Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

272results about How to "Excellent soft magnetic properties" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

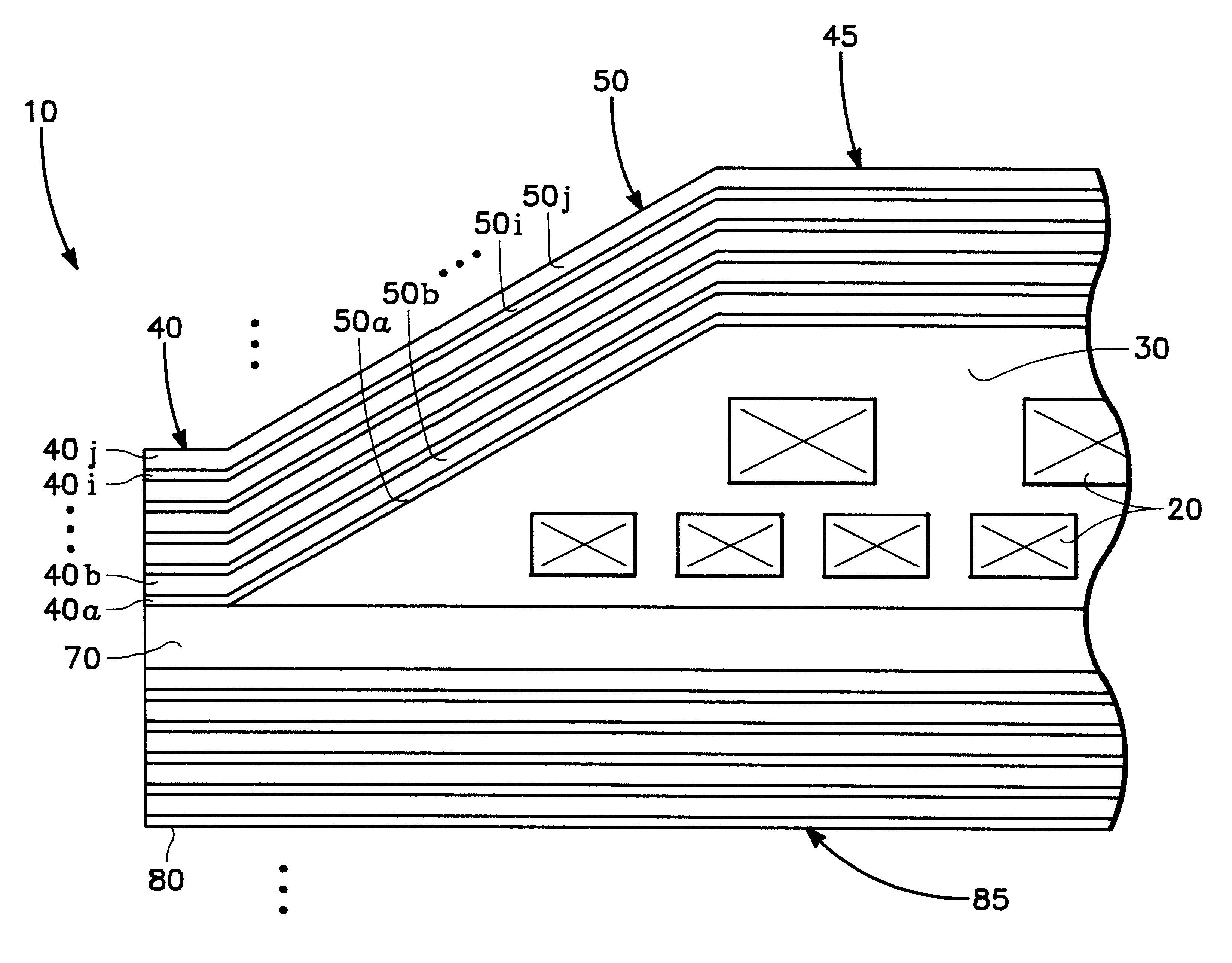

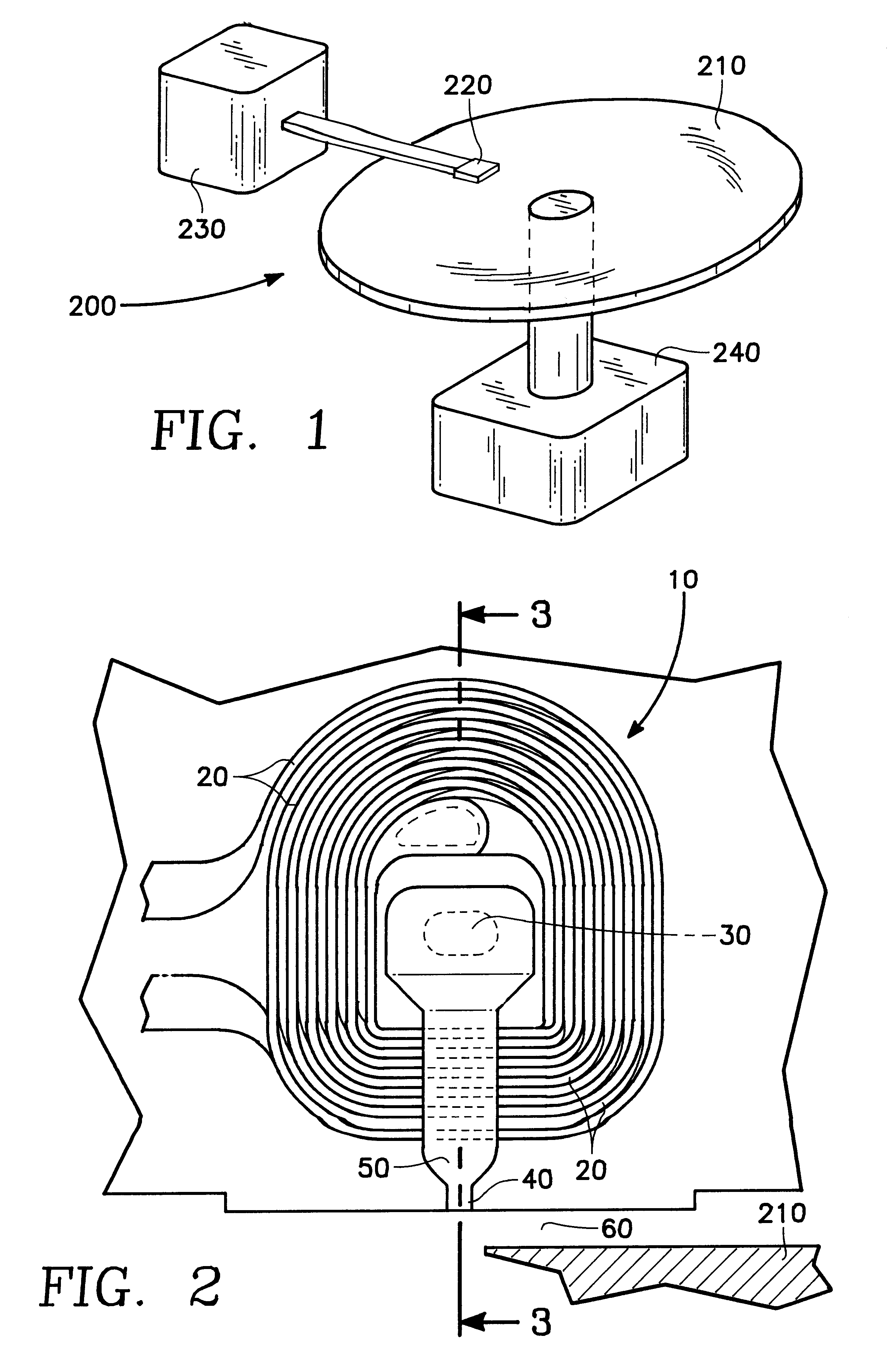

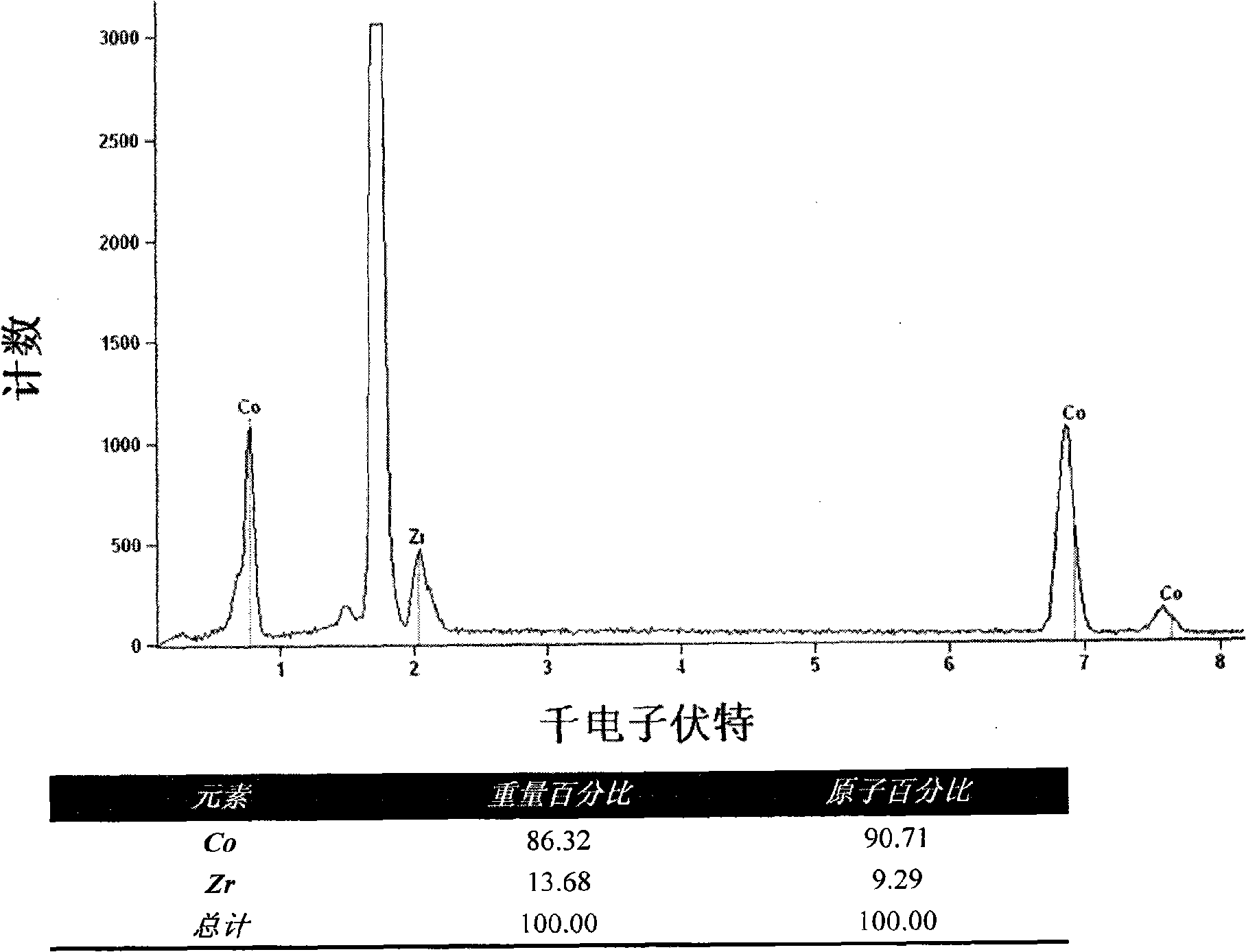

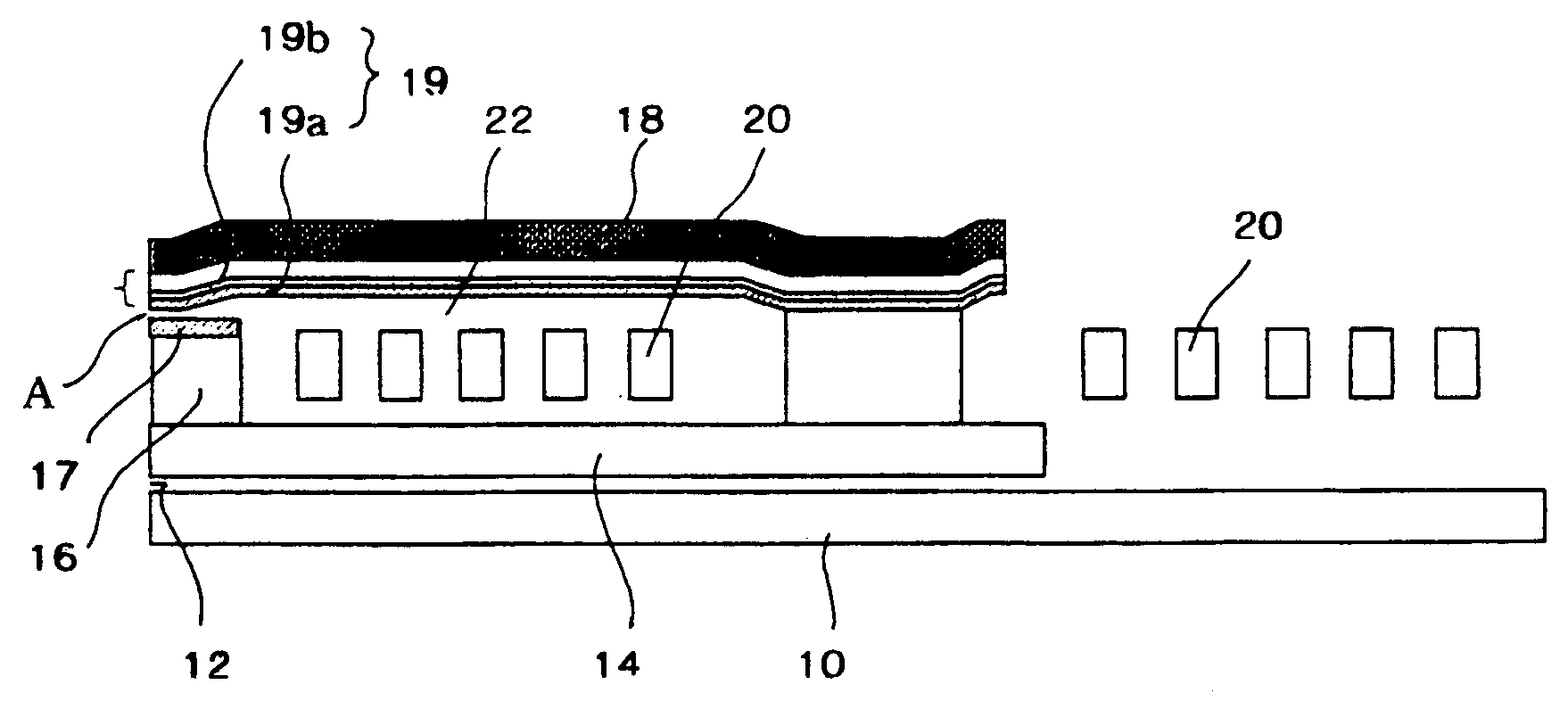

Thin film write head with improved laminated flux carrying structure and method of fabrication

InactiveUS6233116B1High resistivityExcellent soft magnetic propertiesConstruction of head windingsHeads using thin filmsLower poleHigh resistivity

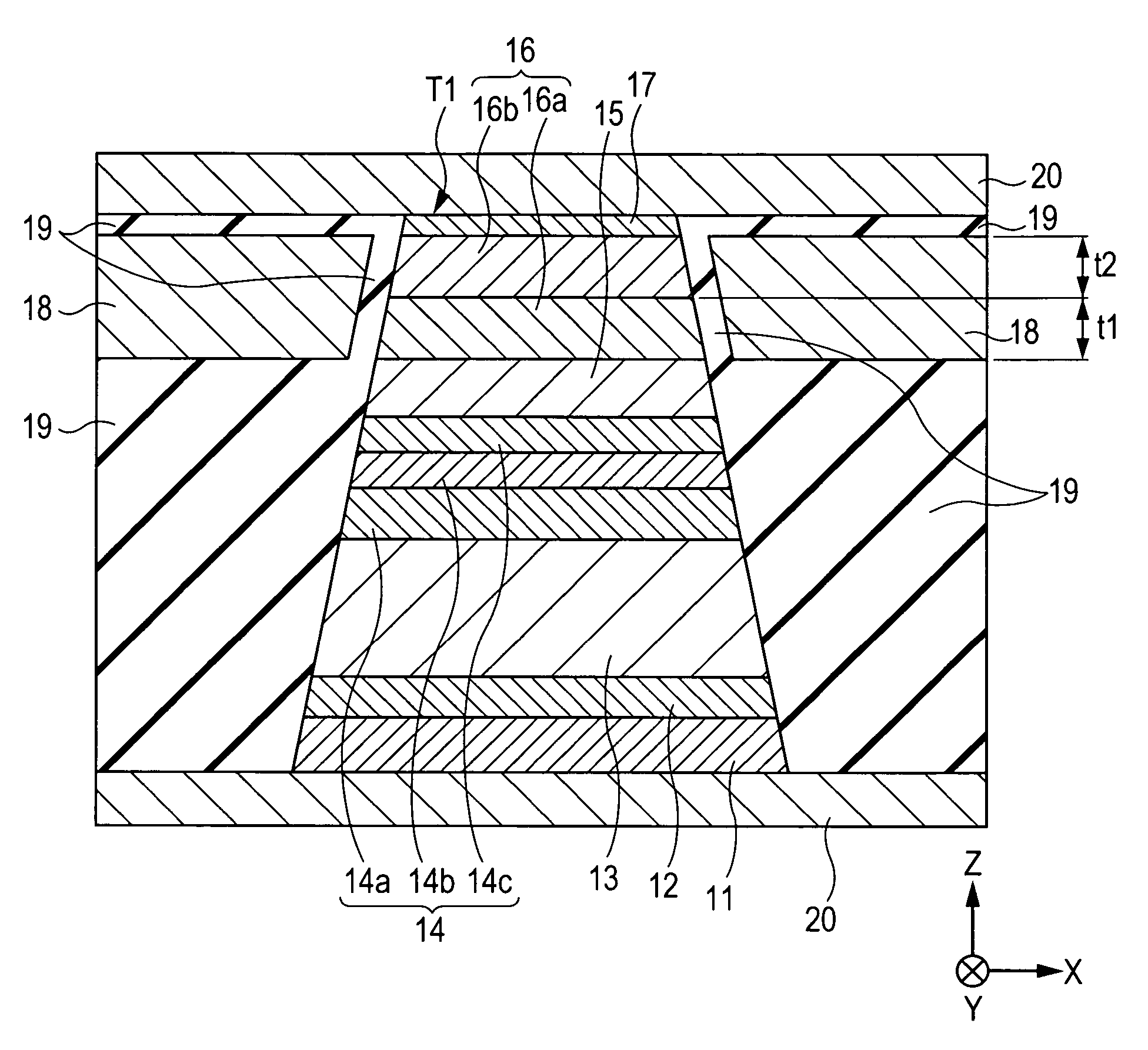

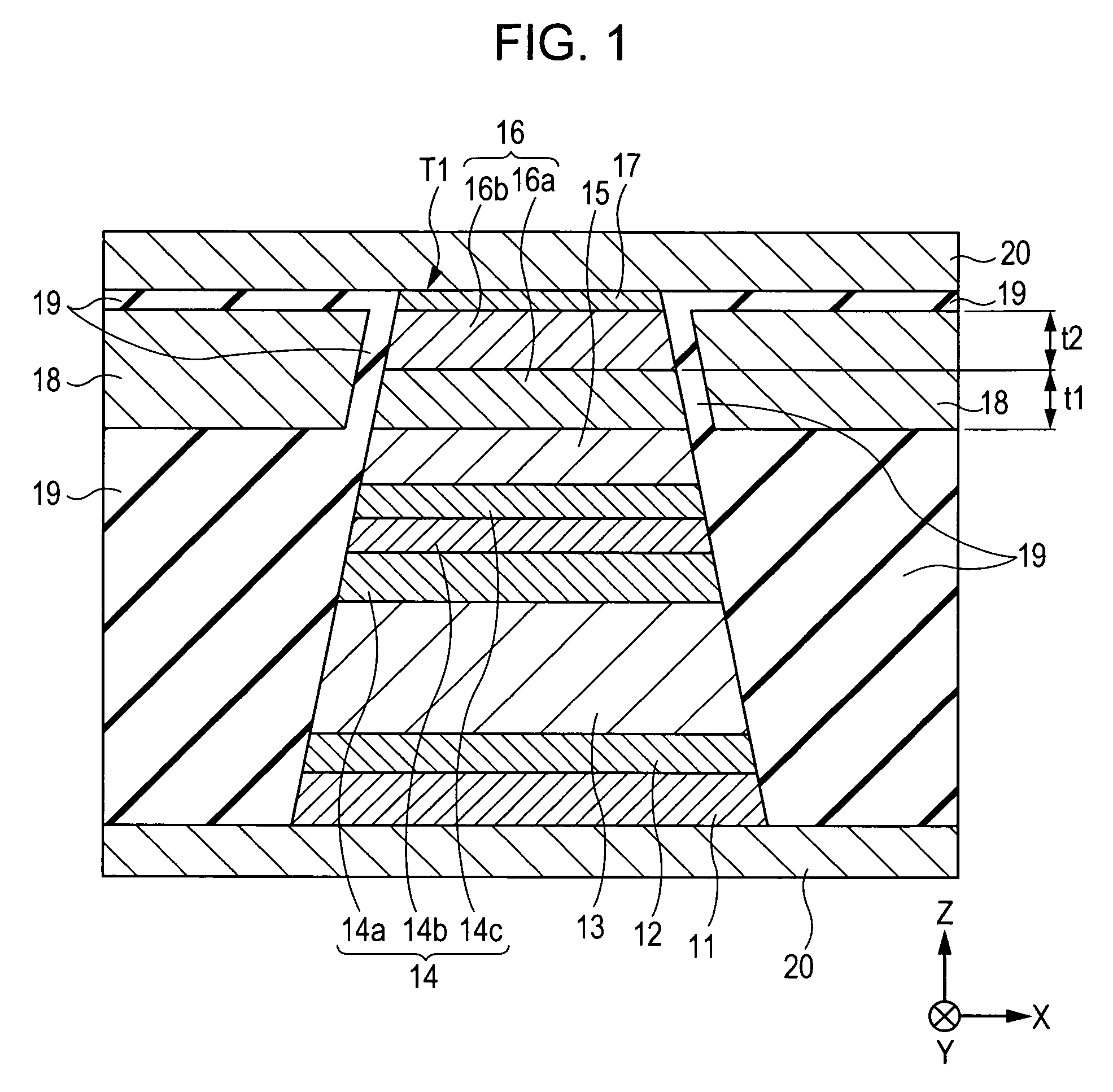

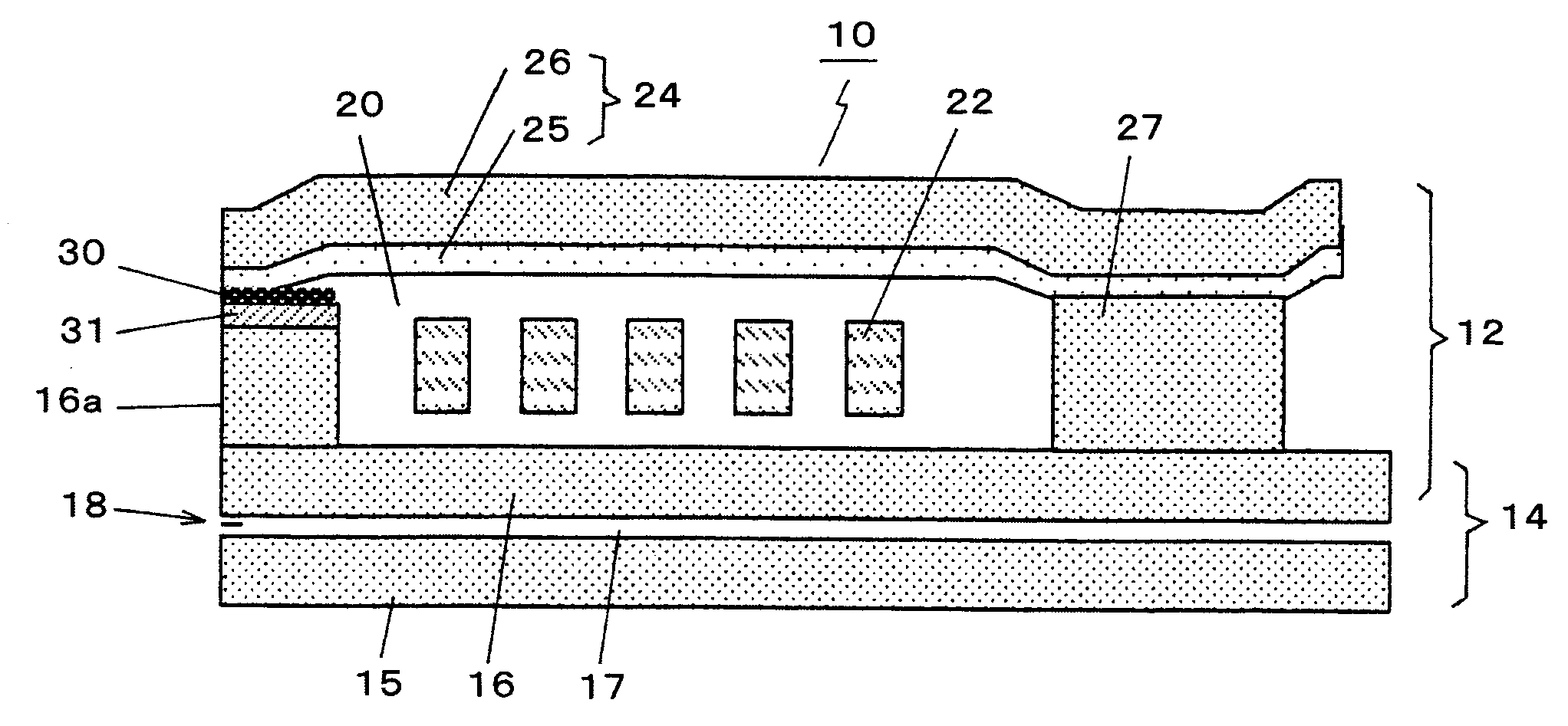

The present invention provides a thin film write head having an improved laminated flux carrying structure and method of fabrication. The preferred embodiment provides laminated layers of: high moment magnetic material, and easily aligned high resistivity magnetic material. In the preferred embodiment, the easily aligned laminating layer induces uniaxial anisotropy, by exchange coupling, to improve uniaxial anisotropy in the high moment material. This allows deposition induced uniaxial anisotropy by DC magnetron sputtering and also provides improved post deposition annealing, if desired. It is preferred to laminate FeXN, such as FeRhN, or other crystalline structure material, with an amorphous alloy material, preferably Co based, such as CoZrCr. In the preferred embodiment, upper and lower pole structures may both be laminated as discussed above. Such laminated structures have higher Bs than structures with insulative laminates, and yokes and pole tips and may be integrally formed, if desired, because flux may travel along or across the laminating layers. The preferred embodiment of the present invention improves soft magnetic properties, reduces eddy currents, improves hard axis alignment while not deleteriously affecting the coercivity, permeability, and magnetostriction of the structure, thus allowing for improved high frequency operation.

Owner:WESTERN DIGITAL TECH INC +1

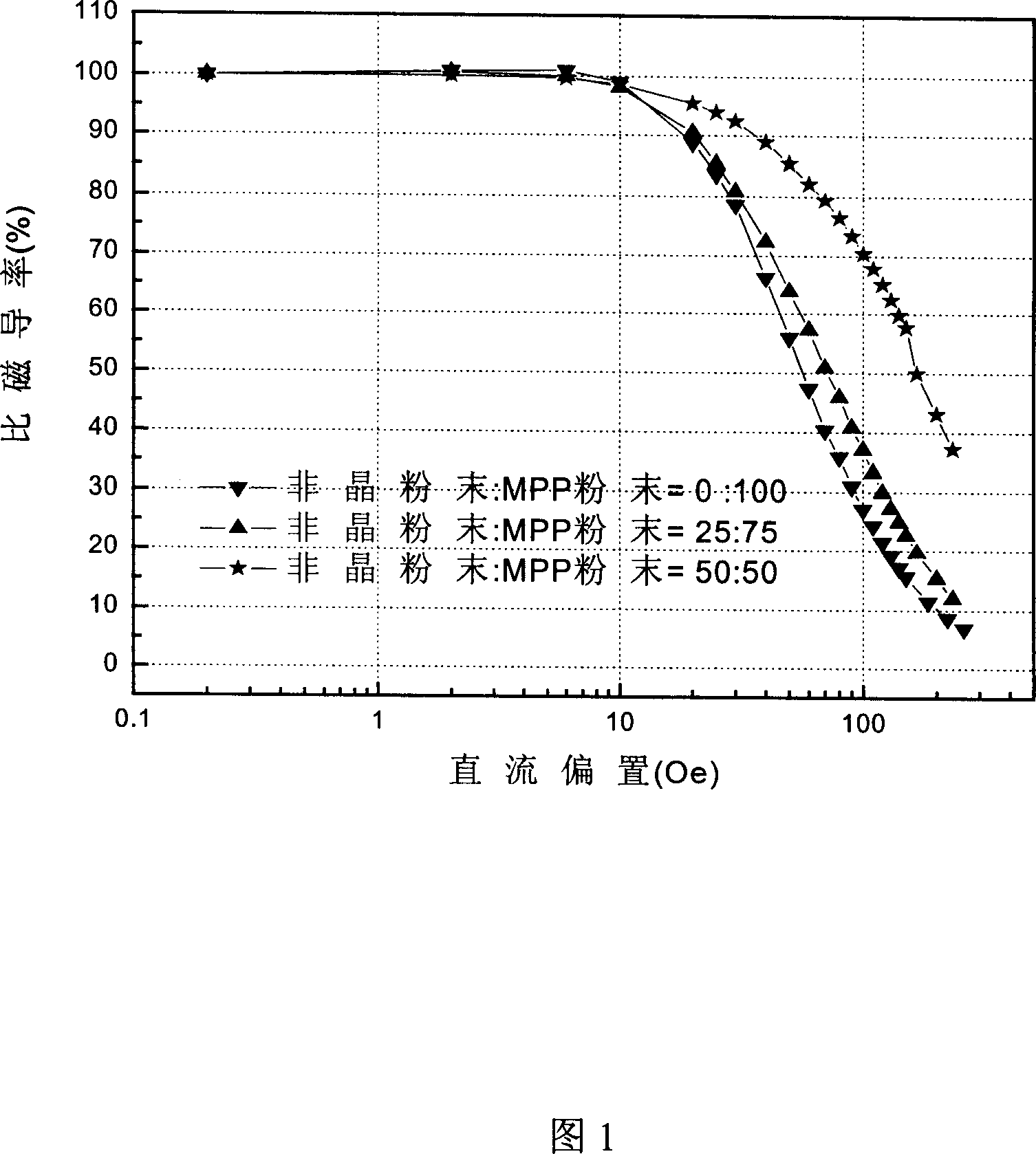

Composite powder, magnetic powder core for magnetic powder and preparation method thereof

InactiveCN101118797AExcellent soft magnetic propertiesIncrease the amount of participationInorganic material magnetismInductances/transformers/magnets manufactureAl powderIron powder

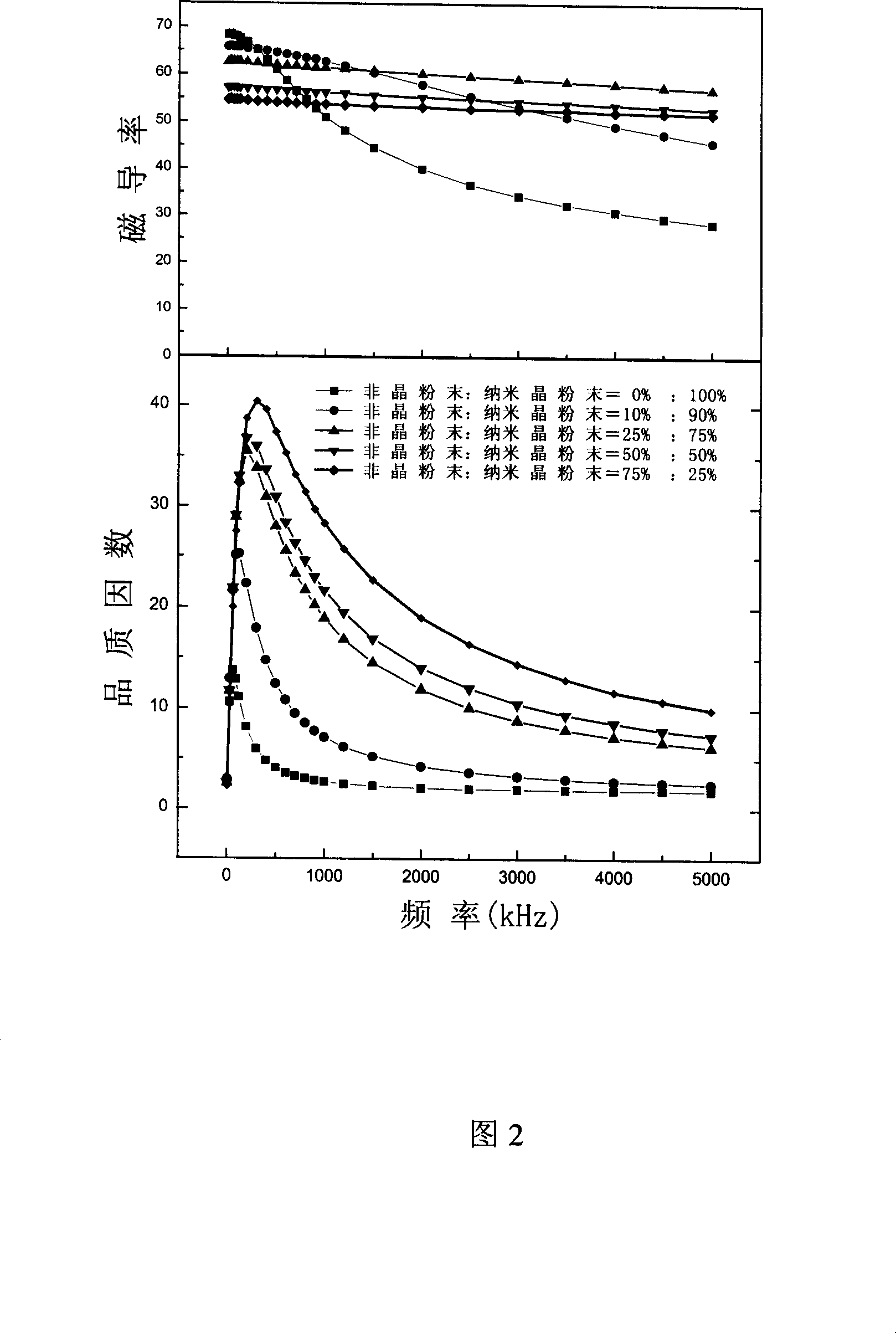

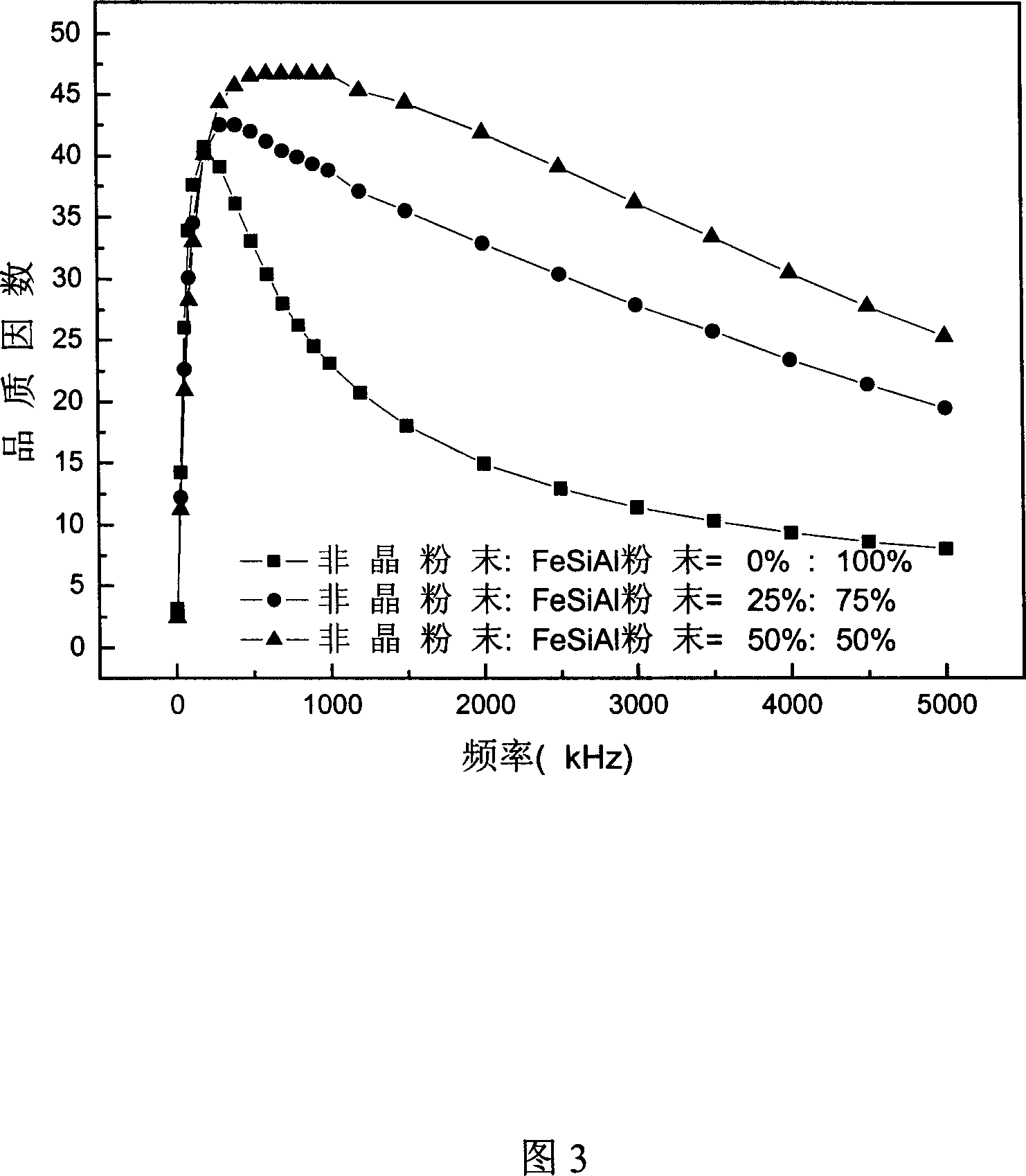

The present invention provides a magnetic powder core, composite powder used for the magnetic powder core, and a production method for the both. The composite powder is blended and formed by powder A and powder B, the content of which comprises 50-96wt percent of the powder A and 4-50wt percent of the powder B; wherein, the powder A is one out of iron powder, Fe-Si powder, Fe-Si-Al powder, Fe-based nanometer crystal powder, Fe-base amorphous powder, Fe-Ni powder and Fe-Ni-Mo powder; the powder B has different demand characteristics compared with the powder A and is selected from at least one out of iron powder, Fe-Si powder, Fe-Si-Al powder, Fe-based nanometer crystal powder, Fe-based amorphous powder, Fe-Ni powder and Fe-Ni-Mo powder. The powder B can be Fe-based soft magnetic amorphous powder as the insulating agent, which can reduce the wastage of magnetic powder core and make up for the declining magnetic conductivity of magnetic powder core caused by the traditional insulating agent. The excellent of soft magnetic properties of the insulating agent is utilized to improve frequency features of the magnetic powder core.

Owner:ADVANCED TECHNOLOGY & MATERIALS CO LTD

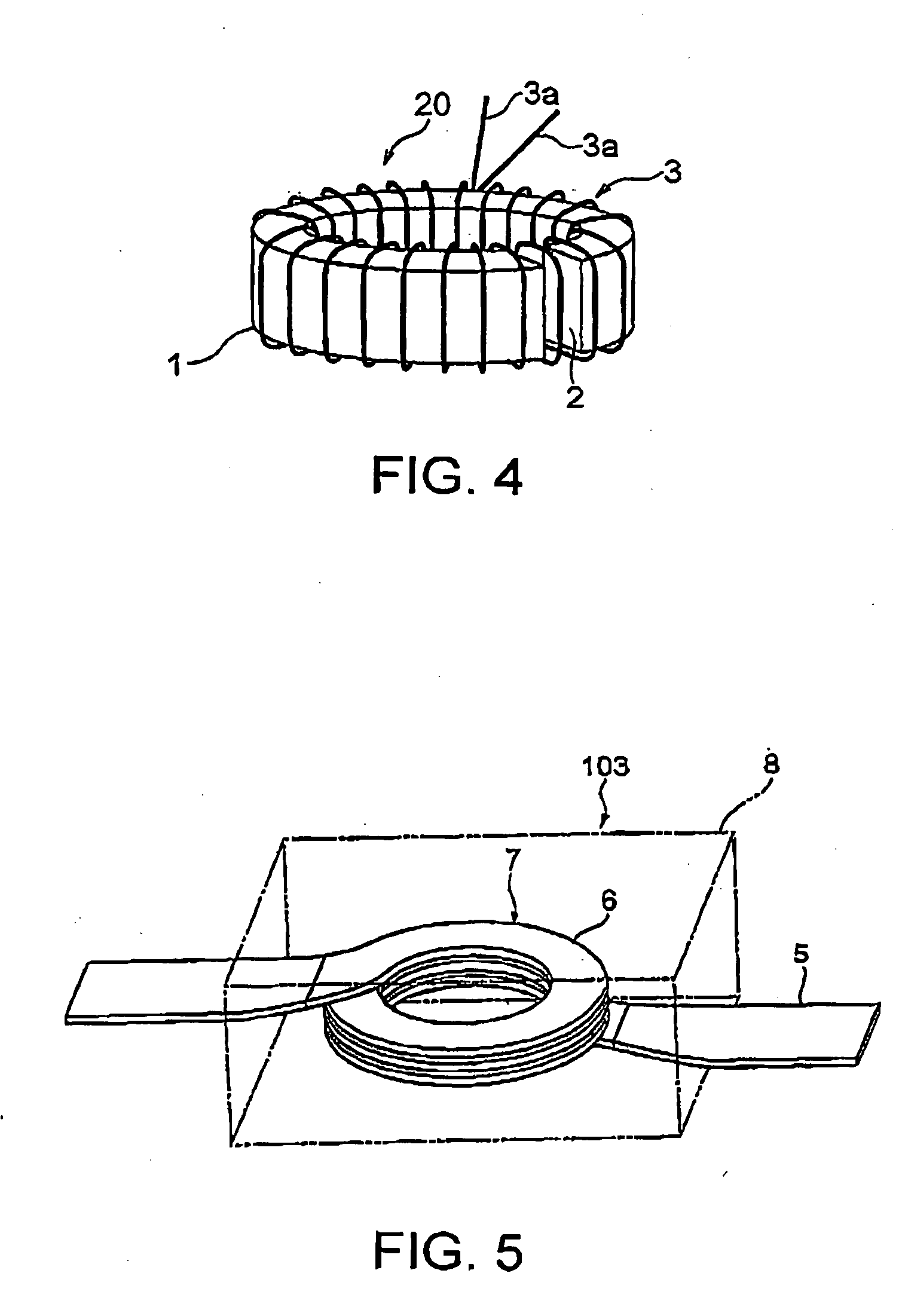

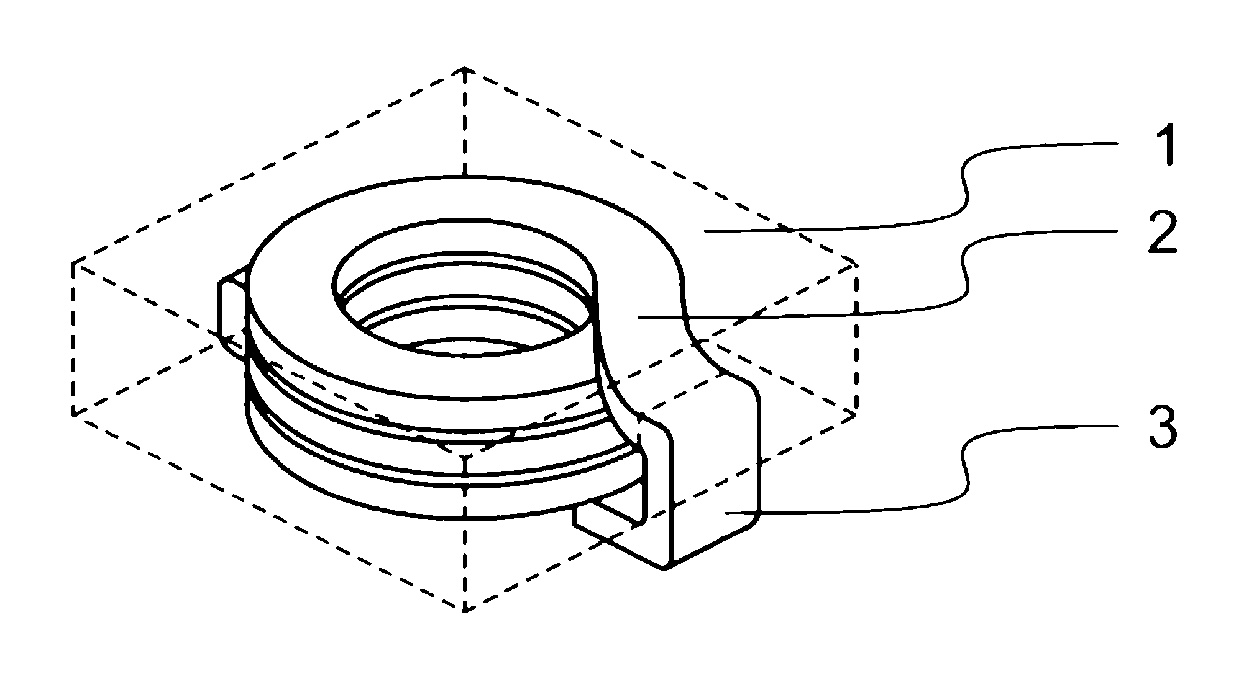

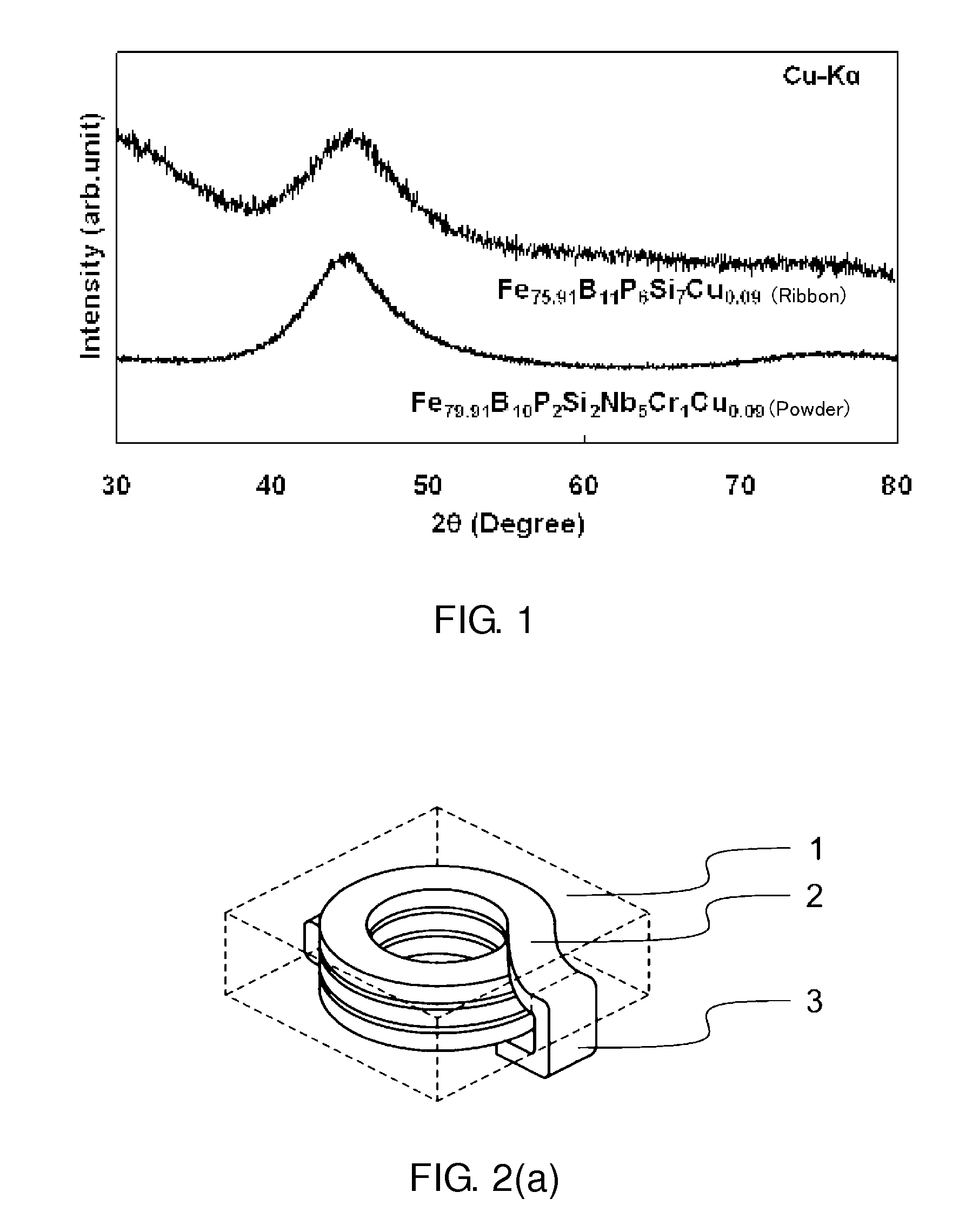

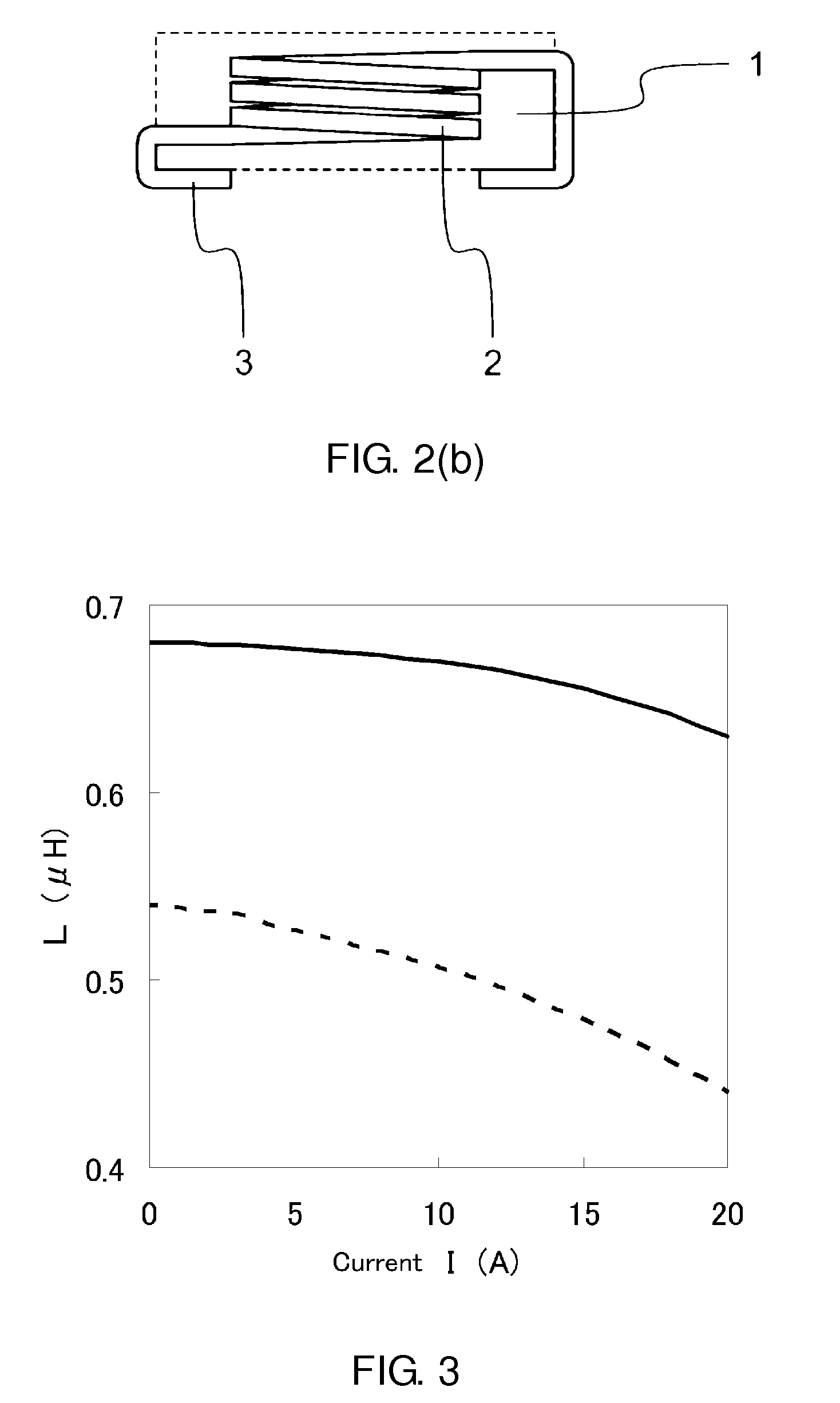

Amorphous soft magnetic alloy and inductance component using the same

InactiveUS20070175545A1Excellent in amorphous-forming abilityExcellent soft magnetic propertiesTransformers/inductances detailsInductances/transformers/magnets manufactureMetallurgyInductor

To provide an amorphous soft magnetic alloy having a supercooled liquid region and excellent in amorphous-forming ability and soft magnetic properties, by selecting and optimizing an alloy composition, and to further provide a ribbon, a powder, a high-frequency magnetic core, and a bulk member each using such an amorphous soft magnetic alloy. The amorphous soft magnetic alloy has a composition expressed by a formula of (Fe1-αTMα)100-w-x-y-zPwBxLySiz, wherein unavoidable impurities are contained, TM is at least one selected from Co and Ni, L is at least one selected from the group consisting of Al, V, Cr, Y, Zr, Mo, Nb, Ta, and W, 0≦α0.98, 2≦w≦16 at %, 2≦x≦16 at %, 0<y≦10 at %, and 0≦z≦8 at %).

Owner:TOKIN CORP +1

Soft magnetic alloy, magnetic component using the same, and thier production methods

ActiveUS20100097171A1Excellent soft magnetic propertiesGood formabilityTransportation and packagingMetal-working apparatusFe basedMagnetic alloy

A soft magnetic alloy contains P, B, and Cu as essential components. As a preferred example, an Fe-based alloy contains Fe of 70 atomic % or more, B of 5 atomic % to 25 atomic %, Cu of 1.5 atomic % or less (excluding zero), and P of 10 atomic or less (excluding zero).

Owner:TOKIN CORP +2

Magnetic sensing element including laminated film composed of half-metal and NiFe alloy as free layer

ActiveUS7466525B2Improve propertiesExcellent soft magnetic propertiesNanomagnetismMagnetic measurementsHalf-metalAlloy

Owner:TDK CORPARATION

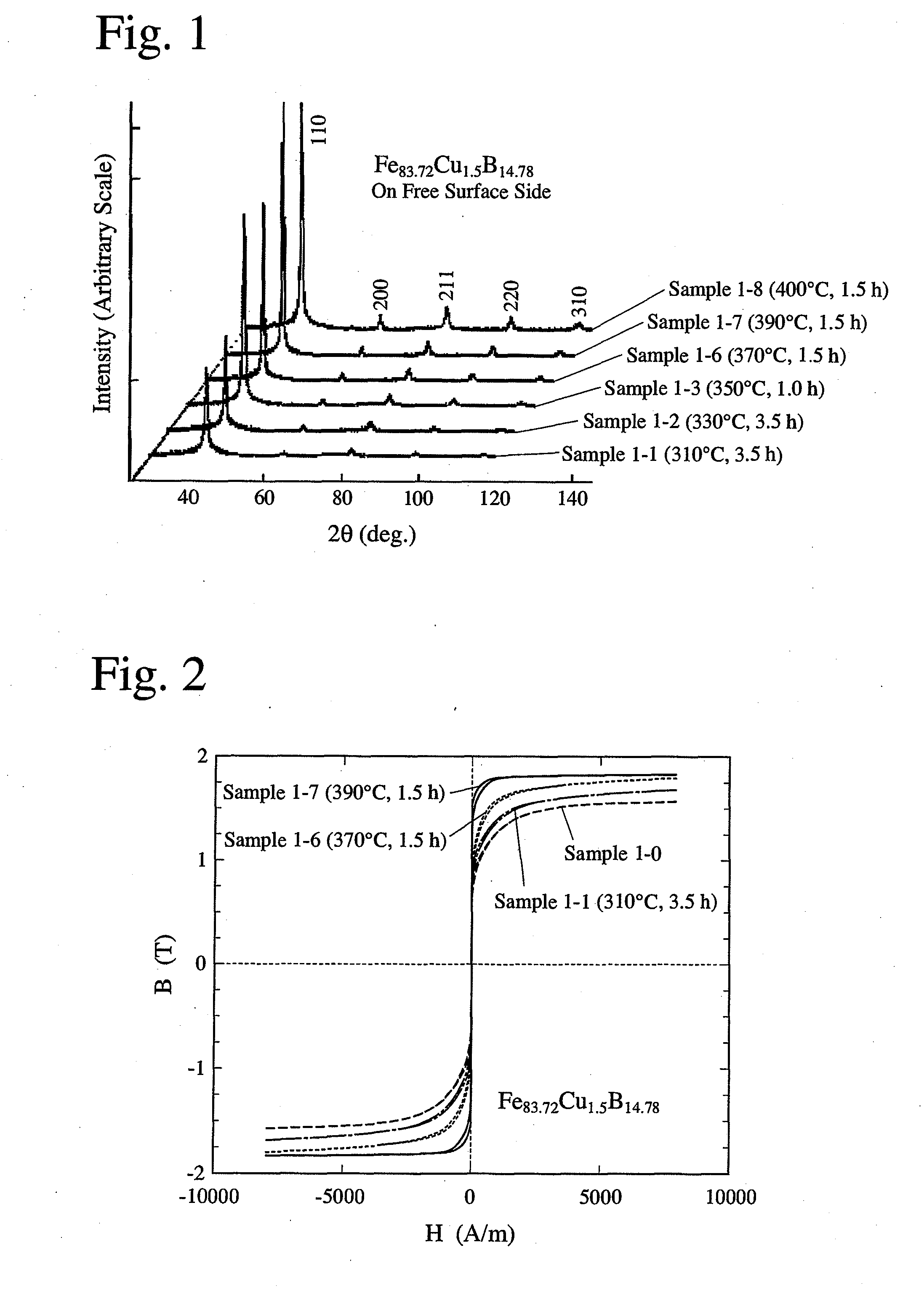

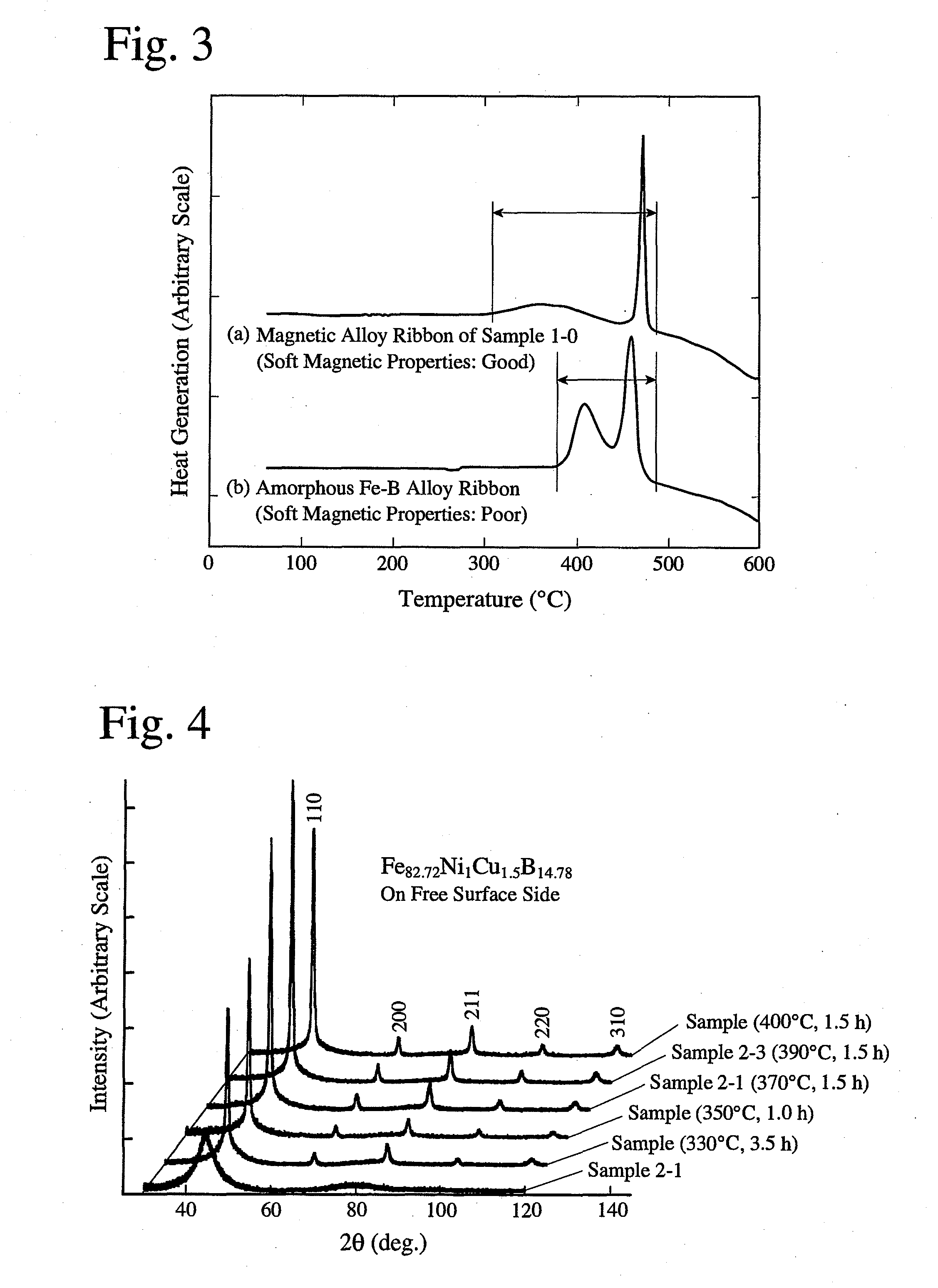

Nano-crystalline, magnetic alloy, its production method, alloy ribbon and magnetic part

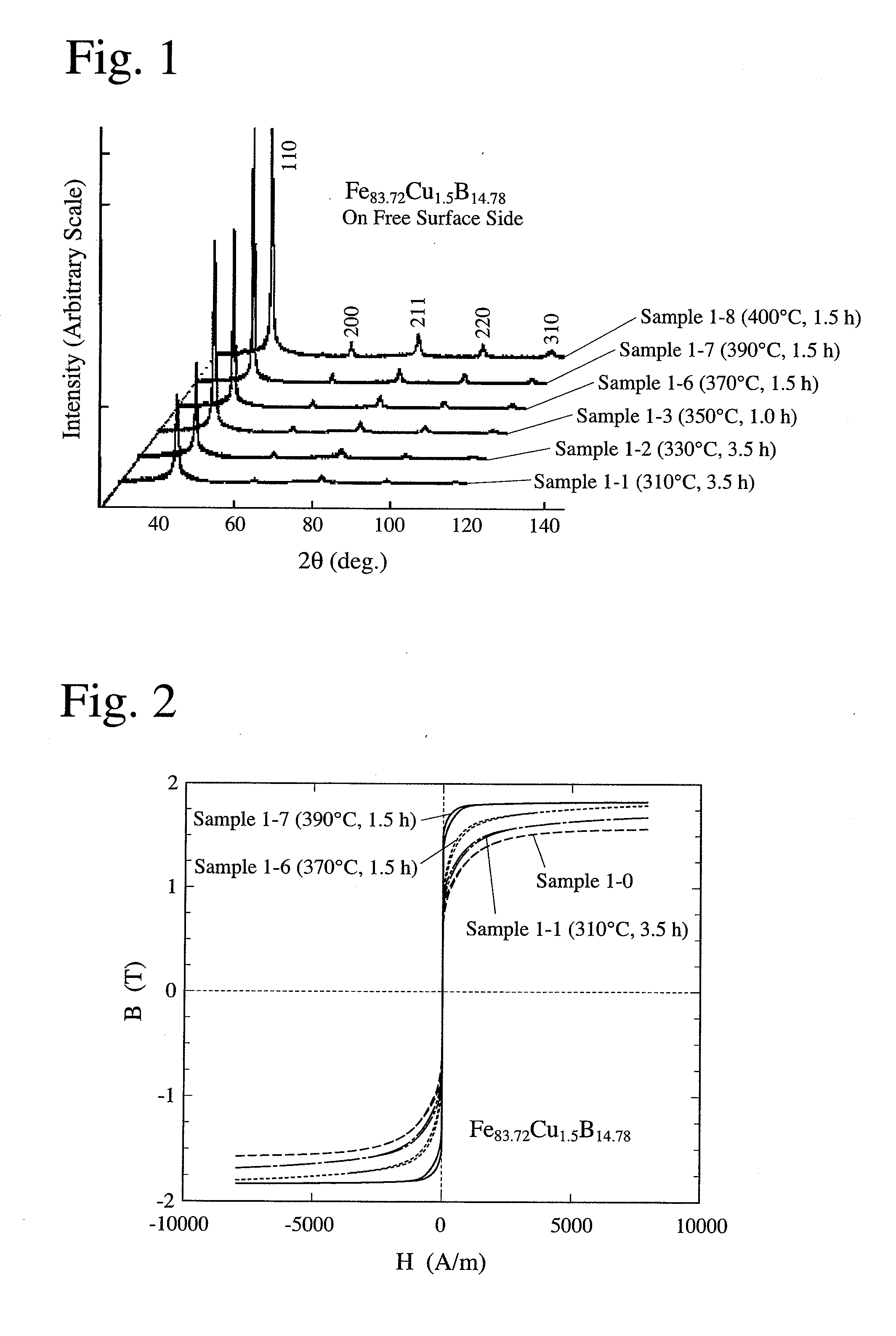

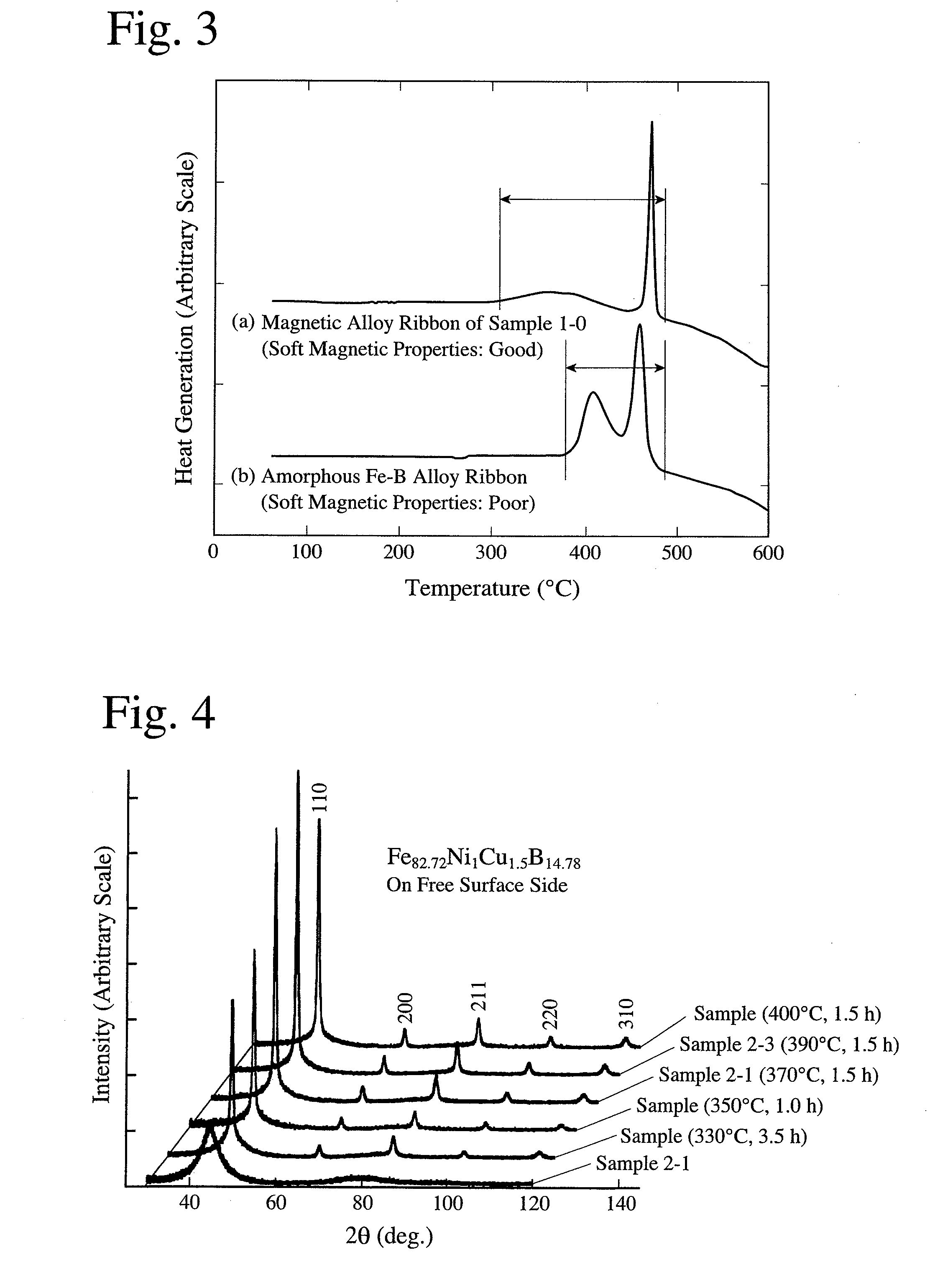

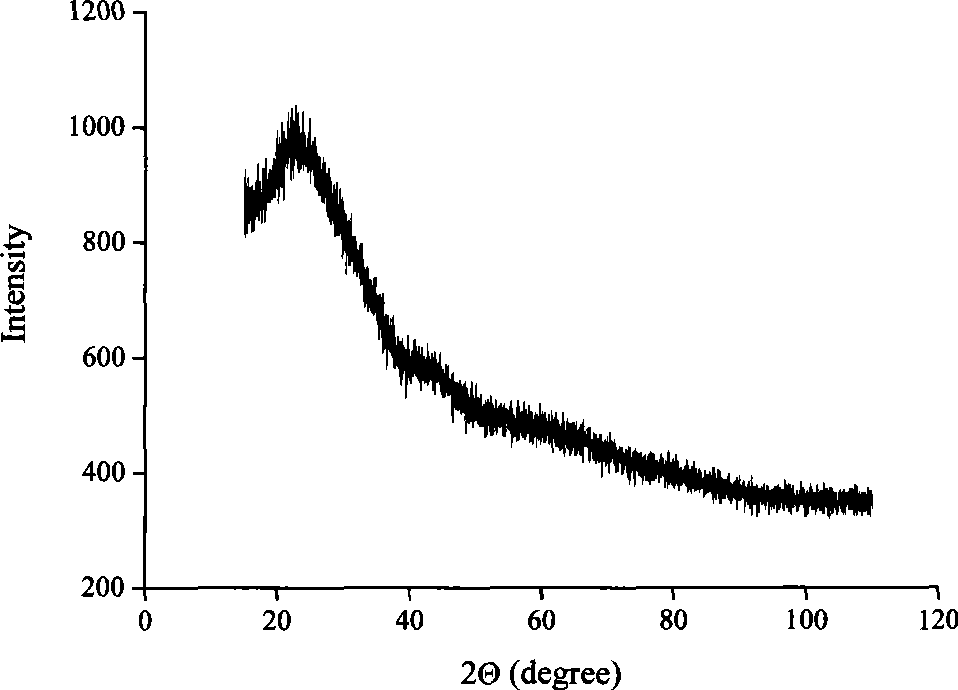

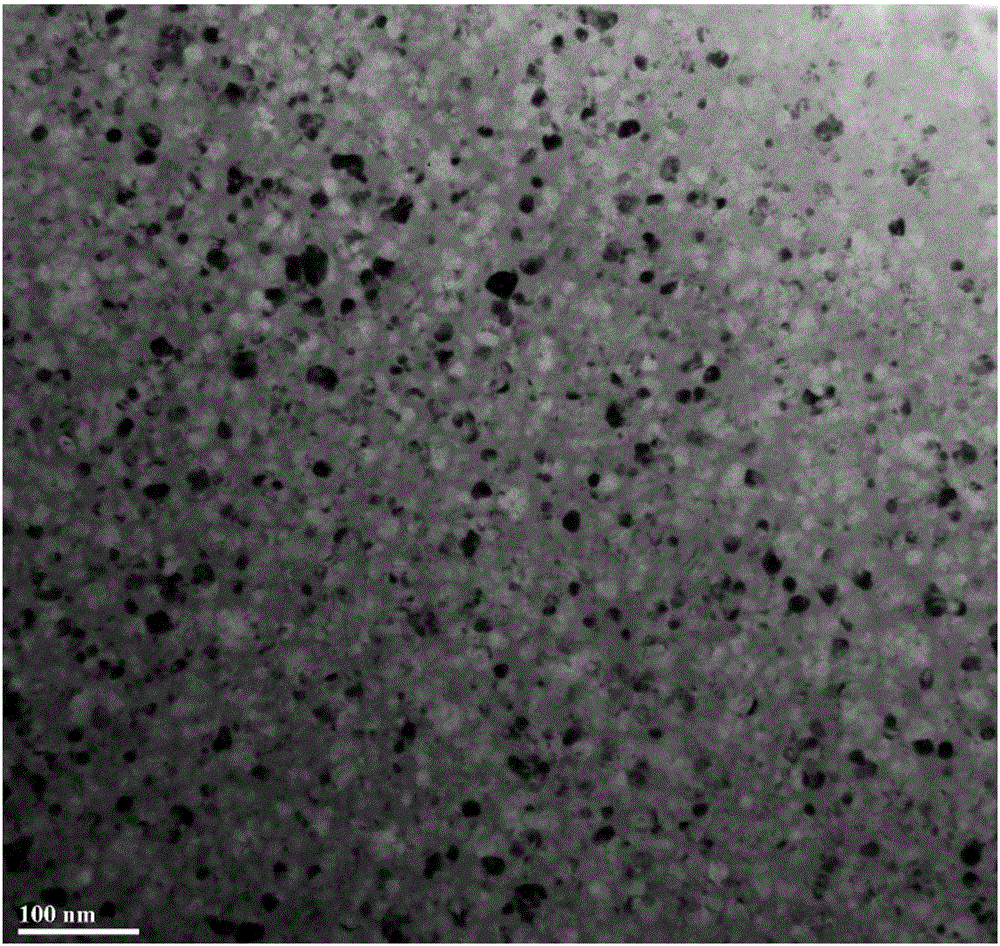

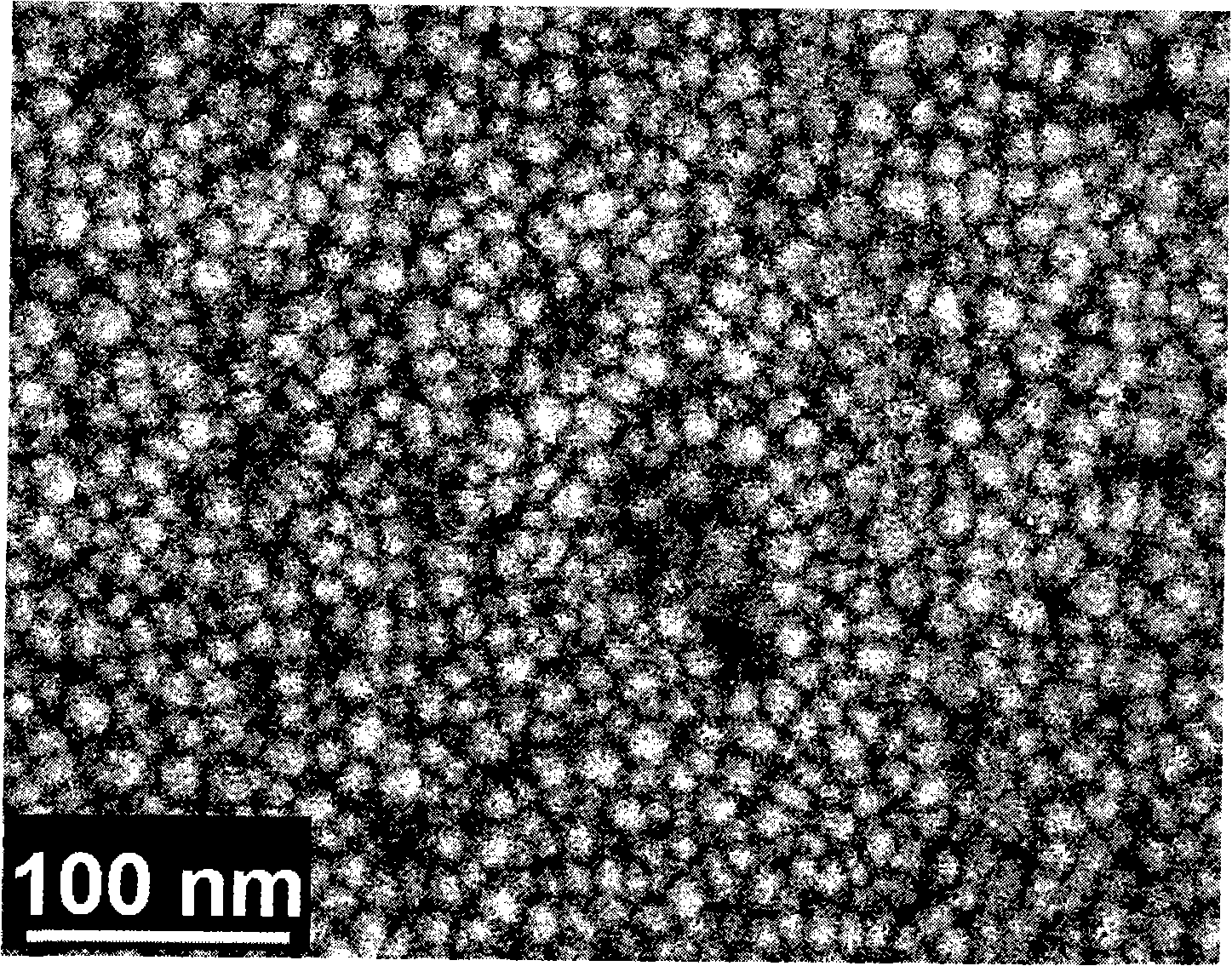

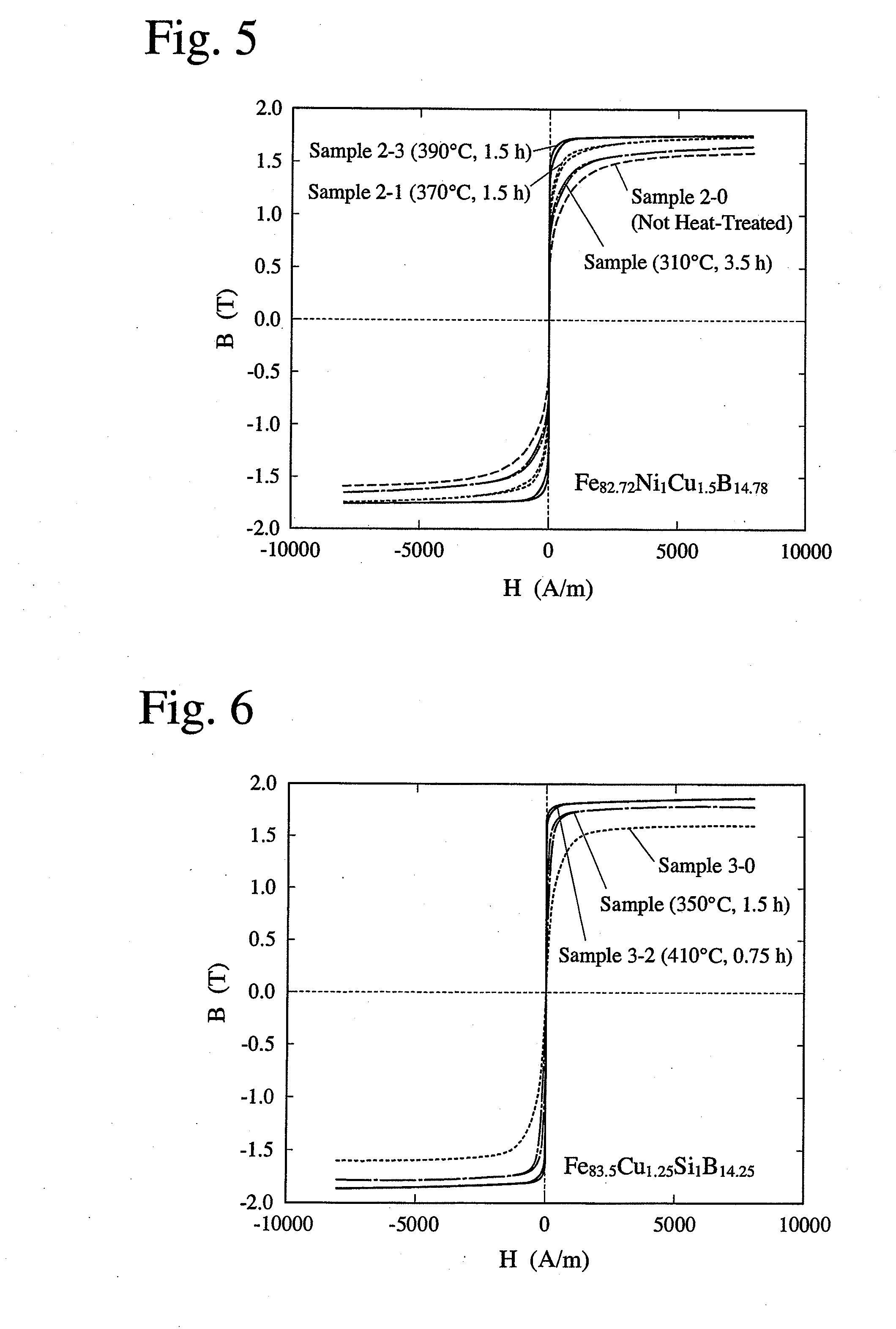

ActiveUS20090266448A1High magnetic flux densityLow coercivityMagnetic materialsVolumetric Mass DensityNano crystalline

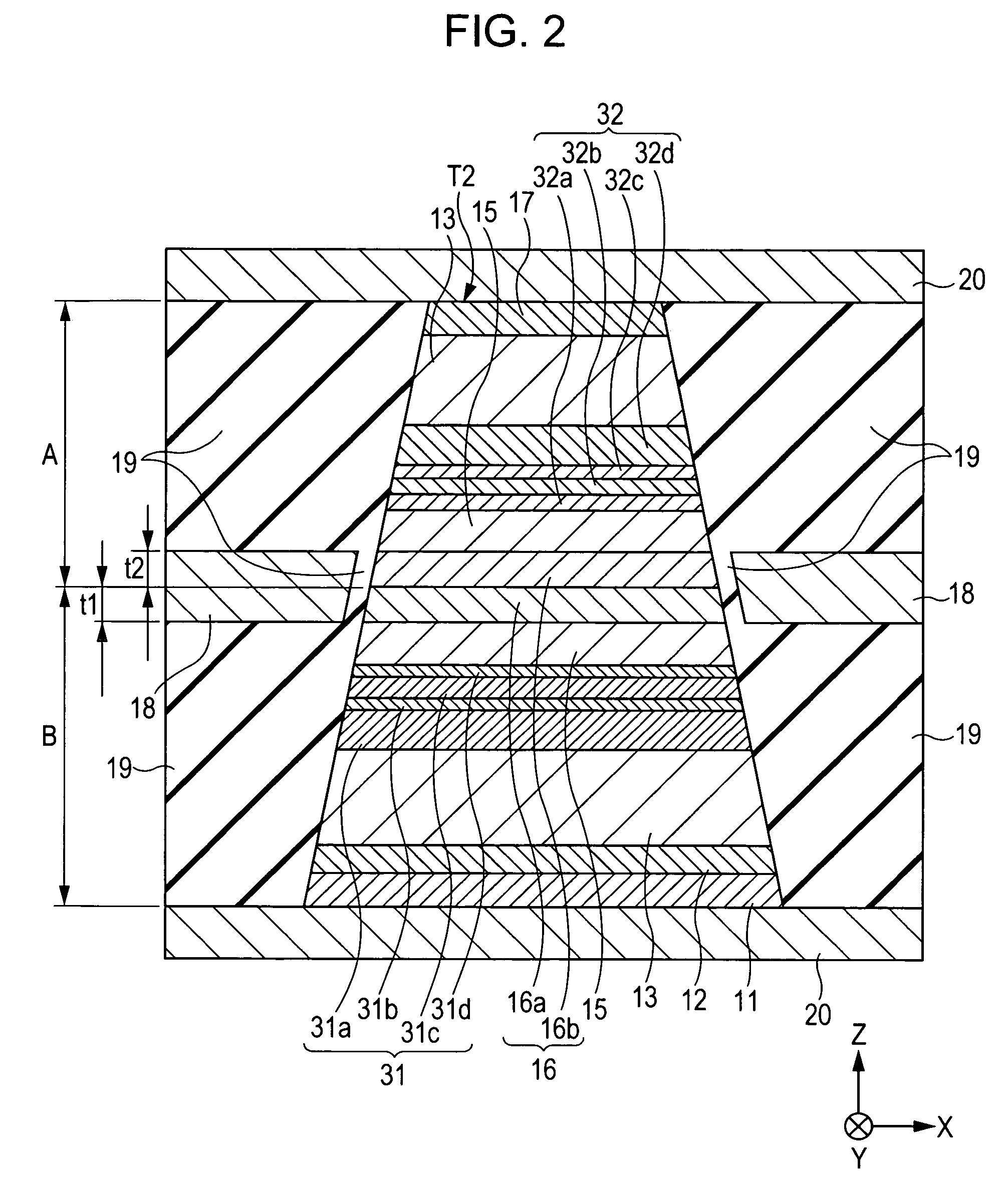

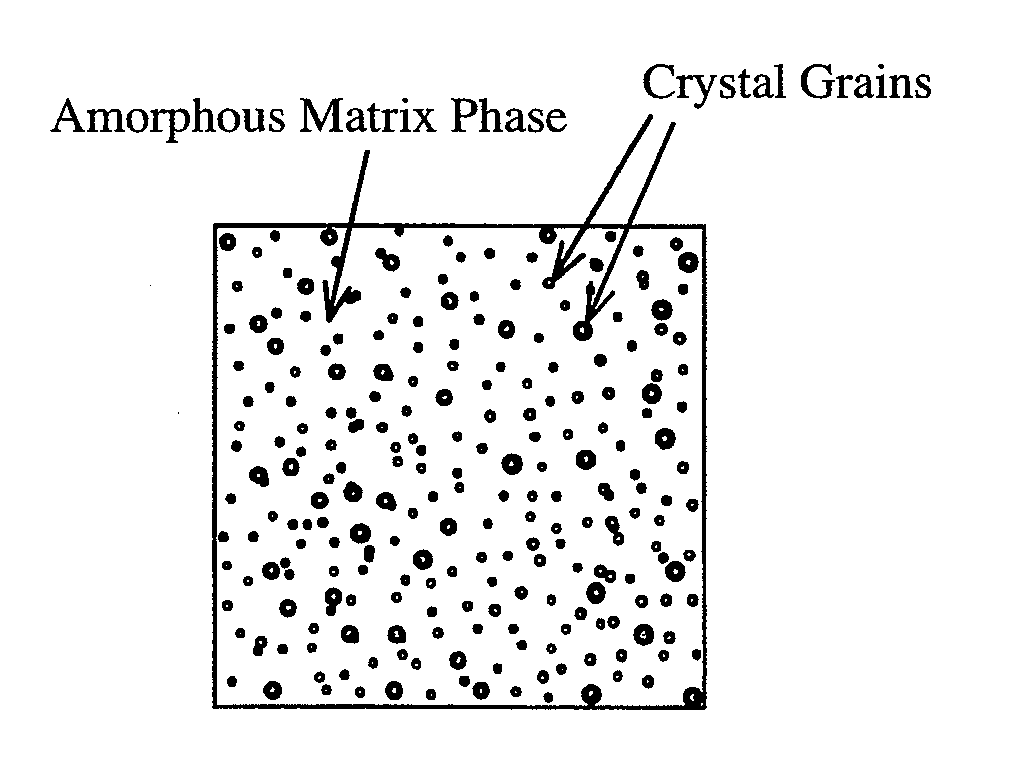

A magnetic alloy having a composition represented by the general formula of Fe100-x-yCuxBy (atomic %), wherein x and y are numbers meeting the conditions of 0.1≦x≦3, and 10≦y≦20, or the general formula of Fe100-x-y-zCuxByXz (atomic %), wherein X is at least one element selected from the group consisting of Si, S, C, P, Al, Ge, Ga and Be, and x, y and z are numbers meeting the conditions of 0.1≦x≦3, 10≦y≦20, 0≦z≦10, and 10<y+z≦24), the magnetic alloy having a structure containing crystal grains having an average diameter of 60 nm or less in an amorphous matrix, and a saturation magnetic flux density of 1.7 T or more.

Owner:HITACHI METALS LTD

Iron-based nanometer crystal magnetically soft alloy and preparation method thereof

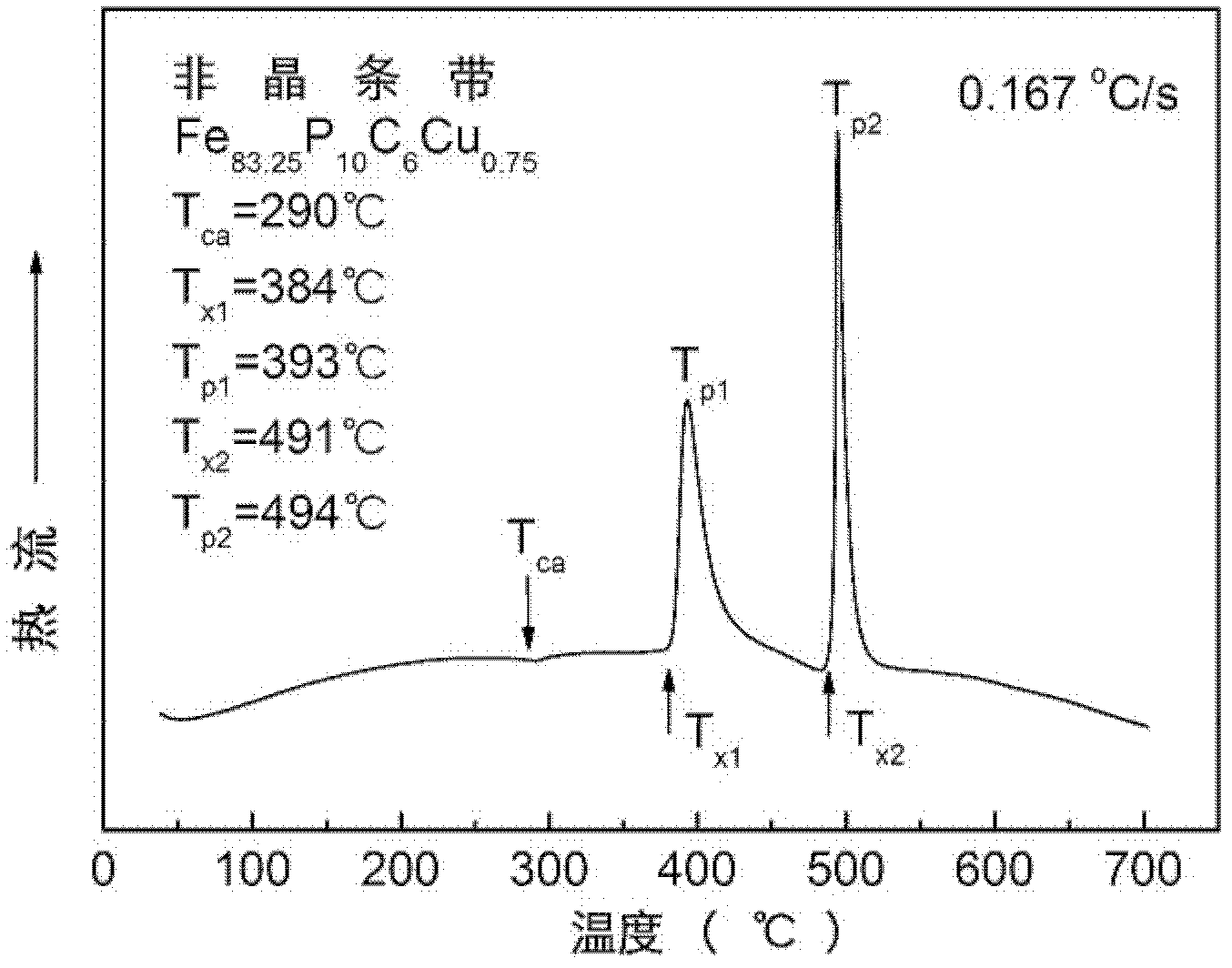

ActiveCN102543347AReduce processing costsHigh saturation magnetic inductionMagnetic materialsAmorphous phaseAlloy

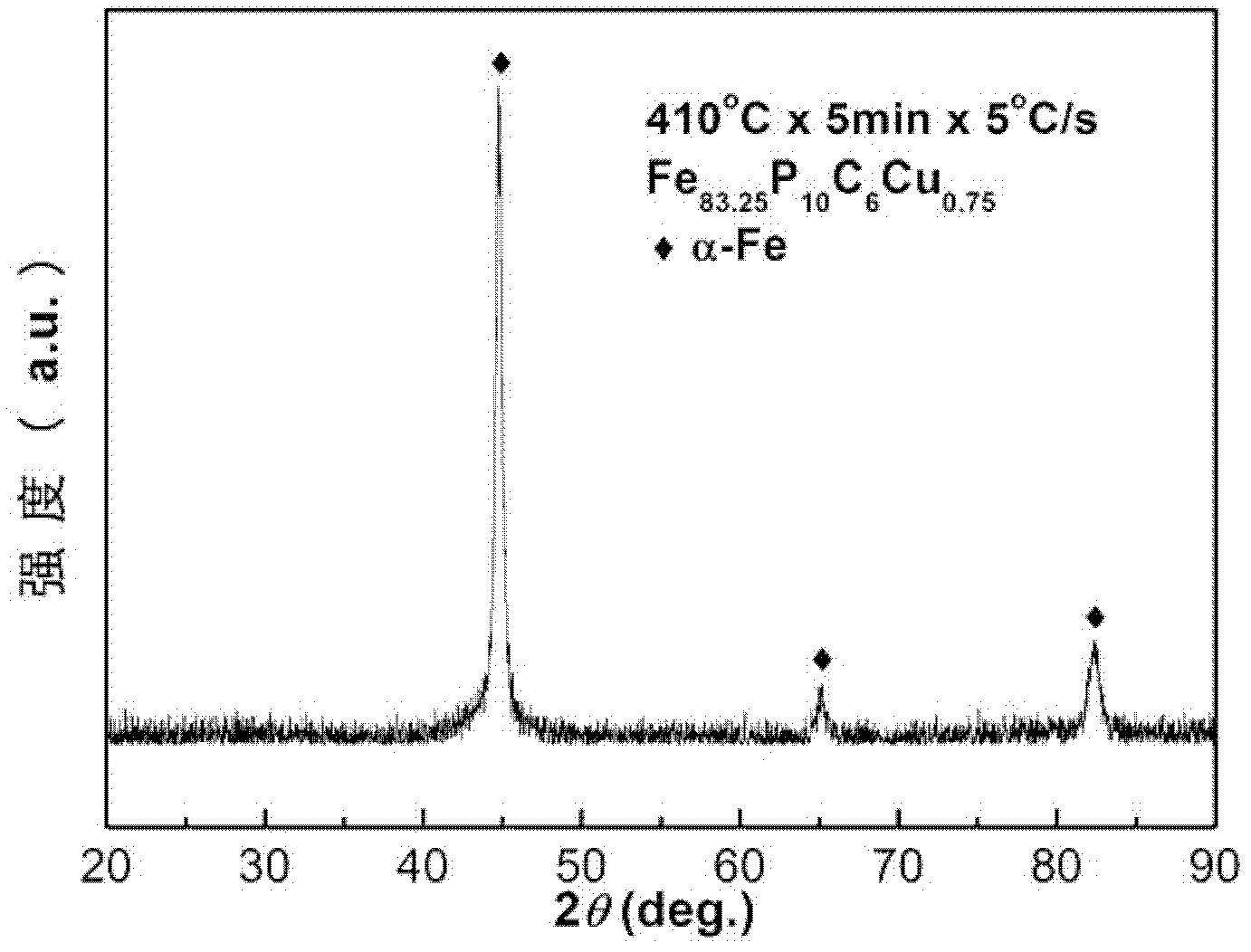

The invention discloses a novel iron-based nanometer crystal magnetically soft alloy and a preparation method thereof. The molecular formula of the iron-based nanometer crystal magnetically soft alloy is FexPyCzMaCub, wherein the M in the molecular formula is one or more than one of B, Si, Al, Cr, Mn, Mo and Ge; x,y,z,a and b respectively represent atom percentage composition of each corresponding component, wherein 70<=x<=90, 1<=y<=20, 1<=z<=20, 0<=a<=10, 0.1<=b<=2, and x+y+z+a+b=100; and a microstructure is coexistence of a body-centered stand alpha-Fe nanometer crystalline phase the size of which is 5-40 nm and a rich phosphatic and carbon amorphous phase. Compared with the existing nanometer crystal magnetically soft alloy, the alloy disclosed by the invention meanwhile has the advantages of high saturation induction density, low coercive force, low iron loss and high magnetic permeability; and in addition, precious metals such as Nb, Zr, Co, Ni, Y and the like are not contained, thus the processing cost is greatly reduced and the application prospect is good.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

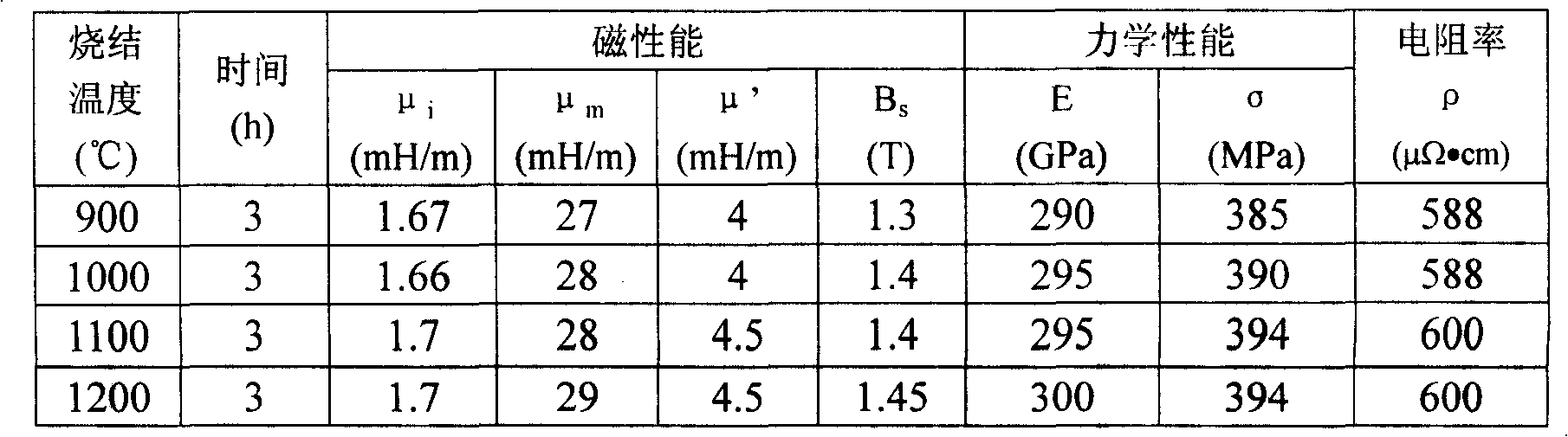

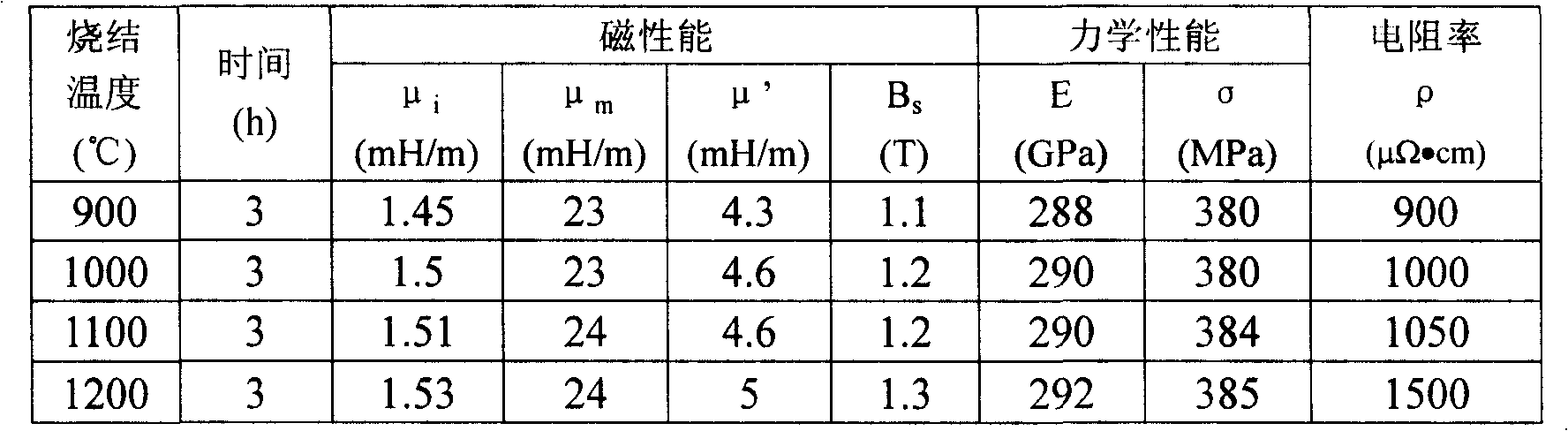

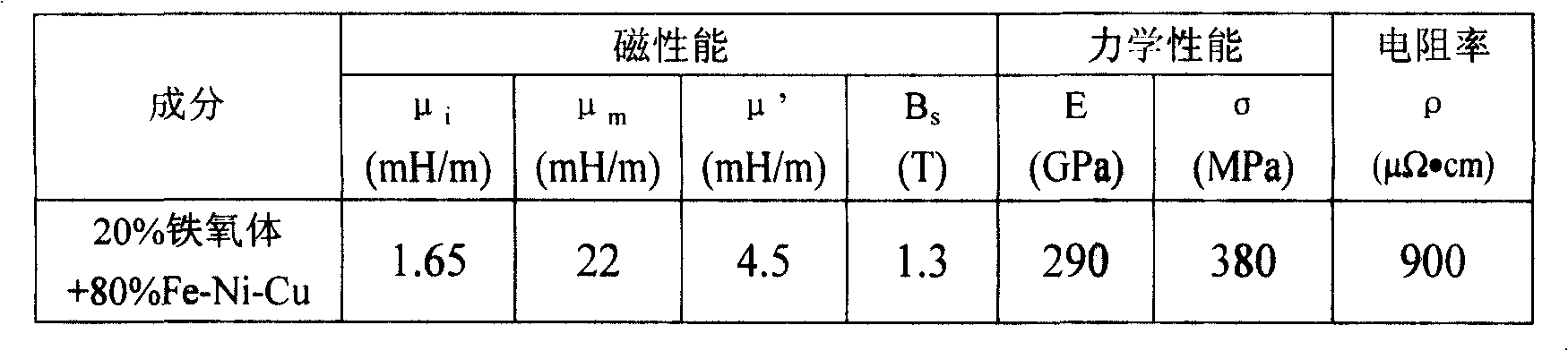

Sintered composite soft magnetic material and method for preparing same

ActiveCN102651264ALower sintering temperatureImprove compactnessInorganic material magnetismRare-earth elementMagnet

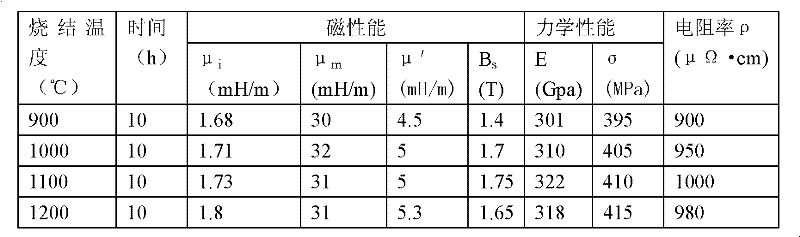

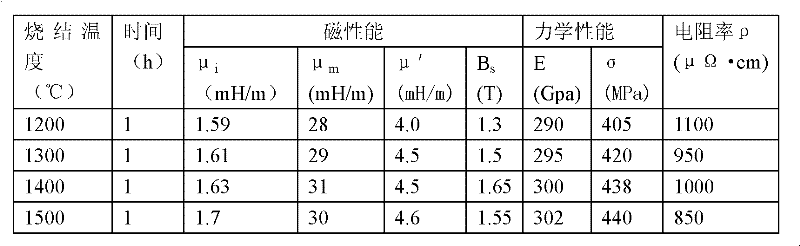

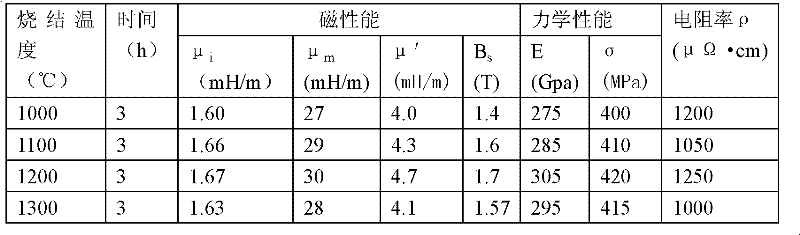

The invention relates to a sintered composite soft magnetic material and a method for preparing the same. The material comprises a metal soft magnetic material, a soft magnetic ferrite and a low-melting-point soft magnetic alloy, wherein the metal soft magnetic material is formed by at least one of an Fe-Ni system, an Fe-Co system, an Fe-Co-V system, an Fe-Al system and an Fe-Al-Me system (Me is one or more than two of Co, Cr and Mo), the soft magnetic ferrite is formed by at least one of an Mn-Zn system, an Ni-Zn-based, an Li-Zn system and a Cu-Zn system, and the low-melting-point soft magnetic alloy is an Re-Fe-M system alloy (Re comprises one or more of 17 rare earth elements including Sc and Y, and M is one or more of metal elements including B, Al, Si, Ti, V, Cr, Mn, Co, Cu, Mo, Ni, Zn, Ga, Nb, Ta and W). The method for preparing the soft magnetic material formed by the components has the advantages that cold pressing and then sintering or hot pressing or spark plasma sintering are selected, and the soft magnetic material not only overcomes the low resistivity of the metal soft magnetic material and the low magnetic induction of the ferrite, but also maintains the excellent performance of the metal soft magnetic material and the soft magnetic ferrite.

Owner:GRIREM ADVANCED MATERIALS CO LTD

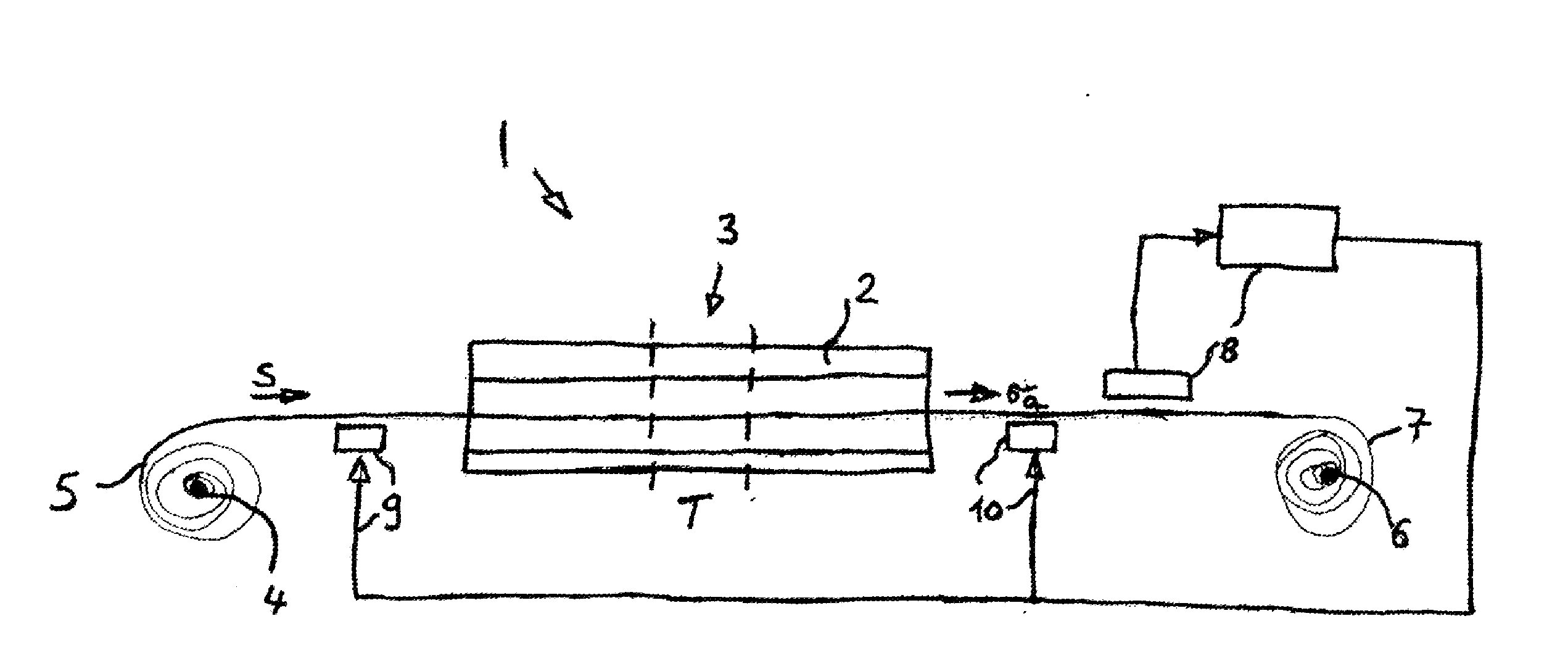

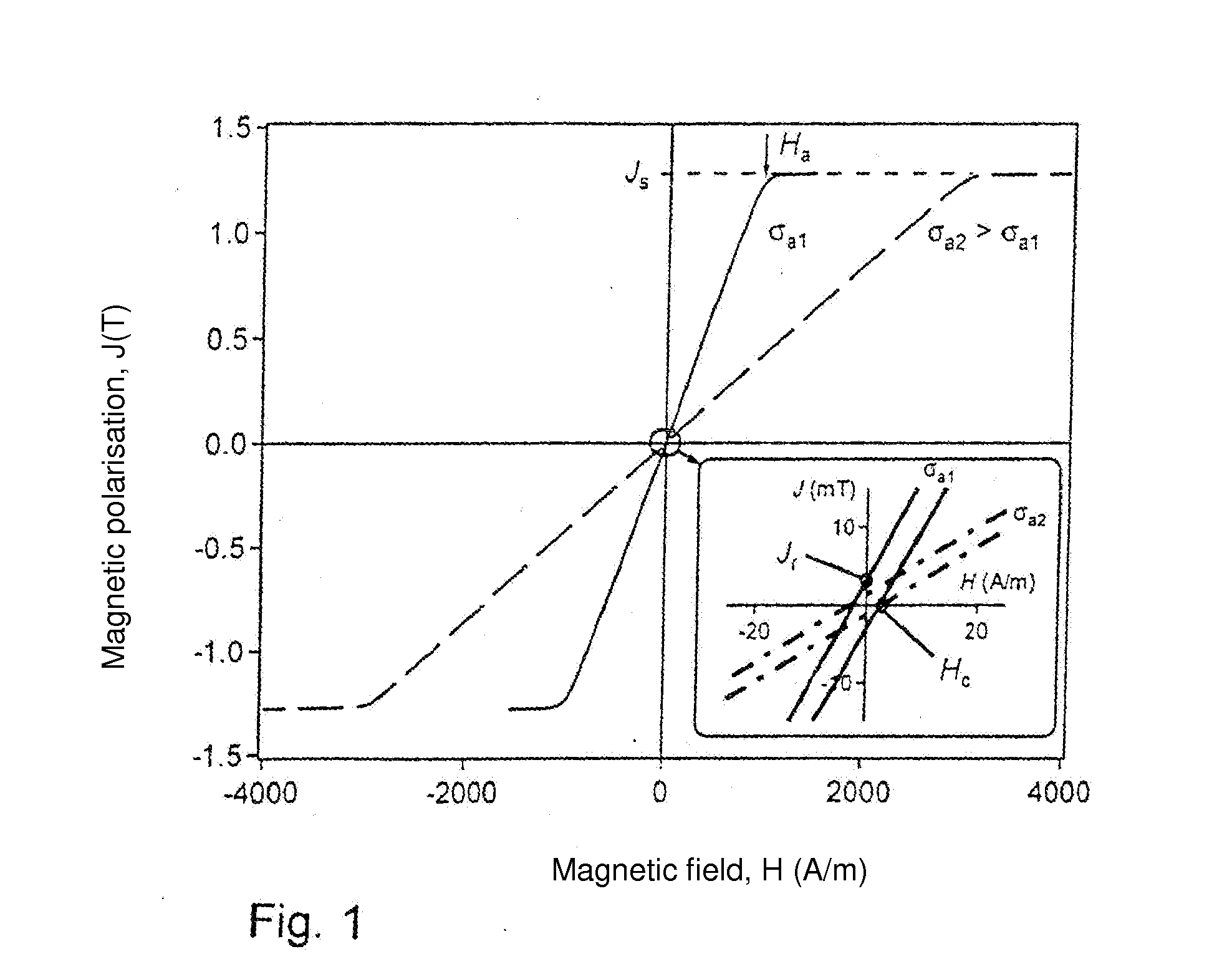

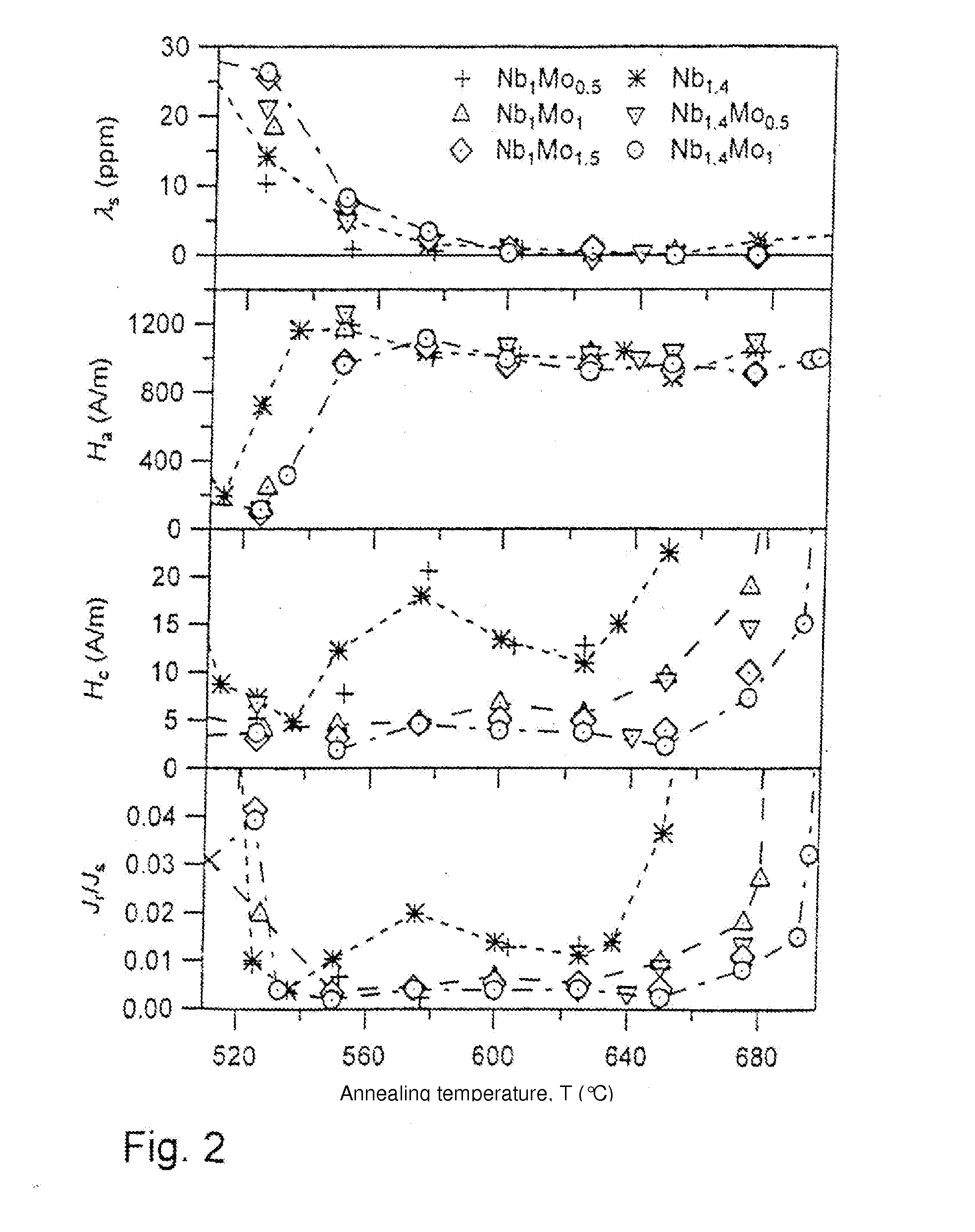

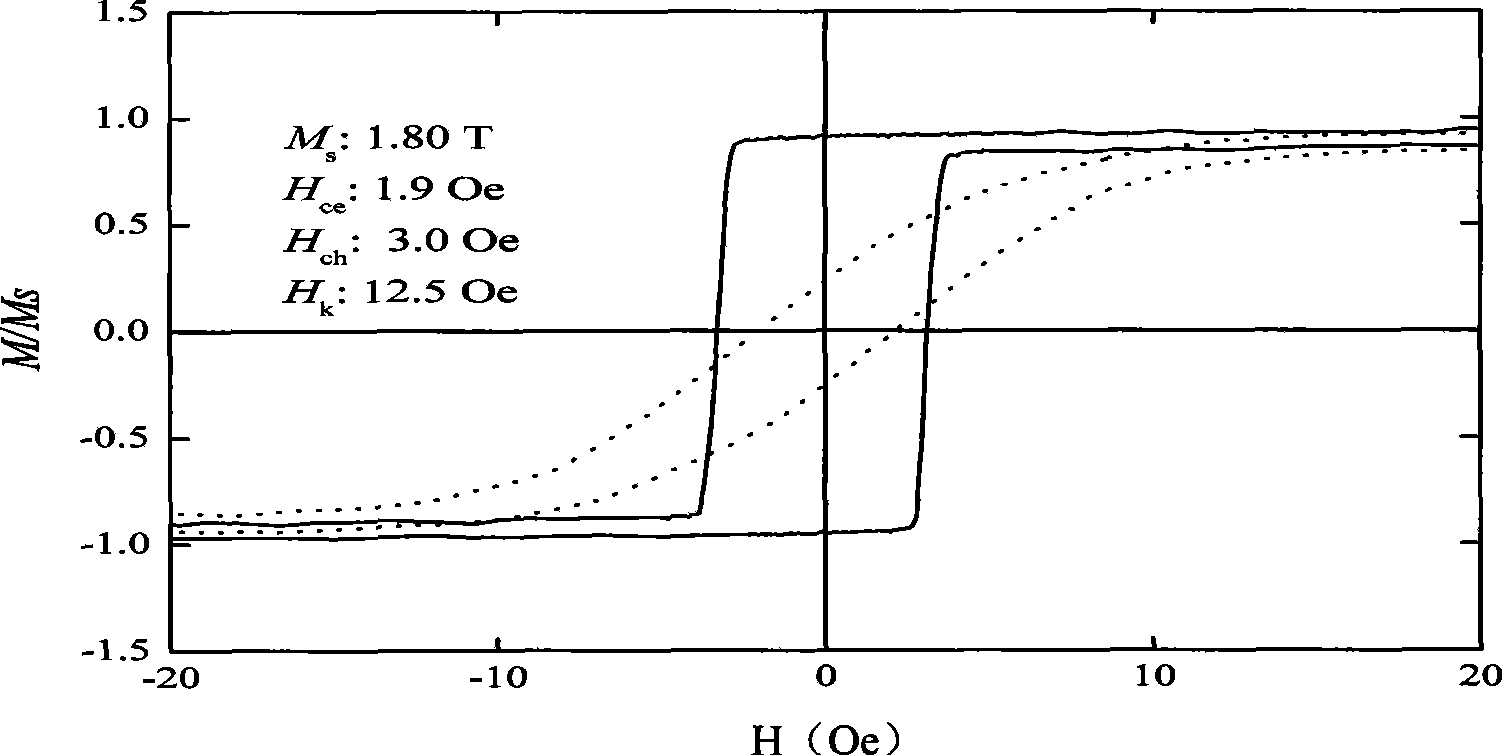

Alloy, magnet core and method for producing a strip from an alloy

ActiveUS20140104024A1Degradation of magnetic propertyUniformity of soft magnetic propertyInductances/transformers/magnets manufactureMagnetic materialsAlloyImpurity

An alloy of Fe100-a-b-c-d-x-y-zCuaNbbMcTdSixByZz and up to 1 atomic % impurities; M is one or more of Mo or Ta, T is one or more of V, Cr, Co or Ni and Z is one or more of C, P or Ge, wherein 0.0 atomic % a <1.5 atomic %, 0.0 atomic % b <3.0 atomic %, 0.2 atomic % c 4.0 atomic %, 0.0 atomic % d <5.0 atomic %, 12.0 atomic %<x<18.0 atomic %, 5.0 atomic %<y<12.0 atomic % and 0.0 atomic % z<2.0 atomic %, and wherein 2.0 atomic % (b+c) 4.0 atomic %, produced in the form of a strip and having a nanocrystalline structure in which at least 50% by volume of the grains have an average size of less than 100 nm, a remanence ratio Jr / Js<0.02, Jr being the remanent polarisation and Js being the saturation polarisation, and a coercitive field strength Hc which is less than 1% of the anisotropic field strength Ha and / or less than 10 A / m.

Owner:VACUUMSCHMELZE GMBH & CO KG

High-efficiency soft magnetic material and method for producing the same

InactiveCN101246773AGuaranteed mechanical propertiesExcellent soft magnetic propertiesInorganic material magnetismInductances/transformers/magnets manufactureMetalMagnet

The invention relates to a highly efficient soft magnetic material and the preparing method thereof. The soft magnetic material is composed of metal soft magnetic material and soft magnetic ferrite, the metal soft magnetic material is composed of at least one selected from Fe-Ni-Me system (Me is one or more than two selected form Cu, Cr, Nb, V, W, Si, Pd, Zn, Al, Ti and Mn), Fe-Co system, Fe-Co-V system, Fe-Al system and Fe-Al-Me system (Me is one or more than two selected form Co, Cr and Mo), the soft magnetic ferrite is composed of at least one selected form Mn-Zn system, Ni-Zn system, Li-Zn system, Cu-Zn system and Mg-Zn system soft magnetic ferrites. The preparing method of the soft magnetic material comprises the steps of: cold pressing, and sintering, hot pressing or spark plasma sintering. The soft magnetic material does not have the drawbacks of low resistivity of the metal soft magnetic and low magnetic strength of the ferrite, as well as keeps the superior properties of the metal soft magnetic and low magnetic strength of the ferrite.

Owner:GRIREM ADVANCED MATERIALS CO LTD

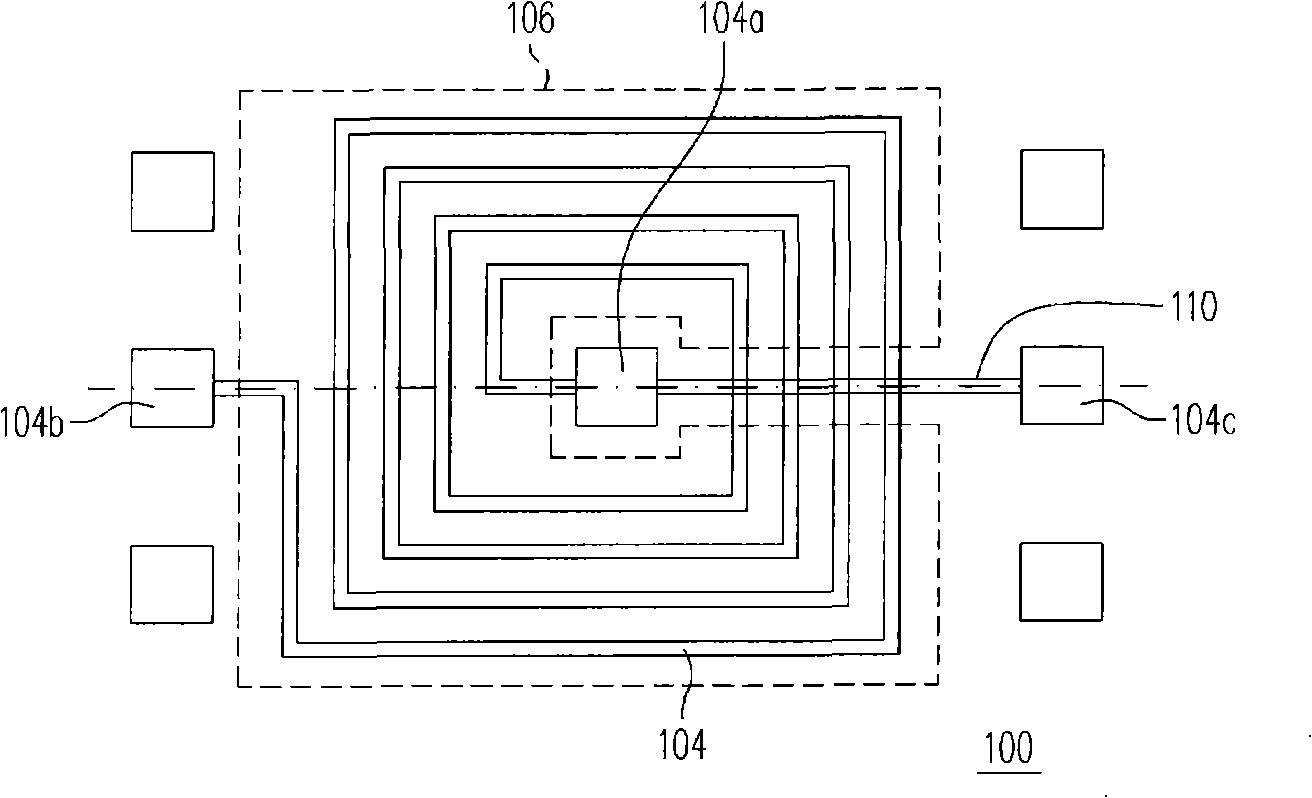

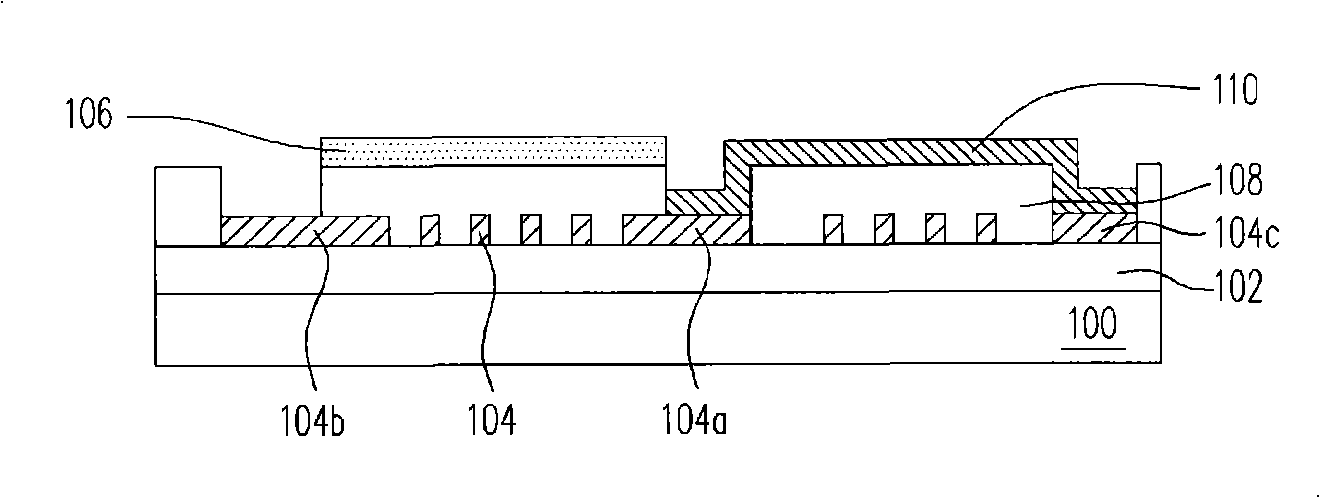

Soft magnetic film inductor and magnetic multi-component alloy thin film

InactiveCN101320617AIncrease disorderHigh nanocrystalline structureInductances/transformers/magnets manufactureMagnetic layersMaterial DesignHigh entropy alloys

A magnetic complex alloy film is suitable for high frequency operation. This magnetic complex alloy film is used for improving the quality factors of the film inductance under high frequency operation and improving the inductance value. This magnetic complex alloy film achieves that the magnetic complex alloy film still has good soft magnetic property when under high frequency operation mainly through leading the materials design concept of complex high-entropy alloy and utilizing some material properties of the complex high-entropy alloy, such as high randomness, nano microcrystalline structure, low coercive field and high resistivity.

Owner:IND TECH RES INST

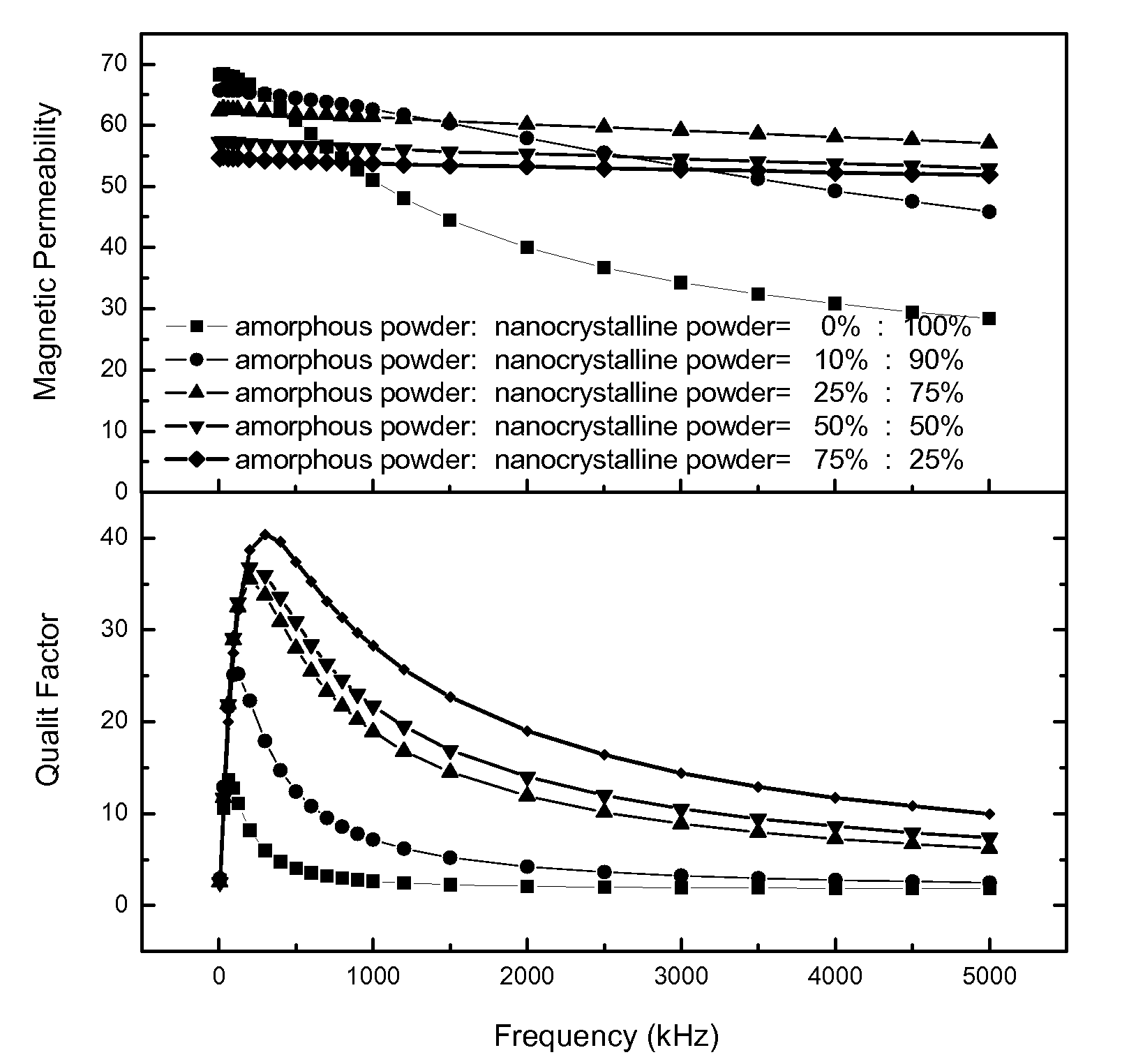

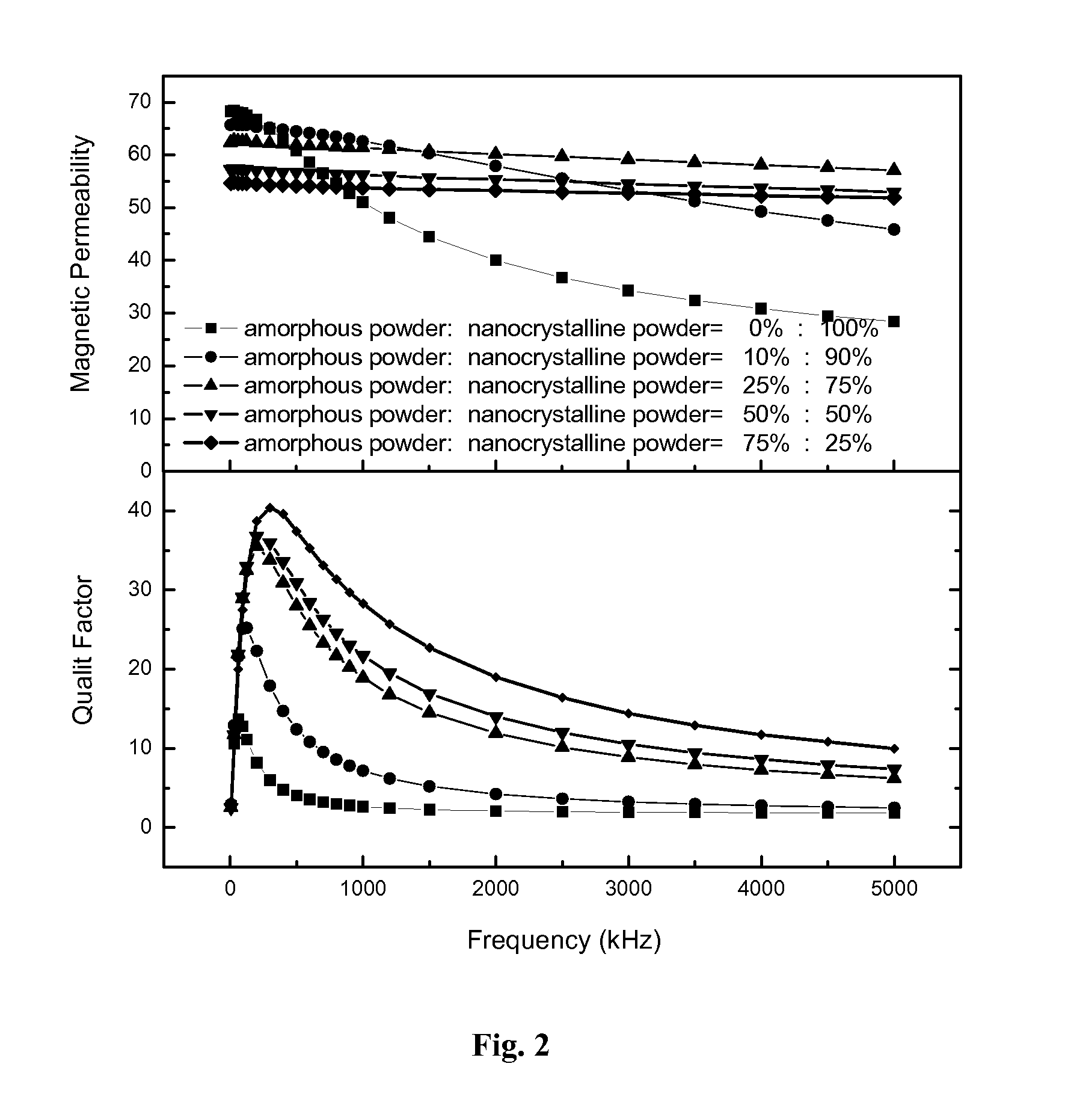

Compound magnetic powder and magnetic powder cores, and methods for making them thereof

ActiveUS20070144614A1Reduce penetrationLow core lossTransportation and packagingMetal-working apparatusAl powderIron powder

The present invention provides a compound powder for making magnetic powder cores, a kind of magnetic powder core, and a process for making them. Said compound powder is a mixture composing of powder A and powder B, the content of powder A is 50-96 wt % and the content of powder B is 4-50 wt %, wherein powder A is at least one selected from iron powder, Fe—Si powder, Fe—Si—Al powder, Fe-based nanocrystalline powder, Fe-based amorphous powder, Fe—Ni powder and Fe—Ni—Mo powder; powder B bears different requirement characteristics from powder A and is at least one selected from iron powder, Fe—Si powder, Fe—Si—Al powder, Fe-based nanocrystalline powder, Fe-based amorphous powder, Fe—Ni powder and Fe—Ni—Mo powder. Said powder B adopts Fe-based amorphous soft magnetic powder with good insulation property as insulating agent and thus core loss of magnetic powder core decreases. The decrease of magnetic permeability of magnetic powder core resulting from a traditional insulating agent is remedied and the initial magnetic permeability of magnetic powder core is improved by taking advantage of soft magnetic properties of Fe-based amorphous powder.

Owner:ADVANCED TECHNOLOGY & MATERIALS CO LTD +1

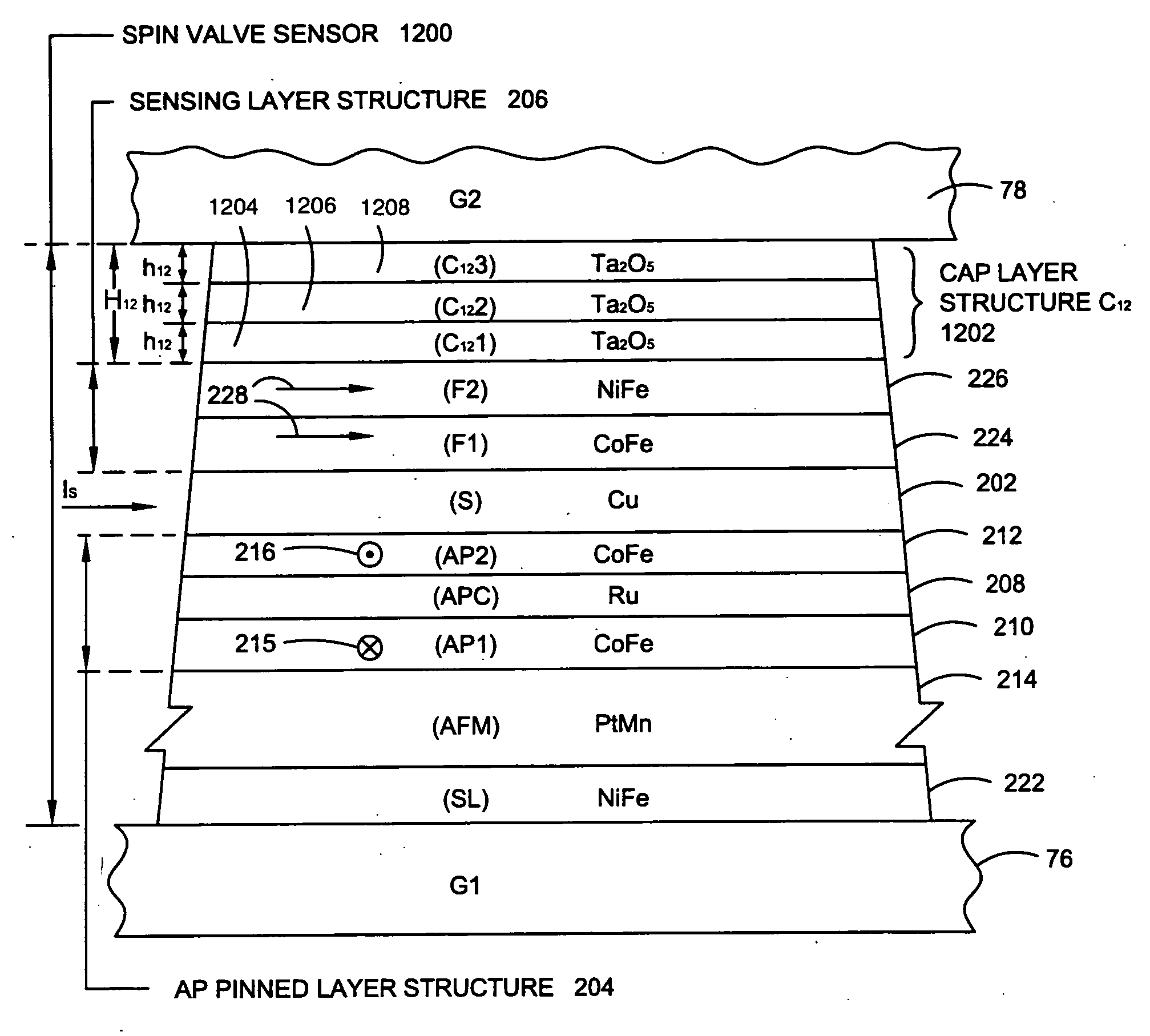

Magnetic sensing devices having an insulator structure with a plurality of oxidized, nitrided, or oxynitrided sublayers and methods of making the same

InactiveUS20070047153A1Excellent soft magnetic propertiesGood effectElectrical transducersNanomagnetismGiant magnetoresistanceRandom access memory

A magnetic sensing device for use in a magnetic head includes a sensor stack structure having a sensing layer structure and an insulator structure formed adjacent the sensing layer structure. The insulator structure includes a plurality of oxidized metallic sublayers, a plurality of nitrided metallic sublayers, or a plurality of oxynitrided metallic sublayers. The insulator structure may be a capping layer structure of a giant magnetoresistance sensor or, alternatively, a tunnel barrier layer structure of a tunneling magnetoresistance sensor or a magnetic random access memory. Advantageously, each treated metallic sublayer is sufficiently uniformly treated so as to increase the magnetoresistive effect and improve soft magnetic properties of the magnetic sensing device. A method for use in forming the magnetic sensing device of the present application includes the steps of forming a sensor stack structure which includes a sensing layer structure; depositing a metallic layer; performing, on the metallic layer, either an oxidation, nitridation, or oxynitridation process; and repeating the steps of depositing and performing one or more times to thereby form an insulator structure.

Owner:WESTERN DIGITAL TECH INC

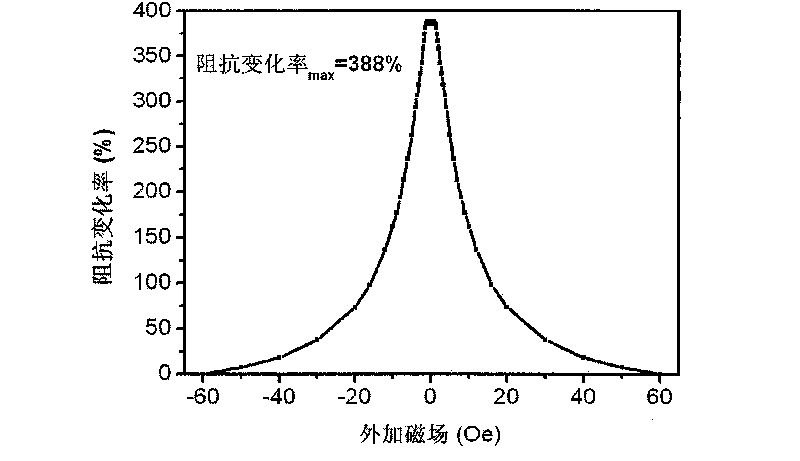

Cobalt base amorphous alloy wire and preparation method thereof

The invention discloses a cobalt base amorphous alloy wire and a preparation method thereof. The molecular formula of the alloy is CoaFebBcSidNbe, wherein a is 60-70 percent, b is 2-10 percent, c is 15-25 percent, d is 3-6 percent, e is 2-6 percent and the summation of a, b, c, d and e is 100 percent. A glass coated spinning method is adopted for preparation method, and a prepared cobalt base amorphous alloy wire material has excellent soft magnetic property and mechanical property and higher colossal magneto resistive change rate and magnetic sensitivity ratio. The invention can greatly improve the colossal magneto resistive change rate and the magnetic sensitivity ratio of the cobalt base amorphous alloy wire, and the properties of the product are superior to that of like products in China at present, thus the cobalt base amorphous alloy wire can be widely applied to the fields of AC sensor technologies and magnetic-sensing sensor technologies.

Owner:NINGBO INNOVATION CENT FOR APPLIED MAGNETICS CO LTD

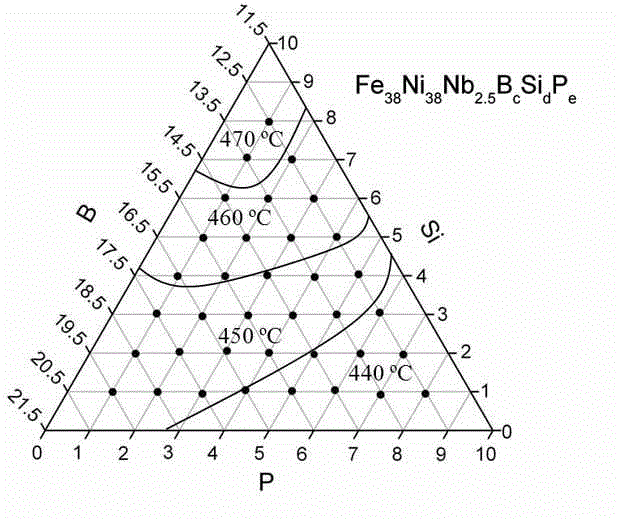

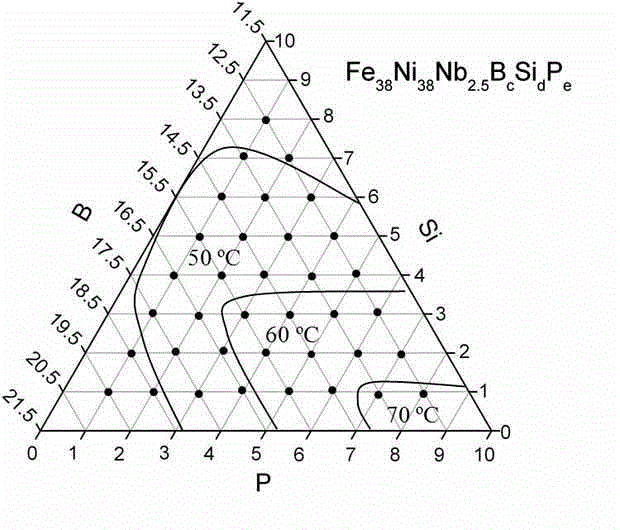

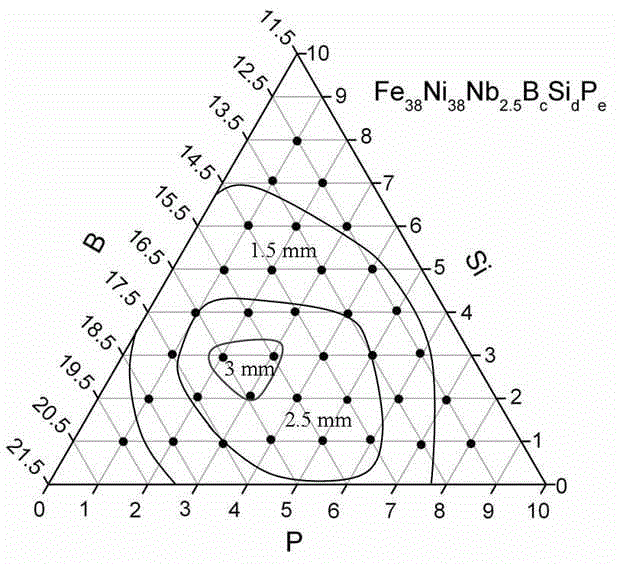

FeNi-based amorphous soft magnetic alloy and preparation method of soft magnetic alloy

ActiveCN102867608AIncrease element contentLarge critical dimensionMagnetic materialsDuctilityPlastic property

The invention discloses a FeNi-based amorphous soft magnetic alloy, of which the formula is FeaNibBcSidPeNbf, wherein a, b, c, d, e and f are atomic percentages; the FeNi-based amorphous soft magnetic alloy is characterized in that a is not less than 10 and not more than 75; b is not less than 5 and not more than 70; c is not less than 4 and not more than 24; d is not less than 0.1 and not more than 15; e is not less than 1 and not more than 14 and f is not less than 0.01 and not more than 6; moreover, the sum of a and b is not less than 72 and not more than 84, and the sum of a, b, c, d, e and f is 100 percent. The FeNi-based amorphous soft magnetic alloy has the characteristics of high content of FeNi elements, large critical dimension, high amorphous formation capacity, excellent soft magnetic performance and mechanical property; the breaking strength is more than 3.3 Gpa and the compressive ductility is more than 7 percent. In addition, the invention further provides a method for preparing FeNi-based amorphous soft magnetic alloy belts or rods.

Owner:朗峰新材料启东有限公司

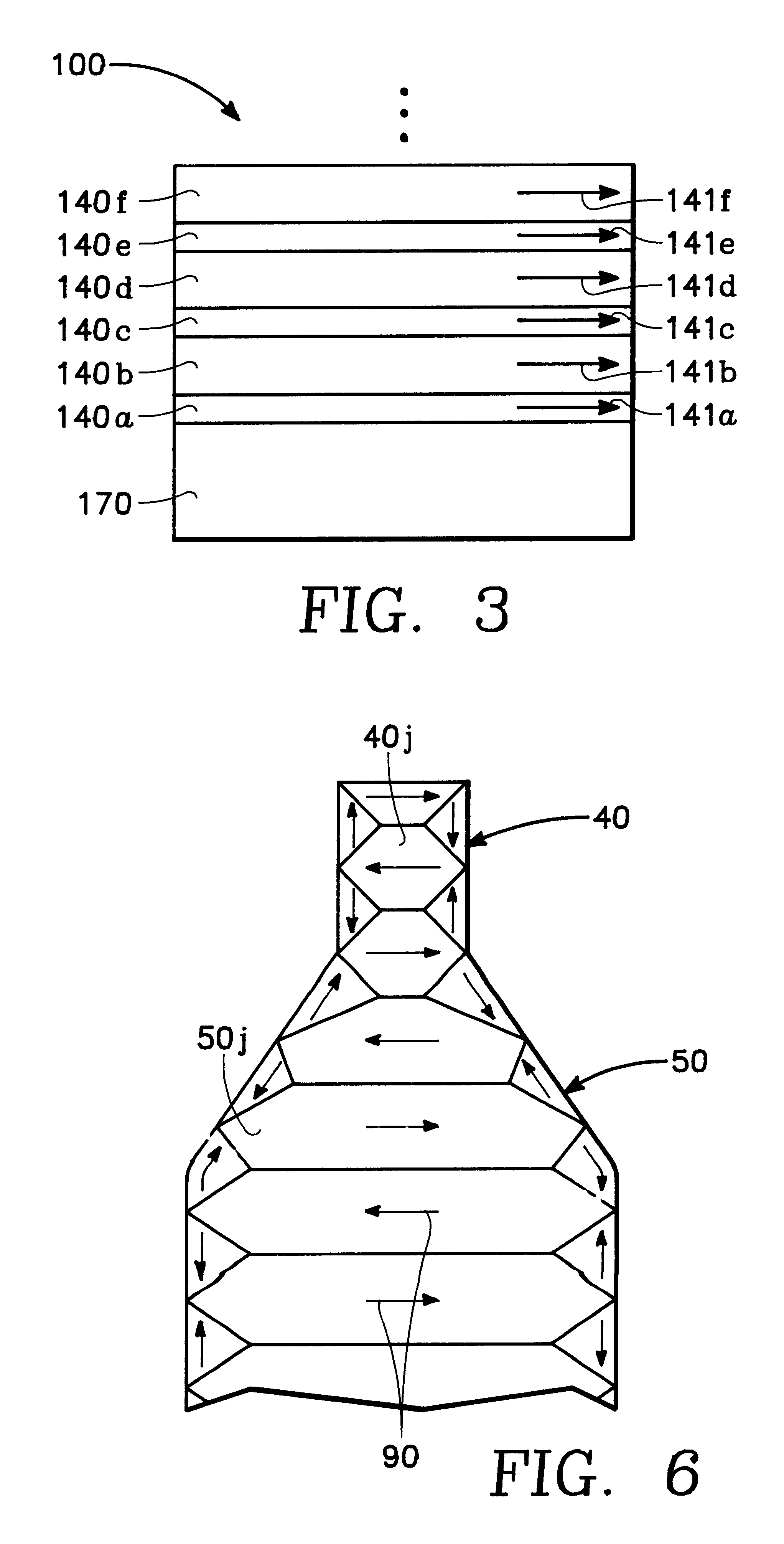

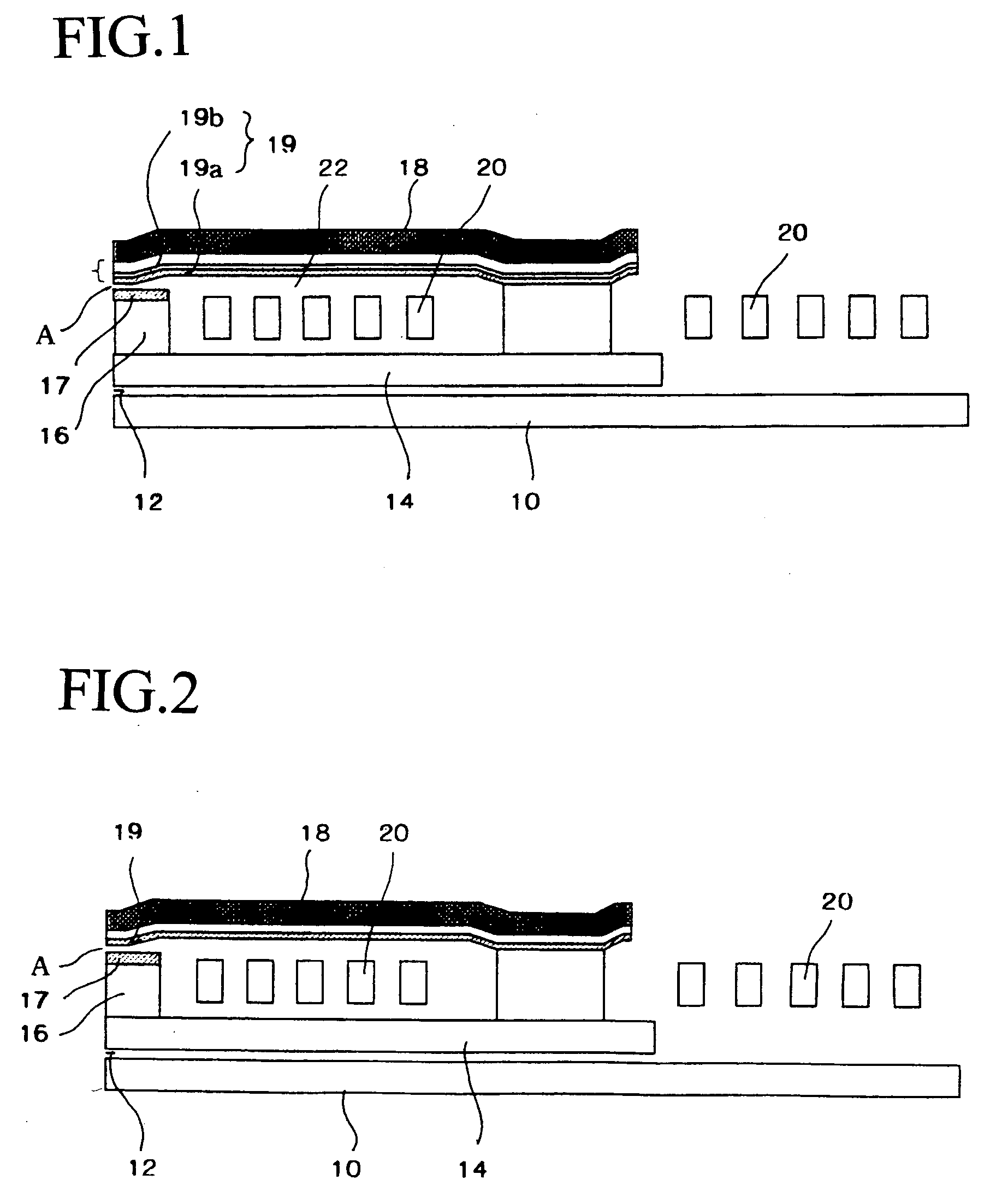

Magnetic thin film or composite magnetic thin film for high frequency and magnetic device Including the same

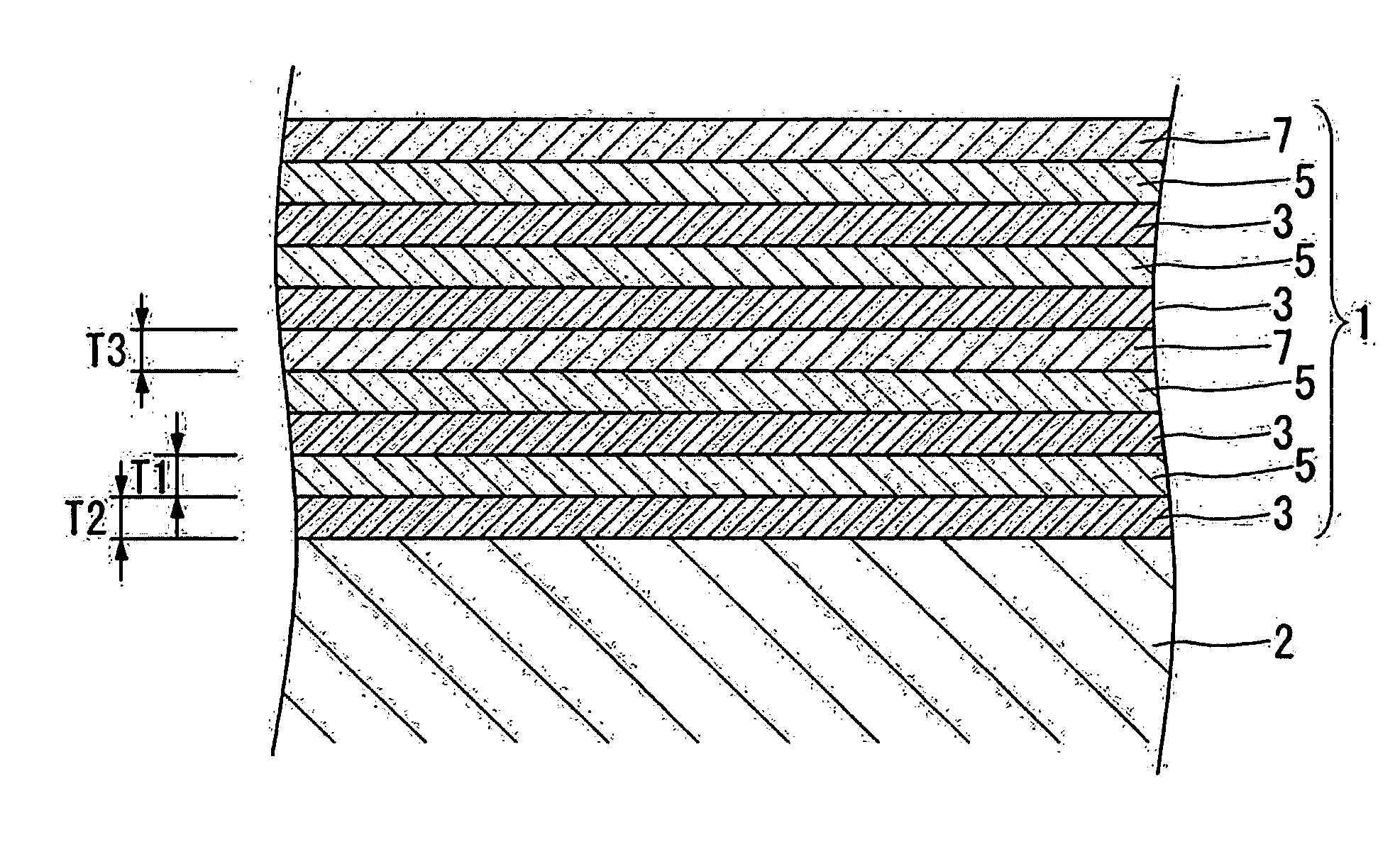

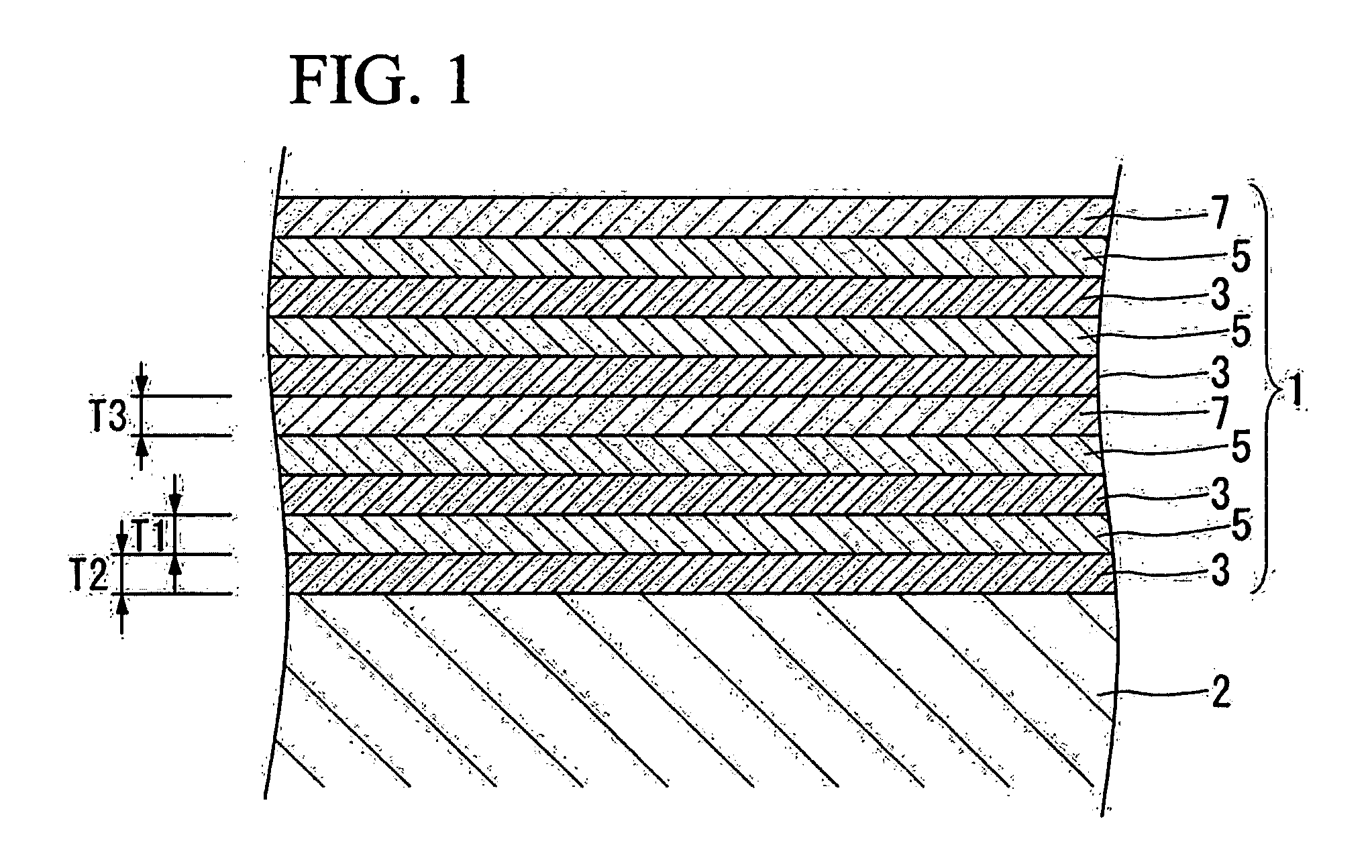

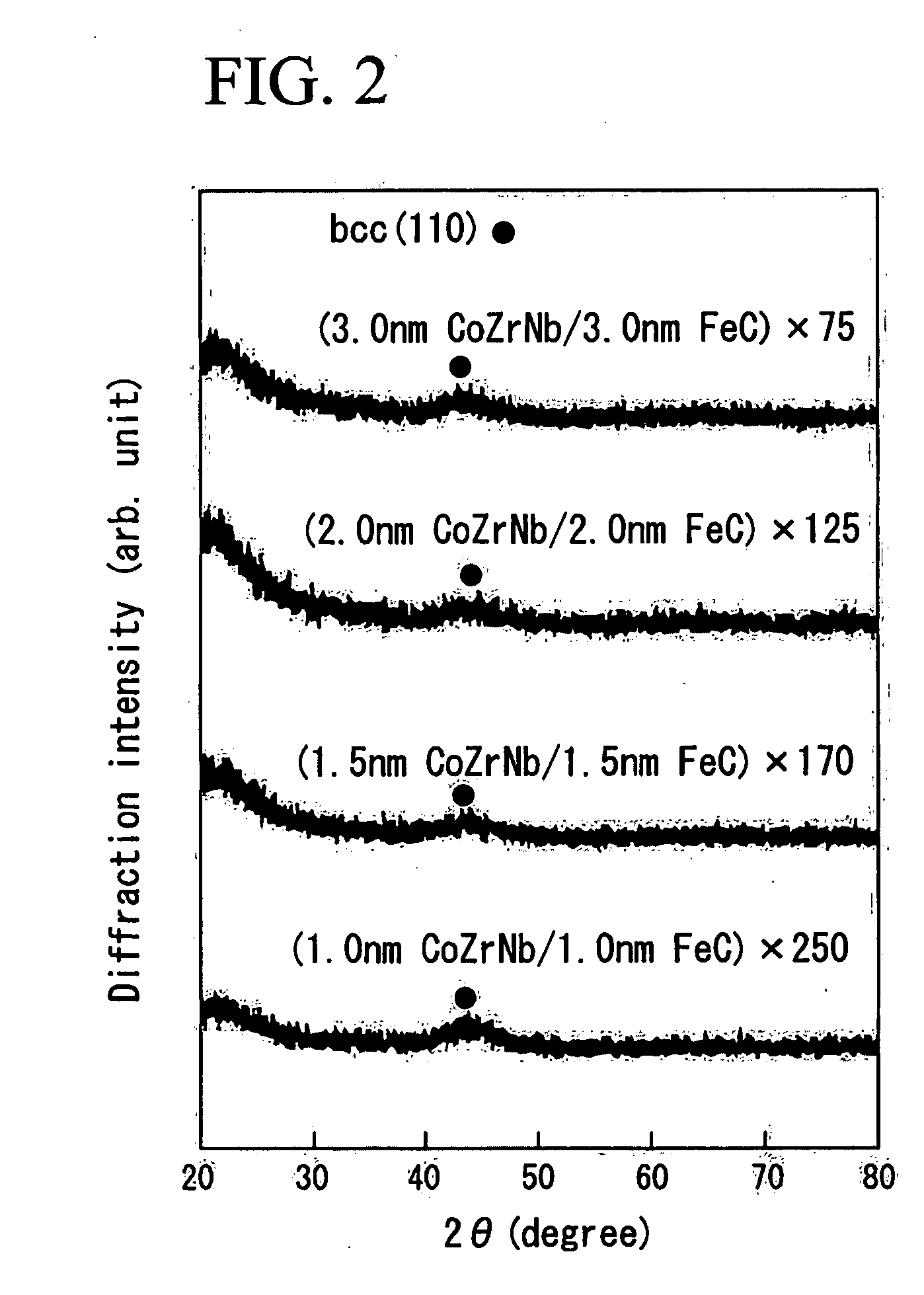

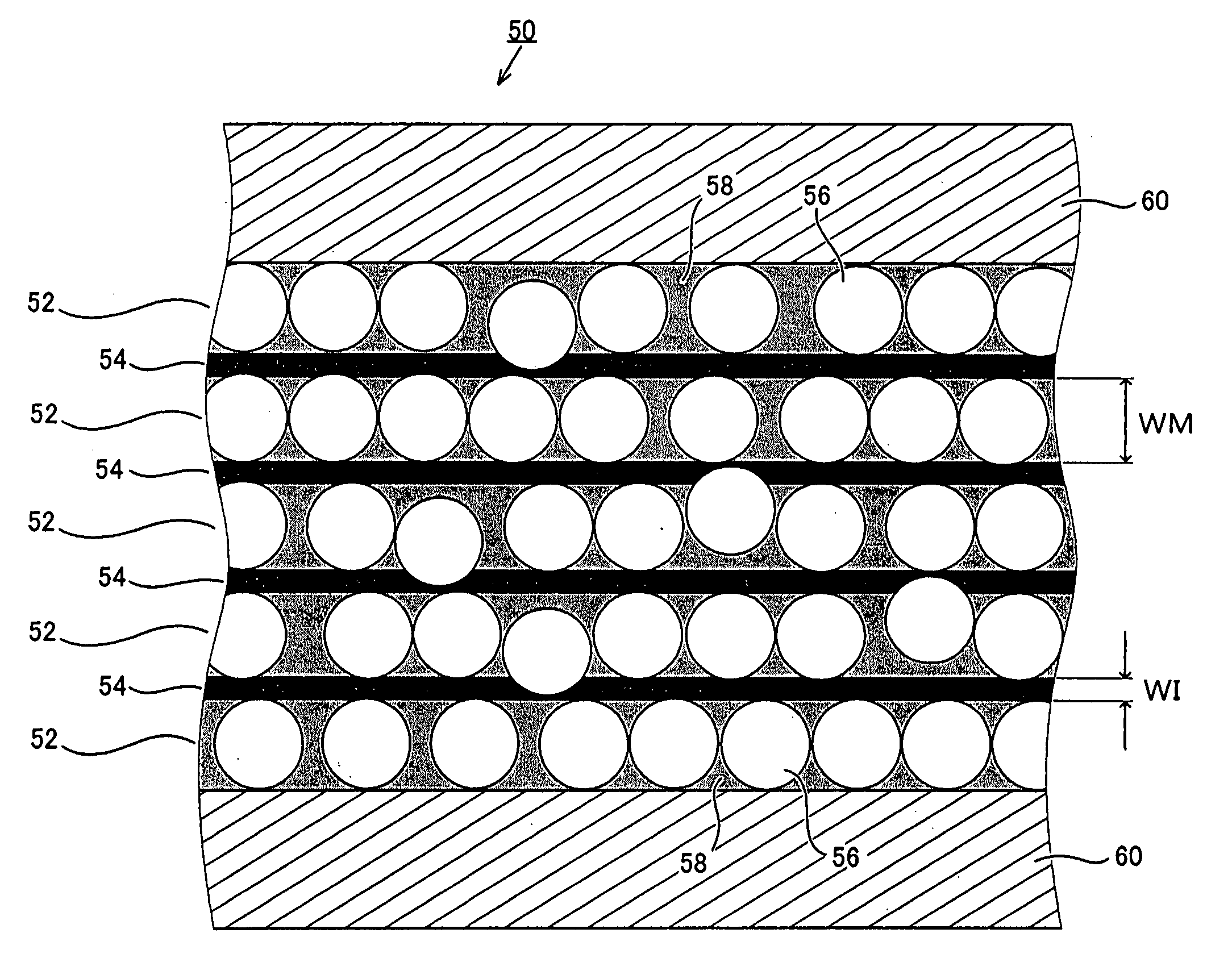

InactiveUS20060257677A1Soft magnetic property be deteriorateLamination number be increaseSolid-state devicesMagnetic layersThin membraneHigh resistivity

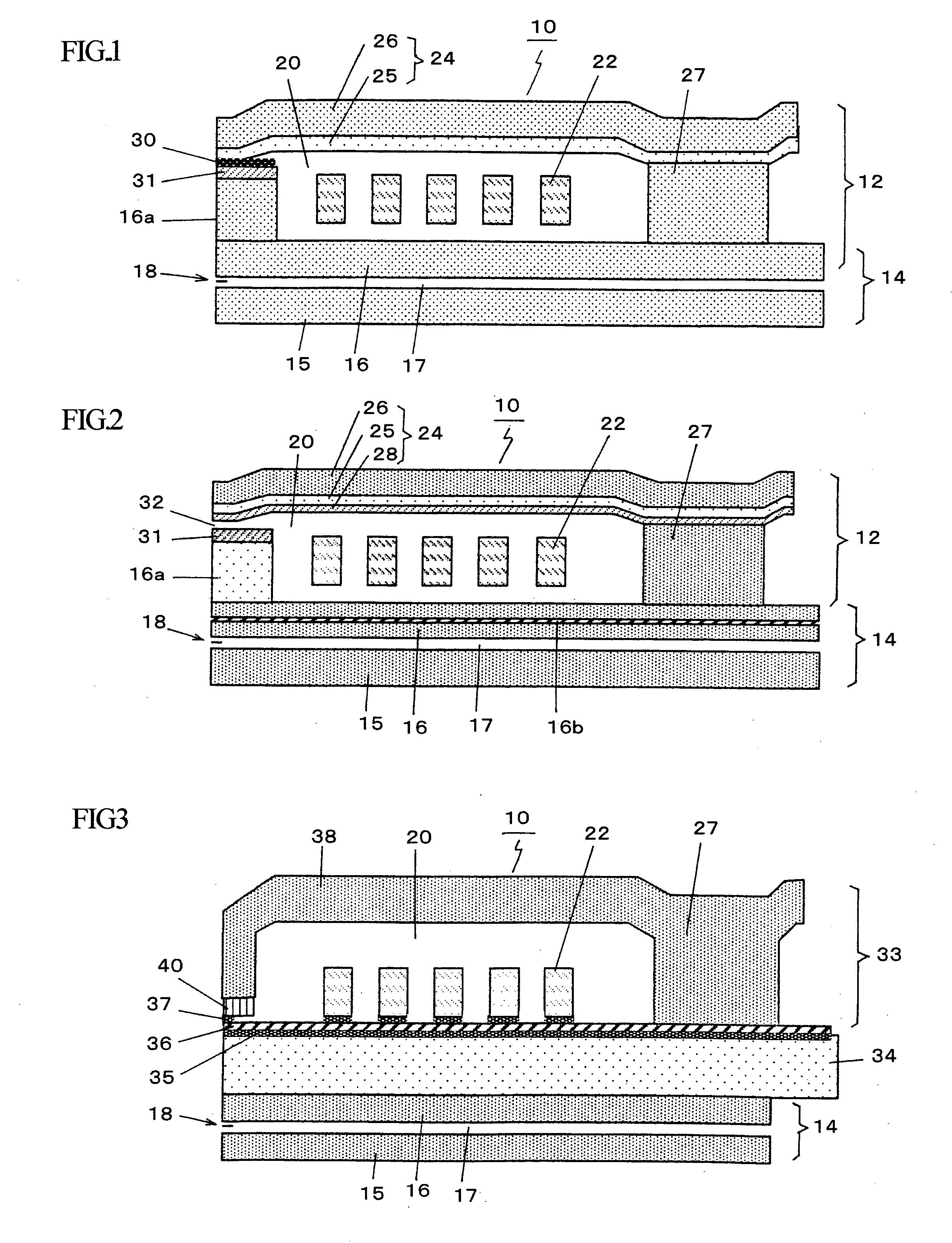

There can be obtained a magnetic thin film for high frequency 1 which has both a high permeability and a high saturation magnetization by combining a T-L composition layer 5 comprising a T-L composition, wherein T is Fe or FeCo, and L is at least one element selected from the group consisting of C, B and N, with a Co based amorphous alloy layer 3 disposed on either of the surfaces of the T-L composition layer 5. Further, there can be obtained a magnetic thin film for high frequency 1 which has both a high permeability and a high saturation magnetization, and at the same time has a high resistivity by further providing the magnetic thin film with, in addition to the T-L composition layer 5 and the Co based amorphous alloy layer 3, a high resistance layer 7 having an electric resistance higher than the T-L composition layer 5 and the Co based amorphous alloy layer 3.

Owner:TDK CORPARATION

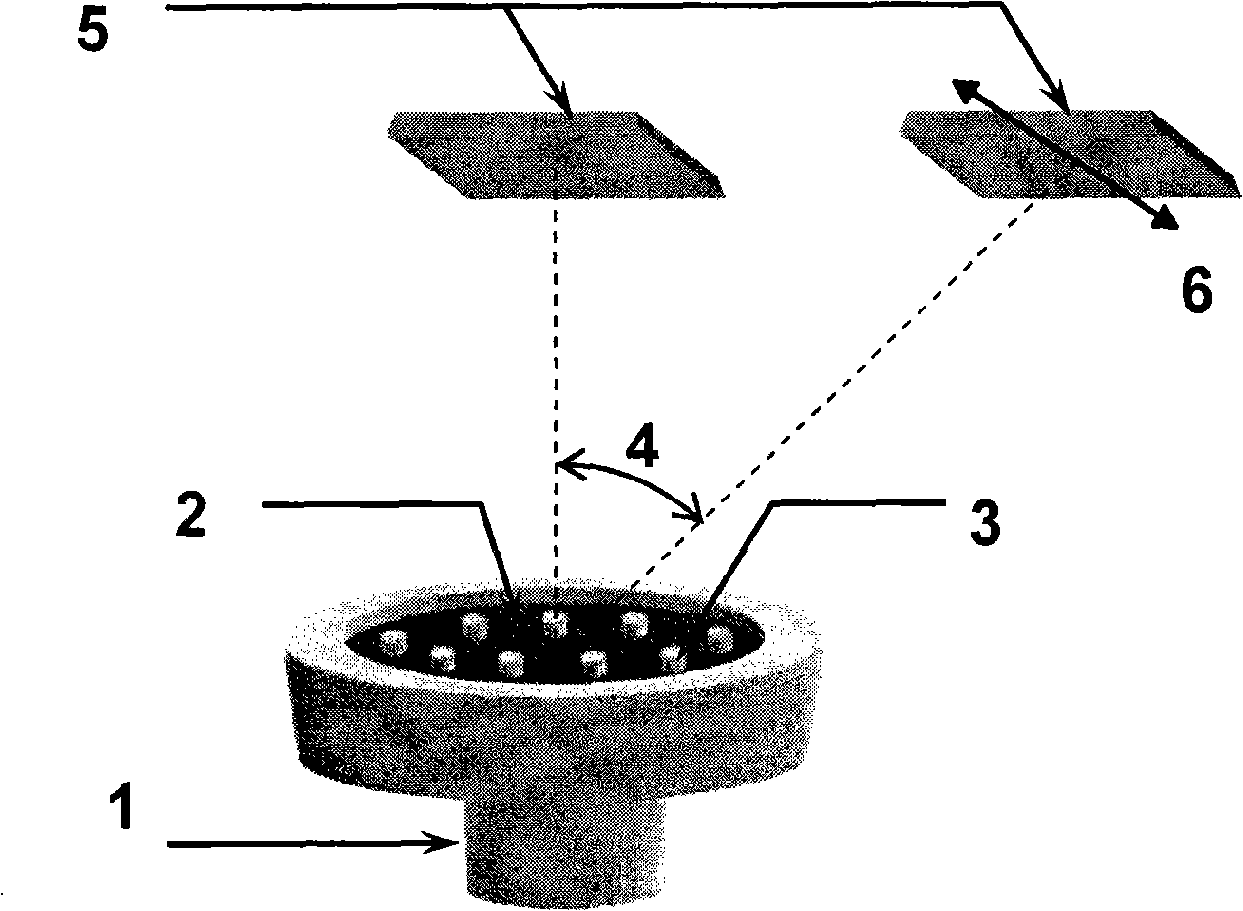

Production method for film generating in-plane uniaxial magnetic anisotropy in non-inducement magnetic field

InactiveCN101429646AExcellent soft magnetic propertiesUniform film formationVacuum evaporation coatingSputtering coatingSputter depositionMagnetic anisotropy

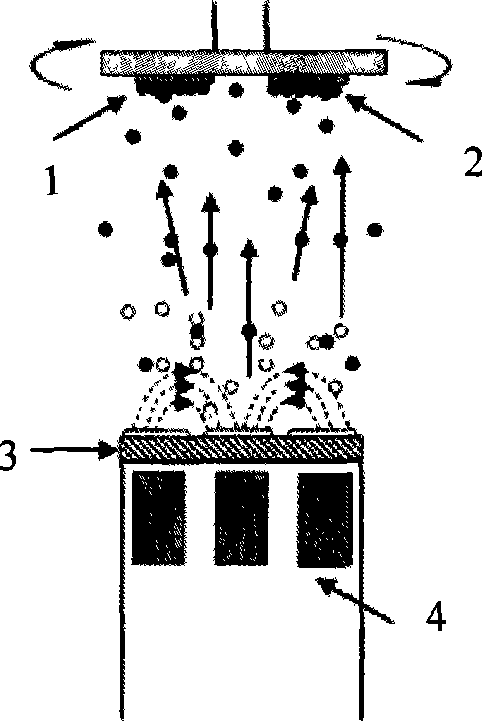

The invention provides a preparation method for an in-plane uniaxial magnetic anisotropic film generated in a non-induction magnetic field, and relates to a soft-magnetic film material. The invention provides the preparation method for the in-plane uniaxial magnetic anisotropic film generated in the non-induction magnetic field. The soft-magnetic film material comprises the following components according to the atomic percentage: 92 to 98 percent of magnetic alloy or magnetic metal and 2 to 8 percent of non-magnetic metal. The preparation method comprises the following steps: assembling a substrate into a sputtering chamber, and installing an iron target and a non-magnetic metal target, or a ferrocobalt target and a non-magnetic metal target; starting a vacuum system for air extraction till the background vacuity of the sputtering chamber is above 5x10<-4>Pa; heating up the substrate to reach a preset temperature of the substrate; and introducing reaction gas into the sputtering chamber to make the target surface build up luminance, carrying out presputtering firstly, then starting a substrate rotating button when the luminance is stable, opening a substrate baffle, and finally carrying out sputtering deposition to obtain the in-plane uniaxial magnetic anisotropic film generated in the non-induction magnetic field.

Owner:XIAMEN UNIV

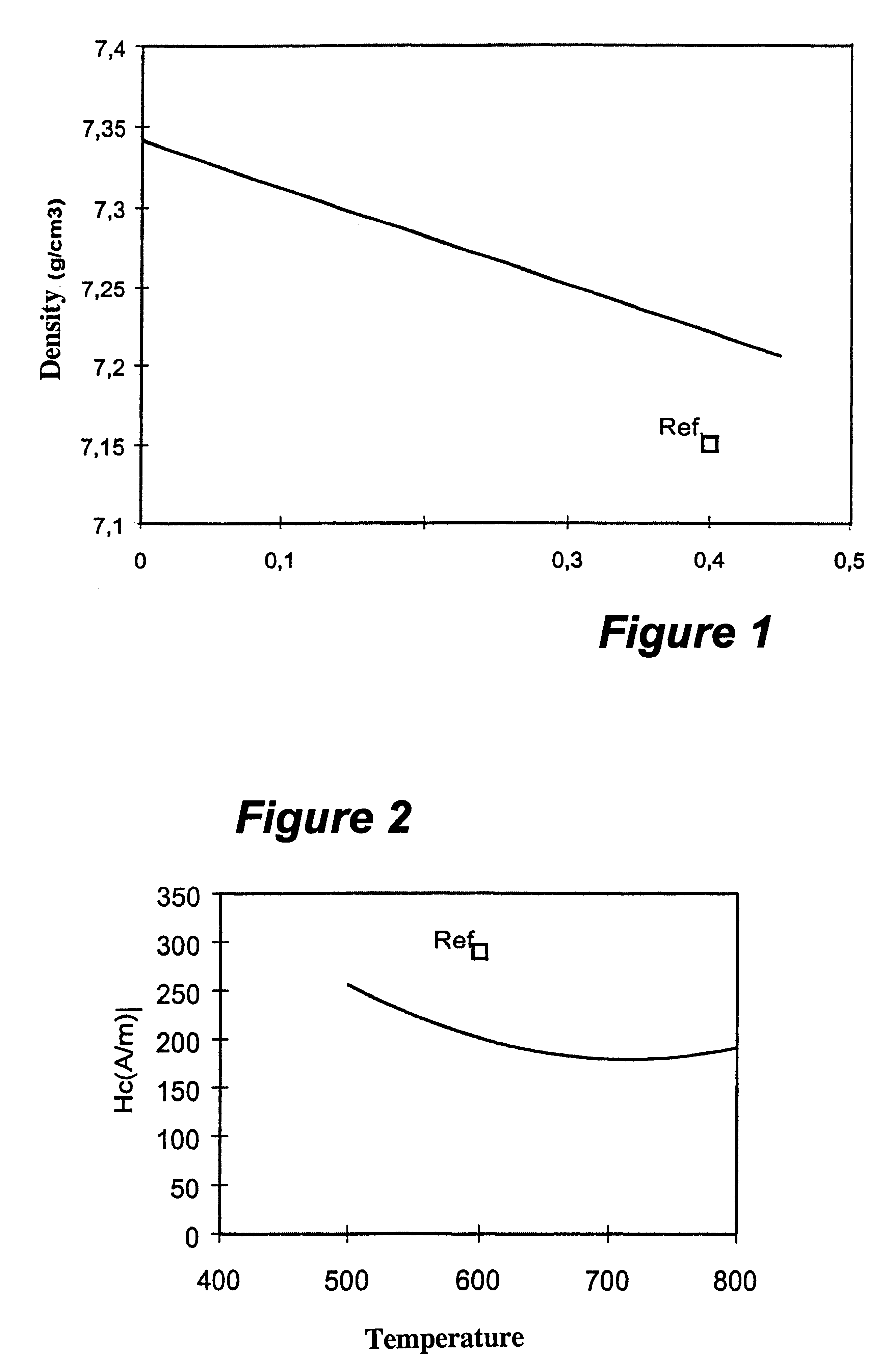

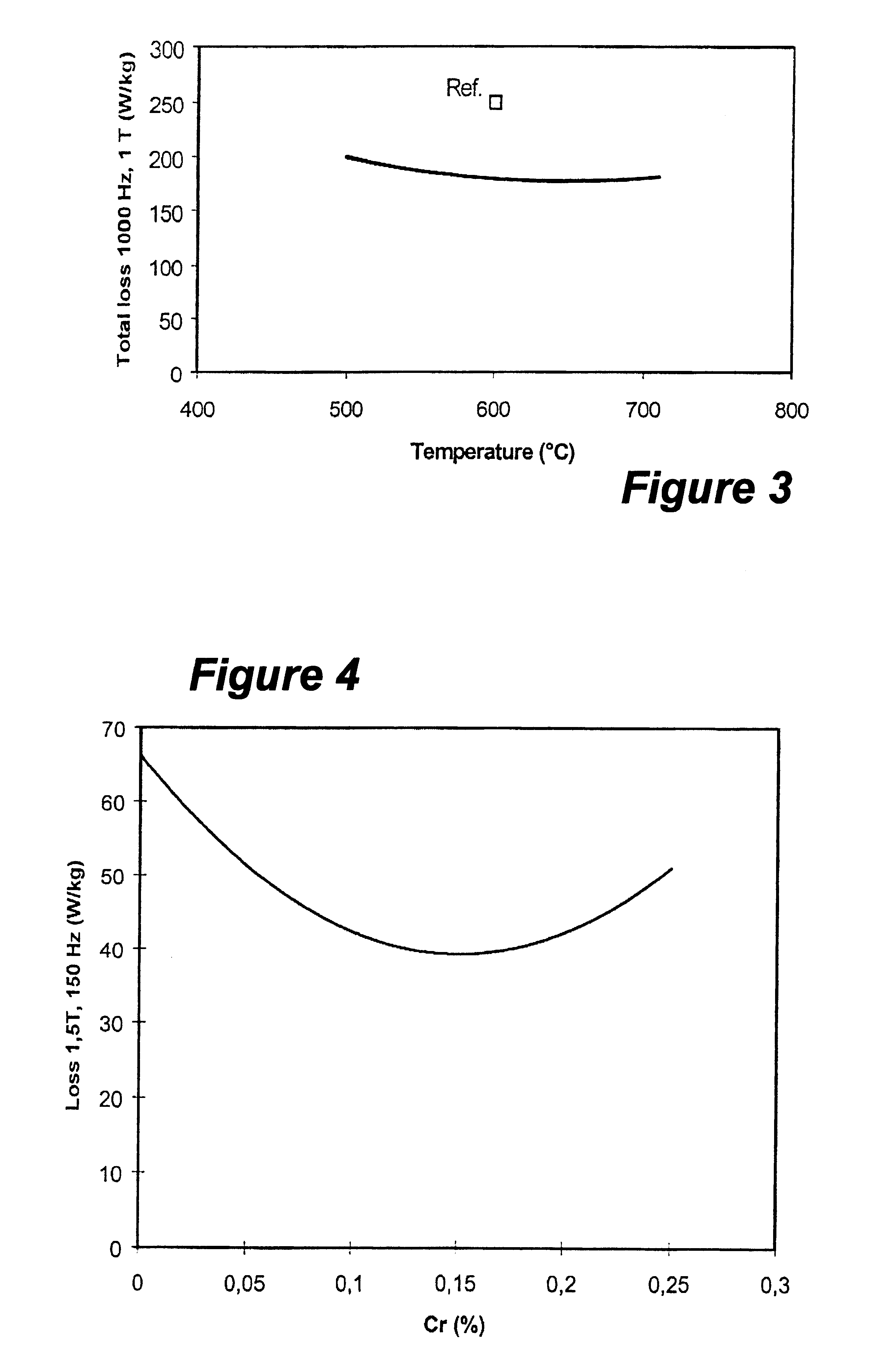

Compressed soft magnetic materials

InactiveUS6419877B1Excellent soft magnetic propertiesReduce lossTransportation and packagingMetal-working apparatusStress reliefCrystallization

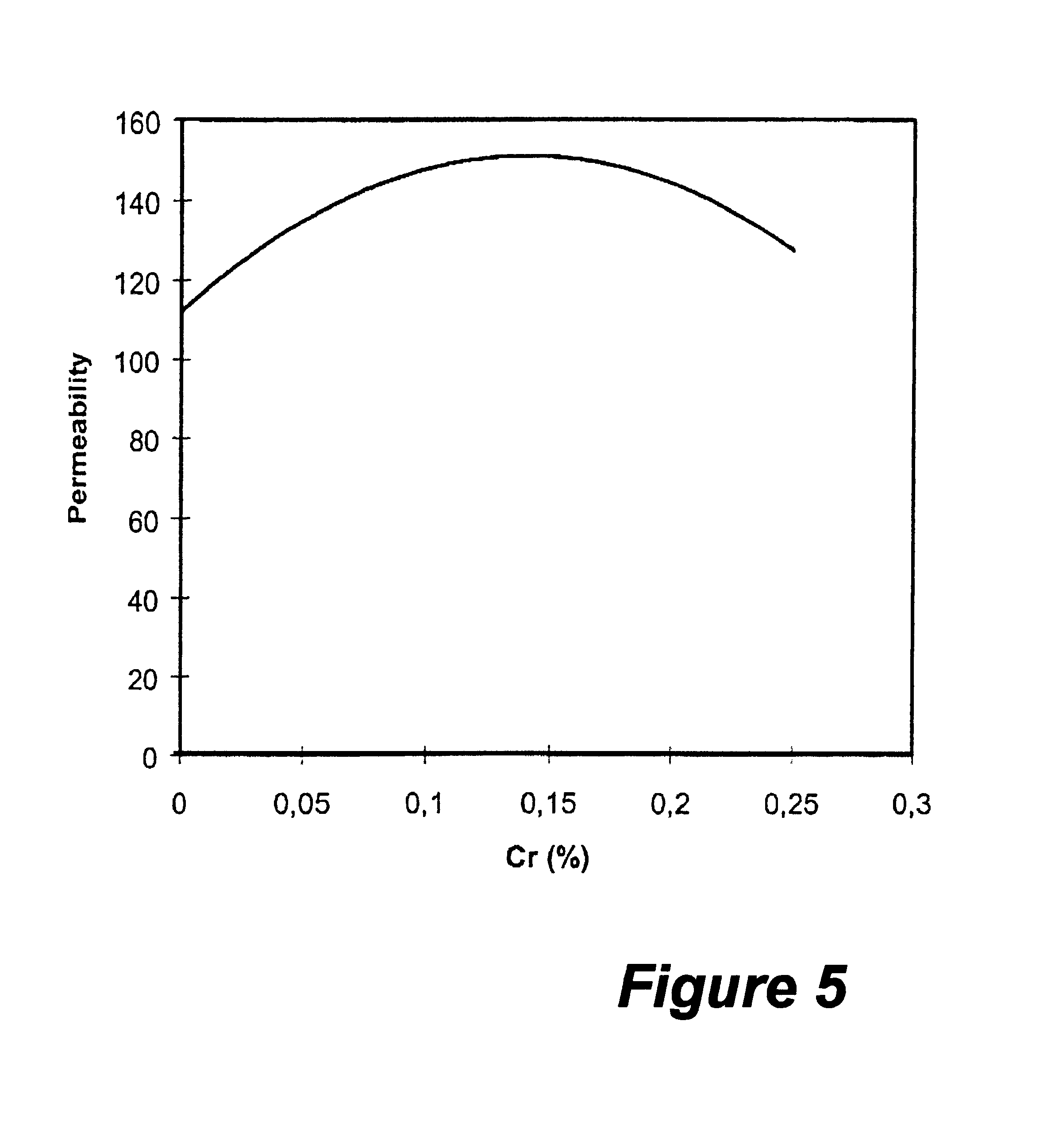

The invention concerns a process for the preparation of a compressed soft magnetic powder core comprising the steps of compacting an iron based powder the particles of which are insulated by a chromium containing layer, at a pressure between 300 and 1500 Mpa. The compacted body is then heated to a temperature sufficient for achieving stress relief and recrystallization of the iron base material.

Owner:HOGANAS AB

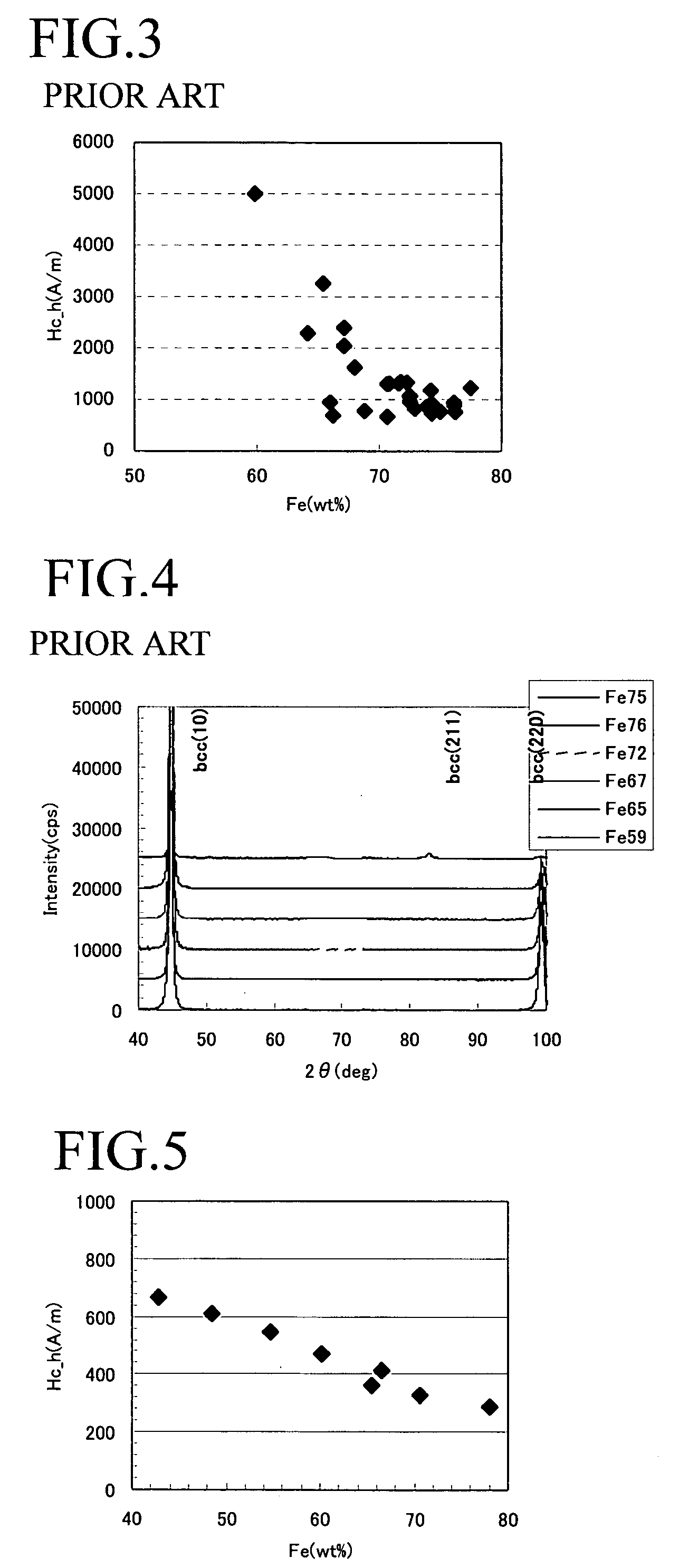

Soft magnetic thin film and magnetic recording head

InactiveUS20060215315A1High frequency responseRecord characteristic be improveManufacture head surfaceNanomagnetismRecording headElectroplating

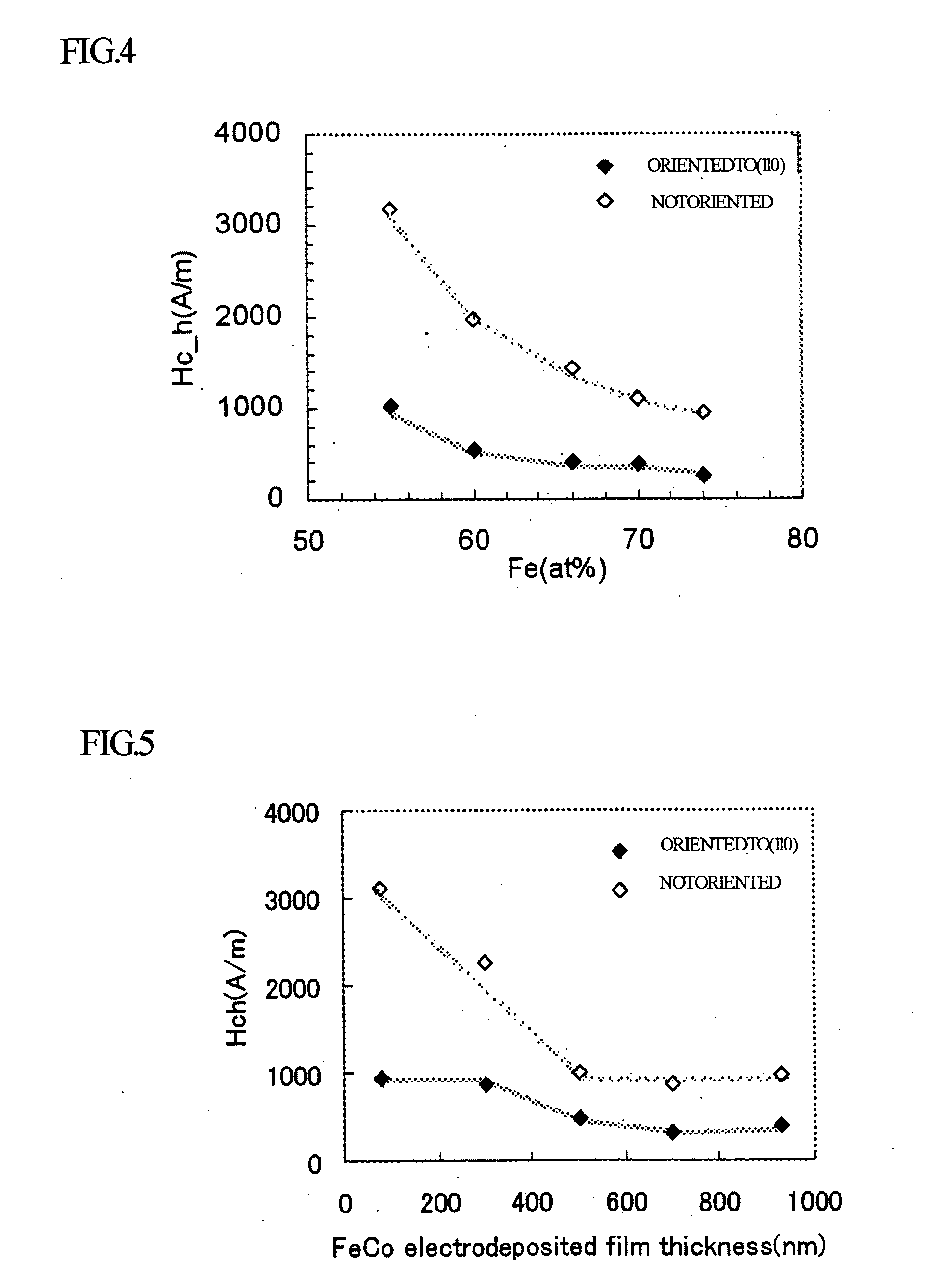

The soft magnetic thin film has high saturation magnetic flux density and good soft magnetic characteristics. The soft magnetic thin film of the present invention is formed by electrolytic plating. The plated film is made of FeCo, whose composition is indicated as FexCo1-x (60≦x≦75 wt %), the FeCo film has a bcc crystal structure, and the crystal of the FeCo film is oriented to a crystal face of (110).

Owner:FUJITSU LTD

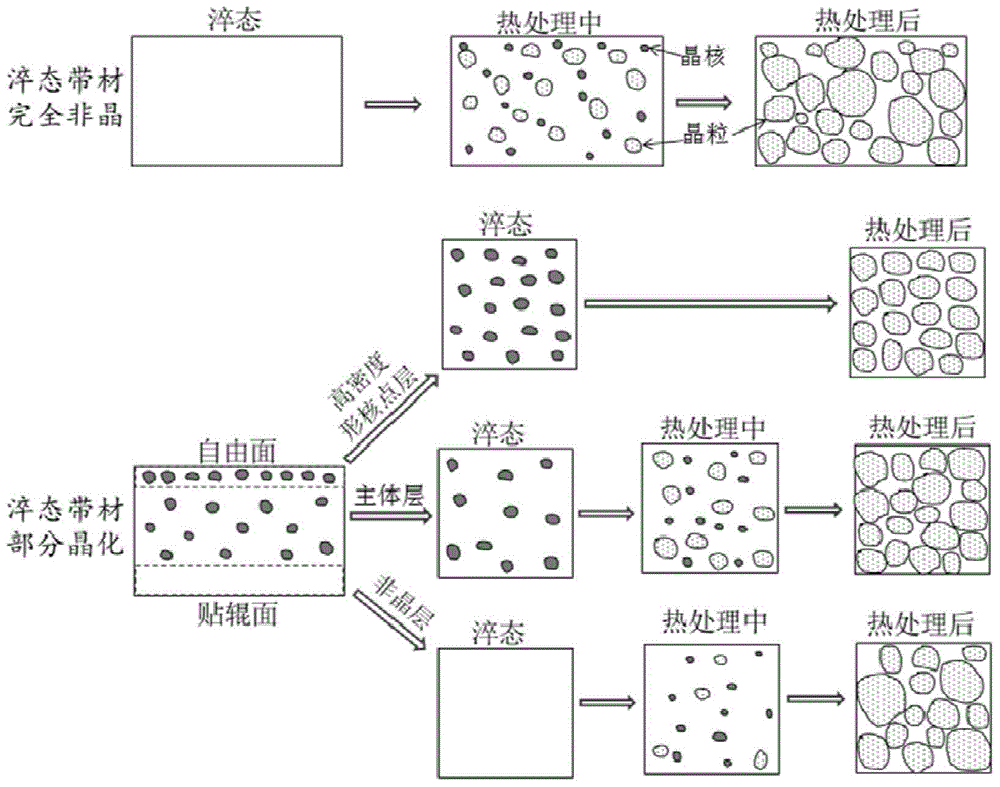

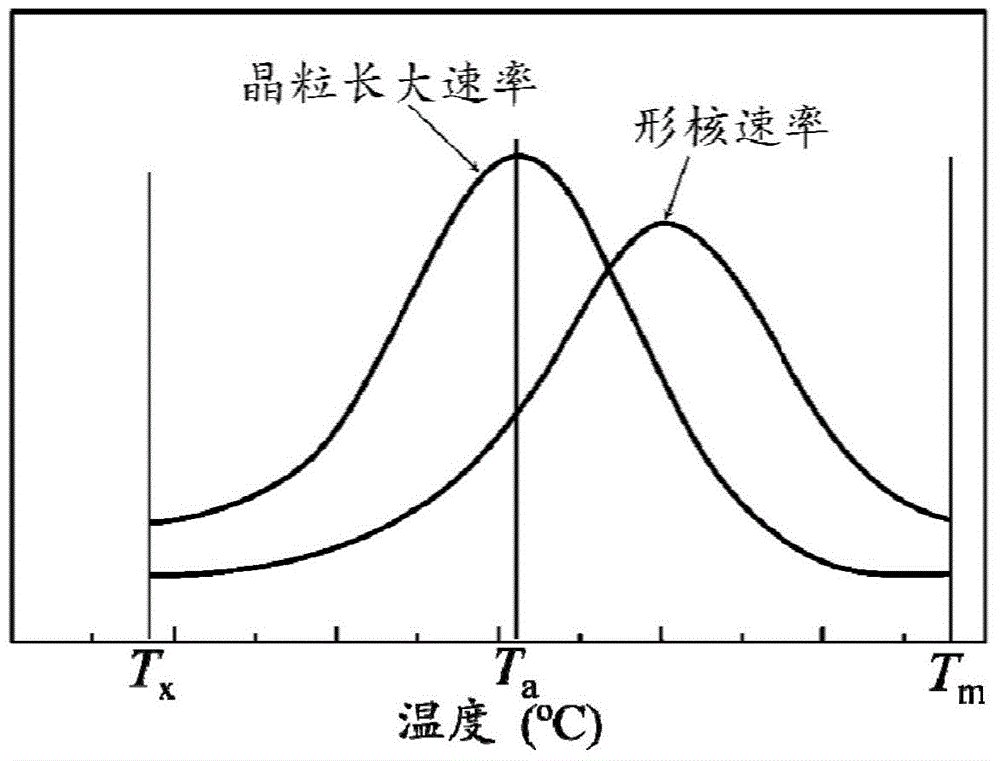

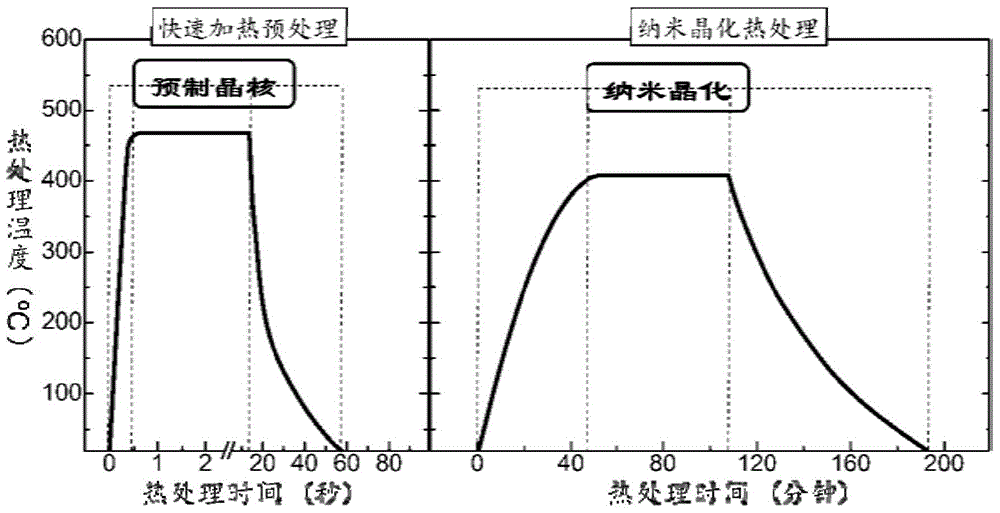

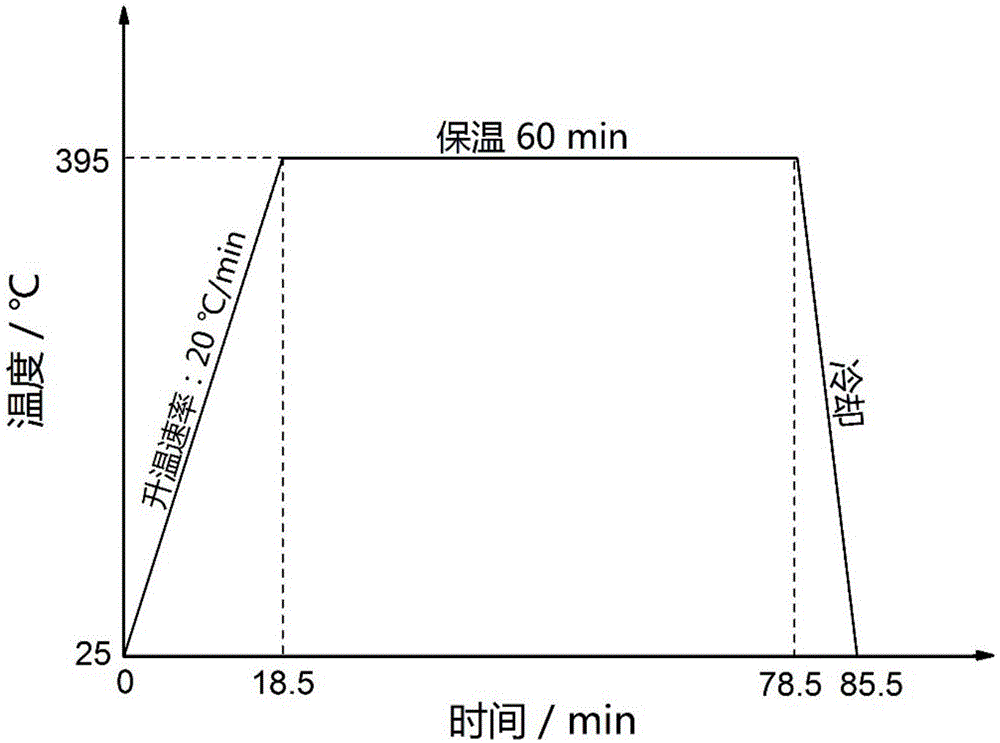

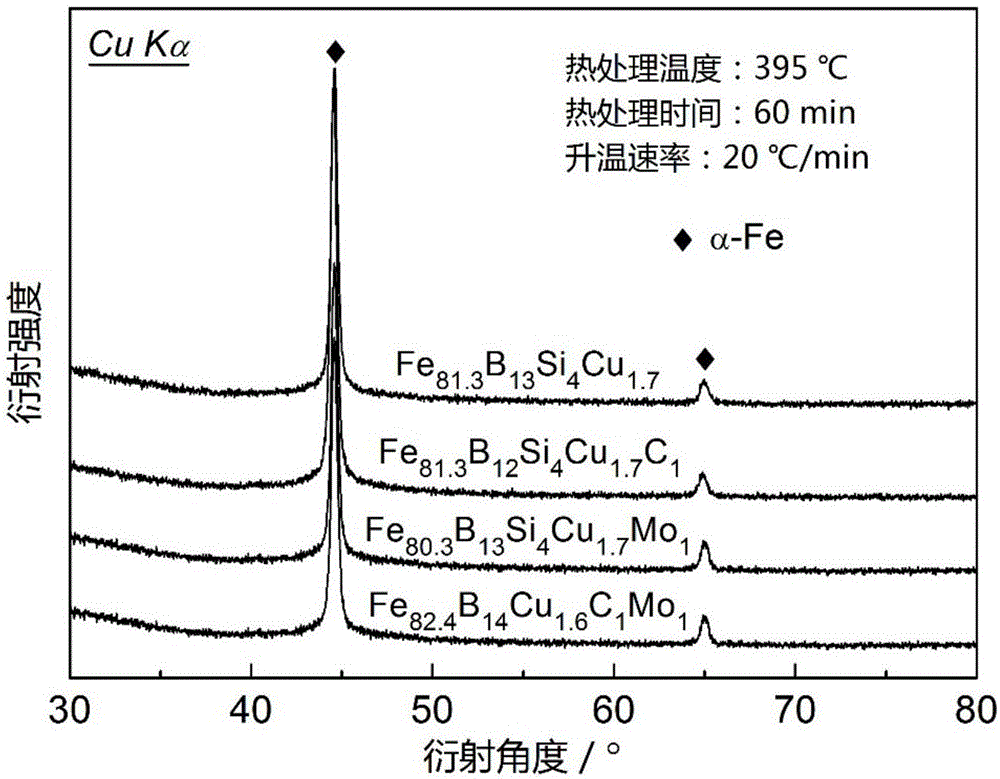

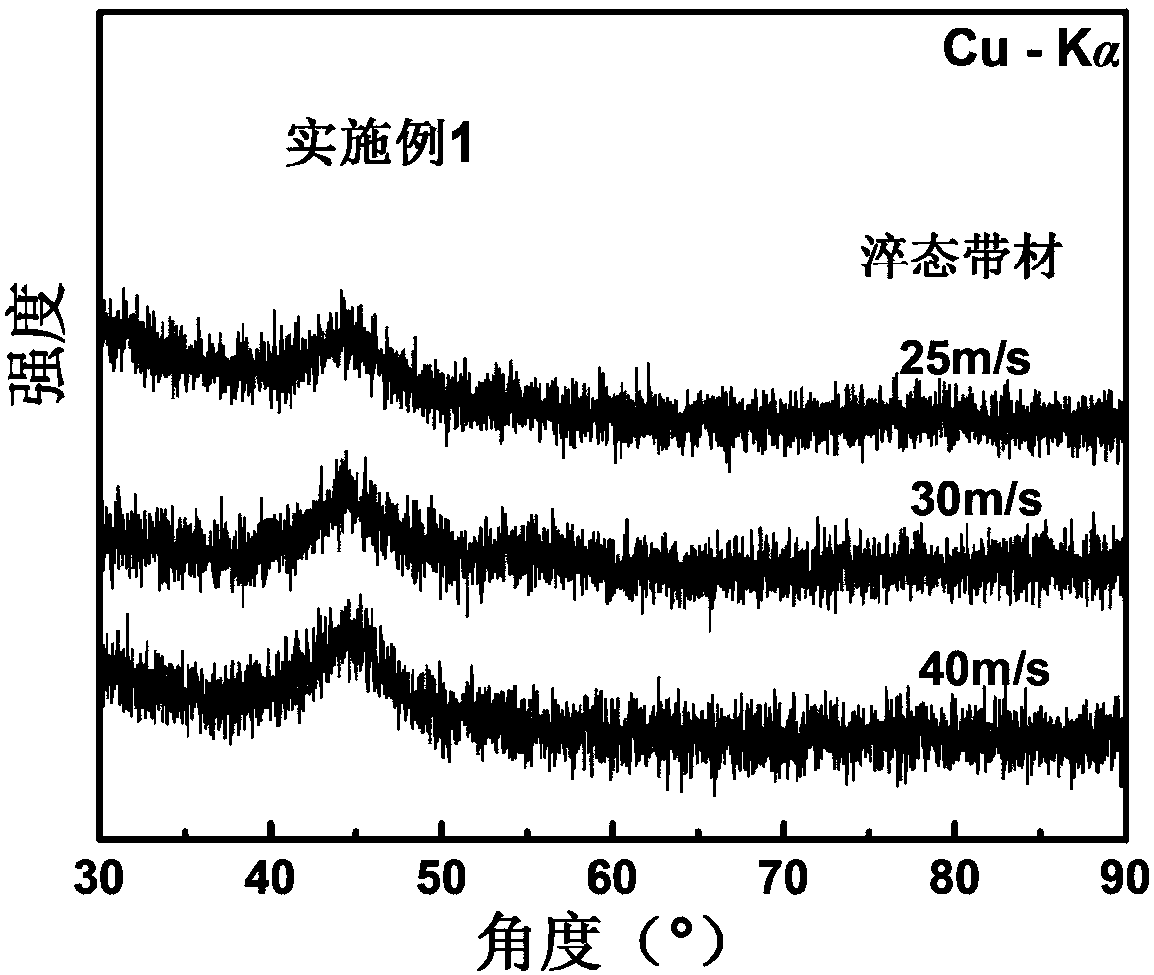

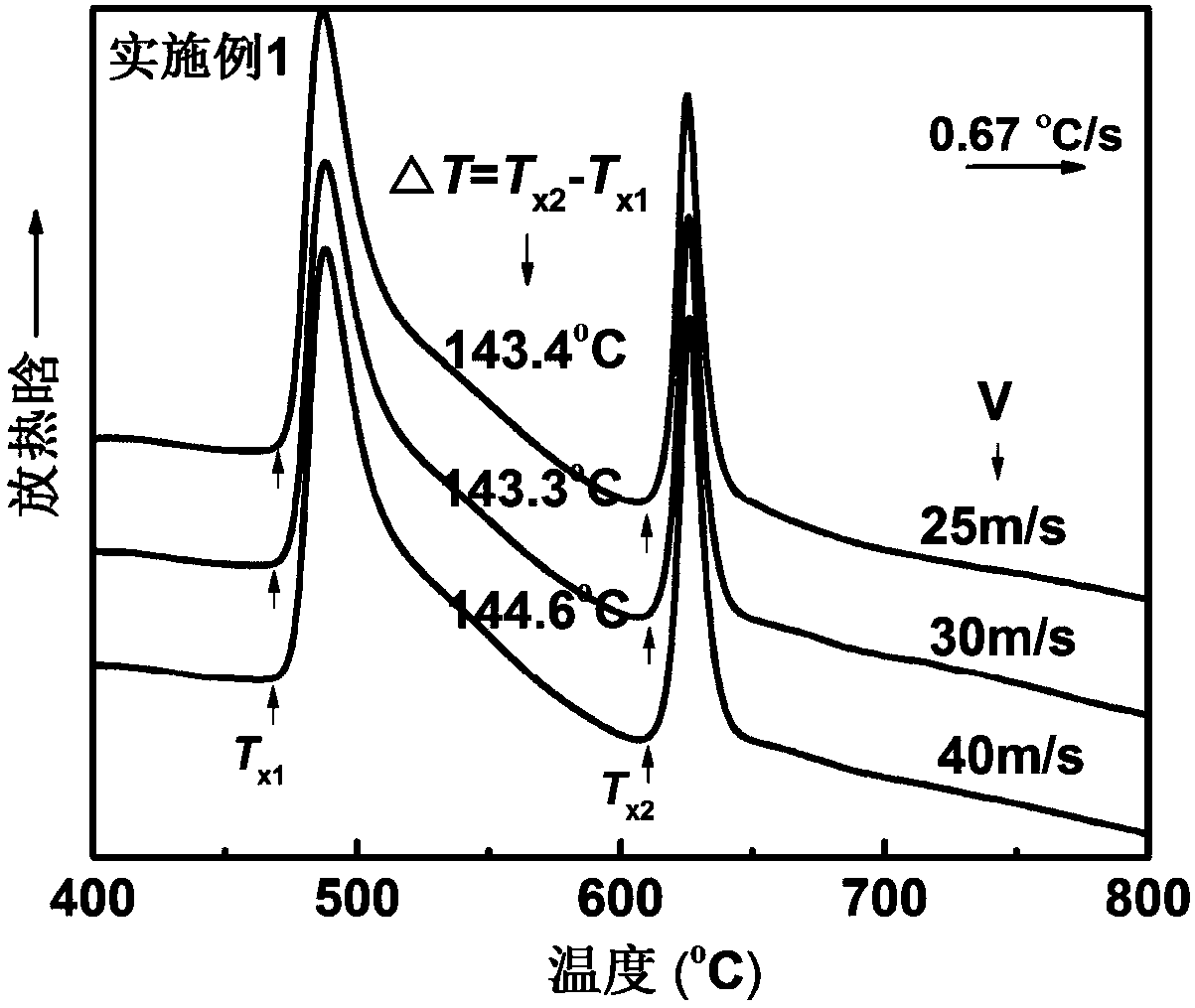

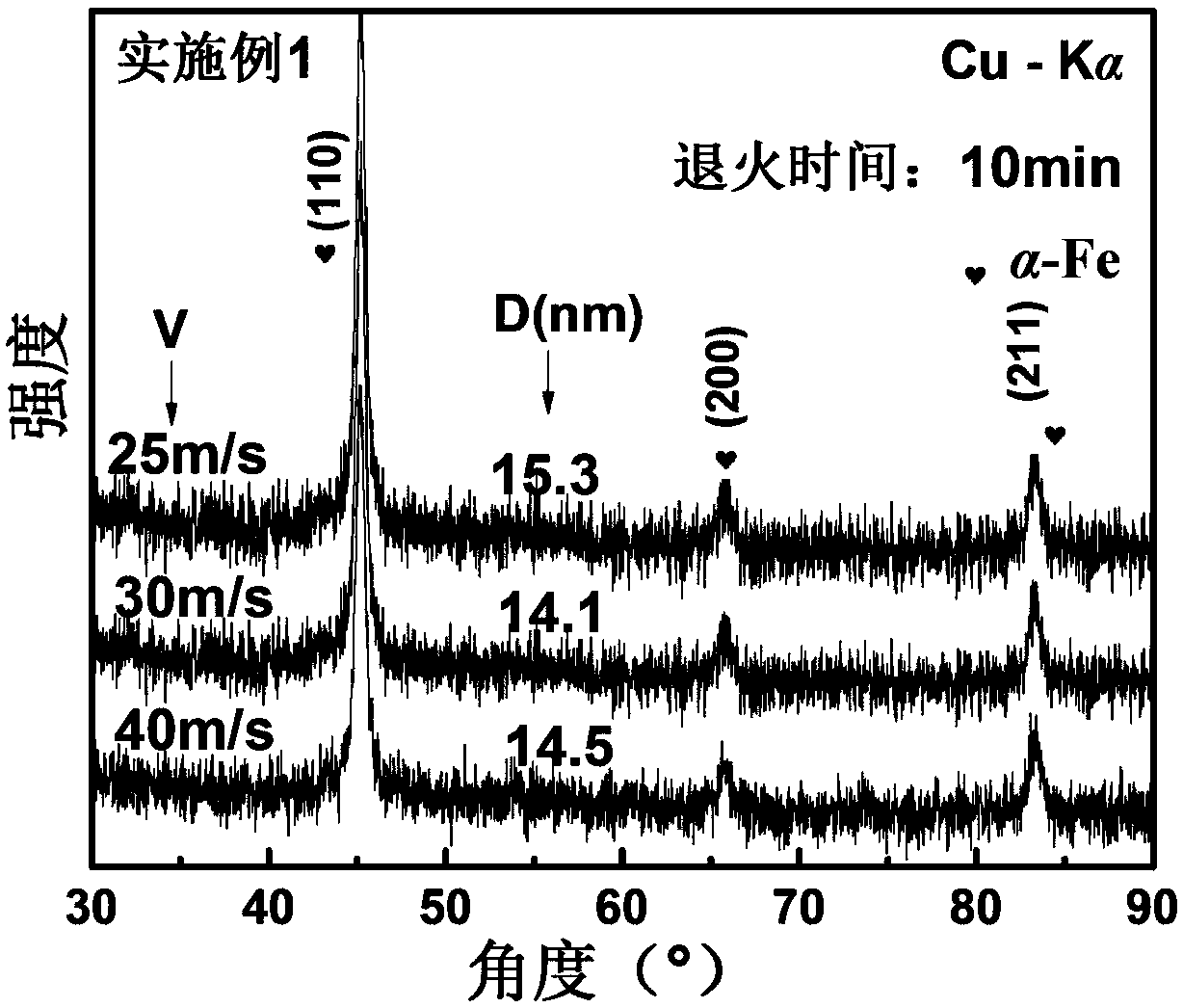

Heat treatment method for preparing nanocrystalline alloy

The invention discloses a heat treatment method for preparing nanocrystalline alloy. According to the method, during the nanocrystalline alloy material preparation by an amorphous crystallization method, a heat treatment process is divided into two steps; in the first step, the characteristics of high heat conductivity and low heat capacity of an amorphous crystallization alloy belt material are used; the fast temperature rise and short-time heat insulation pre-heating treatment is performed; high-density and uniformly-distributed crystal nucleuses are formed in the belt material through excitation; then, in the second step of conventional nano-crystallization heat treatment, high-density crystal particles grow synchronously; the competitive effect between the crystal particles is used for promoting the crystal particle refining. Compared with the existing heat treatment method, the method has the advantages that amorphous crystallization nucleation and crystal particle growth processes are controlled in a separated way; the crystal particle density and the crystallization degree are improved; the crystal particle dimension and the distribution uniformity are improved; in addition, the crystal particles are refined, so that the performance of the alloy is improved.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

Method for preparing hollow iron-rich particle reinforced copper-based monotectic alloy through selective laser melting forming technology

ActiveCN108080636AImprove mechanical propertiesGood electrical propertiesAdditive manufacturing apparatusIncreasing energy efficiencySelective laser meltingChemical composition

The invention discloses a method for preparing a hollow iron-rich particle reinforced copper-based monotectic alloy through a selective laser melting forming technology. The method is characterized bycomprising the following steps that special copper-iron-based alloy powder is subjected to mechanical alloying treatment so as to obtain composite powder to serve as a forming material, wherein the the particle size of the composite powder is 35-50 microns, and the composite powder is composed of a supersaturated copper-iron solid solution with a face-centered cubic crystal structure; and based on a liquid-phase separation principle and a Kirkandall effect, the hollow iron-rich particle reinforced copper-based monotectic alloy is prepared by adopting a selective laser melting method, whereinthe special copper-iron-based alloy powder is composed of pure copper powder and iron-based alloy powder according to a mass ratio of 95:5, 92:8 or 88:12, the iron-based alloy powder comprises the following chemical components, by weight percentage: 72.5wt% of Fe, 12wt% of Ni, 5.0wt% of Nb, 5.0wt% of Cr, 0.6wt% of Si, 2.5wt% of B, 0.2wt% of C, and 0.2wt% of Ce2O3.

Owner:JINAN UNIVERSITY

Nanocrystal magnetically soft alloy with high processing property and high saturation magnetic induction strength, and preparation method therefor

InactiveCN106373690AGood workmanshipHigh saturation magnetic inductionMagnetic materialsThermal insulationAlloy

The invention discloses a nanocrystal magnetically soft alloy with high processing property and high saturation magnetic induction strength, and a preparation method therefor, and belongs to the technical field of a new material. The chemical formula of the nanocrystal magnetically soft alloy is FeBSi<c>Cu<d>C<e>M<f>Z<g>, wherein M is at least one kind of elements Co or Ni; Z is at least one kind of elements Al, Cr, Mn, Ti, Nb, Ta or Mo; a, b, c, d, e, f and g are atomic percentage contents of corresponding elements, and satisfy the formula as follows: a+f is greater than or equal to 80 and less than or equal to 84; b is greater than or equal to 10 and less than or equal to 15; c is greater than or equal to 0 and less than or equal to 6; d is greater than or equal to 1.6 and less than or equal to 2.2; e is greater than or equal to 0 and less than or equal to 2; f is greater than or equal to 0 and less than or equal to 5; and g is greater than or equal to 0 and less than or equal to 2. The alloy is formed by uniformly dispersing an <alpha>-Fe phase, which is obtained by heat treatment of amorphous stripes and has the crystal grain sizes of less than 50nm, into residual amorphous phase tissues, wherein the saturation magnetic induction strength is greater than 1.7T, and the coercivity is less than 15A / m. The alloy has no volatile phosphorus element; in addition, the heat treatment process is simple, and high temperature-rise rate is not required; the heat treatment temperature range and the thermal insulation time range are wide; industrial production can be realized easily; and the nanocrystal magnetically soft alloy and the preparation method therefor are convenient to popularize and use.

Owner:DALIAN UNIV OF TECH

Process for preparing wide-band and wave-absorbing magnetic multilayer membranous

InactiveCN101285170AHigh resonant absorption frequencyResonant absorption frequency adjustmentVacuum evaporation coatingSputtering coatingSputteringWide band

The invention relates to a method for preparing a wide frequency band wave-absorbed layer on a substrate material. The method for preparing a wide frequency band wave-absorbed magnetic film is as follows: firstly, a first magnetic material layer with a cut-off frequency of f1 is generated on the substrate material by adoption of the vacuum sputtering method; secondly, a first isolated layer is generated on the first magnetic material layer; the process is repeated until an n-layered magnetic material film which is formed by magnetic material layers with different cut-off frequencies isolated by isolated layers is formed on the substrate finally, wherein, the isolated layers can be generated by utilization of general physical film forming technology.

Owner:LANZHOU UNIVERSITY

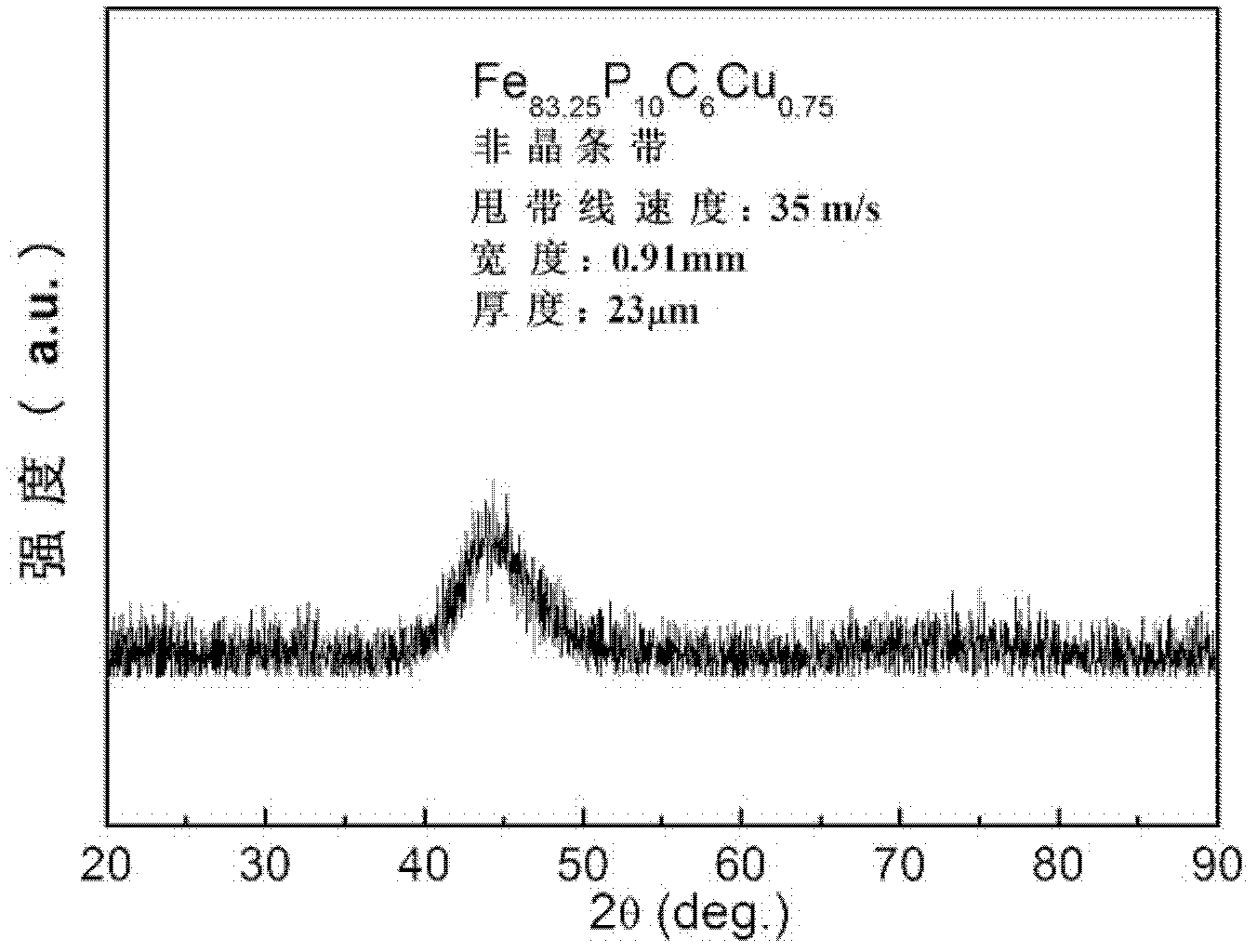

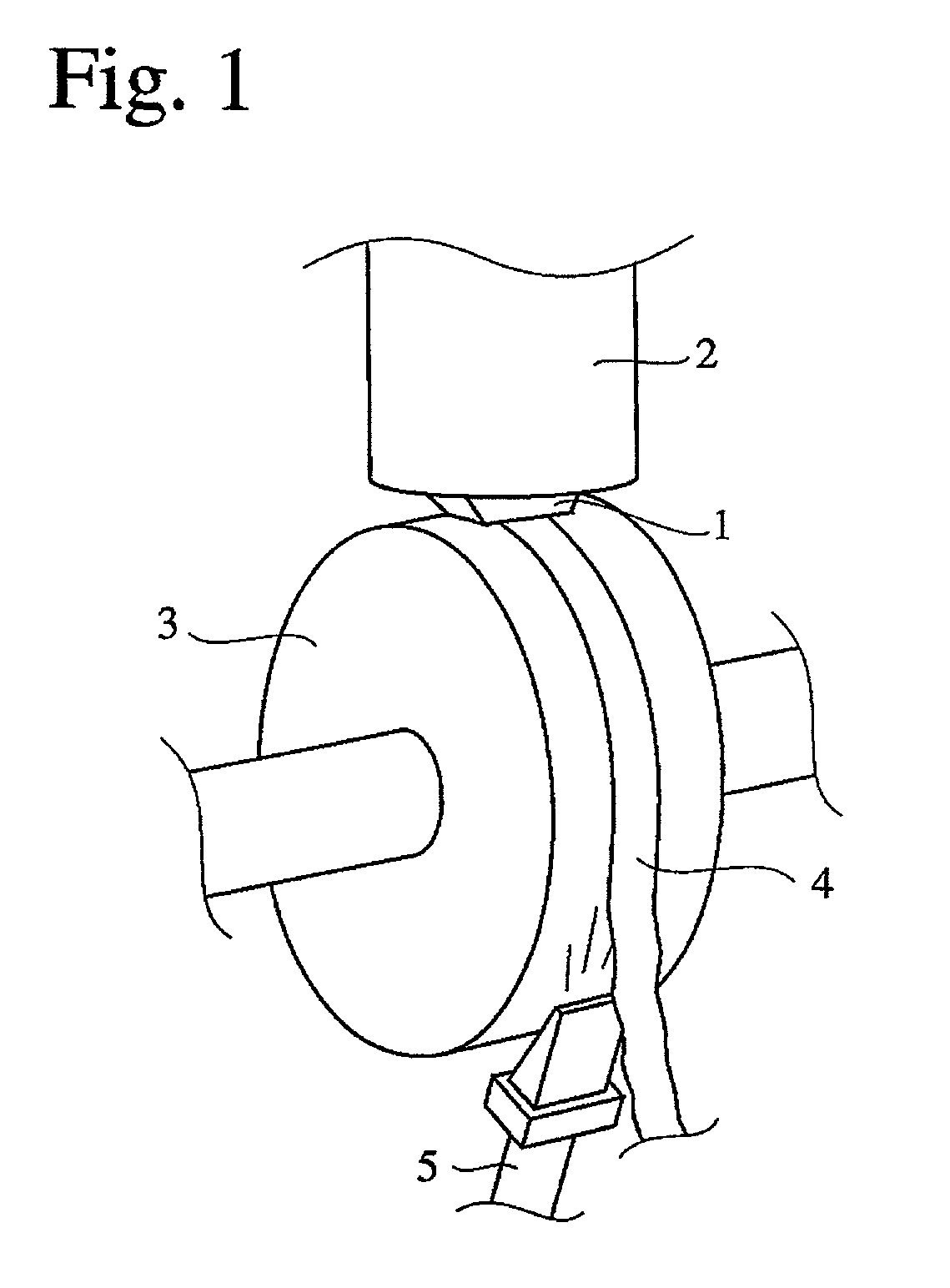

Methods for producing iron-based amorphous alloy ribbon and nanocrystalline material

InactiveUS20010007266A1Excellent soft magnetic propertyExcellent soft magnetic propertiesMagnetic materialsIron basedAlloy

The present invention provides a method for producing a Fe-based amorphous alloy ribbon comprising the steps of: ejecting a molten Fe-based alloy containing 10 atomic % or less of B onto a cooling roll to solidify the molten Fe-based alloy; and peeling the solidified Fe-based alloy from the cooling roll when the solidified Fe-based alloy has a temperature of 100 to 300° C. A Fe-based amorphous alloy ribbon having no crystalline phase is stably, continuously produced without breakage by this method.

Owner:HITACHI METALS LTD

High-magnetic-inductance high-frequency iron-based nanocrystalline soft magnetic alloy and preparation method thereof

ActiveCN110387500AExcellent soft magnetic propertiesImprove thermal stabilityMagnetic materialsTransformerThermal stability

The invention discloses a high-magnetic-inductance high-frequency iron-based nanocrystalline soft magnetic alloy and a preparation method thereof. The molecular formula of the iron-based nanocrystalline soft magnetic alloy is FeaSibBcPdNbeVfMogCuh, the a, the b, the c, the d, the e, the f, the g and the h in the molecular formula correspondingly represent the atomic percentage contents of all thecorresponding alloy elements, and satisfy the following conditions that the a is greater than or equal to 75.5 and less than or equal to 77.5, the b is greater than or equal to 8.5 and less than or equal to 13.5, the c is greater than or equal to 7 and less than or equal to 10, the d is greater than or equal to 0.2 and less than or equal to 1, the e is greater than or equal to 1.0 and less than orequal to 1.7, the f is greater than or equal to 0.05 and less than or equal to 0.4, the g is greater than or equal to 0.1 and less than or equal to 1.5, the h is greater than or equal to 0.8 and lessthan or equal to 1.2, and the sum of the a, the b, the c, the d, the e, the f, the g and the h is 100. The high-magnetic-inductance high-frequency iron-based nanocrystalline soft magnetic alloy material has the advantages of excellent comprehensive soft magnetic performance, low cost, high thermal stability and the like, particularly, the high-frequency performance is good, the magnetic conductivity under the condition of 10 kHz can reach 28000 or above, a good application prospect is achieved, and the high-magnetic-inductance high-frequency iron-based nanocrystalline soft magnetic alloy material can be applied to the technical fields of high-frequency transformers, common mode chokes, wireless charging and the like.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

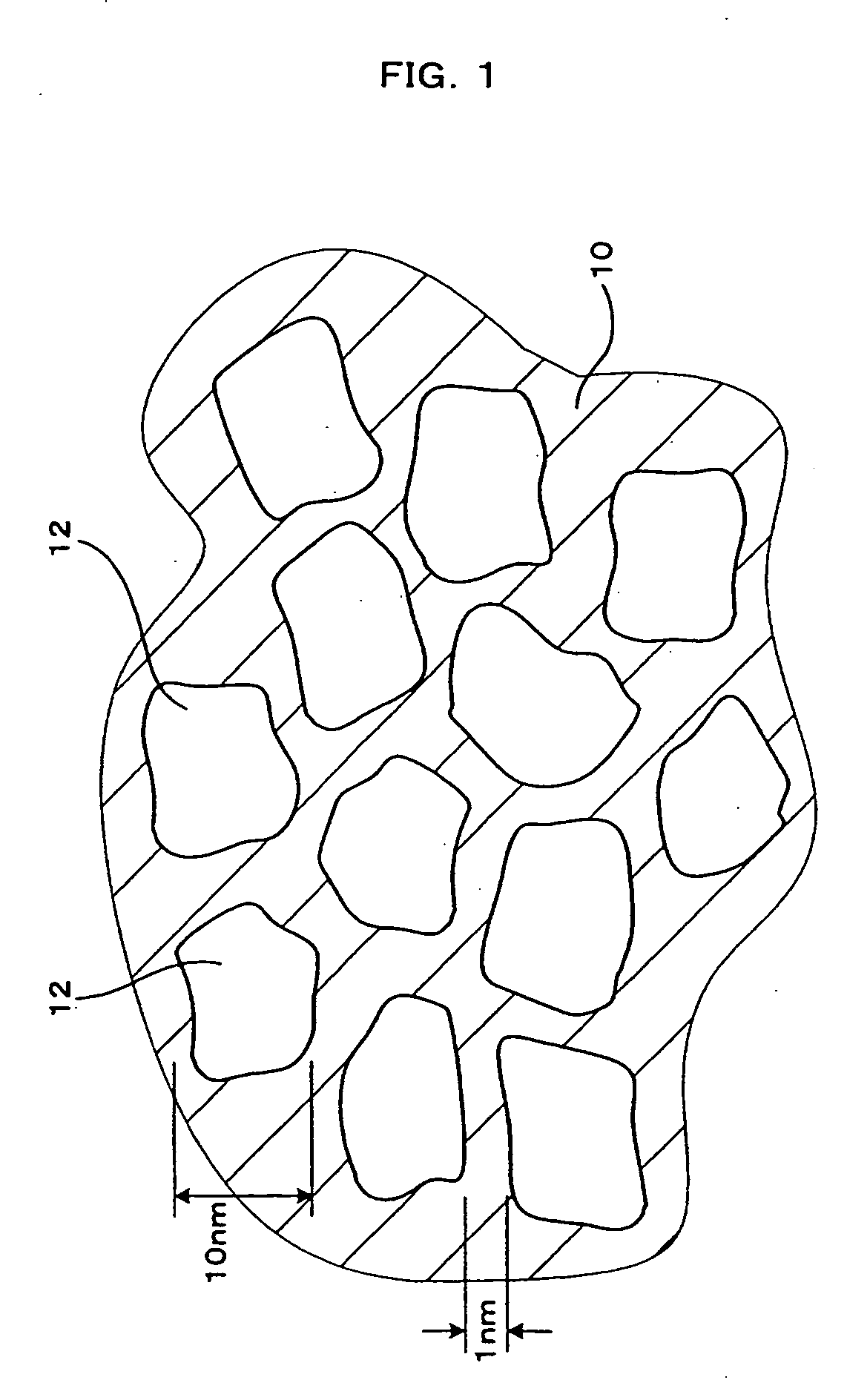

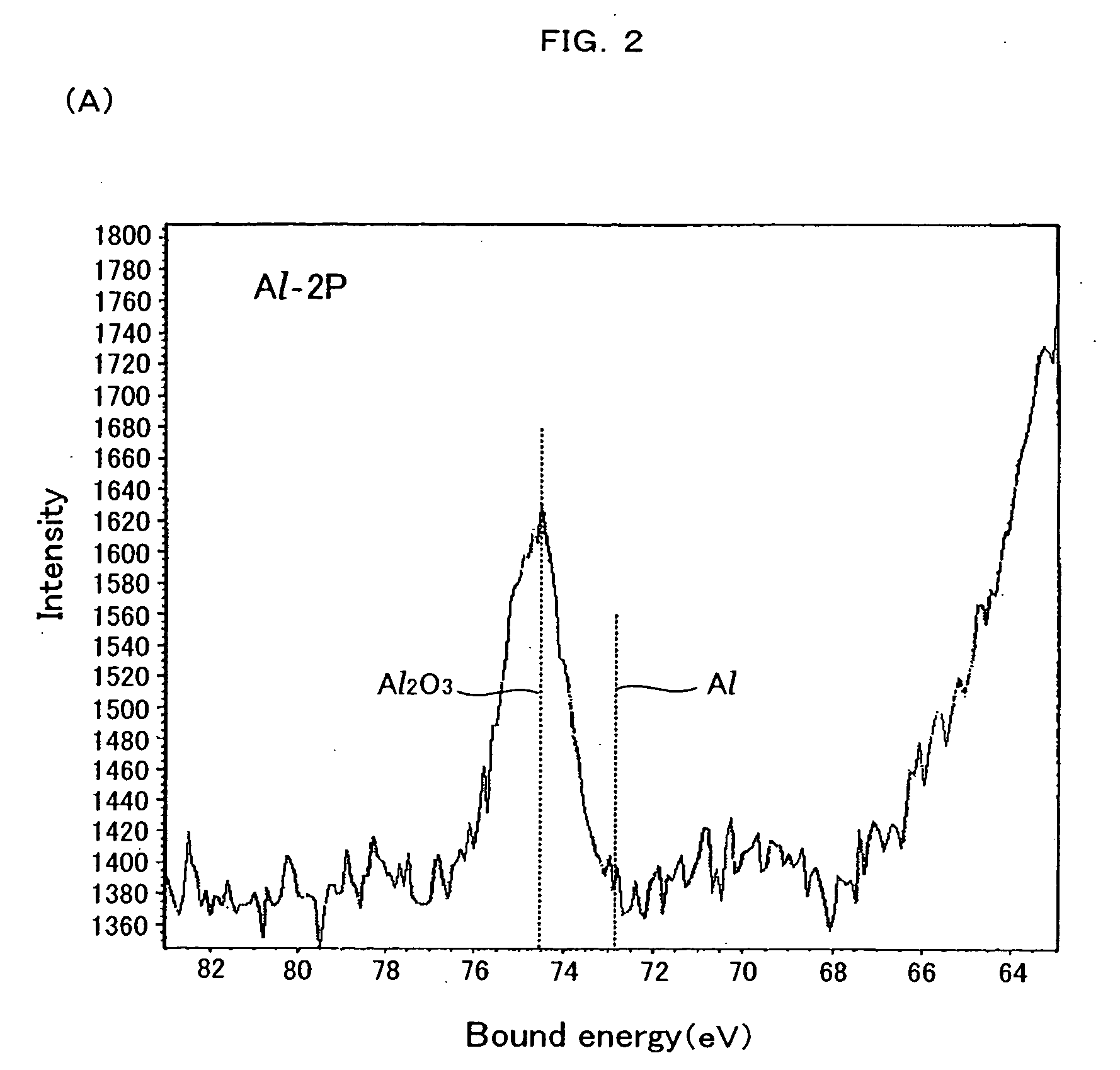

Granular magnetic thin film and method for making the same, multilayered magnetic film, magnetic components and electronic equipment

InactiveUS20040209098A1Improved high-frequency characteristicExcellent soft magnetic propertiesNanostructure applicationNanomagnetismHigh resistivityMaterials science

There are provided a magnetic thin film utilizing a granular film and having excellent high frequency characteristics and a method of manufacturing the same, and a multilayered magnetic film and magnetic components and electronic equipment utilizing the same. A nonreactive sputtering is performed so that there is no oxidation of a magnetic metal, and a saturation magnetization is increased to increase a resonant frequency of permeability. Also, a multi-target simultaneous sputtering is combined with the nonreactive sputtering so that in a granular structure including magnetic grains and an insulating layer a size of the magnetic grains and a thickness of the insulating layer are optimized thereby ensuring a proper magnitude for a crystalline magnetic anisotropy within the grains and excellent soft magnetic properties. Further, the optimization of the thickness of the insulating layer has the effect of improving a resistivity, decreasing an eddy current and improving an exchange interaction between the magnetic grains.

Owner:TAIYO YUDEN KK

Preparing method of amorphous meal soft magnetic powder core

ActiveCN104952583AReduce coercive force and lossReduce core lossInorganic material magnetismPhosphoric acidMagnetic core

The invention discloses a preparing method of an amorphous meal soft magnetic powder core. The preparing method includes the steps of 1, embrittling an amorphous strip, and crushing the amorphous strip embrittled to obtain amorphous metal powder; 2, screening the amorphous metal powder, and performing particle size matching; 3, subjecting the matched amorphous metal powder to passivation; 4, subjecting the amorphous metal powder, passivated by phosphoric acid, to insulation coating; 5, adding binder, and granulating the amorphous metal powder coated; 6, subjecting the granulated amorphous metal powder to magnetic field orientation forming; 7, subjecting a magnetic core, subjected to orientation forming, to axial magnetic thermal treatment; and 8, cooling the magnetic core, subjected to axial magnetic thermal treatment, and performing spraying to obtain a product. The preparing method has the advantages that magnetic domain forms in the amorphous magnetic core, coercive force and loss are lowered, magnetic core loss is further reduced, magnetic conductivity is improved, soft magnetic property of the amorphous magnetic core is improved, and the cost is lowered.

Owner:HENGDIAN GRP DMEGC MAGNETICS CO LTD

Magnetic thin film and method of manufacturing the same

InactiveUS20050053802A1High saturated magnetic flux densityGood soft magnetismManufacture head surfaceLiquid applicationMagnetic characteristicMaterials science

The magnetic thin film has high saturation magnetic flux density and superior soft magnetic characteristics. The magnetic thin film of the present invention comprises: a base layer being made of FeCo / NiFe; and a plated layer being formed on the base layer, the plated layer being made of FeCo.

Owner:FUJITSU LTD

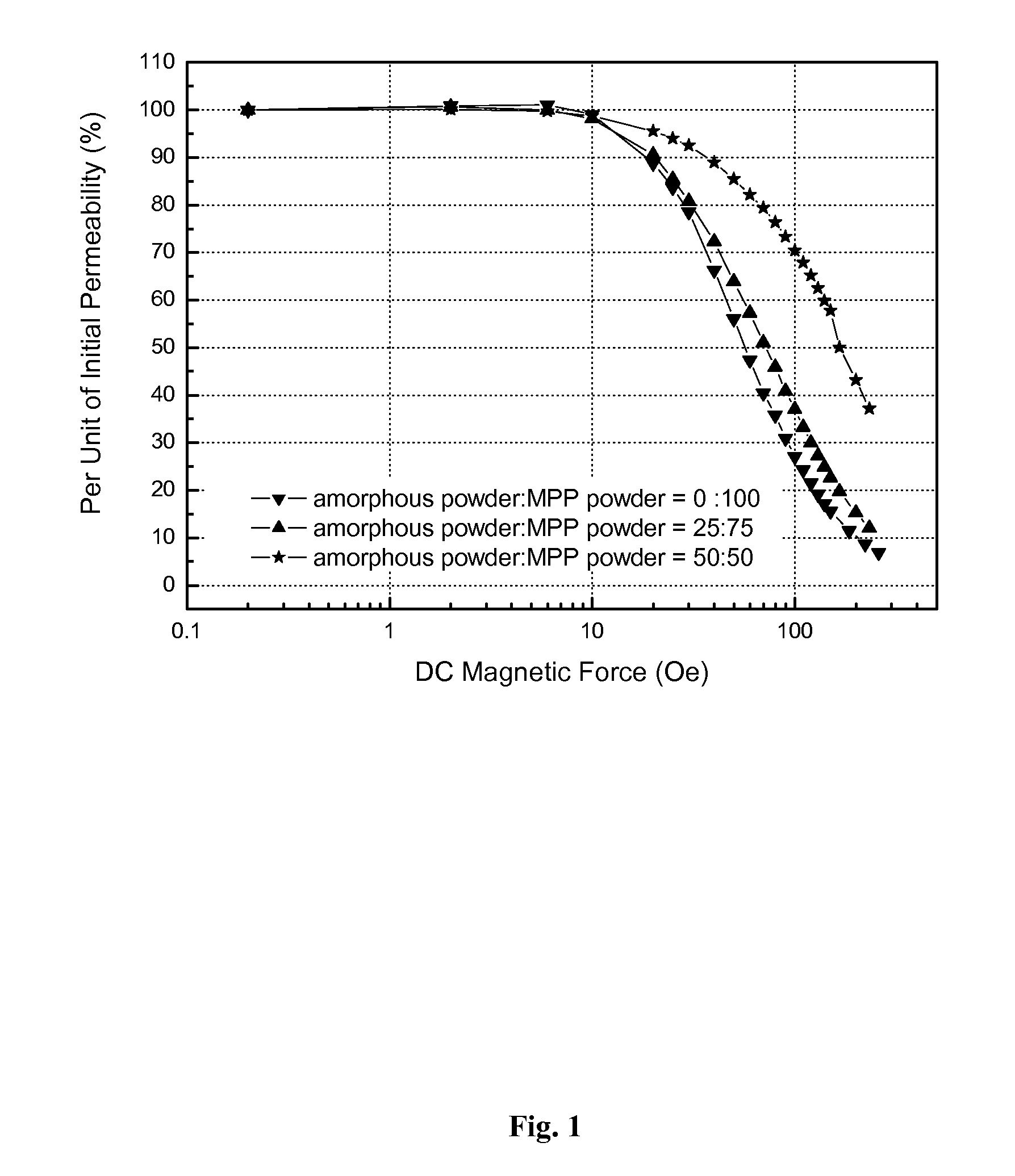

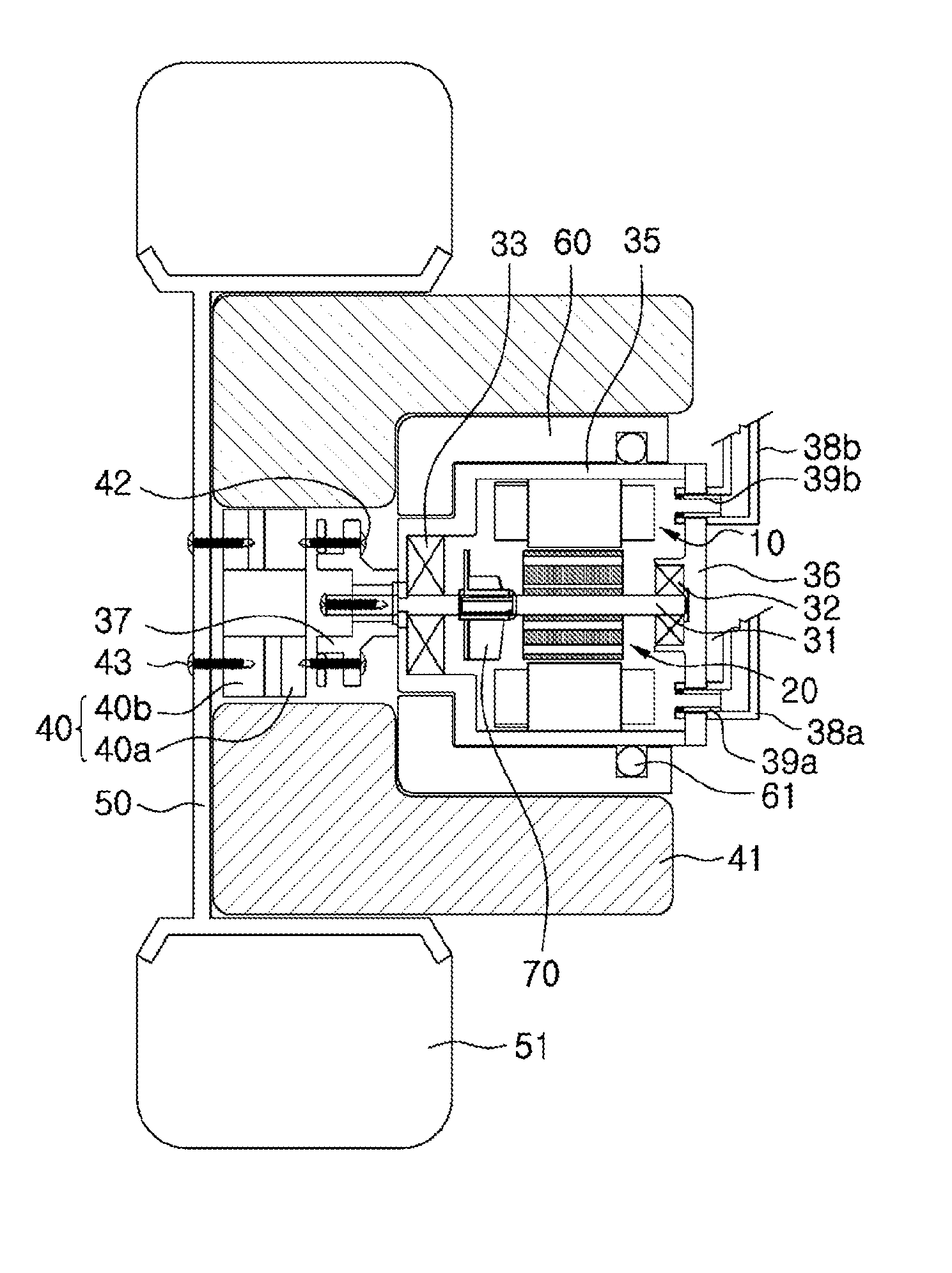

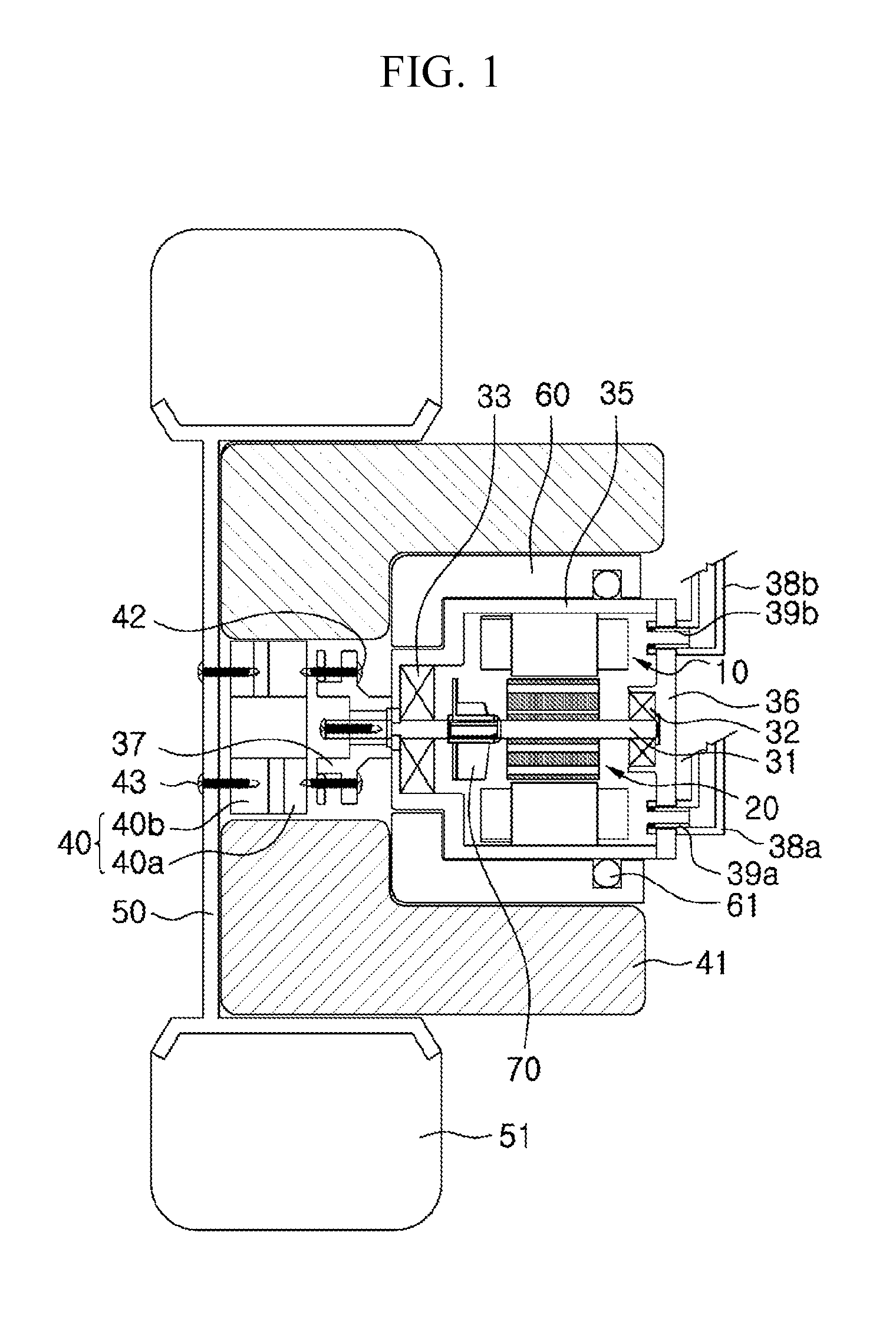

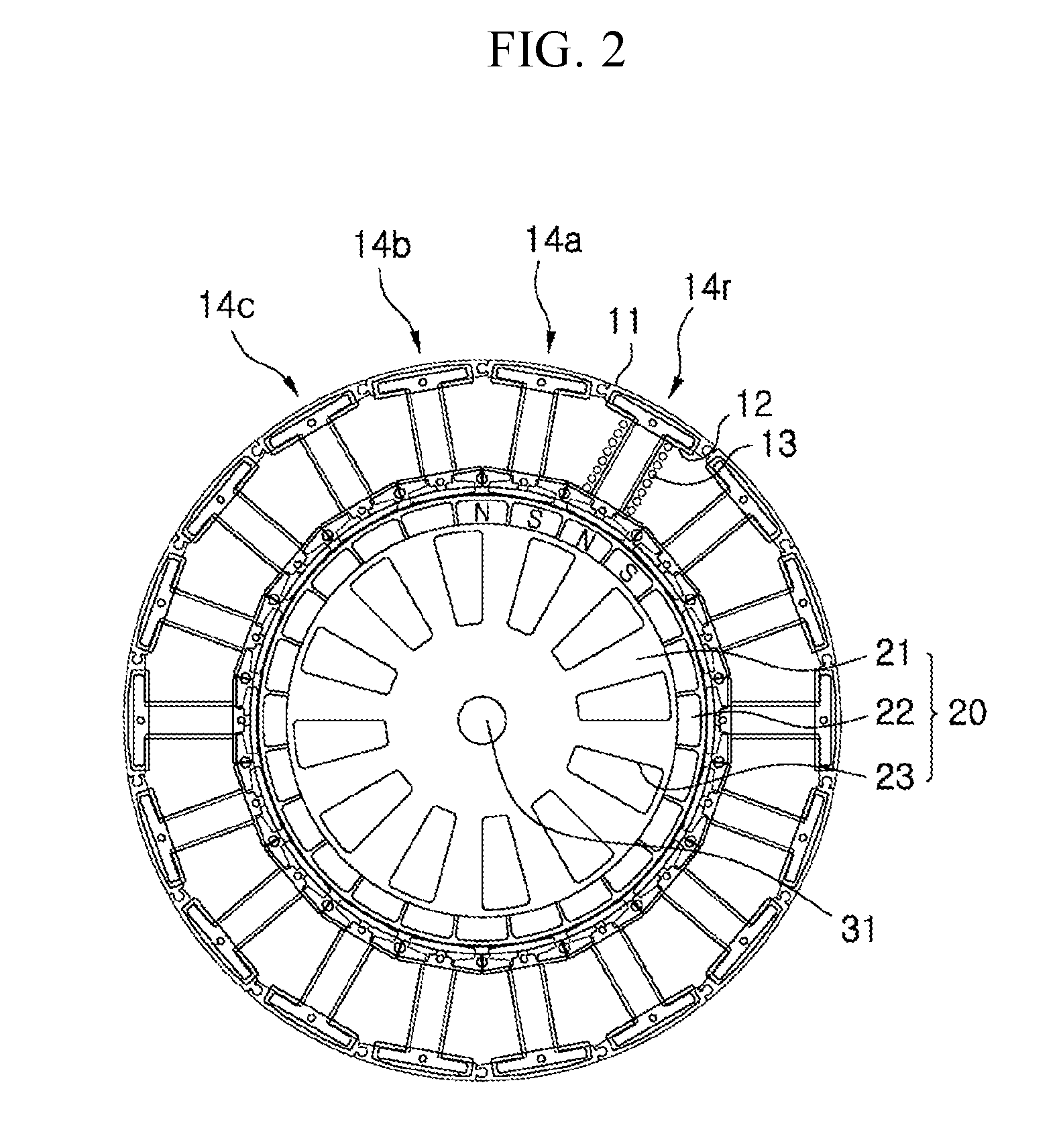

Amorphous magnetic component, electric motor using same and method for manufacturing same

InactiveUS20130264894A1Simple moldingExcellent soft magnetic propertiesMagnetic circuit rotating partsTransportation and packagingCompression moldingMetal powder

An amorphous magnetic component for use in a high-power, high-speed electric motor, in which amorphous metal materials are powdered, compressed, and molded, to be easily molded into magnetic components of a complex shape, and crystalline metal powder of excellent soft magnetic properties is added to the amorphous alloy powder, to promote improvement of a magnetic permeability and improvement of a packing density at the time of compression molding. A method of manufacturing the amorphous magnetic component; includes the steps of: pulverizing ribbons or strips of amorphous alloys to obtain plate-shaped amorphous alloy powder; classifying the amorphous alloy powder, and mixing the amorphous alloy powder with spherical soft magnetic powder, in order to improve magnetic permeability and packing density, to obtain mixed powder; mixing the mixed powder with a binder, to be molded into a shape of the magnetic components; and sintering the molded magnetic components to implement magnetic properties.

Owner:AMOTECH

Nano-crystalline, magnetic alloy, its production method, alloy ribbon and magnetic part

ActiveUS20110085931A1High magnetic flux densityLow coercivityMagnetic materialsAmorphous matrixNano crystalline

Owner:HITACHI METALS LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com