Method for recycling rice milk

A technology for rice slurry water and rice soaking, which is applied in the preparation of alcoholic beverages, flocculation/sedimentation water/sewage treatment, etc. The effect of alcohol rate, saving water bill, inhibiting reproduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

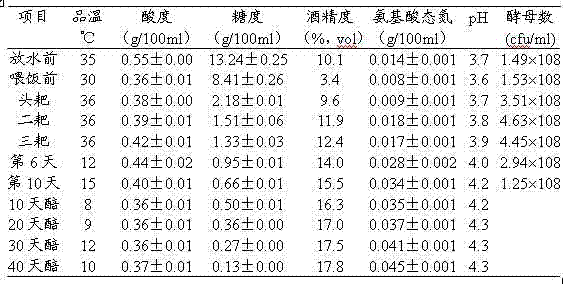

[0024] With the ratio of rice:water 1:1.1, soak the rice with tap water for 24 hours. After the obtained rice soaking water is naturally clarified for 24 hours, take the upper layer of rice slurry water for circular soaking of rice, and use tap water for the insufficient part Make up, after the rice soaking is finished, the rice soaking water is recovered again for natural clarification, and the circular rice soaking clarification is carried out in this way. As shown in Table 1, during this process, the total acidity of rice milk water began to rise rapidly, and then gradually leveled off. Total sugars increased rapidly at first, then decreased, and finally leveled off gradually. Due to the formation of organic acids such as lactic acid, the pH drops from neutral at the beginning to about 4 after the second recycling. Amino acid nitrogen gradually increased. The content of lactic acid bacteria in the rice milk water gradually increased from 1.81??106cfu / mL at the end of the ...

Embodiment 2

[0032]For the convenience of steaming rice, 50% of the rice milk water can be recycled. Soak the rice in tap water for 18 hours at a temperature of 24°C, and drench the rice with tap water. The rice pulp water obtained after soaking and drenching the rice is first recovered in a large tank, and after natural clarification for 18 hours, the rice pulp water in the upper layer is used: tap water = Mix 1:1 for rice soaking, and soak rice with tap water every time, and the rice slurry water obtained after soaking and washing rice is recycled into a large tank again for natural clarification, and so on. When the recovered rice milk water has peculiar smell at last, change the water, clean the large rice soaking tank and the rice milk water clarification tank, then start soaking rice with tap water, start a new cycle soaking rice clarification, and brew yellow rice wine.

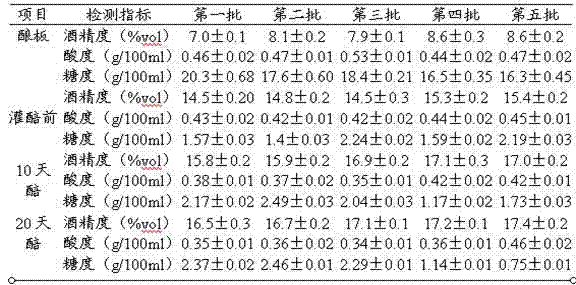

[0033] The observation of the effects of 2 batches of productive rice milk water recycling on the organic matter...

Embodiment 3

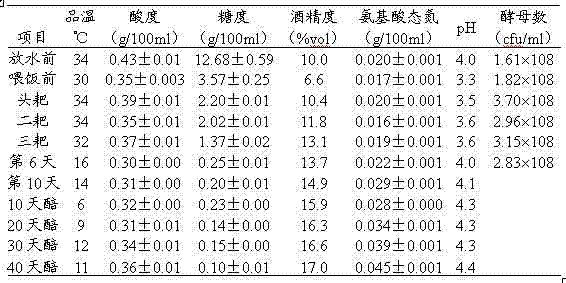

[0039] Soak the rice in tap water for 20 hours at a temperature of 25°C. Drench the rice with tap water. The rice milk water obtained after soaking and rinsing the rice is recovered in a large tank. After natural clarification for 20 hours, the obtained rice milk water is used for clarification. For rice soaking, the insufficient part is made up with tap water, and the rice is soaked with tap water every time. The rice slurry water obtained after soaking and soaking rice is recycled into a large tank again for natural clarification, and the circular soaking and clarification of rice is carried out in turn. When the reclaimed rice milk water has peculiar smell at last, change the water, clean the large rice soaking tank and the rice milk water clarification tank, then start soaking rice with tap water, start a new cycle soaking rice clarification, and brew yellow rice wine.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com