Microporous-mesoporous molecular sieve containing noble metal, preparation method and application to catalytic reduction of p-nitrophenol

A technology of mesoporous molecular sieves and noble metals, which is applied in the direction of molecular sieve catalysts, molecular sieve compounds, molecular sieves and base exchange compounds, etc., can solve the problems of lack of mesoporous channels, high synthesis cost, and poisonous body, and achieve good dispersion and stable packaging. The effect of improving the covering effect and reducing the industrial cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

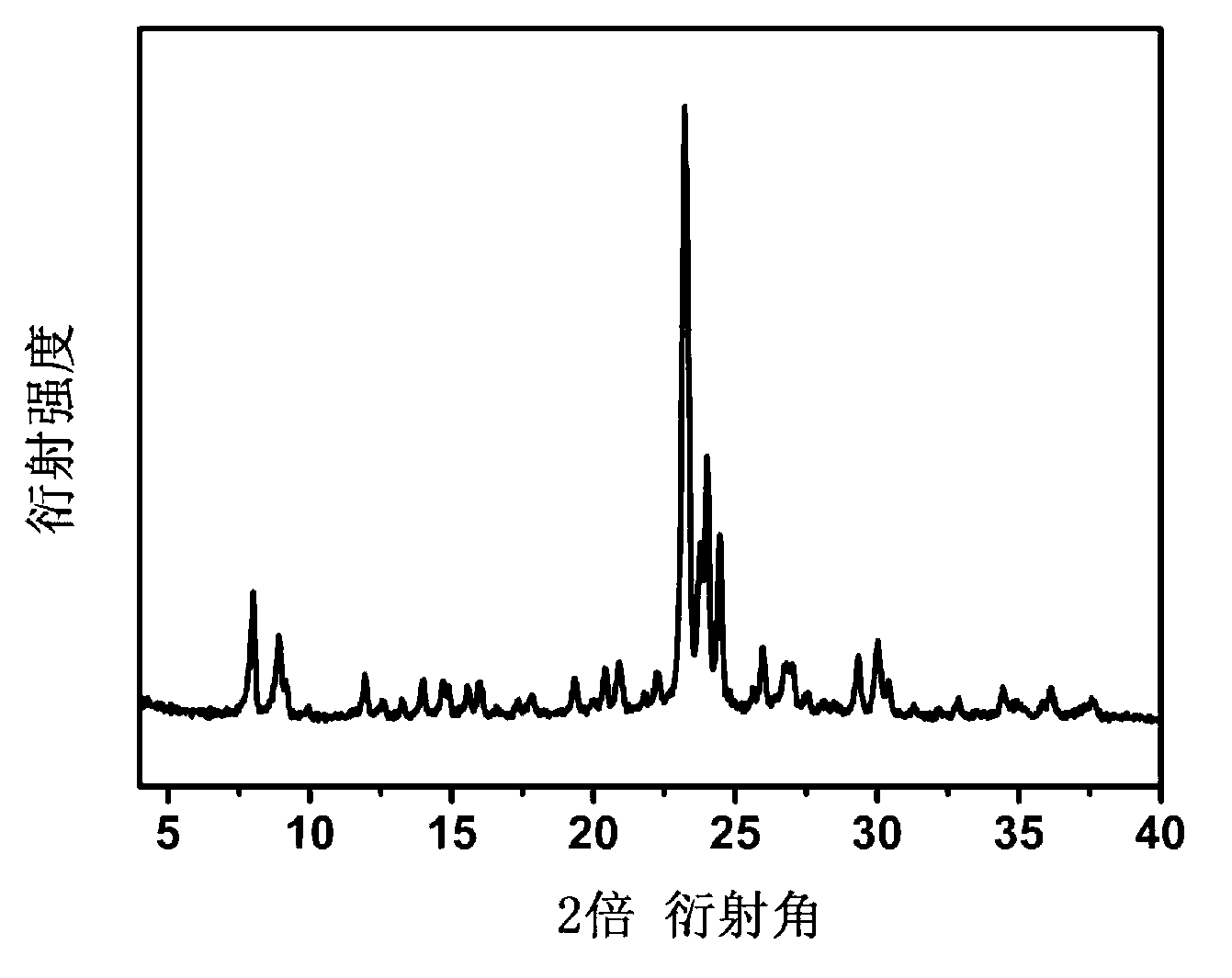

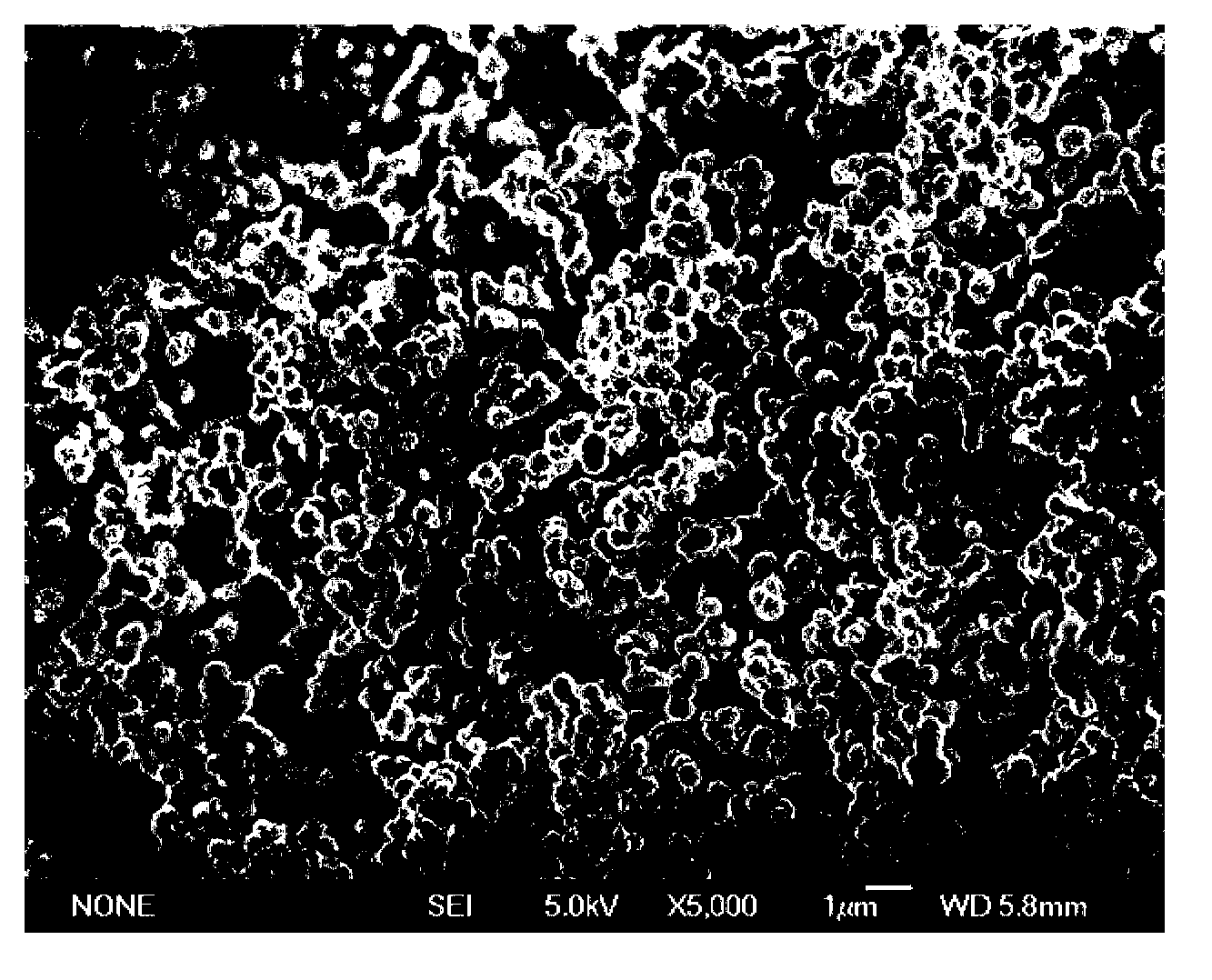

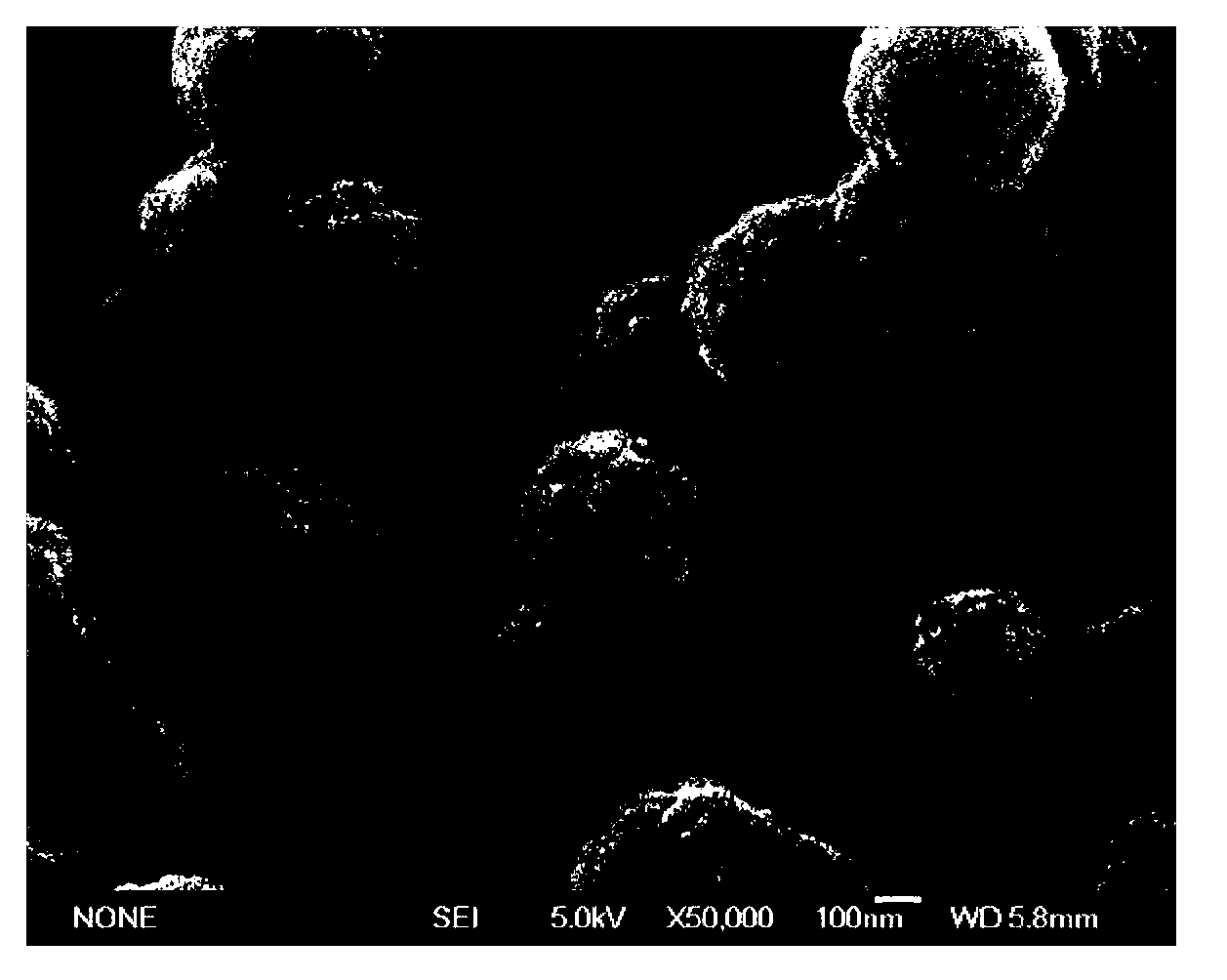

[0062] Embodiment 1: the microporous-mesoporous silicalite-1 molecular sieve containing noble metal Pt of synthetic pure silicon

[0063] The synthesis of Pt nanoparticles was as described in the document Chem. Mater. 2000, 12, 1622-1627. The synthesized particles were precipitated, centrifuged, and redispersed in water into 3×10 -3 mol / L solution.

[0064] Under the condition of 40°C water bath, sequentially add coupling pore-forming agent (polyvinylpyrrolidone), silicon source (tetraethyl silicate), alkali source (tetrapropylammonium hydroxide) into the aqueous solution of noble metal nanoparticles, and stir To form a sol-gel; wherein the molar composition of silicon source: alkali source: platinum source: coupled pore-forming agent: water = 100: 10: 0.3: 0.1: 500, the silicon source is SiO 2 The platinum source is measured as Pt. The prepared sol-gel was aged at 60°C under airtight conditions for 12 hours and then dried at 80°C under non-airtight conditions for 12 hours ...

Embodiment 2

[0065] Embodiment 2: the microporous-mesoporous silicalite-1 molecular sieve containing noble metal Pd of synthetic pure silicon

[0066] The synthesis of Pd nanoparticles was as described in the document Chem. Mater. 2000, 12, 1622-1627. The synthesized particles were precipitated, centrifuged, and redispersed in water into 3×10 -3 mol / L solution.

[0067]Under the condition of 40°C water bath, sequentially add coupling pore-forming agent (polyvinylpyrrolidone), silicon source (tetraethyl silicate), alkali source (tetrapropylammonium hydroxide) into the aqueous solution of noble metal nanoparticles, and stir To form a sol-gel; wherein the molar composition of silicon source: alkali source: palladium source: coupled pore-forming agent: water = 100: 10: 0.3: 0.2: 1500, the silicon source is SiO 2 In terms of palladium source in terms of Pd. The prepared sol-gel was aged at 60°C under airtight conditions for 12 hours and then dried at 80°C under non-airtight conditions for 12...

Embodiment 3

[0068] Embodiment 3: Synthetic microporous-mesoporous ZSM-5 molecular sieve containing precious metal Pt doped with metal Al

[0069] The synthesis of Pt nanoparticles was as described in the document Chem. Mater. 2000, 12, 1622-1627. The synthesized particles were precipitated, centrifuged, and redispersed in water into 3×10 -3 mol / L solution.

[0070] Under the condition of water bath at 40°C, sequentially add coupling pore-forming agent (polyvinylpyrrolidone), silicon source (tetraethyl silicate), aluminum source (aluminum isopropoxide), alkali source ( Tetrapropylammonium hydroxide), stirring to form a sol-gel; wherein the molar composition silicon source: aluminum source: alkali source: platinum source: coupling pore-forming agent: water = 100: 3: 10: 0.3: 0.2: 1500, SiO 2 In terms of aluminum source as Al 2 o 3 The platinum source is measured as Pt. The prepared sol-gel was aged at 60°C under airtight conditions for 12 hours and then dried at 80°C under non-airtigh...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com