Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

2214 results about "Hydrodesulfurization" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Hydrodesulfurization (HDS) is a catalytic chemical process widely used to remove sulfur (S) from natural gas and from refined petroleum products, such as gasoline or petrol, jet fuel, kerosene, diesel fuel, and fuel oils. The purpose of removing the sulfur, and creating products such as ultra-low-sulfur diesel, is to reduce the sulfur dioxide (SO₂) emissions that result from using those fuels in automotive vehicles, aircraft, railroad locomotives, ships, gas or oil burning power plants, residential and industrial furnaces, and other forms of fuel combustion.

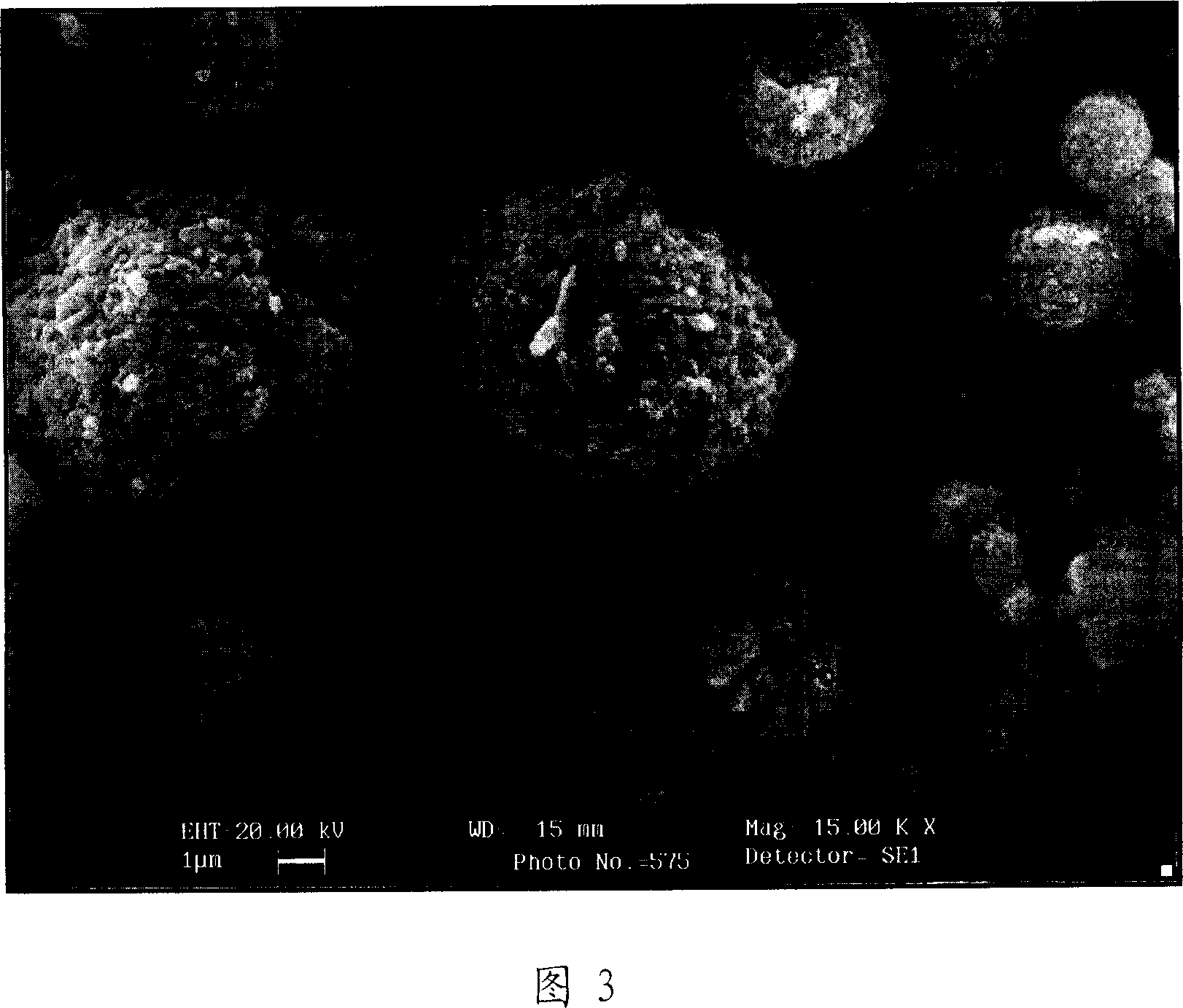

Composite molecular sieve and hydrodesulfurization catalyst prepared with composite molecular sieve as carrier

ActiveCN105251527AGood dispersionModerate dispersionMolecular sieve catalystsHydrocarbon oils refiningMolecular sieveSulfur

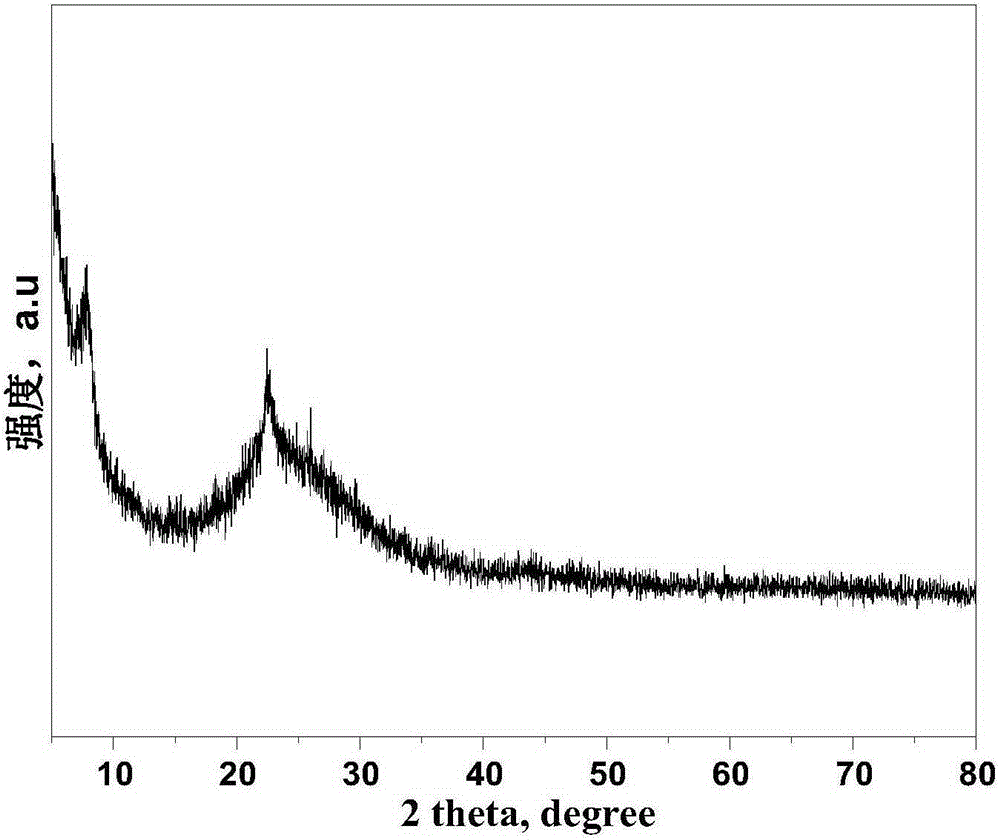

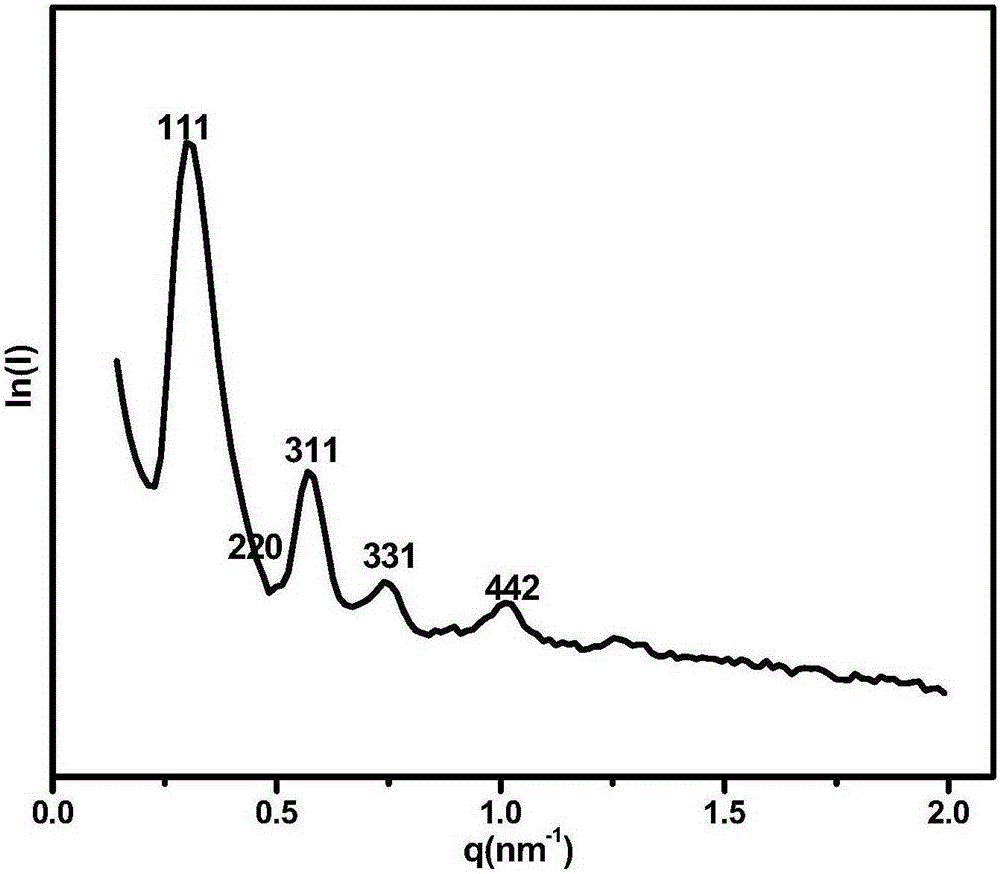

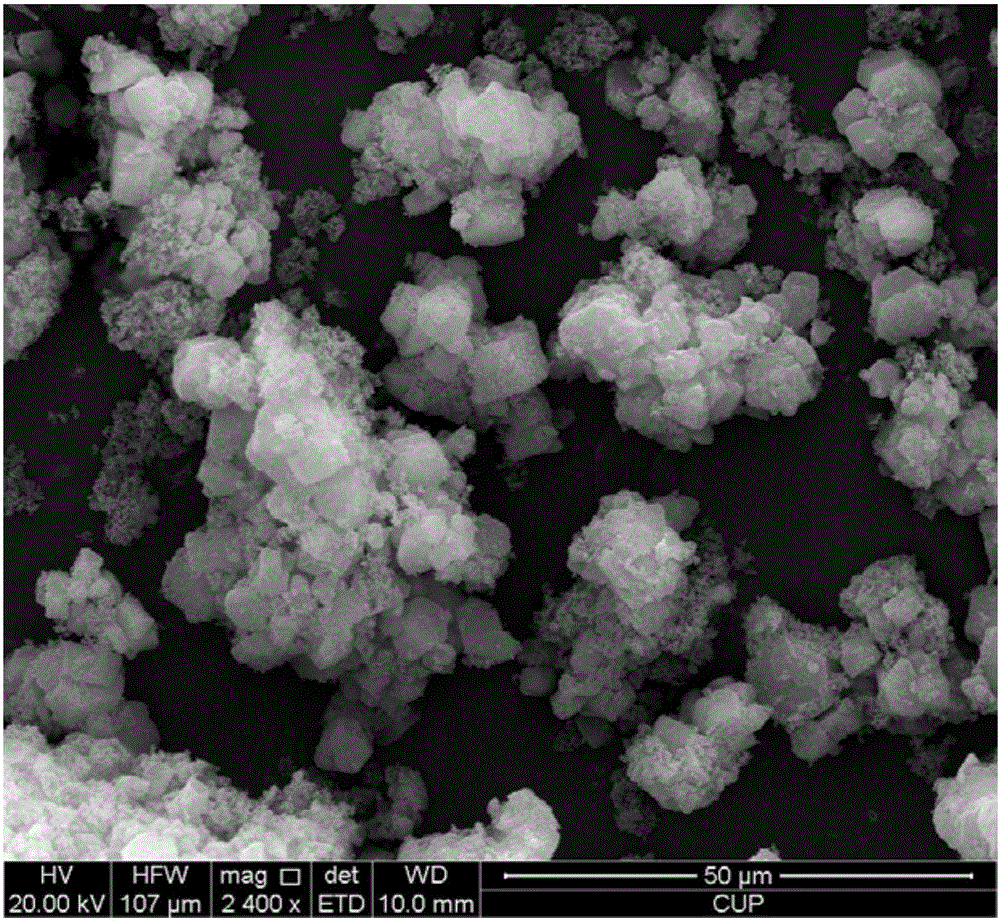

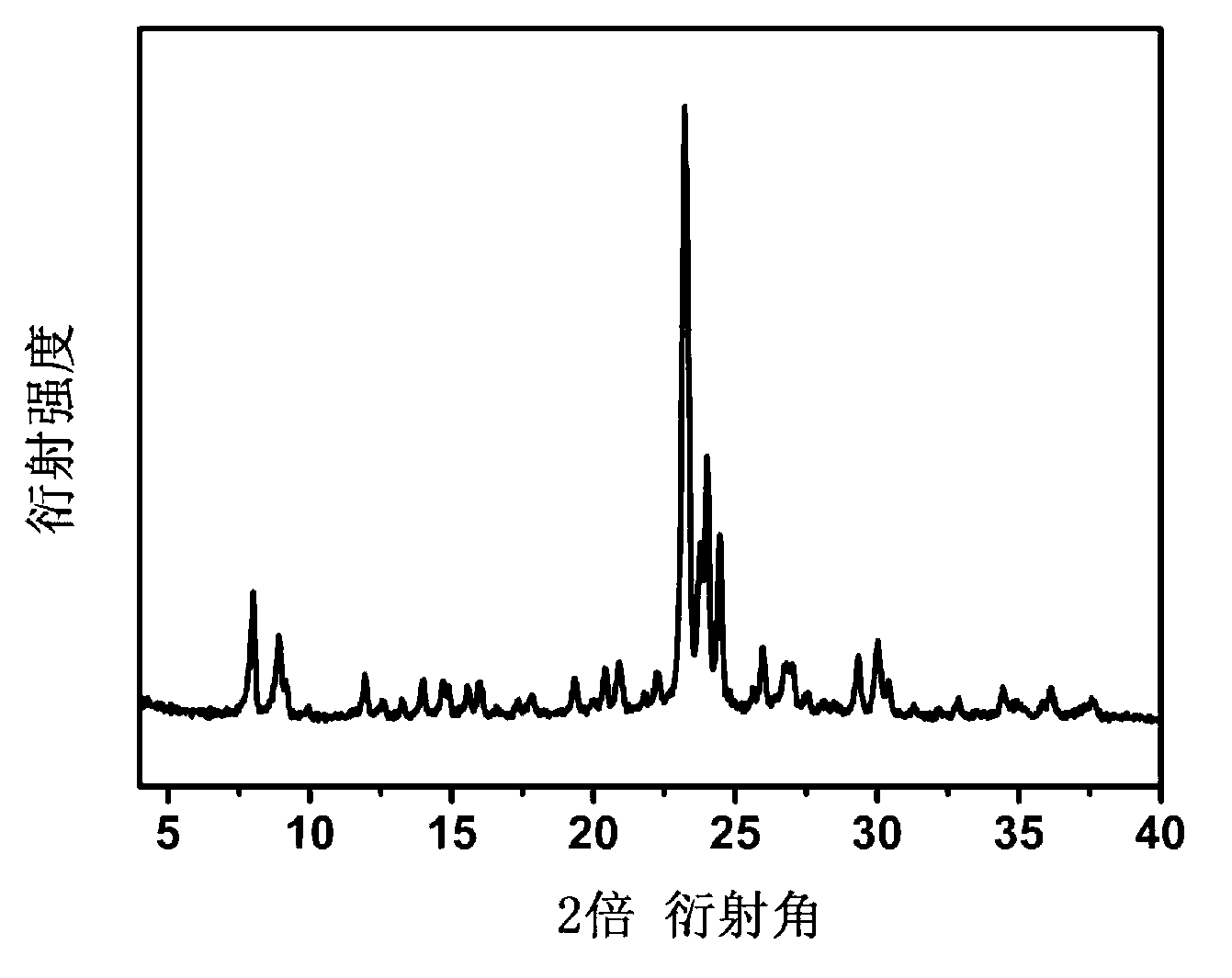

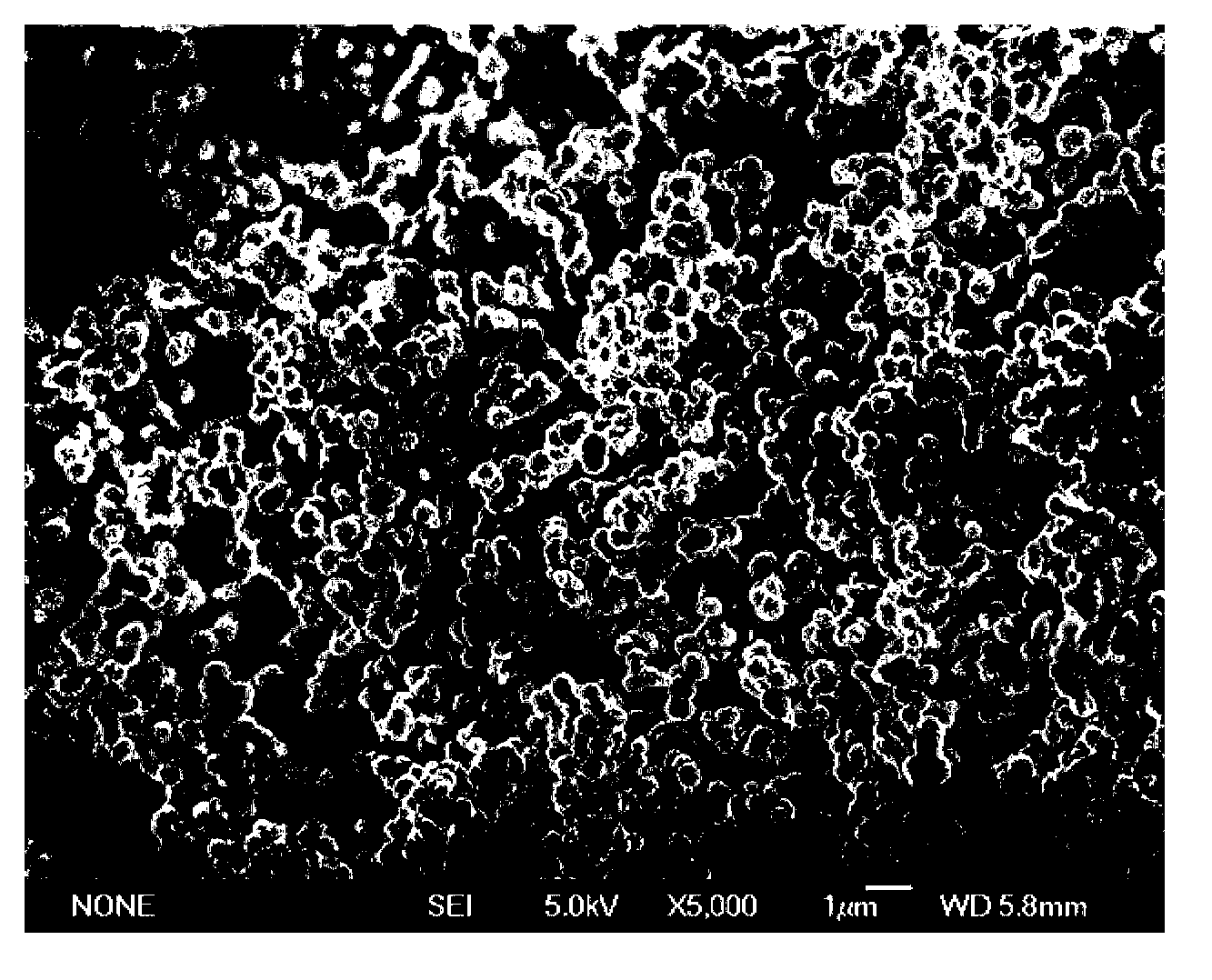

The invention provides a composite molecular sieve and a hydrodesulfurization catalyst prepared with the composite molecular sieve as a carrier. According to the composite molecular sieve and the hydrodesulfurization catalyst, the Beta-FDU-12 composite molecular sieve is of a bimodal porous structure, namely a Beta micropore and an FDU-12 mesoporous, the superficial area of the composite molecular sieve is 800-1000m<2>.g<-1>, the pore diameter is 14-25 nm, and the pore volume is 0.4-0.9 cm<3>.g<-1>.The hydrodesulfurization catalyst prepared with the Beta-FDU-12 composite molecular sieve as the carrier is outstanding in performance, the yield of FCC diesel oil can be higher than 99%, the denitrification percent can be higher than 98%, and the sulphur content is lower than 10 ppm.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

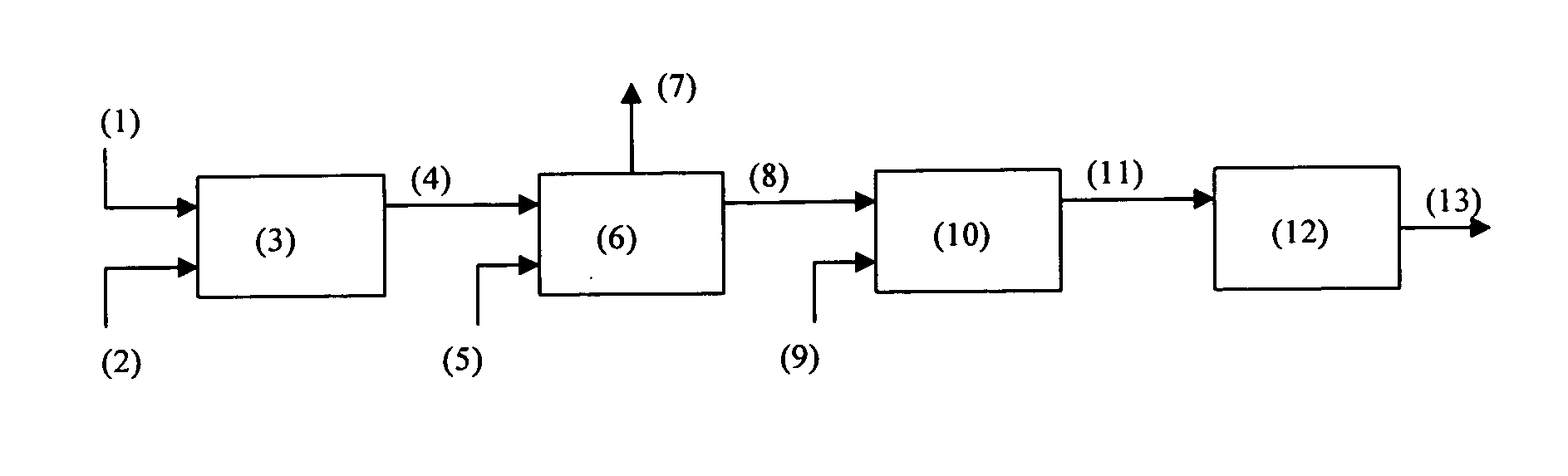

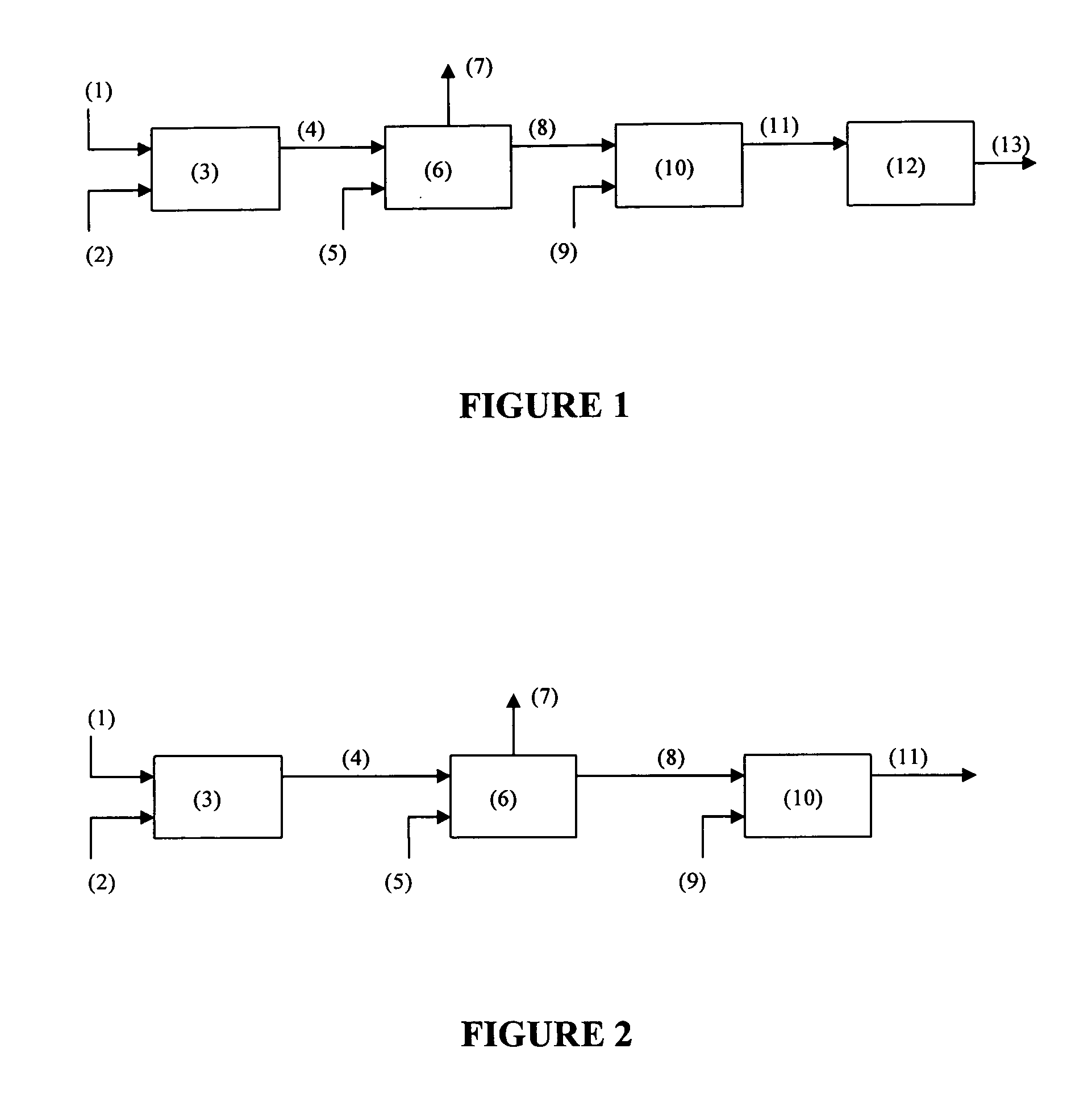

Two stage process for hydrodesulfurizing distillates using bulk multimetallic catalyst

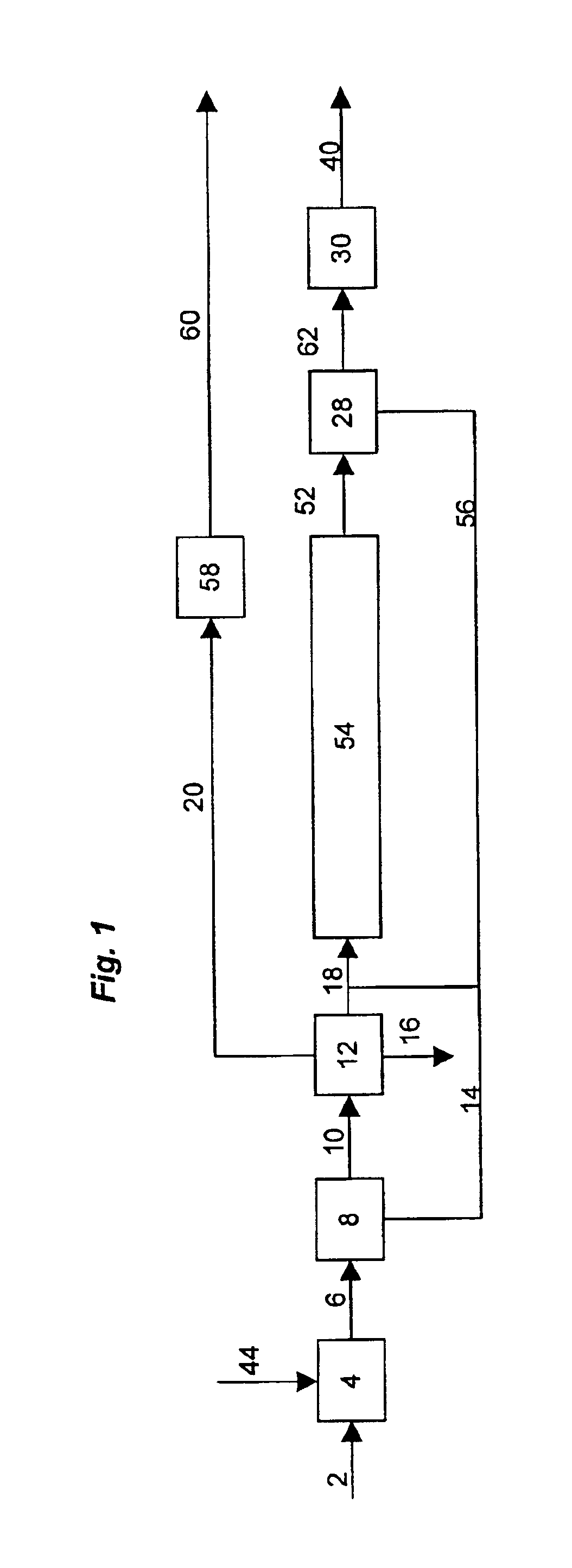

InactiveUS6929738B1Preparation by oxo-reaction and reductionOrganic compound preparationLiquid productHydrogen

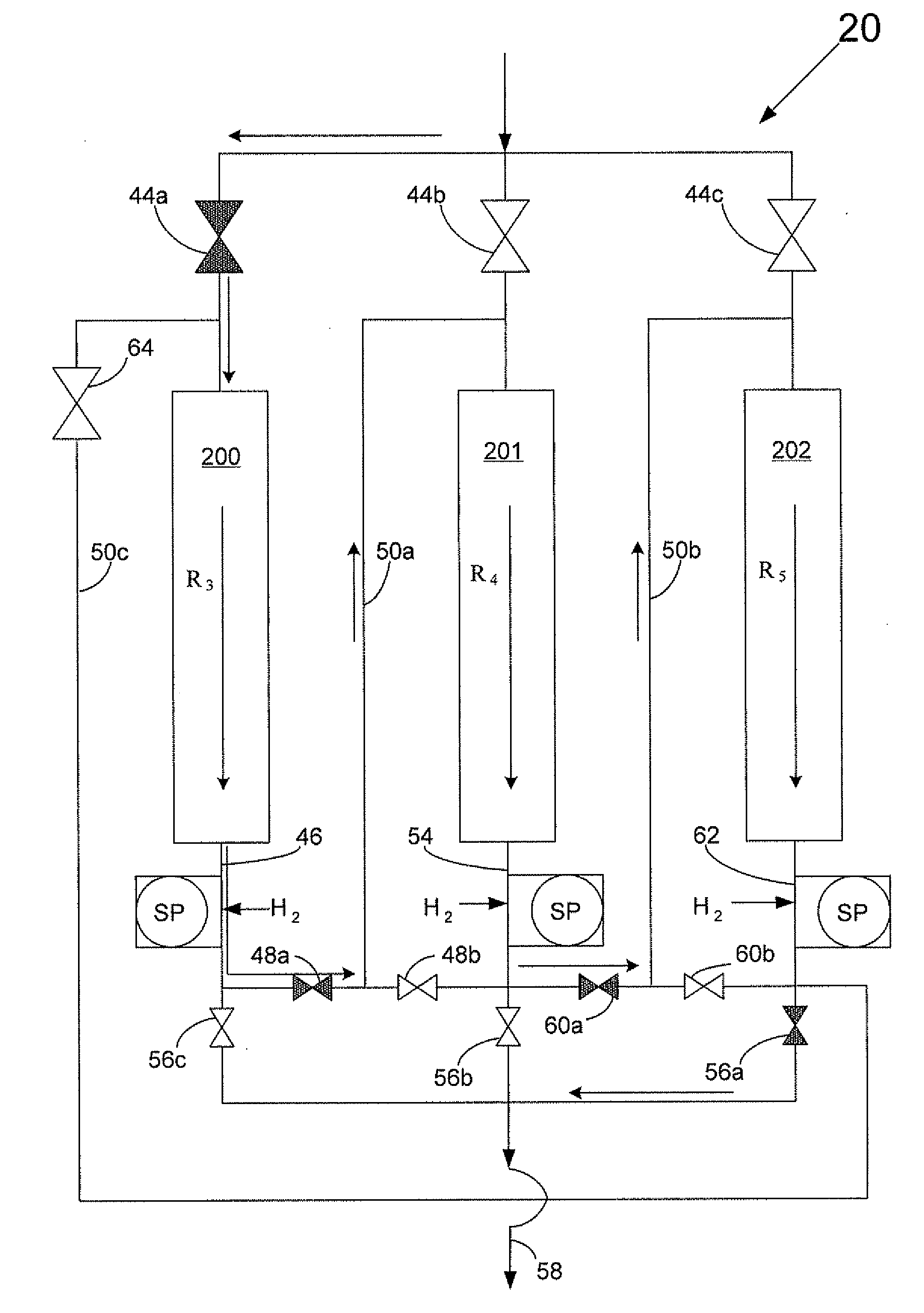

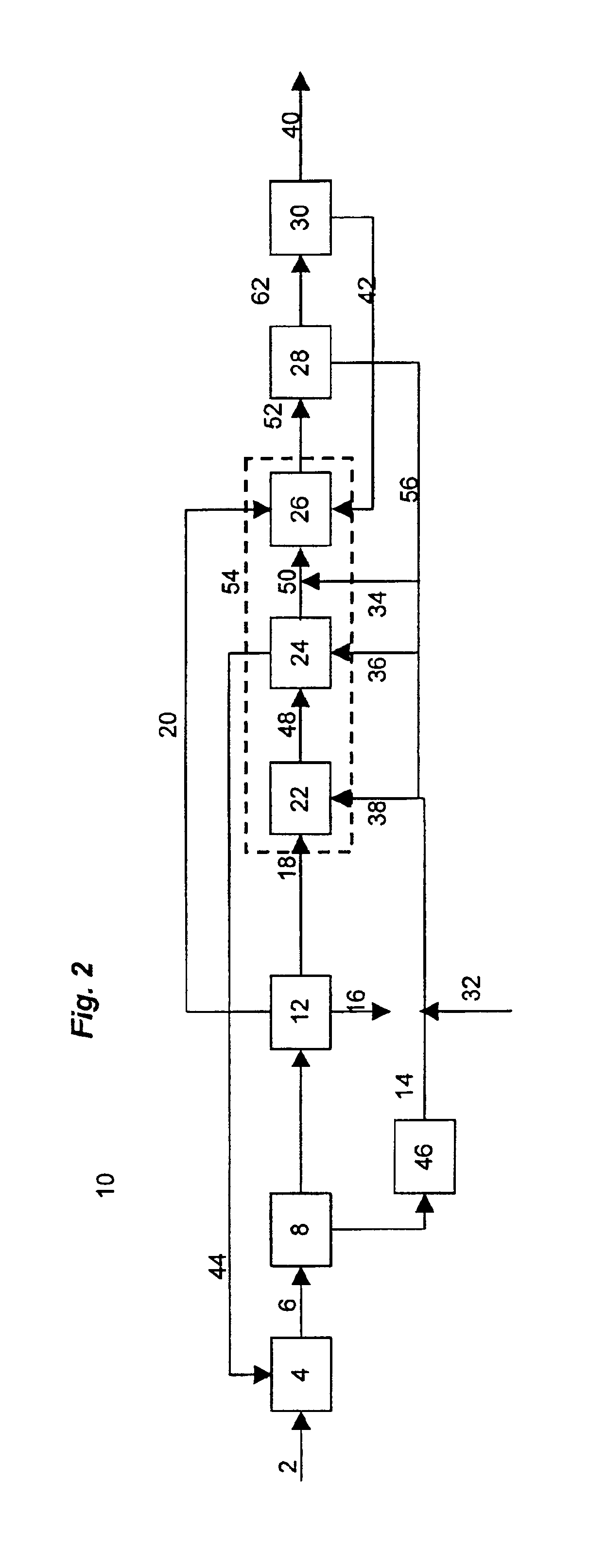

A two stage hydrodesulfurizing process for producing low sulfur distillates. A distillate boiling range feedstock containing in excess of about 3,000 wppm sulfur is hydrodesulfurized in a first hydrodesulfurizing stage containing one or more reaction zones in the presence of hydrogen and a hydrodesulfurizing catalyst. The liquid product stream thereof is passed to a first separation stage wherein a vapor phase product stream and a liquid product stream are produced. The liquid product stream, which has a substantially lower sulfur and nitrogen content then the original feedstream is passed to a second hydrodesulfurizing stage also containing one or more reaction zones where it is reacted in the presence of hydrogen and a second hydrodesulfurizing catalyst at hydrodesulfurizing conditions. The catalyst in any one or more reaction zones is a bulk multimetallic catalyst comprised of at least one Group VIII non-noble metal and at least two Group VIB metals.

Owner:EXXON RES & ENG CO

Method for producing low sulfur gasoline

InactiveCN1465668AReduce sulfur contentReduce saturationTreatment with hydrotreatment processesHydrogenHydrodesulfurization

The method for producing low-sulfur gasoline includes the following steps: cutting gasoline raw material into light fraction and heavy fraction, making the light fraction undergo the processes of alkali refinement treatment and removing mercaptans, making the heavy fraction and hydrogen gas together by contacted with hydrogenation desulfurization catalyst to make selective hydrogenation desulfurization reaction, then hydrogenated gasoline fraction undergo the process of hydrogenation or non-hydrogenation to remove mercaptans, then mixing the above-mentioned desulfurized light and heavy fractions so as to obtain the invented gasoline product whose olefine saturation rate is less than 30%, and sulfur content is less than 200 ppm.

Owner:CHINA PETROLEUM & CHEM CORP +1

Selective hydrogenation catalyst for gasoline and process

InactiveCN1488721AGood choiceHigh selectivityRefining to eliminate hetero atomsActive componentHydrodesulfurization

The present invention relates to a selective hydro-desulfurization catalyst of gasoline and process for using said catalyst. Said invented catayst uses alumina as carrier, uses molybdenum and cobalt as active component, at the same time contains adjuvant potassium and phosphorus, and the optimized atomic ratio of phosphorus and potassium is 1-2. Said invented catalyst has good selectivity and stability, and at the same time has proper activity, and is mainly used for selective hydro-desulfurization of catalytic cracked gasoline.

Owner:CHINA PETROLEUM & CHEM CORP +1

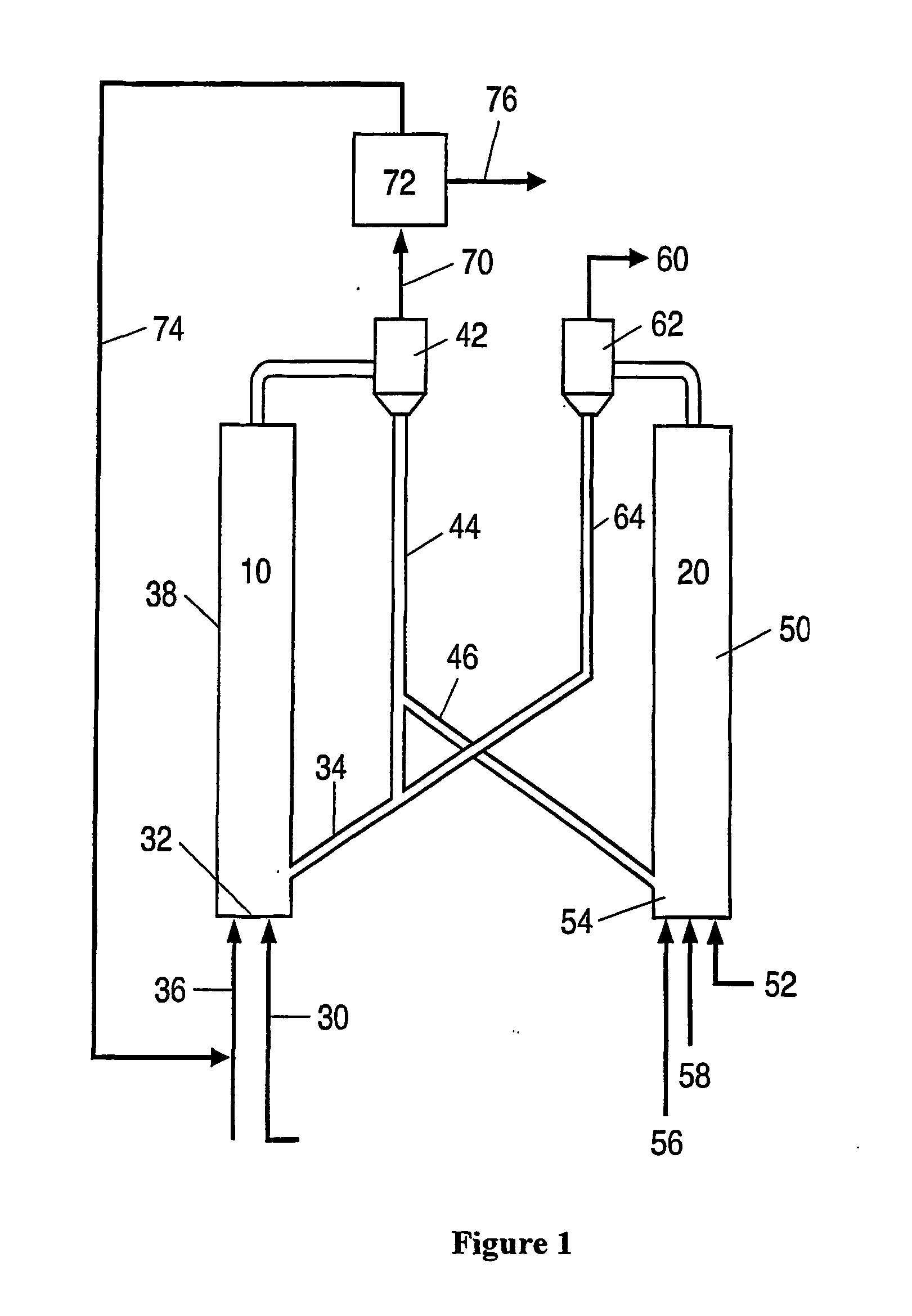

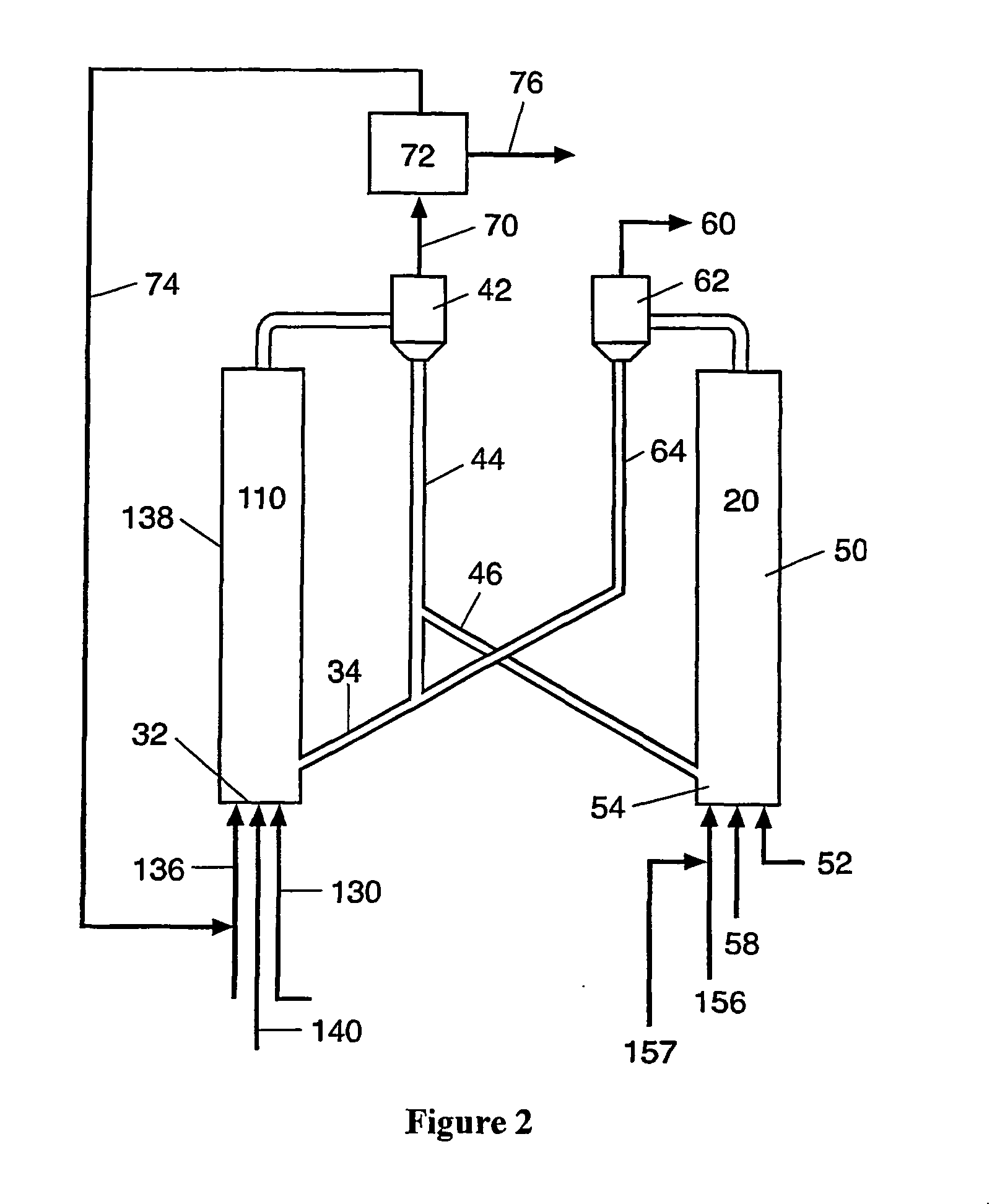

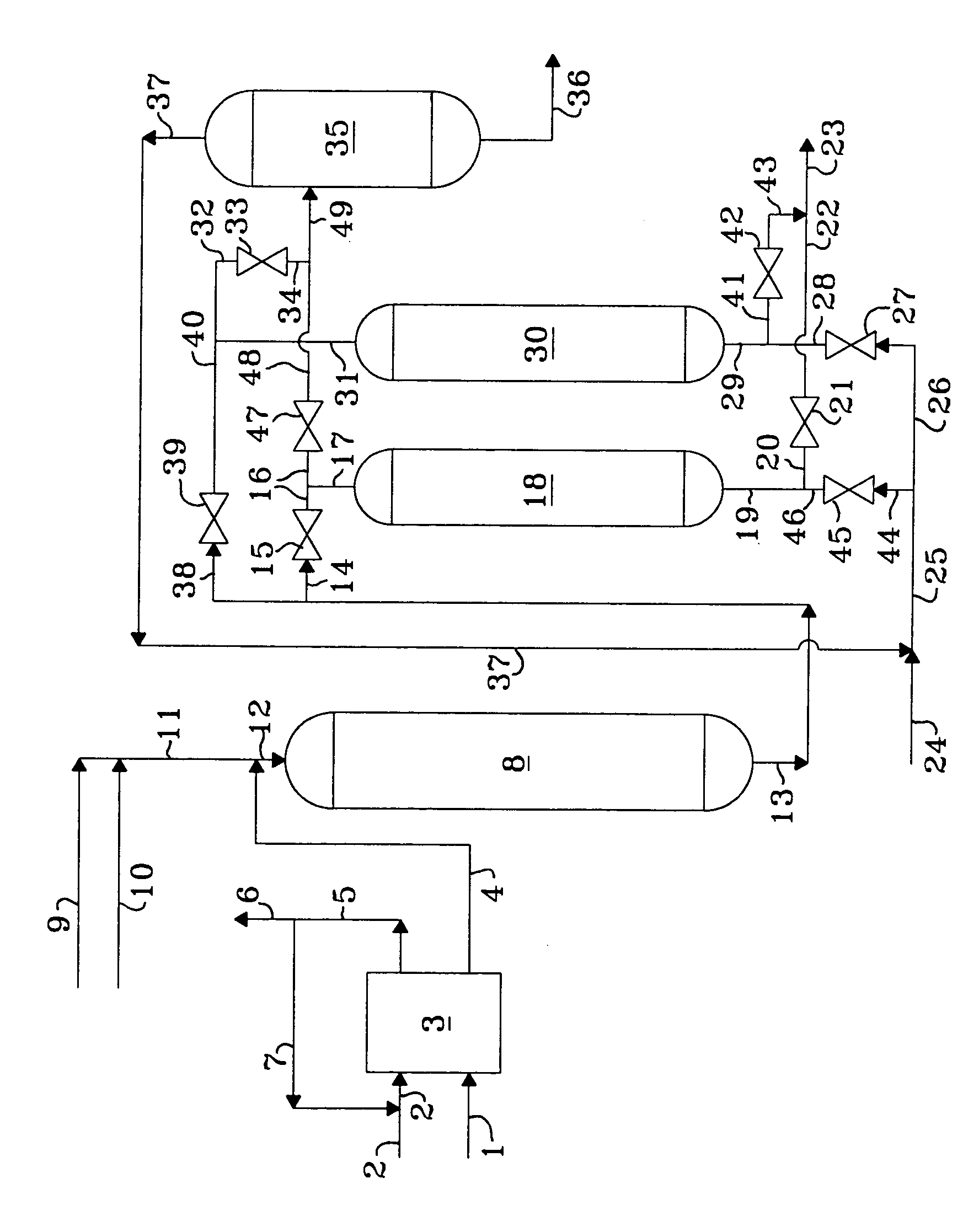

Process for desulfurizing hydrocarbon fuels and fuel components

InactiveUS20050098478A1Substantial sulfur removalLow costCatalytic crackingHydrocarbon oils refiningHydrodesulfurizationSorbent

Processes are disclosed for removing sulfur, including cyclic and polycyclic organic sulfur components such as thiophenes and benzothiophenes, from a hydrocarbon feedstock including fuels and fuel components. The feedstock is contacted with a regenerable sorbent material capable of selectively adsorbing the sulfur compounds present in the hydrocarbon feedstock in the absence of a hydrodesulfurization catalyst. In one embodiment, the sorbent can be an active metal oxide sulfur sorbent in combination with a refractory inorganic oxide cracking catalyst support. In another embodiment, the sorbent can be a metal-substituted refractory inorganic oxide cracking catalyst wherein the metal is a metal which is capable in its oxide form, of adsorption of reduced sulfur compounds by conversion of the metal oxide to a metal sulfide. The processes are preferably carried out in a transport bed reactor.

Owner:RES TRIANGLE INST

Microporous-mesoporous molecular sieve containing noble metal, preparation method and application to catalytic reduction of p-nitrophenol

InactiveCN103011189AReduce pollutionLow cost of industrializationMolecular sieve catalystsOrganic compound preparationWater bathsDispersity

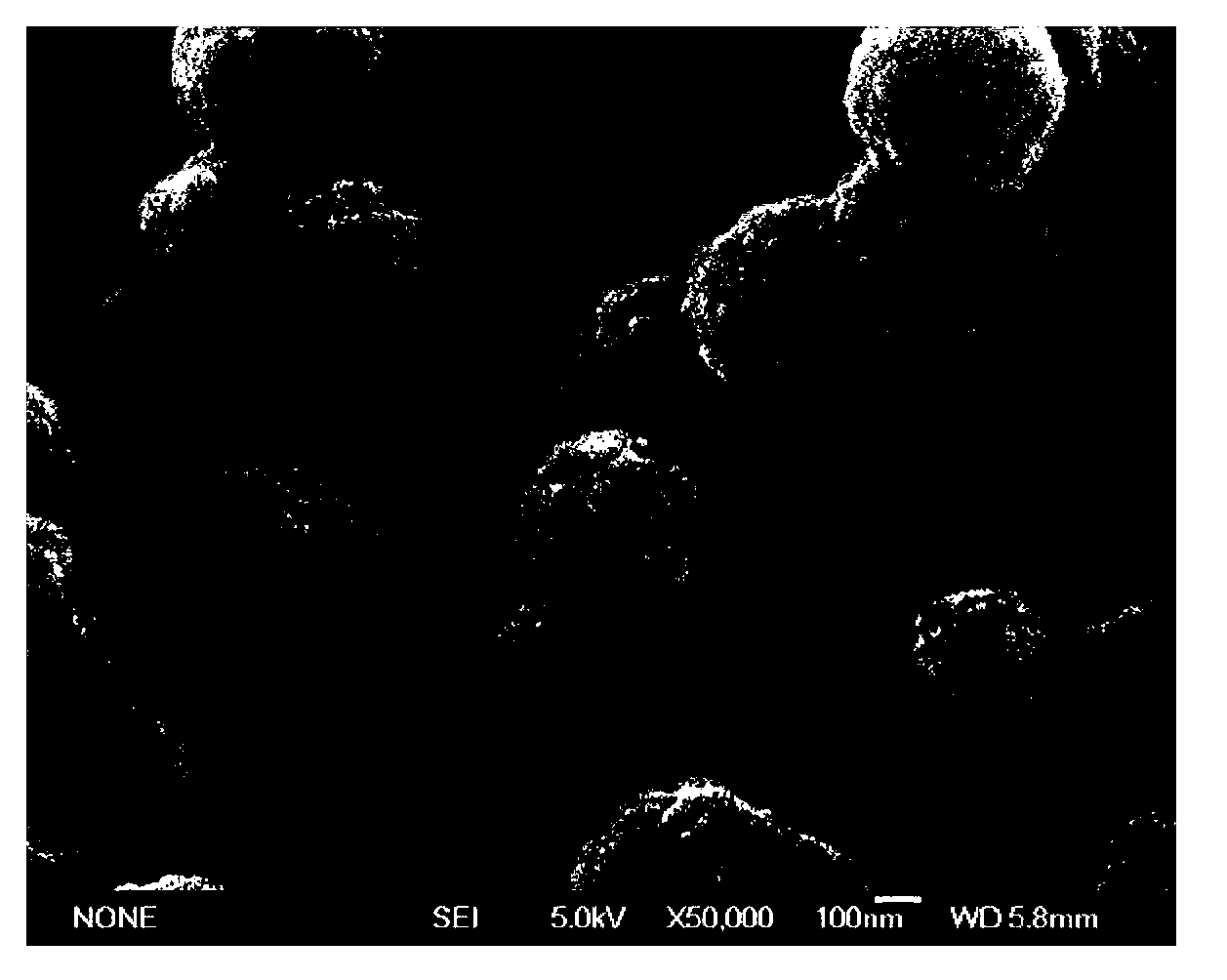

The invention belongs to the technical field of molecular sieve preparation, and particularly relates to an in-situ preparation method for a microporous-mesoporous molecular sieve containing noble metal. The in-situ preparation method comprises the steps as follows: adding a coupling pore-forming agent, a silicon source, an aluminum source or a titanium source, and an alkali source into a water solution of noble metal nano particles in sequence under the water bath condition; and ageing, drying, crystallizing, drying and carrying out high-temperature calcination to obtain the microporous-mesoporous molecular sieve containing the noble metal. The prepared microporous-mesoporous molecular sieve is provided with a hierarchical pore structure; the noble metal nano particles with high dispersity are covered in situ while a mesoporous structure is generated; and a synthetic method is convenient and simple, saves energy and reduces emission. A multifunctional catalyst prepared with the method integrates the advantages of the microporous channels of the molecular sieve, the transgranular meso pores and the intergranular meso pores of the molecular sieve and the noble metal nano particles, and is more suitable for catalytic reactions of sulfur-containing large molecules such as hydrogen desulfurization and the like.

Owner:JILIN UNIV

High temperature naphtha desulfurization using a low metal and partially deactivated catalyst

InactiveUS6231754B1Catalyst regeneration/reactivationMetal/metal-oxides/metal-hydroxide catalystsNaphthaThiol

A high temperature naphtha desulfurization process with reduced olefin saturation employs a partially spent and low metals content hydrodesulfurization catalyst having from 2-40% the activity of a new catalyst. The catalytic metals preferably include Co and Mo in an atomic ratio of from 0.1 to 1. The catalyst is preferably at least partially regenerable, has less than 500 wppm of a total of one or more of nickel, iron and vanadium and preferably has no more than 12 wt. % catalytic metal calculated as the oxide. This permits selective deep desulfurization, with reduced olefin saturation, low product mercaptan levels and little or need for downstream mercaptan removal.

Owner:EXXON RES & ENG CO

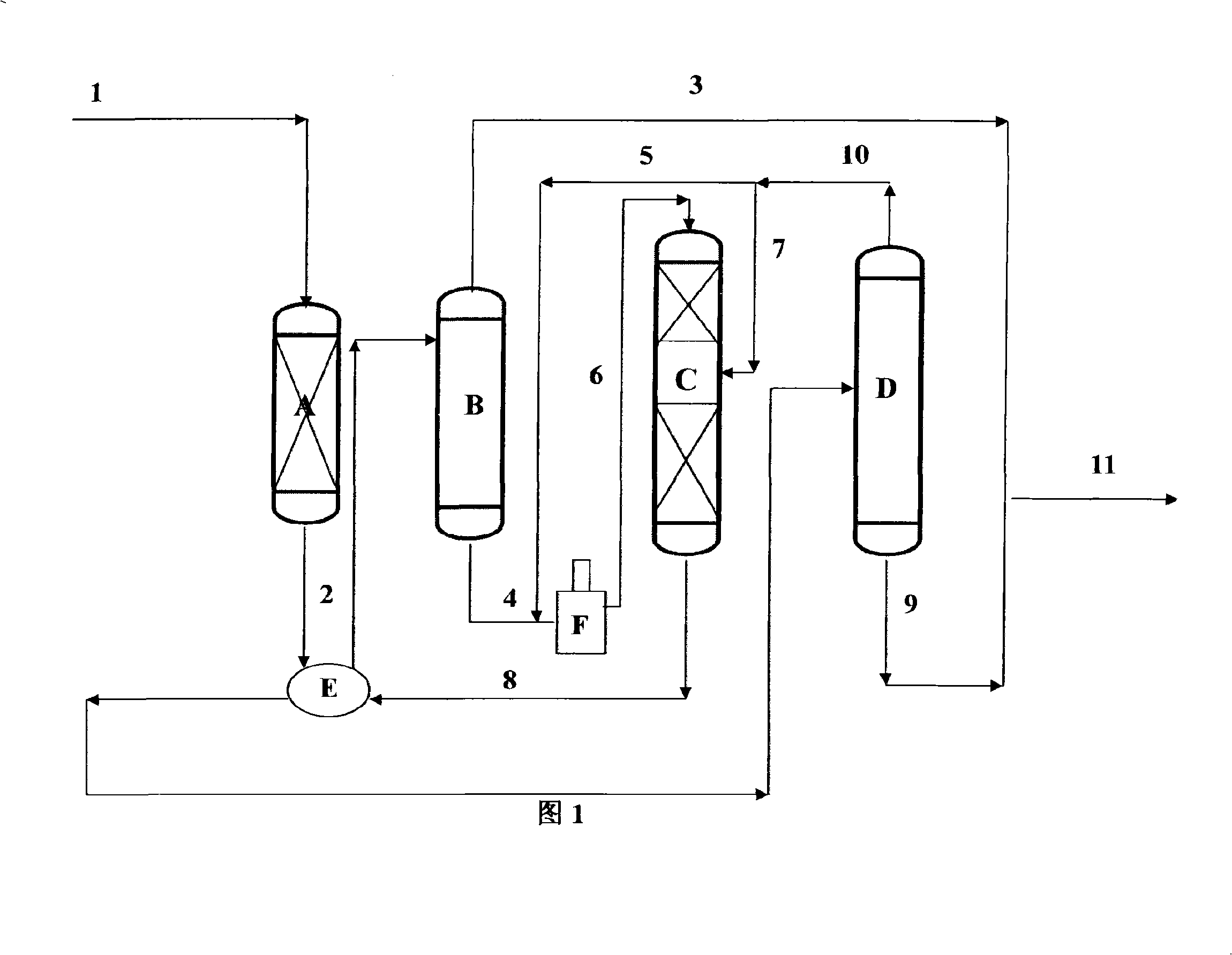

Process for catalytic hydrotreating of sour crude oils

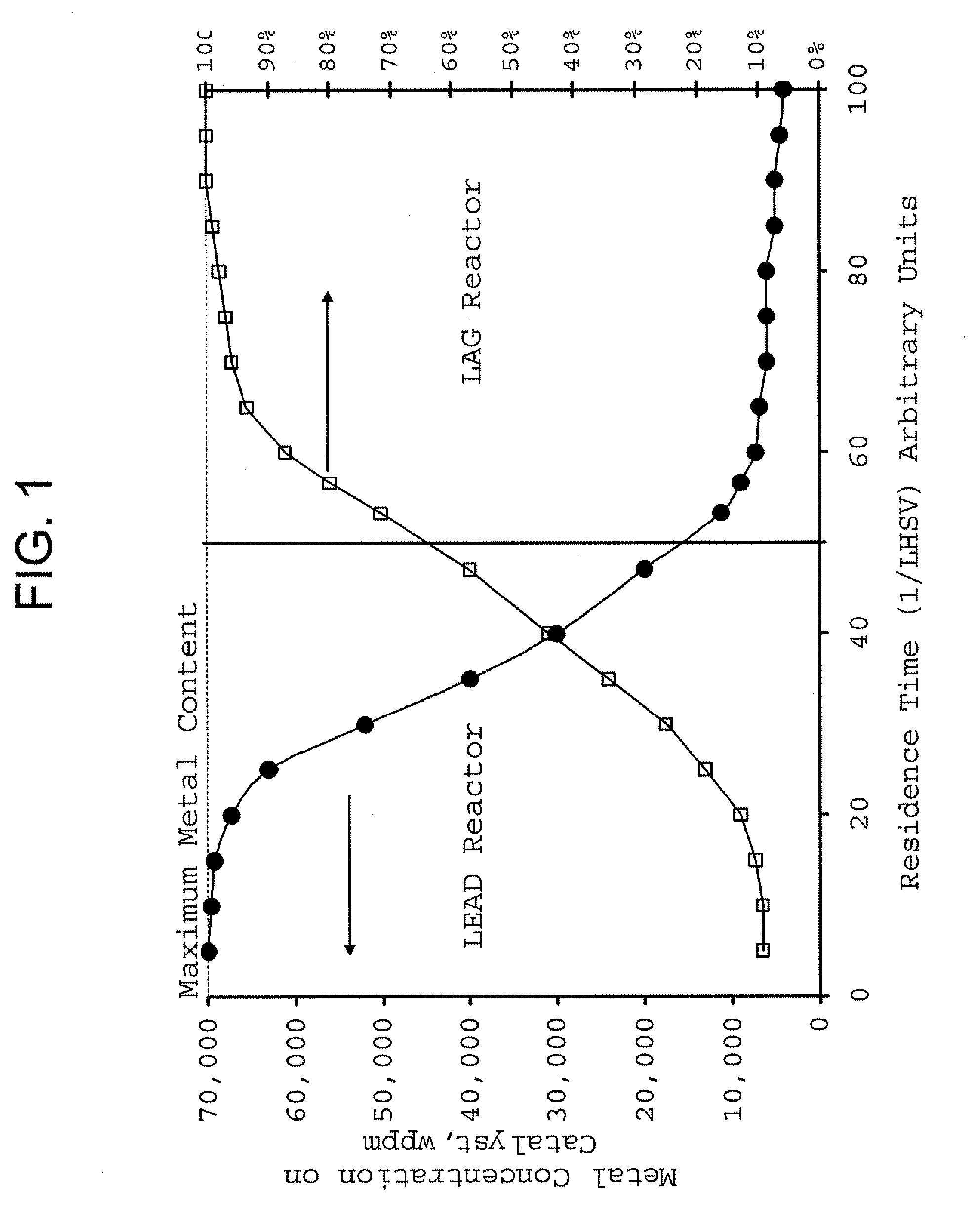

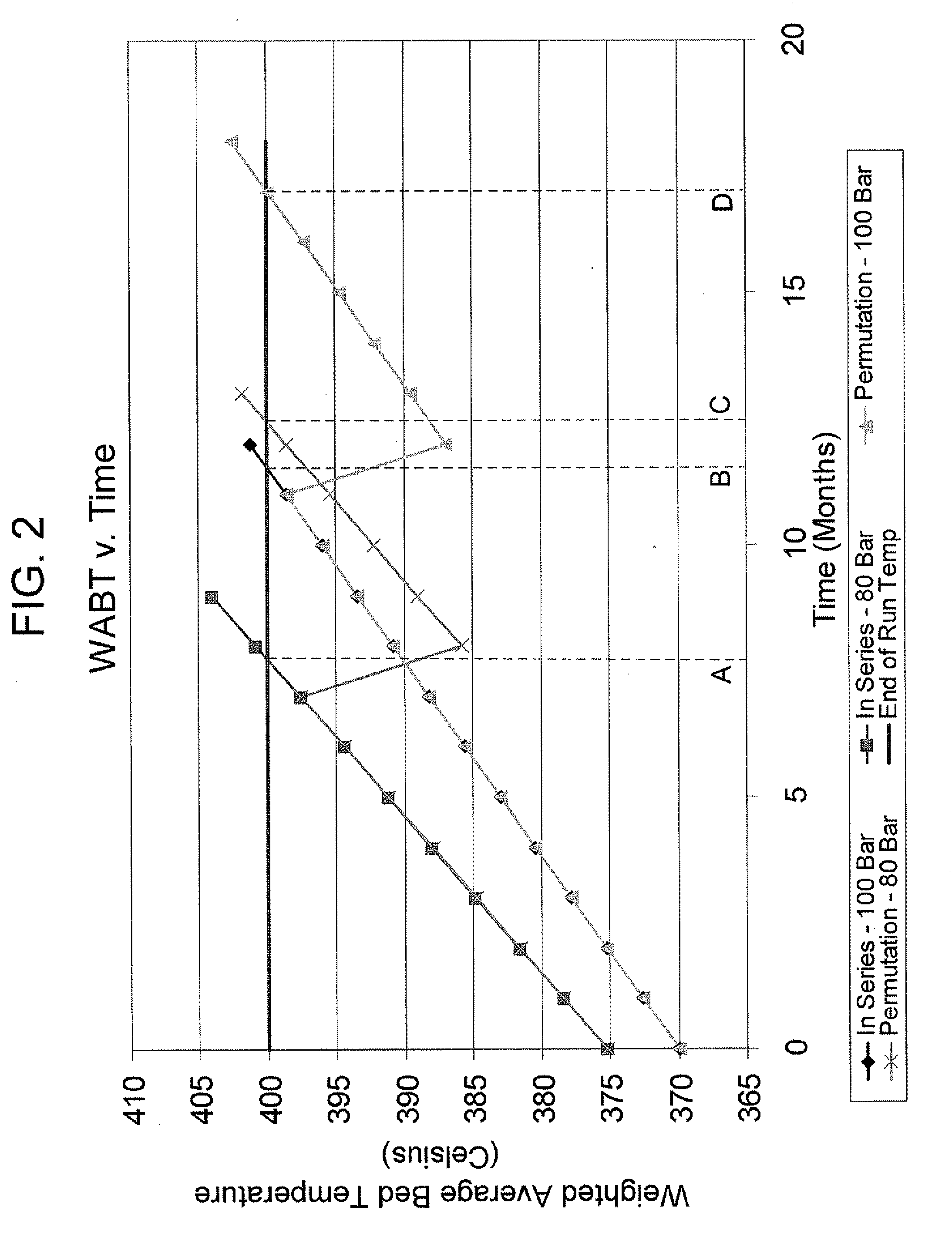

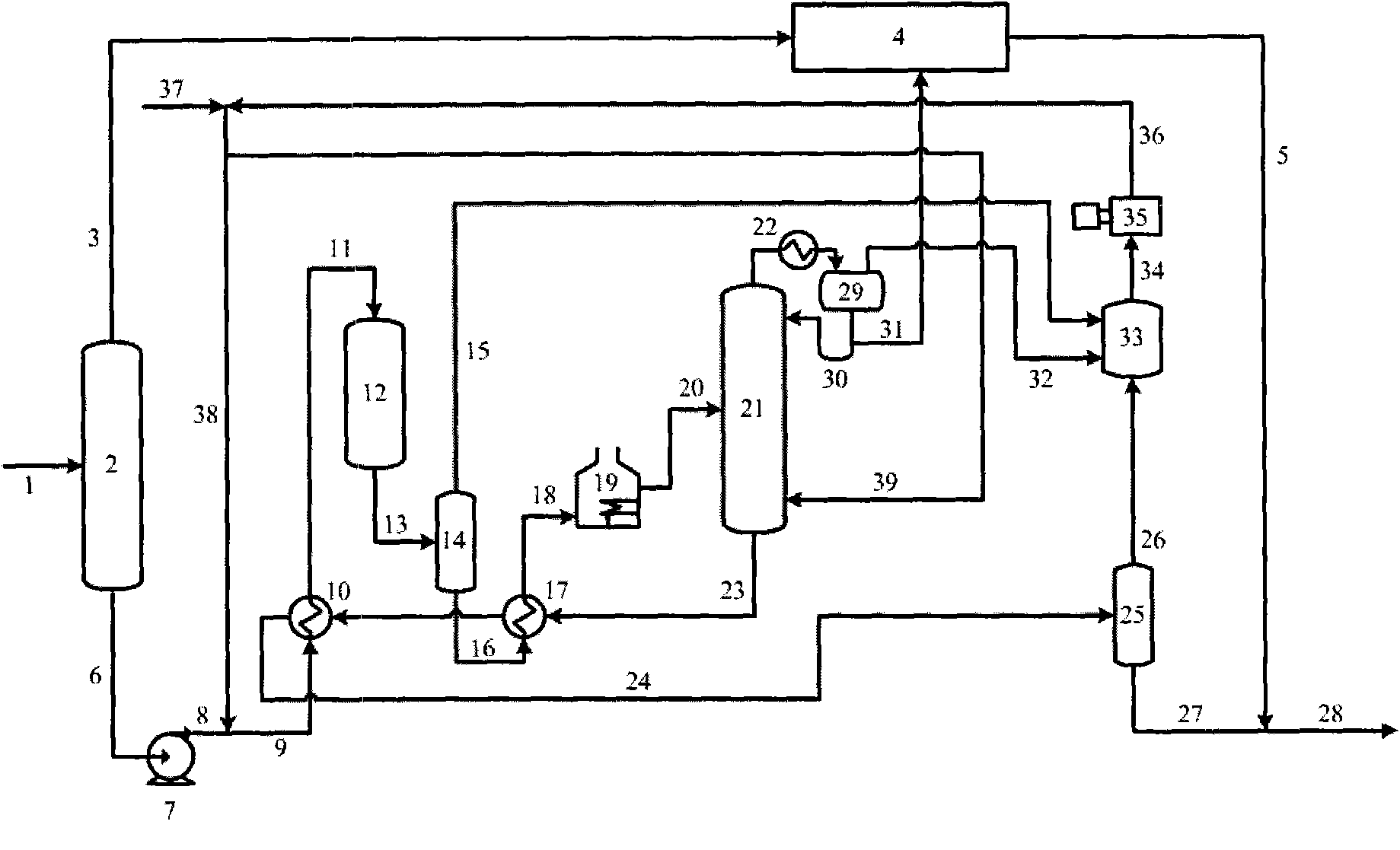

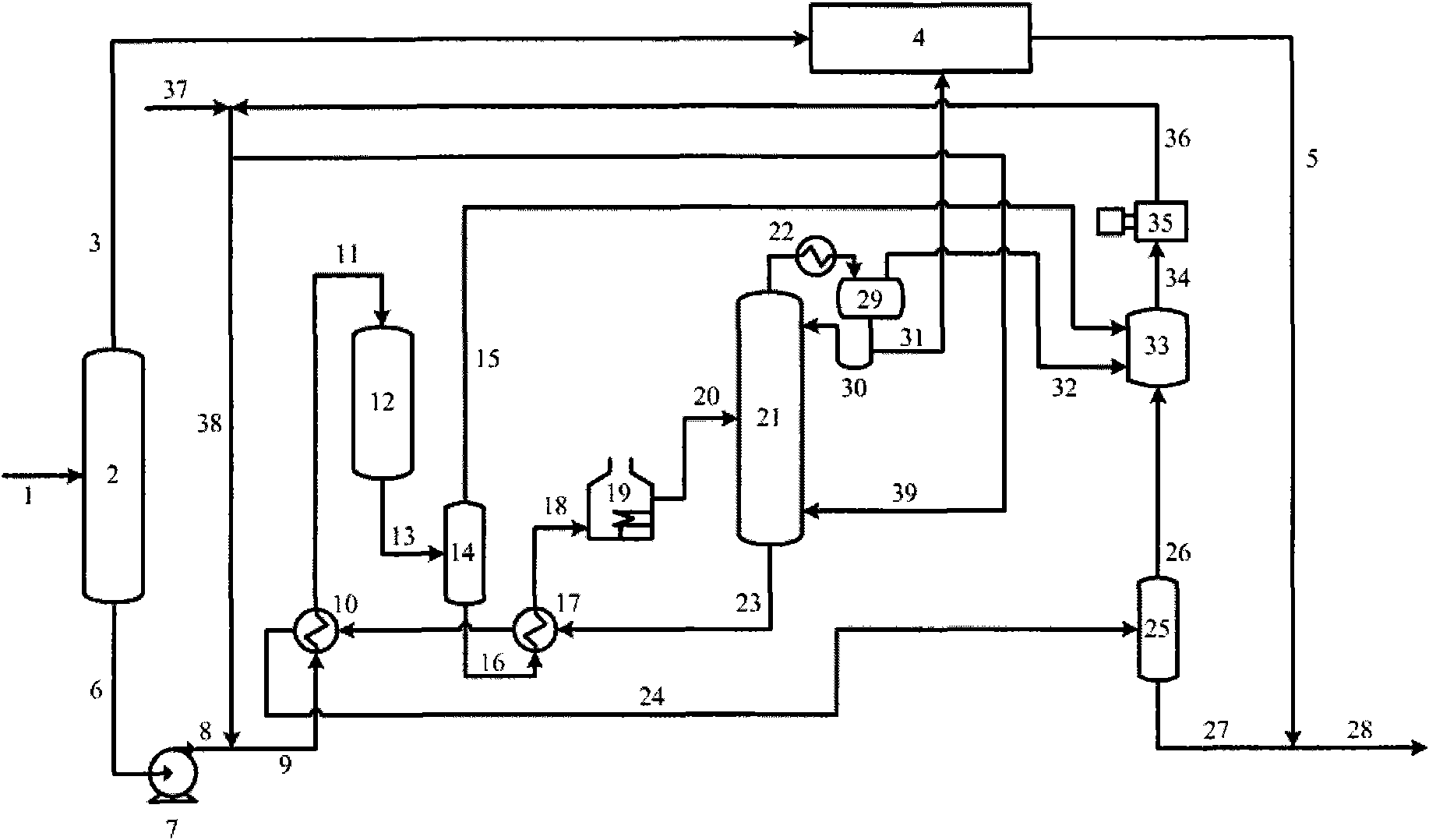

ActiveUS20090139902A1Improve catalyst utilizationImproves HDS activityTreatment with hydrotreatment processesFilter regenerationHydrodesulfurizationSulfur

A continuous process for upgrading sour crude oil by treating the sour crude oil in a two step process that includes a hydro-demetallization section and a hydro-desulfurization section, both of which are constructed in a permutable fashion so as to optimize the operating conditions and catalyst lifespan to produce a high value crude oil having low sulfur and low organometallic impurities.

Owner:SAUDI ARABIAN OIL CO

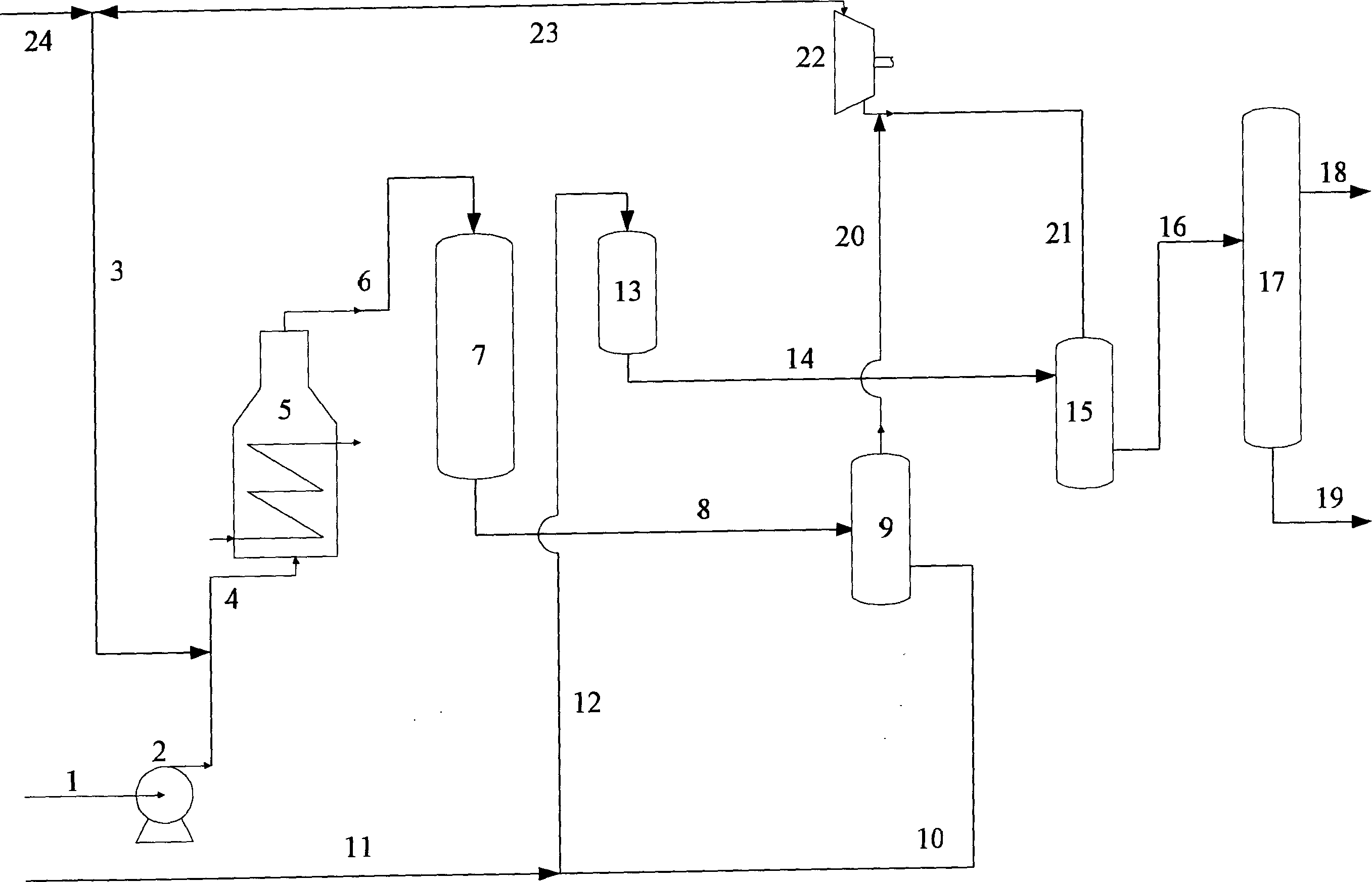

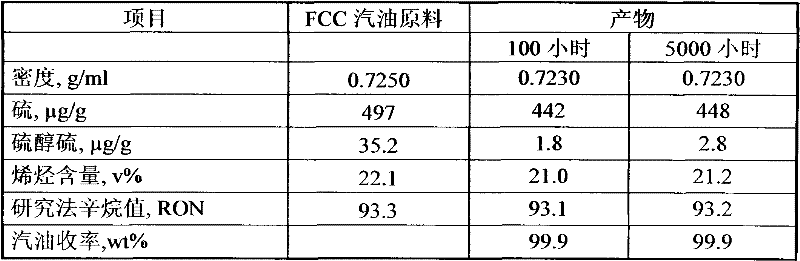

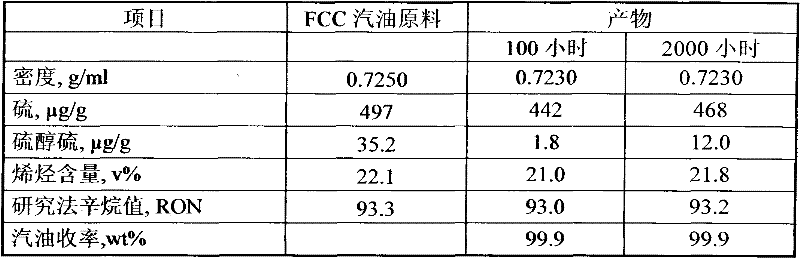

Gasoline hydrodesulfurization method

ActiveCN101787307ASmall mercaptan sulfur contentReduce lossesTreatment with hydrotreatment processesHydrodesulfurizationGasoline

The invention relates to a gasoline hydrodesulfurization method, which comprises the following steps that: gasoline raw materials are fractionated into light fraction gasoline and heavy fraction gasoline, wherein the light fraction gasoline is removed mercaptan sulfer through caustic washing refining, the heavy fraction gasoline carries out a hydrogenation diene-removal reaction, a selective hydrodesulfurization reaction and a selective hydrogenation mercaptan sulfer-removal reaction respectively through two hydrogenation reactors, and the obtained hydrogenation heavy fraction gasoline and the refined light fraction gasoline are mixed to obtain full fraction gasoline with ultra-low sulfur. According to the method provided by the invention, under the condition that the desulfurization degree reaches a target, the full fraction gasoline product have small mercaptan sulfur content, less olefin saturation and small octane value loss. The mercaptan sulfur content of the obtained dull fraction gasoline product is less than 10Mug / g, the total sulfur content is reduced under 50Mug / g, and the octane value RON loss is less than 1.0 unit, particularly, the total sulfur content of the full fraction gasoline product is reduced under 10 Mug / g, and the octane value RON loss is less than 1.5 units.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method of gasoline desulfurization

A process for desulfurizing gasoline includes such steps as dividing raw gasoline into light gasoline fraction and heavy gasoline fraction, hydrodesulfurizing the heavy one, separating gas phase from the resultant by high-pressure separator, mixing residual liquid with fresh H2, hydrodesulfurizing again, separating H2-enriched gas by said separator for cyclic use, and stabilizing in stabilizing tower to obtain qualified product.

Owner:CHINA PETROLEUM & CHEM CORP +1

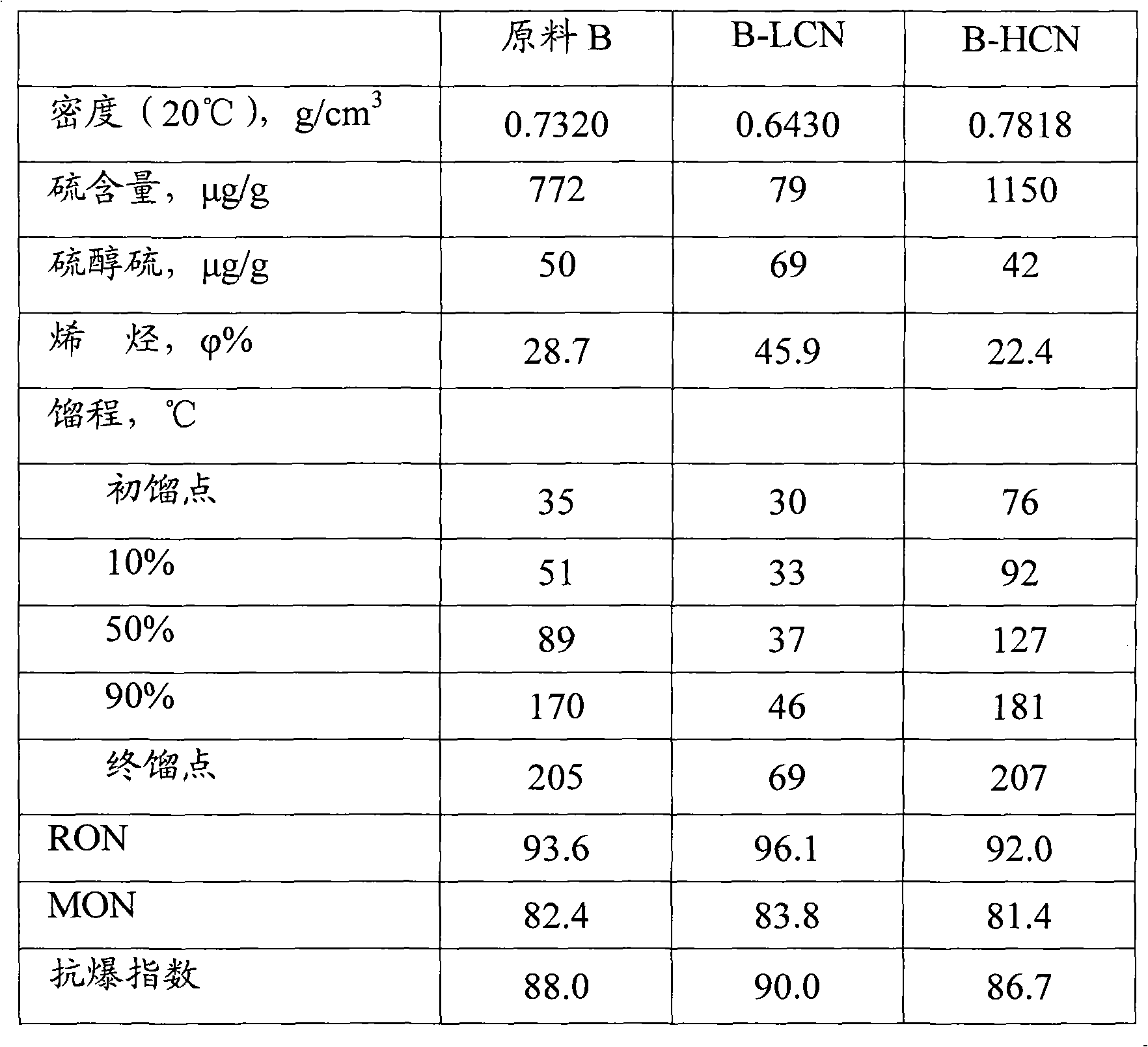

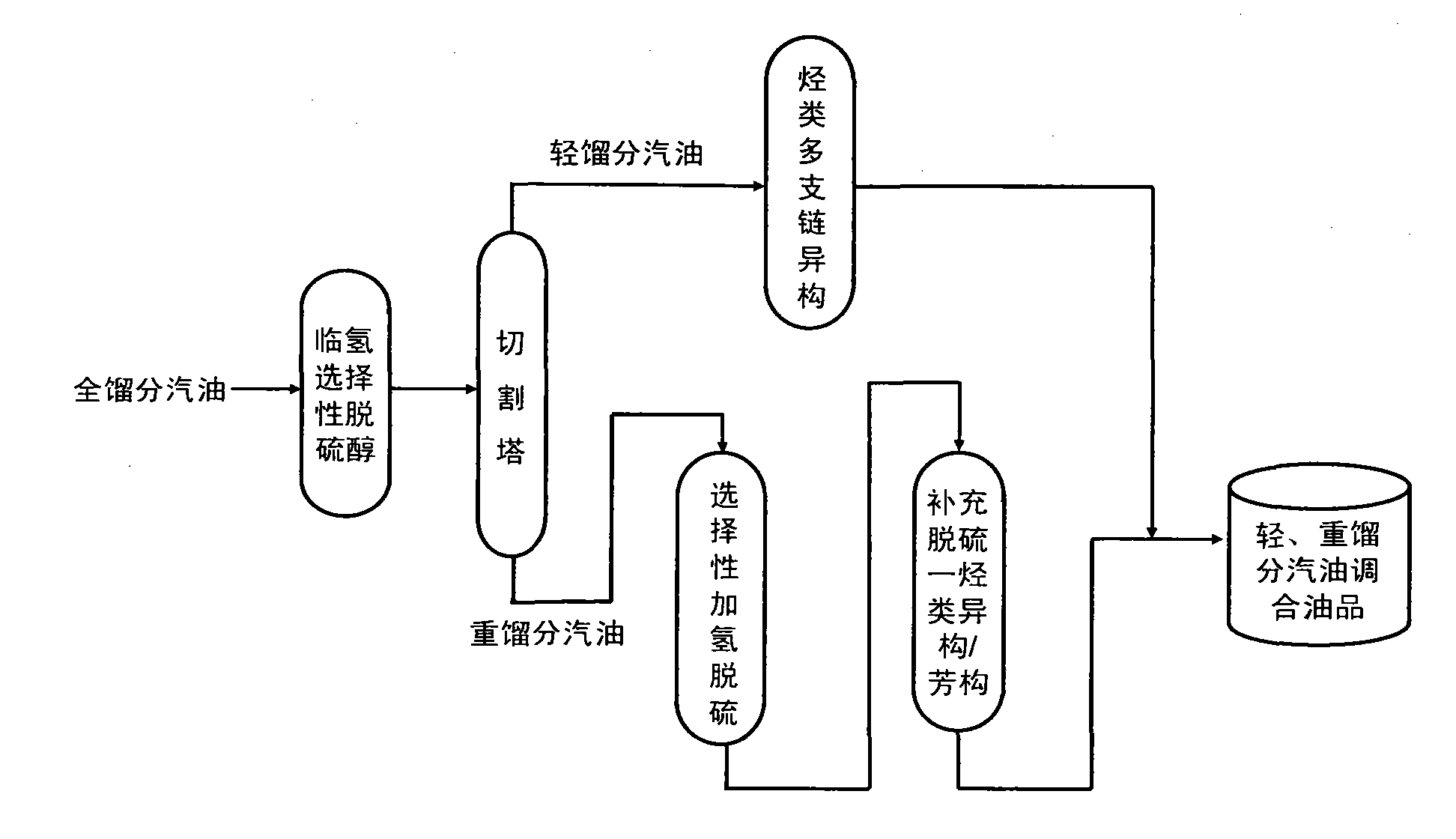

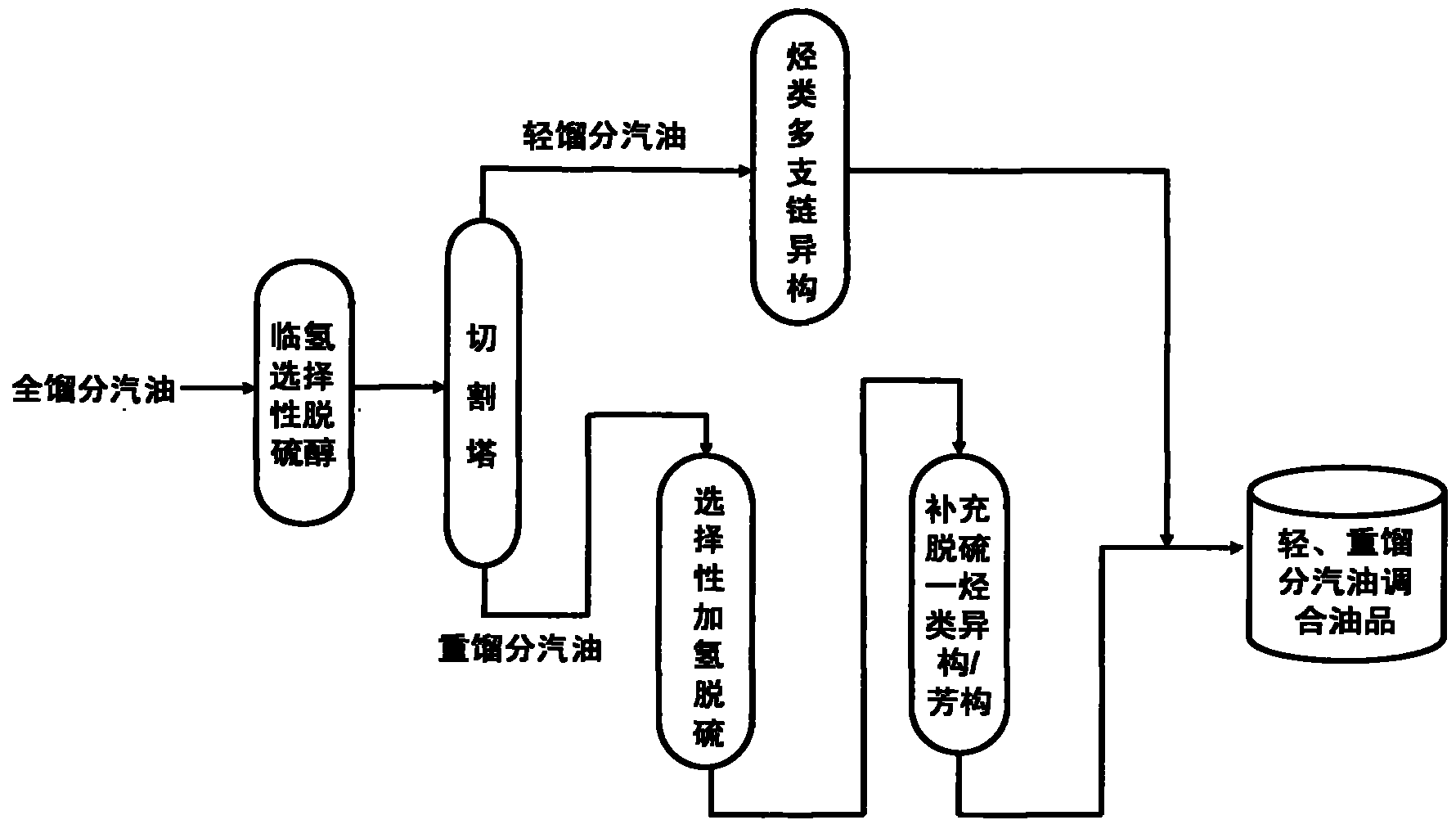

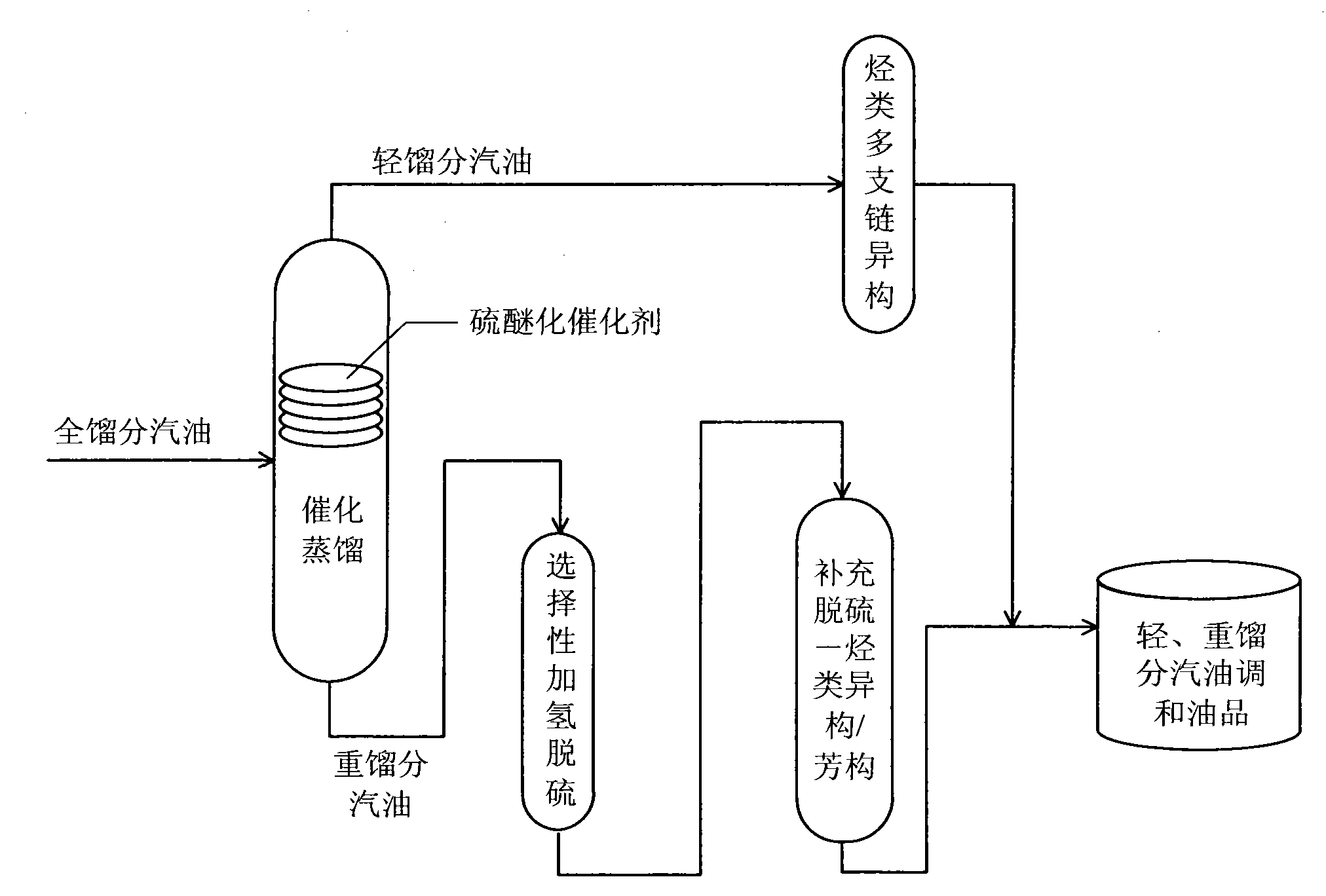

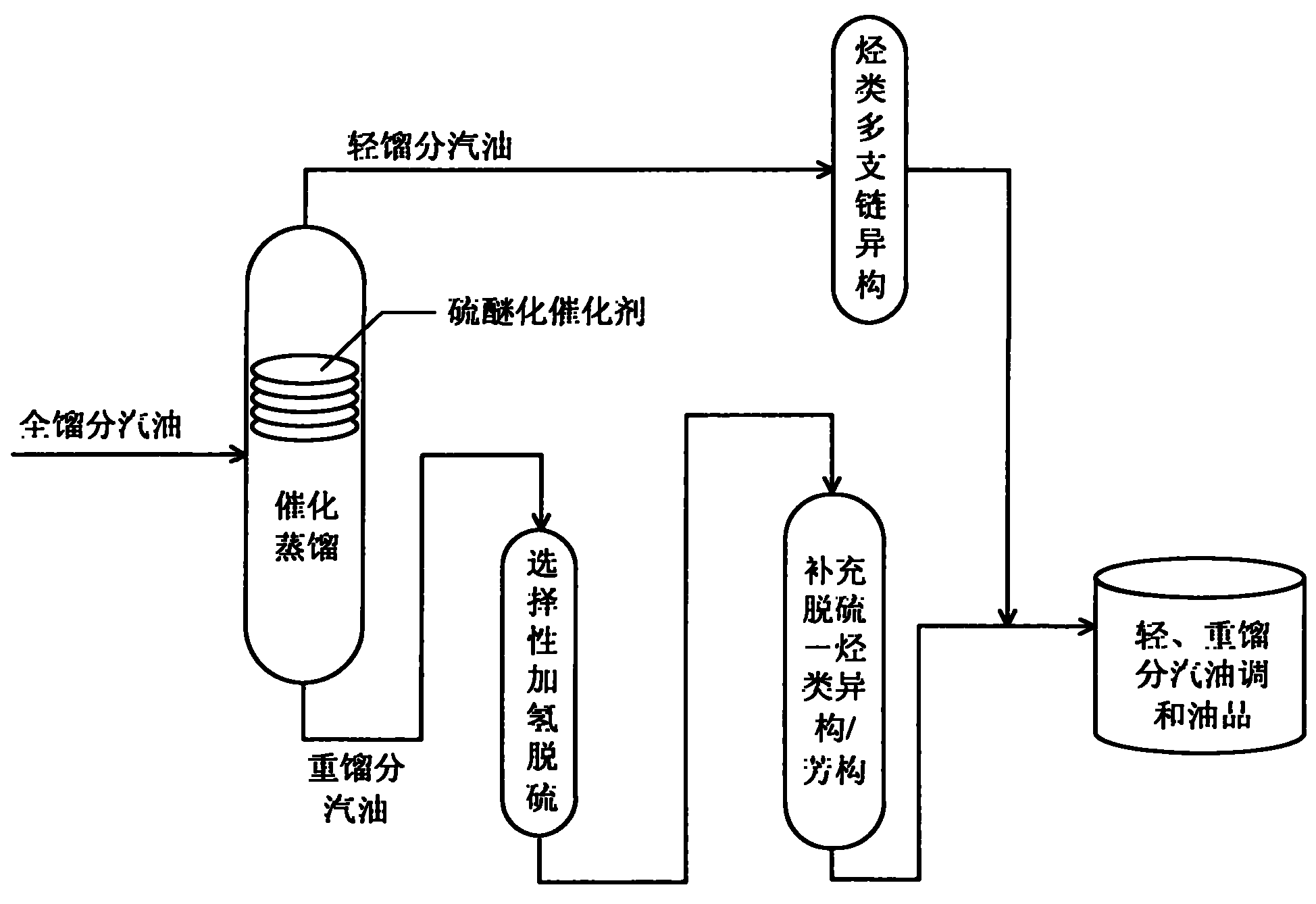

Efficient coupling hydro-upgrading method for producing gasoline with ultra-low sulfur and high octane number

ActiveCN101885983AImprove octaneOctane recoveryTreatment with hydrotreatment processesIsomerizationAlcohol

The invention relates to an efficient coupling hydro-upgrading method for producing gasoline with ultra-low sulfur and a high octane number. The method comprises the following steps of: distilling inferior full cut gasoline at 50-90 DEG C to obtain light cut gasoline and heavy cut gasoline; making the light cut gasoline contact with a hydrocarbon multi-branched isomerization catalyst; making the heavy cut gasoline contact with a selective hydrogenation desulfurization catalyst and a complement desulfurization isomerization / aromatization catalyst sequentially; and finally, mixing the treated light cut gasoline with the treated heavy cut gasoline to obtain the gasoline with the ultra-low sulfur and the high octane number. The method further comprises the step of: before the distillation, making the inferior full cut gasoline contact with a hydro-selective desulfurization alcohol catalyst, or, before making the light cut gasoline contact with a hydrocarbon multi-branched isomerization catalyst, making the light cut gasoline contact with the hydro-selective desulfurization alcohol catalyst. The efficient coupling hydro-upgrading method is suitable for the hydro-upgrading treatment of inferior gasoline with ultrahigh sulfur and high olefin, reduces the sulfur content after the upgrading treatment to below 5mu g / g (no sulfur substantially) and can maintain the octane number and higher yield of products.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

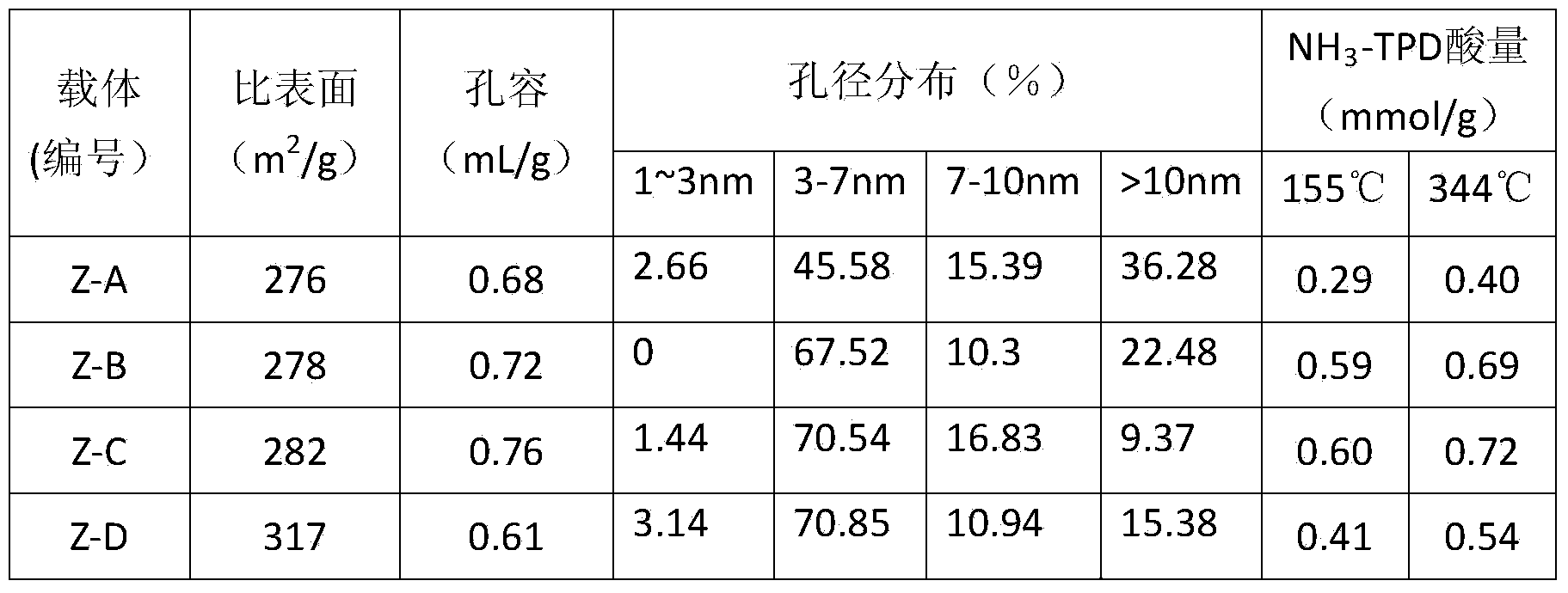

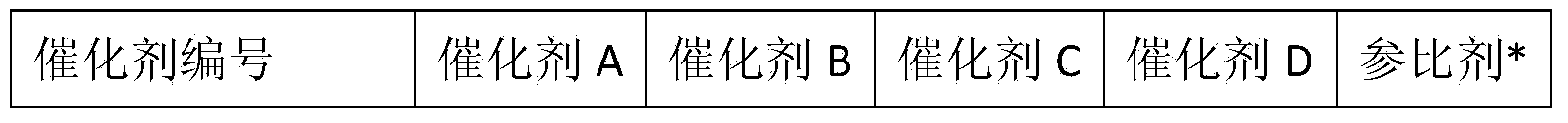

Diesel hydrodesulfurization and denitrification catalyst and preparation method thereof

InactiveCN103551162AGood dispersionIncrease profitMetal/metal-oxides/metal-hydroxide catalystsRefining to eliminate hetero atomsHydrodesulfurizationOxide composite

The invention discloses a diesel hydrodesulfurization and denitrification catalyst. The catalyst comprises the following compositions: a carrier, an additive, and an active metal, wherein the carrier is an Al2O3-ZrO2-TiO2-SiO2 multibasic oxide composite carrier; the additive is phosphorus; nickel, cobalt, molybdenum and tungsten are taken as active components; through taking the catalyst as a benchmark, in terms of oxides, the catalyst comprises the following components in percentage by weight, 1-6wt% of cobalt oxide, 1-15wt% of nickel oxide, 2-12wt% of molybdenum oxide, 12-35wt% of tungsten oxide and 1.5-5wt% of an additive phosphorus pentoxide; and the pore volume of the catalyst is not less than 0.2 mL / g, the specific surface area of the catalyst is not less than 140 m<2> / g, and the mechanical strength of the catalyst is not less than 15N / mm; and the composite carrier comprises the following components in percentage by weight: 2-15wt% of titanium oxide, 2-20wt% of silicon oxide, 5-15wt% of zirconium oxide, and the balance of aluminum oxide.

Owner:CHINA NAT OFFSHORE OIL CORP +2

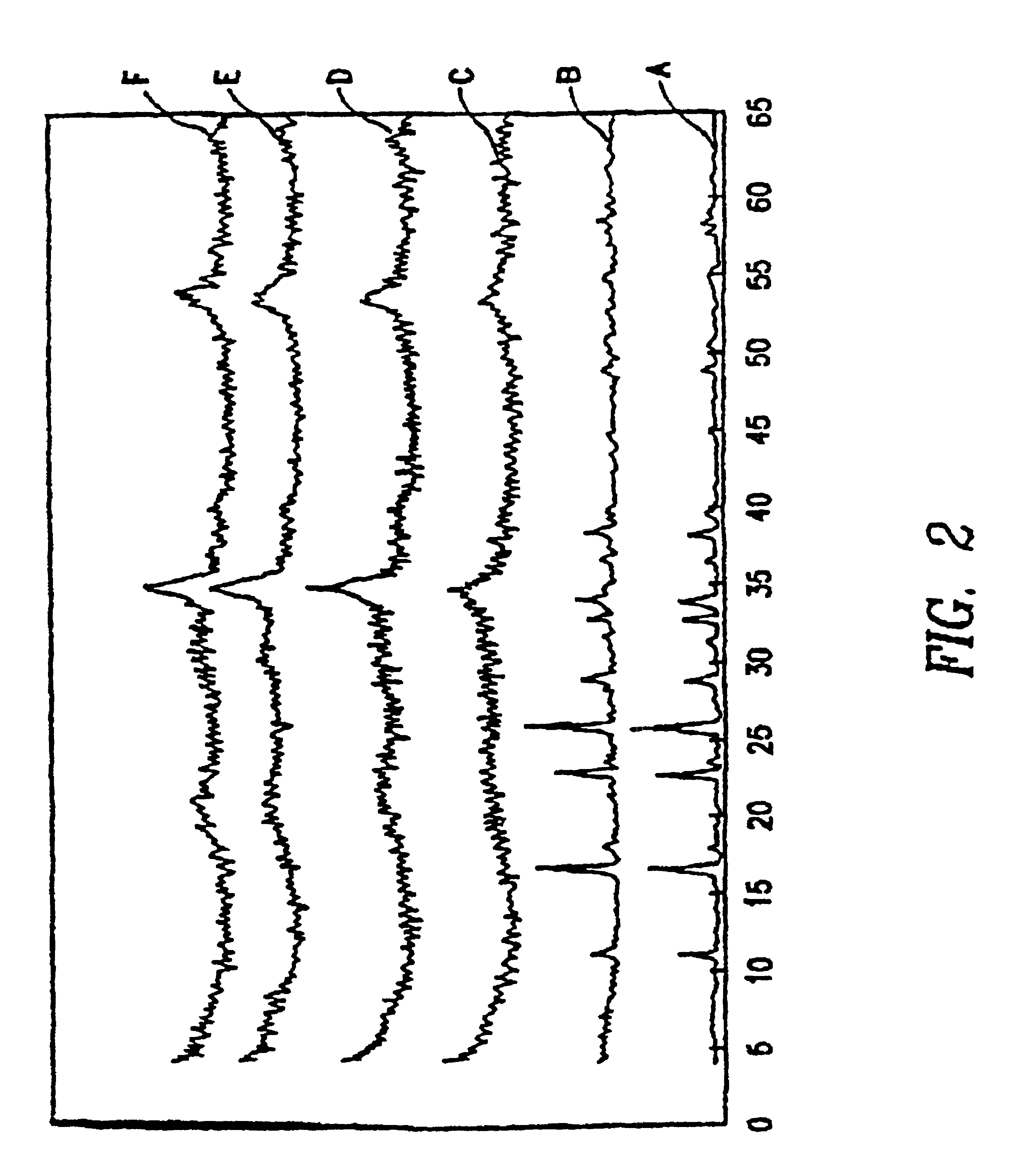

Selective naphtha hydrodesulfurization with high temperature mercaptan decomposition

A process for the selective hydrodesulfurization of olefinic naphtha streams containing a substantial amount of organically bound sulfur and olefins. The olefinic naphtha stream is selectively desulfurized in a first hydrodesulfurization reaction stage. This effluent stream is then contacted with a stripping agent in a H2S removal zone, such as steam or an amine solution, to remove H2S from the effluent stream, thereby reducing the H2S partial pressure of the process stream. The process stream is then subjected to a second desulfurization reaction stage followed by a mercaptan decomposition stage to reduce the content of mercaptan sulfur in the final product stream. In a second embodiment, the effluent stream from the first hydrodesulfurization reaction stage, after being subjected to the H2S removal zone, is fed directly to the mercaptan decomposition stage where total sulfur content and mercaptan sulfur content are reduced in the final product stream.

Owner:EXXON RES & ENG CO

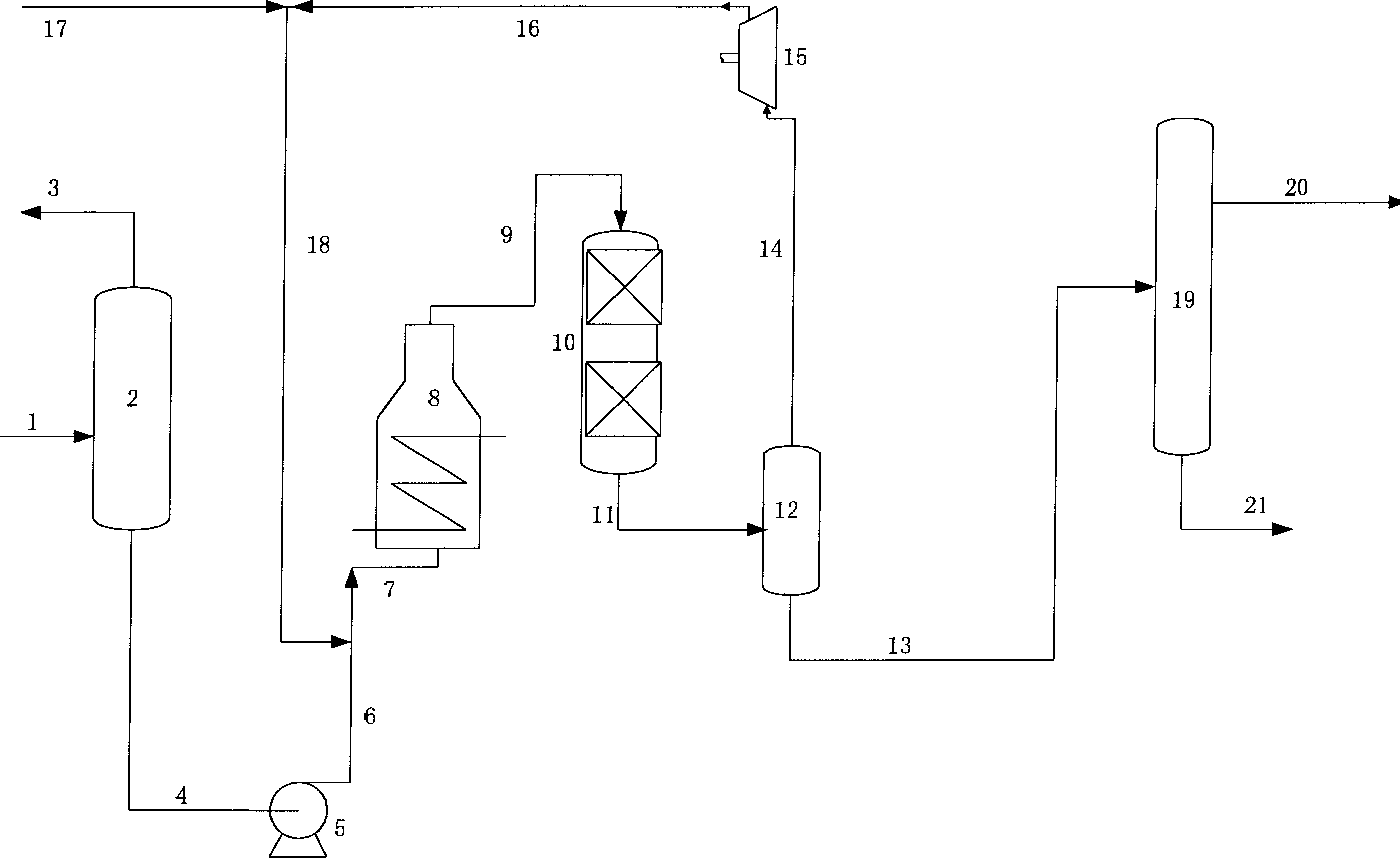

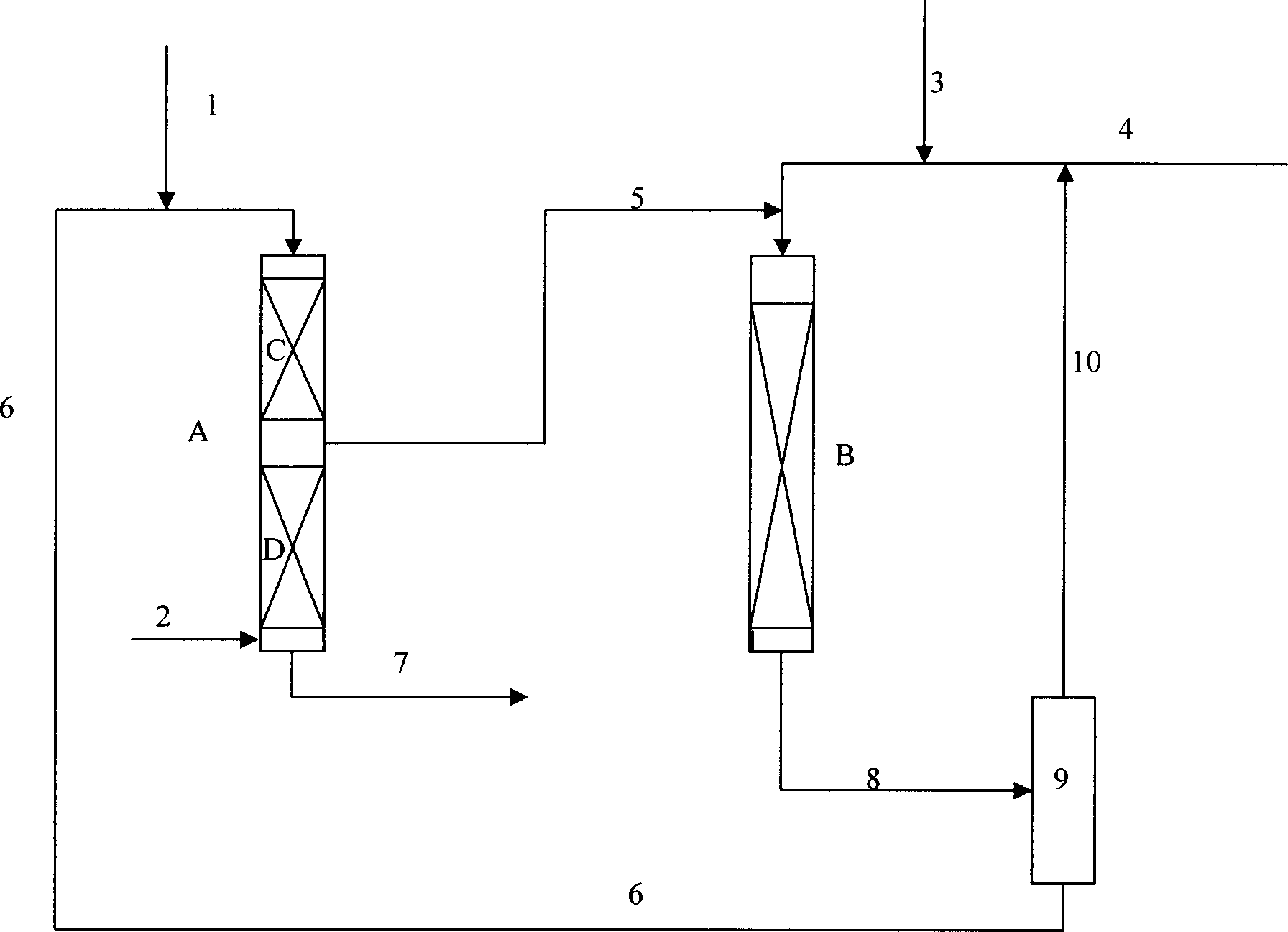

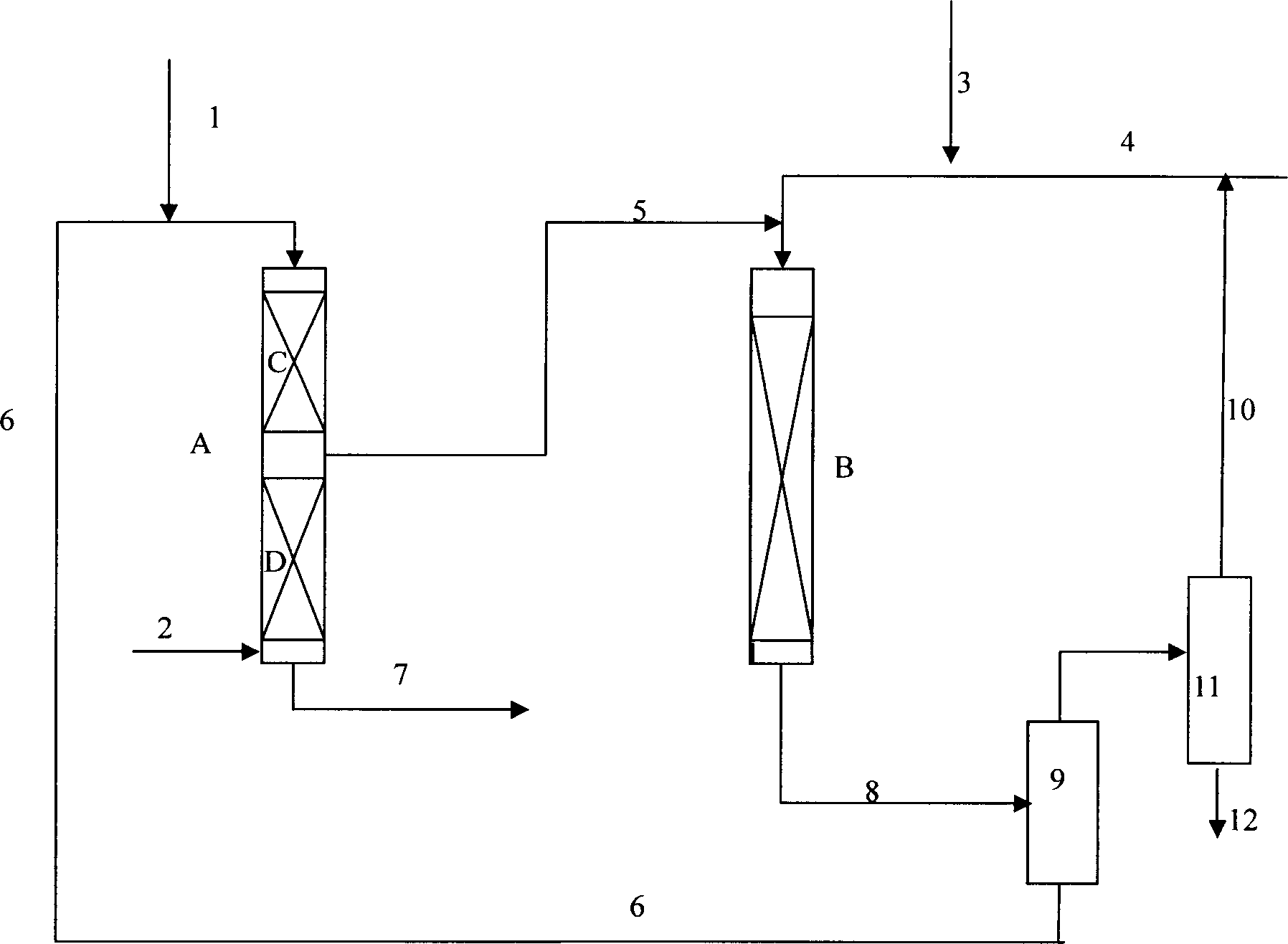

Deep desulphurizing and dearomating process for diesel oil

InactiveCN1552812AReduce loadIncrease flexibilityRefining to eliminate hetero atomsHydrodesulfurizationHydrogenation reaction

The invention relates to deep desulfurization and dearomatization of diesel fuel. A conventional co-current hydrofining reactor is connected with deep hydrodesulfurization and dearomatization reactors. Raw oil gets through the conventional hydrofining reactor firstly, reacted liquid phase material is mixed with fresh hydrogen to feed into the tops of deep hydrodesulfurization and dearomatization reactors, taking gas-liquid co-current hydrogenation, and then, reacted material is separated in gas-liquid separating zone. Gas phase is discharged and fed into the conventional hydrofining reactor, and liquid phase flows down to contact with fresh hydrogen inlet from the bottom of the reactor, finally, refined product is discharged from the bottom of the reactor. The invention process eliminates hepatic gas etc. impurity influence to arena saturation reaction in deep hydrodesulfurization and dearomatization reacting system of process now available, utilizes fully fresh hydrogen resource in the system, improves system reacting activity, usability of different raw oil, controllability and stability of counter- current hydrogenation reaction, and has better flexibility.

Owner:CHINA PETROLEUM & CHEM CORP +1

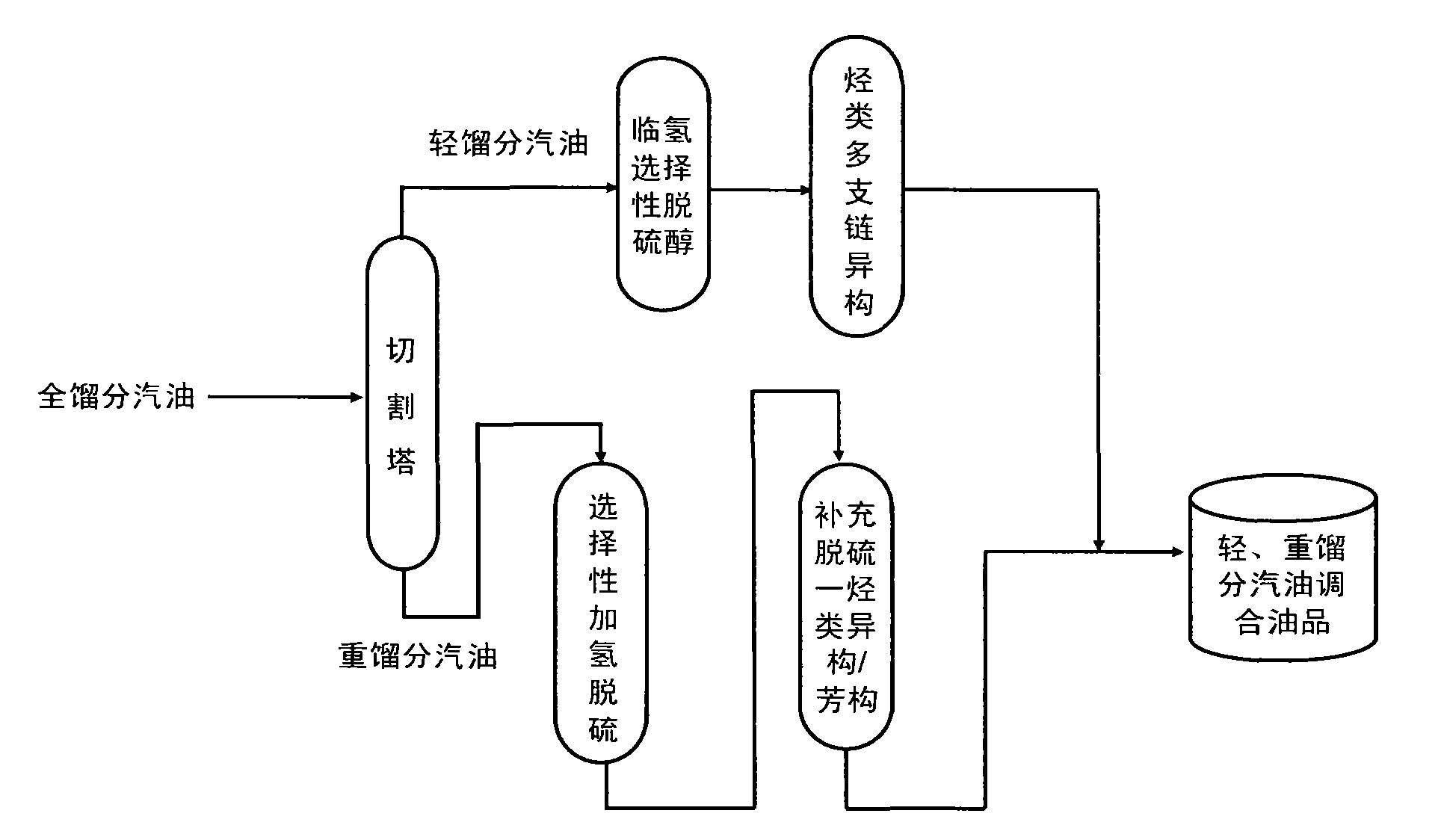

Production method for ultra-low sulfur and high-octane number gasoline

ActiveCN101885985ATake advantage ofIncrease temperatureTreatment with hydrotreatment processesIsomerizationHydrodesulfurization

The invention relates to a production method for ultra-low sulfur and high-octane number gasoline. The method comprises the following steps of: filling a poor-quality full range gasoline raw material in a reaction distillation column to contact the material with a sulfoether catalyst to perform a sulfur ether reaction and fraction cutting so that low-boiling point sulfides, such as thiol and thiophene, are converted into high-boiling point sulfoether which is then transferred into heavy fraction gasoline, wherein the cutting fractionation temperature of light fraction gasoline and the heavy fraction gasoline is 50 to 90 DEG C; contacting the light fraction gasoline with a hydrocarbon highly branched isomerization catalyst; contacting the heavy fraction gasoline with a selective hydrodesulfurization catalyst and a desulfurization-hydrocarbon isomerization / aromatization catalyst; and mixing the treated light fraction gasoline and the heavy fraction gasoline to obtain the ultra-low sulfur and high-octane number gasoline. The method is suitable for modifying poor-quality gasoline, can reach better desulfurization and olefin reduction effects on ultra-high sulfur and high-olefin poor-quality catalytic gasoline, and can maintain or increase the octane number of the product and keep a higher product yield after reaction.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

Process for the desulfurization of hydrocarbonacecus oil

InactiveUS20050040078A1Easily and economically reducing sulfur contentHigh recovery rateRefining with oxygen compoundsTreatment with plural serial refining stagesHydrodesulfurizationSulfur

A process for the desulfurization of hydrocarbonaceous oil wherein the hydrocarbonaceous oil is contacted with a hydrodesulfurization catalyst in a hydrodesulfurization reaction zone to reduce the sulfur level to a relatively low level then contacting the resulting hydrocarbonaceous stream from the hydrodesulfurization zone with an oxidizing agent to convert the residual, low level of sulfur compounds into sulfur-oxidated compounds. The resulting hydrocarbonaceous oil stream containing the sulfur-oxidated compounds is separated after decomposing any residual oxidizing agent by contacting the stream with an adsorbent material to adsorb the sulfur-oxidated compounds to produce a hydrocarbonaceous oil stream having a reduced concentration of sulfur-oxidated compounds. The spent adsorbent is regenerated and subsequently returned to adsorbent service.

Owner:UOP LLC

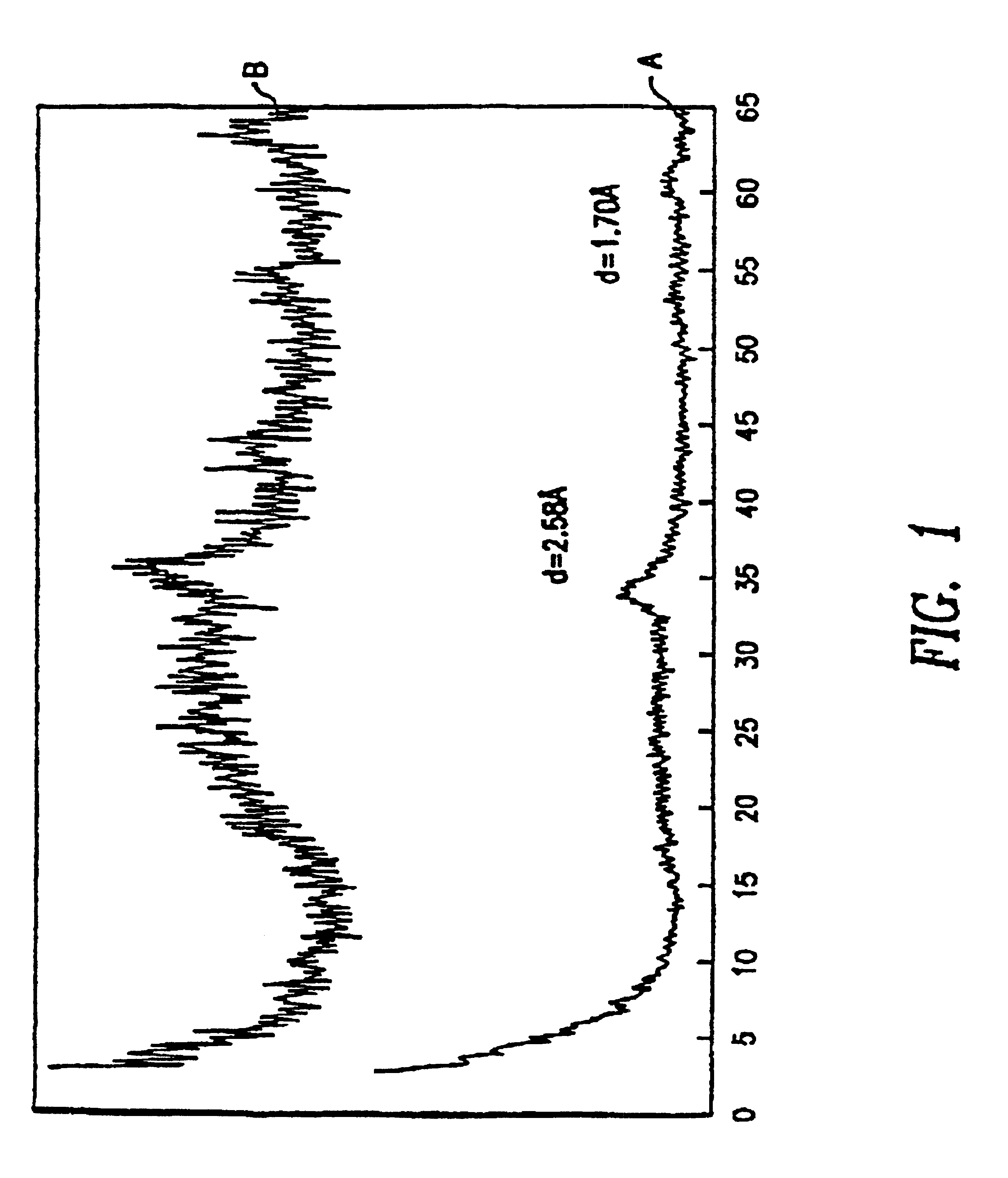

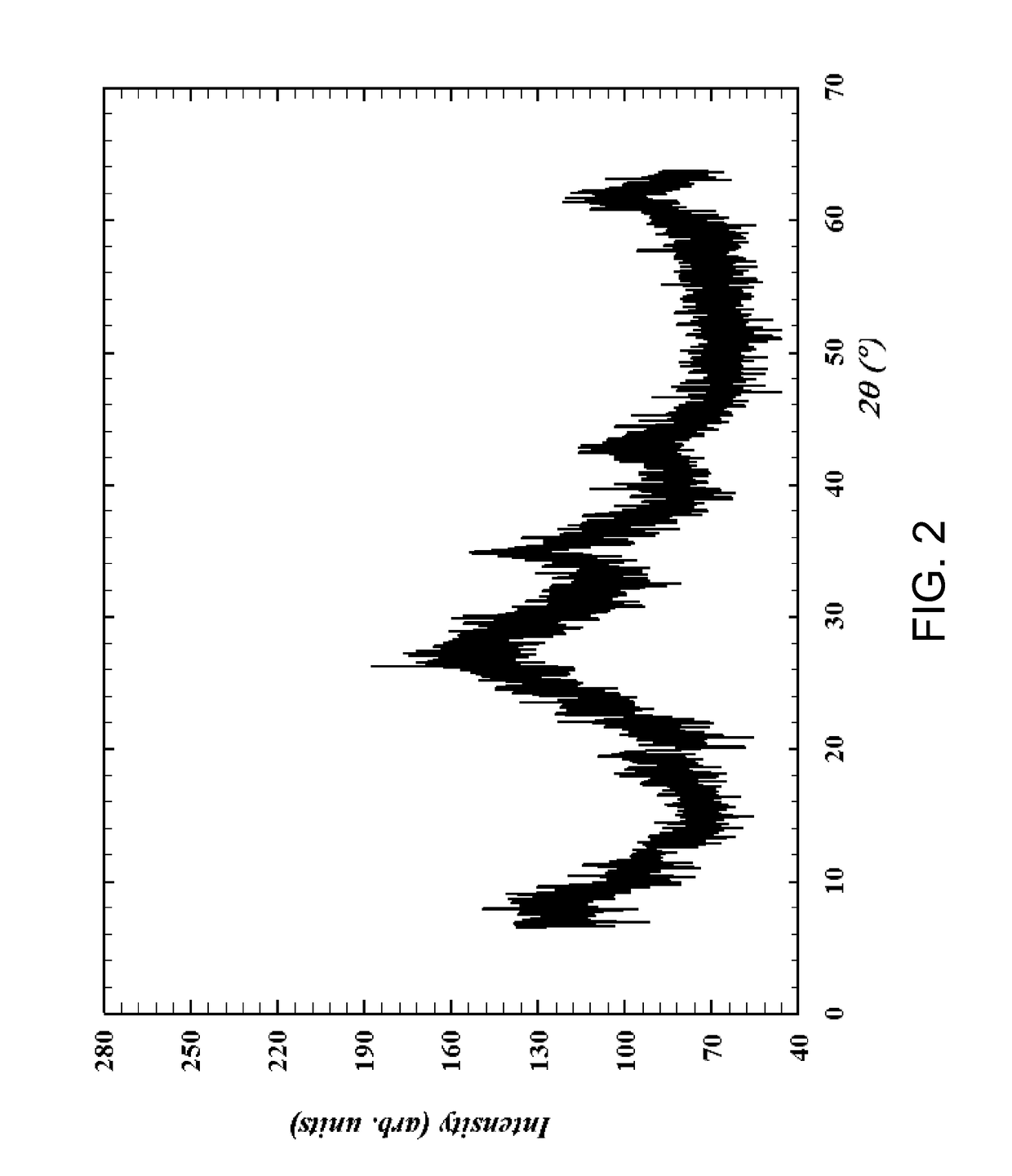

Novel mixed metal oxides

ActiveUS20170165645A1Catalyst activation/preparationHydrocarbon oil crackingHydrodesulfurizationMaterials science

A unique mixed metal molybdotungstate material has been developed. The material may be used as a hydroprocessing catalyst. The hydroprocessing may include hydrodenitrification, hydrodesulfurization, hydrodemetallation, hydrodearomatization, hydrodesilication, hydroisomerization, hydrotreating, hydrofining, and hydrocracking.

Owner:UOP LLC

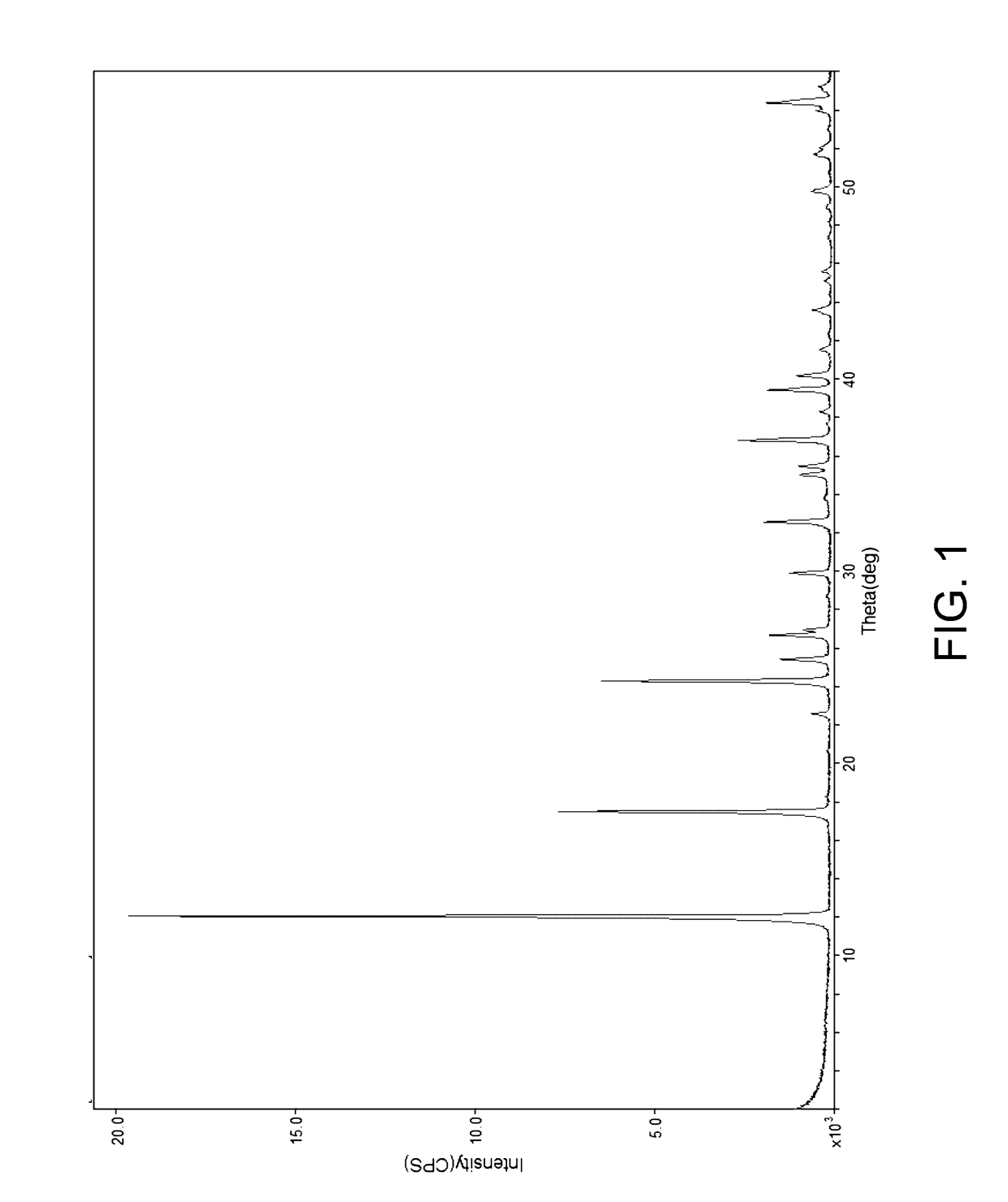

ZSM-5/SAPO-11 composite zeolite and catalytically cracked gasoline hydrogenation quality-improved catalyzer and the methoer for preparing the same

ActiveCN101081370AImprove product qualityEquilibrium HydrodesulfurizationMolecular sieve catalystsHydrocarbon oils refiningIsomerizationHydrodesulfurization

The present invention is one kind of catalyst with ZSM-5 / SAPO-11 composite zeolite for hydrogenating and modifying catalytically cracked gasoline and its preparation process. The composite zeolite is prepared through compounding solution A with aluminum sulfate, sulfuric acid and water; compounding solution B with water glass, tetraethyl ammonium hydroxide and water; mixing solution A and solution B to form homogeneous colloid; crystallizing the colloid mixture at 150-180 deg.c for 24-72 hr; adding phosphoric acid, pseudoboehite, silica sol and SAPO-11 synthesizing template agent; and final crystallizing at 170-200 deg.c for 24-48 hr to obtain sodium type composite zeolite. The catalyst with the composite zeolite as carrier has excellent hydrogenating and desulfurizing performance, high stability, high gasoline yield, high isomerization activity and certain aromatization activity, and may be applied in producing high quality clean gasoline product.

Owner:BEIJING CUP GREEN CATALYTIC TECH

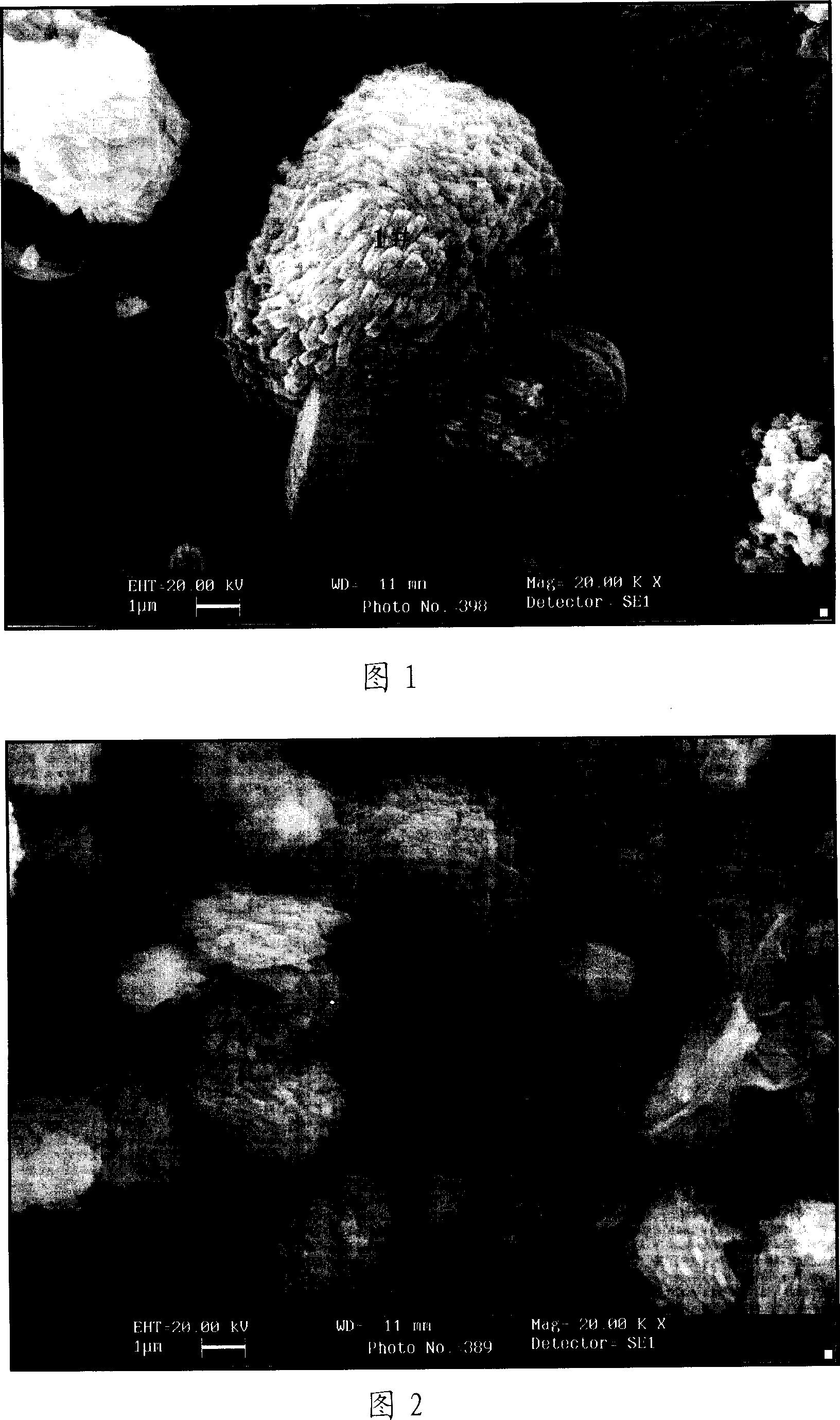

Heavy oil hydrogenating treatment catalyst and preparation method thereof

ActiveCN101433848AIncrease the areaLarge hole volumeMetal/metal-oxides/metal-hydroxide catalystsRefining to eliminate hetero atomsHydrodesulfurizationPore diameter

The invention discloses a heavy oil hydrotreating catalyst and a preparation method thereof. The method for preparing the catalyst adopts a complete mixed kneading method; a carrier material comprises pseudo-boehmite glue powder and alumina powder; and an active metallic solution contains nonionic surfactant. The catalyst prepared by the method has the characteristics of large pore volume and pore diameter, proper specific surface area, even active metal dispersion and the like, and can be used in the processes of heavy oil hydrodemetalization, hydrodesulfurization and the like.

Owner:CHINA PETROLEUM & CHEM CORP +1

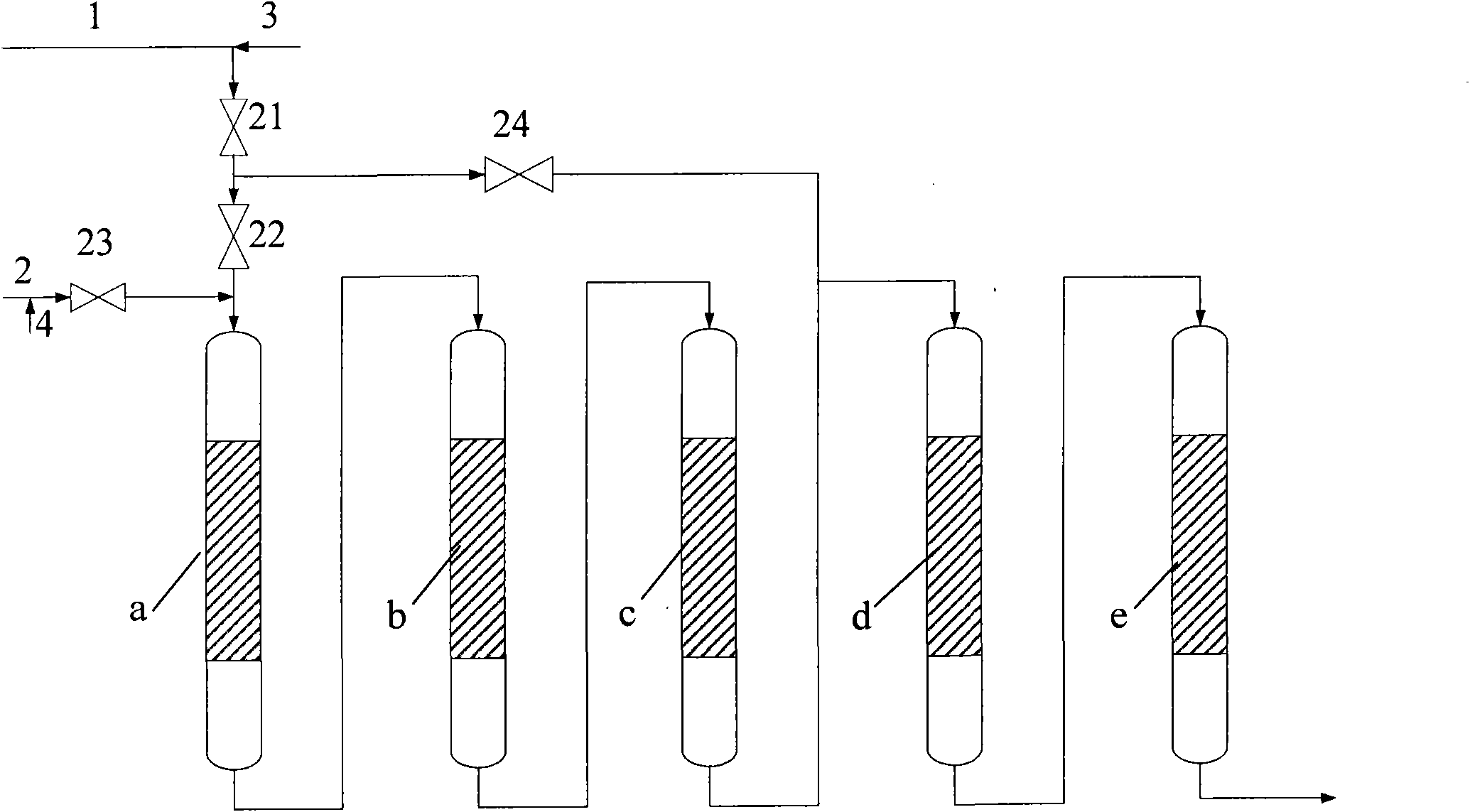

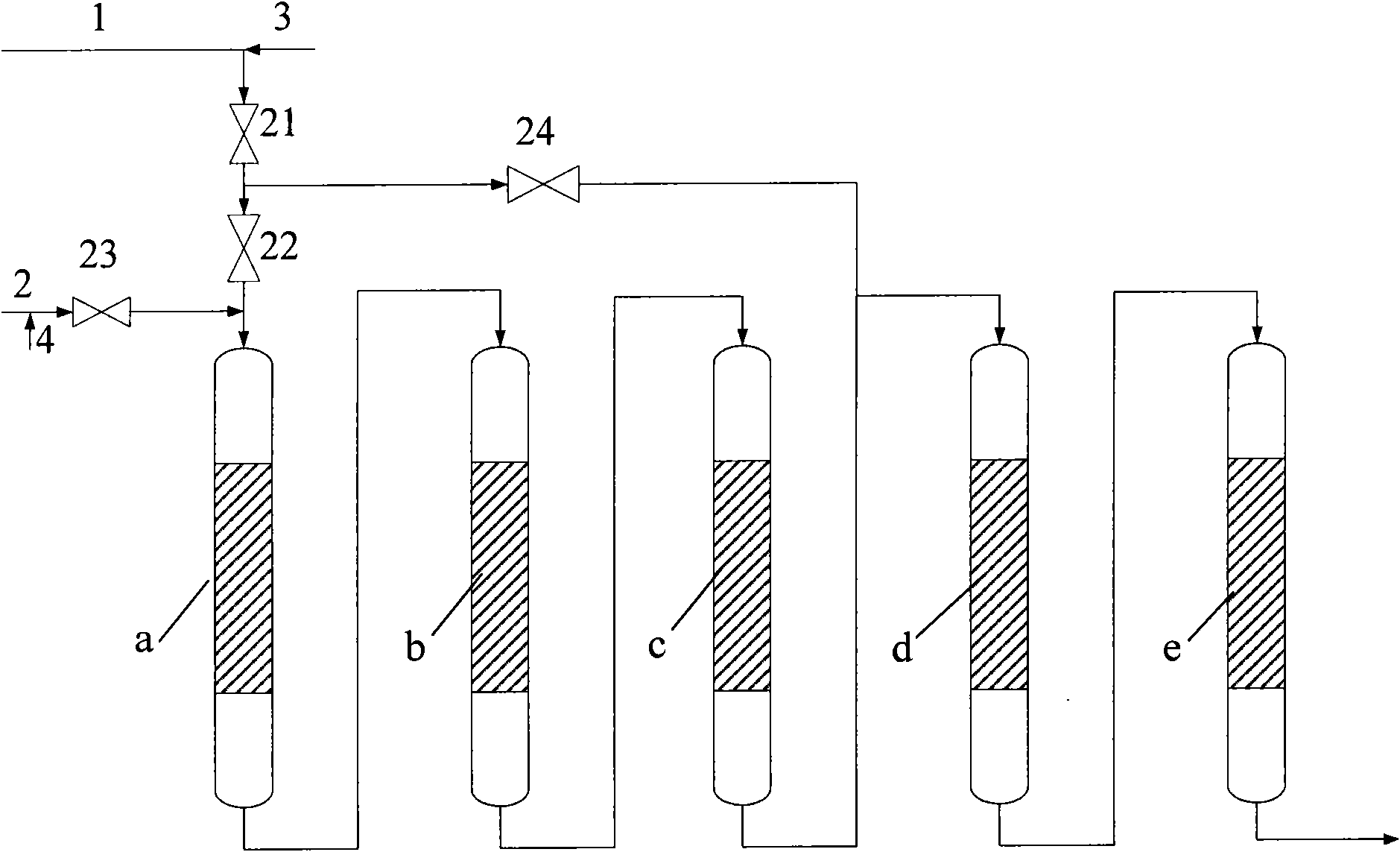

Process for producing sweet gas for poor-quality gasoline distillate

ActiveCN101307255AReduce lossesTreatment with hydrotreatment processesLow activityHydrodesulfurization

The invention discloses a method for producing low-sulfur gasoline by inferior gasoline fractions. Firstly, full-range inferior gasoline raw material is oxidized and deodorized by a fixed bed, mercaptan sulfur is transformed into disulfide, then an oxidized and deodorized product is fractionated into light cut and heavy cut, the heavy cut is subject to the selective hydrodesulfurization through combining high-activity / low-activity and hydrodesulfurization catalyst, and a desulfurization product is mixed with the light cut to produce a clean gasoline product. Compared with the prior art, the method can effectively desulfurize the inferior gasoline fractions and has less octane number loss at the same time; under the preferable condition, the sulfur content of the gasoline product can reach less than 10 mu g / g.

Owner:CHINA PETROLEUM & CHEM CORP +1

Impregnating solution of hydrogenation catalyst, its preparation method, hydrogenation catalyst and preparation method thereof

ActiveCN103055956AImprove hydrodesulfurization activityHigh activityMolecular sieve catalystsCatalyst activation/preparationHydrodesulfurizationDecane

The invention provides an impregnating solution of a hydrogenation catalyst and its preparation method. The method includes: preparing a VIII-th group metal compound and a first organic complexing agent into an aqueous solution A; preparing a VIB-th group metal compound into an aqueous solution B; and mixing the aqueous solution A and the aqueous solution B. Specifically, the ligand of the first organic complexing agent at least contains the coordination atom N. The invention also provides a hydrogenation catalyst and a preparation method thereof. Compared with current catalysts, the hydrogenation catalyst provided in the invention has high hydrodesulfurization activity. For example, a mixed solution of n-decane with a 4, 6-dimethyldibenzothiophene (4, 6-DMDBT) content of 0.59wt% is adopted as the raw material, and hydrodesulfurization activity contrast evaluation is performed on the catalyst provided in the invention and a contrast catalyst. In terms of a contrast catalyst activity of 100, the hydrodesulfurization activity of the catalyst provided in the invention can reach 120.

Owner:CHINA PETROLEUM & CHEM CORP +1

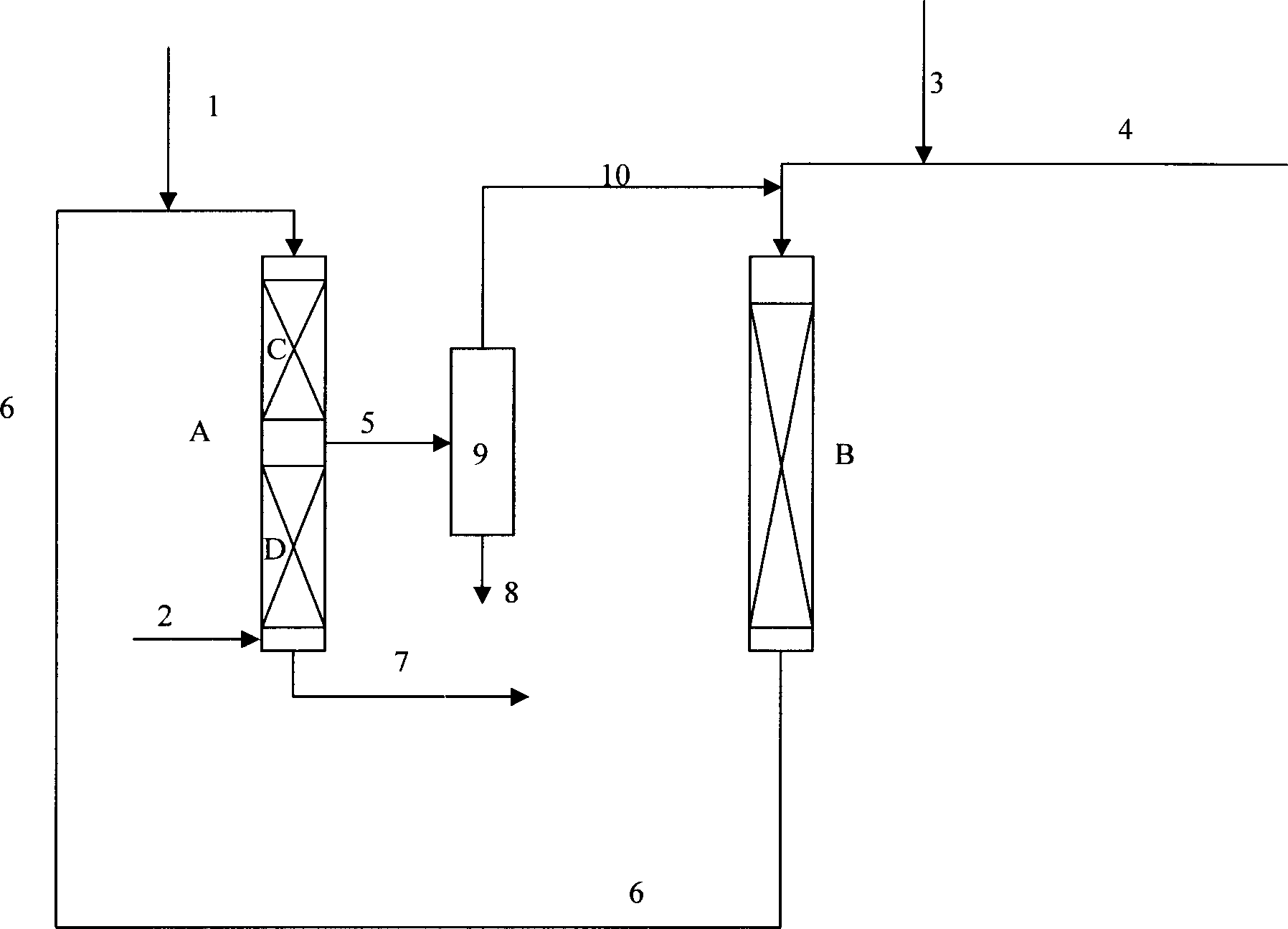

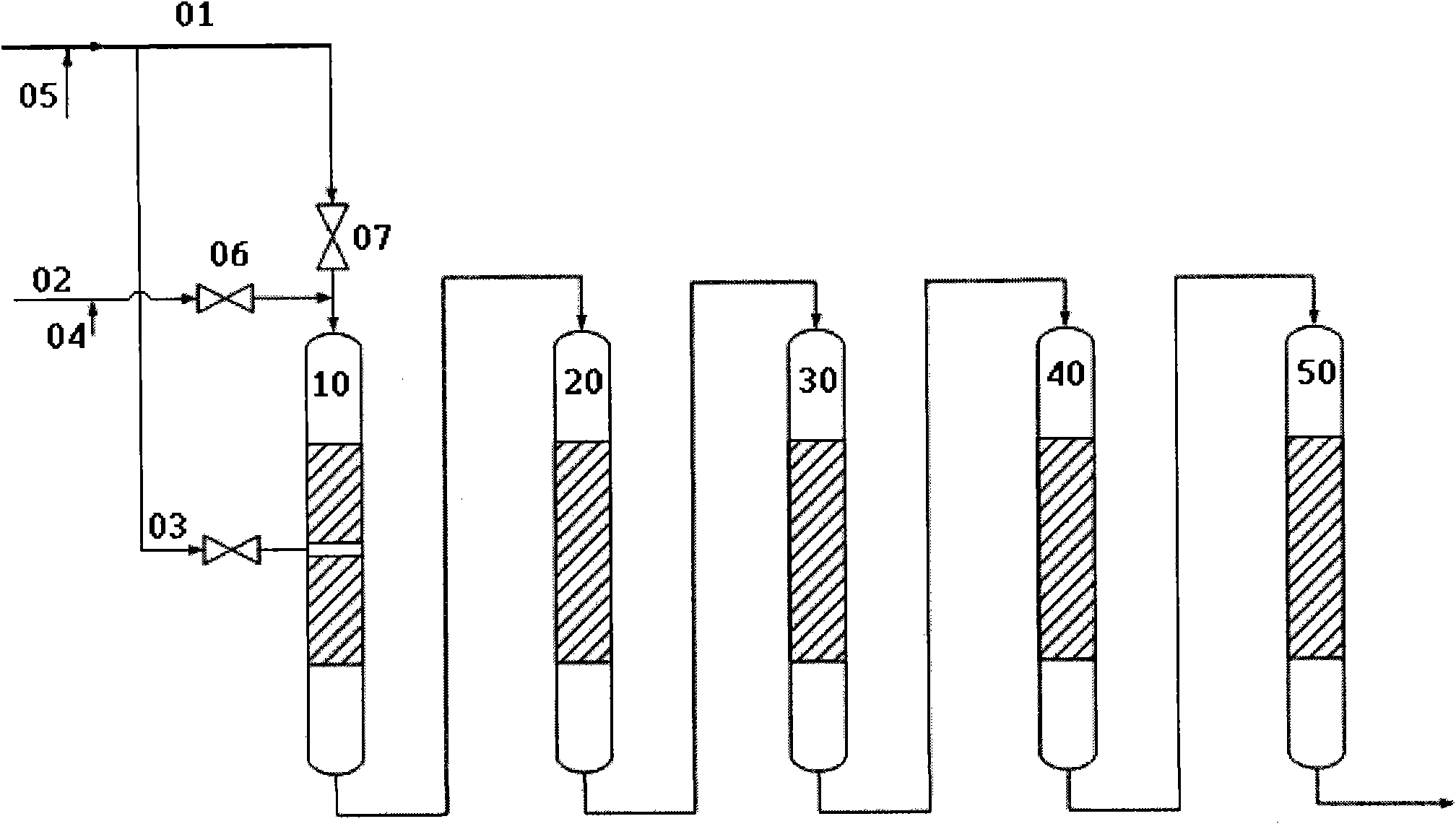

Hydrogenation method for residual oil

ActiveCN101768468ATake advantage ofExtended operating cycleTreatment with hydrotreatment processesHydrodesulfurizationHydrogenation reaction

The invention provides a hydrogenation method for residual oil. The method includes the following steps: under the condition of hydrogenation reaction, residual oil raw materials and hydrogen gas are sequentially guided into two hydrogenation reaction zones connected in series to carry out contact reaction with a plurality of catalyst beds in the hydrogenation reaction zones; according to the flowing directions of a reactant and the hydrogen gas, the first and second hydrogenation reaction zones respectively comprise a hydrogenation protecting catalyst, a hydrogenation de-metallization catalyst and a hydrogenation desulfurization catalyst which are sequentially filled in the catalyst beds; when the pressure drop of at least one catalyst bed in the first hydrogenation reaction zone reaches the upper limit or hot spots appear in the reaction zone, at least one part of the residual oil raw materials and the hydrogen gas is directly guided into the second hydrogenation reaction zone. Compared with the prior art, the method in the invention can prolong the running period of a residual oil hydrogenation device, thereby increasing the running efficiency of the device and improving the economical property of the device as well.

Owner:CHINA PETROLEUM & CHEM CORP +1

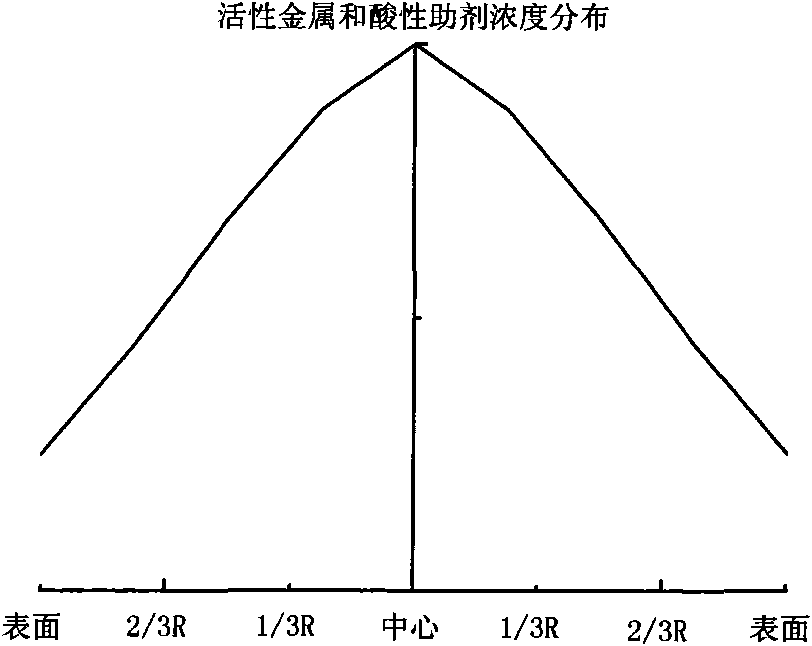

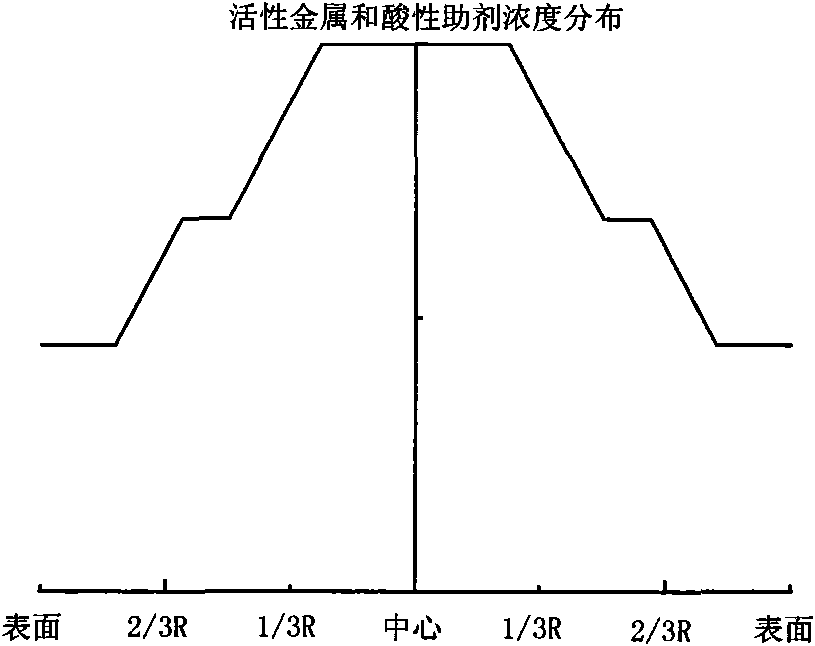

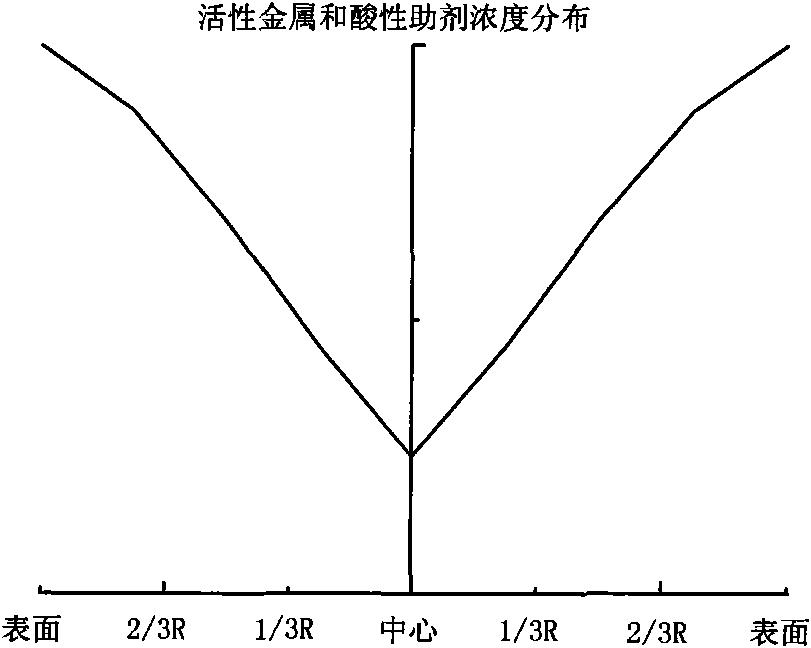

Grading composition of hydrogenation catalyst

ActiveCN101928592AGood demetallizationGood charcoal removalRefining to eliminate hetero atomsPorosityMetal catalyst

The invention relates to a grading composition of a hydrogenation catalyst. From top to bottom, a reactor is filled with hydrodemetallization and a hydrodesulfurization catalyst; raw materials flow from top to bottom, and along with the flowing direction of raw materials, the activity of the catalyst gradually increases, the pore size gradually decreases, the grain size gradually decreases and the porosity gradually decreases; the hydrodemetallization catalyst and the hydrodesulfurization catalyst are both formed by one or more demetallization catalysts; concentrations of active metal components and acid auxiliary agents are in nonuniform distribution, and from the surface to the center of catalyst grains, the concentrations of the active metal components and acid auxiliary agents of the hydrodemetallization catalyst are of gradient increase, and the concentrations of the active metal components and acid auxiliary agents of the hydrodesulfurization catalyst are of gradient decrease; and based on weight content, the demetallization catalyst accounts for 15 to 80 percent, and the desulfurization catalyst accounts for 20 to 85 percent. The grading composition of the invention is applied to hydrogenation catalysis of oil and residual oil of heavy ends and has the advantages of possessing better activity and stability of demetallization, residual carbon removal and desulfurization, controlling temperature rise of a catalyst bed and degreasing the deactivation speed of the catalyst.

Owner:PETROCHINA CO LTD

Crude oil desulfurization

InactiveUS6841062B2Reduce operating costsLow costHydrocarbon oil crackingTreatment with hydrotreatment processesSulfurHydrodesulfurization

This invention relates to a crude oil desulfurization process which comprises hydrodesulfurizing a crude oil feed in a crude desulfurization unit. The desulfurized crude oil is then separated into a light gas oil fraction, a vacuum gas oil fraction and a vacuum residuum fraction. The vacuum gas oil is hydrocracked to form at least one low sulfur fuel product. The light gas oil fraction is hydrotreated. The vacuum gas oil may be hydrocracked in one or more stages. Hydrocracking in the second stage, if present, will convert of at least 20% of the first zone effluent, to create a low sulfur light gas oil fraction. The light gas oil fraction may then be hydrotreated.

Owner:CHEVROU USA INC

Hydrodesulfurization Catalyst for Petroleum Hydrocarbons and Process for Hydrodesulfurization Using the Same

InactiveUS20070175797A1High desulfurization activityHigher stable desulfurization activityPhysical/chemical process catalystsRefining to eliminate hetero atomsHydrodesulfurizationPetroleum

The present invention provides a hydrodesulfurization that can attain an extremely high depth of desulfurization to a sulfur content of 10 ppm by mass and maintain such a high desulfurization activity for a long period of time. The catalyst comprises an inorganic porous support containing alumina and phosphorus, at least one active metal selected from the metals of Group 8 of the periodic table, and at least one metal selected from the metals of Group 6A of the periodic table, the Group 8 metal and the Group 6A metal being contained in a molar ratio defined by (oxide of the Group 8 metal) / (oxide of the Group 6A metal) ranging from 0.055 to 0.150, and the content of the Group 6A metal in terms of oxide being in the range of 30 to 40 percent by mass based on the mass of the catalyst.

Owner:NIPPON OIL CORP

Method for non-hydroaromatizating and desulfurizing catalytically cracked gasoline

InactiveCN1485414ANo change in octaneMeet environmental protection requirementsTreatment with hydrotreatment processesHydrogenHydrodesulfurization

A process of crackling and aromatizing gasoline, and desulfurizing. It comprises: all fractions of crackling gasoline by catalysizing or light fractions entering an aromatizing desulfurizing reactor,and aromatizing olefin, hydrogenating and desulfurizing with hydrogen produced by aromatizing are hydrogenated, reducing the contents of olefin and sulfur in gasoline, deodorizing the products, then obtaining high-grade gasoline product.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

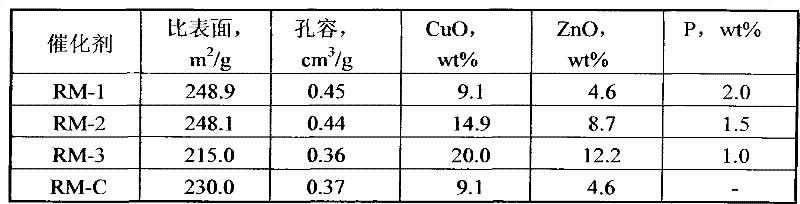

Hydrogenation dethiolizing catalyst, preparation method thereof and application thereof

ActiveCN102451694AMetal/metal-oxides/metal-hydroxide catalystsRefining to eliminate hetero atomsActive componentHydrodesulfurization

The invention discloses a hydrogenation dethiolizing catalyst, a preparation method thereof and an application thereof. The catalyst which treats alumina or siliceous alumina as a carrier, copper and zinc as active components and phosphor as an assistant component comprises, by weight, 5-30% of copper oxide, 3-15% of zinc oxide and 0.5-30% of the assistant phosphor. The catalyst is prepared with a one-time saturation dipping technology. Compared with present catalysts, the catalyst of the invention can be applied to selective hydrogenation dethiolizing reactions on light oil products, and the catalyst has the characteristics of high dethiolizing activity, low olefin hydrogenation activity, difficult loss of the active components, and long running period.

Owner:CHINA PETROLEUM & CHEM CORP +1

Fraction oil hydrodesulfurizing catalyst and its prepn process

ActiveCN101089132AOvercoming the defects of deep hydrodesulfurizationEnhanced deep hydrodesulfurization activityRefining to eliminate hetero atomsActive componentHydrodesulfurization

The present invention discloses one kind of fraction oil hydrodesulfurizing catalyst and its preparation process. The catalyst has alumina or silicon-containing alumina as carrier, W, Mo, Ni and Co as active components, and phosphorus assistant. It is prepared through saturation co-soaking process, and has active metal components possessing synergistic effect high dispersed, and high activity, especially high hydrodesulfurizing activity. It is used in the hydrodesulfurizing process, especially deep hydrodesulfurizing process, of various kinds of fraction oil.

Owner:CHINA PETROLEUM & CHEM CORP +1

Selective hydrogenation desulfurization method for gasoline

ActiveCN101314734AReduce lossesIncrease flexibilityHydrocarbon oils refiningHydrogenHydrodesulfurization

A gasoline selective hydrodesulfurization method comprises the following steps: mixing full-range gasoline and / or heave gasoline distillate with hydrogen, carrying out selective hydrodesulfurization reaction in the presence of hydrodesulfurization catalyst I and hydrodesulfurization catalyst II, and cooling and separating the resultants to obtain hydrogenated gasoline distillate, wherein the heavy gasoline distillate is obtained by cutting full-range gasoline at a cutting temperature of 50 to 75 DEG C, and the hydrodesulfurization catalyst I and hydrodesulfurization catalyst II are VIB-group metal and / or VIII-group non-noble metal catalysts loaded on aluminum and / or silica-alumina carrier. The method can be used for processing catalytic cracking gasoline to obtain gasoline product with sulfur content meeting EuroIV emission standard or even meeting EuroV emission standard, and the gasoline product has less octane number loss and RON loss less than 2.0.

Owner:CHINA PETROLEUM & CHEM CORP +1

Boron containing hydrodesulphurization catalyst and preparation method thereof

ActiveCN101314130AHigh desulfurization activityMetal/metal-oxides/metal-hydroxide catalystsRefining to eliminate hetero atomsHydrodesulfurizationBoron containing

The invention discloses a boron-bearing hydrodesulfurization catalyst and a preparation method thereof. The boron-bearing hydrodesulfurization catalyst contains a carrier, at least one VIB hydrogenative reactive metal composition and at least one VIII hydrogenative reactive metal composition and boron; the catalyst is calculated by oxide and a catalyst is taken as a reference, the content of the VIB metal composition is between 0.5 and 35 weight percent, the content of the VIII metal composition is between 0.1 and 10 weight percent, the content of the boron is between 0.2 and 6 weight percent, and the content of the carrier is between 49 and 99.2 weight percent, wherein, the carrier contains alumina provided with a delta and / or theta structure. Compared with the prior catalyst, the catalyst has higher hydrodesulfurization activity.

Owner:CHINA PETROLEUM & CHEM CORP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com