Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

491 results about "Rice milk" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Rice milk is a grain milk made from rice. It is mostly made from brown rice and commonly unsweetened. The sweetness in most rice milk varieties is generated by a natural enzymatic process that cleaves the carbohydrates into sugars, especially glucose, similar to the Japanese amazake. Some rice milks may nevertheless be sweetened with sugarcane syrup or other sugars.

Microalgae-Based Beverages

InactiveUS20100297295A1Great tasteLower levelMilk preparationDough treatmentEmulsionAdditive ingredient

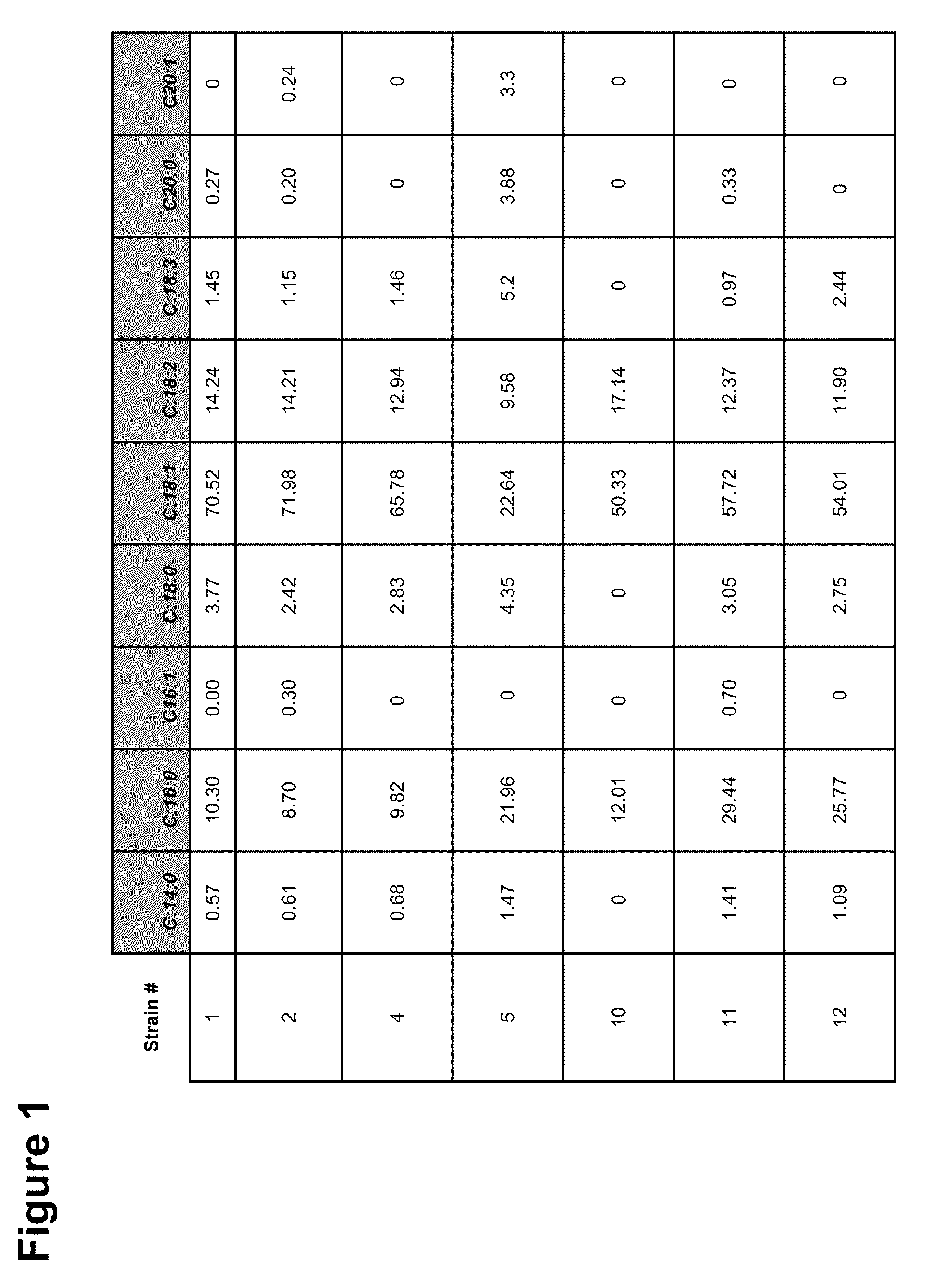

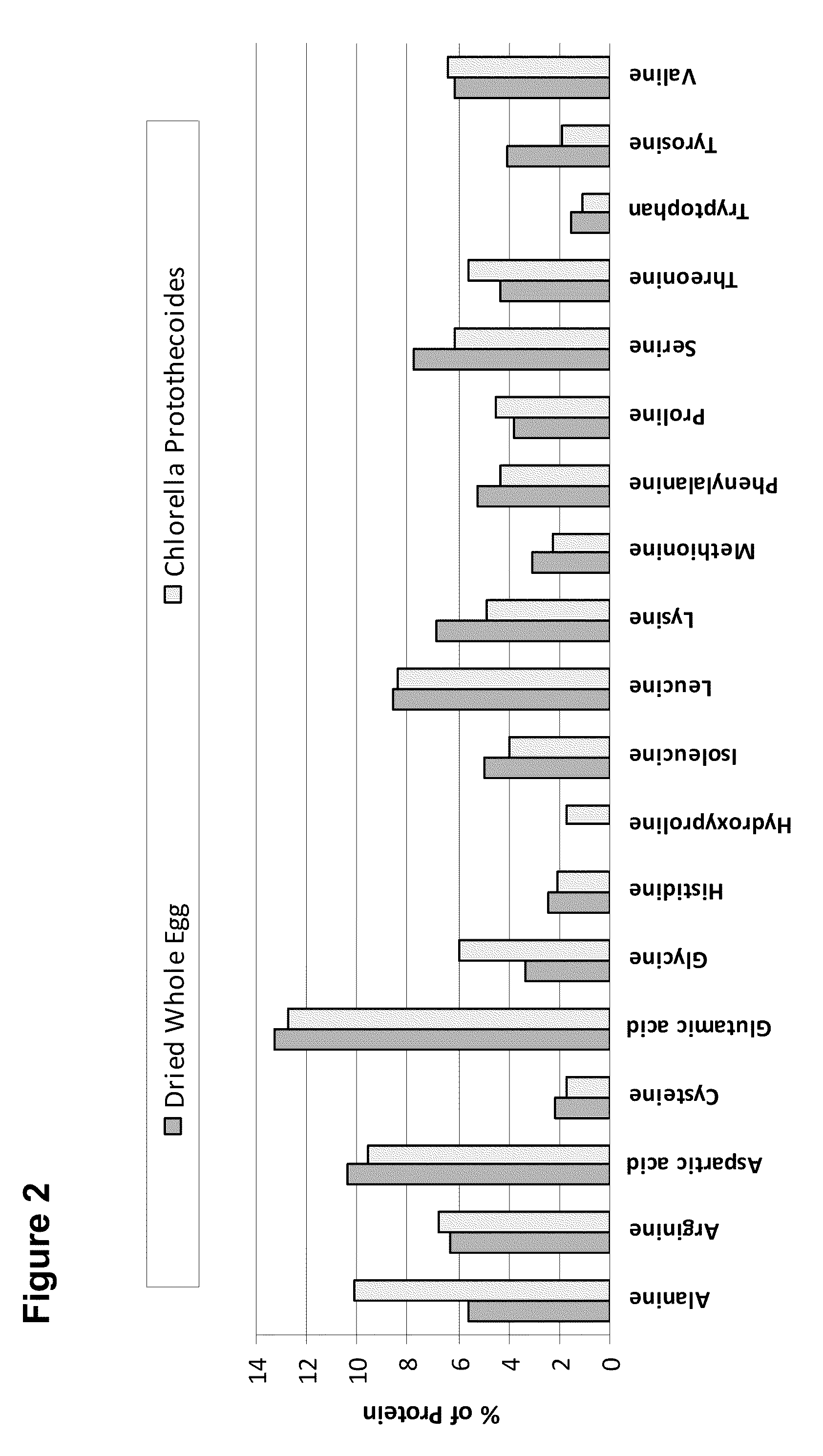

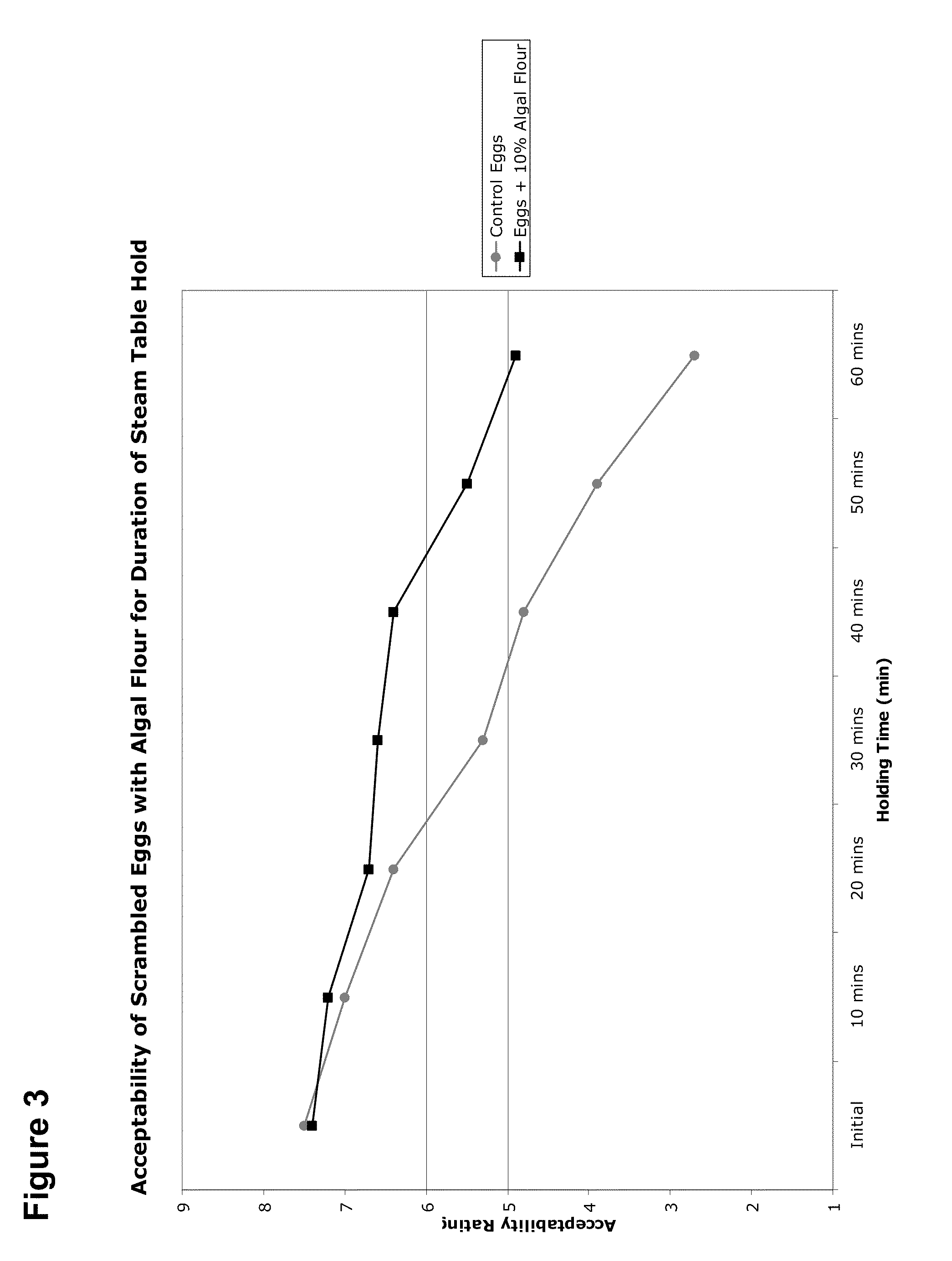

The invention provides novel beverages and raw materials for the manufacture thereof, such beverage and raw materials containing microalgae of various species with varying components. Attributes of the microalgal biomass used in the invention include nutrition-providing materials such as carotenoids, dietary fiber, tocotrienols and tocopherols, and varying lipid compositions, particularly low levels of saturated lipids. Attributes of the microalgal biomass used in the invention include structural attributes such as improved mouth feel compared to alternative milk products such as soy milk and rice milk. The novel beverages provide delivery systems for high nutrition materials found in microalgae. The invention provides a new category of finished beverages based on microalgae (such as refrigerated and shelf stable liquids and emulsions) as well as compositions for augmenting properties of current beverages through inclusion of novel microalgae-based materials as ingredients.

Owner:TERRAVIA HLDG INC

Whole grain non-dairy milk production, products and use

ActiveUS20070014892A1Increase coverageReserved functionDough treatmentWort preparationSlurryWhole milk

A method comprising selection of unbroken whole grain rice that are first washed, or whole grain corn that is first reduced in size, and then making an aqueous slurry that is subsequently wet milled to release all the protein, fat, fiber, and starch components normally held in the structure of the grain. The resulting slurry can be reacted with heat to gelatinize the starch and the subsequent product dried. Also, the heated slurry containing the liberated components can be treated to enzymatic hydrolysis via the process of liquefaction and optionally saccharification, producing whole grain rice milk products having diverse carbohydrate compositions. The whole grain milk products are characterized by a nutritional composition containing substantially all the nutritional components of the whole grain, being an opaque whole milk colloid, having smooth texture versus pulpiness, lacking in all bitterness normally associated with whole grain products, and having a variety of sweetness levels from non-sweet to very sweet.

Owner:STEUBEN FOODS

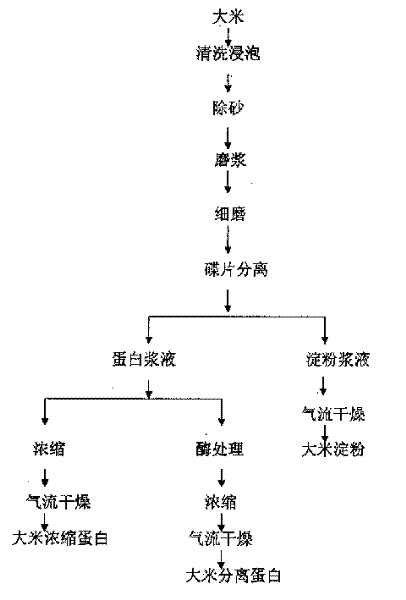

Method for extracting rice protein from rice

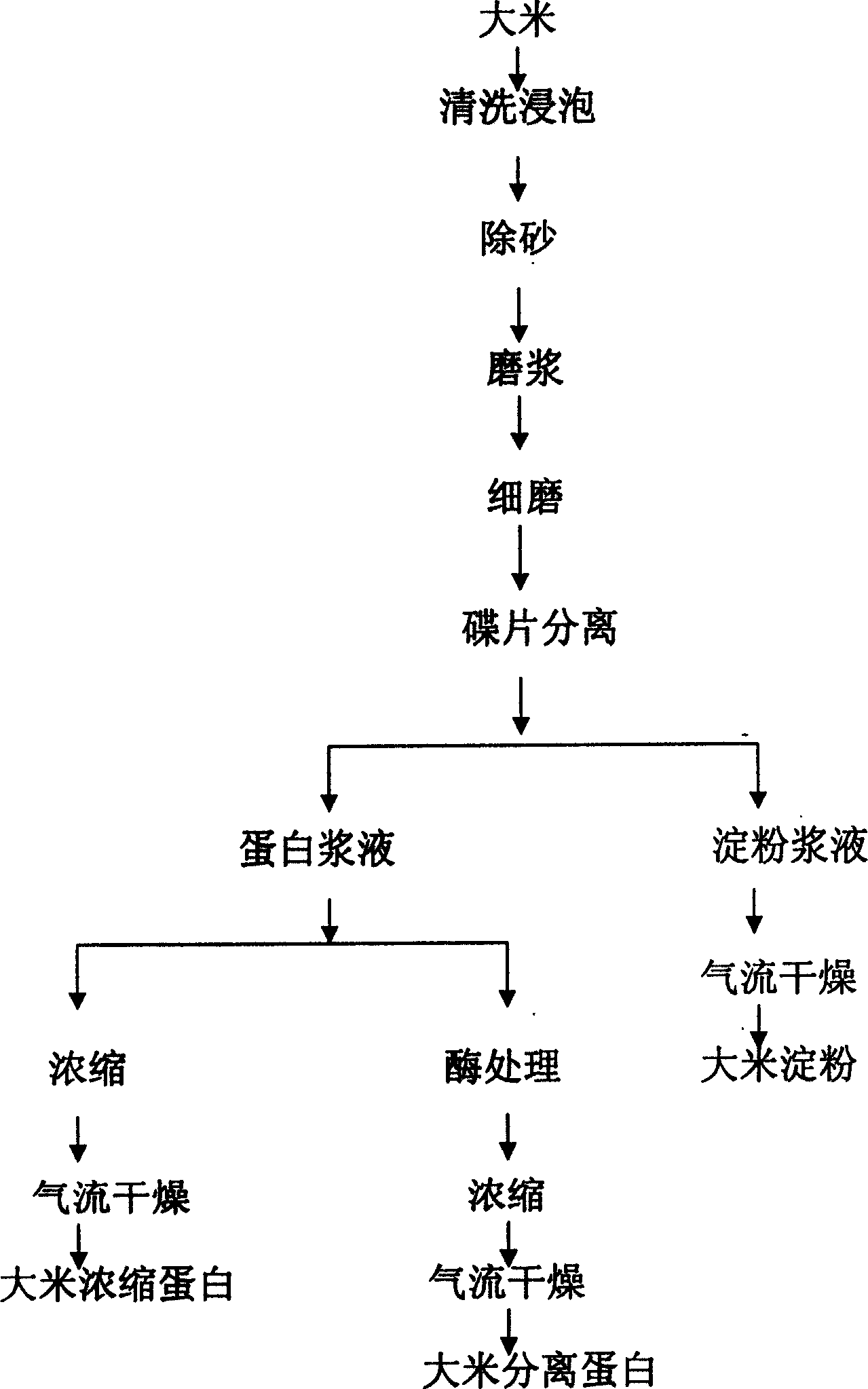

The present invention discloses a method for extracting rice protein from rice. Said method includes the following steps: cleaning rice, soaking, removing sand, grinding to make pulp, concentrating and drying rice protein; also includes the steps of fine-grinding rice pulp, adopting dished separating machine to make multistage separation and making the protein pulp undergo the process of enzyme treatment. The described enzyme treatment is characterized by that in the multistage separated and combined rice protein pulp the following enzymes are successively added to make reaction: adding 0.05%-0.2% of amylase, temp. is 60-70 deg.C and time is 40-60 min; adding 0.05%-0.2% of cellulase, temp. is 40-50 deg.C and time is 2-3 hr; and adding 0.1%-1% of lipase, temp. is 40-60 deg.C and time is 2-3 hr. Said method can implement industrial production of rice protein.

Owner:GAEA GEM RICE

Method for preparing germinated brown rice milk beverage by compound lactobacillus fermentation

The invention provides a method for preparing germinated brown rice milk beverage by compound lactobacillus fermentation, which comprises the following steps of: preparing four lactobacillus direct-throwing fermentation agents such as lactobacillus rhamnosus, pediococcus acidilactici, streptococcus thermophilus and lactobacillus brevis; then soaking brown rice for 10 hours at 30 DEG C, and germinating for 12 hours at 2 DEG C to prepare germinated brown rice; adding 3 times water into the germinated brown rice, grinding milk by adopting colloid, gelatinizing and saccharifying the milk, adding 150 grams of direct-throwing fermentation agents into each ton of liquid rice milk, and performing standing fermentation for 6 hours at the temperature of between 38 and 40 DEG C; and centrifuging the liquid rice milk at 5,000 revolutions per minute, removing residue, adding xylitol according to the clear liquid volume for blending, filtering the liquid by using a hollow fiber membrane, performing ultrahigh-temperature instantaneous sterilization for 2 seconds at 143 DEG C, and filling the liquid with pillow-type package or tetra package to obtain a finished product.

Owner:黑龙江大荒春酒业有限公司

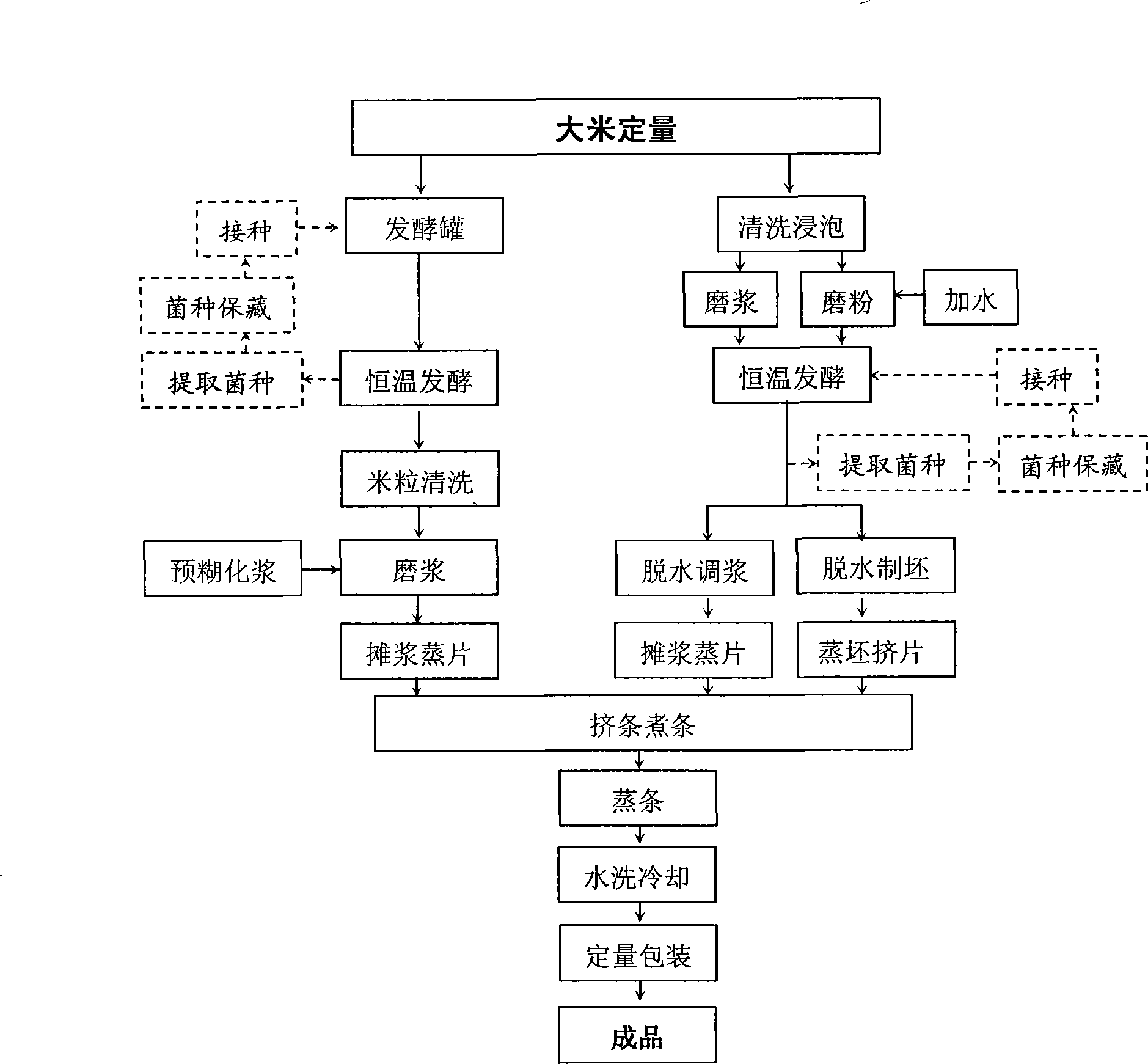

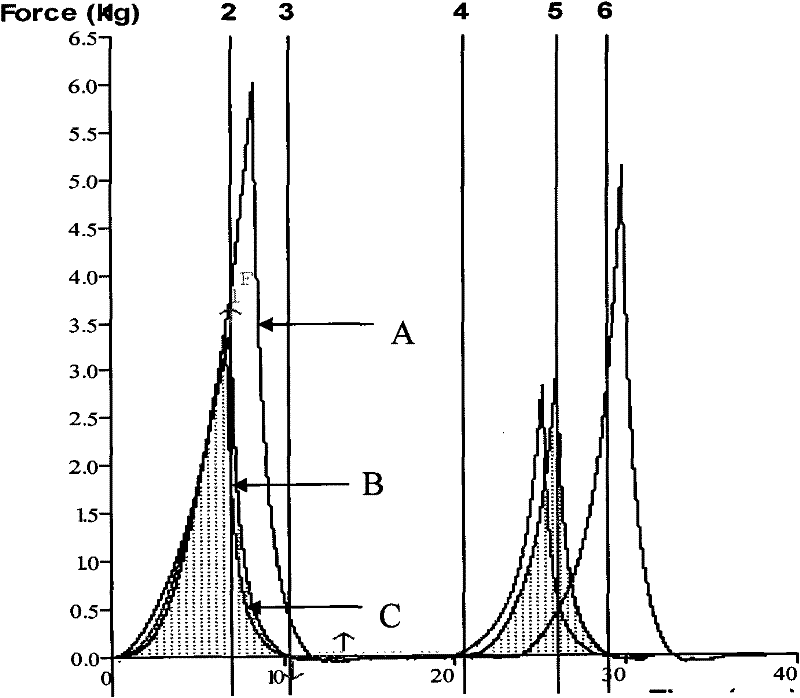

Method for processing lactic acid bacteria fermentation rice-flour noodles

InactiveCN101248852AShorten the production cycleReduce manufacturing costFood preparationBiotechnologyBroken rice

The invention discloses a processing method for fermenting rice flour by lactobacillus, namely using the lactobacillus to ferment and produce rice flour food with high quality, belonging to the technology field of food process. The technical proposal comprises the following steps of grinding the rice flour to thick liquid, spreading the thick liquid to steam a sheet, extruding and cooking rice bars, steaming the rice bars, and washing and cooling the rice bars. The processing method is characterized in that the selected material is rice or broken rice with amylose starch content more than 20%, the lactobacillus is added into the rice flour for fermentation at a constant temperature before or after grinding the rice flour to thick liquid, the number of the lactobacillus is 10<6> - 10<11>cfu / ml, the fermentation temperature is 30-50 DEG C, and the fermentation time is 8-18 hours. The processing method avoids the danger of latent miscellaneous bacteria by adopting pure strain enrichment fermentation, improves the flexibility and ensures the cleanness and the quality of the rice flour by utilizing pre-pasting rice milk instead of reserved rice sheet and fermented glutinous rice, and saves production cost due to the short production period.

Owner:CHINA AGRI UNIV

Method for extracting rice protein by using rice

InactiveCN101695334AHigh purityNot transgenderVegetable proteins working-upHigh concentrationRice protein

The invention discloses a method for extracting rice protein by using rice, which comprises the following steps: soaking and grinding, rice milk adjustment, primary liquefying, centrifugal separation, homogenizing, washing, centrifuging, enzymolysis, enzyme inactivation, screen separation, washing, centrifuging, drying, crushing and packing so as to obtain the rice protein. The method overcomes the defects that the high-concentration alkali liquor has damage effect on rice protein amino acid in an alkali extraction process, the quality of the extracted rice protein is poor, and the purity and sanitary index of the extracted protein cannot reach the edible standard; and in other methods for extracting the rice protein by using enzyme preparations, the rice milk is liquefied at a temperature of over 95 DEG C and then is dried at the high temperature, so the rice protein is denatured, the color is darkened, and the function of the rice protein is damaged. The extracting method of the invention keeps good physical functionality of the rice protein, implements industrialization of the extraction and production of the rice protein, and meanwhile improves the production conversion rate and quality of rice starch sugar.

Owner:北京佳沃臻诚科技有限公司

Zymolysis rice milk beverage and preparation method thereof

InactiveCN101181088AFully dispersedImprove product qualityFood preparationWater bathsCarboxymethyl cellulose

The invention discloses a fermentation rice milk drink and a preparation method thereof, which adopts fermentation rice as raw material that is processed through immersion, water bathing, cooking, fermentation, beating and pulp refining, and then the pH value of the obtained emulsion is adjusted; thermostable alpha-amylase Unikamyl HT is added according to a portion of 10 kilograms of the material being added with 3 to 5ml of thermostable alpha-amylase Unikamyl HT; then the obtained starch milk is sent into the ejector device through a flow meter; through flash cooking, the temperature of the obtained material should rise to 95 to 98 DEG C; then thermal insulation, enzyme stabilization, cooling and pH value regulation are done; efficient glucoamylase Unikase GA is added according to the portion of 10 kilograms of the material being added with 5 to 15ml of efficient glucoamylase Unikase GA; the temperature of the obtained material should rise to 100 DEG C, and the killing of enzyme is done; next, the obtained material are added with water, citric acid, xanthan and sodium carboxymethyl cellulose; the temperature raises by 55 to 60 DEG C so as to do secondary homogeneous; finally, the super-high-temperature sterilization and aseptic packing are done. The fermentation rice has specific flavor of rice wine, and is characterized by sweet and fragrant taste, light yellow or ivory color, being rich in nutrition and with the functions of health care and skin-maintaining and stable storage.

Owner:SOUTH CHINA UNIV OF TECH

Fermented rice cake and preparation method thereof

The invention relates to a rice product, in particular to a fermented rice cake and a preparation method thereof. The inventor takes more than ten years to study and experiment, and provides a proportion of raw materials of the fermented rice cake, particularly a ratio of rice to water so as to provide a process basis for the preparation of the fermented rice cake. The inventor also provides a preparation method for the fermented rice cake. In the method, the technical key points for grinding rice milk are improved, and the fermented rice milk is heated in a constant-temperature heating mode to shorten the fermentation time of the rice milk, so that the prepared fermented rice cake does not have sour taste, and the technical problem which cannot be solved by persons in the field for a long time is solved.

Owner:陈忠良

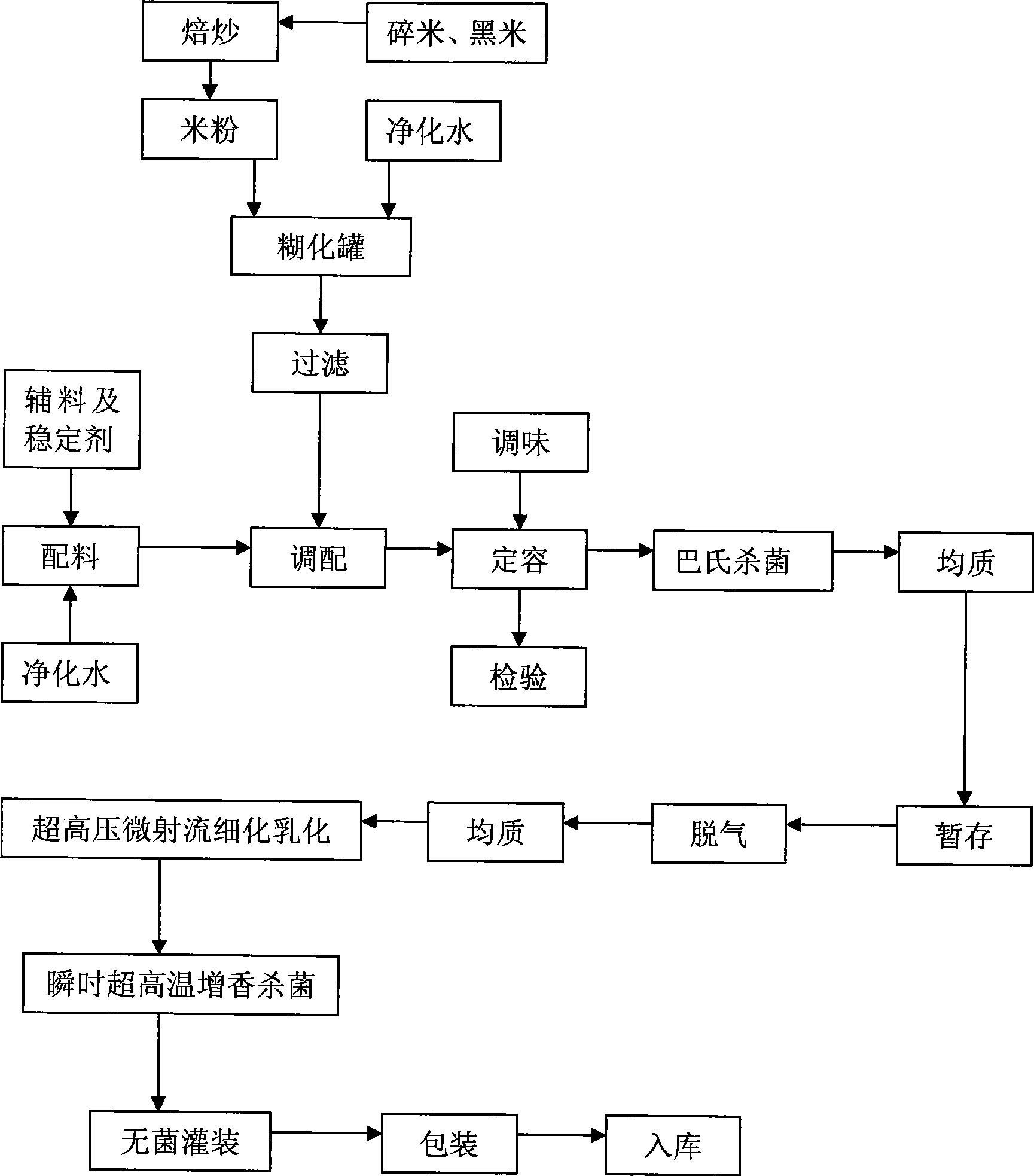

Non-enzymolysis rice milk beverage and preparation method thereof

InactiveCN101438845AOvercome the bottleneck of stabilityExtended shelf lifeFood preparationMilk substitutesNon enzymaticImpurity

The invention provides a non-enzymatic rice milk beverage and a preparation method thereof, wherein, the non-enzymatic rice milk beverage takes crushed rice and black rice as main material, and the method for preparing the non-enzymatic rice milk beverage comprises the steps of screening out impurities, roasting, crushing, non-enzymatic gelatinization, preparation, homogenization, refinement, emulsification, sterilization, packaging, etc. The crushed rice and the black rice are taken as the main material of the non-enzymatic rice milk beverage; the preparation method adopts the dynamic supervoltage microjet technology to refine and emulsify materials; emulsified stabilizing agent is added during the preparation process; and instant ultrahigh-temperature flash evaporation technology is adopted for aromatizing and sterilizing the materials.

Owner:NANCHANG UNIV

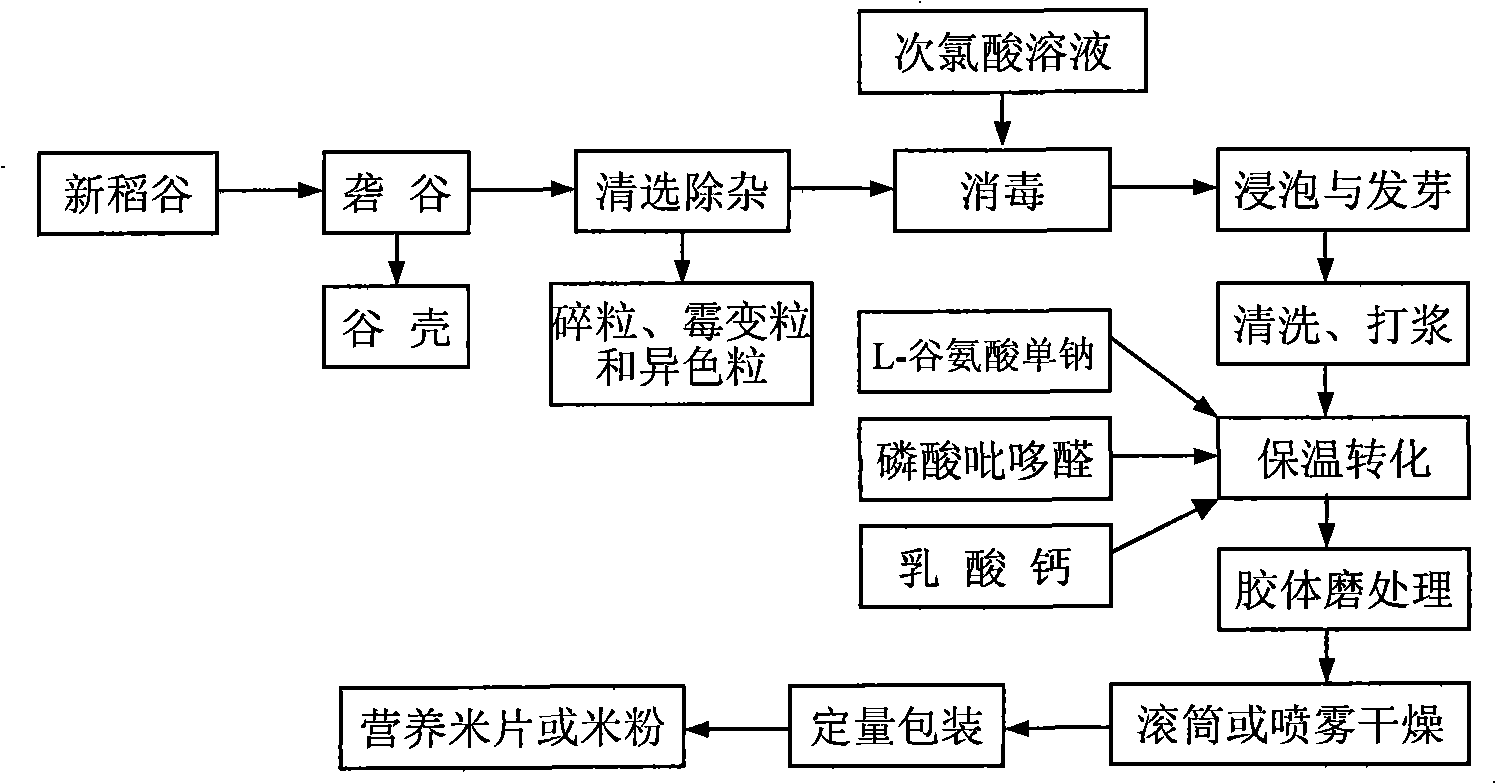

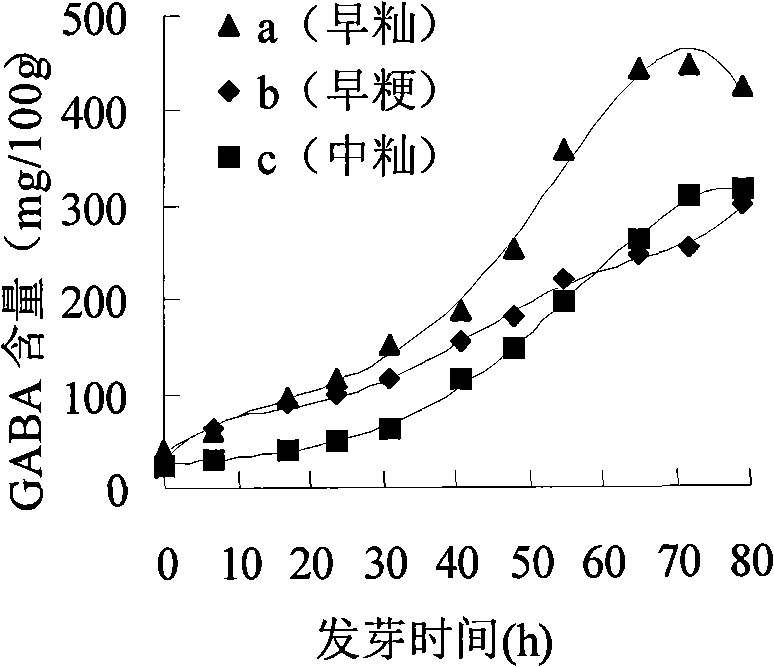

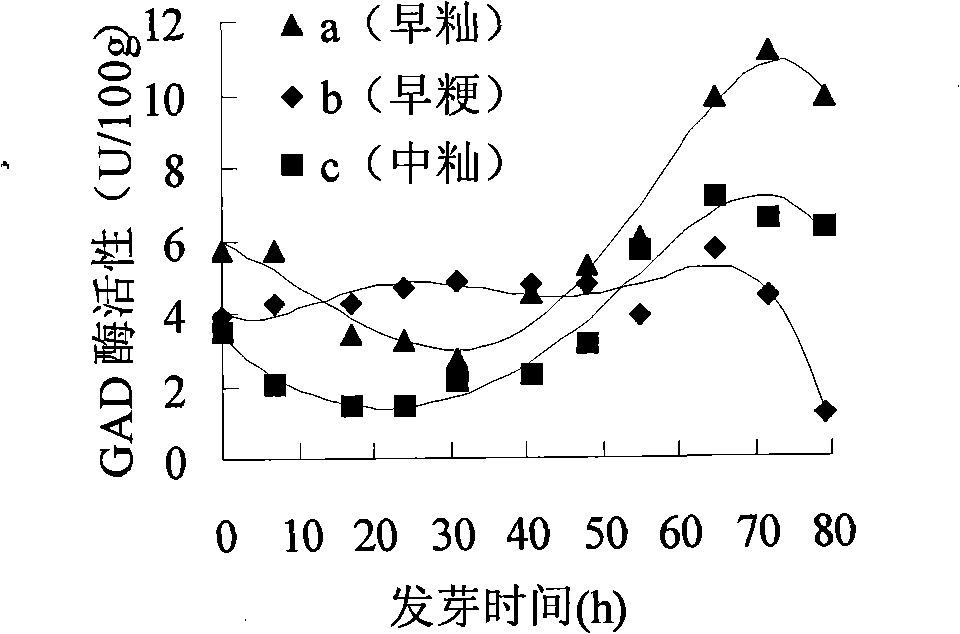

Rice product rich in gamma-aminobutyric acid and method for producing the same

The invention belongs to the technical field of rice deep processing, in particular to a production method of a functional rice product which has a special sweet flavor and is rich in Gamma-aminobutyric acid and a product thereof, the rice product is produced by virtue of the activities of high glutamate decarboxylase, amylase and protease in germinated brown rice of an indica type rice or a non glutinous rice. The invention takes the indica type rice or the non glutinous brown rice as a raw material which carries out the steps of cleaning, disinfection, soaking, germination, cleaning, beating into rice milk, heat insulation, transformation, drum drying or spray drying, and the like, to be produced into functional nutrition rice flake or rice powder which is rich in Gamma-aminobutyric acid. Compared with the prior art, the rice product makes full use of the activities of the glutamate decarboxylase, the amylase and the protease in the germinated brown rice; the produced rice product has the special sweet flavor; by calculating based on dry basis, the content of Gamma-aminobutyric acid is high (1,000-1,400mg / 100g), and the nutritional value and the digestibility are high. The rice product of the invention can be taken as the functional food for resisting fatigue and reducing blood lipid.

Owner:HUAZHONG AGRI UNIV

Health-care rice for men and preparation method thereof

The invention relates to the field of health-care food and in particular relates to health-care rice. The health-care rice for men is characterized in that the raw materials of the health-care rice include black beans, black rice, black sesame, oat, gordon euryale seed, medlar and pumpkin seeds. The raw materials are ground and then extruded into rice grains, thus preparing the health-care rice; and the health-care rice is coated with a rice milk layer. The health-care rice has mild efficacy, nourishes the liver and kidney, blackens the hair and improves the eyesight, nourishes the spleen and benefits qi, enhances the body vitality and is suitable for health care and body building of men.

Owner:SHANGHAI YIYANGTANG FOOD TECH

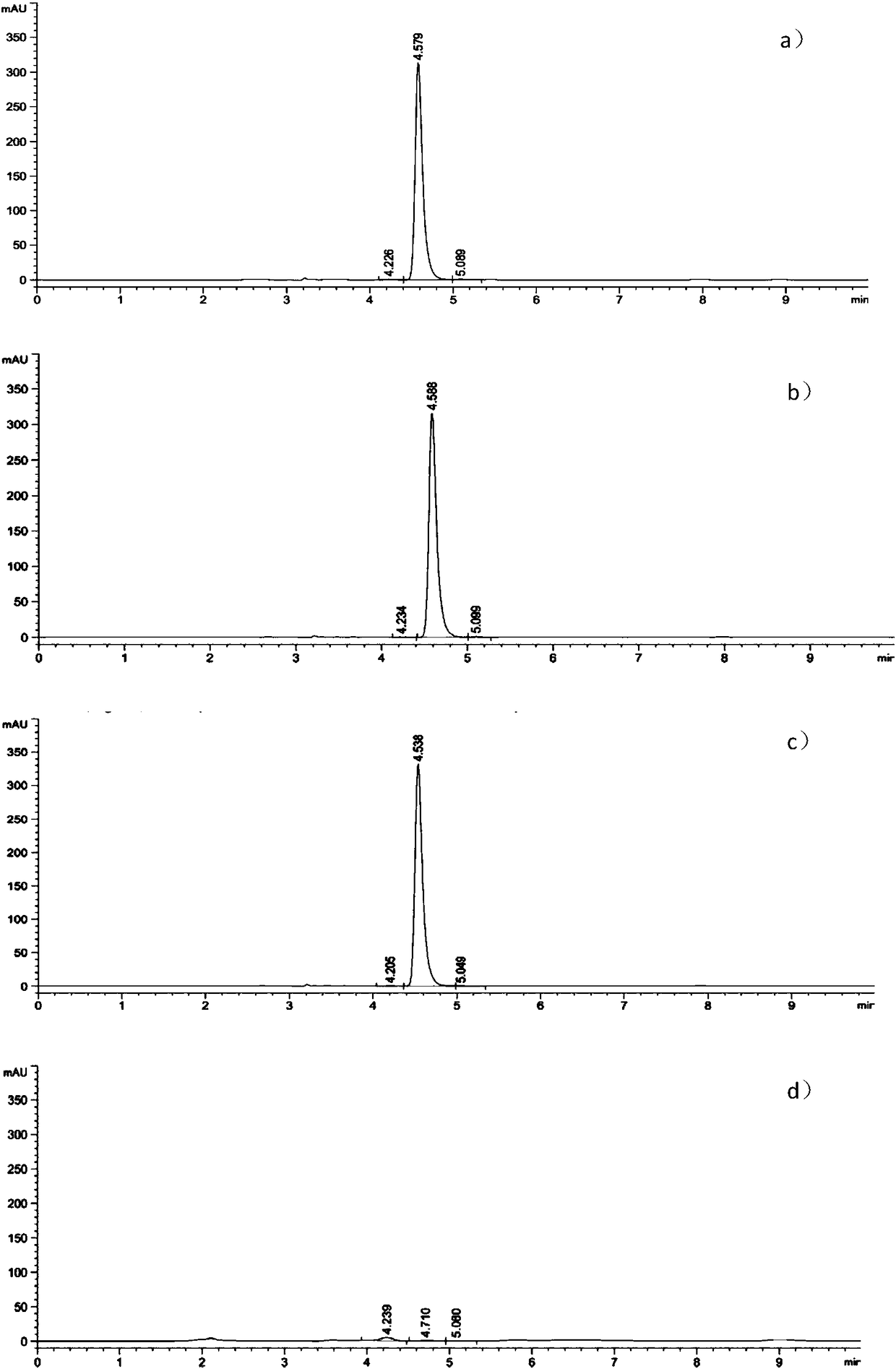

Lactobacillus plantarum and application thereof in rice wine brewing

ActiveCN103421723AWill not harmCompliance with safety regulationsBacteriaMicroorganism based processesMicroorganismReady to use

The invention discloses Lactobacillus plantarum and application of the Lactobacillus plantarum in rice wine brewing and belongs to the field of food biotechnology. The bacterial strain is named Lactobacillus plantarum. The bacterial strain is obtained from rice milk in a screened mode, the bacterial strain is preserved in the China general microbiological culture collection center in September 3, 2013, and the preservation number is CGMCC No.8097. The Lactobacillus plantarum and a ready-to-use starter of the Lactobacillus plantarum can be used for rice wine brewing, so that the production process is controllable and slightly affected by seasons, operation is simple and convenient, and the Lactobacillus plantarum has important significance in the innovation of the rice wine brewing technology.

Owner:JIANGNAN UNIV +1

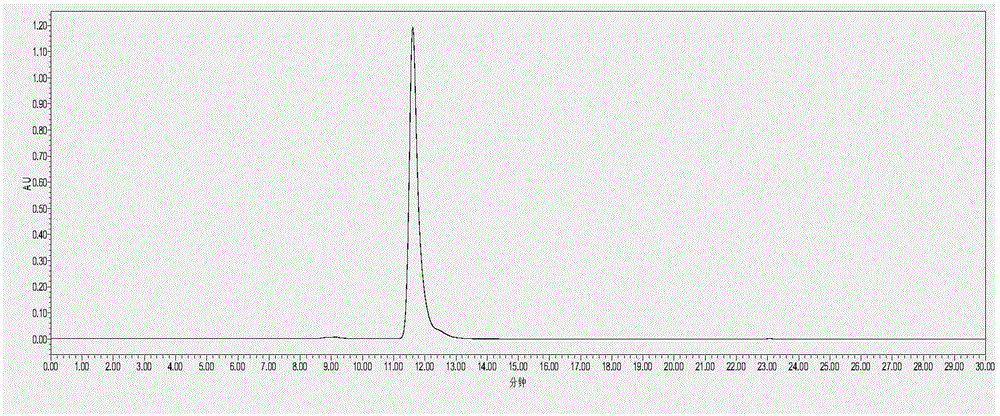

Preparation method of probiotic fermented rice milk

The invention provides a preparation method of probiotic fermented rice milk. Three probiotics of lactobacillus rhamnosus, lactobacillus paracasei subsp. paracasei, and lactobacillus brevis are used as original strains, and compound probiotic freeze-dried powder is obtained through amplification culture, powdery freeze-dried strain preparation, and freeze-dried powder complex formulation. The probiotic fermented rice milk is prepared by the following steps: obtaining rice, brown rice and drinking water according to a weight ratio of 2:1:7, performing pulp refining in a colloid mill, sieving by a 80-mesh fine sieve to prepare mixed rice milk pulp, adding 5% white sugar, performing liquefaction by high temperature resistant alpha-amylase, performing saccharification by glucoamylase, performing hydrolyzation by papain, inoculating the compound probiotic freeze-dried powder according to a ratio of 0.01%, allowing the powder to stand and performing fermentation for 4 hours, well mixing, and performing aseptic filling.

Owner:HEILONGJIANG LONGWA GRAIN OIL IMPORT & EXPORT

Preparation method of nano lactobacillus beverage

ActiveCN102018257ASolve the problem of prone to starch agingSolve agingFood preparationBiotechnologyAmylase

The invention relates to a preparation method of a nano lactobacillus beverage. The method comprises the following steps of: (1) frying rice till the rice becomes brown; (2) adding the fried rice to water and soaking; (3) pouring the well-soaked rice and water together into a grinding machine to grind; (4) heating the ground rice milk to gelatinize; (5) cooling the gelatinized rice milk to 45-60 DEG C, respectively adding glucoamylase and medium-temperature alpha-amylase to saccharify so as to prepare saccharified liquid; (6) proportioning a proportioning solution from the following components in percentage by weight: 10-40 percent of saccharified liquid, 0.01-0.5 percent of sucrose ester, 0.01-0.2 percent of xanthan gum, 4-12 percent of sucrose, 0.1-2 percent of milk powder and the balance of water; (7) sterilizing the proportioning solution; (8) cooling the proportioning solution, adding DVS (Directed Vat Set) lactobacillus which is 0.01-0.1 percent by weight of the proportioning solution; and (9) fermenting the inoculated saccharified liquid to obtain a finished product. The invention solves the problem of easy starch retrogradation of lactobacillus beverages of starch and crops under a refrigeration condition, is suitable for people with weak spleen or weak stomach and can also stimulate the appetite.

Owner:SYNBIOTECH BIOTECHNOLOGY YANGZHOU CO LTD

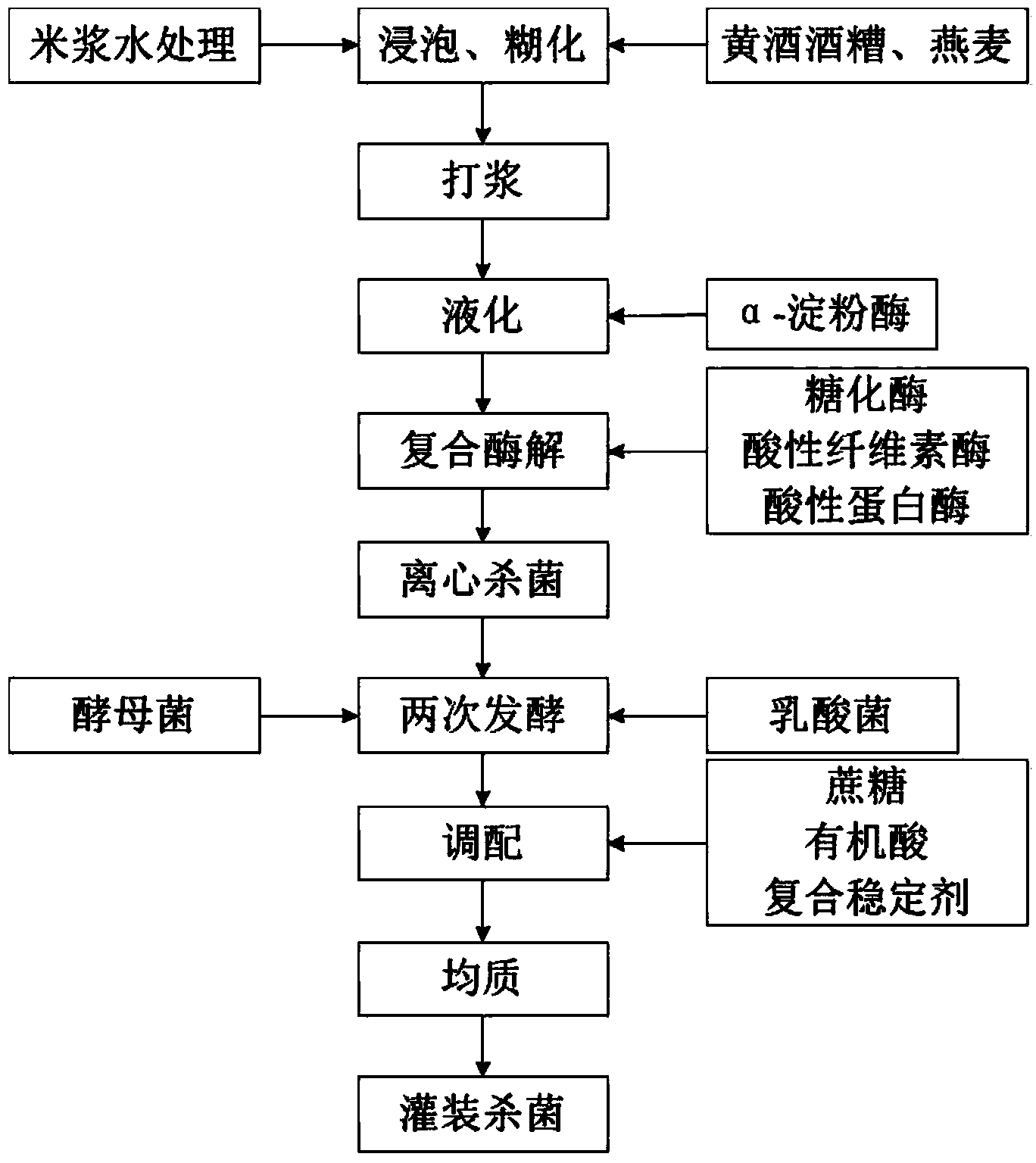

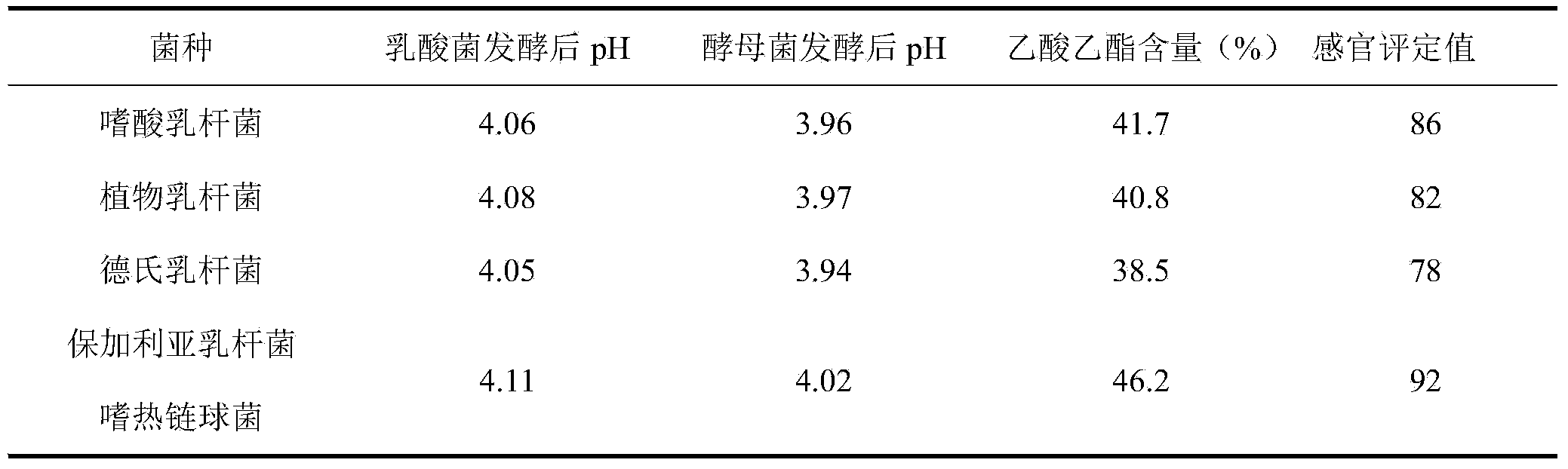

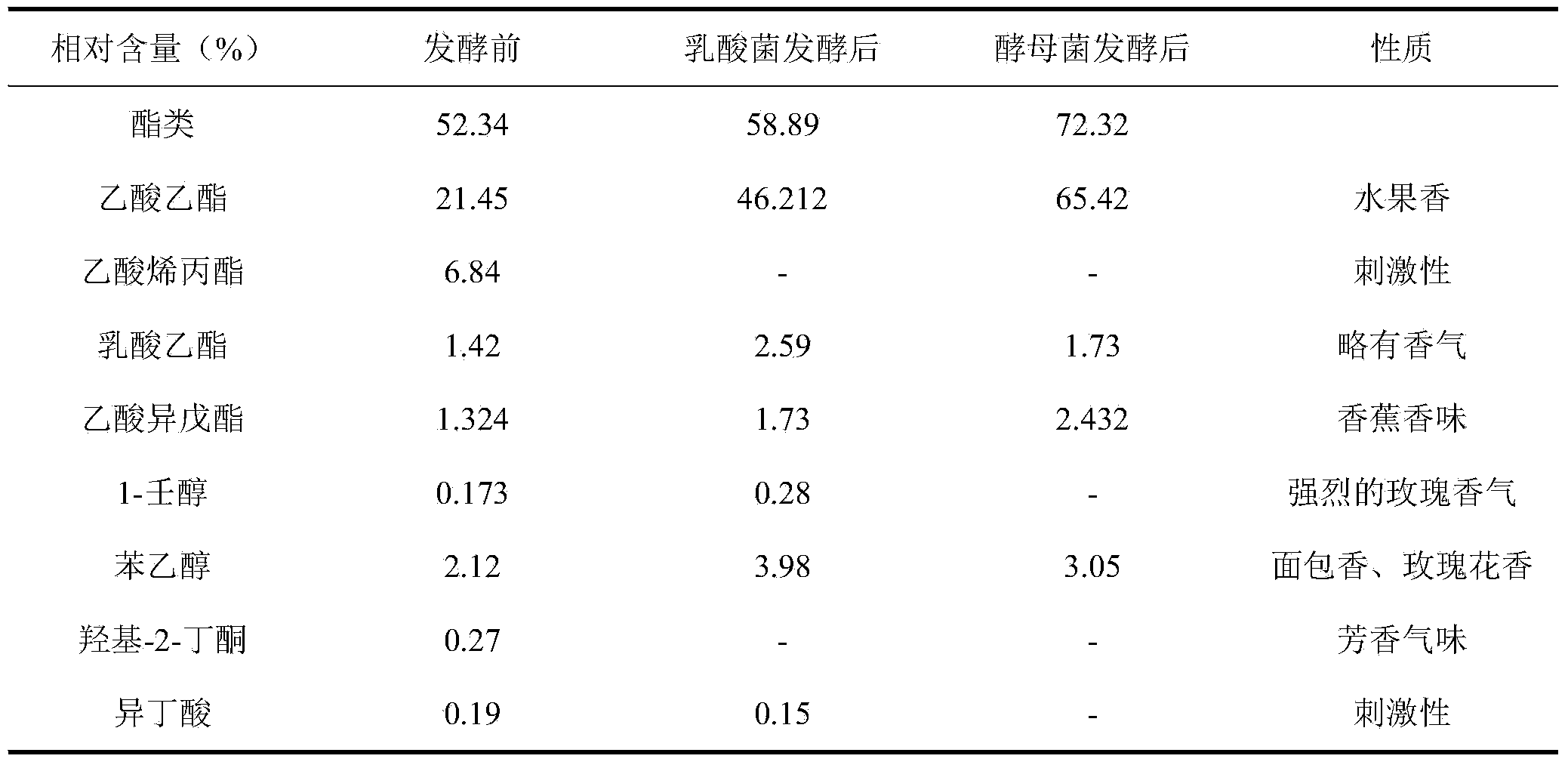

Method for preparing lactic acid fermentation beverage by using yellow wine lees

ActiveCN104382159ASolve outputSolve UtilizationLactobacillusStrepto/lacto-coccusAdditive ingredientFood flavor

The invention discloses a method for preparing a lactic acid fermentation beverage by using yellow wine lees and belongs to the technical field of food processing. According to the method, the yellow wine lees containing a plurality of amino acids, vitamins and fragrance substances which are produced by fermenting yellow wine, and oat are used as main raw materials; the rice immersing pulp water processed during the production of the yellow wine is used as the production water; a lactic acid fermentation beverage good in taste and rich in nutrition is prepared by a technology of carrying out enzymolysis twice and fermentation twice. The method for preparing the lactic acid fermentation beverage by using yellow wine lees comprises the following steps: mixing the wine lees with the oat according to a certain ratio to prepare raw pulp, gelatinizing, liquefying, saccharifying, fermenting, mixing, homogenizing, filling and sterilizing; the prepared lactic acid bacteria beverage is high in stability; the content of the amino acids and the fragrance substances is obviously higher than that in other cereal beverages. The lactic acid bacteria beverage is coordinated in color, free of impurity and delamination, has natural fermented mellow flavor and fruit flavor, is moderate in sour and sweet tastes, and has a certain health effect.

Owner:JIANGNAN UNIV

Cosmetic with fermented original rice milk, method for manufacturing cosmetic and application thereof

ActiveCN105193658ANatural absorptionGuaranteed stabilityCosmetic preparationsToilet preparationsBiotechnologyBifidobacterium bifidum

The invention discloses a cosmetic with fermented original rice milk, a method for manufacturing the cosmetic and application thereof. A process for preparing the fermented original rice milk includes steps of fermenting and cultivating initial systems with bifidobacterium bifidum, dry rice flour and water to obtain the fermented original rice milk. A bacterium is the bifidobacterium bifidum. As proved by experiments, the cosmetic, the method and the application have the advantages that the fermented original rice milk does not contain optional chemical components, accordingly, the cosmetic can be directly used as a finished product of facial masks or essence or toner and is natural as compared with other products on current markets, and optional negative effects on the skins of users can be prevented; small components can be acquired by the aid of the method as compared with common extraction methods, and accordingly the cosmetic can be easily sufficiently absorbed by the skins of the users.

Owner:SHANGHAI BIOTRULY BIOTECH CO LTD

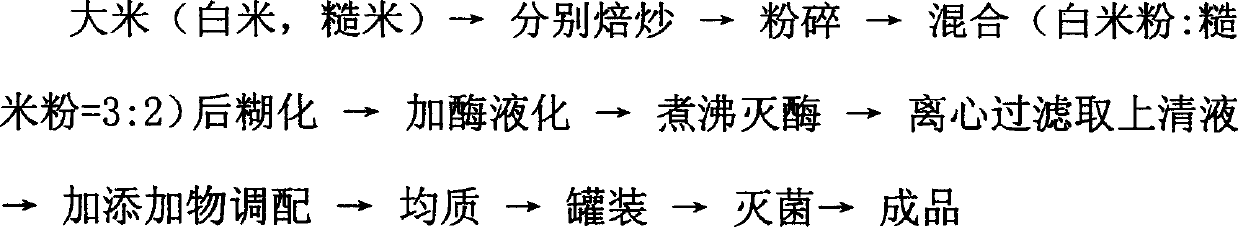

Rice emulsion drink production method

A method of producing a kind of rice-milk drink. It comprises, removing impurities from unpolished rice or polished rice, crushing, roasting at 140í½180degree C, adding water and boiling to be mash, grinding, adding 1í½3íÙamylase at 80í½85degree C relative to the amount of starch and processing for 40-50min, adding 1í½3íÙdiastatic enzyme at 55í½ 62degree Crelative to the amount of starch and processing for 10-15hours, inactivating enzymes and filtering and getting cleanified liquid, adding 1í½3úÑ plant cream or 0.5í½1úÑ plant fat, 1í½ 3úÑ maltodextriníó0.1úÑí½0.3íÙ sodium sulfite, mixing, homogenizing, packing into cans, disinfecting, and stocking.

Owner:GAEA GEM RICE

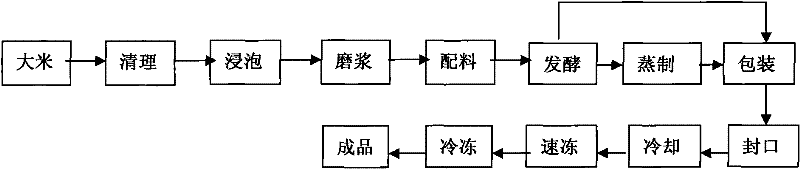

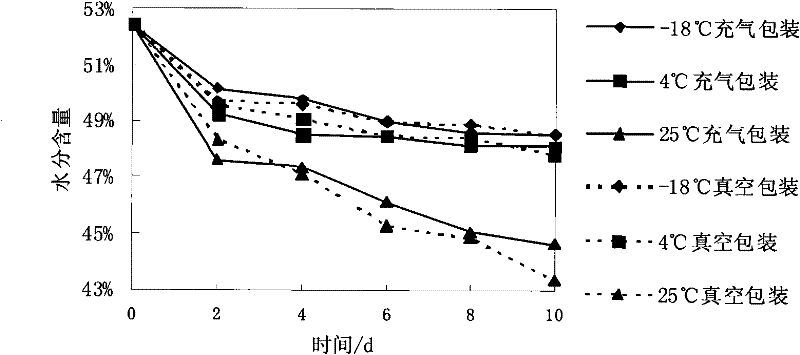

Method for preparing preserved rice steamed sponge cake and application thereof

The invention belongs to the technical field of food processing and food preservation and particularly relates to a method for preparing a preserved rice steamed sponge cake and application thereof. The method is characterized by: packaging ground rice milk fermented by a ferment, quickly freezing the rice milk at the temperature of 50 to 20 DEG C below zero for 30 minutes, freeze-storing the rice milk at the temperature of 30 to 8 DEG C below zero to obtain the pulp of the preserved rice steamed sponge cake; or steaming the fermented rice milk at the temperature of 100 DEG C for 20 minutes to the formed rice steamed sponge cake, packaging the formed rice steamed sponge cake, quickly freezing the formed rice steamed sponge cake at the temperature of 50 to 20 DEG C below zero for 30 minutes, freeze-storing the formed rice steamed sponge cake at the temperature of 30 to 8 DEG C below zero to obtain the preserved instant formed rice steamed sponge cake. The rice steamed sponge cake has the characteristics of convenient eating, good flavor and nutrients, hygiene, safety and the like.

Owner:HUAZHONG AGRI UNIV

Lactobacillus hilgardii and application of lactobacillus hilgardii in yellow rice wine brewing

ActiveCN103451134AWill not harmSave rice soaking processBacteriaMicroorganism based processesMicroorganismHigh density

The invention discloses lactobacillus hilgardii. The lactobacillus hilgardi strain is screened from waste rice milk, is preserved in China General Microbiological Culture Collection Center (CGMCC) on September 3, 2013 and has a preservation number of CGMCC No.8098. The strain can be prepared into a ready-to-use starter after being activated and cultured at a high density. The lactobacillus hilgardi disclosed by the invention and the ready-to-use starter made from the lactobacillus hilgardi can be applied to the brewing of yellow rice wine; by virtue of the lactobacillus hilgard and the ready-to-use starter of the lactobacillus hilgardi, the production process is controllable, is rarely influenced by season, and is simple and convenient to operate; and the lactobacillus hilgard and the ready-to-use starter of the lactobacillus hilgardi are significant for the innovation of the process for brewing the yellow rice wine.

Owner:JIANGNAN UNIV

Red bayberry milky tea beverage

InactiveCN103250793AHas the function of food therapy and health careUnique aromaMilk preparationWhey proteinWhey protein powder

The invention discloses red bayberry milky tea beverage. The milky tea beverage is prepared from the following raw materials in parts by weight: 50-60 parts of skim milk, 5-9 parts of sweet potato leaves, 30-40 parts of composite rice milk, 12-15 parts of extract of traditional Chinese medicine, 3-5 parts of honey, 4-8 parts of millet flour, 4-5 parts of red bayberry flesh, 1-2 parts of fried peanut powder, and 3-5 parts of whey protein powder. The milky tea beverage disclosed by the invention is mellow in taste, unique in formula, simple, convenient and easy in process implementation, and has unique sour of the red bayberry, and the produced milky tea has rich rice aroma, and simultaneously has certain effects of dietary therapy, health care and life nourishing.

Owner:BENGBU JINWANG FOOD

Eurotium cristatum fermentation type rice milk health care beverage and preparation method thereof

InactiveCN103999946AAppearance color is differentSmell differentMilk substitutesFlavorAdditive ingredient

The invention discloses eurotium cristatum fermentation type rice milk health care beverage and a preparation method thereof; the fermentation type rice milk beverage uses eurotium cristatum as fermentation strain, and comprises 210-260 mug / mL of fungal polysaccharides produced by fermentation. The invention also discloses a preparation method of the eurotium cristatum fermentation type rice milk health care beverage. The eurotium cristatum is used for production of the fermentation type rice milk beverage, and the new rice milk beverage with unique flavor and rich polysaccharides and other health factors can be prepared. The eurotium cristatum fermentation type rice milk health care beverage is orange brown or brown in appearance color, has a unique fungus flower fragrance produced by fermentation of the eurotium cristatum, and is pure in taste and delicate in texture, and the content of the functional ingredient fungal polysaccharides in the beverage is 210-260mu g / ml.

Owner:CENTRAL SOUTH UNIVERSITY OF FORESTRY AND TECHNOLOGY

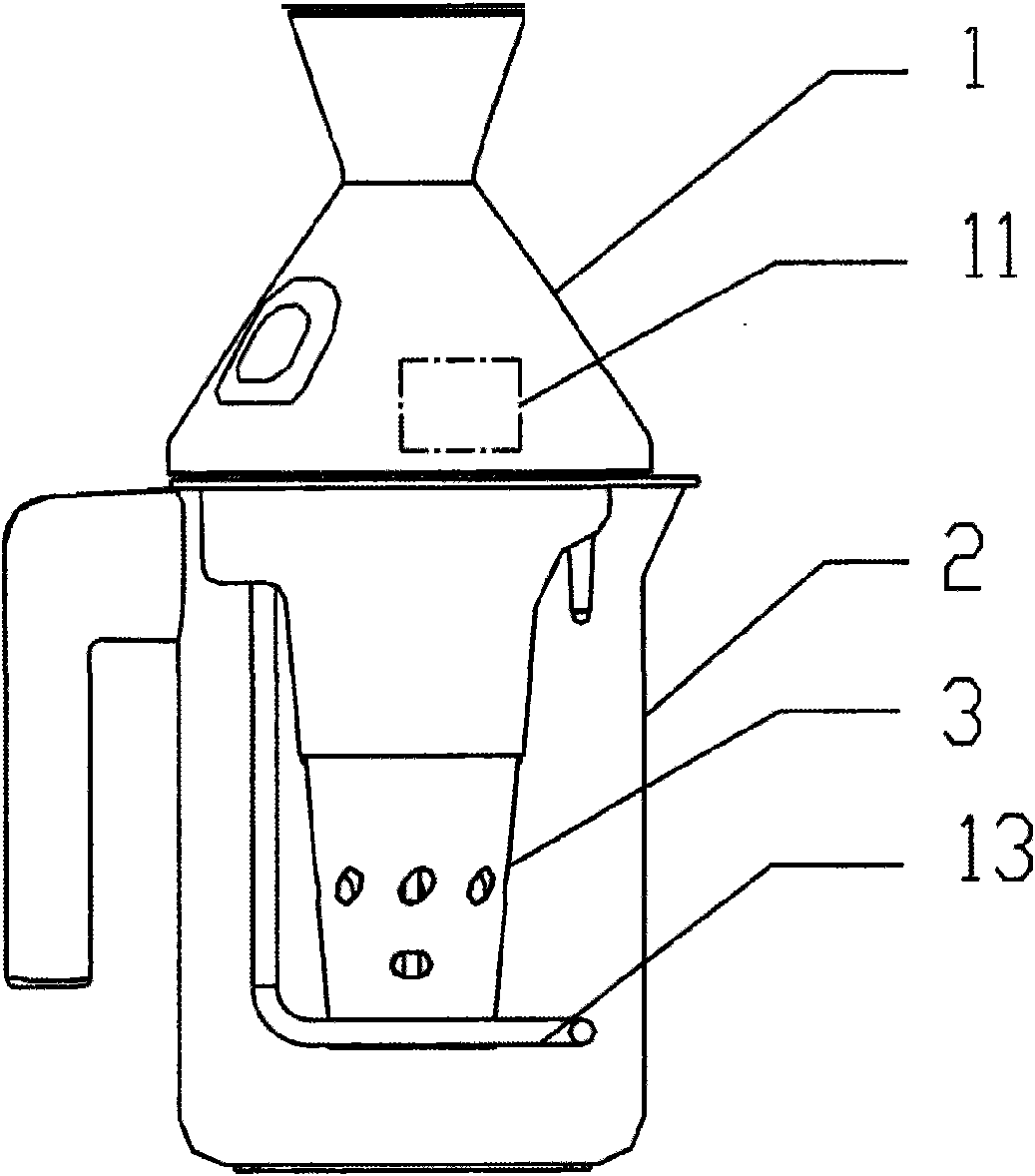

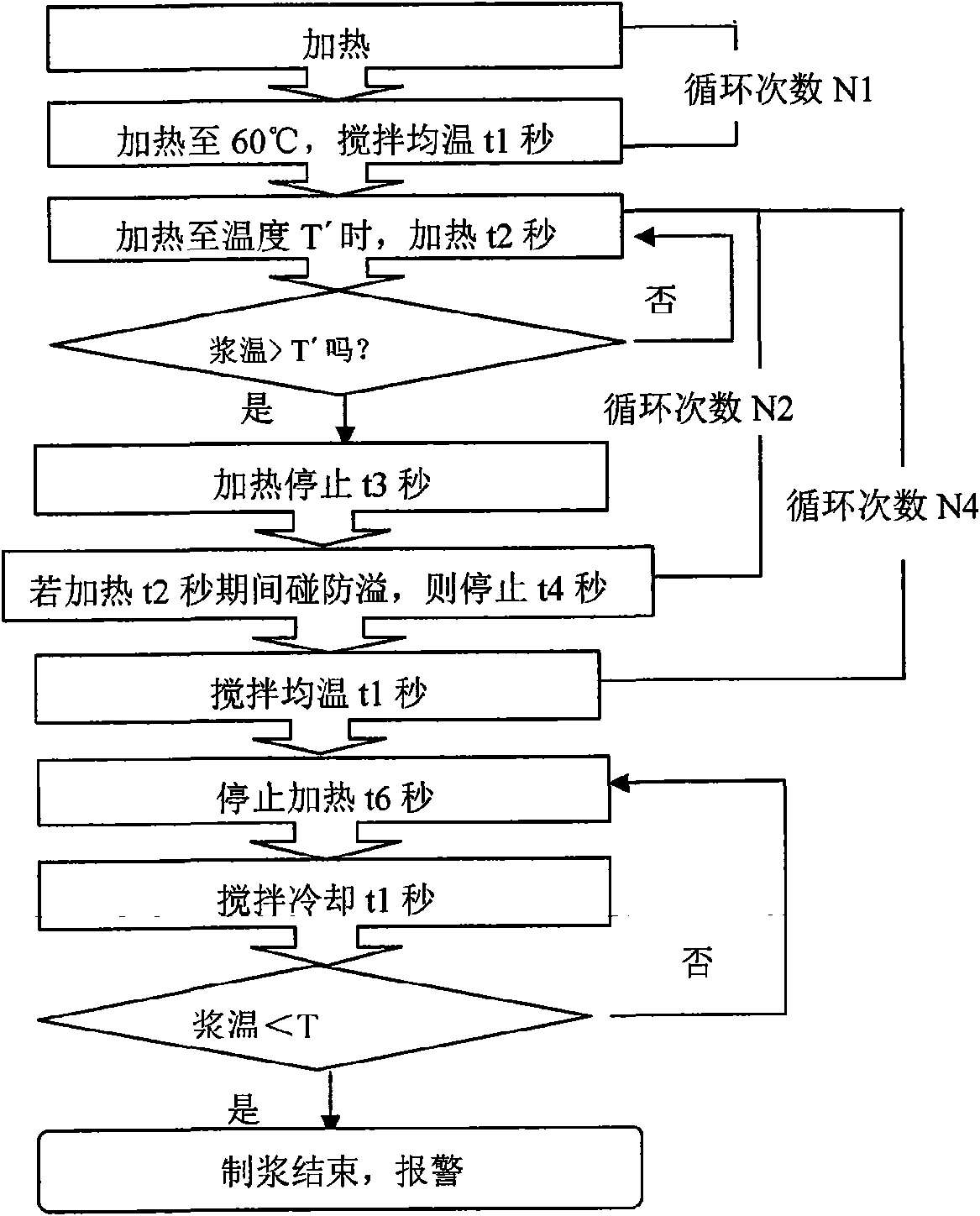

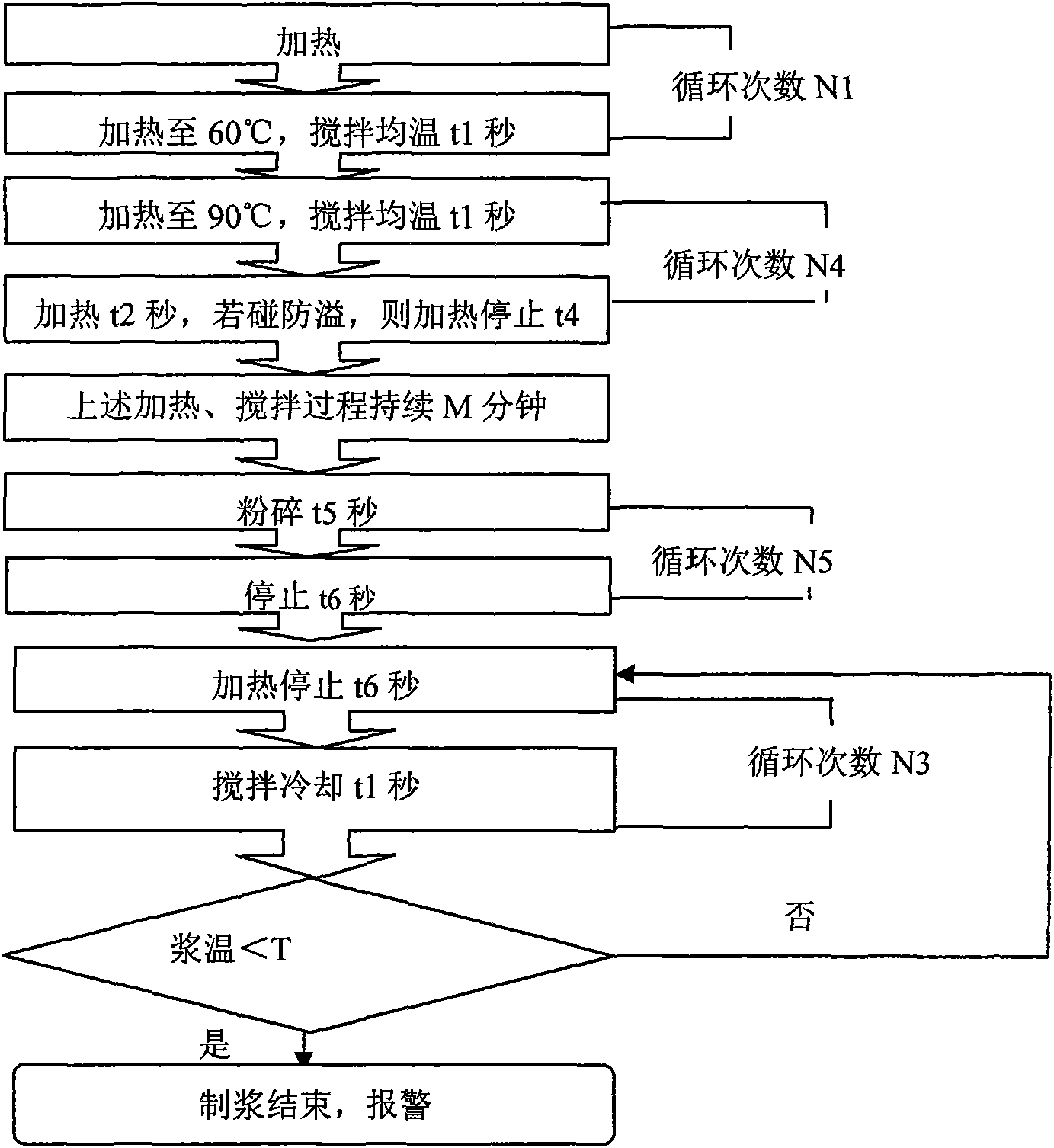

Method for preparing rice milk and soybean milk maker thereof

ActiveCN101579074AImprove pasting effectGreat tasteBeverage vesselsFood preparationKitchen utensilsEngineering

The invention relates to a food processing method for kitchenware, in particular to a method for preparing rice milk by a soybean milk maker, which at least comprises the following steps: (a) a boiling step, namely heating water and materials held in a cup body of the soybean milk maker until the materials are boiled, and entering the next step; and (b) a pasting step, namely stopping the heating, stirring the materials by cutter blades driven by a motor until the temperature of the milk fluid mixed by the materials and the water is reduced to a pasting temperature T. The soybean milk maker realizing the method for preparing the rice milk comprises a handpiece, the cup body, a heating device, a grinding device, the motor and a circuit control panel, and is characterized in that: the working procedure for preparing milk by the soybean milk maker comprises any method for preparing the rice milk in claims 1-9. The invention provides a method for preparing the rice milk and a soybean milk maker realizing the method. When the method and the soybean milk maker are adopted to prepare the rice milk, the boiled rice milk is difficultly layered, has good pasting effect and is difficult to paste a tube.

Owner:JOYOUNG CO LTD

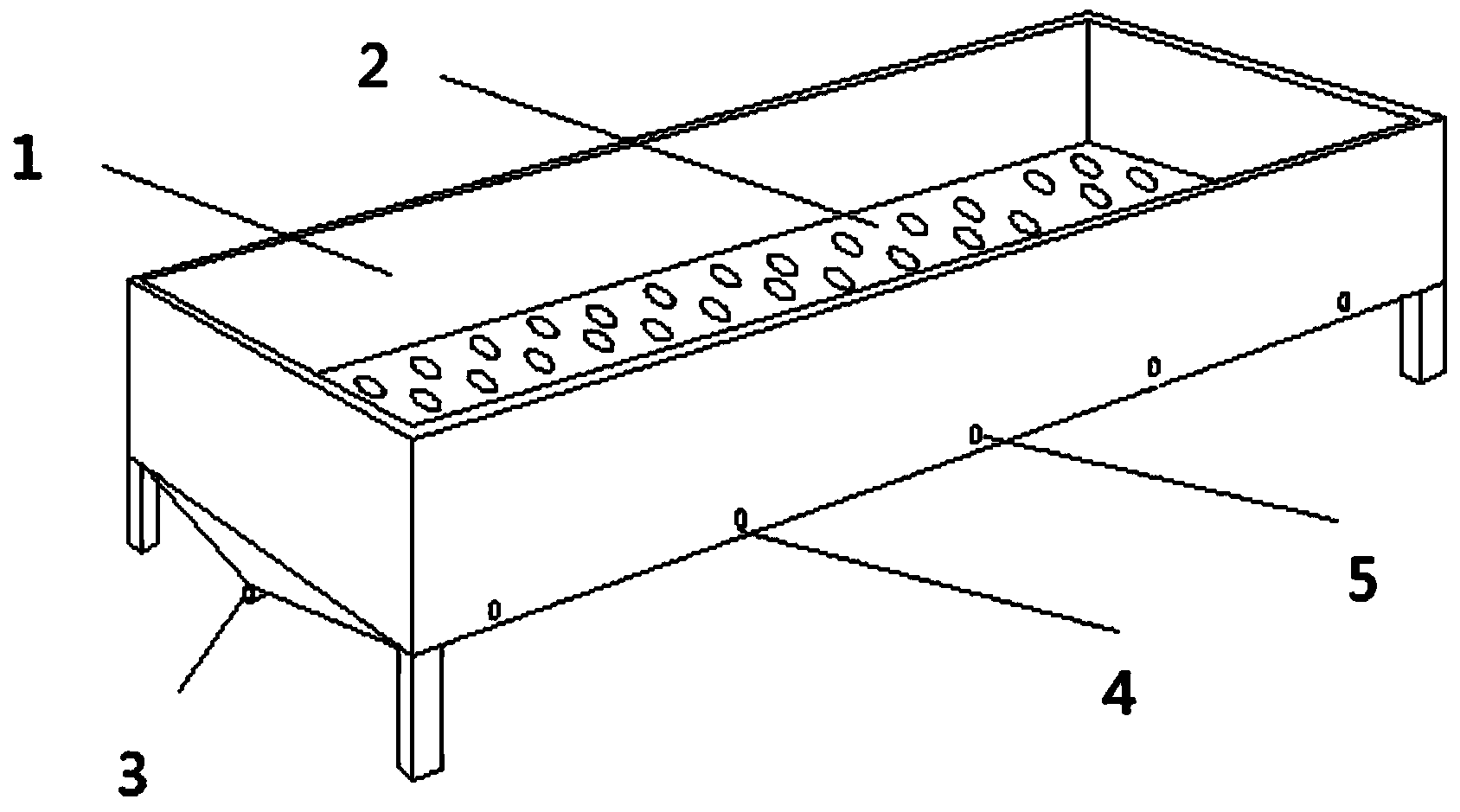

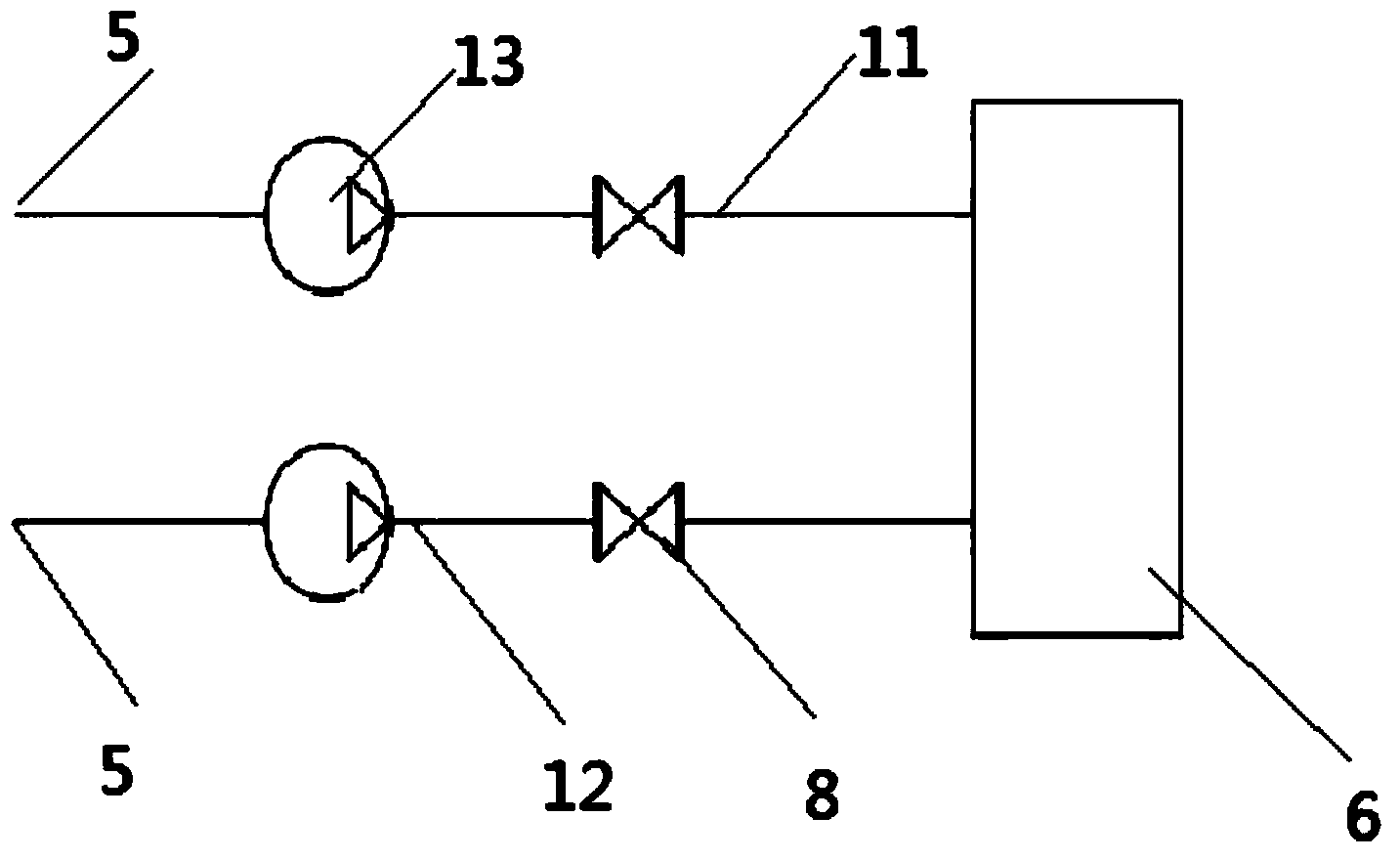

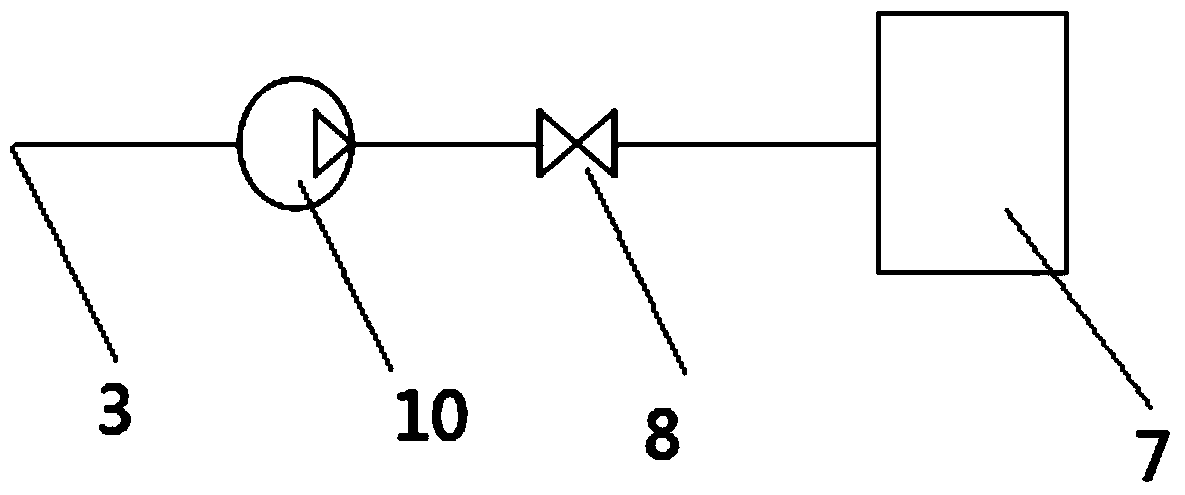

Millet wine production and fermentation device and production technology thereof

ActiveCN103923796APromote generationFavorable cookingAlcoholic beverage preparationSteepingHigh pressure

The invention provides a millet wine production and fermentation device integrated with rice milk zero discharge, rice steeping, rice steaming and fermentation, and a millet wine production method using the device. The millet wine production and fermentation device comprises a fermentation tank with a relief hole and a limber hole; a sieve plate is arranged at the bottom of the fermentation tank to form an interlayer space; and an air blowing device capable of providing high-pressure air and hot steam is arranged below the sieve plate. The millet wine production method comprises the following steps: drawing off the water, steeping rice, draining away water, steaming rice, blowing air, emptying, fermenting (raking), blowing down and the like, and the steps are finished in an integrated fermentation device. The millet wine production and fermentation device has the characteristics that the traditional steps of steeping rice, steaming rice and fermenting finished in different containers are finished in a same container in a concentrated manner, the rice milk can be recycled, and zero emission of the rice milk in millet wine production is achieved.

Owner:绍兴市抱龙山酒业有限公司

Honey, bean sprout and black fungus fermented drink

InactiveCN104621661AImprove stabilityRich in vitaminsFood ingredient functionsFood preparationAgaricWhite rice

The invention relates to a honey, bean sprout and black fungus fermented drink. The honey, bean sprout and black fungus fermented drink is prepared from the following raw materials in parts by weight: 200-205 parts of soybean sprouts, 85-100 parts of honey, 100-105 parts of green tea juice, 5-7 parts of black fungus, 60-70 parts of white rice vinegar, 60-70 parts of ginseng fruits and the like. Because of being prepared from soybean sprouts, honey and the like, the honey, bean sprout and black fungus fermented drink disclosed by the invention is rich in vitamins and dietary fibre and low in calorie; matched with black fungus and grouting rice milk, the honey, bean sprout and black fungus fermented drink is capable of maintaining beauty, keeping young and slimming; furthermore, the stability of the honey, bean sprout and black fungus fermented drink is good; and in addition, by means of addition of extracts, such as forget-me-not, dandelion, maca and sanchi flower, the honey, bean sprout and black fungus fermented drink has a certain effects of clearing away heart-fire, improving eyesight and increasing immunity.

Owner:FENGYANG RUICHENG FOOD TECH

Preparation method of unpolished rice fermented raw solution for cosmetics and product of preparation method

ActiveCN108324633AImprove conversion efficiencyIncrease productionCosmetic preparationsToilet preparationsImpurityRice milk

The invention provides a preparation method of an unpolished rice fermented raw solution for cosmetics. The preparation method comprises the following steps: after accelerating germination of unpolished rice, crushing the unpolished rice into unpolished rice powder; then preparing the unpolished rice powder into rice milk; after carrying out enzymolysis, adding saccharomycetes and fermenting; removing impurities and bacteria from a fermentation solution to obtain a finished product. According to the preparation method provided by the invention, a fermentation process can be controlled and active substances in the unpolished rice is efficiently enriched within extremely short time; the preparation method has the advantages of short period, controllable process, easiness for amplifying a technology and stable product; the solution has high content of active substances and a good effect, is easy to absorb, is safe and healthy and meets the requirements of cosmetic raw materials.

Owner:BLOOMAGE BIOTECHNOLOGY CORP LTD +1

Pure natural colorful sausage powder and its preparation method

The present invention discloses one kind of naturally colored salad sausage jelly and its production process. The salad sausage jelly consists of at least one kind of color rice slurry and proper amount of stuffing, and the color rice slurry is produced with rice 50 weight portions, glutinous rice 10 weight portions, water 100 weight portions and color vegetable juice 50 weight portions. The production process includes the following steps: washing rice and glutinous rice and soaking for 8 hr; squeezing fresh vegetable to obtain color vegetable juice; mixing color vegetable juice and rice soaking water and milling to produce color rice slurry; spreading color rice slurry in 0.8-1.0 mm thickness on wet cloth inside tray and adding proper amount of stuffing; high temperature steaming for 90 sec; scraping off the rice jelly and winding. The naturally colored salad sausage jelly has rich nutrients and different colors.

Owner:庞兆广

Black glutinous rice corn yellow rice wine and producing method thereof

InactiveCN101121916ASolve the pollution problemImprove working environmentAlcoholic beverage preparationWaxy cornWorking environment

The invention discloses a black waxy-corn wine and a brewing method. The wine takes black waxy-corn as raw material, and is prepared through a plurality of procedures such as imbibition, shelling, de-embryonation, storage in a jar, adding sacchariferous agent / fermenting agent / enzyme preparation, fermentation, pressing, clarification, heating, aging and filtering. The invention adopts puffing technology instead of steaming method, as a result, the problem that the maize is difficult to steam is solved, and contamination by rice-pulp water is avoided; the procedures of rice soaking, steaming and stir-frying are left out, and energy can be saved by 35 percent; the working environment and the sanitary condition are improved, large amount of water is saved and loss of starchy is reduced; the production cost is lowered and the productivity is improved. The product has rich nutrients and sound health-care effect; the product is characterized by excellent quality: orange-yellow or puce appearance, fresh, crystal and bright; with special mellowness of rice wine, free of any strange sweetness; tasty and refreshing and free of any off-flavor; the wine body is well-coordinated, and has typical features of rice wine.

Owner:张钟

Method for recycling rice milk

ActiveCN102173488AInhibition of reproductionGrowth inhibitionAlcoholic beverage preparationWater/sewage treatment by flocculation/precipitationSteepingWine industry

The invention relates to a byproduct in rice steeping and drip washing procedures in the yellow wine industry, and in particular relates to a method for recycling rice milk, belonging to the technical field of water treatment in the wine-making industry. The method is characterized by adopting tap water to steep the rice at the temperature of 24-26 DEG C for 18-24 hours; performing drip washing on the rice with tap water; recycling the rice milk obtained after the rice is subjected to steeping and drip washing, and separating the rice milk after standing for 18-24 hours to obtain the clear rice milk; and then maintaining the temperature of the clear rice milk at 24-26 DEG C and then ensuring the clear rice milk to flow back to a rice steeping container to be used for cyclic rice steeping.By using the method, recycling of the rice milk not only causes no negative effect on the quality of the yellow wine, but also is beneficial to an improvement of the quality of the yellow wine.

Owner:WUZHANMAO WINE

Method for making yellow wine from recycled rice milk water

InactiveCN104911065AAchieve recyclingReduce acidityAlcoholic beverage preparationBiotechnologyWater use

The invention relates to a method for making yellow wine from recycled rice milk water. The method comprises the following steps: (1) weighing a certain amount of rice and soaking in proportion; and (2) taking rice milk water, heating till boiling, preserving heat, cooling to the room temperature, and adding the cooled rice milk water into yellow wine fermented mash in proportion, wherein the adding amounts of rice milk water are respectively 0.2%, 40% and 60%, the use of clean water is correspondingly reduced, the total water use amount remains unchanged, the total water addition amount in soaking and rice steaming processes is 3.5 times the amount of raw materials, the use amount of distiller's yeast is controlled at 10%, wheat koji is replaced by virtue of 2% of liquifying enzyme, saccharifying enzyme and protease, the primary fermentation temperature is 28 DEG C, the primary fermentation time is 7 days, the secondary fermentation temperature is 18 DEG C, and the secondary fermentation time is 14 days. According to the method, rice milk water is recycled to be used in the production process of the yellow wine and can be used for partially replacing feeding water under the conditions that the cost is not increased and the product quality is guaranteed, so that the cyclic utilization of rice milk water is realized, the treatment cost is lowered, and the energy-saving and cost-reducing purposes are achieved.

Owner:SHAOXING UNIVERSITY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com