Method for preparing silicon nitride porous ceramic by gel injection moulding

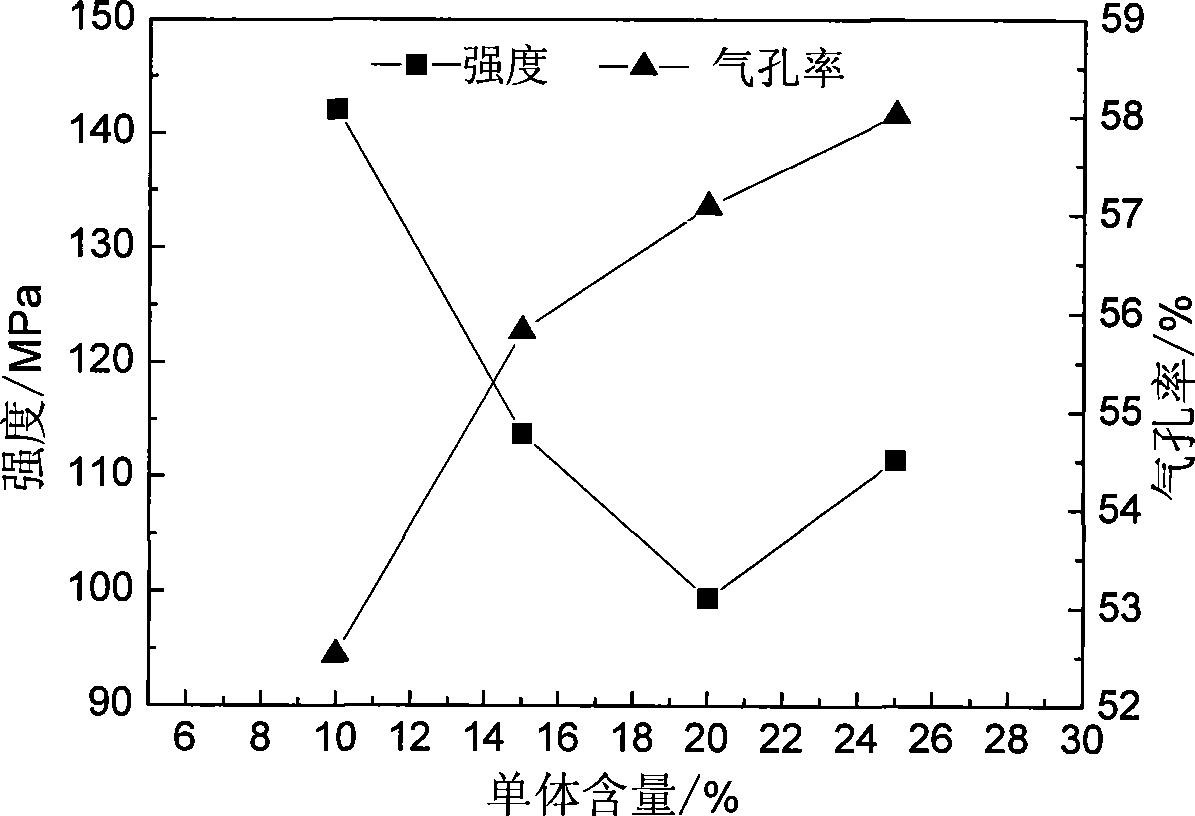

A technology of porous ceramics and gel injection molding, applied in the field of porous ceramics, can solve the problems of low strength, different particle sizes, uneven distribution of pore-forming agents, etc., and achieve the effect of high porosity and high strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] Embodiment 1: A kind of method that utilizes gel casting method to prepare silicon nitride porous ceramics, this method comprises: prepare slurry, prepare green body, degrease and sinter:

[0038] (1) Preparation of slurry: 10 parts by weight of acrylamide (AM), 3 parts by weight of crosslinking agent, 1 part by weight of dispersant and 86 parts by weight of water are mixed to prepare a premix; add 45 parts by weight of nitrogen to the premix Silica powder and 7 parts by weight of sintering aid, adjust the pH value to 9, and make a slurry after ball milling for 12 hours; Al in the sintering aid 2 o 3 and Y 2 o 3 The ratio is 1:1;

[0039] (2) Preparation of green body: the slurry is vacuum degassed, adding 0.1 parts by weight of initiator, degassed again, and injected into the mold. Under the condition of 60°C, react for 50 minutes to make the slurry gel solidify and demould. ℃ and 98% humidity conditions to obtain green body;

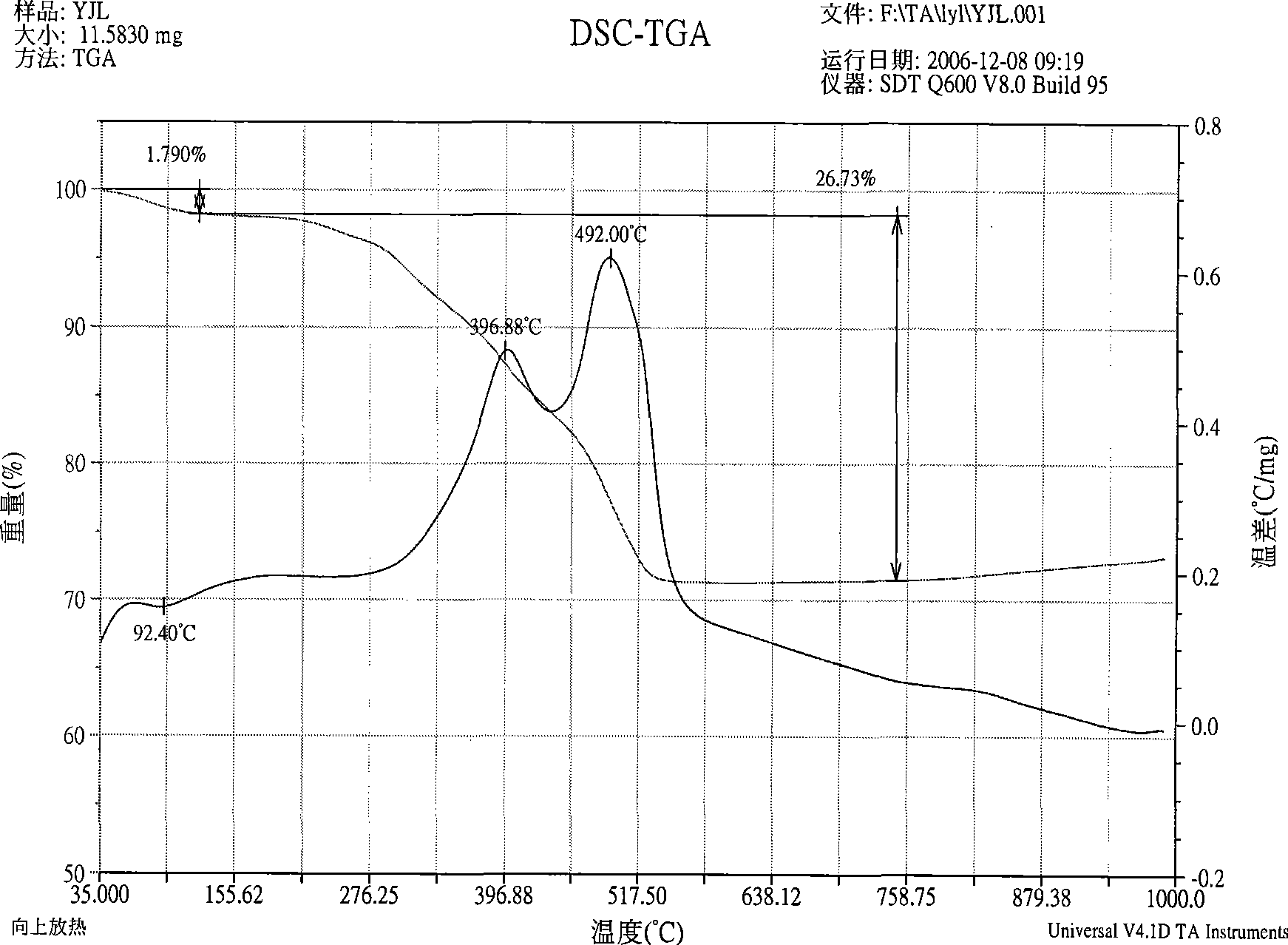

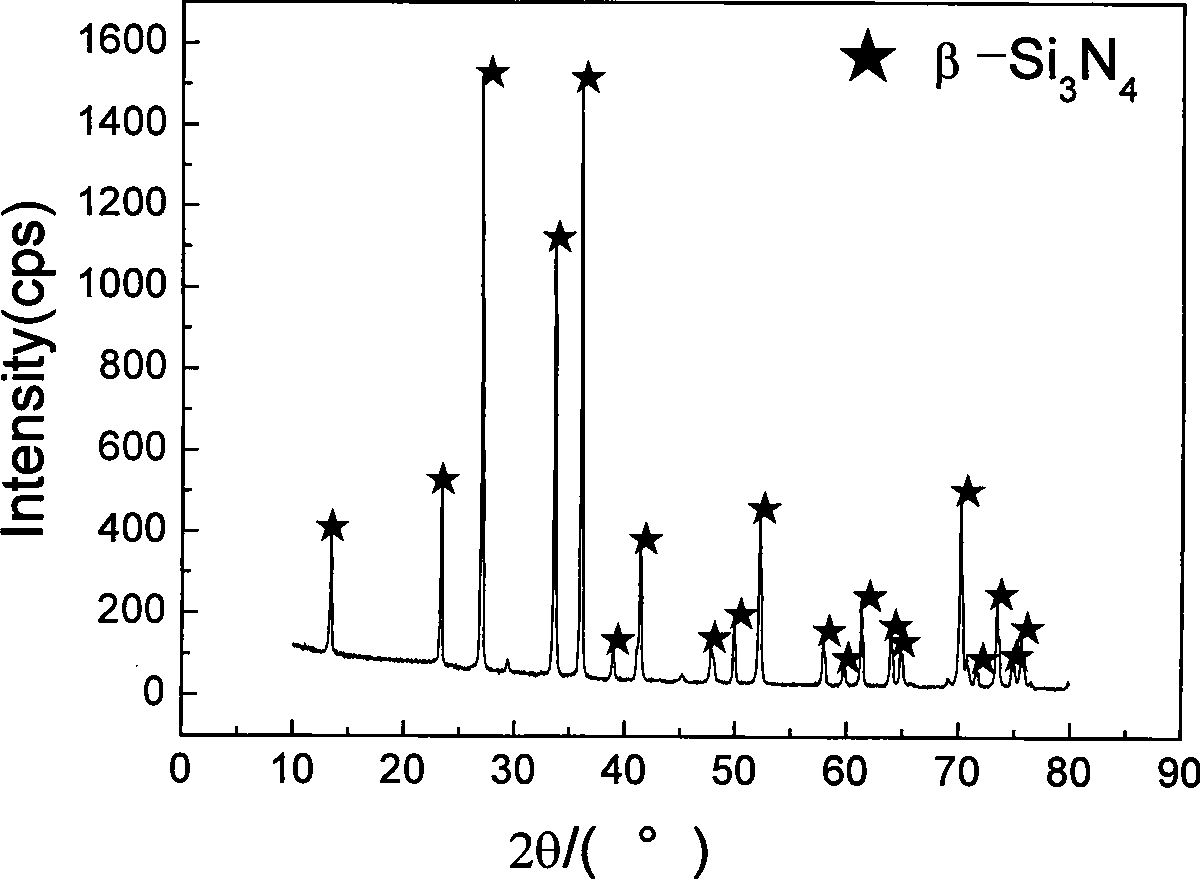

[0040] (3) Body degreasing: The degr...

Embodiment 2

[0042] Embodiment 2: A kind of method that utilizes gel casting method to prepare silicon nitride porous ceramics, this method comprises: prepare slurry, prepare green body, degrease and sinter:

[0043] (1) Preparation of slurry: 25 parts by weight of acrylamide (AM), 8 parts by weight of crosslinking agent, 1 part by weight of dispersant and 66 parts by weight of water are mixed to prepare a premix; add 40 parts by weight of nitrogen to the premix Silica powder and 3 parts by weight of sintering aid, adjust the pH value to 11, and make a slurry after ball milling for 12 hours; Al in the sintering aid 2 o 3 and Y 2 o 3 The ratio is 1:3;

[0044] (2) Preparation of green body: the slurry is vacuum degassed, and 20 parts by weight of initiator is added, degassed again, and injected into the mold. Under the condition of 65°C, react for 30 minutes to make the slurry gel and solidify, and demould. ℃ and 98% humidity conditions to obtain green body;

[0045] (3) Body degreasin...

Embodiment 3

[0047] Embodiment 3: A kind of method that utilizes gel casting method to prepare silicon nitride porous ceramics, this method comprises: prepare slurry, prepare green body, degrease and sinter:

[0048] (1) Preparation of slurry: 25 parts by weight of acrylamide (AM), 10 parts by weight of crosslinking agent, 1 part by weight of dispersant and 64 parts by weight of water are mixed to prepare a premix; add 50 parts by weight of nitrogen to the premix Silica powder and 10 parts by weight of sintering aid, adjust the pH value to 11, and make a slurry after ball milling for 12 hours; Al in the sintering aid 2 o 3 and Y 2 o 3 The ratio is 3:1;

[0049] (2) Preparation of green body: the slurry is degassed in vacuum, 10 parts by weight of initiator is added, degassed again, and injected into the mold. Under the condition of 65°C, react for 60 minutes to make the slurry gel and solidify, and demould. ℃ and 98% humidity conditions to obtain green body;

[0050] (3) Body degreasi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bending strength | aaaaa | aaaaa |

| Bending strength | aaaaa | aaaaa |

| Bending strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com