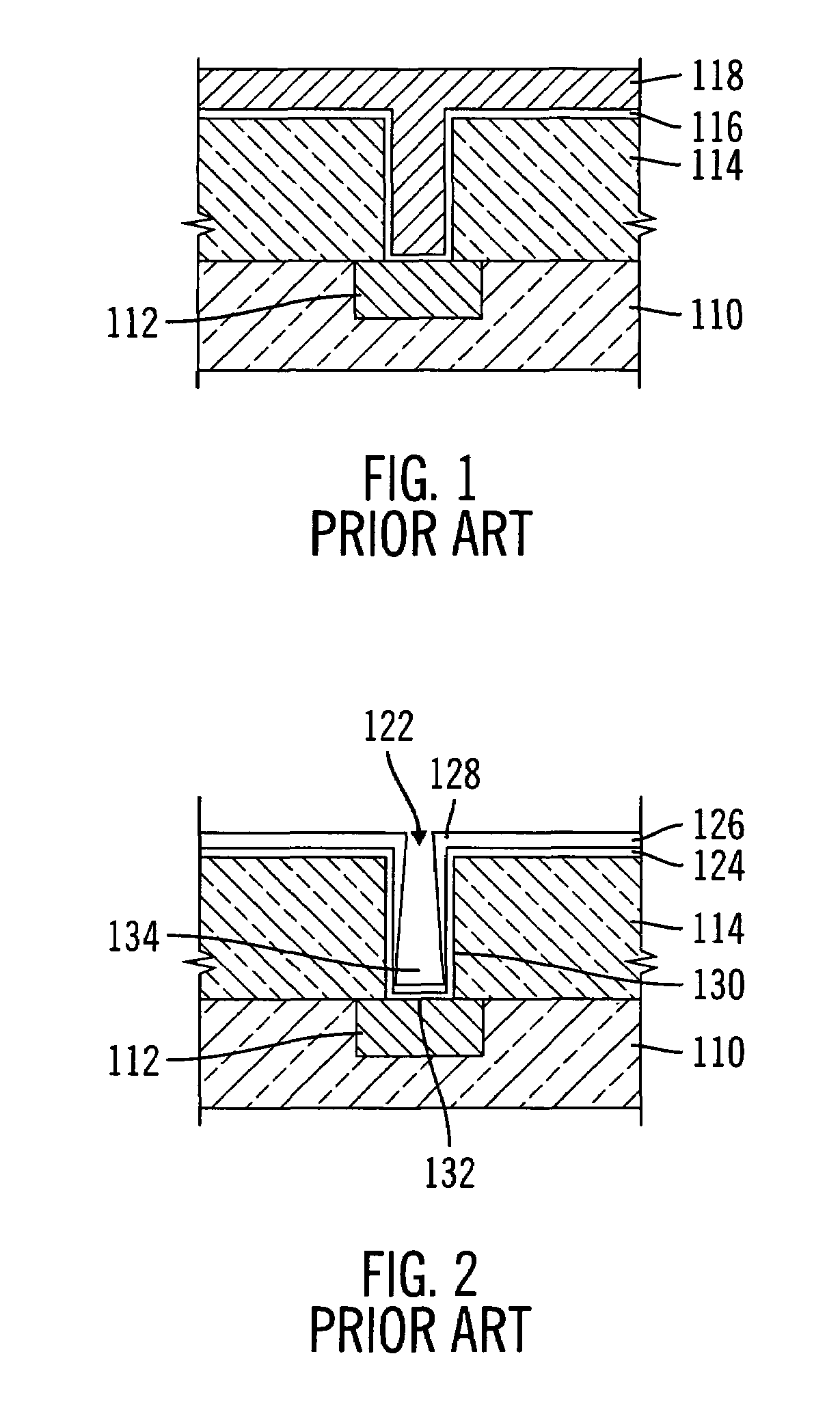

Sputter deposition and etching of metallization seed layer for overhang and sidewall improvement

ActiveUS20060030151A1High selectivitySolid-state devicesSemiconductor/solid-state device manufacturingEtchingElectrochemistry

An integrated sputtering method and reactor for copper or aluminum seed layers in which a plasma sputter reactor initially deposits a thin conformal layer onto a substrate including a high-aspect ratio hole subject to the formation of overhangs. After the seed deposition, the same sputter reactor is used to sputter etch the substrate with energetic light ions, especially helium, having an energy sufficiently low that it selectively etches the metallization to the heavier underlying barrier layer, for example, copper over tantalum or aluminum over titanium. An RF inductive coil generates the plasma during the sputtering etching while the target power is turned off. A final copper flash step deposits copper over the bare barrier field region before copper is electrochemically plated to fill the hole. The invention also includes a simultaneous sputter deposition and sputter etch, and an energetic ion processing of the copper seed sidewall.

Owner:APPLIED MATERIALS INC

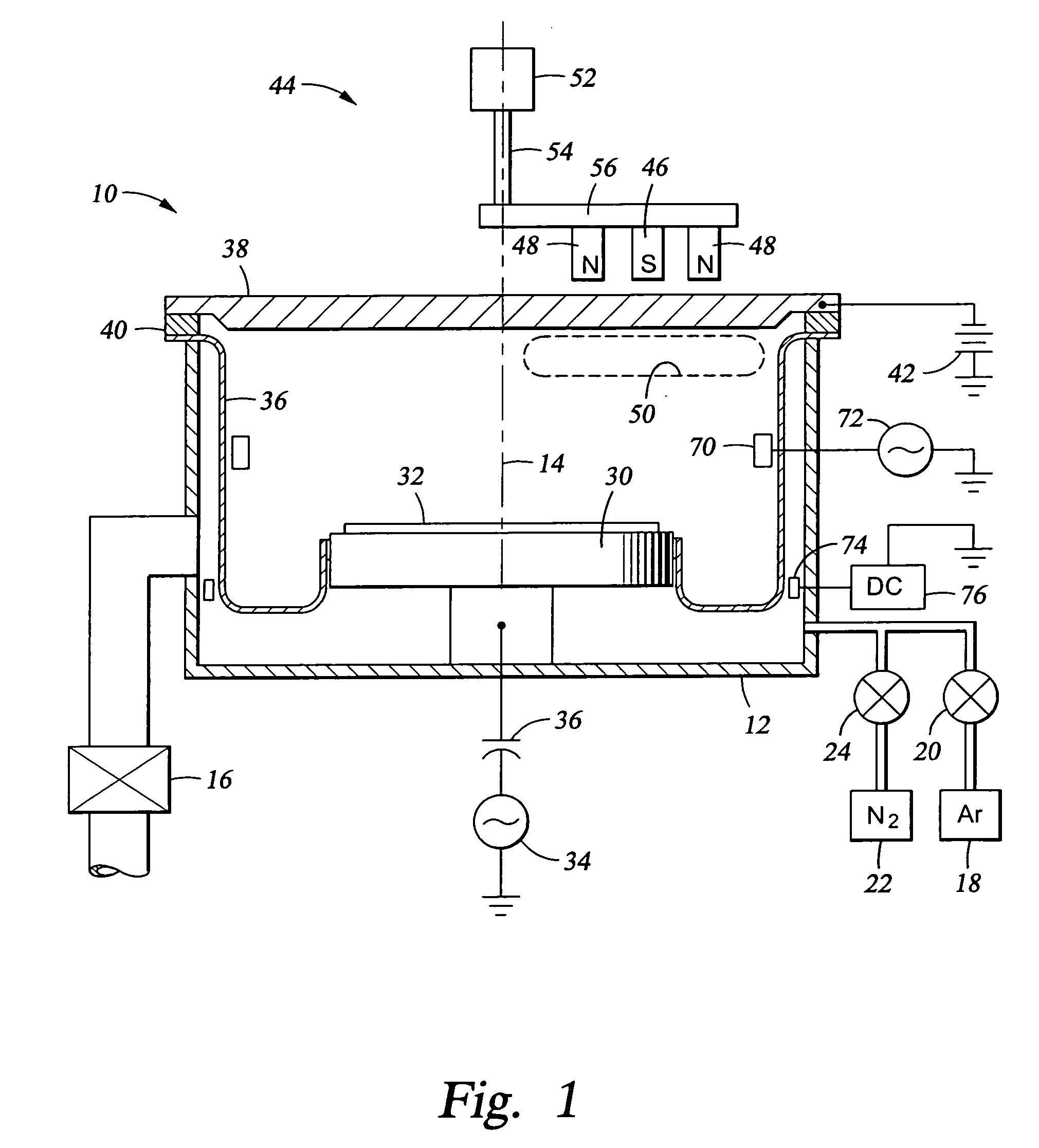

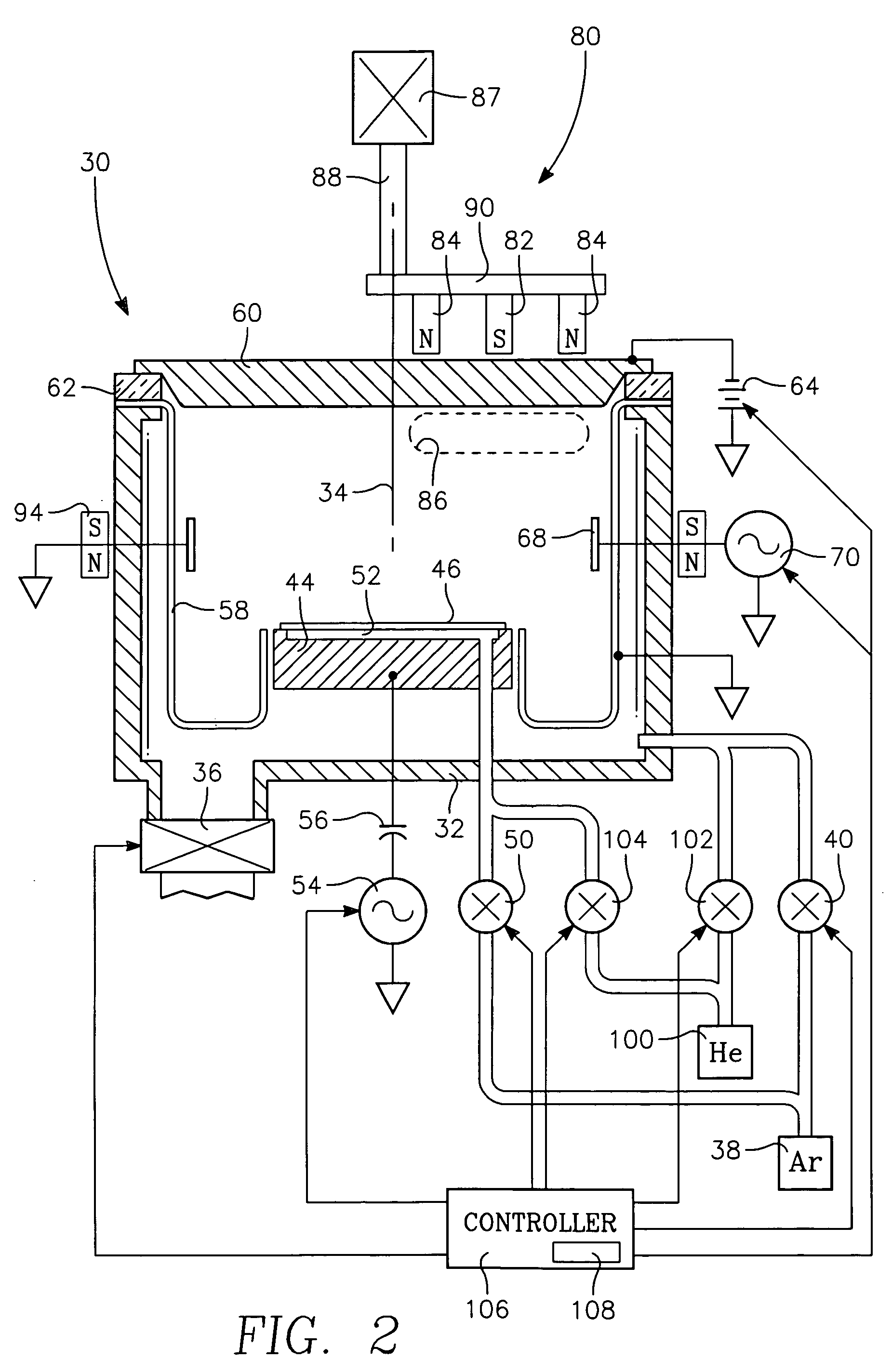

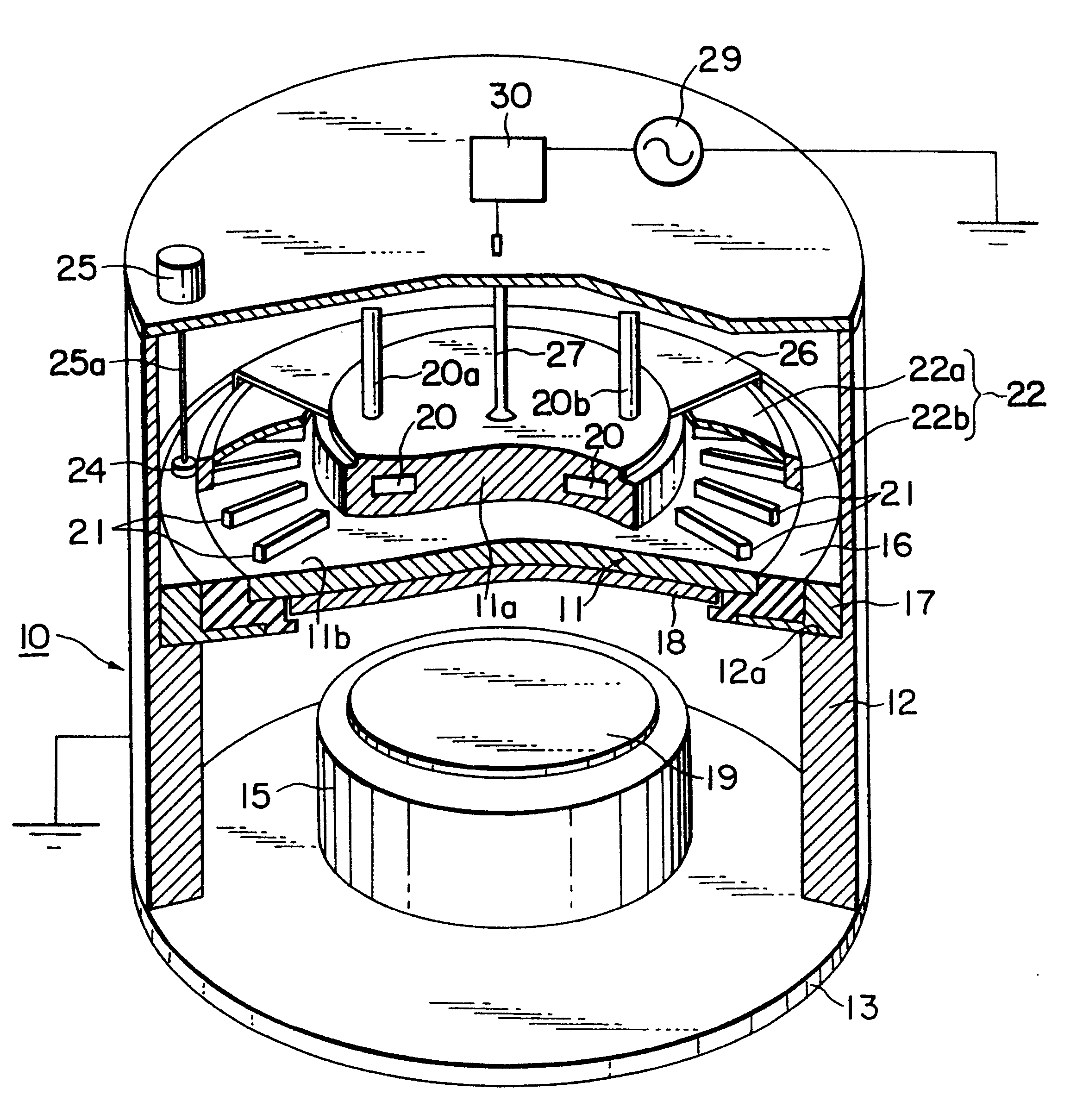

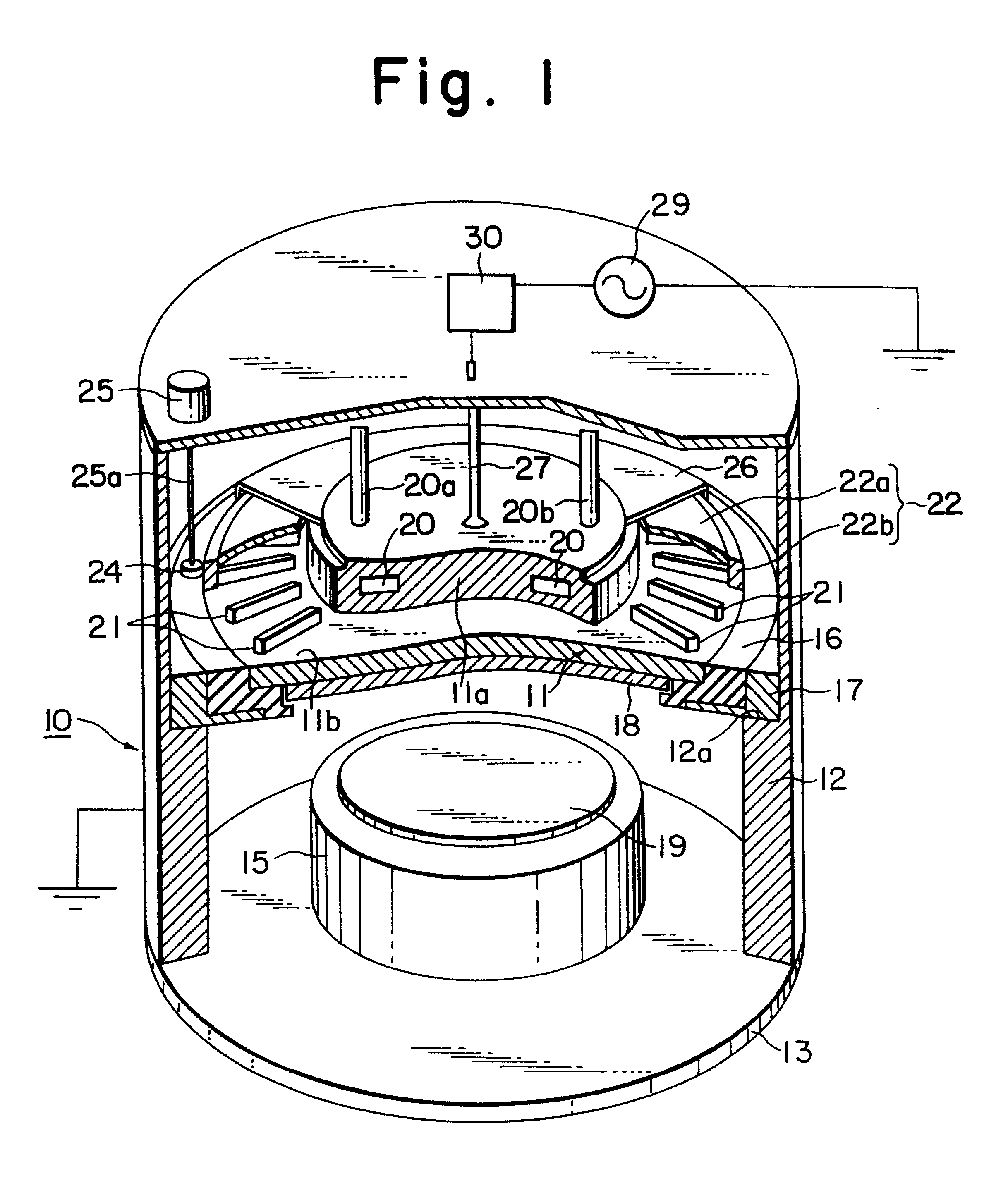

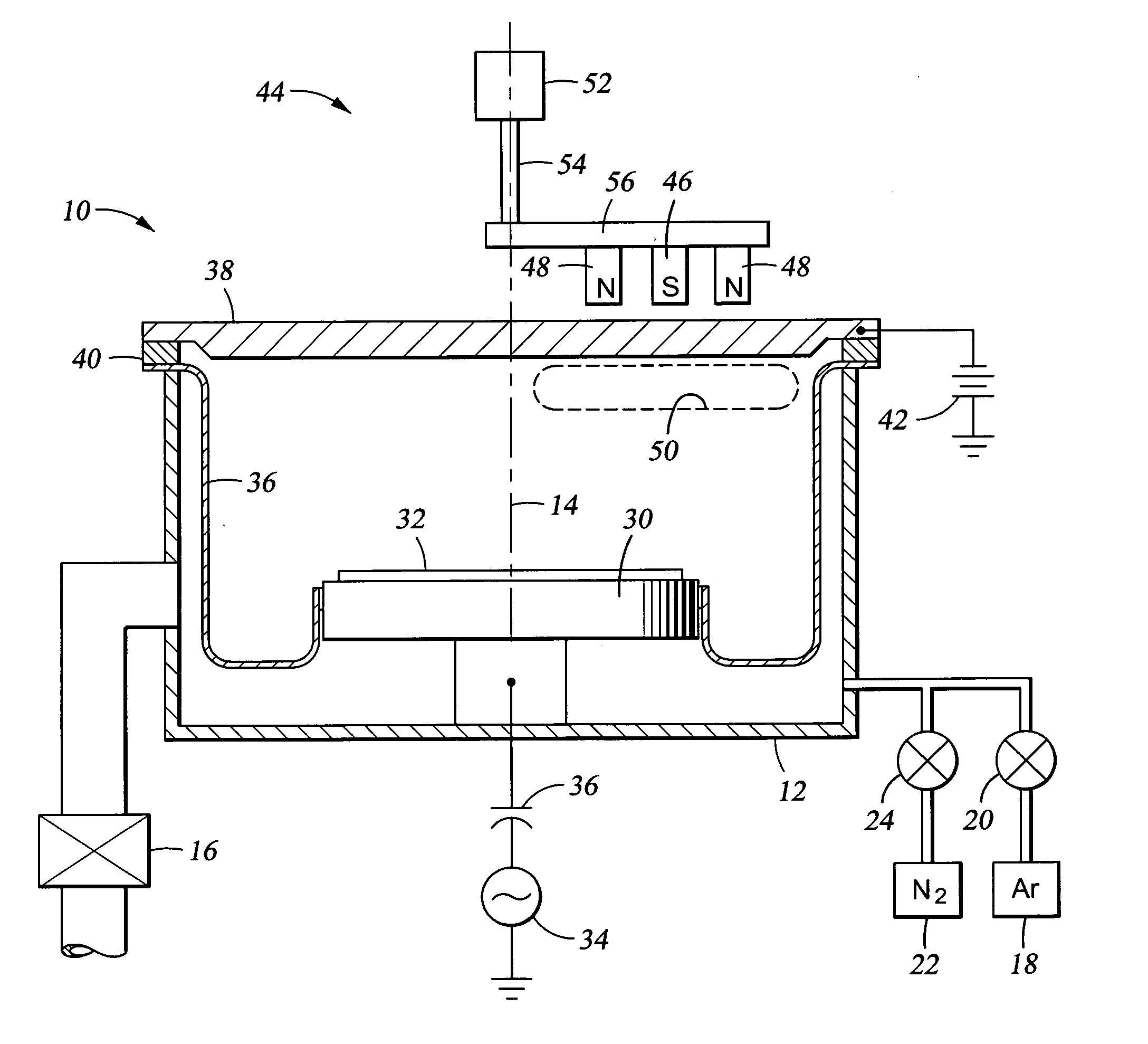

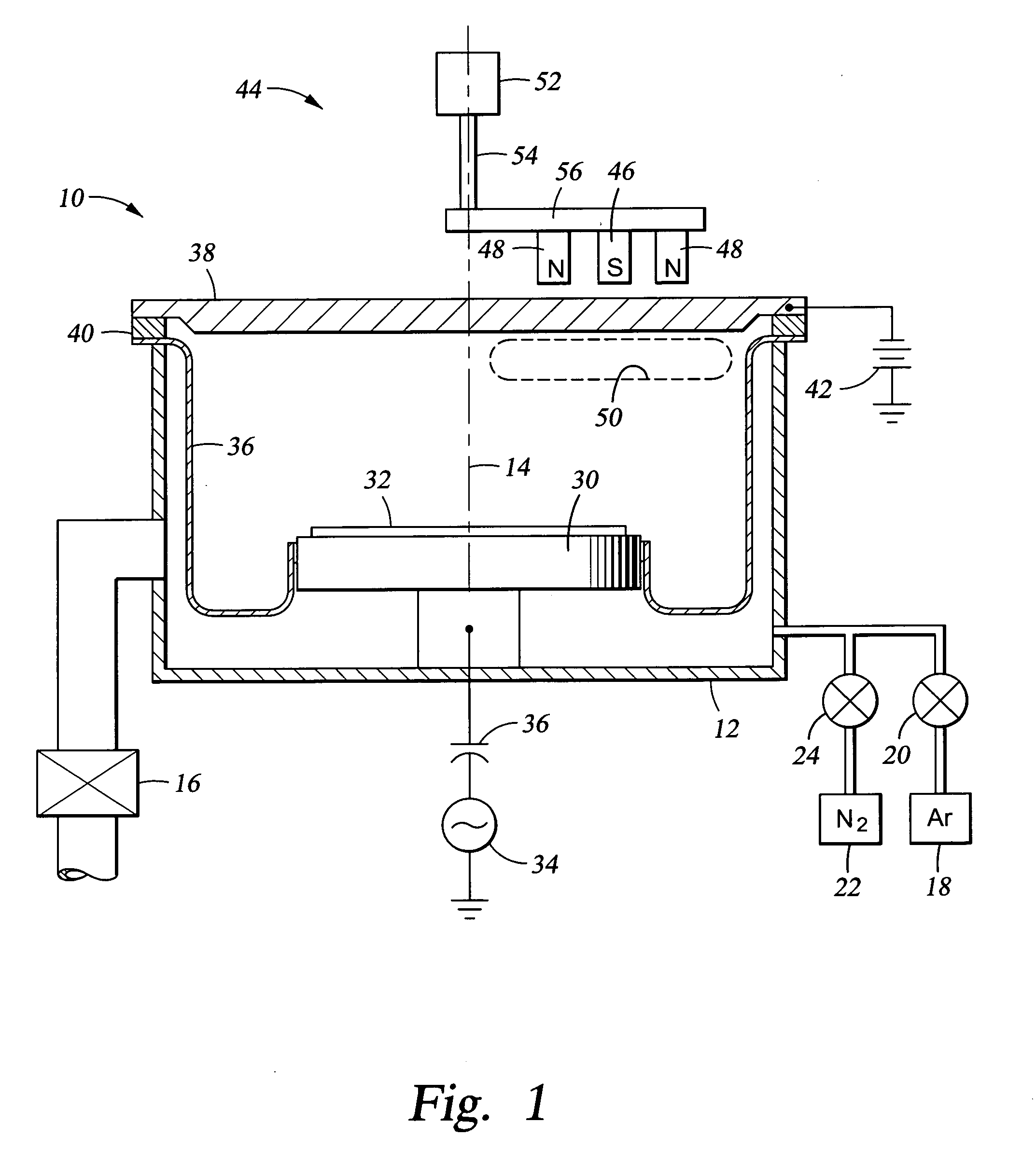

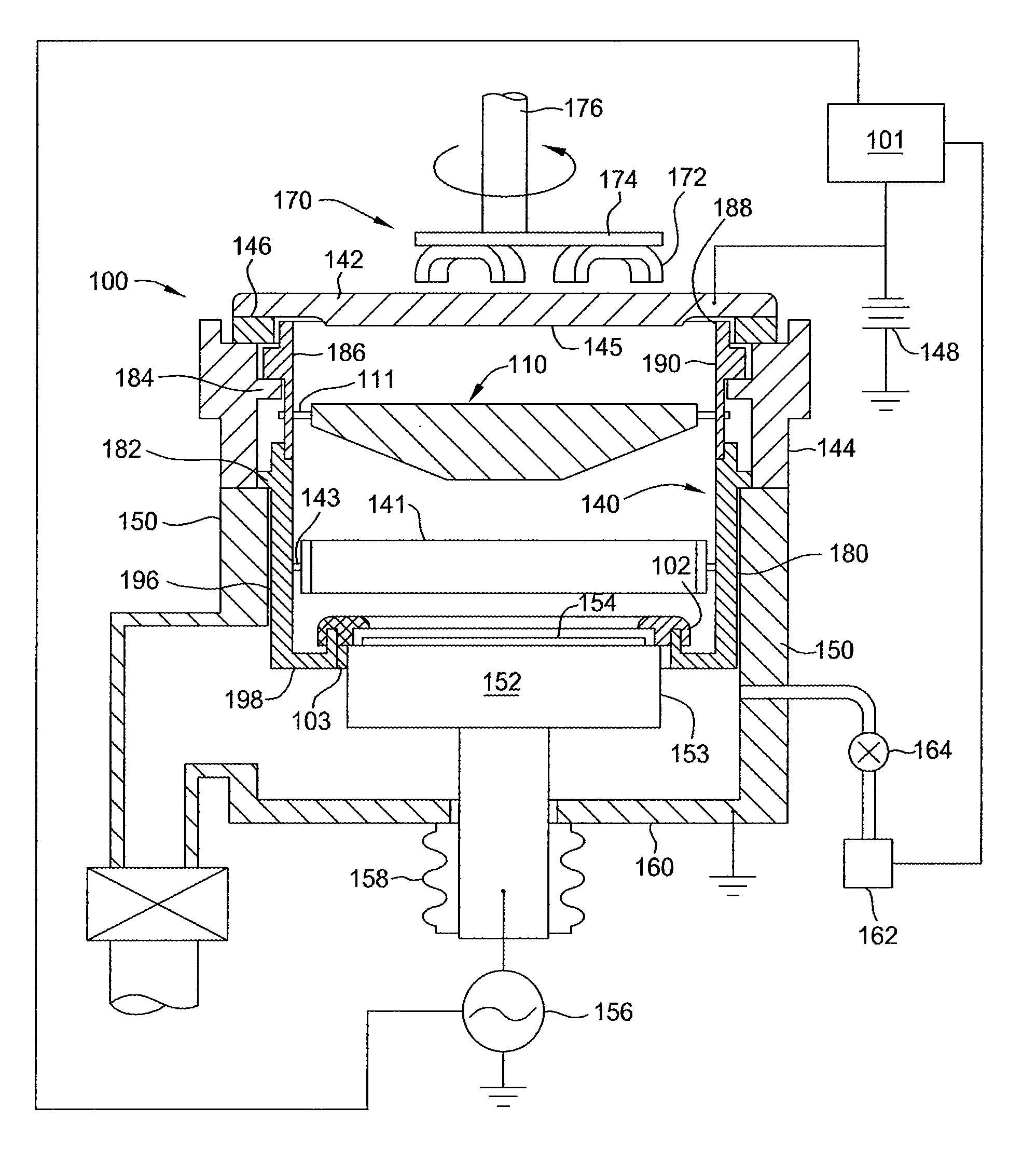

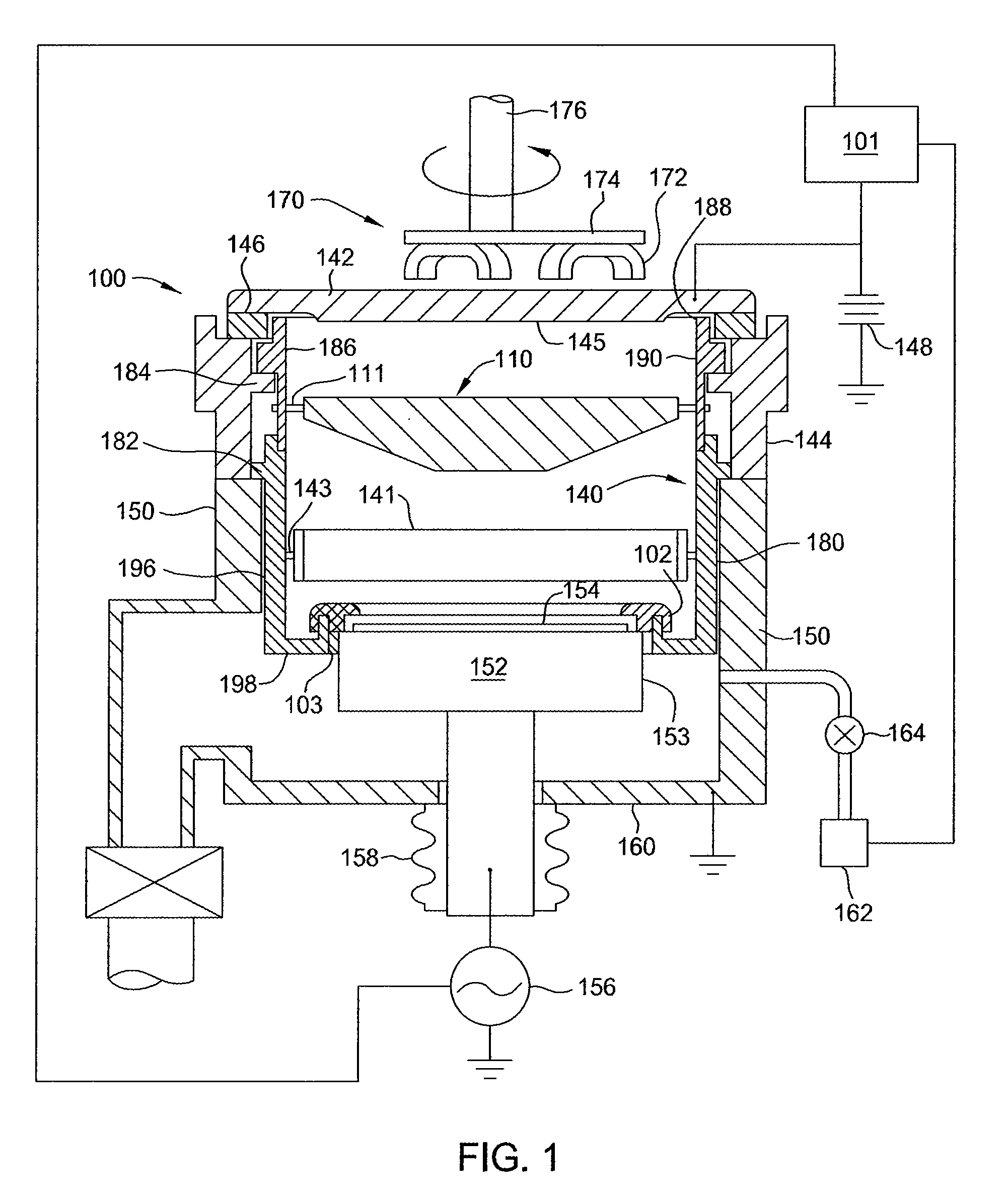

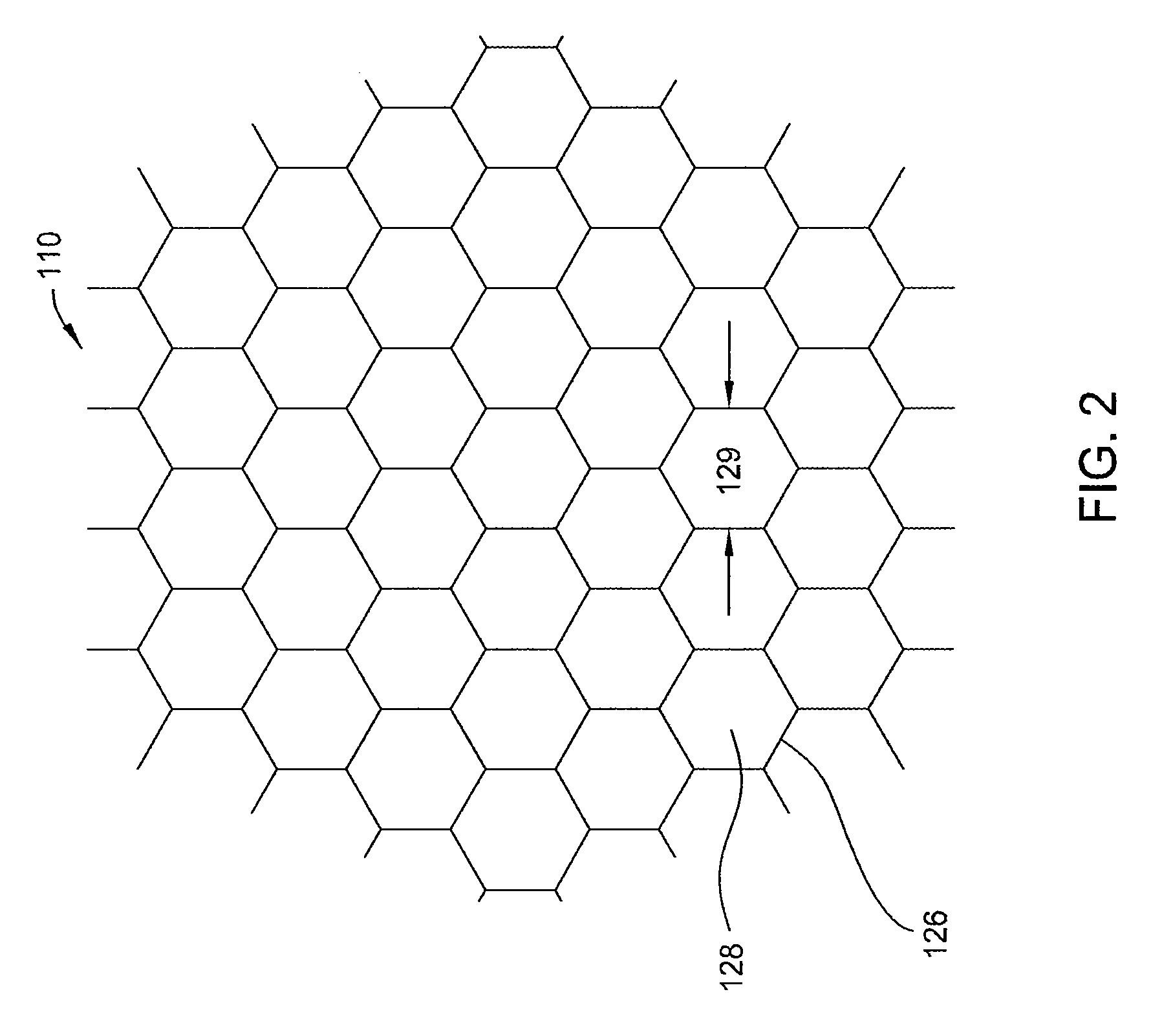

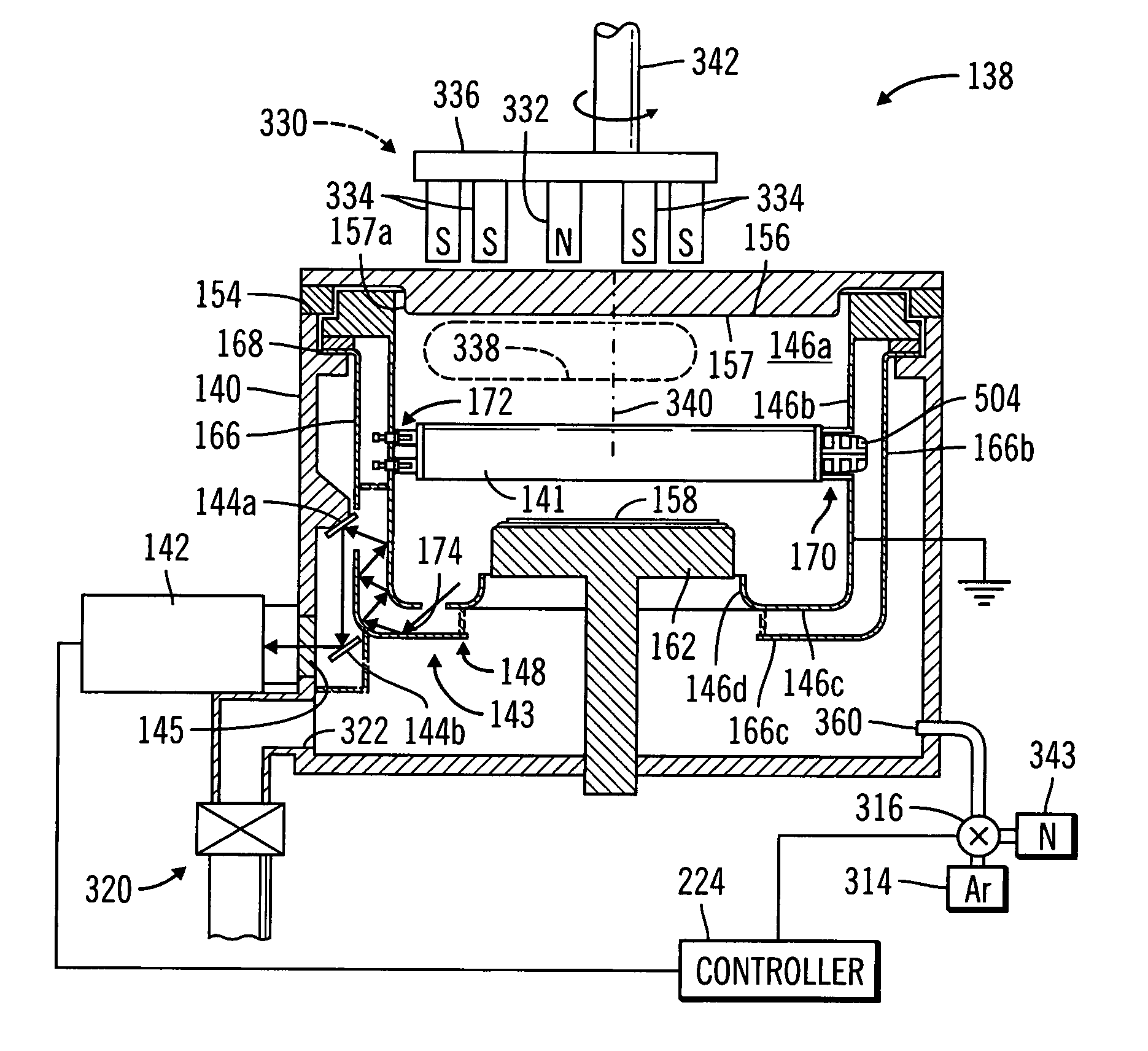

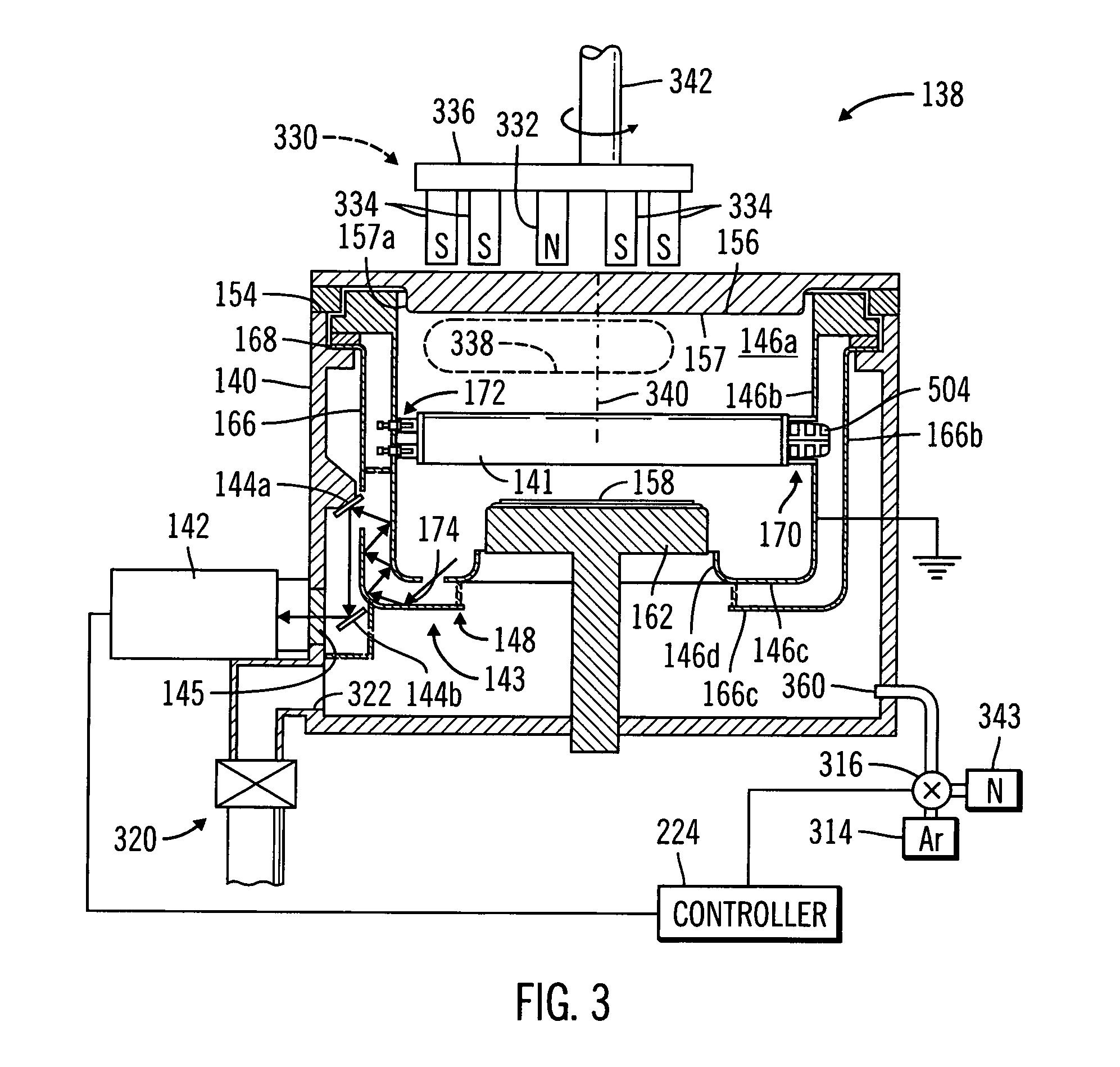

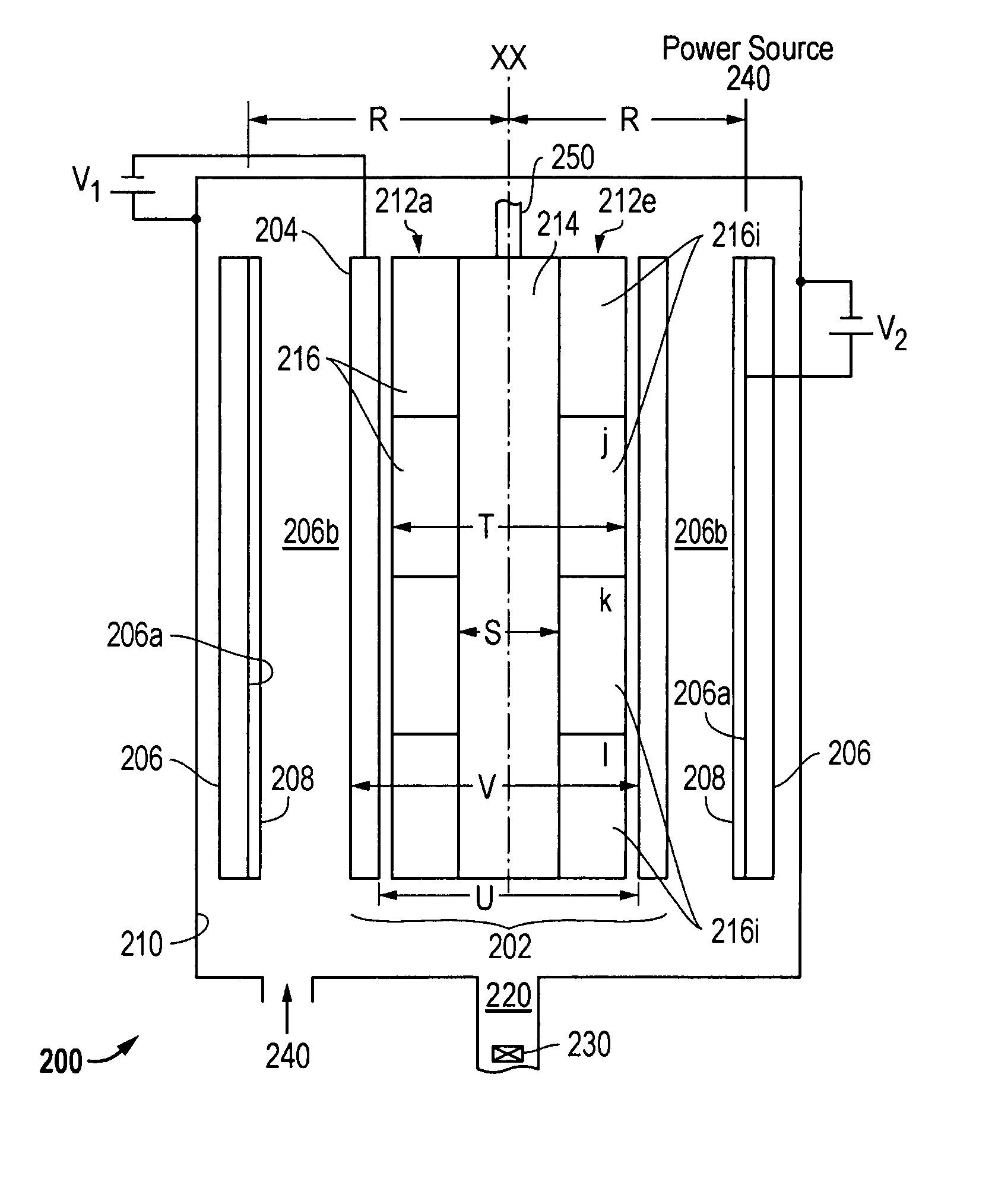

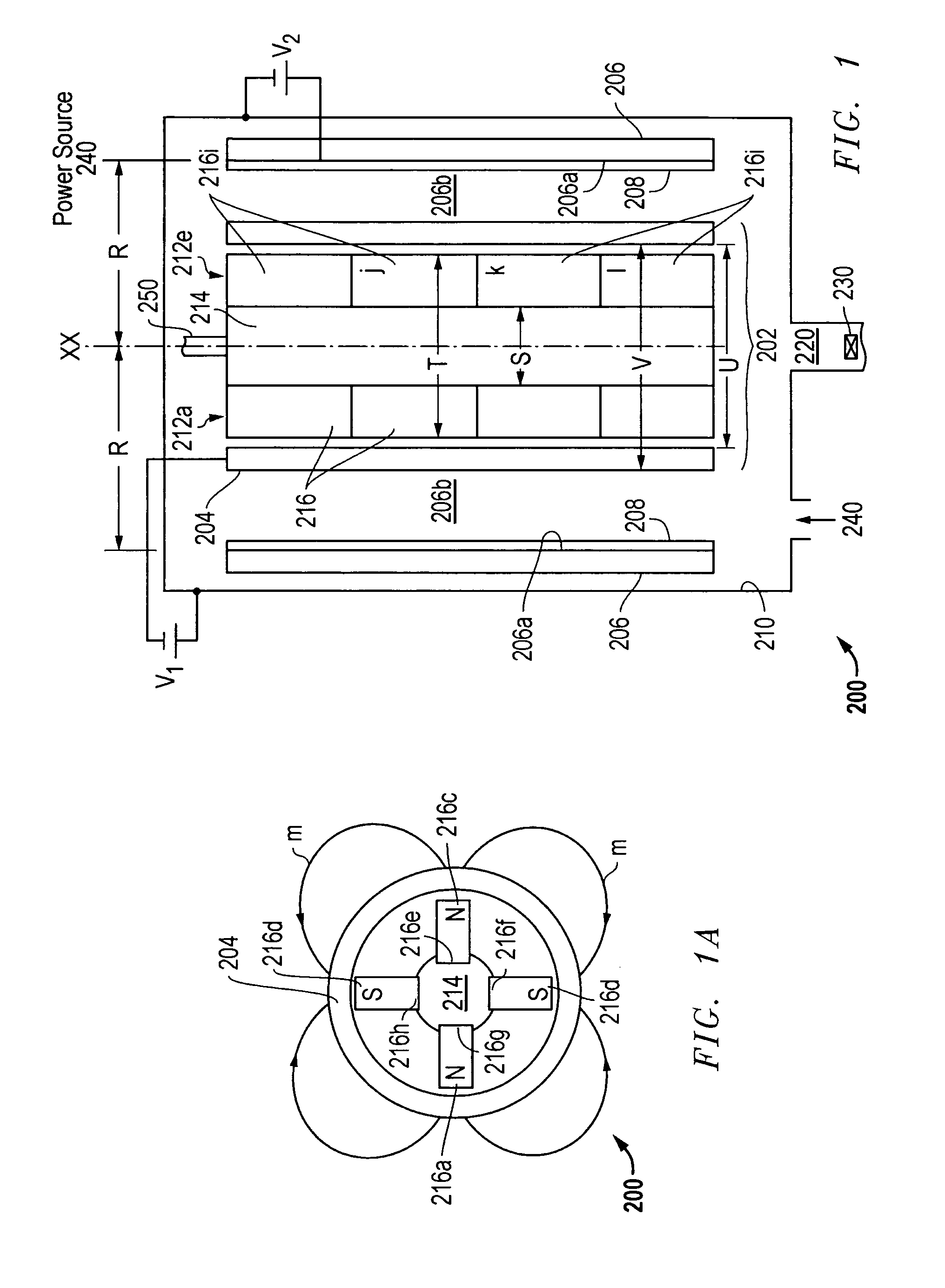

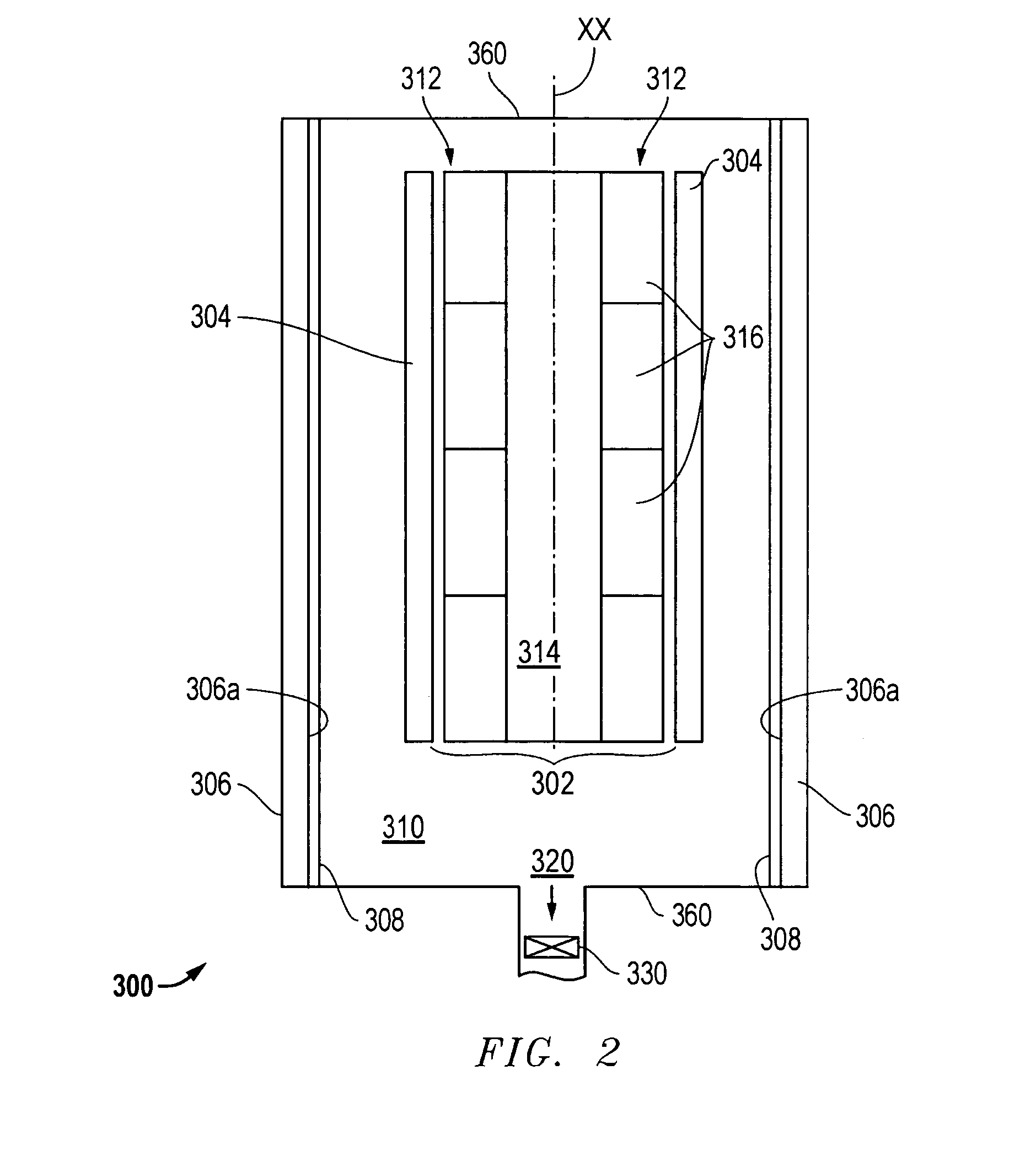

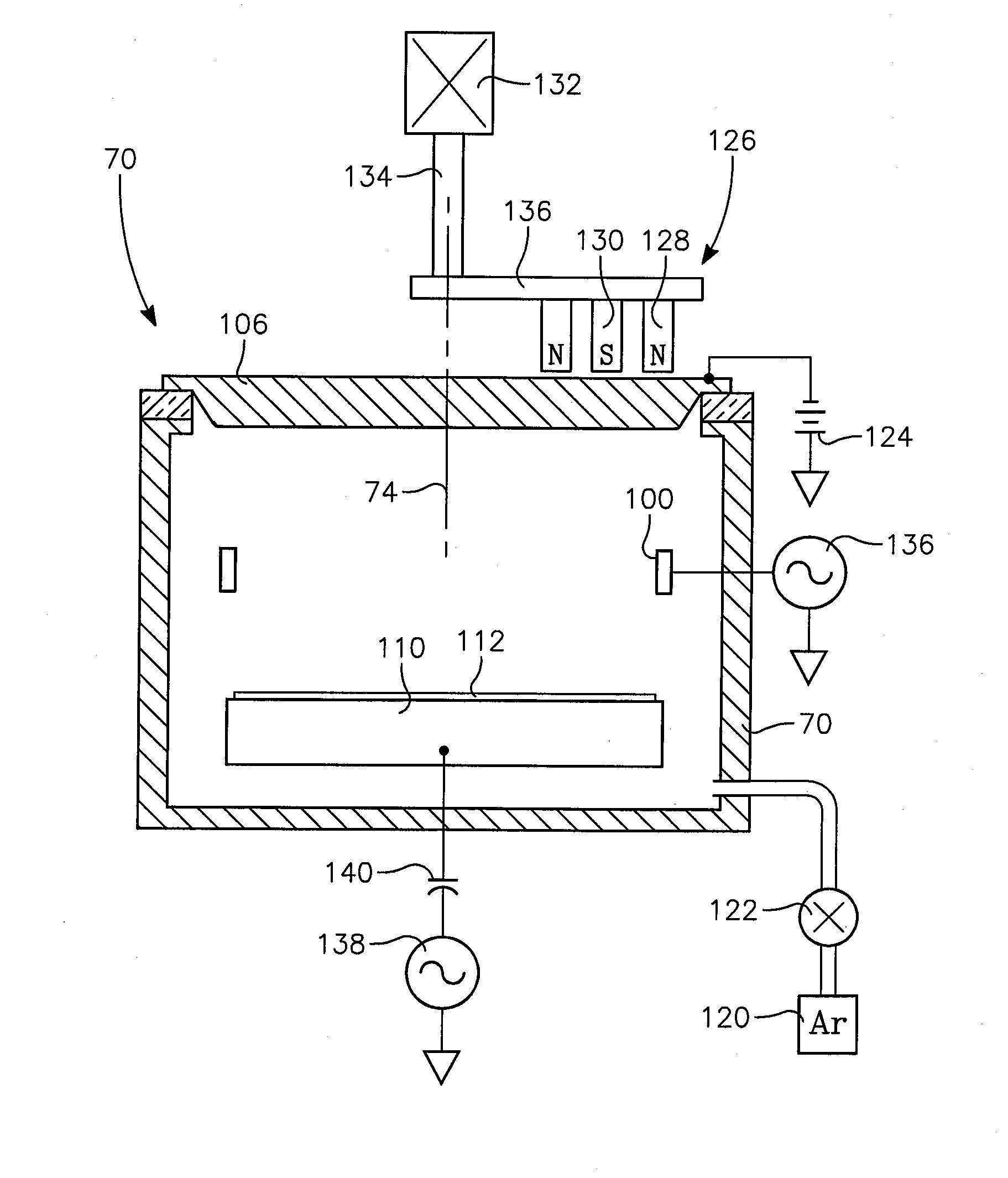

Plasma processing system for sputter deposition applications

A plasma processing system for sputter deposition application is configured by a reactor including two parallel capacitively-coupled electrodes called upper and lower electrodes, and a multi-pole magnet arrangement over the outer region of the upper electrode. The magnets are assembled on a metal ring in order to rotate over the upper electrode. The target plate is fixed to the upper electrode which is given only a high-frequency rf current, or high-frequency rf current and a DC voltage together. The lower electrode where the substrate is placed, is given a MF, HF or VHF rf current in order to generate a negative self bias voltage on the lower electrode to extract ionized sputtered-atoms that fill contact-holes on the substrate surface.

Owner:ANELVA CORP

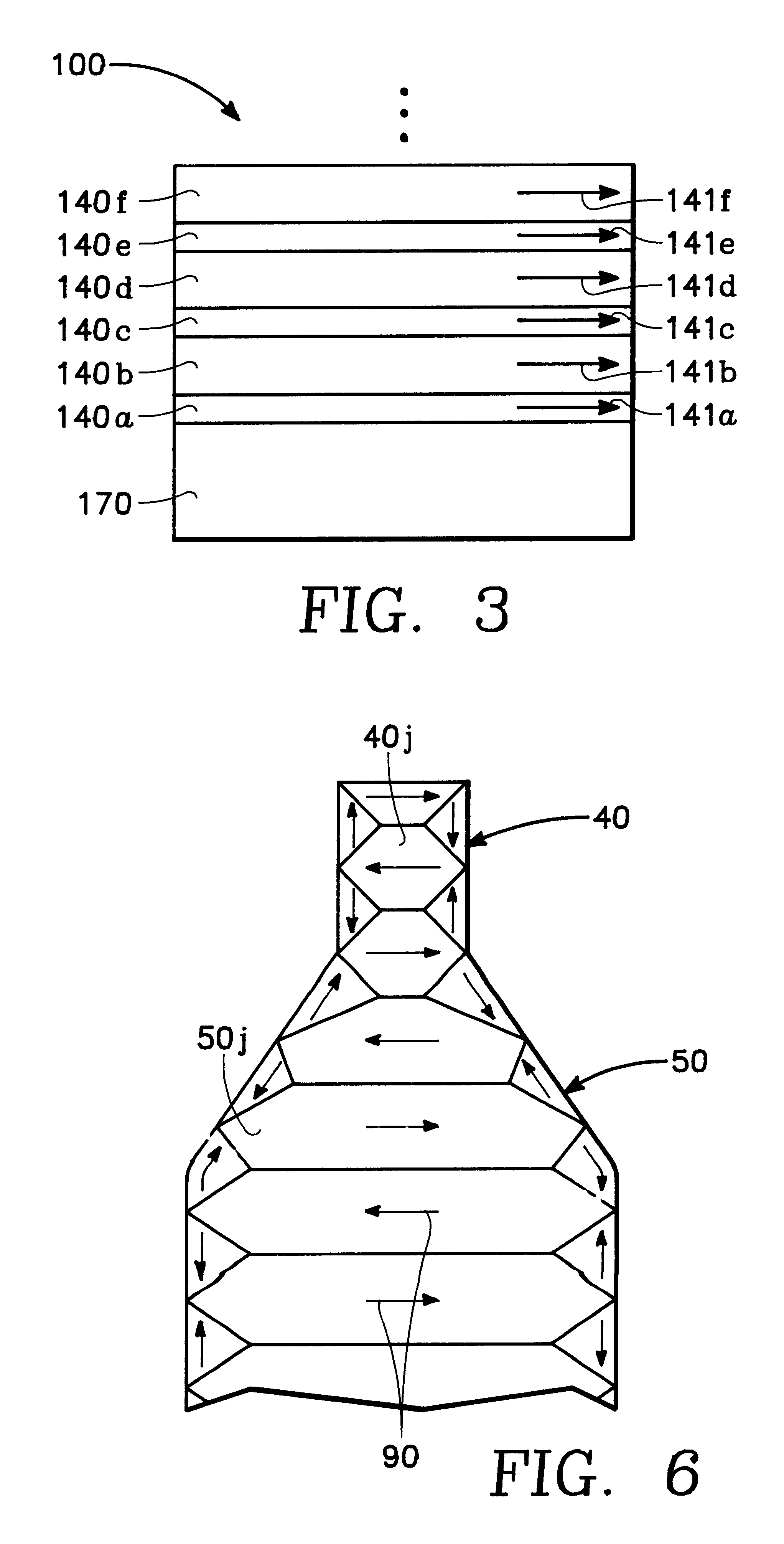

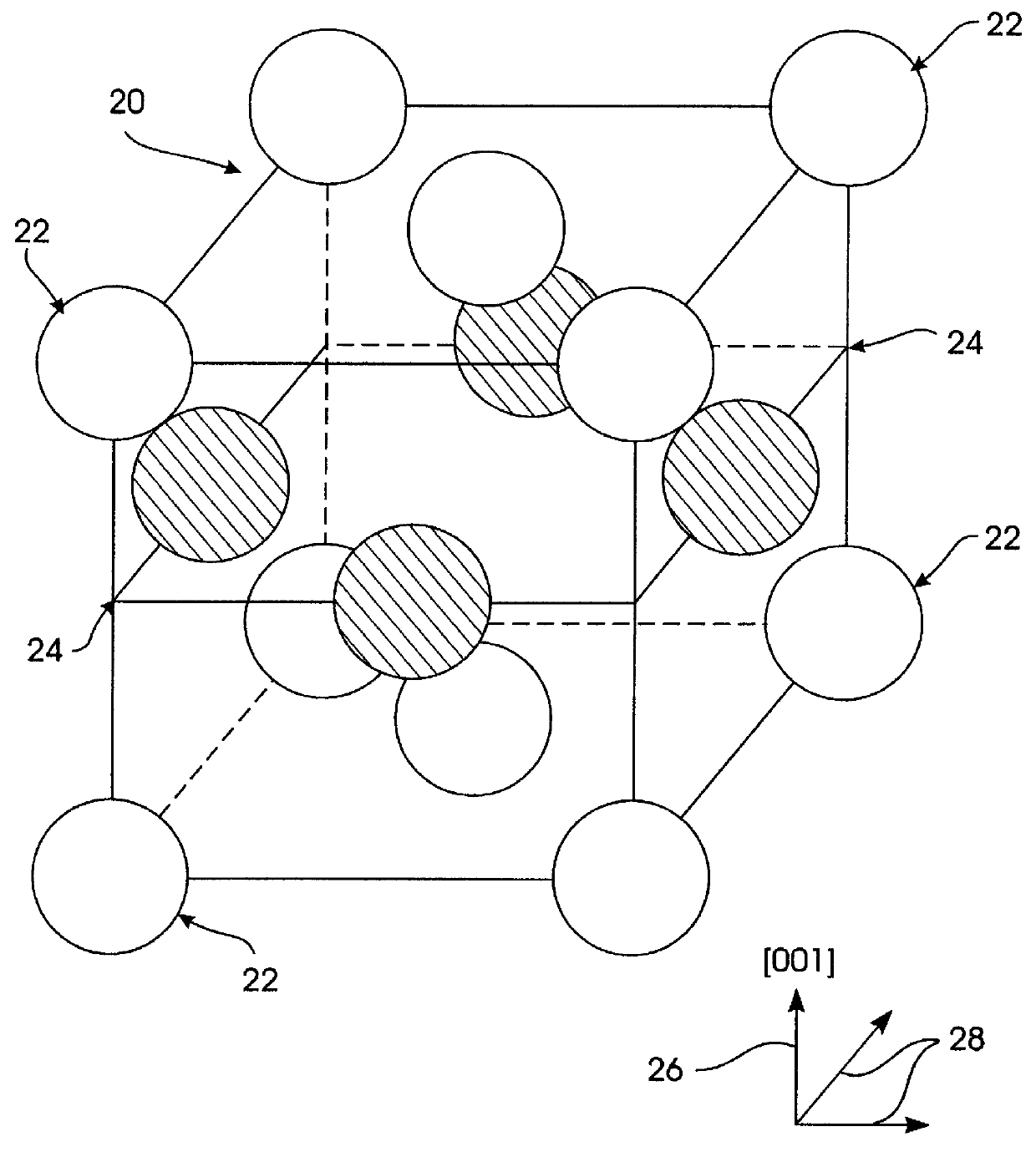

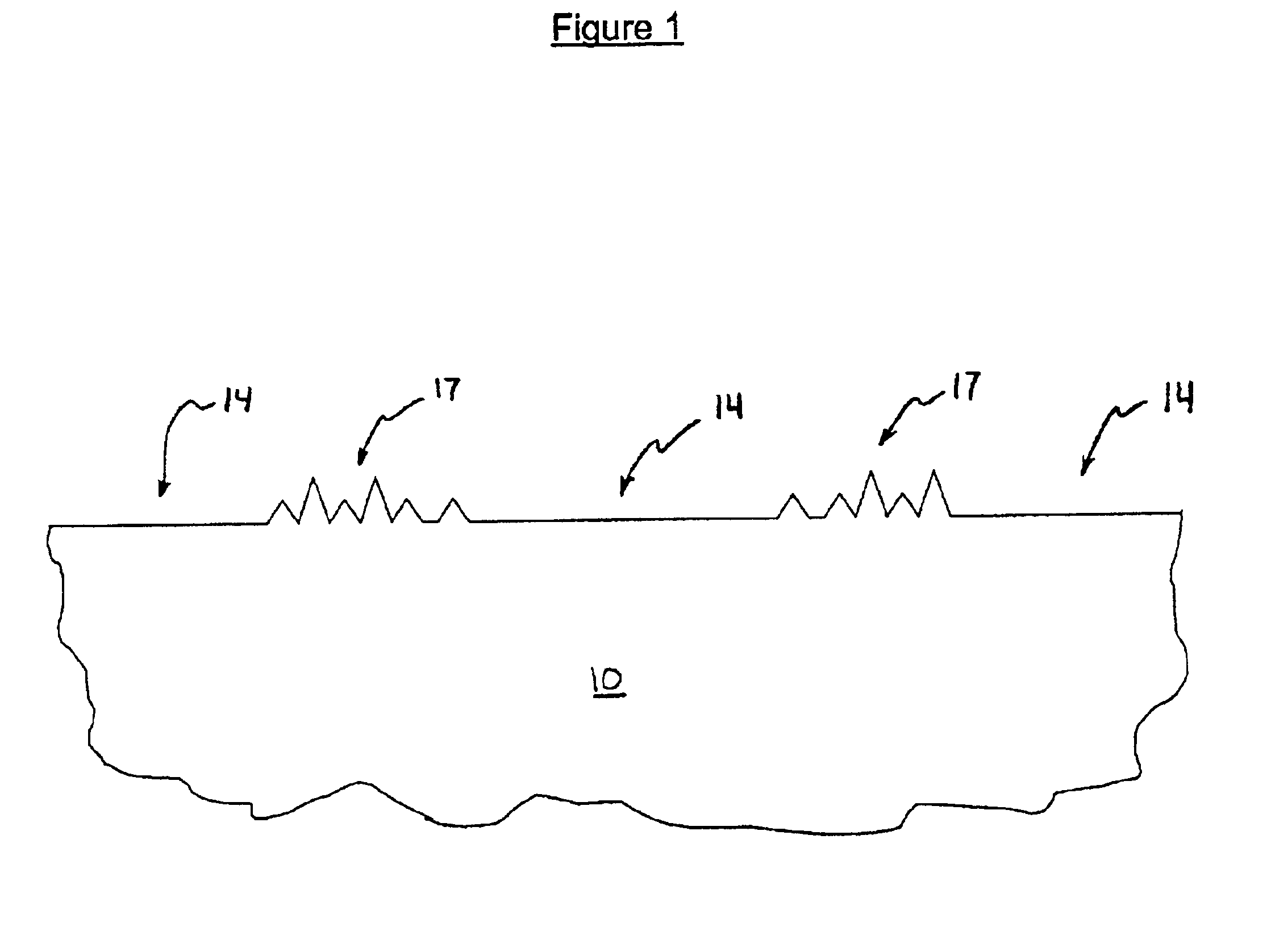

Horizontal magnetic recording media having grains of chemically-ordered FEPT of COPT

InactiveUS6086974ABase layers for recording layersRecord information storageAlloyMagnetocrystalline anisotropy

A horizontal magnetic recording medium that has as its magnetic film a granular film with grains of a chemically-ordered FePt or FePtX (or CoPt or CoPtX) alloy in the tetragonal L10 structure uses an etched seed layer beneath the granular film. The granular magnetic film reveals a very high magnetocrystalline anisotropy within the individual grains. The film is produced by sputtering from a single alloy target or cosputtering from several targets. The granular structure and the chemical ordering are controlled by means of sputter parameters, e.g., temperature and deposition rate, and by the use of the etched seed layer that provides a structure for the subsequently sputter-deposited granular magnetic film. The structure of the seed layer is obtained by sputter etching, plasma etching, ion irradiation, or laser irradiation. The magnetic properties, i.e., Hc and areal moment density Mrt, are controlled by the granularity (grain size and grain distribution), the degree of chemical ordering, and the addition of one or more nonmagnetic materials, such as Cr, Ag, Cu, Ta, or B. The resulting granular magnetic film has magnetic properties suitable for application in high-density, horizontal magnetic recording media.

Owner:HITACHI GLOBAL STORAGE TECH NETHERLANDS BV

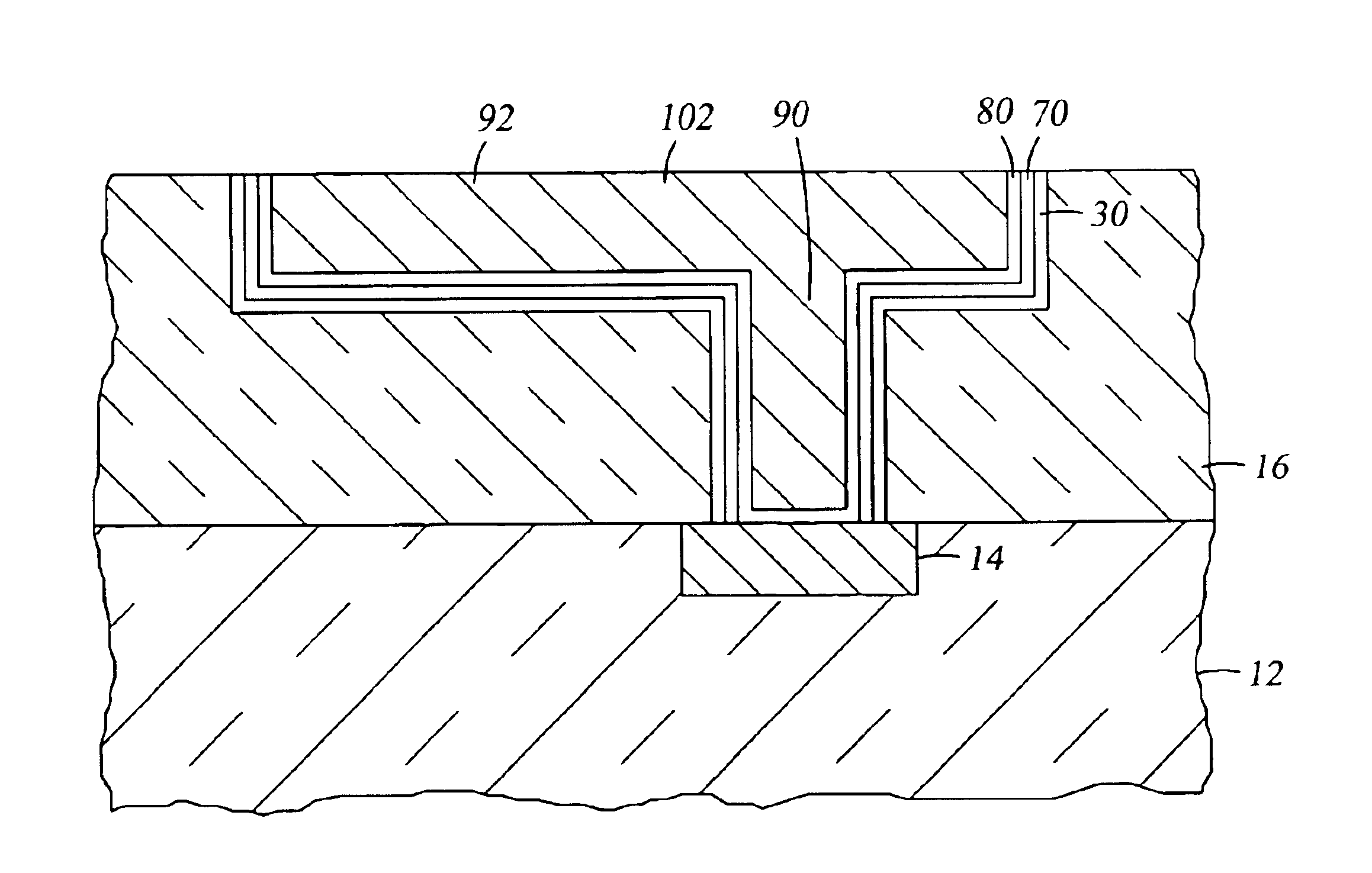

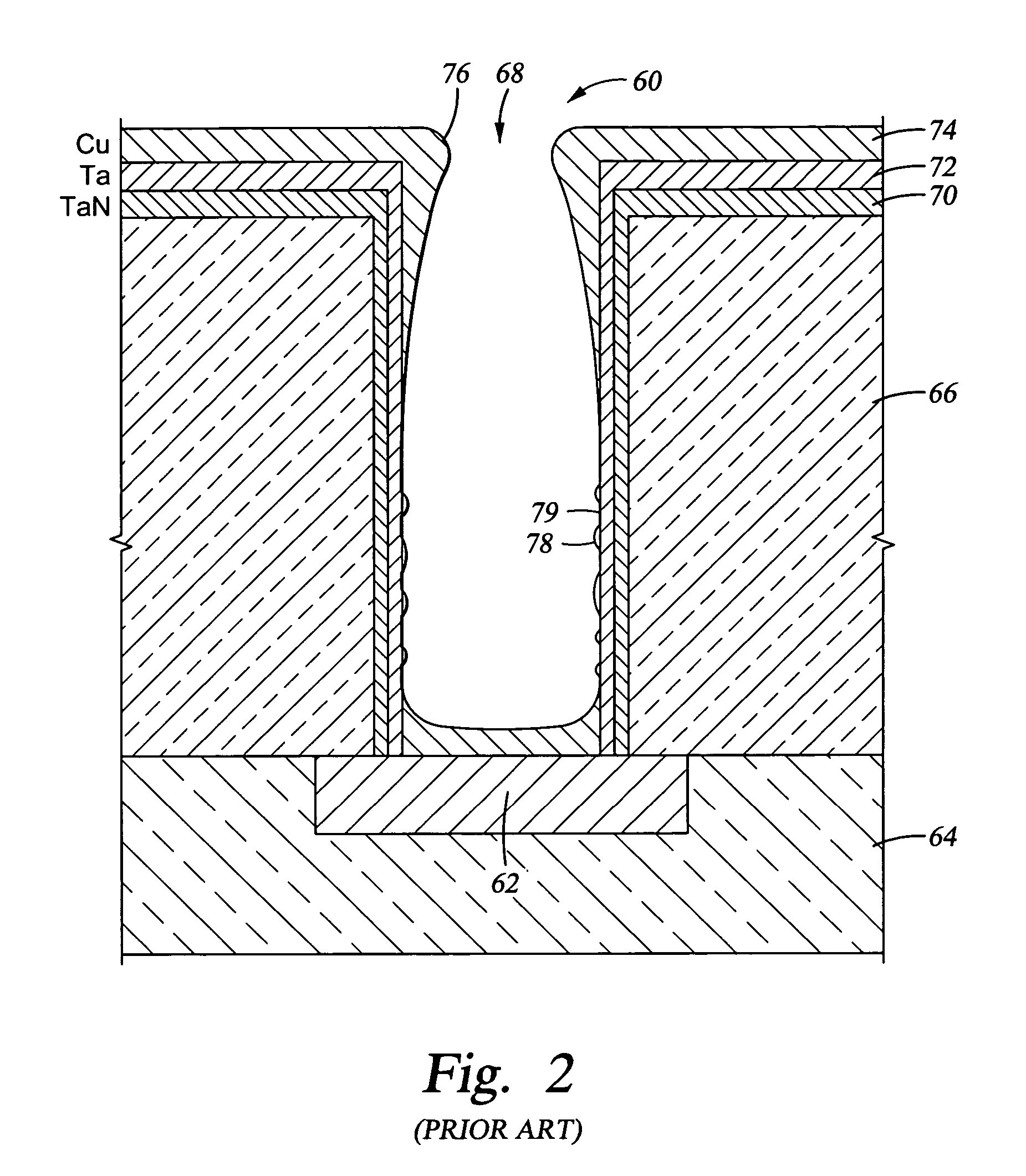

Tantalum barrier layer for copper metallization

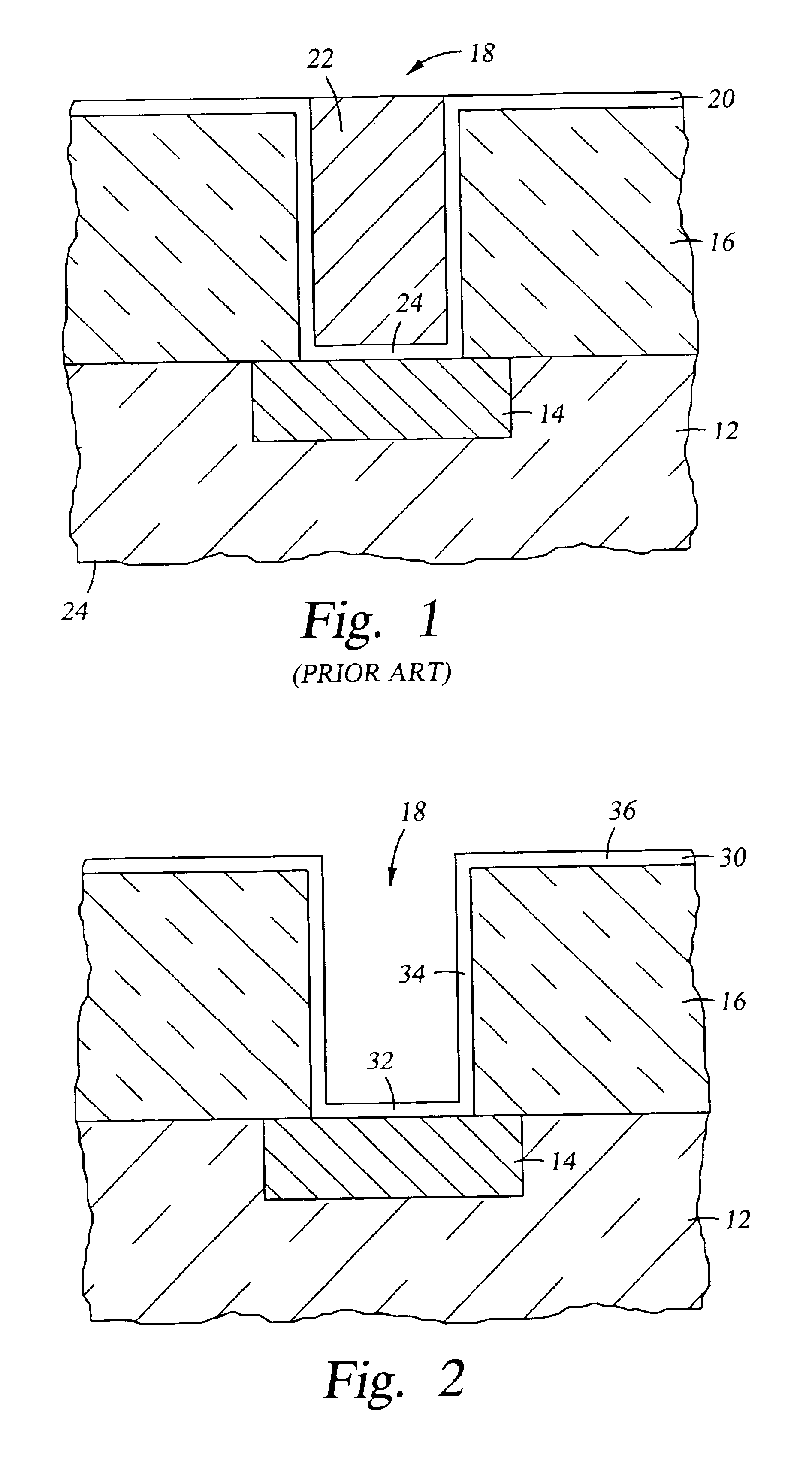

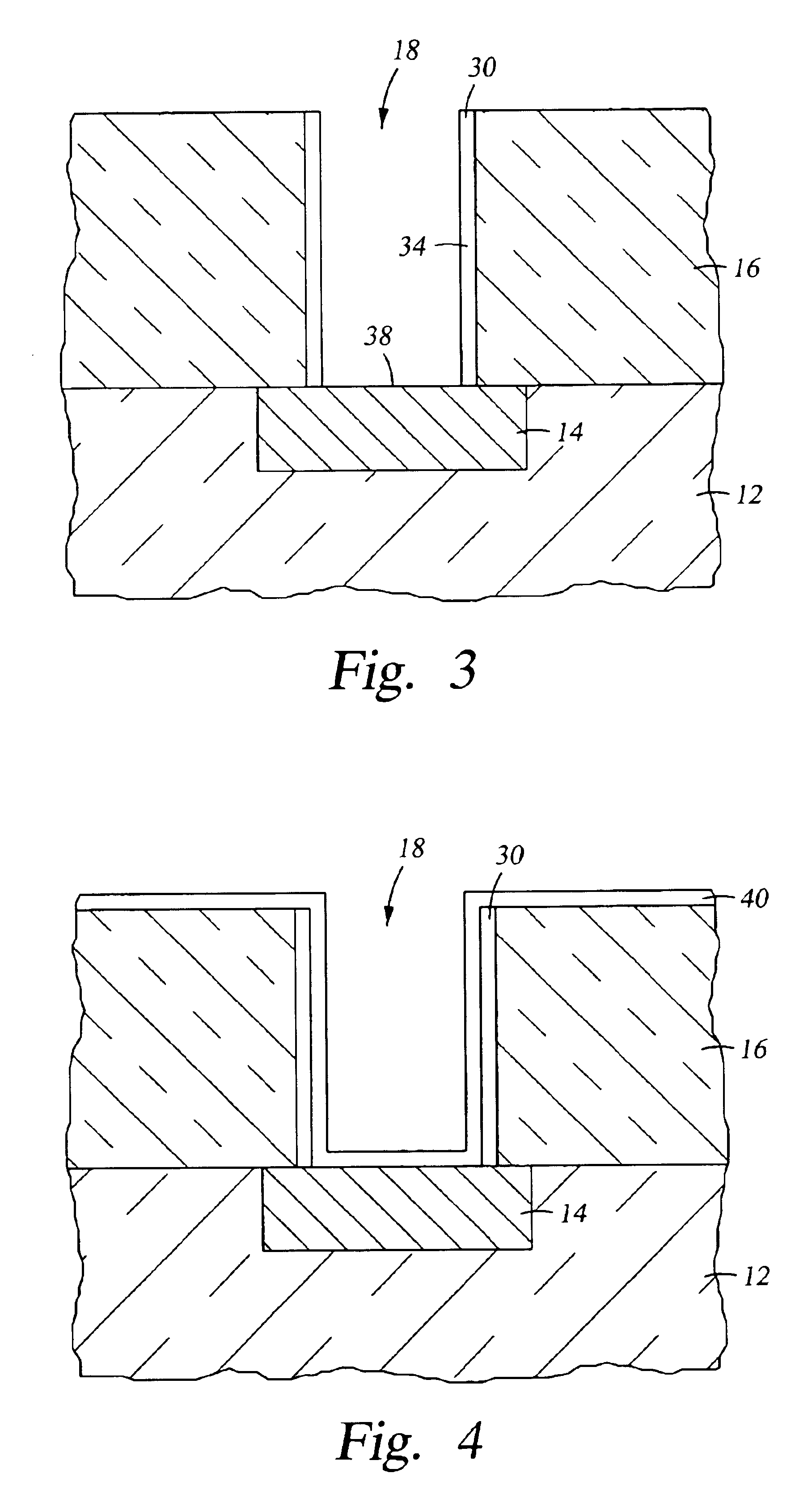

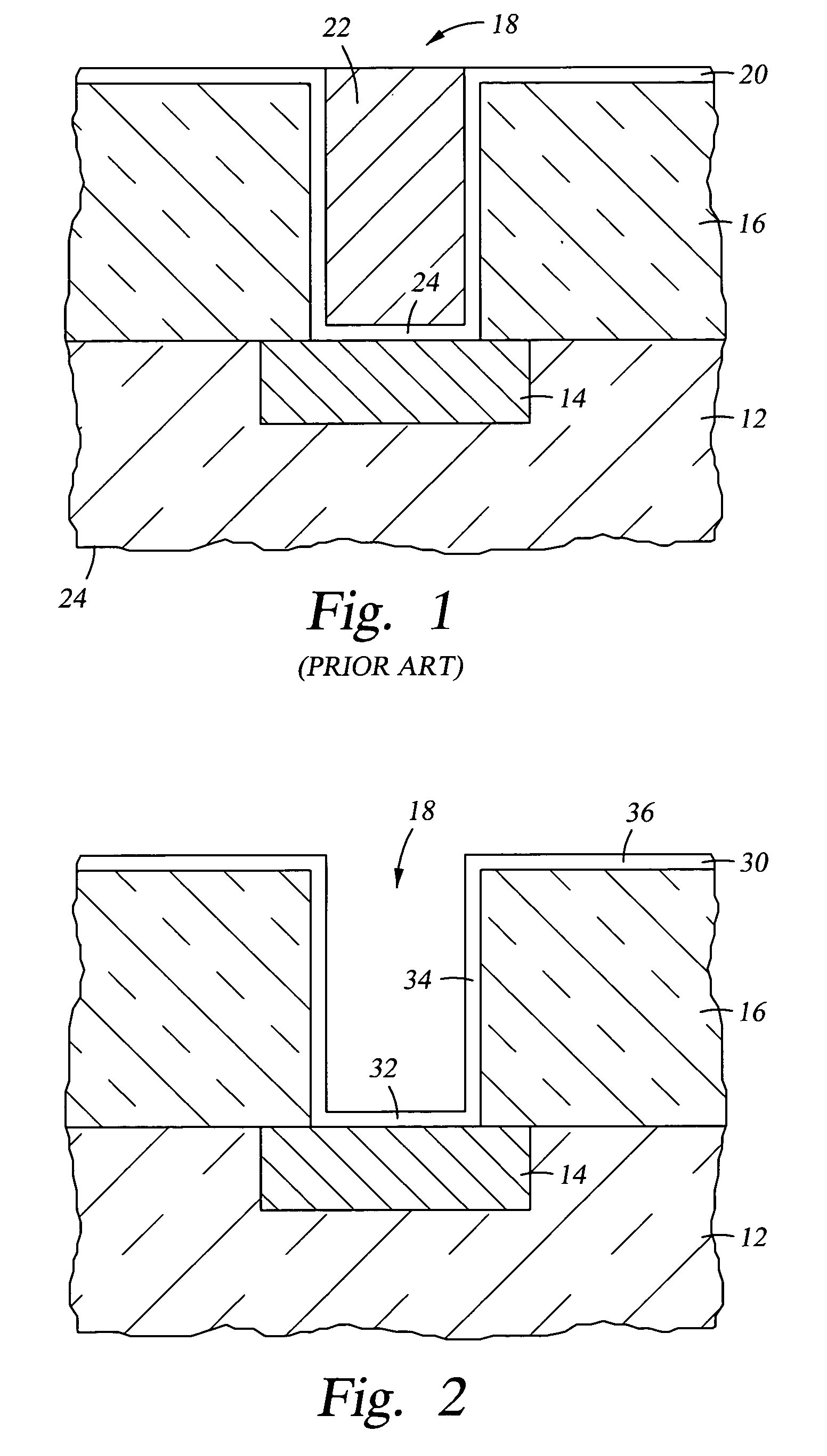

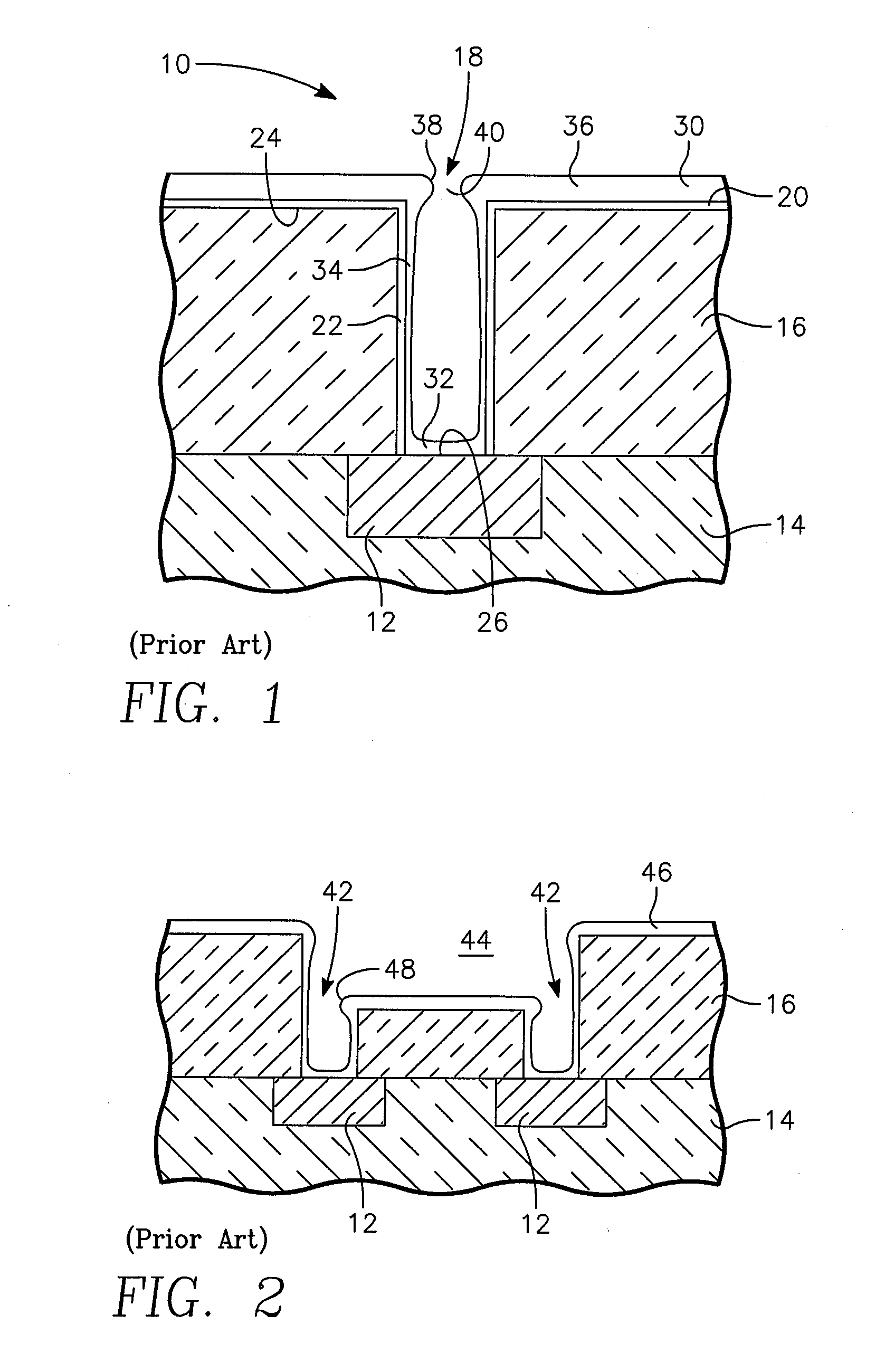

A method of forming barrier layers in a via hole extending through an inter-level dielectric layer and including a preformed first barrier coated onto the bottom and sidewalls of the via holes. In a single plasma sputter reactor, a first step sputters the wafer rather than the target with high energy ions to remove the barrier layer from the bottom of the via but not from the sidewalls and a second step sputter deposits a second barrier layer, for example of Ta / TaN, onto the via bottom and sidewalls. The two steps may be differentiated by power applied to the target, by chamber pressure, or by wafer bias. The second step may include the simultaneous removal of the first barrier layer from the via bottom and sputter deposition of the second barrier layer onto the via sidewalls.

Owner:APPLIED MATERIALS INC

Tantalum barrier layer for copper metallization

A method of forming barrier layers in a via hole extending through an inter-level dielectric layer and including a preformed first barrier coated onto the bottom and sidewalls of the via holes. In a single plasma sputter reactor, a first step sputters the wafer rather than the target with high energy ions to remove the barrier layer from the bottom of the via but not from the sidewalls and a second step sputter deposits a second barrier layer, for example of Ta / TaN, onto the via bottom and sidewalls. The two steps may be differentiated by power applied to the target, by chamber pressure, or by wafer bias. The second step may include the simultaneous removal of the first barrier layer from the via bottom and sputter deposition of the second barrier layer onto the via sidewalls.

Owner:APPLIED MATERIALS INC

Buffer layer for front electrode structure in photovoltaic device or the like

InactiveUS20080223430A1Improve matchIncreased durabilityPV power plantsFinal product manufactureSulfurWork function

Certain example embodiments of this invention relate to an electrode structure (e.g., front electrode structure) for use in a photovoltaic device or the like. In certain example embodiments, a buffer layer (e.g., of or including tin oxide) is provided between the front electrode and the semiconductor absorber film in a photovoltaic device. The buffer layer may be deposited via sputtering, and may or may not be doped in certain example instances. In an example context of use in CdS / CdTe photovoltaic devices, the buffer layer is advantageous in that it (one or more of): (a) provides a good work-function match to a possible CdS / CdTe film and the front electrode; (b) provides good durability in that it is better able to withstand attacks of sulfur vapors at elevated temperatures during possible CdS / CdTe processing; (c) may be at least partially conductive; and / or (d) provides good mechanical durability.

Owner:GUARDIAN GLASS LLC

Conductive barrier layer, especially an alloy of ruthenium and tantalum and sputter deposition thereof

InactiveUS20060251872A1Semiconductor/solid-state device detailsVacuum evaporation coatingDielectricRuthenium

A fabrication method, a product structure, a fabrication method, and a sputtering target for the deposition of a conductive barrier or other liner layer in an interconnect structure. The barrier layer comprises a conductive metal of a refractory noble metal alloy, such as a ruthenium / tantalum alloy, which may be amorphous though it is not required to be so. The barrier layer may be sputtered from a target of similar composition. The barrier and target composition may be chosen from a combination of the refractory metals and the platinum-group metals as well as RuTa. A copper noble seed layer may be formed of an alloy of copper and ruthenium in contact to a barrier layer over the dielectric.

Owner:APPLIED MATERIALS INC

Front electrode including transparent conductive coating on patterned glass substrate for use in photovoltaic device and method of making same

InactiveUS20080107799A1Reduced visible light reflectionImprove conductivityPV power plantsVacuum evaporation coatingQuantum efficiencyConductive coating

This invention relates to a photovoltaic device including an electrode such as a front electrode / contact. In certain example embodiments, the front electrode of the photovoltaic device includes a multi-layered transparent conductive coating which is sputter-deposited on a textured surface of a patterned glass substrate. In certain example embodiments, a maximum transmission area of the substantially transparent conductive front electrode is located under a peak area of a quantum efficiency (QE) curve of the photovoltaic device and a light source spectrum used to power the photovoltaic device.

Owner:GUARDIAN GLASS LLC

Wafer processing deposition shielding components

Embodiments described herein generally relate to an apparatus and method for uniform sputter depositing of materials into the bottom and sidewalls of high aspect ratio features on a substrate. In one embodiment, a collimator for mechanical and electrical coupling with a shield member positioned between a sputtering target and a substrate support pedestal is provided. The collimator comprises a central region and a peripheral region, wherein the collimator has a plurality of apertures extending therethrough and where the apertures located in the central region have a higher aspect ratio than the apertures located in the peripheral region.

Owner:APPLIED MATERIALS INC

End point detection for sputtering and resputtering

InactiveUS7048837B2Avoid depositionRaise the ratioCellsSemiconductor/solid-state device testing/measurementReactor systemElectrical conductor

Plasma etching or resputtering of a layer of sputtered materials including opaque metal conductor materials may be controlled in a sputter reactor system. In one embodiment, resputtering of a sputter deposited layer is performed after material has been sputtered deposited and while additional material is being sputter deposited onto a substrate. A path positioned within a chamber of the system directs light or other radiation emitted by the plasma to a chamber window or other optical view-port which is protected by a shield against deposition by the conductor material. In one embodiment, the radiation path is folded to reflect plasma light around the chamber shield and through the window to a detector positioned outside the chamber window. Although deposition material may be deposited onto portions of the folded radiation path, in many applications, the deposition material will be sufficiently reflective to permit the emission spectra to be detected by a spectrometer or other suitable detector without significant signal loss. The etching or resputtering may be terminated when the detector detects that an underlying layer has been reached or when some other suitable process point has been reached.

Owner:APPLIED MATERIALS INC

Method for magnetron sputter deposition

A method for depositing a coating on an interior surface of a hollowed workpiece. The method comprises providing the hollowed workpiece in a vacuum chamber, the hollowed workpiece comprising an interior surface substantially defining a bore having a longitudinal axis; positioning a magnetron within thed bore along substantially the length of said longitudinal axis and substantially radially equidistant from the interior surface, said magnetron comprising an external sputter target material; and, generating a circumferential magnetic field about the sputter target material for a time and under sputter deposition conditions effective to produce an interior surface comprising a substantially uniform coating comprising said sputter target material.

Owner:SOUTHWEST RES INST

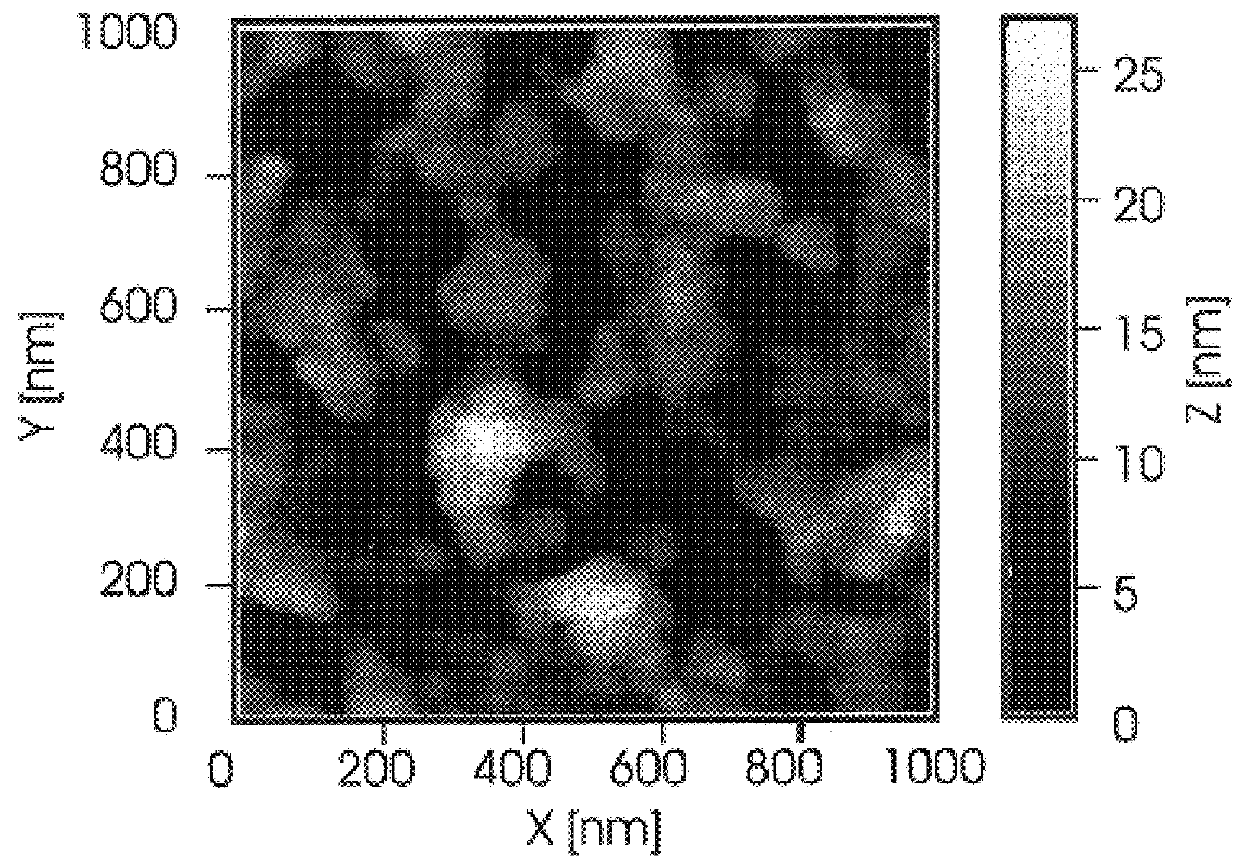

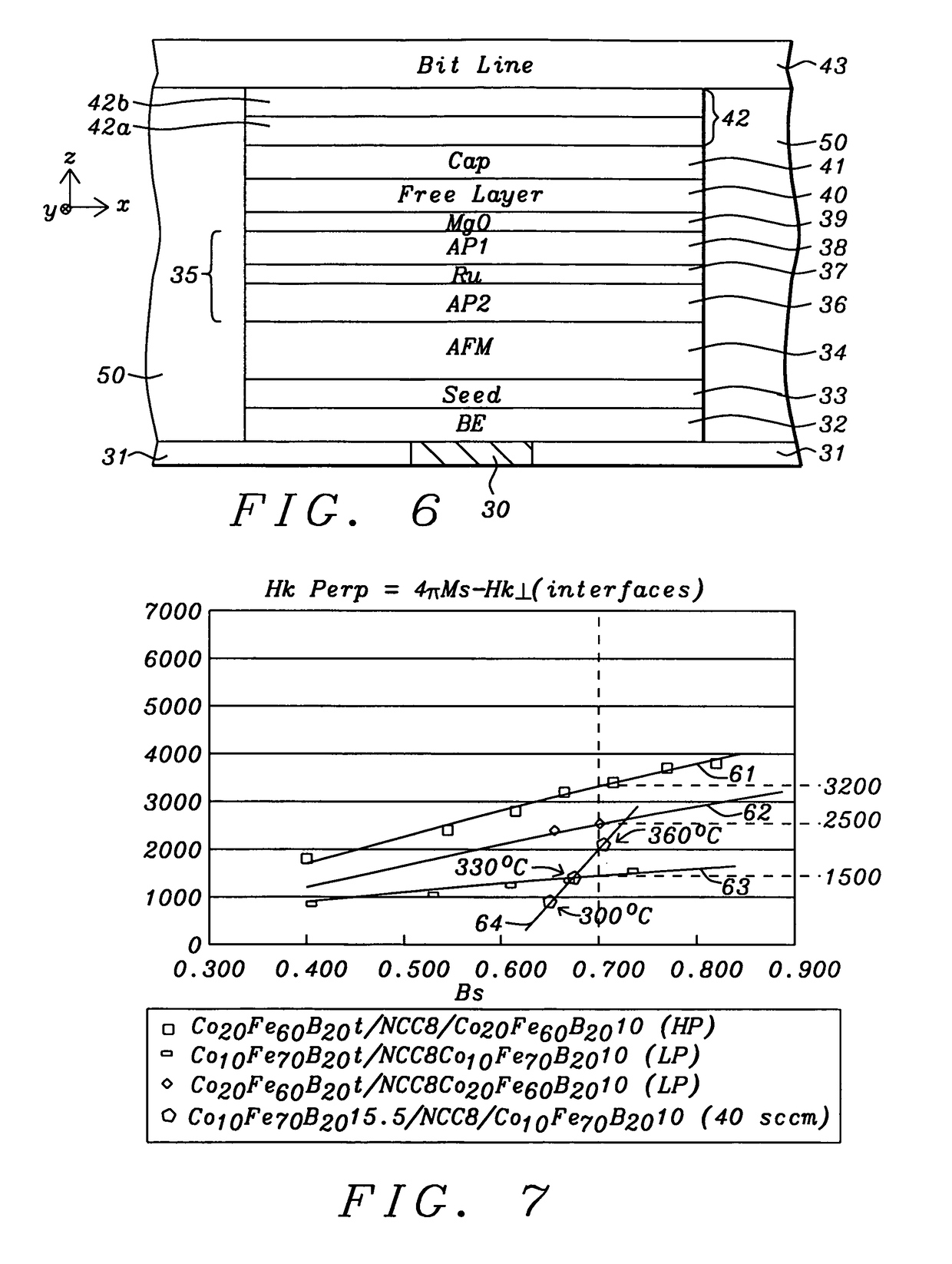

Structure and method for enhancing interfacial perpendicular anisotropy in CoFe(B)/MgO/CoFe(B) magnetic tunnel junctions

ActiveUS8470462B2Magnetic measurementsMagnetic materials for record carriersSwitched currentPerpendicular anisotropy

A STT-RAM MTJ is disclosed with a MgO tunnel barrier formed by natural oxidation process. A Co10Fe70B20 / NCC / Co10Fe70B20, Co10Fe70B20 / NCC / Co10Fe70B20 / NCC, or Co10Fe70B20 / NCC / Co10Fe70B20 / NCC / Co10Fe70B20 free layer configuration where NCC is a nanocurrent channel layer made of Fe(20%)-SiO2 is used to minimize Jc0 while enabling higher thermal stability, write voltage, read voltage, Ho, and Hc values that satisfy 64 Mb design requirements. The NCC layer is about 10 Angstroms thick to match the minimum Fe(Si) grain diameter size. The MTJ is annealed with a temperature of about 330° C. to maintain a high magnetoresistive ratio while maximizing Hk⊥(interfacial) for the free layer thereby reducing Heff and lowering the switching current. The Co10Fe70B20 layers are sputter deposited with a low pressure process with a power of about 15 Watts and an Ar flow rate of 40 standard cubic centimeters per minute to lower Heff for the free layer.

Owner:TAIWAN SEMICON MFG CO LTD

Method for reactive sputter deposition of a magnesium oxide (MgO) tunnel barrier in a magnetic tunnel junction

As part of the fabrication of a magnetic tunnel junction (MTJ), a magnesium oxide (MgO) tunnel barrier is reactively sputter deposited from a Mg target in the presence of reactive oxygen gas (O2) in the “high-voltage” state to assure that deposition occurs with the Mg target in its metallic mode, i.e., no or minimal oxidation. Because the metallic mode of the Mg target has a finite lifetime, a set of O2 flow rates and associated sputter deposition times are established, with each flow rate and deposition time assuring that deposition occurs with the Mg target in the metallic mode and resulting in a known tunnel barrier thickness. The commencement of undesirable Mg target oxidation is associated with a decrease in target voltage, so the sputtering can also be terminated by monitoring the target voltage and terminating application of power to the target when the voltage reaches a predetermined value.

Owner:HITACHI GLOBAL STORAGE TECH NETHERLANDS BV

Transparent article having protective silicon nitride film

Transparent articles comprising transparent, nonmetallic substrate and a transparent film stack is sputter deposited on the substrate. The film stack is characterized by including at least one infrared reflective metal film, a dielectric film over the metal film, and a protective silicon nitride film of 10 Å to 150 Å in thickness over the said dielectric film. The dielectric film desirably has substantially the same index of refraction as does silicon nitride and is contiguous with the silicon nitride film.

Owner:CARDINAL CG CO

Thin film coating having transparent base layer

InactiveUS6919133B2Reduce decreaseReduce formationVacuum evaporation coatingSputtering coatingLow emissivityOptoelectronics

The invention provides thin film coatings that have a transparent base layer. For example, the invention provides low-emissivity coatings with a transparent base layer. In certain embodiments, a silicon dioxide base layer is used. Methods of producing thin film coatings having a transparent base layer are provided as well. In one embodiment, sputter deposition is utilized to produce these coatings.

Owner:CARDINAL CG

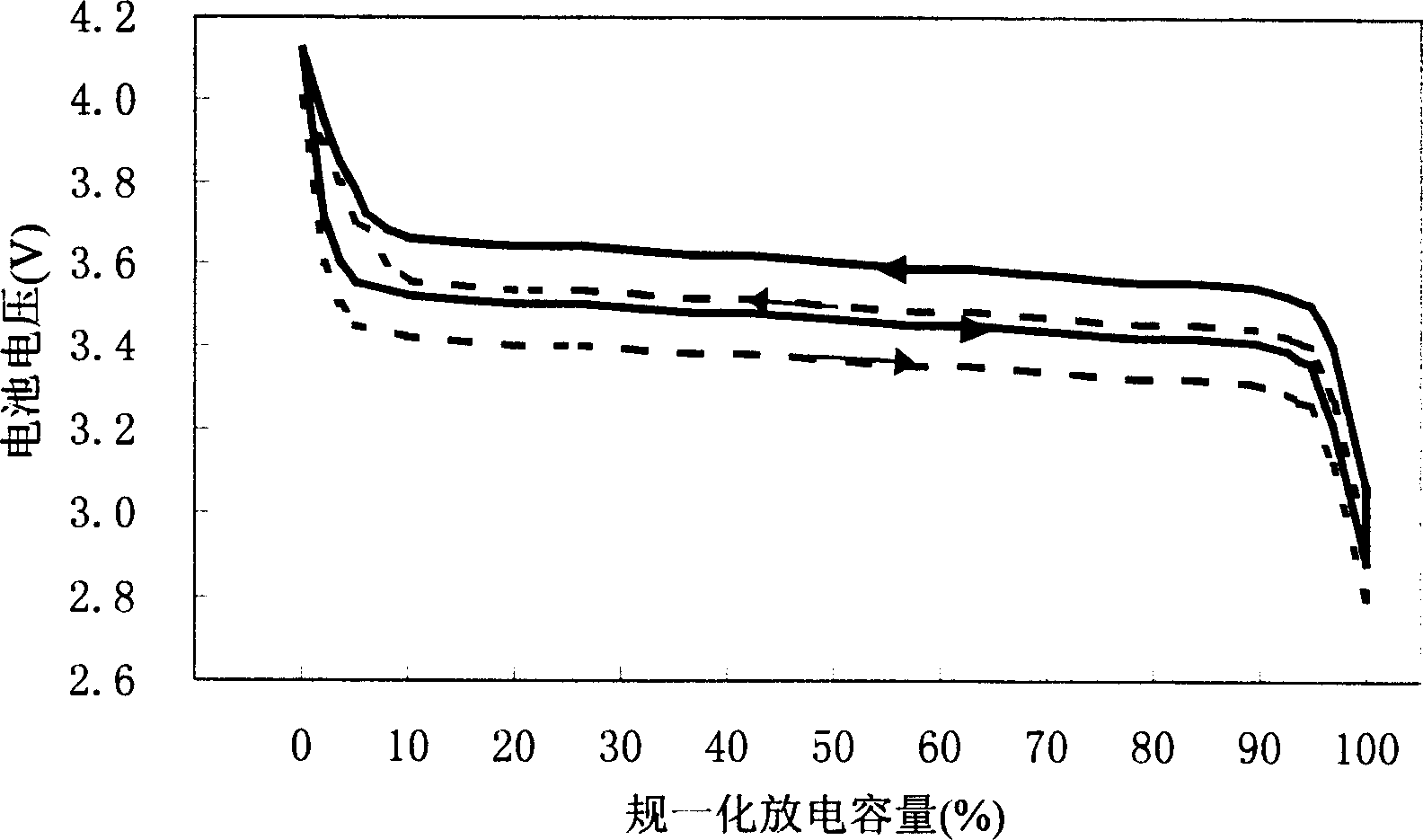

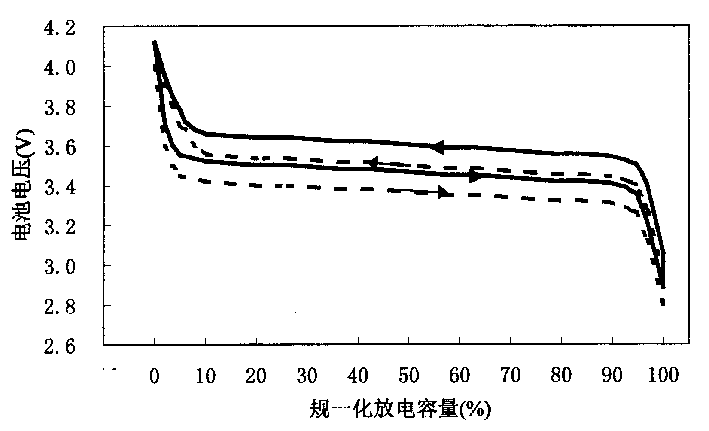

Lithium cell positive electrode materials and preparing method thereof

InactiveCN1457111AImprove conductivityHigh conductivity at room temperatureElectrode thermal treatmentPositive electrodesNano structuringElectrical battery

The chemical general formula of the material is expressed as follows: LixM1-xFePO4, where M is selected from Mg2+, Ca2+...P5+ etc. With conduction adulterant added, reaction at 500-900 deg.C for 10 hr. by using metal oxide, phoshpate, fluoride etc. and non saturated crystal of Li-Fe phoshpate through nonstoichiometric method obtains the crystal of Li-Fe phosphate with high conductivity, which can be expressed as LiFePO4-y. The formula of material prepared by using method of pressurized type substitution ion is LixM1-xFezM'1-z. The formula of material of solid power prepared by using method of solid phase reaction is as LixM1-xFezMn1-zPO4. The formula of anode material in nano structure prepared by using method of vacuum sputter deposition is LixFePO4-y, whose conductivity and discharge capacity can reach 10 to the power -2 S / cm and 240 Ah / g.

Owner:徐瑞松

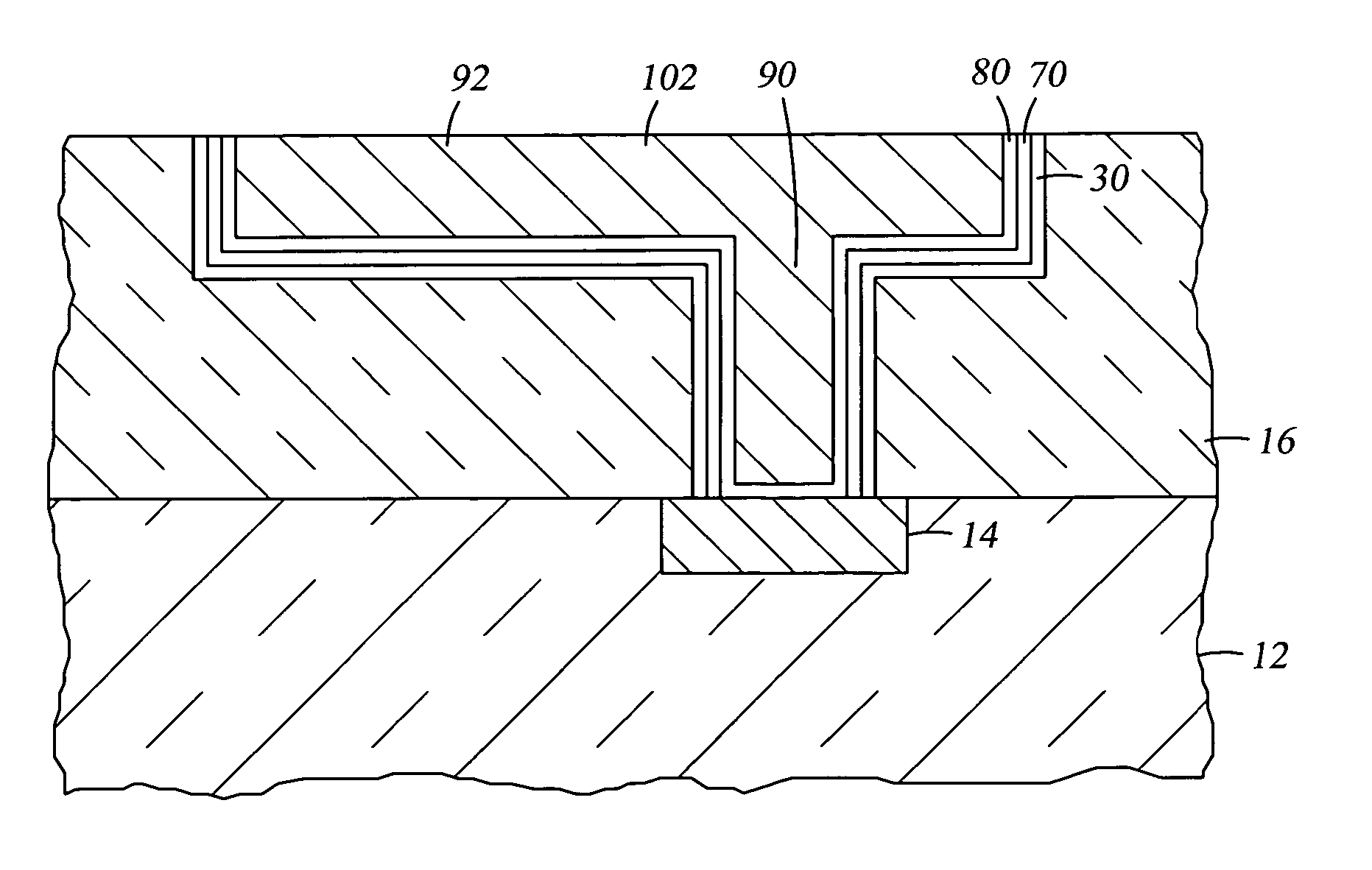

Resputtered copper seed layer

InactiveUS20080190760A1Increase pressureReduce stressElectric discharge tubesVacuum evaporation coatingSputter depositionElectrochemistry

An integrated copper deposition process, particularly useful for forming a copper seed layer in a narrow via prior to electrochemical plating of copper, including at least one cycle of sputter deposition of copper followed by sputter etching of the deposited copper, preferably performed in a same sputter chamber. The deposition is performed under conditions promoting high copper ionization fractions and strong wafer biasing to draw the copper ions into the via. The etching may be done with argon ions, preferably inductively excited by an RF coil around the chamber, or by copper ions, which may be formed with high target power and intense magnetron or by use of the RF coil. Two or more cycles of deposition / etch may be performed. A final flash deposition may be performed with high copper ionization and low wafer biasing.

Owner:APPLIED MATERIALS INC

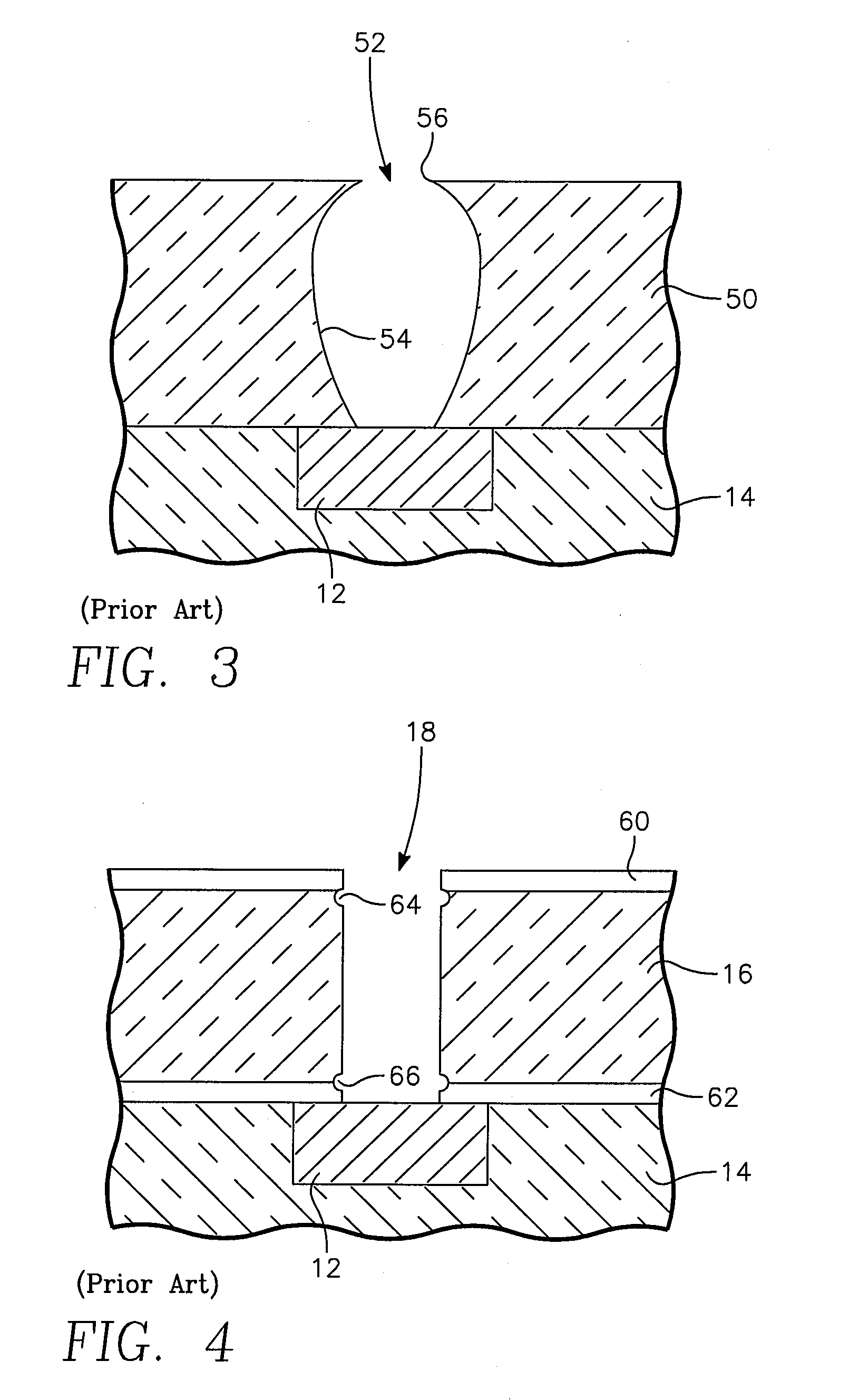

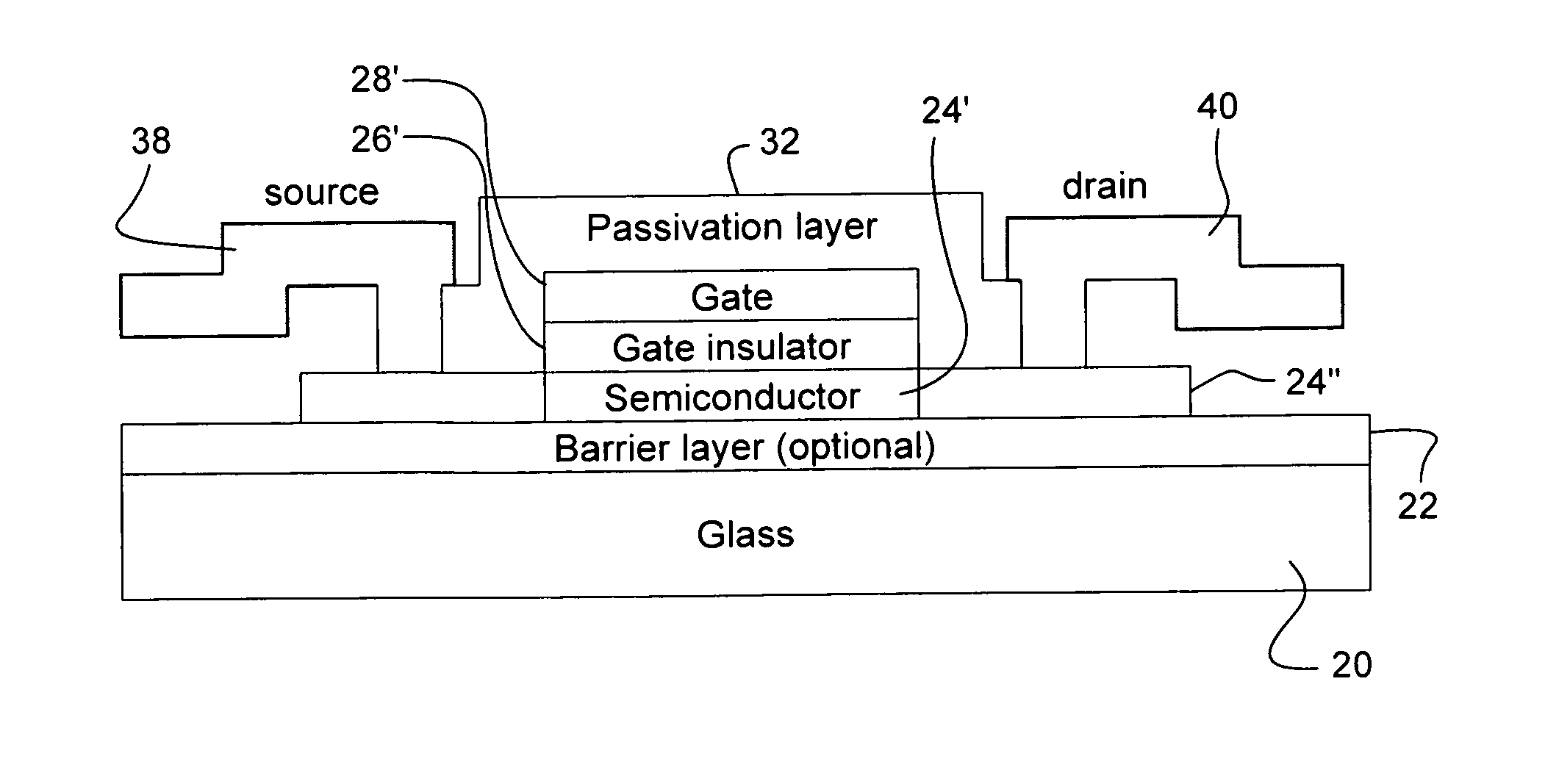

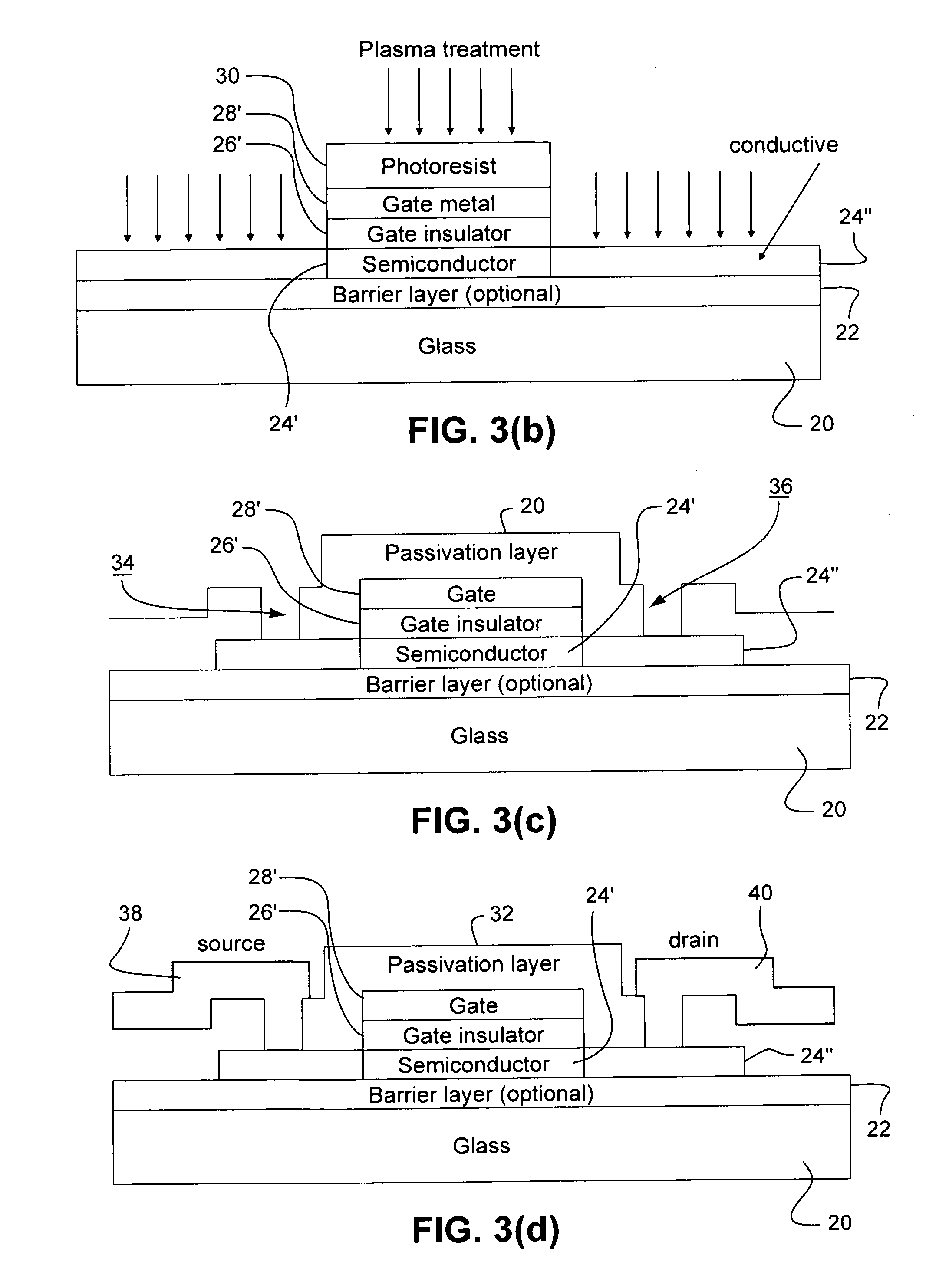

Method of making oxide thin film transistor array

InactiveUS8530273B2Improve economyImprove conductivitySolid-state devicesSemiconductor/solid-state device manufacturingOxide thin-film transistorRoom temperature

Owner:GUARDIAN GLASS LLC

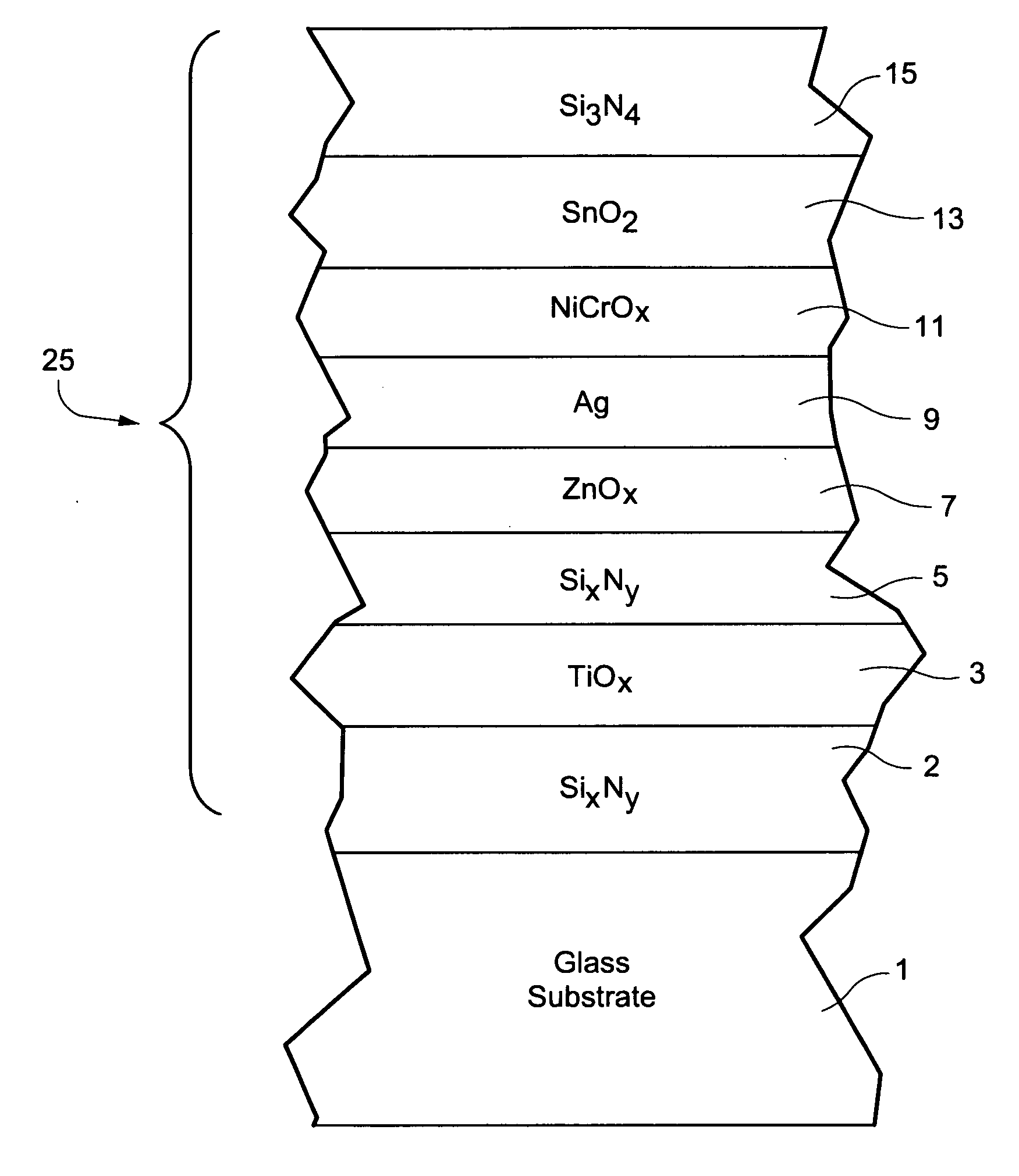

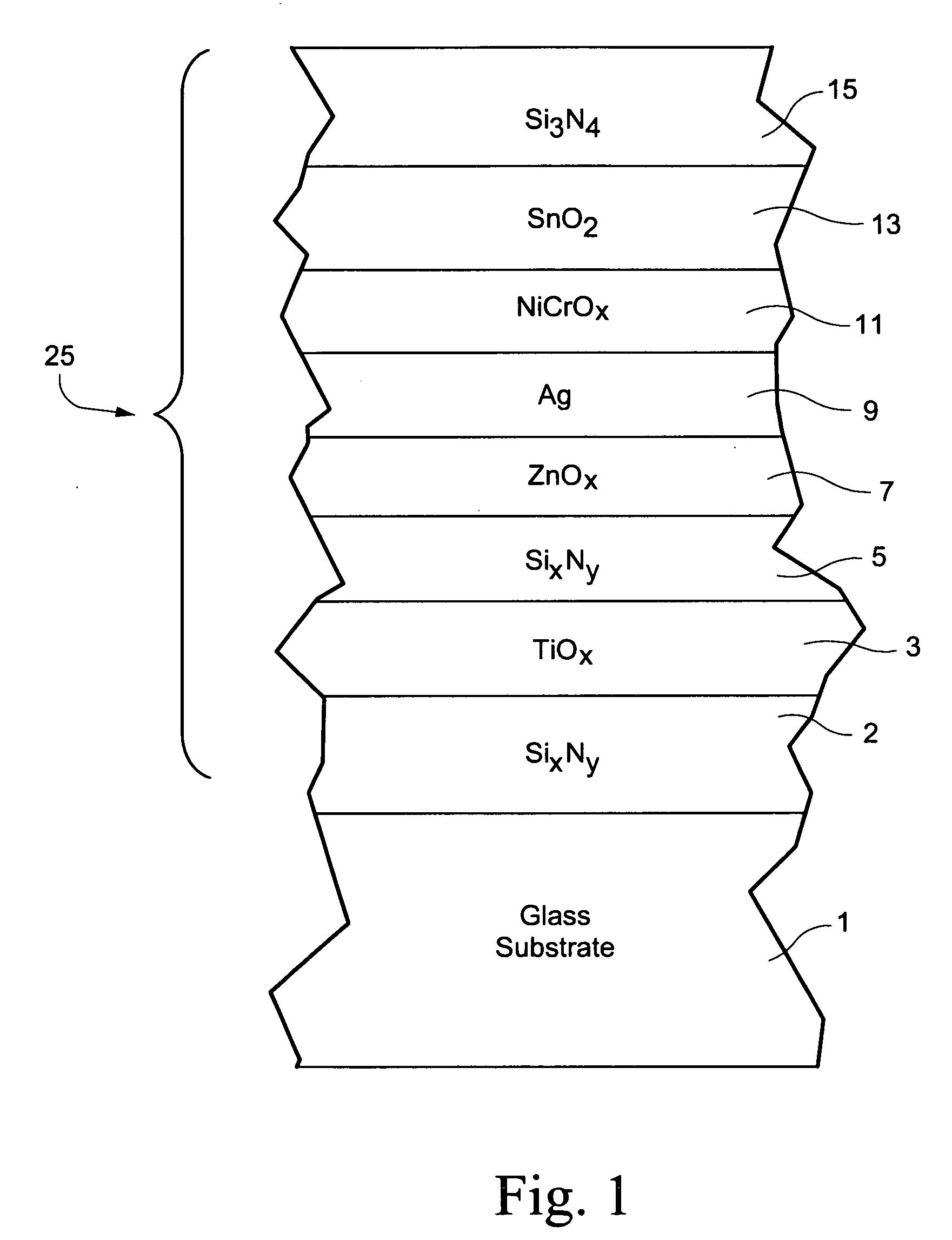

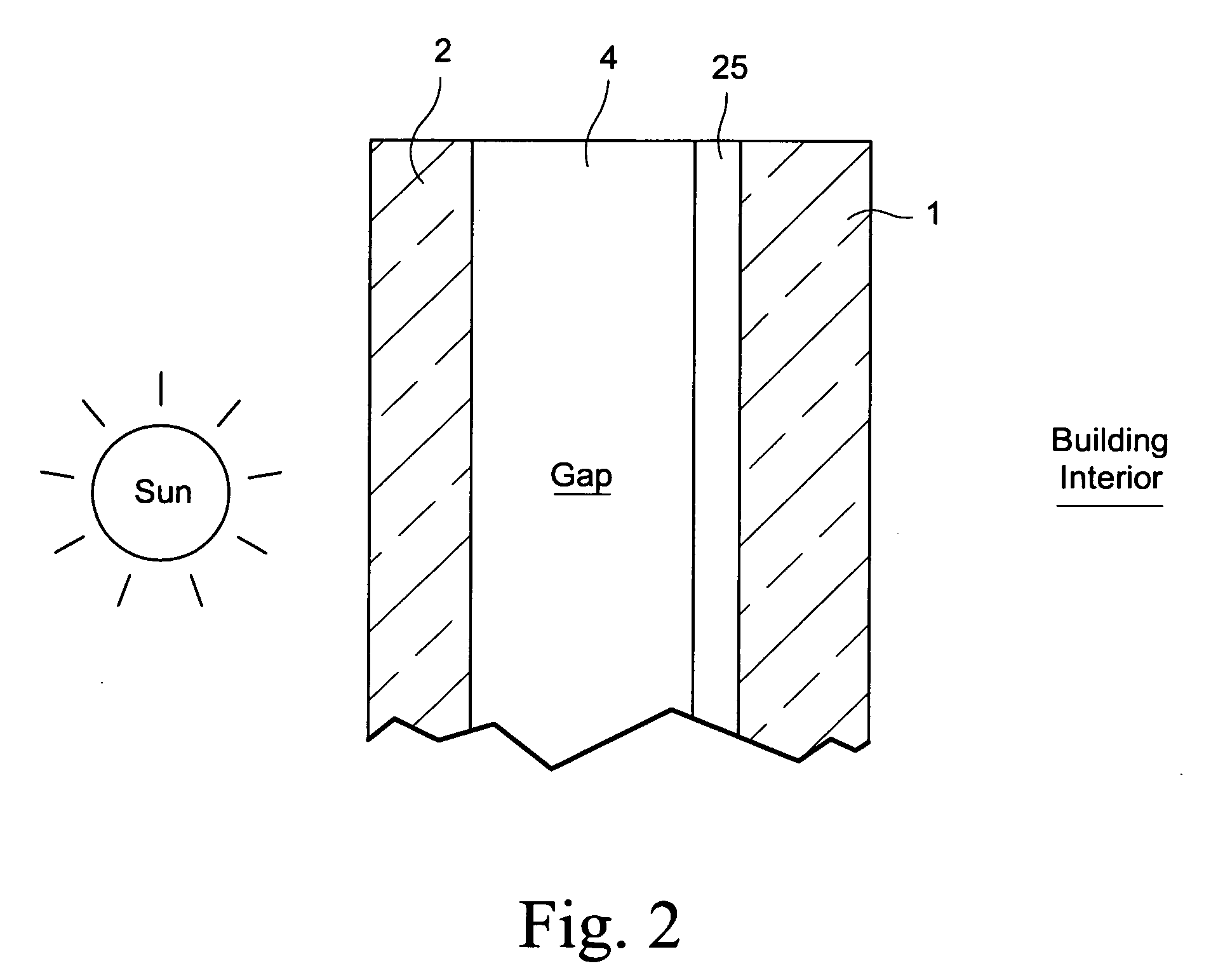

Coated article with IR reflecting layer and method of making same

InactiveUS20090263596A1Low emissivityReduce sheet resistanceVacuum evaporation coatingSputtering coatingMetallurgyNitrogen gas

Example embodiments of this invention relate to a coated article including an infrared (IR) reflecting layer of a material such as silver or the like, for use in an insulating glass (IG) window unit for example. In certain example embodiments, the coating is a single-silver type coating, and includes an overcoat including an uppermost layer of or including silicon nitride and a layer of or including tin oxide immediately under and contacting the silicon nitride based overcoat. In certain example embodiments, the thicknesses of the silicon nitride based overcoat and the tin oxide based layer are balanced (e.g., substantially equal, or equal plus / minus about 10%). It has surprisingly been found that such balancing results in an improvement in thermal cycling performance and improved mechanical durability. In certain example embodiments, the coating may realize surprisingly good substantially neutral film side reflective coloration, and may achieve an improved visible transmission, SHGC ratio and low U-values. Moreover, in certain example embodiments, stress in the overcoat of the coating may be reduced by reducing nitrogen gas flow (N2 ml / kW) and cathode power during a sputter-deposition process, thereby further improving thermal cycling performance.

Owner:GUARDIAN EURO S A R L +1

Continuous deposition process and apparatus for manufacturing cadmium telluride photovoltaic devices

InactiveUS20100184249A1Refined grain sizeAvoid condensationCellsVacuum evaporation coatingGas phaseSource material

A continuous deposition process and apparatus for depositing semiconductor layers containing cadmium, tellurium or sulfur as a principal constituent on transparent substrates to form photovoltaic devices as the substrates are continuously conveyed through the deposition apparatus is described. The film deposition process for a photovoltaic device having an n-type window layer and three p-type absorber layers in contiguous contact is carried out by a modular continuous deposition apparatus which has a plurality of processing stations connected in series for depositing successive layers of semiconductor films onto continuously conveying substrates. The fabrication starts by providing an optically transparent substrate coated with a transparent conductive oxide layer, onto which an n-type window layer formed of CdS or CdZnS is sputter deposited. After the window layer is deposited, a first absorber layer is deposited thereon by sputter deposition. Thereafter, a second absorber layer formed of CdTe is deposited onto the first absorber layer by a novel vapor deposition process in which the CdTe film forming vapor is generated by sublimation of a CdTe source material. After the second absorber layer is deposited, a third absorber layer formed of CdHgTe is deposited thereon by sputter deposition. The substrates are continuously conveyed through the modular continuous deposition apparatus as successive layers of semiconductor films are deposited thereon.

Owner:CHEN YUNG TIN

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com