Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

623 results about "Chemical storage" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Chemical storage is the storage of controlled chemicals or hazardous materials in chemical stores, chemical storage cabinets, or similar devices. Improper chemical storage can result in the creation of workplace safety hazards including the presence of heat, fire, explosion and leakage of toxic gas.

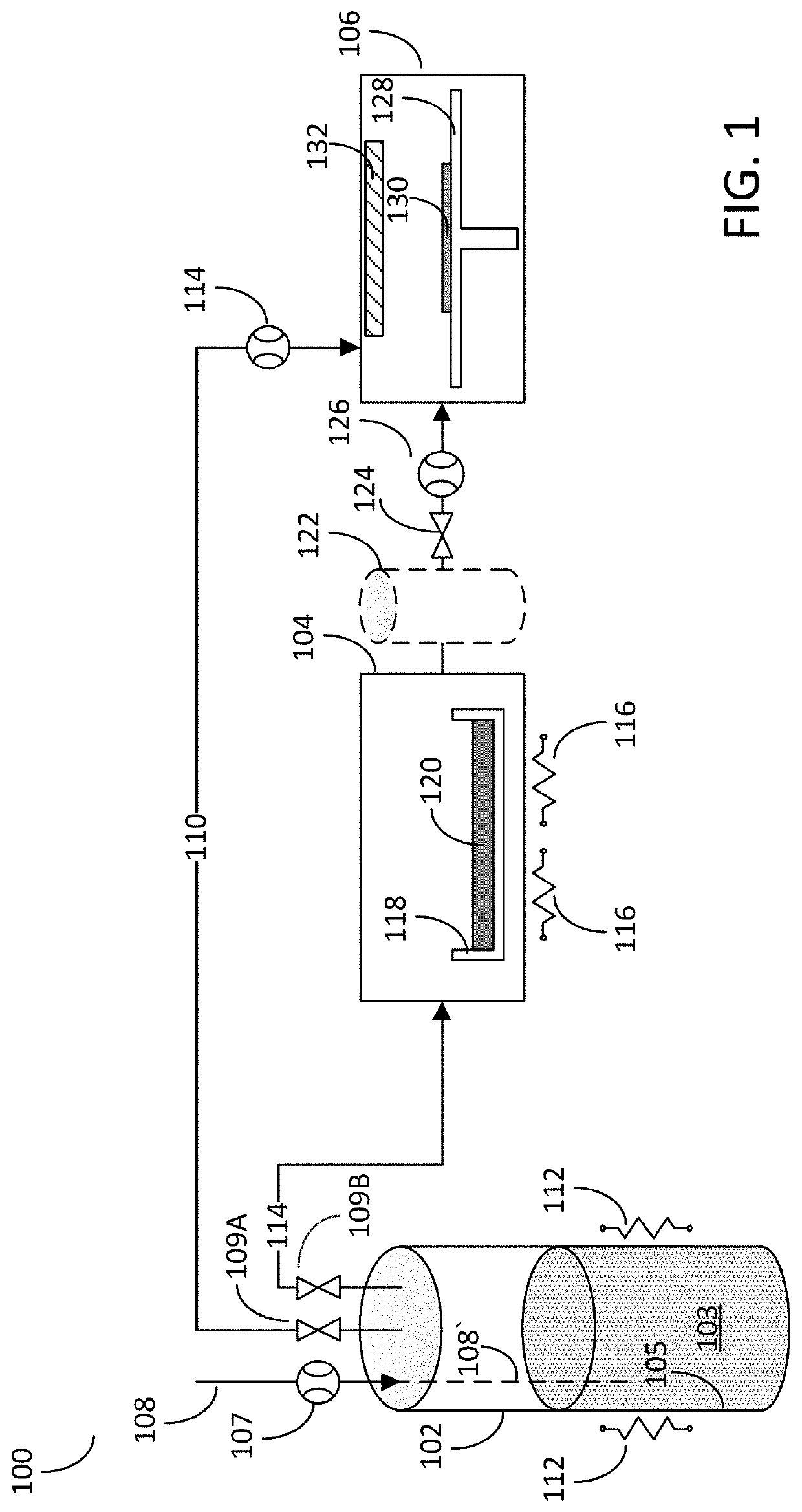

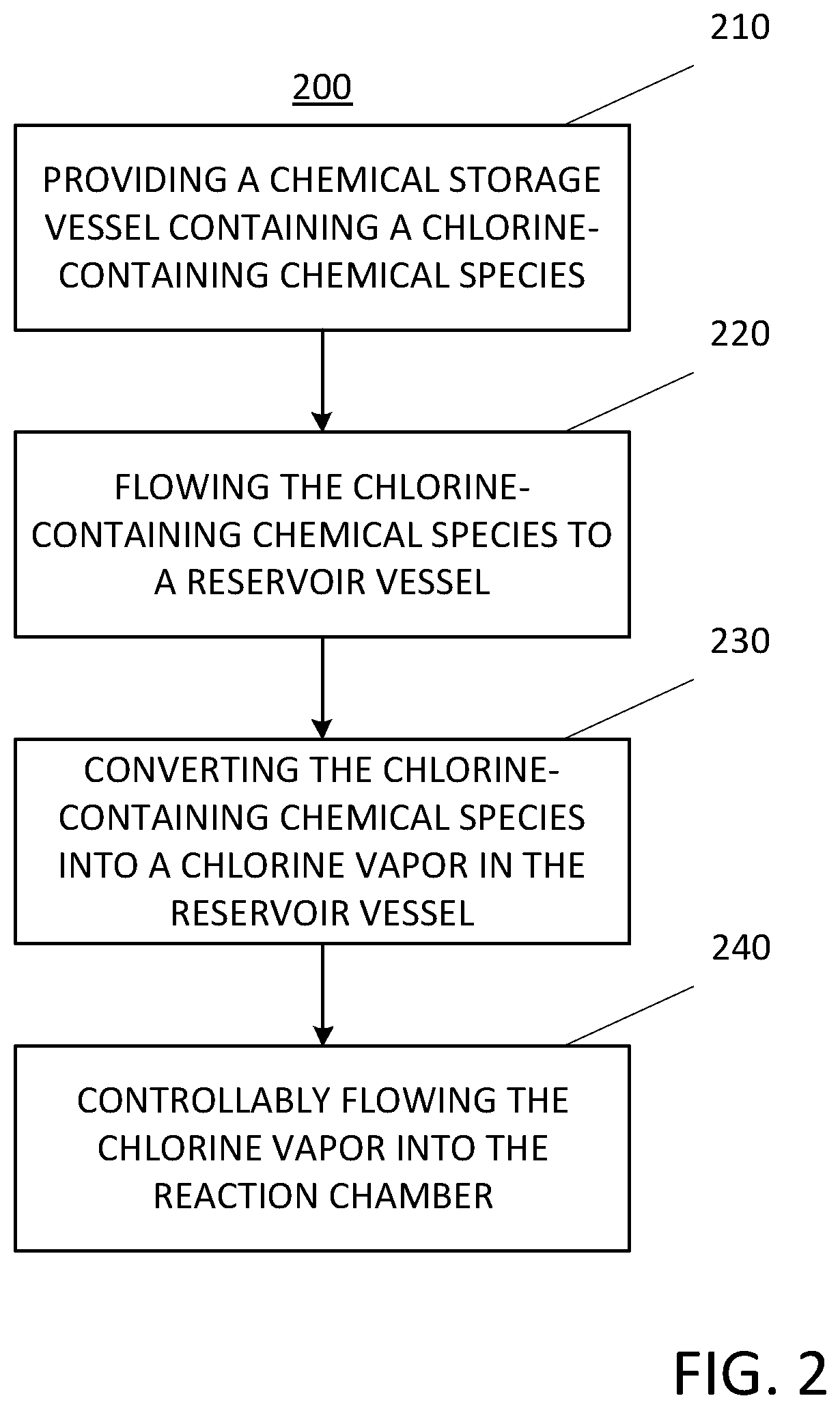

Chemical dispensing apparatus and methods for dispensing a chemical to a reaction chamber

ActiveUS20200279758A1Electric discharge tubesSemiconductor/solid-state device manufacturingChemical storageChemical species

A chemical dispensing apparatus for providing a chlorine vapor to a reaction chamber is disclosed. The chemical dispensing apparatus may include: a chemical storage vessel configured for storing a chlorine-containing chemical species, a reservoir vessel in fluid communication with the chemical storage vessel, the reservoir vessel configured for converting the chlorine-containing chemical species to the chlorine vapor, and a reaction chamber in fluid communication with the reservoir vessel. Methods for dispensing a chlorine vapor to a reaction chamber are also disclosed.

Owner:ASM IP HLDG BV

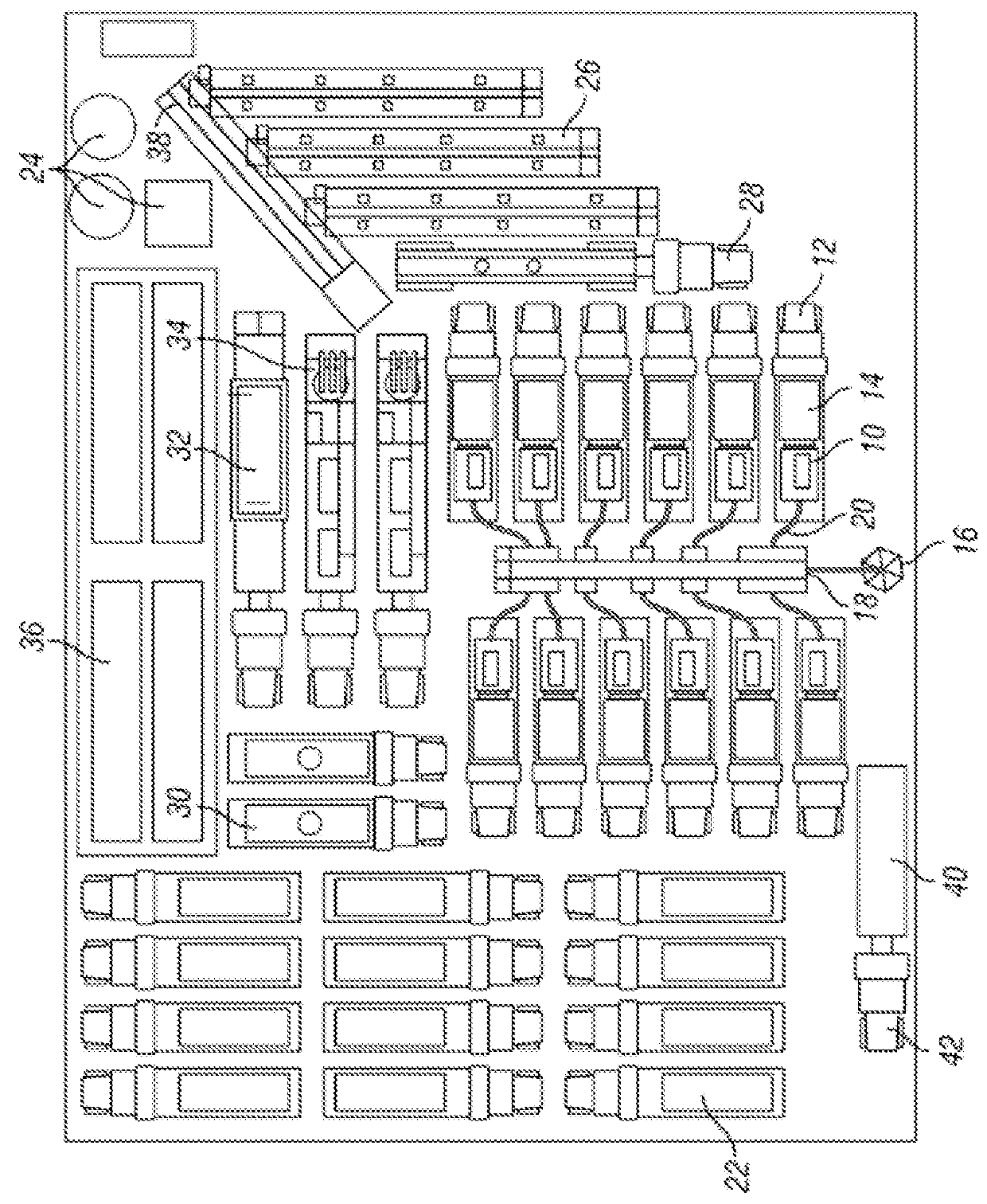

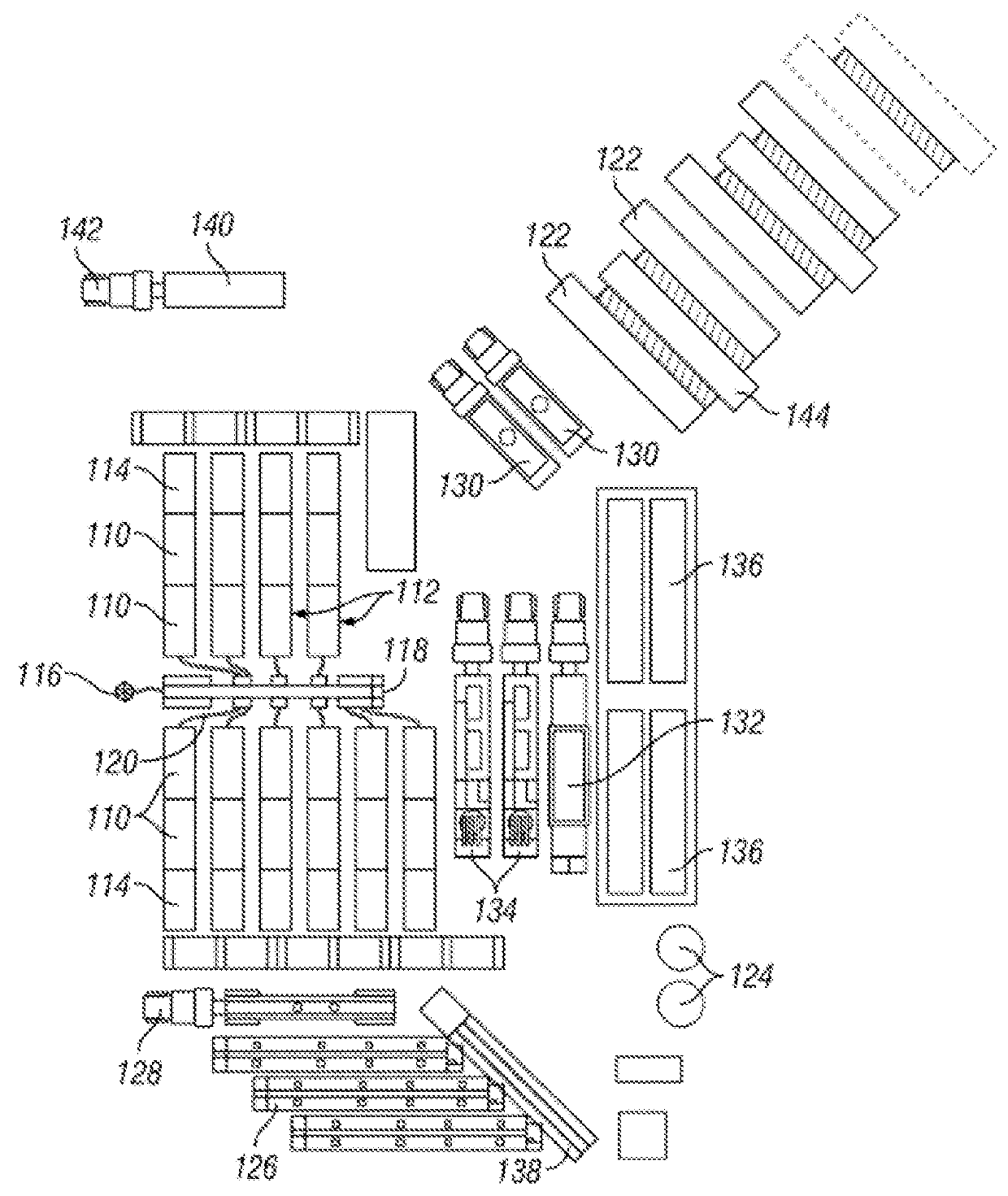

System for centralized monitoring and control of electric powered hydraulic fracturing fleet

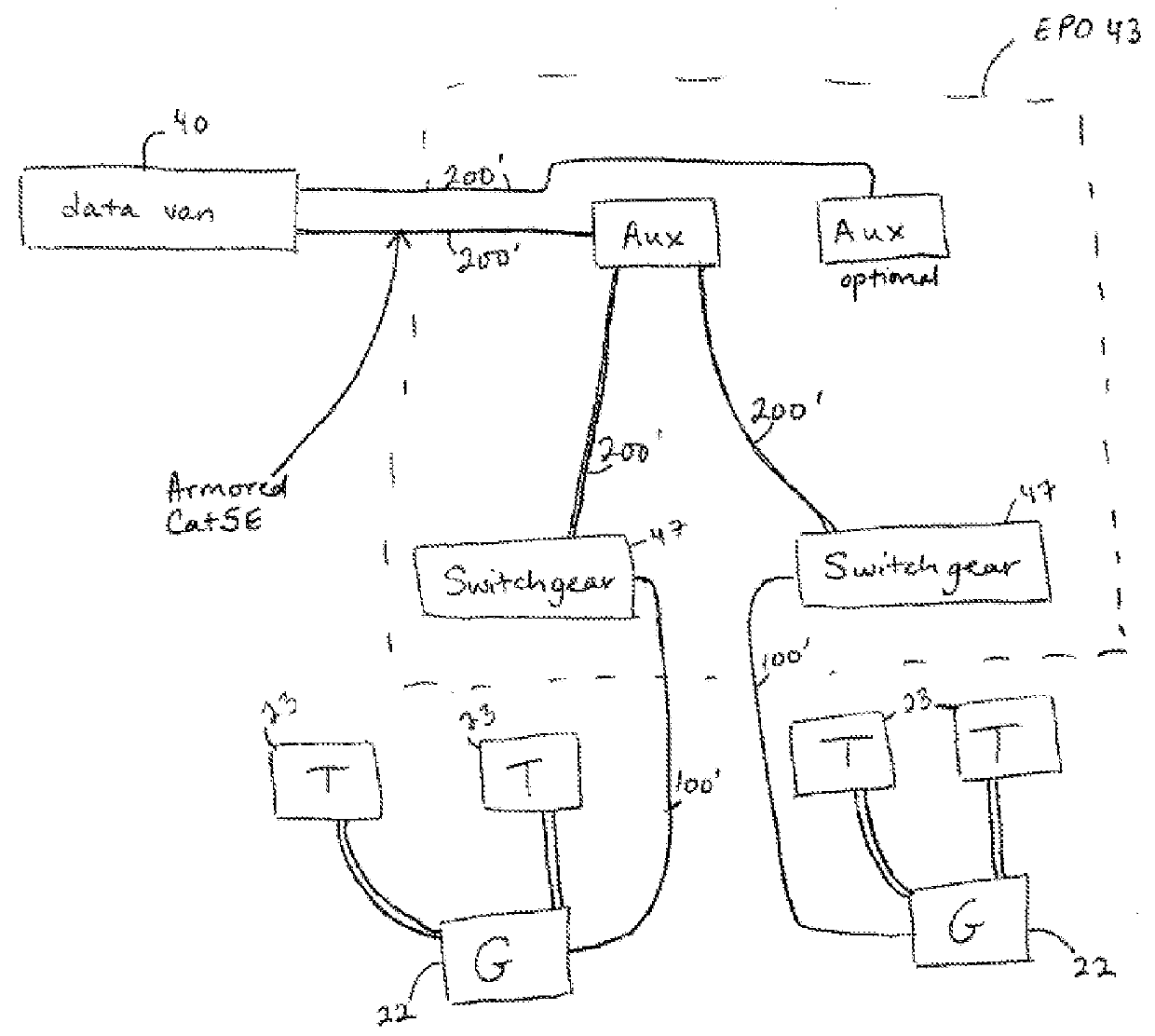

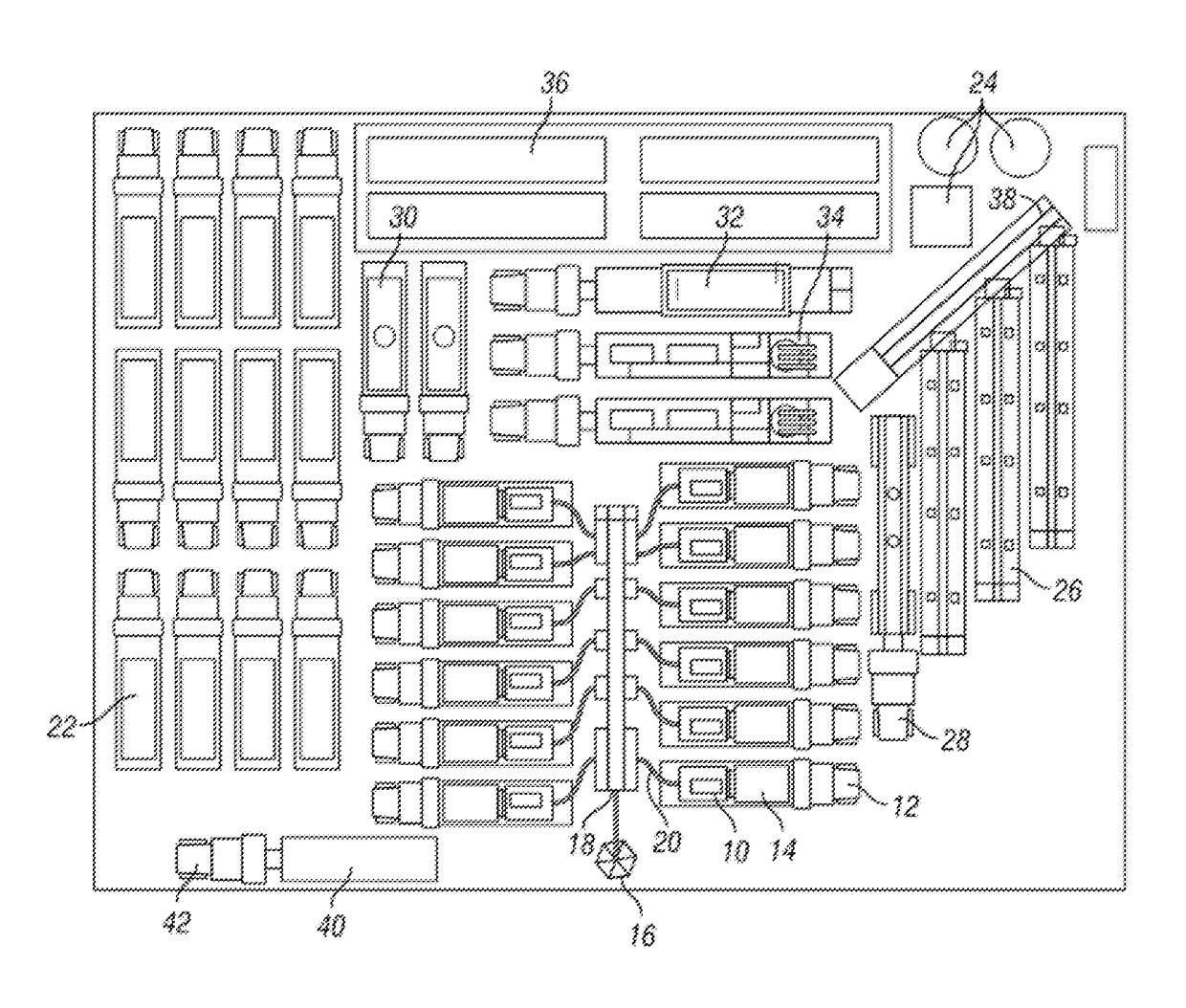

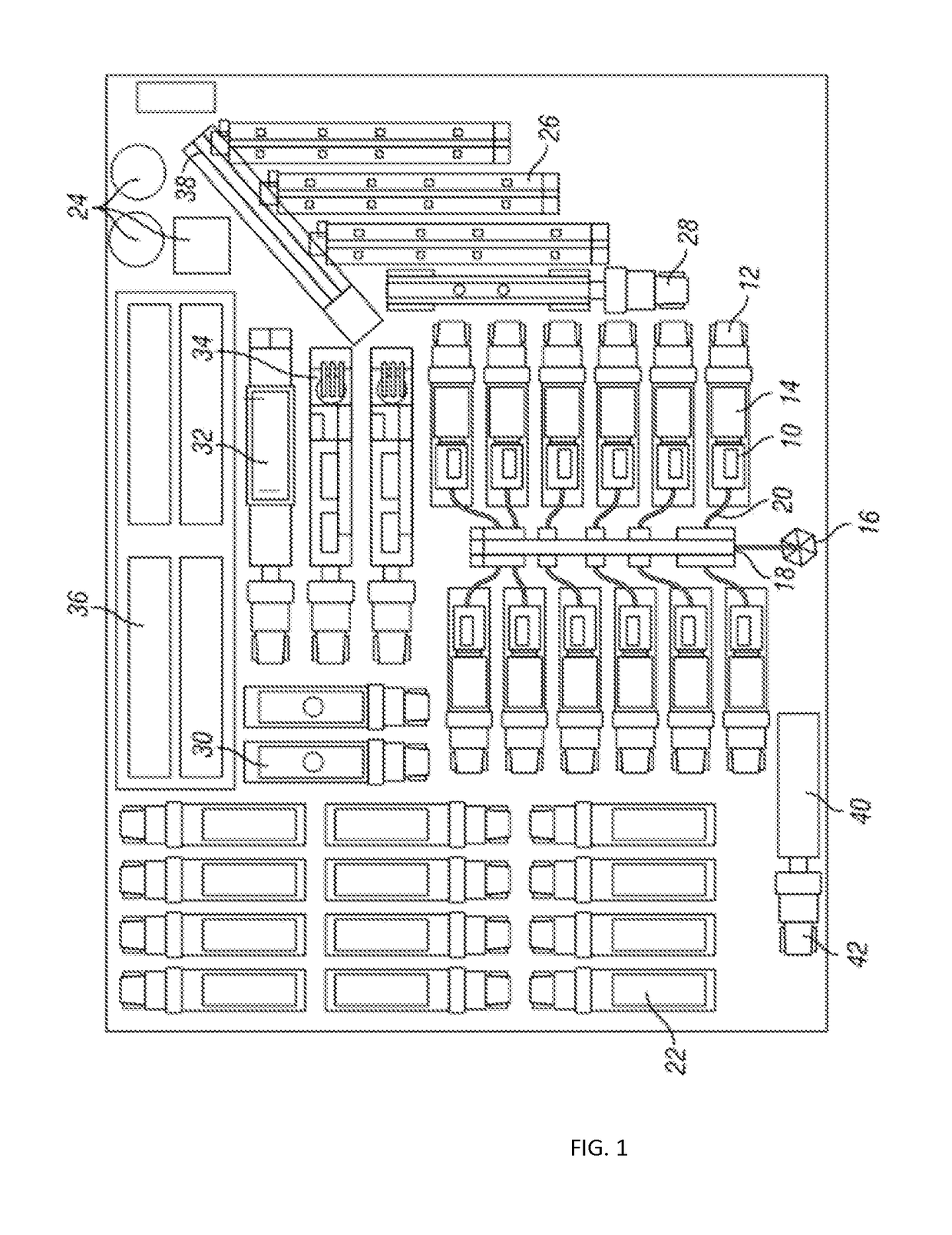

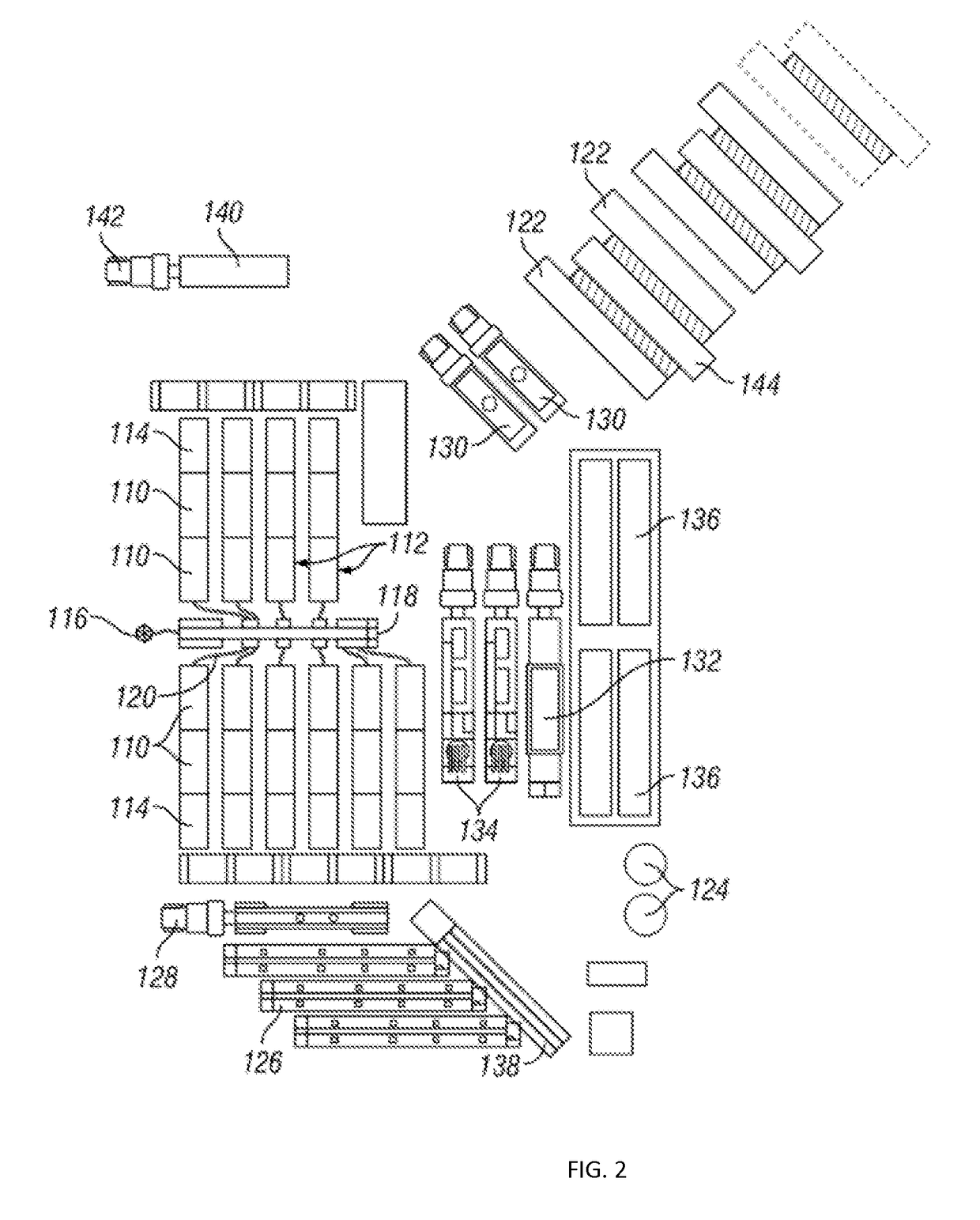

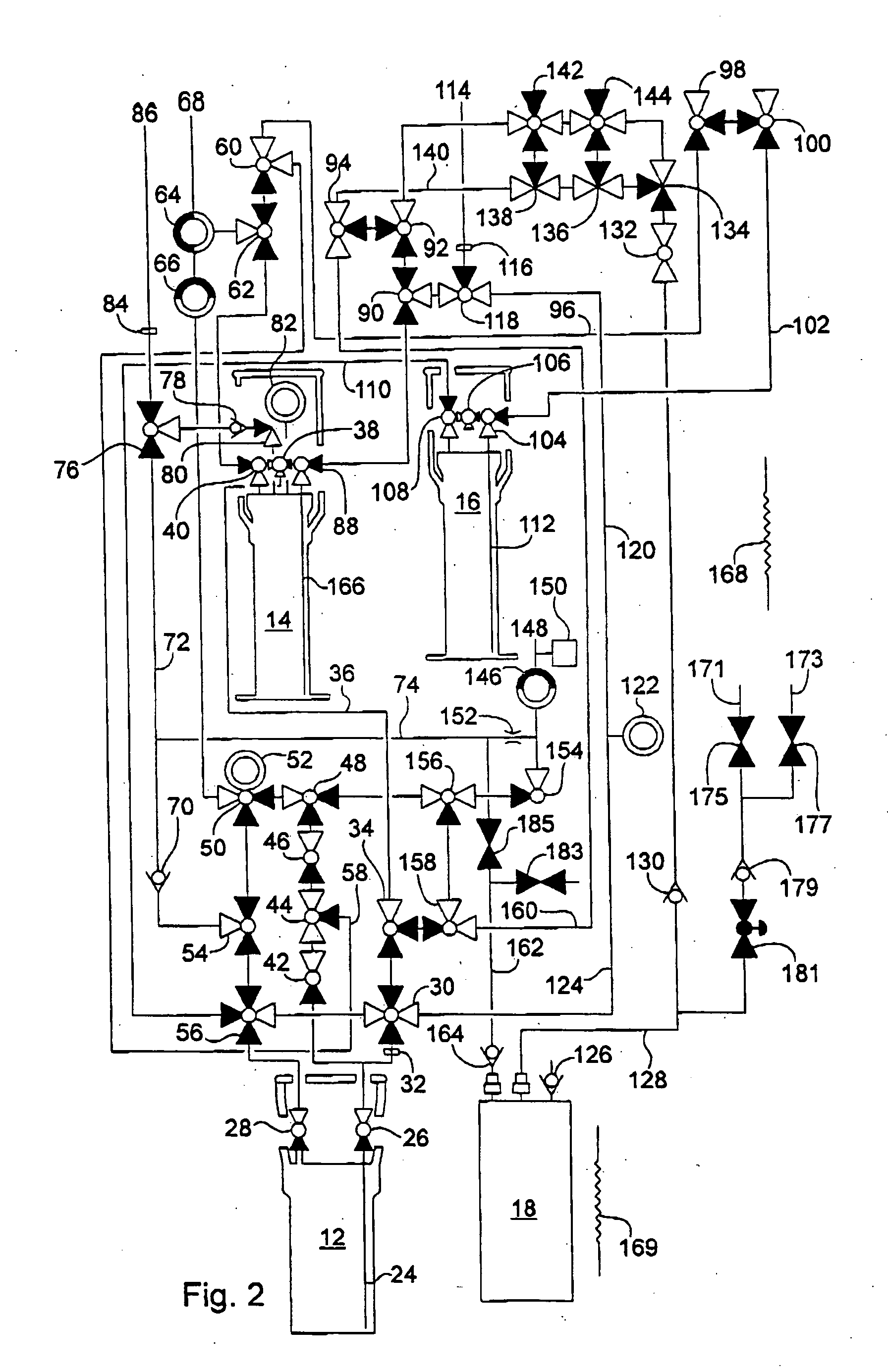

A system and method are disclosed for centralized monitoring and control of a hydraulic fracturing operation. The system includes an electric powered fracturing fleet and a centralized control unit coupled to the electric powered fracturing fleet. The electric powered fracturing fleet can include a combination of one or more of: electric powered pumps, turbine generators, blenders, sand silos, chemical storage units, conveyor belts, manifold trailers, hydration units, variable frequency drives, switchgear, transformers, and compressors. The centralized control unit can be configured to monitor and / or control one or more operating characteristics of the electric powered fracturing fleet.

Owner:US WELL SERVICS LLC

System for centralized monitoring and control of electric powered hydraulic fracturing fleet

A system and method are disclosed for centralized monitoring and control of a hydraulic fracturing operation. The system includes an electric powered fracturing fleet and a centralized control unit coupled to the electric powered fracturing fleet. The electric powered fracturing fleet can include a combination of one or more of: electric powered pumps, turbine generators, blenders, sand silos, chemical storage units, conveyor belts, manifold trailers, hydration units, variable frequency drives, switchgear, transformers, and compressors. The centralized control unit can be configured to monitor and / or control one or more operating characteristics of the electric powered fracturing fleet.

Owner:US WELL SERVICS LLC

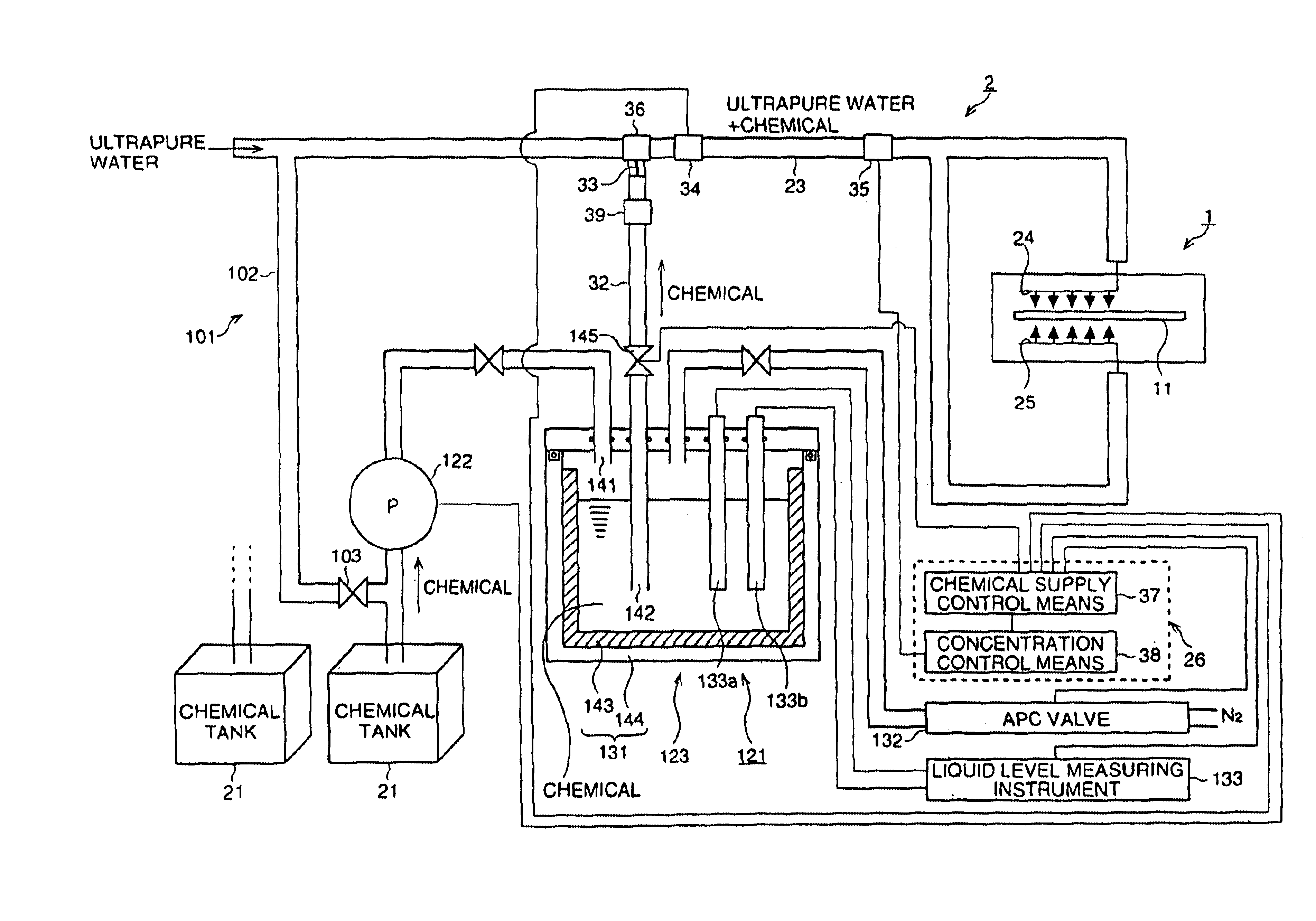

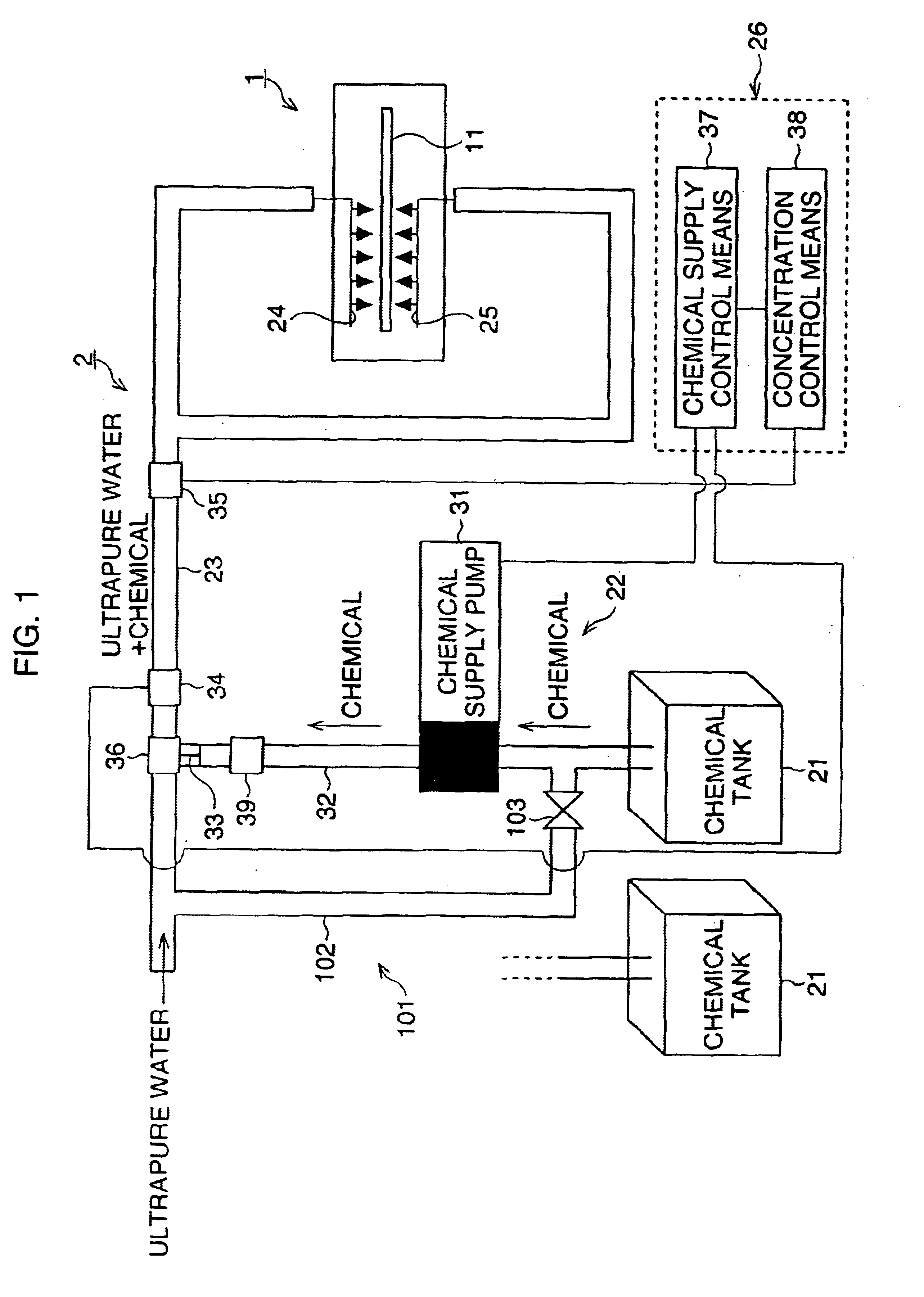

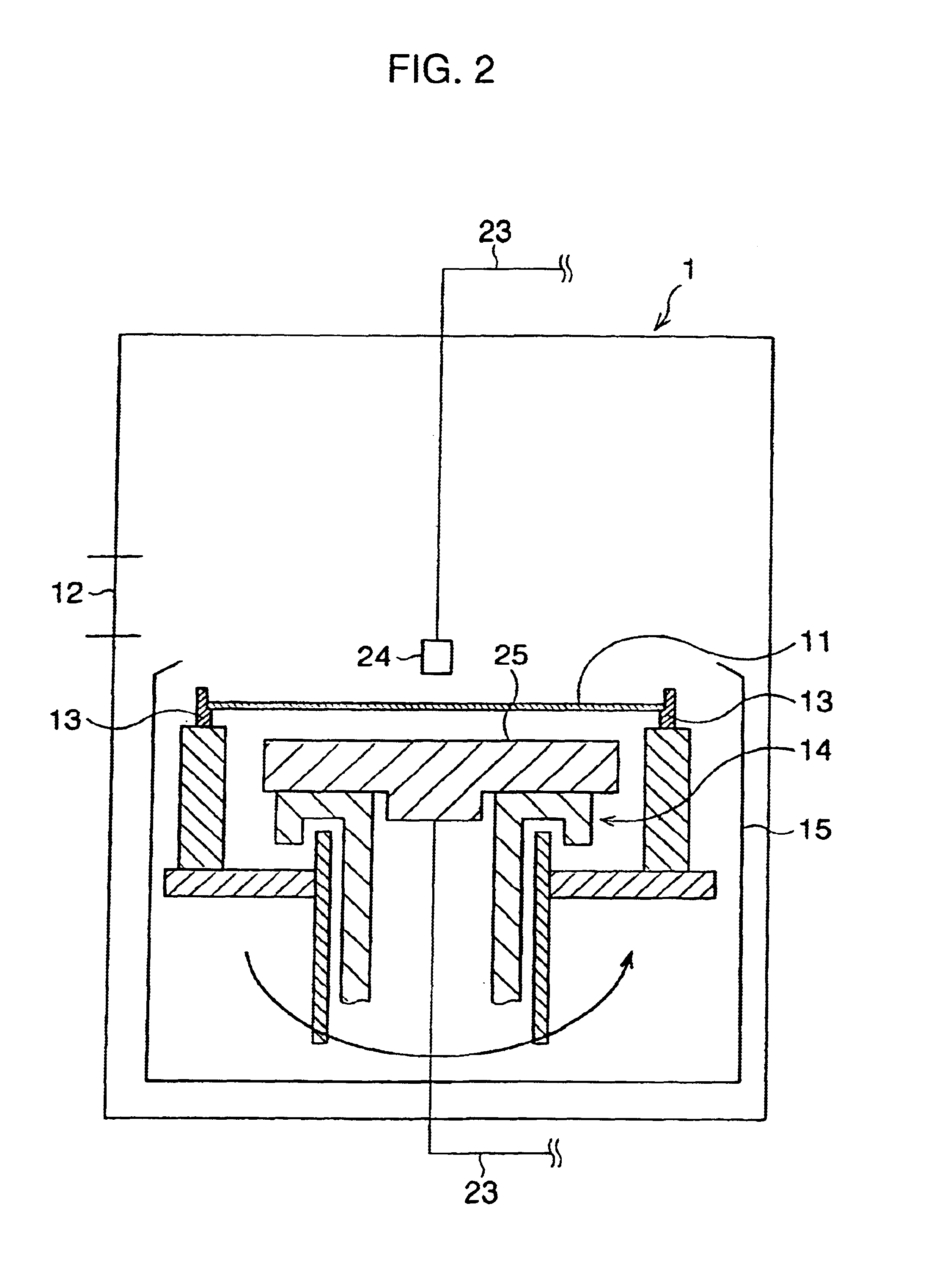

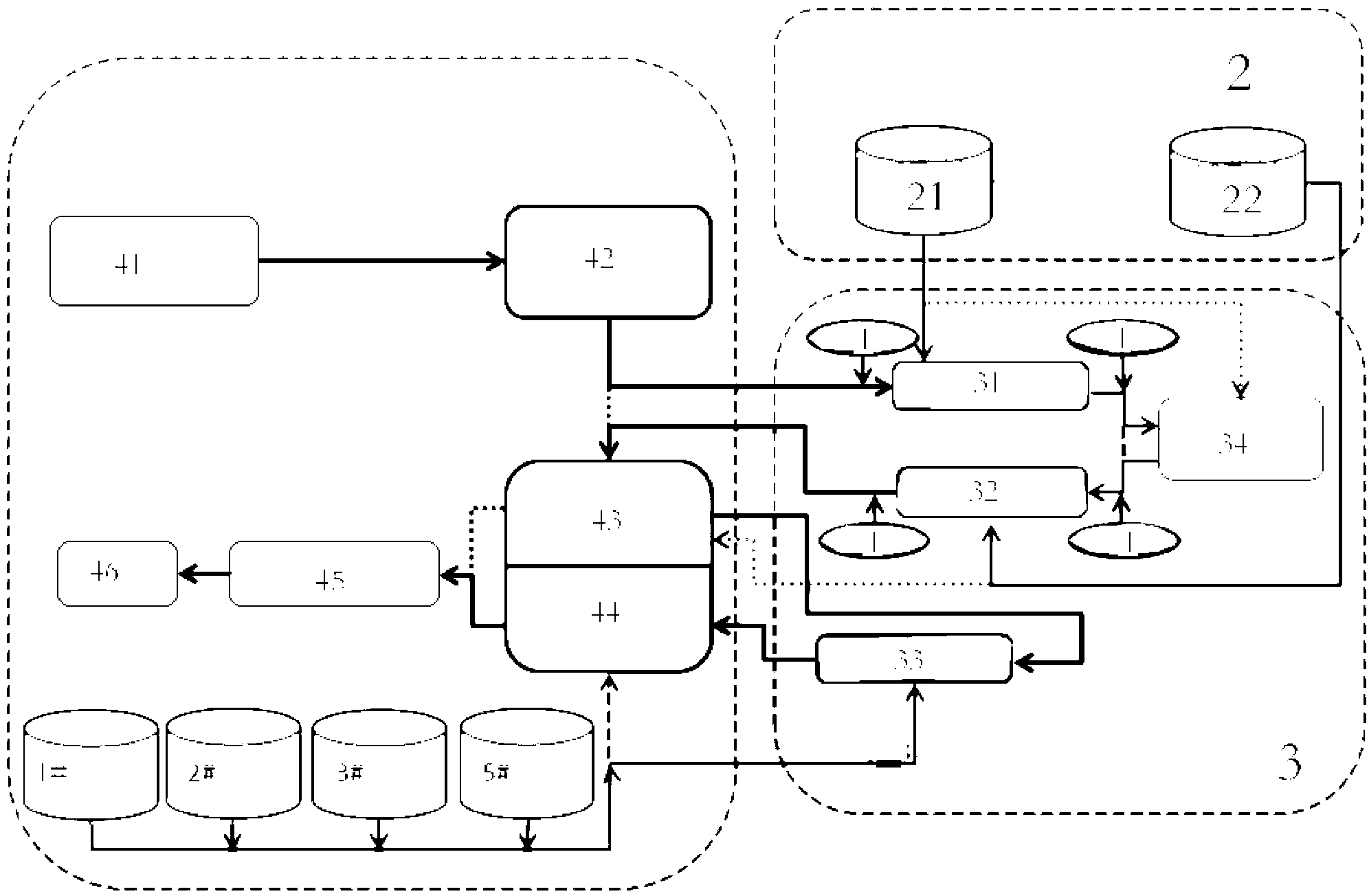

Chemical supply system

InactiveUS6764212B1Improve anti-corrosion performanceEasy to control its porosityDiaphragm valvesShaking/oscillating/vibrating mixersChemical storageMiniaturization

A chemical supply system comprises, as principal elements, a chemical storage tank in which a liquid chemical for cleaning is stored in the state of its formulated concentrate, a chemical supply apparatus connected to the chemical storage tank for positively performing chemical supply, a piping system connected to the chemical supply apparatus to form a supply flow passage that is a passage for ultrapure water which the liquid chemical is to be mixed with, a pair of discharge nozzles disposed at end portions of the piping system so as to oppose surfaces of a wafer set in a cleaning chamber to supply a cleaning liquid onto the surfaces. Thereby, remarkable miniaturization / simplification of a cleaning liquid supply system including chemical tanks is intended, it is made possible easily and rapidly to compound and supply a cleaning liquid at an accurate chemical concentration, and particles or the like being generated and mixing in a cleaning liquid, are suppressed to the extremity.

Owner:ULTRACLEAN TECH RES INST

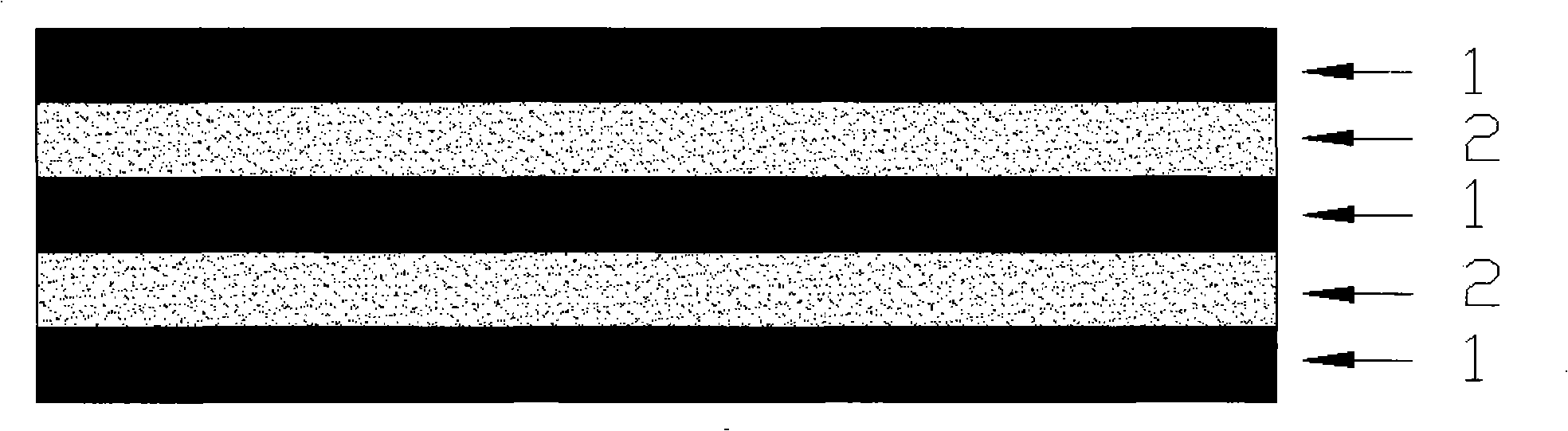

High-temperature-resisting composite isolation film and preparation method thereof

ActiveCN102751460AUniform pore size distributionGuarantee the safety of useCell component detailsChemical storageComposite film

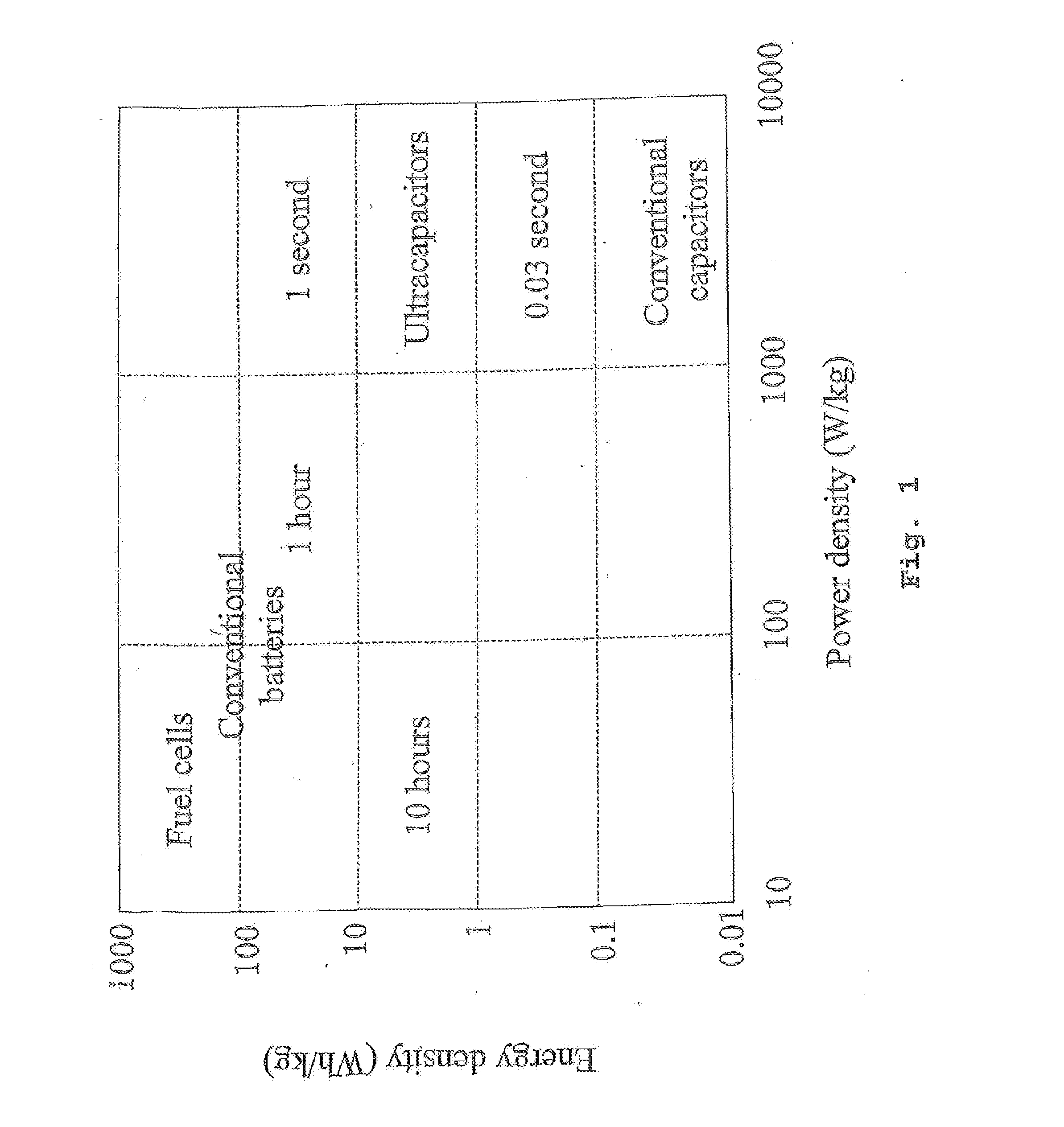

The invention discloses a high-temperature-resisting composite isolation film which is suitable to be used as an isolation film in a lithium ion battery, and a preparation method thereof. The invention aims at solving the problem in the existing lithium ion battery that the isolation film has poor high-temperature resistance, so that thermo-runaway can occur. The high-temperature-resisting composite isolation film provided by the invention is prepared through dry compound of a polyphenylene sulfide film and a polyolefin micro-porous film. A polyphenylene sulfide film-casting mother liquor is subjected to on-line extrusion and film casting; an obtained film is subjected to dry compound with the polyolefin micro-porous film; and an obtained composite film is subjected to extraction, washing, and drying, such that the high-temperature-resisting composite isolation film is prepared. The high-temperature-resisting composite isolation film provided by the invention can resist a high temperature of 250 DEG C. The film is especially suitable to be applied in lithium ion batteries, and is suitable to be applied as an isolation film in other chemical storage batteries and super-capacitors.

Owner:HANGZHOU FUMO NEW MATERIAL TECH

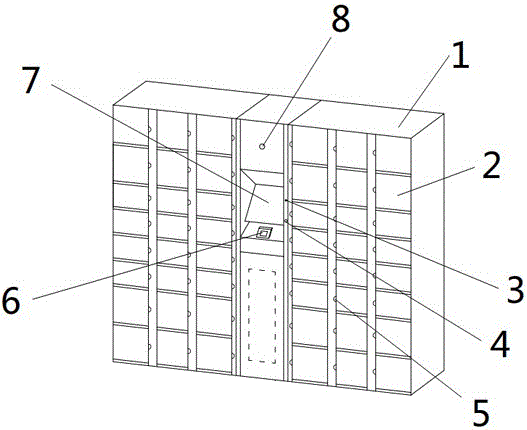

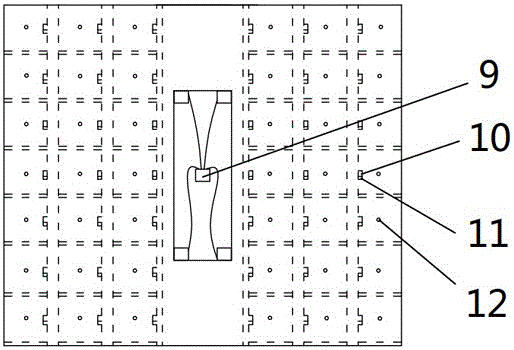

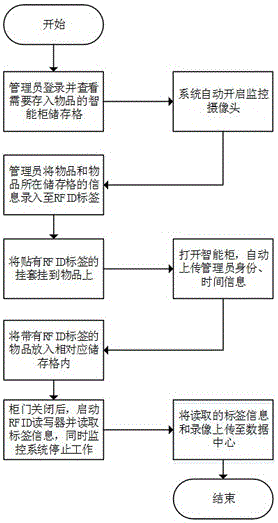

Chemical intelligent management method and chemical intelligent management system

InactiveCN105761041AMention reliabilityMentioned securityHazardous material storageLogisticsChemical storageInternet privacy

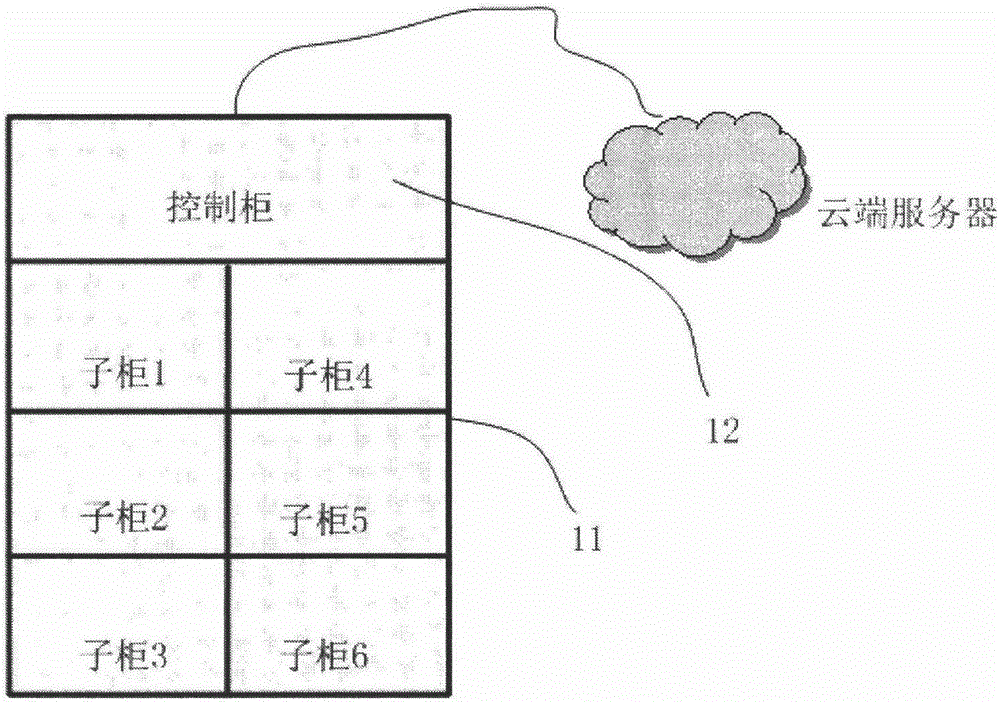

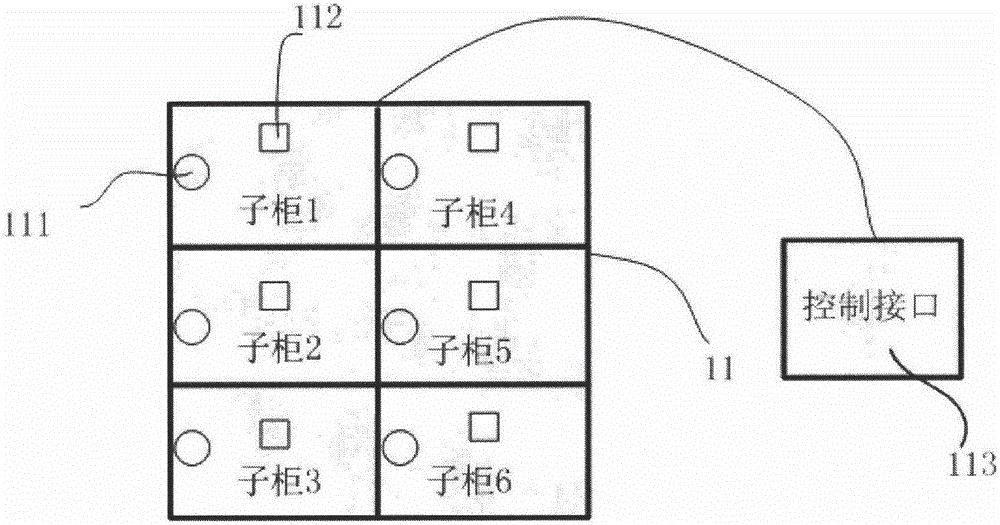

The invention relates to a chemical intelligent management method and a chemical intelligent management system. The system comprises a chemical intelligent cabinet, a cloud server, and intelligent terminal software. The chemical intelligent cabinet is connected to the cloud server in a wired or wireless manner. The intelligent terminal is connected to the cloud server in a wired or wireless manner. The chemical intelligent cabinet is used for storing a variety of chemicals with label information and sending corresponding chemical information to the cloud server. The cloud server is used for receiving and storing chemical information and processing data. The intelligent terminal software is used for issuing a receiving or returning request to the chemical intelligent cabinet via the cloud server, and implementing orderly reception or return of chemicals after the cloud server responds to the request and sends out an authorization signal. According to the chemical intelligent management system of the invention, the communication and Internet-of-things technologies are utilized and the intelligent security cabinet is taken as a carrier to make a chemical storage step, a chemical reception step and a chemical return step implemented in an intelligent, remote and informationized manner.

Owner:苏州银橡智能科技有限公司

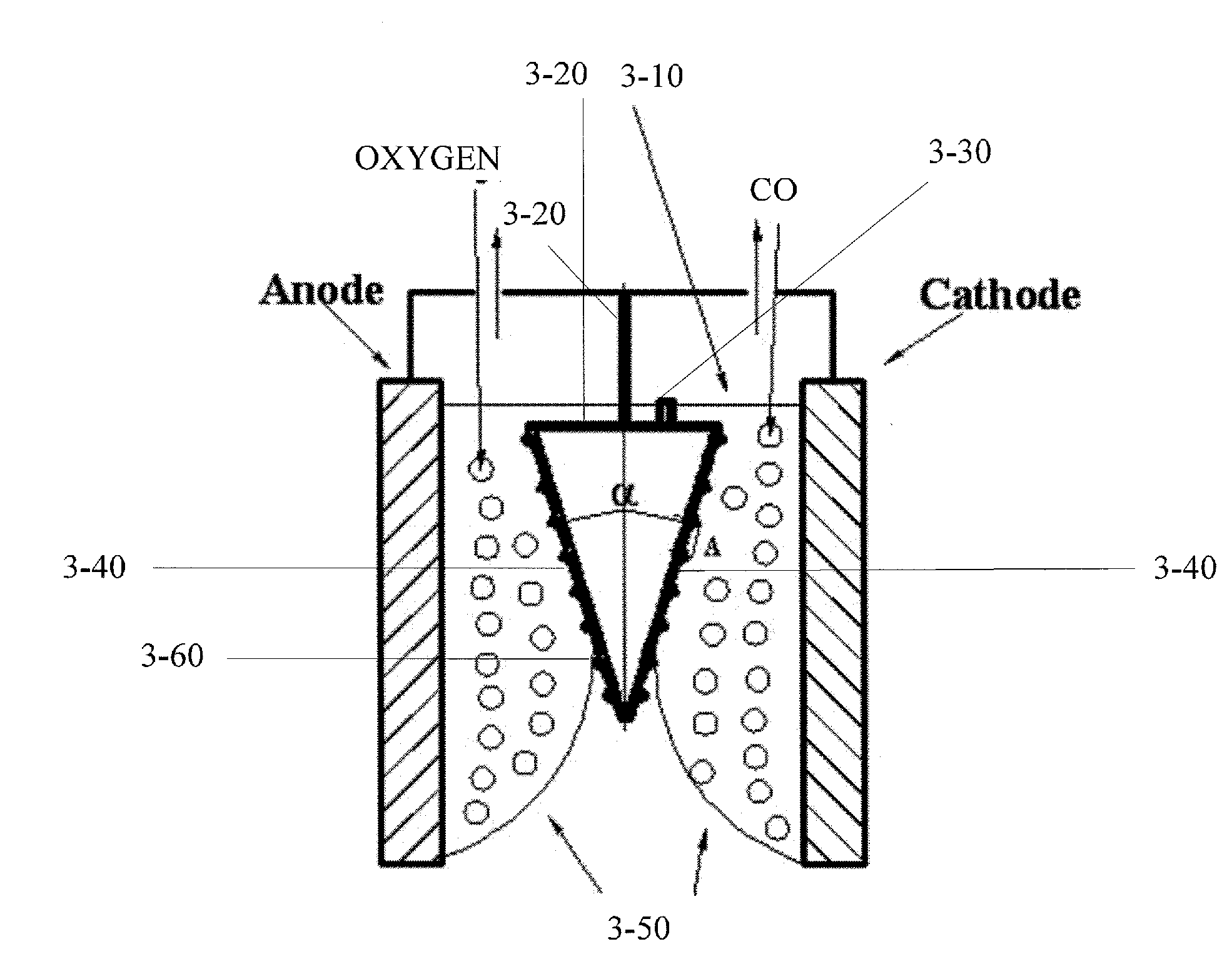

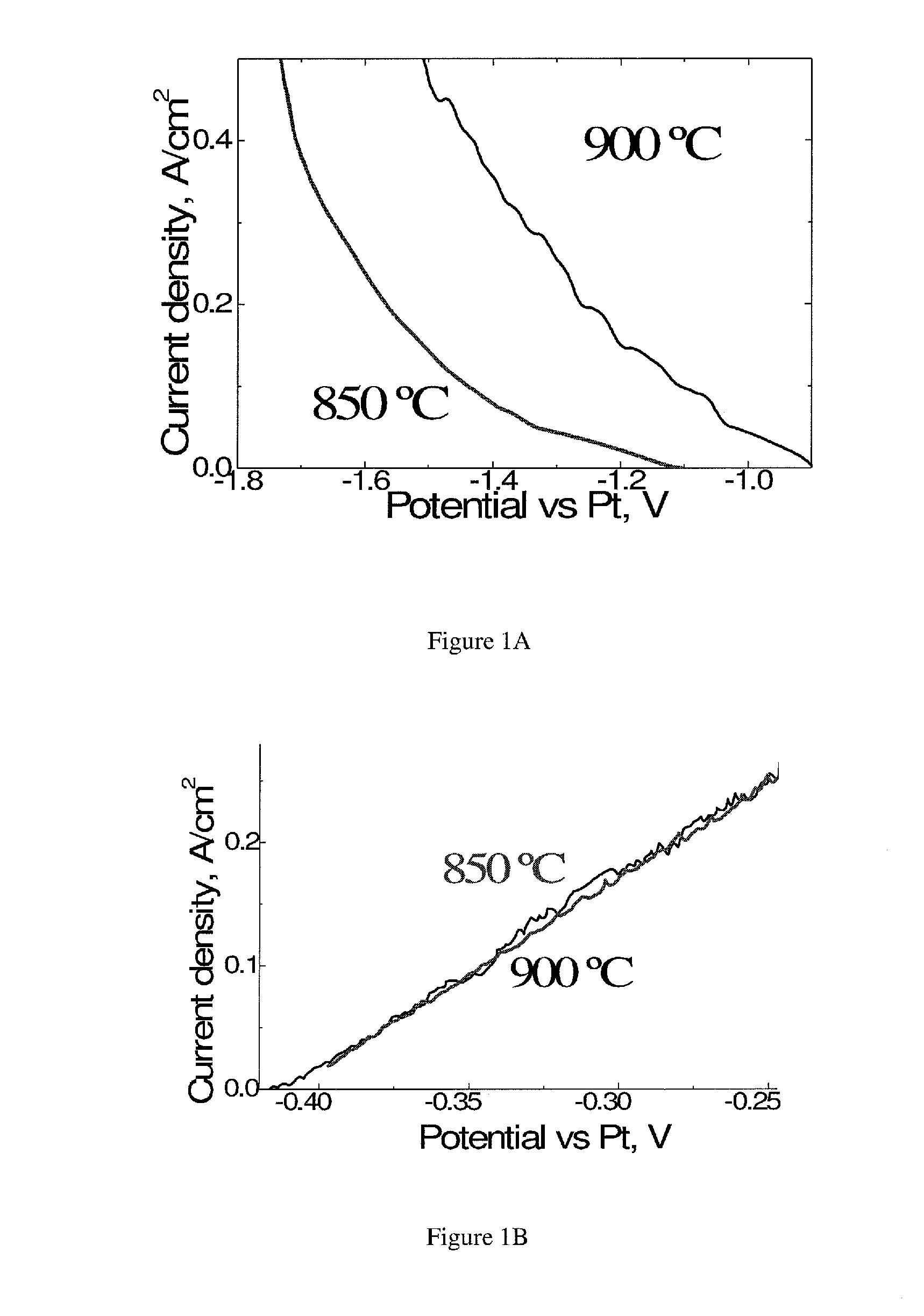

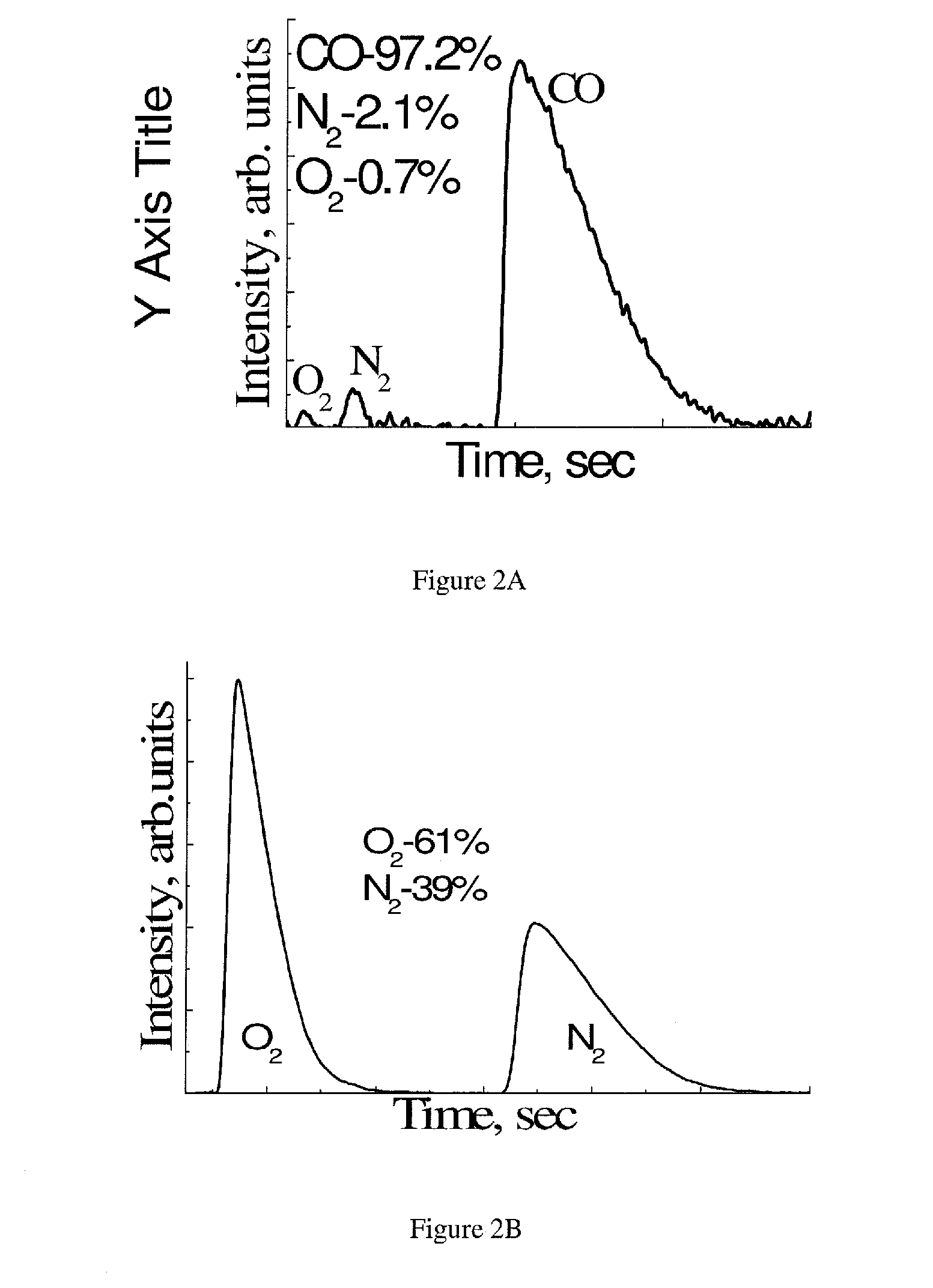

Methods and apparatus of electrochemical production of carbon monoxide, and uses thereof

The present invention relates to an electrolytic process, methods and apparatus for the preparation of carbon monoxide and in particular to electrolysis of molten carbonates to yield carbon monoxide which may be used for chemical storage of electrical energy and further as chemical feedstock for other organic products.

Owner:YEDA RES & DEV CO LTD

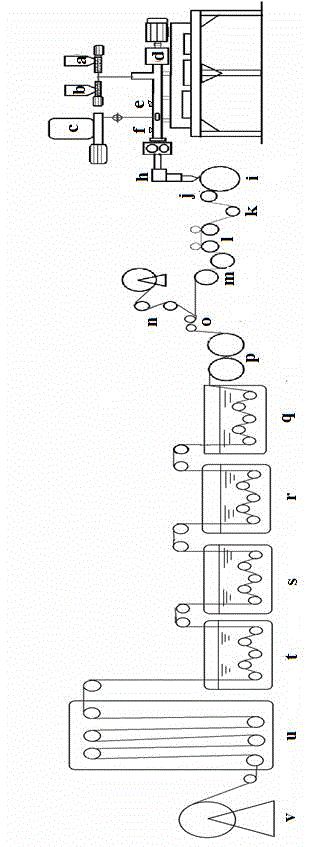

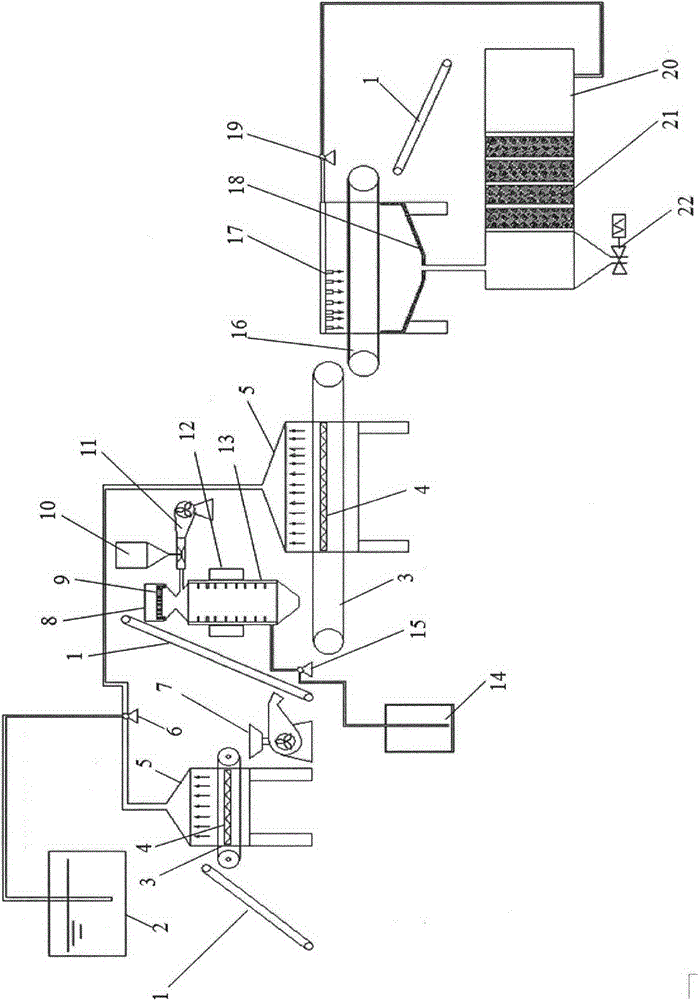

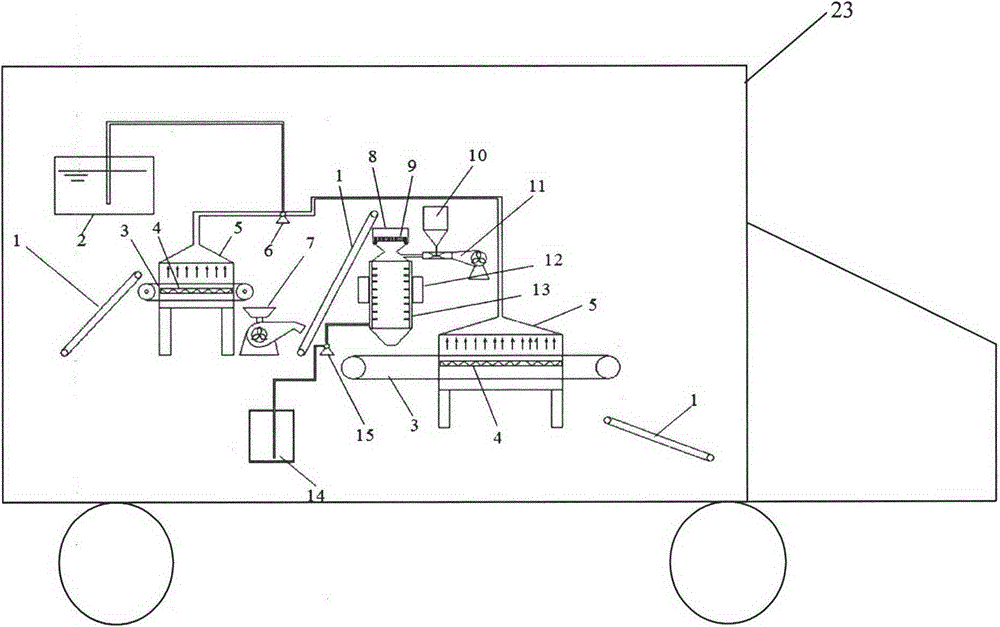

Integrated and comprehensive soil in-place position-changing combined remedying equipment

ActiveCN105013806AAchieving Heterotopic Continuous Joint RepairImprove repair efficiencyContaminated soil reclamationEnvironmental resistancePeristaltic pump

The invention discloses integrated and comprehensive soil in-place position-changing combined remedying equipment, and belongs to the technical field of soil remedying. The equipment mainly comprises feeding and discharging machines, heating baking channels, conveying belts, a vacuum pump, a smashing device, a mixer, a solid chemical adding tank, a Venturi conveying pump, an ultrasonic atomizer, a peristaltic pump, a liquid chemical storage tank, a drip washing device, an activated carbon adsorption purification tank, a mud discharging electromagnetic valve and an absorbent storage tank. The modularized design is adopted for the whole set of remedying equipment, flexible matching and combining can be performed according to different types of polluted soil to be remedied, and therefore the cost is lowered. The whole set of equipment can be installed on a trailer to achieve moving operation. The equipment has the multiple remedying functions of thermal desorption treatment, chemical oxidation / restoration, chemical drip washing and others, can achieve in-place position-changing combined remedying on soil containing organic pollutants and heavy metal combined pollution, and is high in remedying efficiency, wide in range, free of harmful gas emissions, safe and environmentally friendly.

Owner:南京康地环保科技有限公司

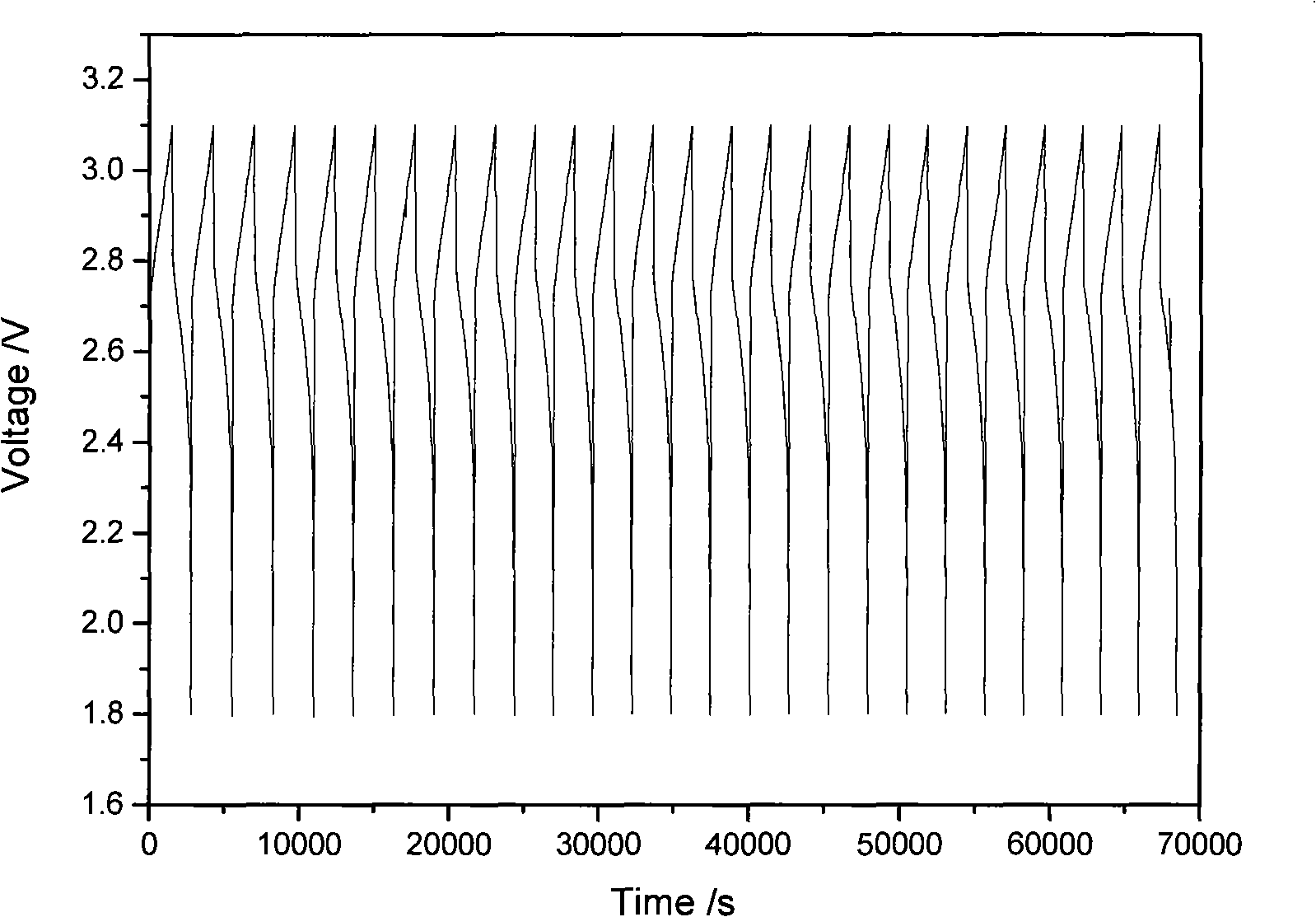

Flexibility enhanced bipolar plate for liquid energy-storing battery and manufacture thereof

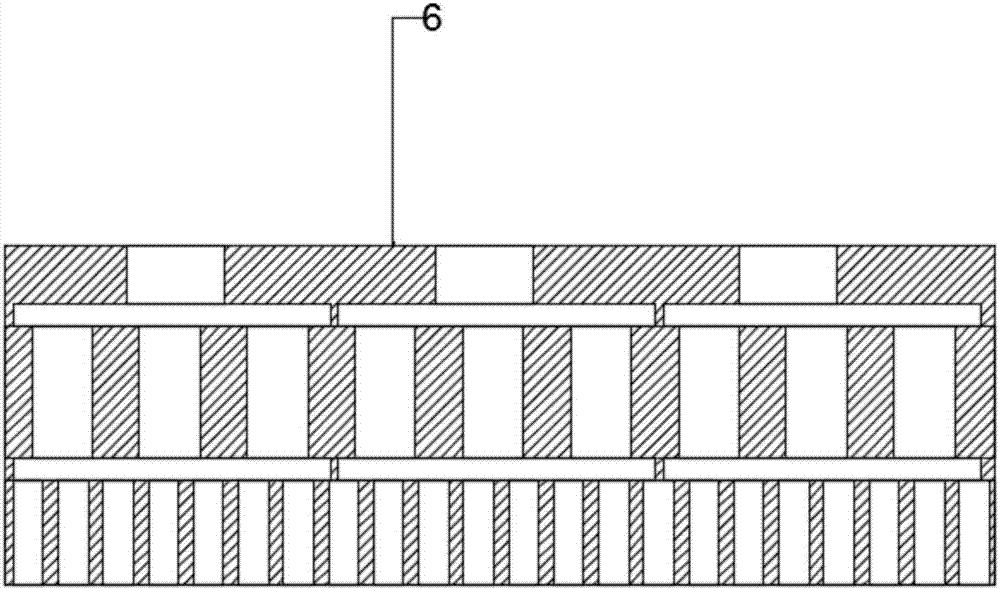

ActiveCN101308924AGood liquid resistanceImprove Coulombic efficiencyElectrode manufacturing processesActive material electrodesChemical storageRedox

The invention relates to a redox flow storage battery in chemical storage technology, and in particular relates to a reinforcing soft graphite bipolar plate used in a redox flow storage battery and the fabrication method thereof. The bipolar plate is composed of soft graphite layers and a carbon conductive composite material layer, which are staggered and are spliced together. The external two layers are soft graphite layers. The invention adopts carbon conductive composite material to reinforce the soft graphite plate and introduces heat pressing technique to fabricate a reinforcing soft graphite bipolar plate which is of good conductivity and good liquidity resistance and mechanical property. The reinforcing soft graphite bipolar plate is simple in fabrication technique and the reinforcing soft graphite bipolar plate made through the technique is low in cost and is easy to realize in batch production.

Owner:DALIAN RONGKE POWER

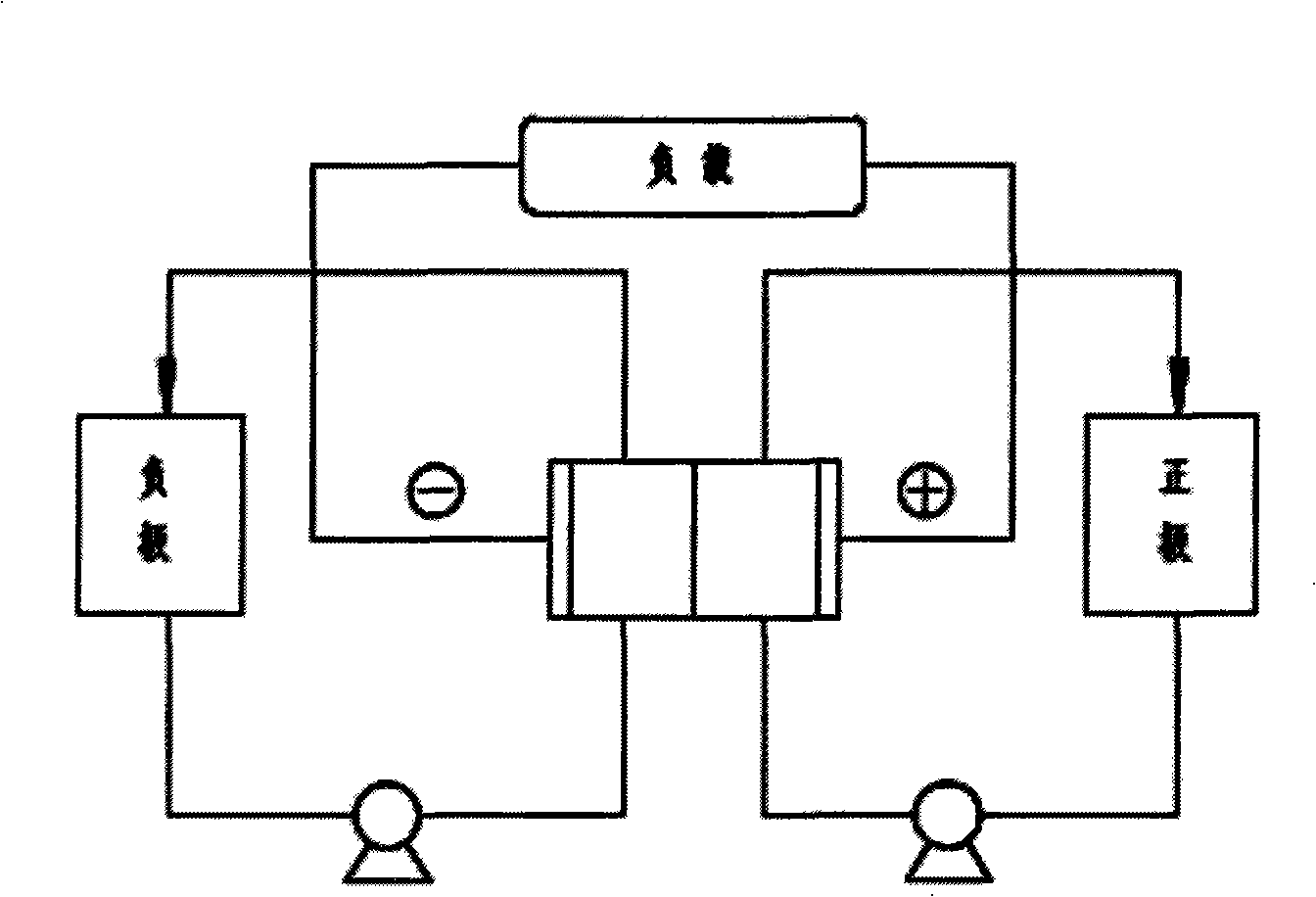

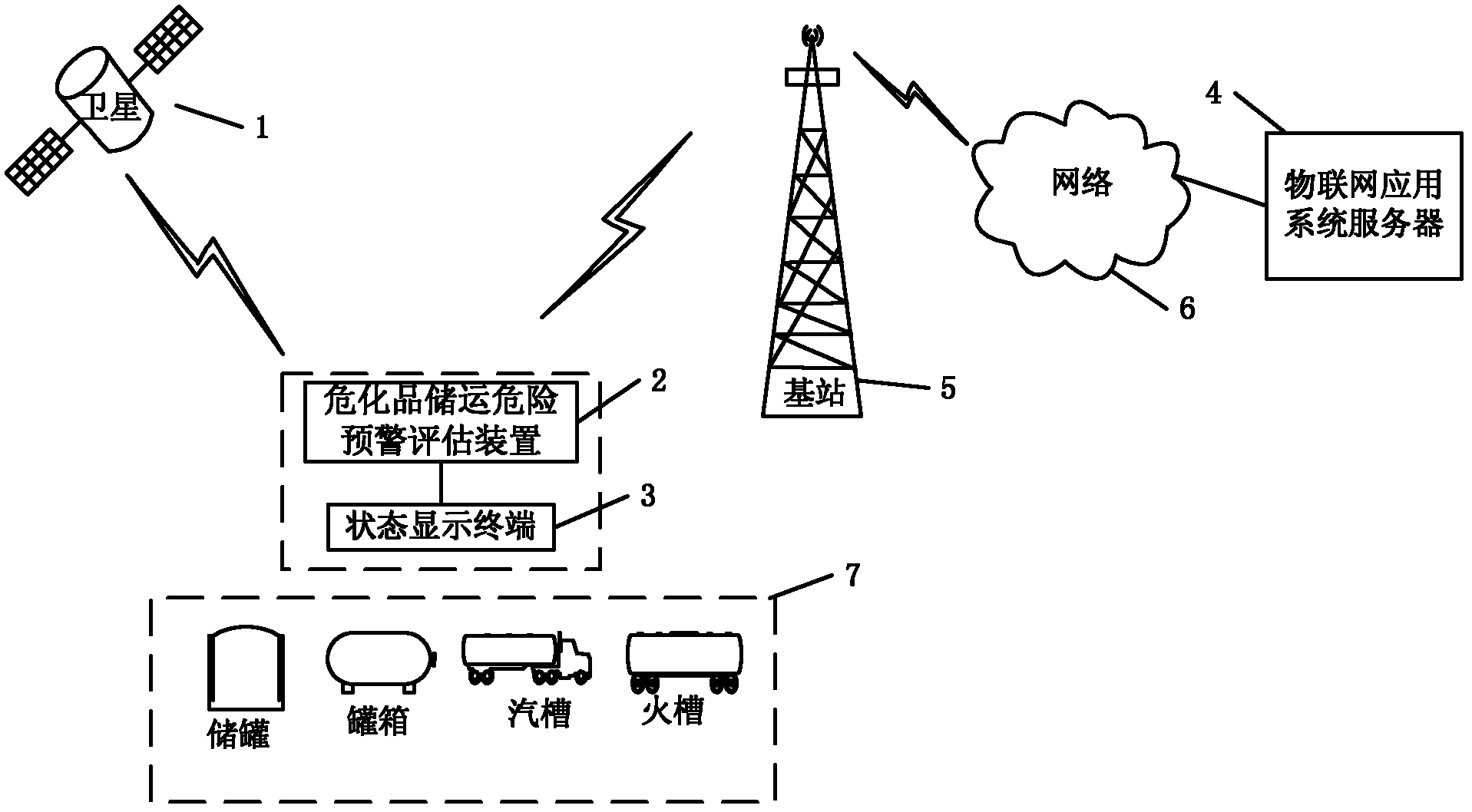

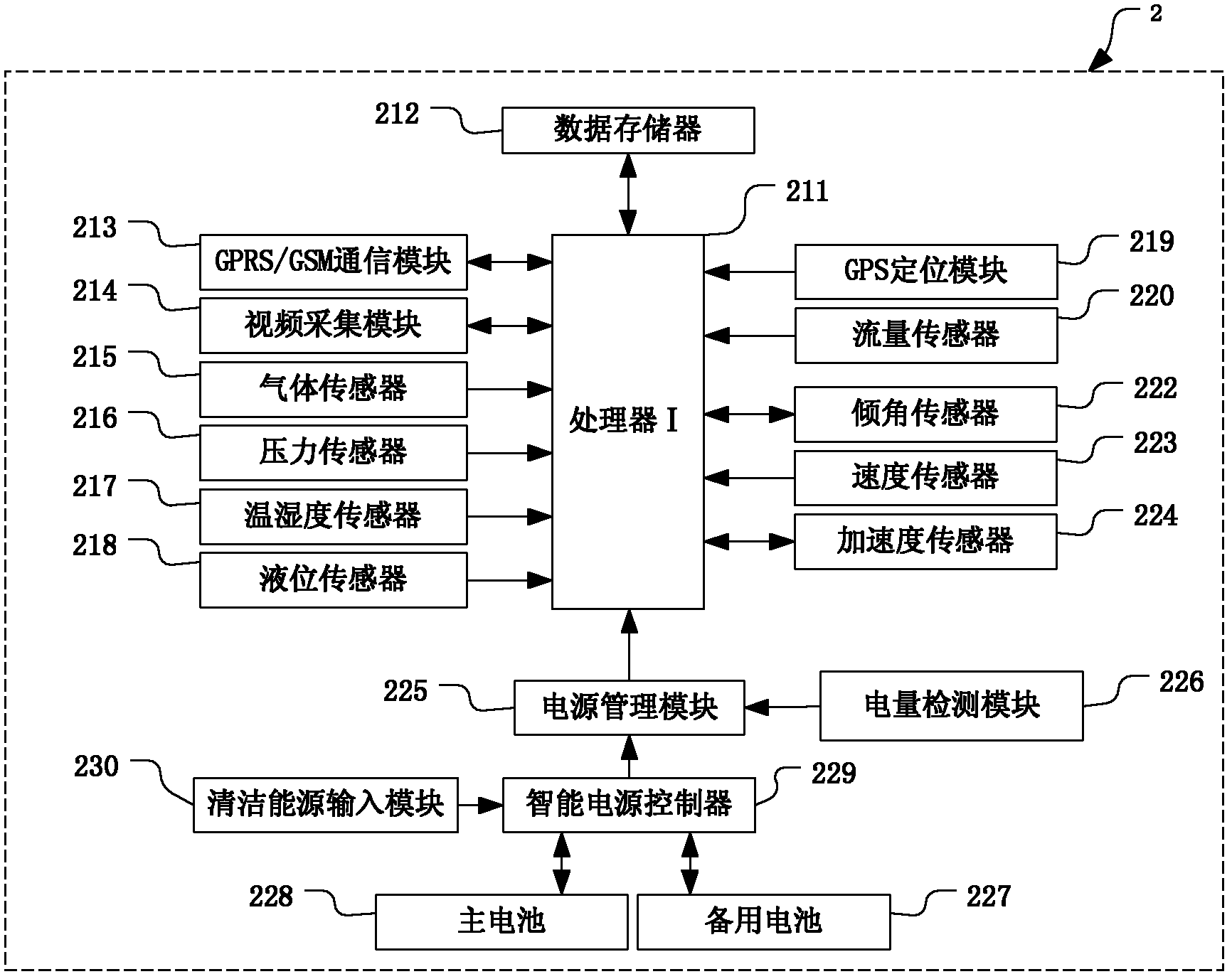

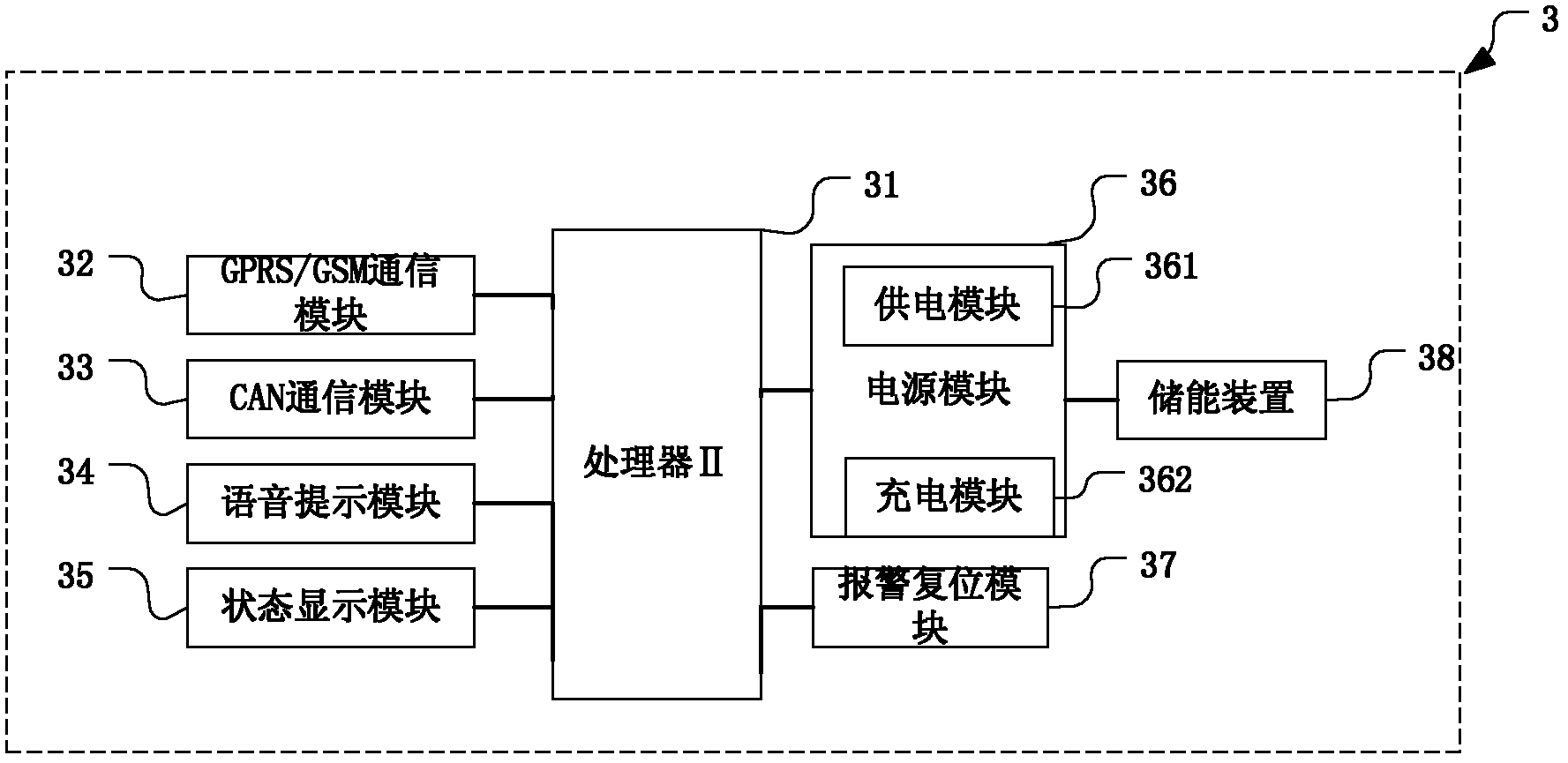

Dangerous chemical storage and transportation danger early warning and assessment device and pre-warning system

InactiveCN102621966AWith collection functionImprove securityTotal factory controlProgramme total factory controlChemical storageData connection

Owner:蚂蚁能源服务有限公司

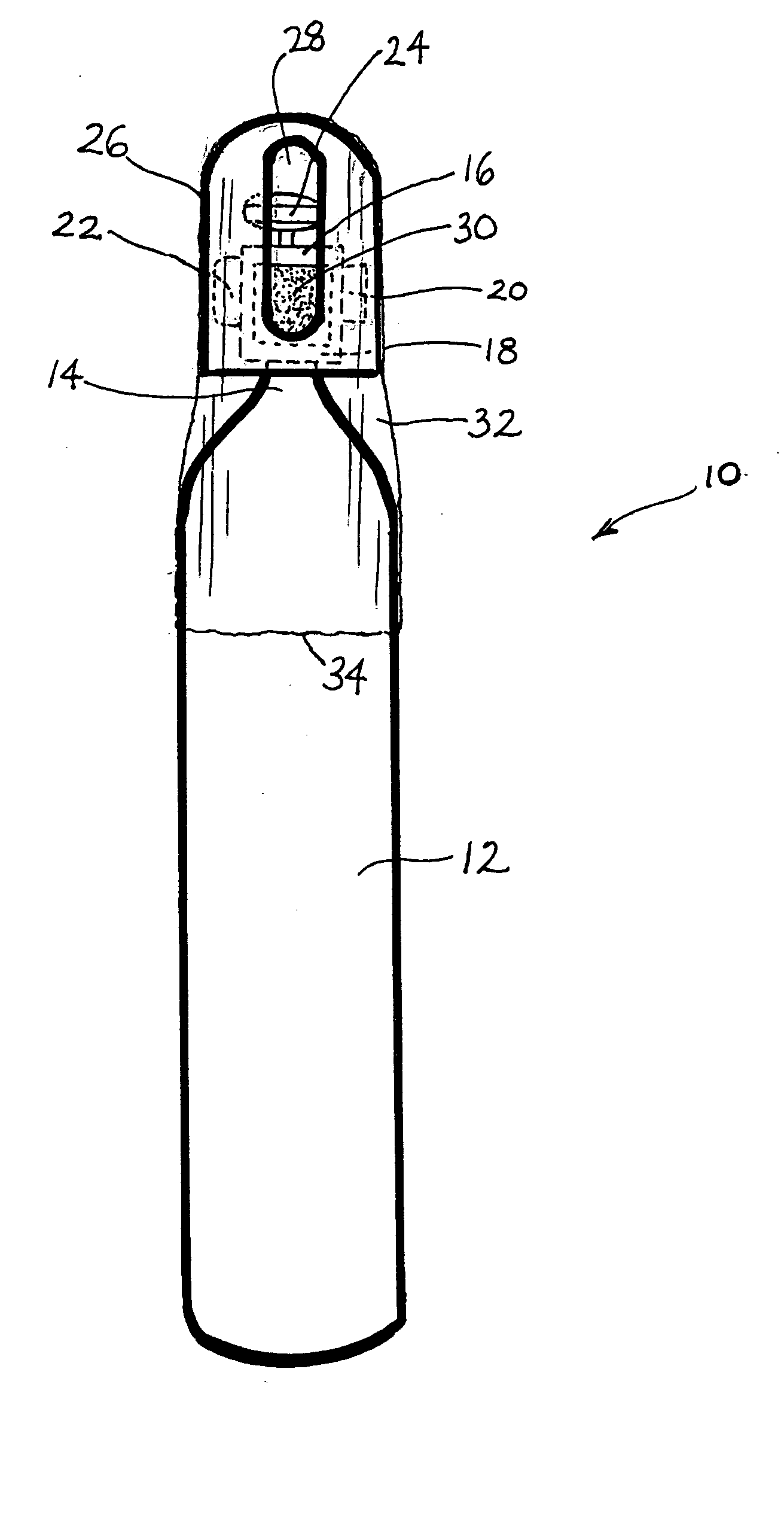

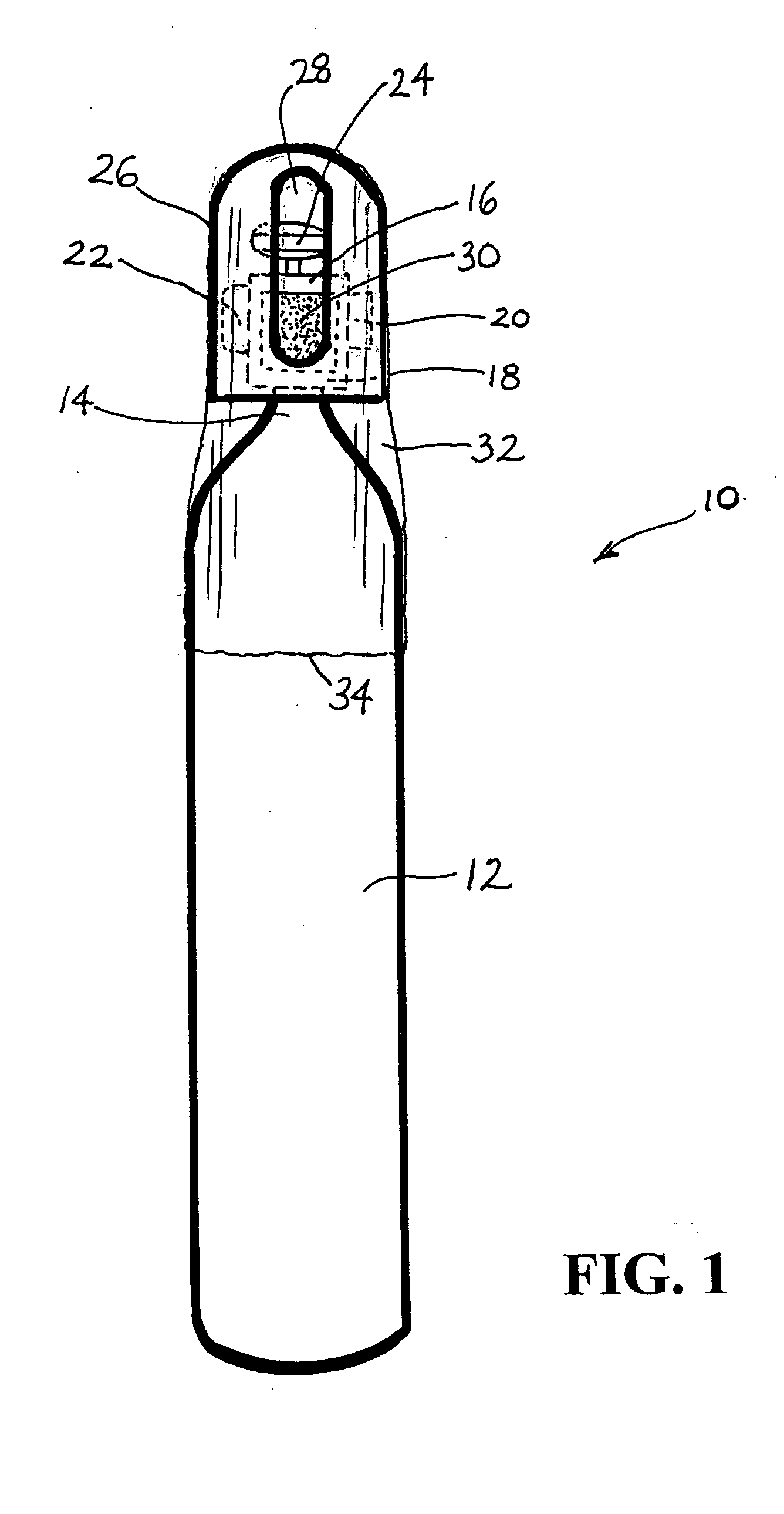

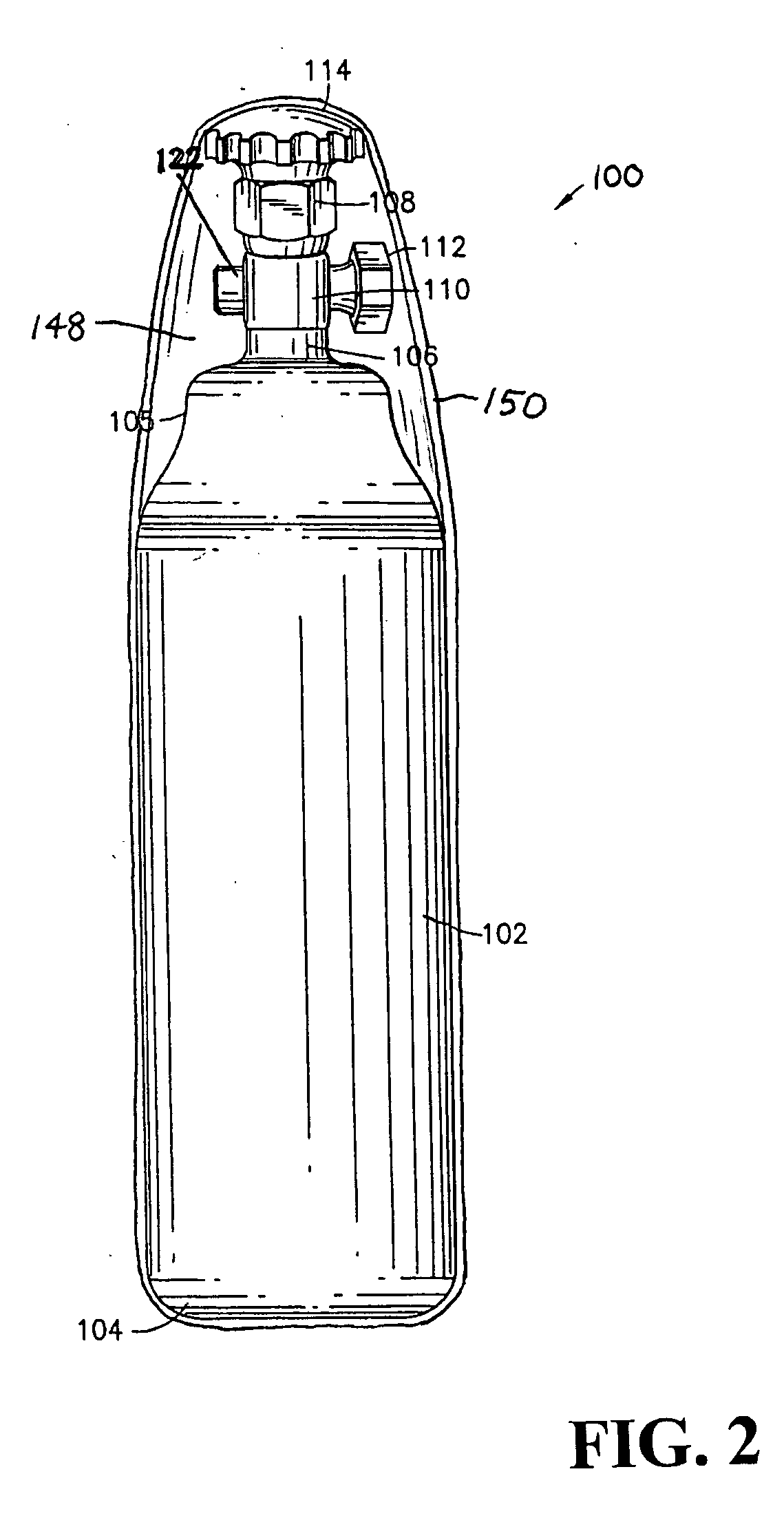

Fluid storage and dispensing vessels having colorimetrically veriflable leak-tightness, and method of making same

A chemical storage and dispensing vessel having associated therewith a colorimetric member that is effective to change color in exposure to leakage of a gas contained in the vessel. The colorimetric member may be constituted by a film, e.g., of a shrink-wrap character, that contains or is otherwise associated with a calorimetric agent undergoing color change in exposure to fluid leaking from the vessel. Such shrink-wrap film may be applied to a portion of the vessel susceptible to leakage, or alternatively to the entire vessel, so that the film is calorimetrically effective to indicate the occurrence of a leakage event by visually perceptible change of color.

Owner:ENTEGRIS INC

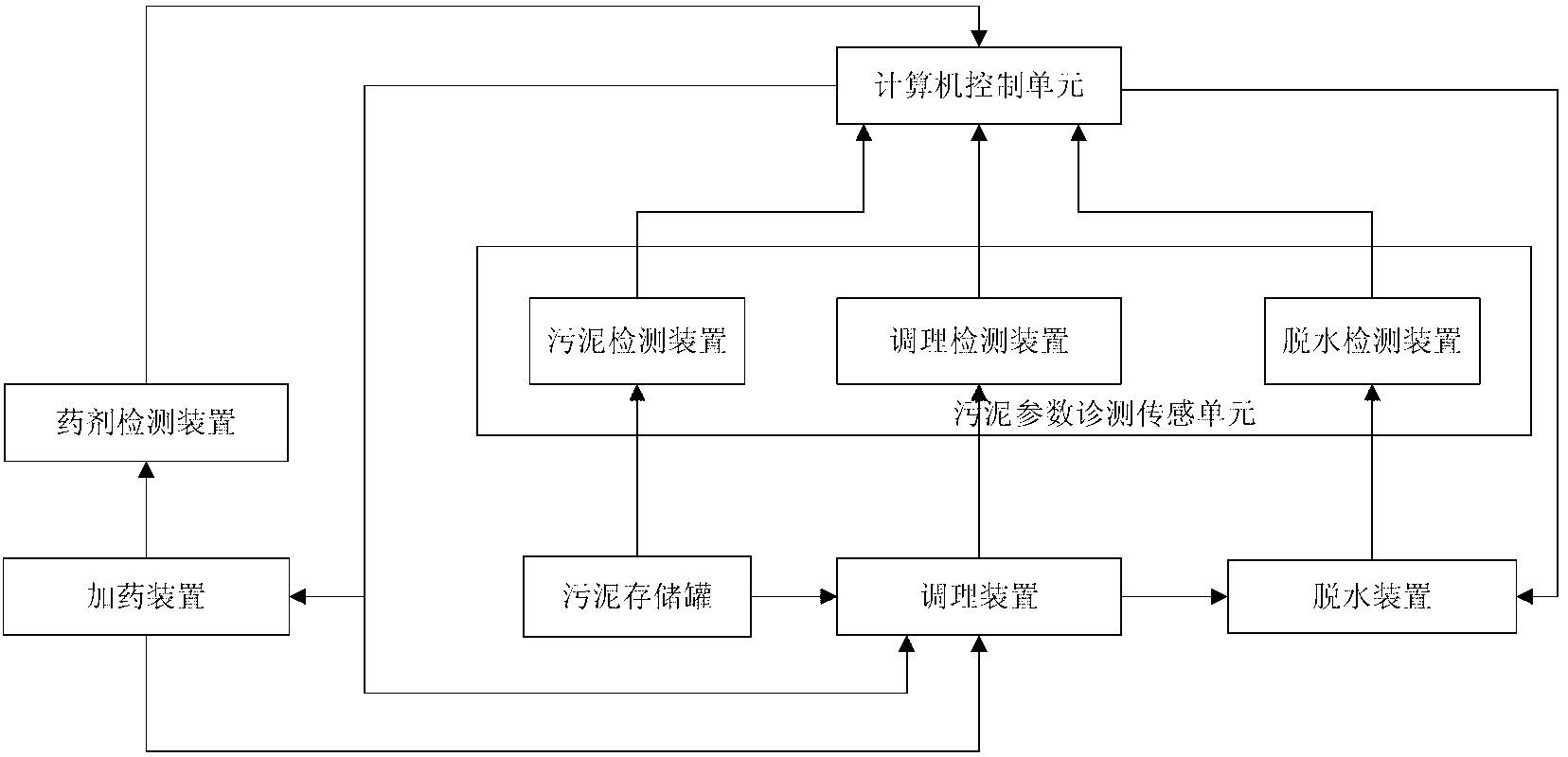

Intelligent conditioning system for deep dewatering of sludge

ActiveCN103241918ALower output qualitySludge treatment by de-watering/drying/thickeningSimultaneous control of multiple variablesChemical storageCaloric values

The invention discloses an intelligent conditioning system for deep dewatering of sludge, which comprises a dosing module, wherein the dosing module comprises an automatic dispensing system, a dosing system and chemical storage and throwing systems. According to the invention, an intelligent diagnosis system diagnoses each part in the reaction process of a sludge treatment device, and transmits the diagnosis result to a control unit; the control unit analyzes the diagnosis result, and controls the dosing system to perform dosing operation according to a control result; and through the treatment of the invention, the sludge moisture content is reduced from the originally 80-98% to 35-60%, the final sludge output mass is reduced by at least 50%, the sludge can still keep 70% or above (about 600-3000 kilocalories per kilogram) of the original organic caloric value after the sludge moisture content is reduced, and the sludge can be further treated by incineration and drying.

Owner:JIANGSU GREEN WAY ENVIRONMENTAL PROTECTION TECH

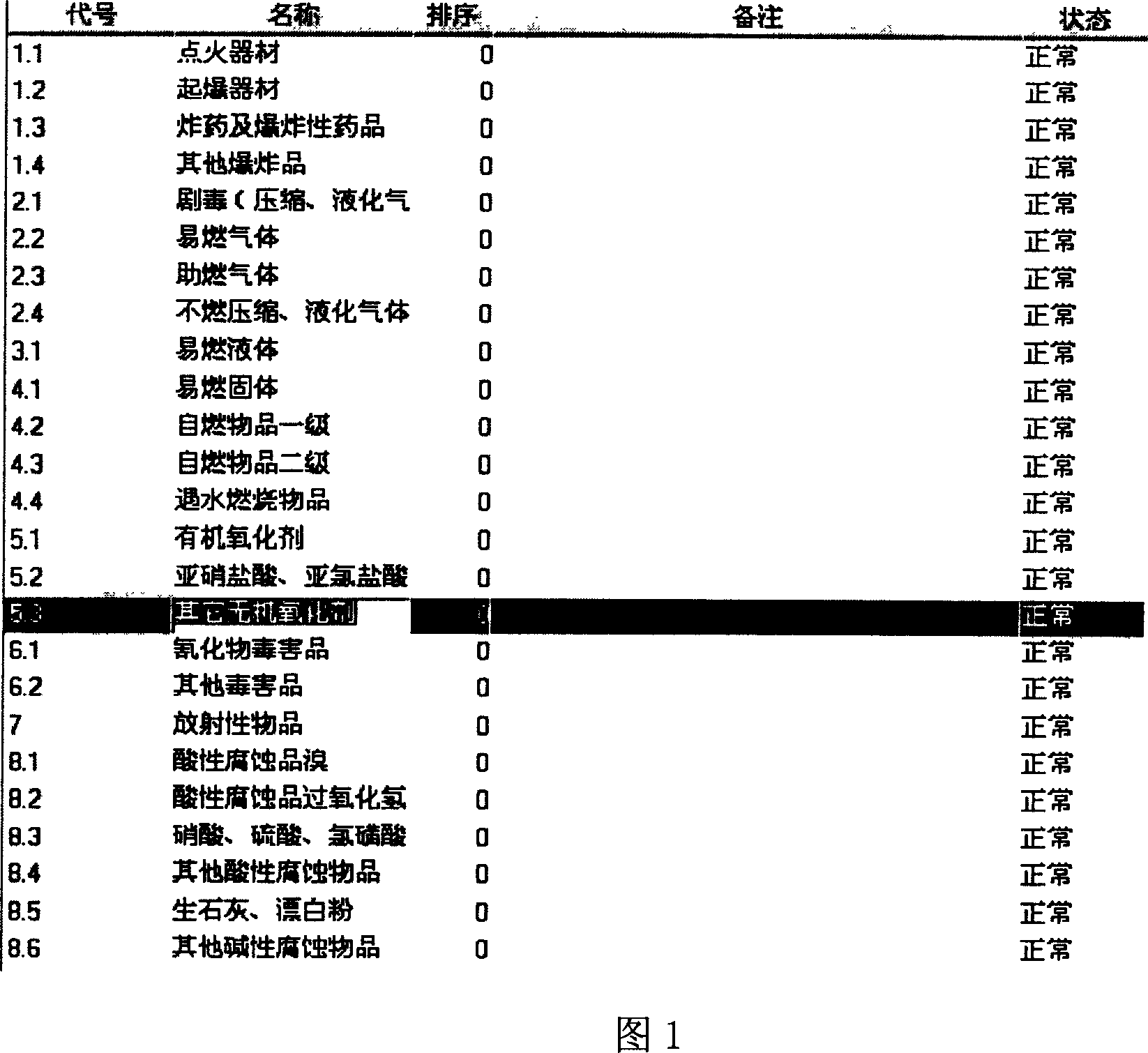

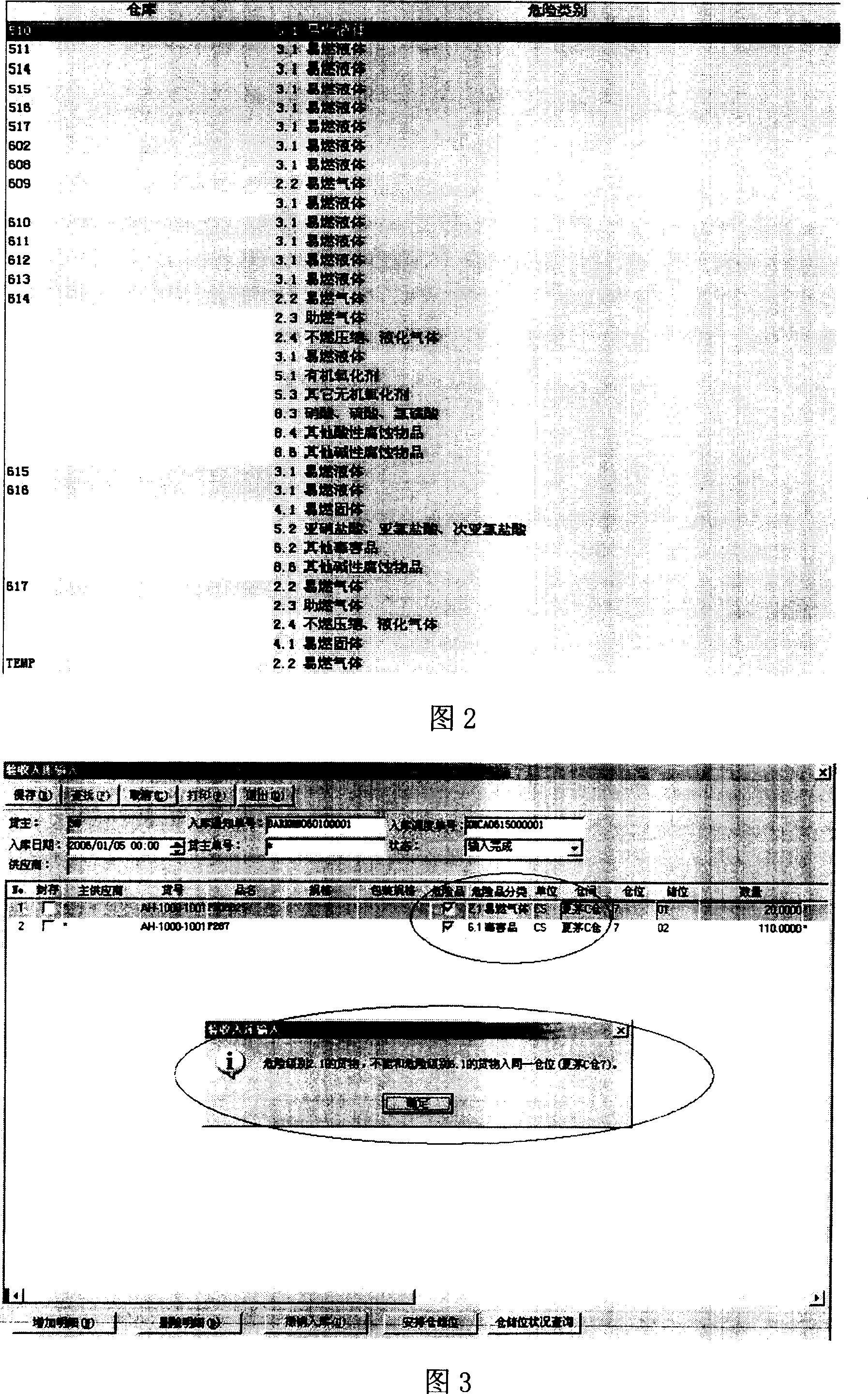

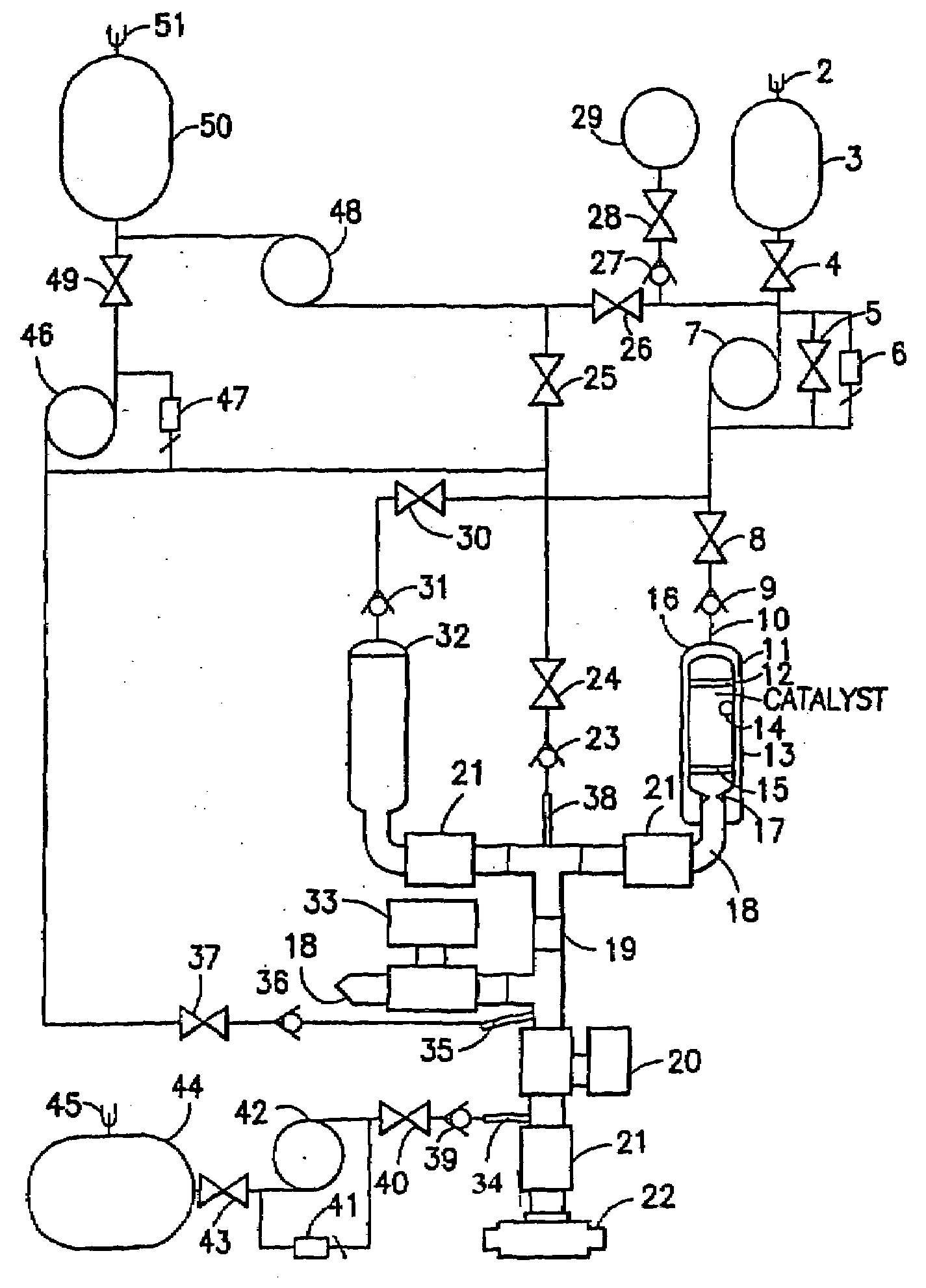

Dangerous chemicals placing and storage management method

InactiveCN101118614AEnsure safetyImprove accuracyLogisticsStorage devicesChemical storageApproaches of management

Owner:上海现代物流投资发展有限公司

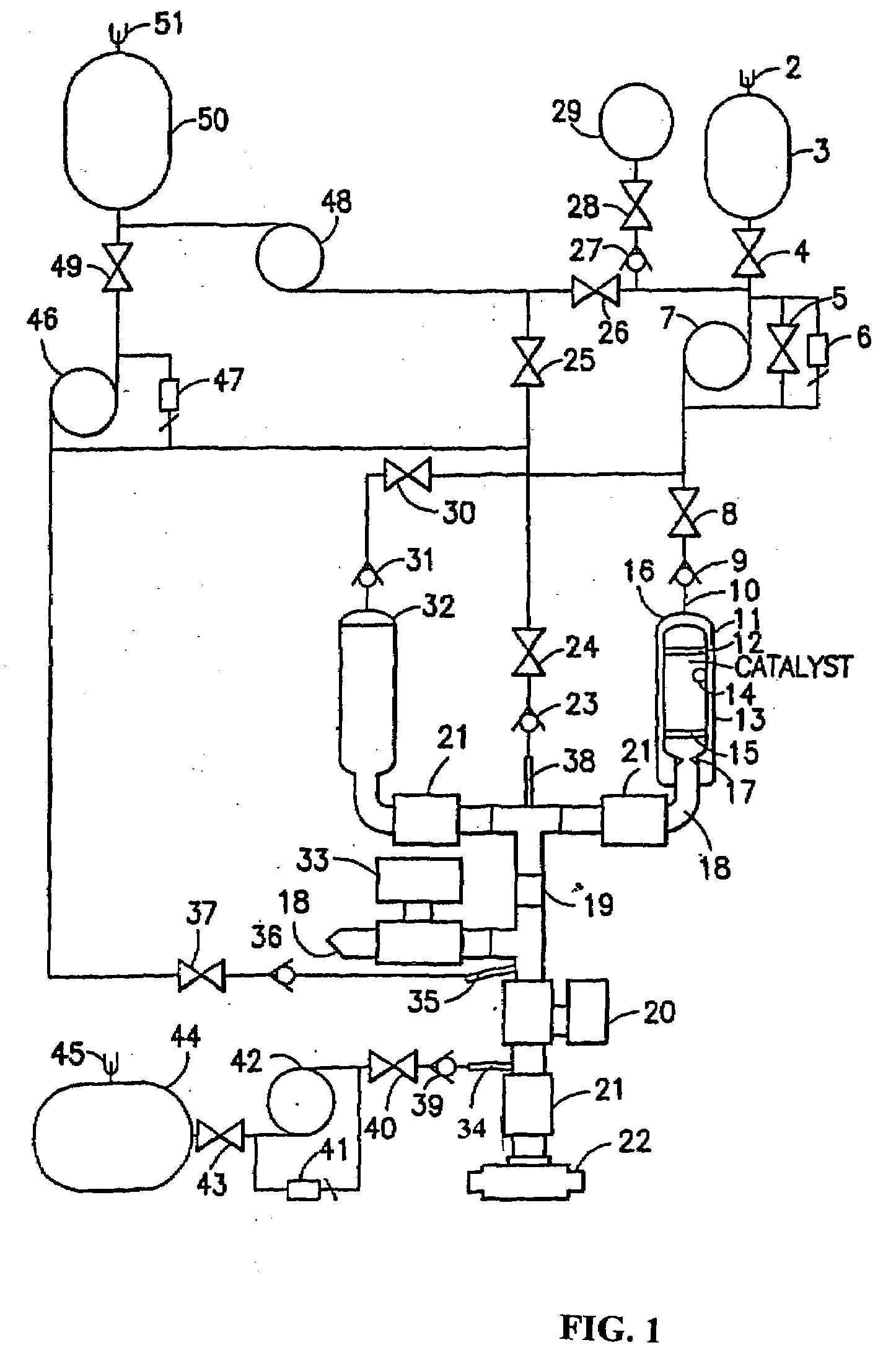

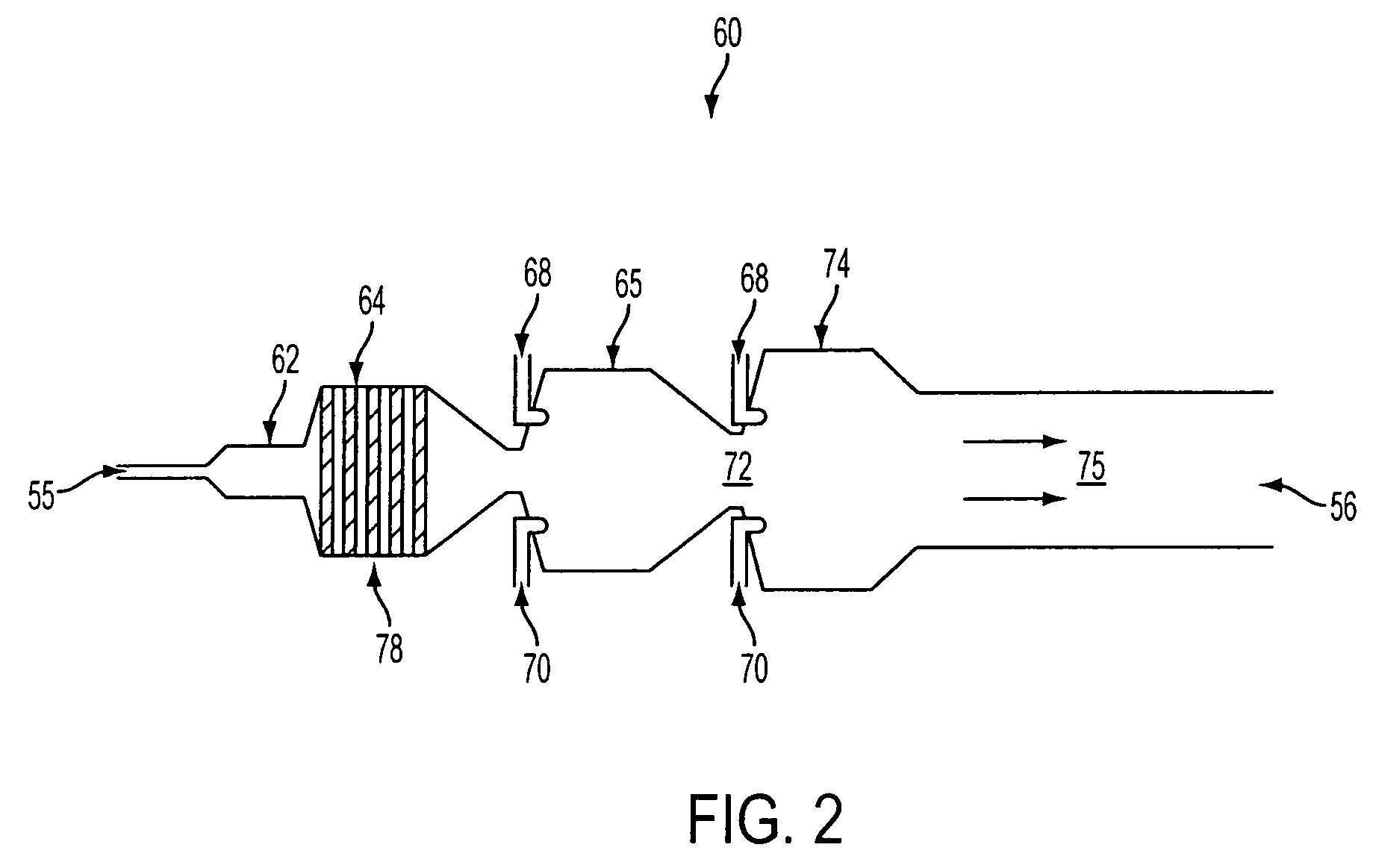

Engine/steam generator with afterburner

InactiveUS20080087434A1Efficient use ofReduce the possibility of corrosionExothermal chemical reaction heat productionDrilling rodsChemical storageCombustion chamber

An engine / steam generator which converts hydrogen peroxide to superheated steam and oxygen and having an afterburner that together with a reducing agent, utilizes the oxygen, thereby supplying oxygen free super-heated steam under pressure for oil well stimulation. Fluids such as water and KH30 can be injected into the engine / stem generator. The invention also relates to an apparatus and methods of incineration, soil remediation, land fill remediation, controlled vault burning, chemical atomization / vaporization, home heating, generation of electricity, diesel engine exhaust cleaning, steam turbine, gas path cleaner for jet engines, steam cleaning, natural gas engine power booster emission reducer, chemical storage tank cleaning, portable gas drive, and metal tempering.

Owner:UNITED ENERGY CORP

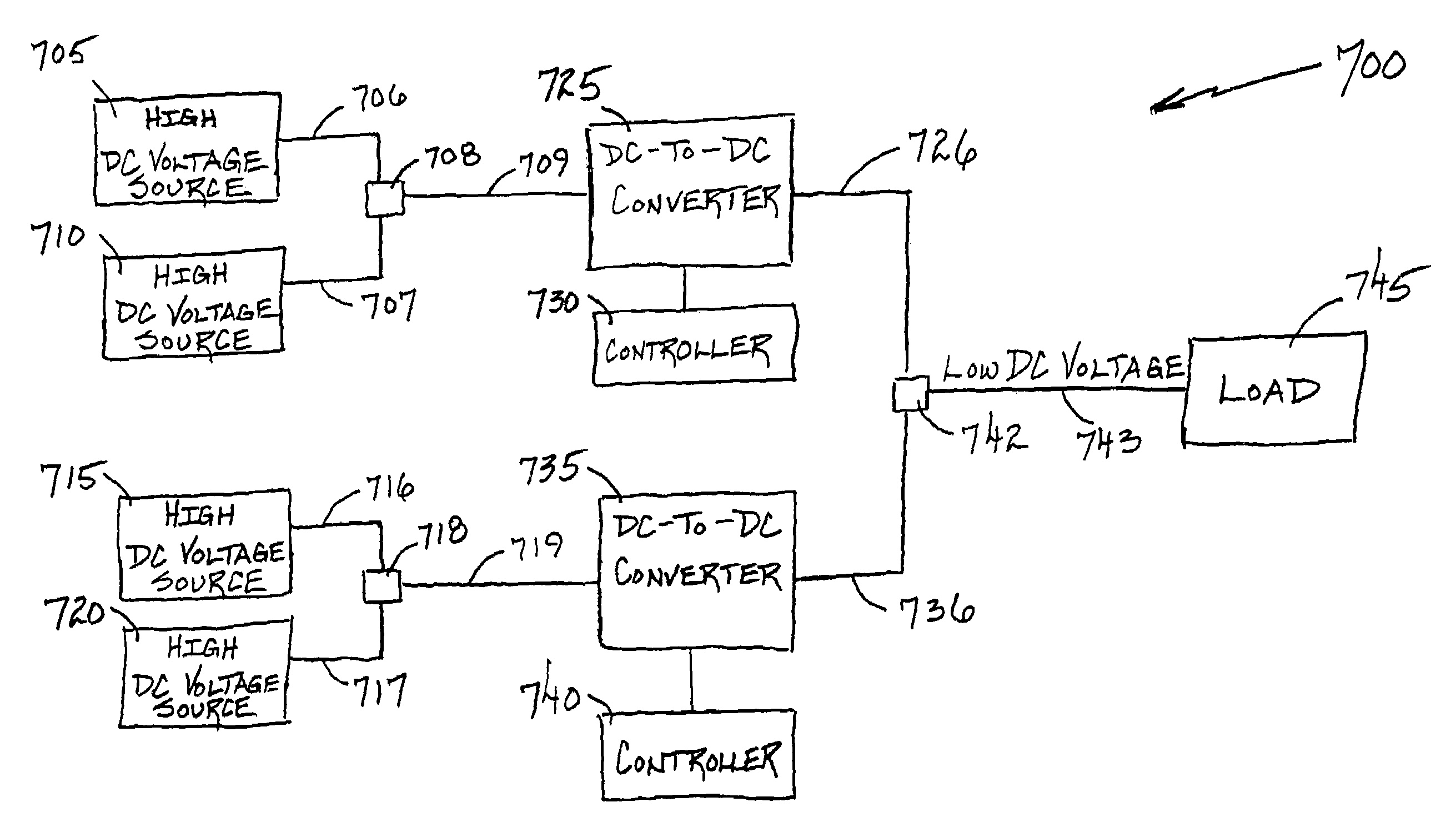

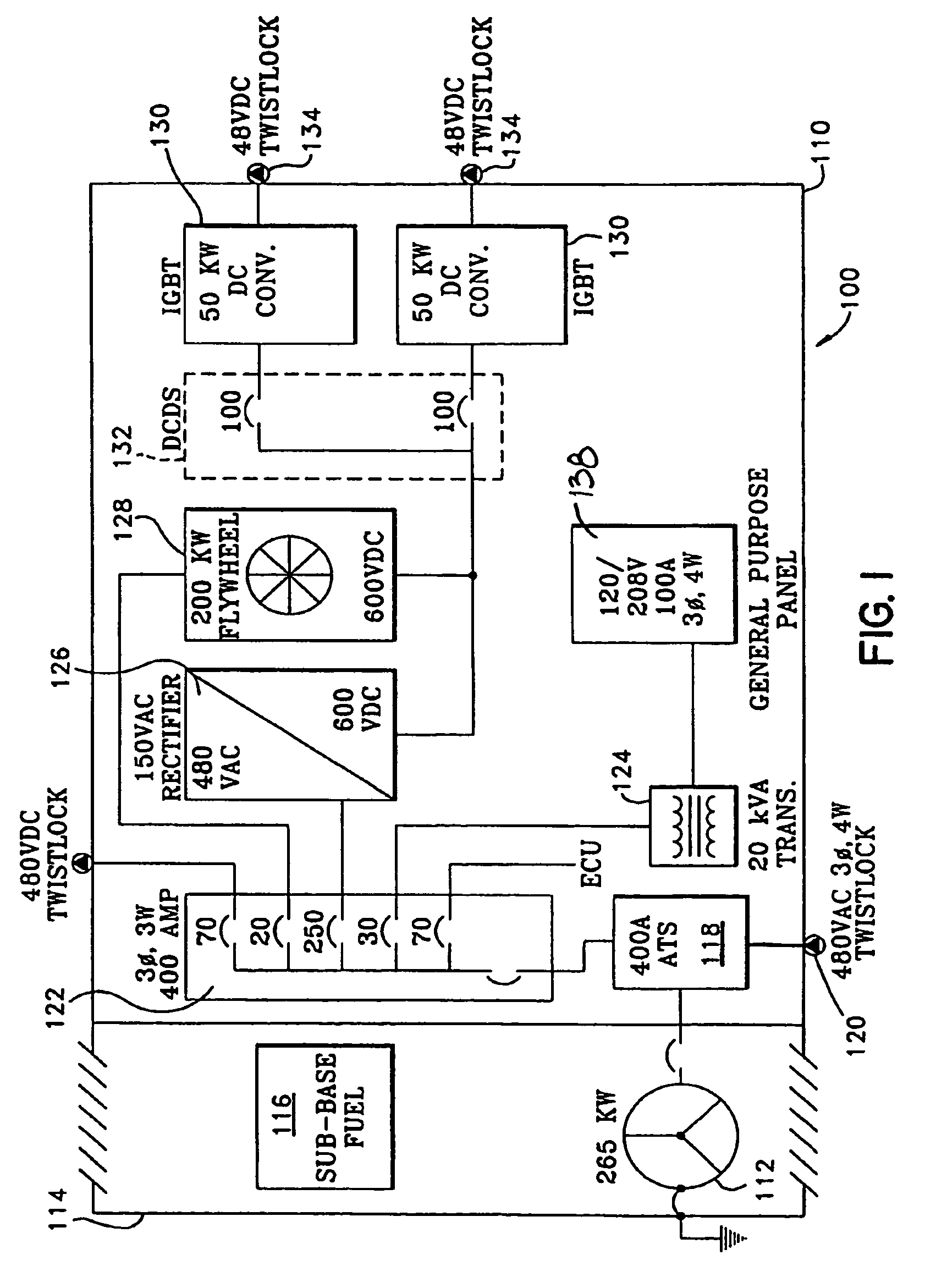

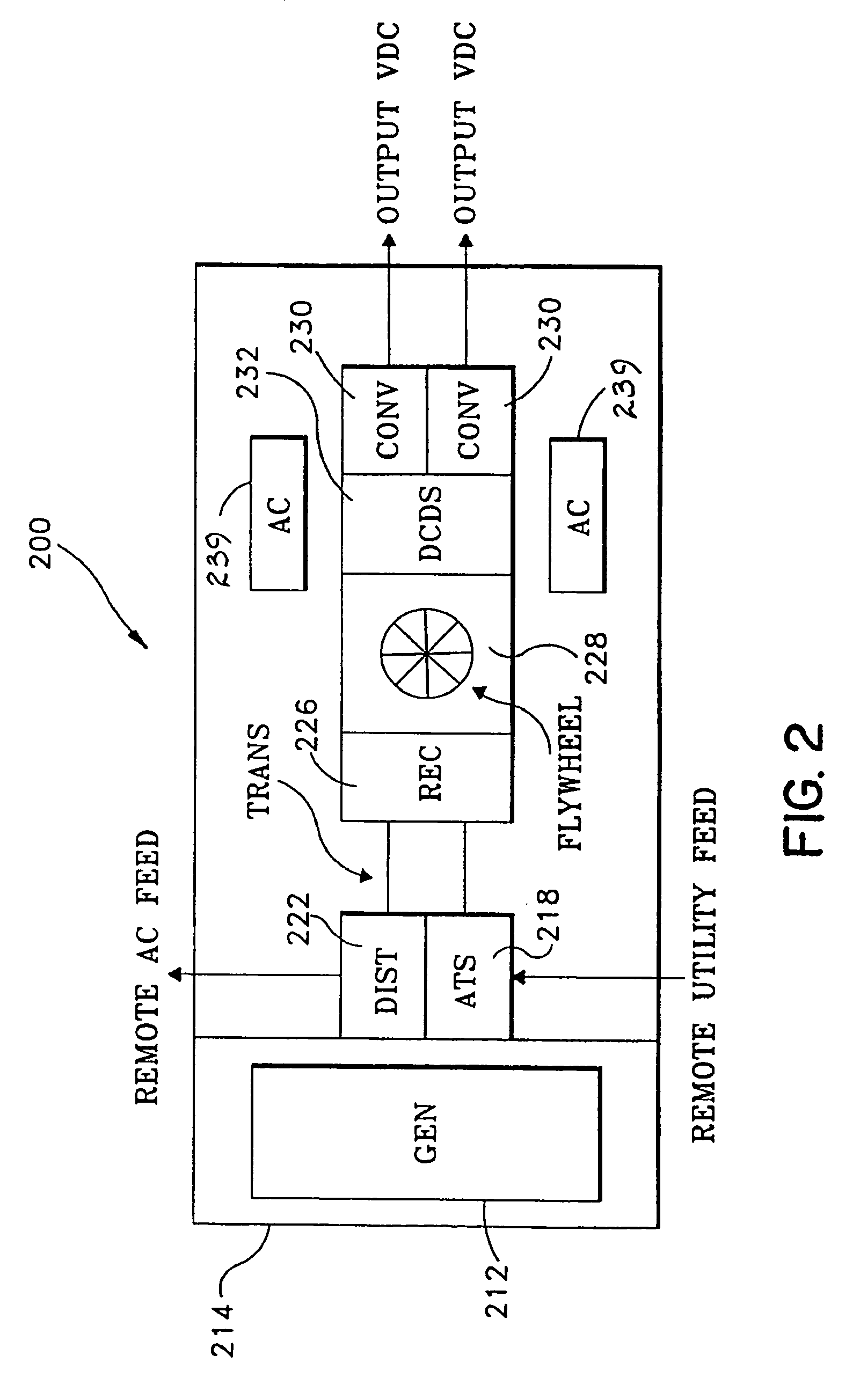

Apparatus for providing high quality power

ActiveUS7141894B2Improve power reliabilityLower requirementDc network circuit arrangementsBatteries circuit arrangementsChemical storageData center

The system disclosed herein is primarily utilized in the 23–48 volt DC telco, data center and industrial production industry. It will effectively replace today's requirement of purchasing, installing, maintaining and replacing chemical storage batteries. The solution will be capable of deployment partially and in full, inside the building, outside of the building in environmentally enclosed containers or in a mobile version. Additionally, the distribution voltage application will allow for reduction in the size of the power distribution wiring as well as creating an environment that requires less cooling of the critical equipment. This effectively leads to less infrastructure space and equipment, i.e. UPS, air conditioning units, static switch units, generators and chillers, for the same amount of processing, and significantly increases overall system reliability. The system regulates AC power and produces DC power that is considered uninterruptible and that is high quality in nature.

Owner:VALIDUS DC SYSTEMS

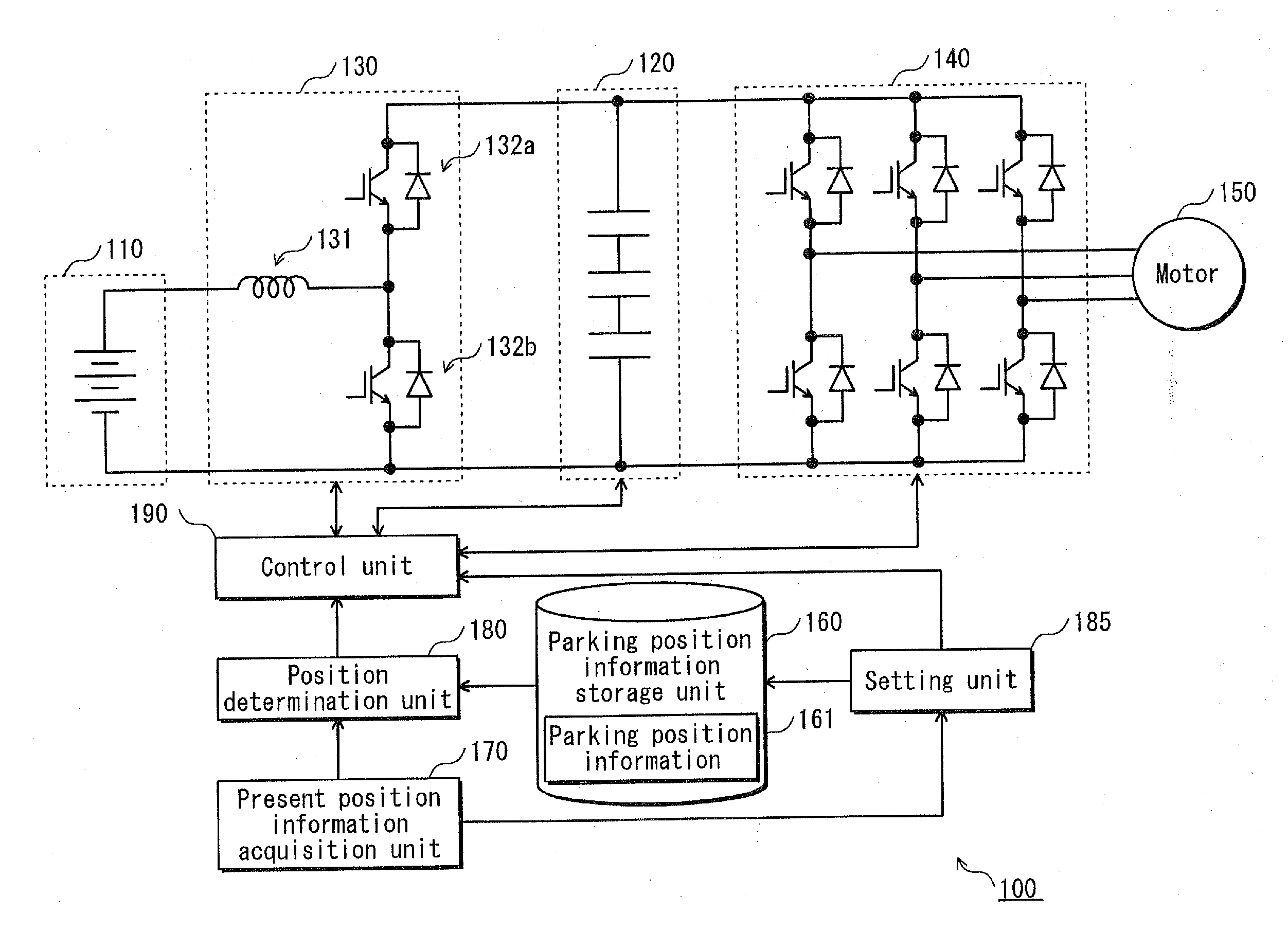

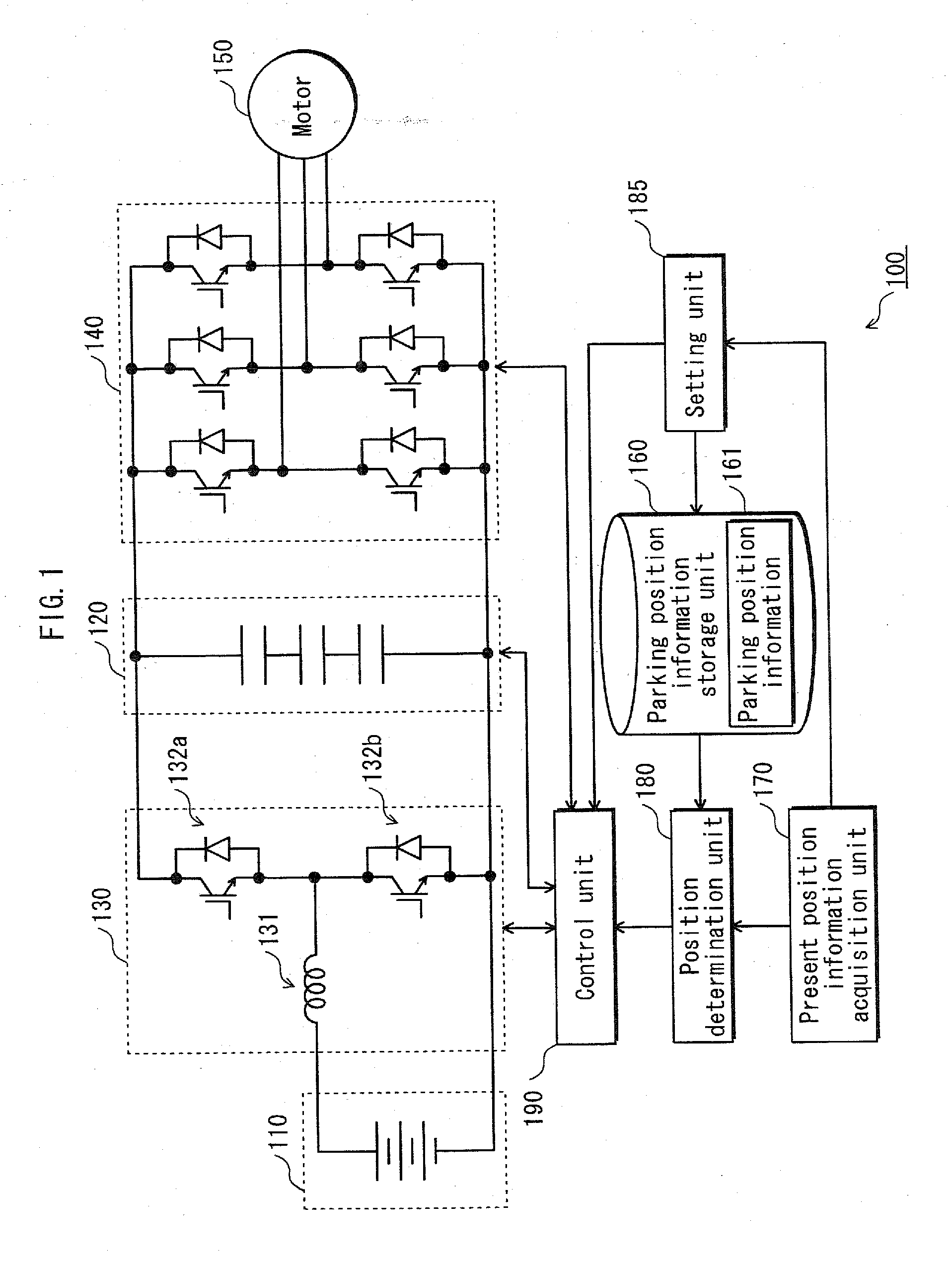

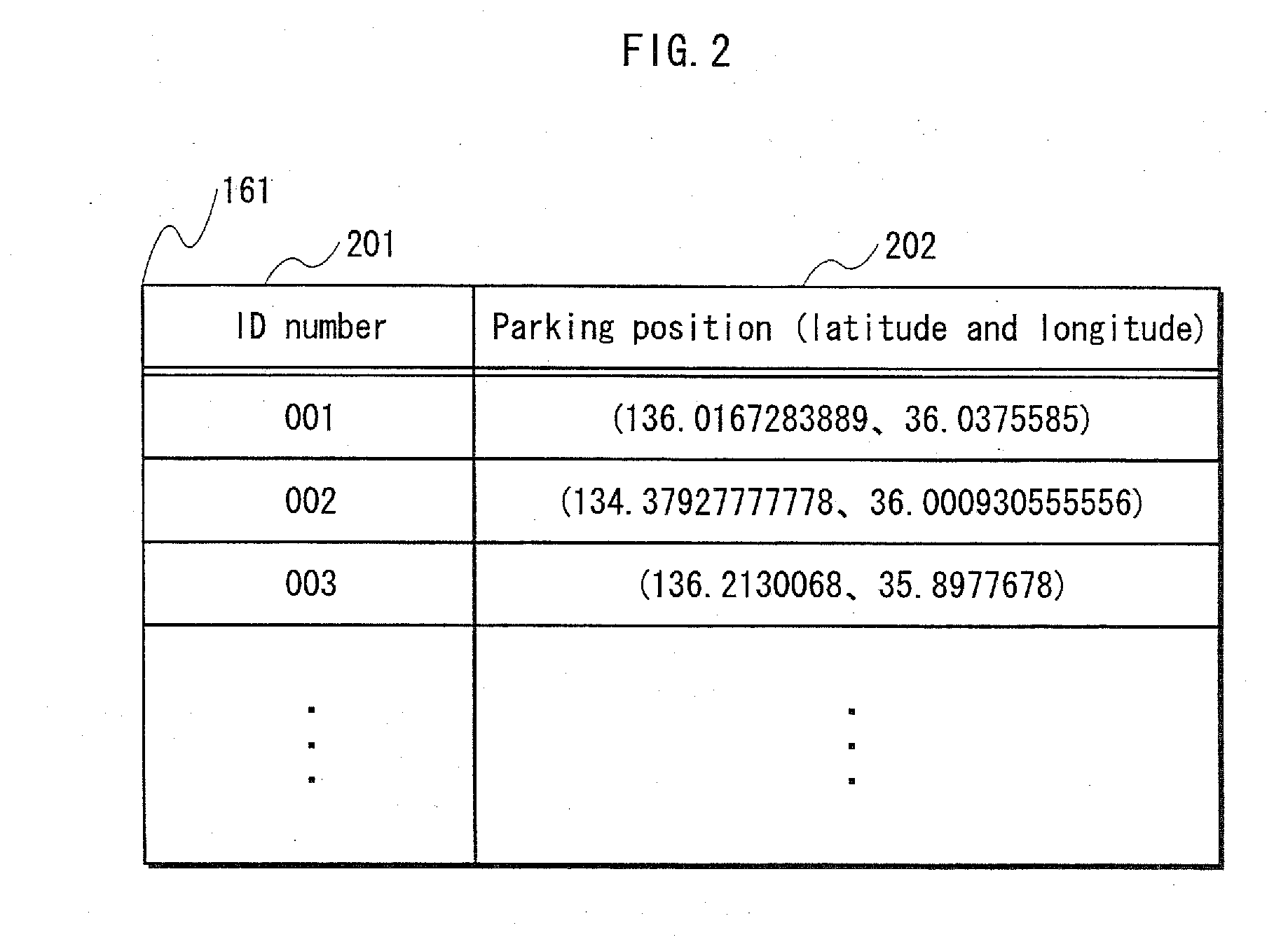

Vehicle control system and automobile

InactiveUS20120089286A1Reduce voltageLess energy lossDigital data processing detailsPropulsion by capacitorsChemical storageEngineering

A vehicle control system includes: a chemical storage unit 110 such as a lithium ion battery; a physical storage unit 120 such as a capacitor; an inverter 140 that is driven upon receiving a direct current from the storage units 110 and 120; and a motor 150 that is driven upon receiving an alternating current output from the inverter 140. The vehicle control system comprises: a position determination unit 180 for determining, based on present position information acquired by a present position information acquisition unit 170, whether a vehicle is approaching a parking position indicated by parking position information 161; and a control unit 190 for, when the vehicle is determined to be approaching the parking position, controlling the use of the electric power of the physical storage unit 120, such as charging the chemical storage unit 110 with electric power from the physical storage unit 120.

Owner:PANASONIC CORP

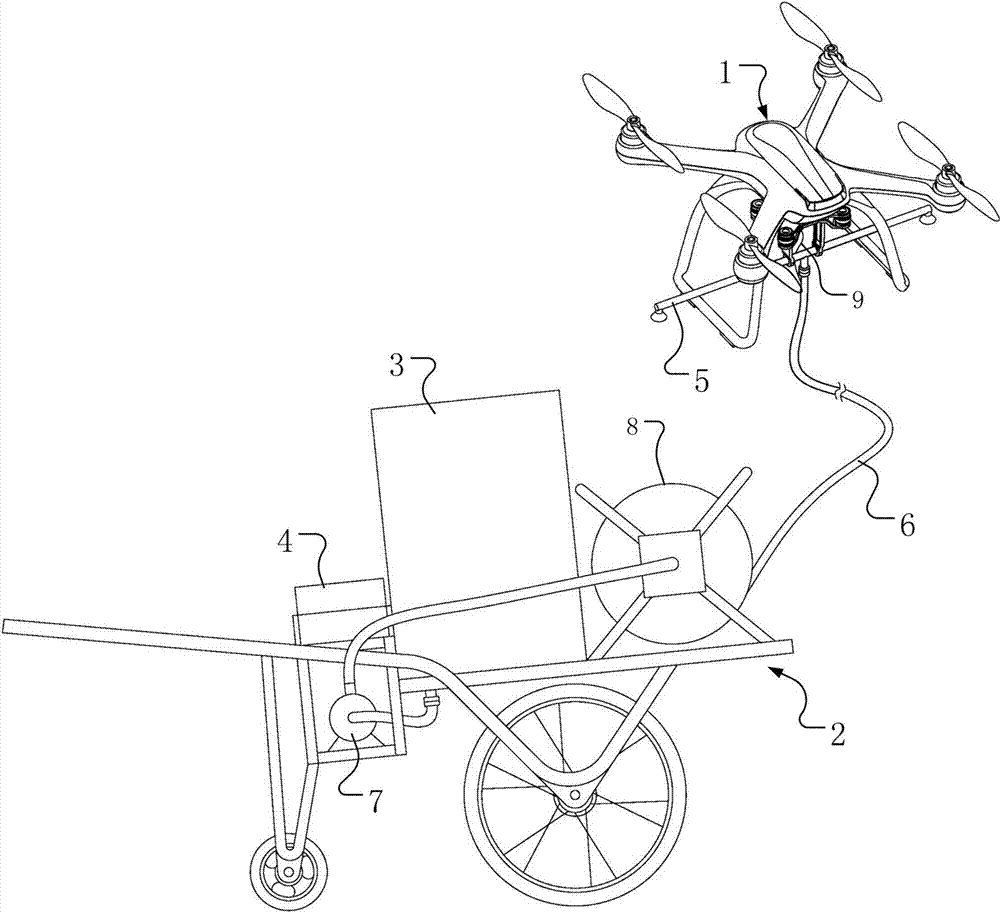

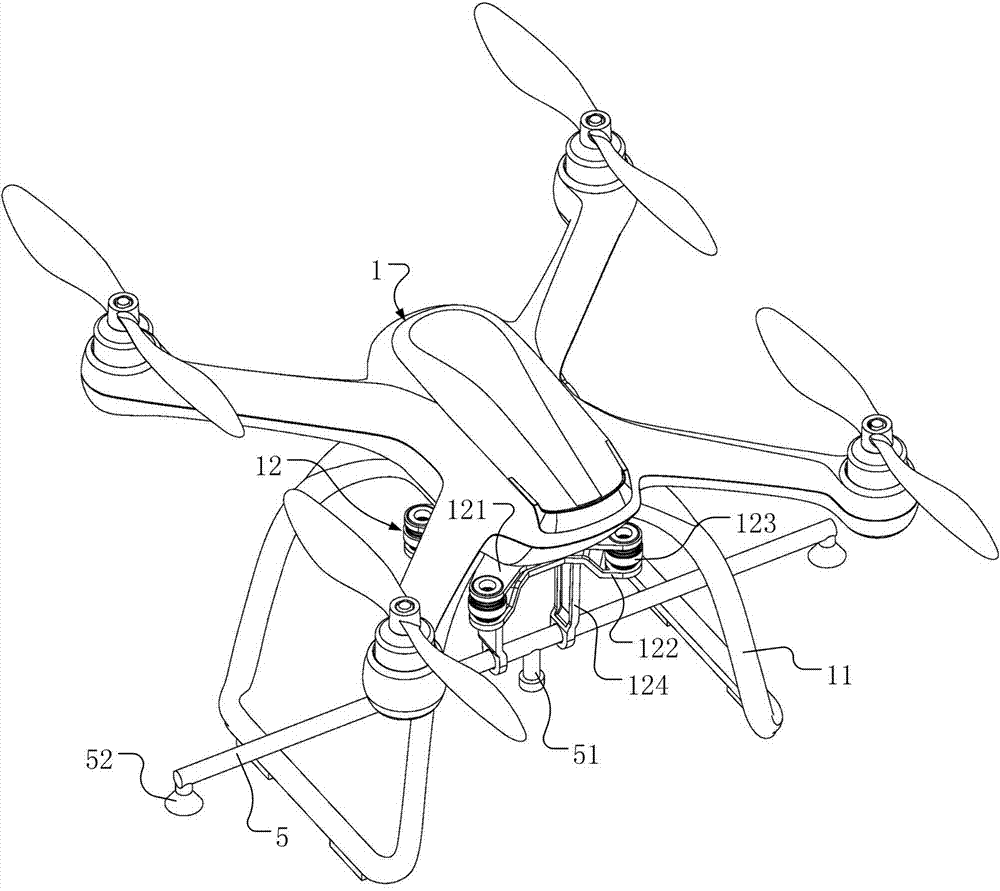

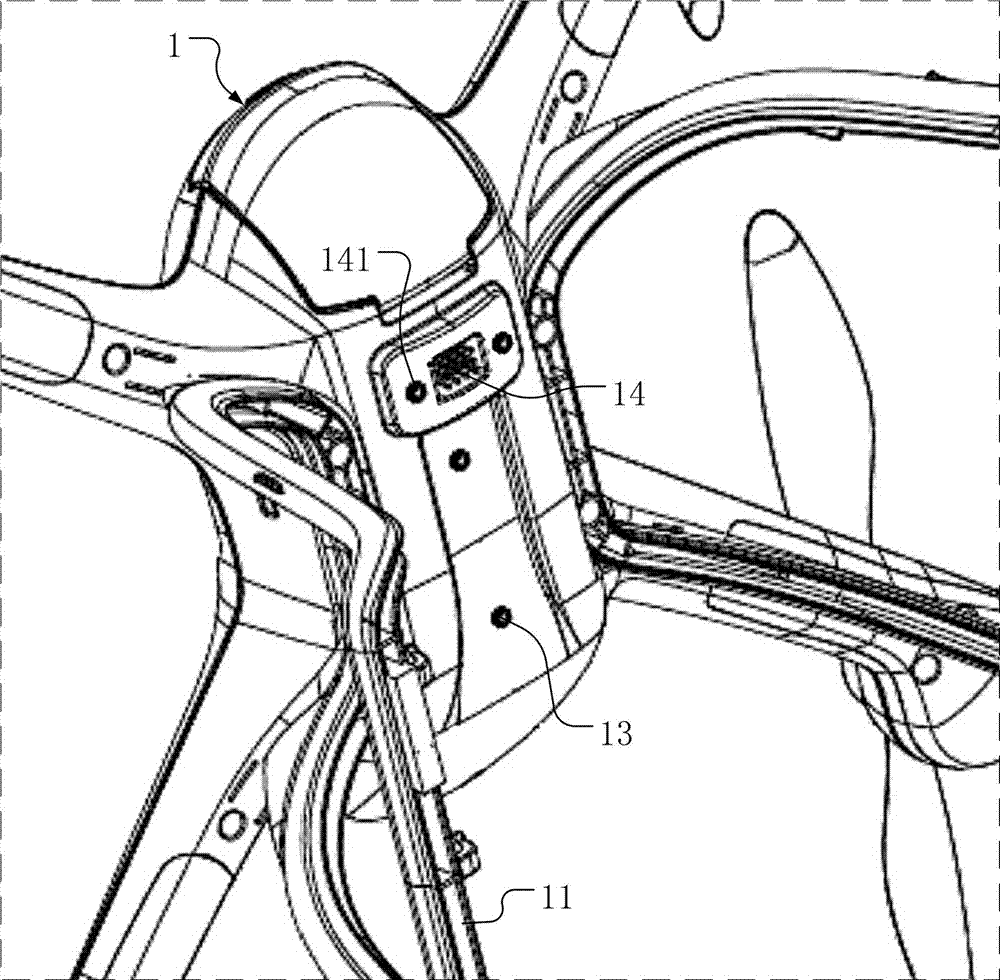

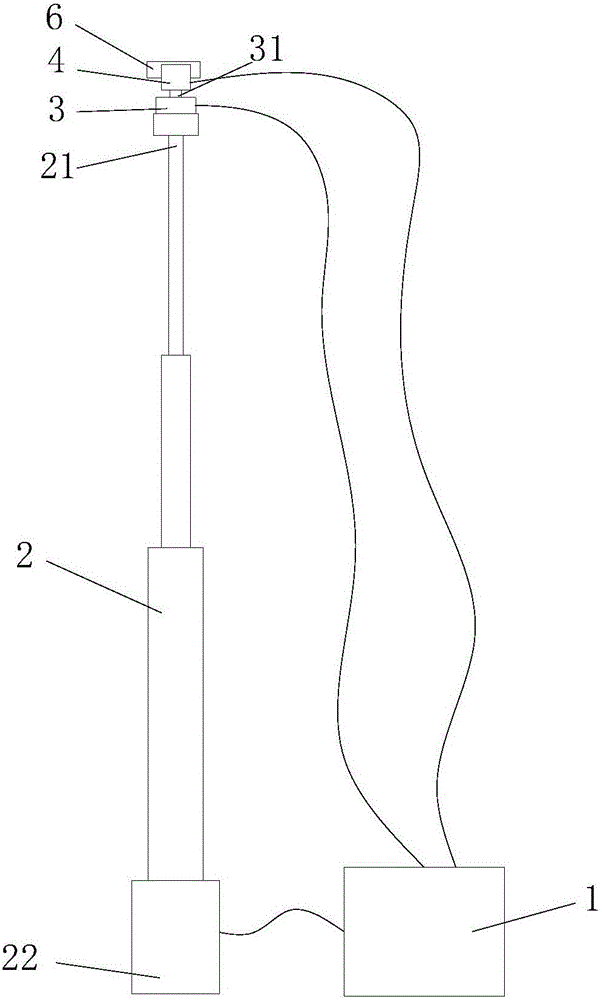

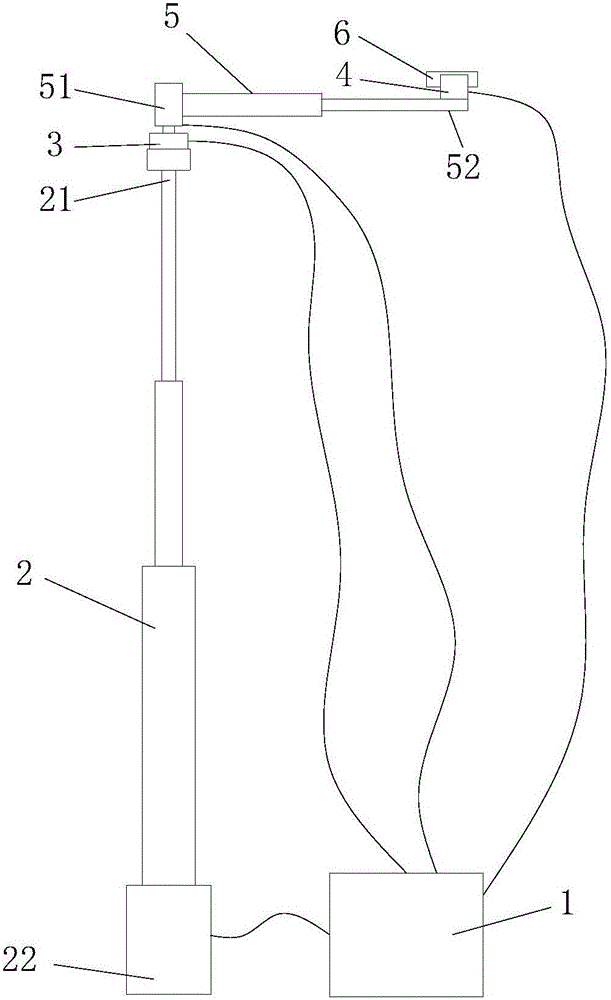

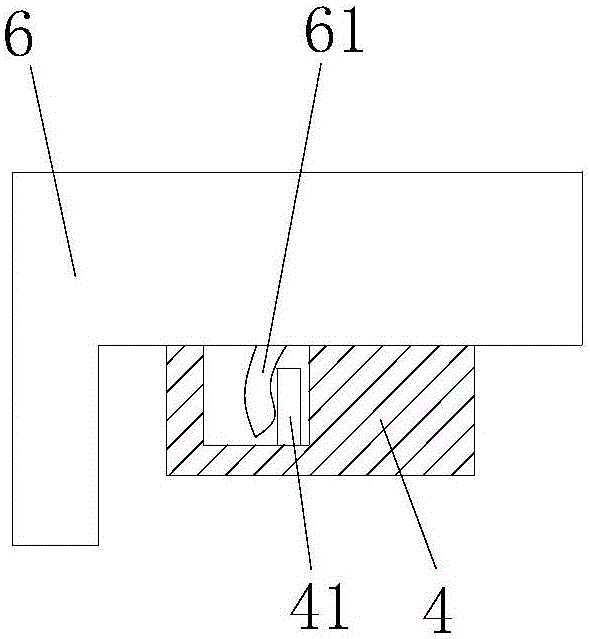

Unmanned aerial vehicle chemical sprinkling device

InactiveCN104512551AReduce loadAvoid situations that require the development of special agentsAircraft componentsLaunching weaponsChemical storageProcess engineering

The invention discloses an unmanned aerial vehicle chemical sprinkling device which comprises an unmanned aerial vehicle body, a carrying cart as well as a chemical storage bucket, a chemical liquid conveying assembly and a storage battery which are fixedly loaded on the carrying vehicle, wherein a chemical liquid sprayer is hung on the unmanned aerial vehicle body; the chemical liquid conveying assembly comprises a chemical conveying hose, a chemical liquid conveying pump and an automatic hose reel; a liquid discharging pipe is arranged at the bottom of the chemical storage bucket and connected to the liquid inlet of the chemical liquid conveying pump; the chemical conveying hose is wound on the automatic hose reel; the two ends of the chemical conveying hose can be connected to the pump liquid outlet of the chemical liquid conveying pump and the chemical liquid sprayer respectively; the storage battery is used for supplying power to the unmanned aerial vehicle body and the chemical liquid conveying pump; a flexible power supply connection line is detachably and electrically connected between the storage battery and the unmanned aerial vehicle body.

Owner:JIUJIANG SONGTIAN ENG

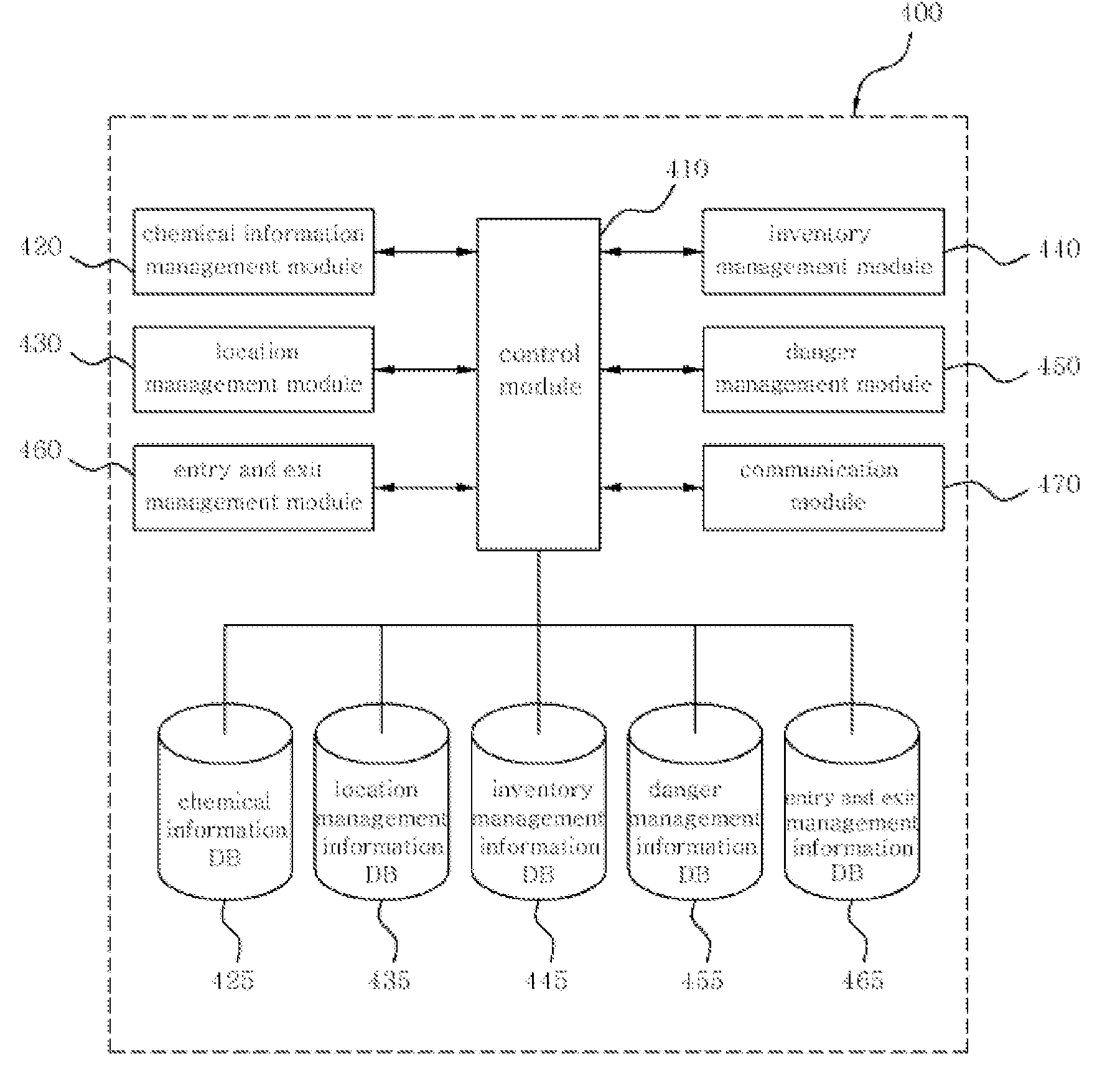

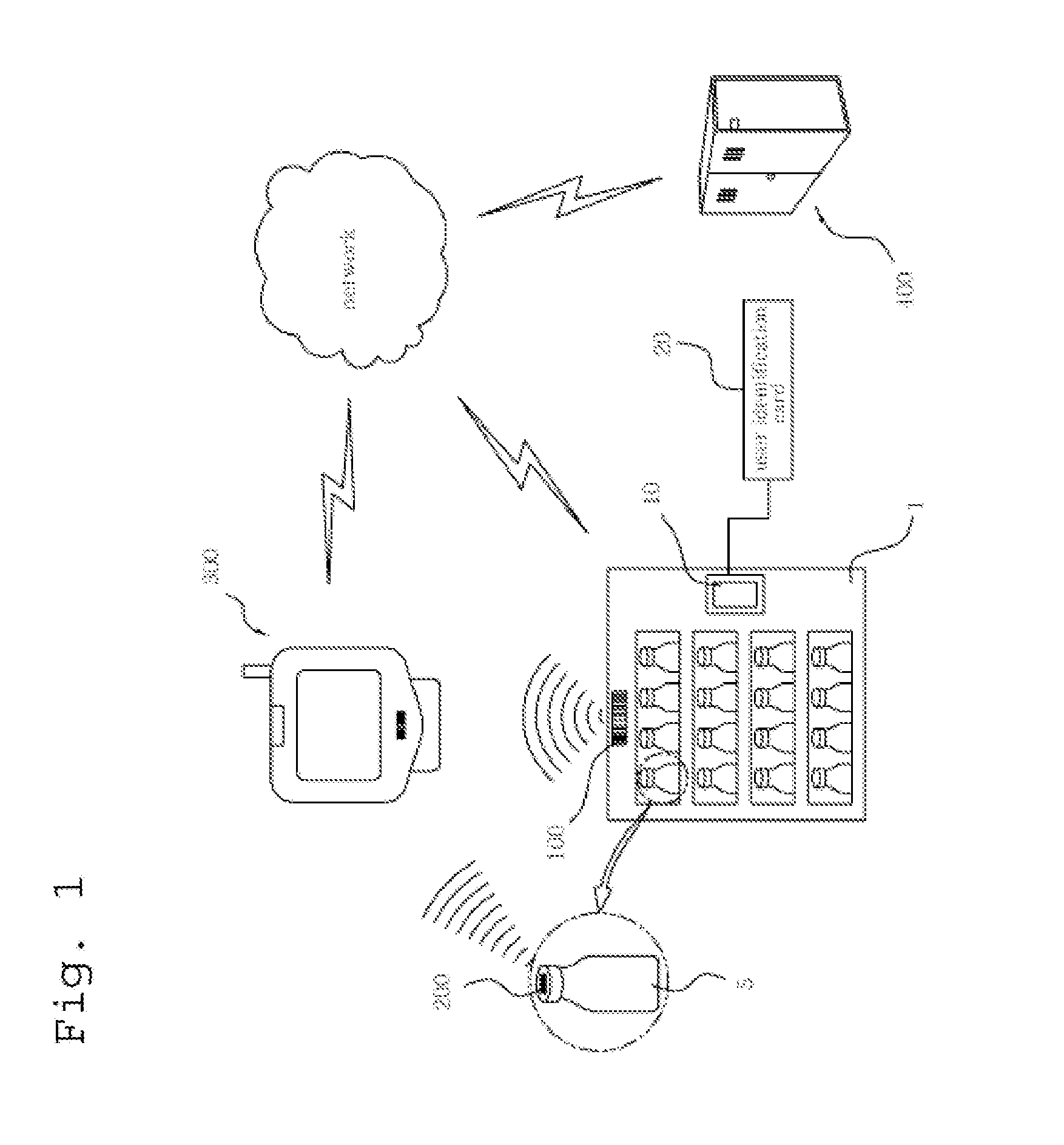

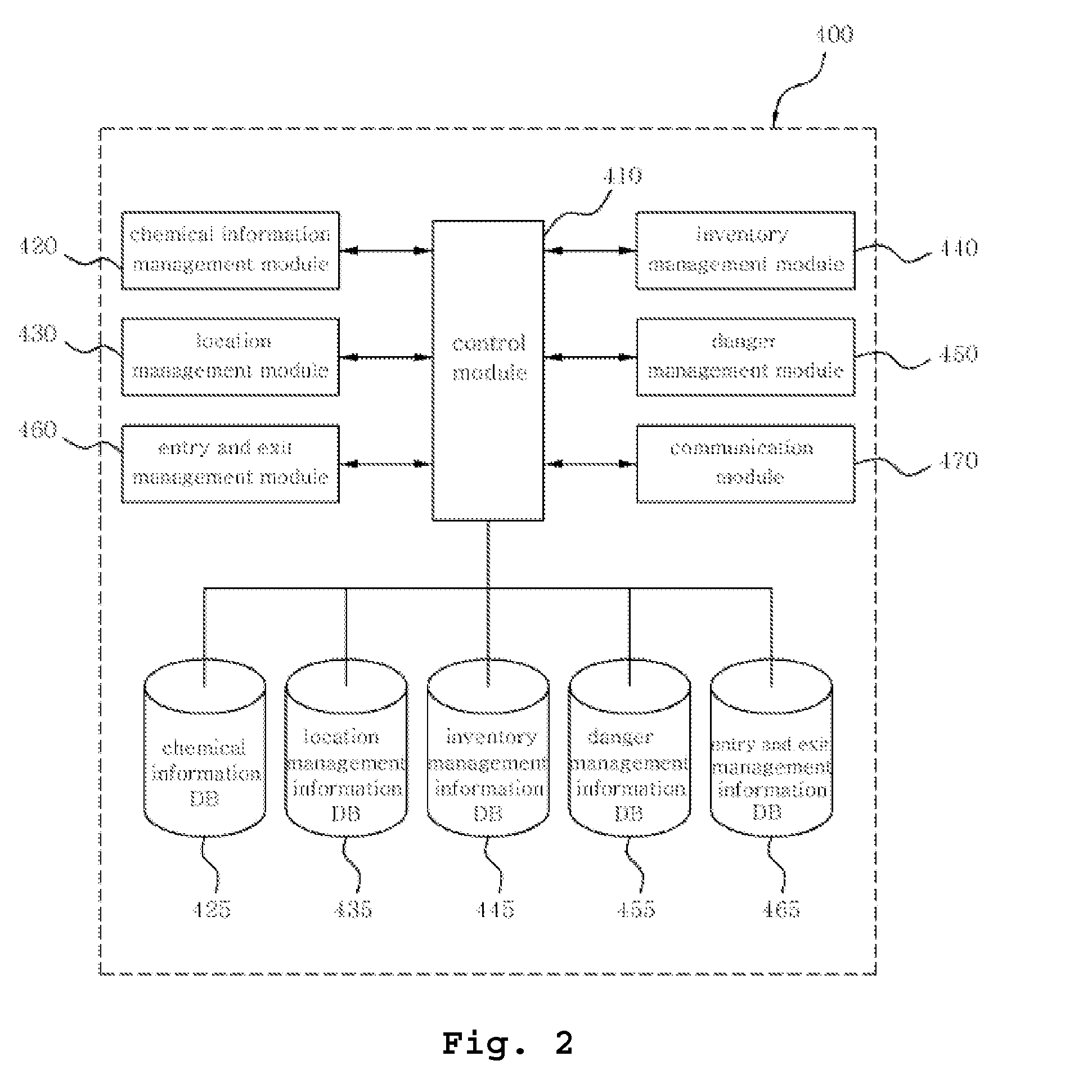

System for managing chemicals using RFID

InactiveUS20090243856A1Efficient managementSubscribers indirect connectionRecord carriers used with machinesChemical storageChemical management

Disclosed herein is a system for managing chemicals using Radio-Frequency Identification (RFID). A storage facility identification tag, attached to a chemical storage facility in a laboratory, stores the unique identification code of the chemical storage facility and a list of chemicals. A chemical identification tag, attached to the cover of a chemical container, stores the unique identification code of the chemical storage facility and chemical-related information. A mobile terminal, provided with an RFID reader, receives and outputs the unique identification code of the chemical storage facility, the list of the chemicals, and the chemical-related information. A chemical management server receives information, stores the chemical-related information, manages the use details and inventory quantity of the chemical, checks the storage location of the chemical container and provides warning when the storage location of the chemical container is wrong, and provides warning and information about countermeasures when a danger situation occurs.

Owner:REPUBLIC OF KOREA (MINIST OF FOOD & DRUG SAFETY)

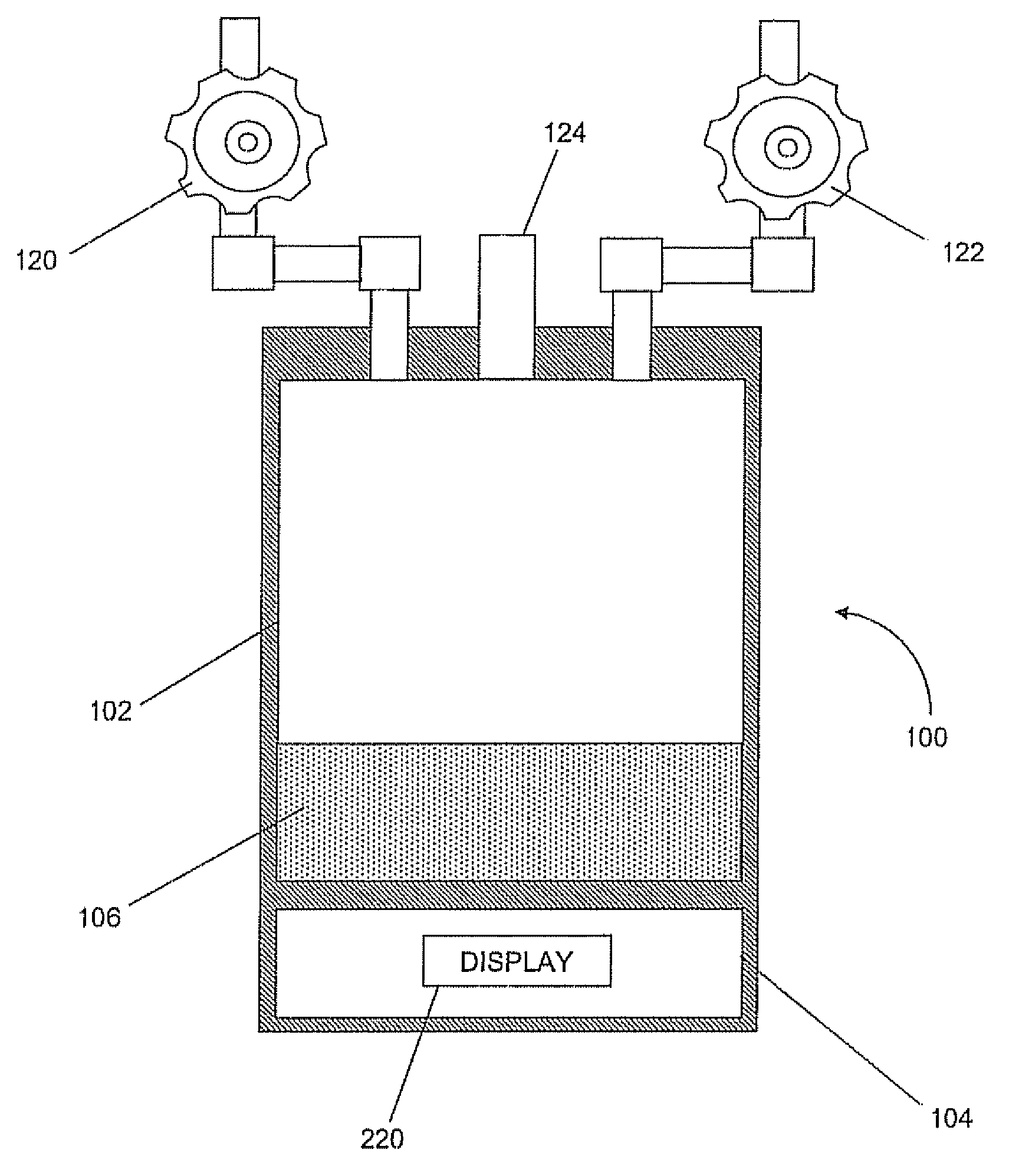

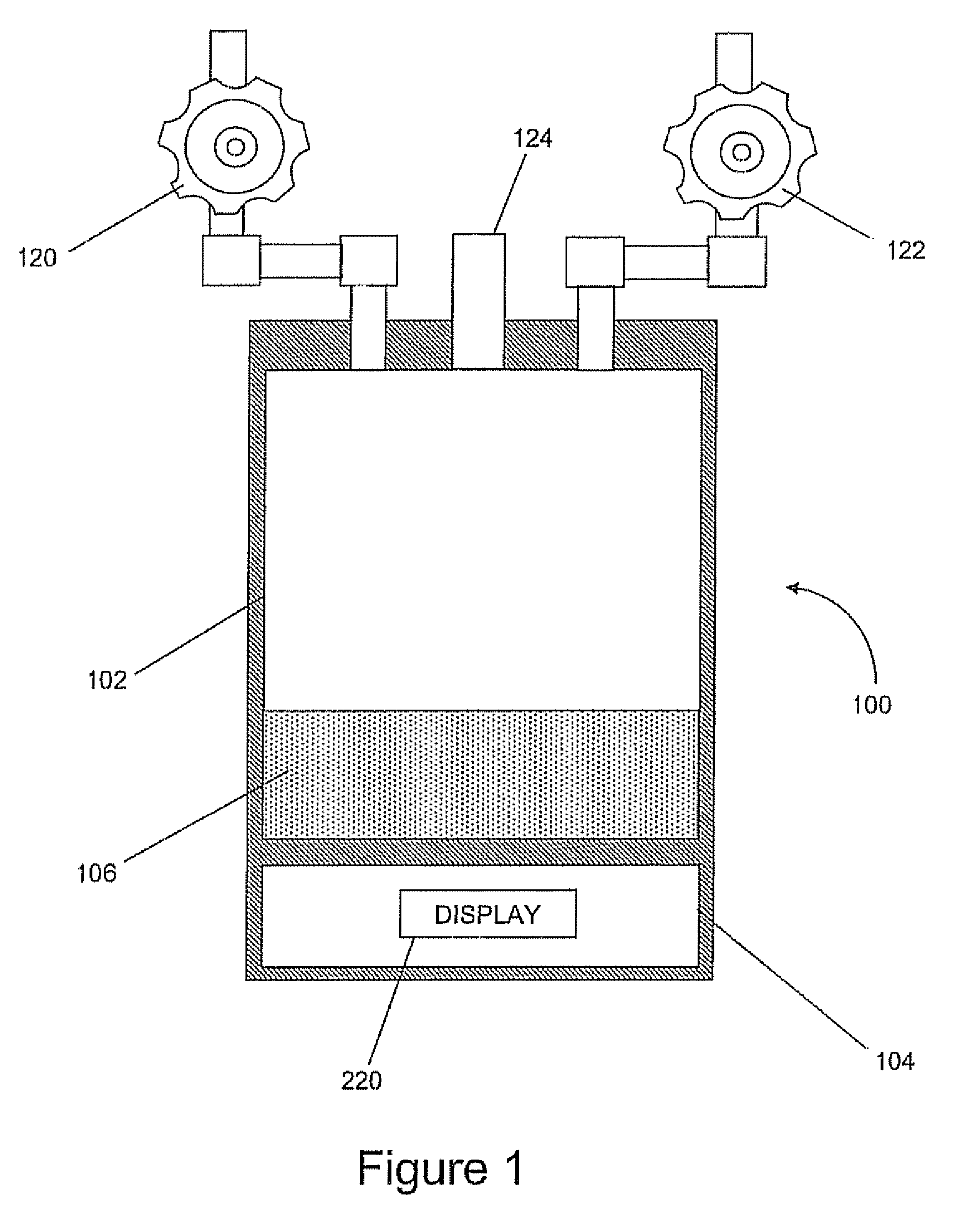

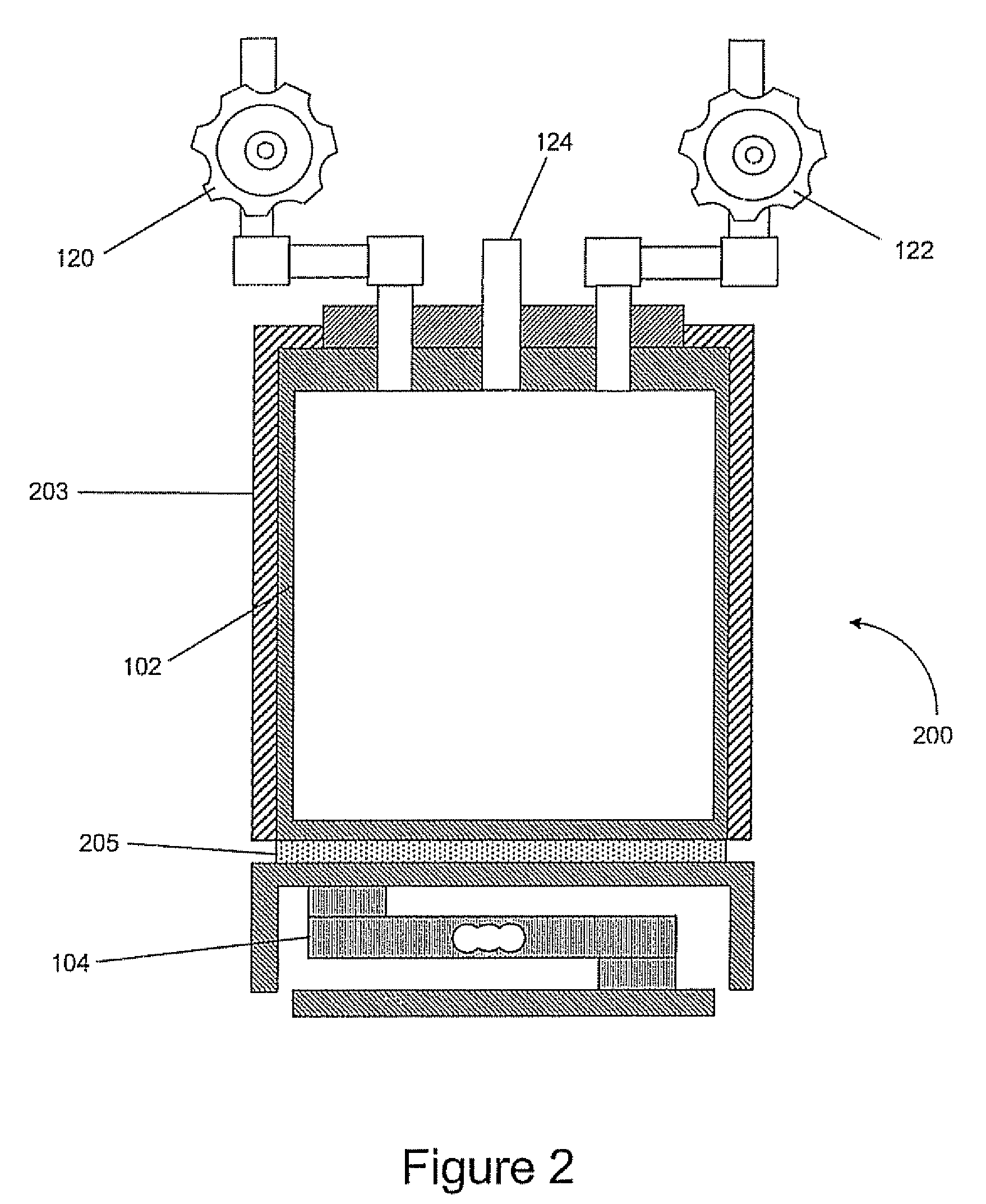

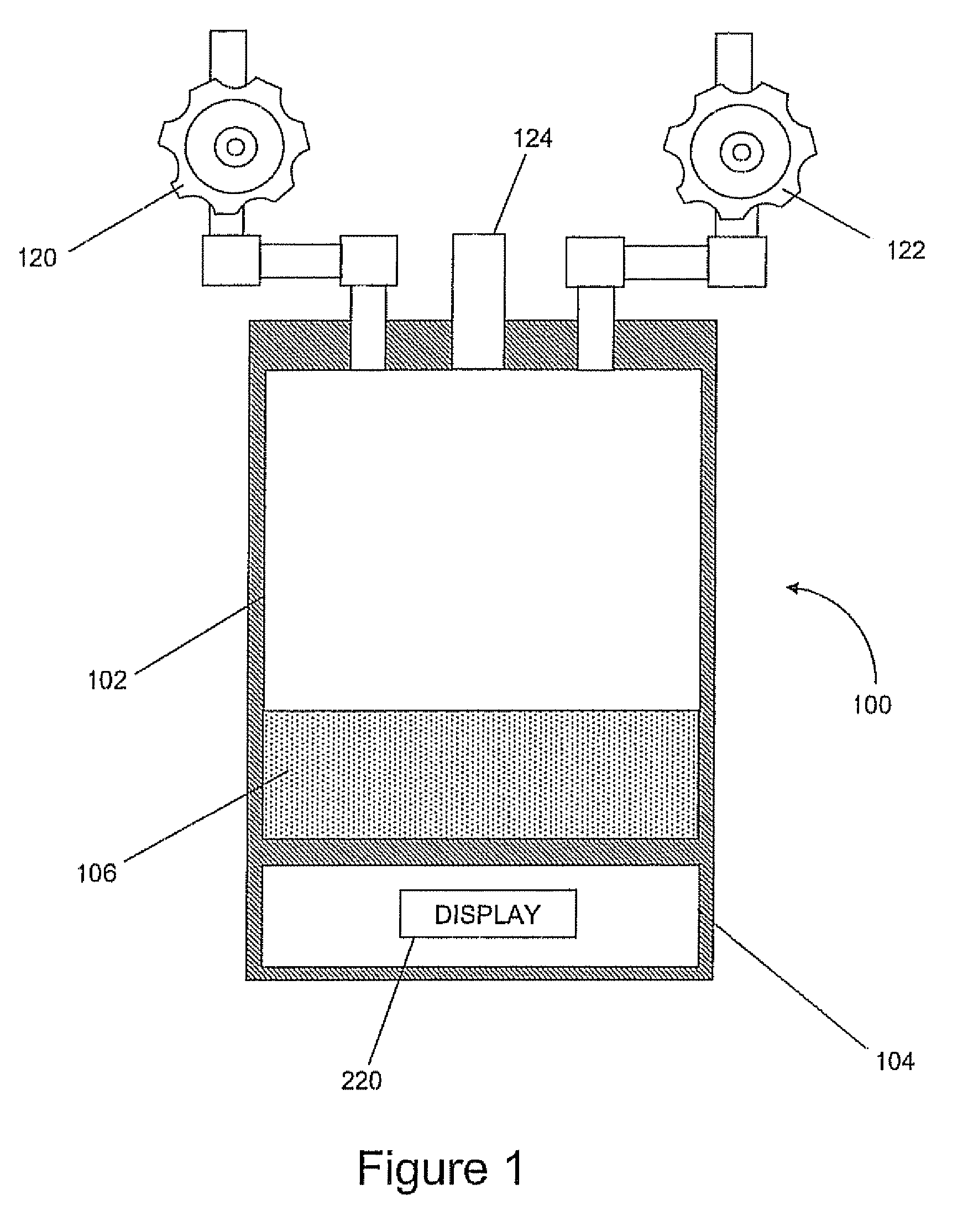

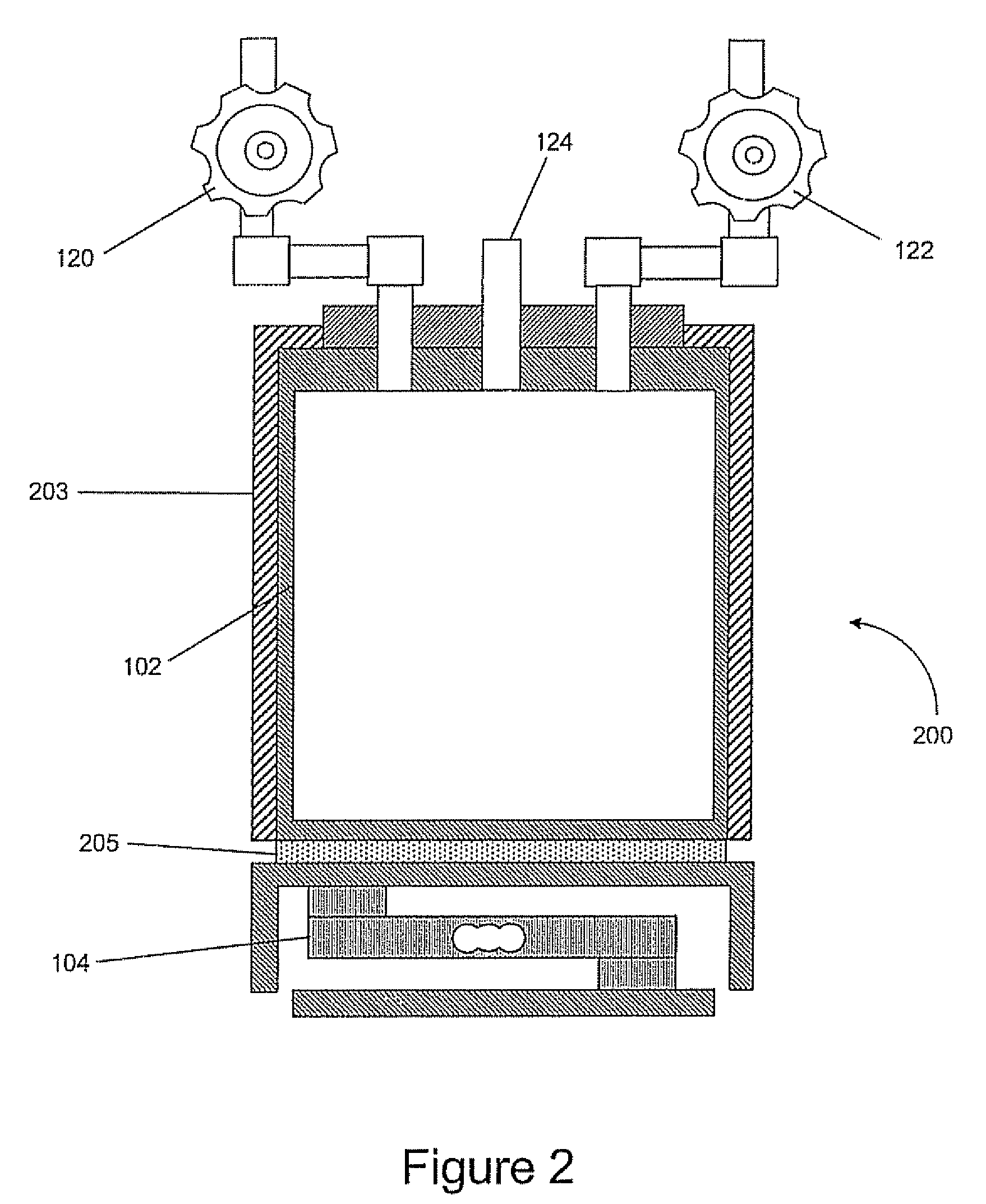

Chemical storage device with integrated load cell

ActiveUS20070062270A1Weight increaseEasy to useWeighing apparatus using fluid action balancingLiquid transferring devicesChemical storageCompound (substance)

A chemical storage device and a method for monitoring chemical usage are described herein. The device and disclosed method utilize a chemical storage canister and a load cell integrated into one transportable unit. The load cell is capable of compensating for the added weight of attached dispensing devices used in the semiconductor industry. Additionally, the load cell continuously displays the weight of the chemicals as they are withdrawn from the chemical storage device. These functionalities are included in the control logic of the load cell which is incorporated into the load cell itself.

Owner:AIR LIQUIDE ELECTRONICS US LP

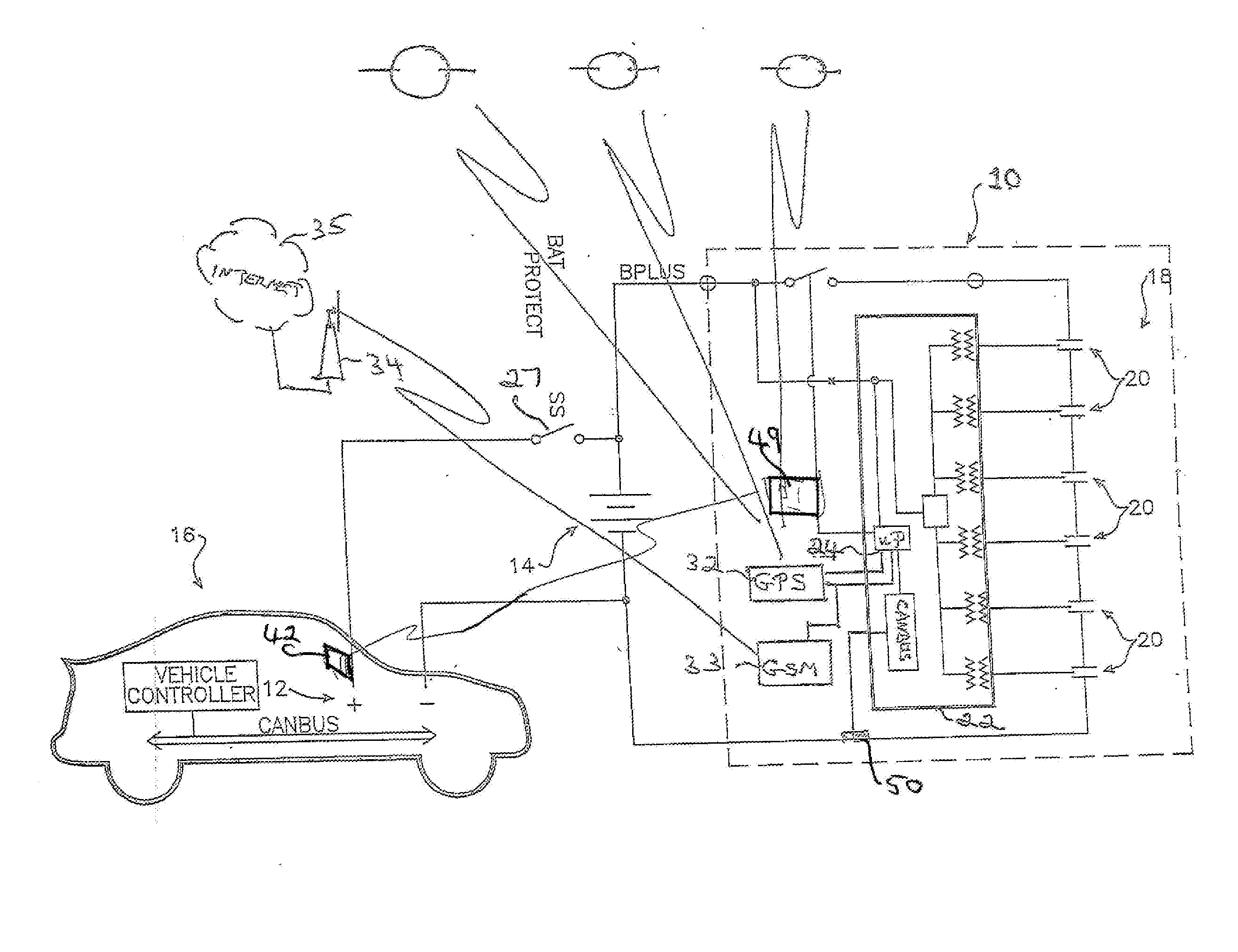

Electrical system enhancer

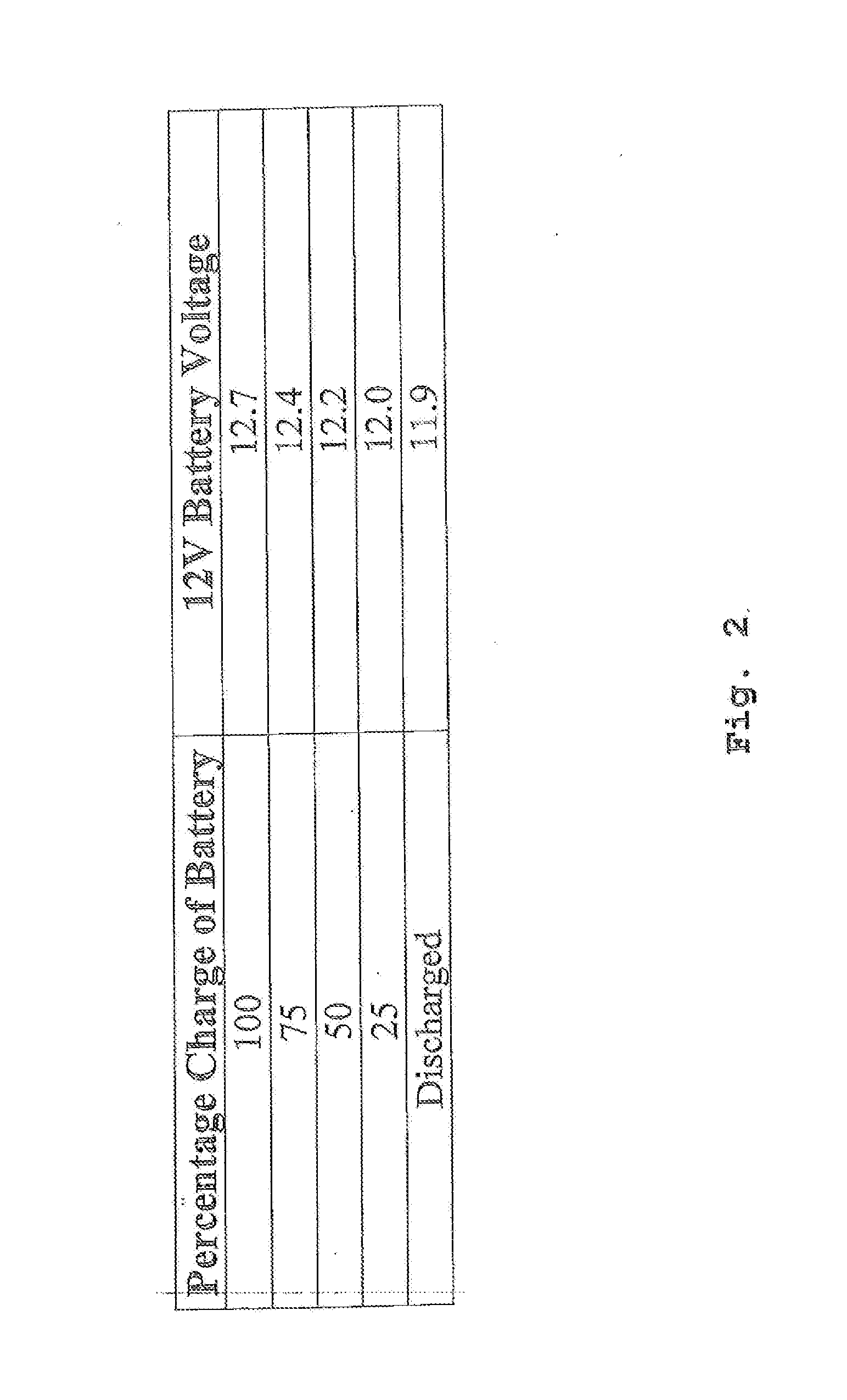

ActiveUS20160297317A1Improve power densityLower internal resistanceCircuit monitoring/indicationIndicating/monitoring circuitsChemical storageElectricity

An electrical system enhancer for an electrical system; the electrical system including a chemical storage battery; the, enhancer including an array of ultra capacitors arid an intelligent trickle charge circuit; the array of ultra capacitors controllably, switchably, electrically connectable to the chemical, storage battery under the control of the trickle charge circuit. Also disclosed is a method of enhancing performance of a vehicle electrical system by interconnecting a storage battery of the vehicle with an array of ultra capacitors; the array of ultra capacitors controllably, switchably electrically connected to the vehicle electric chemical storage battery by means of an intelligent trickle charge circuit. In a particular preferred form the trickle charge circuit includes a microprocessor programmed to connect and disconnect the chemical storage battery to and from the array of ultra capacitors under pre-defined conditions whilst retaining electrical connection between the battery and the trickle charged circuit.

Owner:SMART START TECH

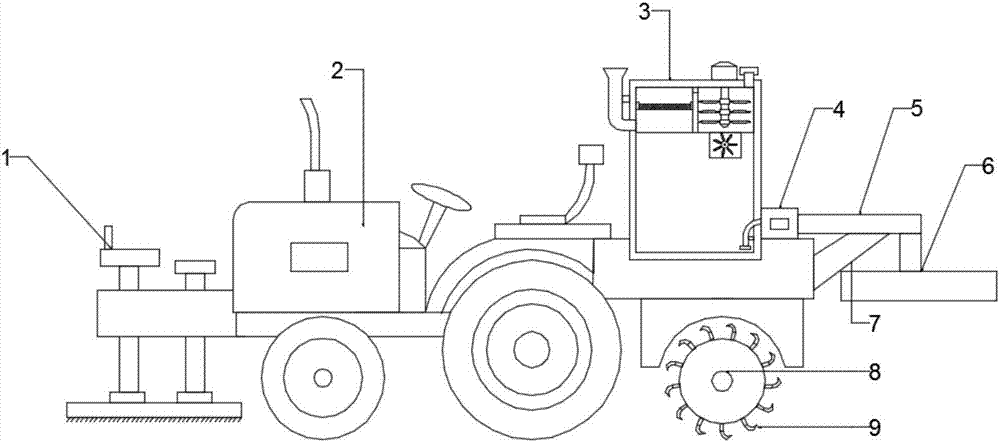

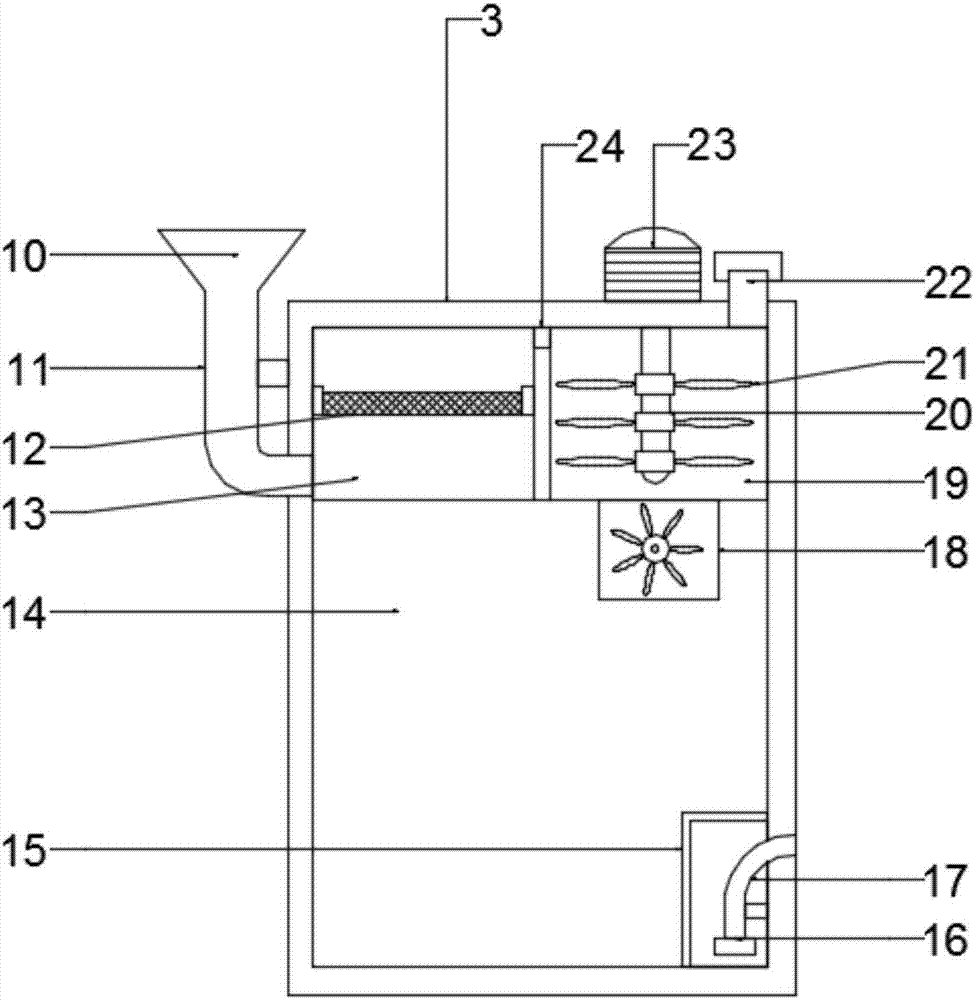

Small soil treatment device with soil turning and spraying functions

InactiveCN107377609AGood governanceSolve problems that are not easy to manageContaminated soil reclamationChemical storageSoil treatment

The invention discloses a soil-turning and spray-type small soil treatment equipment, comprising a diesel engine and a medicine box. The diesel locomotive is provided with a soil-turning device, and the diesel engine is provided with a rotating shaft at the rear. A pump is provided, a medicine-passing water pipe is fixed on the right side of the pumping pump, a medicine-spraying plate is fixed at the end of the medicine-passing water pipe, and the medicine box is provided with a water tank, a medicine storage room and a mixing box. The invention of the soil turning and spraying type small soil treatment equipment breaks the soil and sprays the liquid medicine, which solves the problem that the soil is dry and agglomerated, which is inconvenient to control. Even better, the filter device can effectively remove impurities in the water to avoid mixing into the potion and affecting the soil quality.

Owner:佛山市广师自动化科技有限公司

Anticorrosive coating for chemical storage tank and construction method thereof

InactiveCN105665258ASolve the technical problem of high failure rate of inner layer corrosion protectionGuaranteed protective effectPretreated surfacesAnti-corrosive paintsChemical storageSand blasting

The invention provides an anticorrosive coating for a chemical storage tank and a construction method thereof. The anticorrosive coating comprises at least two anticorrosive coating units sequentially connected on the inner wall of the chemical storage tank, wherein each anticorrosive coating unit comprises a primer layer and a sprayed polyurea layer, the thickness of the primer layer of each basic anticorrosive coating unit is 10-100 microns, and the thickness of the sprayed polyurea layer is 0.5-1 mm. The inner wall of the chemical storage tank connected with each primer layer is obtained through sand blasting treatment or through sand blasting and acid pickling treatment sequentially. The thickness of each basic anticorrosive coating unit of the anticorrosive coating is small, the anticorrosive coating can be completed through one-time construction, and the polyurea layers are free of joints and tightly combine with the inner wall of the chemical storage tank to form a complete isolation layer. By adding an acid pickling step, tiny sharp corners on the surface subjected to the sand blasting treatment are decreased, the phenomenon that the basic anticorrosive coating cannot completely cover the surface of the inner wall is prevented, and the continuity of the basic anticorrosive coating is ensured.

Owner:TIANJIN DAPURUI TECH CO LTD

Dangerous chemical storage cabinet

InactiveCN106774562ASecure AccessSafeguard storageIndividual entry/exit registersSimultaneous control of multiple variablesVideo monitoringChemical storage

The invention relates to a dangerous chemical storage cabinet. The dangerous chemical storage cabinet comprises a cabinet body, wherein the cabinet body comprises a plurality of storage cells, a door is mounted on each storage cell, an electronic lock connected with a main control device is arranged between each door and the corresponding storage cell, the main control device is provided with an identity authentication device, an information acquisition device, an input-output device, a video monitoring device, an alarm device and a wireless data transmission device, the main control device is connected with a remote server; and a temperature sensor, a humidity sensor, a smoke detector, a dehumidifying machine core and a cooler are arranged in each storage cell of the cabinet body. According to the dangerous chemical storage cabinet provided by the invention, a storage environment for dangerous chemicals in the cabinet can be monitored in real time and adjusted automatically; the storage information of the dangerous chemicals and the condition of entering and exiting the cabinet body of the dangerous chemicals are read in real time; the problems that information management cannot implemented in time and is not perfect, and the safety supervision is not in place during manual operation are solved, supervision level and working efficiency are effectively improved, and the storage and access security of the dangerous chemicals is guaranteed.

Owner:ZHEJIANG UNIV OF TECH

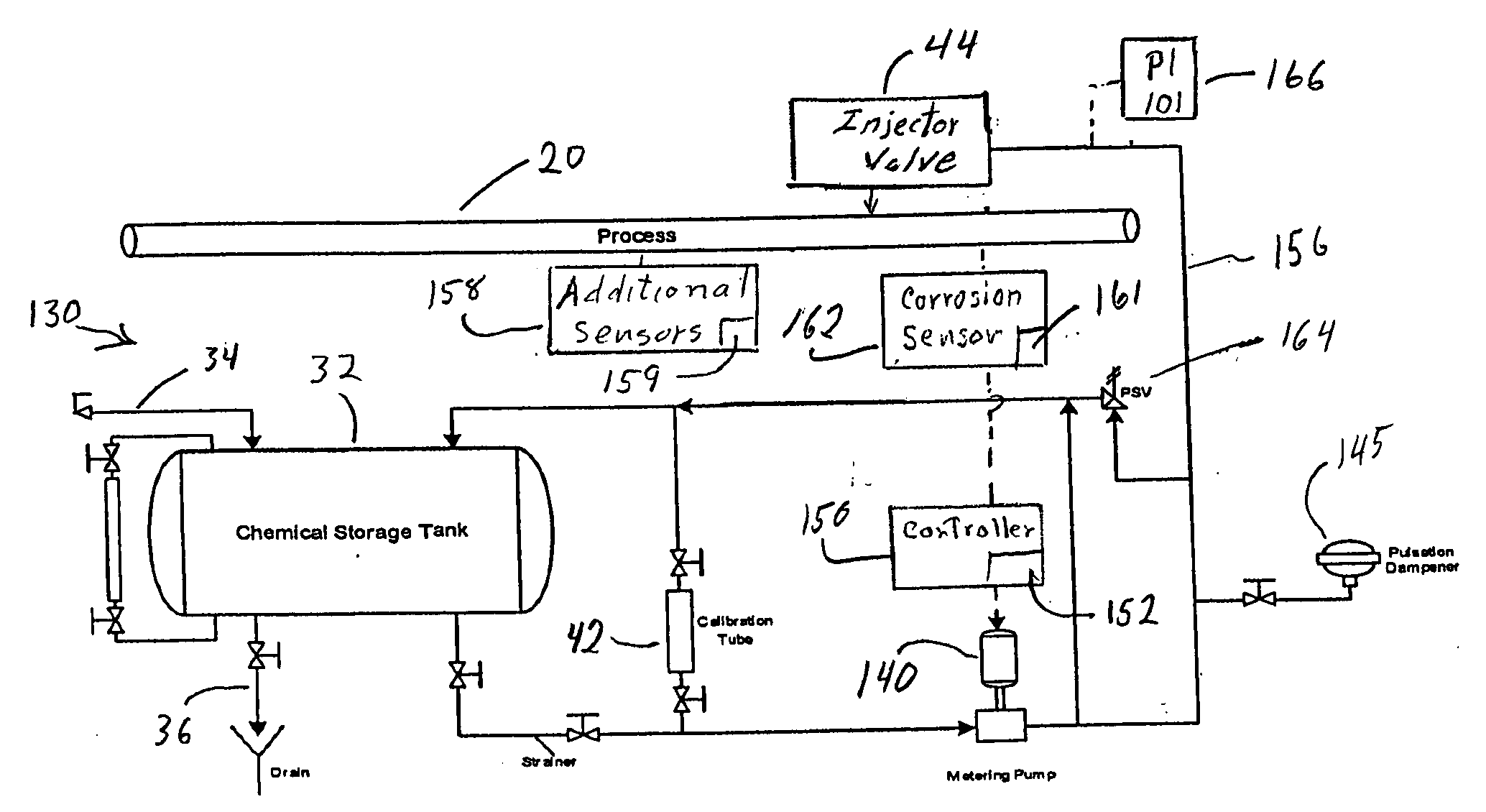

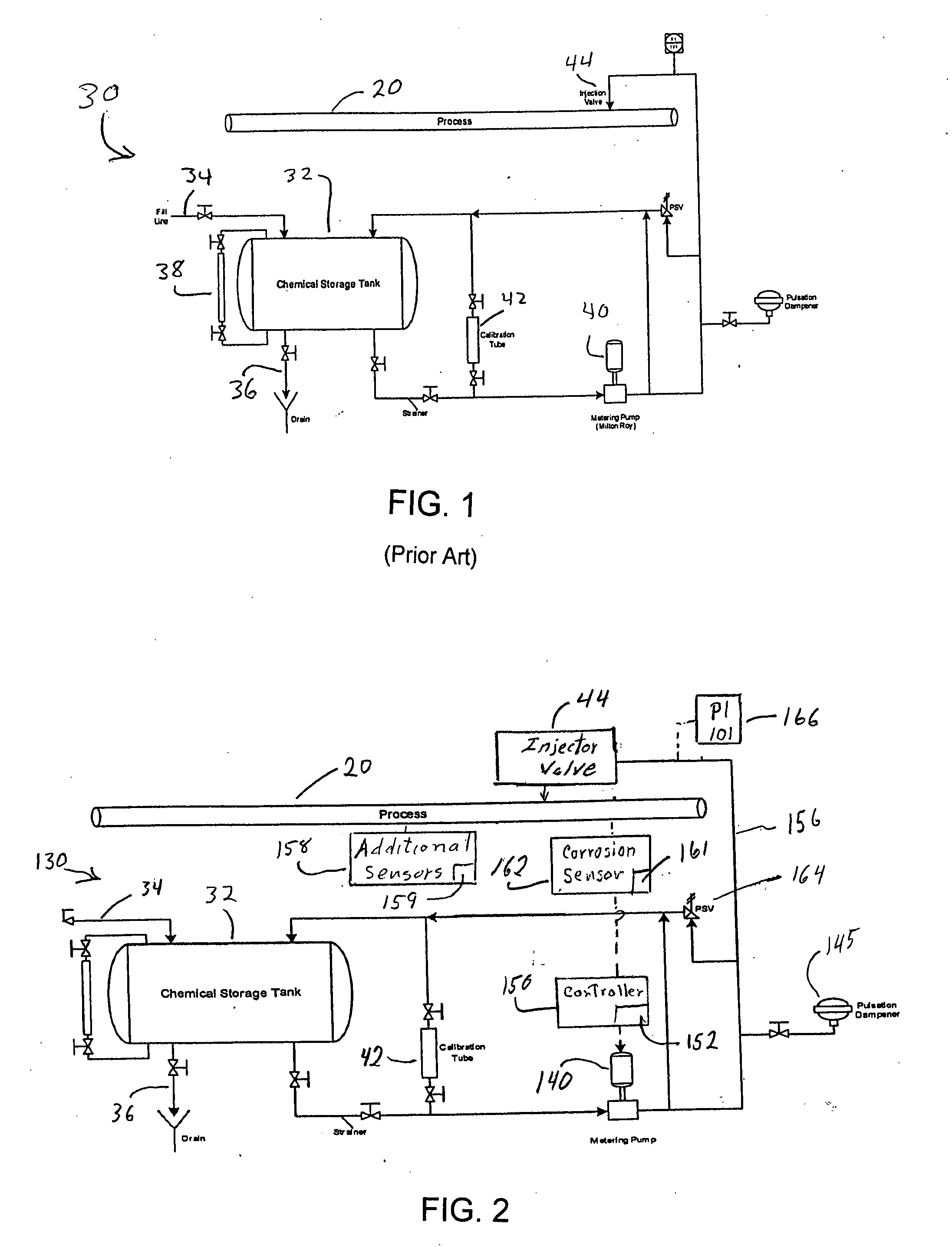

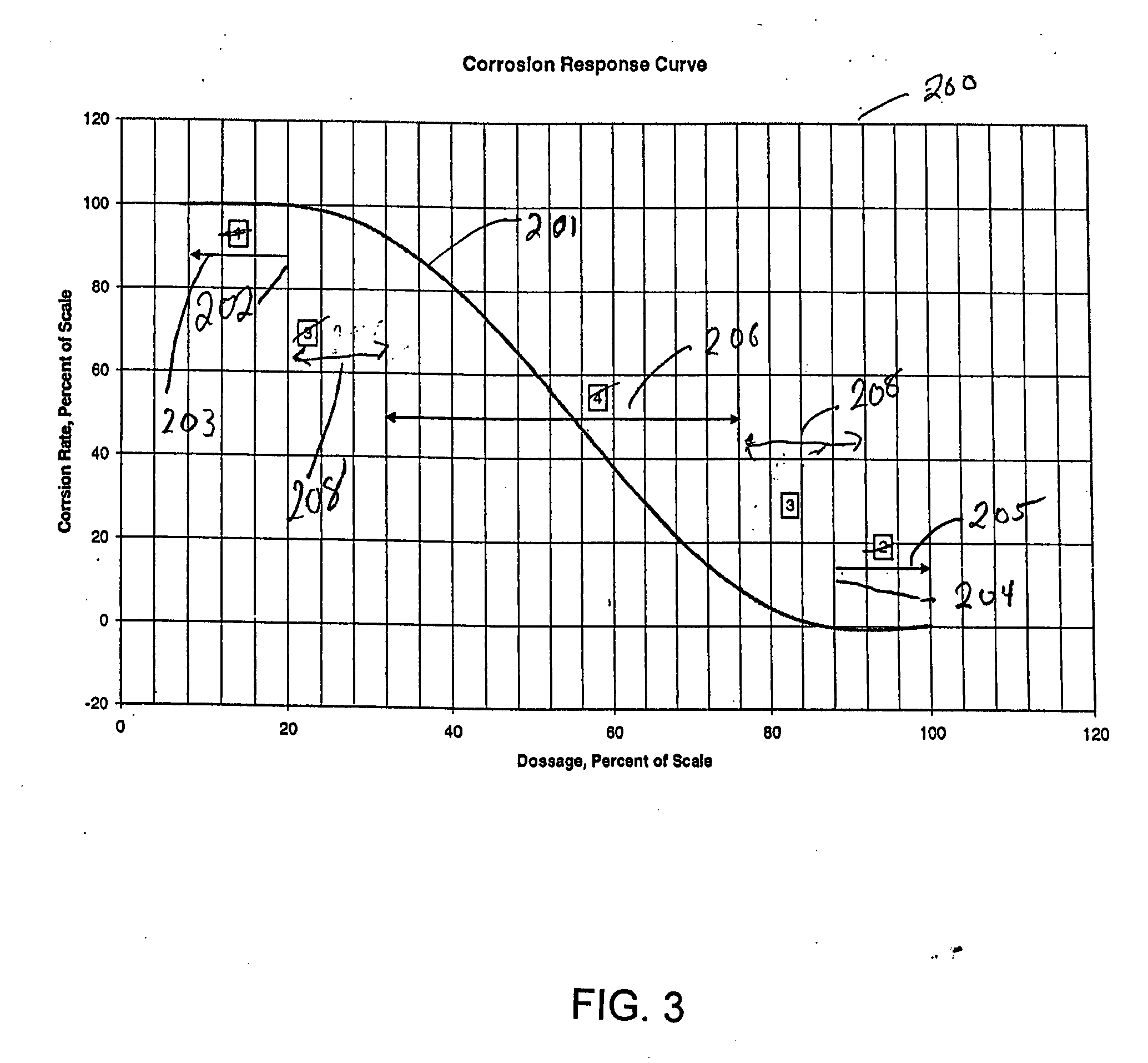

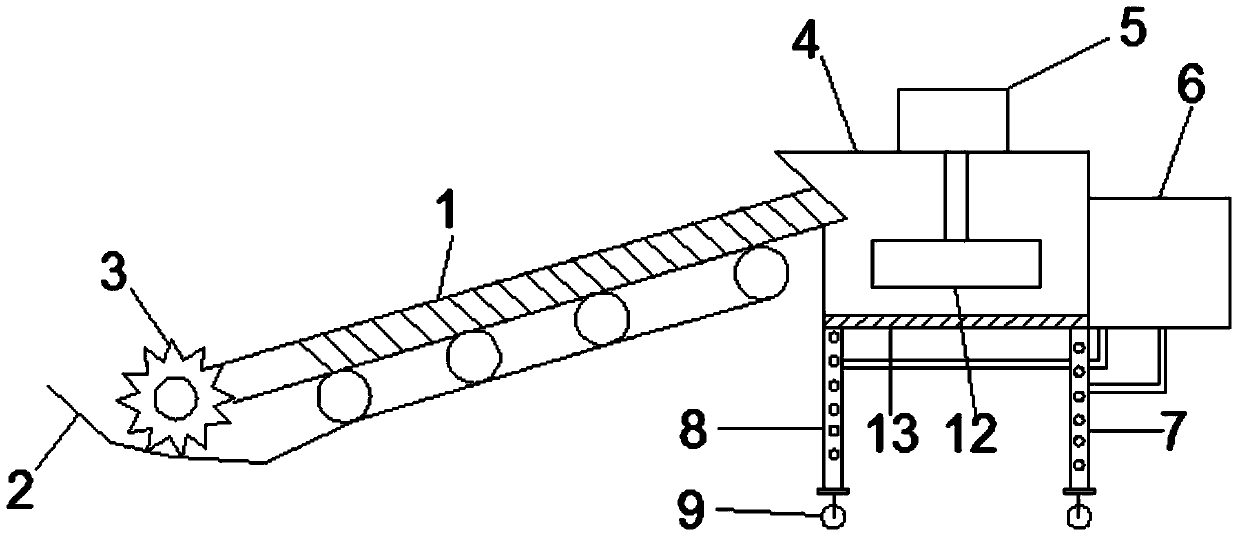

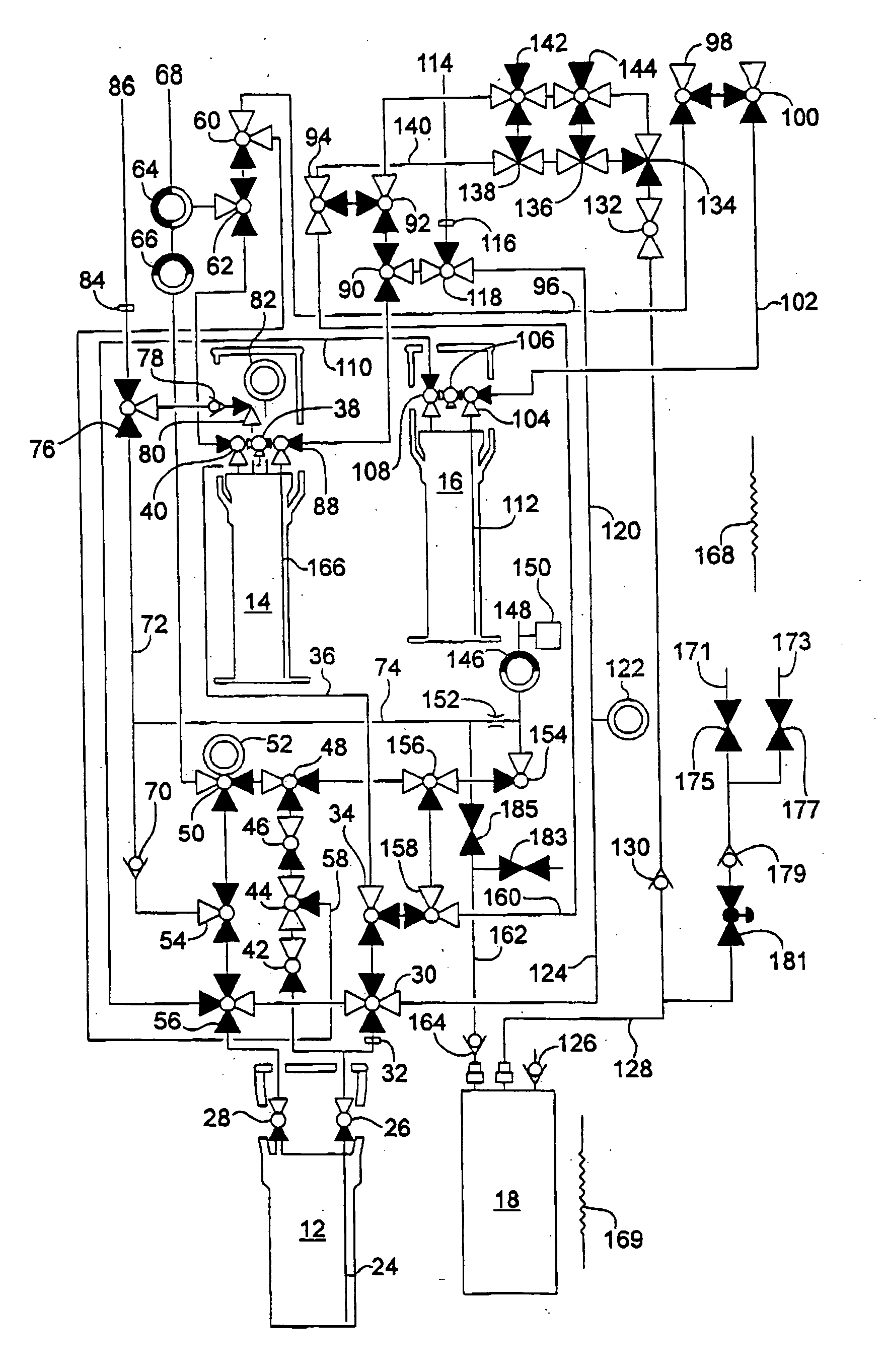

Chemical treatment system and method

InactiveUS20090107921A1Solid sorbent liquid separationMixer accessoriesChemical treatmentChemical storage

A chemical treatment system that injects one or more dosage chemical solutions into a process. Conditions of the process are sensed by sensors, communicated to a chemical treatment management system. The chemical treatment management system processes the process conditions and issues command signals to one or more chemical storage systems to provide a dosage of chemical to the process. The chemical storage systems each comprise a chemical storage tank, a level sensor for the tank, a controller and a pump. The controller uses the command signals for varying in real time the dosage of the chemical solution by varying the pump operation. The chemical treatment management system also uses additional data from the chemical storage systems, such as tank level, and from other sources to provide the command signals and alerts / alarms and other user information.

Owner:HONEYWELL INT INC

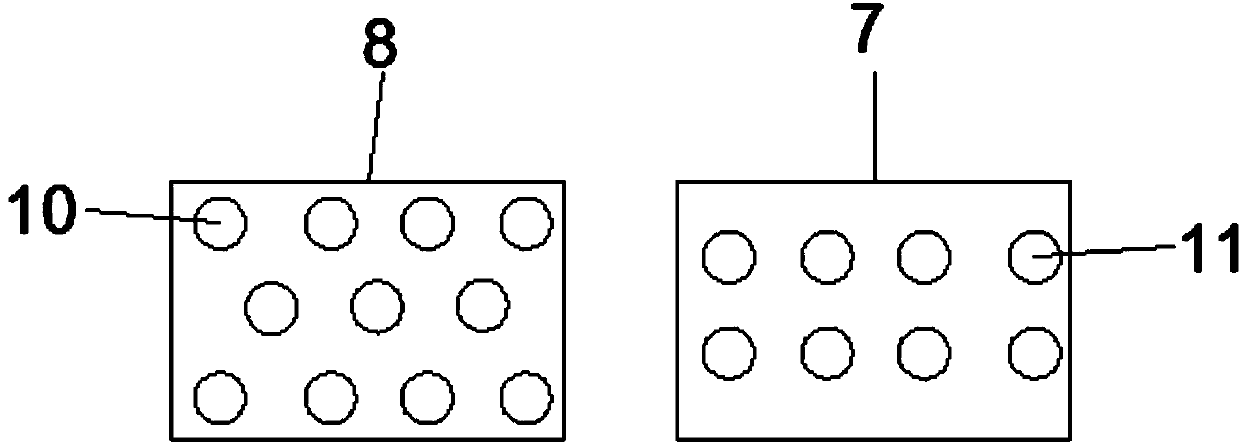

Soil screening remediation device

InactiveCN104170550AImprove repair effectEfficient removalSoil lifting machinesGatherer machinesChemical storageSoil treatment

The invention relates to the technical field of agricultural devices, in particular to a soil screening remediation device. The soil screening remediation device comprises a soil conveying belt, a soil taking shovel is mounted at the front end of the soil conveying belt, the rear end of the soil conveying belt is connected with a soil treatment tank, a film adsorption mechanism is mounted in the soil treatment tank, a screening device is mounted under the film adsorption mechanism, and a chemical spraying device is mounted below the spraying device and connected with a chemical storage tank through a delivery pipe. Through the soil screening remediation device, processes of soil turning, crushing, screening, chemical spraying, remediation and the like can be performed simultaneously, screening effect is good, mulching films and solid impurities can be removed effectively, and separation efficiency is high; the soil screening remediation device is simple in structure, chemical spraying holes in the chemical spraying device are arranged alternatively, chemical and soil are mixed more uniformly, time for soil impurity removal and remediation is short, and the remedied soil can be kept soft and highly breathable within a long time.

Owner:DANYANG BAODE ECOLOGICAL AGRI & FORESTRYDEV

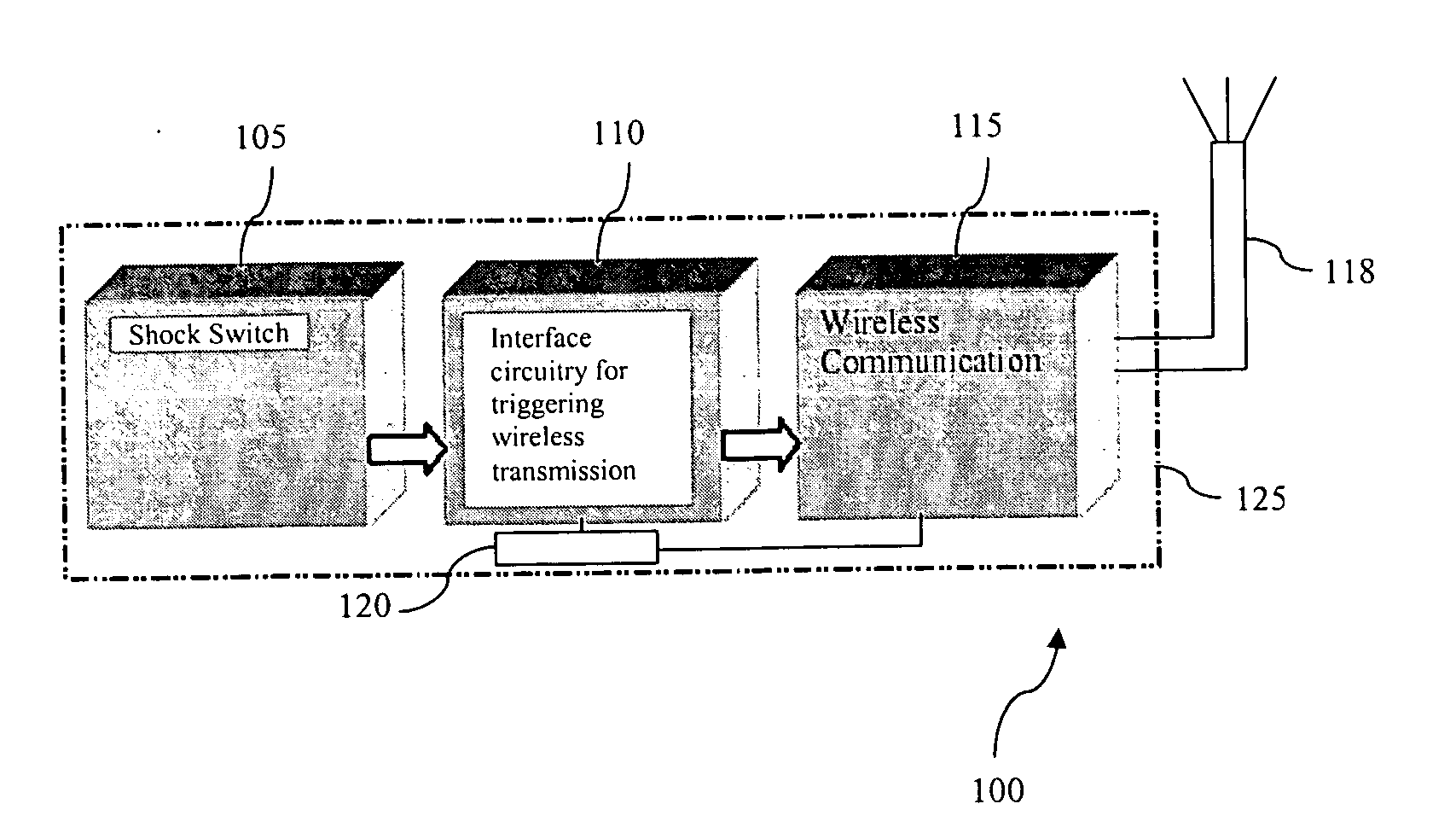

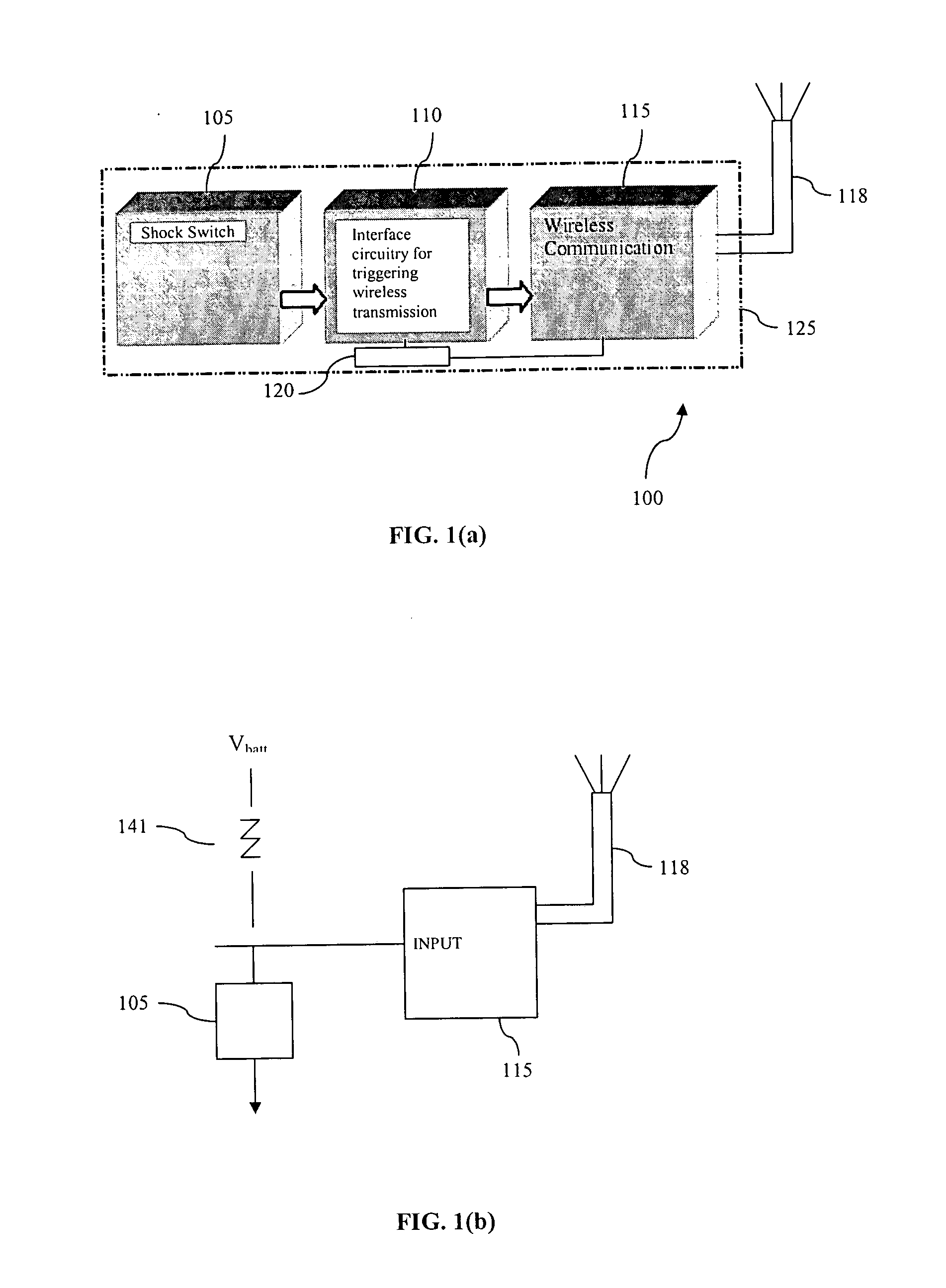

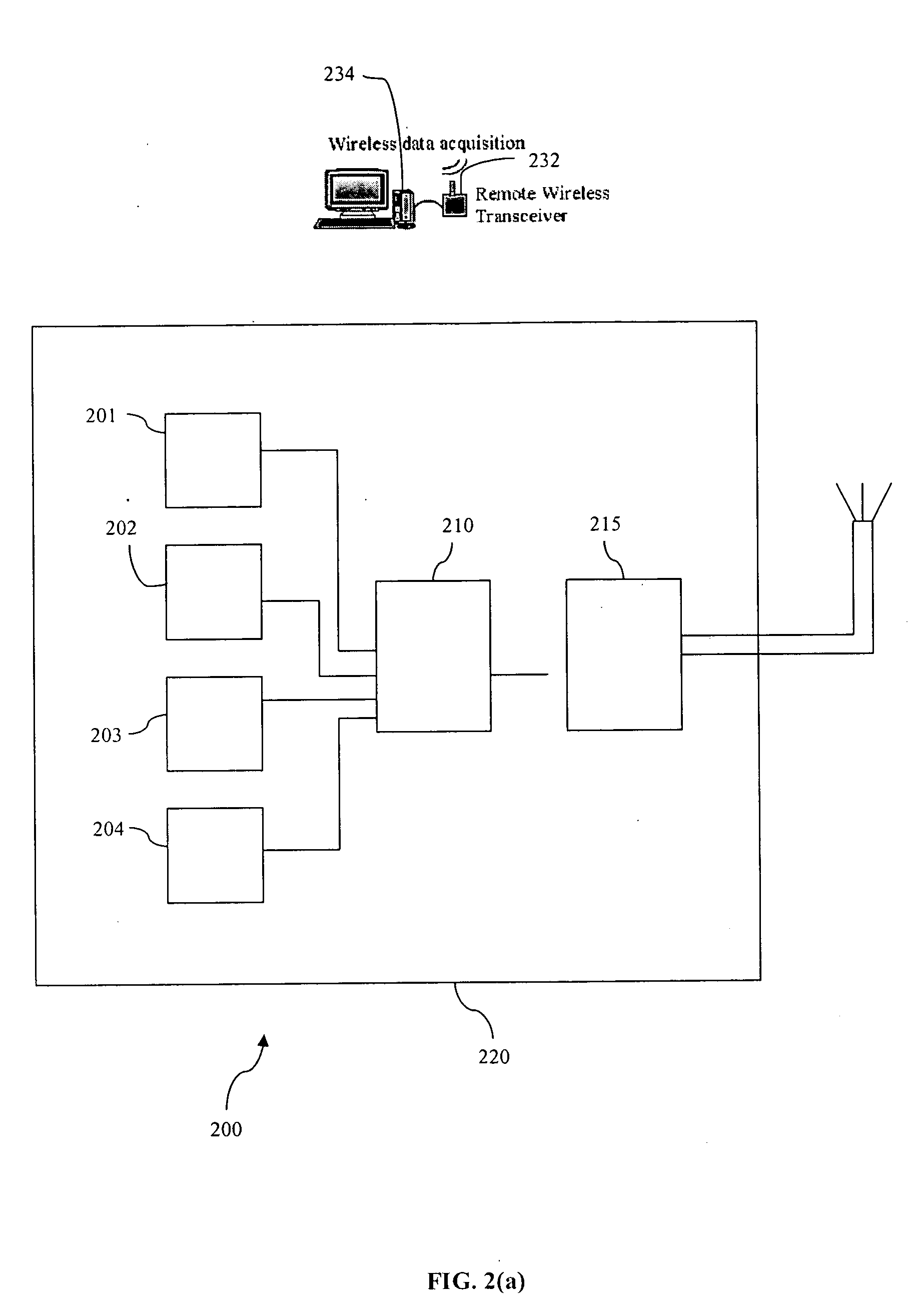

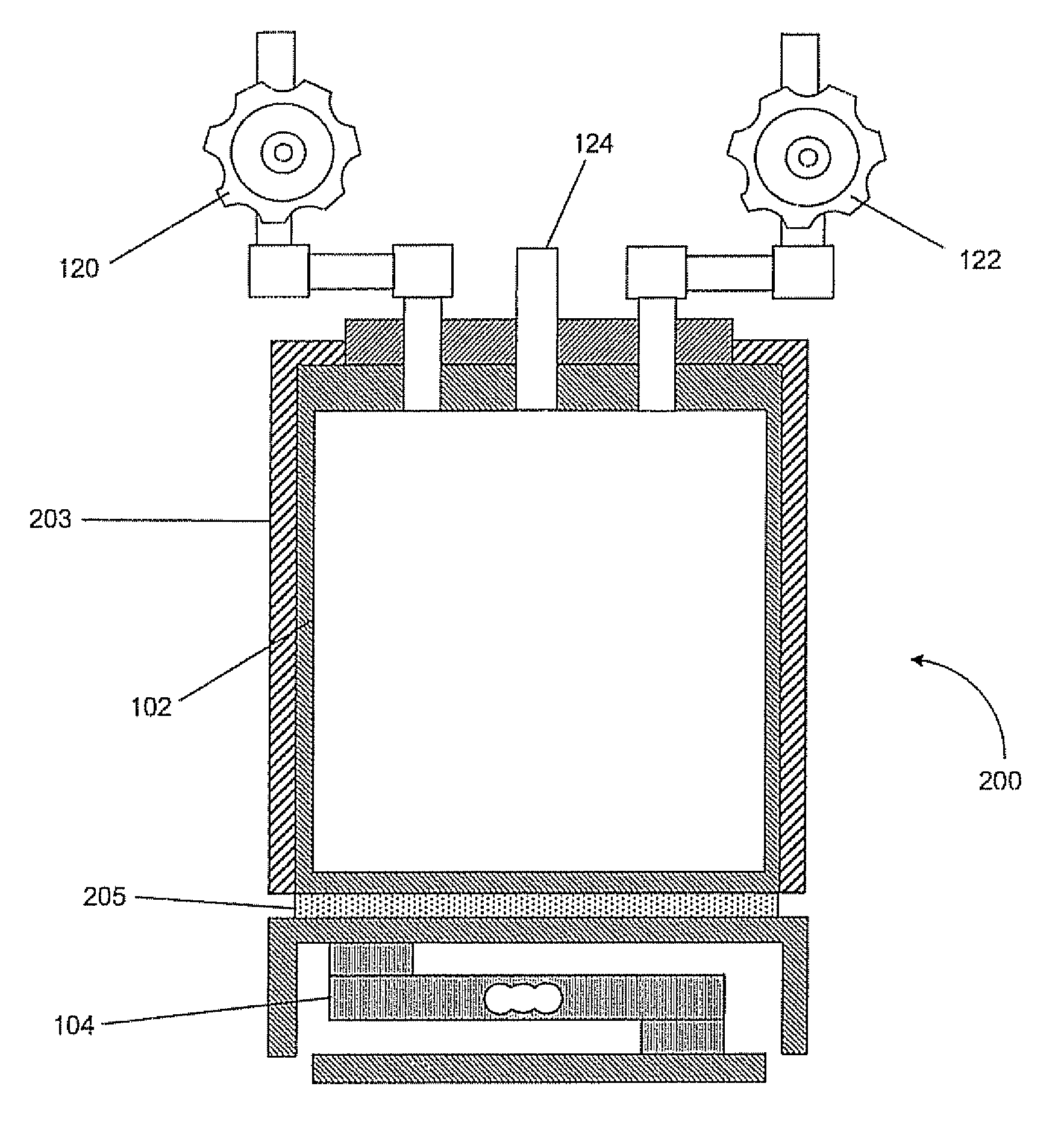

Remote shock sensing and notification system

A low-power shock sensing system includes at least one shock sensor physically coupled to a chemical storage tank to be monitored for impacts, and an RF transmitter which is in a low-power idle state in the absence of a triggering signal. The system includes interference circuitry including or activated by the shock sensor, wherein an output of the interface circuitry is coupled to an input of the RF transmitter. The interface circuitry triggers the RF transmitting with the triggering signal to transmit an alarm message to at least one remote location when the sensor senses a shock greater than a predetermined threshold. In one embodiment the shock sensor is a shock switch which provides an open and a closed state, the open state being a low power idle state.

Owner:UT BATTELLE LLC

Chemical storage device with integrated load cell

ActiveUS7770448B2Easy to useWeighing apparatus using fluid action balancingLiquid transferring devicesChemical storageLoad cell

A chemical storage device and a method for monitoring chemical usage are described herein. The device and disclosed method utilize a chemical storage canister and a load cell integrated into one transportable unit. The load cell is capable of compensating for the added weight of attached dispensing devices used in the semiconductor industry. Additionally, the load cell continuously displays the weight of the chemicals as they are withdrawn from the chemical storage device. These functionalities are included in the control logic of the load cell which is incorporated into the load cell itself.

Owner:AIR LIQUIDE ELECTRONICS US LP

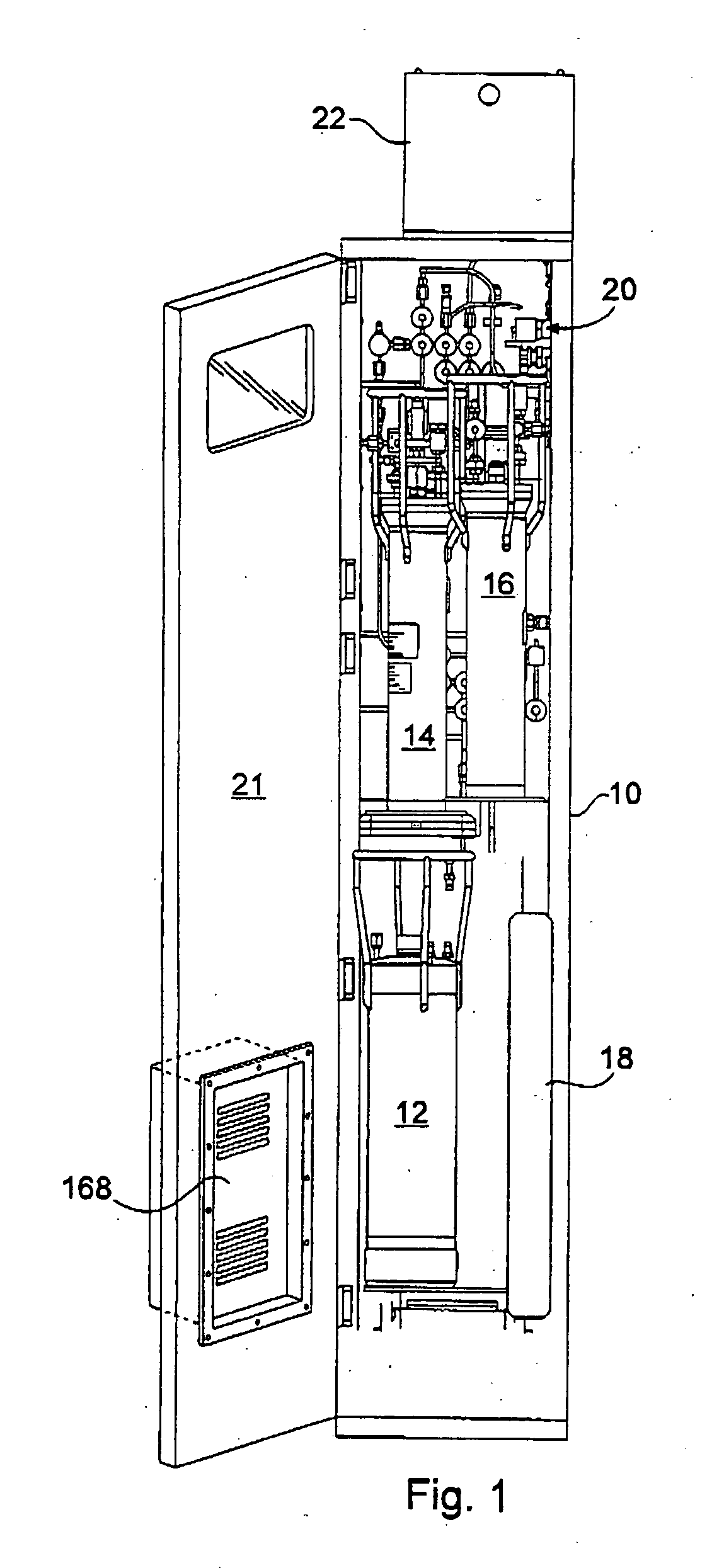

Cabinet for chemical delivery with solvent purging and removal

InactiveUS20050229970A1Container filling methodsGas handling applicationsChemical storageSolvent evaporation

The present invention is an apparatus and process for storing and delivering a low vapor pressure process chemical to a process tool for semiconductor fabrication, comprising: a) a bulk container for storing the process chemical; b) a process container for delivering the process chemical to the process tool; c) a first manifold for delivering process chemical from the bulk container to the process container; d) a solvent container containing a quantity of solvent, e) a second manifold for delivering the process chemical from the process container to a process tool; f) a solvent recovery container for containing used solvent and removed process chemical, and, g) a solvent evaporator to differentially remove solvent from process chemical in the solvent recovery container by entrainment in a carrier gas, vacuum removal, heating or combinations thereof. The containers can be baffled on their inert gas inlets. The cabinet can be heated.

Owner:VERSUM MATERIALS US LLC

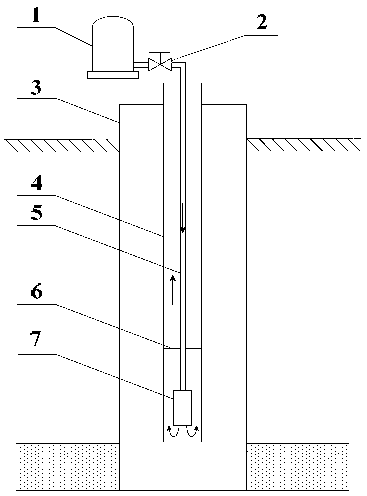

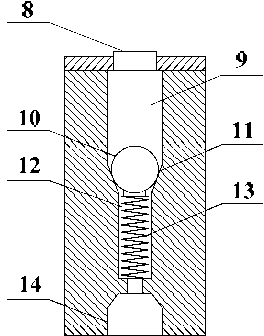

Automatic chemical feeding device and method in foam-drainage gas recovery well

InactiveCN103291266APrevent floodingExtend the stable production periodFluid removalChemical storageDifferential pressure

The invention relates to an automatic chemical feeding device and method in a foam-drainage gas recovery well. The automatic chemical feeding device mainly comprises a ground chemical storage tank, a thin pipe valve, a thin pipe, a pressure difference control valve, an oil pipe and a casing. The ground chemical storage tank, the thin pipe valve, the thin pipe and the pressure difference control valve form a chemical feeding channel, the thin pipe and the oil pipe form an annular liquid discharge channel, and the pressure difference control valve mainly comprises a chemical inlet, an upper cavity, a valve spool ball, a conical valve seat, a lower cavity, a spring and a chemical outlet. The upper end of the pressure difference control valve is stressed by chemical gravity (constant in pressure), and the lower end thereof is stressed by return pressure at bottom of the well. The more the accumulated liquid is, the higher the return pressure at the bottom of the well is and the lower the downward pressure difference stressed on the valve spool ball is, so that the spring can overcome the pressure difference to support the valve spool ball upwards and chemicals are begun to be added. After the accumulated liquid is discharged, the pressure difference is larger than elastic force of the spring and presses the valve spool ball to stop chemical feeding. The automatic chemical feeding device can automatically feed and stop feeding chemicals according to level of the accumulated liquid, and the chemicals and the accumulated liquid at the bottom can be guaranteed to be sufficiently mixed.

Owner:SOUTHWEST PETROLEUM UNIV

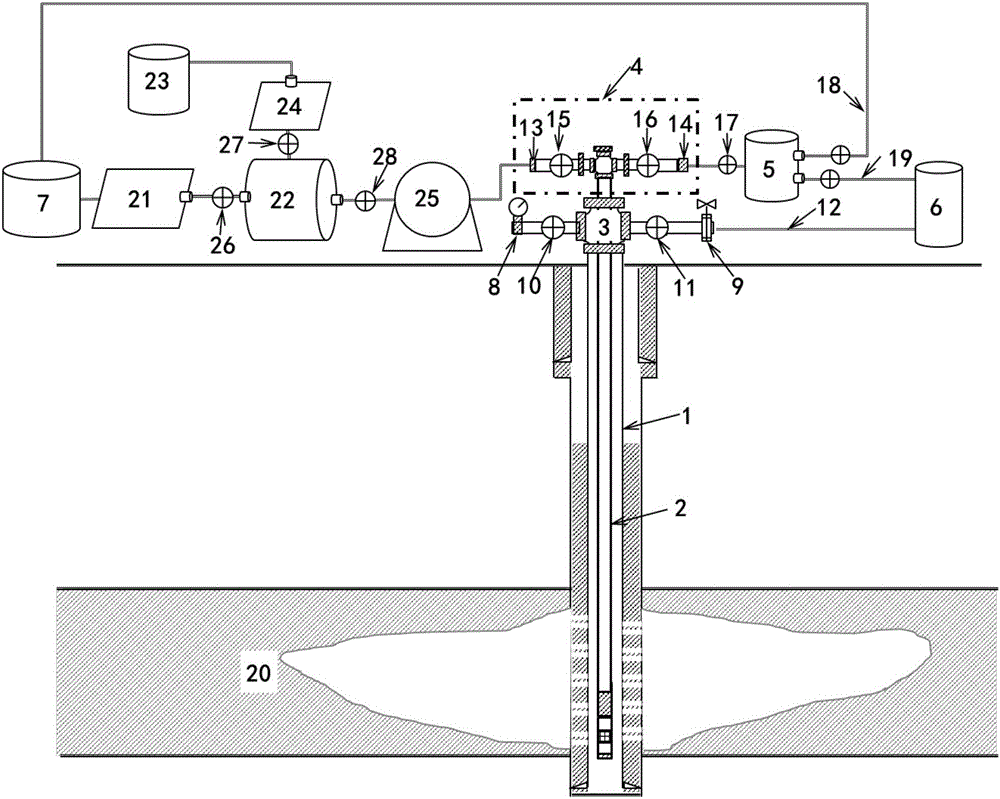

System and method for automatically generating CO2 foam and exploiting coalbed methane in huff-puff mode underground

ActiveCN105971573ASolve processing problemsSmall footprintOther gas emission reduction technologiesFluid removalChemical storageWater storage

The invention belongs to the field of oil-gas field development engineering, and particularly relates to a system and method for automatically generating CO2 foam and exploiting coalbed methane in a huff-puff mode underground. The system comprises a water storage device, a prying installation type sewage treatment device, a chemical mixing device, a chemical storage tank, intelligent dosing equipment and a prying installation type water injection device; the water storage device, the prying installation type sewage treatment device, the chemical mixing device, the prying installation type water injection device and an oil nozzle connector of a well mouth gas exploitation tree are sequentially connected through pipelines; the chemical storage tank, the intelligent dosing equipment and a chemical inlet of the chemical mixing device are sequentially connected through chemical supply pipelines. The system is easy and convenient to operate, the method is easy to implement, a gas generating agent solution system, an active water system and a gas releasing agent solution system slug are sequentially injected into a target coalbed by the well mouth gas exploitation tree, an oil pipe and a pump hanging tool through the prying installation type water injection device, a CO2 foam system is automatically generated underground, and the coalbed methane desorption and exploitation speed can be effectively increased.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com