Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

2534 results about "Al powder" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Processes for incorporating inert gas in a cement composition containing spherical beads

ActiveUS20050098317A1High densityModifies its propertySolid waste managementFluid removalAl powderPhysical chemistry

The present invention provides a process for forming cement in a well bore. In this process, a cement composition is formed that comprises a cement and one or more beads mixed with the cement. The cement composition containing the beads is displaced into the well bore, and an inert gas phase is introduced to the cement composition to control a density of the cement composition. The inert gas phase can be introduced by adding a gas generating material to the cement composition and / or a porous material to the cement composition. In an embodiment, the gas generating material is a nitrogen generating material that may be activated by an oxidizing agent. In another embodiment, the gas generating material is a hydrogen generating material, e.g., an aluminum powder. The present invention further provides a cement composition comprising a cement, one or more beads combined with the cement, and an inert gas phase created by, e.g., a gas generating material and / or a porous material.

Owner:HALLIBURTON ENERGY SERVICES INC

Utilization of poly(ethylene terephthalate) plastic and composition-modified barium titanate powders in a matrix that allows polarization and the use of integrated-circuit technologies for the production of lightweight ultrahigh electrical energy storage units (EESU)

InactiveUS7466536B1Low costLower sintering temperatureCell electrodesFixed capacitor dielectricManufacturing technologyBarium titanate

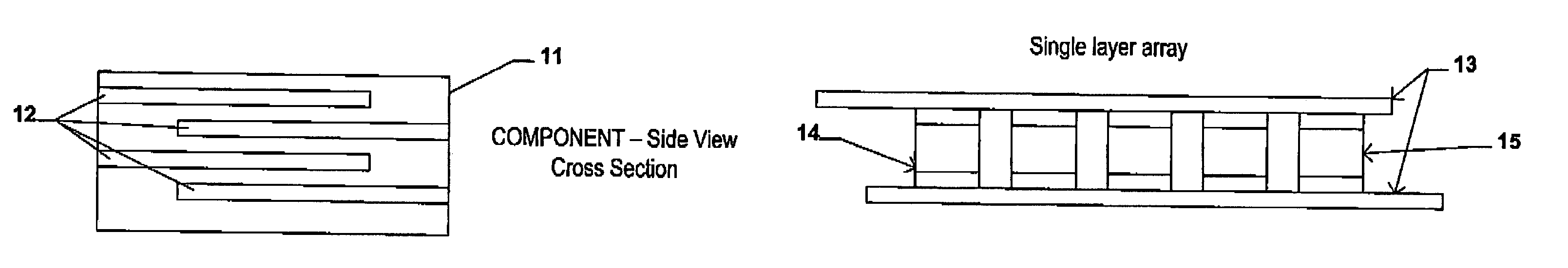

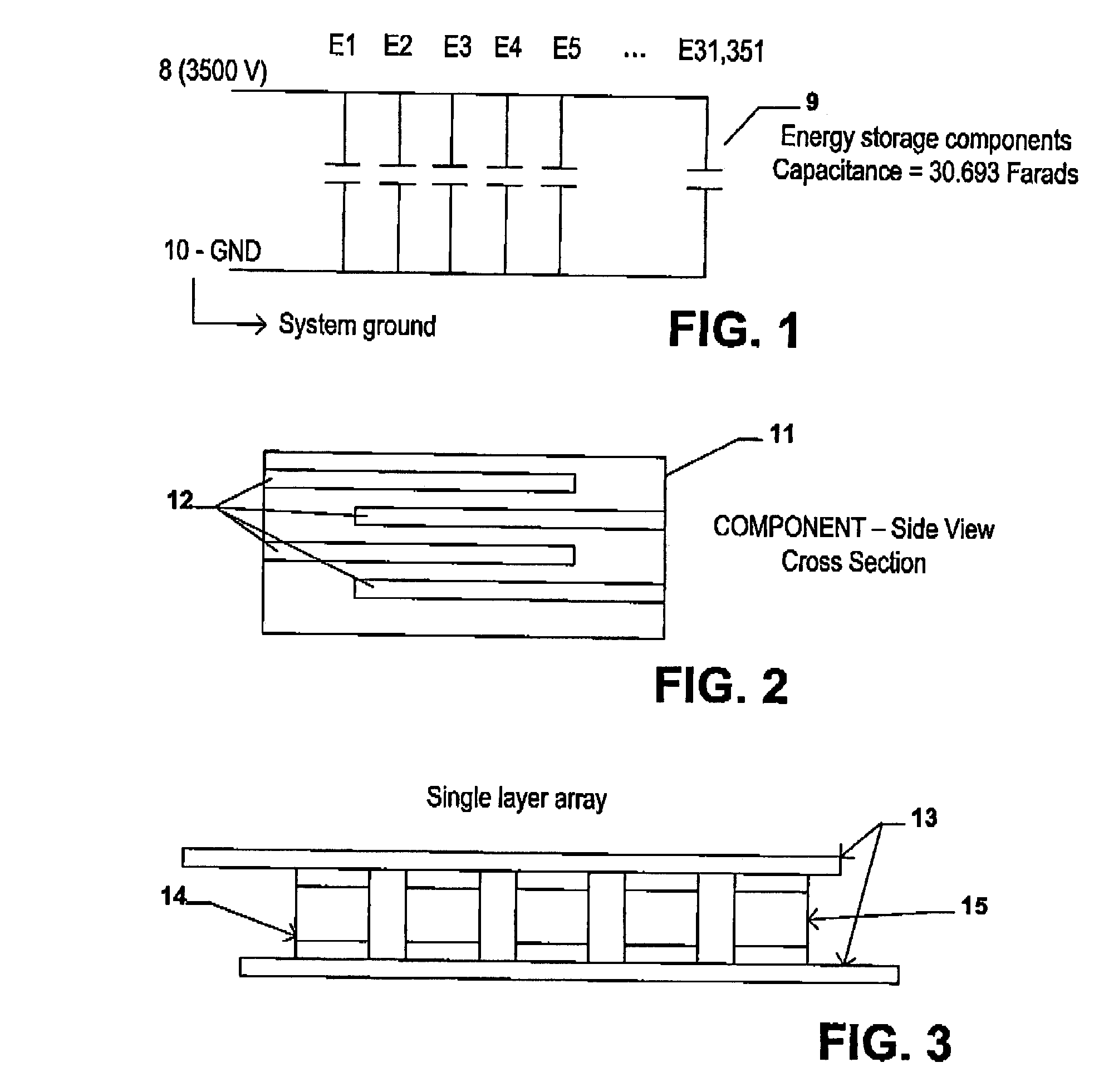

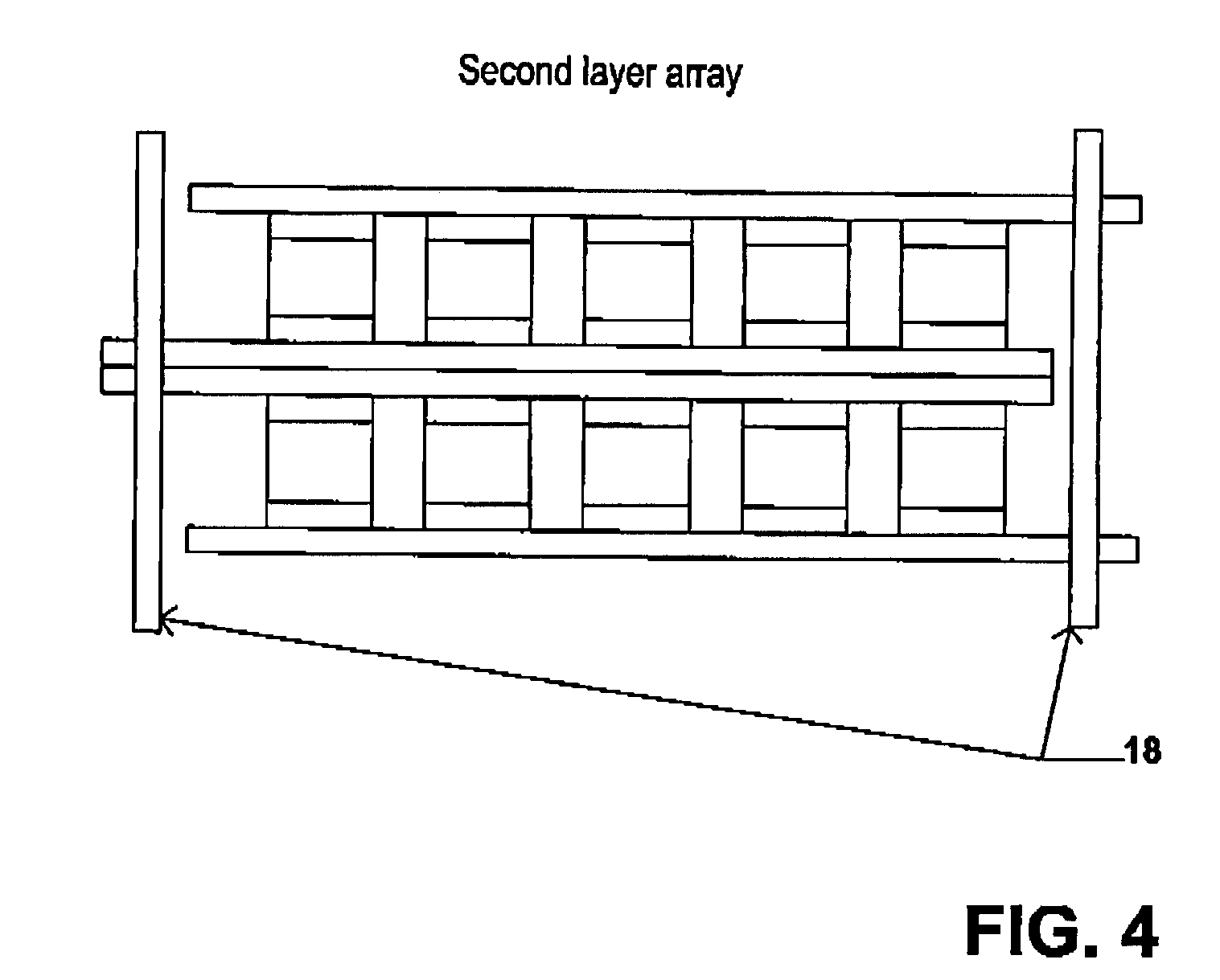

An electrical-energy-storage unit (EESU) has as a basis material a high-permittivity composition-modified barium titanate ceramic powder. This powder is single coated with aluminum oxide and then immersed in a matrix of poly(ethylene terephthalate) (PET) plastic for use in screen-printing systems. The ink that is used to process the powders via screen-printing is based on a nitrocellulose resin that provide a binder burnout, sintering, and hot isostatic pressing temperatures that are allowed by the PET plastic. These lower temperatures that are in the range of 40° C. to 150° C. also allows aluminum powder to be used for the electrode material. The components of the EESU are manufactured with the use of conventional ceramic and plastic fabrication techniques which include screen printing alternating multilayers of aluminum electrodes and high-permittivity composition-modified barium titanate powder, sintering to a closed-pore porous body, followed by hot-isostatic pressing to a void-free body. The 31,351 components are configured into a multilayer array with the use of a solder-bump technique as the enabling technology so as to provide a parallel configuration of components that has the capability to store at least 52.22 kW·h of electrical energy. The total weight of an EESU with this amount of electrical energy storage is 281.56 pounds including the box, connectors, and associated hardware.

Owner:EESTOR

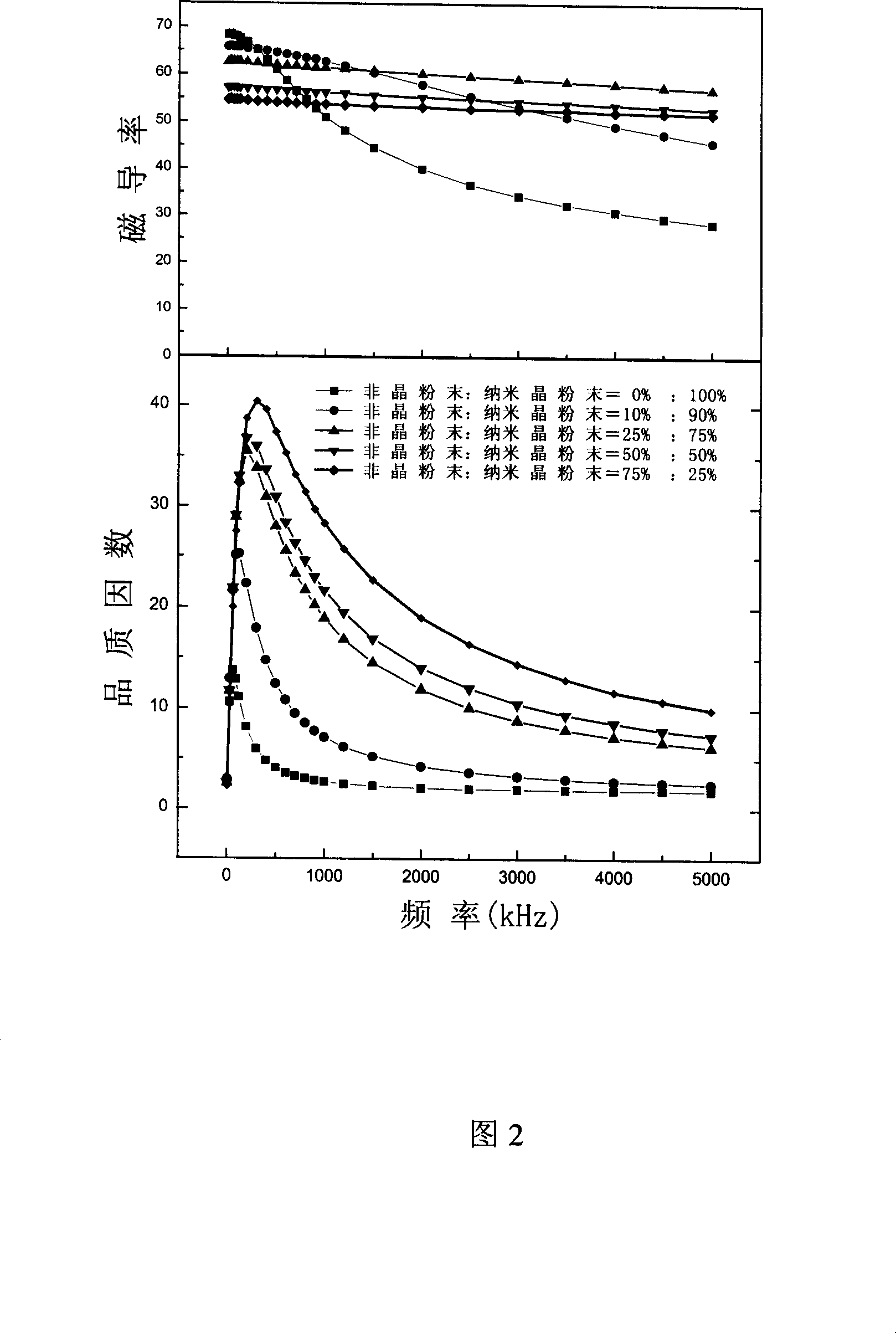

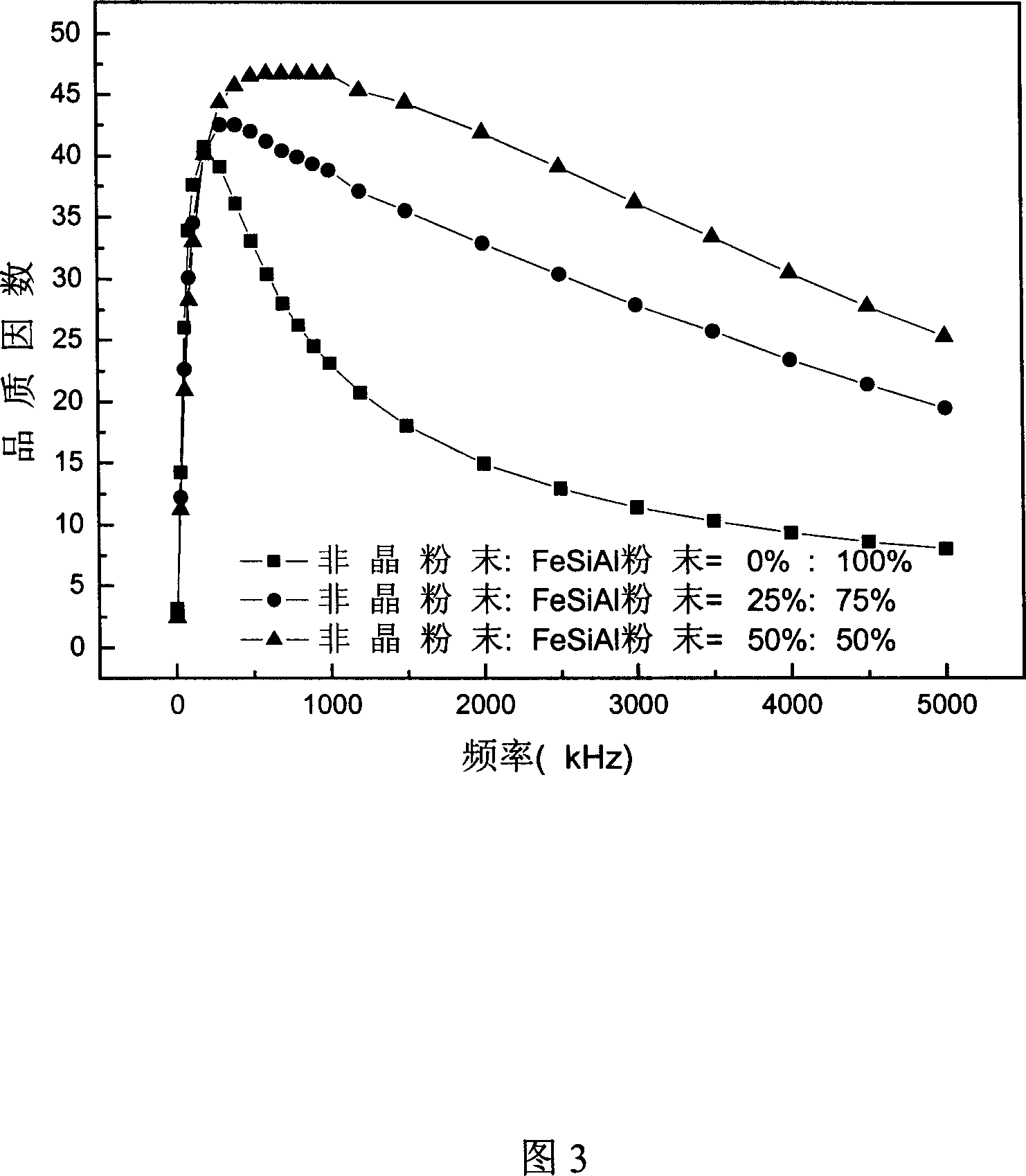

Composite powder, magnetic powder core for magnetic powder and preparation method thereof

InactiveCN101118797AExcellent soft magnetic propertiesIncrease the amount of participationInorganic material magnetismInductances/transformers/magnets manufactureAl powderIron powder

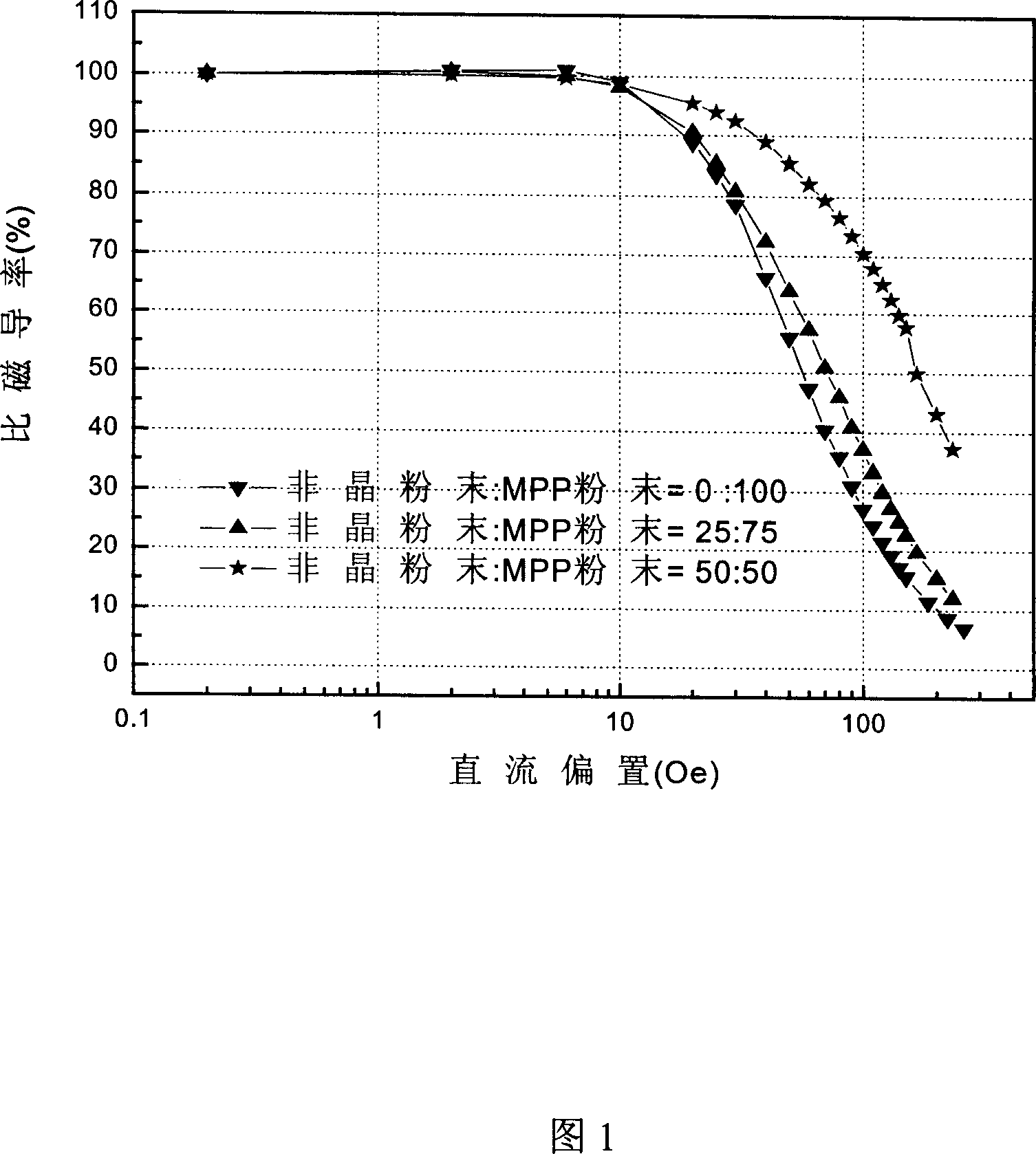

The present invention provides a magnetic powder core, composite powder used for the magnetic powder core, and a production method for the both. The composite powder is blended and formed by powder A and powder B, the content of which comprises 50-96wt percent of the powder A and 4-50wt percent of the powder B; wherein, the powder A is one out of iron powder, Fe-Si powder, Fe-Si-Al powder, Fe-based nanometer crystal powder, Fe-base amorphous powder, Fe-Ni powder and Fe-Ni-Mo powder; the powder B has different demand characteristics compared with the powder A and is selected from at least one out of iron powder, Fe-Si powder, Fe-Si-Al powder, Fe-based nanometer crystal powder, Fe-based amorphous powder, Fe-Ni powder and Fe-Ni-Mo powder. The powder B can be Fe-based soft magnetic amorphous powder as the insulating agent, which can reduce the wastage of magnetic powder core and make up for the declining magnetic conductivity of magnetic powder core caused by the traditional insulating agent. The excellent of soft magnetic properties of the insulating agent is utilized to improve frequency features of the magnetic powder core.

Owner:ADVANCED TECHNOLOGY & MATERIALS CO LTD

Heat preservation and energy saving type lightweight, gas filled wall bricks, and preparation method

This invention relates to a method for preparing heat-insulating and energy-saving lightweight aerated wall bricks, which are prepared from aggregate, gelation agent, aeration agent, heat-insulating material and water. The aggregate is composed of slag or river sand, glass microbeads, floating beads, closed perlite, and expanded perlite. The gelation agent is composed of cement, gypsum and lime. The aeration agent is Al powder. The fiber heat-insulating material is composed of high-Al powder, tripolite, ceramic fibers, mineral wool, sepiolite, expanded vermiculite, glass cotton and palygorskite. The wall bricks have such advantages as high compressive strength, low heat conductivity, high heat-insulating performance, high fireproof and damp-proof performances, rapid and convenient construction, and no need for composite heat-insulating layer.

Owner:徐振飞

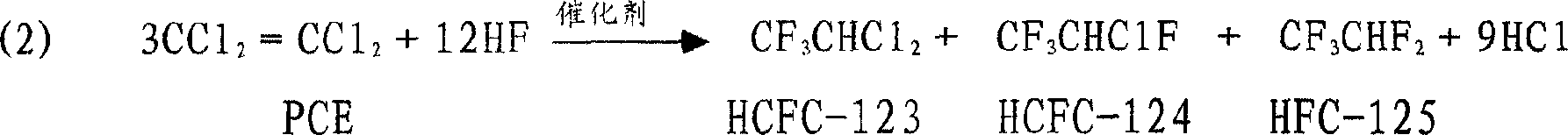

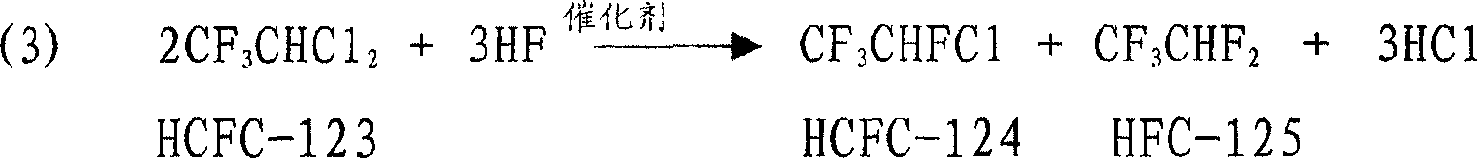

Florination catalyst, its manufacturing method and use

ActiveCN1651137AInhibitionReduce the temperaturePreparation by halogen replacementMetal/metal-oxides/metal-hydroxide catalystsHydrogen fluorideAl powder

Owner:XIAN MODERN CHEM RES INST

Composition and preparation method of silicon solar battery electrode slurry

InactiveCN101651155AEnhanced ohmic contactReduced series resistanceRenewable energy productsSemiconductor devicesBack surface fieldOhm

The invention relates to composition and a preparation method of silicon solar battery electrode slurry. The silicon solar battery electrode slurry comprises silicon solar battery sunny slope grid electrode silver slurry, back surface field silver-aluminium slurry and back surface field aluminium slurry which are used for preparing an ohm contact layer containing silicon alloy powder. In the invention, silver powder, aluminium powder, a simple substance element and the silicon alloy powder are used as raw materials, and an organic bond and an inorganic bond are used as accessories, and after the raw materials and the accessories are evenly mixed, a three-roller rolling mill is utilized to roll the mixture into the silicon solar battery electrode slurry of which the fineness is 20.0-25.0mum and the viscosity is 20000-40000mpa.s.

Owner:谭富彬

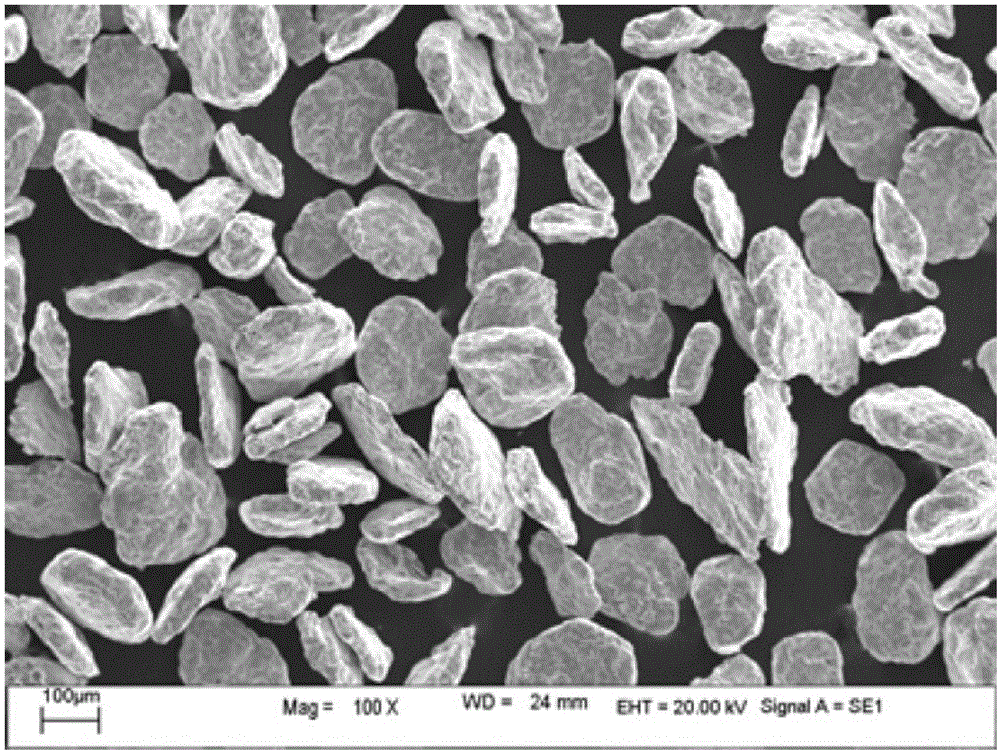

Titanium alloy based dispersion-strengthened composites

Titanium based metal matrix composites reinforced with ceramic particulate are well known, based on a blend of titanium alloy powders with ceramic powders, e.g., aluminum oxide powders, utilizing a low energy ball milling process, followed by cold compacting and sintering to produce an appropriate composite. This prior art process is disadvantaged from the point of view that there are virtually no particles in the blend below the micrometer size range, which lack has a deleterious effect on the subsequent processing of the composite. This problem has been overcome by utilizing dry high energy intensive milling in the process, which has the effect of providing the necessary number of small particles below the micrometer size range as well as enhancing the reactivity of different particles with one another. In order to produce a titanium base alloy alumina metal matrix composite, titanium dioxide powder is blended with aluminum powder and subjected to dry high energy intensive milling until the separate particle phases achieve a size of 500 nanometers maximum. The intermediate powder product is then heated to form the titanium alloy / amumina metal matrix composite in which the ceramic particles have an average diameter of no more than 3 mu, and the oxide consists of more than 10% and less than 60% by volume fraction of the total composite. The composites have extensive application to tough and strong engineering alloys.

Owner:TITANOX DEV

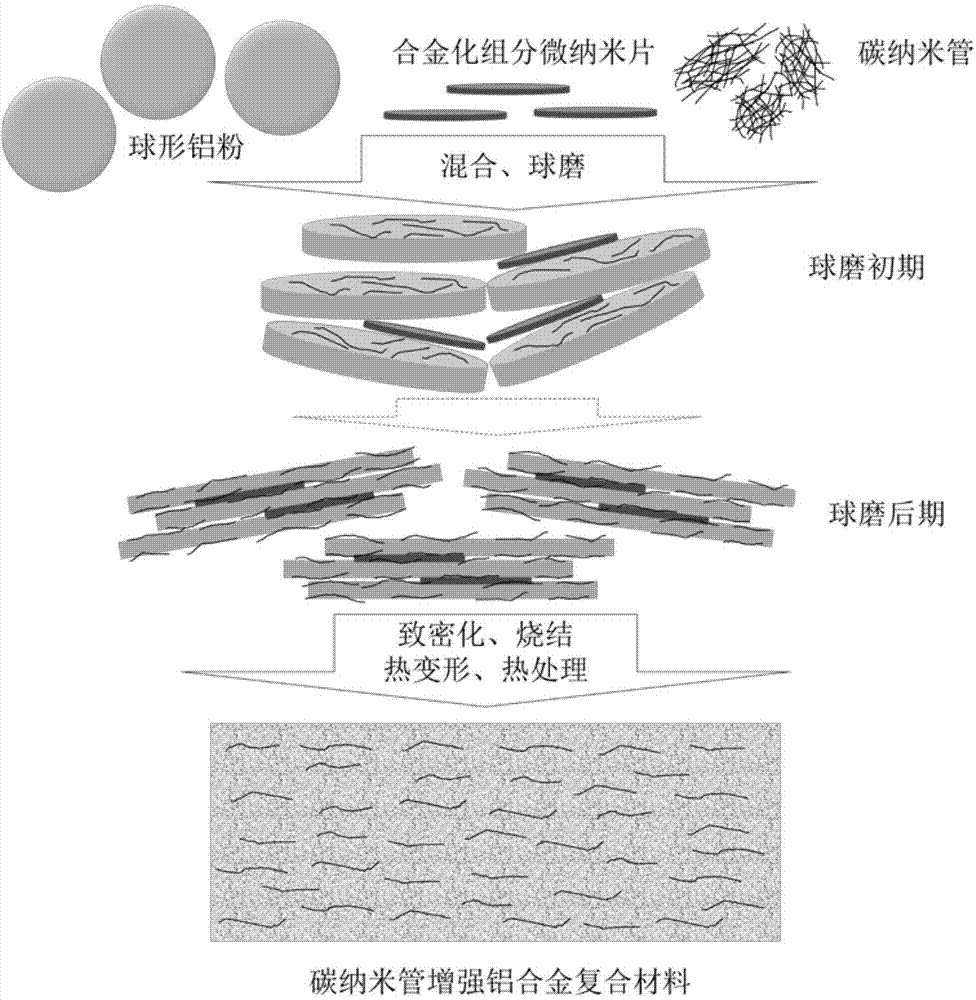

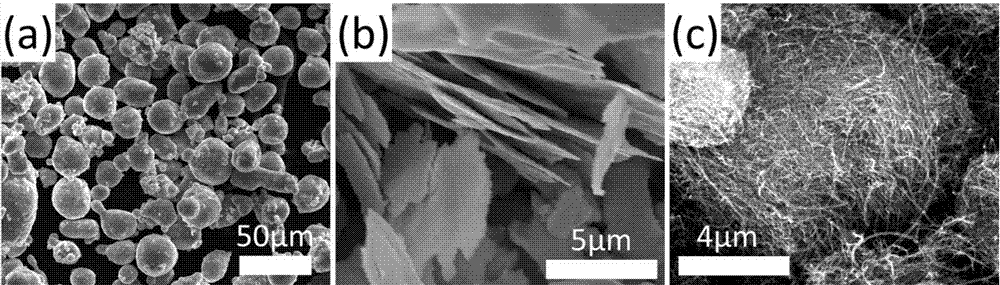

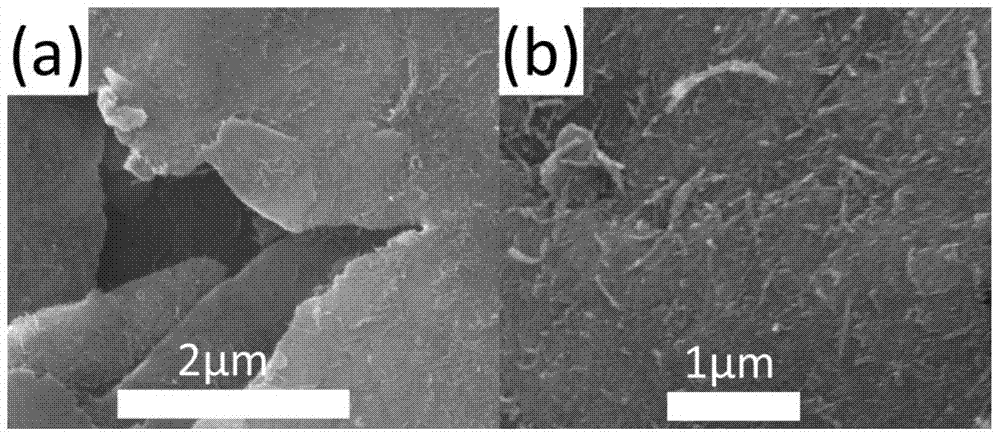

Powder metallurgy preparation method of carbon nanotube reinforced aluminum alloy composite material

ActiveCN103789564ARapid precipitation strengtheningReliable and efficient processMicro nanoThermal deformation

The invention provides a powder metallurgy preparation method of a carbon nanotube reinforced aluminum alloy composite material. The method comprises the following steps: pre-preparing micro-nano flake powder of an alloying component, subsequently ball-milling the powder with a carbon nanotube and spherical pure aluminum powder to prepare flake composite powder, and further performing densifying, sintering, thermal deformation processing and thermal treatment to achieve alloying so as to finally obtain the carbon nanotube reinforced aluminum alloy composite material. Uniform compounding of the matrix aluminum powder, the carbon nanotube and the alloying component can be achieved through limited ball-milling, and meanwhile dangerous elements or uneasy grinding elements such as magnesium and silicon which are high in activity and likely to combust and explode are avoided by adopting the stable and easily ground pre-alloying aluminum powder, so that the security and the reliability are improved; in addition, because of large interlayer boundary and small layer thickness distance, the flake structure is beneficial for uniformly dispersing the alloying component and forming refined dispersed separated phase. The method is beneficial for bringing the effects of composite reinforcement of carbon nanotubes and alloy reinforcement into play to the maximum extent, is energy-saving and time-saving, and is safe and feasible.

Owner:SHANGHAI JIAO TONG UNIV

Composite ceramic filter core and preparation method thereof

InactiveCN102924067AGood mesoporous materialHas a hydrophobic surfaceFiltration separationCeramicwareActivated carbonComposite ceramic

The invention relates to a composite ceramic filter core and a preparation method thereof, in particular to a low-temperature sintering and high-strength diatomaceous earth composite ceramic filter core containing multi-walled carbon nanotubes and a preparation method thereof. The composite ceramic filter core comprises, by mass, 60-80% of refined diatomaceous earth, 12-20 parts of activated carbon, 4.5-9 parts of dispersing agent, 2-6 parts of sintering additives, 1-3 parts of antibacterial agents and 0.5-2 parts of carbon nanotubes. According to the low-temperature sintering and high-strength diatomaceous earth composite ceramic filter core containing the carbon nanotubes, due to the fact that the multi-walled carbon nanotubes are evenly distributed in the composite ceramic filter core, mechanical performance of the ceramic filter core can be improved, and the multi-walled carbon nanotubes are of mesoporous structures simultaneously and can perform effective adsorption on remove heavy metal ions in water. In addition, the sintering temperature is reduced to be below 950 DEG C by adding micron-sized metal aluminum powder, natural nano micropores of the diatomaceous earth are reserved, the mechanical strength of the ceramic filter core is further improved, and the compression strength is above 0.5GPa.

Owner:珠海启月生物科技有限公司

Leadless electronic slurry composition for solar silicon photovoltaic cell and preparation method thereof

InactiveCN101345263AHigh electrical conductivityRefined nanocrystalline structureFinal product manufactureSemiconductor devicesAdhesiveSlurry

The invention discloses a compounding and a preparation method for lead-free electronic slurry used for a solar silicon photocell; according to the mass percentage, the slurry is obtained by preparing 70 to 75 percent of aluminium powders, 20 to 25 percent of organic adhesive, 1 to 5 percent of inorganic glass powders and 1 to 5 percent of additives; the aluminium powder is ball-shaped aluminium powder with the surface covered by an aluminium nitride protection layer, with the purity not less than 99.9 percent and the average grain size of 2 to 6 microns; simultaneously, organic adhesives consisting of ethyl cellulose, resin, hexadecanol, diethyleneglycol monomethyl ether, diethyleneglycol monobutyl ether, terpineol and n-butyl alcohol are added into the aluminium powder; the inorganic glass powder is silicon dioxide, boracic acid, alumina, antimony oxide and zirconia; the additive consists of Span and pump oil. The product prepared by the method of the invention has no dust generation or aluminium peeling phenomenon and achieves the requirement of no lead and environmental protection.

Owner:NANTONG UNIVERSITY

Method for melting nickel-base high temperature alloy with electro-slag furnace

The invention relates to a method for melting a nickel-base high temperature alloy with an electro-slag furnace. The method includes the following methods: loading materials, welding a high temperature alloy electrode and a false electrode to be smelted together, and placing slag materials at the bottom of a crystallizer; blowing the welded electrodes with inert gases, and closing a protection cover; protecting a smelting closing smoke exhaust valve, and feeding an Ar gas into the crystallizer and the protection cover; striking an arc and melting slag; cleaning smelting slag materials, starting a smelting period, and swinging a slag resistor for less than 0.5 m omega during the smelting process; adding oxidizing agents, and adding metal aluminum powder continuously or at intervals to serve as deoxidizing agents during an electro-slag re-melting process; adopting feeding thorough three stages, power feeding is decreased rapidly, power feeding is decreased slowly, and finally heat is preserved at constant power; and casting a die, cooling and demolding the die. According to the method for melting the nickel-base high temperature alloy with the electro-slag furnace, the surface of a nickel-base high temperature steel ingot has no slag groove defect, and the burning losses of Al and Ti are less than or equal to 5%.

Owner:SHANXI TAIGANG STAINLESS STEEL CO LTD

Oily high-temperature resistant protective coating material, application thereof and titanium ingot production method

The invention discloses an oily high-temperature resistant protective coating material. The oily high-temperature resistant protective coating material is obtained after a raw material mixture is uniformly mixed, wherein the raw material mixture contains an oxidation protecting agent and an oily film forming agent; the oxidation protecting agent contains Al powder and Fe powder which are in the weight ratio of 1: (0.01-0.1). The invention further discloses an application of the oily high-temperature resistant protective coating material in titanium ingot production and a titanium ingot production method. The oily high-temperature resistant protective coating material disclosed by the invention has the advantages that the condition that the surface of a titanium ingot is not subjected to oxidation cracking under the condition that the titanium ingot undergoes constant temperature for 8 hours at the high temperature of 1,000 DEG C can be guaranteed, the forming possibility of an oxygen dissolved layer can be greatly reduced, and the yield and production efficiency of a titanium material are increased; the construction environment is not affected; the preparation process is simple; a variety of coating manners, such as pneumatic spraying, vacuum spraying and brushing, can be adopted. The titanium ingot production method disclosed by the invention has good economic and social benefits and has relatively broad popularization and application prospects in titanium plate and titanium tube production industries.

Owner:PANZHIHUA IRON & STEEL RES INST OF PANGANG GROUP

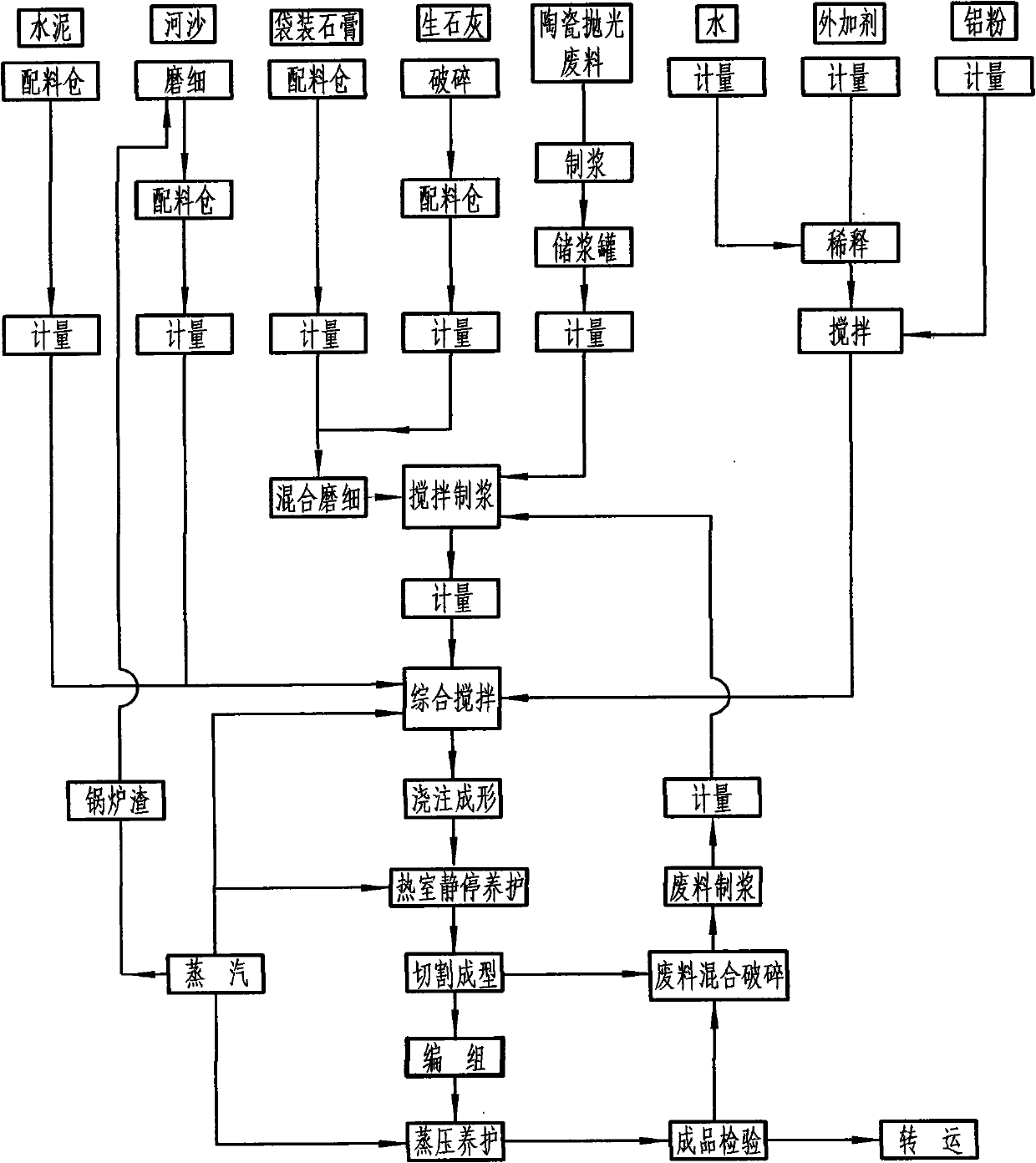

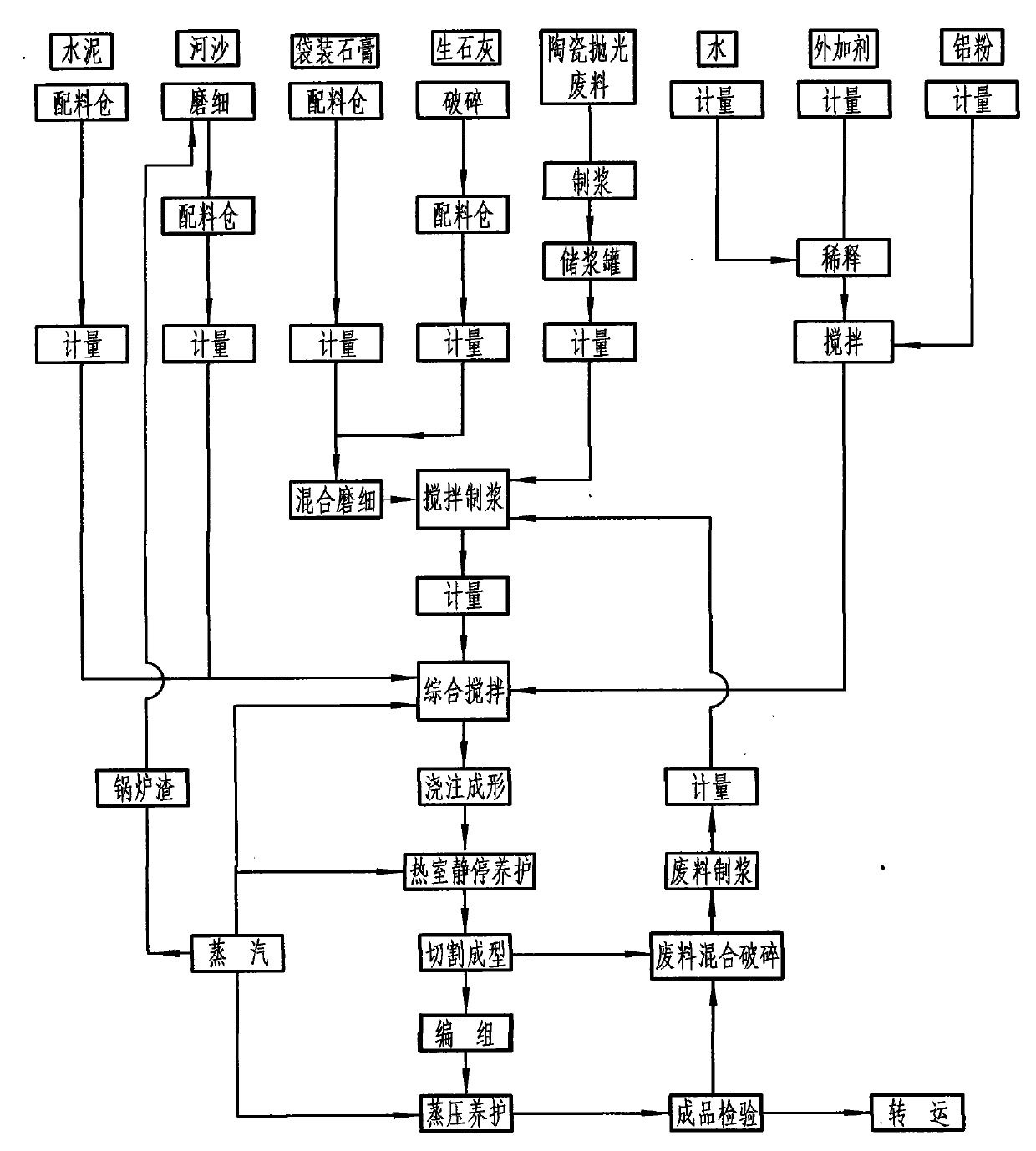

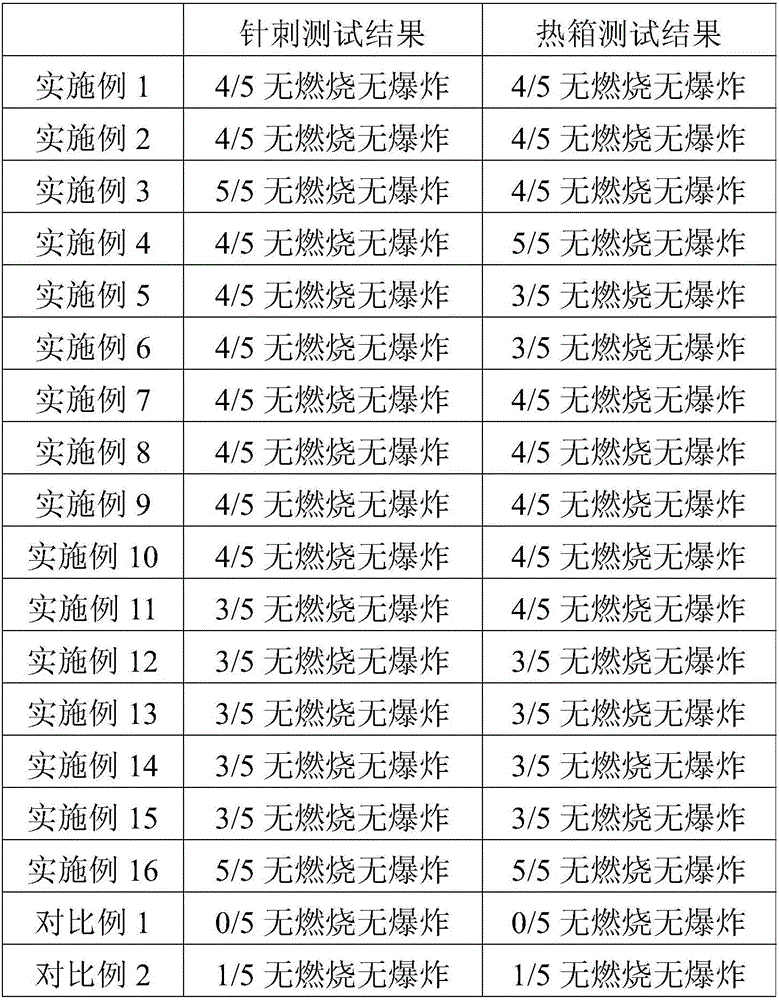

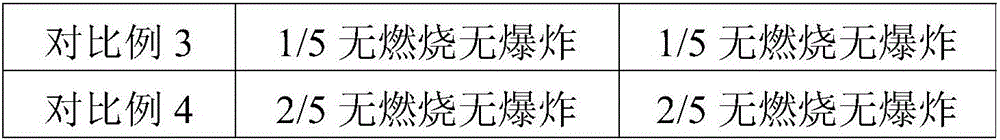

Autoclaved aerated concrete building block and preparation method thereof

The invention discloses an autoclaved aerated concrete building block, which is prepared by adding water into 50 to 55 weight parts of ceramic polishing waste, 10 to 15 weight parts of fine sand, 20 to 24 weight parts of calcined lime, 10 to 20 weight parts of cement, 0.05 to 0.09 weight part of aluminum powder and 3 to 5 weight parts of gypsum. The invention also discloses a preparation method for the autoclaved aerated concrete building block, which comprises the production processes of raw material fetching, slurry preparation, proportioning and pouring, standing and curing in a hot chamber, blank cutting, grouping, autoclaved maintenance, finished product inspection, recycle of waste liquid, waste slag and waste products and the like. The obtained autoclaved aerated concrete building block has the characteristics of high forming speed, light weight, high strength, heat insulation, sound insulation, good fireproof performance, low elasticity, seismic resistance, convenient construction and the like. The preparation method realizes utilization of the ceramic polishing waste, reduces the discharge of wastes of the ceramic industry, and is favorable for protection of ecological environment.

Owner:周石镭 +3

Electrode and preparation method therefor

ActiveCN107437622AImprove the high conductivity at room temperatureHigh strengthCell electrodesSecondary cellsLow-density polyethyleneEpoxy

The invention provides an electrode and a preparation method therefor. The electrode comprises a current collector and an active material layer arranged on the current collector; the electrode also comprises a coating layer arranged between the current collector and the active material layer; the coating layer comprises a polymer substrate and a conductive agent; the polymer substrate is selected from one or more of low-density polyethylene, high-density polyethylene, epoxy resin, polyvinylidene fluoride, an ethylene-ethyl acrylate copolymer, an ethylene-vinyl acetate copolymer, polybutylene, cellulose acetate and polyamide; and the conductive agent is selected from one or more of acanthosphere-shaped Ni powder, acanthosphere-shaped Cu powder, acanthosphere Al powder and acanthosphere-shaped tungsten carbide. The electrode has the advantages of low normal-temperature resistor and high PTC strength, so that improvement of safety performance of a lithium ion battery can be facilitated.

Owner:CONTEMPORARY AMPEREX TECH CO

TiAl intermetallic compound-based solid seif-lubricating composite material and preparation method thereof

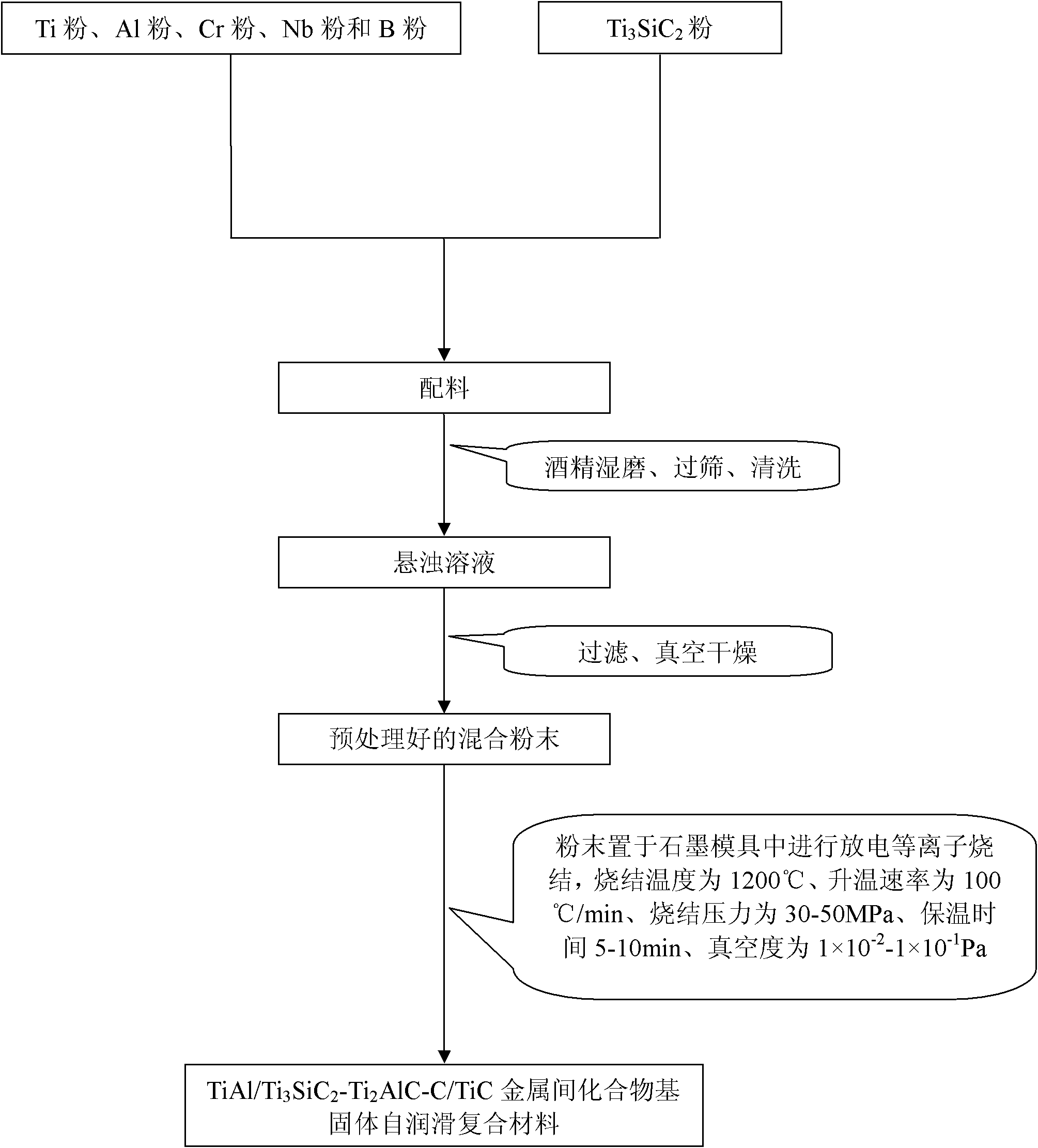

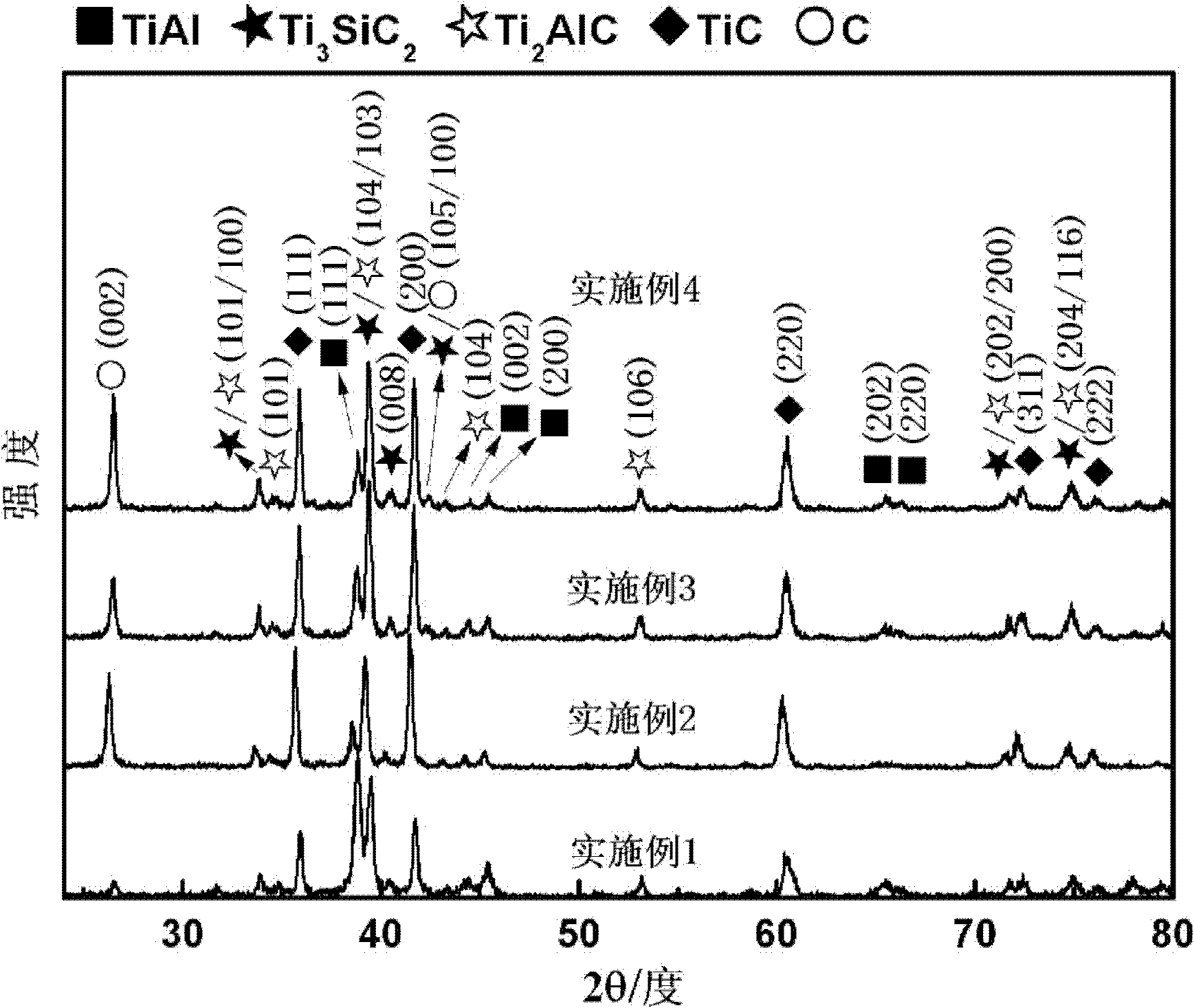

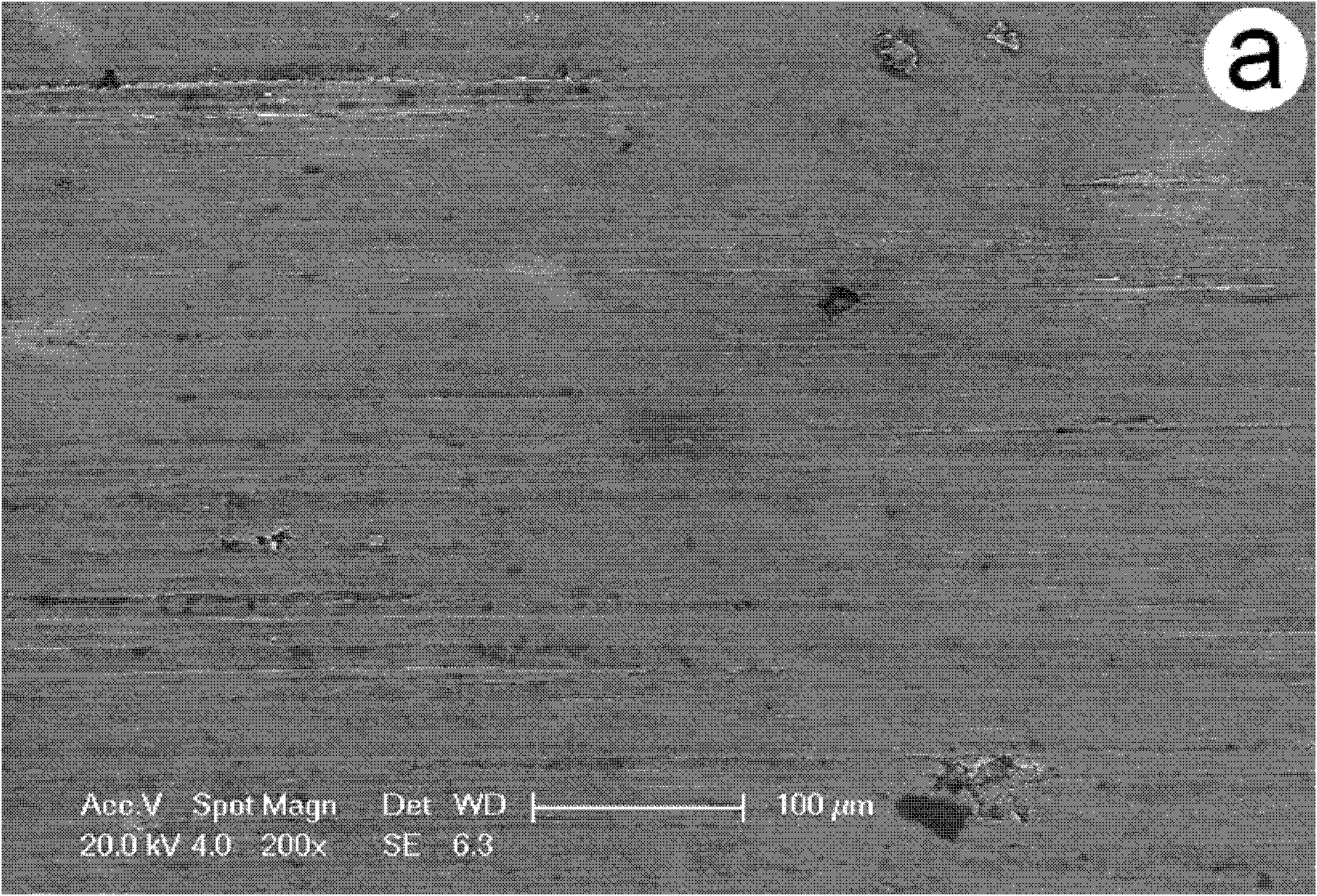

The invention relates to a TiAl intermetallic compound-based solid seif-lubricating composite material which comprises Ti3SiC2, Ti2AlC and C which are used as the ternary composite lubricating phase and TiC which is used as the reinforced phase, and a preparation method thereof. The TiAl intermetallic compound-based solid seif-lubricating composite material is characterized in that the material is prepared from Ti powder, Al powder, Cr powder, Nb powder, B powder and Ti3SiC2 powder, wherein the molar ratio of Ti, Al, Cr, Nb and B is 48:47:2:2:1 and the dosage of the Ti3SiC2 powder is 5-20wt.% of the total weight of the Ti powder, Al powder, Cr powder, Nb powder and B powder. The TiAl / Ti3SiC2-Ti2AlC-C / TiC intermetallic compound-based solid seif-lubricating composite material synthesized by the method is novel in component design (the intermetallic compound matrix, the composite lubricating phase and the reinforced phase), high in density, good in tribological properties, stable in technological parameters, fast and simple in preparation process and easy in operation and the method is suitable to be used to prepare the high performance TiAl intermetallic compound-based solid seif-lubricating composite material.

Owner:WUHAN UNIV OF TECH

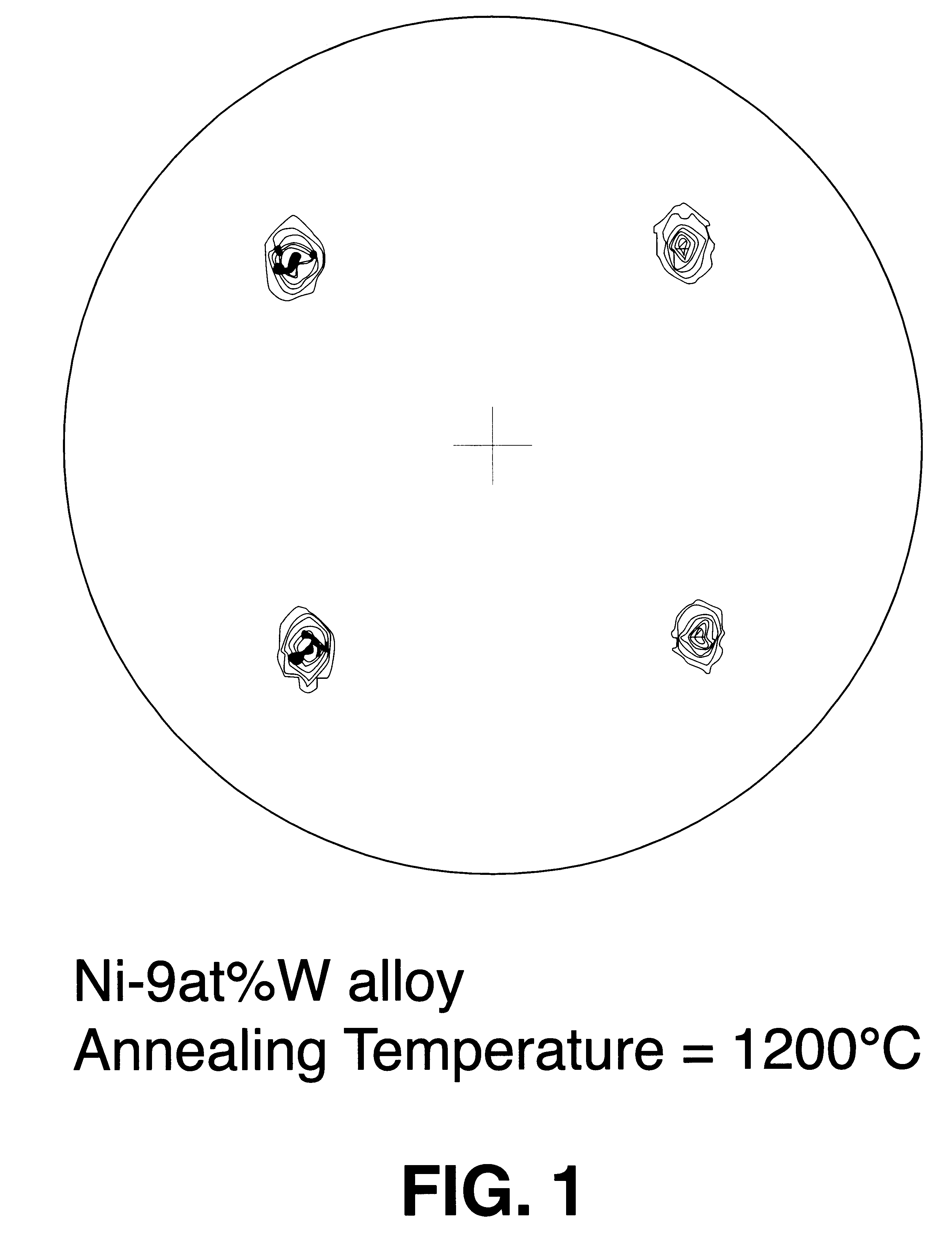

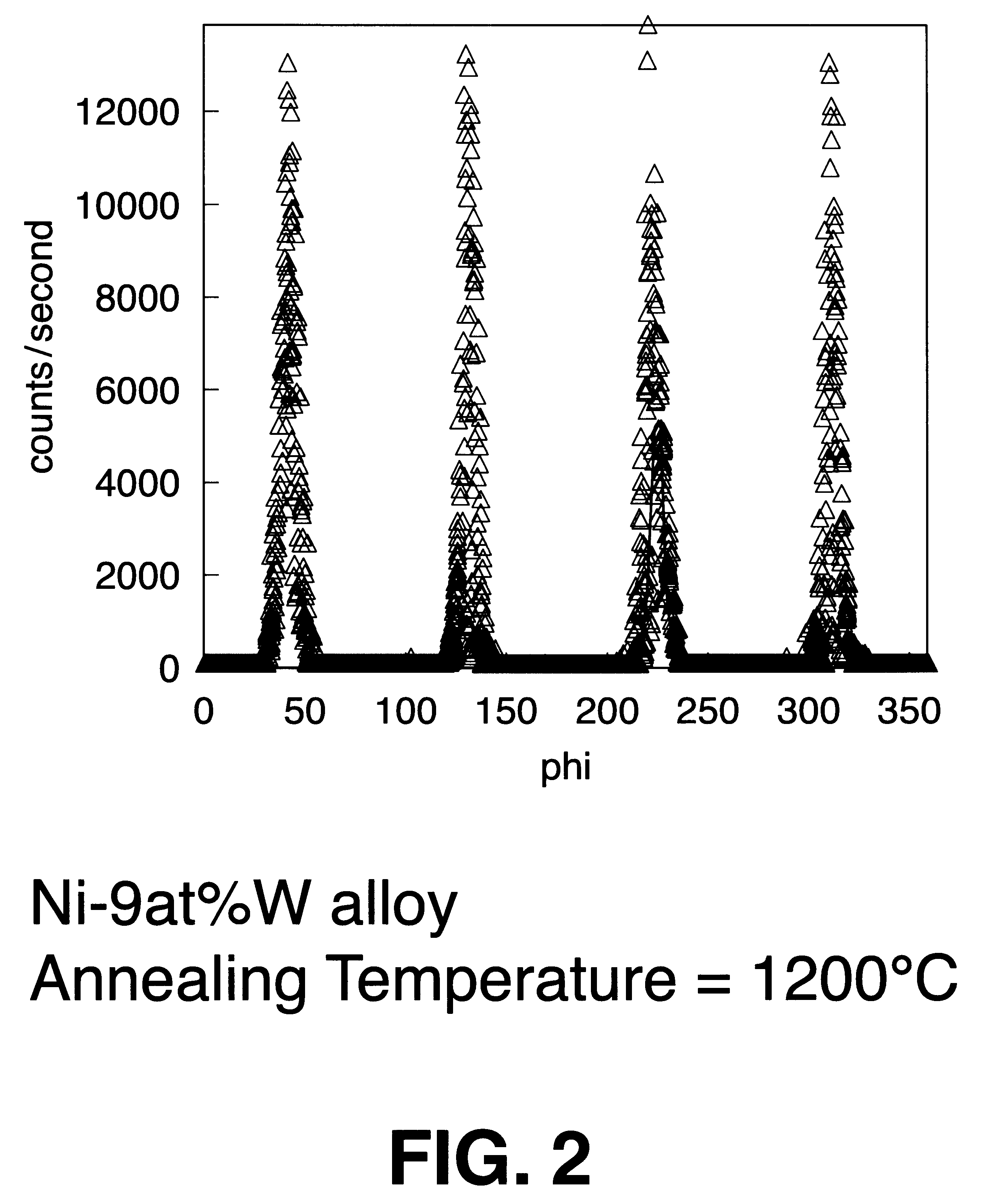

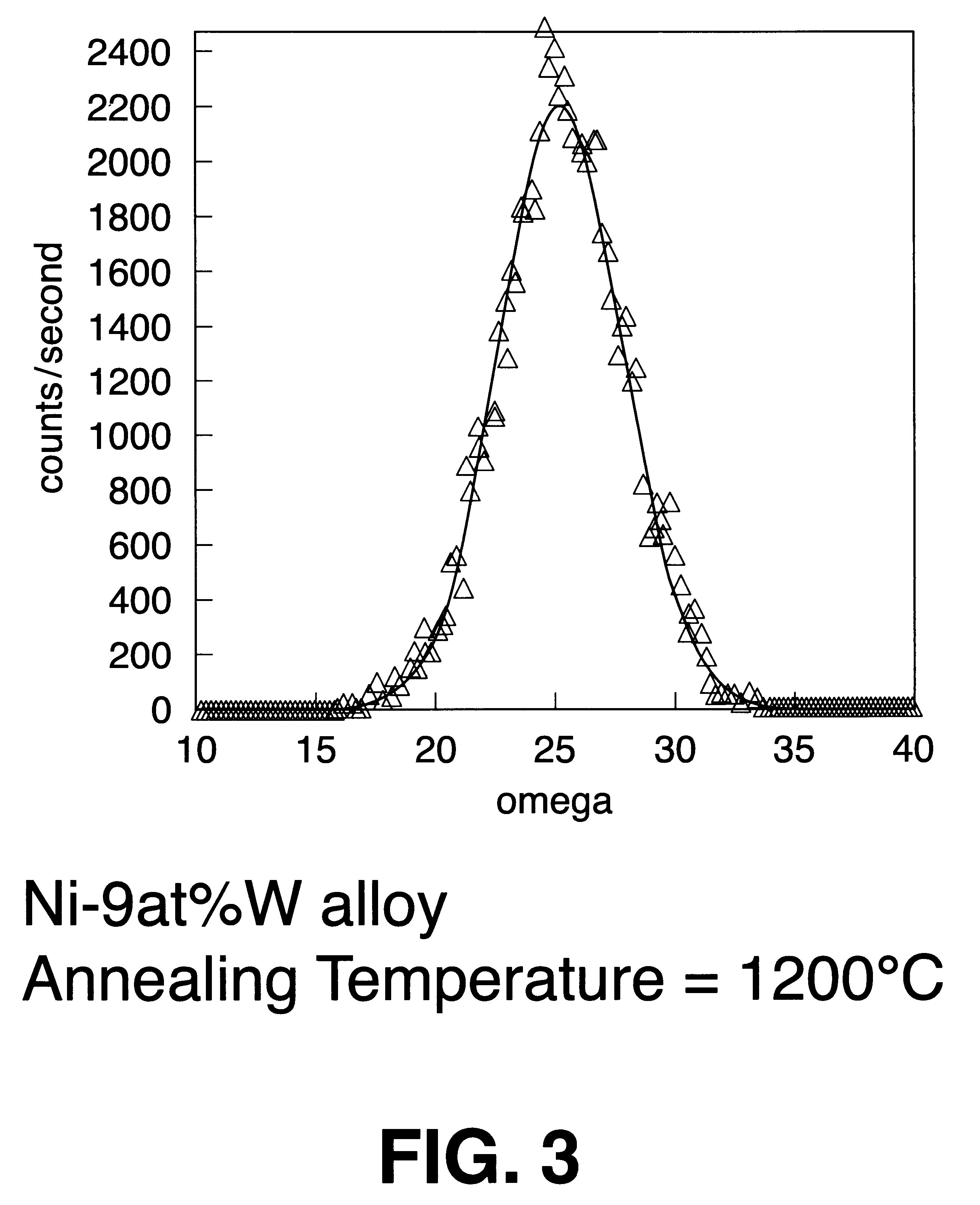

Biaxially textured articles formed by power metallurgy

InactiveUS6610414B2Inorganic material magnetismSuperconductor device manufacture/treatmentAl powderPowder mixture

A biaxially textured alloy article having a magnetism less than pure Ni includes a rolled and annealed compacted and sintered powder-metallurgy preform article, the preform article having been formed from a powder mixture selected from the group of mixtures consisting of: at least 60 at % Ni powder and at least one of Cr powder, W powder, V powder, Mo powder, Cu powder, Al powder, Ce powder, YSZ powder, Y powder, Mg powder, and RE powder; the article having a fine and homogeneous grain structure; and having a dominant cube oriented {100}<100> orientation texture; and further having a Curie temperature less than that of pure Ni.

Owner:UT BATTELLE LLC

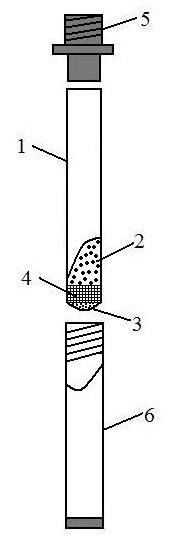

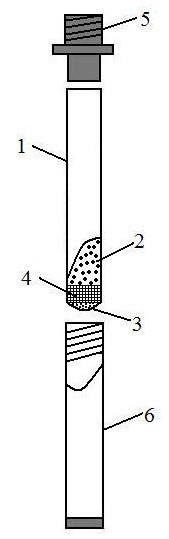

Portable welding pen

ActiveCN102151982ASimple ingredientsEnsure consistencyAlumino-thermic welding apparatusAl powderEngineering

The invention discloses a portable welding pen, which belongs to the field of welding and cutting technique. The portable welding pen comprises a powder tube filled with a thermit, an ignition head on the head part of the powder tube, and an ignition segment between the ignition head and the thermit, wherein the tail part of the powder tube is closed by a clamping end with external threads on one end; the ignition head is made of red phosphorus; the ignition segment adopts thermit welding pyrophoric powder; the thermit contains an exothermic agent, a slagging flux and an alloying agent; the exothermic agent contains CuO powder 60 to 70 wt% and Al powder 15 to 20 wt%; the slagging flux contains CaF2 powder 4 to 8 wt% and CaSO4 powder 5 to 7 wt%; and the alloying agent contains ferromanganese powder 1 to 3 wt% and ferronickel powder 2 to 4 wt%. When in use, the welding pen can be used for welding and cutting workpieces by withdrawing the pen tube, screwing the pen tube on the clamping end, holding the pen tube and then igniting the ignition head at the front end of the welding pen. The welding pen has low manufacture cost, and is small and portable. The welding pen is particularly suitable for the welding and cutting operation of steel and copper materials under emergence conditions, and has the advantages of high welding quality and high cutting speed.

Owner:常熟紫金知识产权服务有限公司

Technology of preparing aluminium oxide based continuous fibers by sol-gel process

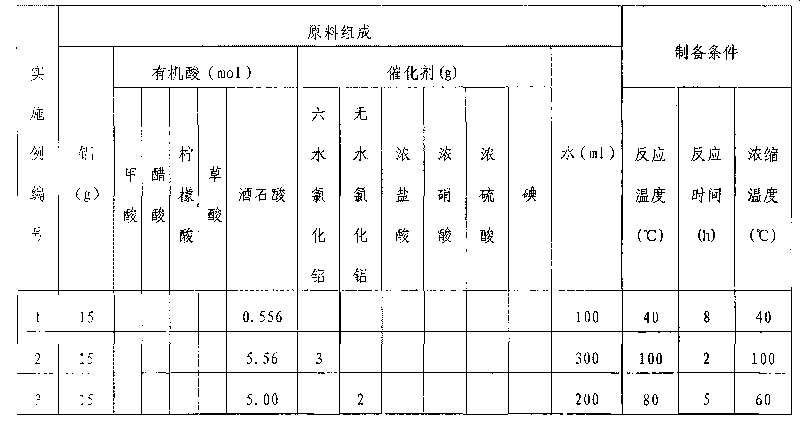

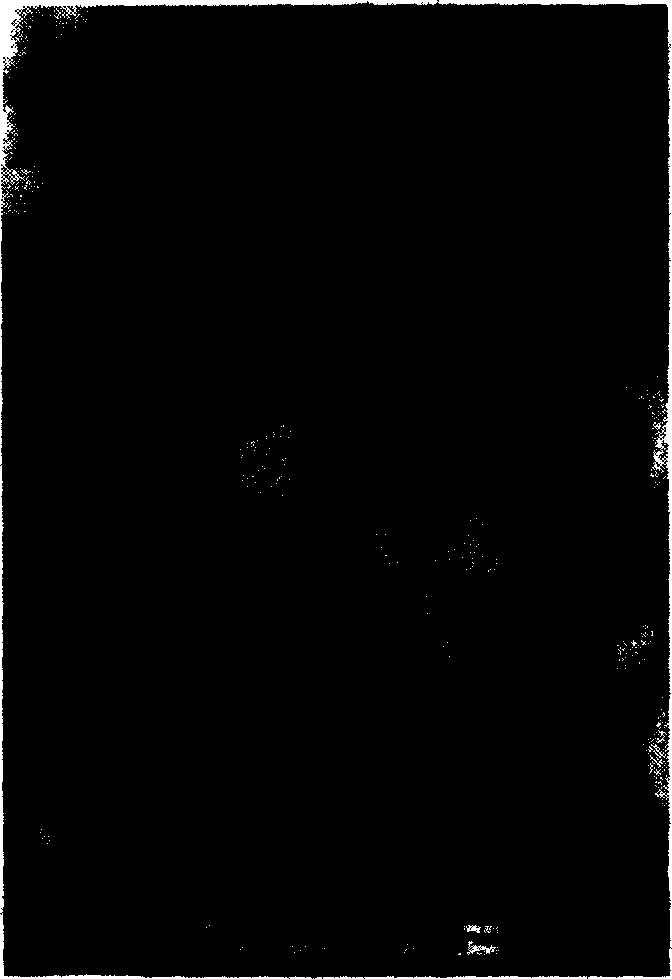

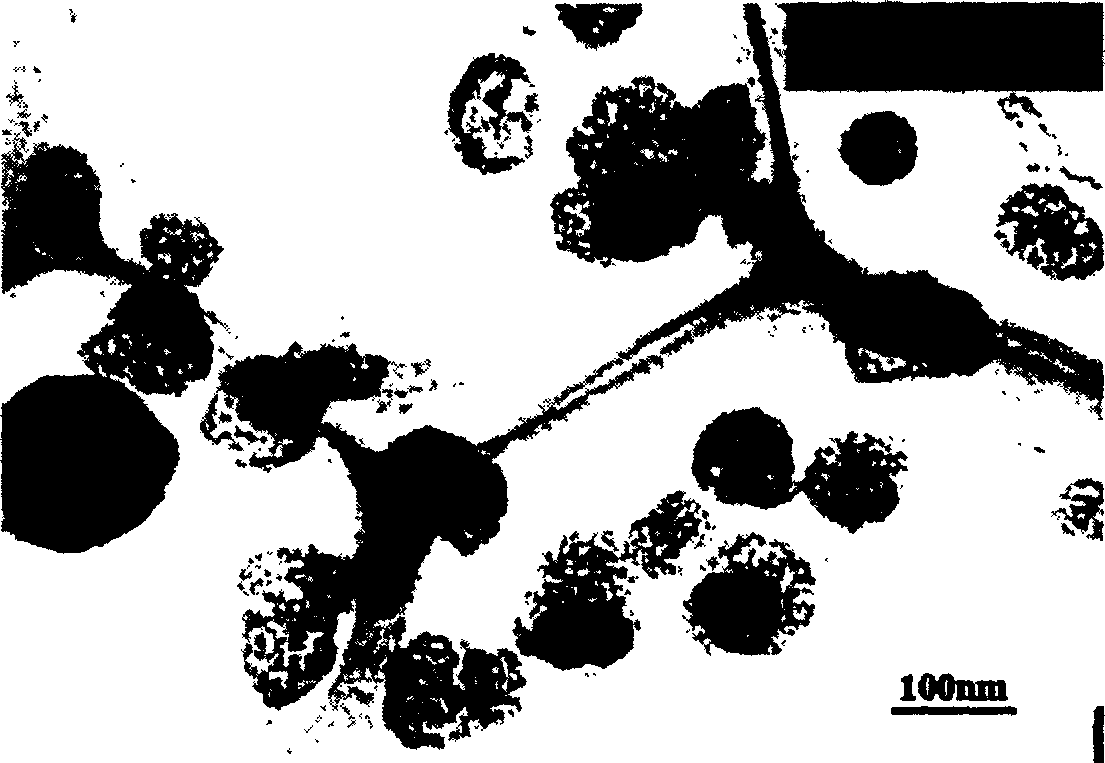

The invention discloses technology of preparing aluminium oxide based continuous fibers by a sol-gel process, which is characterized by adding one or more organic acid containing 1-8 carbon atoms into distilled water, adding aluminum powder and a catalyst after the mixture is evenly mixed and ensuring the mixture to react under the conditions of continuous stirring and reflux condensation under certain temperature to obtain transparent aluminum carboxylate solution; evaporating redundant organic acid in the aluminum carboxylate solution and then adding a solvent, a silicon-containing additive and a given quantity of spinning assistants to obtain precursor solution of aluminium oxide based fibers; concentrating the solution to obtain precursor sol of spinnable aluminium oxide based fibers; spinning by a dry or wet method to obtain aluminium oxide based continuous precursor fibers containing organics; and drying and sintering the precursor fibers to obtain the aluminium oxide based fibers. The aluminium oxide based continuous fibers prepared by the technology can be used in reinforcement in the composite, further improve the strength, ductility and heat resistance of the material and are widely applied in the fields of aerospace, automobile and the like.

Owner:XI AN JIAOTONG UNIV

Lead-free Al-back-surface-field (BSF) paste for crystalline silicon solar battery and preparation method thereof

ActiveCN101582462AReduce warpageGood dispersionFinal product manufactureMetal/alloy conductorsScreen printingOhmic contact

The invention provides a lead-free Al-back-surface-field (BSF) paste for a crystalline silicon solar battery and a preparation method thereof. The paste is made of 72-82 parts of aluminium powder, 0.1-2 parts of zirconia powder, 0.1-5 parts of inorganic bonding agent, 15-25 parts of organic bonding agent and 1-3 parts of auxiliary agent. After being processed by screen painting and sintering, the paste forms Al-BSF on a silicon chip, the BSF and the silicon chip form good ohmic contact and have good adhesive attraction; an aluminum film does not fall off, the battery has high transfer efficiency, and a battery piece has low warpage.

Owner:GUANGZHOU RUXING TECH DEV +1

Method for manufacturing soft magnet silicon-aluminium magnetic powder core

InactiveCN1622236ADoes not affect electromagnetic performanceReduce curing stressInorganic material magnetismInductances/transformers/magnets manufactureAl powderBreaking strength

The production process of soft magnetic Fe-Si-Al powder core includes the steps of compounding magnetic powder in different sizes, surface treatment, mixing magnetic powder, insulating agent, adhesive and demolding agent, molding, curing, magnetic heat treatment, soaking and surface coating. The present invention has the advantages of: breaking strength after curing in radial direction of 7-12 kg, less surface stripping, small demolding force, final breaking strength in radial direction of 17-24 kg, no influence of the insulating lacquer on electromagnetic performance and capability of realizing automatic production.

Owner:王锋 +1

Method of preparing nano powderusing liquid nitrogen low temperature ball mill

A process for preparing the nanoparticles with high thermal stability by low-temp ball grinding in liquefied nitrogen features that the micron-class Ni powder and Al powder are ground by stainless steel balls at -110- -160 deg.C for 1-15 hr to obtain their nanoparticles while generate nano-class NOx which can increase the thermal stability of said nanoparticles.

Owner:UNIV OF SCI & TECH BEIJING

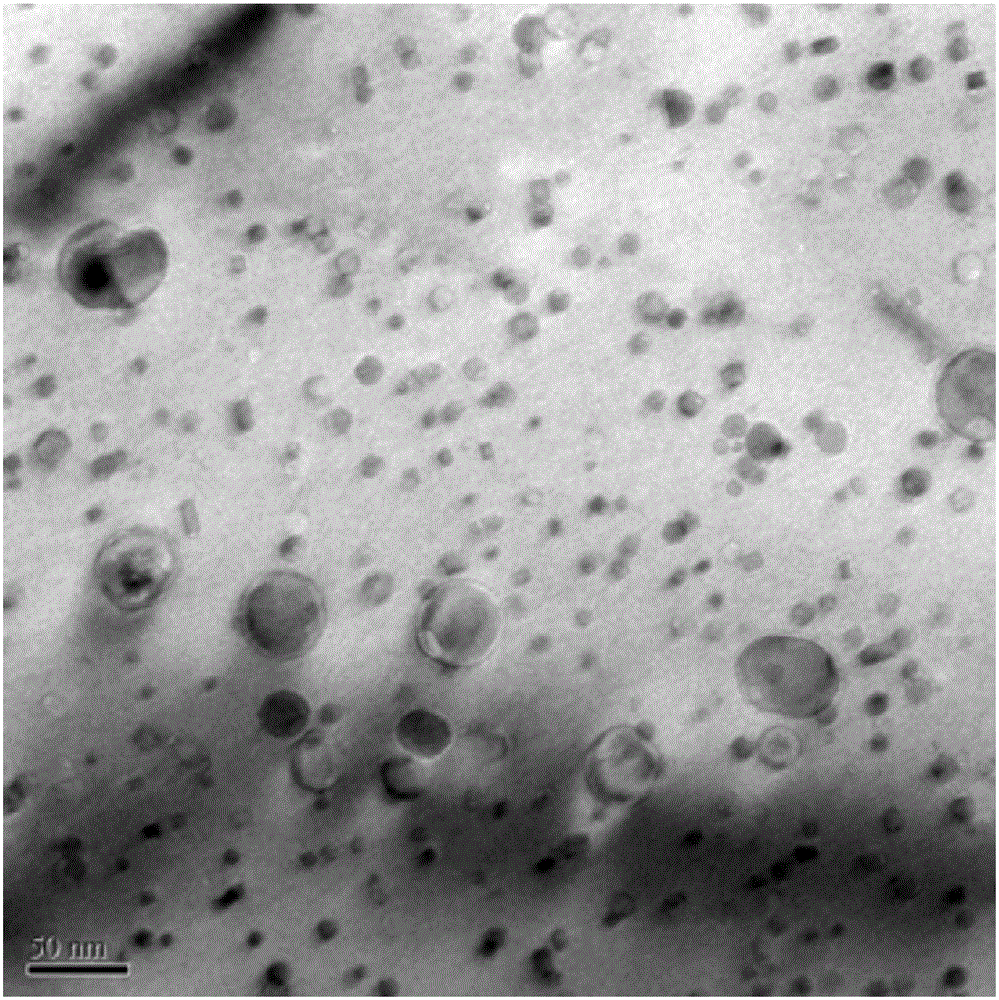

Preparation method of lithium ion battery porous silicon carbon composite negative material

InactiveCN102709565AInhibition of volume changeSmall volume changeCell electrodesAcid etchingCarbon composites

The invention puts forwards a preparation method of a lithium ion battery porous silicon carbon composite negative material. The prepared porous silicon carbon composite material simultaneously has the characteristics of high capacity and excellent circulating stability. Micron silicon and nanometer aluminum powder are promoted to be compounded by utilizing a high-energy ball milling method, a porous silicon material can be formed through acid etching, and through a porous structure, the volume change of silicon in the discharging process is relieved to a great extent. Meanwhile, the stress generated by the volume change of the silicon can be effectively buffered through taking graphite as a dispersion matrix and in combination with a secondary surface amorphous carbon coating technology of the composite material, so that the circulating stability of the material is improved. The preparation method of the material has the advantages of simplicity, low cost and easiness in industrial production.

Owner:力芯(青岛)新能源材料有限公司

Aluminium nitride ceramic substrate, and preparation method thereof

InactiveCN107188568AHigh thermal conductivityReduce manufacturing costAuxillary shaping apparatusSolventDefoaming Agents

The invention discloses an aluminium nitride ceramic substrate, and a preparation method thereof. The aluminium nitride ceramic substrate is prepared from an aluminium nitride ceramic tape casting slurry. The aluminium nitride ceramic tape casting slurry comprises aluminium nitride powder, a sintering air, a dispersant, a solvent, a plasticizer, a binder, and a defoaming agent. The preparation method comprises following steps: 1, primary ball milling is carried out; 2, secondary ball milling is carried out; 3, vacuum defoaming is carried out; 4, an obtained mixed slurry obtained via step 3 is subjected to tape casting, is subjected to heating on a film band, is cooled naturally, and is peeled off from the film band so as to obtain aluminium nitride tape casting sheets; 5, the aluminium nitride tape casting sheets are overlapped so as to obtain an aluminium nitride green body; 6, additive removing is carried out so as to obtain an aluminium nitride blank; and 7, sintering is carried out so as to obtain aluminium nitride ceramic. According to the preparation method, aluminium nitride is obtained via tape casting of a benzene-free, ketone-free, nontoxic organic solvent, and the sintering aid is added, so that the aluminium nitride ceramic substrate can be obtained via sintering at a relatively low temperature.

Owner:RENMIN UNIVERSITY OF CHINA

Zinc-nickel seeping layer ferrous metal corrosion protection process

ActiveCN101319300AHigh hardnessImprove wear resistanceSolid state diffusion coatingAl powderRolling resistance

The invention discloses a process for resisting ferrous metal corrosion of a zinc nickel diffusion layer. The process comprises the steps of alkaline degreasing, shot blasting, heating diffusion layer, water washing dust removal and colorful closing according to the requirement of a customer, wherein in the heating diffusion layer step, the zinc nickel diffusion layer and a metal matrix are put in a sealed metallic container and heated; the zinc nickel diffusion layer is prepared by evenly mixing the following powders in mass proportion: 20 to 30 percent of Zn powder, 0.5 to 1.4 percent of Ni powder, 3 to 12 percent of Al powder, 2 to 6 percent of rare earth, 1 to 4 percent of NH4Cl ammonium chloride, the balance being Al2O3 powder. The diffusion layer has the advantages of high rigidity, good wear resistance, unchangeableness of original mechanical performances of products, high adhesion strength, bumping and rolling resistance, good solderability, moisture and heat resistance and acid and alkali resistance; the diffusion layer has uniform thickness and compactness, and appearances of finished products have good uniformity; and no three-waste emission occurs during the course of processing, so the process belongs to the clean production process and is environment-friendly.

Owner:CHONGQING DAYOU SURFACE TECH

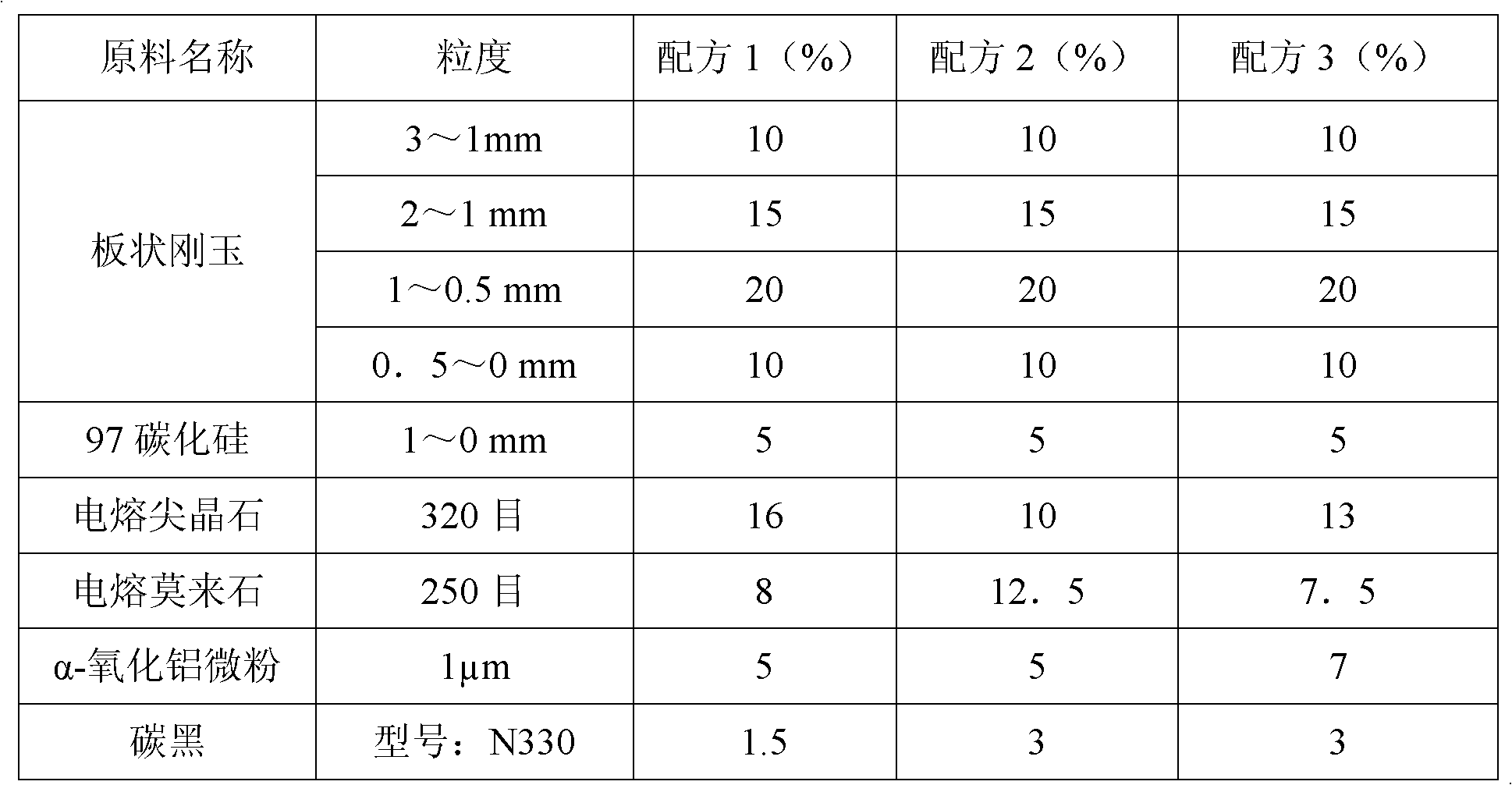

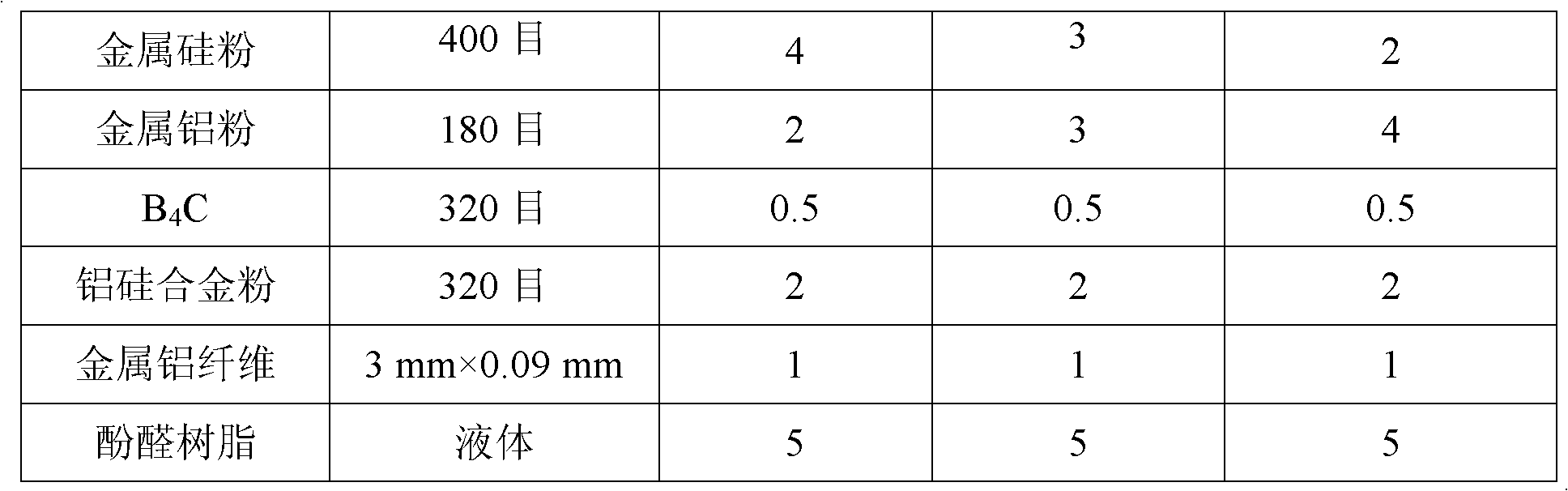

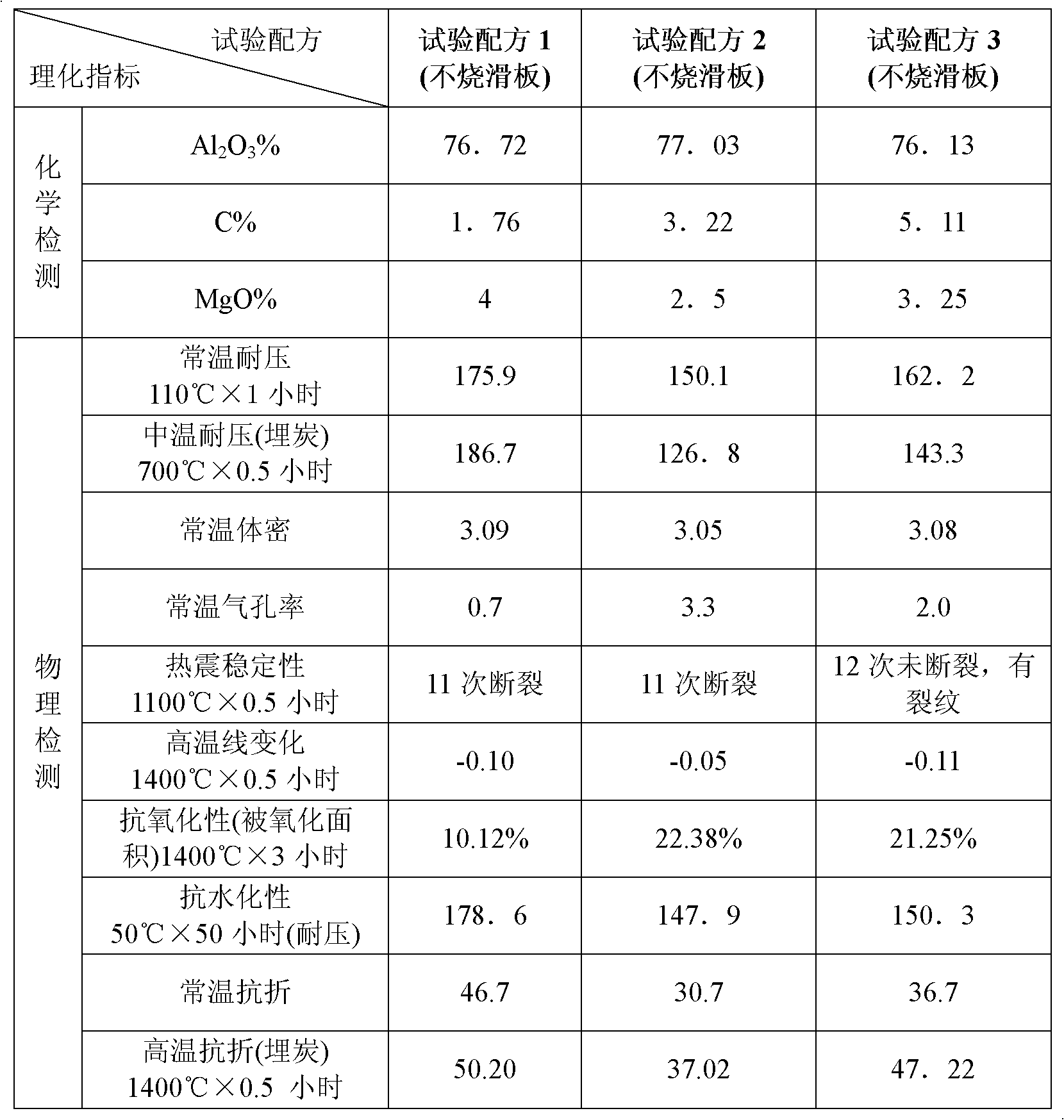

Metal ceramic combination sintering free low carbon sliding plate brick and preparation method thereof

The invention discloses a metal ceramic combination sintering free low carbon sliding plate brick and a preparation method thereof. The sliding plate brick comprises the following components according to weight percentage: 50%-60% of sintered plate shape alundum, 10%-25% of electric melting akerite, 5%-15% of electric melting mullite, 1%-3% of soot carbon, 3%-8% of Alpha- aluminum oxide micropowder, 5%-10% of silicon carbide, 2%-5% of metallic silicon powder,1%-5% of metallic aluminium powder, 0.5%-1% of boron carbide, 1%-3% of aluminum-silicon alloy powder, and 0.5%-2% of metallic aluminium fiber. In the invention, the product has low carbon, high thermal state strength, thermal shock resistance and good oxidation resistance, hole reaming is uniform, galling is less and the crack is verysmall; the process of the invention is characterized in that drying is carried out at a low temperature, the production cycle is shortened from 30 days originally to 7 days, the natural gas consumption is reduced to 2.5% of original technology, and the sintering free low carbon sliding plate brick is indeed belongs to the environmental protective and energy-saving and environmental material resistance product.

Owner:无锡市南方耐材有限公司

Oxide-dispersion-strengthening ferrite/martensitic steel and preparing method

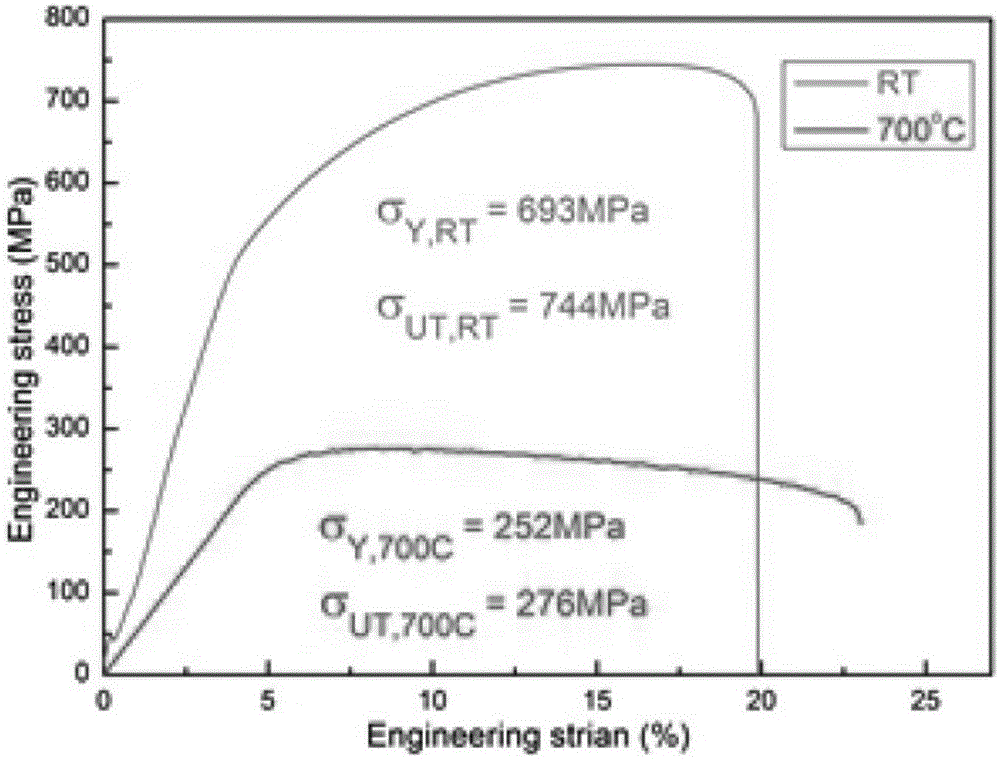

The invention relates to oxide-dispersion-strengthening ferrite / martensitic steel with the excellent high-temperature strength and the good oxidation resistance and a preparing method of the oxide-dispersion-strengthening ferrite / martensitic steel. The oxide-dispersion-strengthening ferrite / martensitic steel comprises 8% to 10% of Cr, 0.5% to 2% of W, 1.5% to 5.5% of Al, 0.1% to 0.4% of V, 0.1% to 0.5% of Mn, 0% to 1.0% of Zr, 0% to 1.0% of Hf and 0.25% to 0.5% of Y2O3. The content of C and the content of N are controlled to be lower than 0.1%, and at least one kind of the Hf and the Zr is contained; the oxygen content of atomized powder is controlled to be lower than 0.05 wt.%, the atomized powder with the particle size ranging from 50 meshes to 200 meshes is selected to be mechanically alloyed with Al powder, Zr powder, Hf powder and Y2O3 powder, and the size of obtained powder ranges from 90 micrometers to 200 micrometers; silicate glass is used for wrapping, compressing and molding, the pressure is started to be boosted to 120 MPa to 180 MPa at the temperature of 850 DEG C, a two-stage sintering manner in which the temperature ranging from 850 DEG C to 950 DEG C is kept for 1 hour and the temperature ranging from 1050 DEG C to 1150 DEG C is kept for 1 hour is adopted, the tensile strength of the finally-obtained ferrite / martensitic steel at the temperature of 700 DEG C ranges from 250 MPa to 320 MPa, and the ductility of the finally-obtained ferrite / martensitic steel at the temperature of 700 DEG C ranges from 18% to 32%; and the oxidation performance of the dispersion-strengthening steel is also greatly improved on the premise that the high-temperature strength and the high-temperature plasticity are guaranteed, and after 100-h oxidation is carried out at the temperature of 850 DEG C, the oxidation weight increase only ranges from 0.0327 mg / cm<3> to 0.098 mg / cm<3>.

Owner:UNIV OF SCI & TECH BEIJING

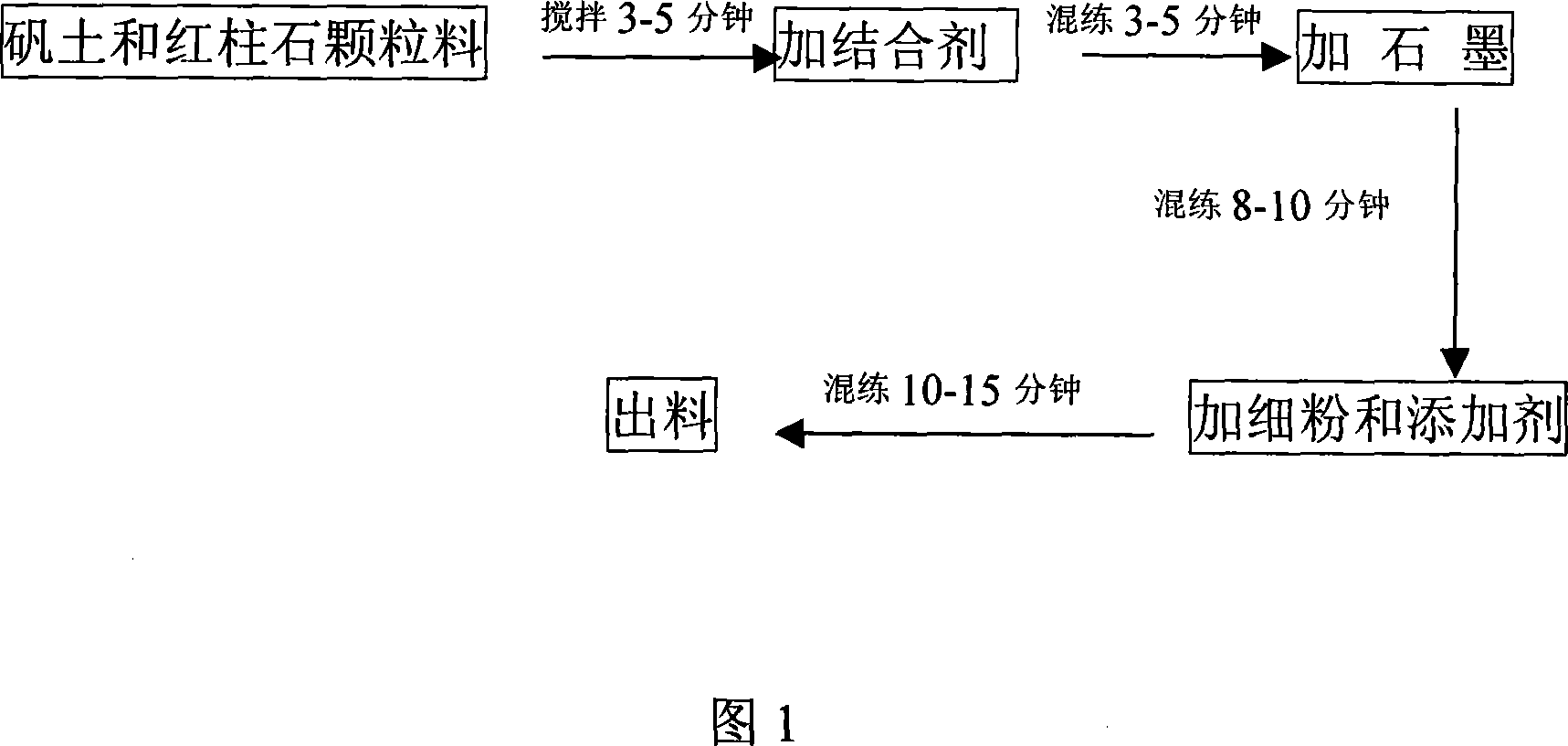

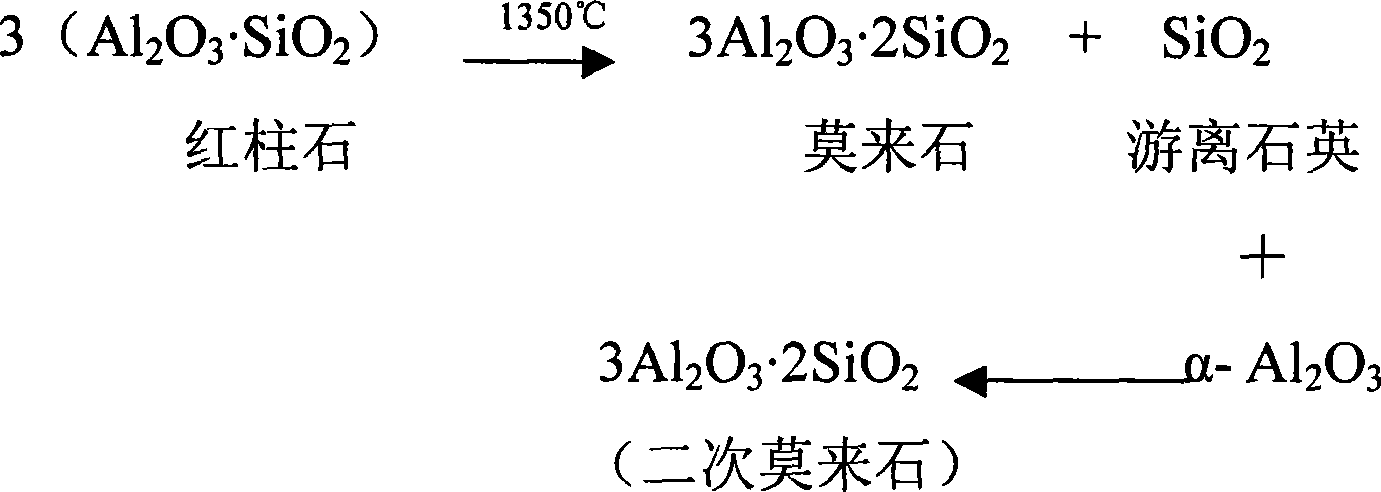

Alumina base andalusite-SiC-C brick, manufacturing method and its application

InactiveCN101045636AImprove medium and high temperature physical propertiesImprove antioxidant capacityAl powderBrick

An alumine-based andalusite-SiC-C brick used for the 300-ton molten iron ladle with long service life features that two kinds of andalusite are used to take part in mullite reaction to form the mullite network frame, and Al powder and Si powder are used for improving its antioxidizing performance and medium-and high-temp physical properties. Its preparing process includes pugging, shaping, baking, etc.

Owner:上海柯瑞冶金炉料有限公司

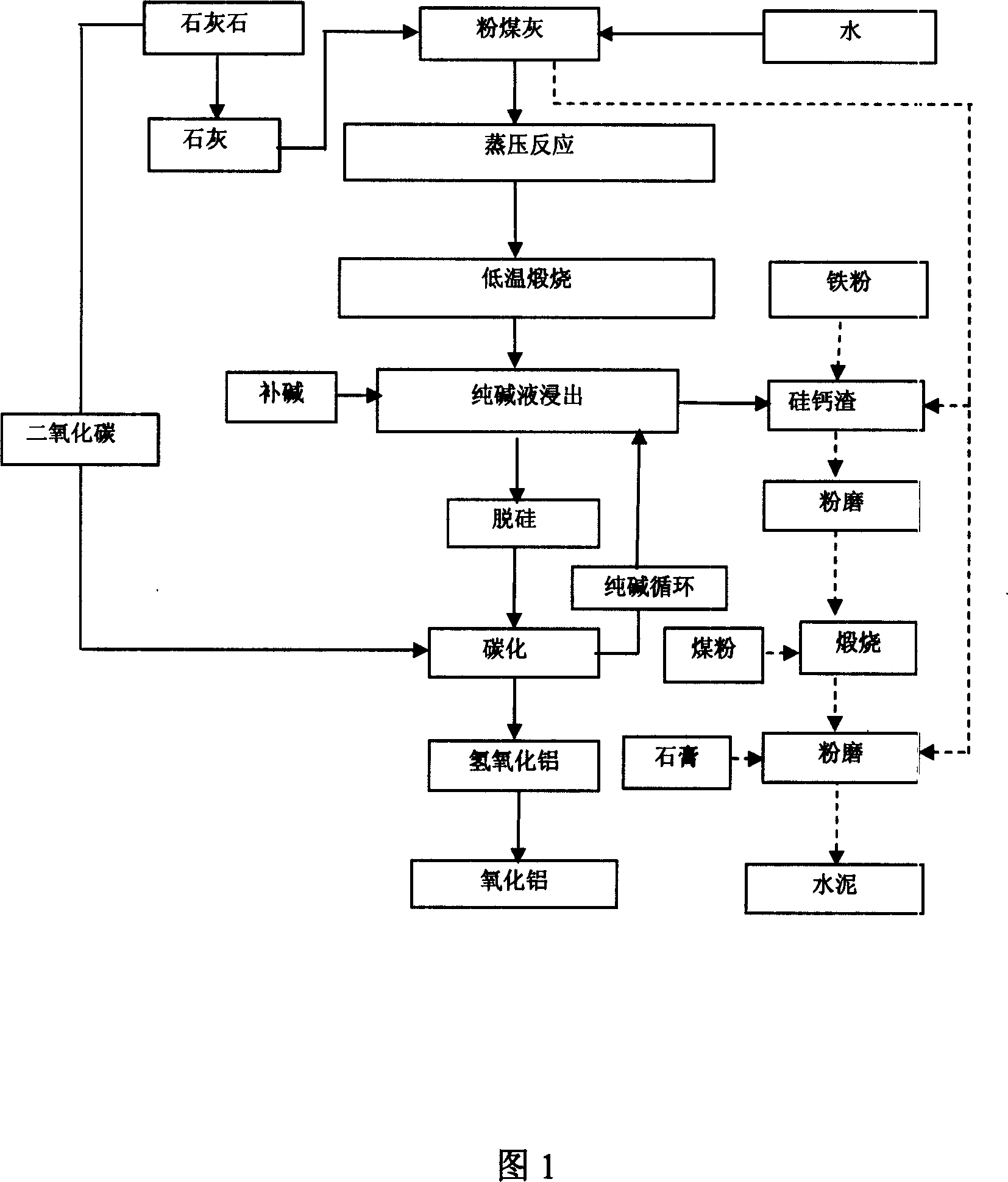

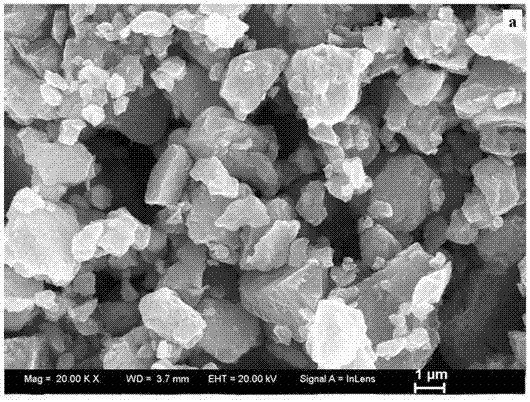

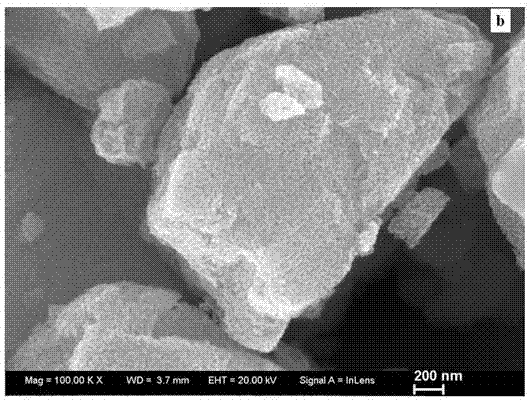

Method for extracting alumin from aluminous fly-ash and method for producing cement from fag end

InactiveCN101028936AReduce manufacturing costAluminium oxide/hydroxide preparationCement productionAl powderSteam pressure

A process for extracting aluminum oxide from high-Al powdered coal ash and using the residual dregs to prepare cement includes such steps as mixing with lime and water, steam pressure reaction to generate the resultant containing hydrated calcium silicoaluminate and calcium hydroxide, calcining, extracting in sodium carbonate solution to obtain aluminum oxide, desiliconizing, carbonizing, calcining to obtain high-purity aluminum oxide, and using the SiCa dregs to prepare cement.

Owner:CHANGAN UNIV

Method for preparing nanometer porous copper powder

The invention discloses a method for preparing nanometer porous copper powder. The method comprises the following steps of: weighing pure copper powder and pure aluminum powder in a ratio of Al-Cu alloy ingredients; adding the pure copper powder, pure aluminum powder and grinding balls into a ball-milling tank, adding a grinding aid, and performing mechanical alloying treatment in a ball-milling machine to obtain Al-Cu alloy powder; and performing dealloying on the obtained Al-Cu alloy powder in alkaline solution, and washing a sample until the sample is neutral to obtain the nanometer porouscopper powder. Precursor alloy is prepared by a mechanical alloying method, and a process is simple; precursor alloy powder has small sizes, so the corrosion time is shortened greatly (within 1 hour generally), and the production efficiency is improved greatly; and the hole size of the prepared nanometer porous copper is only between 15 and 80 nanometers and is reduced greatly, the porous copper is the powdery sample, and a specific surface area is improved greatly.

Owner:UNIV OF JINAN

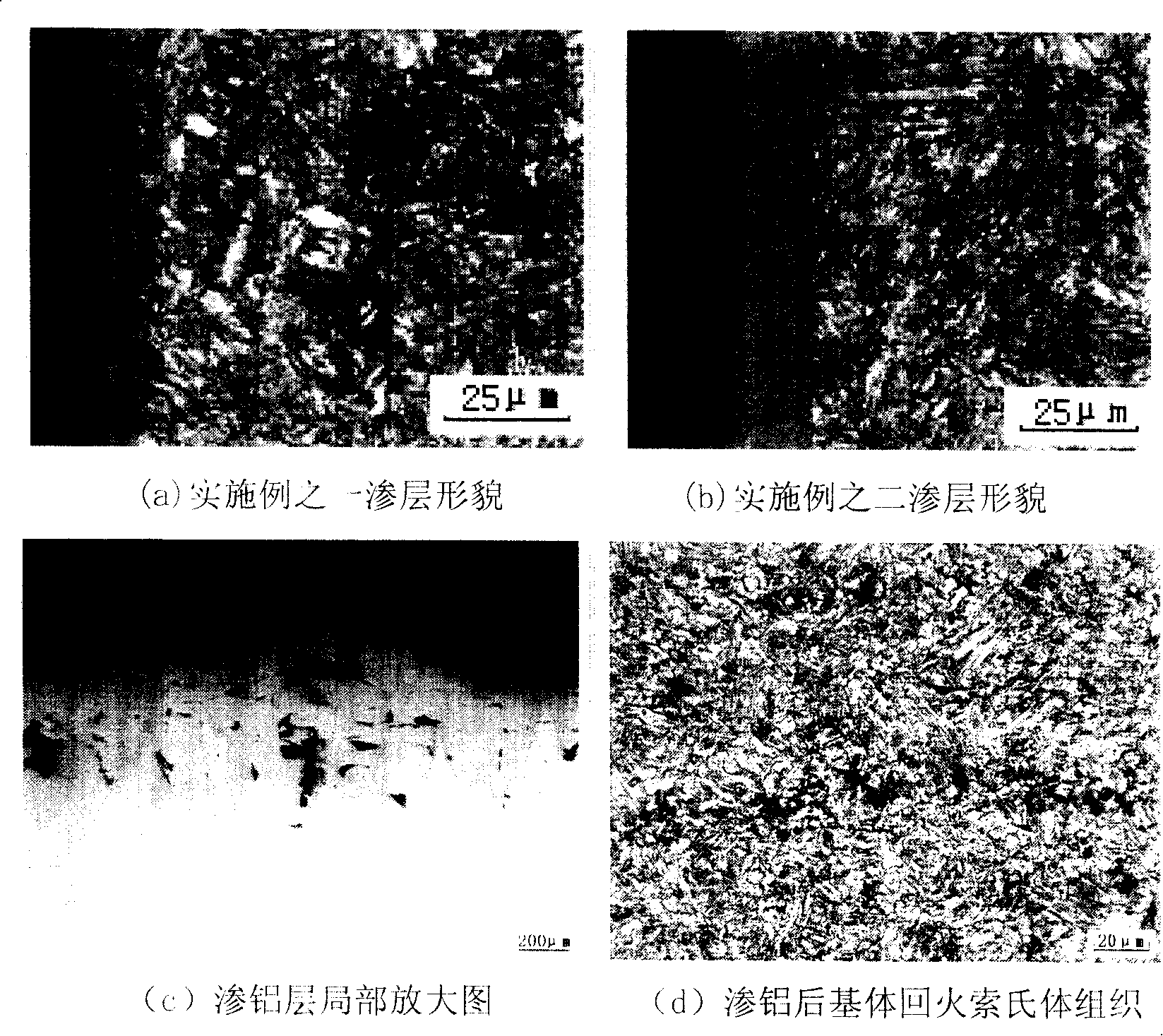

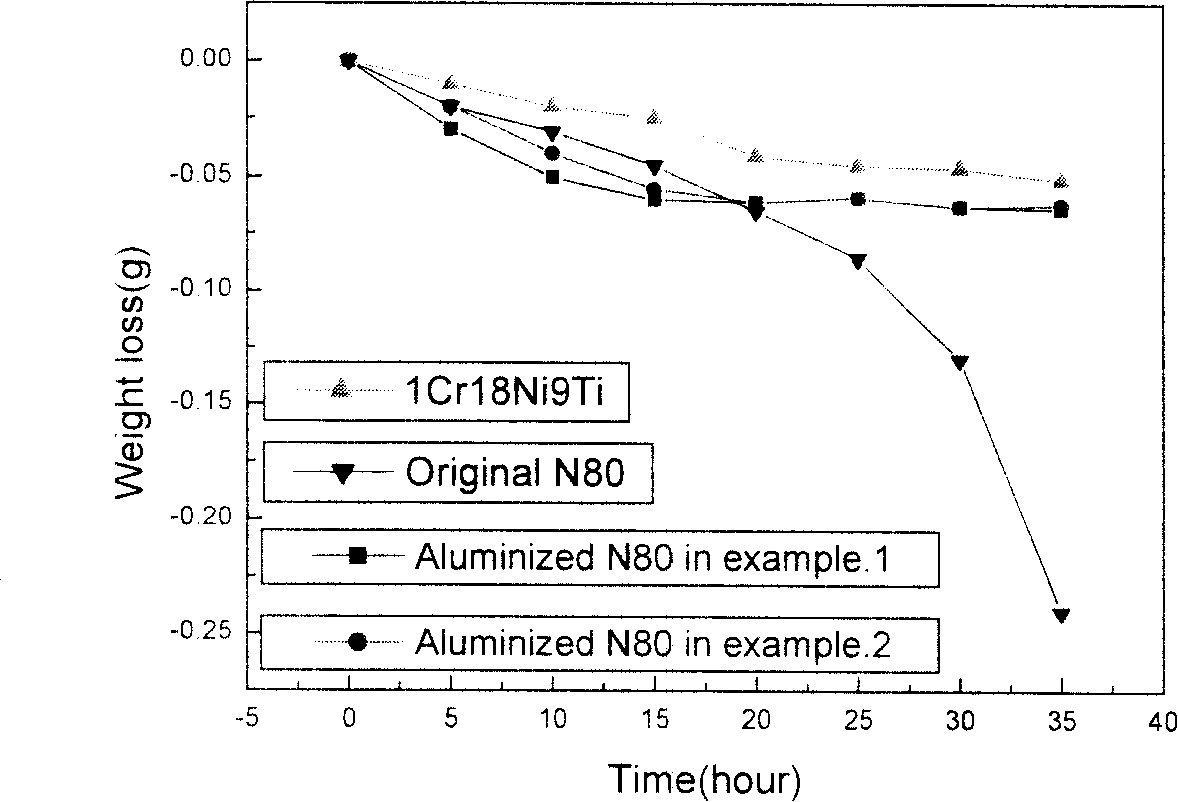

Oil and bushing low-temperature powder embedding aluminizing agent for petroleum

ActiveCN101165204AHigh bonding strengthDiffusion fastSolid state diffusion coatingAl powderSodium fluoride

The low temperature quick aluminizing agent specially for petroleum pipe and casing consists of metal source, activator, catalyst and stuffing. The metal source consists of 150-mesh Al powder in 10-20 wt% of the aluminizing agent, 120-mesh Zn powder in 10-25 wt%, 150-mesh Zn-Fe alloy powder in 10-20 wt% and / or 150-mesh Fe-Al alloy powder in 10-15 wt%. The activator consists of ammonium chloride, aluminum chloride, sodium fluoride and / or potassium bifluoride. The catalyst consists of 100-mesh Mo powder in 0-3 wt% and La and Os 0-3 wt%, with La and Os in the weight ratio of 1 to 1. The stuffing is 100-mesh alumina powder. The aluminizing agent is applied at 380-500 deg.c to obtain aluminized layer.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com