Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

979 results about "Vacuum deposition" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Vacuum deposition is a family of processes used to deposit layers of material atom-by-atom or molecule-by-molecule on a solid surface. These processes operate at pressures well below atmospheric pressure (i.e., vacuum). The deposited layers can range from a thickness of one atom up to millimeters, forming freestanding structures. Multiple layers of different materials can be used, for example to form optical coatings. The process can be qualified based on the vapor source; physical vapor deposition uses a liquid or solid source and chemical vapor deposition uses a chemical vapor.

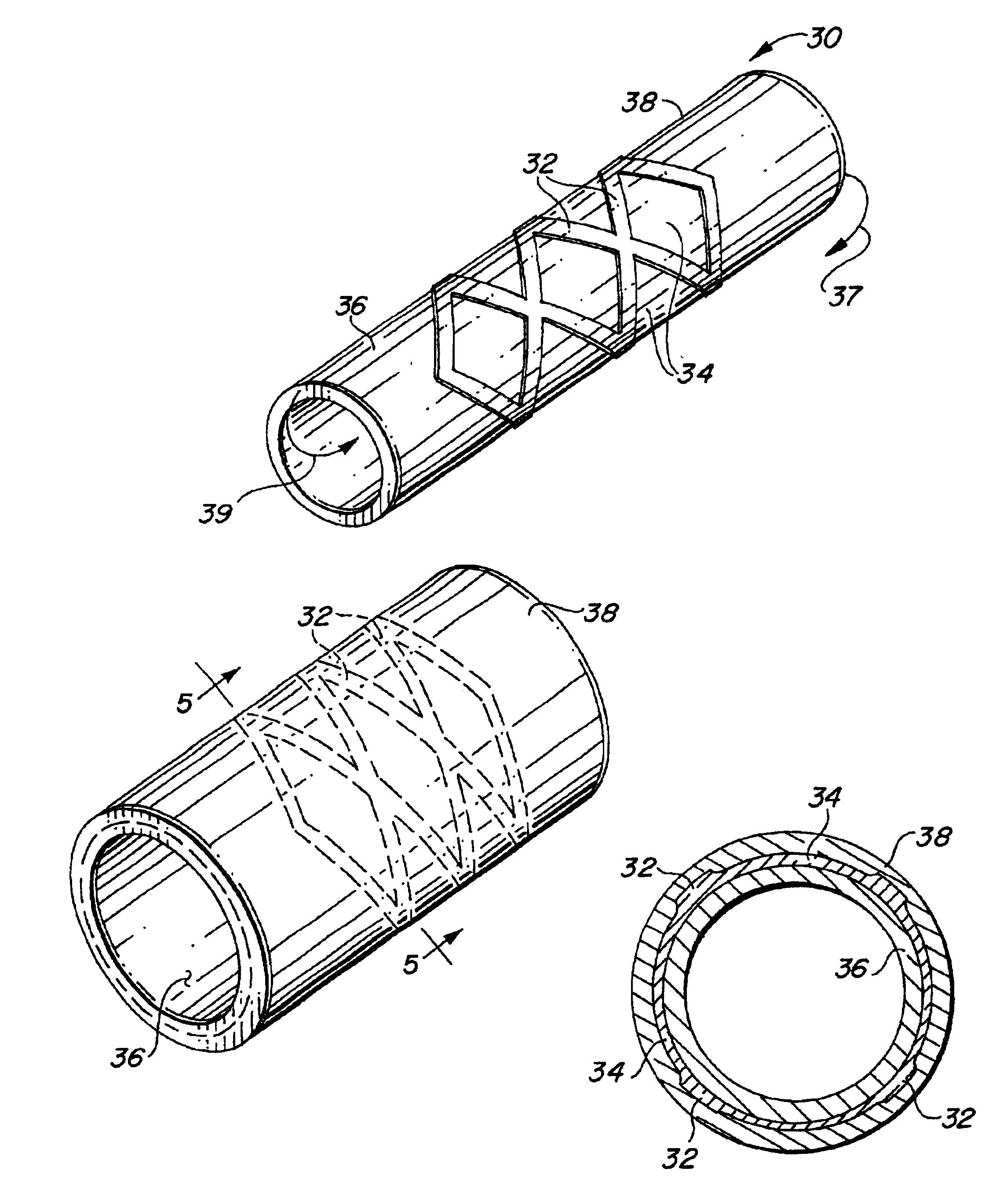

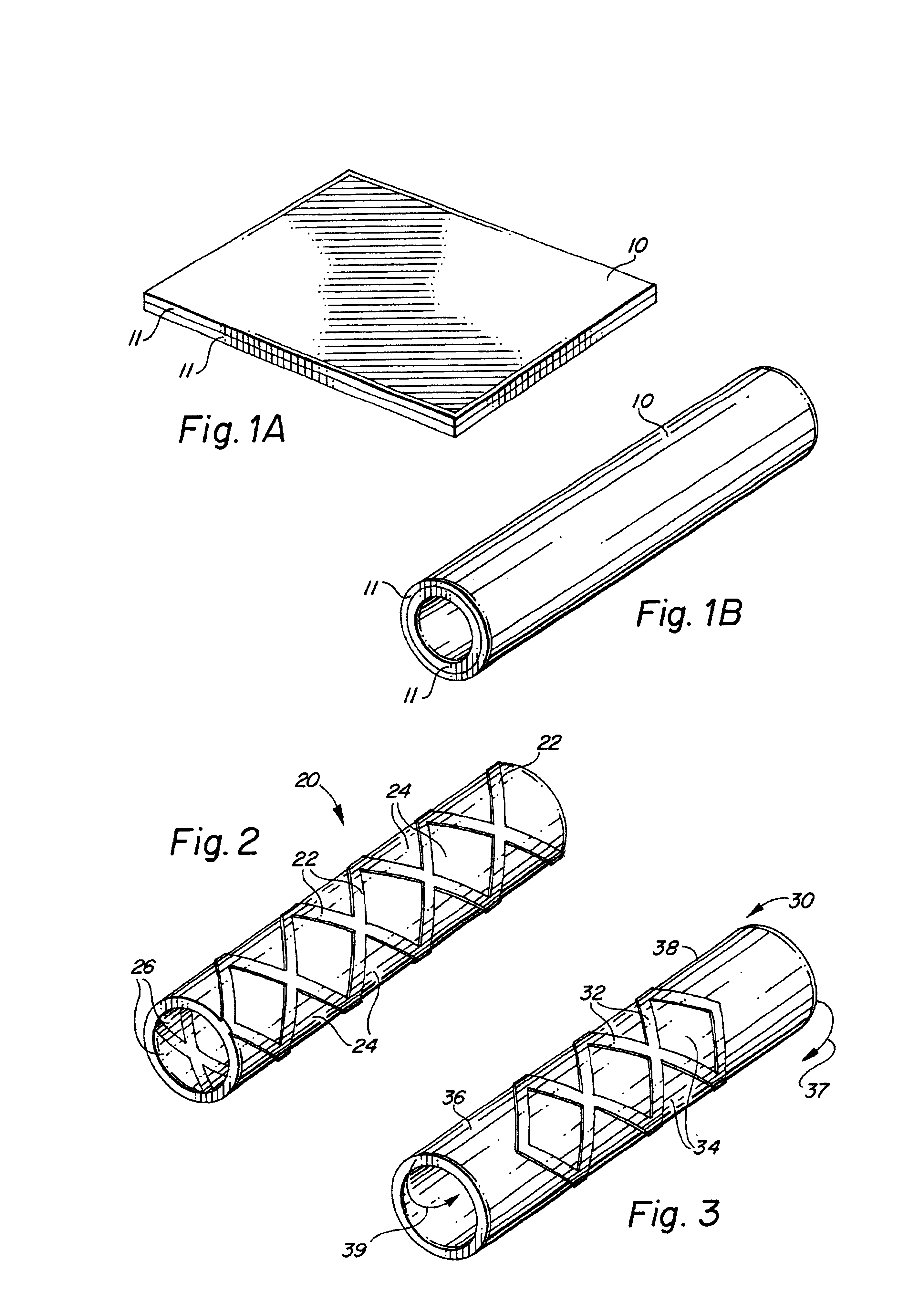

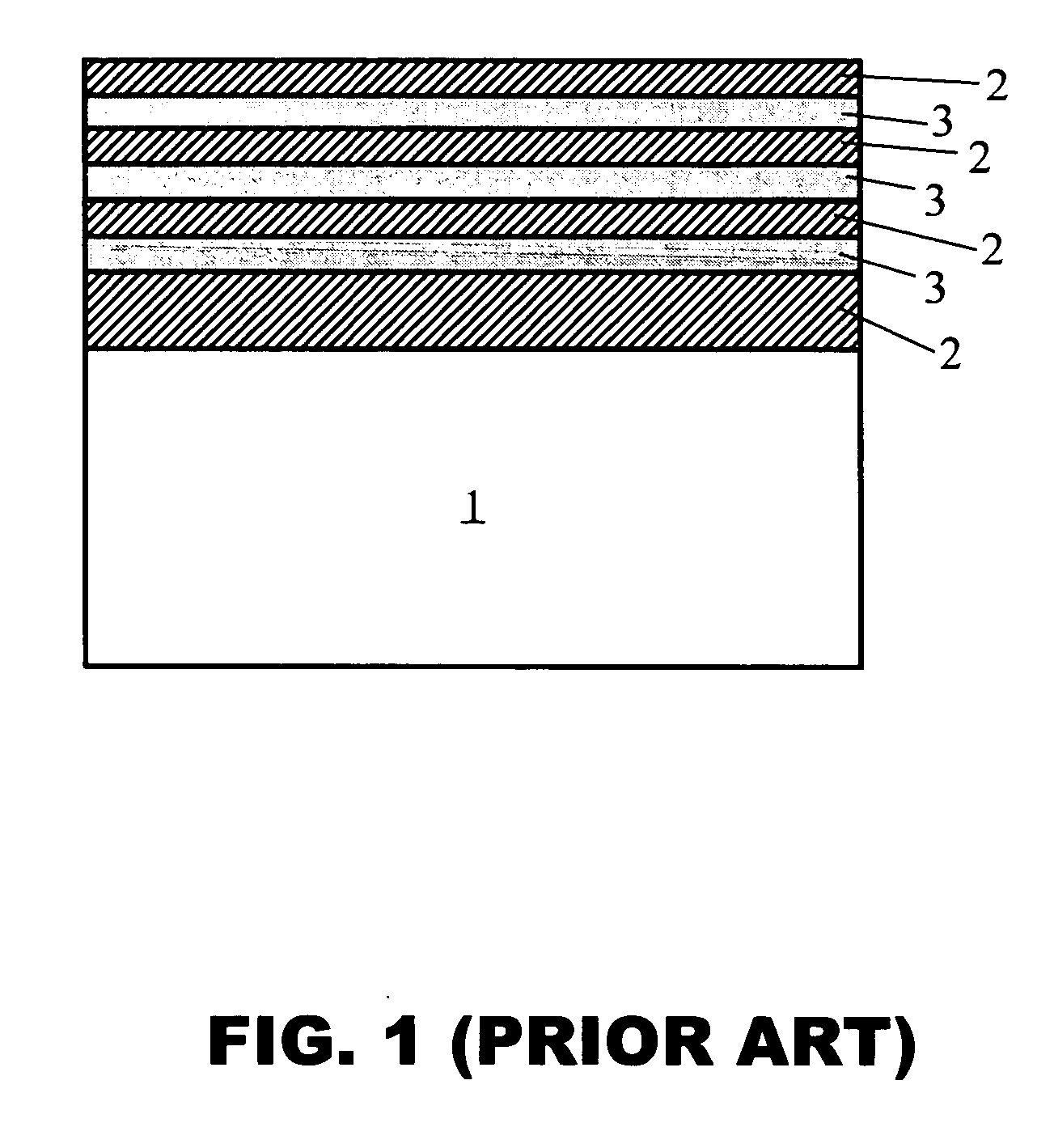

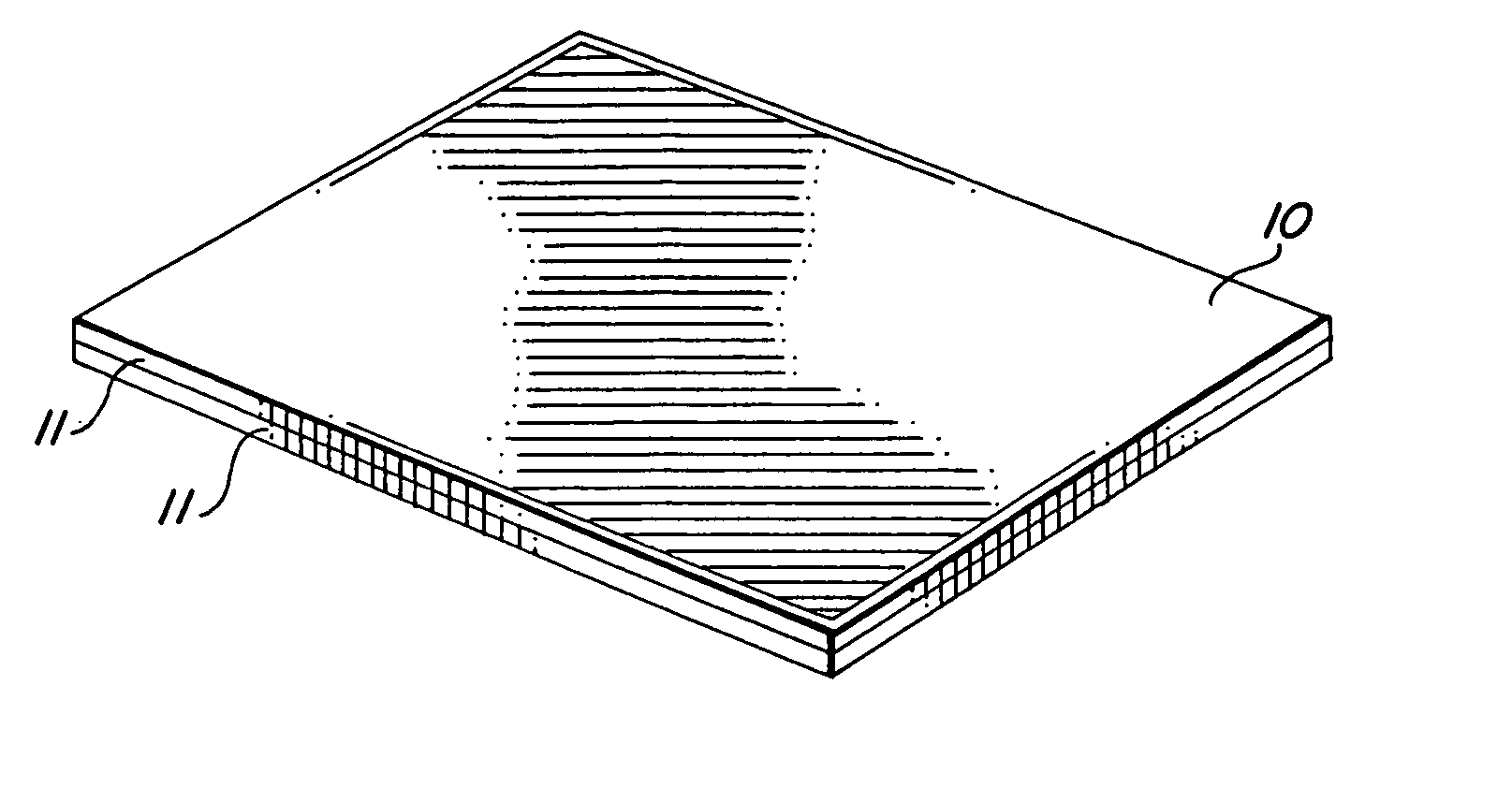

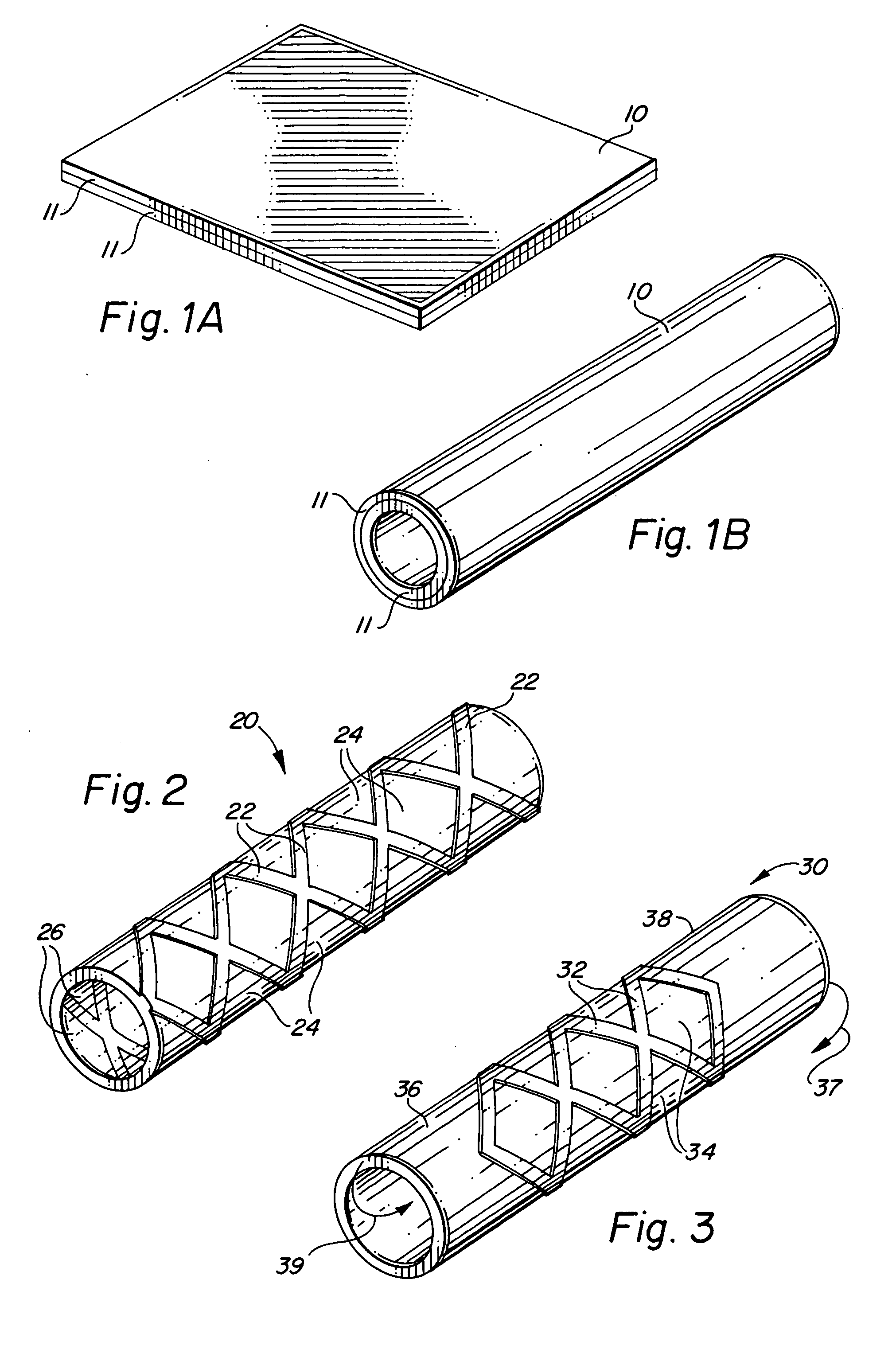

Self-supporting laminated films, structural materials and medical devices manufactured therefrom and methods of making same

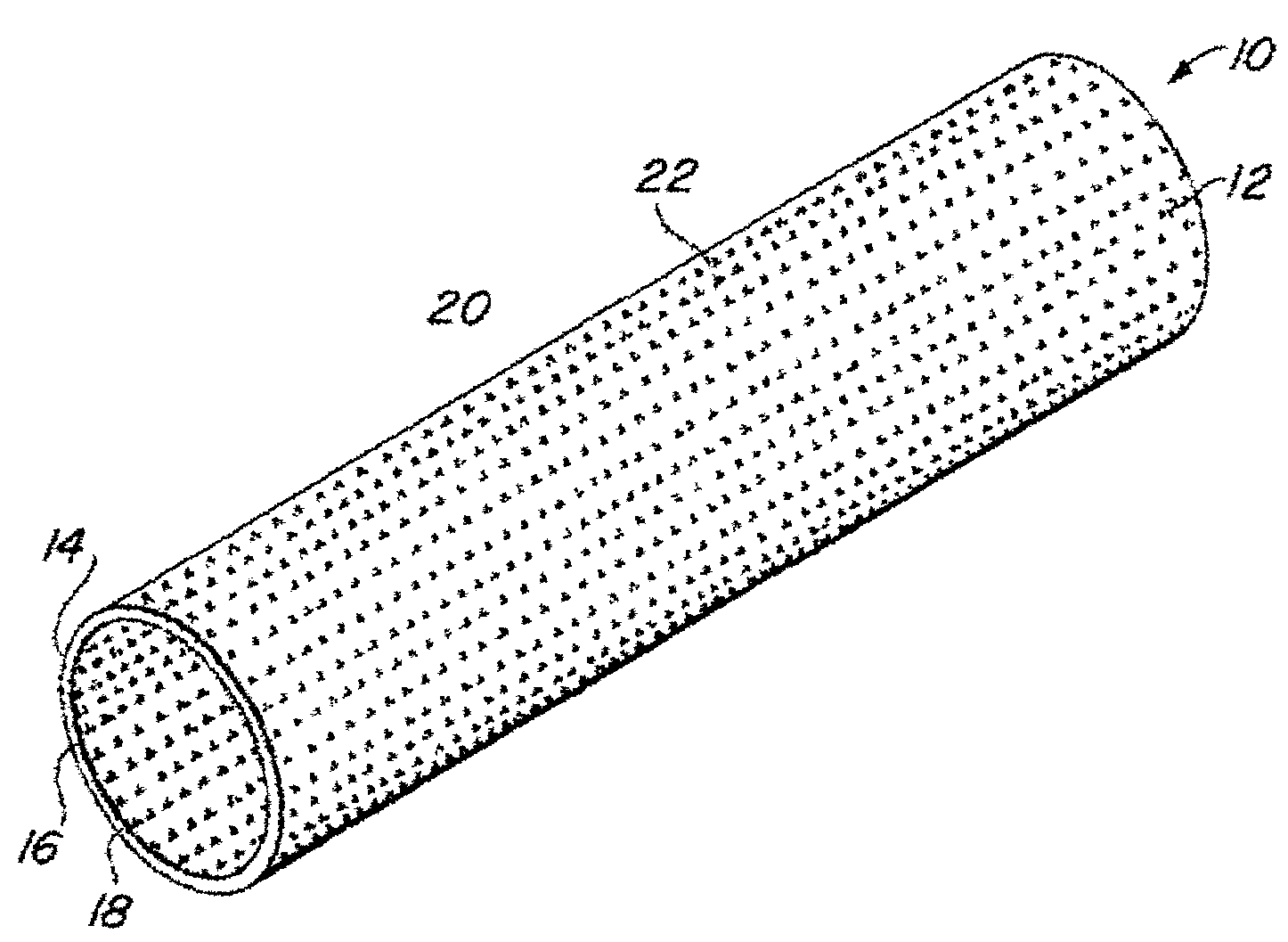

Metal foils, wires, and seamless tubes with increased mechanical strength are provided. As opposed to wrought materials that are made of a single metal or alloy, these materials are made of two or more layers forming a laminate structure. Laminate structures are known to increase mechanical strength of sheet materials such as wood and paper products and are used in the area of thin films to increase film hardness, as well as toughness. Laminate metal foils have not been used or developed because the standard metal forming technologies, such as rolling and extrusion, for example, do not lend themselves to the production of laminate structures. Vacuum deposition technologies can be developed to yield laminate metal structures with improved mechanical properties. In addition, laminate structures can be designed to provide special qualities by including layers that have special properties such as superelasticity, shape memory, radio-opacity, corrosion resistance etc. Examples of articles which may be made by the inventive laminate structures include implantable medical devices that are fabricated from the laminated deposited films and which present a blood or body fluid and tissue contact surface that has controlled heterogeneities in material constitution. An endoluminal stent-graft and web-stent that is made of a laminated film material deposited and etched into regions of structural members and web regions subtending interstitial regions between the structural members. An endoluminal graft is also provided which is made of a biocompatible metal or metal-like material. The endoluminal stent-graft is characterized by having controlled heterogeneities in the stent material along the blood flow surface of the stent and the method of fabricating the stent using vacuum deposition methods.

Owner:VACTRONIX SCI LLC

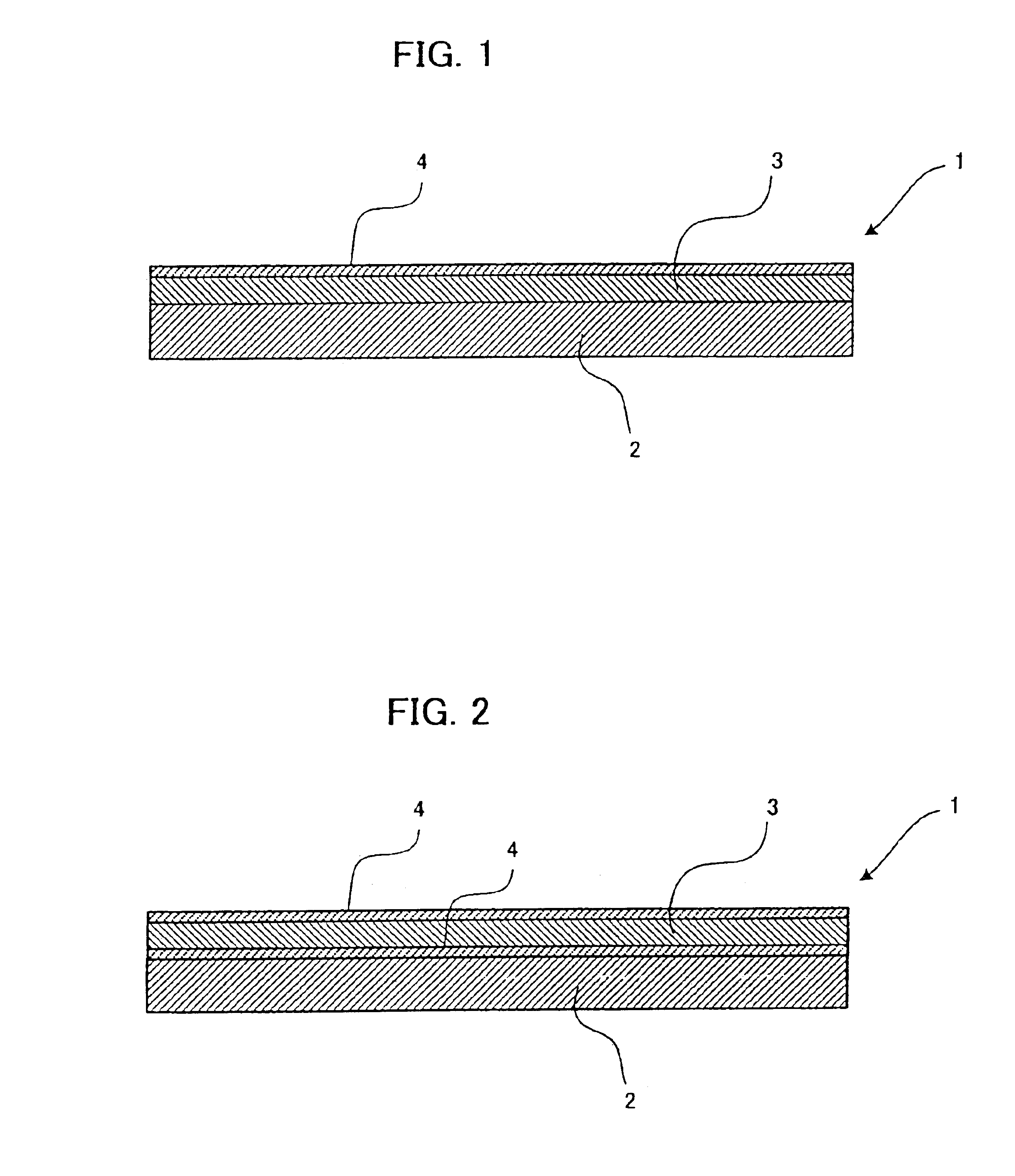

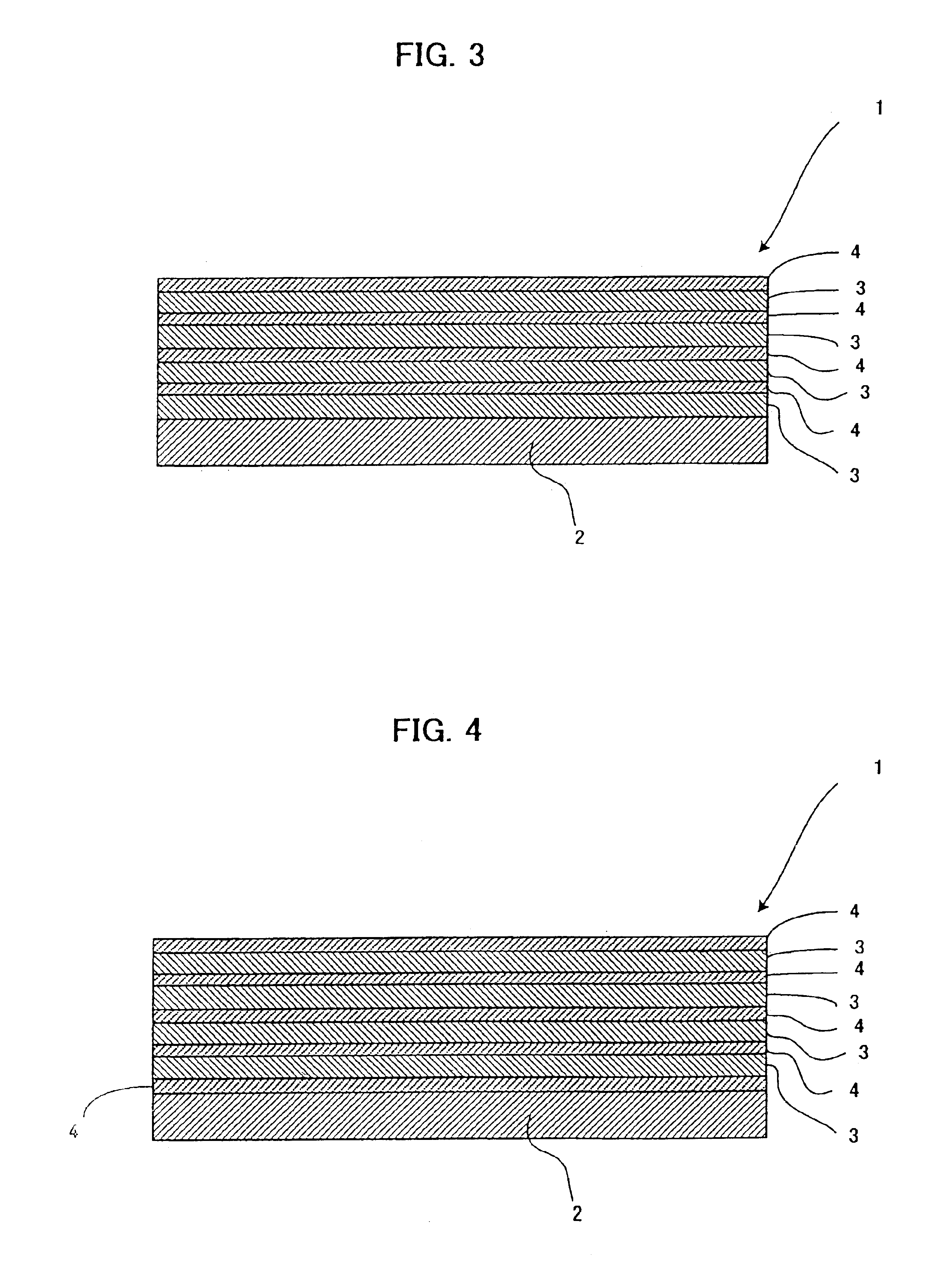

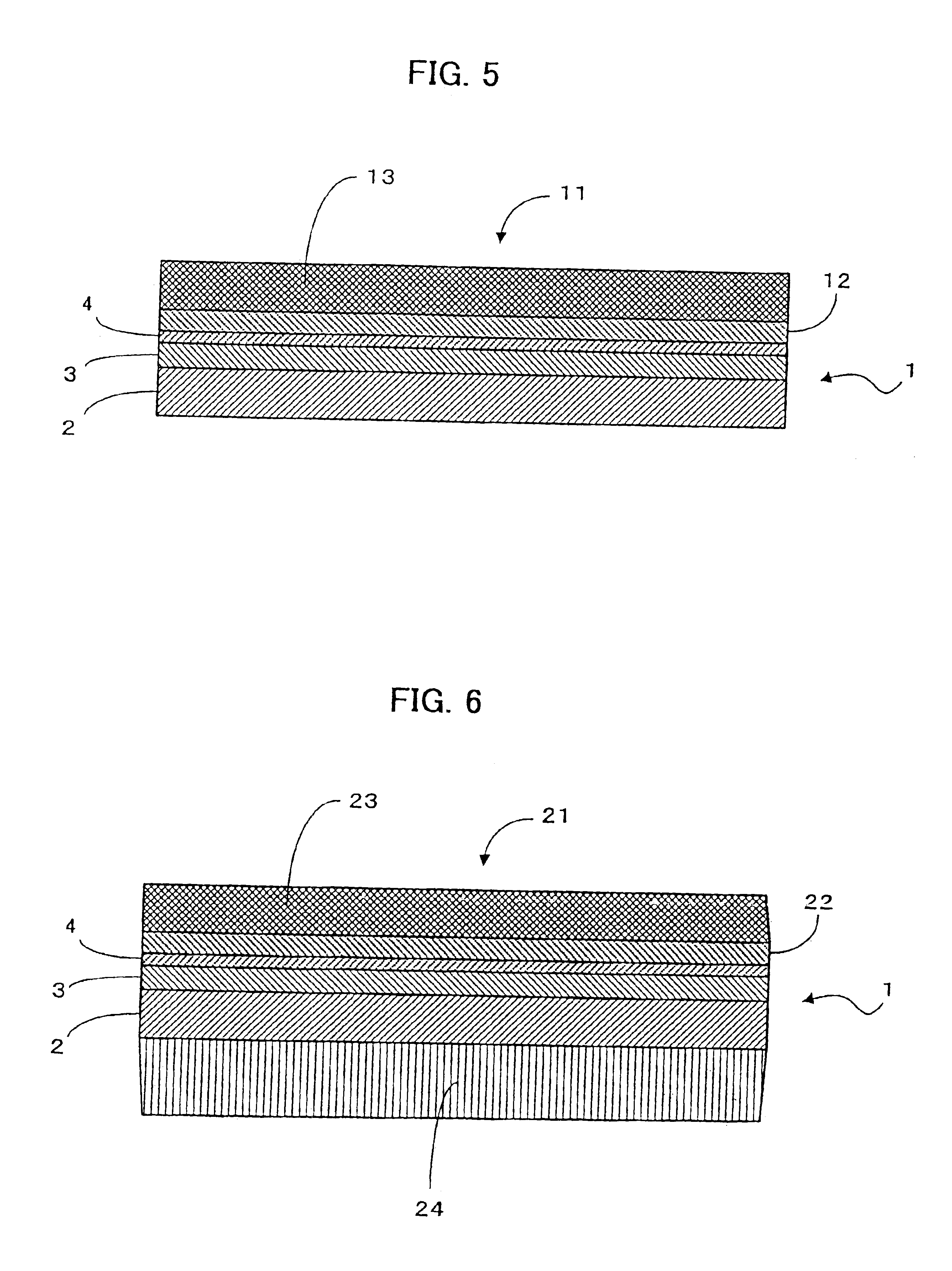

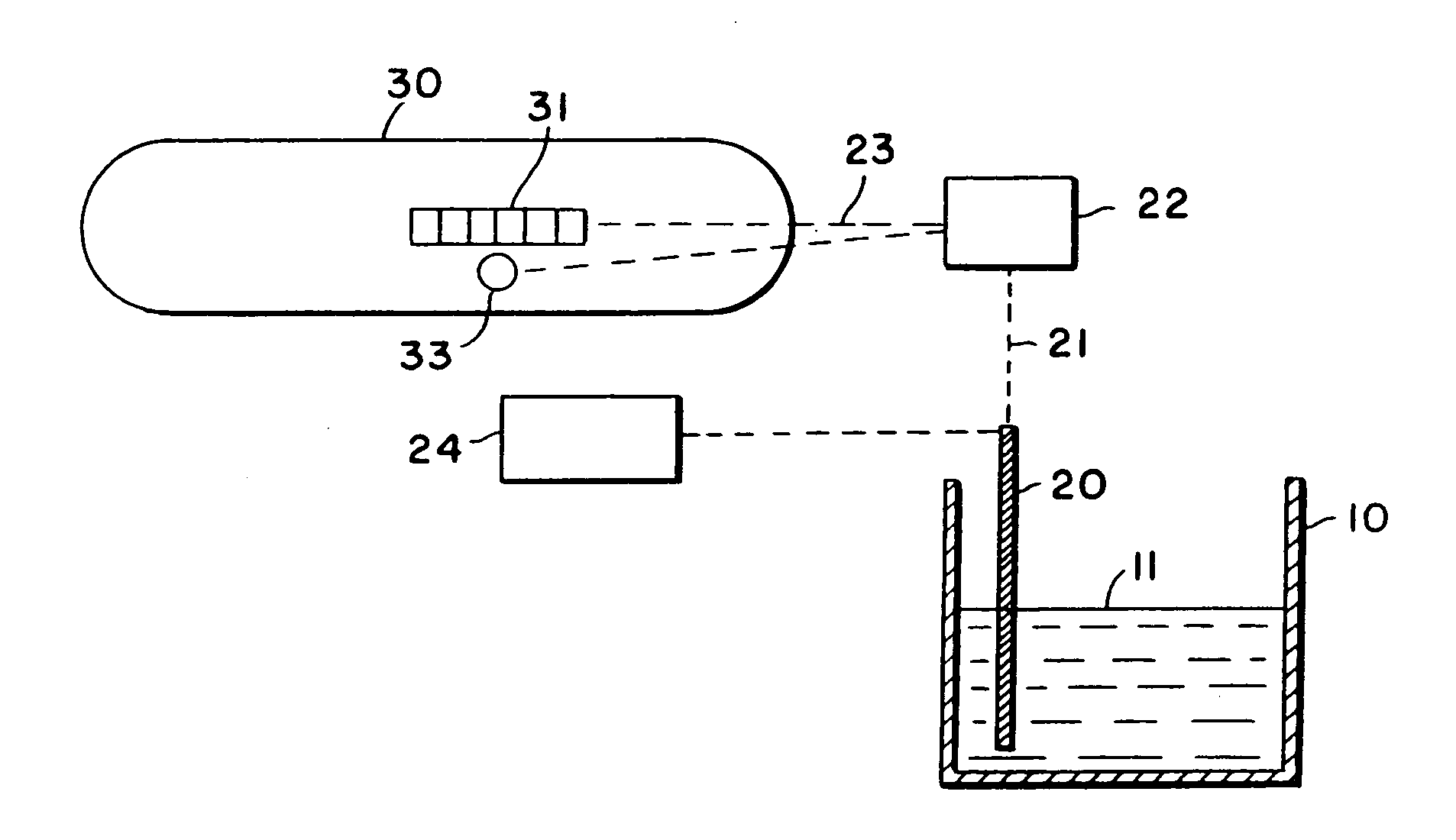

Process for producing multilayered gas-barrier film

InactiveUS20120003500A1Satisfactory productivityExcellent gas barrier performanceLiquid surface applicatorsSynthetic resin layered productsPolymer scienceThin membrane

Provided are a method for producing a film, which is satisfactory in productivity, exhibits high gas-barrier property immediately after production, and has excellent adhesive strength between constituent layers while maintaining the excellent gas-barrier property, and a gas-barrier film, which is obtained by the method. The method for producing a gas-barrier film includes the steps of; (1) forming an inorganic thin film by a vacuum deposition method on at least one surface of a base film; (2) forming a thin film by a plasma CVD method on the inorganic thin film formed in the step (1); and (3) forming an inorganic thin film by the vacuum deposition method on the thin film formed in the step (2), in which each of the steps (1) and (3), and the step (2) are sequentially carried out at a pressure of 1×10−7 to 1 Pa, and at a pressure of 1×10−3 to 1×102 Pa, respectively.

Owner:MITSUBISHI PLASTICS INC

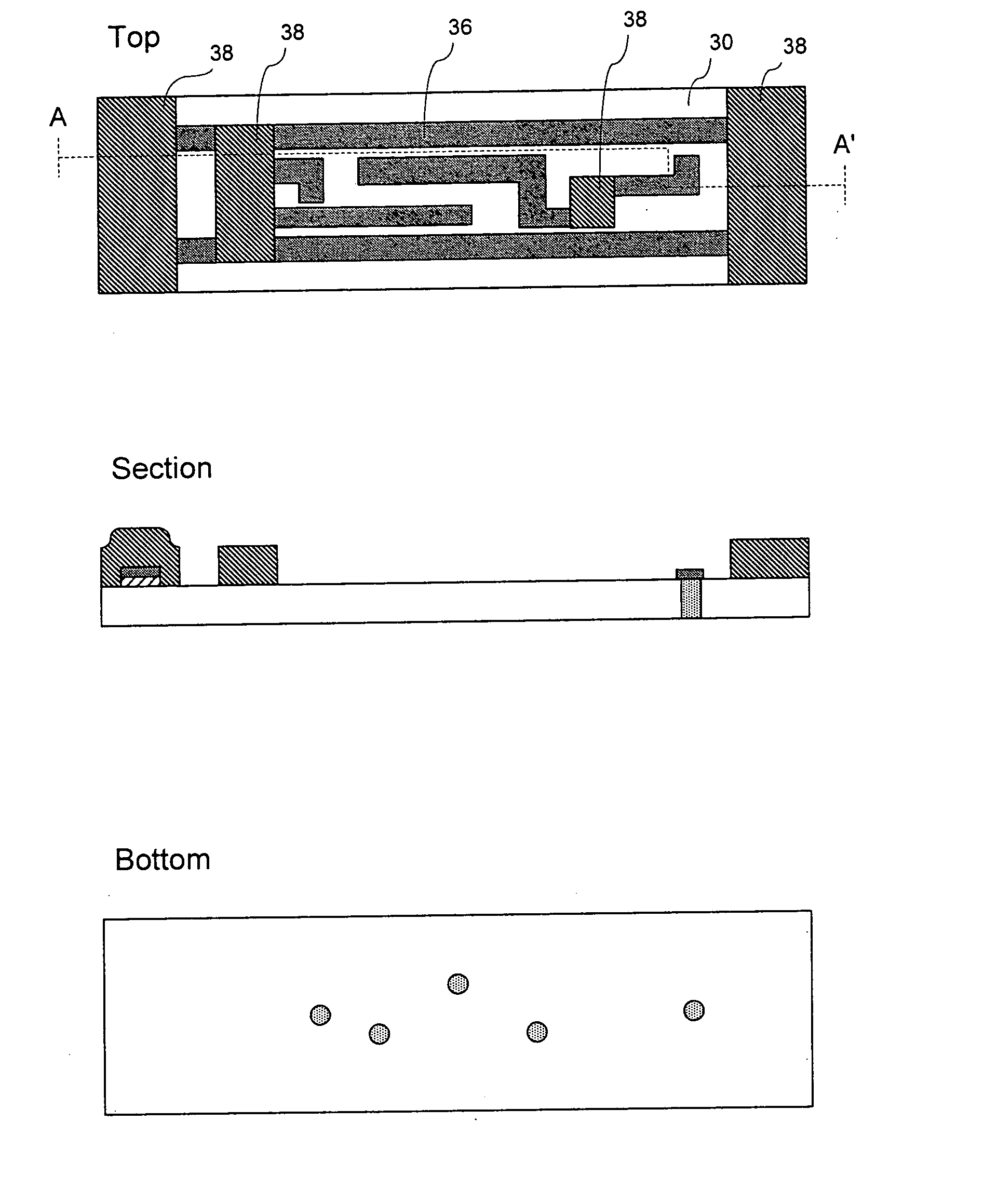

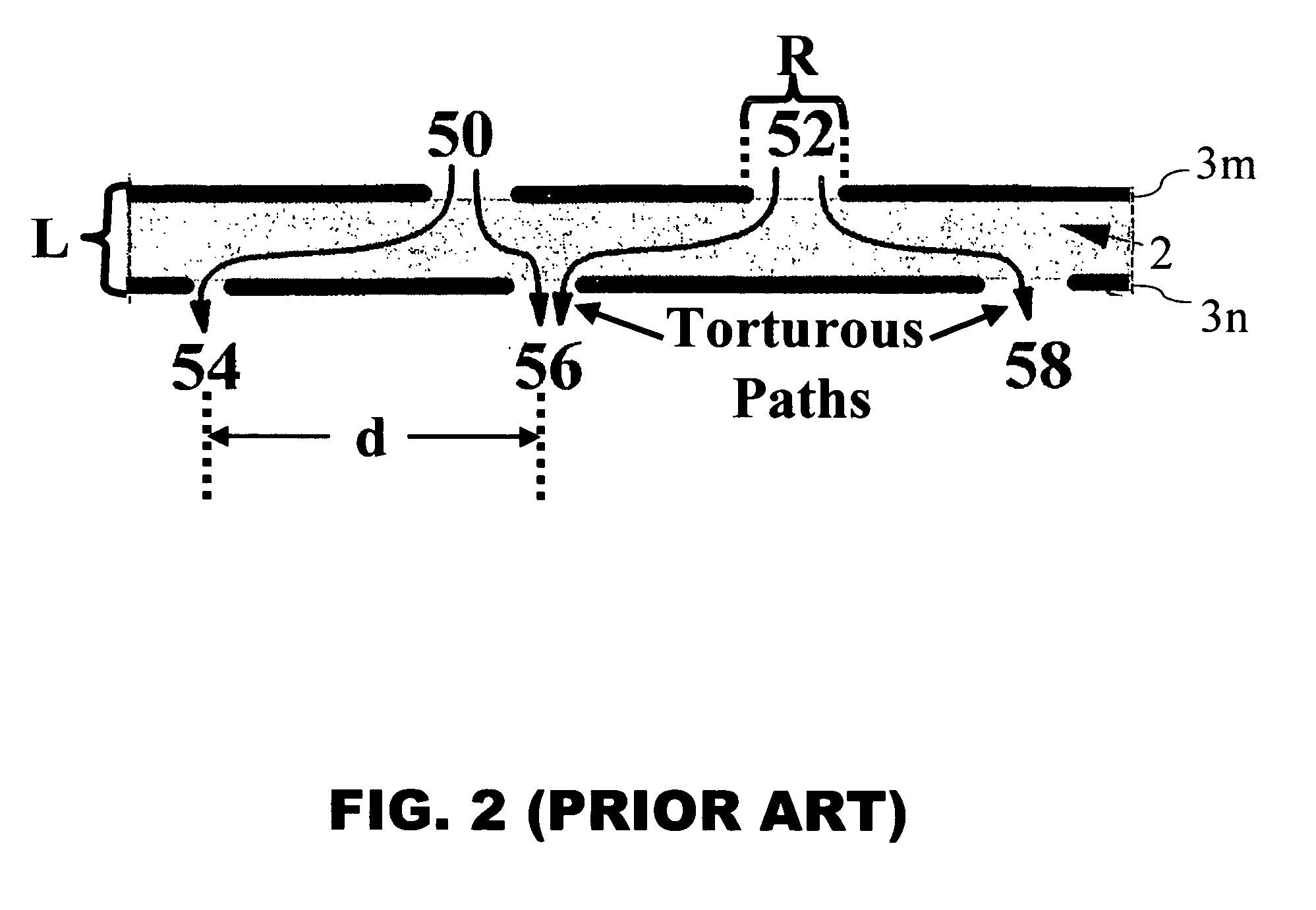

High reliability multlayer circuit substrates and methods for their formation

InactiveUS20040061234A1Semiconductor/solid-state device detailsPrinted circuit aspectsElectrical conductorOptoelectronics

A multilayer circuit substrate for multi-chip modules or hybrid circuits includes a dielectric base substrate, conductors formed on the base substrate and a vacuum deposited dielectric thin film formed over the conductors and the base substrate. The vacuum deposited dielectric thin film is patterned using sacrificial structures formed by shadow mask techniques. Substrates formed in this manner enable significant increases in interconnect density and significant reduction of over-all substrate thickness.

Owner:MEDTRONIC MIMIMED INC

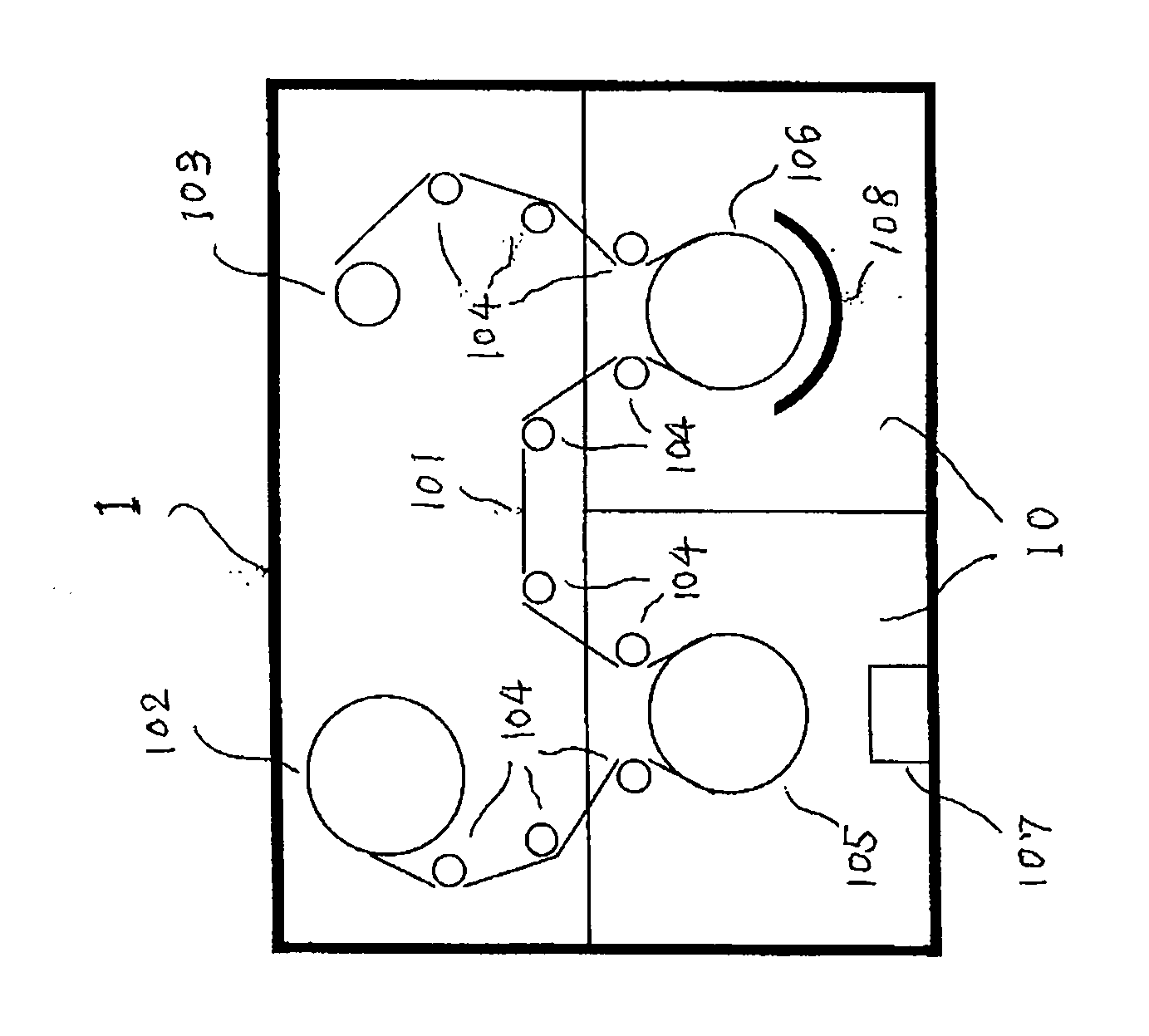

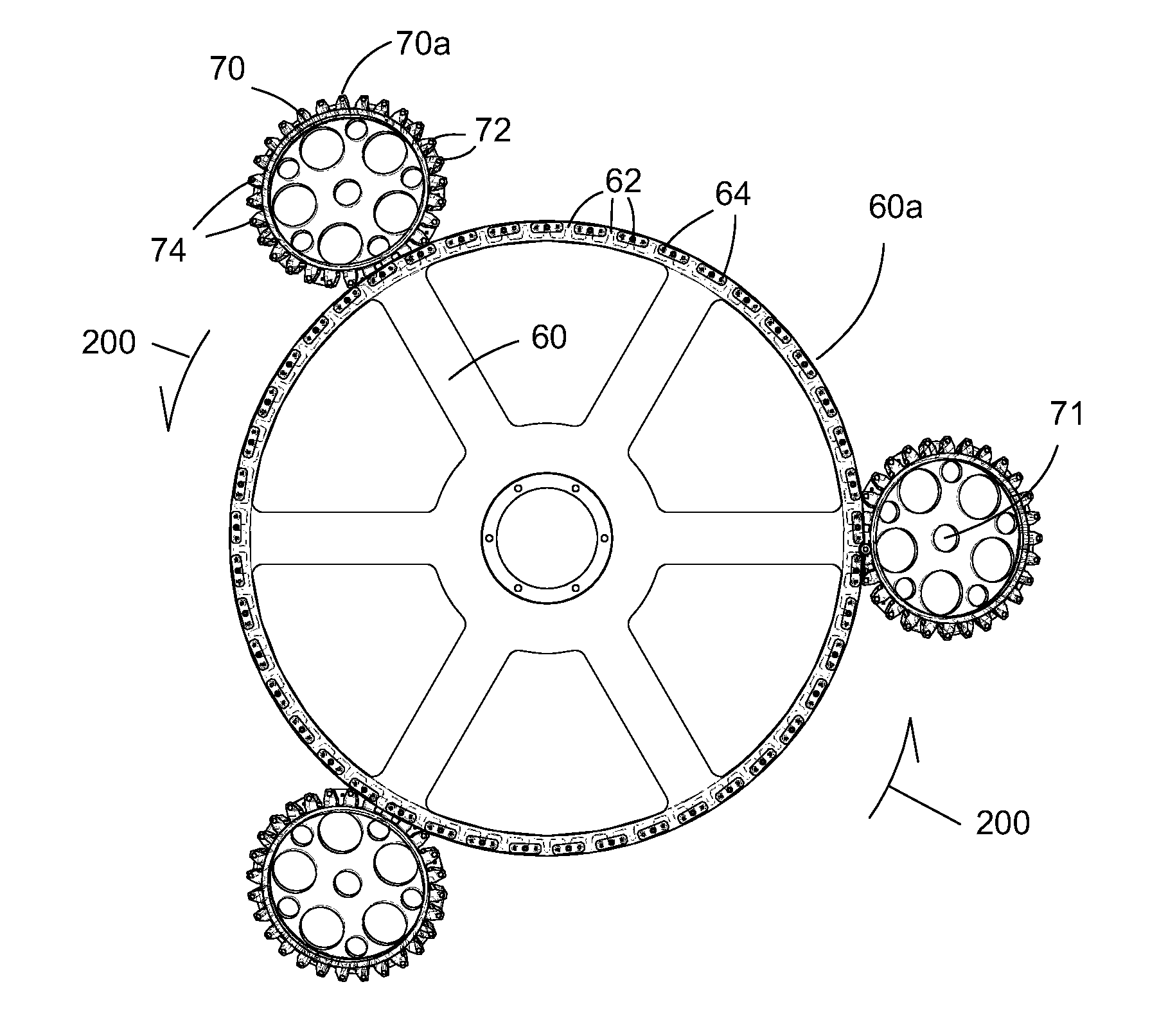

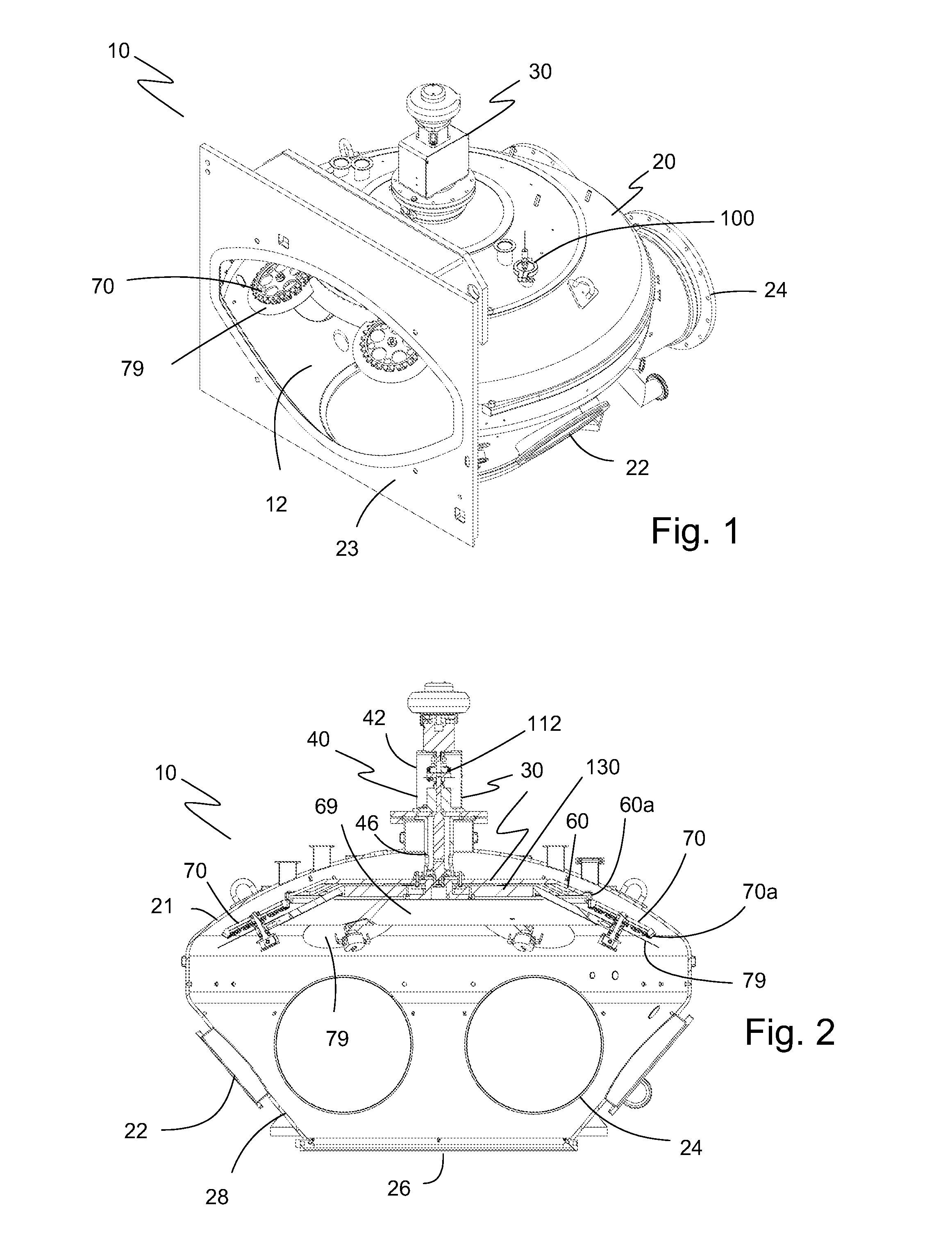

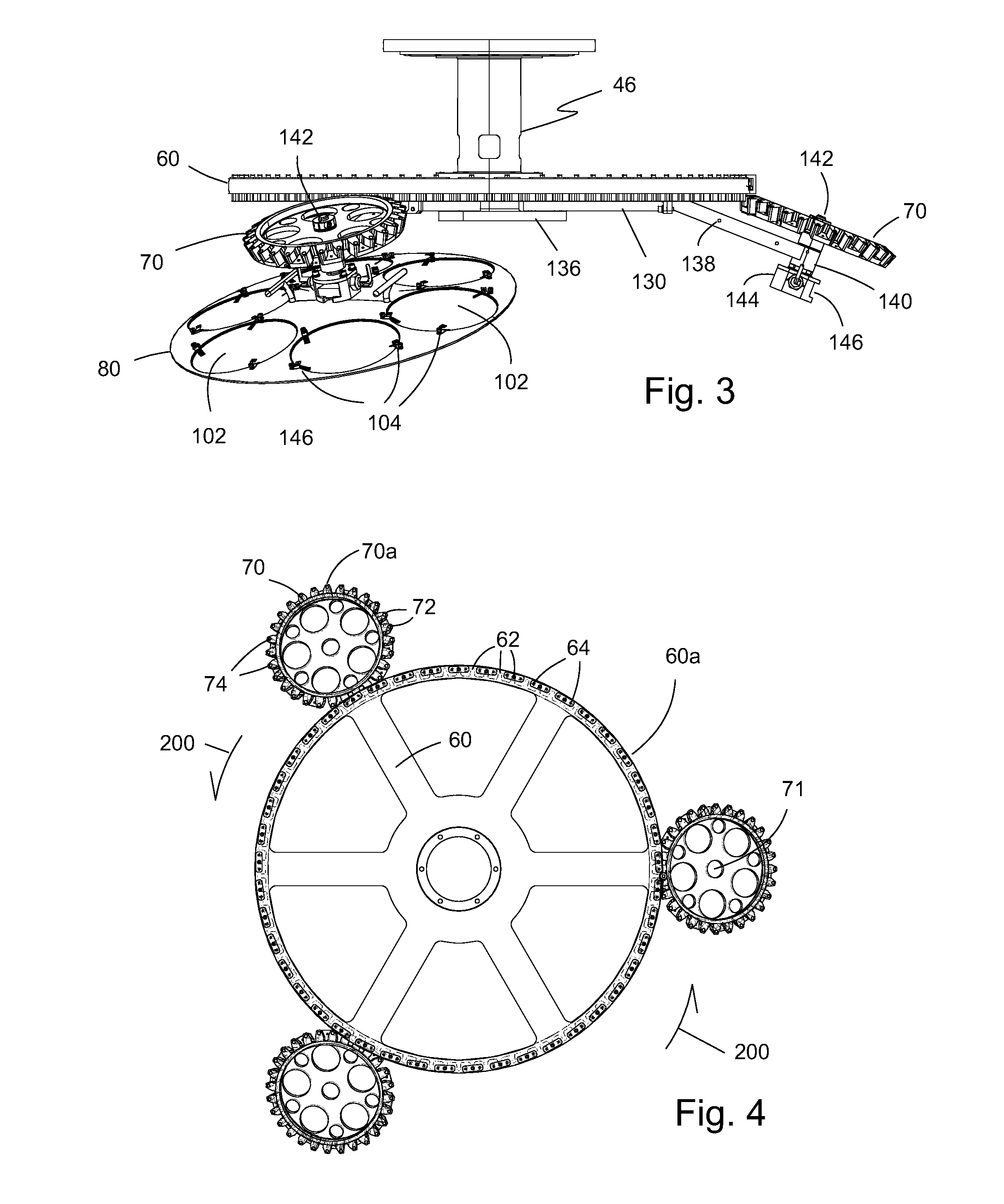

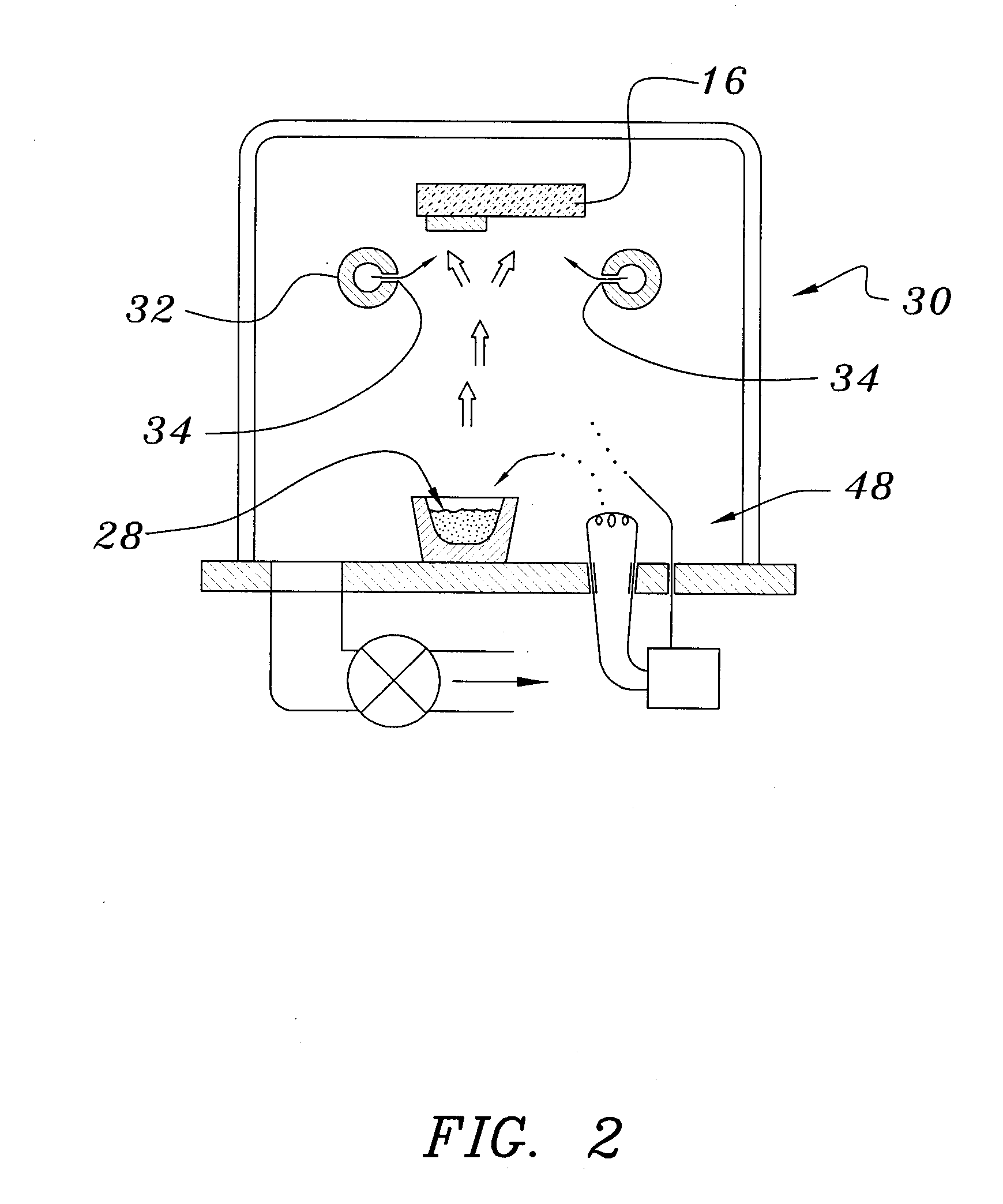

Non-contact magnetic drive assembly with mechanical stop elements

ActiveUS20130095973A1Improve throughputMinimizing particulate contaminationVacuum evaporation coatingSemiconductor/solid-state device manufacturingMechanical driveVacuum deposition

A non-contact magnetic drive assembly with mechanical stop elements for a vacuum deposition system employing a lift-off process having a HULA configuration featuring a plurality of magnets coupled in an annular orientation to a central ring and an orbital ring, each magnet of the orbital ring becomes superposed with a magnet of the central ring as the orbital ring rotates, and a central drive component driving either the central ring, the orbital ring around the central ring or both simultaneously, the central drive component provides a rotational speed allowing non-contact, magnetic drive rotation of the orbital ring around the central ring until a difference between a magnetic drive torque of the superposed magnets and the rotational speed of the central drive component causes the superposed magnets to decouple enabling mechanical drive rotation by interactive contact between a plurality of central ring teeth and a plurality of orbital ring.

Owner:FERROTEC USA CORP

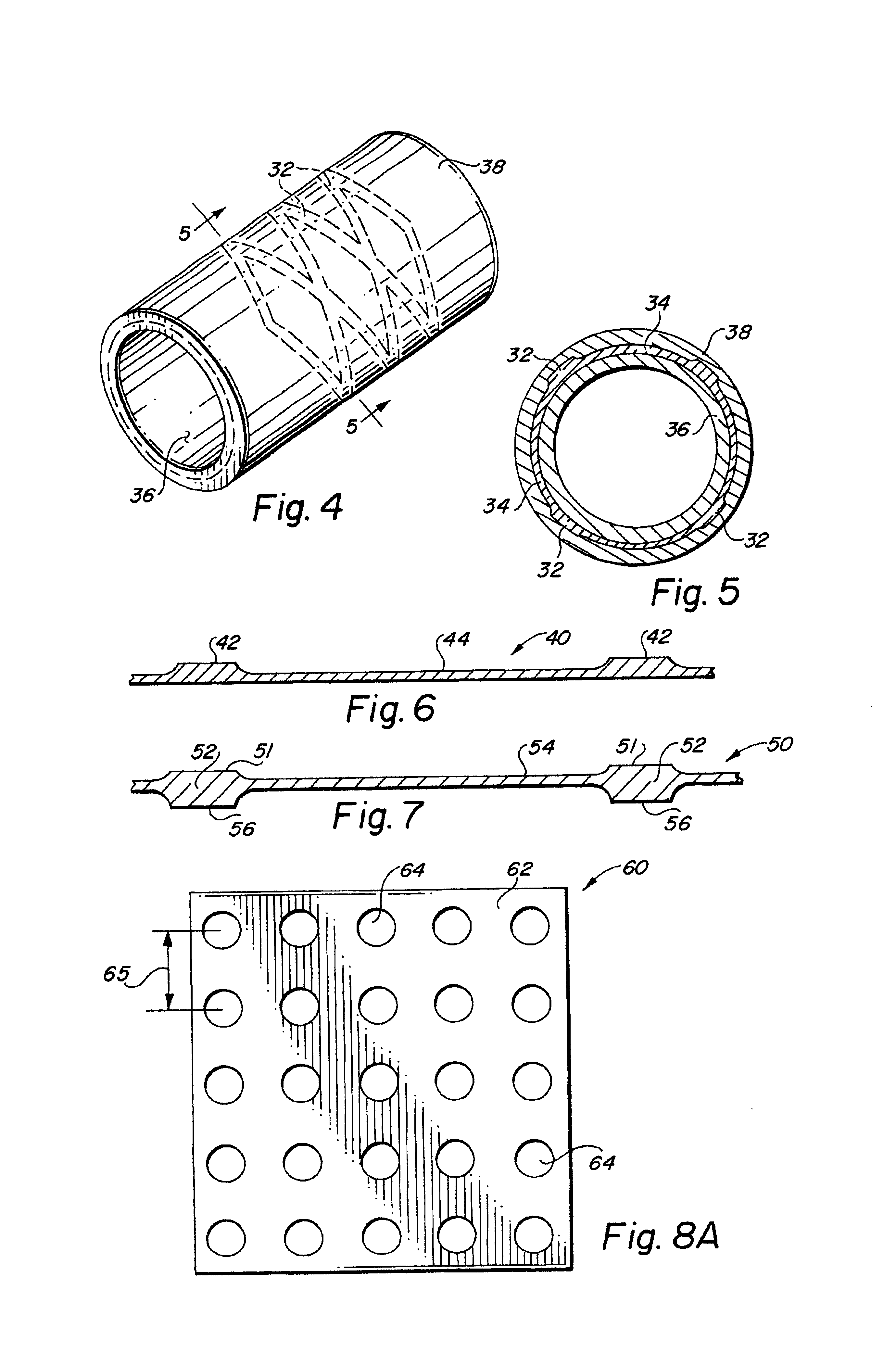

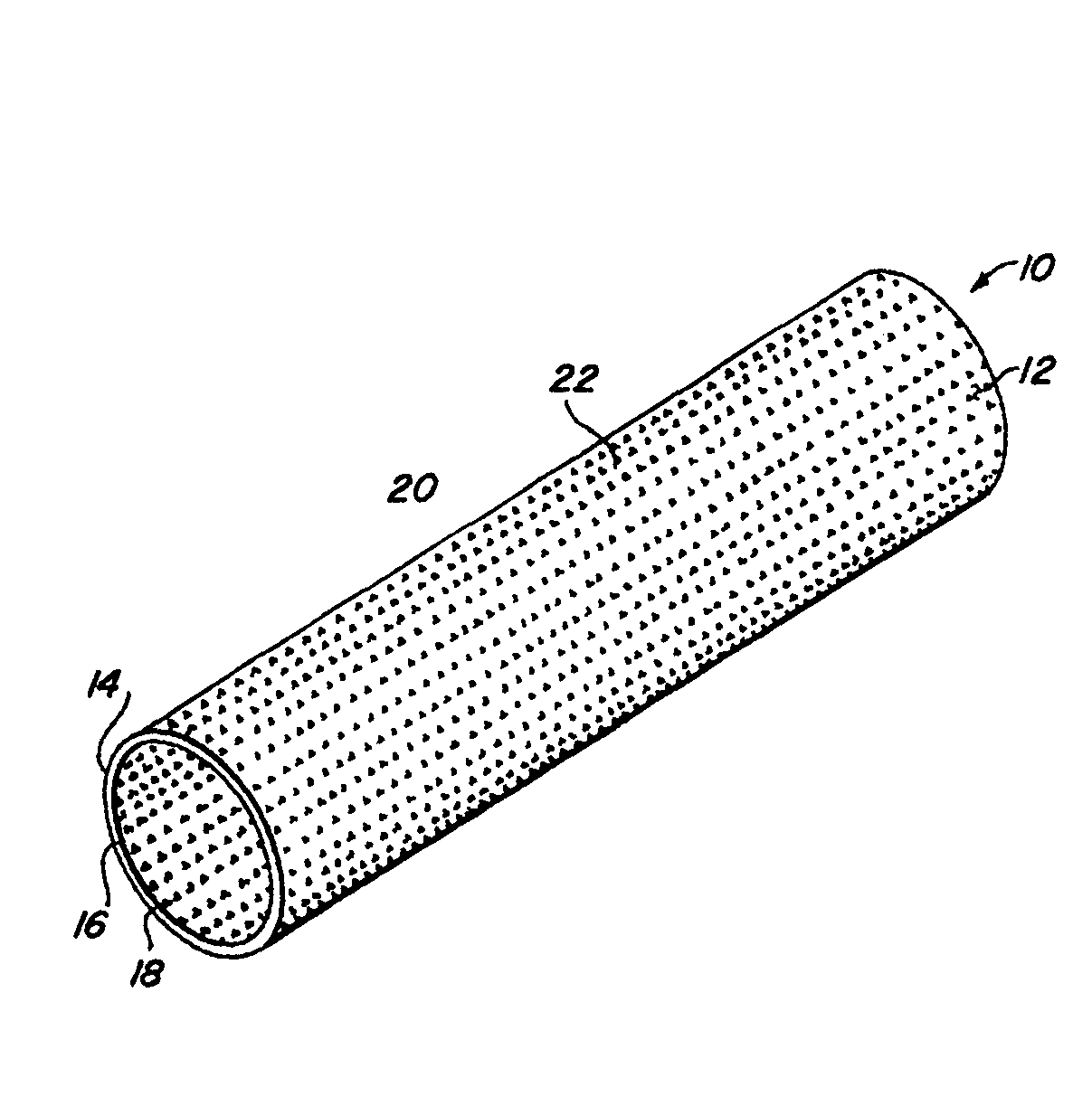

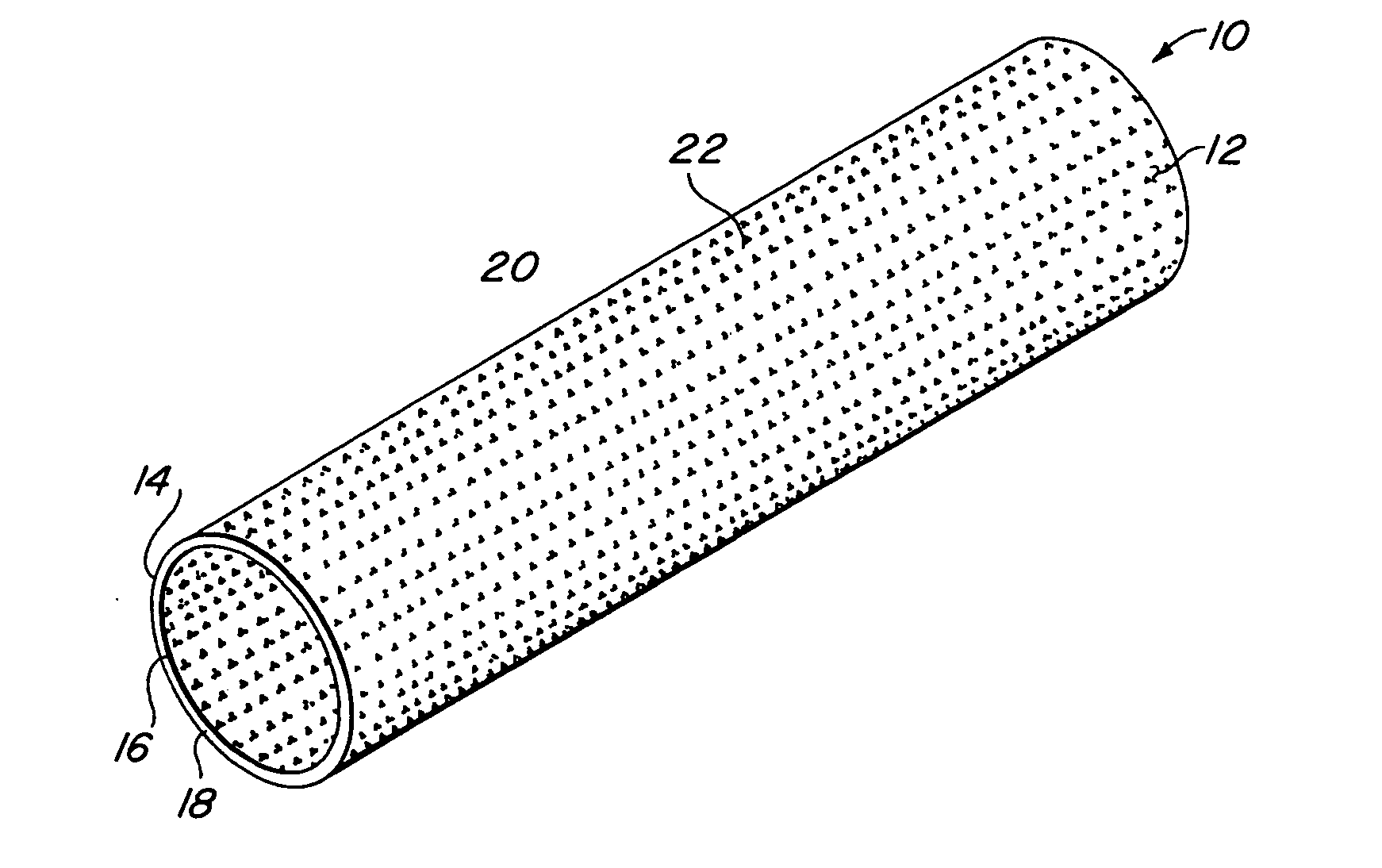

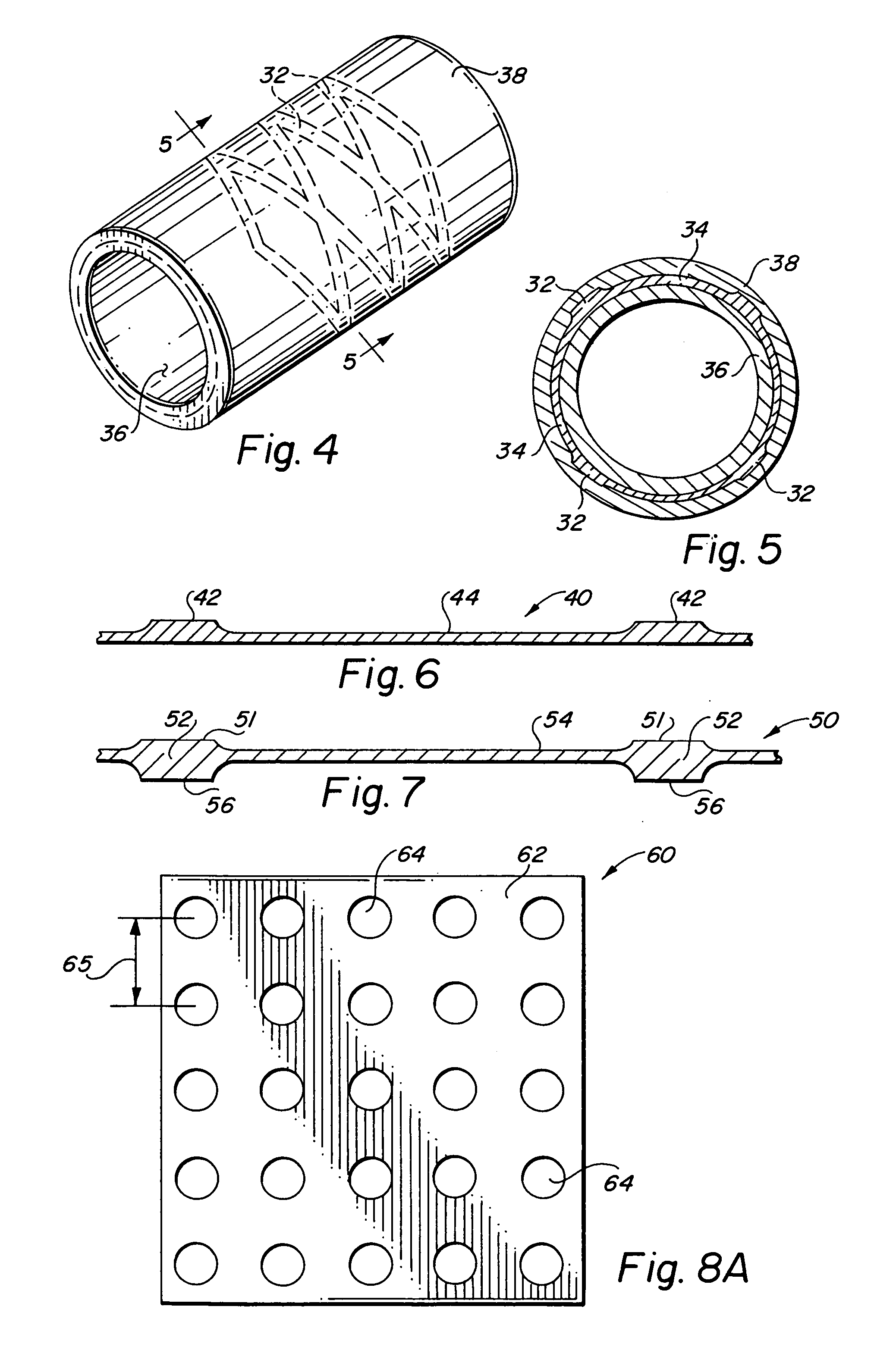

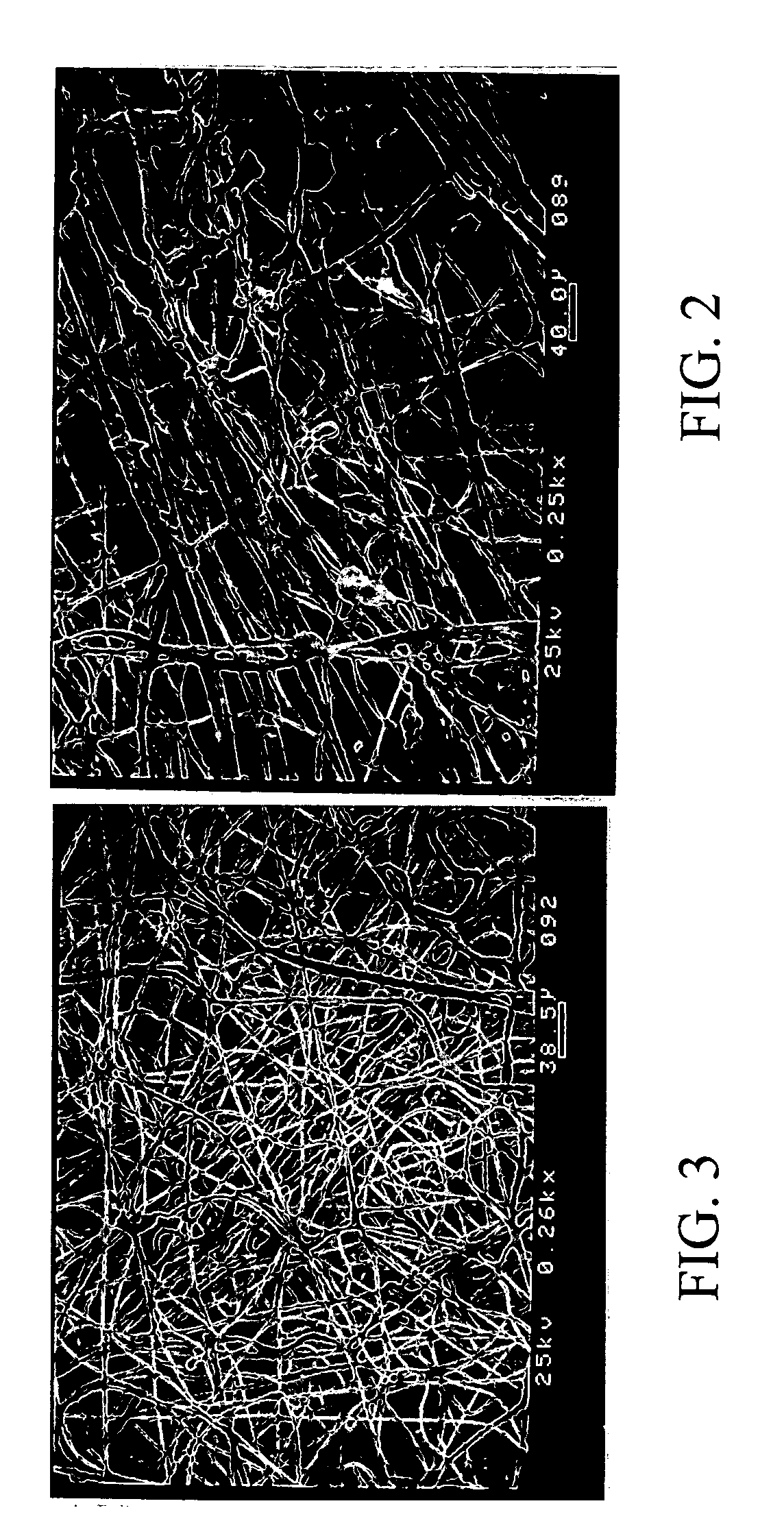

Complaint implantable medical devices and methods of making same

InactiveUS6936066B2Give flexibilityFacilitating transmural endothelializationStentsHeart valvesSurgical GraftMetallic materials

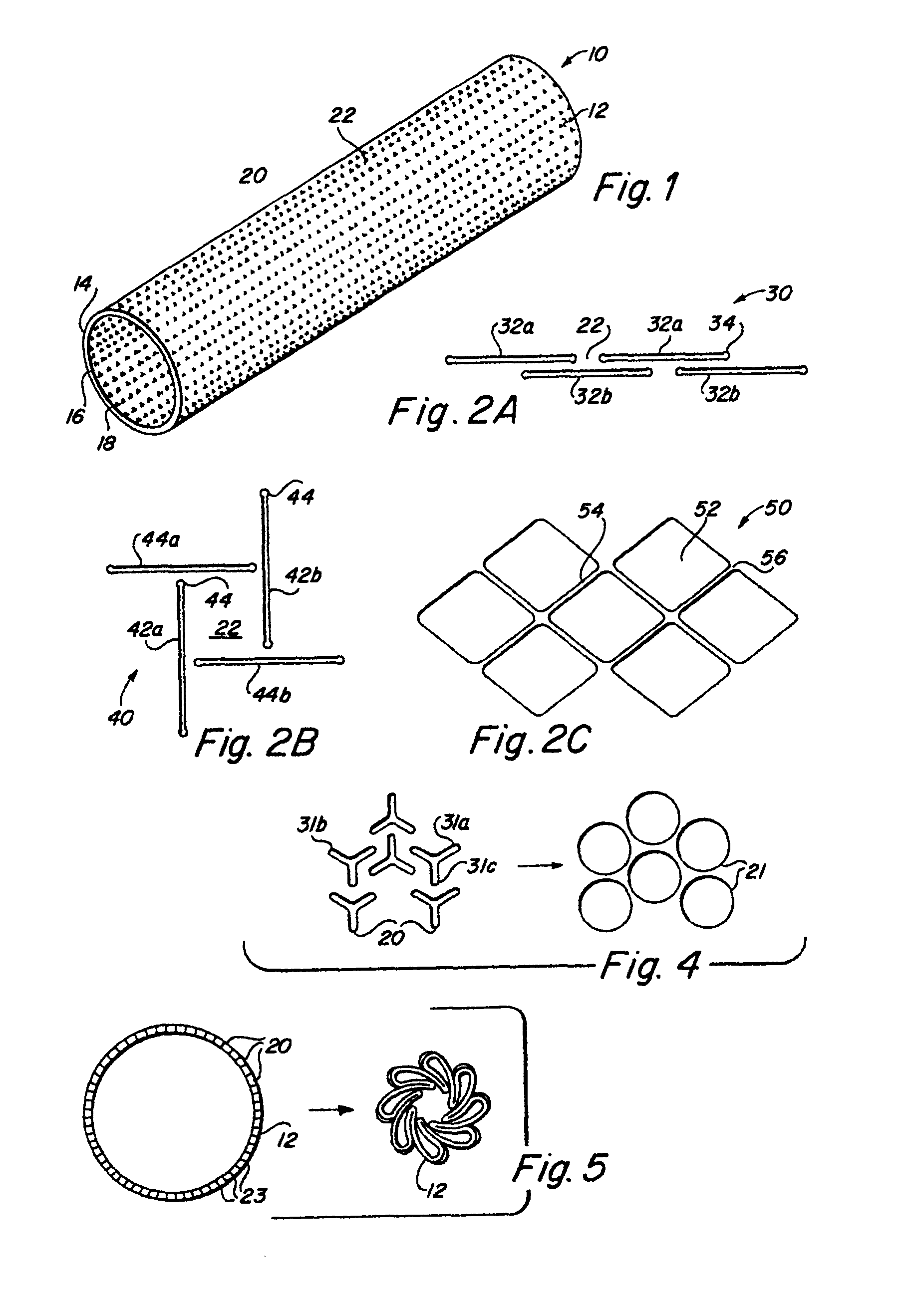

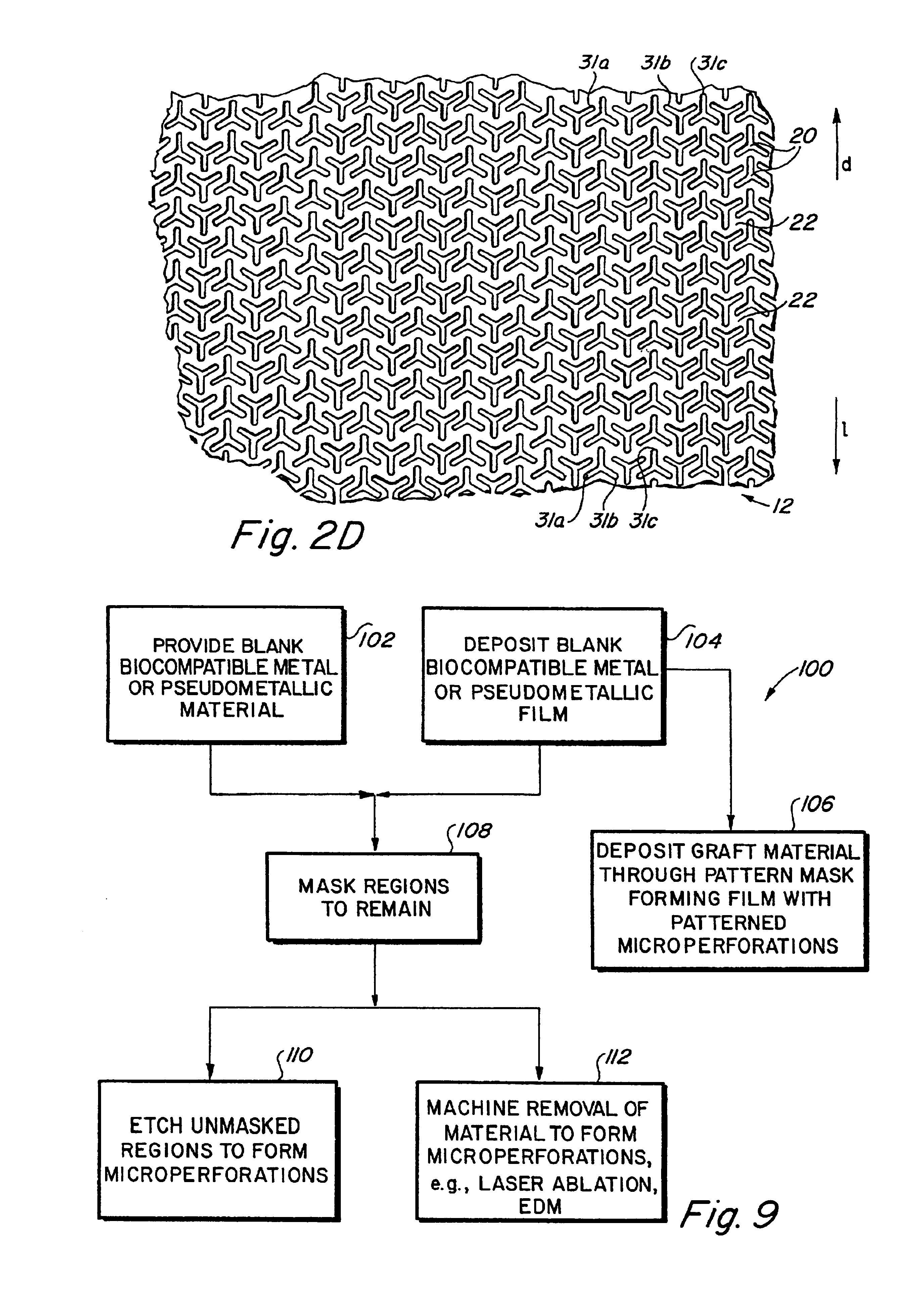

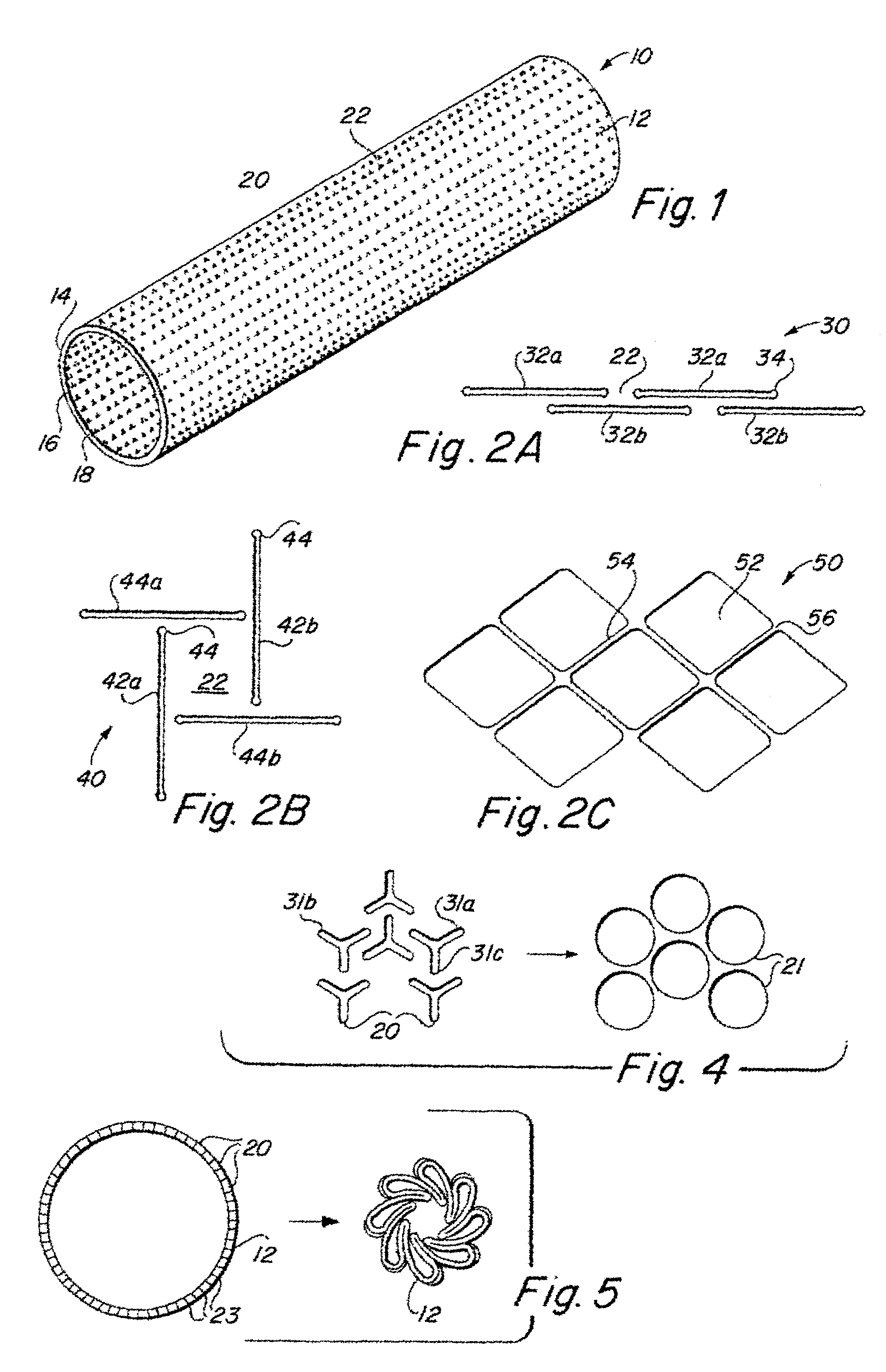

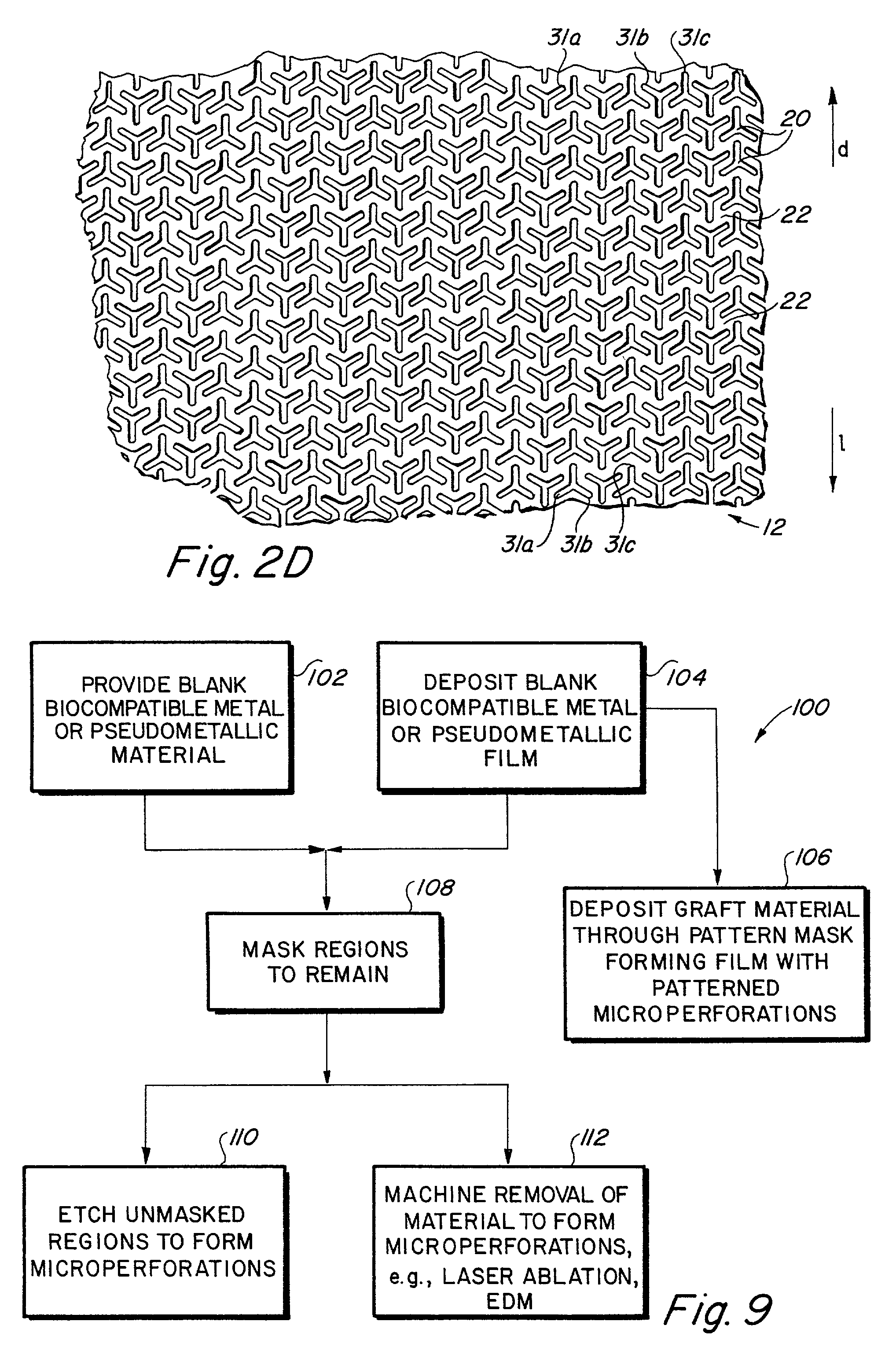

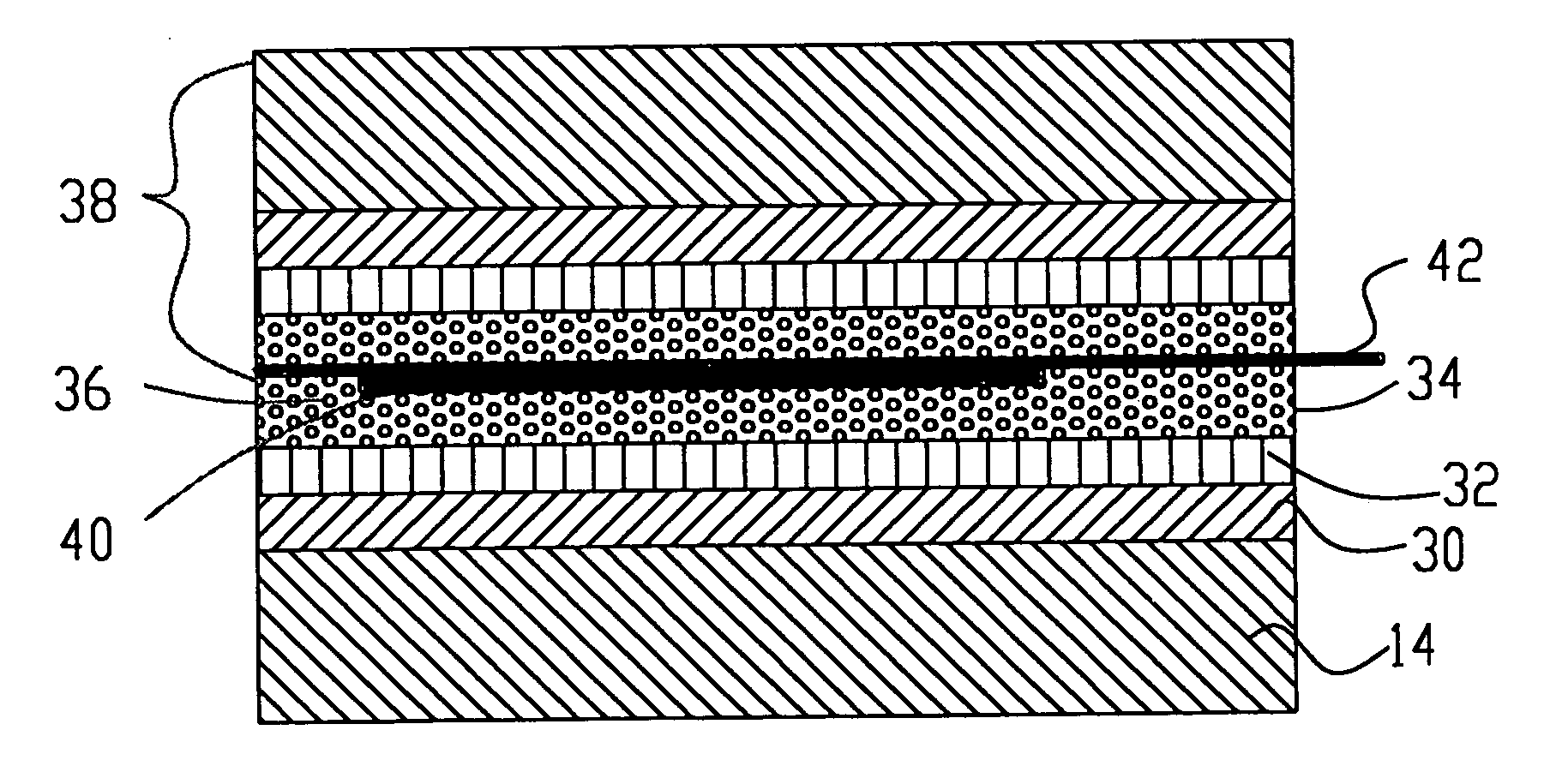

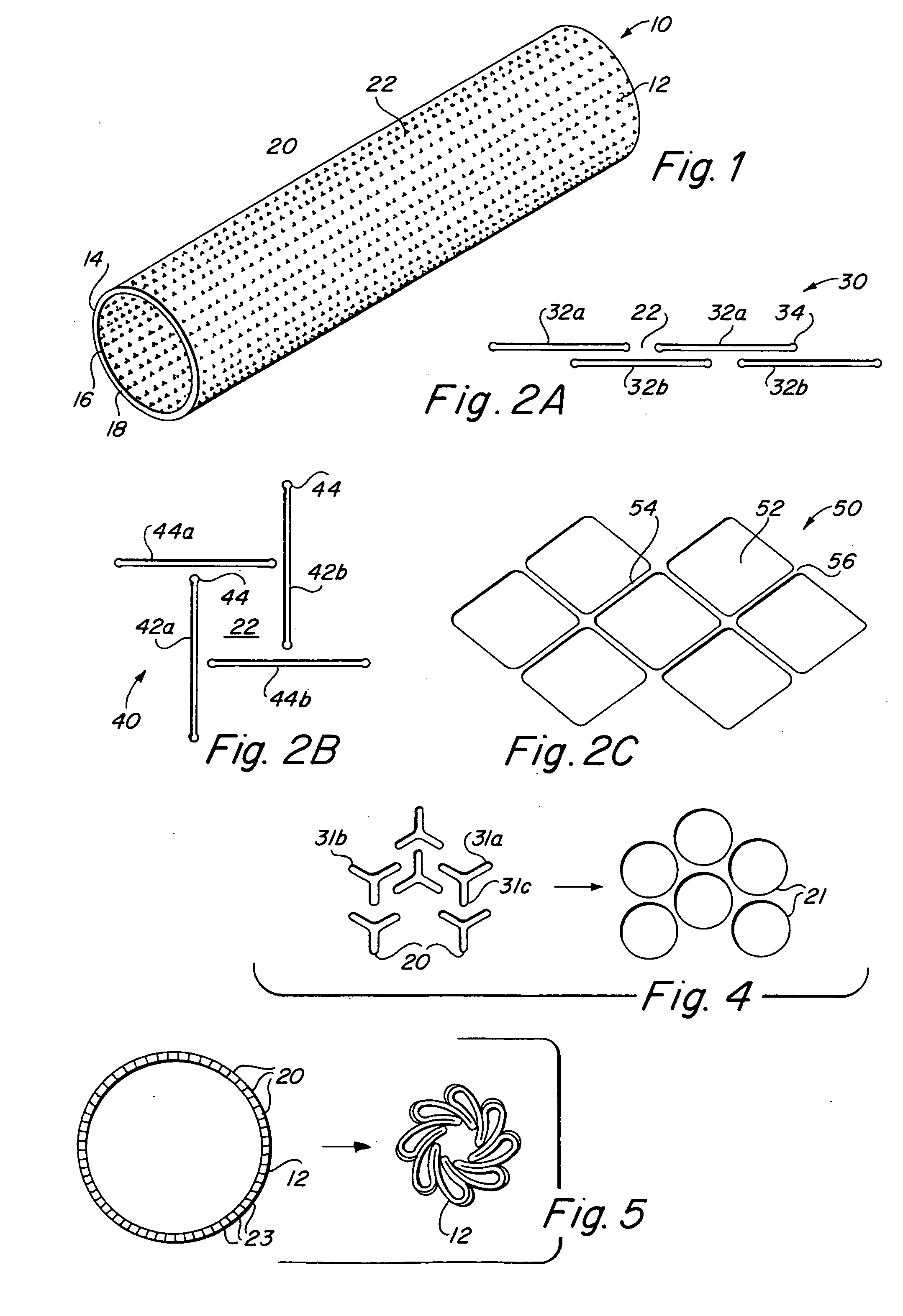

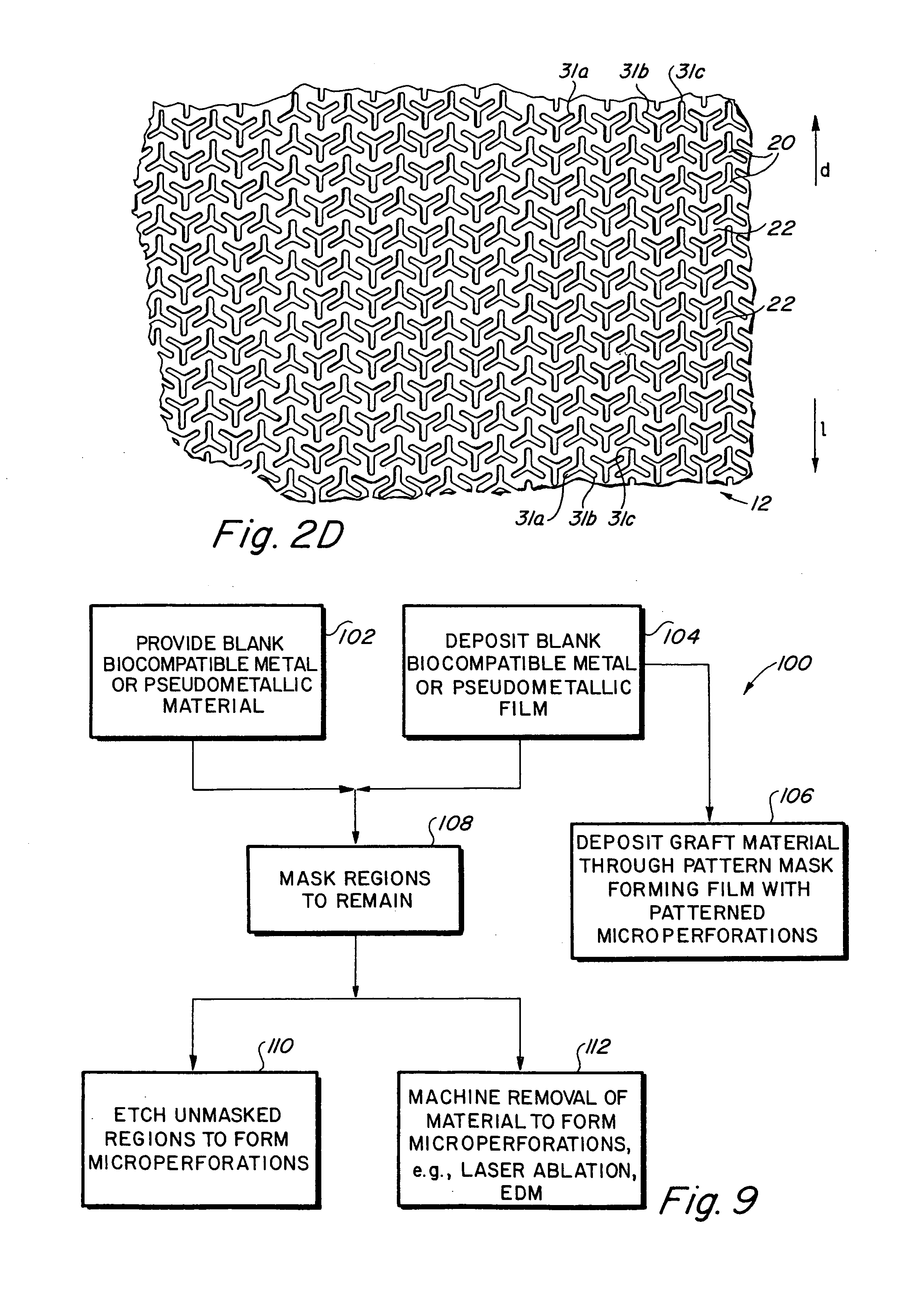

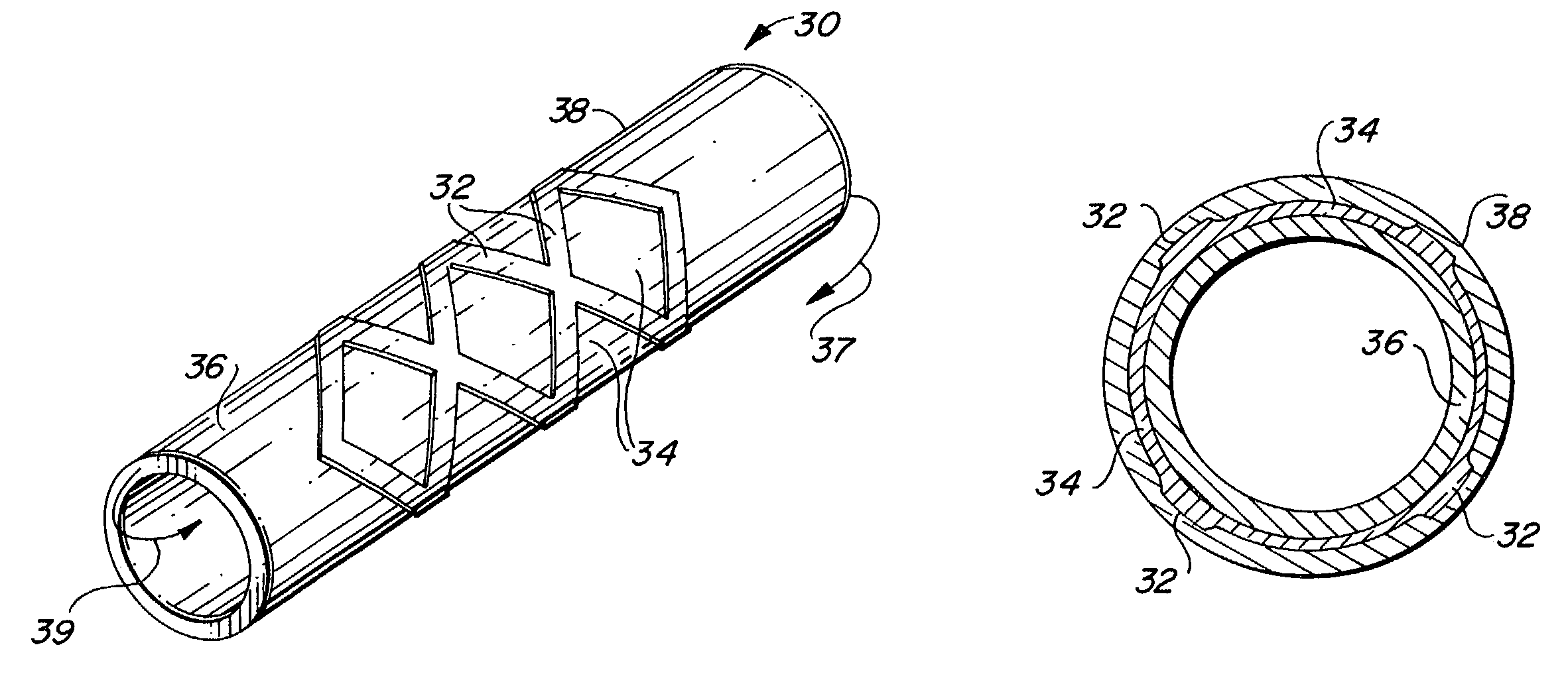

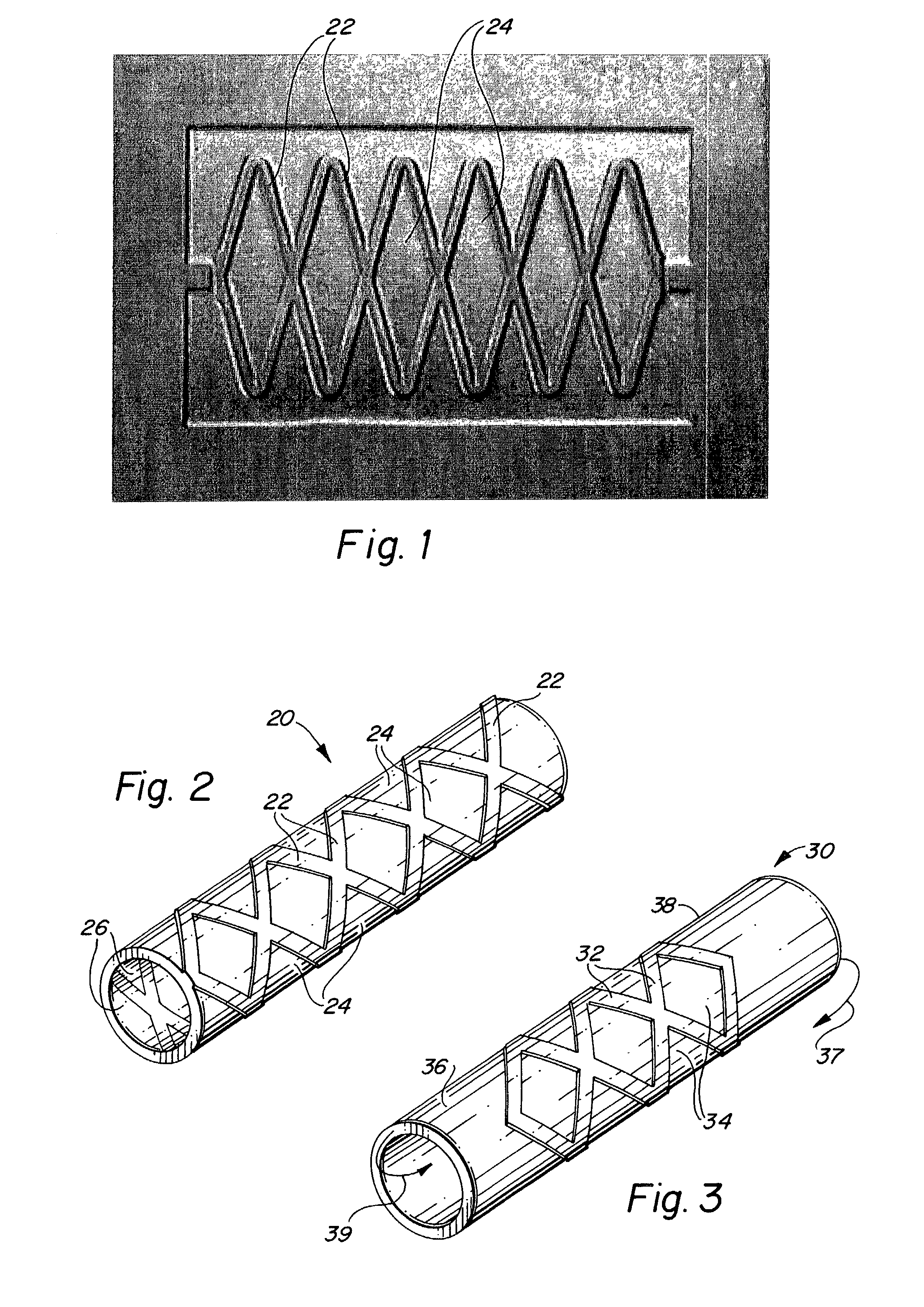

Implantable medical grafts fabricated of metallic or pseudometallic films of biocompatible materials having a plurality of microperforations passing through the film in a pattern that imparts fabric-like qualities to the graft or permits the geometric deformation of the graft. The implantable graft is preferably fabricated by vacuum deposition of metallic and / or pseudometallic materials into either single or multi-layered structures with the plurality of microperforations either being formed during deposition or after deposition by selective removal of sections of the deposited film. The implantable medical grafts are suitable for use as endoluminal or surgical grafts and may be used as vascular grafts, stent-grafts, skin grafts, shunts, bone grafts, surgical patches, non-vascular conduits, valvular leaflets, filters, occlusion membranes, artificial sphincters, tendons and ligaments.

Owner:VACTRONIX SCI LLC

Self-supporting metallic implantable grafts, compliant implantable medical devices and methods of making same

Implantable medical grafts fabricated of metallic or pseudometallic films of biocompatible materials having a plurality of microperforations passing through the film in a pattern that imparts fabric-like qualities to the graft or permits the geometric deformation of the graft. The implantable graft is preferably fabricated by vacuum deposition of metallic and / or pseudometallic materials into either single or multi-layered structures with the plurality of microperforations either being formed during deposition or after deposition by selective removal of sections of the deposited film. The implantable medical grafts are suitable for use as endoluminal or surgical grafts and may be used as vascular grafts, stent-grafts, skin grafts, shunts, bone grafts, surgical patches, non-vascular conduits, valvular leaflets, filters, occlusion membranes, artificial sphincters, tendons and ligaments.

Owner:VACTRONIX SCI LLC

Composite modular barrier structures and packages

InactiveUS20050249901A1Improve barrier propertiesRemove moistureNanotechWrappersNanoparticleDesiccant

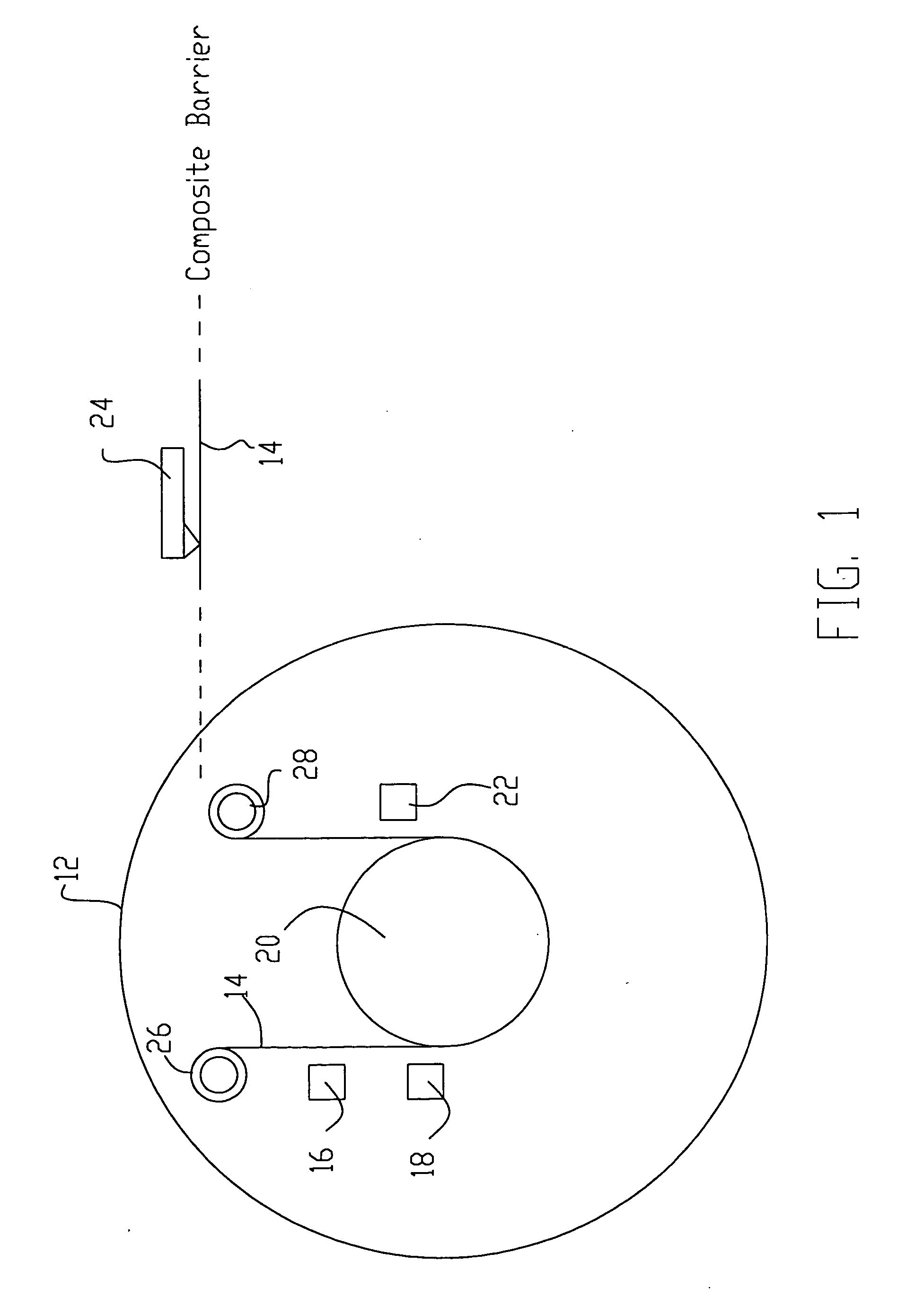

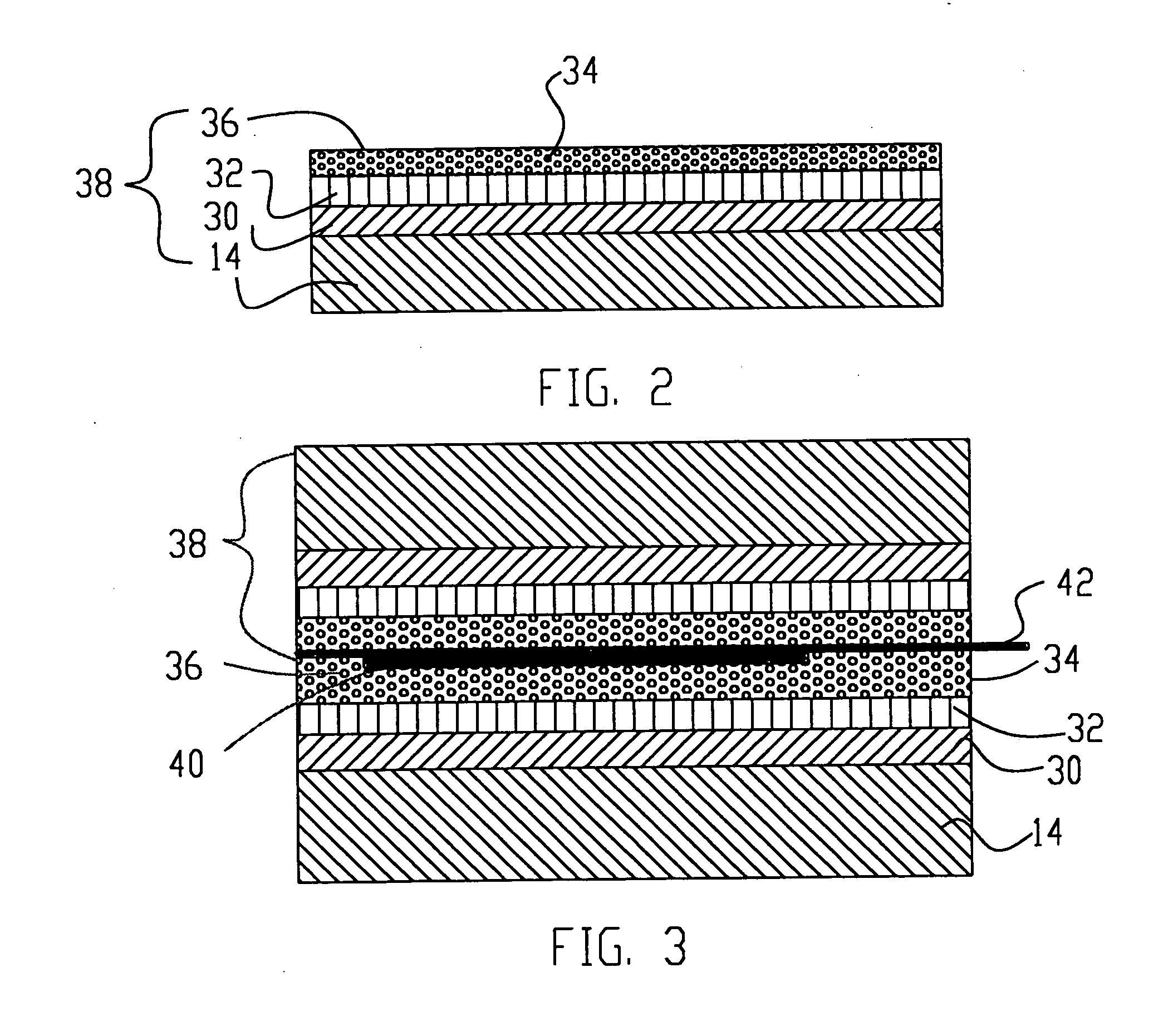

A composite multi-layer barrier is produced by first vapor depositing a barrier under vacuum over a substrate of interest and then depositing an additional barrier at atmospheric pressure in a preferably thermoplastic layer. The resulting multi-layer barrier is then used to coat an article of interest in a lamination process wherein the thermoplastic layer is fused onto itself and the surface of the article. The vacuum-deposited barrier may consists of a first leveling polymer layer followed by an inorganic barrier material sputtered over the leveling layer and of an additional polymeric layer flash evaporated, deposited, and cured under vacuum. The thermoplastic polymeric layer is then deposited by extrusion, drawdown or roll coating at atmospheric pressure. The resulting multi-layer barrier may be stacked using the thermoplastic layer as bonding agent. Nano-particles may be included in the thermoplastic layer to improve the barrier properties of the structure. A desiccant material may also be included or added as a separate layer.

Owner:SIGMA LAB OF ARIZONA

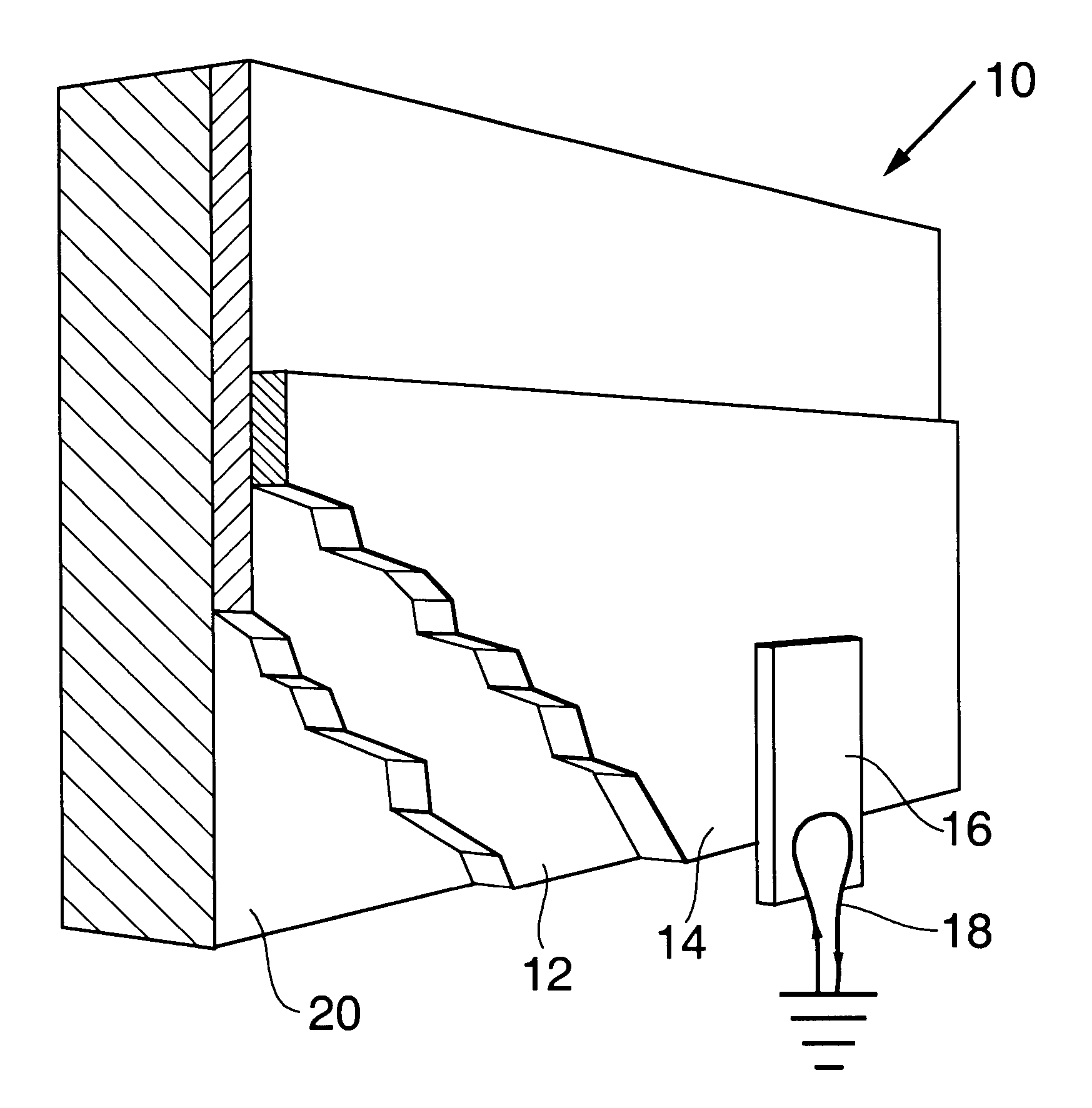

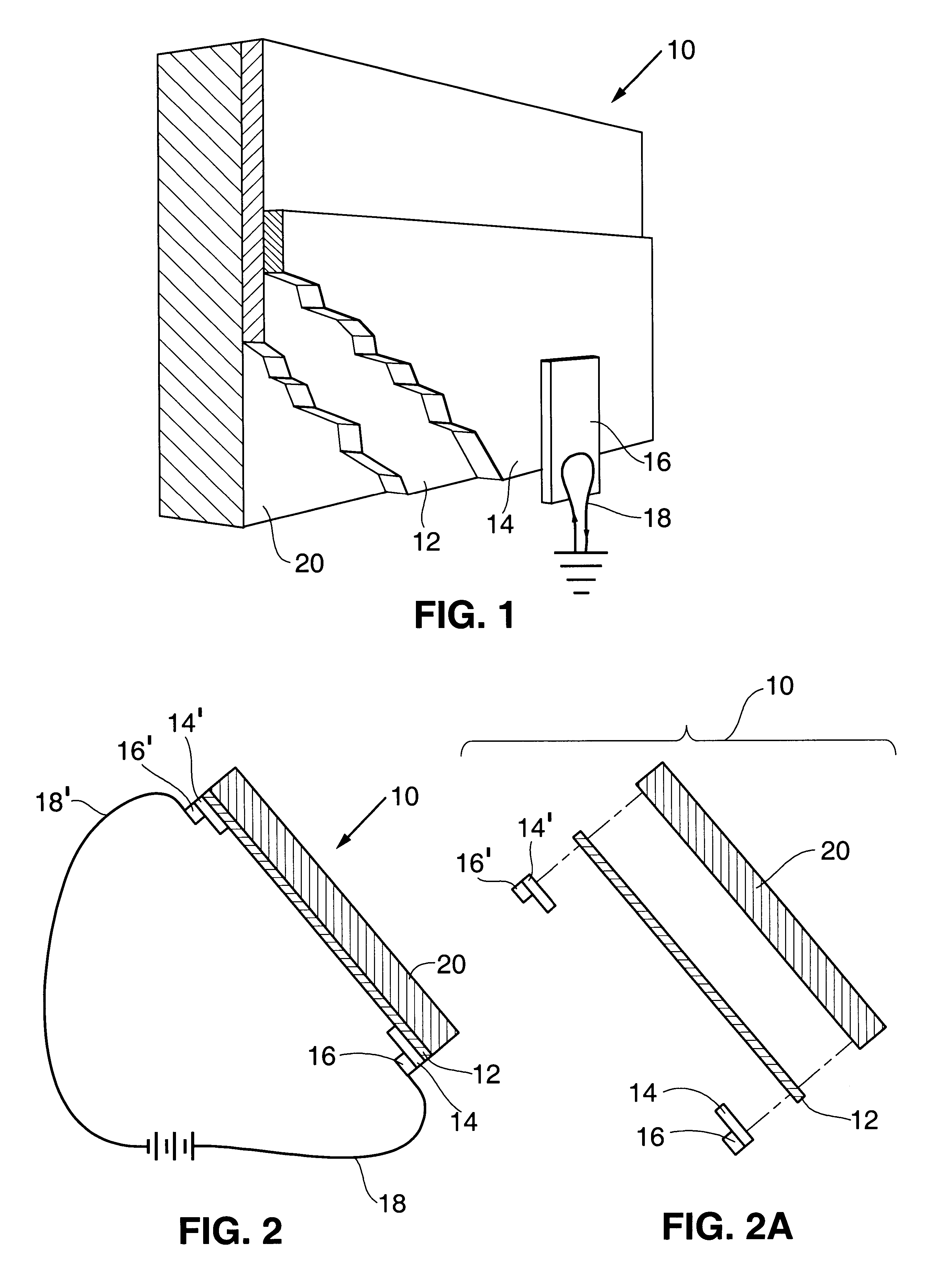

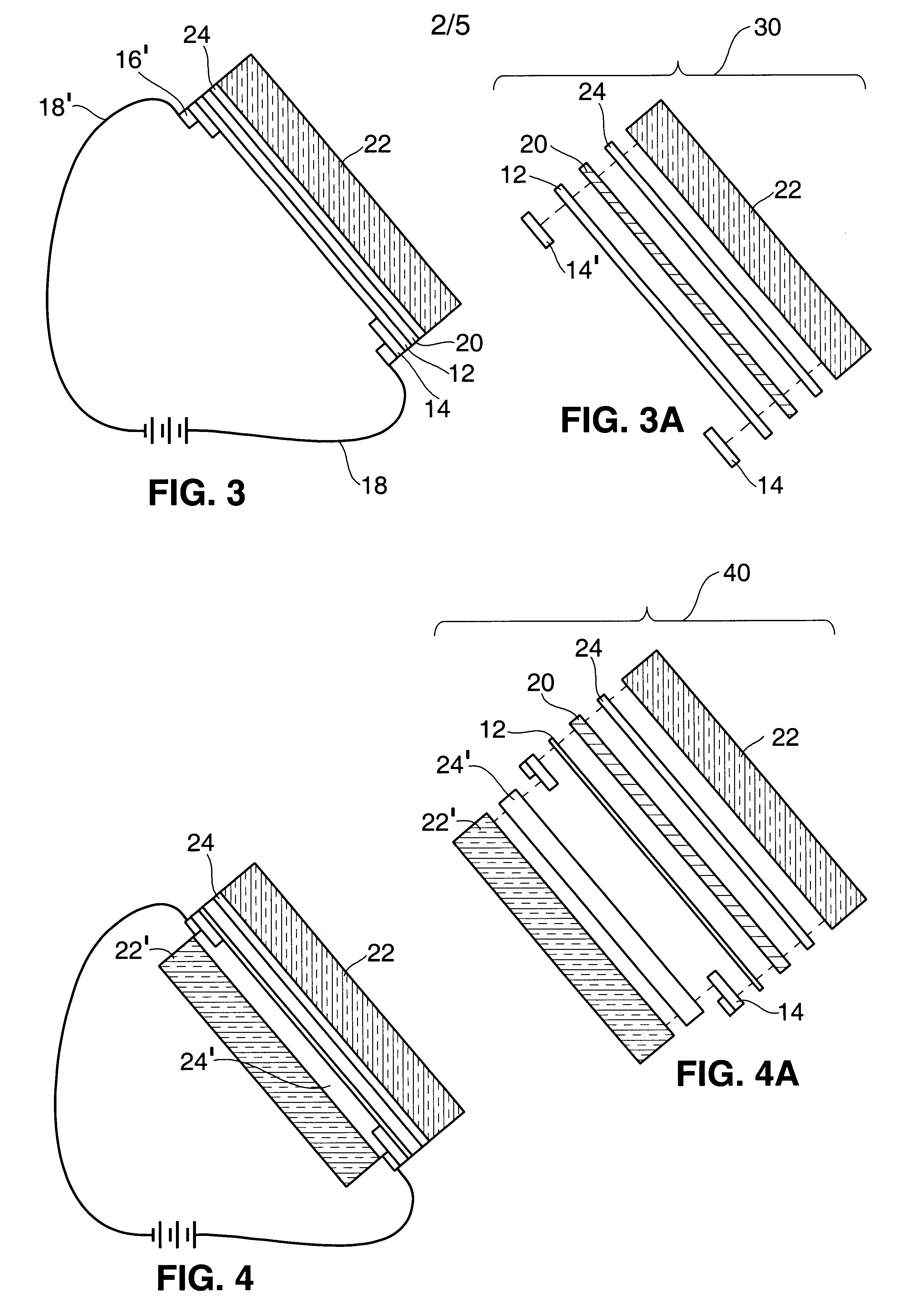

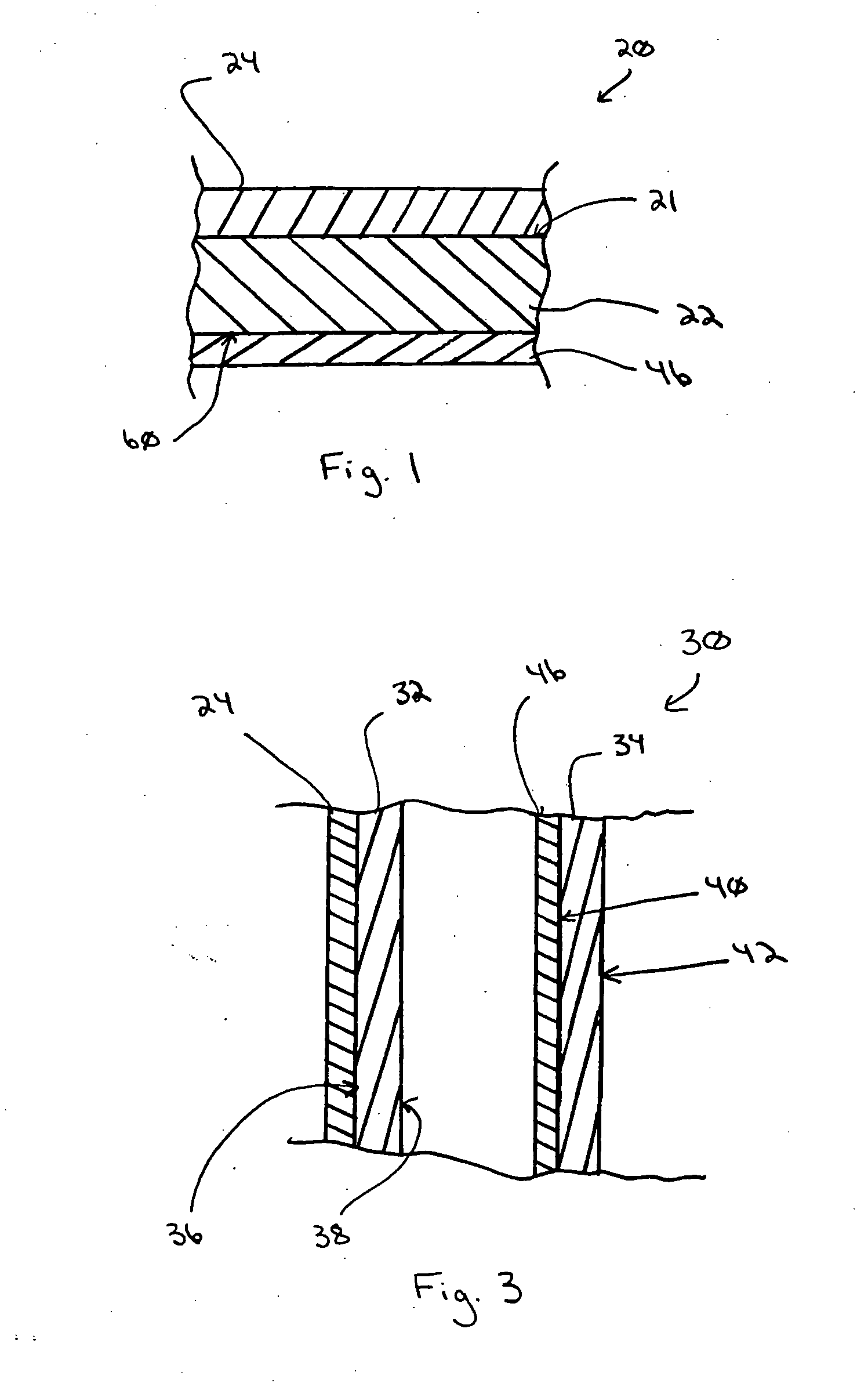

Vacuum deposition of bus bars onto conductive transparent films

InactiveUS6204480B1Suitable for processingWindowsConductive layers on insulating-supportsElectrical resistance and conductanceElectrical connection

Vacuum deposition processes such as sputter-depositing are employed to deposit electrically conductive bus bars onto thin film transparent conductor sheets. These assemblies provide efficient and durable electrical connections to the conductor sheets which can be laminated into glazing structures such as automotive windshields to provide resistance heating for defogging and deicing or the provide an electrical connection for in-window antennas and in window radiation shields.

Owner:SOUTHWALL TECH INC

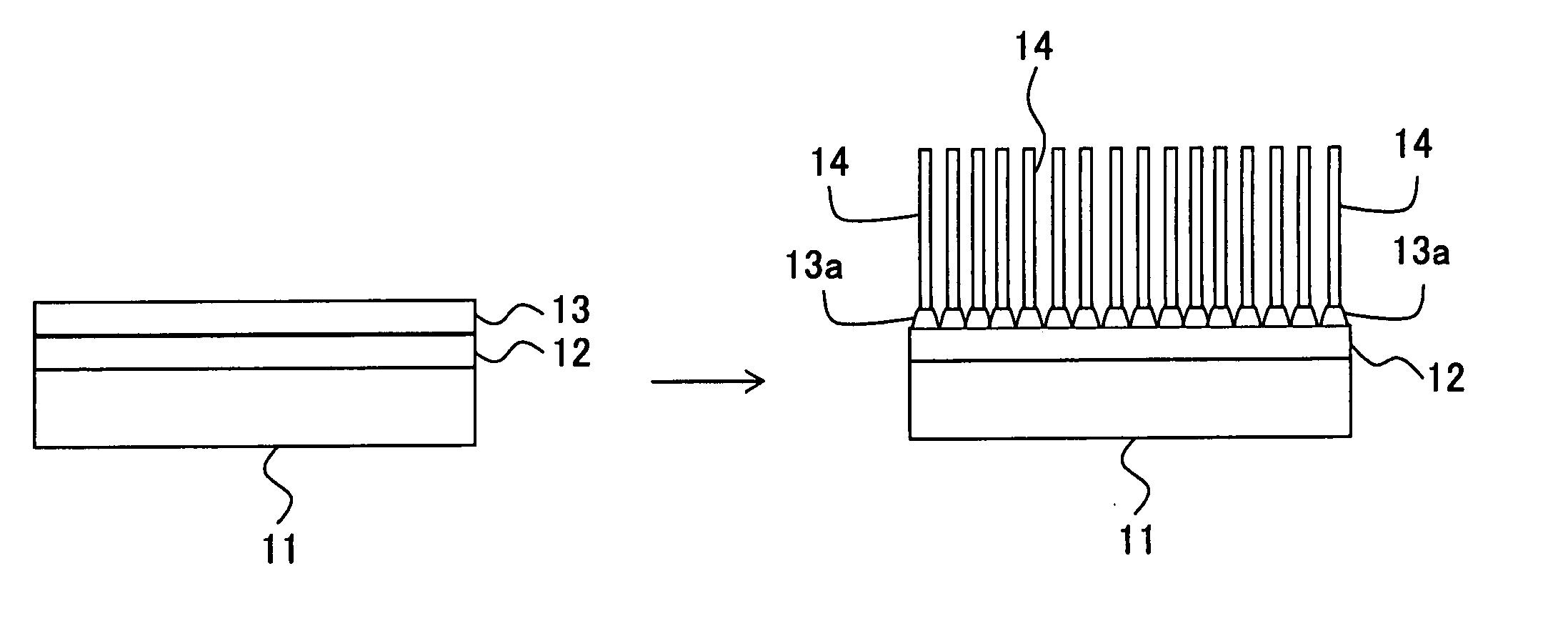

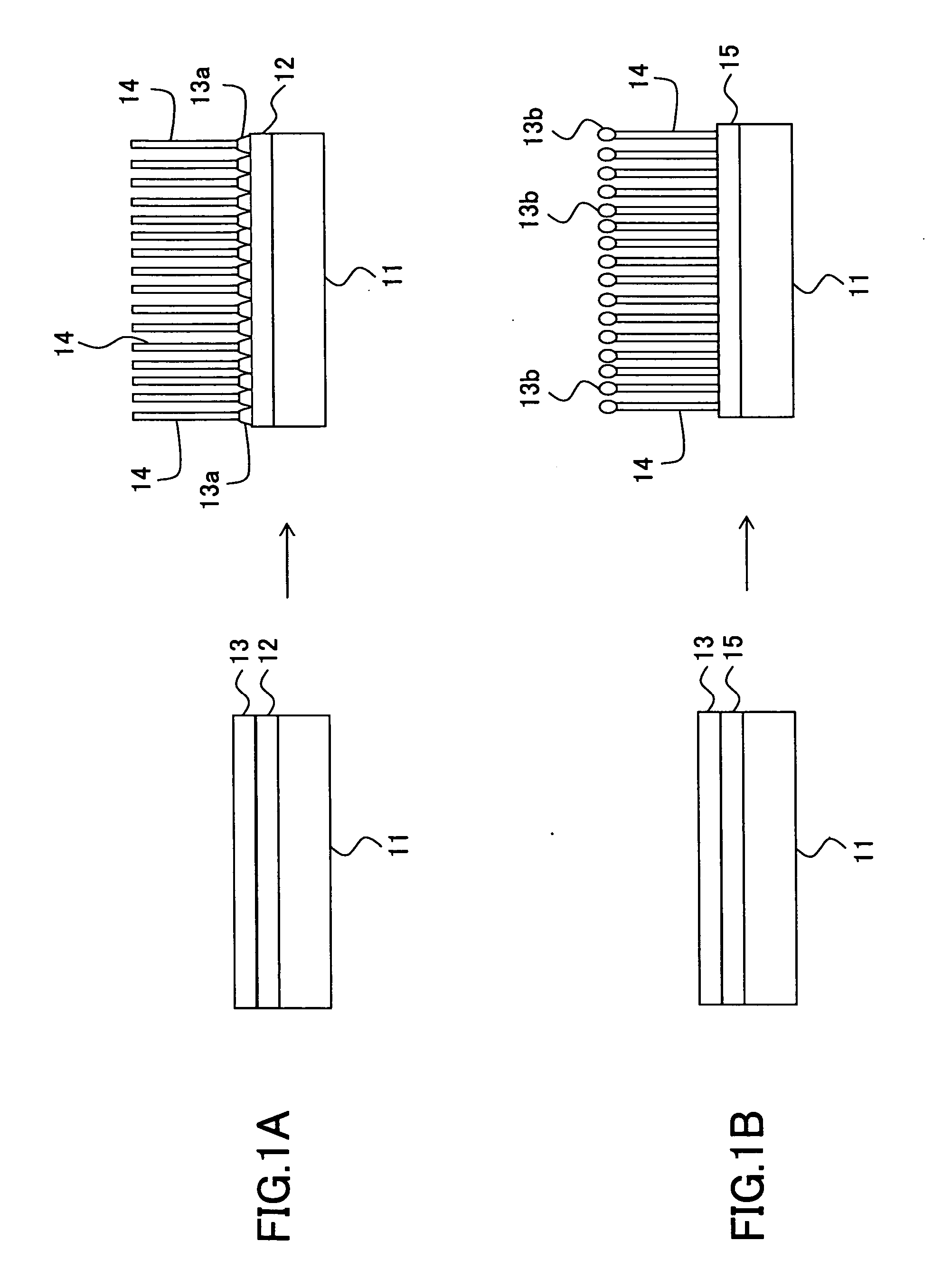

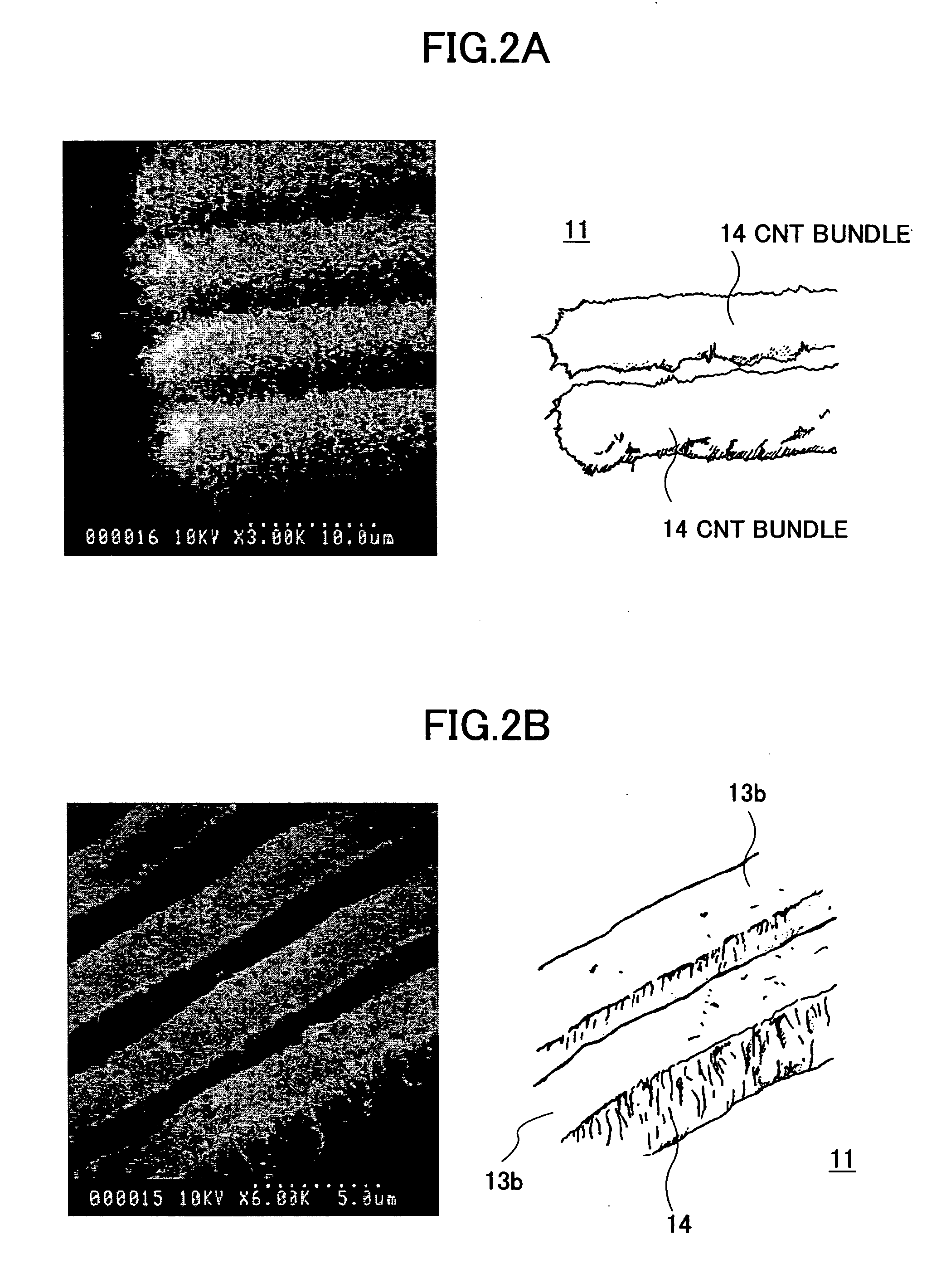

Semiconductor device and method of manufacturing the same

ActiveUS20050215049A1Eliminate disadvantagesSemiconductor/solid-state device detailsNanoinformaticsSputteringDevice material

A method of manufacturing a semiconductor device having an interconnection part formed of multiple carbon nanotubes is disclosed. The method includes the steps of (a) forming a growth mode control layer controlling the growth mode of the carbon nanotubes, (b) forming a catalyst layer on the growth mode control layer, and (c) causing the carbon nanotubes to grow by heating the catalyst layer by thermal CVD so that the carbon nanotubes serve as the interconnection part. The growth mode control layer is formed by sputtering or vacuum deposition in an atmospheric gas, using a metal selected from a group of Ti, Mo, V, Nb, and W. The growth mode is controlled in accordance with a predetermined concentration of oxygen gas of the atmospheric gas.

Owner:FUJITSU LTD

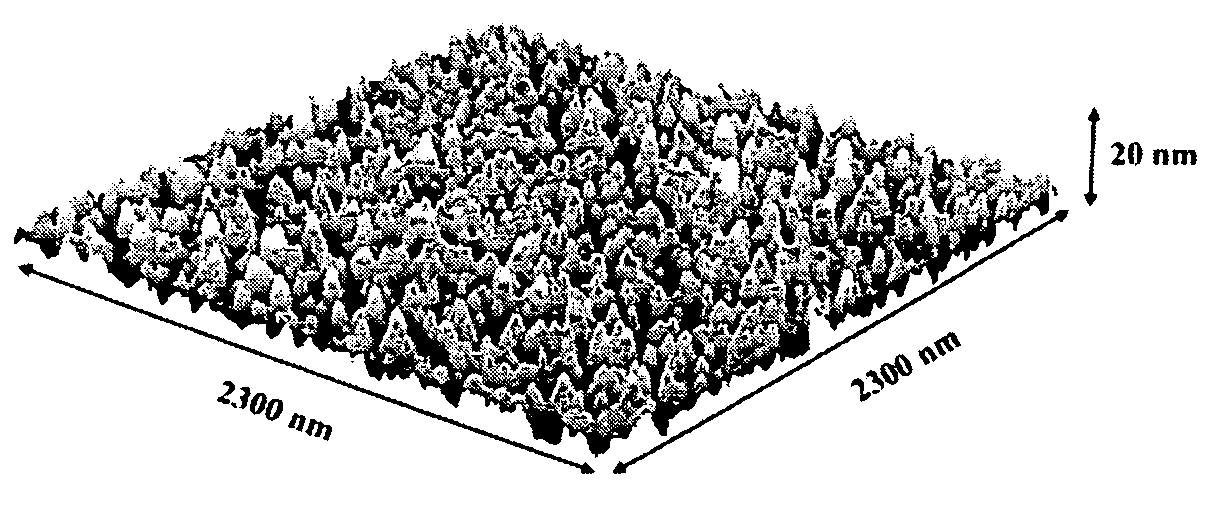

Nanophase multilayer barrier and process

InactiveUS20050051763A1Improve toughnessHigh fracture-resistanceSolid-state devicesSemiconductor/solid-state device manufacturingPliabilityEngineering

A thin film barrier structure and process is disclosed, which is seen as particularly useful for use in devices that require protection from such common environmental species as oxygen and water. The disclosed barrier structure is of particular utility for such devices as implemented on flexible substrates, such as may be desirable for OLED-based or LCD-based devices. The disclosed barrier structure provides superior barrier properties, flexibility, as well as commercial-scale reproducibility, through the use of a novel organic / inorganic nanocomposite structure formed by infiltration of a porous inorganic layer by an organic material. The composite structure is produced by vacuum deposition techniques in the first preferred embodiment.

Owner:HELICON RES

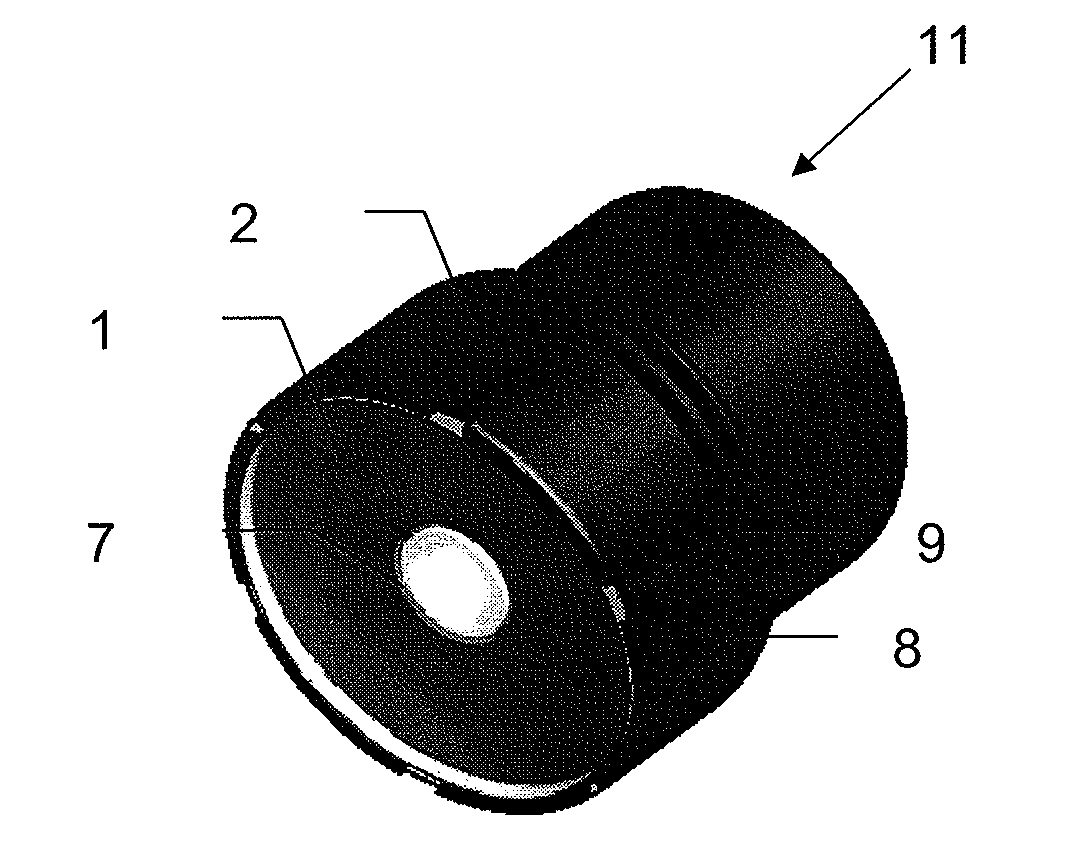

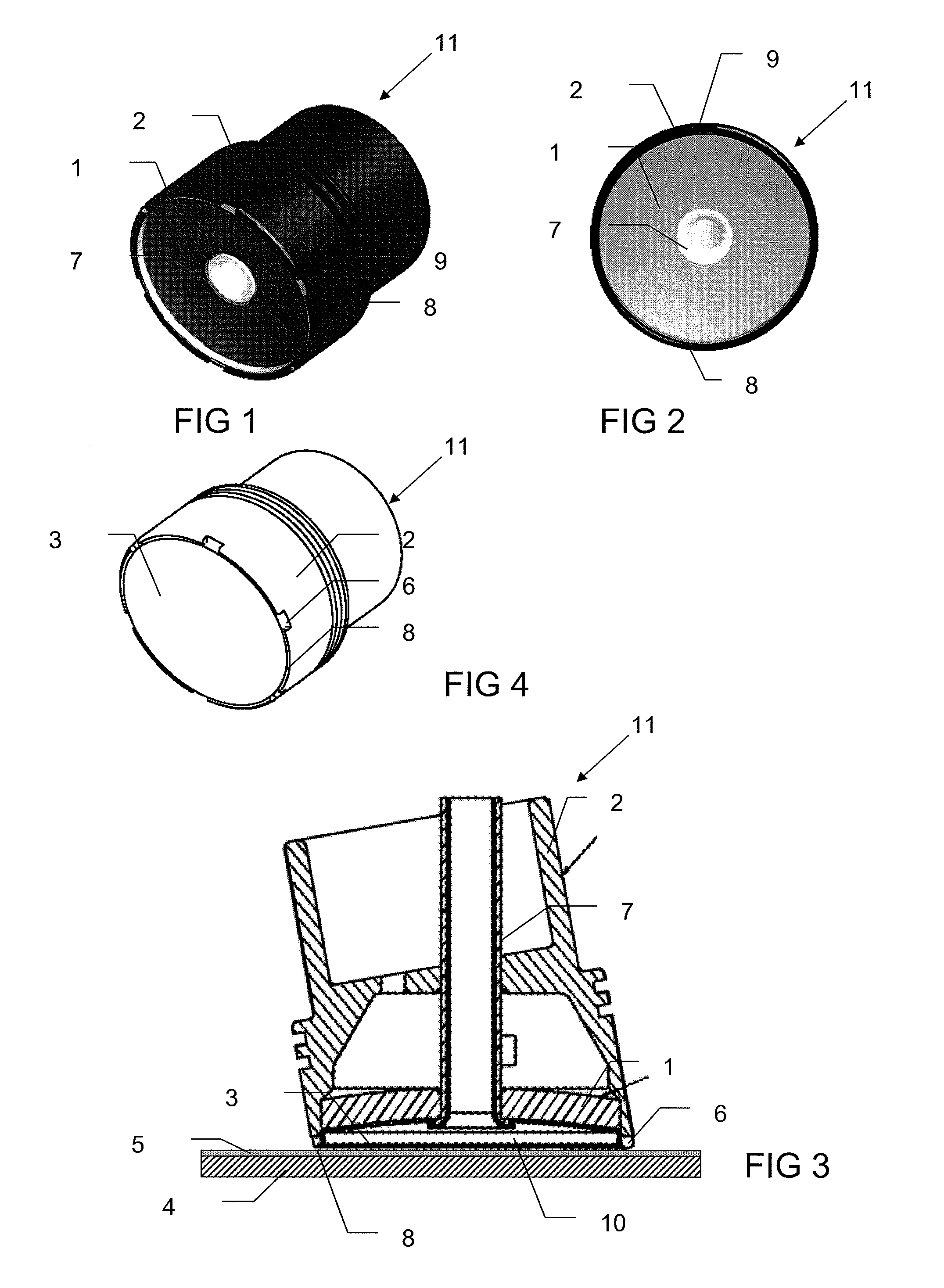

Method for manufacturing a membrane and object provided with such a membrane

InactiveUS20100109480A1Simple and efficientUltrasonic/sonic/infrasonic diagnosticsUltrasound therapyUltrasonic sensorMembrane configuration

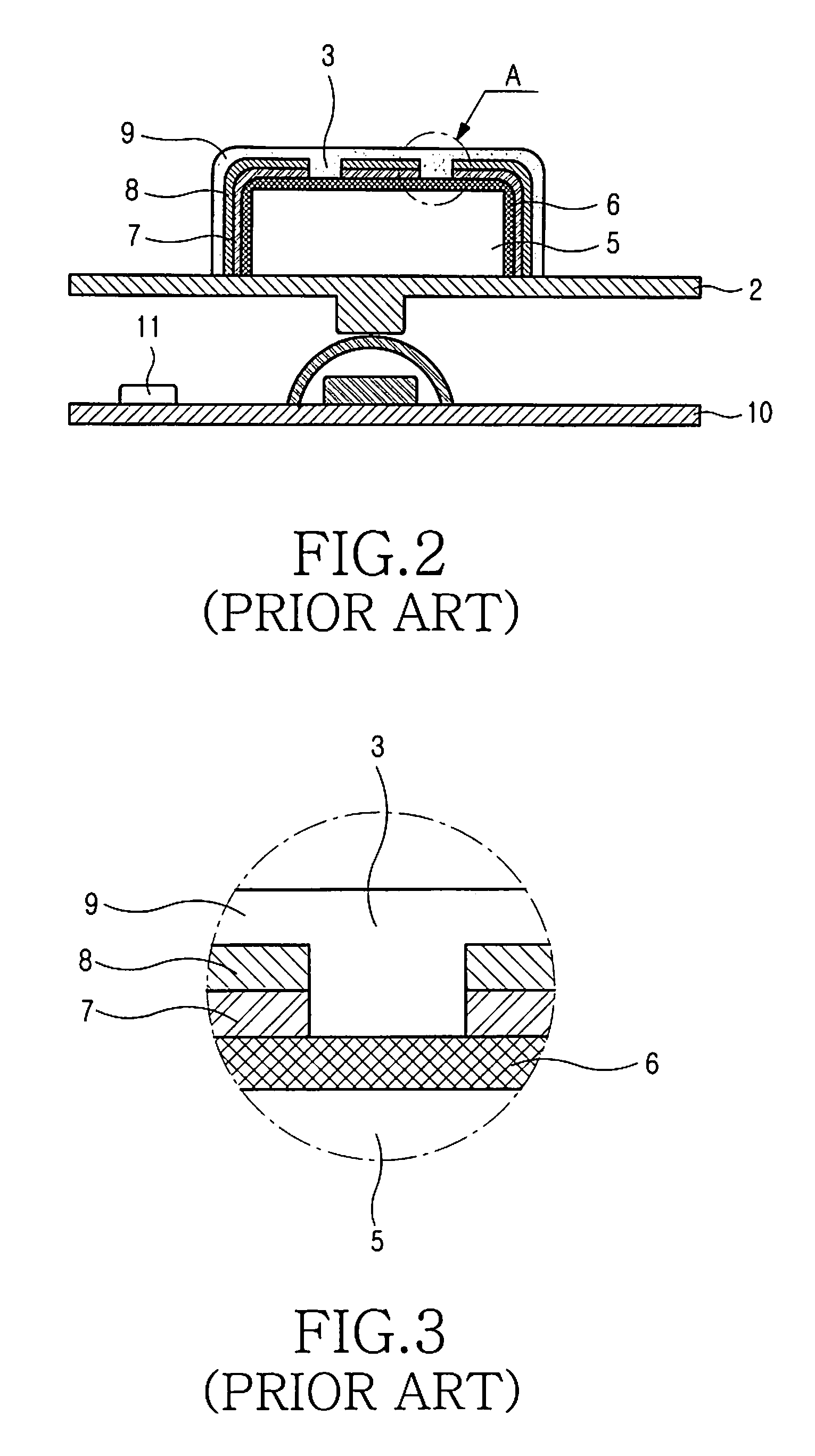

The present invention relates to a method for manufacturing a membrane or wall (3) of a material, which is capable of vapour / vacuum deposition, over an opening of an object (2). The method includes: placing the opening with a defined rim against a backing surface (4) coated with a layer (5) repellent to the depositable material; depositing of the depositable material on the object (2) and the backing surface (4) to form an element; separation of the element from the hacking surface (4) leaving a membrane (3) integral with the element. The invention also relates to such an object provided with a membrane (3), and particularly an ultrasonic transducer (11) provided with a front membrane (3).

Owner:ULTRAZONIX DNT

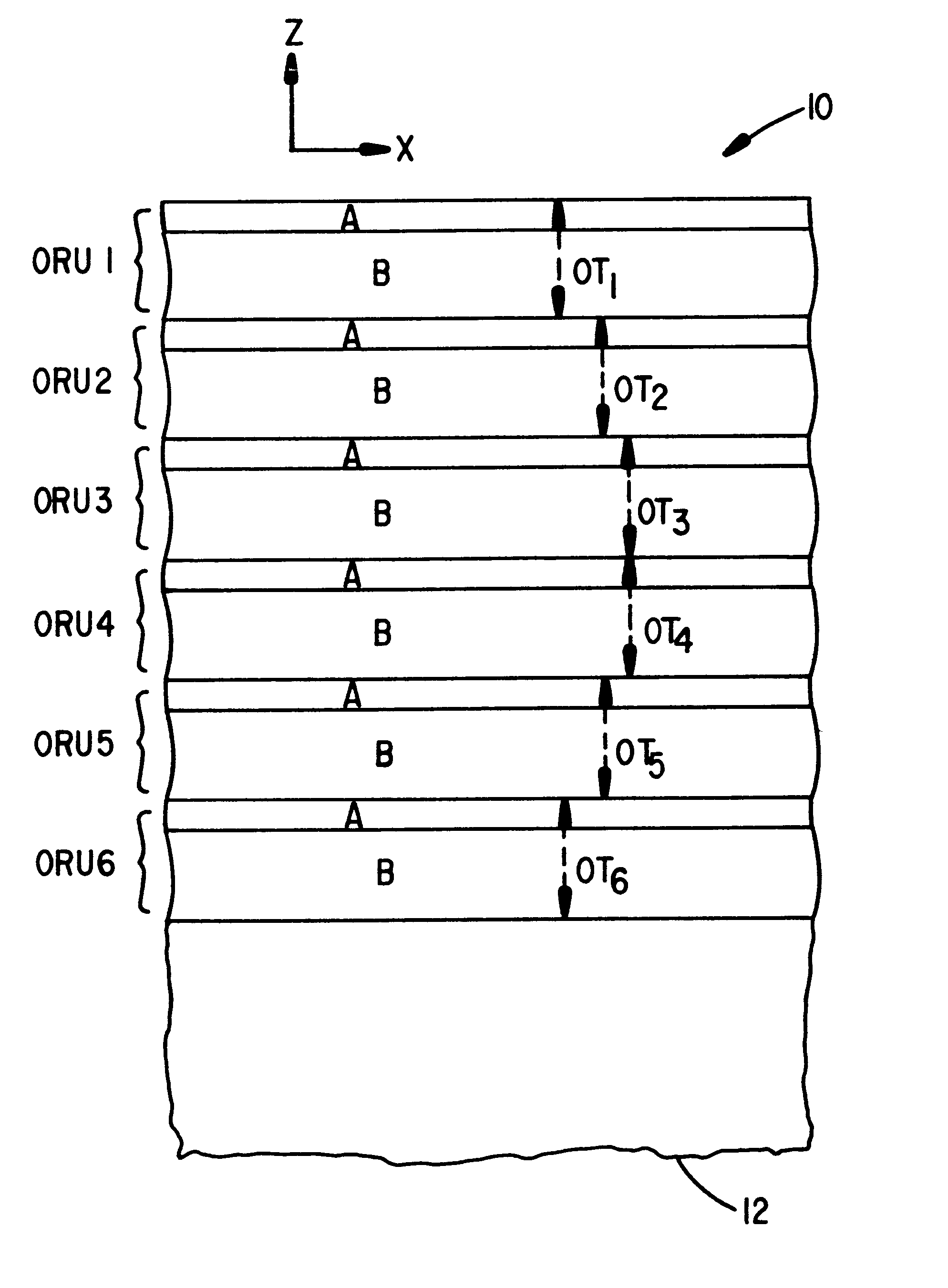

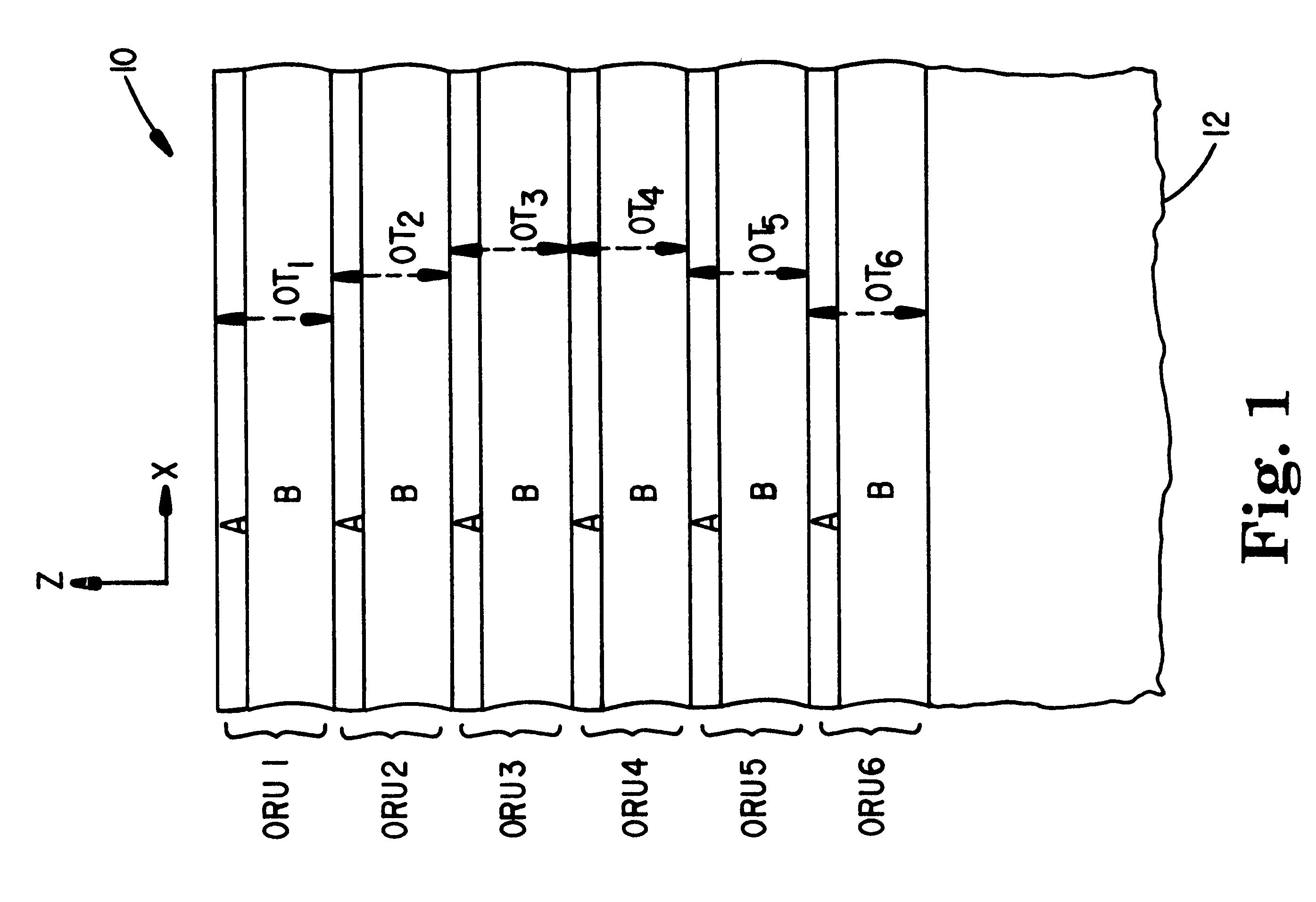

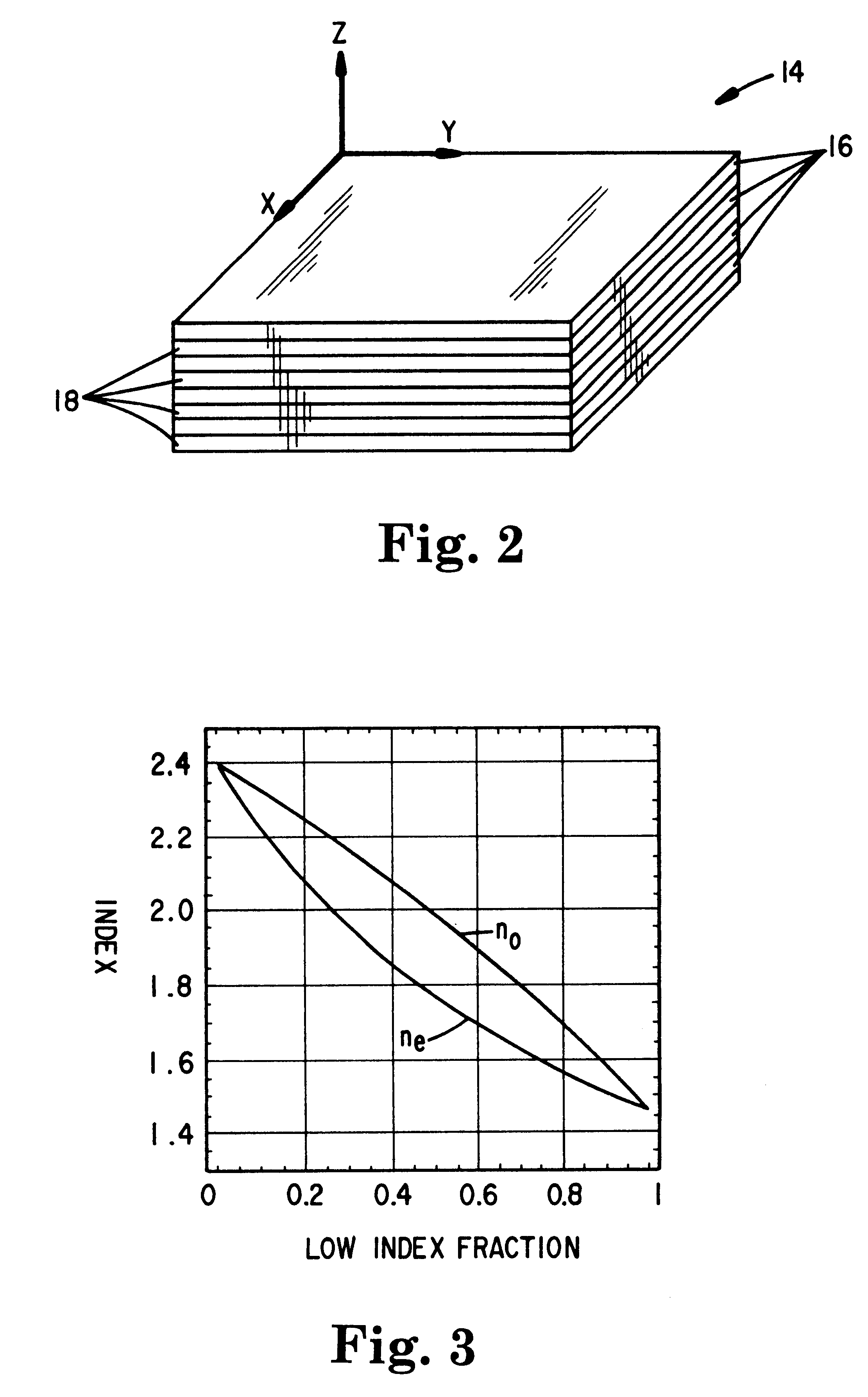

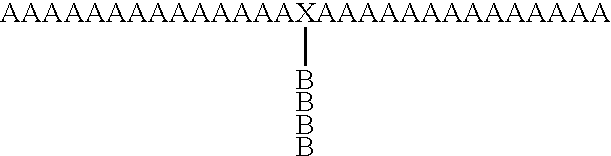

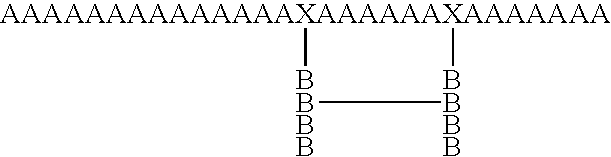

Birefringent reflectors using isotropic materials and form birefringence

Multilayer thin film reflectors, such as mirrors and reflective polarizers, are described in which form birefringent optical layers are incorporated into a plurality of optical repeat units in the film. The form birefringent layers exhibit birefringence as a result of microscopic structures that have a dimension that is small compared to the wavelength of light but large compared to molecular distances. The optical layers within the optical repeat units have out-of-plane indices of refraction that are tailored to produce desired effects as a function of incidence angle for p-polarized light. The multilayer reflectors can be made by conventional vacuum deposition techniques using known inorganic optical materials, but can also be made entirely with polymeric materials by co-extrusion or other processes.

Owner:3M INNOVATIVE PROPERTIES CO

Process for making antimicrobial polymer articles

This invention relates to a process for making articles antimicrobial and odor inhibiting, which comprises using vacuum deposition and electron beam techniques to graft amino-reactive functional groups onto polymeric material which the article comprises, followed by contacting the polymeric material with a chitosan solution.

Owner:EI DU PONT DE NEMOURS & CO

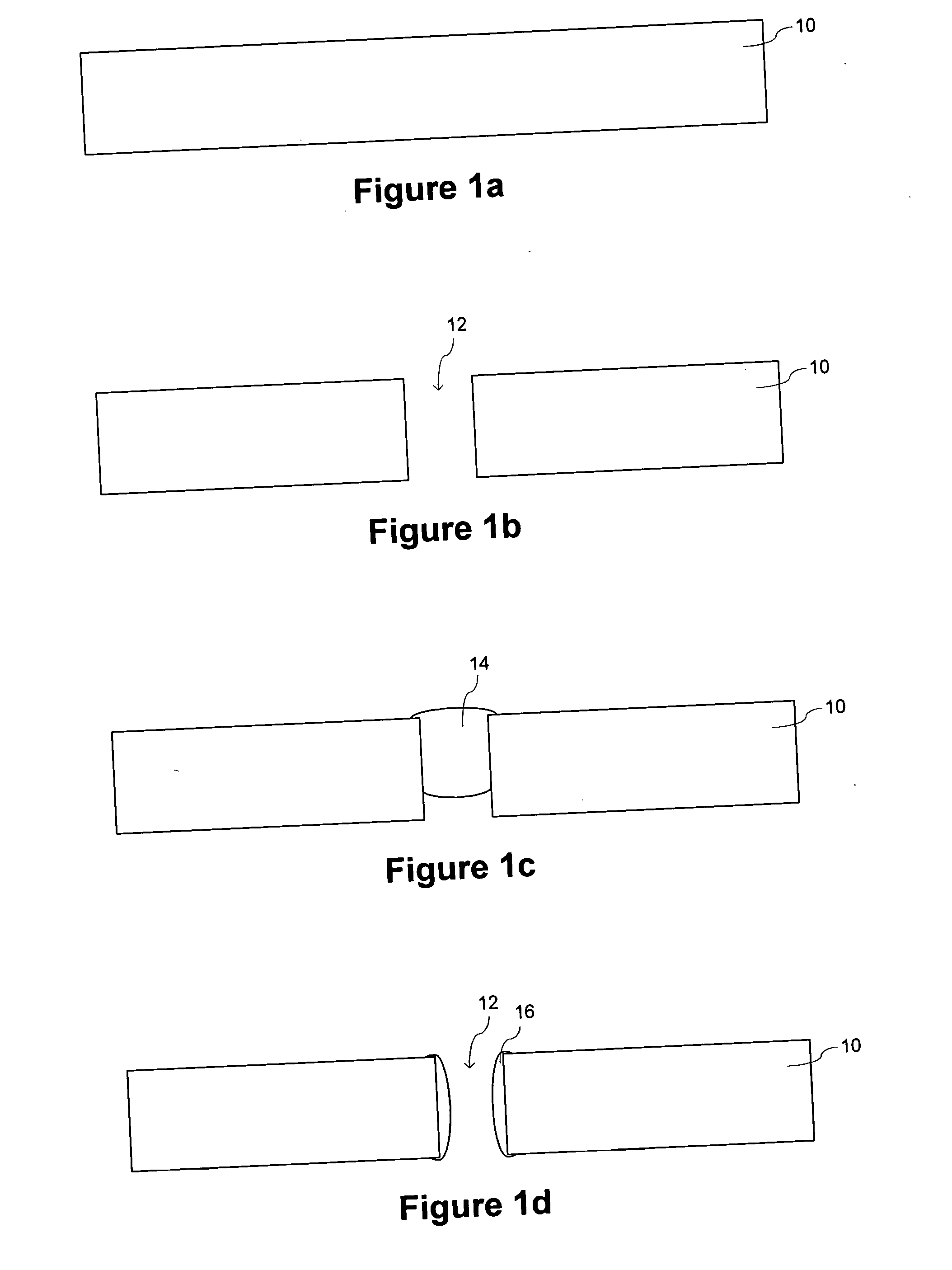

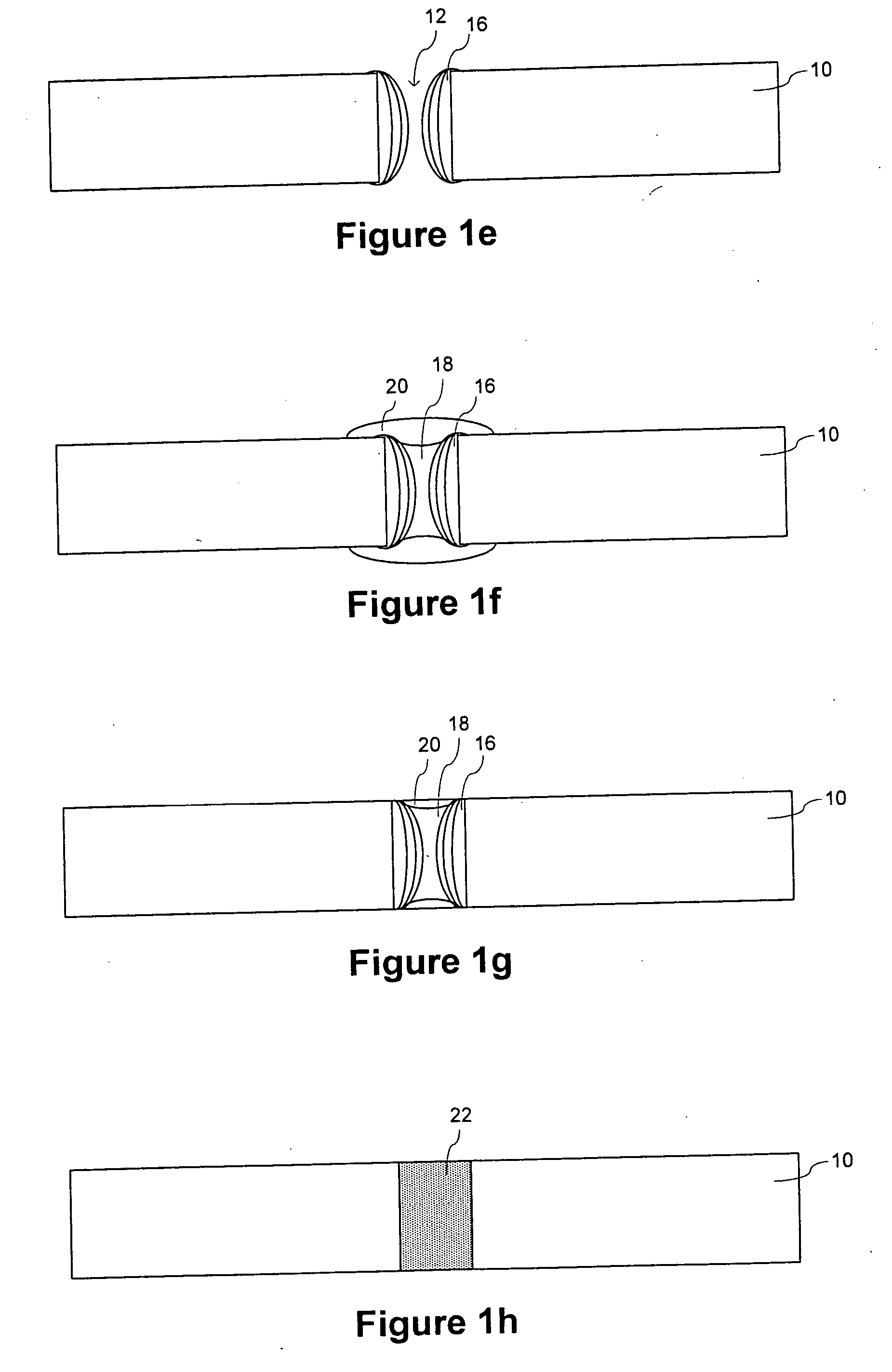

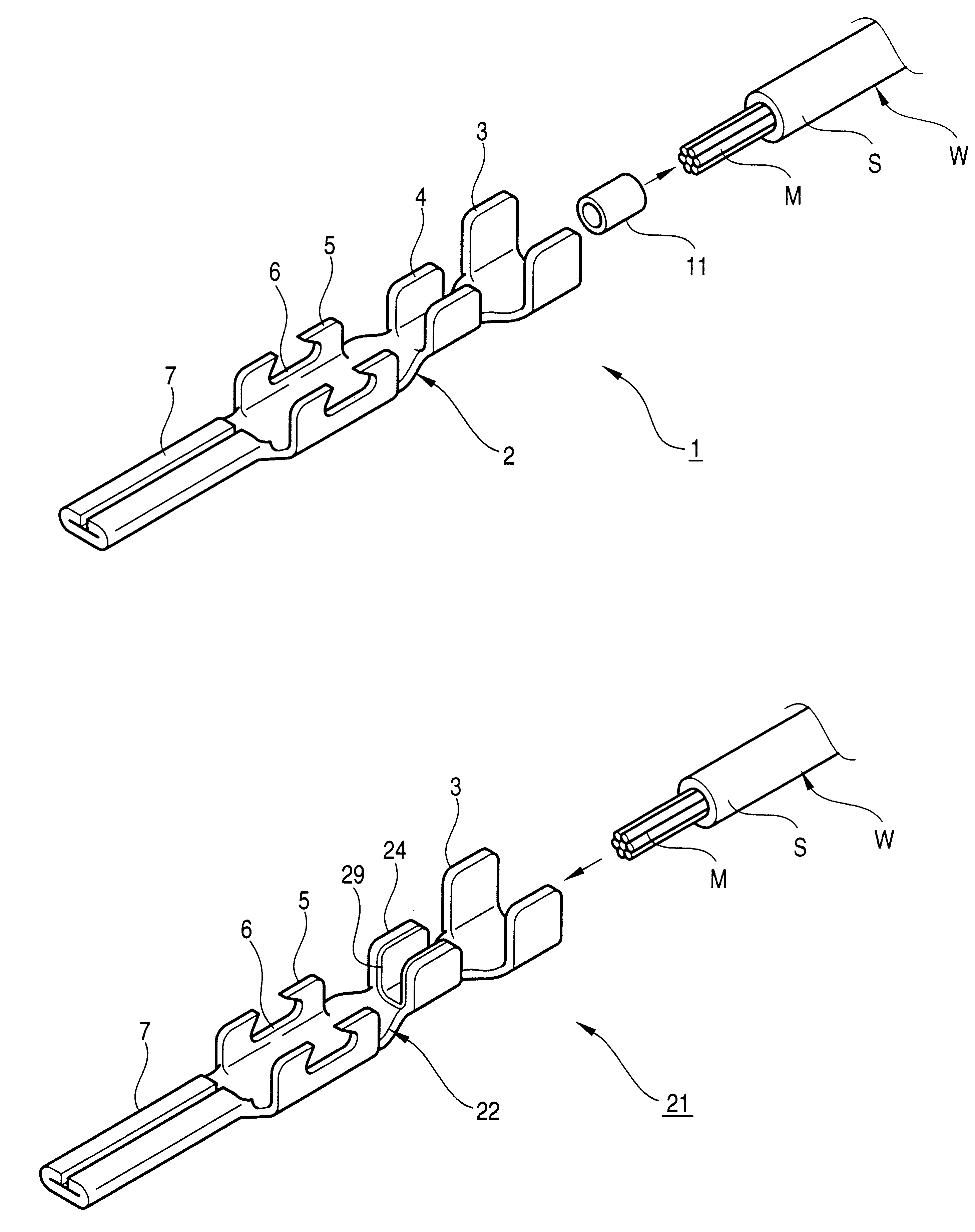

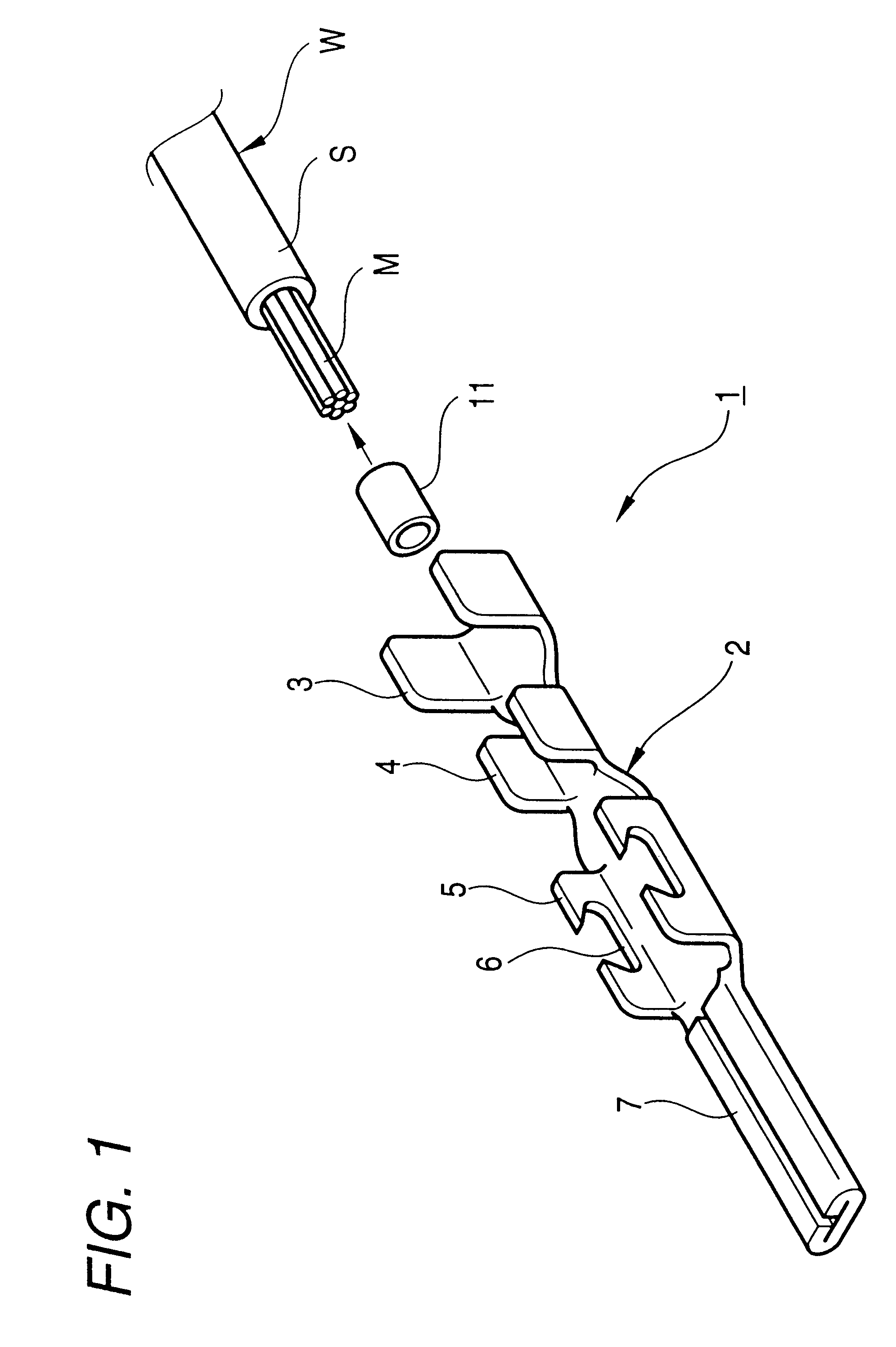

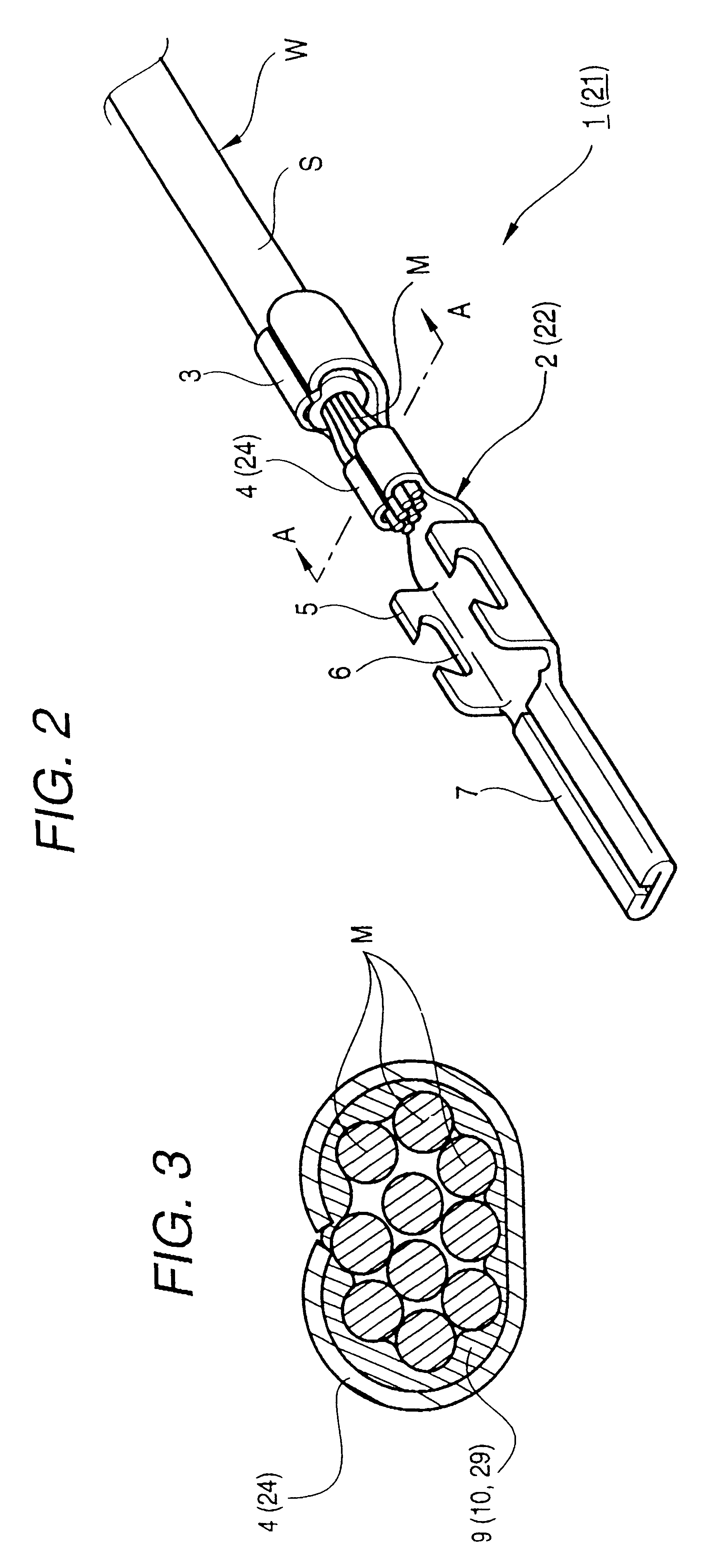

Method of and structure for connecting electric wire and connecting terminal

InactiveUS6334798B1Soldered/welded conductive connectionsConnections effected by permanent deformationElectrical conductorEngineering

In a structure 21 for connecting an electric wire and a connecting terminal in the invention, a ductile metal film 29 is formed in advance on an inner surface of a conductor caulking portion 24 of a crimp terminal 22 by such as plating, vacuum deposition, or adhesion. Then, the conductor caulking portion 24 in the rear portion of the crimp terminal 22 is caulked onto core wire portions M in a state of being stripped and extended in the axial direction from an end of a sheathed wire W to thereby establish connection. Subsequently, the metal film 29 is fused on heating. Accordingly, the ductile metal film 29 enters gaps between the inner surface of the conductor caulking portion 24 and the core wire portions M and between adjacent ones of the core wire portions M by the caulking stress. Hence, the area of contact between the conductor caulking portion 24 and the core wire portions M via the metal film 29 increases, and conductivity improves, thereby making it possible to suppress heat generation.

Owner:YAZAKI CORP

Compliant implantable medical devices and methods of making same

Owner:VACTRONIX SCI LLC

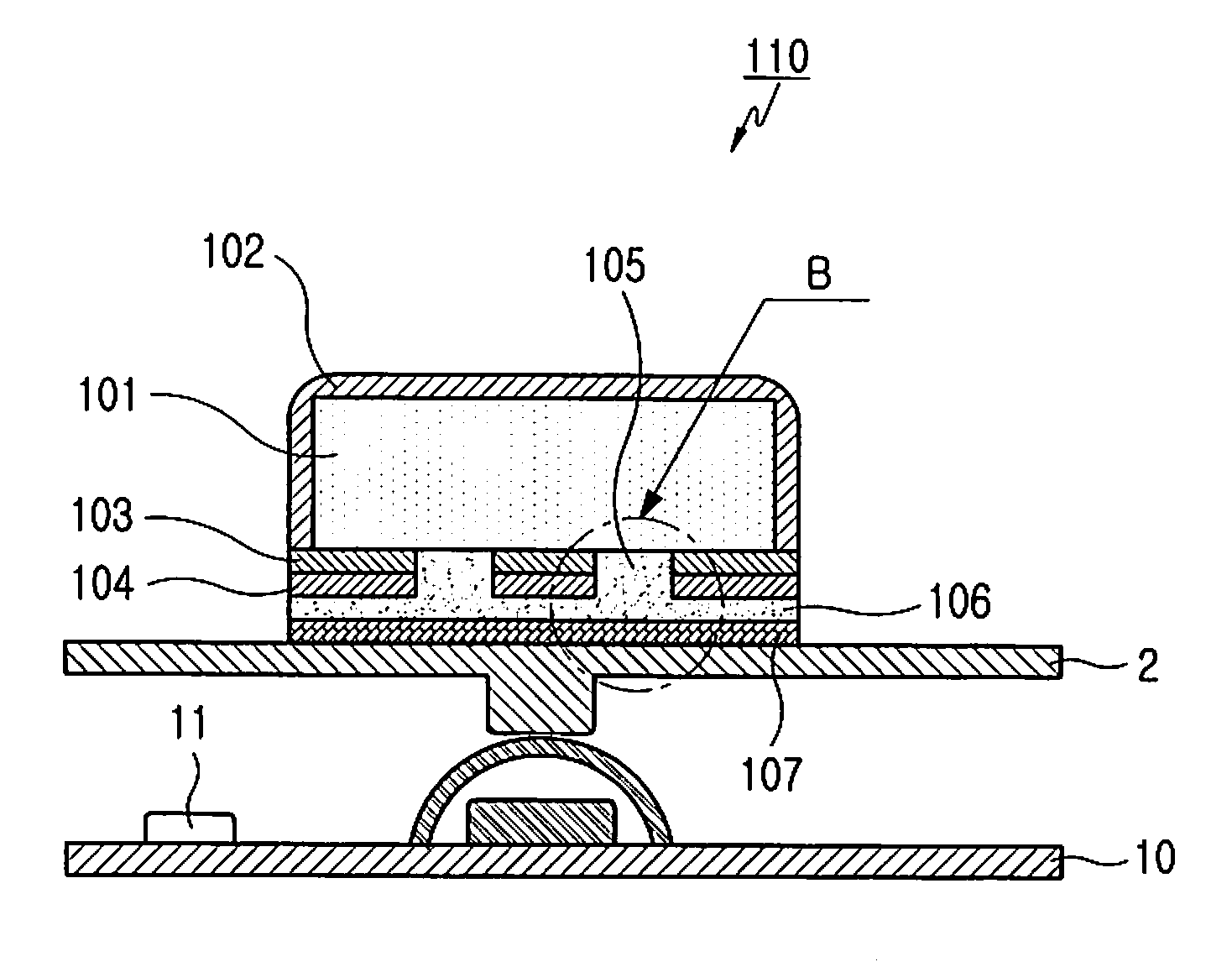

Manufacturing method of keypad for mobile phone and keypad manufactured thereby

ActiveUS7414213B2Increase resistanceHigh hardnessInput/output for user-computer interactionEmergency actuatorsLaser processingLacquer

Disclosed is a manufacturing method of a keypad for a mobile phone and the keypad manufactured thereby, in which a vacuum deposition layer and a cellophane paper are attached to a lower surface of a key in the keypad. The keypad for a mobile phone includes a plurality of keys, each key includes a key body of a transparent resin material and a high-hardness transparent coating layer coated onto a surface of the key body in order to increase hardness, and each key comprises a key background color paint layer for color presentation, coated onto a lower surface of the key body; an opaque paint layer coated onto a lower surface of the key background color paint layer; a transparent marking portion formed by performing a laser processing according to a shape of a numeral, a character, or a symbol with respect to the lower surface of the key body so as to remove the color paint layer and the opaque paint layer; a metallic vacuum deposition layer formed on the lower surface of the key body and a lower surface of the opaque paint layer; and a transparent color-printed layer or a cellophane paper attached to a lower surface of the metallic vacuum deposition layer so as to present various colors.

Owner:ROVI GUIDES INC

Endoluminal implantable stent-grafts

An implantable endoluminal device that is fabricated from materials that present a blood or body fluid and tissue contact surface that has controlled heterogeneities in material constitution. An endoluminal stent-graft and web-stent that is made of an monolithic material deposited into a monolayer and etched into regions of structural members and web regions subtending interstitial regions between the structural members. An endoluminal graft is also provided which is made of a biocompatible metal or metal-like material. The endoluminal stent-graft is characterized by having controlled heterogeneities in the stent material along the blood flow surface of the stent and the method of fabricating the stent using vacuum deposition methods.

Owner:VACTRONIX SCI LLC

Gas barrier film

InactiveUS6905769B2Excellent gas barrier propertiesGood weather resistanceFlexible coversWrappersProduct gasWater repellent

It is an object of the present invention to provide a gas barrier film improved in gas barrier characteristics by decreasing the adsorbent of the surface of a gas barrier layer to water and the like. The present invention attains the above object by providing a gas barrier film comprising a substrate, a gas barrier layer which is a vacuum deposition film, formed on one surface or both surfaces of the above substrate, and a water-repellent layer which is a film having water repellency, formed on the above gas barrier layer.

Owner:DAI NIPPON PRINTING CO LTD

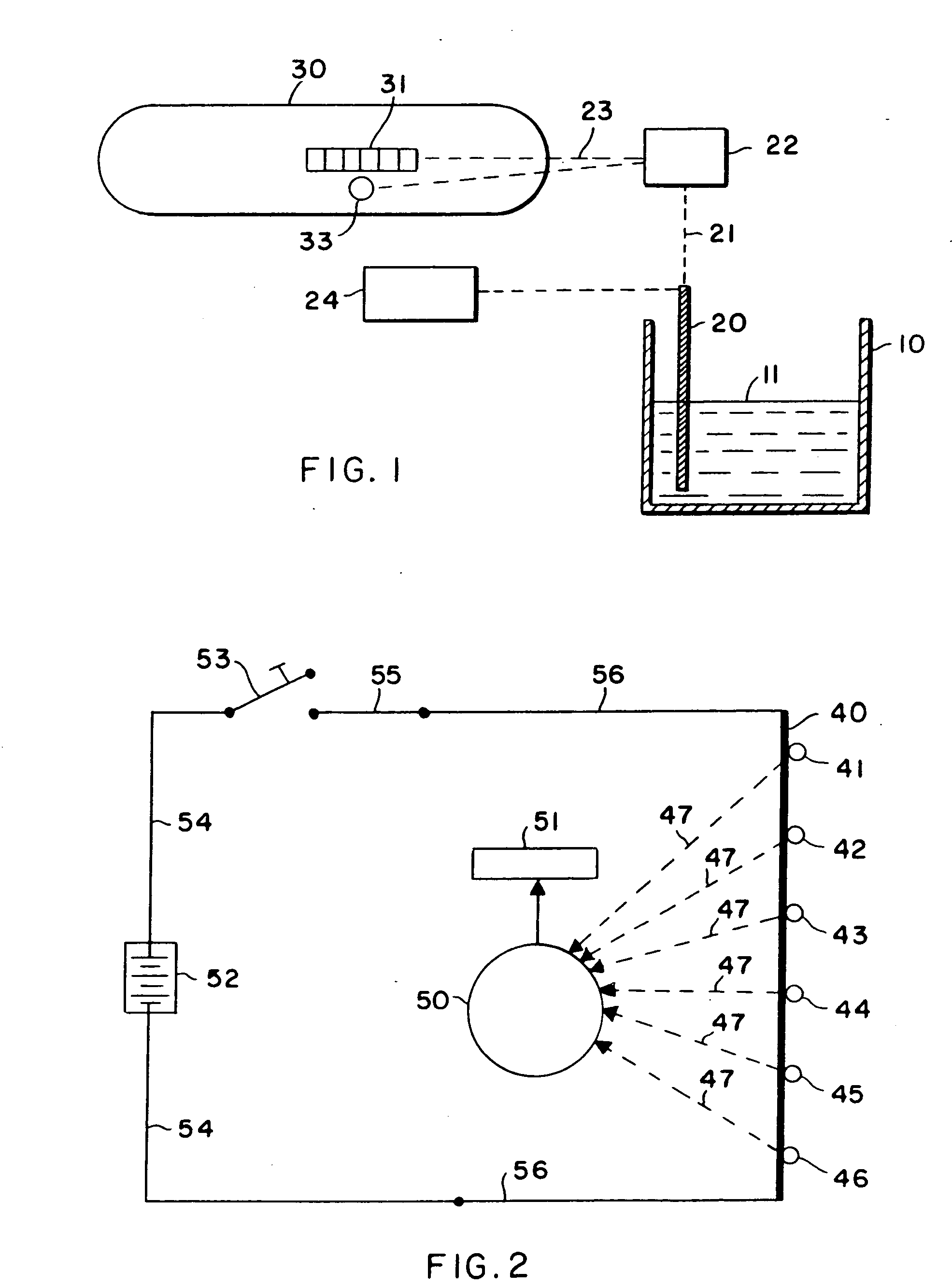

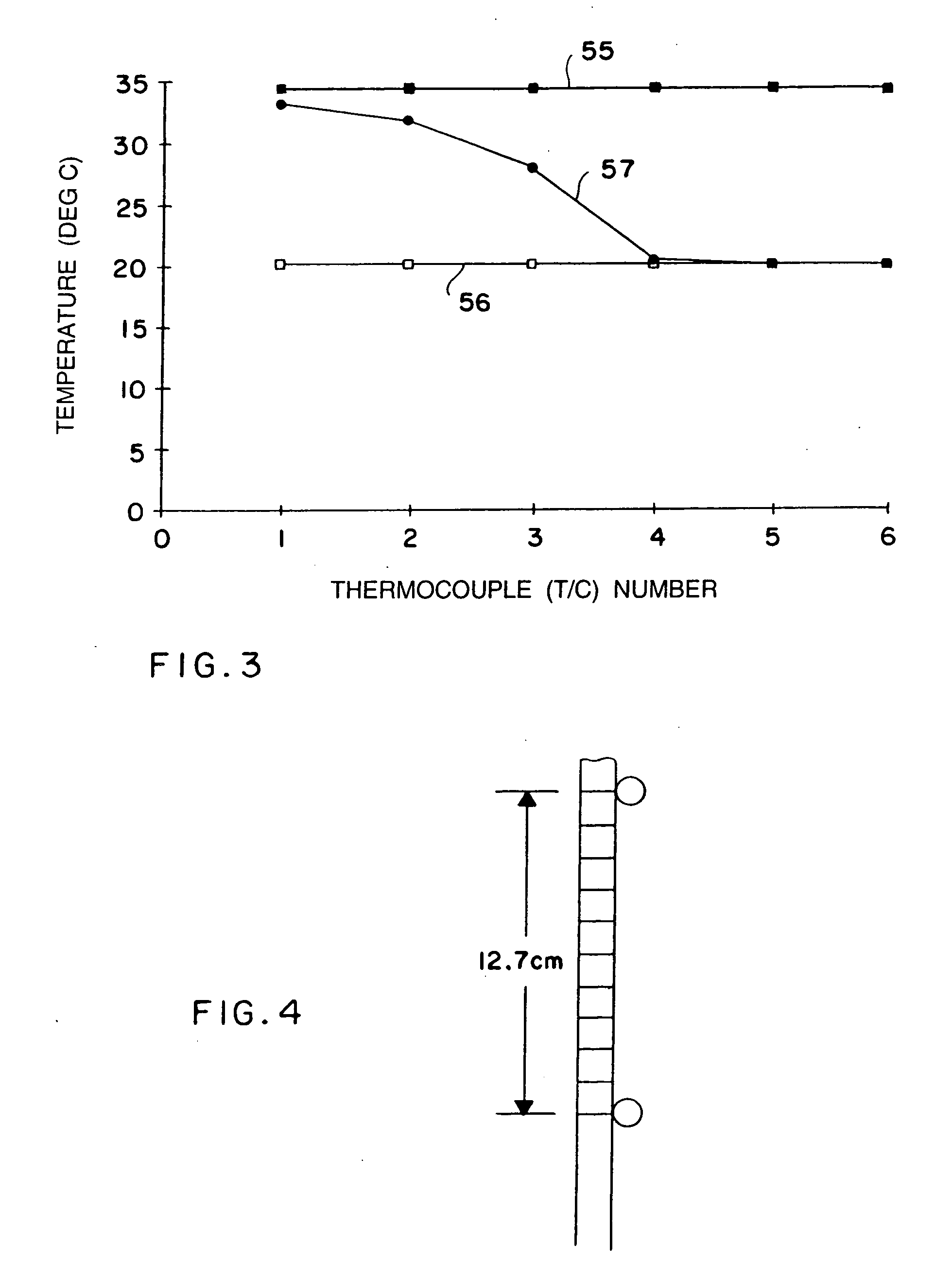

Liquid sensor and ice detector

InactiveUS20050126282A1Difference in efficiencyRemove heat moreMachines/enginesLubrication indication devicesScreen printingLiquid temperature

An improved apparatus and a method of measuring and interpreting reliably, simply and accurately the information on continuous liquid level, liquid temperature and other liquid properties within a vessel. The apparatus could be made of a powered heater element and temperature sensors can be screen-printed, vacuum deposited, etched, welded, soldered or plated on one or both sides of a single rigid or a flexible substrate. The geometry of the heater determines the curve shape, such as steepness or shallowness of a temperature profile along a heater. Various parallel and serial configurations of thermocouples or temperature sensors can be used to measure the temperature along a heater. Simultaneous measurements from all the temperature sensors, before and after heat is applied, are used to generate accurate temperature profiles for the entire heater. Different features of the temperature profiles will determine accurately the liquid level, liquid temperature and other liquid properties. Apparatus of the invention may also be used to detect ice formation.

Owner:MAATUK JOSEF

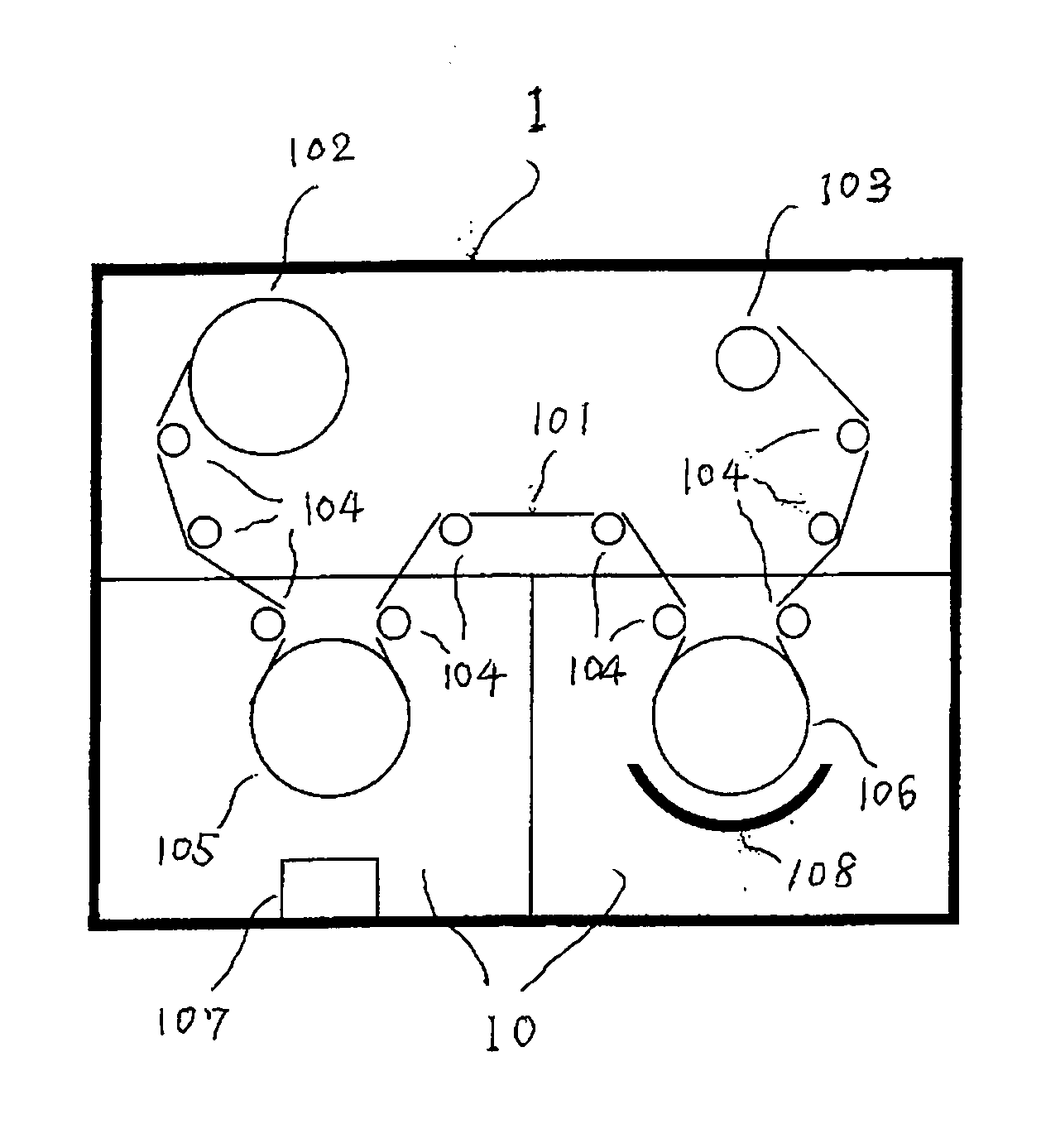

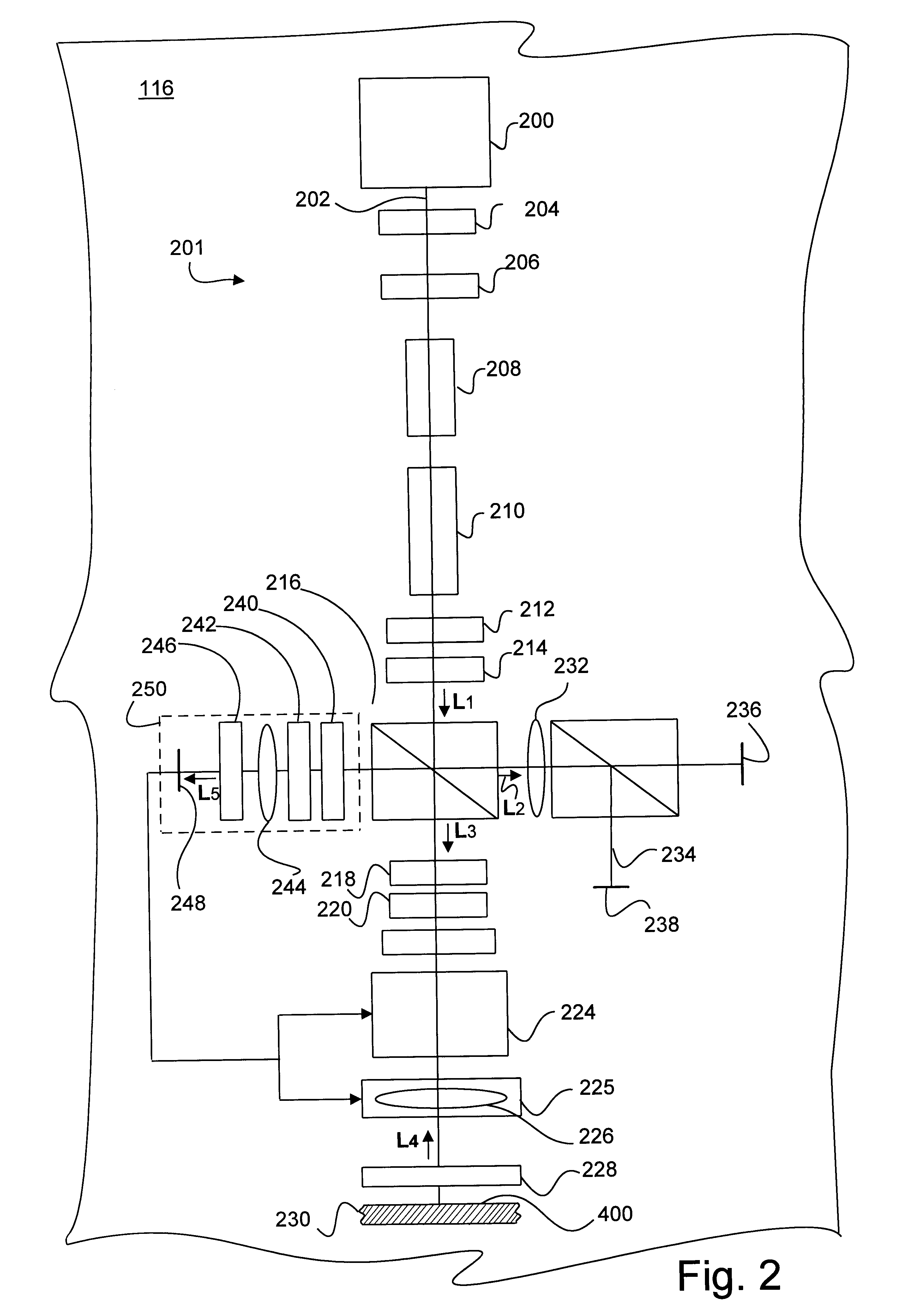

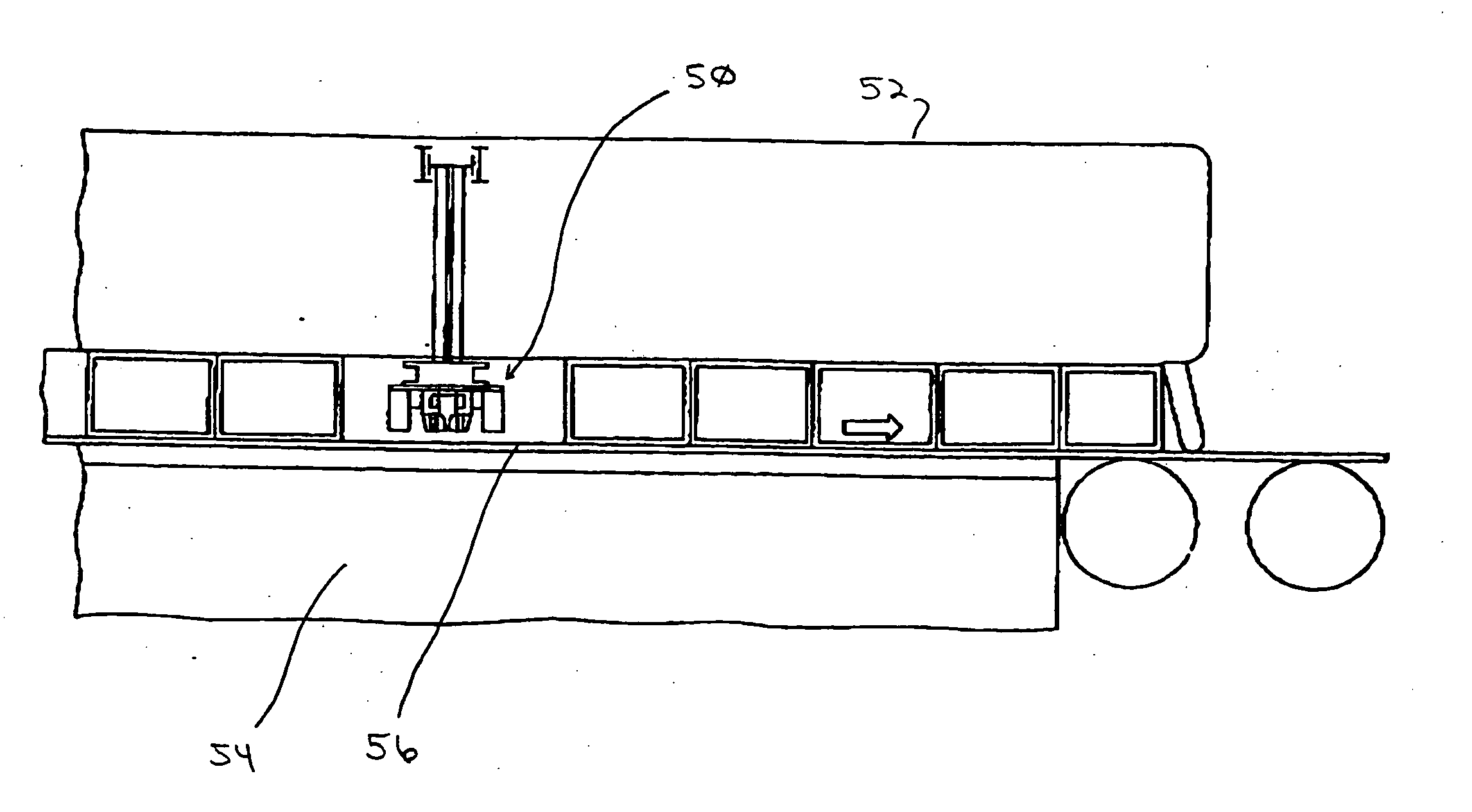

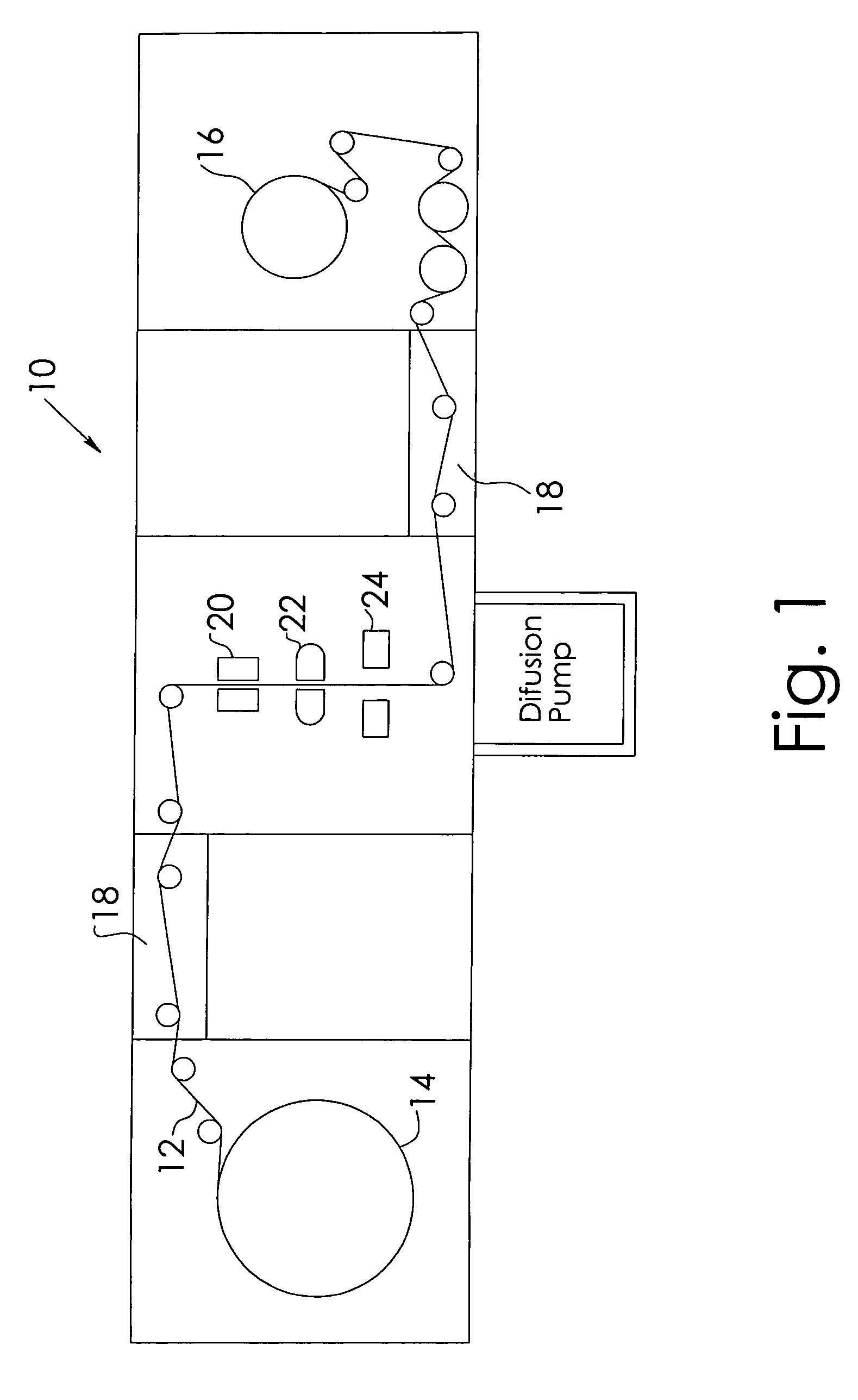

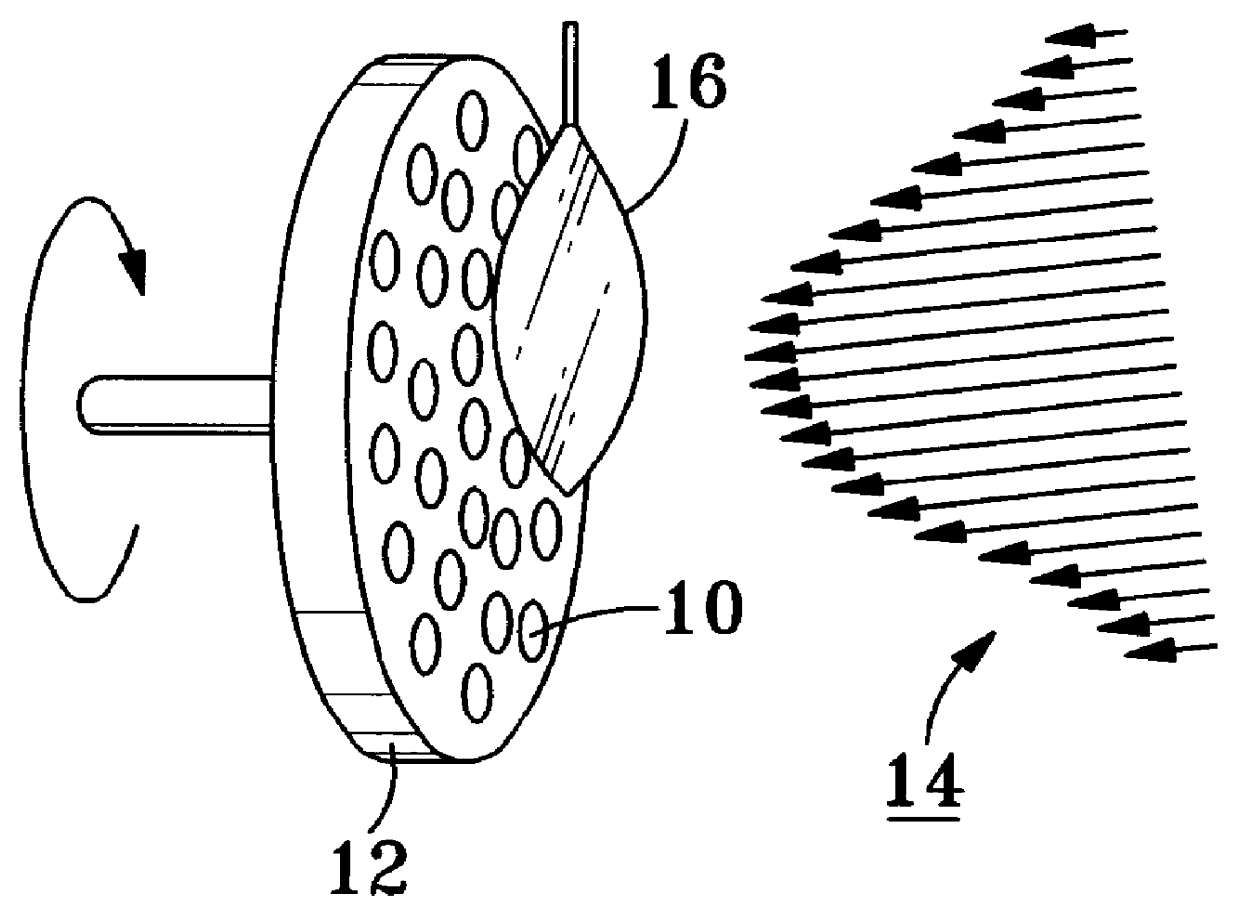

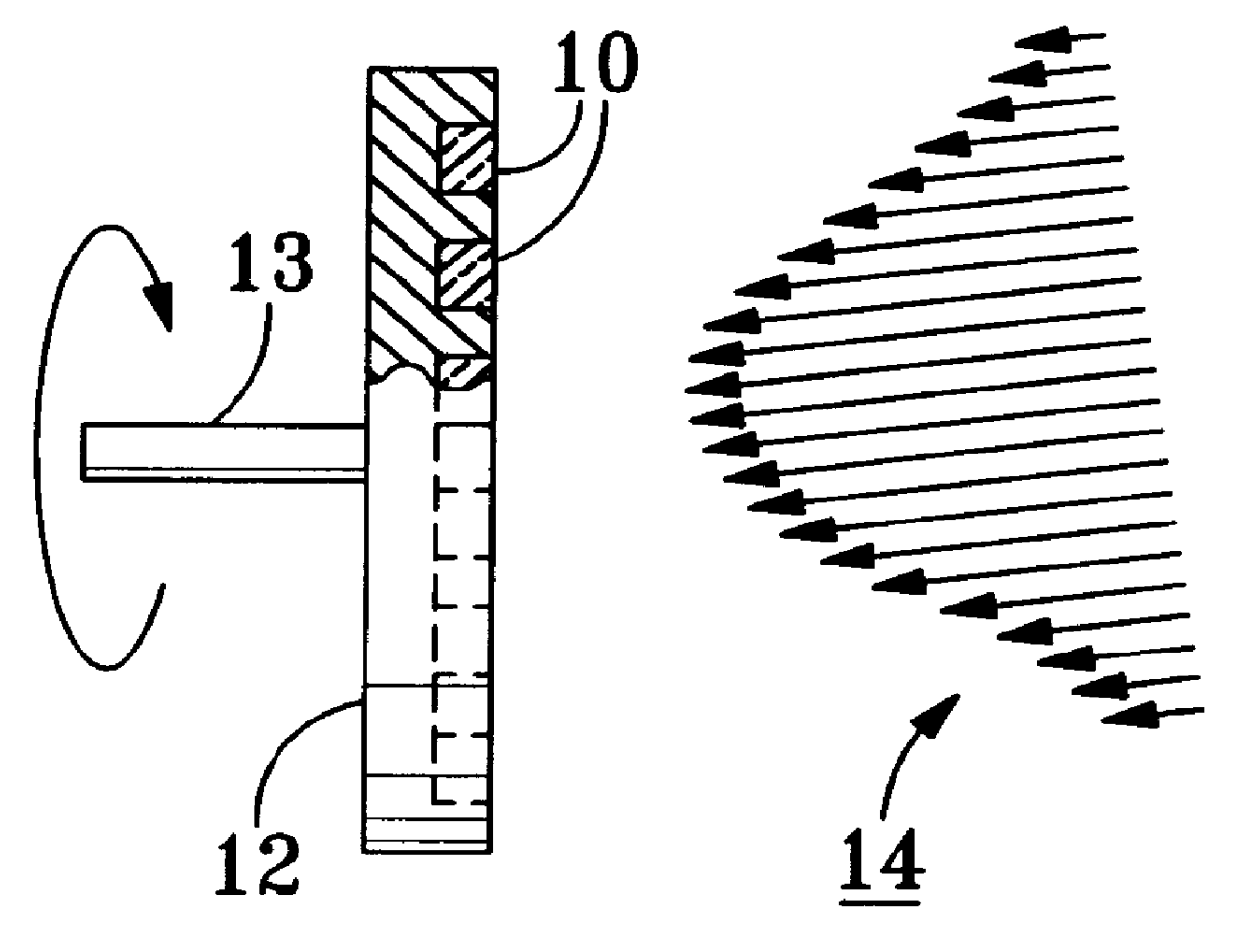

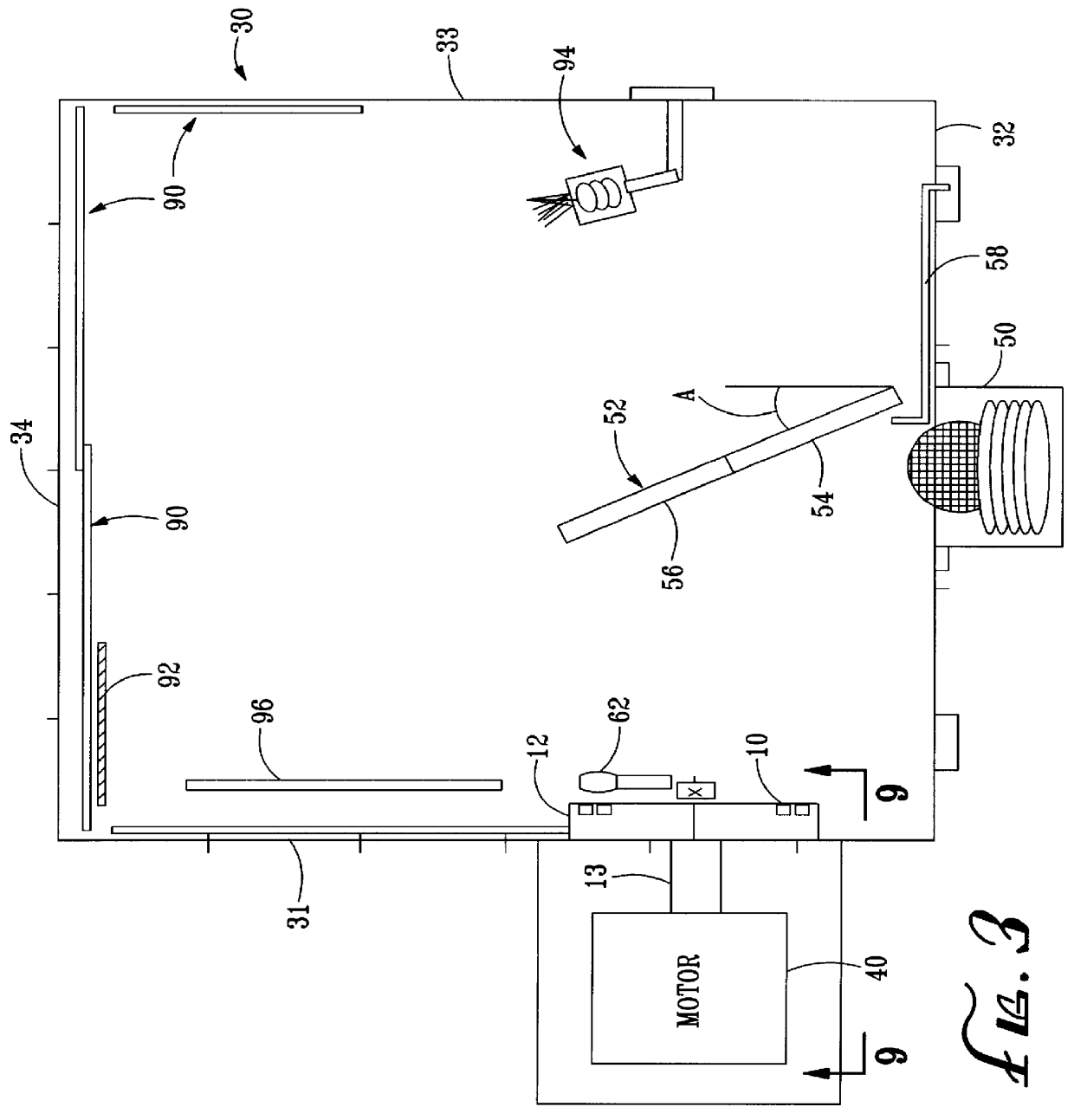

Multiple station vacuum deposition apparatus for texturing a substrate using a scanning beam

A stationary vacuum deposition machine for use in a method for processing substrates to make magnetic hard disks includes a series of stations and a transport. The series of stations includes an entrance station for receiving substrates into the machine and a predetermined station. The transport operates in a cycle with each cycle including a transport phase and a stationary phase. The transport causes all the substrates that are in the machine to be moved during the transport phase, and be temporarily held stationary during the stationary phase, such that during each stationary phase a predetermined one of the stations is occupied by one of the substrates while each of a plurality of others of the stations is occupied by a respective one of a plurality of others of the substrates. The machine further includes a plurality of vacuum deposition stations and a scanning beam generator. Each vacuum deposition station operates during each stationary phase such that each station causes a thin film to be deposited on a respective one of the substrates. The scanning beam generator directs a scanning beam at the substrate occupying the predetermined station while the substrate is held stationary to produce a textured pattern.

Owner:WESTERN DIGITAL TECH INC

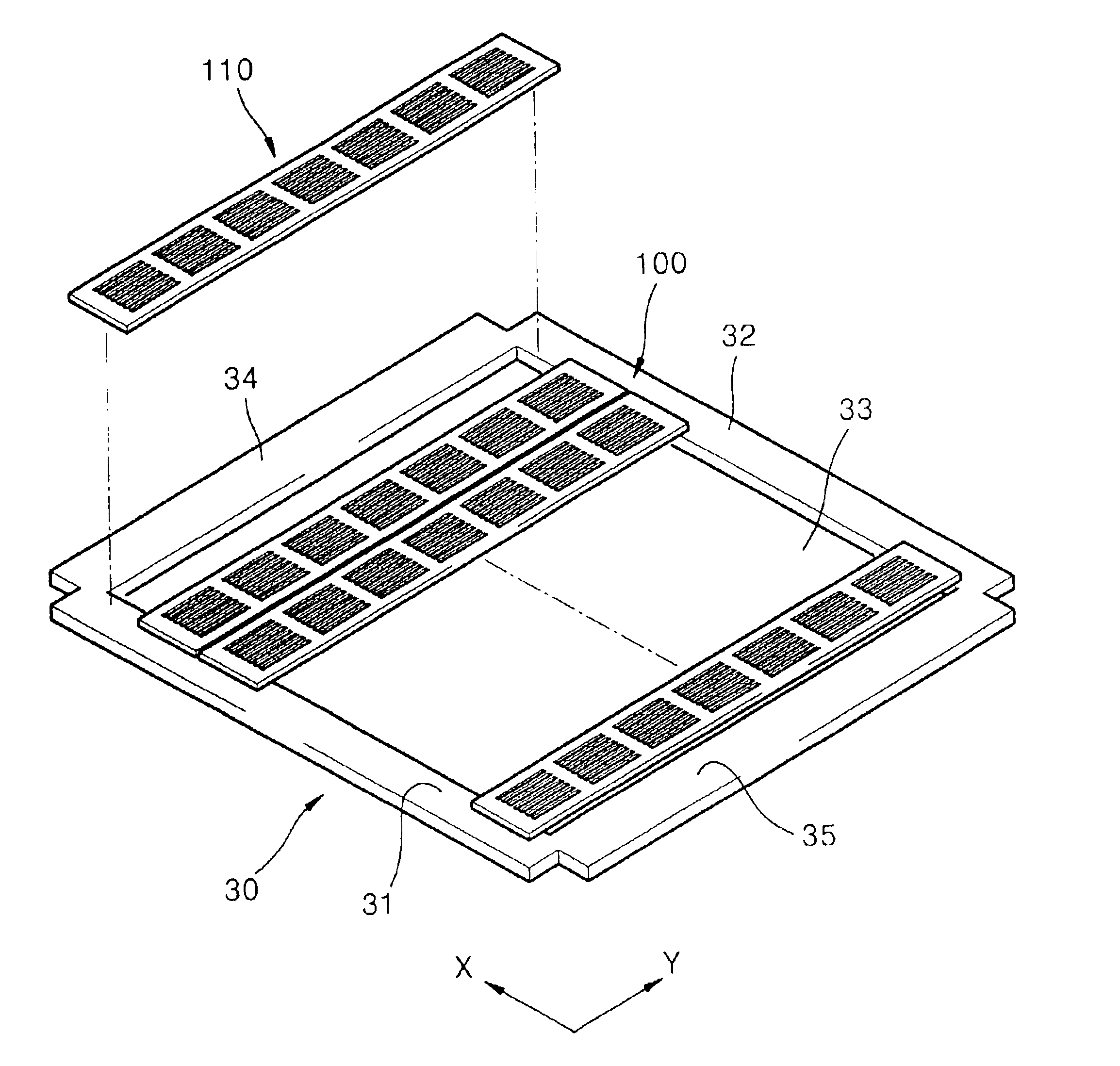

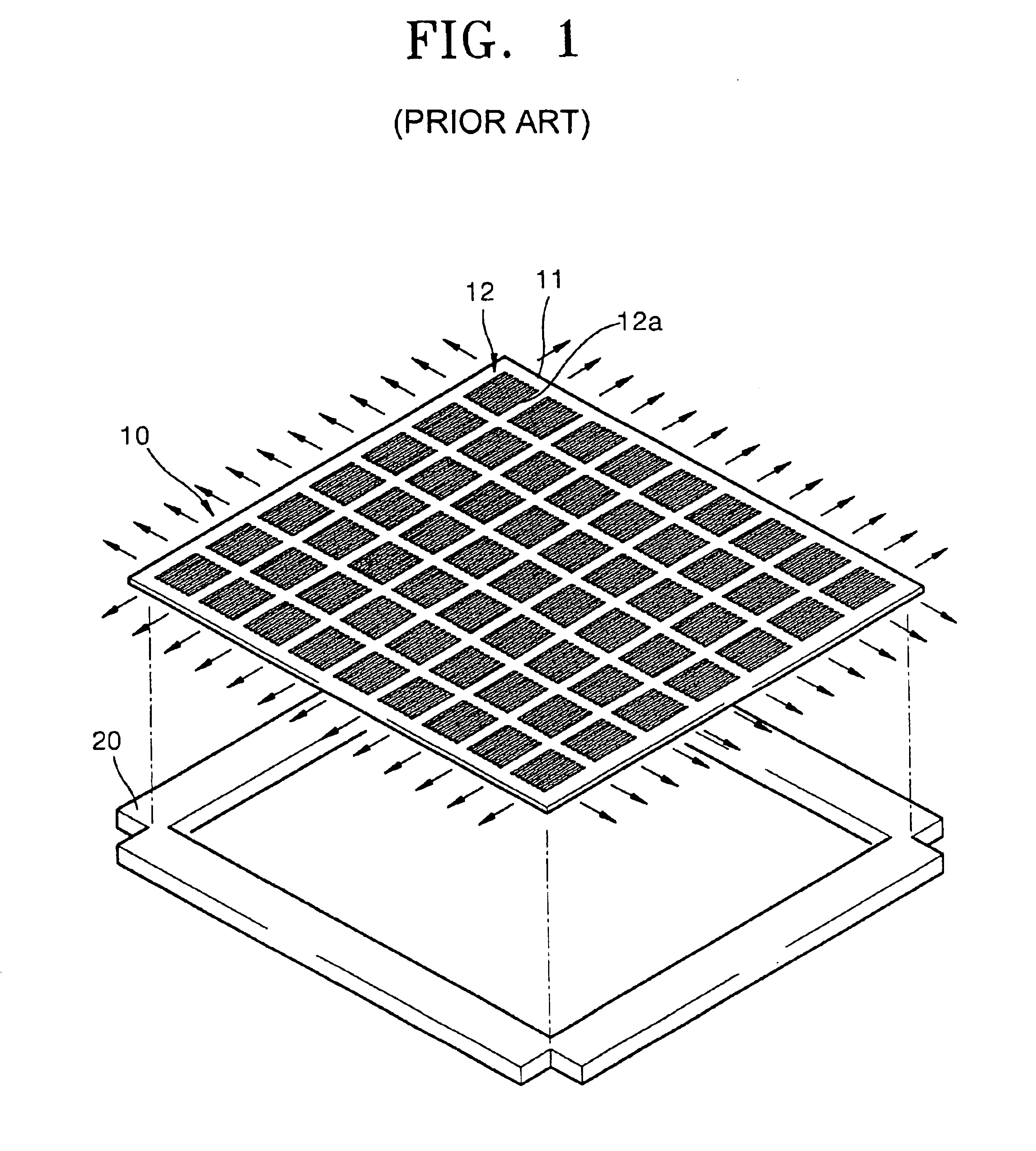

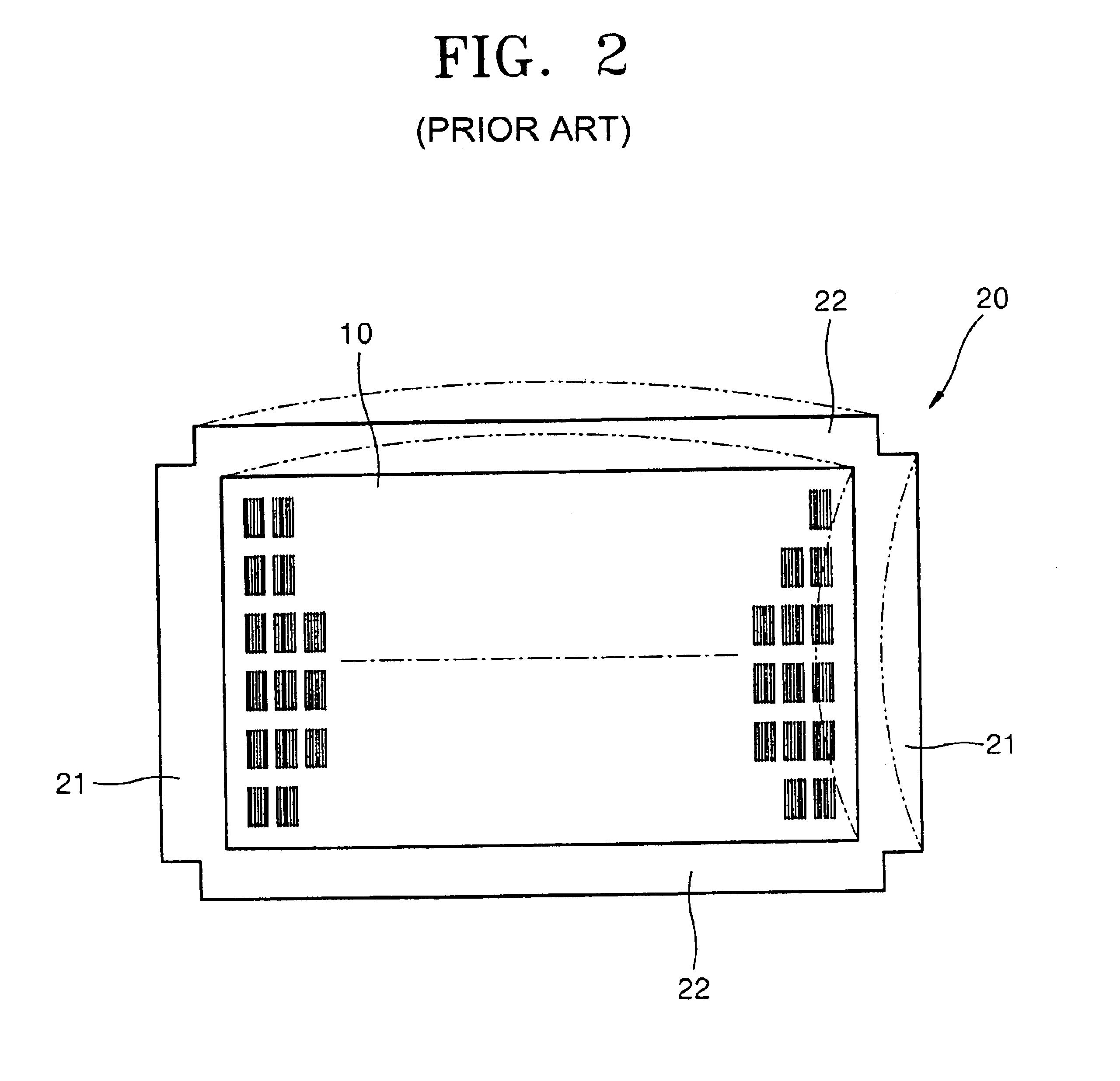

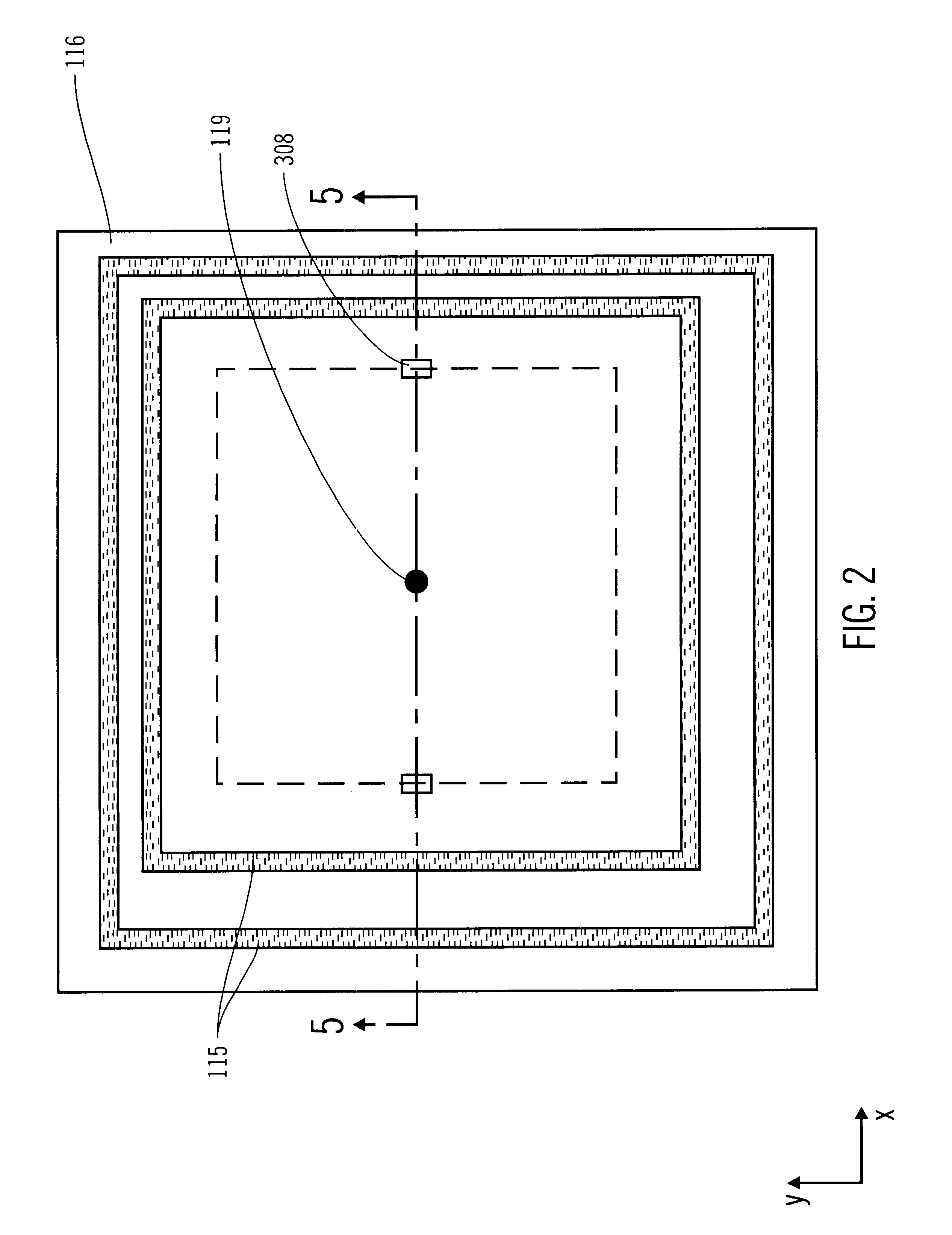

Tension mask assembly for use in vacuum deposition of thin film of organic electroluminescent device

InactiveUS6858086B2Easy to adjustVariation in pattern widthCellsLiquid surface applicatorsVacuum depositionMechanical engineering

A mask frame assembly used in vacuum deposition of thin films of an organic electroluminescent device. The mask frame assembly includes a frame having an opening and at least two unit masks which each have at least one unit masking pattern portion in the direction of the unit mask and two edges which are fixed to the frame under tension.

Owner:SAMSUNG DISPLAY CO LTD

Photo-induced hydrophilic article and method of making same

InactiveUS20070218265A1Easy to cleanEasy to wipeSynthetic resin layered productsVacuum evaporation coatingHydrophilic coatingSpray pyrolysis

Methods and articles are disclosed in which a substrate is provided with a photo-induced hydrophilic surface by forming a photo-induced hydrophilic coating on the substrate by spray pyrolysis, chemical vapor deposition, or magnetron sputter vacuum deposition. The coating can have a thickness of 50 Å to 500 Å, a root mean square roughness of less than 5, preferably less than 2, and photocatalytic activity of less than 3.0×10−3 cm−1 min−1±2.0×10−3 cm−1 min−1. The substrate includes glass substrates, including glass sheets and continuous float glass ribbons.

Owner:VITRO FLAT GLASS LLC

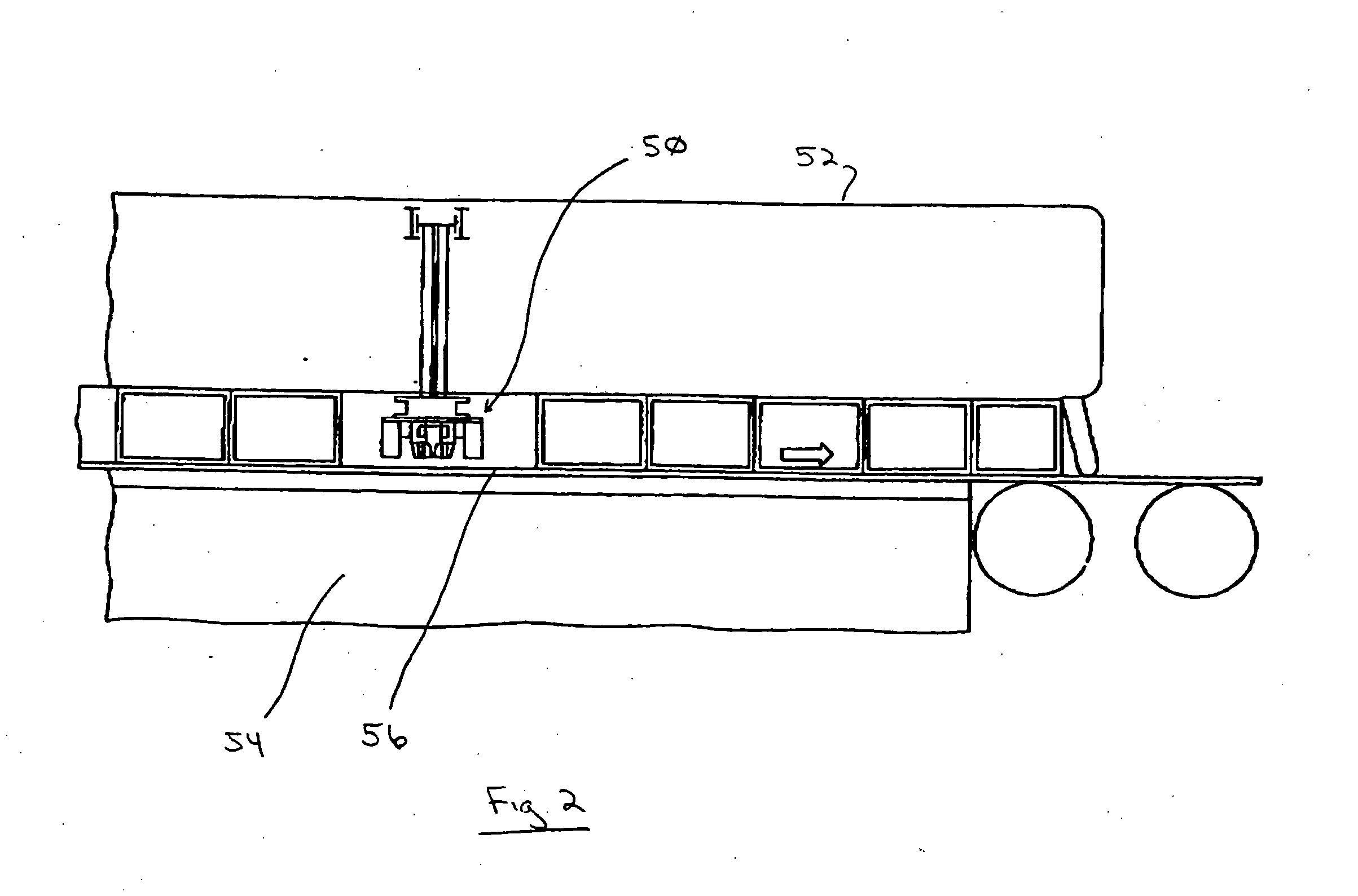

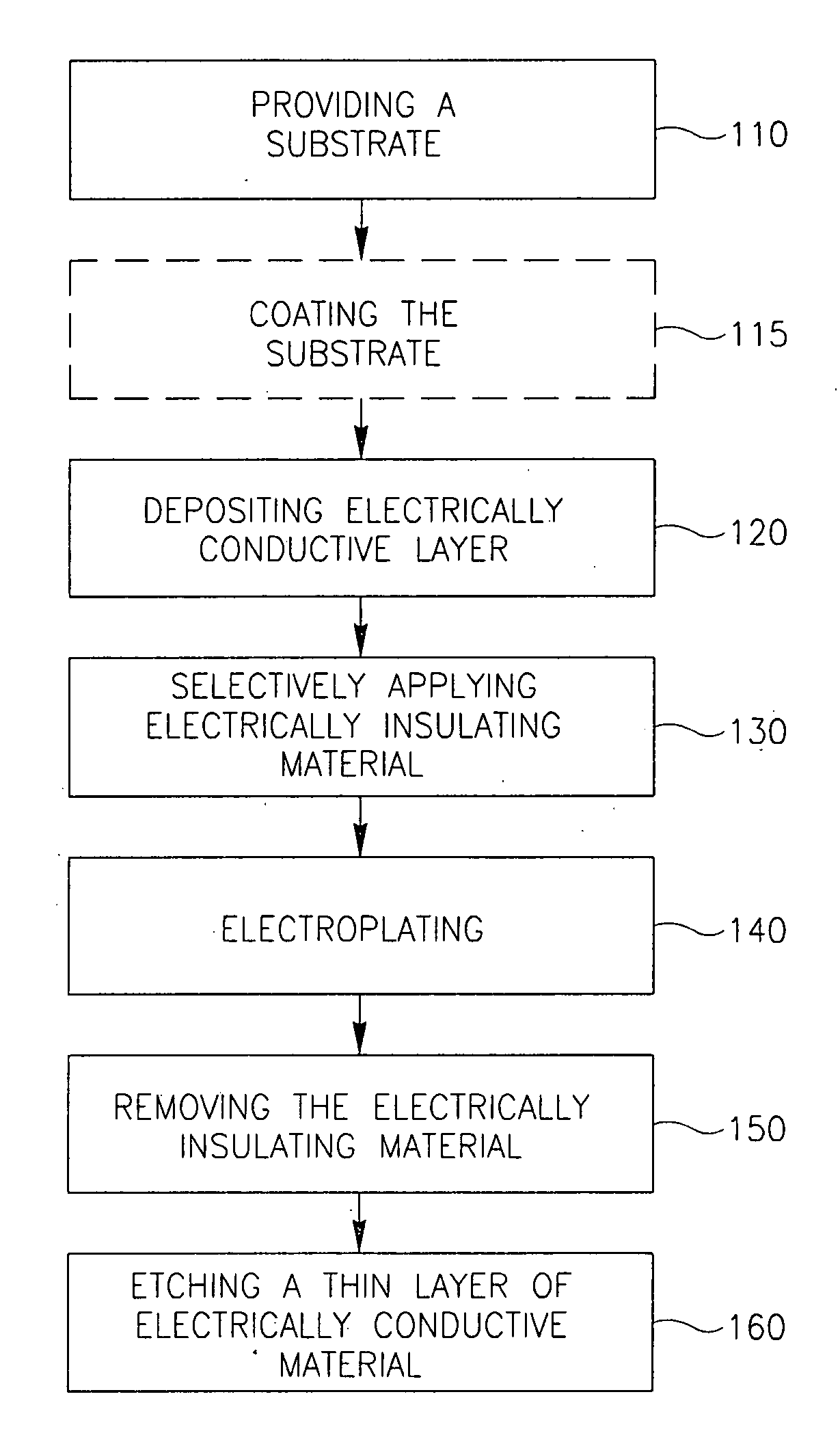

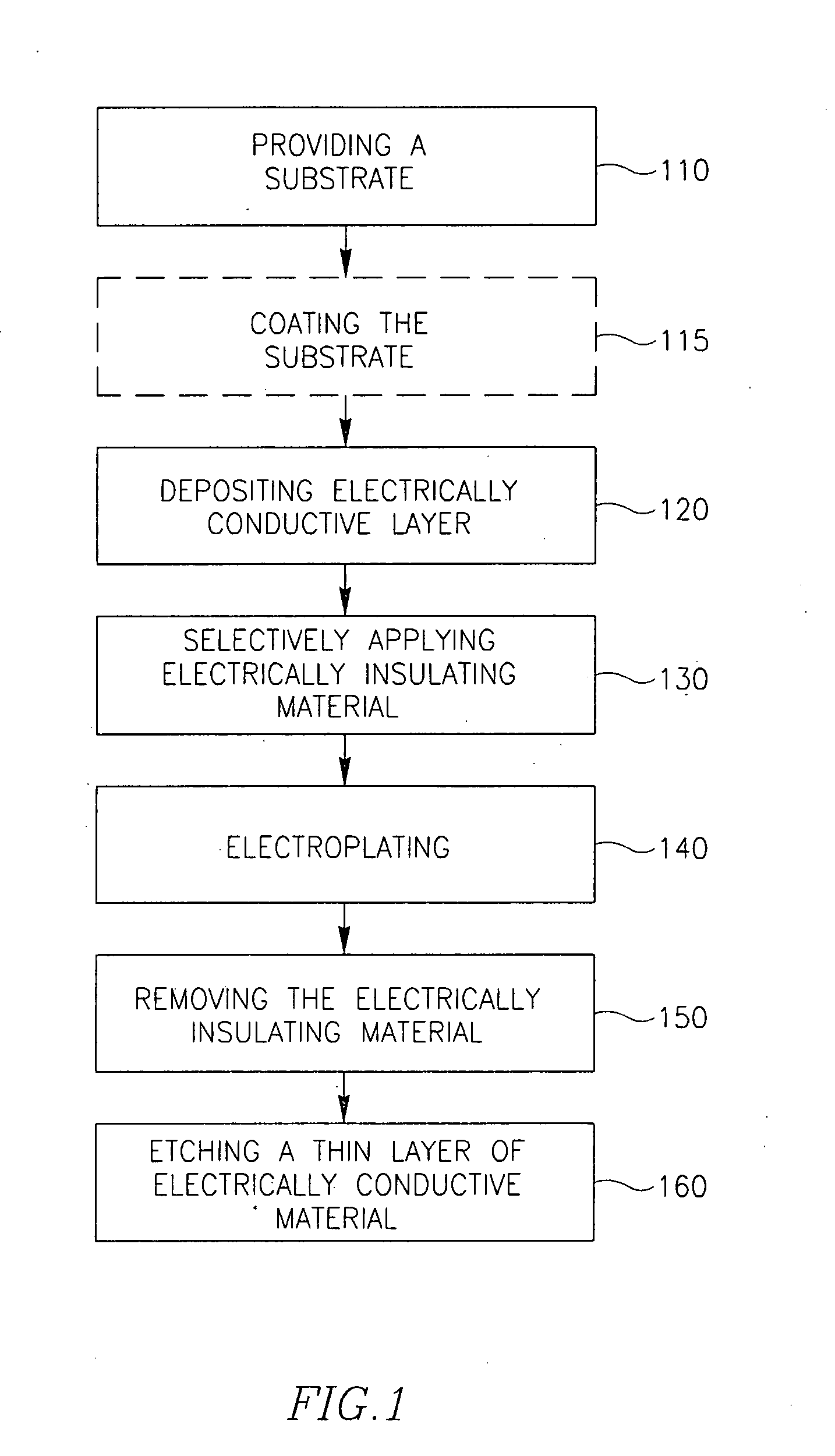

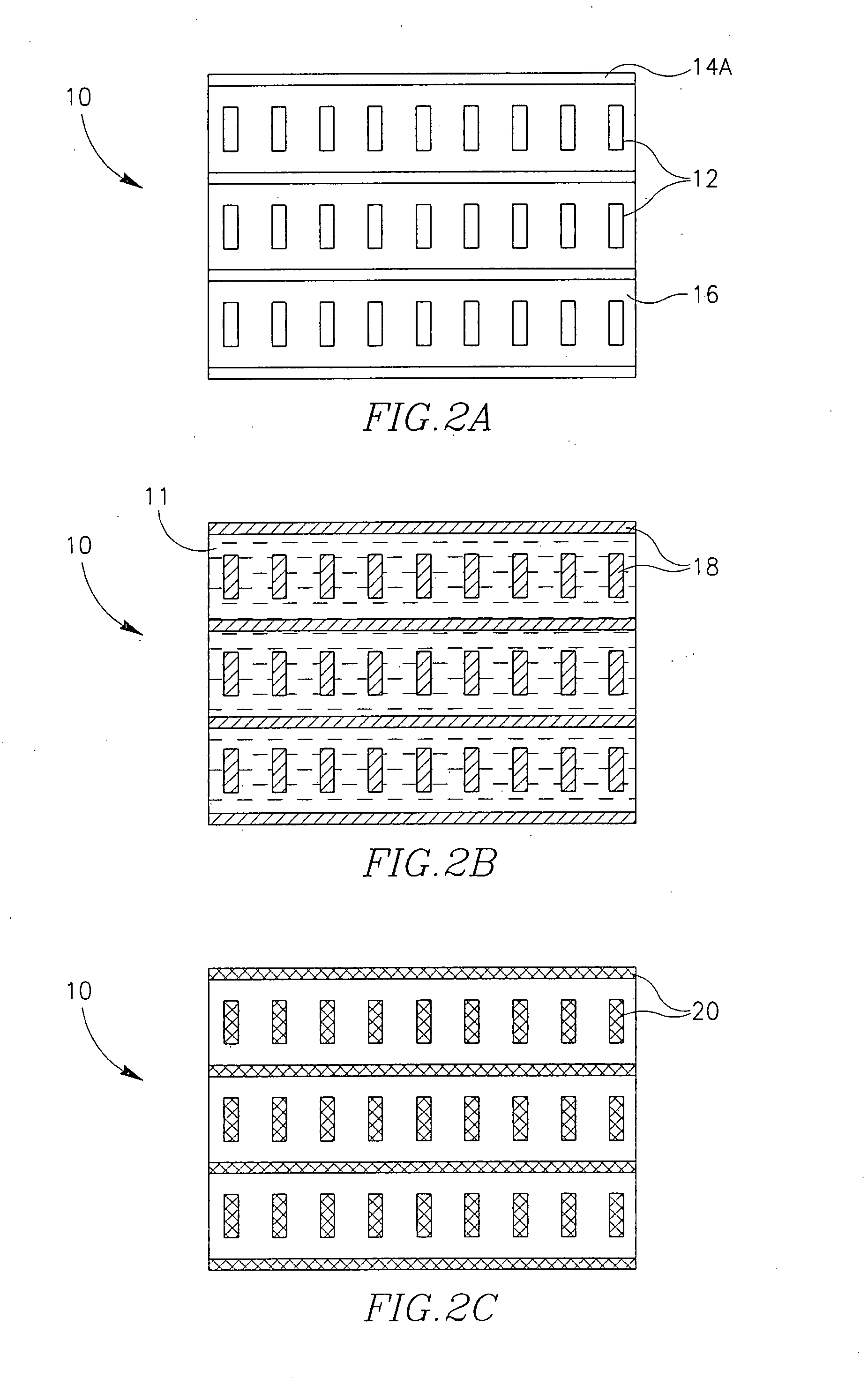

Patterns of conductive objects on a substrate and method of producing thereof

ActiveUS20070226994A1Line/current collector detailsWave amplification devicesConductive materialsEngineering

According to embodiments of the present invention, a method for manufacturing a pattern of conductive elements on a substrate is provided. The method includes depositing in a vacuum deposition chamber an electrically conductive material onto the substrate to form a base layer. Then, the method includes selectively applying an electric insulating agent on selective areas of the base layer. Then, areas of the base layer that are not covered with the insulating material are electroplated with a second electrically conductive layer. The electric insulating agent is then removed from the substrate and the base layer is chemically etched thus removing the base layer that was covered with the insulating material and selectively exposing the substrate to create the pattern of conductive objects on the substrate.

Owner:HANITA COATINGS R C A

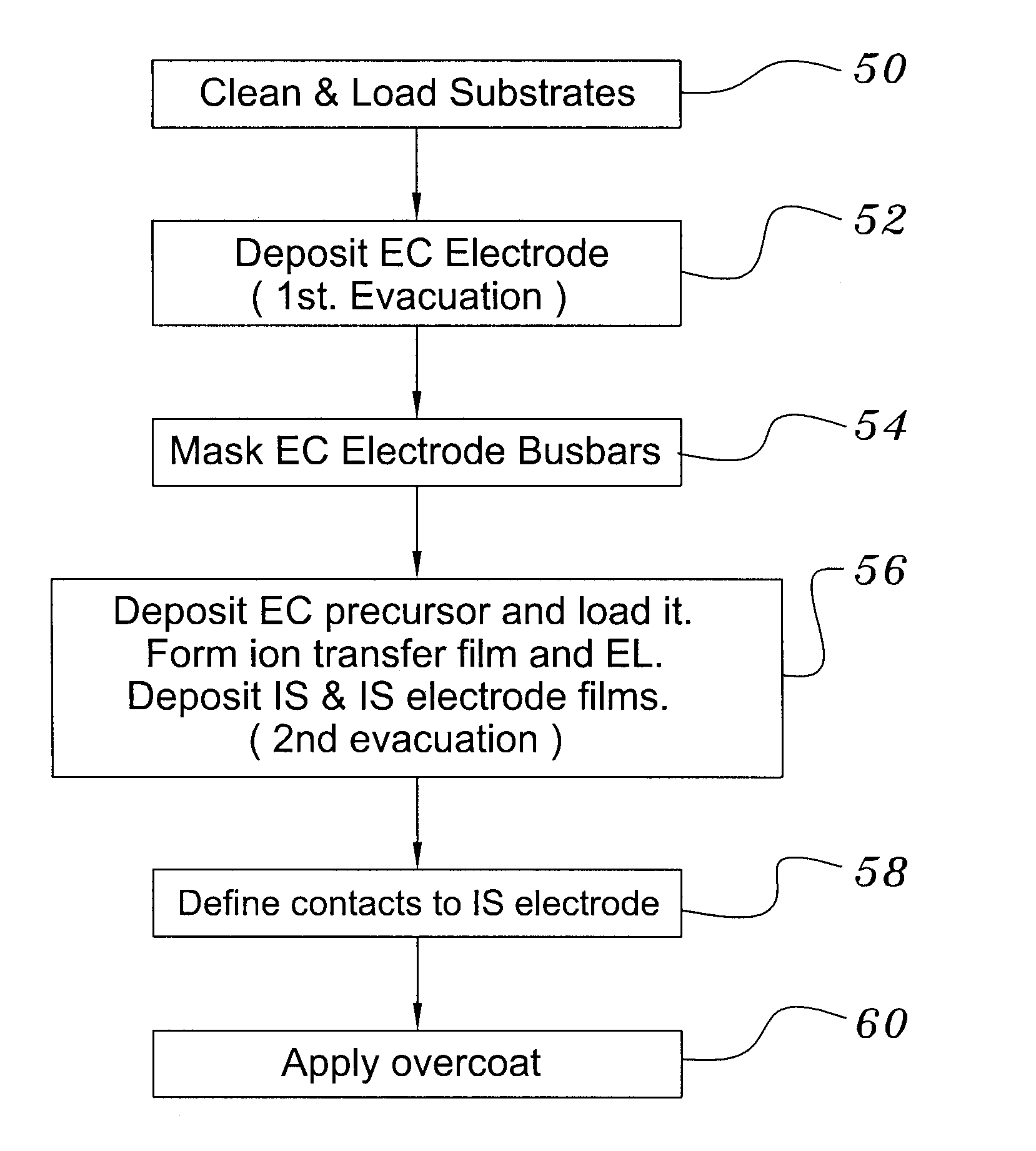

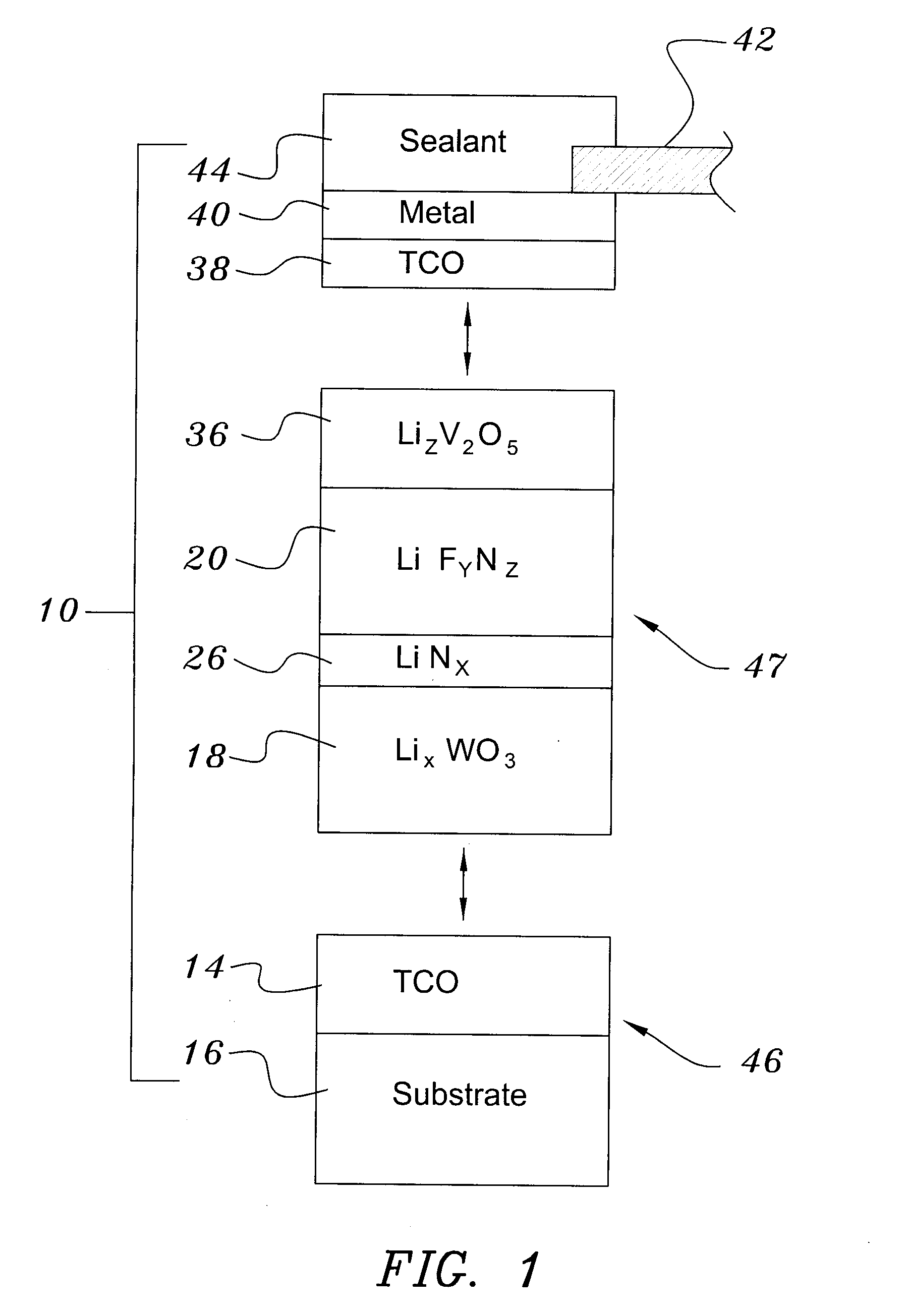

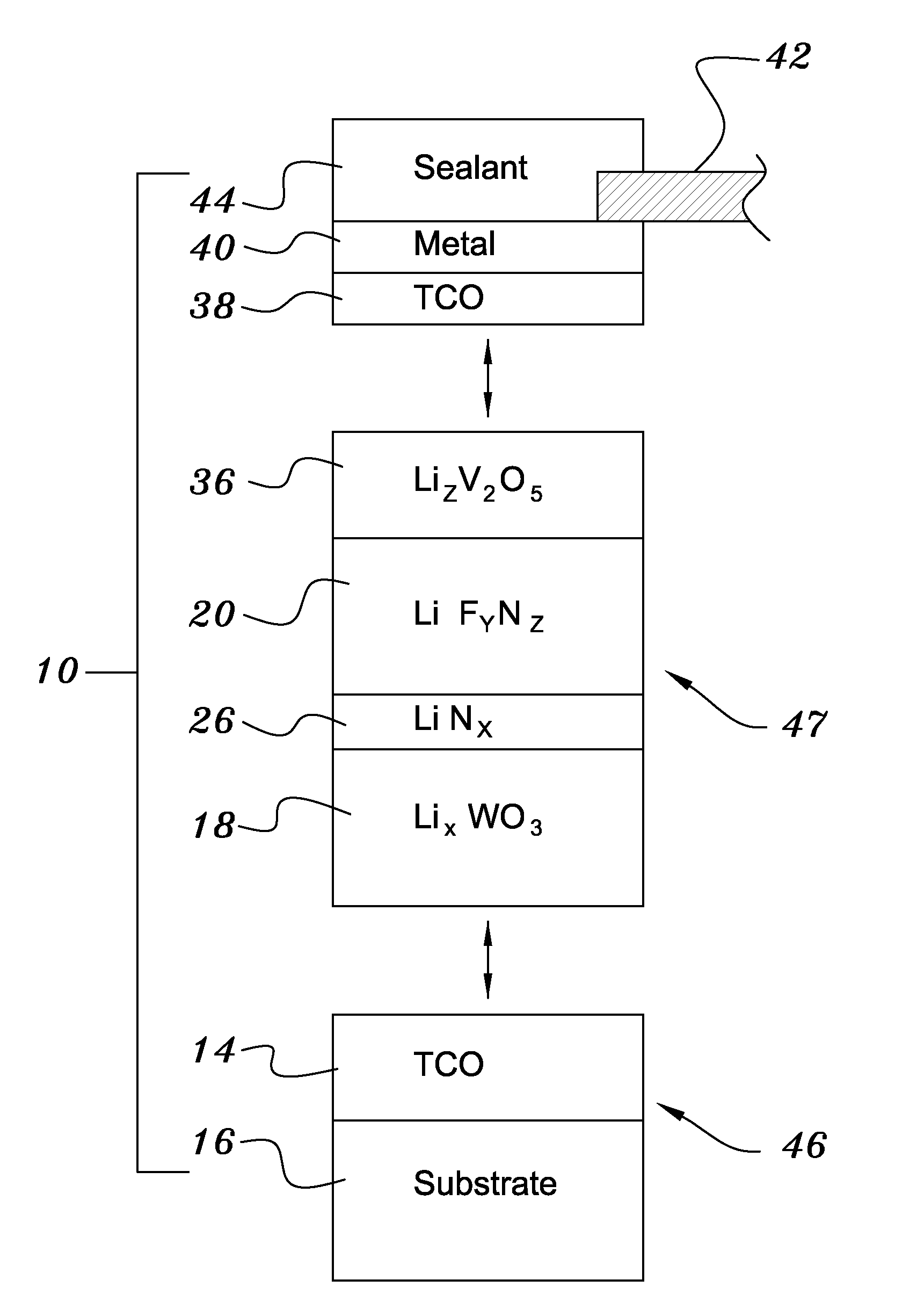

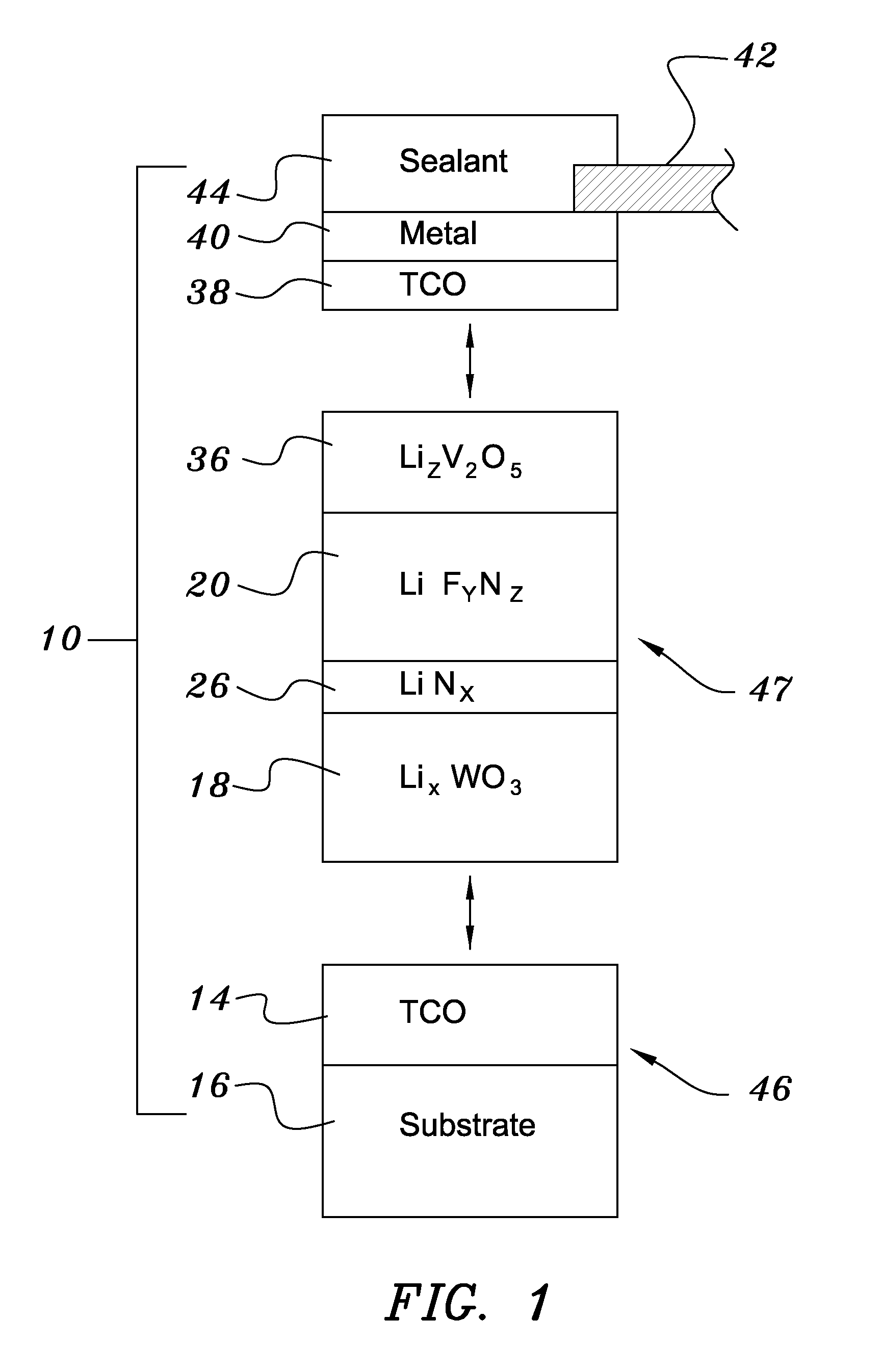

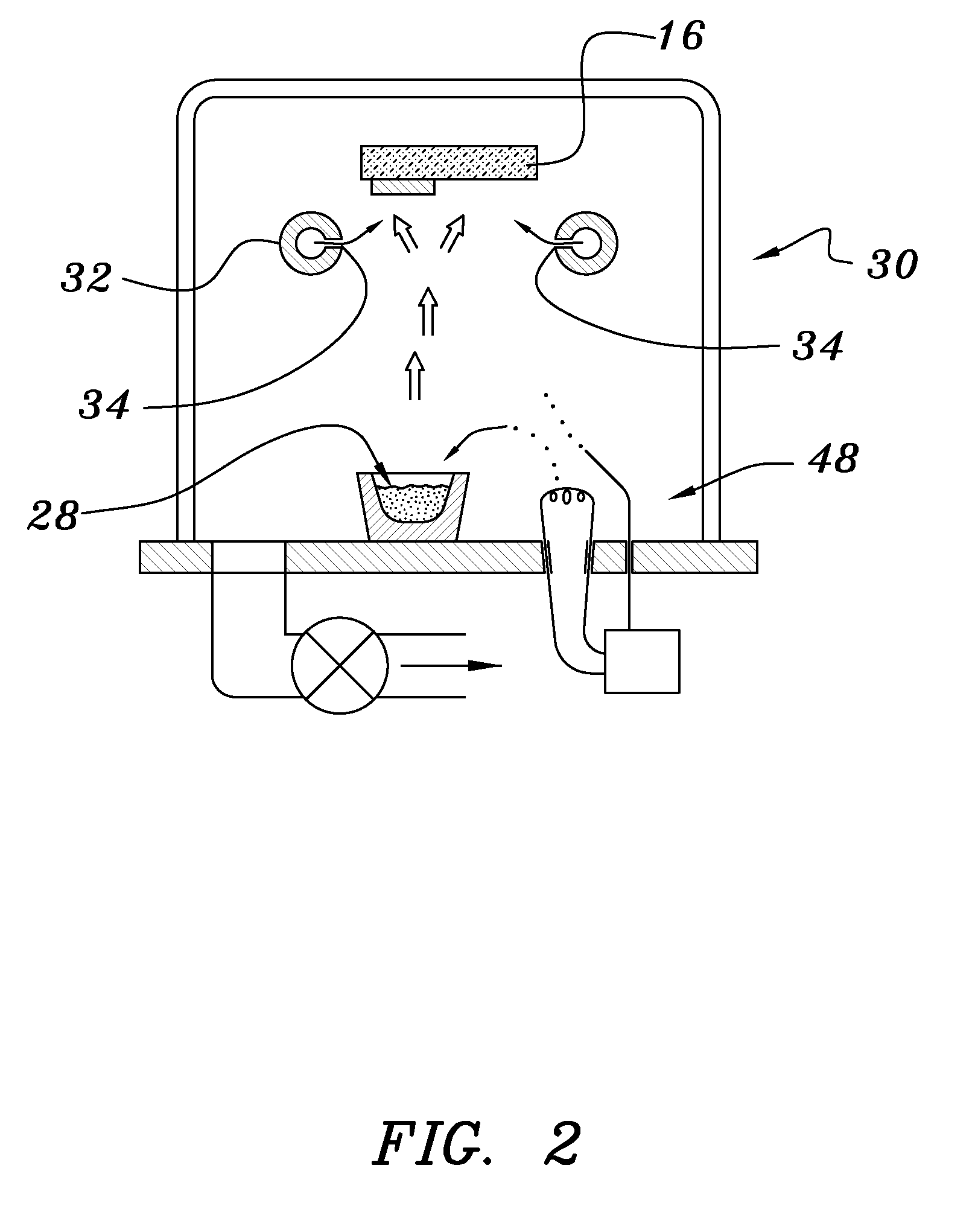

Electrochromic Device with Self-forming Ion transfer Layer and Lithium Fluoro-Nitride Electrolyte

ActiveUS20070292606A1Solve many processesReduce usageCoatingsSpecial surfacesEvaporationElectrochromism

A method of preparing an electrochromic device involves forming multiple layers of selected materials on a substrate in a vacuum processing chamber. A first of these layers is an electrode layer deposited directly on the substrate and used for making contact to a subsequently deposited precursor film, preferably tungsten oxide, from which an electrochromic layer is formed by lithium loading in the presence of ionized nitrogen. This not only forms the electrochromic layer by diffusion of the lithium into the tungsten oxide, but also forms a thin lithium nitride ion transfer layer on the then exposed surface. Subsequently, a lithium fluoro-nitride electrolyte layer is formed on the ion transfer layer by evaporation from a lithium fluoride source in the presence of ionized nitrogen. An ion storage layer, which may be a vanadium oxide and a transparent second electrode layer are subsequently vacuum deposited.

Owner:ECLIPSE ENERGY SYST

Self-supporting laminated films, structural materials and medical devices manufactured therefrom and methods of making same

Metal foils, wires, and seamless tubes with increased mechanical strength are provided. As opposed to wrought materials that are made of a single metal or alloy, these materials are made of two or more layers forming a laminate structure. Laminate structures are known to increase mechanical strength of sheet materials such as wood and paper products and are used in the area of thin films to increase film hardness, as well as toughness. Laminate metal foils have not been used or developed because the standard metal forming technologies, such as rolling and extrusion, for example, do not lend themselves to the production of laminate structures. Vacuum deposition technologies can be developed to yield laminate metal structures with improved mechanical properties. In addition, laminate structures can be designed to provide special qualities by including layers that have special properties such as superelasticity, shape memory, radio-opacity, corrosion resistance etc. Examples of articles which may be made by the inventive laminate structures include implantable medical devices that are fabricated from the laminated deposited films and which present a blood or body fluid and tissue contact surface that has controlled heterogeneities in material constitution. An endoluminal stent-graft and web-stent that is made of a laminated film material deposited and etched into regions of structural members and web regions subtending interstitial regions between the structural members. An endoluminal graft is also provided which is made of a biocompatible metal or metal-like material. The endoluminal stent-graft is characterized by having controlled heterogeneities in the stent material along the blood flow surface of the stent and the method of fabricating the stent using vacuum deposition methods.

Owner:VACTRONIX SCI LLC

Electrochromic device with self-forming ion transfer layer and lithium-fluoro-nitride electrolyte

ActiveUS7265891B1Solve many processesReduce usageElectrolytic capacitorsNon-linear opticsEvaporationElectrochromism

An electrochromic device is prepared by forming multiple layers of selected materials on a substrate in a vacuum processing chamber. A first of these layers is an electrode layer deposited directly on the substrate and used for making contact to a subsequently deposited precursor film, preferably tungsten oxide, from which an electrochromic layer is formed by lithium loading in the presence of ionized nitrogen. This not only forms the electrochromic layer by diffusion of the lithium into the tungsten oxide, but also forms a thin lithium nitride ion transfer layer on the then exposed surface. Subsequently, a lithium fluoro-nitride electrolyte layer is formed on the ion transfer layer by evaporation from a lithium fluoride source in the presence of ionized nitrogen. An ion storage layer, which may be a vanadium oxide and a transparent second electrode layer are subsequently vacuum deposited.

Owner:ECLIPSE ENERGY SYST

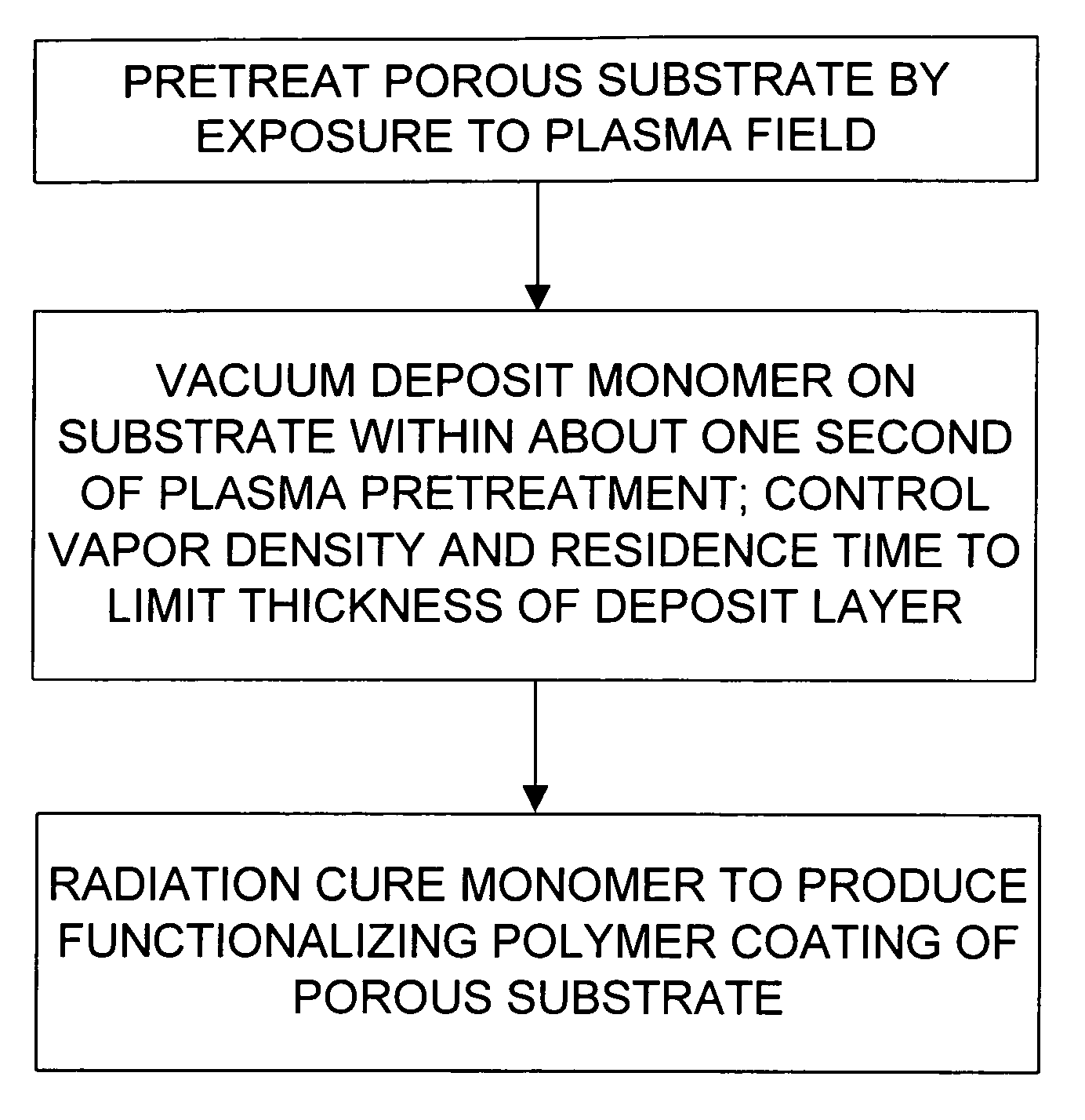

Functionalization of porous materials by vacuum deposition of polymers

InactiveUS7157117B2Improve reflectivityReduced durabilitySemi-permeable membranesMembranesPorous substrateFiber

A porous substrate is pretreated in a plasma field and a functionalizing monomer is immediately flash-evaporated, deposited and cured over the porous substrate in a vacuum vapor-deposition chamber. By judiciously controlling the process so that the resulting polymer coating adheres to the surface of individual fibers in ultra-thin layers (approximately 0.02–3.0 μm) that do not extend across the pores in the material, the porosity of the porous substrate is essentially unaffected while the fibers and the final product acquire the desired functionality. The resulting polymer layer is also used to improve the adherence and durability of metallic and ceramic coatings.

Owner:SIGMA LAB OF ARIZONA

Micromachined voltage controlled optical attenuator

InactiveUS6343178B1Improve seismic performanceReduce the starting voltageMirrorsCoupling light guidesUltrasound attenuationSemiconductor structure

This invention provides a very sensitive optical attenuator, which can be used to couple and attenuate optical signals between optical fibers with a wide range of attenuation level. Such an optical attenuator includes a flexible conductive membrane to be moved by an external force, such as electrostatic force, to achieve deformation of the conductive membrane. The conductive membrane can be formed, for example, by a vacuum deposited silicon nitride film. A thin metallic, conductive layer is then deposited on the flexible membrane to form a reflective mirror to receive and reflect incident optical signals. The semiconductor structure includes one or more spacing posts, with which the first structural member is to be joined and bonded. Electrodes are placed on the semiconductor structure in close proximity to the flexible membrane. At various areas of the semiconductor structure, additional spacing posts are added to cause deformation of the conductive membrane when a voltage is applied between the membrane and the electrodes on the semiconductor structure.

Owner:CISCO TECH INC

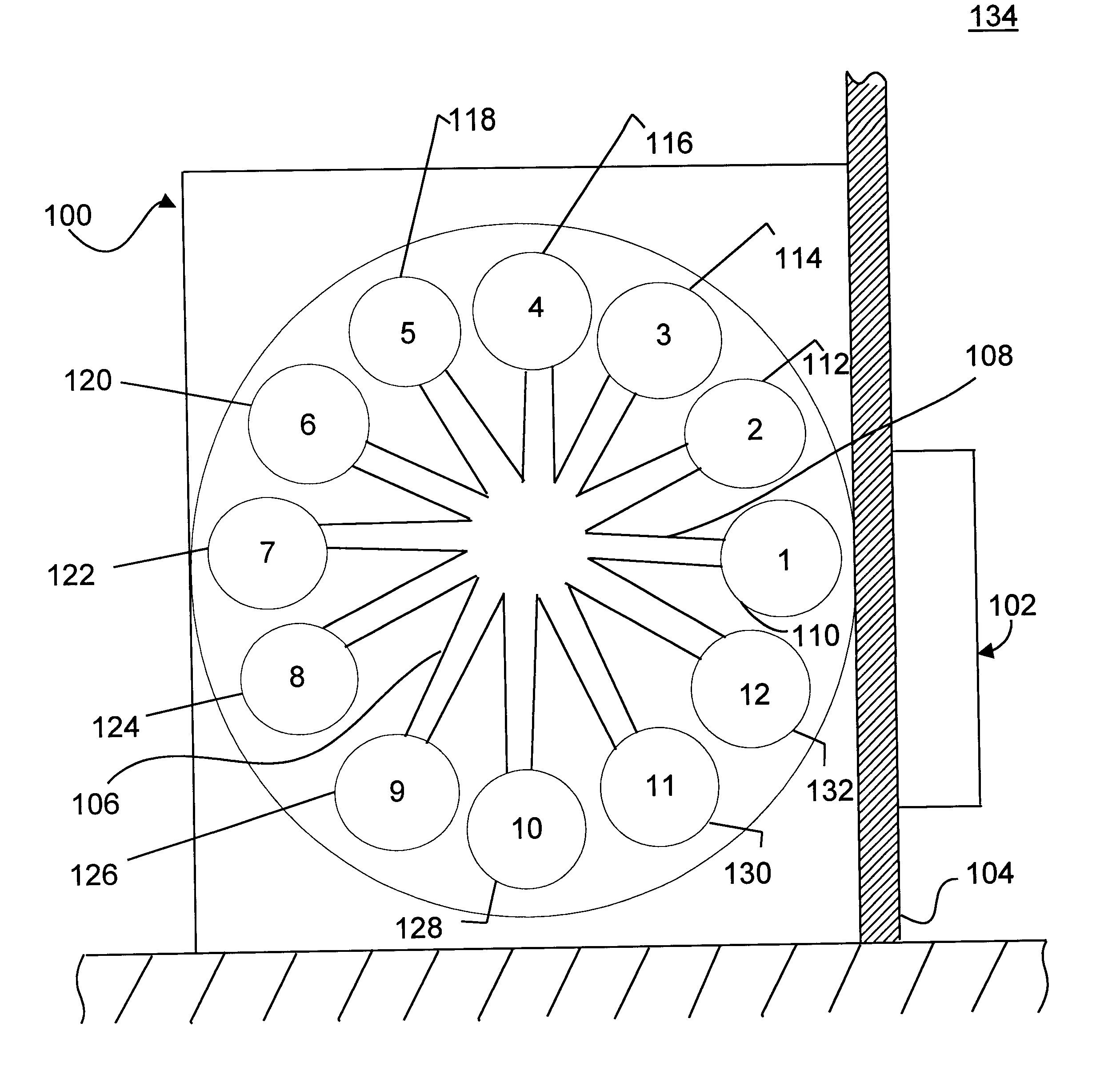

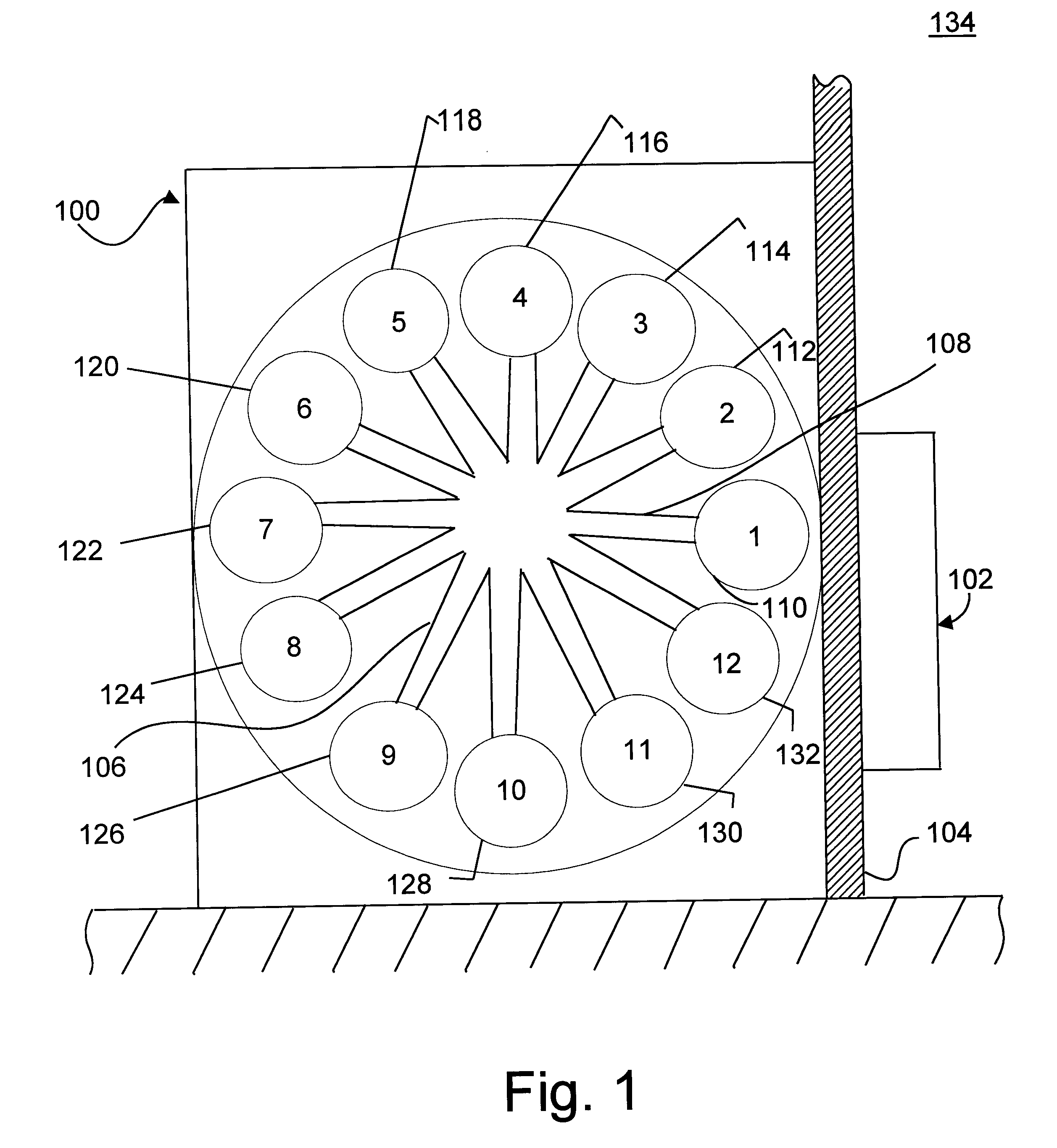

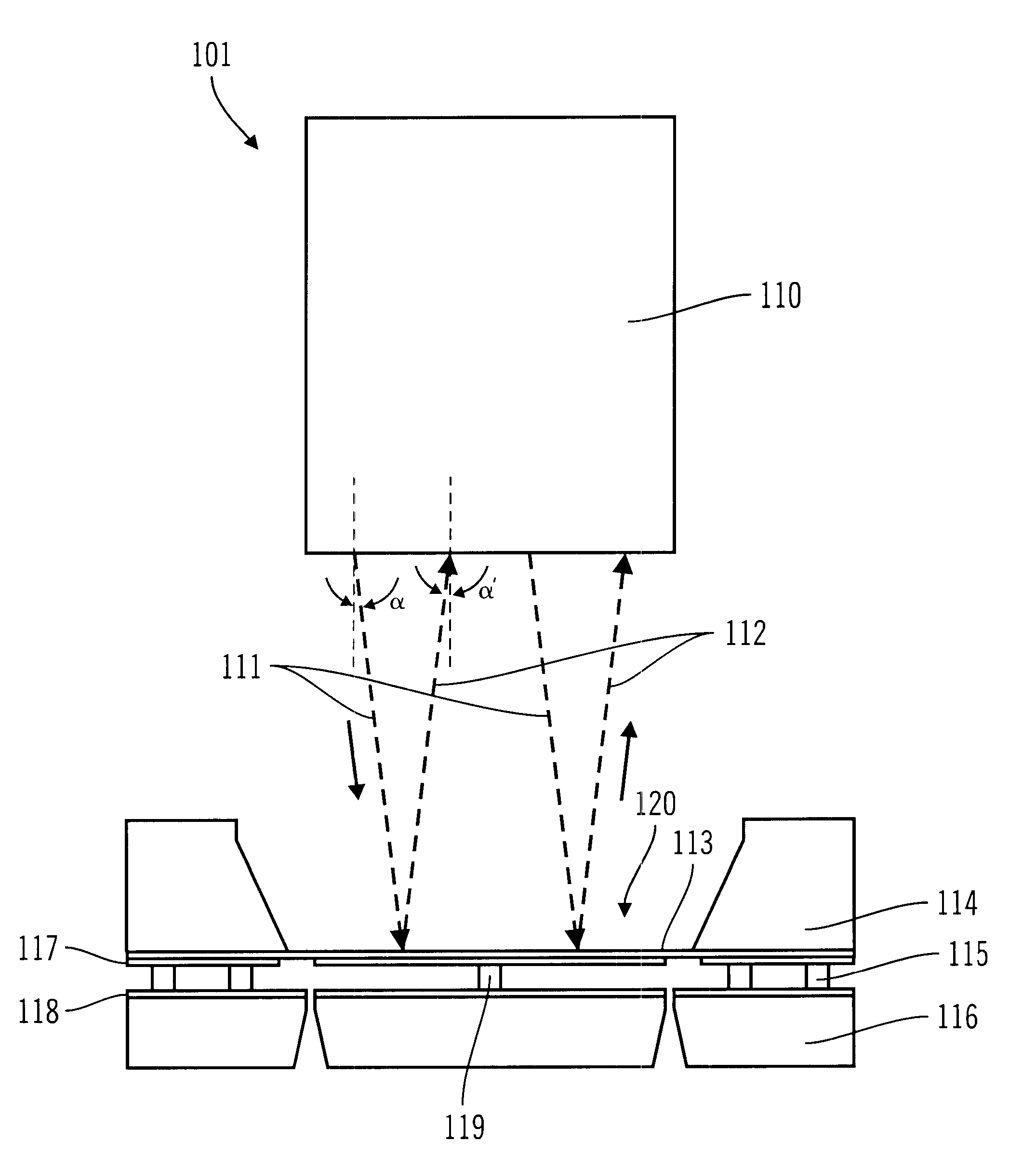

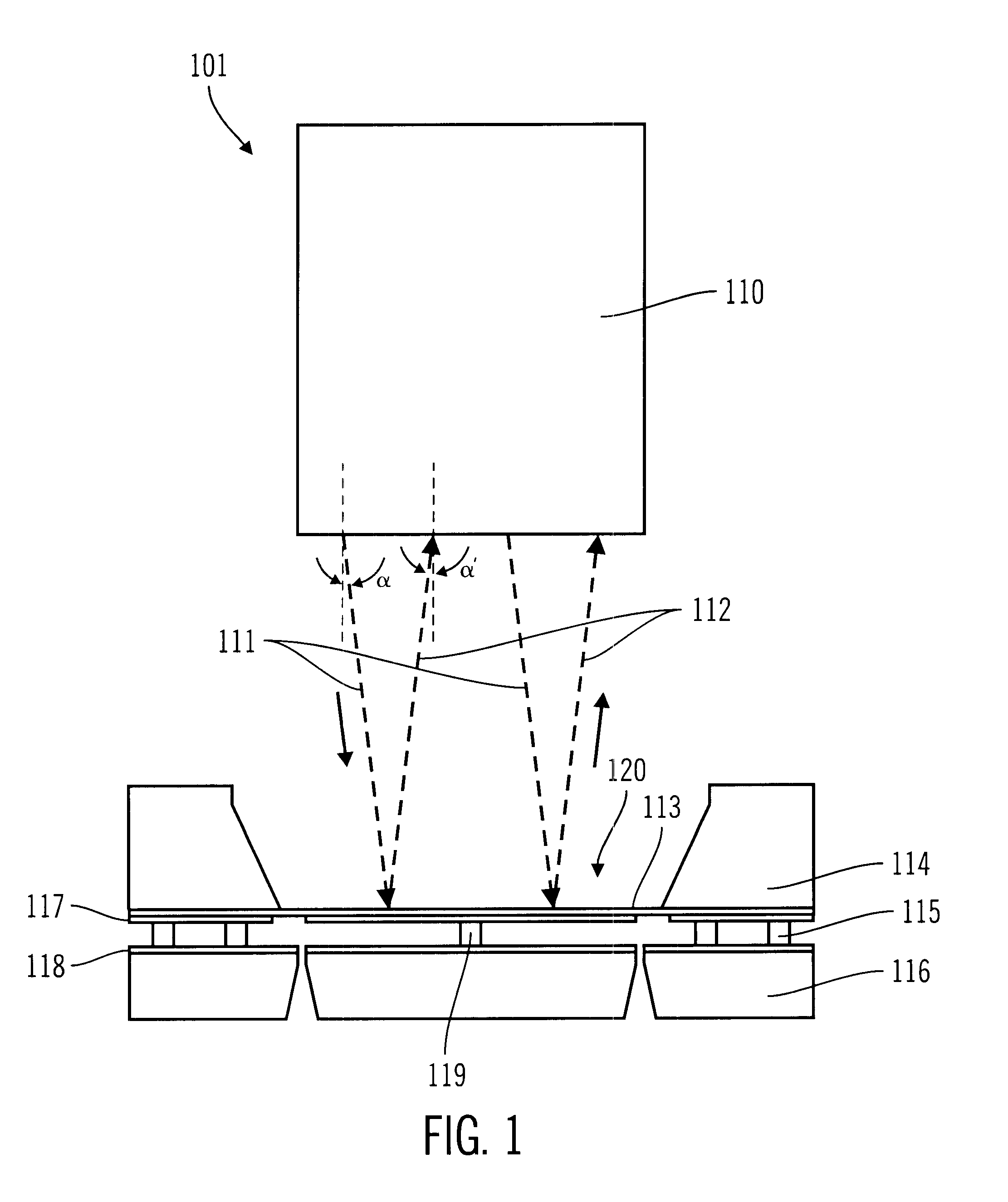

Use of multiple masks to control uniformity in coating deposition

The uniformity of individual layers of multiple coating materials deposited on a substrate in a vacuum deposition process (such as for manufacturing mirrors for use in ring laser gyroscopes) is improved by an apparatus and method that include changing the masks placed in front of the substrate upon which the coating materials are to be deposited. Separate masks are tuned for each particular coating material to compensate for the unique plume shape of the material, and provide a uniform deposition of that particular coating material. Each mask is positioned in front of the substrate when the material for which the mask has been tuned is being deposited. The masks are changed when the coating material is changed, without venting the chamber.

Owner:NORTHROP GRUMMAN SYST CORP

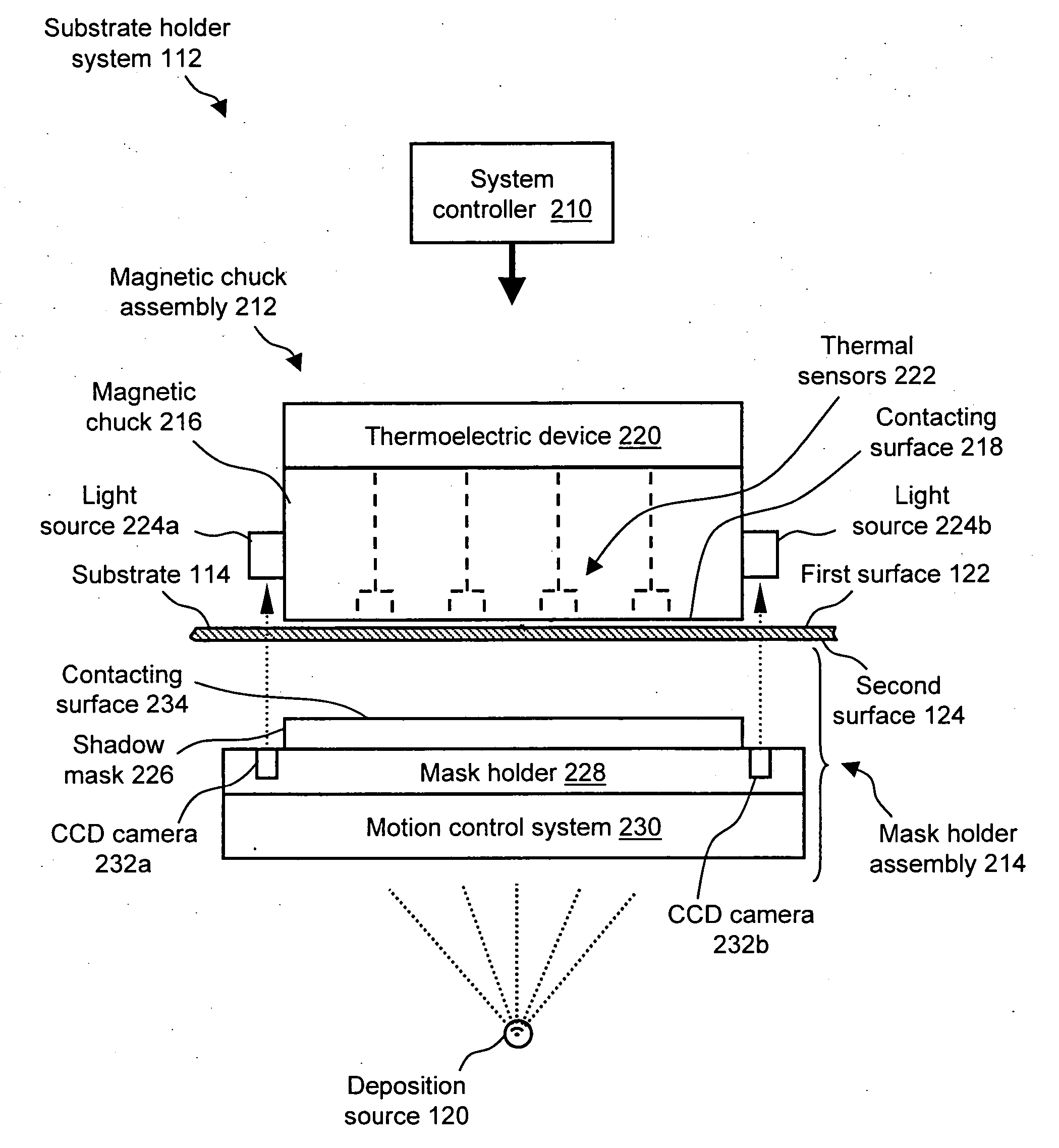

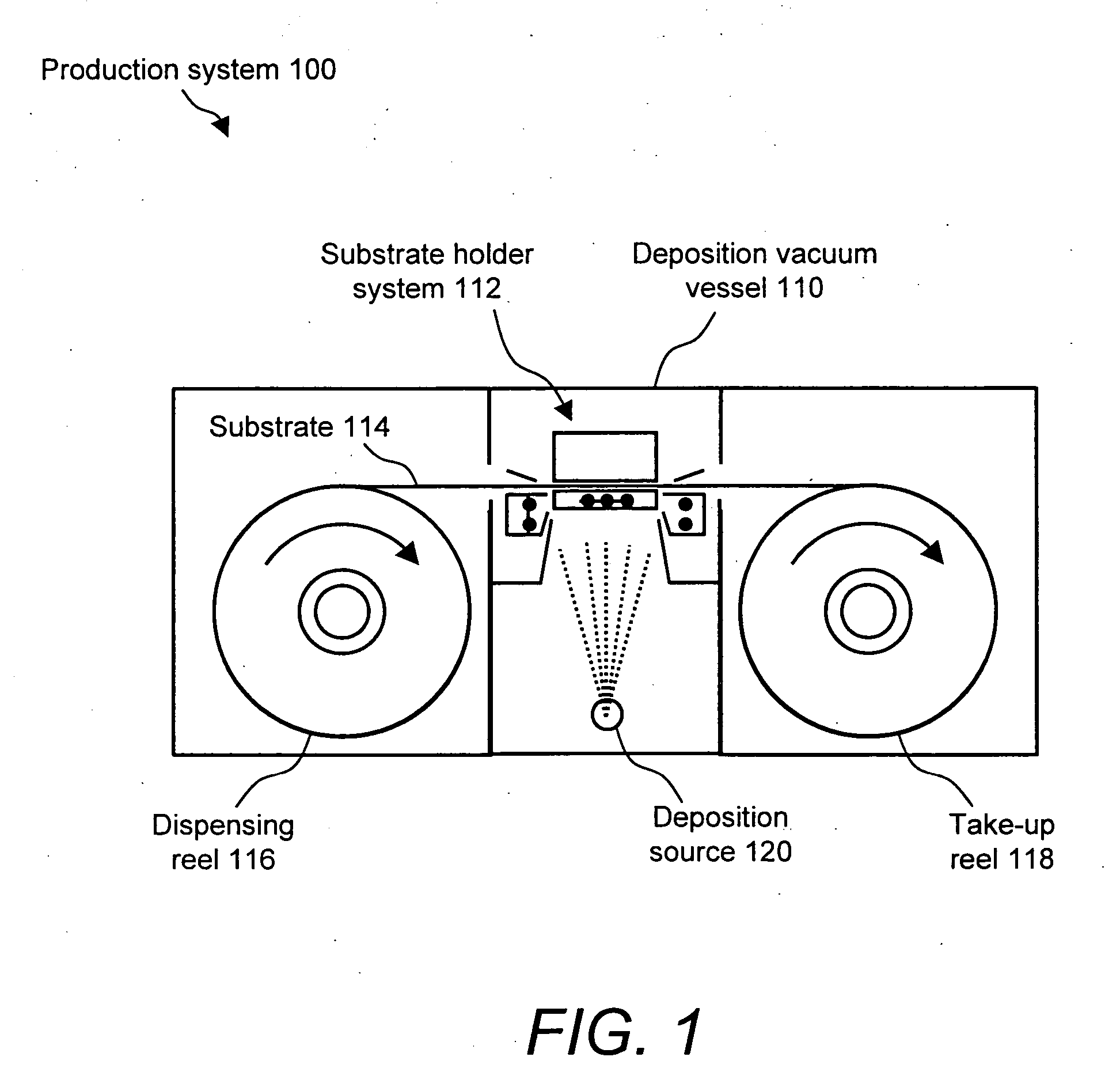

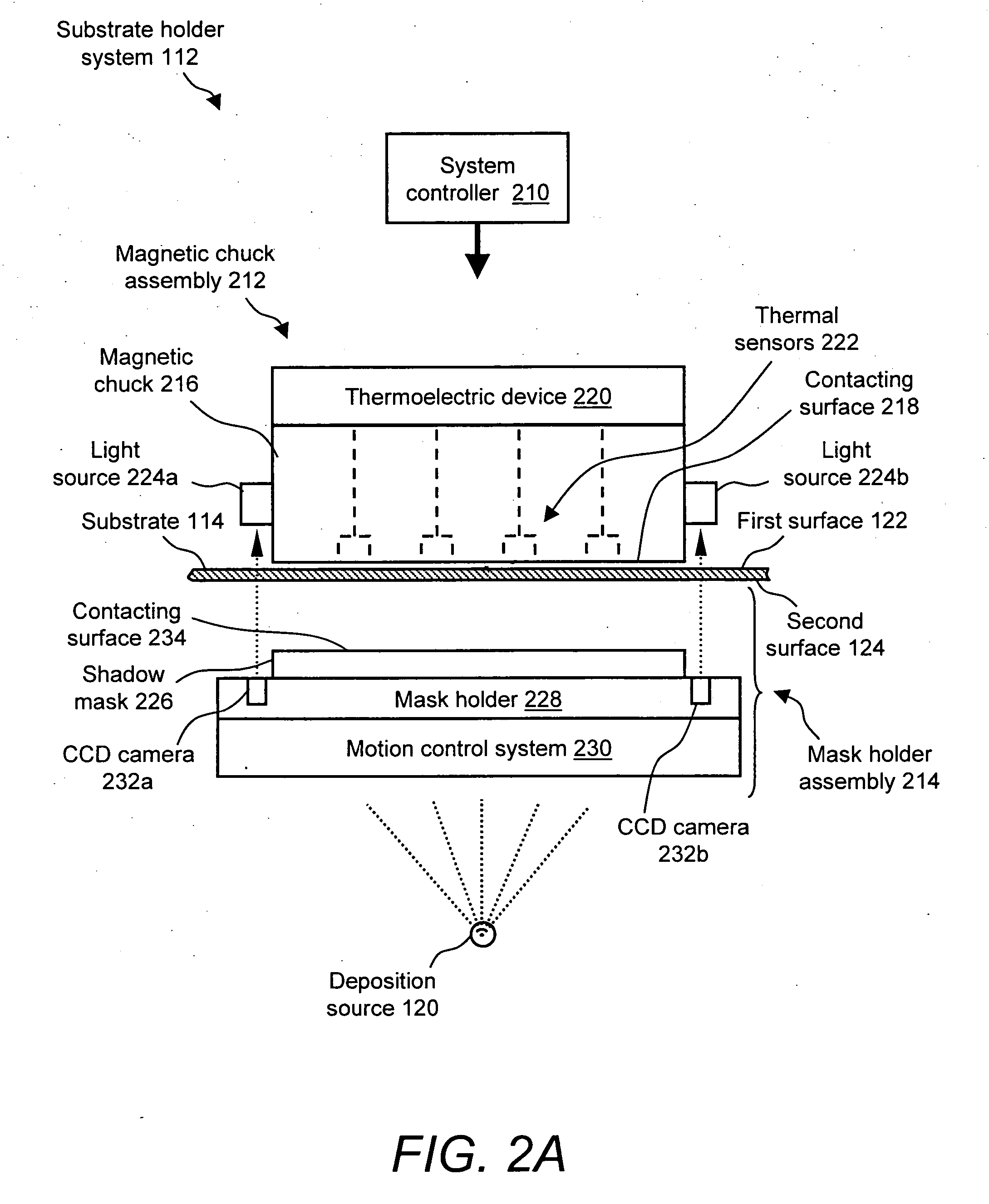

Substrate-to-mask alignment and securing system with temperature control for use in an automated shadow mask vacuum deposition process

InactiveUS20060086321A1Vacuum evaporation coatingSputtering coatingTemperature controlControl system

The present invention is a substrate holder system for and method of providing a substrate-to-mask alignment mechanism, securing mechanism and temperature control mechanism. The substrate holder system is suitable for use in an automated shadow mask vacuum deposition process. The substrate holder system includes a system controller, and a substrate arranged between a magnetic chuck assembly and a mask holder assembly. The magnetic chuck assembly includes a magnetic chuck, a thermoelectric device, a plurality of thermal sensors and a plurality of light sources. The mask holder assembly includes a shadow mask, a mask holder, a motion control system and a plurality of cameras. The substrate holder system of the present invention provides close contact between the substrate and the shadow mask thereby avoiding the possibility of evaporant material entering into a gap therebetween.

Owner:ADVANTECH GLOBAL LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com