Method and system for preparing restaurant-kitchen wastes into livestock and poultry feed

A technology for food waste and livestock and poultry feed, which is applied in the direction of feed, animal feed, animal feed, etc., can solve the problems of large impact on the quality of resource-based products, high processing costs, and high material content, and achieve the purpose of inhibiting growth and pathogenic microorganisms The reproduction, fresh-keeping effect and sensory quality are good, and the effect of increasing the true protein content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

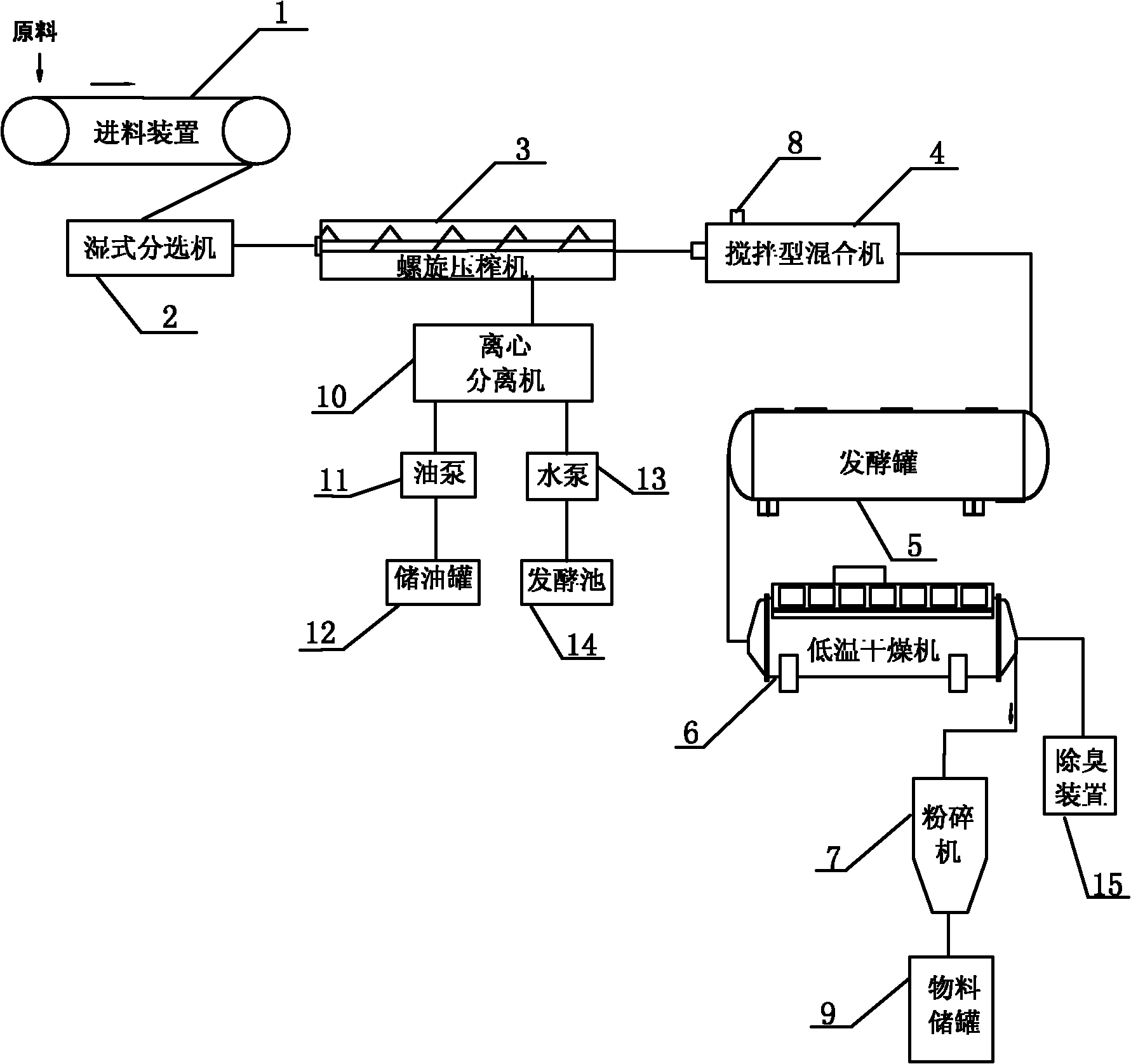

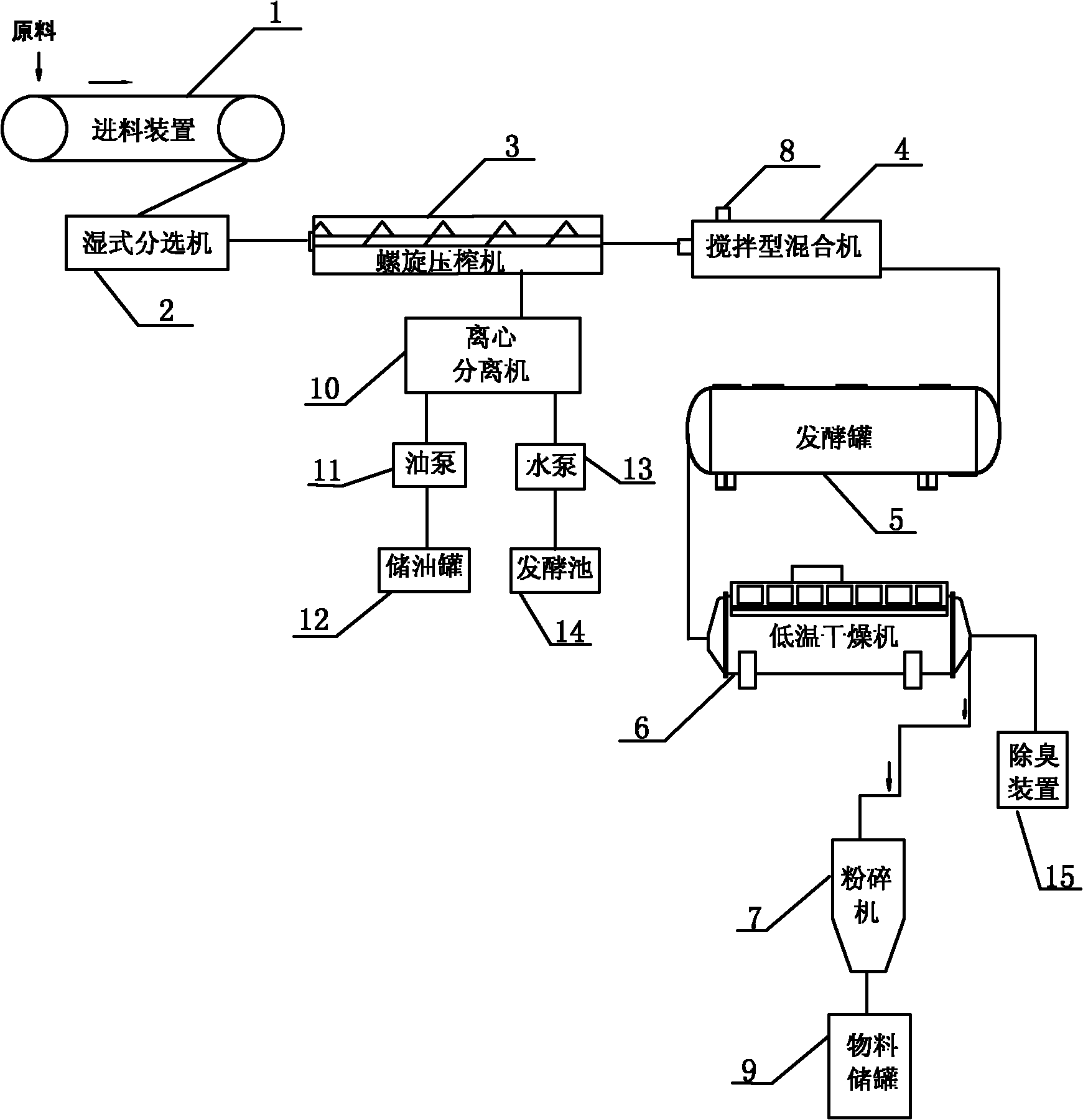

[0026] The present invention is a processing method for fermenting food waste into livestock and poultry feed, using food waste as raw material, comprising the following steps:

[0027] (1) Sorting pretreatment The collected food waste is sorted in a wet sorting machine, and all non-biodegradable components such as plastic, glass, various metals, shells and wooden objects are automatically sorted Sorted out to obtain biodegradable food waste;

[0028] (2) Solid-liquid separation The biodegradable kitchen waste obtained in step (1) is sent into a screw press through a screw conveyor for solid-liquid separation to obtain a solid isolate and a liquid isolate;

[0029] (3) Conditioning is based on the solid isolate obtained in step (2), and 100 kilograms of solid isolate, 15 kilograms of bran, 15 kilograms of corn flour and 5 kilograms of rice bran are prepared and mixed to obtain a mixture with a moisture content of 60%. Material 135 kg;

[0030] (4) Fermentation is that the mo...

Embodiment 2

[0054] The present invention is a processing method for fermenting food waste into livestock and poultry feed, using food waste as raw material, comprising the following steps:

[0055] (1) Sorting pretreatment The collected food waste is sorted in a wet sorting machine, and all non-biodegradable components such as plastic, glass, various metals, shells and other sundries are automatically sorted out , to obtain biodegradable food waste;

[0056] (2) Solid-liquid separation The biodegradable kitchen waste obtained in step (1) is sent to a screw press through a screw conveyor for solid-liquid separation to obtain solid and liquid isolates;

[0057] (3) Conditioning Based on the solid isolate obtained in step (2), take 100 kg of solid isolate, 20 kg of bran, 20 kg of corn flour and 8 kg of bran for deployment to obtain a mixture with a moisture content of 55%. Material 148 kg;

[0058] (4) Fermentation Add 22.2 kg of compound bacteria agent to the mixed material with a moistur...

Embodiment 3

[0063] The present invention is a processing method for fermenting food waste into livestock and poultry feed, using food waste as raw material, comprising the following steps:

[0064] (1) Sorting pretreatment The collected food waste is sorted in a wet sorting machine, and all non-biodegradable components such as plastic, glass, various metals, shells and other sundries are automatically sorted out , to obtain biodegradable food waste;

[0065] (2) Solid-liquid separation The biodegradable kitchen waste obtained in step (1) is sent to a screw press through a screw conveyor for solid-liquid separation to obtain solid and liquid isolates;

[0066] (3) Conditioning Based on the solid isolate obtained in step (2), take 100 kg of solid isolate, 25 kg of bran, 25 kg of corn flour and 10 kg of rice bran to prepare a mixed material with a moisture content of 50%. 160 kg;

[0067] (4) Fermentation Add 32 kg of compound bacterial agent to the mixed material with a moisture content o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com