Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

3822 results about "Liquefaction" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

In materials science, liquefaction is a process that generates a liquid from a solid or a gas or that generates a non-liquid phase which behaves in accordance with fluid dynamics. It occurs both naturally and artificially. As an example of the latter, a "major commercial application of liquefaction is the liquefaction of air to allow separation of the constituents, such as oxygen, nitrogen, and the noble gases." Another is the conversion of solid coal into a liquid form usable as a substitute for liquid fuels.

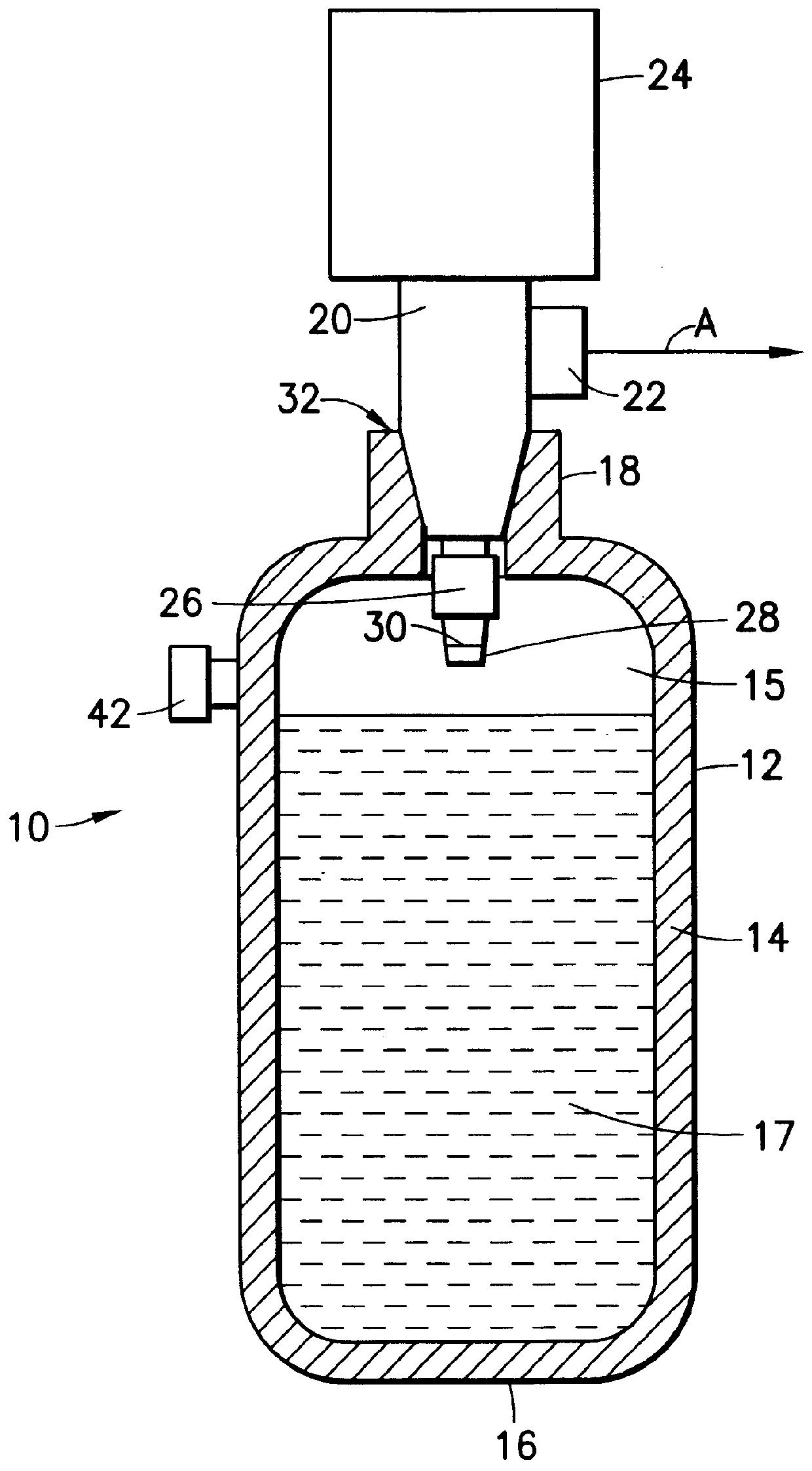

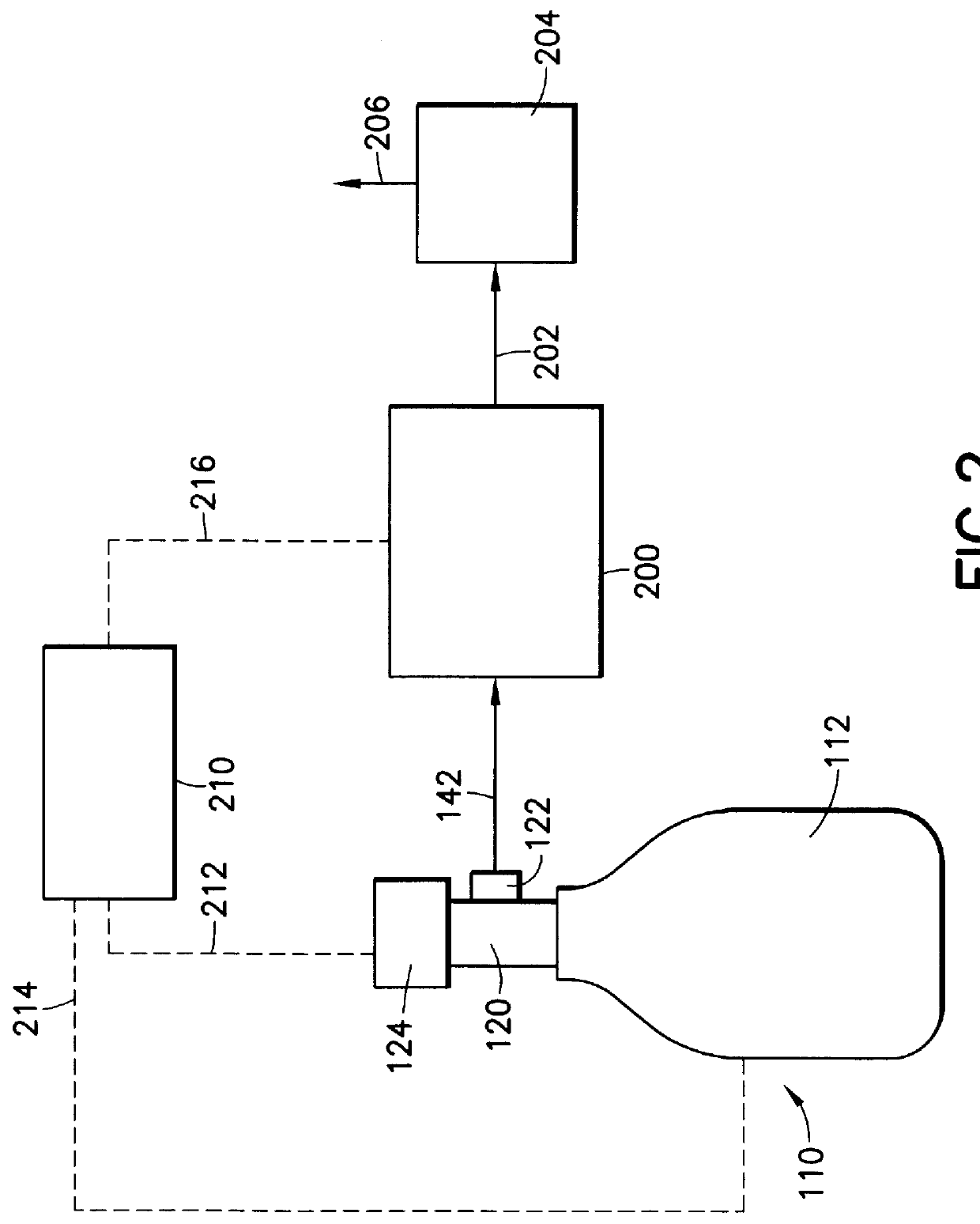

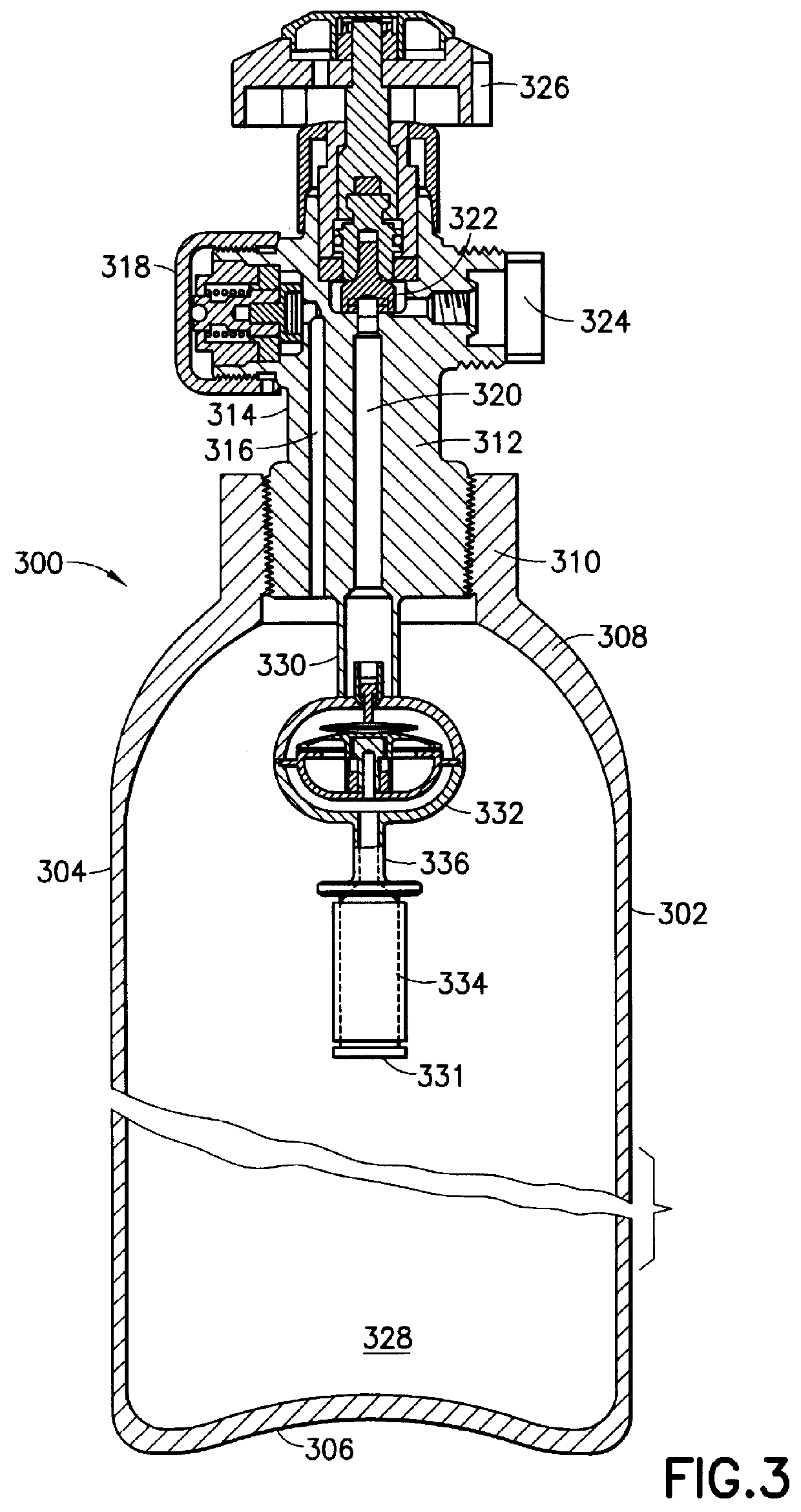

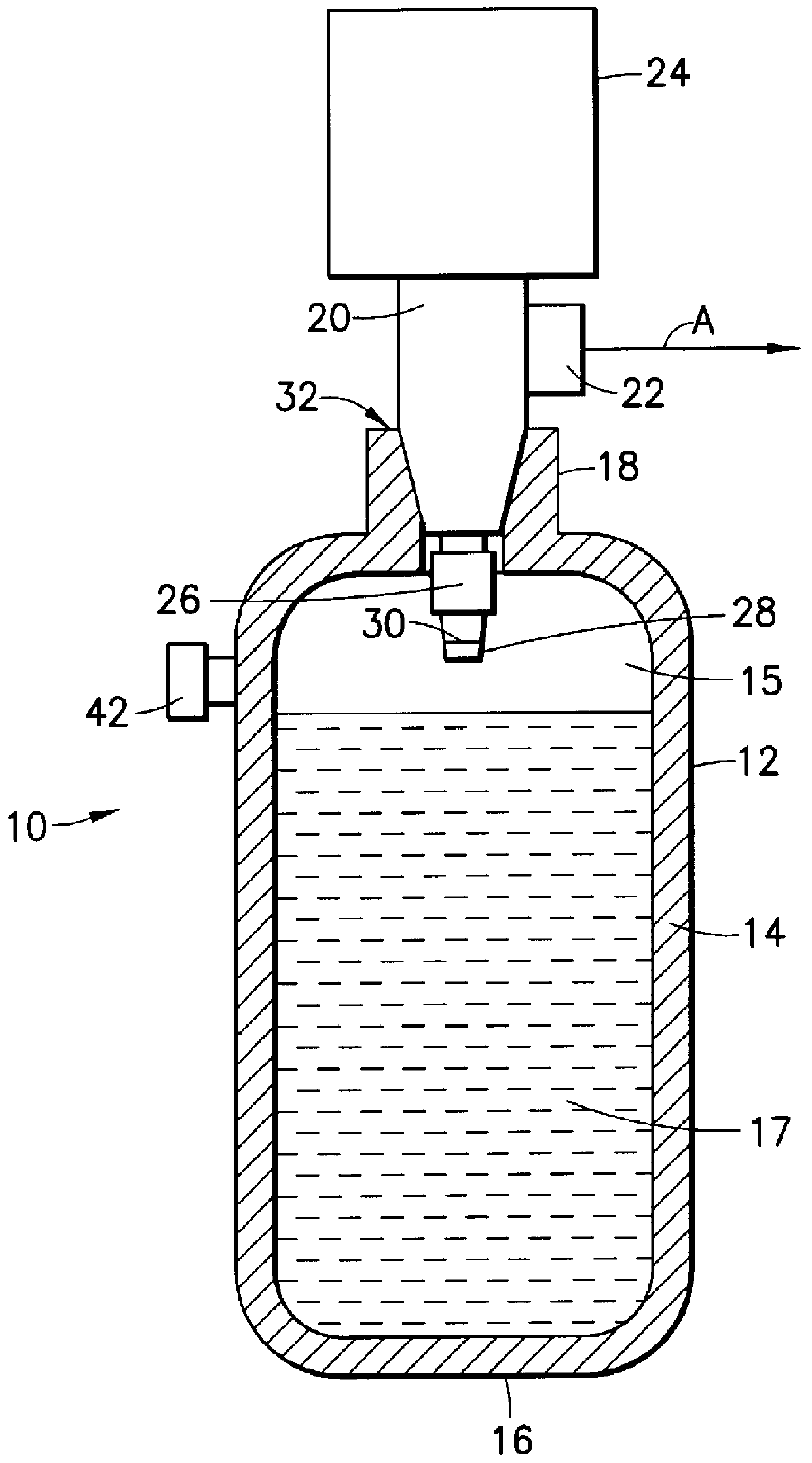

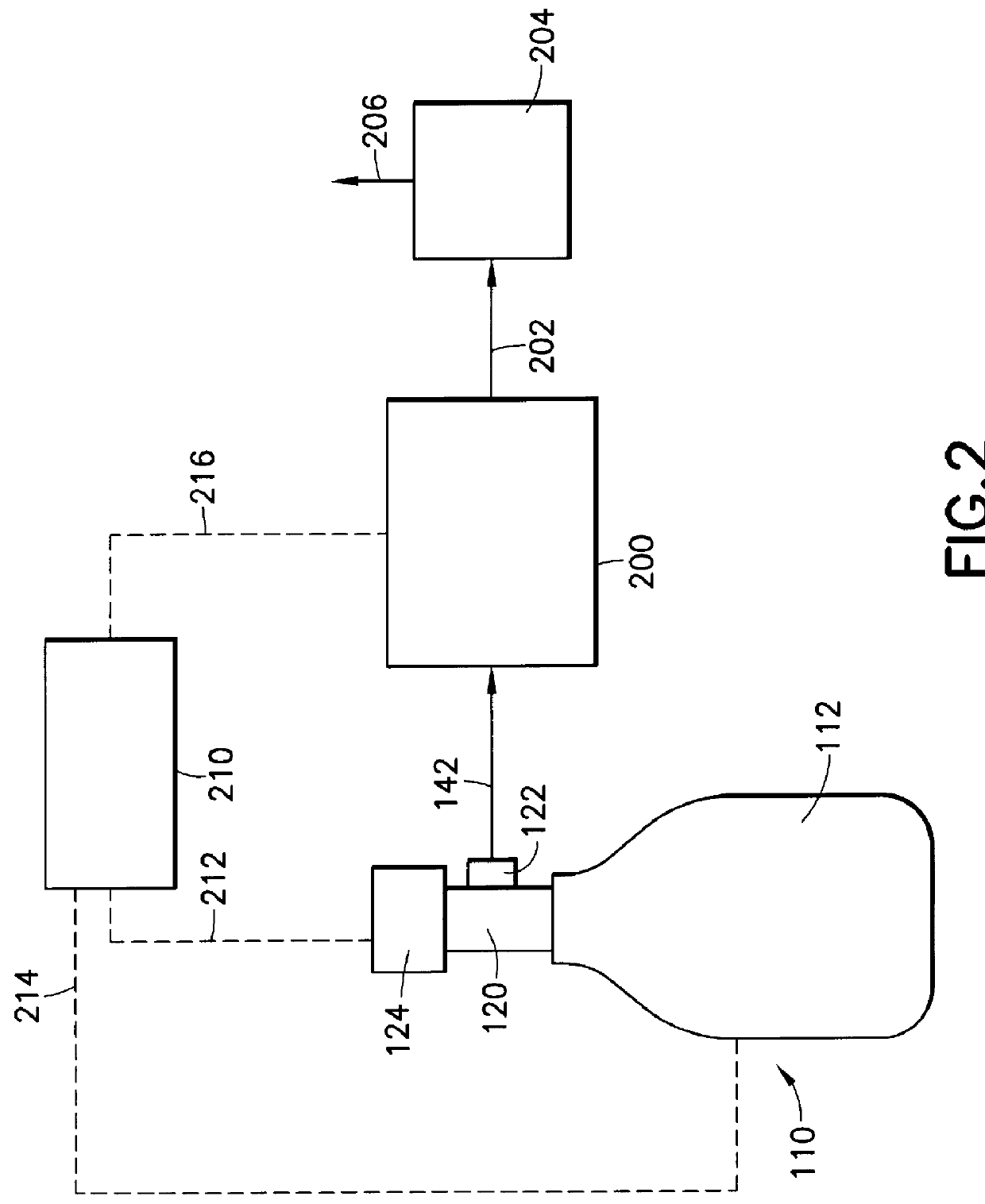

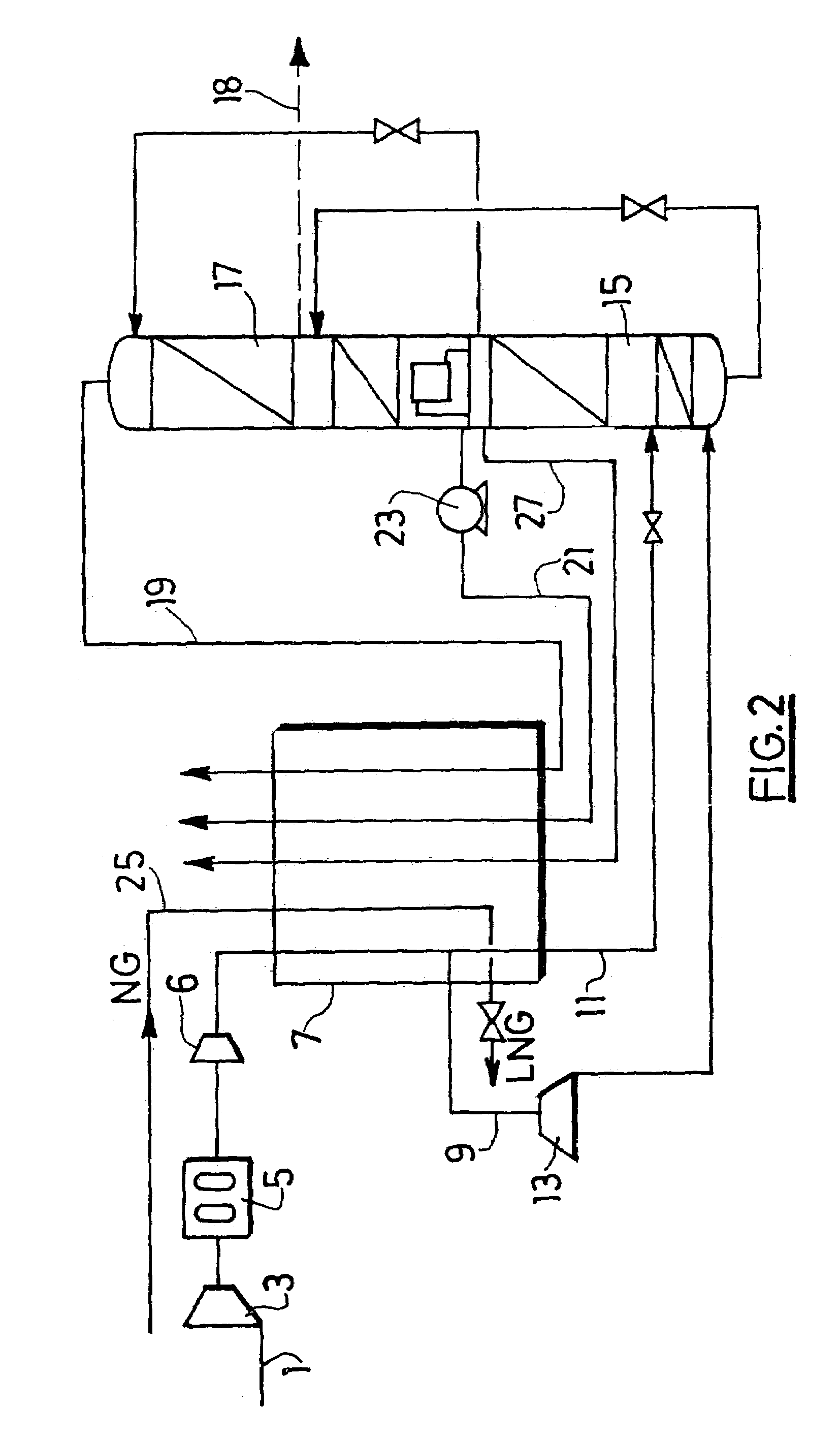

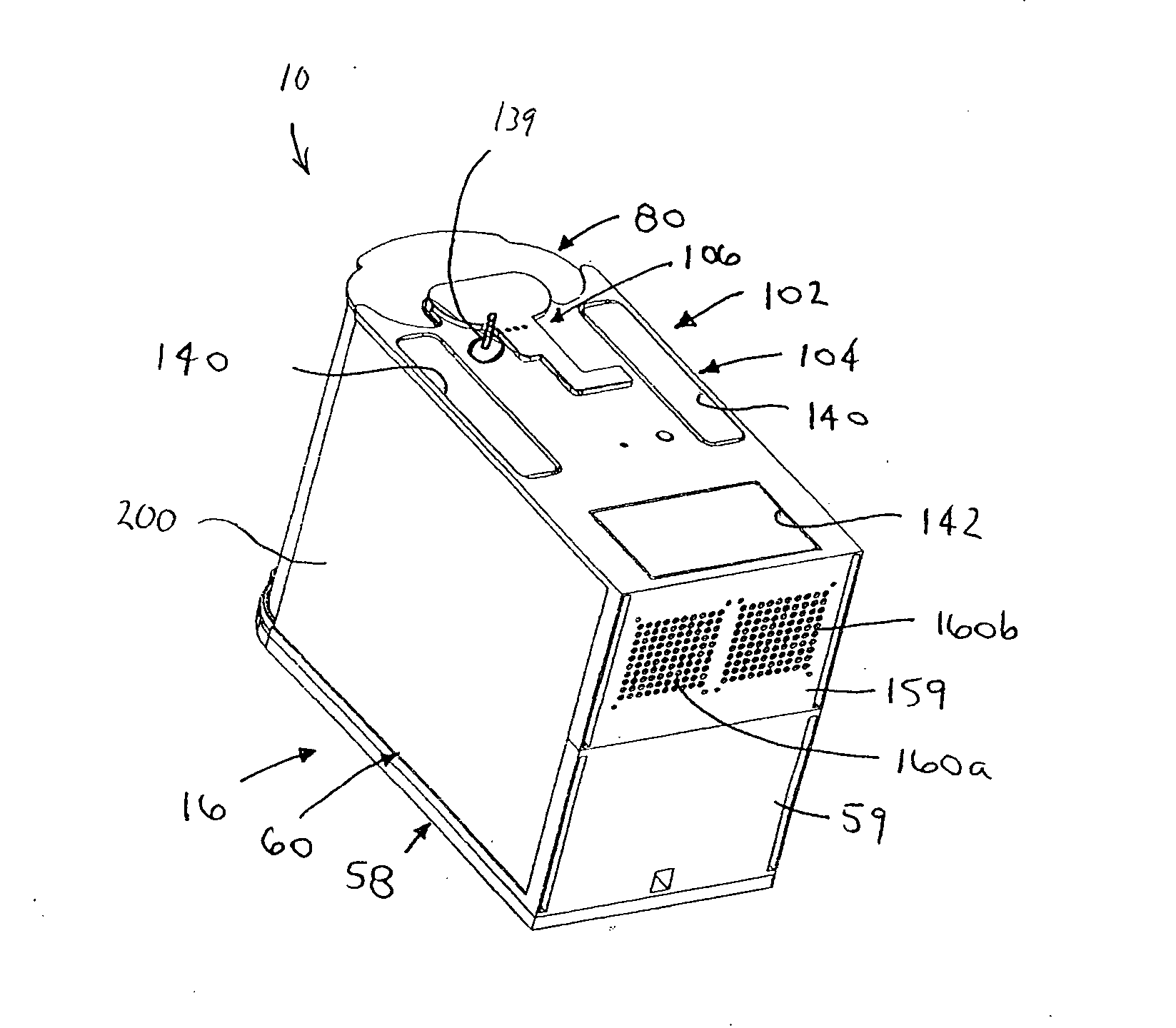

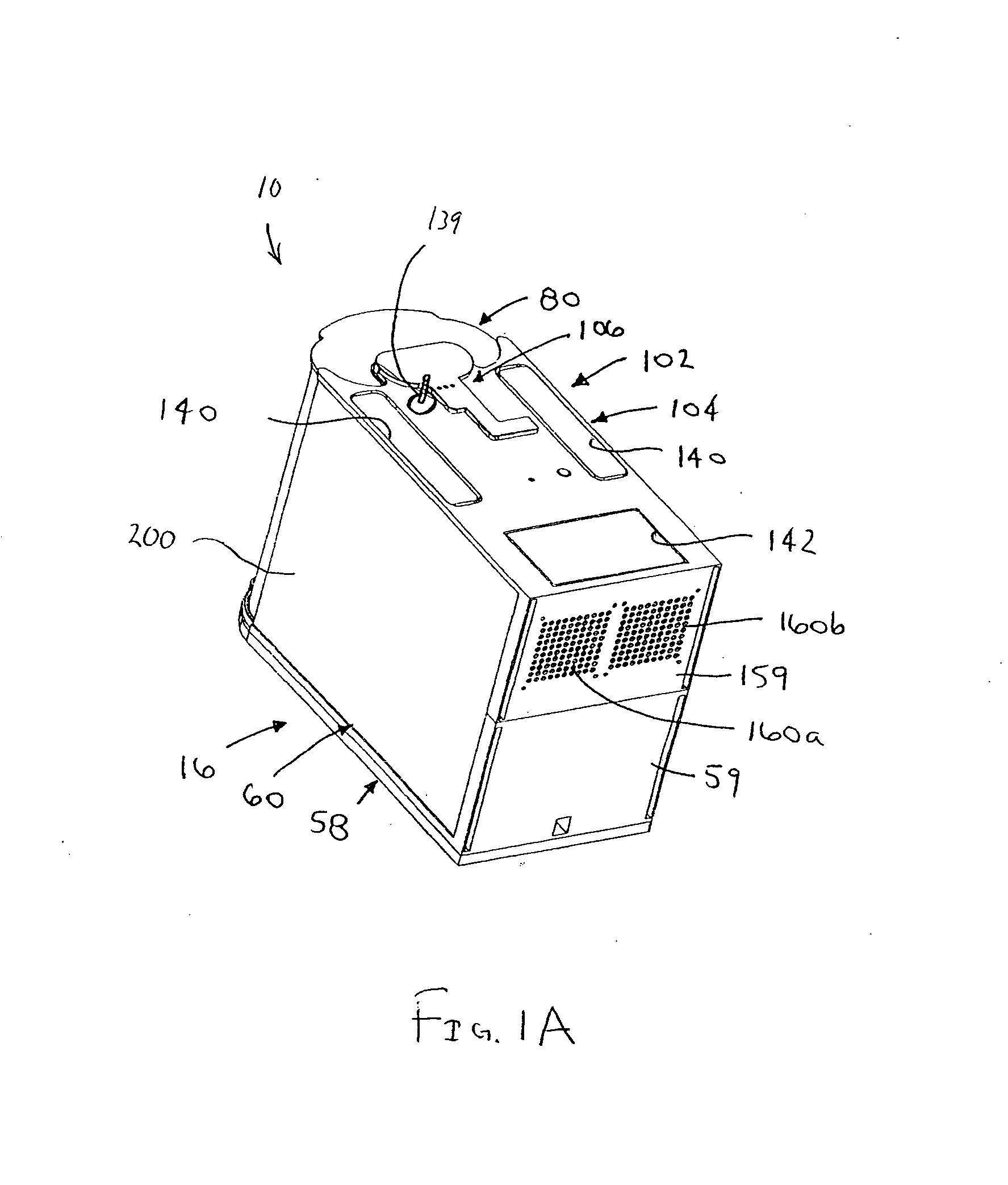

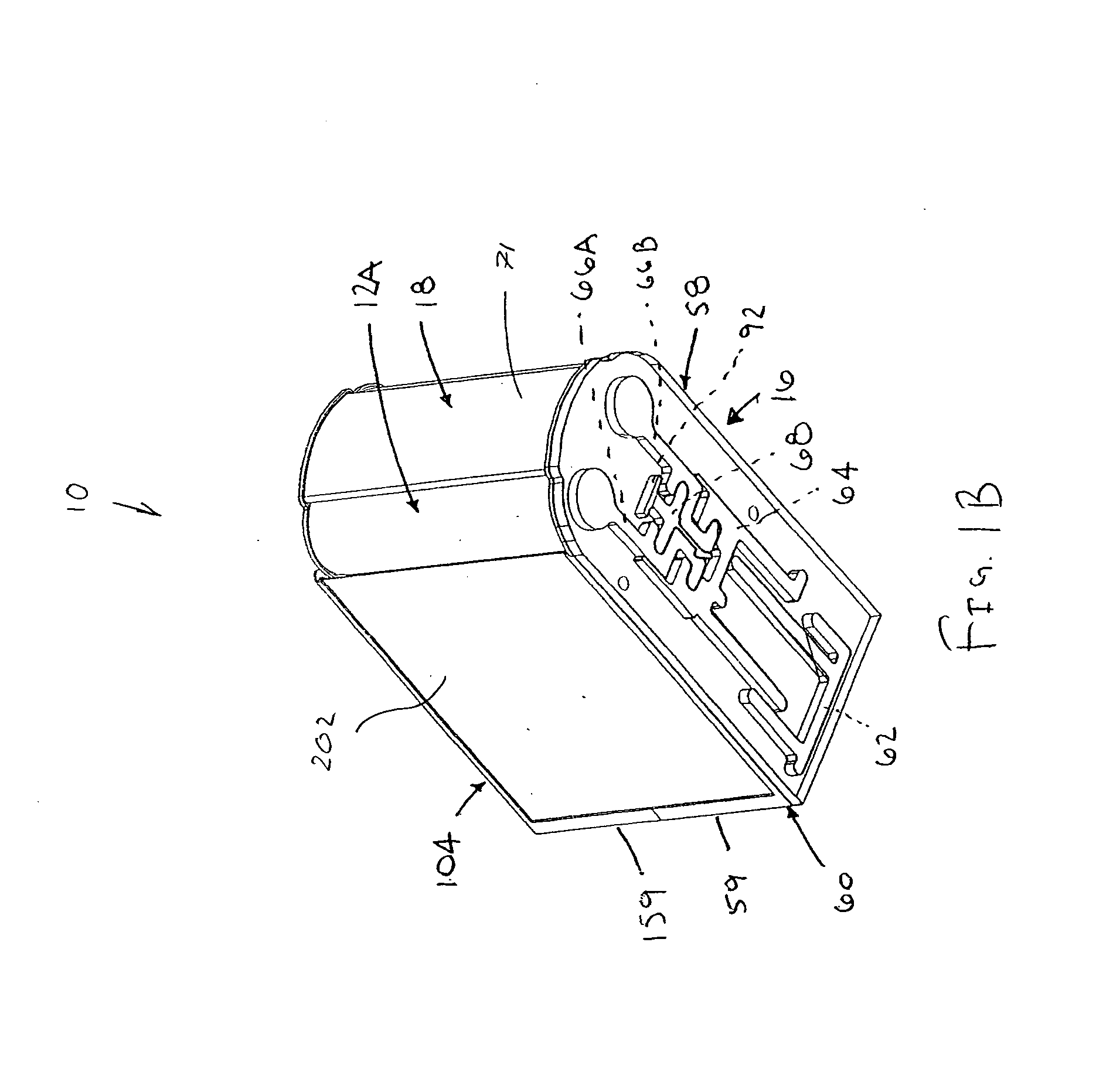

Fluid storage and dispensing system

InactiveUS6089027ACostPerformanceContainer filling methodsVacuum evaporation coatingSingle stageSorbent

A fluid storage and dispensing system comprising a vessel for holding a fluid at a desired pressure. The vessel has a pressure regulator, e.g., a single-stage or multi-stage regulator, associated with a port of the vessel, and set at a predetermined pressure. A dispensing assembly, e.g., including a flow control means such as a valve, is arranged in gas / vapor flow communication with the regulator, whereby the opening of the valve effects dispensing of gas / vapor from the vessel. The fluid in the vessel may be constituted by a liquid that is confined in the vessel at a pressure in excess of its liquefaction pressure at prevailing temperature conditions, e.g., ambient (room) temperature. In another aspect, the vessel contains a solid-phase sorbent material having sorbable gas adsorbed thereon, at a pressure in excess of 50 psig. The vessel may have a >1 inch NGT threaded neck opening, to accommodate the installation of an interior regulator.

Owner:ENTEGRIS INC

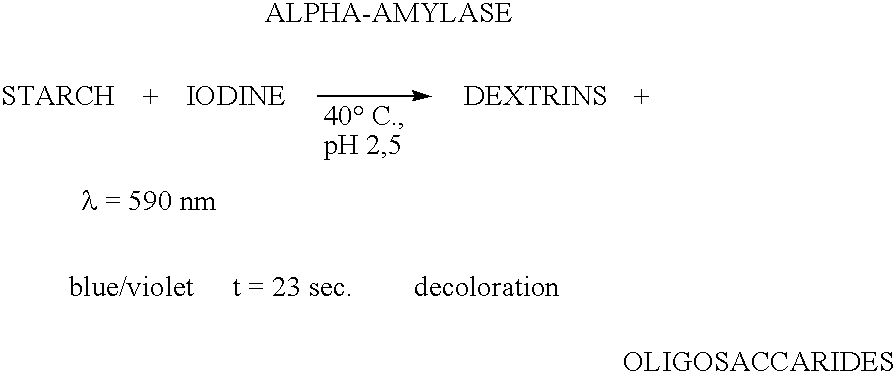

Enzymes for starch processing

InactiveUS20050054071A1Increased acid alpha-amylase activityImprove enzyme stabilitySugar derivativesBacteriaBiotechnologyCarbohydrate-binding protein

The present invention relates to a hybrid enzyme comprising carbohydrate-binding module amino acid sequence and a fungal alpha-amylase amino acid sequence and to a variant of a fungal wild type enzyme comprising a carbohydrate-binding module and an alpha-amylase catalytic module. The invention also relates to the use of the hybrid enzyme or the variant in starch liquefaction.

Owner:NOVOZYMES AS +1

Fluid storage and dispensing system

InactiveUS6101816AMinimize the possibilityUse minimizedContainer filling methodsVacuum evaporation coatingLiquid stateProduct gas

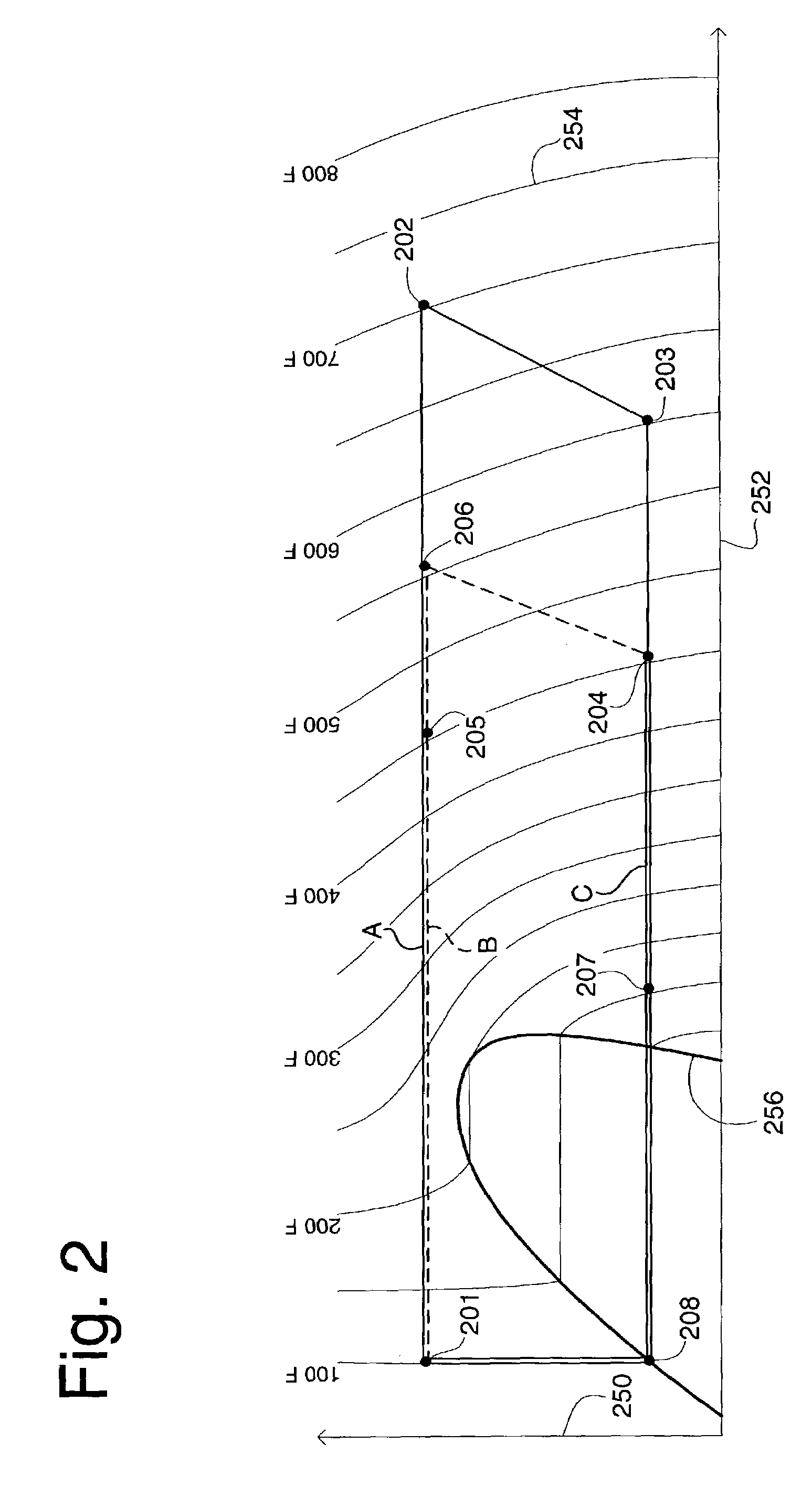

A fluid storage and dispensing system comprising a vessel for holding a fluid at a desired pressure. The vessel has a pressure regulator associated with a port of the vessel, and set at a predetermined pressure. A dispensing assembly, e.g, including a flow control means such as a valve, is arranged in gas / vapor flow communication with the regulator, whereby the opening of the valve effects dispensing of gas / vapor from the vessel. The fluid in the vessel may be constituted by a liquid which is confined in the vessel at a pressure in excess of its liquefaction pressure at prevailing temperature conditions, e.g., ambient (room) temperature. A phase separator such as a gas / vapor-permeable liquid-impermeable membrane, may be associated with the regulator, as a barrier to flow of liquid into the regulator, when the contained fluid in the vessel is in a liquid state.

Owner:ENTEGRIS INC

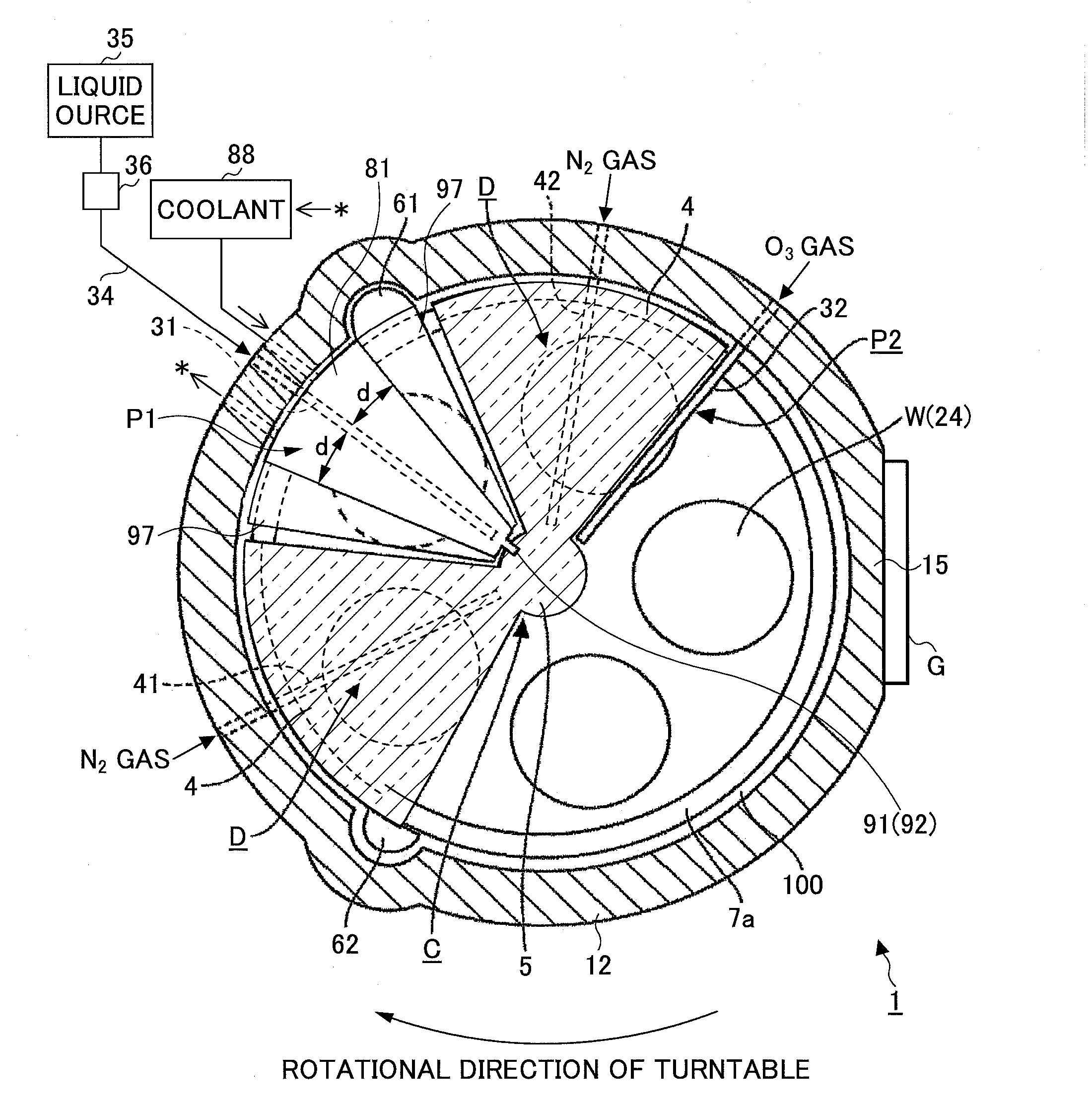

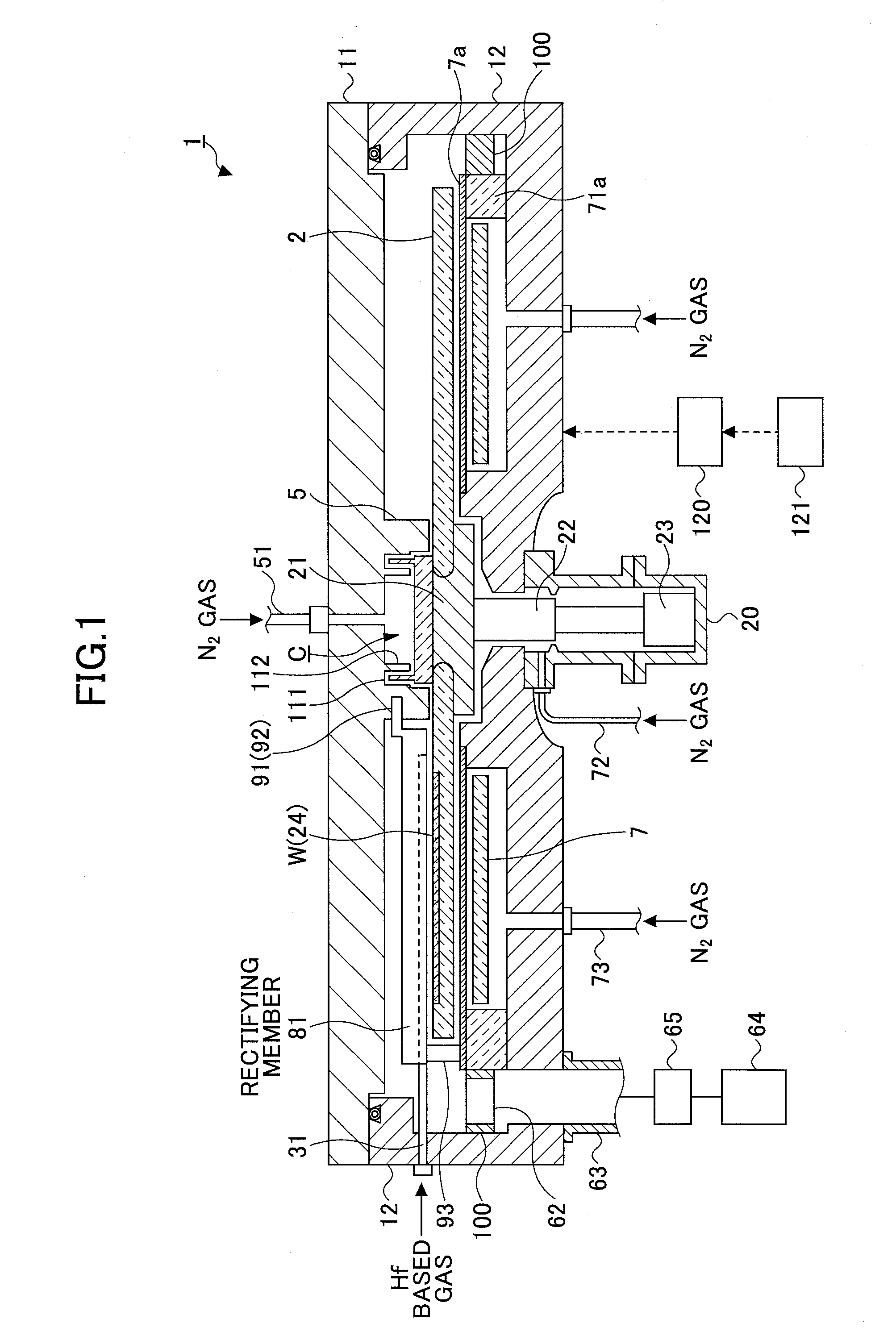

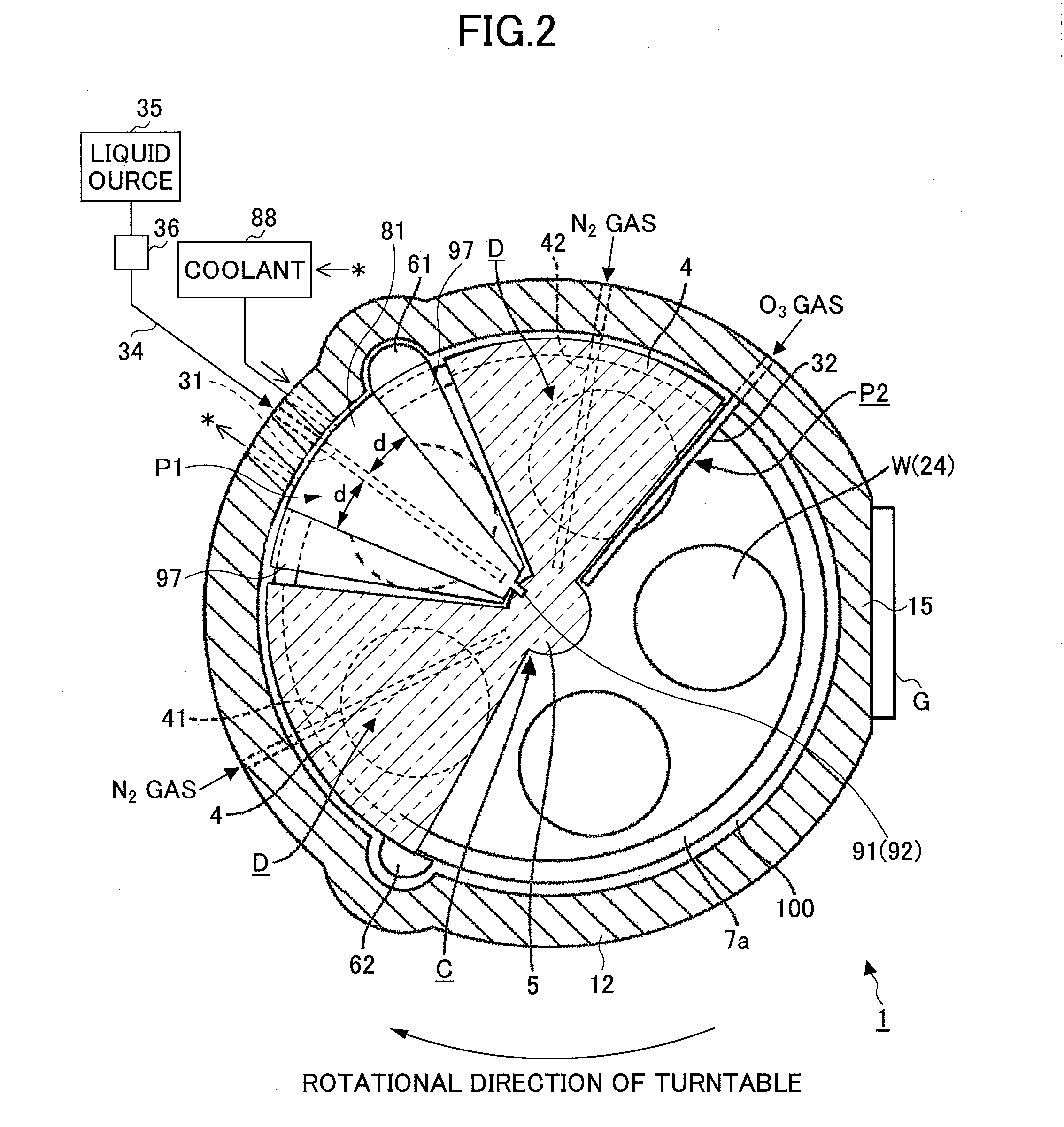

Film deposition apparatus

In discharging a source gas from a first process gas nozzle, rectifying members including a coolant flow passage provided in a concertinaing manner therein are arranged both sides of the first process gas nozzle. Then, a coolant at a temperature higher than a liquefaction temperature of the source gas and lower than a thermal decomposition temperature of the source gas is flown through the coolant flow passage, by which the first process gas nozzle is cooled through the rectifying member.

Owner:TOKYO ELECTRON LTD

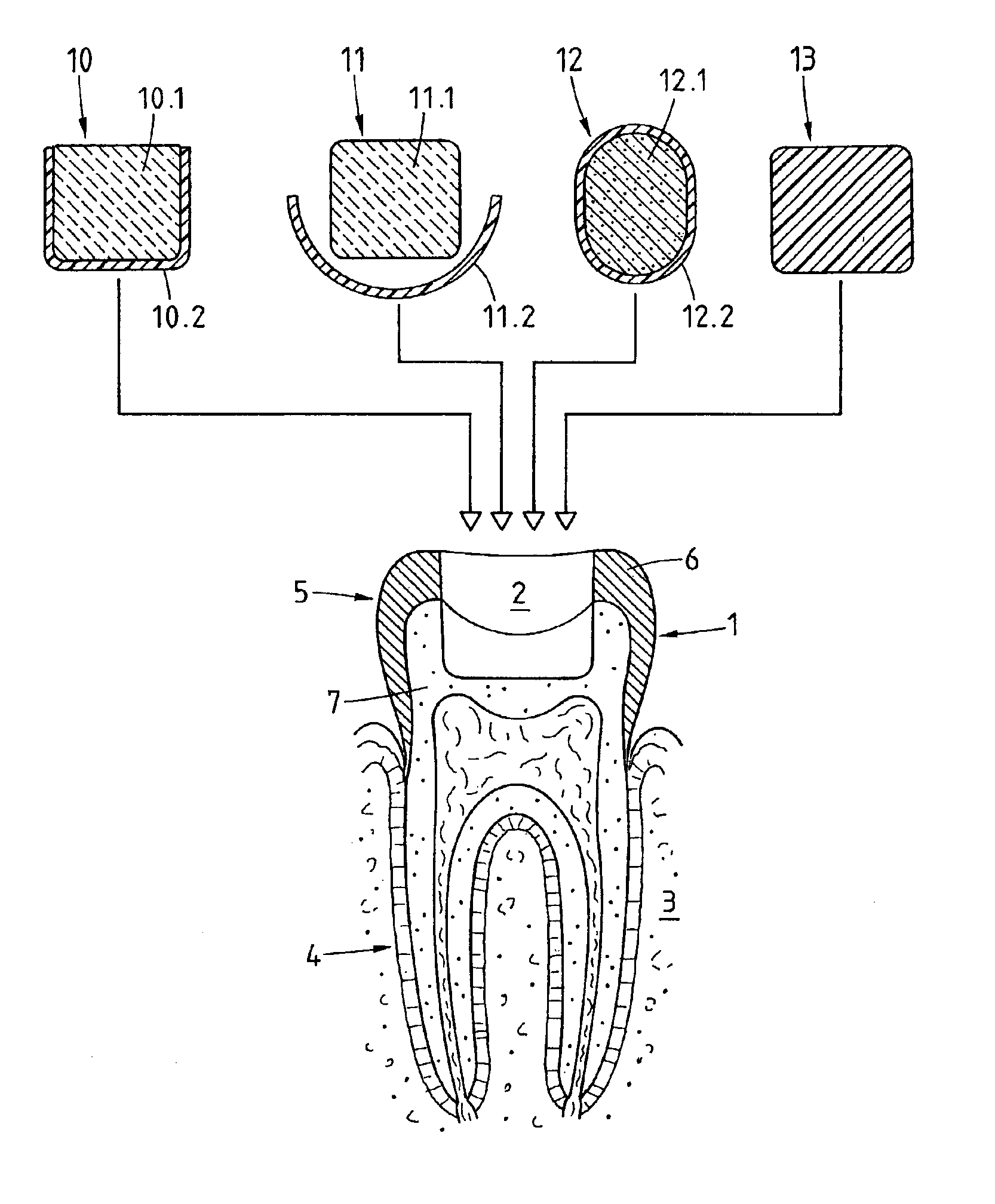

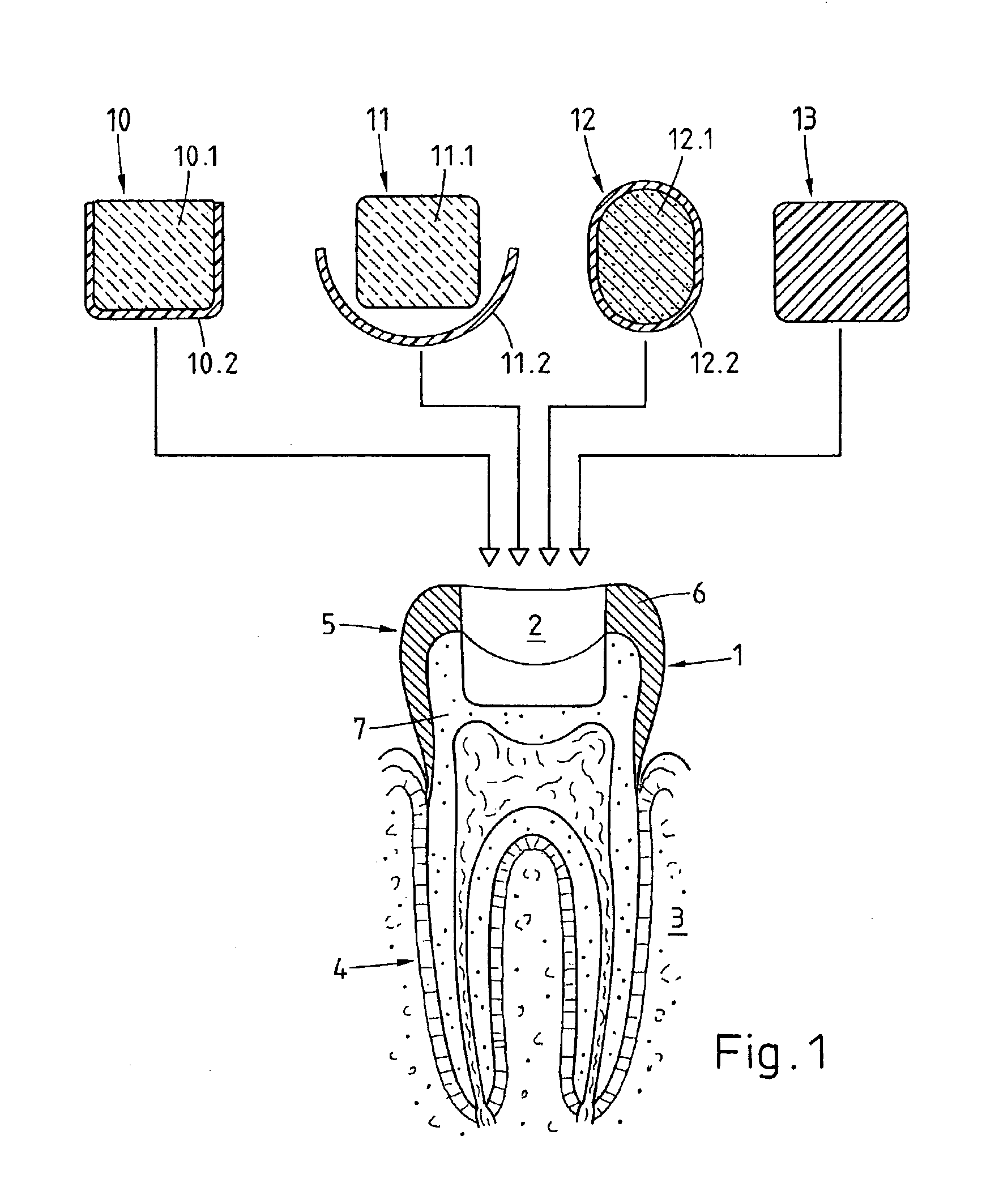

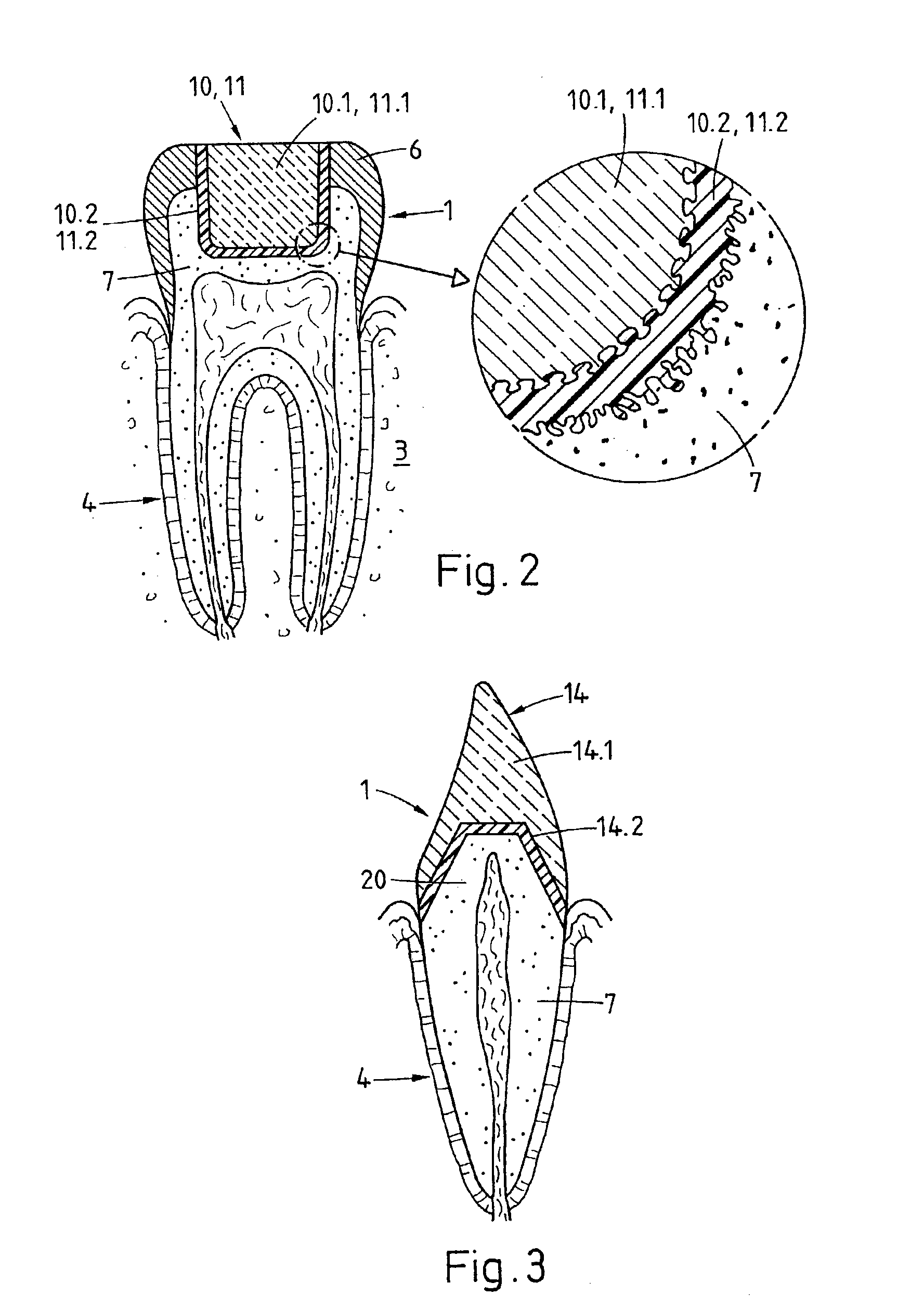

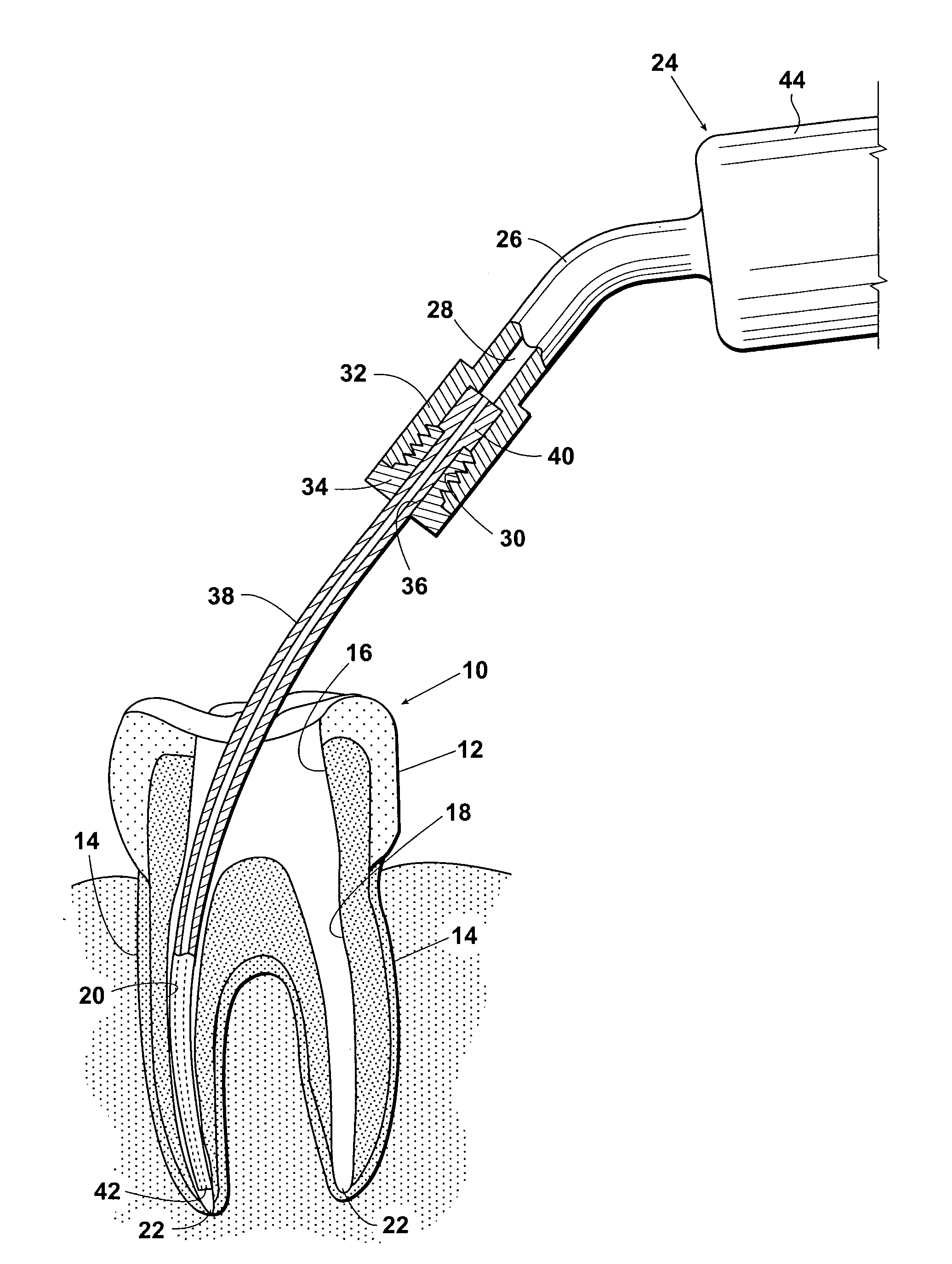

Preparation for being fastened on a natural tooth part or tooth and corresponding fastening method

ActiveUS6955540B2Reduce Shrinkage ProblemsRelieve stressDental implantsImpression capsStress concentrationNatural tooth

A preparation (10, 11,12,13) to be fixed to a natural tooth part or tooth, in particular for the replacement of a load-bearing tooth part, is for example a filling for a drilled-out tooth (1), a crown, bridge or prosthesis to be placed on a tooth stub, or a tooth pin to be fixed in a tooth root for fastening an artificial tooth, a bridge or a prosthesis. The preparation has surface regions which consist of a material with thermoplastic properties. The preparation (10, 11, 12,13) is designed in a manner such that it has oscillation properties with such low damping losses that for a liquefaction of the material with thermoplastic properties by way of oscillations there are local stress concentrations required, and in a manner such that such stress concentrations only occur in the region of the preparation surface. The preparation is positioned on a suitably prepared natural tooth part in a manner such that the material with the thermoplastic properties is in contact or may be brought into contact with the dentin surface and / or enamel surface. The preparation is then made to mechanically oscillate and is simultaneously pressed against the natural tooth part, whereby the material with the thermoplastic properties is at least partly liquefied and brought into intimate contact with the dentin or enamel surface in a manner such that after solidification it forms a positive fit and / or material fit connection. Teeth restored with such preparations have a high stability and a long life, which in particular is attributed to the fact that the thermoplastic material, in contrast to cements used for the same purpose, shrinks less and has the ability to relieve internal stress by creeping.

Owner:WOODWELDING

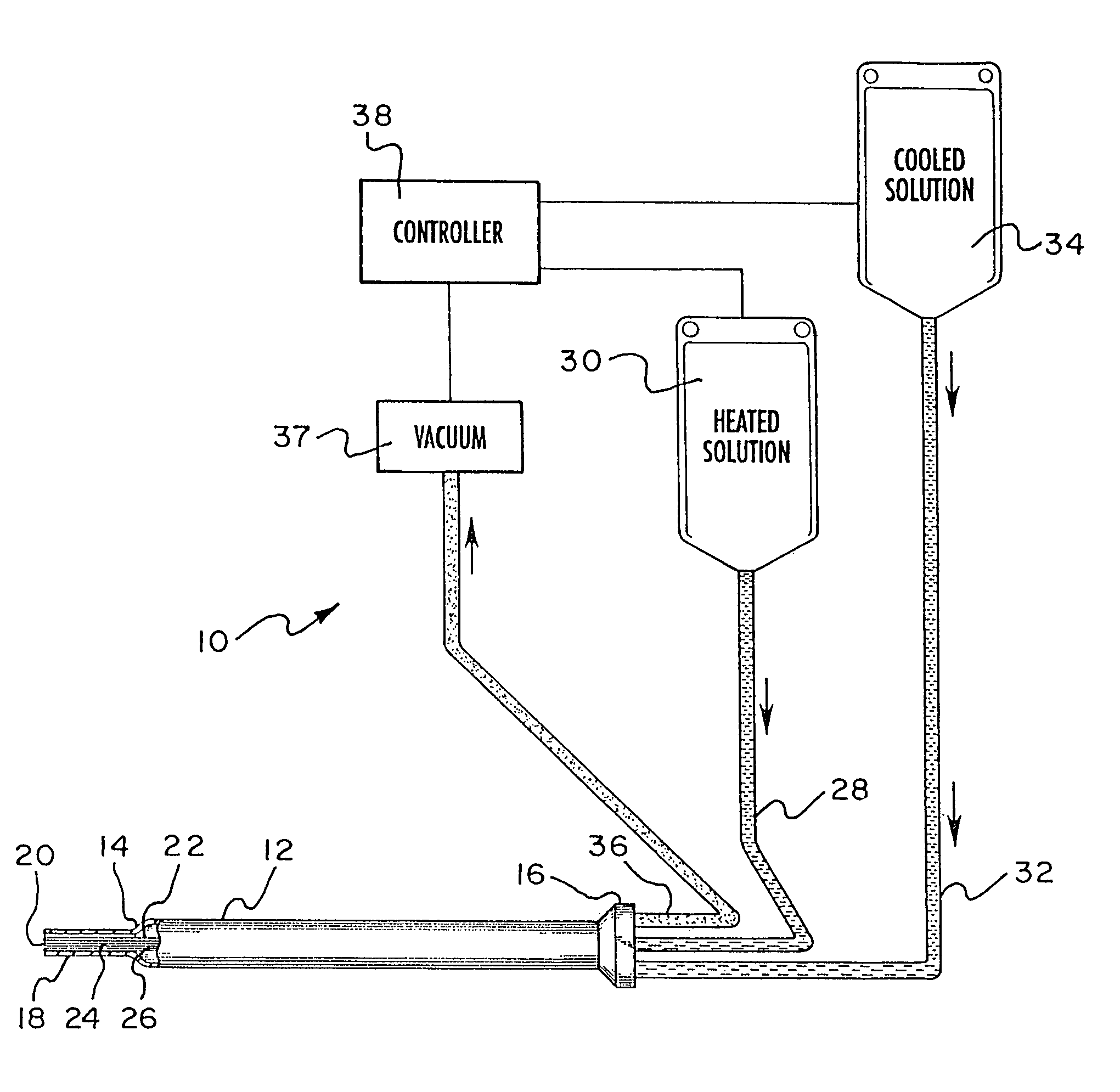

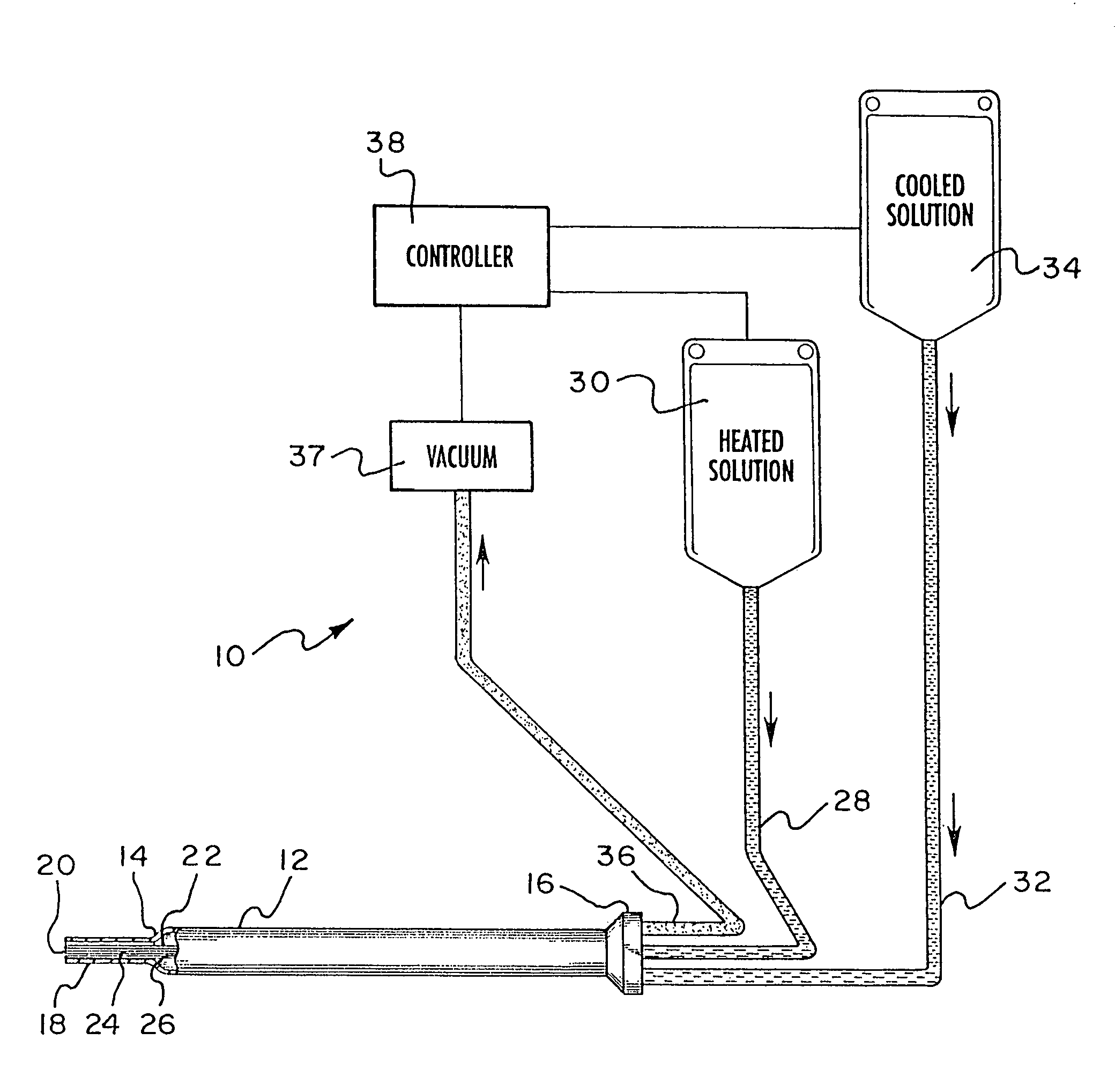

Tissue liquefaction and aspiration for dental treatment

A method and apparatus are disclosed for liquefying target tissue within a body and aspirating the same while leaving non-target tissue intact. A biocompatible fluid is heated and contacted with target tissue so that the target tissue is melted while non-target tissue remains intact. As the target tissue is being melted it is also aspirated from the body.

Owner:ANDREW MARK S +1

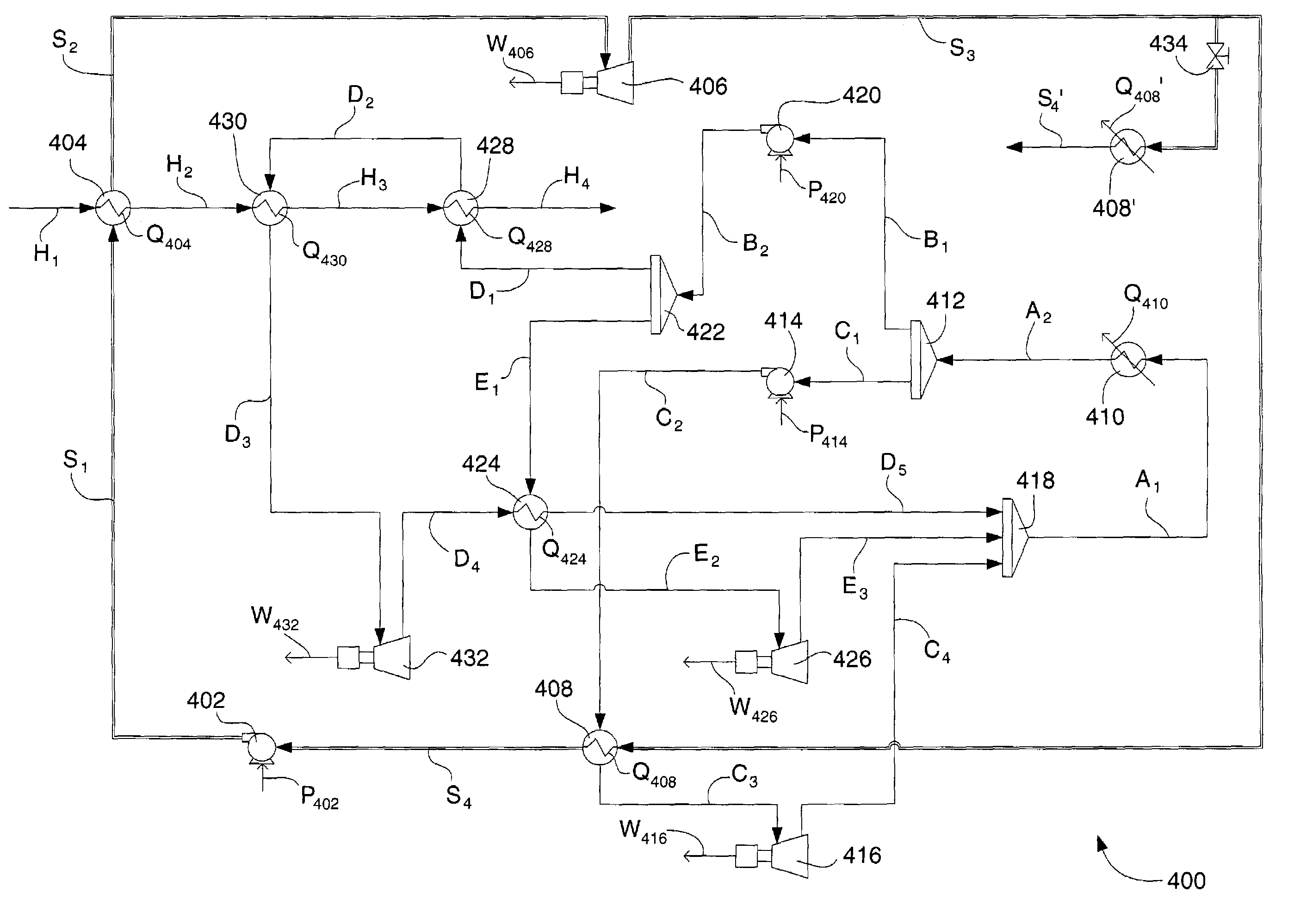

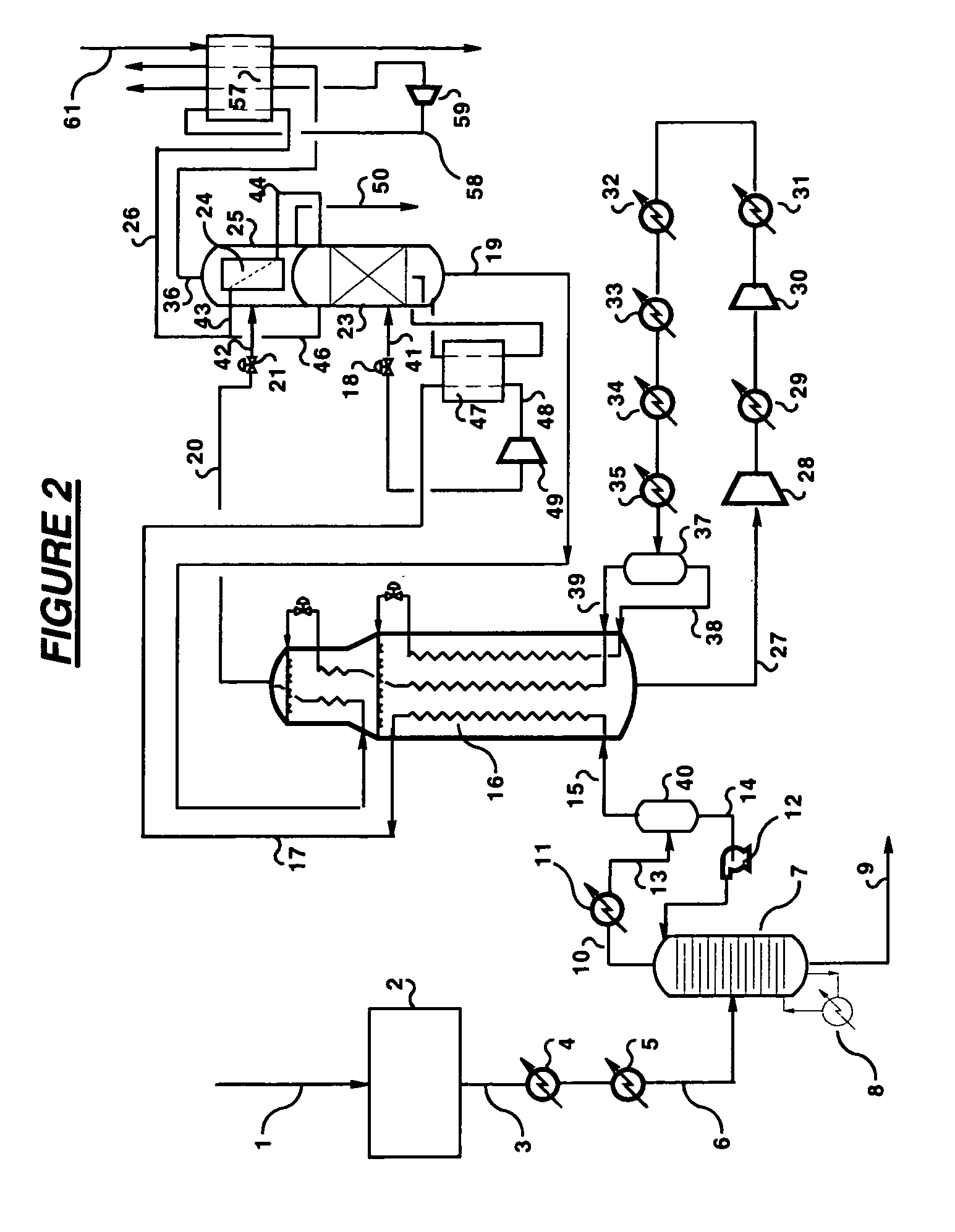

Cascading closed loop cycle power generation

InactiveUS7096665B2Improve power efficiencyIncrease pressureEnergy industrySteam accumulatorsLiquid propaneSteam condensation

Owner:UNIVERSAL TECH

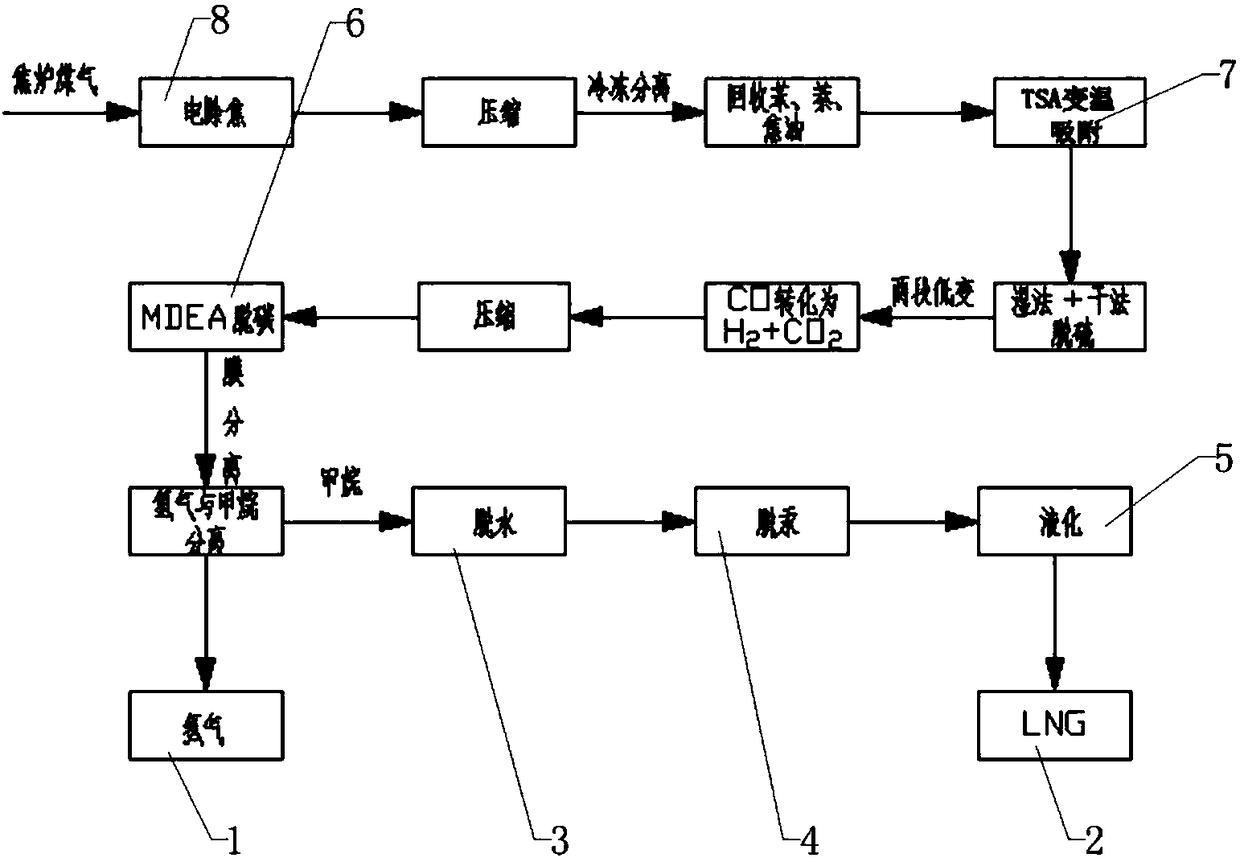

Method for preparing hydrogen and LNG from coke oven gas

InactiveCN108179046ALow investment costLow running costHydrogenGaseous fuelsHigh concentrationSeparation technology

The invention provides a method for preparing hydrogen and LNG from coke oven gas. The method comprises the following steps: electric decoking; boosting of the coke oven gas by a compression system; cooling of the raw gas coke oven gas by using the BOG gas (the BOG gas is a gas formed after the passive heating gasification of LNG) of LNG in order to further remove tar, benzene, naphthalene and like substances in the coke oven gas; and pretreatment using a TSA process to finely remove macromolecular impurities, such as tar, benzene, naphthalene and the like; wet and dry two-stage desulfurization for removing sulfides in the coke oven gas; two-stage low pressure shifting for a reaction of CO and water vapor to form CO2 and hydrogen; and pressurization using a compressor, an MDEA solution process for removing carbon dioxide, a membrane separation technology for separating hydrogen and methane, separation, concentration and purification of the hydrogen and methane, and dehydration, demercuration and liquefaction of the separated high-concentration methane to obtain the LNG. The coke oven gas is finally converted into the hydrogen and the LNG which have high values, so the energy of thecoke oven gas is fully used, and the environment is protected.

Owner:SICHUAN HENGRI GAS ENG CO LTD

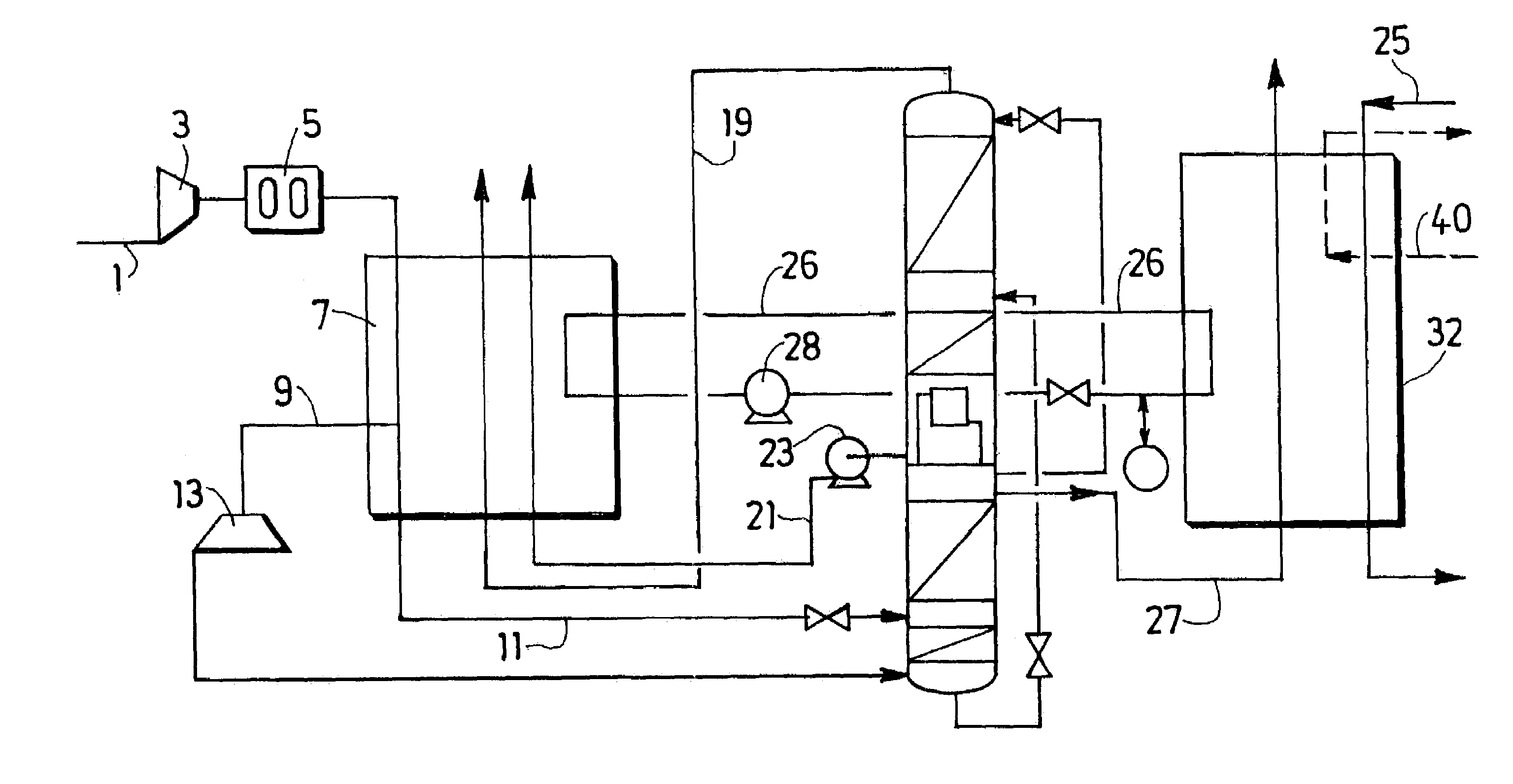

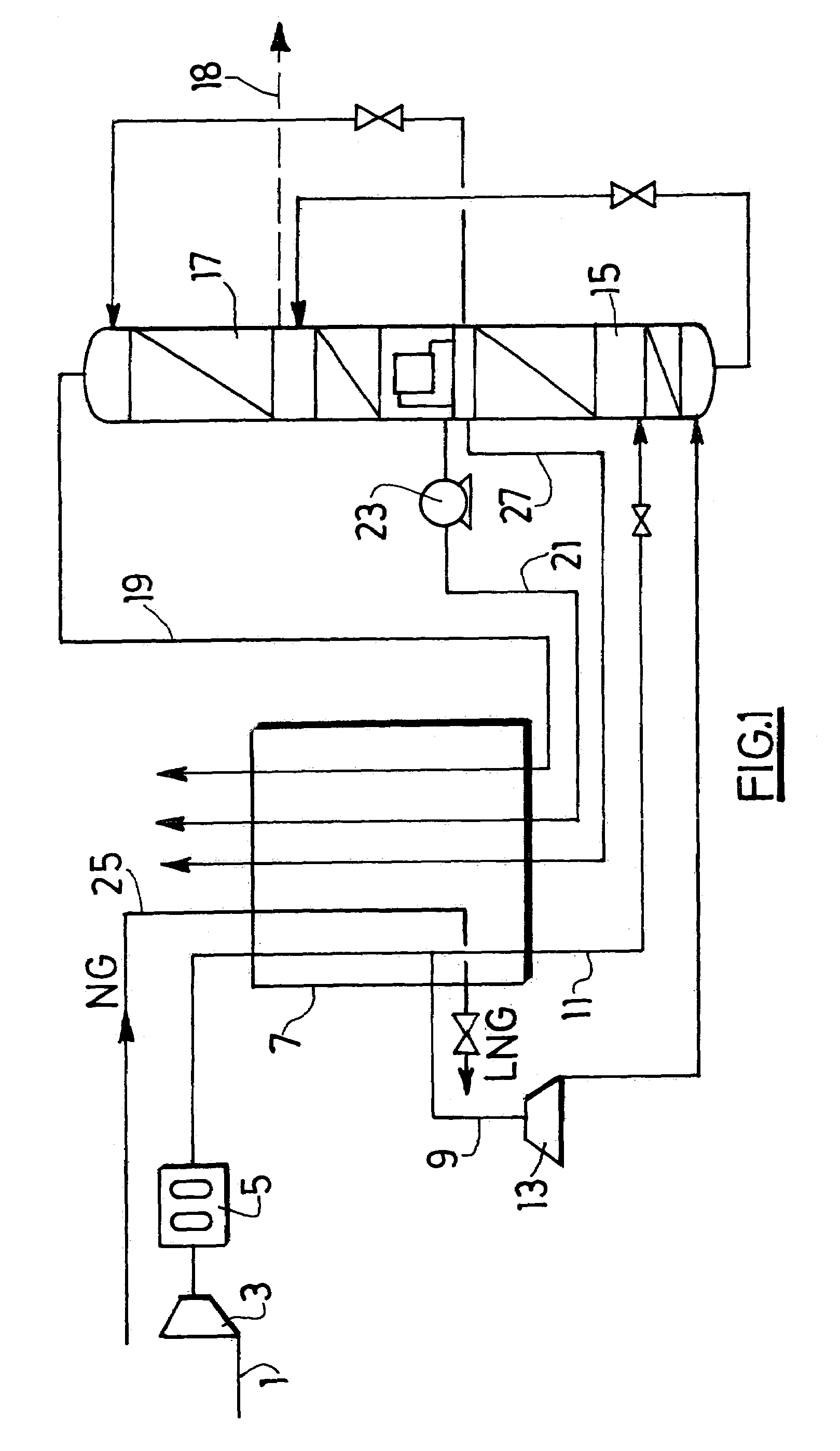

Combined air separation natural gas liquefaction plant

ActiveUS7143606B2Increase power consumptionIncrease the number ofSolidificationLiquefactionFractionating columnProcess engineering

In an integrated process and apparatus for the separation of air by cryogenic distillation and liquefaction of natural gas in which at least part of the refrigeration required to liquefy the natural gas is derived from at least one cryogenic air distillation plant comprising a main heat exchanger (7) and distillation columns (15, 17), wherein the natural gas (25) liquefies by indirect heat exchange in a heat exchanger (7, 32, 34) with a cold fluid (21, 26), the cold fluid being sent to the heat exchanger at least partially in liquid form and undergoing at least a partial vaporisation in the heat exchanger.

Owner:LAIR LIQUIDE SA POUR LETUDE & LEXPLOITATION DES PROCEDES GEORGES CLAUDE

Natural gas liquefaction

A process for liquefying natural gas in conjunction with producing a liquid stream containing predominantly hydrocarbons heavier than methane is disclosed. In the process, the natural gas stream to be liquefied is partially cooled, expanded to an intermediate pressure, and supplied to a distillation column. The bottom product from this distillation column preferentially contains the majority of any hydrocarbons heavier than methane that would otherwise reduce the purity of the liquefied natural gas. The residual gas stream from the distillation column is compressed to a higher intermediate pressure, cooled under pressure to condense it, and then expanded to low pressure to form the liquefied natural gas stream.

Owner:UOP LLC

Natural gas liquefaction

A process for liquefying natural gas in conjunction with producing a liquid stream containing predominantly hydrocarbons heavier than methane is disclosed. In the process, the natural gas stream to be liquefied is partially cooled and divided into first and second streams. The first stream is further cooled to condense substantially all of it, expanded to an intermediate pressure, and then supplied to a distillation column at a first mid-column feed position. The second stream is also expanded to intermediate pressure and is then supplied to the column at a second lower mid-column feed position. A distillation stream is withdrawn from the column below the feed point of the second stream and is cooled to condense at least a part of it, forming a reflux stream. At least a portion of the reflux stream is directed to the distillation column as its top feed. The bottom product from this distillation column preferentially contains the majority of any hydrocarbons heavier than methane that would otherwise reduce the purity of the liquefied natural gas. The residual gas stream from the distillation column is compressed to a higher intermediate pressure, cooled under pressure to condense it, and then expanded to low pressure to form the liquefied natural gas stream.

Owner:UOP LLC

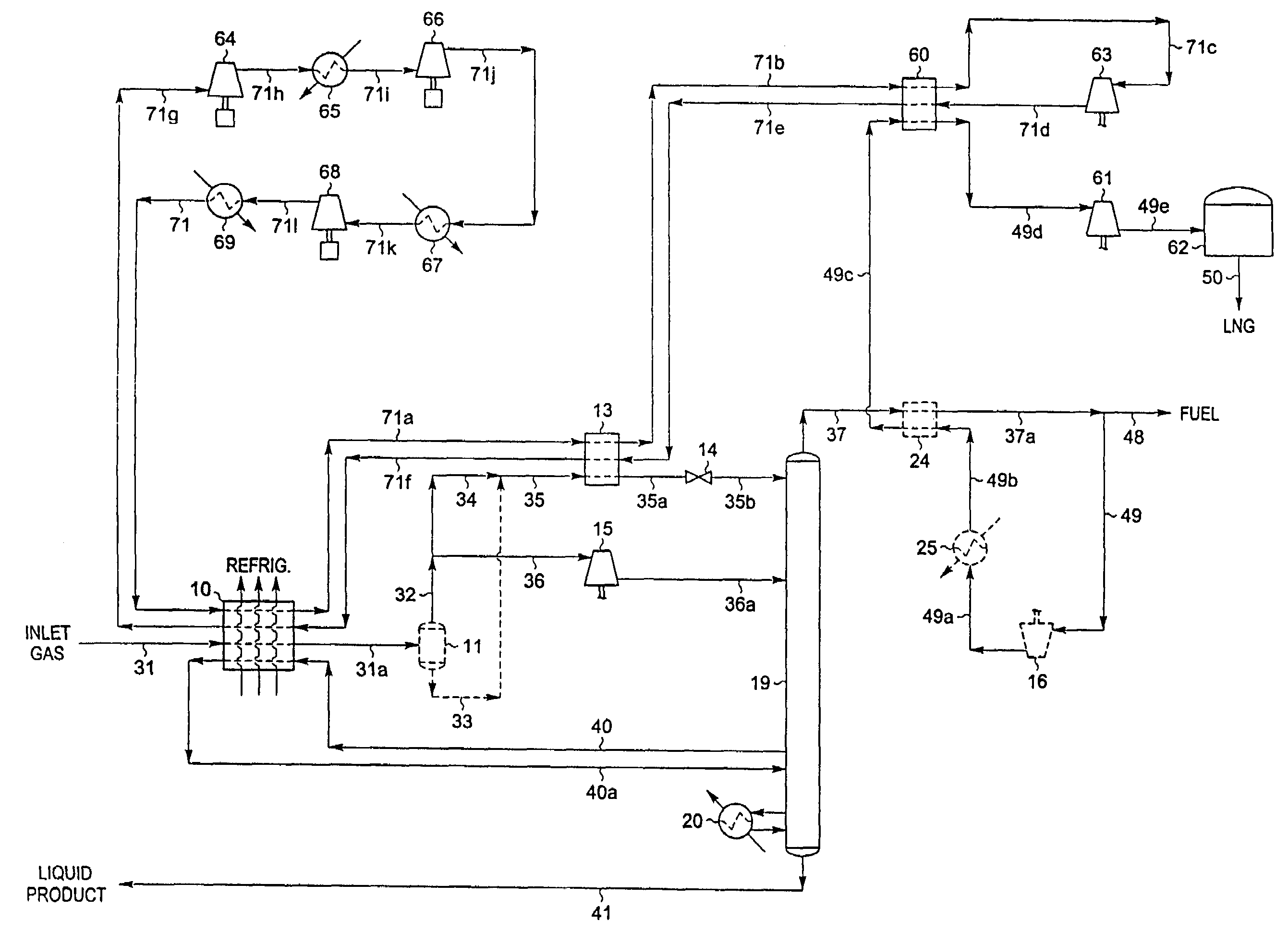

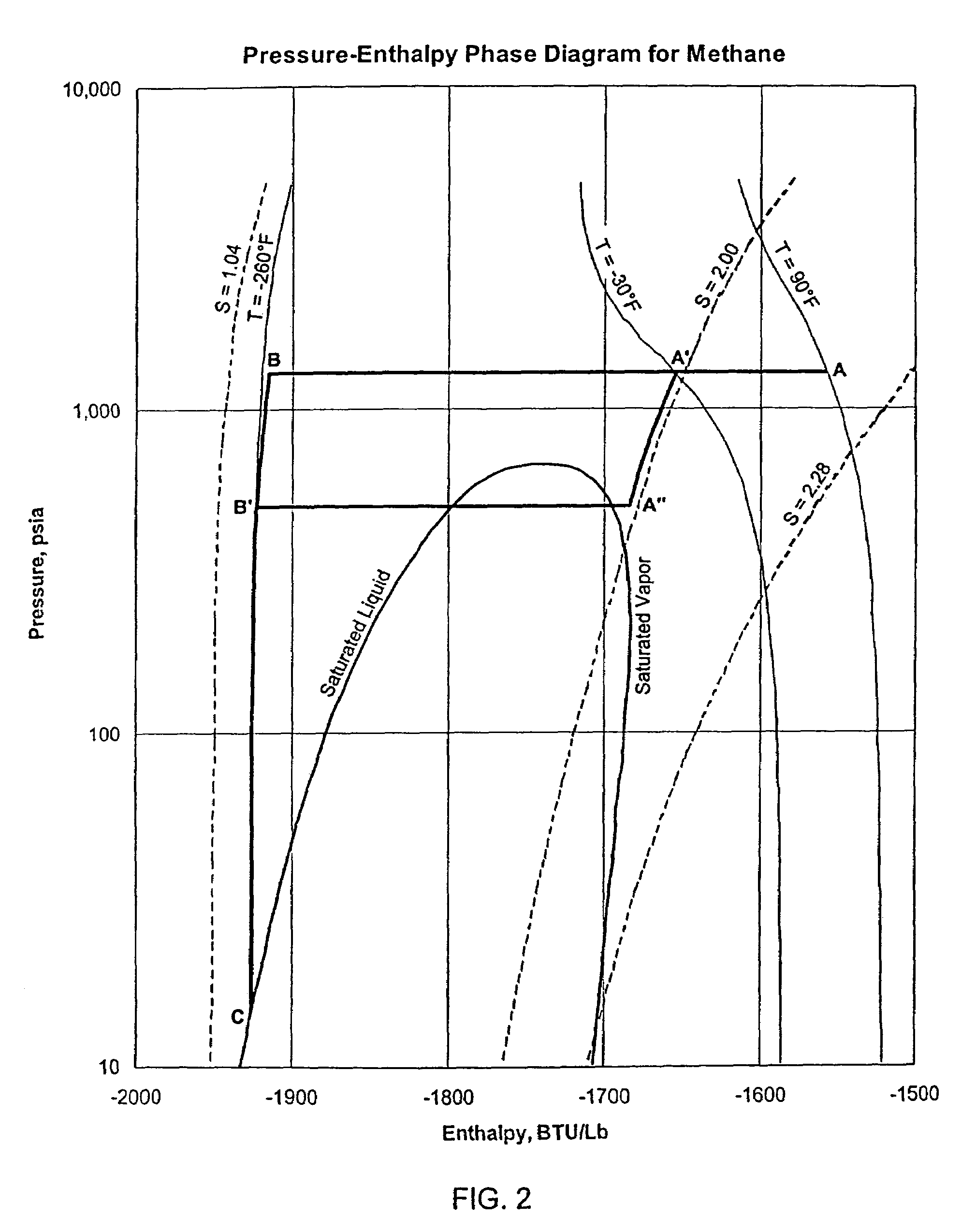

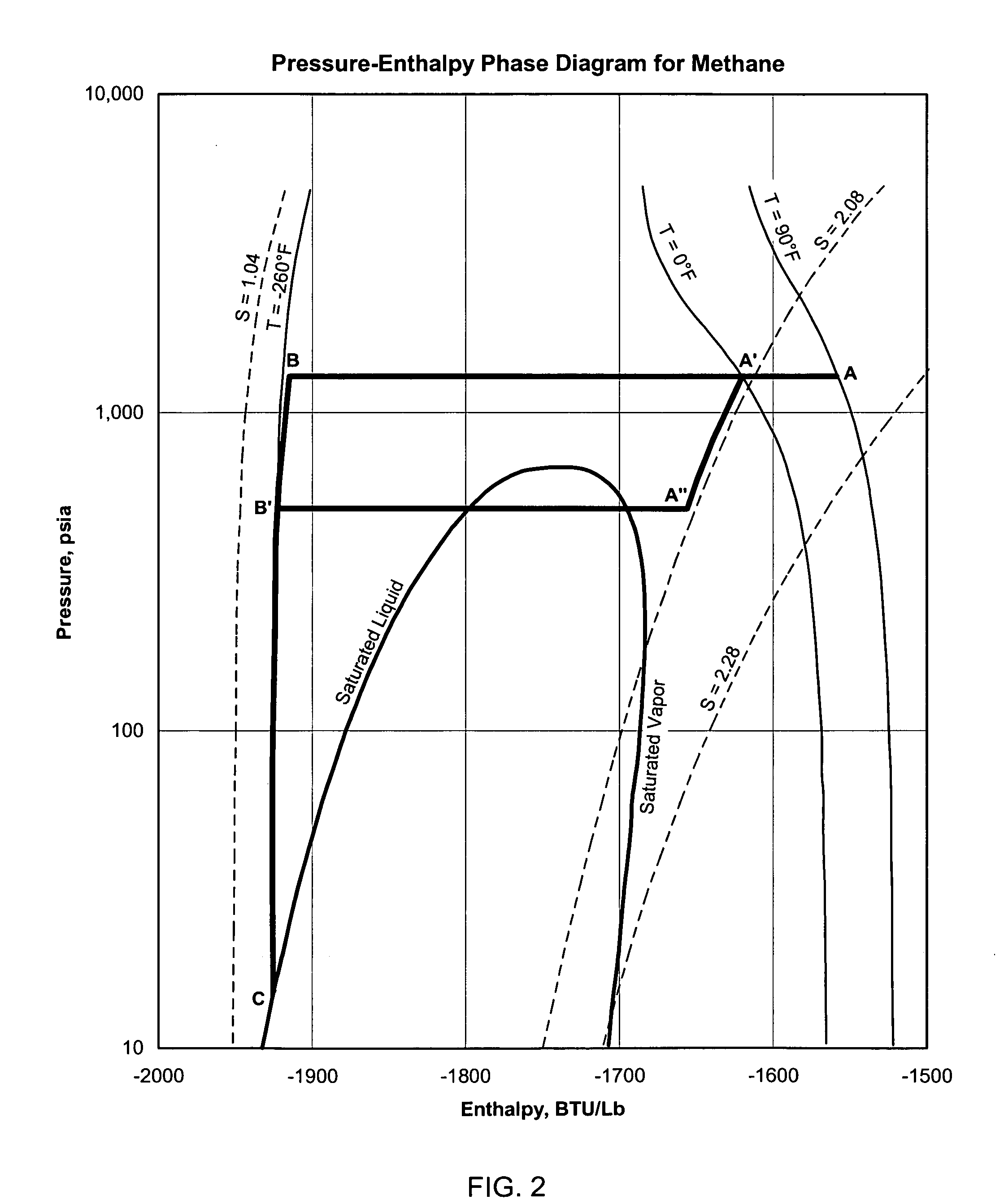

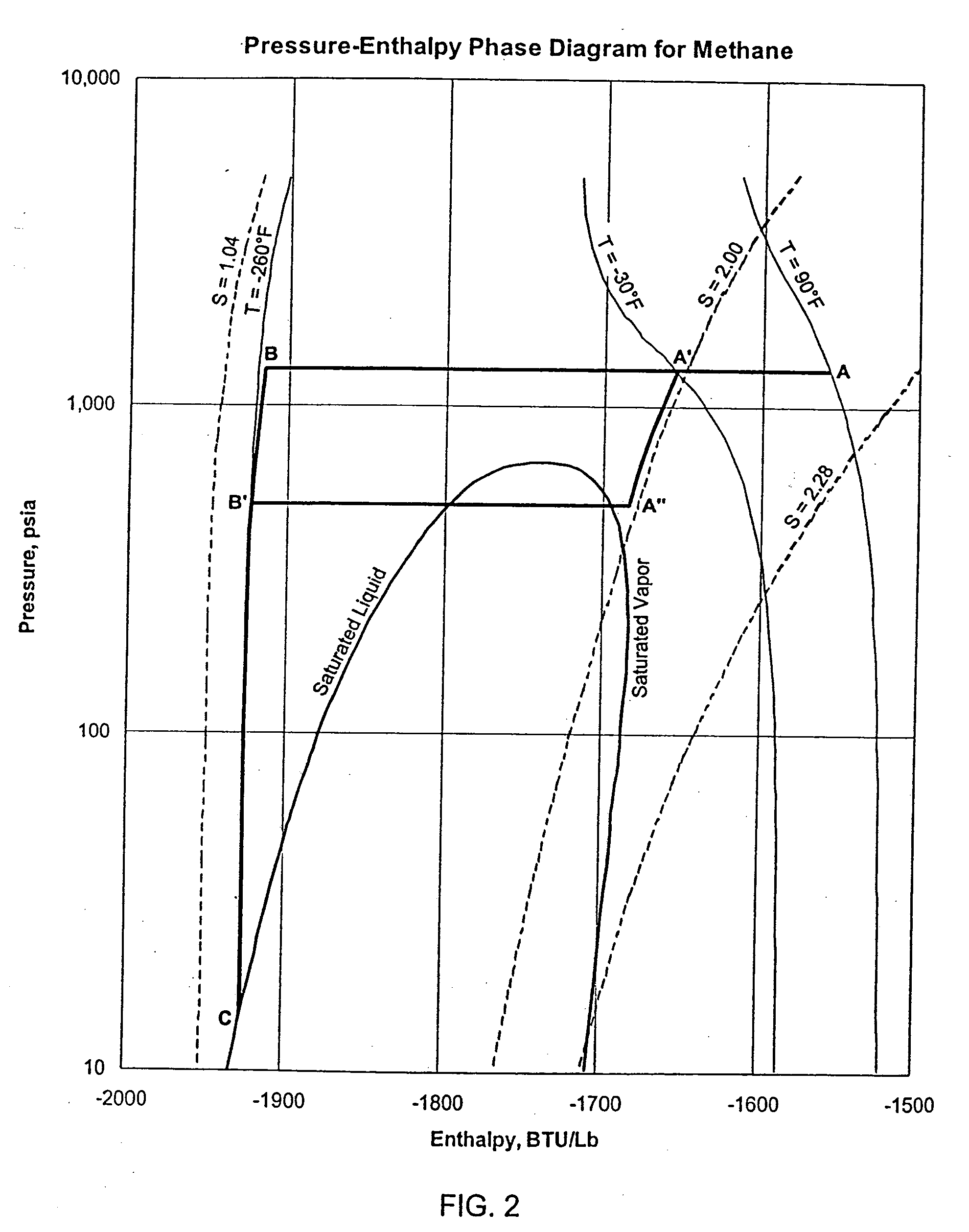

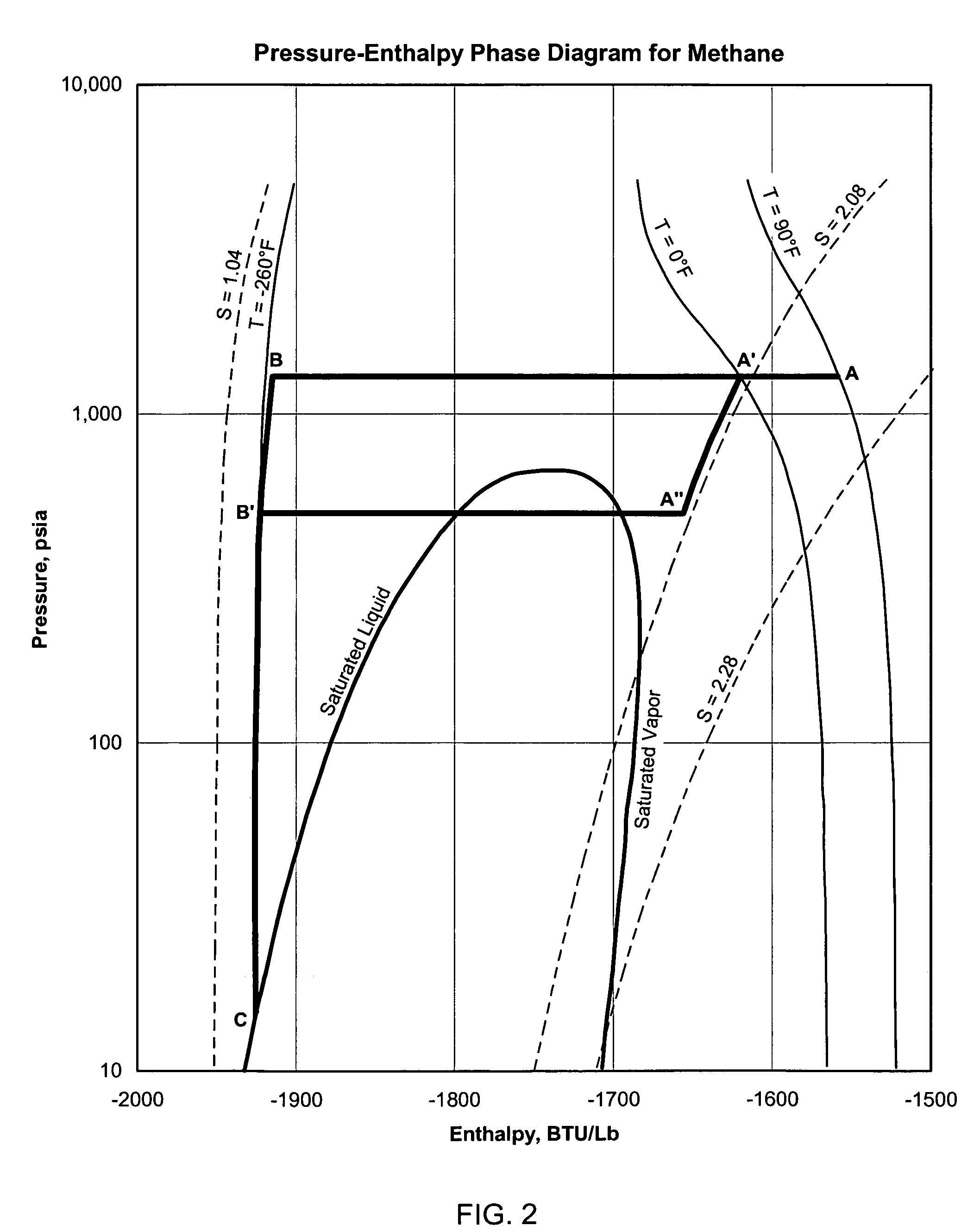

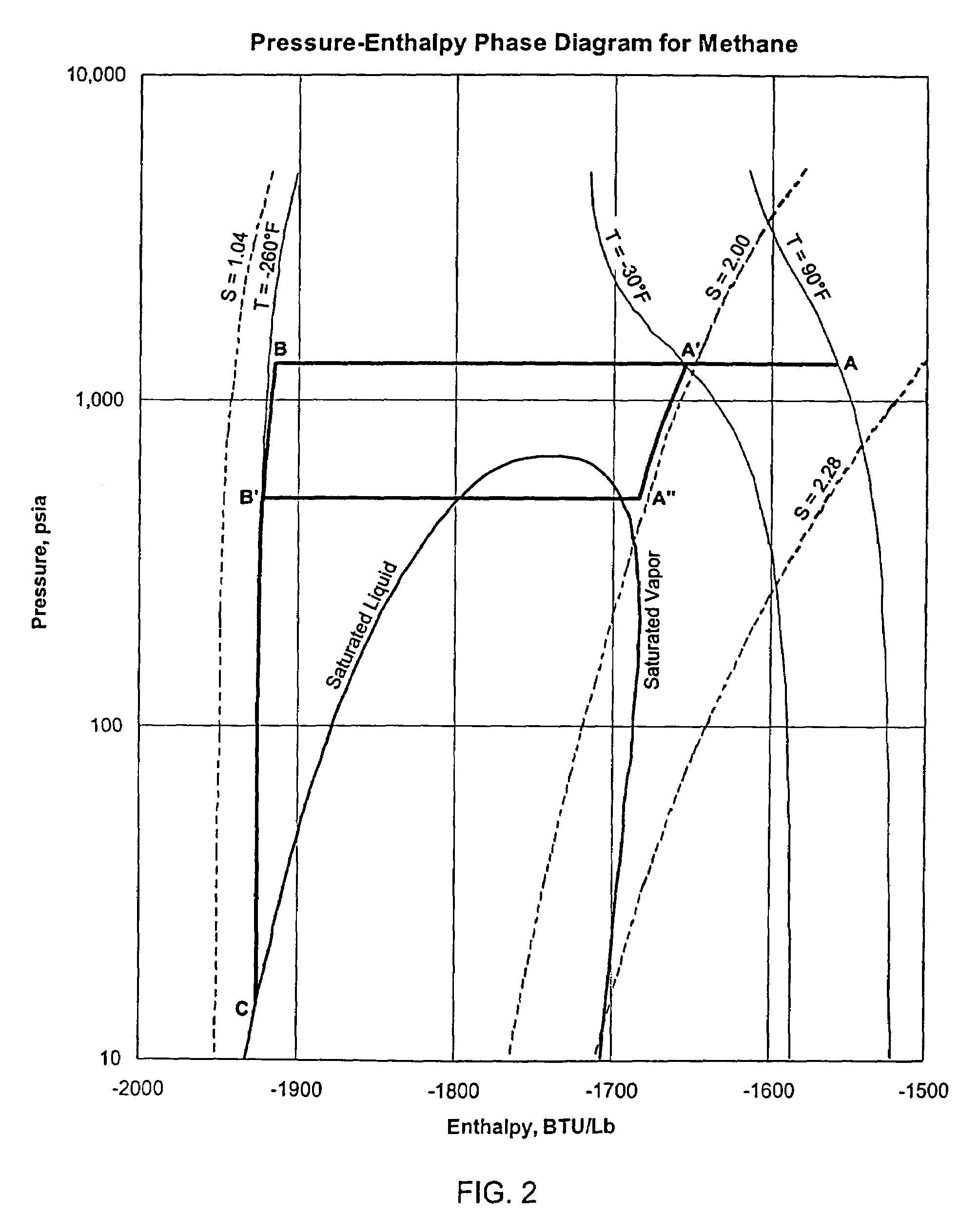

Natural Gas Liquefaction Process

The described invention relates to processes and systems for treating a gas stream, particularly one rich in methane for forming liquefied natural gas (LNG), said process including: (a) providing a gas stream; (b) providing a refrigerant; (c) compressing said refrigerant to provide a compressed refrigerant; (d) cooling said compressed refrigerant by indirect heat exchange with a cooling fluid; (e) expanding the refrigerant of (d) to cool said refrigerant, thereby producing an expanded, cooled refrigerant; (f) passing said expanded, cooled refrigerant to a first heat exchange area; (g) compressing the gas stream of (a) to a pressure of from greater than or equal to 1,000 psia to less than or equal to 4,500 psia; (h) cooling said compressed gas stream by indirect heat exchange with an external cooling fluid; and heat exchanging the compressed gas stream with the expanded, cooled refrigerant stream.

Owner:EXXONMOBIL UPSTREAM RES CO

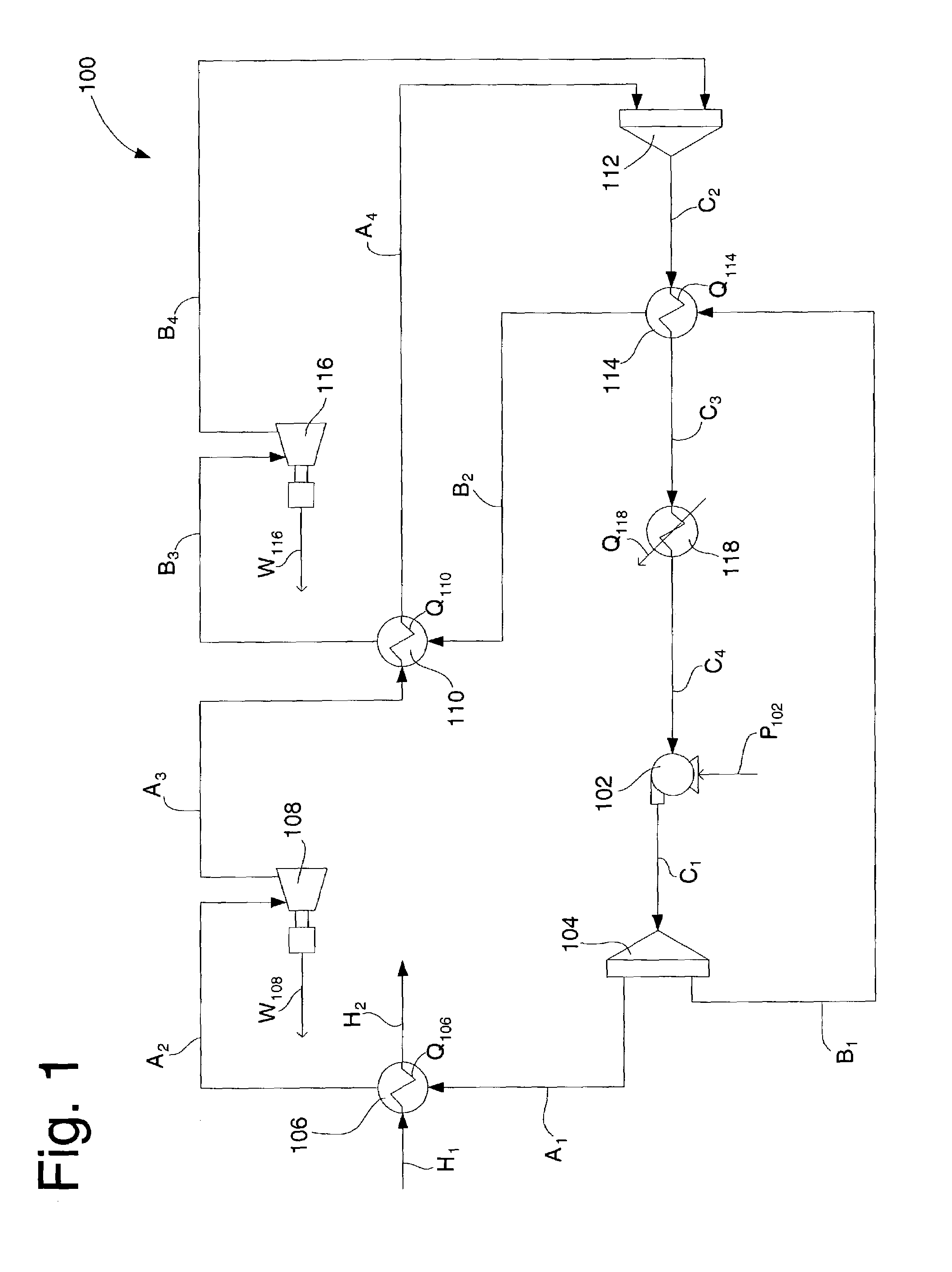

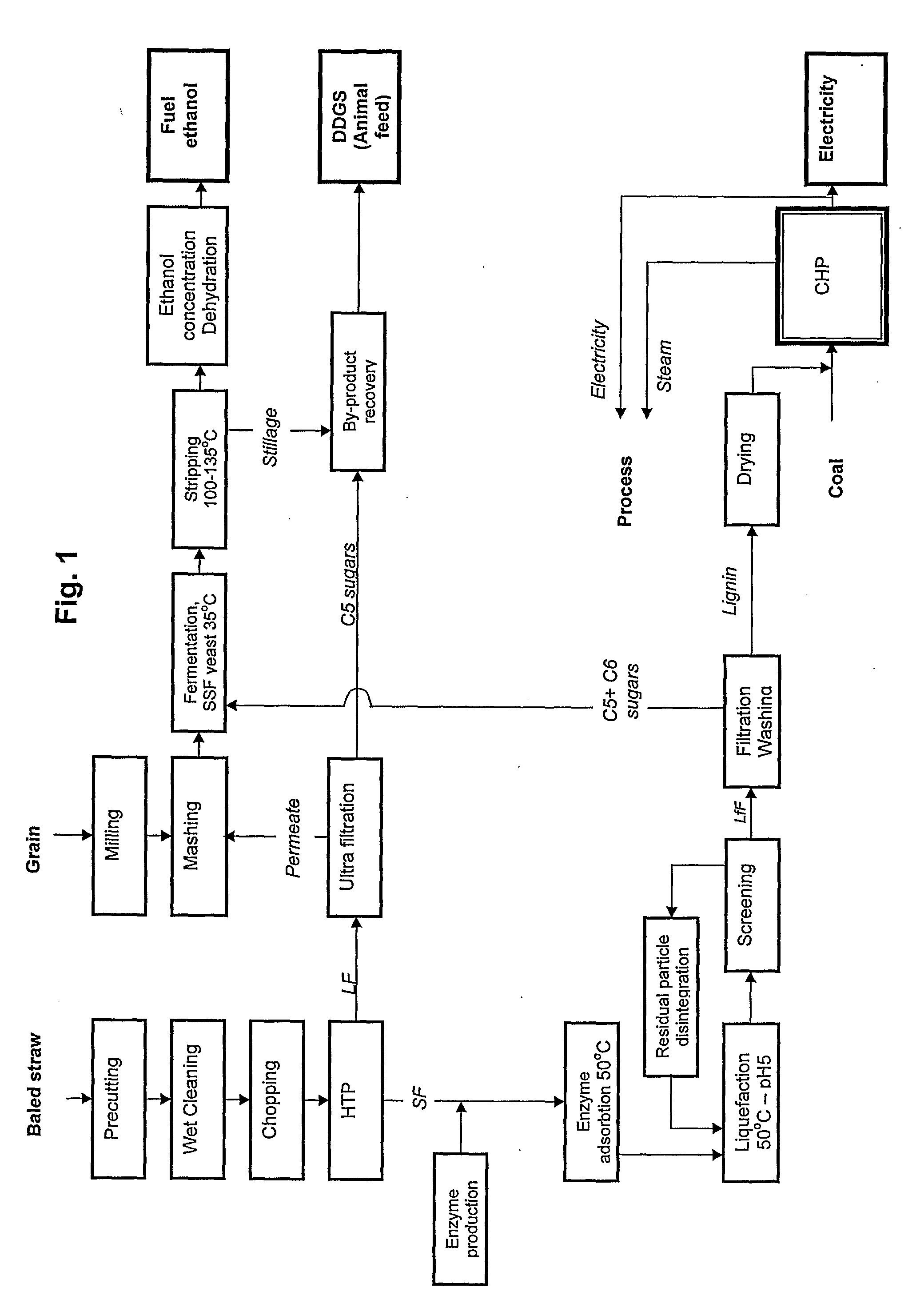

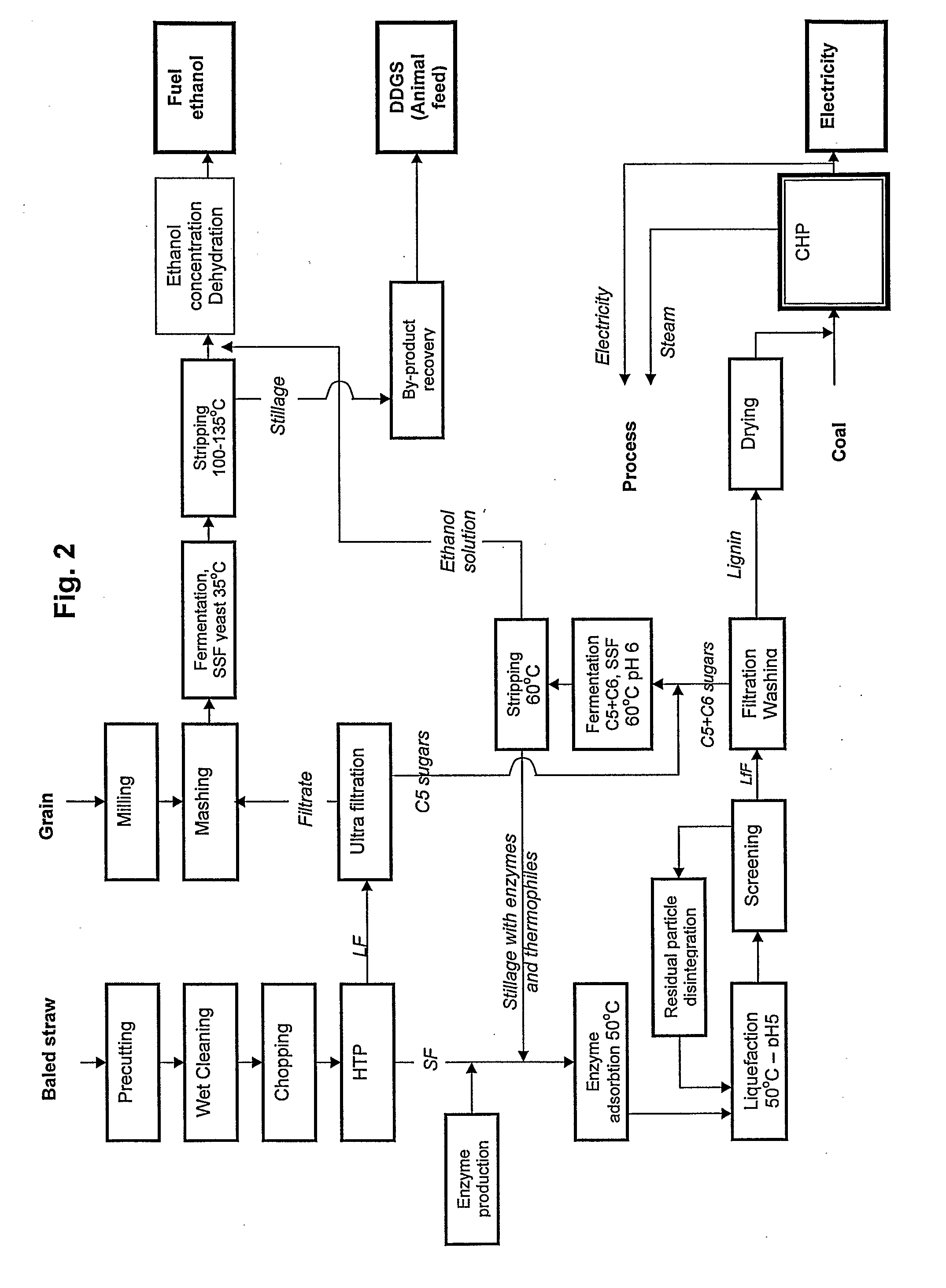

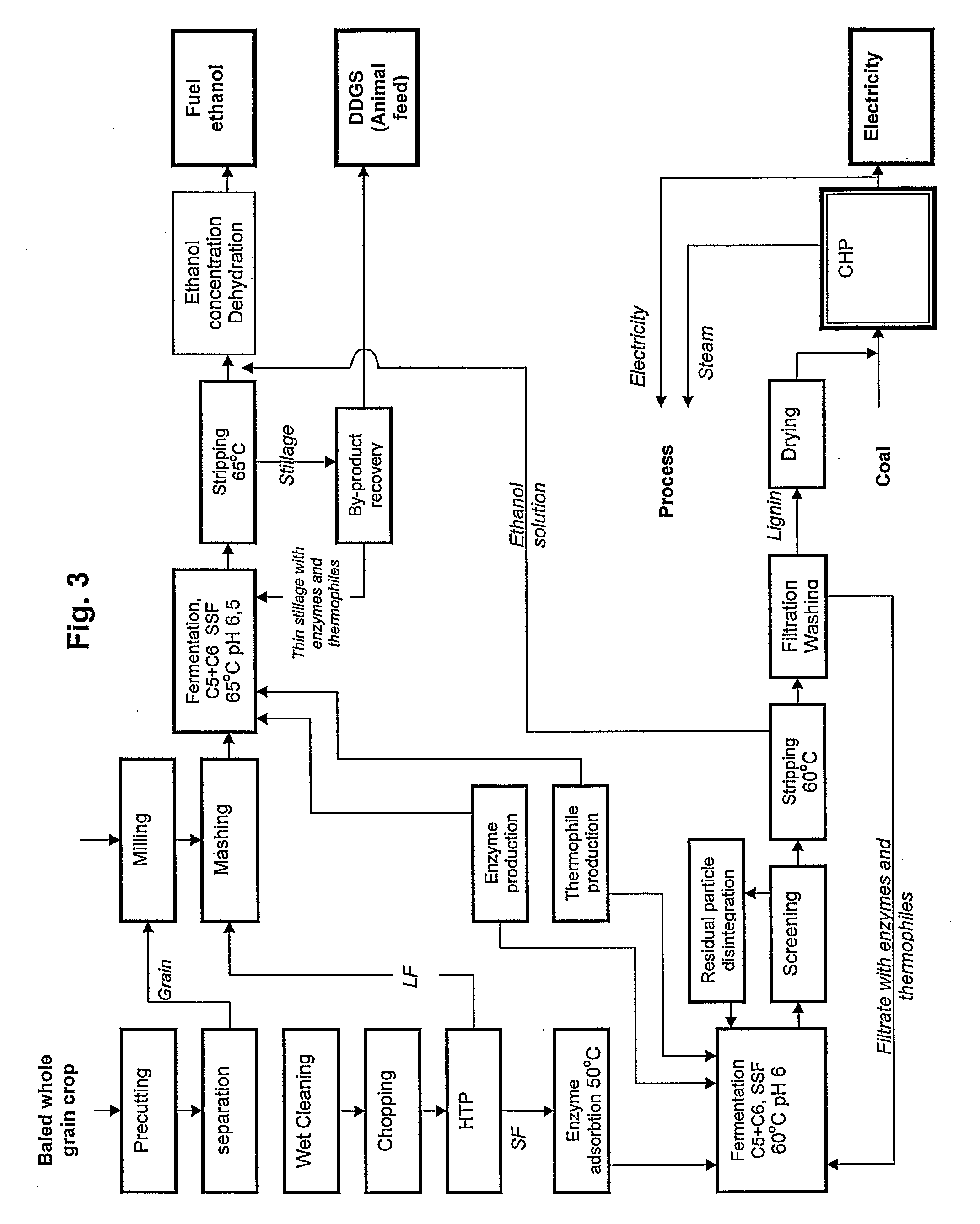

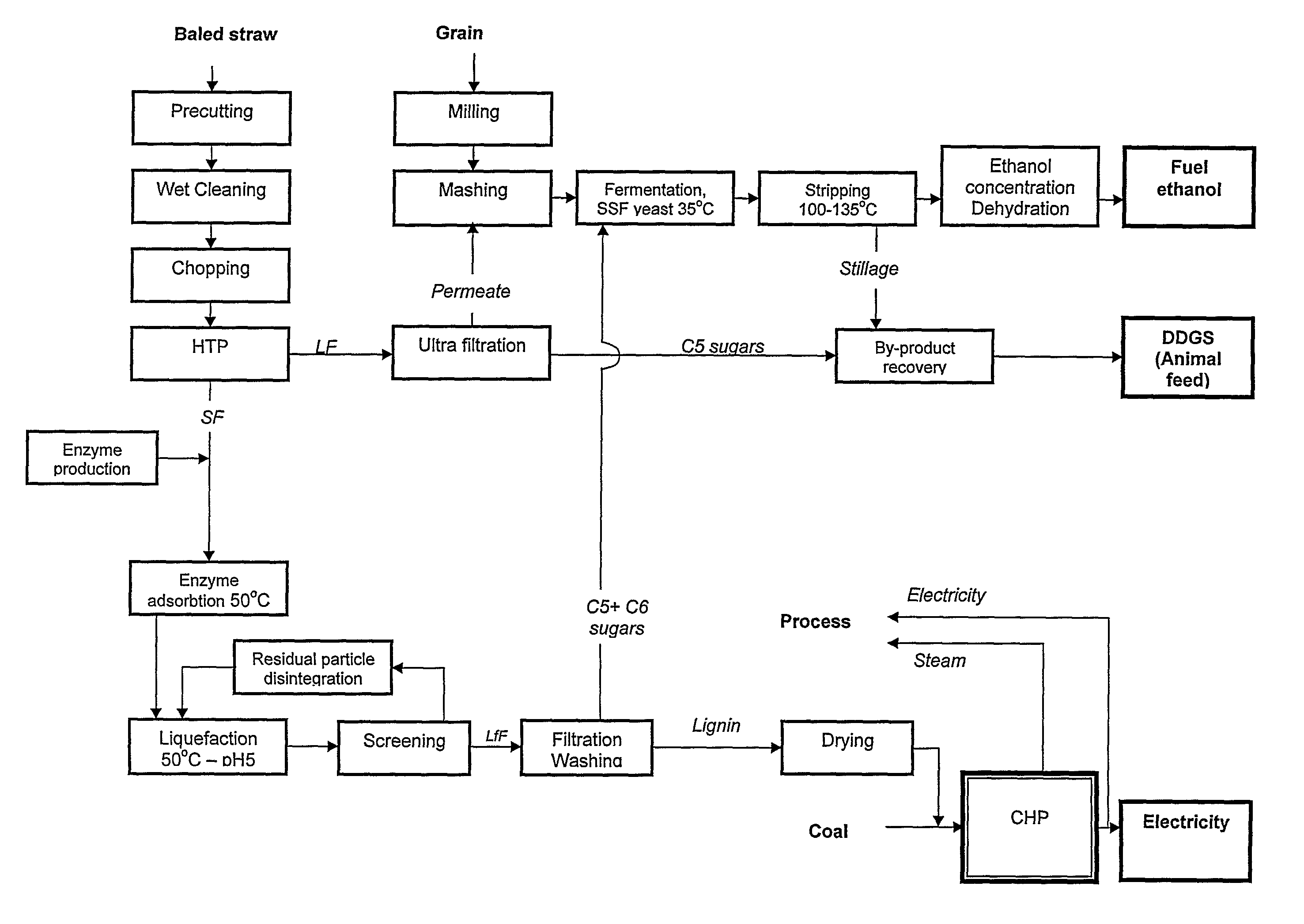

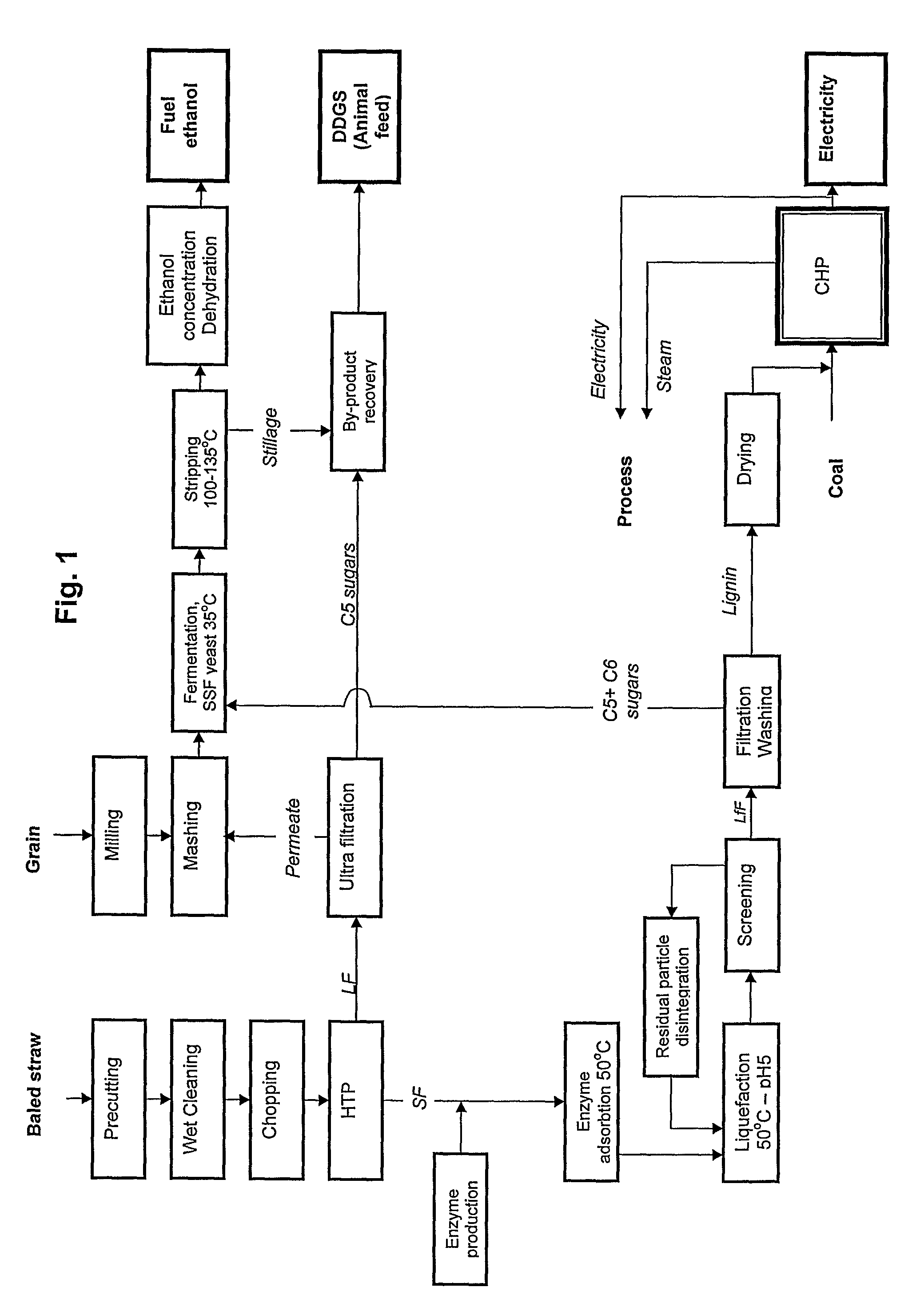

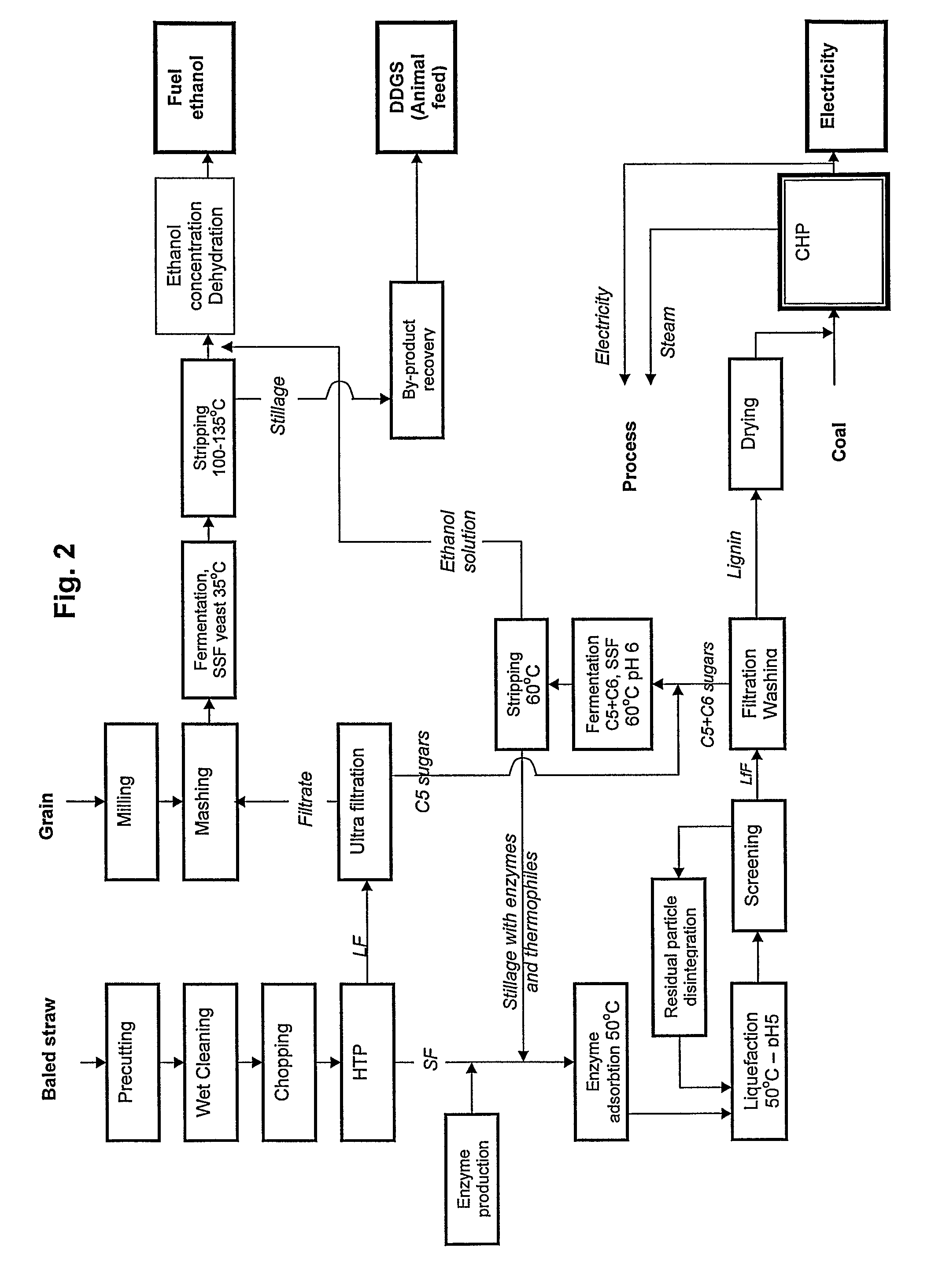

Method and apparatus for conversion of cellulosic material to ethanol

ActiveUS20100041119A1Low costDown rate of fermentationBiological substance pretreatmentsBiofuelsFiberCellulose

The present invention provides an apparatus and a method for conversion of cellulosic material, such as chopped straw and corn stover, and household waste, to ethanol and other products. The cellulosic material is subjected to continuous hydrothermal pre-treatment without addition of chemicals, and a liquid and a fibre fraction are produced. The fibre fraction is subjected to enzymatic liquefaction and saccharification. The method of the present invention comprises:performing the hydrothermal pre-treatment by subjecting the cellulosic material to at least one soaking operation, and conveying the cellulosic material through at least one pressurised reactor, and subjecting the cellulosic material to at least one pressing operation, creating a fibre fraction and a liquid fraction;selecting the temperature and residence time for the hydrothermal pretreatment, so that the fibrous structure of the feedstock is maintained and at least 80% of the lignin is maintained in the fibre fraction.

Owner:INBICON AS

Portable oxygen concentrator

A portable oxygen concentrator includes a pressure swing absorption system defined by a relatively rigid housing adapted to generate a flow of oxygen enriched gas and a battery adapted to provide power to the pressure swing absorption system. The oxygen concentrator has a total weight of less than about 10 lbs, has a maximum flow of 100% O2 equivalent gas of about 0.9 lpm, has a total volume less than about 800 in3, and gas a battery life of at least about 8 hours. The present invention also using a liquefaction or transfill system in combination with such an oxygen concentrator.

Owner:PHILIPS RS NORTH AMERICA LLC

Natural gas liquefaction

A process for liquefying natural gas in conjunction with producing a liquid stream containing predominantly hydrocarbons heavier than methane is disclosed. In the process, the natural gas stream to be liquefied is partially cooled, expanded to an intermediate pressure, and supplied to a distillation column. The bottom product from this distillation column preferentially contains the majority of any hydrocarbons heavier than methane that would otherwise reduce the purity of the liquefied natural gas. The residual gas stream from the distillation column is compressed to a higher intermediate pressure, cooled under pressure to condense it, and then expanded to low pressure to form the liquefied natural gas stream.

Owner:UOP LLC

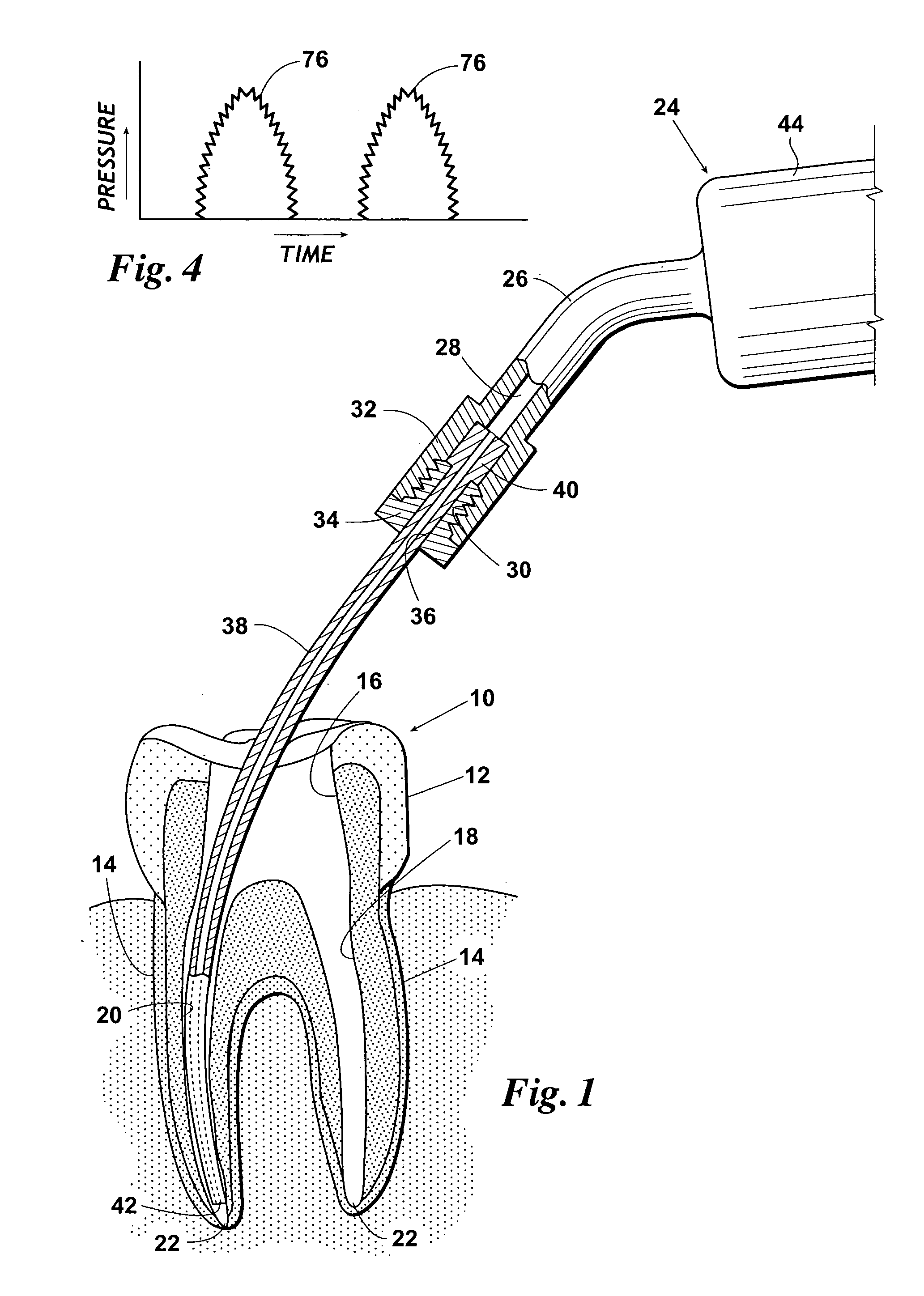

Endodontic procedure employing simultaneous liquefaction and acoustic debridgement

InactiveUS20060257819A1Augments dislodgementAugments removalDental toolsTooth rinsingENDODONTIC PROCEDURESPulse pressure

An ultrasonic liquefaction endodontic system having a graspable hand piece having a flow passageway therethrough. An ultrasonic energy generator is secured to the hand piece. A flexible injection tube is dimensioned for insertion into a tooth root canal. A source of flushing fluid under pulsed pressure is connected to the hand piece by which fluid pressure pulses having ultrasonic energy superimposed thereon are forced into a root canal.

Owner:JOHNSON DOUGLAS B

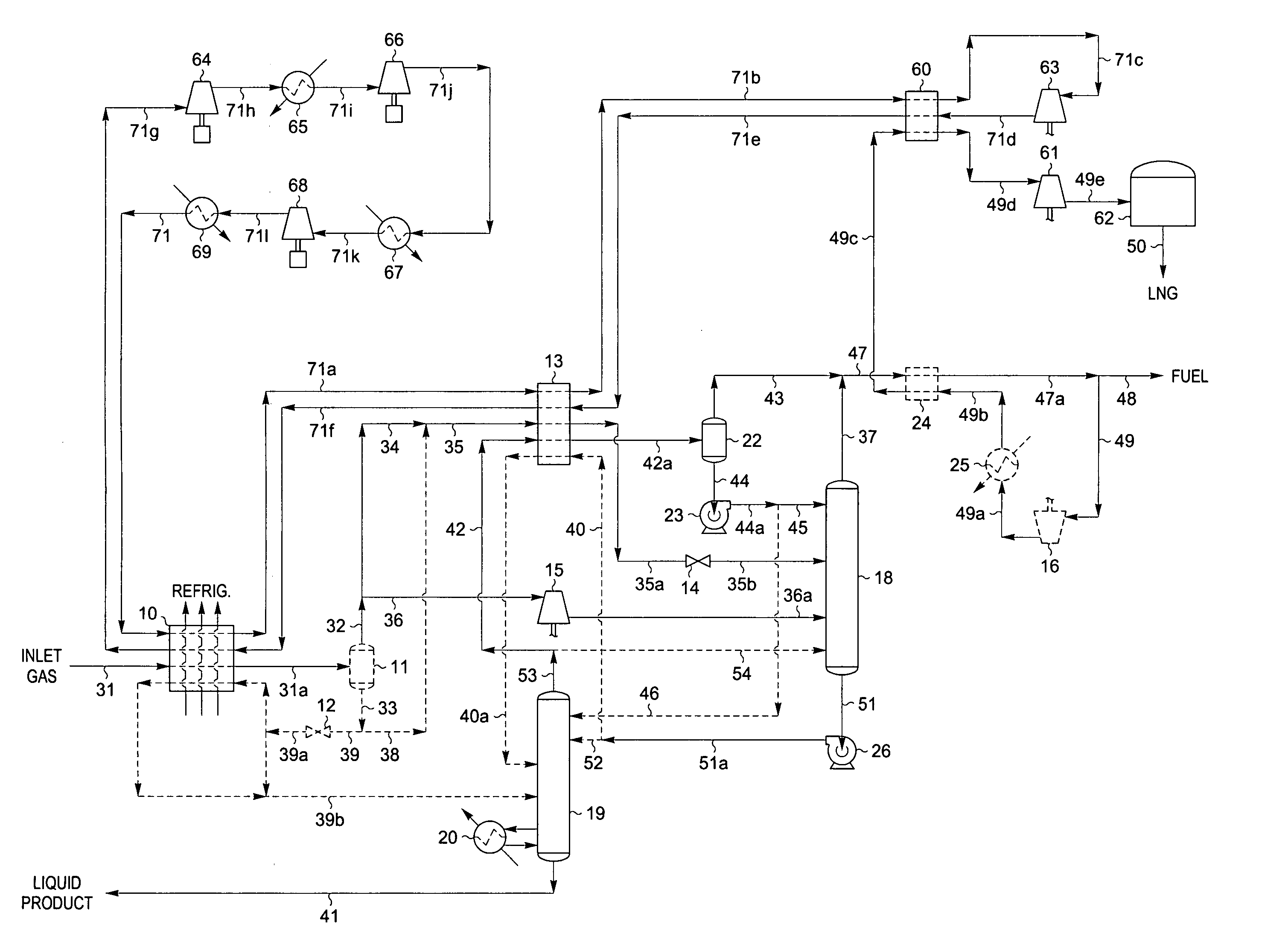

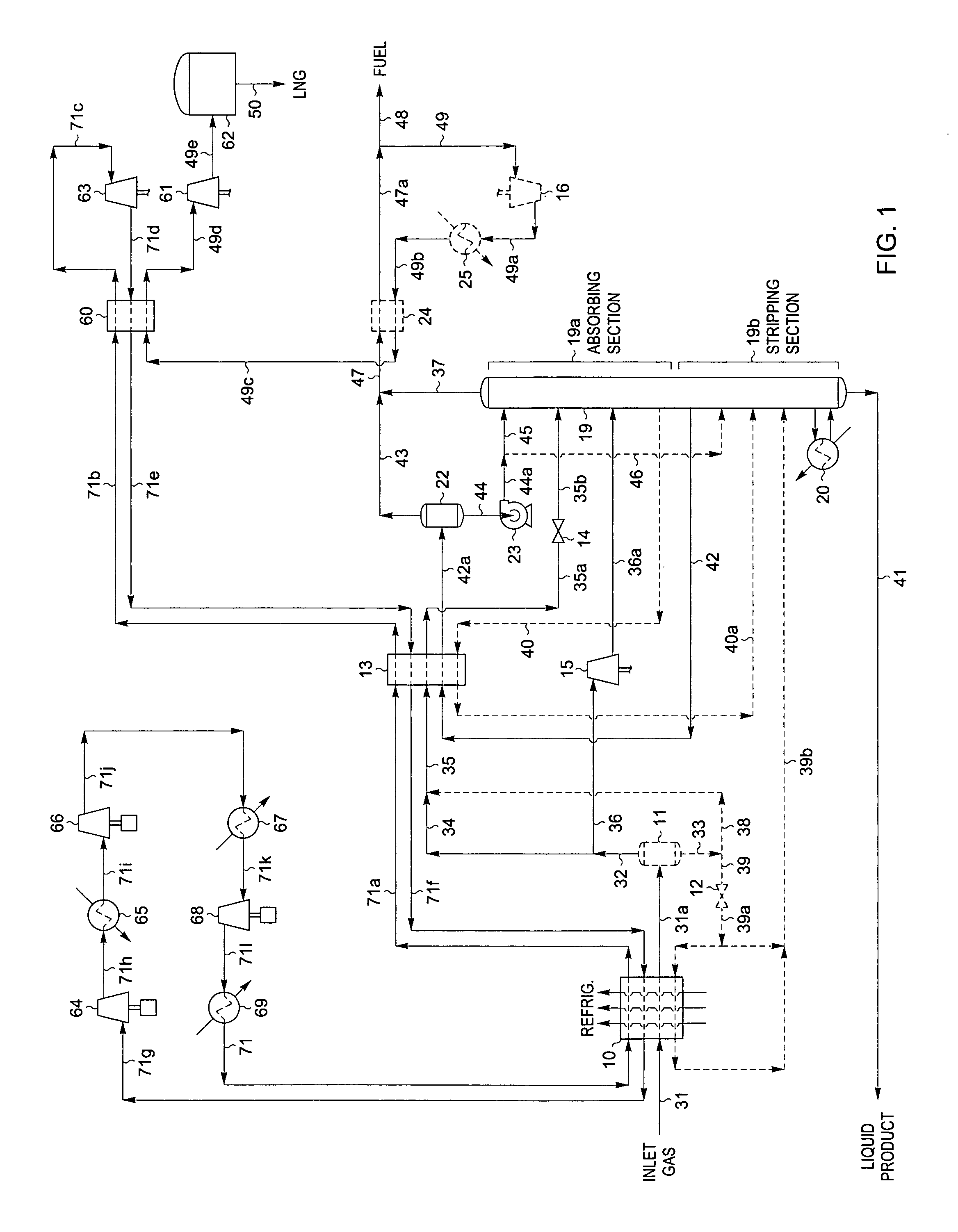

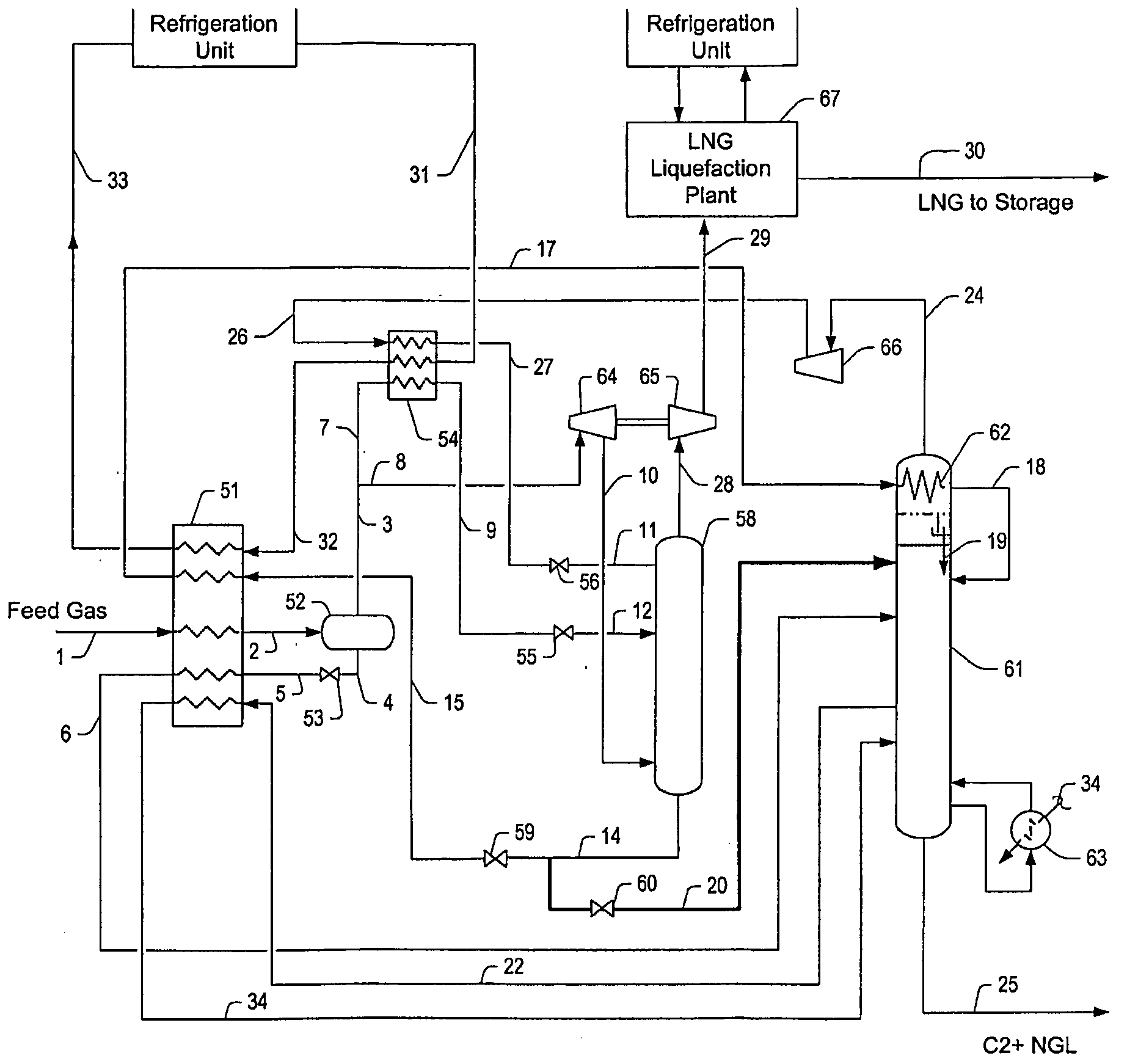

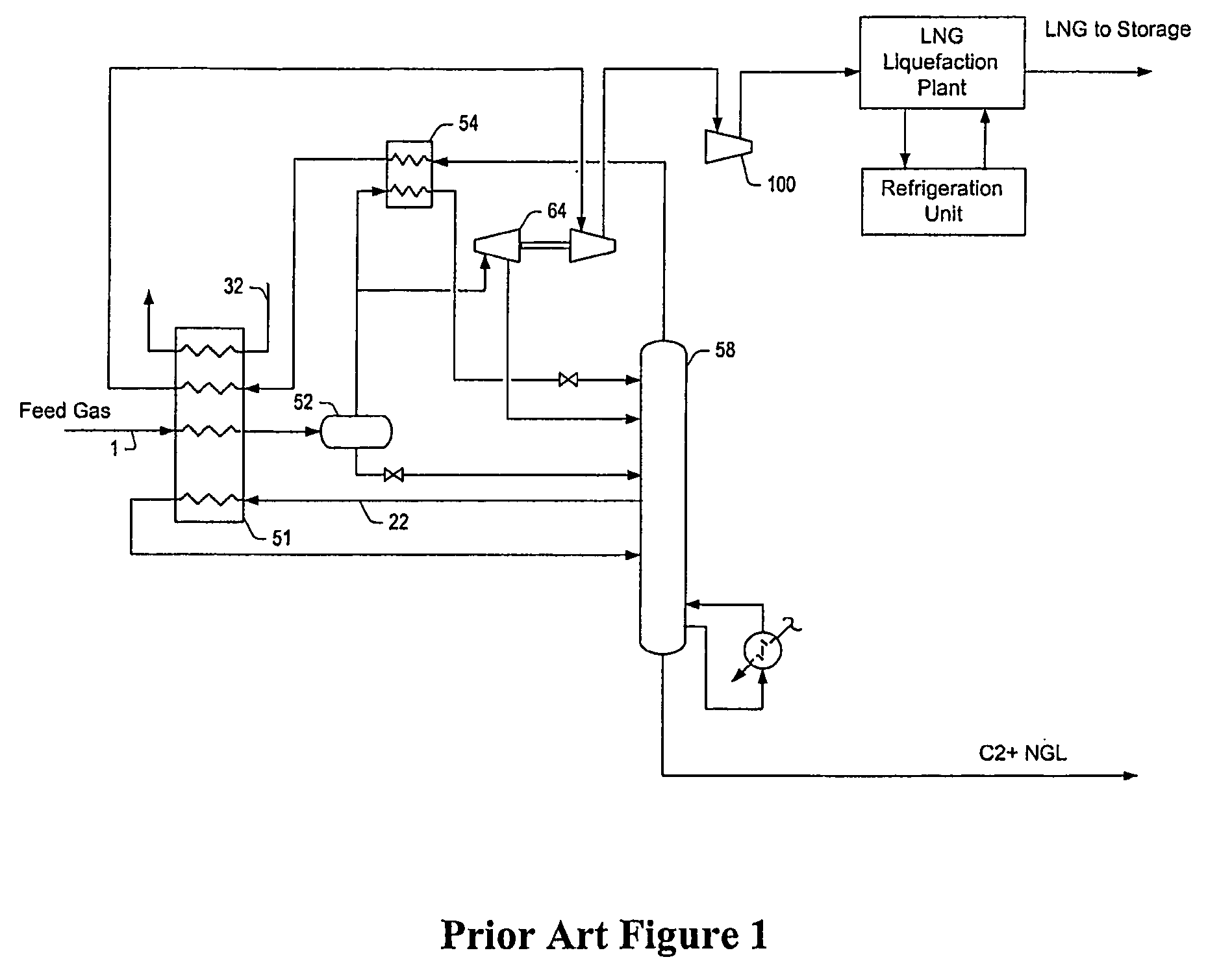

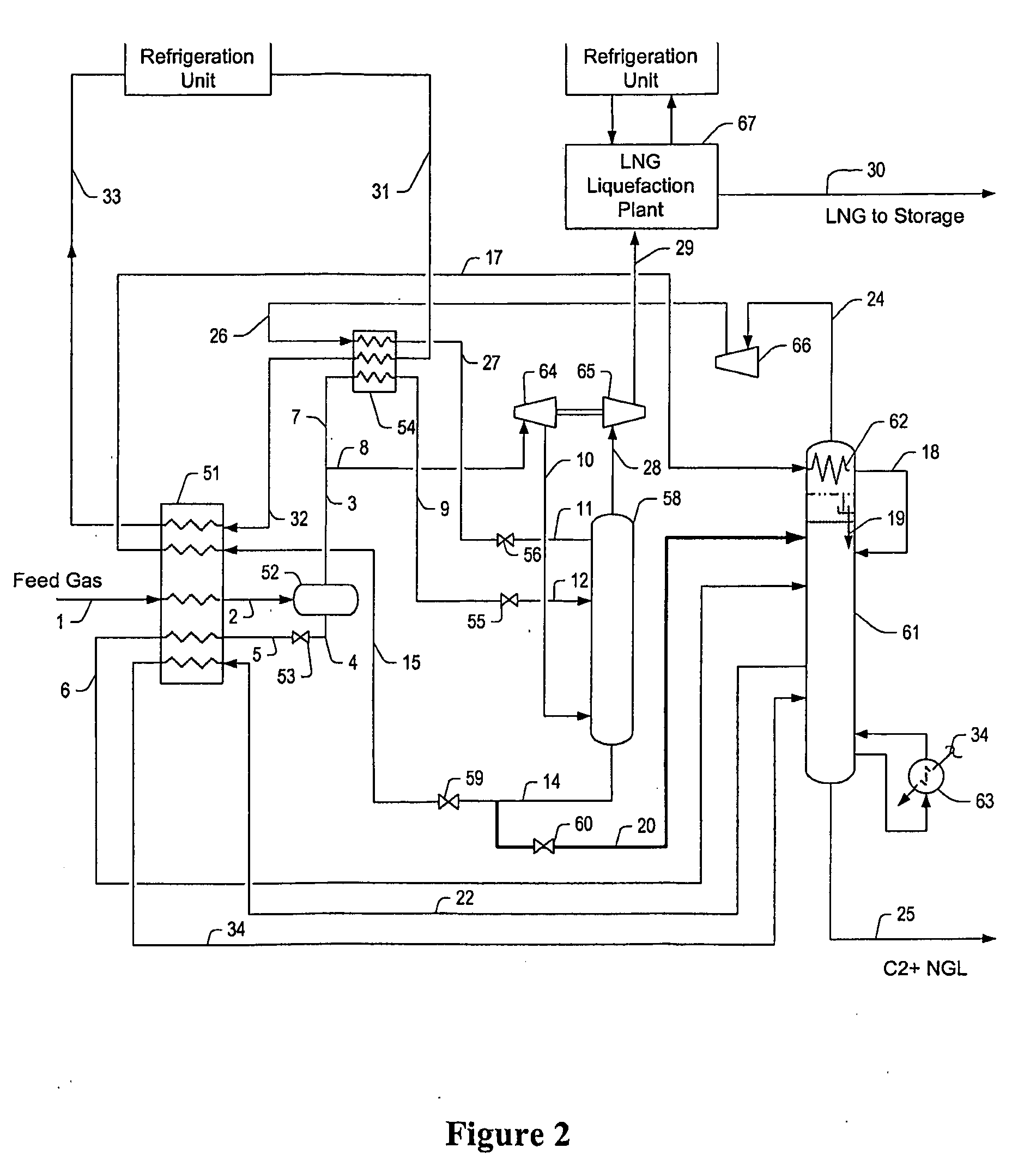

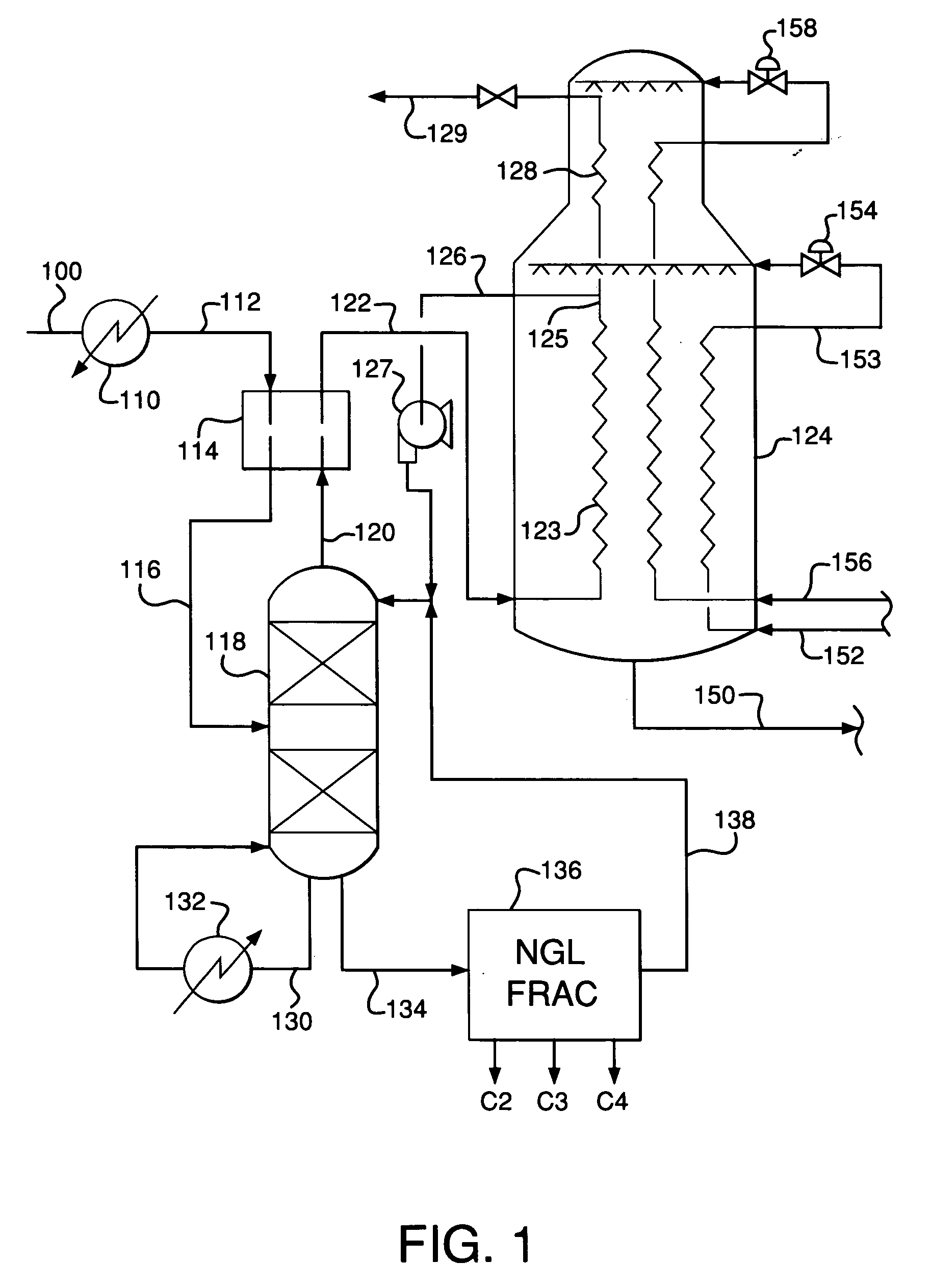

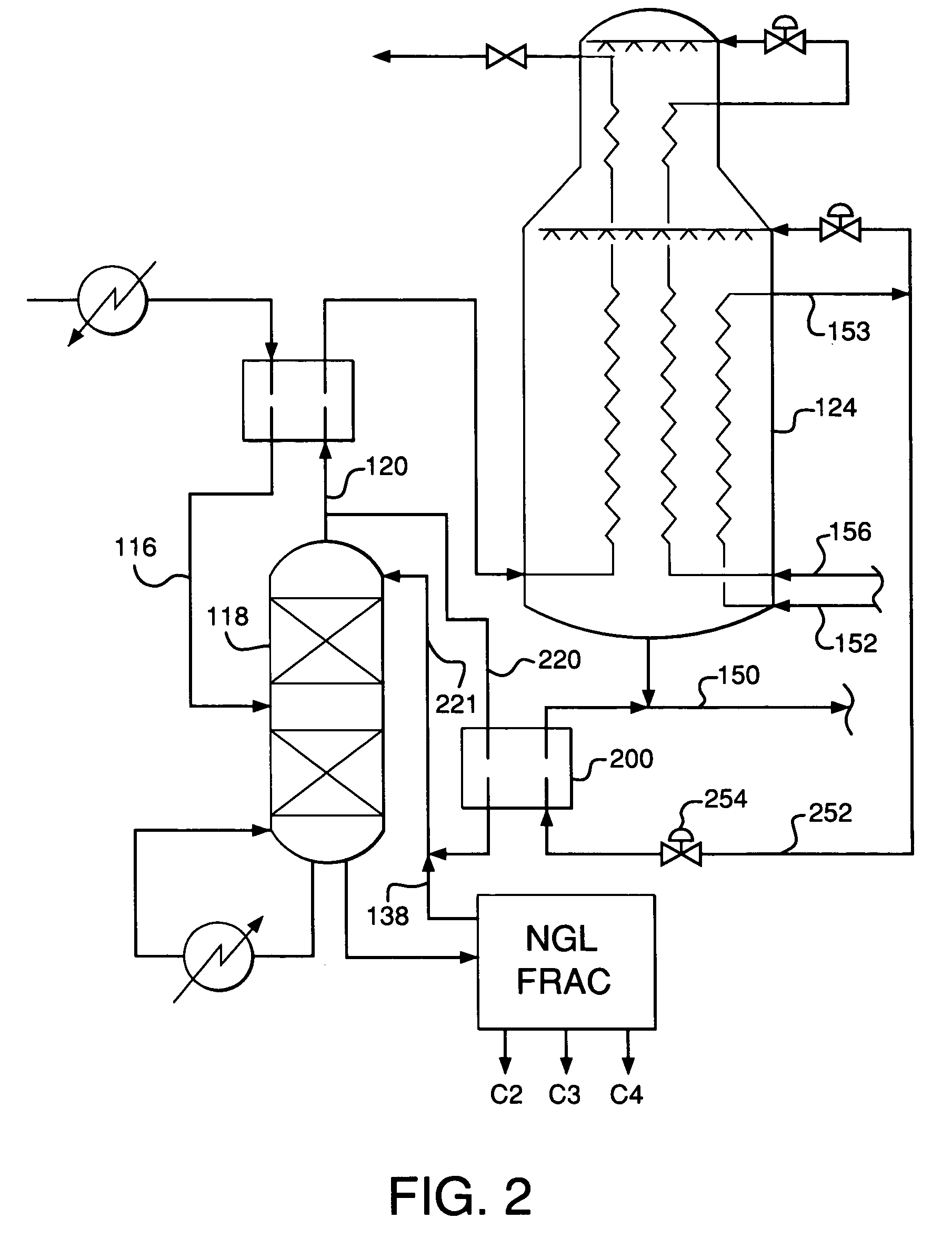

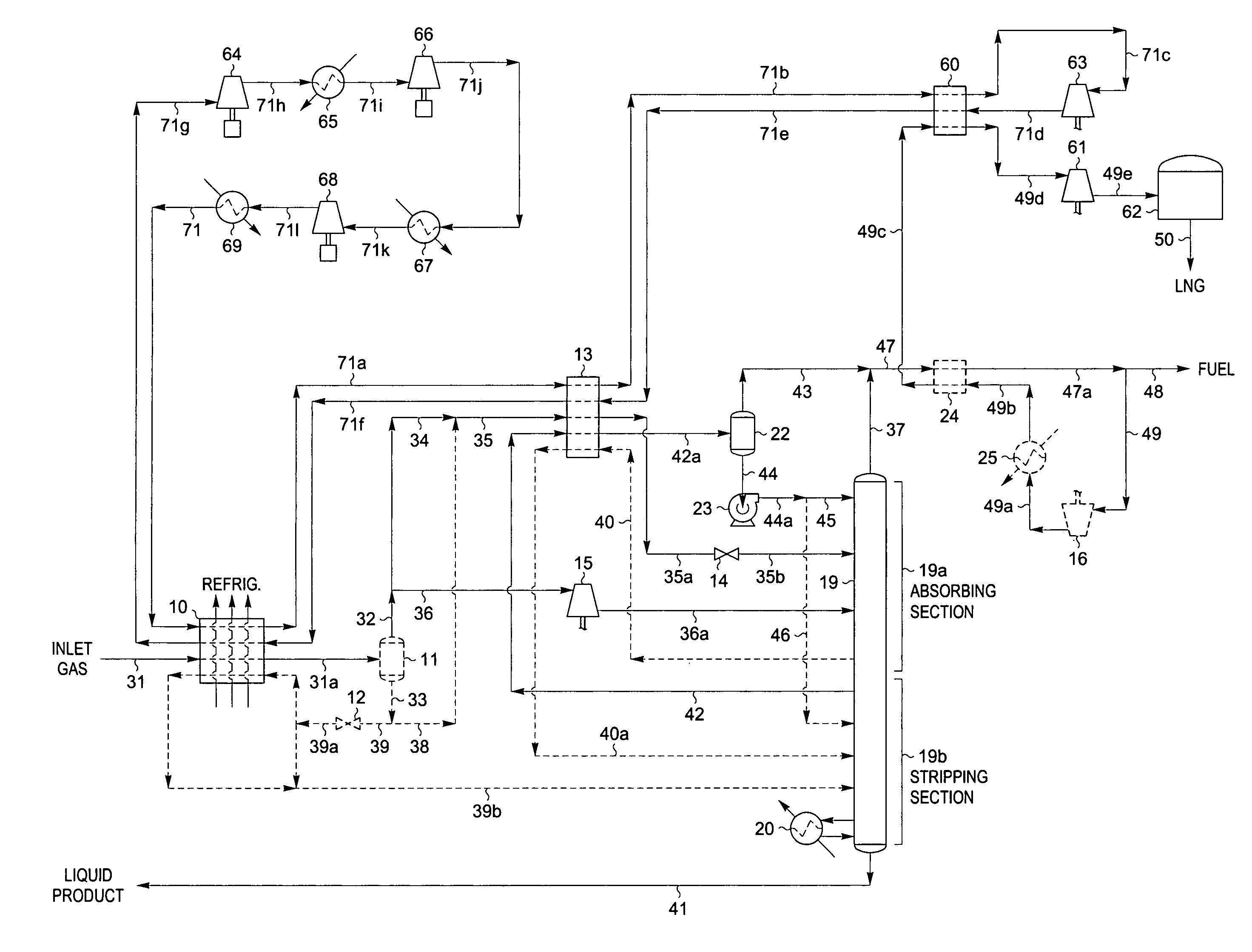

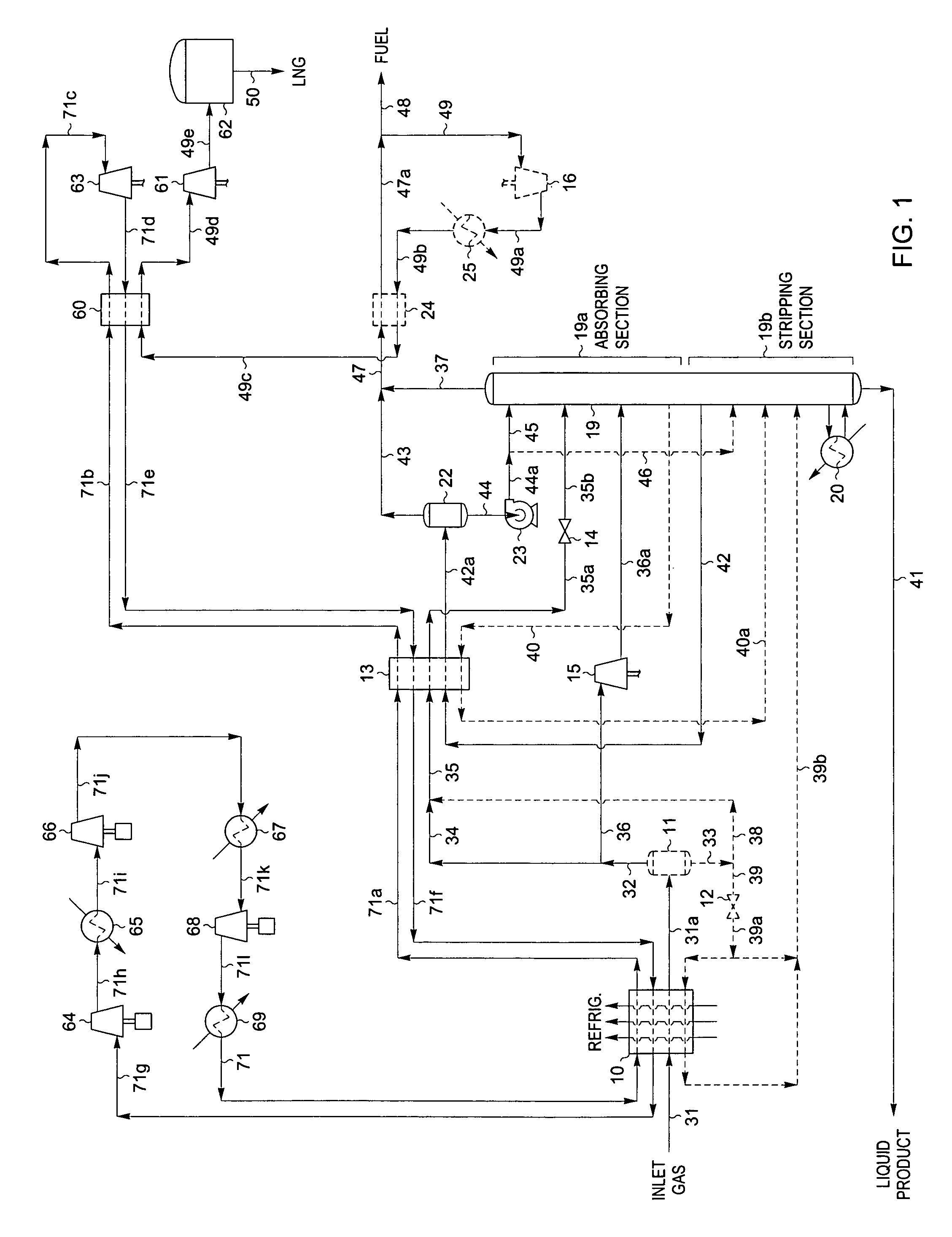

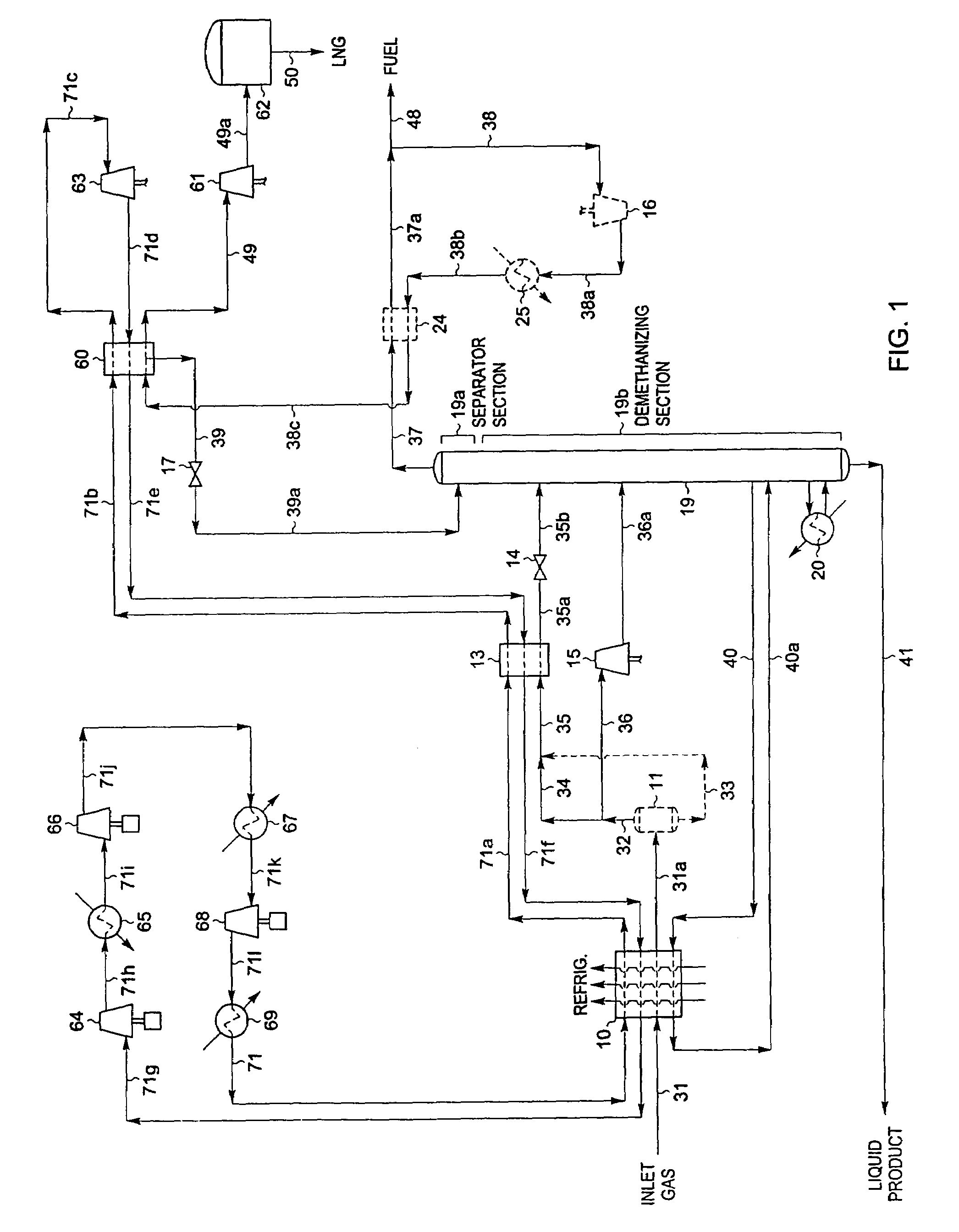

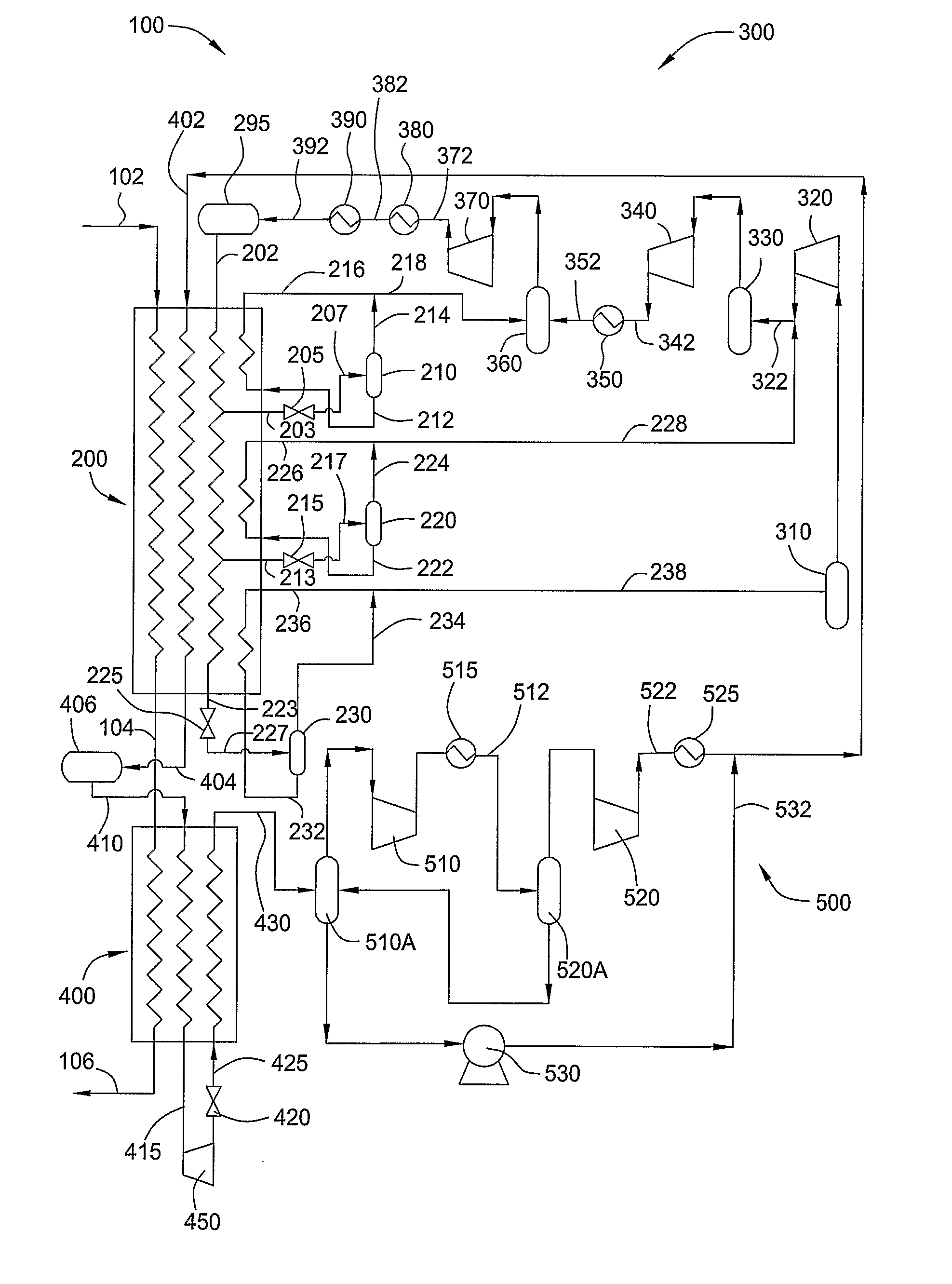

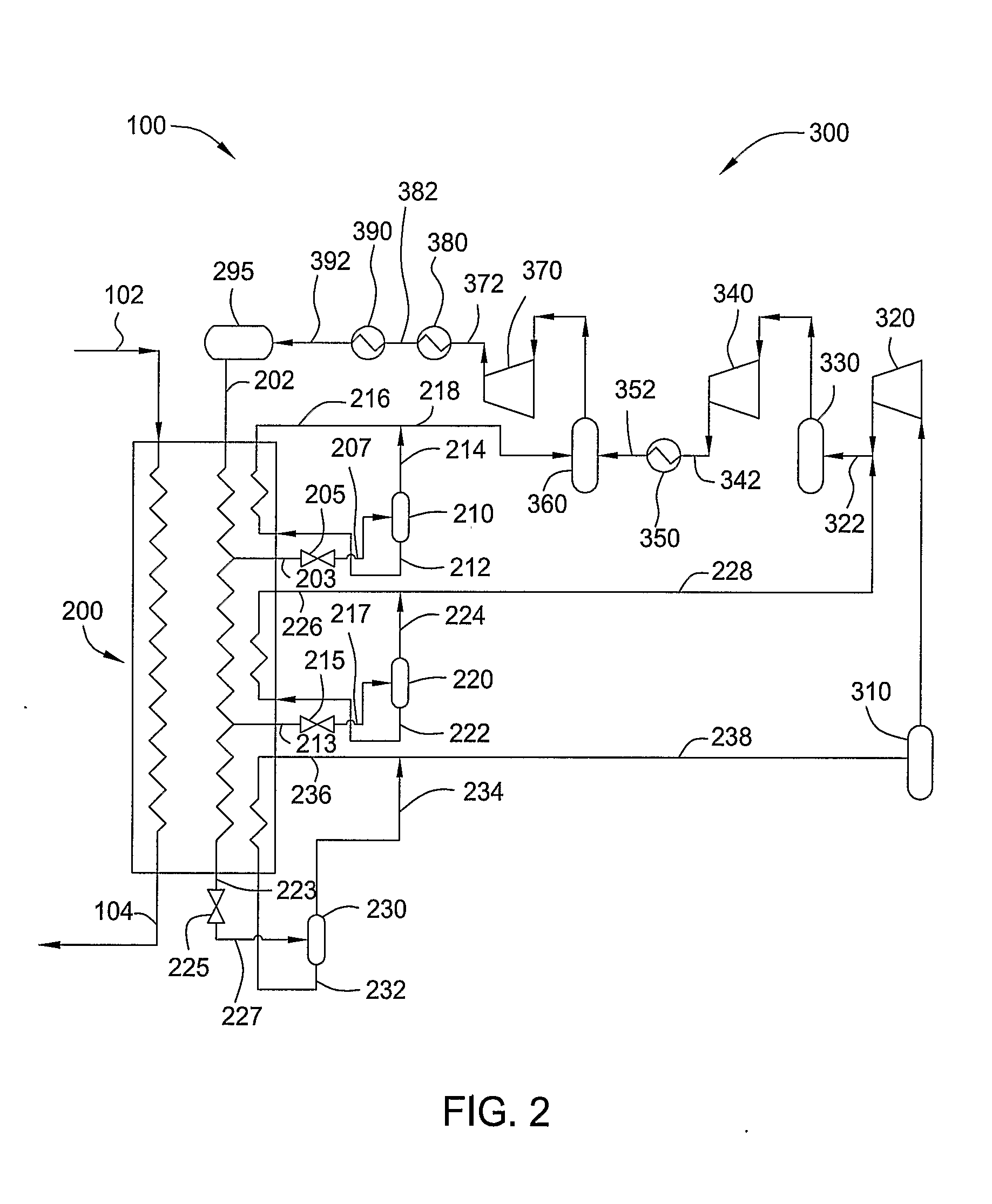

Intergrated Ngl Recovery and Lng Liquefaction

Contemplated plants include a refluxed absorber and a distillation column, wherein the absorber is operated at a higher pressure than the distillation column to thereby produce a cryogenic pressurized lean gas. The lean gas is further compressed to a pressure suitable for liquefaction using energy from feed gas vapor expansion. Desired separation of C2 products is ensured by temperature control of the absorber and distillation column using flow ratios of various streams within the plant, and by dividing the separation process into two portions at different pressures.

Owner:FLUOR TECH CORP

Integrated NGL recovery in the production of liquefied natural gas

Process for the liquefaction of natural gas and the recovery of components heavier than methane wherein natural gas is cooled and separated in a first distillation column into an overhead vapor enriched in methane and a bottoms stream enriched in components heavier than methane, wherein the first distillation column utilizes a liquefied methane-containing reflux stream. This reflux stream may be provided by a condensed portion of the overhead vapor or a portion of totally condensed overhead vapor that is subsequently warmed. The bottoms stream may be separated in one or more additional distillation columns to provide one or more product streams, any of which are partially or totally withdrawn as recovered hydrocarbons. A stream of unrecovered liquid hydrocarbons may be combined with either the condensed portion of the overhead vapor or a portion of totally condensed overhead vapor that is subsequently warmed.

Owner:AIR PROD & CHEM INC

Method for producing fuel oil by biomass hydrothermal liquefaction

InactiveCN101805629AImprove conversion ratePotential for industrial applicationsLiquid hydrocarbon mixture productionMass ratioReaction temperature

The invention discloses a method for producing fuel oil by biomass hydrothermal liquefaction. The method is characterized by comprising the following steps: fully mixing a biomass raw material and solvent water (or adding catalyst water solution) to prepare seriflux, wherein a mass ratio of a catalyst to the raw material is 1:10 to 1:50, and the mass ratio of the raw material to water is 1:2 to 1:8; performing a reaction in a slurry bed reactor under a reducing atmosphere; controlling a liquefaction reaction temperature between 300 and 450 DEG C, a reaction pressure between 5 and 30 MPa and reaction time between 5 and 40 minutes; after the reaction, separating a product to obtain the fuel oil, solid residue, water, gas and the like. The method has the advantages of achieving complete biomass conversion, high oil product productivity, obtaining an oil product with a heat value equal to that of standard oil, relieving dependence on fossil energy, contributing to environment protection, lowering production cost and achieving good social and economic benefits.

Owner:EAST CHINA UNIV OF SCI & TECH

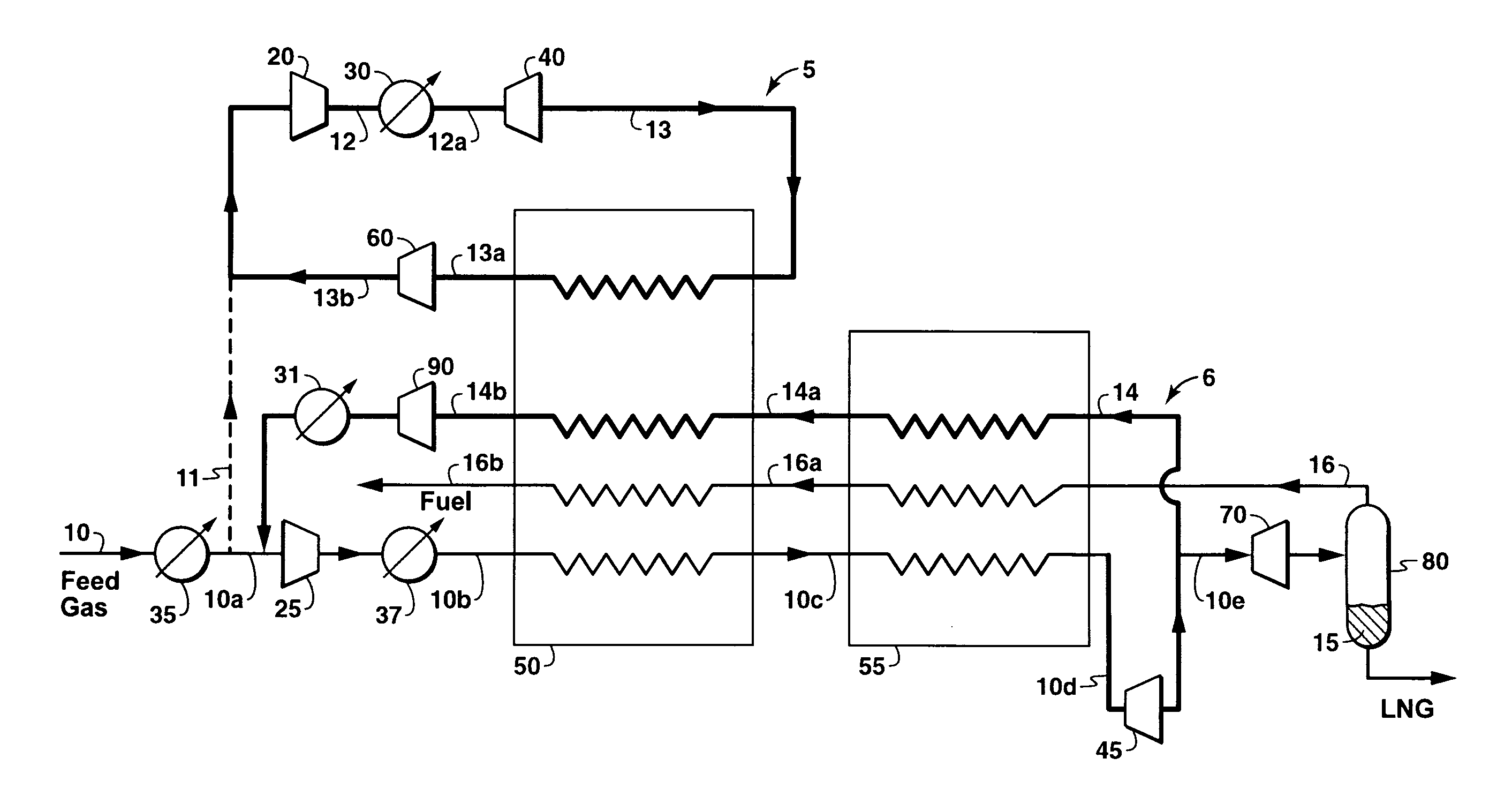

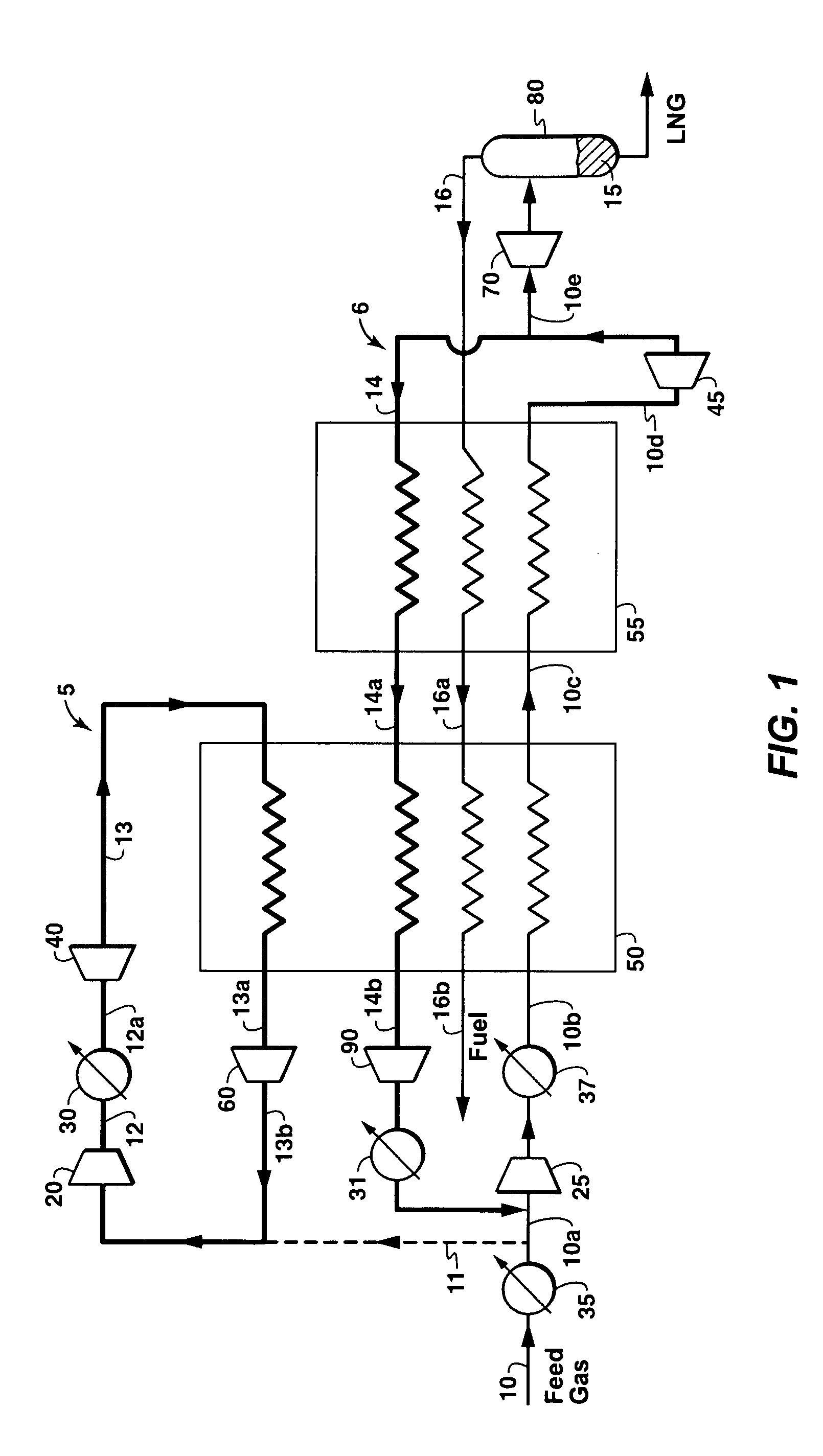

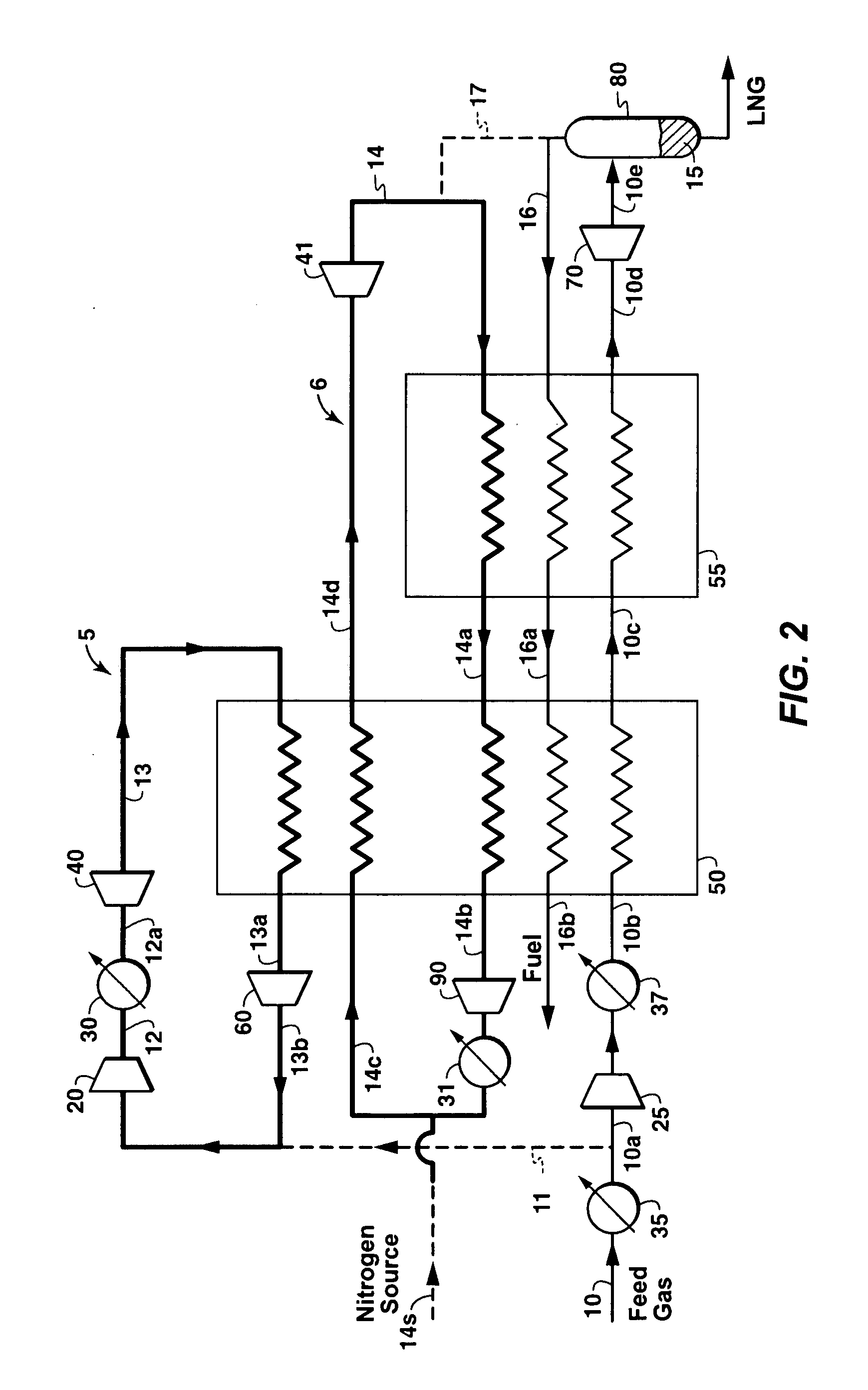

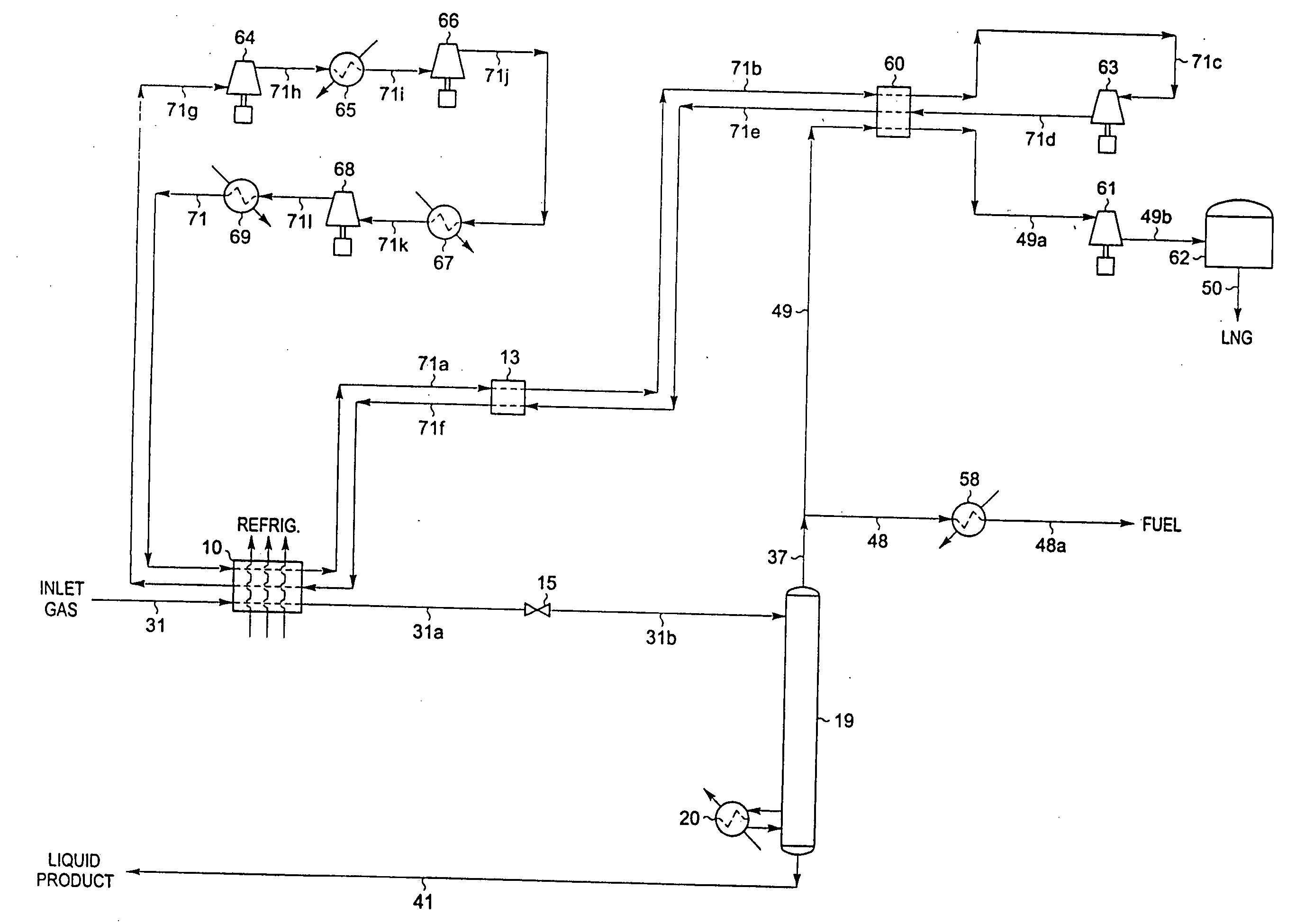

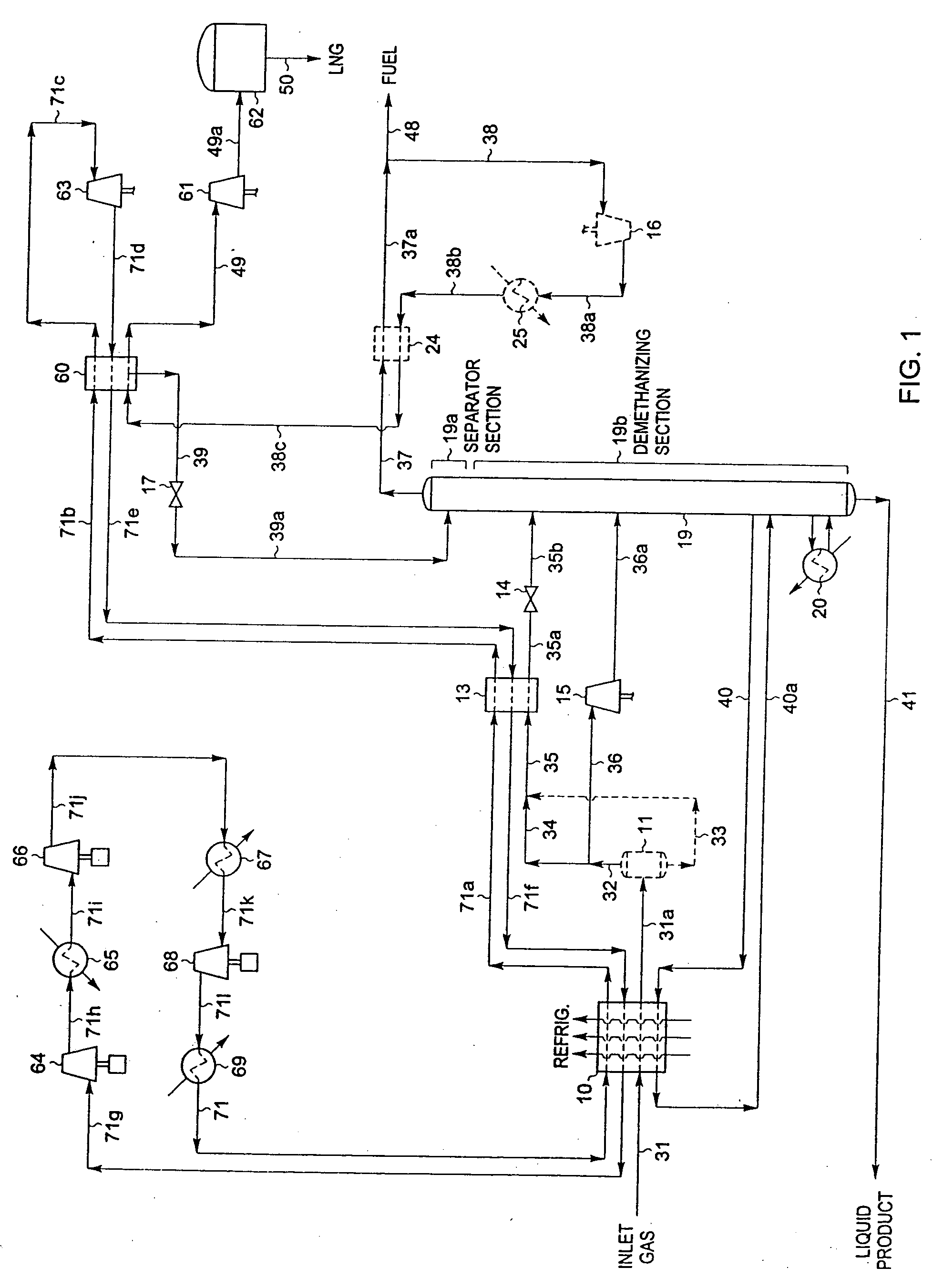

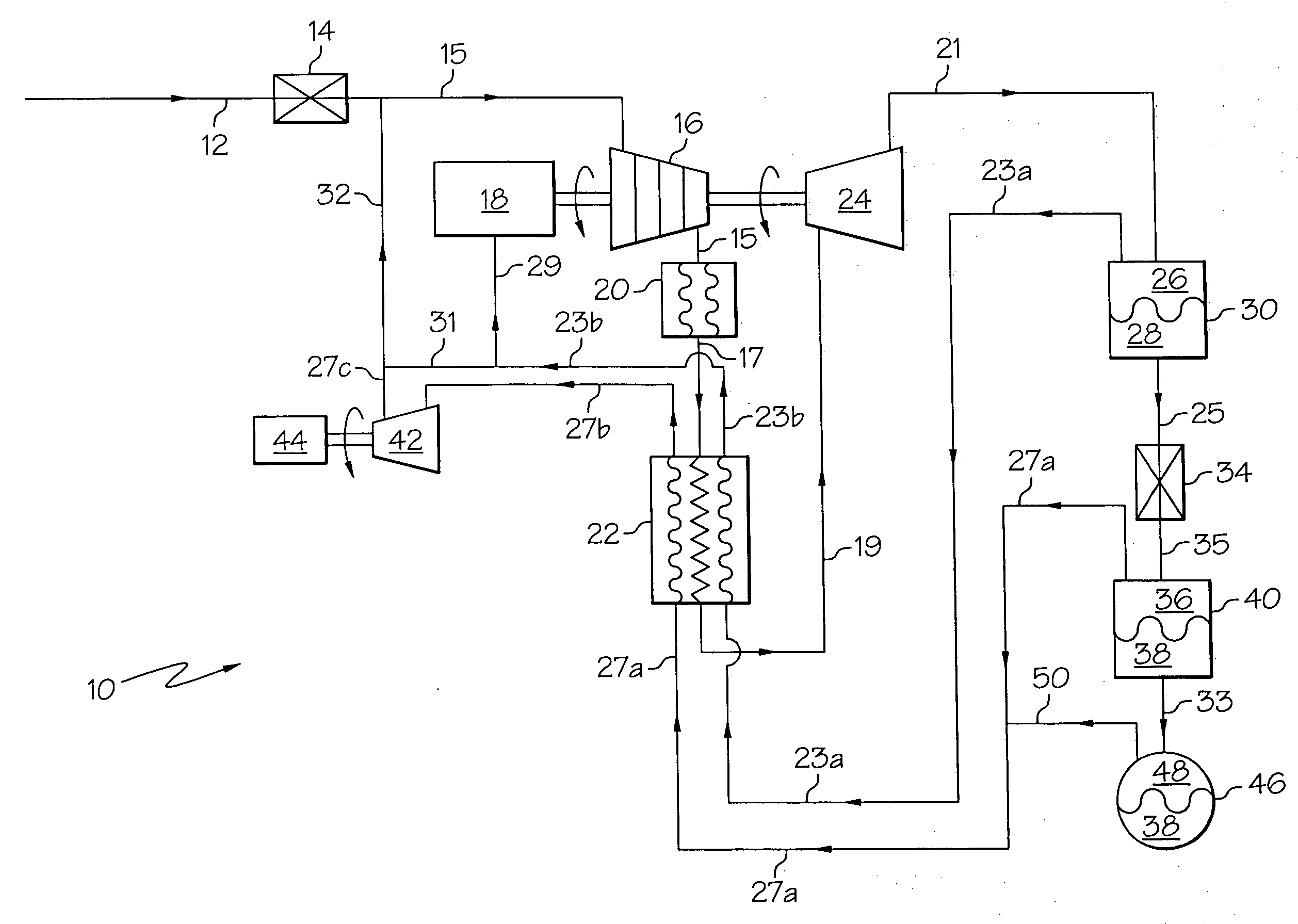

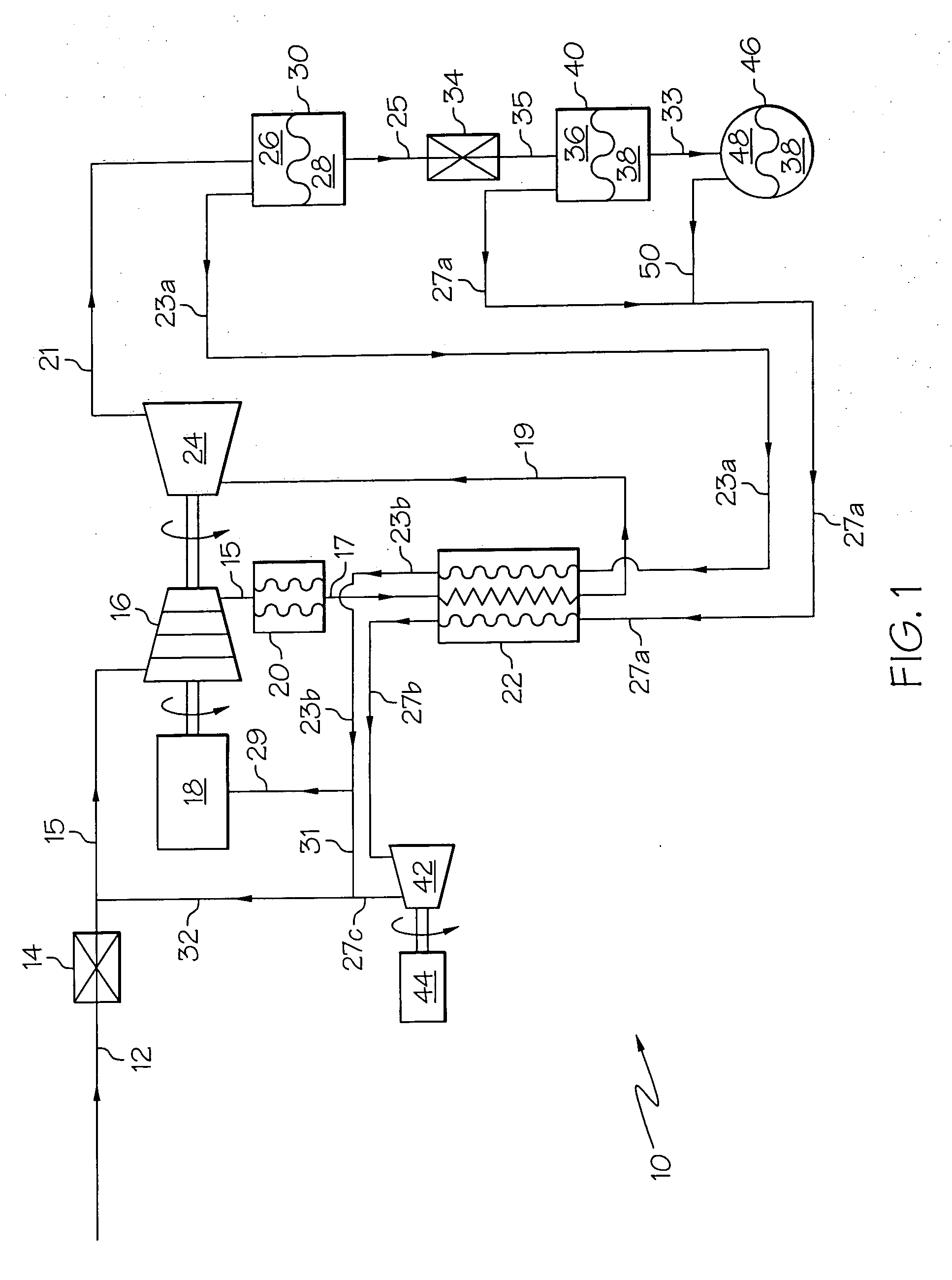

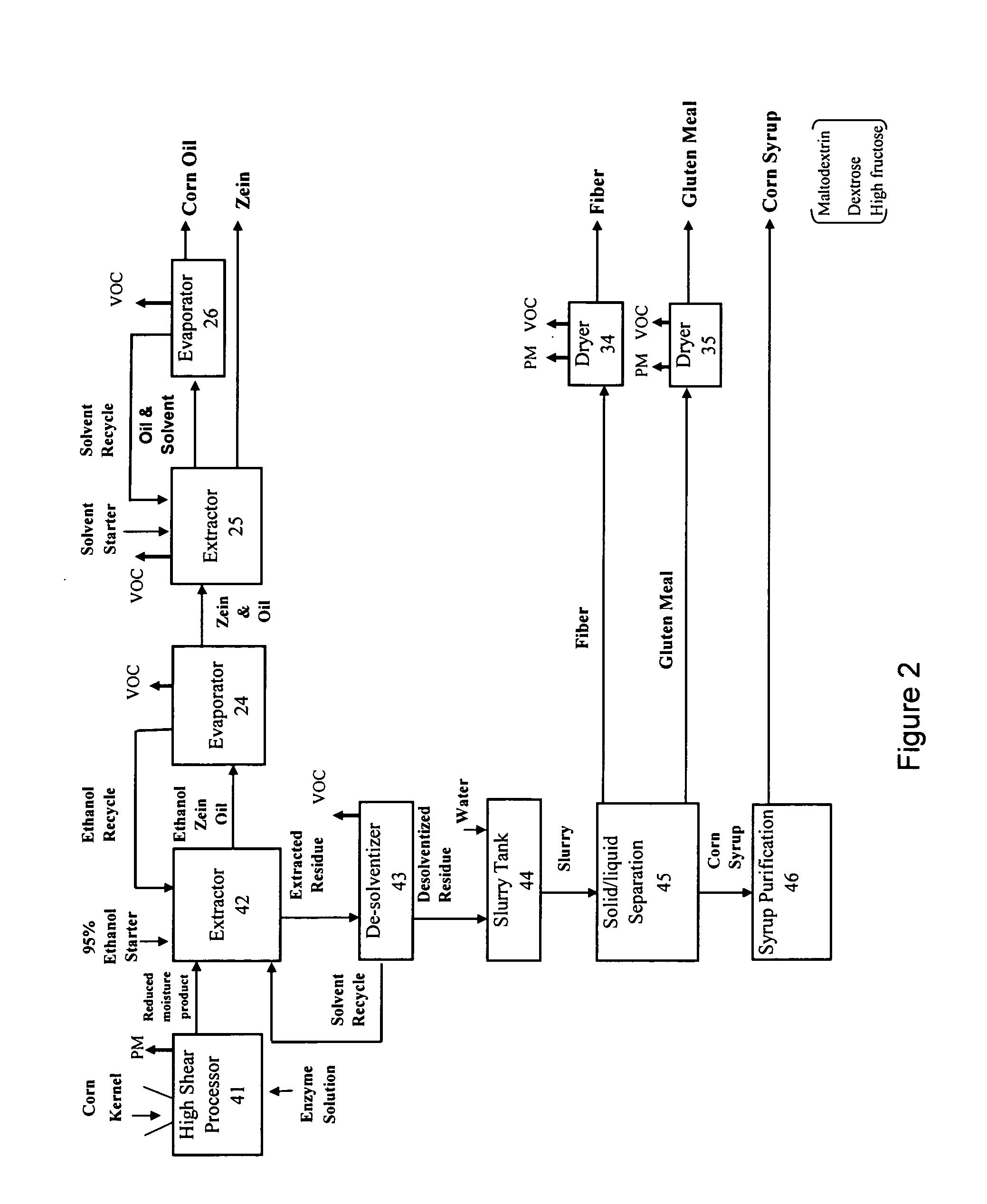

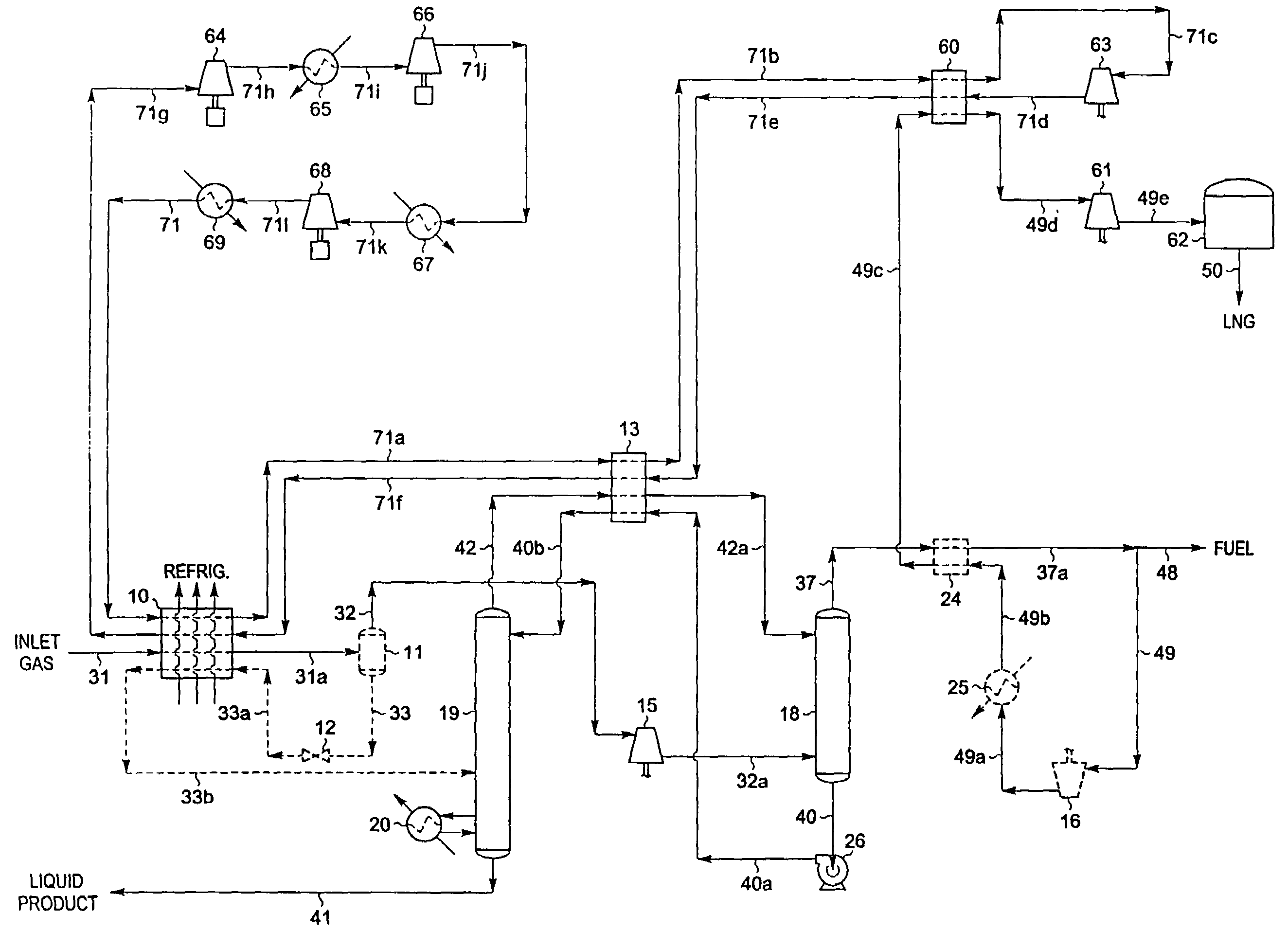

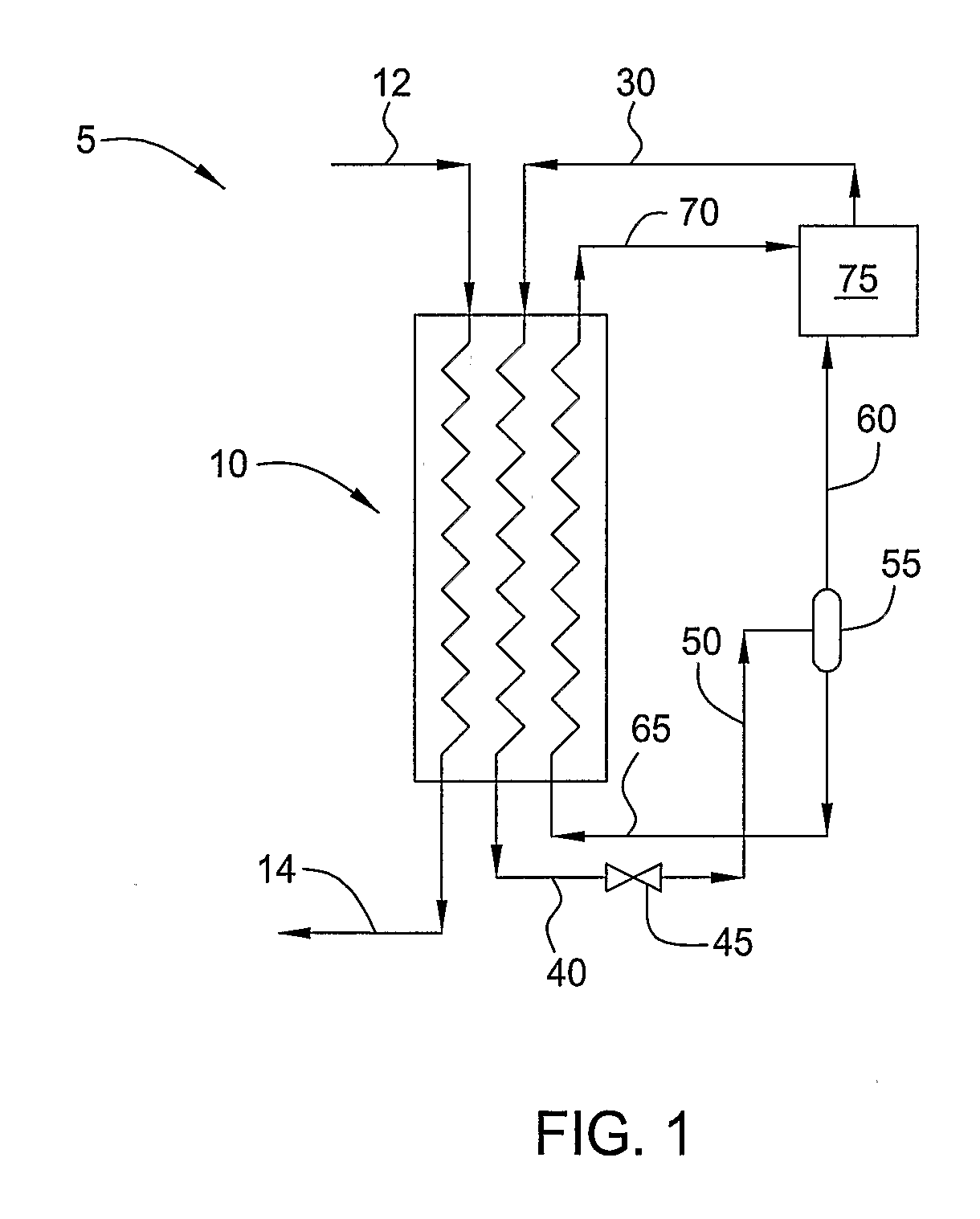

Compact, modular method and apparatus for liquefying natural gas

InactiveUS20060213222A1Cost efficientSolidificationLiquefactionCompressed natural gasProcess engineering

A compact and modular cryogenic method and apparatus for liquefying natural gas. The liquefaction process is highly efficient and requires no external refrigeration system, and the apparatus is small enough to be transportable from one remote site to another. A compressed natural gas feed stream is cooled and then expanded to form a bi-phase stream comprising a first refrigerated vapor component and a first liquid component. The first liquid component is then separated from the bi-phase stream and expanded to form a second bi-phase stream comprising a second refrigerated vapor component and a second liquid component. The second liquid component is then introduced into a means configured for storage and transport. The remaining feed stream can then be recycled, and at least a substantial portion of the original feed stream can be processed into liquefied natural gas (LNG). The first and second vapor components are recycled through the system and comprise at least a portion of the feed stream in the repeated steps.

Owner:CAMBRIDGE CRYOGENICS TECH

Whole grain non-dairy milk production, products and use

ActiveUS20070014892A1Increase coverageReserved functionDough treatmentWort preparationSlurryWhole milk

A method comprising selection of unbroken whole grain rice that are first washed, or whole grain corn that is first reduced in size, and then making an aqueous slurry that is subsequently wet milled to release all the protein, fat, fiber, and starch components normally held in the structure of the grain. The resulting slurry can be reacted with heat to gelatinize the starch and the subsequent product dried. Also, the heated slurry containing the liberated components can be treated to enzymatic hydrolysis via the process of liquefaction and optionally saccharification, producing whole grain rice milk products having diverse carbohydrate compositions. The whole grain milk products are characterized by a nutritional composition containing substantially all the nutritional components of the whole grain, being an opaque whole milk colloid, having smooth texture versus pulpiness, lacking in all bitterness normally associated with whole grain products, and having a variety of sweetness levels from non-sweet to very sweet.

Owner:STEUBEN FOODS

Natural gas liquefaction

A process for liquefying natural gas in conjunction with producing a liquid stream containing predominantly hydrocarbons heavier than methane is disclosed. In the process, the natural gas stream to be liquefied is partially cooled and divided into first and second streams. The first stream is further cooled to condense substantially all of it, expanded to an intermediate pressure, and then supplied to a distillation column at a first mid-column feed position. The second stream is also expanded to intermediate pressure and is then supplied to the column at a second lower mid-column feed position. A distillation stream is withdrawn from the column below the feed point of the second stream and is cooled to condense at least a part of it, forming a reflux stream. At least a portion of the reflux stream is directed to the distillation column as its top feed. The bottom product from this distillation column preferentially contains the majority of any hydrocarbons heavier than methane that would otherwise reduce the purity of the liquefied natural gas. The residual gas stream from the distillation column is compressed to a higher intermediate pressure, cooled under pressure to condense it, and then expanded to low pressure to form the liquefied natural gas stream.

Owner:UOP LLC

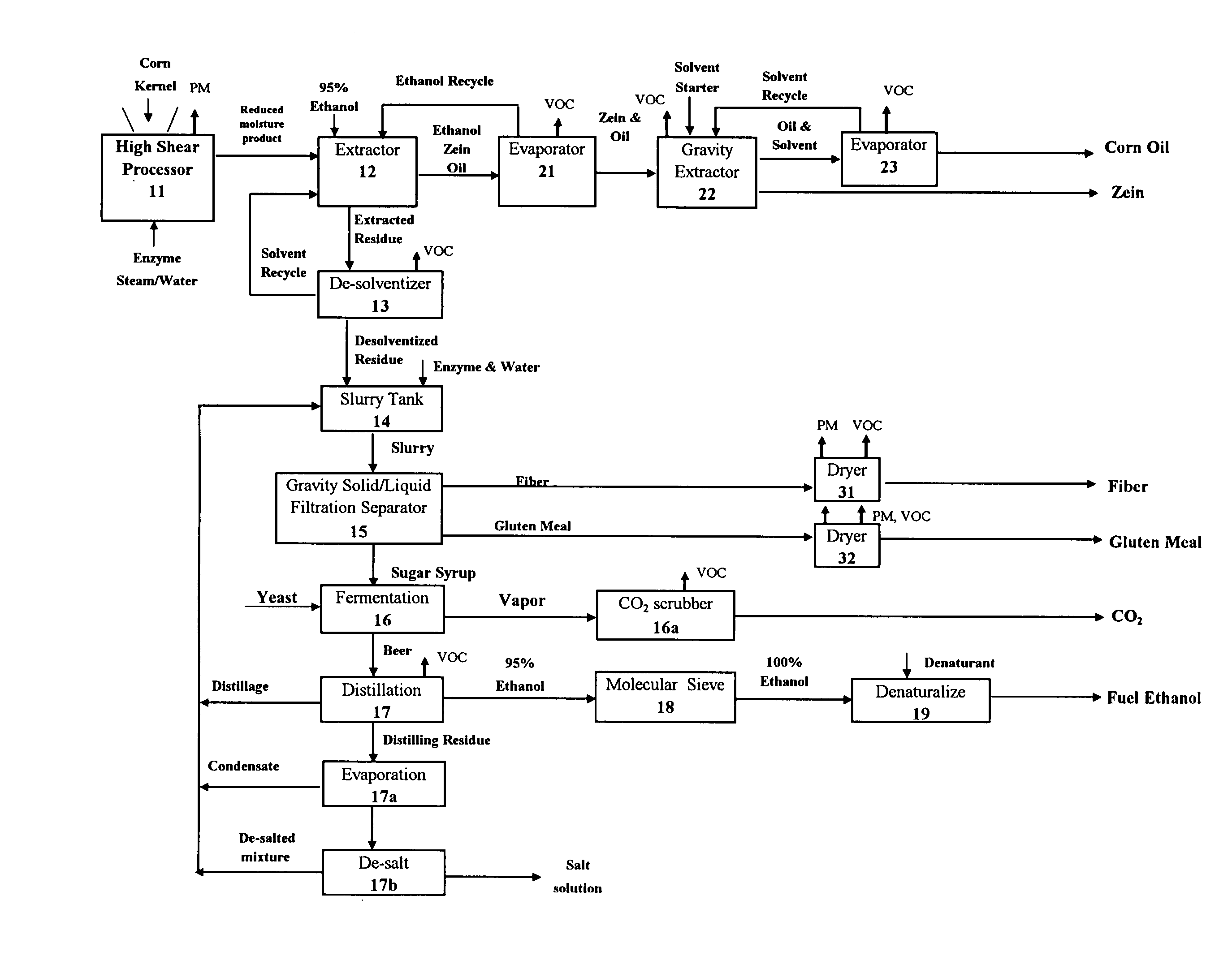

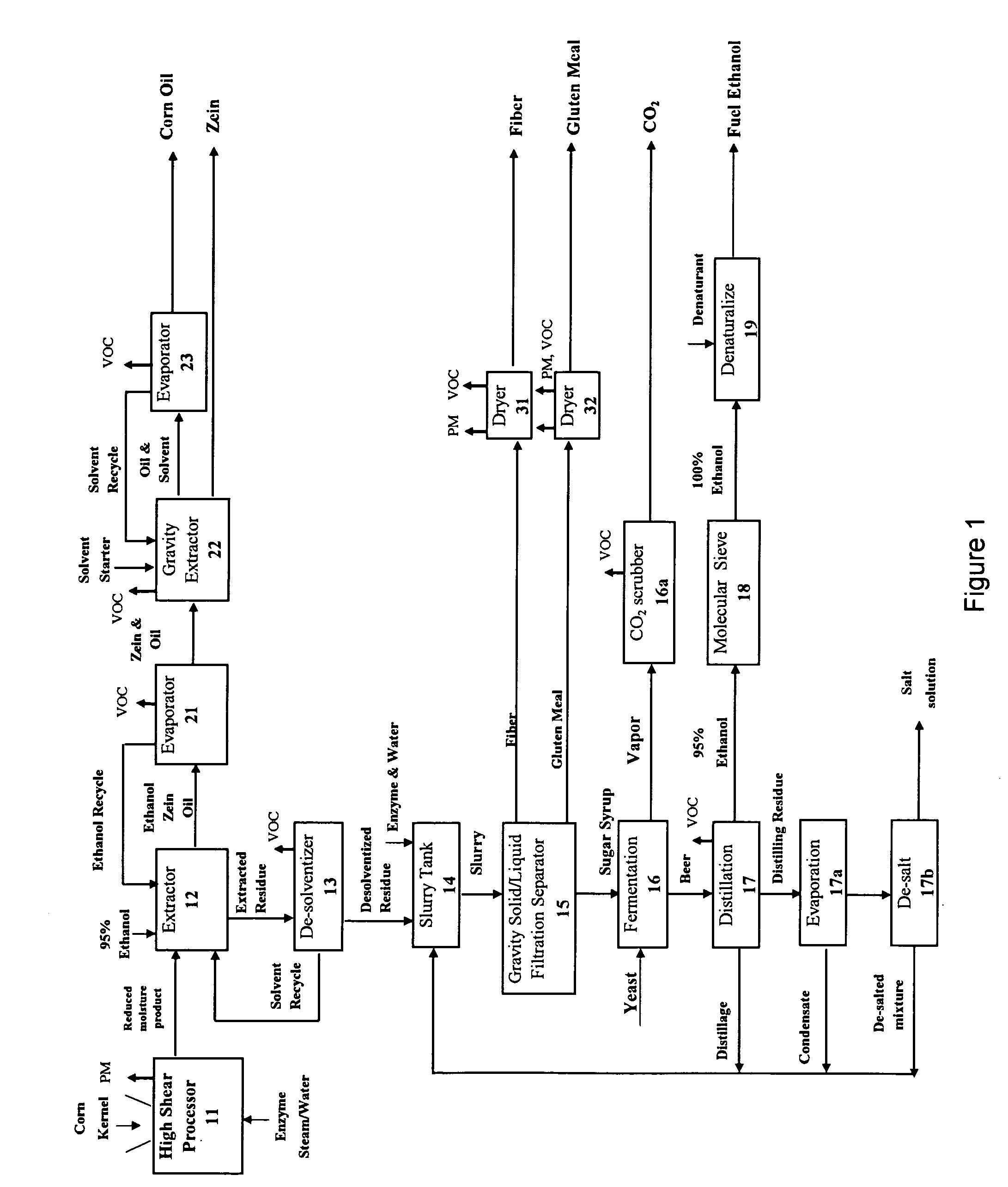

Starchy material processed to produce one or more products comprising starch, ethanol, sugar syrup, oil, protein, fiber, gluten meal, and mixtures thereof

InactiveUS20070014905A1Reduce processIncrease shearProtein composition from eggsConfectioneryFiberFood grade

The invention provides a method and system of processing a starchy material that can advantageously produce ethanol, sugar syrup, or starch as the chief products along with food-grade co-products such as, but not limited to oil, protein, fiber, and gluten meal. The invention can apply such a force to a starchy material that is at a superambient temperature with a high shear processor to mill, mix, and gelatinize some of the starch. A liquefaction enzyme can be introduced into the high shear processor to liquefy the processed product. The moisture content of the processed starchy material can be reduced, which preferably occurs in the high shear processor. Some of the co-products such as the oil, protein, fiber and gluten meal can be separated prior to the sugar syrup purification or ethanol fermentation steps.

Owner:PURDUE RES FOUND INC

Natural gas liquefaction

A process for liquefying natural gas in conjunction with producing a liquid stream containing predominantly hydrocarbons heavier than methane is disclosed. In the process, the natural gas stream to be liquefied is partially cooled, expanded to an intermediate pressure, and supplied to a distillation column. The bottom product from this distillation column preferentially contains the majority of any hydrocarbons heavier than methane that would otherwise reduce the purity of the liquefied natural gas. The residual gas stream from the distillation column is compressed to a higher intermediate pressure, cooled under pressure to condense it, and then expanded to low pressure to form the liquefied natural gas stream.

Owner:ORTLOFF ENGINEERS

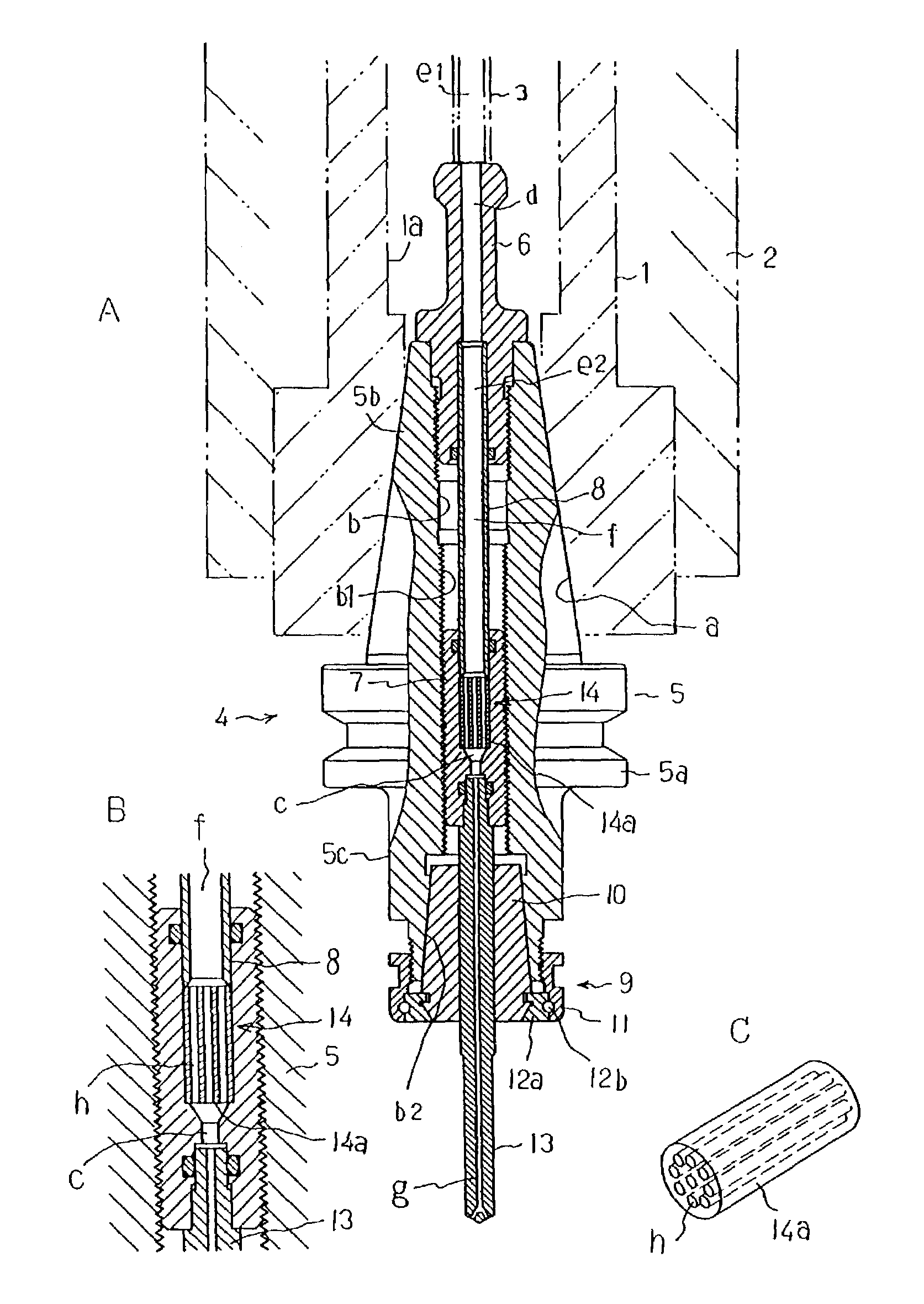

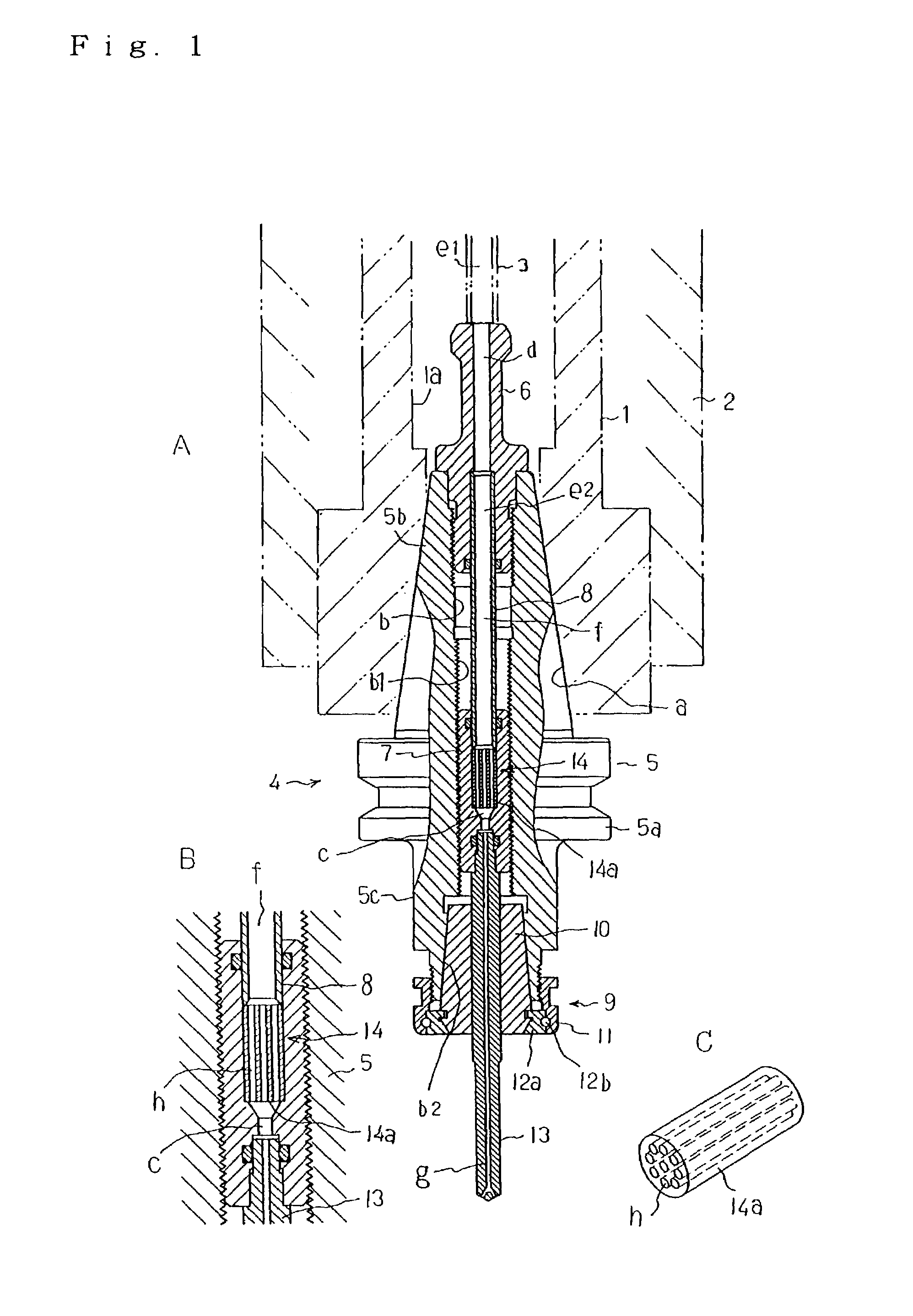

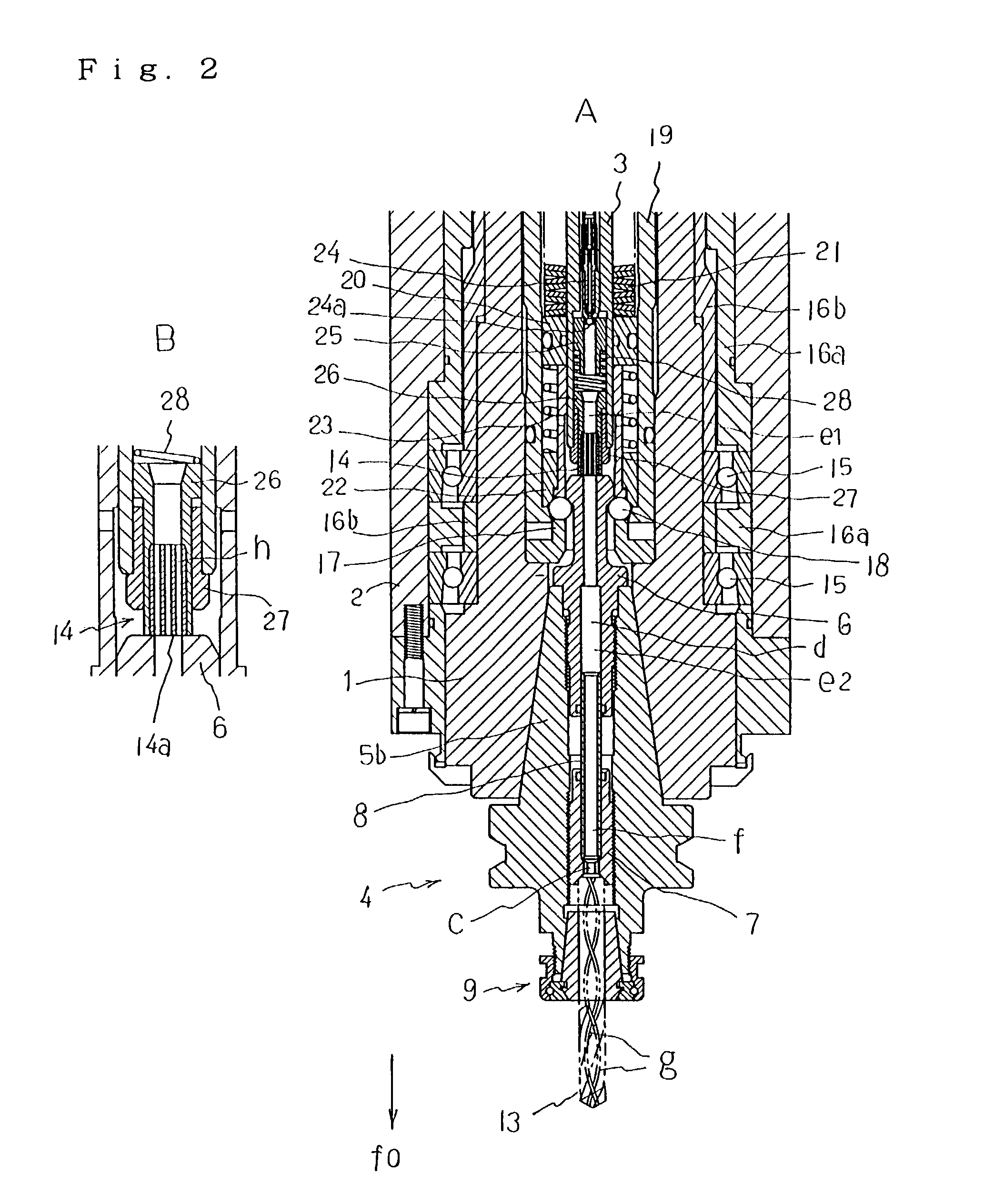

Cutting fluid device for a spindle of a machine tool

InactiveUS7048481B2Easy to producePrevent liquefactionTransportation and packagingMulti-purpose machinesMachine toolCutting fluid

A spindle device of a machine tool, which can prevent the liquefaction of atomized cutting fluid in atomized cutting fluid passage downstream of a straightening unit 14, enhance a responsiveness to an ejecting start or stop instruction, and prevent a waste of cutting fluid. The spindle device for a machine tool has atomized cutting liquid passage (e1, e2) each having a single-shape passage section and formed inside the device ranging from the spindle 1 to the tip end of a cutting tool 13 mounted thereto in one piece, and is operated so as to eject atomized cutting tool 13 via the atomized cutting fluid passages (e1, e2), wherein a straightening unit 14 formed with a plurality of small-diameter passages h are provided in the middle of the cutting liquid passages (e1, e2).

Owner:HORKOS

Method and apparatus for conversion of cellulosic material to ethanol

ActiveUS8123864B2Low costDown rate of fermentationBiological substance pretreatmentsBiofuelsFiberCellulose

The present invention provides an apparatus and a method for conversion of cellulosic material, such as chopped straw and corn stover, and household waste, to ethanol and other products. The cellulosic material is subjected to continuous hydrothermal pre-treatment without addition of chemicals, and a liquid and a fiber fraction are produced. The fiber fraction is subjected to enzymatic liquefaction and saccharification. The method of the present invention comprises:performing the hydrothermal pre-treatment by subjecting the cellulosic material to at least one soaking operation, and conveying the cellulosic material through at least one pressurized reactor, and subjecting the cellulosic material to at least one pressing operation, creating a fiber fraction and a liquid fraction;selecting the temperature and residence time for the hydrothermal pretreatment, so that the fibrous structure of the feedstock is maintained and at least 80% of the lignin is maintained in the fiber fraction.

Owner:INBICON AS

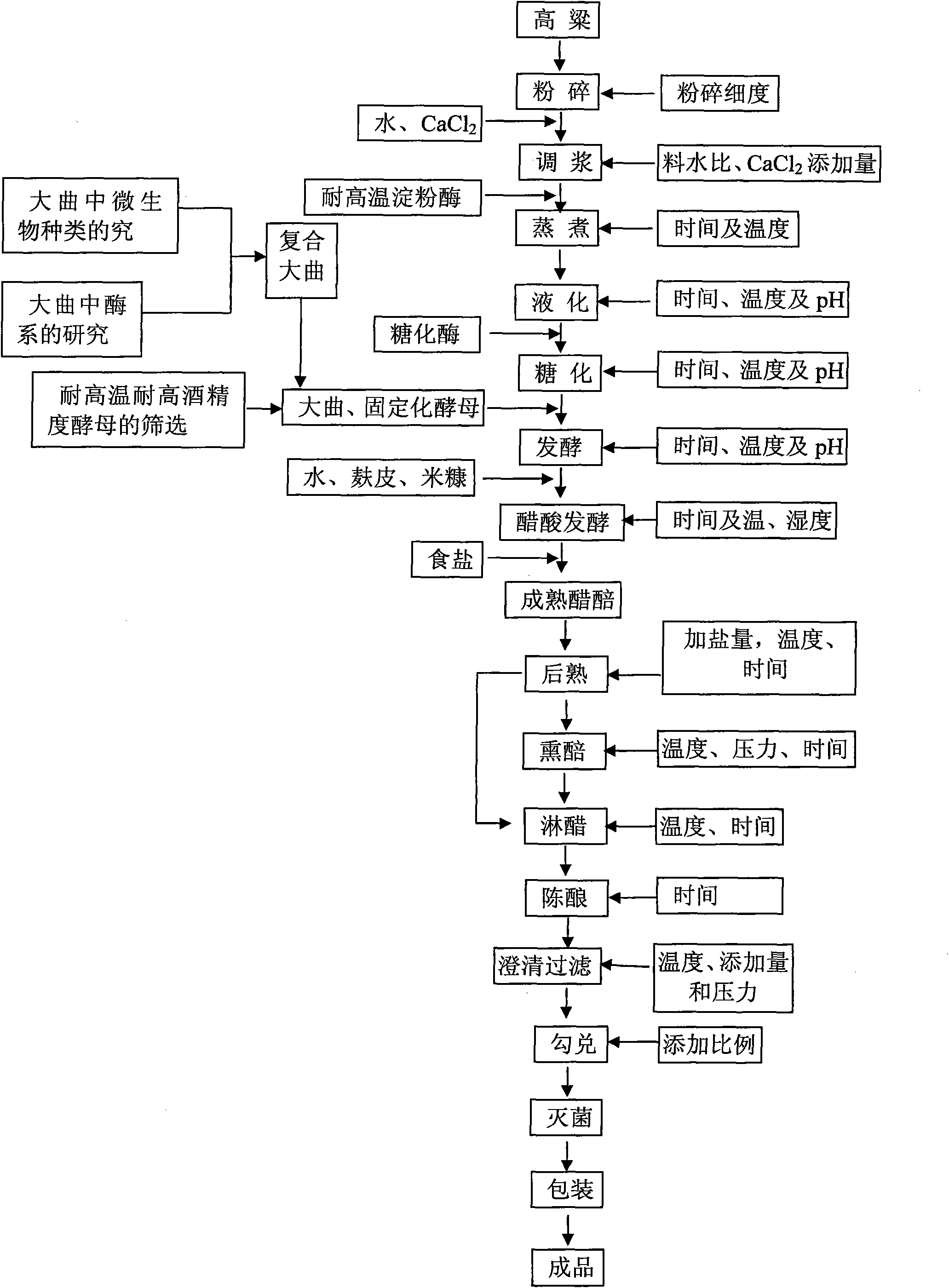

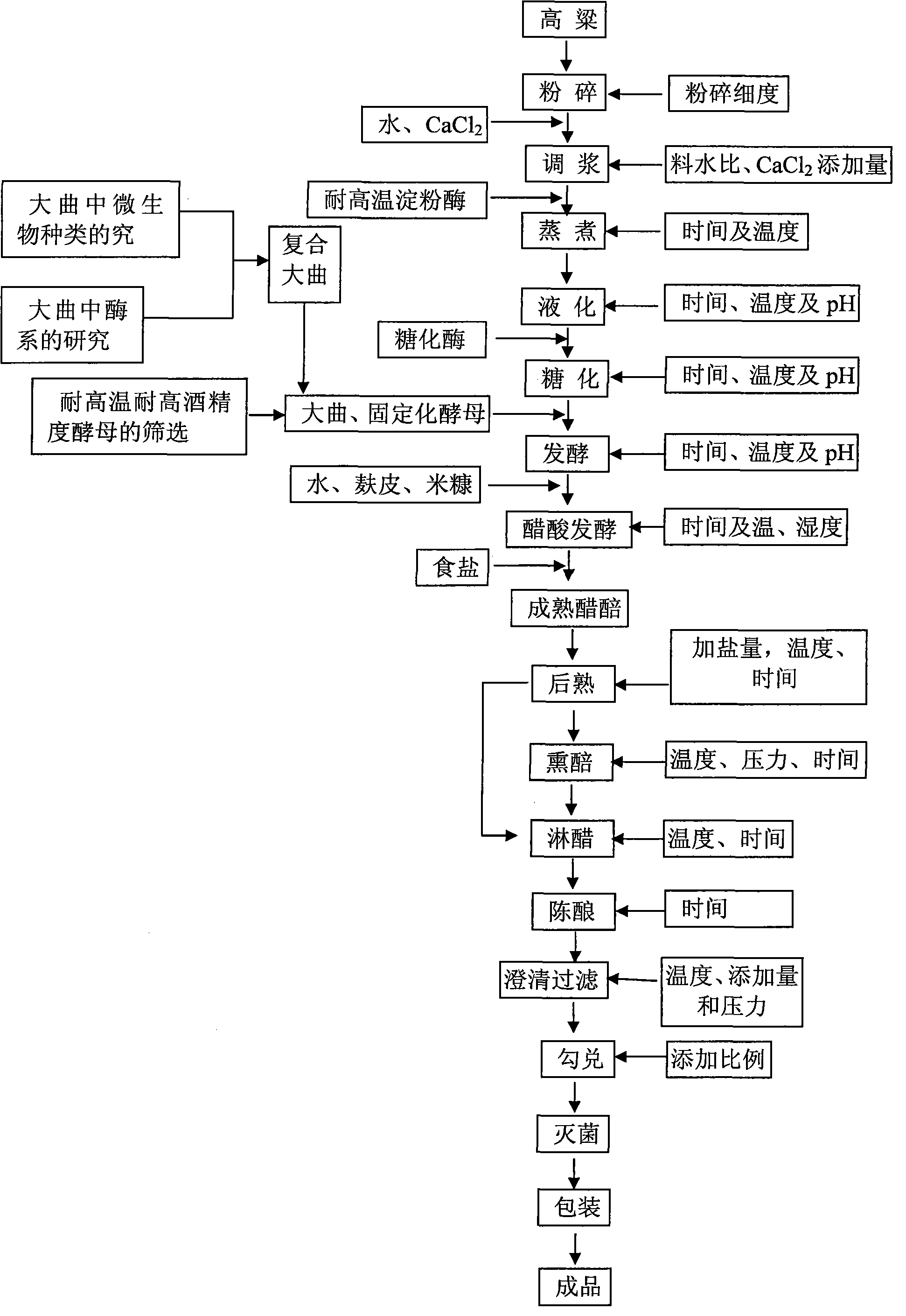

Standardized and industrialized production process for Shanxi mature vinegar

ActiveCN101857833ASystematization of processHigh technology contentMicroorganism based processesVinegar preparationMaterials processingSaccharomyces

The invention relates to a production process for vinegar, in particular to the standardized and industrialized production process for Shanxi mature vinegar, which solves the problems of long production process period, complex process, unstable product quality, low raw material utilization rate and the like, of the prior production process. The production process comprises the following steps of: performing material processing before alcoholic fermentation, crushing, mixing, liquefaction and saccharification; selecting high-temperature resistant and high-alcoholic strength resistant saccharomyces, and adding a composite yeast to perform alcoholic fermentation; adding the composite acetic bacteria into vinegar residue, stirring with a vinegar residue stirrer, fermenting the vinegar residue in an acetyl hydrate fermenting tank, and turning the vinegar residue with a vinegar residue turning machine; tamping the vinegar residue in the acetyl hydrate fermenting tank, covering a layer of table salt on the tamped vinegar residue, and standing the vinegar residue; fuming the vinegar residue by the combination of a vinegar residue fuming furnace and a steam vinegar residue fuming jar; pouring vinegar; ageing the vinegar; clarifying the vinegar with a crude acidic protease, and filtering the vinegar with kieselguhr; blending the vinegar and the traditional Shanxi mature vinegar; sterilizing the vinegar; and packing the vinegar. The process of the invention has the advantages of systematized flow, standardized technological parameters, scale production procedure, normalized product quality and optimized production process.

Owner:山西金龙鱼梁汾醋业有限公司

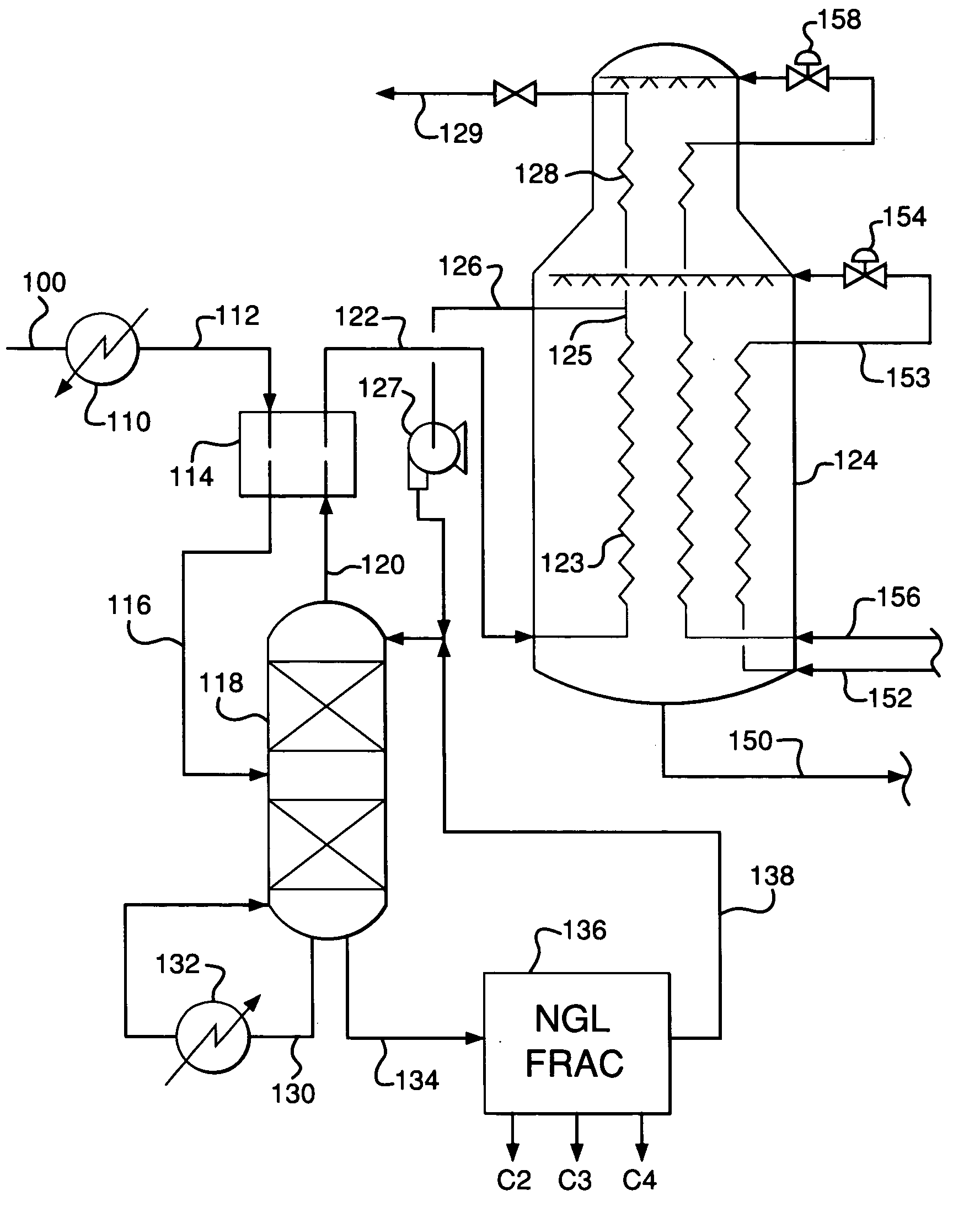

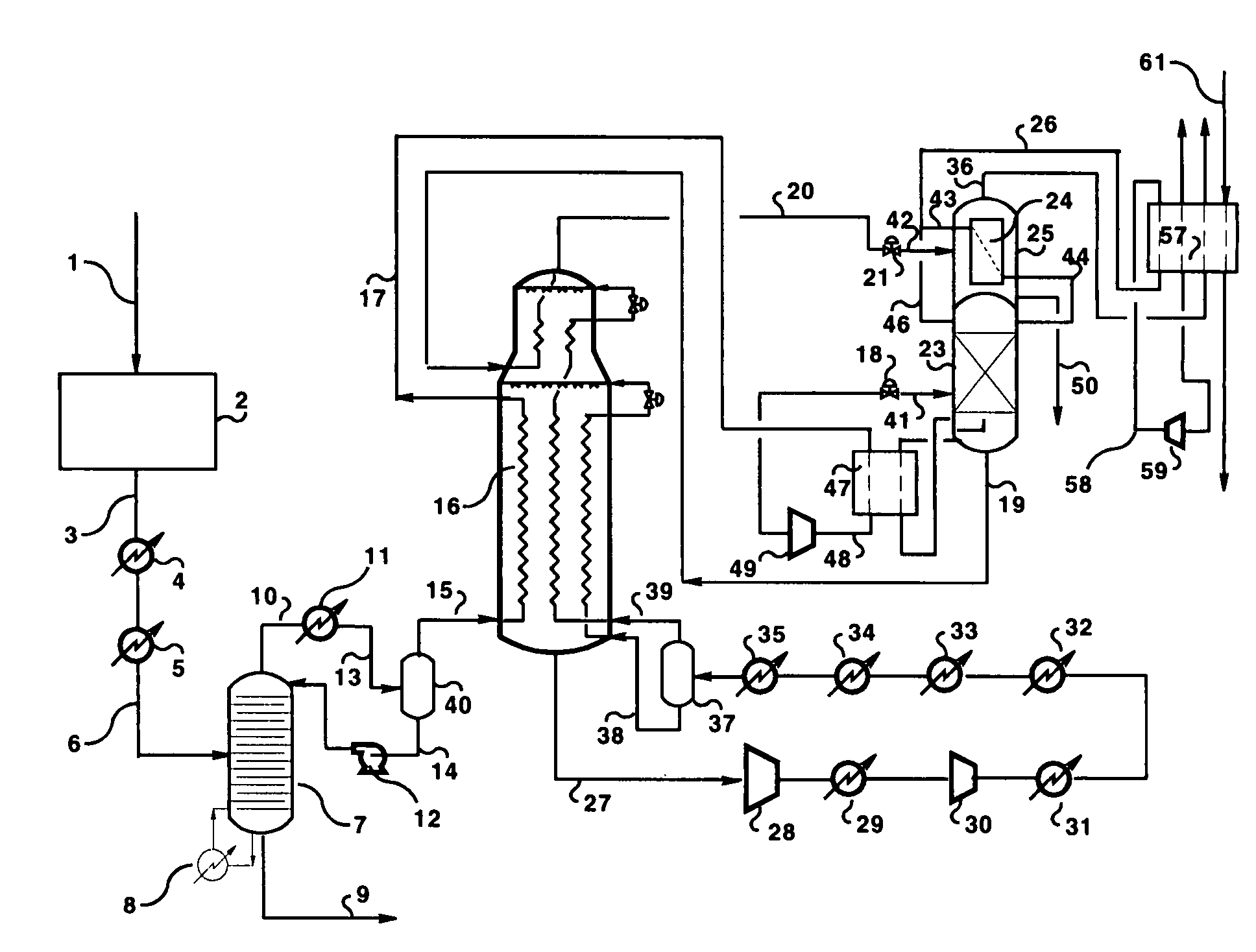

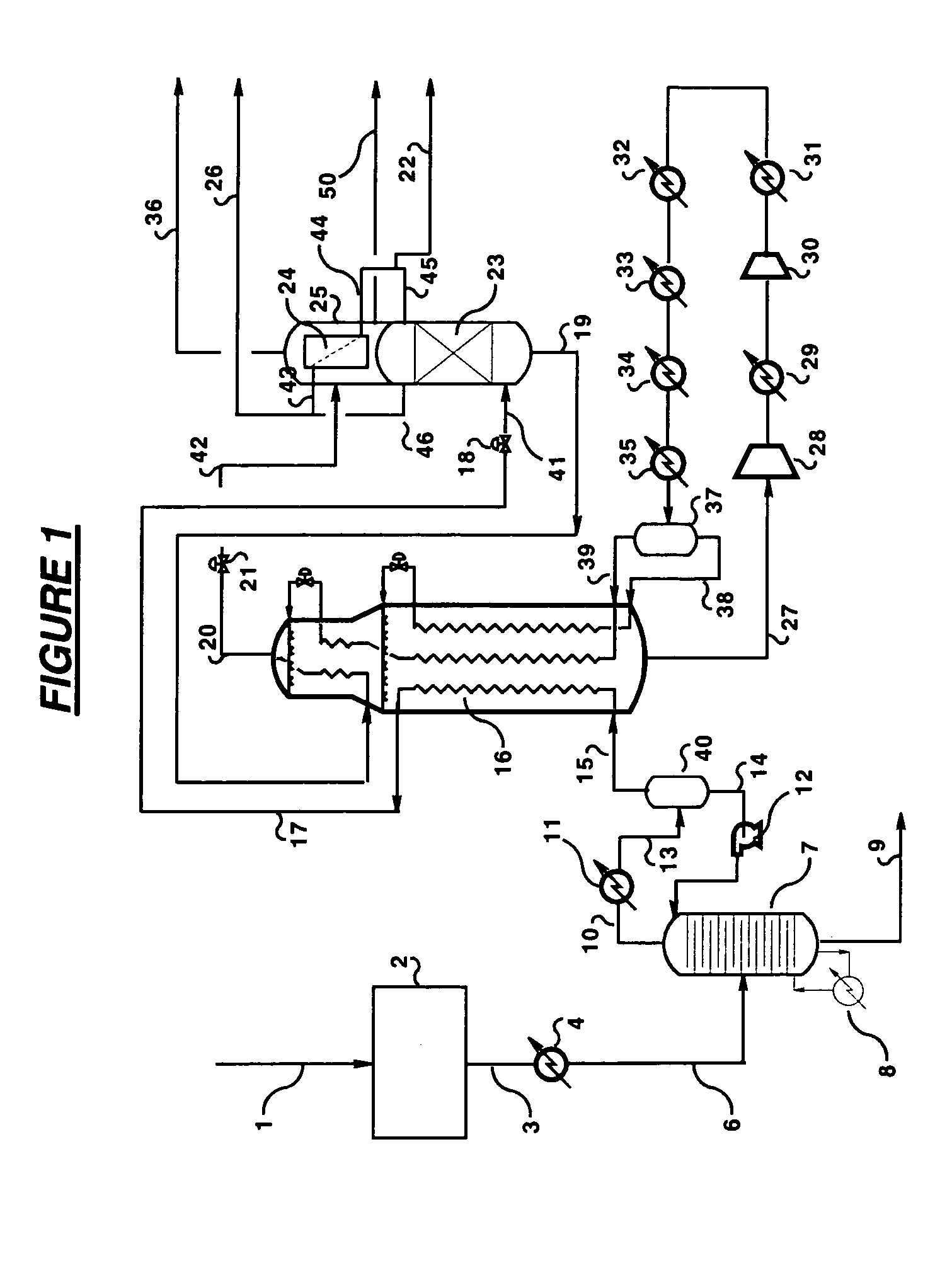

Dual stage nitrogen rejection from liquefied natural gas

Nitrogen is removed from a liquefied natural gas feed (41) by a two stage separation in which the liquefied natural gas (41) is first fractionated (23) to provide a first nitrogen-enriched overhead vapour stream (46) and a nitrogen-containing bottoms liquid stream (19) and then at least a portion of said bottoms liquid stream (19) is fractionated (25) to provide a second nitrogen-enriched overhead vapour stream (36) that is of lower purity than said first overhead vapour stream (46) and a purified liquefied natural gas stream (50). The first fractionation is conducted in a distillation column (23) refluxed (45) with nitrogen overhead (43) condensed in a condenser (24) located in a flash drum (25) in which the second fractionation is conducted. The second nitrogen-enriched overhead vapour stream (36) provides fuel gas for use in the natural gas liquefaction plant.

Owner:AIR PROD & CHEM INC

Amylum crops femented beverage and method of preparing the same

The invention relates to a beverage and a preparation method thereof, in particular relates to a fermented starch crop beverage and the preparation method thereof, and belongs to the technology field of food. The beverage has the steps as follows: (1) starch crops are processed through jordaning after being soaked; (2) gelatinization is performed; (3) heat preservation liquefaction and heating inactivation are performed; (4) heat preservation saccharification is performed; (5) filtering is performed; (6) sterilization is performed; (7) fermentation is performed; (8) the processed starch crops are homogenized, sterilized, cooled, and canned. The method not only provides a novel deep-processed way of starch crops, but also obtains a novel beverage.

Owner:丹尼斯克(中国)有限公司

Mixed Refrigerant Liquefaction Process

A method for liquefying a natural gas stream is provided. In one embodiment, the method includes placing a mixed component refrigerant in a heat exchange area with a process stream; separating the mixed component refrigerant at one or more pressure levels to produce a refrigerant vapor and a refrigerant liquid; bypassing the refrigerant vapor around the heat exchange area to a compression unit; and passing the refrigerant liquid to the heat exchange area. In another embodiment, the method further includes partially evaporating the refrigerant liquid stream within the heat exchange area to retain a liquid fraction of at least 1% by weight.

Owner:STONE JOHN B +2

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com