Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

1081 results about "Halohydrocarbon" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Organic compound that contains carbon and hydrogen, with halogen atoms substituting for one or more hydrogens.

Preparation of fluorinated olefins via catalytic dehydrohalogenation of halogenated hydrocarbons

ActiveUS20090043136A1Physical/chemical process catalystsPreparation by hydrogen halide split-offHalohydrocarbonHydrogen atom

A process for making a fluorinated olefin having the step of dehydrochlorinating a hydrochlorofluorocarbon having at least one hydrogen atom and at least one chlorine atom on adjacent carbon atoms, preferably carried out in the presence of a catalyst selected from the group consisting of (i) one or more metal halides, (ii) one or more halogenated metal oxides, (iii) one or more zero-valent metals / metal alloys, (iv) a combination of two or more of the foregoing.

Owner:HONEYWELL INT INC

Florination catalyst, its manufacturing method and use

ActiveCN1651137AInhibitionReduce the temperaturePreparation by halogen replacementMetal/metal-oxides/metal-hydroxide catalystsHydrogen fluorideAl powder

Owner:XIAN MODERN CHEM RES INST

Methods for forming amorphous ultra-high molecular weight polyalphaolefin drag reducing agents

InactiveUS6015779AReduce frictional energy lossHigh molecular weightOther chemical processesLiquid organic insulatorsHalohydrocarbonAlpha-olefin

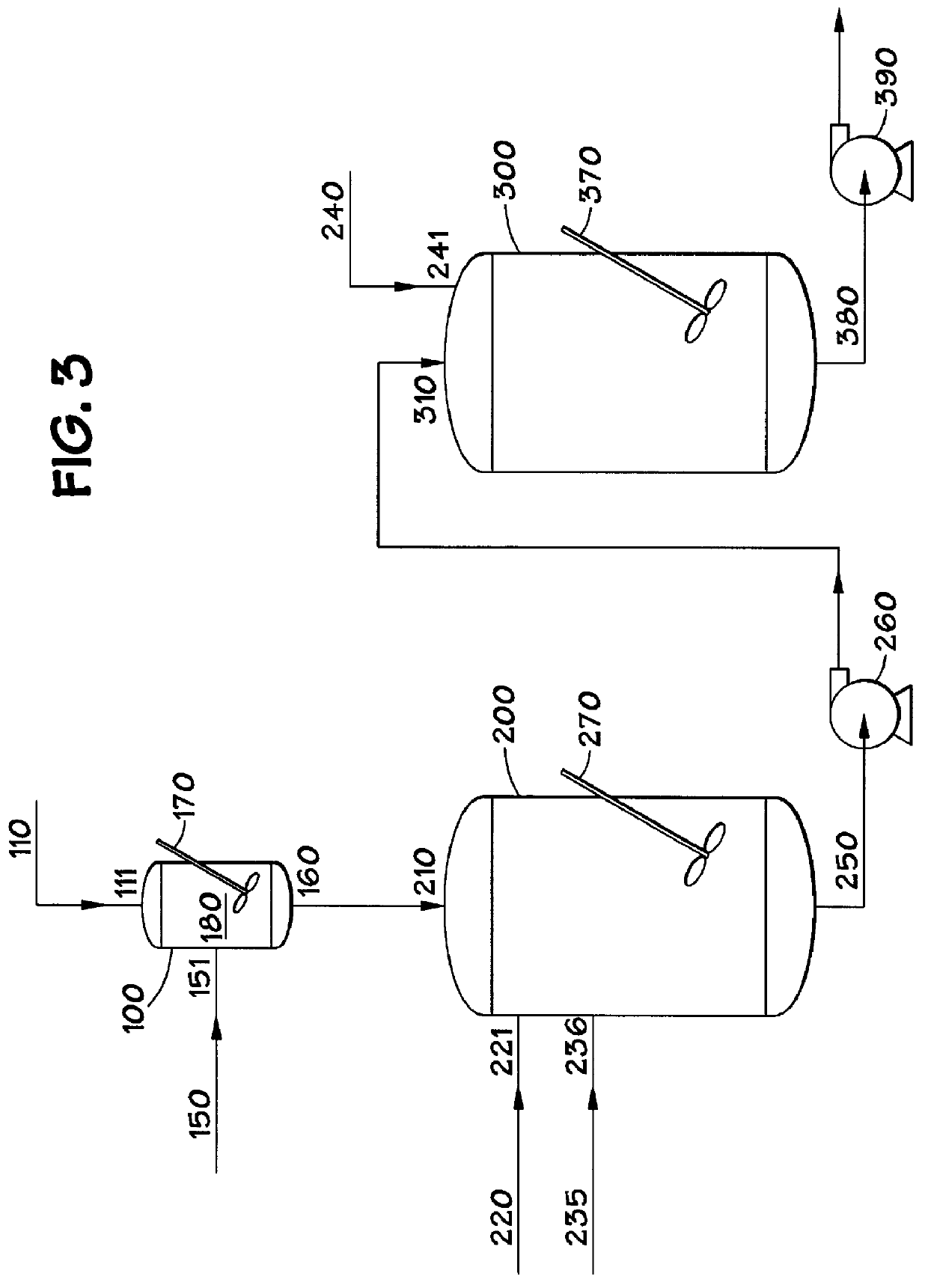

A composition including polyalphaolefins that function as drag reducing agents and a process for the preparation of polyalphaolefins that function as drag reducing agents are disclosed. The process includes contacting alpha olefin monomers with a catalyst system, which includes a catalyst and an activator (co-catalyst) in a reactant mixture. The catalyst is a transition metal catalyst, preferably titanium trichloride, and the co-catalyst may include an alkylaluminoxane, alone or in combination, with a dialkylaluminum halide or a halohydrocarbon. The polymerization of the alpha olefin monomers produces a non-crystalline, ultra-high molecular weight polyalphaolefin having an inherent viscosity of at least 10 dL / g. The addition of the alkylaluminoxane during the polymerization process provides for a non-crystalline, ultra-high molecular weight polyalphaolefin and a more uniform molecular weight distribution of the resulting polyalphaolefin, thereby creating a drag reducing agent superior to known drag reducing agents. A process for forming a drag reducing agent comprising a non-crystalline, ultra-high molecular weight polyalphaolefin having an inherent viscosity of about at least 10 dL / g and a process for reducing drag in a conduit are also disclosed.

Owner:MPOWER SPECIALTY CHEM

Mediated electrochemical oxidation of halogenated hydrocarbon waste materials

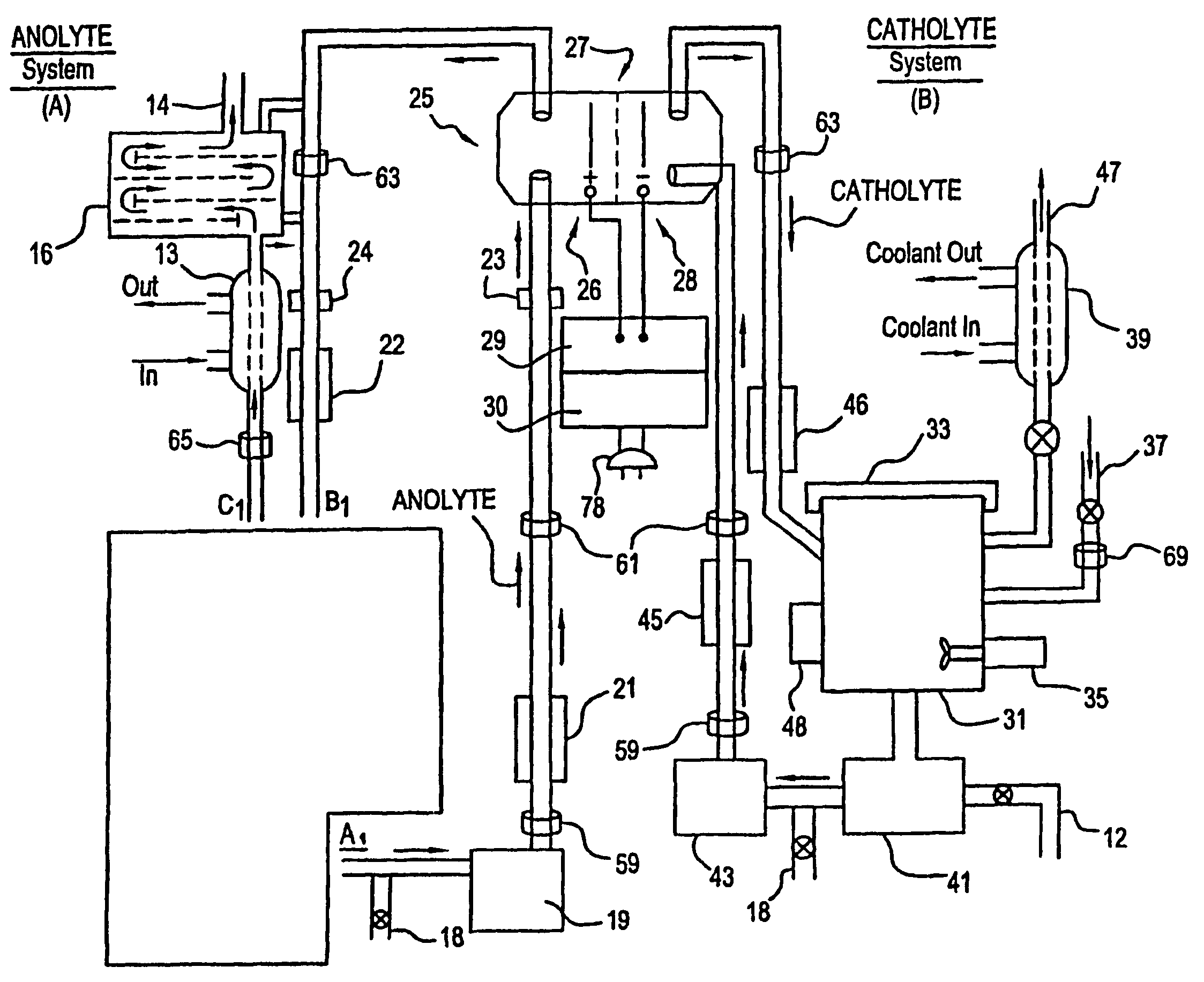

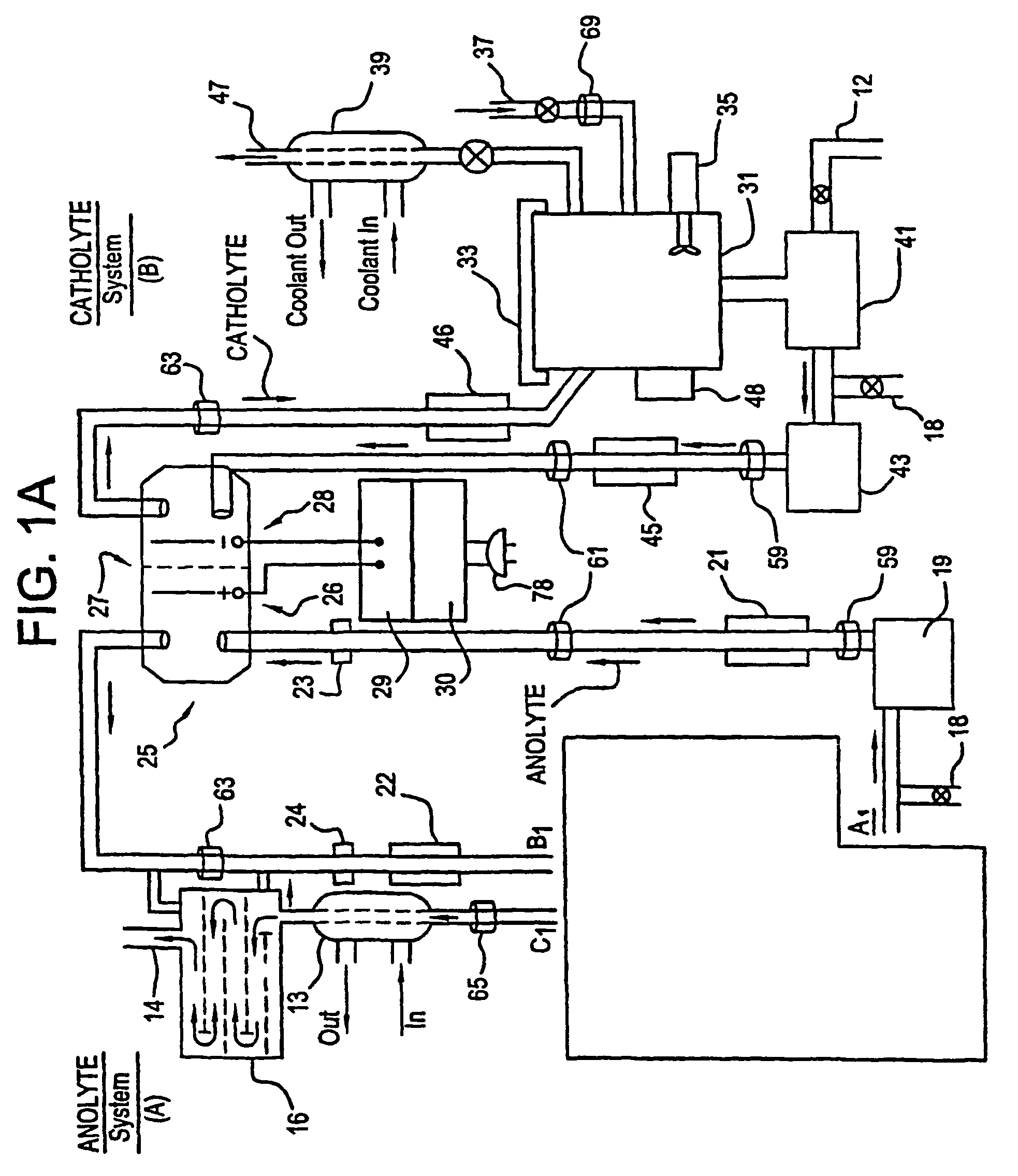

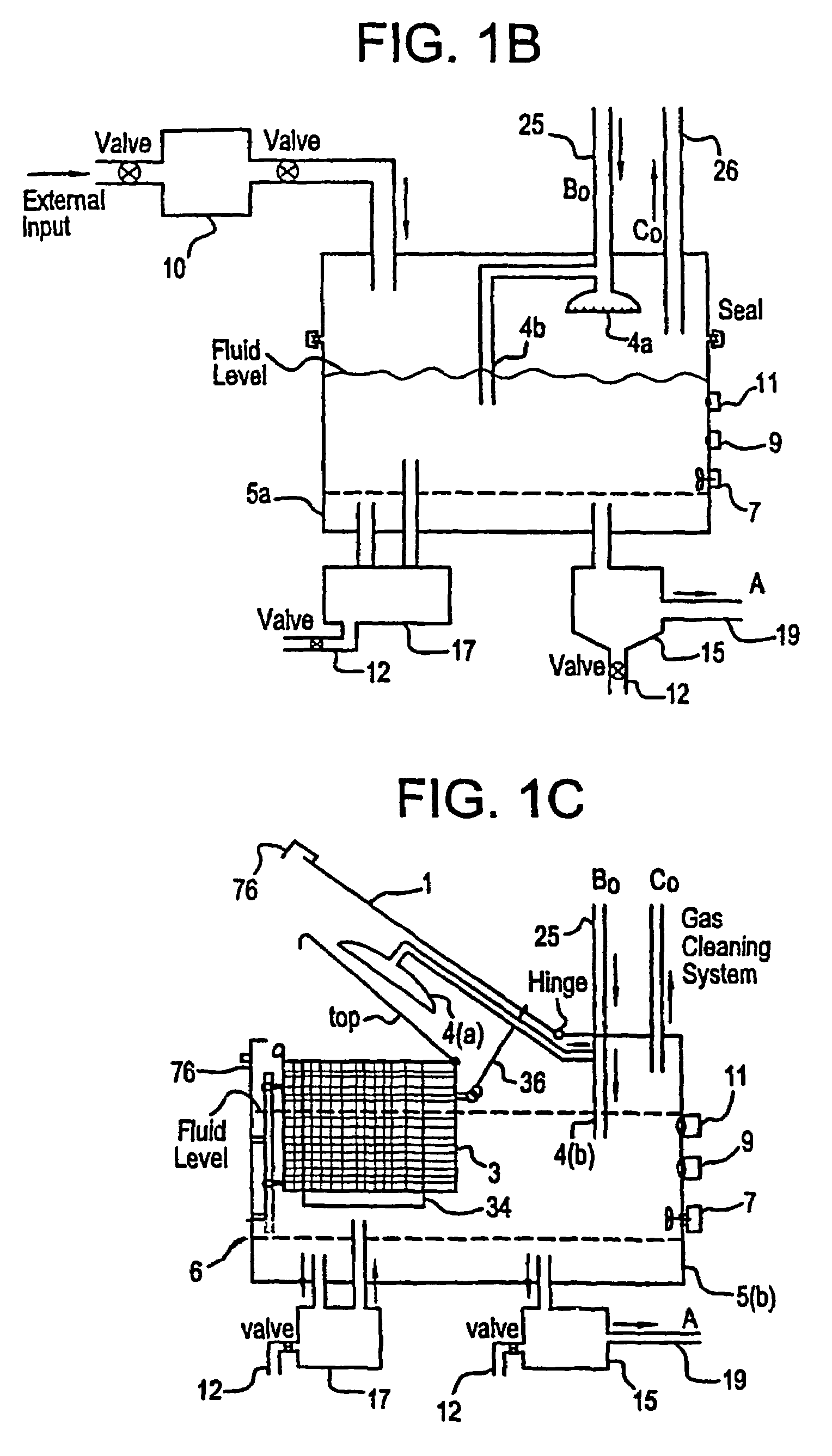

InactiveUS7479215B2Improve efficiencyLiquid separation by electricityTreatment involving filtrationHalohydrocarbonPhysical chemistry

Owner:SCIMIST LNC

Carbon deposit scavenging agent for combustion chamber and spark plug, and preparation method of the same

InactiveCN102363739AInorganic/elemental detergent compounding agentsNon-ionic surface-active compoundsIonKetone

The invention discloses a carbon deposit scavenging agent for a combustion chamber and a spark plug, and a preparation method of the same. Water is taken as a medium for the scavenging agent, so that the scavenging agent is safe and environmentally friendly, and produces no secondary pollution. The scavenging agent comprises the following components: 2-10 wt% of non-ionic polyethenoxy ether surfactant; 2-8 wt% of anionic fatty acid salt surfactant; 5-20 wt% of alcohol, alcohol ether and ketone organic solvent; 0.5-5 wt% of inorganic base; 0-2 wt% of buffer; 0-3 wt% of metal corrosion inhibitor; and 50-91.5 wt% of deionized water. The composite surfactant used in the scavenging agent can emulsify the carbon deposit effectively so as to soften, loosen and deform the inflexible carbon deposit, and simultaneously can improve the seepage force of the scavenging agent; the alcohol organic solvent further dissolves the carbon deposit; the inorganic base decomposes oil and fat compounds; the buffer maintains certain basicity; and the corrosion inhibitor reduces corrosion on metallic elements in a cleaning process. The carbon deposit scavenging agent provided by the invention can eliminate the carbon deposit adhered to the top of a combustion chamber piston, an intake valve, a vent valve, the spark plug and the inner wall of a spark plug hole, quickly and efficiently. The scavenging agent provided by the invention is completely prepared by environmental materials, and is free of the components, such as aromatic hydrocarbon, halogenated hydrocarbon and the like, which are harmful to human body, so that the scavenging agent is safe for human body and has no pollution to the environment and the atmosphere.

Owner:SHENZHEN CHIEF CAR CARE PRODS DEV

Antifoam formulations

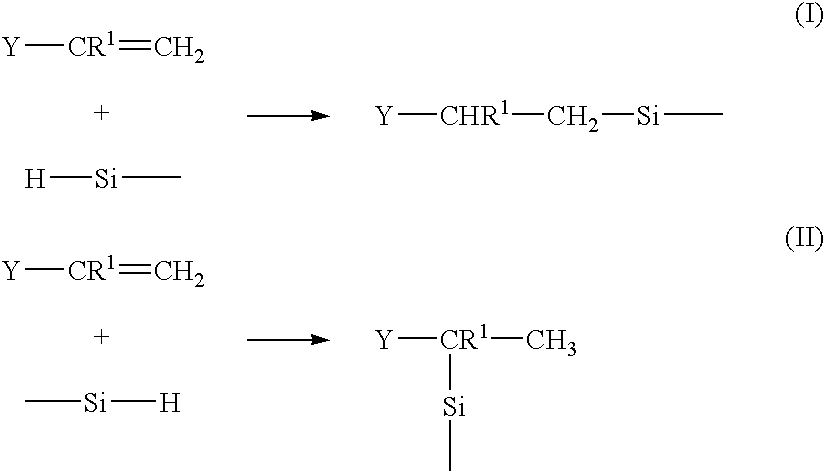

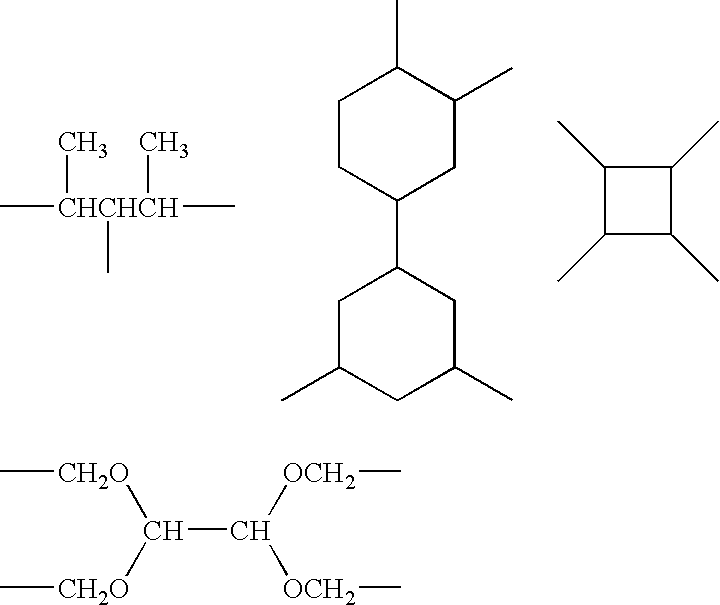

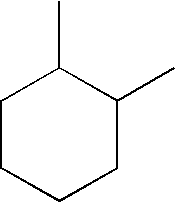

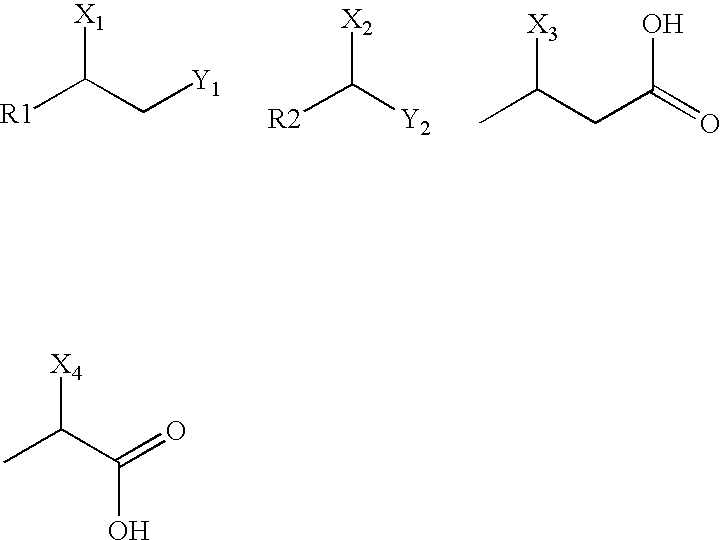

ActiveUS7105581B2Improve efficiencyGroup 4/14 element organic compoundsDefoamers additionAntifoam agentSiloxane

An antifoam formulations comprise(A) antifoam agent based on siloxanes and(B) branched polyether / polysiloxane copolymers comprising structural units of the formulaY[—CnH2n—(R2SiO)m—Ap—R2Si—G]x (I)in which Y is a multivalent, optionally heteroatom-containing hydrocarbon radical, R are monovalent optionally halogenated hydrocarbon radicals, A is a radical —R2Si—R2—(R2SiO)m—, G is a monovalent radical —CfH2f-2k—Z or a divalent radical —CnH2n— bonded to a radical Y, Z—(R6)v—(OCH2CH2)a[OCH2CH(CH3)]b[OCH2CH(CH2CH3)]c—OR3,in which R3 is hydrogen, a hydrocarbon radical, or a radical R—C(O)—, R6 is a divalent hydrocarbon radical, v is 0 or 1, a, b and c are 0 or an integer between 1 and 1000, the sum (a+b+c) being from 2 to 2000, x is 3 to 10, f is 2 to 12, k is 0 or 1, n is 2 to 12, m is at least 1, and p is 0 or a positive integer, the branched polyether / polysiloxane copolymers (B) containing on average at least one group Z.

Owner:WACKER CHEM GMBH

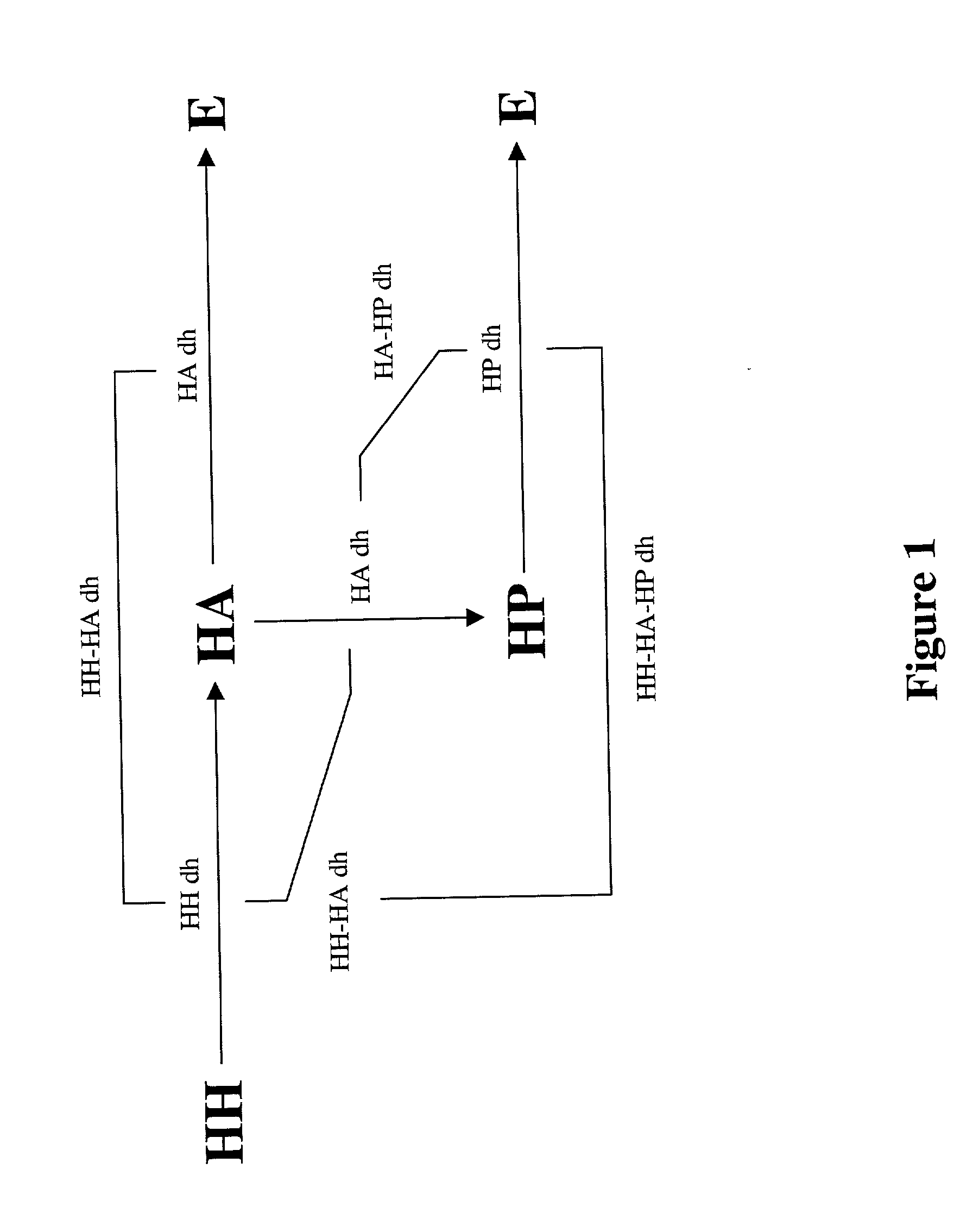

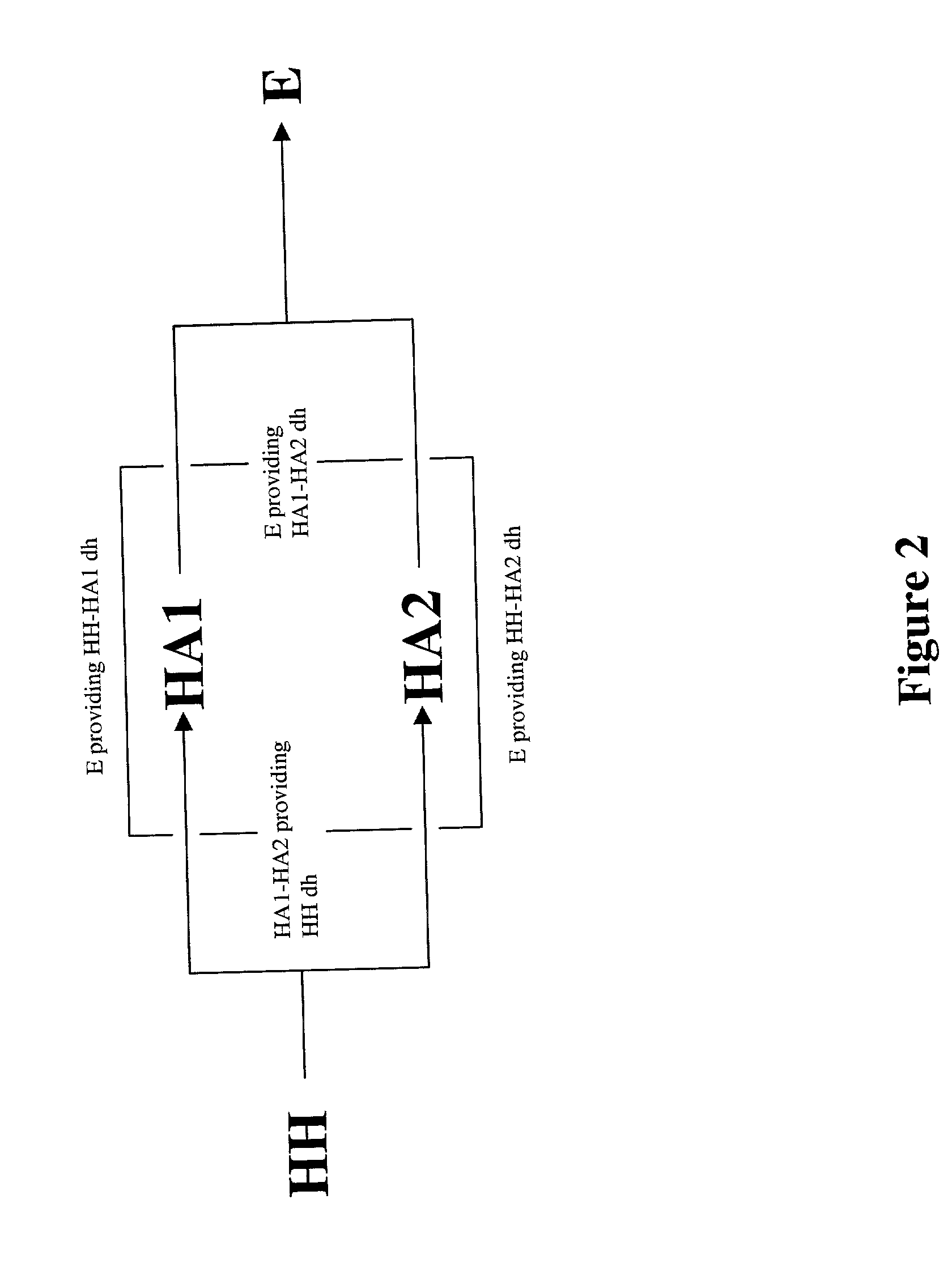

Alteration of hydrolase genes and screening of the resulting libraries for the ability to catalyze specific reactions

The present invention relates to halocarbon and halohydrocarbon chemistry, including methods of dehalogenating halocarbons and halohydrocarbons to provide, inter alia, alcohols, polyols, and epoxides. In general, the methods involve reaction pathways catalyzed by altered hydrolase enzymes that can provide stereoselective or stereospecific reaction products. The invention also includes methods of providing altered nucleic acids that encode altered dehalogenase or other hydrolase enzymes. Additionally, the invention includes various reaction formats and kits.

Owner:MAXYGEN

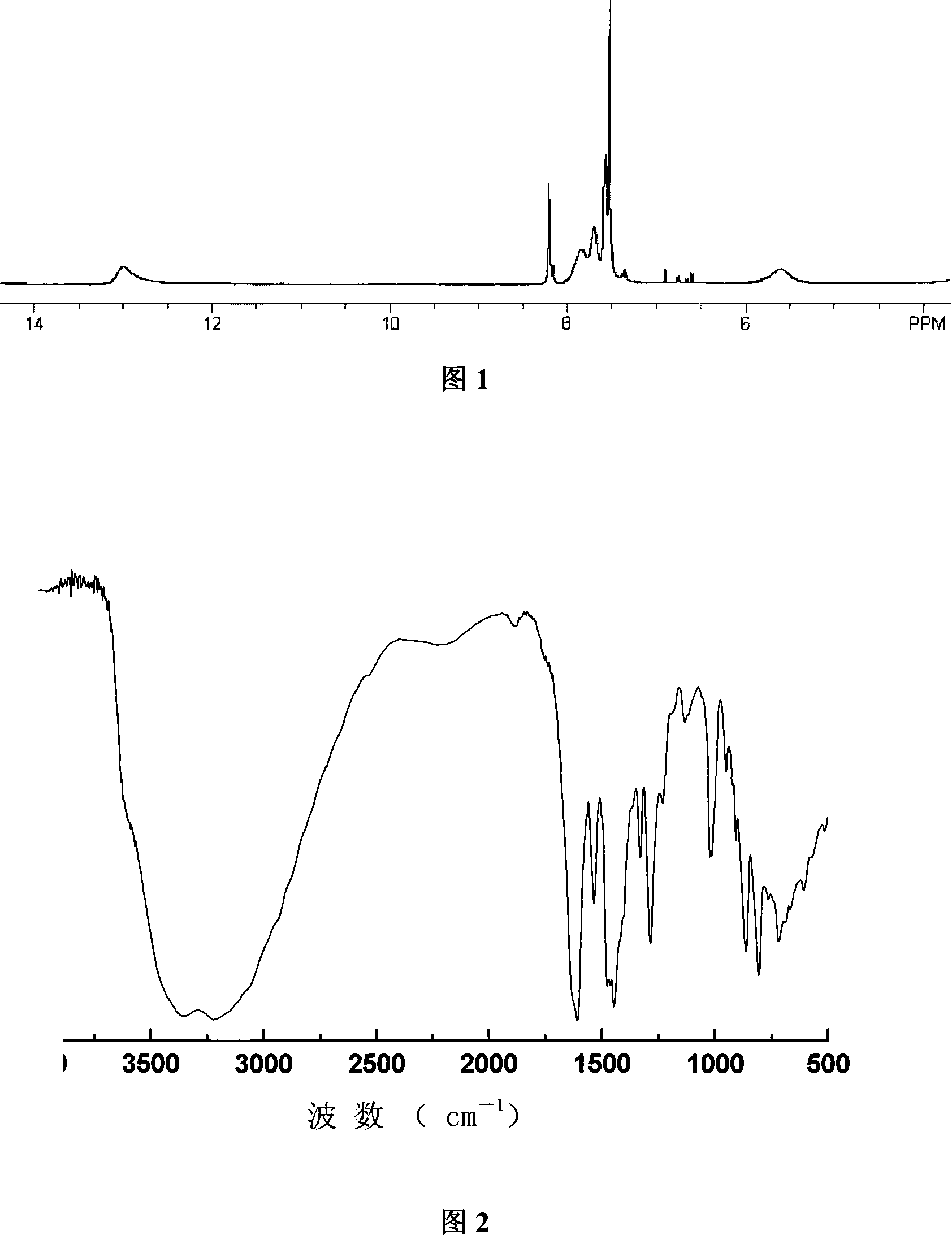

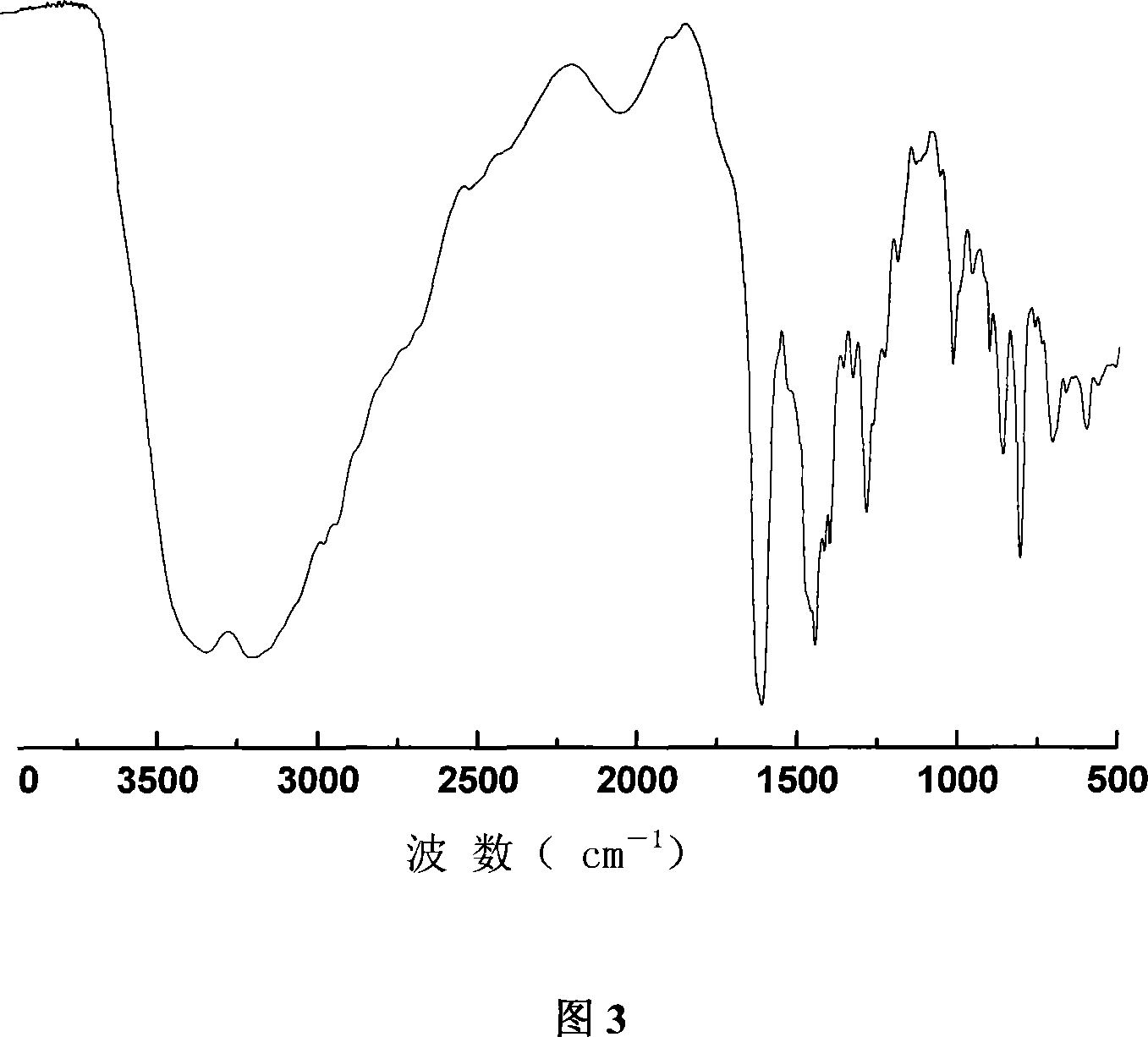

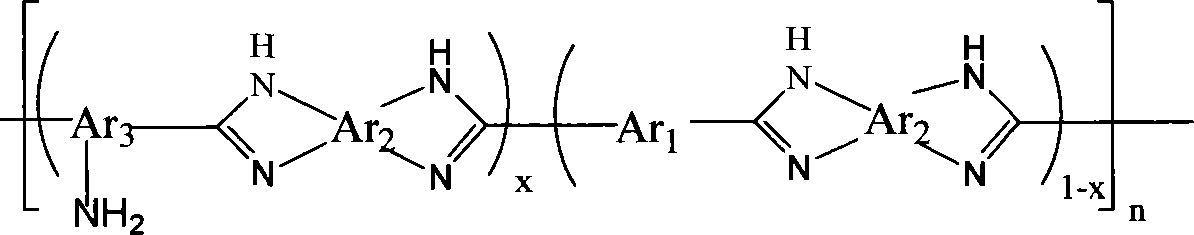

Production method for 2 or multi-halohydrocarbon crosslinked polybenzimidazole crosslinked membrane

The invention relates to a preparation method of a polybenzimidazole crosslinking membrane that is crosslinked with bihalohydrocarbon or polyhalohydrocarbon, which takes amino dibasic acid and aromatic tetraamine as monomer raw material and polyphosphoric acid as reaction medium and reaction is carried out for 5-30 hours at 150-220 DEG C under the nitrogen protection condition so as to obtain homopolymer containing amino polybenzimidazole, and takes the amino dibasic acid, nonaminonic dibasic acid and the aromatic tetraamine as the monomer raw materials to prepare copolymer containing amino polyphosphoric under the same conditions. The prepared homopolymer and the copolymer of the polybenzimidazole have good dissolvability in solvents of dimethyl sulphoxide, N, N-dimethylacetamide, phosphate, vitriol and methane-sulforic acid, etc. Both the structures of the homopolymer and the copolymer of the polybenzimidazole contain amino that can be used for crosslinking. The bihalohydrocarbon or the polyhalohydrocarbon is used as cross linking agent. The polybenzimidazole crosslinking membrane with good property can be prepared through crosslinking reaction of the amino contained in the polybenzimidazole and the bihalohydrocarbon or the polyhalohydrocarbon.

Owner:SHANGHAI JIAO TONG UNIV

Compositions for removing hydrocarbons and halogenated hydrocarbons from contaminated environments

InactiveCN1668535AReduce concentrationLow costOther chemical processesWater treatment compoundsSorbentSulfate

The invention provides a bioremediation composition for in situ bioremediation of soil and / or groundwater contaminated with hydrocarbons, comprising an adsorbent capable of adsorbing said hydrocarbons, a mixture of facultative anaerobes capable of metabolizing said hydrocarbon under sulfate-reduction conditions, a sulfate-containing compound that releases sulfate over a period of time, and a nutrient system for promoting growth of said anaerobes, wherein said nutrient system includes a sulfide scavenging agent.

Owner:REMEDIATION PROD INC

Catalyst for olefin polymerization reaction and preparation method and applications thereof

The invention provides a catalyst component for olefin polymerization or copolymerization and a preparation method thereof. The preparation method comprises the following steps of: dissolving magnesiumhalide in a system containing an organic epoxy compound, an organic phosphorus compound and halohydrocarbon to form a solution; and in the presence of an auxiliary precipitation agent, reacting a titanium compound with the obtained solution, and precipitating the catalyst with magnesium and titanium for sediment. The preparation method of the catalyst active component has the advantages of easy obtaining of raw materials, lower production cost and high catalytic activity during using for propene polymerization or copolymerization, and is suitable for a variety of polymerization processes, such as a serous fluid method, a bulk method, a gas phase method and the like.

Owner:CHINA PETROLEUM & CHEM CORP +1

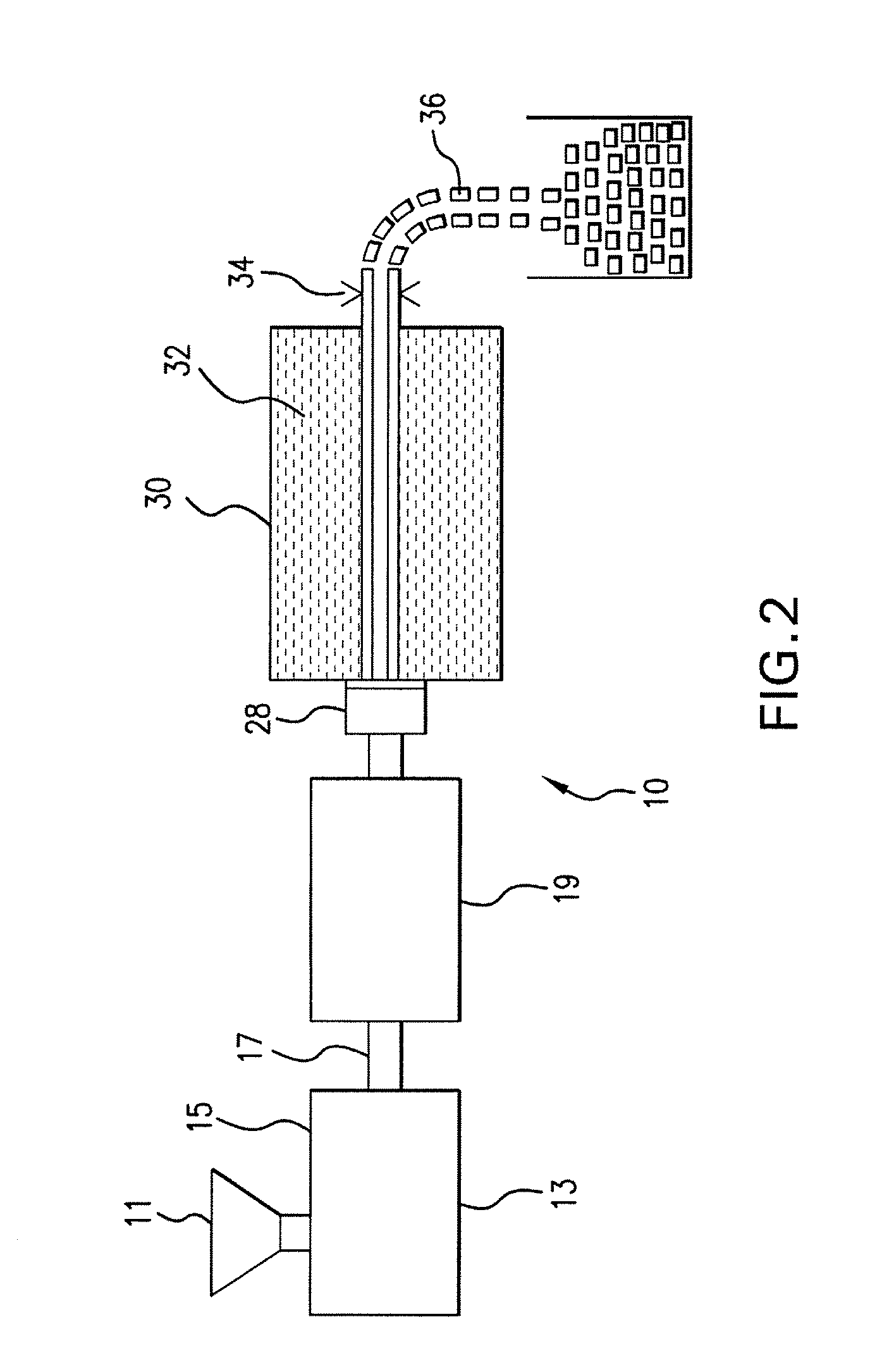

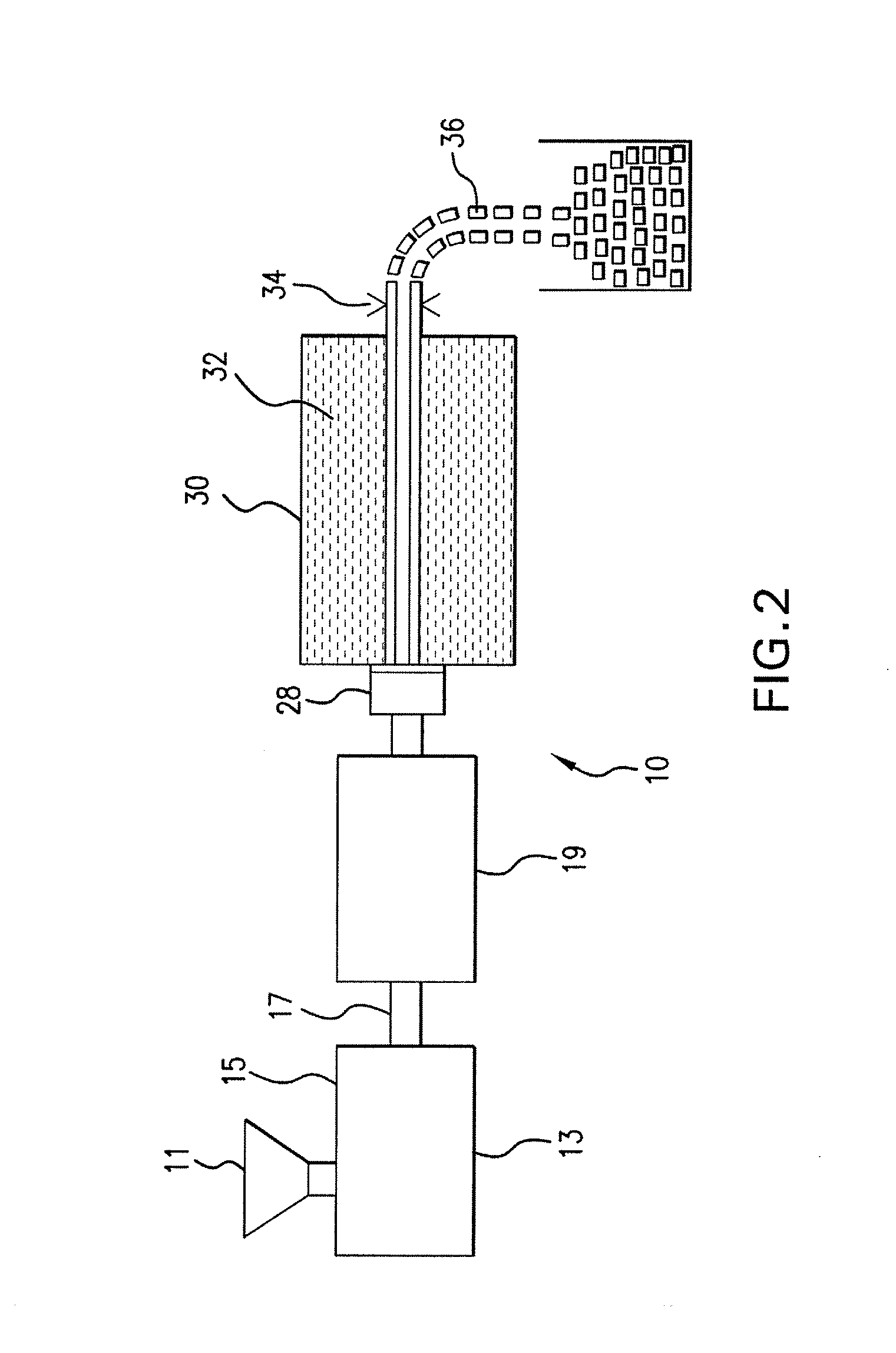

Functionalized Copolymers of Terminally Functionalized Perfluoro (Alkyl Vinyl Ether) Reactor Wall for Photochemical Reactions, Process for Increasing Fluorine Content in Hydrocaebons and Halohydrocarbons and Olefin Production

InactiveUS20070265368A1Preparation by hydrogen halide split-offCatalyst activation/preparationVinyl etherHalohydrocarbon

A photochemical reaction apparatus including a reactor and a light source situated so that light from the light source is directed through a portion of the reactor wall is disclosed. The apparatus is characterized by the portion of the reaction wall comprising a functionalized copolymer of a terminally functionalized perfluoro(alkyl vinyl ether). Also described is a photochemical reaction process using said reactor. The functional group of the copolymer of the apparatus and the process is selected from —SO2F, —SO2CI, —SO3H, —CO2R (where R is H or C1-C3 alkyl), —PO3H2, and salts thereof. A process for increasing the flourine content of at least one compound selected from hydrocarbons and halohydrocarbons, comprising: (a) photochlorinating said at least one compound, and (b) reacting the halogenated hydrocarbon in (a) with HF. A process for producing an olefinic compound, comprising: (a) photochlorinating at least one compound selected from hydrocarbons and halohydrocarbons containing at least two carbon atoms and at least two hydrogen atoms to produce a halogenated hydrocarbon containing a hydrogen substituent and a chlorine substituent on adjacent carbon atoms; and (b) subjecting the halogenated hydrocarbon produced in (a) to dehydrohalogenation.

Owner:EI DU PONT DE NEMOURS & CO

Expanded and extruded polyolefin foams made with methyl formate-based blowing agents

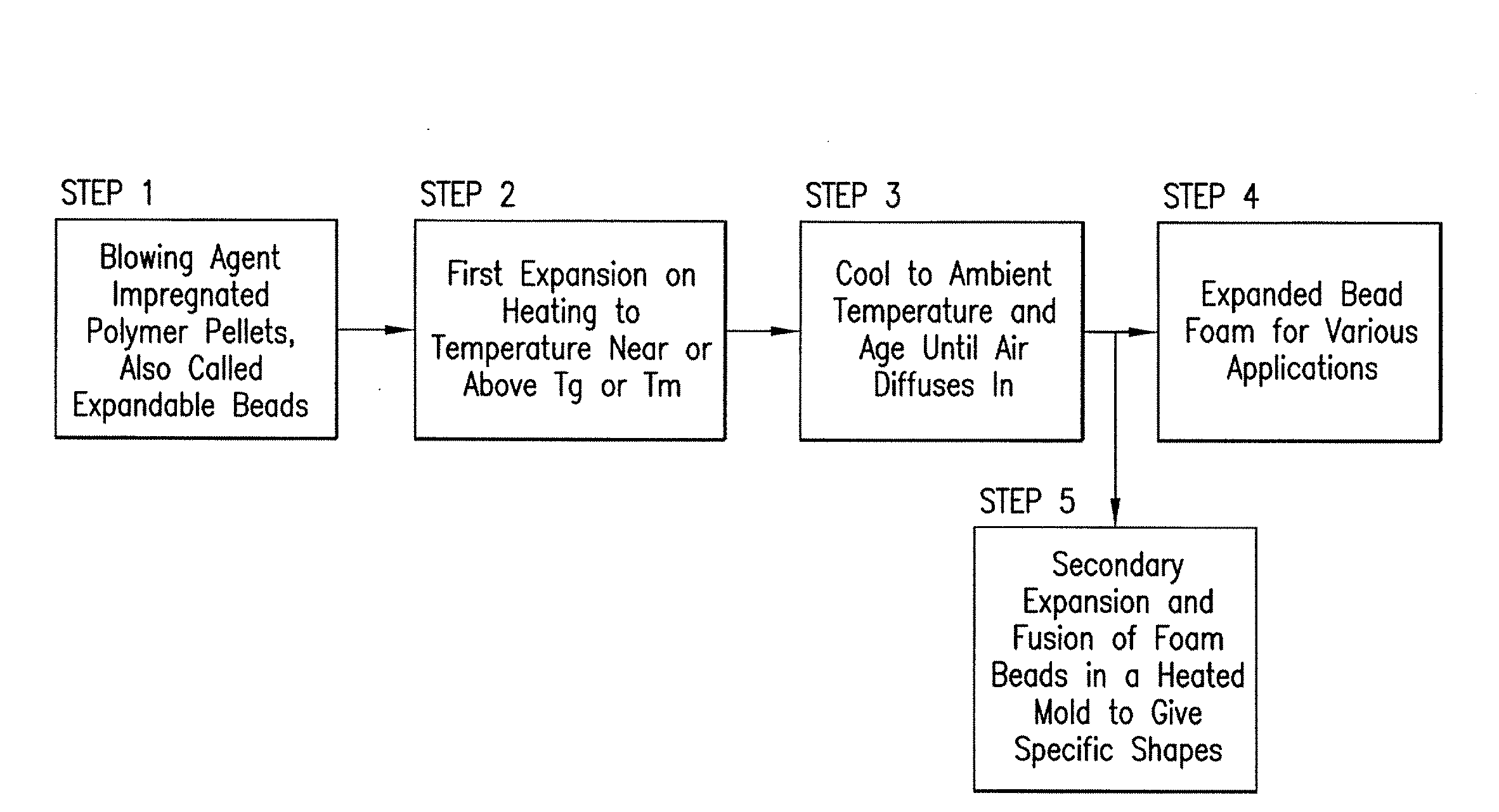

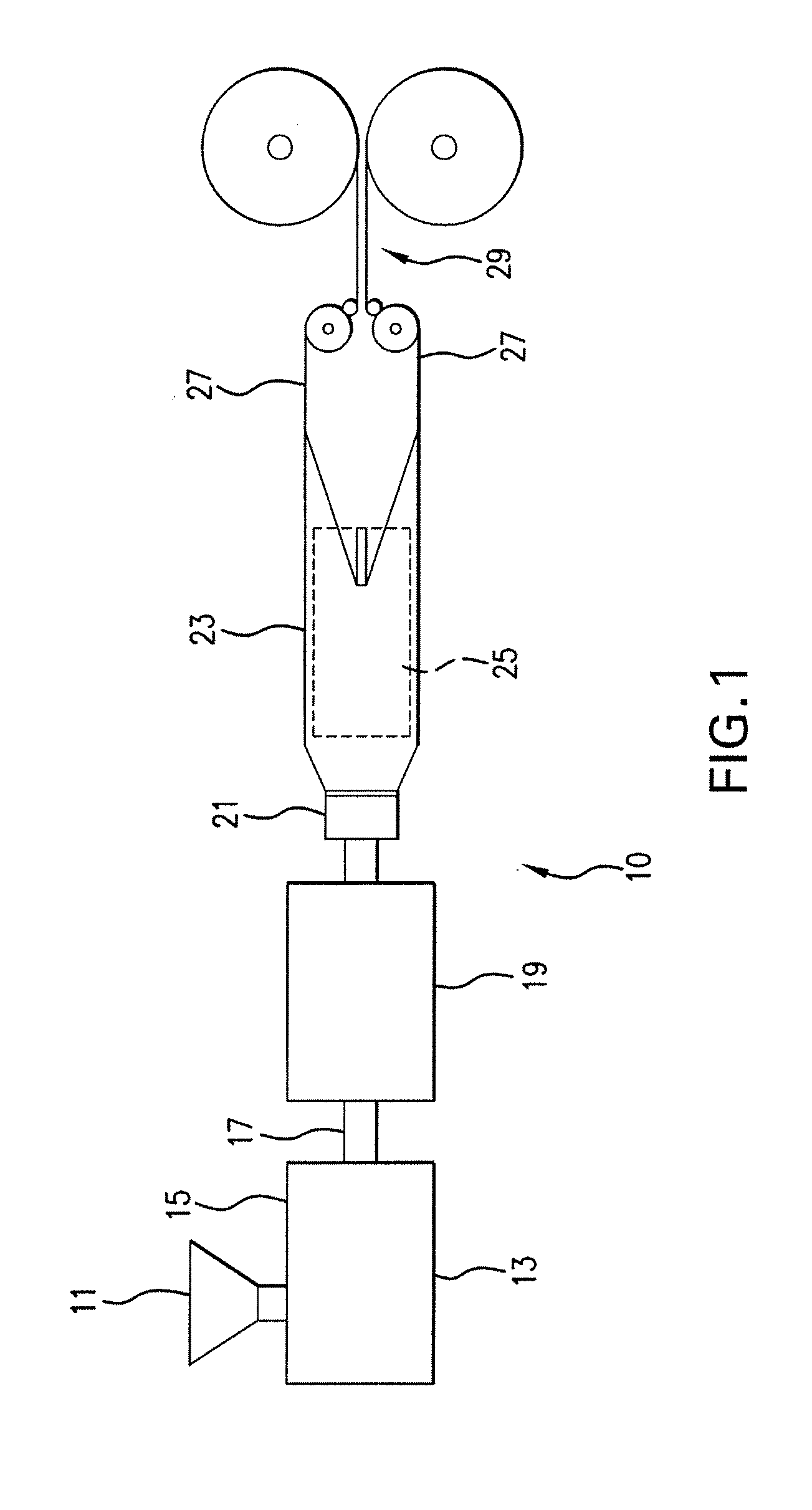

Expanded and extruded polyolefin foams are obtained using environmentally benign non-VOC methyl formate as a blowing agent. The blowing agent can be a blend further including at least one co-blowing agent, preferably an environmentally friendly species (e.g., non-VOC), which is either a physical co-blowing agent (e.g. an inorganic agent, a hydrocarbon, a halogenated hydrocarbon, a hydrocarbon with polar, functional group(s) or any combination thereof), or a chemical co-blowing agent, or combinations thereof. The blowing agent blend can include any combination of methyl formate and one or more co-blowing agents. The polymer foam can include polyethylene, polypropylene or a combination thereof. The methyl formate-based blowing agent blends produce stable foams for various applications, including containers, packaging systems, as well as for insulation and protective cushioning. Processes for the preparation of such foams are also provided.

Owner:PACTIV CORP

Halogenated biaryl heterocyclic compounds and methods of making and using the same

The present invention relates generally to the field of anti-infective, anti-proliferative, anti-inflammatory, and prokinetic agents. More particularly, the invention relates to a family of compounds having at least one halogenated hydrocarbon moiety, a biaryl moiety, and at least one heterocyclic moiety, that are useful as such agents.

Owner:MELINTA SUBSIDIARY CORP

Expanded and extruded biodegradable and reduced emission foams made with methyl formate-based blowing agents

Expanded and extruded biodegradable polymer foams are obtained using biodegradable polymers and environmentally benign non-VOC methyl formate as a blowing agent. The blowing agent can be a blend further including at least one co-blowing agent, preferably an environmentally friendly species (e.g., non-VOC), which is either a physical co-blowing agent (e.g. an inorganic agent, a hydrocarbon, a halogenated hydrocarbon, a hydrocarbon with polar, functional group(s), water or any combination thereof), or a chemical co-blowing agent, or combinations thereof. The blowing agent blend can include any combination of methyl formate and one or more co-blowing agents. The polymer foam can include a biodegradable polymer or its blends with other biodegradable polymers or conventional (non-biodegradable) polymers. The methyl formate-based blowing agent blends produce stable foams for various applications, including containers, packaging systems, as well as for insulation and protective cushioning. Processes for the preparation of such foams are also provided.

Owner:PACTIV CORP

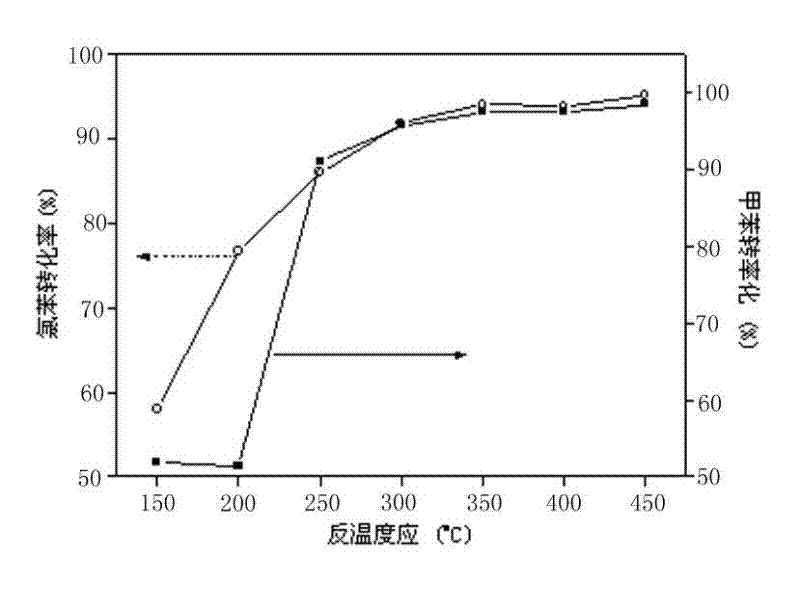

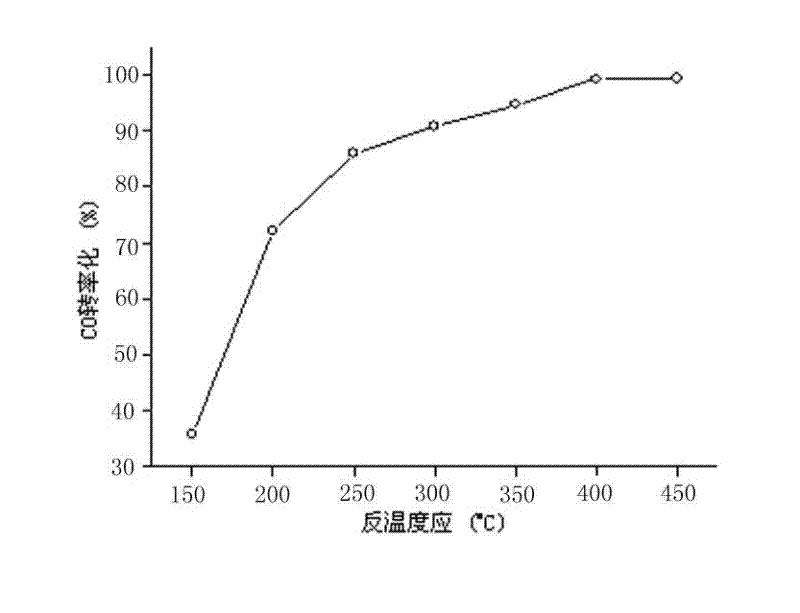

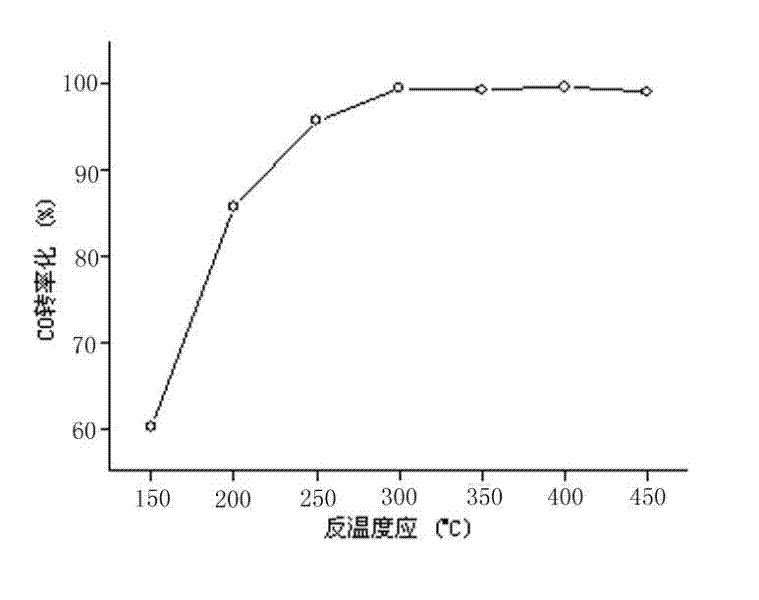

Catalyst containing nickel-iron-manganese compound oxide for processing industrial waste gas and preparation method thereof

InactiveCN102240557AHigh strength combinationSuitable for handlingMolecular sieve catalystsDispersed particle separationAlkaneRare earth

The invention relates to a catalyst containing nickel-iron-manganese compound oxide for processing industrial waste gas and a preparation method thereof and belongs to the fields of atmospheric pollution abatement technique and environment-friendly catalytic material. In the catalyst, the nickel-iron-manganese compound oxide is taken as a first active component; one or two of other transition metal, rare-earth metal or precious metal oxides are taken as a second active component; a self-made carrier or natural inorganic material carrier is taken as the carrier of the catalyst; and the contents (in percentage by weight) of the loads of the first and the second active components are respectively 5-20% and 0-10% on the basis of the weight of the carrier. The catalyst is a polymorphous catalyst, which can be spherical, columnar, starlike, bar-shaped, netty, flaky, ringlike, strip-shaped, block-shaped, honeycomb or powdery. The catalyst can be used for completely catalytically oxidizing CO(carbon monoxide), alkane, halogenated hydrocarbon, aromatic hydrocarbon and heterocyclic compounds at 200-350 DEG C. The catalyst containing nickel-iron-manganese compound oxide for processing industrial waste gas has the advantages of low initiation temperature, high conversion efficiency, low cost, wide application scope, and meets the industrial waste gas treatment requirements of various enterprises.

Owner:NANJING UNIV OF TECH

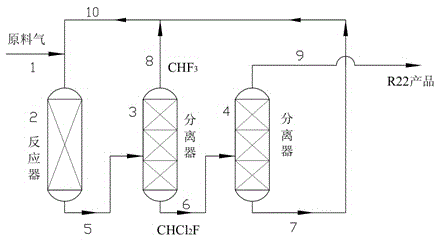

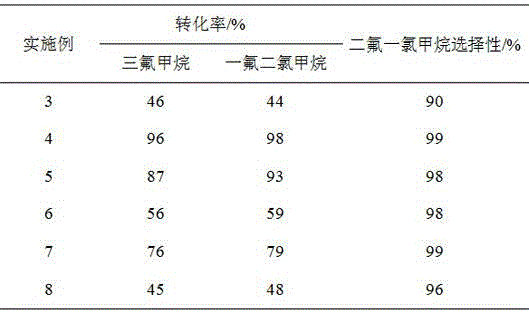

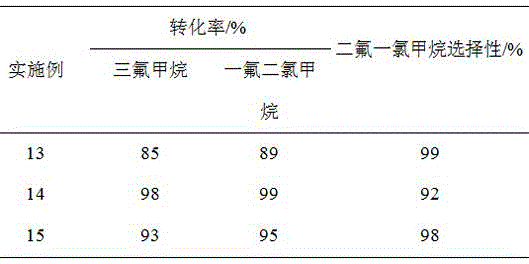

Method for resource utilization of fluoroform

ActiveCN104628513AReduce processing costsReduce equipment investmentPreparation by halogen replacementChemical recyclingHalohydrocarbonResource utilization

The invention discloses a method for resource utilization of fluoroform. The method is characterized by mixing fluoroform with one or a plurality of halohydrocarbon, converting the mixture into a product containing monochlorodifluoromethane in the presence of a catalyst, and reacting unreacted fluoroform with other reaction products in a reactor. According to the method, chlorofluorocarbon containing chlorine or bromine or chlorofluorocarbon which contains chlorine or bromine and needs to be processed during a production process is utilized as reaction material to perform chlorine / fluorine exchange reaction with fluoroform to prepare monochlorodifluoromethane, better economic benefits and social benefits are provided; and in products, monochlorodifluoromethane can be recycled though separation, remained waste gas does not need to be processed, and can still enter the reactor as gas reacted with fluoroform, the conversion rate of reactants is improved, and zero-discharge is realized.

Owner:ZHEJIANG LANTIAN ENVIRONMENTAL PROTECTION HI TECH

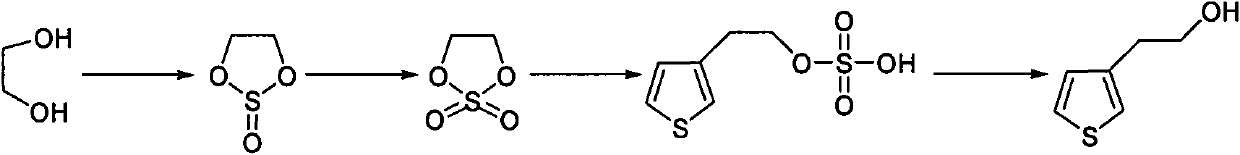

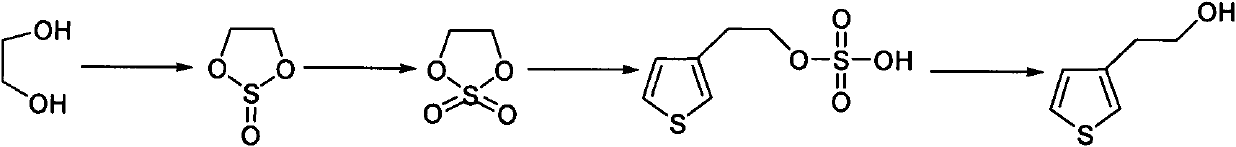

Synthetic method of thiophene-3-ethanol

The invention discloses a synthetic method of thiophene-3-ethanol. The method comprises the following steps of: adding a halogenated hydrocarbon solvent and ethylene glycol into a reaction kettle, dropwise adding thionyl chloride and preserving heat for reacting; separating liquid and extracting to obtain an organic phase containing a substance shown in the specifications; adding a ruthenium trichloride aqueous solution and a sodium bicarbonate aqueous solution in the presence of the halogenated hydrocarbon solvent and dropwise adding a sodium hypochlorite aqueous solution; after detecting that a system does not have oxidizing property, performing liquid separation, concentration, devitrification and drying to obtain a substance shown in the specifications, adding an ester solvent and butyl lithium into a reaction kettle, adding a prepared ester solution of tribromothiofuran and a prepared ester solution of the substance, separating the liquid and extracting to obtain a system containing a substance shown in the specifications; and adding a dilute sulfuric acid into the system containing the substance shown in the specifications, concentrating, neutralizing, extracting and concentrating to obtain an end product. The method has the advantages of high reaction purity and yield, stable process condition, easiness for operation and mass production capability; and the thiophene-3-ethanol is prepared from tribromothiofuran by performing low-temperature lithiation, so that the use of epoxy ethane serving as an explosive hazard is avoided, and mass production becomes possible.

Owner:ASYMCHEM LAB TIANJIN +4

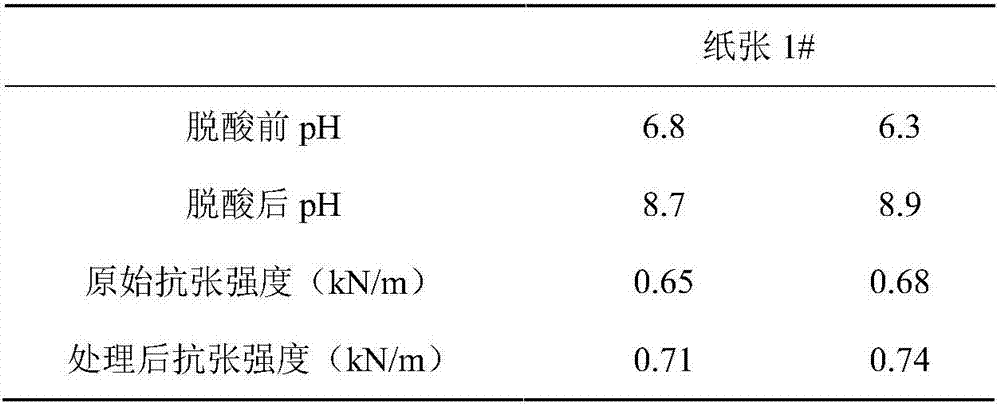

Deacidification liquid having paper strengthening effect and preparation method thereof

ActiveCN107012736ALower pH valueModerately alkalineOld paper after-treatmentHalohydrocarbonColor changes

The invention belongs to the technical field of ancient books and paper deacidification and discloses a deacidification liquid having paper strengthening effect and a preparation method thereof. The deacidification liquid is composed of 0.01-1wt% of magnesium-aluminum bimetal hydroxide and a roasting product thereof, 0.001-1wt% of surfactant, 0.001-1% of paper strengthening agent and halohydrocarbon with purity of 98-99.988wt%. Various modes of spraying, soaking or atomizing can be adopted to deacidify and strengthen acidified and aged paper. The deacidification liquid is mild in property, PH value is lower than 12, writing color fading is not caused, paper is reinforced and is safe, environment-friendly and recyclable by deacidification, the PH value of the paper can be controlled within a proper range, and certain alkali retaining amount can be acquired; the paper is free of deformation, adhesion and writing or color change after being acidified, and the objective of prolonging preservation life of ancient books and acidified paper materials can be achieved.

Owner:TSINGHUA UNIV +1

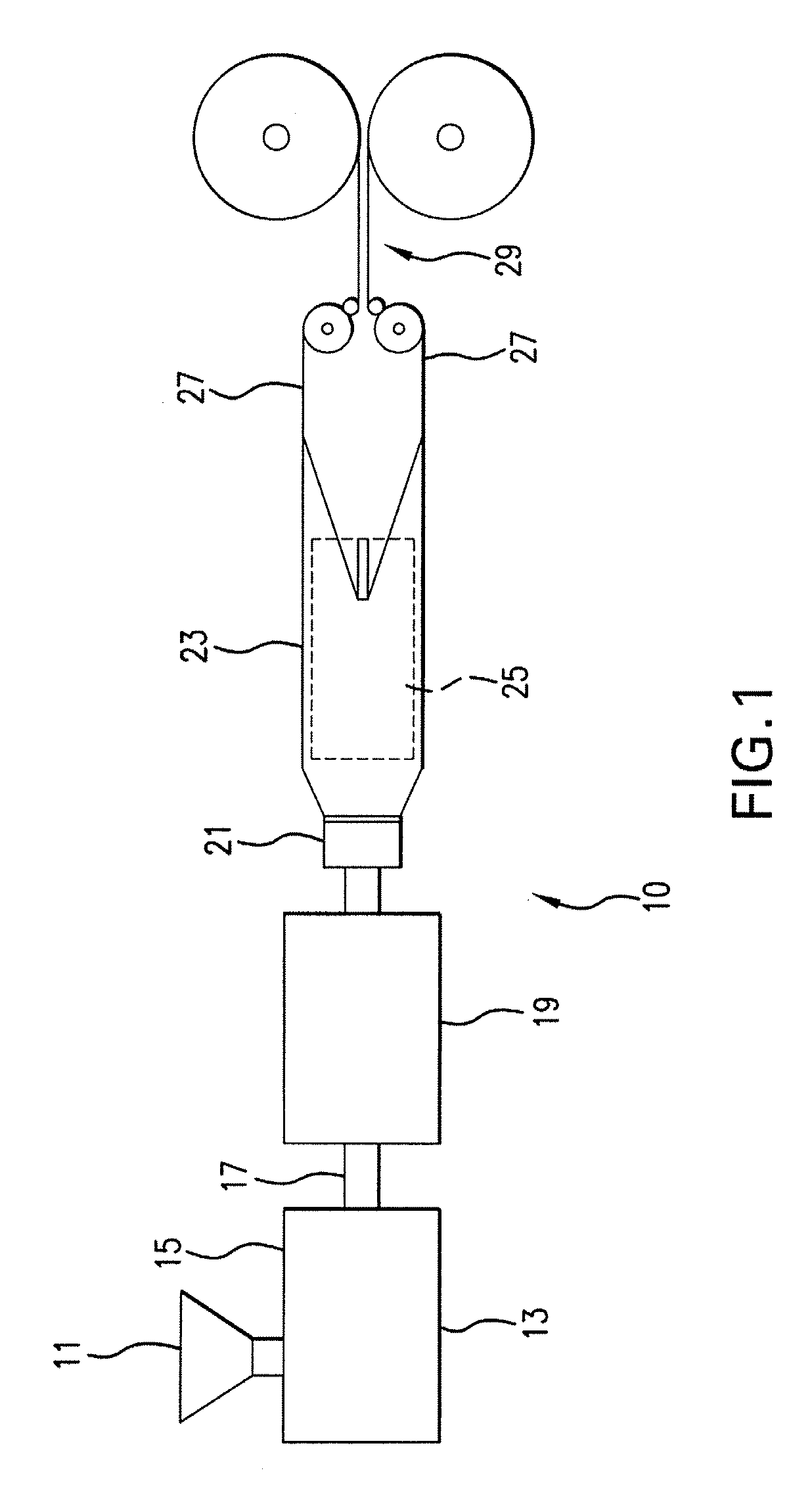

Use of copolymers of perfluoro(alkyl vinyl ether) for photochemical reactions

InactiveUS7943015B2Impression capsPreparation by hydrogen halide split-offVinyl etherHalohydrocarbon

A photochemical reaction apparatus including a reactor and a light source situated so that light from the light source is directed through a portion of the reactor wall is disclosed. The apparatus is characterized by the portion of the reaction wall comprising a copolymer of a perfluoro (alkyl vinyl ether). The perfluoro (alkyl vinyl ether) is selected from the group consisting of CF30CF═CF2, C2F5OCF═CF2, C3F7OCF═F2, and mixture thereof. Also disclosed is a photochemical reaction process wherein light from a light source is directed through said reactor wall to interact with reactants in said reactor. A process for increasing the fluorine content of at least one compound selected from hydrocarbons and halohydrocarbons, comprising: (a) photochlorinating said at least one compound; and (b) reacting the halogenated hydrocarbon produced in (a) with HF. A process for producing an olefinic compound, comprising: (a) photochlorinating at least one compound selected from hydrocarbons and halohydrocarbons containing at least two carbon atoms and at least two hydrogen atoms to produce a halogenated hydrocarbon containing a hydrogen substituent and a chlorine substituent on adjacent carbon atoms; and (b) subjecting the halogenated hydrocarbon produced in (a) to dehydrohalogenation.

Owner:EI DU PONT DE NEMOURS & CO

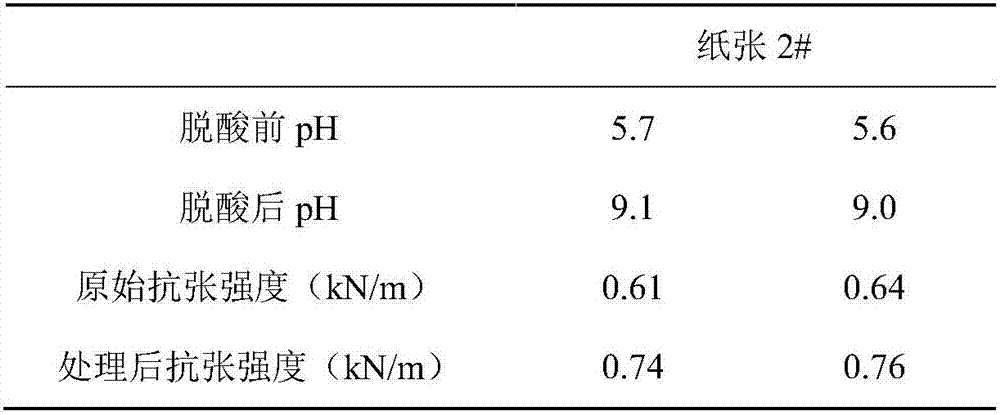

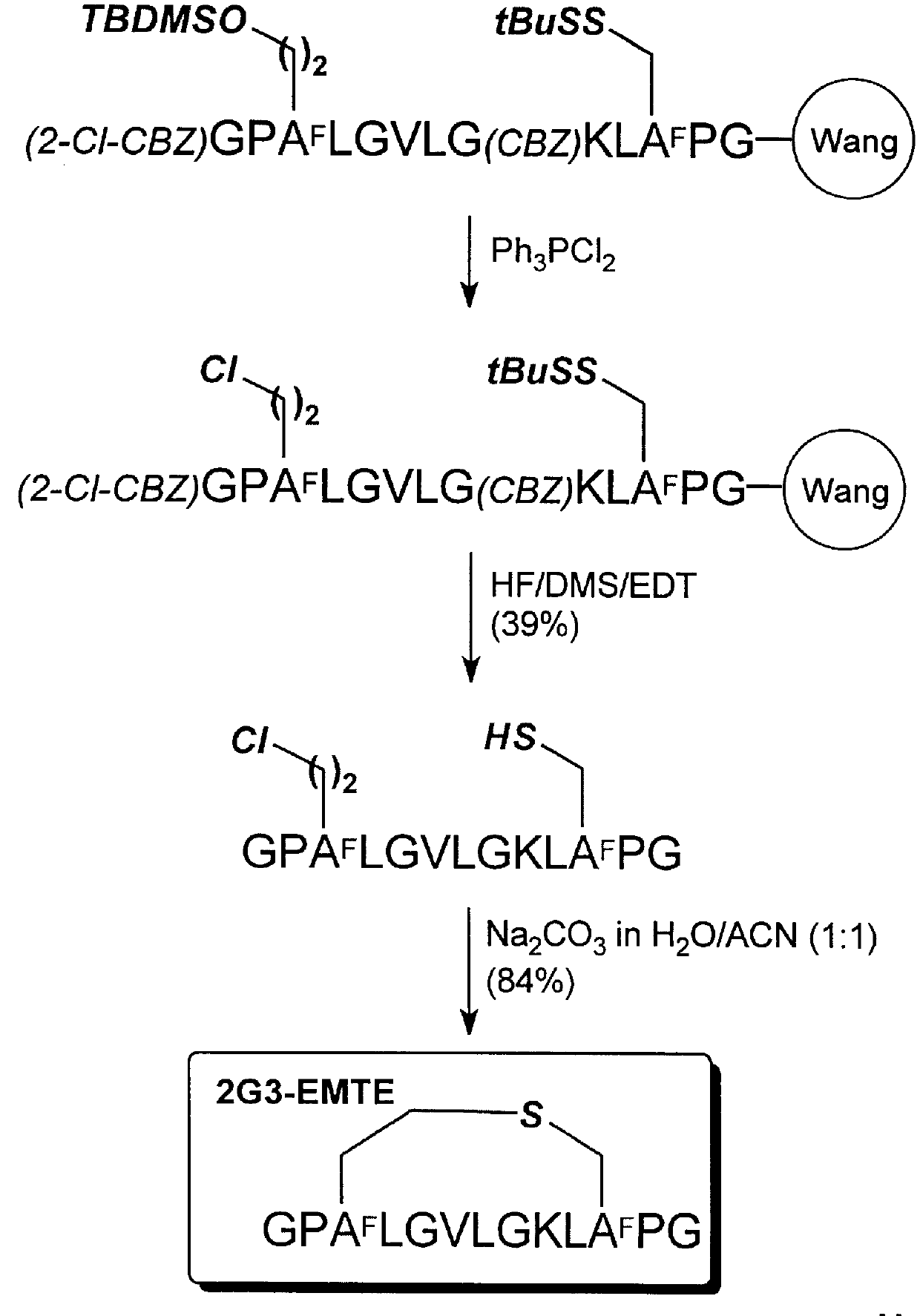

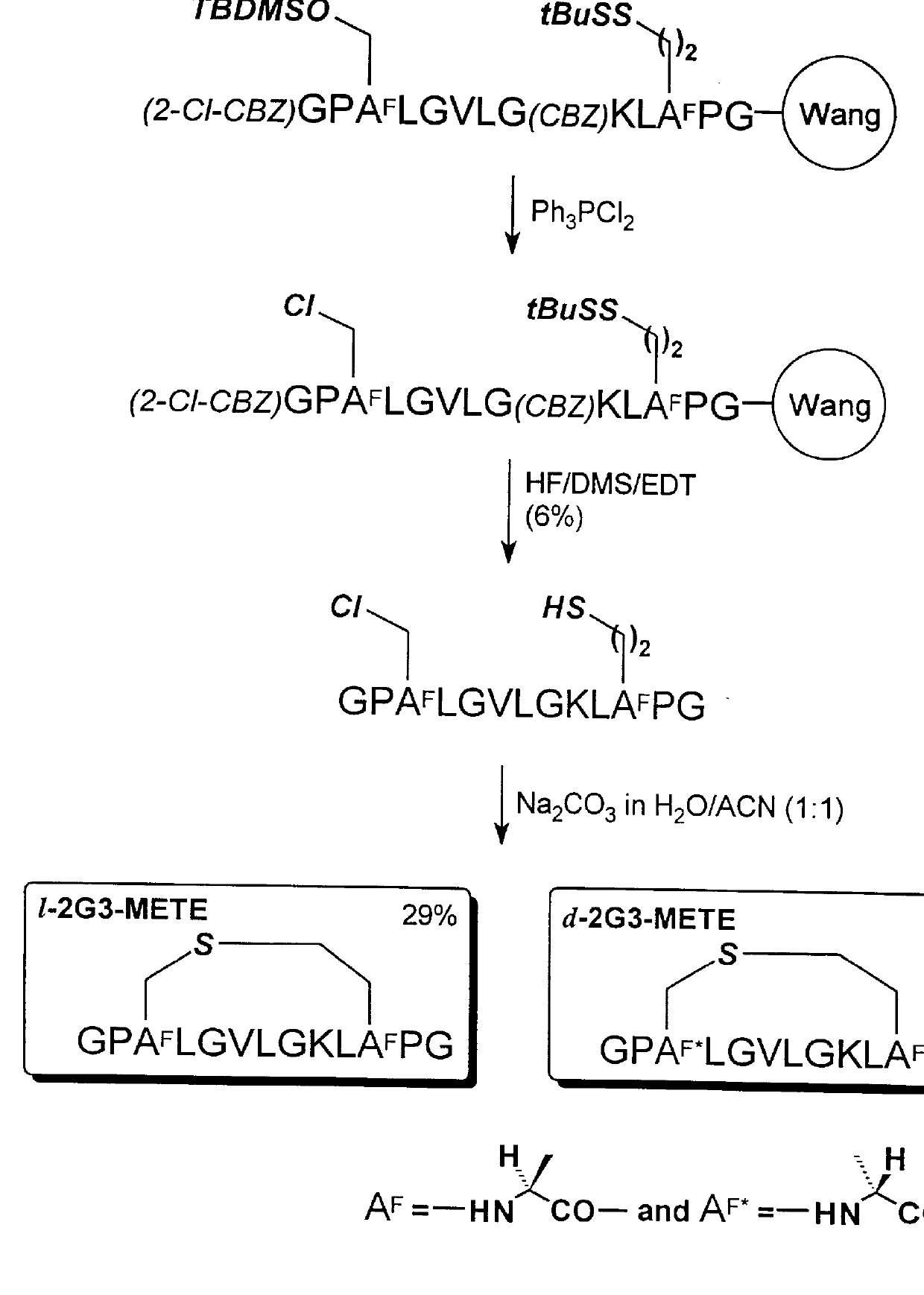

Cyclic polypeptides comprising a thioether linkage and methods for their preparation

This invention relates generally to cyclic polypeptides comprising a thioether linkage and methods for their preparation. More particularly, this invention relates to halogenated polypeptides having at least one haloalanine-like amino acid, and methods for their preparation which involve converting the hydroxyl group (i.e., -OH) of a serine-like amino acid to a halo group (i.e., -X where X is Cl, Br, or I) with the aid of a phosphorus-based halogenation reagent such as a triphenylphosphine dihalide (i.e., (C6H5)3PX2, wherein X is Cl, Br, or I), a triphenylphosphite dihalide (i.e., (C6H5O)3PX2, wherein X is Cl, Br, or I), or a mixture of triphenylphosphine or triphenylphosphite with a halohydrocarbon (i.e., "halo-conversion"). This invention also relates to cyclic polypeptides having at least one polypeptide loop comprising a thioether linkage, and methods for their preparation which employ halogenated polypeptides and which involve intramolecular alkylation of the thiol group of a cysteine-like amino acid by the halo group of a haloalanine-like amino acid under suitable basic conditions to form a thioether linkage (i.e., "cyclization").

Owner:LA JOLLA PHARMA

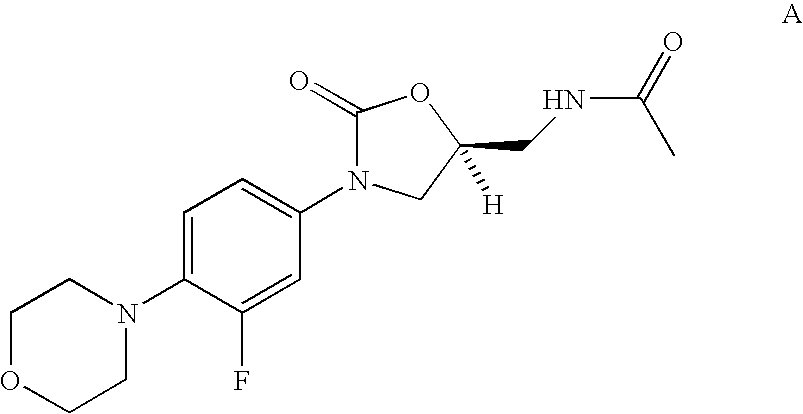

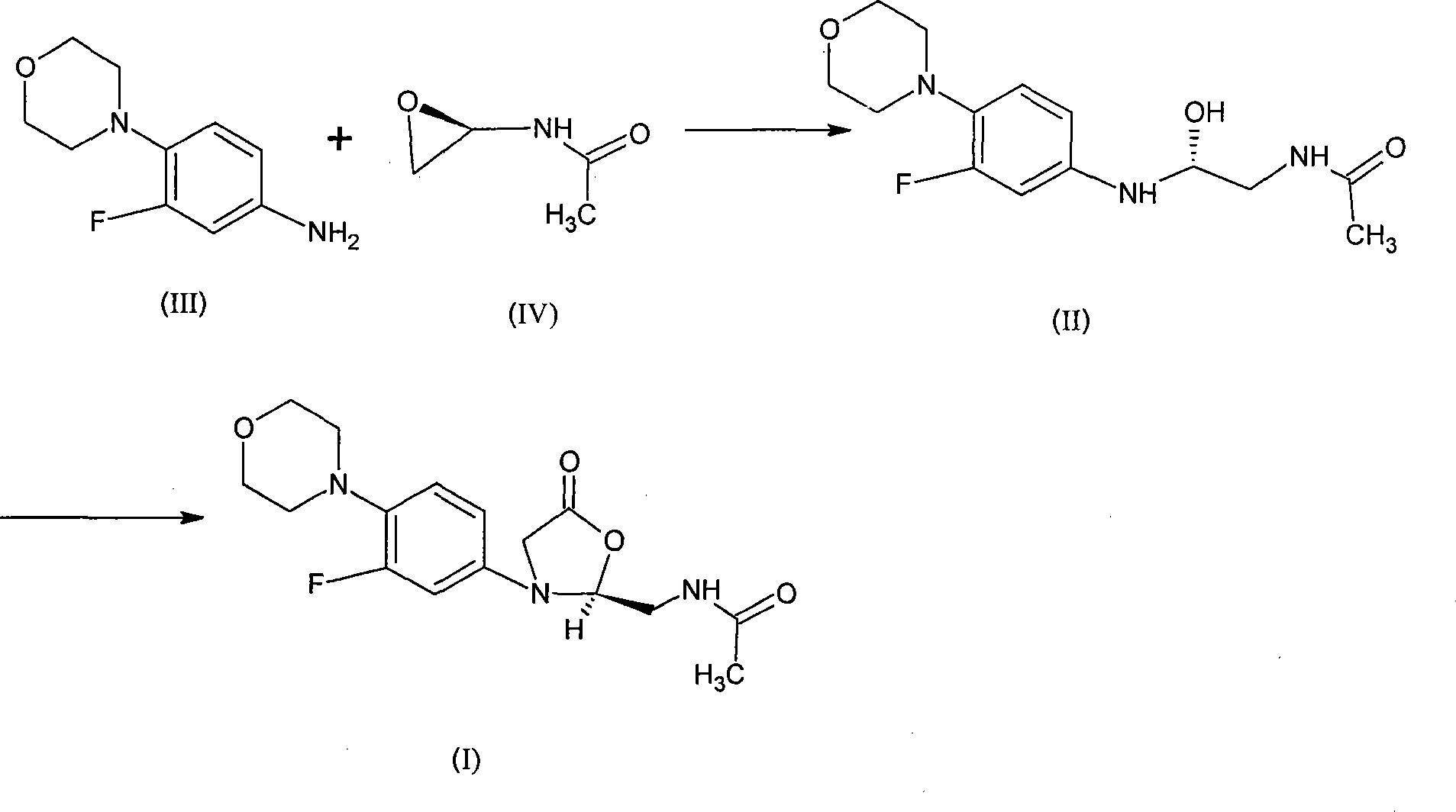

Synthesis of linezolid

InactiveCN101220001ASimple stepsMild reaction conditionsAntibacterial agentsOrganic chemistryEpoxyHalohydrocarbon

The invention relates to a synthetic method for linezolid, which dissolves a 3-fluoro-4- morpholinyl laniline and an N-2(R)-epoxy acetamide in an organic solvent to react for 10 to 30 hours in a temperature of 20 to 100 DEG C, and acquires an N-{2(R)-2-[(3-fluoro-4 morpholine-4-base phenyl) amino]-2-hydroxy ethyl}; then an acquired compound and a carbonylation agent are dissolved in a halohydrocarbon organic solvent and reacted for 0.5 to 5 hours in a temperature of 0-50 DEG C under the catalysis of a base catalyst, thereby acquiring the linezolid. The method of the invention uses an ordinary reagent and normal plant conditions in industry, the reaction condition is mild and the steps are simple.

Owner:ZHEJIANG BOTAI CHEM

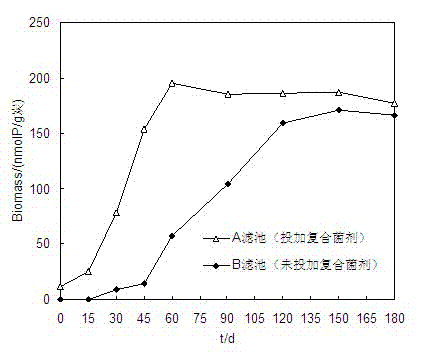

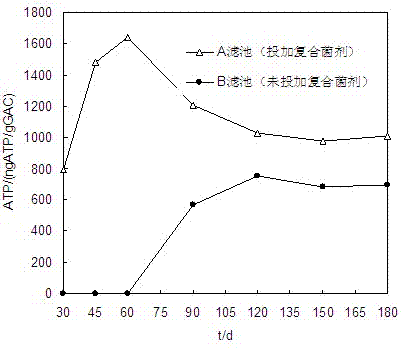

Preparation method and application for compound fungus agent for degrading organic matter

InactiveCN102344899AImprove biological activityImprove adsorption capacityBacteriaWater contaminantsBiotechnologyBenzoic acid

The invention relates to a preparation method for a compound fungus agent for specifically degrading an organic matter for a biological enhancing water treatment system. The compound fungus agent is added into a biological treatment process, has high biological activity, a stable effect and low cost, is easy to adsorb on the surface of a carrier and is difficult to lose. The preparation method issimple and practical, and has a short preparation period and low cost. The compound fungus agent comprises the following four strains: 20 to 30 percent of pseudomonas-stutzeri, 20 to 30 percent of pseudomonas putida, 10 to 20 percent of pseudomonas-pertucinogena and 30 to 50 percent of bacillus subtilis. The compound fungus agent is prepared by combining and screening the strains, performing slant culture and primary culture, mixing according to the proportion, and performing secondary cycle culture. The preparation method is widely used in a biological enhancing water treatment process, has a long-term and stable operation period, and has specific degradation ability for toxic and harmful organic pollutants such as halogenated hydrocarbons, phenol, benzoic acid, aromatics, polycyclic aromatic hydrocarbon, heterocyclic compounds, phthalic acid ester and the like.

Owner:SHENYANG JIANZHU UNIVERSITY

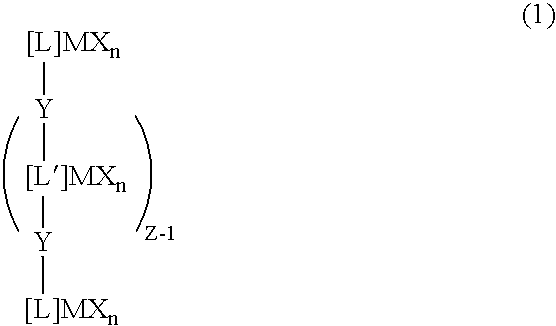

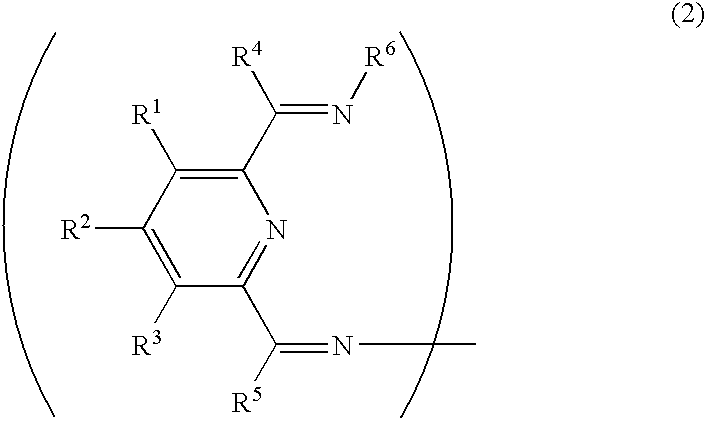

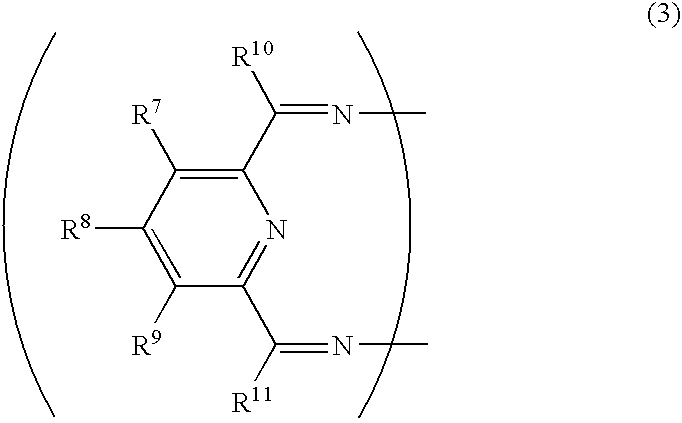

Transition metal compound, olefin polymerization catalyst, and method of polymerizing olefin

InactiveUS6841693B1Organic-compounds/hydrides/coordination-complexes catalystsIron group organic compounds without C-metal linkagesHydrogen atomHalogen

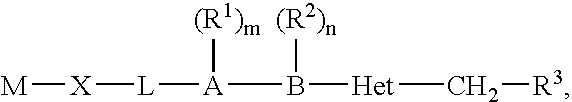

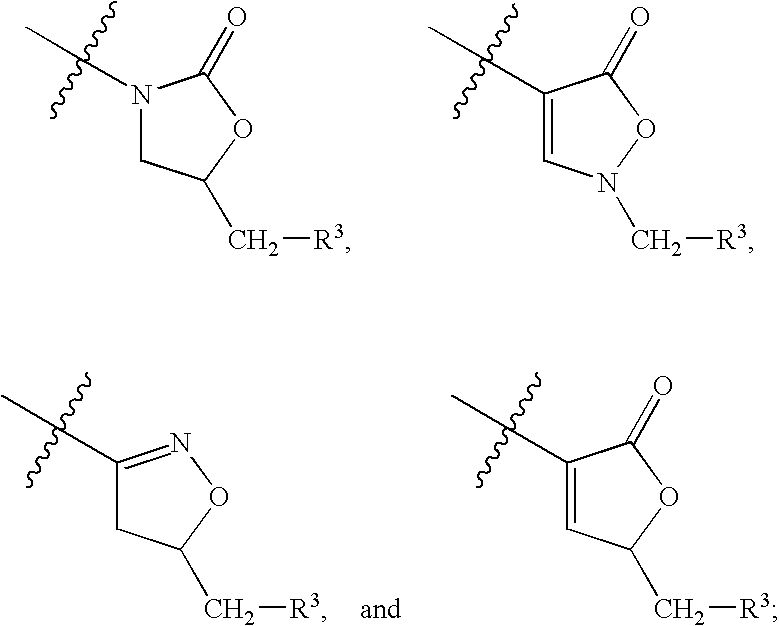

A transition metal compound of Groups to 10 of the Periodic Table, represented by the following formula (1): wherein M represents a transition metal of Groups 8 to 10 of the Periodic Table; L, electrically neutral, represents a hetero atom-containing hydrocarbon group represented by the following formula (2) wherein R1 to R5 each independently represent a hydrogen atom, a halogen atom, a hydrocarbon group having form 1 to 20 carbon atoms, a halogenohydrocarbon group having from 1 to 20 carbon atoms, or a hetero atom-containing group, and optionally these groups are bonded to each other to form a ring; R6 represents a hydrogen atom, a hydrocarbon group having form 1 to 40 carbon atoms, a halogenohydrocarbon group having from 1 to 40 carton atoms, or a hetero atom-containing group;L′ electrically neutral, represents a hetero atom-containing hydrocarbon group represented by the following formula (3) wherein R7 to R11 each independently represent a hydrogen atom, a halogen atom, a hydrocarbon group having from 1 to 20 carbon atoms, a halogenohydrocarbon group having from 1 to 20 carbon atoms, or a hetero atom-containing group, and optionally these groups are bonded to each other to form a ring;X represents a covalent-bonding or ionic-bonding group, and a plurality of X's are the same or different; Y represents an aromatic group-containing crosslinking group; Z is an integer of 1 or more, indicating the degree of polymerization of the compound; n indicates the atomic valency of M; and each of M, L, and Y are the same or different.

Owner:IDEMITSU KOSAN CO LTD

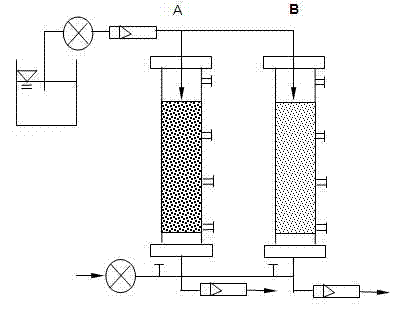

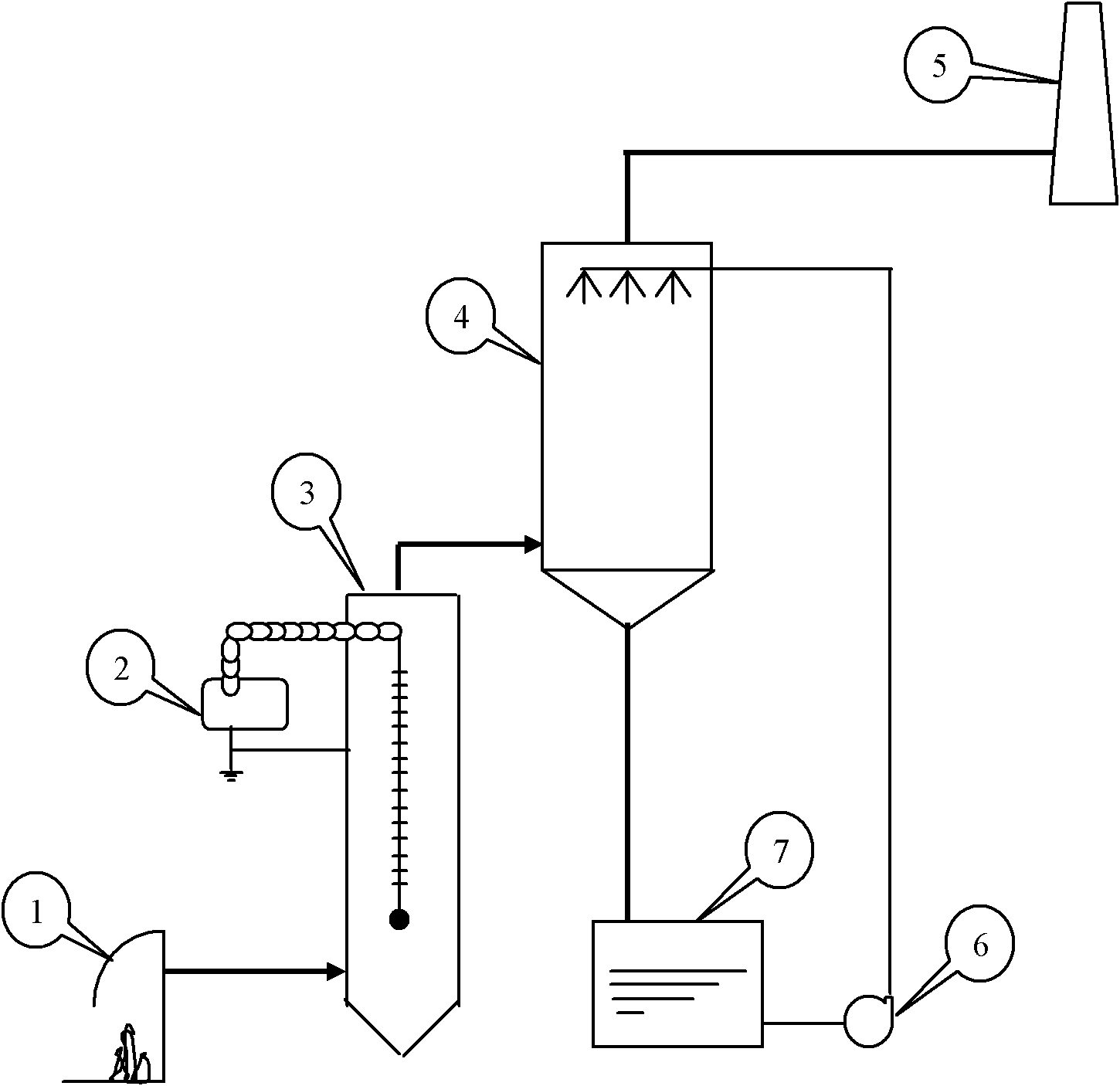

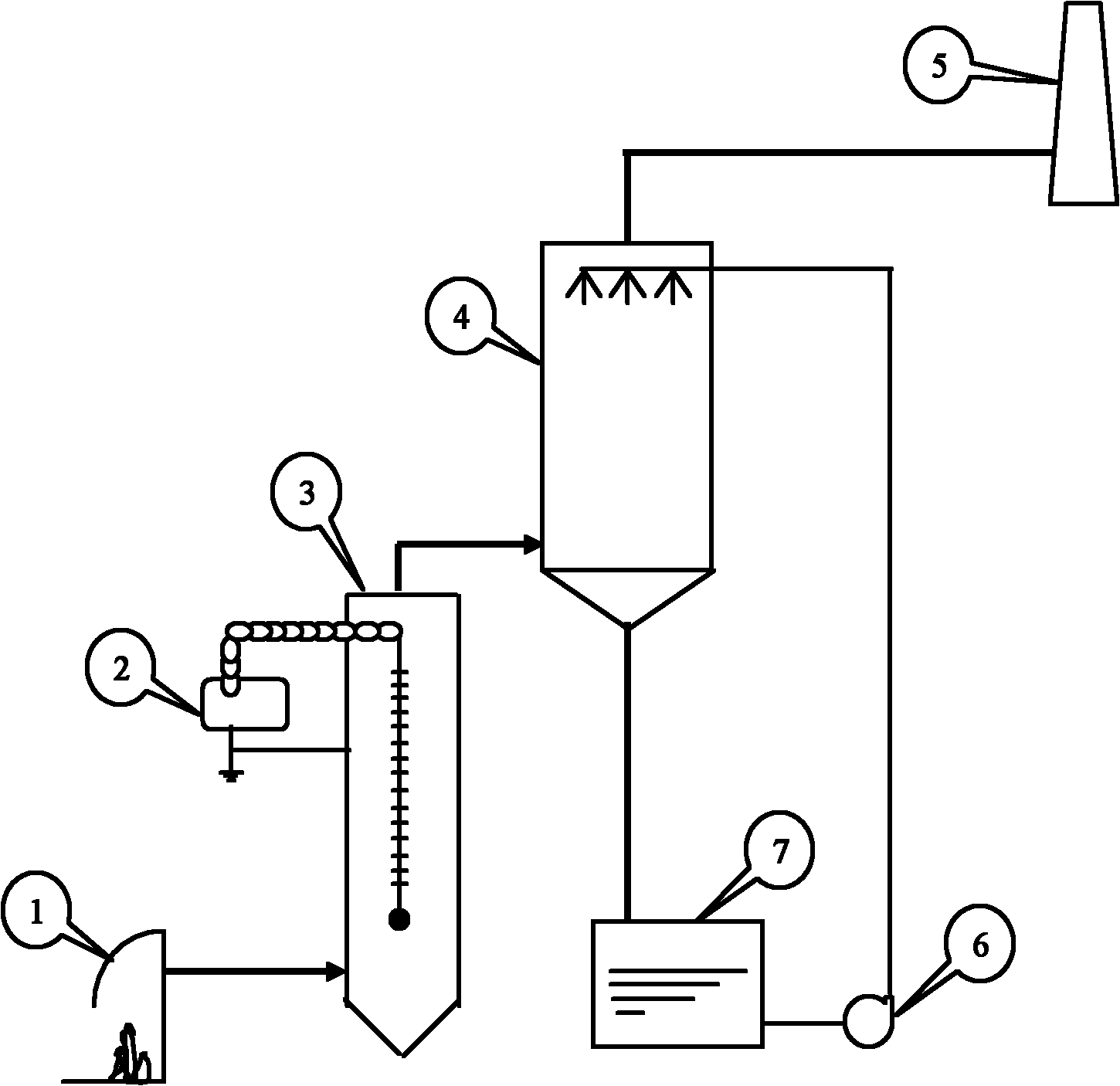

Method and device for treating nondegradable organic waste gas by combining low-temperature plasma with organisms

ActiveCN102059047AAchieve purificationMeet emission requirementsDispersed particle separationAtmospheric airHigh energy

The invention discloses a method and device for treating nondegradable organic waste gas by combining low-temperature plasma with organisms. After being collected, organic waste gas is sequentially treated through a low-temperature plasma reactor and a biological treatment reactor and finally exhausted to the atmosphere through a chimney. In the low-temperature plasma reactor, polycyclic aromatichydrocarbon, halogenated hydrocarbon, heterocycle compounds and an organic nitrile compound which are insoluble in water and nonbiodegradable are oxidized into low-carbon organic acid, alcohol, esterand other organic compounds which are soluble in water and biodegradable by utilizing substances with strong oxidizing property, such as O3, OH., H2O2, O. and high-energy electrons generated by high voltage discharge. In the biological treatment reactor, the organic acid, the alcohol, the ester and other organic compounds are further converted into CO2, H2O and other inorganic compounds under theaction of microorganisms. Through the treatment, the total purification efficiency of nondegradable organic compounds containing benzene, methylbenzene, dimethylbenzene, phenol and the like in waste gas can be up to over 90 percent.

Owner:山东航源环境科技有限公司

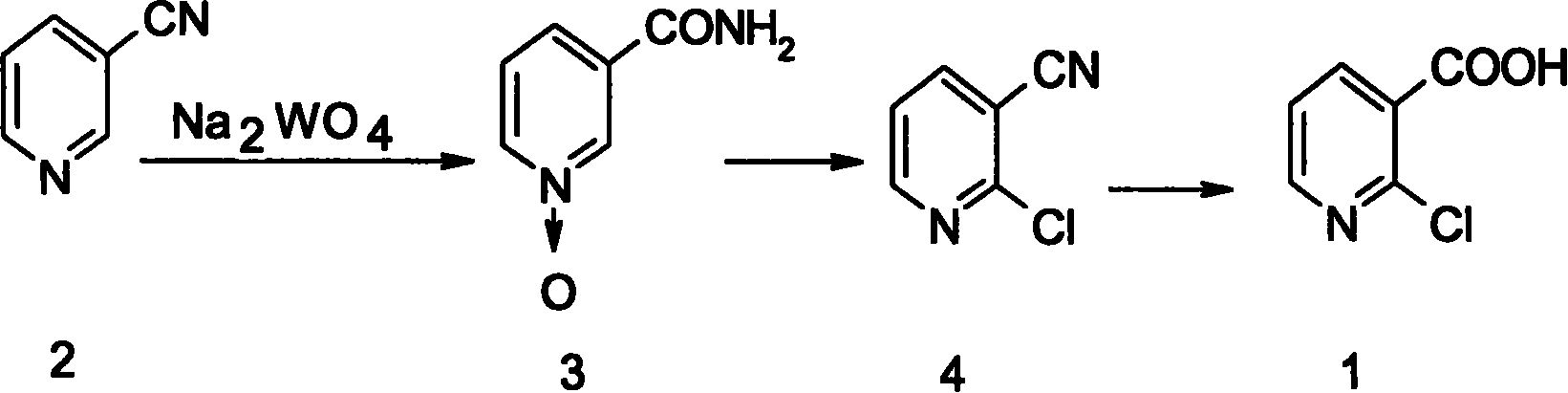

Preparation method of 2-chloronicotinic acid

InactiveCN101117332ANot easy to decomposeLittle pollutionOrganic chemistryHalohydrocarbonPositive pressure

The invention discloses a preparation process for 2-Chloronicotinic acid. In the prior art, the disadvantage is that the overdosed catalyzer is used and has a bad effect, the oxidation yields are very low; during the chlorination reaction, POCl3 can make chloro-substitutions on a plurality of positions of nicolinamide- N- oxido, which leads to that the chloro-substitution products on 2-position have low yields. In the invention, with the existence of acetyl pyruvic molybdenum, the 3-Pyridinecarbonitrile takes water as the solvent and is dripped in 20 to 30 percent of H2O2, and then is made a heat preservation to realize a full oxidation reaction; under the anhydrous reaction and with the positive pressure protection of nitrogen, the acquired nicolinamide- N- oxido is cooled between minus 10 and 10 DEG C to be diluted by the halohydrocarbon solvent, and then is dripped in the organic base, and is reacted with the chlorination reagent under the action of phenyl dichlorophosphate; the strong alkaline solution is used to make a dehydration reaction with the acquired 2-chloro-3-cyanopyridine. The invention takes the acetyl pyruvic molybdenum as the catalyzer and oxidizer, has high oxidation yields; adopts the organic base as the acid-binding agent, makes chloro-substitutions between the chlorination reagent and the nicolinamide- N- oxido, and has above 85 percent of chloro-substitution yields.

Owner:ZHEJIANG MEDICINE CO LTD XINCHANG PHAMACEUTICAL FACTORY

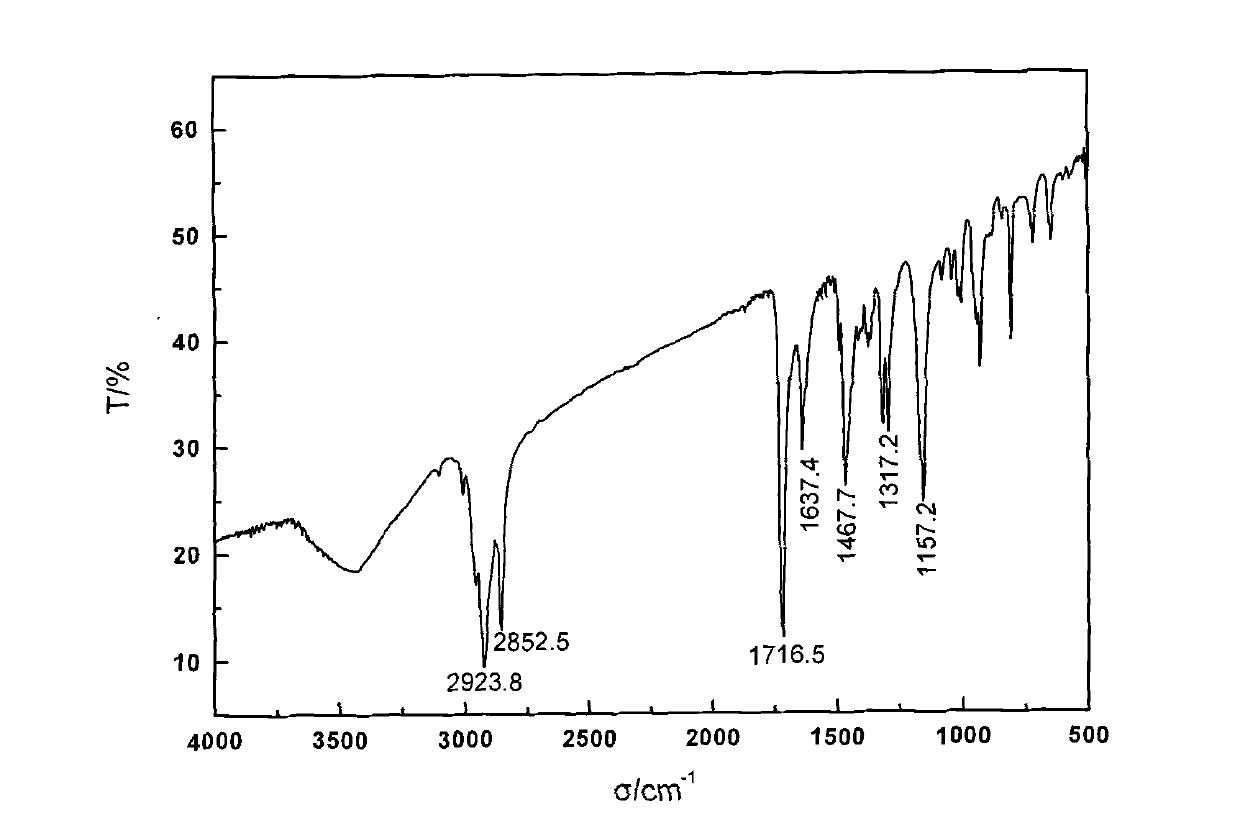

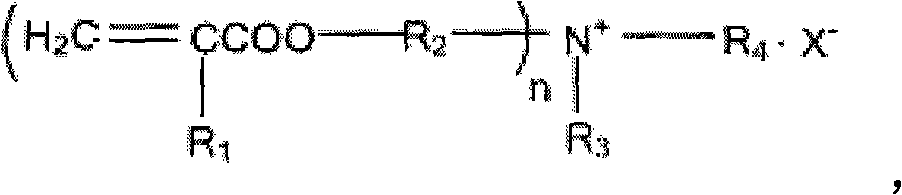

Cross-linked polyquaternary ammonium salt type antibiosis monomer, preparation method of cross-linked polyquaternary ammonium salt type antibiosis monomer and application of cross-linked polyquaternary ammonium salt type antibiosis monomer in dentistry repairing materials

InactiveCN102079713AHigh purityGood compatibilityAntibacterial agentsImpression capsCross-linkQuaternary ammonium cation

The invention discloses a cross-linked polyquaternary ammonium salt type antibiosis monomer, a preparation method of the cross-linked polyquaternary ammonium salt type antibiosis monomer and application of the cross-linked polyquaternary ammonium salt type antibiosis monomer in dentistry repairing materials. In the preparation method, monomer bonds are connected to a dentistry resin-based material, so as to endow antibiosis property to the resin-based material. The structure general formula of the cross-linked polyquaternary ammonium salt type antibiosis monomer is shown in the specification. The preparation method comprises the following steps: 1, adding a solvent in tertiary amine substance, and adding halohydrocarbon substance for reflux reaction so as to obtain a product A, adding acyl chloride for reflux reaction by using toluene, benzene, dichloromethane or tetrahydrofuran so as to obtain quaternary ammonium salt B, and purifying the quaternary ammonium salt B; and 2, adding the acyl chloride and tertiary amine substancem by using the toluene, benzene, dichloromethane or tetrahydrofuran as the solvent, adding triethylamine as auxiliary, reacting to obtain the tertiary amine containing C=C, the tertiary amine takes acetone, metjylene dichloride and acetonitrile as the solvents, adding the halohydrocarbon for reflux reaction, and then purifying the quaternary ammonium salt monomer. In the invention, reaction steps are simple, the purity of the monomer is high, and the monomer has better compatibility and higher safety as compared with the common dentistry repairing resin monomer.

Owner:NANJING UNIV OF SCI & TECH

Regeneration of spent paraffin dehydrogenation catalyst

InactiveUS20150111720A1Other chemical processesCatalyst regeneration/reactivationHydrogenDehydrogenation

There is provided a method for regenerating a spent dehydrogenation catalyst used in the conversion of n-paraffin to olefin. The method comprises method steps for removing the coke by treating the catalyst with an ozone-oxygen stream followed by an oxygen stream. The catalyst is stabilized by passing a nitrogen stream and the stabilized catalyst is rejuvenated by passing an air-nitrogen stream containing a halogenated hydrocarbon. This is followed by reducing the metal oxide in the catalyst by passing hydrogen-nitrogen stream.

Owner:RELIANCE INDUSTRIES LIMITED

Method for preparing biomass liquefied oil by biomass catalytic liquefaction

InactiveCN101407727AMild conditions for liquefactionSimple processLiquid hydrocarbon mixture productionAlcoholHalohydrocarbon

The invention discloses a method for preparing biomass liquefied oil by the catalytic liquefaction of the biomass, and relates to a method for preparing the bio-oil by the liquefaction of the biomass, which belongs to the field of chemical and industrial catalysis. The method for preparing the bio-oil comprises the steps as follows: arranging the biomass, solid acid and an aqueous solution containing C1-C3 monobasic alcohol in a pressure vessel; stirring and heating up the mixture to the temperature of 200 to 280 DEG C, with the pressure of 2 and 7MPa and the time of 0.5 to 10 hours; then cooling down the mixture to normal temperature and filtering the mixture; using C1-C3 halohydrocarbon to carry out extraction and refining to the obtained filtrate and filter residues respectively; combining the extracting and refining liquid and removing the halohydrocarbon and alcohol to prepare the biomass liquefied oil. Used independently as a technique for biological energy conversion, and with moderate conditions and yield as high as about 65 percent, the method is free from the discharging of alkaline solution and salt solution in the production process, thus laying the foundation for the industrial and clean utilization of the biomass.

Owner:YANGZHOU UNIV

Supercritical liquefaction method for biomass

InactiveCN1687315AWide variety of sourcesLiquid hydrocarbon mixture productionBio-feedstockHalohydrocarbonAlcohol

The present invention relates to a method for preparing biological oil by utilizing biomass liquefications. Said method includes the following main steps: placing biomass, catalyst and aqueous solution of monohydric alcohol of C1-C3 into a pressure-resisting container with stirring device, in the presence of inert gas stirring for 50-70 min, heating to 230-310 deg.C and pressurizing to 8-15 MPa, retaining said state for 10-60 min., cooling and regulating pH value of the obtained material to 1-3, then filtering, using halohydrocarbon of C1-C4 to respectively extract the obtained filtrate and filter residue, combining extracts and removing halohydrocarbon so as to obtain biomass liquefied oil.

Owner:EAST CHINA UNIV OF SCI & TECH

LED gallium arsenide substrate dewaxing cleaning agent

InactiveCN101974377AImprove solubilityAvoid the disadvantage of low flash pointSurface-active non-soap compounds and soap mixture detergentsAlkaneHalohydrocarbon

Owner:JIANGSU TIANHENG NANO SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com