Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

3299 results about "Oil separation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

An oil water separator (OWS) is a piece of equipment used to separate oil and water mixtures into their separate components.There are many different types of oil-water separator. Each has different oil separation capability and are used in different industries. Oil water separators are designed and selected after consideration of oil separation performance parameters and life cycle cost ...

Compressor

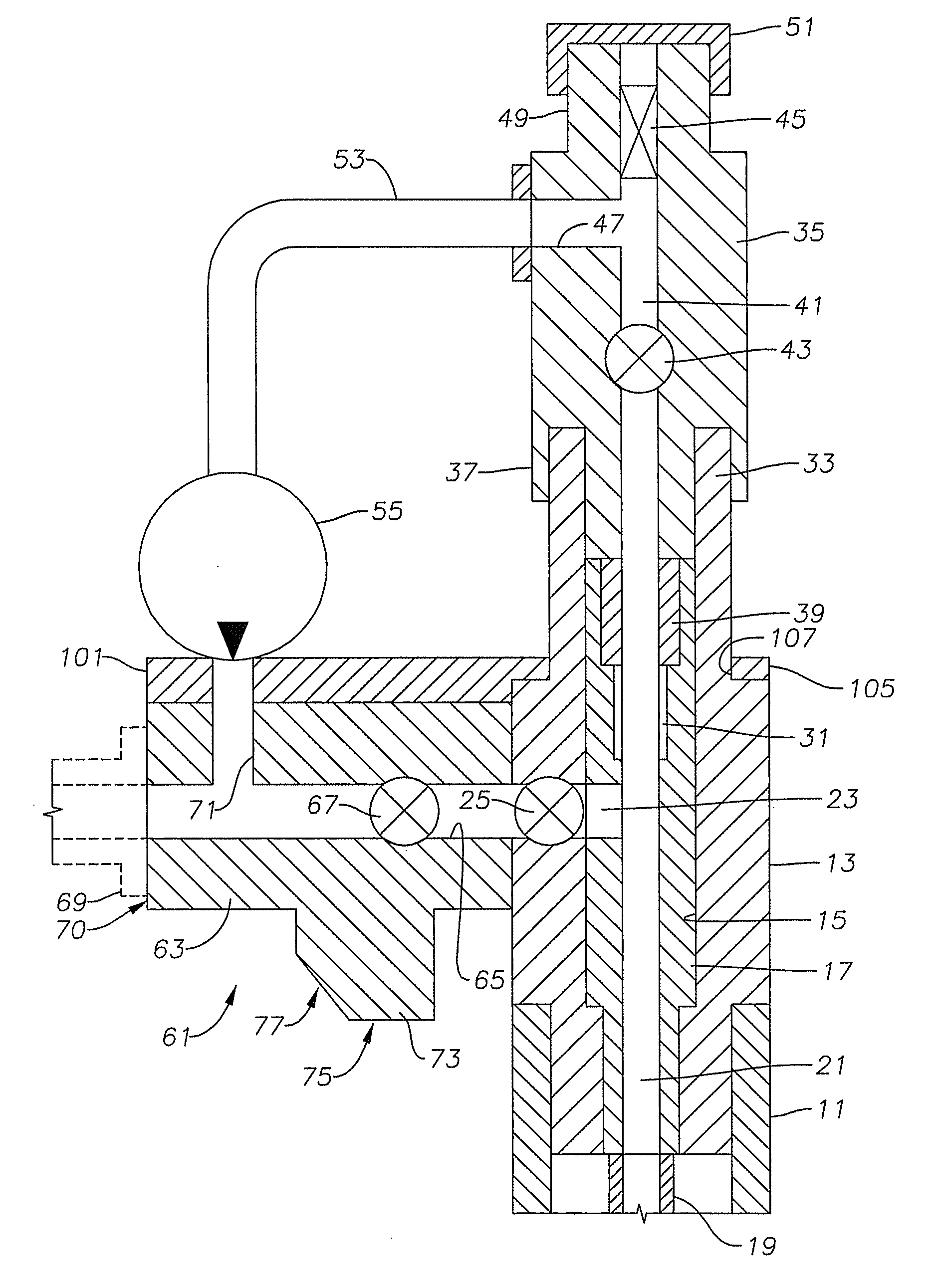

ActiveUS6960070B2Easy to fixPrecise alignmentRotary/oscillating piston combinations for elastic fluidsEngine of arcuate-engagement typeDrive shaftEngineering

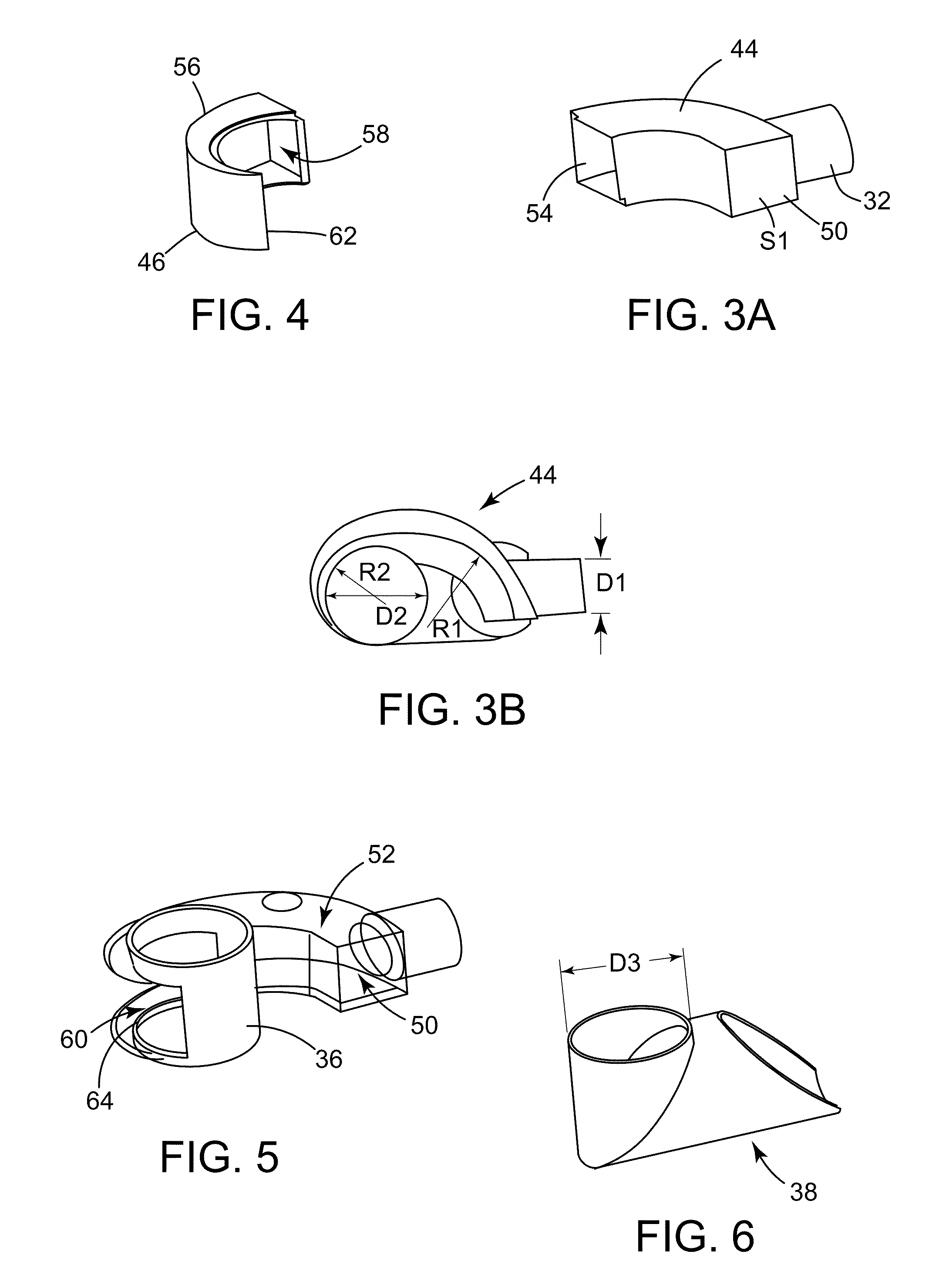

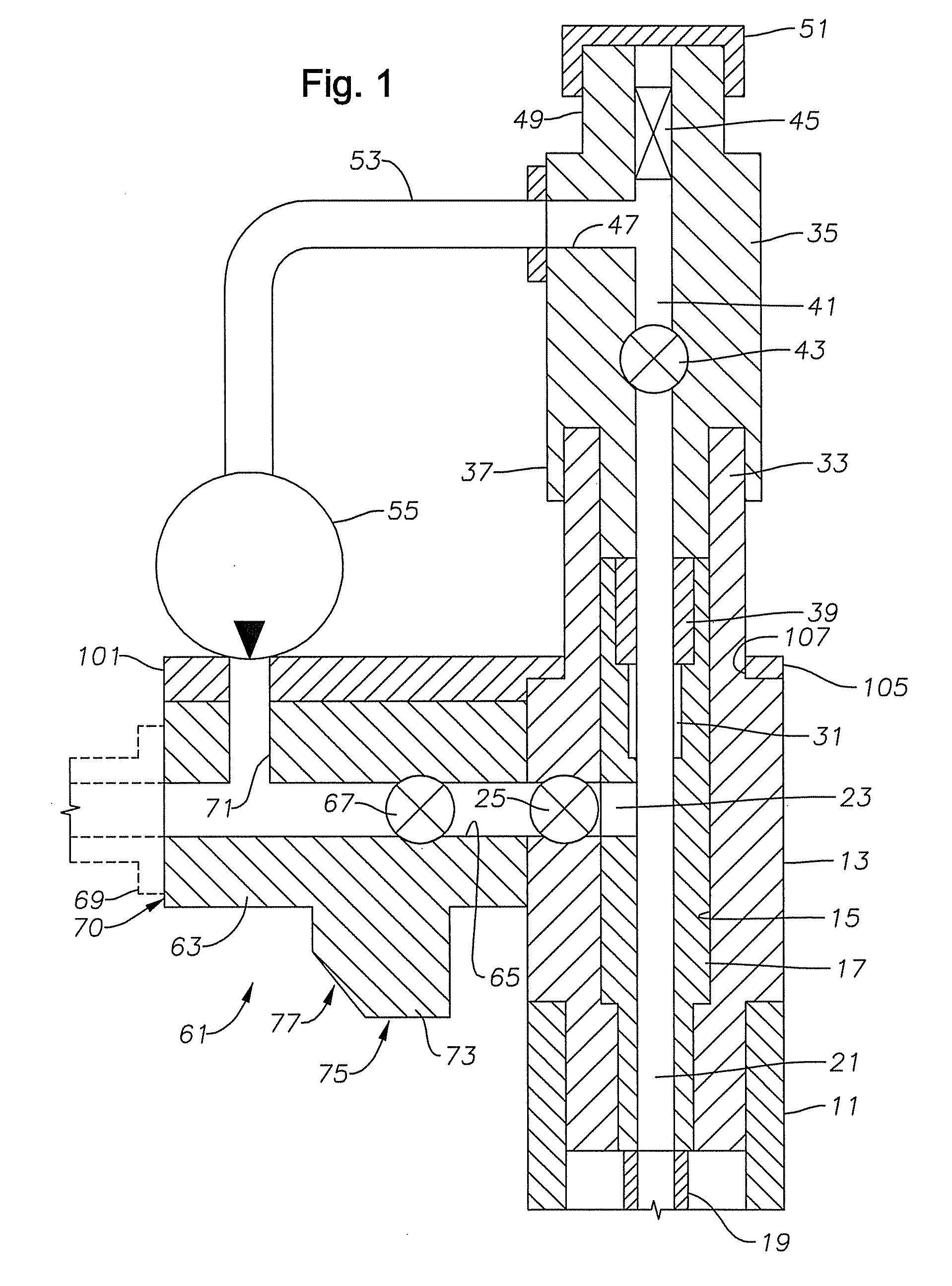

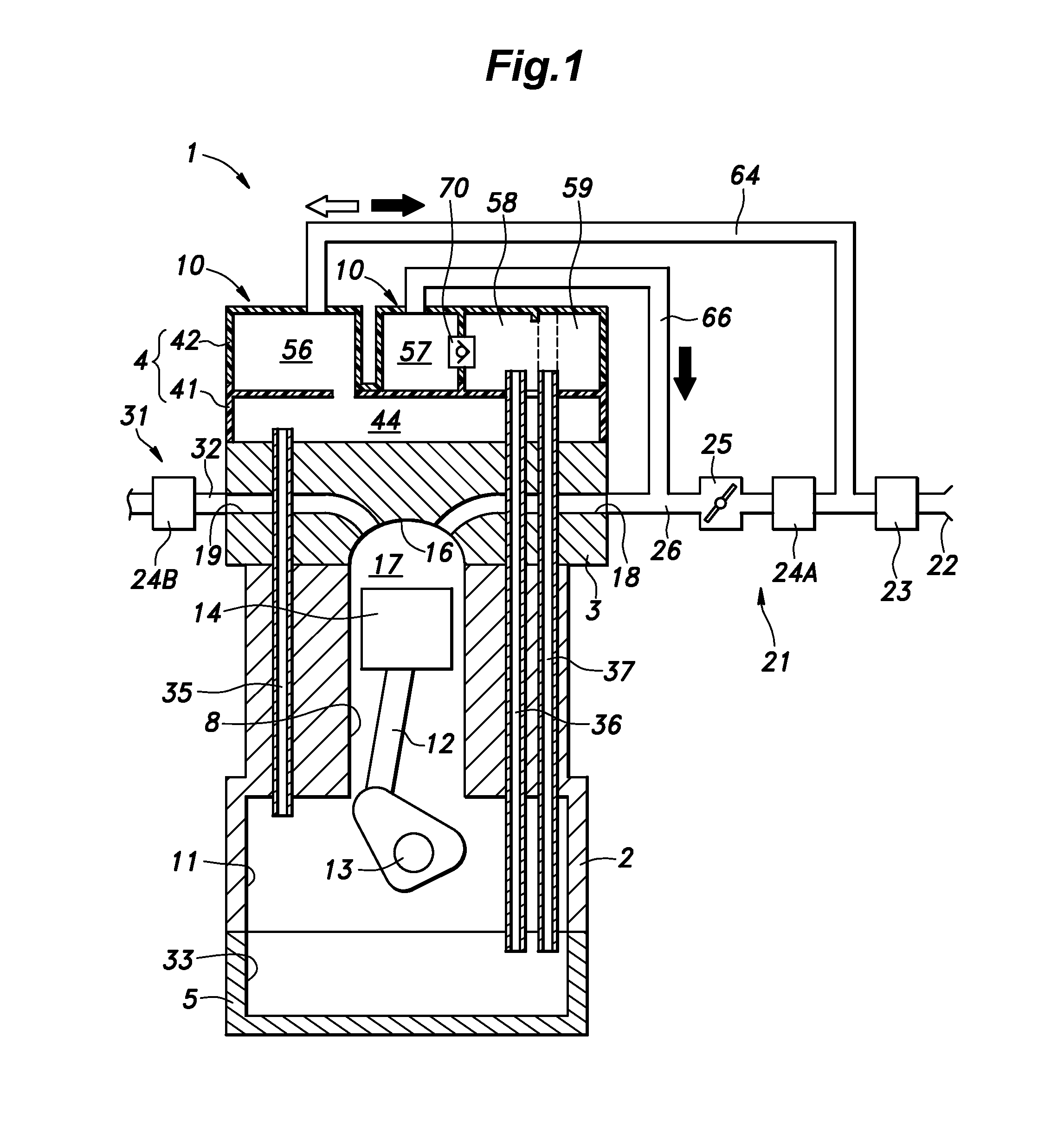

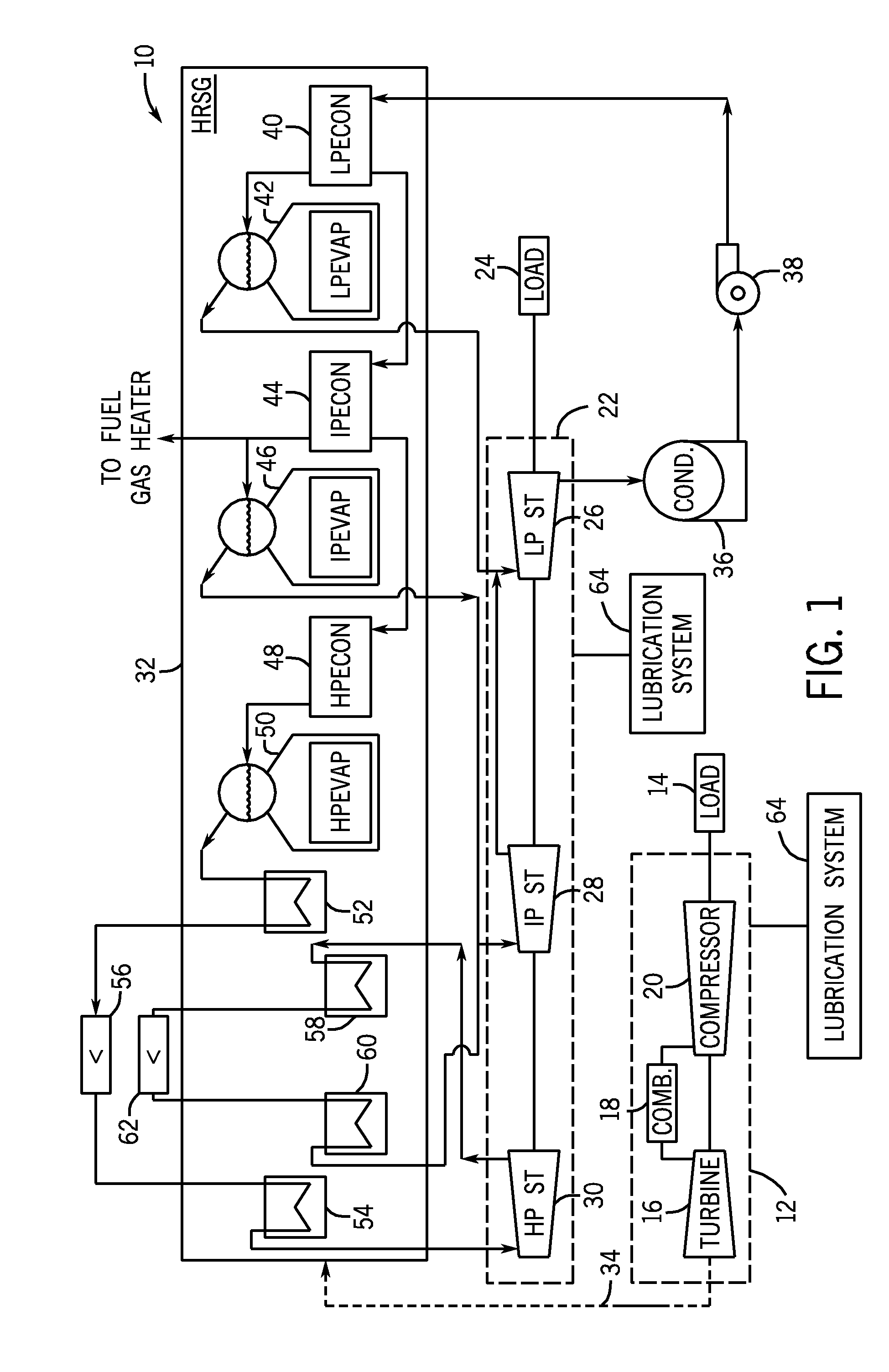

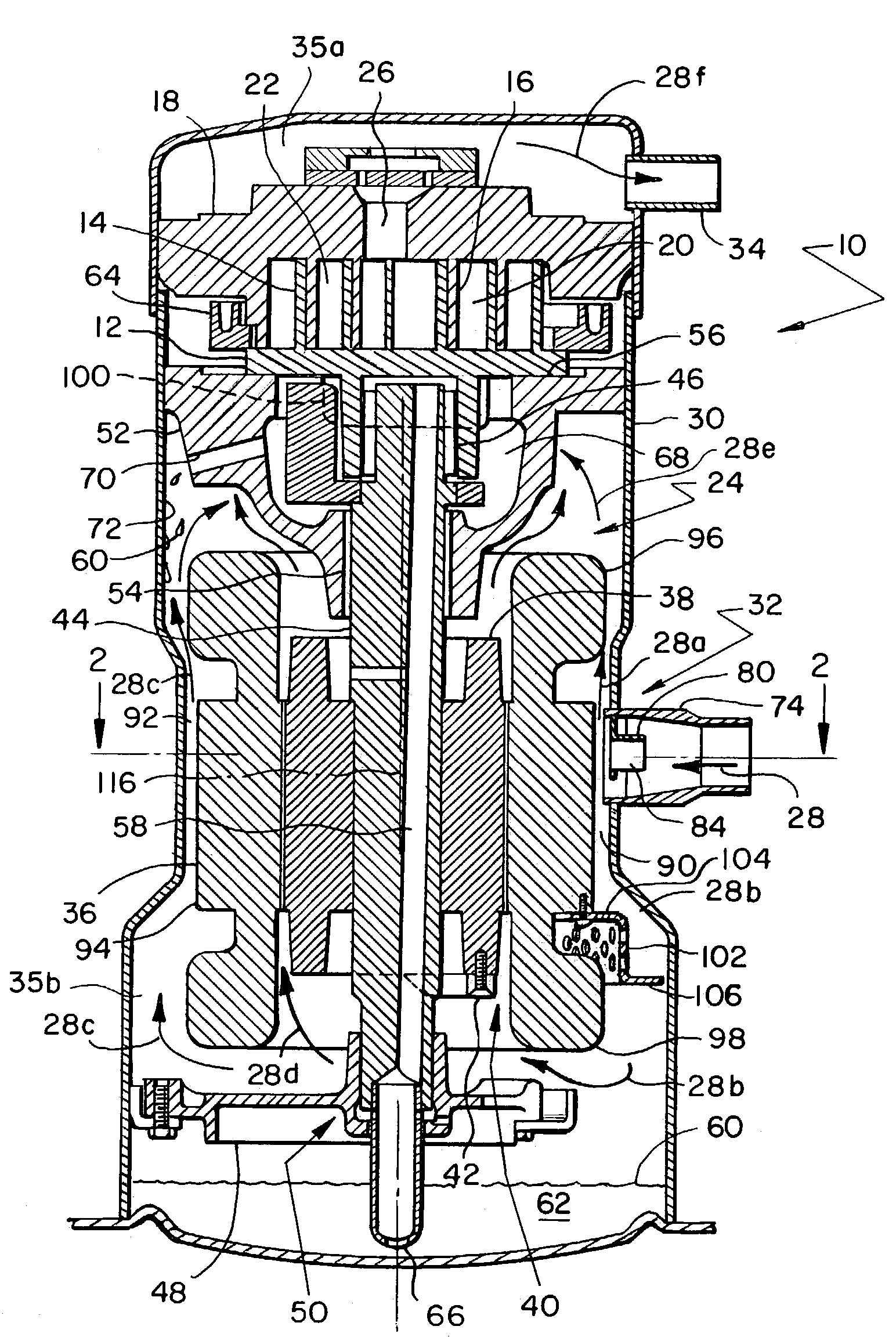

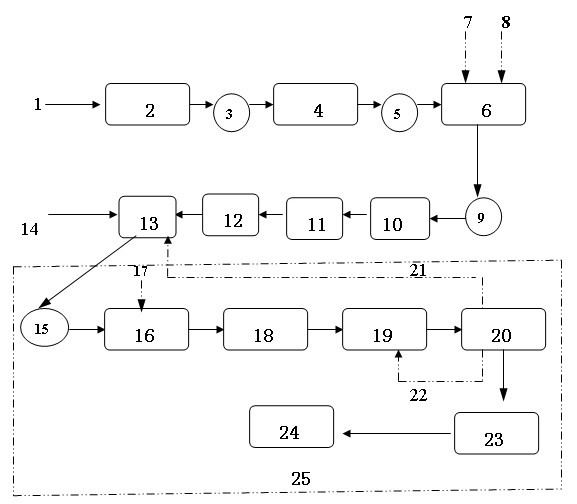

In order to improve a compressor for refrigerant, comprising an outer housing, a scroll compressor arranged in the outer housing and having a first compressor member arranged stationarily in the outer housing and a second compressor member which is movable relative to the first compressor member, the compressor members each having a base and first and second scroll ribs, respectively, which rise above the respective base and engage in one another such that the second compressor member is movable relative to the first compressor member on an orbital path about a central axis for the purpose of compressing the refrigerant, a drive unit for the second compressor member having an eccentric drive, a drive shaft, a drive motor arranged in a motor housing and having drawn-in refrigerant flowing around it as well as a bearing unit for the drive shaft which comprises a first bearing member connected to the outer housing, in such a manner that the refrigerant drawn in by the scroll compressor is free from lubricating oil to as great an extent as possible it is suggested that the refrigerant flow through an oil separator, which is arranged in the outer housing between this and the drive unit, after flowing around the drive motor and prior to entering the scroll compressor.

Owner:BITZER KUEHLMASCHINENBAU GMBH

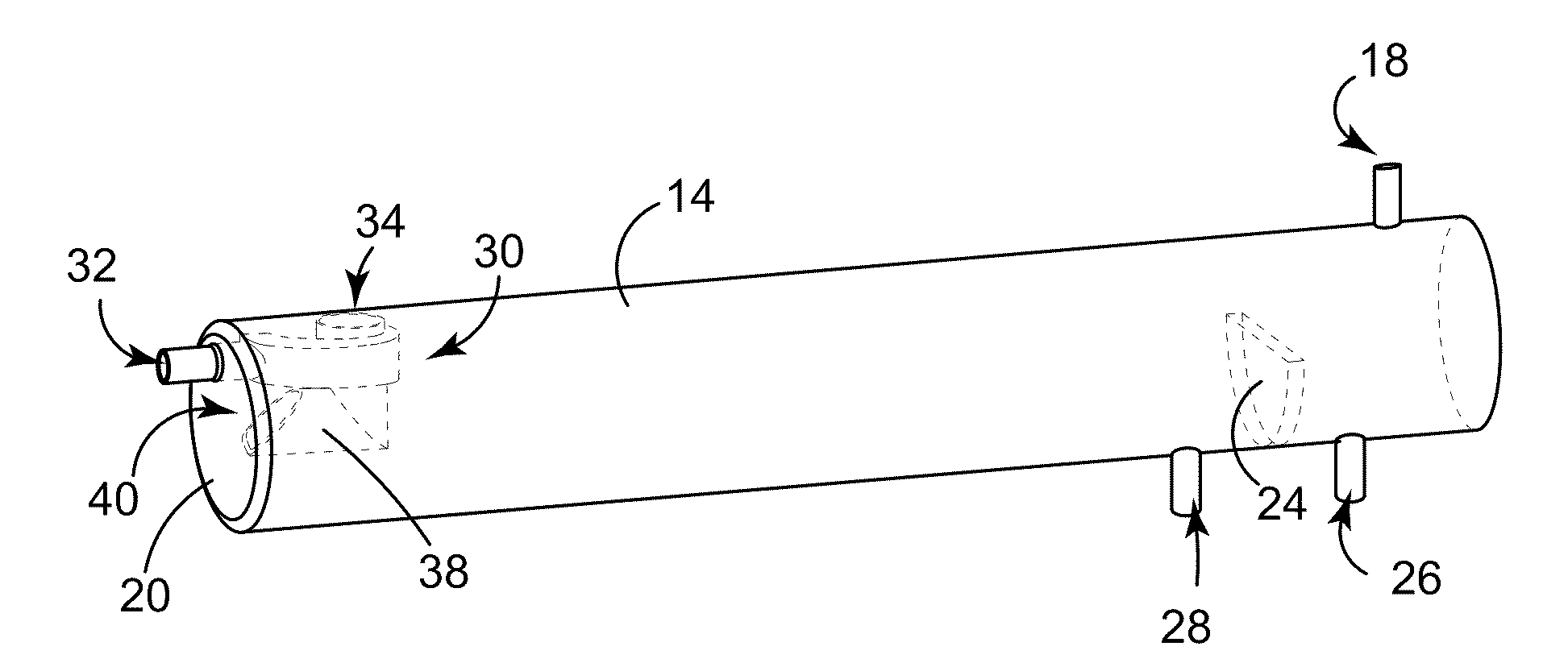

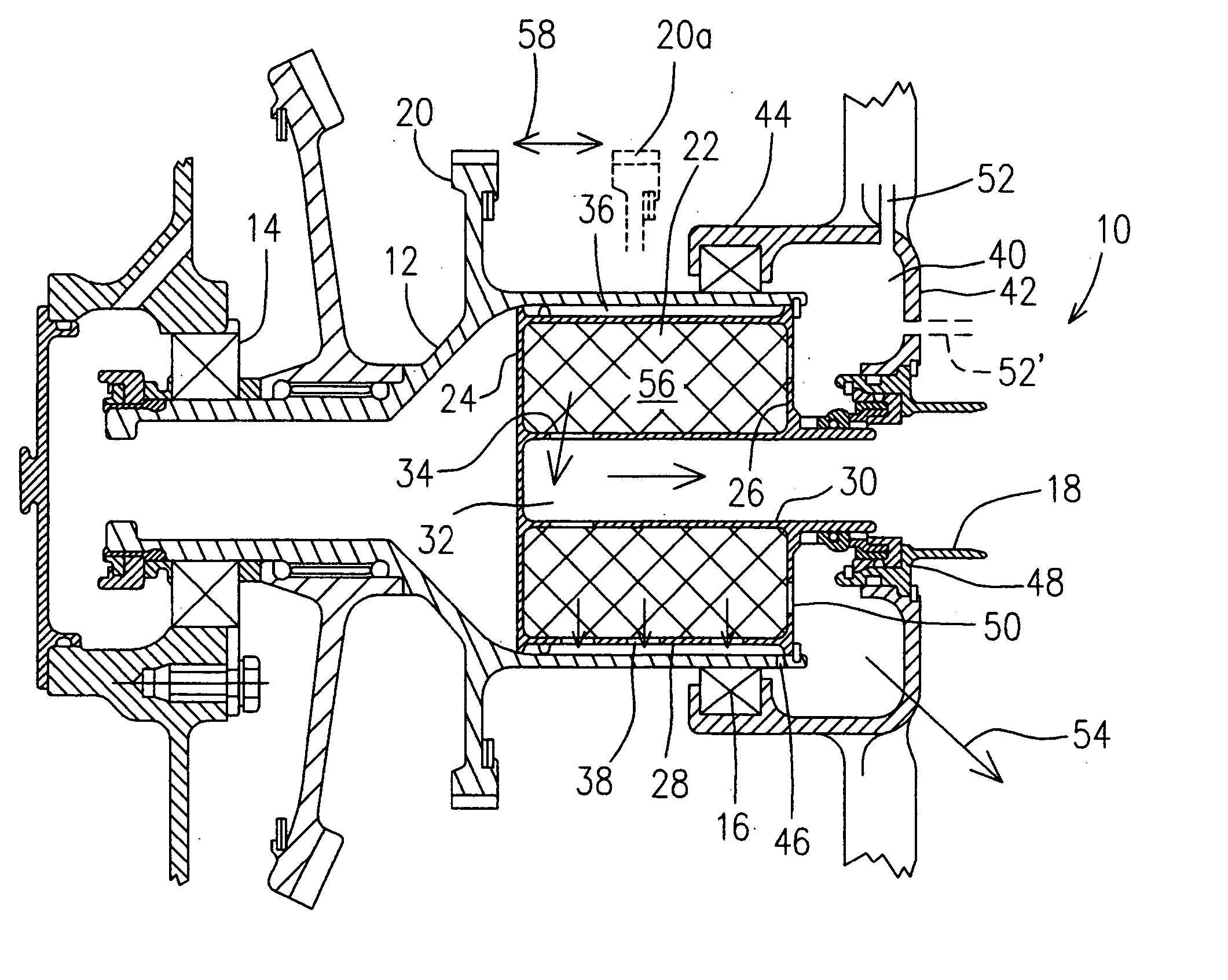

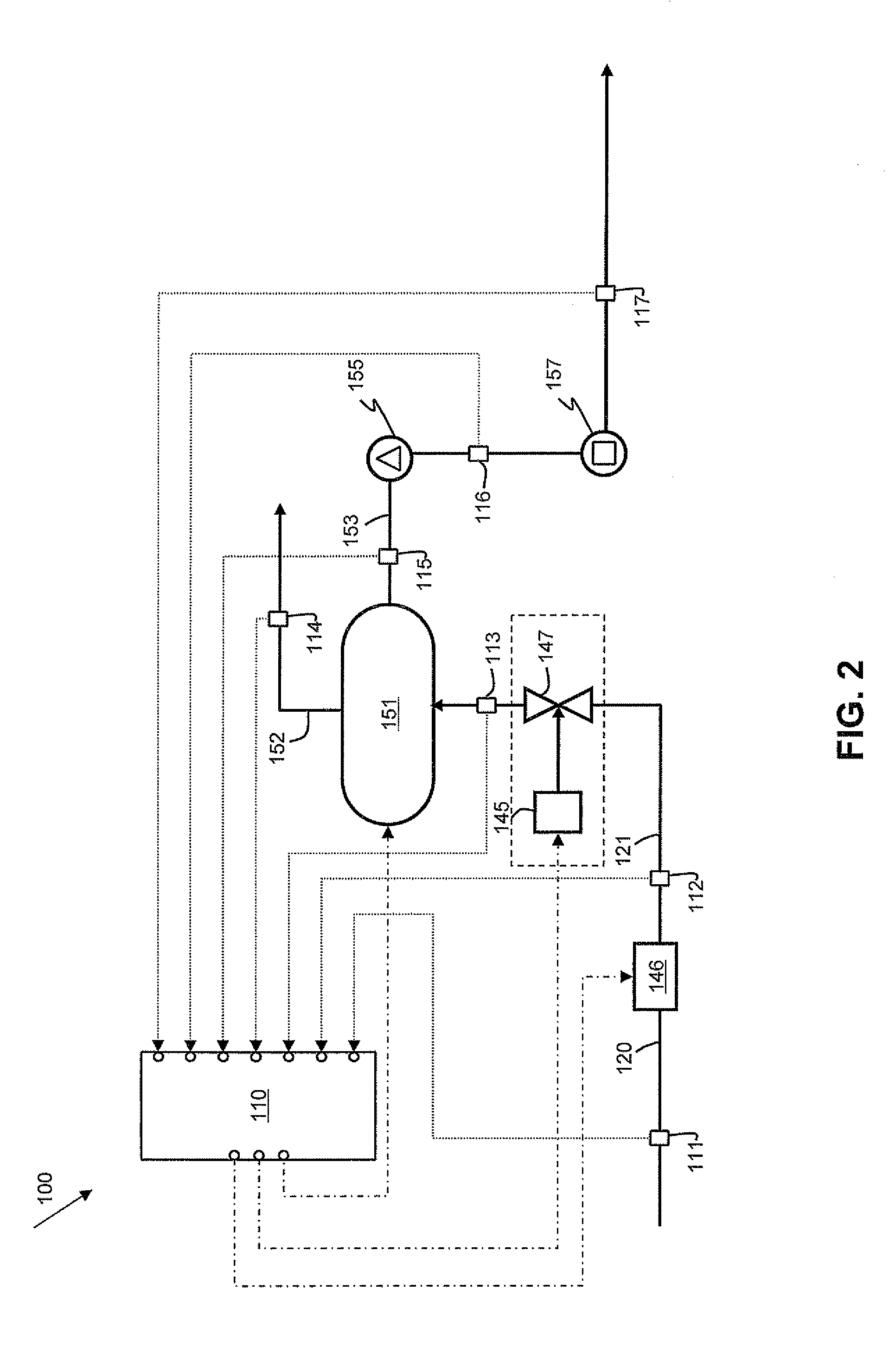

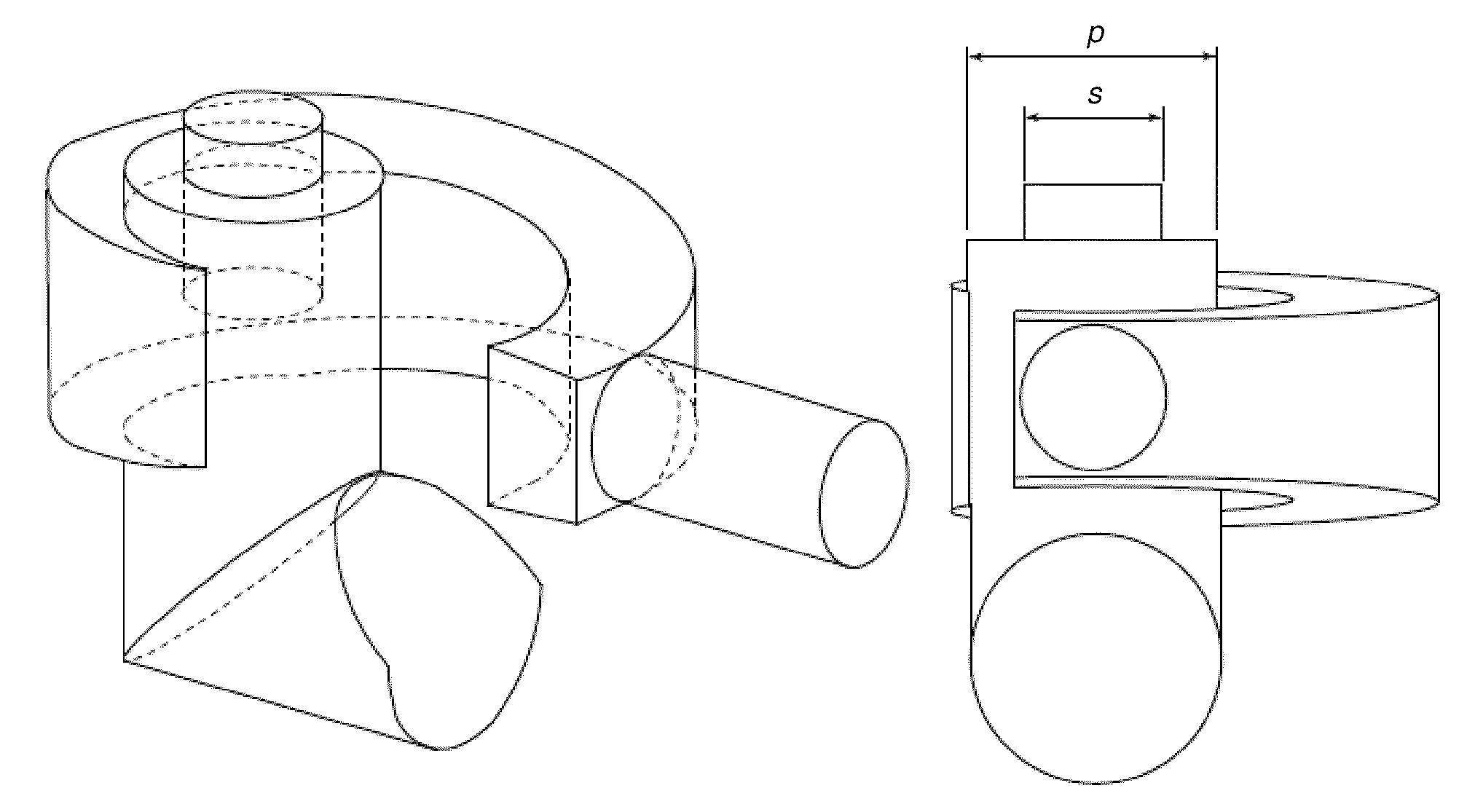

Apparatus for separation of gas-liquid mixtures and promoting coalescence of liquids

ActiveUS20110247500A1Reduce momentumPromote droplet coalescenceLiquid degasificationReversed direction vortexChemical physicsOil separation

Provided herein is a conditioning apparatus that includes a geometrical configuration having an inlet flow deceleration conduit and a cyclonic tube to effectuate both liquid-gas separation and droplet coalescence. The apparatus is typically positioned at the inlet of a separator vessel used for removing water and gas from extracted crude oil containing entrained water and gas. The apparatus promotes droplet coalescence and gas separation for mixed fluids flowing into an existing water and oil separation device.

Owner:SAUDI ARABIAN OIL CO

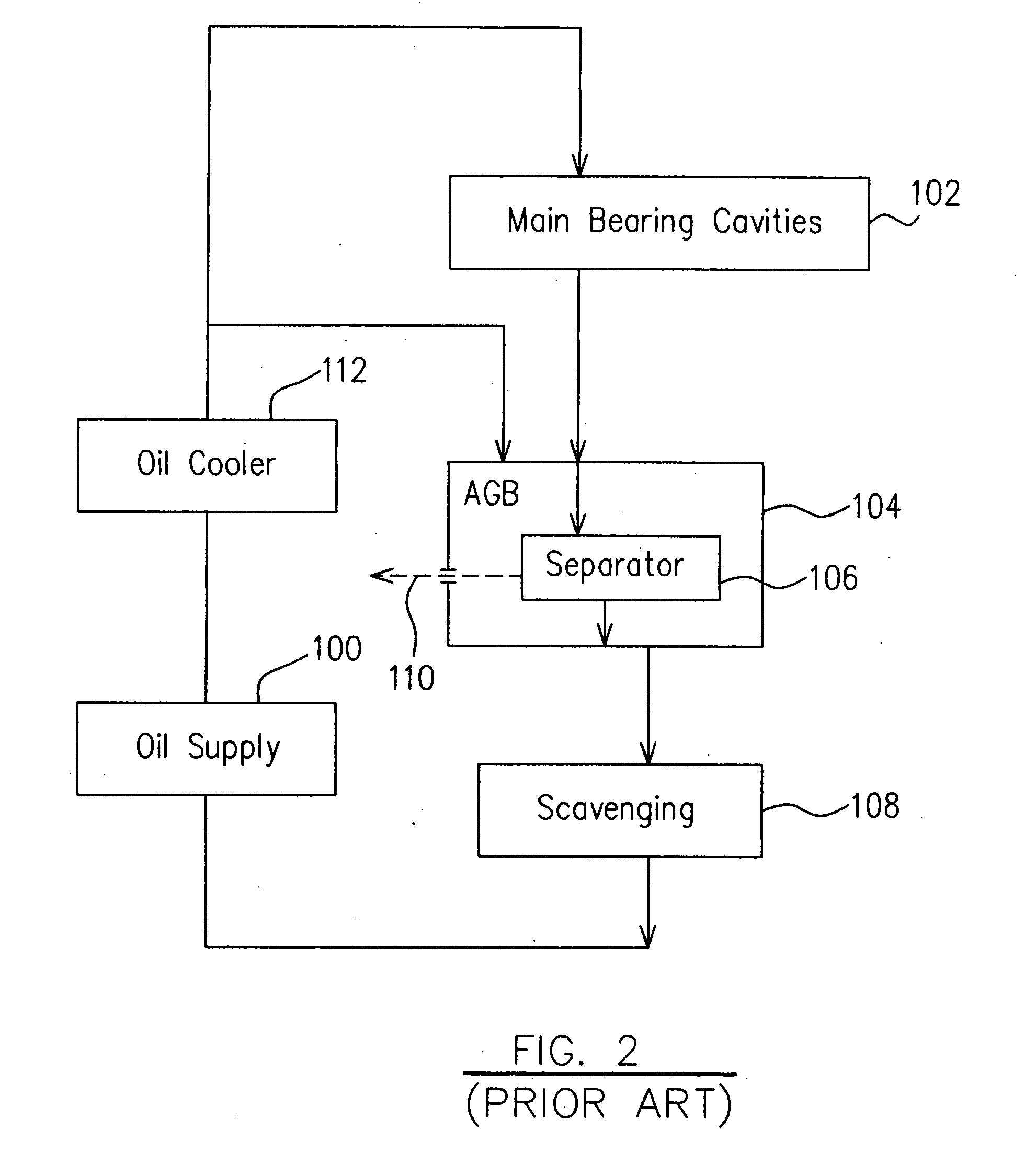

Air/oil separation system and method

ActiveUS20050211093A1Reduce heat transferReduce the temperatureCombination devicesLiquid degasificationOil separationEngineering

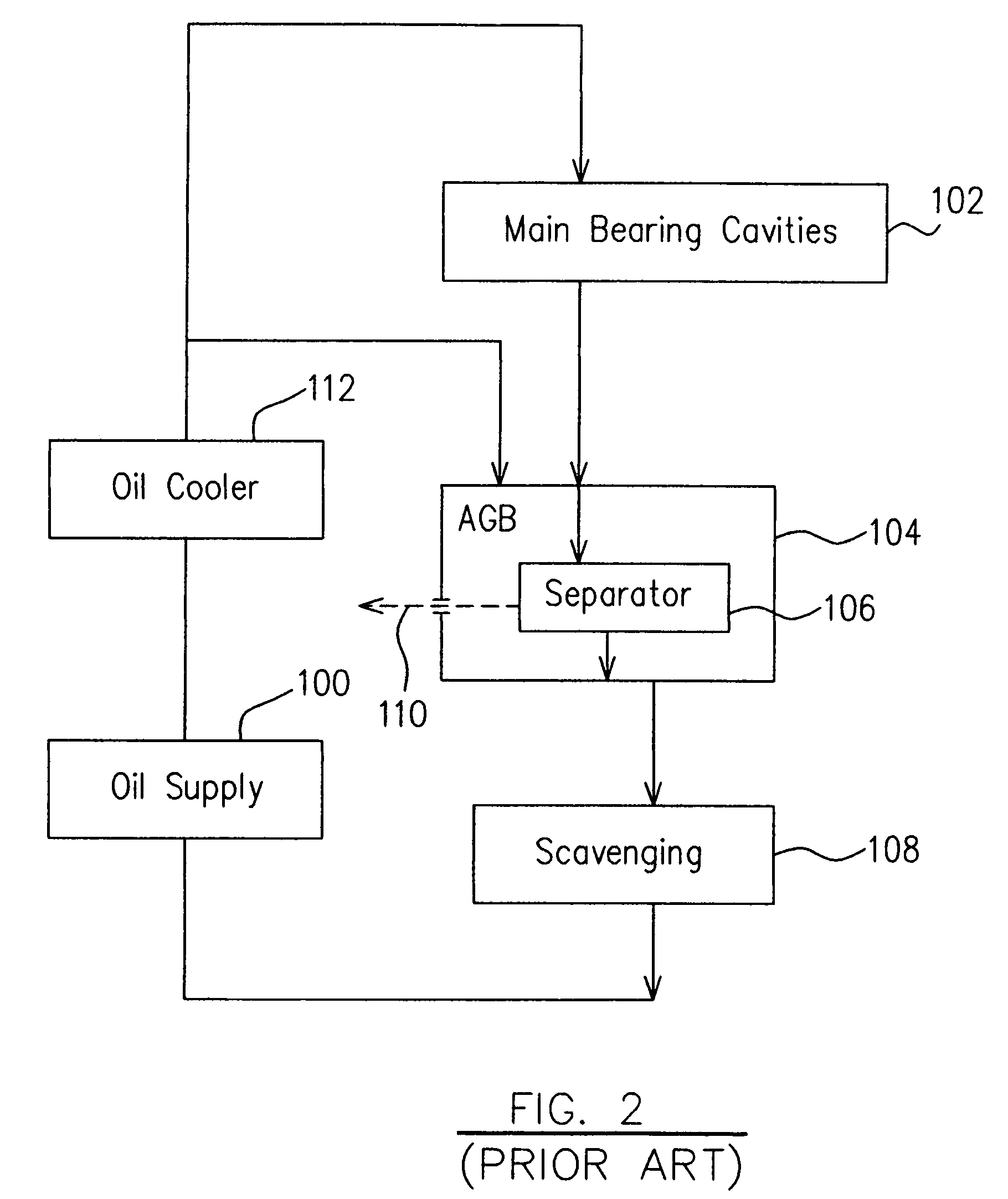

A centrifugal air / oil separation system communicates with bearing cavities of the engine and substantially isolates separated oil from contacting the gearbox.

Owner:PRATT & WHITNEY CANADA CORP

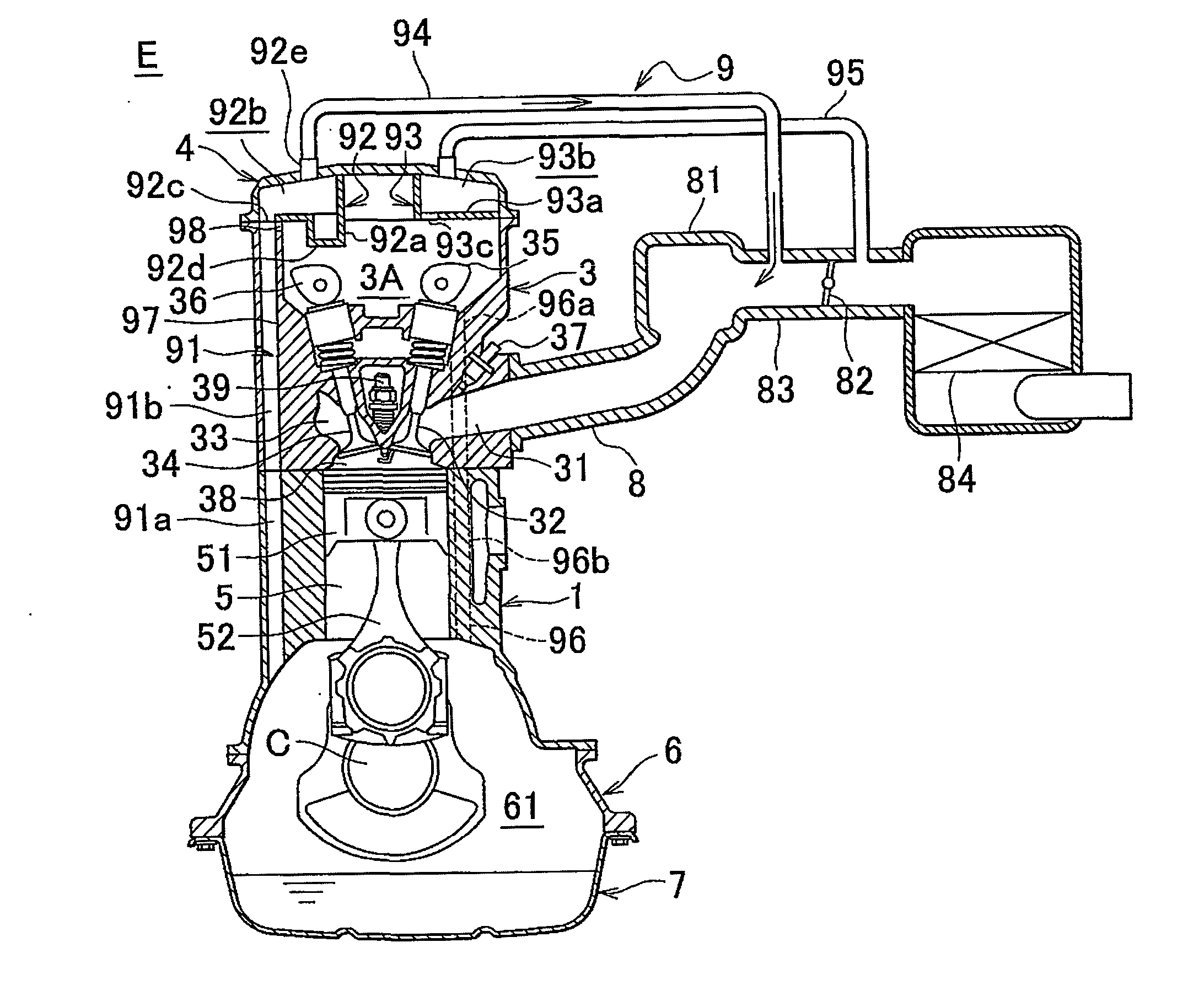

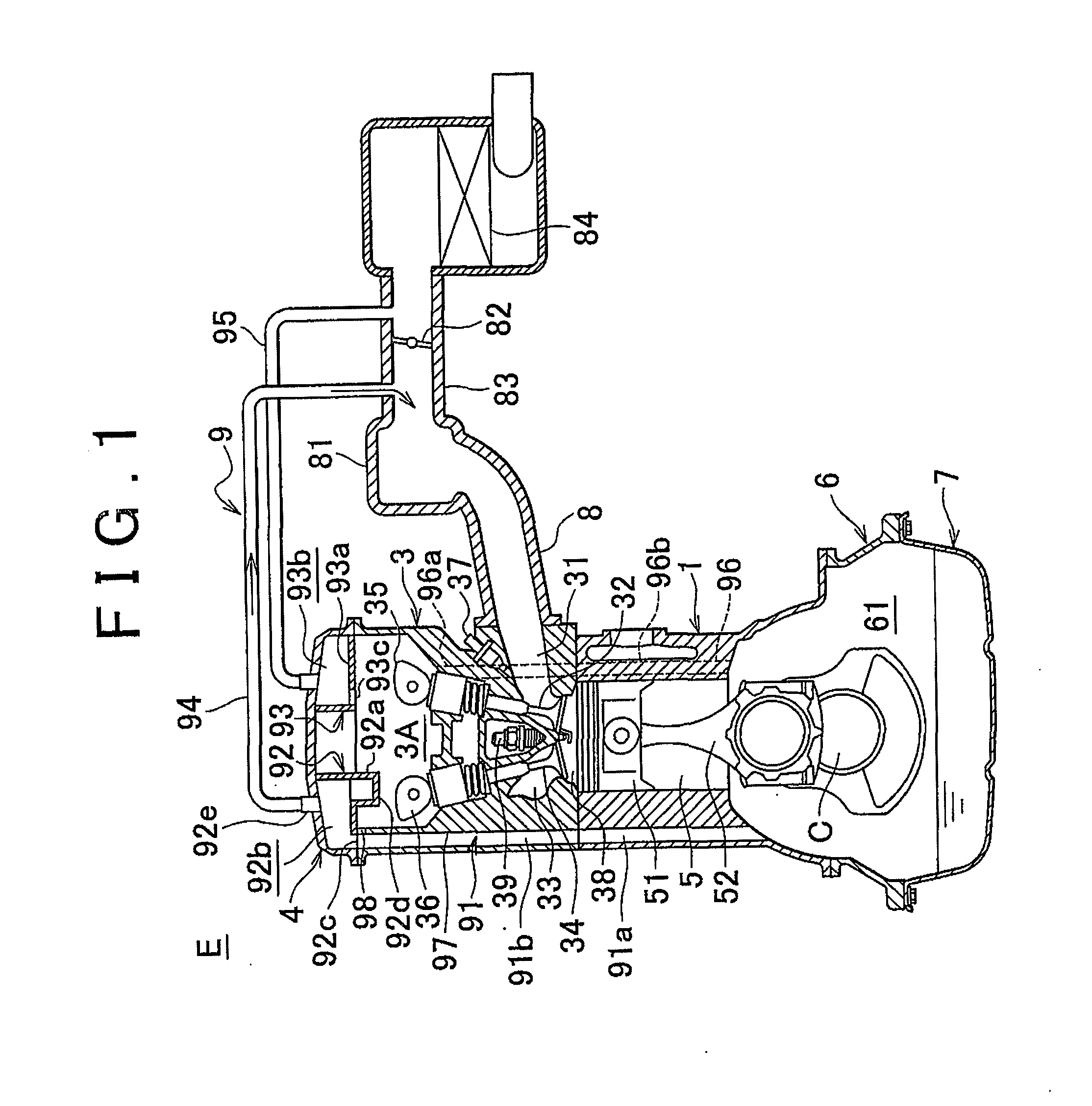

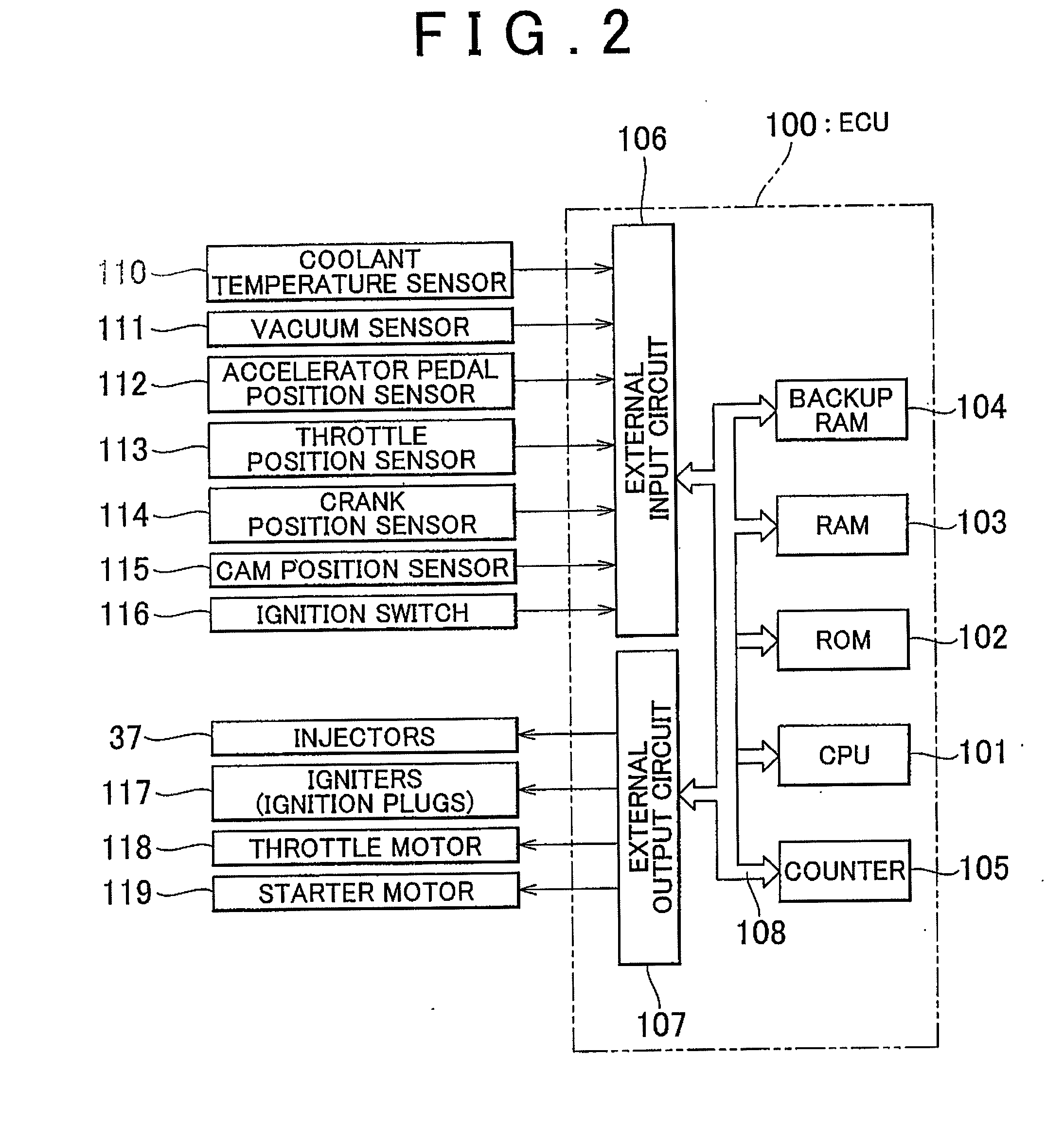

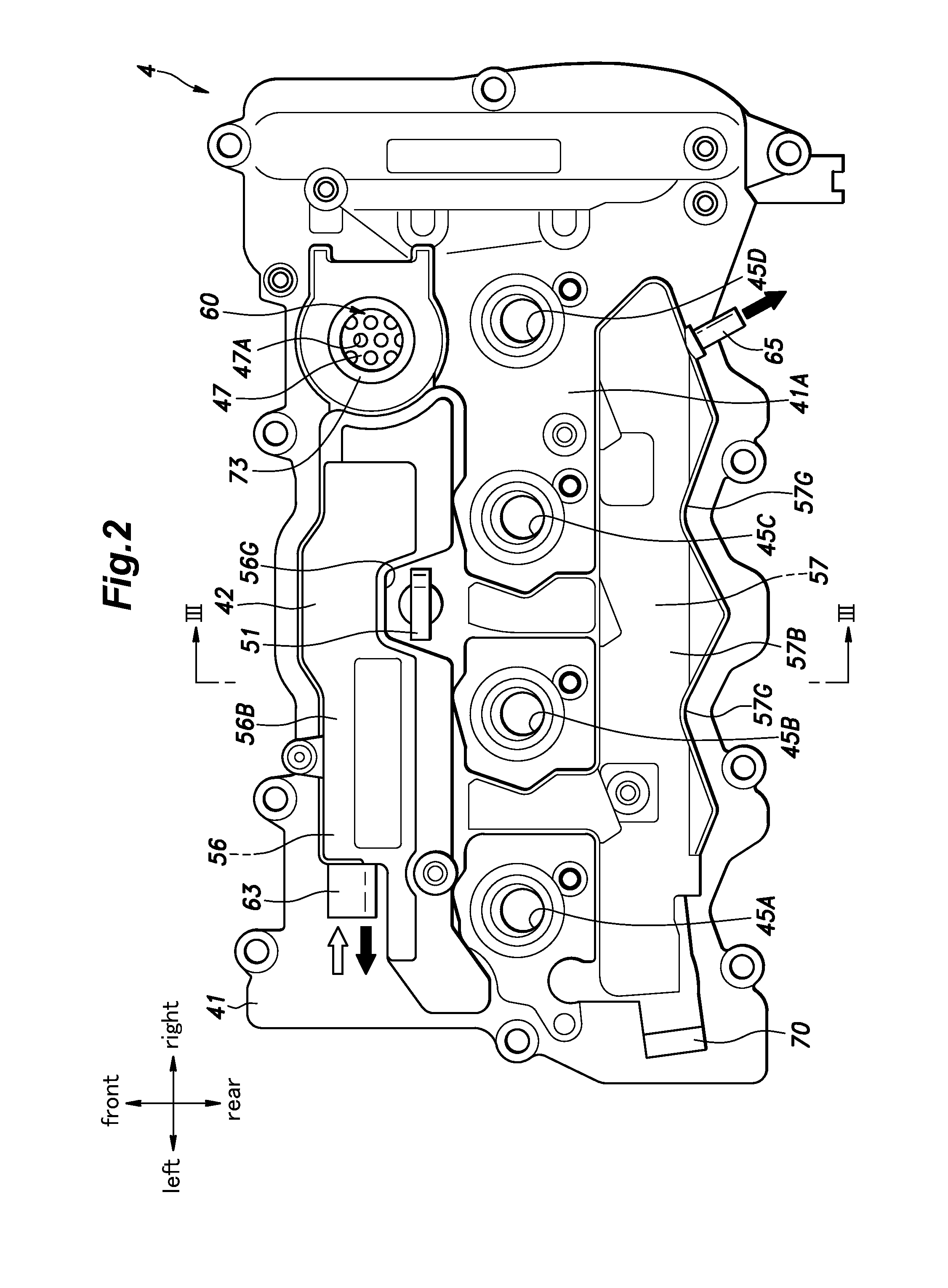

Positive crankcase ventilation system, cylinder head used for positive crankcase ventilation system, internal combustion engine including positive crankcase ventilation system, and positive crankcase ventilation method

InactiveUS20100101514A1Reduce manufacturing costSimple processCylinder headsCombustion enginesCylinder headEngineering

A blow-by gas collection passage (91) extends in a cylinder block (1) and a cylinder head (3). A crank chamber (61) is connected to an oil separator (92) through the blow-by gas collection passage (91). A cutout portion is formed in an upper end portion of a wall portion (97) of the blow-by gas collection passage (91), and the oil separator (92) contacts an upper surface of the cylinder head (3) to form a connection portion (98) through which the blow-by gas collection passage (91) is connected to a cam chamber (3A). Thus, new air in the cam chamber (3A) flows into the blow-by gas collection passage (91) at an inlet portion of the oil separator (92) through the connection portion (98) to dilute the blow-by gas.

Owner:TOYOTA JIDOSHA KK

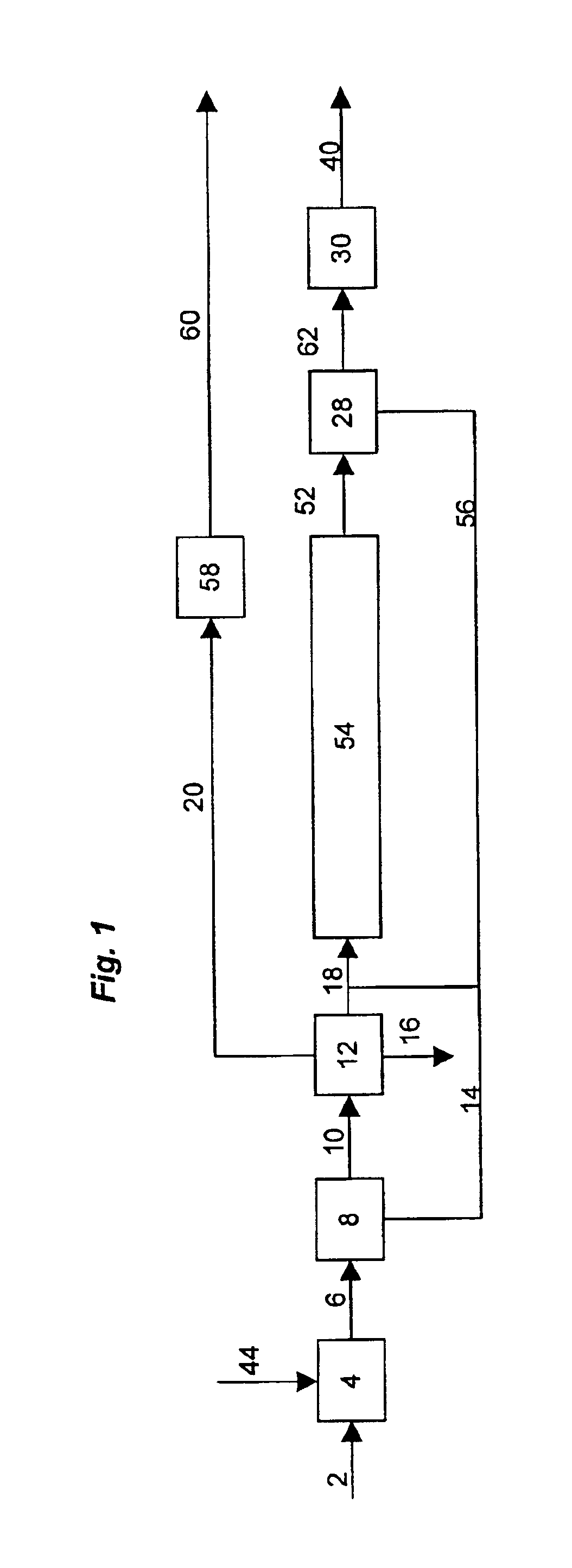

Crude oil desulfurization

InactiveUS6841062B2Reduce operating costsLow costHydrocarbon oil crackingTreatment with hydrotreatment processesSulfurHydrodesulfurization

This invention relates to a crude oil desulfurization process which comprises hydrodesulfurizing a crude oil feed in a crude desulfurization unit. The desulfurized crude oil is then separated into a light gas oil fraction, a vacuum gas oil fraction and a vacuum residuum fraction. The vacuum gas oil is hydrocracked to form at least one low sulfur fuel product. The light gas oil fraction is hydrotreated. The vacuum gas oil may be hydrocracked in one or more stages. Hydrocracking in the second stage, if present, will convert of at least 20% of the first zone effluent, to create a low sulfur light gas oil fraction. The light gas oil fraction may then be hydrotreated.

Owner:CHEVROU USA INC

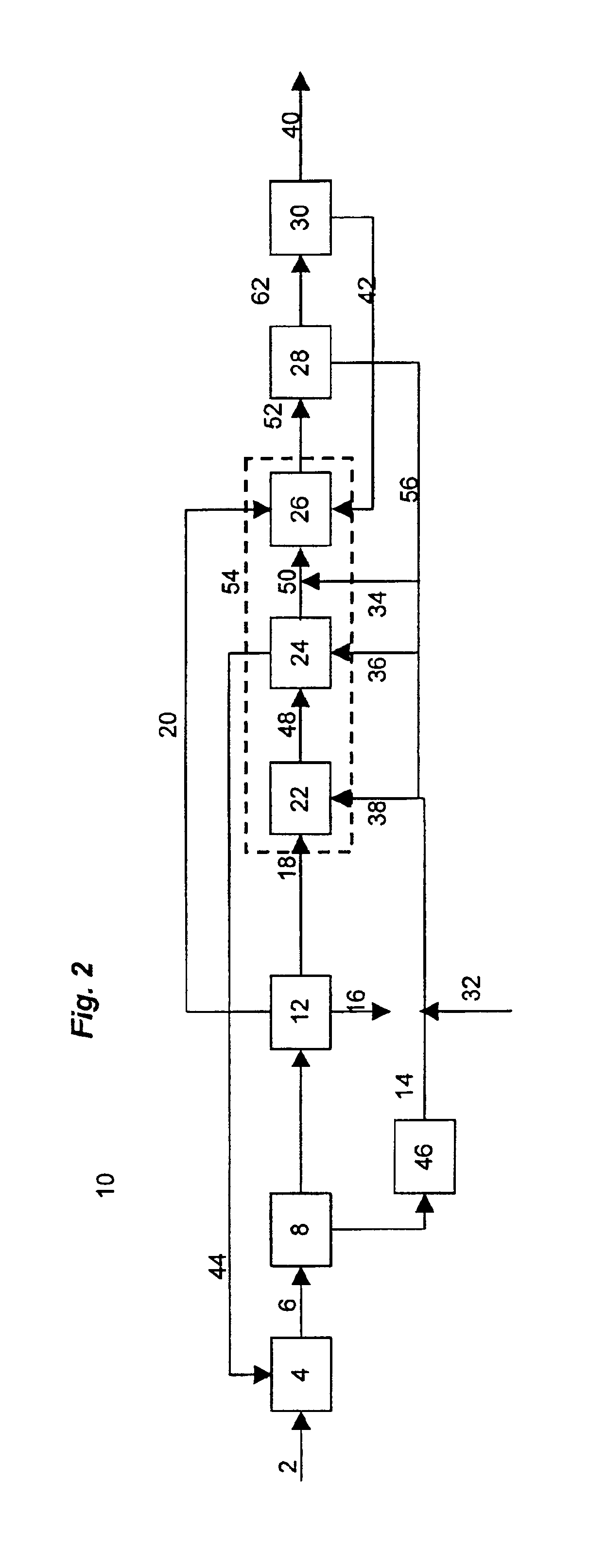

Dynamic demulsification system for use in a gas-oil separation plant

ActiveUS20130026082A1Low viscosityLiquid separation auxillary apparatusLiquid separation by electricityMicrowaveOil separation

A dynamic water / oil demulsification system for a gas-oil separation plant (GOSP) includes:an in-line microwave treatment subsystem upstream of one or more of each of a dehydrator vessel, desalter vessel and / or water / oil separator vessel, each of which vessels receives a water-oil emulsion;sensors that monitor and transmit data corresponding to properties of the water-oil emulsion in or downstream of the respective vessel(s); anda processor / controller associated with the in-line microwave treatment subsystem that initiates the application of microwave energy to the emulsion(s) based on the data from the sensors.

Owner:SAUDI ARABIAN OIL CO

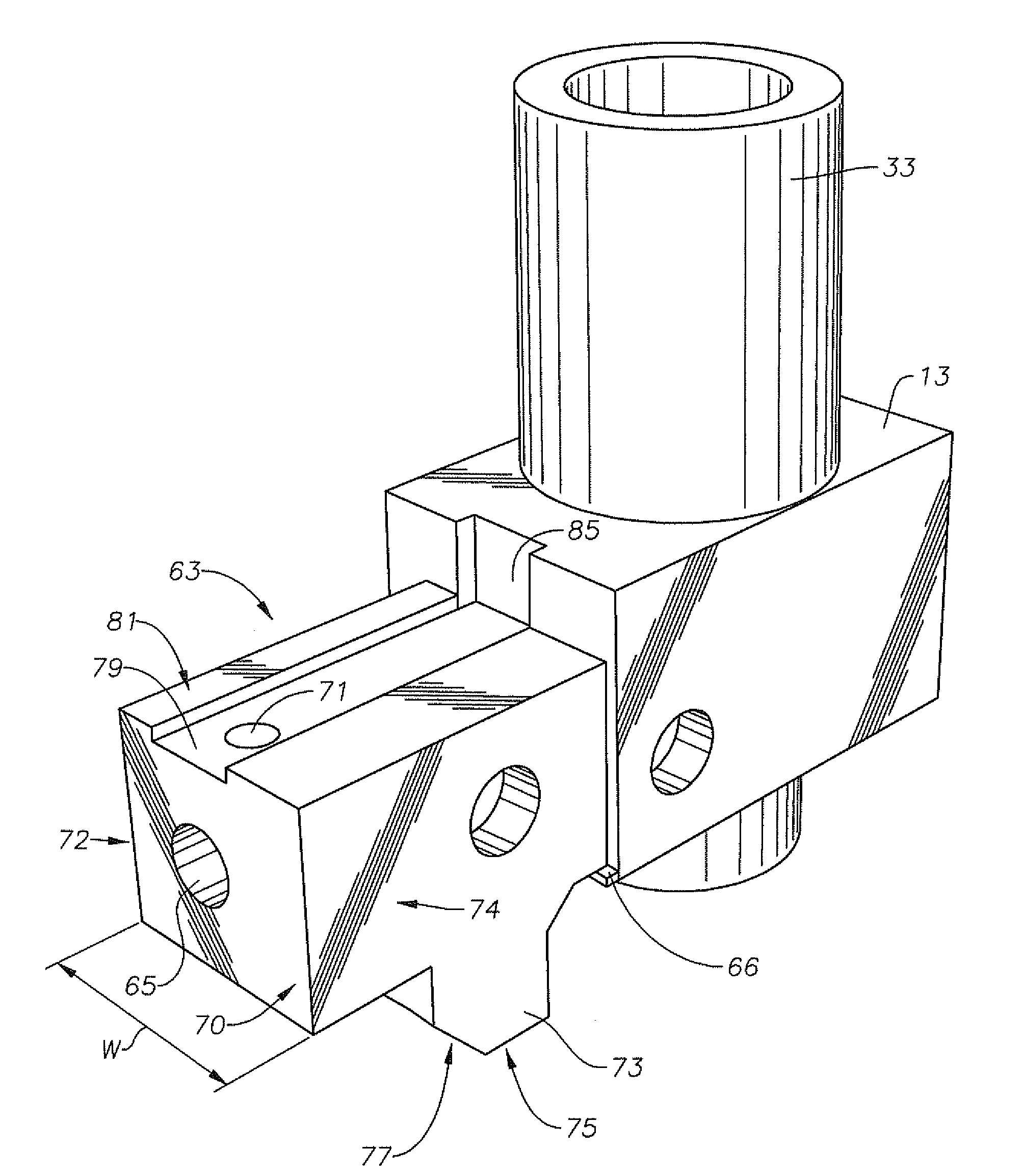

Utility skid tree support system for subsea wellhead

A utility skid tree system for subsea wellheads enables a tree to be mounted by and interface with utility skids. Production bore access is provided through an extended production wing block. The system reacts and transfers installation loads and potential snag loads to the conductor. The tree accepts skids for flow boosting, metering, water-oil separation, etc. A conventional choke may be fitted outboard of the utility insert profile.

Owner:VETCO GRAY

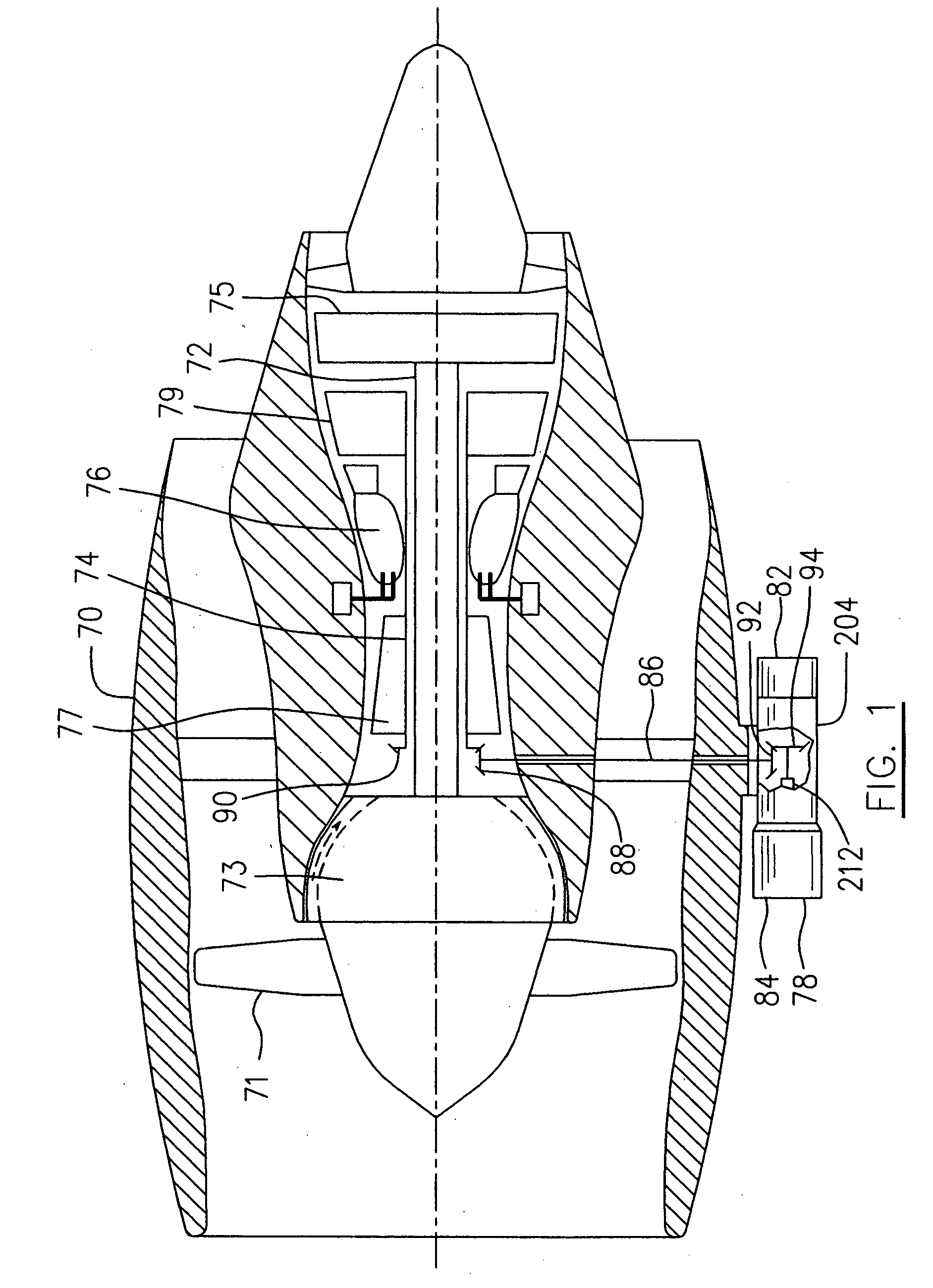

Air/oil separating device

InactiveUS20060032486A1Simple designCheap manufacturingLiquid degasificationInternal combustion piston enginesOil separationCrankcase

An air / oil separating device for removing oil that has become entrained in blow-by gases passing through a crankcase of an internal combustion engine. The air / oil separating device includes a spiral element forming a spiral passageway and a perforated tube. As the air / oil stream passes through the spiral passageway and contacts its walls, a certain amount of the entrained oil is removed or scavenged such that it collects at the bottom of the spiral passageway. The treated air stream, now having less entrained oil, passes into the perforated tube and exits at an upper axial end, while the collected oil drains back into the crankcase via a lower axial end of the perforated tube. The air / oil separating device can be incorporated within a cap assembly also having an oil-fill cap and / or a PCV valve.

Owner:SHILOH IND INC

Oil separator for blowby gas

InactiveUS20070215128A1Smooth sectionEasy dischargeCombustion enginesCrankcase ventillationOil separationEngineering

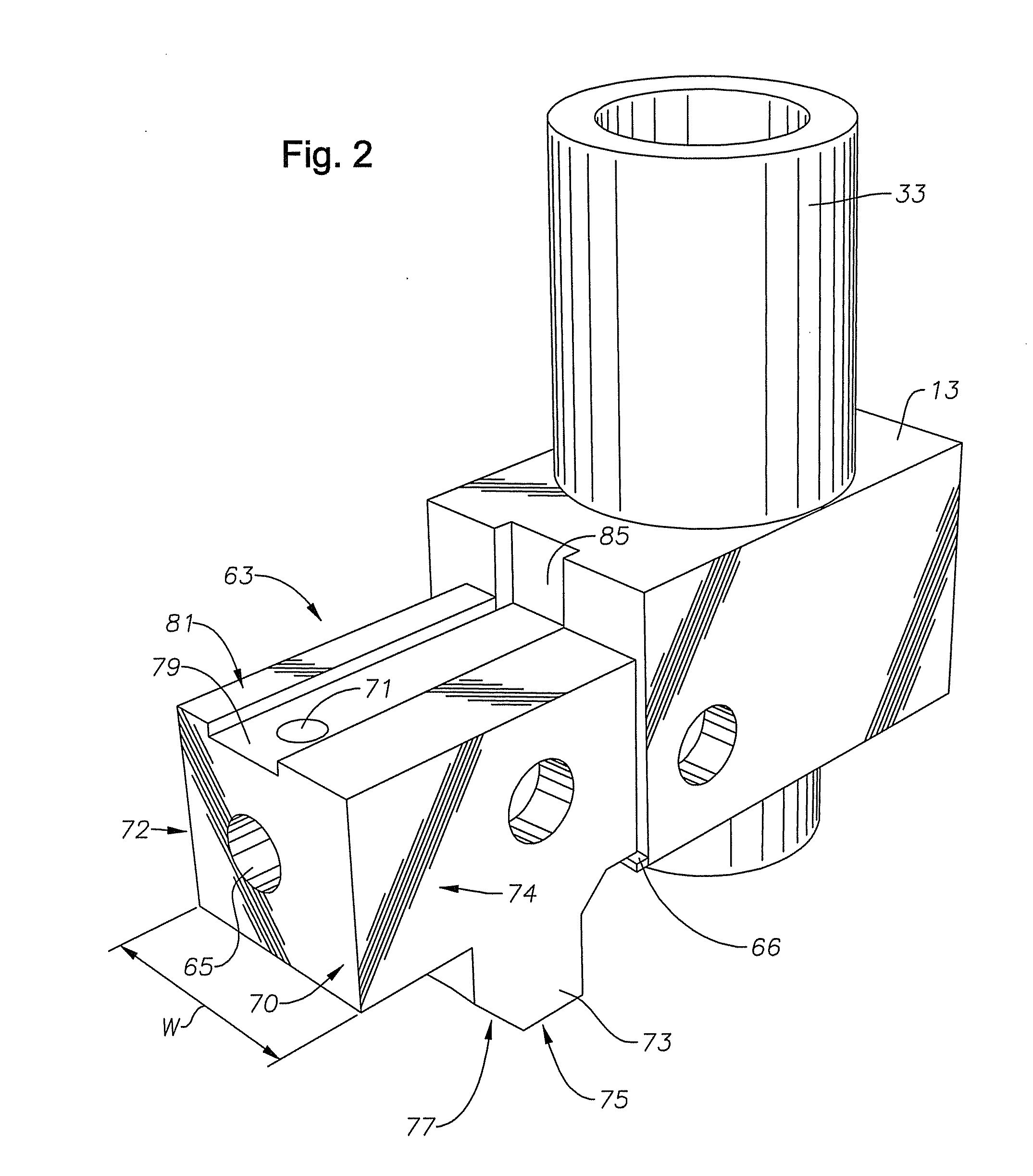

There is provided an oil separator for blowby gas exhibiting excellent oil separation performance in a stable manner. In a common flow path section of a gas flow passage in which the blowby gas flows and an oil passage provided with a bottom of the common flow path section where oil that has been separated from blowby gas by separation means provided midway along the gas flow passage, the width of a part of the common flow path section is regulated so as to become gradually smaller towards the bottom of the common flow path section, and a flow passage regulating section, for making part of the common flow path section that has the width regulated a restricted section, is provided so as to extend upwards from the bottom of the common flow path section.

Owner:KOJIMA PRESS IND CO LTD +2

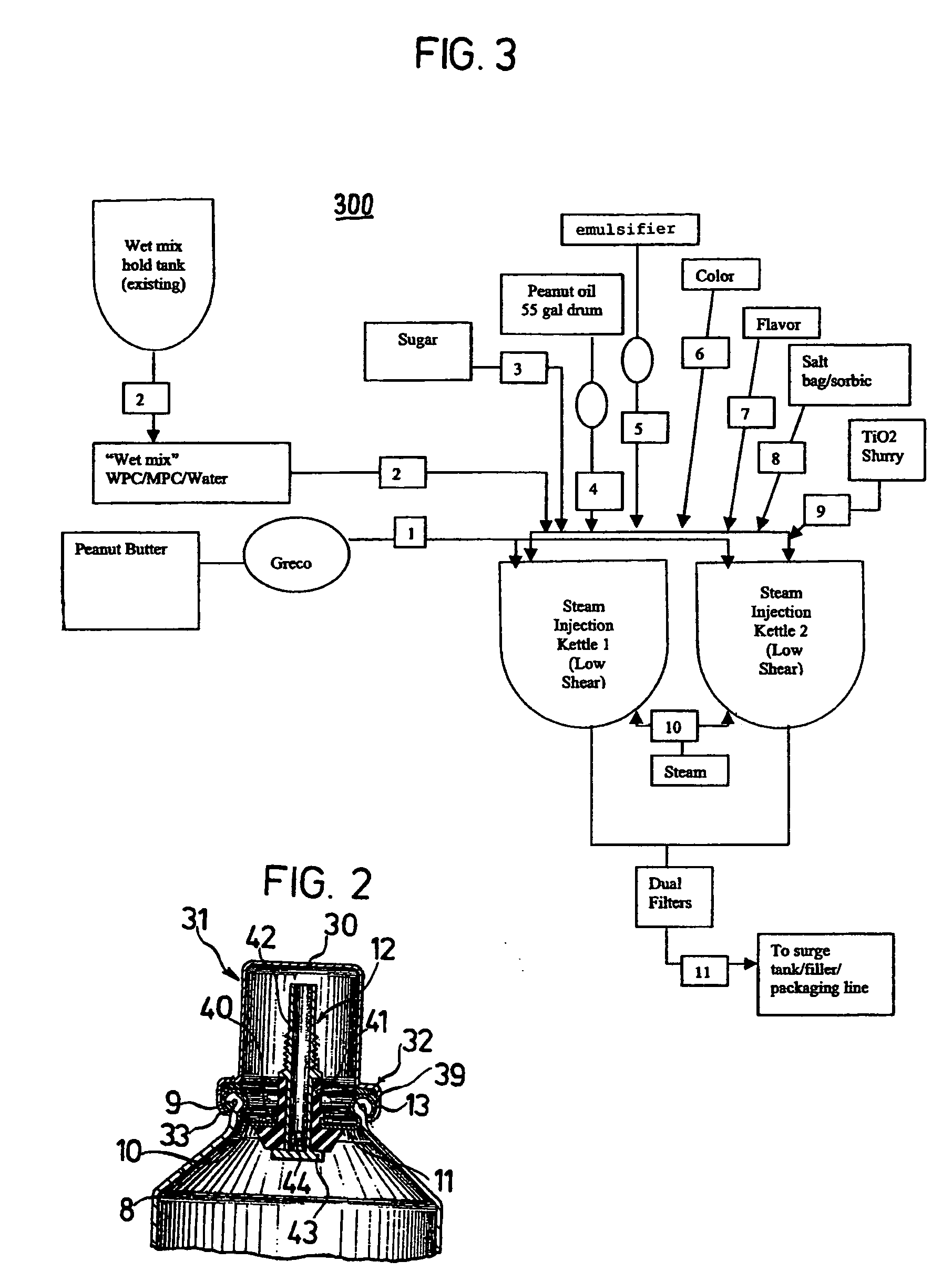

Edible spread composition and packaged product

An edible spread composition comprises a homogenous mixture of plant fiber-containing material, edible oil, water, and an effective amount of an emulsifier that prevents separation of oil from the plant fiber and other mixture solids that otherwise occurs in its absence when the edible spread composition is discharged while held under pressure. The edible spread composition may be, for instance, a peanut butter spread composition or a chocolate spread composition. There also is a packaged spread product comprising the edible spread composition that is held inside a pressurized container and dispensed without experiencing oil separation.

Owner:KRAFT FOODS GRP BRANDS LLC

Method for treating coking wastewater

InactiveCN101781067AReduce CODPromotes electrochemical corrosionTreatment with aerobic and anaerobic processesMultistage water/sewage treatmentActivated sludgeCyanide compound

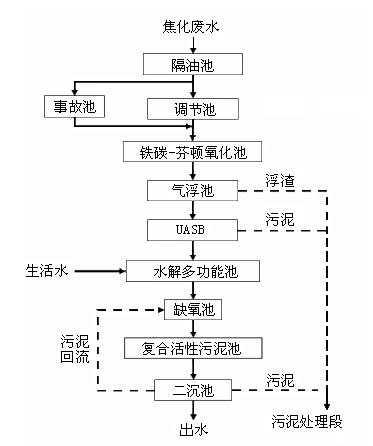

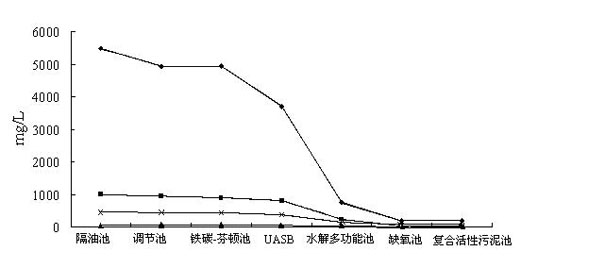

The invention discloses a method for treating coking wastewater, which relates to the method for treating wastewater and aims to solve the problems that an activated sludge method for treating the coking wastewater has the disadvantage of relatively poorer effect on the removal of organic substances and the treated water is difficult to reach the secondary discharge standard of the Integrated Wastewater Discharge Standard (GB8978-96). The method comprises that: the coking wastewater is discharged after passing through an oil separation tank, an adjusting tank, an iron carbon-Fenton oxidation pond, an up-flow anaerobic sludge bed reactor, a multifunctional hydrolyzing pond, an anaerobic tank, a composite active sludge tank and a secondary sedimentation tank, wherein the coking wastewater can also pass through a floatation tank. The coking wastewater treated by the method of the invention has a pH value of 5 to 8 and the rate of removal of Cu2+ from the coking wastewater of 69 to 85 percent, contains 300 to 450mg / L phenol and less than 15mg / L cyanide and therefore reaches the secondary discharge standard of the Integrated Wastewater Discharge Standard (GB8978-96).

Owner:HARBIN INST OF TECH

Air/oil separation system and method

ActiveUS7063734B2Extended seal lifeCombination devicesLiquid degasificationOil separationEngineering

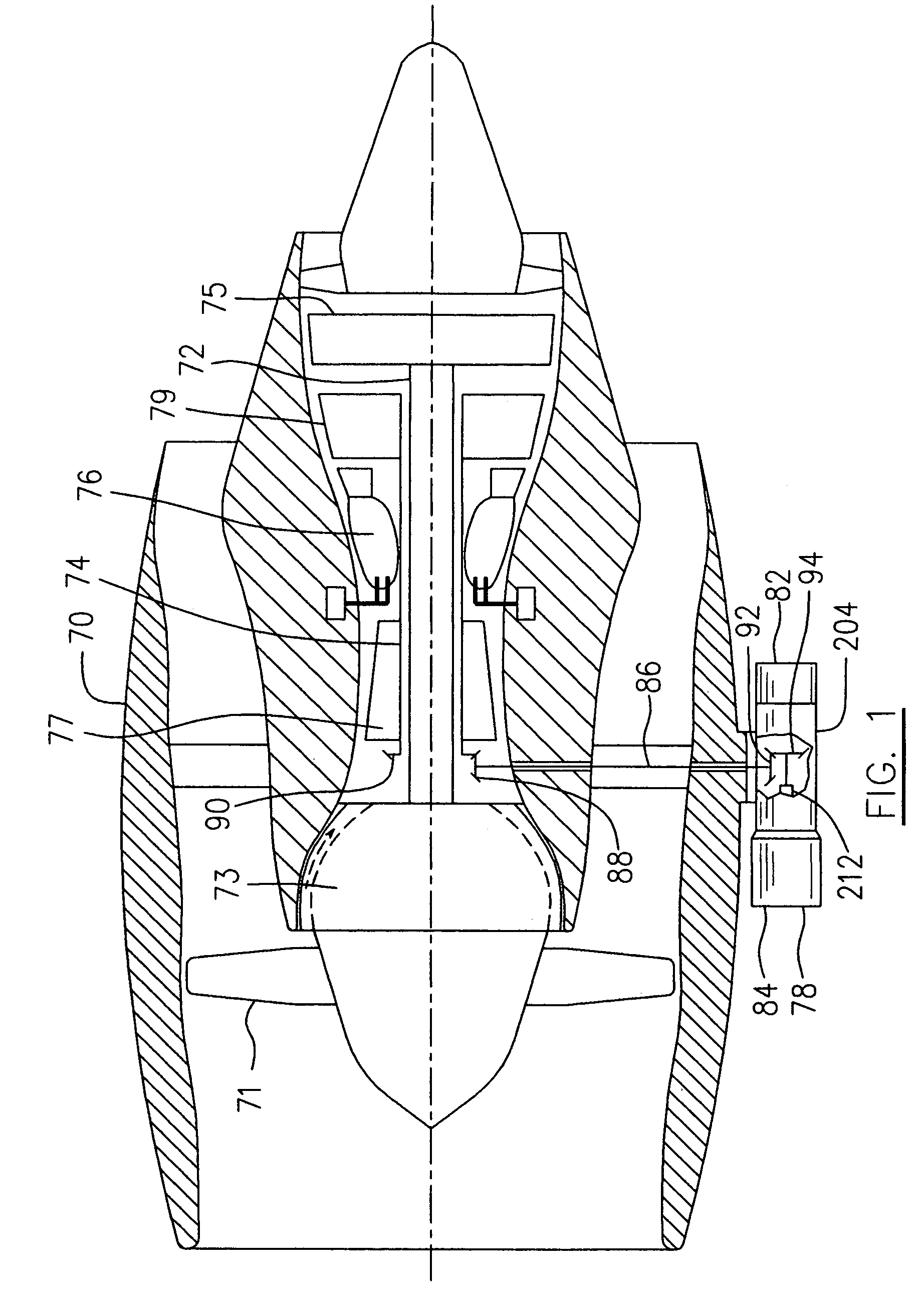

A centrifugal air / oil separation system communicates with bearing cavities of the engine and substantially isolates separated oil from contacting the gearbox.

Owner:PRATT & WHITNEY CANADA CORP

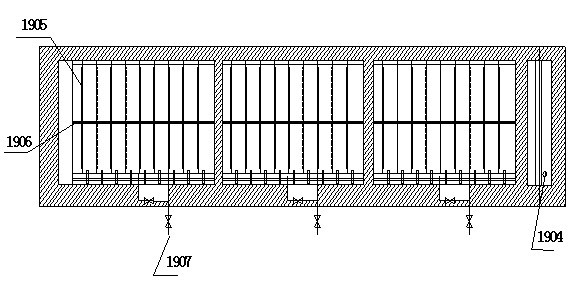

Oil separation device for internal combustion engine

ActiveUS20160265404A1Improve oil separation effectInternal combustion piston enginesNon-fuel substance addition to fuelOil separationInternal combustion engine

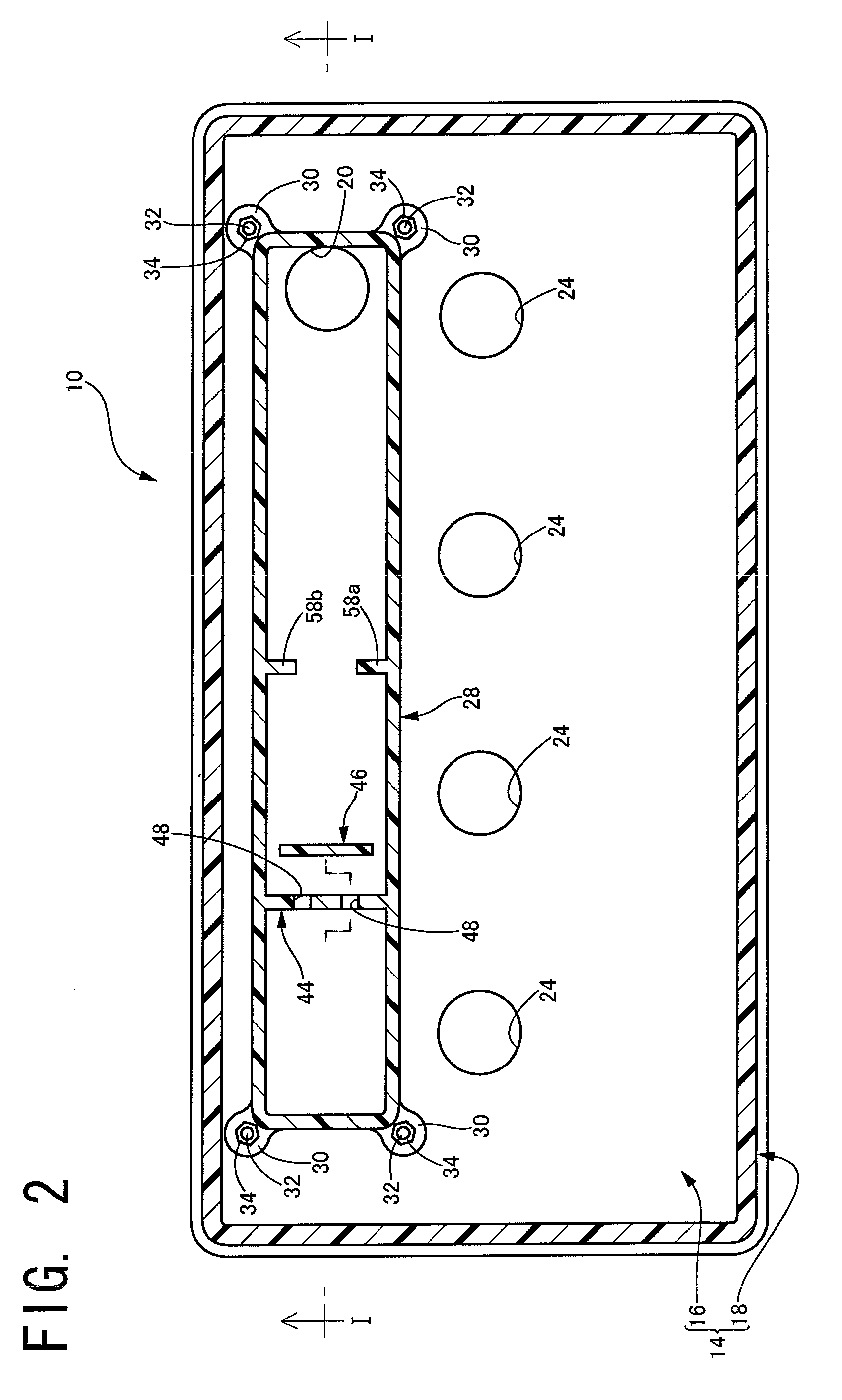

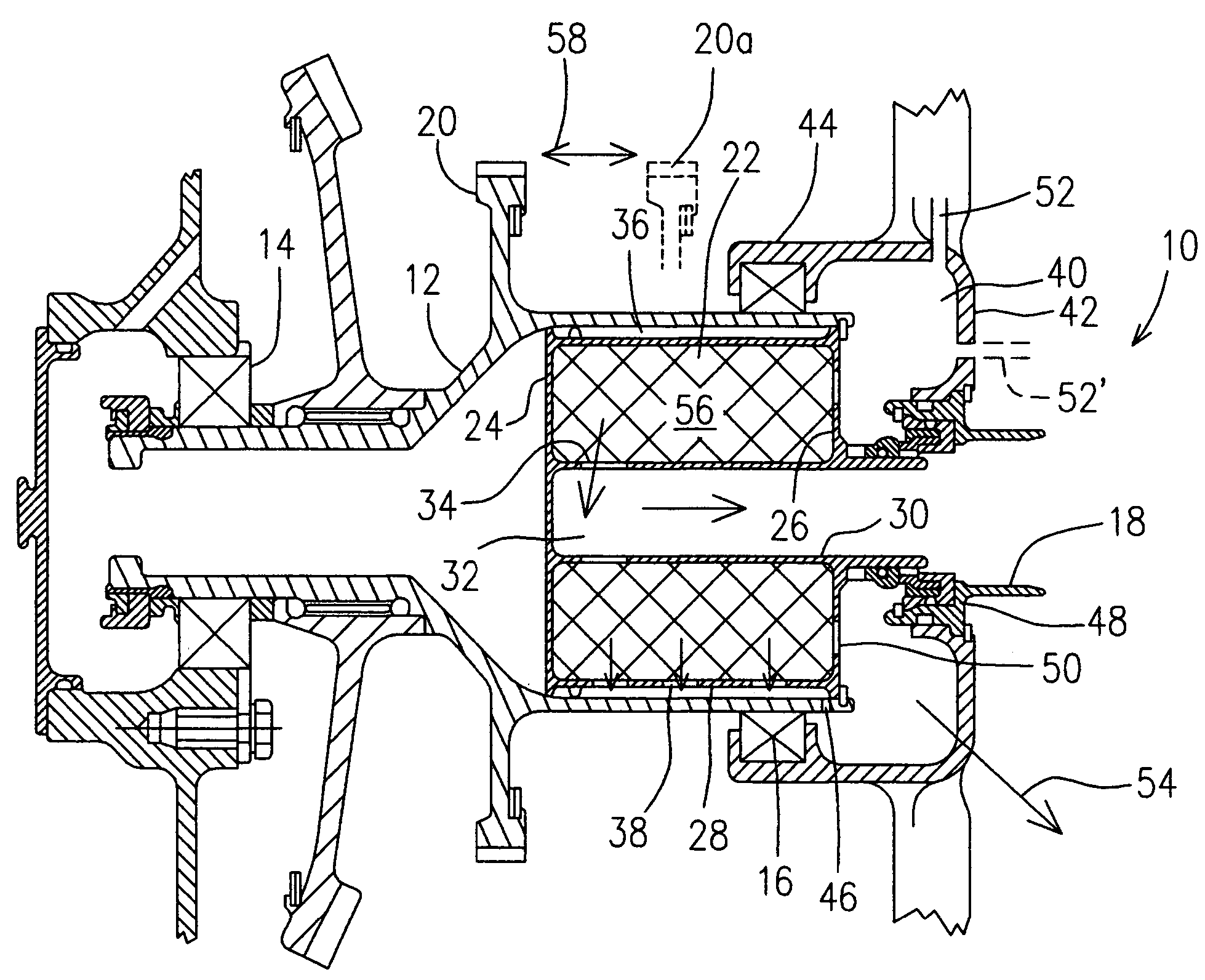

To improve the oil separation performance in an oil separation device for an internal combustion engine. The oil separation device (10) comprises a gas liquid separation passage (56) internally defined by a lower wall, an upper wall and a pair of side walls, and extending in a horizontal direction, a gas inlet (54) and a gas outlet (63) provided on either end of the gas liquid separation passage, a plurality of lower partition walls (56H) projecting upward from the lower wall, and a plurality of upper partition walls (56J) projecting downward from the upper wall. The lower partition walls and the upper partition wall are tilted with respective the length wise direction in plan view so as to define a spiral passage. The lower wall is inclined with respect to a horizontal plane such that an upstream part of the lower wall is lower than a downstream part of the lower wall with respect to a direction of the swirl flow.

Owner:HONDA MOTOR CO LTD

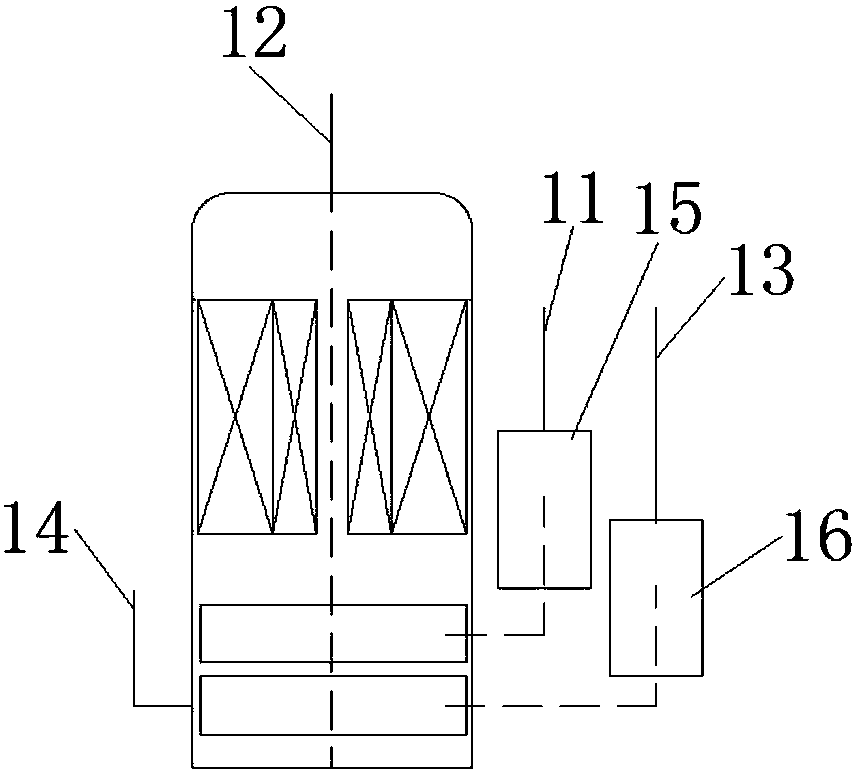

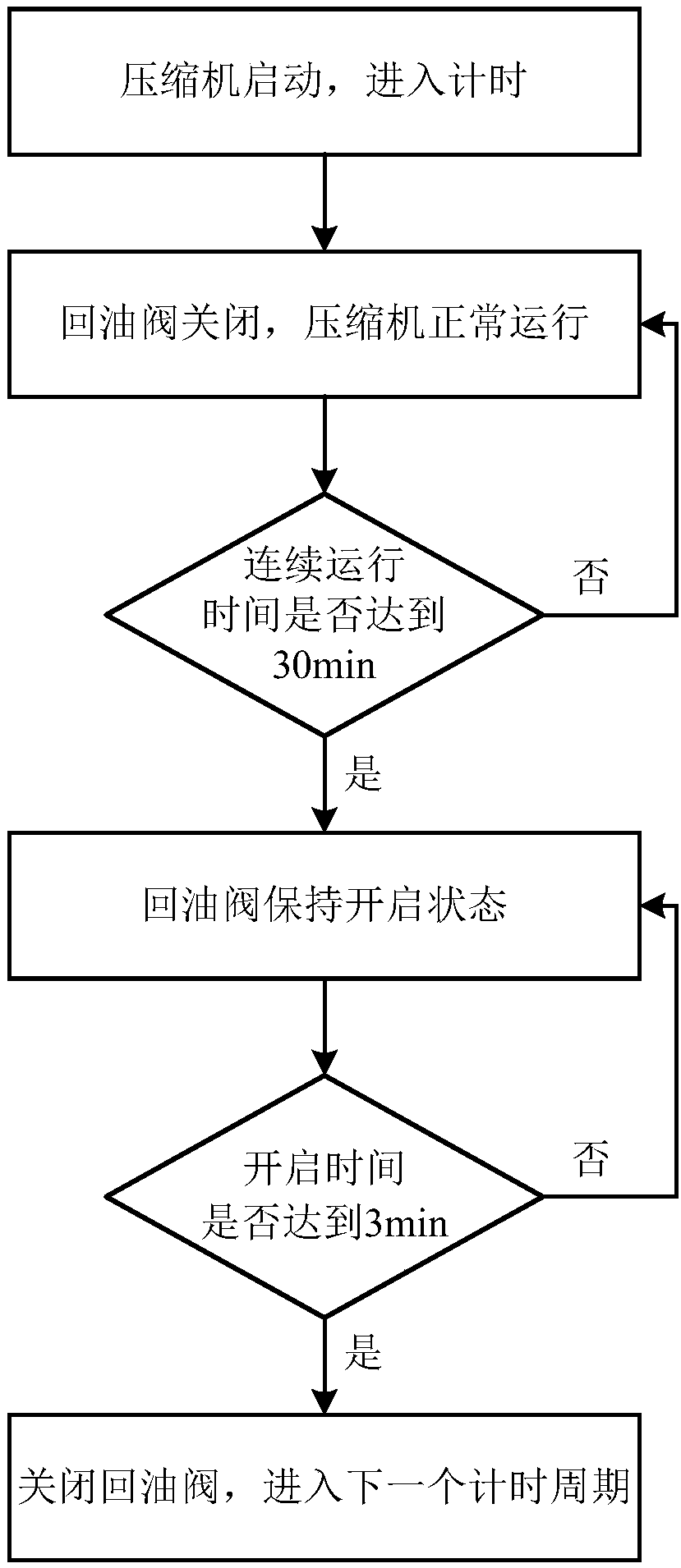

Oil return control device, air conditioning system and oil return control method of air conditioning system

ActiveCN108180680ASolve the problem of excessive exhaust oil discharge rateReduced exhaust oil discharge rateMechanical apparatusFluid circulation arrangementOil separationAir conditioning

The invention discloses an oil return control device, an air conditioning system and an oil return control method of the air conditioning system. The oil return control device comprises an oil separation mechanism and an oil return control assembly, wherein the oil separation mechanism is arranged at an exhaust port of a lower row of exhaust cylinders in a compressor comprising two or more parallel cylinders, and is used for separating and obtaining lubricating oil from exhaust gas of the lower row of exhaust cylinders, and the oil return control assembly is arranged between the oil separationmechanism and an oil pool at the bottom of the compressor, and is used for controlling the lubricating oil to return to the oil pool according to the pressure difference between exhaust ports of thetwo or more exhaust cylinders in the compressor. According to the scheme, the defects that in the prior art, a lower cylinder is prone to wear, short in service life, low in running reliability and the like can be overcome, so that the beneficial effects that the lower cylinder is not prone to wear, long in service life and high in running reliability are achieved.

Owner:GREE ELECTRIC APPLIANCES INC

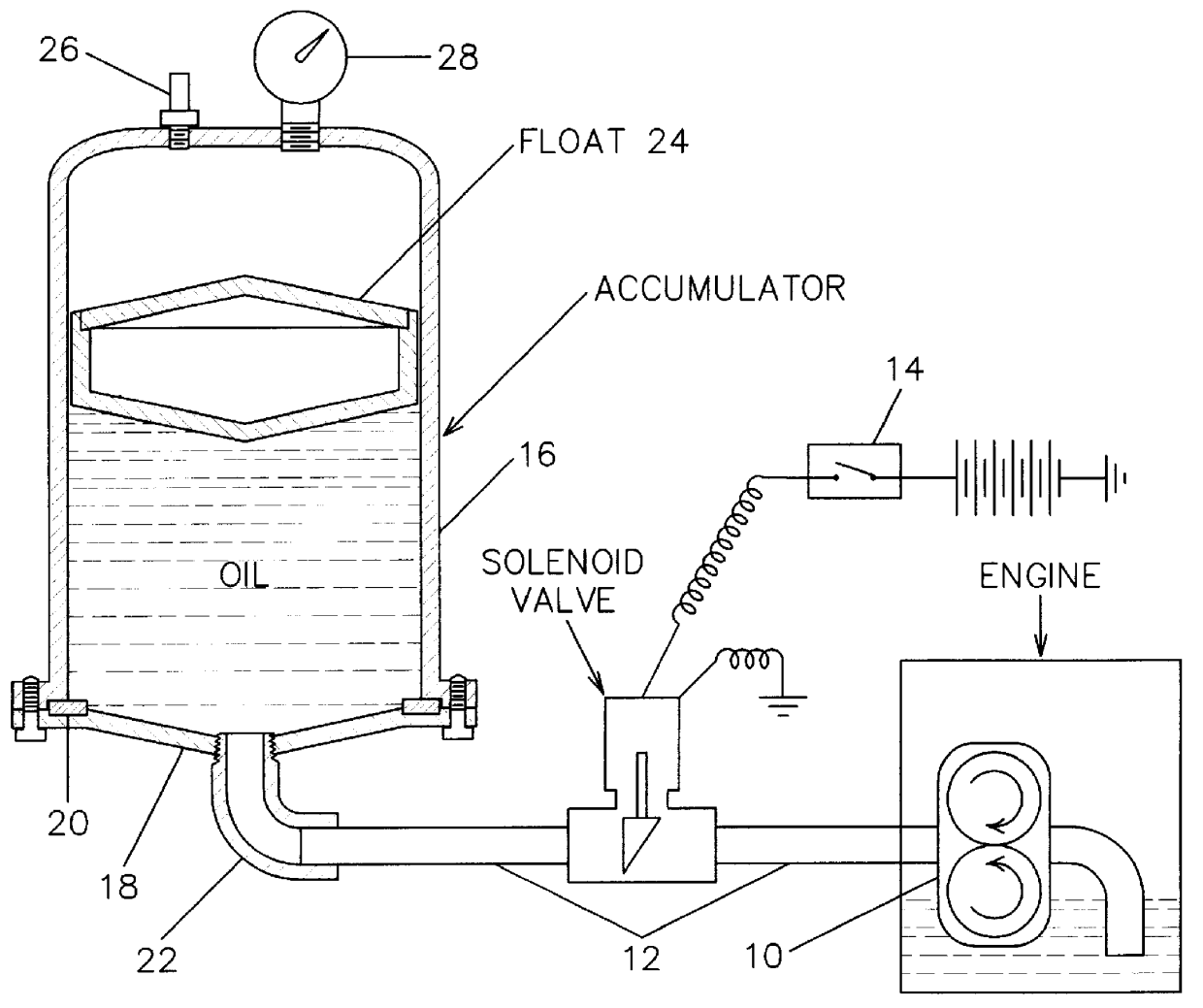

Engine-pressurized prestart oiler

InactiveUS6148789AEasy to modifyMinimal modificationLubrication of auxillariesLubricant conduit arrangementsAutomatic controlSolenoid valve

An engine-pressurized prestart oiler for an engine having pressure lubrication is provided, which rapidly lubricates critical engine bearing surfaces prior to the starting sequence. An accumulator for storing oil and pressurized air contains an air-oil separation float, which essentially fills the internal cross-sectional area and prevents absorption of the air. Discharge and recharge of the accumulator is preferably implemented by a normally closed solenoid valve. Discharge is controlled either manually by a switch or automatically by circuitry containing ignition-off time and accumulator pressure comparators, a starter interrupter, and a prestart oiling timer. Recharge is automatic, as the solenoid valve allows oil flow whenever the engine oil pressure sufficiently exceeds the accumulator pressure. A conduit connects the accumulator, solenoid valve, and engine, connecting to the engine either at the oil pressure sensor port or through an adaptor installed between the oil filter and the oil filter mount.

Owner:JOHNS RALPH HOWARD

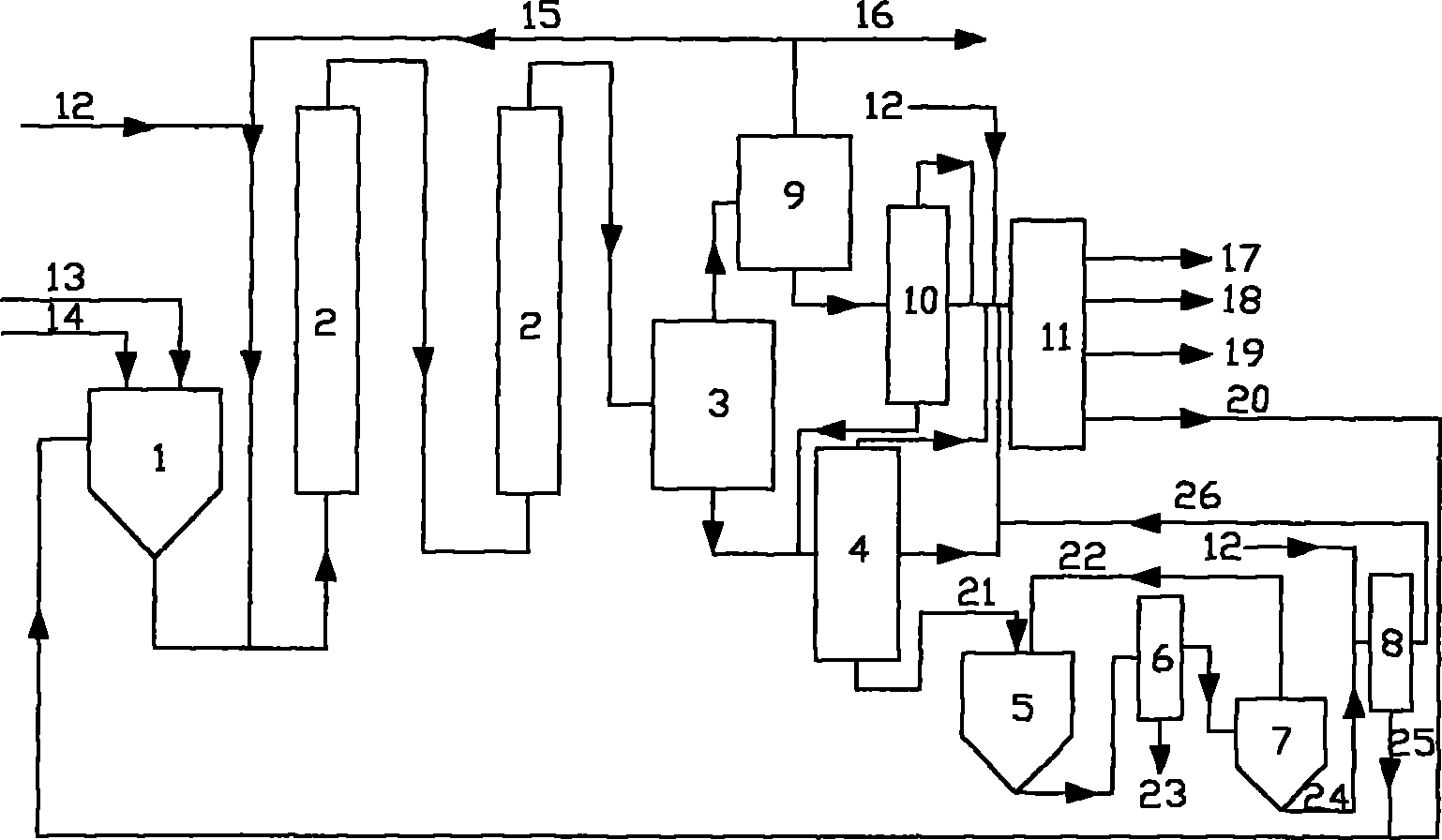

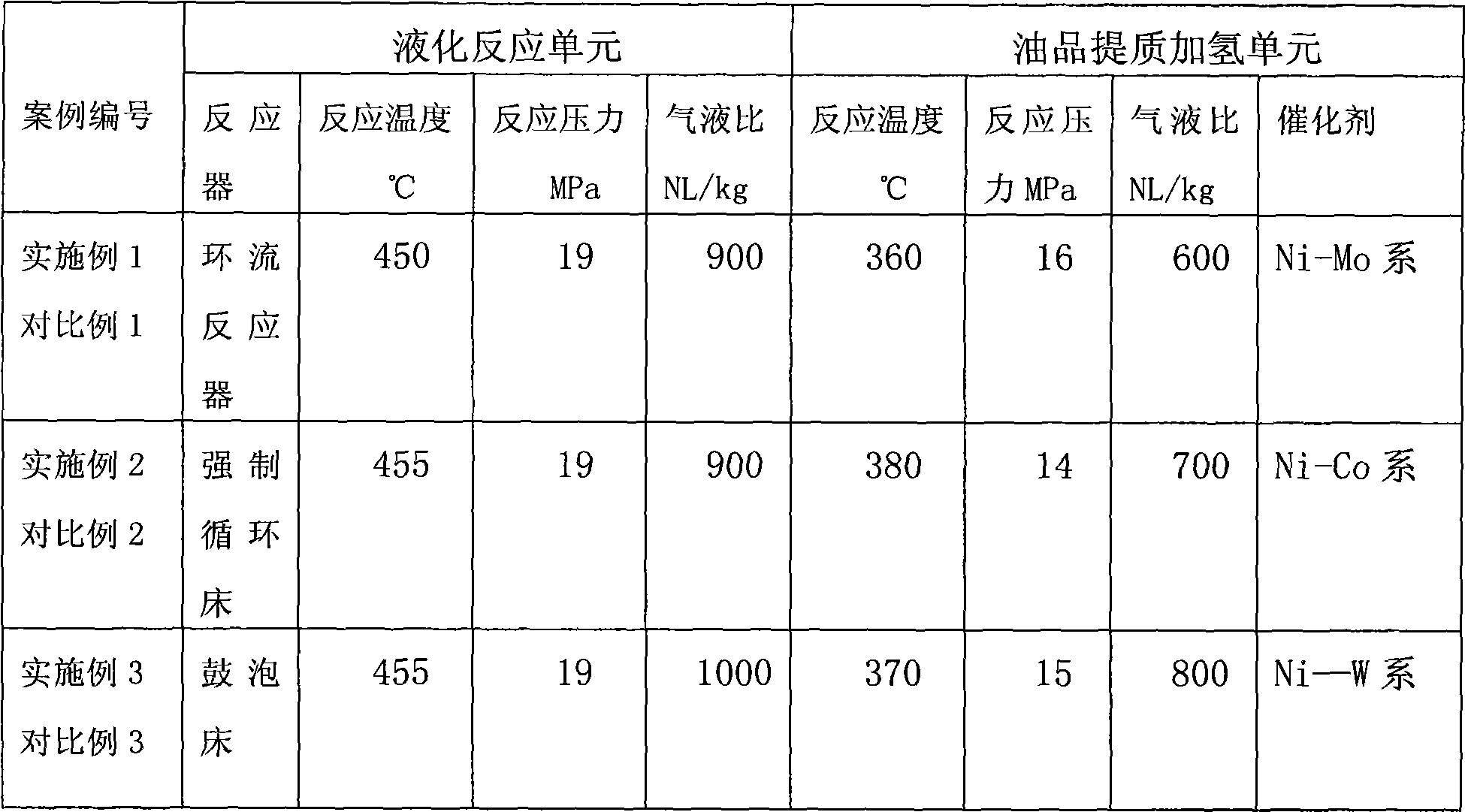

Method for directly liquefying coals with function of maximizing utilization of liquefied residues

ActiveCN102010741AGreat operating flexibilityHigh air hold-upLiquid hydrocarbon mixture productionTreatment with hydrotreatment processesEconomic benefitsOil separation

The invention relates to a method for directly liquefying coals with a function of maximizing utilization of liquefied residues. The method comprises the following technical steps: preparing coal paste; carrying out hydrotreating and liquefaction on the coal paste; carrying out oil separation treatment on the obtained oil product; carrying out upgrading and hydrotreating on the obtained product; carrying out hot extraction on the residues and then carrying out solid-liquid separation on the residues; and recovering the solvent; and carrying out hydrotreating treatment on the mixture of heavy oils and asphalt materials so as to obtain the final product, then taking the heavy oils as recycled solvent to prepare the coal paste, and the like. The method provided by the invention has the advantages that because of organically combining the liquefaction process and the residue extraction, the utilization of liquefied residues is maximized, the conversion rate of coal is improved, the yieldsof light and middle oils subjected to coal liquefaction are improved by 10 to 60 percent, and the quality of oil is improved, thereby greatly enhancing the economic benefits of direct coal liquefaction plants and improving environment protection; and the method provided by the invention has important economic and social significances, and can widely be applied to the field of coal direct liquefaction.

Owner:CHINA COAL RES INST

Processing method for recycling electroplating concentrated control zone electroplating waste water resource

ActiveCN101633544AMaximize quality recoveryIncrease contentFatty/oily/floating substances removal devicesWaste water treatment from metallurgical processHandling systemPollution

The invention relates to a processing method for recycling an electroplating concentrated control zone electroplating waste water resource, which comprises the following steps: firstly, preprocessing the inverted trough water in the electroplating production process, recycling valuable metals in the inverted trough water, and respectively filling the pretreated tail water in corresponding processing systems according to kinds; then, recycling copper, nickel and chromium resources in the corresponding processing system; afterwards, mixing other drain away water in a base station and the waste water with recycled copper, nickel and chromium resources, and then carrying out integrated structure breaking, neutralizing and coagulating sedimentation, and mixing the treated waste water and the pretreated water by treatment of oil separation, oil removal and coagulating sedimentation for biochemical treatment; and finally, discharging the effluent which reaches the standard. The method not only enables the electroplating waste water to reach the standard and can be discharged stably, but also recycles the valuable resources in the waste water in low cost, greatly reduces the secondary pollution and realizes the clean production of electroplating waste water control and the environmental requirements of the electroplating concentrated control zone.

Owner:ZHEJIANG HI TECH ENVIRONMENTAL TECH

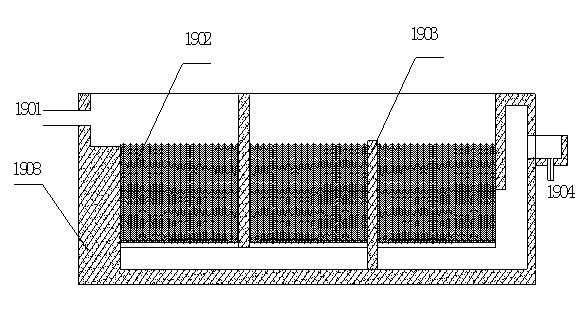

Water and oil separation system

ActiveUS20130146536A1Efficiently and completely performReduce dirtSedimentation separationLoose filtering material filtersOil separationInner membrane

A separation system includes at least a hydrocyclone and one or more membranes. In another aspect, a separation system includes a membrane having graduated and / or asymmetrical pore sizes. A further aspect of a separation system includes an inner membrane, an outer membrane and a hydrocyclonic flow between the membranes.

Owner:BOARD OF TRUSTEES OPERATING MICHIGAN STATE UNIV

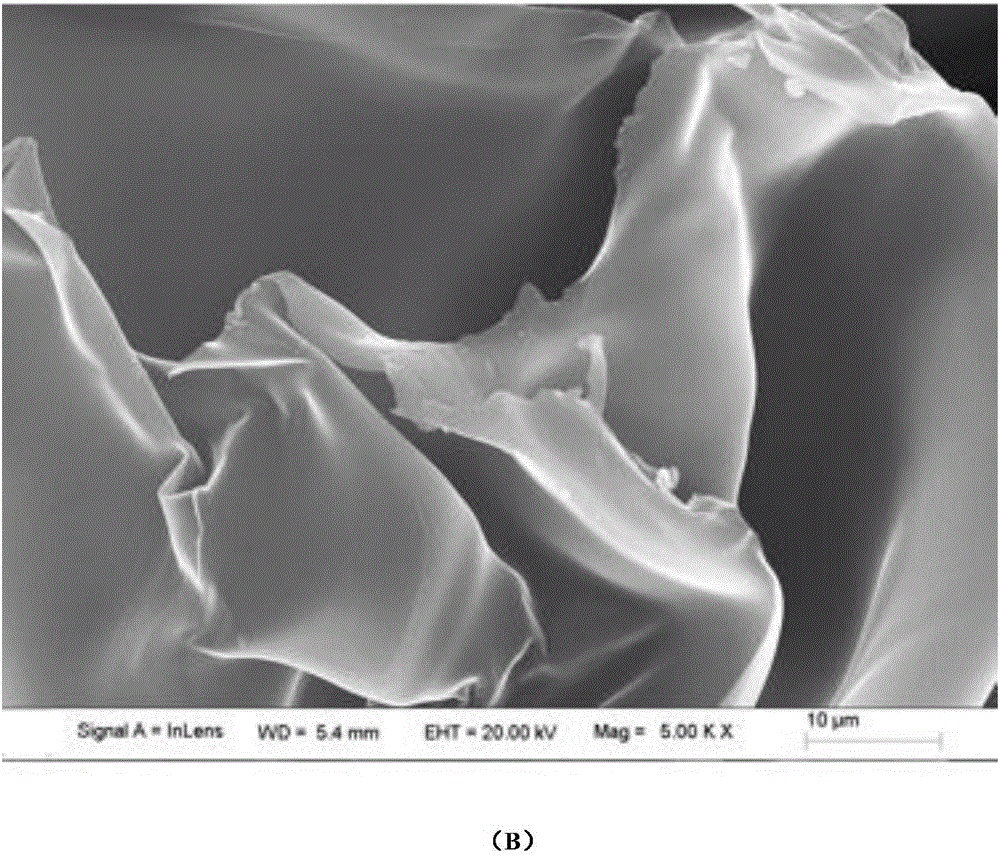

Preparing method of polyimide aerogels and hybrid aerogels thereof

InactiveCN106317407ALow dielectric constantReduce dielectric lossMonocomponent synthetic polymer artificial filamentMicrostrip patch antennaFiber

The invention discloses a preparing method of polyimide aerogels and hybrid aerogels thereof, belonging to the field of aerogels. In the preparing of the polyimide precursor, the polyamic acid precipitated fiber having a large specific surface area is dissolved in an aqueous solution of triethylamine, then stirred and dissolved. And the thermal imidization is directly frozen and dried without a long sol-gel process to obtain the polyimide aerogels. At the same time, by introducing the filler with different functional characteristics, the functional diversity of polyimide hybrid aerogels is realized. The prepared hybrid aerogels can be used as flexible conductors, microstrip patch antennas, catalysts, water and oil separation membranes, high performance adsorbent materials, etc., and can be used in the fields of flexible wearable microelectronics, aerospace communications, photocatalysis and oil leakage, etc. The application scope of polyimide materials and aerogels materials is expanded, the value of products is enhanced, the preparing cycle is shortened, and its industrialization process is promoted.

Owner:BEIJING UNIV OF CHEM TECH

Coal chemical industry high-concentration wastewater treatment method and apparatus

ActiveCN103910460AImprove biodegradabilityReduce pollutionMultistage water/sewage treatmentHigh concentrationTreatment effect

The invention provides a coal chemical industry high-concentration wastewater treatment method and an apparatus which can solve the problems of low flux and high membrane pollution when an MBR (membrane bioreactor) is used for coal chemical industry wastewater treatment in the prior art. The coal chemical industry high-concentration wastewater treatment apparatus comprises an oil separation device, a flocculation reaction device communicated with the oil separation device, an ultra-micro air flotation device communicated with the flocculation reaction device, an advanced oxidation device communicated with the ultra-micro air flotation device, a hydrolysis and acidification device communicated with the advanced oxidation device, a denitrification device communicated with the hydrolysis and acidification device, an anoxic device communicated with the denitrification device, and an aerobic MBR device which comprises a plurality of MBR membranes arranged in the aerobic MBR device and is communicated with the anoxic device. The coal chemical industry high-concentration wastewater treatment method and the device provided by the invention have the beneficial effects that the pretreatment is complete, the subsequent treatment difficulty is low, and the biochemical treatment effect is ensured so as to be favorable for reducing membrane pollution; in addition, the cleaning frequency of the membranes is low and the service life is long; and furthermore, the MBR outlet water is stable, suspended matters are avoided, and the deep treatment effect can be further ensured.

Owner:GO HIGHER ENVIRONMENT GRP CO LTD

Edible spread composition and packaged product

Owner:KRAFT FOODS GRP BRANDS LLC

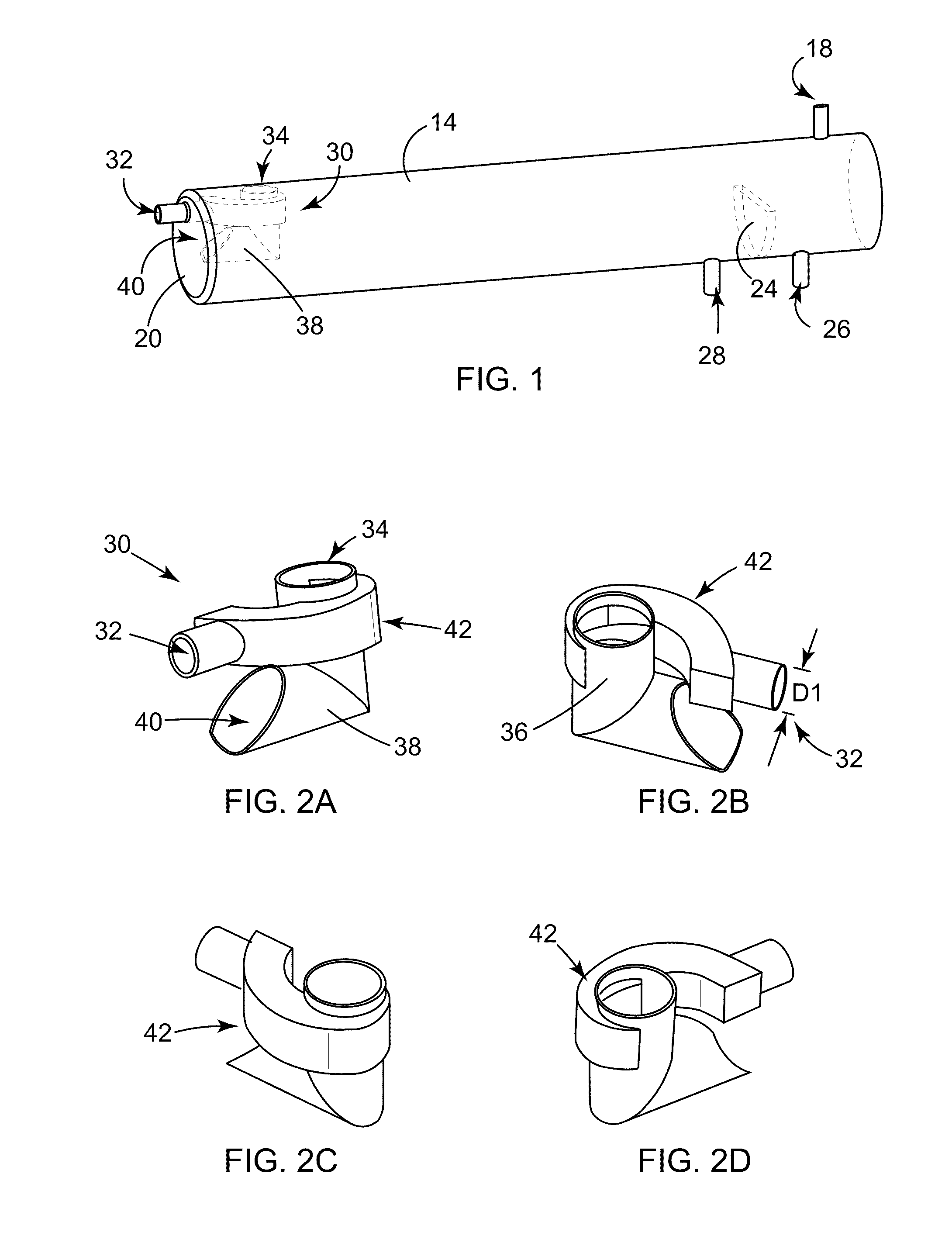

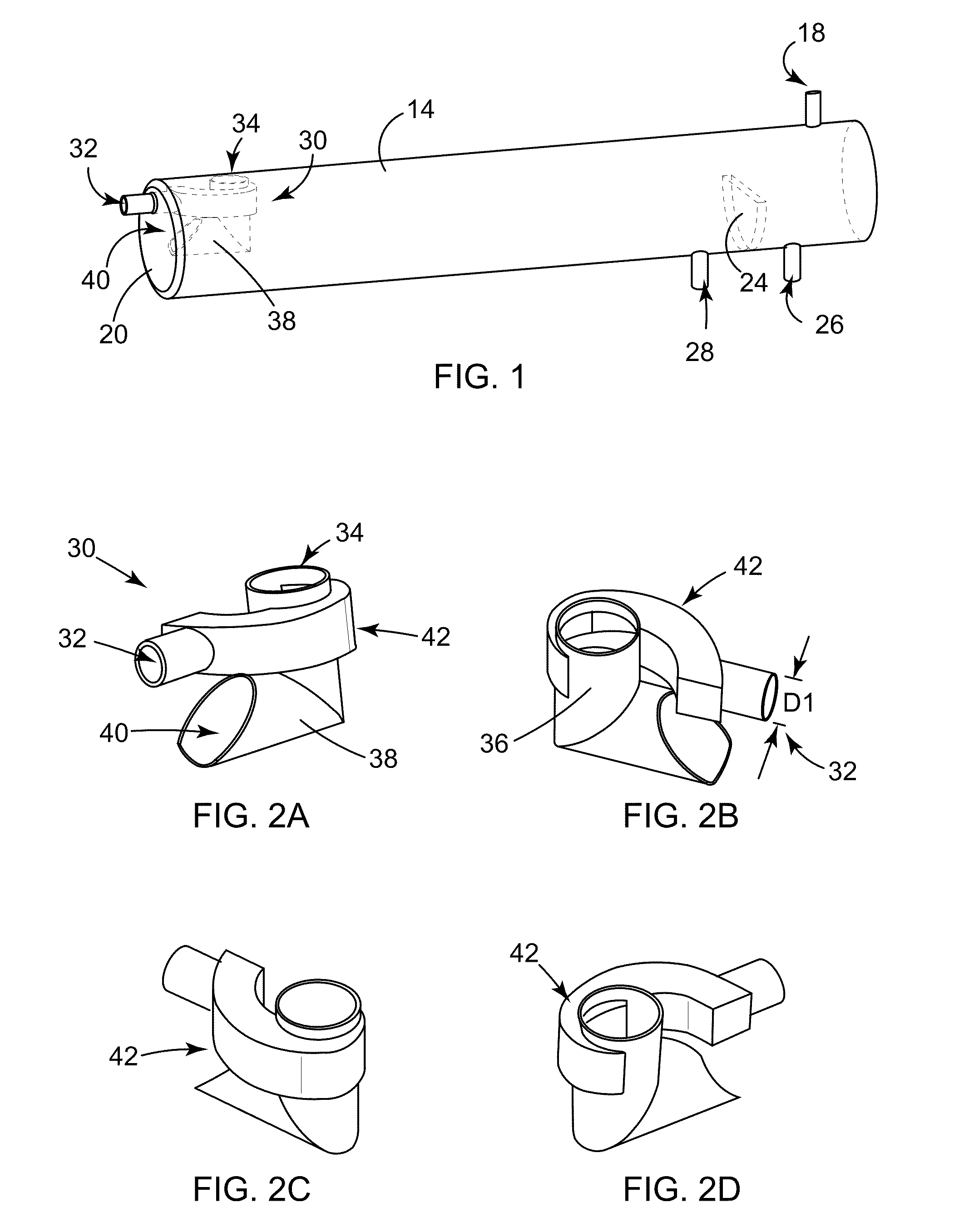

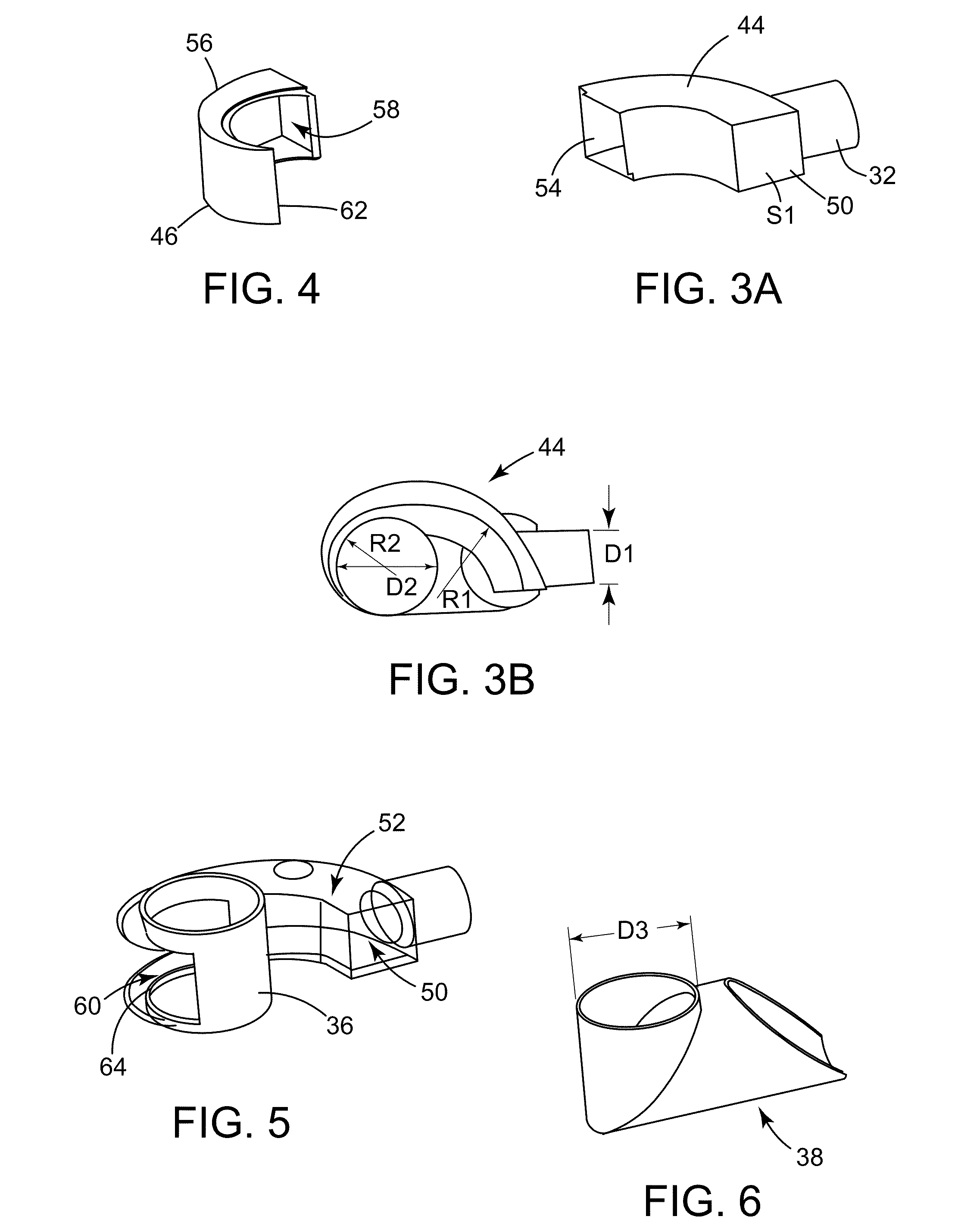

Method and apparatus for separating air and oil

Methods and devices for separating oil from a mixture of oil and air are provided. In various embodiments, an air / oil separator includes a cylindrical housing that creates a circular flow path of the air and oil. Further, the air / oil separator may include various flow guides that improve the air / oil separation properties of the separator. Other embodiments include a turbine engine with a lubrication system that includes the improved air / oil separator.

Owner:GENERAL ELECTRIC CO

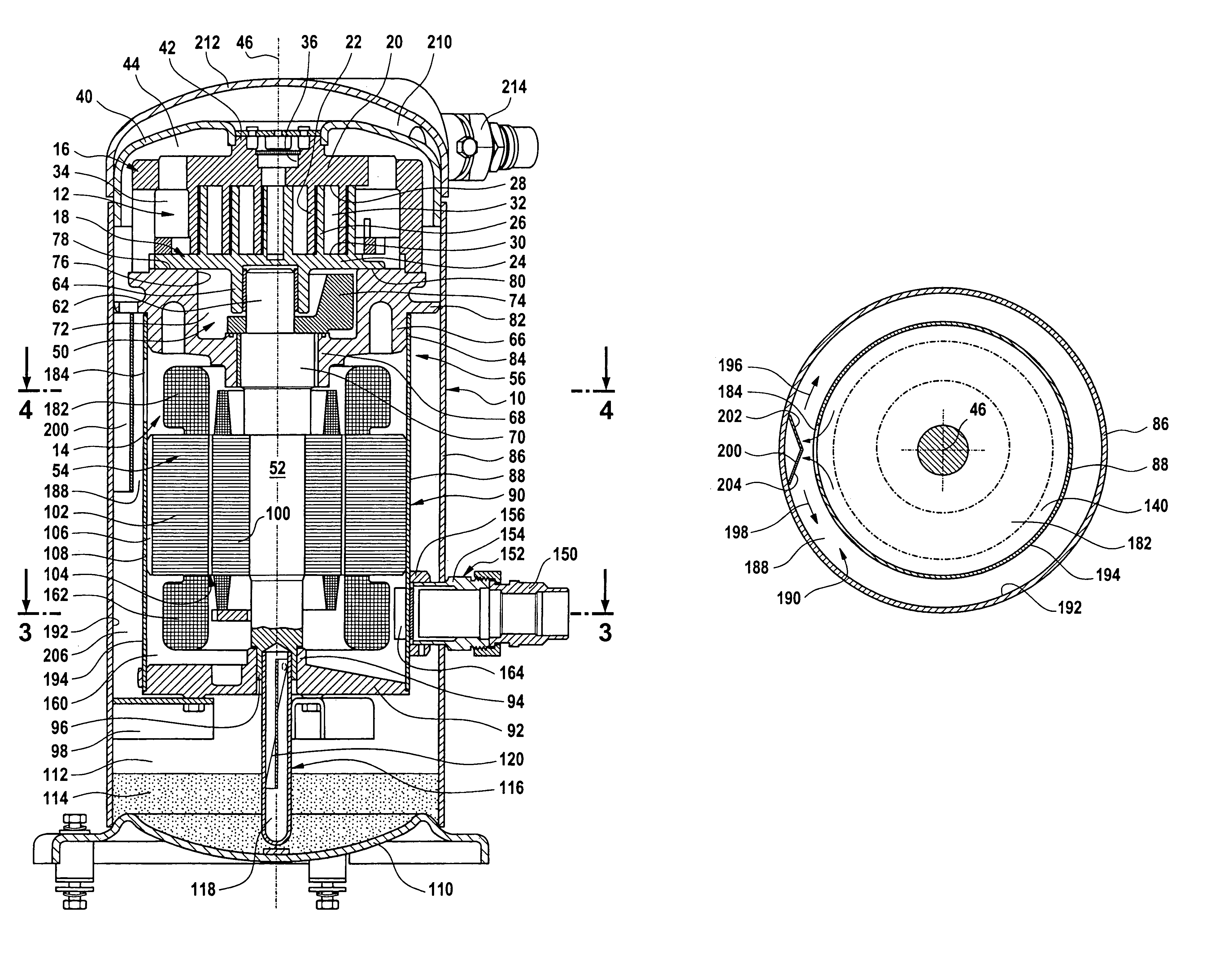

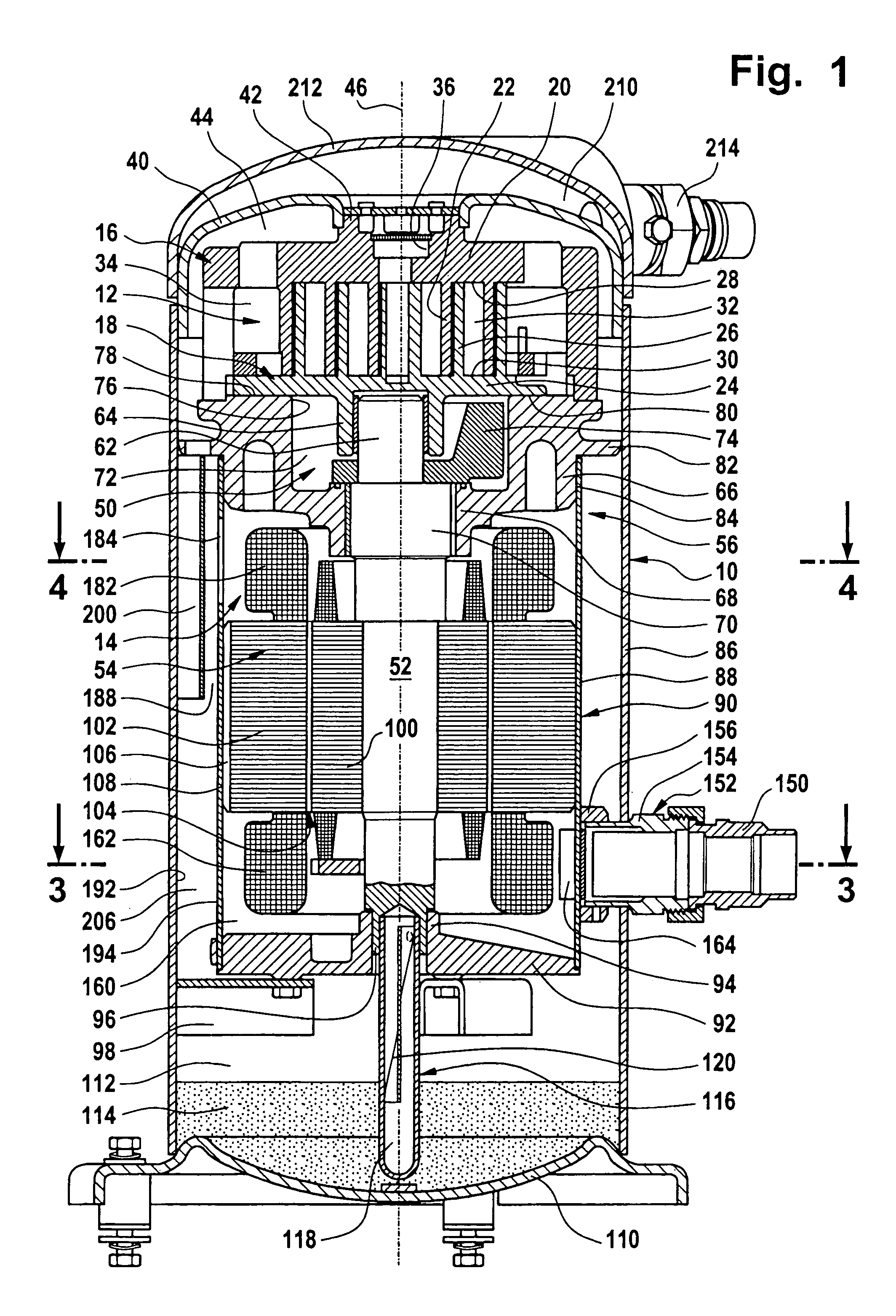

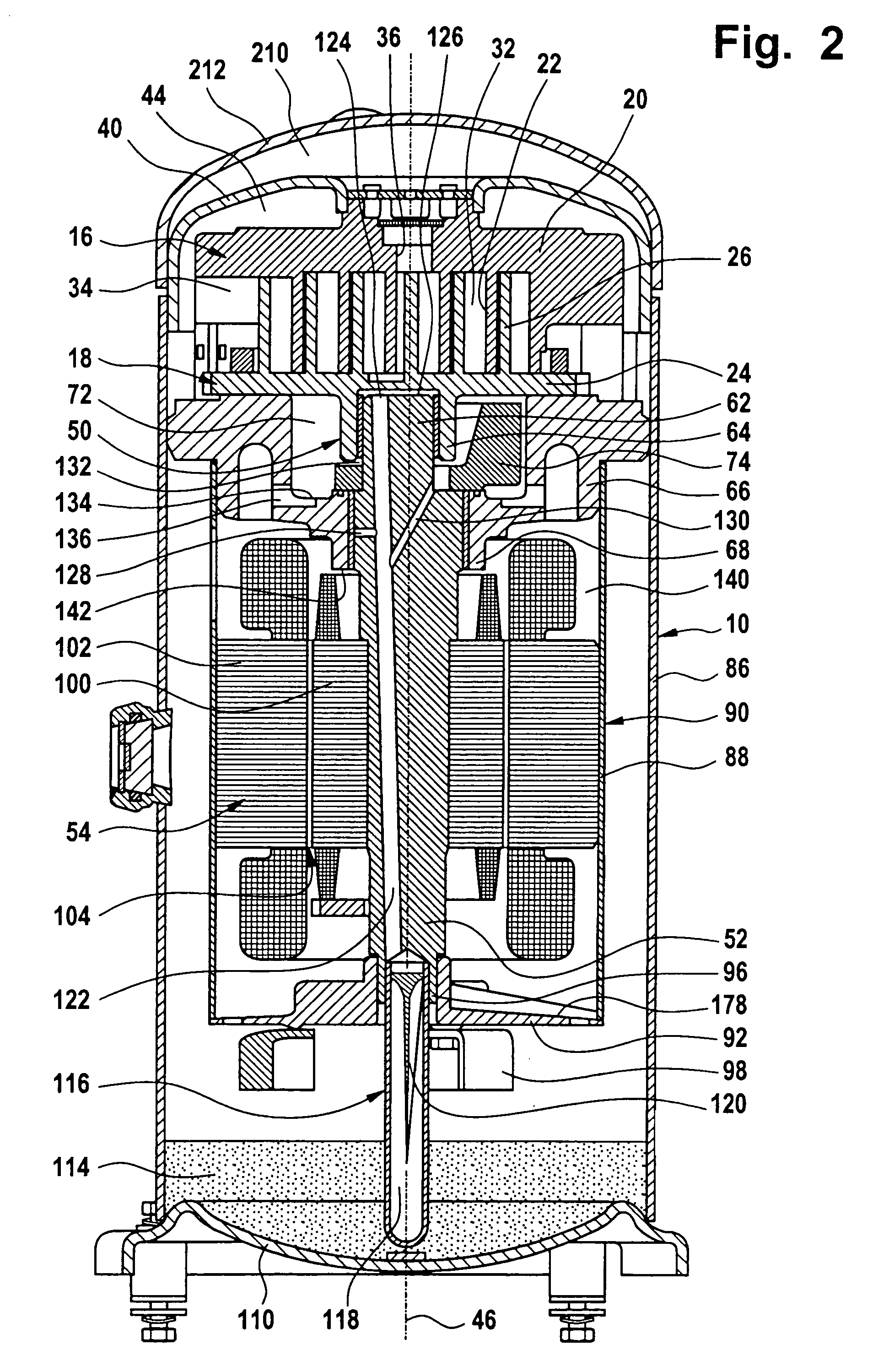

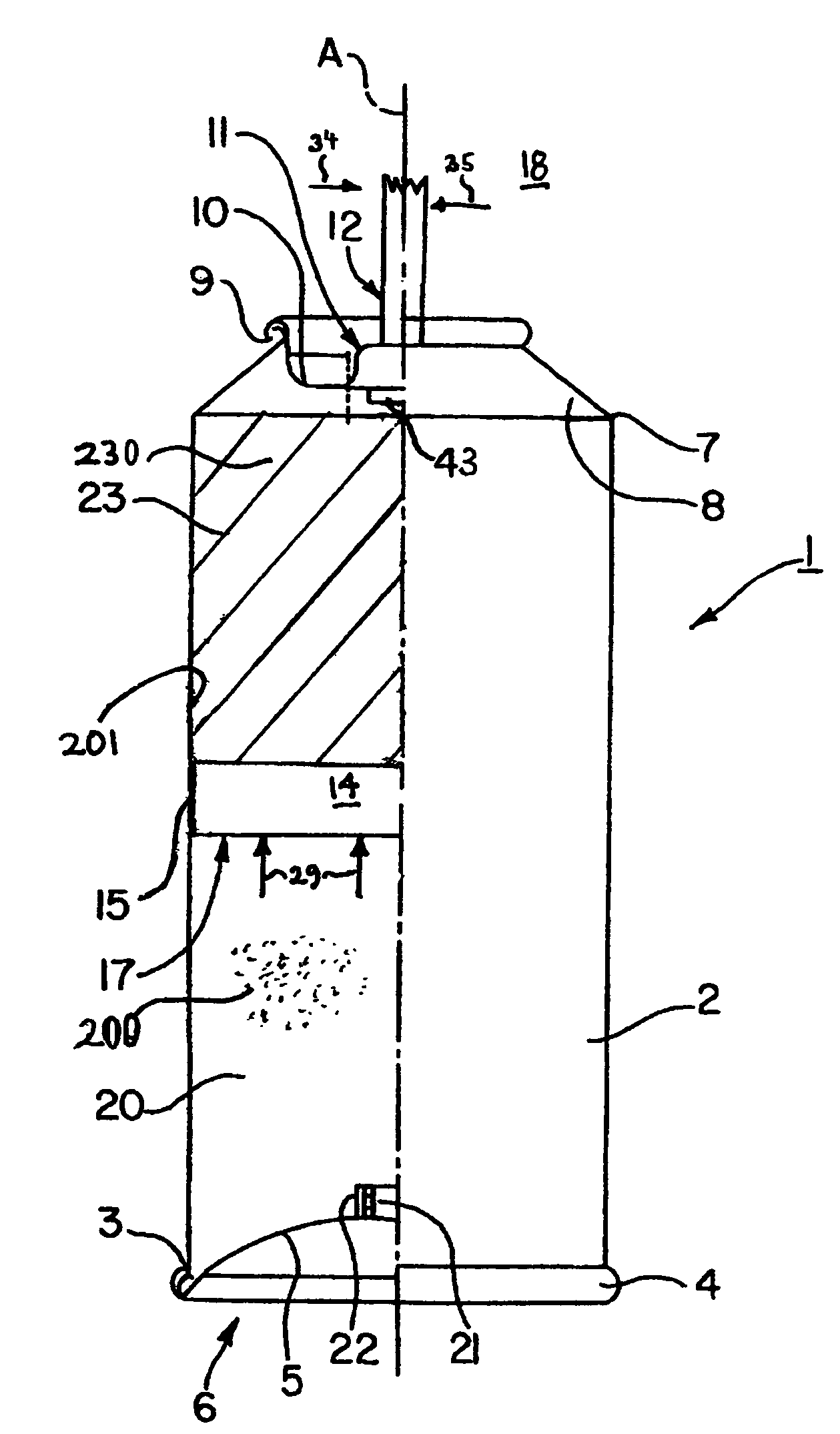

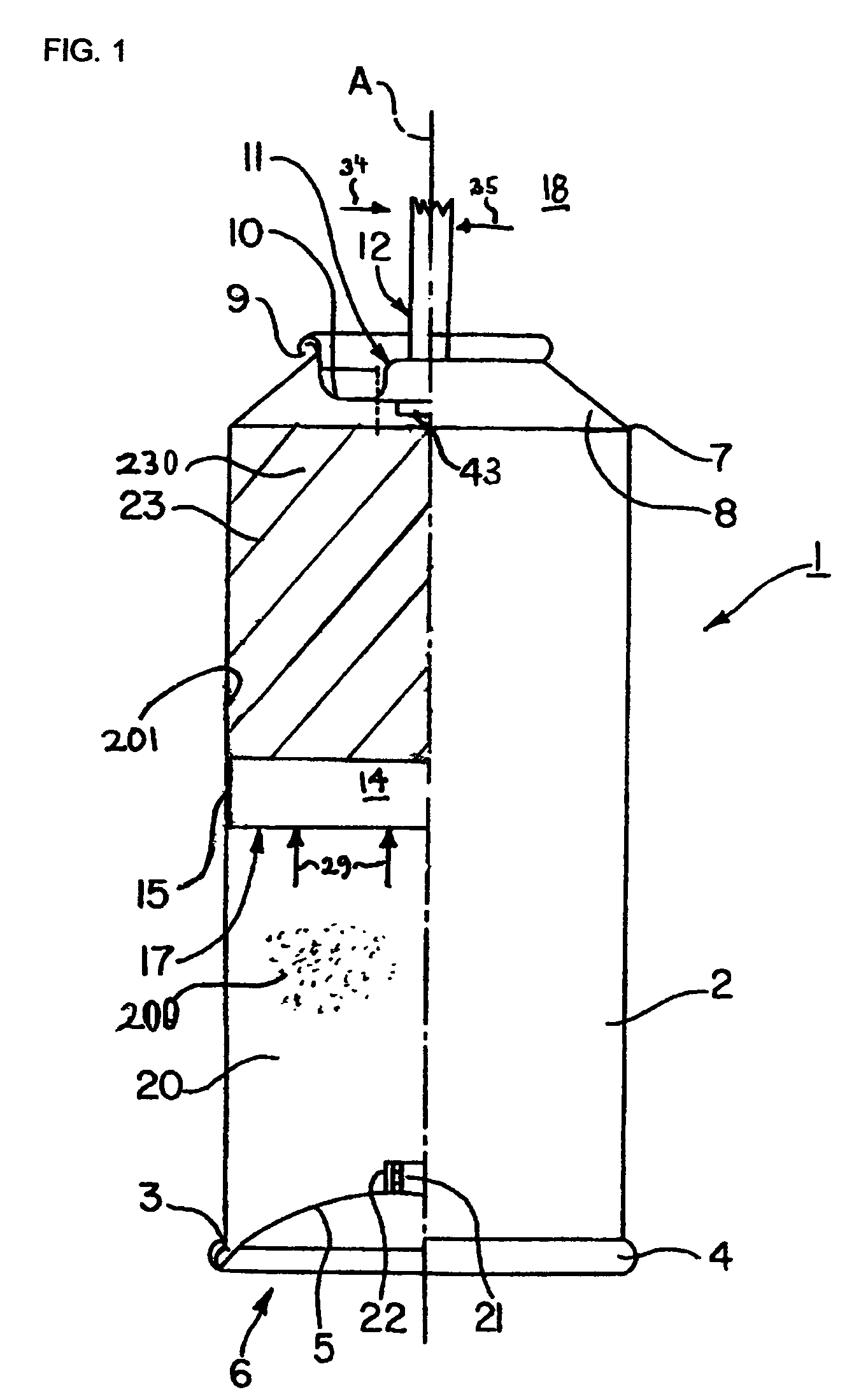

Scroll compressor with bifurcated flow pattern

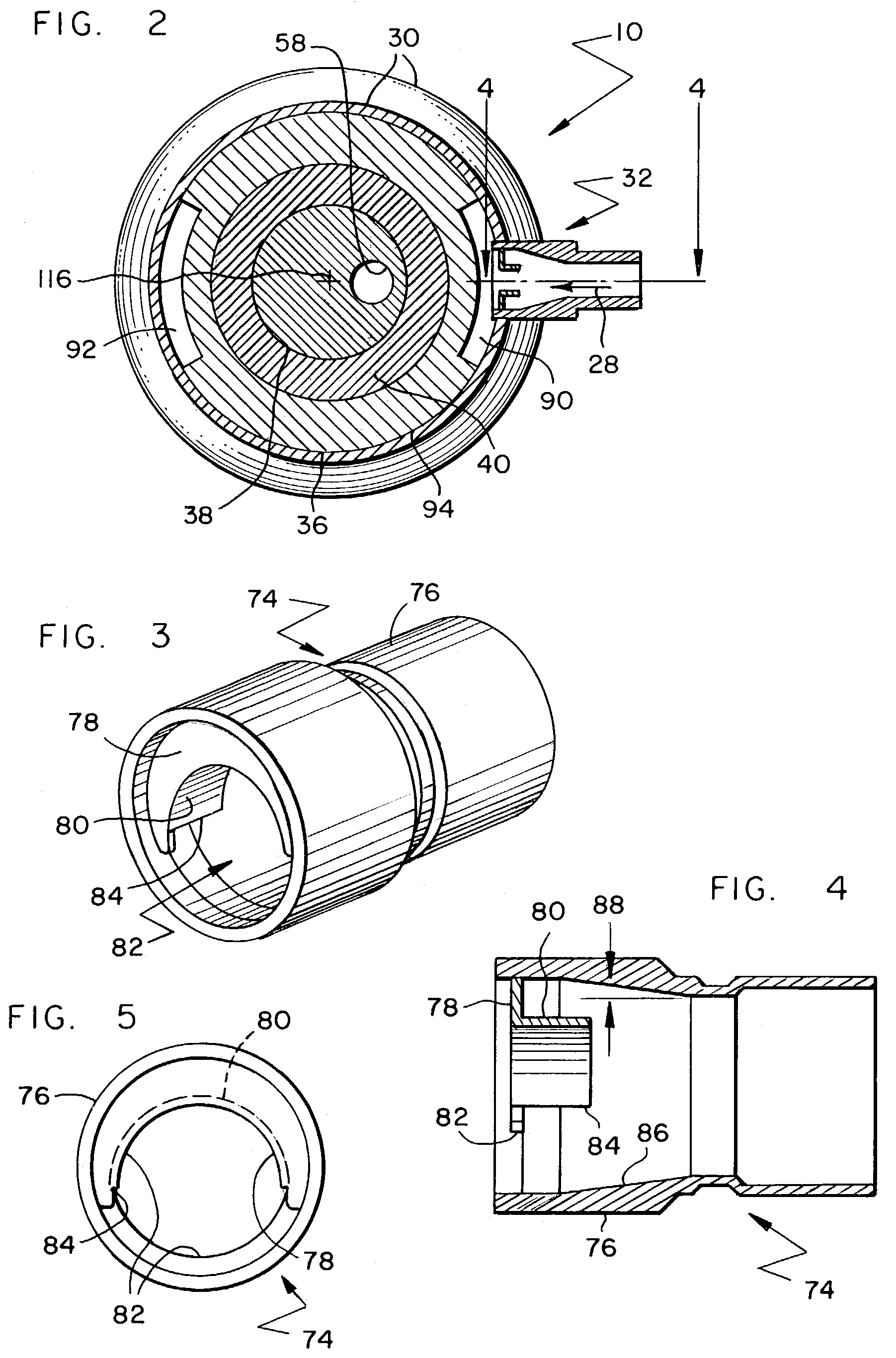

ActiveUS7311501B2Reduce oilShorten speedRotary/oscillating piston combinations for elastic fluidsPositive displacement pump componentsOil separationEngineering

A scroll compressor includes various features that promote a bifurcated flow pattern of gas through a compressor shell to reduce oil entrainment. After entering the shell, some gas travels upward, which reduces the volume of gas traveling downward toward an oil sump. To accomplish this, the compressor's motor can be surrounded by a sleeve having upper and lower apertures for directing the flow to the motor's upper and lower stator end turns. In some embodiments, a suction inlet is strategically positioned relative to two gas passageways that are between the stator and the compressor shell. The inlet's position is such that one passageway receives incoming gas and divides the flow in opposite directions: upward and downward. The other passageway only conveys the gas upward. In addition, a suction baffle, a diffuser, a streamlined counterweight and / or a suction line oil trap can also help promote gas / oil separation or minimize oil entrainment.

Owner:TRANE INT INC

Method for treatment of waste emulsion

InactiveCN101792239AEasy to separateSimple processWaste water treatment from metallurgical processMultistage water/sewage treatmentElectrolysisWaste oil

The invention discloses a method for the treatment of waste emulsion, more particularly a method for the treatment of waste emulsion generated in the machining processes such as cutting, grinding and the like. The method comprises the following steps: separation of stored emulsion breakers, mechanical air flotation, ion-carbon electrolysis, coagulating sedimentation, oil separation with inclined plate, microorganism purification, sedimentation, sand filtering, etc.; the method has the advantages of simple technology and standard-reaching wastewater, and devices for the implementation of the method have small floor area, little investment, low running cost, low energy consumption, maximal recycling of waste oil resource and prominent operability and is widely suitable for machining and the treatment of waste emulsion in other industries. The waste oil recycled according to the method is completely capable of being used for the production of patented product, the protective grease, thus idealized application of resources is achieved.

Owner:成都蜀光石油化学有限公司

Novel PE film

ActiveCN101480861AGood heat sealingGood oil separation functionFlexible coversWrappersLow-density polyethyleneLinear low-density polyethylene

The invention discloses a novel PE film which is formed by coextrusion of three layerswhich are respectively an outer layer, a middle layer and an inner layer; thickness ratio among the outer layer, the middle layer and the inner layer is 1 plus / minus 0.3 : 1 plus / minus 0.3 : 1 plus / minus 0.3; raw materials of the outer layer are low-density polythene and linear low-density polythene with weight ratio of 1 : 1 to 1 : 8; raw materials of the middle layer are polypropylene and metallocene linear low-density polythene with weight ratio of 1 : 0.2 to 1 : 10; and raw materials of the inner layer are the linear low-density polythene, the metallocene linear low-density polythene and anti-block agent with weight ratio of 100 : 100 : 2to 100 : 10 : 1. The novel PE film has the advantages that modification is carried out on the middle layer by the polypropylene, the film has favorable heat sealing performance by adding the metallocene linear low-density polythene into the middle layer and the inner layer to cause molecules of the PE film after the modification to interlink to form a space stereo formation, and the molecule density is increased, thereby the purpose of preventing oil molecules from permeating is achieved, and the PE film is enabled to have favorable oil separation function.

Owner:KINDERWAY PACKAGING XIAMEN CO LTD

Apparatus for separation of gas-liquid mixtures and promoting coalescence of liquids

ActiveUS8337603B2Promotes coalescenceEasy to separateLiquid degasificationReversed direction vortexChemical physicsOil separation

Provided herein is a conditioning apparatus that includes a geometrical configuration having an inlet flow deceleration conduit and a cyclonic tube to effectuate both liquid-gas separation and droplet coalescence. The apparatus is typically positioned at the inlet of a separator vessel used for removing water and gas from extracted crude oil containing entrained water and gas. The apparatus promotes droplet coalescence and gas separation for mixed fluids flowing into an existing water and oil separation device.

Owner:SAUDI ARABIAN OIL CO

Utility skid tree support system for subsea wellhead

A utility skid tree system for subsea wellheads enables a tree to be mounted by and interface with utility skids. Production bore access is provided through an extended production wing block. The system reacts and transfers installation loads and potential snag loads to the conductor. The tree accepts skids for flow boosting, metering, water-oil separation, etc. A conventional choke may be fitted outboard of the utility insert profile.

Owner:VETCO GRAY

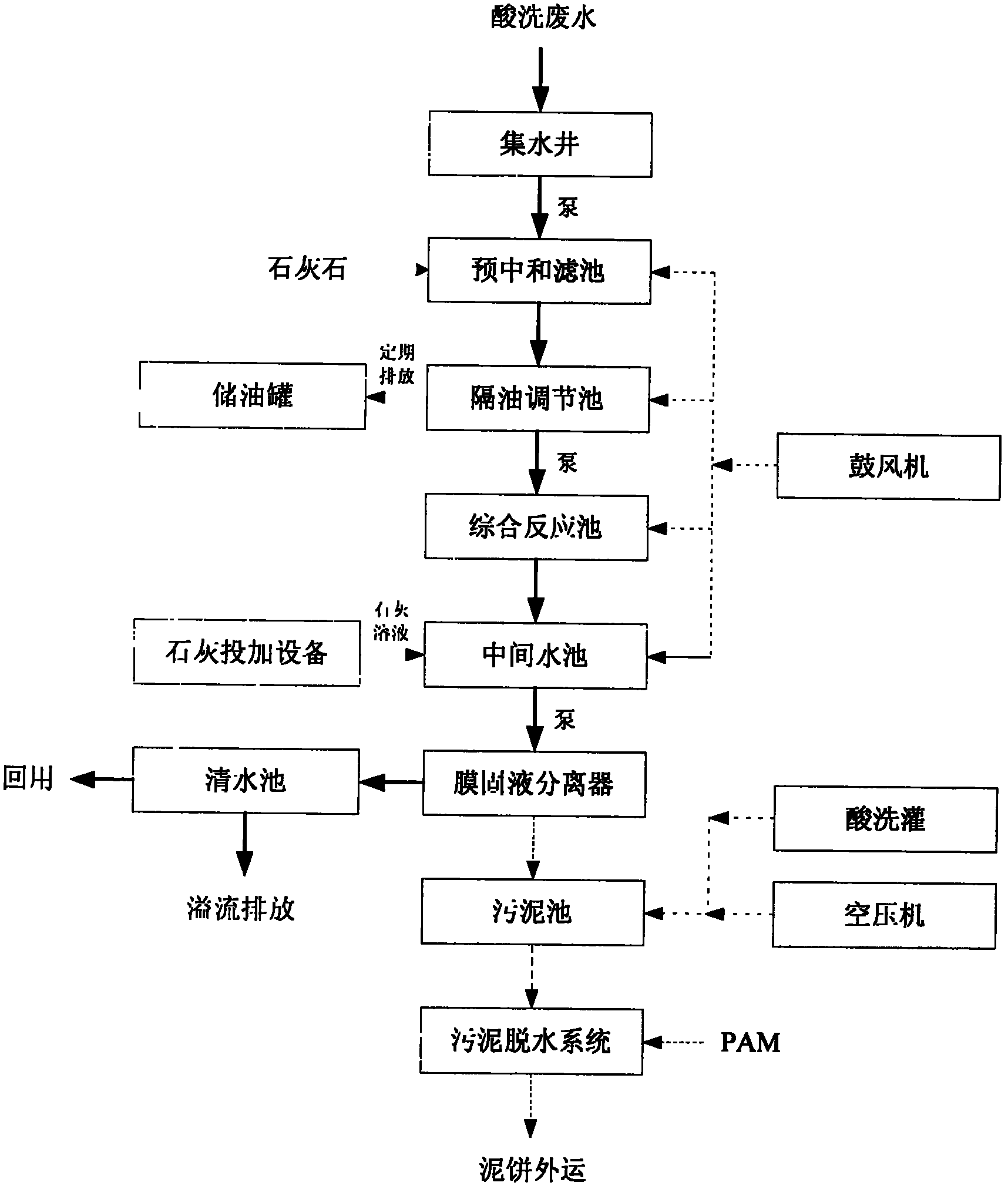

Method for treating acid-washing wastewater and metallic ions in iron and steel industry

InactiveCN102107963ALow running costGuaranteed uptimeWater contaminantsMultistage water/sewage treatmentFerric hydroxideZinc hydroxide

The invention provides a method for treating acid-washing wastewater and metallic ions in iron and steel industry, which comprises steps as follows: acid-washing wastewater naturally flows into a water collecting well and enters a preneutralization filter chamber under the elevation action of a pump, the preneutralization filter chamber is provided with 10-200mm limestone which is in a graded distribution mode, and after the acid-washing wastewater is preneutralized by the limestone, the pH value of the effluent water is controlled at 5-6, wherein the method provided by the invention greatly lowers the chemical expenses and operating cost as compared with the conventional method of directly adding an alkali solution; the acid-washing wastewater, which is subjected to initial pH value regulation, naturally flows into an oil separation regulating chamber, so that iron ions in the wastewater react with the alkali solution to form a precipitation mixture of ferric hydroxide, zinc hydroxide and the like; and the wastewater is elevated into a membrane solid-liquid separator to complete solid-liquid separation, so that the wastewater can be discharged after reaching the standard. The invention thoroughly solves the problems that the precipitate can not easily settle, the iron can not be easily removed, and the iron ions are dissolved out. The invention has the advantages of simple technique, high economy, low requirements for technical levels of workers, and high controllability, is reliable to operate, and has wide market prospects.

Owner:TIANJIN ACADEMY OF ENVIRONMENTAL SCI

Switchable two-stage and cascade marine energy-saving ultralow-temperature refrigeration system

ActiveUS20160334143A1Save energyImprove efficiencyMechanical apparatusAuxillariesVapor–liquid separatorSolenoid valve

The present invention discloses a switchable two-stage and cascade marine energy-saving ultralow-temperature refrigeration system which comprises a high-temperature level refrigeration system, a low-temperature level refrigeration system, a hot fluorine defrosting system of a high-temperature level air cooler and a hot fluorine defrosting system of a low-temperature level air cooler. The hot fluorine defrosting system of the high-temperature level air cooler comprises a high-temperature level compressor of which the outlet is divided into two paths through a first oil separator; and the second path is connected with an air suction port of the high-temperature level compressor through a first solenoid valve, the high-temperature level air cooler, a third solenoid valve, a first pressure relief valve, a first gas-liquid separator, a first one-way valve and a first heat regenerator. The hot fluorine defrosting system of the low-temperature level air cooler comprises a low-temperature level compressor of which the outlet is divided into two paths through a precooler and a second oil separator; and the second path is connected with an air suction port of the low-temperature level compressor through an eighth solenoid valve, the low-temperature level air cooler, a sixth solenoid valve. a second pressure relief valve, a second gas-liquid separator, a third one-way valve and a second heat regenerator. The present invention has the obvious effects of large refrigeration section, high cooling rate, good energy-saving effect and thorough defrosting.

Owner:SHANGHAI OCEAN UNIV

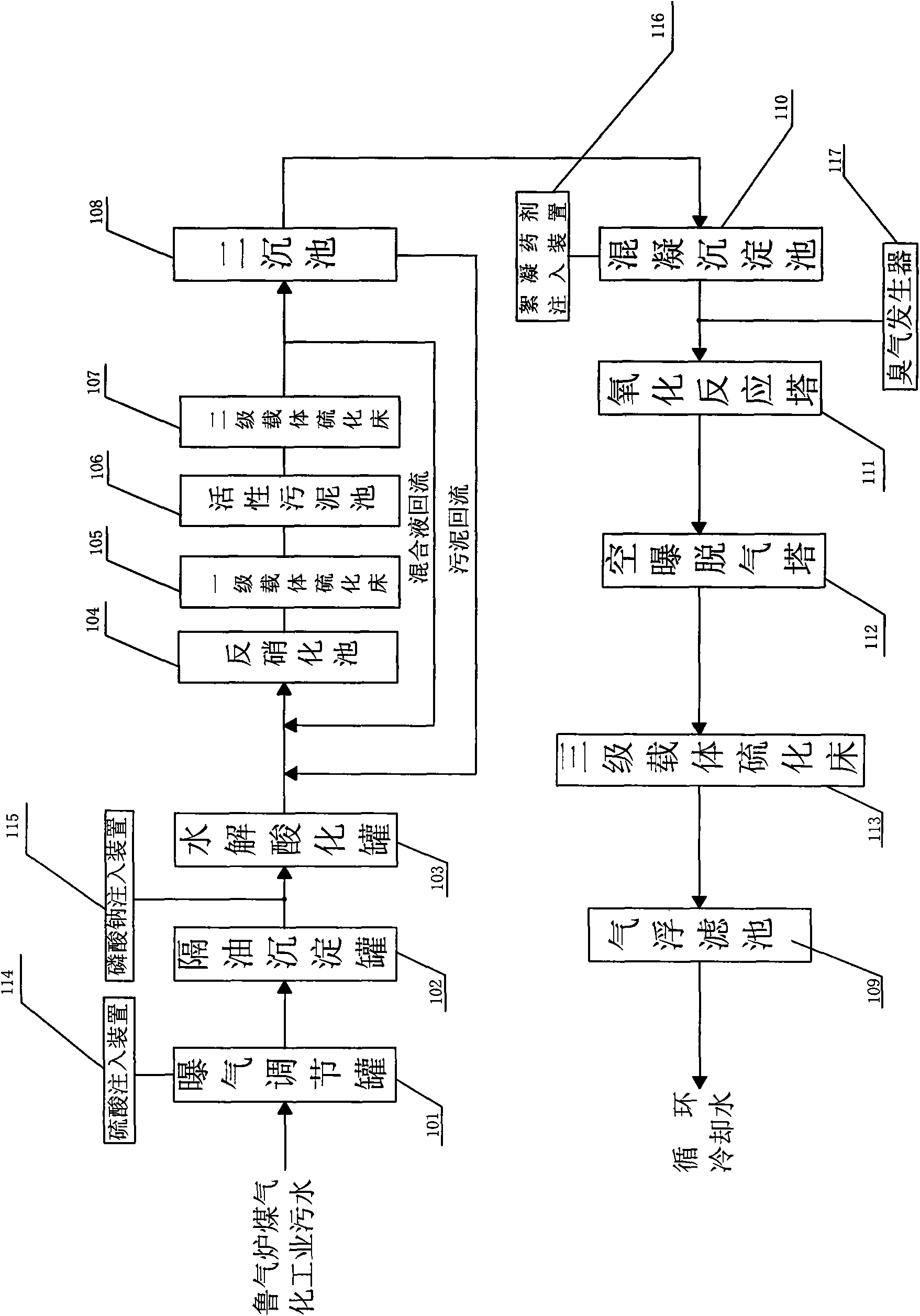

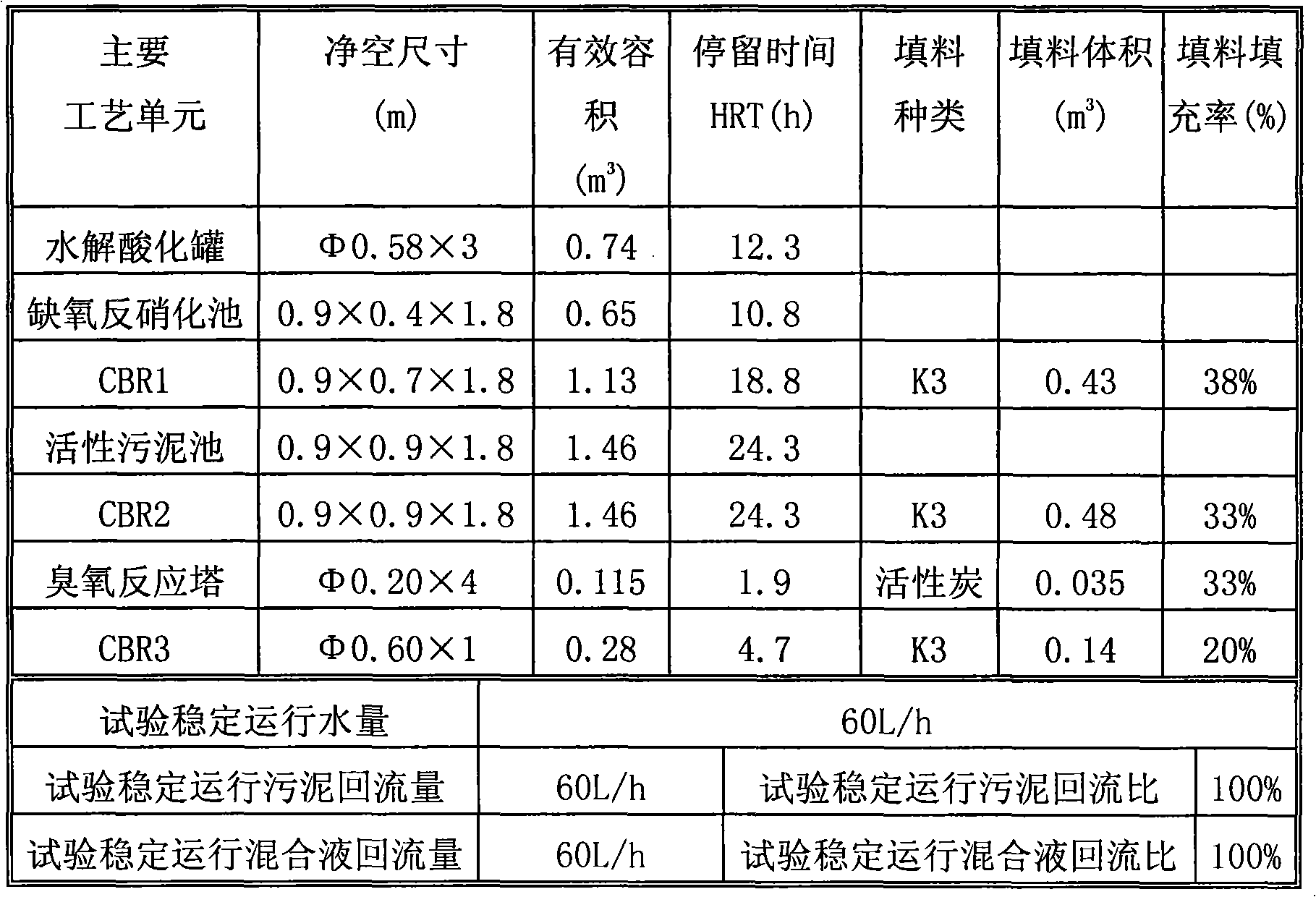

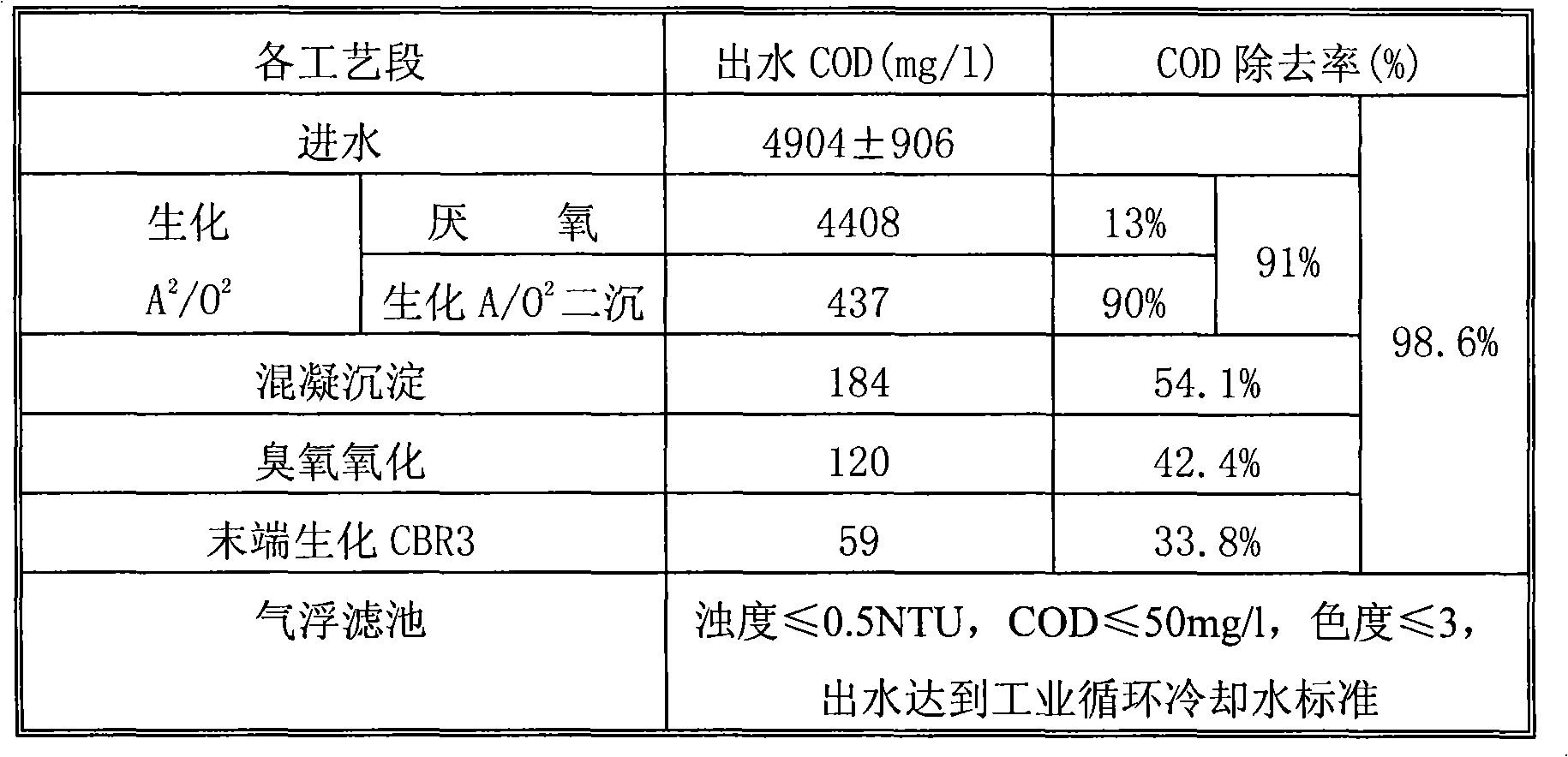

Lurgi furnace coal gasification wastewater treatment and reuse technology

ActiveCN101607777AImprove impact resistanceGuaranteed uptimeTreatment with aerobic and anaerobic processesMultistage water/sewage treatmentCoal gasification wastewaterActivated sludge

The invention discloses a Lurgi furnace coal gasification wastewater treatment and reuse technology, comprising the steps of adopting aeration adjustment, oil separation and sedimentation, hydrolysis acidification, denitrification treatment, first order carrier fluidized bed decarburization, residual COD removement with activated sludge, second order carrier fluidized bed ammonia / nitrogen removement, sludge-water separation, precipitation, oxidation reaction, residual ozone removement, organic waste removement and floating filter treatment to treat the coal gasification wastewater of a Lurgi furnace coal gasification factory and obtaining water which can be reused. The invention has simple operation and low process cost and the treated effluent can be used as the cooling water of boiler furnaces, thus fully recycling the treated Lurgi furnace coal gasification wastewater.

Owner:DASMART ENVIRONMENTAL SCI & TECH (BEIJING) CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com