Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

386 results about "Shrink wrap" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Shrink wrap, also shrink film, is a material made up of polymer plastic film. When heat is applied, it shrinks tightly over whatever it is covering. Heat can be applied with a handheld heat gun (electric or gas), or the product and film can pass through a heat tunnel on a conveyor.

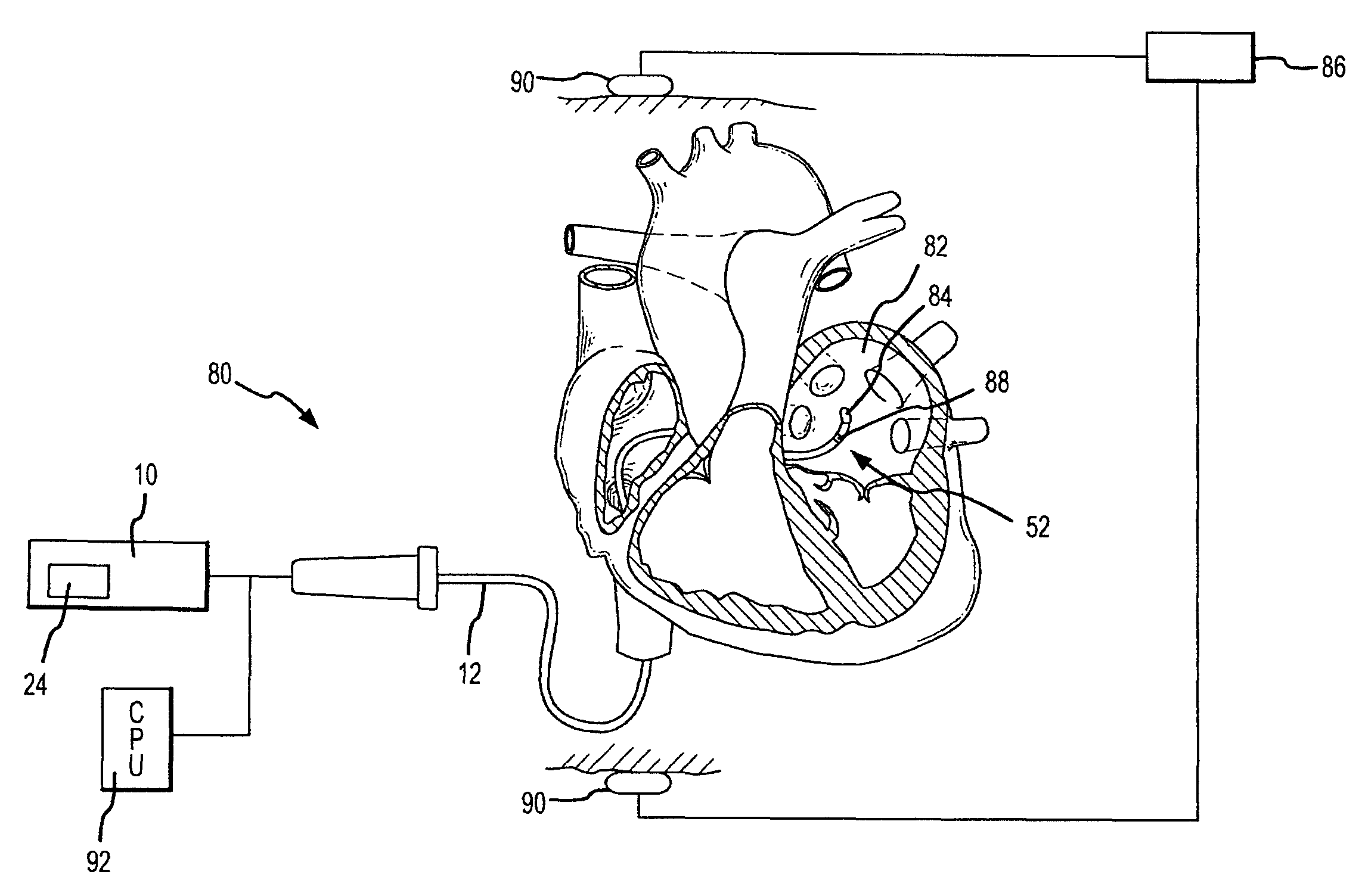

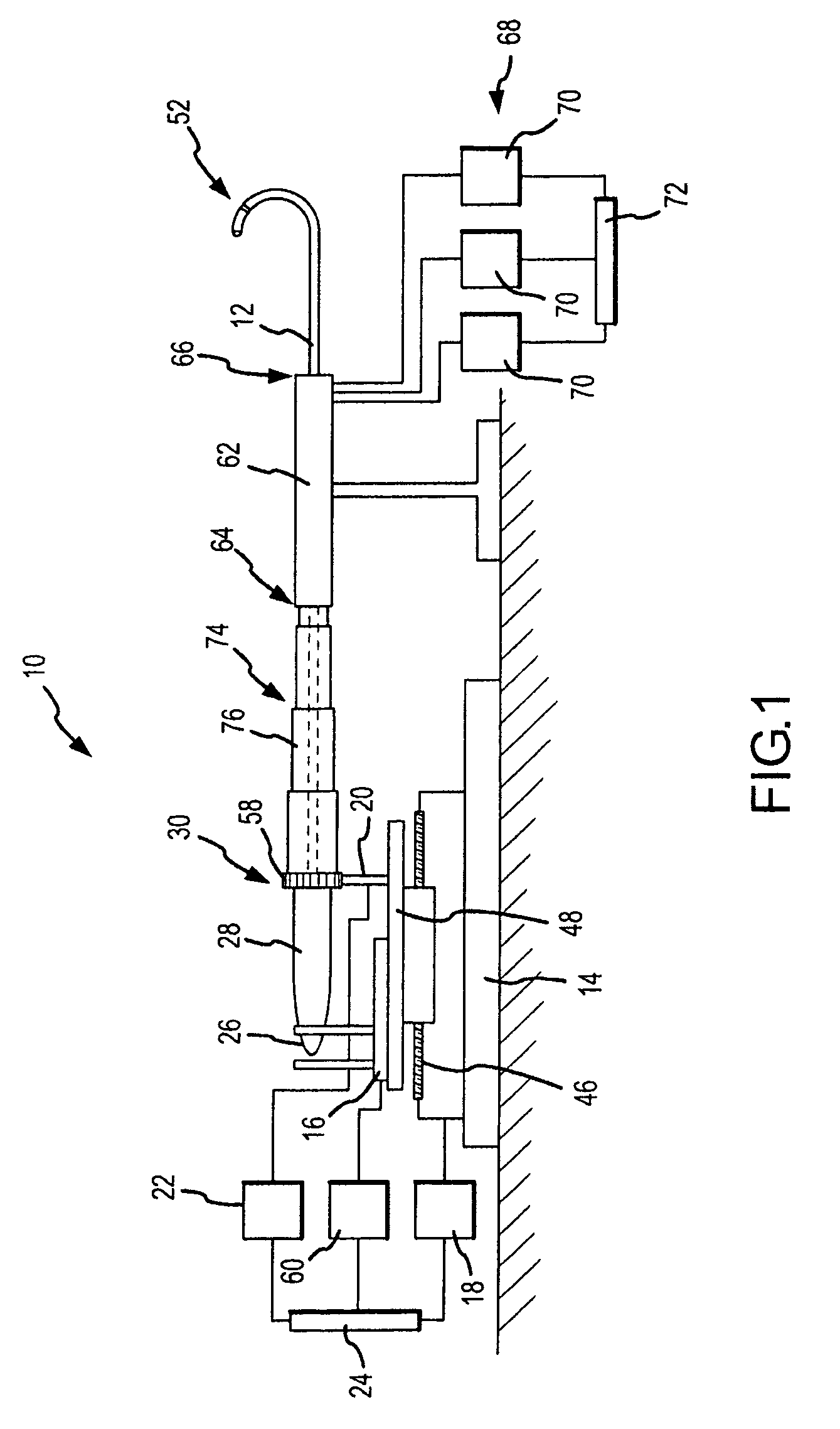

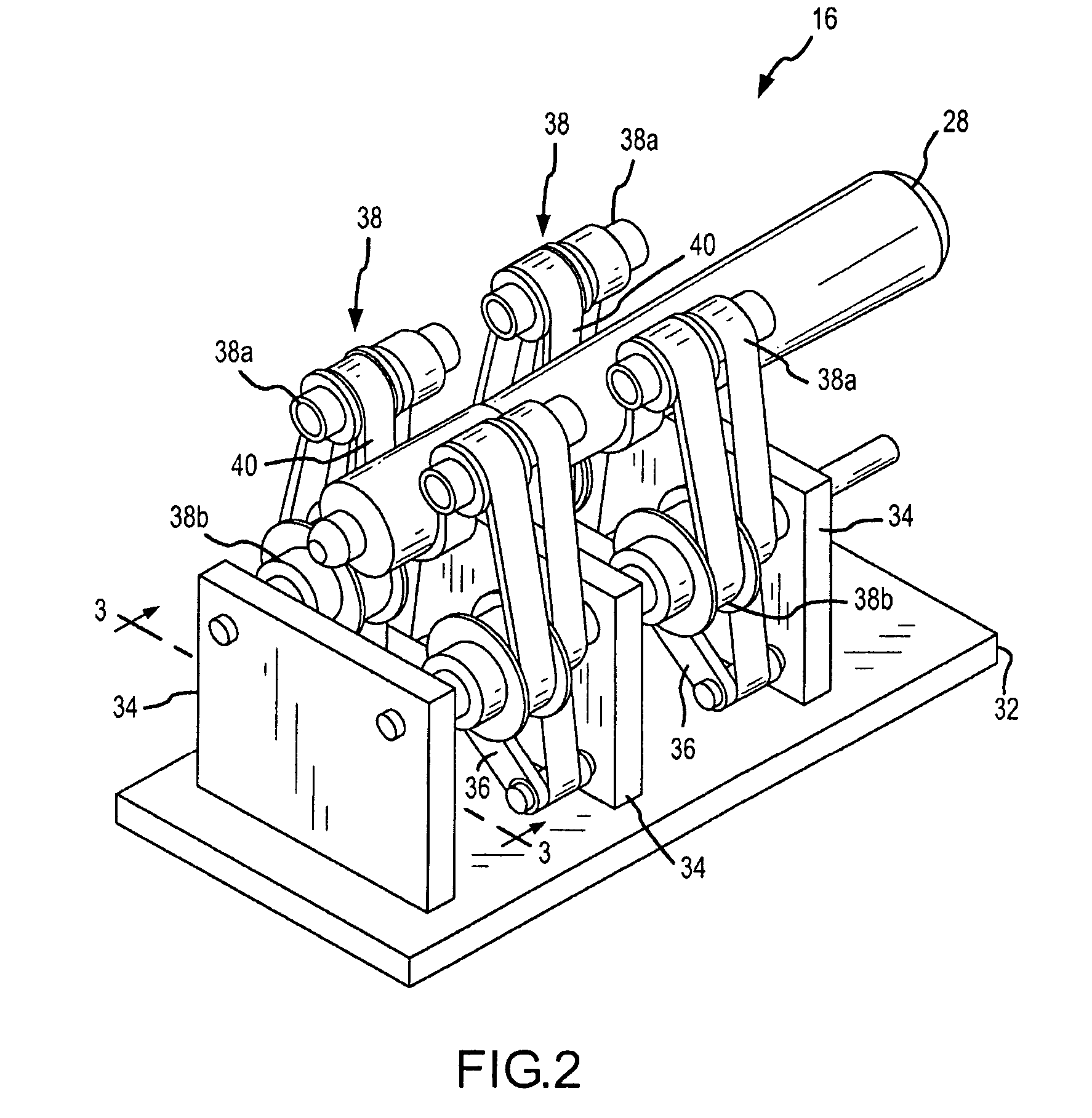

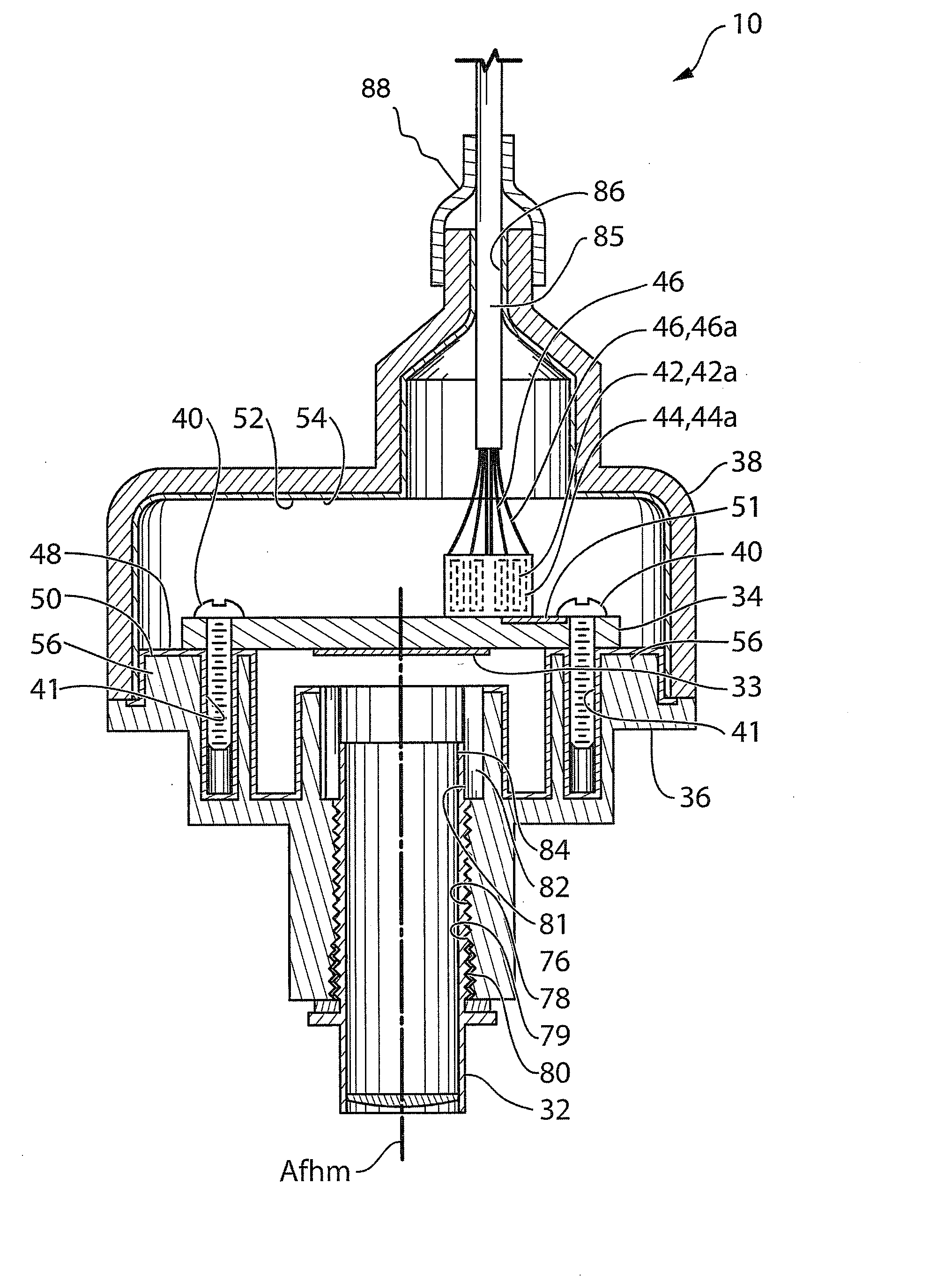

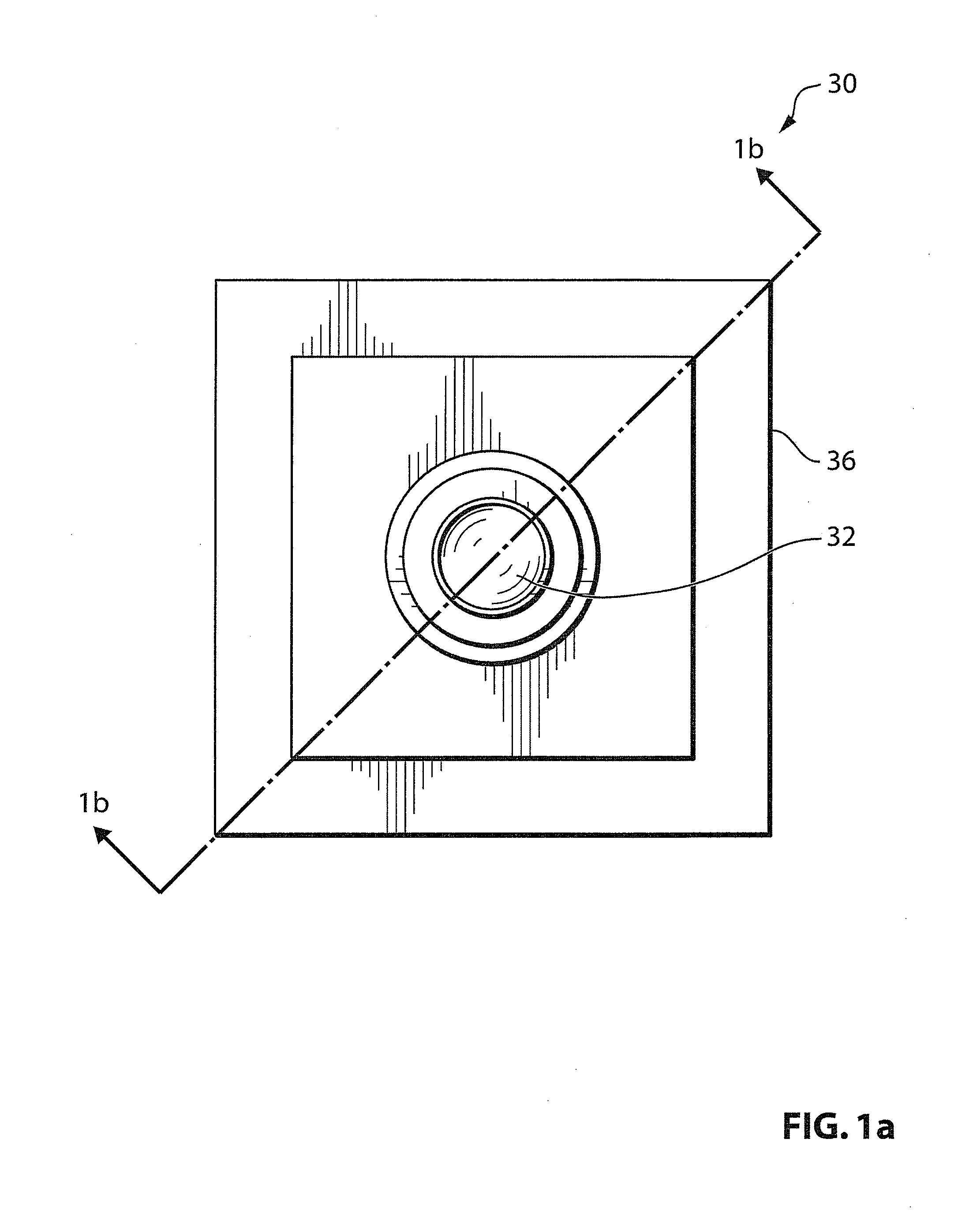

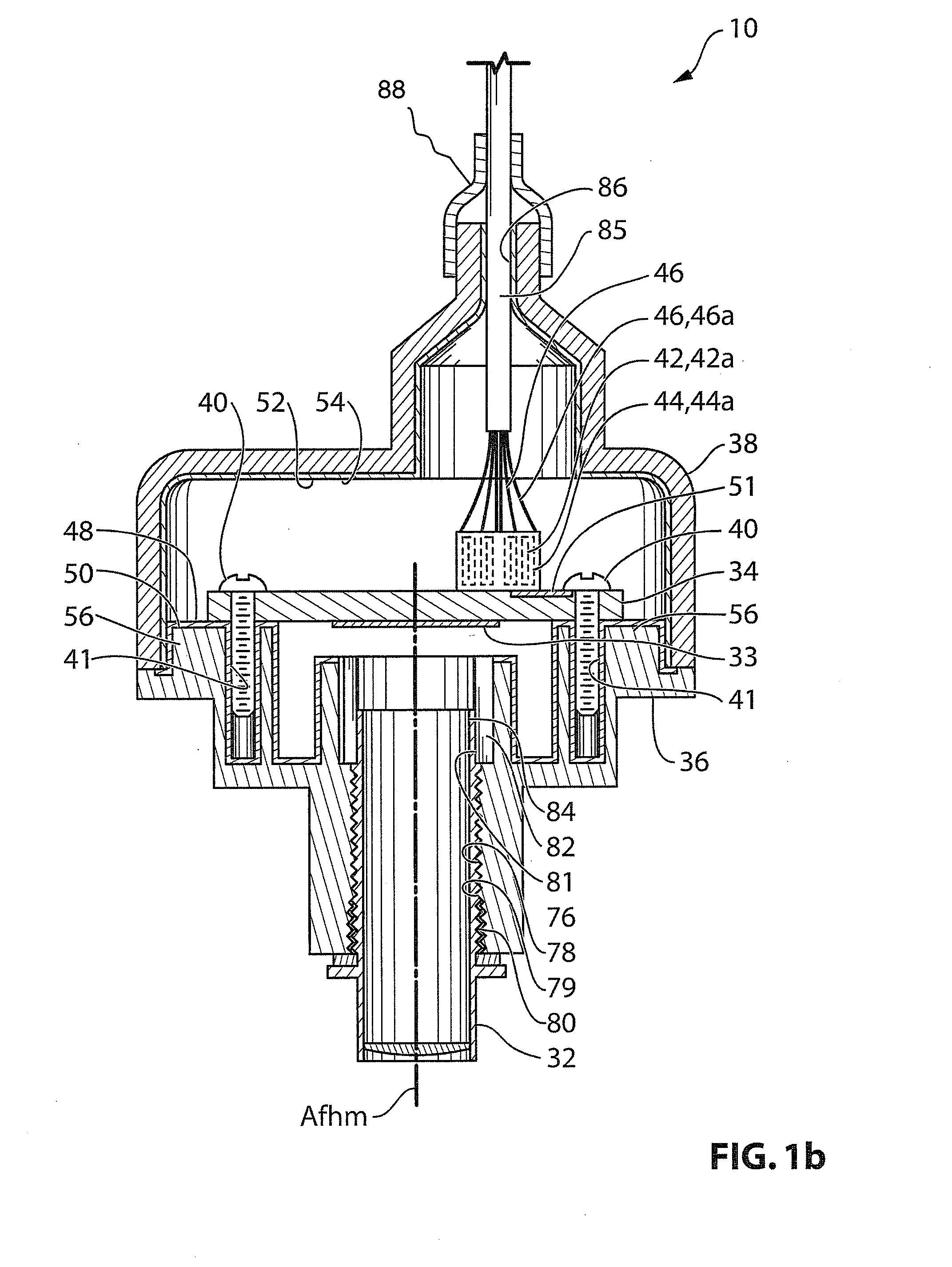

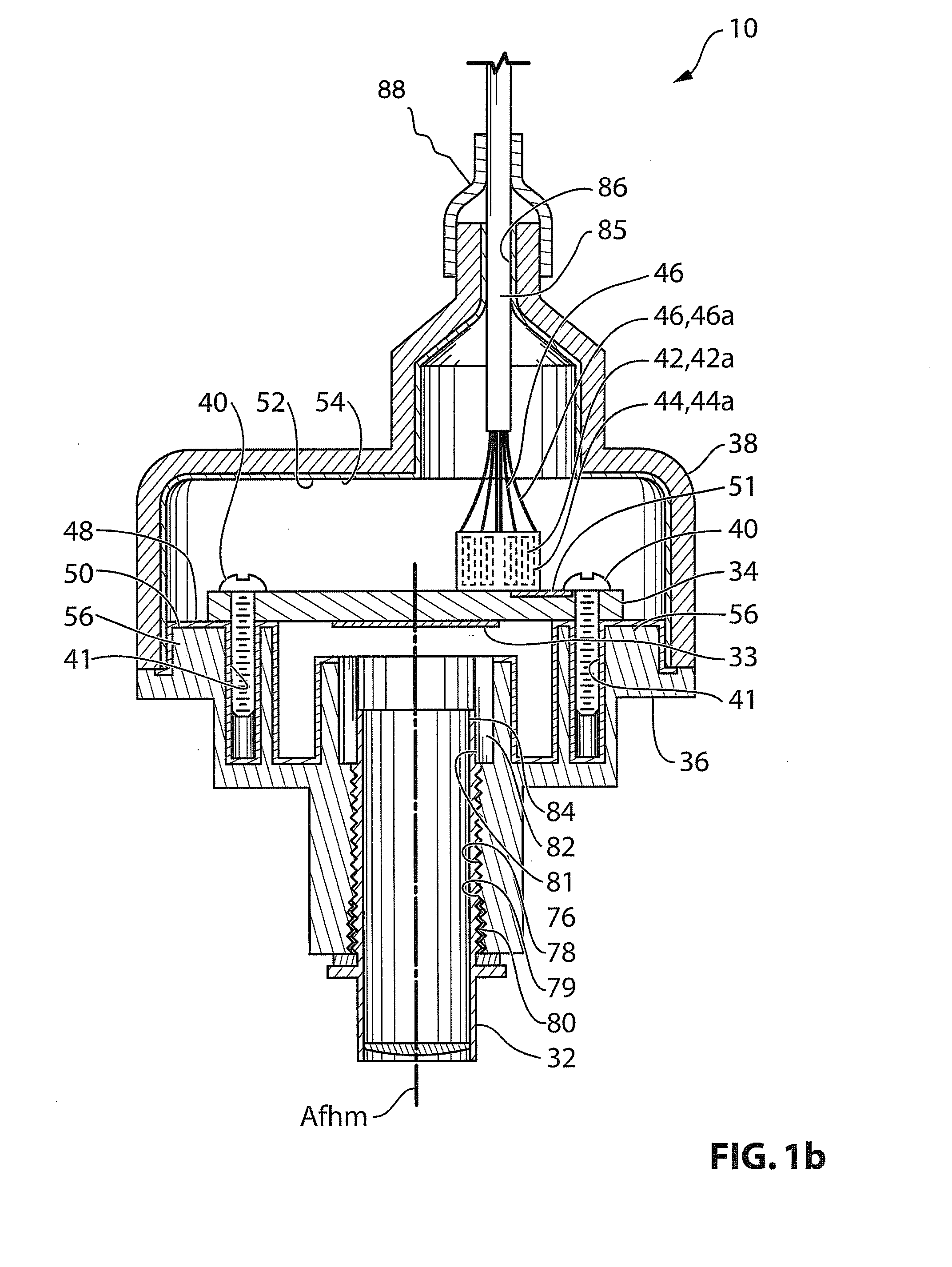

Robotic surgical system and method for surface modeling

ActiveUS7974674B2Reduce exposureMinimization requirementsElectrotherapySurgical navigation systemsCardiac surfaceEngineering

Owner:ST JUDE MEDICAL ATRIAL FIBRILLATION DIV

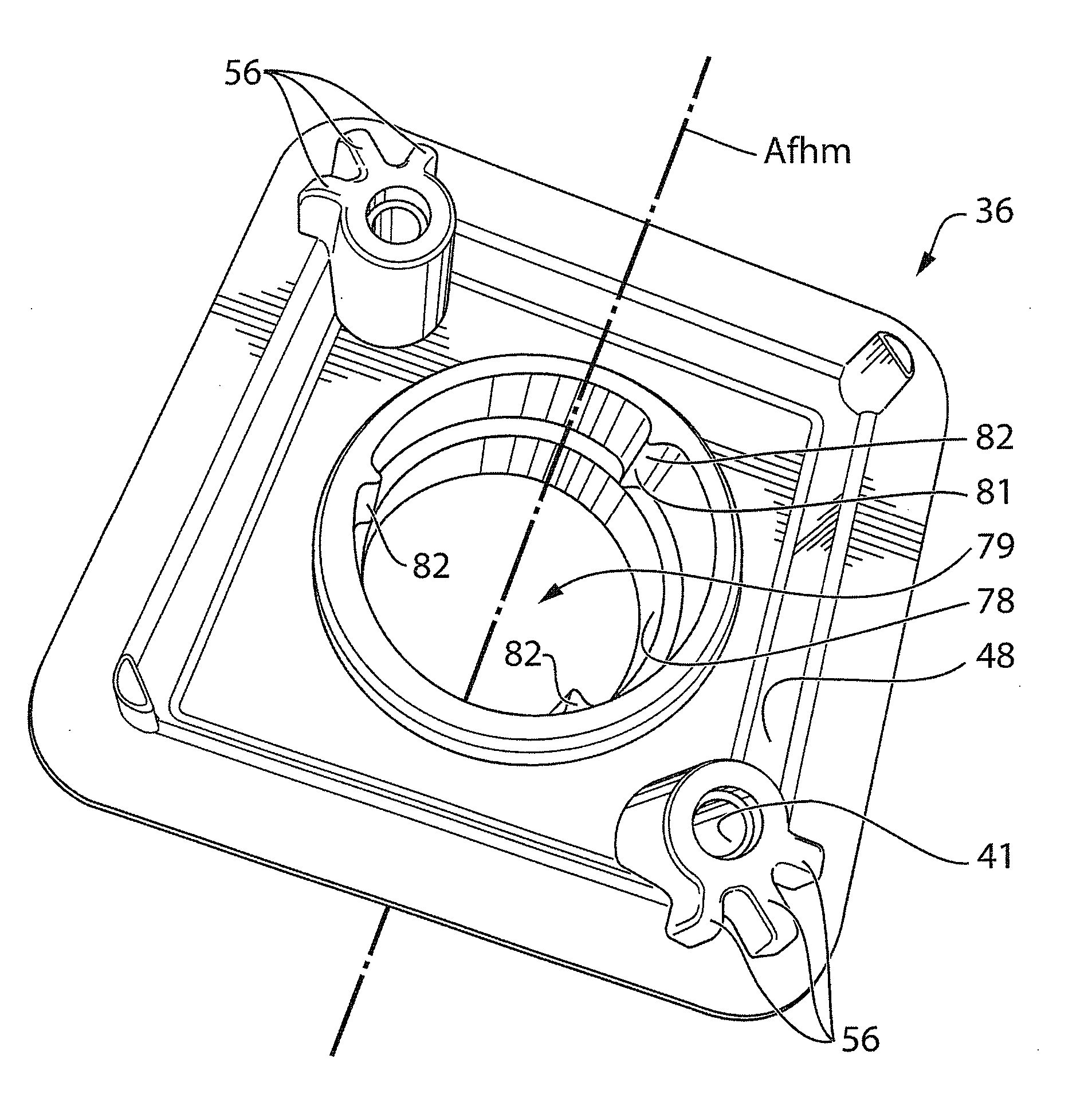

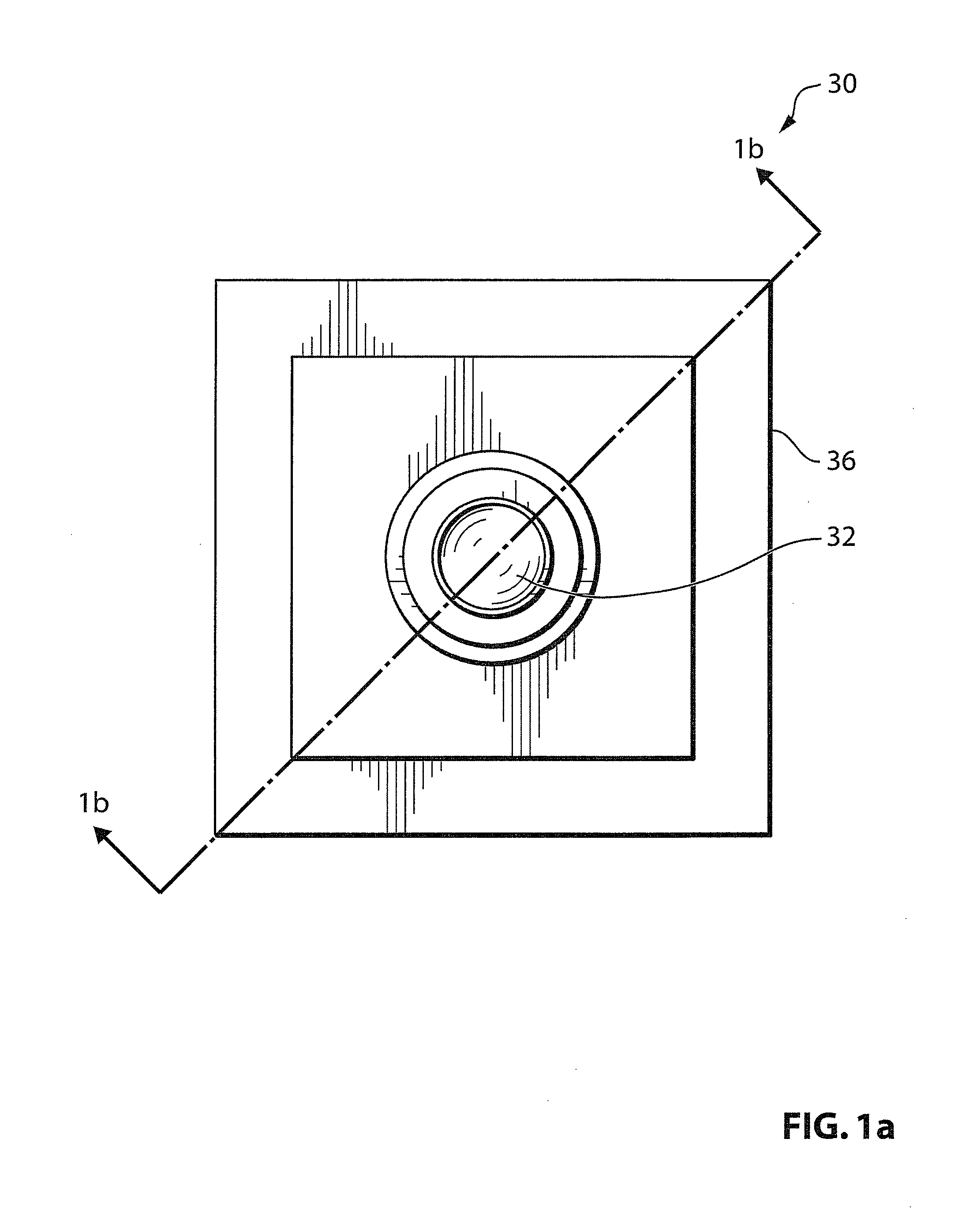

Compact Camera and Cable System for Vehicular Applications

ActiveUS20100097519A1Television system detailsColor television detailsInterference fitConductive coating

In one aspect, the invention is directed to a camera for mounting on a vehicle, wherein the camera housing made up of two housing members, with a conductive coating on the interior of each of the housing members. The two housing members mate together using an interference fit, to provide a greater assurance that they are electrically connected to each other. One of the housing members is connected to ground. In another aspect, the invention provides a camera module that has a housing and a wire harness or wire or lead that is electrically connected to circuitry of the camera and that extends through the camera housing for electrical connection to a vehicle wire harness or the like. The wire or lead extends through a portion of the housing with the housing disposed at the wire prior to connection of the wire to the circuitry of the camera. The electrical connection of the wire to the camera circuitry is made as the housing is assembled. The joint at where the wire extends outward from the housing portion is sealed, such as via shrink wrapping or the like.

Owner:MAGNA ELECTRONICS

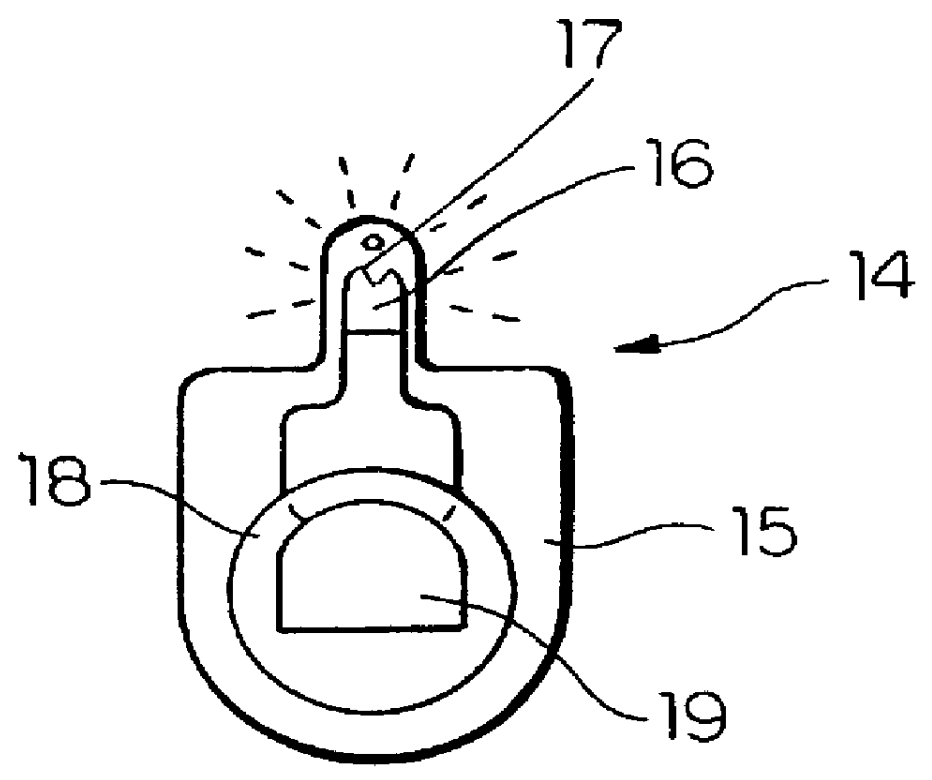

Decorative packaging with special effects

A package wrap for decoratively covering a container having side walls defining an interior space for carrying a product therein, includes a flexible thin sheet of polymeric material adapted to be shrink-wrapped onto the exterior of the container. An illuminating or a sound producing device is positioned between the flexible thin sheet of polymeric material and the exterior of the container so that when the flexible sheet of polymeric material is shrink-wrapped onto the container, the illuminating device or the sound device will be held securely in place. The illuminating device is adapted to be illuminated upon activation by a pressure, motion, or acoustically sensitive switch. The sound device is adapted to produce an audible signal upon activation by a pressure or motion sensitive switch. When the illuminating device is activated, illumination therefrom will be visible through the flexible thin sheet of polymeric material to enhance and highlight a printed pattern on the exterior of the package wrap.

Owner:DECICCO RICHARD J

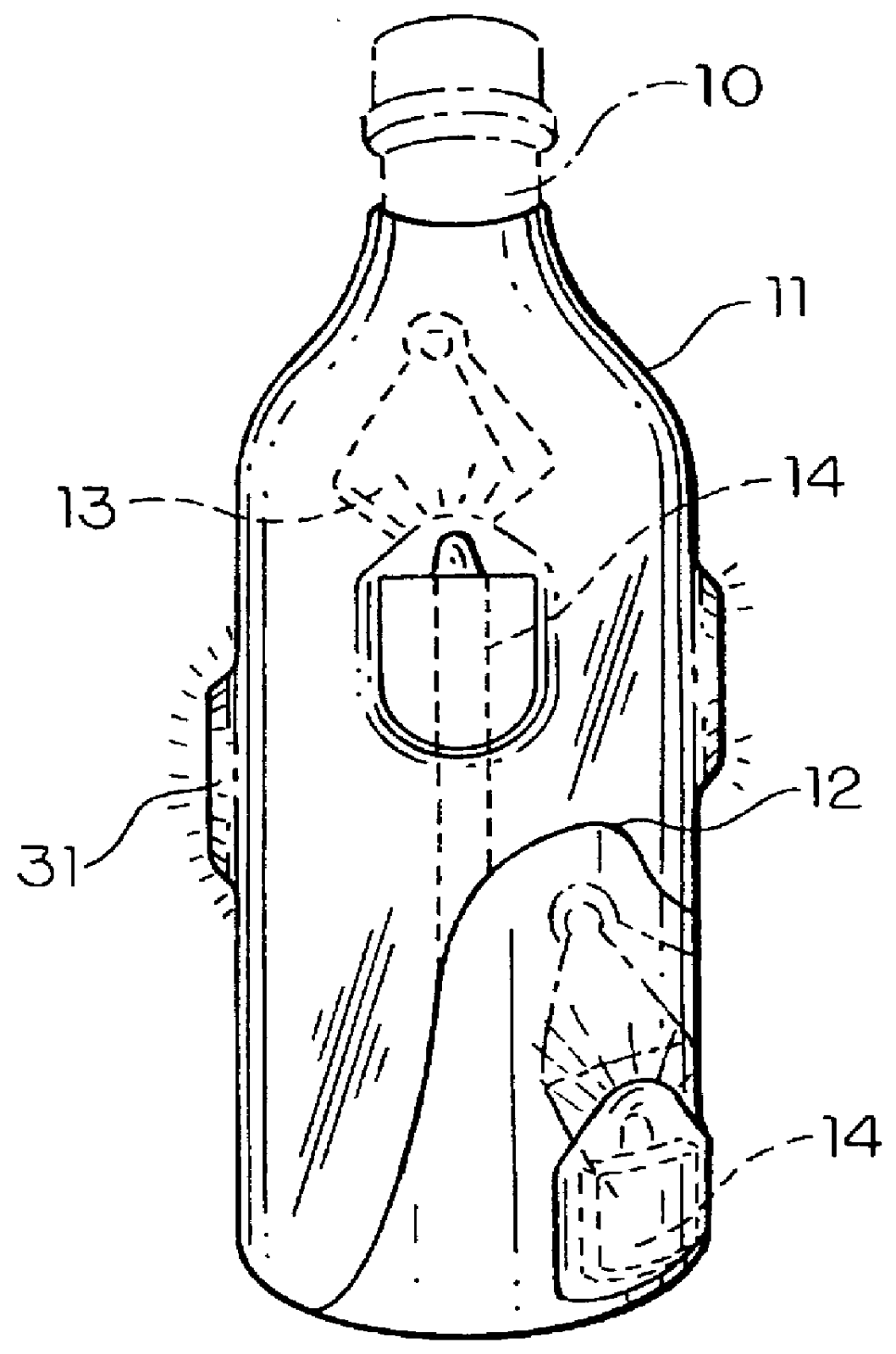

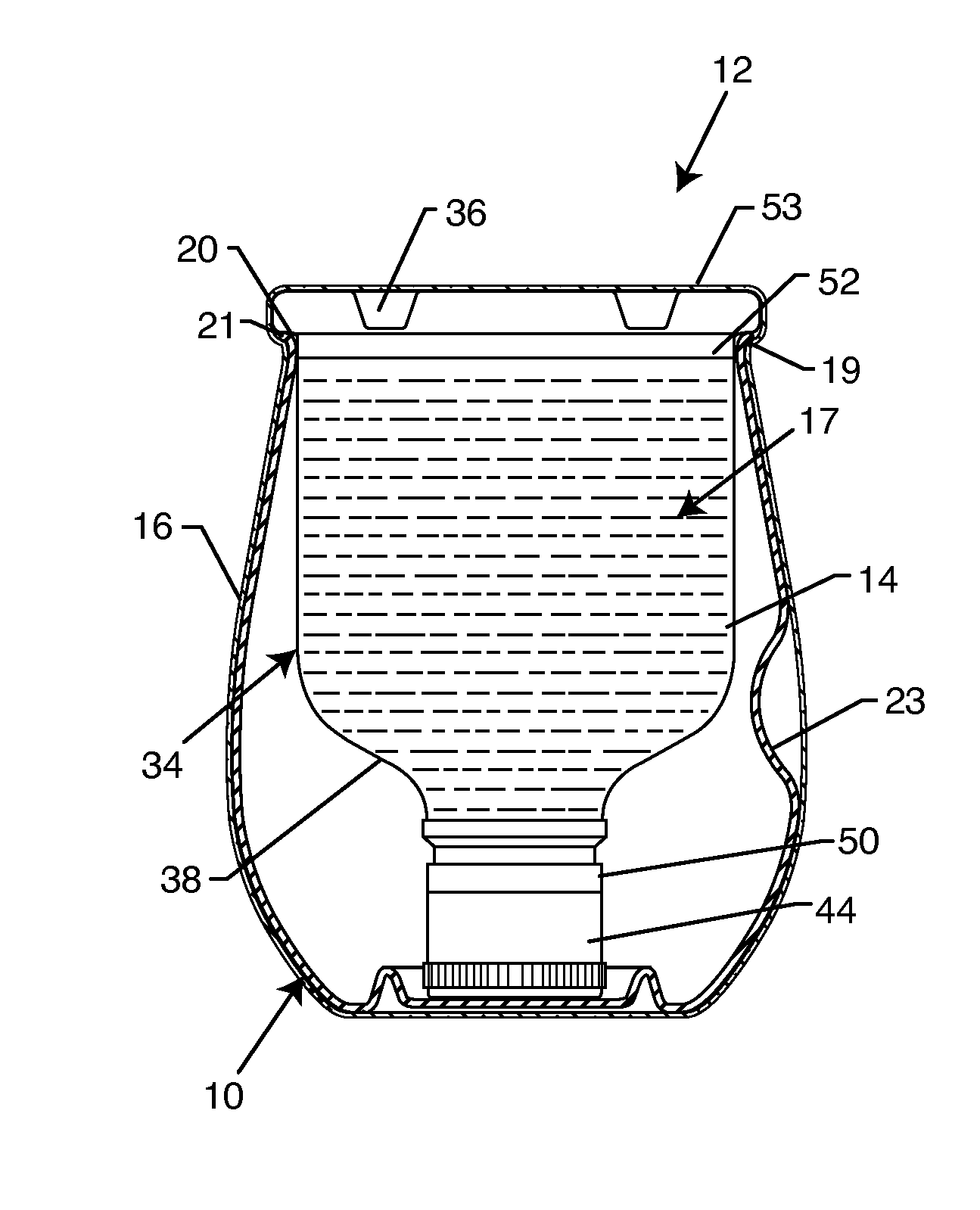

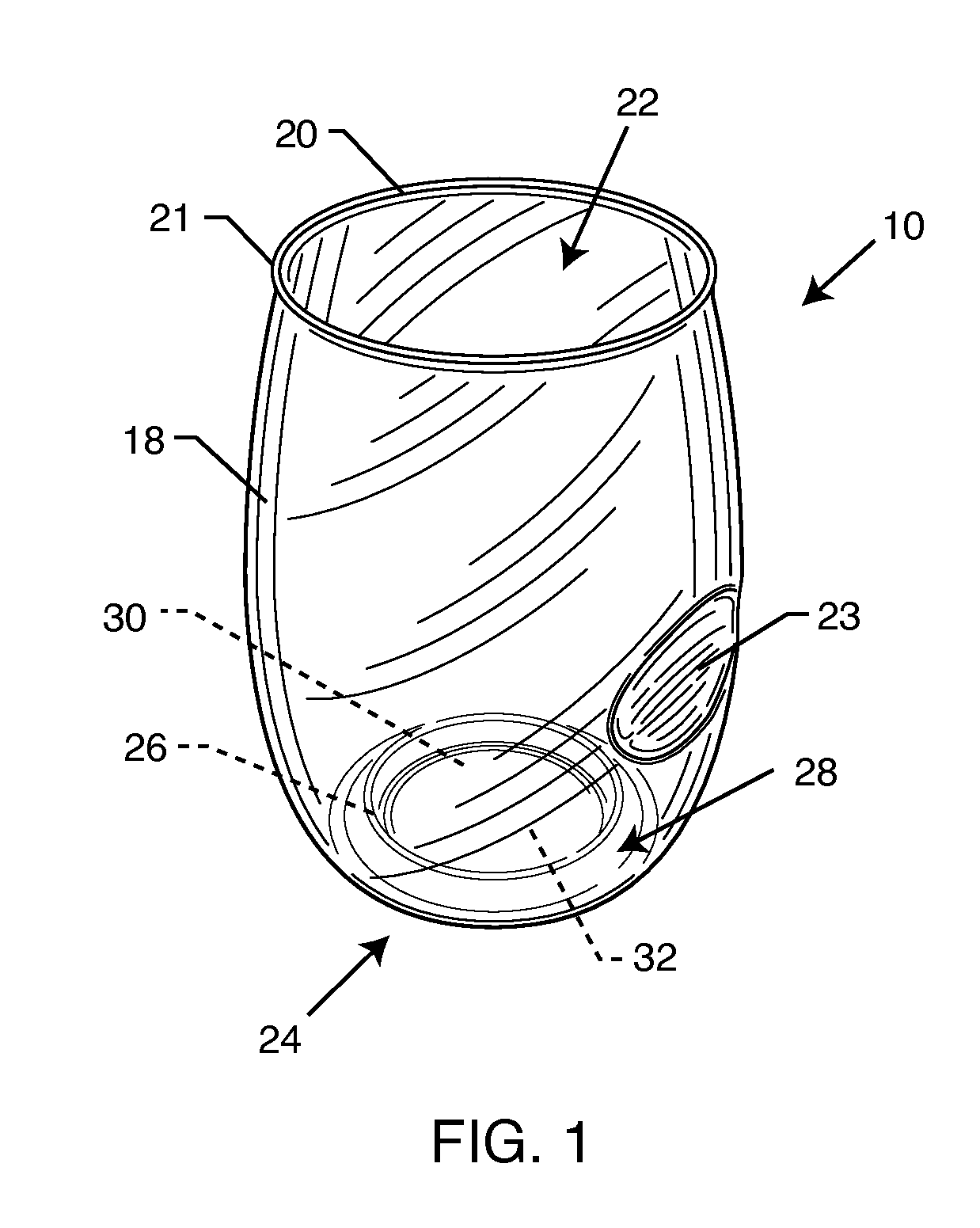

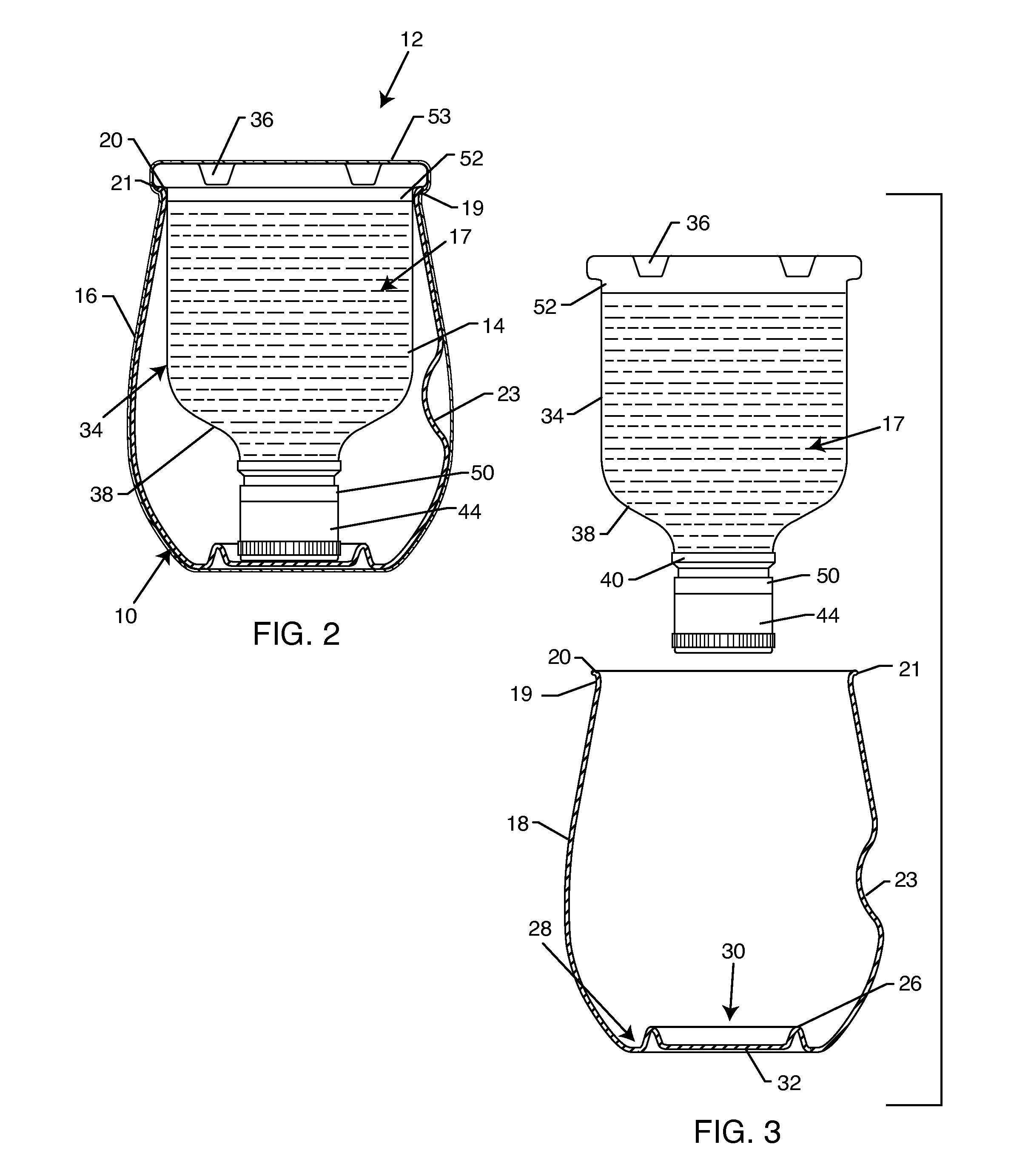

Combined wine glass and wine bottle package

ActiveUS20110132781A1Add seatsImprove cooperationClosure capsContainer/bottle contructionWine bottleEngineering

A combined wine glass and wine bottle package includes a wine glass constructed from molded plastic with an upper body defining an upwardly narrowed flume for concentrating the wine bouquet, in combination with a contoured lower base defining an annular moat surrounding a central punt. A wine bottle is sized to fit substantially, in an inverted orientation relative to the glass, into the wine glass, with a removable bottle cap nested within the central punt, and with an upper rim of the wine bottle snap-fitted into a shallow groove formed in the wine bottle near a lower end thereof. This entire package is sterile-wrapped in a sealed shrink-wrap plastic or the like. The package can be opened when desired to permit removal of the wine bottle from the wine glass, following by bottle opening and pouring of the contents into the wine glass.

Owner:GOVINO +1

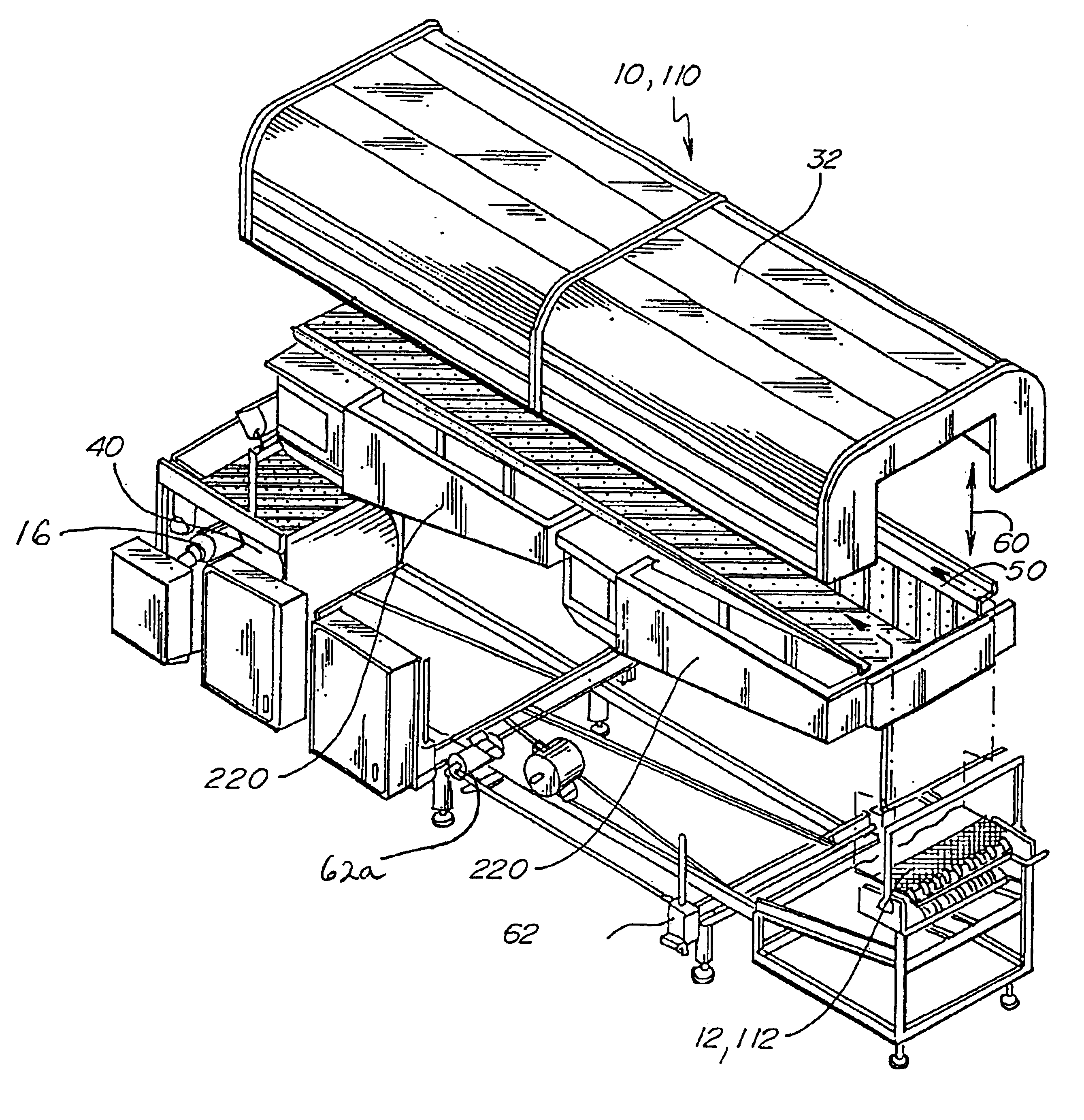

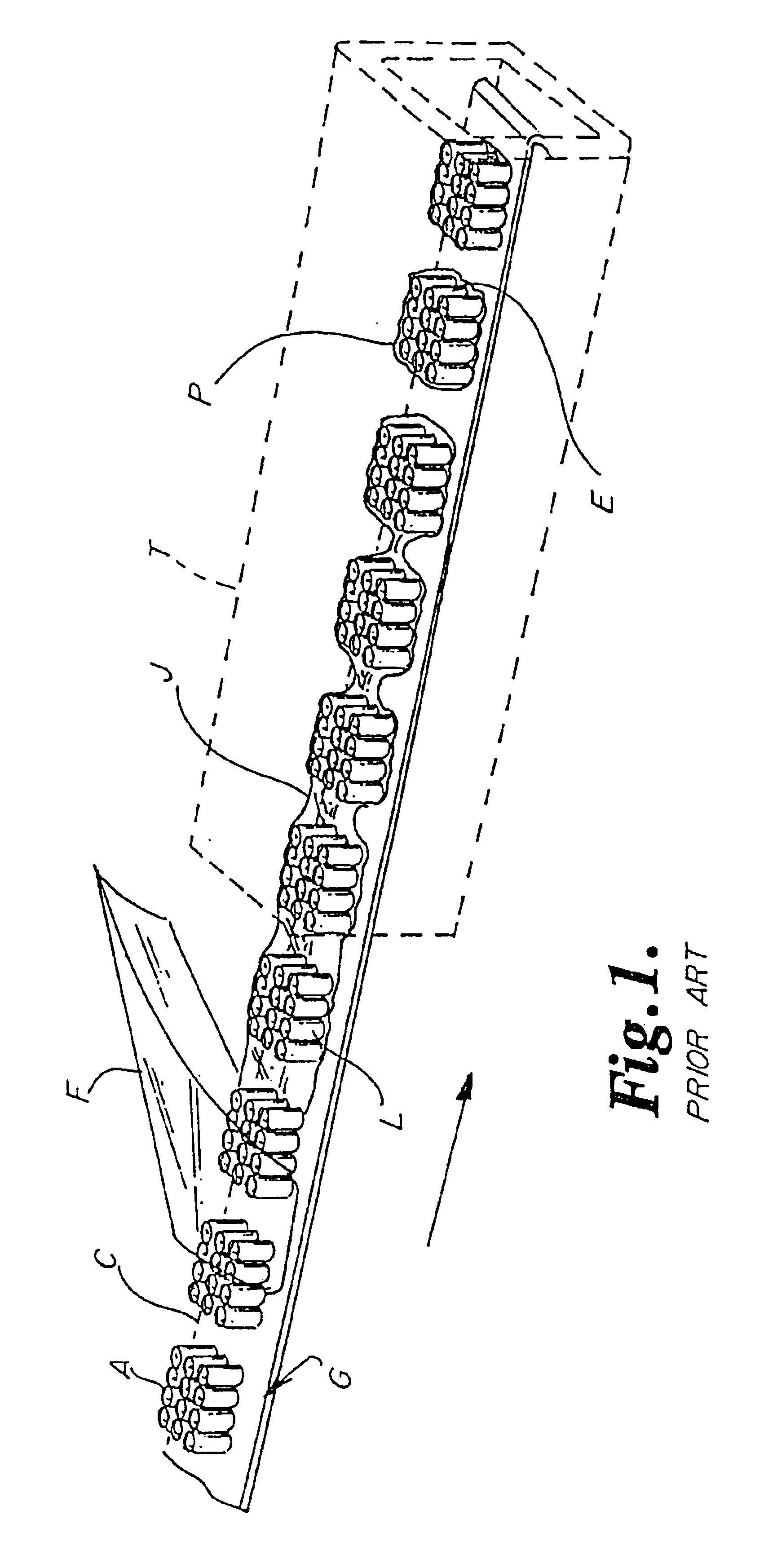

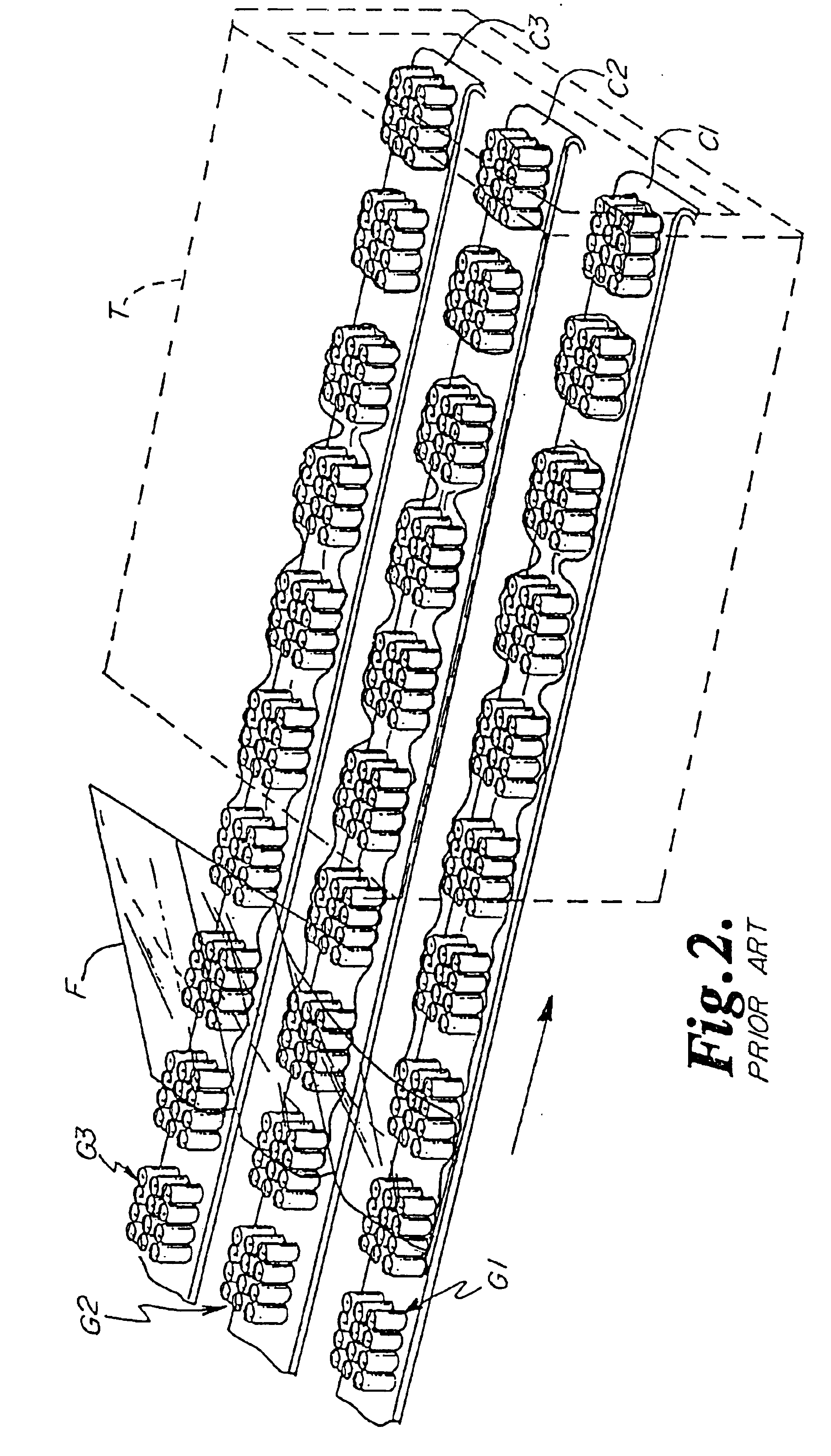

Heat tunnel for film shrinking

InactiveUS7155876B2Minimal distortionMinimum of wrinkles.Wrappers shrinkageFurnace componentsProcess engineeringShrink wrap

Owner:DOUGLAS MACHINE LIABILITY

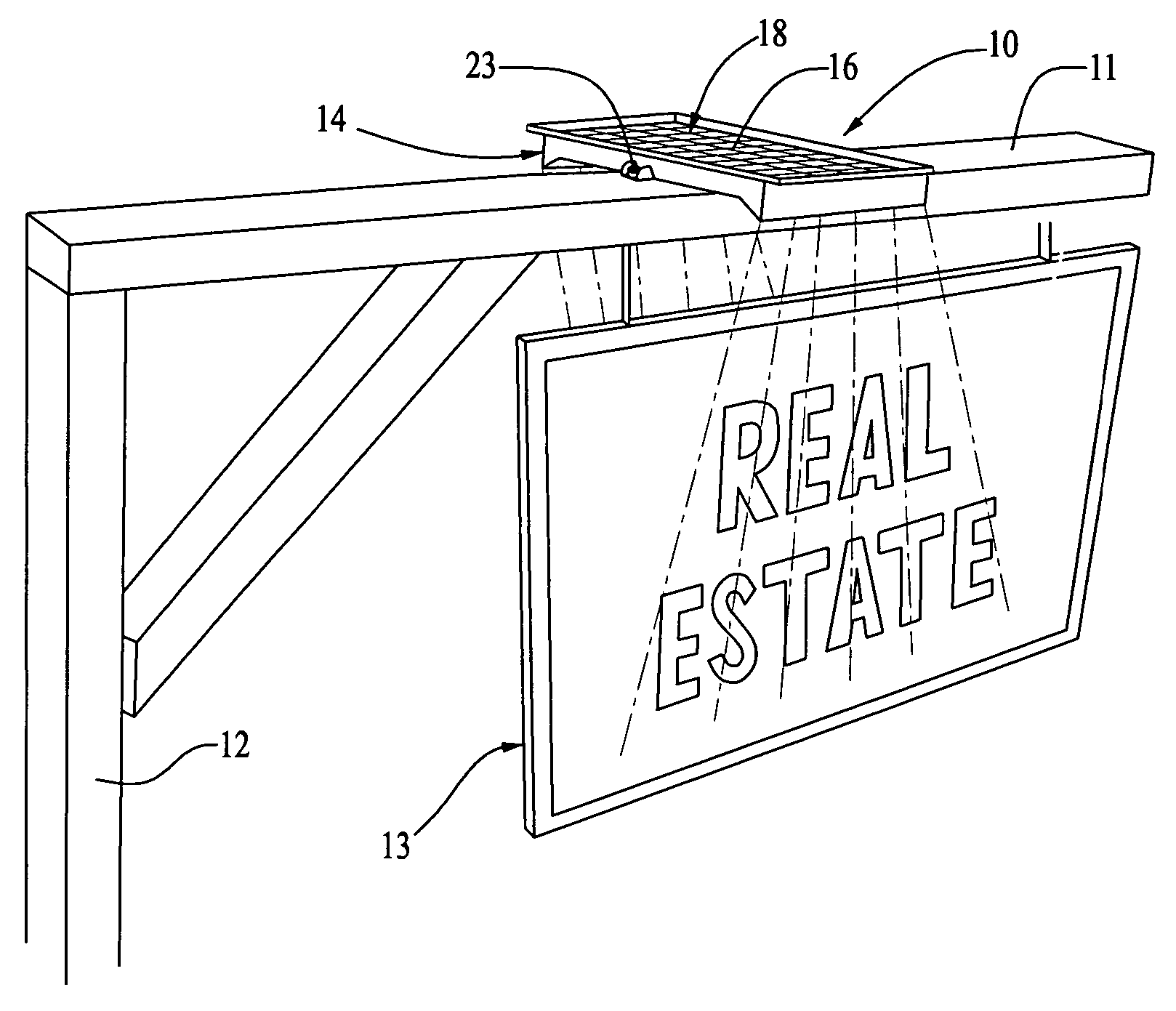

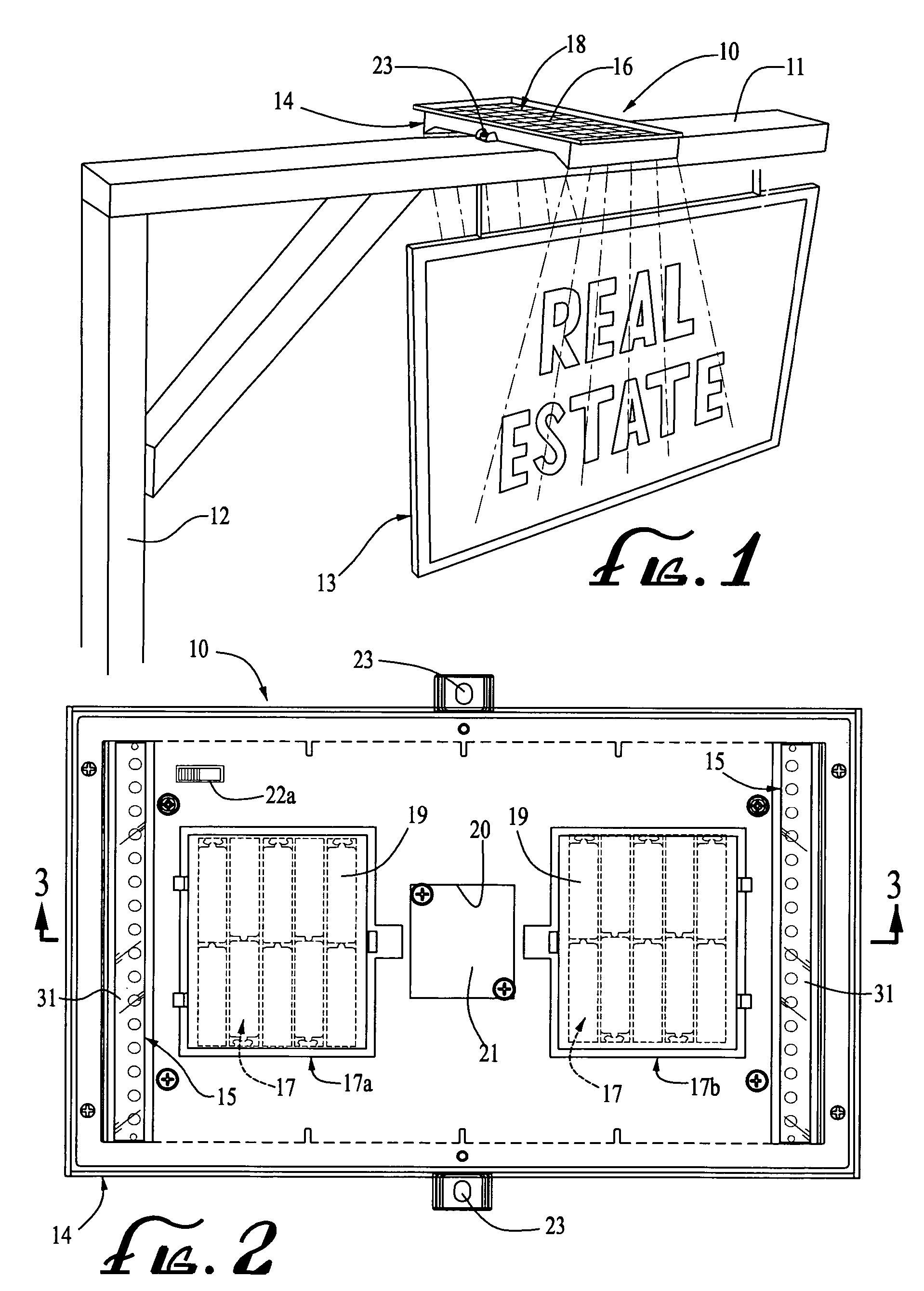

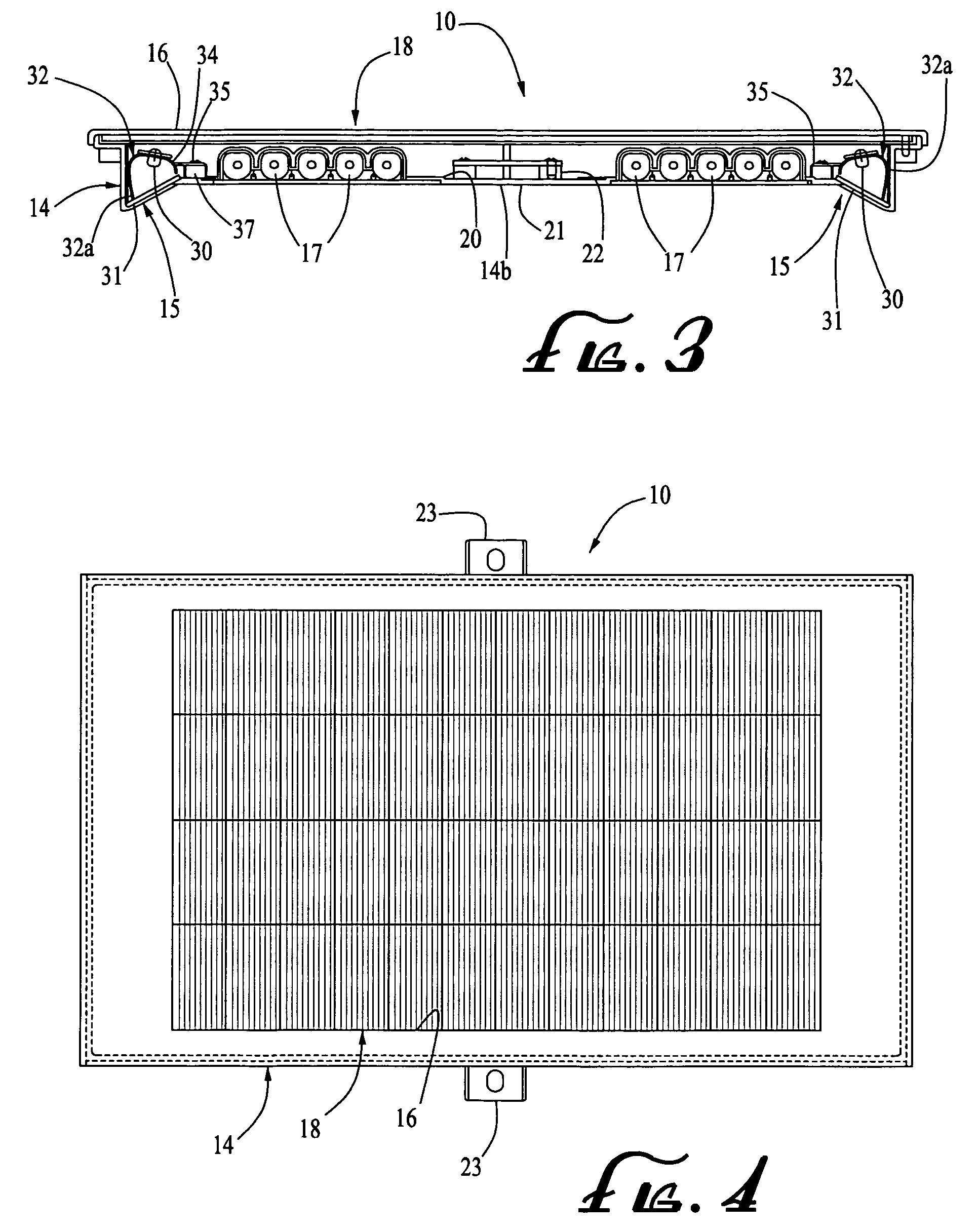

Sign lighting system

InactiveUS20060050528A1Prevent theftPrevent tamperingAircraft componentsLighting support devicesSign postingEffect light

A real estate sign post having a crossbar on which a modular lighting unit is secured by two theft-resistant screws having non-circular holes in their heads and shielded by upstanding walls on mounting brackets. The lighting unit is enclosed in a box-like housing with a solar panel in the top side, slot-like lamp openings at opposite ends of the bottom side, and elongated arrays of LED's mounted in concave reflectors for directing light toward opposite sides of a real estate sign. Battery packs enclosed in shrink wrap and a controller are enclosed in the housing. An alternative embodiment mounts fluorescent bulbs in reflectors that are supported on opposite sides of a base unit by elongated arms.

Owner:LYONS CHRISTOPHER L

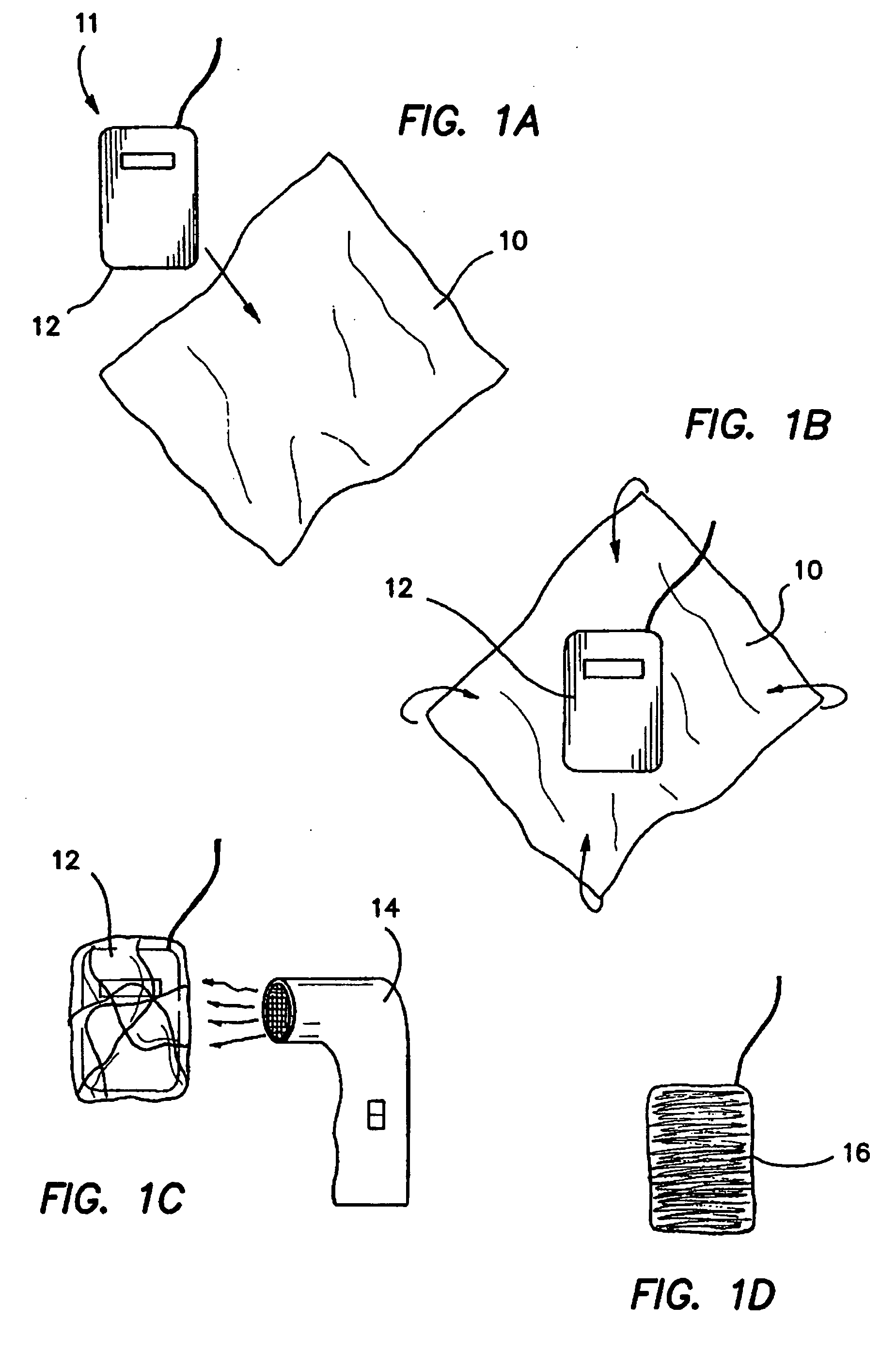

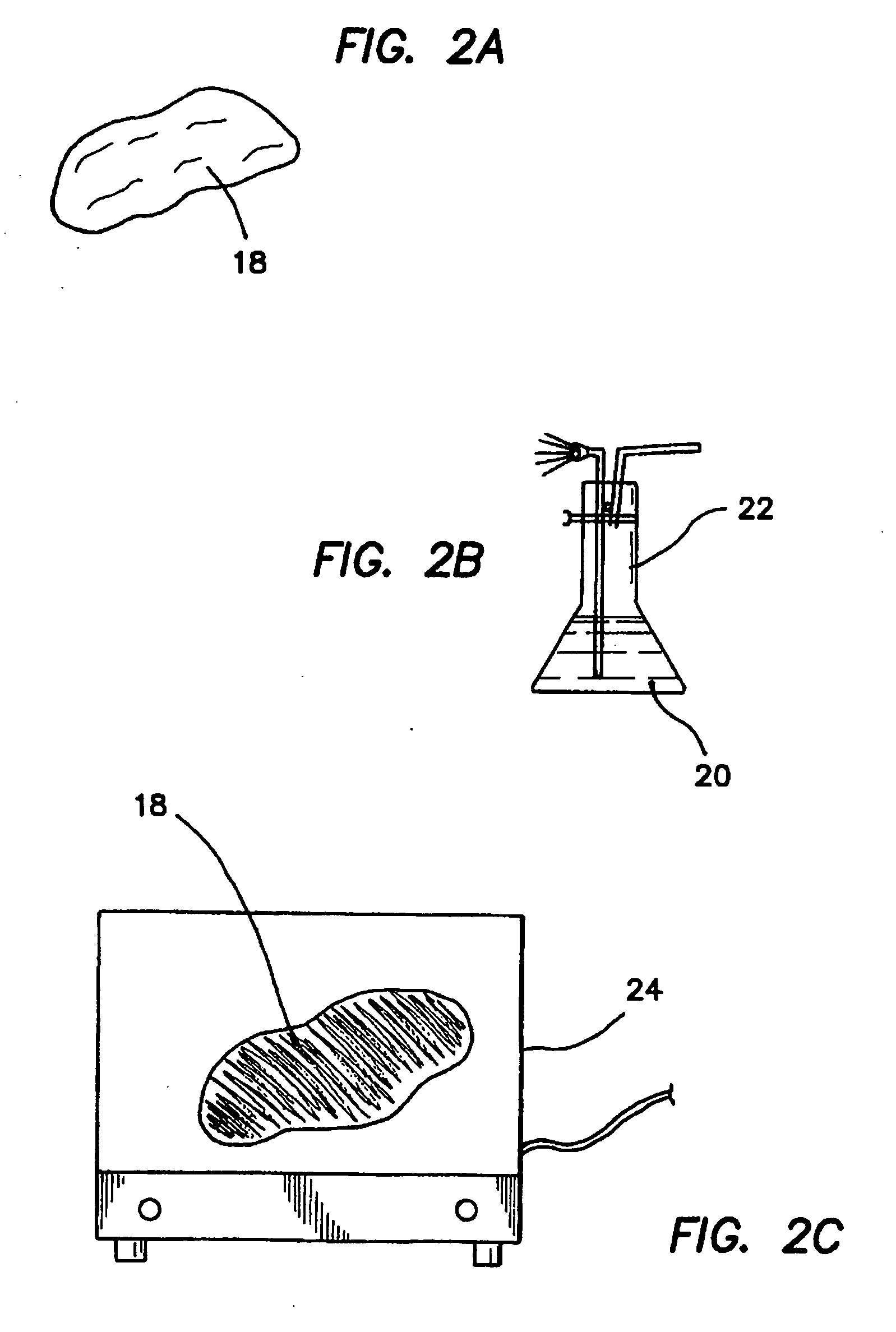

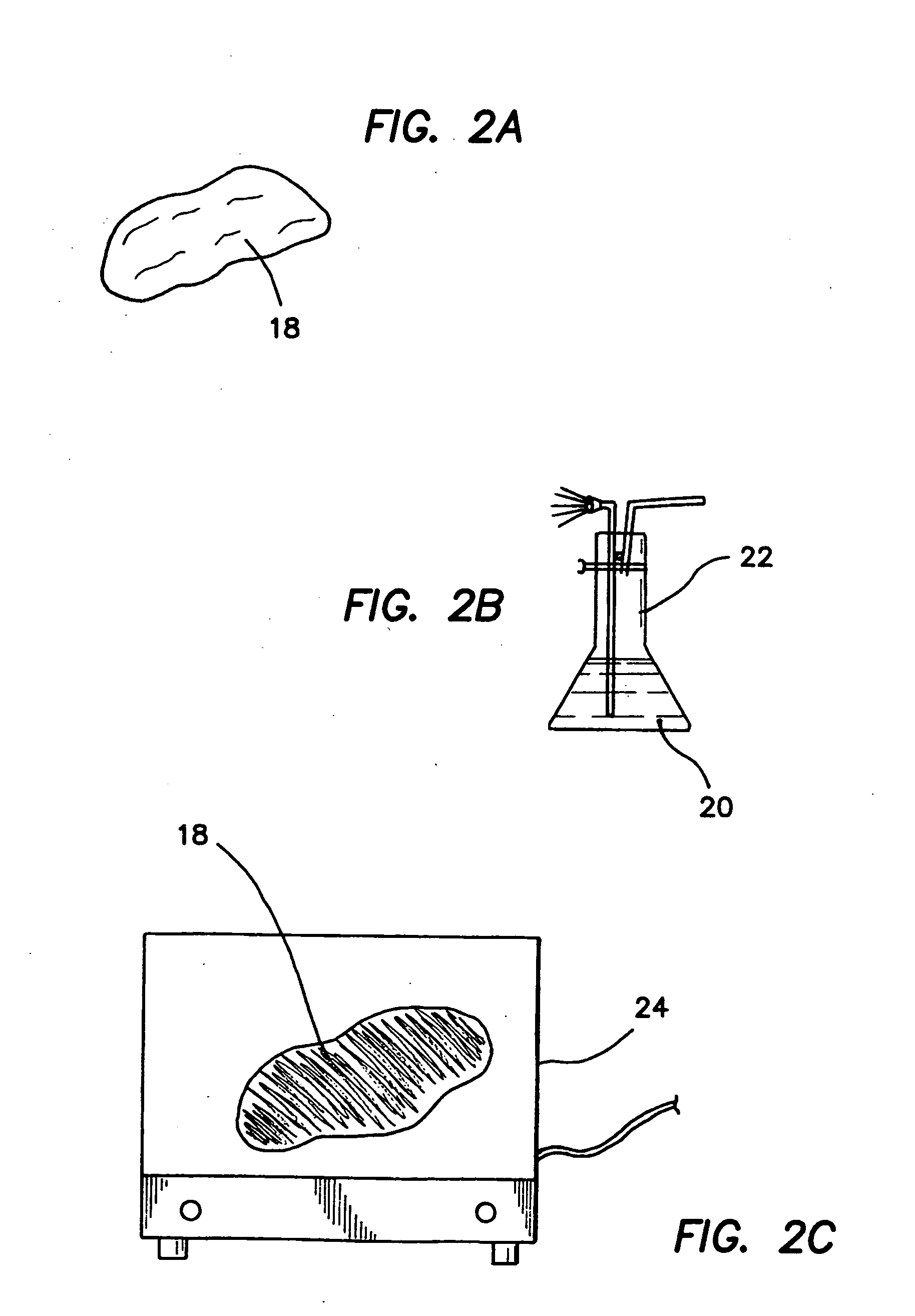

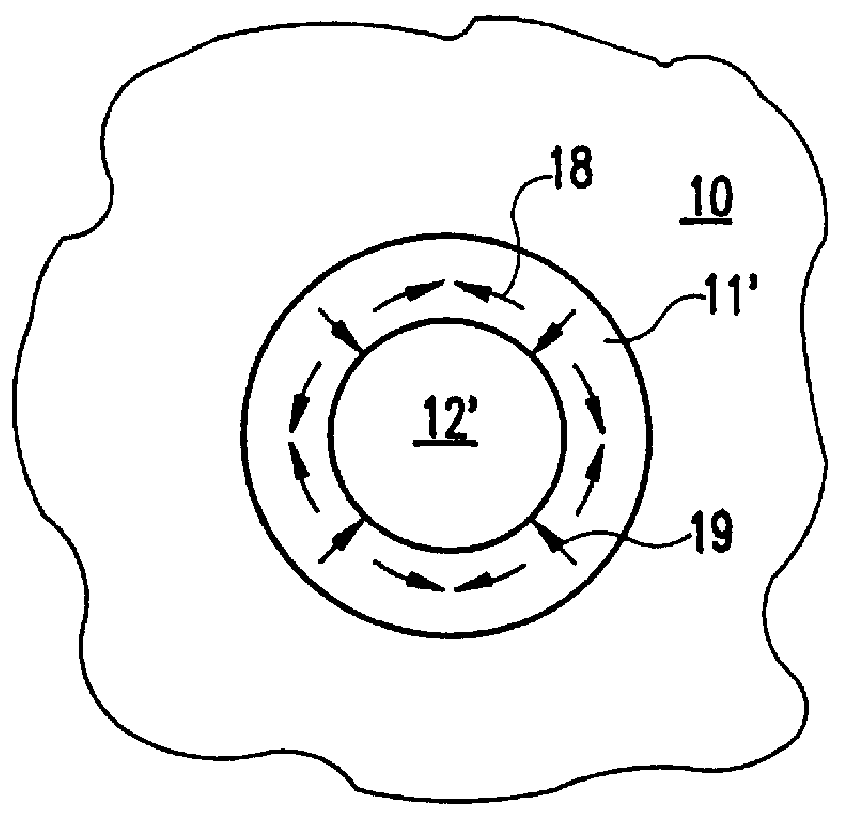

Apparatus and method for preventing adhesions between an implant and surrounding tissues

An anti-adhesion membrane is placed onto an implant introduced into a surgical site of a patient to prevent post-surgical adhesions between the implant and surrounding tissue. The implant may comprise either biological material, such as a transplanted organ, or non-biological material such as a medical device. The membrane may be applied in a variety of ways. In one example, a membrane according to the present invention is shrink-wrapped around a pace-maker. In another example, a breast implant is spray-coated or dipped with the membrane material.

Owner:MAST BIOSURGERY

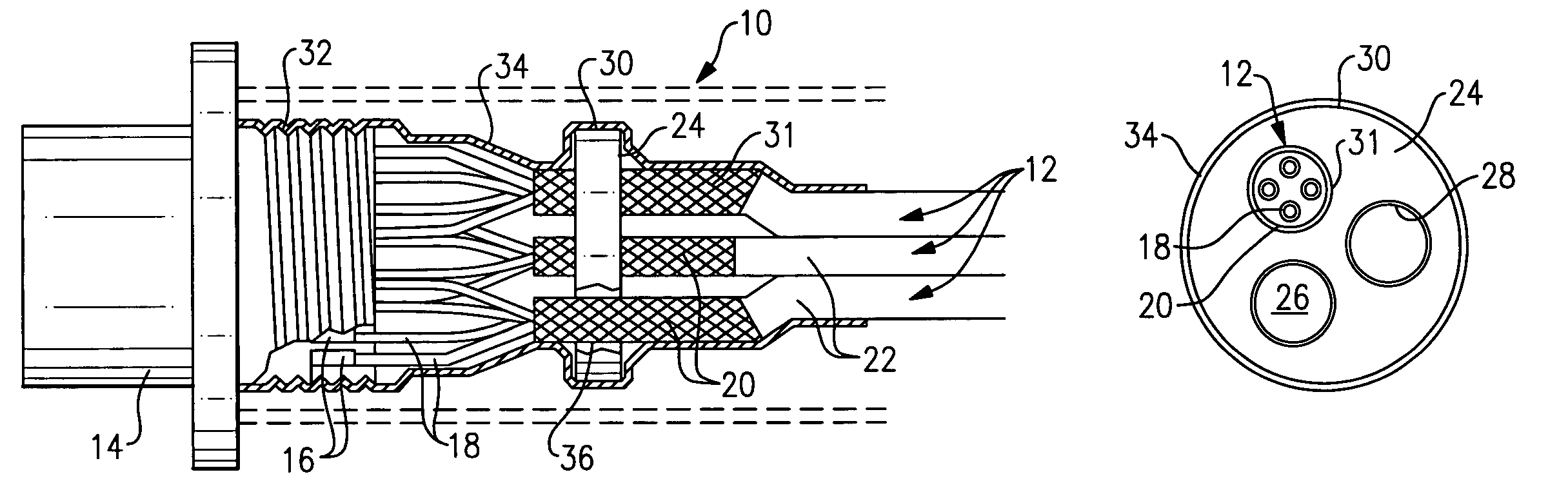

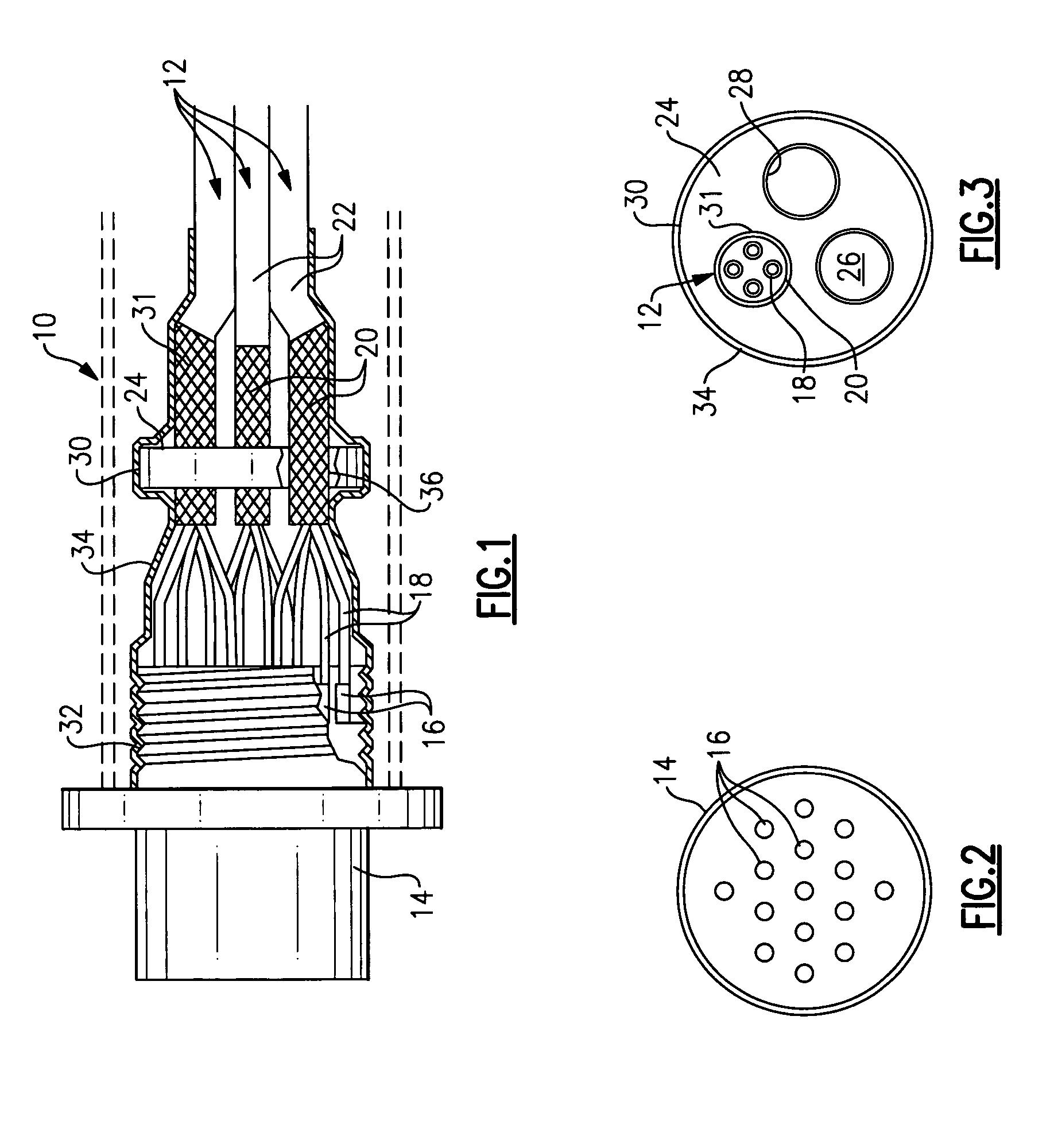

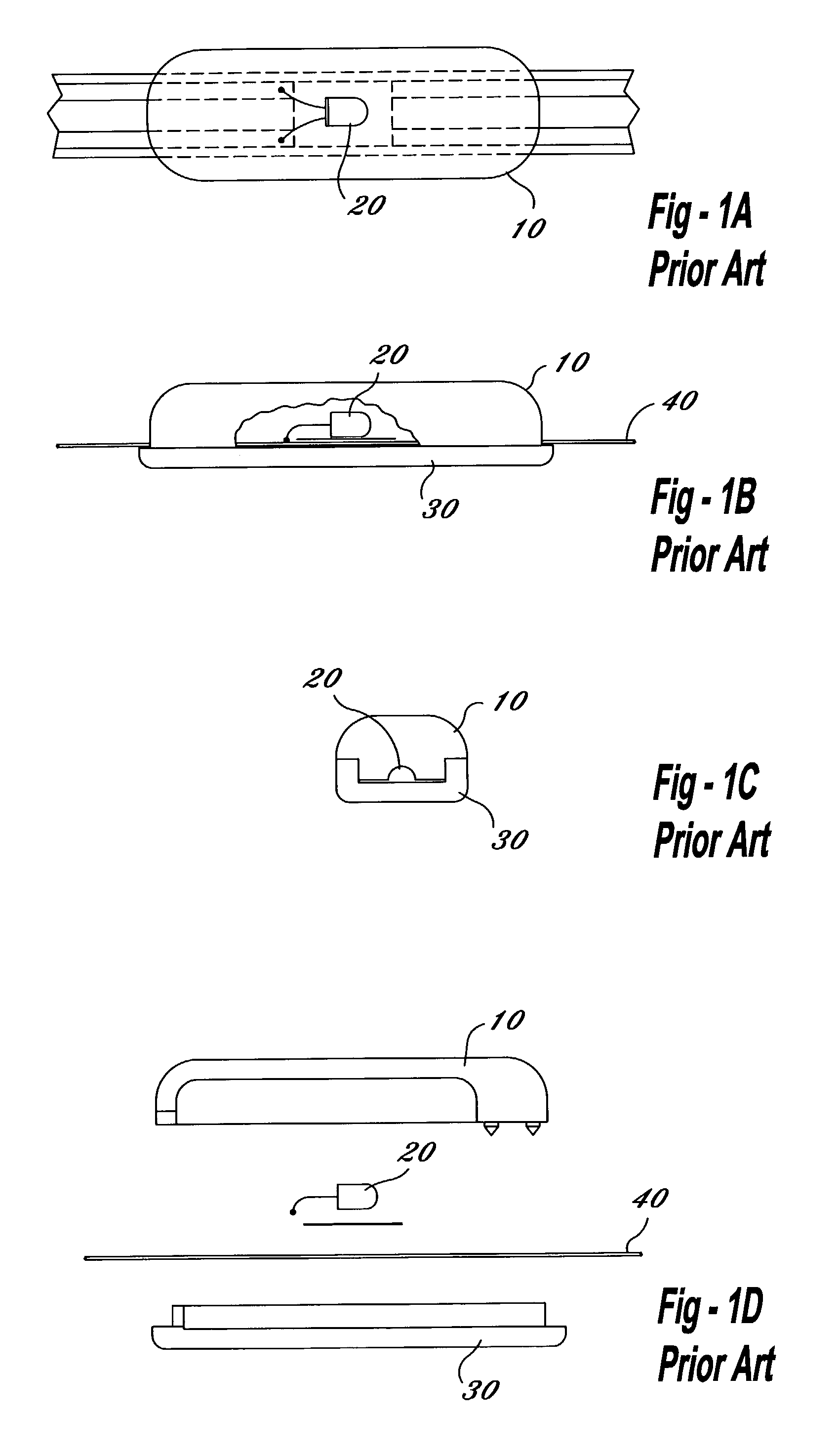

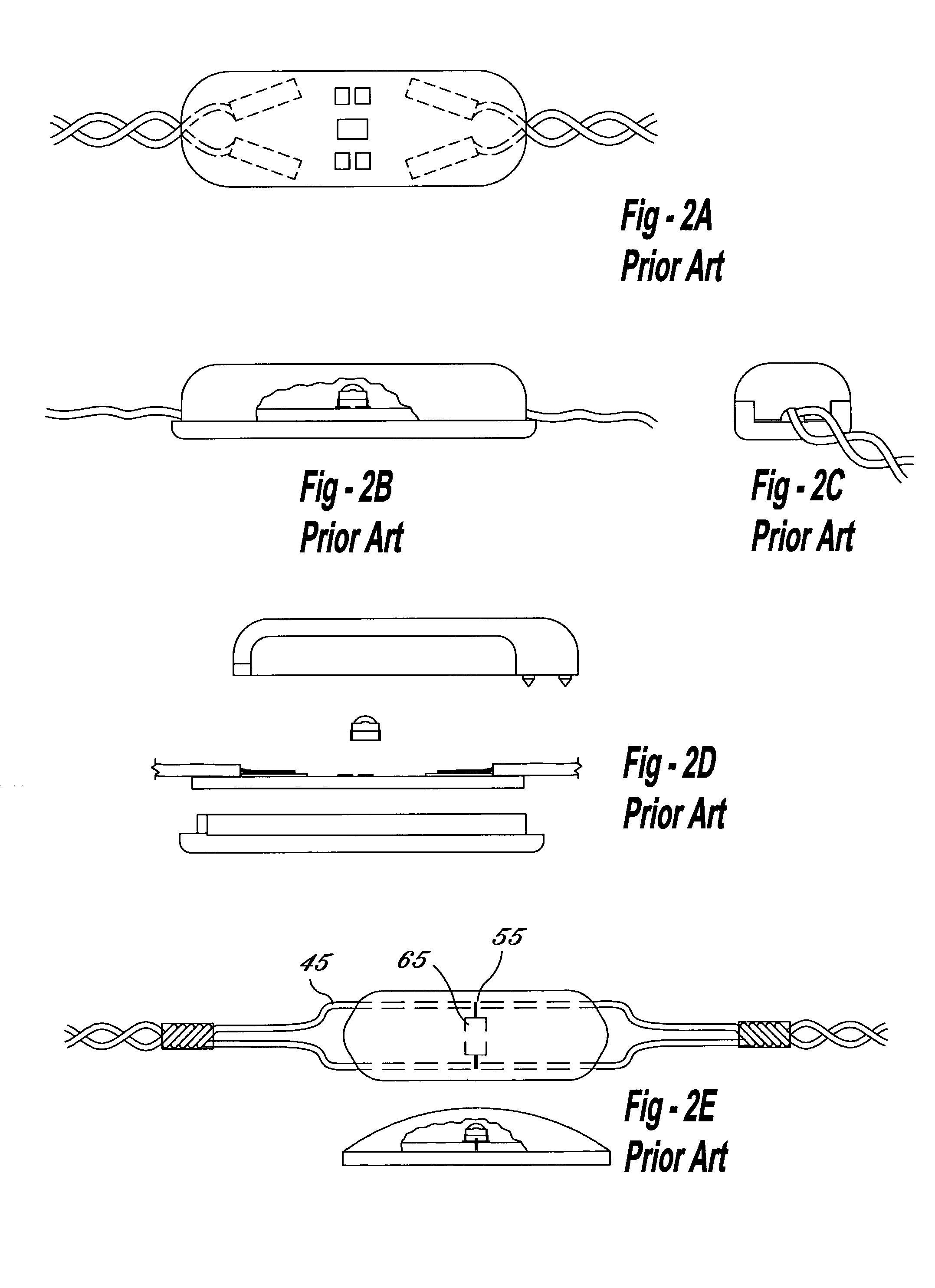

Shielding for electrical cable assemblies

An electrical cable assembly is provided including multiple cables having wires. The cables each include a shield. A connector receives ends of the wires and includes an outer surface. A conductive shield ring has an outer periphery and includes multiple holes receiving the cables. The shield of each cable engages an inner surface provided by a corresponding hole in the shield ring. In one example, the circumference of each shield is soldered to the corresponding hole. A wrap engages the outer periphery and the outer surface to electrically connect the connector to the shields. In one example, the wrap is conductive heat shrink wrap that surrounds and engages the entire outer surface of the shield ring.

Owner:HAMILTON SUNDSTRAND CORP

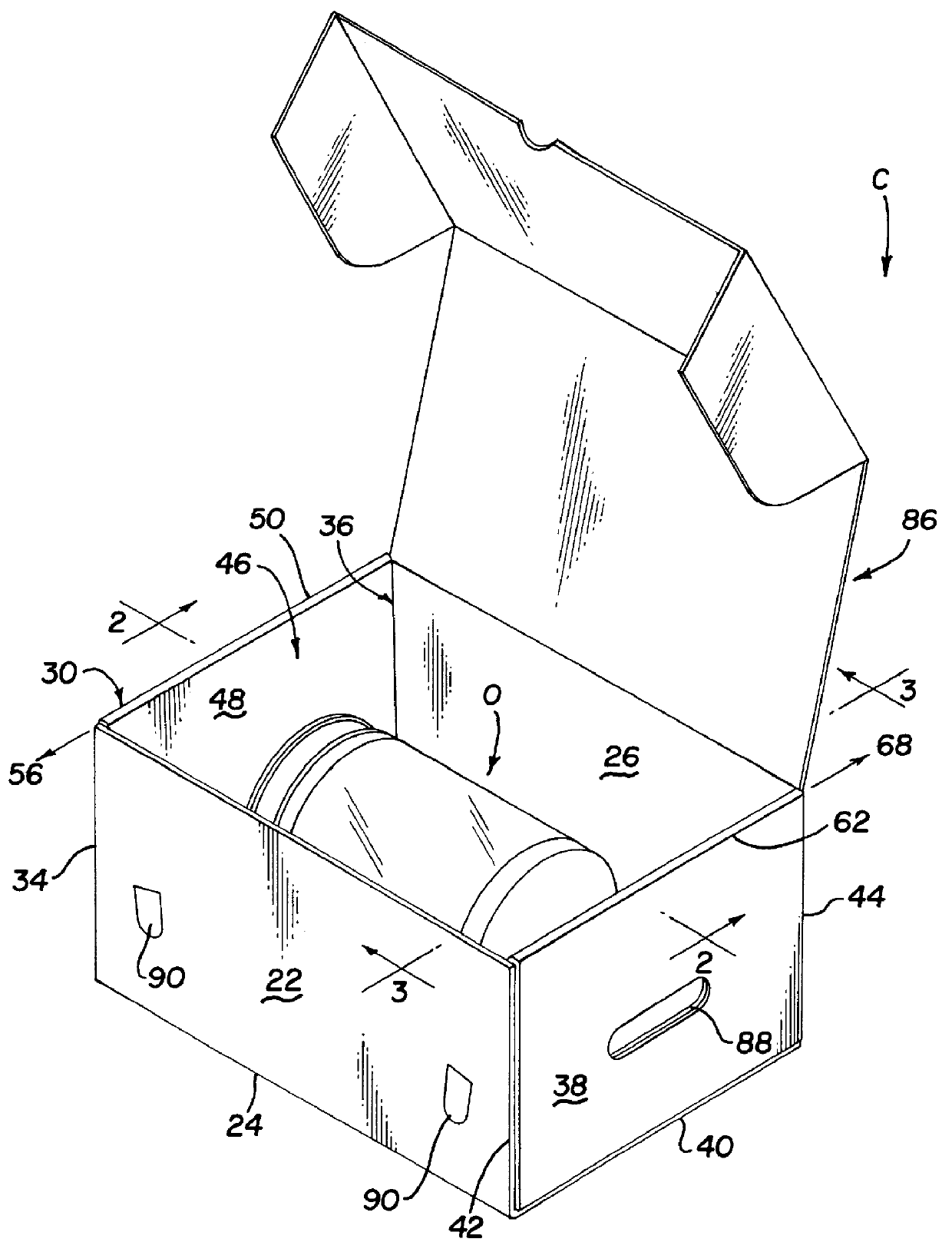

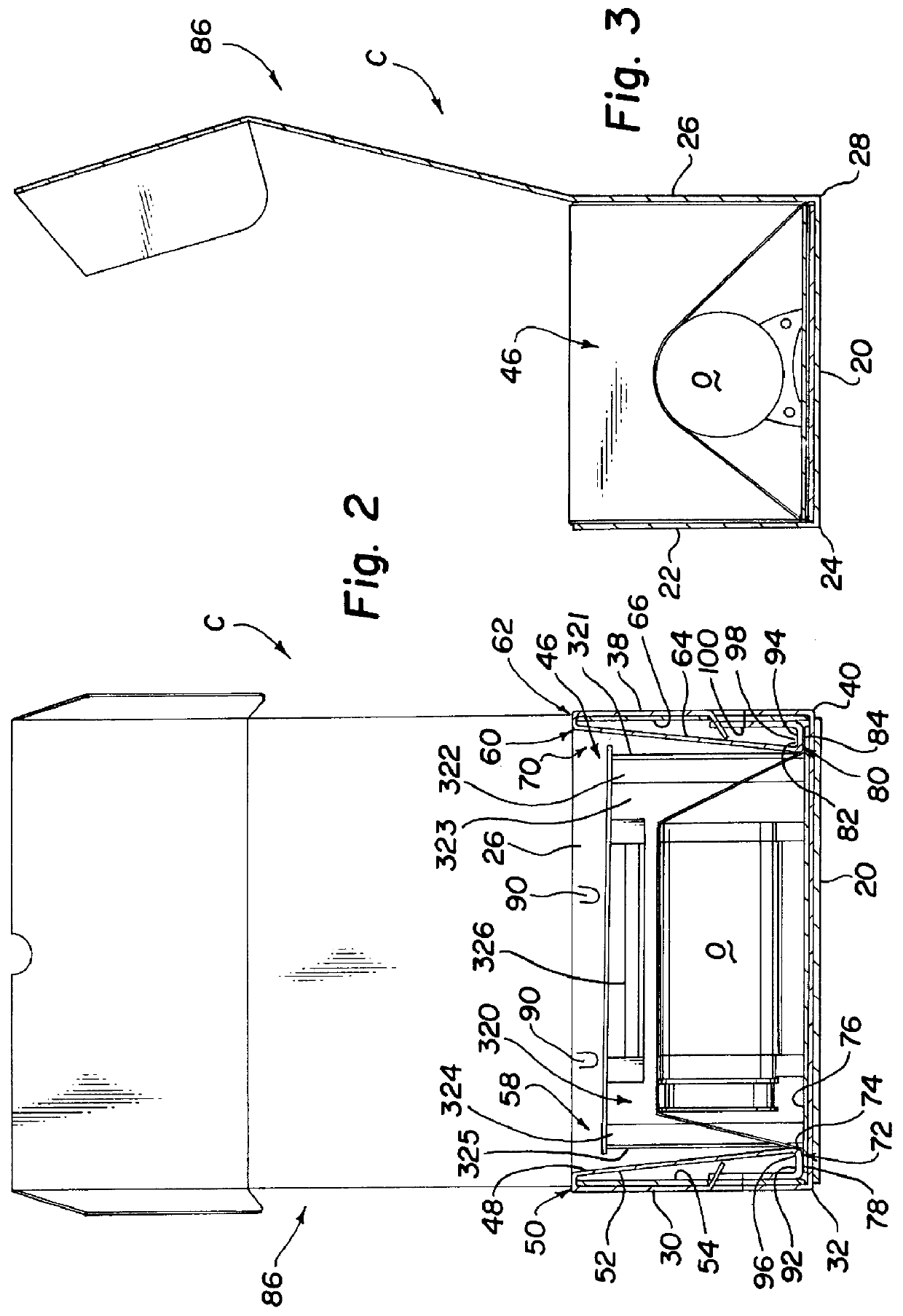

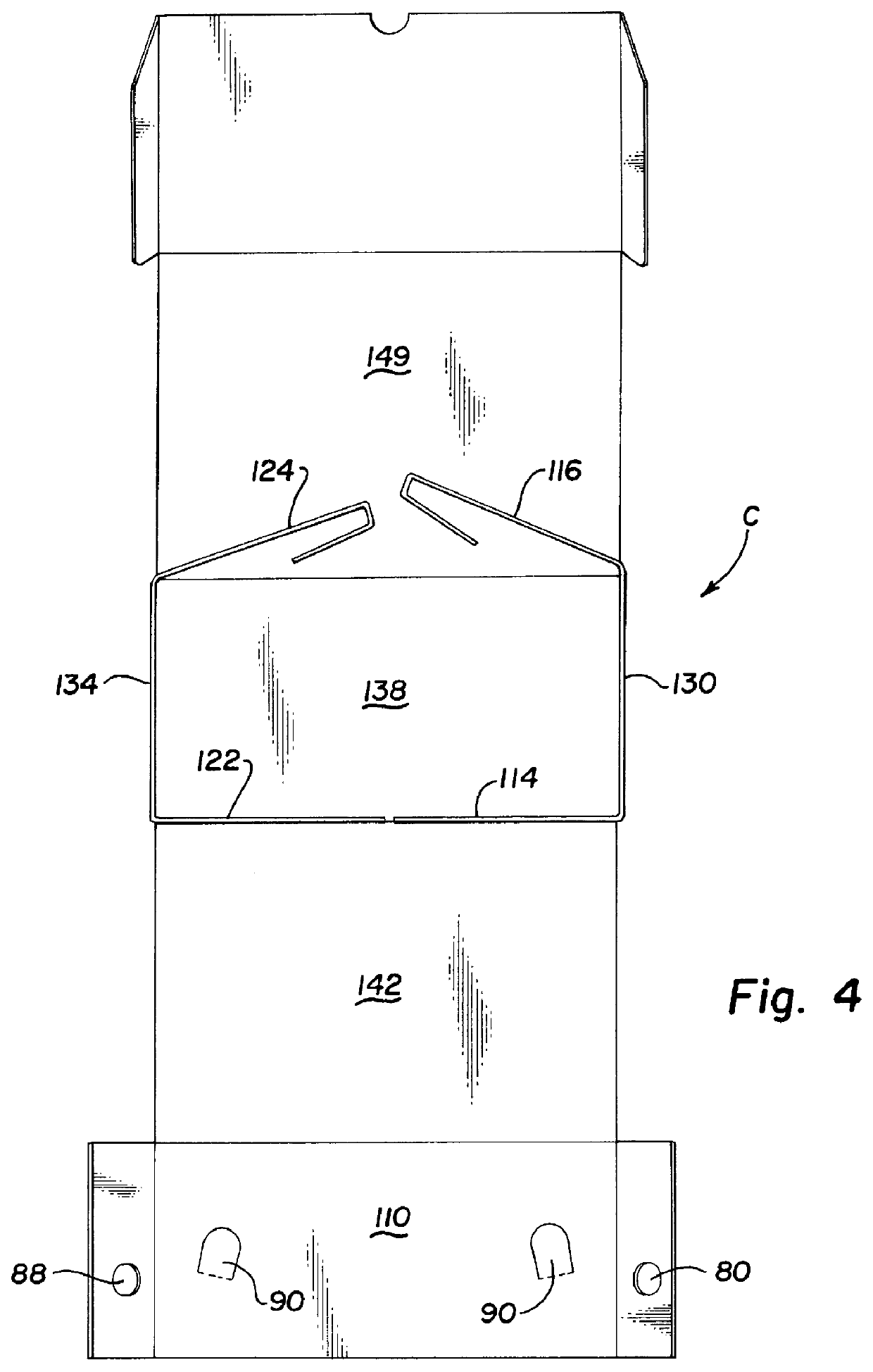

Shrink package

A shrink-wrapping pallet (P) for packages includes a pallet member (150) having essentially rigid first and adjacent second sections (152 and 154). The first and second sections (152 and 154) each include an upper and lower surfaces (156, 168, 160 and 162) and opposing inner and outer edges (164, 166, 168 and 170). The first and second sections (152 and 154) are joined along the inner edges (164 and 166) of the first and second sections. The pallet (P) is adapted to hold a selected object (O) to be secured on the upper surface (156) of the first section (152) of the pallet member (150). A flexible film (172) is secured to the pallet member (150) near the outer edges (168 and 170) of the first and the second sections of the pallet member (150). A pocket (178) that is adapted to hold the object (O) to secured is formed between the upper surface (156) of the first section and an opposing lower surface (180) of the film (172).

Owner:KPCMASTERS CRAFT INT

Heat-shrinkable laminated film, molded product and heat-shrinkable label comprising the film, and container

ActiveUS20130224412A1Good heat shrinkabilitySolve easy peelingBottlesSynthetic resin layered productsPolyesterRoom temperature

A heat-shrinkable laminated film having: (A) layer mainly having a polyester series resin; (C) layer mainly having a polystyrene series resin or mixture of polyester series and polystyrene series resins; and (B) layer mainly having polyester series and polystyrene series resins and disposed between (A) and (C) layers, the film having excellent heat-shrinkability, transparency, and interlayer-adhesiveness at room temperature, not easily peeled in a high-temperature treatment, inhibited from whitening when bent during processing, and suitable for shrinkage-packaging, shrink-bond-packaging, etc., with (B) layer having: a hard polyester series resin or mixture of hard polyester series and soft polyester series resins; and soft styrene series resin, hard styrene series resin, or mixture thereof, or with a content of the (B) layer polyester series resin smaller than that of the (A) layer one, and a content of the (C) layer polyester series resin smaller than that of the (B) layer one.

Owner:MITSUBISHI CHEM CORP

Heat-Shrinkable Laminate Film, Molded Product and Heat Shrinkable Label Employing the Film, and Container

ActiveUS20080026170A1Low temperature shrinkabilityLittle natural shrinkageStampsWrappers shrinkageSurface layerWarm water

To provide a heat-shrinkable laminate film excellent in film elasticity (rigidity at room temperature), shrink finishing quality, transparency when incorporated as recycled and natural shrinkage and having delamination of the film suppressed, so that it is suitable for application in shrink wrapping, shrink bundling wrapping, shrink label, etc., and a plastic container provided with a heat shrinkable label made of such a film.A laminated film comprising a surface layer (S layer) composed mainly of a polyester resin, an intermediate layer (M layer) composed mainly of a styrene resin and an adhesive layer (AD layer) composed mainly of an adhesive resin, wherein its heat shrinkage is at least 30% in at least one direction when it is dipped in warm water of 80° C. for 10 seconds, or its tensile modulus of elasticity in a direction perpendicular to the main shrink direction is at least 1,200 MPa.

Owner:MITSUBISHI CHEM CORP

Apparatus and method for preventing adhesions between an implant and surrounding tissues

An anti-adhesion membrane is placed onto an implant introduced into a surgical site of a patient to prevent post-surgical adhesions between the implant and surrounding tissue. The implant may comprise either biological material, such as a transplanted organ, or non-biological material such as a medical device. The membrane may be applied in a variety of ways. In one example, a membrane according to the present invention is shrink-wrapped around a pace-maker. In another example, a breast implant is spray-coated or dipped with the membrane material.

Owner:MAST BIOSURGERY

Compact camera and cable system for vehicular applications

ActiveUS8482664B2Television system detailsColor television detailsInterference fitConductive coating

Owner:MAGNA ELECTRONICS INC

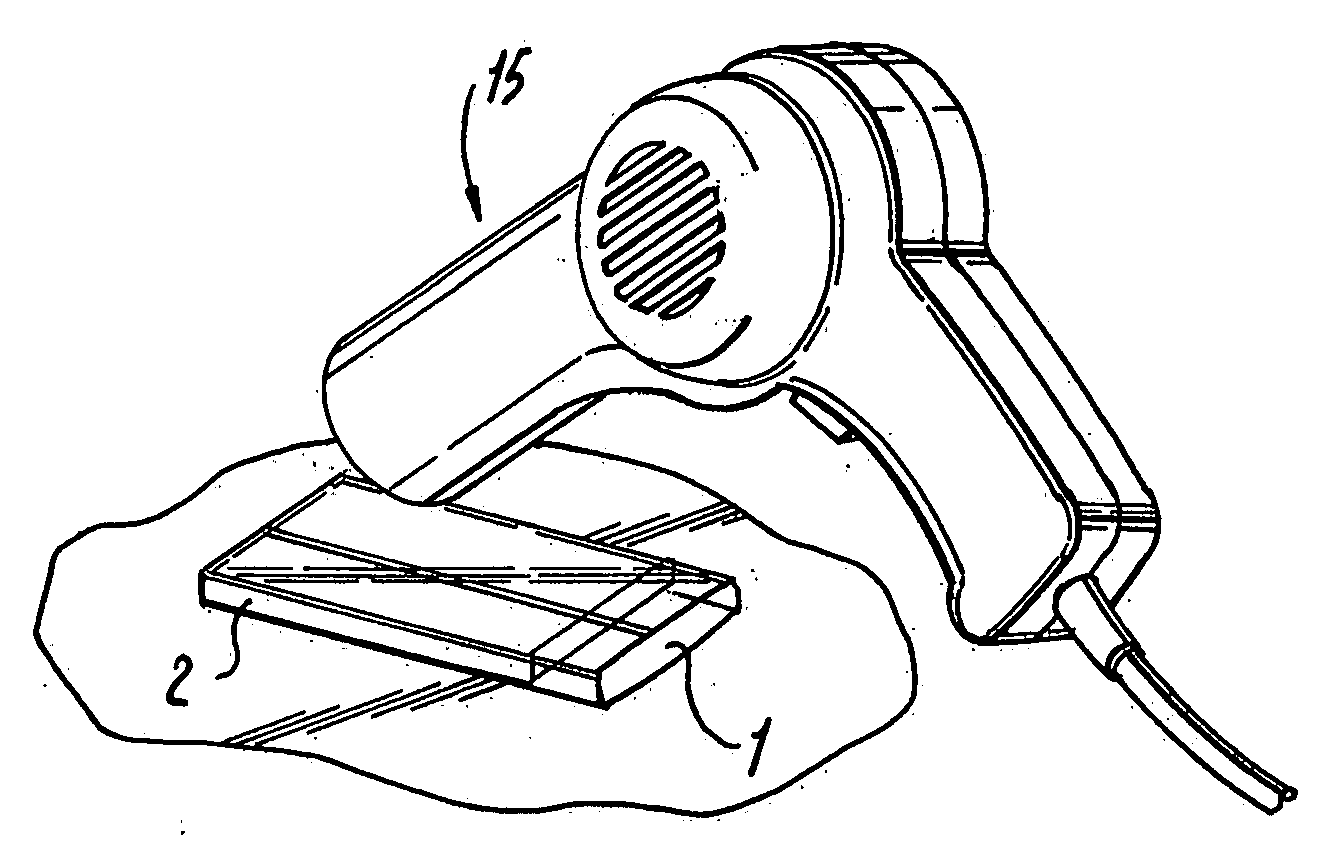

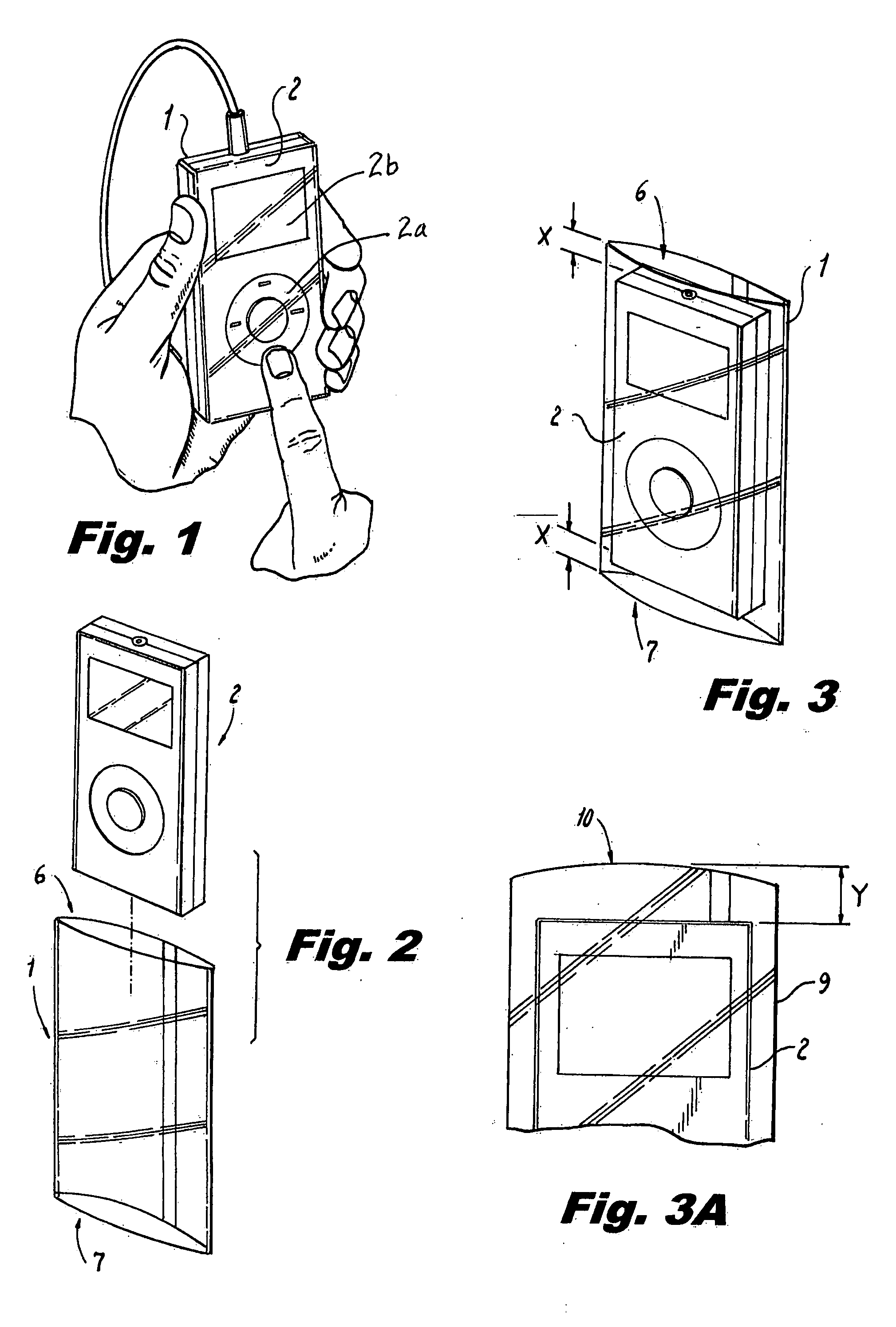

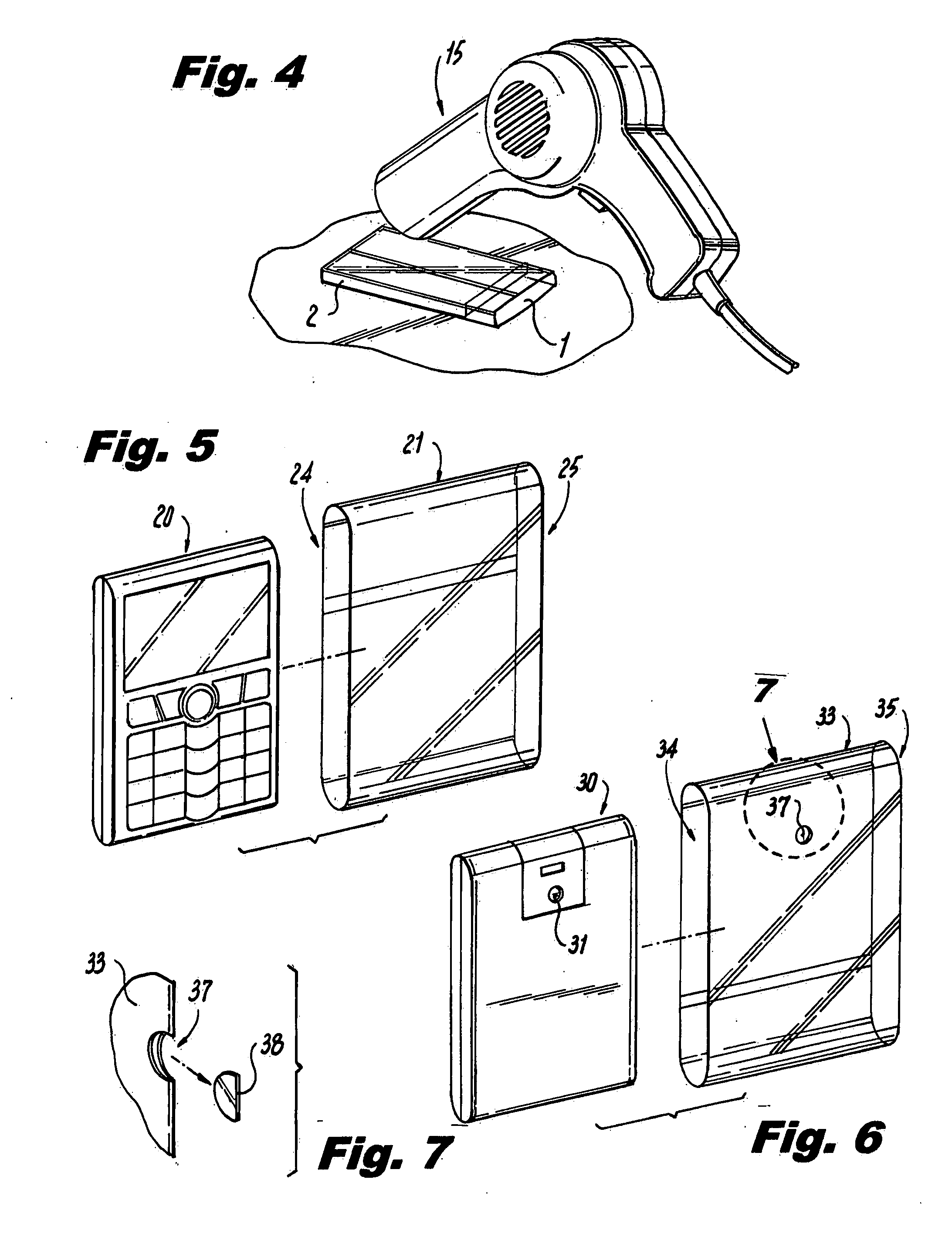

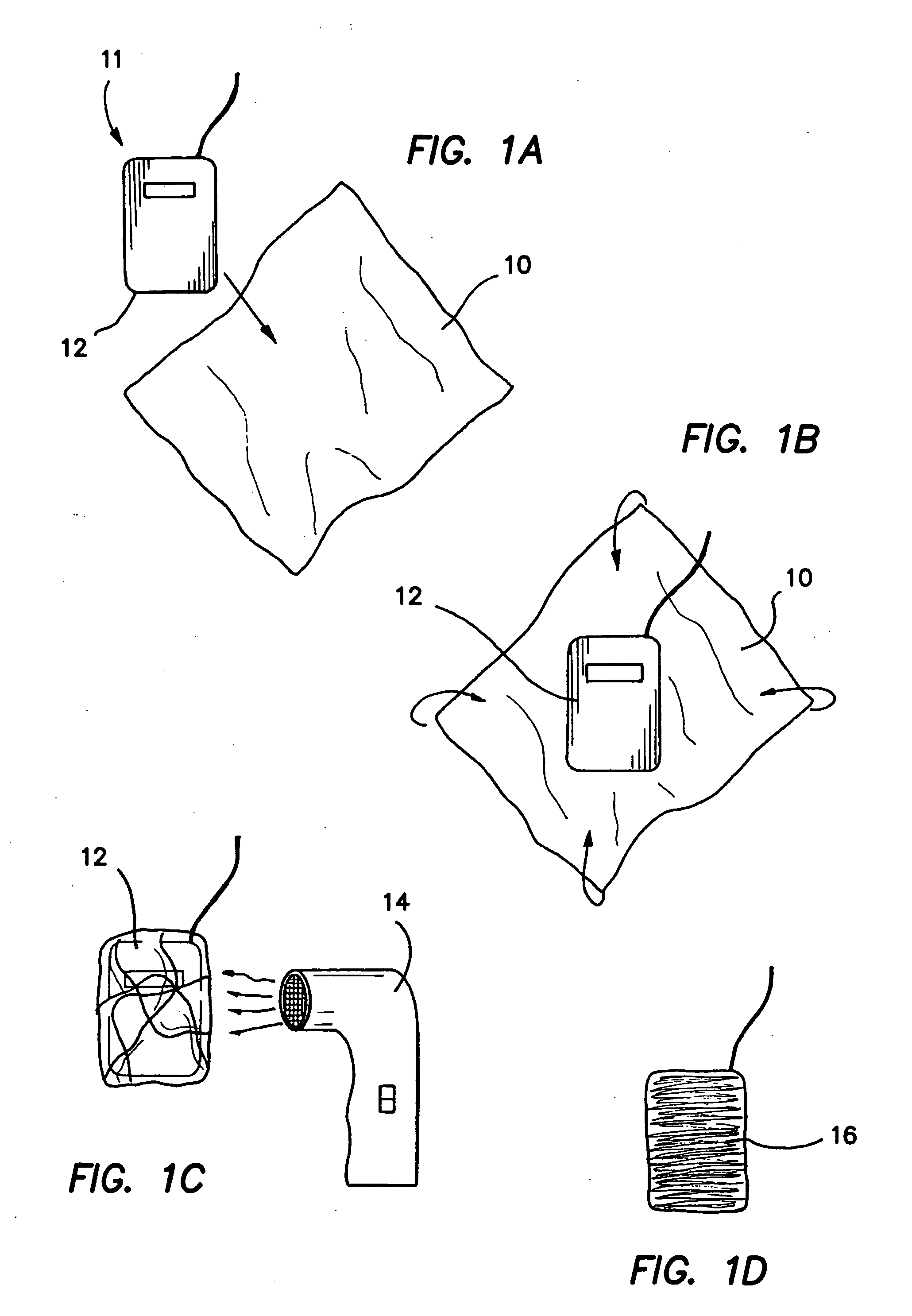

Shrink wrap sleeves for electronic devices

InactiveUS20080206498A1Better form fitClearance can be providedWrappers shrinkageShrinkage connectionsCamera phoneCamera lens

A retrofit heat-sensitive shrink wrap sleeve is placed over a tetrahedral hand-held personal electronic device to be covered, having four adjacent lateral planar sides and two remaining planar sides perpendicular to the lateral planar sides. The sleeve is aligned with the device, and then shrunk to a form fit by heating all surfaces using an ordinary hair dryer. For certain devices such as personal music / video player devices (e.g.—iPod® of Apple Corporation), the sleeve is open at top and bottom thereby providing clearance for access to connectors which are typically placed on those surfaces of the device. For other types of device such as a personal digital assistant (PDA) / camera phone device, it is more appropriate for the sleeve to be open at both sides to permit access to connectors and ports on the side. In such case, a port is provided for the camera lens of the camera phone device.

Owner:ALLEN PETER

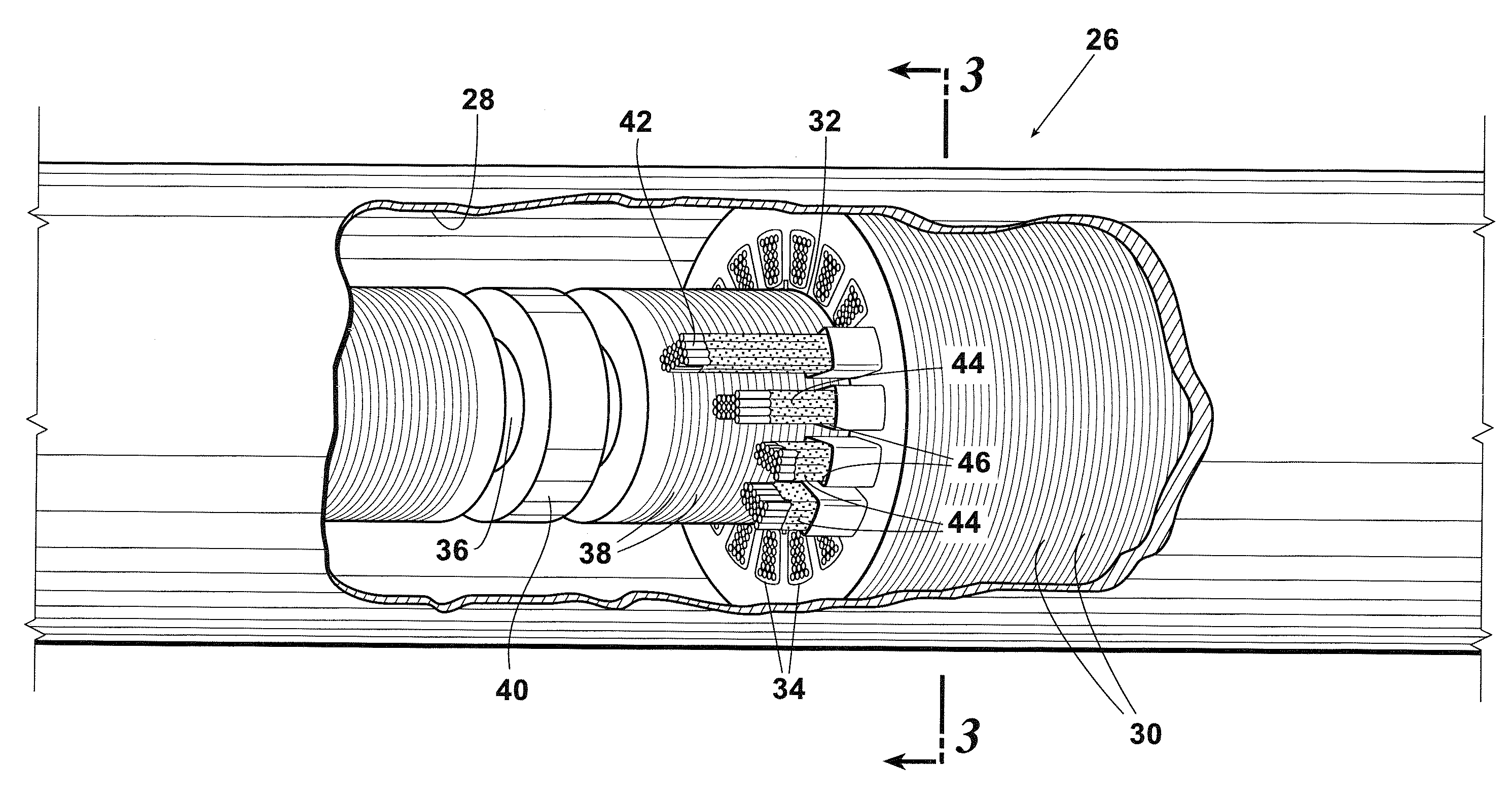

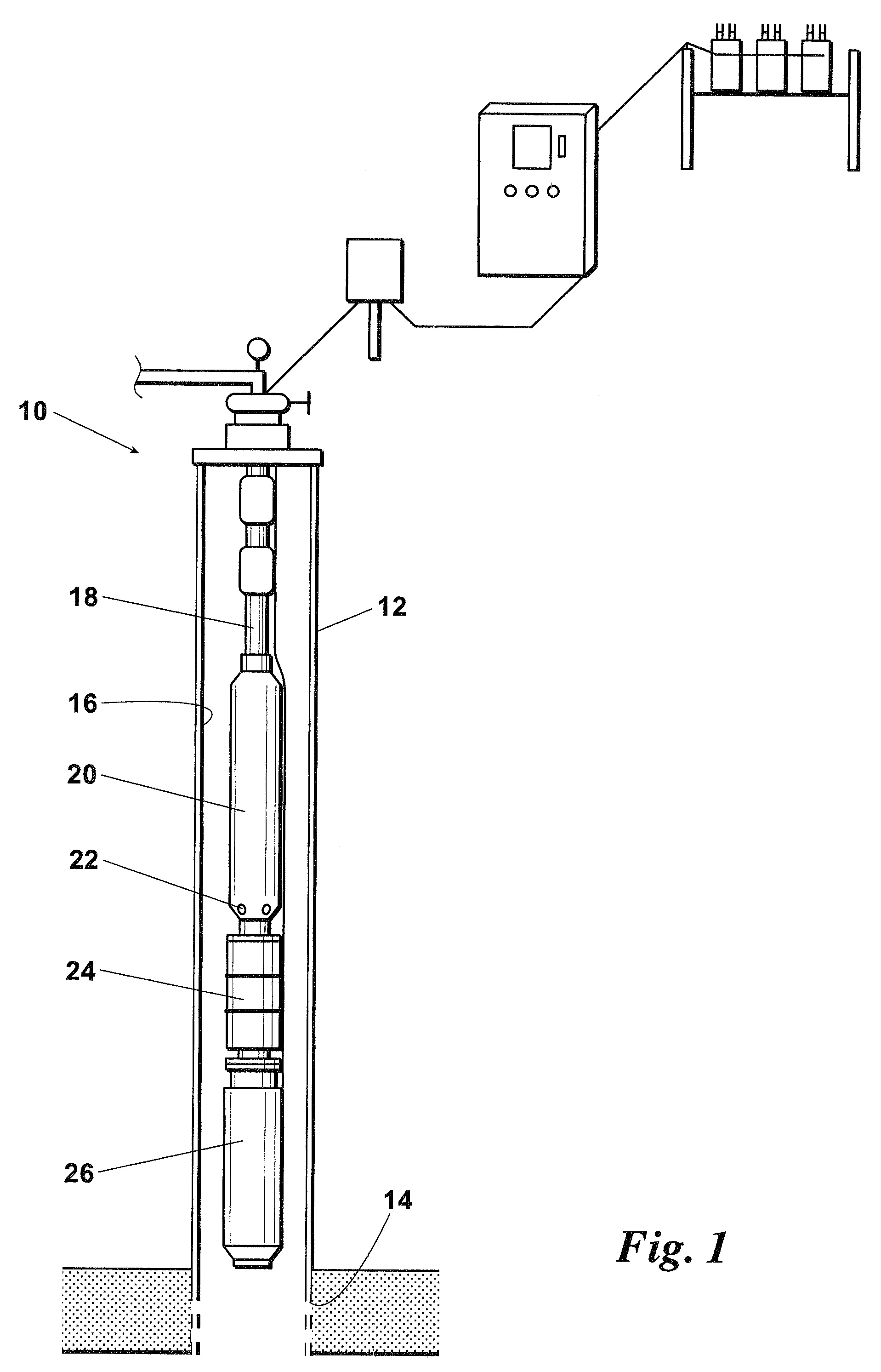

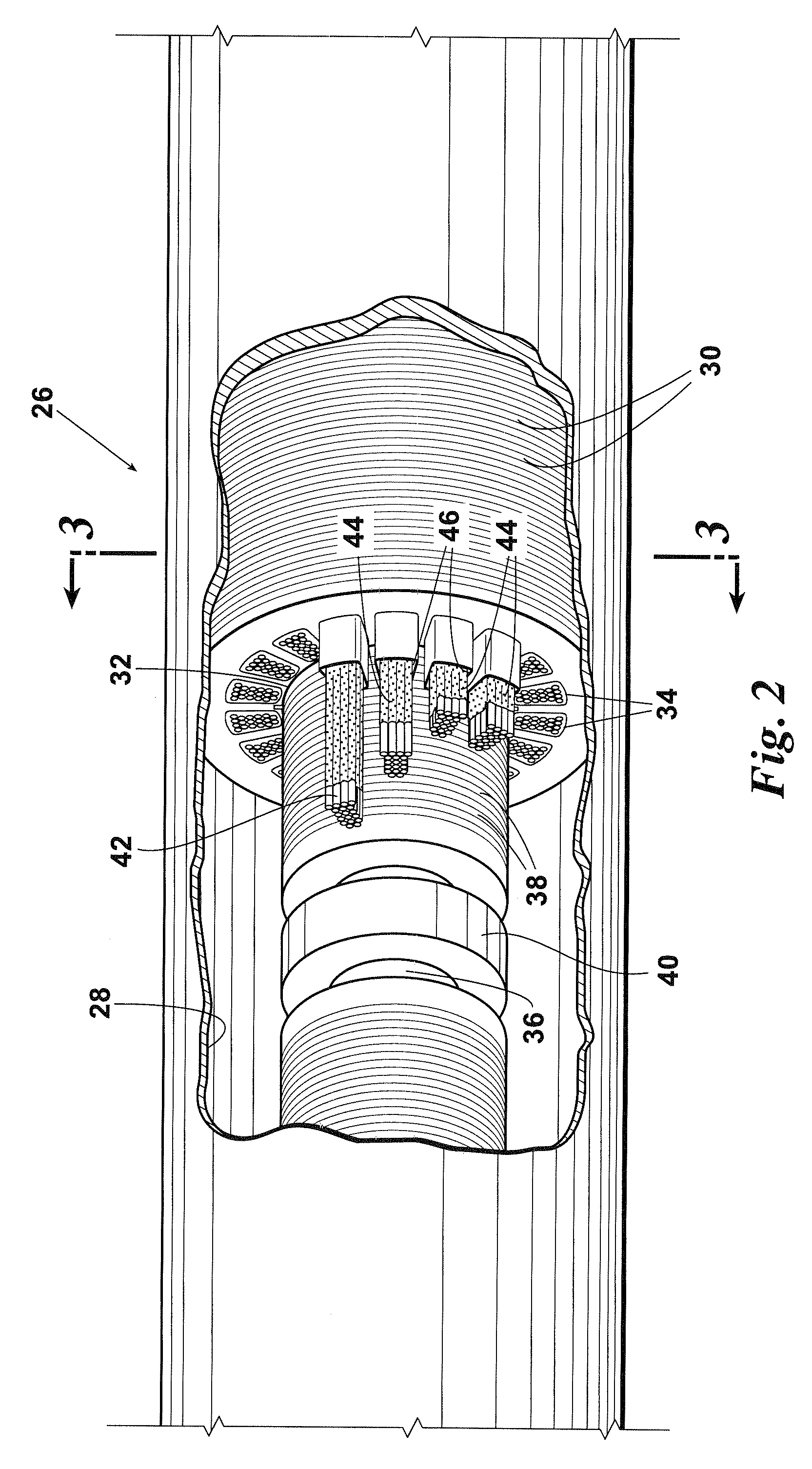

Shrink tube encapsulated magnet wire for electrical submersible motors

InactiveUS20090091202A1Reducing hot spotFreedom of movementWrappers shrinkageWindings insulation shape/form/constructionShrink wrapConductor Coil

An electrical motor for an electrical submersible pump wherein the electrical motor has increased heat transfer capabilities. The electrical motor includes a housing and a plurality of stator laminations within the housing. Each stator lamination defines a central orifice and a plurality of lamination slots. A plurality of magnet wires pass through each of the plurality of lamination slots formed by the stacked plurality of stator laminations. Shrink wrap surrounds each of the plurality of magnet wires to secure the magnet wires in bundles. The result is that the wires are effectively bound together in a manner that allows oil to move freely inside the lamination slots surrounding the wire bundles. Since fluid can pass between and around the windings, the overall winding temperature will be normalized, essentially reducing hot spots that occur in prior art designs.

Owner:BAKER HUGHES INC

Apparatus and method for preventing adhesions between an implant and surrounding tissues

InactiveUS20070154525A1Avoid adverse reactionsSuture equipmentsDental implantsBreast implantSurgical site

An anti-adhesion membrane is placed onto an implant introduced into a surgical site of a patient to prevent post-surgical adhesions between the implant and surrounding tissue. The implant may comprise either biological material, such as a transplanted organ, or non-biological material such as a medical device. The membrane may be applied in a variety of ways. In one example, a membrane according to the present invention is shrink-wrapped around a pace-maker. In another example, a breast implant is spray-coated or dipped with the membrane material.

Owner:MAST BIOSURGERY

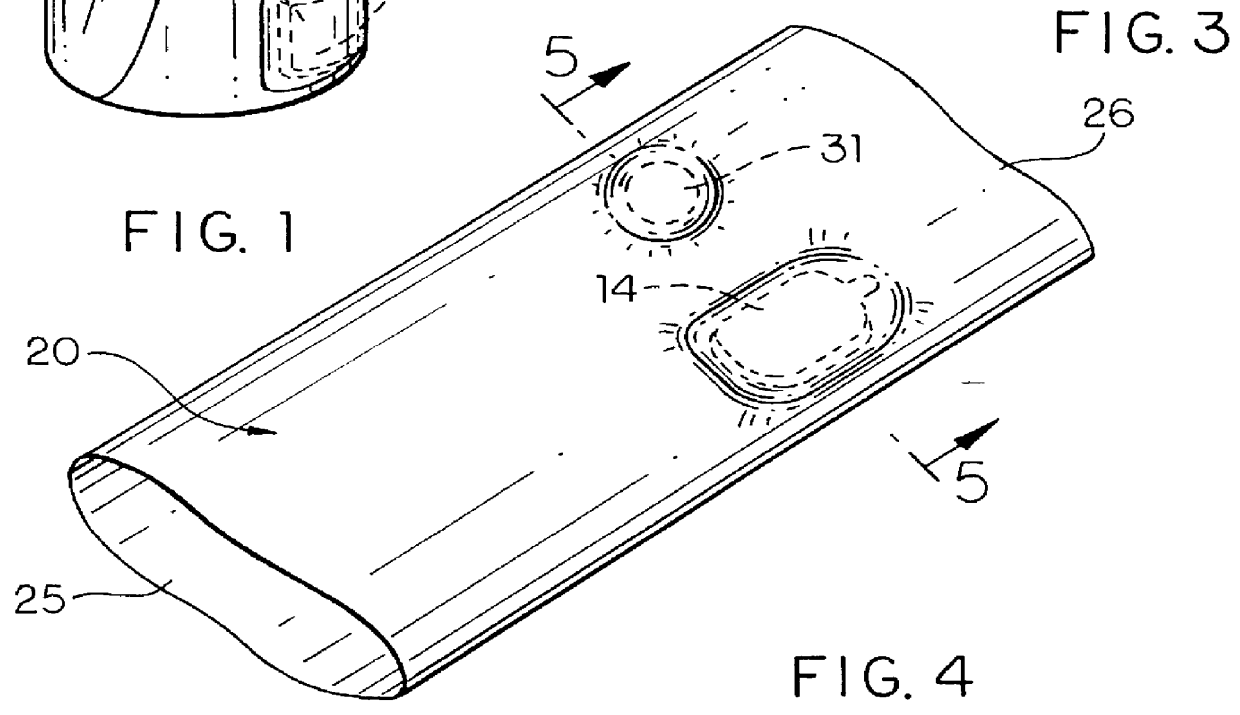

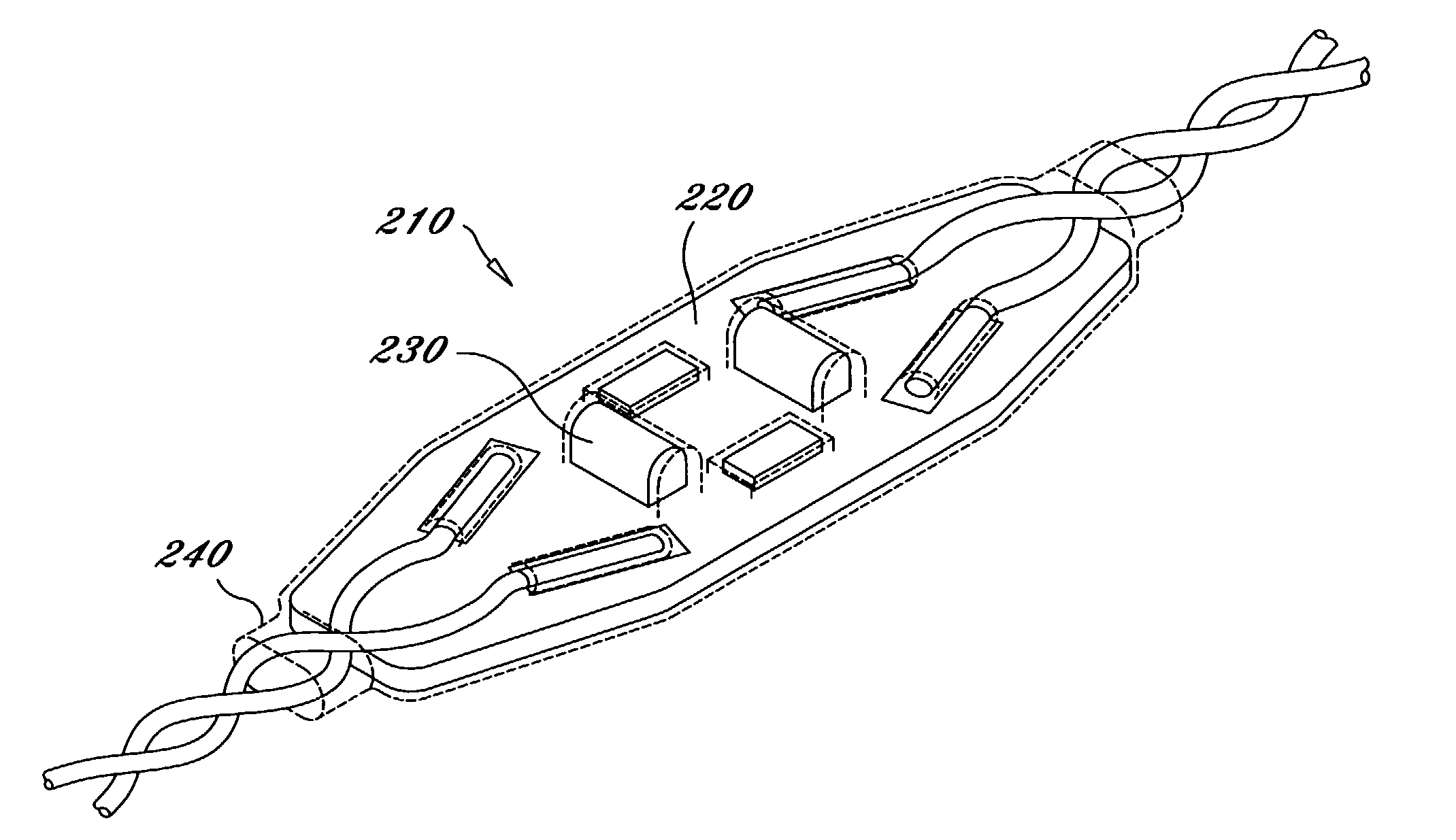

Aircraft escape slide lighting system

InactiveUS7018079B1Improve securityComplete coveragePoint-like light sourceLighting support devicesDecrease weightEngineering

The present invention is a lighting system for providing illumination to an aircraft evacuation slide. Light sources are safely utilized with an existing evacuation slide, a substantial improvement over prior assemblies that use a hard, plastic housing enclosing the light source. The invention increases light transmission, eliminates housing cracking, inadvertent puncturing, clouding, and decreases weight and cost of conventional slide systems. Each assembly comprises a mounting surface and a printed circuit board thereon, light sources, preferably light-emitting diodes (LEDs) mounted on the mounting surface, the light sources illuminating the aircraft evacuation slide, and a flexible containment covering, such as a heat shrink wrap that covers the assembly and protects the light sources. A protective shield can cover the mounting surface while allowing the LEDs to protrude through an aperture in the shield, protecting the LEDs from damaging forces while allowing light to illuminate the landing area.

Owner:ASTRONICS DME LLC

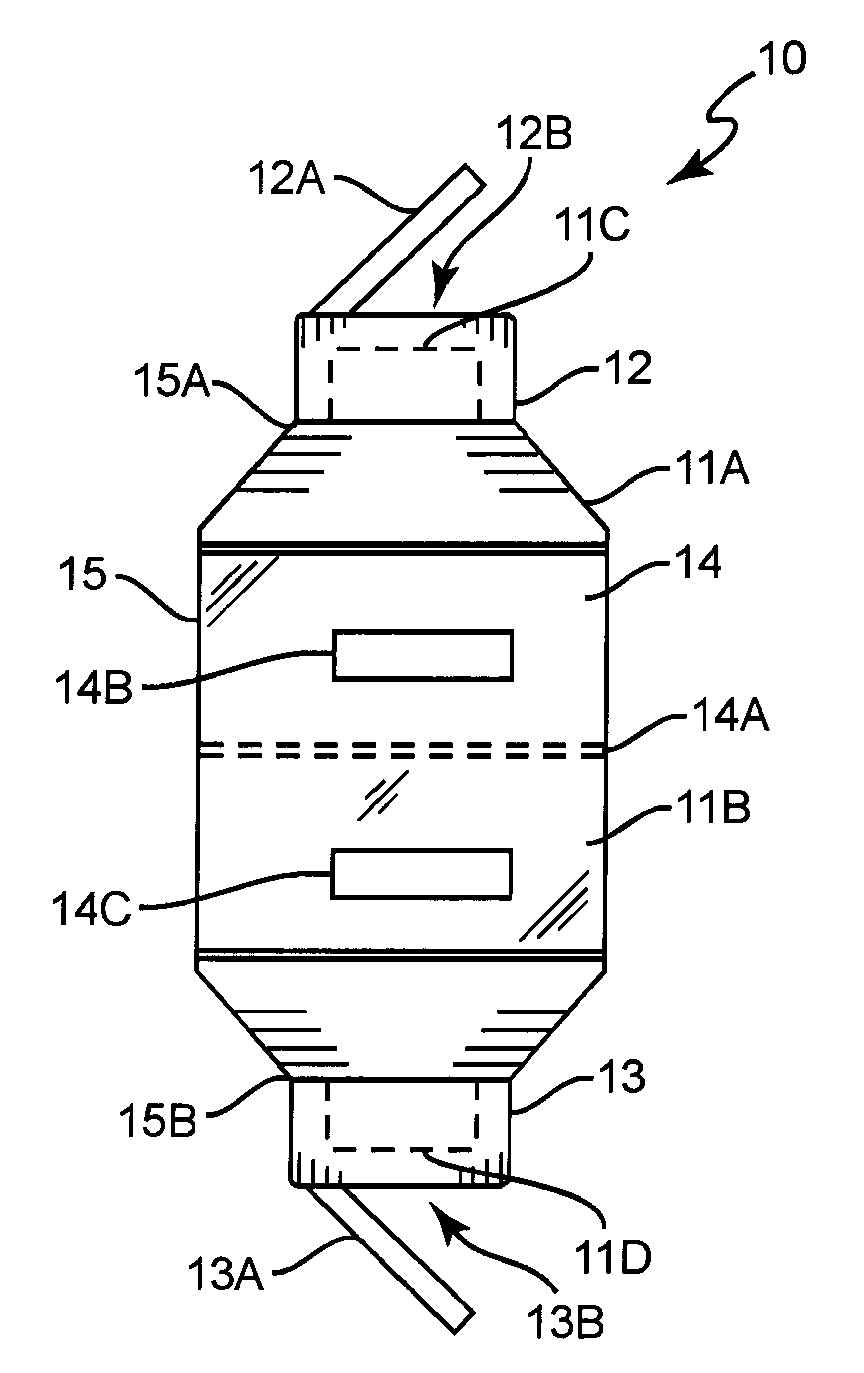

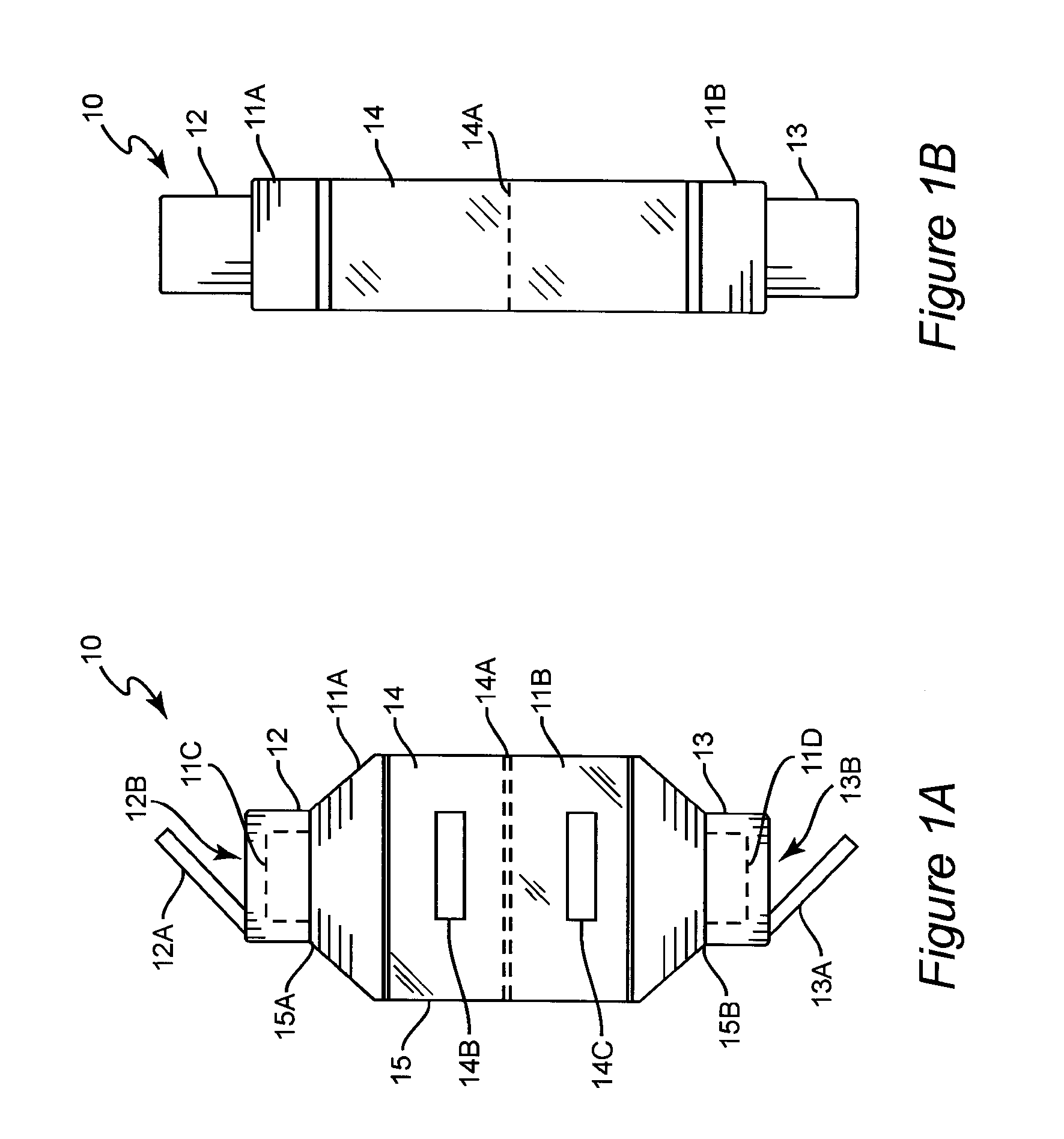

Dual sided container

A container has openings at each end and has two compartments for holding two complementary materials. The container stands on either end and can dispense one of the two materials from each end. In one embodiment the container is separable into two individual containers. The individual containers are attached together using various means such as shrink wrap material, perforated strips, interlocking sections and the like.

Owner:HILL DANIEL JASON +1

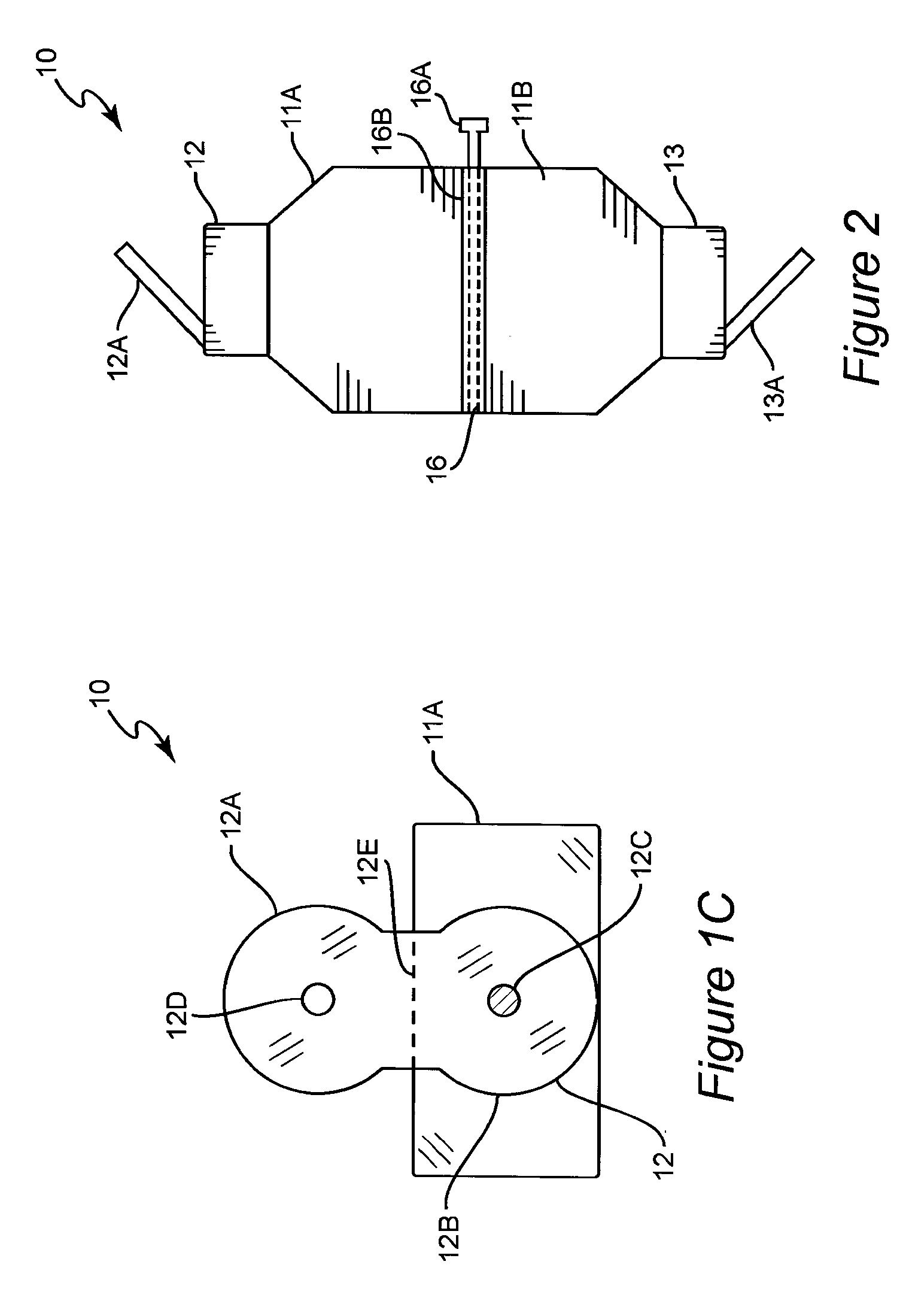

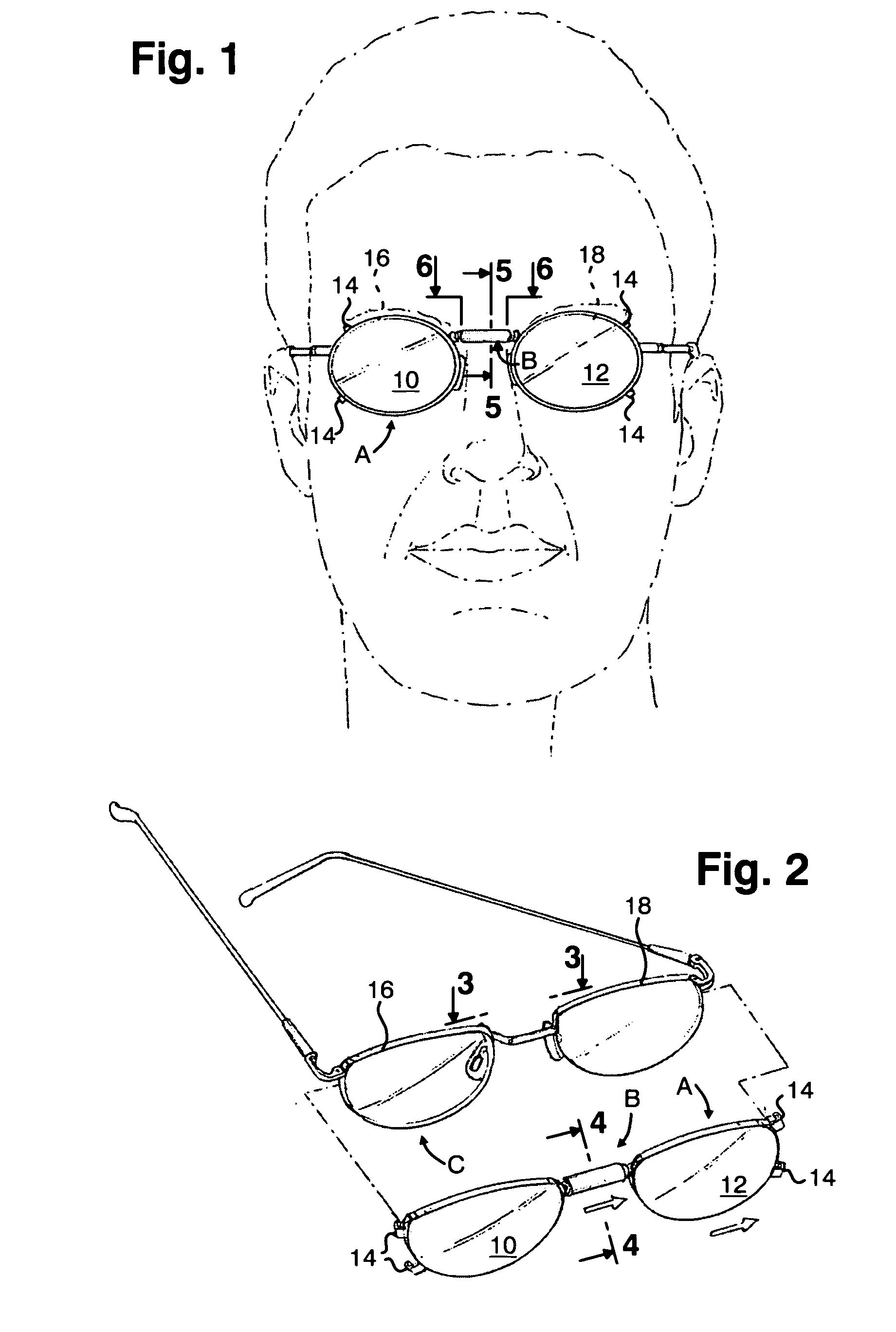

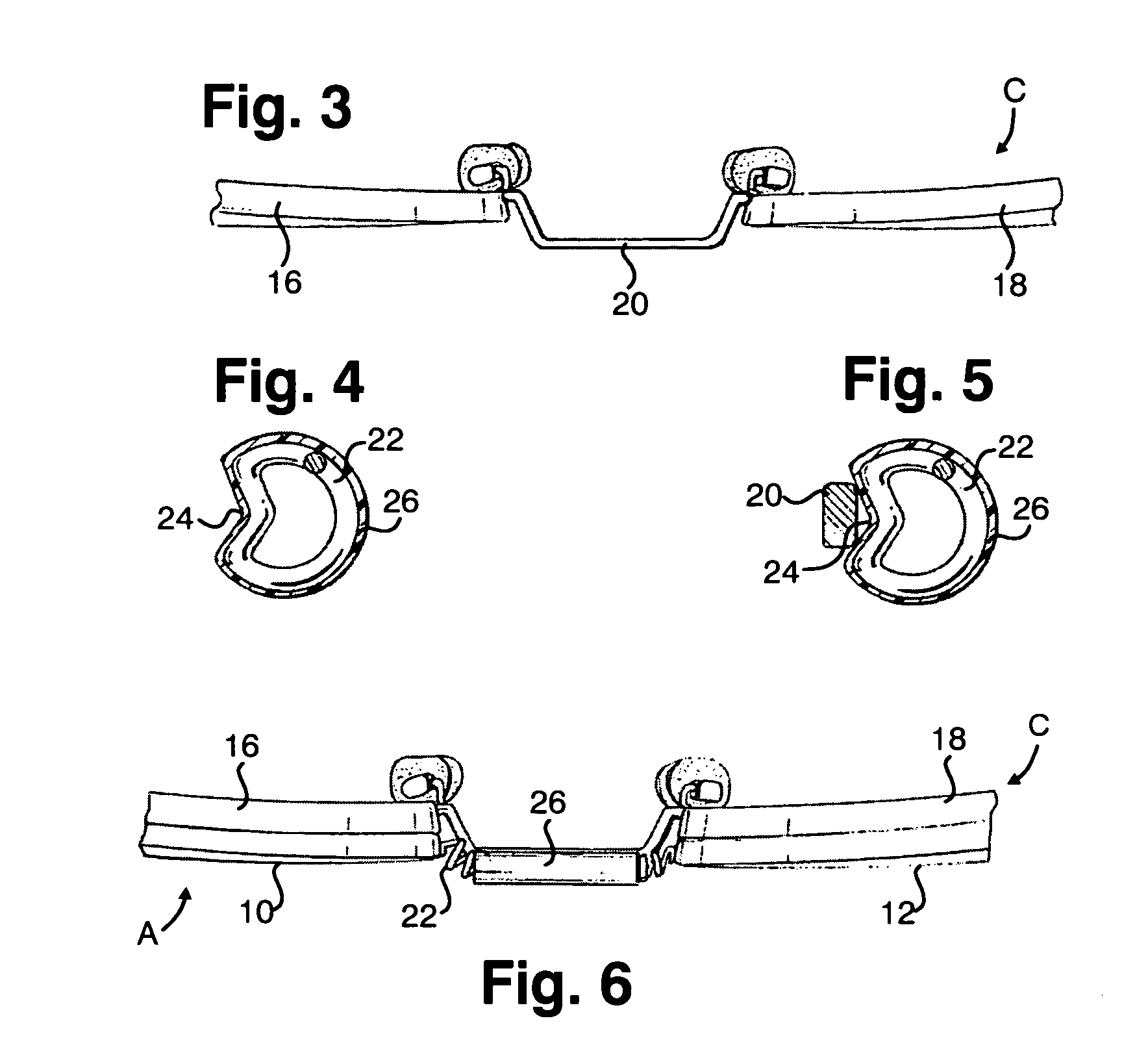

Clip-on with flexible and expandable bridge member

Owner:OPSALES

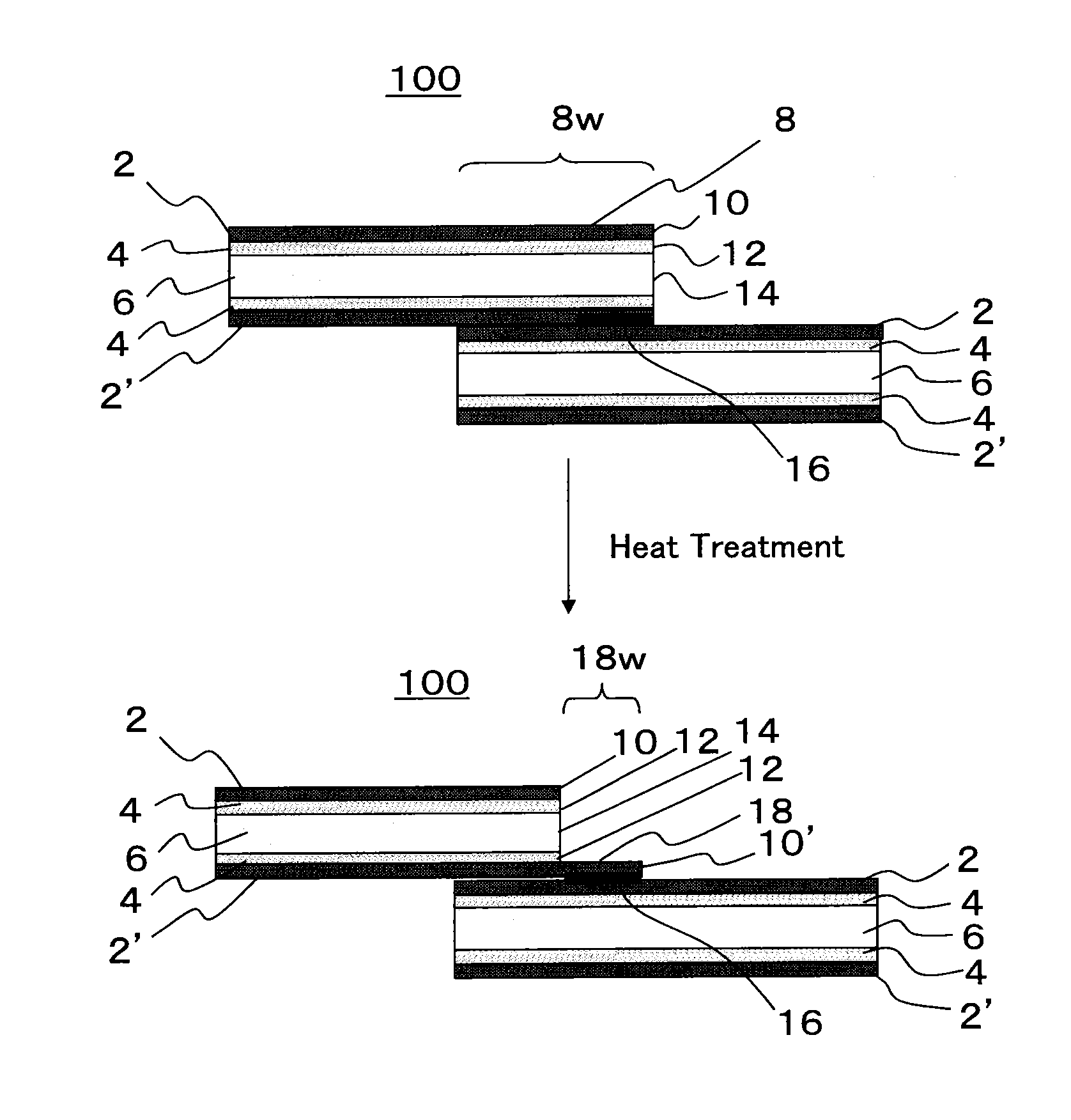

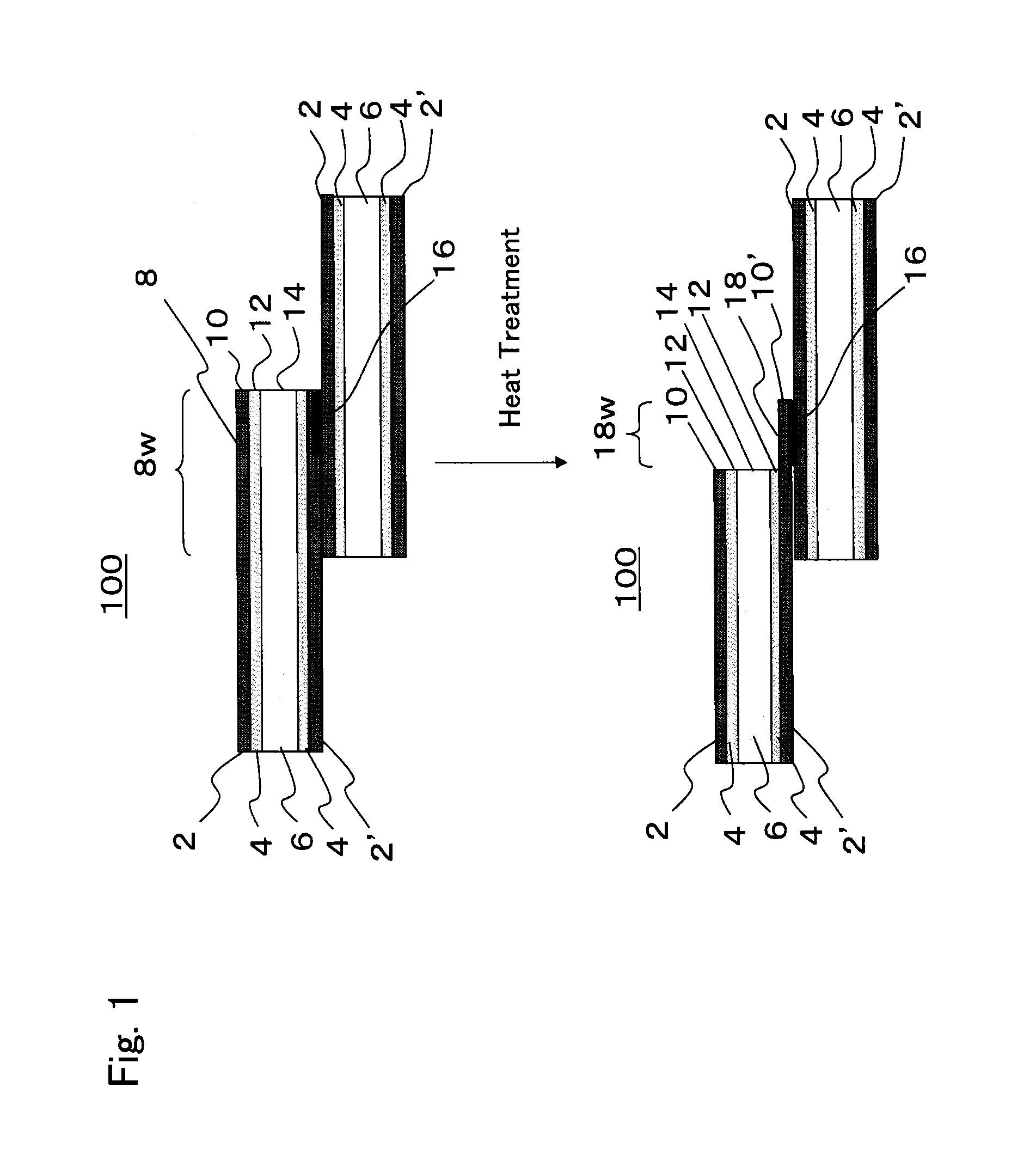

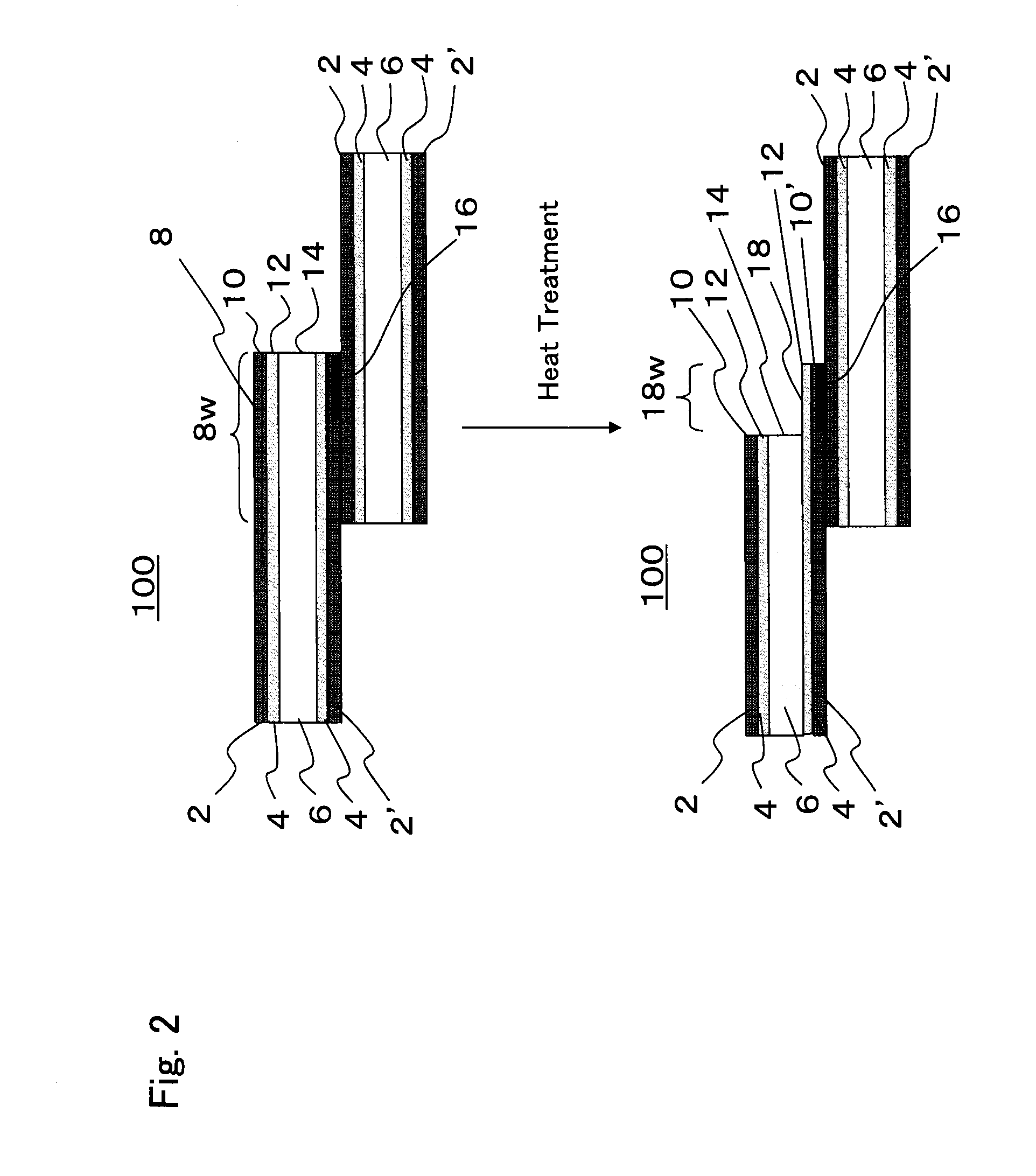

Shrink-wrap collar from DRAM deep trenches

InactiveUS6069049AReliable formingImprove integration densitySolid-state devicesSemiconductor/solid-state device manufacturingShrink wrapDislocation

Crystal lattice dislocations in material surrounding trench capacitors and other trench structures are avoided by alteration of stresses such as decreasing compressive stresses and / or development of persistent tensile forces within material deposited in the trench and thus at the material interface formed by the trench. Such alteration of stresses is achieved by volume reduction of a film deposited in the trench. The material is preferably a hydrogenated nitride of silicon, boron or silicon-carbon alloy which may be reduced in volume by partial or substantially complete dehydrogenation during subsequent heat treatment at temperatures where the film will exhibit substantial creep resistance. The amount of volume reduction can be closely controlled by control of concentration of hydrogen or other gas or volatile material in the film. Further fine adjustment of stresses can be achieved in combination with this mechanism by volume reduction of other materials which may be used, in part, to confine the film through other mechanisms such as annealing.

Owner:SIEMENS MOBILITY INC

Shrink packaging barrier film

A film comprises a barrier layer including PVdC or EVOH, a skin layer, and an intermediate layer comprising at least about 50% of propylene / ethylene copolymer. The film has at least about 10% free shrink in at least one direction at 85° C. The film is useful in making barrier shrink bags.

Owner:CRYOVAC ILLC

Heat-Shrinkable Laminated Film, Molded Product and Heat-Shrinkable Label Employing the Film, and Container

InactiveUS20080057236A1Excellent shrink finishing qualityConvenience filmStampsWrappers shrinkagePolyesterSurface layer

The present invention provides a heat-shrinkable laminated film, which exhibits excellent film rigidity, shrink finishing quality, transparency of the recycled film, and a small natural shrinkage, with suppressed film interlayer peeling and shrinking stress, and which is applicable to shrinkable packing, shrinkable bond-packing, shrinkable label and the like. The heat-shrinkable laminated film comprises: a surface layer (S layer) composed of a polyester series resin composition containing a polyvalent carboxylic acid residue and a polyvalent alcohol residue; a middle layer (M layer) composed of a styrene series resin composition; and an adhesive layer (AD layer) which contains a copolymer of styrene series hydrocarbon and a conjugated dienic hydrocarbon or hydrogenated derivatives thereof, and having a styrene series hydrocarbon content rate to the entire copolymer or hydrogenated derivatives is 5˜40 mass % or less. An elongation modulus of the film in a direction perpendicular to a main shrinking direction of the film is 1200 MPa or more, and a shrinking stress in the main shrinking direction of the film is 8 MPa or less or a rupture elongation at 23° C. is 40% or more.

Owner:MITSUBISHI PLASTICS INC

Color-coded shrink wrapped closure system

A packaging system for improved management of cap inventory when different beverages, such as different types of milk (skim, 1%, 2% and whole) or water (spring, distilled, fortified, mineral etc.) are bottled in the same bottling lines at various facilities. The system includes maintaining a supply of standard caps, which may be free of colorants or pigments, and a supplies of reels of different colored (or differently printed) shrink sleeve material. The different types of beverage are bottled in containers that have a single standard cap and standard uniform bottles, and the different contents of said bottles are differentiated from one another by the application of colored (or distinctively printed) shrink sleeves or bands. The cap and / or the bottle neck are adapted to be engaged by the shrink band in a way that protects the bottle from being tampered with, and when threaded caps are used, helps prevent the inadvertent loosening of the caps during in shipment.

Owner:BLACKHAWK MOLDING

Fluid storage and dispensing vessels having colorimetrically veriflable leak-tightness, and method of making same

A chemical storage and dispensing vessel having associated therewith a colorimetric member that is effective to change color in exposure to leakage of a gas contained in the vessel. The colorimetric member may be constituted by a film, e.g., of a shrink-wrap character, that contains or is otherwise associated with a calorimetric agent undergoing color change in exposure to fluid leaking from the vessel. Such shrink-wrap film may be applied to a portion of the vessel susceptible to leakage, or alternatively to the entire vessel, so that the film is calorimetrically effective to indicate the occurrence of a leakage event by visually perceptible change of color.

Owner:ENTEGRIS INC

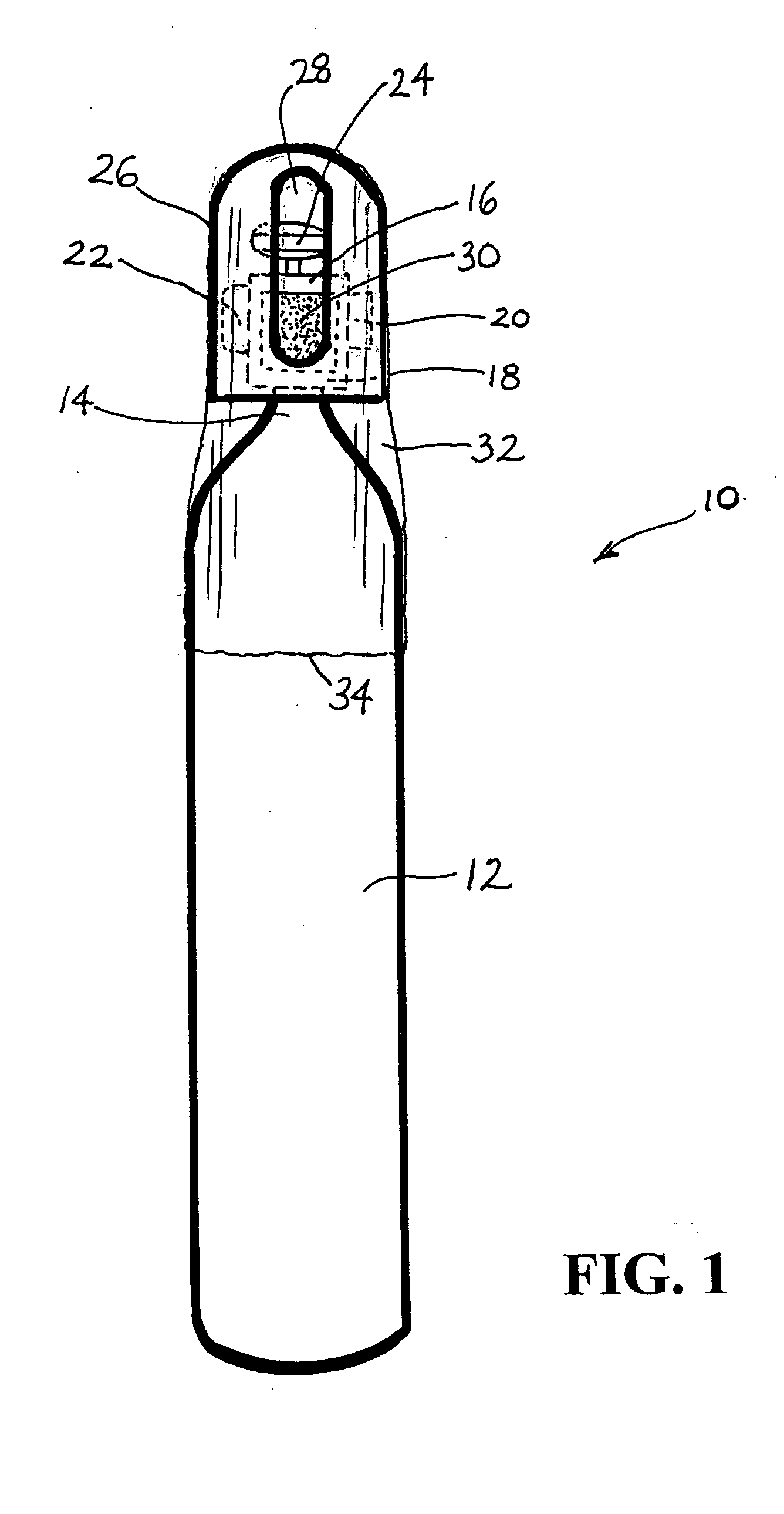

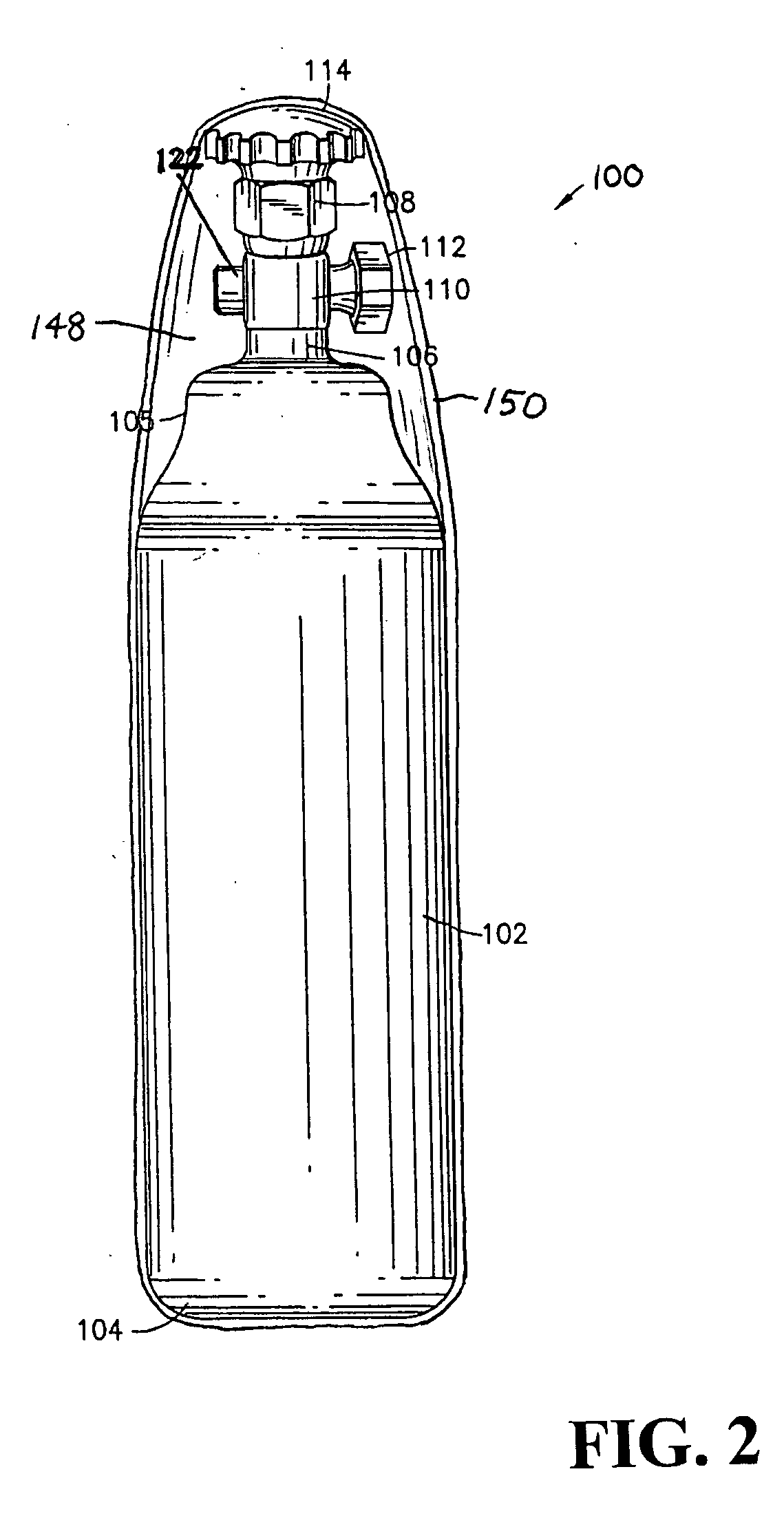

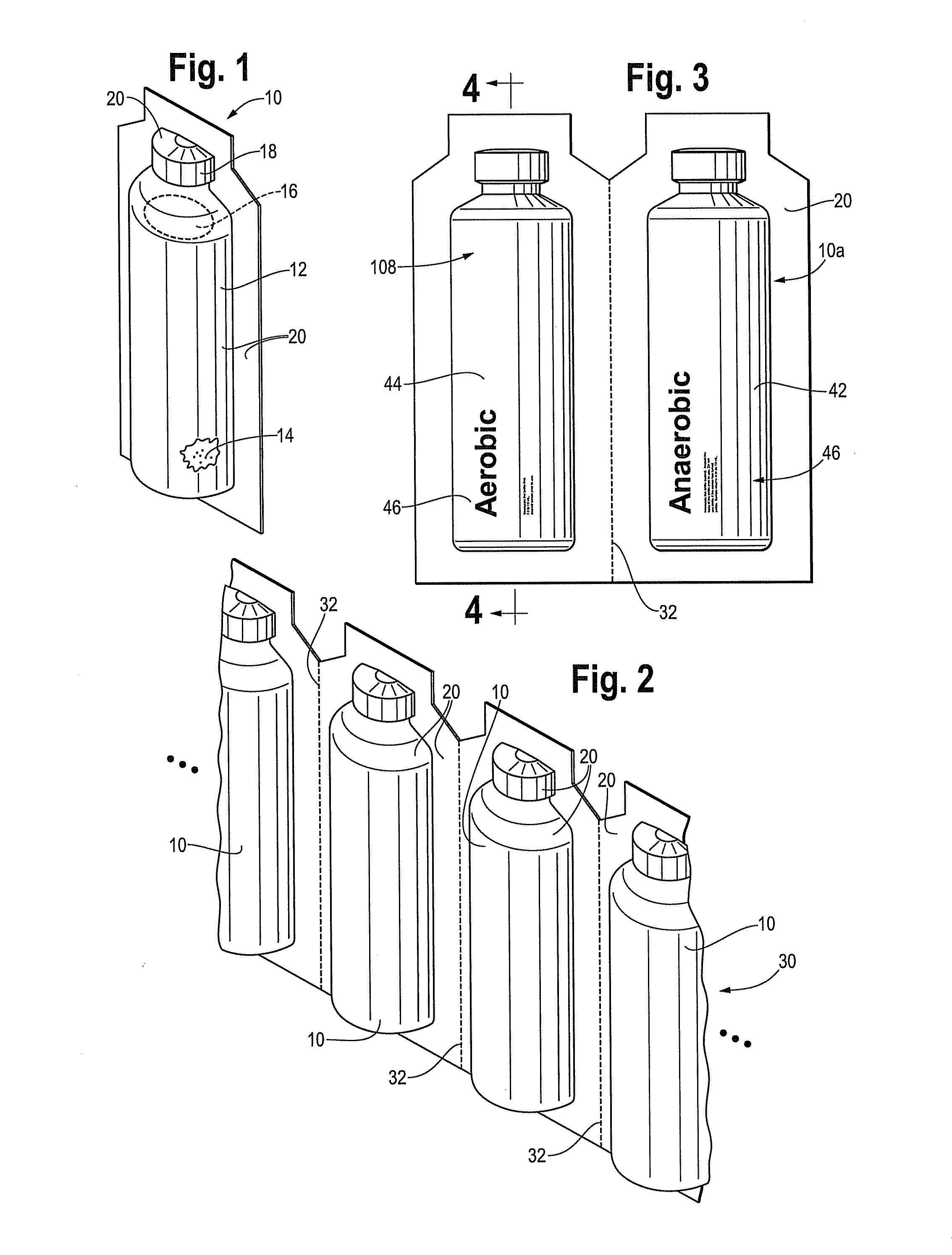

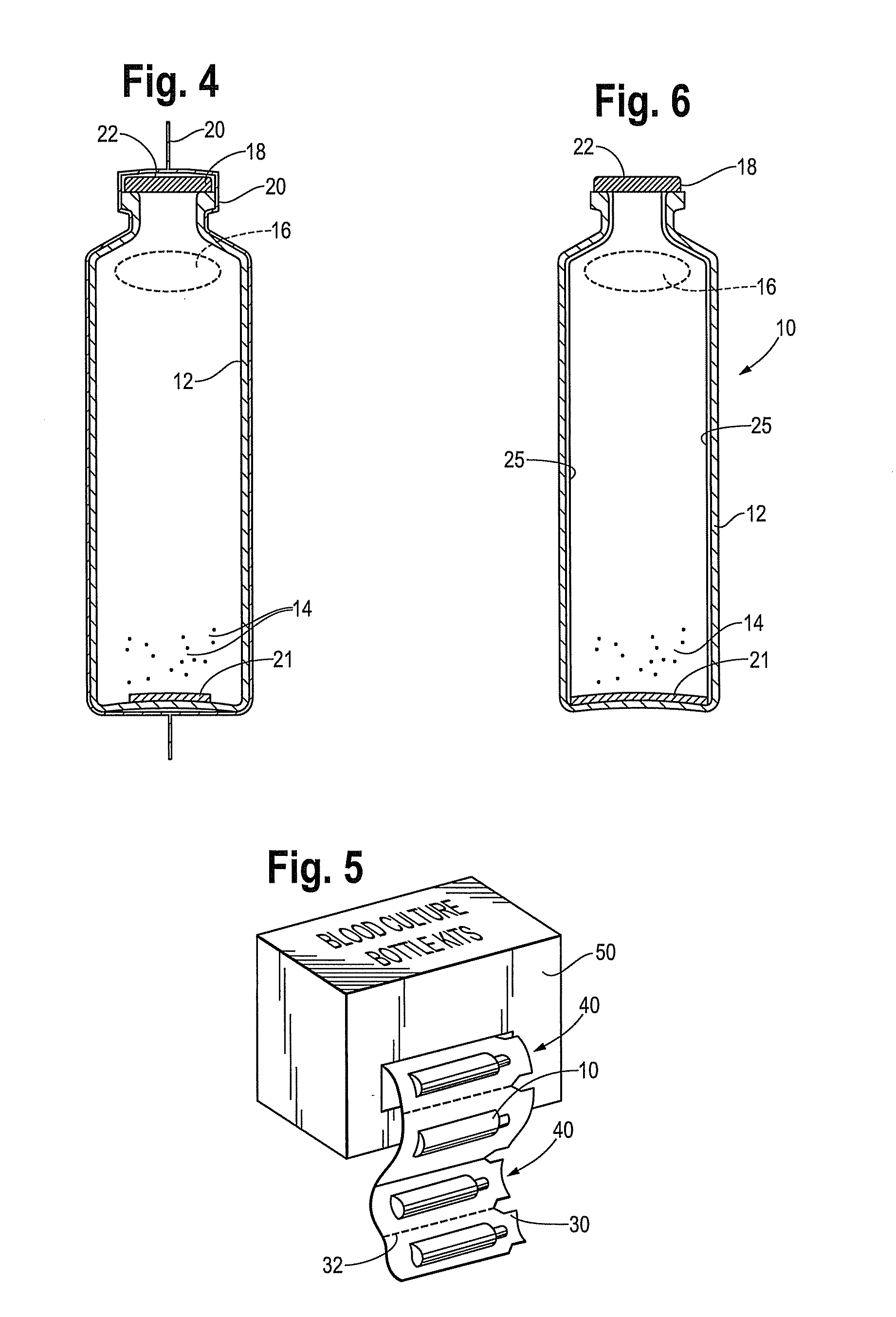

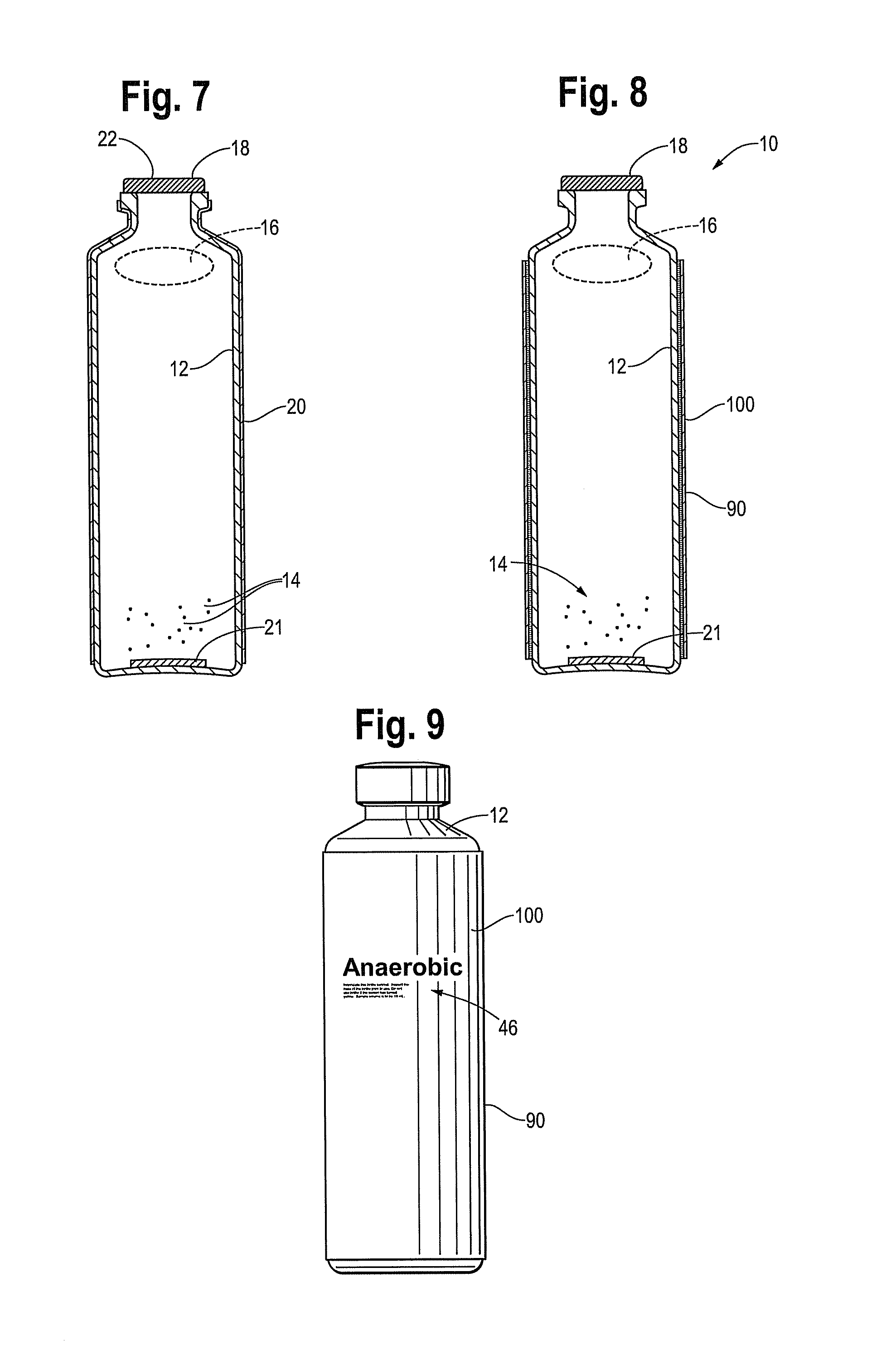

Single layer plastic test sample culture bottle

InactiveUS20110081714A1Reduce manufacturing complexityCheap manufacturingBioreactor/fermenter combinationsBiological substance pretreatmentsPlastic materialsAdhesive

A bottle for culturing a test sample, e.g., blood, includes a plastic vessel made from a single layer of plastic material. The bottle features a gas barrier. In one embodiment the gas barrier is in the form of a plastic shrink-wrap partially or alternatively completely enveloping the plastic vessel. Other embodiments feature a silica or glass coating to the bottle to provide the gas barrier. Other embodiments are made from a gas barrier plastic which is also autoclavable and possesses sufficient strength characteristics. Another embodiment features a single layer plastic bottle and a gas barrier adhesive label covering the cylindrical side wall of the bottle. Kits comprising two or more of such bottles and methods of manufacturing the bottles are also disclosed.

Owner:BIOMERIEUX INC

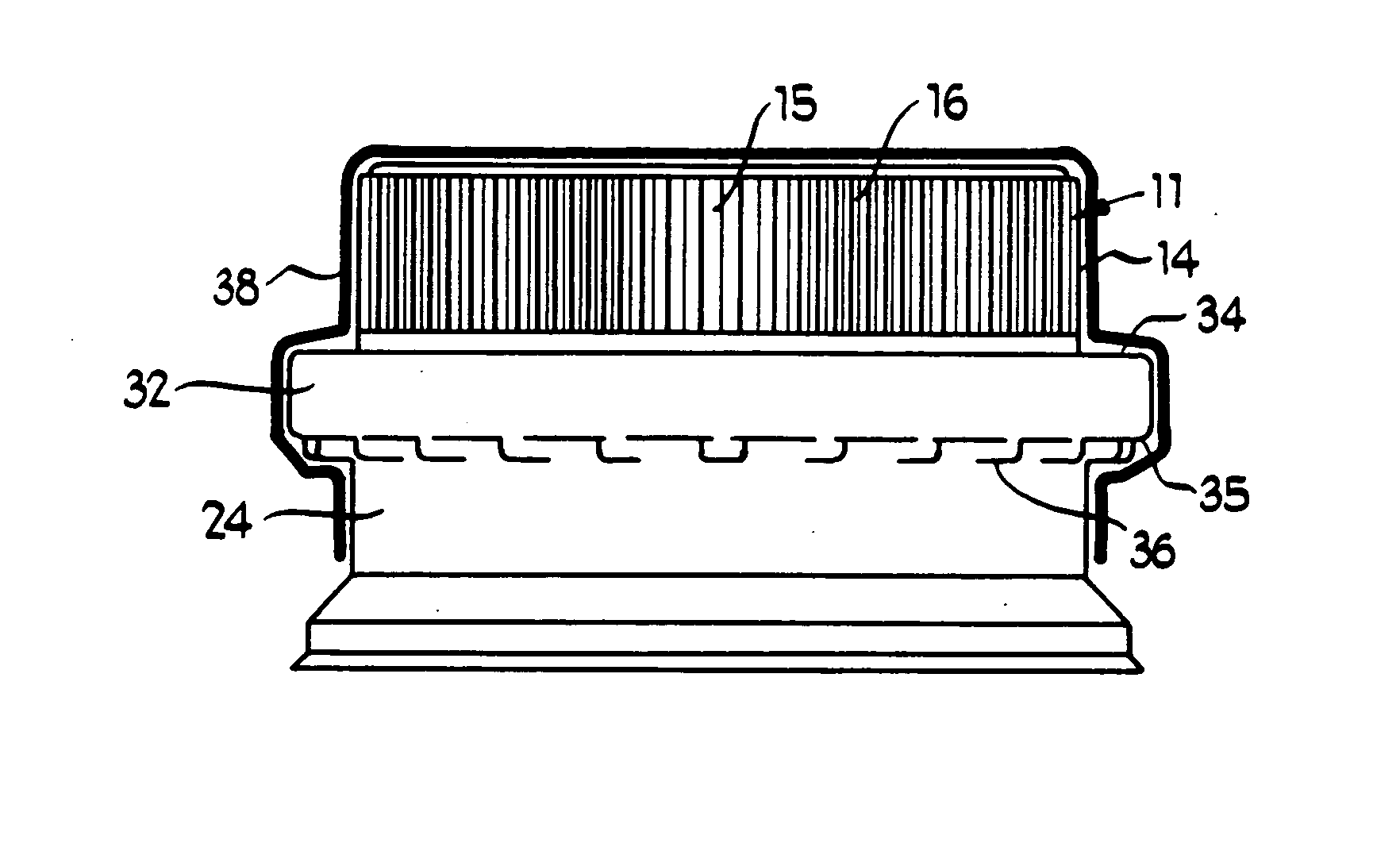

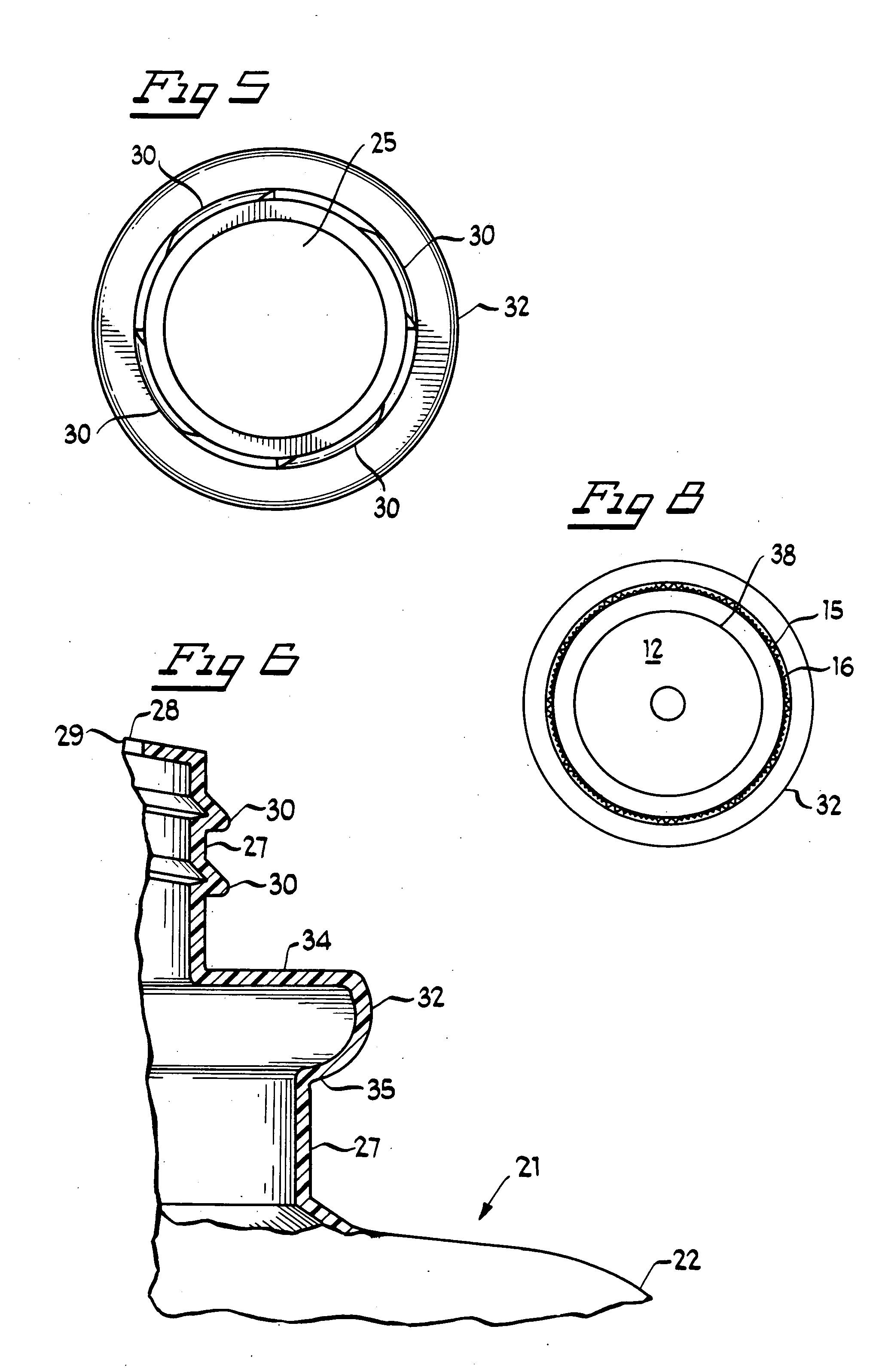

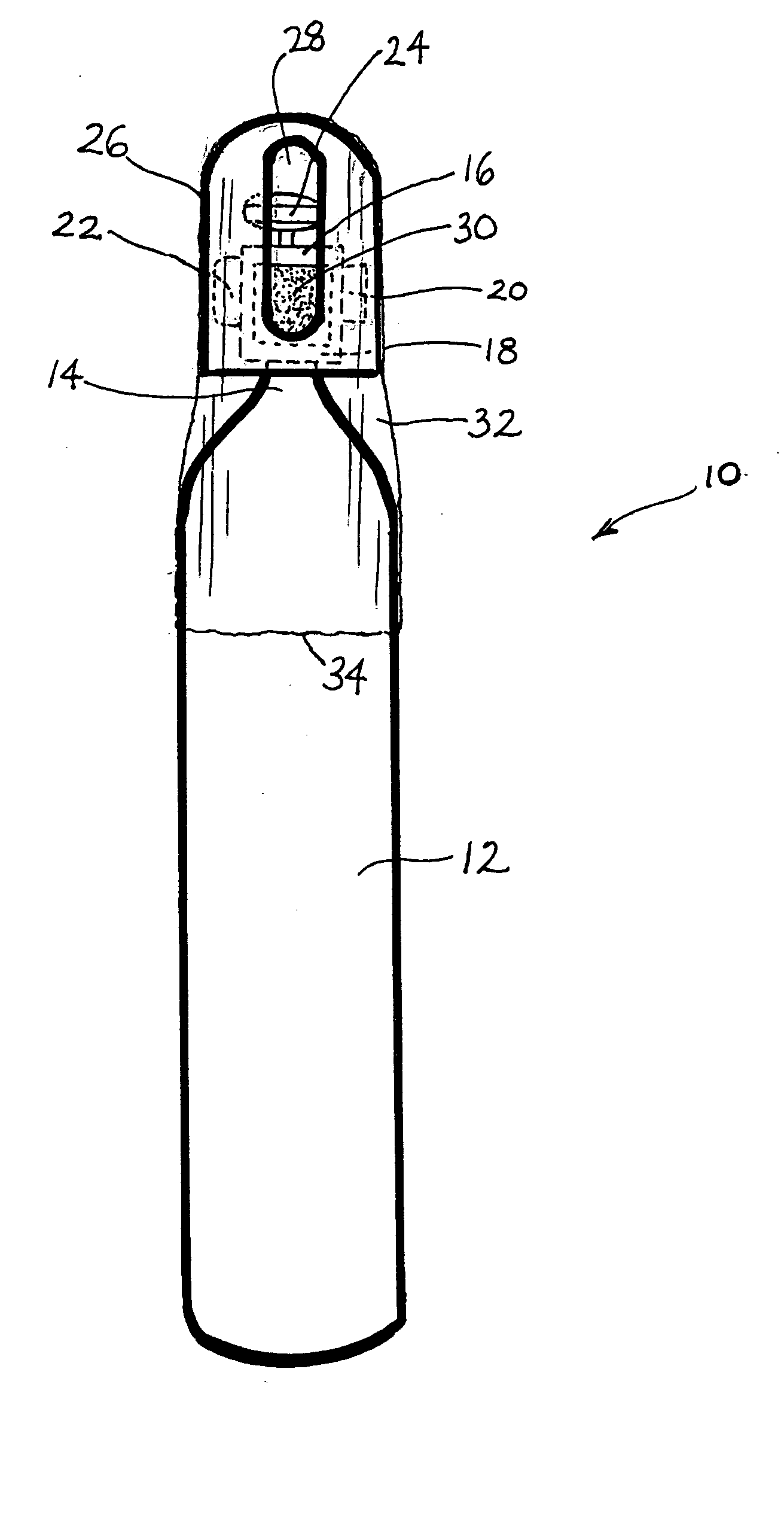

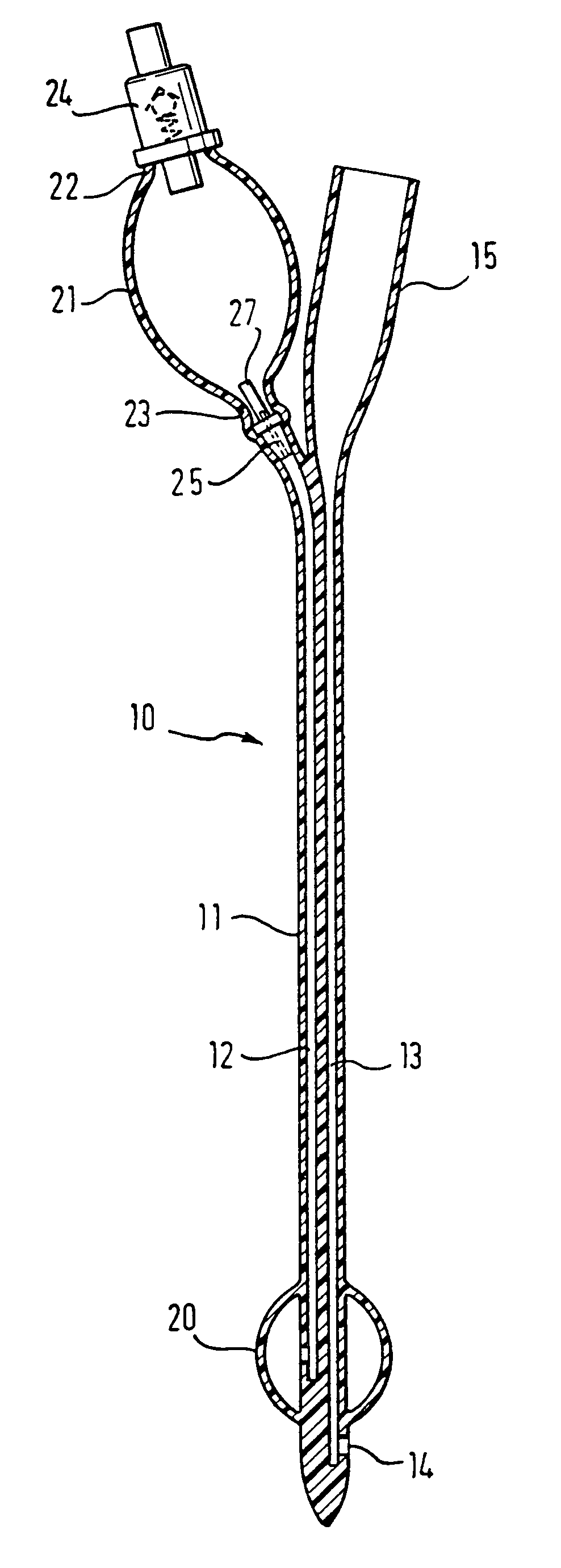

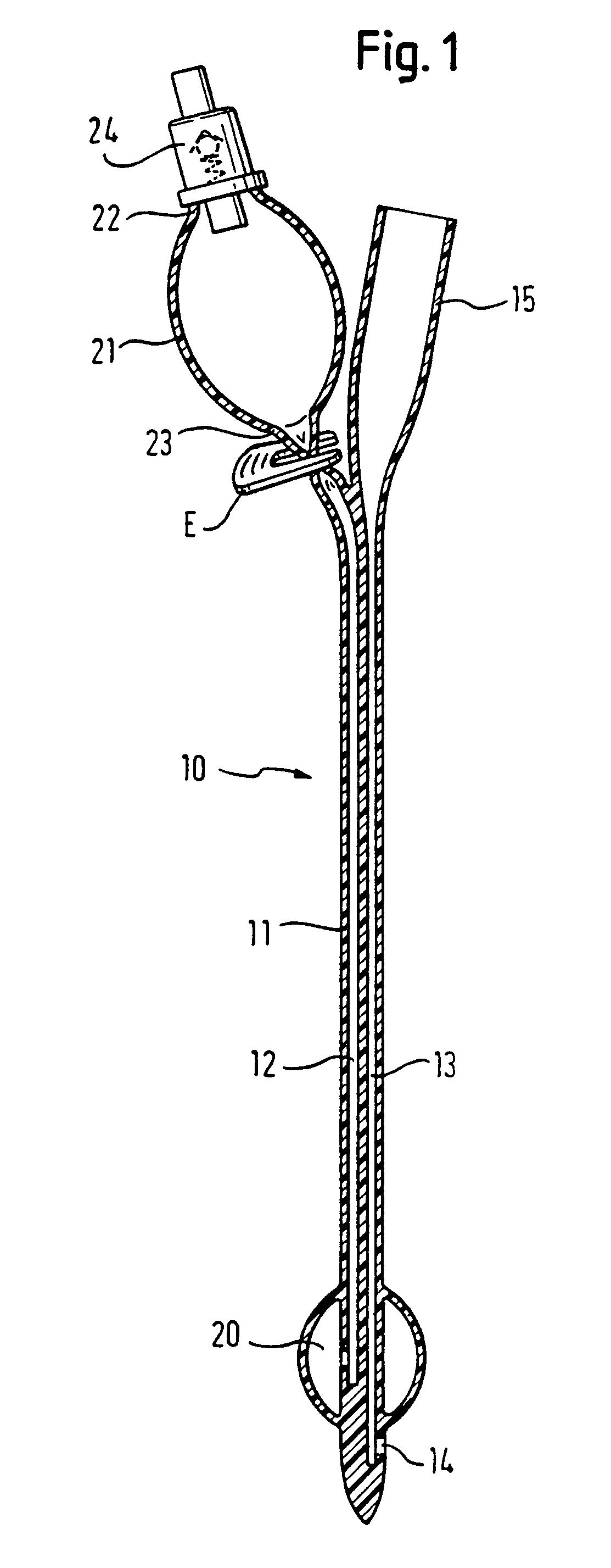

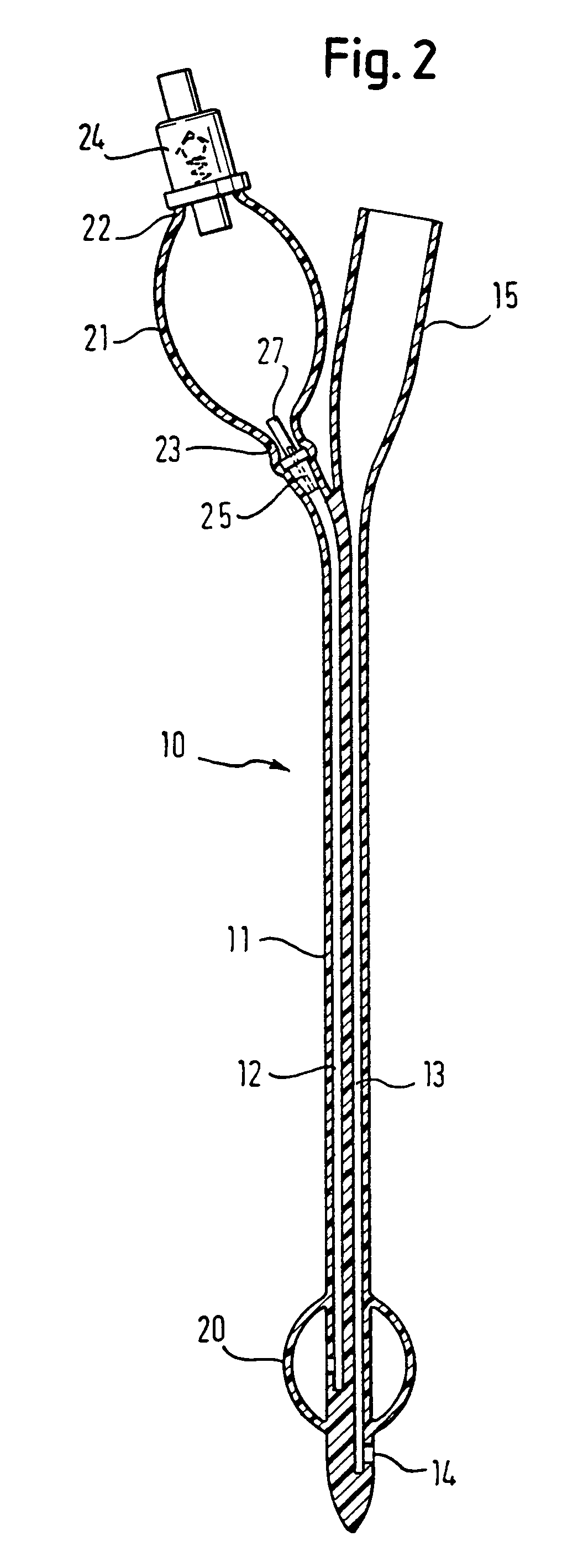

Medical device with elastomeric bulb

In a pre-filled Foley catheter for urine drainage, the conventional clip for releasing sterile water from a bulb (21) at the proximal end of the catheter, to fill the anchor bulb (20) at the distal end of the device, is replaced by a plug (25) which has an annular portion connected to a thin stem (27) by a circle of weakness. Snapping the stem (27) from the annulus provides a tactile signal through the opaque latex lumen that the catheter has been actuated. There is no separate clip to be disposed of. The interface between the latex and the plug remains undisturbed. Further improvement in the shelf-life and convenience of use of the catheter is delivered by the use of a sleeve, which can be of shrink-wrap material, around the bulb (21) and optionally also around the drain coupling (15) of the catheter. Apparatus for placing the plug and the sleeve is also described.

Owner:CR BARD INC

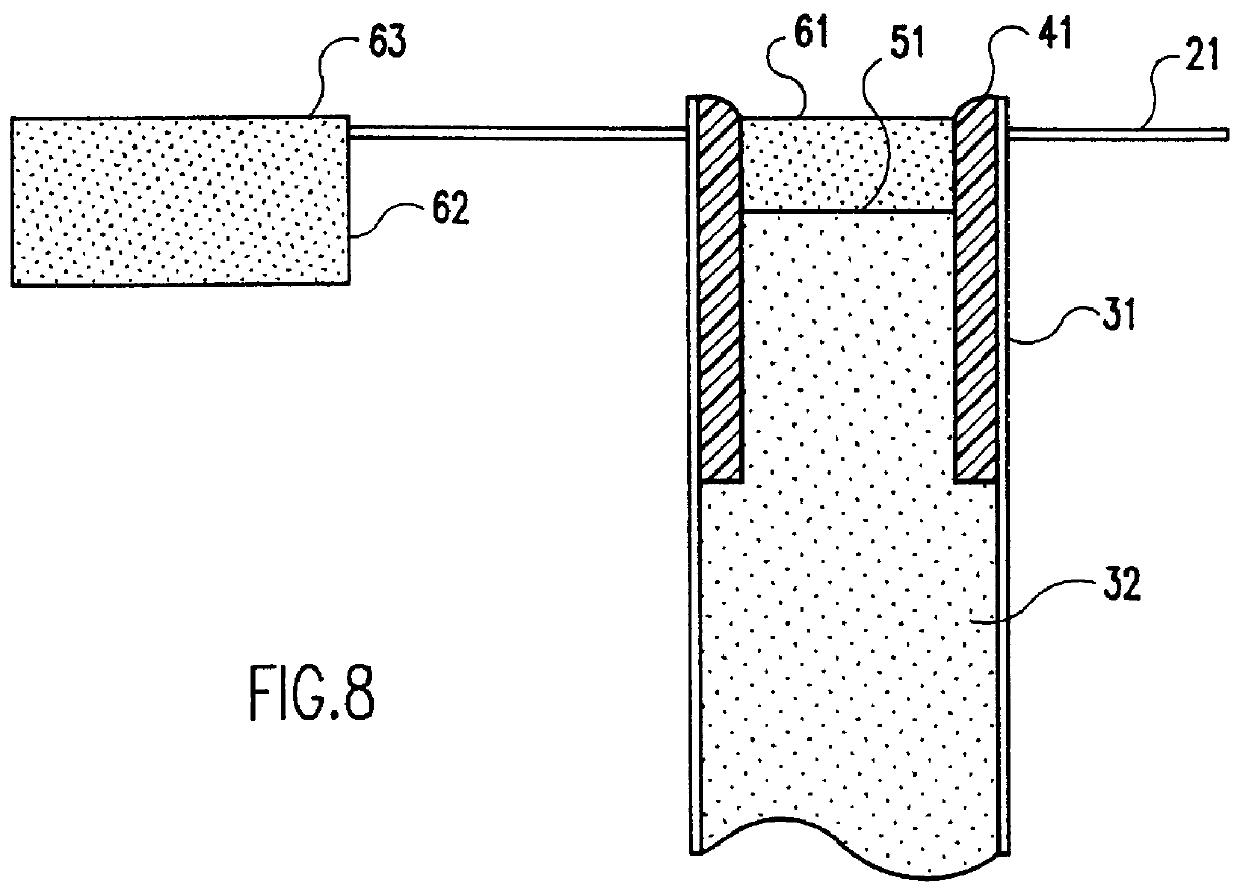

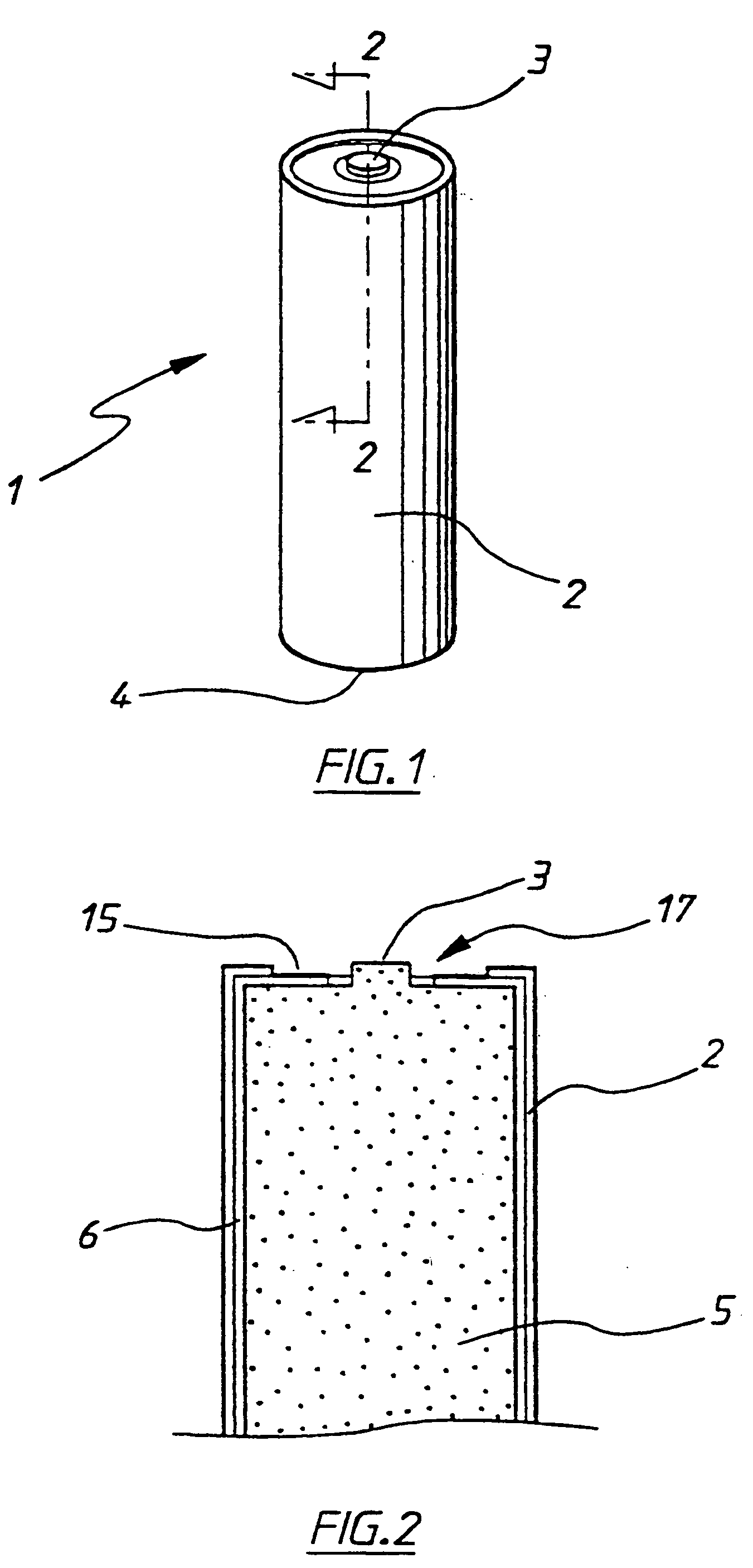

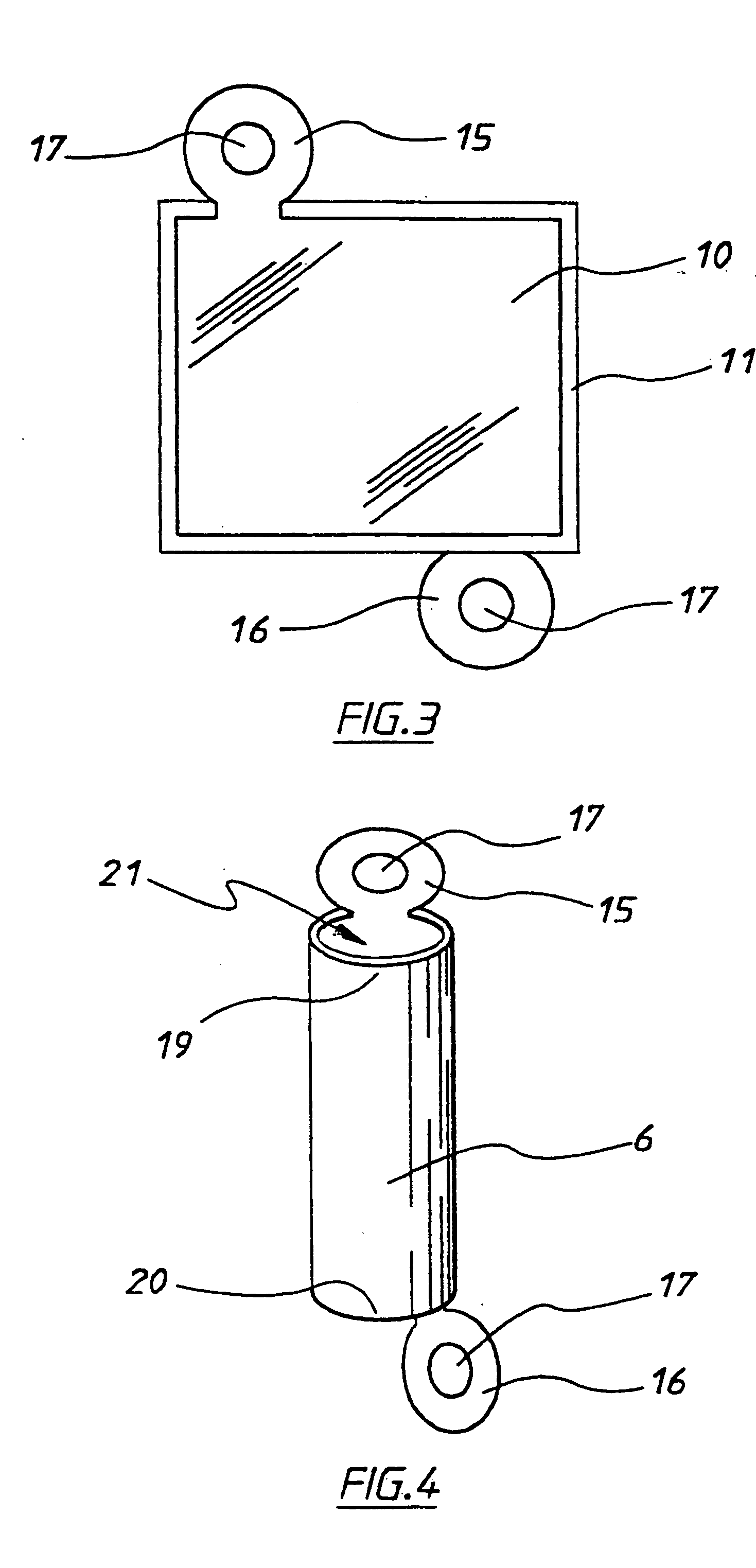

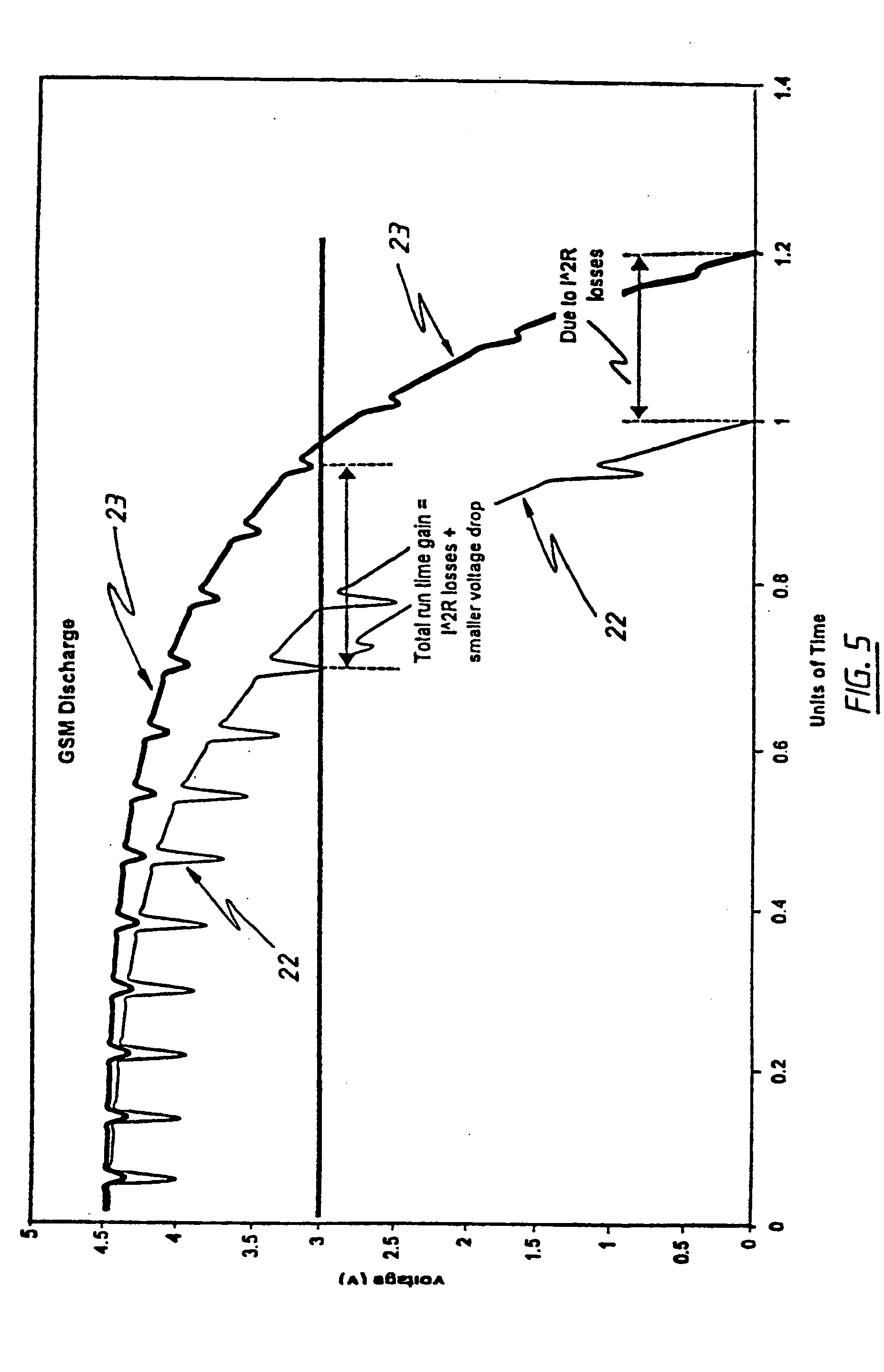

Energy storage device

InactiveUS20050083021A1Dc network circuit arrangementsBatteries circuit arrangementsElectrical batterySupercapacitor

An energy storage device includes a cylindrical shrink wrap housing having two opposed metal terminals. An electrochemical device in the form of a dry cell alkaline battery is disposed within the housing for providing an electrical potential between the terminals. An electric double layer supercapacitor is wrapped around and mounted to the housing and connected to the terminals in parallel with the battery.

Owner:CAP XX LTD

Heat-shrinkable film of polylactic acid film

The heat shrinkable film of polylactic acid-based resin used for shrink packaging, shrink bundling, shrink label and the like, can prevent shrinking in the machinery direction after stretching and can show a good appearance after shrinking. The heat shrinkable film of polylactic acid-based resin comprises at least one layer formed by using mainly a resin composition which contains polylactic acid-based resin and aliphatic polyester “A” having a melting point of 100 to 170° C. and a glass transition temperature of 0° C. or less, in which the heat shrinkable film of polylactic acid-based resin is stretched in at least one direction.

Owner:MITSUBISHI CHEM CORP

Heat-shrinkable film of polylactic acid film

The heat shrinkable film of polylactic acid-based resin used for shrink packaging, shrink bundling, shrink label and the like, can prevent shrinking in the machinery direction after stretching and can show a good appearance after shrinking. The heat shrinkable film of polylactic acid-based resin comprises at least one layer formed by using mainly a resin composition which contains polylactic acid-based resin and aliphatic polyester “A” having a melting point of 100 to 170° C. and a glass transition temperature of 0° C. or less, in which the heat shrinkable film of polylactic acid-based resin is stretched in at least one direction.

Owner:MITSUBISHI CHEM CORP

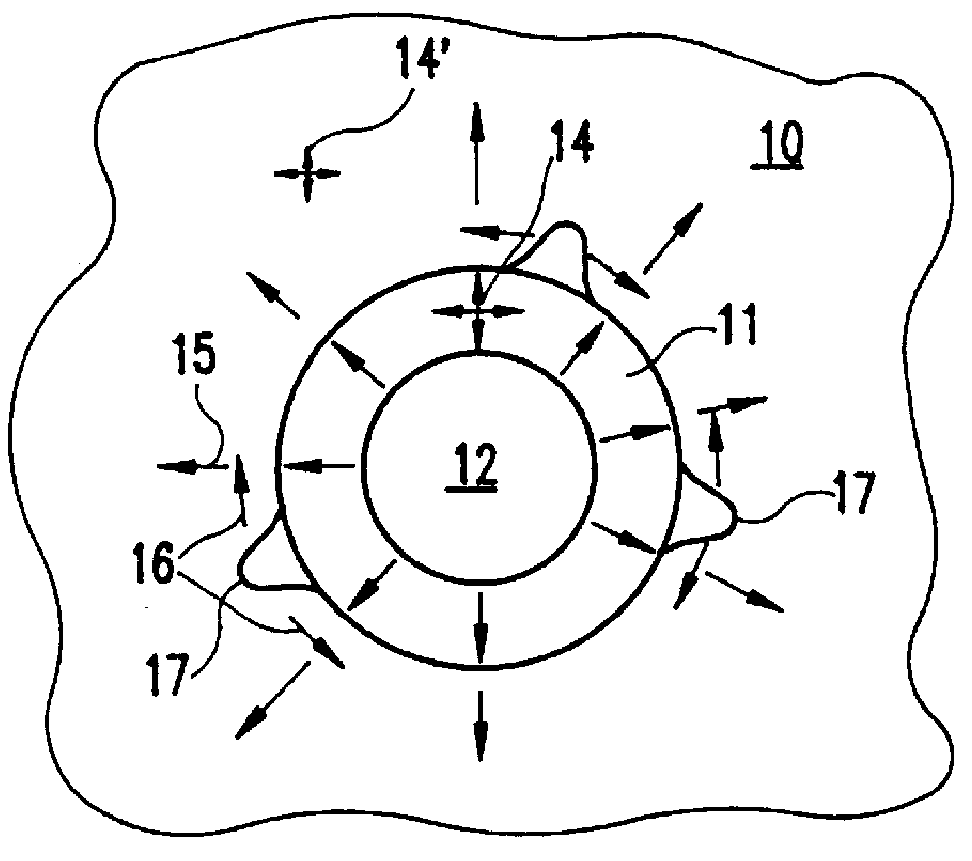

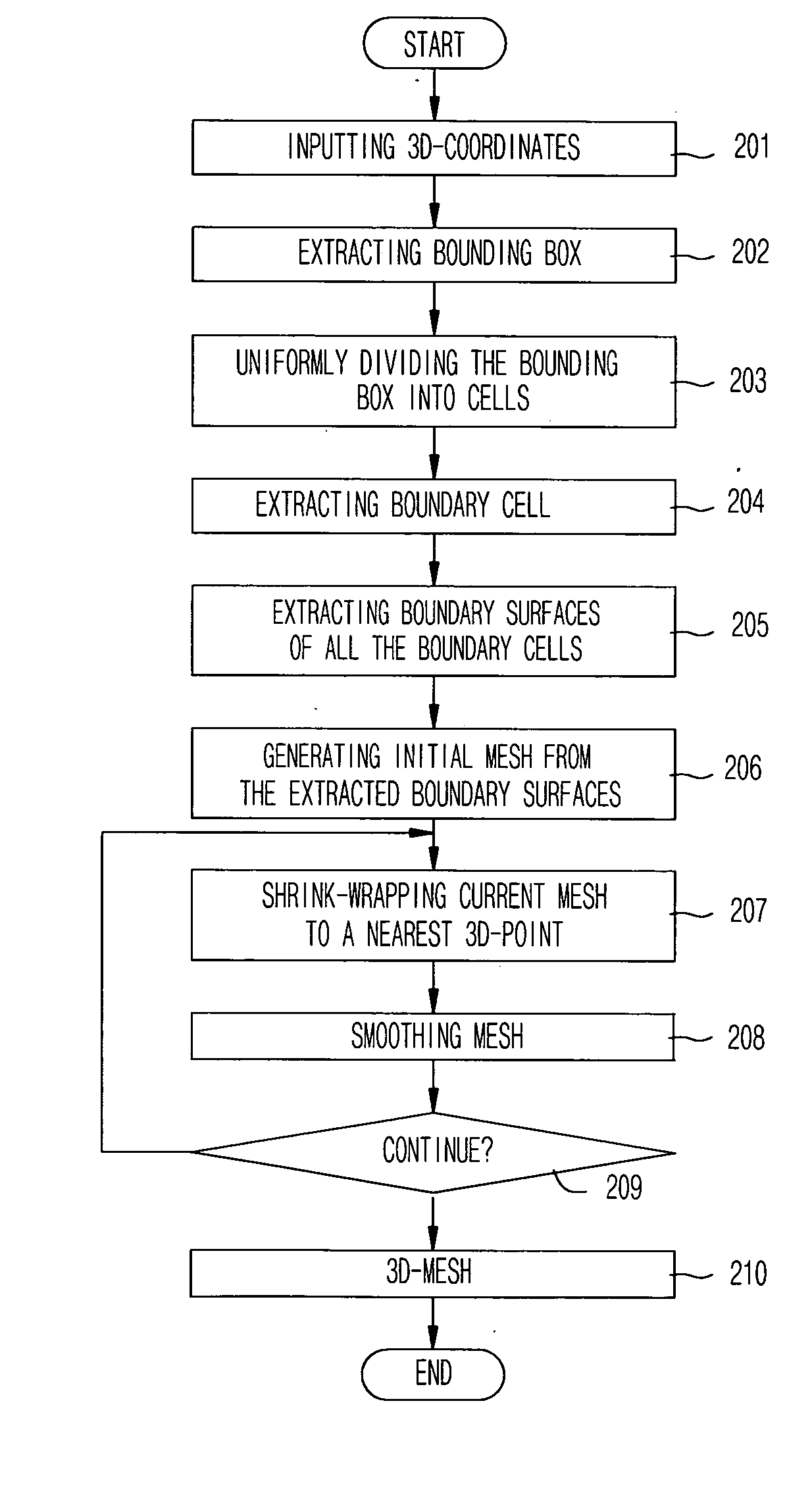

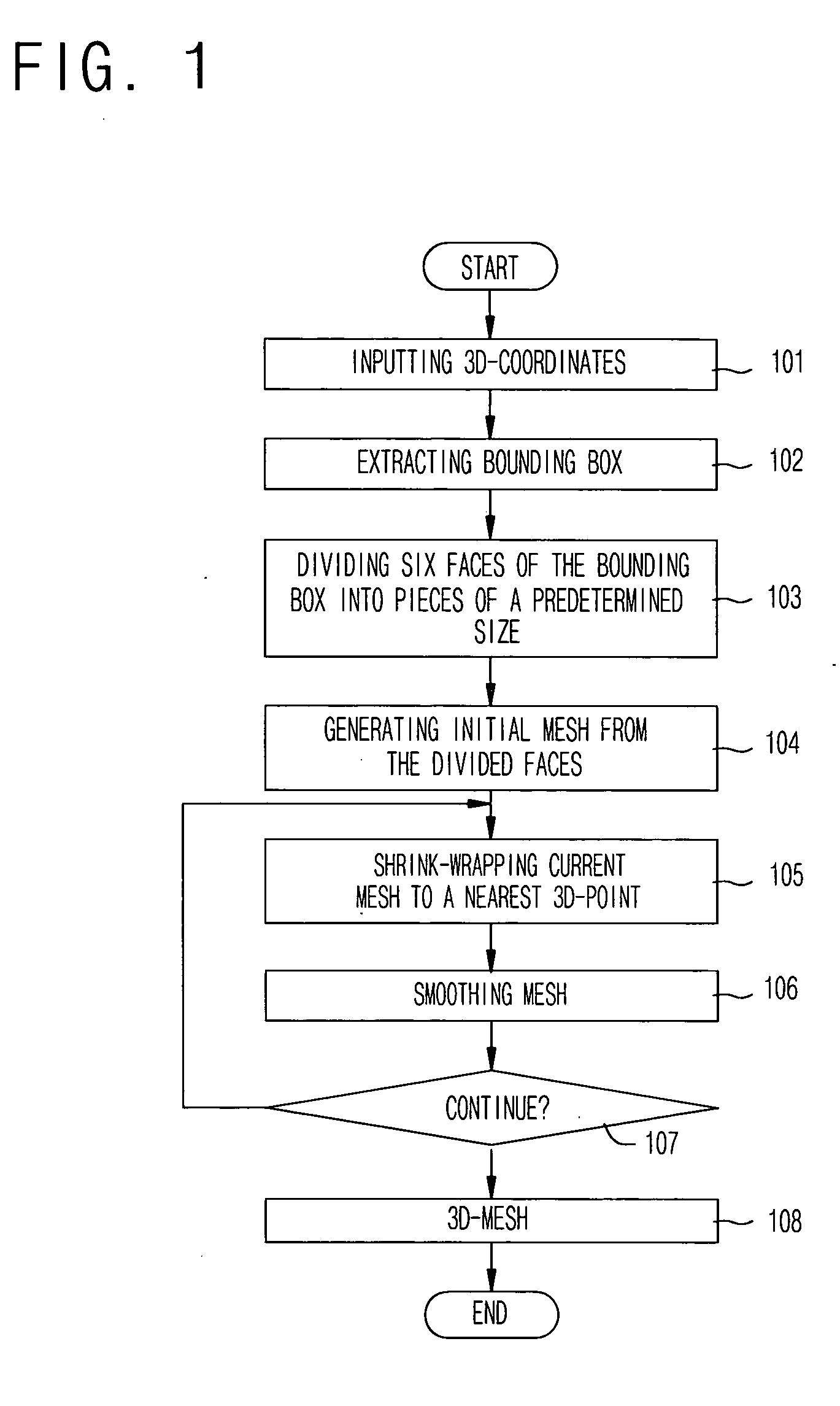

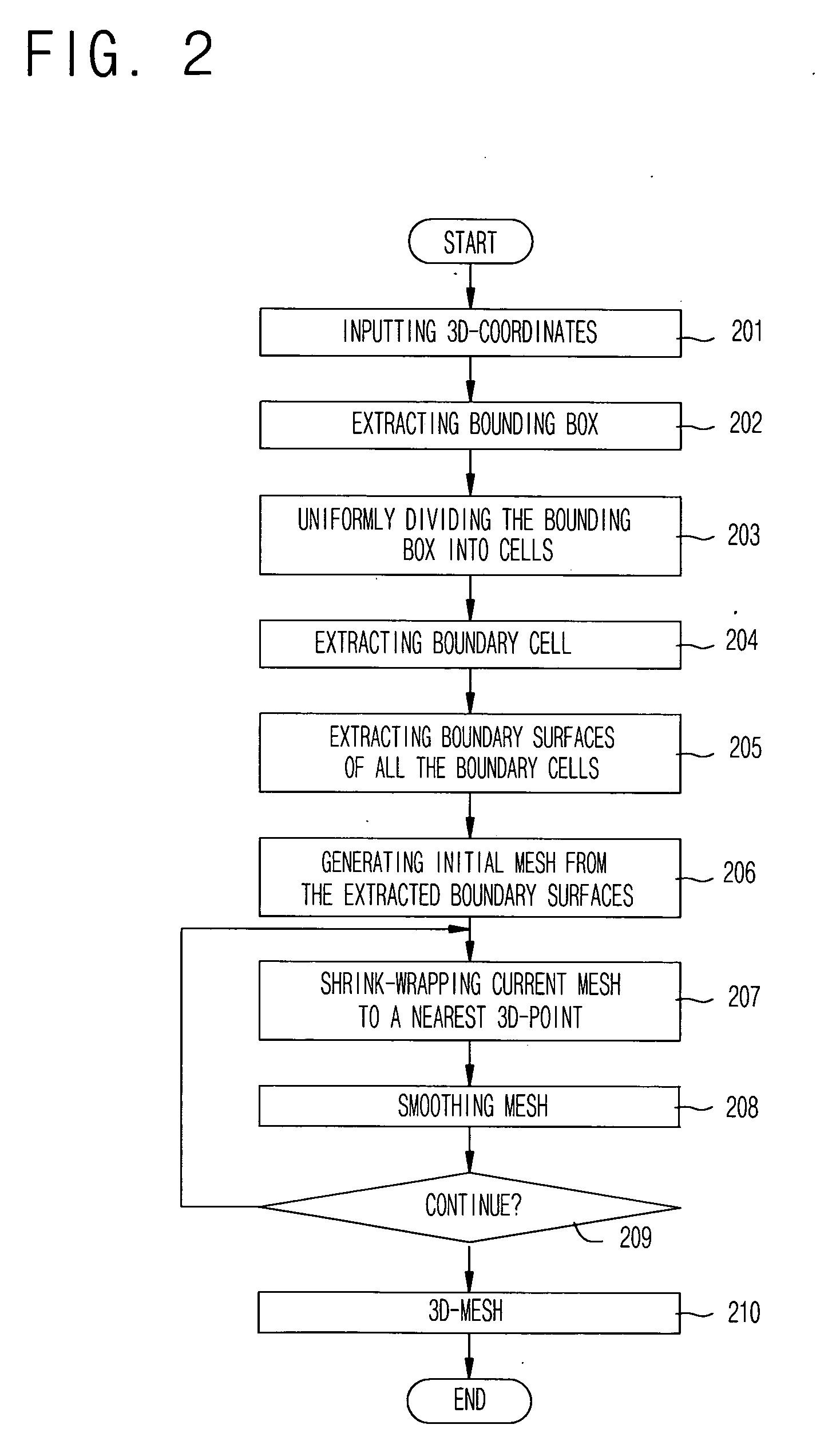

Method for generating 3D mesh from 3D points by using shrink-wrapping scheme of boundary cells

InactiveUS20050134586A1Decreasing elapsed timeShorten the timeImage generation3D-image renderingMinimum bounding boxComputer graphics (images)

The present invention relates to a method for generating a mesh model representing a 3D surface from unorganized 3D points extracted from a 3D scanner by using a shrink-wrapping scheme of boundary cells. A method for generating 3-dimensional mesh according to the present invention comprises the steps of: (a) receiving unorganized 3D point coordinates extracted by a 3D scanner or a digitizer; (b) extracting a minimum bounding box including all the point coordinates and uniformly dividing the extracted bounding box into cells of a predetermined size; (c) extracting a boundary cell including at least one point from the cells, extracting a boundary surface from all the boundary cells, and generating an initial mesh by summing extracted boundary surfaces; (d) calculating distances between each vertex constituting the mesh and the several points, finding a nearest point, and moving the vertex to the nearest point; and (e) averaging location of each shrink-wrapped vertex and location of the neighboring vertexes, and moving the shrink-wrapped vertex to center of neighboring vertexes.

Owner:ELECTRONICS & TELECOMM RES INST

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com