Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

24052results about How to "Shorten the production cycle" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

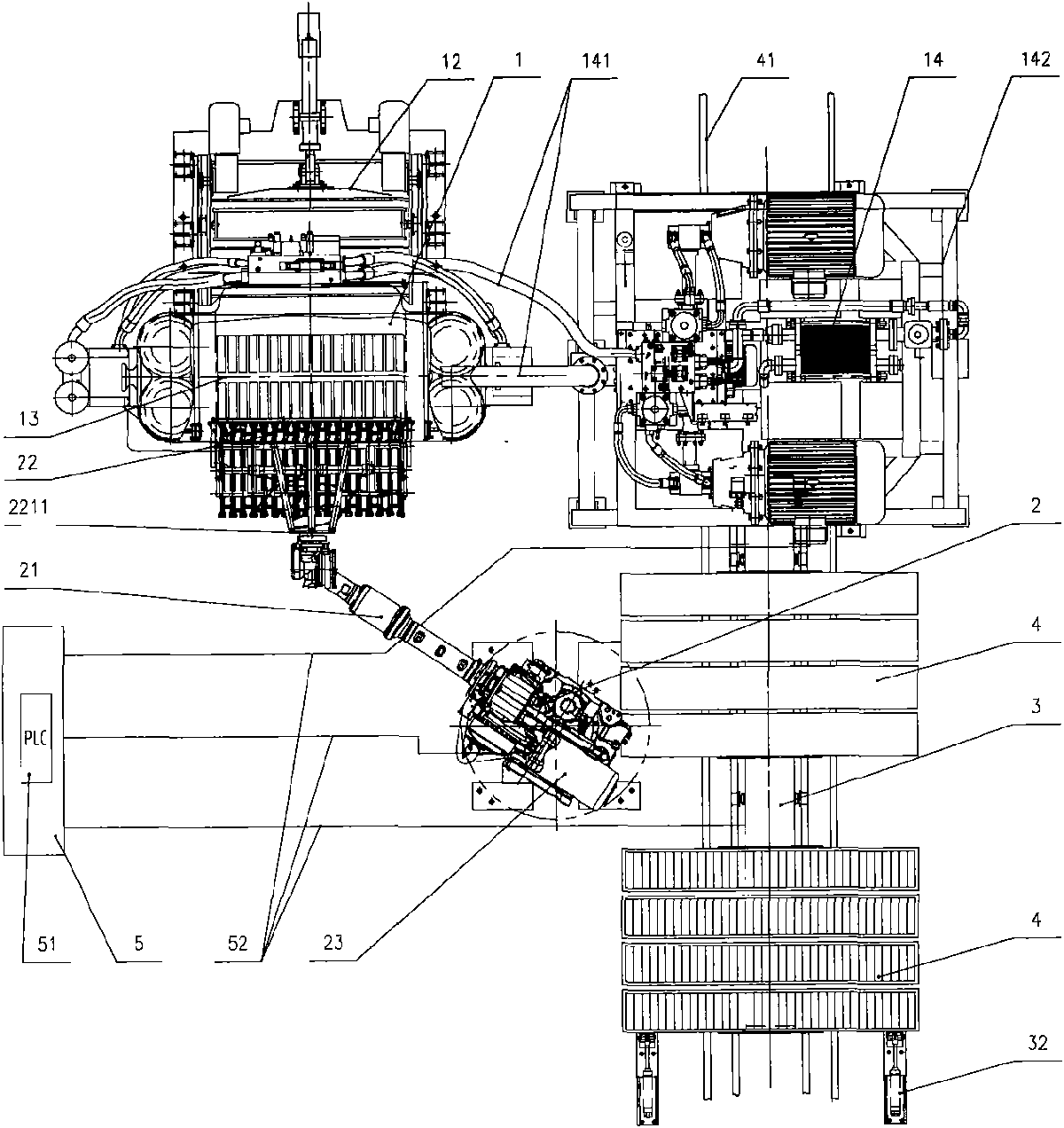

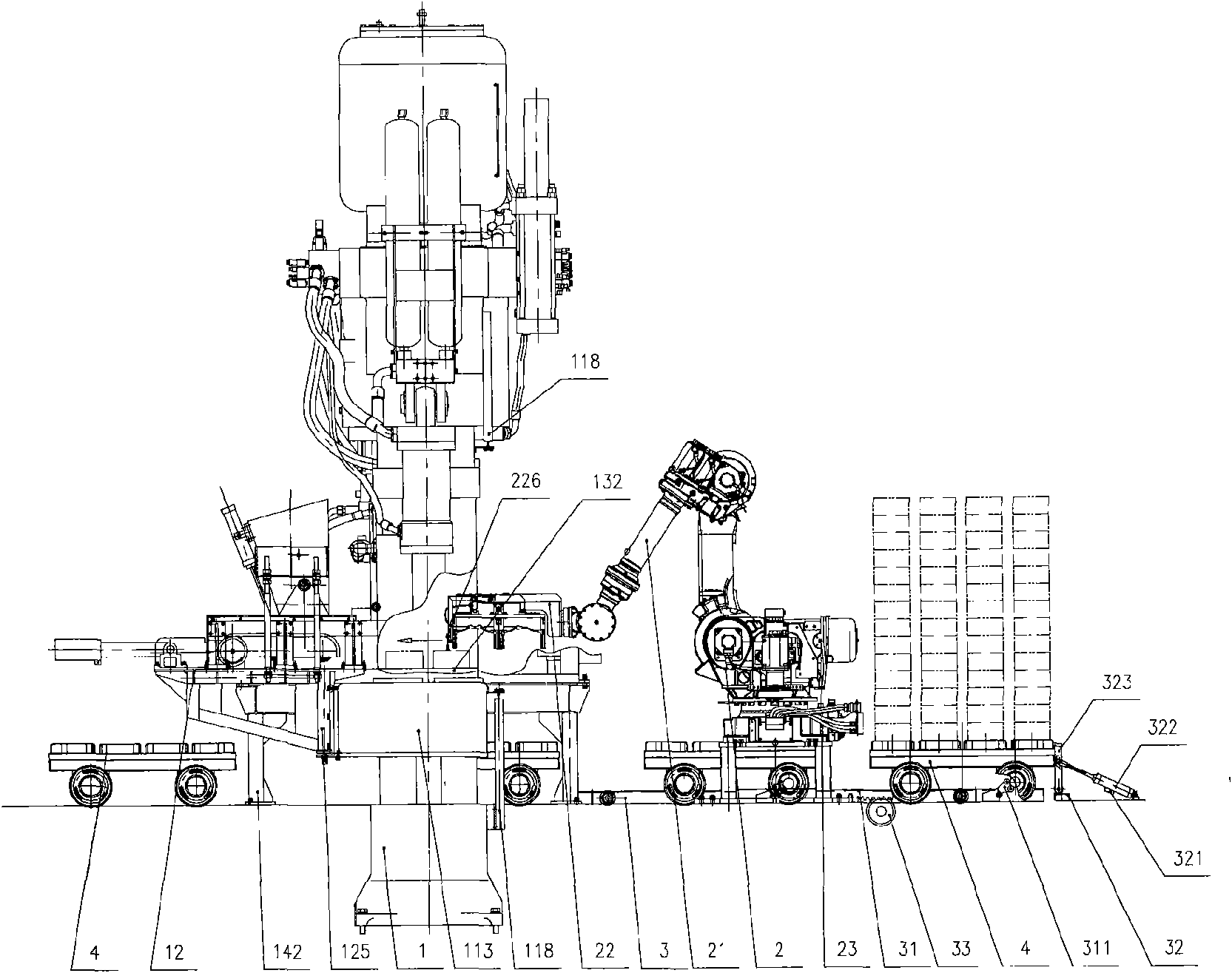

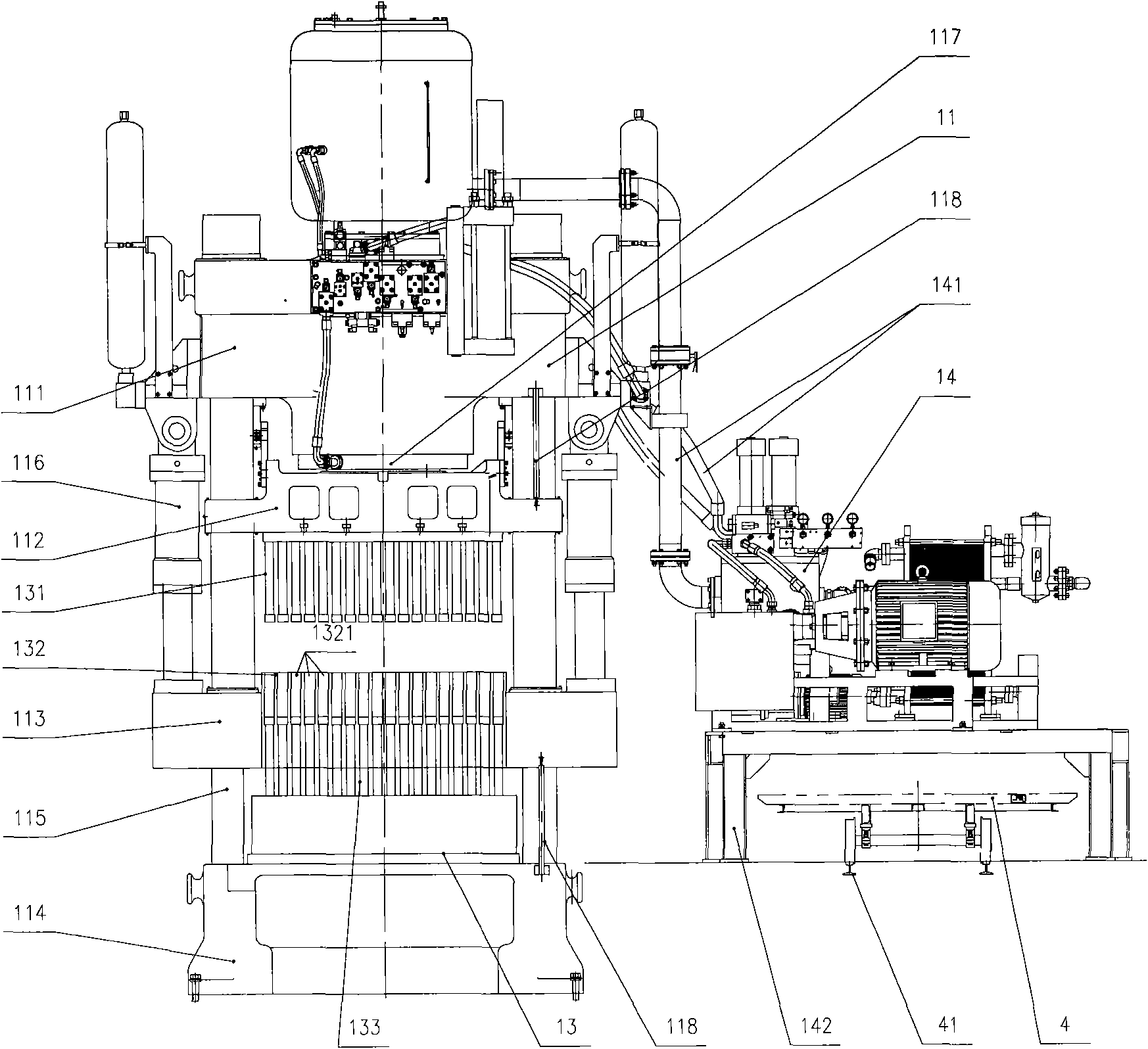

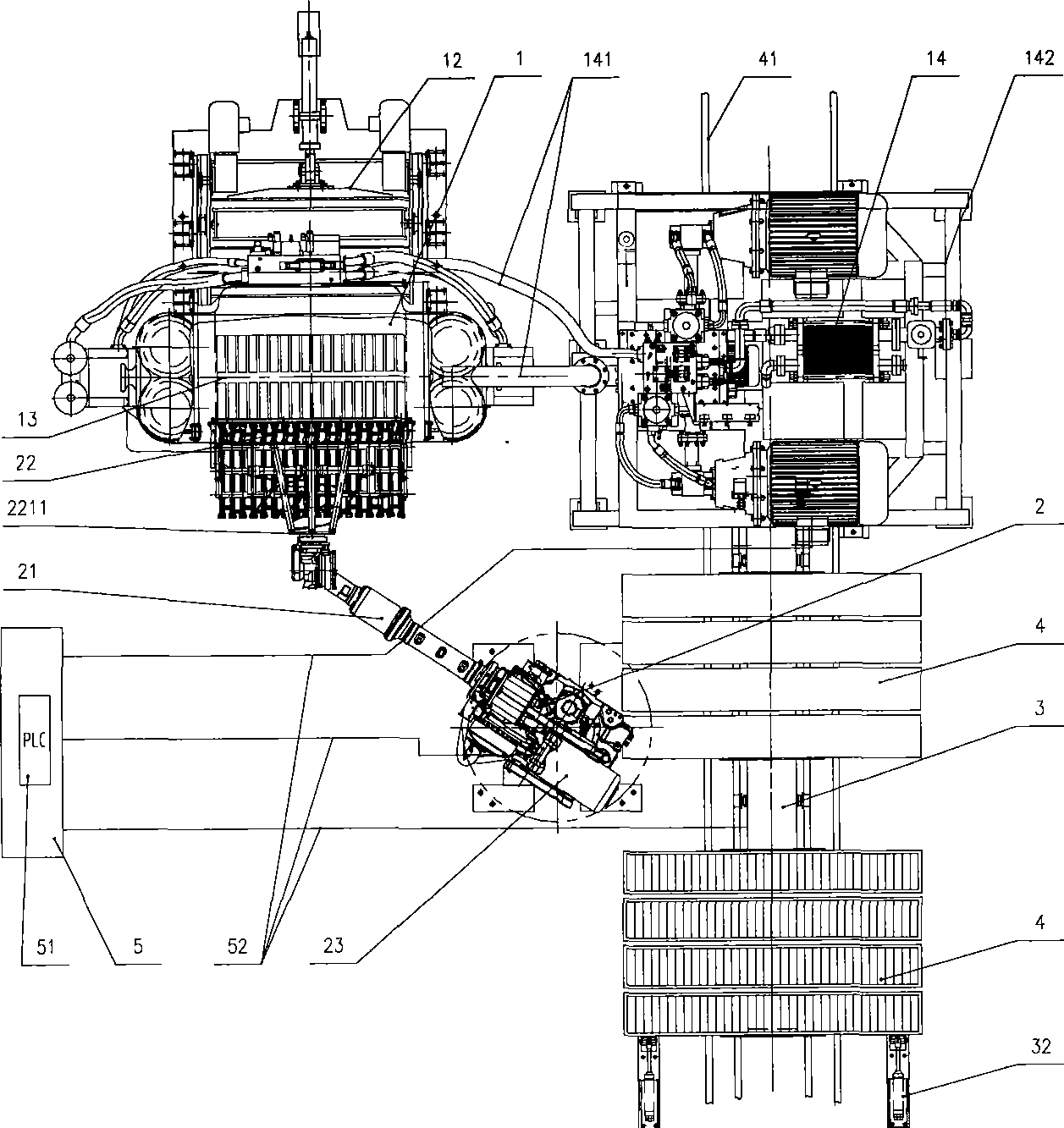

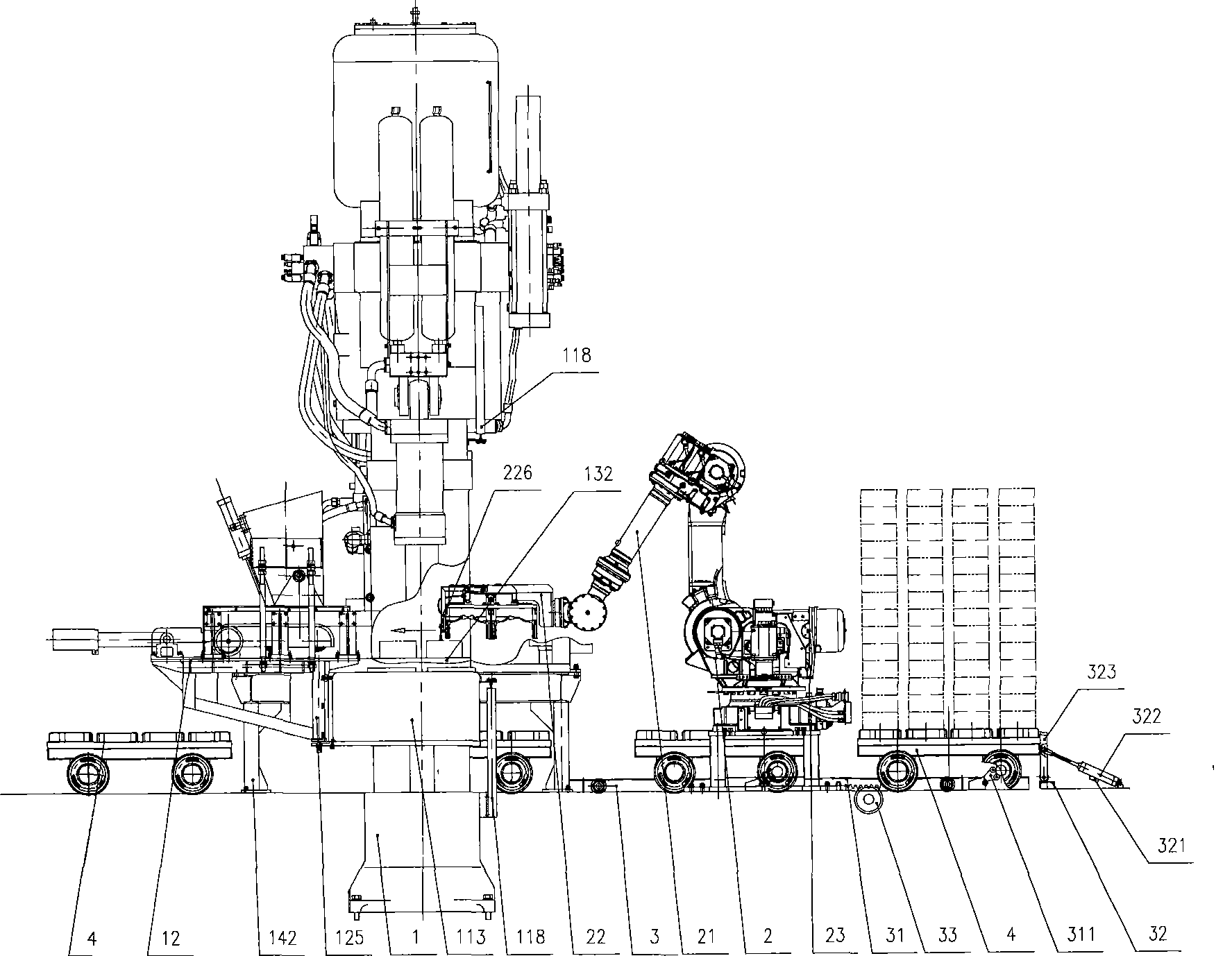

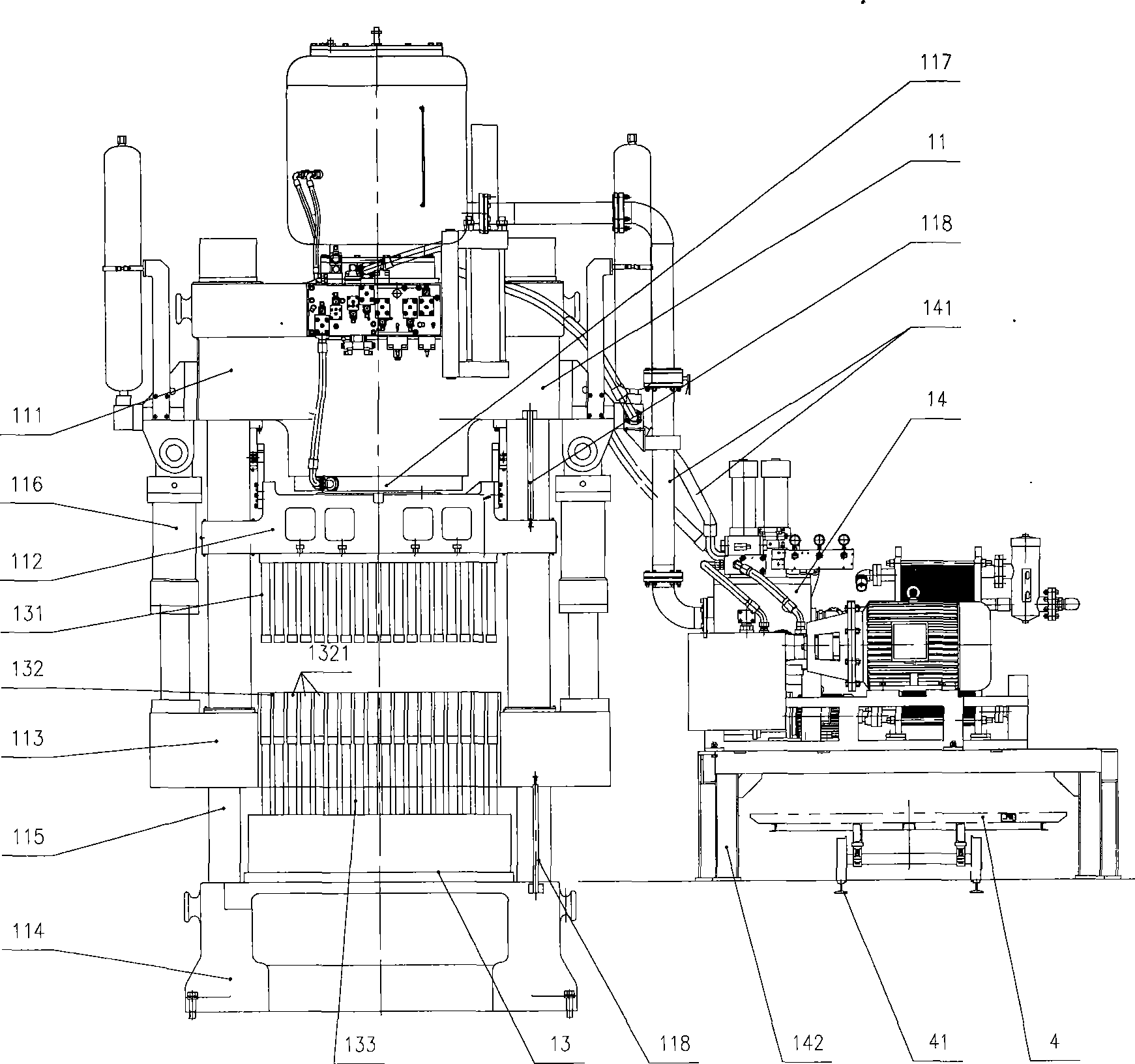

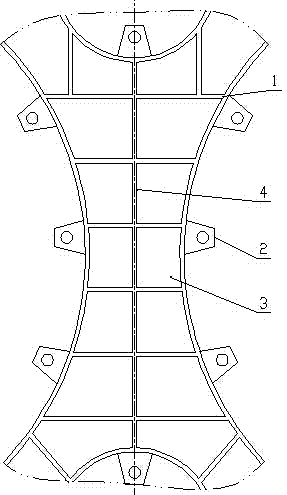

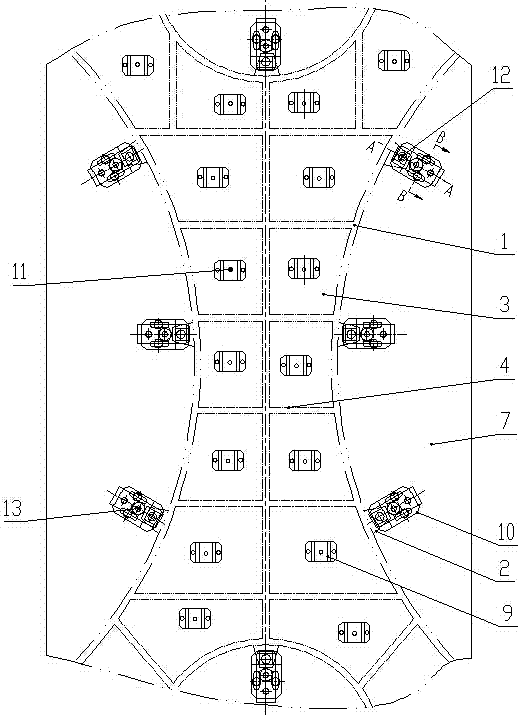

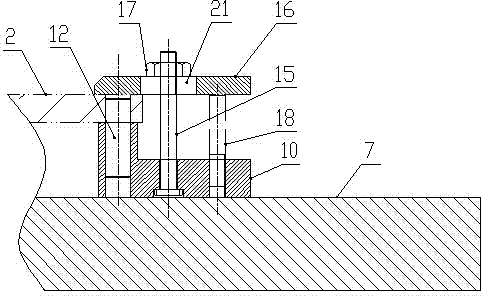

Fully automatic hydroform and intelligent stacking device for bricks

ActiveCN101574833AEnsure mutual coordinationReduce multiple handling linksDischarging arrangementCeramic shaping plantsBogieBrick

The invention relates to a brick making machine, in particular to a fully automatic hydroform and intelligent stacking device for bricks. The device comprises a brick molding press, a stacking robot, an automatic feeding machine, a steam curing bogie and an electric control device, and has the following structural key points that the stacking robot is arranged between the brick molding press and the automatic feeding machine; the automatic feeding machine carries out positioning and feeding for the steam curing bogie; and the electric control device is connected with the drive device and the sensor of each part through electric circuits. Thus, through the programmed instructions in a PLC module of the electric control device, action interlocking of the brick molding press, the stacking robot and the automatic feeding machine is realized so as to ensure action coordination among each part and realize automatic production during the entire working procedure from feeding raw materials into a material frame for distribution to outputting full bogies of green bricks; in addition, a stacking manipulator directly enters into the brick molding press to clean green bricks, and directly piles up the green bricks on the steam curing bogie, thereby reducing the carrying times of the green bricks, improving the quality of the green bricks, shortening production cycle and increasing production efficiency.

Owner:洛阳腾和达智能装备有限公司

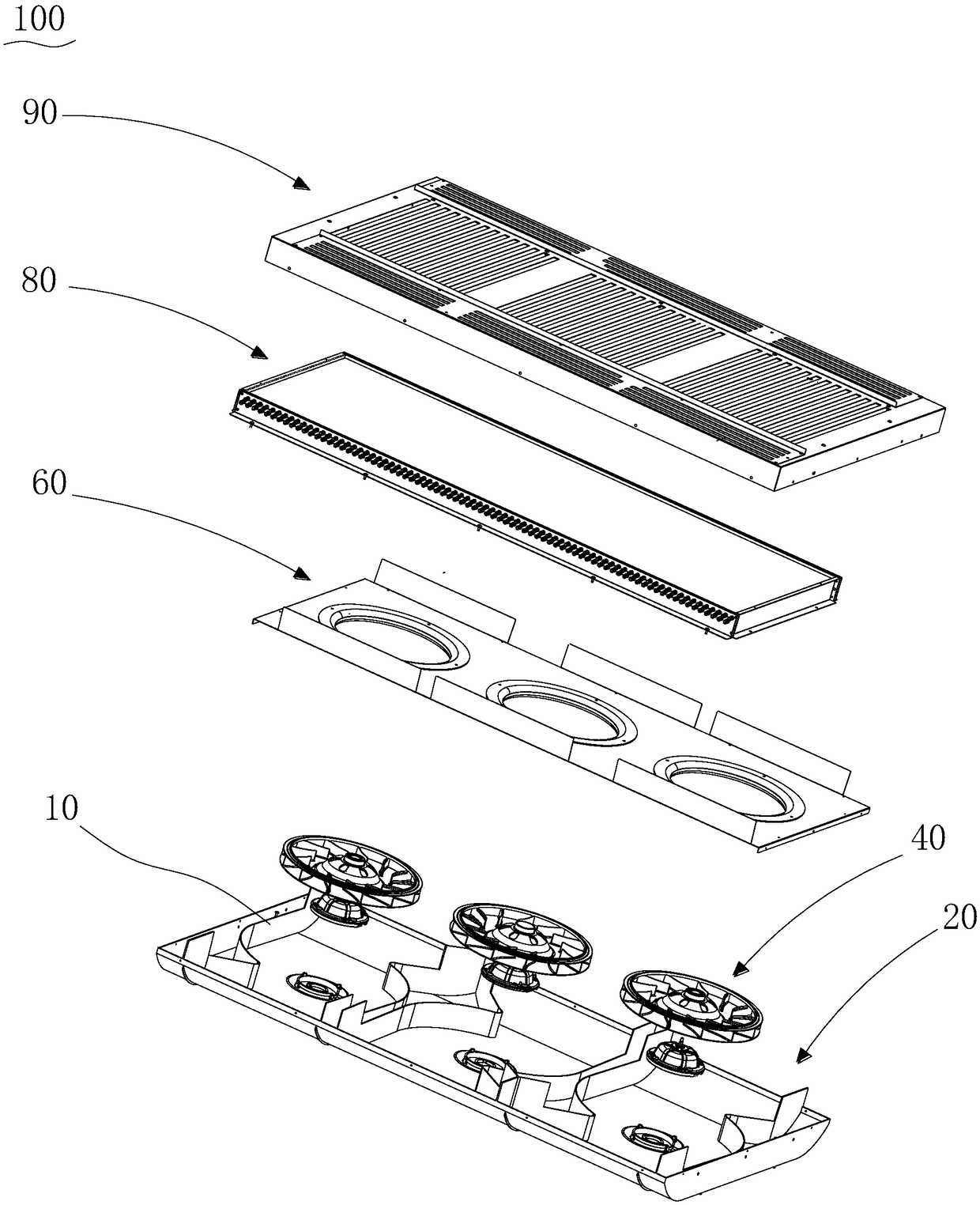

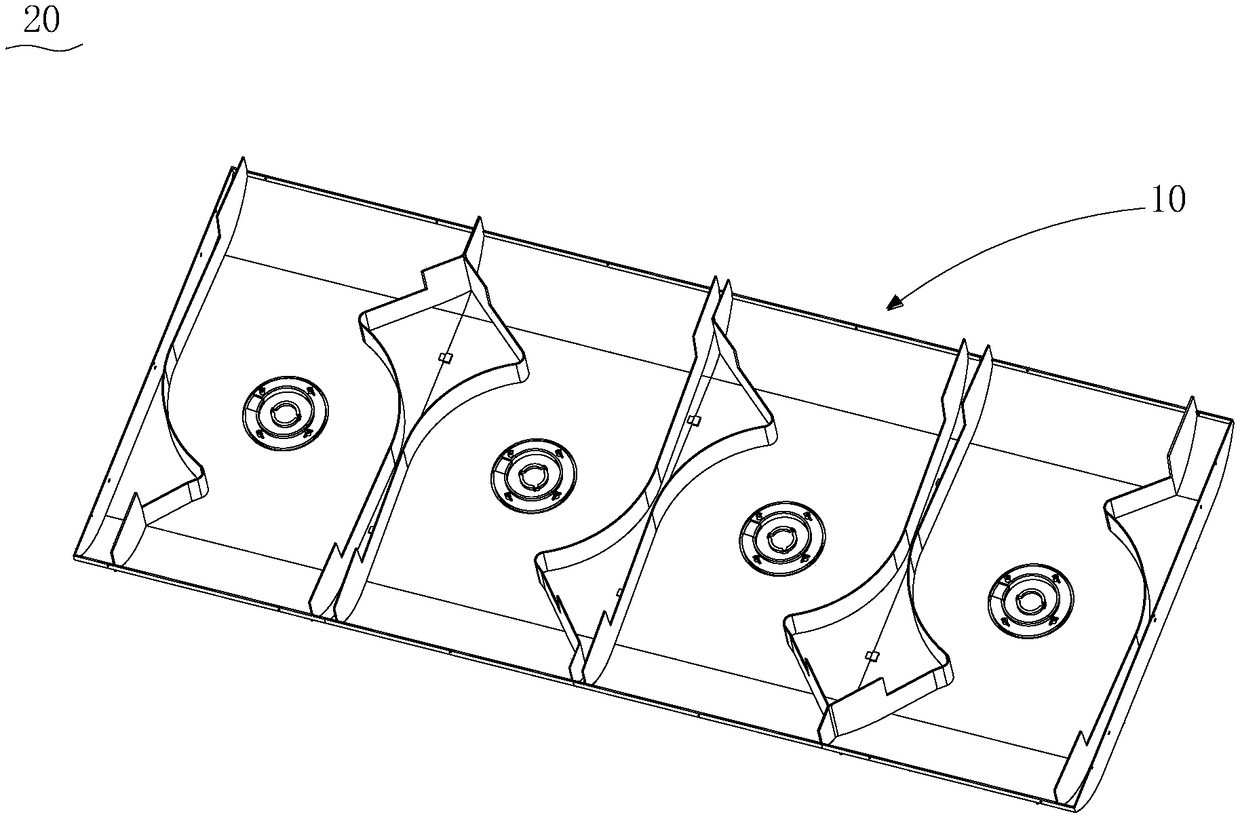

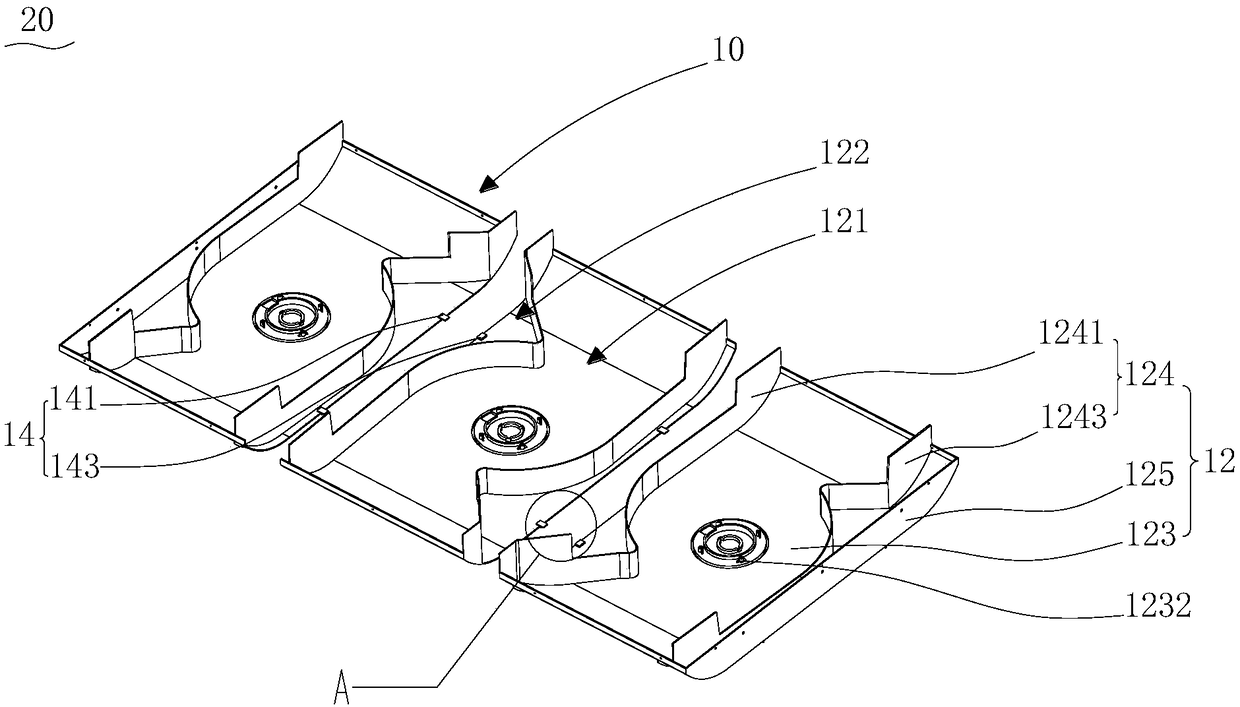

Air channel module and air channel structure with air channel module and air conditioner

InactiveCN109000352AReduce design costReduce manufacturing costDucting arrangementsLighting and heating apparatusEngineeringFan blade

The invention relates to an air channel module and an air channel structure with the air channel module and an air conditioner. The air channel module comprises an air channel main body and a connecting assembly, wherein the air channel main body comprises an air field area in which an airflow air channel is formed, and the airflow air channel is provided with two opposite air outlets; the connecting assembly is arranged on the air channel main body; and a plurality of air channel modules can be connected with each other by virtue of respective connecting assemblies so as to form the air channel structure with a plurality of air field areas. According to the air channel module, different number of air channel modules can form different air channel structures so as to install different number of fan blades, so that the air channel module can be applied to series of products with different heat transfer periods, and the different air channel structures do not need to be independently designed and manufactured according to the products with the different heat transfer periods, so that the design and production cost is effectively reduced, and the production cycle is shortened.

Owner:GREE ELECTRIC APPLIANCES INC

Fully automatic hydroform and intelligent stacking device for bricks

ActiveCN101574833BEnsure mutual coordinationReduce multiple handling linksDischarging arrangementCeramic shaping plantsBogieBrick

The invention relates to a brick making machine, in particular to a fully automatic hydroform and intelligent stacking device for bricks. The device comprises a brick molding press, a stacking robot, an automatic feeding machine, a steam curing bogie and an electric control device, and has the following structural key points that the stacking robot is arranged between the brick molding press and the automatic feeding machine; the automatic feeding machine carries out positioning and feeding for the steam curing bogie; and the electric control device is connected with the drive device and the sensor of each part through electric circuits. Thus, through the programmed instructions in a PLC module of the electric control device, action interlocking of the brick molding press, the stacking robot and the automatic feeding machine is realized so as to ensure action coordination among each part and realize automatic production during the entire working procedure from feeding raw materials into a material frame for distribution to outputting full bogies of green bricks; in addition, a stacking manipulator directly enters into the brick molding press to clean green bricks, and directly piles up the green bricks on the steam curing bogie, thereby reducing the carrying times of the green bricks, improving the quality of the green bricks, shortening production cycle and increasing production efficiency.

Owner:洛阳腾和达智能装备有限公司

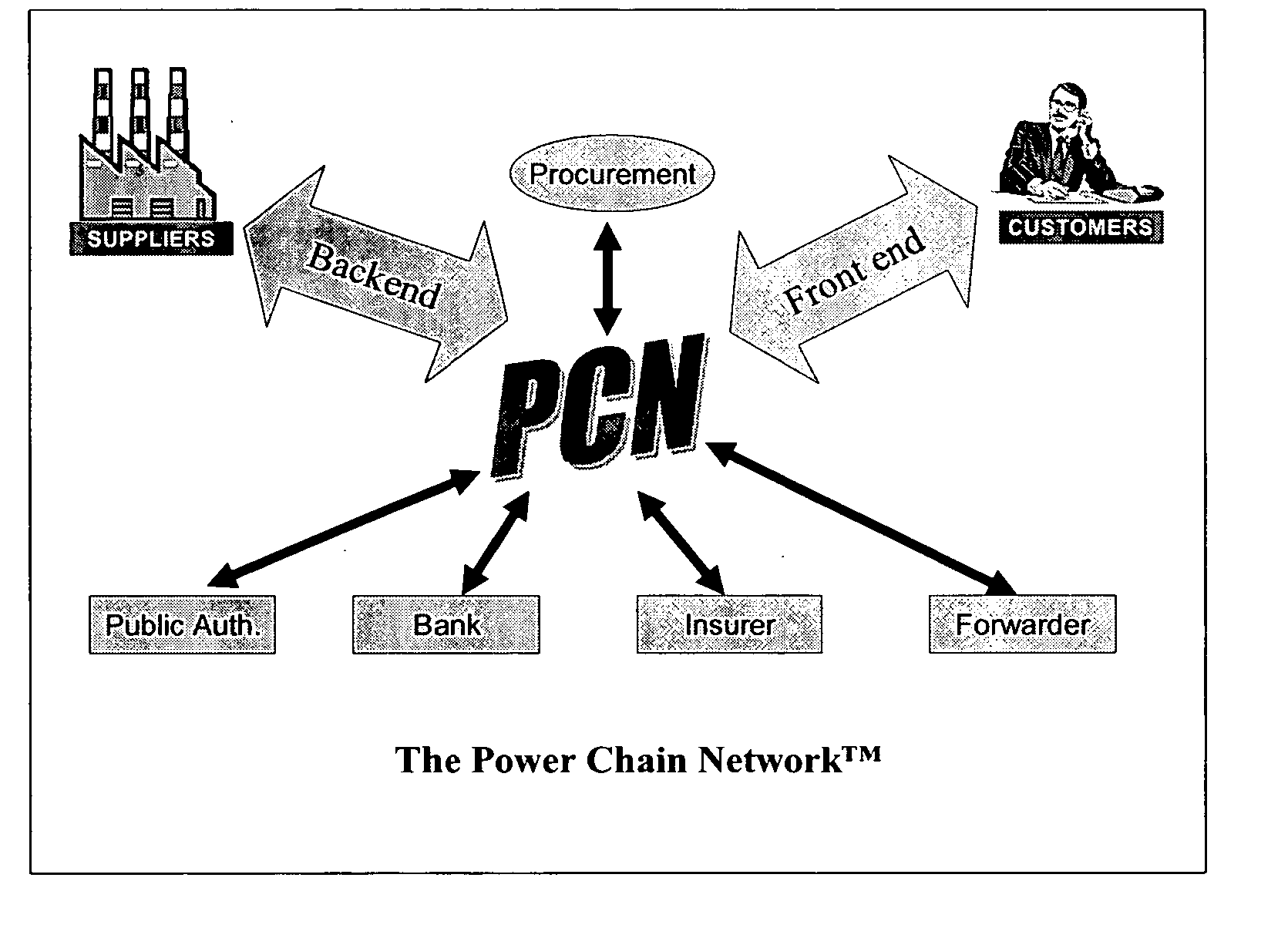

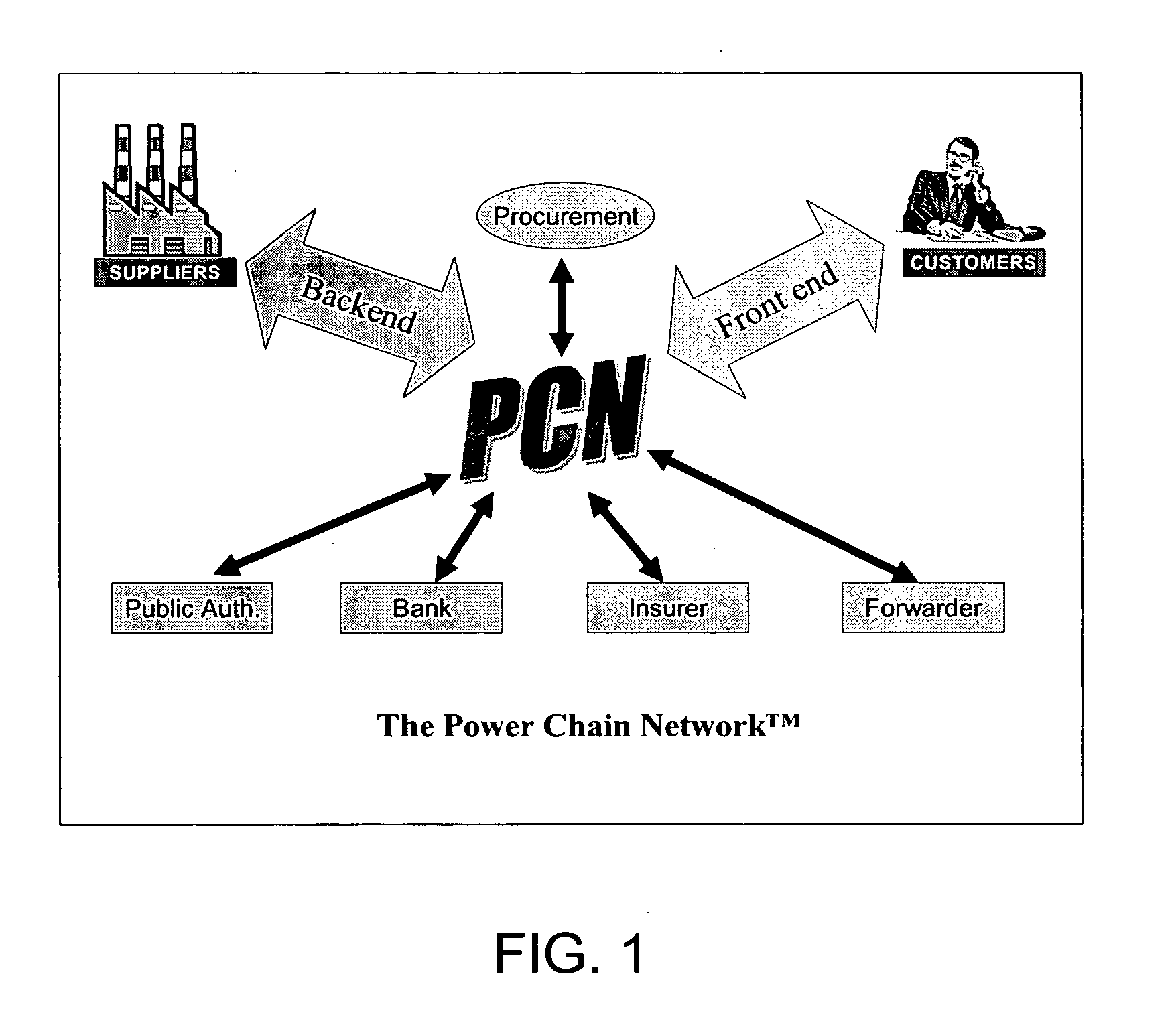

E-commerce business methodologies for supply and demand chain management

InactiveUS20060089886A1Eliminate inefficienciesIncrease flexibilityCommerceLogistics managementInformation support

A system and method for providing integrated logistics services. In the system, an electronic trading facility, a logistics services group, a commercial-finance group; and an information-support group are organized and arranged to communicate and exchange information with each other over the Internet in order to provide logistics services to a customer.

Owner:WONG ANTHONY

Lithium ion battery positive pole material cobalt nickel oxide manganses lithium and method for making same

ActiveCN101202343AHigh specific capacityExcellent cycle characteristicsElectrode manufacturing processesLithium compoundsLithium oxideAntioxidant

The invention relates to a nickel cobalt manganese lithium oxide material used for an anode of a li-ion battery and a preparation method. The invention belongs to the li-ion battery technical field. The nickel cobalt manganese lithium oxide material used for the anode of the li-ion battery is a li-rich laminated structure with the chemical component of Li1+zM1-x-yNixCoyO2; wherein, z is less than or equal to 0.2 and more than or equal to 0.05, x is less than or equal to 0.8 and more than 0.1, and y is less than or equal to 0.5 and more than 0.1. The preparation method of the invention is that dissoluble salt of the nickel, cobalt and manganese is taken as the raw material; ammonia or ammonium salt is taken as complexing agent; sodium hydroxide is taken as precipitator; water-dissoluble dispersant and water-dissoluble antioxidant or inert gas are added for control and protection; in a cocurrent flow type the solution is added to a reaction vessel for reaction; after alkalescence disposal, aging procedure, solid-liquid separation and washing and drying, the nickel cobalt manganese oxide is uniformly mixed with the lithium raw material; the nickel cobalt manganese lithium oxide powder is obtained by sintering the mixed powder which is divided into three temperature areas. The invention has the advantages of high specific capacity, good circulation performance, ideal crystal texture, short production period, low power loss, and being suitable for industrial production, etc.

Owner:CHINA ELECTRONIC TECH GRP CORP NO 18 RES INST +1

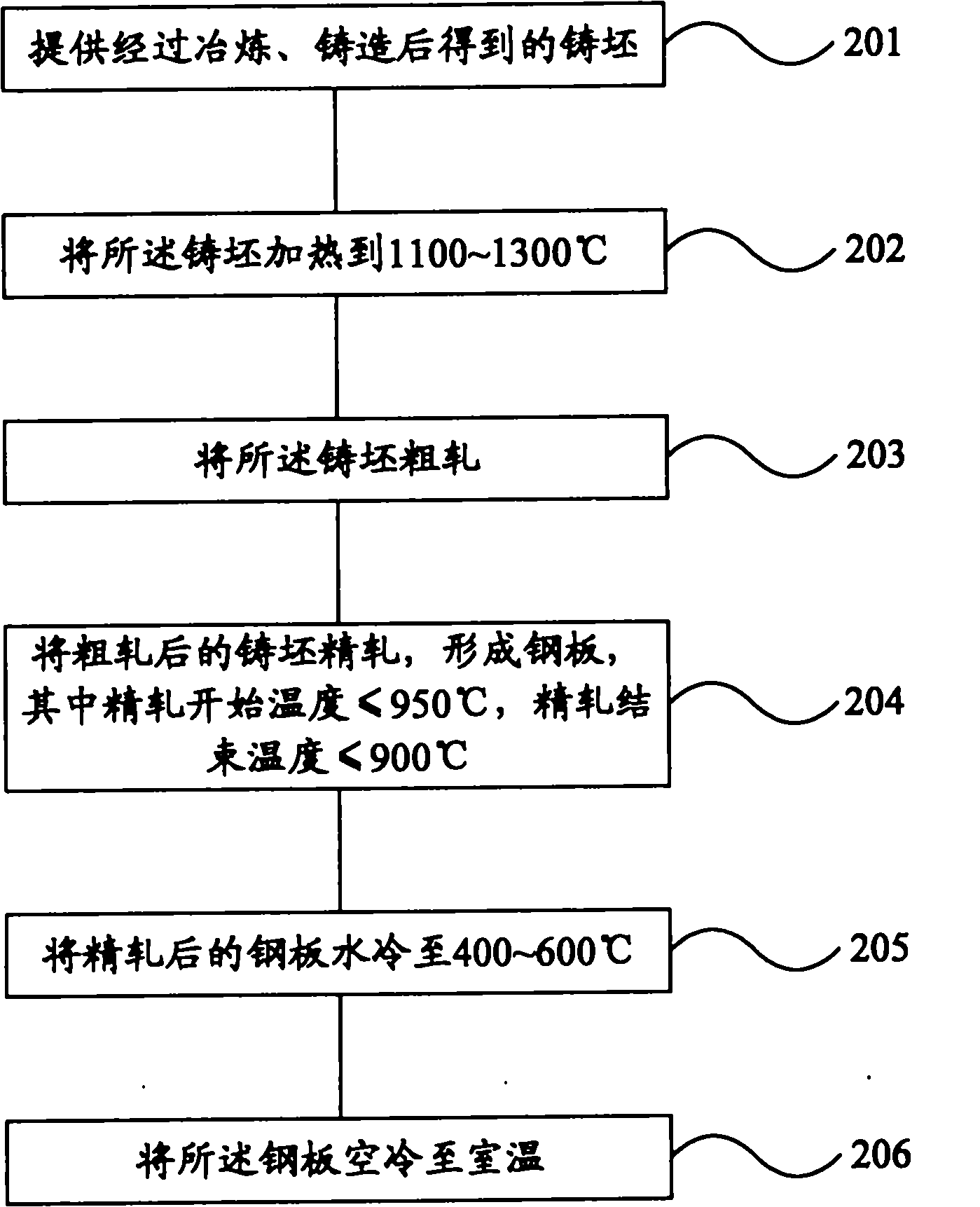

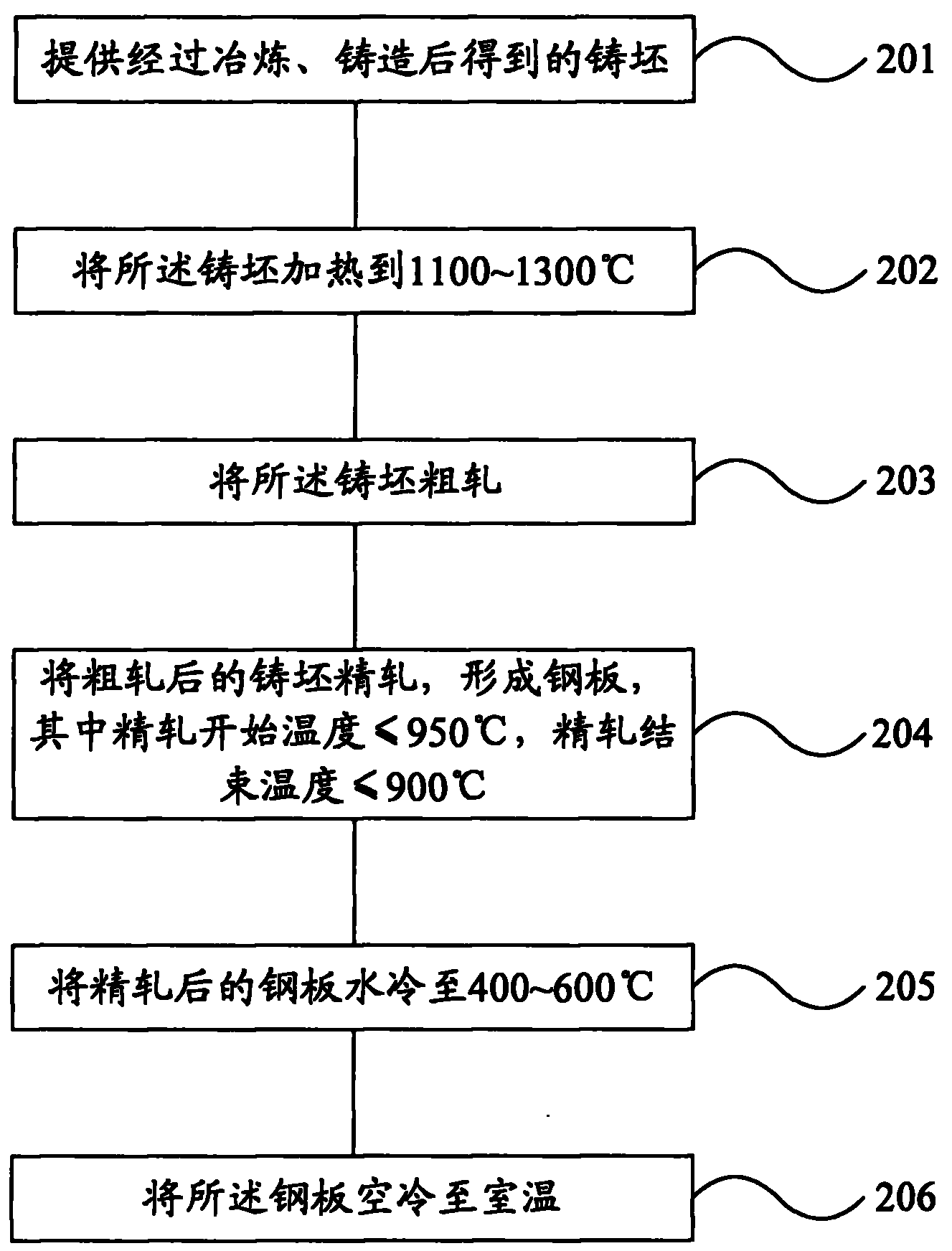

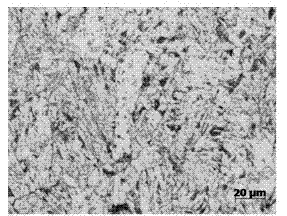

Weather resistant steel plate and manufacturing method thereof

ActiveCN102168229AGood atmospheric corrosion resistanceImprove low temperature impact toughnessRoll force/gap control deviceTemperature control deviceSheet steelImpurity

The present invention provides a weather resistant steel plate, which comprises components of, by mass percent, 0.02 to 0.10 of C, 0.10 to 0.40 of Si, 1.0 to 1.6 of Mn, less than or equal to 0.025 of P, less than or equal to 0.015 of S, 0.20 to 0.50 of Cu, 0.30 to 0.60 of Cr, 0.10 to 0.50 of Ni, less than or equal to 0.40 of Mo, less than or equal to 0.060 of Nb, less than or equal to 0.060 of V,0.010 to 0.035 of Ti, less than or equal to 0.0030 of B, less than or equal to 0.0050 of Ca, 0.015 to 0.050 of Al, and the balance Fe and other unavoidable impurities. Correspondingly, the present invention also provides a manufacturing method of the weather resistant steel plate. Through reasonable distribution ratio of alloy components, the method provided in the invention can obtain a high-strength and high-toughness weather resistant steel plate with good corrosion resisting performance, high yield strength and tensile strength, and excellent low temperature impact toughness. The steel plate also possesses good weldability, being able to carry out welding without preheating or employ lower preheating temperature welding. The steel plate provided in the invention can be widely applied to large-scale steel structure engineering such as building structures, bridges, etc.

Owner:BAOSHAN IRON & STEEL CO LTD

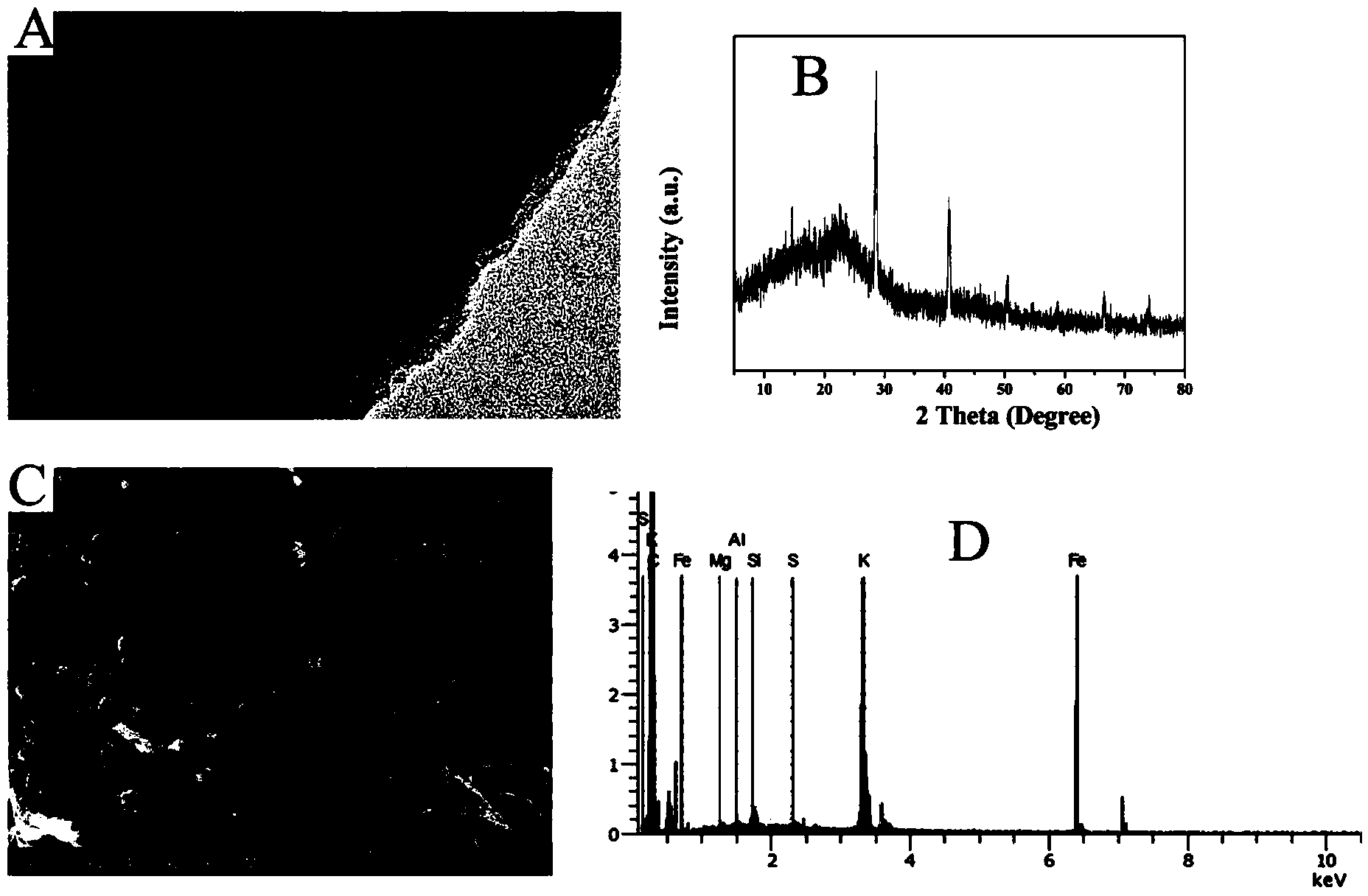

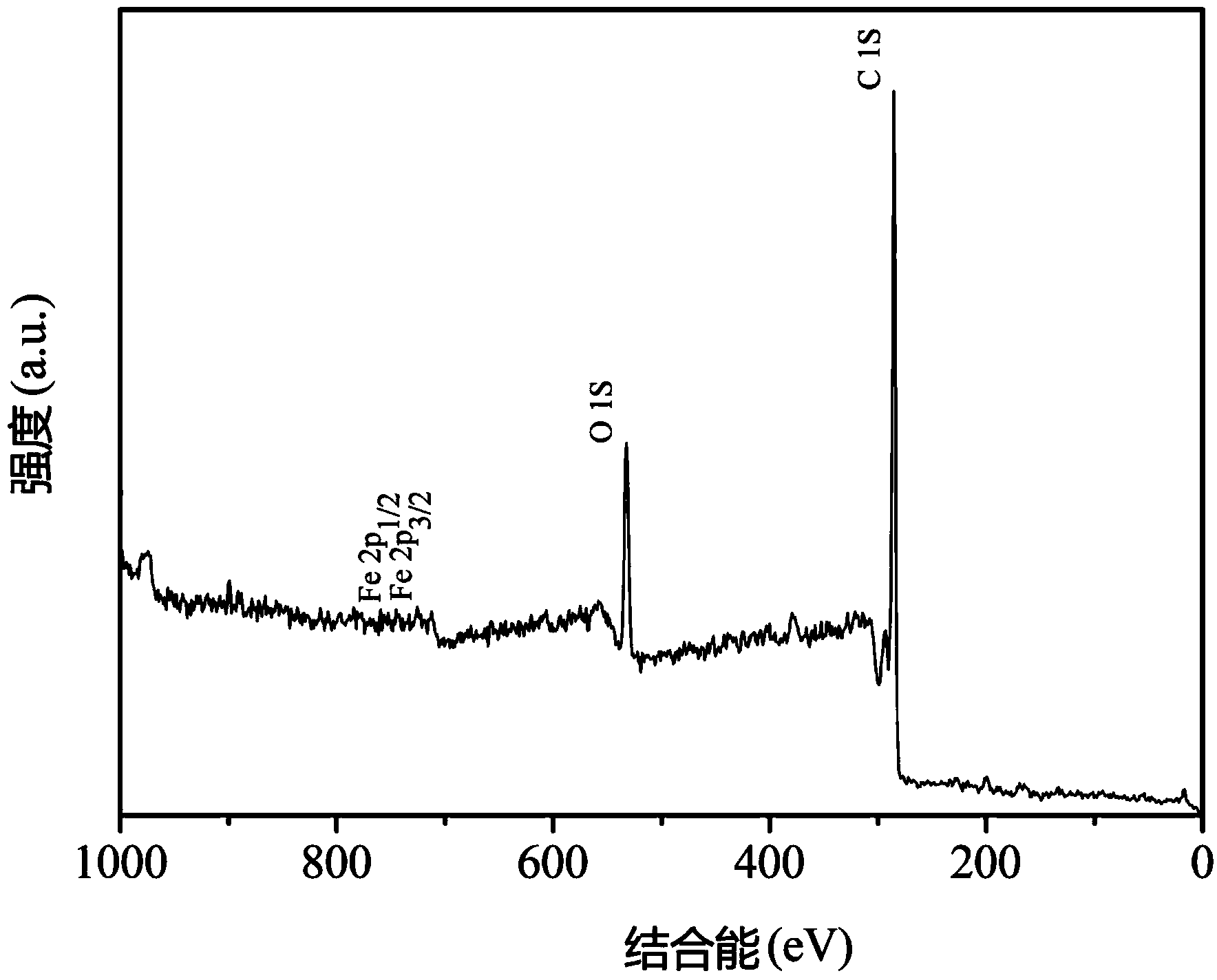

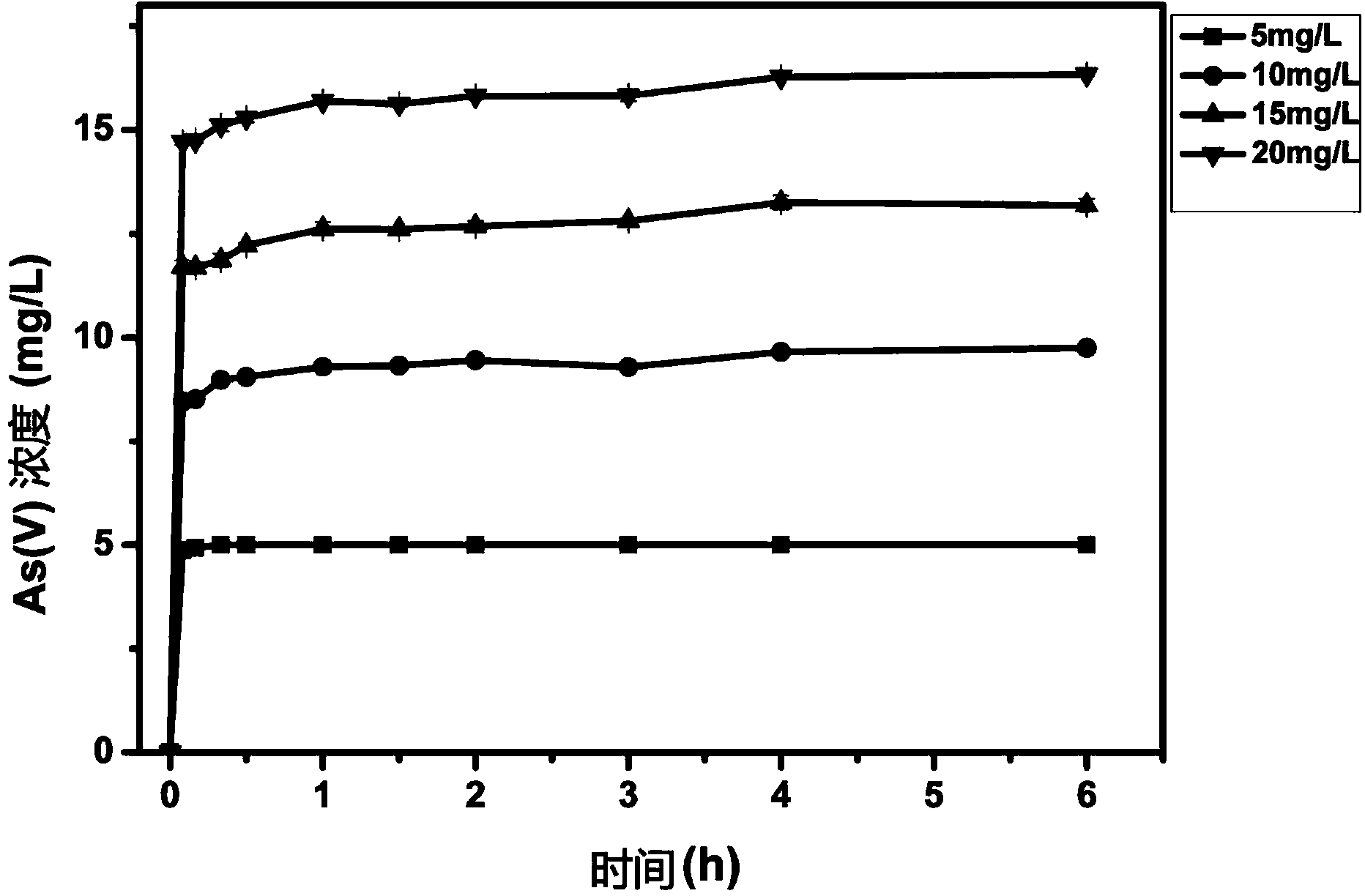

Iron-based bio-char material, preparation process thereof, and application thereof in soil pollution treatment

ActiveCN104388094AImprove performanceReduced bioavailabilityTransportation and packagingContaminated soil reclamationCarbonizationSoil heavy metals

The invention relates to the technical field of soil heavy metal remediation, and specifically discloses a method for preparing an iron-based bio-char material, a prepared iron-based bio-char material, and a method for applying the iron-based bio-char material in treating soil heavy metal pollution. According to the material, biomass is adopted as a raw material; a high-temperature carbonization method is adopted; during the bio-char preparation process, an iron-containing compound is added, such that iron is doped according to a certain ratio, and the iron-based bio-char material with special structure and function is formed. The material has the advantages of simple preparation process, low production cost, and short production period. The obtained iron-based bio-char material has a unique effect in repairing arsenic-cadmium composite polluted soil. With the material, bio-availability of arsenic and cadmium in soil can be effectively reduced, arsenic and cadmium contents in agricultural products planted in the arsenic-cadmium composite polluted soil can be greatly reduced, and no toxic or side effect is caused on crops. The material is safe to apply, and can be used in a large scale in treatment of arsenic-cadmium composite polluted soil.

Owner:GUANGDONG INST OF ECO ENVIRONMENT & SOIL SCI

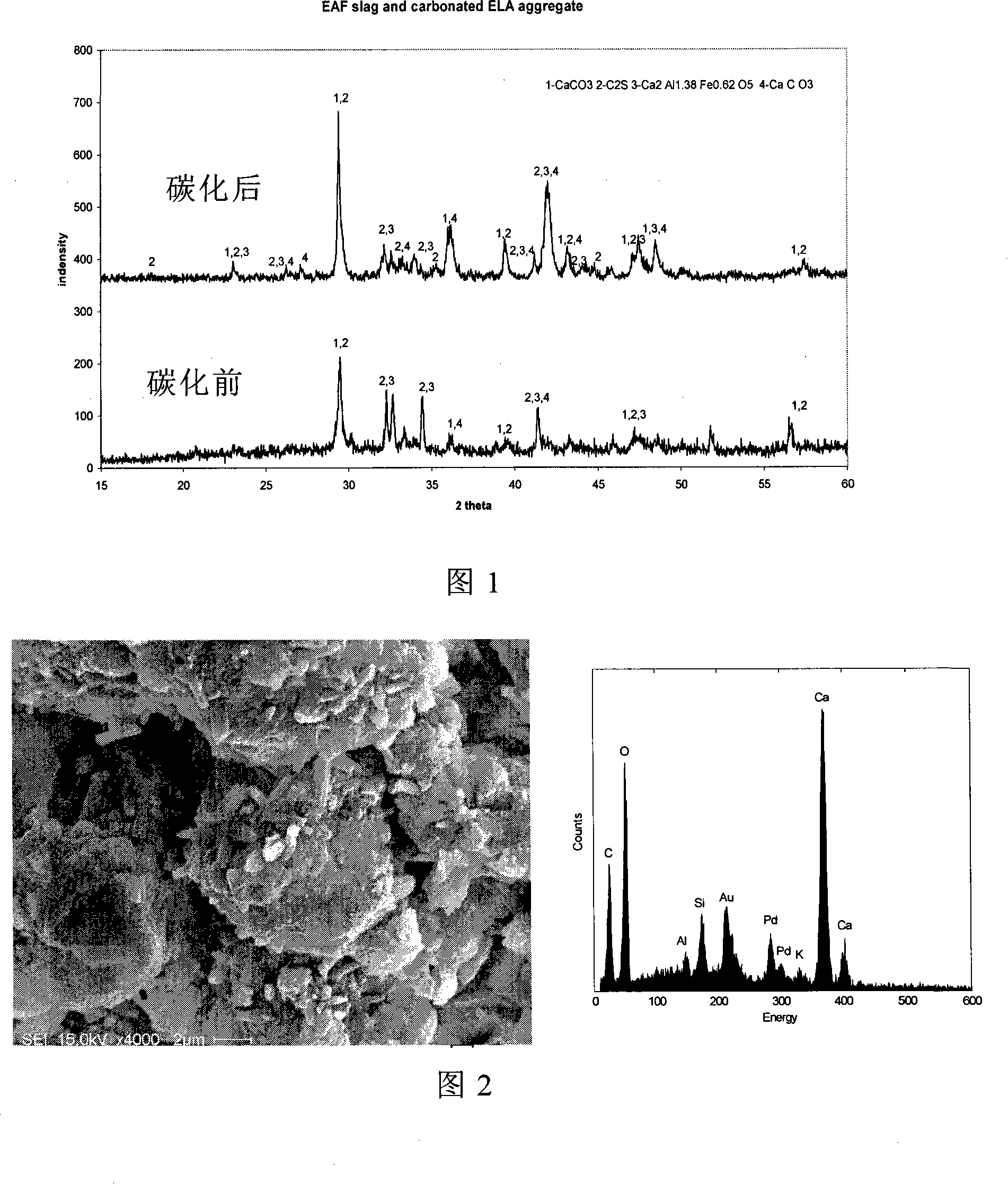

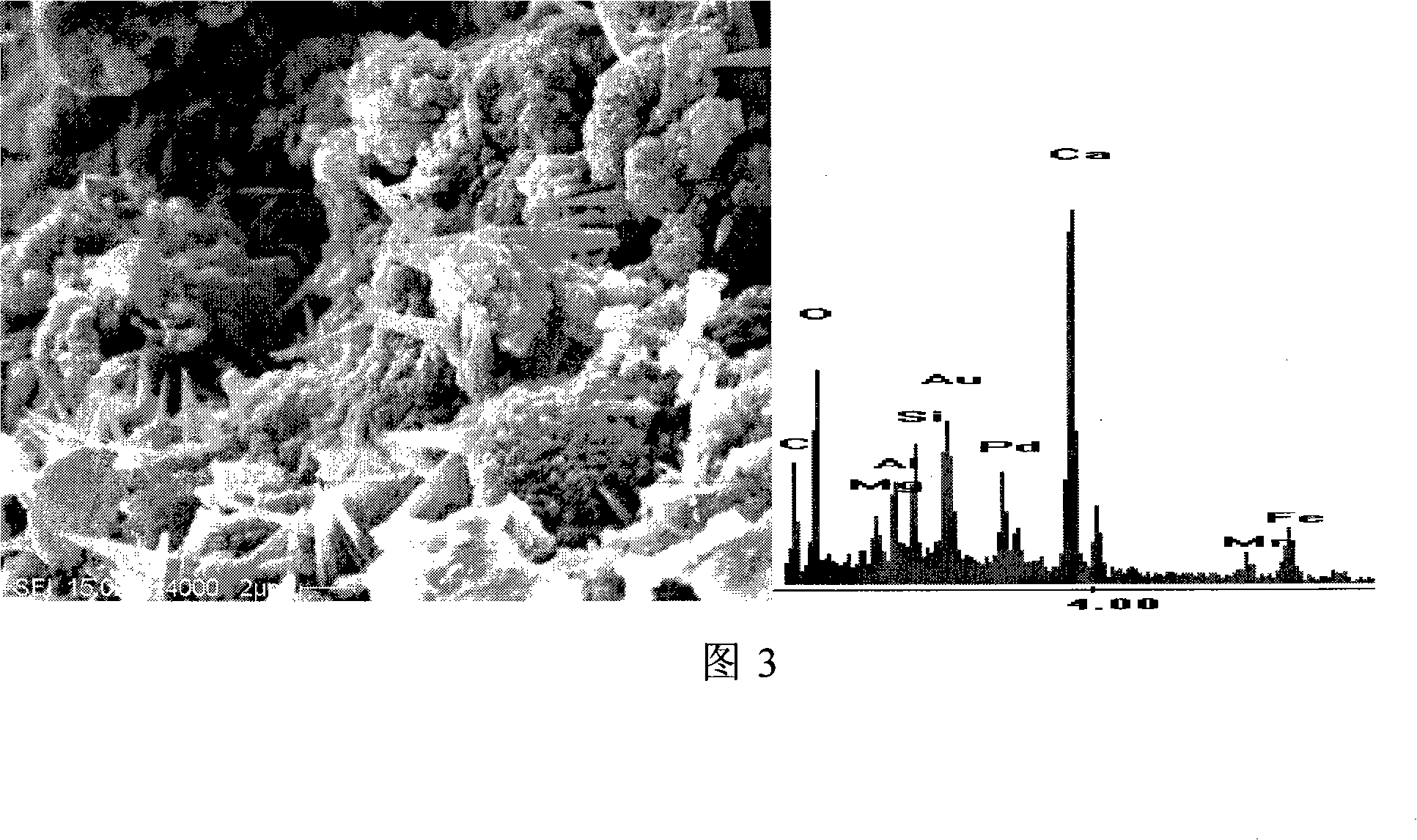

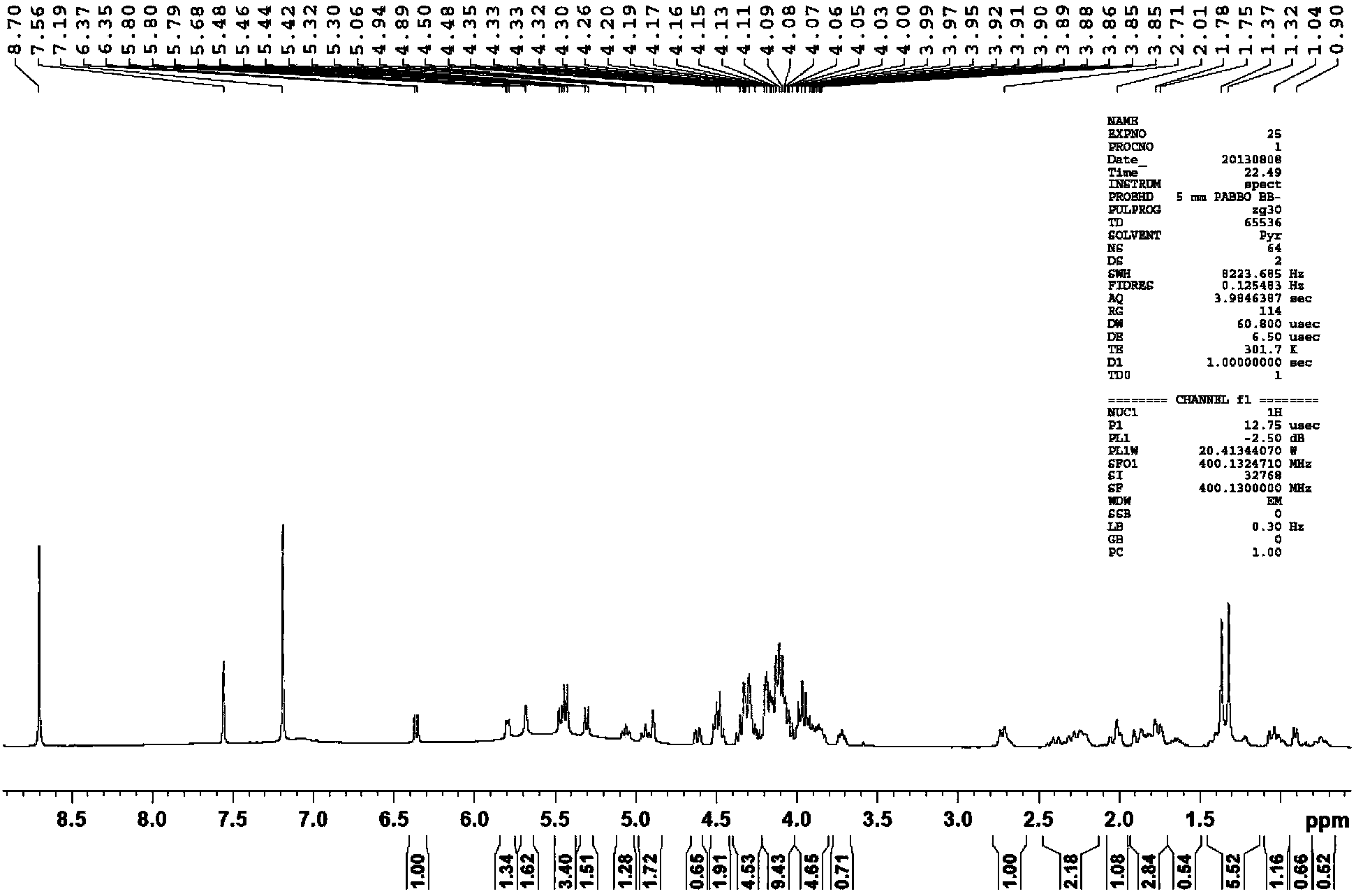

Carbonization maintenance aerated concrete

The present invention relates to a carbonized maintained aerated concrete prepared by utilizing steel slag and cements to absorb the carbon dioxide gas. The carbonized maintenance aerated concrete is manufactured by adopting the following method: the steel slag or cement containing carbonized components can be taken as raw materials, the air-entraining agents and the water are added in the raw materials. After being mixed uniformly, the generated mixtures are pressed and manufactured into the aerated concrete. Under the maintenance of the carbonized gas, the aerated concrete is made into the carbonized maintained aerated concrete; the weight percentage that the carbonized components take in the raw materials is no less than 20 percent; the carbonized gas is the carbon dioxide gas; the maintain conditions are that the concentration of the carbon dioxide is larger than wt15 percent, the pressure of the curing gas is larger than 1bar and the carbonization and maintenance temperature ranges from 30 to 200 Celsius system. The industrial waste gas is utilized for the technology, thus reducing the exhaust of the greenhouse gas, the carbon dioxide, preparing the aerated concrete products with good performance and shortening the production cycle. The beneficial effects of the present invention are that the waste is utilized, the environment is protected, the energy is saved and the cost is low.

Owner:UNIV OF JINAN

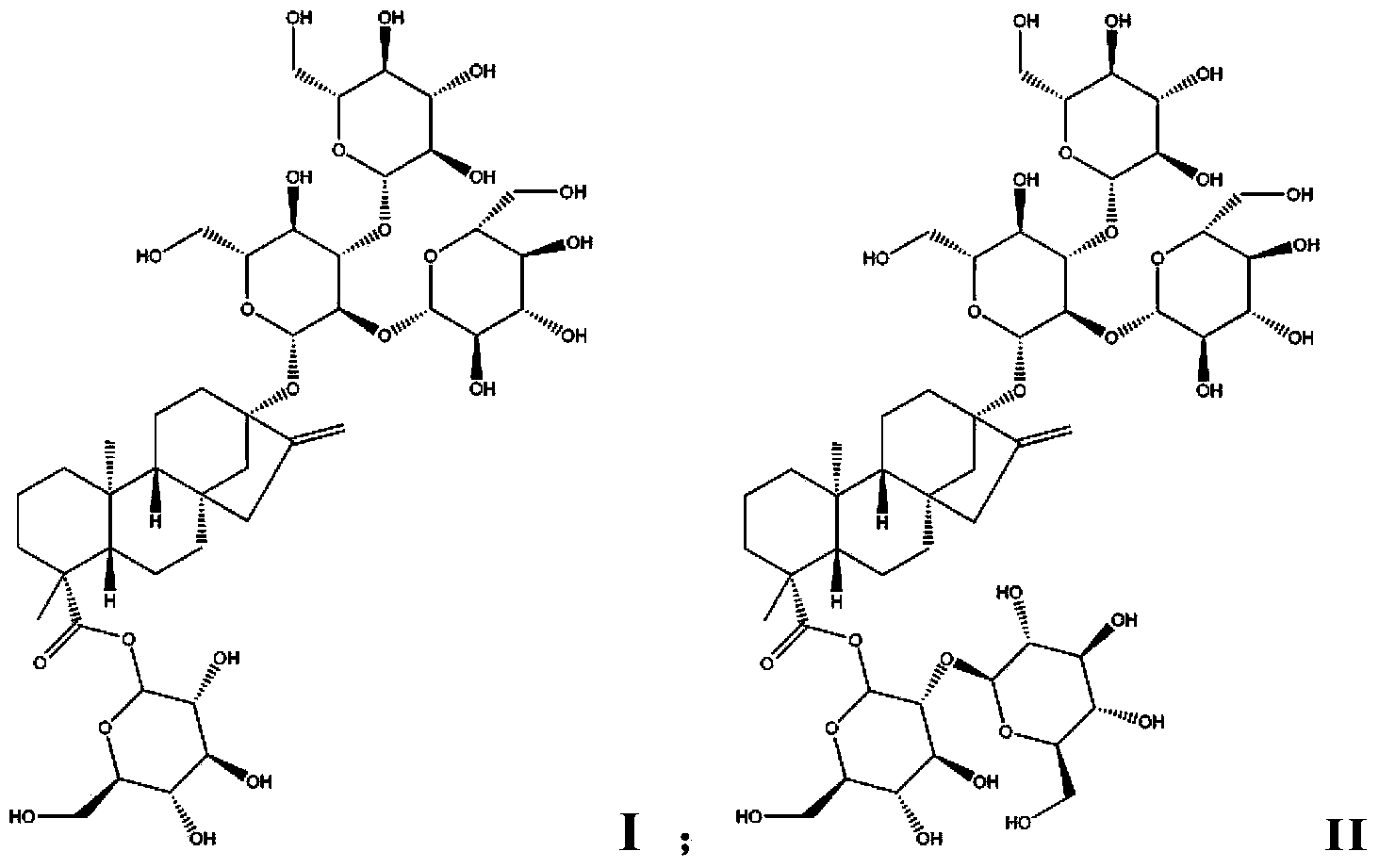

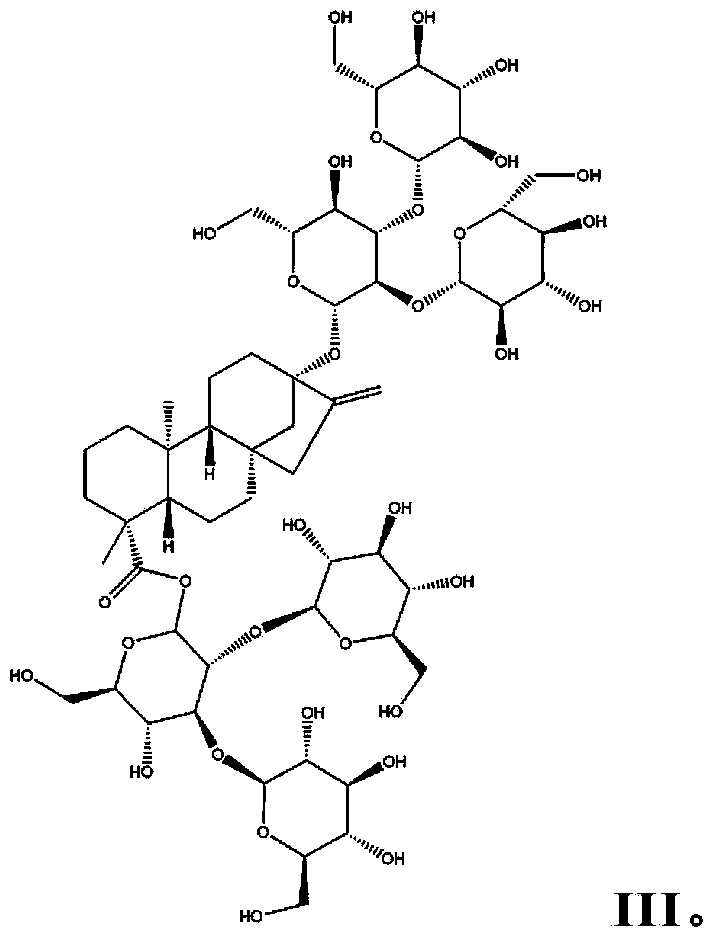

Method for preparing rebaudioside M through enzyme method

ActiveCN103397064AReduce manufacturing costShorten the production cycleMicroorganism based processesFermentationEnzyme methodUdp glucosyltransferase

The invention relates to a method for preparing rebaudioside M through an enzyme method. According to the method, rebaudioside A or rebaudioside D is used as a substrate, and the substrate reacts to generate the rebaudioside M in the presence of a glucosyl donor under the catalytic action of UDP-glucosyltransferase and / or recombinant cells containing the UDP-glucosyltransferase. The method for preparing rebaudioside M through an enzyme method has important application value; and compared with the existing technology of extracting rebaudioside M from stevia rebaudian leaves, the method provided by the invention obviously shortens the production cycle, improves the productivity and lowers the cost, and can provide products having higher purity. Thus, the method can be used in the food and beverage industry in a more economical manner.

Owner:PEPSICO INC

Copper bismuth catalyst and preparation method thereof

ActiveCN102658158AImprove wear performanceExtended service lifeOrganic compound preparationHydroxy compound preparationCooking & bakingAlcohol

The invention relates to a copper bismuth catalyst for combining chemically into 1, 4-butynediol with formaldehyde and ethyne and a preparation method thereof. The preparation method comprises the following steps of: preparing mixed solution which contains copper salt, bismuth salt, magnesium salt and dispersant; dropping alcoholic solution with an organic silicon source into the mixed solution; adjusting a pH value of the mixed solution with alkaline solution to obtain mixed precipitate; and further aging, washing, drying and baking in inert atmosphere to obtain the copper bismuth catalyst with C-MgO-SiO2 a carrier, in the catalyst, the content of CuO accounts for 25-50 weight percent, and the content of Bi2O3 accounts for 2-6 weight percent. The catalyst is applied in a reaction of combining chemically into 1, 4-butynediol with formaldehyde and ethyne, and has high catalytic activity and high selectivity.

Owner:SHANXI UNIV

Start working method for hydrocracking process

ActiveCN101492613AHigh vulcanization rateHigh Sulfur Utilization EfficiencyHydrocarbon oil crackingSulfurEconomic benefits

The invention discloses a hydrocracking process operation method. Hydrocracking pre-refining catalyst is treated by precuring outside a reactor while hydrocracking catalyst is not treated or is partially treated by precuring outside the reactor. Curing ingredient introduced by the hydrocracking pre-refining catalyst and the hydrocracking catalyst precured outside the reactor accounts for 90-120% of the theoretical sulfur demand for all the catalyst. The hydro cracking pre-refining catalyst and the hydro cracking catalyst are layered in the reactor and then activated by heating, so that all the catalyst is sulfurated effectively. The method of the invention can precure the hydrocracking pre-refining catalyst outside the reactor or precure the hydrocracking pre-refining catalyst and partial hydrocracking catalyst outside the reactor, thus reducing the catalyst requiring precuring outside the reactor, reducing the production period and production cost of the precuring catalyst and improving the economic benefit and production security.

Owner:CHINA PETROLEUM & CHEM CORP +1

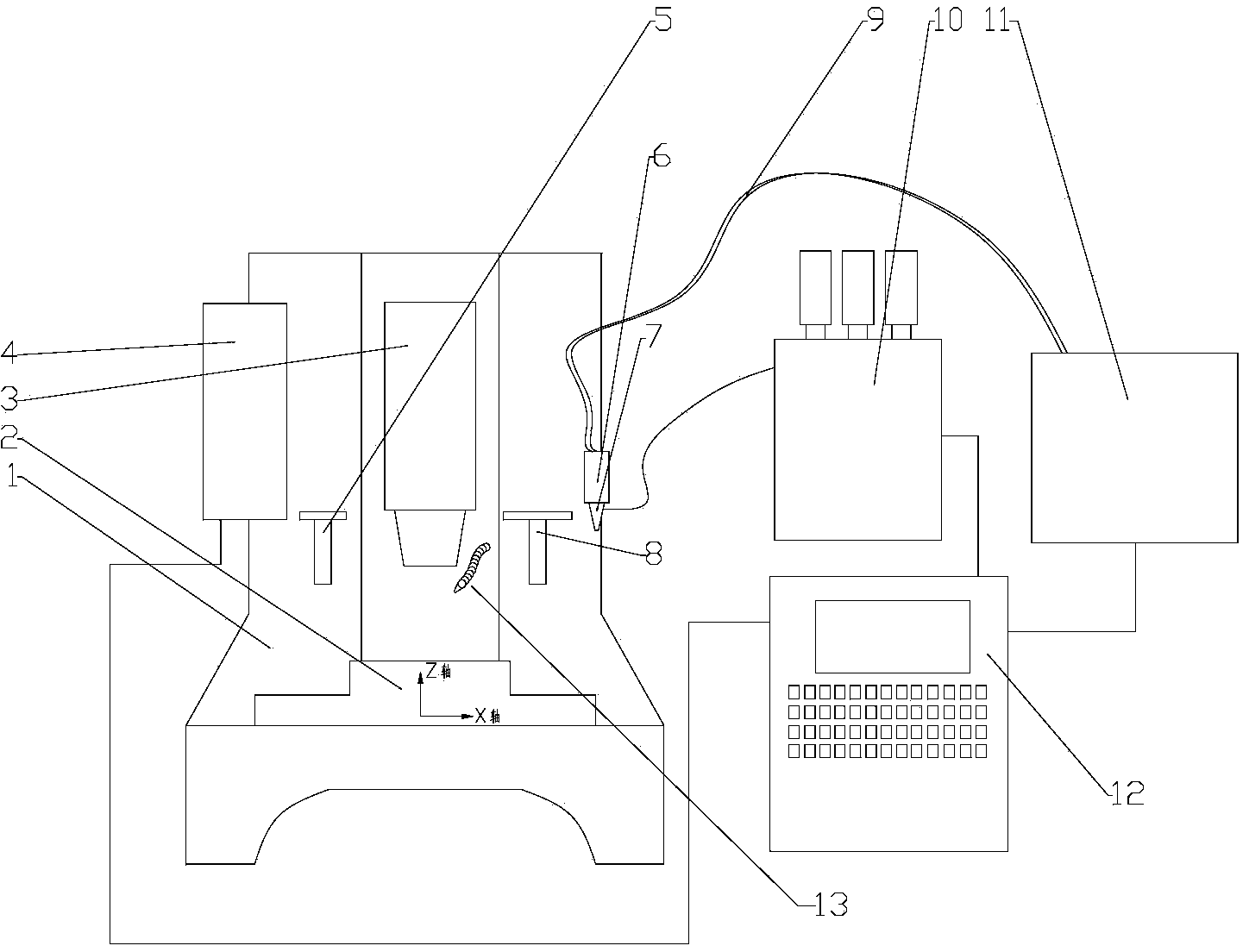

Combined additive and subtractive manufacturing machine tool

ActiveCN104384936AGuaranteed complexityGuaranteed processing effectOther manufacturing equipments/toolsUltrasonic vibrationMachining process

The invention belongs to the field of machine tool design, and relates to a combined additive and subtractive manufacturing machine tool, which comprises a body, a workbench, a main shaft, a numerical control system, a subtractive machining module and an additive manufacturing module. According to the combined additive and subtractive manufacturing machine tool, the additive manufacturing module is controlled by the numerical control system to form a basic structure of a required part on the workbench, then the subtractive machining module is controlled by the numerical control system to perform subtractive machining on the basic structure obtained by additive manufacturing, a function of applying ultrasonic vibration to a cutter and a gas cooling function are realized in a subtractive machining process, and the whole combined additive / subtractive manufacturing process is finally implemented. The combined additive and subtractive manufacturing machine tool can be used for realizing the efficient and precise combined additive and subtractive manufacturing of the component, the manufacturability of a complex part is improved, the production cycle is shortened, and the manufacturing accuracy of the complex part is ensured.

Owner:DALIAN UNIV OF TECH

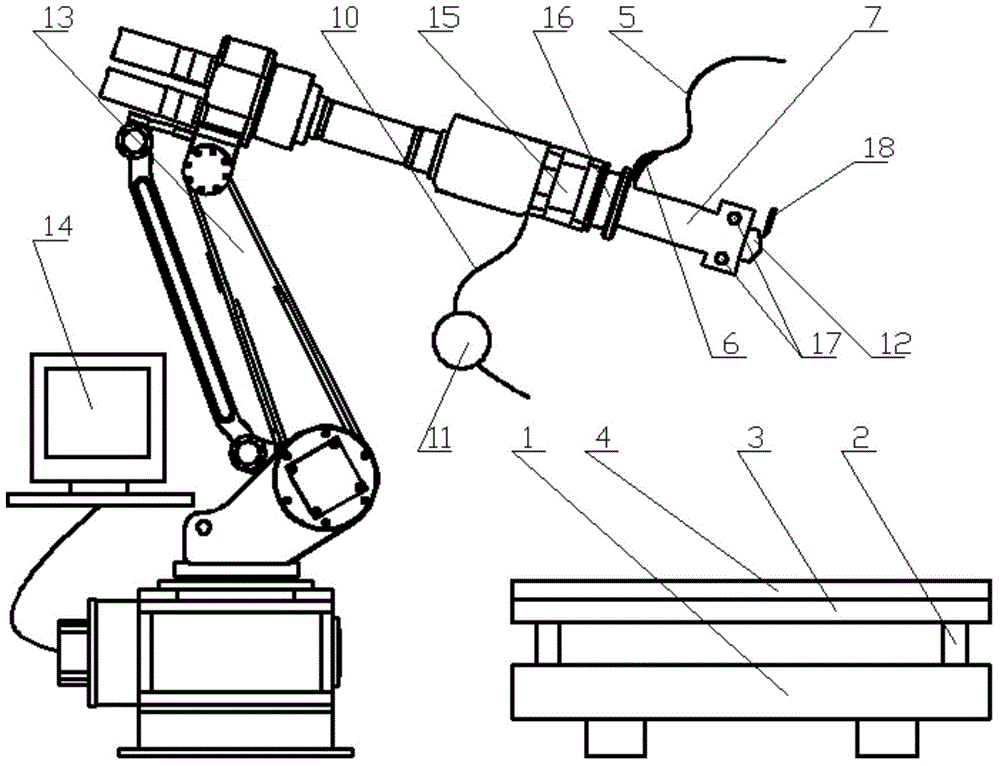

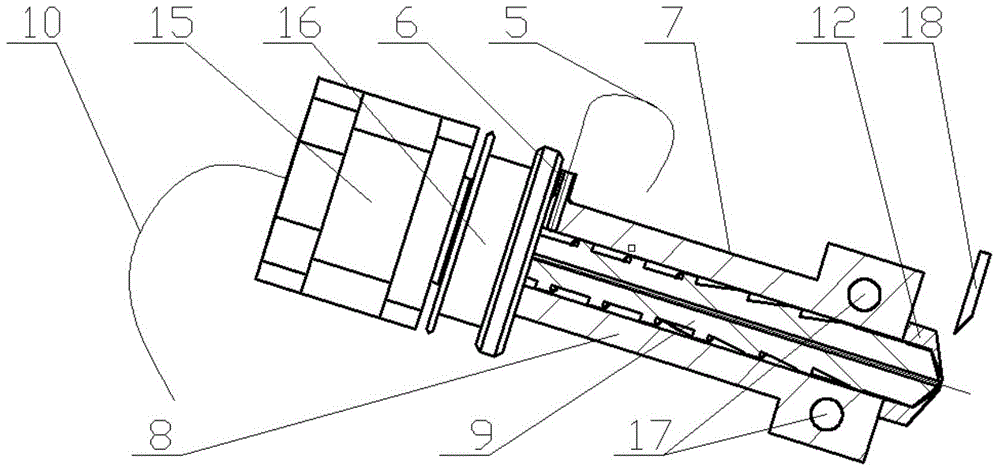

Multi-degree-of-freedom 3D printer of fiber reinforced composite material and printing method thereof

The invention discloses a multi-degree-of-freedom 3D printer of a fiber reinforced composite material and a printing method thereof. The 3D printing can be performed with any angle and any movement locus by making use of the flexibility of a manipulator; and a 3D printing head mounted on the multi-degree-of-freedom 3D printer can perform the 3D printing of a high-strength short fiber reinforced composite material, and can perform the splicing and the weaving of continuous resin-based long fiber to produce a structural body of a continuous fiber reinforced resin-based composite material. The multi-degree-of-freedom 3D printer can precisely control the orientation of reinforced fiber in a composite material part in the 3D printing process, and can realize the quick production of the composite material part with specific mechanical, electric and thermal performances and a complex structure. Meanwhile, a mold customized beforehand and a pretreated fiber prepreg tape are not needed in the process; and the multi-degree-of-freedom 3D printer is not only suitable for the production of large parts, but also suitable for the large-batch production of small parts, so that the production cost and the production period are largely reduced, and the wide application of the composite material parts is further promoted.

Owner:XI AN JIAOTONG UNIV

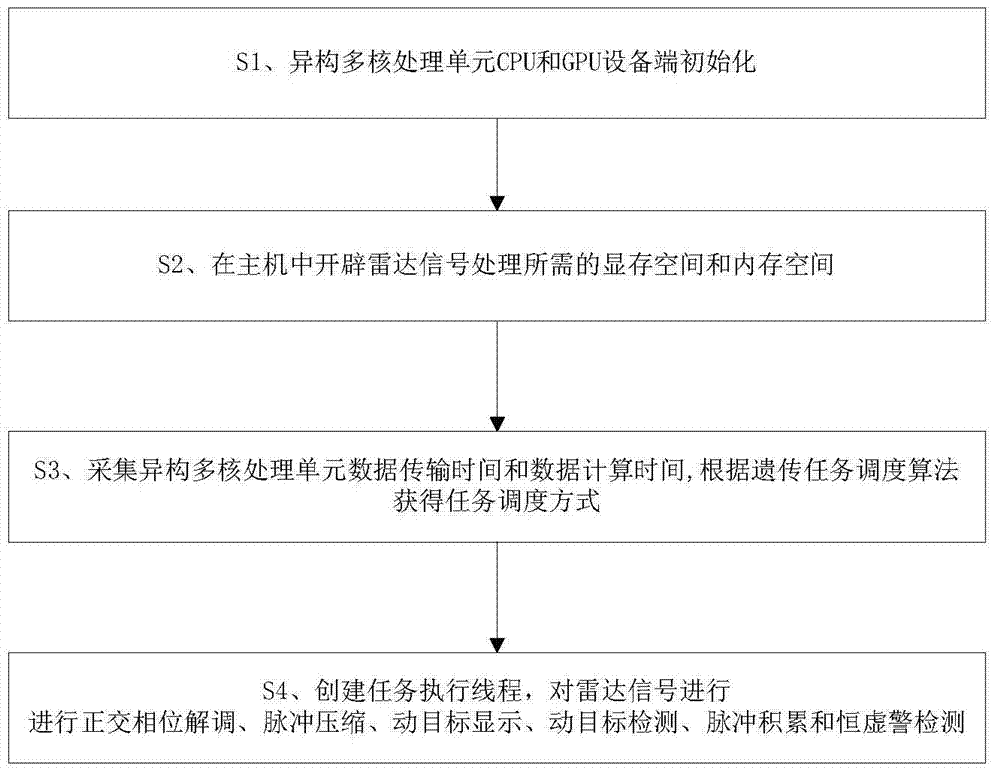

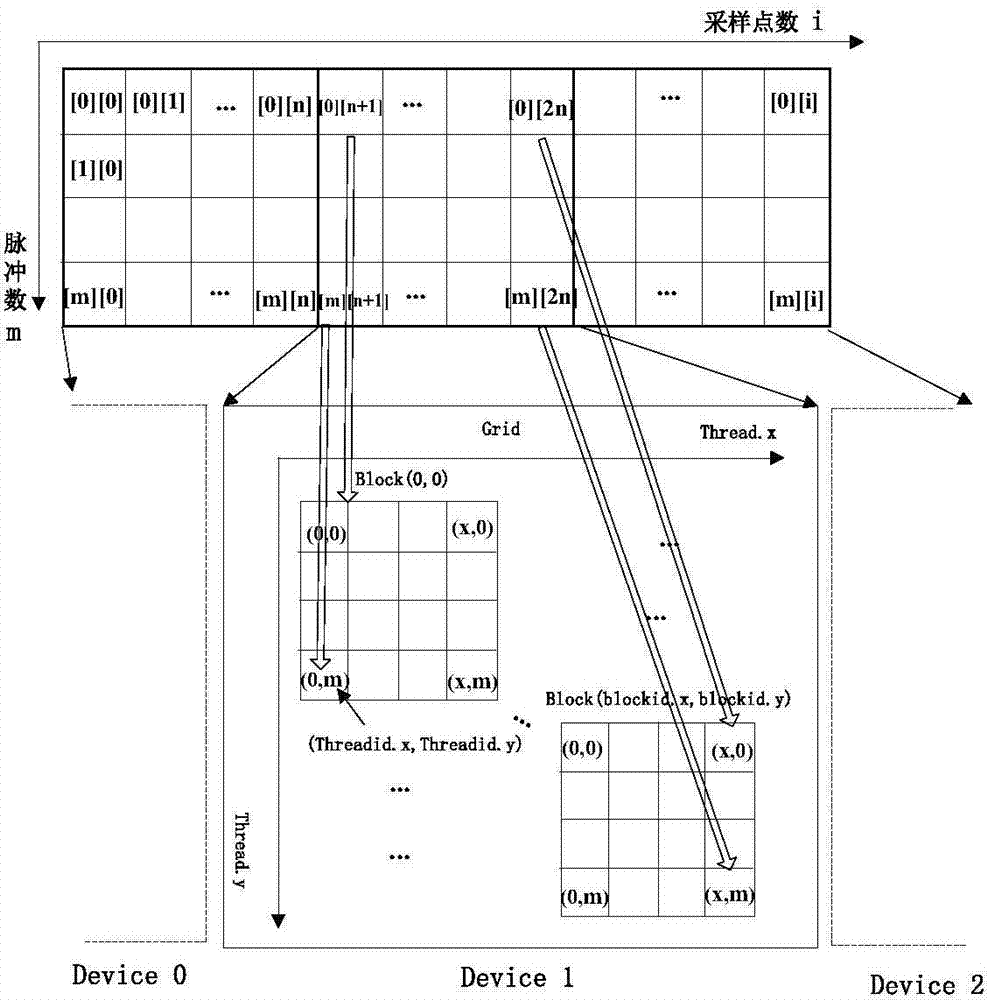

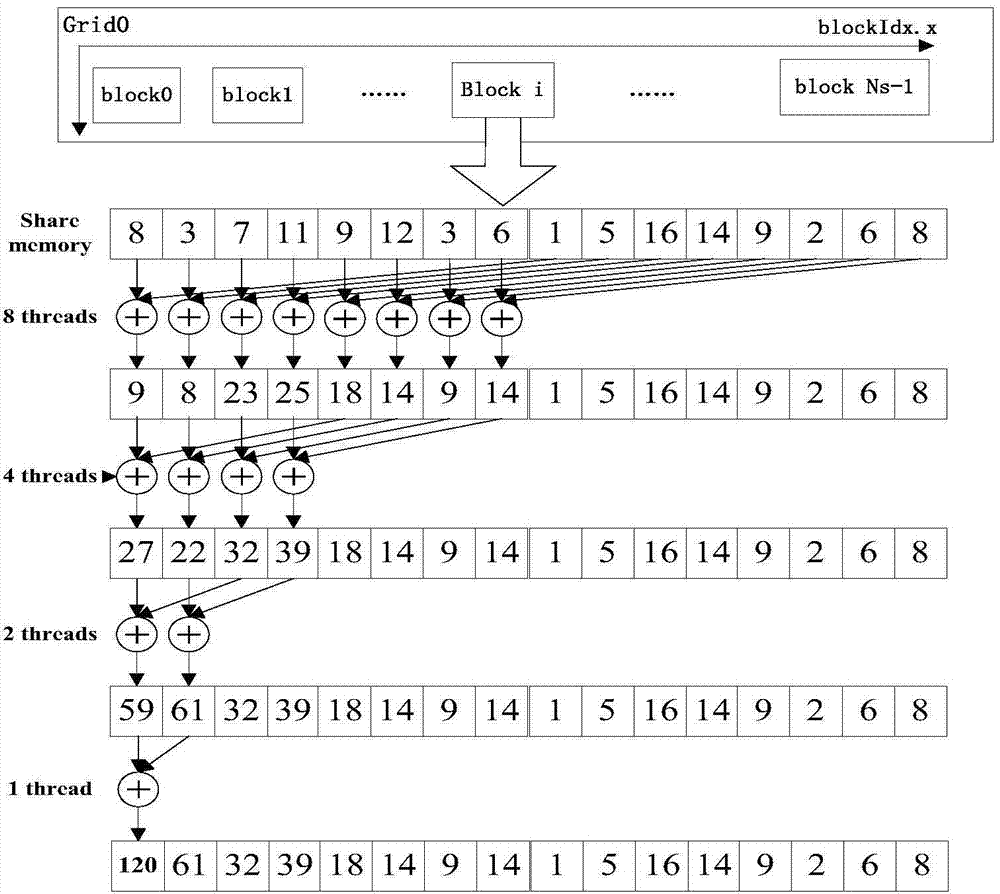

Radar signal parallel processing method and system based on heterogeneous multinucleated system

ActiveCN104849698AImprove compatibilityLow costWave based measurement systemsVideo memoryRadar signal processing

The invention discloses a radar signal parallel processing method and system based on a heterogeneous multinucleated system. The method comprises the following steps: S1, initializing equipment-end parameters, opening up a task execution thread, and dividing thread grids of data processing and the dimensions of a thread block; S2, opening up a video memory space and a memory space which are needed for the signal processing; S3, acquiring data transmission and calculating time needed by signal processing of a single time, and scheduling a genetic task scheduling algorithm to obtain a task scheduling mode; and S4, acquiring laser sampling data for storing in the memory space by means of segments according to a time sequence, sending the data to a CPU and a GPU according to the task scheduling mode, mapping sampling points to each thread and performing concurrent execution according to the thread grids and the dimensions of the thread block, and scheduling a filter coefficient to perform orthogonal phase demodulation, pulse compression, moving object display, moving object detection, pulse accumulation and constant false alarm detection on the sampling data. By applying the method and system provided by the invention, the speed of a general processor in executing the signal processing is improved, and the requirement for real-time performance of radar signal processing is met.

Owner:NAVAL UNIV OF ENG PLA

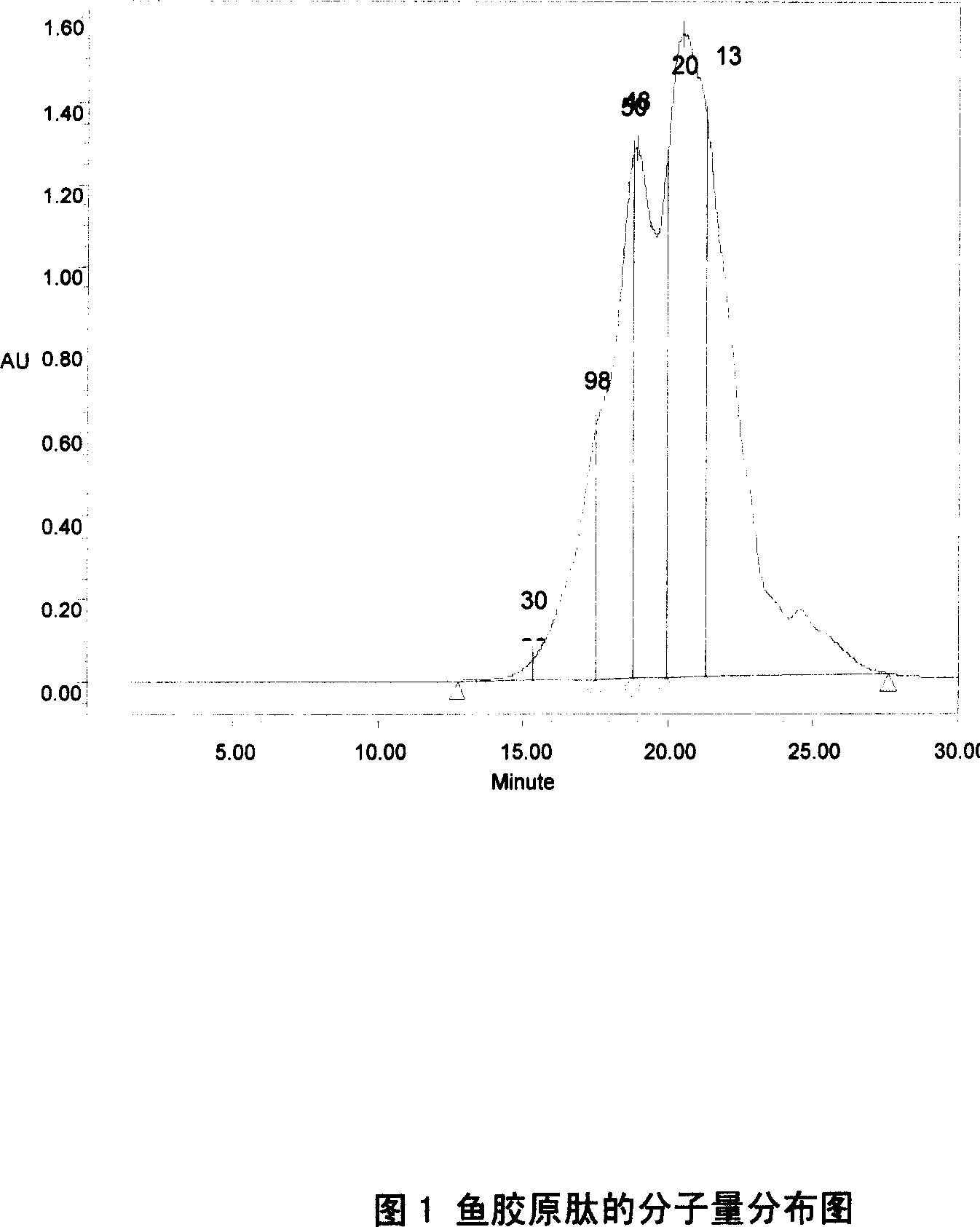

Industry method of producing fish collagen peptide from fish skin and bone by an enzyme method

ActiveCN101061827ASimple processShorten the production cycleAnimal proteins working-upComplex proteinFish products

The invention discloses a special method to extract collagen from fish peel and bone with complex prolease, which comprises the following steps: choosing salmon, AnKang fish peel and processing waste of fish product as raw material; unfreezing; washing; scaling off; degreasing; grinding; enzymolyzing; separating; de-oiling; ultra filtering; condensing; spray-drying; getting the product. This invention possesses simple craft and short production circle.

Owner:CHINA NAT RES INST OF FOOD & FERMENTATION IND CO LTD +1

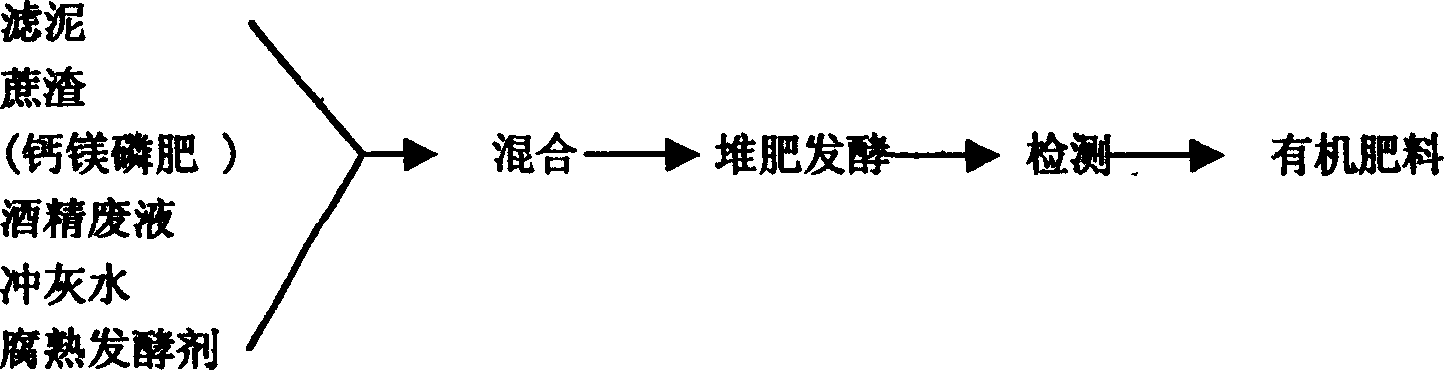

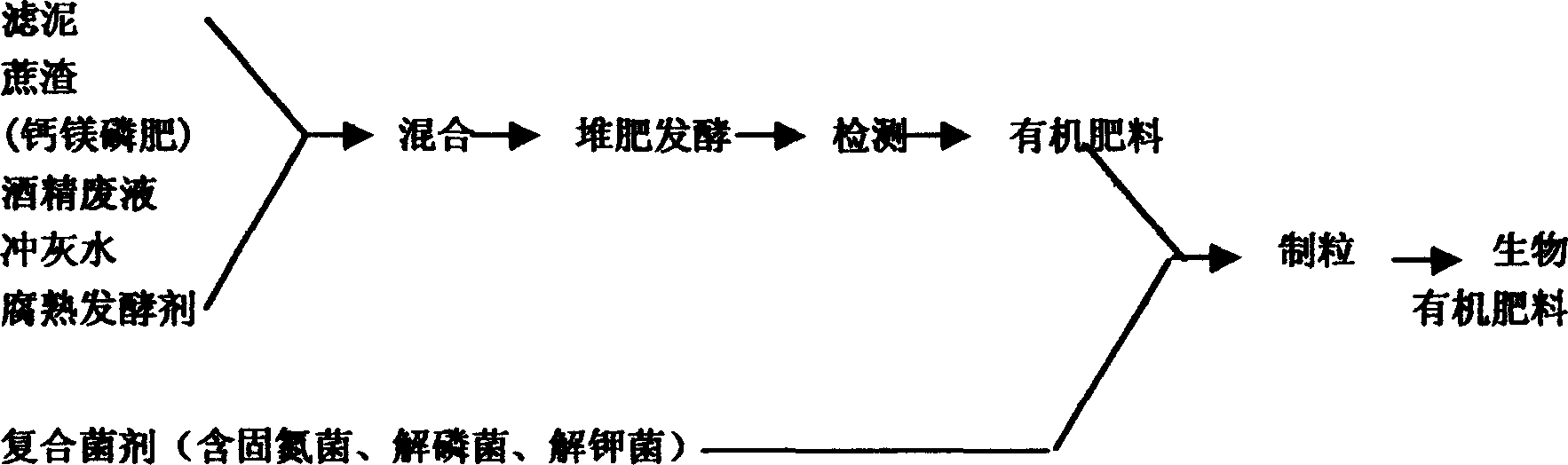

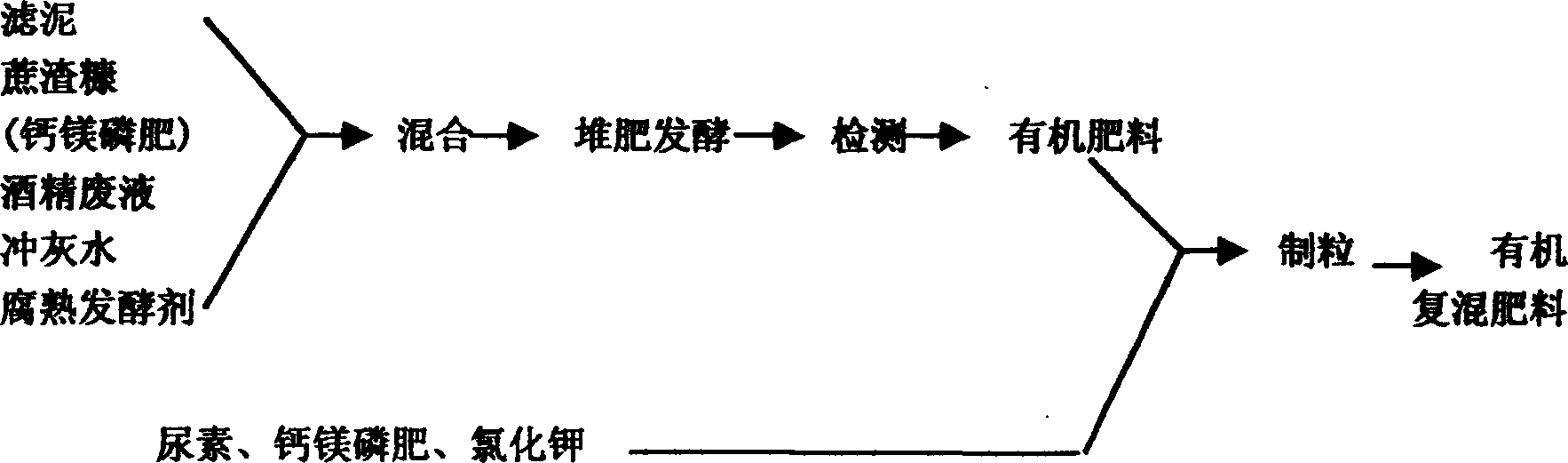

Organic fertilizer composed of waste liquid and waste residue and decomposing leaven from sugar refinery and method for preparing the same

InactiveCN1546437AExpand production scaleFast fermentationBio-organic fraction processingOrganic fertiliser preparationInorganic fertilizerSlag

The invention relates to an organic fertilizer mainly comprises sugar factory discard solution and waste slag as well as decomposed leaven and process for preparation, which comprises fermentation material and decomposed leaven, wherein the composition and weight ratio of the fermentation material are, molasses alcohol discard solution or / and ash flushing water 10-82%, cane trash or / and filtering mud 18-90%, and the rest is one or combination of combination stalks, turfy soil, animal excrement, inorganic fertilizer and soil, whose weight percent is 0-15%. The decomposed leaven comprises cellulose decomposition bacteria, himicellulose disassembling bacterium, protein disassembling bacterium.

Owner:HUAZHONG AGRICULTURAL UNIVERSITY

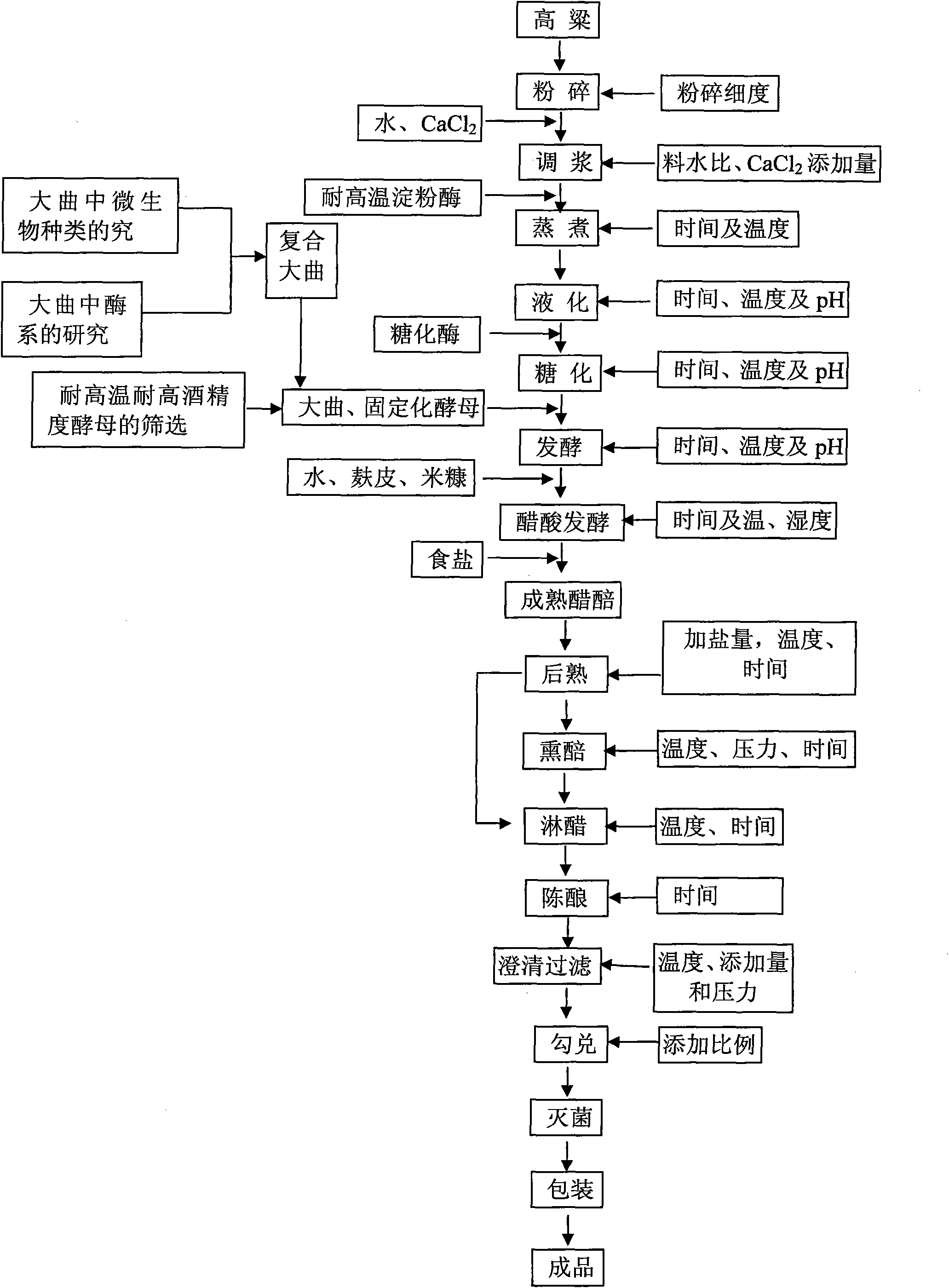

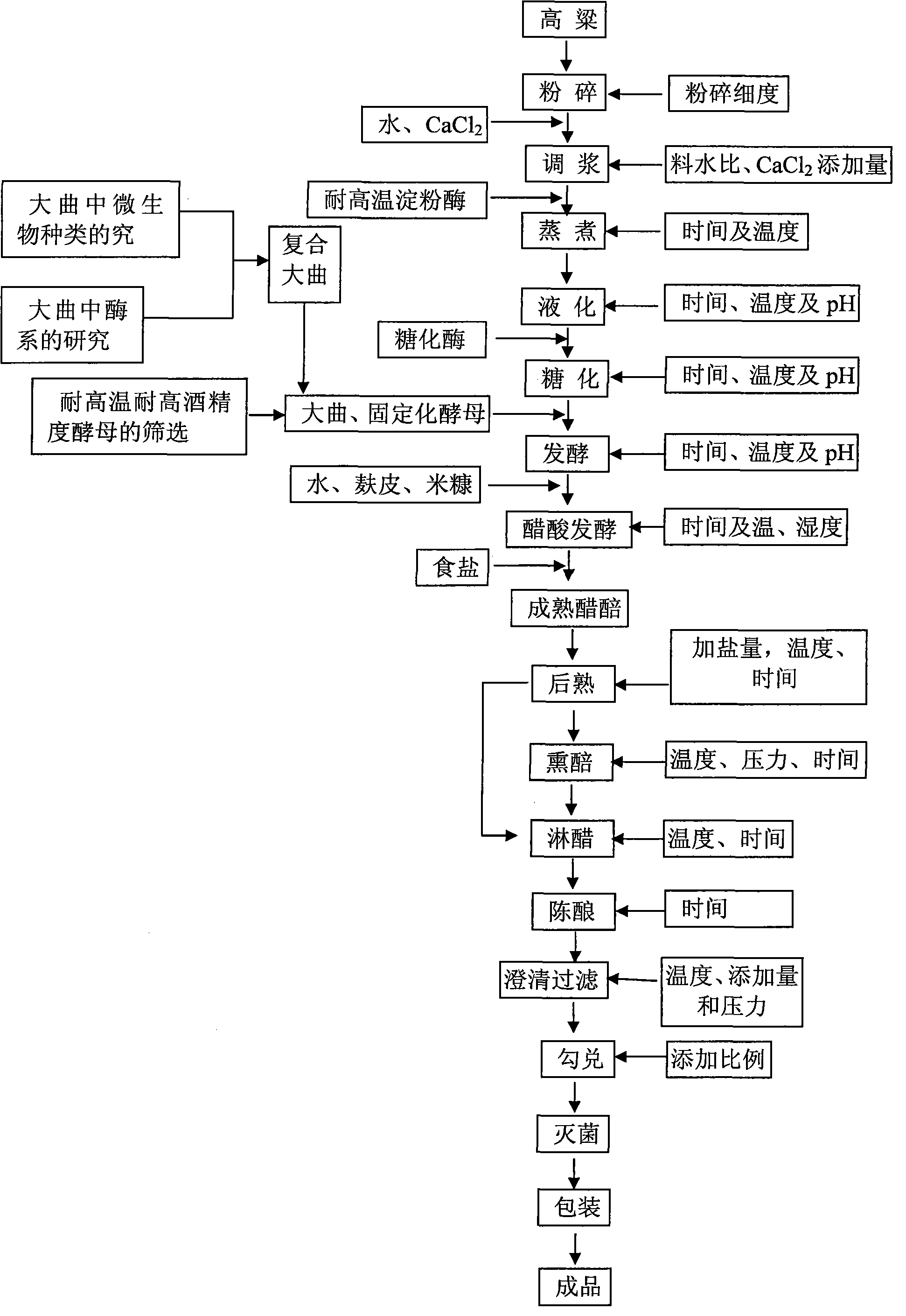

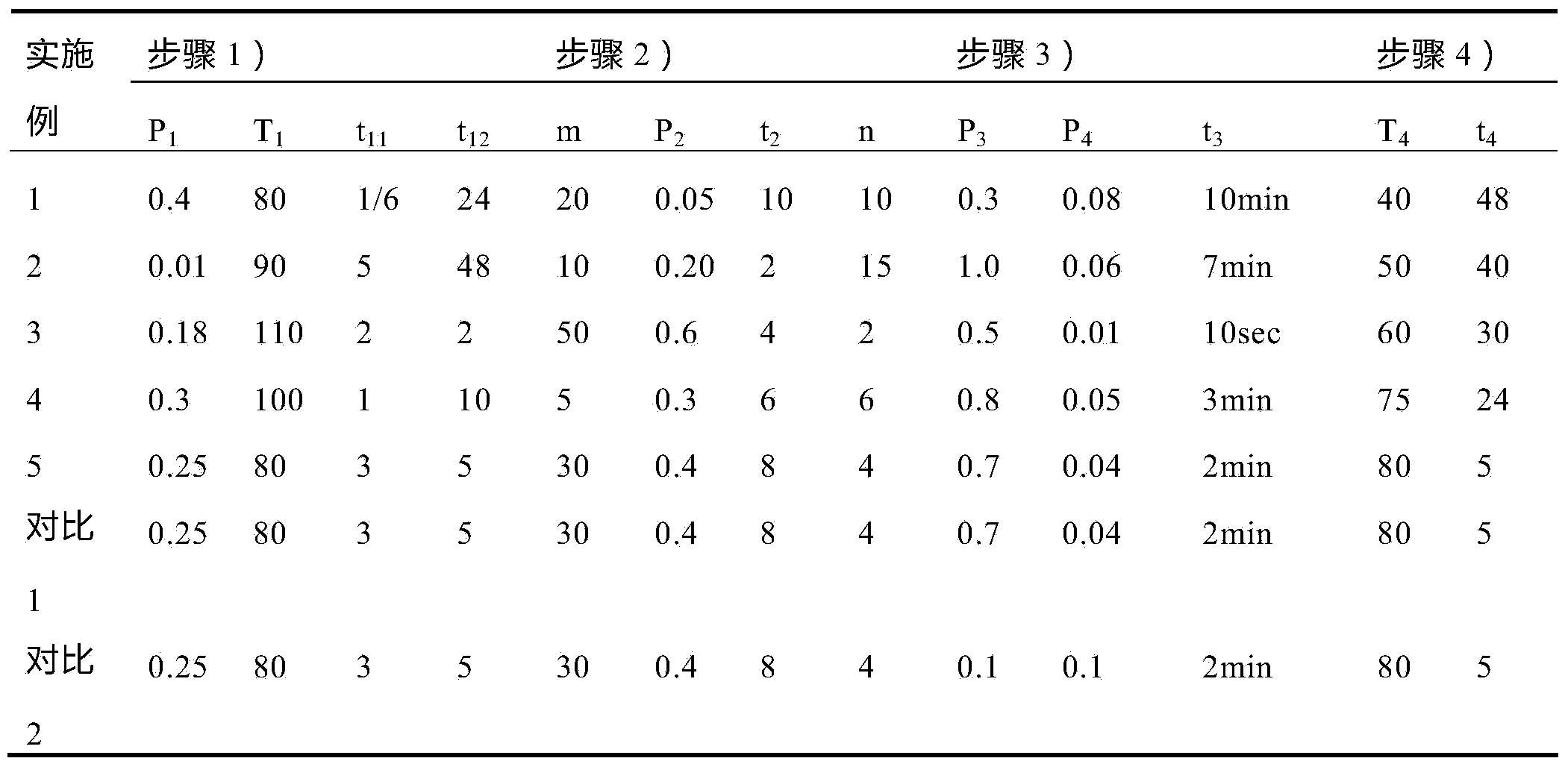

Standardized and industrialized production process for Shanxi mature vinegar

ActiveCN101857833ASystematization of processHigh technology contentMicroorganism based processesVinegar preparationMaterials processingSaccharomyces

The invention relates to a production process for vinegar, in particular to the standardized and industrialized production process for Shanxi mature vinegar, which solves the problems of long production process period, complex process, unstable product quality, low raw material utilization rate and the like, of the prior production process. The production process comprises the following steps of: performing material processing before alcoholic fermentation, crushing, mixing, liquefaction and saccharification; selecting high-temperature resistant and high-alcoholic strength resistant saccharomyces, and adding a composite yeast to perform alcoholic fermentation; adding the composite acetic bacteria into vinegar residue, stirring with a vinegar residue stirrer, fermenting the vinegar residue in an acetyl hydrate fermenting tank, and turning the vinegar residue with a vinegar residue turning machine; tamping the vinegar residue in the acetyl hydrate fermenting tank, covering a layer of table salt on the tamped vinegar residue, and standing the vinegar residue; fuming the vinegar residue by the combination of a vinegar residue fuming furnace and a steam vinegar residue fuming jar; pouring vinegar; ageing the vinegar; clarifying the vinegar with a crude acidic protease, and filtering the vinegar with kieselguhr; blending the vinegar and the traditional Shanxi mature vinegar; sterilizing the vinegar; and packing the vinegar. The process of the invention has the advantages of systematized flow, standardized technological parameters, scale production procedure, normalized product quality and optimized production process.

Owner:山西金龙鱼梁汾醋业有限公司

Method for preparing modified aqueous adhesion agent of polyurethane

InactiveCN101003715AIncrease the degree of cross-linkingImprove cohesive strengthPolyureas/polyurethane adhesivesEpoxyPolyester

This invention discloses a method for preparing modified aqueous polyurethane adhesive. The method comprises: (1) modifying epoxy resin with modifier to obtain modified epoxy resin; (2) reacting polyisocyanate with polyester or polyol polyether, and adding chain extender to obtain polyurethane with prepolymer; (3) modifying polyurethane prepolymer with modified epoxy resin to obtain modified polyurethane prepolymer; (4) adding water, dispersing by a high-speed disperser, and adding neutralizer and crosslinking agent to obtain modified aqueous polyurethane adhesive. This invention introduces epoxy resin into the modification of aqueous polyurethane adhesive, thus combines high modulus, high strength and good chemical resistance of epoxy resin with the advantages of polyurethane resin. The modified aqueous polyurethane adhesive can meet the needs of automobile inner decoration materials. The method has such advantages as simple process, and low cost.

Owner:SOUTH CHINA UNIV OF TECH

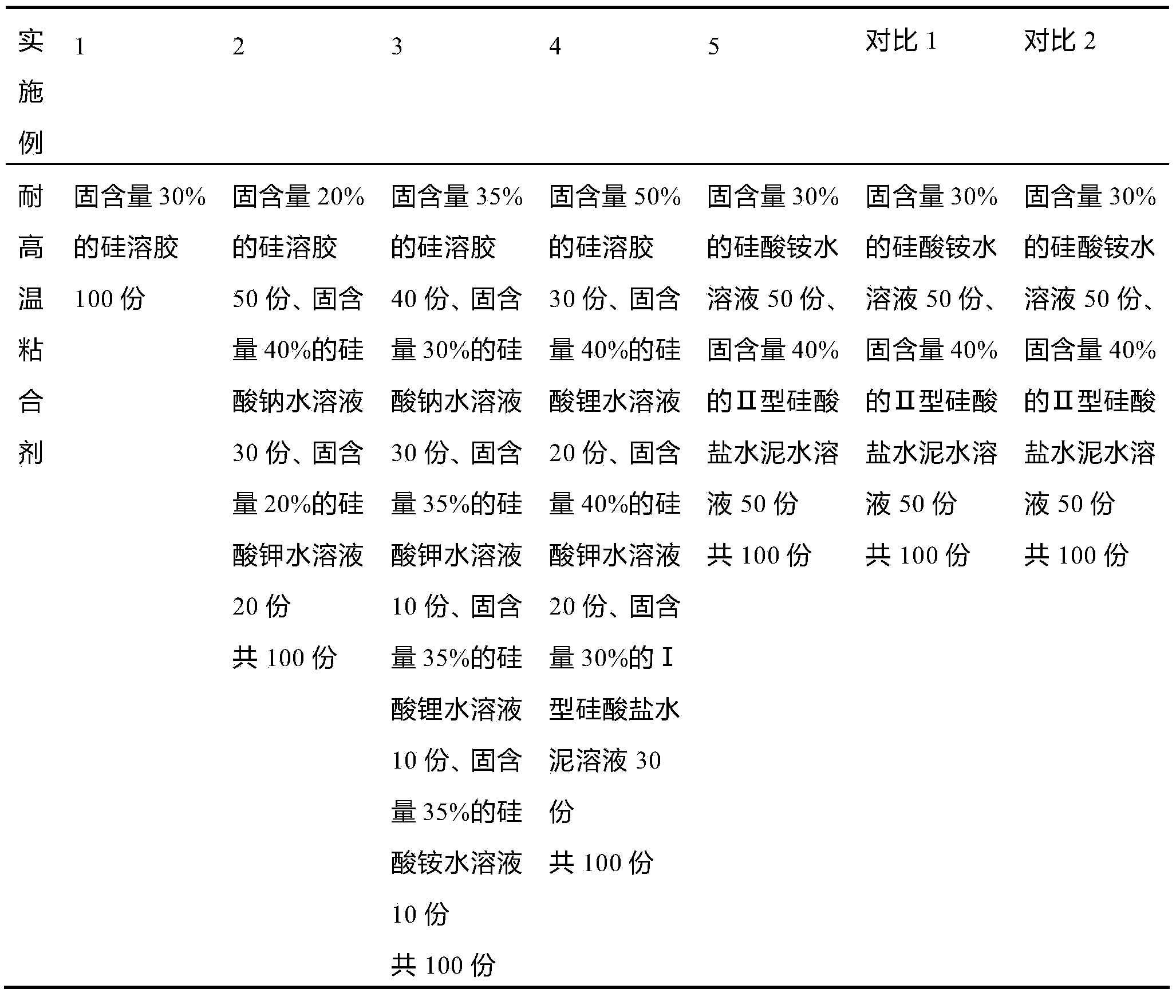

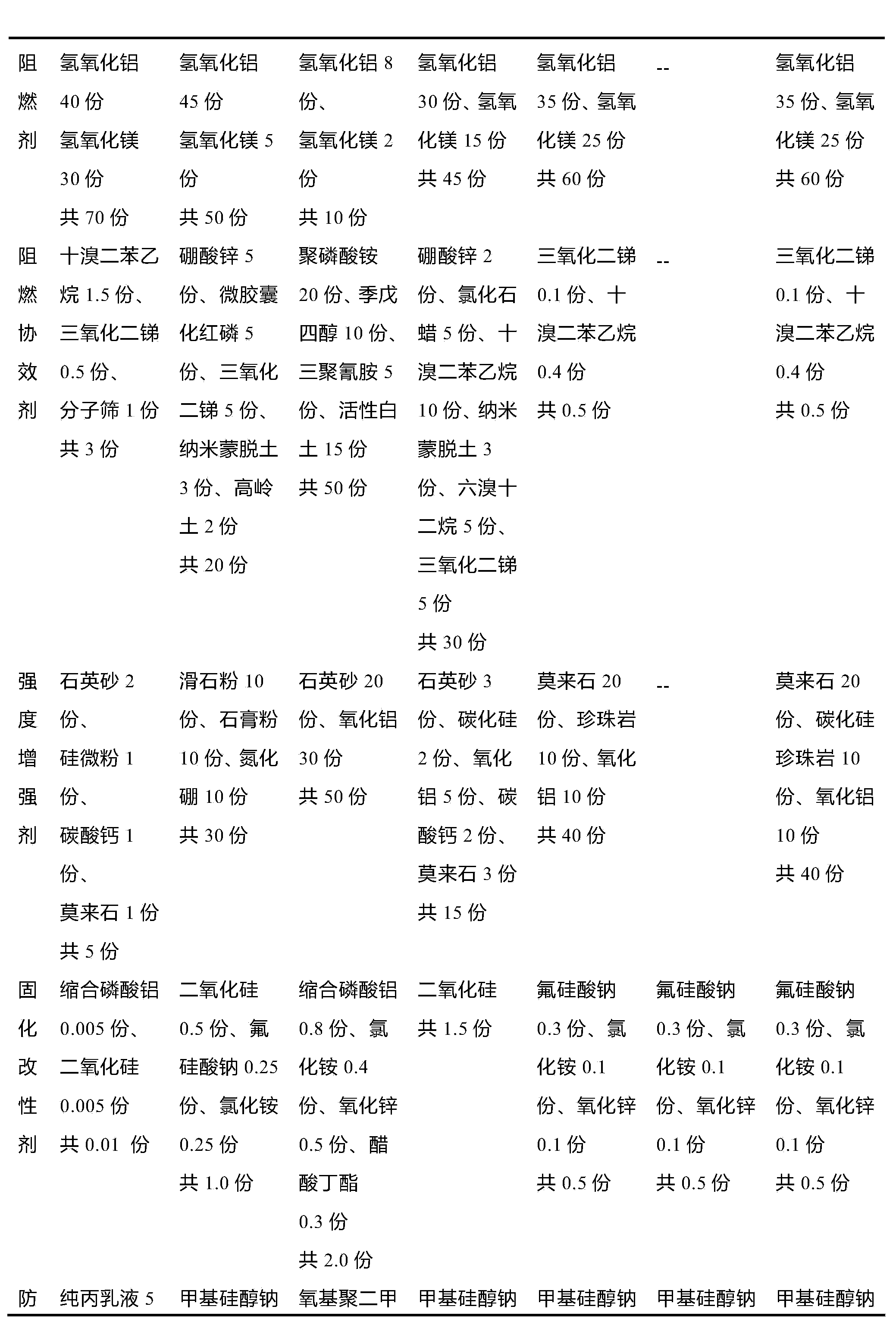

Fire-proof adhesive and application thereof

ActiveCN104099028AReduce total calorific valueImprove thermal conductivityNon-macromolecular adhesive additivesMacromolecular adhesive additivesCombustionAdhesive

The invention discloses a fire-proof adhesive and application thereof. The fire-proof adhesive comprises the following components by parts: 100 parts of high-temperature bonding agent, 10-70 parts of fire retardant, 0.5-50 parts of flame retardant synergist, 5-50 parts of strength enhancer, 0.05-20.0 parts of water-proof modifying agent and 0.01-2.0 parts of curing modifying agent. By adopting the fire-proof adhesive and a preparation method of a fire-retardant EPS (Expandable Polystyrene) foam heat-insulating plate, the combustion performance and physicochemical performance of the fire-retardant EPS foam heat-insulating plate can be improved remarkably. For example, the heat-conducting coefficient can be lowered below 0.055w / m.k, the specific gravity can be lower than 150Kg / M<3>, the compressive strength is higher than 150KPa, and the heat value is less than 3MJ / kg.

Owner:应急管理部四川消防研究所

Plane wing titanium alloy thin-wall web efficient numerical control machining technology

A plane wing titanium alloy thin-wall web efficient numerical control machining technology comprises the following steps that (1) blanking is carried out; (2) web outer contour machining is carried out, and an ear piece for locating is machined; (3) a web is clamped, and a cavity on the front face of the web is machined; (4) a web side wall is machined; (5) web quick converting is carried out, and a cavity on the back face of the web is machined; (6) the locating ear piece is removed by milling; and (7) quality testing is carried out. The rigidity of a machining technology system is improved, unstressed machining is achieved, by optimized design of a feed track, the stability of a machining process is improved, machining speed is increased, titanium alloy shallow cutting large feeding milling technology parameters are used, heat deforming during machining is lowered, rectifying processes are omitted, the metal removing rate is improved by 30%-50%, finally, machining efficiency is obviously improved, the clamping time of workpieces is obviously shortened through a quick-reloading technology, the repeated locating accuracy of clamping is guaranteed, and accordingly numerically-controlled machine tool machining efficiency is greatly improved.

Owner:HUANGHE S & T COLLEGE

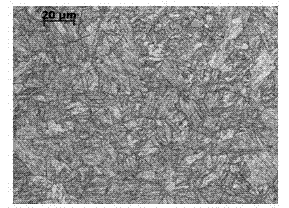

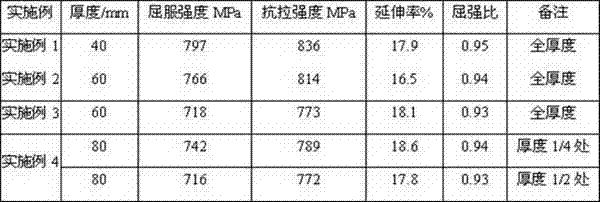

Superhigh-strength high-toughness steel plate for ocean engineering and production method thereof

The invention discloses a superhigh-strength high-toughness steel plate for ocean engineering and a manufacturing method thereof. The superhigh-strength high-toughness steel plate comprises the following chemical components in percentage by weight: 0.06-0.10% of C, 0.20-0.40% of Si, 1.10-1.65% of Mn, at most 0.010% of P, at most 0.0020% of S, 0.030-0.050% of Nb, 0.020-0.060% of V, 0.006-0.015% of Ti, 0.60-1.30% of Ni, 0.30-0.60% of Cr, 0.20-0.60% of Cu, 0.40-0.60% of Mo, 0.020-0.040% of Alt, and the balance of Fe and inevitable impurities. The production method comprises the following steps: smelting in a converter, rolling on a Steckel reversing mill, and finally carrying out hardening and tempering heat treatment by a TMCP (thermomechanical rolling process) technique. The steel plate has favorable properties: the tensile strength is 770-840 MPa, the yield strength is 710-800 MPa, the elongation percentage is 16-19%, the -40 DEG C low-temperature lateral impact and low-temperature ageing impact properties are greater than or equal to 90J, and the cold bending resistance is qualified; and thus, the steel plate has the advantages of ultrahigh strength, excellent low-temperature impact and low-temperature ageing impact properties, and stable production technique.

Owner:NANJING IRON & STEEL CO LTD

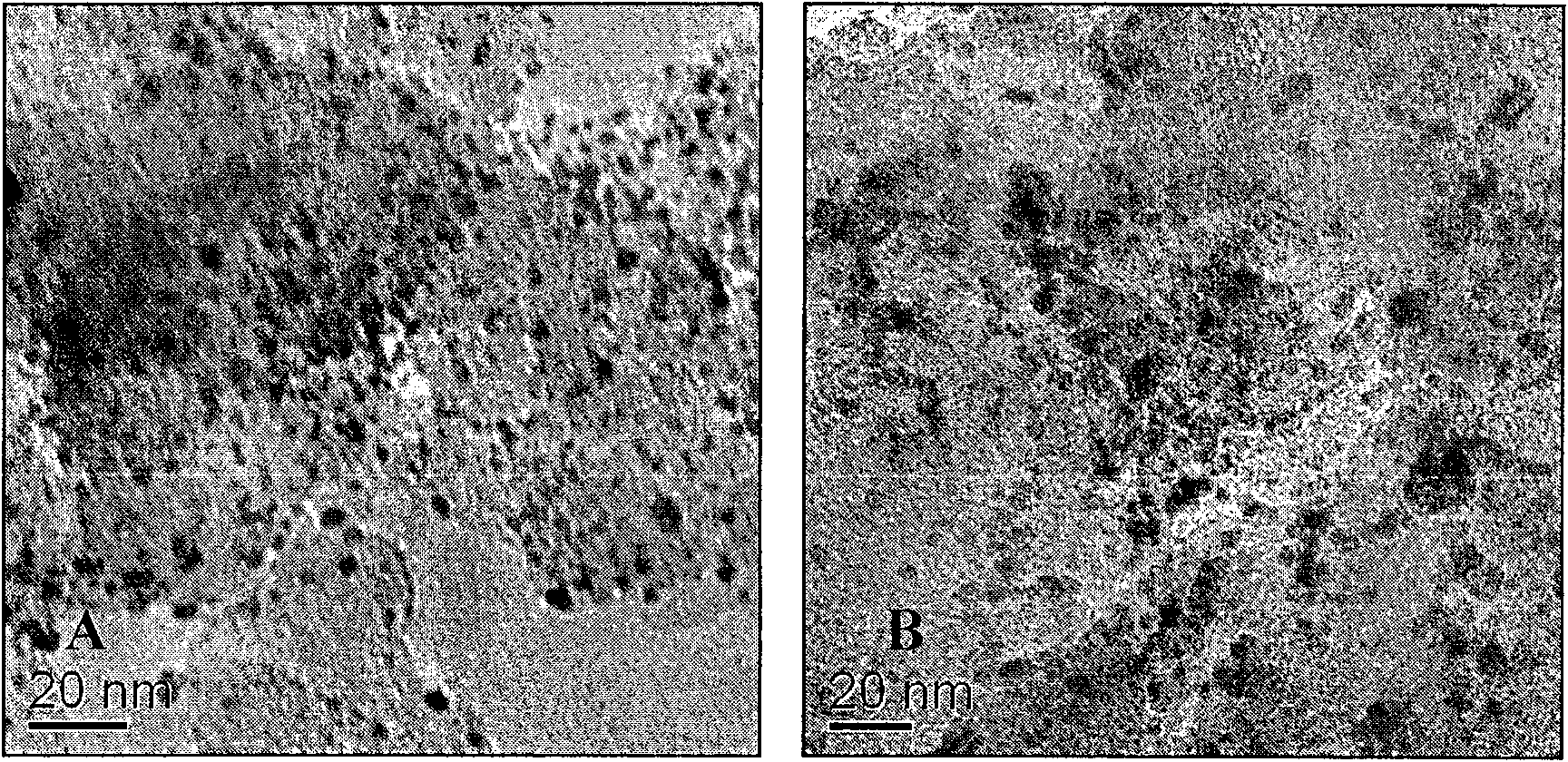

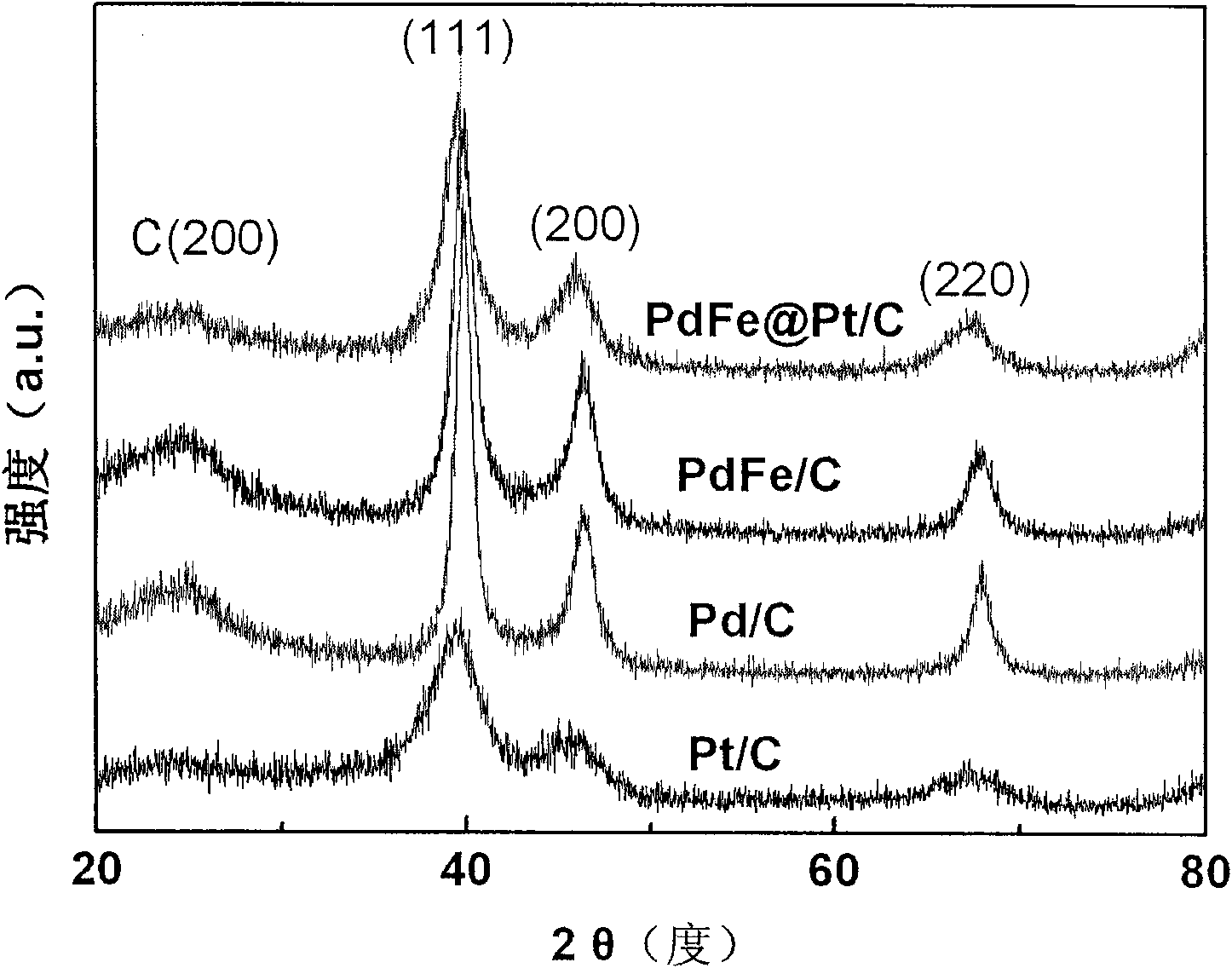

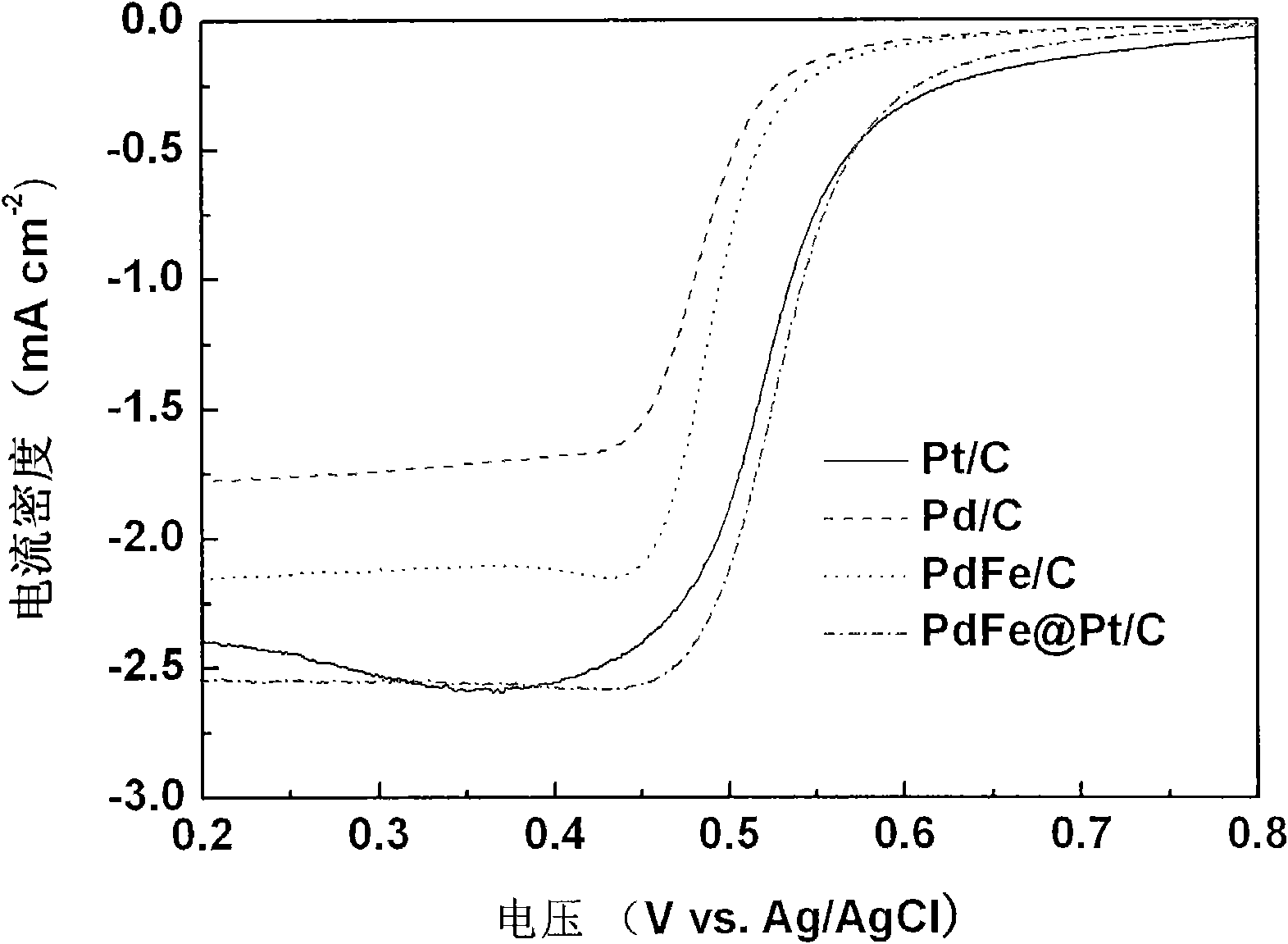

Low-platinum high active core-shell structure catalyst and preparation method thereof

InactiveCN101664685AAddress performance and costSimple preparation processCell electrodesCatalyst activation/preparationChemistryCarbon nanotube

The invention provides a high active core-shell structure catalyst used for low temperature fuel cell. The preparation method comprises the following steps: adopting carbon powder or carbon nanotubesas carrier, coating single-layer or two-layer platinum which is reduced by reductant, on the metal-based core to form a core-shell structure and loading the structure on carbon powder or carbon nanotubes carrier. The catalyst has low platinum loading and high catalytic activity so that platinum loading is low, the activity of the catalyst is high; the contradiction between the cost and performanceof catalyst is effectively solved, and the high active core-shell structure catalyst plays an extremely important role in solving the current problems of the fuel cell.

Owner:NORTHWEST NORMAL UNIVERSITY

Preparation method of hollow-structure metal or ceramic part

InactiveCN102351542AShort cycleShorten the production cycleCeramic shaping apparatusAdhesiveCo injection

The invention relates to a preparation method of a hollow-structure metal or ceramic part, which comprises the following steps: selecting metal or ceramic powder as the raw material, mixing, and granulating to obtain a feed material; selecting a core material; injecting the core material into a die by co-injection molding to obtain a core in hollow shape, and injecting the metal or ceramic feed material to be completely coated on the core, thereby obtaining a green body; and carrying out solvent extraction and heating on the green body to remove the adhesive and core, and sintering to obtain the hollow-structure product. The invention implements one-step molding of the hollow metal or ceramic part; from the raw material to the product, the production cycle is short, and the automation degree of equipment is high, thereby greatly enhancing the efficiency and forming a randomly complex and completely hollow die cavity; and thus, the invention can be used for preparing a completely hollow part with no joint, greatly lowers the cost of the product, and is especially suitable for preparing hollow metal and ceramic parts.

Owner:CENT SOUTH UNIV

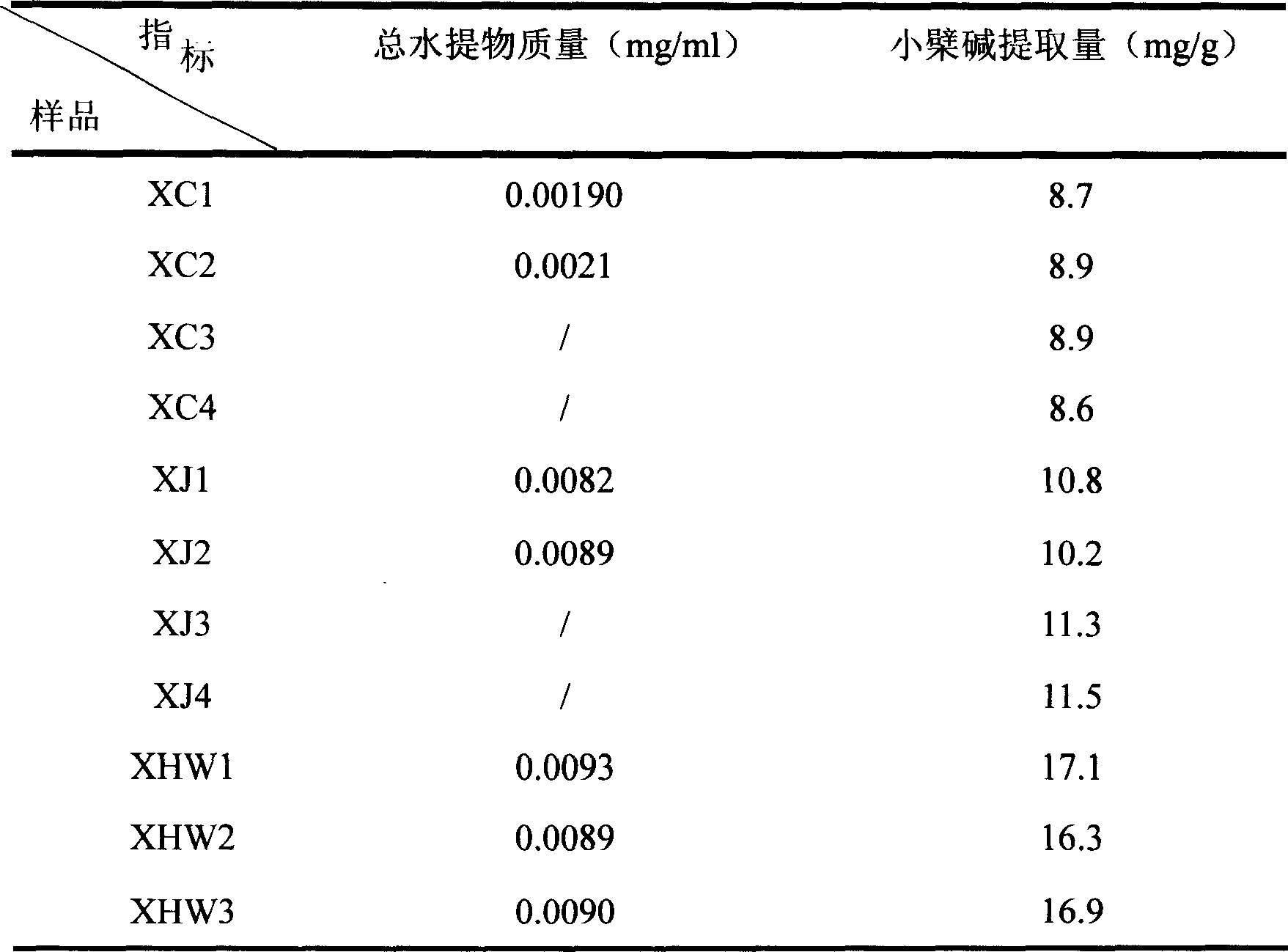

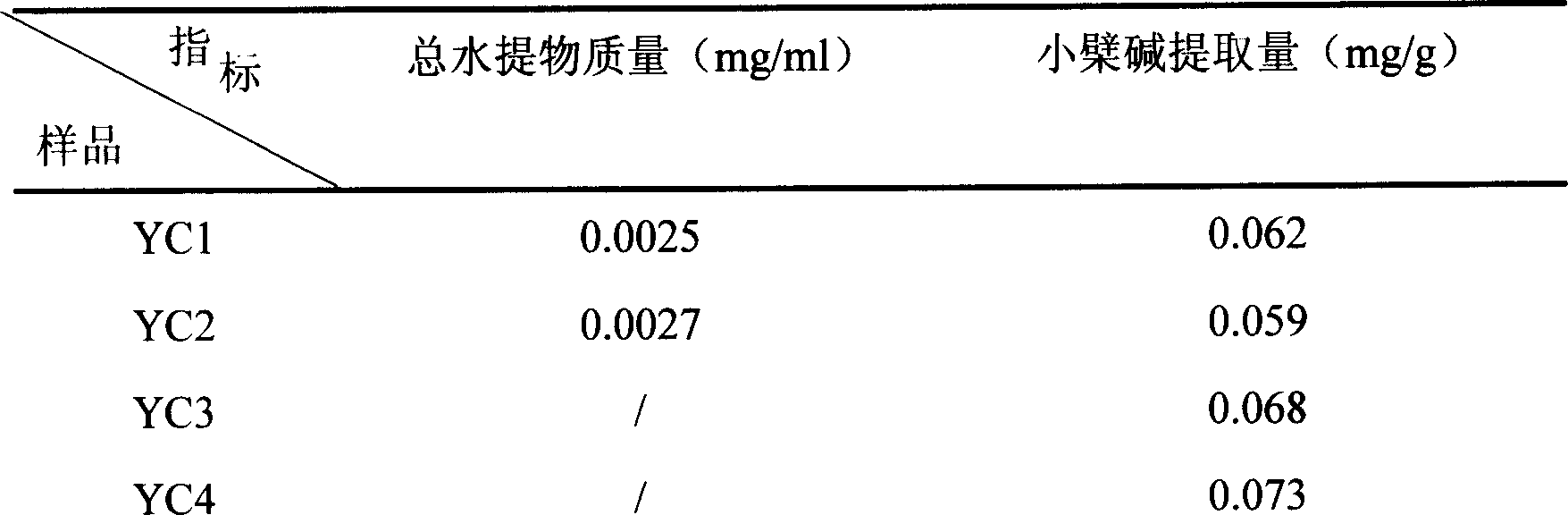

Effective plant component extracting process

InactiveCN1986029AChange microscopic propertiesEasy extractionSolid solvent extractionOrganic solventAlcohol

The effective plant component extracting process includes mechanically crushing the mixture of solid plant material and proper amount of chemical assistant, and the subsequent extraction of the effective component with water or alcohol. The mechanical crushing can produce micro shearing strain in the interface, break cell wall, expose fresh cut surface and produce mutual adsorption and other action between the grain clusters and molecular groups of the chemical assistant and the effective component, so as to alter the microscopic performance of the effective plant component, raise the leached amount by 80-400 %, short the extracting period greatly, raise the extracting efficiency obviously raise the extraction specificity and selectivity, minimize the organic solvent in use, lower the extraction cost and raise the bioavailability of the extracted matter.

Owner:DALIAN SEM BIOLOGICAL ENG TECH

Yield strength 700MPa grade atmospheric corrosion resistant steel and method for manufacturing same

ActiveCN101135029AImprove mechanical propertiesSuitable for thin designTemperature control deviceHeat treatment process controlSheet steelWeather resistance

The atmospheric corrosion resistant steel with yield strength of 700 MPa level has the chemical composition comprising C 0.05-0.10 wt%, Si not more than 0.50 wt%, Mn 0.8-1.6 wt%, P not more than 0.020 wt%, S not more than 0.010 wt%, Al 0.01-0.05 wt%, Cu 0.20-0.55 wt%, Cr 0.40-0.80 wt%, Ni 0.12-0.40 wt%, Ca 0.001-0.006 wt%, N 0.001-0.006 wt% and Fe and inevitable impurity for the rest. Its production process includes the following steps: 1. smelting and casting to form steel billet; 2. heating the steel billet to over 1200 deg.c, finish rolling at 950 deg.c in the final temperature lower than 910 deg.c and lowered with the increased plate thickness; and 3. cooling in the rate of 5-15 deg / s to 450-650 deg.c, winding and air cooling to room temperature. The atmospheric corrosion resistant steel has excellent comprehensive mechanical performance, yield strength over 700 MPa, high weather resistance and other advantages.

Owner:BAOSHAN IRON & STEEL CO LTD

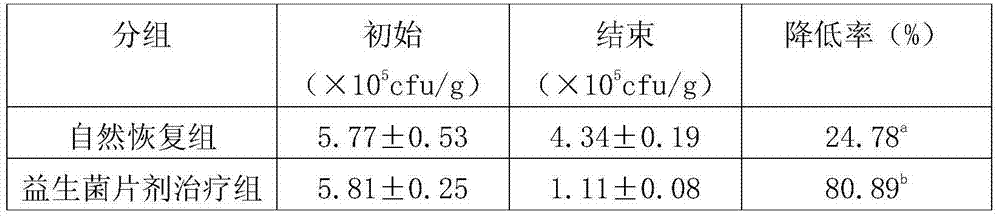

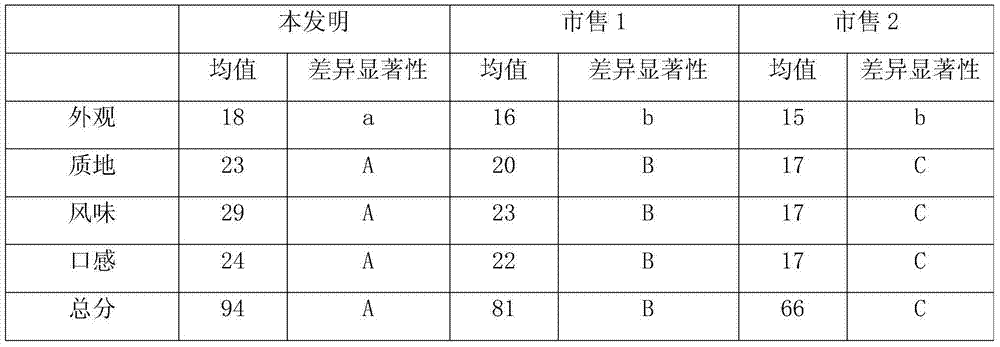

Fruit and vegetable probiotic tablet and preparation method thereof

ActiveCN104489646AHigh survival rate of live bacteriaImprove stabilityNatural extract food ingredientsFood ingredient functionsCelluloseDrug biological activity

The present invention discloses a fruit and vegetable probiotic tablet and a preparation method thereof. The fruit and vegetable probiotic tablet uses probiotic powders such as lactobacillus plantarum powder as the main raw material, and the preparation method scientifically mixes modified dietary fibers, fruit and vegetable powder, oligosaccharides, plant extracts, protein powder, tea leaf extracts and traditional Chinese medicine extracts and etc., thus improves the content of soluble celluloses which are of real significance for probiotic flora, enhances the physiological activity of celluloses, thereby increases the species of intestinal probiotic flora as well as significantly enhances the colonization ability and time of endogenous and exogenous probiotics in the human intestinal tracts, effectively inhibits the growth and reproduction of harmful intestinal bacteria, especially gram-negative bacteria, and fully regulates the composition of the intestinal probiotic flora. The prepared fruit and vegetable probiotic tablet has a high biological activity, a long human intestinal colonization time, and a significant weight loss effect, and is suitable for a wide range of people.

Owner:南京旭优食品技术有限公司

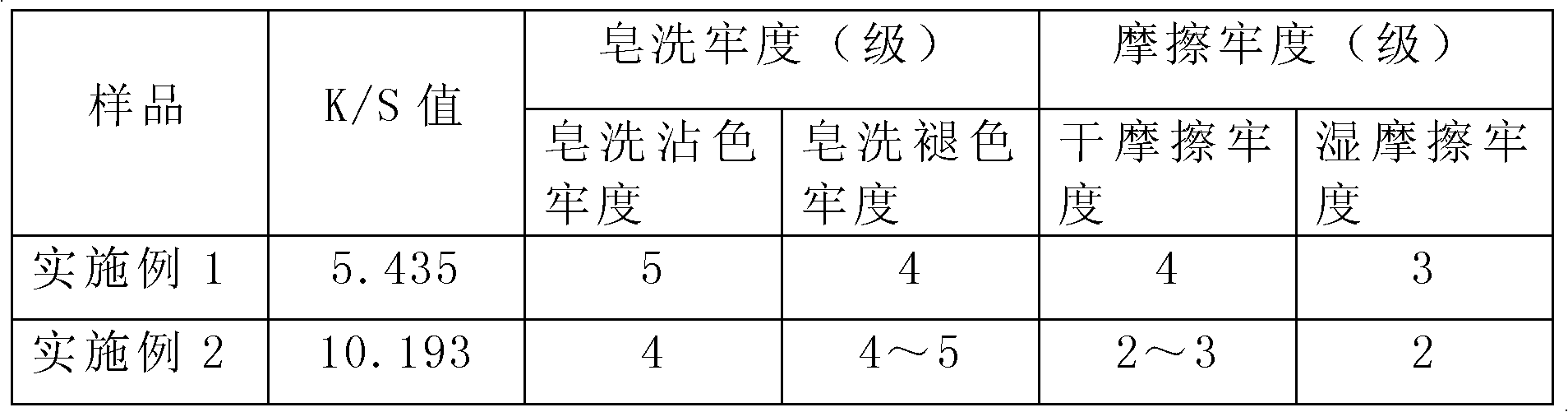

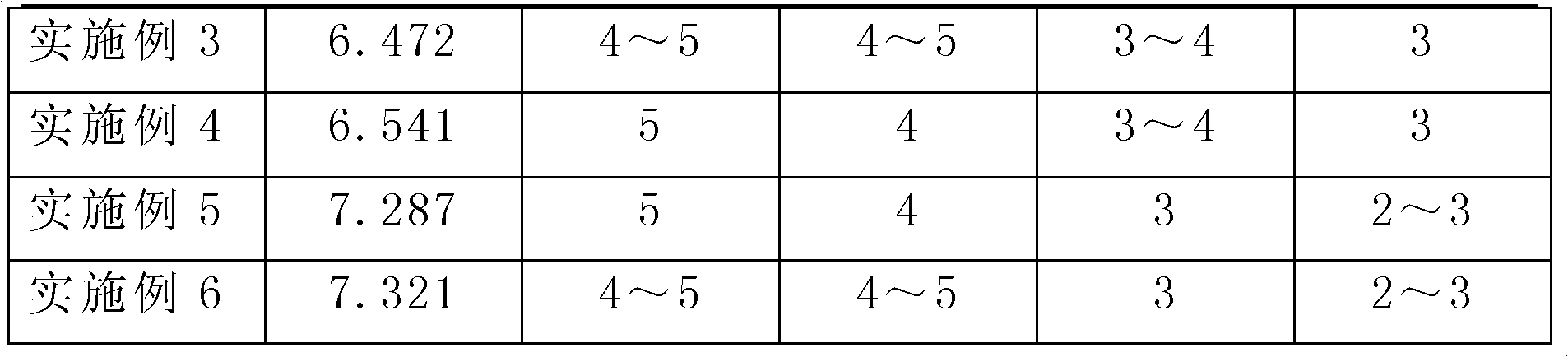

Method of dyeing fabric by using dye

ActiveCN102535194ASoft touchImprove washing fastnessBiochemical fibre treatmentDry-cleaning apparatus for textilesTextile printerEngineering

The invention provides a method for dyeing fabric by using a dye, belonging to the technical field of textile printing and dyeing and aiming to the solve the problems of complex process, low dyeing rate, poor dyeing uniformity and poor color fastness and hand feel of dyed fabric of the existing method for dyeing the fabric by using the dye. The method comprises the following steps of: desizing the fabric, scouring, bleaching and mercerizing; adding the dye, a cationic modifier, a leveling agent, a dispersant, an alkaline reagent and a wet rubbing fastness enhancer to water, and mixing uniformly to prepare a dyeing solution; soaking the fabric into the dyeing solution, and controlling temperature and liquor ratio to dye; steaming the dyed fabric for colour fixation, washing by water and drying to finish dyeing the fabric by using the dye. The method for dyeing the fabric by using the dye is simple, ensures the high dyeing rate and the uniform dyeing, and ensures that the dyed fabric has good washing fastness and rubbing fastness and a soft feel.

Owner:台州东海翔染整有限公司

Thick steel plate for low temperature use and capable of being welded in superhigh energy and its production process

ActiveCN101045976AImprove low temperature toughnessHigh strengthTemperature control deviceHeat treatment process controlSteel platesCrystallite

The thick steel plate for low temperature use and capable of being welded in superhigh energy has the material comprising C 0.030-0.050 wt%, Si not more than 0.2 wt%, Mn 1.50-1.80 wt%, P not more than 0.01 wt%, S not more than 0.002 wt%, Nb 0.010-0.020 wt%, Als 0.040-0.060 wt%, Ti 0.008-0.012 wt%, N not more than 0.0035 wt%, Ca 0.001-0.005 wt%, B 0.001-0.003 wt%, and Fe and inevitable impurity for the rest, with Pcm not more than 0.18 wt%. The present invention has low alloy steel as basis, properly raised Als content, C / Mn ratio of 0.020-0.050, Ti-B microalloying, Ca or REM treatment, Ti / N ratio of 3.0-3.5, optimized TMCP treatment, microscopic structure comprising small amount of ferrite and diffused bainite crystal of average crystal grain size below 15 micron, excellent mechanical performance and welding performance, and is especially suitable for being used as high strength ship deck, low temperature pressure container, offshore platform, etc.

Owner:BAOSHAN IRON & STEEL CO LTD

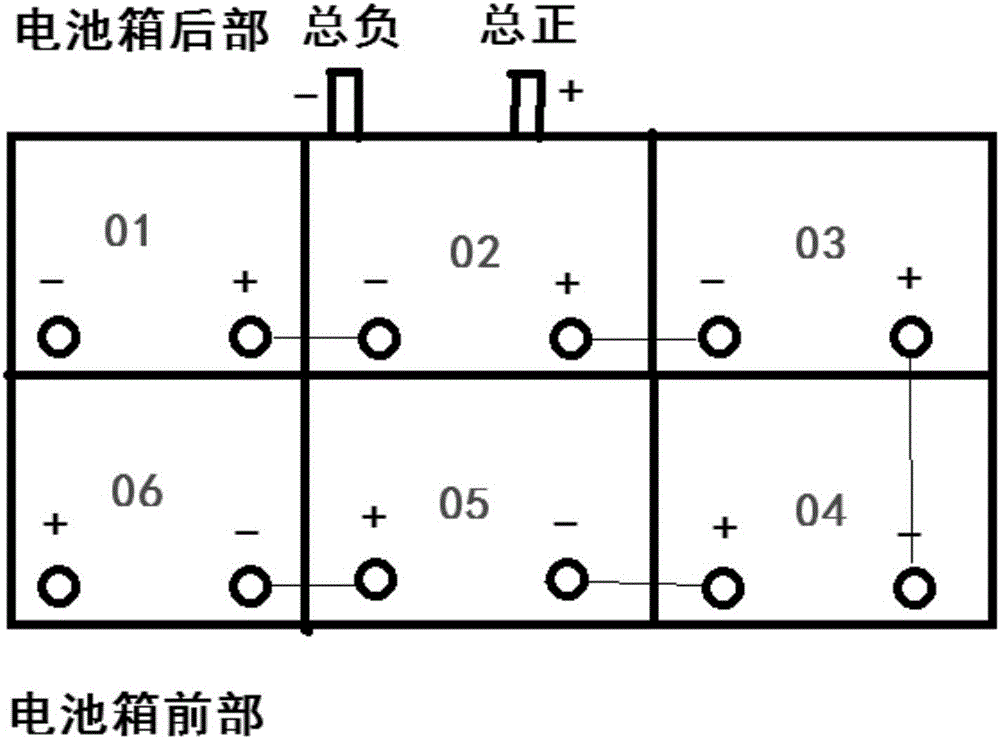

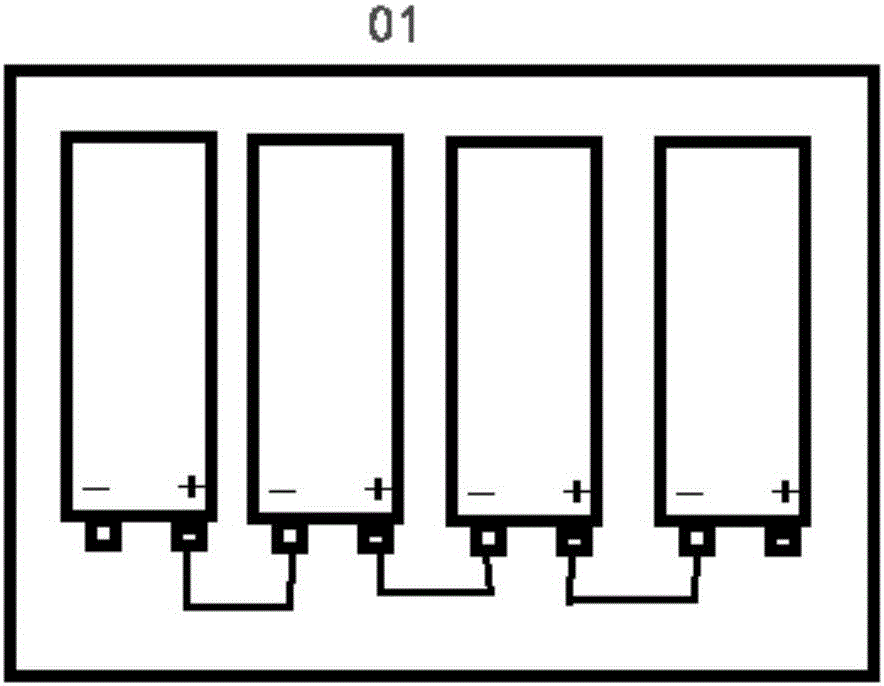

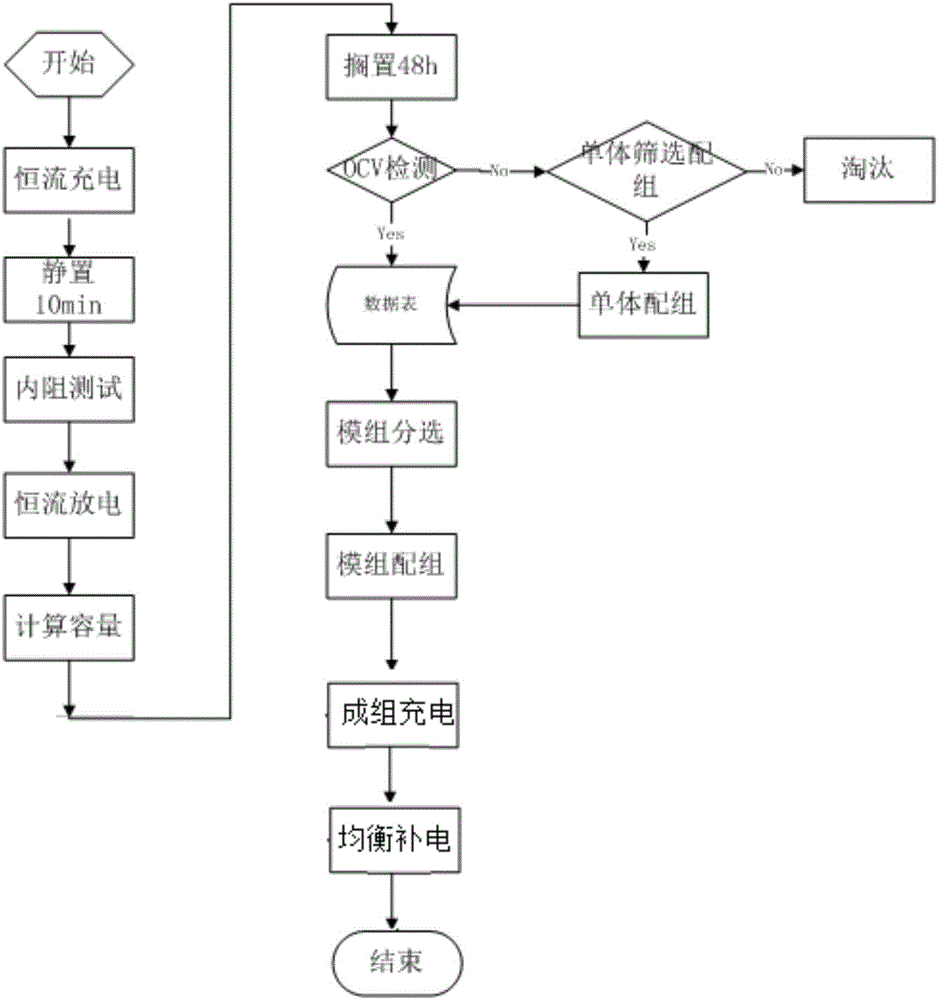

Recycling detection, screening and matching method and device for battery module

ActiveCN106785178AImprove consistencyShorten the production cycleFinal product manufactureElectrical testingPower batteryInternal resistance

The invention relates to recycling detection, screening and matching method and device for battery modules. The method comprises the steps of carrying out charge and discharge performance testing on retired battery modules after standing by taking the battery modules as the maximum screening units to obtain maximum voltage and minimum voltage of single batteries; and when an absolute value of a difference value between the maximum voltage and minimum voltage is smaller than a set voltage difference threshold, judging that the retired battery modules can be recycled and carrying out matching according to the internal resistance and the capacity of the battery modules. The consistency of the single batteries is considered, the retired power battery modules are not split into single batteries for screening and matching, the battery modules are taken as objects for screening and matching, and the battery modules with good consistency of the single batteries are matched through judging open-circuit voltage of the single batteries. The work difficulty of cascade utilization of the matched batteries is greatly simplified, and the screened and matched power battery packs are short in production cycle, relatively high in consistency and low in manufacturing cost.

Owner:XJ POWER CO LTD +4

Method for welding thin steel plate

InactiveCN101745718AAvoid deformationShort production cycleArc welding apparatusSteel platesSheet steel

The invention discloses a method for welding a thin steel plate. The method is characterized by comprising the following steps: preparing before welding, namely flattening the plate before assembly to flatten the surface of the plate; flattening a profile before assembly; and machining edge-board blanking by adopting an edge planer or cutting the blanking by plasma to ensure uniform assembly clearance. During arc welding of the jointed plate, the assembly clearance is less than 0.5 millimeters; the misalignment edge e of the plate edge is less than 0.15t, and the nonuniform or out-of-tolerance local clearance is polished or cut to be smooth without deformation due to the adoption of oxy-acetylene cutting, wherein the t is less than or equal to 8 millimeters; the three parts of positioned welding and welding are reasonably designed, so the welding of the thin steel plate has a complete system; therefore, the method can effectively prevent the thin steel plate of a ship deck from deforming during welding, and achieves the targets of short production period and good thin plate welding quality.

Owner:浙江东海岸船业有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com