Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

3449results about "Discharging arrangement" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

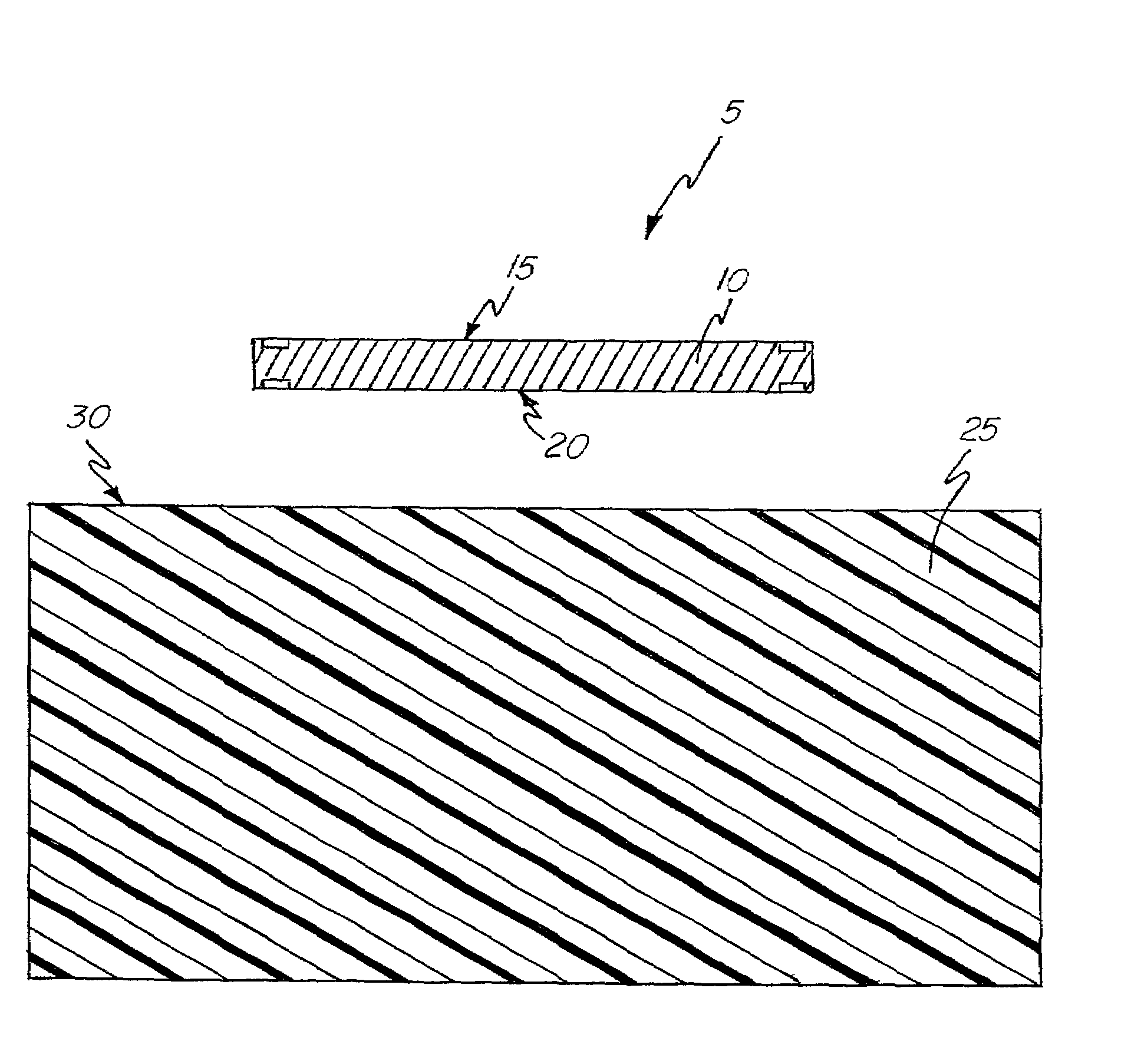

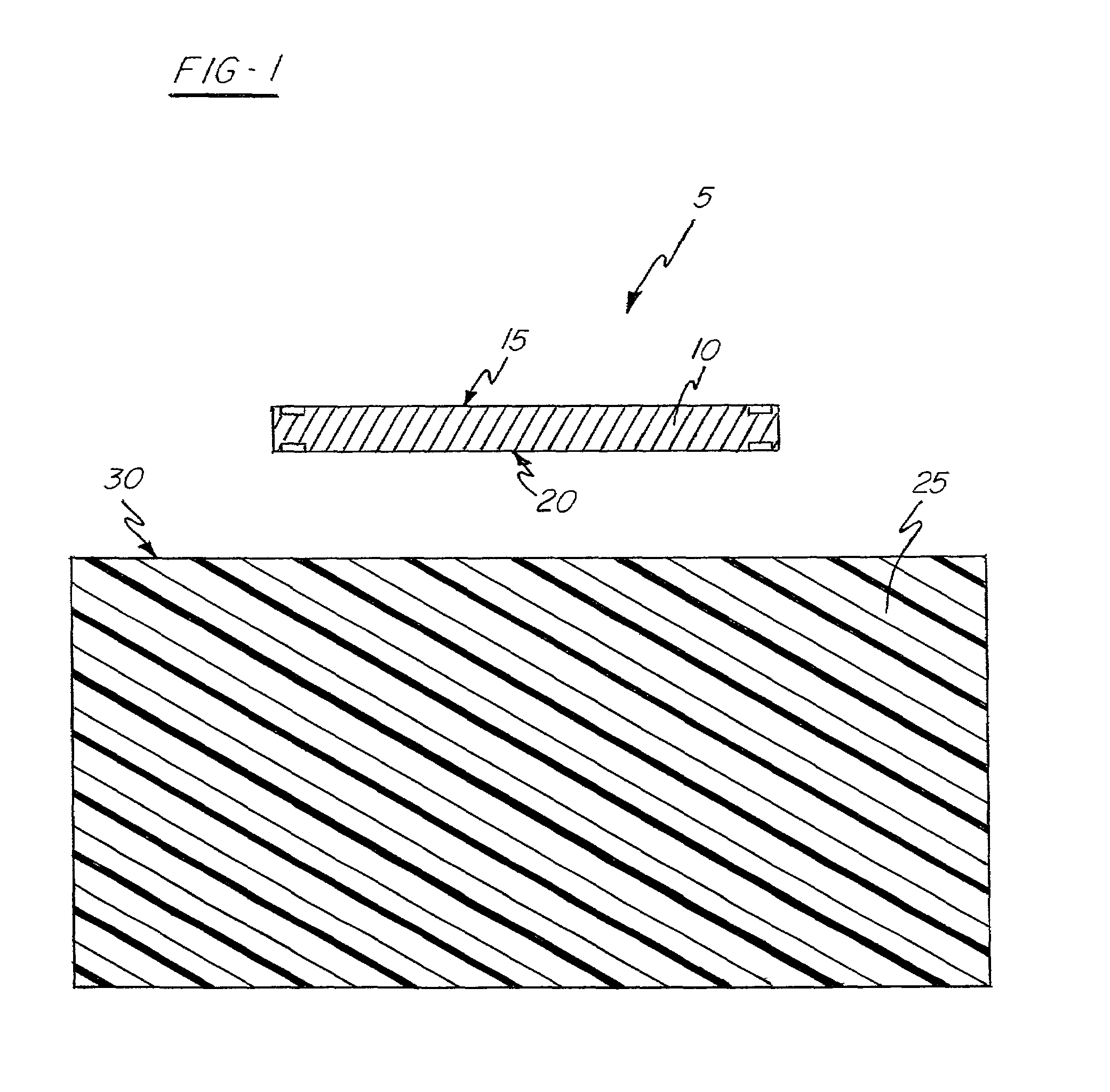

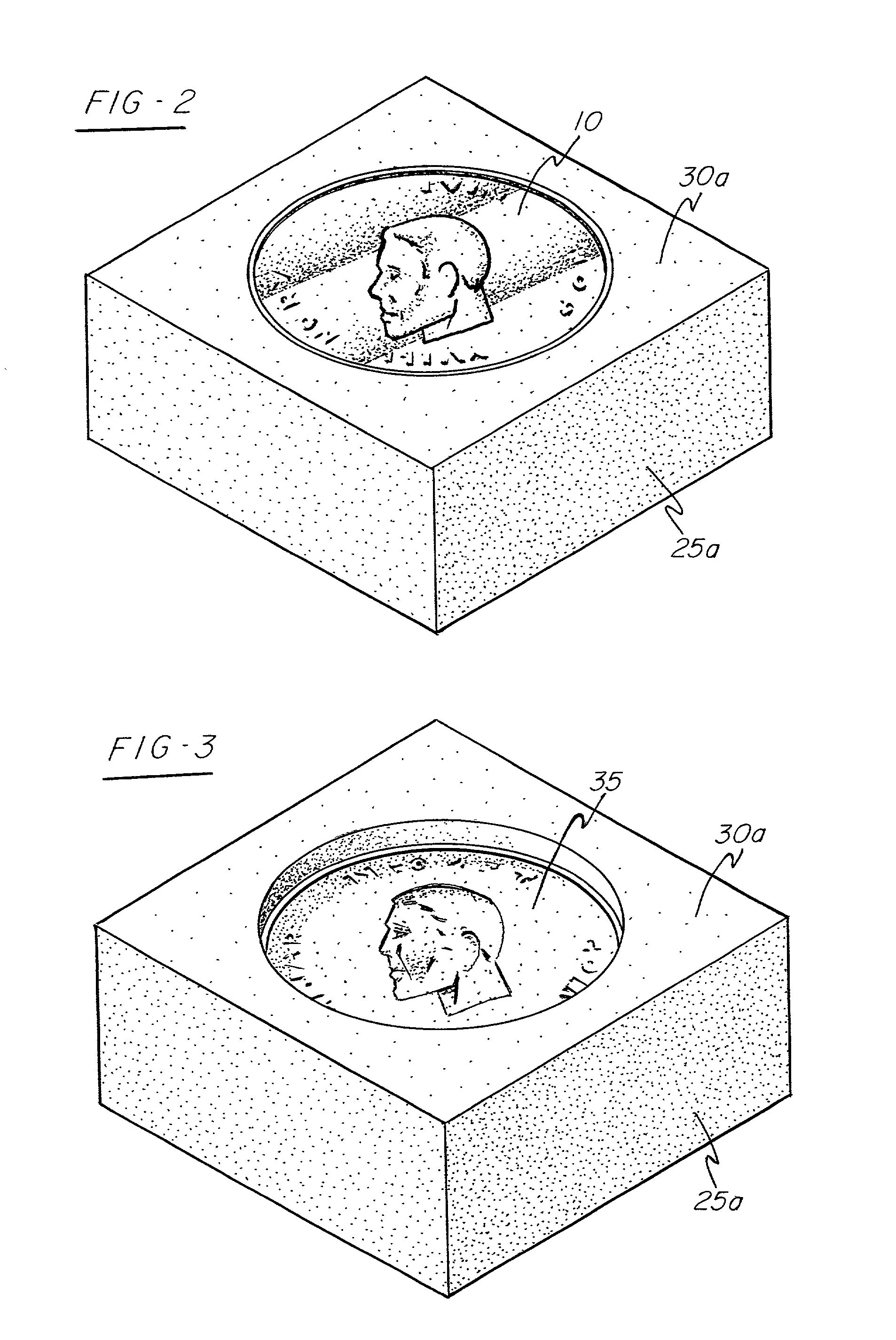

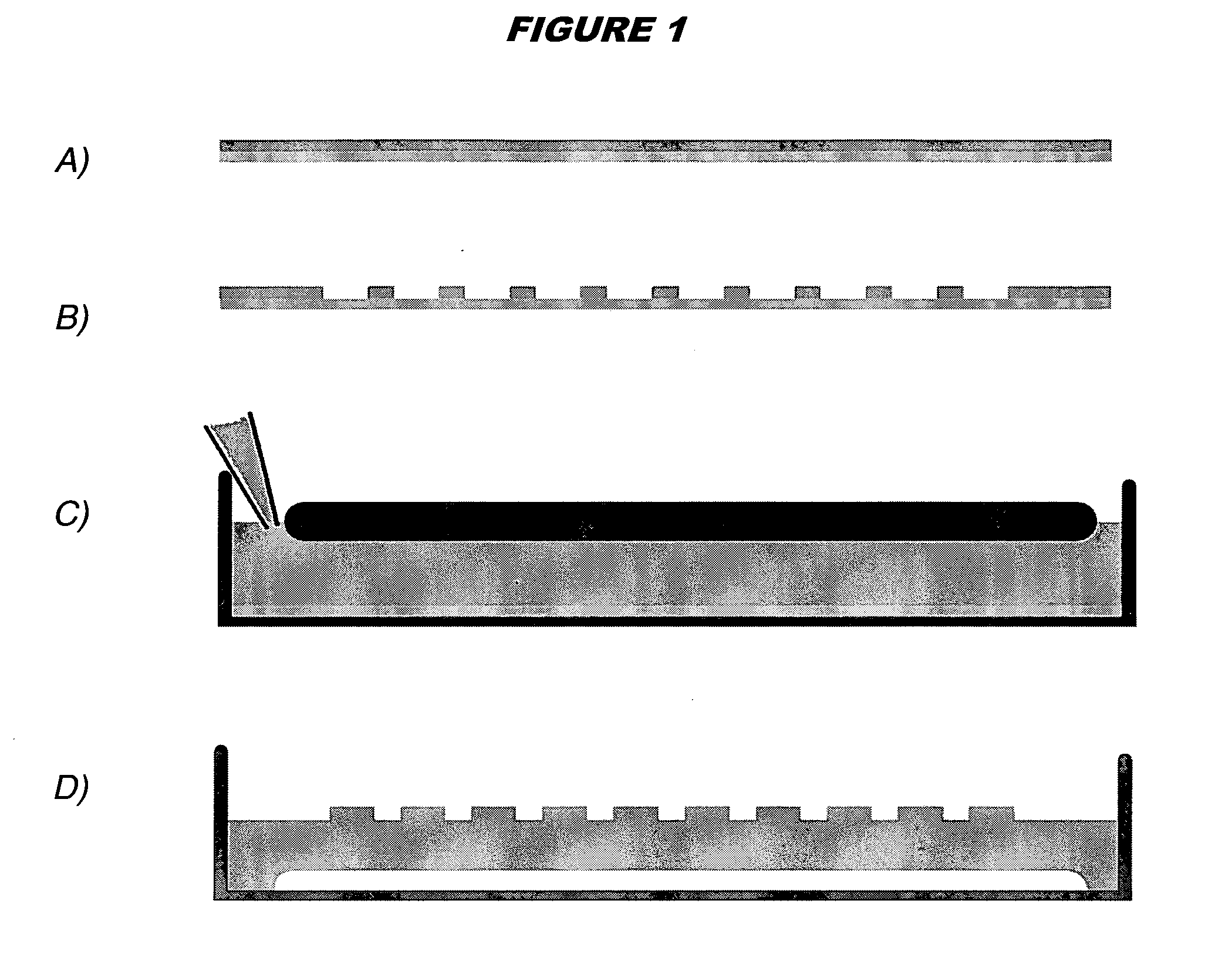

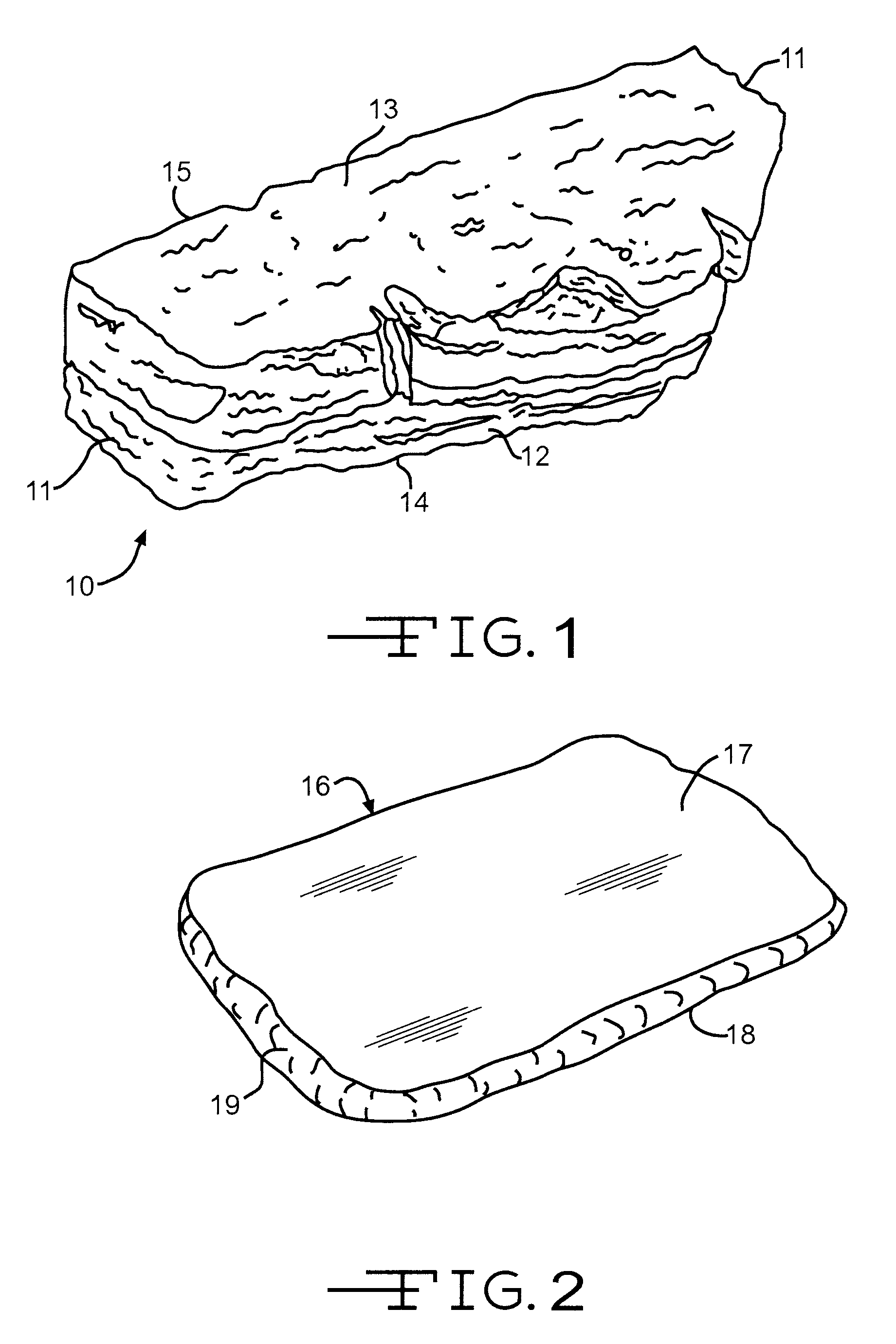

Structural and optical applications for shape memory polymers (SMP)

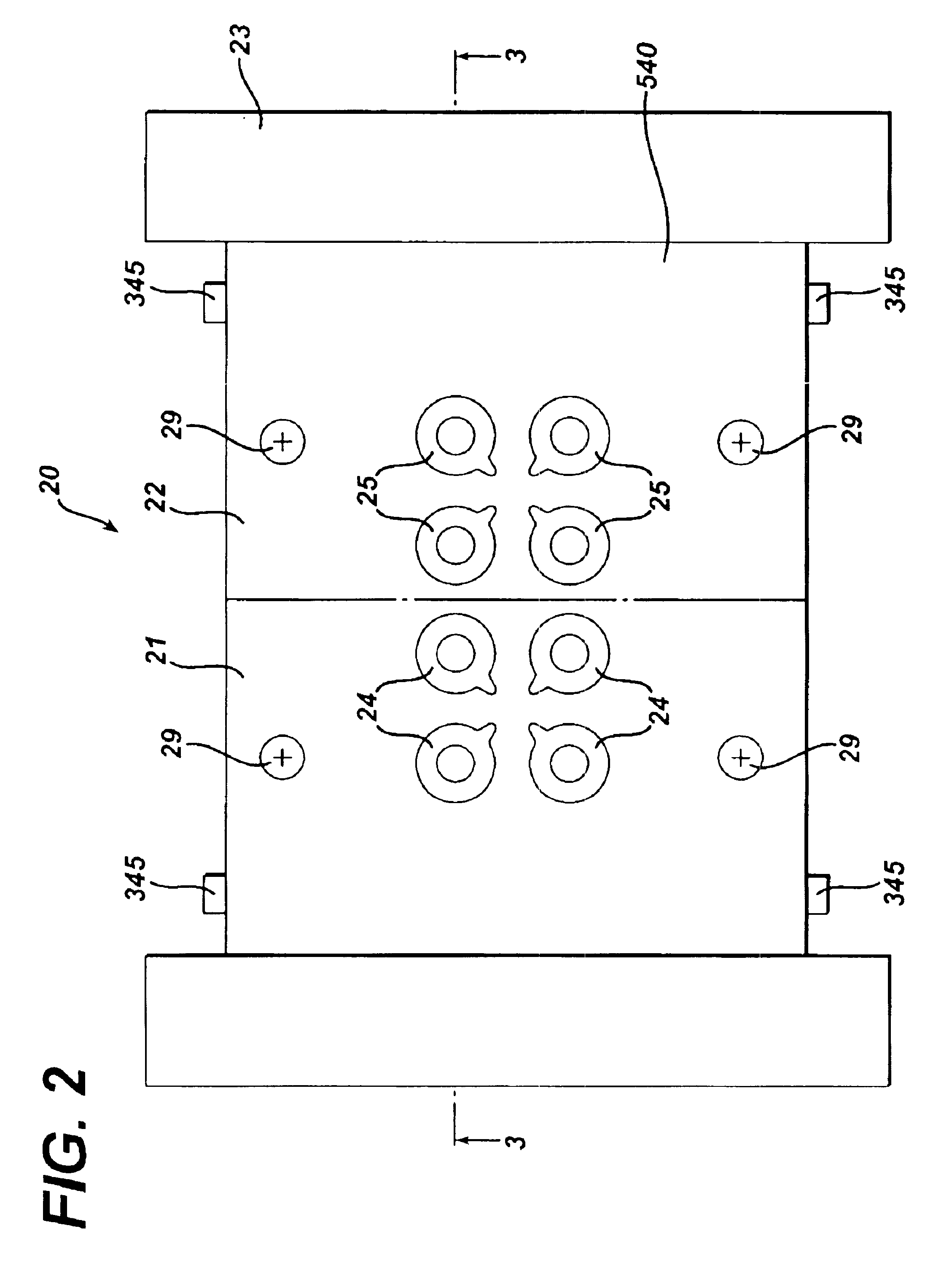

InactiveUS6986855B1Easy to processReduce handling costsDischarging arrangementMouldsVisual inspectionUltraviolet

The methods of manufacturing molds from shape memory materials and molds made thereby, in accordance with the present invention, provide numerous advantages for molding castable composite parts. The initial mold cost is low enough to accommodate economical production of as few as a single part incorporating high surface definition and intricate three dimensional detail. The preferred methods and molds made thereby are transparent, thereby, curing of the corresponding part by ultra-violet and infra-red light is made possible, as well as, visual inspection during injection and curing of the given resin. Removal of the cured part from within the mold is simplified.

Owner:SPINTECH LLC

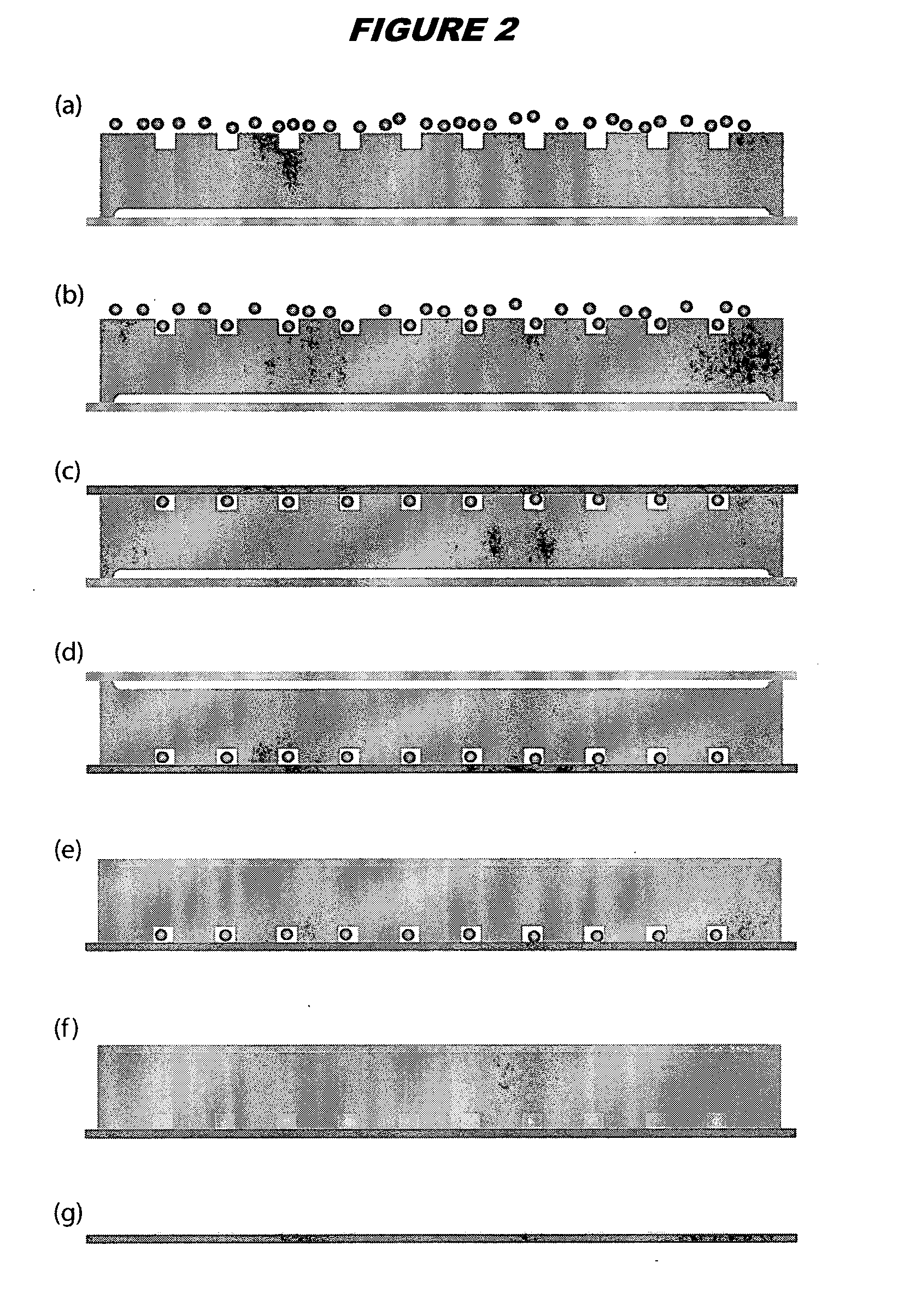

Picowell capture devices for analysing single cells or other particles

InactiveUS20120156675A1Easy to adaptCompared rapidly and convenientlyBioreactor/fermenter combinationsBiological substance pretreatmentsIndividual analysisBiopolymer

Owner:OXFORD GENE TECH IP

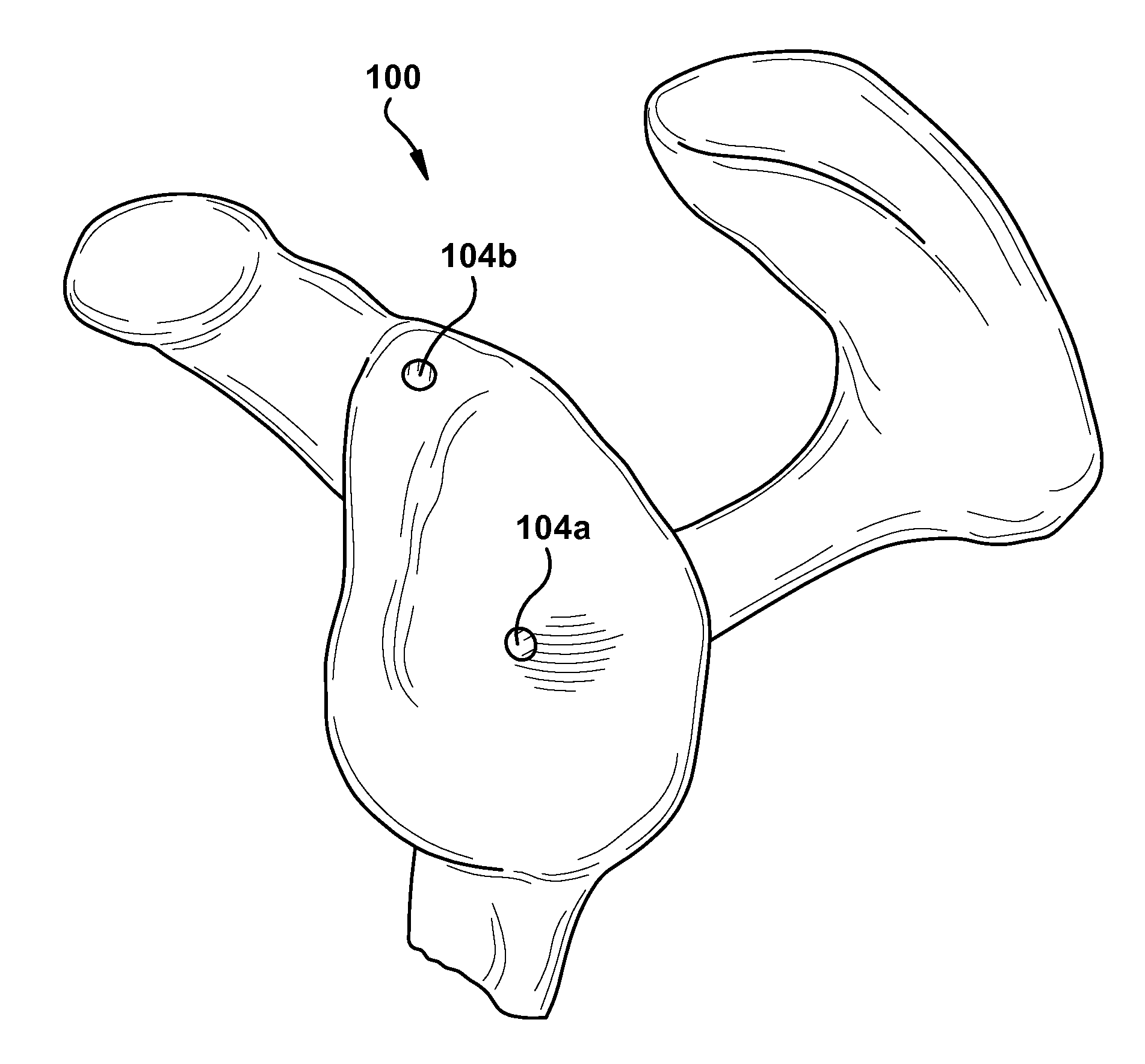

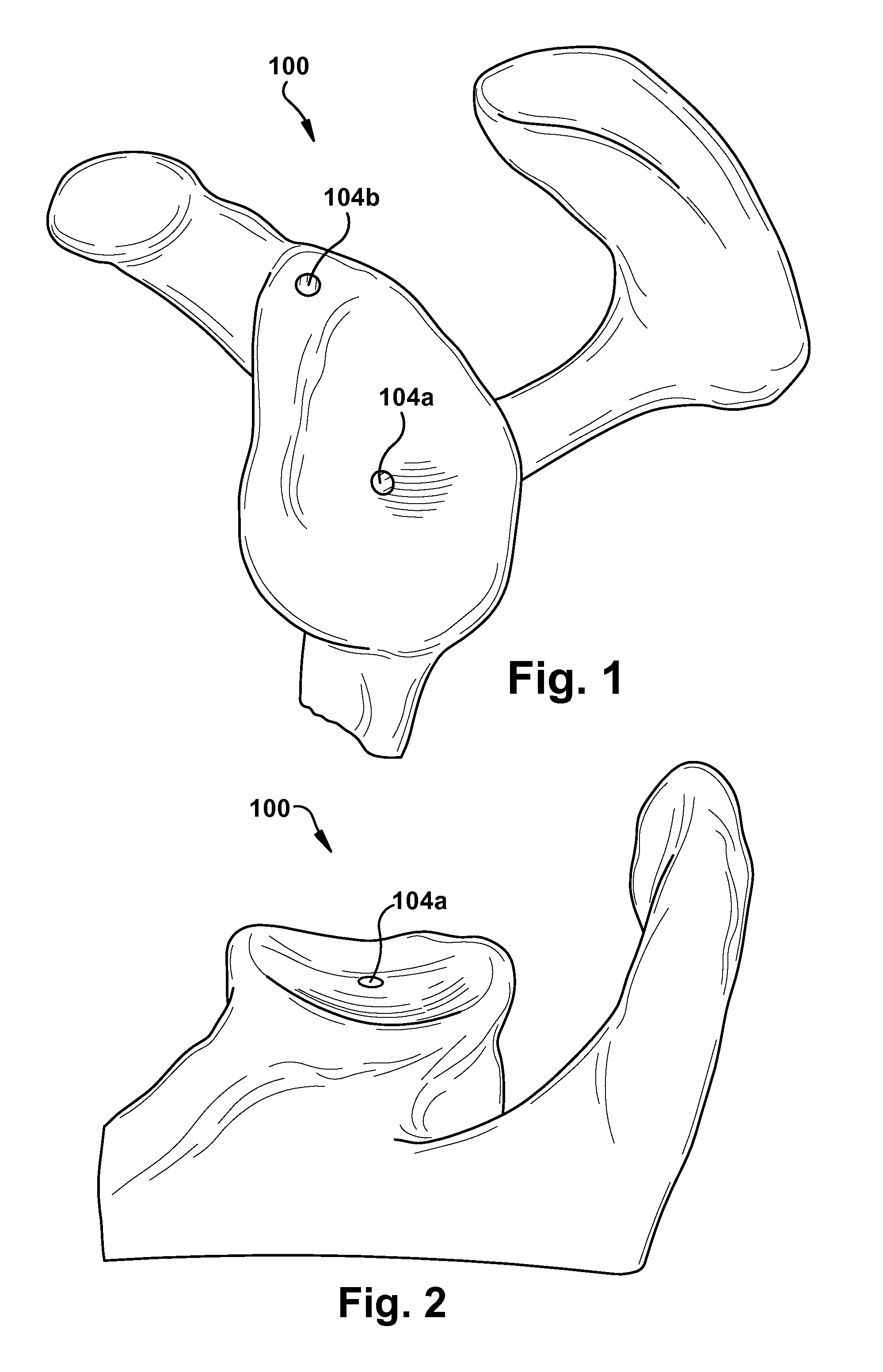

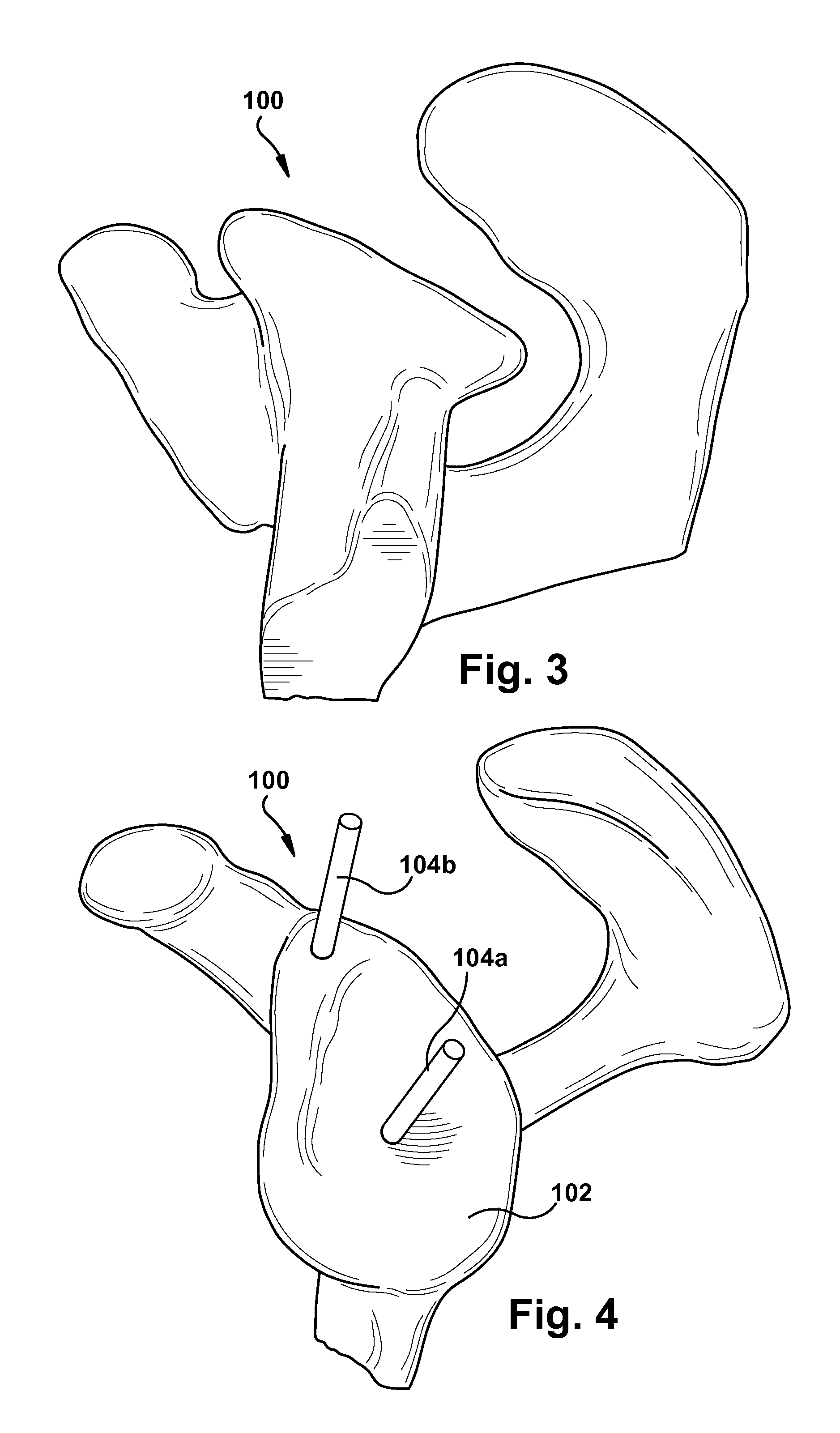

Method and system for producing at least one patient-specific surgical aid

InactiveUS20130119579A1Additive manufacturing apparatusDischarging arrangementTarget surfacePhysical model

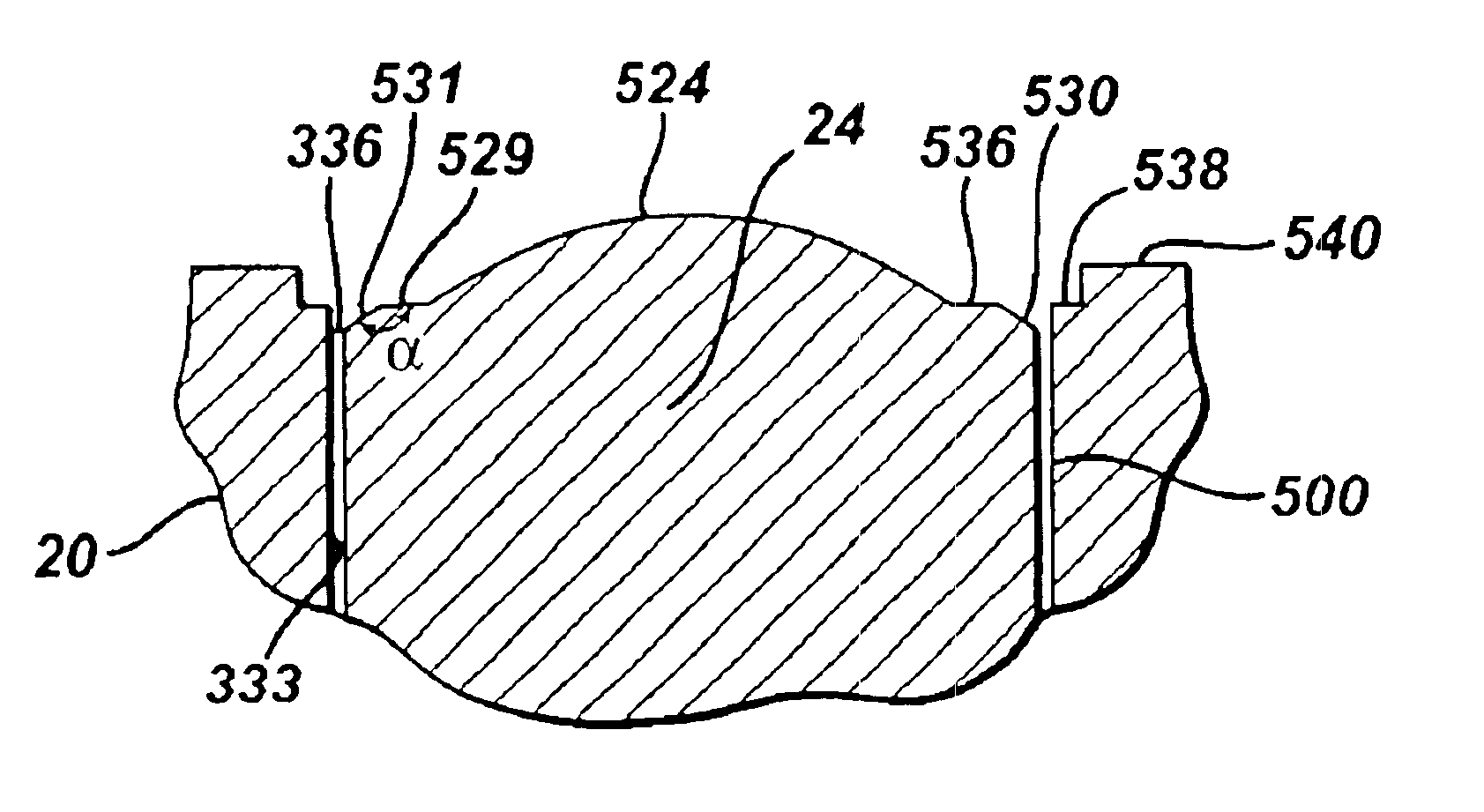

A method for producing at least one patient-specific surgical aid includes providing a physical model of a native patient tissue. The physical model has at least one surface of interest. A constraining wall is placed in contact with at least a portion of the physical model. A moldable substance is placed into contact with at least a portion of the surface of interest. An impression of the surface of interest is maintained upon the moldable substance. The moldable substance is solidified into a patient-specific surgical aid. The patient-specific surgical aid is removed from the physical model. A system for producing at least one patient-specific surgical aid is also disclosed.

Owner:THE CLEVELAND CLINIC FOUND

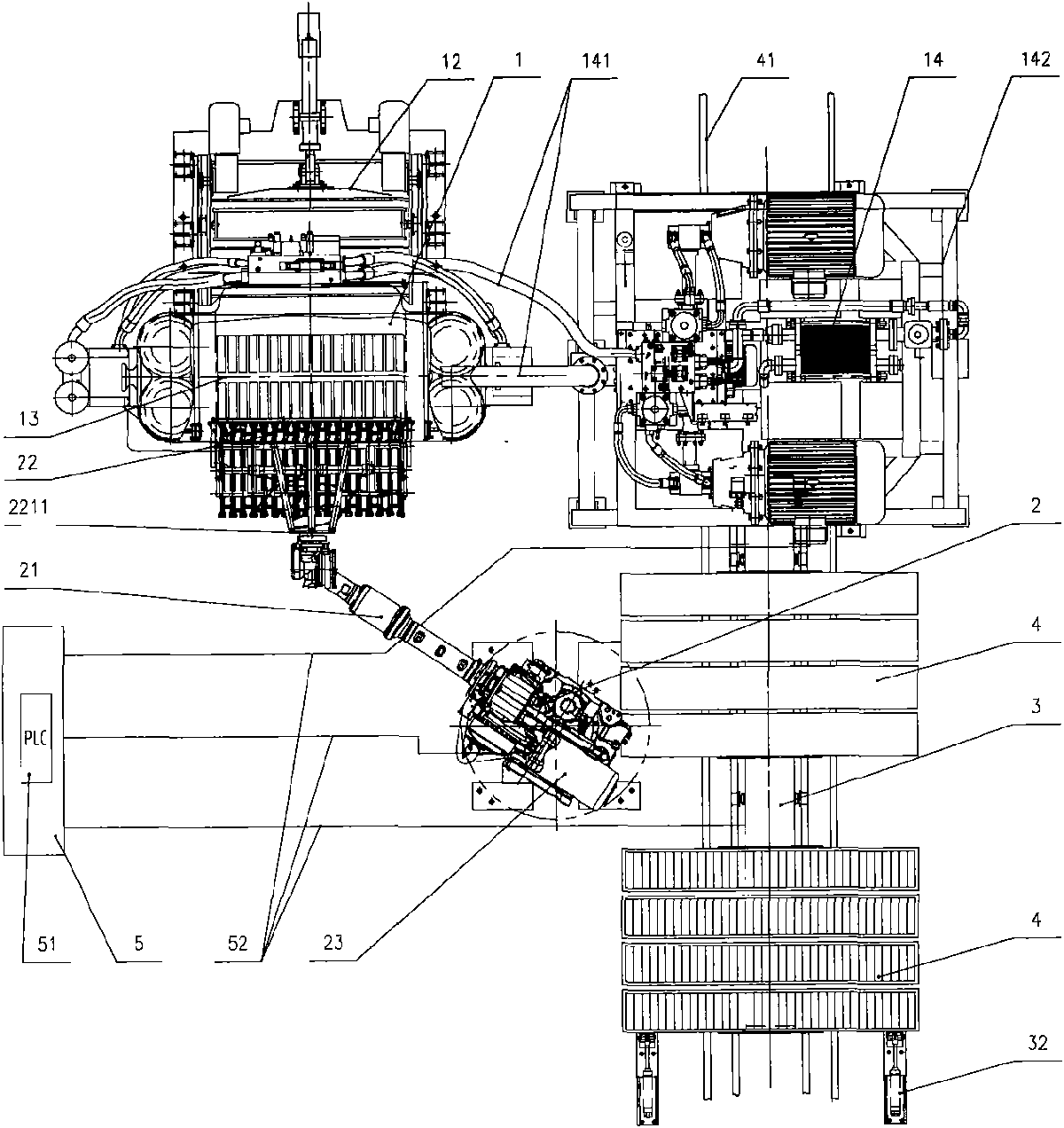

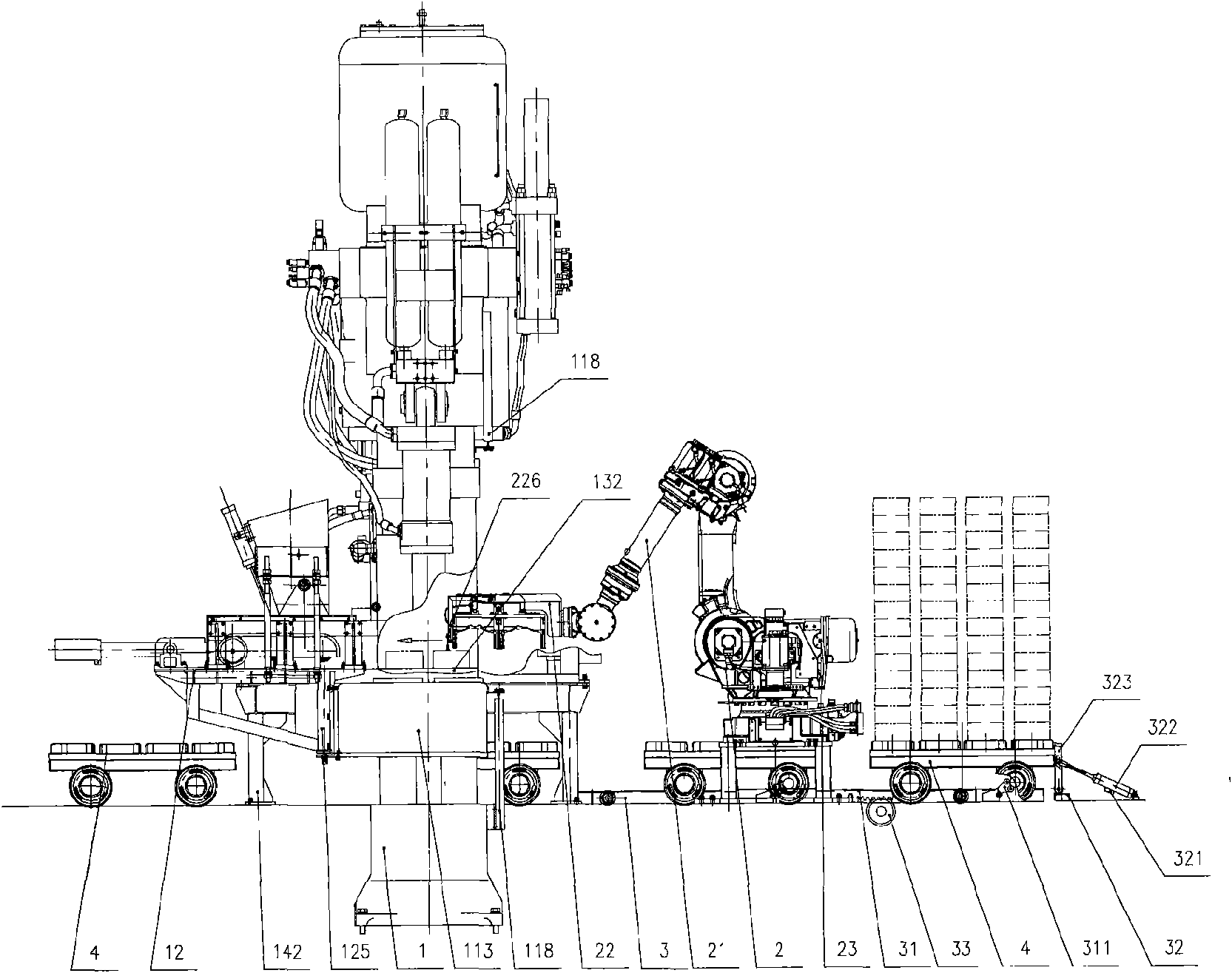

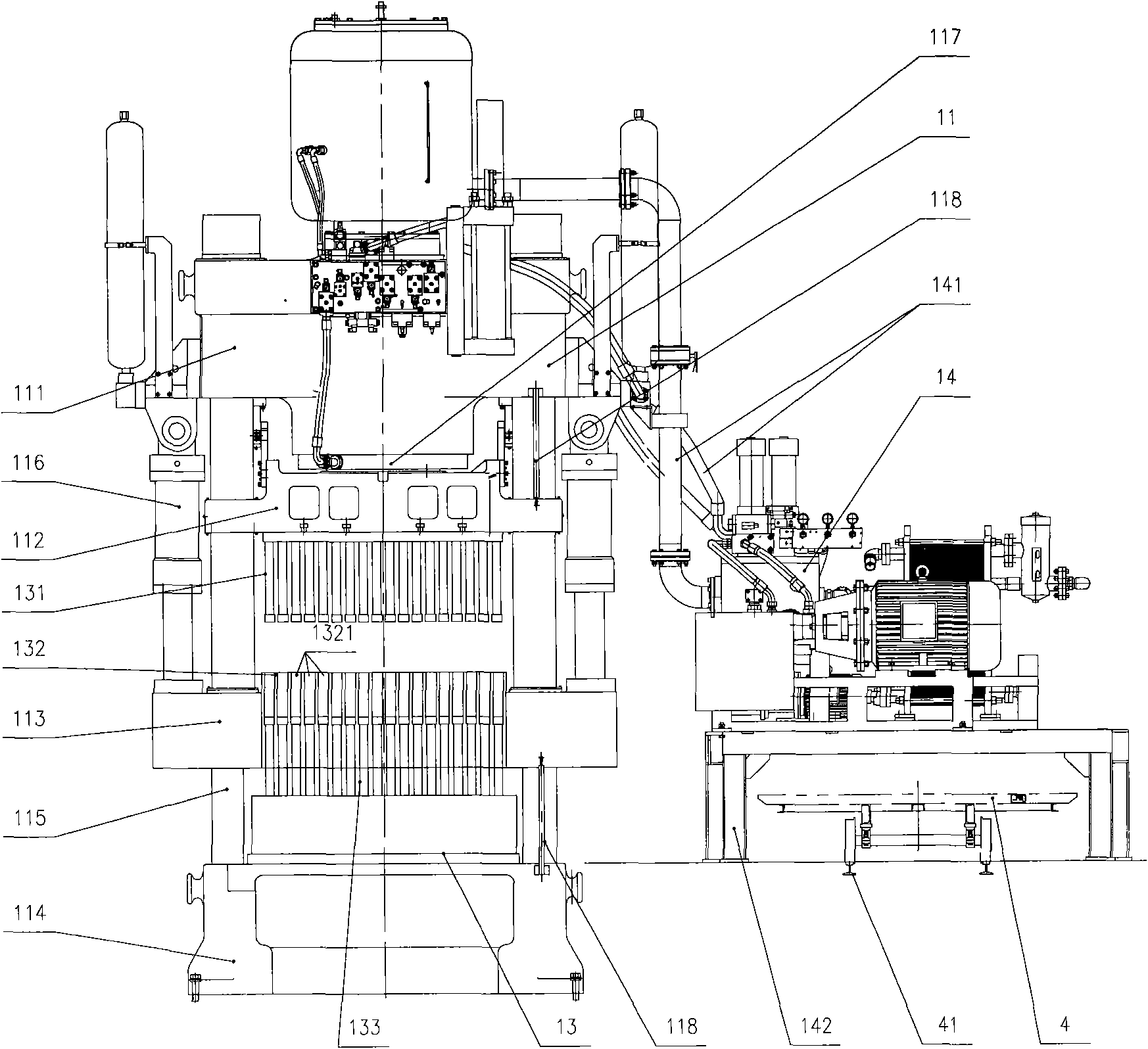

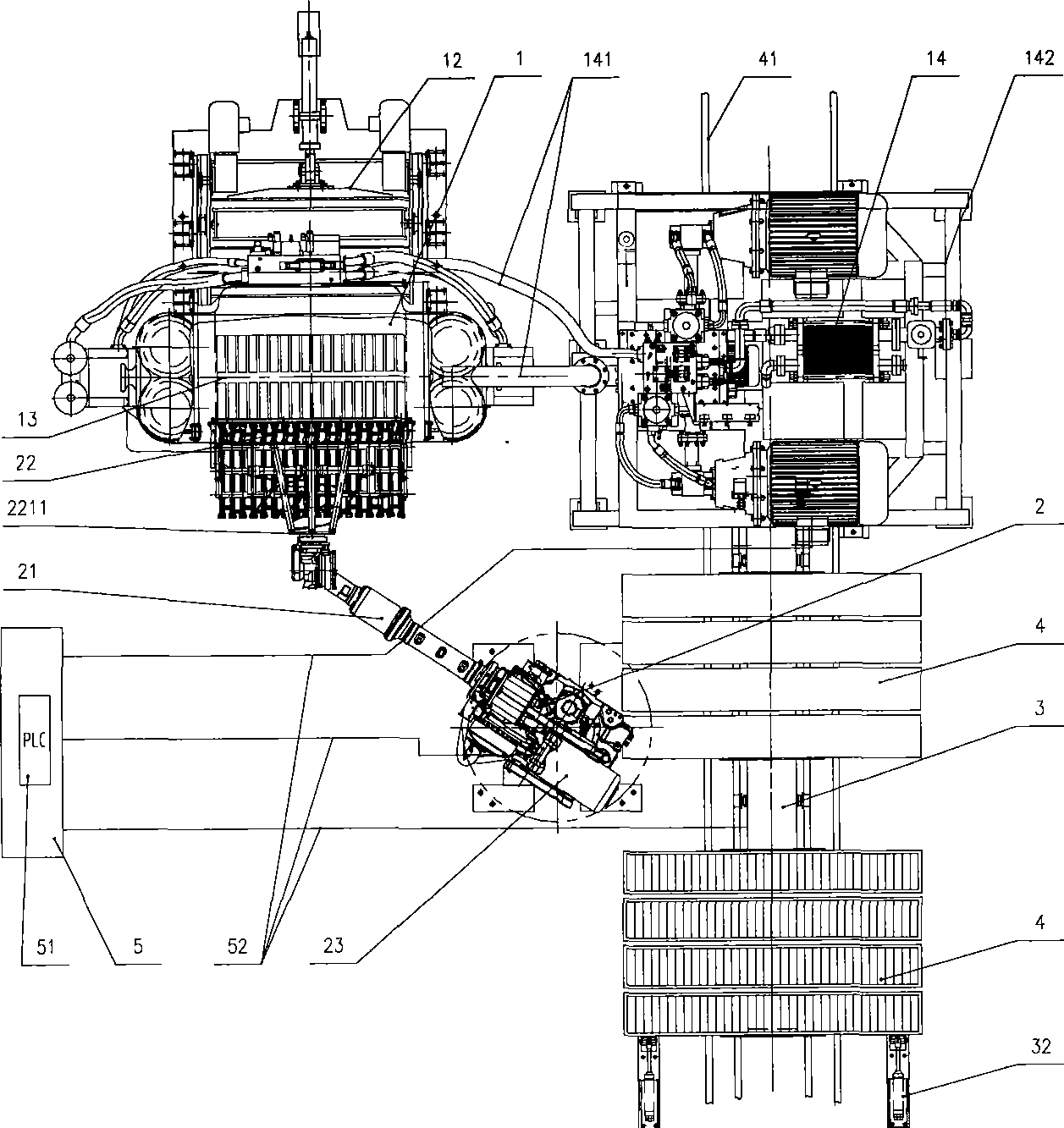

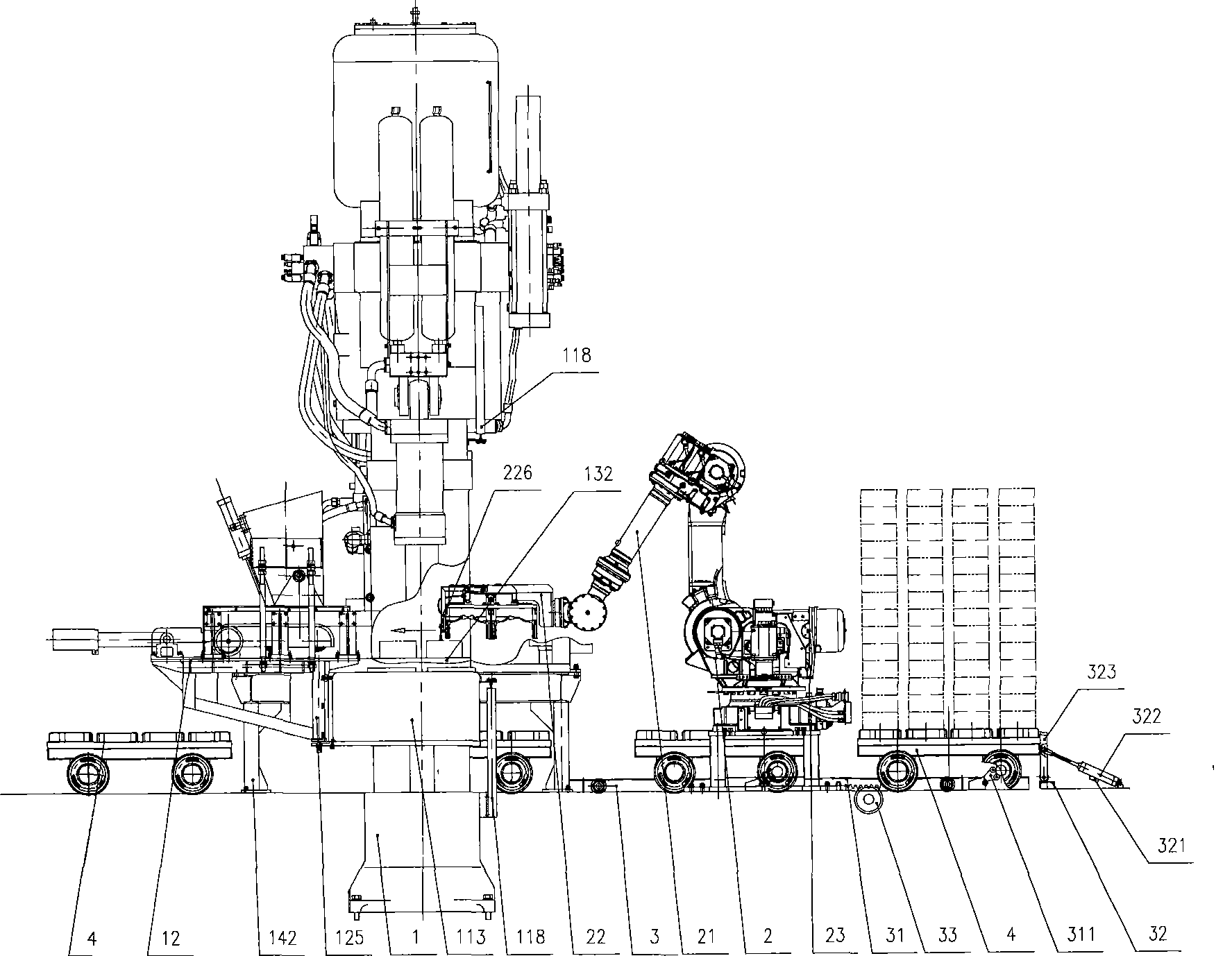

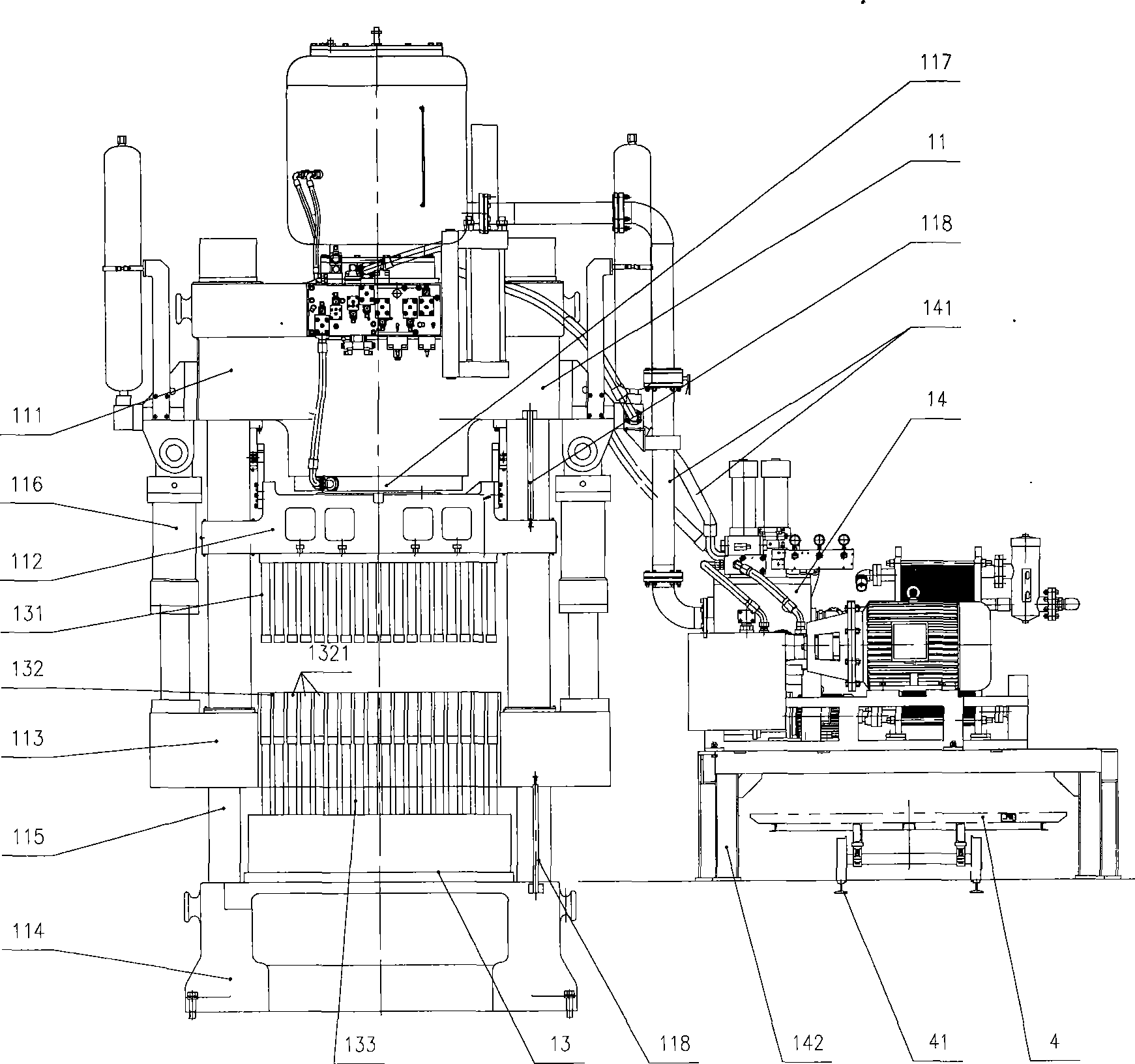

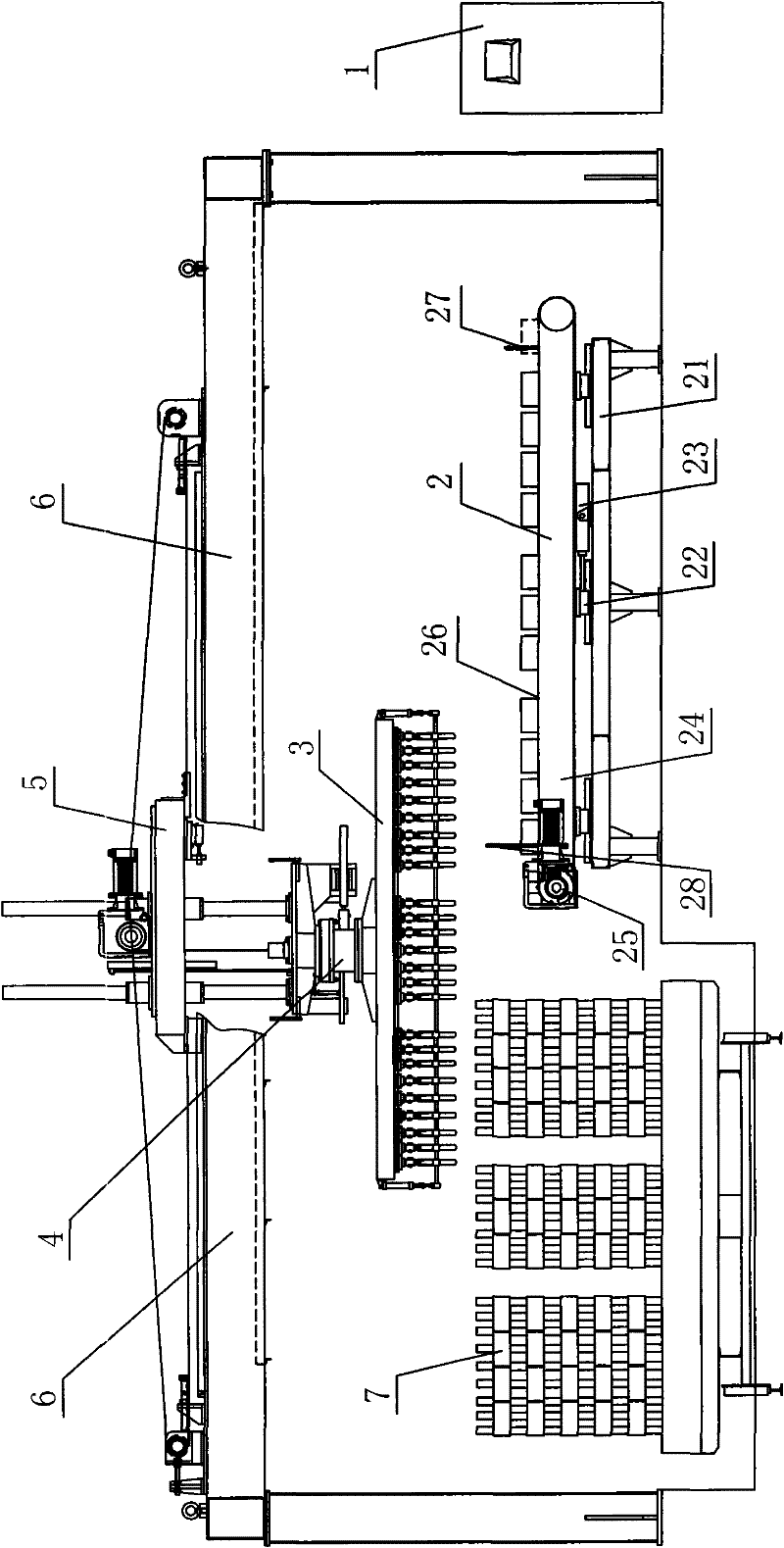

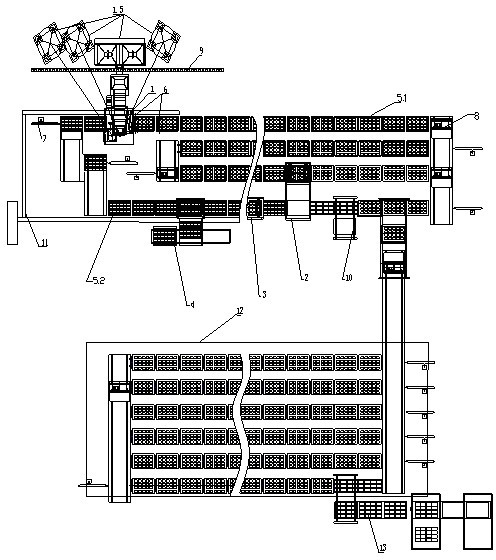

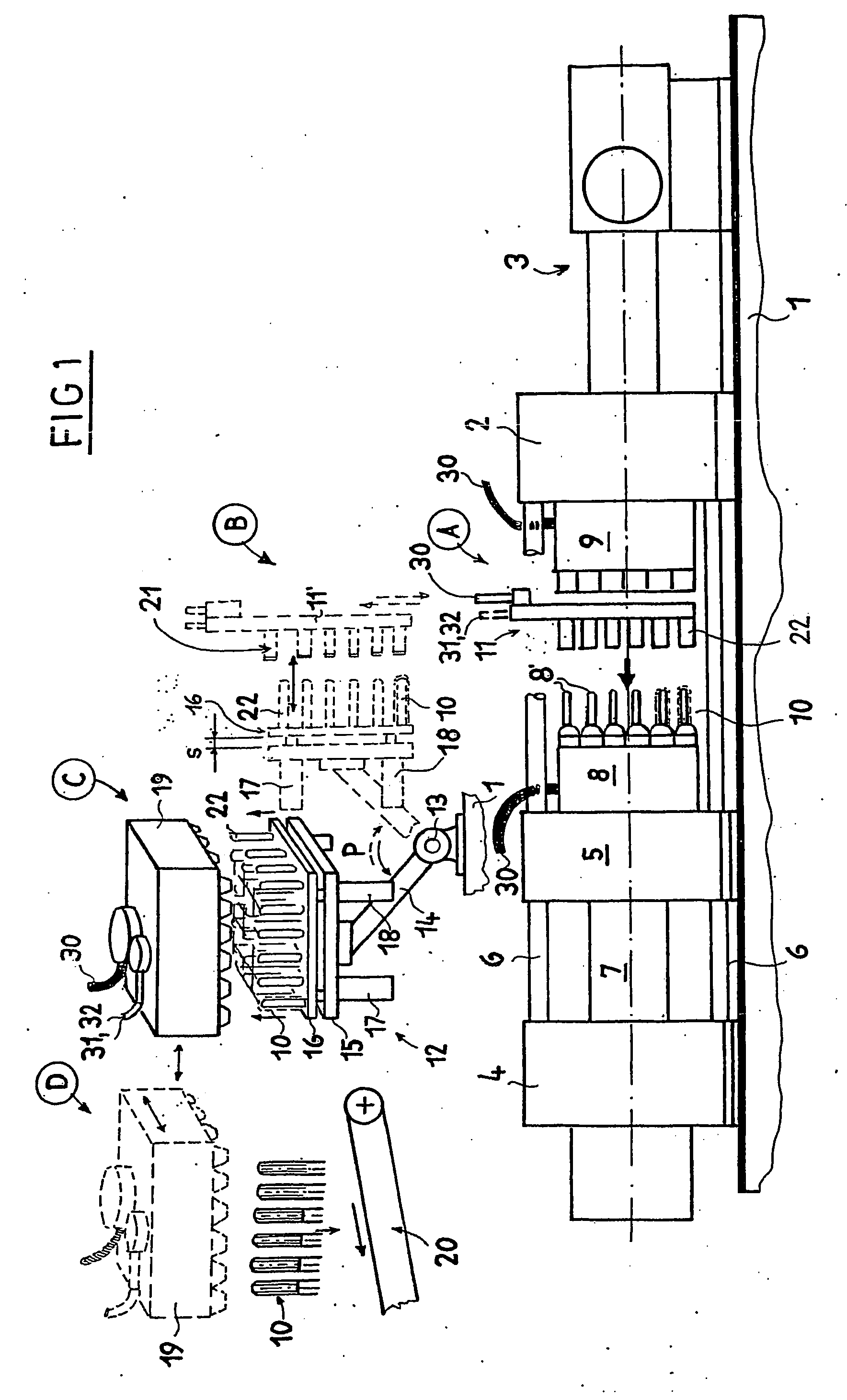

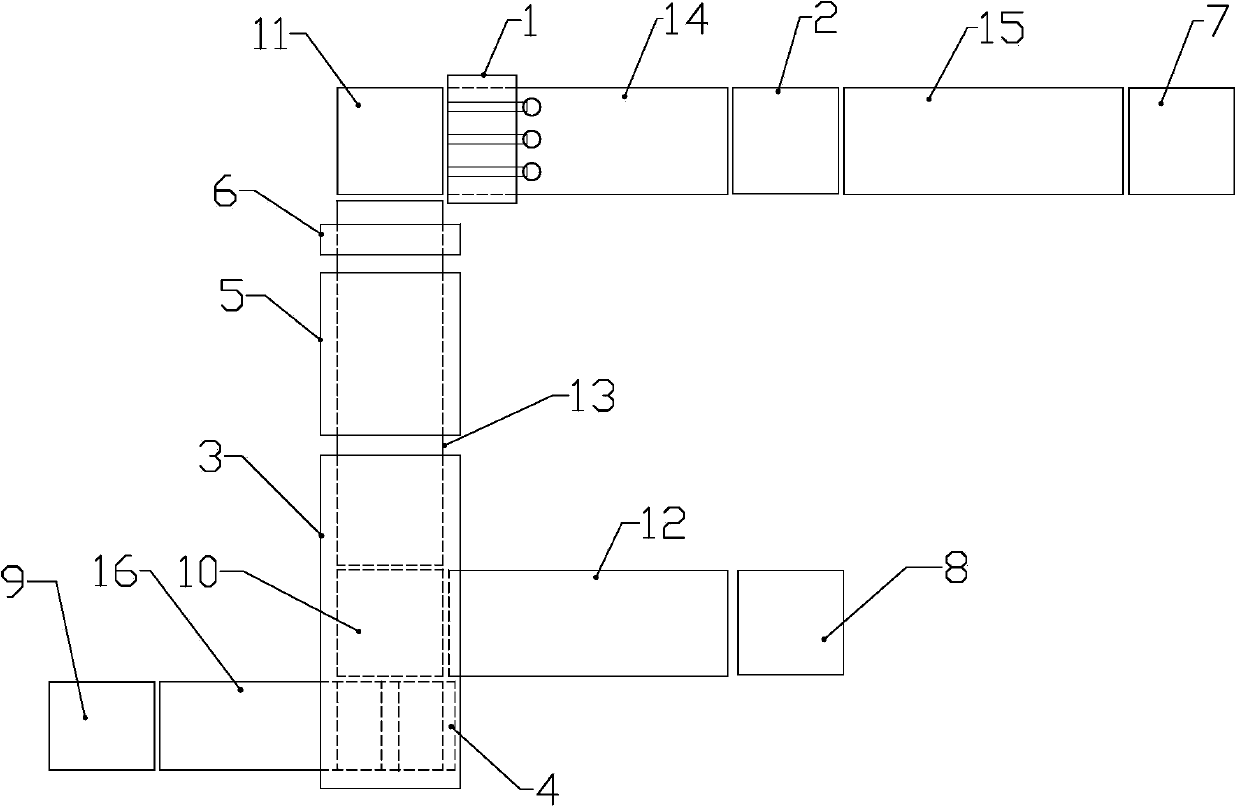

Fully automatic hydroform and intelligent stacking device for bricks

ActiveCN101574833AEnsure mutual coordinationReduce multiple handling linksDischarging arrangementCeramic shaping plantsBogieBrick

The invention relates to a brick making machine, in particular to a fully automatic hydroform and intelligent stacking device for bricks. The device comprises a brick molding press, a stacking robot, an automatic feeding machine, a steam curing bogie and an electric control device, and has the following structural key points that the stacking robot is arranged between the brick molding press and the automatic feeding machine; the automatic feeding machine carries out positioning and feeding for the steam curing bogie; and the electric control device is connected with the drive device and the sensor of each part through electric circuits. Thus, through the programmed instructions in a PLC module of the electric control device, action interlocking of the brick molding press, the stacking robot and the automatic feeding machine is realized so as to ensure action coordination among each part and realize automatic production during the entire working procedure from feeding raw materials into a material frame for distribution to outputting full bogies of green bricks; in addition, a stacking manipulator directly enters into the brick molding press to clean green bricks, and directly piles up the green bricks on the steam curing bogie, thereby reducing the carrying times of the green bricks, improving the quality of the green bricks, shortening production cycle and increasing production efficiency.

Owner:洛阳腾和达智能装备有限公司

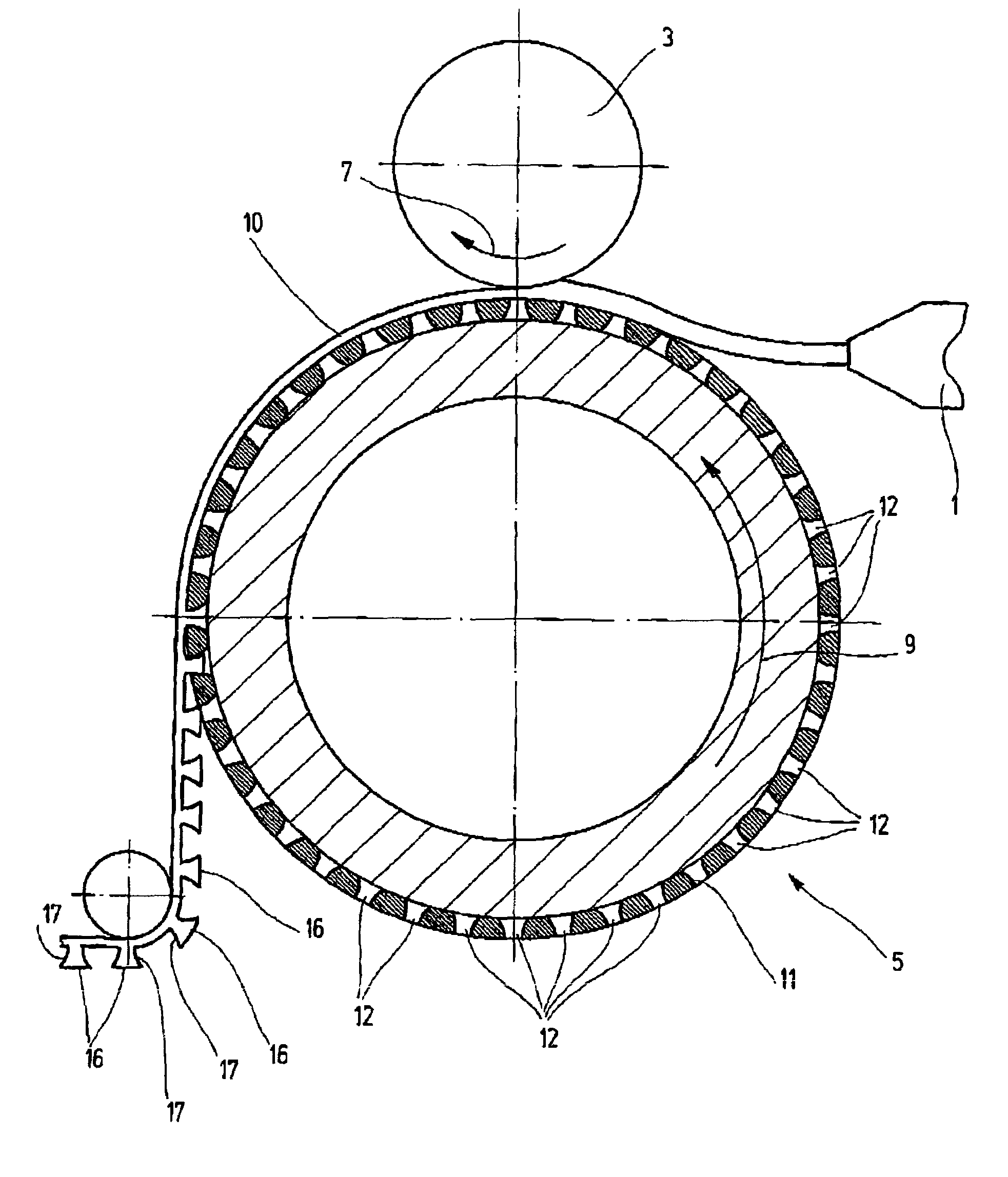

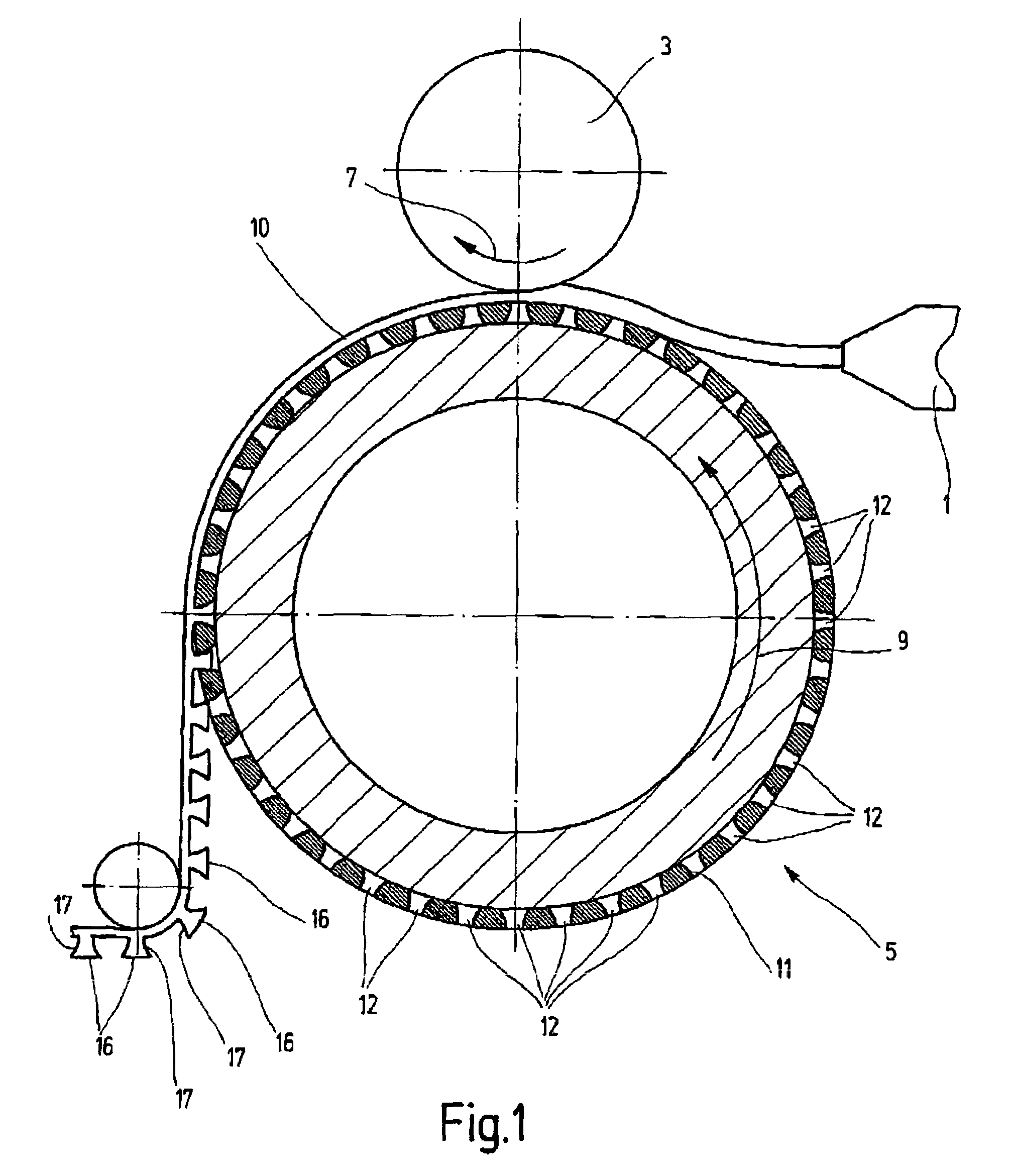

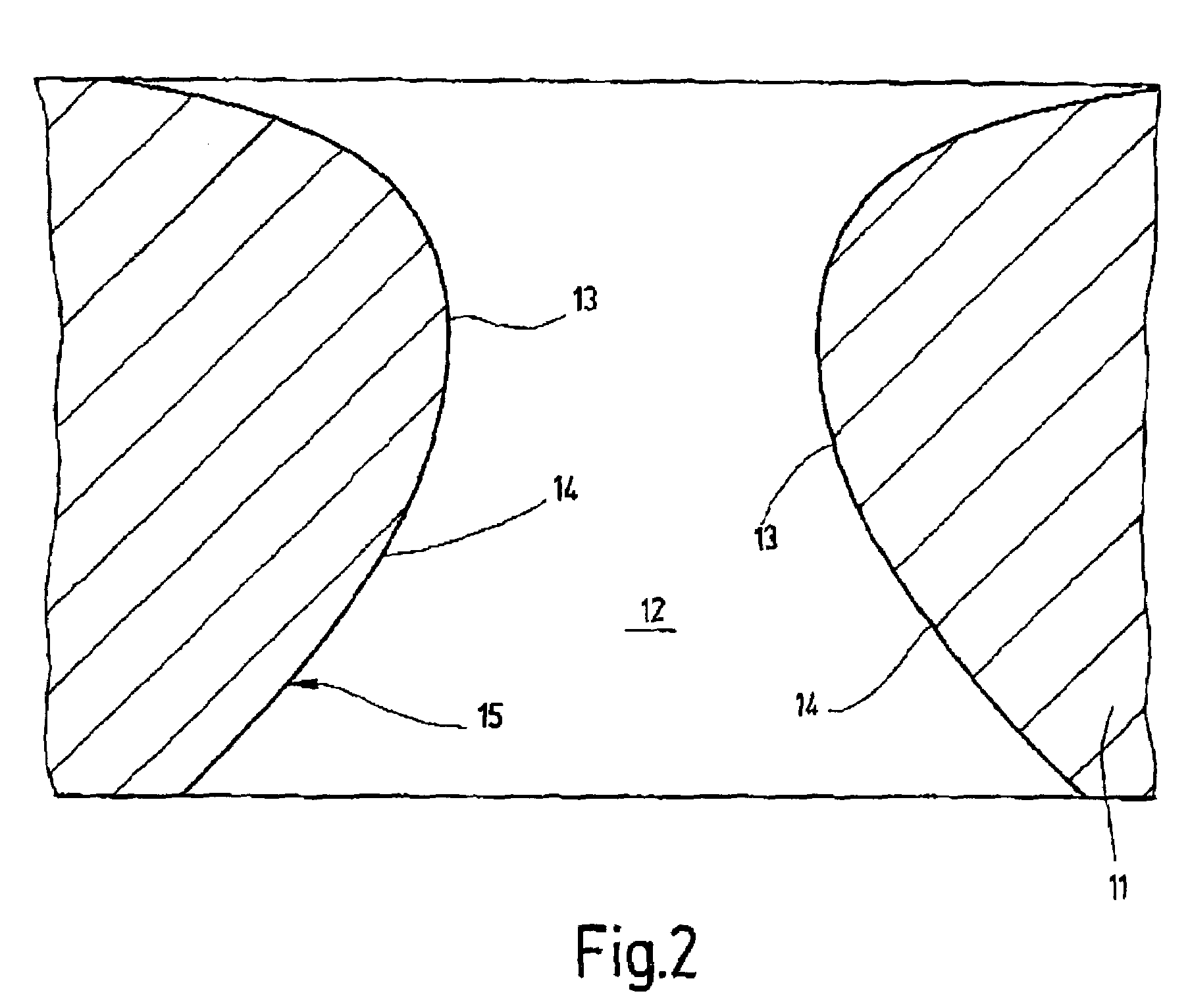

Method for producing an adhesive closing element

InactiveUS7198743B2Easy to demouldFavorable closing behaviorDischarging arrangementArtificial filament physical treatmentEngineeringHooking

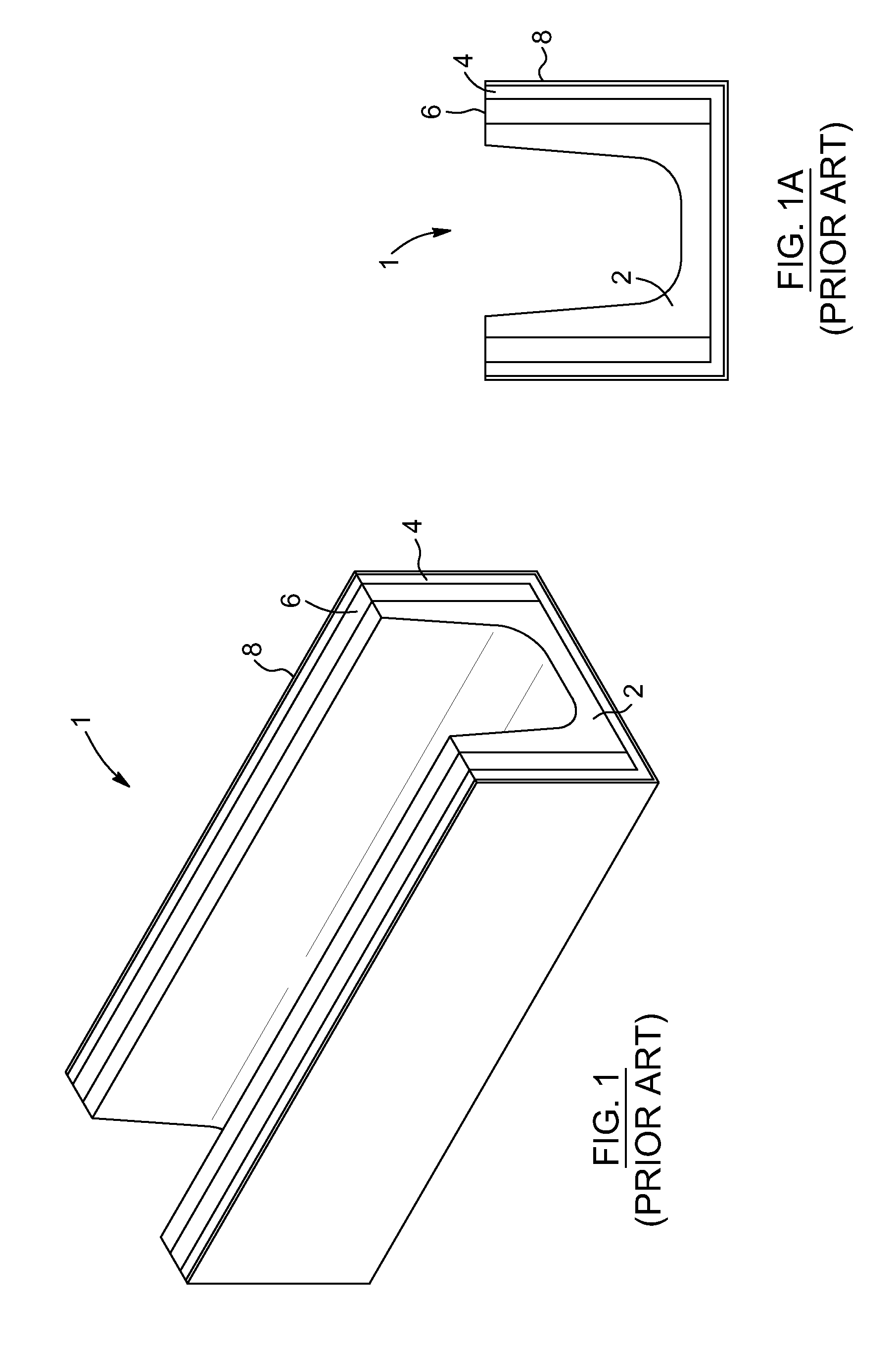

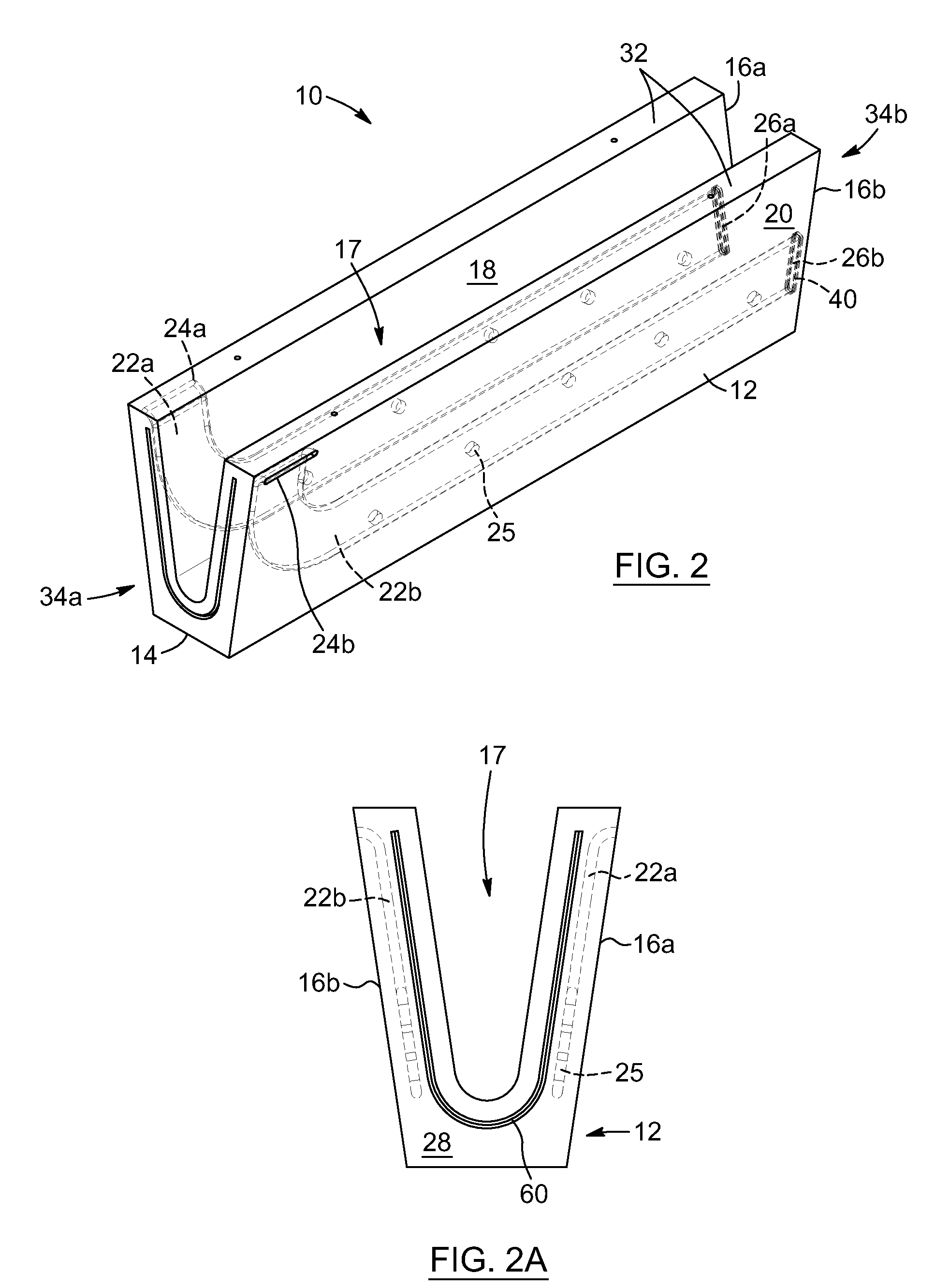

A process for produces an adhesive closing element including a plurality of hook elements connected to a backing (10) forming a single piece with the hook elements and being disposed symmetrically thereon. The hook elements are provided in the form of a stem component (17) having a head piece (16). A deformable material is introduced into a forming zone in between a production master (3) and a forming tool (5). The opposite-lying defining walls, at least when seen in a longitudinal section of the respective forming cavity (12), are provided with a continuous convex trajectory. A continuous transition between the cross-sectional forms of the stem component (17) and the head piece (16) is provided for a hooking of the backing (10) resulting in seamless removal.

Owner:GOTTLIEB BINDER

Fully automatic hydroform and intelligent stacking device for bricks

ActiveCN101574833BEnsure mutual coordinationReduce multiple handling linksDischarging arrangementCeramic shaping plantsBogieBrick

The invention relates to a brick making machine, in particular to a fully automatic hydroform and intelligent stacking device for bricks. The device comprises a brick molding press, a stacking robot, an automatic feeding machine, a steam curing bogie and an electric control device, and has the following structural key points that the stacking robot is arranged between the brick molding press and the automatic feeding machine; the automatic feeding machine carries out positioning and feeding for the steam curing bogie; and the electric control device is connected with the drive device and the sensor of each part through electric circuits. Thus, through the programmed instructions in a PLC module of the electric control device, action interlocking of the brick molding press, the stacking robot and the automatic feeding machine is realized so as to ensure action coordination among each part and realize automatic production during the entire working procedure from feeding raw materials into a material frame for distribution to outputting full bogies of green bricks; in addition, a stacking manipulator directly enters into the brick molding press to clean green bricks, and directly piles up the green bricks on the steam curing bogie, thereby reducing the carrying times of the green bricks, improving the quality of the green bricks, shortening production cycle and increasing production efficiency.

Owner:洛阳腾和达智能装备有限公司

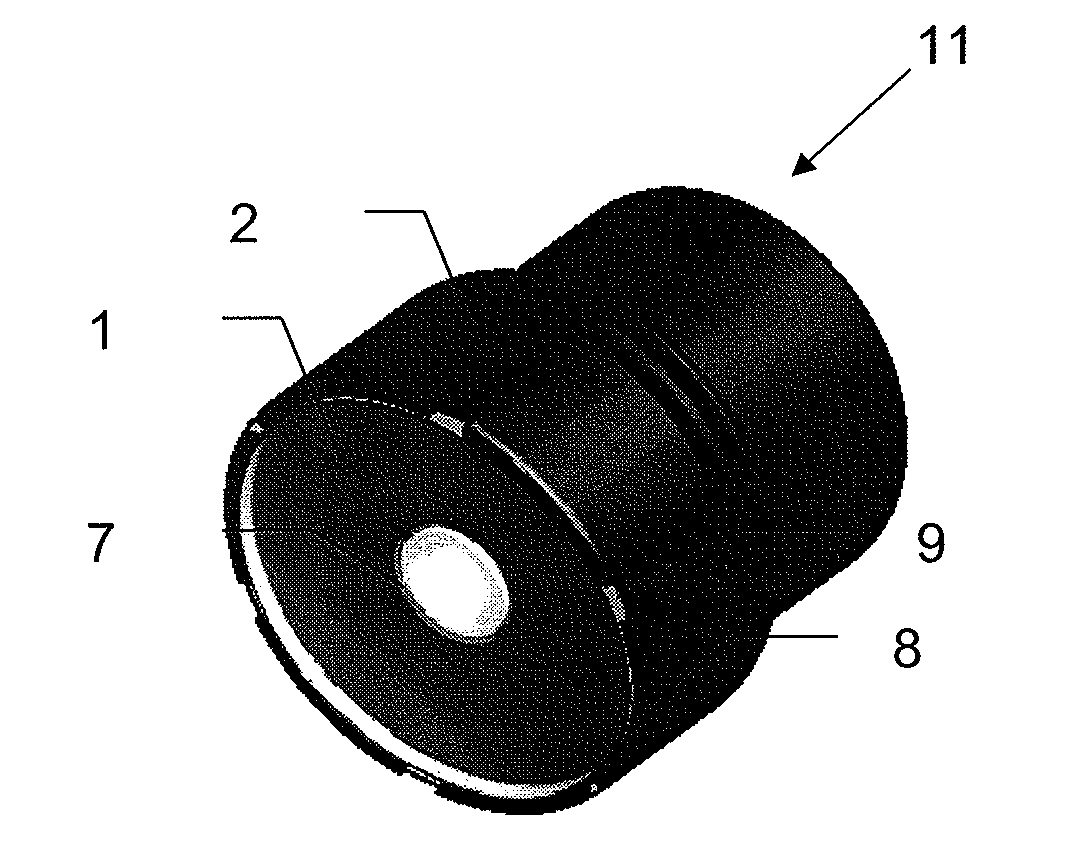

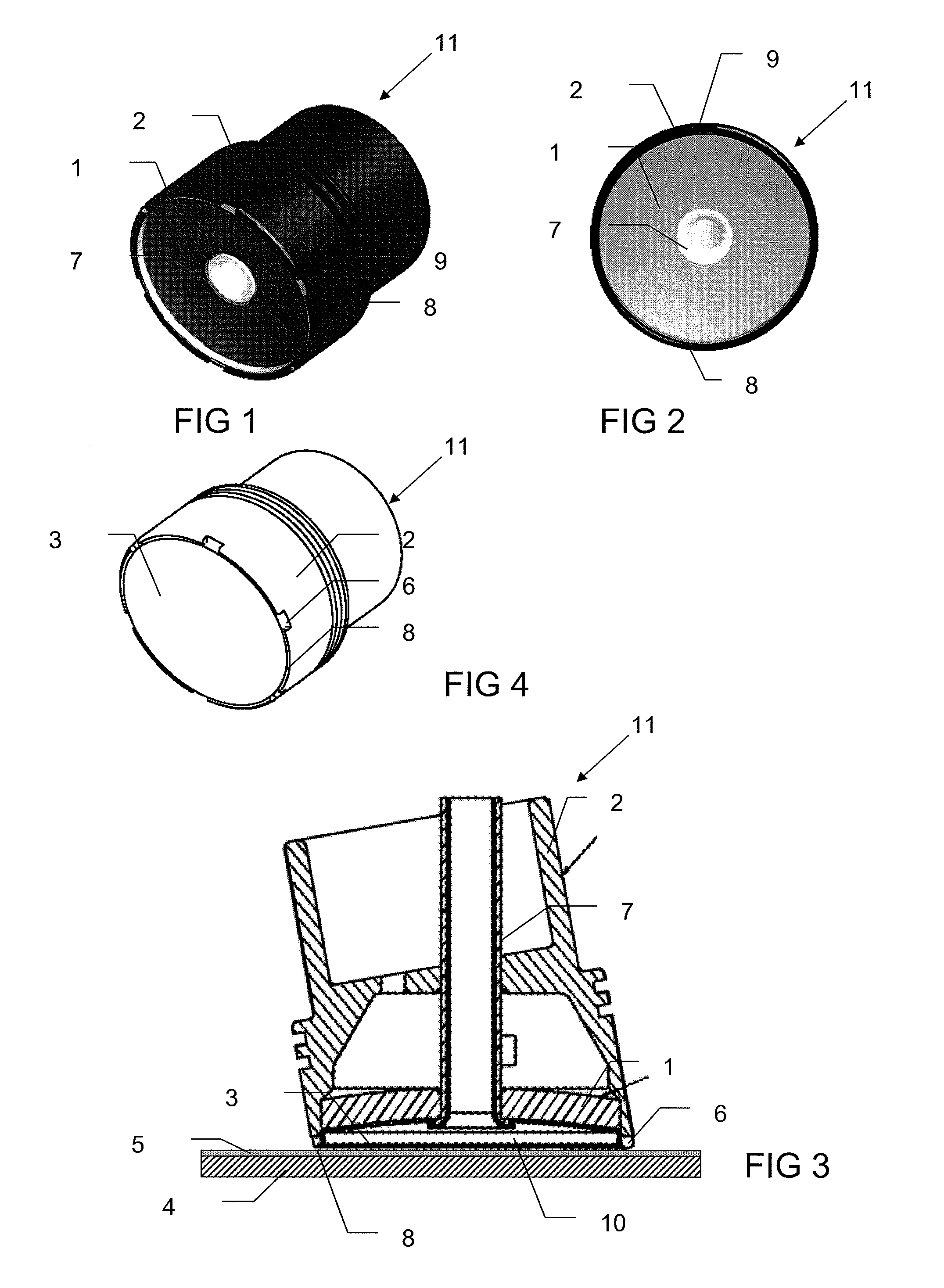

Method for manufacturing a membrane and object provided with such a membrane

InactiveUS20100109480A1Simple and efficientUltrasonic/sonic/infrasonic diagnosticsUltrasound therapyUltrasonic sensorMembrane configuration

The present invention relates to a method for manufacturing a membrane or wall (3) of a material, which is capable of vapour / vacuum deposition, over an opening of an object (2). The method includes: placing the opening with a defined rim against a backing surface (4) coated with a layer (5) repellent to the depositable material; depositing of the depositable material on the object (2) and the backing surface (4) to form an element; separation of the element from the hacking surface (4) leaving a membrane (3) integral with the element. The invention also relates to such an object provided with a membrane (3), and particularly an ultrasonic transducer (11) provided with a front membrane (3).

Owner:ULTRAZONIX DNT

Fluorescence detector, filter device and related methods

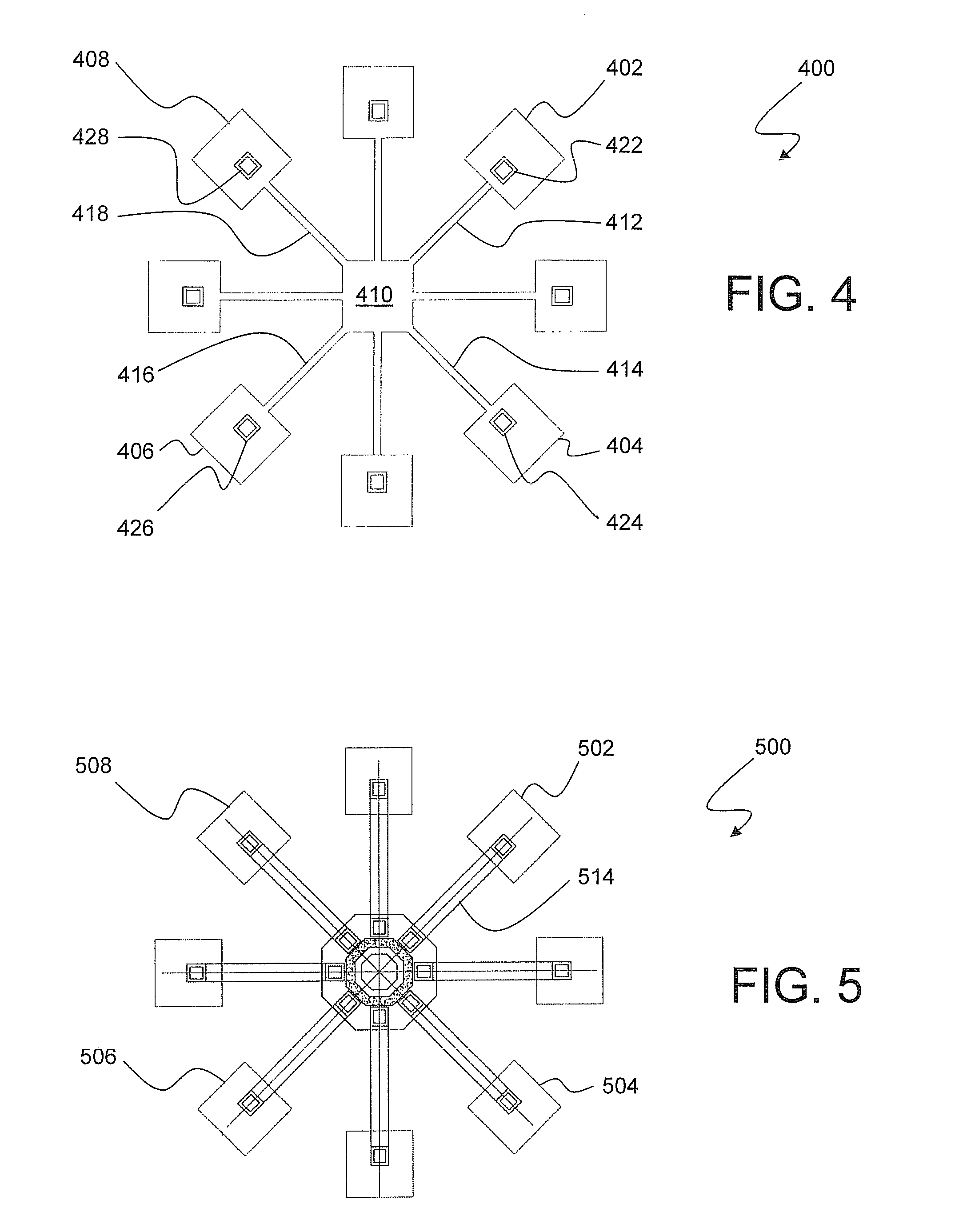

ActiveUS20080013092A1Small sizeIncrease costSemi-permeable membranesDischarging arrangementAntigenFluorescent light

Microfluidic assay detectors and microfluidic assay detection methods are disclosed. A microfluidic chip is coupled to a light emitting device, emission filters and excitation filters. Excited fluorescent light is detected by a camera and a lens. The correspondent reading allows parallel detection of features such as antigens and biomarkers. A microfluidic filter and related methods are also disclosed. The filter can be used with on-chip fluid filtration such as whole blood filtration for microfluidic blood analysis. The filter is able to filter the necessary volume of fluid and in particular blood in an acceptable time frame.

Owner:CALIFORNIA INST OF TECH

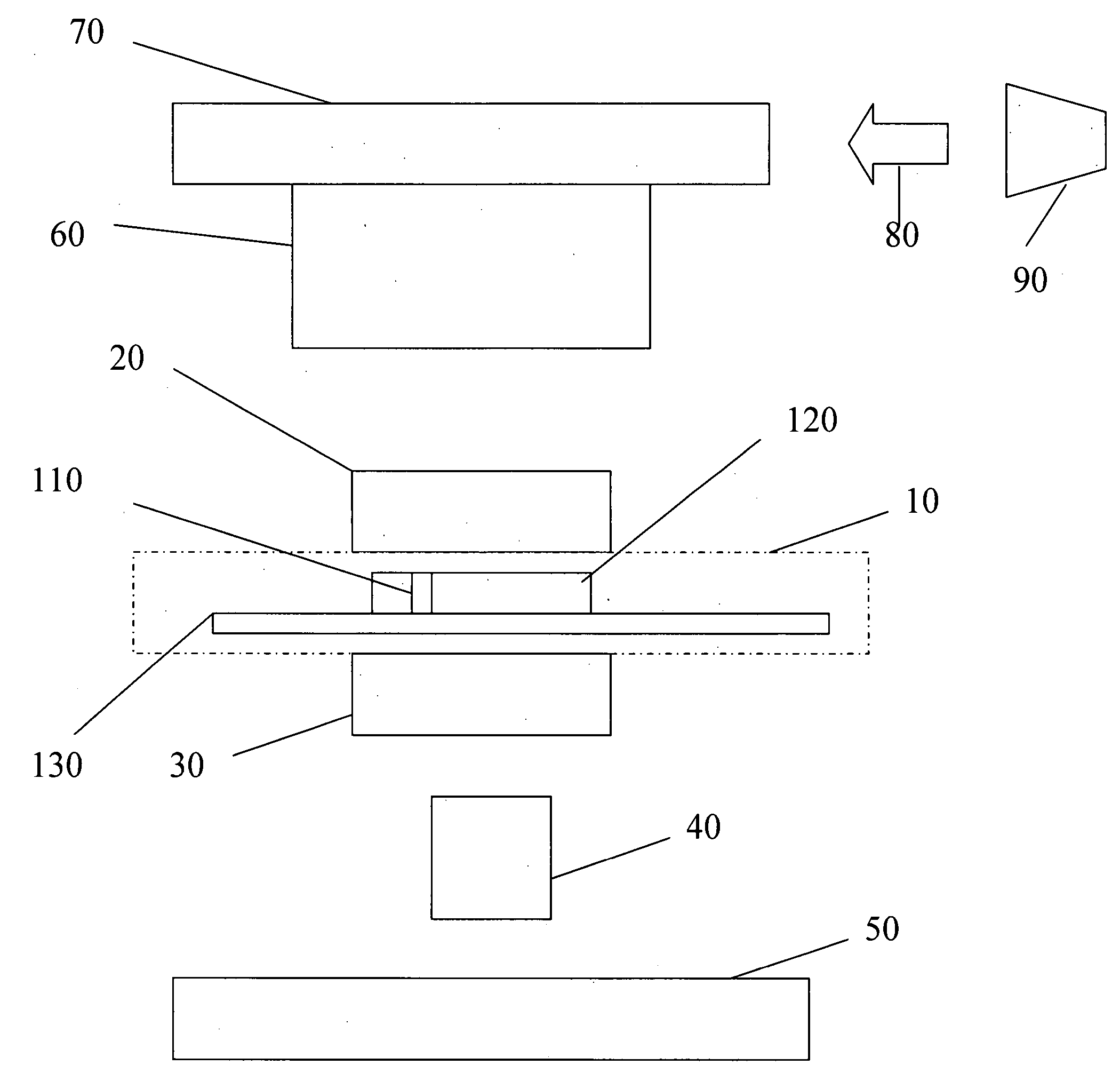

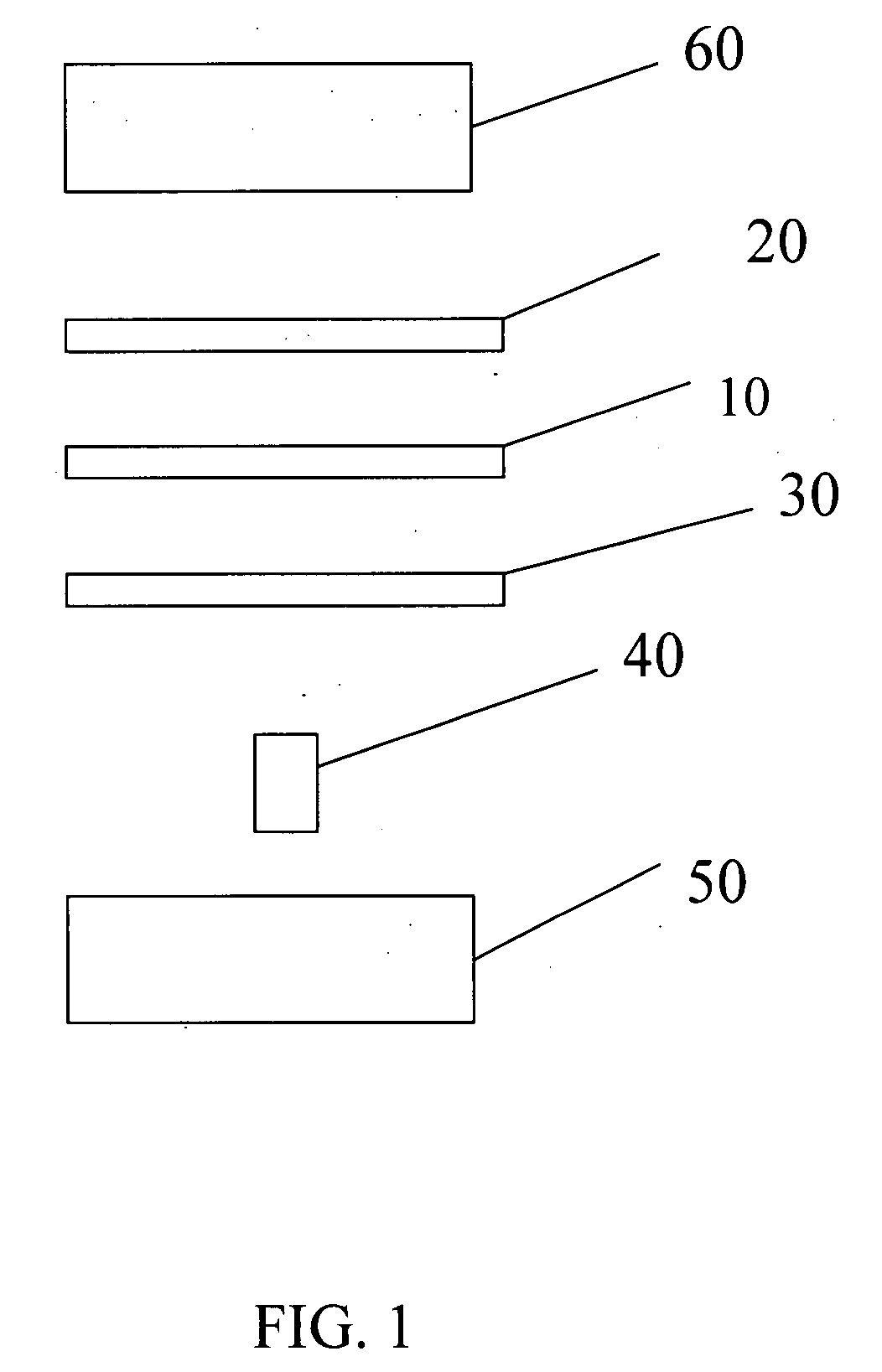

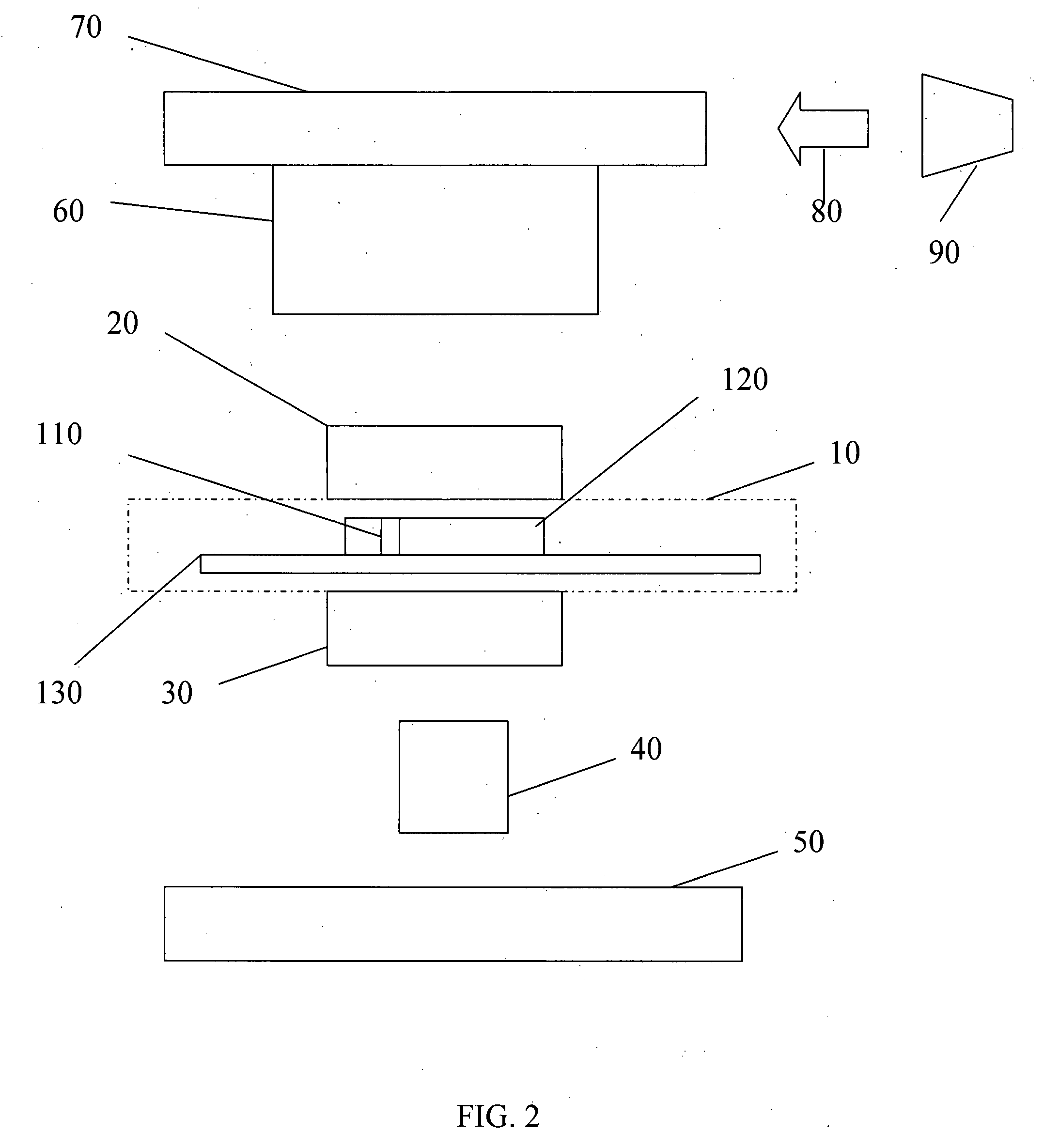

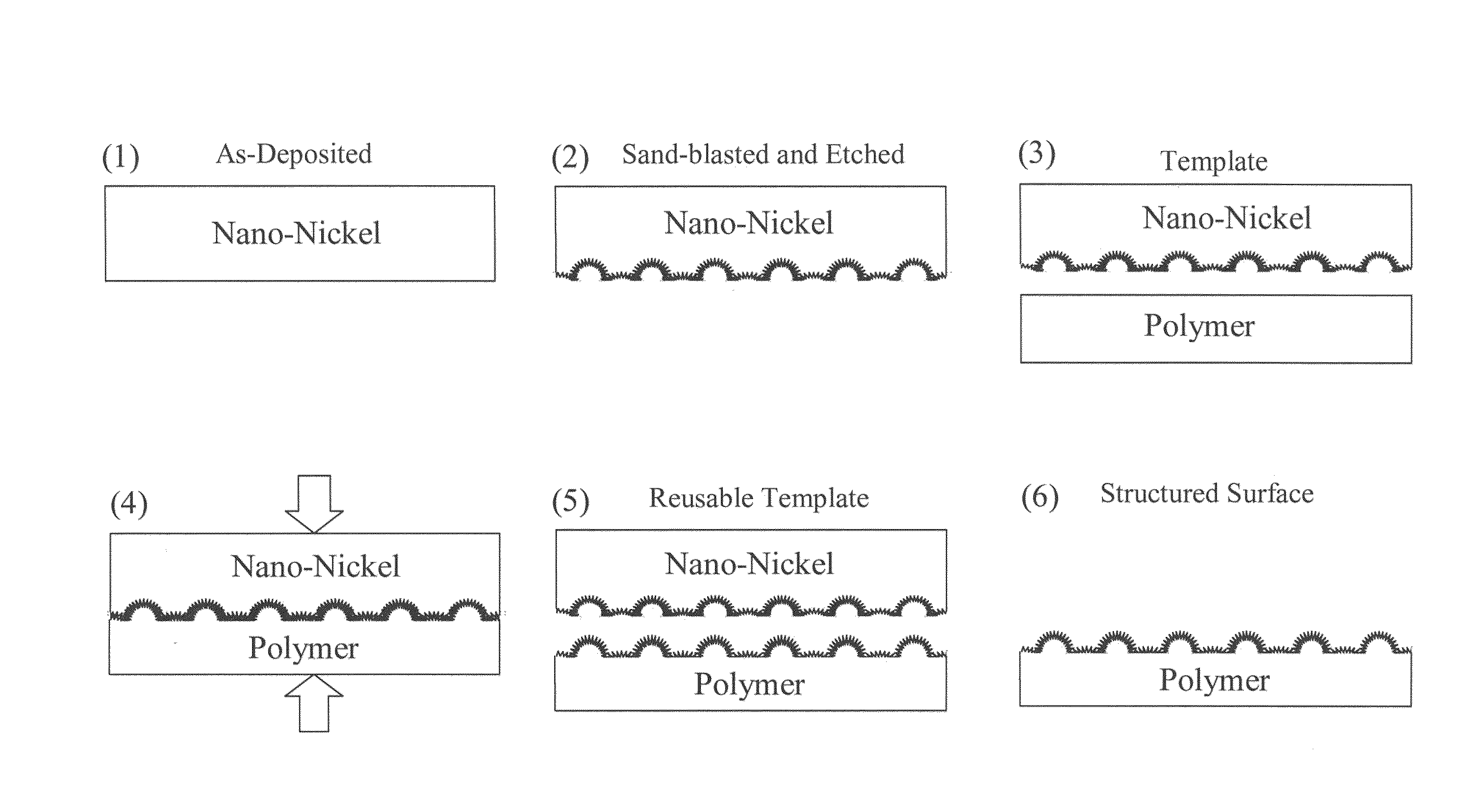

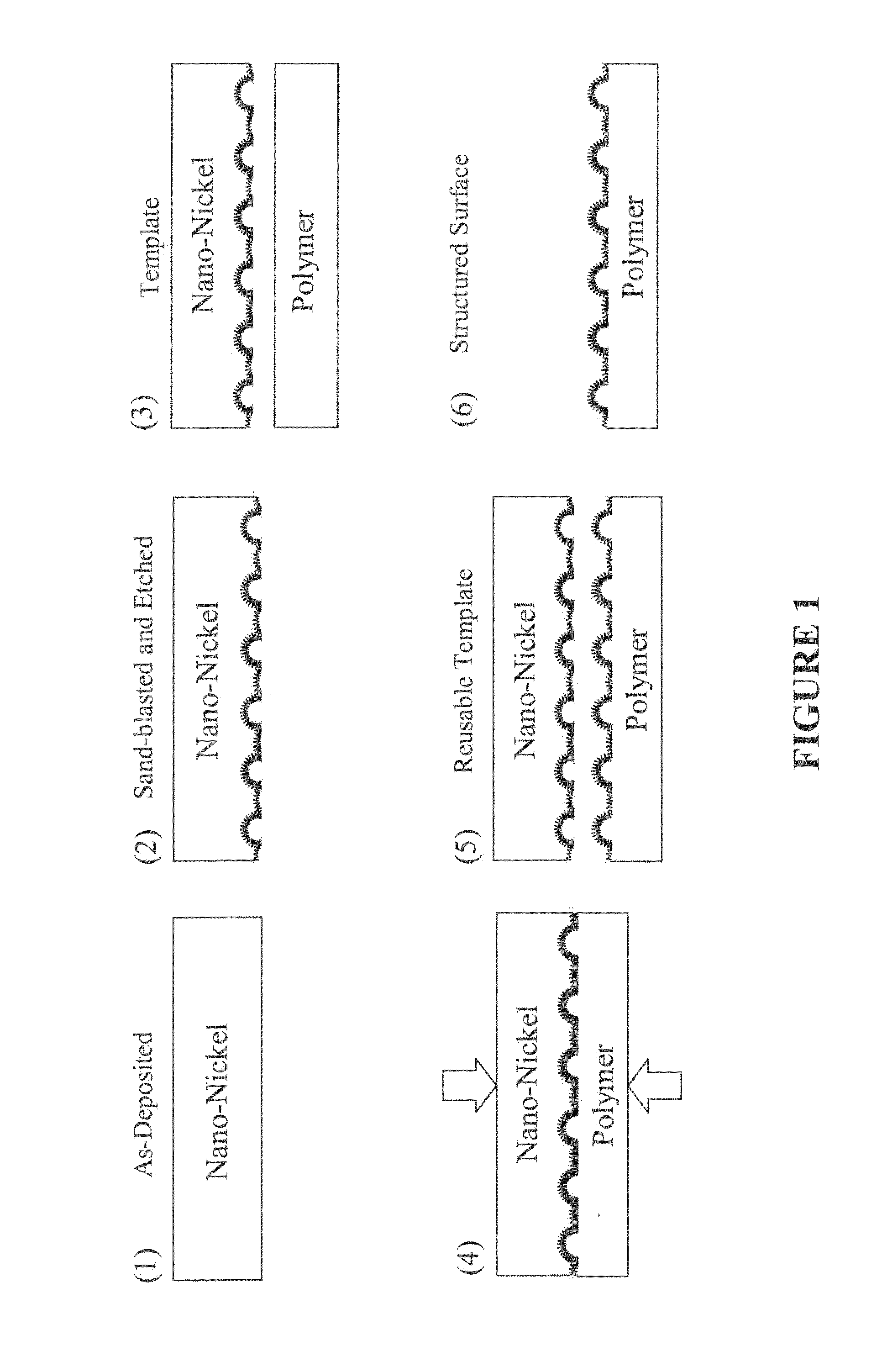

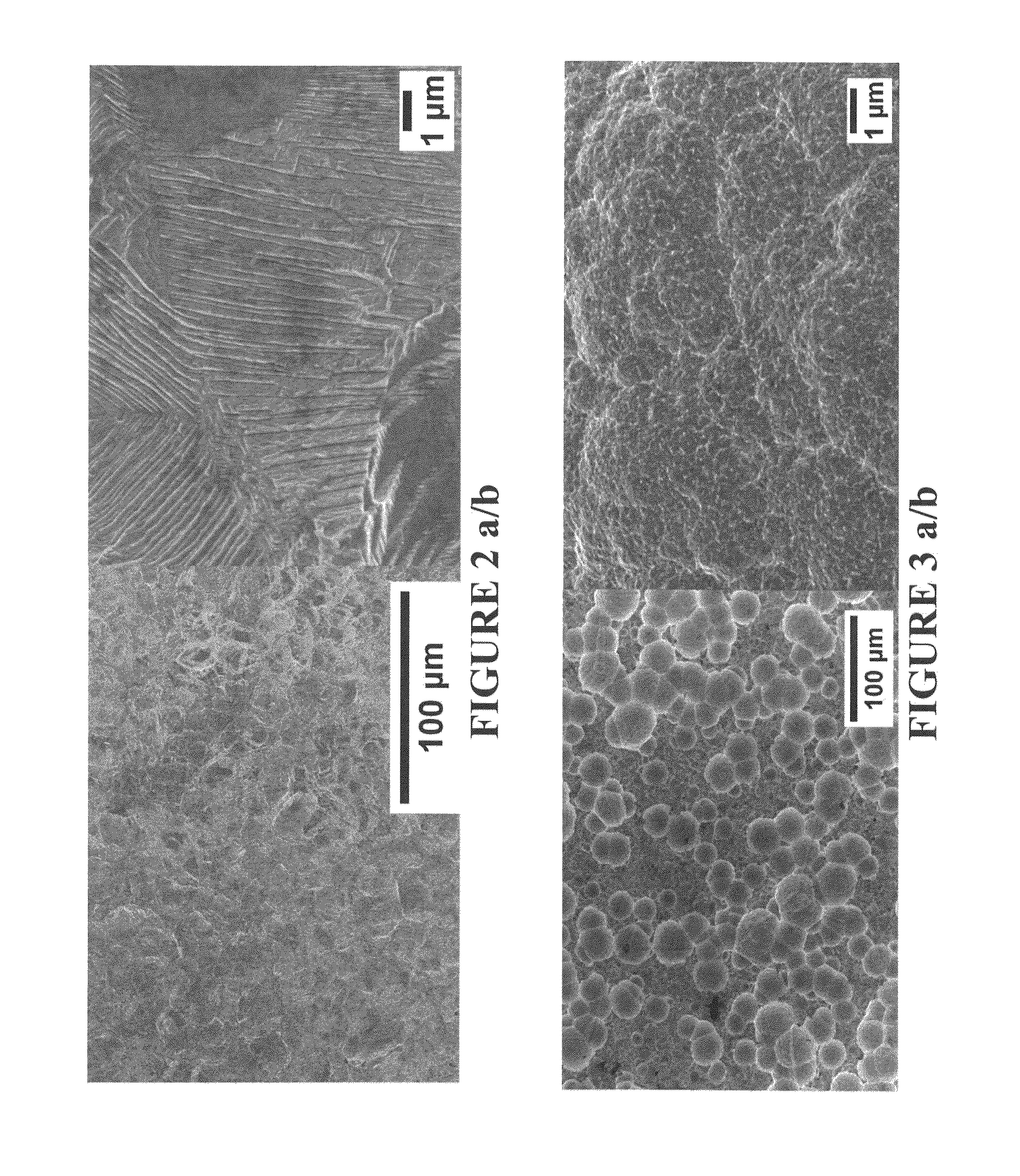

Articles with super-hydrophobic and/or self-cleaning surfaces and method of making same

ActiveUS20110287203A1Lower contact angleLarge scaleDischarging arrangementMouldsFine grainSelf-cleaning surfaces

Super-hydrophobic and self-cleaning articles produced by imprinting exposed surfaces with suitable fine-grained and / or amorphous metallic embossing dies to transfer a dual surface structure, including ultra-fine features less than or equal to 100 nm embedded in and overlaying a surface topography with macro-surface structures greater than or equal to 1 micron are disclosed.

Owner:INTEGRAN TECH

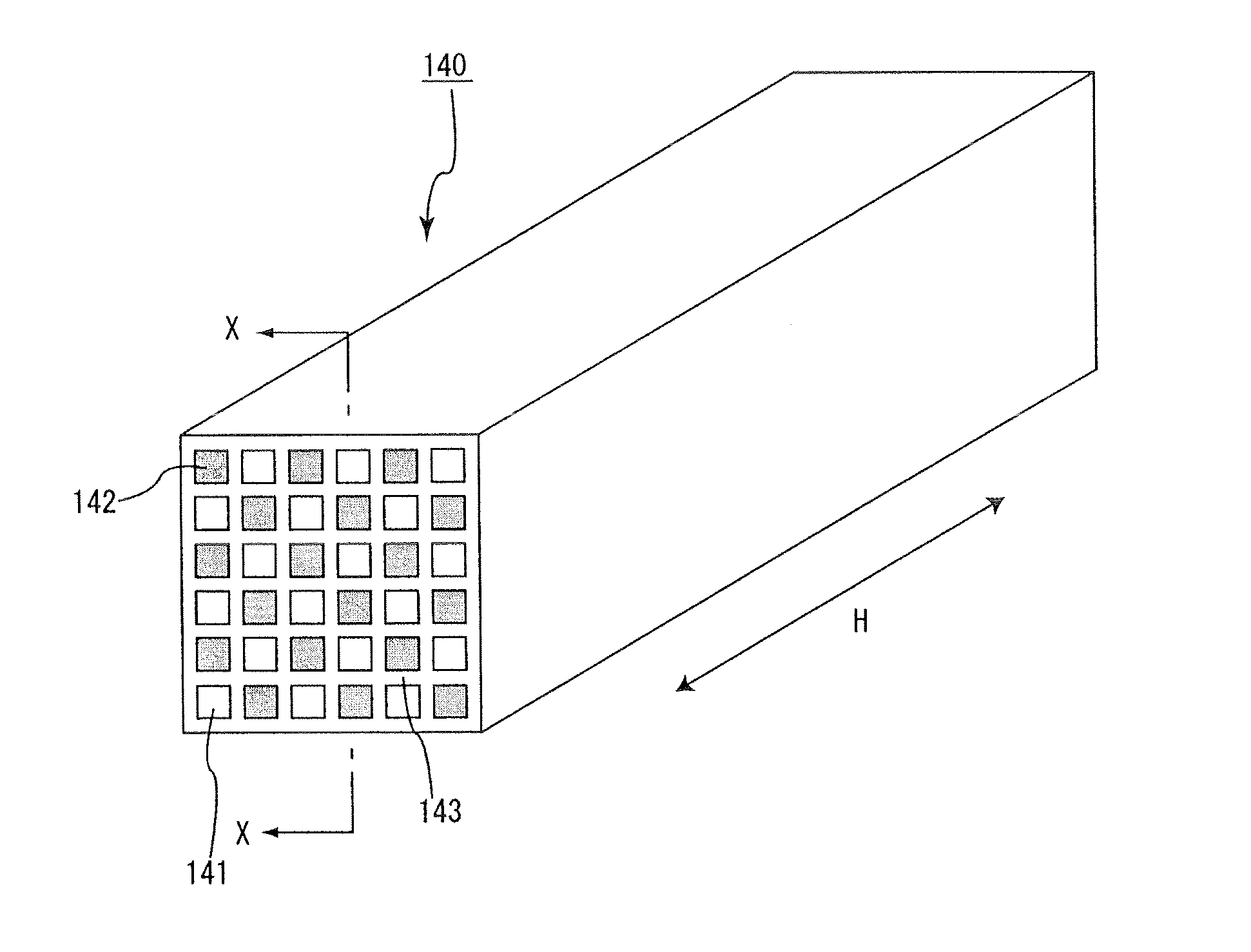

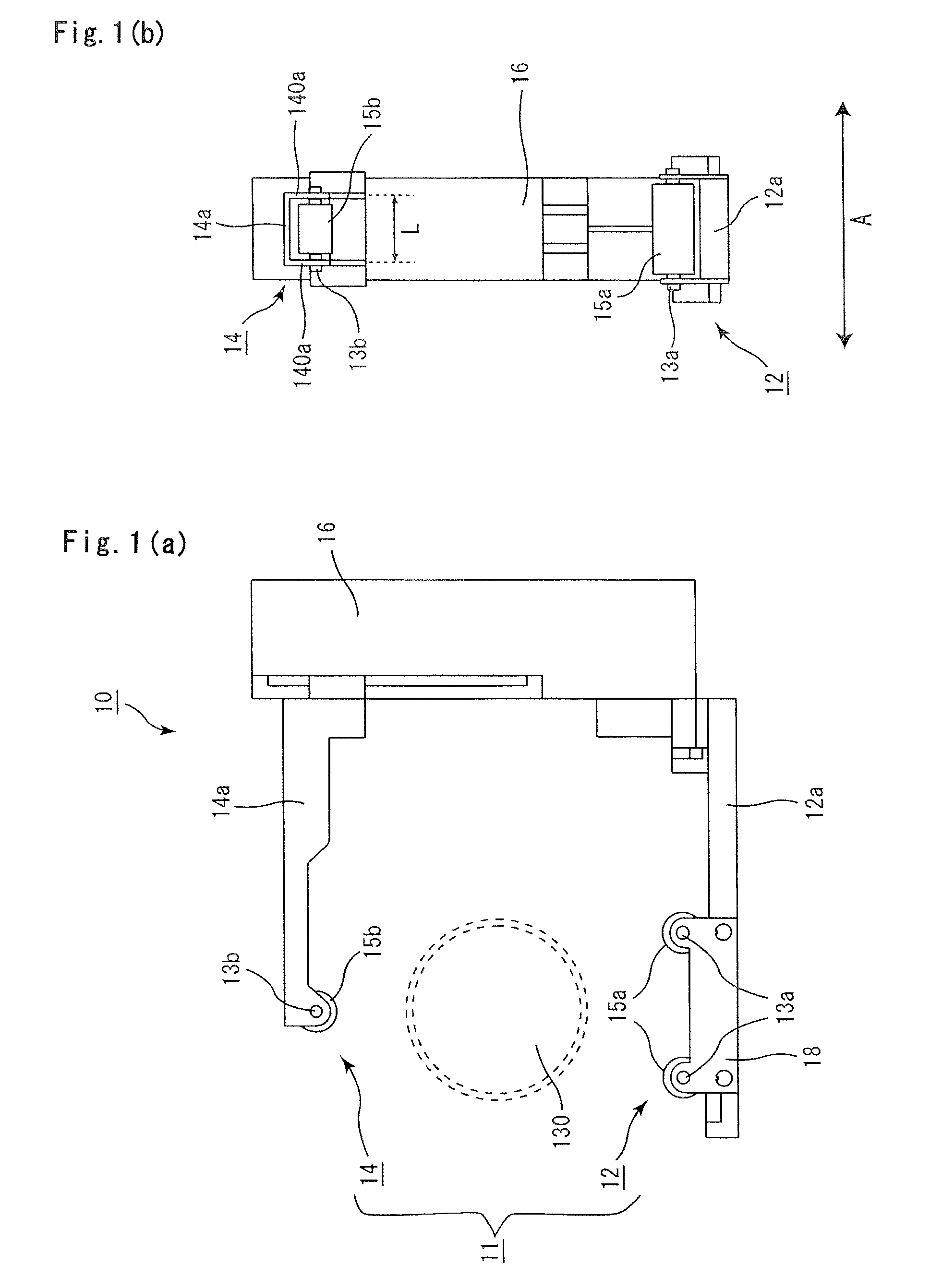

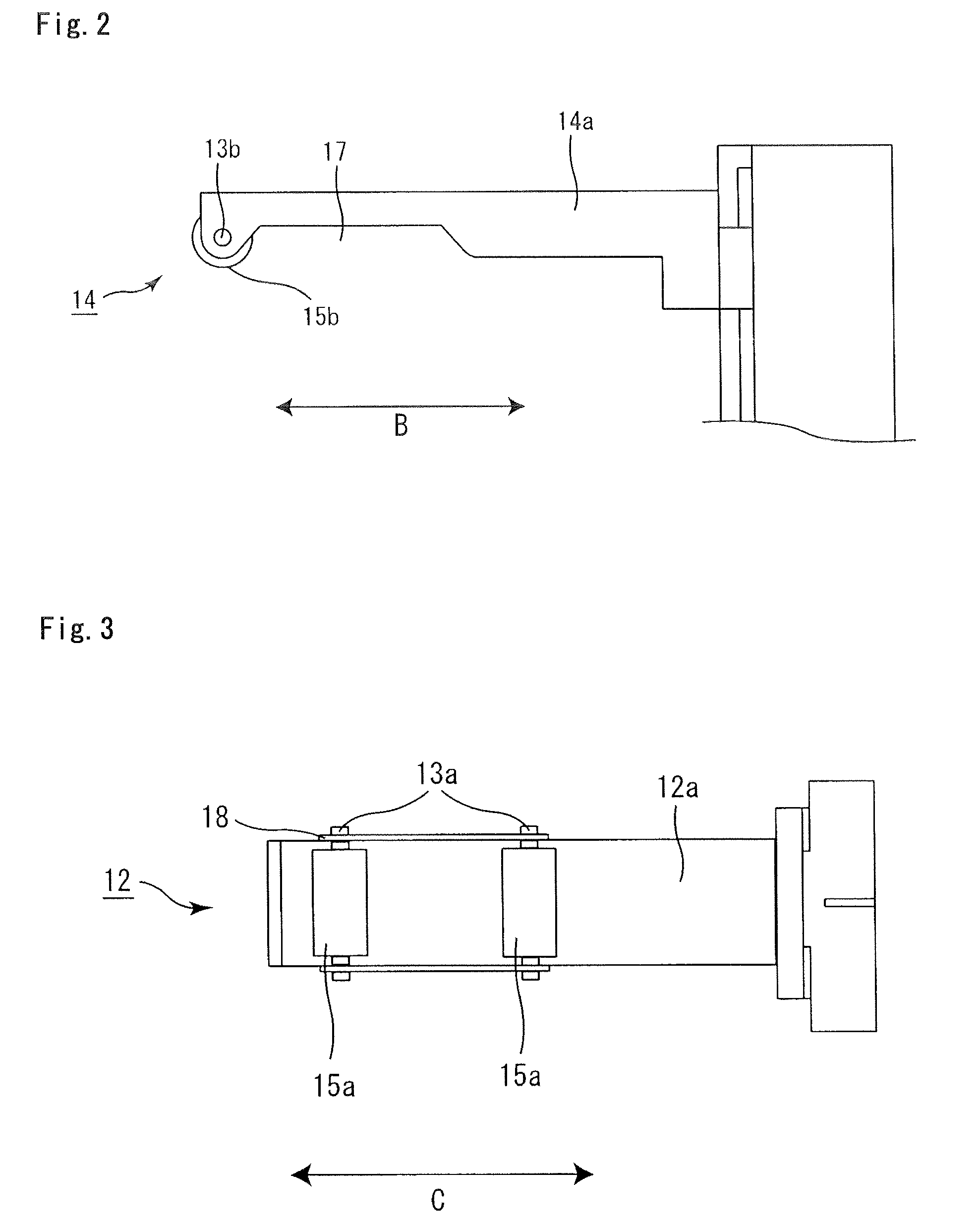

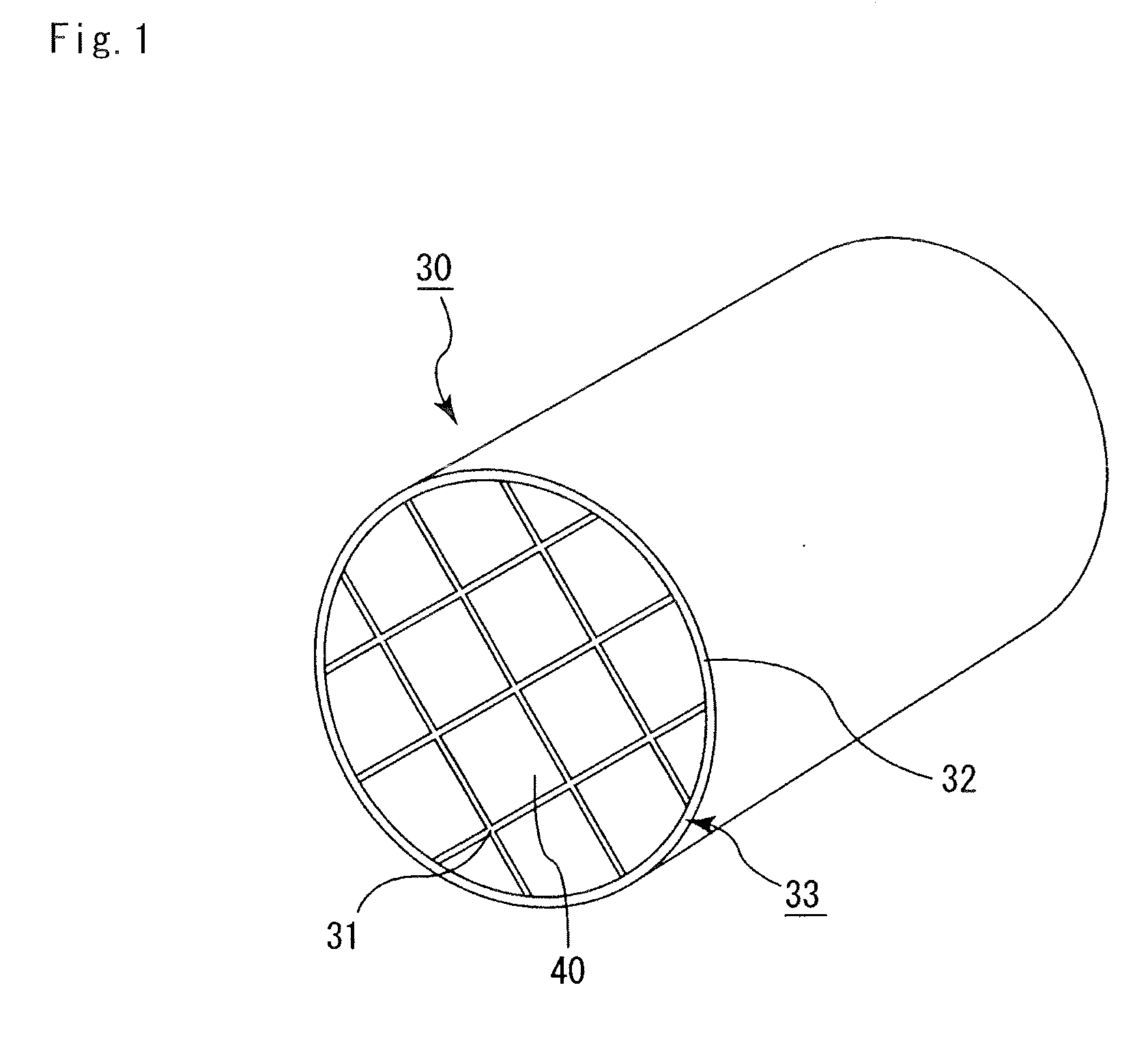

Holding apparatus and method for manufacturing honeycomb structure

ActiveUS20080088072A1Discharging arrangementAuxillary shaping apparatusEngineeringMechanical engineering

Owner:IBIDEN CO LTD

Method for manufacturing a honeycomb structure, honeycomb molded body receiving apparatus, honeycomb molded body taking-out apparatus

InactiveUS20080116200A1Discharging arrangementCeramic shaping plantsHoneycomb structureMaterials science

A method for manufacturing a honeycomb structure includes producing a pillar-shaped honeycomb molded body in which a plurality of cells are placed in parallel with one another in a longitudinal direction with a cell wall therebetween by molding a ceramic raw material; and producing a honeycomb fired body by carrying out a single or a plurality of treatments including at least a firing treatment on the honeycomb molded body. The method further includes temporarily storing the treated honeycomb molded body on which the single or plurality of treatments have been carried out in a molded body storage container; taking out the treated honeycomb molded body placed in the molded body storage container from the molded body storage container; and conveying the taken-out honeycomb molded body to a subsequent process.

Owner:IBIDEN CO LTD

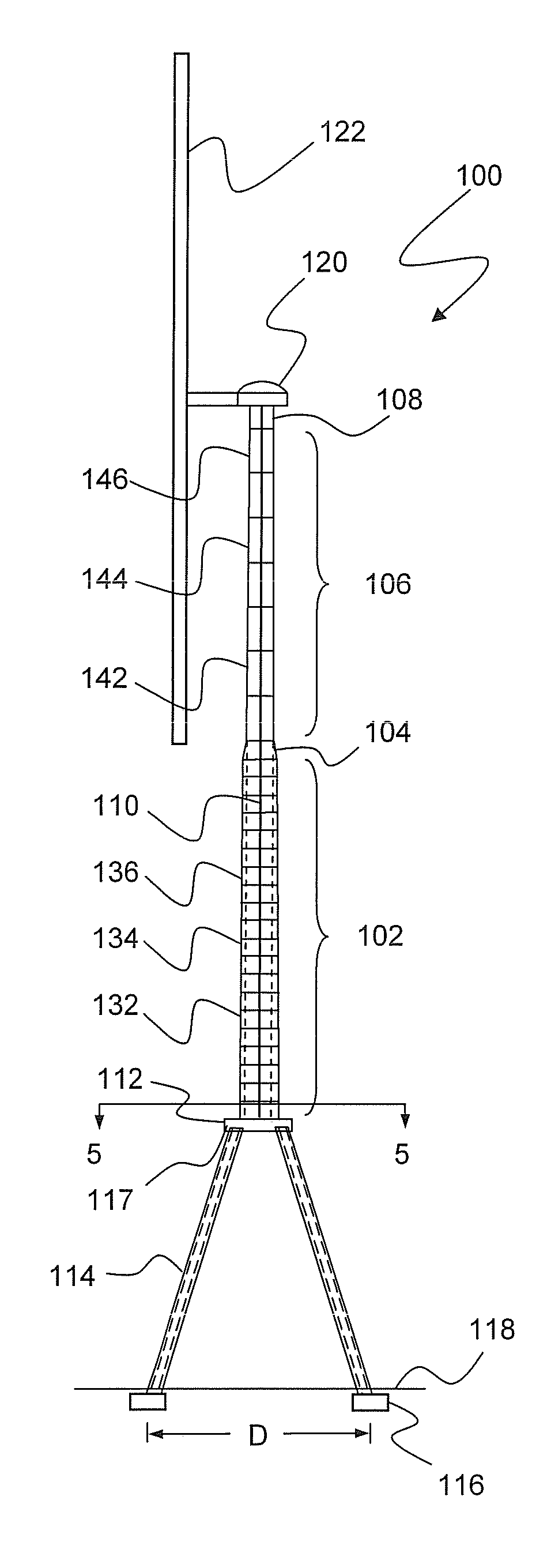

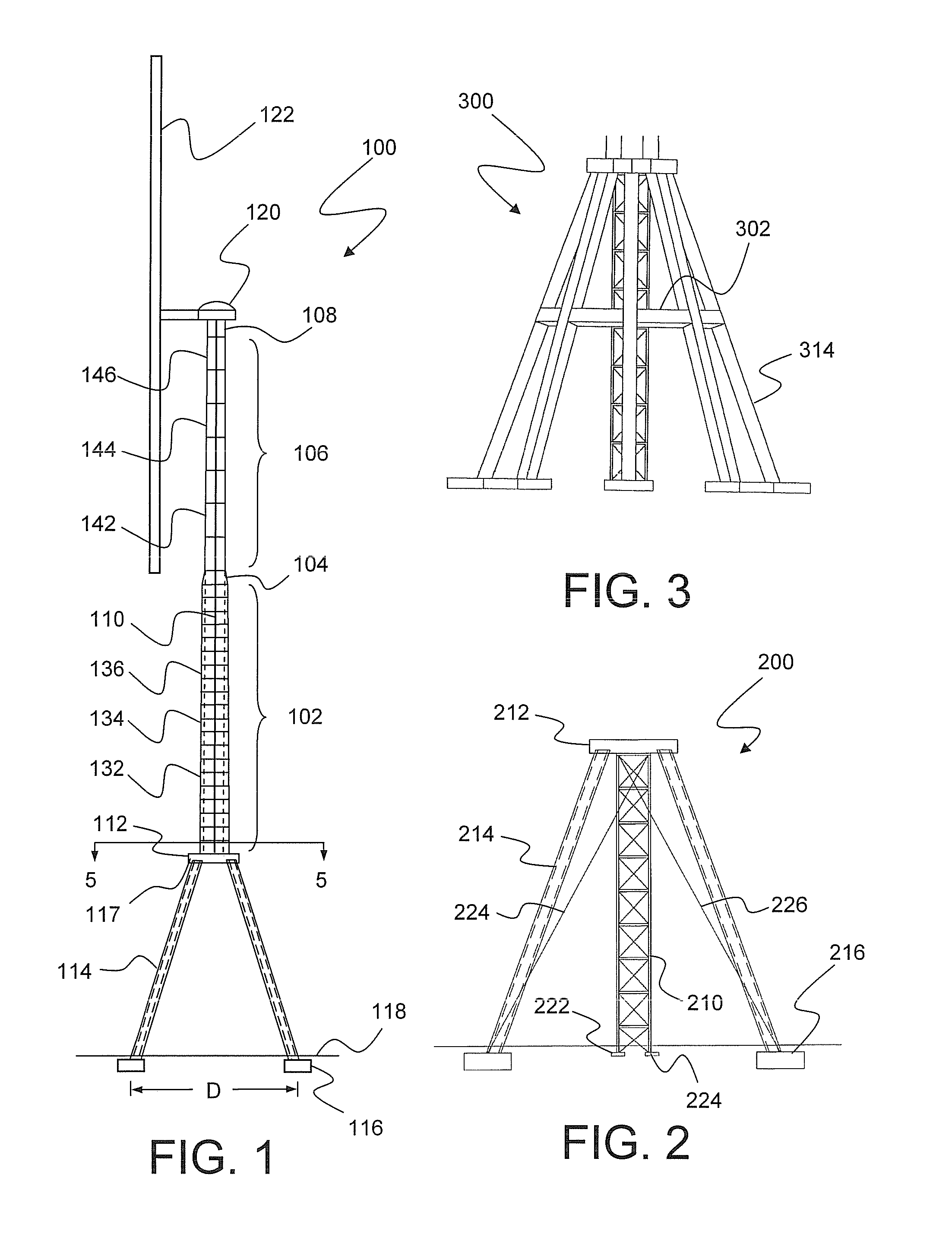

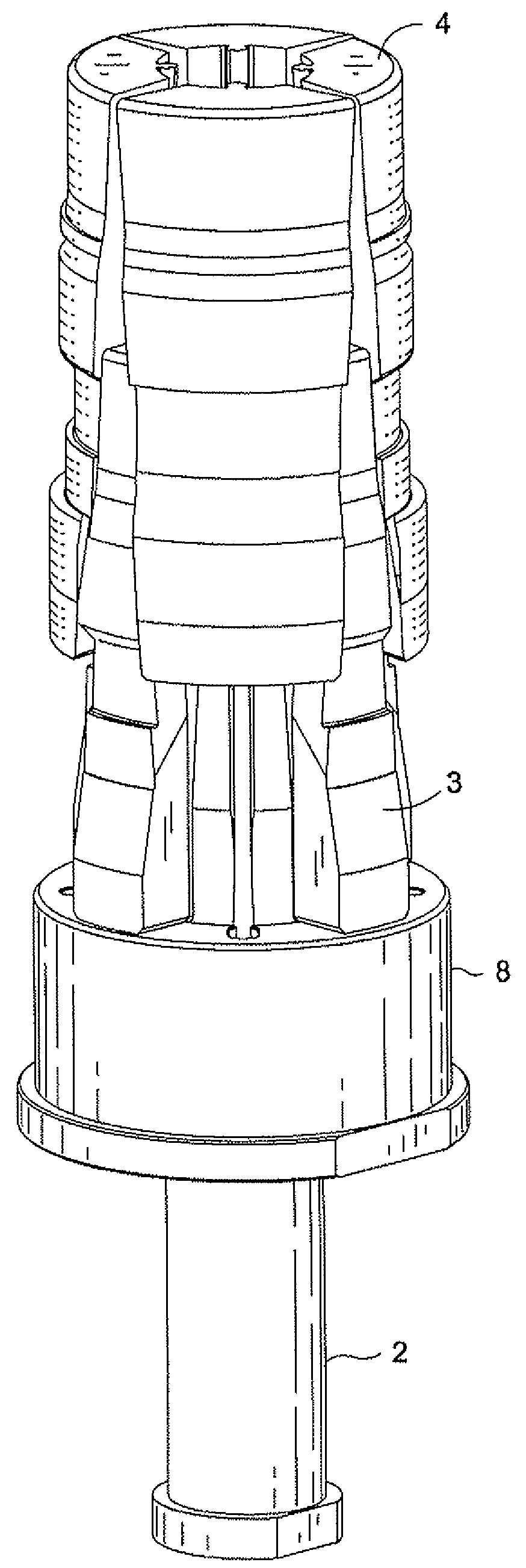

Base support for wind-driven power generators

Disclosed are apparatus and corresponding methodology for providing a base support, such as including concrete, and used such as for a wind-driven generator. Precast concrete cylinders are stacked in place upon a platform that may be partially precast and partially cast in place during assembly and supported, in certain embodiments, by plural concrete legs, the other ends of which are supported on a unitary or subdivided concrete foundation. In other embodiments, the platform may be supported by ribbed concrete panels. The concrete cylinders are glued together using an epoxy and then secured by an internal vertical post tension system extending from the platform to the upper most cylinder. Different types of concrete are used between upper and lower sections of the stacked cylinders. The lower section uses reinforced concrete while the upper section used ultra high performance fiber reinforced concrete.

Owner:TINDALL CORP

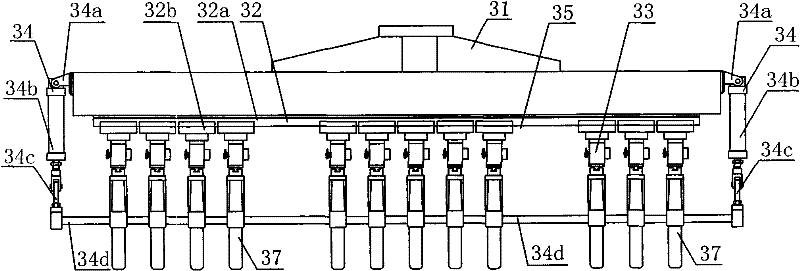

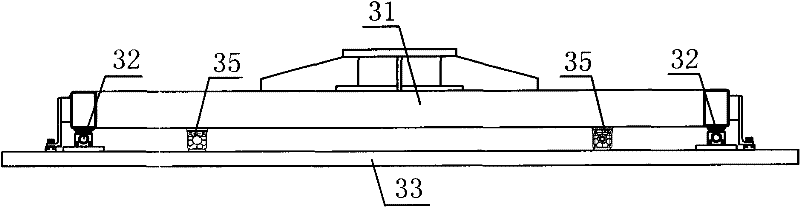

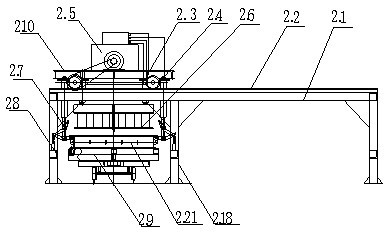

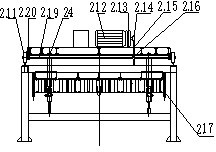

Automatic adobe stacking device

ActiveCN102225719AIncrease productivityImprove stack qualityDischarging arrangementStacking articlesAutomatic controlMechanical engineering

The invention provides an automatic adobe stacking device. The device comprises an automatic control device, an adobe group conveying mechanism, a horizontal travelling mechanism, a vertical lifting mechanism arranged on the horizontal travelling mechanism, a rotation mechanism fixed on the lower end of the vertical lifting mechanism and an adobe grabbing mechanism fixed on the lower end of the rotation mechanism, wherein the adobe group conveying mechanism is arranged below the adobe grabbing mechanism; and the automatic control device is respectively connected with the adobe group conveyingmechanism, the horizontal travelling mechanism, the vertical lifting mechanism, the rotation mechanism and the adobe grabbing mechanism so as to control the operation of the mechanisms. The adobe automatic stacking device has the advantages of accurate positioning, stable direction steering, neatly stacked adobes, firmly overlapped upper and lower adobes, simple structure, high automatic degree and easiness for operation, so that the labor intensity of workers is reduced, the production efficiency of stacking is greatly improved, and the stacking quality of adobe stacks is improved.

Owner:信阳雄狮装备科技股份有限公司

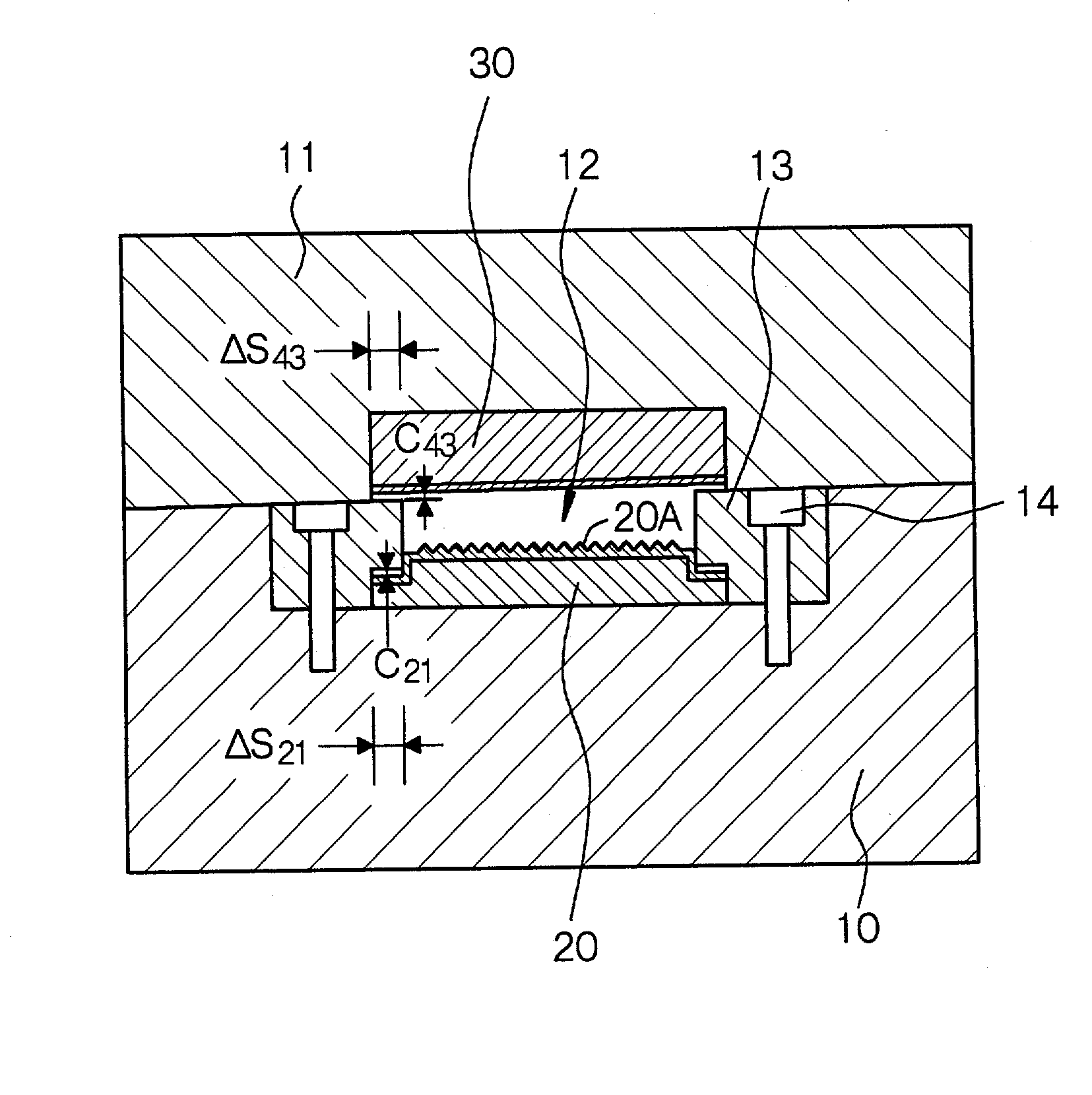

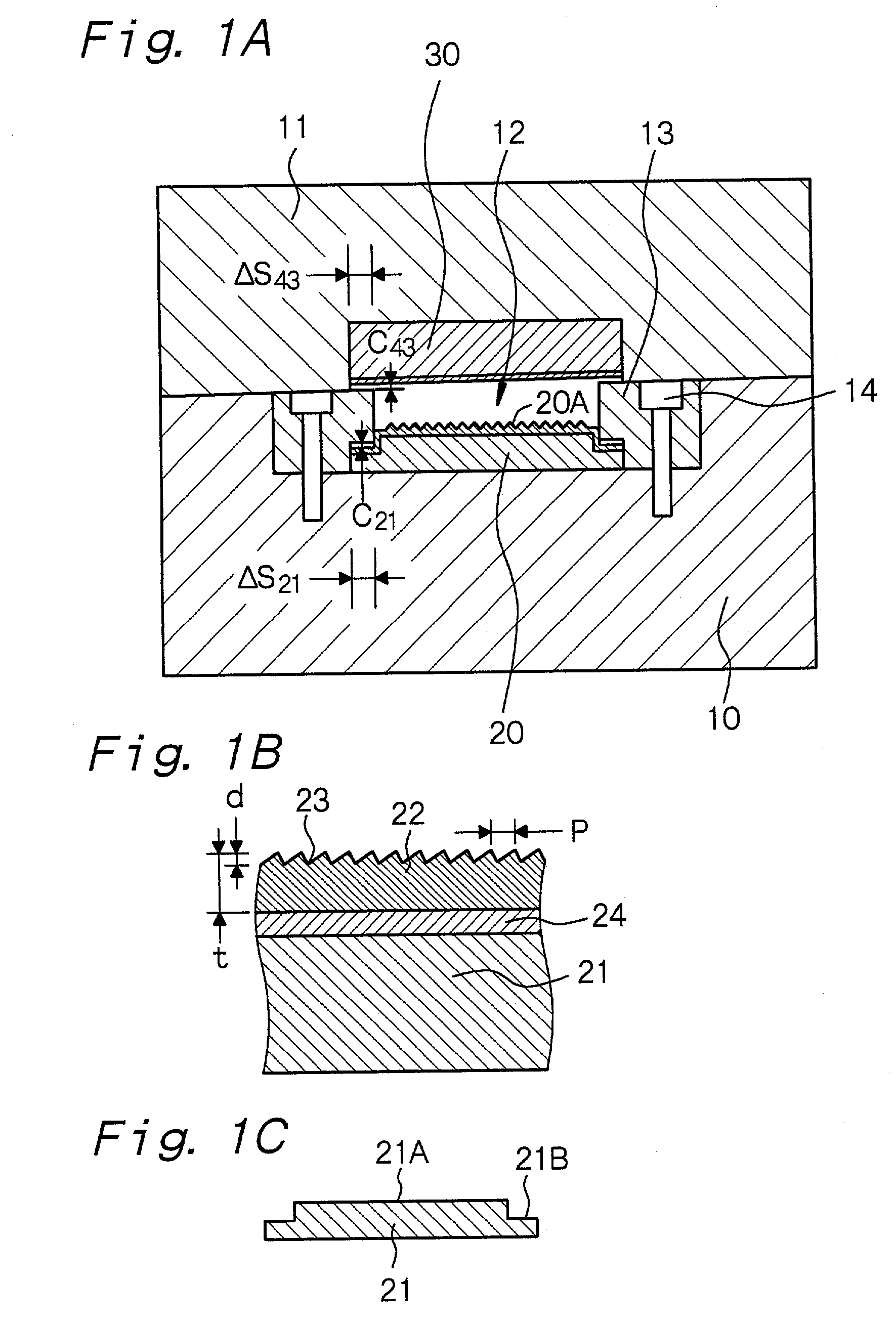

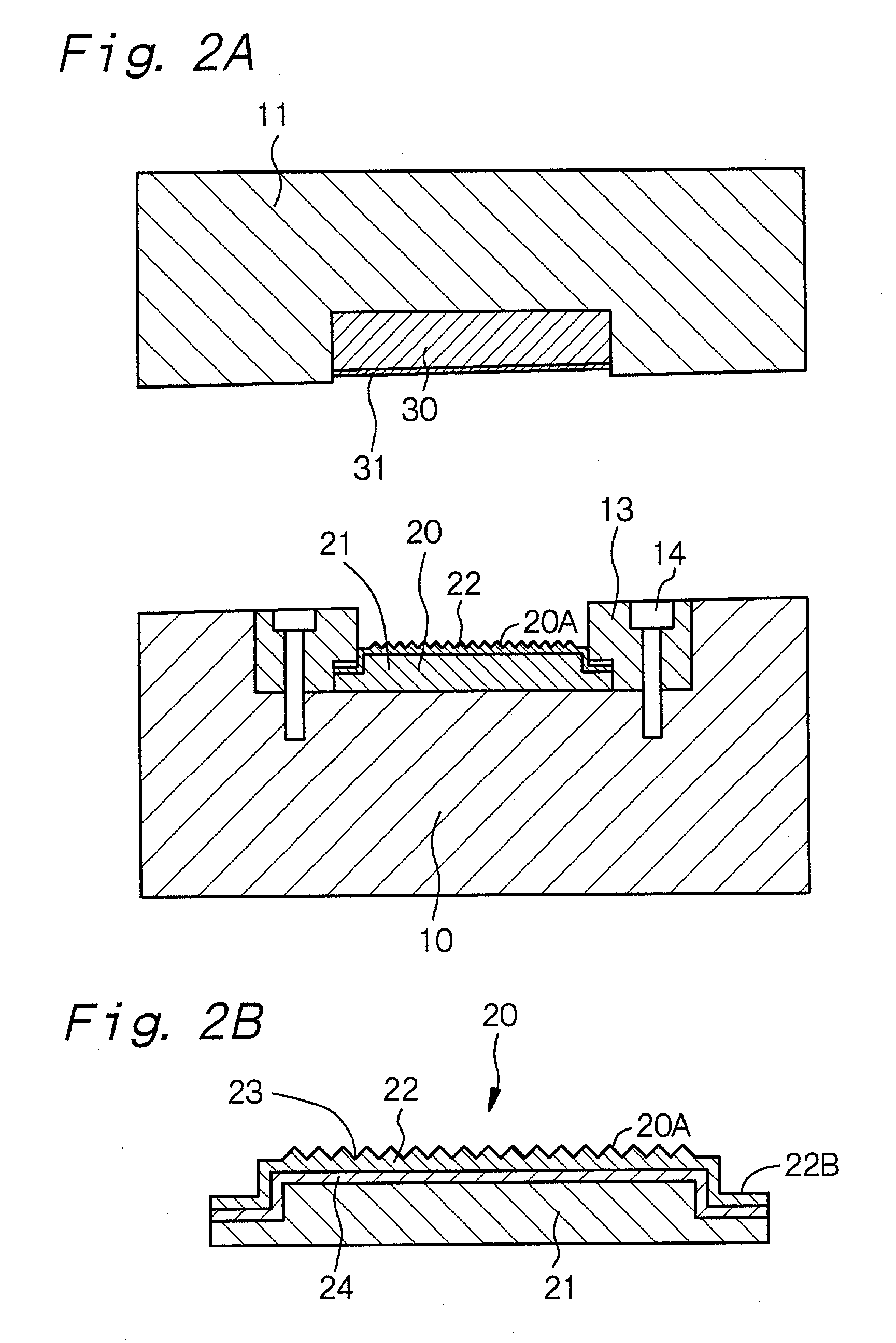

Light guide plate made of transparent resin, molding method thereof, insert block, mold assembly, and area light apparatus

InactiveUS20020181224A1Accurately reliably formedCorrect formatMechanical apparatusMouldsLight guideMechanical engineering

A light guide plate which is made of a transparent resin and has a first main surface and a second main surface opposite to said first main surface, said first main surface having a surface portion provided with convex portions having a height of 5x10-7 m to 6x10-5 m each and a pitch of 5x10-7 m to 4x10-4 m, each convex portion having a tip portion, and the convex portions of at least 80% of the total convex portions having the tip portions having a radius of curvature of 2x10-6 m or less.

Owner:MITSUBISHI ENG PLASTICS CORP

Receptacle for handling molten metal, casting assembly and manufacturing method

InactiveUS20130334744A1Simpler and less cumbersomeEasy to manufactureMelt-holding vesselsDischarging arrangementRefractoryEngineering

A receptacle for handling molten metal is provided. The receptacle has bottom and side walls and includes a refractory defining a cavity within which the molten metal is conveyed or contained. The receptacle has at least one channel extending within at least one of its walls. The channel has an inlet and an outlet. The inlet is connectable to a source for circulating a fluid within the channel. The outlet allows the fluid to be expelled from said channel. The channel allows, when the fluid is circulated in it, to regulate the temperature of the refractory and thereby of the metal conveyed or contained. A casting assembly and a method for casting the refractory are also provided.

Owner:PYROTECK INC

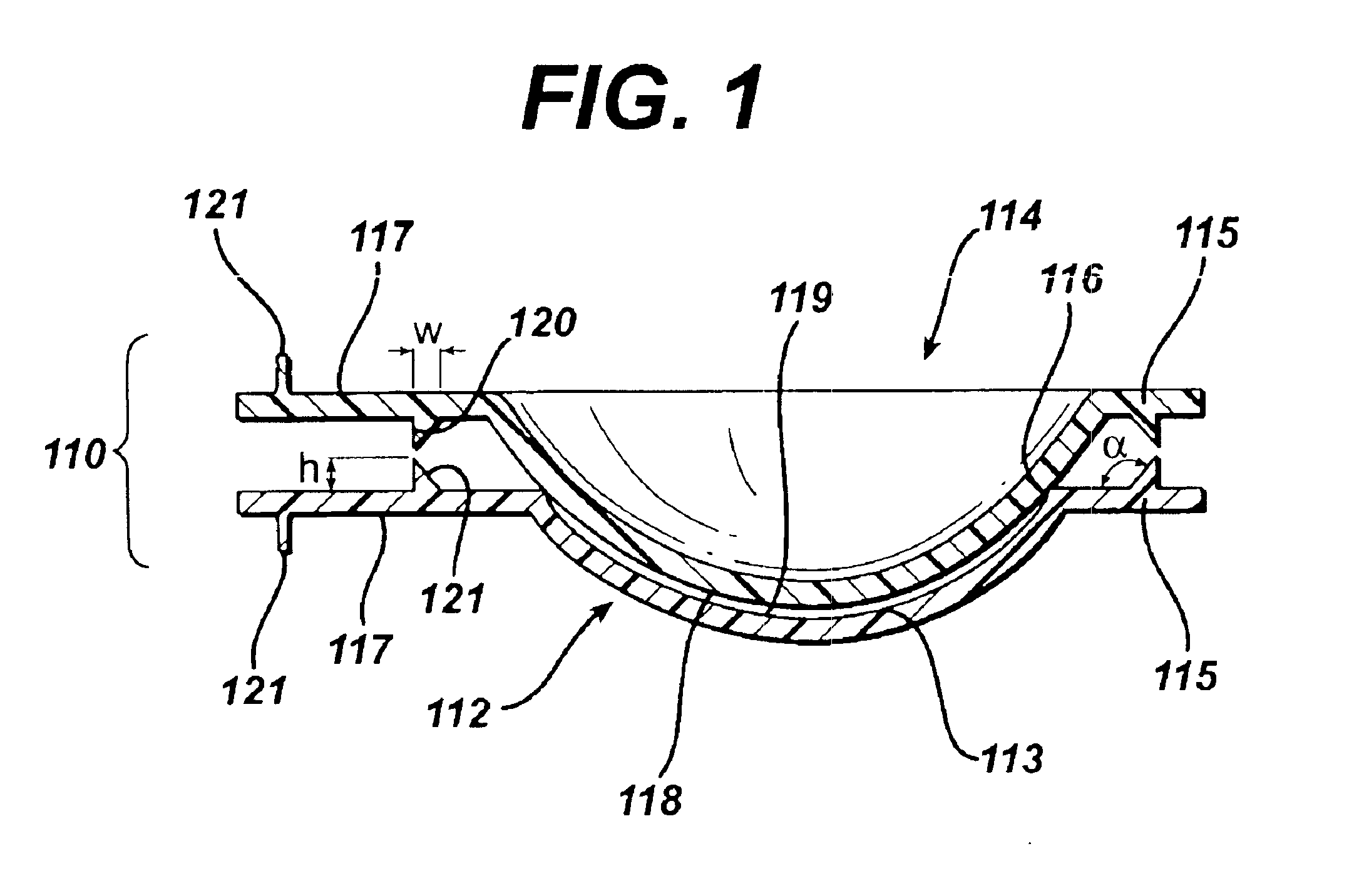

Systems and methods for producing silicone hydrogel contact lenses

Systems and methods for producing silicone hydrogel contact lenses are described. Certain of the present systems include a contact lens mold forming station, a station for filling a contact lens mold section with a lens precursor composition and for placing a second mold section on the filled mold section to form a contact lens mold assembly, a curing station for forming a contact lens, a mold assembly separation station, and an extraction / hydration station. Certain of the present methods include forming a plurality of mold sections, placing a lens precursor composition on a surface of a first mold section, placing a second mold section on the first mold section, polymerizing the lens precursor composition, separating the first and second mold sections, removing the silicone hydrogel contact lens from one of the mold sections, extracting extractable components from the contact lens, and hydrating the contact lens.

Owner:COOPERVISION INT LTD

Method and mold for making ophthalmic devices

Owner:JOHNSON & JOHNSON VISION CARE INC

Production line for self-insulation building blocks

InactiveCN102555052AReduce occupancyReduce consumptionDischarging arrangementCeramic shaping plantsProduction lineBrick

The invention relates to a tool used in an insulation brick manufacturing process, in particular to a production line for self-insulation building blocks, which comprises a stirring machine. The production line is characterized in that automatic metering devices are arranged on a feeding port and at the bottom of the stirring machine, a production track capable of automatically conveying molds isdisposed below a distributing port of the stirring machine, a stripper is further arranged on the production track and is spaced from the stirring machine by a proper distance, a return track and a track leading into a maintenance area are respectively disposed on two sides of the other end of the stripper, the return track sequentially penetrates through a cleaning area, an oil injection area and a core setting area, a link plate machine is arranged at the other end of the maintenance area, and a manipulator is disposed at the other end of the link plate machine. The production line is high in production efficiency and annual yield, occupied land area and workshop investment are reduced, operating expense is saved, and the production line can operate continuously.

Owner:张建兴

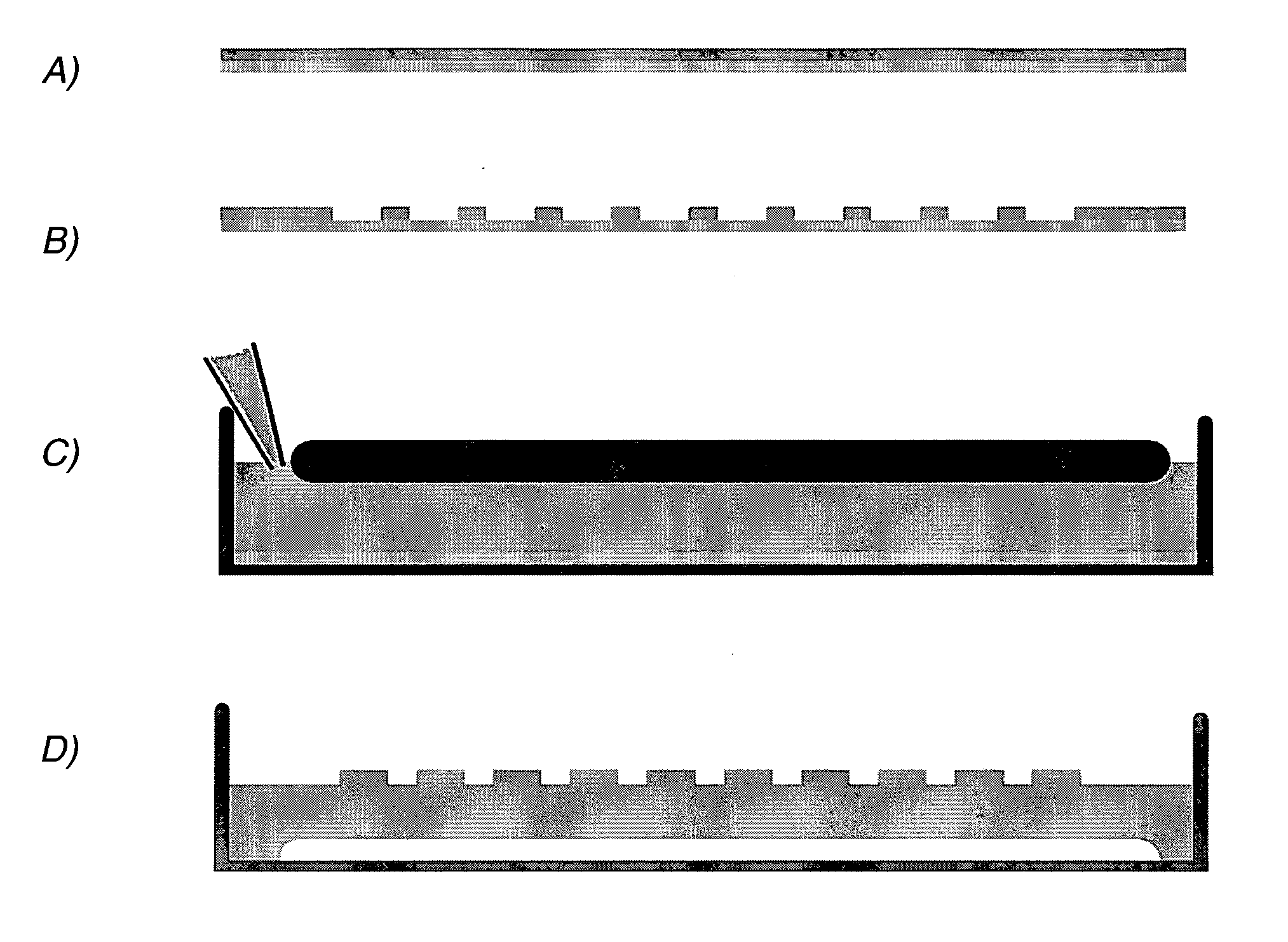

Elevator and method for tilting solid image build platform for reducing air entrainment and for build release

ActiveUS20080179787A1Reduce viscosityImprove bindingMouldsConfectioneryAir entrainmentHigh intensity

A solid imaging apparatus is provided that includes a replaceable cartridge containing a source of build material and an extendable and retractable flexible transport film for transporting the build material layer-by-layer from the cartridge to the surface of a build in an image plane. An operator using the device needs merely to remove a spent cartridge and replace it with a fresh cartridge to continue solid imaging virtually uninterrupted. The apparatus also includes the capability of withdrawing and inserting an imager without the operator having to perform a separate alignment step. A brush attached to the transport film and forming part of the cartridge provides for intra-layer removal of excess uncured build material. If desired, the apparatus can produce a fully reacted build. A high intensity UV source cures the build between layers. An injection molded build pad is designed to hold a build in an inverted position for improving the build. The invention also provides for tilting the build elevator to reduce air entrainment and for releasing the build from the image plane.

Owner:3D SYST INC

Method for producing composite silica particles

InactiveUS20120264599A1Improve utilization efficiencyLiquid surface applicatorsSilicaSilica particleSolvent

Disclosed is a method for producing composite silica particles and hollow silica particles that can improve the utilization efficiency of a hydrophobic organic substance. It is a method for producing composite silica particles each of which is provided with an outer shell part having a mesoporous structure formed from a silica-containing component and which includes a hydrophobic organic substance in the interior of the aforementioned outer shell part, and involves adding an aqueous solvent to the hydrophobic organic substance and emulsifying, and forming the outer shell part having the mesoporous structure formed from the silica-containing component on the surface of an emulsified oil droplet of the aforementioned hydrophobic organic substance.

Owner:KAO CORP

Assembly of free-standing films using a layer-by-layer process

InactiveUS20010046564A1Easy to controlRetain biological activityMaterial nanotechnologyMouldsCross-linkEngineering

A method for the layer-by-layer assembly of a free standing thin film includes the steps of preparing a support with a suitable substrate; forming a thin film having a plurality of layers onto the substrate utilizing a layer-by-layer assembly process; removing the substrate and thin film from the support; and separating the substrate from the thin film. Various compounds improving the strength, flexibility, tension and other mechanical properties may be included in the assembly to improve the structural quality of the film. Similar effect may also be achieved by cross-linking the applied layers.

Owner:BOARD OF REGENTS FOR OKLAHOMA STATE UNIVERSITY +1

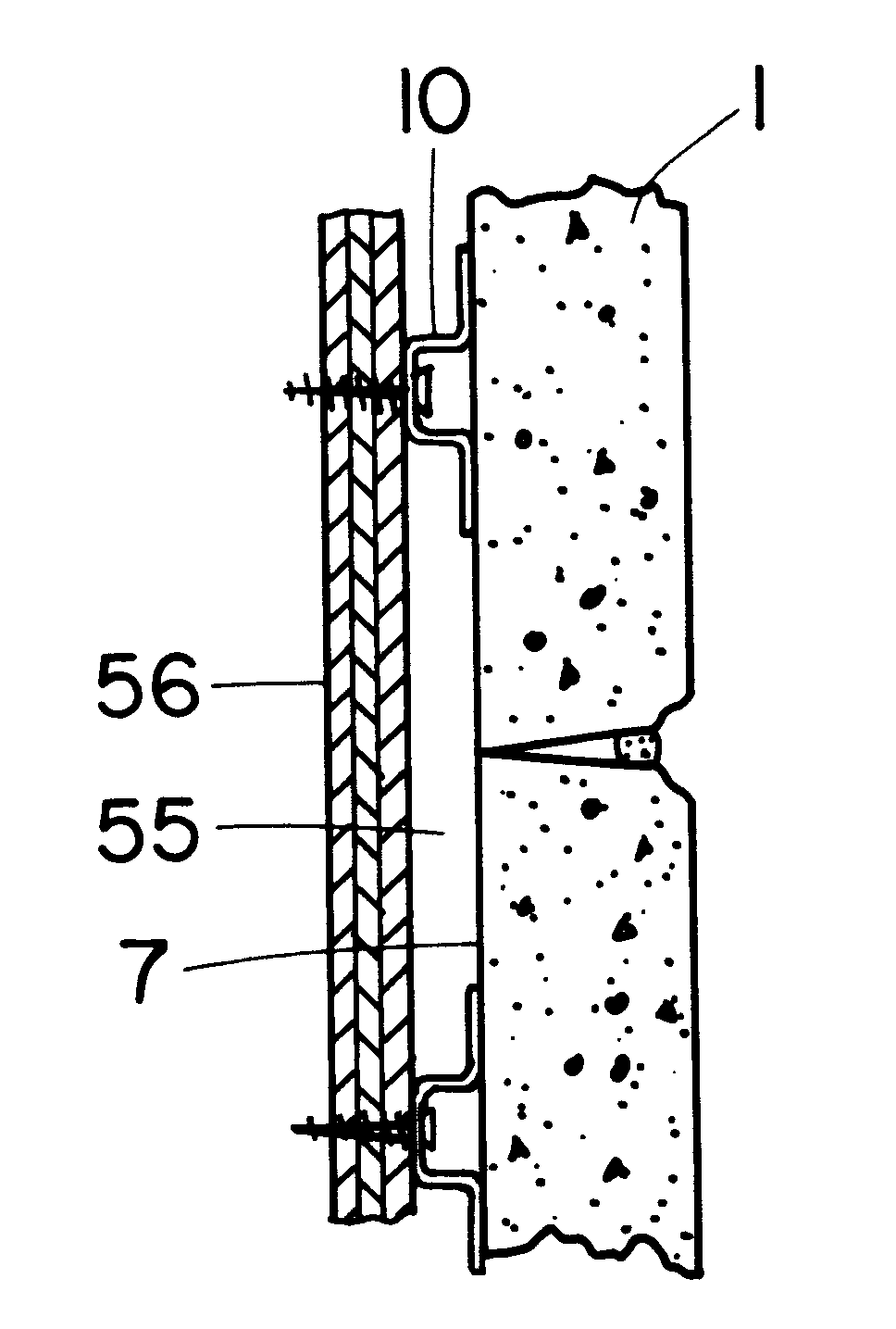

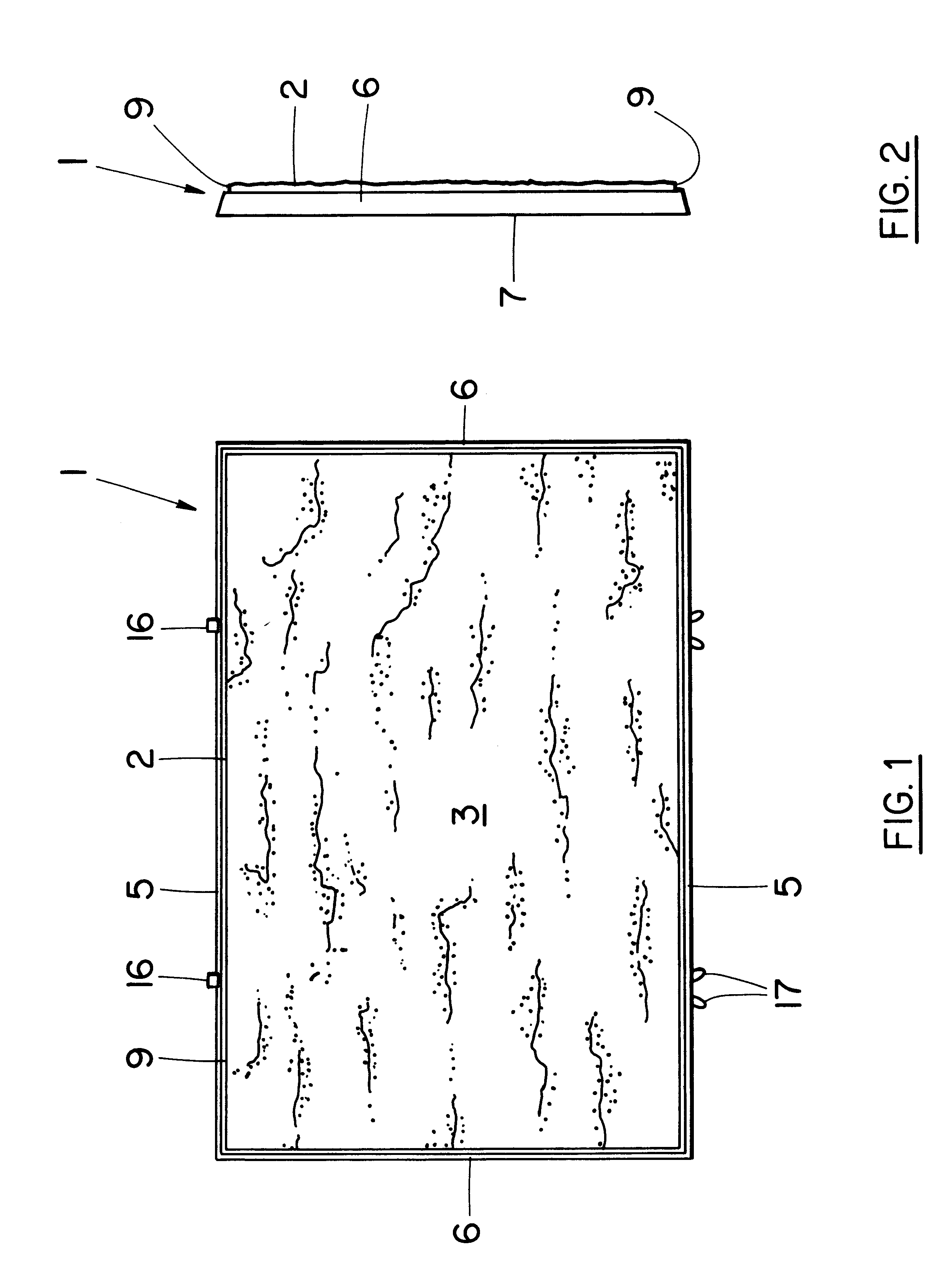

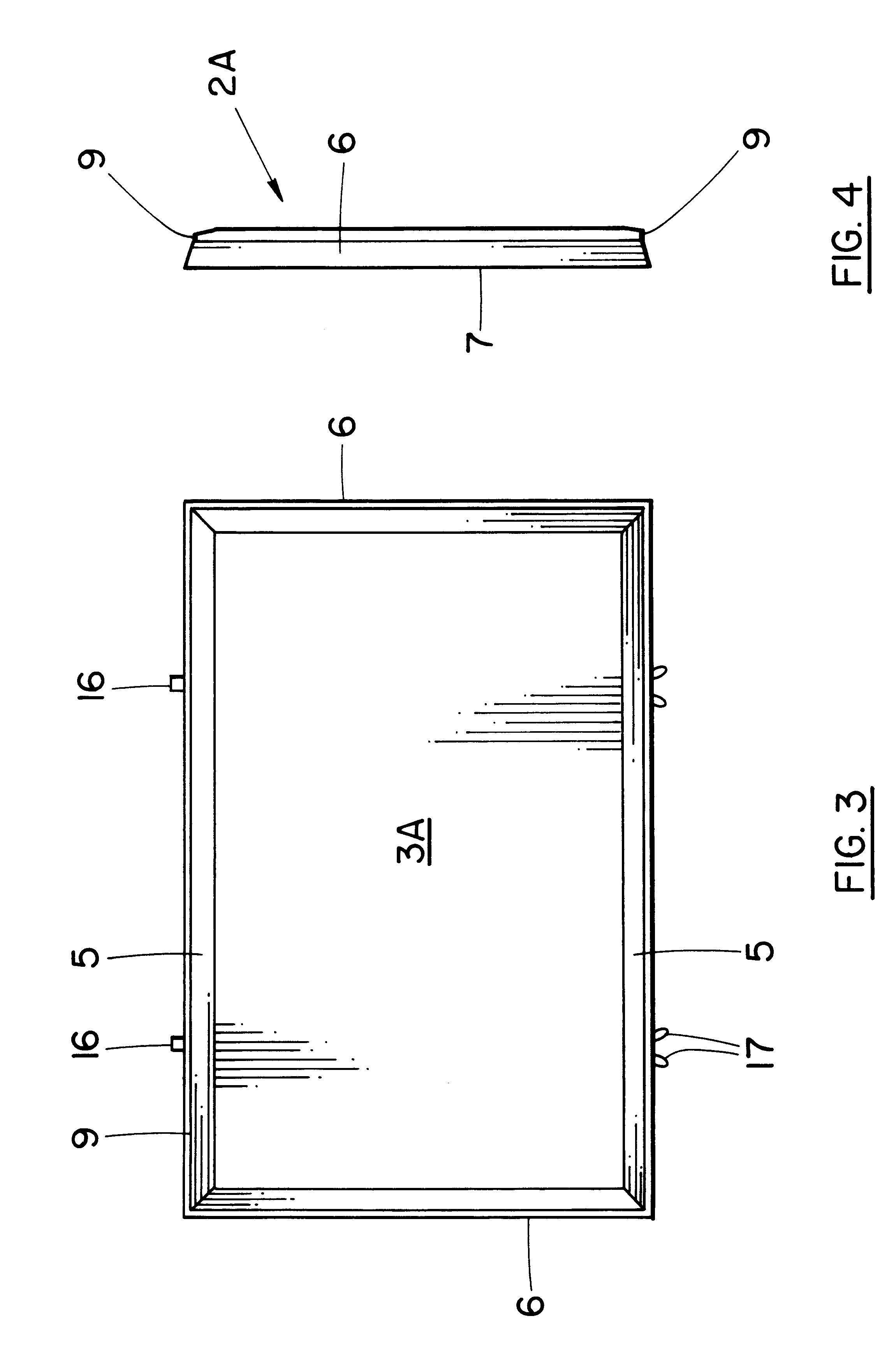

Concrete panel construction

A concrete panel system comprising a plurality of concrete panels arranged in side-by-side fashion on a substantially vertical supporting wall, each of the panels comprising a rectangular body having a front surface and a rear surface and beveled side edges, the side edges each forming an angle of between eighty-five and ninety degrees with the rear surface, and a concave caulking groove lying between and connecting each of the beveled side edges with the front face, the side edges of adjacent panels forming a V-joint between the adjacent panels, a flexible sealant material in a portion of the caulking grooves of adjacent panels and a portion of the V-joint for providing a seal between adjacent panels, and a hanger element embedded in the rear of the panels for securing the panels to the supporting wall.

Owner:STONETILE CANADA

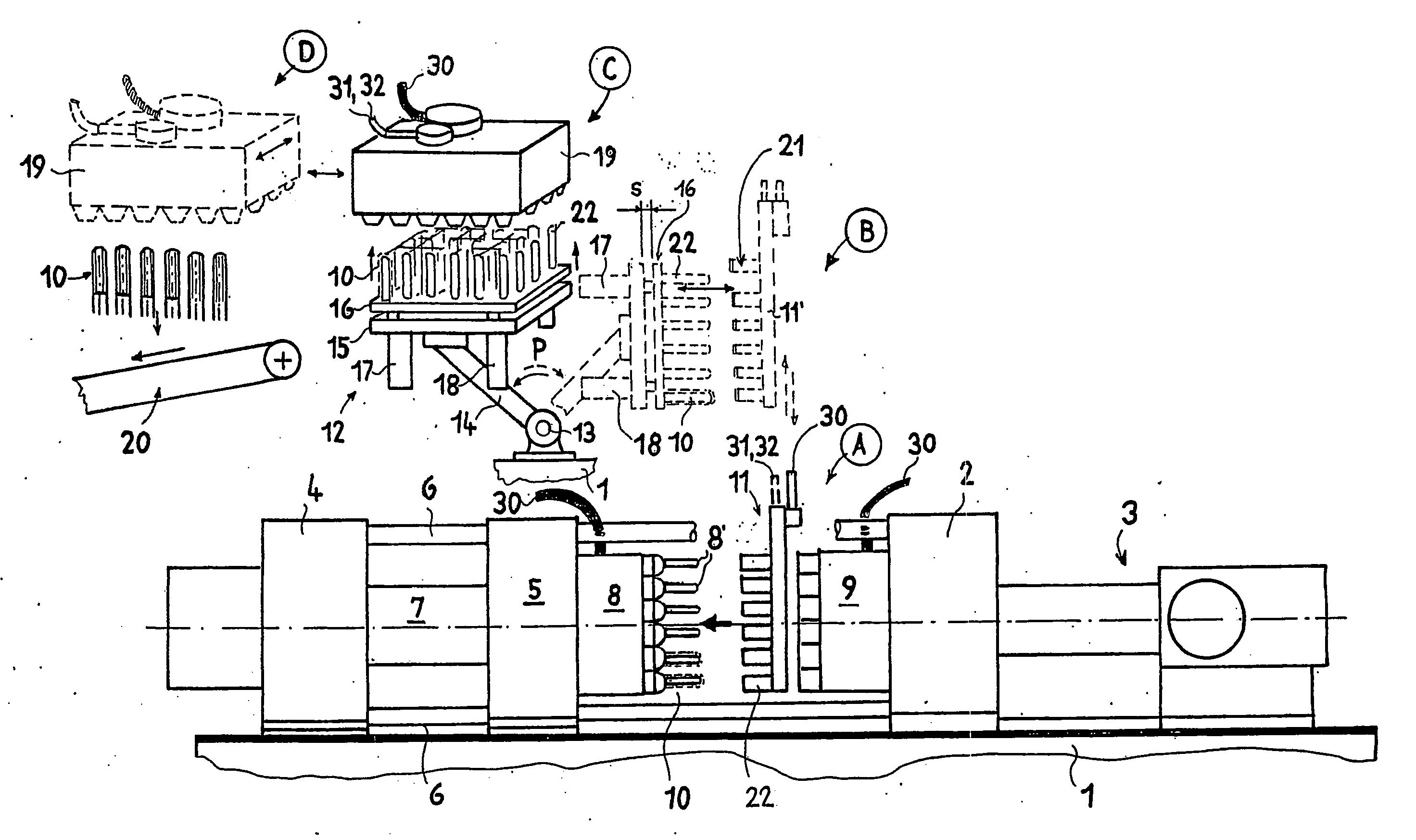

Method and device for the secondary treatment and the cooling of preforms

InactiveUS20060138696A1The temperature drops quicklyShort injection cycleDischarging arrangementMouldsTime delaysEngineering

The invention relates to a method and a device for the secondary treatment and the cooling of preforms (10) once they have been removed from the open mould halves (18, 9) of an injection moulding machine. The preforms are removed from the open moulds (18, 9) while still hot, by means of water-cooled cooling sleeves (21) of a removal device (11), and are subjected to intensive cooling during the duration of an injection moulding cycle. Both the entire inner side and the entire outer side of the blow-moulded part (10) are subjected to intensive cooling. Secondary cooling is then carried out, the duration thereof being equal to a multiple of the duration of an injection moulding cycle. After being removed from the casting moulds, the preforms are dynamically introduced into the cooling sleeves (21) until they fully touch the walls thereof. The inner cooling is carried out in a time-delayed manner.

Owner:NETABTAL MASCHEN

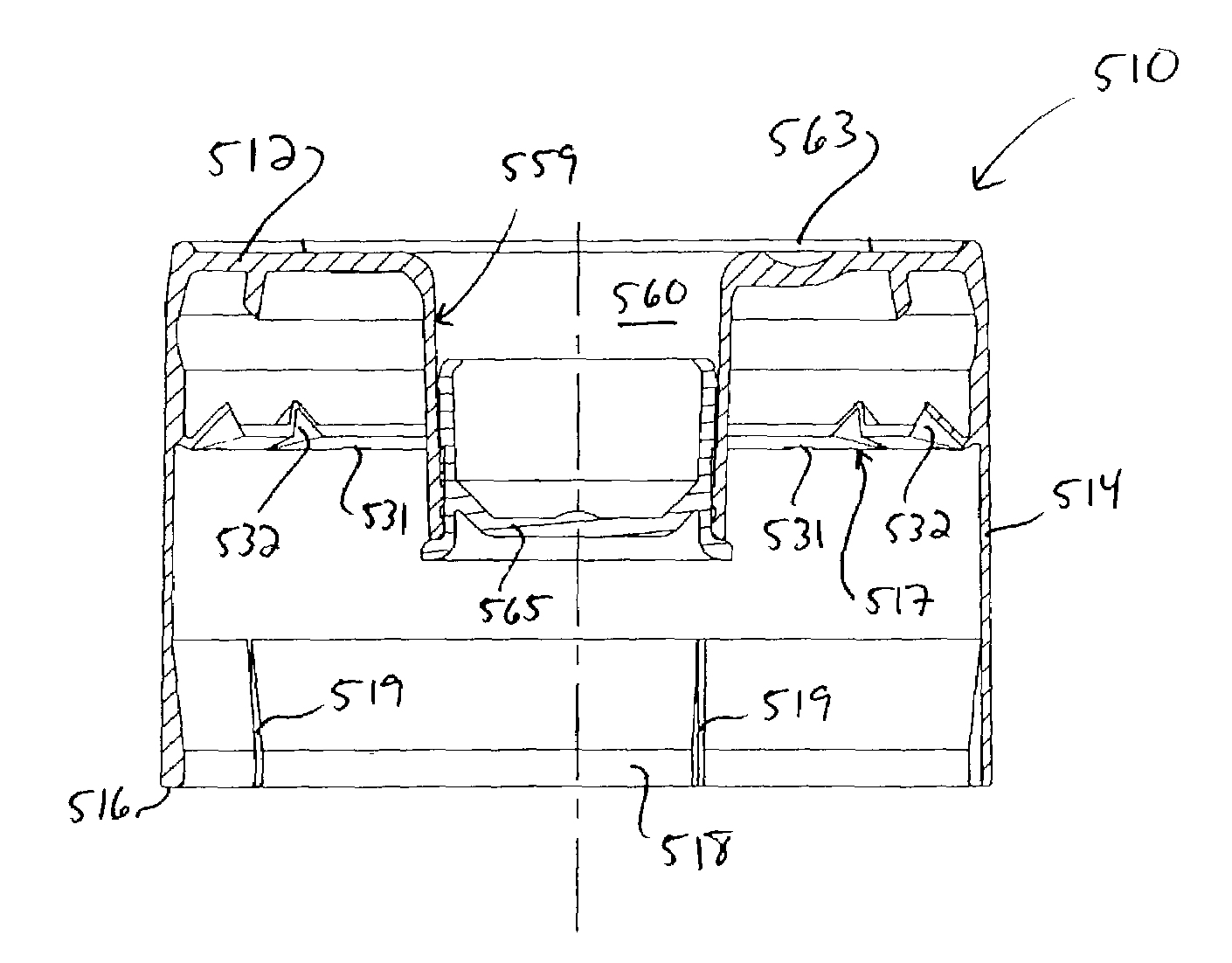

Mechanically collapsible core for injection molding

InactiveUS20090152770A1Easily withdrawnDischarging arrangementMouldsEngineeringInjection molding machine

The invention relates to a mechanically-collapsible core device includes a central pin having a plurality of engaging members, a plurality of first collapsible core members each having an engaging member that engages with a respective engaging member of the central pin, a base member having a plurality of engaging members, and a plurality of second collapsible core members each having an engaging member that engages with a respective engaging member of the base member. The pin is retracted from a home position, thereby causing the first core members to collapse inward. The base member is then retracted, thereby causing the second core members to translate inward and linearly. The result is that the core device collapses inward in size so as to permit the device to be removed from the inside of a molded article.

Owner:CANON VIRGINIA

Method and apparatus for forming concrete blocks

A method and apparatus for forming a concrete block in form having a resilient insert forming a cavity in which the block is cast and a rigid support for the resilient insert. After the block has cured, the form is inverted. One or more areas of the insert are tethered to the support so that at least a portion of the insert can fall a short distance from the support. The weight of the cast block sufficiently deforms the insert to allow the block to fall free from the insert. When the form is again inverted to its upright position, the insert falls back into the support and returns to its original shape.

Owner:ROSETTA HARDSCAPES

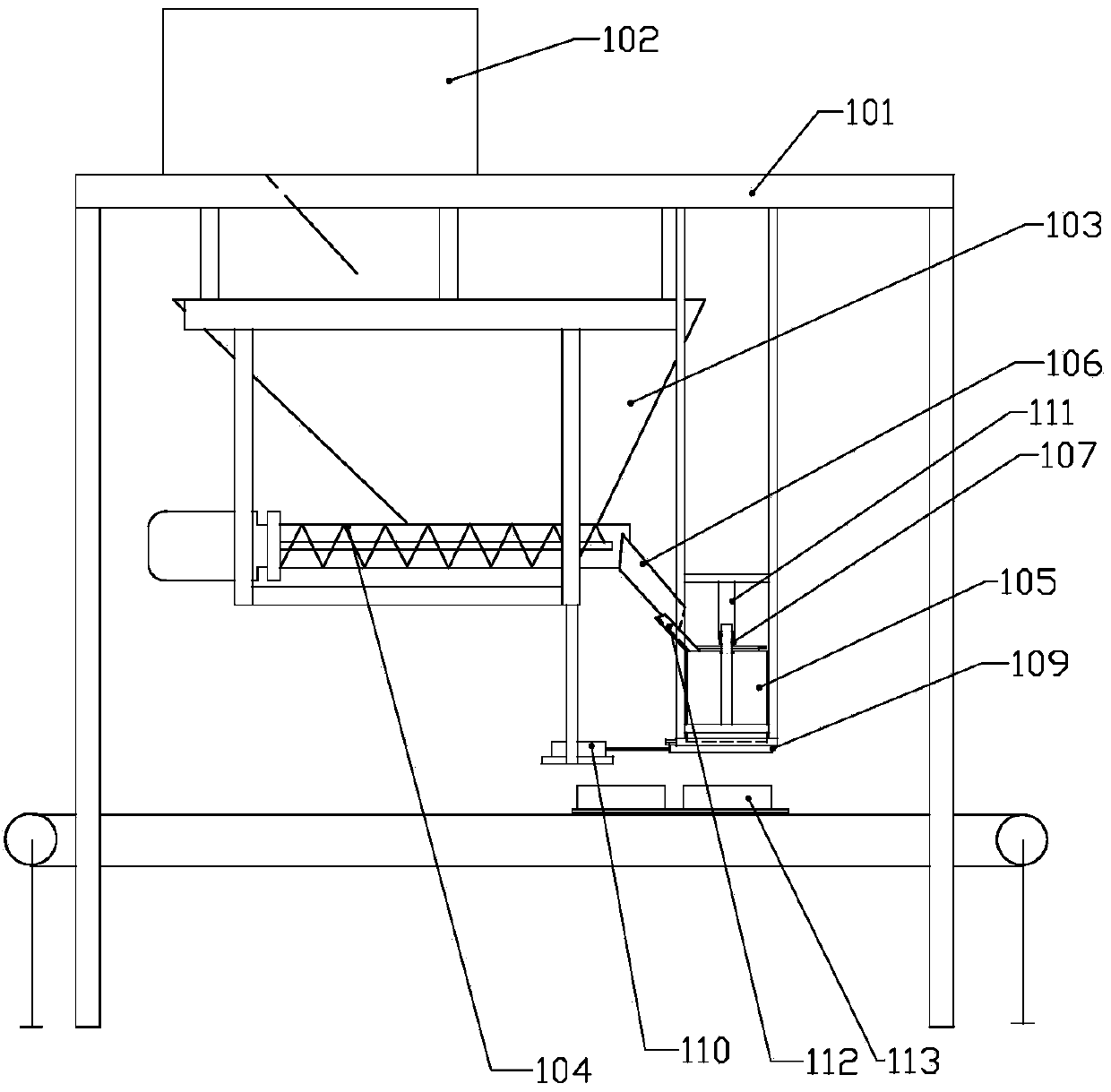

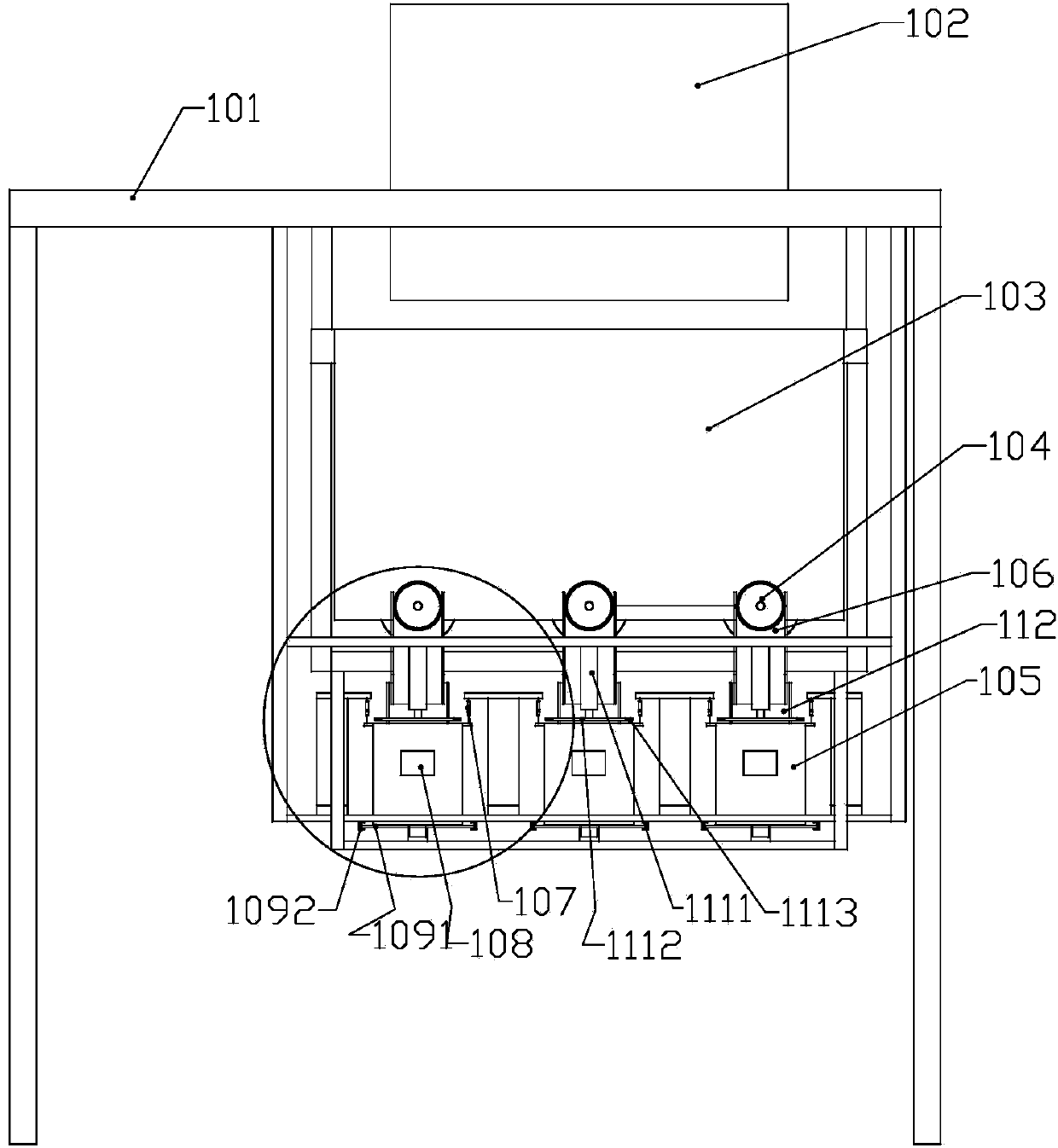

Automatic production line of small plastic-concrete components

ActiveCN104191513AObvious price advantageIncrease production capacityDischarging arrangementDischarging apparatusProduction lineHigh volume manufacturing

The invention discloses an automatic production line of small plastic-concrete components, and belongs to production equipment of small plastic-concrete components. The automatic production line of the small plastic-concrete components structurally comprises a metering pouring machine, a vibration table, a mechanical grip transporter, a turnover stripper machine, a die cleaning machine, a color pouring machine, stacking machines, turning platforms and conveyers. The stacking machines comprise the first stacking machine, the second stacking machine and the third stacking machine. The turning platforms comprises the first turning platform and the second turning platform. The conveyors comprise the first conveyor, the second conveyor, the third conveyor, the fourth conveyor and the fifth conveyor. The mechanical grip transporter is arranged at the upper portion of the front of the turnover stripper machine, the first turning platform and the second turning platform and the die cleaning machine and the color pouring machine are sequentially arranged at the upper portion of the second conveyor behind the mechanical grip transporter from front to back. The automatic production line of the small plastic-concrete components has the advantages of reducing the labor intensity of workers, saving time and labor, improving the production efficiency, improving the product quality, being capable of meeting the requirements for mass production within short time and the like.

Owner:JINAN DONGYUAN CEMENT PROD CO LTD

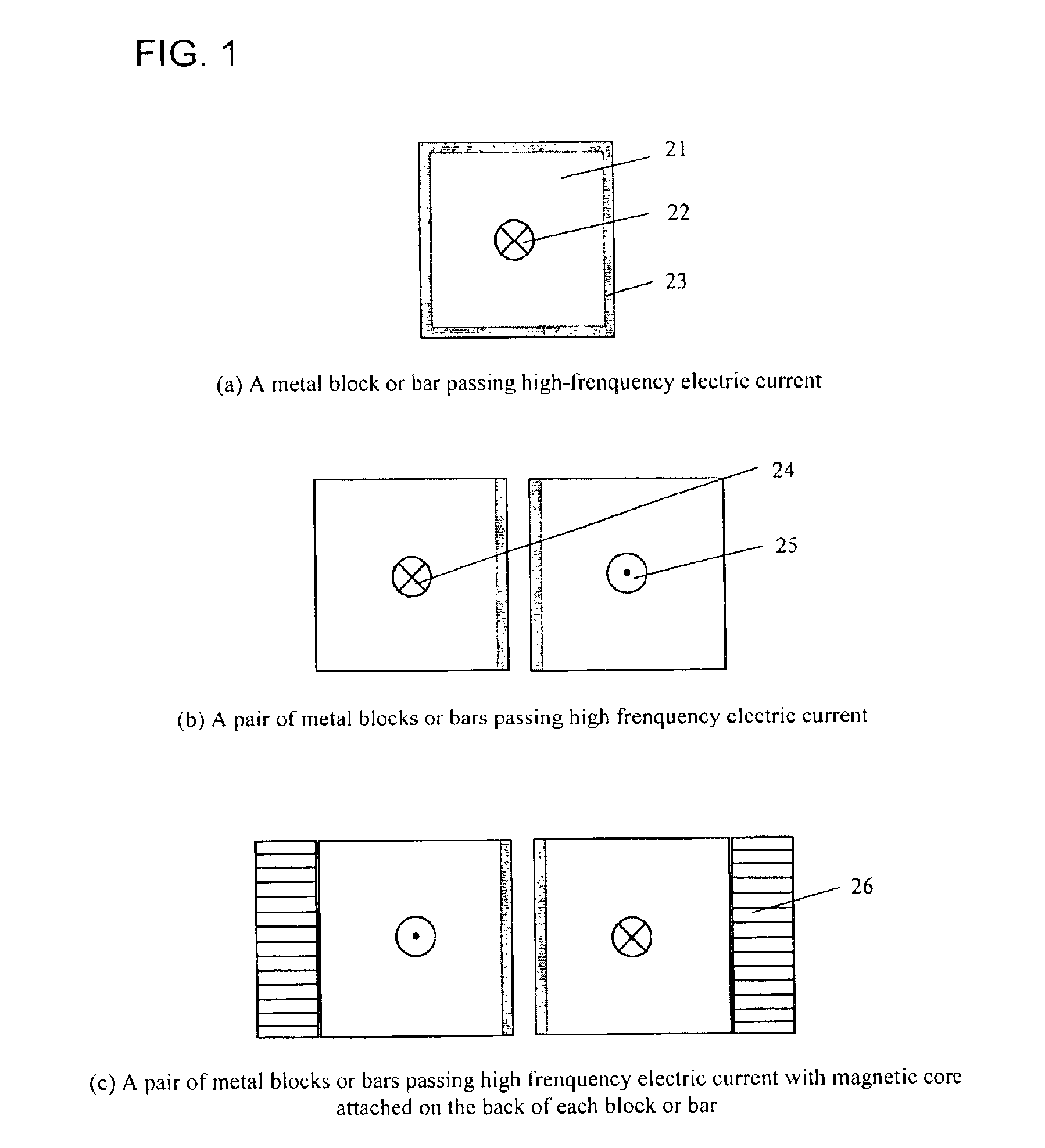

Method for rapid mold heating and cooling

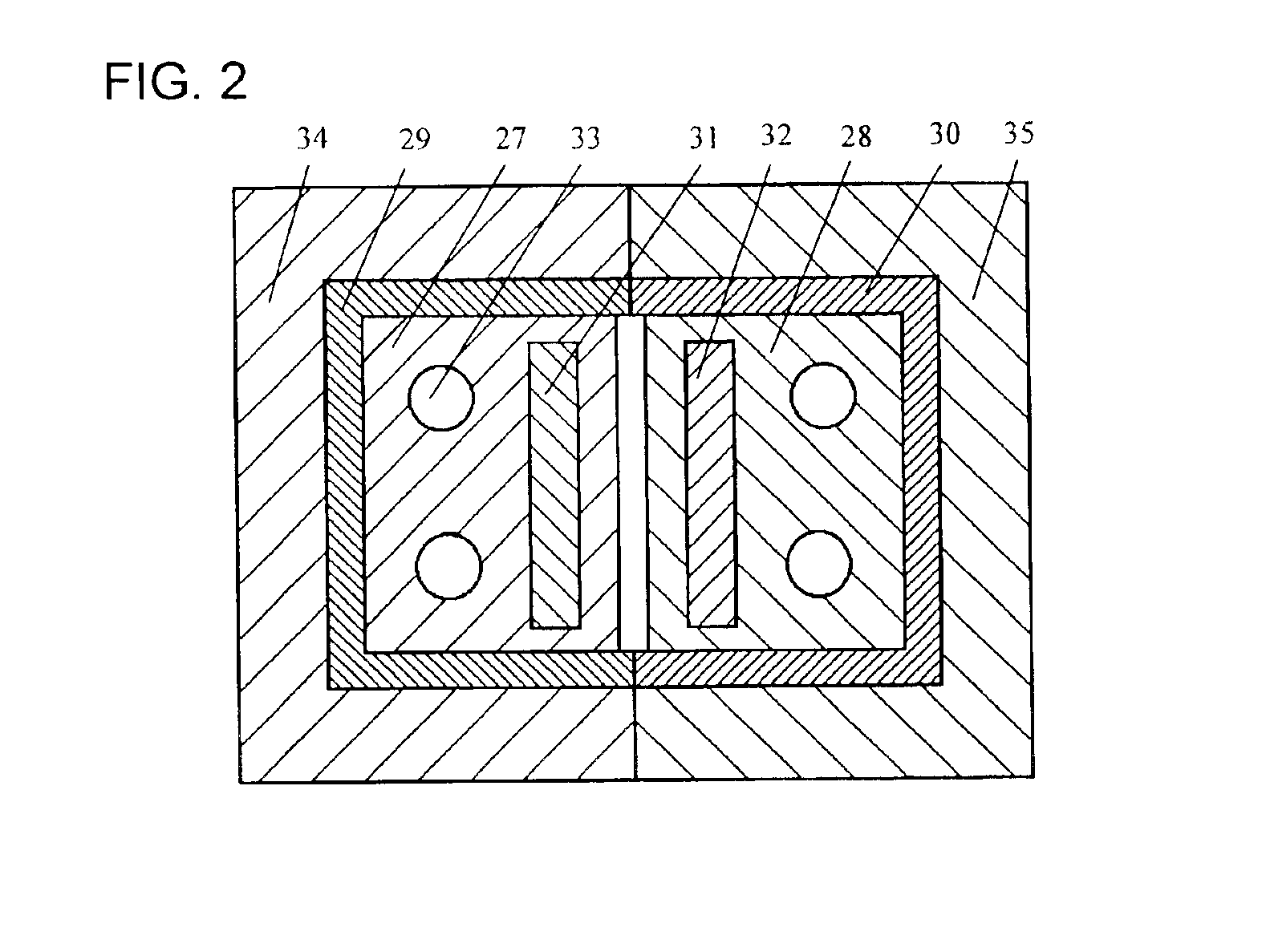

InactiveUS6846445B2Fast heatingFast coolingAdditive manufacturing apparatusDischarging arrangementThermal insulationShell molding

A method for rapidly heating a mold cavity to a predetermined temperature preferably above the softening or melting temperature of the molding material prior to and during the molding stage thereby increasing moldability and improving quality of molded parts. The mold cavity is formed by two metallic halves on which high-frequency electric current is applied and an electric circuit involving the two halves is formed. Due to the proximity effect, the electrical current flows on the inner surfaces of the two cavity halves, thus rapidly heating the mold cavity. Proper use of insulation behind the cavity surface helps increase heating efficiency. Conformal on-off cooling channels provide both thermal insulation during the heating phase and rapidly cooling of the molded article during the cooling phase.

Owner:KIM BYUNG +1

Injection moulding of a catheter

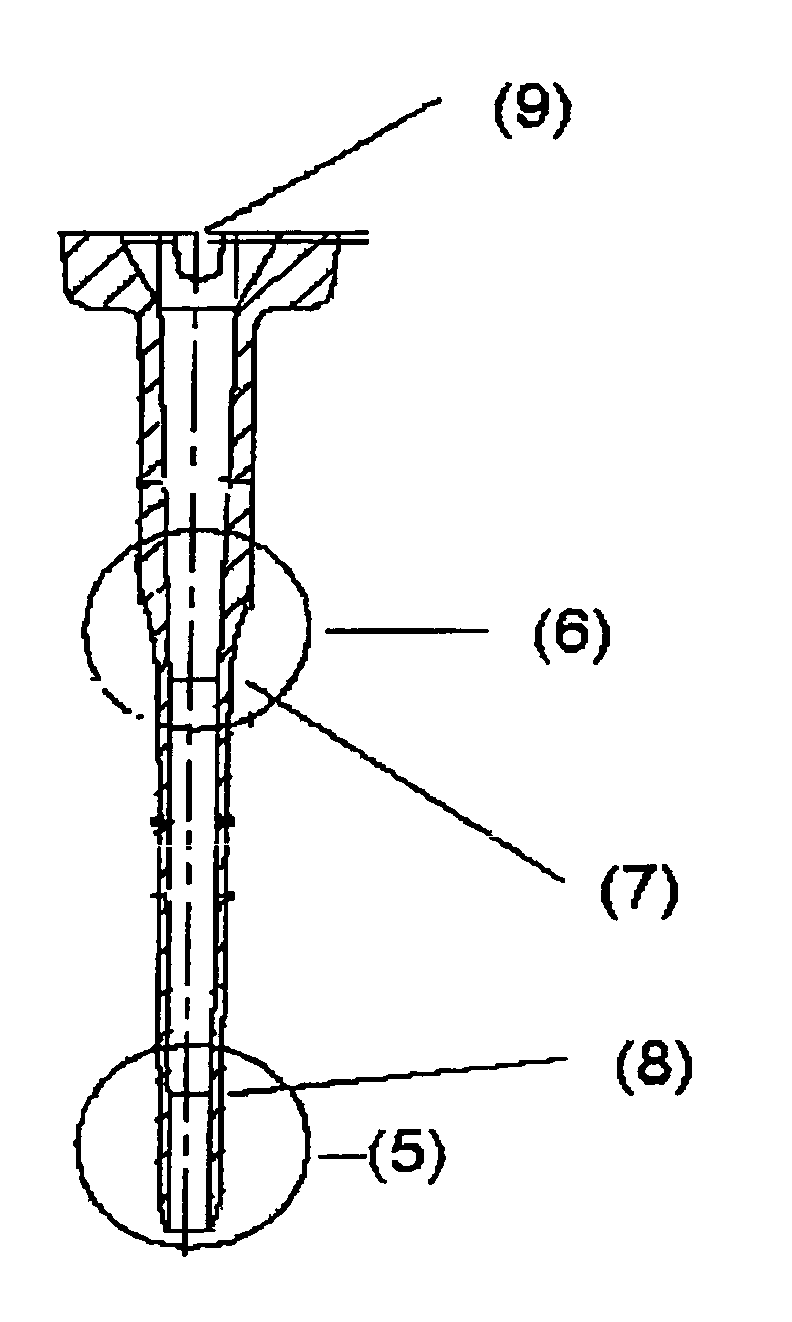

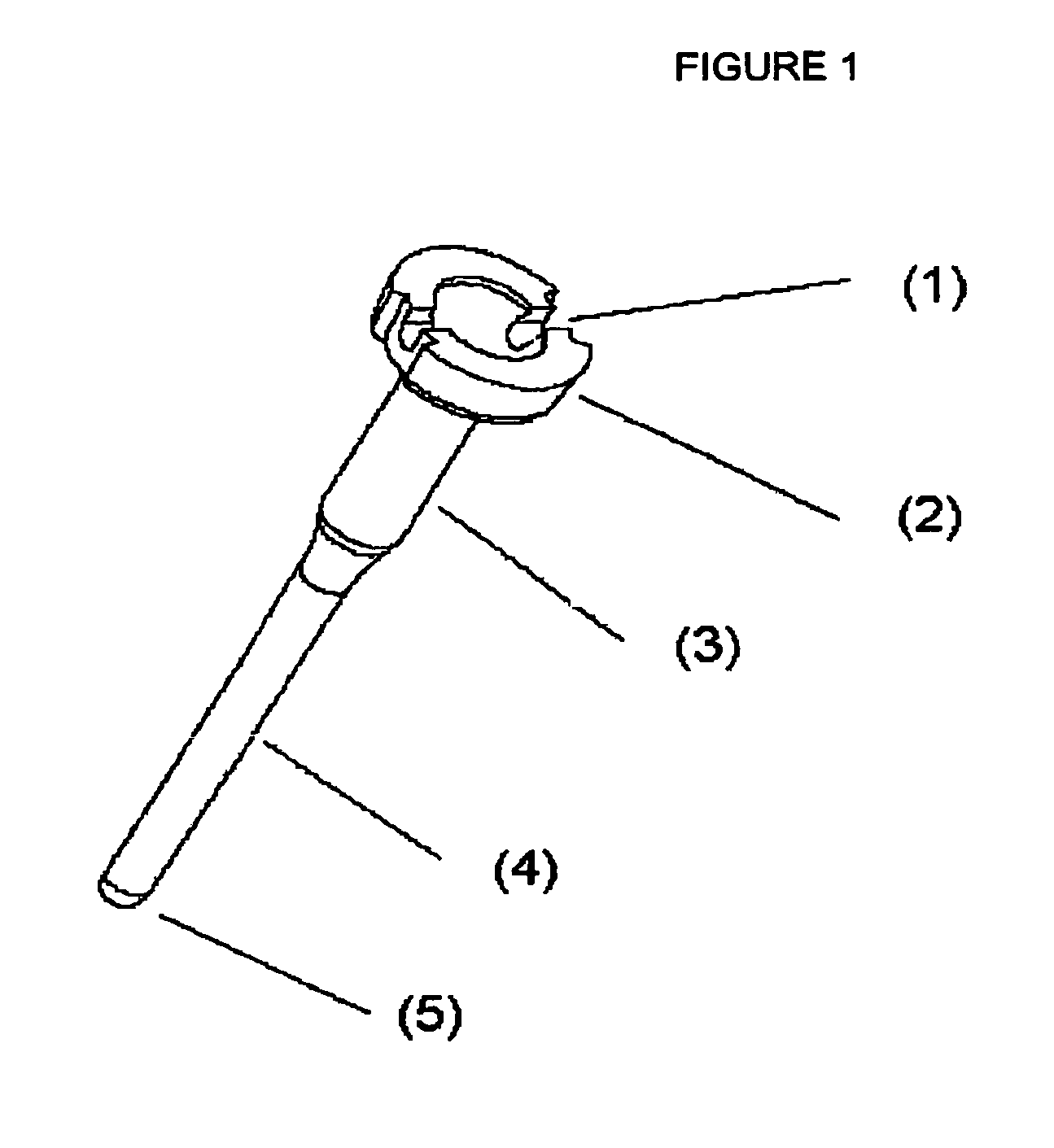

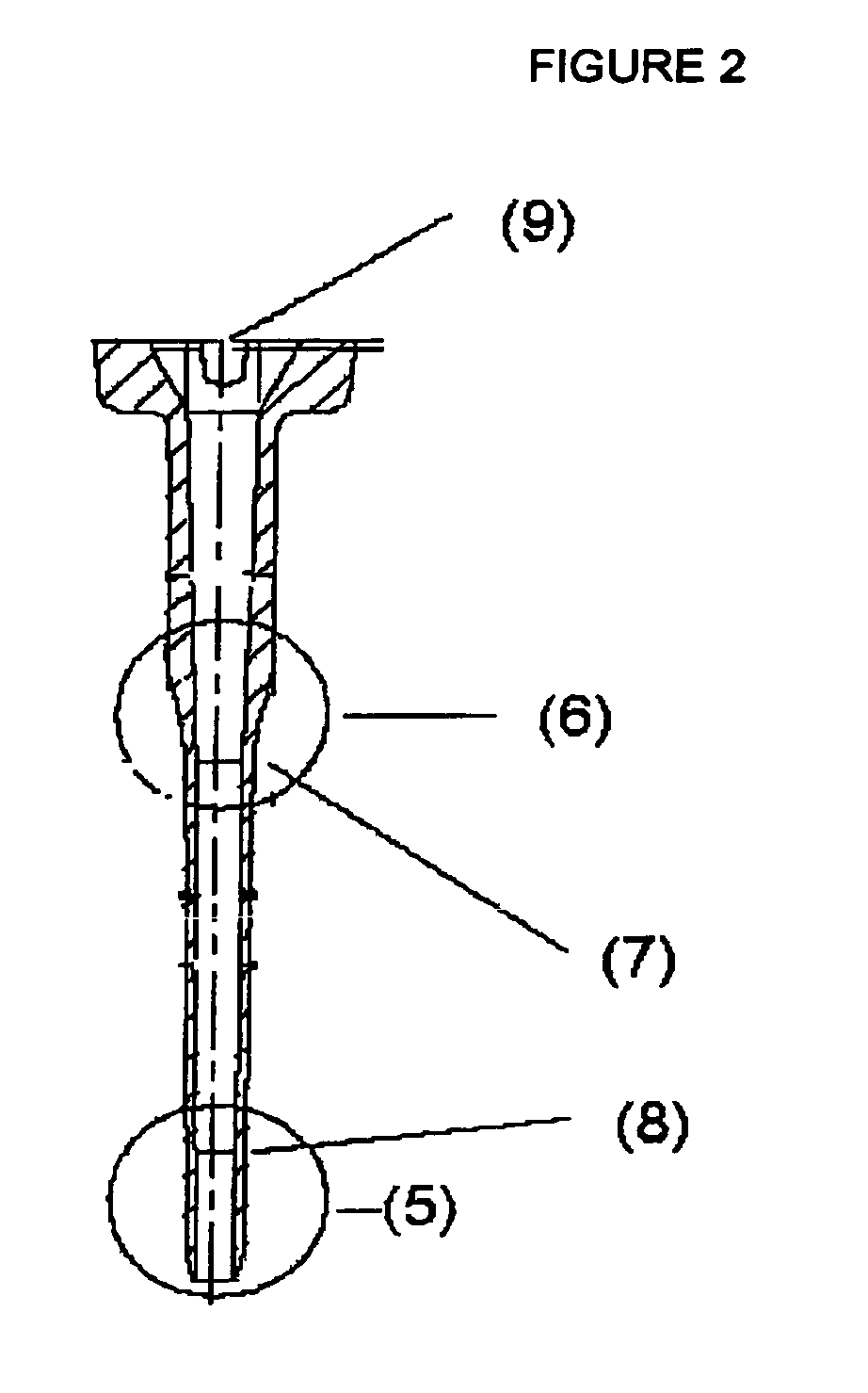

ActiveUS7431876B2Simple and cheap processDischarging arrangementMouldsInjection mouldingNeedle catheter

A method for one-piece injection molding of a soft needle catheter having a hub and a tube-shaped flexible part. According to the method, a molten polymer is fed into a mold which includes a core that is used to form the interior of the catheter, the core defining a hub cavity and a tube-shaped cavity. The hub cavity includes a cone-shaped part and a cylindrical part, with the cone-shaped part extending into the tube-shaped cavity. When the polymer is sufficiently cured, the core is removed from the catheter and the catheter is removed from the mold.

Owner:UNOMEDICAL AS

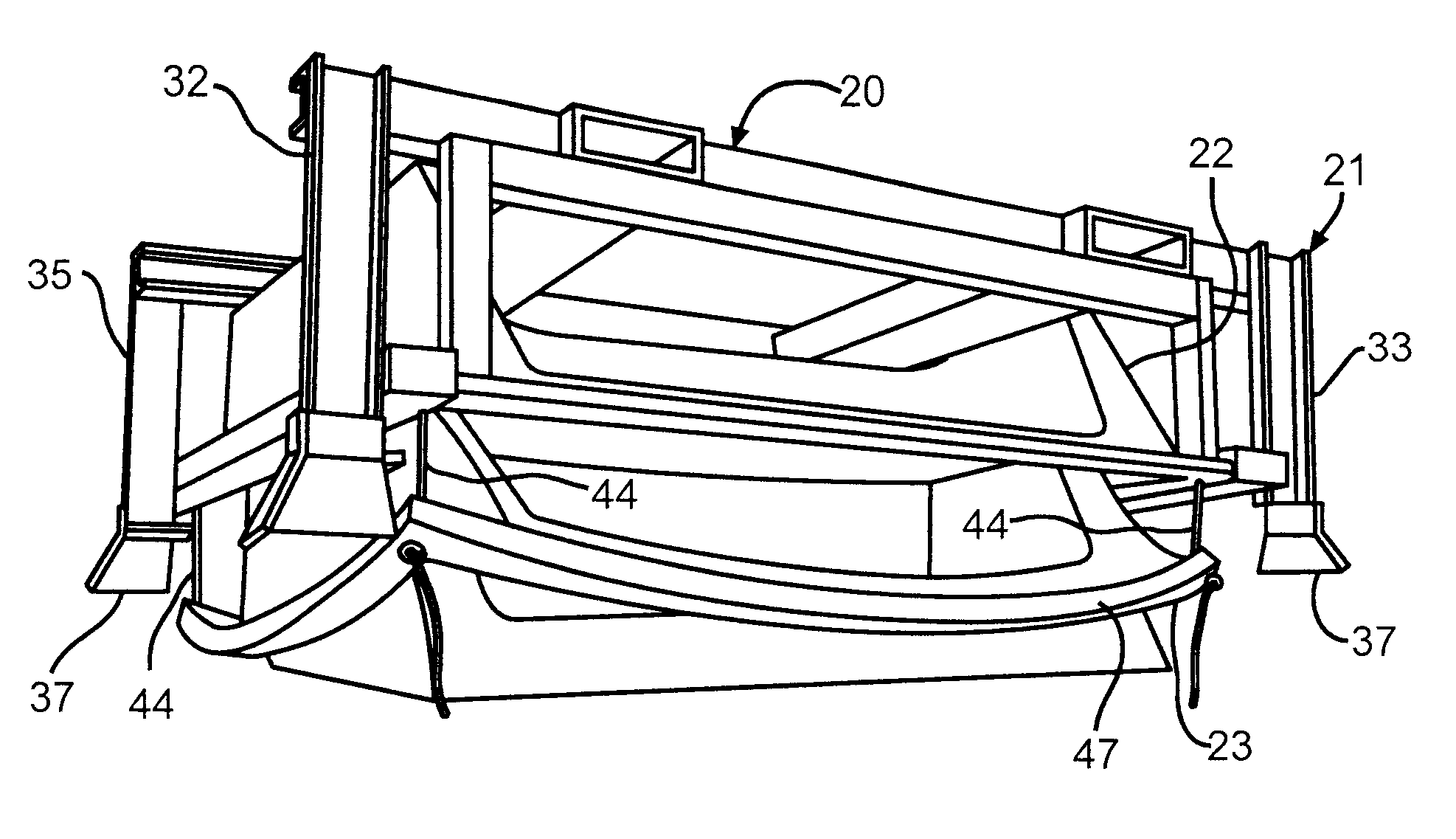

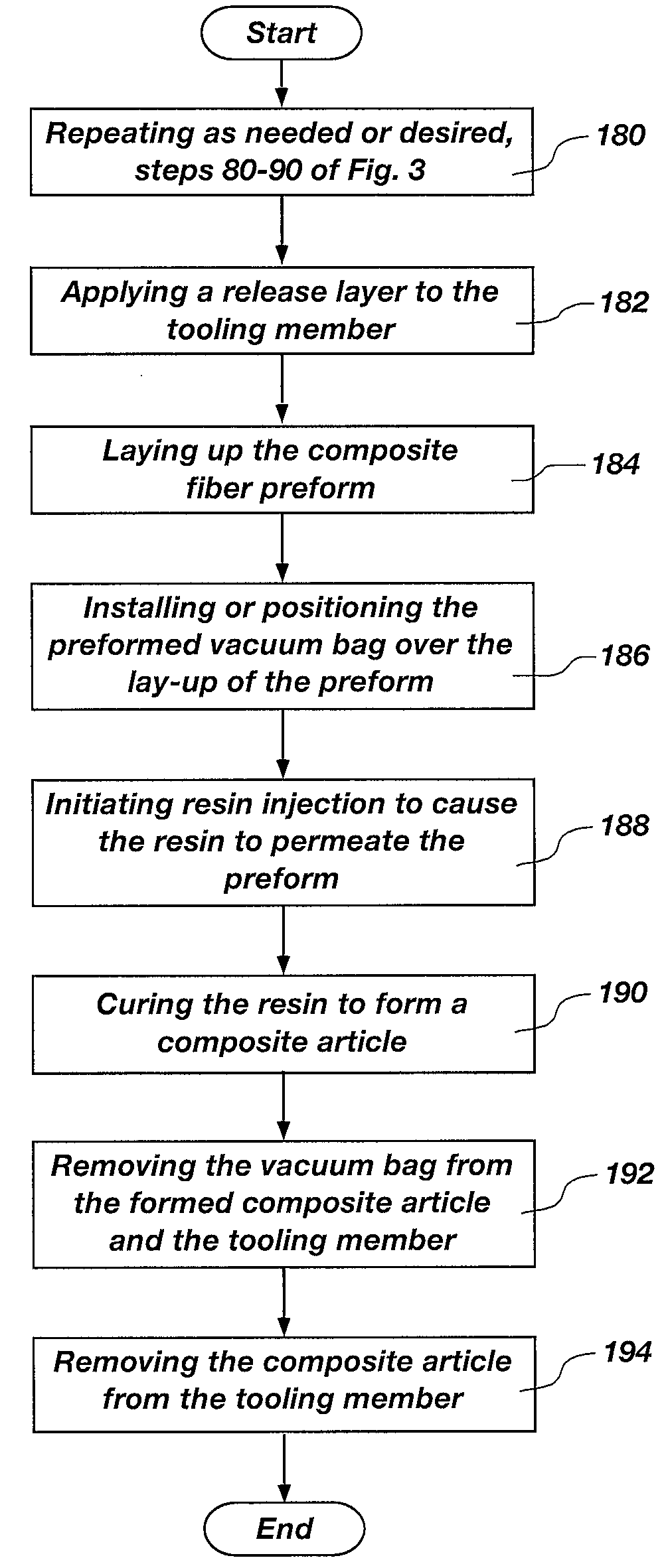

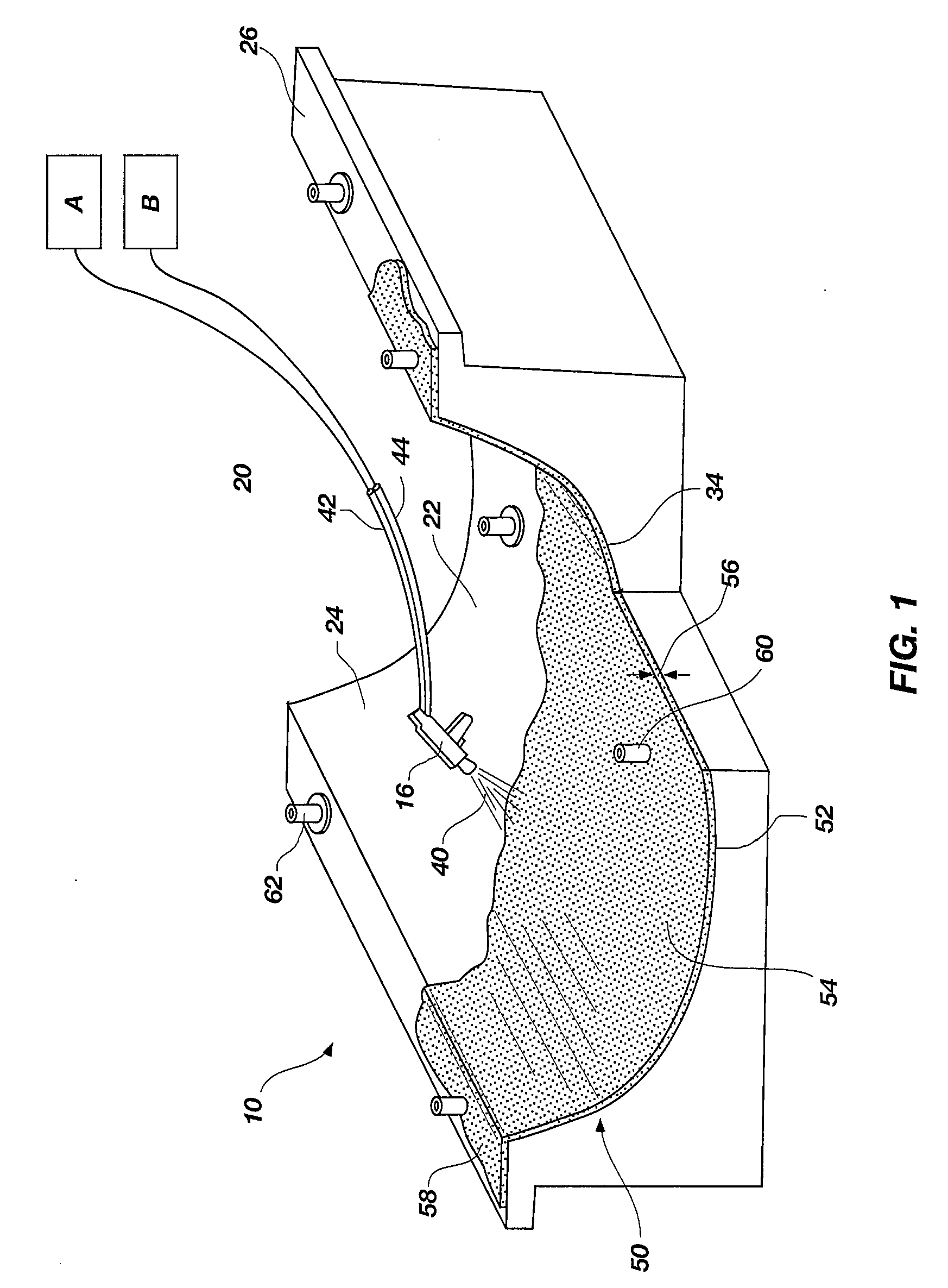

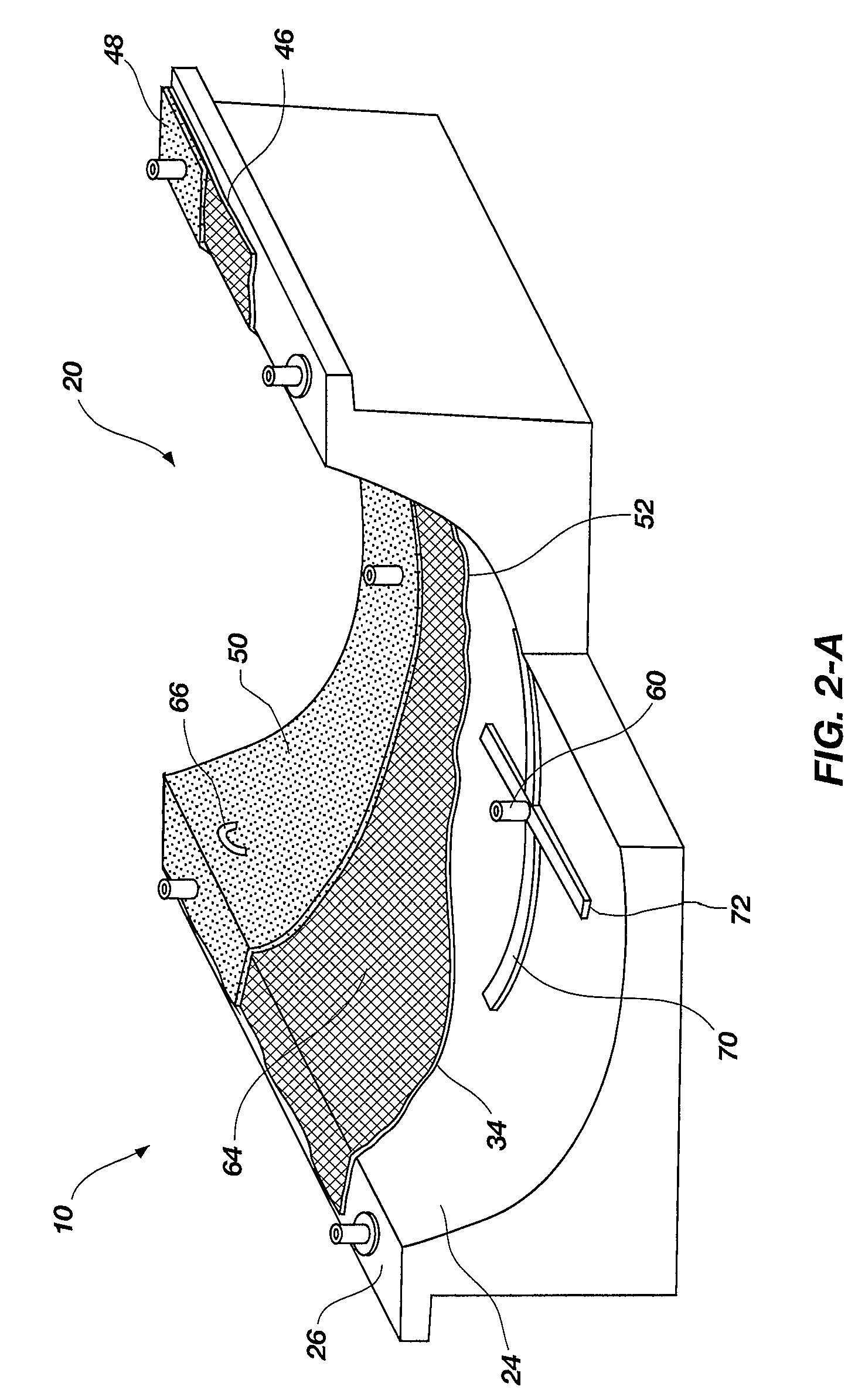

Multi-function vacuum bag for composite part manufacture

A multi-function vacuum bag for use in the manufacture of composites, wherein the vacuum bag may be configured to provide all-in-one capabilities, namely to function as the vacuum bag, a caul or caul sheet, release layer and / or a breather, as well as to provide other functions. Specifically, the multi-function vacuum bag allows a separate breather or breather material, a separate caul or caul layer, and a release or release layer all to be eliminated, if desired, as the multi-function vacuum bag is capable of performing the functions of each of these once formed. Furthermore, the multi-function vacuum bag may be used with various composite manufacturing process, such as VARTM or resin infusion processes, various vacuum bagging processes, filament winding processes, and others.

Owner:AMERICAN CONSULTING TECH

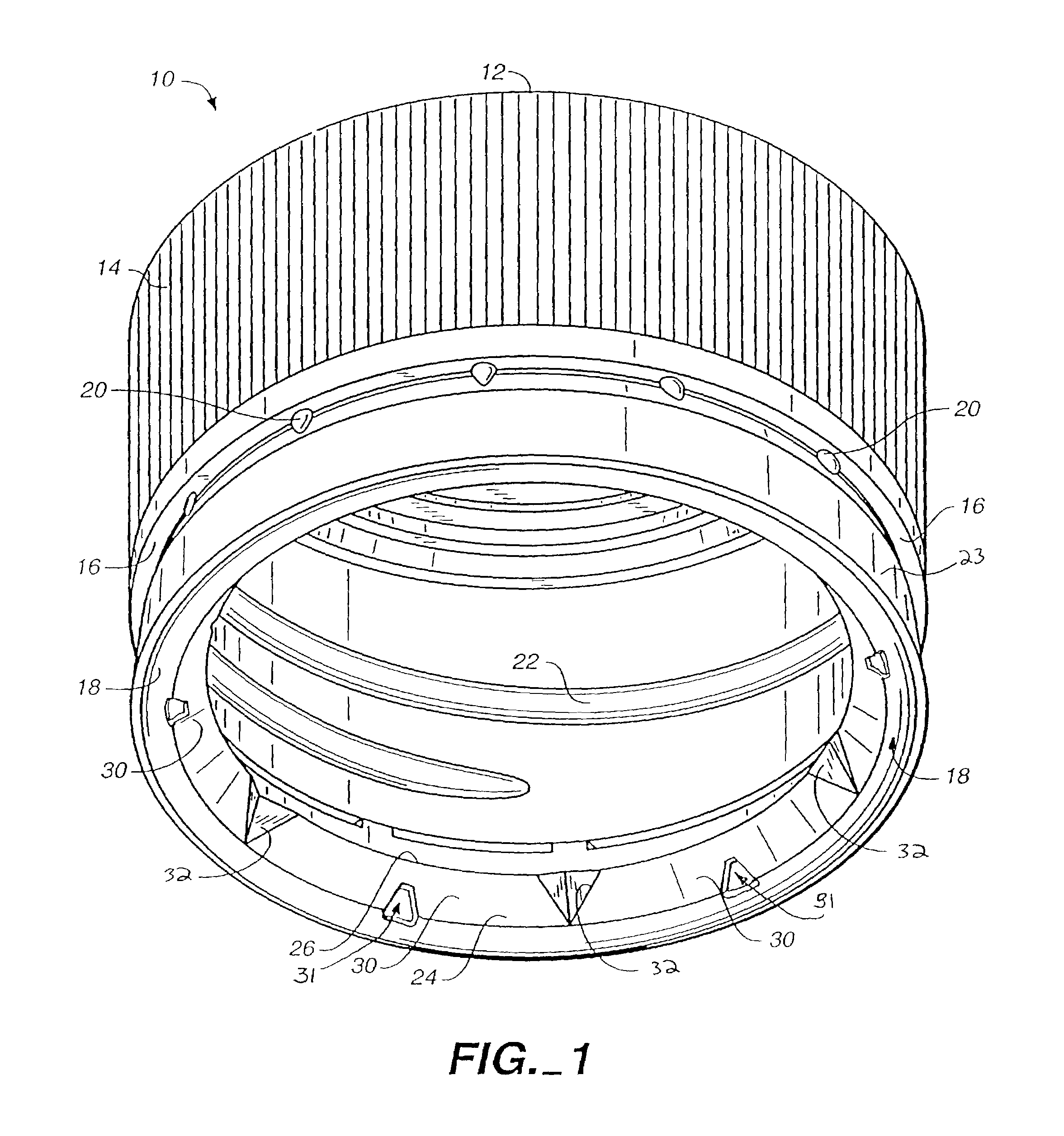

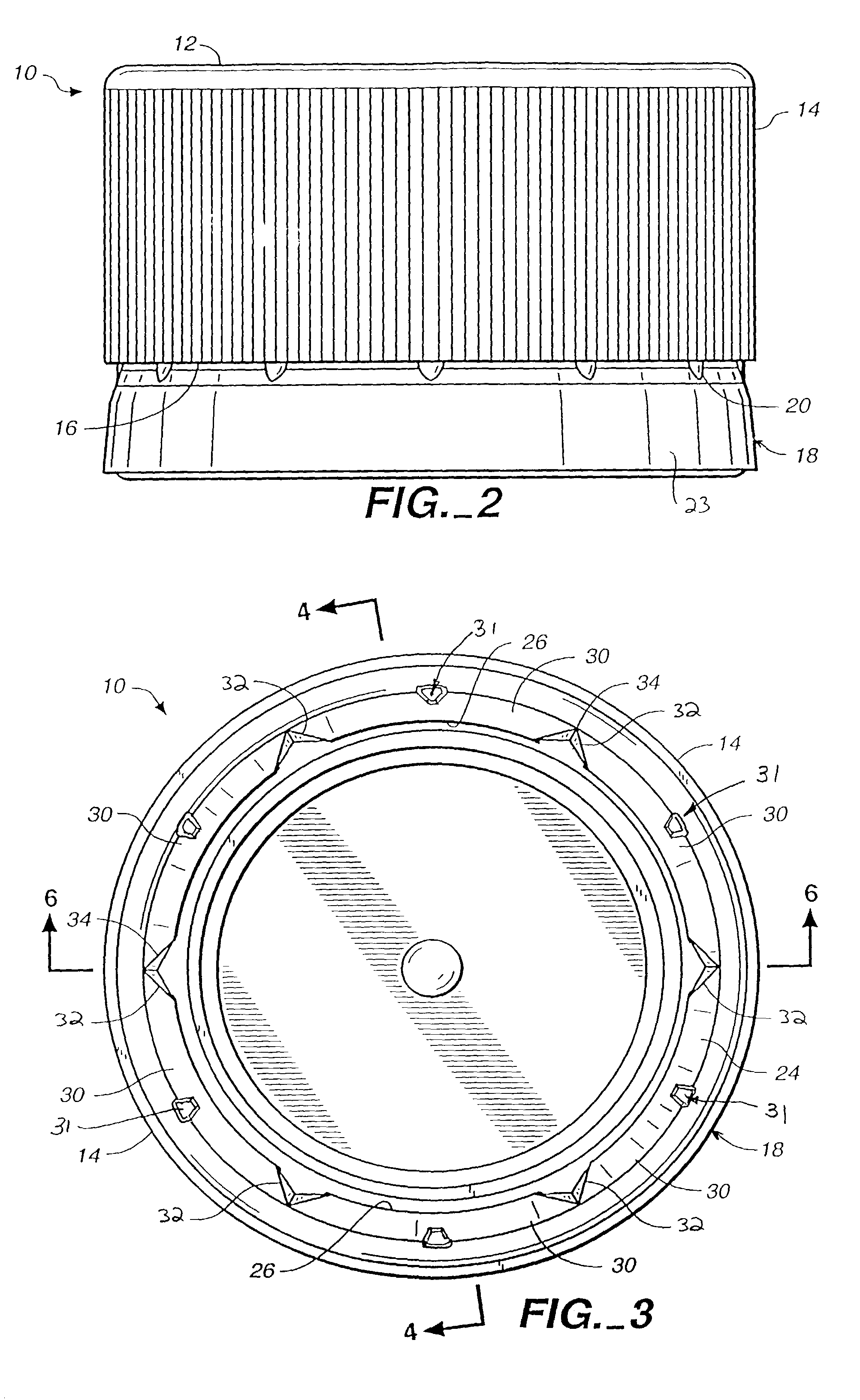

Tamper evident bottle cap

A closure for sealing the opening of a container. The closure may include an angled plug. The container includes an external thread configuration and the closure includes an internal thread configuration which are adapted to pass over each other with one of the external and internal thread configurations having at least one thread lead and the other having at least twice as many thread leads. The closure includes an inwardly turned retaining rim extends at least partially upwardly. The retaining rim has an attachment boss and an upwardly extending line of weakness adjacent the attachment boss such that when the closure is removed from the container, the line of weakness tears allowing the tamper-evidencing band to remain with the closure upon removal from the container. The closure may include a top having a periphery, an annular skirt depending downwardly from the periphery and including a lower edge and a line of weakness extending upwardly from the lower edge, a tear tab extending downwardly from the skirt below the lower edge, and a tamper-evidencing locking member including an inwardly extending locking ring that extends radially inwardly from the skirt intermediate the top and the bottom edge, the retaining rim including a free edge that is adapted to engage the radially extending locking bead of the container when the closure is removed from the container neck. A method of molding a closure including a tamper-evidencing band is also disclosed.

Owner:PORTOLA PACKING INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com