Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

1055results about How to "Uniform pore size distribution" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

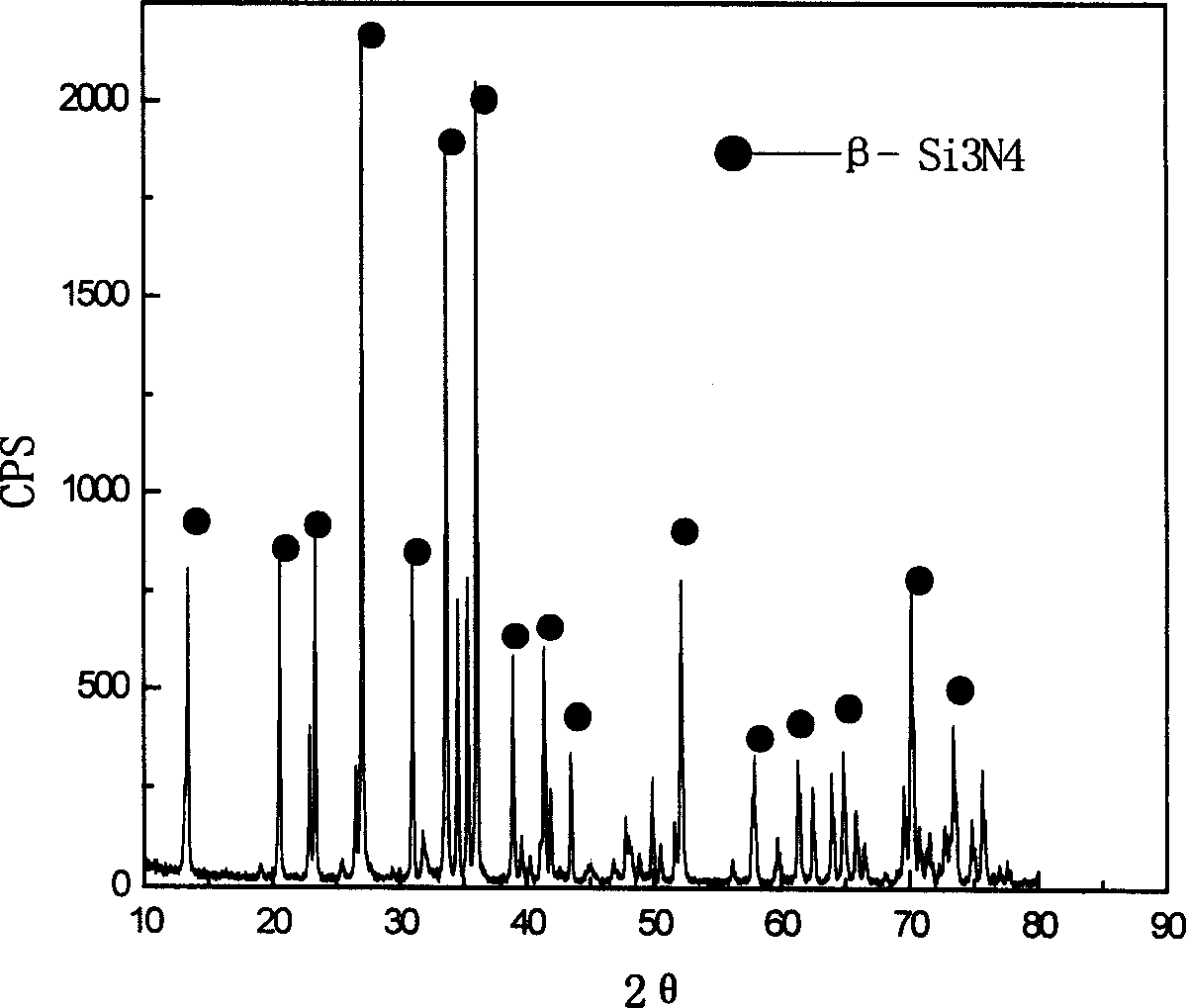

Method for preparing silicon nitride/silicon carbide porous ceramic

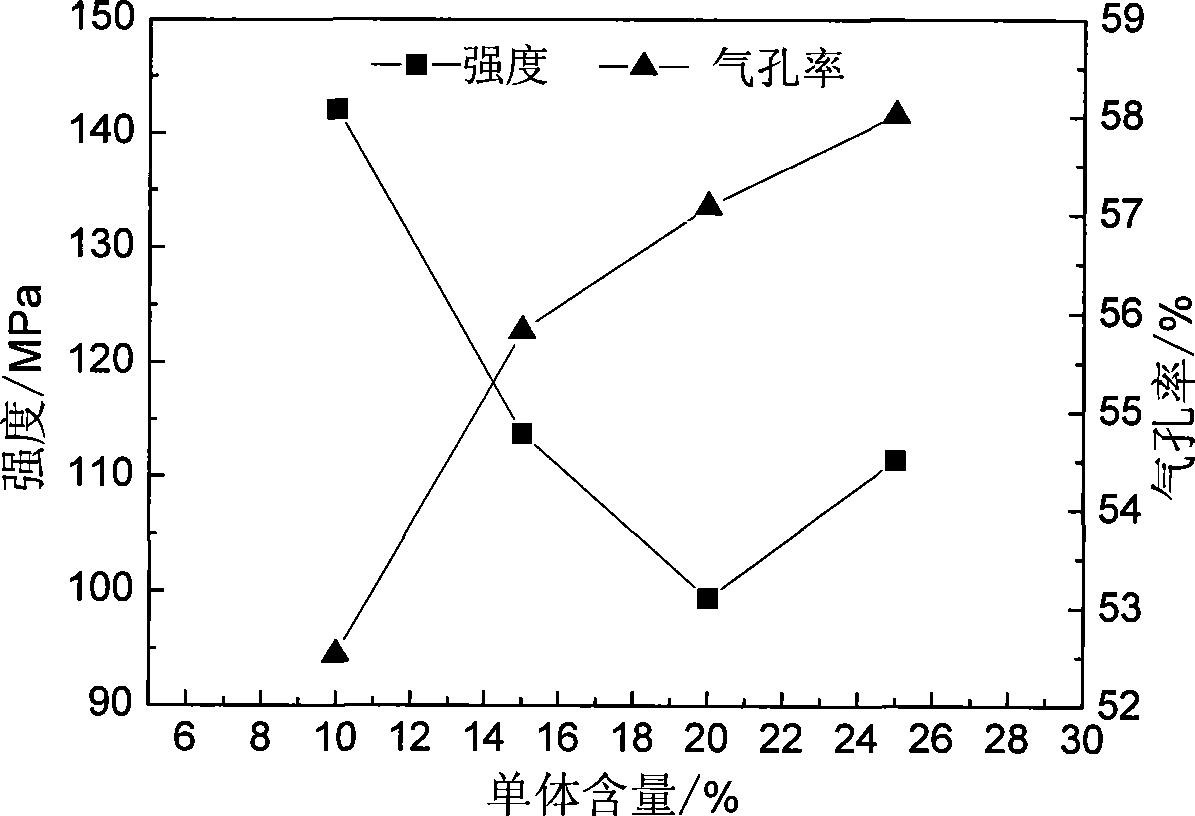

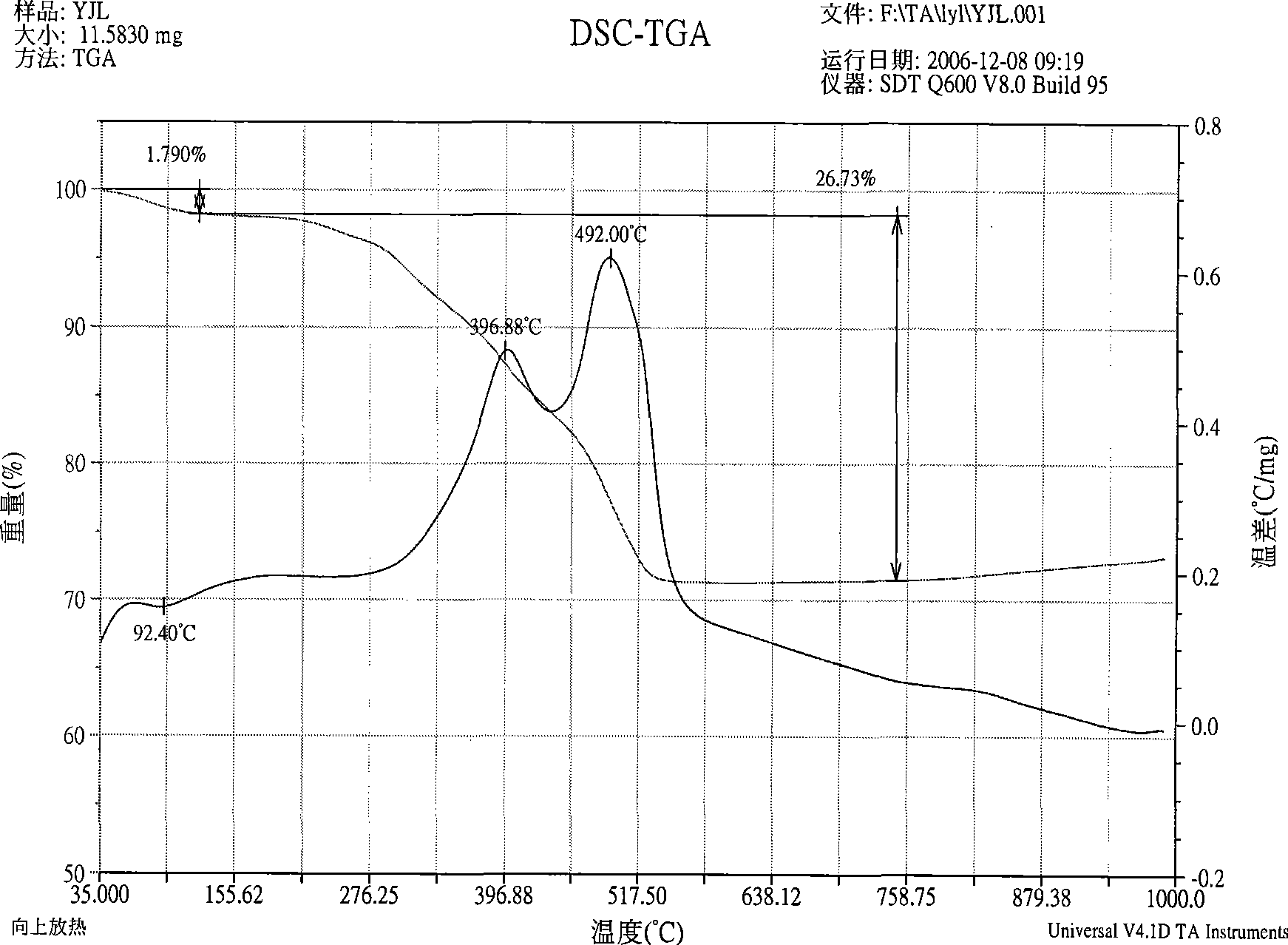

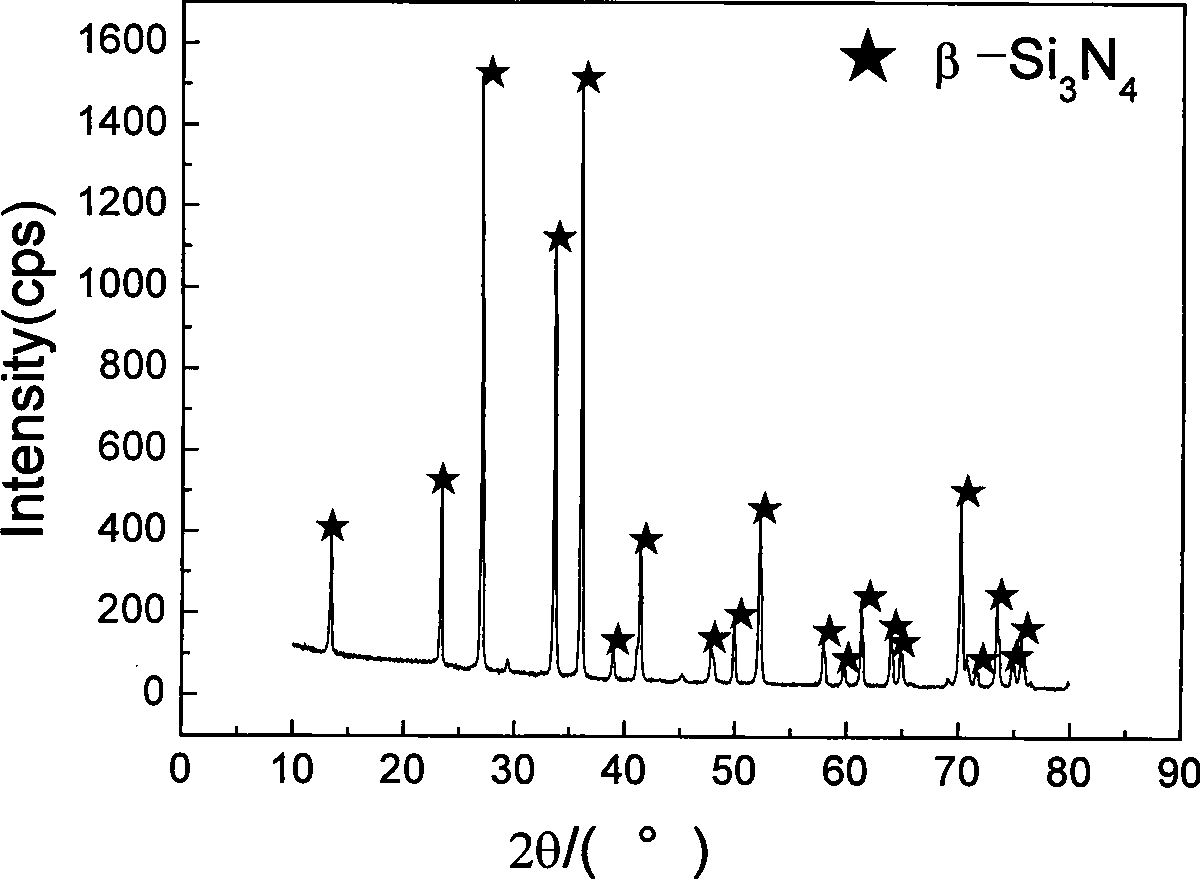

The present invention belongs to the field of porous ceramic material technology, and is the preparation process of one low cost and high performance porous silicon nitride / silicon carbide ceramic. The preparation process includes compounding material, forming and sintering as the conventional ceramic material preparing steps. It features that phenolic resin used as pore creating agent and carbon source is in-situ produced into SiC phase through the carbon hot reduction during sintering; and that Si3N4, Al2O3, Y2O3 and phenolic resin in certain proportion are produced into slurry through adding anhydrous alcohol and mixing for 12-24 hr and stoved into powder; and that the ceramic powder is processed through formation, cracking to eliminate glue, carbon hot reduction and sintering to produce the porous ceramic material with porosity of 40-70 %, strength of 70-160 MPa and low cost.

Owner:XI AN JIAOTONG UNIV

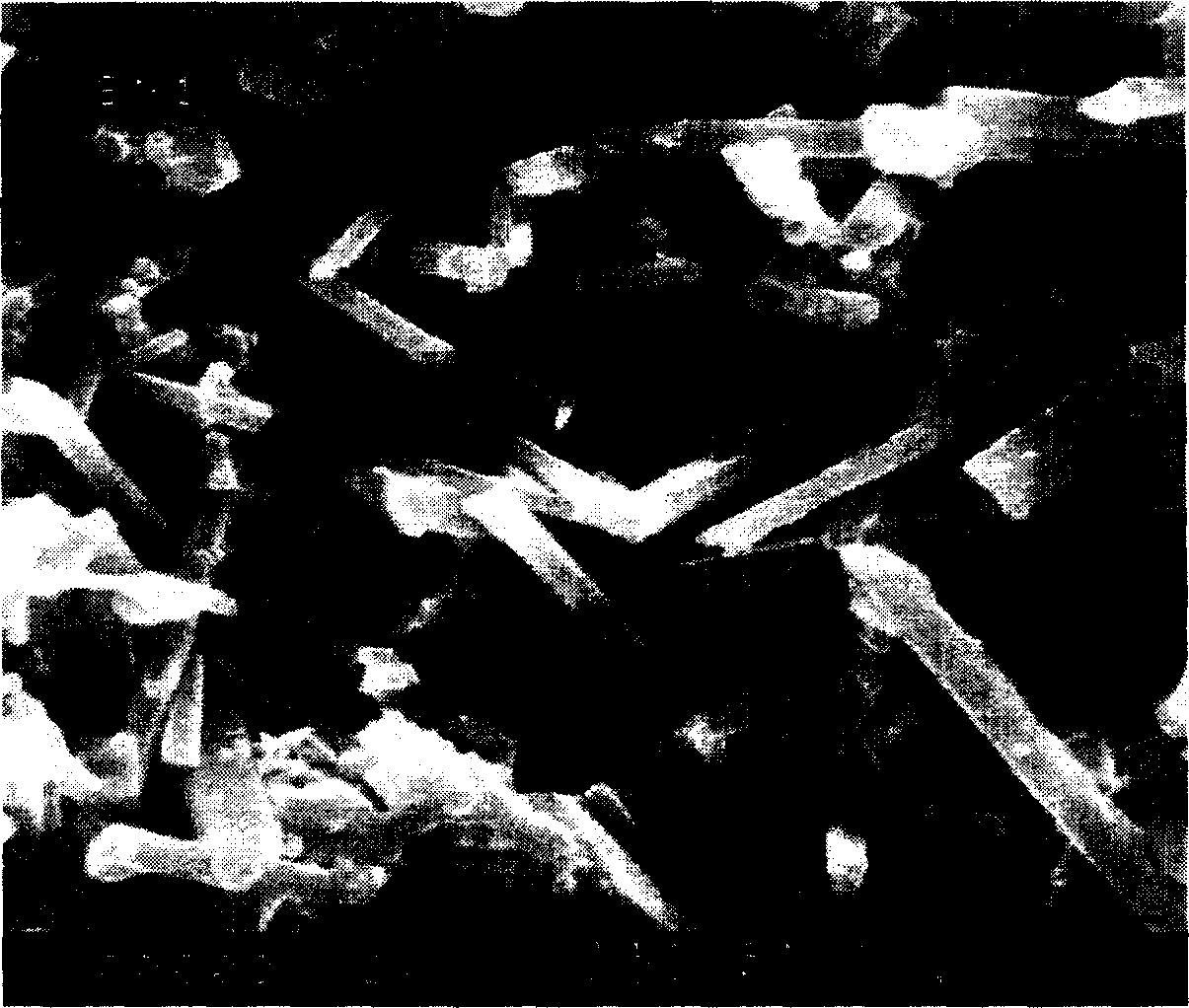

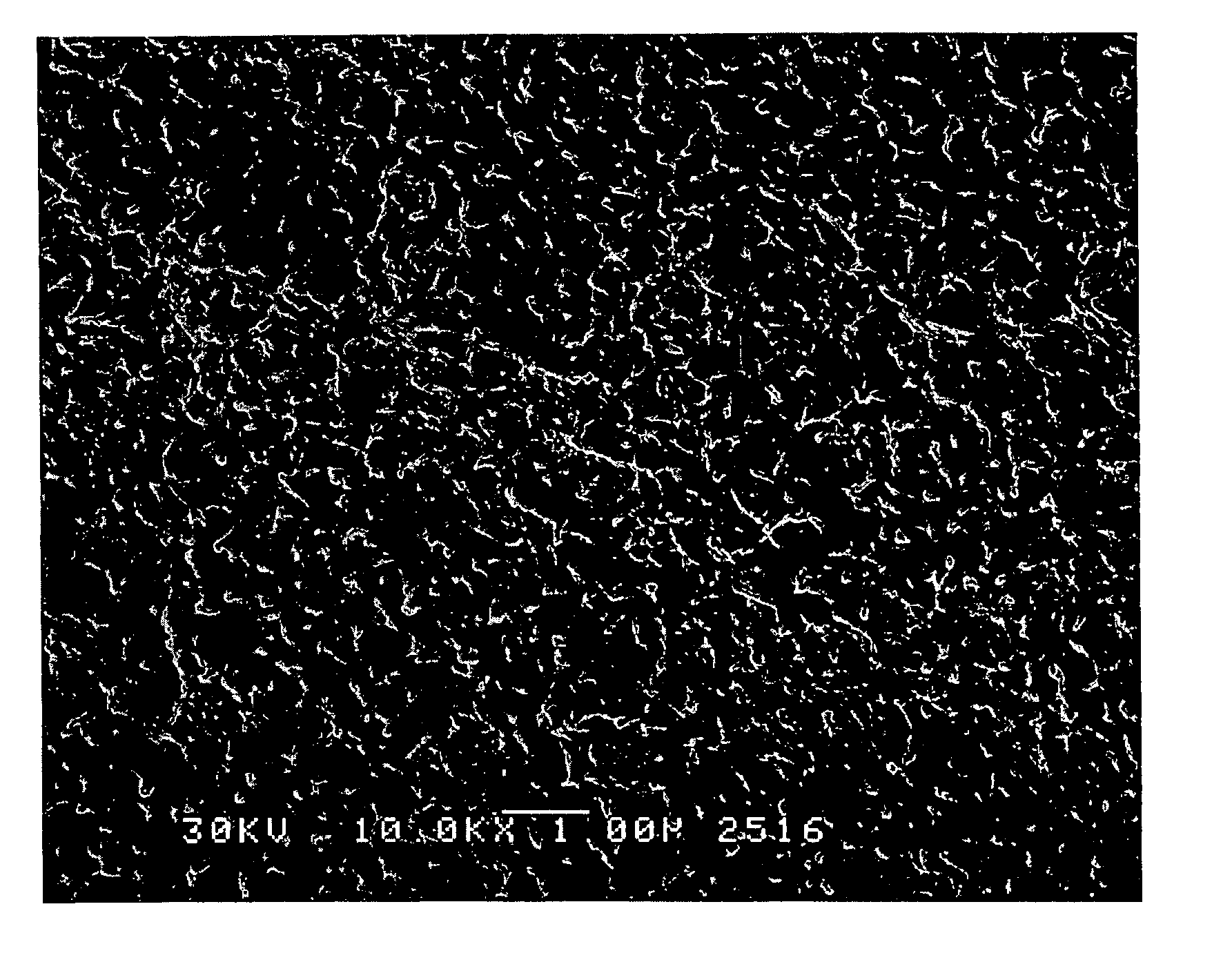

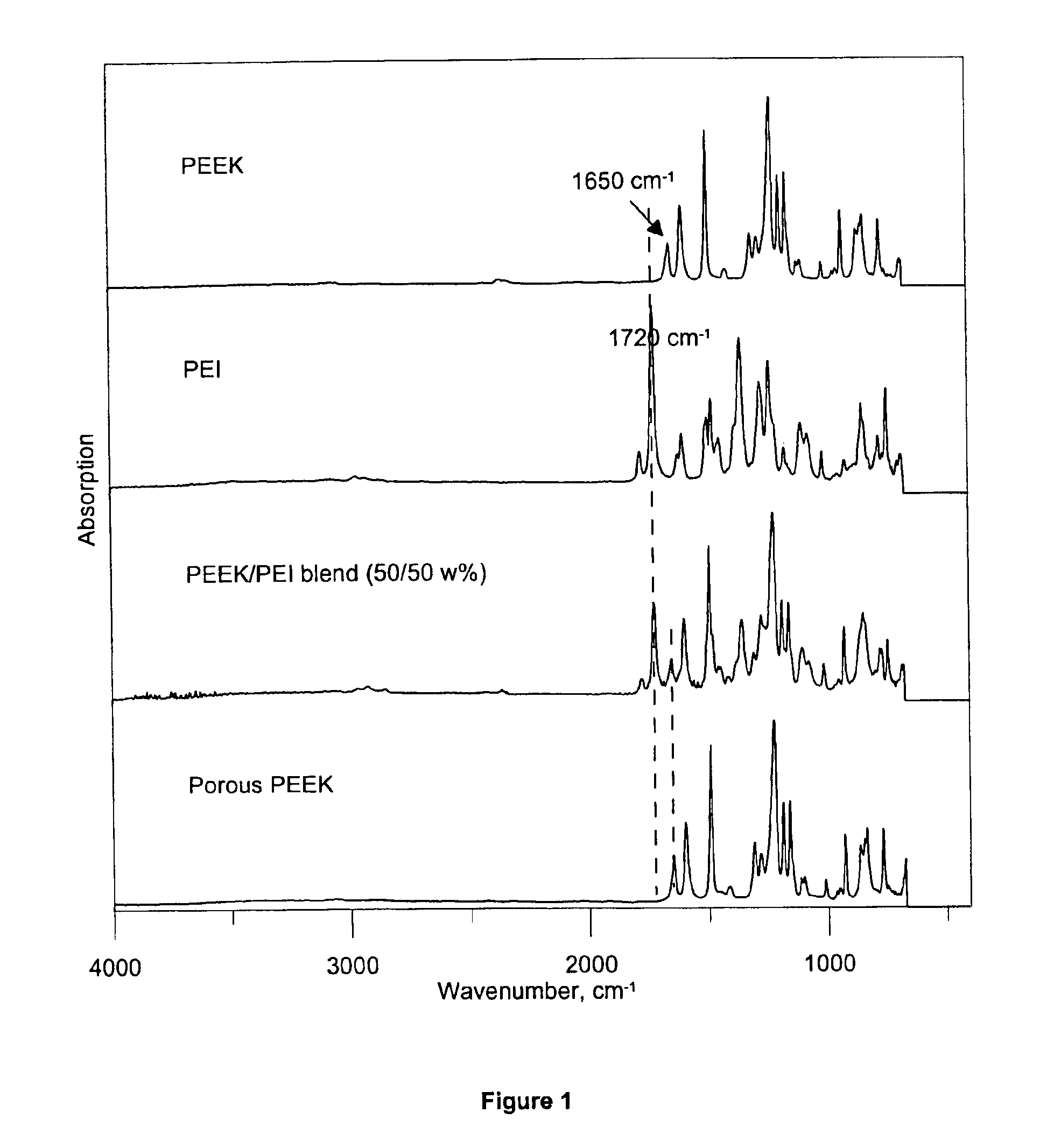

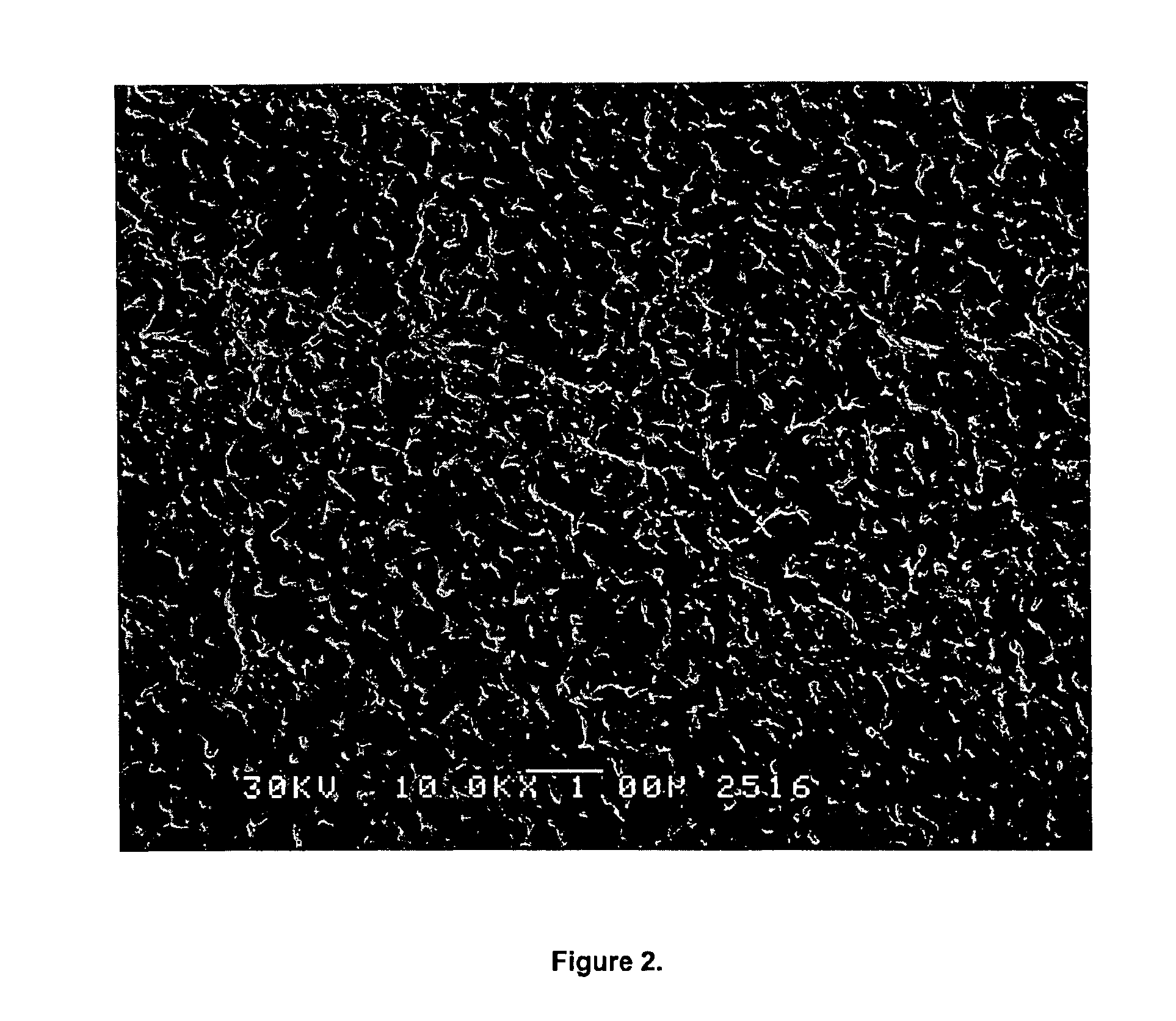

Porous poly(aryl ether ketone) membranes, processes for their preparation and use thereof

ActiveUS6887408B2Simple and cost-effective and industrially feasibleIncreased porous structureMembranesSemi-permeable membranesArylPorous medium

Porous poly(aryl ether ketone) (PAEK) articles are prepared from PAEK / polyimide blends by selective chemical decomposition and subsequent removal of the polyimide phase. Porous PAEK articles exhibit highly interconnected pore structure and a narrow pore size distribution. The porous PAEK articles of the present invention can be utilized as a porous media for a broad range of applications, including membranes for fluid separations, such as microfiltration, ultrafiltration, nanofiltration, and as a sorption media.

Owner:MASSACHUSETTS DEV FINANCE AGENCY

Method for preparing silicon nitride porous ceramic by gel injection moulding

The invention discloses a method for preparing silicon nitride porous ceramic by a gel mold injection method. The method comprises slurry preparation, blank preparation and degreasing and sintering of the blank to obtain the silicon nitride porous ceramic with porosity ranging from 49 to 63 percent, buckling strength ranging from 54 to 234MPa and pore-size distribution ranging from 0.1 to 1.0 mum. The method can prepare the silicon nitride porous ceramic with high performance and high strength only by utilizing numerous gel micromolecules formed by organic monomer solidification in a high temperature oxidation decomposition process. The porous ceramic prepared by the method has fine pores and narrow pore-size distribution. Meanwhile, the method can prepare porous ceramic products with large size and complicated shape.

Owner:XI AN JIAOTONG UNIV +1

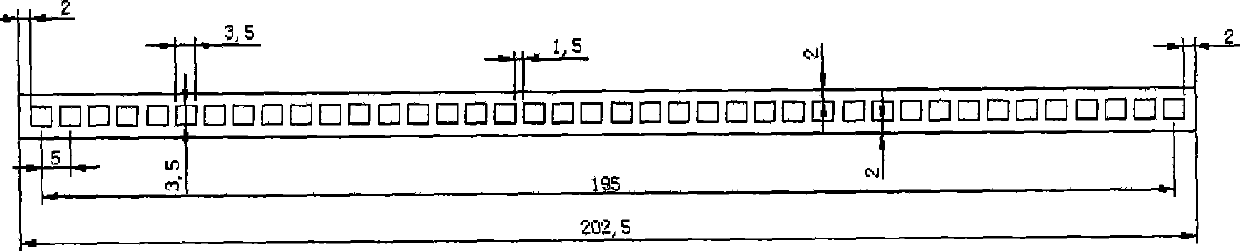

Preparation method of hollow flat plate structure type ceramic filter membrane element

ActiveCN103623711ALower sintering temperatureSmall filter resistanceSemi-permeable membranesAluminium hydroxideChemical separation

The invention provides a preparation method of a hollow flat plate structure type ceramic filter membrane element. The method comprises the following steps: (1) preparing a hollow structure type ceramic membrane supporting body by using an extrusion molding method, namely sintering aluminum hydroxide obtained by calcination at 600 DEG C as a main raw material to prepare the ceramic membrane supporting body; (2) preparing the ceramic filter membrane by using a plasma spray method. When the ceramic membrane supporting body is prepared, the selected and used raw material is calcined aluminum hydroxide, so that the sintering temperature of the ceramic membrane supporting body can be greatly reduced, and the sufficient strength of the supporting body can be guaranteed; when the ceramic filter membrane layer is prepared, the thickness of the filter membrane can be excellently controlled by using the plasma spray process, and the filter resistance is reduced; the membrane layer has the uniform pore size distribution and the high separation accuracy; the membrane layer is closely combined with the supporting body. The ceramic filter membrane is prepared by using plasma spraying without sintering, so that the process is simple, the production cost of the ceramic filter membrane can be effectively reduced, the production efficiency is improved, and the process can be widely applied to the fields of sewage treatment and filtration, solid-liquid chemical separation, and the like.

Owner:雅安沃克林环保科技有限公司

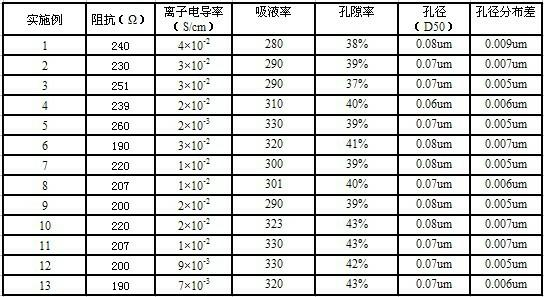

Separator for lithium ion secondary battery, method for manufacture thereof, and lithium ion secondary battery

ActiveUS20110171535A1Less fluctuationUniform densityMaterial nanotechnologyPretreated surfacesLithiumInorganic particle

Disclosed are a separator for lithium ion secondary batteries, having an inorganic layer formed from inorganic particles, characterized in that the inorganic particles have a particle diameter distribution in which the 50% cumulative particle diameter D50 is in the range of 100 nm to 500 nm, the 10% cumulative particle diameter D10 is 0.5D50 or more, and the 90% cumulative particle diameter D90 is 2D50 or less; a method for manufacturing the separator; and a lithium ion secondary battery using the separator. When the separator is used, there can be produced a lithium ion secondary battery in which a short circuit caused by contraction or melting can be definitely prevented, as well as the current density applied to the electrodes during charging and discharging is uniform so that charging and discharging can be efficiently achieved.

Owner:NIPPON BAIRIIN

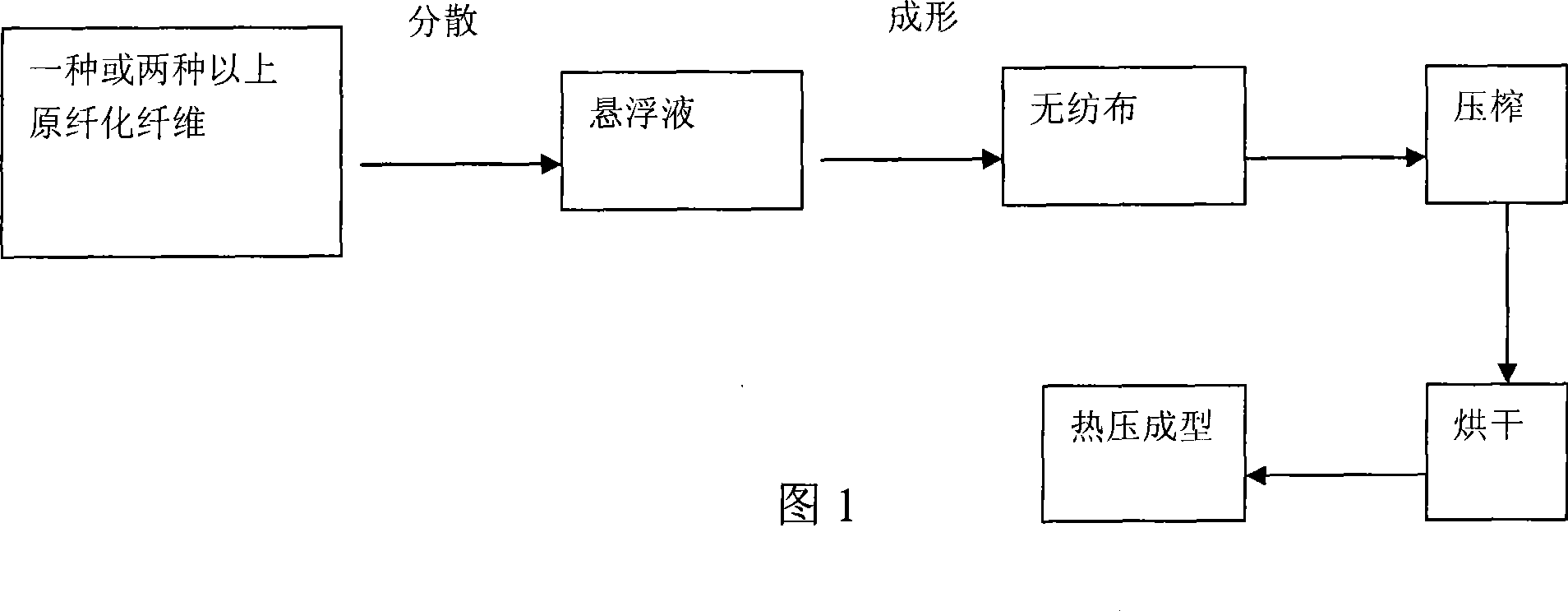

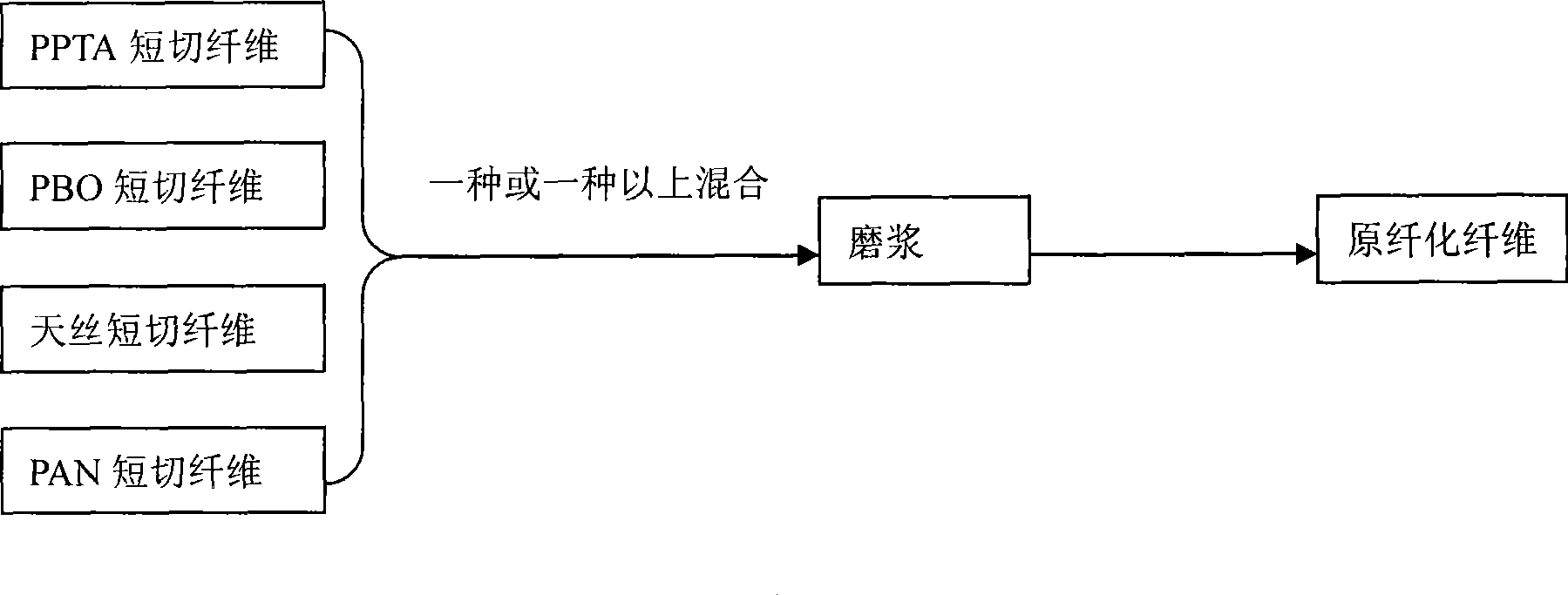

Multiple layer composite micropore filtration separation material and preparation method and use thereof

ActiveCN101380535AImprove uniformityUniform pore size distributionSemi-permeable membranesCell component detailsMicropore FilterElectrical battery

The invention relates to a multi-layer composite micropore filter separation material, a method for preparing the material and the application thereof, wherein, the preparation method comprises the following steps: (1) the fiber which can be fibrillated is prepared into fully fibrillated fiber material by pulping process; (2) the slurry is obtained after the fully fibrillated fiber material is dispersed in water; (3) advancing to the net and shaping are carried out, a layer of nonwoven fabric is placed on a shaping net, the above slurry is dehydrated on the nonwoven fabric directly for compound molding; (4) drying is carried out for obtaining the product. The product can also be processed by hot press molding. The method can be operated easily, is applicable for application of large scale, the obtained multi-layer composite high temperature resistance micropore filter separation material has the outstanding performance of high temperature resistance, meanwhile the uniformity of the holes is excellent, the average aperture can reach 10nm-1mum, and the method can be used in such fields as preparing filter material, battery septum material, electrolytic capacitor paper and double electric layers capacitor septum, etc.

Owner:ZHUZHOU TIMES FIBER PIONEER MATERIAL TECH CO LTD

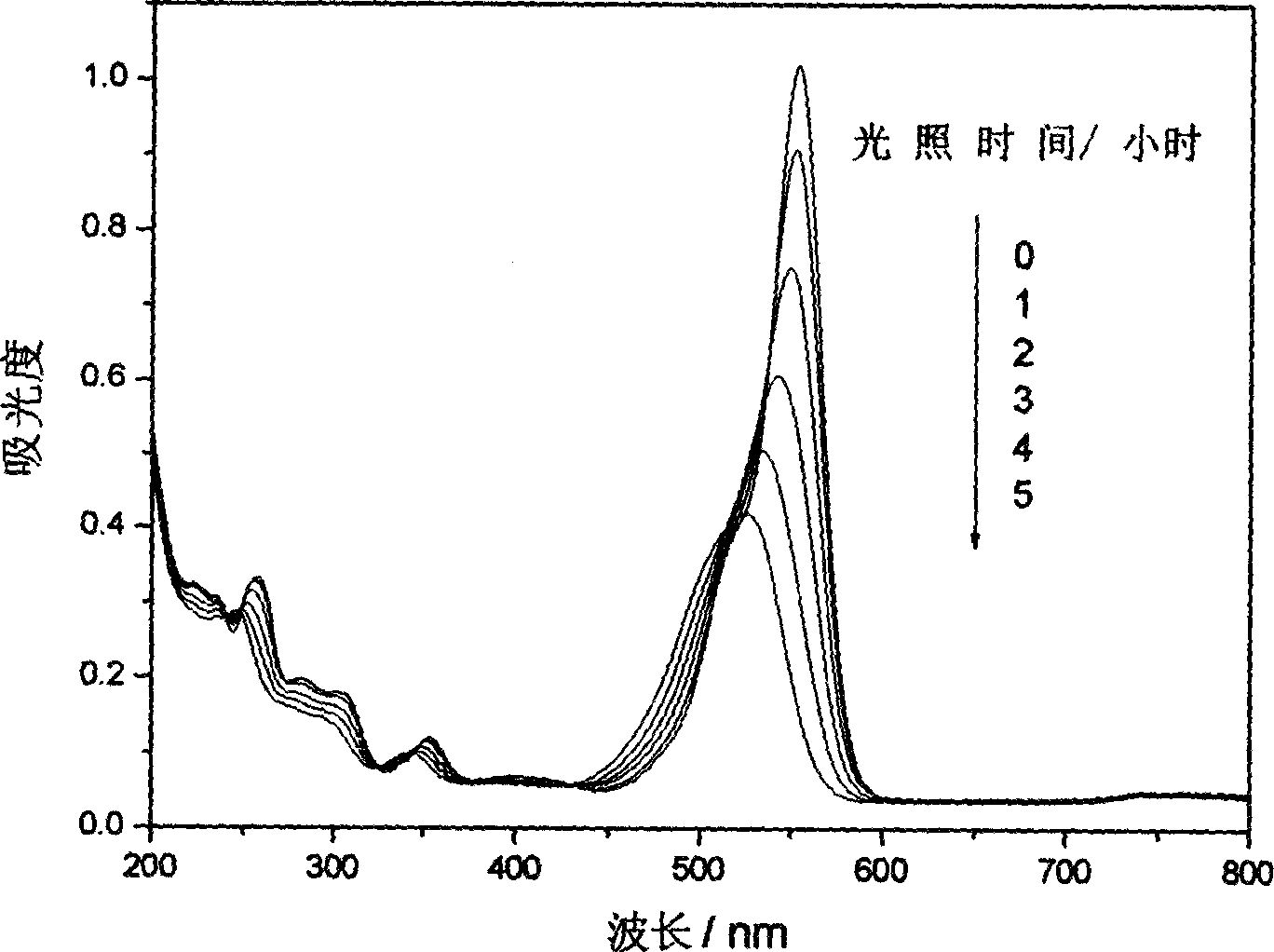

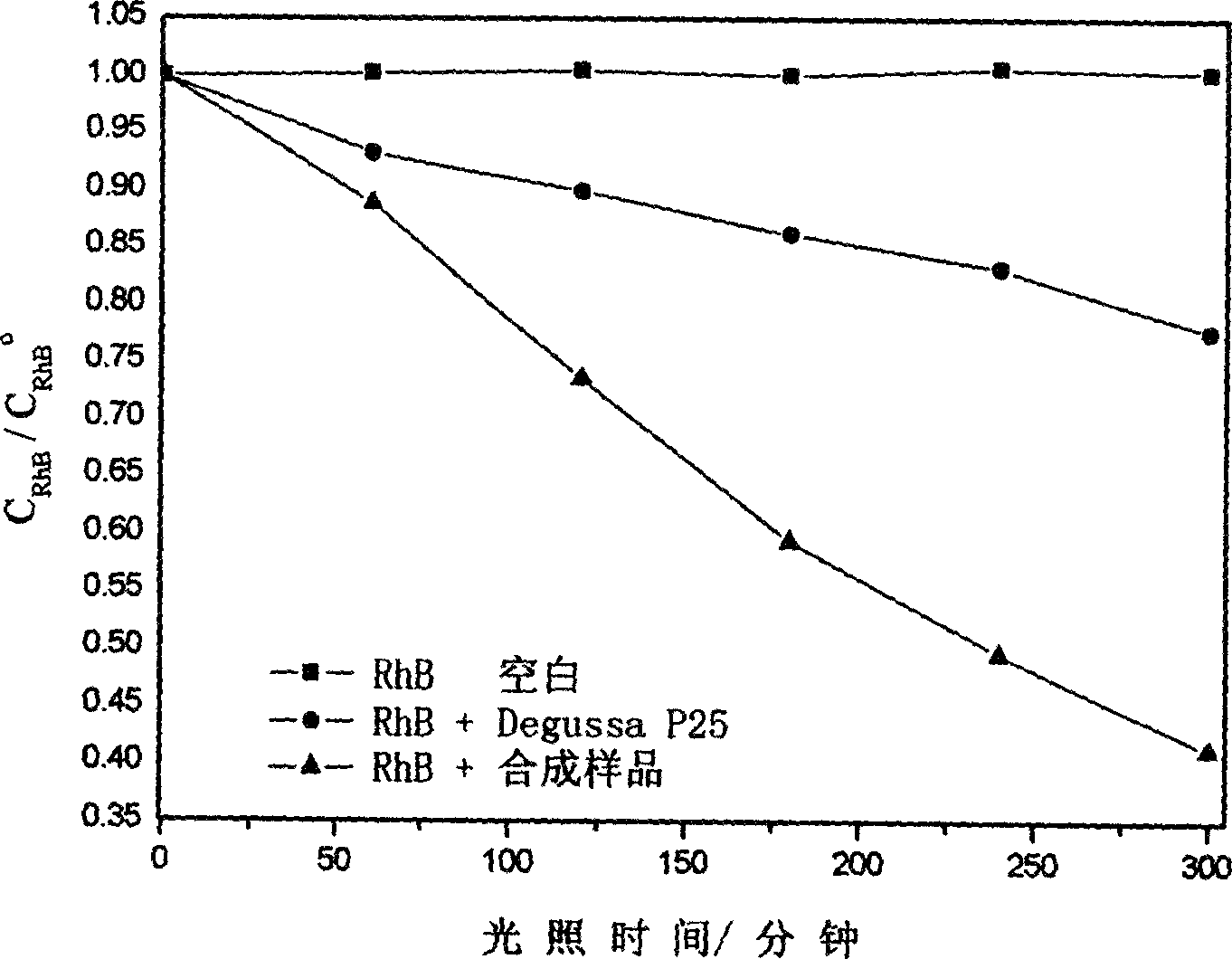

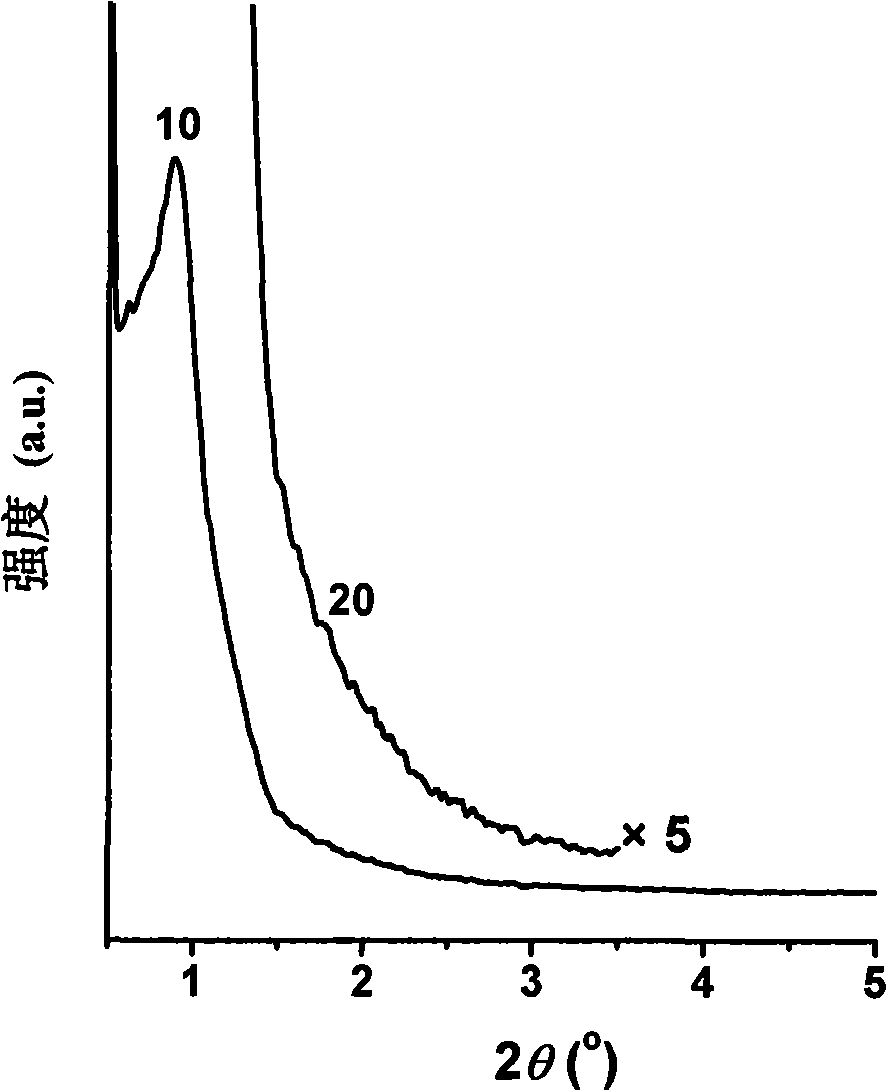

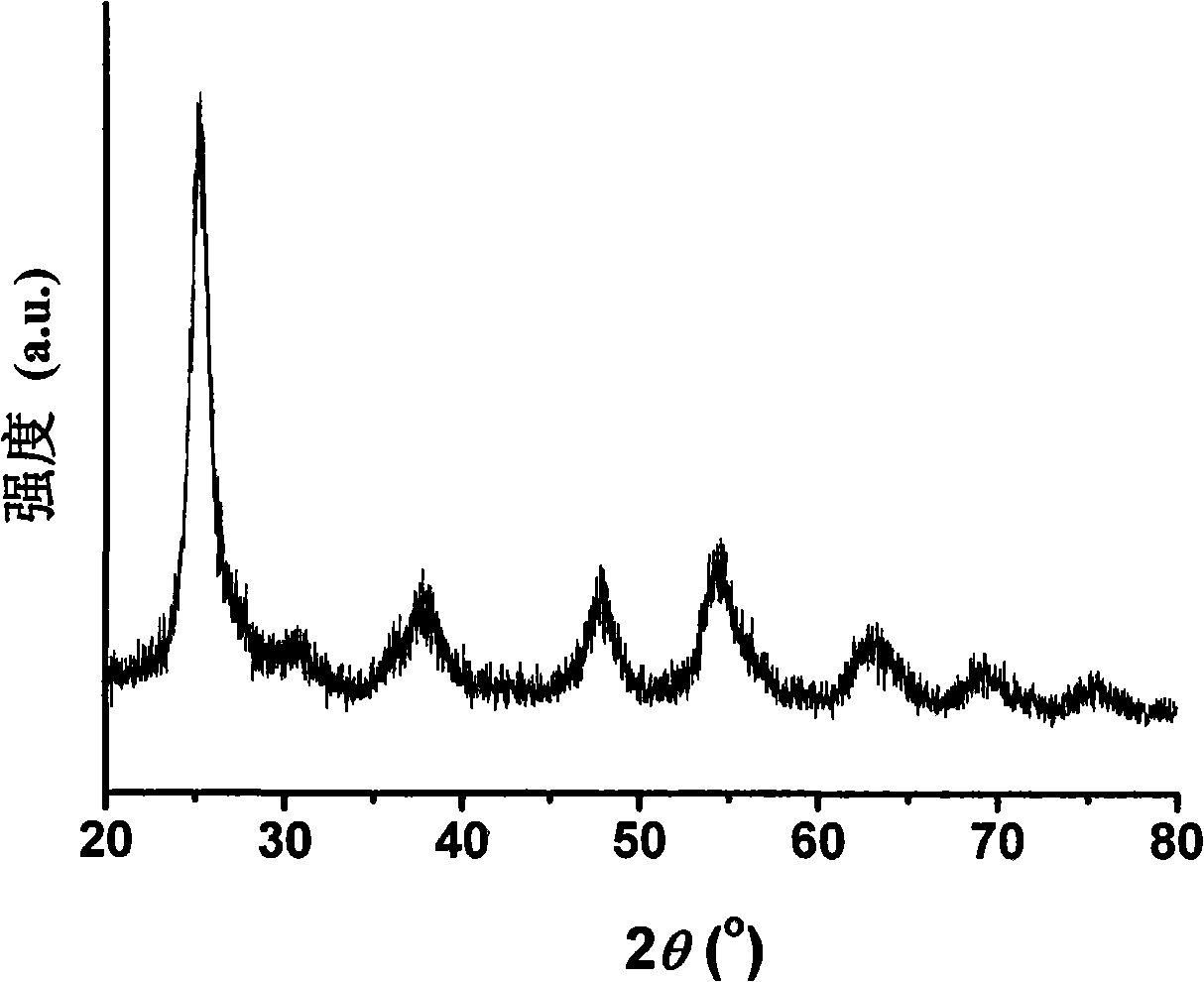

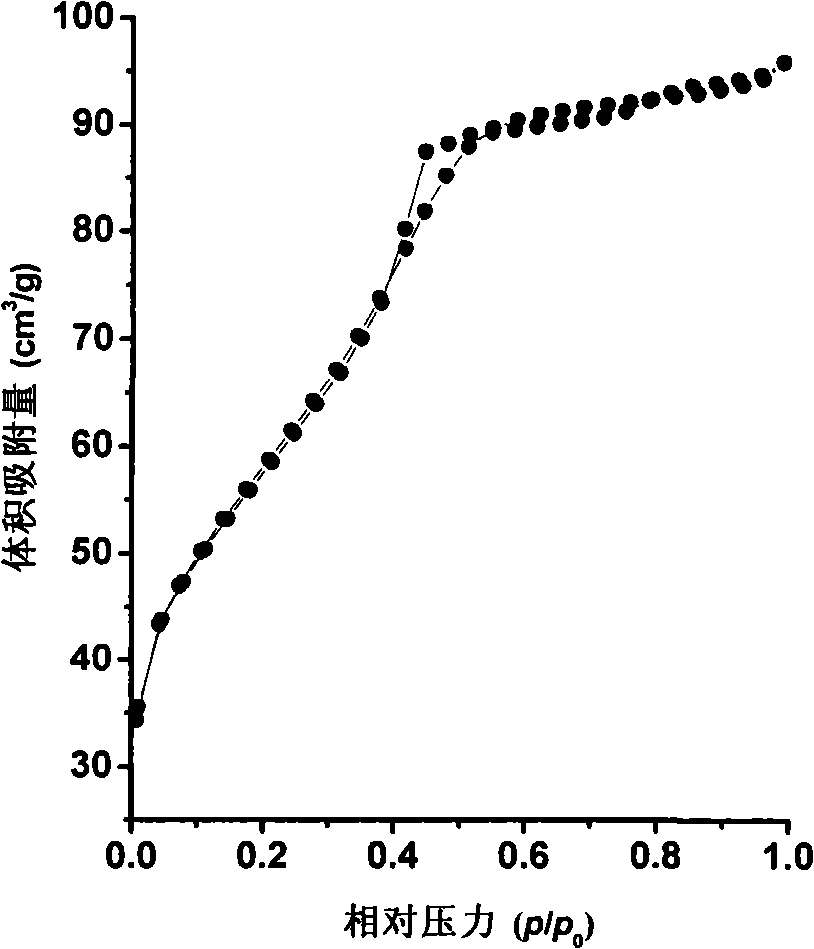

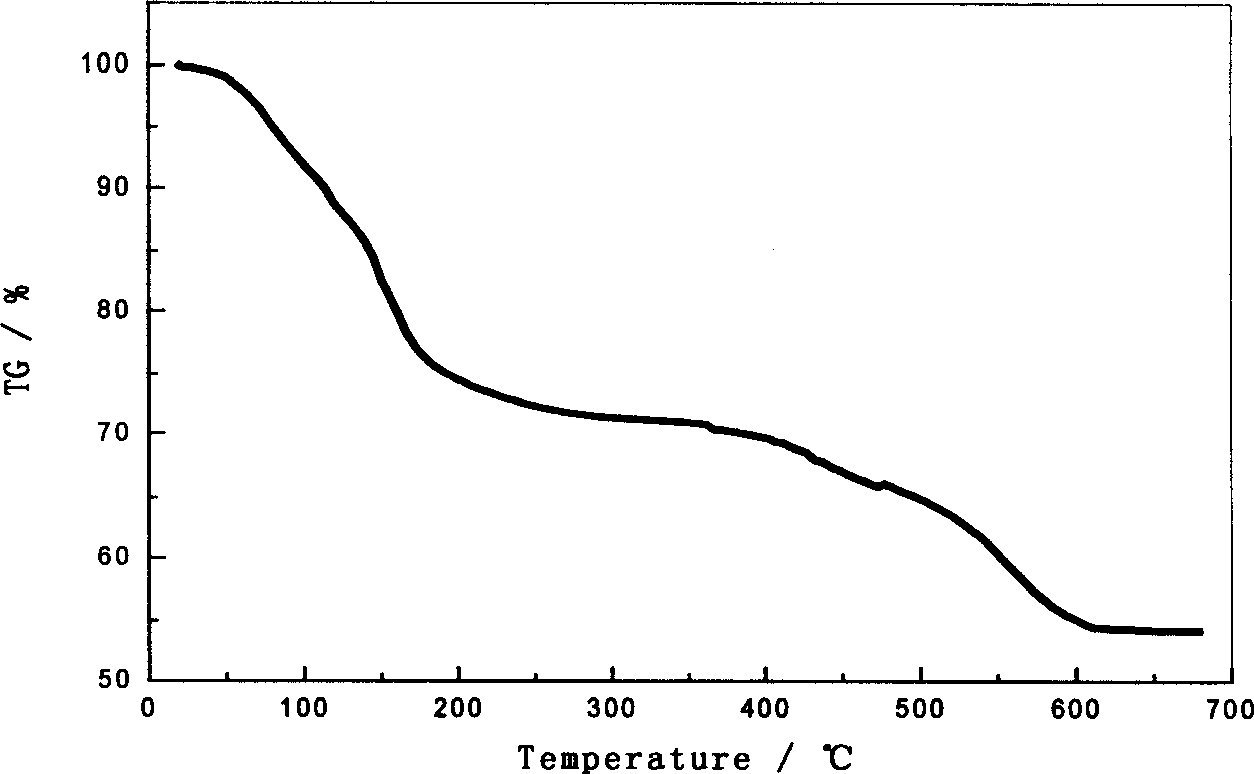

Mesoporous WO[3-x] visible-light-driven photocatalyst with oxygen vacancy as well as preparation method and application thereof

InactiveCN104874389AEasy to adjustEfficient use ofMetal/metal-oxides/metal-hydroxide catalystsOxygen vacancyMesoporous silica

The invention discloses a mesoporous WO[3-x] visible-light-driven photocatalyst with oxygen vacancy and a preparation method thereof. The method comprises the following steps: calcinating at a controlled temperature of 350-600 DEG C in air so as to obtain a mesoporous silica molecular sieve KIT-6 loaded with tungsten trioxide by taking mesoporous silica molecular sieve KIT-6 as a hard template and a silicotungstic acid or phosphotungstic acid hydrate as a tungsten trioxide precursor; then calcinating at a controlled temperature of 450-550 DEG C so as to obtain a mesoporous silica molecular sieve KIT-6 provided with oxygen vacancy and loaded with tungsten trioxide by utilizing H2 as a reducing agent; and finally, removing the mesoporous silica molecular sieve KIT-6 by use of a 10wt% HF aqueous solution, thereby obtaining the mesoporous WO[3-x] visible-light-driven photocatalyst with oxygen vacancy and relatively large specific surface area and pore diameter. The mesoporous WO[3-x] visible-light-driven photocatalyst with oxygen vacancy is capable of effectively utilizing lights to rapidly catalyze CO2 so as to generate methane, and is high in catalysis efficiency, simple in preparation process and needed equipment, environmentally friendly in preparation process and free from pollution.

Owner:SHANGHAI INST OF TECH

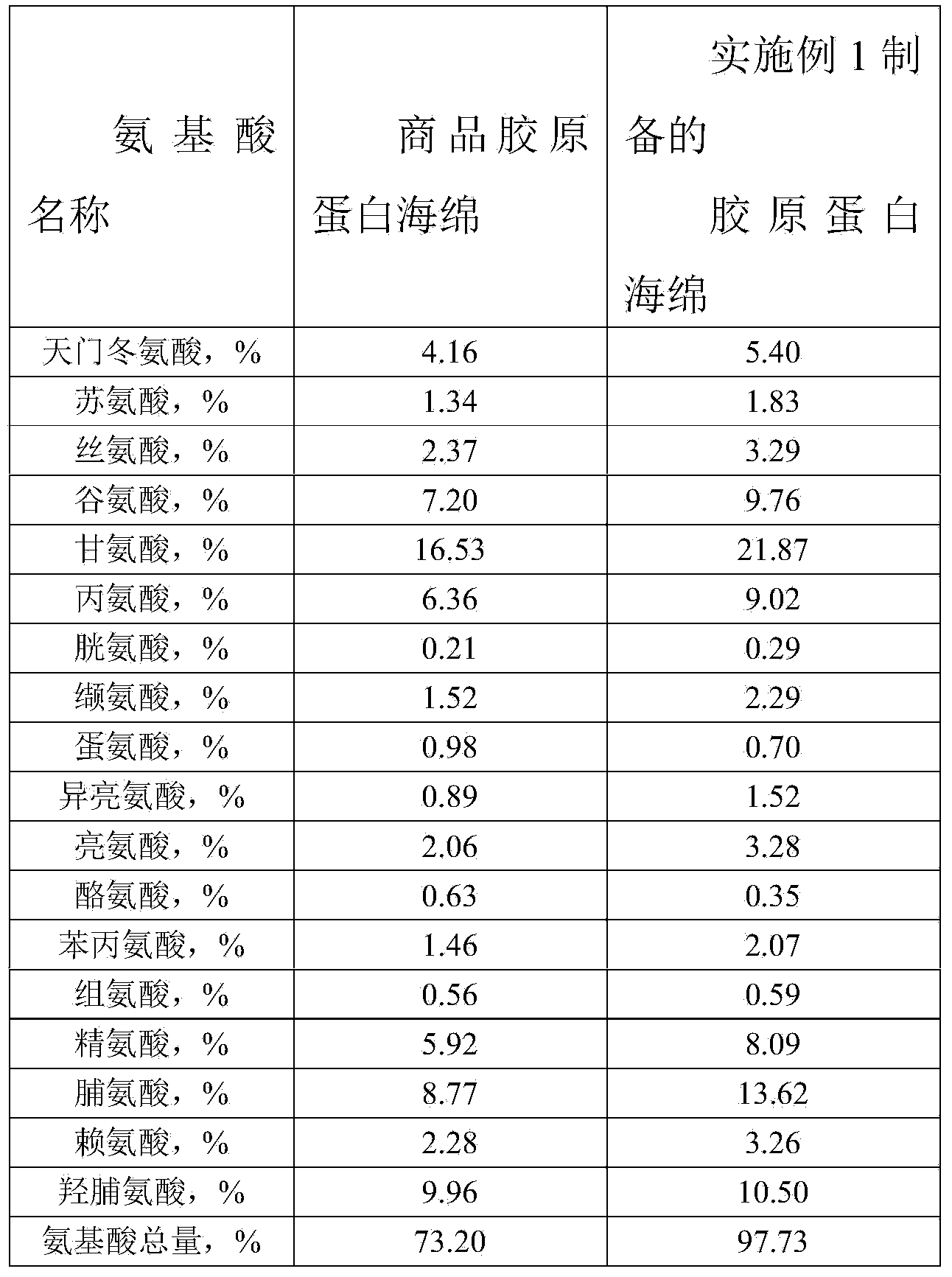

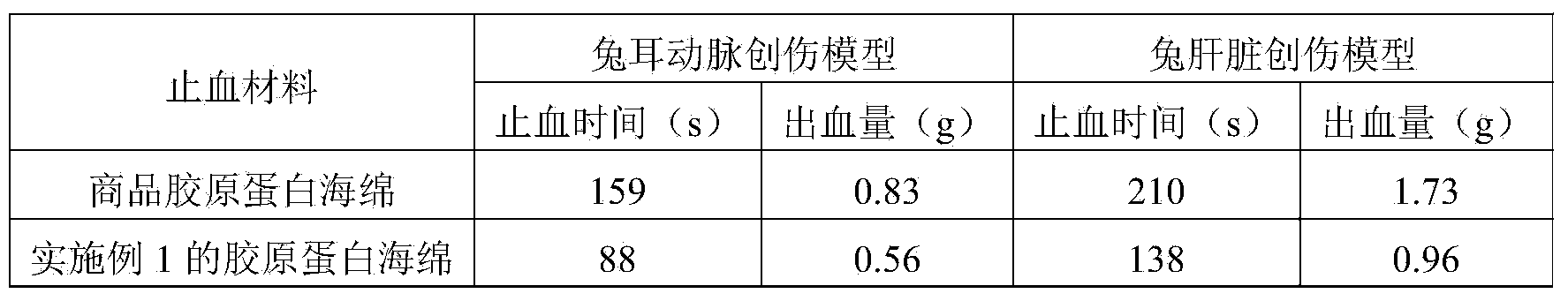

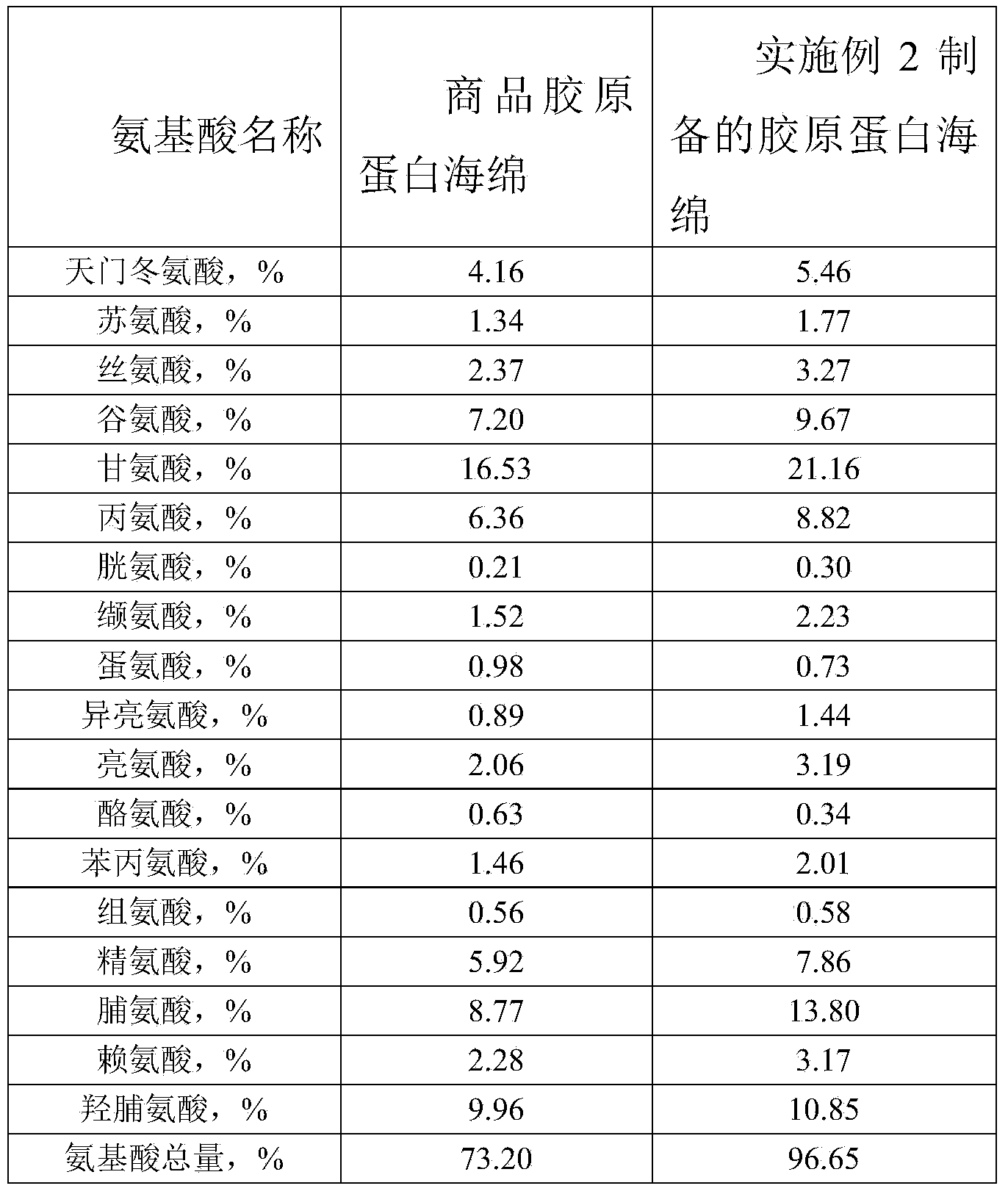

Preparation method of high-purity collagen protein sponge

InactiveCN103772734AGood removal effectHigh purityConnective tissue peptidesPeptide preparation methodsFreeze-dryingCollagen sponge

The invention provides a preparation method of high-purity collagen protein sponge, and relates to a preparation method of collagen protein sponge. The preparation method of the high-purity collagen protein sponge is used for solving the problems that the collagen protein sponge prepared by using a conventional method is long in production cycle and low in yield and purity and has poor hemostasis performance. The preparation method of the high-purity collagen protein sponge comprises the following steps: step one. pretreating fresh bovine heel tendons; step two. extracting collagen protein; step three. centrifuging; step four. salting out; step five. dissolving; step six. carrying out gradient dialysis; step seven. pre-freezing; step eight. carrying out freeze drying; and step nine. sterilizing. The final product prepared by using the method has a smooth and flat surface and relatively good hemostatic performance and is uniform in pore size distribution. The product has relatively high purity (the total amount of amino acids reaches 97.73%), an obvious hemostatic effect and no abnormal taste, is safe, non-toxic, high in yield and short in time; liquid is clear without impurities; the production cycle is shortened; the whole preparation process is carried out at a room temperature; the biological activity of the collagen protein is maintained; and the application of the high-purity collagen protein sponge in clinical is improved.

Owner:HARBIN INST OF TECH

Low temperature process of preparing carbon-doped mesoporous TiO2 visible light catalyst

InactiveCN1857769ALarge specific surface areaUniform pore size distributionPhysical/chemical process catalystsTitaniumSolvent

The present invention relates to preparation process of carbon-doped mesoporous TiO2 visible light catalyst, and belongs to the field of nanometer catalyst material technology. The present invention features that amorphous titania powder prepared with titanium containing compound through hydrolysis and used as the titanium source and saccharide compound as carbon source are produced into the carbon-doped mesoporous TiO2 visible light catalyst through heat treatment in water or solvent, suction filtering, washing and drying. The carbon-doped mesoporous TiO2 visible light catalyst has specific surface area up to 126 sq m / g, homogeneous pore size of about 8 nm, high visible light catalytic activity, simple synthesis path and easy control of the technological process.

Owner:HUAZHONG NORMAL UNIV

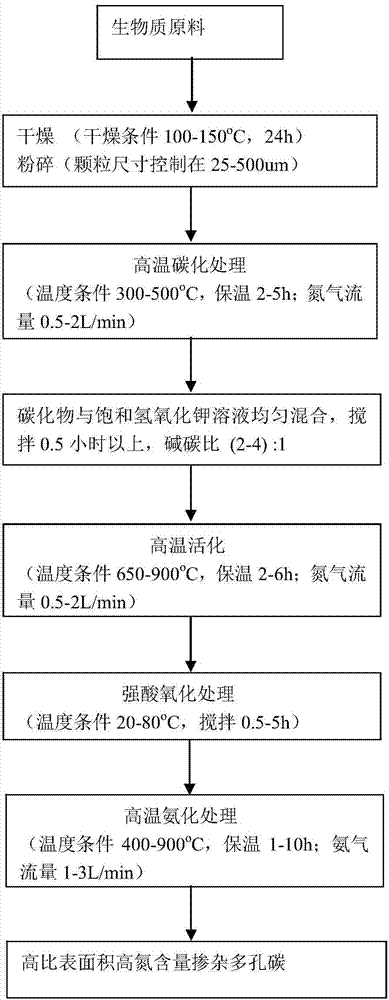

Preparation method of high nitrogen content-doped porous carbon with high specific surface area

ActiveCN103922305AHigh nitrogen contentNitrogen content controlCarbon preparation/purificationPorous carbonStrong acids

The invention discloses a preparation method of high nitrogen content-doped porous carbon with a high specific surface area. The preparation method comprises the following steps: drying and smashing a biomass raw material to obtain particles and carbonizing the particles in a nitrogen atmosphere at a high temperature to obtain carbide; then, dispersing the carbide in a potassium hydroxide solution, and stirring and drying to obtain an alkali and carbon mixture; activating the alkali and carbon mixture at the high temperature in the nitrogen atmosphere, and washing, filtering and drying to obtain the porous carbon material; uniformly dispersing the porous carbon material in a strong acid solution for oxidation treatment, and filtering, washing and drying to obtain an oxidized porous carbon material; and finally, ammonifying the oxidized porous carbon material at the high temperature in an ammonia atmosphere to obtain the high nitrogen content-doped porous carbon with the high specific surface area. The specific surface area of the doped porous carbon is 2500-3500<m2> / g, the pore diameter of the material is 0.5-6nm and the nitrogen content is 4-12%. The method disclosed by the invention is simple and effective, easy to operate, convenient for batch production on a large scale and suitable for application in industrial production.

Owner:TONGJI UNIV

Polypropylene hollow fiber microporous membrane and preparation method thereof

ActiveCN101862601AHigh strengthUniform pore size distributionSemi-permeable membranesFiberHollow fibre

The invention discloses a polypropylene hollow fiber microporous membrane and a preparation method thereof. The hollow fiber microporous membrane comprises the following components in percentage by weight: 15-45% of polypropylene, 50-80% of thinner and 0.1-5% of additive. The preparation method of the hollow fiber microporous membrane is realized on the basis of a thermotropic phase separation process. The preparation method of the polypropylene hollow fiber microporous membrane is simple and easy to industrialize, and has low requirements on equipment, the prepared hollow fiber microporous membrane has the advantages of high strength, uniform pore diameter distribution, high porosity and the like, the pore diameter of the hollow fiber microporous membrane can be controlled between 0.1 and 0.45mu m, and the porosity is 60-85%, so the hollow fiber microporous membrane has large water flux, is not easy to block in use, can be widely used for feeding water treatment, and is particularly suitable for the membrane bioreactor technology and other water treatment fields.

Owner:三泰(青岛)膜科技有限公司

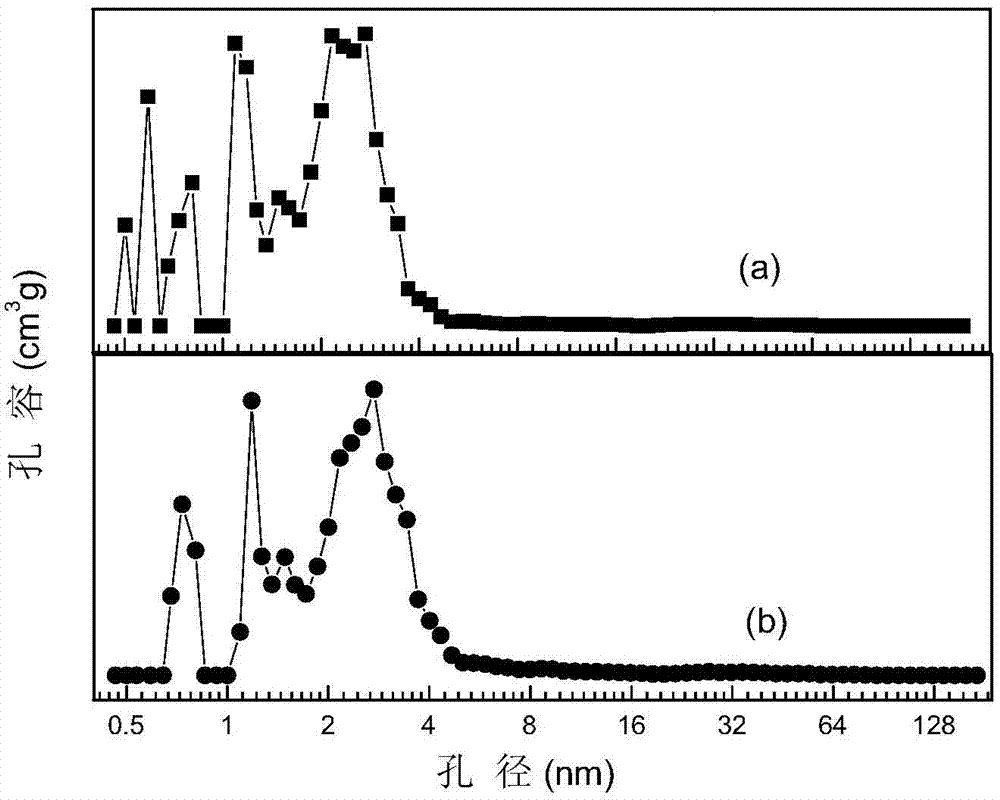

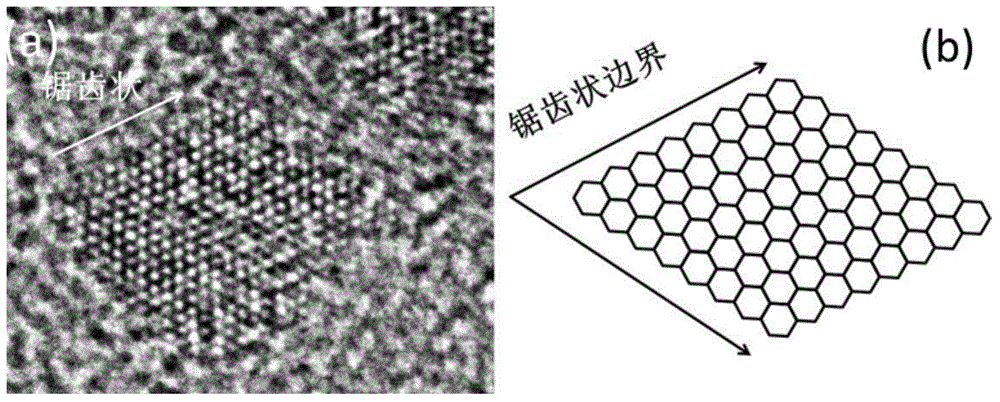

Porous graphene and graphene quantum dot and preparation method of porous graphene and graphene quantum dot

ActiveCN104555999AUniform pore size distributionExcellent oxygen reduction catalytic activityPorous grapheneCvd graphene

The invention discloses porous graphene and a graphene quantum dot. The porous graphene comprises, but is not limited to 2-9 atomic layers, wherein each atomic layer simultaneously comprises crystal lattices and holes of graphene, but is not limited to the holes of which the apertures are 2-10nm; the area of the holes accounts for about 5%-40% of total area of each atomic layer. The graphene quantum dot is characterized by comprising 1-5 atomic layers; the boundary is in a sawtooth shape; and the dimension of the quantum dot is 2-10nm. The porous graphene disclosed by the invention is uniform in aperture distribution, and not equal in interlayer spacing; and the graphene quantum dot has the advantages of high luminous efficacy, good crystal form and few defects.

Owner:SHANXI INST OF COAL CHEM CHINESE ACAD OF SCI

Silicon carbide ceramic support body and preparation method thereof

InactiveCN102389719AHigh strengthExtended service lifeSemi-permeable membranesHydrogen atmospherePlasticizer

The invention relates to a silicon carbide ceramic support body and a preparation method thereof. The raw material powder of the support body is mixed powder consisting of silicon carbide powder 1 and silicon carbide powder 2, wherein the silicon carbide powder 1 has a median particle diameter D50 of 25-45mu m, the silicon carbide powder 2 has a median particle diameter D50 of less than 5mu m, the ratio of the D50 of the silicon carbide powder 1 to the D50 of the silicon carbide powder 2 is not less than 6, and the consumption of the silicon carbide powder 2 is 0.5-13 percent of the weight of the used silicon carbide powder 1. The raw material powder is mixed with a solvent, an adhering agent, a plasticizer and a pore-forming agent to form pug, the pug is subjected to stamping to form a raw blank, the raw blank is dewatered and degreased to form a calcined product, and the calcined product is sintered in argon or hydrogen atmosphere or vacuum to form the support body of a recrystallized silicon carbide ceramic membrane. The support body of the recrystallized silicon carbide ceramic membrane has filtering flux and strength which are higher than those of the traditional commercial support body of an aluminum oxide ceramic membrane.

Owner:SANDA FILM SCI & TECH XIAMEN

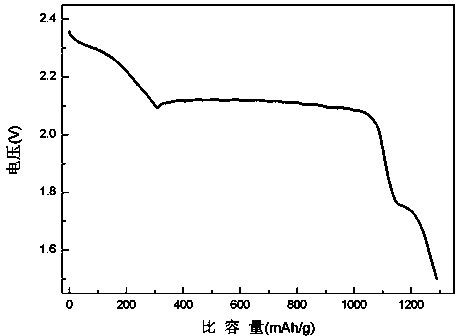

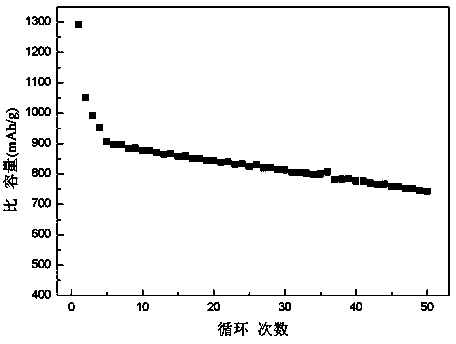

Preparation method of S/TiO2 composite material for anode of sodium-sulfur battery

ActiveCN103840143AImprove conductivityIncrease profitElectrode carriers/collectorsLi-accumulatorsSulfur electrodeHYDROSOL

The invention provides a preparation method of an S / TiO2 composite material for an anode of a sodium-sulfur battery. The preparation method comprises the following steps: dissolving butyl titanate, a template agent and a hydrolysis inhibitor into absolute ethyl alcohol; adding a mixed solution of de-ionized water and the absolute ethyl alcohol to form semi-transparent sol; transferring the sol into a high-pressure reaction kettle to react; calcining a solid product in air to remove the template agent to obtain meso-porous titanium dioxide; dispersing the meso-porous titanium dioxide into a sodium thiosulfate solution dissolved with a surfactant; adding hydrochloric acid to react; washing the solid product by a lot of the de-ionized water and drying; and eating under the protection of an inert atmosphere to obtain the S / TiO2 composite material. The meso-porous titanium dioxide prepared by the preparation method is large in specific surface area, high in porosity and strong in adsorption capability; the electrical conductivity of sulfur can be improved and a lot of nano sulfur and polysulfide can be contained; the polysulfide can be effectively prevented from being dissolved and diffused in electrolyte, and the utilization rate of the sulfur is improved; meanwhile, the structure of the meso-porous titanium dioxide is stable and a pore channel cannot be easily damaged, so as to have buffering effects on volume expansion and retraction in a charging / discharging process of a sulfur electrode.

Owner:CENT SOUTH UNIV

Preparation method of titanium dioxide aerogel

ActiveCN103086426ALarge specific surface areaLow densityTitanium dioxideSurface-active agentsLow density

The invention discloses a preparation method of titanium dioxide aerogel. The method comprises the following steps of: (1) firstly dissolving butyl titanate in ethanol, adding a surface active agent in the mixture, and magnetically stirring the resulting solution to obtain a mixed solution A; (2) dissolving a chelating agent in a mixed solution of the ethanol and water, and uniformly stirring the resulting solution to obtain a mixed solution B; (3) adding the mixed solution B into the mixed solution A, adding a drying control chemical additive in the mixed solution, stirring and standing the resulting solution, to obtain the titanium dioxide gel; (4) orderly aging, soaking and washing the titanium dioxide gel; (5) drying the product obtained in the step 4; and (6) thermally treating the dried product obtained from the step 5 at the temperature of 200-300 DEG C for 3-5 hours to obtain the final titanium dioxide aerogel. By virtue of the method, the titanium dioxide aerogel with a relatively large specific area, relatively low density, and uniform pore size distribution can be prepared.

Owner:ZHEJIANG UNIV

Medium-low temperature SCR denitration mesoporous molecular sieve catalyst and preparation method and application method thereof

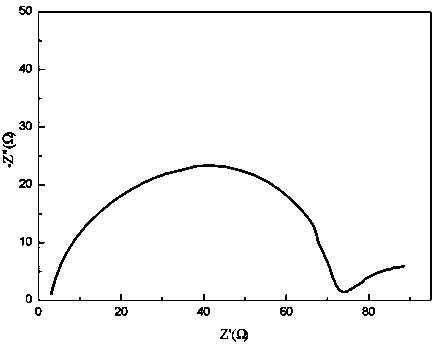

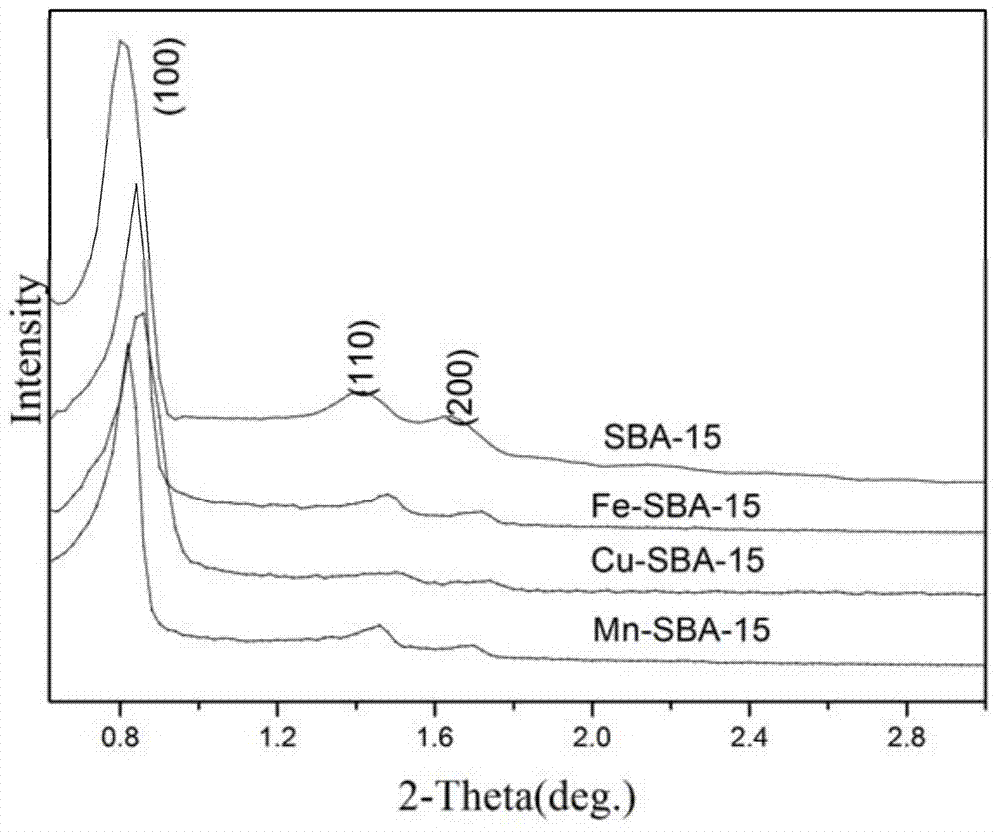

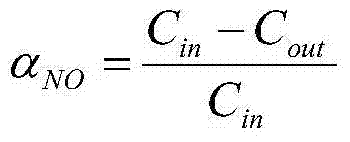

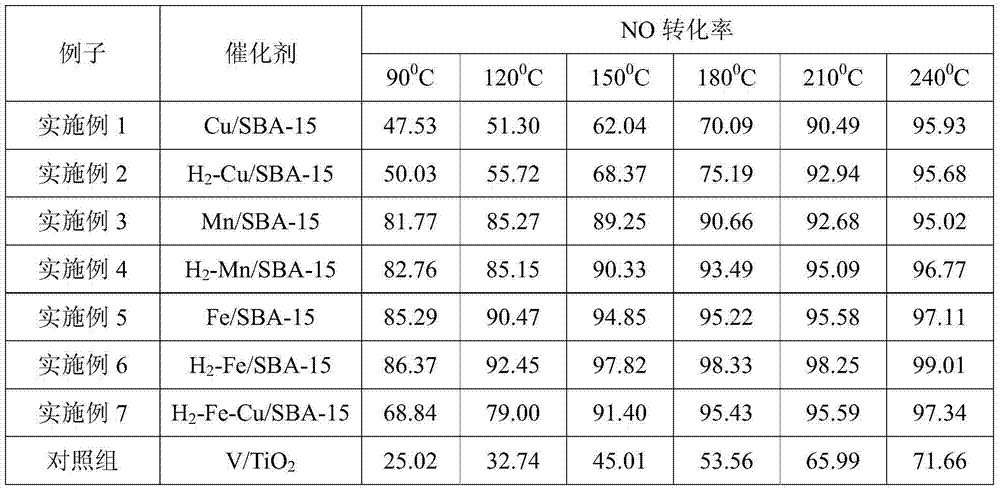

InactiveCN104492471AGood dispersionImprove medium and low temperature denitrification efficiencyMolecular sieve catalystsDispersed particle separationMolecular sieveActive component

The invention provides a medium-low temperature SCR denitration mesoporous molecular sieve catalyst and a preparation method and an application method of the medium-low temperature SCR denitration mesoporous molecular sieve catalyst. The catalyst is prepared from active components and a carrier, wherein the active components are one or more of iron, copper and manganese, and the carrier is an SBA-15 silicon dioxide mesoporous molecular sieve and has the characteristics of large specific surface area and uniform pore size distribution. According to the medium-low temperature SCR denitration mesoporous molecular sieve catalyst, the active components can be uniformly dispersed on the surface of the SBA-15, the effective active sites for catalytic reaction can be increased, the denitration efficiency of the catalyst is improved at a medium-low temperature interval of 90 DEG C-240 DEG C, and the catalyst can achieve better denitration effect after H2 reduction activation, and can achieve the denitration efficiency at medium-low temperature up to 80-99%.

Owner:CENT SOUTH UNIV

Preparation method of low-cost porous graphene

Owner:FUZHOU UNIV

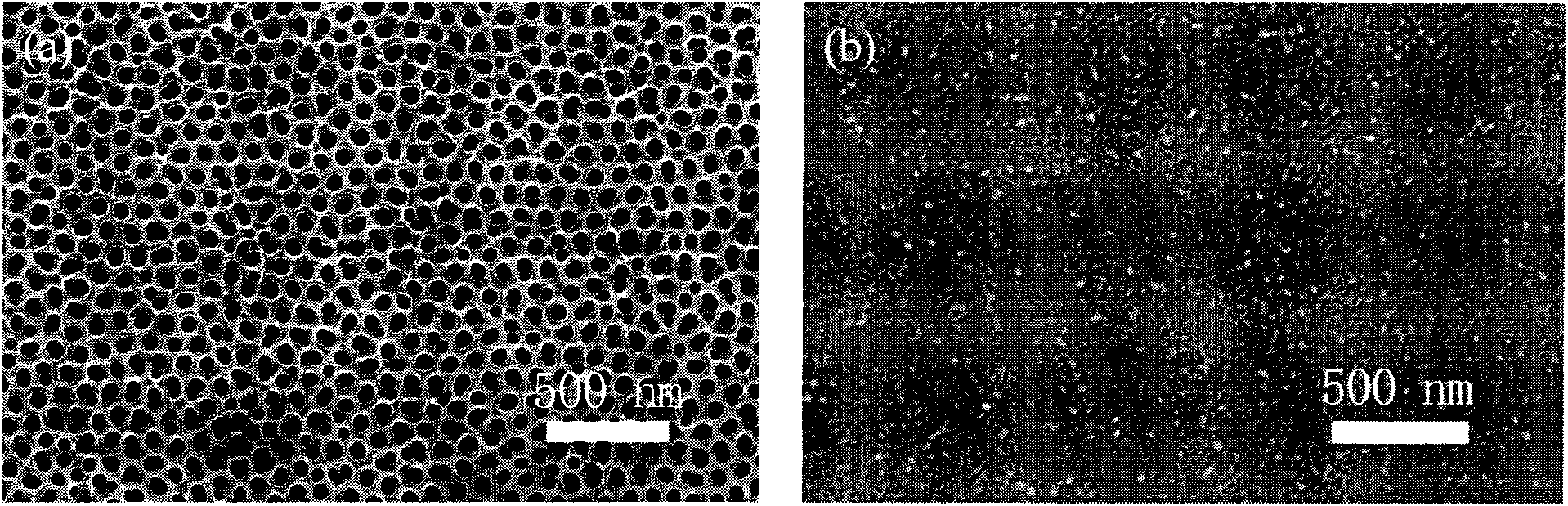

Method for preparing pore diameter controllable through hole anodized aluminum oxide film

The invention relates to technology for preparing an anodized aluminum oxide film, in particular to a method for preparing a pore diameter controllable through hole anodized aluminum oxide film. The method comprises the following steps of: performing anode electrolysis treatment on an anodized aluminum oxide film with an aluminum substrate in mixed solution of perchloric acid and acetone to obtain a pore diameter controllable anodized aluminum oxide film with two open ends in short time (2-300 seconds), wherein the pore diameters at the top end and the bottom end fo the anodized aluminum oxide film are accurately controllable in ranges of between 10 and 100nm and between 5 and 25nm; and putting the aluminum oxide film with the aluminum substrate subjected to stage depressurization-method oxidation into acetone solution of perchloric acid, and applying voltage 5-15V higher than film forming voltage for anode electrolysis treatment to obtain the pore diameter controllable through hole anodized aluminum oxide film. In the method, the pore diameters at the top end and the bottom end of the anodized aluminum oxide film can be respectively controlled, holing and removal of the aluminum substrate are completed by one step, and a plurality of problems of complicated process, time consumption, difficult control of pore diameters and the like in the conventional process for preparing the through hole anodized aluminum oxide film.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

Method for preparing silicon-aluminum aerogel by using fly ash as raw material through normal pressure drying

The invention discloses a method for preparing silicon-aluminum aerogel by using fly ash as a raw material through normal pressure drying, which comprises the following steps of: mixing, grinding and calcining the fly ash and sodium carbonate to enable acidic oxides and amphoteric oxides in the fly ash to react with the sodium carbonate, then dissolving a sintered material with hydrochloric acid, and carrying out suction filtration to obtain a filtrate, i.e. silicon-aluminum sol; settling and aging the silicon-aluminum sol to form silicon-aluminum gel; soaking with circulating water to remove chloride ions; soaking with an ethanol solvent instead of water; soaking with an organosilicon compound as a surface hydrophobic agent for surface hydrophobic treatment; and preparing the silicon-aluminum aerogel through normal pressure drying. The invention uses the industrial waste fly ash as the raw material to replace an organosilicon source with high price and a certain toxicity, and uses normal pressure drying to replace supercritical drying, so the safety performance is greatly enhanced, the production cost is greatly lowered; and the method has simple process and convenient operation and is suitable for large-scale production. The prepared silicon-aluminum aerogel can be widely applied to the fields of heat insulating materials and the like.

Owner:SOUTHWEAT UNIV OF SCI & TECH

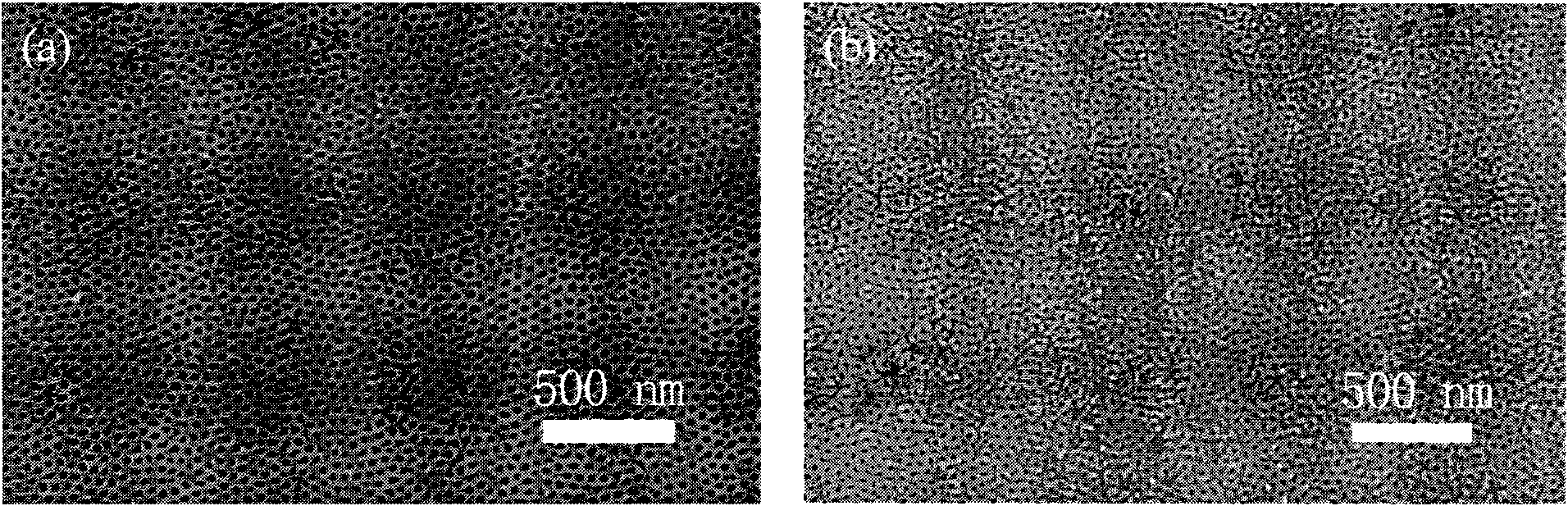

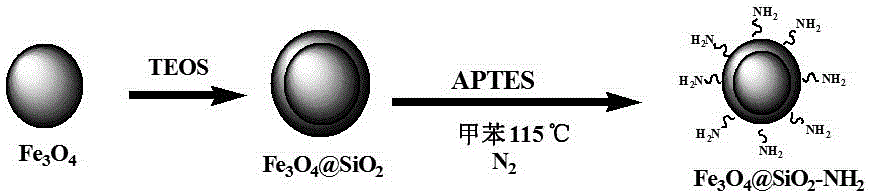

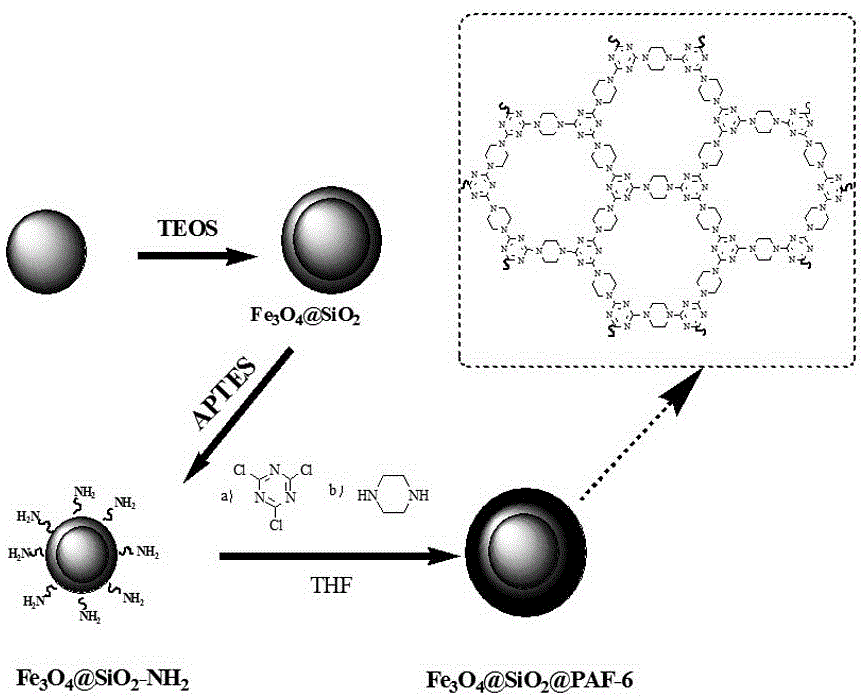

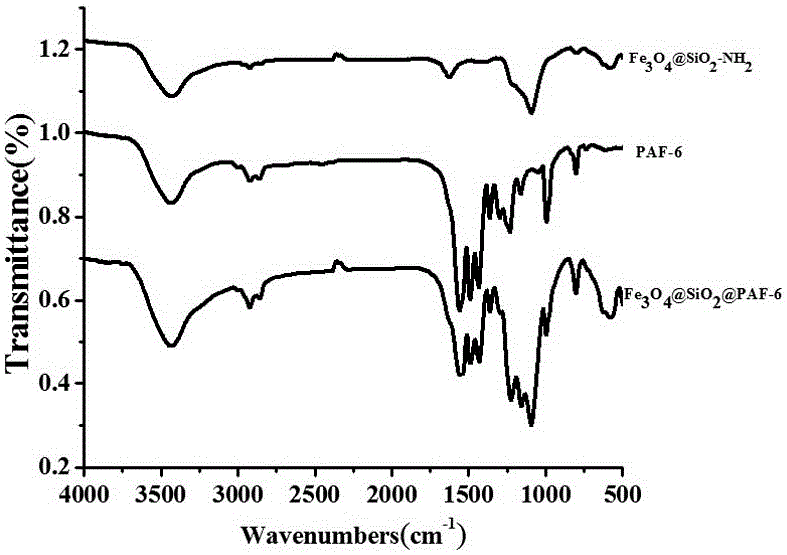

Magnetic PAFs solid-phase extracting agent and preparation method and application thereof

ActiveCN105879842AEasy to separateAvoid inconvenienceOther chemical processesWater contaminantsSilanesCarboxylic acid

The invention discloses a magnetic PAFs solid-phase extracting agent. A preparation method of the magnetic PAFs solid-phase extracting agent includes allowing 3-aminopropyl triethoxy silylation ferroferric oxide to have a temperature-programmed reaction with piperazine and cyanuric chloride in the presence of N, N-diisopropylethylamine to obtain the magnetic PAFs solid-phase extracting agent. The magnetic PAFs solid-phase extracting agent and the preparation method thereof have the advantages that the prepared magnetic PAFs solid-phase extracting agent is good in dispersity and stable in core-shell structure; the preparation method is simple, low in cost, widely applicable, capable of achieving repeated material recycling, and the like; a covalent organic framework bonded to the ferroferric oxide can provide various action sites such as an inclusion interaction site, a hydrogen-bond interaction site, a pi-pi interaction site and an anion exchange site, so that the covalent organic framework has specific recognition and retention acting force on polar substances such as phenols and carboxylic acids.

Owner:ZHENGZHOU UNIV

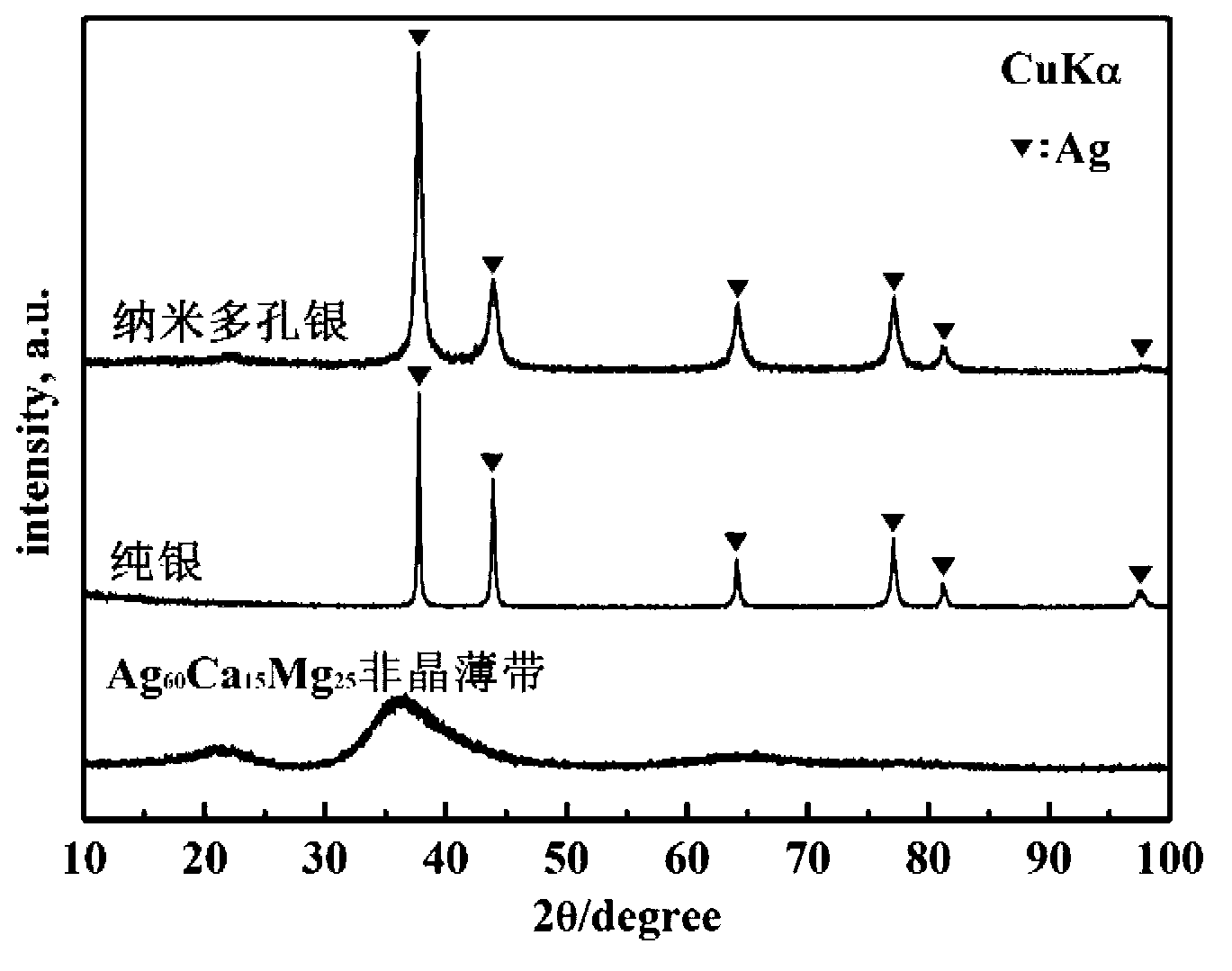

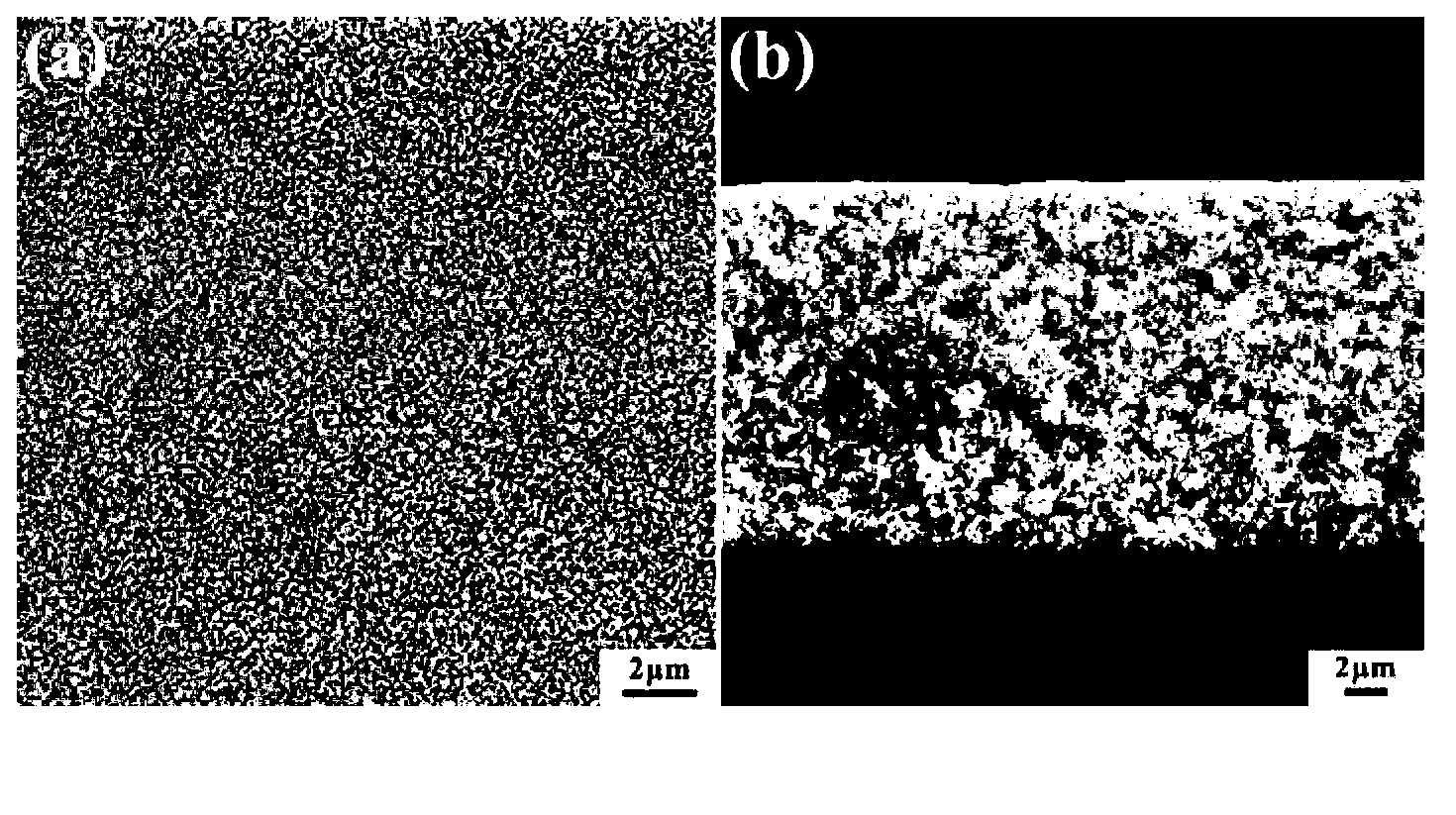

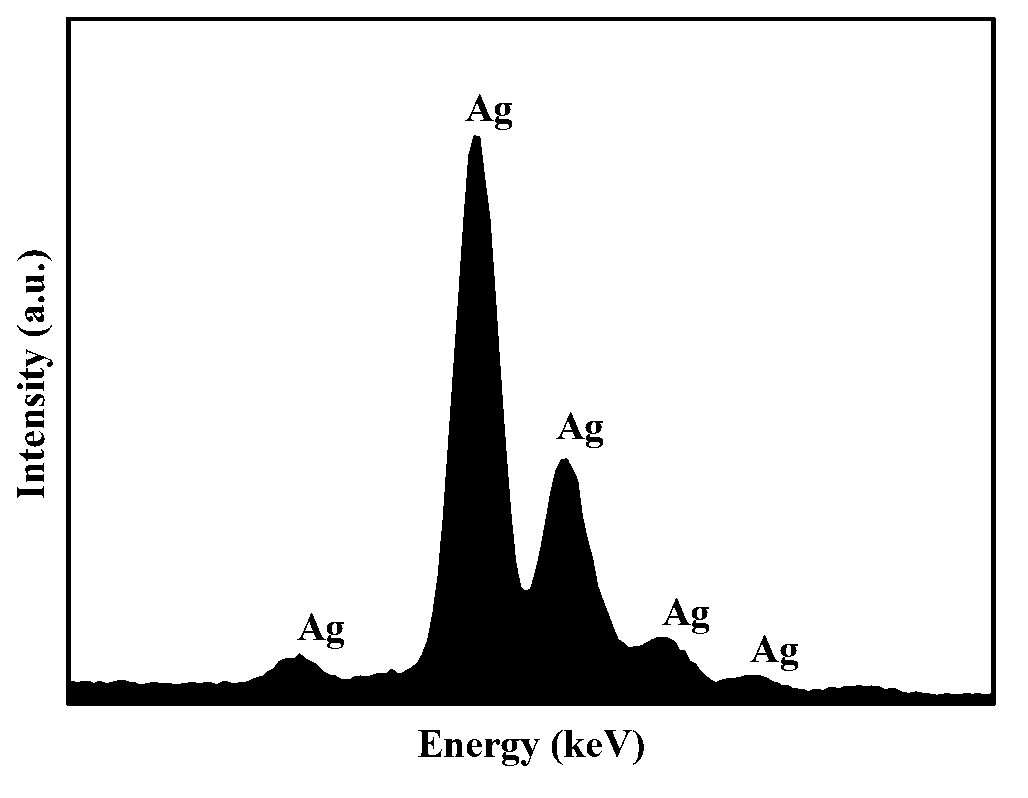

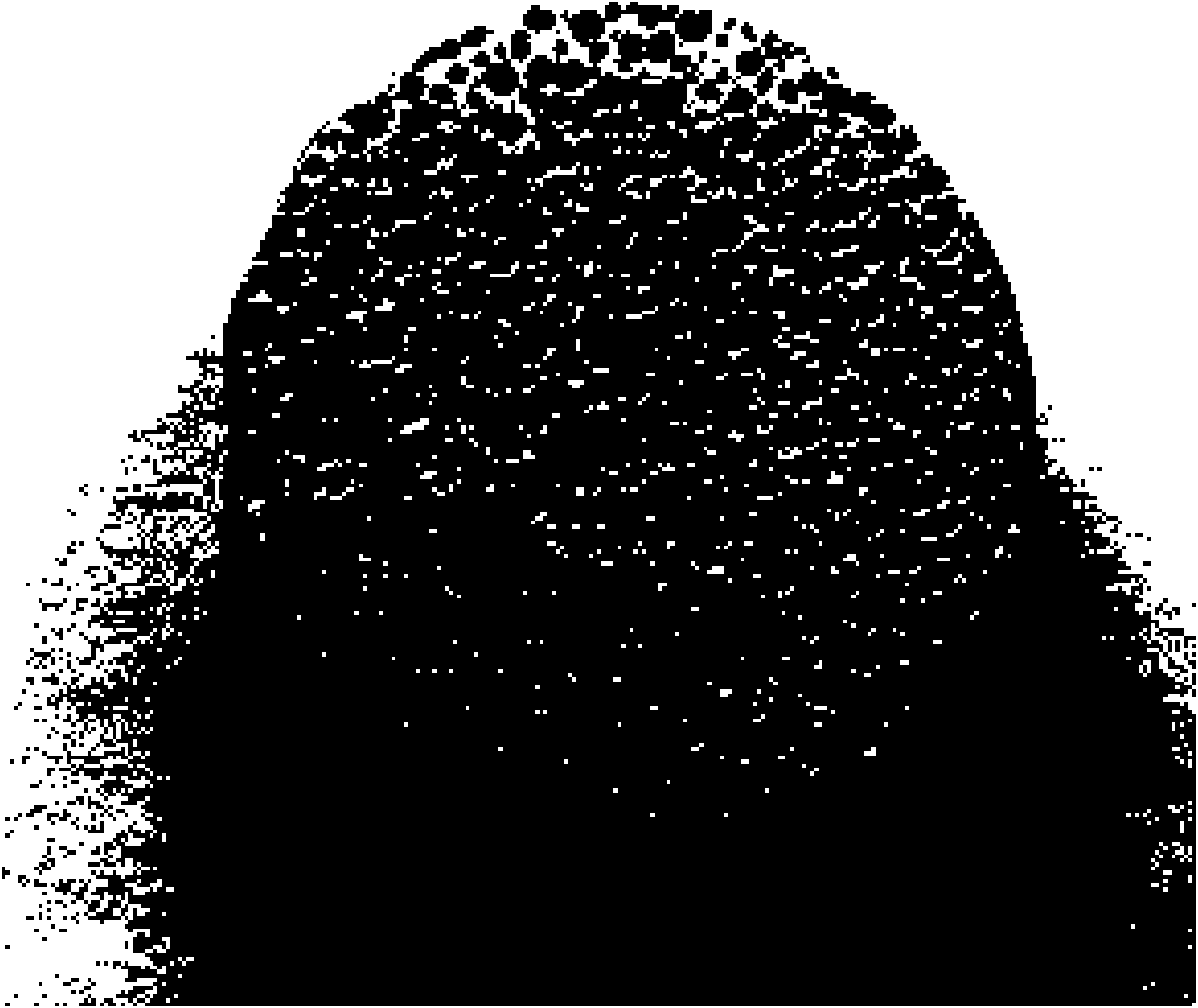

Method for preparing nano porous silver based on Ag-based amorphous alloy

The invention belongs to the field of preparation of nano porous metal materials, and relates to a method for preparing nano porous silver based on an Ag-based amorphous alloy. By the method, the nano porous silver with the aperture of 20-100 nm is finally obtained by preparing a series of Ag-Mg-Ca amorphous alloy thin bands by taking the Ag-based amorphous alloy as a precursor by a solvent quick quenching method and then removing Mg and Ca elements by performing electric chemical alloy component corrosion removal by proper electrolyte. By the method, the structure and the size of the nano porous silver are adjusted and controlled by controlling the amorphous alloy components or electric chemical corrosion temperature; the operation technology is simple; and furthermore, the nano porous silver is extremely high in surface-enhancement raman scattering (SERS) performance and has a wide application prospect in the fields of environment friendliness, catalysis and biological sensors.

Owner:UNIV OF SCI & TECH BEIJING

Method for preparing ceramic particle reinforced foamed aluminum-matrix composite material

The invention relates to a method for preparing a ceramic particle reinforced foamed aluminum-matrix composite material, which relates to a method for preparing a foamed aluminum-matrix composite material. The method solves the problems of high production cost and nonuniform pore distribution of the obtained foamed aluminum-matrix composite material due to a foaming agent TiH2 adopted in a conventional melt-foaming method which is expensive, needs pretreatment and has a difficultly controlled decomposition rate. The method comprises the following steps of: mixing aluminum alloy powder, ceramic particles and calcium carbonate (CaCO3) powder and placing a mixture into a graphite mould; placing the graphite mould into a vacuum hotpressing sintering furnace to prepare a prefabricated body; and performing forward extrusion, heating and foaming on the prefabricated body to obtain the ceramic particle reinforced foamed aluminum-matrix composite material. By using a powder metallurgic method and taking the CaCO3 powder as a foaming agent, the method has the advantages of low price, no pretreatment, simple process, stable decomposition rate, convenience for industrial production and uniform pore distribution of the obtained composite material which has a pore diameter of 0.5 to 2 mm, a porosity of 40 to 82 percent and a compressive yield strength of 36 to 70 MPa.

Owner:HARBIN INST OF TECH

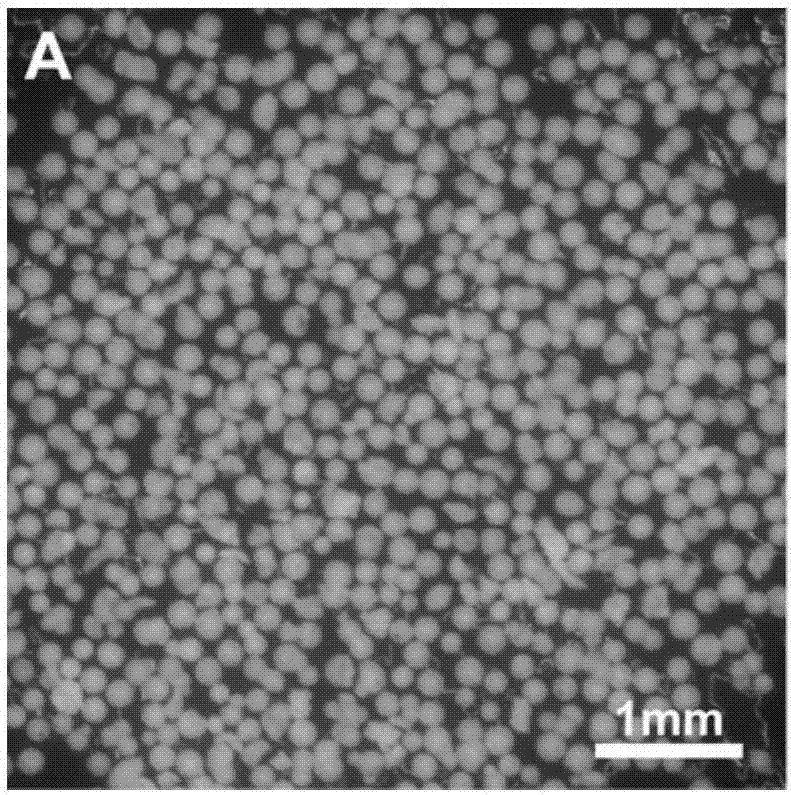

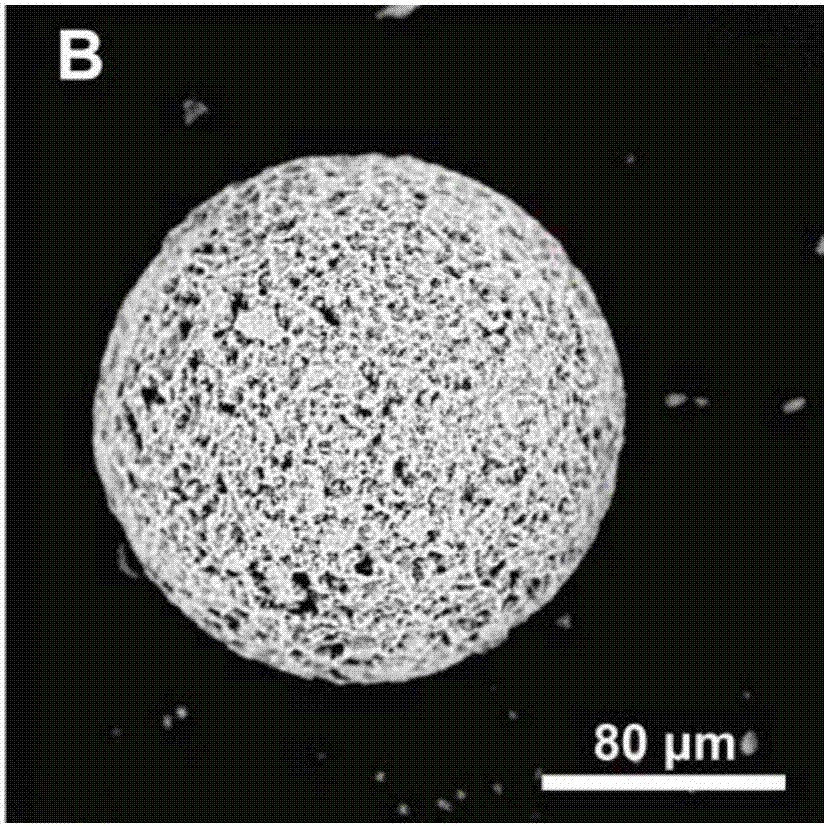

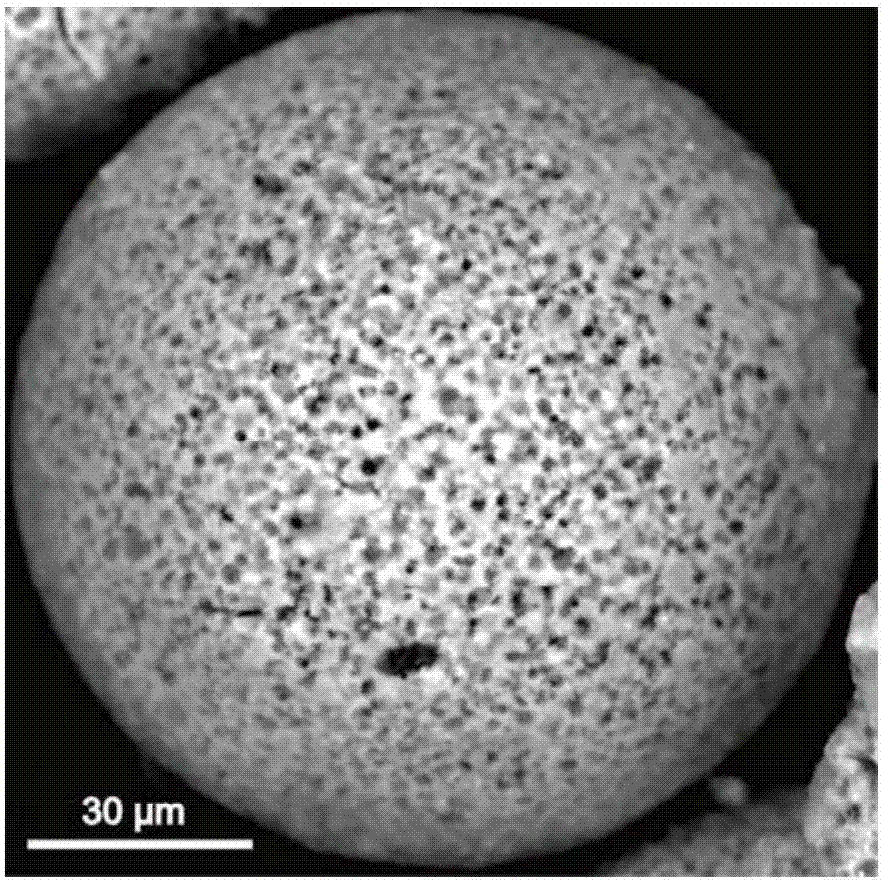

Preparation method and application of porous geological polymer microspheres

ActiveCN107973559AHigh Microsphere EfficiencyParticle size adjustableOther chemical processesRadioactive contaminantsMicrosphereSorbent

The invention discloses a preparation method of porous geological polymer microspheres. The porous geological polymer microspheres are prepared by a dispersion suspension solidification method. Compared with the prior art, low-temperature curing and one-shot molding granulation are realized without requirements of high-temperature calcination and curing and addition of other auxiliaries; and at the same time, large-scale use of solid wastes is realized, and raw materials are widely available, cost is low, process is simple, and the whole process is non-toxic and pollution-free; in addition, the preparation efficiency is high with a ball-forming degree exceeding 90%; the size of the particles can be adjusted, and the pore size distribution is uniform; the pore volume is large, and can be regulated, and a specific surface area of the microspheres reaches 110m2 / g, thus, the porous geological polymer microspheres can be directly used for packed columns for column separation. Experiments show that the porous geological polymer microspheres have a good adsorption effect on heavy metals, and can be used as adsorbents for heavy metals, and have a broad application prospect in the aspect ofremoving heavy metals and radioactive elements in water.

Owner:GUANGXI UNIV

Ordered mesoporous nanocrystalline titanic oxide/carbon compound material and synthetic method

InactiveCN101322937AImprove featuresLarge specific surface areaPhysical/chemical process catalystsCarbon compositesTitanium oxide

The invention discloses a synthetic method for an ordered mesoporous nanocrystal titanium / carbon dioxide composite material with high content of titanium dioxide. Resol with the molecular weight of 200 to 500, triblock copolymer and mixed titanium source form an ordered mesophase in a highly volatile organic solvent system by self assembly induced by solvent volatilization and then the ordered mesoporous nanocrystal titanium / carbon dioxide composite material is obtained after calcination in nitrogen atmosphere. The composite material prepared has ordered pore canal structure, high specific surface which is 100 to 400m<2> / g, large pore volume which is 0.1 to 0.5cm<3> / g and even aperture which is about 2.3 to 5.0nm. The synthetic method overcomes the disadvantages that the specific surface of titanium dioxide is low and the pore canal structure is easy to collapse during the course of crystallization, successfully introduces carbon component to obtain the ordered mesoporous nanocrystal titanium / carbon dioxide composite material and has the advantages of simple synthetic operation, cheap raw material price and low device requirement.

Owner:SHANGHAI NORMAL UNIVERSITY

Alumina-magnesia refractory brick containing light porous aggregate and its making process

The present invention relates to one kind of alumina-magnesia refractory brick containing light porous aggregate and its production process. The technological scheme is that the alumina-silica refractory brick is produced with light porous Al2O3-MgO refractory material 30-70 wt%, compact Al2O3-MgO refractory material 0-35 wt%, fine magnesia powder 5-30 wt%, fine alpha-Al2O3 powder 3-10 wt%, fine corundum powder 0-25 wt% and fine spinel powder 0-25 wt%, and through mixture, adding waste pulp liquid in 3-7 wt% as binding agent, stirring, pressing to form adobe, drying at 100-150 deg.c for 12-48 hr, sintering at 1400-1600 deg.c for 2-5 hr and naturally cooling. The alumina-magnesia refractory brick has high macro porosity, small average pore size, low heat conductivity and high medium erosion resistance, and may be used in the permanent layer or work layer in high temperature kiln, furnace and container.

Owner:WUHAN UNIV OF SCI & TECH

Method for preparing iron-carrying ordered mesoporous carbon materials

The invention discloses a method for preparing novel iron-carrying ordered mesoporous carbon materials. Through a soft template route, under the condition of adding no acid additionally, acid produced by iron-salt precursor hydrolysis of a synthesis system is utilized to catalyze phenolic polycondensation, and iron-salt precursors and phenolic polycondensation products are self-assembled around surfactant and are carbonized in inert atmosphere so as to prepare the iron-carrying ordered mesoporous carbon materials. The obtained iron-carrying ordered mesoporous carbon materials are ordered in height, high in specific surface area (410-586m2 . g-1) and uniform in pore size distribution (3.9 nm). The method realizes the one-step synthesis of the iron-carrying ordered mesoporous carbon materials. Compared with mesoporous carbon synthesis through a hard template route and an impregnating-loading process, the method has the advantages of easy operation, low cost, low requirements for equipment, and the like. The iron-carrying ordered mesoporous carbon materials prepared by the method have wide application prospects in the fields of catalysis, separation, electrode materials, repair to environmental pollutants, and the like.

Owner:NANJING UNIV OF SCI & TECH

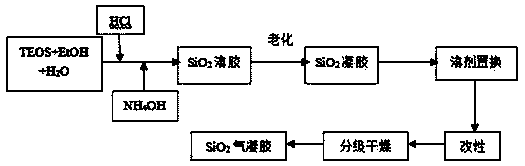

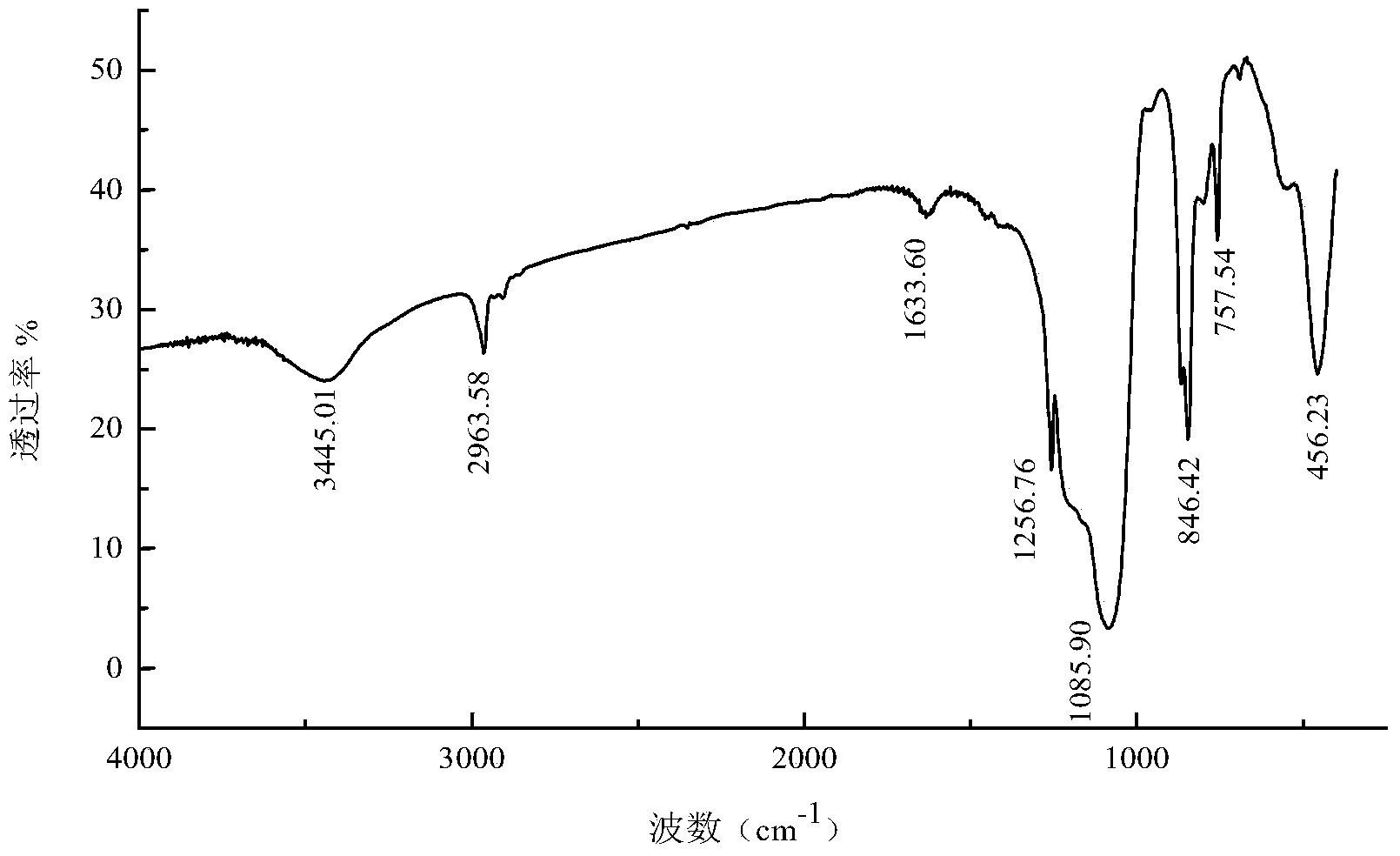

Method for preparing hydrophobic SiO2 aerogel by virtue of normal pressure drying

ActiveCN103936018AEasy to operateThe process is simple and easy to controlSilicaMaterials preparationAlcohol

The invention belongs to the field of aerogel material preparation technologies, and relates to a method for preparing a hydrophobic SiO2 aerogel by virtue of normal pressure drying. During the preparation, a two-step method is adopted, an organic silicon source as precursor, water as a hydrolysis agent, absolute ethyl alcohol as a solvent, acid and alkali as catalysts, and an organic silicon solution and a surface modifier. The preparation method comprises the following steps: mixing and stirring the organic silicon source, the water and the absolute ethyl alcohol in proportion, and respectively adding an acid catalyst and an alkaline catalyst by virtue of an acid and alkali two-step method to regulate pH value so as to form gel; performing solvent replacement on the aged gel, carrying out surface hydrophobic modification, replacing a hydrophilic group on the surface of the gel through a hydrophobic group, so that the gel is hydrophobic; finally, performing normal pressure drying to obtain the hydrophobic SiO2 aerogel. The method disclosed by the invention can be used for reducing the preparation cost of the aerogel; moreover, according to a hydrophobicity test, the contact angle can reach about 158 degrees, thereby showing that the hydrophobicity is good.

Owner:NANJING UNIV OF TECH

Method for preparing anesthesia activated carbon fiber

InactiveCN101230502ALarge specific surface areaWide variety of sourcesFibre chemical featuresVegetal fibresActivated carbonWater vapor

The invention provides a method of preparing a hemp activated carbon fiber, which adopts a hemp fiber or a hemp fabric as the raw material. The method includes the following steps: firstly, the hemp fiber or the hemp fabric is boiled in a pretreating solution, taken out and then dried; secondly, the obtained fiber or hemp fabric is put into a charing furnace, heated for charing under the protection of the nitrogen gas, then cooled to the room temperature and then rinsed repeatedly to be neutral; and thirdly, vapor is entered into the hemp fiber or the hemp fabric for an activation treatment, then dried after the activation treatment and finally a hemp activated carbon fiber is obtained. The specific surface area of the prepared activated carbon fiber is 680-1950m<2> / g and the yield of the activated carbon fiber is 20 to 62 percent.

Owner:THE QUARTERMASTER EQUIPMENT RESEARCH INSTITUTE OF THE GENERAL LOGISITIC DEPARTME +1

Method for preparing porous film by adopting high molecular weight polyolefin and product and application thereof

ActiveCN102153776AHigh mechanical strengthHigh temperature puncture strengthCell component detailsPolymer sciencePolyolefin

The invention discloses a method for preparing a porous film by adopting high molecular weight polyolefin. The method comprises the following steps of: (1) performing soaking treatment on the high molecular weight polyolefin; (2) blending the soaked high molecular weight polyolefin and materials such as thermoplastic resin, auxiliary agent and the like to prepare blended master batch; (3) preparing the obtained blended master batch into a film material; and (4) extracting the film material to obtain the porous film. The porous film has the characteristics of high mechanical strength, high porosity, uniform aperture size, high ion permeability, excellent dielectric property and the like, can be used as a lithium ion battery diaphragm, and has better safety; and the method has simple process and easily controlled conditions, is suitable for mechanized large-scale production, and has low cost and high efficiency.

Owner:LIAOYUAN HONGTU LI ION BATTERY DIAPHRAGM TECH

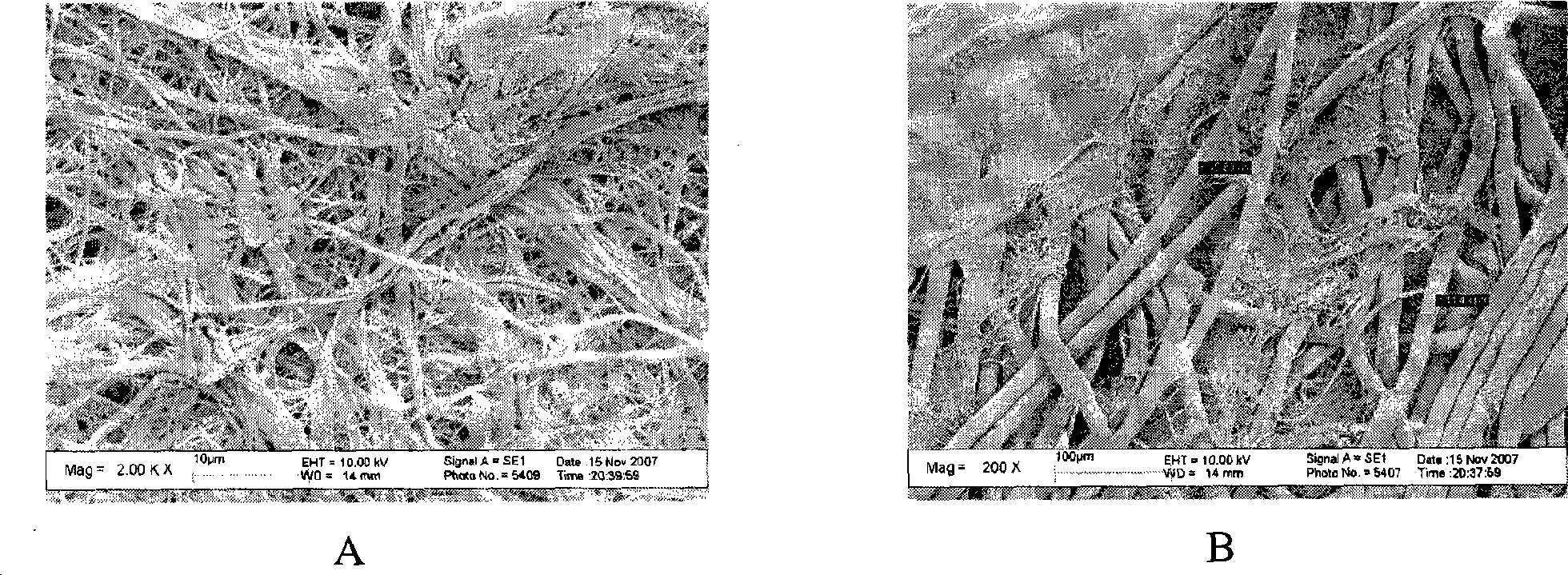

Nonwoven fabric sheet and method for producing same

InactiveUS20070184256A1High porosityUniform pore size distributionLayered productsCeramic shaping apparatusPorosityPolymer science

The nonwoven fabric sheet of the present invention is characterized by a porosity in the range of 0.3 to 0.7 and an average pore size in the range of 0.5 μm to 5.0 μm. The nonwoven fabric sheet of the present invention preferably has a maximum pore size (μm) / average pore size (μm) ratio of 1.30 or lower. The nonwoven fabric sheet of the present invention is obtained by press-molding a nonwoven fabric at a temperature lower than the melting point of the thermoplastic resin which constitutes the nonwoven fabric sheet. According to the present invention, there is provided a nonwoven fabric sheet that has a high porosity, small uniform pore sizes and excellent productivity, which can suitably be used in various applications such as filters, light diffusing material, liquid absorber and heat insulating materials; and a method for producing the nonwoven fabric sheet.

Owner:MITSUI CHEM INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com

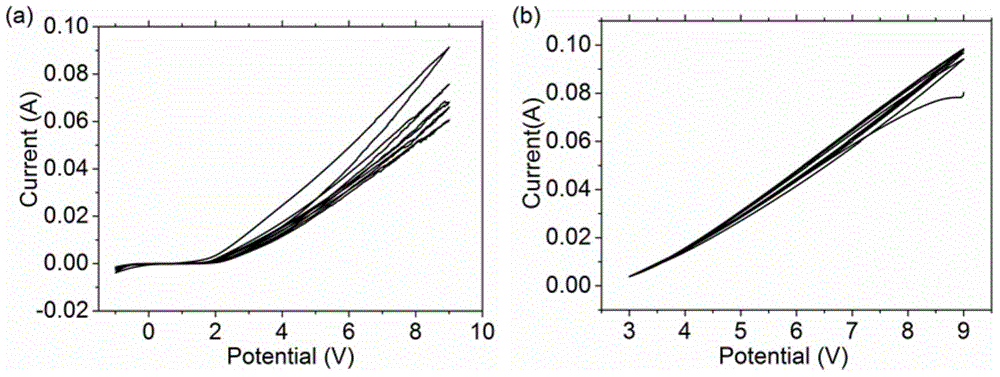

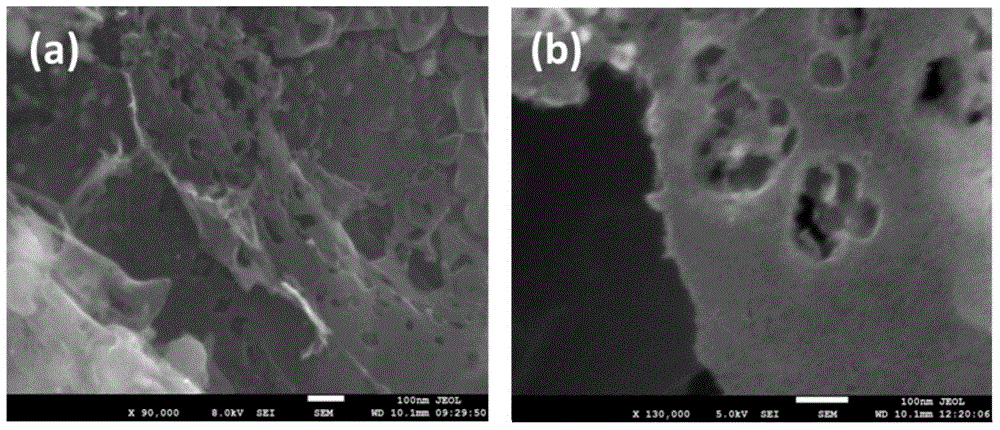

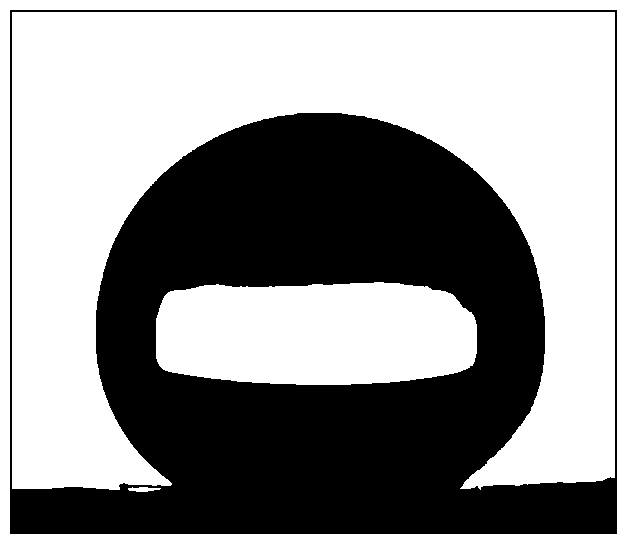

![Mesoporous WO[3-x] visible-light-driven photocatalyst with oxygen vacancy as well as preparation method and application thereof Mesoporous WO[3-x] visible-light-driven photocatalyst with oxygen vacancy as well as preparation method and application thereof](https://images-eureka-patsnap-com.libproxy1.nus.edu.sg/patent_img/371f3b02-68c7-41ef-a7cd-a4dfbefe86ed/1505051449421.PNG)

![Mesoporous WO[3-x] visible-light-driven photocatalyst with oxygen vacancy as well as preparation method and application thereof Mesoporous WO[3-x] visible-light-driven photocatalyst with oxygen vacancy as well as preparation method and application thereof](https://images-eureka-patsnap-com.libproxy1.nus.edu.sg/patent_img/371f3b02-68c7-41ef-a7cd-a4dfbefe86ed/1505051449422.PNG)

![Mesoporous WO[3-x] visible-light-driven photocatalyst with oxygen vacancy as well as preparation method and application thereof Mesoporous WO[3-x] visible-light-driven photocatalyst with oxygen vacancy as well as preparation method and application thereof](https://images-eureka-patsnap-com.libproxy1.nus.edu.sg/patent_img/371f3b02-68c7-41ef-a7cd-a4dfbefe86ed/1505051449423.PNG)