Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

2416results about "Soldered/welded conductive connections" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

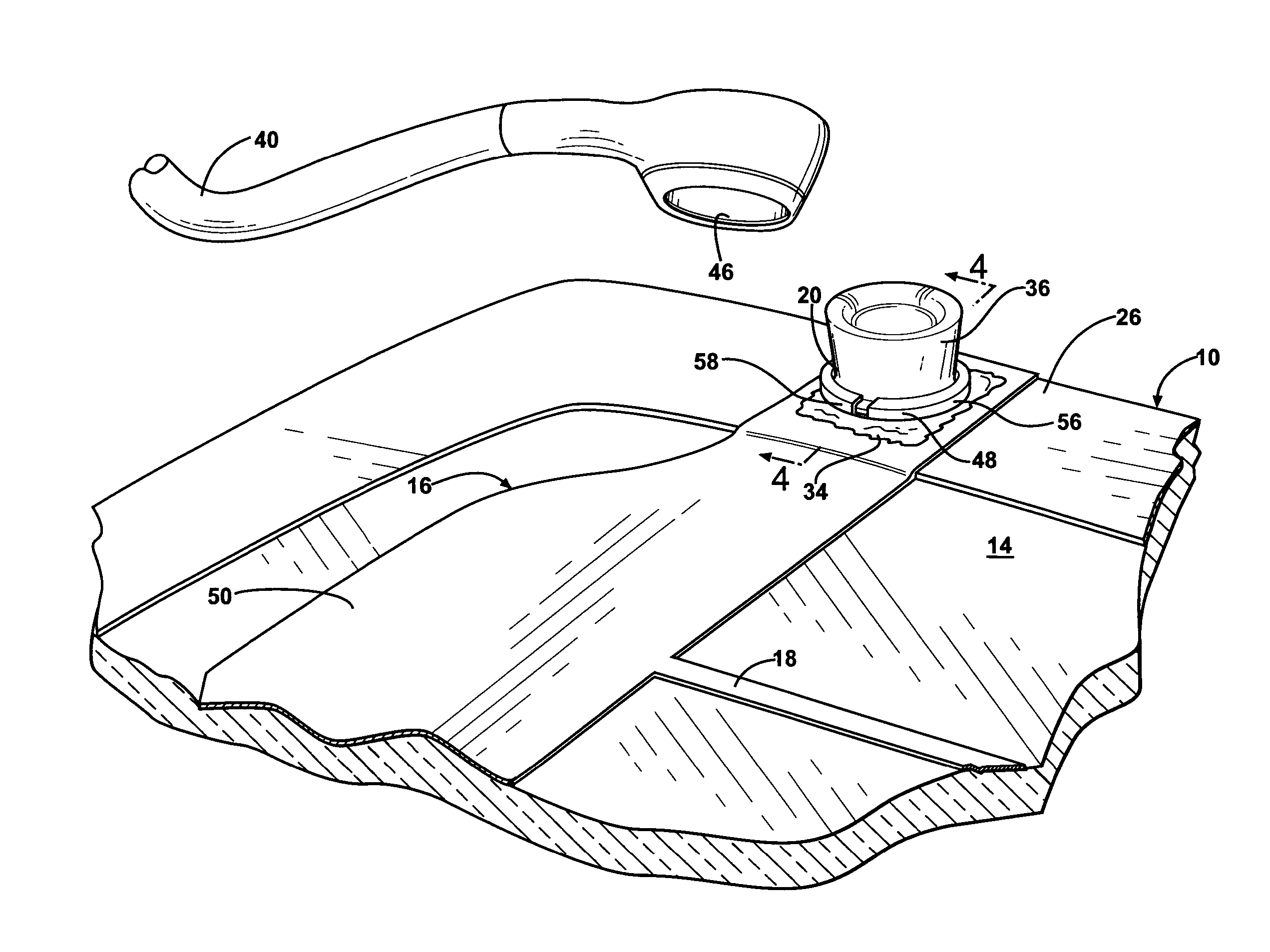

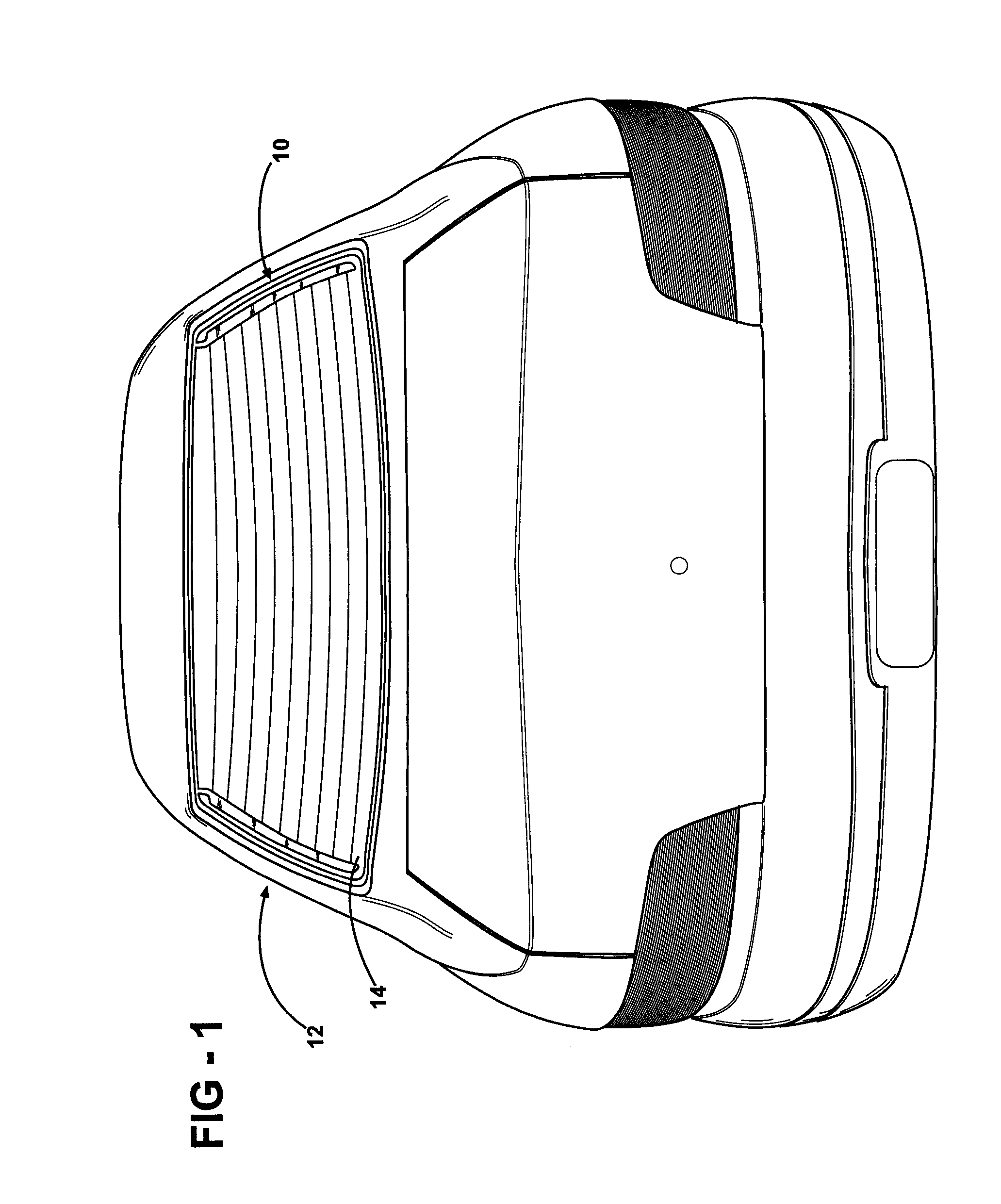

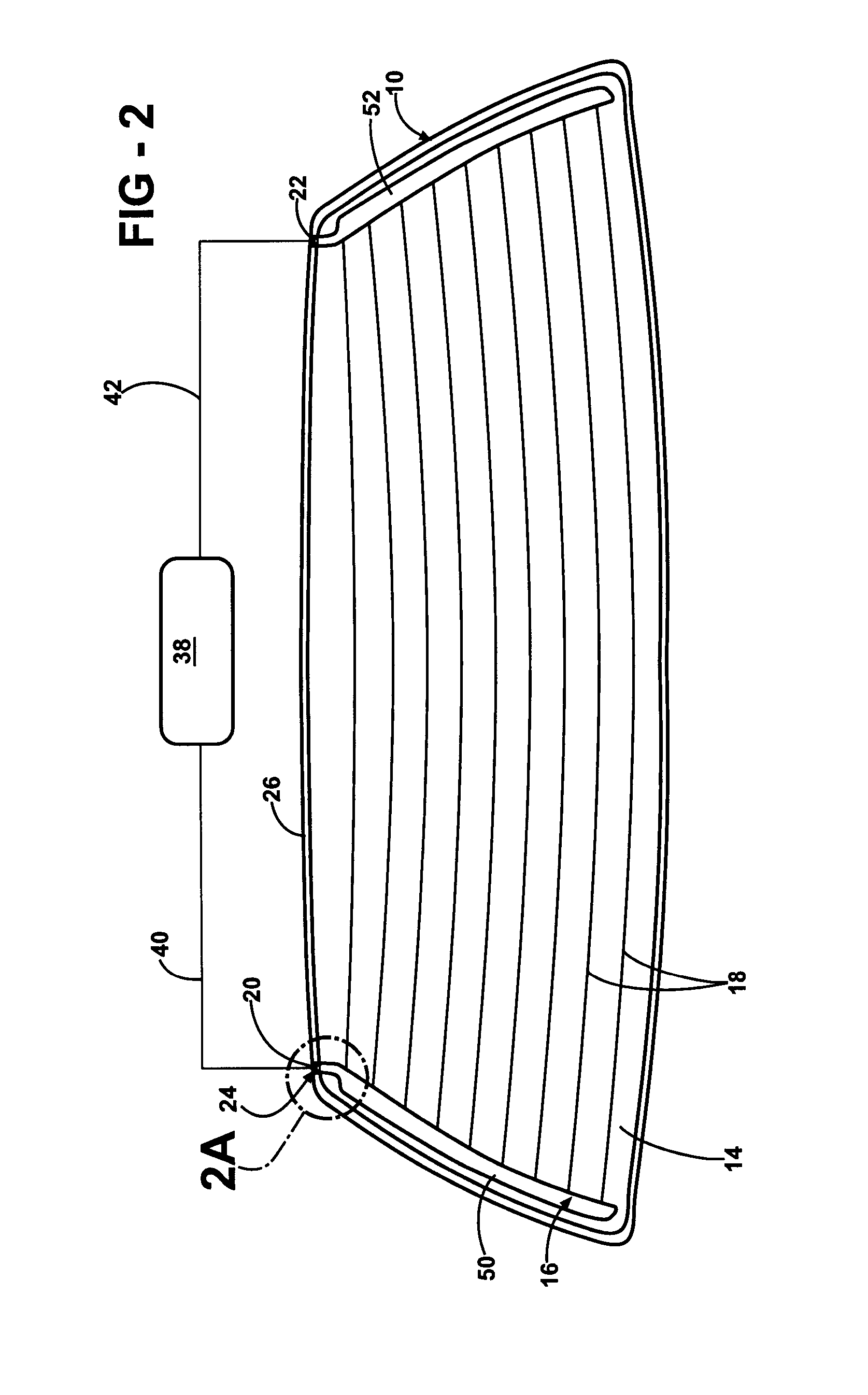

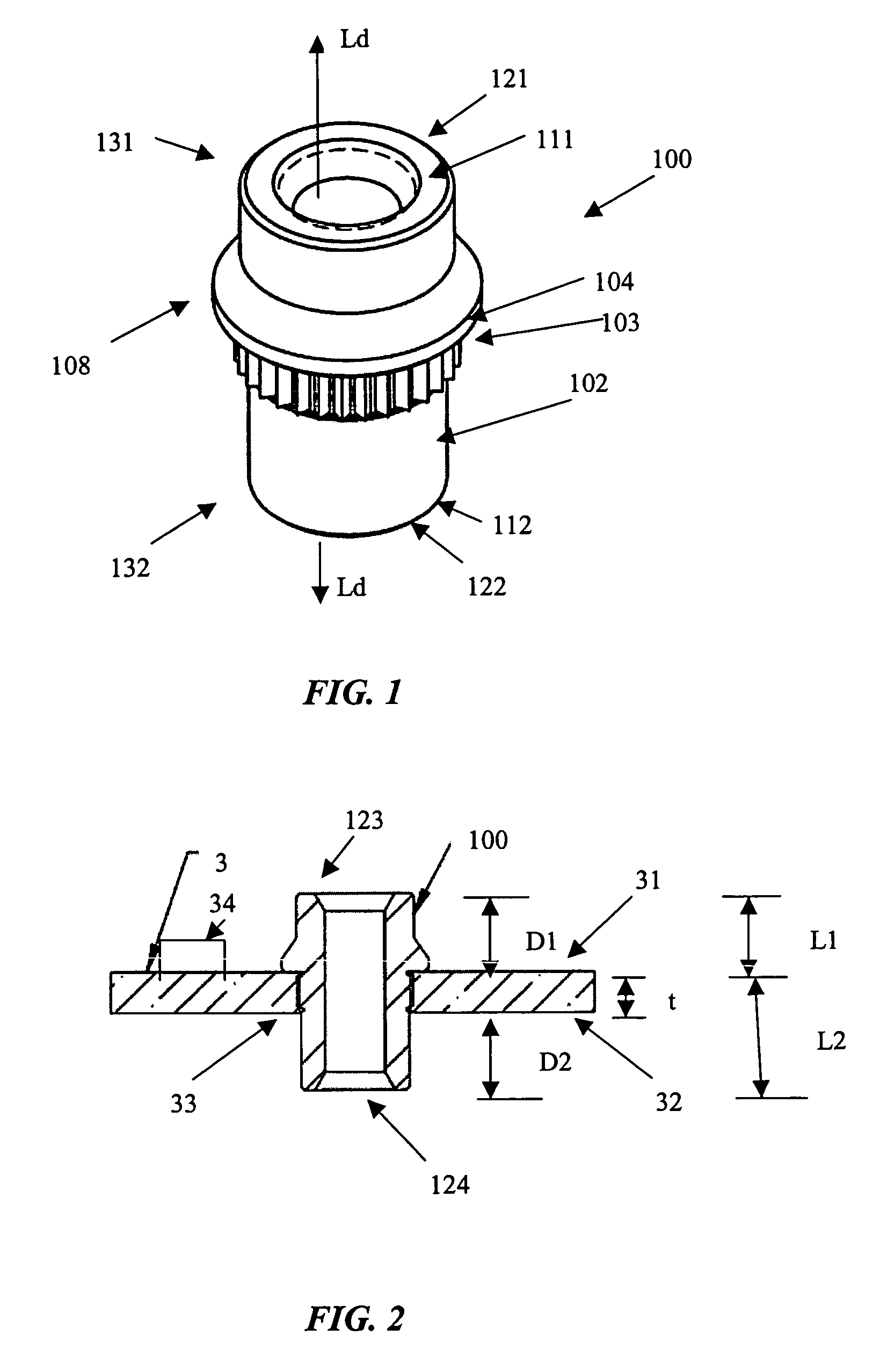

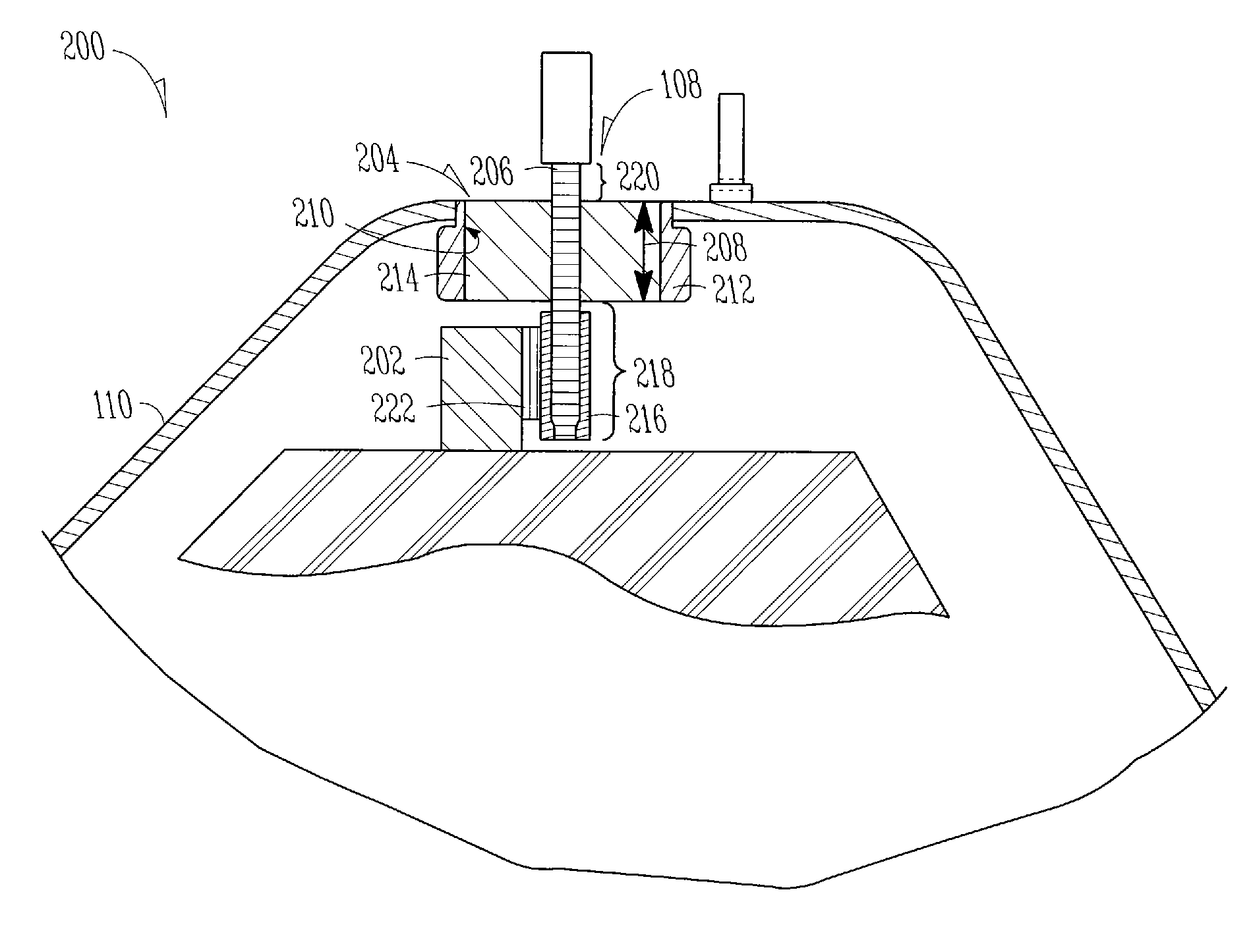

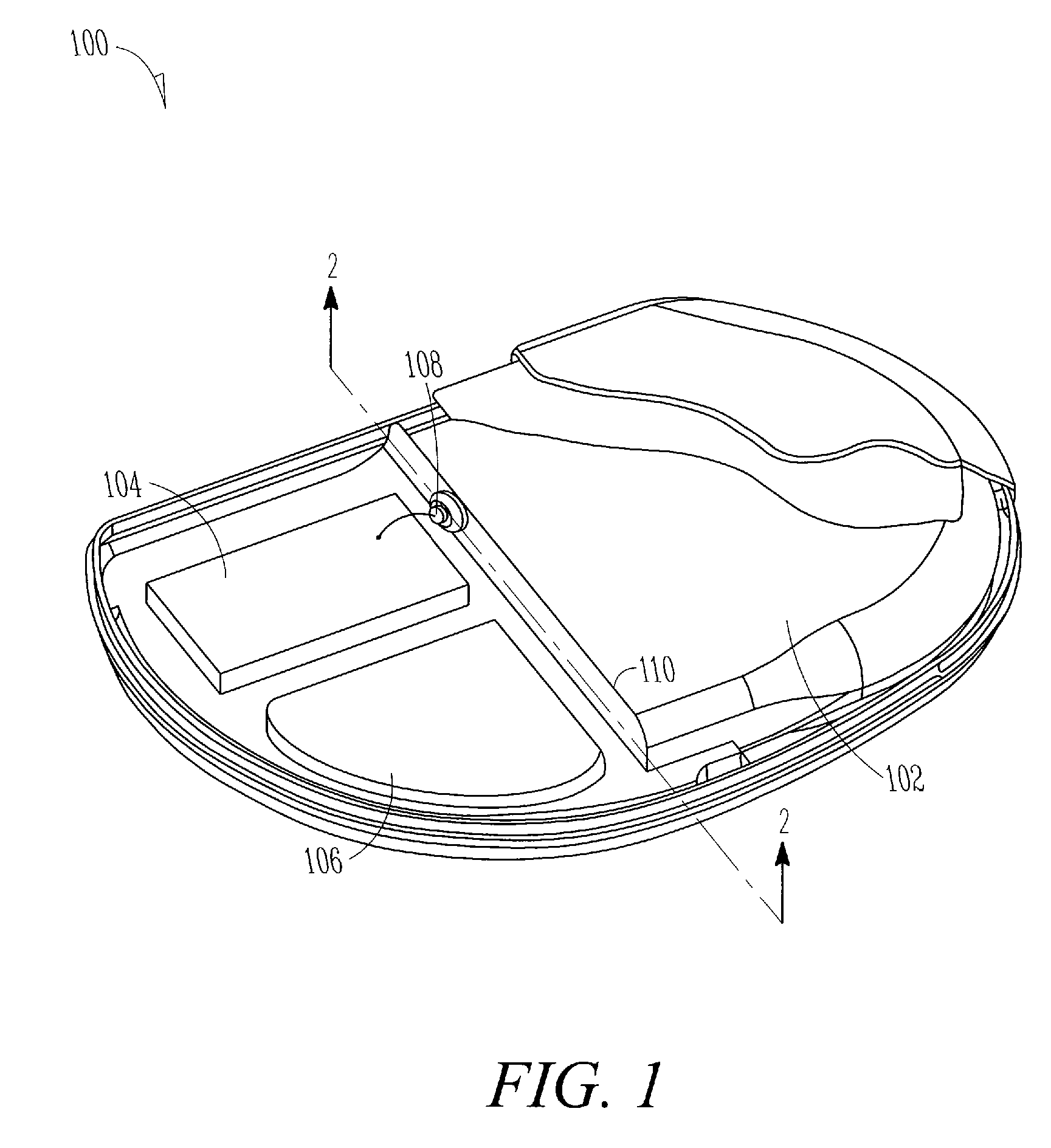

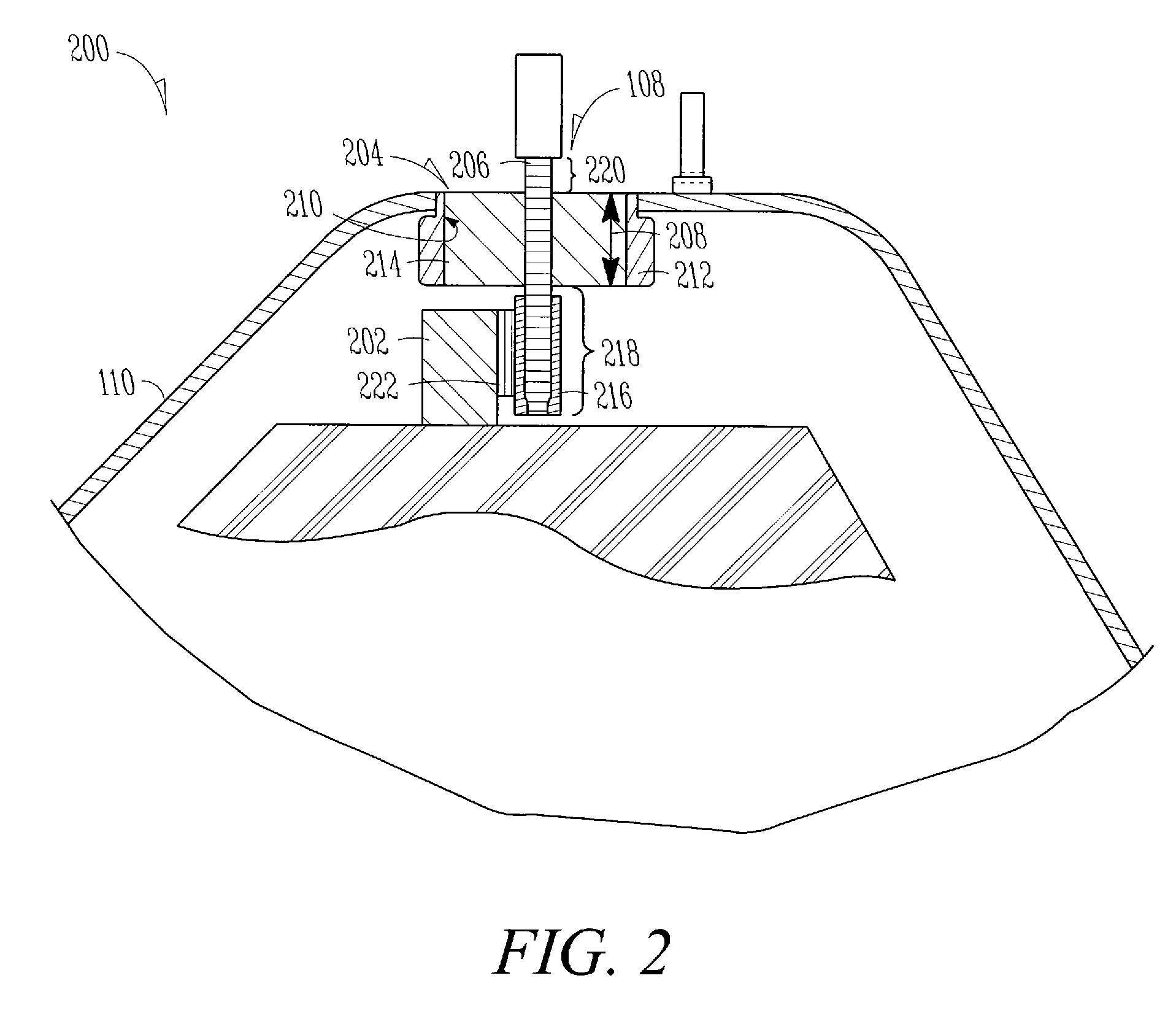

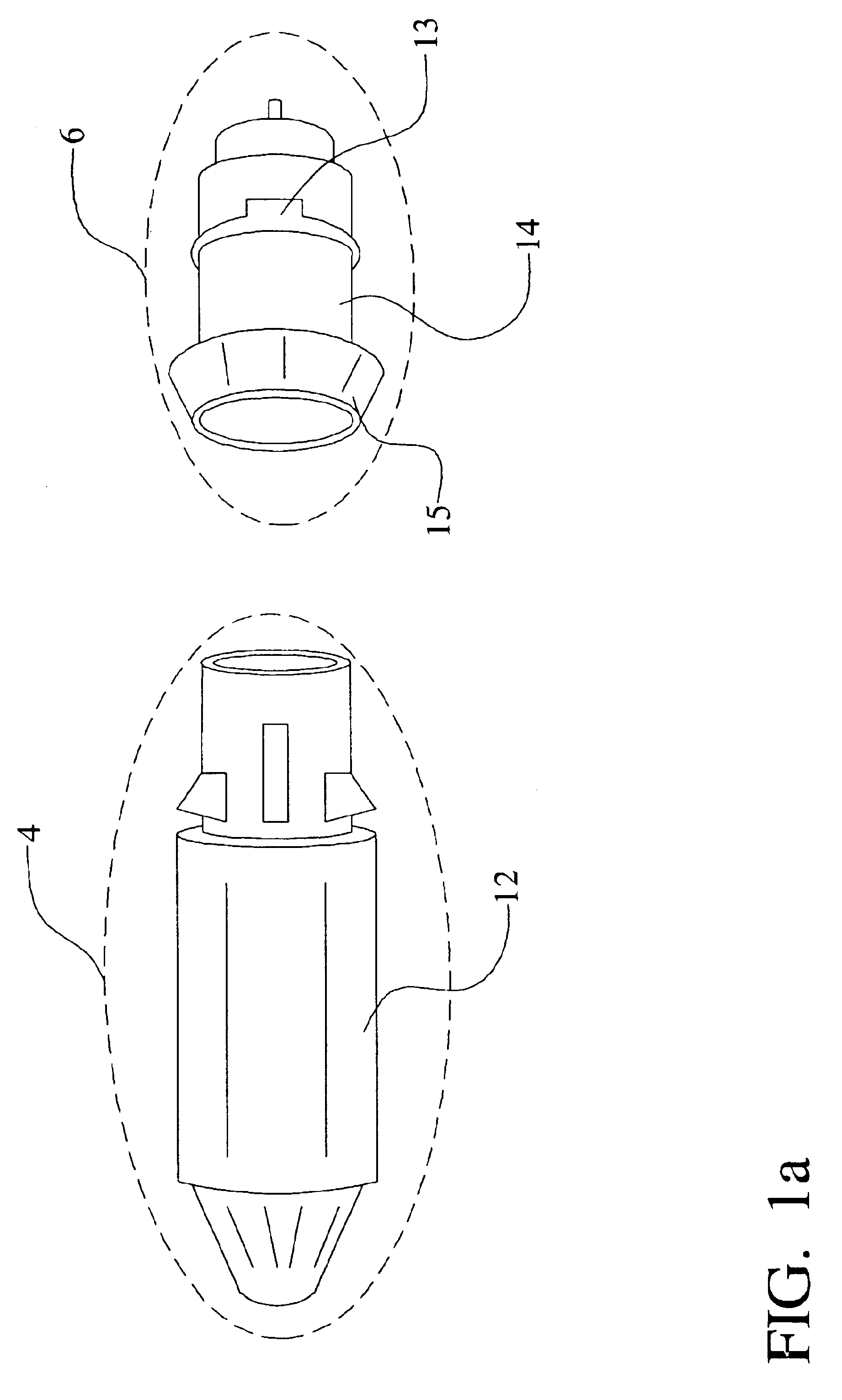

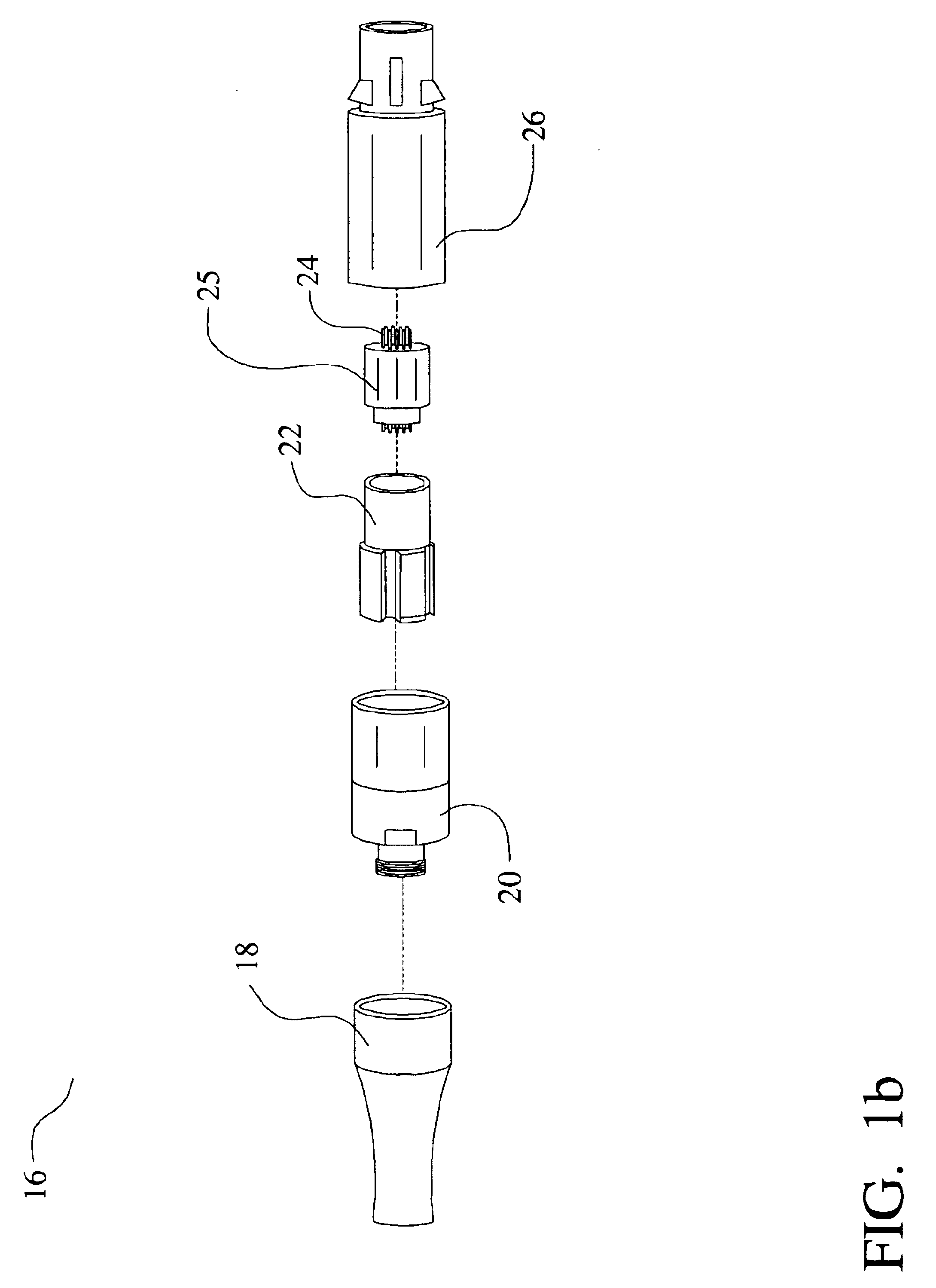

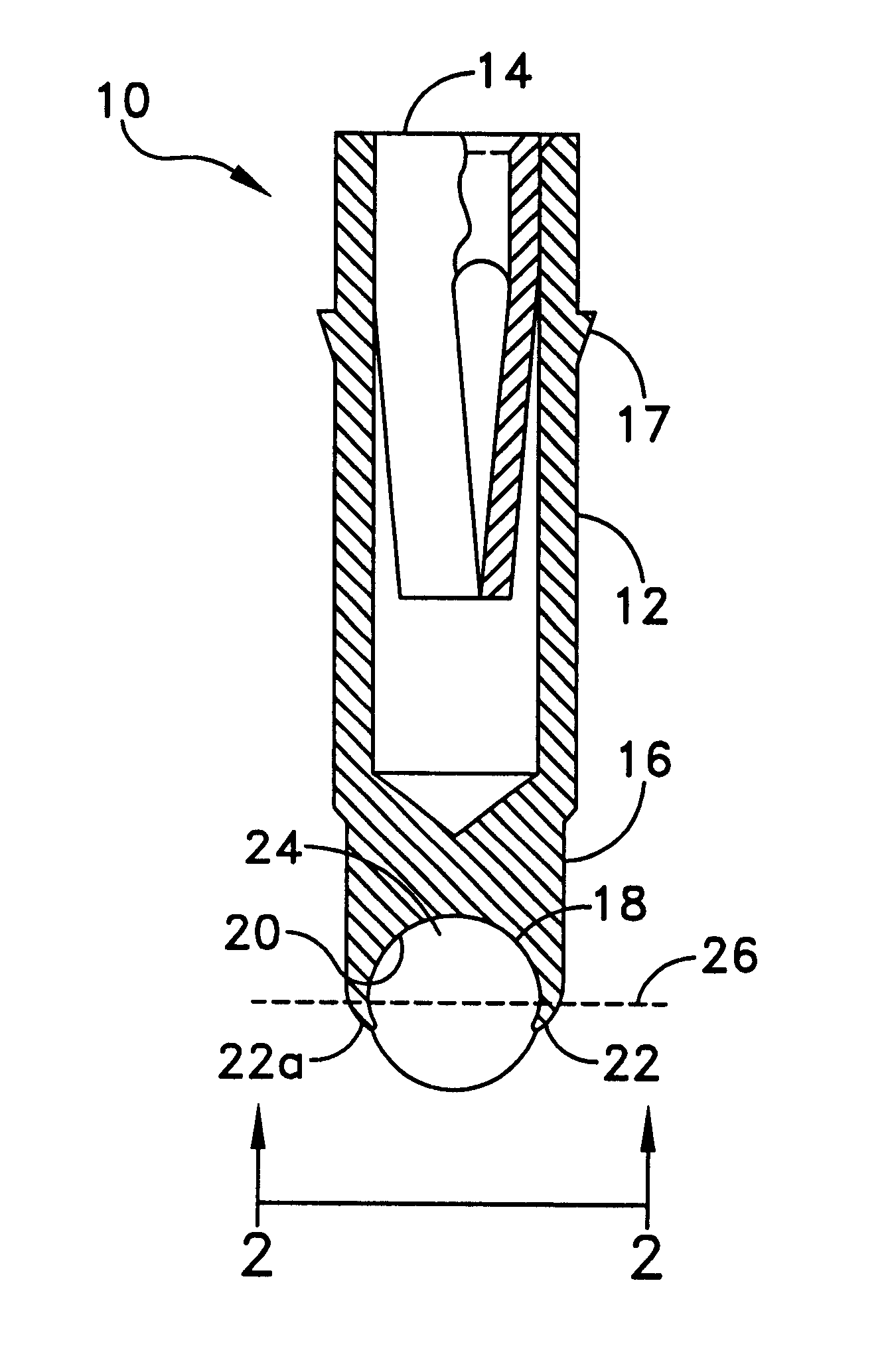

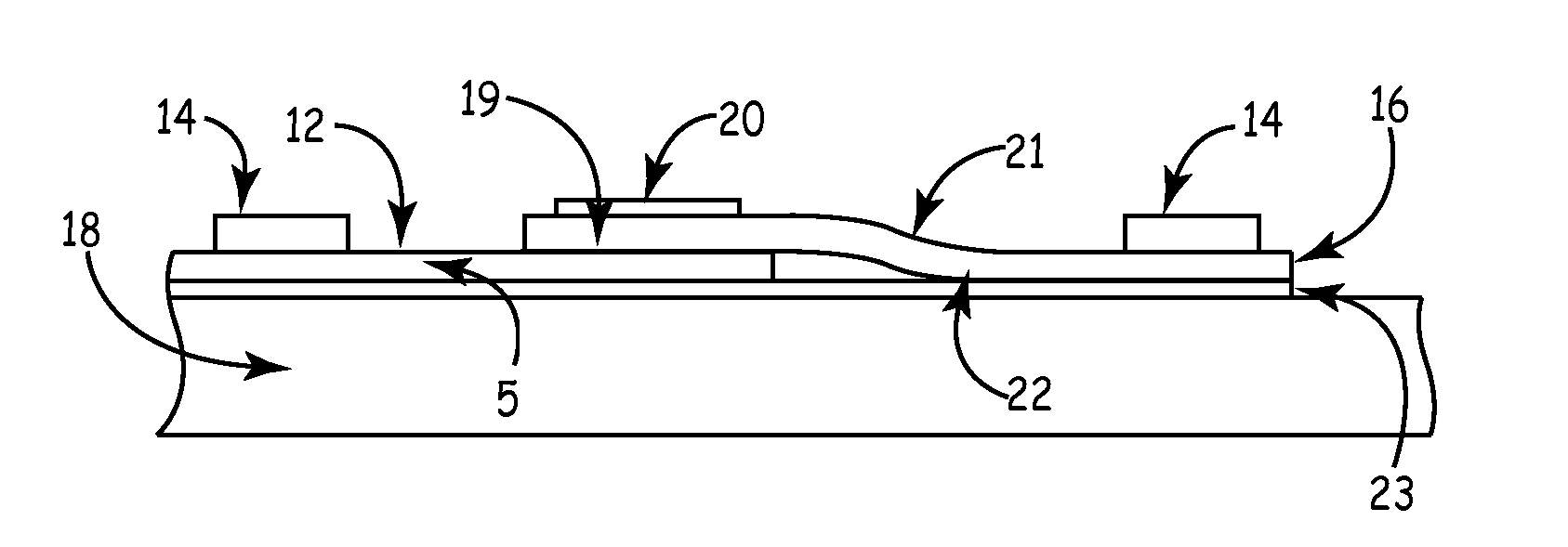

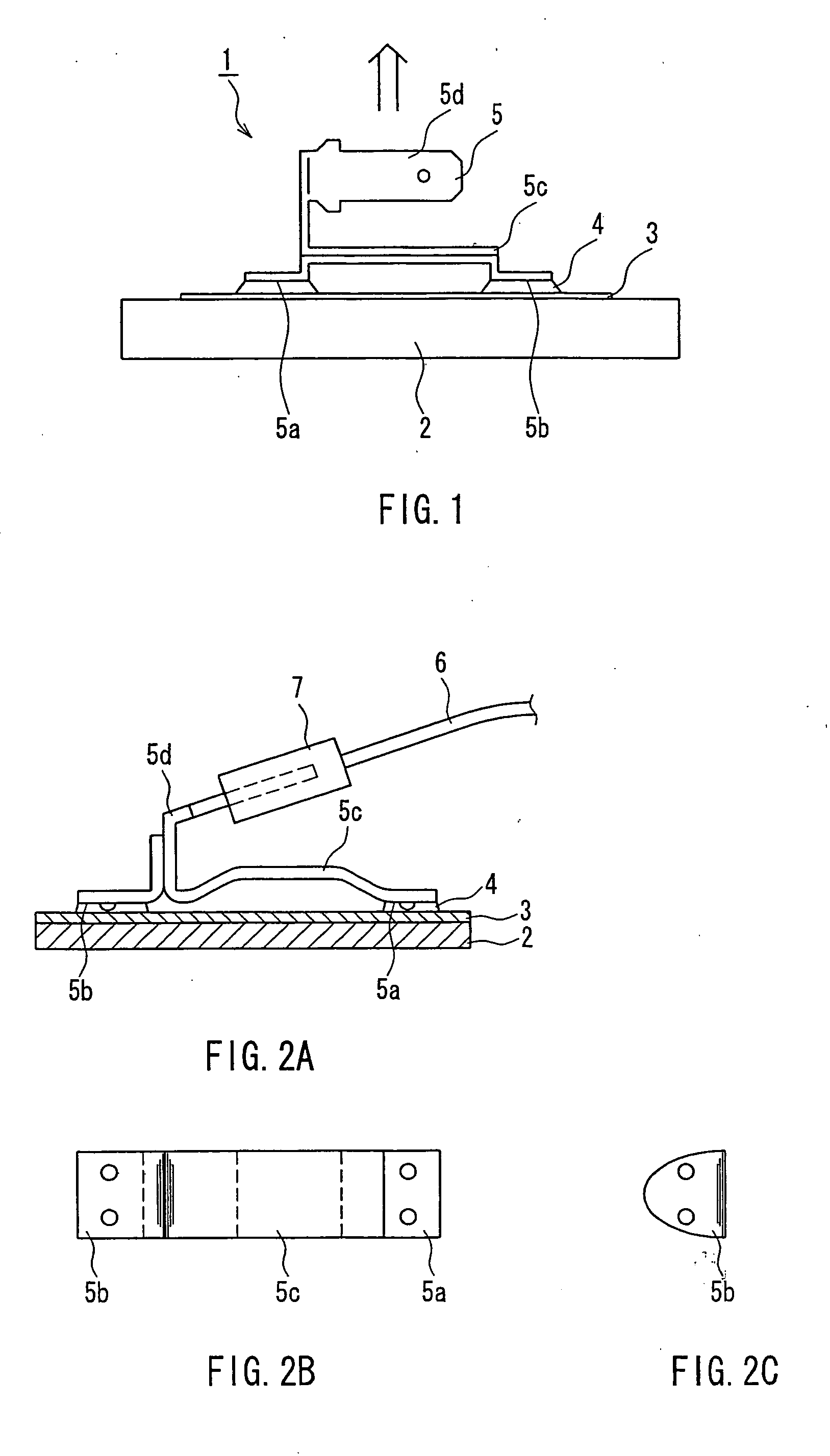

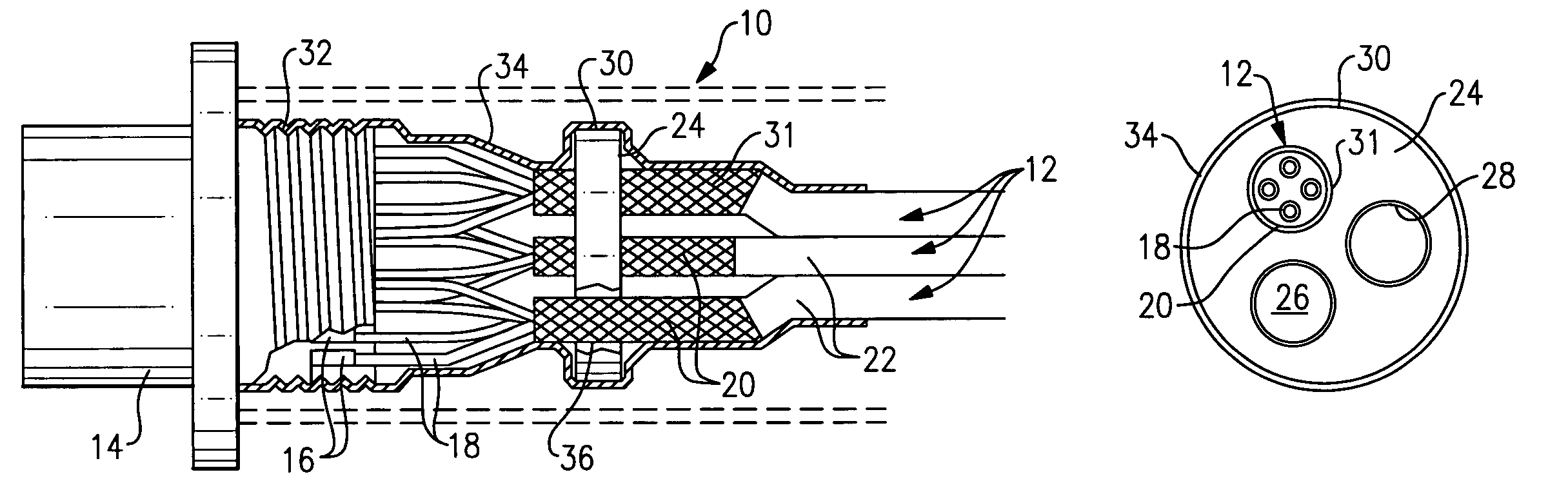

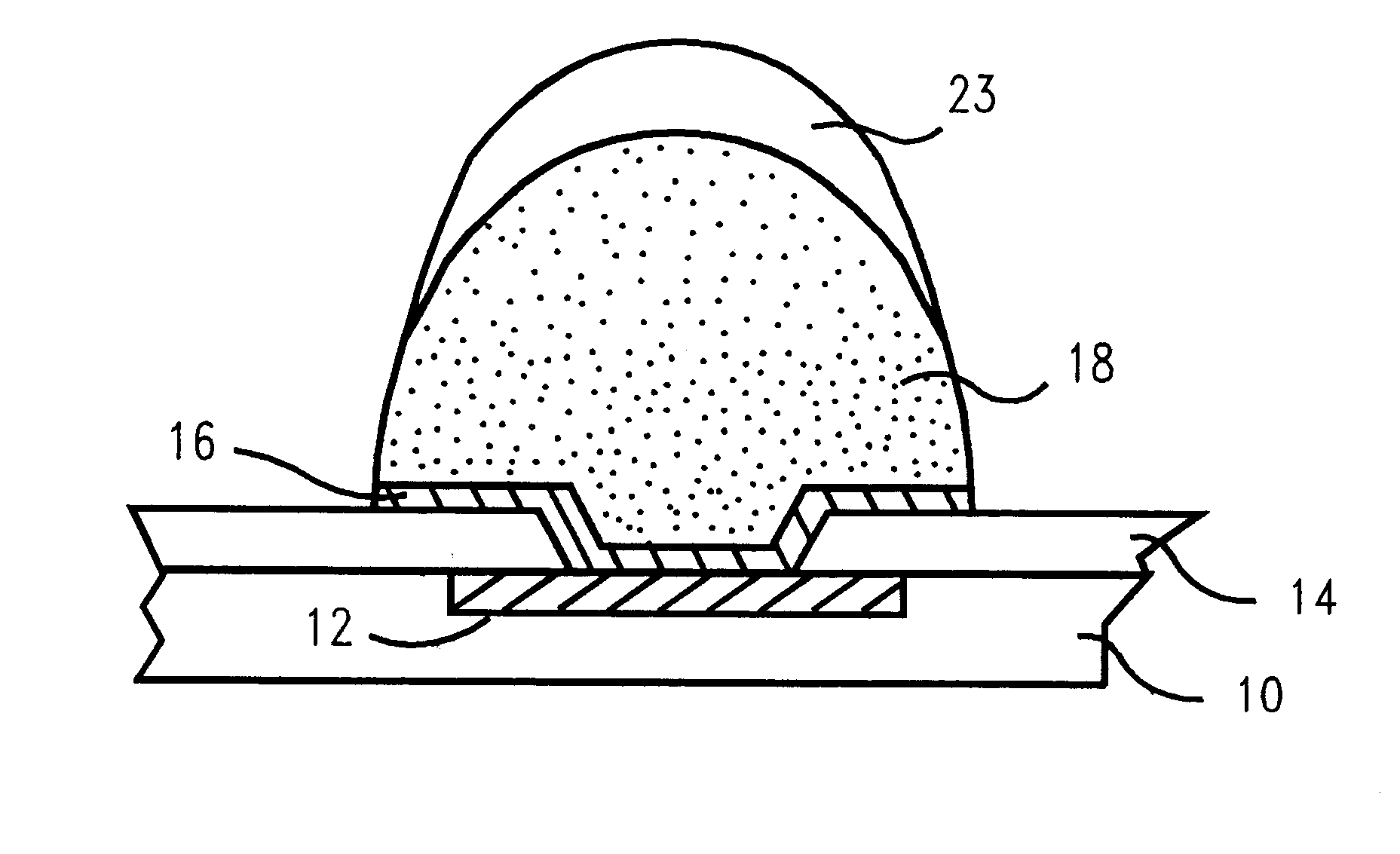

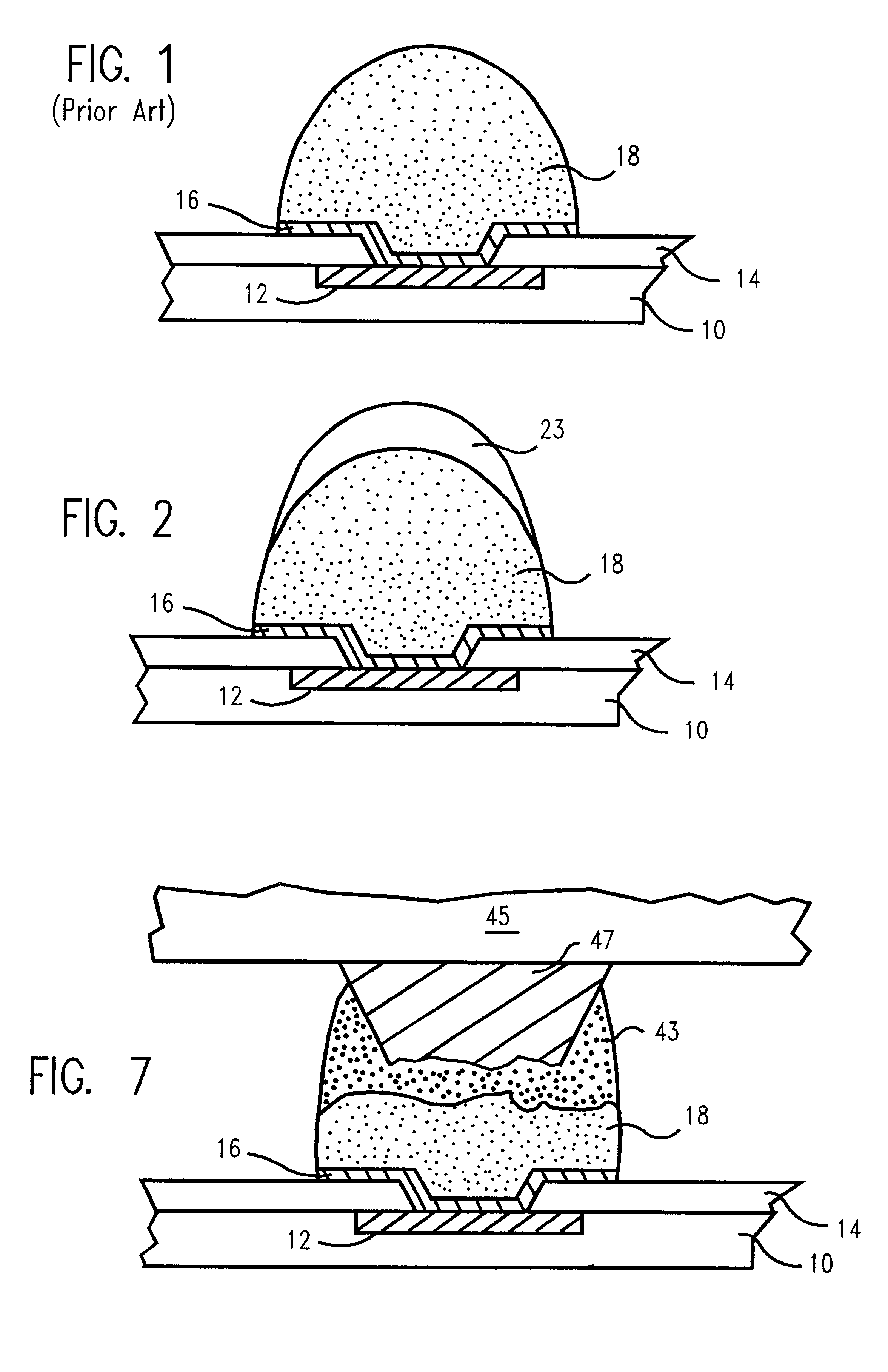

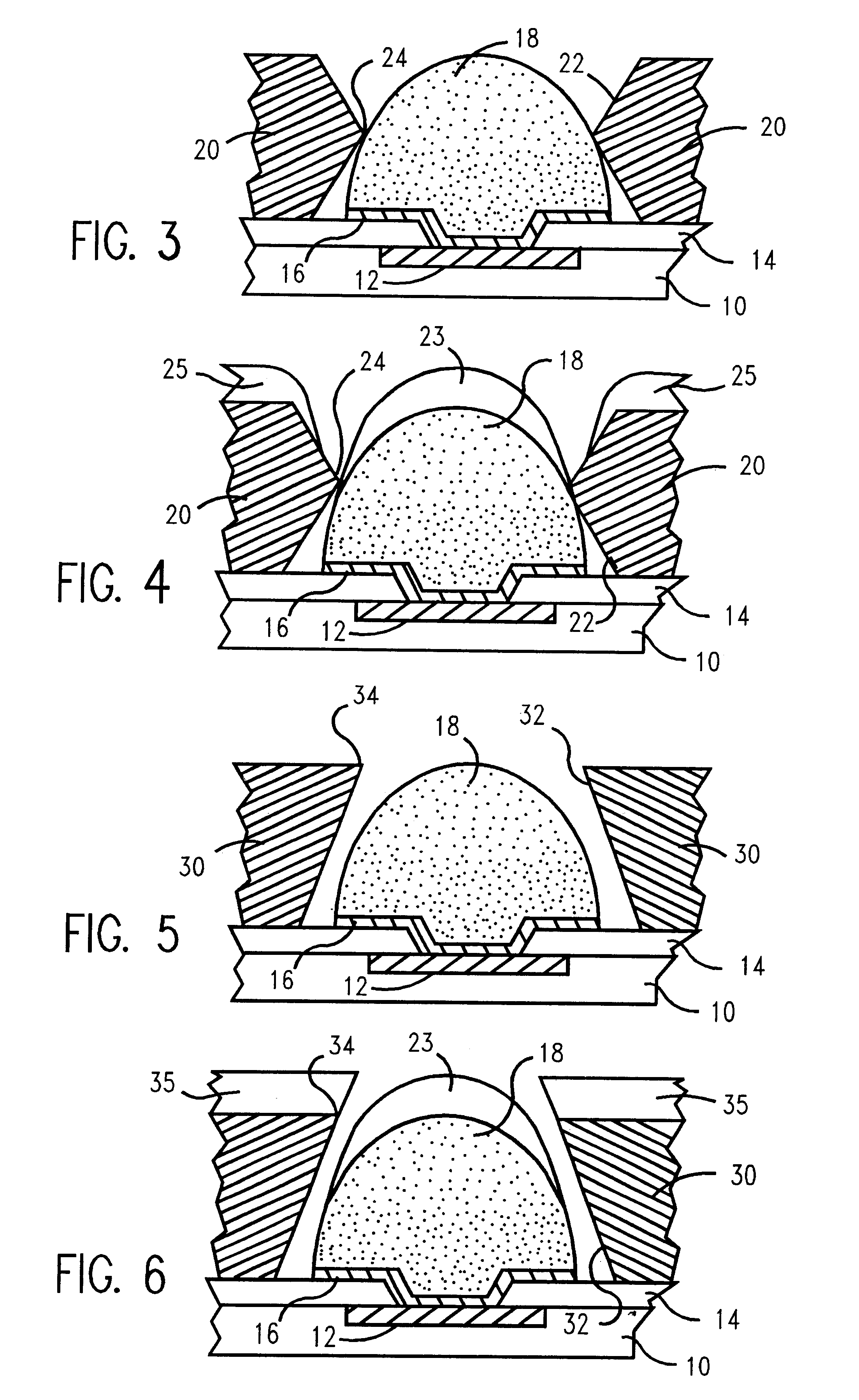

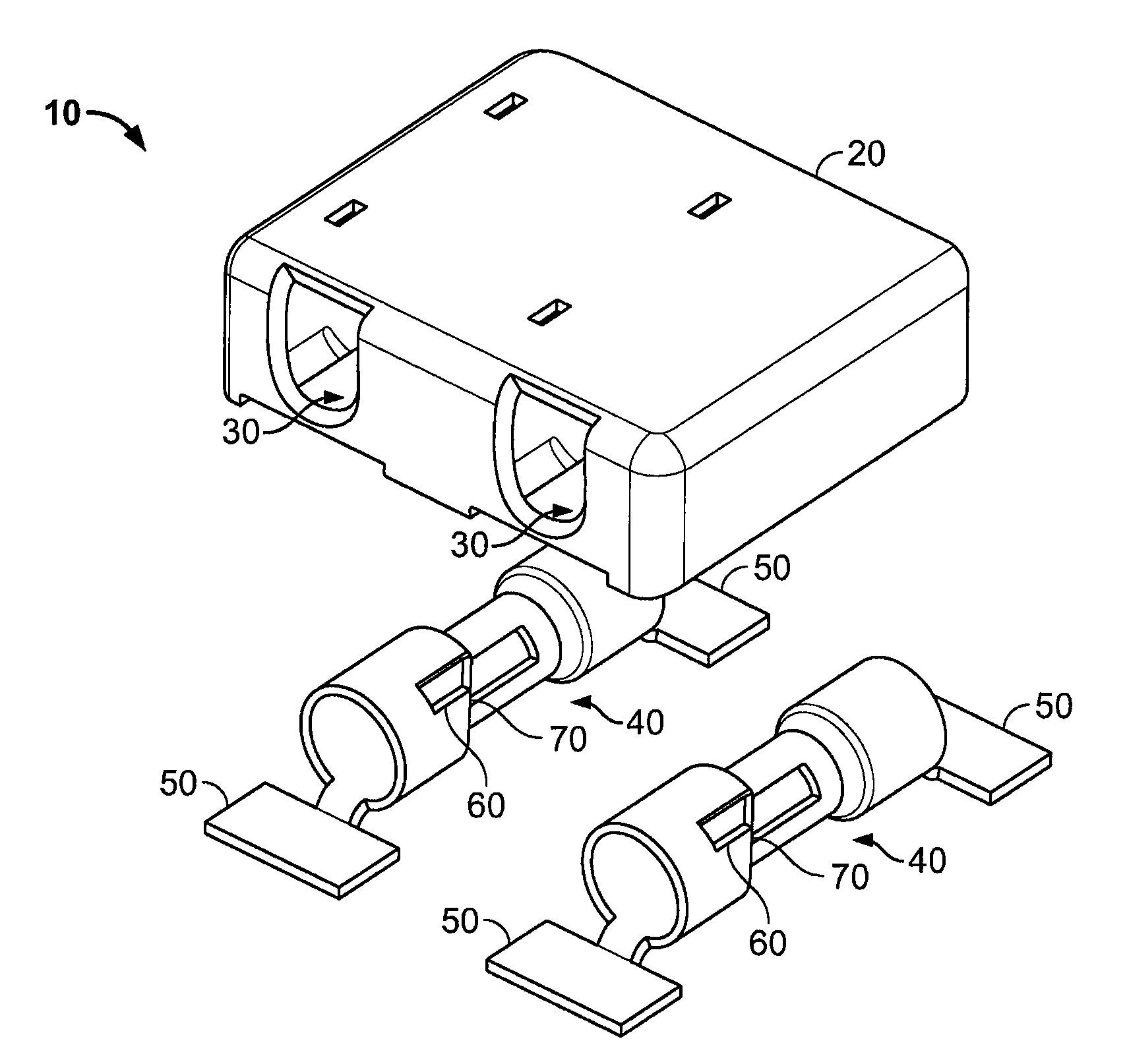

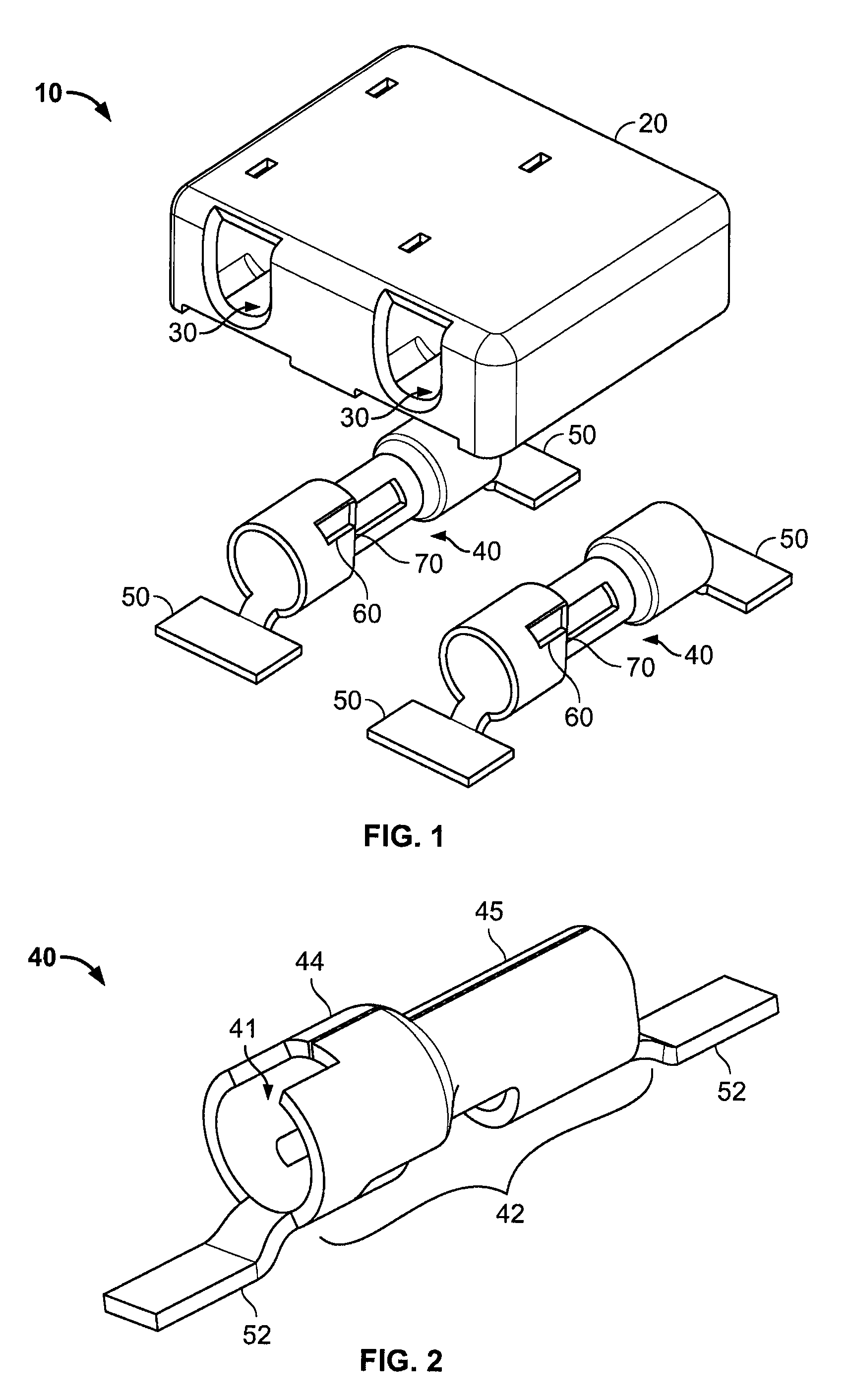

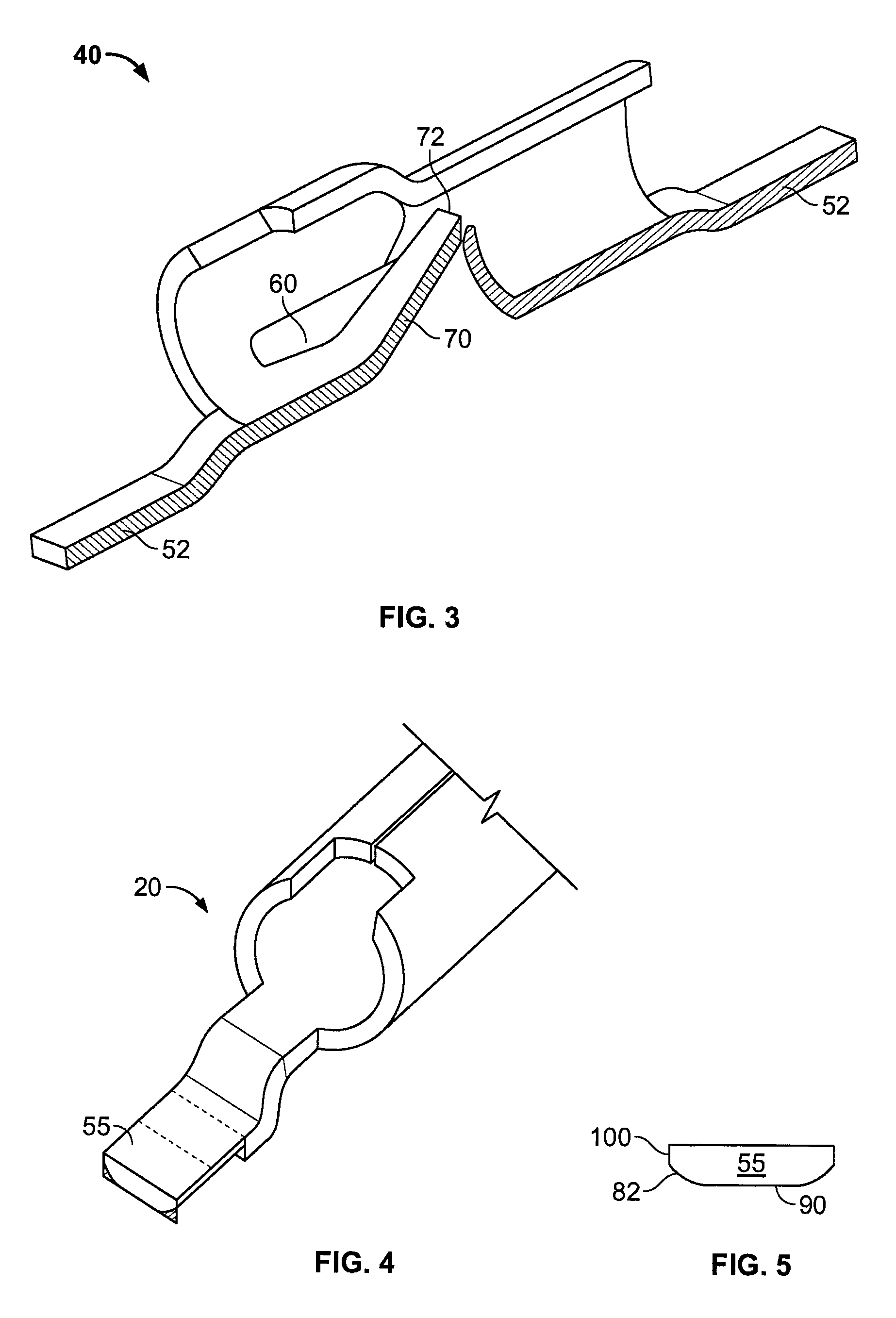

Electrical Connector For A Window Pane Of A Vehicle

InactiveUS20070224842A1Reduce stress concentrationMinimizes mechanical stressElectric discharge tubesSoldered/welded conductive connectionsElectrical conductorCoupling

A window pane has a substrate formed from glass and includes an electrical device including an electrical conductor. An electrical connector is operatively connected to and in electrical communication with the conductor for transferring electrical energy to the conductor. An electrical connector is bonded to the electrical conductor and has a first interacting portion. A terminal is disposed adjacent to the electrical connector and has a second interacting portion for interacting with the first interacting portion to mechanically couple the electrical connector and the terminal. The substrate has a first coefficient of thermal expansion and the connector has a second coefficient of thermal expansion. A difference between the first and second coefficients of thermal expansion is equal to or less than 5×10−6 / ° C. Due to the mechanical coupling between the connector and the terminal, the terminal and connector are less prone to bending, breakage, or delamination than conventional connector structures.

Owner:AGC AUTOMOTIVE AMERICAS

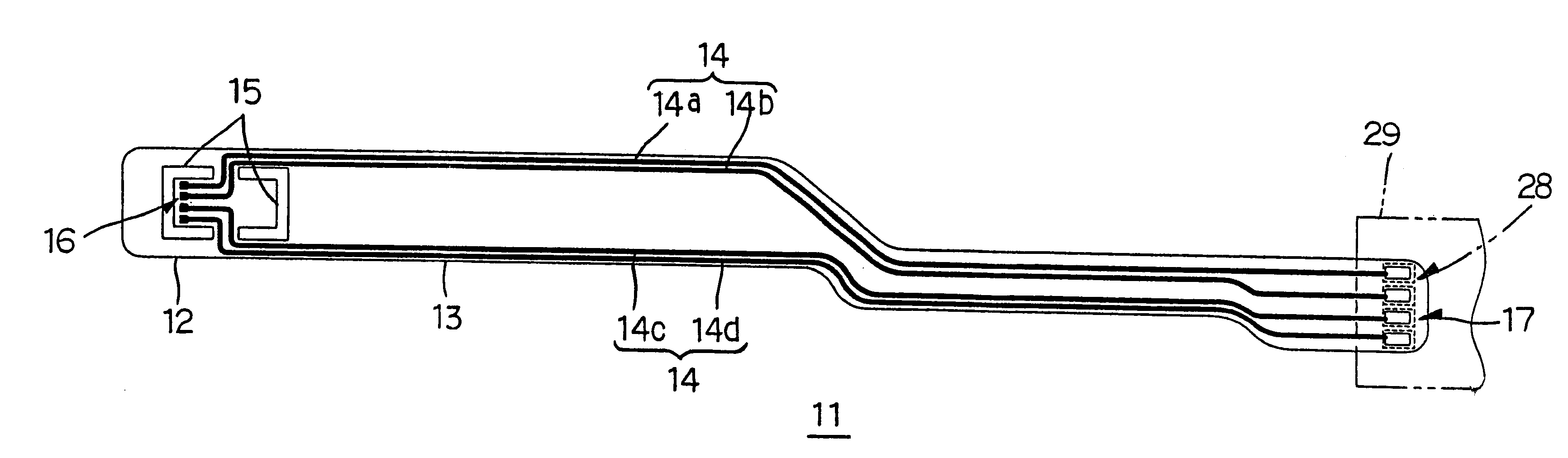

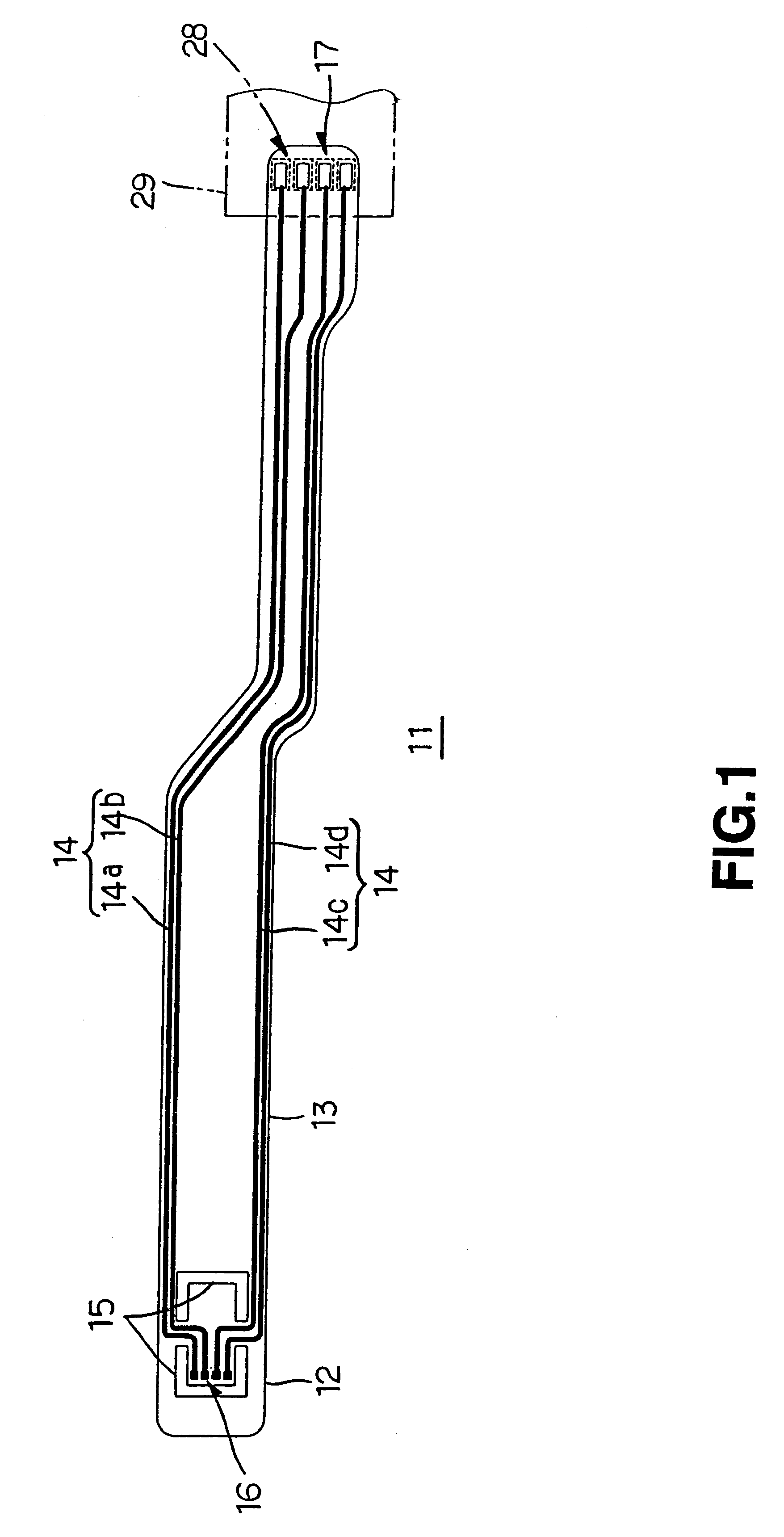

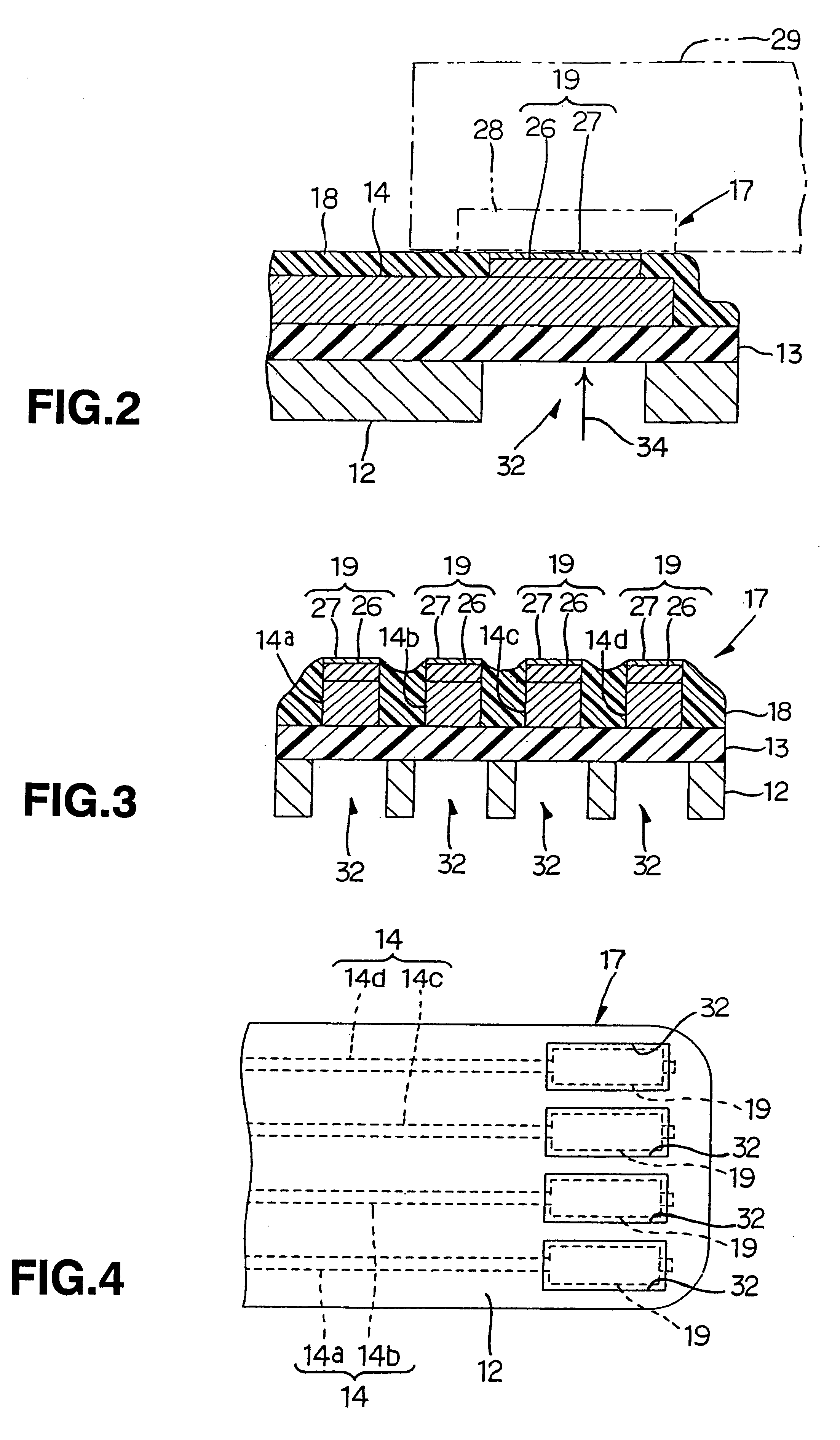

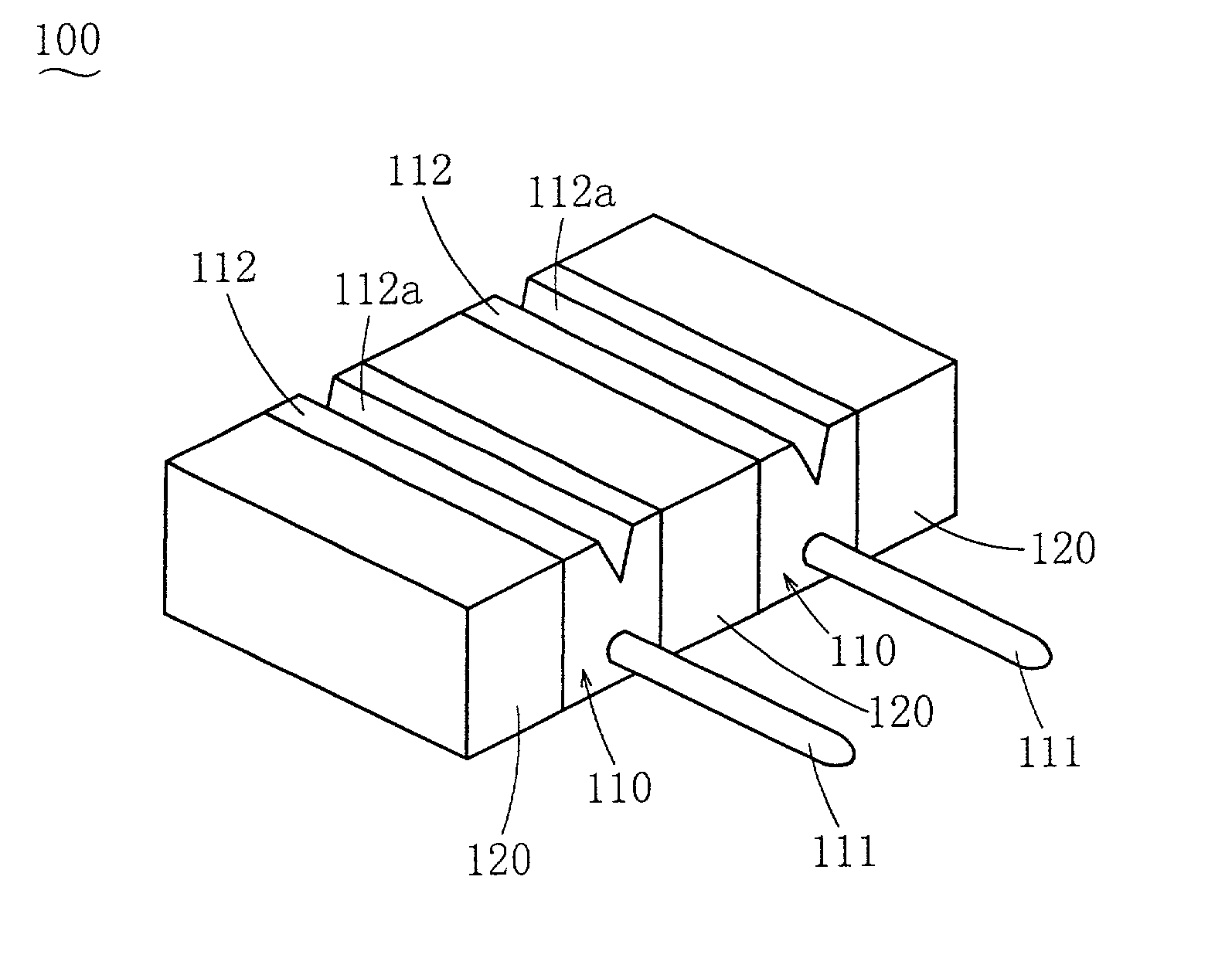

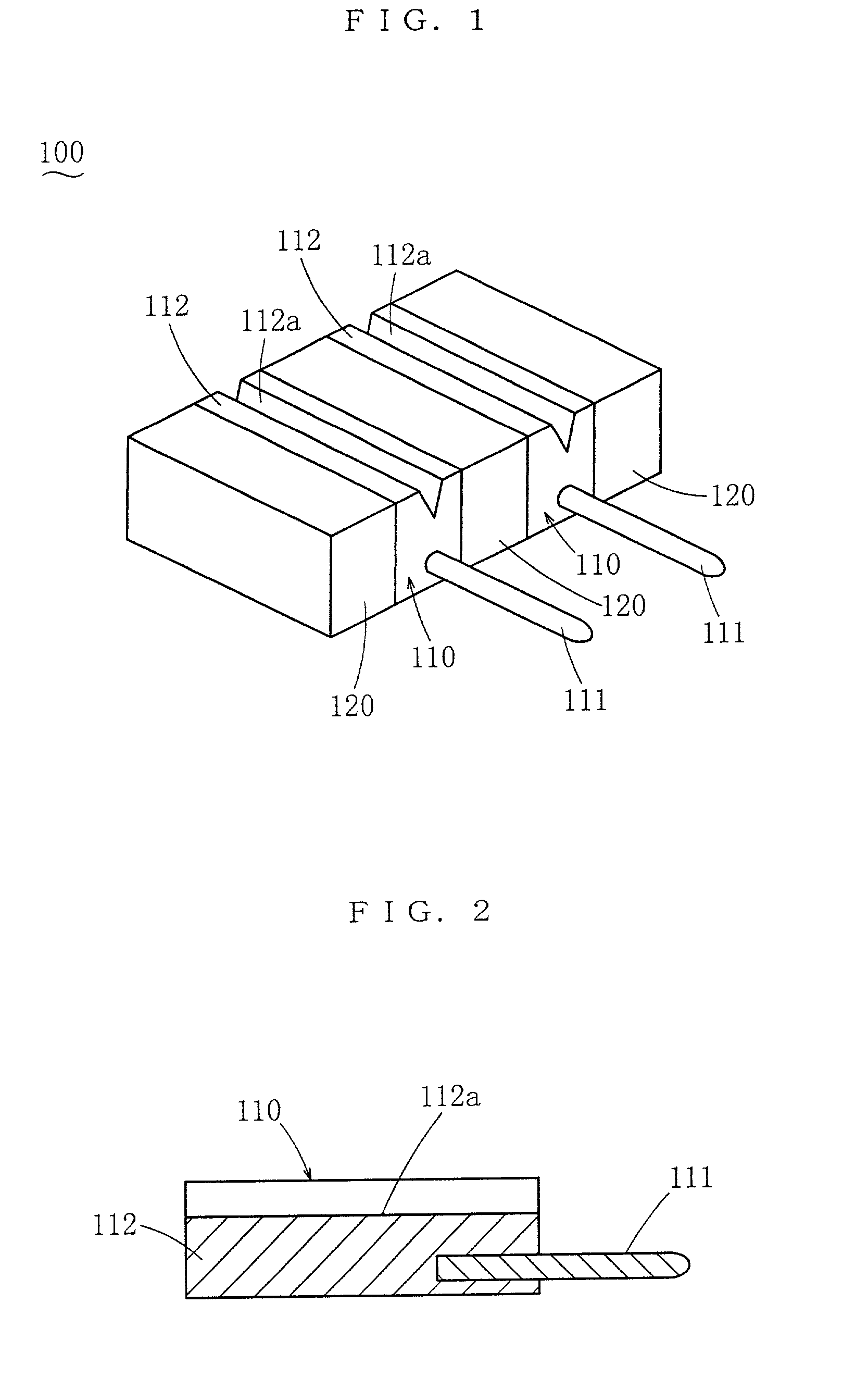

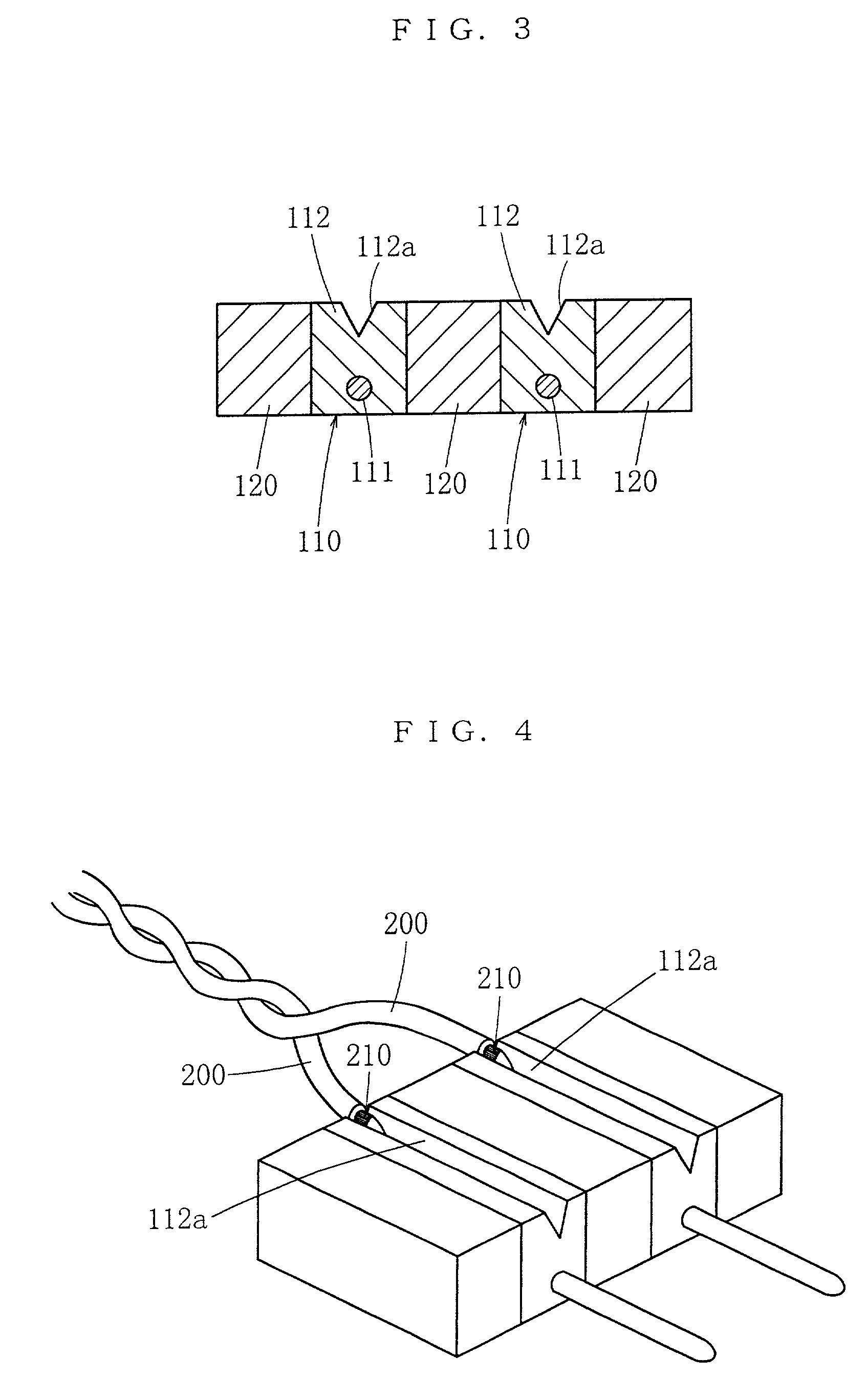

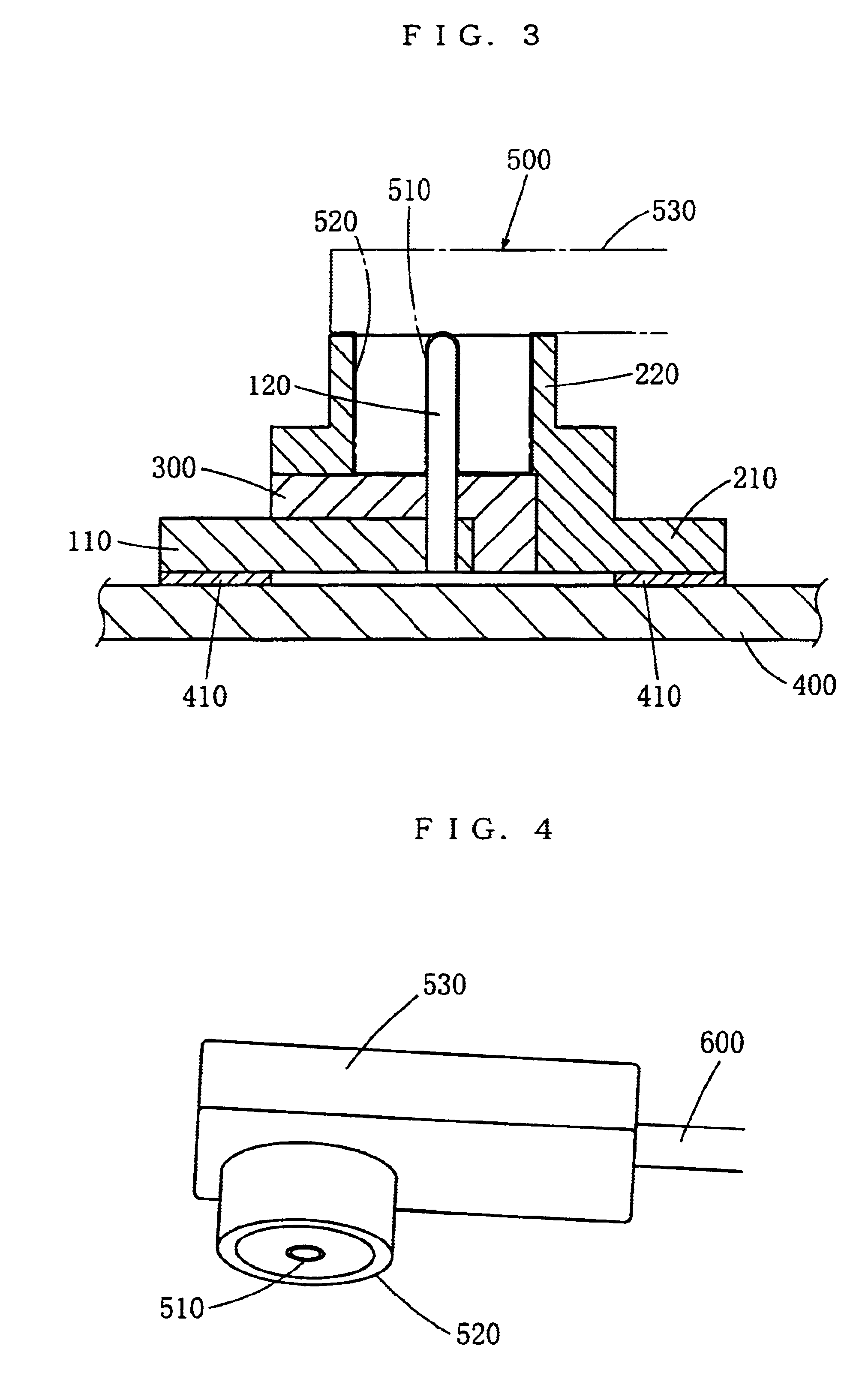

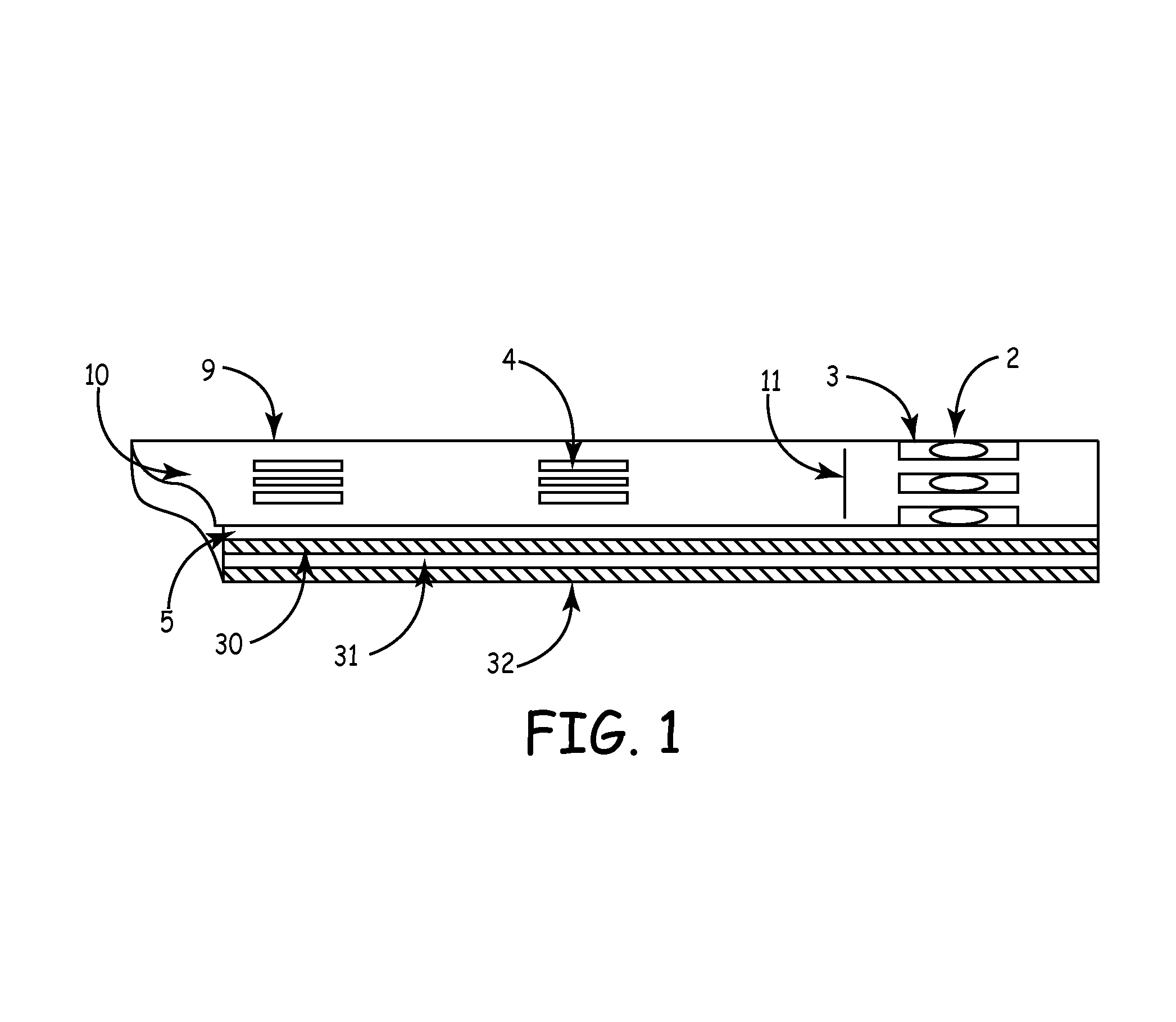

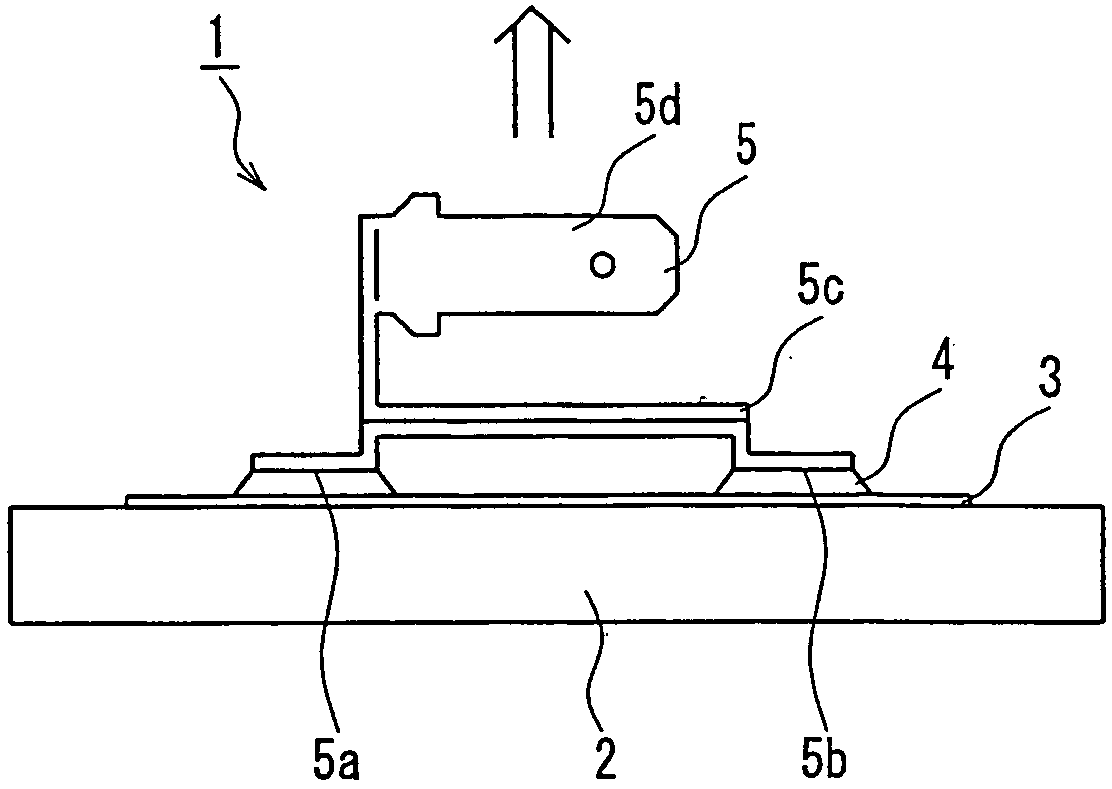

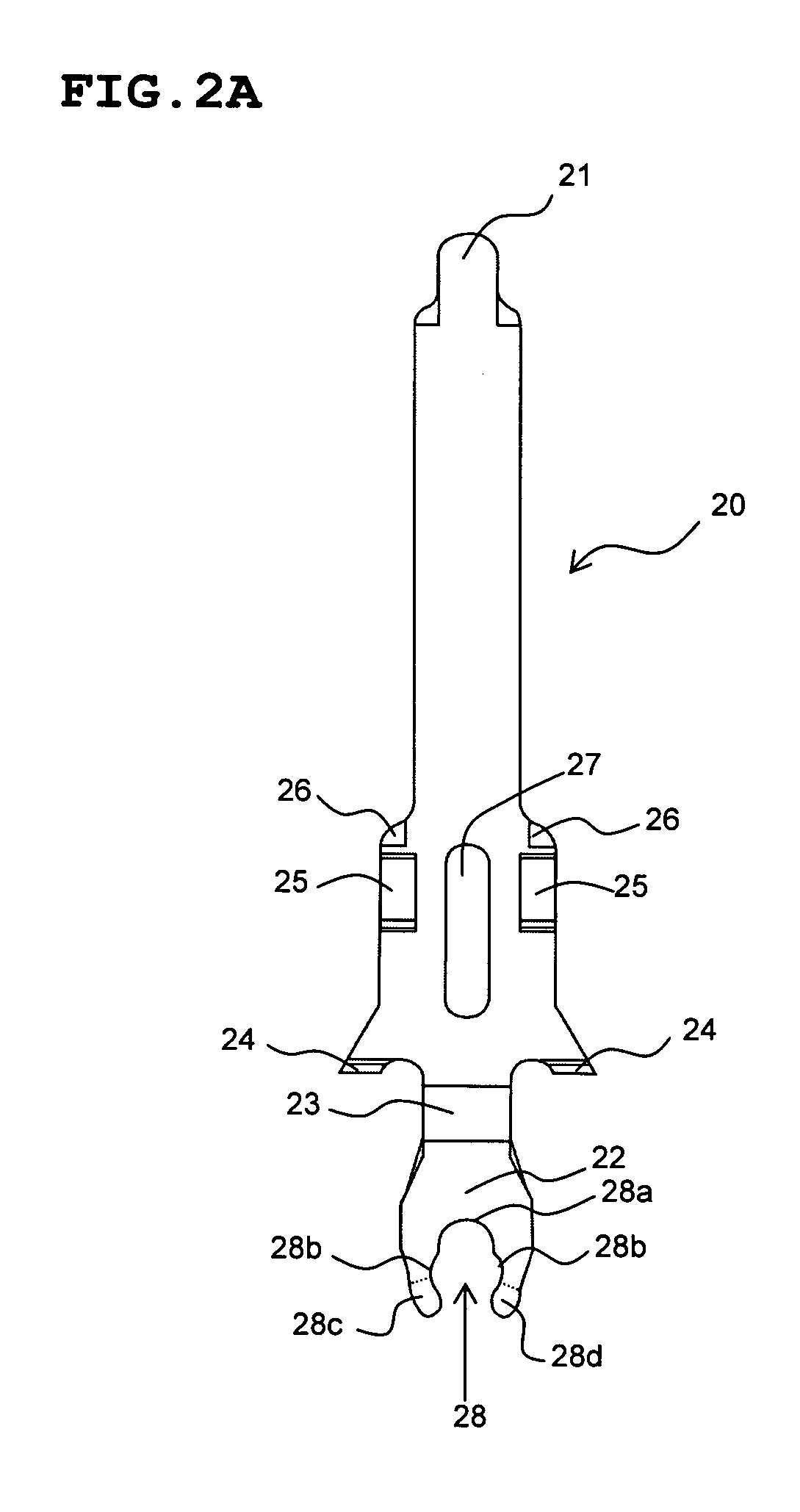

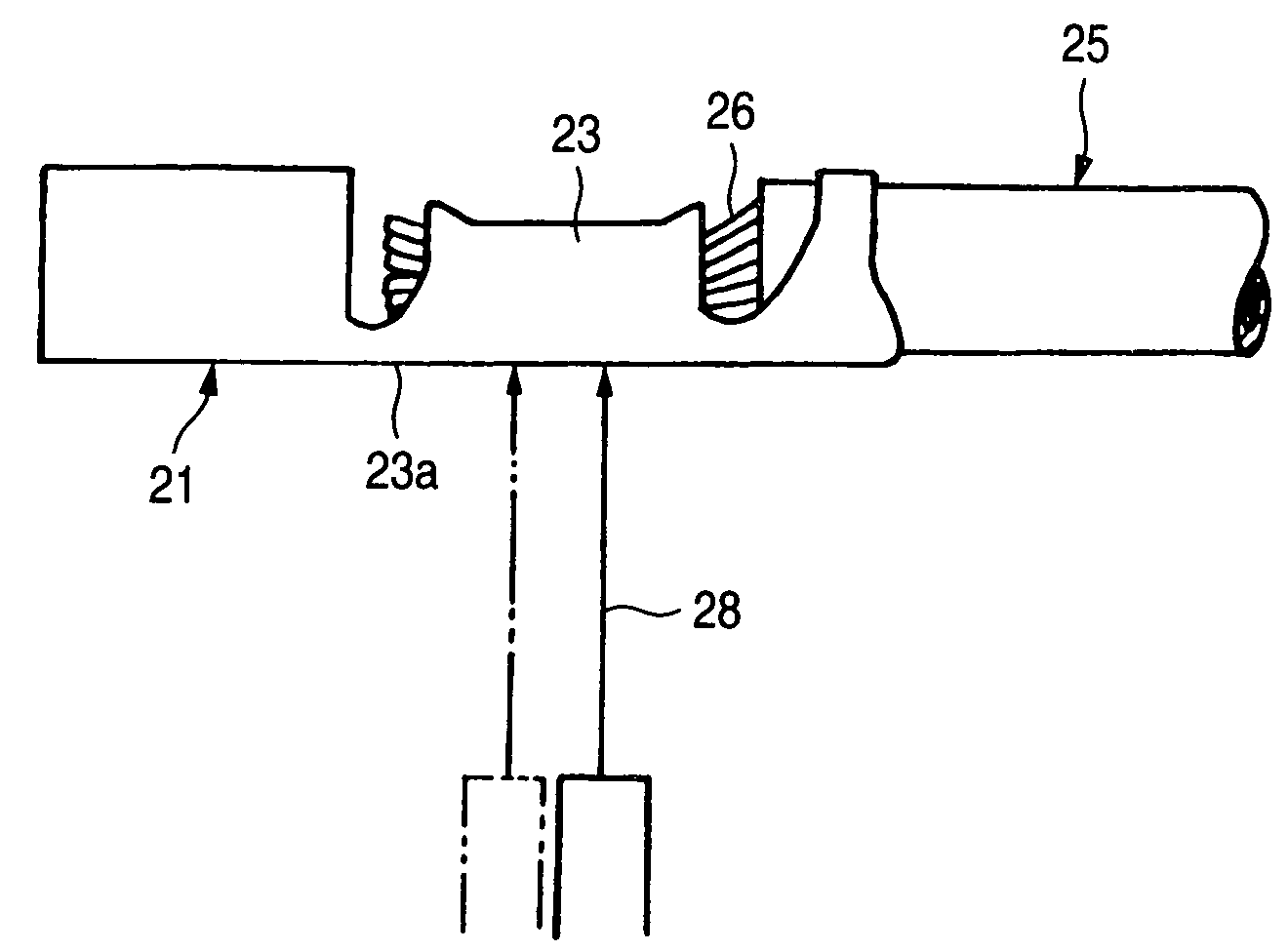

Suspension board with circuit

InactiveUS6399899B1High strengthSimple structureRelieving strain on wire connectionRecord information storageExternal connectionEngineering

To provide a suspension board with circuit that enables its terminals to be bonded to the other terminals with sufficient strength with simple structure, to ensure sufficient bonding reliability, the suspension board with circuit 11 includes a suspension board 12, a base layer 13 formed on the suspension board 12, and a conductive layer 14 formed on the base layer 13 and a cover layer 18 with which the conductive layer 14 is covered, wherein external connection terminals 17 to be bonded to terminals 28 of a read / write board 29 are formed without the suspension board 12 and / or the base layer 13 being formed.

Owner:NITTO DENKO CORP

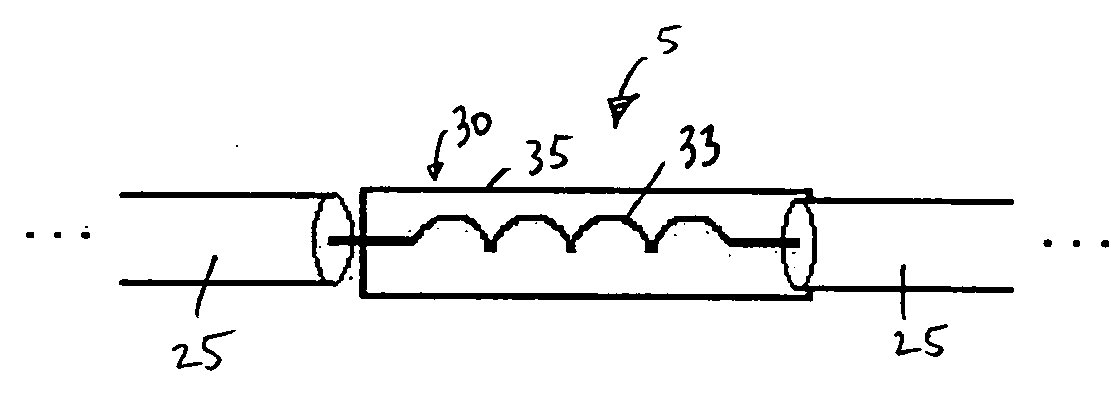

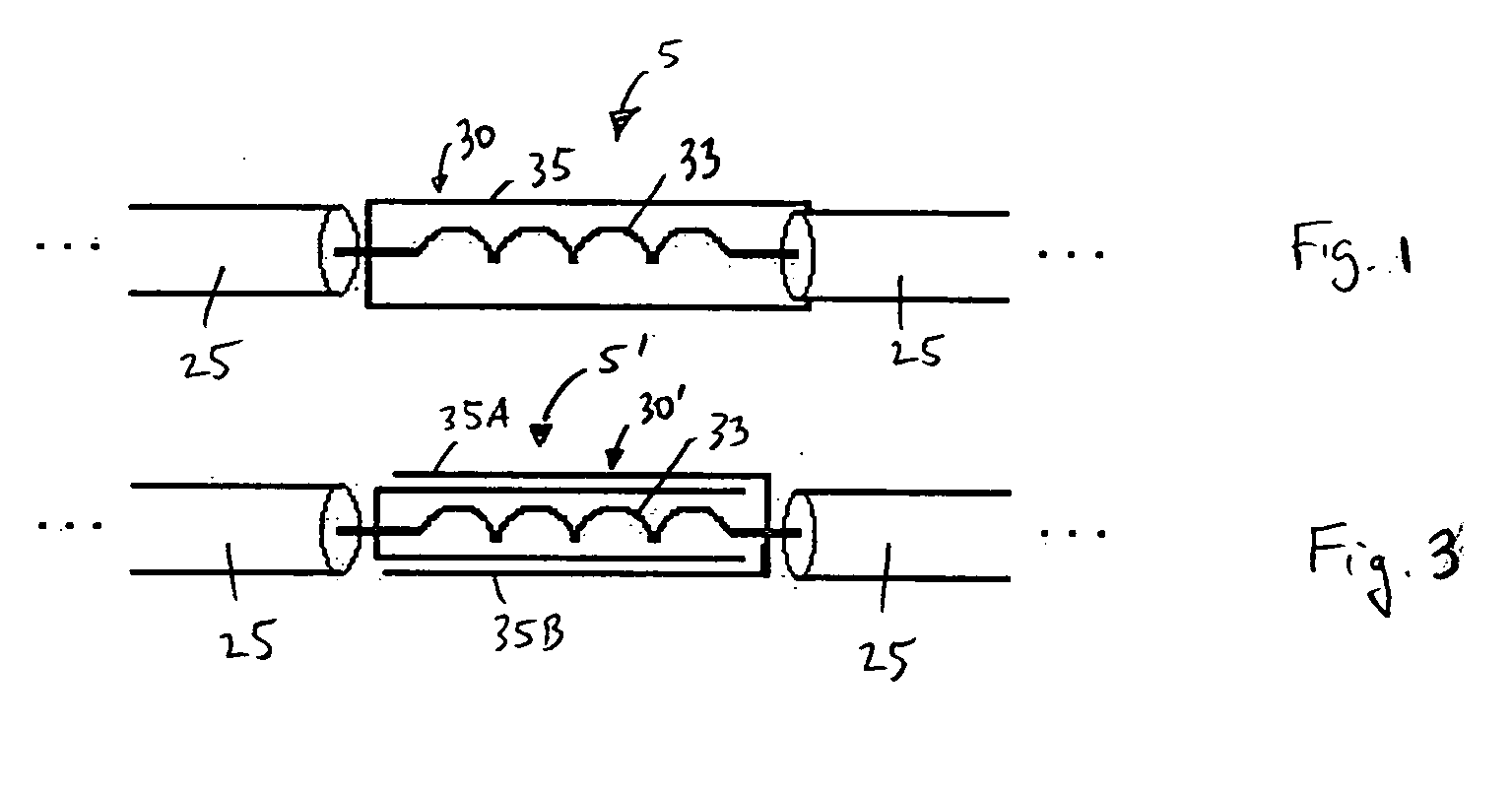

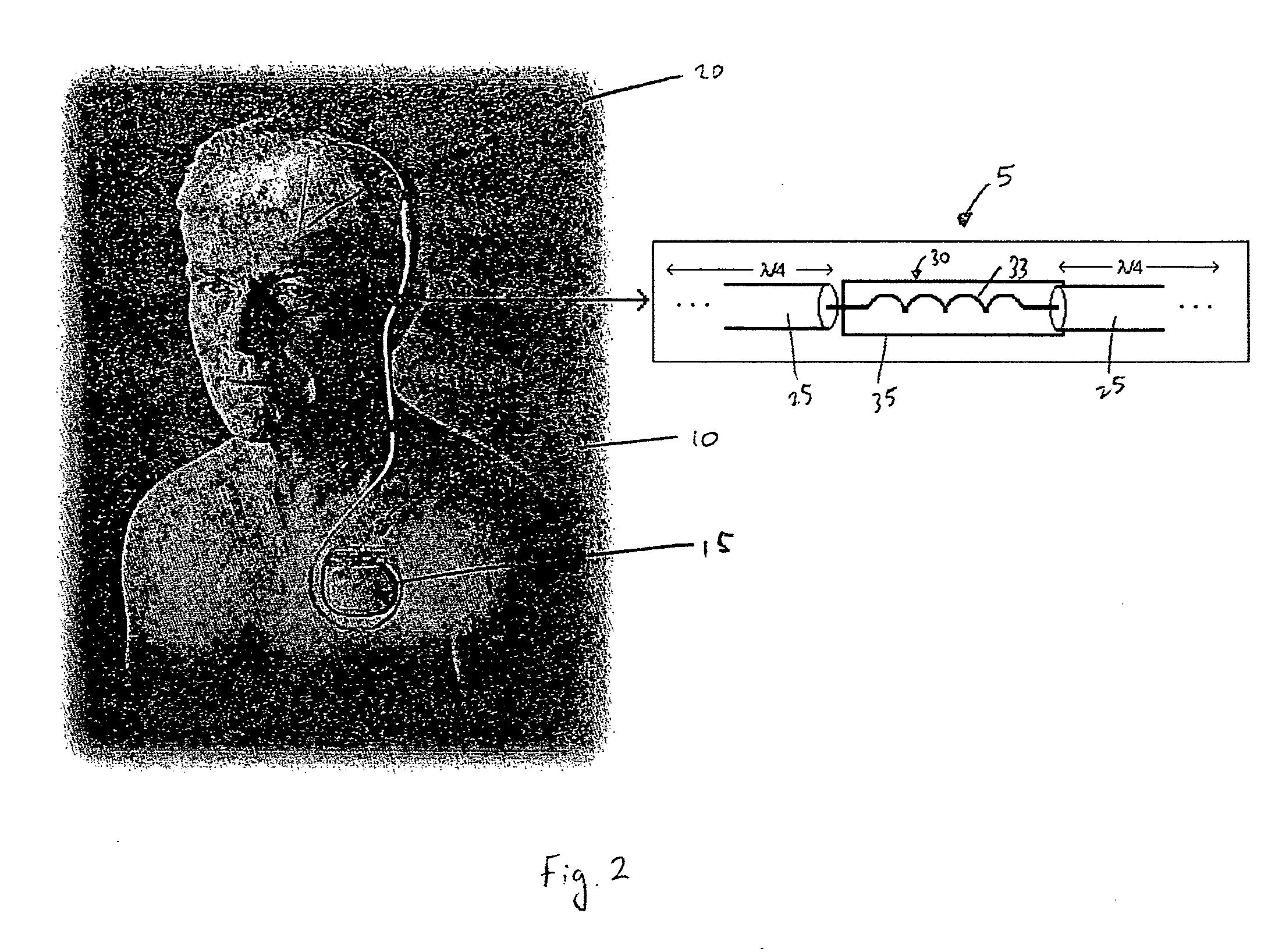

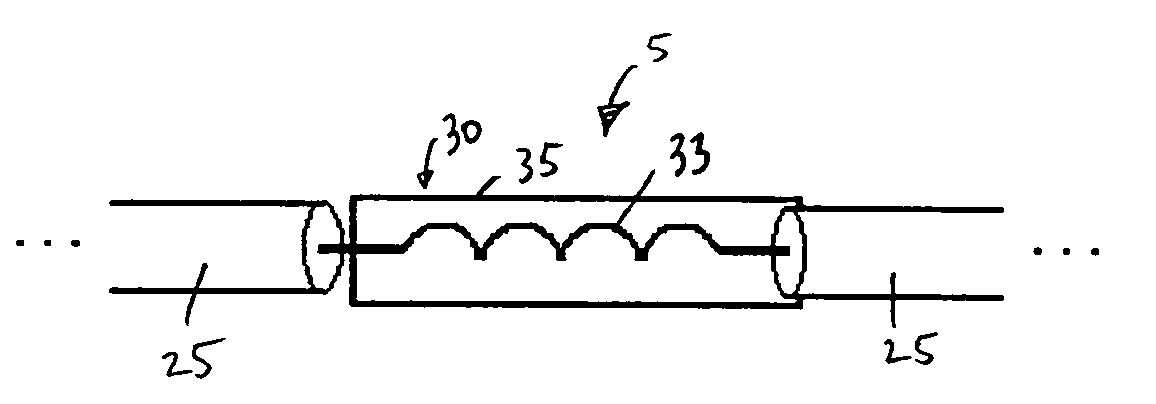

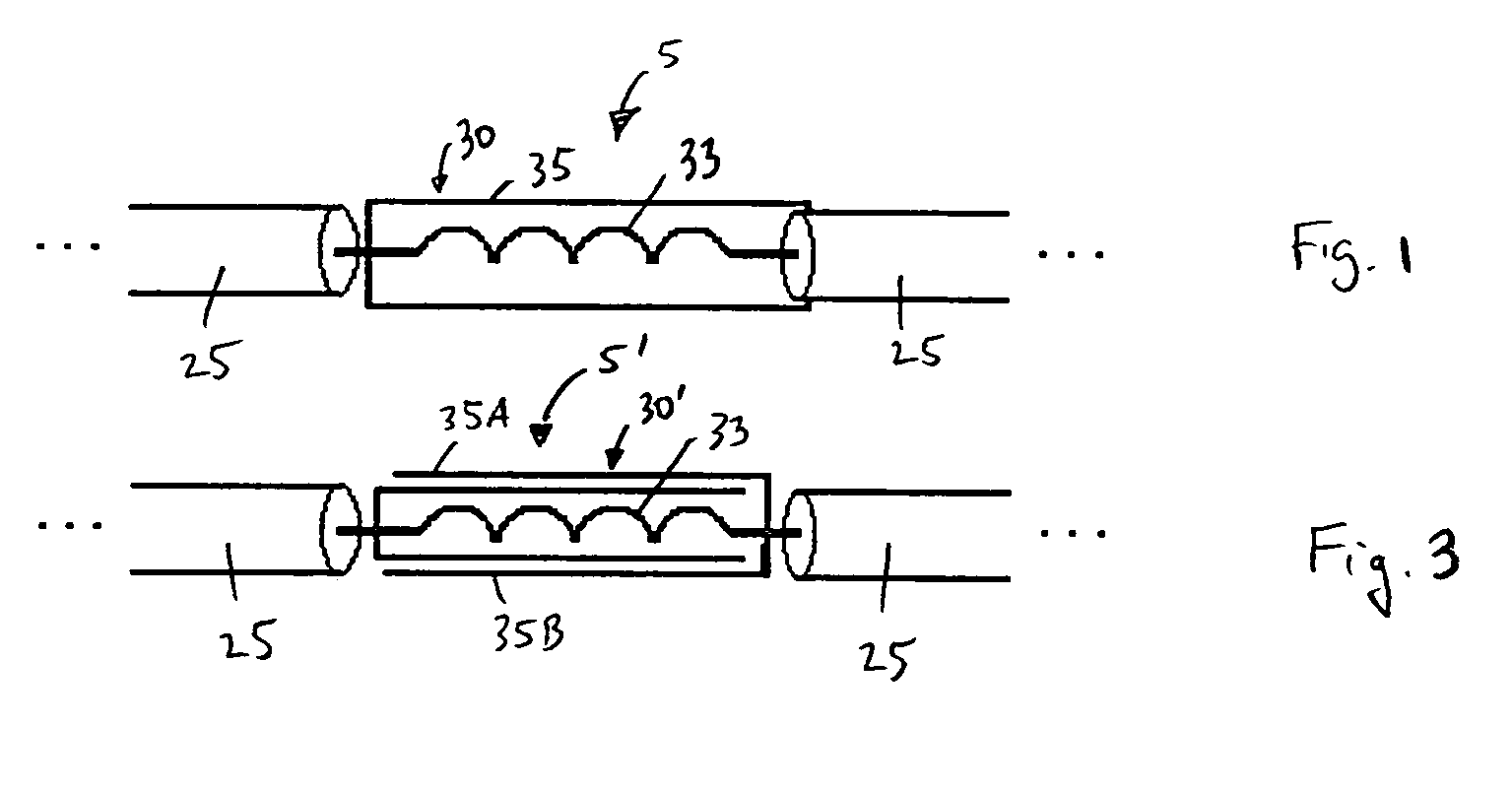

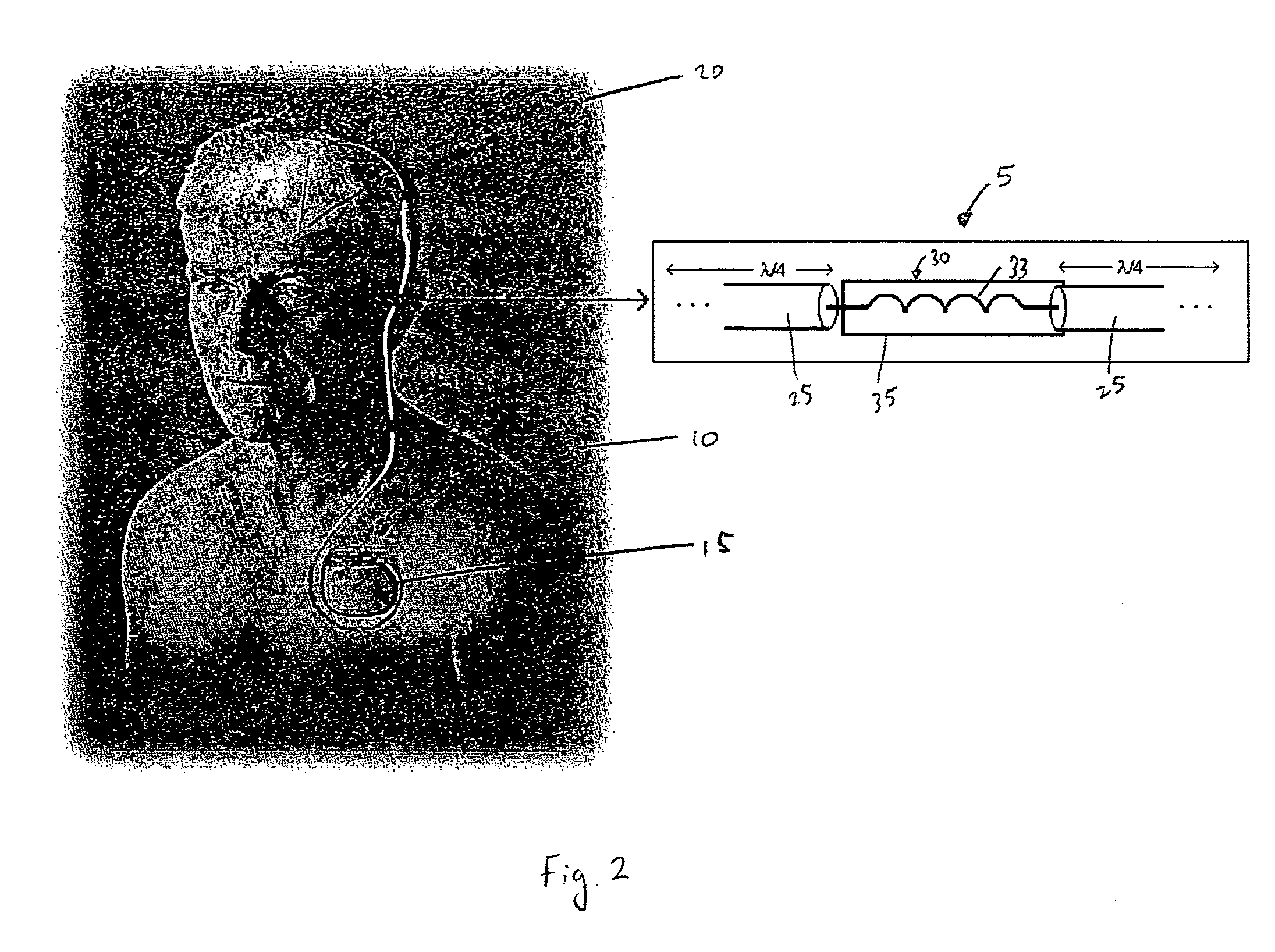

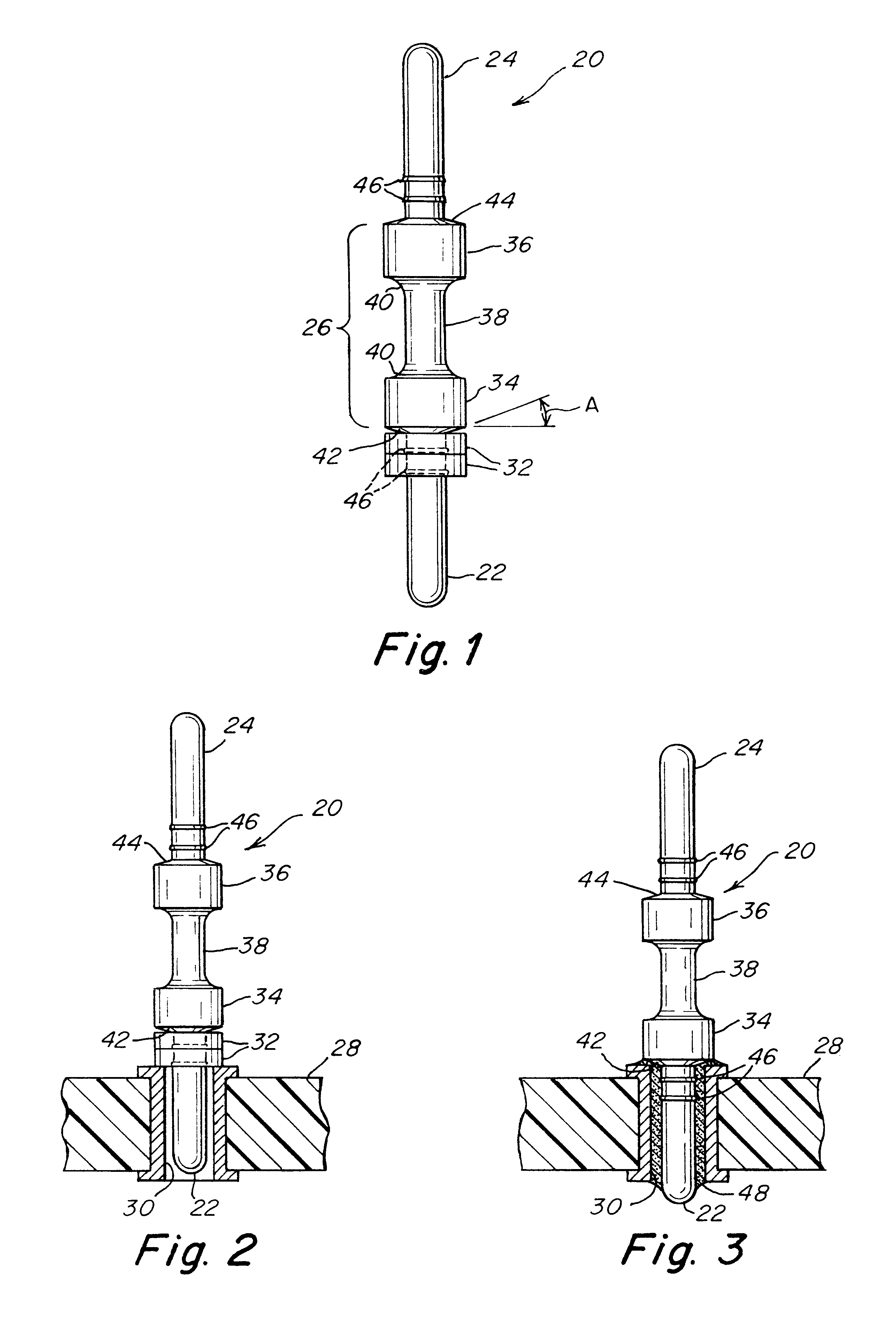

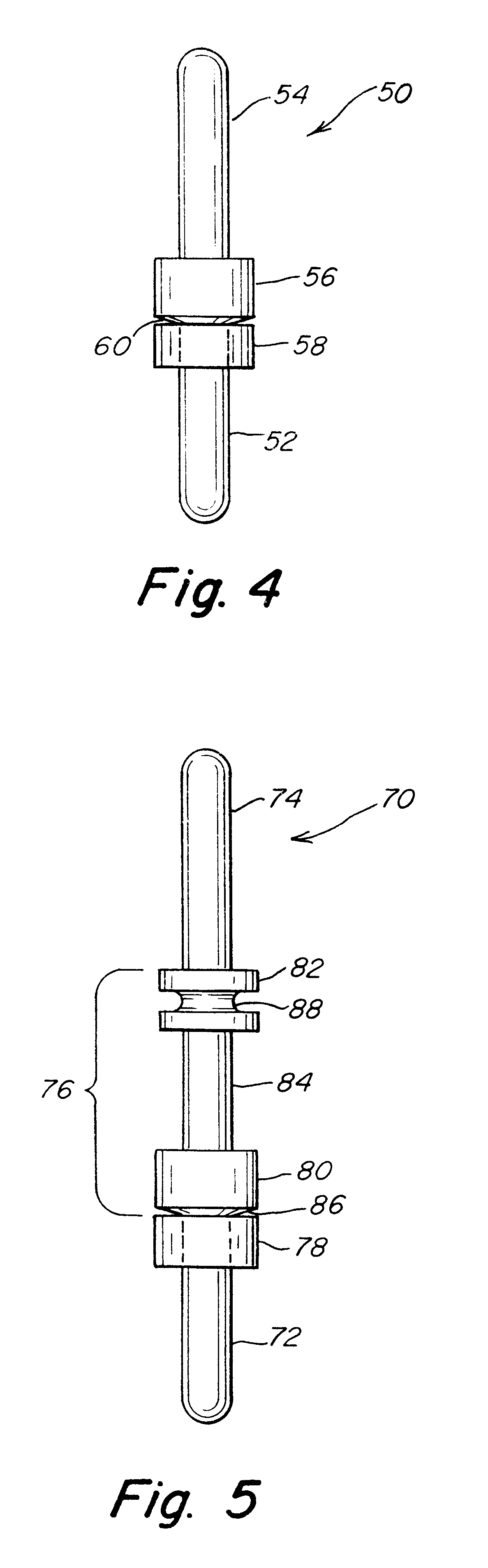

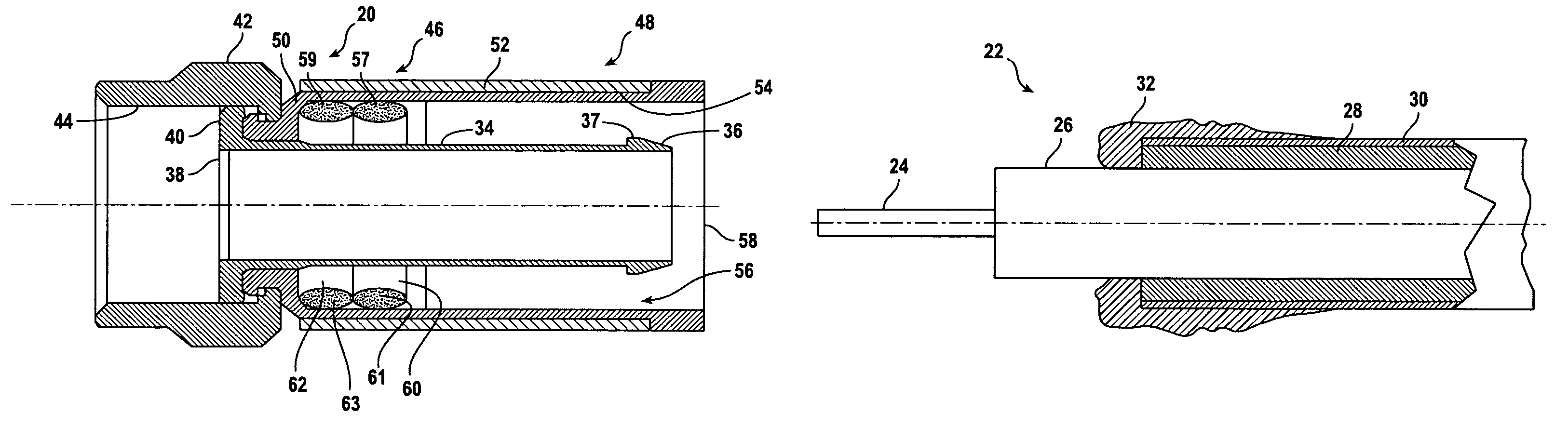

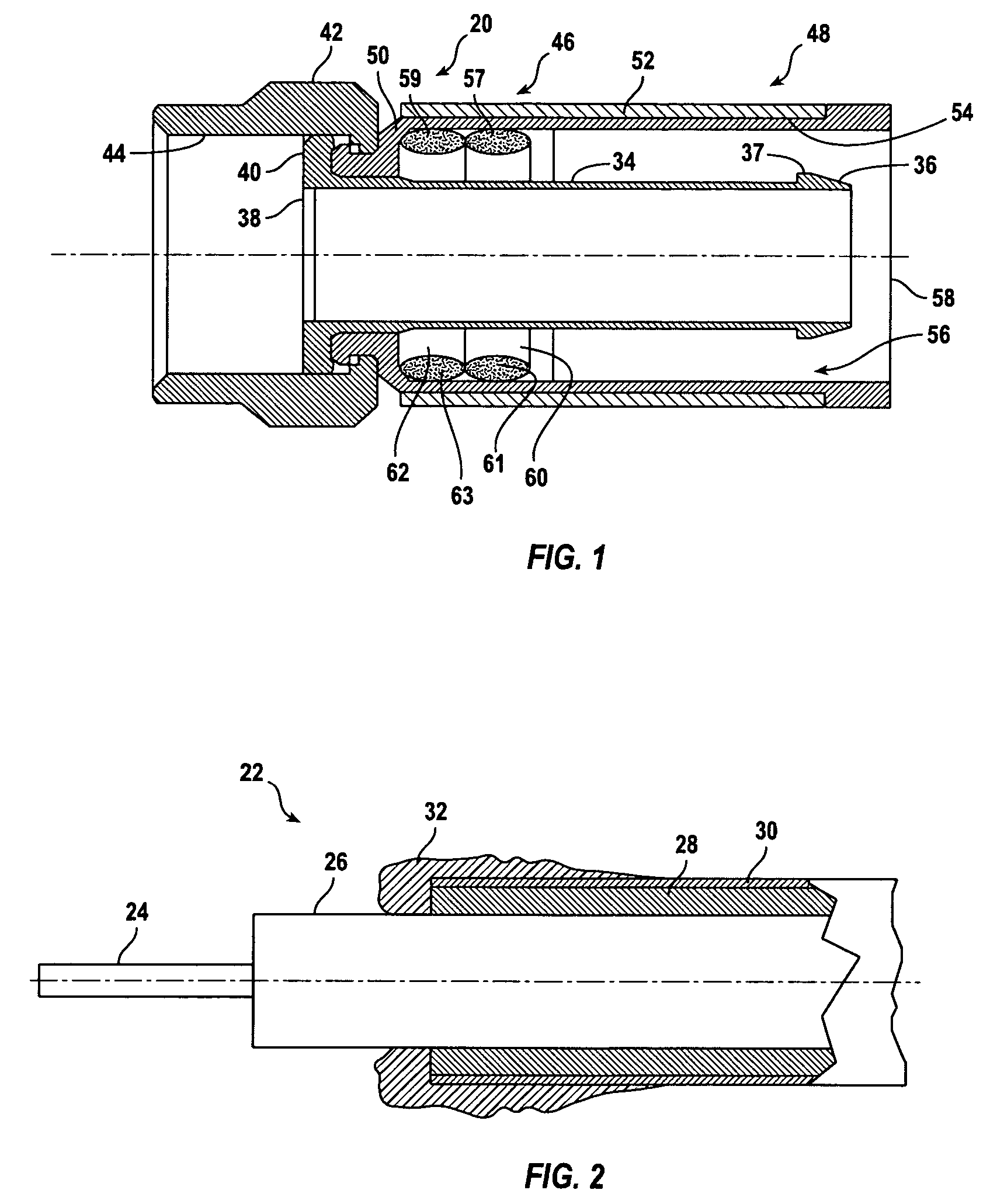

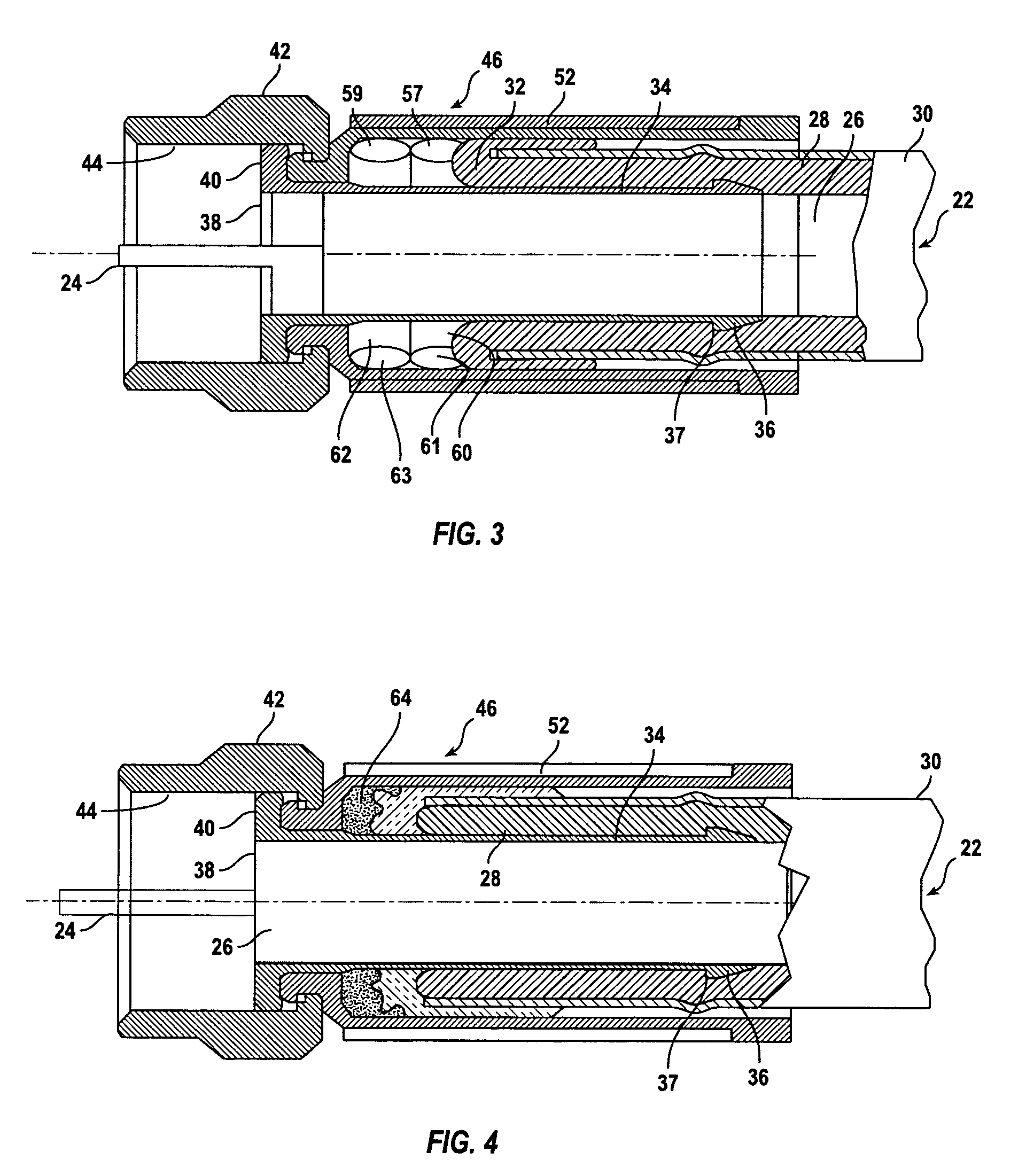

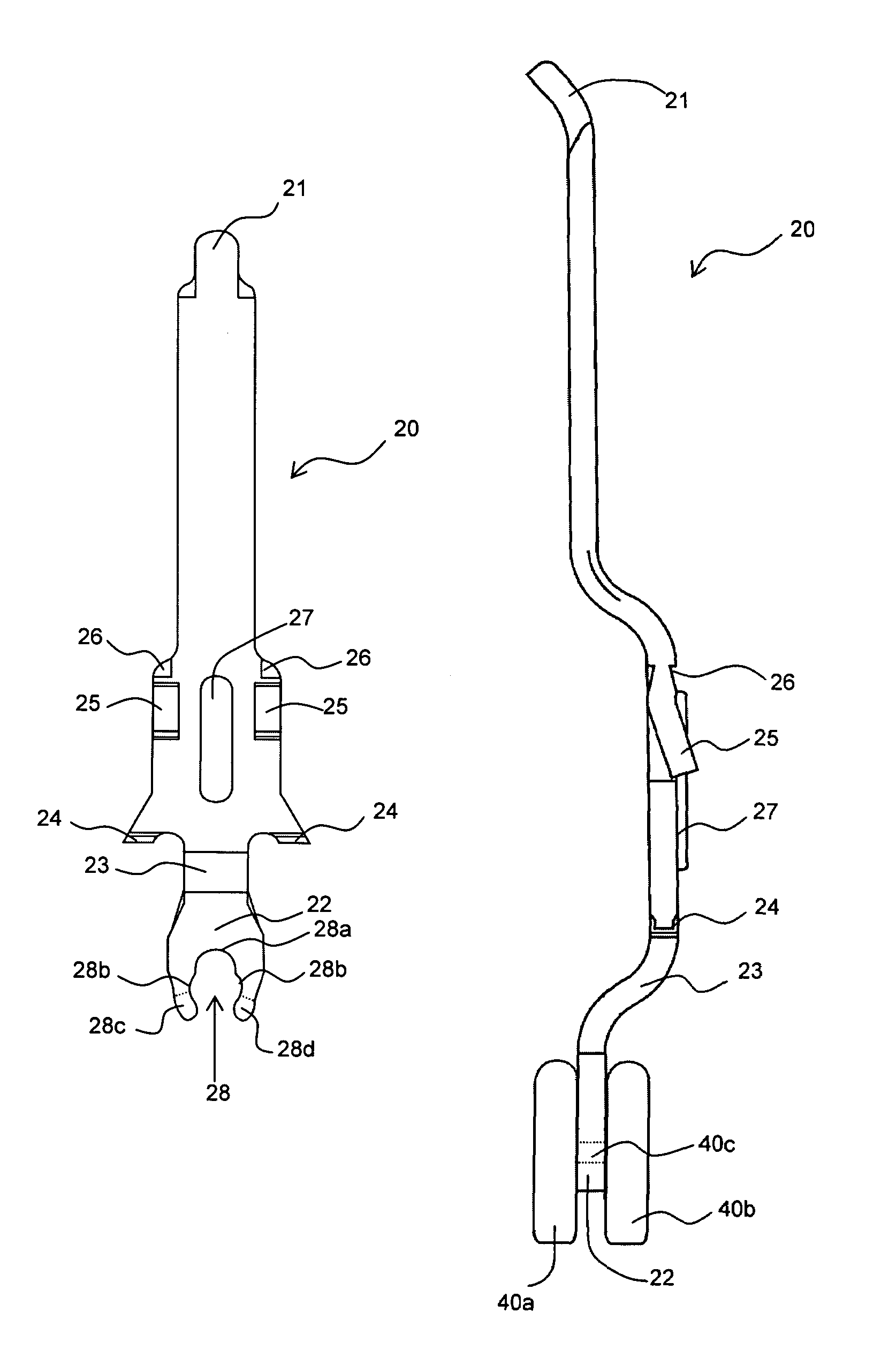

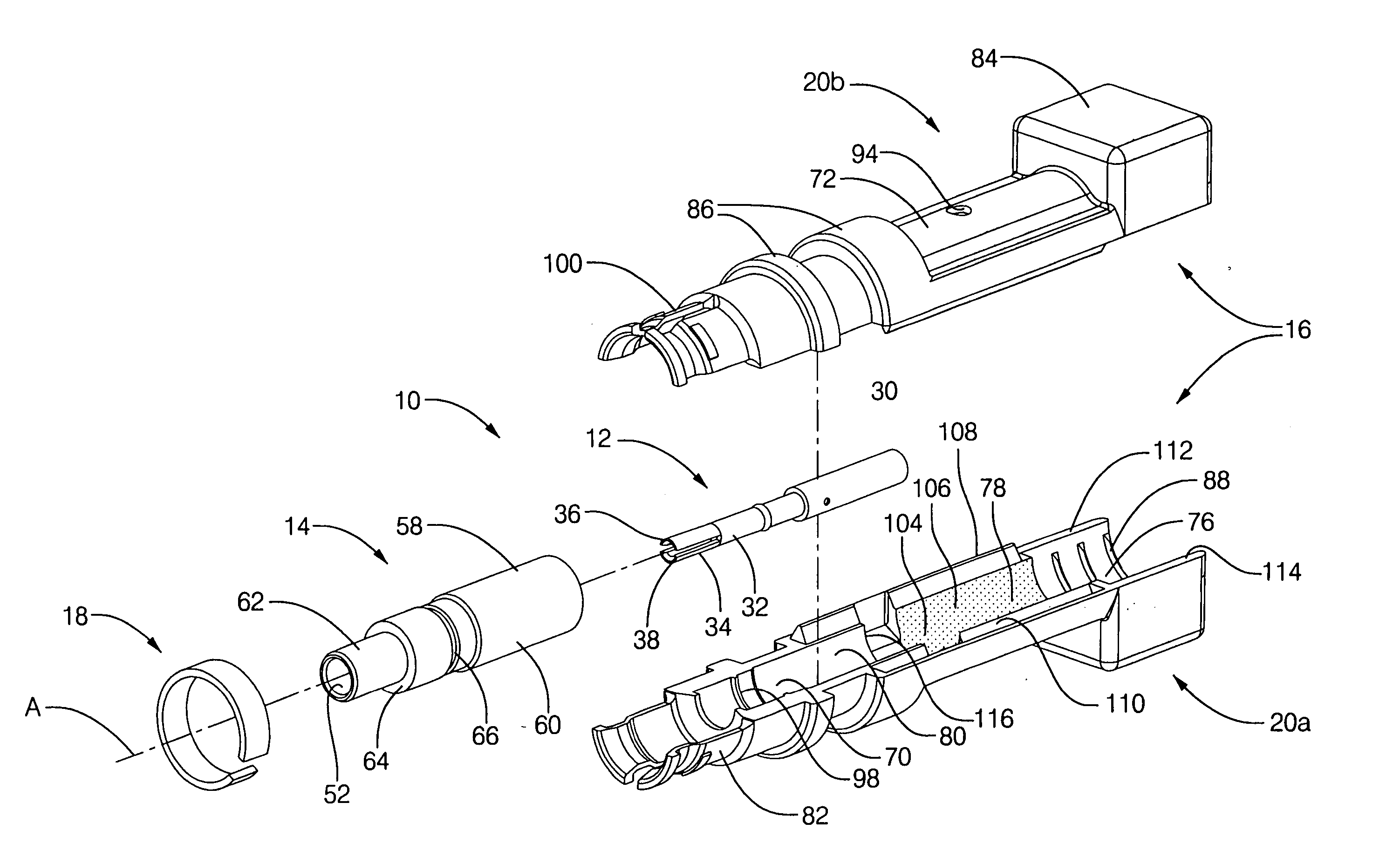

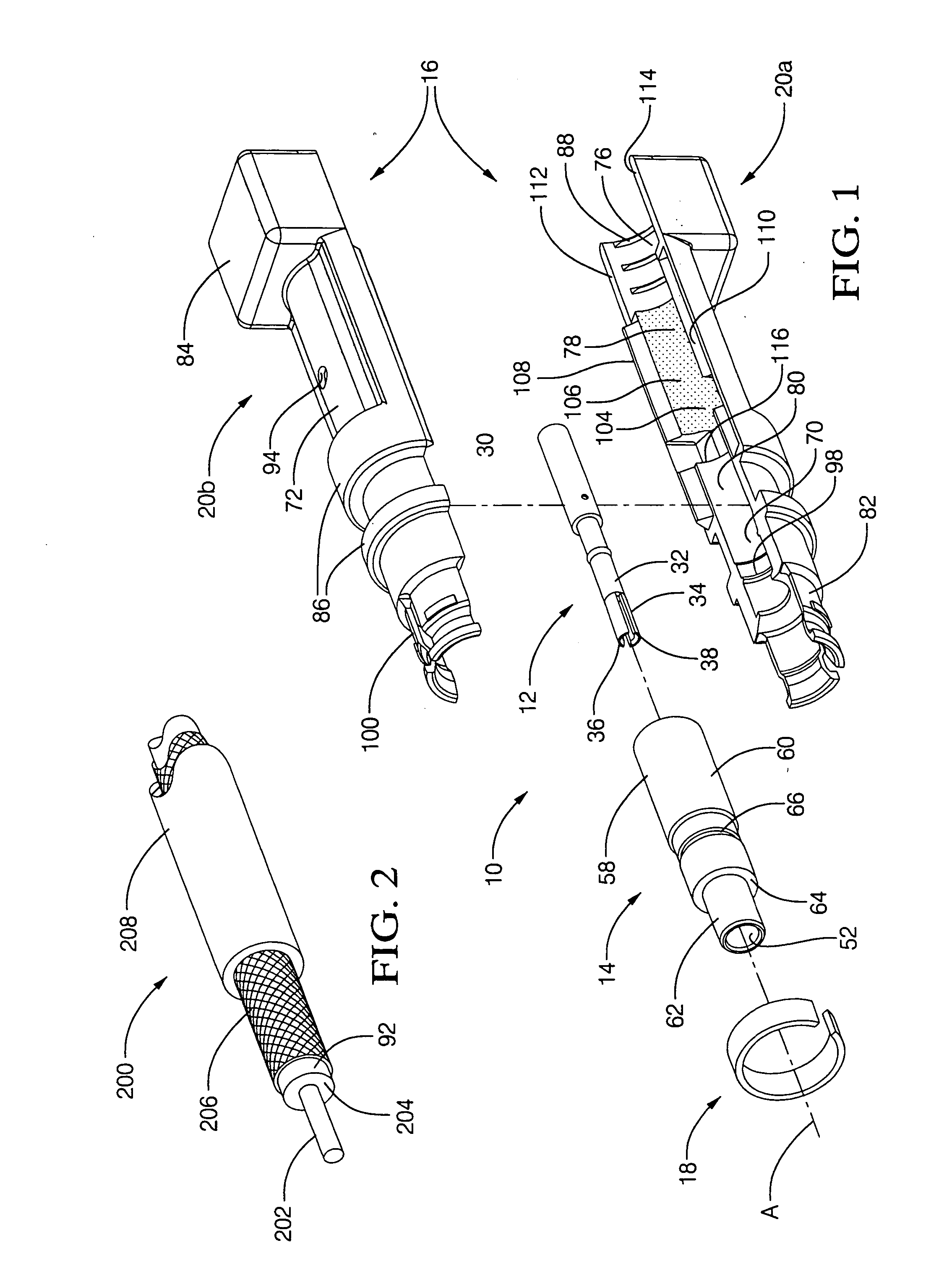

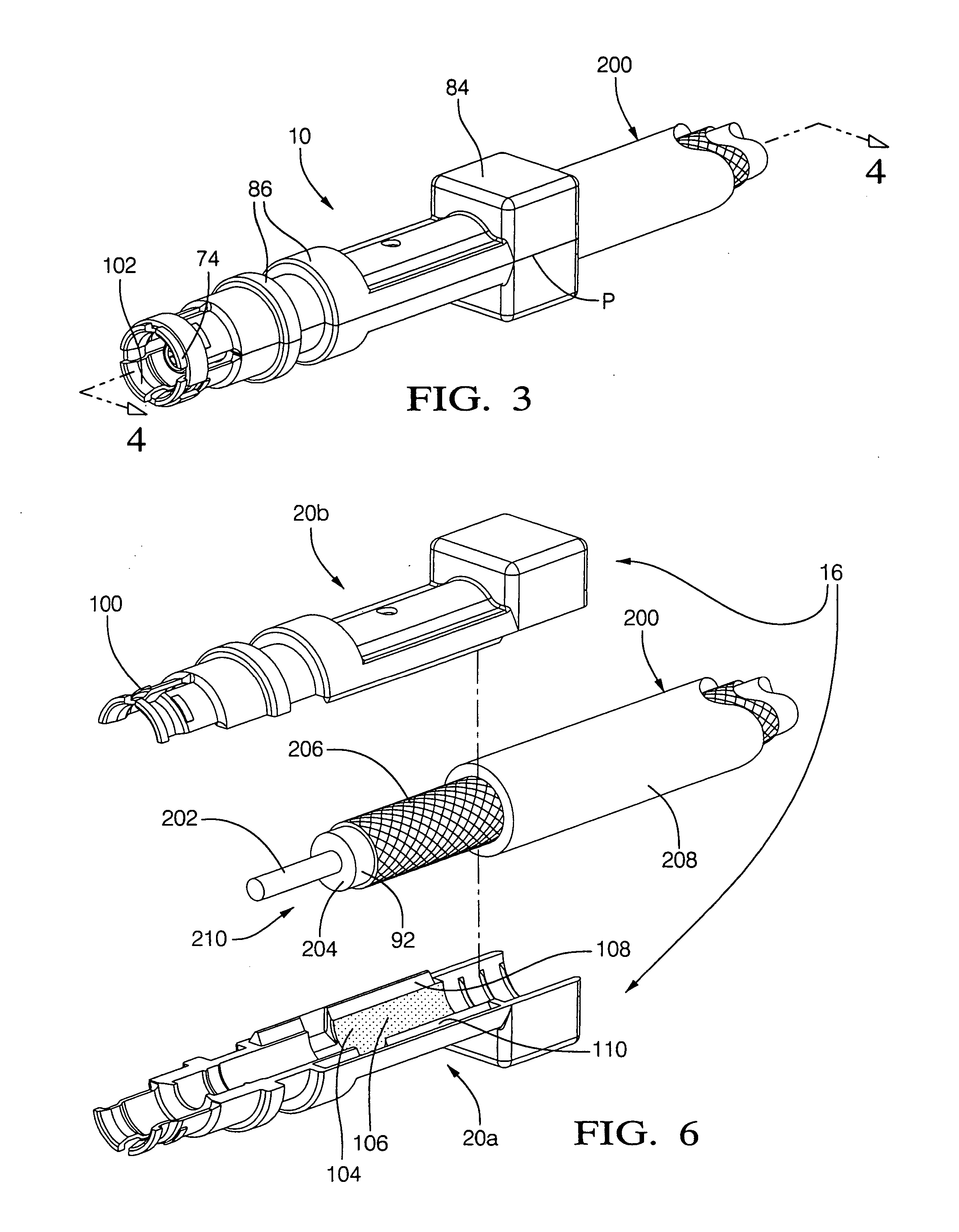

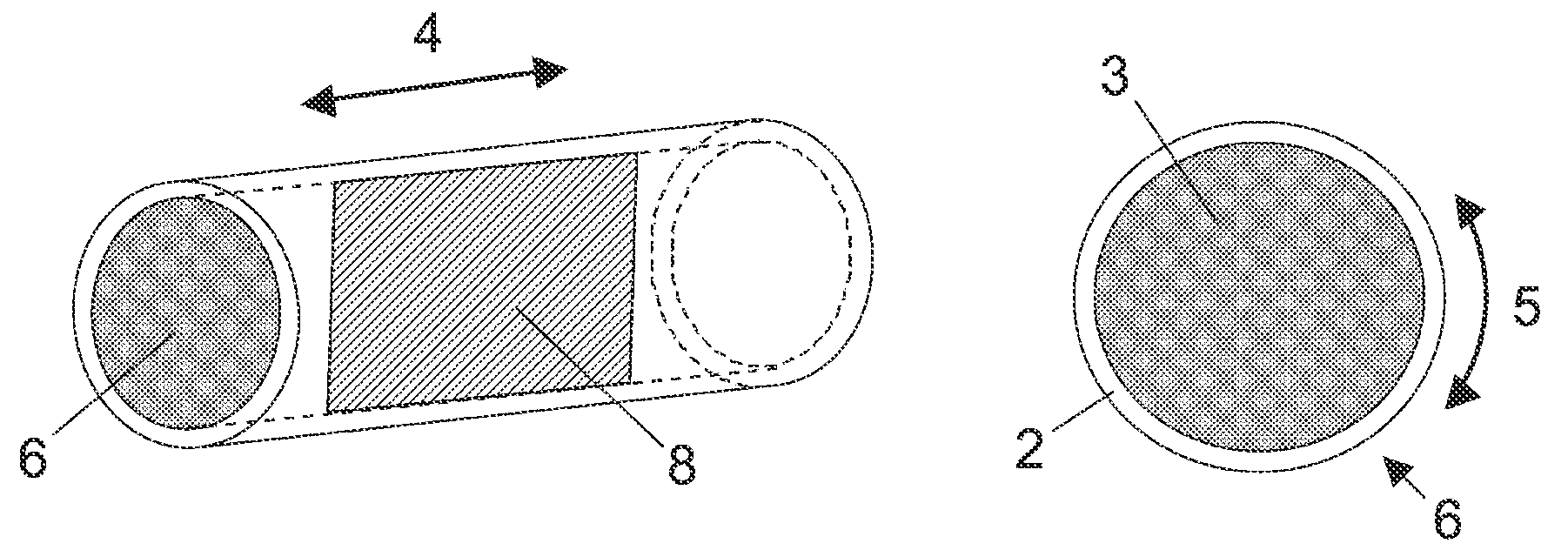

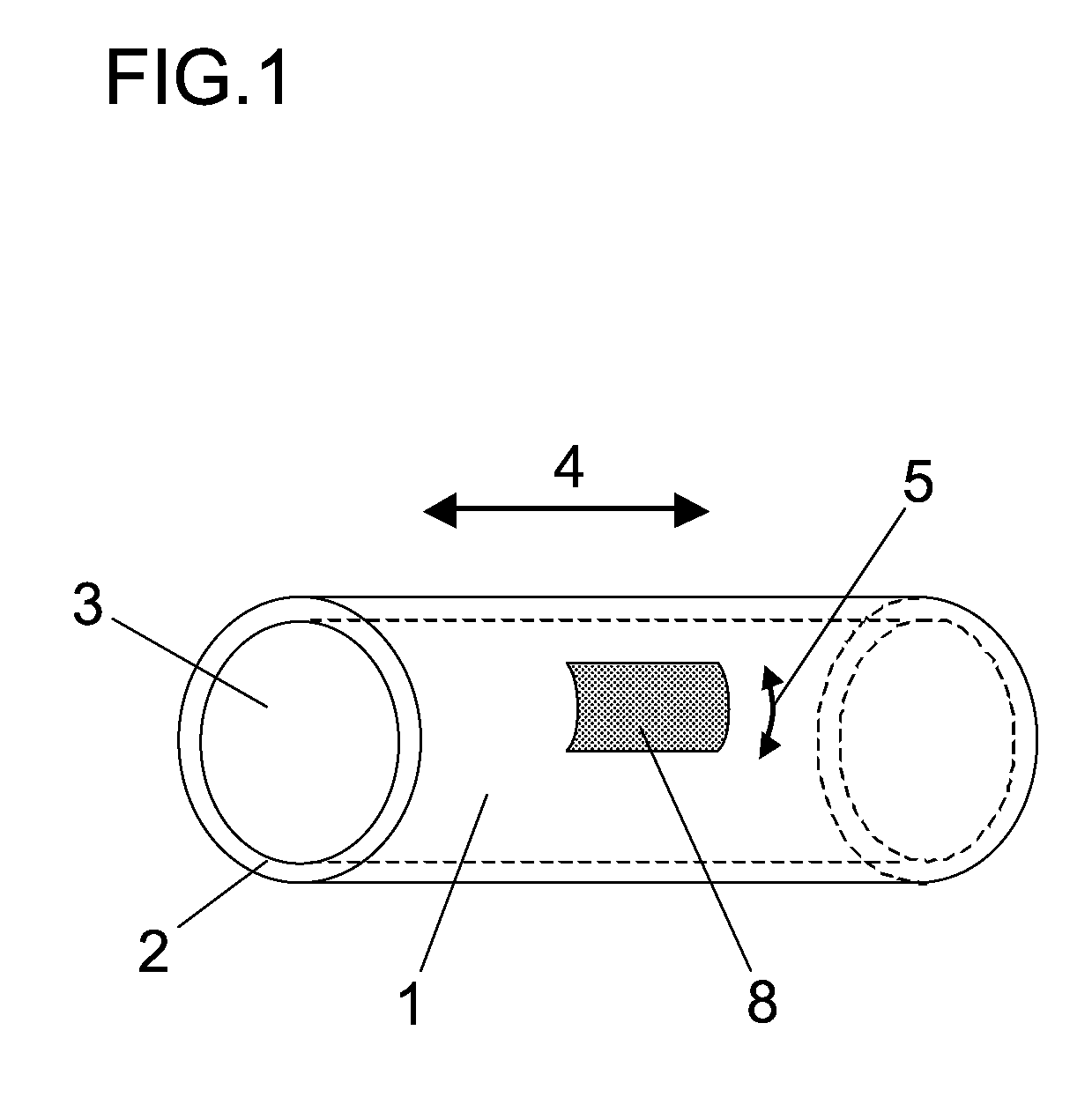

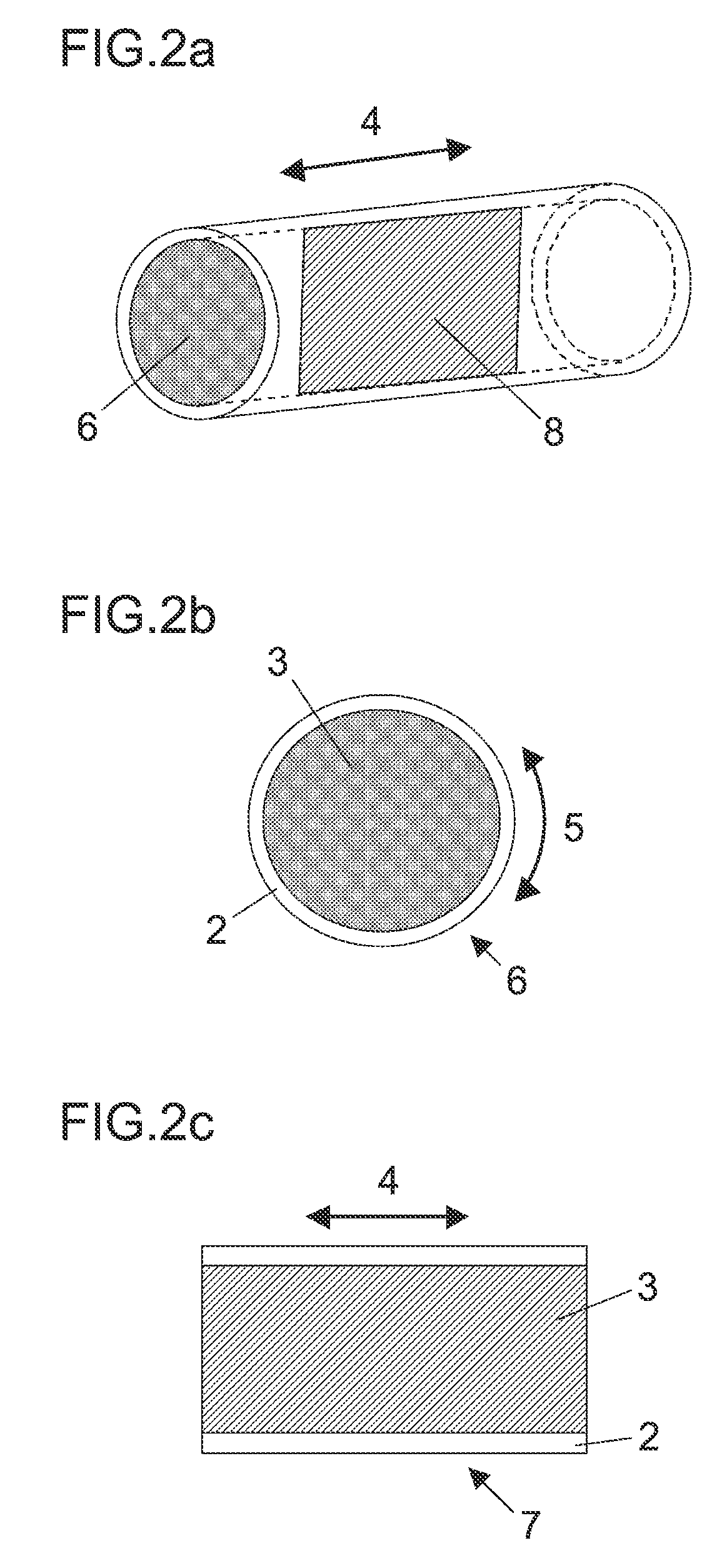

Electrical lead for an electronic device such as an implantable device

ActiveUS20060252314A1Improve shielding effectInternal electrodesCoupling device detailsImplanted deviceEngineering

A lead for an electronic device which resists the induction of a current from an electromagnetic field external to said lead includes one or more pairs of adjacent segments of electrical wire, each of the pairs including a first segment of electrical wire and a second segment of electrical wire. The lead also includes one or more shielded RF chokes, wherein each of the shielded RF chokes is provided between the first segment of electrical wire and the second segment of electrical wire of a respective one of the one or more pairs of adjacent segments. Also, an implantable device that includes a generator for generating one or more electrical pulse and a lead as described for delivering the pulses to tissue within a patient's body. A method for making the described implantable device is also provided.

Owner:SURGIVISION +1

Electrical lead for an electronic device such as an implantable device

Owner:SURGIVISION +1

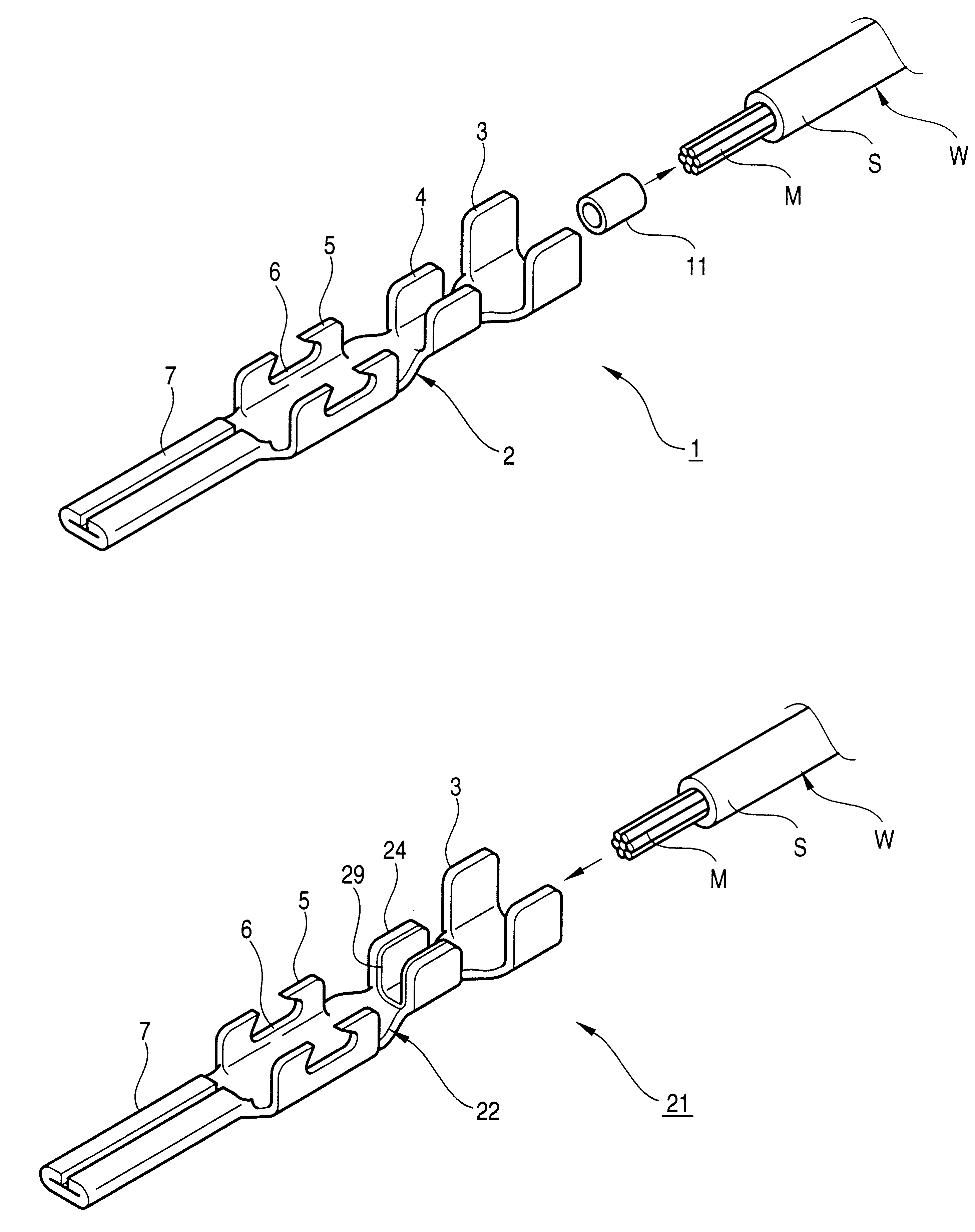

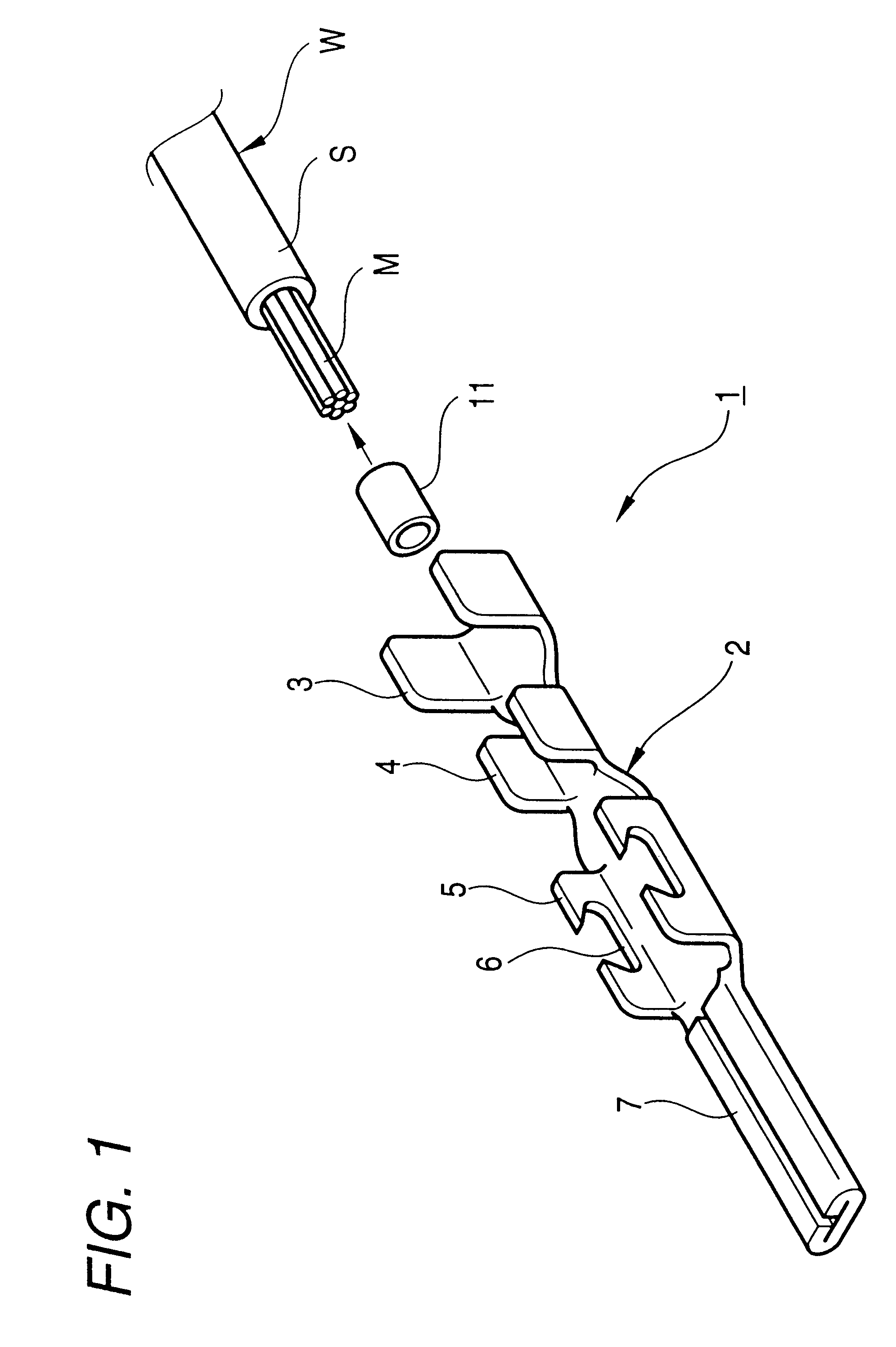

Method of and structure for connecting electric wire and connecting terminal

InactiveUS6334798B1Soldered/welded conductive connectionsConnections effected by permanent deformationElectrical conductorEngineering

In a structure 21 for connecting an electric wire and a connecting terminal in the invention, a ductile metal film 29 is formed in advance on an inner surface of a conductor caulking portion 24 of a crimp terminal 22 by such as plating, vacuum deposition, or adhesion. Then, the conductor caulking portion 24 in the rear portion of the crimp terminal 22 is caulked onto core wire portions M in a state of being stripped and extended in the axial direction from an end of a sheathed wire W to thereby establish connection. Subsequently, the metal film 29 is fused on heating. Accordingly, the ductile metal film 29 enters gaps between the inner surface of the conductor caulking portion 24 and the core wire portions M and between adjacent ones of the core wire portions M by the caulking stress. Hence, the area of contact between the conductor caulking portion 24 and the core wire portions M via the metal film 29 increases, and conductivity improves, thereby making it possible to suppress heat generation.

Owner:YAZAKI CORP

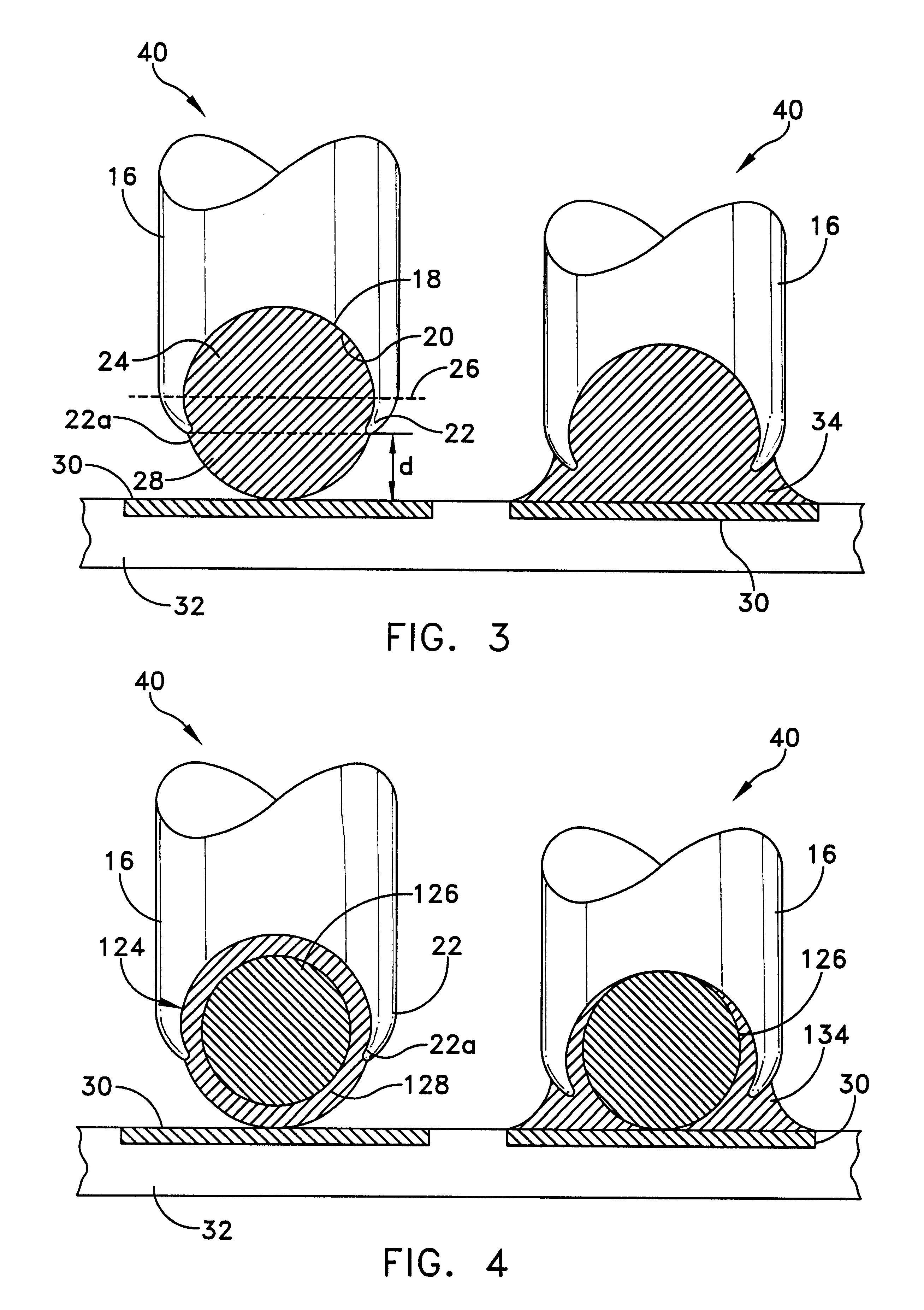

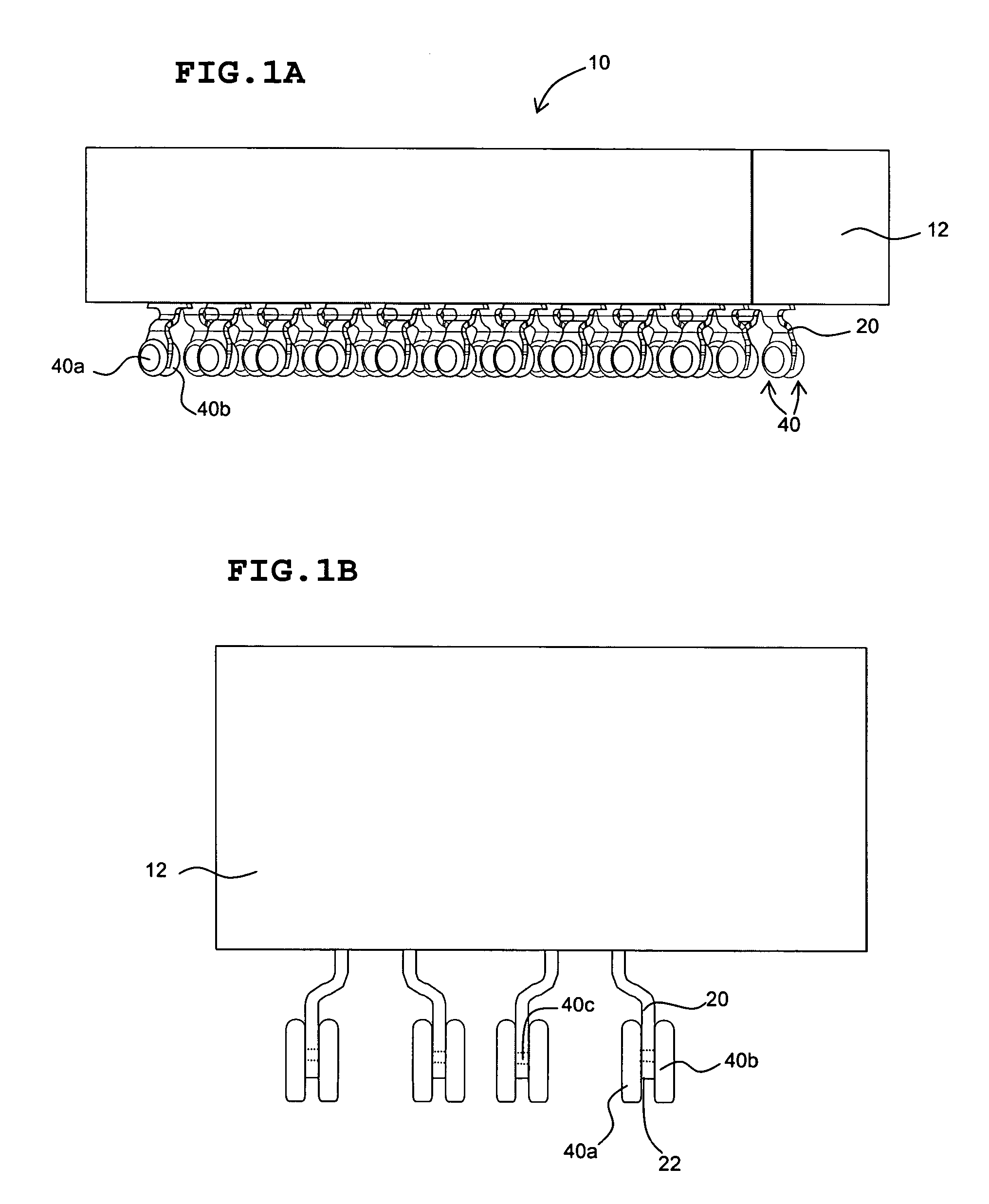

Compliant surface mount electrical contacts for circuit boards and method of making and using same

InactiveUS6997727B1Reduce mechanical stressRelieve pressureLine/current collector detailsIncorrect coupling preventionSurface mountingCurve shape

Owner:ZIERICK MFG

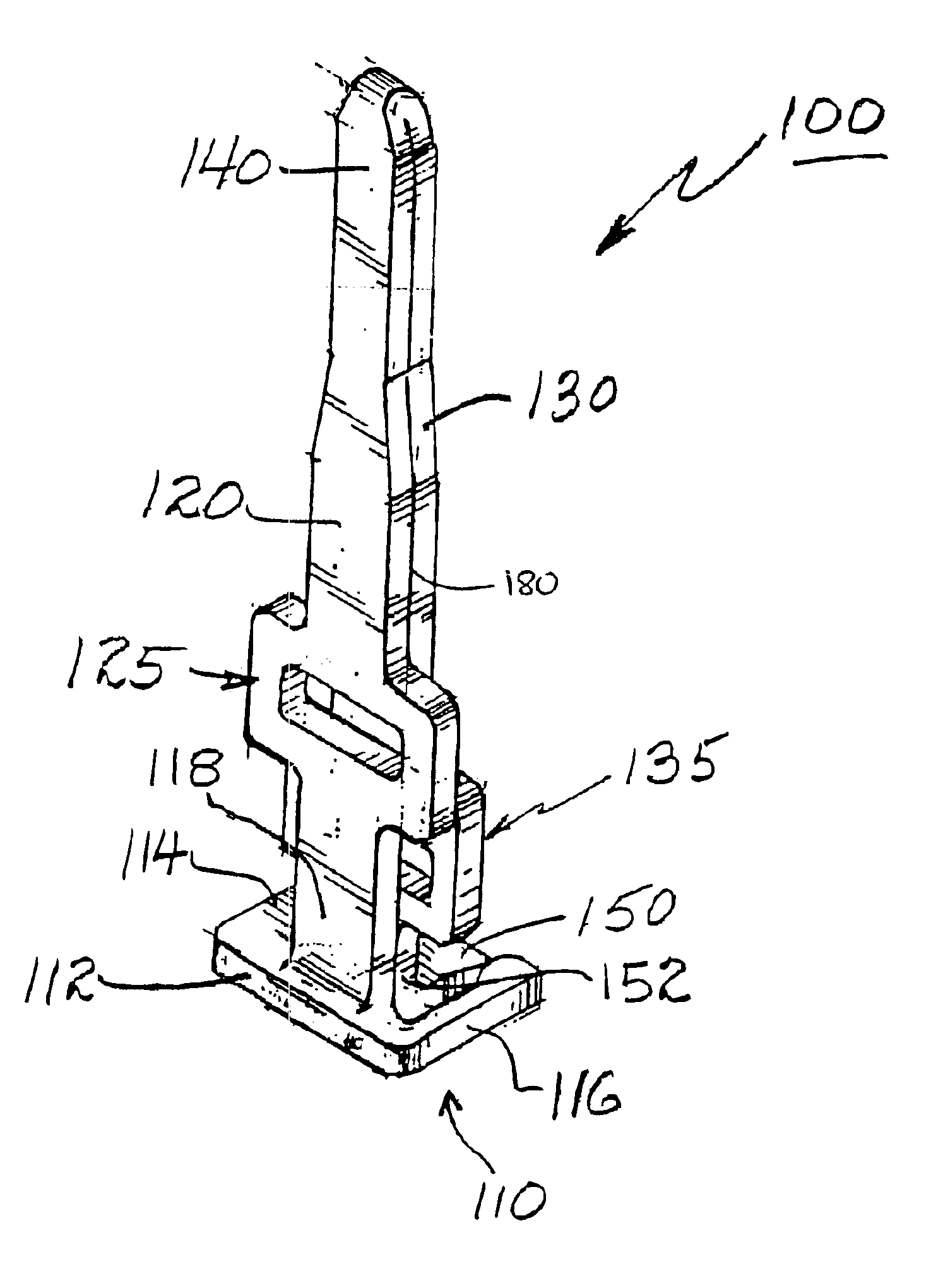

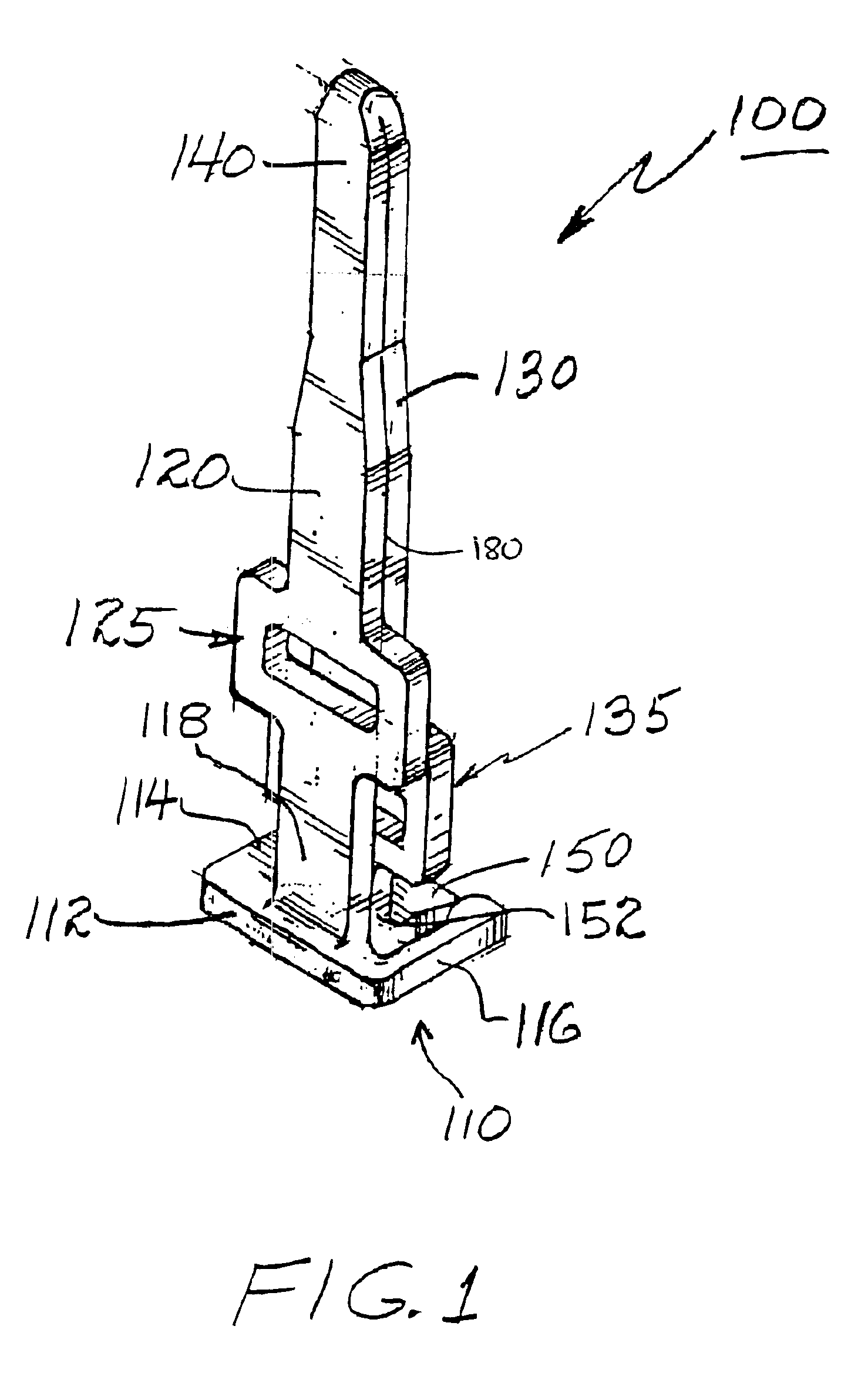

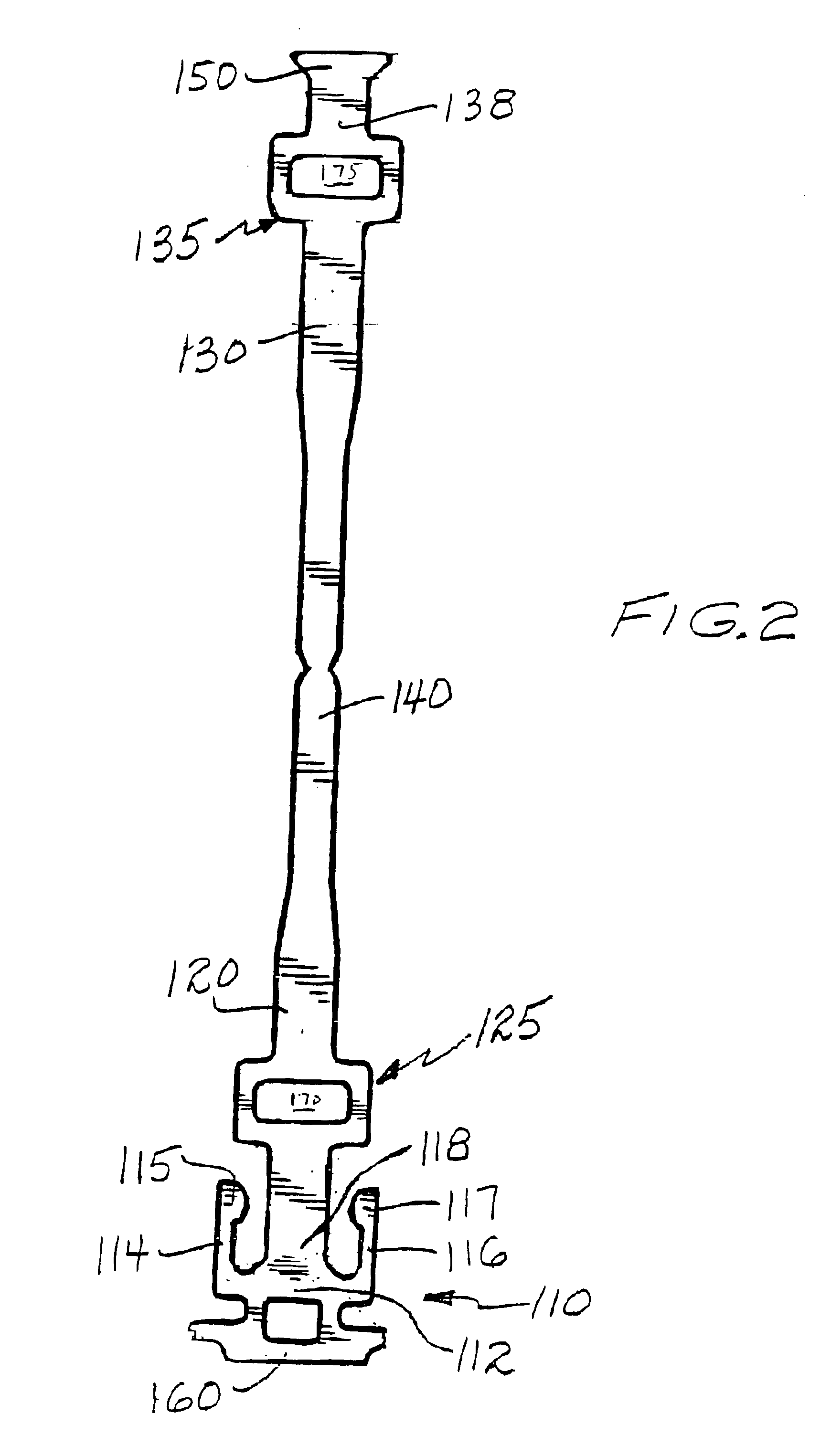

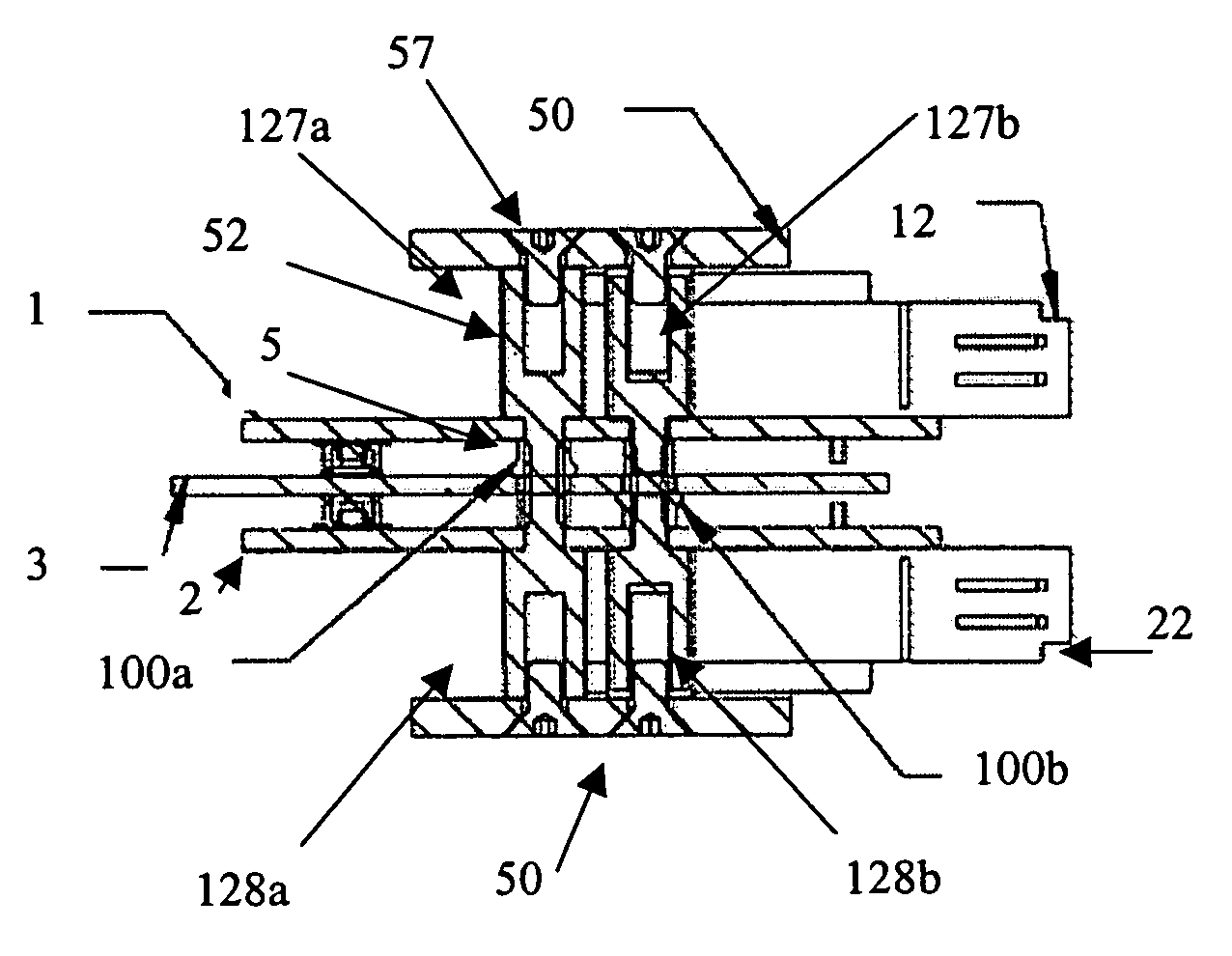

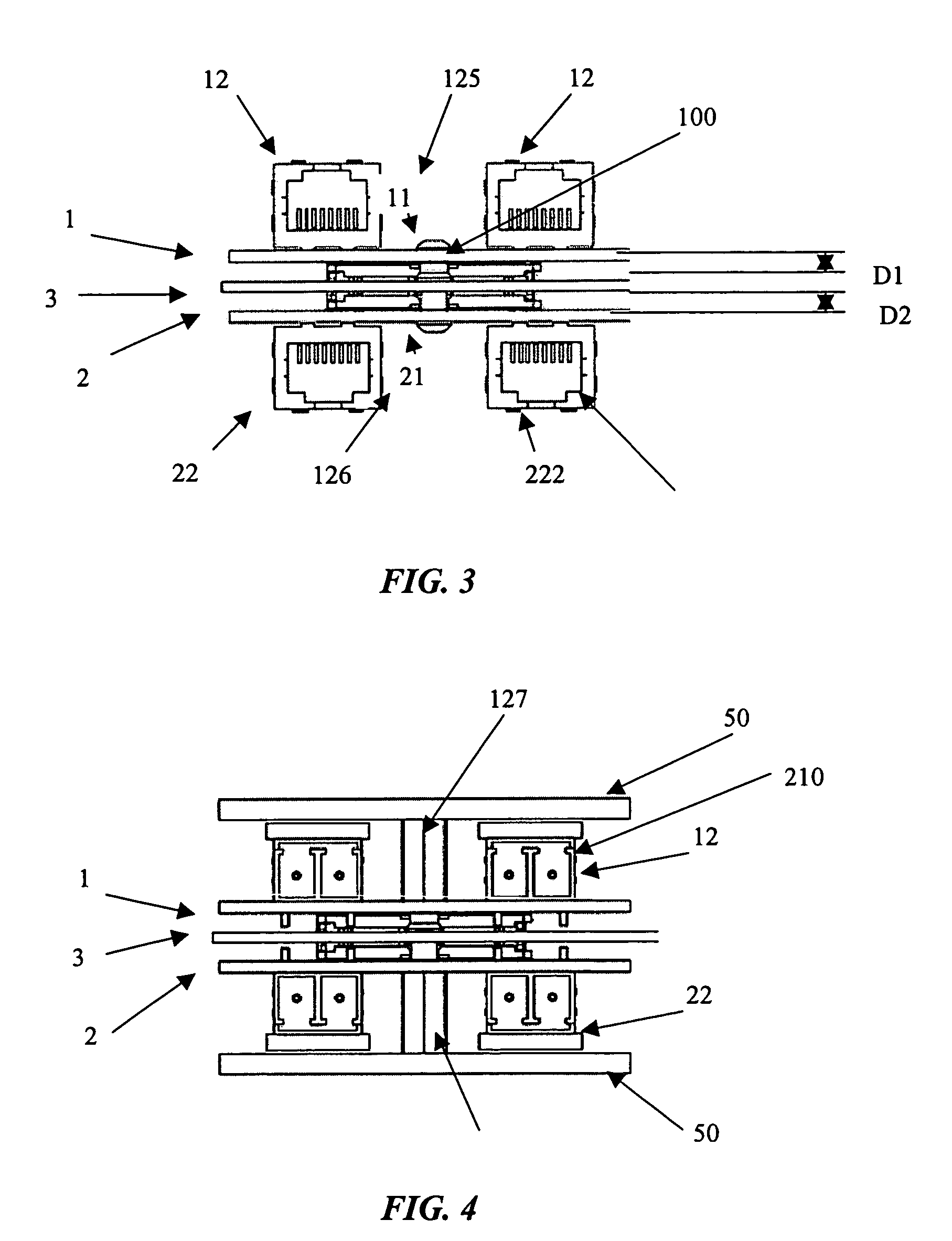

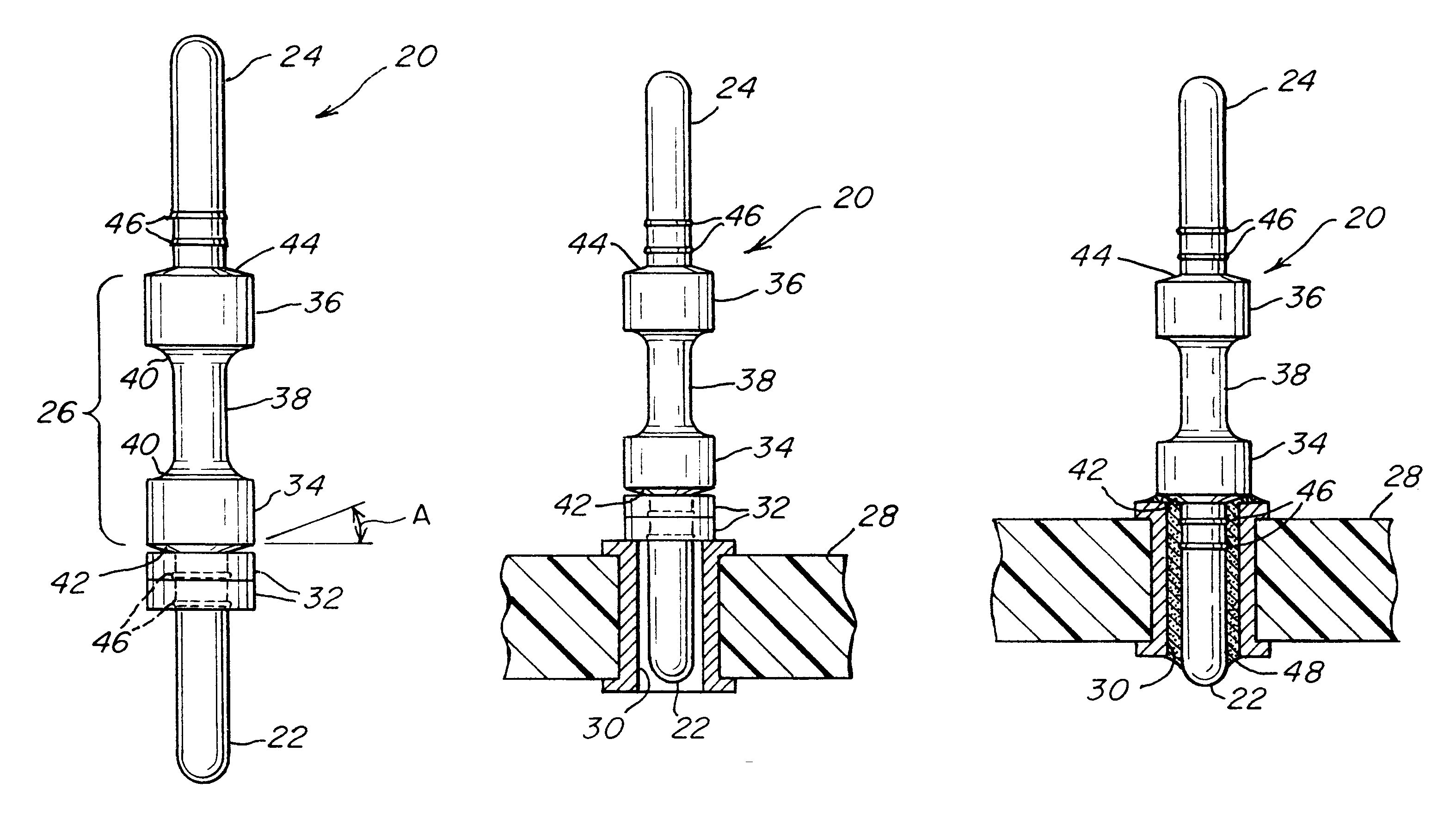

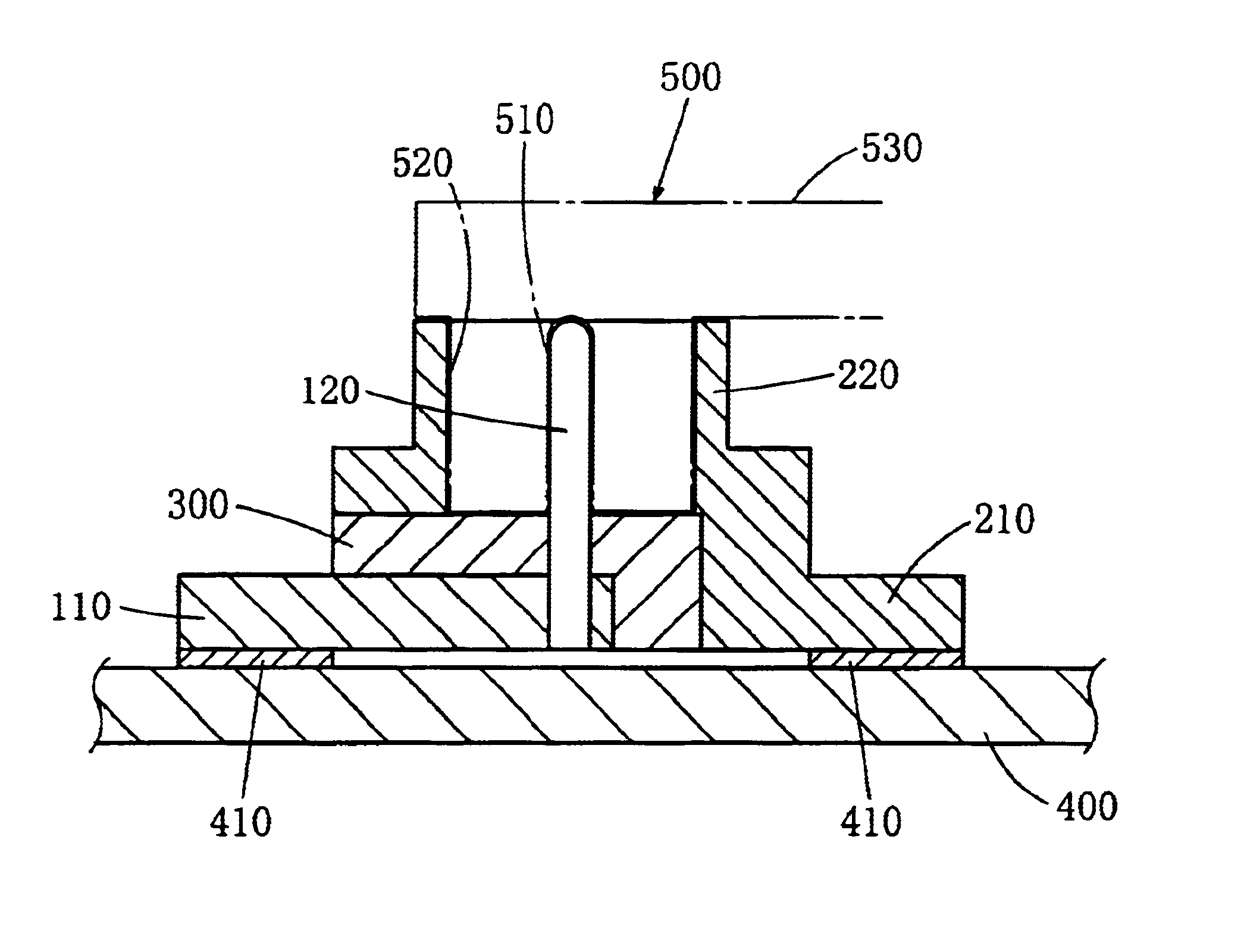

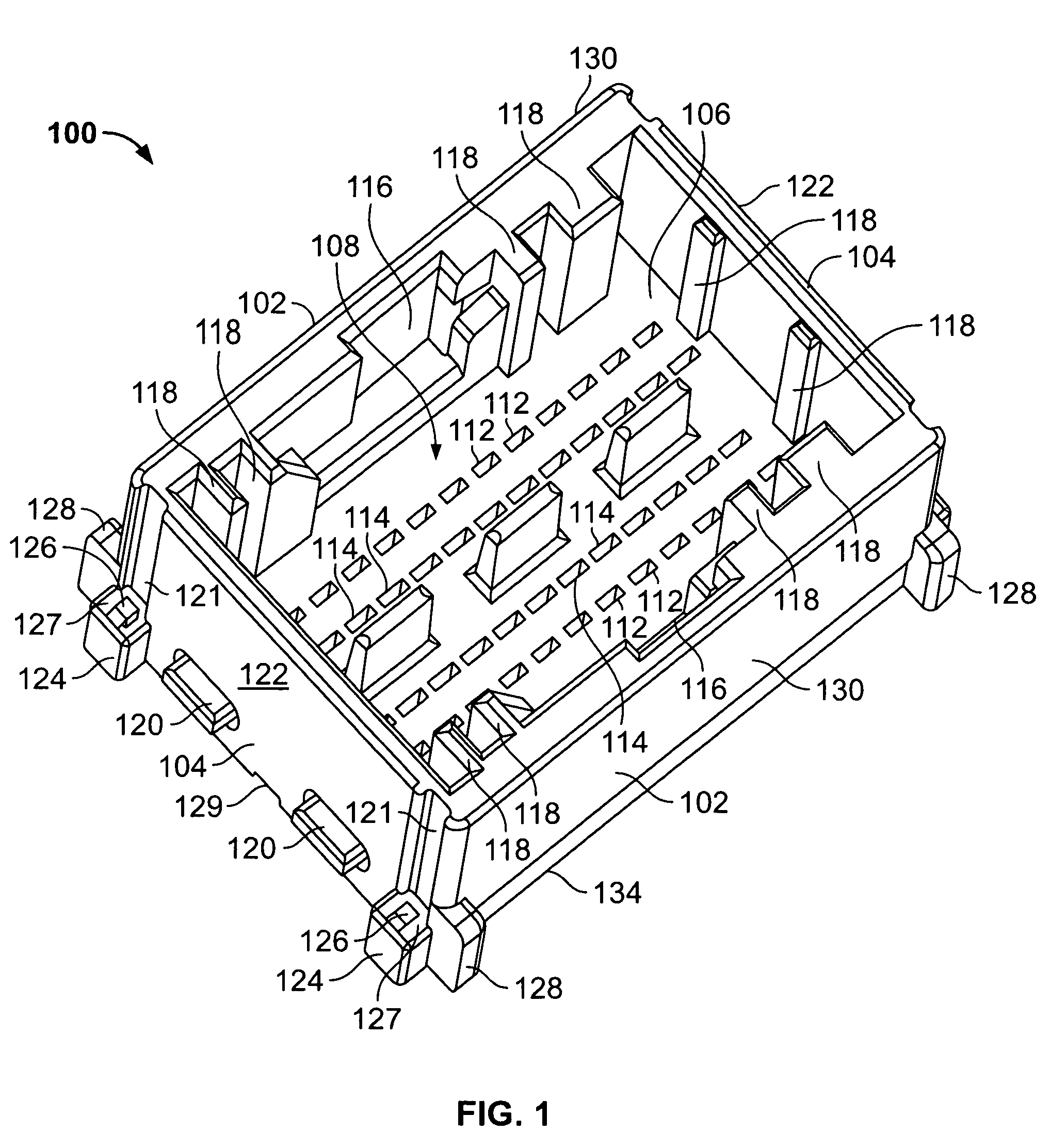

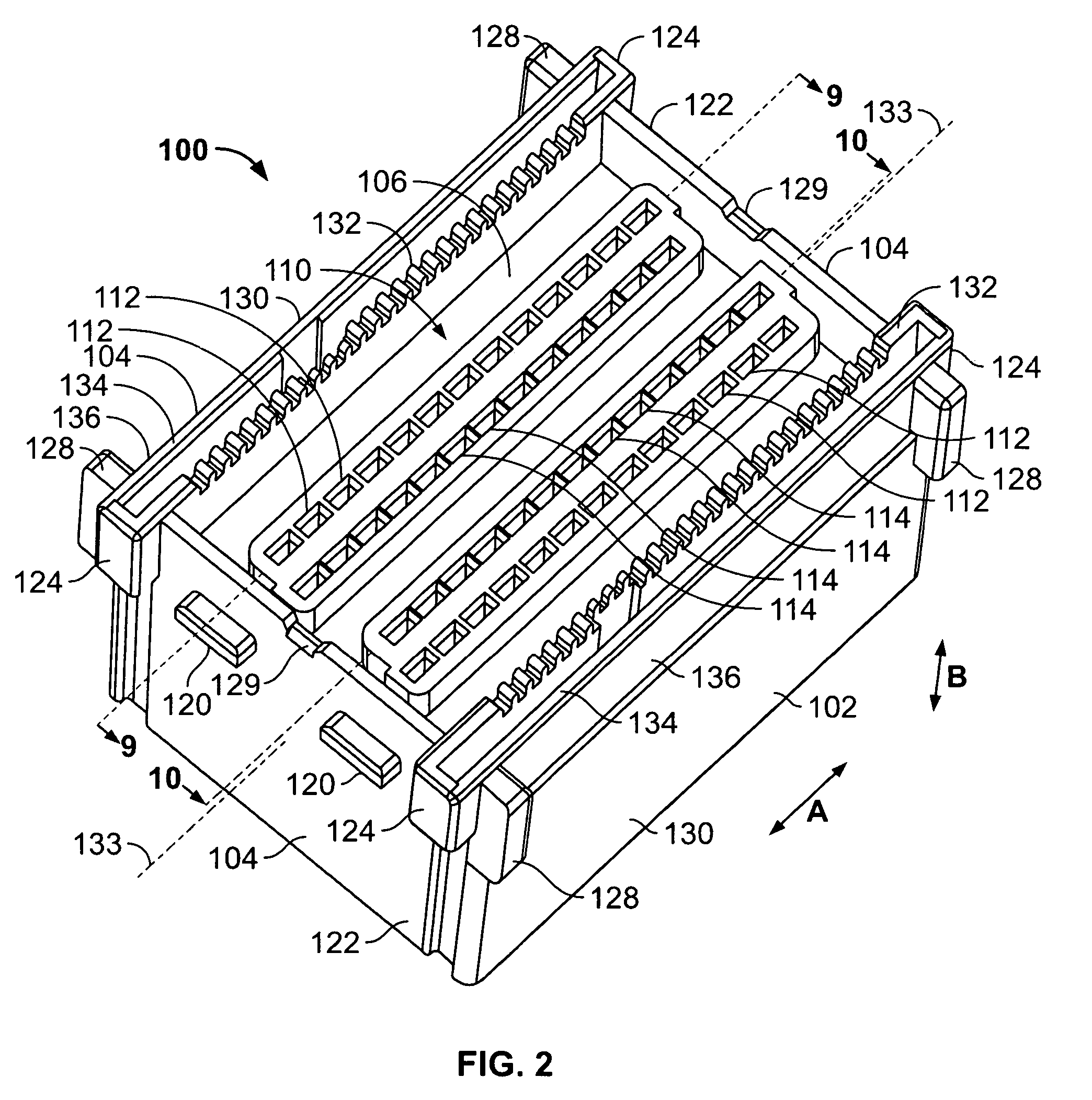

Anchoring member to facilitate fastening daughter boards to a mother board and a method for use

ActiveUS7352593B2Real useReduce complexitySoldered/welded conductive connectionsRack/frame constructionCouplingEngineering

An anchoring member and related method are disclosed for substantially parallel assembly of two additional daughter printed circuit boards (PCB) and heat sink on each side of main of mother PCB, and to retain a predetermined mating distance thereto to retain a predetermined mating distance thereto. The anchoring member comprises an elongated body extending in a longitudinal direction and having a first coupling member on one end for coupling the first daughter board in a substantially perpendicular orientation to the longitudinal direction on a first side of the mother board. The elongated body also comprises a second coupling member at the opposite end from the elongated body from the first coupling member for coupling the second daughter board in a substantially perpendicular orientation to the longitudinal direction on a second side of the mother board. The elongated body also has a positioning flange for positioning the elongated body in an aperture of the mother board at an inserted position and a friction fit surface for interacting with the aperture of the mother board to secure the elongated body in the inserted position.

Owner:SIEMENS CANADA LTD

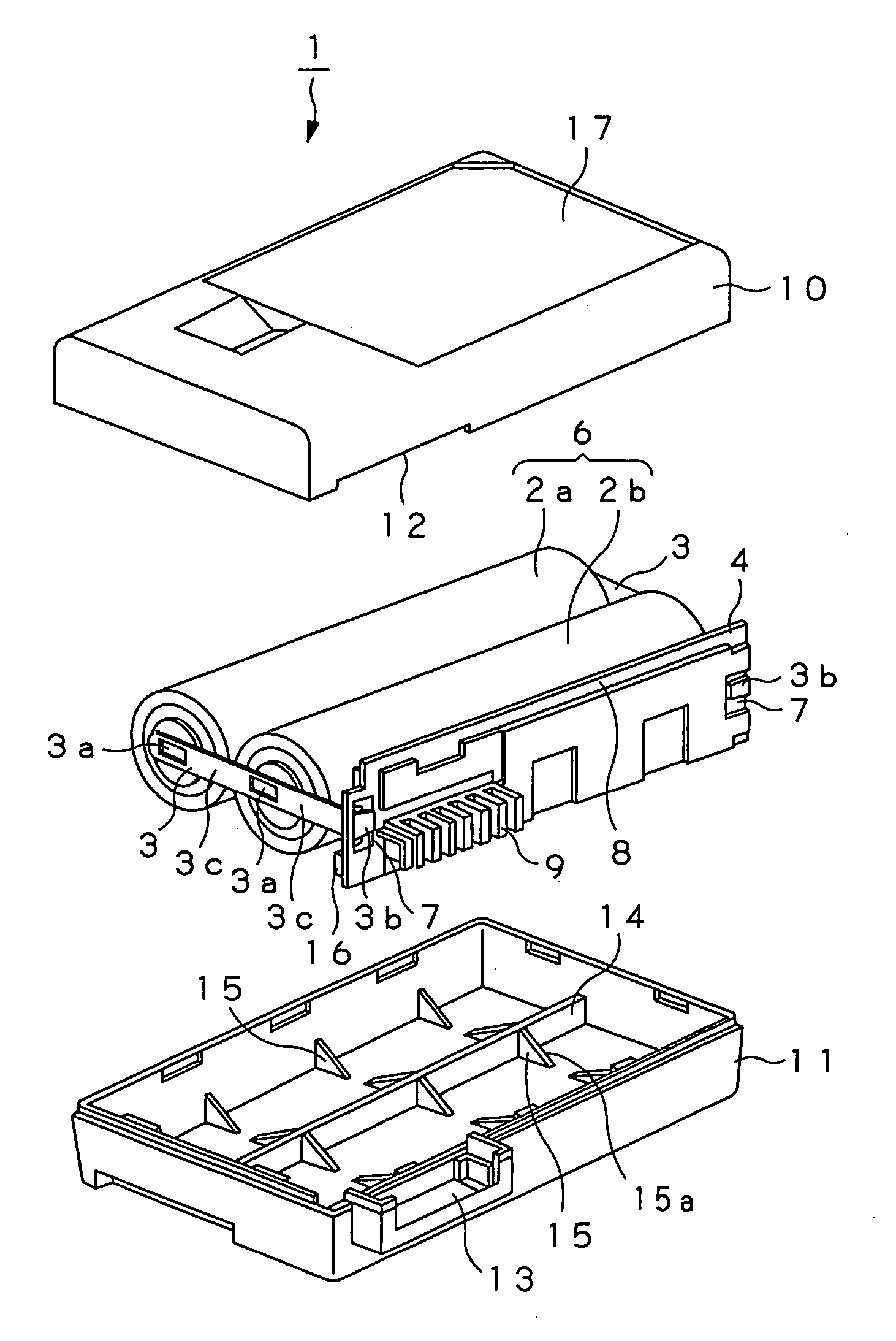

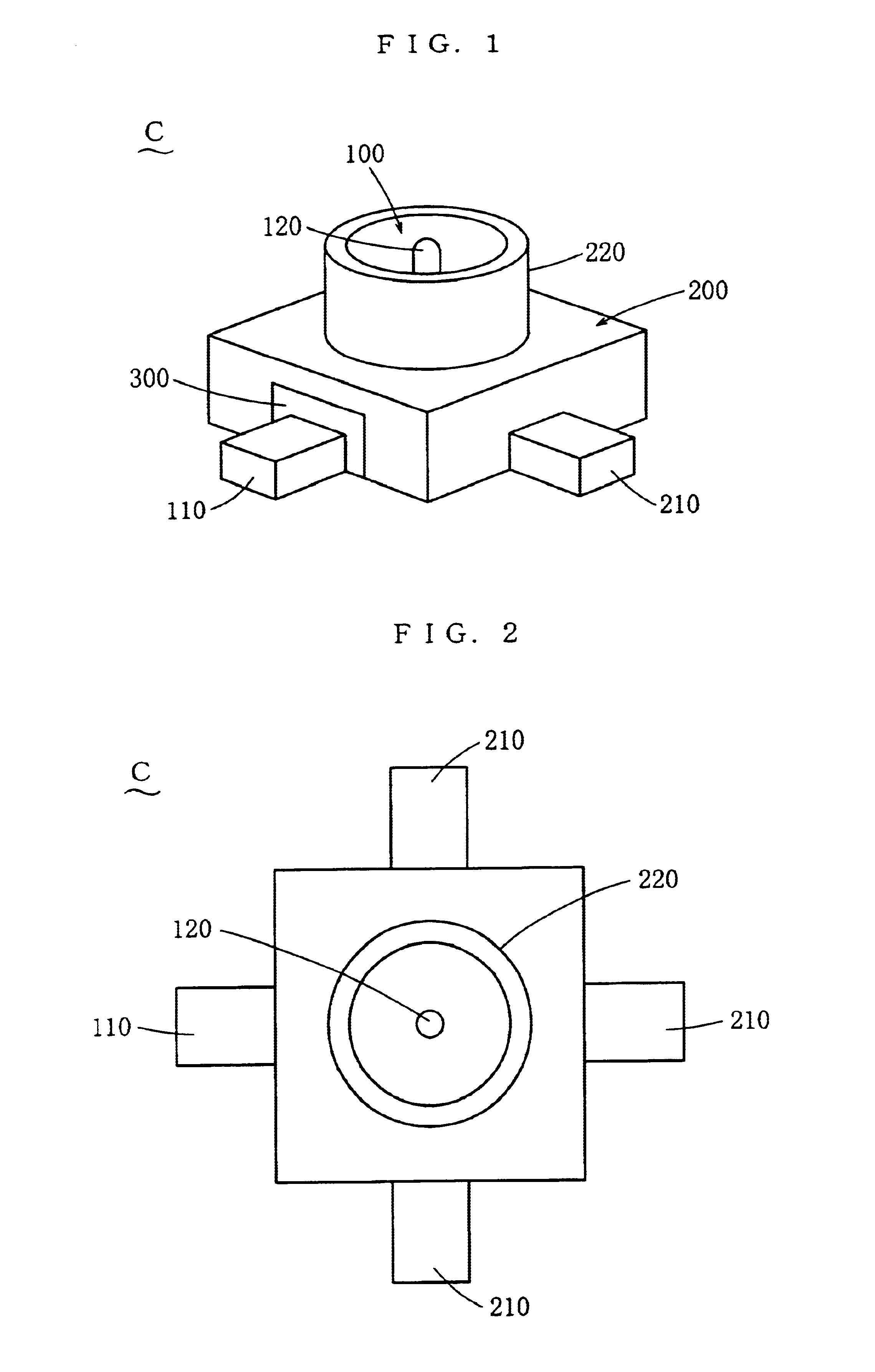

Lead terminal and power supply device

InactiveUS20060032667A1Improve welding strengthImprove electrical resistancePrinted electric component incorporationSoldered/welded conductive connectionsElectricityElectrical resistance and conductance

The present invention is directed to a power supply apparatus in which a battery and a circuit wiring board or boards are electrically connected by using lead terminals. The lead terminal (3) is adapted so that thickness of a welding portion (3a) is caused to be thinner than the thickness of a conductive portion (3b). Thus, current for welding flows to much degree in a thickness direction so that electric resistance of the welding portion becomes large, and heat based on the electric resistance also becomes large. From this fact, welding nugget (63) can be enlarged. As the result of the fact that large welding nugget is formed, the lead terminals are welded to terminal portions (37a) of the battery (2) with high reliability.

Owner:SONY CORP

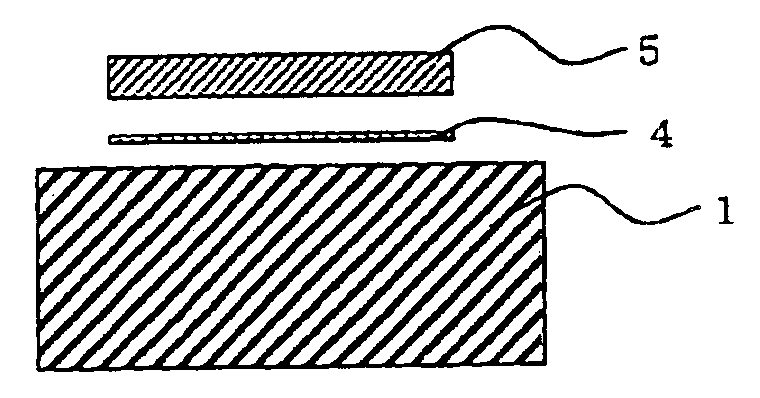

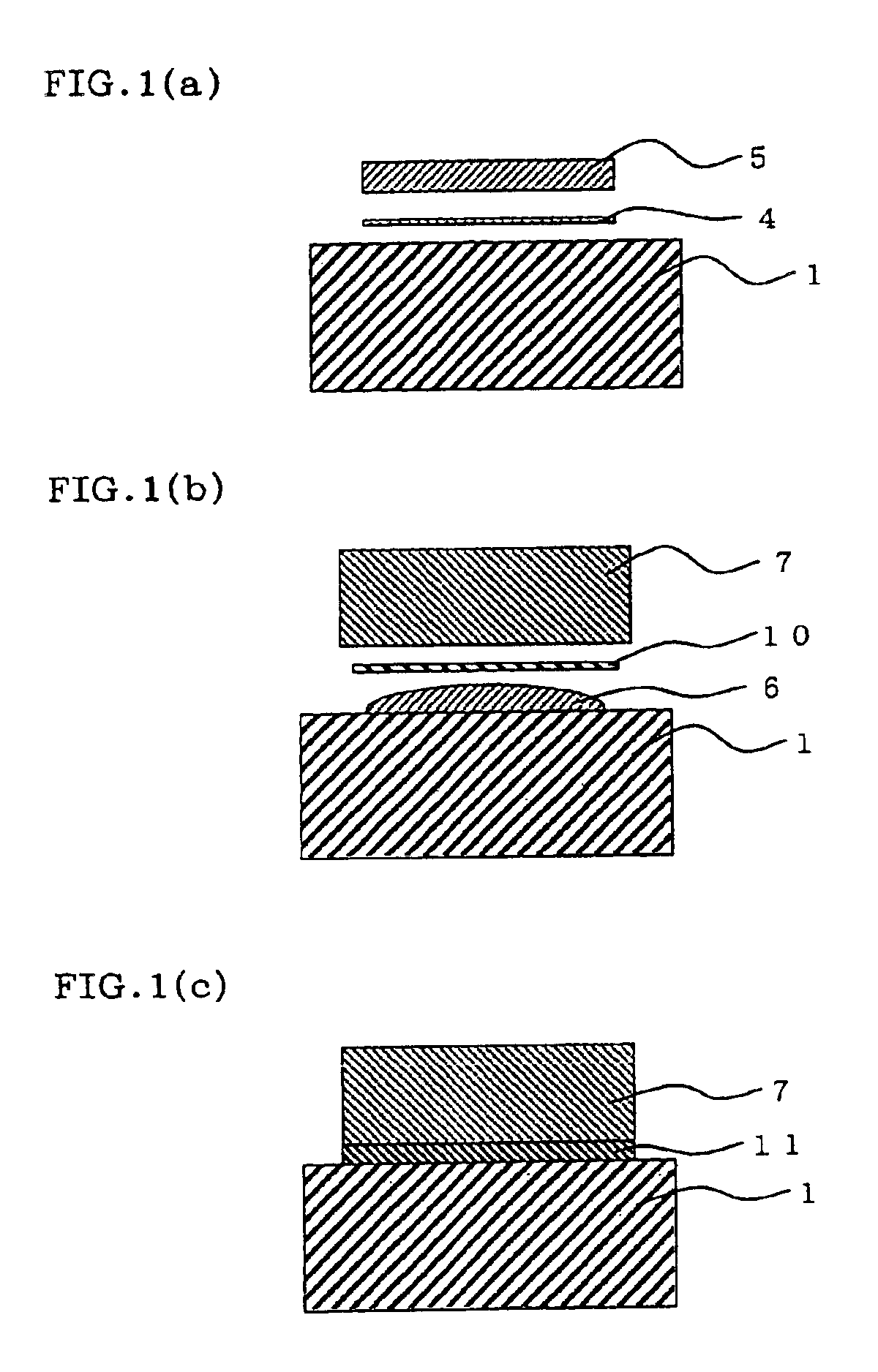

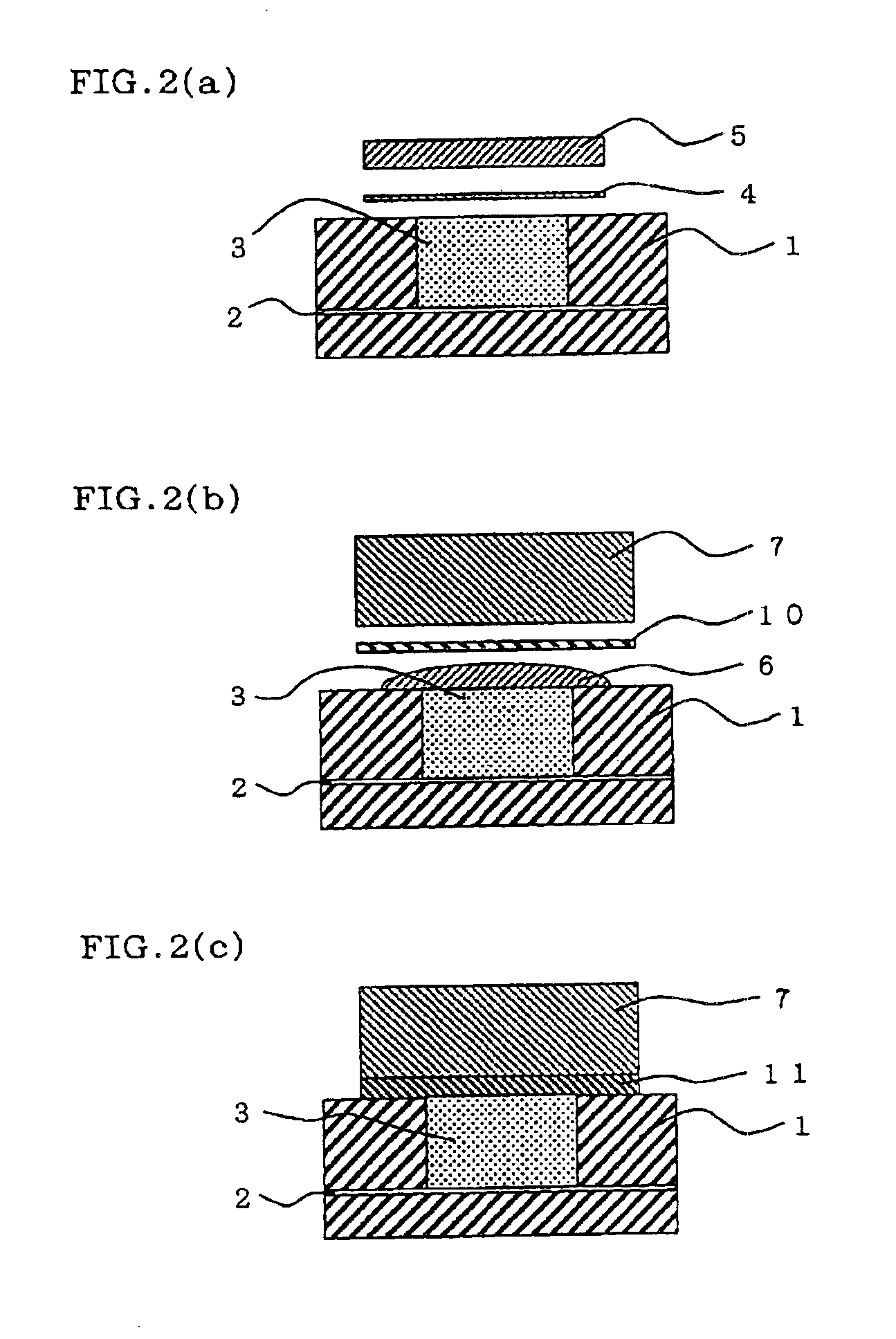

Bonded member comprising different materials, and production method thereof

InactiveUS6918530B2Easy to operateHigh bonding strengthLayered product treatmentSoldered/welded conductive connectionsAlloyLow melting point

A bonded member including a ceramic base material 1 and a metallic member 7 which are bonded together, wherein a solder material 5 comprising Au is disposed on the surface of the ceramic base material 1 via an active metal layer, the active metal layer and the solder material 5 are molten by heating so as to form a precoat layer 6, the metallic member 7 is disposed on the surface of the precoat layer 6 via an insertion metal layer comprising pure metal which may form an alloy having a lower melting point than Au with Au or an alloy of the pure metal and Au, and the insertion metal layer and at least a portion in the vicinity of the interface between the insertion metal layer and the precoat layer 6 are molten by heating to bond the metallic member 7 and the precoat layer 6.

Owner:NGK INSULATORS LTD

Electrical contact for a printed circuit board

InactiveUS6179631B1Printed circuit assemblingLine/current collector detailsSurface mountingElectrical connection

An electrical contact that is mounted on a printed circuit board to provide an electrical connection to the printed circuit board. The contact has the structural integrity of a through-hole component with the capability of being soldered to the circuit board using a surface mount reflow process. The contact includes a pair of elongated, conductive pins with a base disposed therebetween, and a solder preform supported on one of the conductive pins adjacent the base. The pin supporting the solder preform is insertable into a plated-through hole on the circuit board so that the solder preform can be reflowed into the hole along the pin to form a solder joint between the contact and the hole. The contact may include a retainer to secure the solder preform to the pin and the end of the base adjacent the pin may be beveled to facilitate gas ventilation from the hole during the soldering process. The base may be configured so that it can be grasped with a test instrument or support a wire connection to the contact. The contact may be symmetrical so that the solder preform can be supported on either conductive pin.

Owner:EMC IP HLDG CO LLC

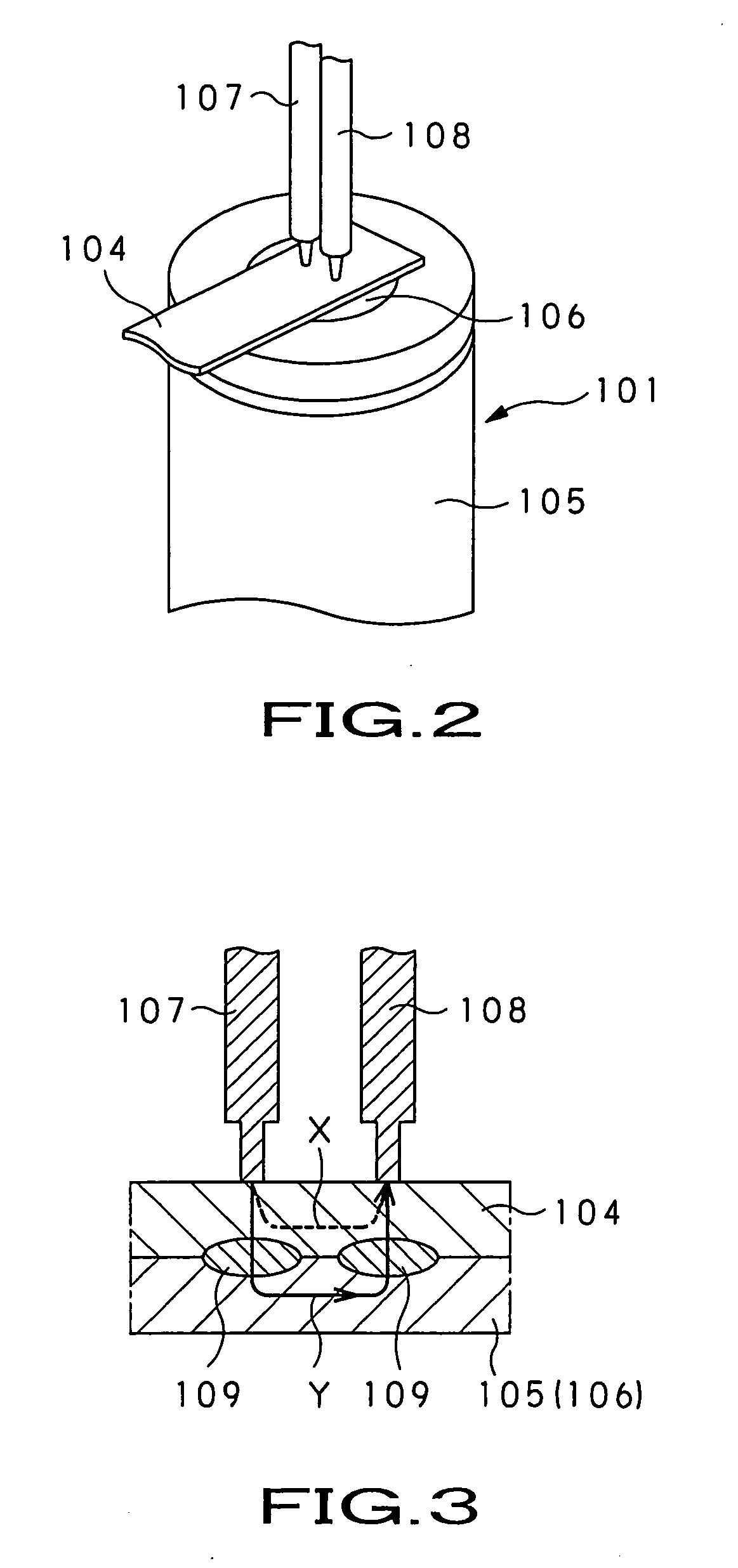

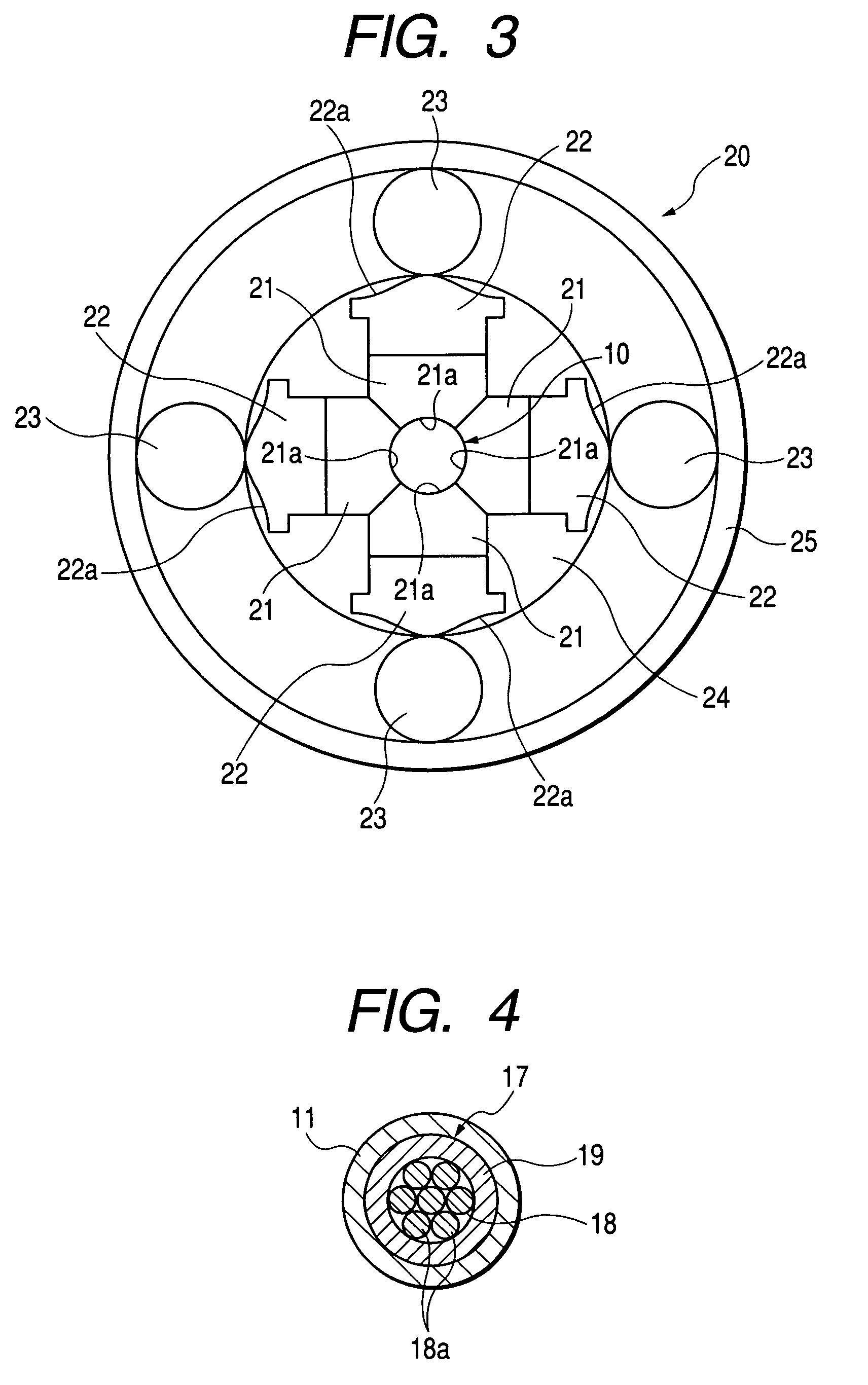

Electric connector for twisted pair cable using resin solder and a method of connecting electric wire to the electric connector

InactiveUS20020142676A1Firmly connectedIncrease the cross-sectional areaContact member assembly/disassemblySoldered/welded conductive connectionsElectricityElectrical conductor

The objectives of the present invention include to connect a twisted pair cable to the electric connector without undoing the twist of the end of the twisted pair cable, to accurately keep the twist of the twisted pair cable up to the end thereof, to make the twisted pair cable fully exhibit its noise cancellation effect, and to maximize impedance matching. The electric connector for twisted pair cable using resin solder according to the present invention comprises a pair of electric contacts having the first connecting part, which fits with the counterpart connector, and the second connecting part, to which the conductor of the electric wire is connected, and an insulating member, which insulates and holds these electric contacts. In each of the electric contacts, at least a part of the second connecting part, to which the conductor of the electric wire is connected, is made of a lead-free ultrahigh-conductive plastic being a conductive resin composite.

Owner:JST MFG CO LTD

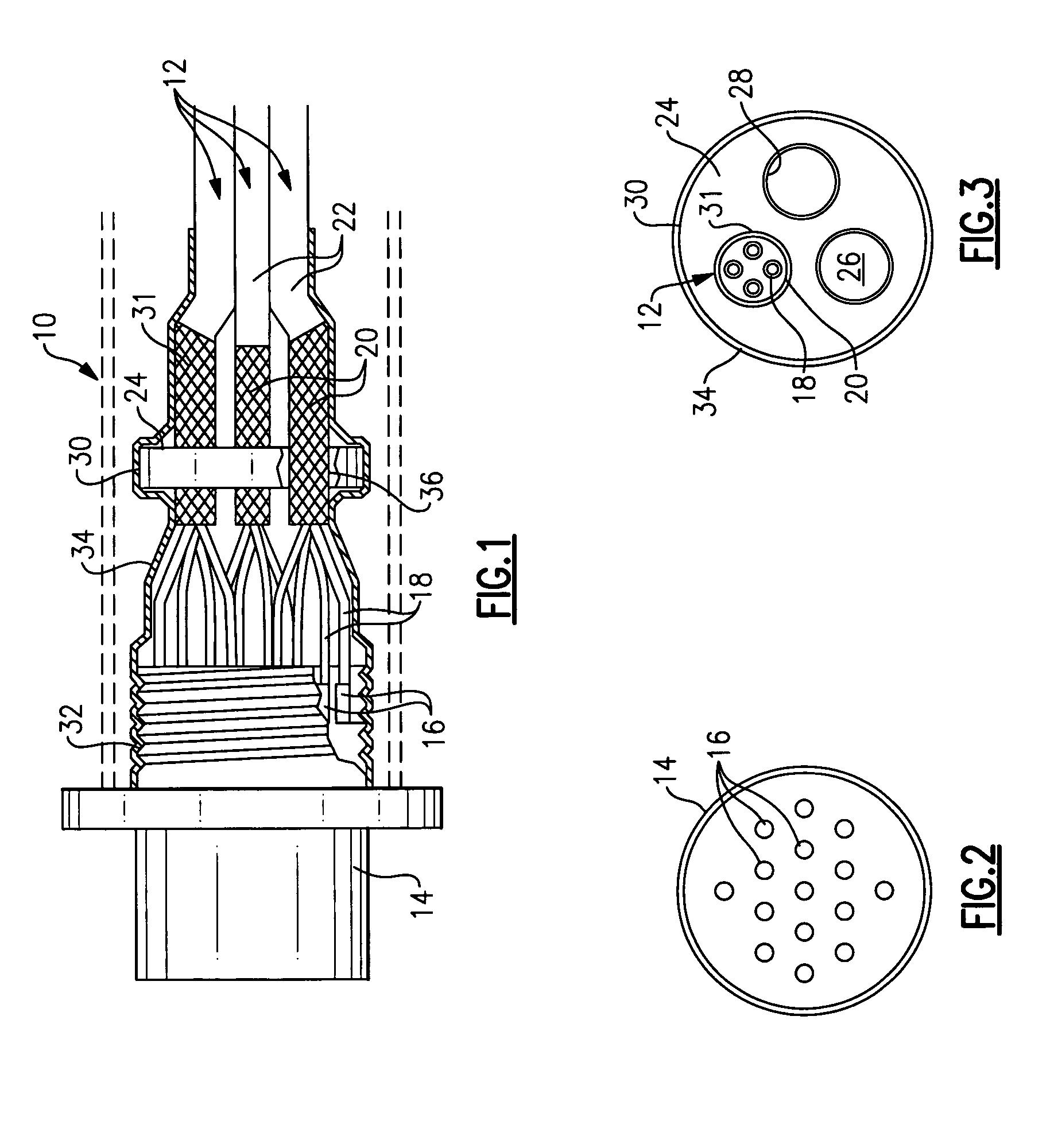

Feedthrough assembly including sleeve and methods related thereto

InactiveUS7561917B2Heart defibrillatorsSoldered/welded conductive connectionsElectrical conductorBiomedical engineering

Owner:CARDIAC PACEMAKERS INC

Low cost electrical cable connector housings and cable heads manufactured from conductive loaded resin-based materials

InactiveUS6947012B2Soldered/welded conductive connectionsAntennas earthing switches associationElectrical conductorEngineering

Electrical connector housings are formed of a conductive loaded resin-based material which provides superior protection from EMI and RFI by absorbing such interfering signals. The conductive loaded resin-based material comprises micron conductive powder(s), conductive fiber(s), or a combination thereof, in a base resin host. The percentage by weight of the conductive powder(s), conductive fiber(s), or a combination thereof is between about 20% and 40% of the weight of the conductive loaded resin-based material. The micron conductive powders are formed from non-metals, such as carbon, graphite, that may also be metallic plated, or the like, or from metals such as stainless steel, nickel, copper, silver, that may also be metallic plated, or the like, or from a combination of non-metal, plated, or in combination with, metal powders. The micron conductor fibers preferably are of nickel plated carbon fiber, stainless steel fiber, copper fiber, silver fiber, or the like.

Owner:INTEGRAL TECHNOLOGY INC

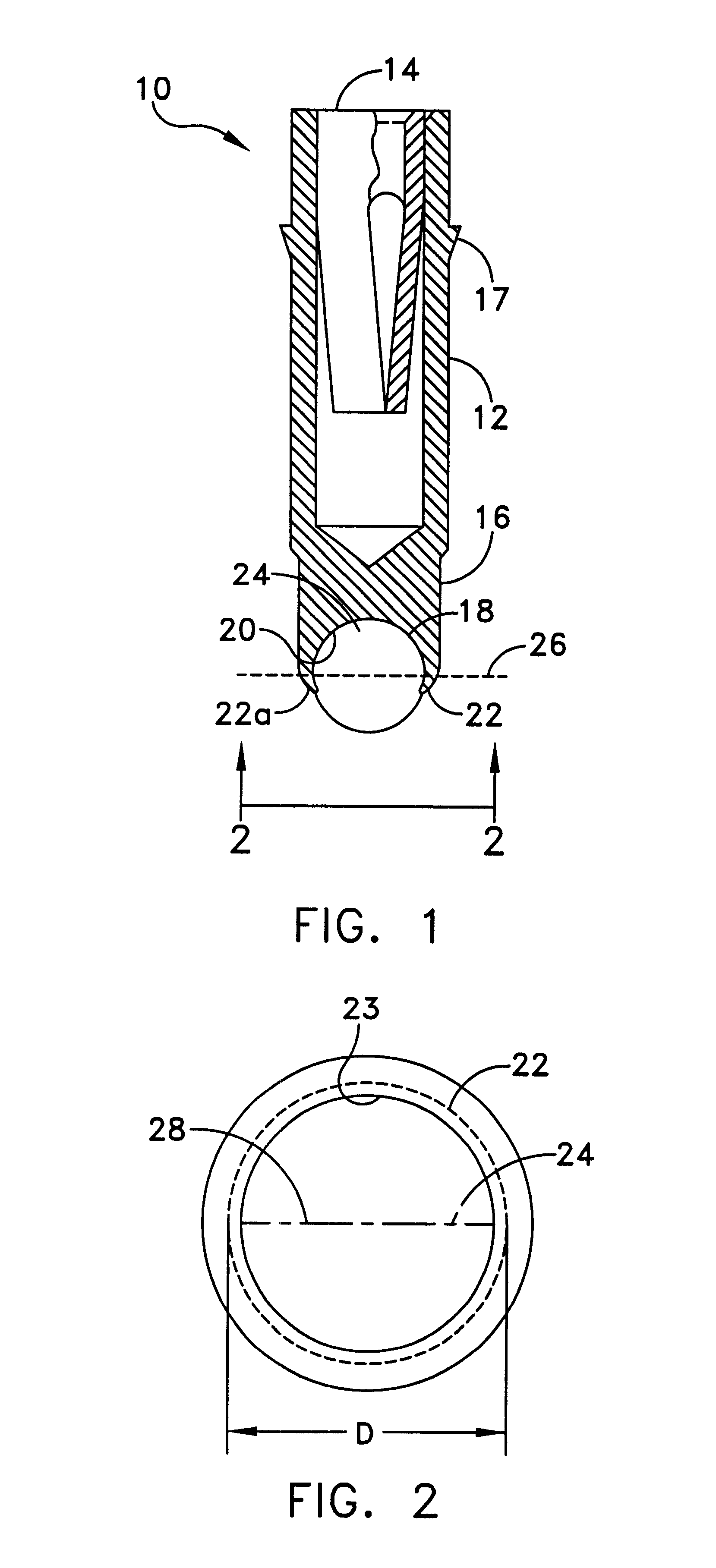

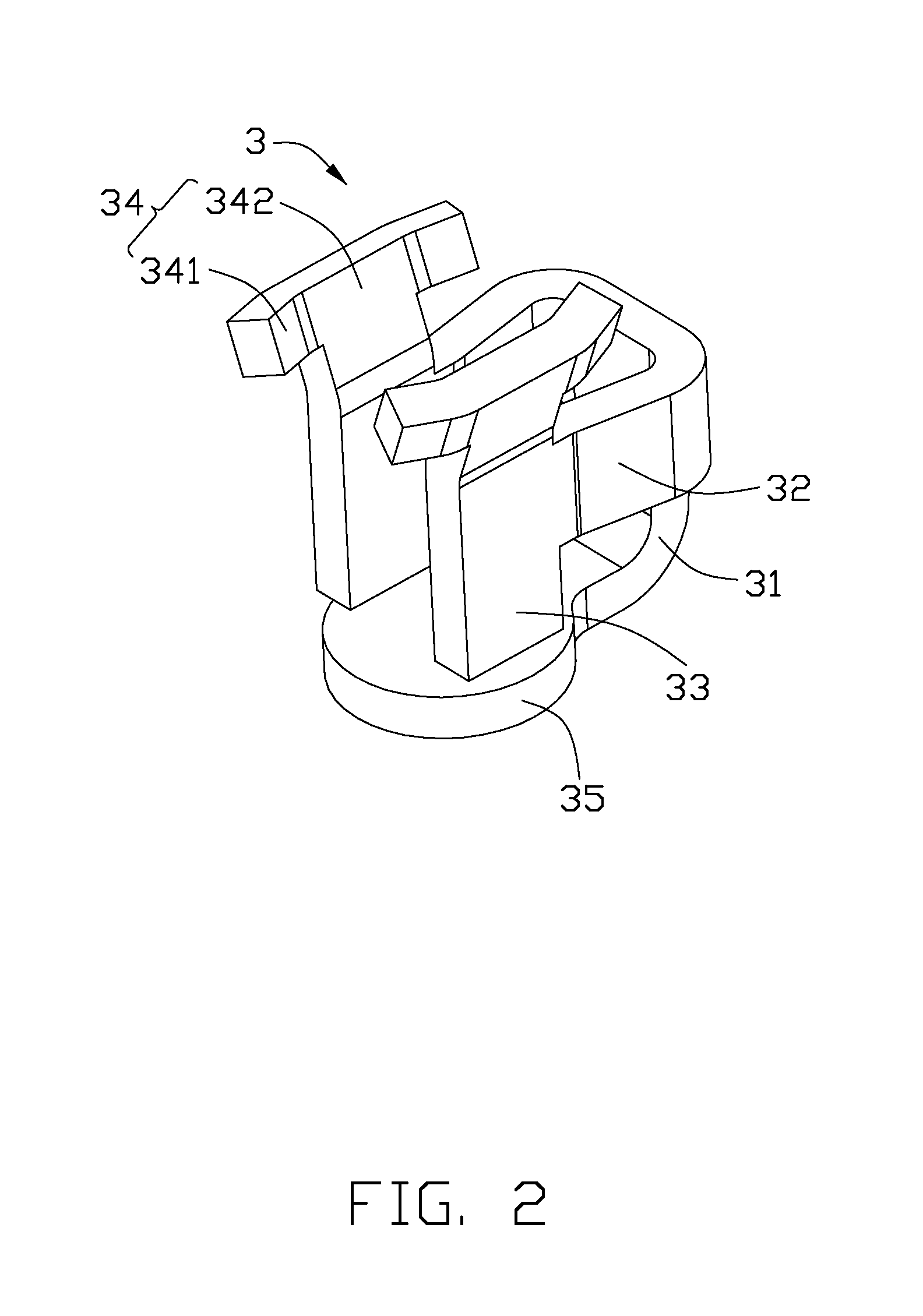

Solder ball terminal

A solder ball terminal includes a body portion, a spherical socket disposed at one end of the body portion, the spherical socket including an interior wall terminating in an annular lip, wherein the annular lip defines an opening of the spherical socket and a solder ball disposed within the socket such that a portion of the solder ball extends through the opening and beyond the annular lip.

Owner:TATE JOHN O

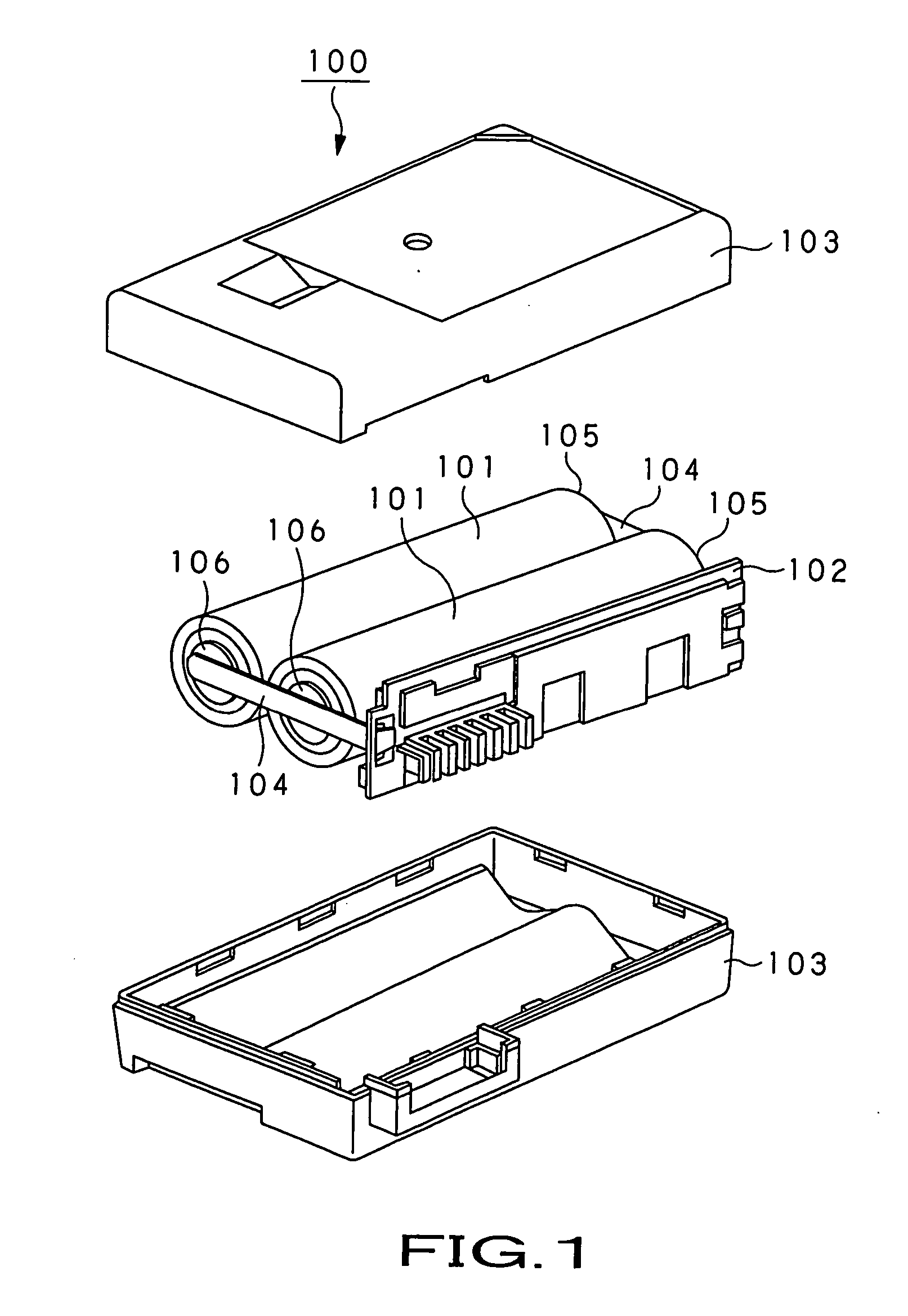

Electric contact and an electric connector both using resin solder and a method of connecting them to a printed circuit board

InactiveUS6717065B2Increase the cross-sectional areaGreat freedomTwo pole connectionsContact member assembly/disassemblyElectrical conductorEngineering

An electric contact using resin solder is connected to a printed circuit board, which has a conductor provided on a surface thereof. This electric contact comprises a leg, which contacts the conductor of the printed circuit board, and a connecting part, which is connected to the conductor of the counterpart member. At least a part of the leg, which contacts the conductor of the printed circuit board, is made of a lead-free ultrahigh-conductive plastic being a conductive resin composite. An electric connector includes the electric contact and an insulating housing, which holds the electric contact so that the part of the leg, which contacts the conductor of the printed circuit board, is exposed.

Owner:JST MFG CO LTD

Chemically attached coaxial connector

ActiveUS7331820B2Increase volumeOptimize volumeRelieving strain on wire connectionSoldered/welded conductive connectionsCoaxial cableChemical composition

A coaxial connector for attaching the end of a coaxial cable to an equipment port includes a tubular post, a coupler, a body member having a cylindrical sleeve, and one or more reservoirs containing a chemical component disposed between the post and the cylindrical sleeve. Insertion of the coaxial cable into the connector opens the reservoir, releases the chemical component, and secures the jacket of the cable within the cylindrical sleeve. The chemical component(s) can include an adhesive, a volume-expanding material, and / or an agent that swells the jacket of the cable. Two or more chemical components may be stored in two or more adjacent reservoirs.

Owner:PPC BROADBAND INC

Circuit boards interconnected by overlapping plated through holes portions

ActiveUS8007286B1Point-like light sourceSoldered/welded conductive connectionsEngineeringElectrical and Electronics engineering

In some embodiments, an interconnectable circuit board may include one or more of the following features: (a) a first electrically conductive pad located on a top of the circuit board, (b) a plated through hole on the conductive pad which passes through the circuit board, (c) a second electrically conductive pad coupled to the plated through hole; the second conductive pad capable of being electrically connected to a third electrically conductive pad attached to a top of a second interconnectable circuit board, (d) cut marks indicating safe locations for separating the circuit board, and (e) a second cut mark adjacent to the first cut mark where the area between the first and second cut mark can be utilized to make a safe cut through the circuit board.

Owner:METROSPEC TECH

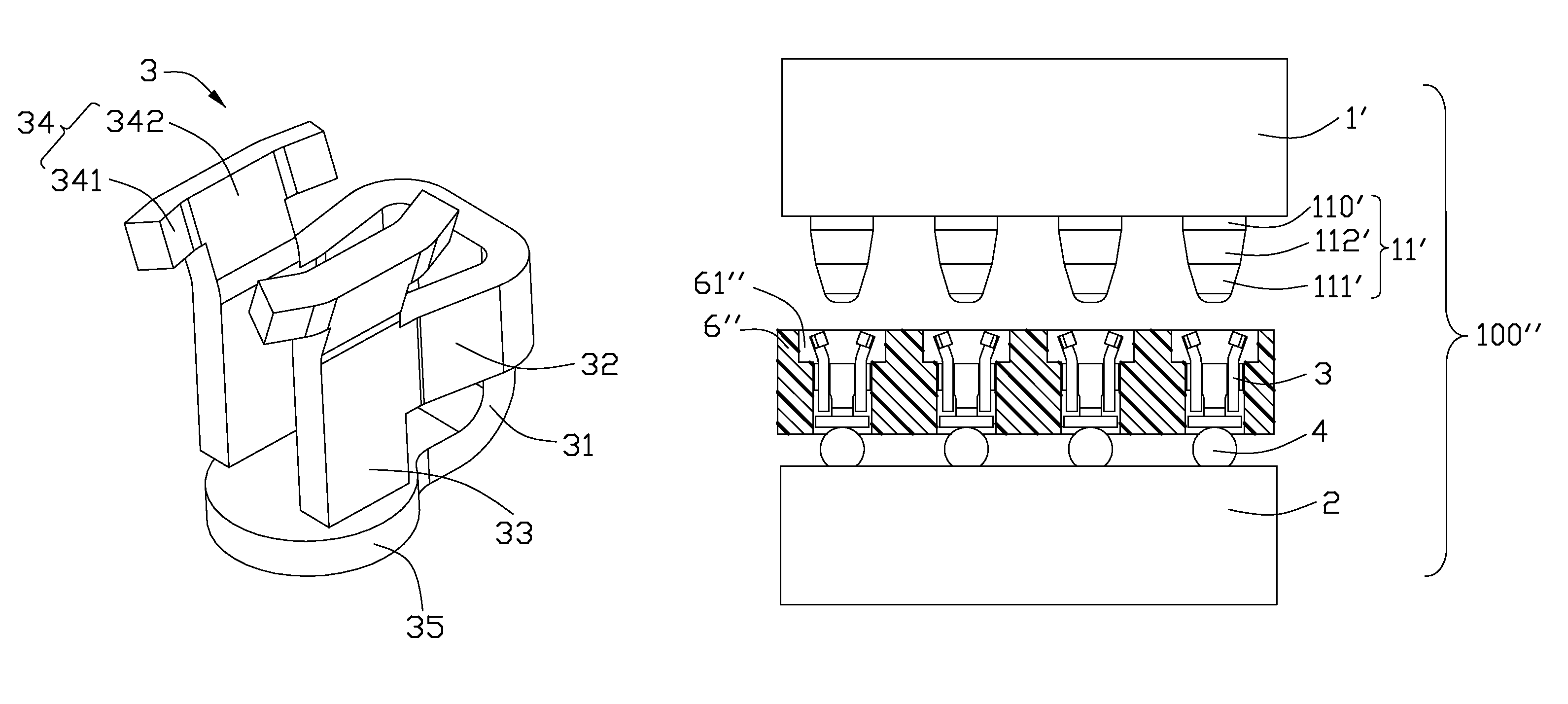

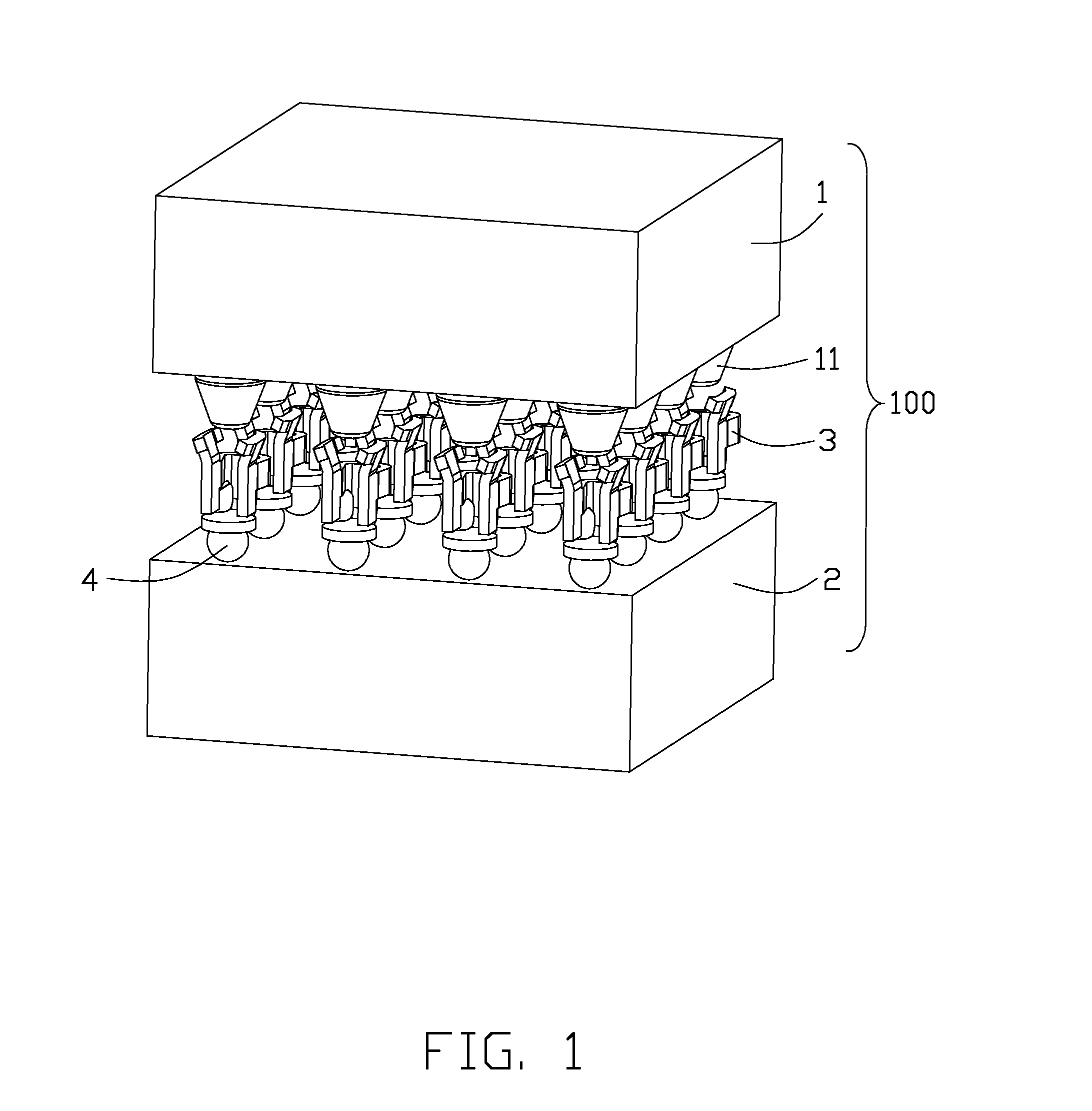

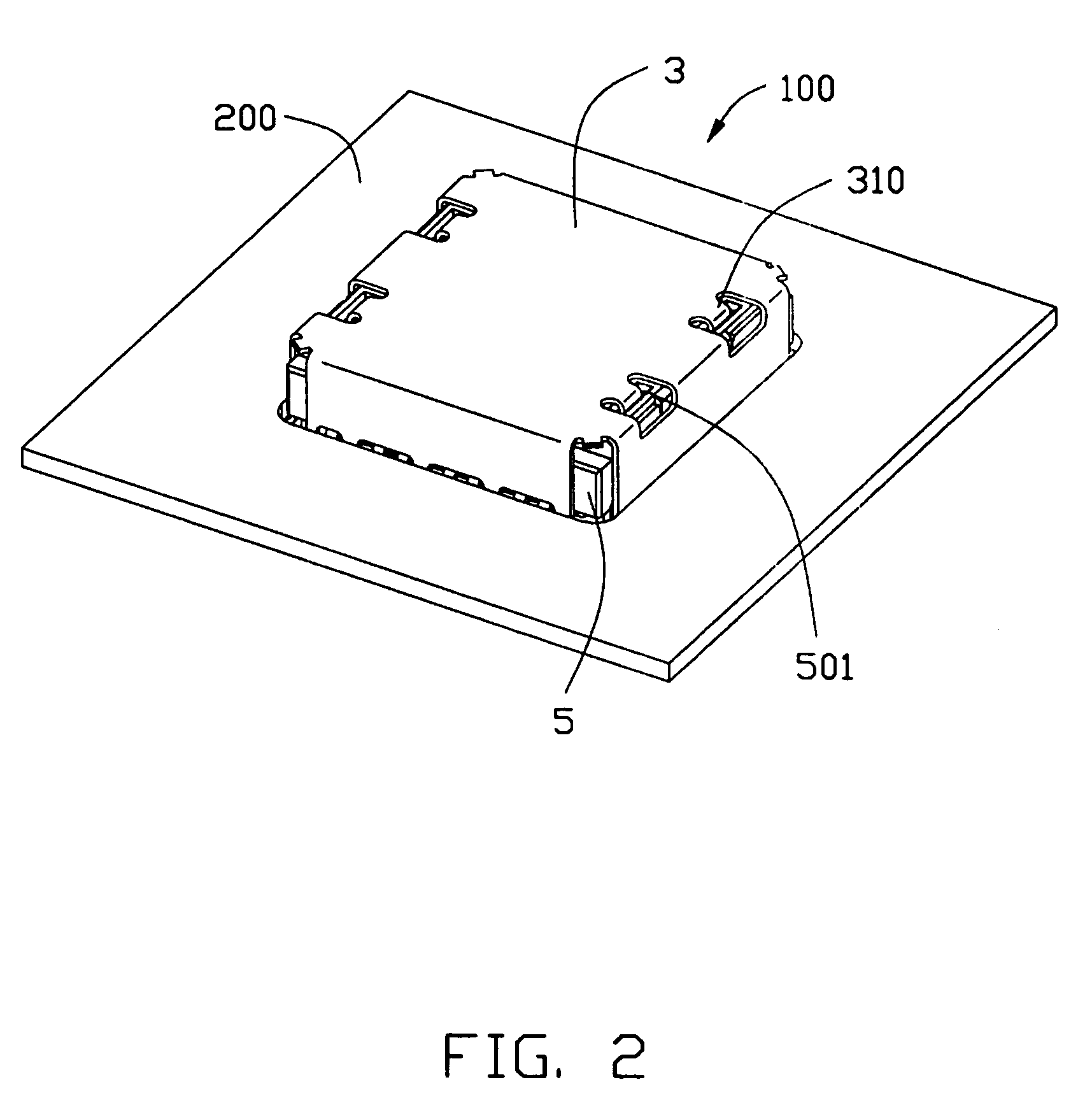

Electrical connector assembly having electrical connector with low profile and processor with cone pins

InactiveUS8172591B2Low profileProtection pinIncorrect coupling preventionSoldered/welded conductive connectionsEngineeringElectrical connector

Owner:HON HAI PRECISION IND CO LTD

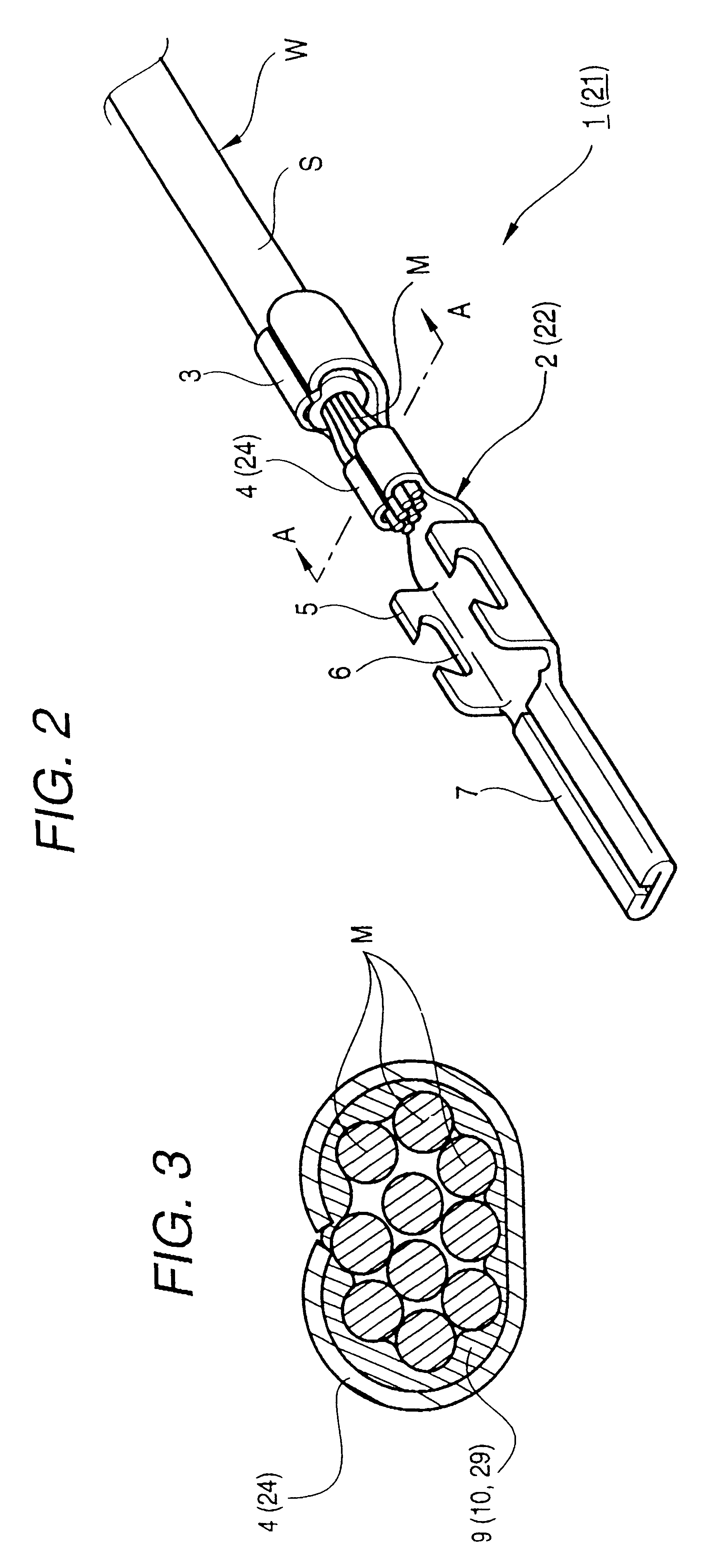

Method of connecting wire and terminal fitting

InactiveUS7374466B2Treatment effectAvoid damageSoldered/welded conductive connectionsCoupling contact membersElectric wireElectrical and Electronics engineering

A method of connecting a terminal fitting and an electric wire, includes the steps of: providing a terminal fitting; providing an electric wire in which a core wire is covered with an insulating sheath; providing a conductive connecting member formed with an insertion hole; inserting the electric wire into the insertion hole of the connecting member; compressing the connecting member radially inwardly so as to caulk an inserted portion of the electric wire uniformly over a whole periphery thereof; and welding the connecting member and the terminal fitting by applying ultrasonic wave.

Owner:YAZAKI CORP

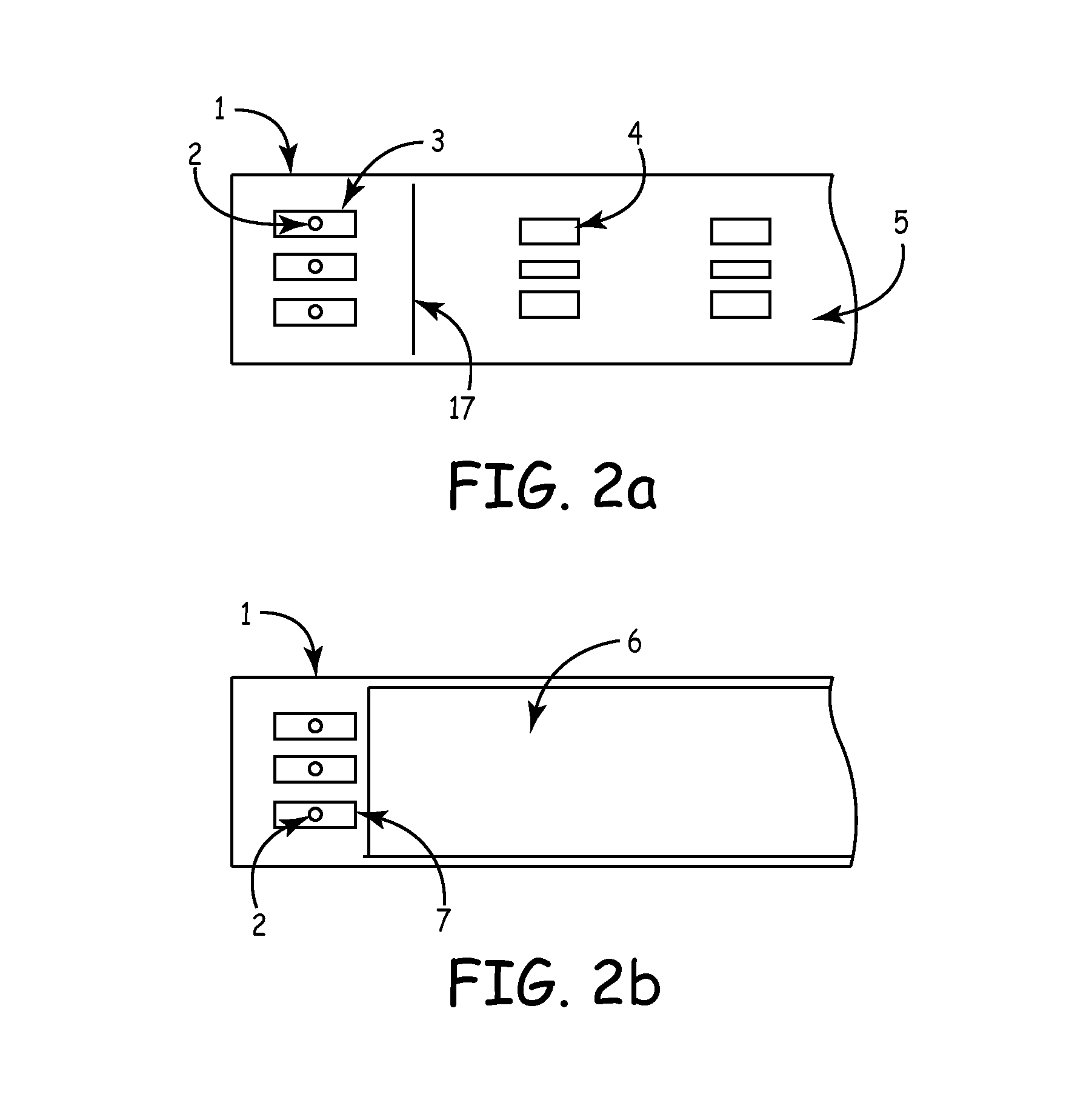

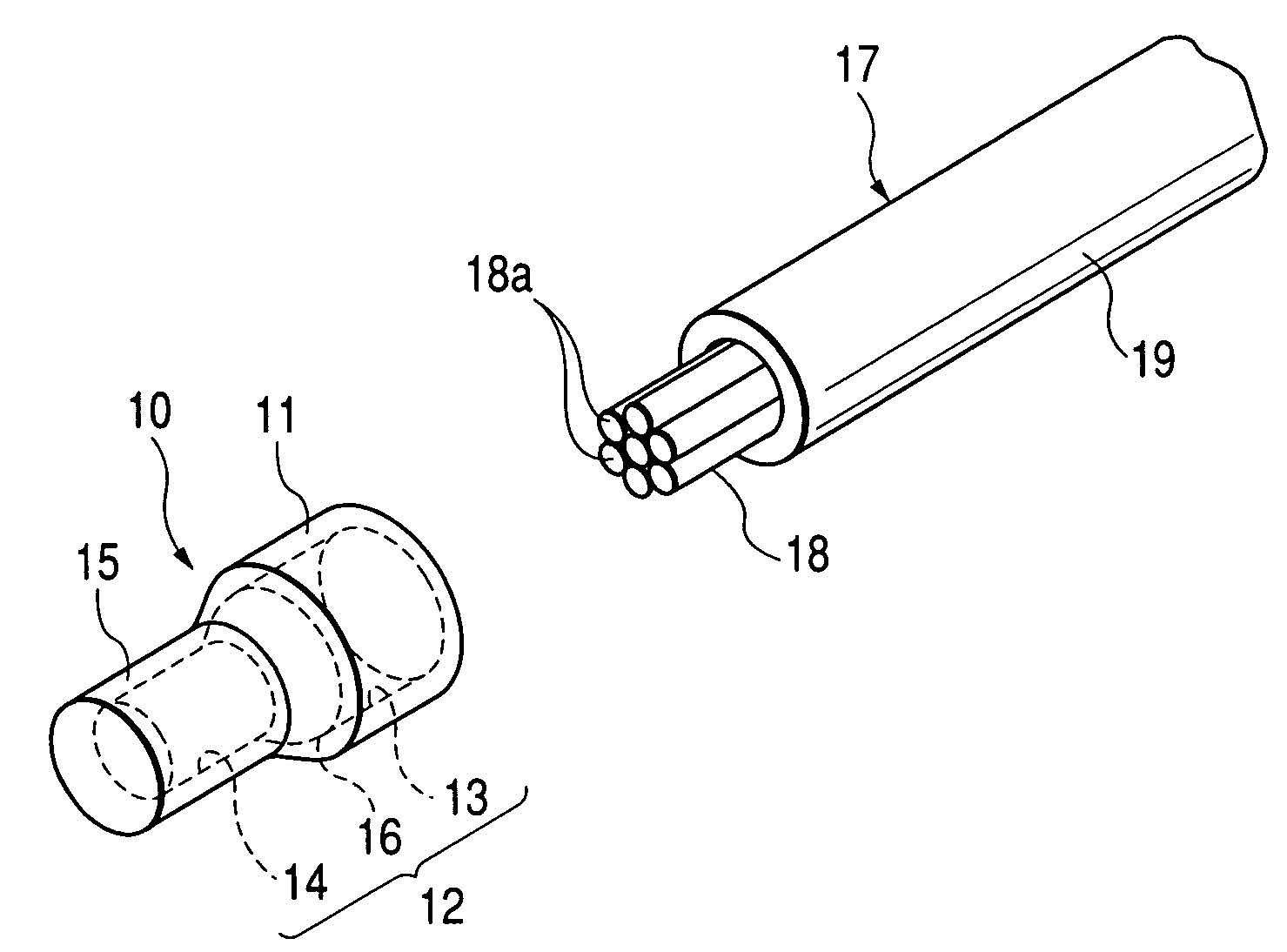

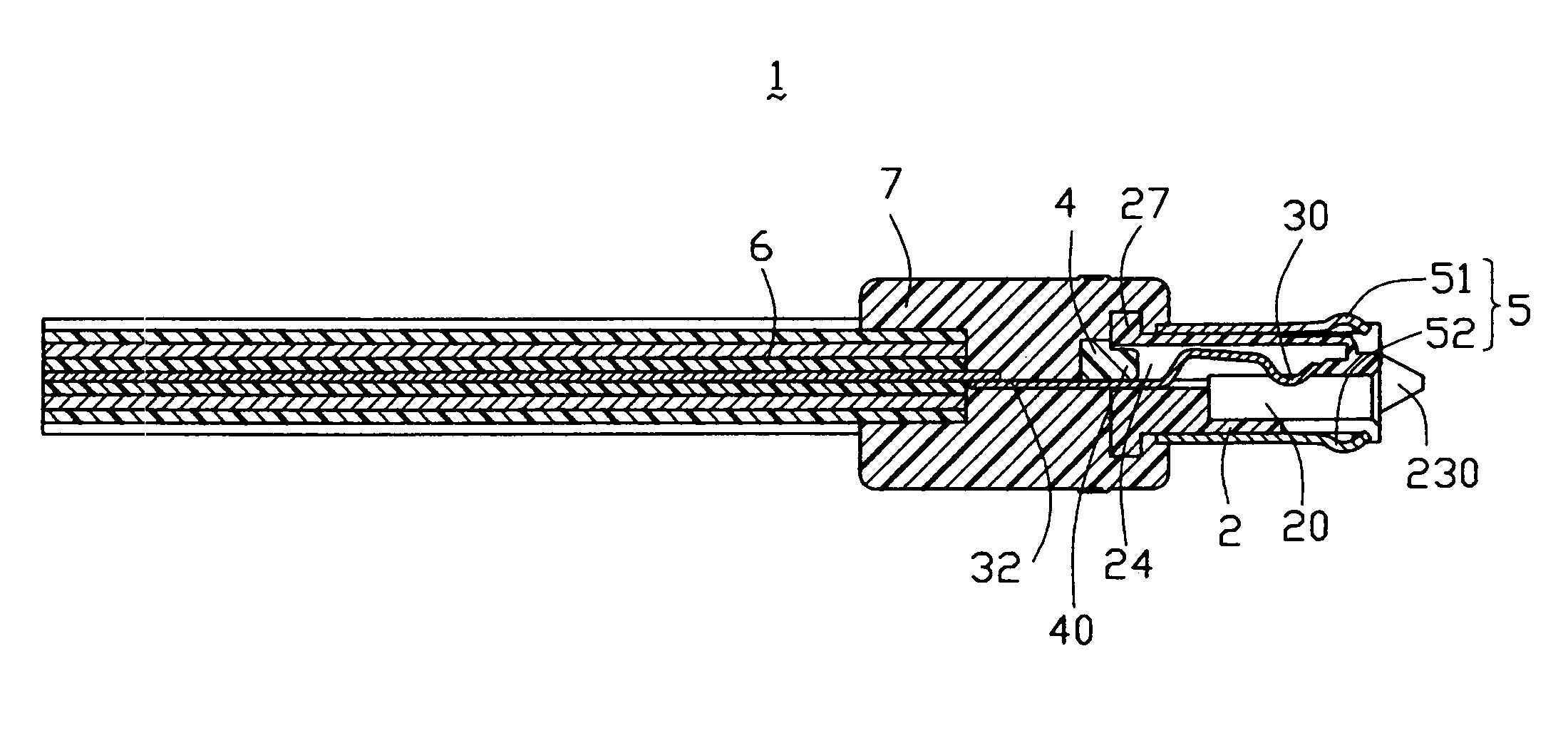

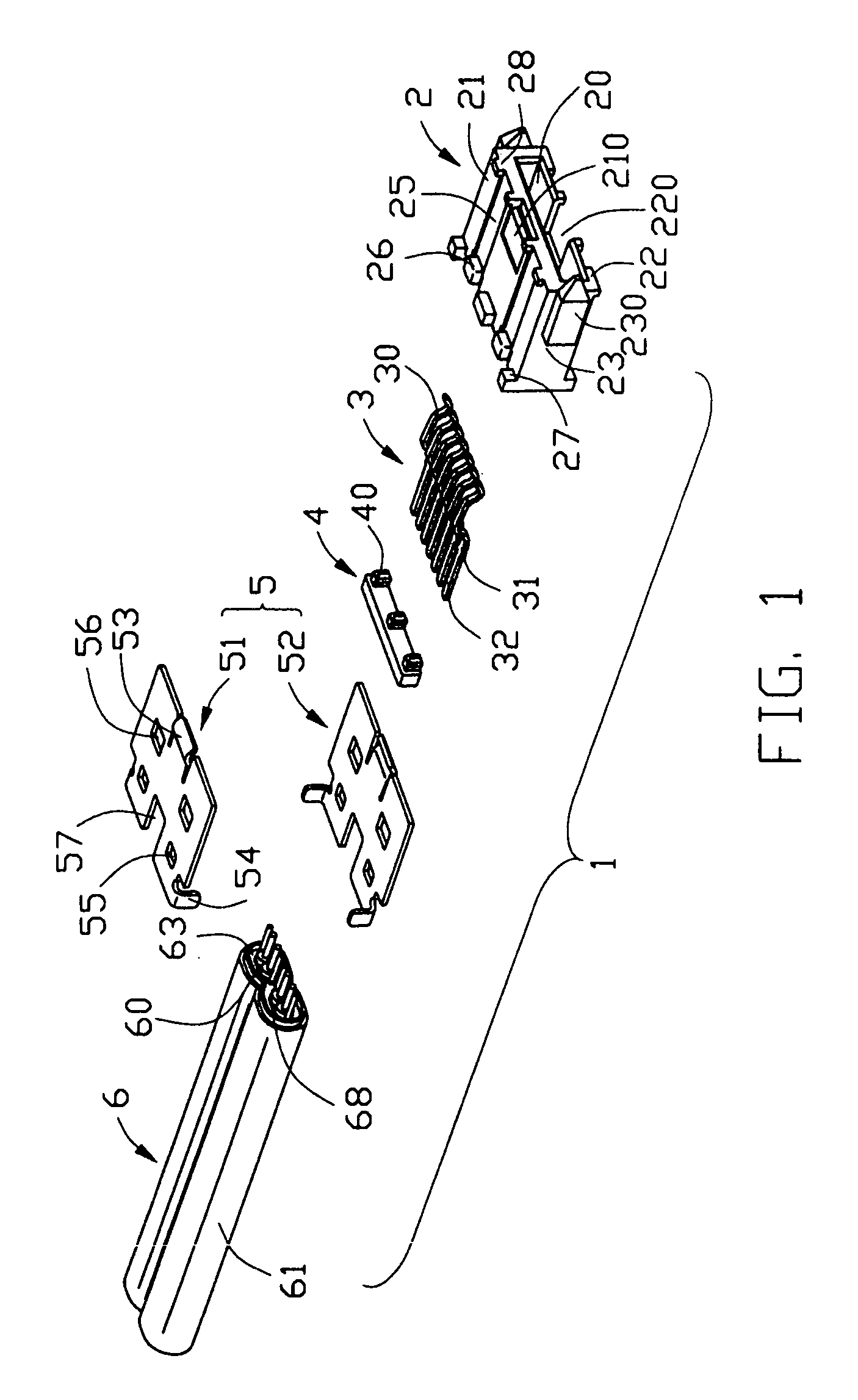

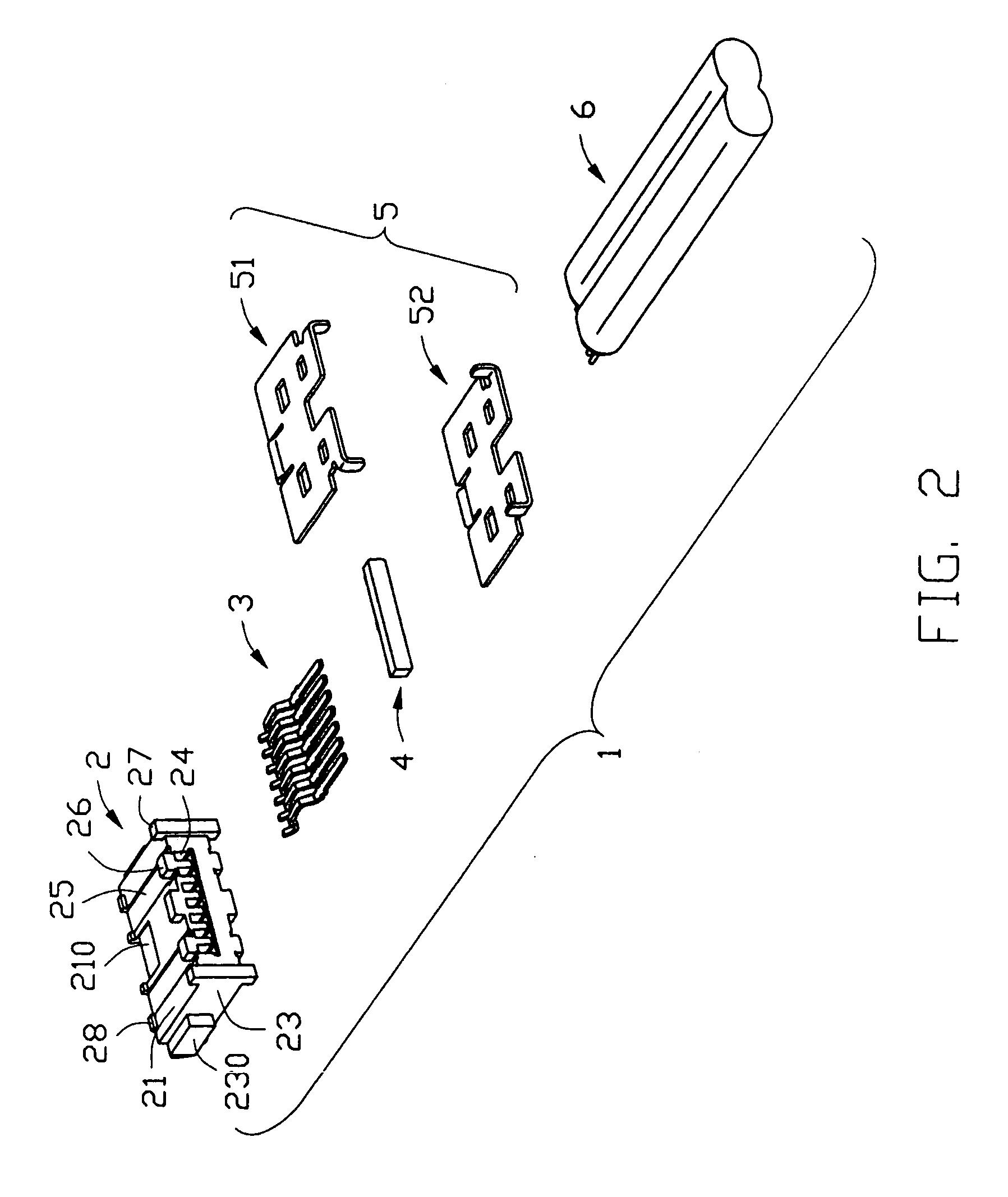

Shielded cable end connector assembly

InactiveUS6910914B1Better shielding protectionRelieving strain on wire connectionSoldered/welded conductive connectionsShielded cableElectrical conductor

A cable end connector assembly (1) includes an insulative housing (2), a number of contacts (3) assembled to the insulative housing in a back-to-front direction, a shielding member (5) assembled to the insulative housing, a cable (6) including a number of signal conductors (62) and drain wires (64) respectively soldered with the contacts, and an insulative cover (7) over-molding rear portions of the insulative housing and the shielding member and a front end of the cable. The housing includes an upper wall (21), a lower wall (22) and a pair of sidewalls (23) connecting with the upper and the lower walls. The shielding member includes a first and a second shielding halves (51, 52) respectively attached to the upper wall and the lower wall of the insulative housing.

Owner:HON HAI PRECISION IND CO LTD

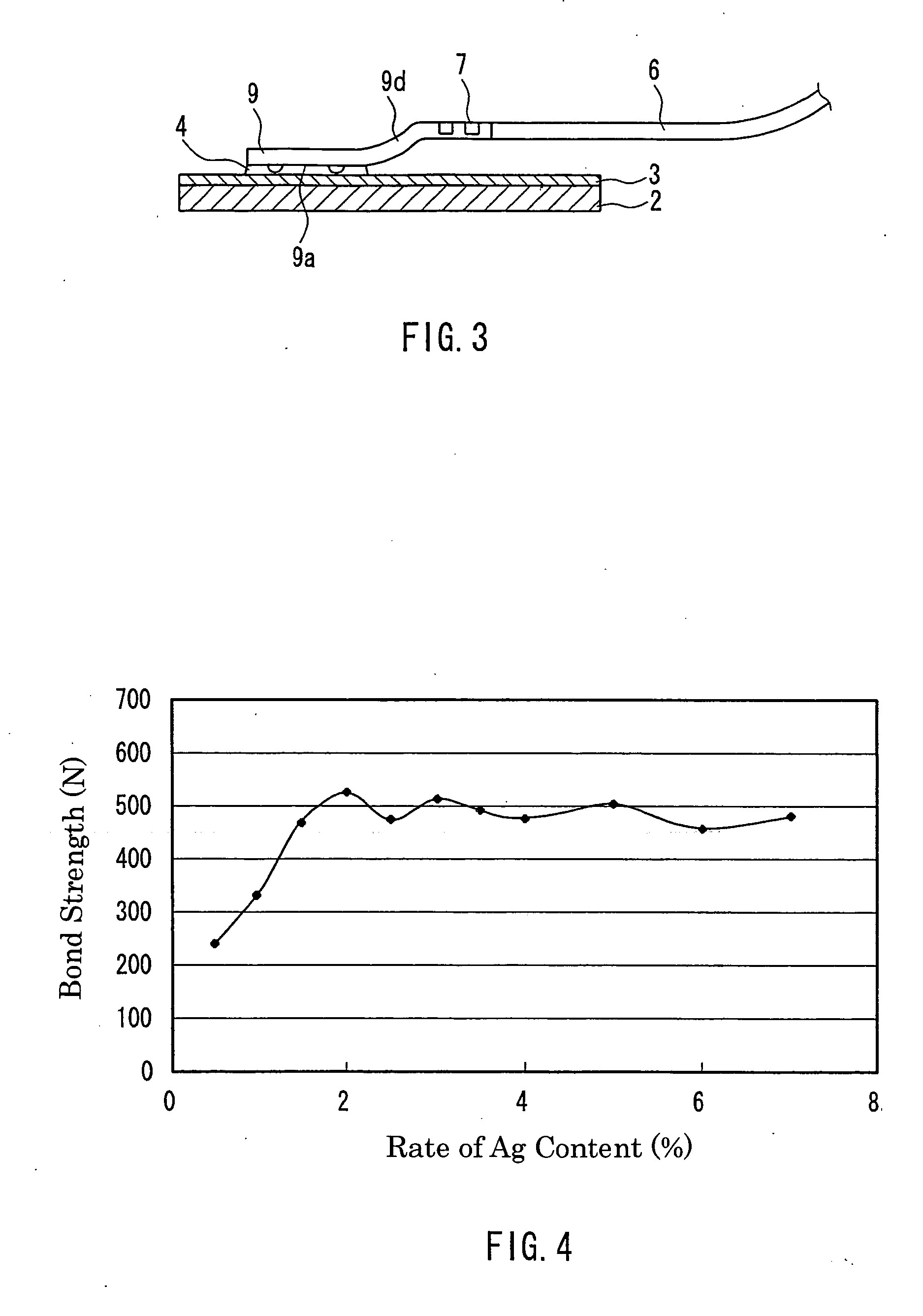

Glass fixture-joined glass article and joint structure using this

ActiveUS20050112291A1Reduced strengthReduce crackingLiquid surface applicatorsAntenna connectorsSilver pasteFrit

The present invention is intended to provide a glass article with a metal member joined thereto in which an electroconductive coating film is formed on at least a part of the surface of the glass article by baking a silver paste that includes Ag particles and a glass frit, a joining plane of the metal member is fixed onto the electroconductive coating film with a lead-free solder alloy containing Sn as a main component, and the lead-free solder alloy contains at least 1.5 mass % of Ag, which prevents the appearance of the electroconductive coating film and the bonding strength from degrading. Furthermore, in the present invention, when using a metal member having at least two joining planes, the total area of the joining planes is set within a range of 37 mm2 to 50 mm2, which allows high bonding strength between the glass article and metal member to be maintained while using the lead-free solder alloy. Moreover, in the present invention, the volume of the lead-free solder alloy to be provided on each joining plane is set to be 1.0 to 2.0 times the product of the area of the joining plane concerned and the thickness of the lead-free solder alloy, which prevents cracks from occurring in the glass article.

Owner:NIPPON SHEET GLASS CO LTD

Connector having improved contacts with fusible members

ActiveUS6969286B1Good coplanarityFirmly connectedPrinted circuit assemblingLine/current collector detailsEngineeringElectrical connector

An electrical connector includes a connector body, a plurality of cores and a plurality of electrically conductive contacts disposed in the cores of the connector body. Each of the contacts includes a fusible member attached thereto. Each of the fusible members includes an intermediate portion and two support members disposed on opposite sides of the intermediate portion. The support members are arranged to hang down below a tail portion of the contacts.

Owner:SAMTEC

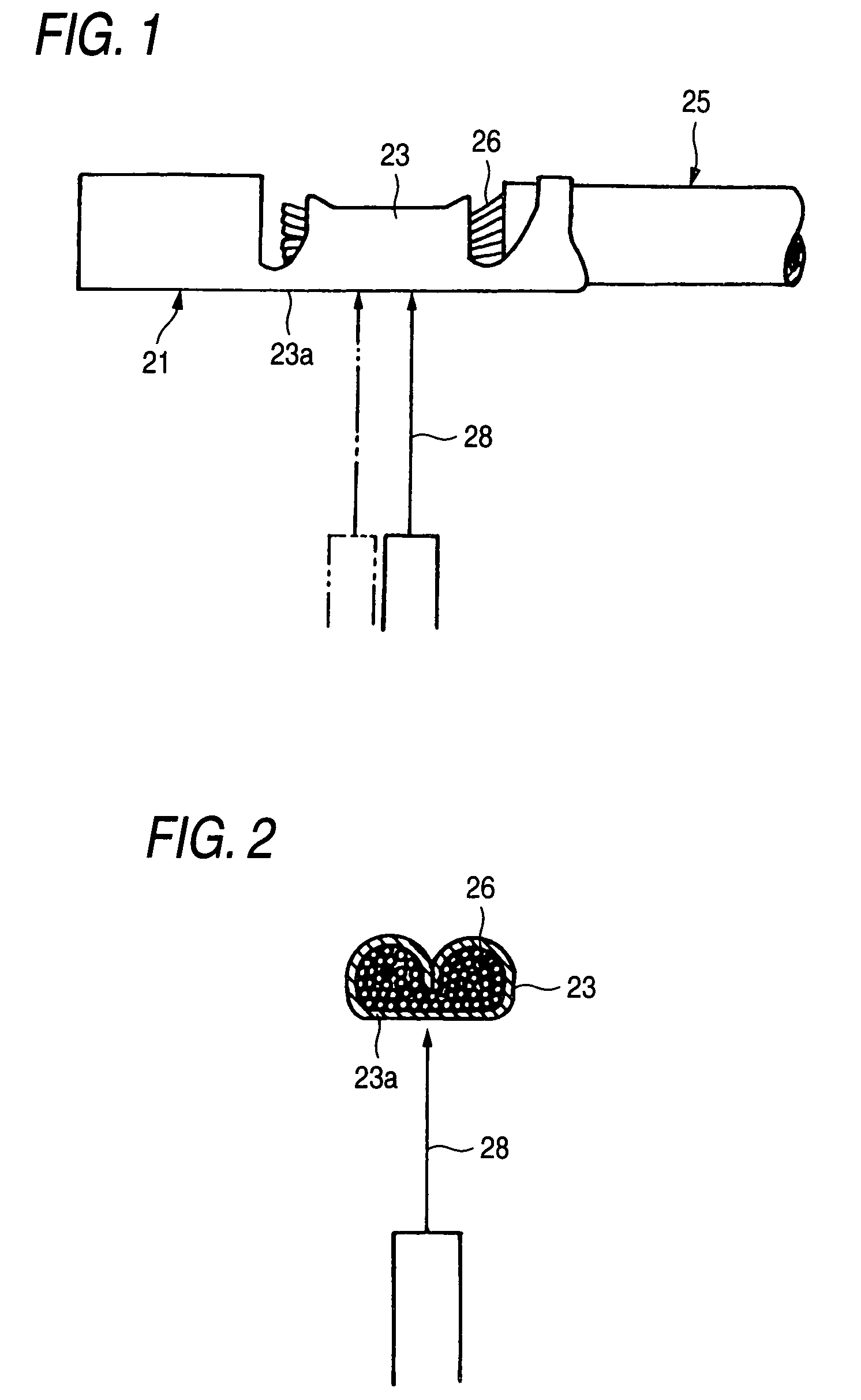

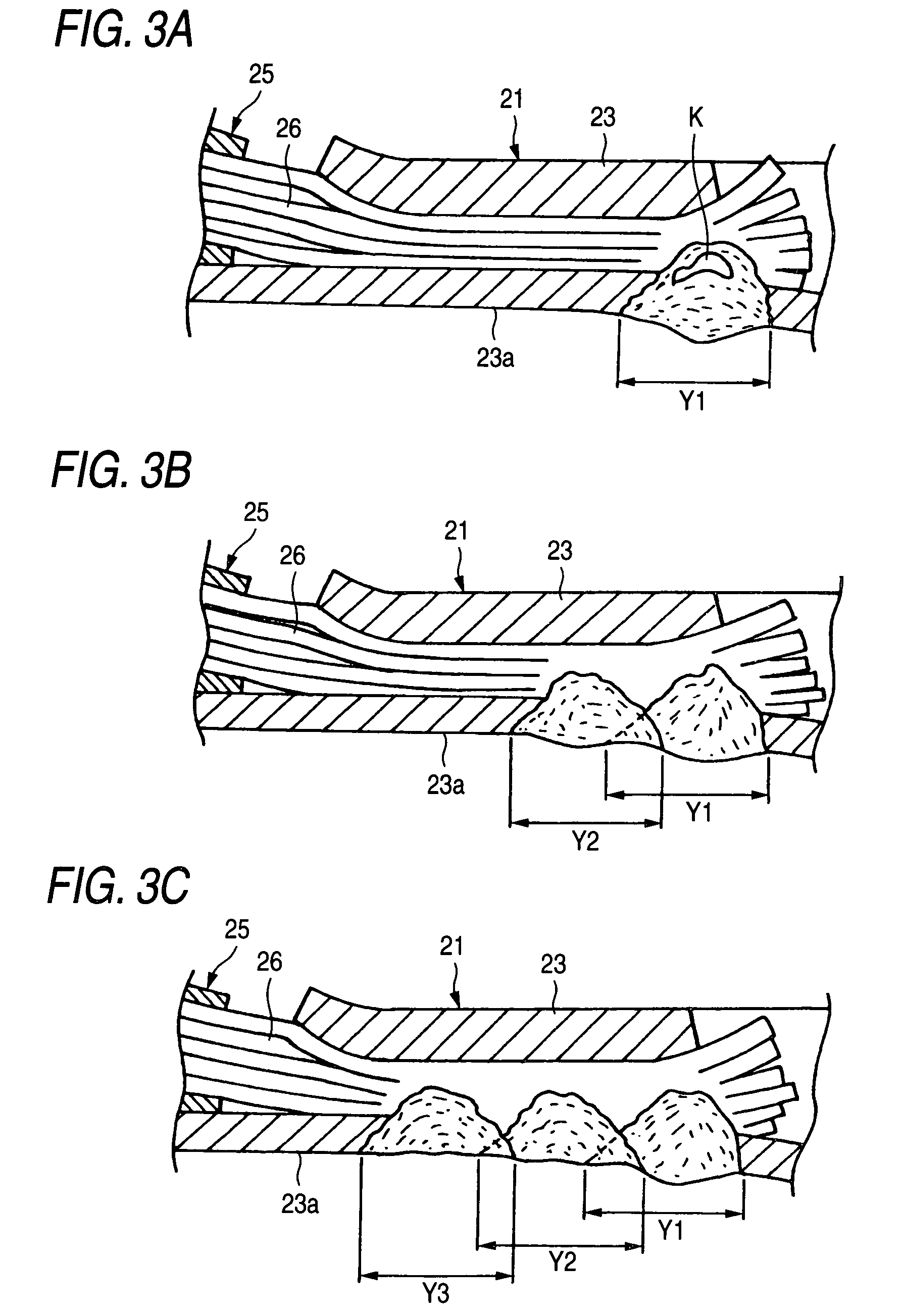

Method of connecting and structure of connecting electric wire and connection terminal

InactiveUS7705265B2Easy to connectIncreasing costSoldered/welded conductive connectionsConnections effected by permanent deformationElectrical conductorIrradiation

After bringing a conductor of an electric wire into press contact to connect with a wire caulking portion of a connection terminal, the conductor and the wire caulking portion are welded to connect by irradiating laser beam to a bottom wall of the wire caulking portion. Laser irradiation is carried out intermittently by three times and the laser irradiation at the second time and thereafter which is carried out later is carried out such that during a time period in which a laser welded portion immediately previously is brought into a predetermined state of elevating temperature, portions or welded regions overlap welded regions in laser irradiation irradiated previously.

Owner:YAZAKI CORP

Terminal assembly for a coaxial cable

InactiveUS20050054237A1Coupling device detailsSoldered/welded conductive connectionsDielectricCylindrical channel

A terminal for a coaxial cable includes an electrically conductive core mounted in a dielectric member. The dielectric member along with the conductive core are positioned within an electrically conductive ground shield. The ground shield includes two identical split-barrel housing members which are joined together. When joined, the housing members form a cylindrical channel having surfaces which intimately contact an exposed length of cable outer conductor layer, creating a conductive connection between the outer conductor layer and the ground shield and structurally maintaining the outer conductor layer concentric to the dielectric sheath and inner conductor of the cable.

Owner:DELPHI TECH INC

Shielding for electrical cable assemblies

An electrical cable assembly is provided including multiple cables having wires. The cables each include a shield. A connector receives ends of the wires and includes an outer surface. A conductive shield ring has an outer periphery and includes multiple holes receiving the cables. The shield of each cable engages an inner surface provided by a corresponding hole in the shield ring. In one example, the circumference of each shield is soldered to the corresponding hole. A wrap engages the outer periphery and the outer surface to electrically connect the connector to the shields. In one example, the wrap is conductive heat shrink wrap that surrounds and engages the entire outer surface of the shield ring.

Owner:HAMILTON SUNDSTRAND CORP

Reflowed solder ball with low melting point metal cap

InactiveUS6259159B1Low costEasy to buildPrinted circuit assemblingFinal product manufactureTinningIndium

A method and structure for a solder interconnection, using solder balls for making a low temperature chip attachment directly to any of the higher levels of packaging substrate is disclosed. After a solder ball has been formed using standard methods it is reflowed to give the solder ball a smooth surface. A layer of low melting point metal, such as, bismuth, indium or tin, preferably, pure tin, is deposited on the top of the solder balls. This structure results in localizing of the eutectic alloy, formed upon subsequent low temperature joining cycle, to the top of the high melting solder ball even after multiple low temperature reflow cycles. This method does not need tinning of the substrate to which the chip is to be joined, which makes this method economical. It has also been noticed that whenever temperature is raised slightly above the eutectic temperature, the structure always forms a liquid fillet around the joint with copper wires. This liquid fillet formation results in substantial thermal fatigue life improvement for reduced stress at interface; and secondly, provides an easy means to remove chip for the purpose of chip burn-in, replacement or field repairs.

Owner:IBM CORP

Surface mount poke in connector

ActiveUS7513793B2Reduce shadowsLow profileLine/current collector detailsFinal product manufactureSurface mountingEngineering

A surface mount poke in connector is disclosed for mounting upon a surface of a printed circuit board, and is particularly applicable for printed circuit boards supporting LEDs. The connector has a securing means for engaging an inserted wire lead without the use of solder.

Owner:TYCO ELECTRONICS LOGISTICS AG (CH)

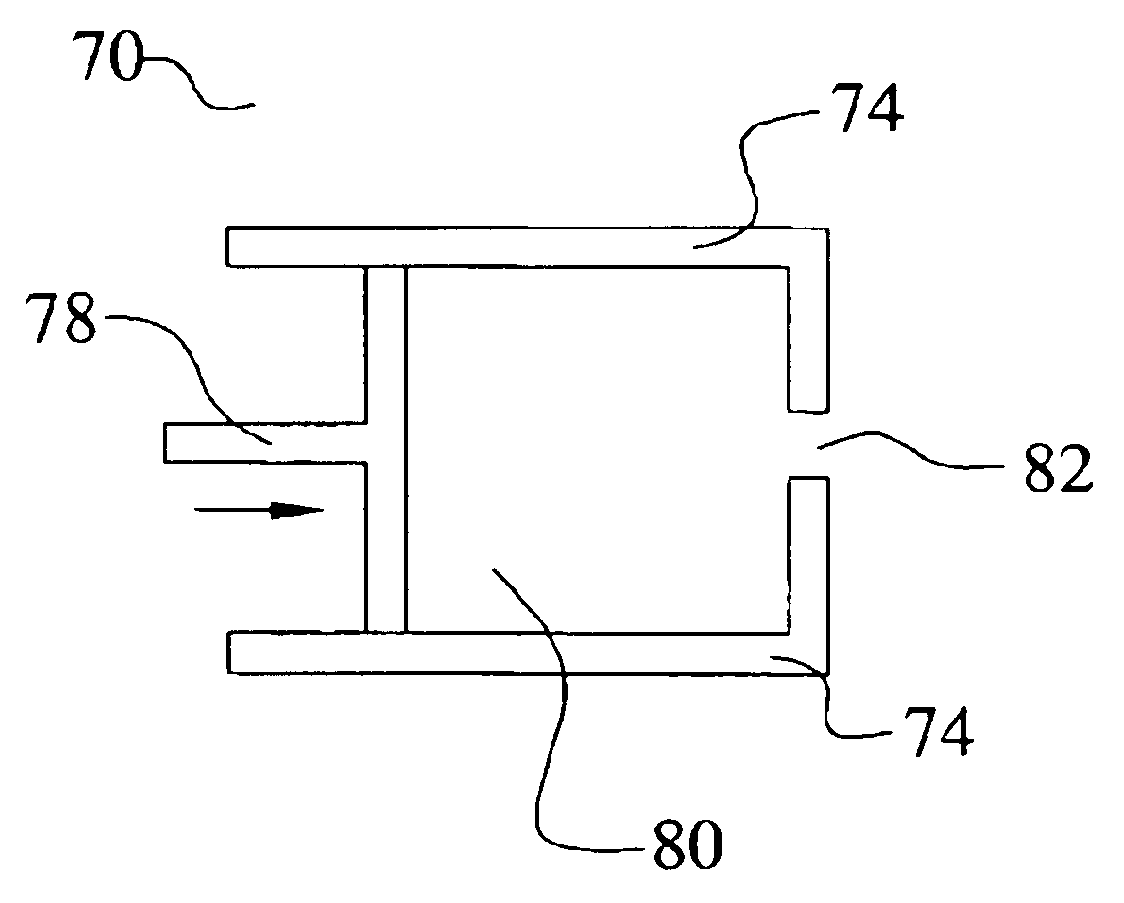

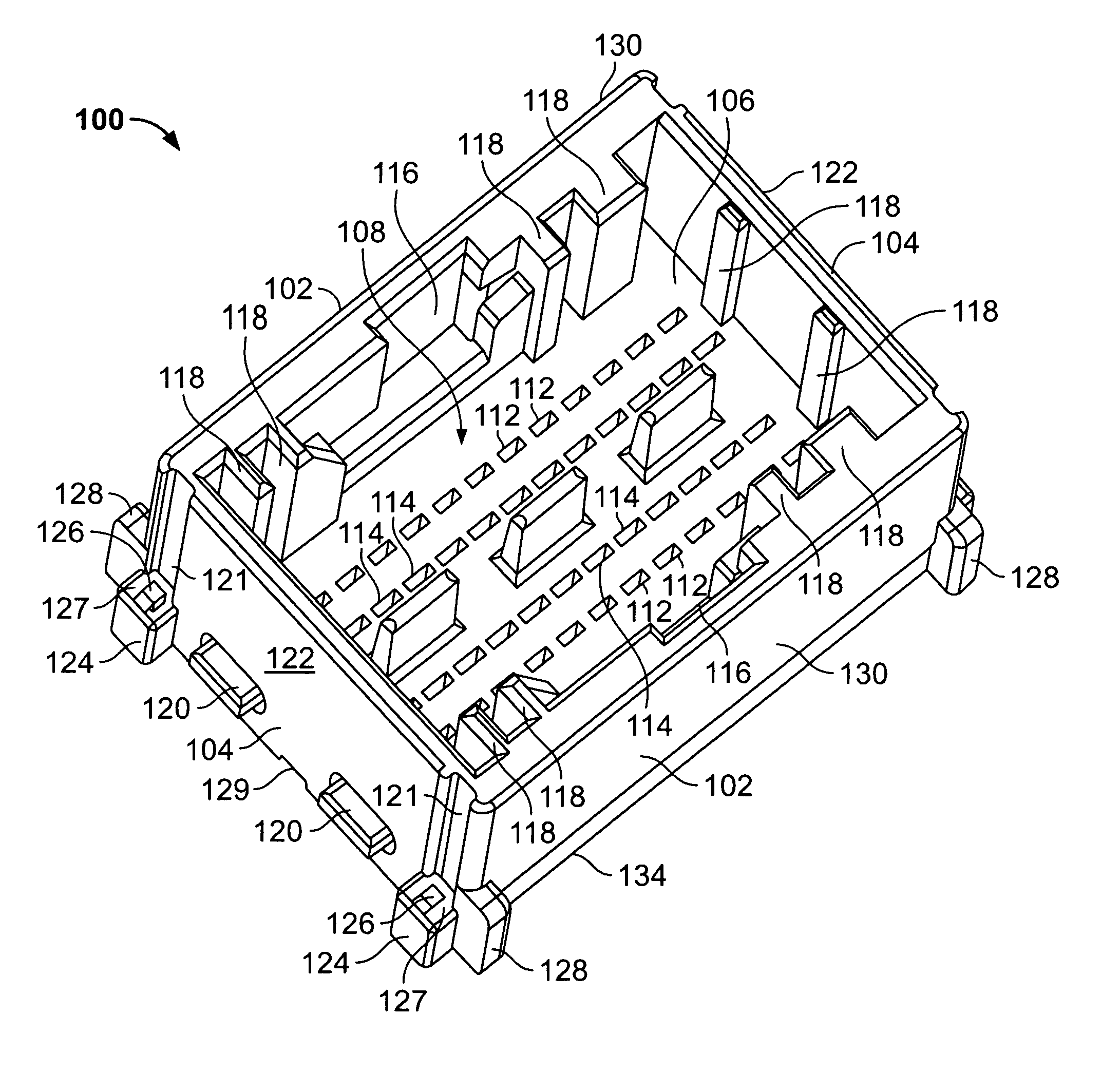

Two piece surface mount header assembly having a contact alignment member

InactiveUS7086872B2Ensure coplanarityVehicle connectorsContact member assembly/disassemblySurface mountingEngineering

A header assembly includes an insulative contact housing having a plurality of walls defining an interior cavity and an insulative alignment housing having at least one alignment rib extending on an exterior surface thereof. The alignment housing is separately provided and independently mounted to the contact housing. A plurality of contacts are included within the cavity and extend through one of the walls to an exterior of the contact housing wherein the contacts flex against the alignment housing and abut the alignment rib, thereby ensuring coplanarity of the contacts for surface mounting to a circuit board.

Owner:TYCO ELECTRONICS LOGISTICS AG (CH)

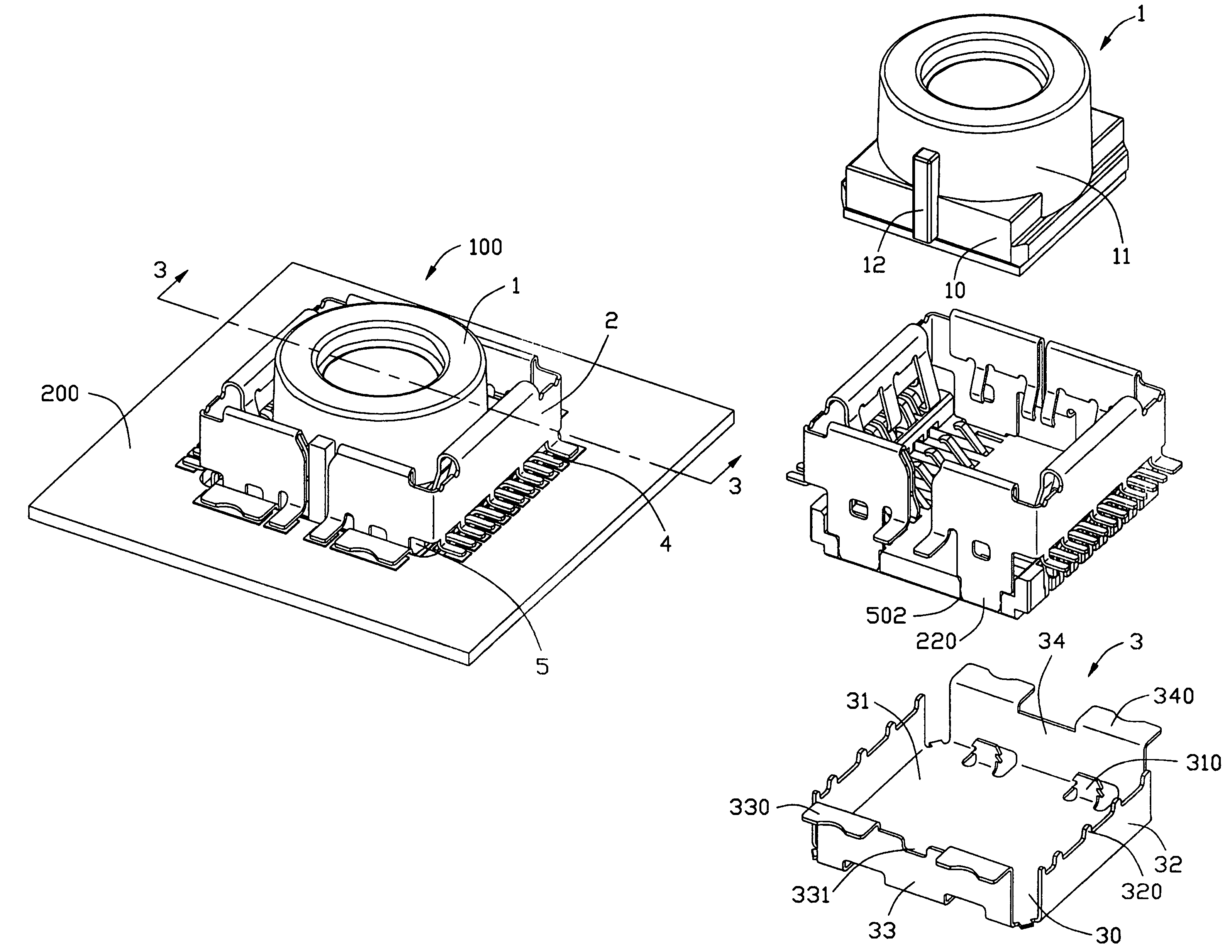

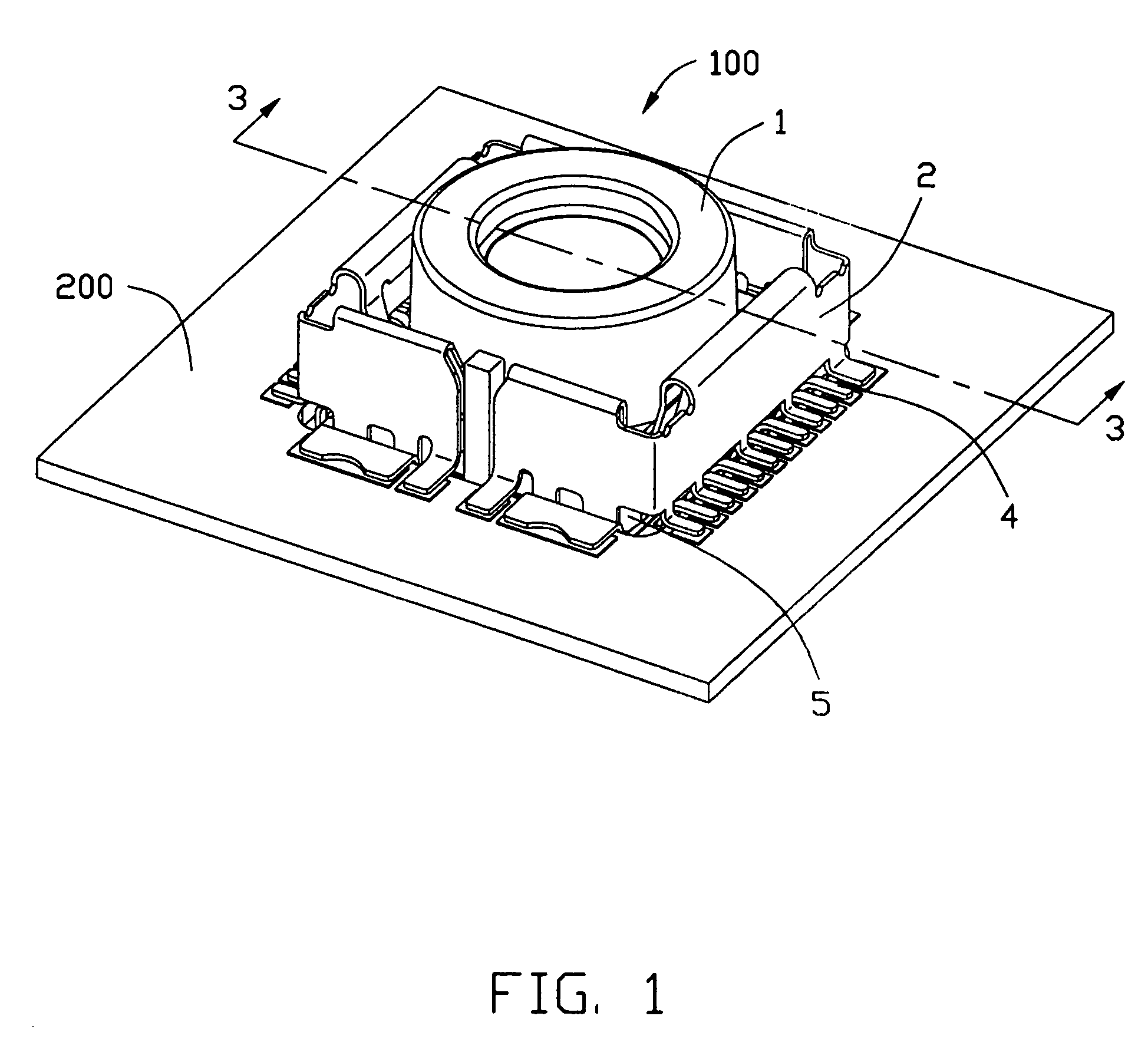

Connector with improved shielding member

InactiveUS7086902B1Effective protectionSoldered/welded conductive connectionsTwo-part coupling devicesElectromagnetic interferenceCamera module

An electrical connector (100) adapted for electrically connecting an electronic element (1) such as a camera module with a substrate (200) comprises a shielding member (2, 3), an insulated housing (5) and a number of contacts (4) retained in the housing. Each contact comprises a contact portion (41) for electrically contacting with the camera module and a solder portion (44) extending out the housing for being soldered on the substrate. The shielding member surrounds the housing to prevent the contact from unexpected Electro Magnetic Interference and comprises a plurality solder legs soldered on the substrate. The solder legs are arranged among the solder portions of the contacts. Typically, the distance between every two adjacent solder legs is not greater than 2.5 millimeters. Therefore, the shielding member can effectively prevents various unexpected interference affecting signal transmission of the camera module.

Owner:HON HAI PRECISION IND CO LTD

Bonding wire for semiconductor device

ActiveUS7952028B2Improve linearityImprove stabilityNon-insulated conductorsSoldered/welded conductive connectionsEngineeringThinning

A high-performance bonding wire that is suitable for semiconductor mounting technology, such as stacked chip bonding, thinning, and fine pitch mounting, where wire lean (leaning) at an upright position of a ball and spring failure can be suppressed and loop linearity and loop height stability are excellent. This bonding wire for a semiconductor device includes a core material made of a conductive metal, and a skin layer formed on the core material and containing a metal different from the core material as a main component; wherein a relationship between an average size (a) of crystal grains in the skin layer on a wire surface along a wire circumferential direction and an average size (b) of crystal grains in the core material on a normal cross section, the normal cross section being a cross section normal to a wire axis, satisfies an inequality of a / b≦0.7.

Owner:NIPPON MICROMETAL CO LTD +1

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com