Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

463 results about "Fe based" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

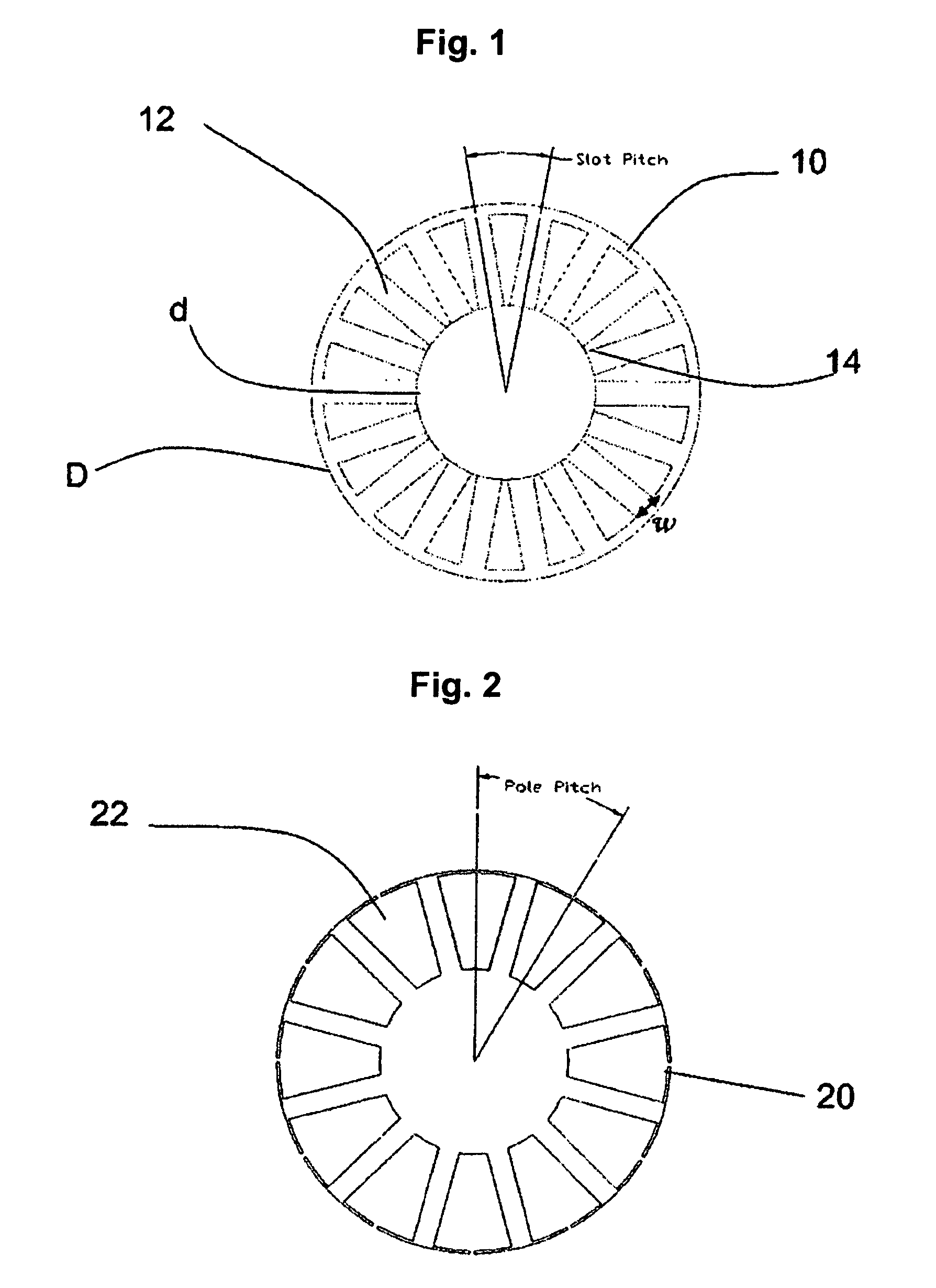

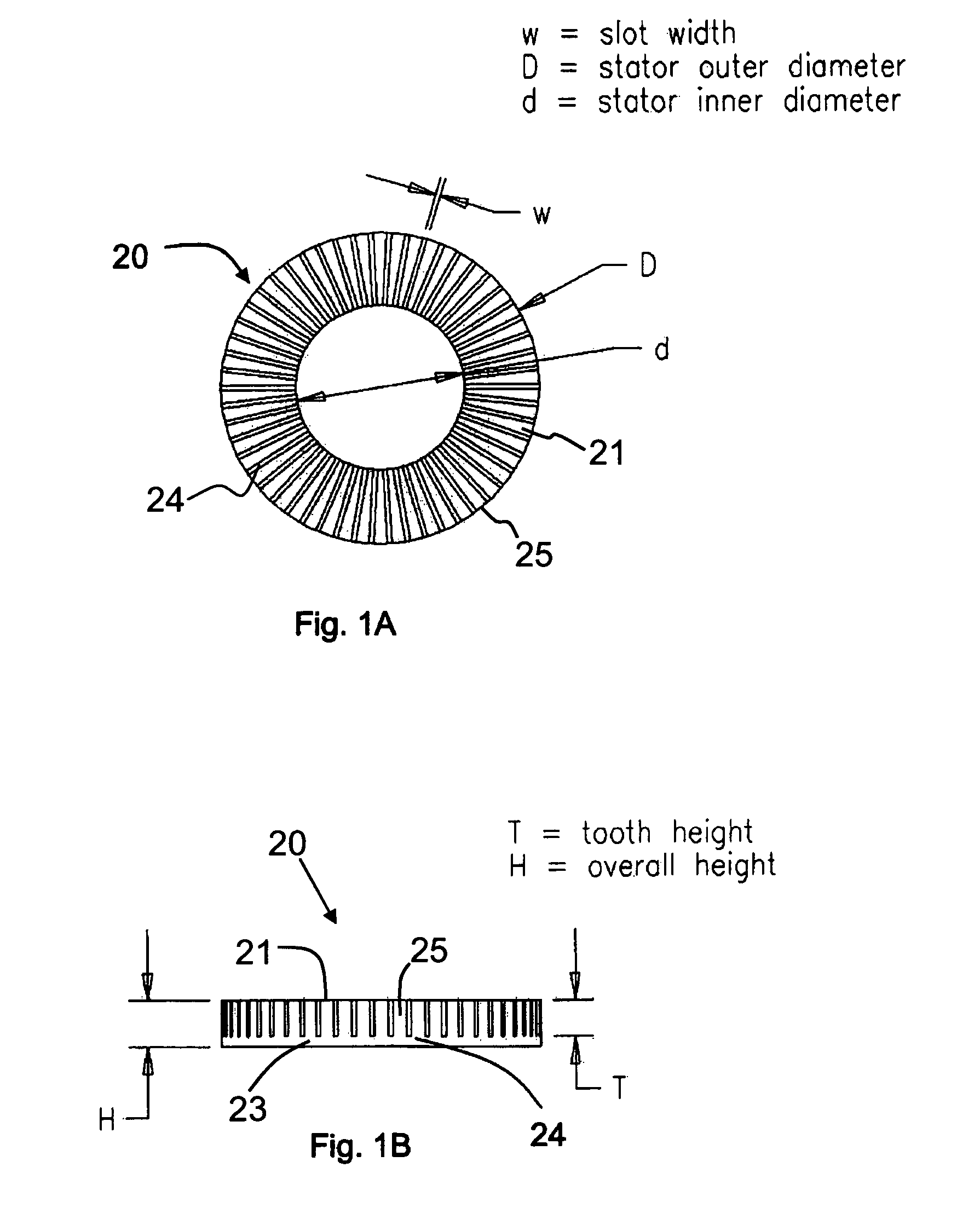

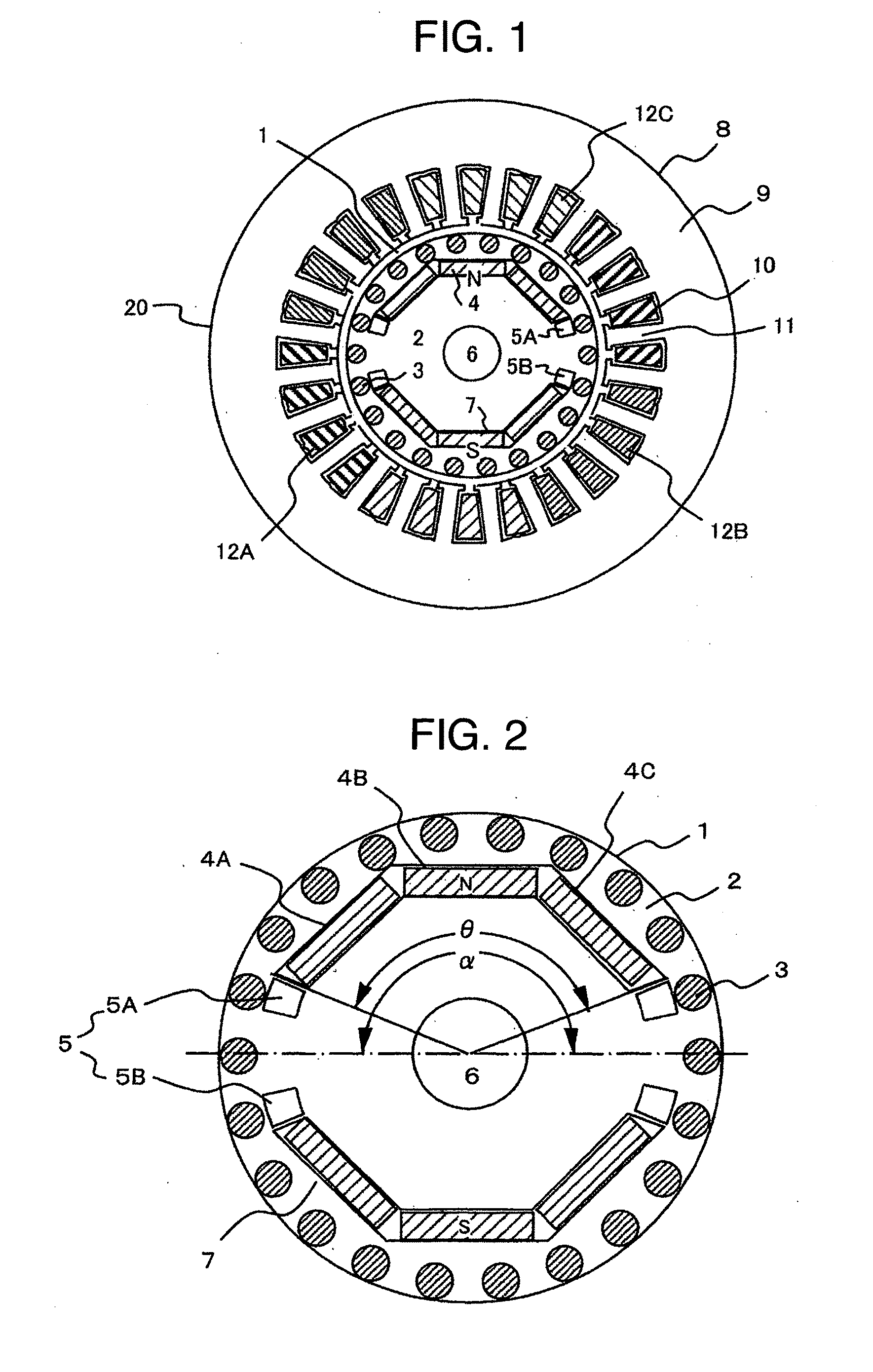

Efficient high-speed electric device using low-loss materials

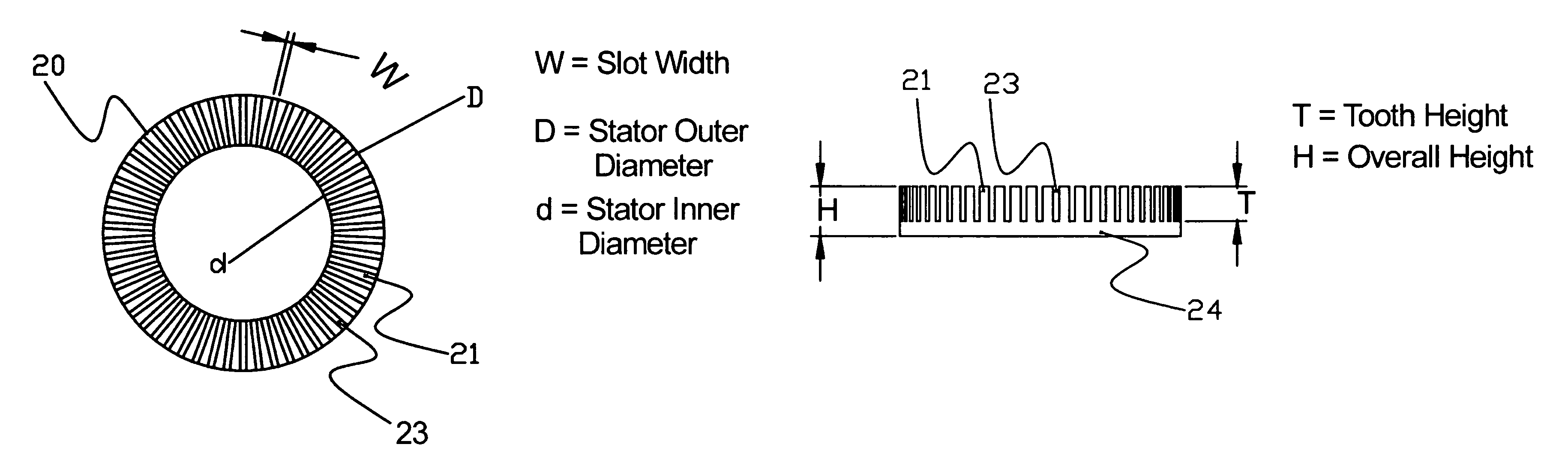

InactiveUS7230361B2Reduce lossHigh frequencyMagnetic circuit rotating partsMagnetic circuit stationary partsEngineeringHigh torque

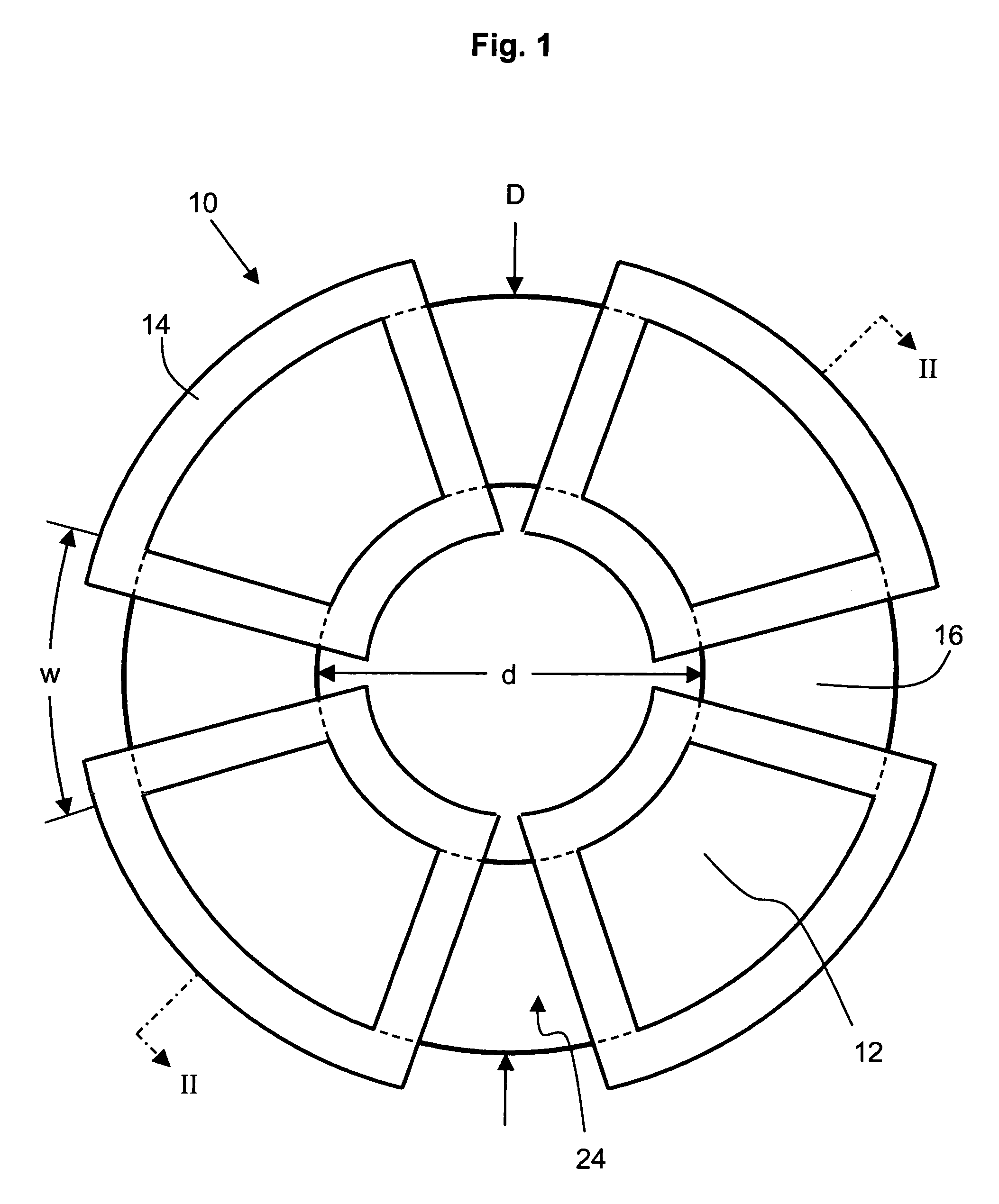

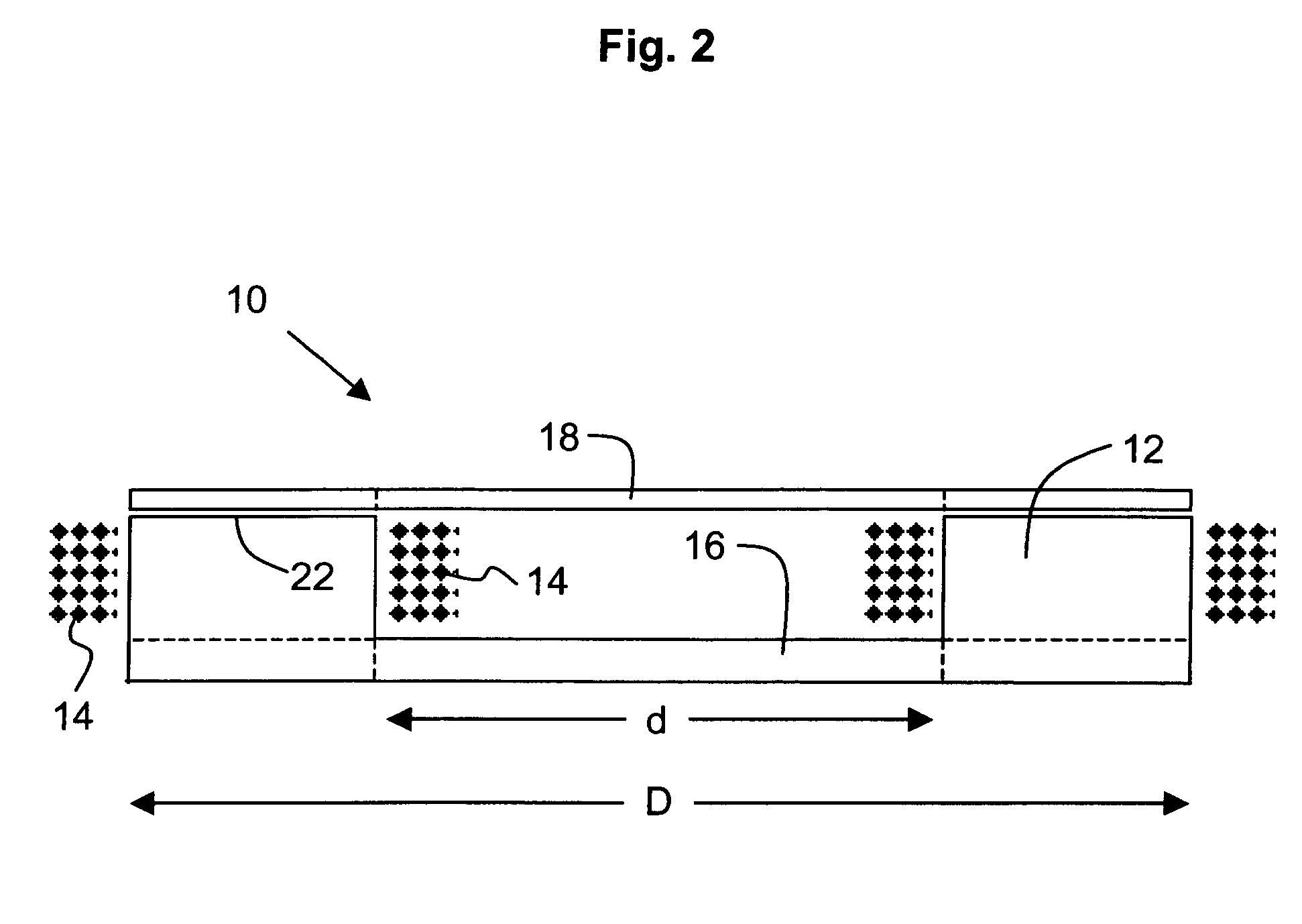

The invention relates generally to an electric device, such as an electric motor, a generator, or a regenerative motor, having a wound stator core made from advanced low-loss material. In preferred embodiments, the electric device is an axial airgap-type configuration. The invention provides an electric device having a high pole count that operates at high commutating frequencies, with high efficiency and high torque and power densities. Advanced low-loss materials exploited by the present invention include amorphous metals, nanocrystalline metals, and optimized Fe-based alloys.

Owner:BERG & BERG ENTERPRISES

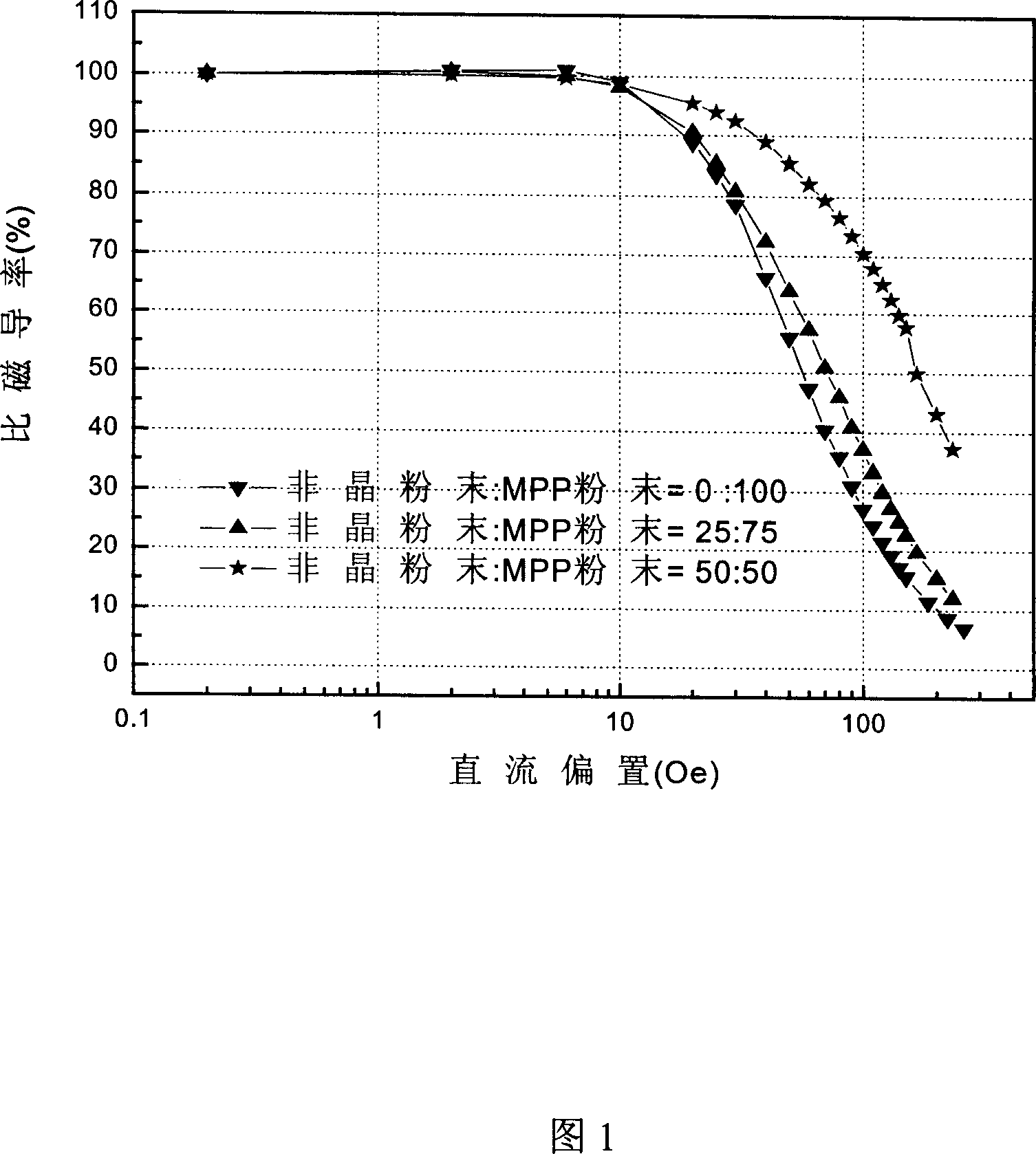

Composite powder, magnetic powder core for magnetic powder and preparation method thereof

InactiveCN101118797AExcellent soft magnetic propertiesIncrease the amount of participationInorganic material magnetismInductances/transformers/magnets manufactureAl powderIron powder

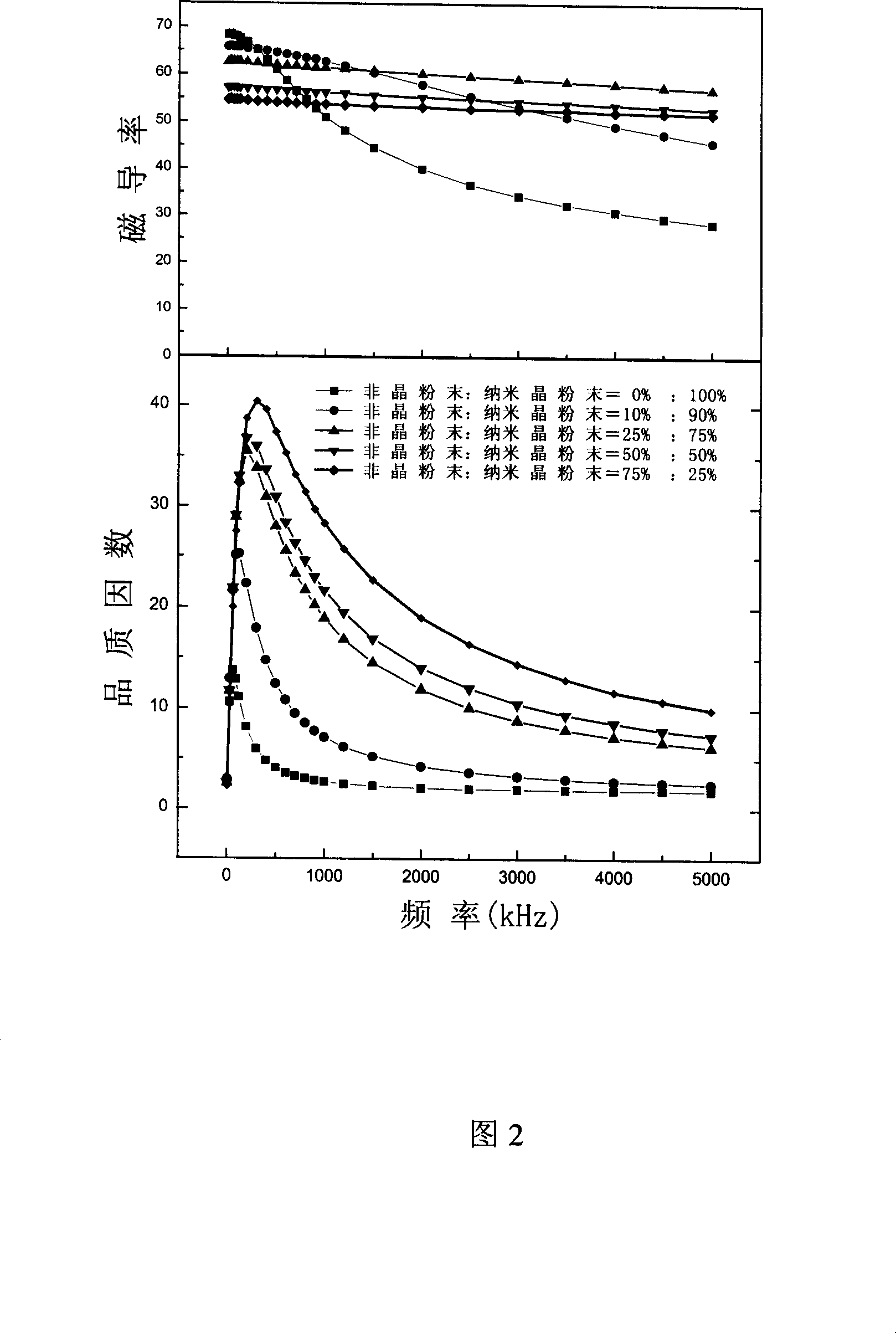

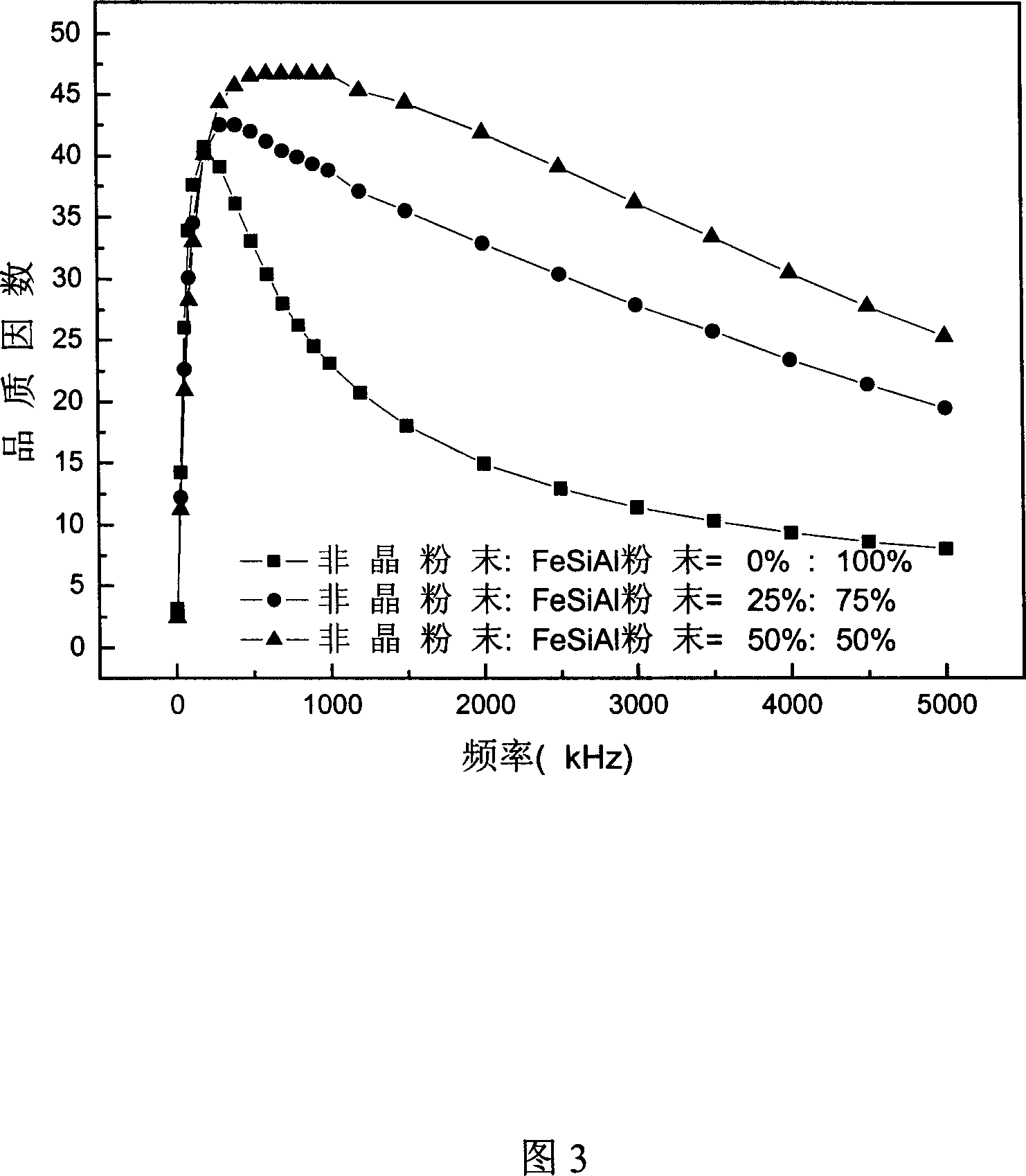

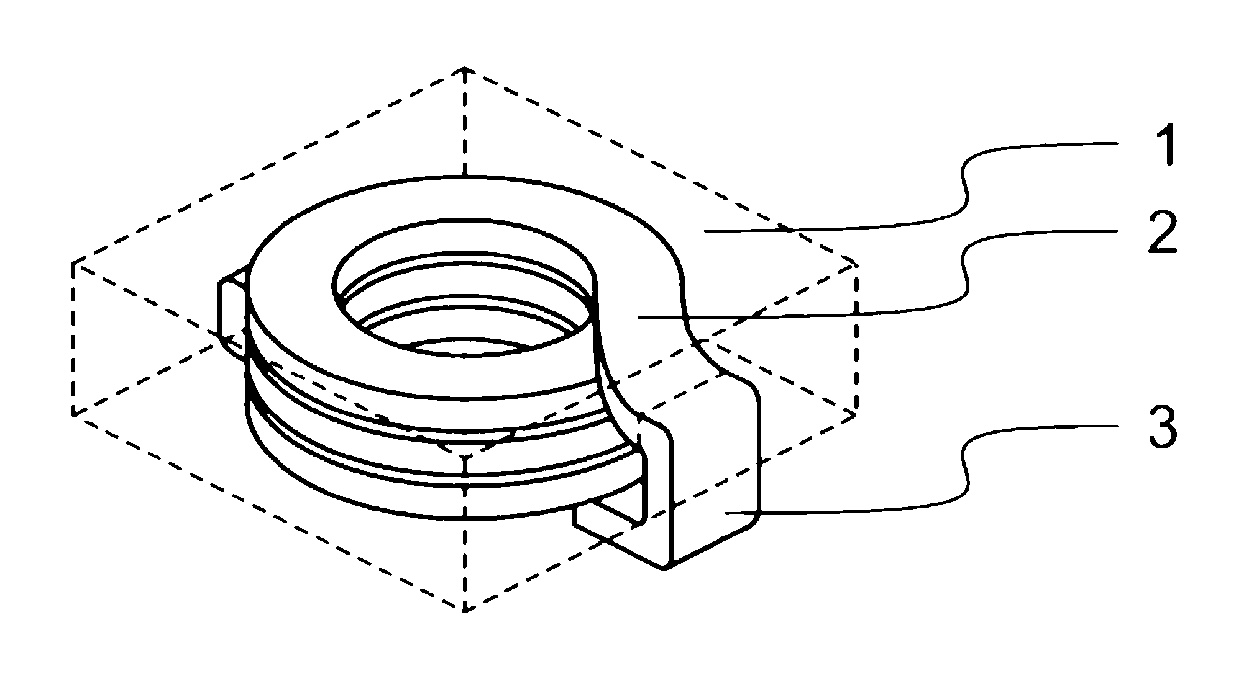

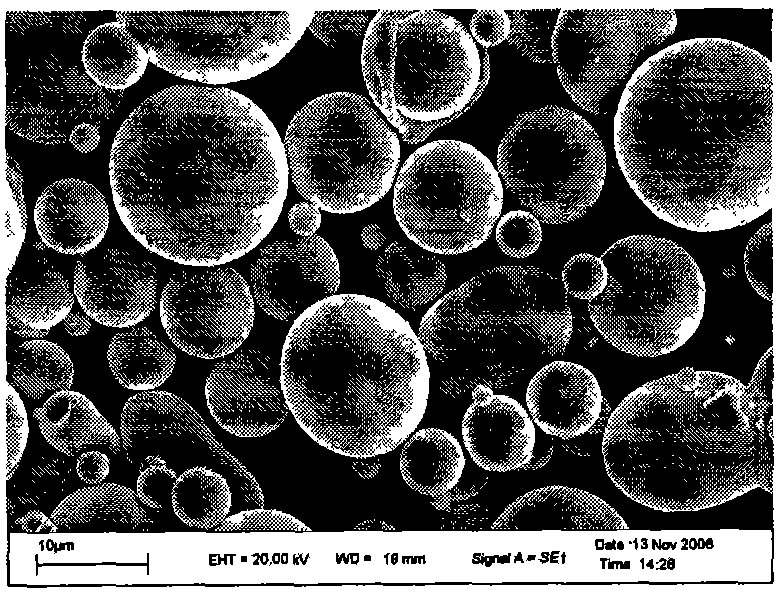

The present invention provides a magnetic powder core, composite powder used for the magnetic powder core, and a production method for the both. The composite powder is blended and formed by powder A and powder B, the content of which comprises 50-96wt percent of the powder A and 4-50wt percent of the powder B; wherein, the powder A is one out of iron powder, Fe-Si powder, Fe-Si-Al powder, Fe-based nanometer crystal powder, Fe-base amorphous powder, Fe-Ni powder and Fe-Ni-Mo powder; the powder B has different demand characteristics compared with the powder A and is selected from at least one out of iron powder, Fe-Si powder, Fe-Si-Al powder, Fe-based nanometer crystal powder, Fe-based amorphous powder, Fe-Ni powder and Fe-Ni-Mo powder. The powder B can be Fe-based soft magnetic amorphous powder as the insulating agent, which can reduce the wastage of magnetic powder core and make up for the declining magnetic conductivity of magnetic powder core caused by the traditional insulating agent. The excellent of soft magnetic properties of the insulating agent is utilized to improve frequency features of the magnetic powder core.

Owner:ADVANCED TECHNOLOGY & MATERIALS CO LTD

Soft magnetic alloy, magnetic component using the same, and thier production methods

ActiveUS20100097171A1Excellent soft magnetic propertiesGood formabilityTransportation and packagingMetal-working apparatusFe basedMagnetic alloy

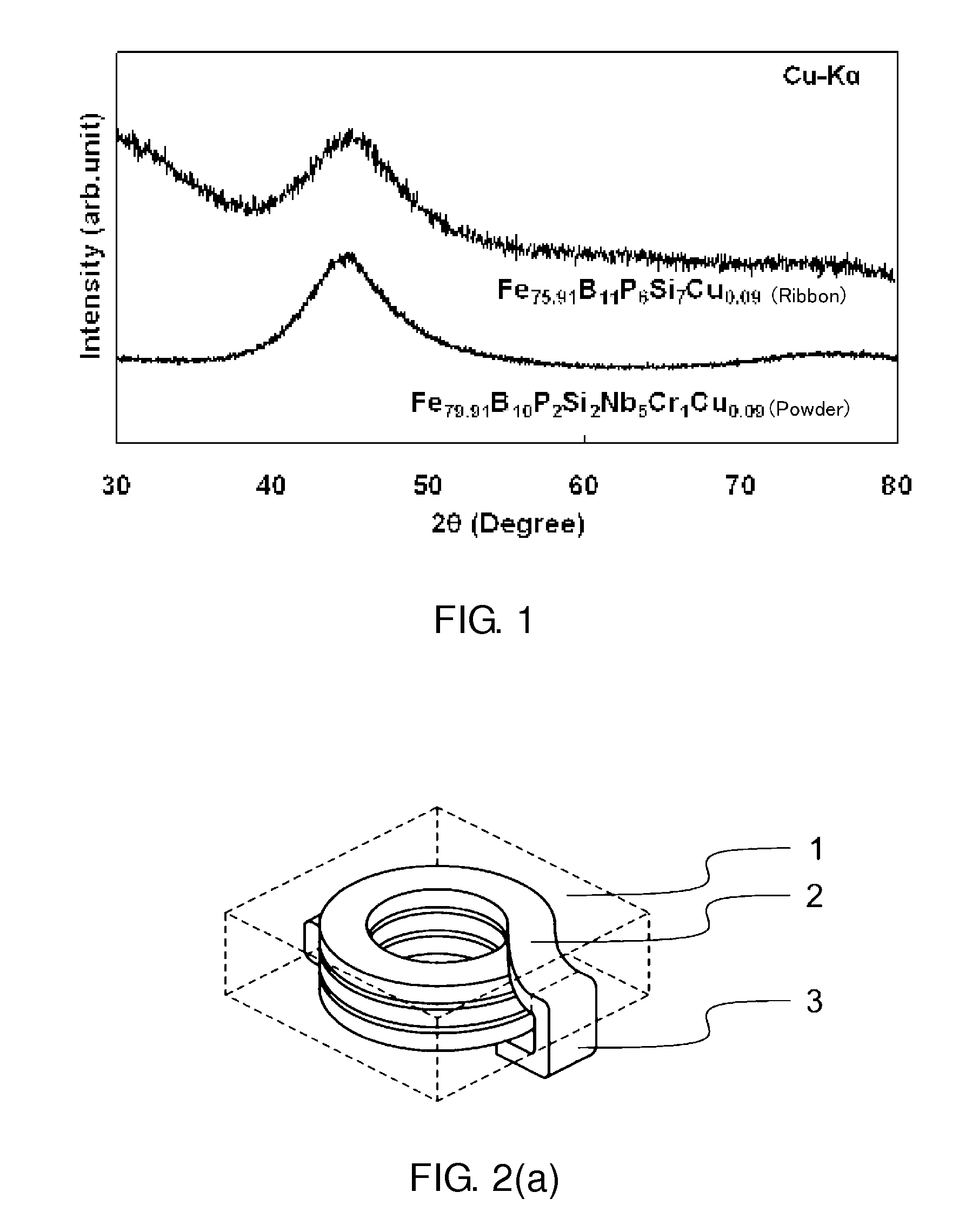

A soft magnetic alloy contains P, B, and Cu as essential components. As a preferred example, an Fe-based alloy contains Fe of 70 atomic % or more, B of 5 atomic % to 25 atomic %, Cu of 1.5 atomic % or less (excluding zero), and P of 10 atomic or less (excluding zero).

Owner:TOKIN CORP +2

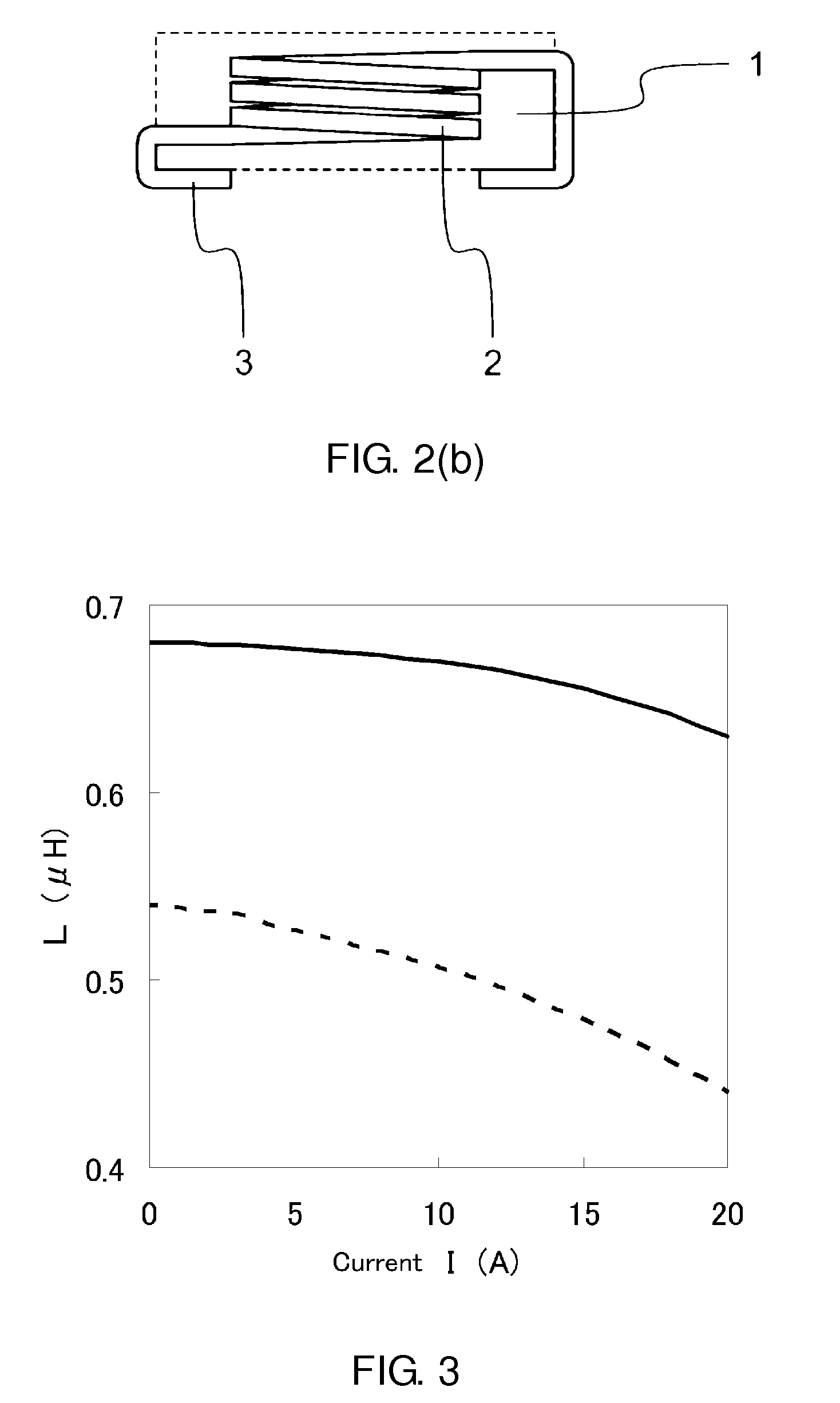

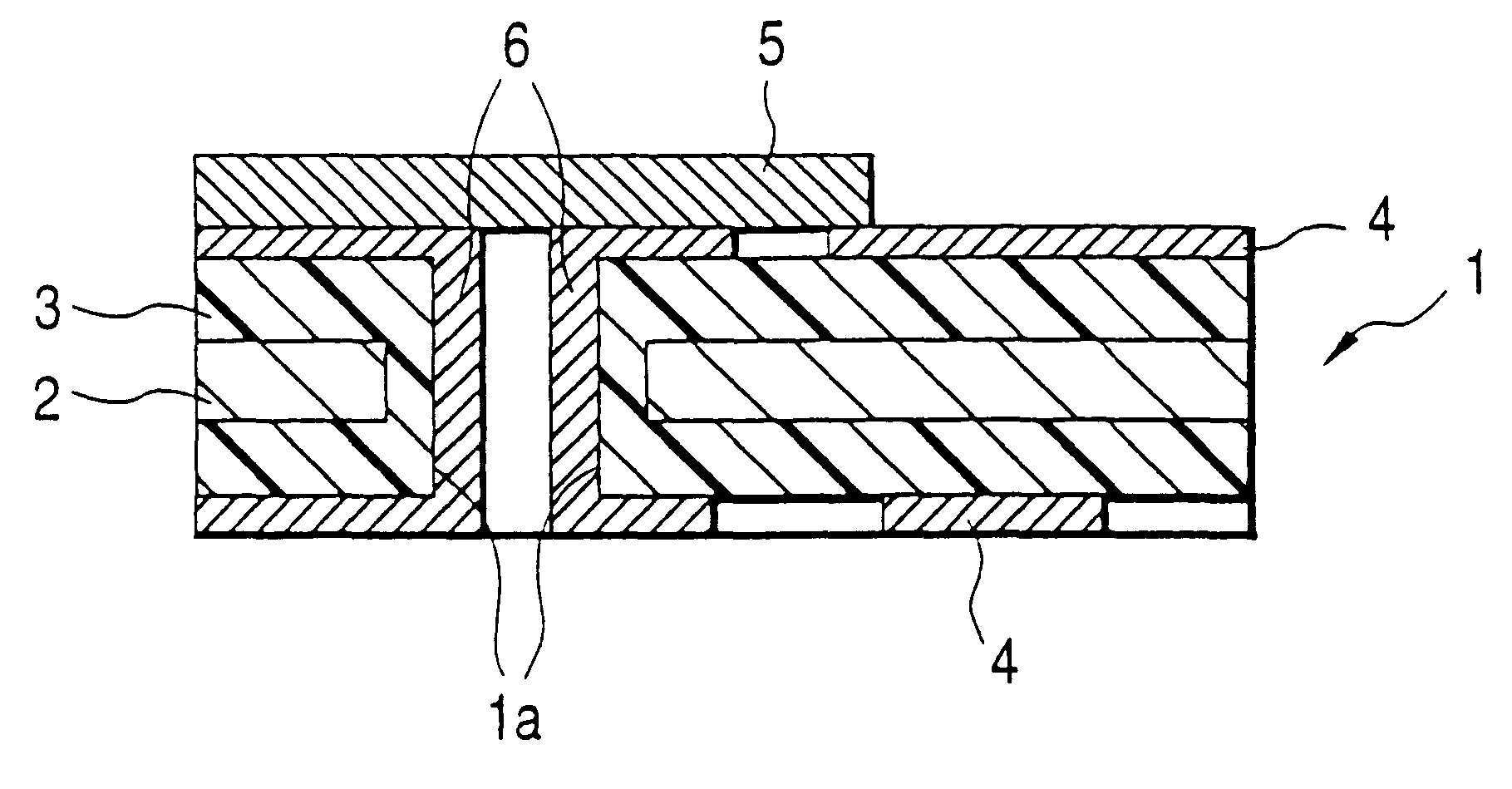

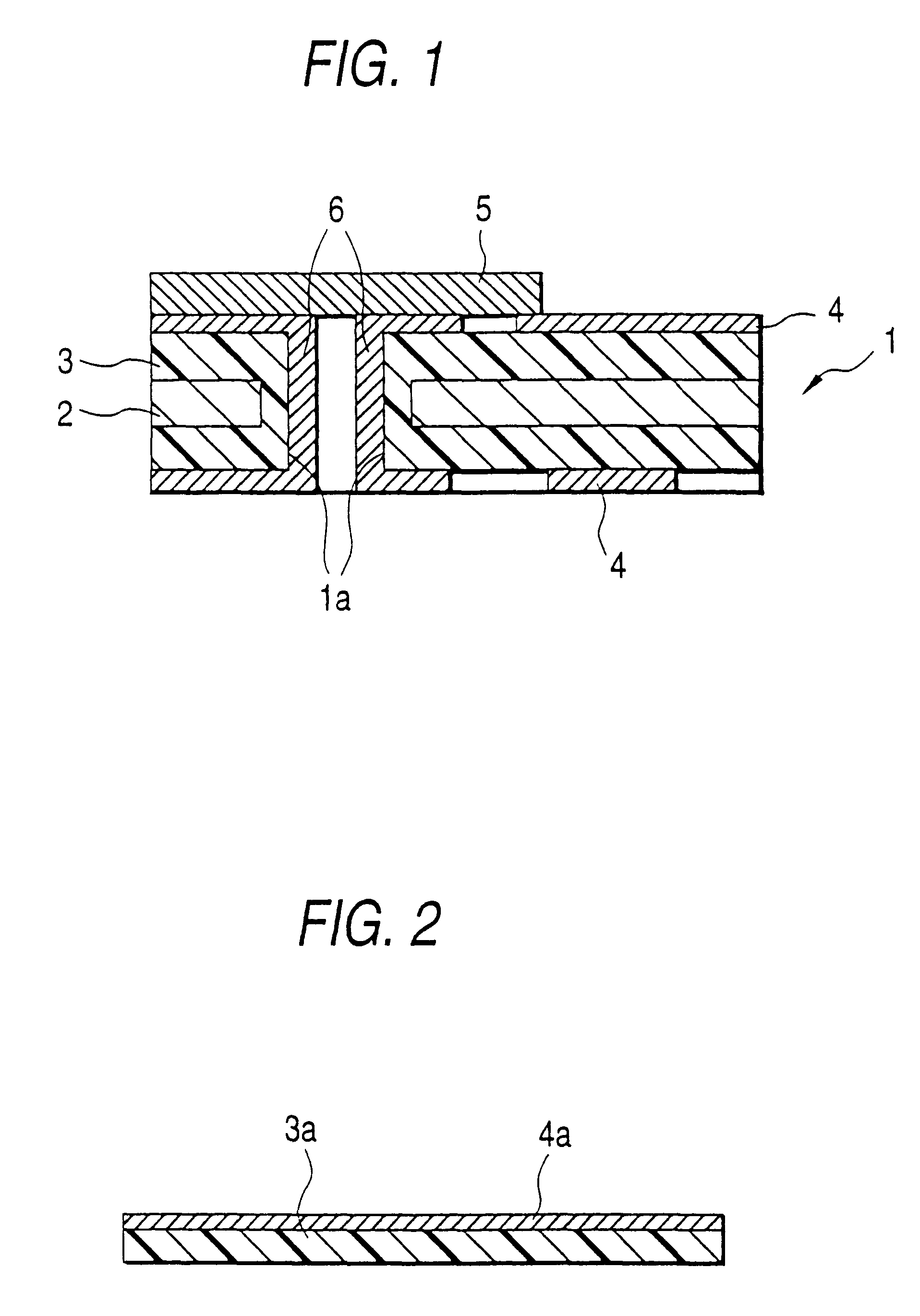

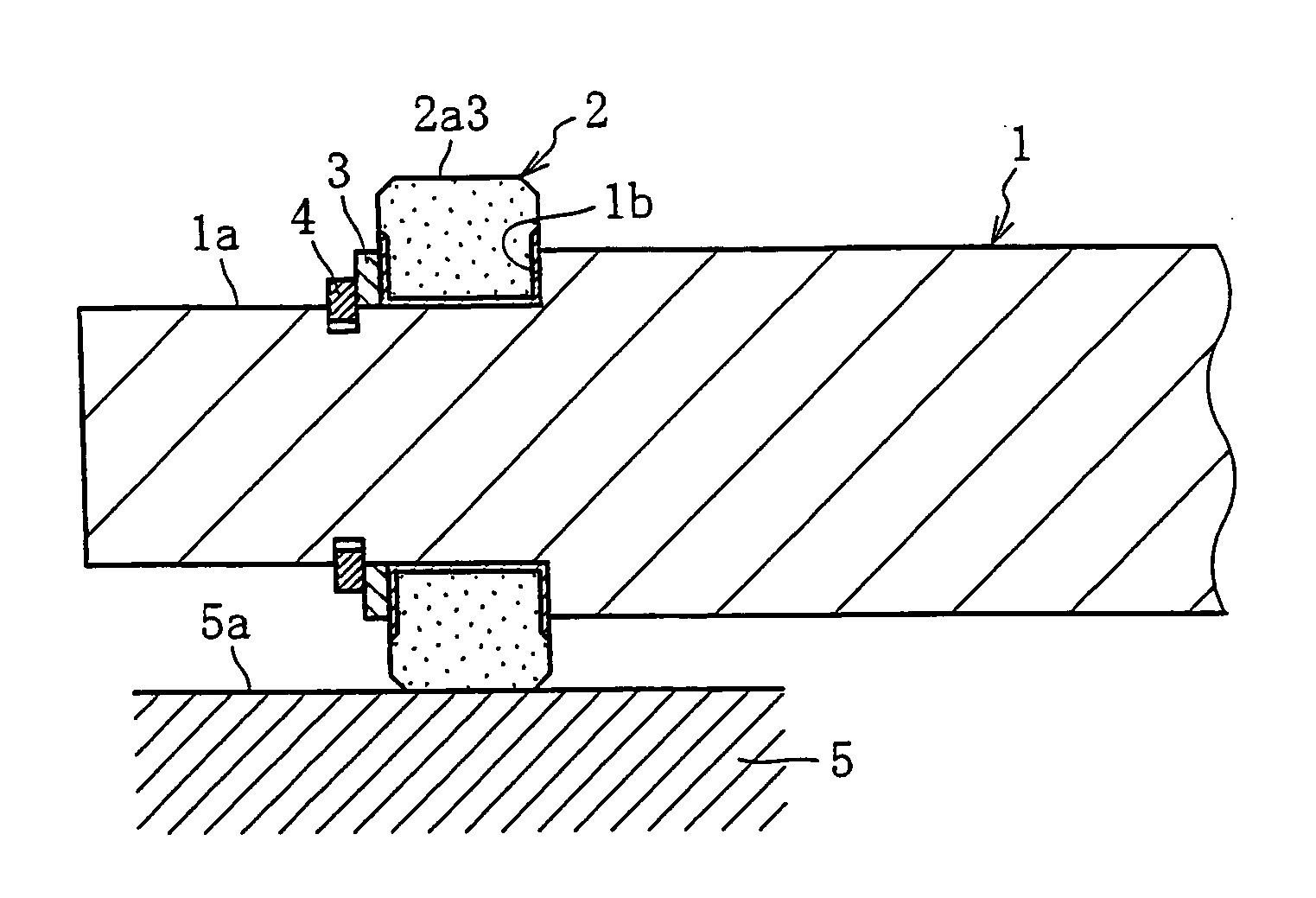

Low thermal expansion circuit board and multilayer wiring circuit board

InactiveUS6180261B1Improve repairabilityEasy to separateSemiconductor/solid-state device detailsSynthetic resin layered productsFe basedEngineering

A low thermal expansion circuit board 1 on which a semiconductor element can be mounted with ease and high reliability, which comprises an insulating layer 3 having an Ni--Fe-based alloy foil or a titanium foil as a core, a wiring conductor 4 on both sides thereof, and an adhesive resin layer 5 on the side on which a semiconductor element is to be mounted.

Owner:NITTO DENKO CORP

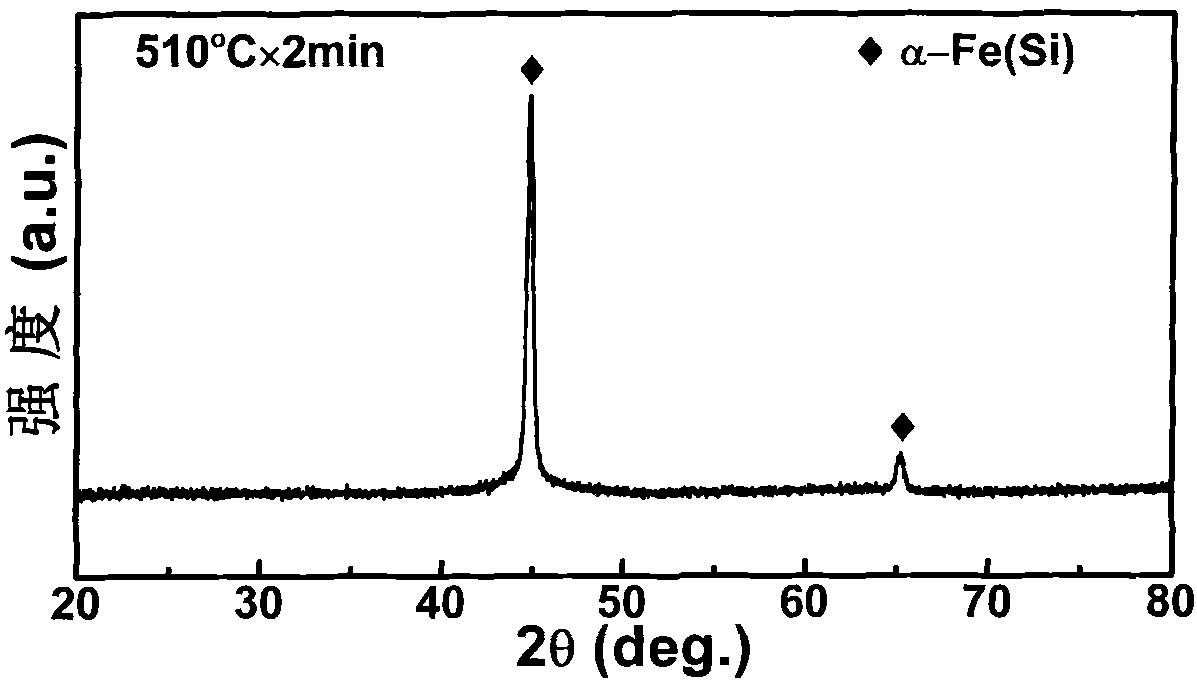

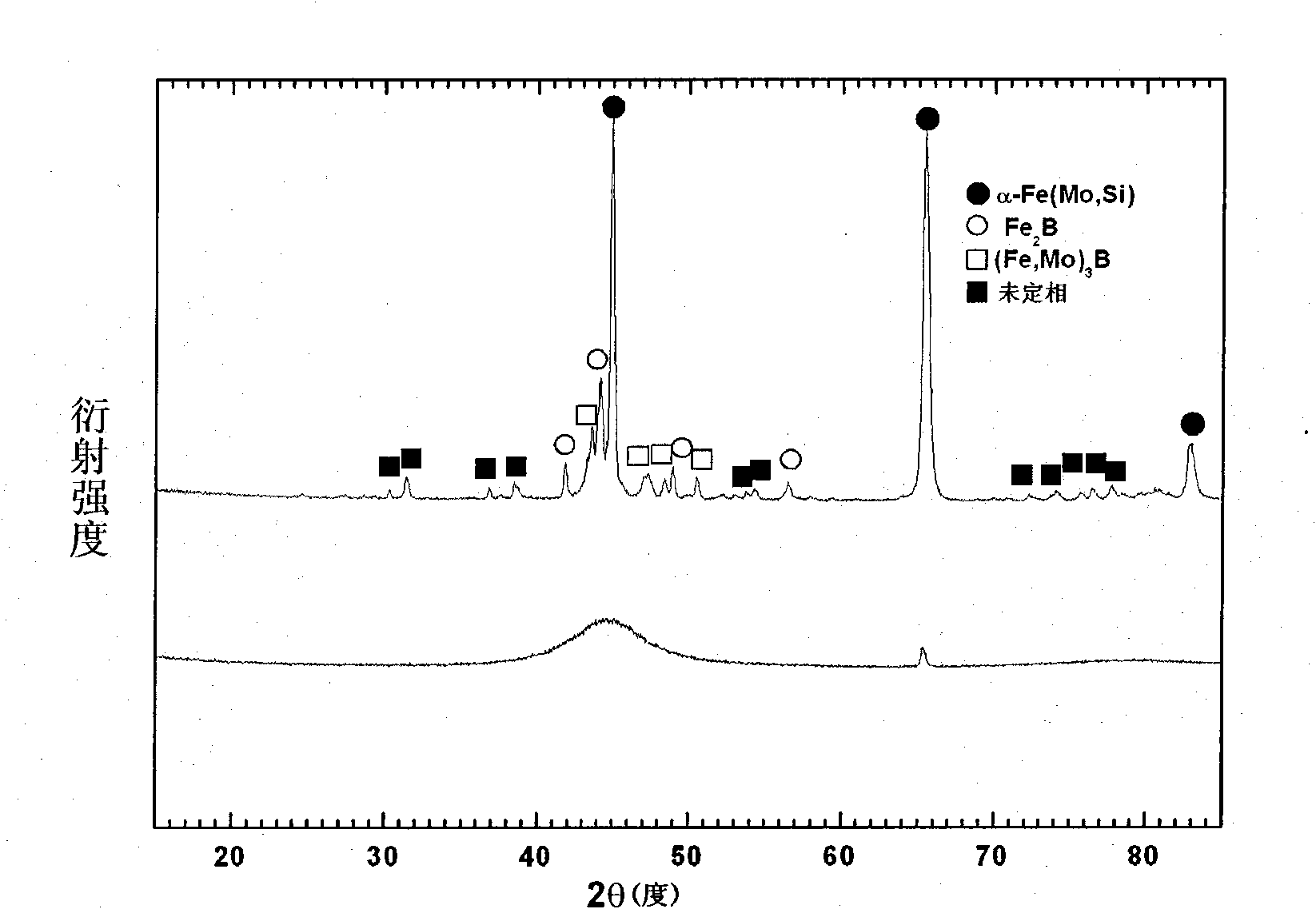

High saturation magnetization intensity Fe-based nanocrystalline magnetically soft alloy material and preparation method thereof

ActiveCN101834046AHigh saturation magnetizationReduce contentMagnetic materialsMagnetizationMicrostructure

The invention relates to a high saturation magnetization intensity Fe-based nanocrystalline magnetically soft alloy material and a preparation method thereof. The high saturation magnetization intensity Fe-based nanocrystalline magnetically soft alloy material is a FexSiyBzPaCub alloy comprising ferrum, silicon, boron, phosphorus and copper, wherein x, y, z, a and b in the formula respectively represent atom percentage content of each corresponding component, x=70-90%, y=1-15%, z=1-20 %, a=1-20% and b=0.1-1%, and x+y+z+a+b=100%; the microstructure of the Fe-based nanocrystalline magnetically soft alloy is as follows: a body-centered cubic Alpha-Fe(Si) nanocrystalline phase with the size of 1-35nm and an amorphous phase rich in phosphorus and boron coexist, and the amorphous phase is the basic phase. The preparation method comprises steps of: preparing proportioned raw materials into an alloy ingot, preparing into amorphous alloy and carrying out other procedures to obtain the high saturation magnetization intensity Fe-based nanocrystalline magnetically soft alloy. The invention can greatly enhance the saturation magnetization intensity of the nanocrystalline magnetically soft alloy, maintain lower coercivity and effectively reduce cost of raw materials simultaneously.

Owner:朗峰新材料启东有限公司

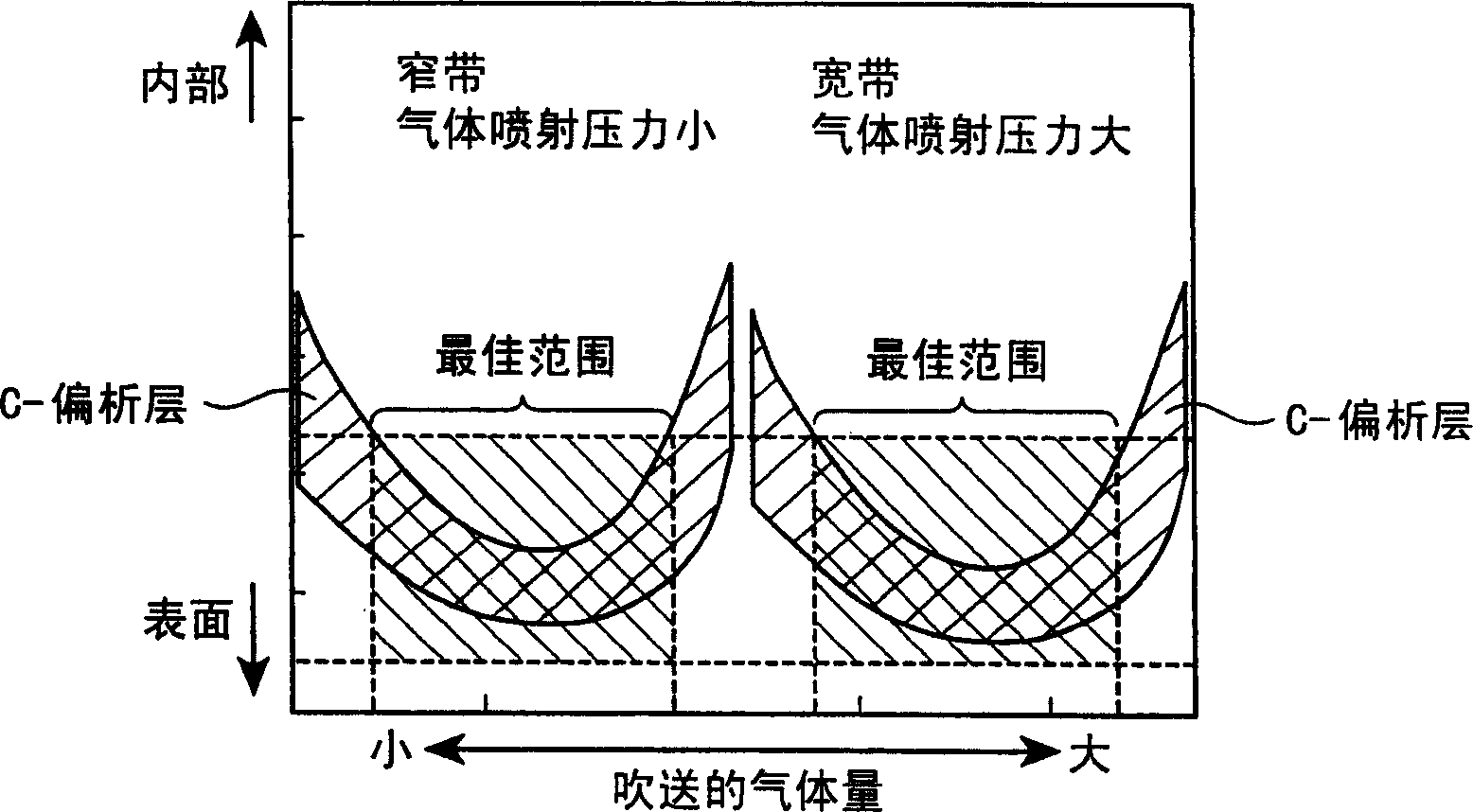

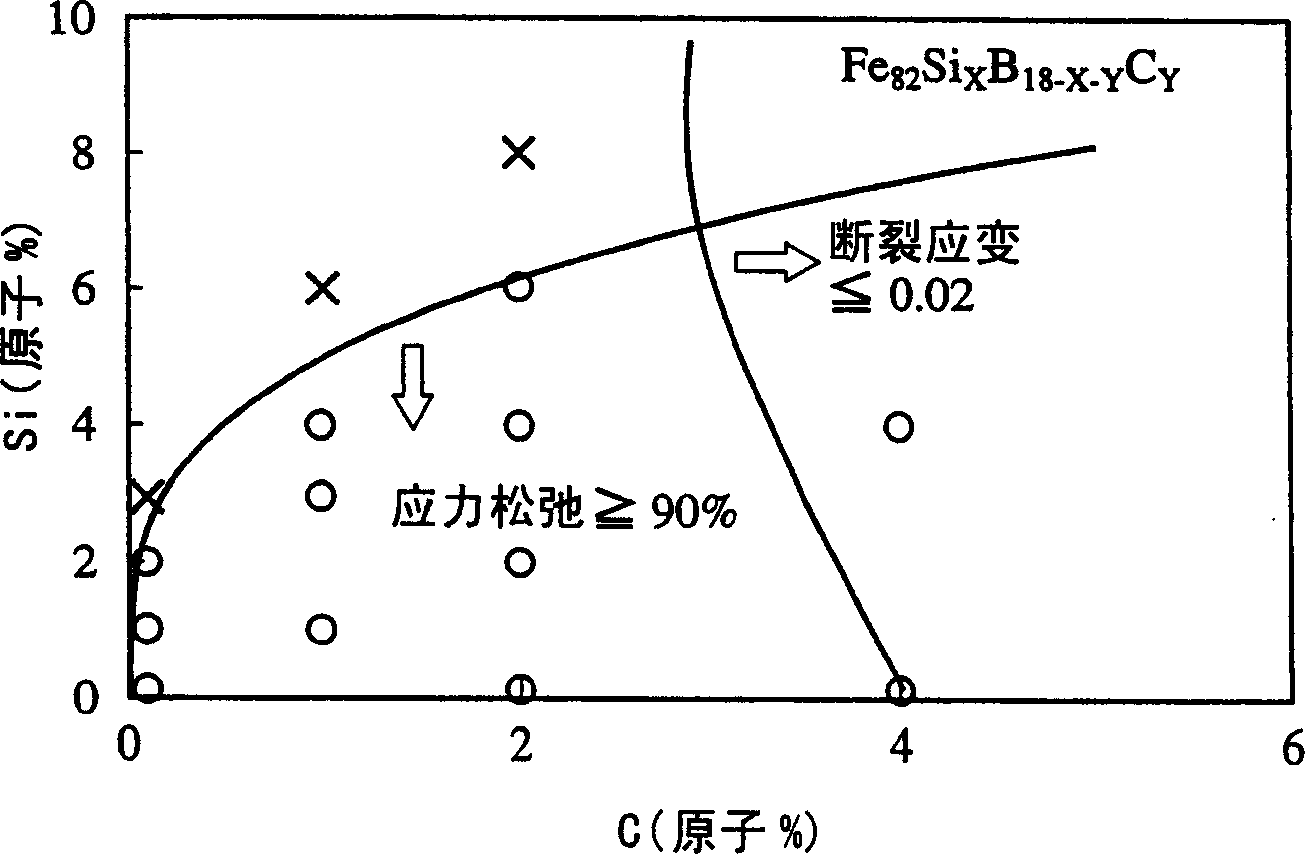

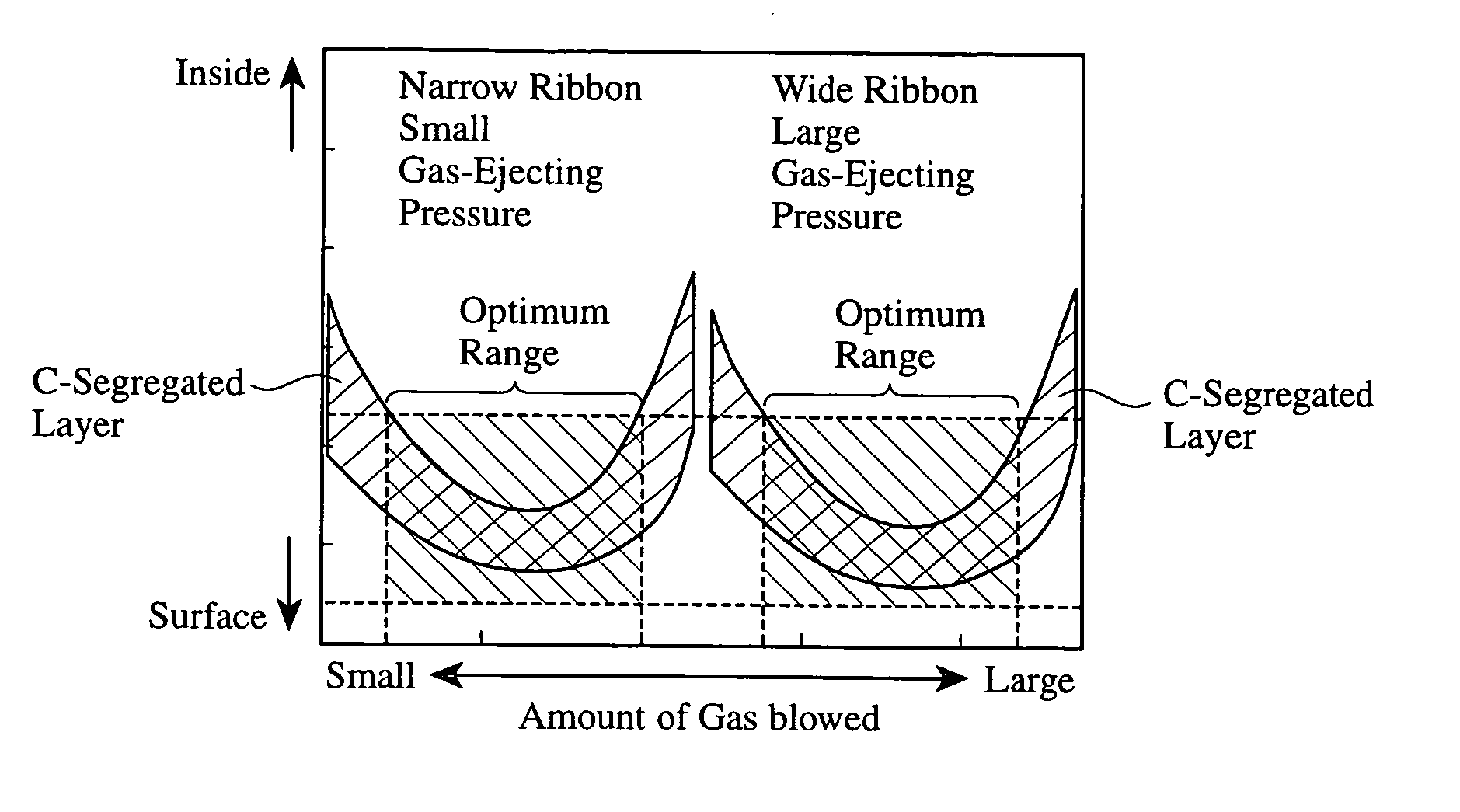

Fe-based amorphous alloy ribbon

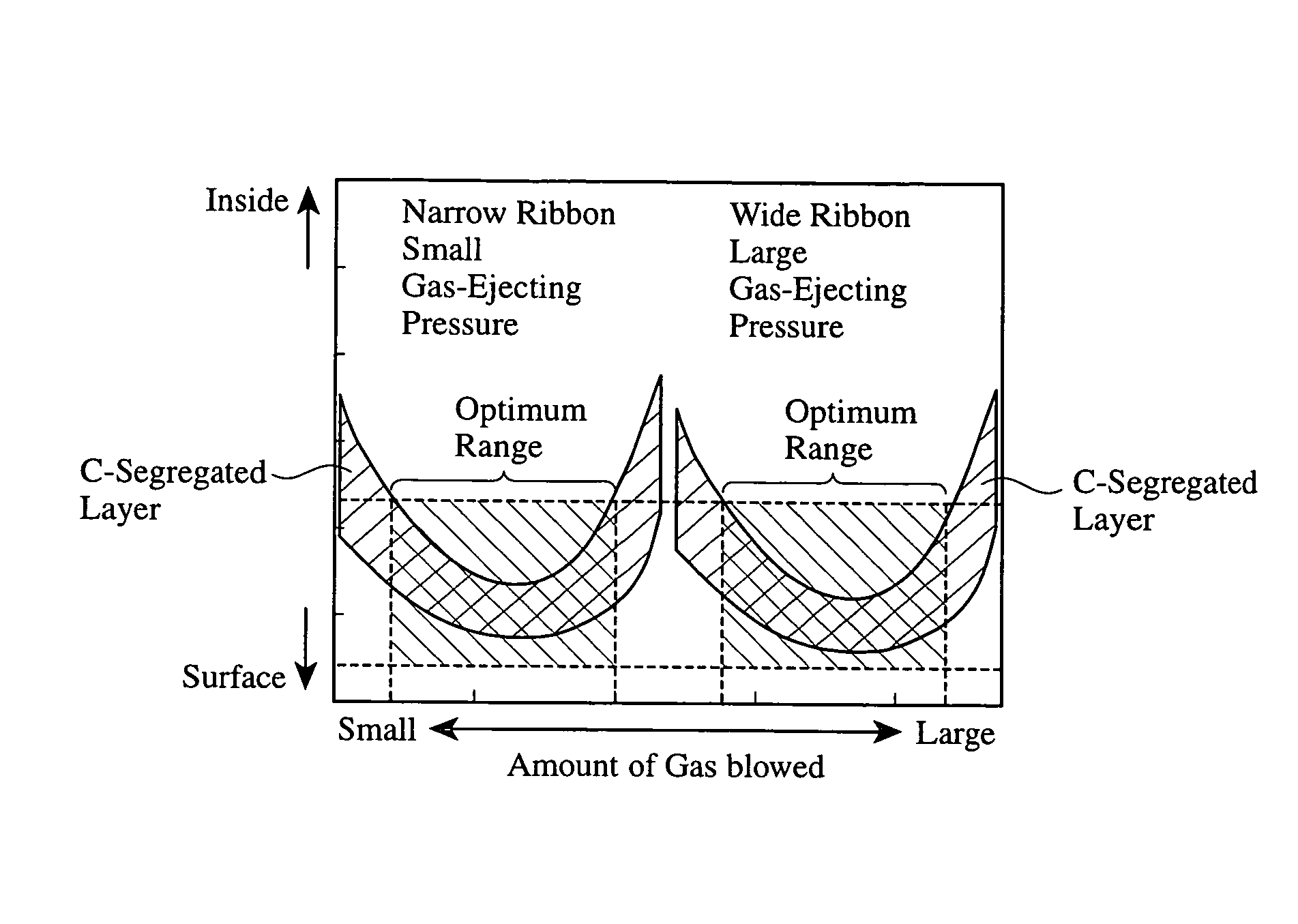

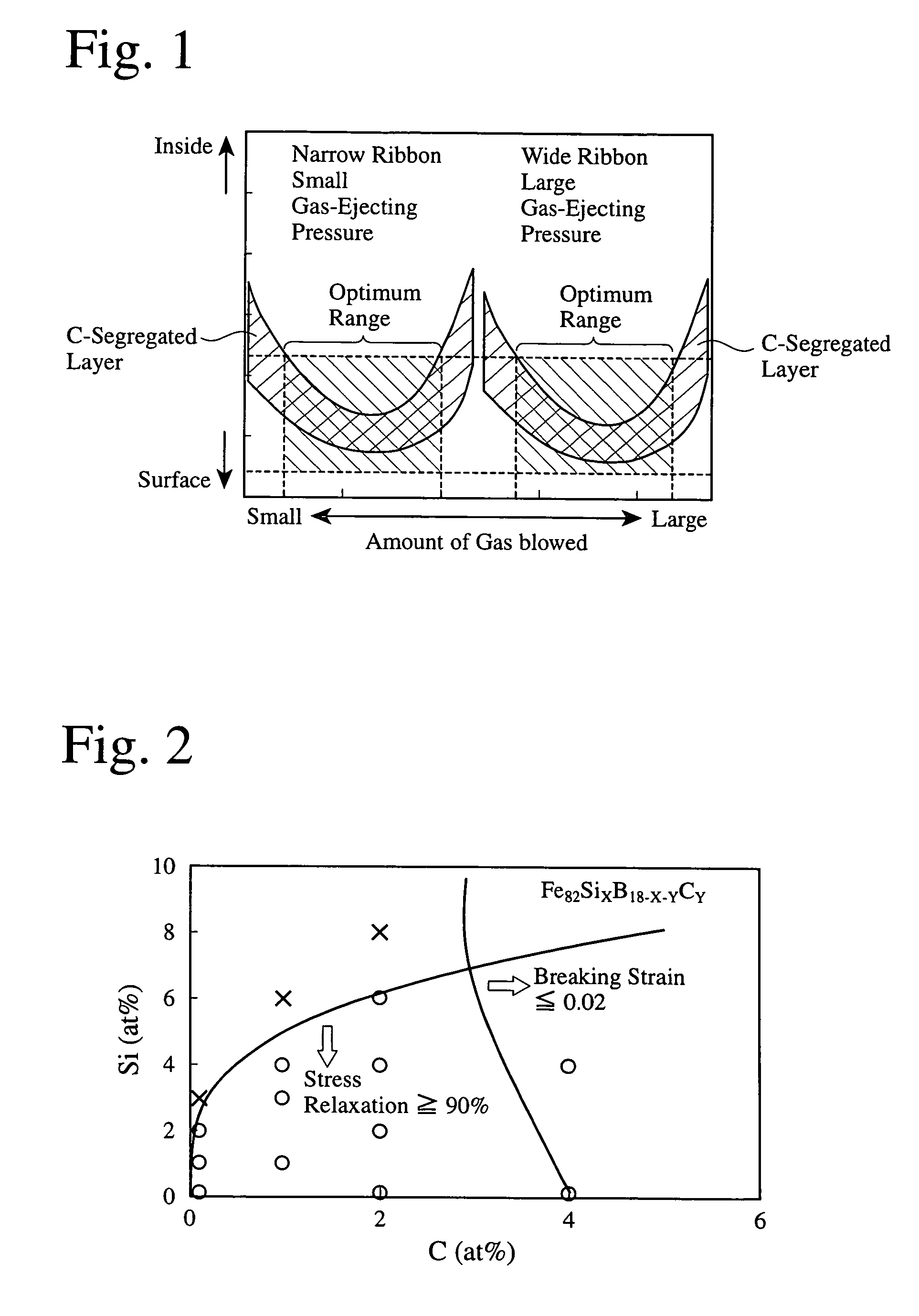

An Fe-based amorphous alloy ribbon having a composition comprising FeaSibBcCd and inevitable impurities, wherein a is 76 to 83.5 atomic %, b is 12 atomic % or less, c is 8 to 18 atomic %, and d is 0.01 to 3 atomic %, the concentration distribution of C measured radially from both surfaces to the inside of said Fe-based amorphous alloy ribbon having a peak within a depth of 2 to 20 nm.

Owner:HITACHI METALS LTD

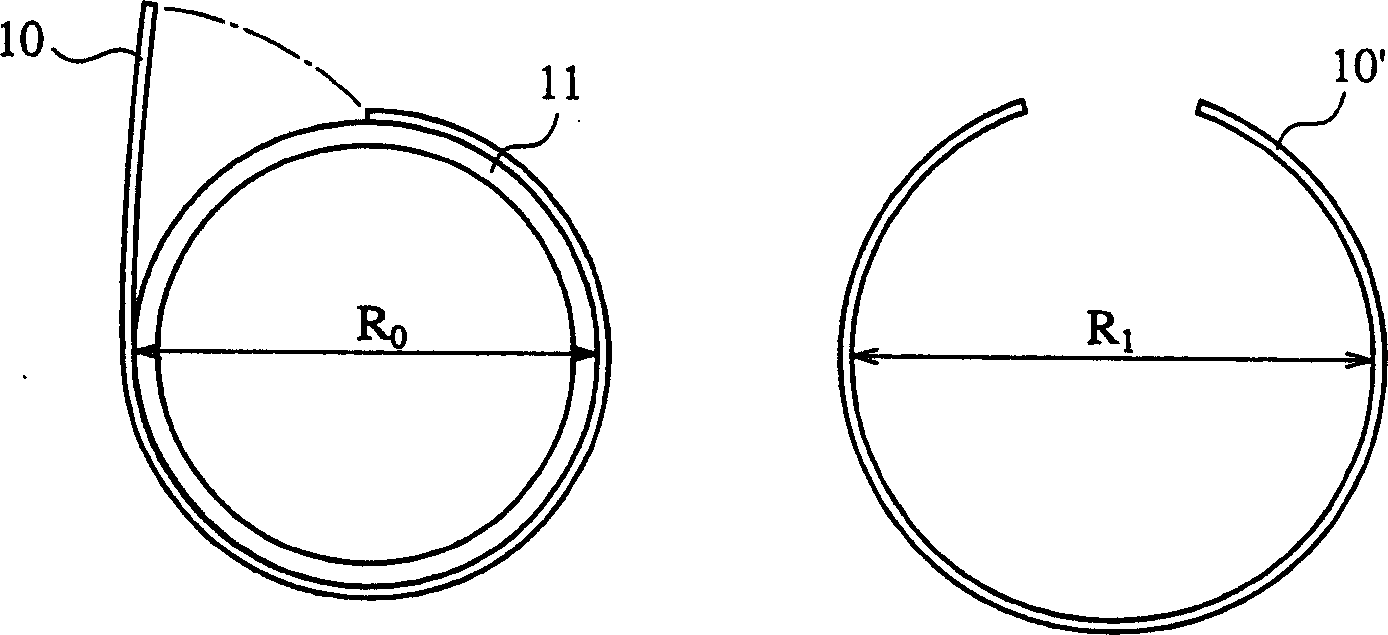

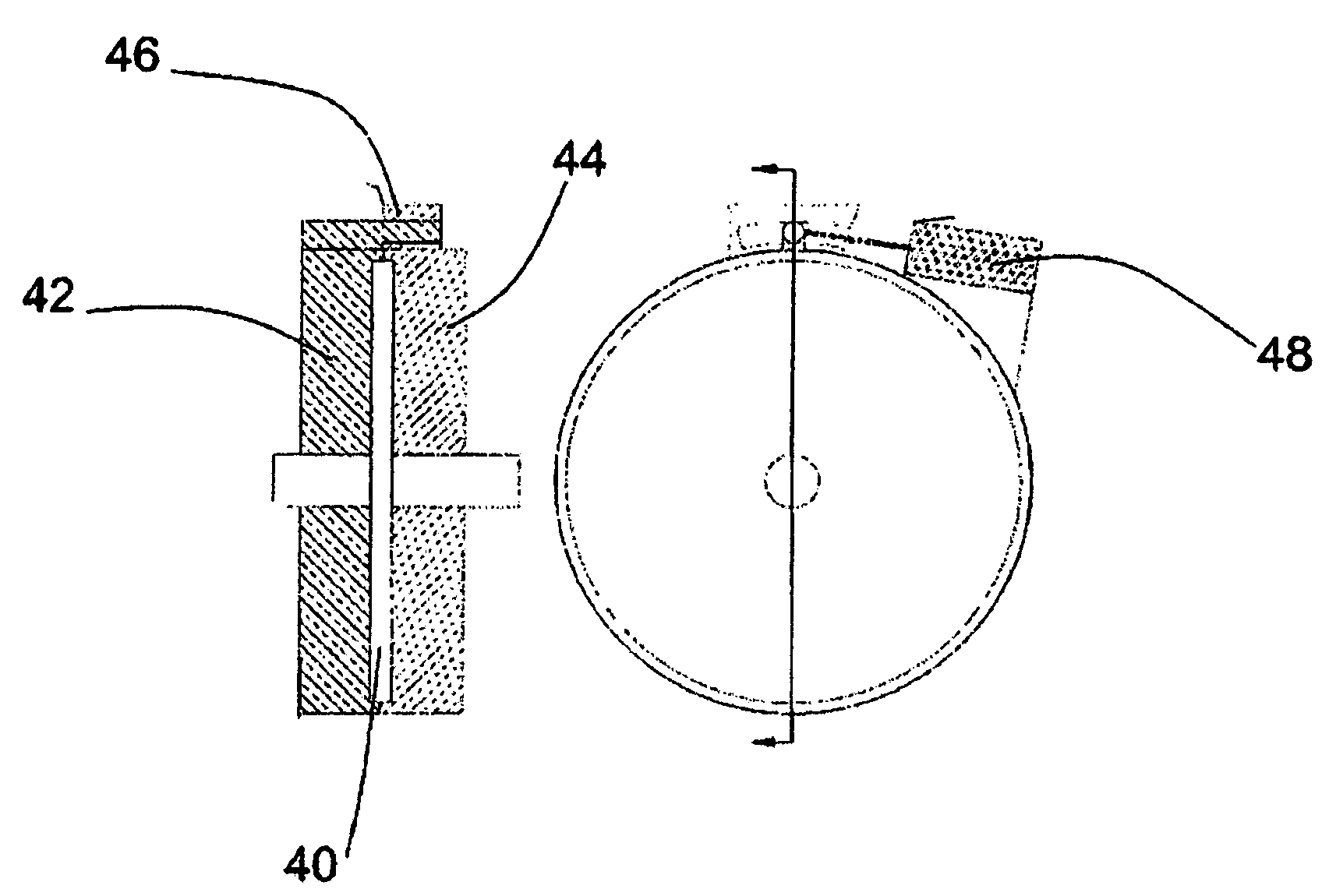

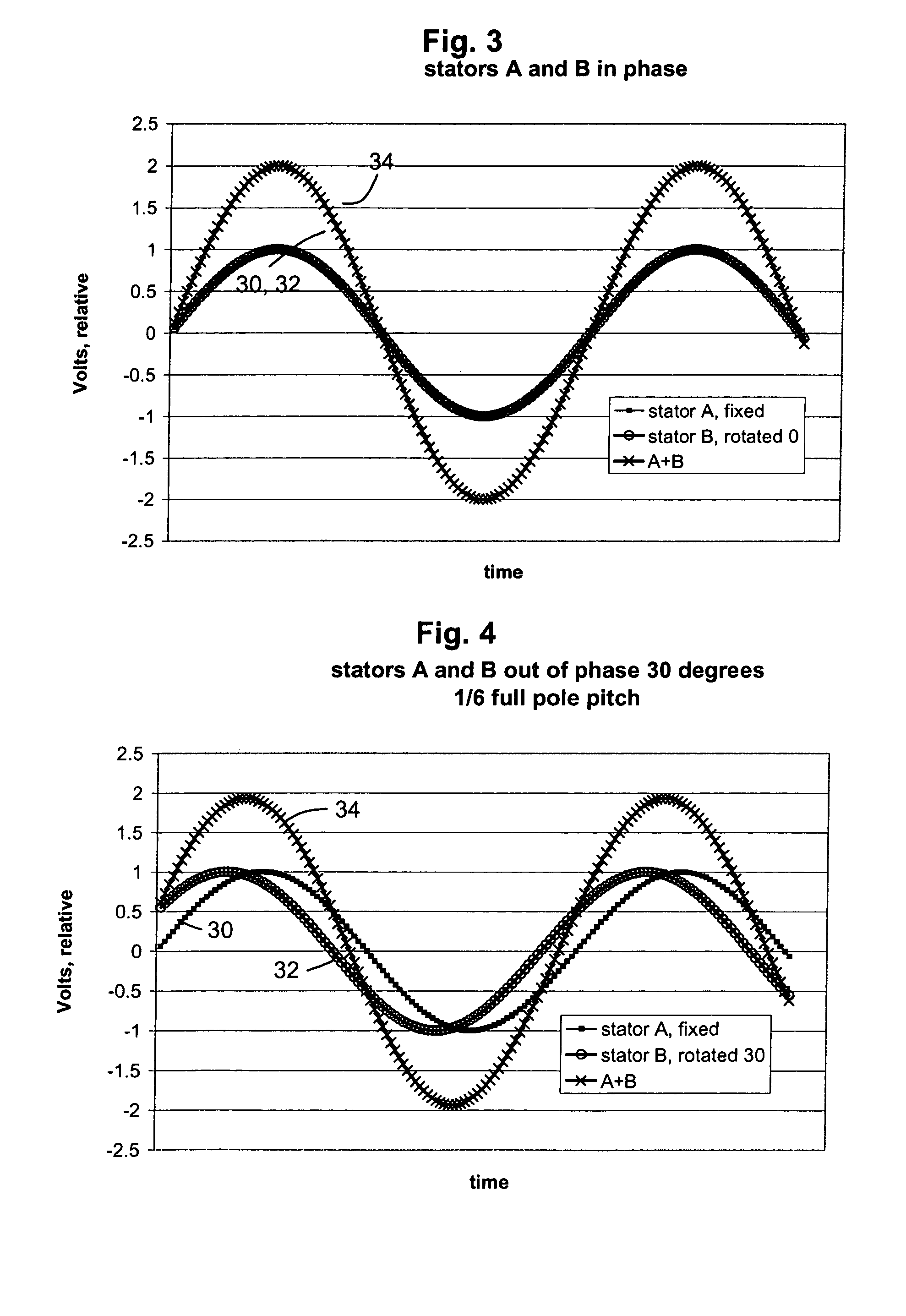

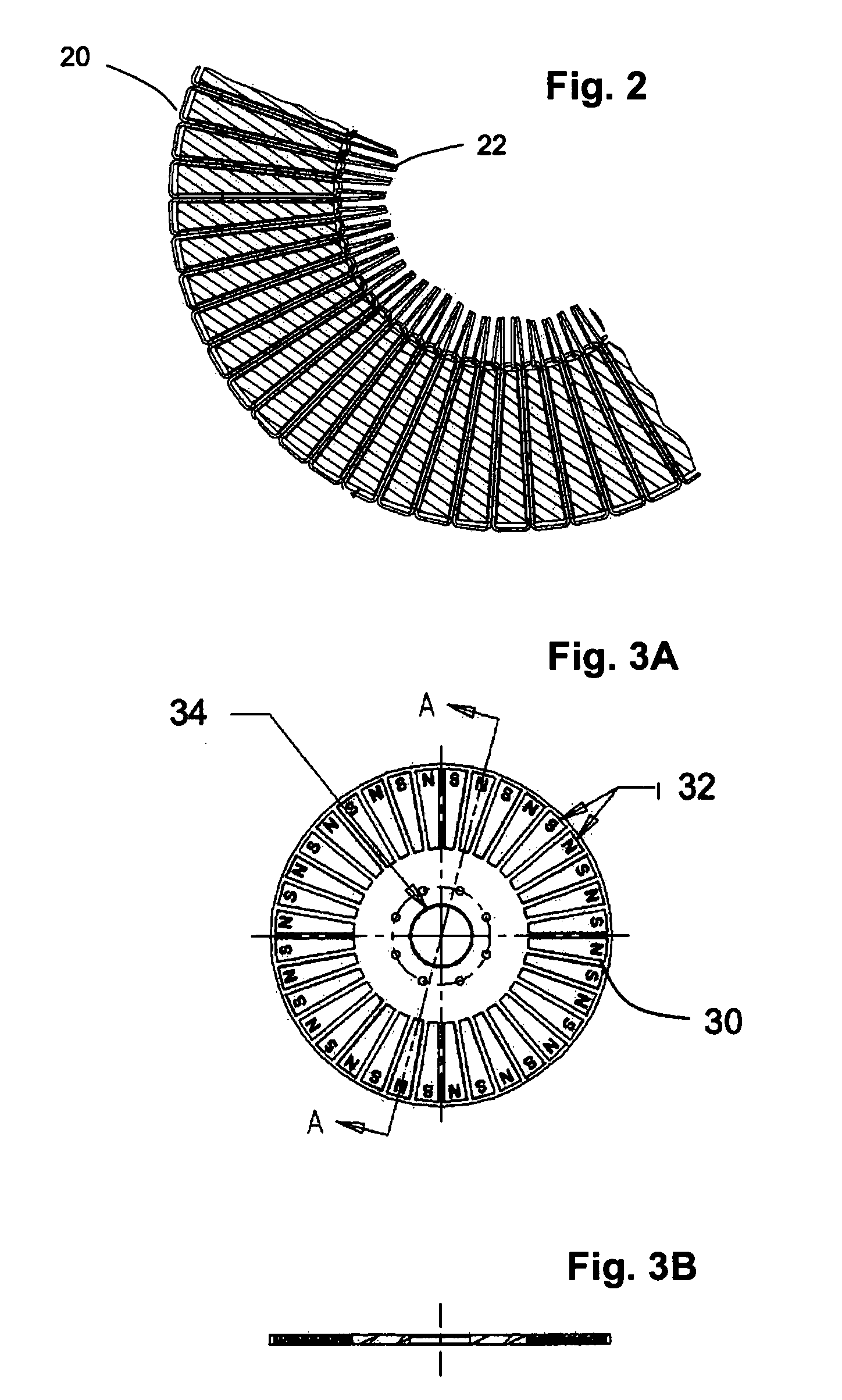

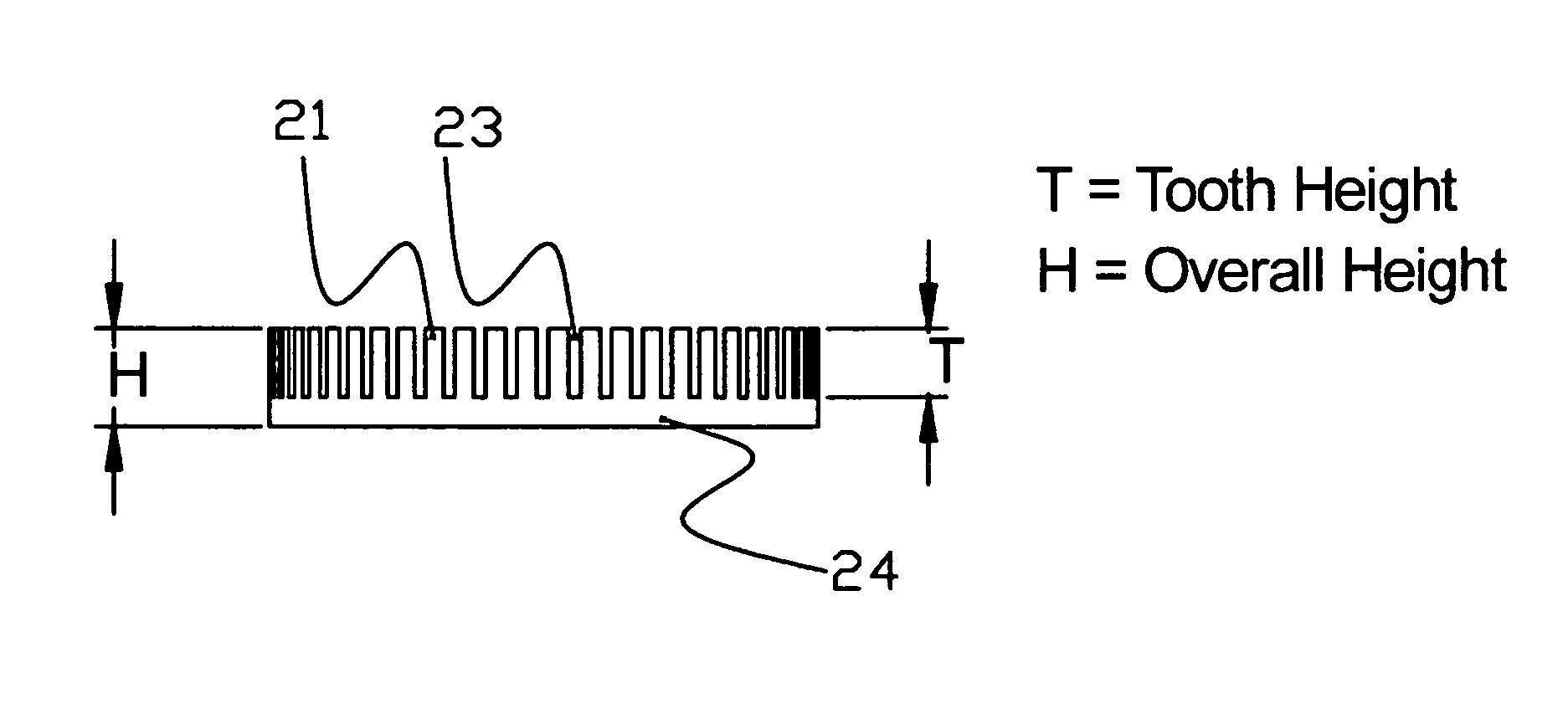

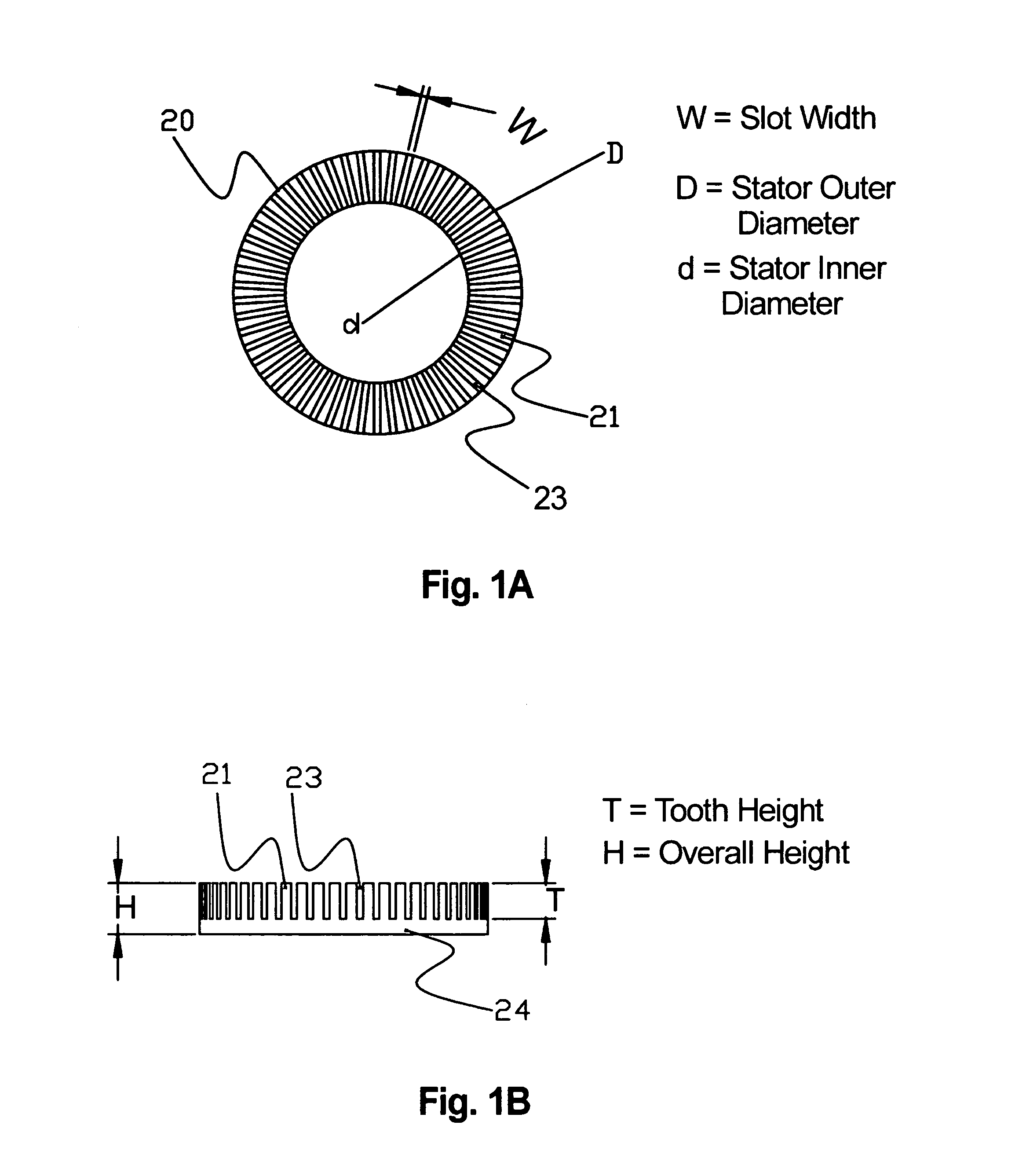

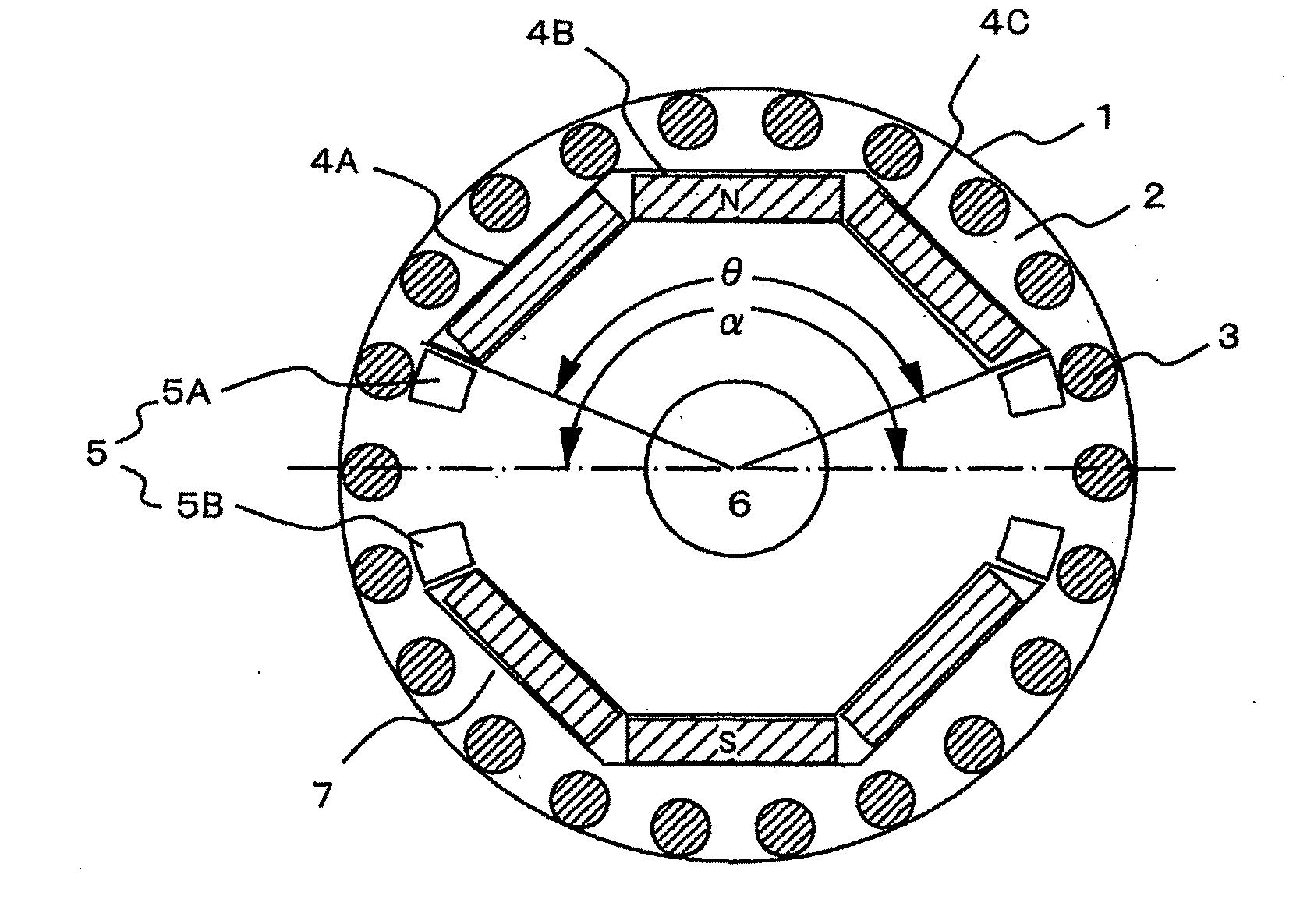

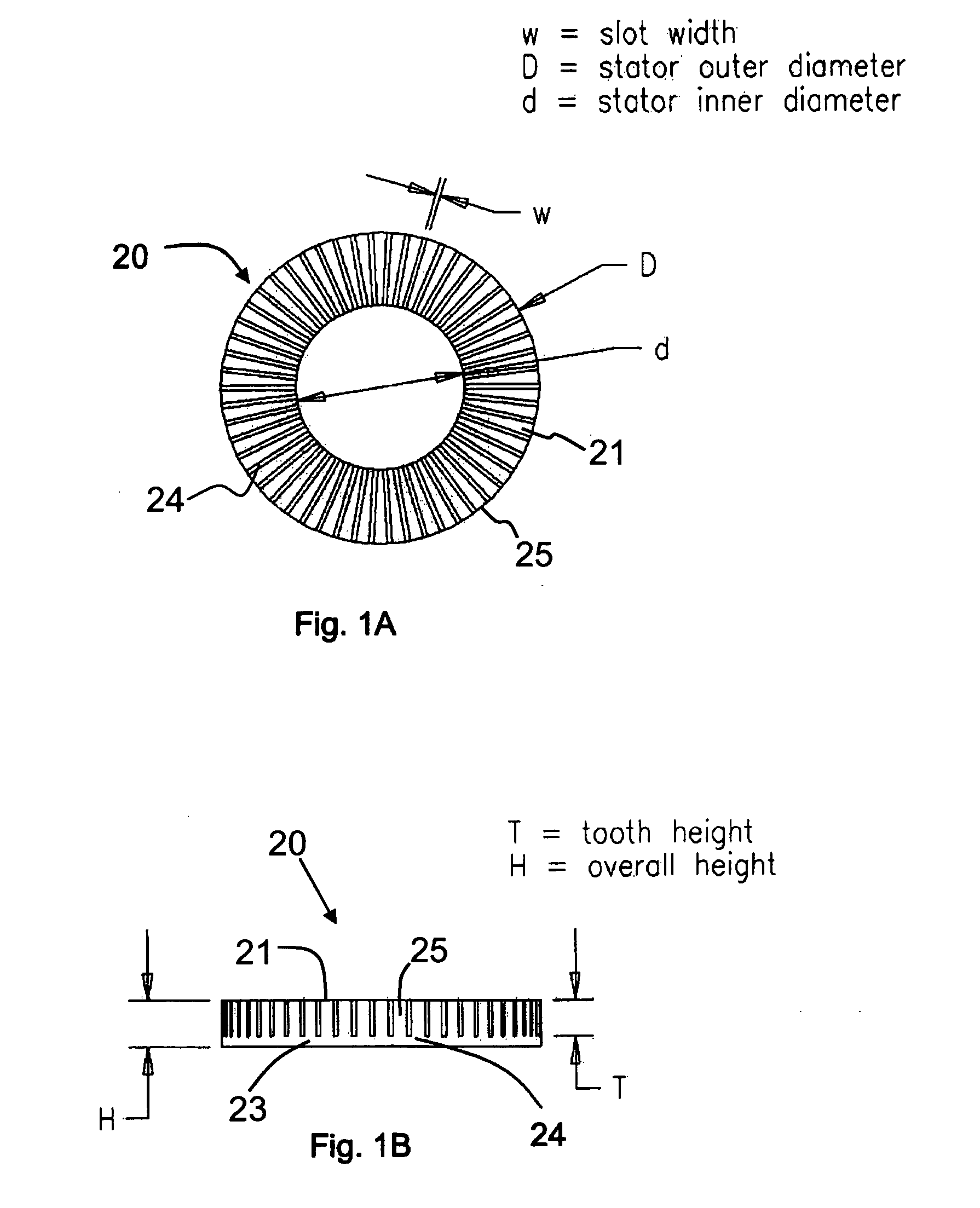

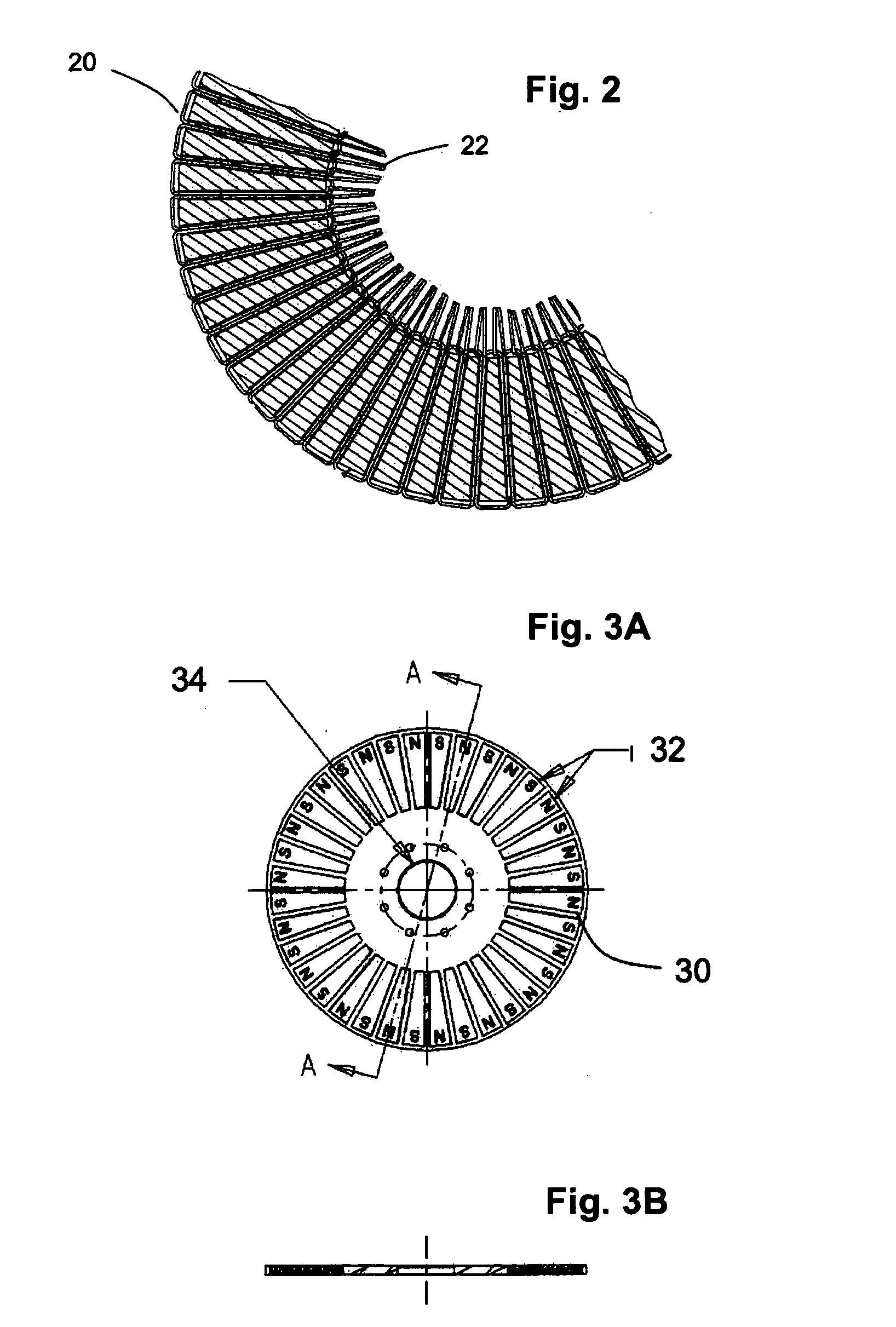

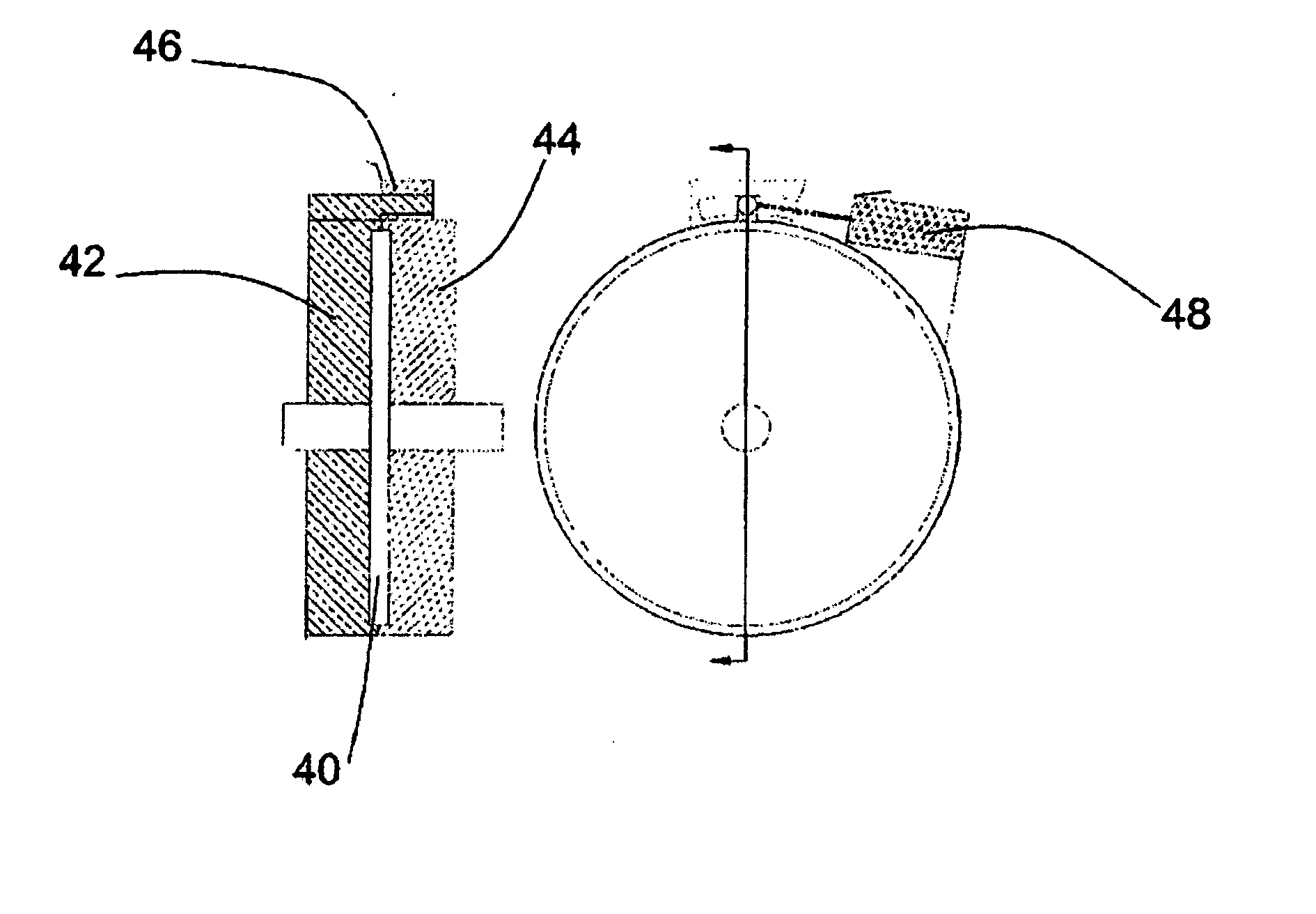

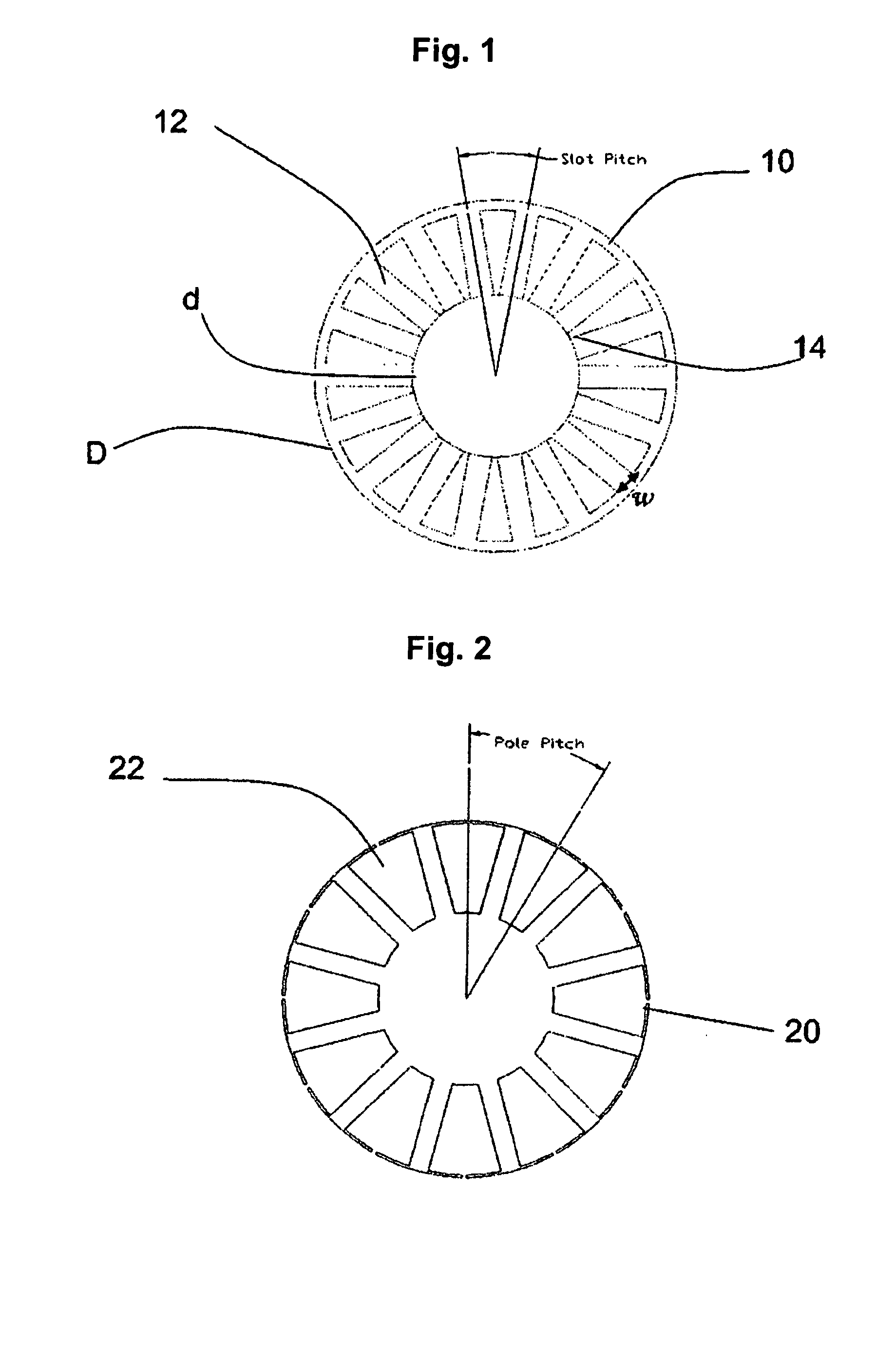

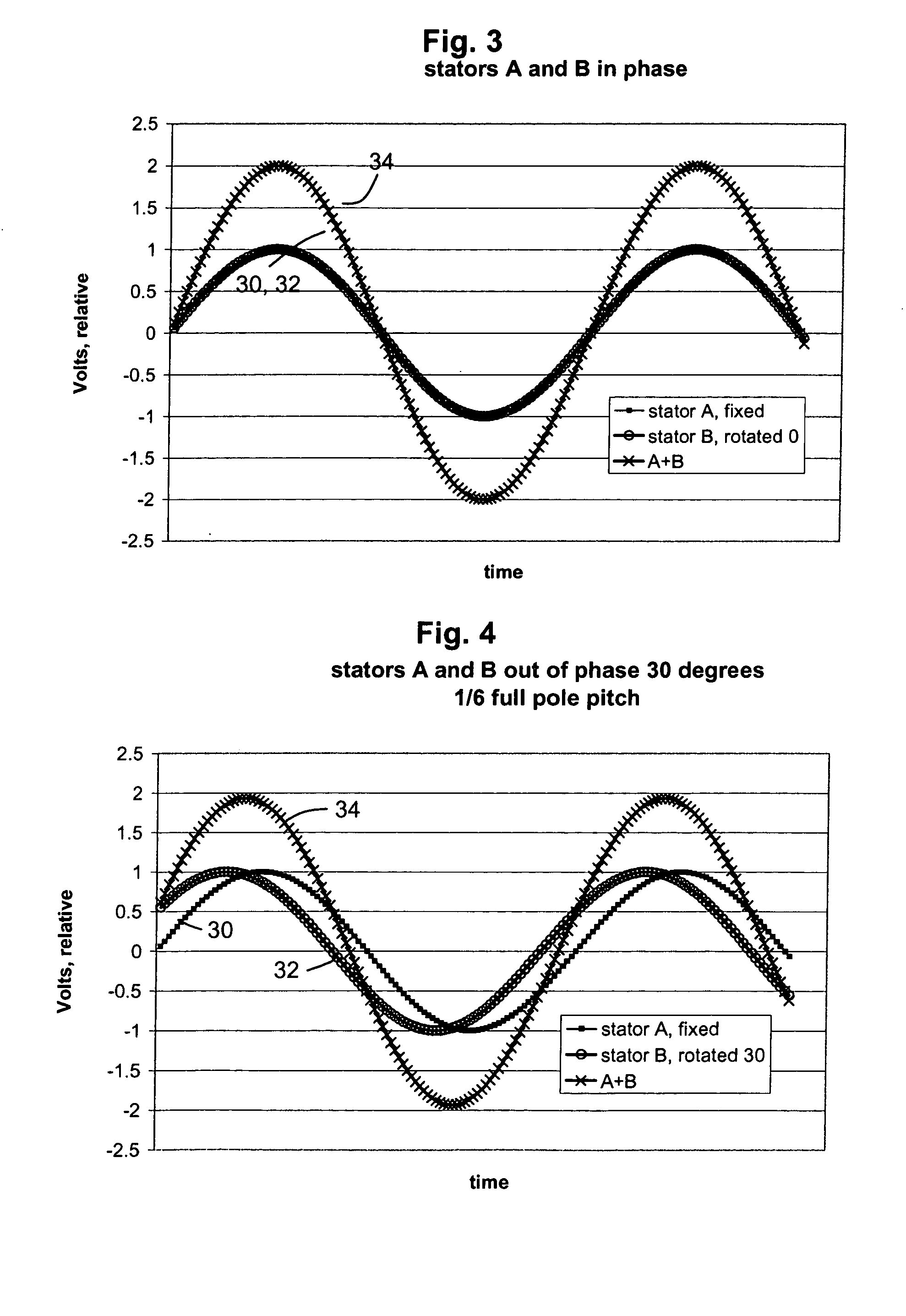

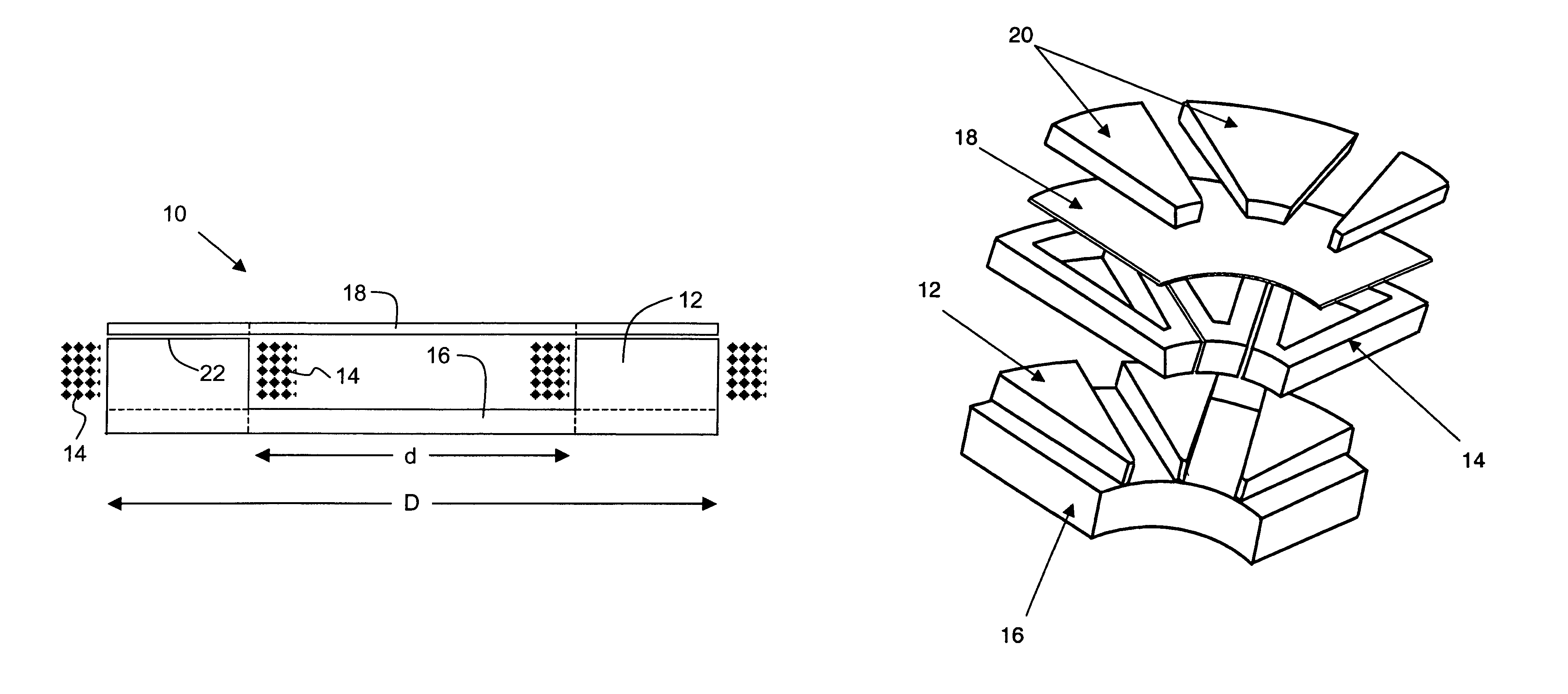

Selective alignment of stators in axial airgap electric devices comprising low-loss materials

InactiveUS7034427B2Bulky designHigh operating requirementsSynchronous generatorsWindingsLow speedFull wave

An axial gap dynamoelectric machine comprises first and second stators disposed coaxially with an intermediate rotor. The stators are selectively aligned with an axial offset between the positions of their respective teeth and slots. The stators comprise toroidal cores having laminated layers composed of a material selected from the group consisting of amorphous and nanocrystalline metals and optimized Fe-based alloy. Optionally, the machine further comprises misalignment means for adjusting the offset of the stators. Adaptive adjustment permits the machine to be operated to in a mode that reduces the back EMF of the motor, allowing constant voltage to be maintained as speed is increased. Reducing back EMF also allows a wider range of operating speed, especially in combination with use of high pole counts. Alternatively, the machine can be operated, e.g. at lower speed, in a constant torque mode. The machine may exploit the high pole count achievable by use of improved soft magnetic materials. Also provided are techniques for reducing torque ripple during operation, and also for using the stator offset in combination with a dual full wave bridge rectifier arrangement.

Owner:BERG & BERG ENTERPRISES

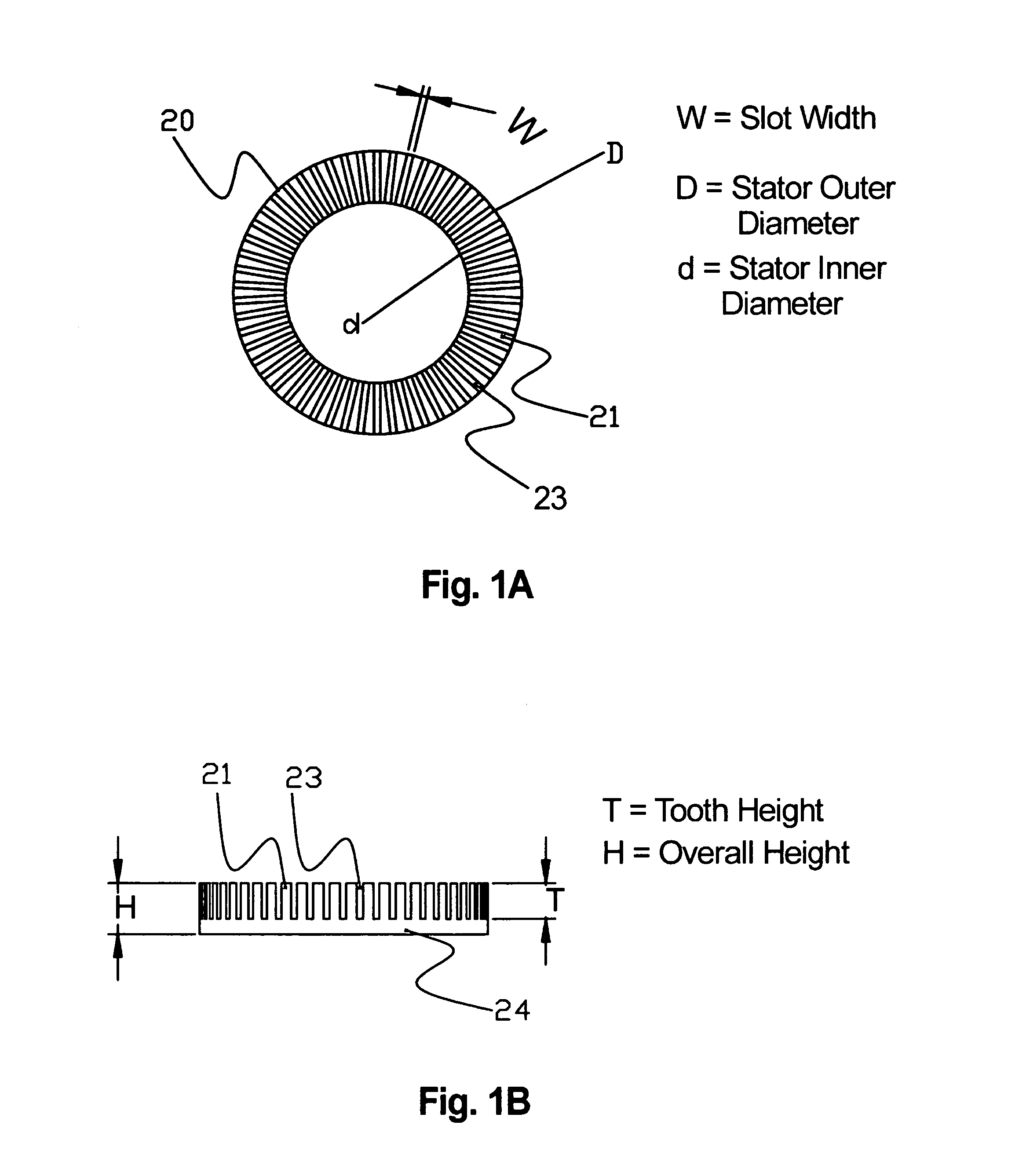

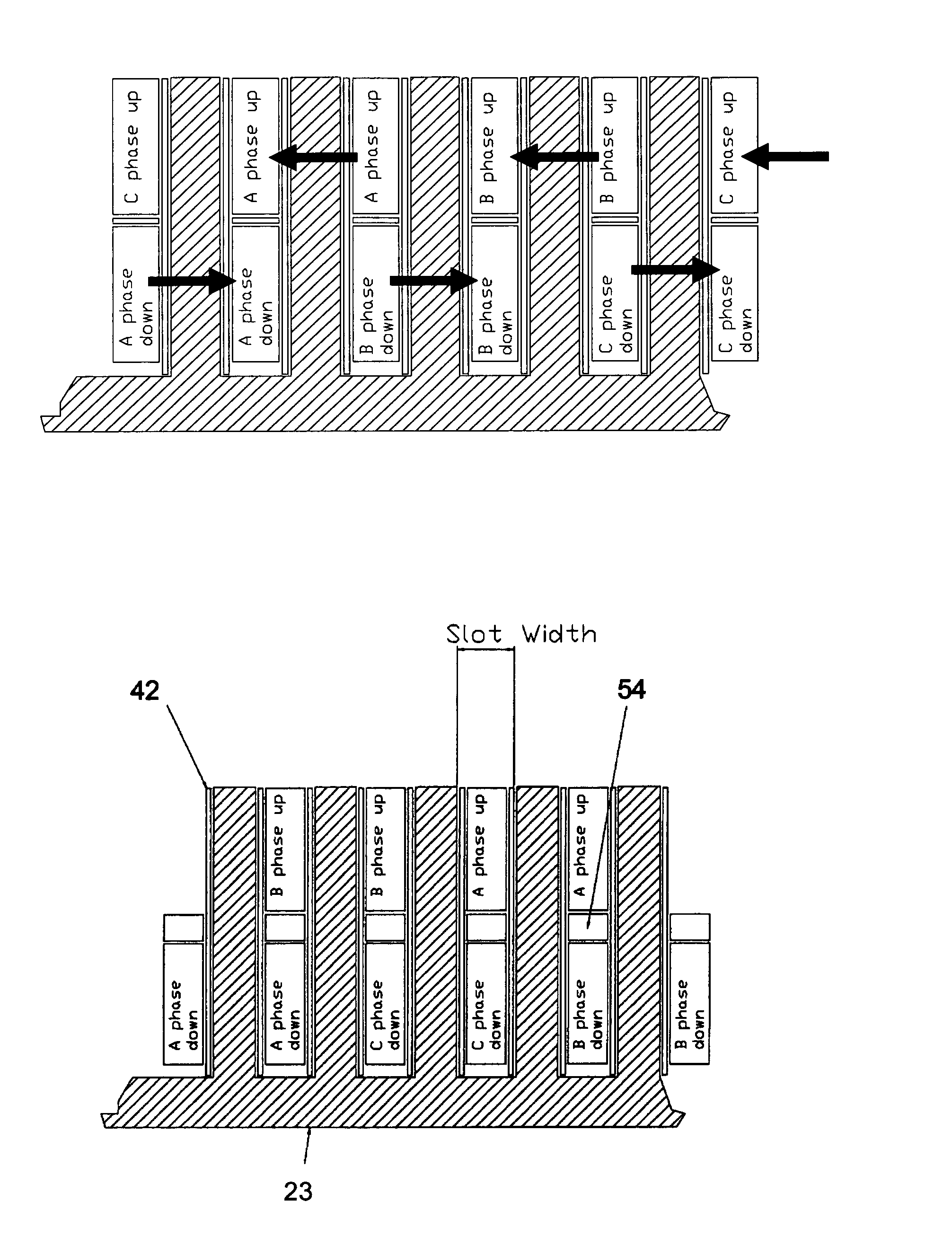

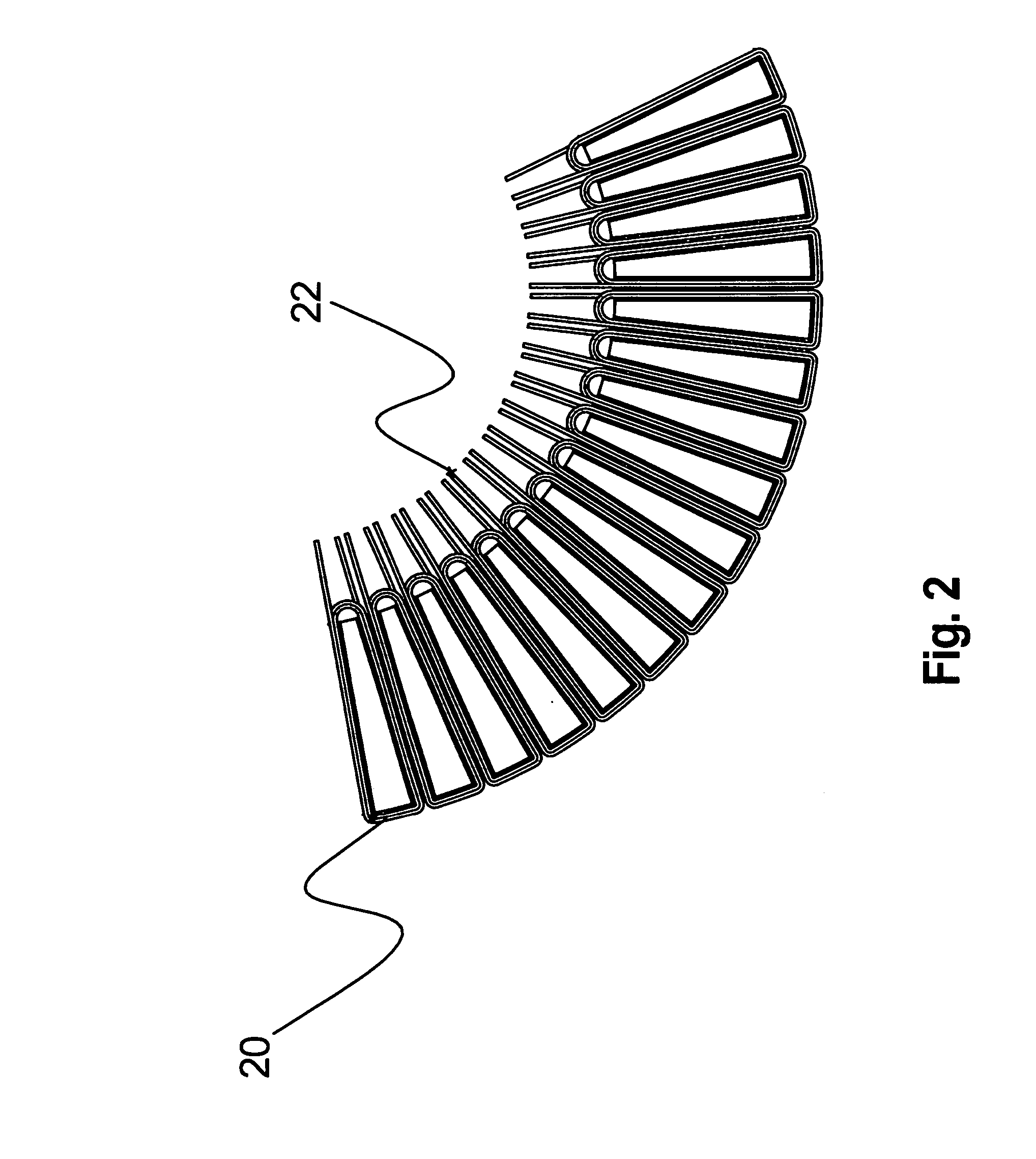

Stator coil arrangement for an axial airgap electric device including low-loss materials

InactiveUS7190101B2Bulky designHigh operating requirementsSynchronous generatorsMagnetic circuit rotating partsElectric machineStator coil

A dynamoelectric, rotating electric machine includes a stator assembly that includes stacked stator coil windings. The machine is preferably a polyphase, axial airgap device. Improved slot filling results from the stacked stator coil configuration. Device performance capability is thereby increased. The stator assembly of the electric device has a magnetic core made from low loss, high frequency material. A high pole count permits the electrical device to operate at high commutating frequencies, with high efficiency, high power density and improved performance characteristics. Low-loss materials incorporated by the device include amorphous metals, nanocrystalline metals, optimized Si—Fe alloys, grain-oriented Fe-based materials or non-grain-oriented Fe-based materials.

Owner:LIGHT ENGINEERING INC

Fe-based amorphous alloy ribbon

ActiveUS7425239B2High magnetic flux densityLow core lossInductances/transformers/magnets manufactureMagnetic materialsTO-18Impurity

An Fe-based amorphous alloy ribbon having a composition comprising FeaSibBcCd and inevitable impurities, wherein a is 80 to 83 atomic %, b is 0.1 to 5 atomic %, c is 14 to 18 atomic %, and d is 0.01 to 3 atomic %, the concentration distribution of C measured radially from both surfaces to the inside of said Fe-based amorphous alloy ribbon having a peak within a depth of 2 to 20 nm.

Owner:HITACHI METALS LTD

Efficient high-speed electric device using low-loss materials

InactiveUS20060208606A1Small increase in core lossImprove efficiencyMagnetic circuit rotating partsMagnetic circuit characterised by magnetic materialsEngineeringVolumetric Mass Density

The invention relates generally to an electric device, such as an electric motor, a generator, or a regenerative motor, having a wound stator core made from advanced low-loss material. In preferred embodiments, the electric device is an axial airgap-type configuration. The invention provides an electric device having a high pole count that operates at high commutating frequencies, with high efficiency and high torque and power densities. Advanced low-loss materials exploited by the present invention include amorphous metals, nanocrystalline metals, and optimized Fe-based alloys.

Owner:BERG & BERG ENTERPRISES

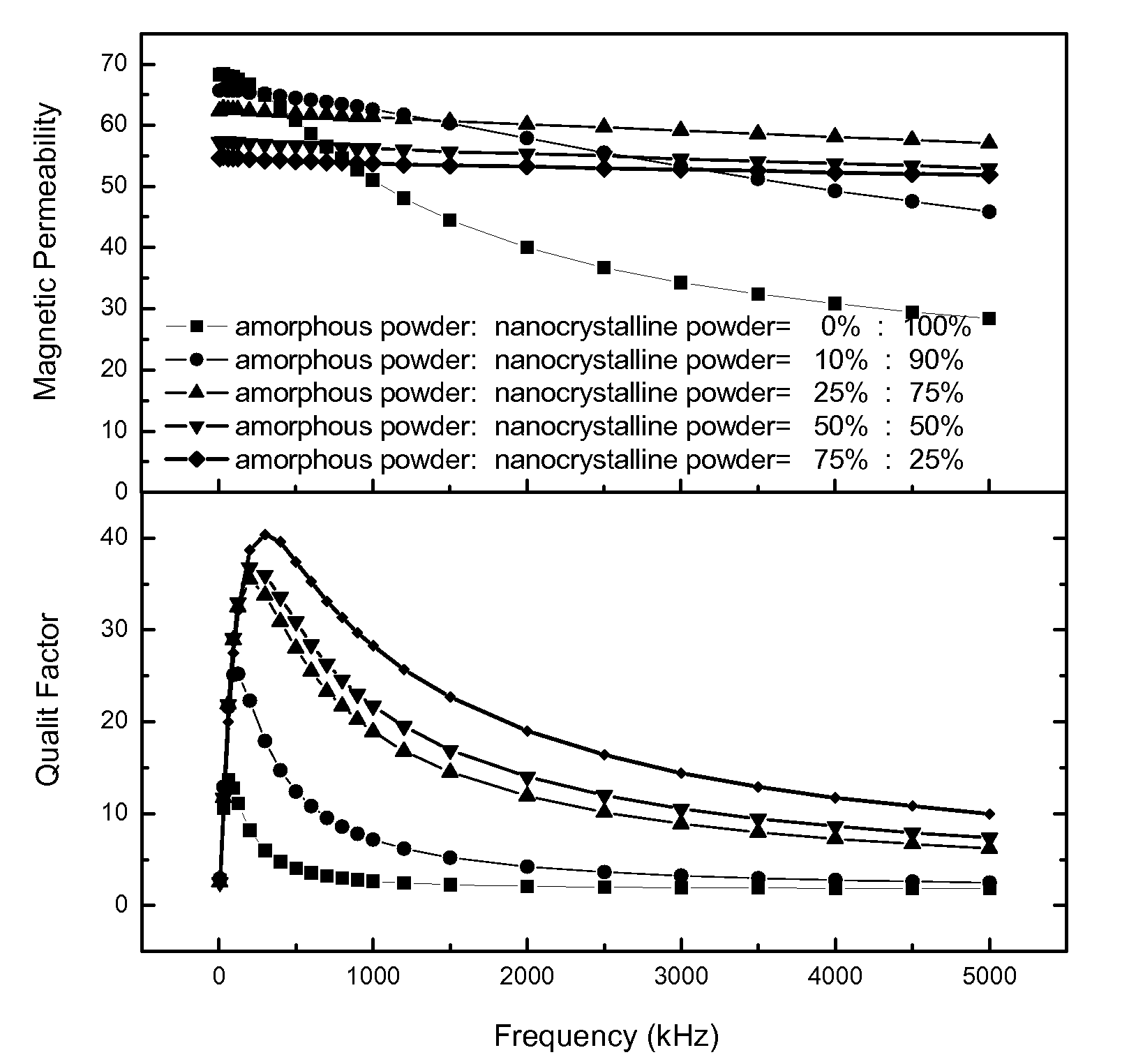

Soft-magnetic powder core and method of preparing the same

ActiveCN101226802AReduce permeabilityReduce AC lossInorganic material magnetismSoft magnetAmorphous phase

The invention relates to magnetic powder cores of soft magnet and a process of preparation thereof, belonging to the technical field of magnetic material. The magnetic powder cores of soft magnet is made from the following magnetic powders, a principal phase formed by one or a plurality of Fe based, Fe-Si based, Fe-B based, Fe-Si-B based and Fe-Al-B based and an amorphous phase which is inlaid in the principal phase and formed by one or plurality of Fe, C, Cu, Nb, Zr and Hf form nanocrystalline powders, wherein the principal phase is amorphous or in nanocrystalline state with average grain size of 3-100 nm. The prepared magnetic powder has the advantages of low eddy current loss, perfect direct current superposition property, suitable for higher frequency and the like.

Owner:CHINA JILIANG UNIV +1

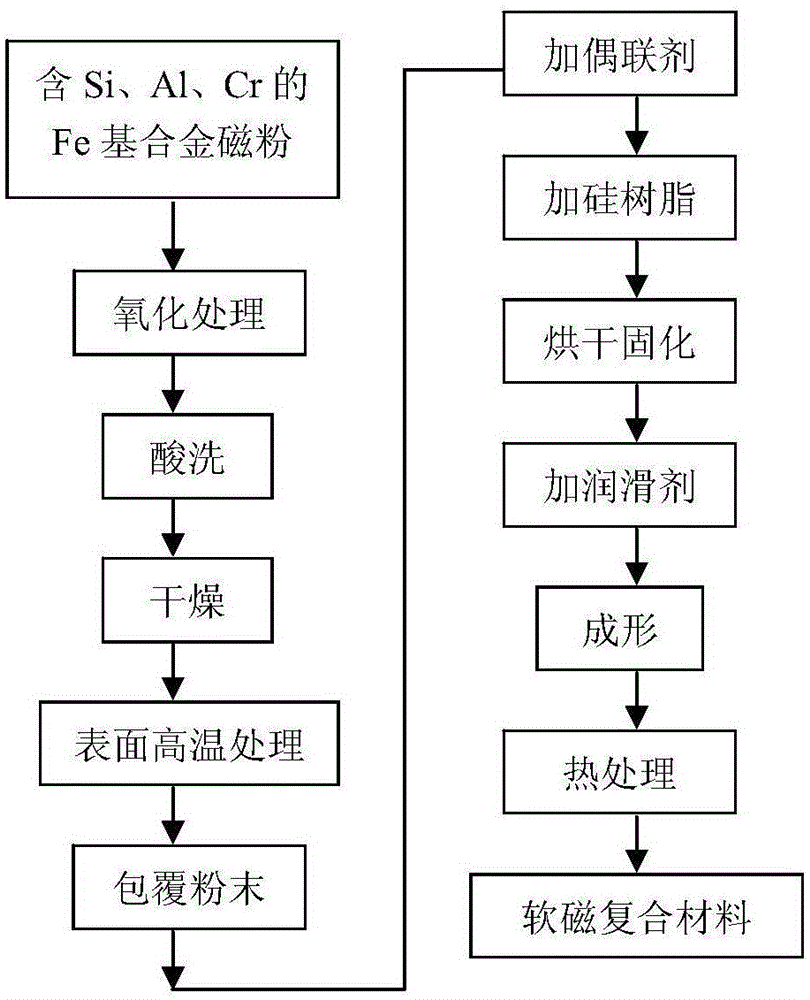

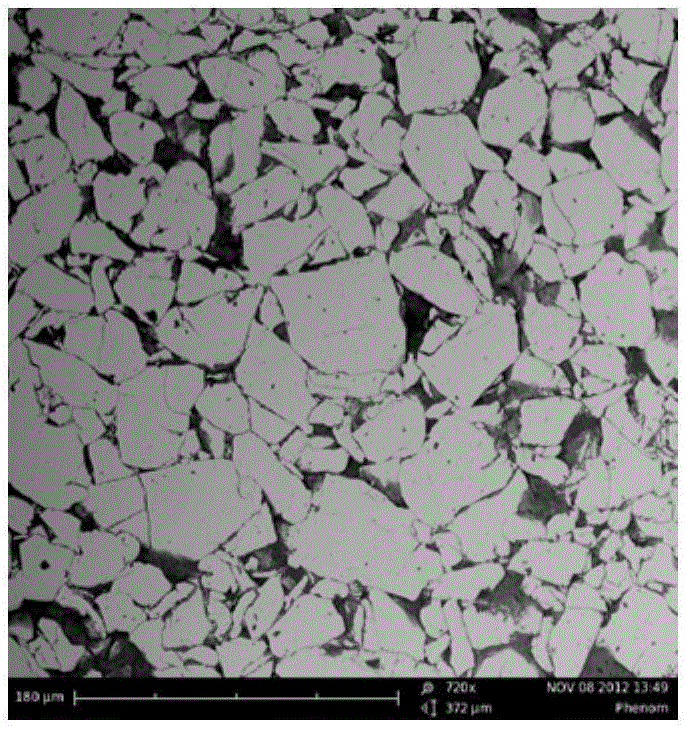

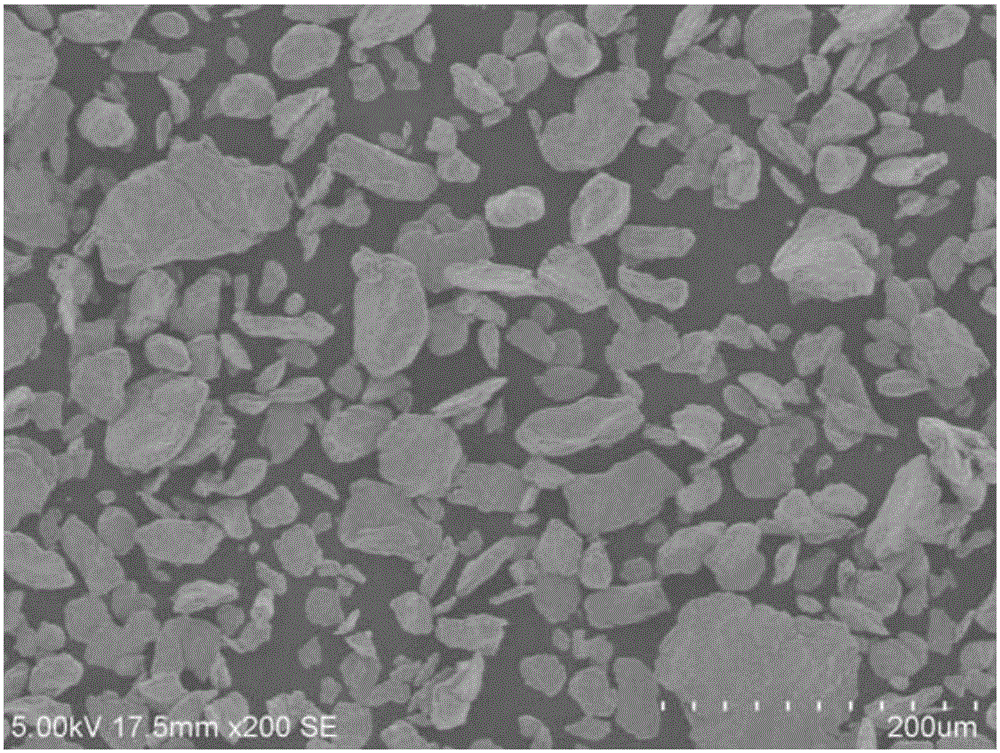

Coating method iron-based magnetically soft alloy powder and preparation method of soft magnet composite material

ActiveCN105149574AHigh resistivityImprove compactnessInorganic material magnetismMagnetic powderOxide

The invention relates to a coating method for iron-based magnetically soft alloy powder and a preparation method of soft magnet composite material. The coating method for iron-based magnetically soft alloy powder comprises the following steps: carrying out accelerated oxidation on iron-based magnetic metal powder at high temperature, forming an oxide layer on the surface of the powder and then carrying out acid pickling, thus obtaining powder with surface coated with SiO2, Al2O3 and Cr2O3 oxides. The preparation method of the soft magnet composite material comprises the following steps: adding coupling agent, silicon resin and lubricating agent to the coated powder, carrying out pressing forming, and then carrying out annealing heat treatment, thus obtaining the soft magnet composite material. According to the invention, the advantage that an oxide produced in reaction of elements including Si, Al and Cr contained in the iron-based magnetically soft alloy powder with oxygen is high in electrical resistivity, small in thermal expansion coefficient and steady in chemical performance and can resist high temperature is fully utilized; the adopted coating technology is to produce a coating layer in situ on the surface of the alloy magnetic powder, and is simple in process, easy to operate and low in cost; the metal soft magnet composite material prepared by adopting the method disclosed by the invention has good magnetic property and frequency stability.

Owner:CENT SOUTH UNIV

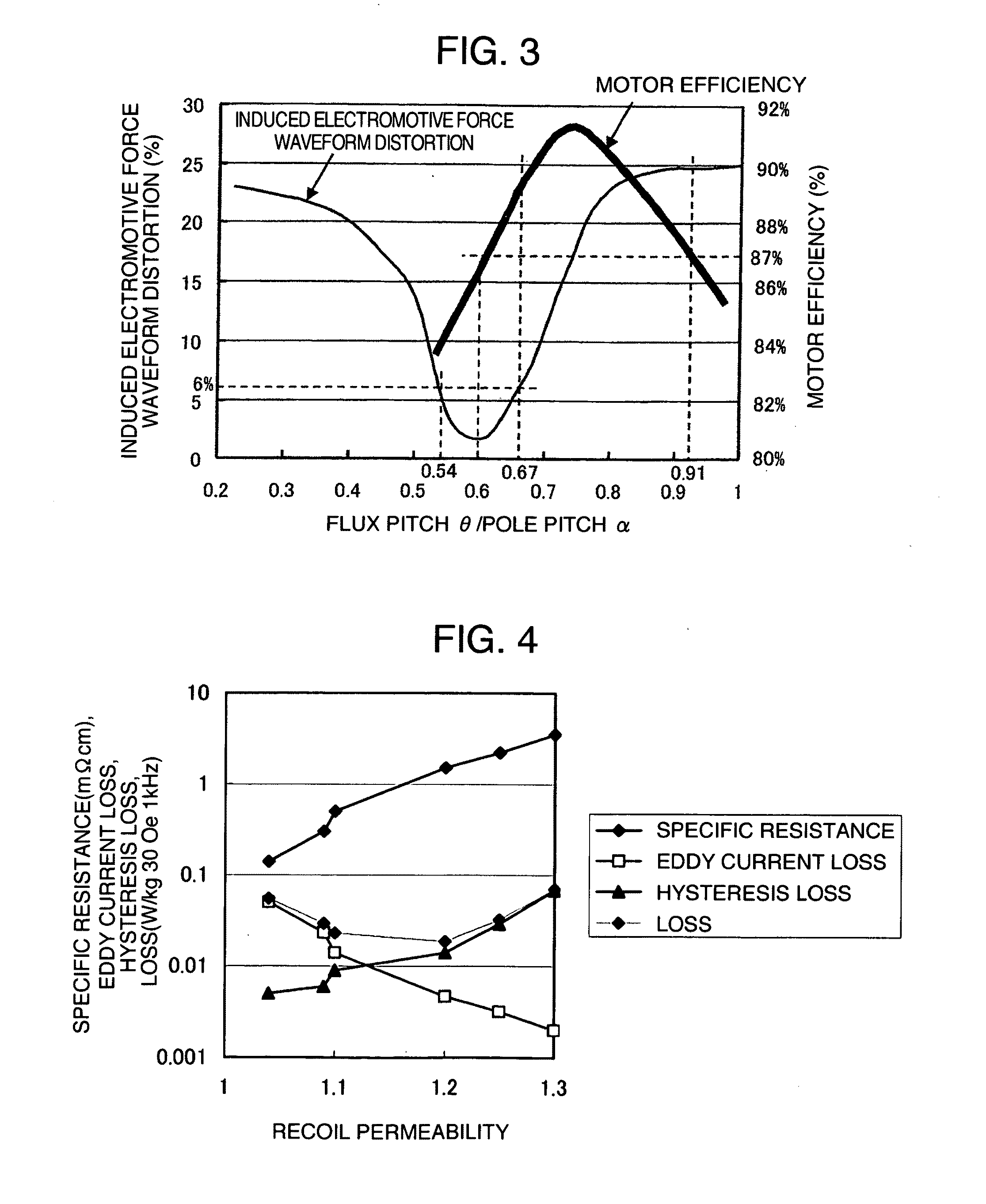

Self starting permanent magnet synchronous motor

InactiveUS20090200885A1Increase resistanceImprove the immunityTransportation and packagingMetal-working apparatusMagnetizationPermanent magnet synchronous motor

The present invention provides a permanent magnet that a fluorine compound is formed on the surfaces of Fe-based magnetic particles, and a recoil permeability is determined in a range of 1.05 to 1.30 by controlling an iron concentration in the fluorine compound to a range of 1 to 50% to reduce a loss due to magnetization rotation, thereby remedying reduction of a residual magnetic flux density and degradation of steady-state characteristics.

Owner:HITACHI LTD

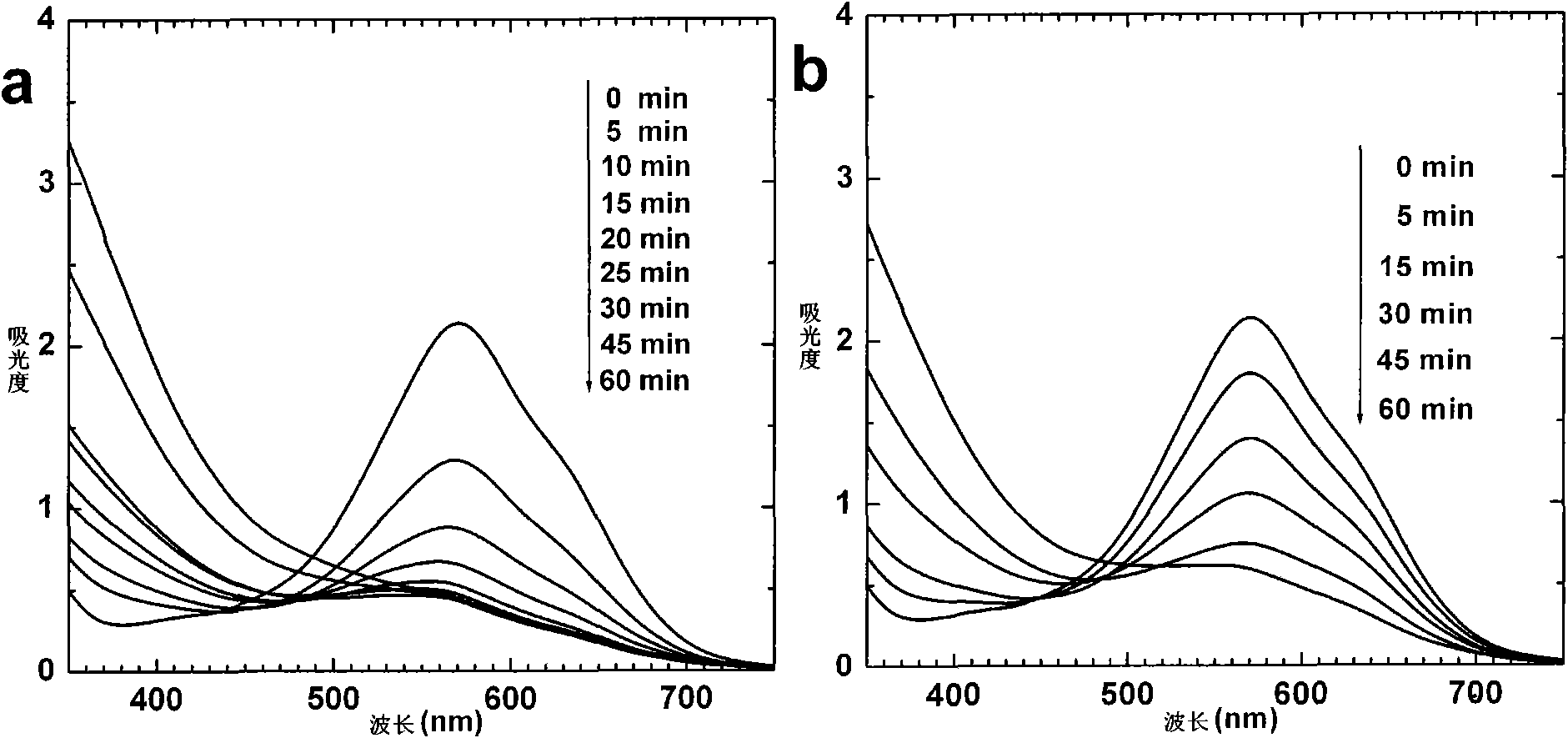

Ferrum-based amorphous alloy strip for treating printing and dyeing wastewater and preparation method thereof

ActiveCN102070236AAchieve amorphizationRetain color removal abilityWaste water treatment from textile industryWater/sewage treatment by reductionIron powderDyeing wastewater

The invention relates to a ferrum (Fe)-based amorphous alloy material, in particular to a Fe-based amorphous alloy strip for treating printing and dyeing wastewater and a preparation method thereof. According to the conventional literatures and technical data, an alloy component with Fe-based amorphous alloy strip forming capacity is selected; and general requirements show that the selected alloy component comprises more than 50 percent of Fe atoms, preferably 60 to 85 percent, so the reduction decoloring capacity of the Fe atoms is exerted. The amorphous alloy strip is obtained by adding a small amount of other elements and performing rapid solidification by using melt spinning equipment. The decrystallization of zero-valent Fe is realized by preprocessing technology; the decoloring capacity of the Fe atoms is kept; the rusting consumption of the Fe in the wastewater treatment process is effectively reduced; the strip is repeatedly and persistently utilized on the premise of guaranteeing the decoloring rate; the technical defects and the application defects in the conventional method for treating the printing and dyeing wastewater by using reducing Fe powder or waste cast Fe scraps are overcome; and the Fe-based amorphous alloy strip relates to the field of potential application of decrystallization technology in the industrial field, and has an extremely high application prospect.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

Highly corrosion-proof abrasion-proof iron matrix amorphous nanocrystalline coating and its preparation method

InactiveCN1730714AExcellent comprehensive performance of corrosion resistance and wear resistanceMolten spray coatingLiquid spraying apparatusThermal sprayingNanostructure

A highly corrosion-proof abrasion-proof iron matrix amorphous nanocrystalline coating and its preparation method consists of, integrating nano technique with non-crystallizing technique, and comprises using Fe-based multielement amorphous alloy powder as spraying powder, making amorphous coating through supersonic flame-spraying, then transforming into amorphous and nanocrystalline composite coating through heat treatment method.

Owner:UNIV OF SCI & TECH BEIJING

Laser cladding repair technique for engine crankshaft

InactiveCN101109083AMelting depth is smallSmall machining allowanceMetallic material coating processesNumerical controlOptoelectronics

The invention relates to an engine crankshaft laser cladding repairing technology based on the following steps. A: the crankshaft surface is treated with oil removing stain removal; B: a DL-HL-T10000 type CO2 laser is selected; a working table with numerically-controlled machine tool is applied; an auto-feeding powder apparatus for laser is used to delivered a Fe-based or Ni-base self-fusing alloy powder to a molten pool, and the Fe-based or Ni-base self-fusing alloy powder is repaired and strengthed on the surface of the crankshaft. The technological parameter features that the cladding power P ranges between 1,000w and 10,000w; the spot dismeter D is between 2mm and 20mm; the scanning speed is at 200 mm per min to 2000mm per min; the overlapping rate is from 20 per cent to 40 per cent. The laser cladding technology of the invention features no pollution, high productivity, low energy consumption, small machining allowance and lower comprehensive cost. In addition, the laser cladding is good to the repair of the wear parts, such as strong associativity, small residual stress, no machining deformation, high surface hardness as well as good abrasion resistance, and becomes a process technology with great developing potential in repairing the components.

Owner:SHENYANG DALU LASER COMPLETE EQUIP

Stator coil arrangement for an axial airgap electric device including low-loss materials

InactiveUS20050093393A1Increased stator slot fillImprove efficiencySynchronous generatorsMagnetic circuit rotating partsElectric machineStator coil

A dynamoelectric, rotating electric machine includes a stator assembly that includes stacked stator coil windings. The machine is preferably a polyphase, axial airgap device. Improved slot filling results from the stacked stator coil configuration. Device performance capability is thereby increased. The stator assembly of the electric device has a magnetic core made from low loss, high frequency material. A high pole count permits the electrical device to operate at high commutating frequencies, with high efficiency, high power density and improved performance characteristics. Low-loss materials incorporated by the device include amorphous metals, nanocrystalline metals, optimized Si—Fe alloys, grain-oriented Fe-based materials or non-grain-oriented Fe-based materials.

Owner:LIGHT ENGINEERING INC

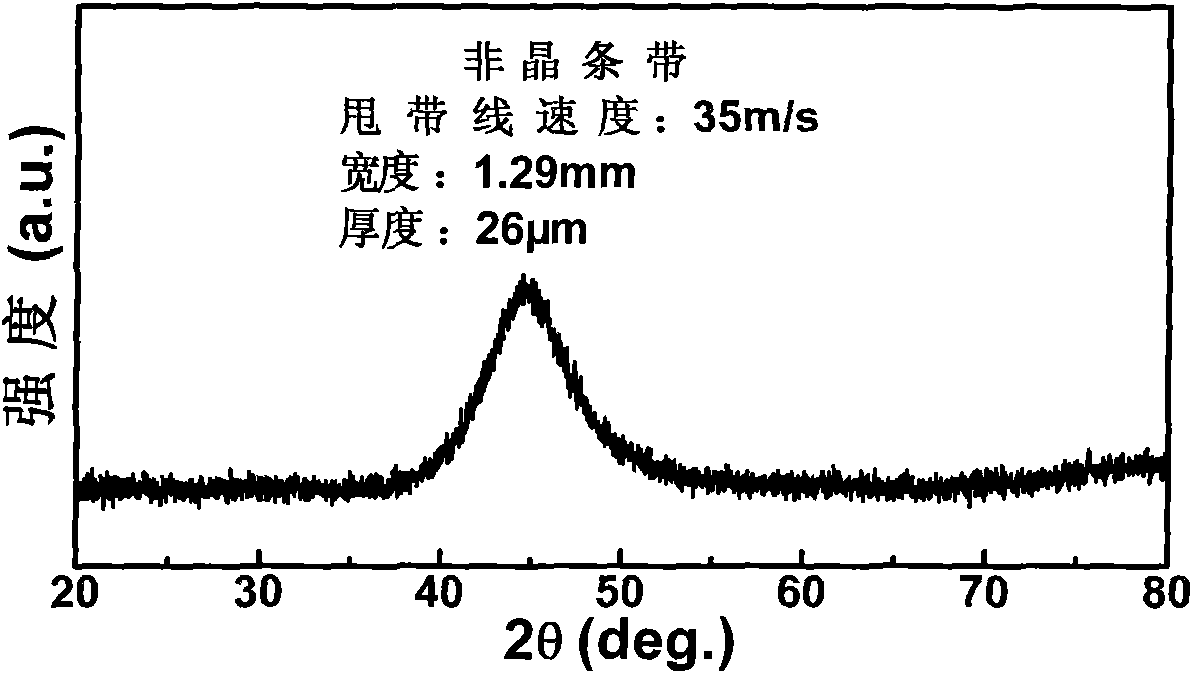

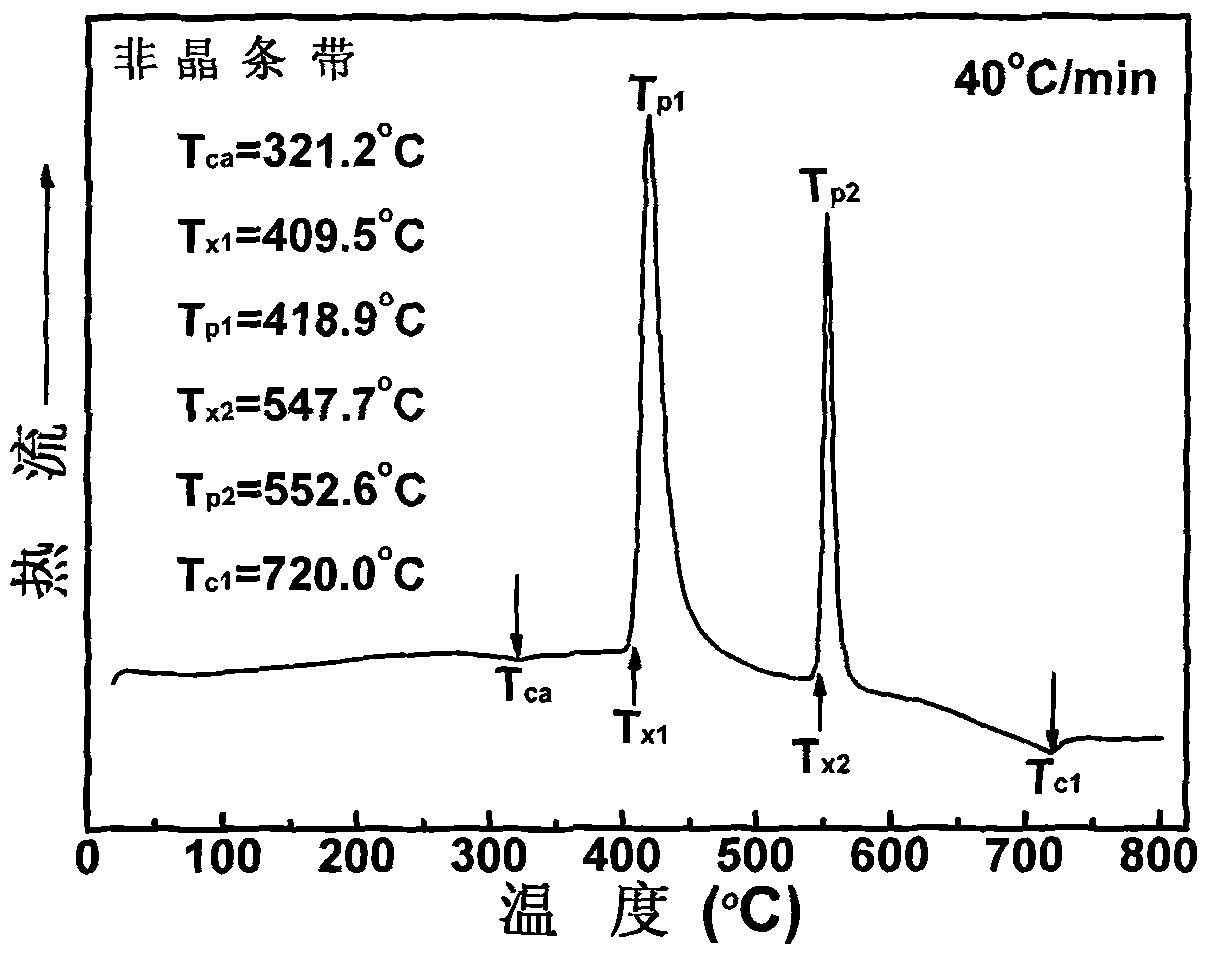

Fe-based amorphous or nanocrystalline soft magnetic alloy and preparation method thereof

InactiveCN101650999AImprovement and optimization of comprehensive soft magnetic propertiesLow costMagnetic materialsElectric arc furnaceAmorphous matrix

The invention discloses a Fe-based amorphous or nanocrystalline soft magnetic alloy, aiming to favorable performance and low cost. Alloy components can be expressed as FeaSibBcCudNbeMf, wherein M is Al, Ni or P; a, b, c, d, e and f are atom percentages, and the change range is as follows: a is more than or equal to 65 and less than or equal to 85, b is more than or equal to 5 and less than or equal to 20, c is more than or equal to 5 and less than or equal to 25, d is more than or equal to 0 and less than or equal to 5, e is more than or equal to 0 and less than or equal to 5, and f is more than or equal to 0.1 and less than or equal to 10; and a+b+c+d+e+f=100. The preparation method comprises the following steps: placing raw materials of pure ferrum, pure copper, and the like into a vacuum electric arc furnace to smelt to obtain an alloy ingot; crushing, placing into a quartz test tube, and preparing an amorphous alloy ribbon by using a single-rolling ribbon throwing method; placing into a tubular annealing furnace, adjusting the temperature to 510-580 DEG C, isothermally annealing under the protection of Ar gas and getting out of the furnace to cool; and obtaining amorphous alloys with different microstructures or nanocrystalline alloys with nanometer crystal particles evenly arranged on an amorphous matrix through controlling alloy cooling speed and heat treatment temperature as well as time.

Owner:TAIYUAN UNIVERSITY OF SCIENCE AND TECHNOLOGY

Fe-based amorphous alloy ribbon

ActiveUS20060000524A1High magnetic flux densityLow core lossInductances/transformers/magnets manufactureMagnetic materialsImpurityFe based

An Fe-based amorphous alloy ribbon having a composition comprising FeaSibBcCd and inevitable impurities, wherein a is 76 to 83.5 atomic %, b is 12 atomic % or less, c is 8 to 18 atomic %, and d is 0.01 to 3 atomic %, the 5 concentration distribution of C measured radially from both surfaces to the inside of said Fe-based amorphous alloy ribbon having a peak within a depth of 2 to 20 nm.

Owner:HITACHI METALS LTD

Method for making Fe-based amorphous metal powders and method for making soft magnetic core using the same

ActiveUS20050028889A1High magnetic flux densityHighly economicalTransportation and packagingMetal-working apparatusMetal powderThermal treatment

A method for making an amorphous soft magnetic core using Fe-based amorphous metal powders is provided. The amorphous soft magnetic powders are obtained by crushing amorphous ribbons produced using a rapid solidification process (RSP). The magnetic core is obtained by performing a preliminary thermal treatment of amorphous metal ribbons made of Fe-based amorphous metal alloy using RSP, crushing the amorphous metal ribbons to thereby obtain amorphous metal powders, classifying the amorphous metal powders to then be mixed into a distribution of powder particles having an optimal uniform composition, mixing the mixed amorphous metal powders with a binder, forming a core, and annealing the formed core to then coat the core with an insulating resin.

Owner:AMOSENSE

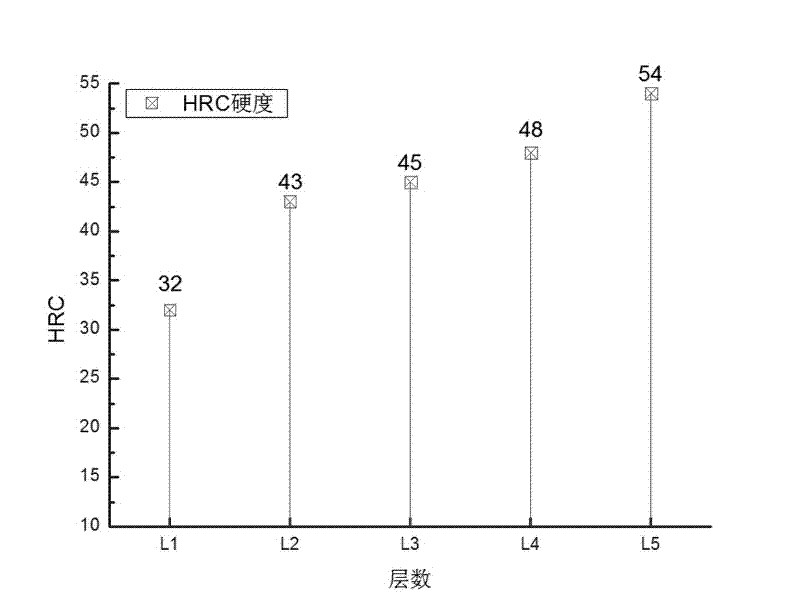

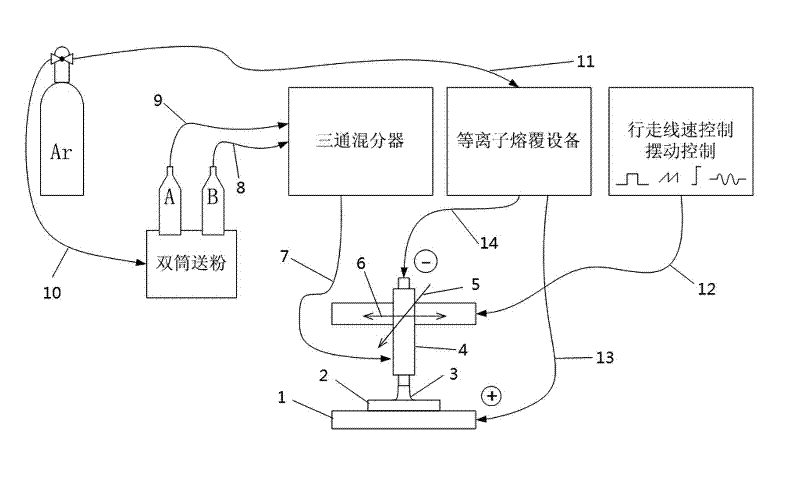

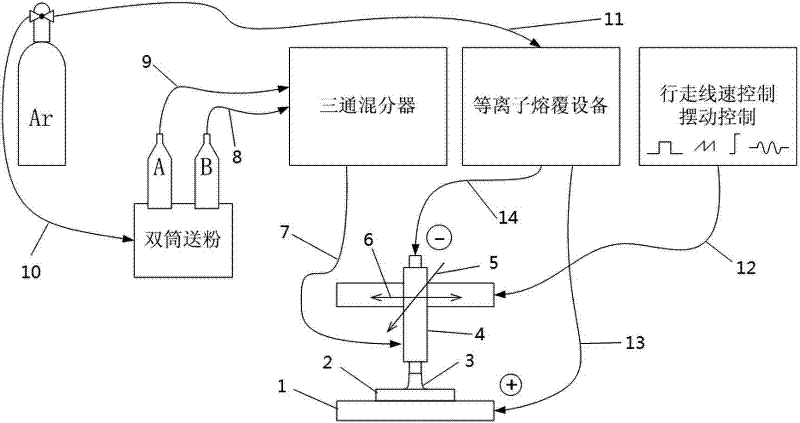

Method for preparing Fe-based WC-Ni gradient coating by using plasma cladding method

InactiveCN102392241AWide selection of materialsFlexible moving processMetallic material coating processesNumerical controlMetal powder

The invention discloses a method for preparing an Fe-based WC-Ni gradient coating by using a plasma cladding method, comprising the steps of: designing the number of layers of the gradient coating and the proportion of ceram A at each layer; supplying the A and metal powder B by a binocular; mixing the powder A and B through a three-way device and then putting the mixture into a coaxial powder feeding cladding gun which is controlled by a numerical control device; controlling the transverse size of the coating by controlling the walking speed, the swinging speed and the swinging amplitude as well as obtaining required coating thickness by controlling the powder feeding amount and the plasma arc power; cleaning the surface after the coating is solidified; and repeating the second to fifth steps to complete the preparation of the coating. In the invention, the used equipment is simple; the investment is low; the length, the width and the thickness of the gradient coating are adjustable; the components in the coating are uniform; the gradient coating can be prepared at local positions of workpieces; and metallurgic combination can be achieved between the coating and matrixes or between coatings with high interface combination strength.

Owner:HUBEI UNIV OF AUTOMOTIVE TECH

Fe-based amorphous nano-coating powder and its argon atomization production

A Fe-based amorphous nano-crystal spraying powder and its argon atomizing production are disclosed. The spraying powder consists of Cr 8-15wt%, Ni 8-16wt%, Si 2.8-5.7wt%, B 2.8-5wt%, W 2-8wt%, Mo 2-8wt%, Co 0.5-1wt%, Al 1-4wt% and Fe residues. The process is carried out by proportioning for ingredients, vacuum smelting, atomizing and screening powders. It has excellent fluidity and stability.

Owner:UNIV OF SCI & TECH BEIJING

Preparation method of Fe-based metal soft magnetic powder core

ActiveCN105185560APowder moldingEasy to shapeInorganic material magnetismInductances/transformers/magnets manufactureEpoxyMaterials preparation

The invention relates to a preparation method of a Fe-based metal soft magnetic powder core, and belongs to the technical field of magnetic material preparation. The method comprises the following steps: with Fe-based flake-like metal soft magnetic powder as raw material powder, carrying out annealing treatment; carrying out passivation and insulated coating treatment on the annealed powder; carrying out drying treatment on the passivated and insulated powder; pressing the dried metal powder into a magnetic powder core blank, and adopting zinc stearate powder as a releasing agent; and carrying out annealing treatment on the molded magnetic powder core blank and spraying a layer of epoxy resin insulating paint on the surface of the magnetic powder core blank, so as to obtain the metal soft magnetic powder core. The density of the magnetic powder core prepared by the method is greatly improved; the density distribution is even; the magnetic powder core has relatively high compactness and good mechanical strength; and meanwhile, the magnetic powder core has relatively high magnetic conductivity and relatively low magnetic loss. In addition, the prepared magnetic powder core also has the characteristics of high magnetic conductivity, high quality factor and low loss.

Owner:有研增材技术有限公司

Selective alignment of stators in axial airgap electric devices comprising low-loss materials

InactiveUS20050040728A1Bulky designHigh operating requirementsSynchronous generatorsWindingsLow speedFull wave

An axial gap dynamoelectric machine comprises first and second stators disposed coaxially with an intermediate rotor. The stators are selectively aligned with an axial offset between the positions of their respective teeth and slots. The stators comprise toroidal cores having laminated layers composed of a material selected from the group consisting of amorphous and nanocrystalline metals and optimized Fe-based alloy. Optionally, the machine further comprises misalignment means for adjusting the offset of the stators. Adaptive adjustment permits the machine to be operated to in a mode that reduces the back EMF of the motor, allowing constant voltage to be maintained as speed is increased. Reducing back EMF also allows a wider range of operating speed, especially in combination with use of high pole counts. Alternatively, the machine can be operated, e.g. at lower speed, in a constant torque mode. The machine may exploit the high pole count achievable by use of improved soft magnetic materials. Also provided are techniques for reducing torque ripple during operation, and also for using the stator offset in combination with a dual full wave bridge rectifier arrangement.

Owner:BERG & BERG ENTERPRISES

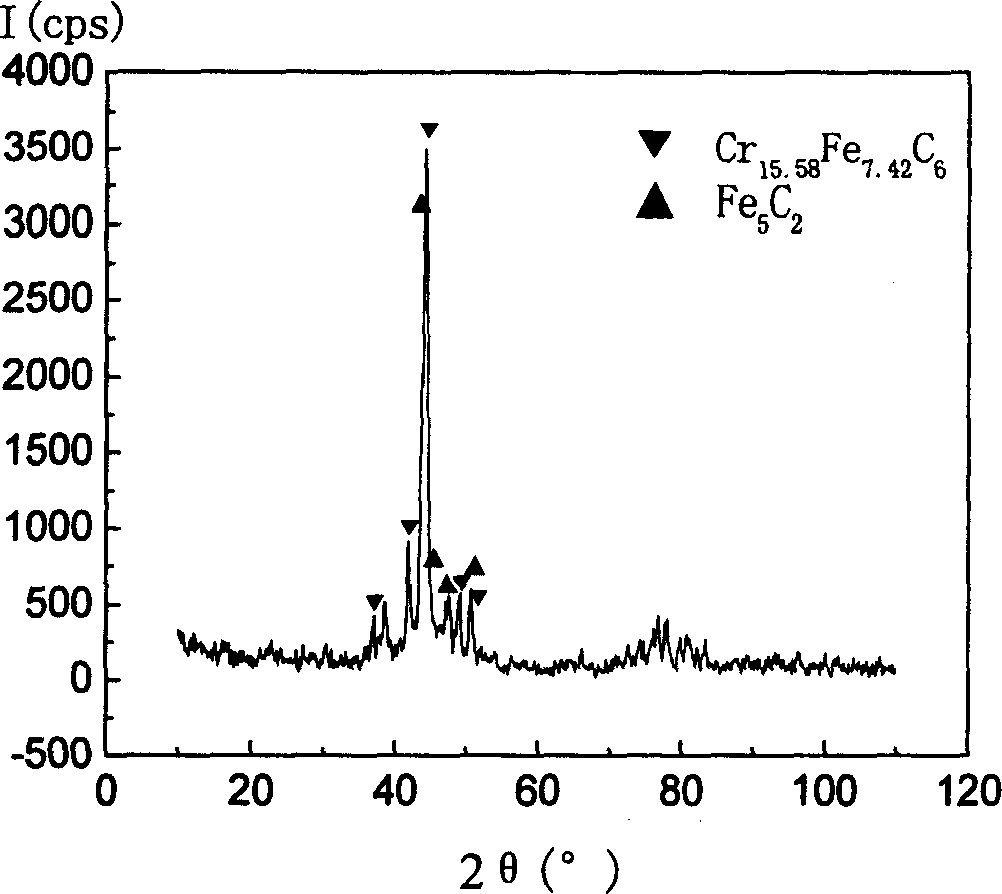

Chromium free hardfacing materials

Disclosed are embodiments of Fe-based alloys for use as a hardfacing material having high hardness while avoiding the use of chromium. The alloys can be twin arc or thermally sprayed as coatings on different types of equipment. In some embodiments, the alloys can be readable even after heating of the alloys.

Owner:SCOPERTA INC

Sliding bearing

InactiveUS20060251348A1High dimensional accuracyHigh rotation accuracyCam-followersRolling contact bearingsMetallic materialsCam

A cam follower includes a shaft member which is cantilevered at one end and a slide bearing fitted onto the outer periphery of the other end of the shaft member. The slide bearing is composed of a cylindrical matrix made of an Fe-based sintered metal material having an Fe content of 90 wt % or more and a slide layer formed from the inner peripheral surface to the both end faces of the matrix. The slide layer is made of a slide material composition having a base material such as polyethylene resin blended with a lubricant such as silicone oil and a globular porous silica impregnated with this lubricant.

Owner:NTN CORP

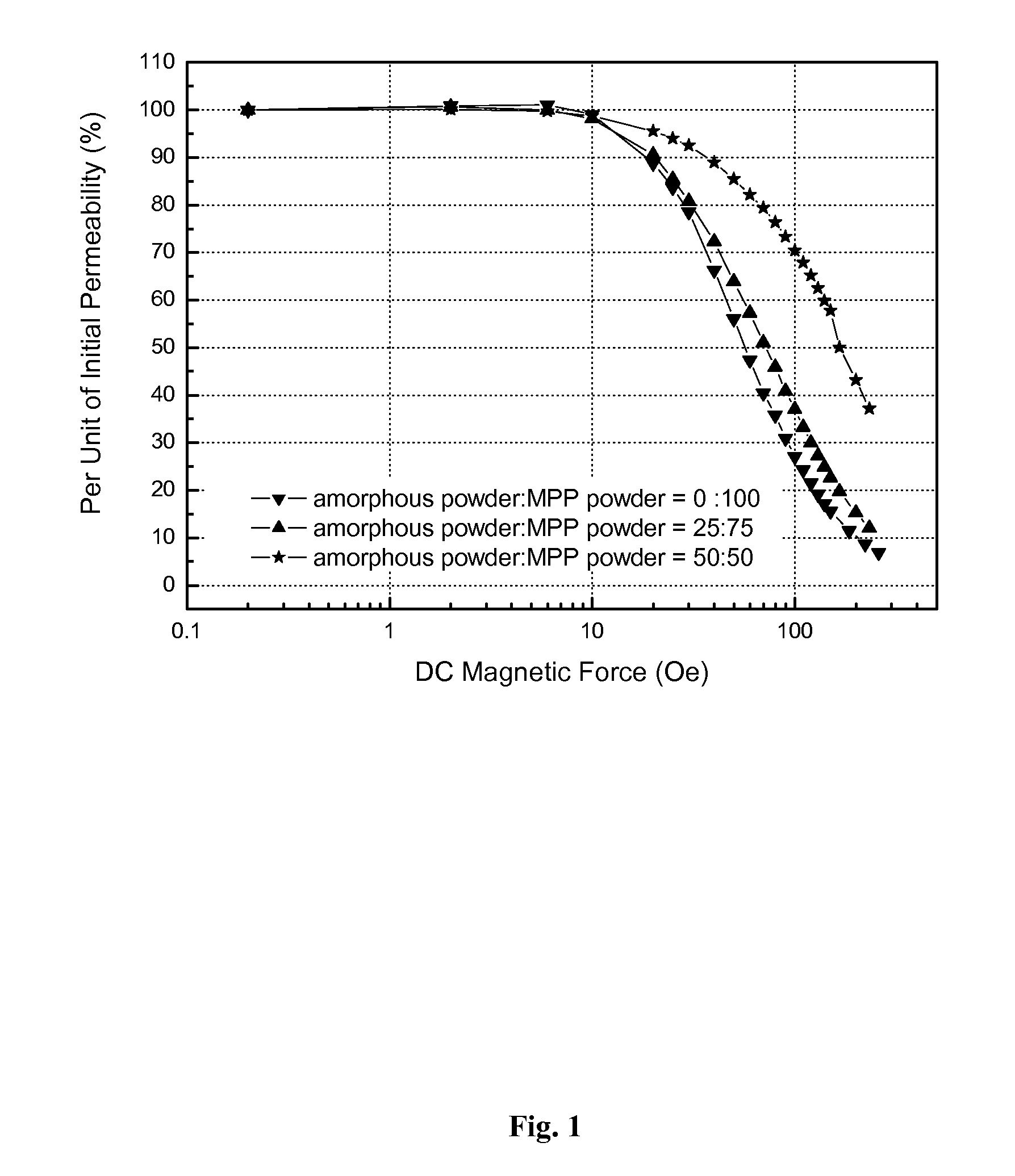

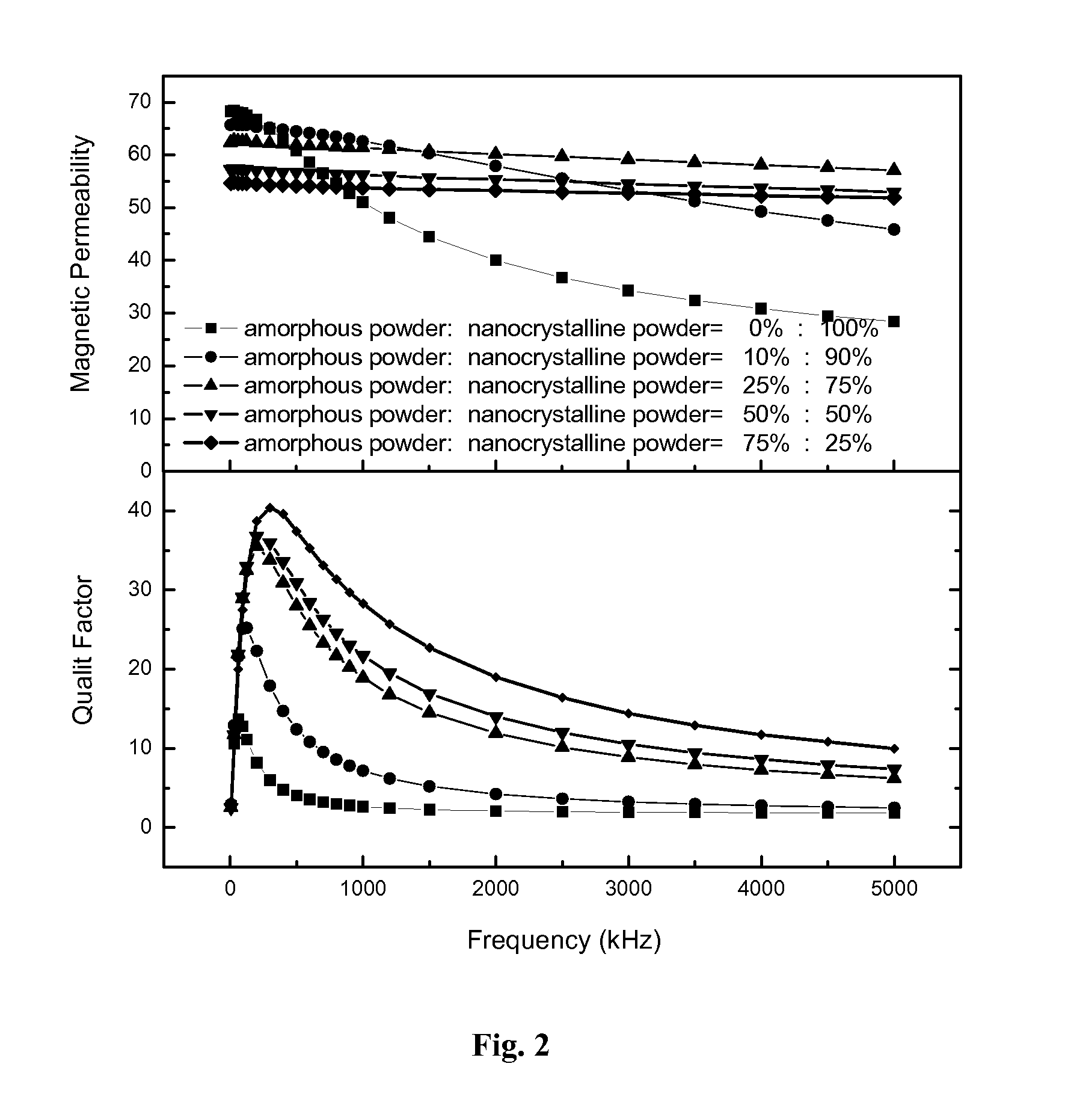

Compound magnetic powder and magnetic powder cores, and methods for making them thereof

ActiveUS20070144614A1Reduce penetrationLow core lossTransportation and packagingMetal-working apparatusAl powderIron powder

The present invention provides a compound powder for making magnetic powder cores, a kind of magnetic powder core, and a process for making them. Said compound powder is a mixture composing of powder A and powder B, the content of powder A is 50-96 wt % and the content of powder B is 4-50 wt %, wherein powder A is at least one selected from iron powder, Fe—Si powder, Fe—Si—Al powder, Fe-based nanocrystalline powder, Fe-based amorphous powder, Fe—Ni powder and Fe—Ni—Mo powder; powder B bears different requirement characteristics from powder A and is at least one selected from iron powder, Fe—Si powder, Fe—Si—Al powder, Fe-based nanocrystalline powder, Fe-based amorphous powder, Fe—Ni powder and Fe—Ni—Mo powder. Said powder B adopts Fe-based amorphous soft magnetic powder with good insulation property as insulating agent and thus core loss of magnetic powder core decreases. The decrease of magnetic permeability of magnetic powder core resulting from a traditional insulating agent is remedied and the initial magnetic permeability of magnetic powder core is improved by taking advantage of soft magnetic properties of Fe-based amorphous powder.

Owner:ADVANCED TECHNOLOGY & MATERIALS CO LTD +1

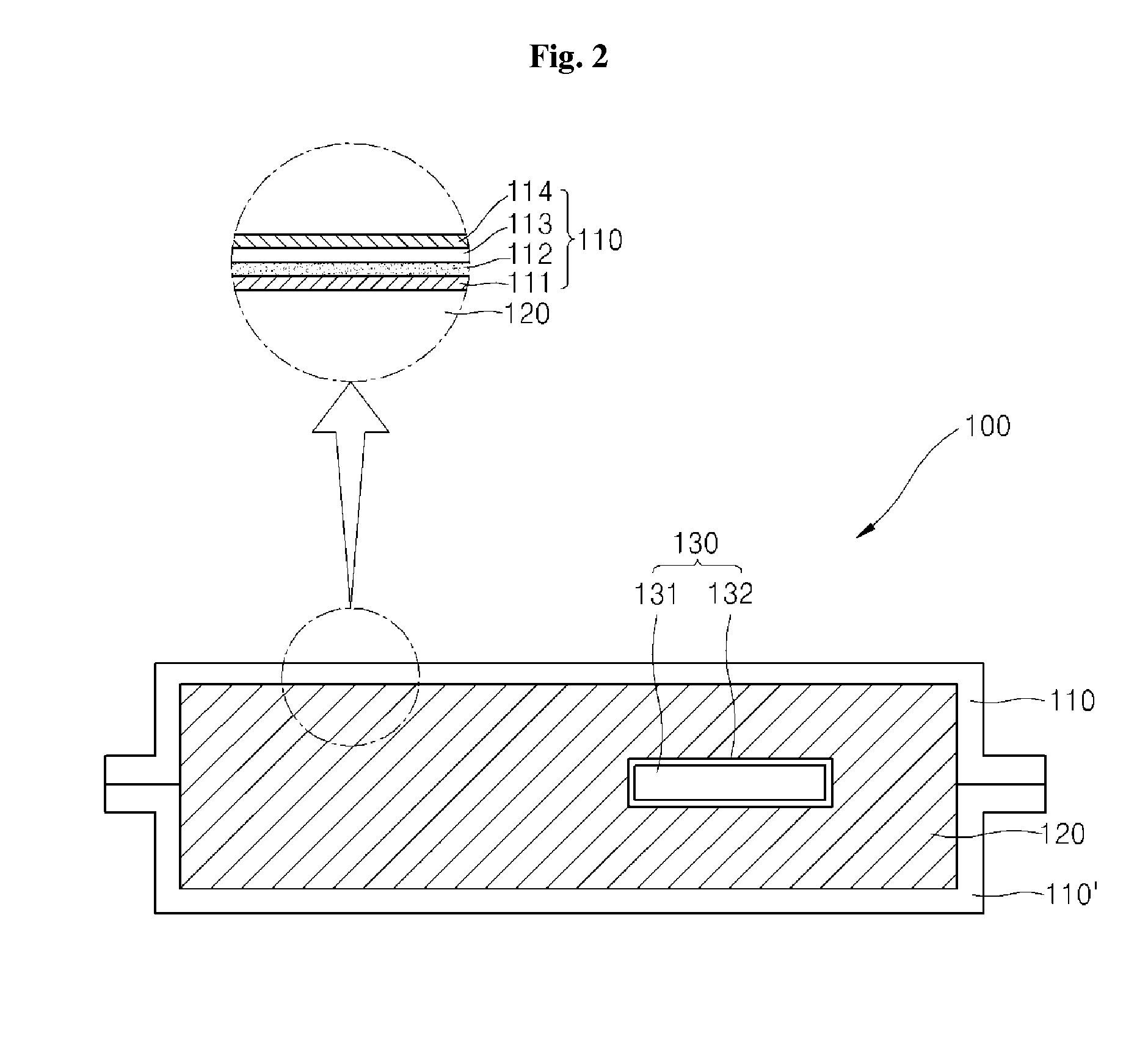

Vacuum thermal insulation material equipped with a getter material for water-fraction and gas adsorption, and production method therefor

ActiveUS20140178626A1Increased durabilityPromote absorptionLamination ancillary operationsThermal insulationThermal insulationNonwoven fabric

Owner:ES GLOBAL CO LTD

Efficient axial airgap electric machine having a frontiron

InactiveUS7105975B2Bulky designHigh operating requirementsMagnetic circuit rotating partsNanotechnologyElectric machineEngineering

Owner:LIGHT ENGINEERING INC

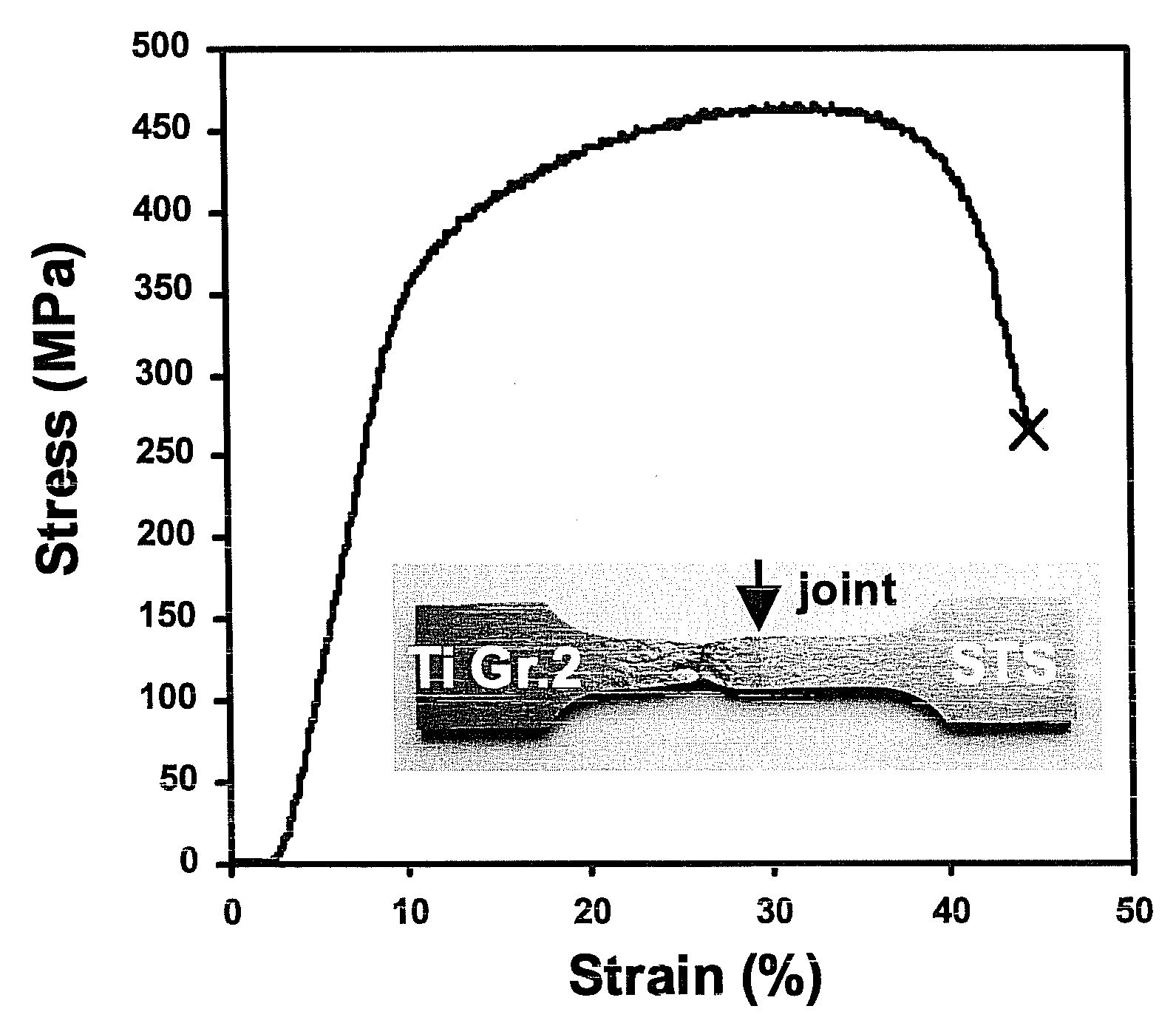

JOINING METHOD BETWEEN Fe-BASED STEELS AND Ti/Ti-BASED ALLOYS HAVING JOINT STRENGTH HIGHER THAN THOSE OF BASE METALS BY USING INTERLAYERS AND THE JOINTS PRODUCED USING THE METHOD

InactiveUS20100124669A1Improve joint strengthAvoid brittleWelding/cutting media/materialsWelding/soldering/cutting articlesHigh intensityAdvanced composite materials

A joining method between Fe-based steel and Ti / Ti-based alloys having a joint strength higher than those of base metals by using interlayers. The production of intermetallic compounds at a joint portion between Fe-based steel and Ti / Ti-based alloys can be prevented using interlayers, and strong interface diffusion bonding can be formed at interfaces between interlayers, thereby producing a high-strength joint. Accordingly, the present disclosure can be used to develop high-strength, high-functional advanced composite materials.

Owner:KOREA ATOMIC ENERGY RES INST +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com