Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

42026 results about "Atmosphere" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

An atmosphere (from Ancient Greek ἀτμός (atmos), meaning 'vapour', and σφαῖρα (sphaira), meaning 'ball' or 'sphere') is a layer or a set of layers of gases surrounding a planet or other material body, that is held in place by the gravity of that body. An atmosphere is more likely to be retained if the gravity it is subject to is high and the temperature of the atmosphere is low.

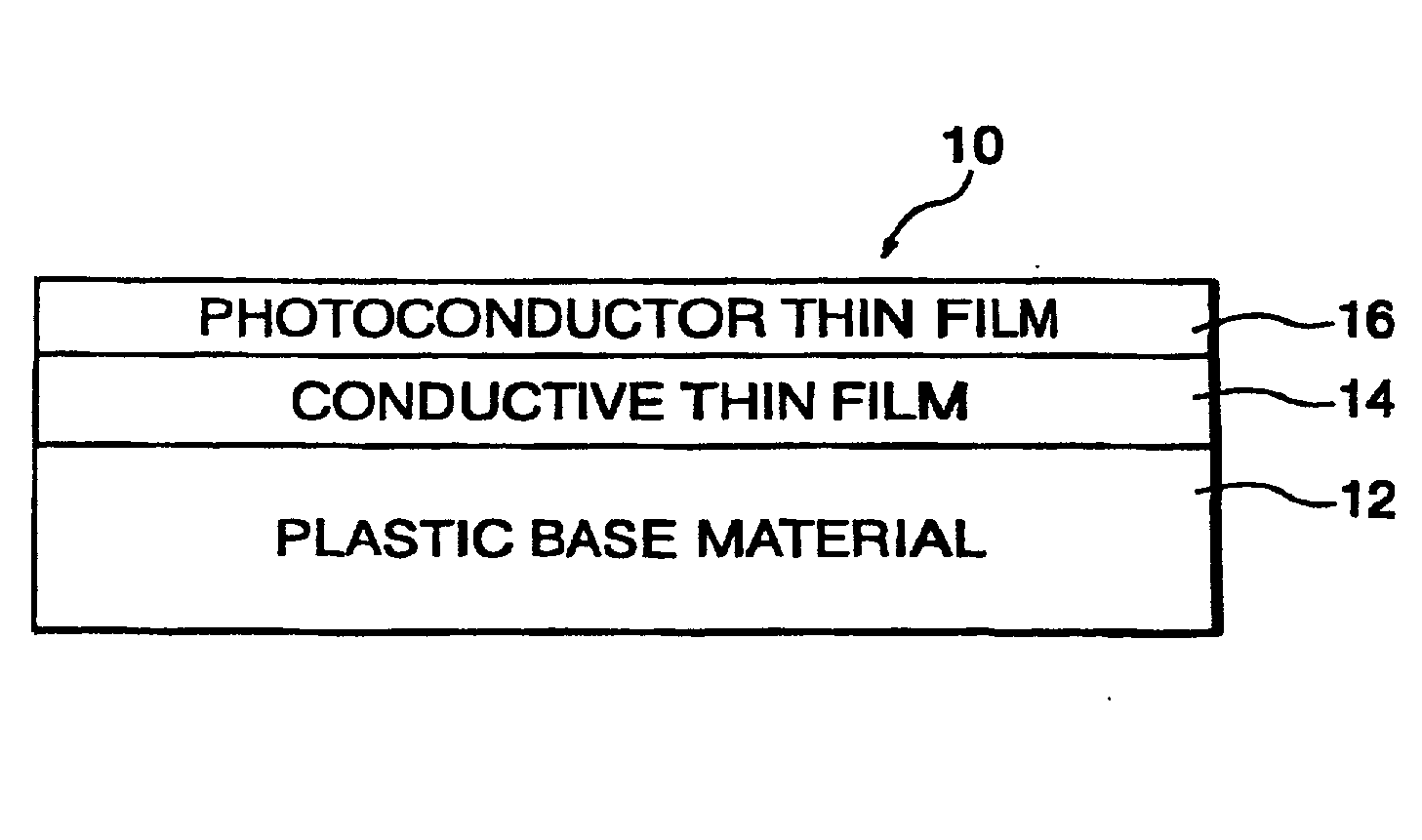

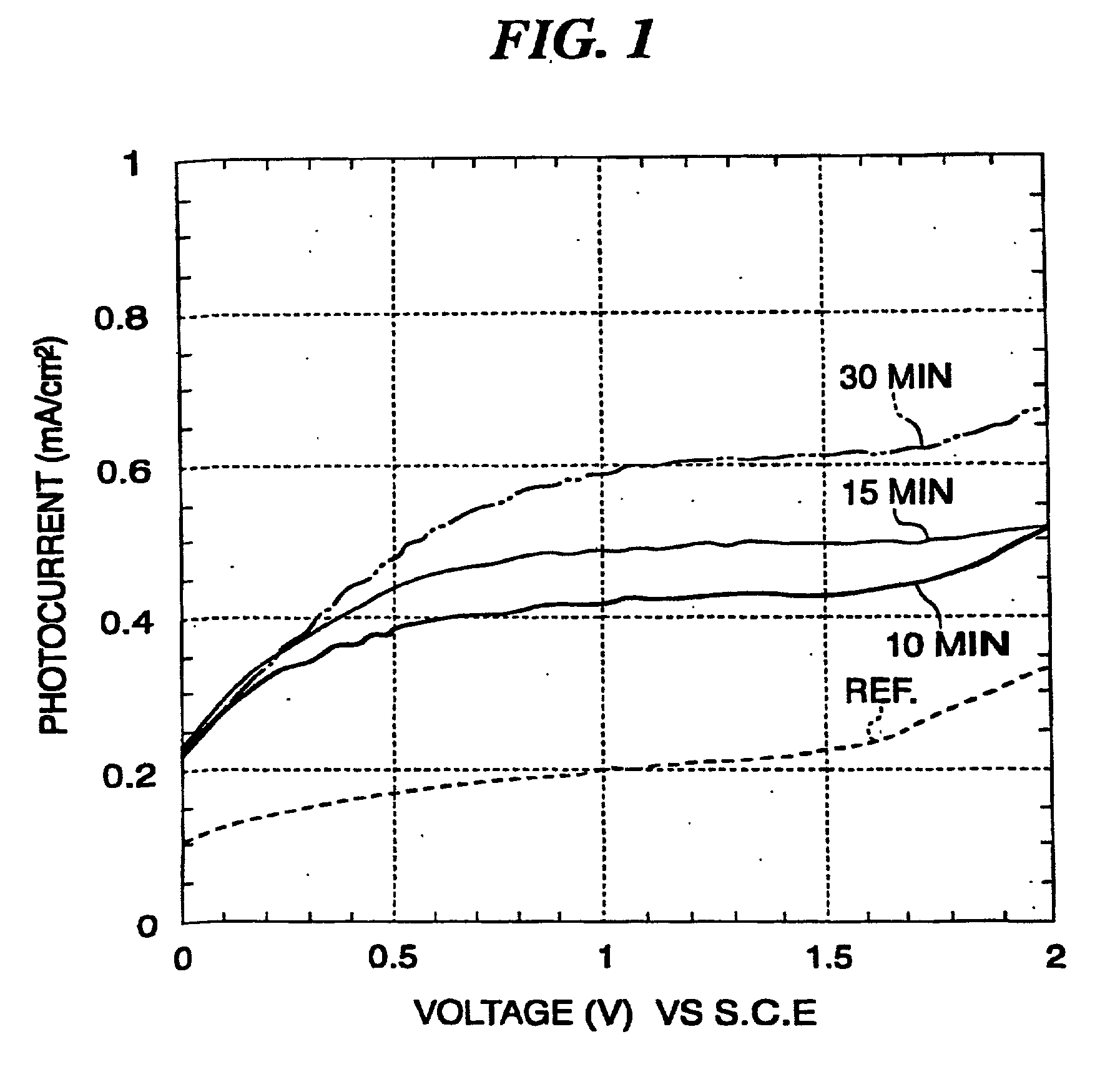

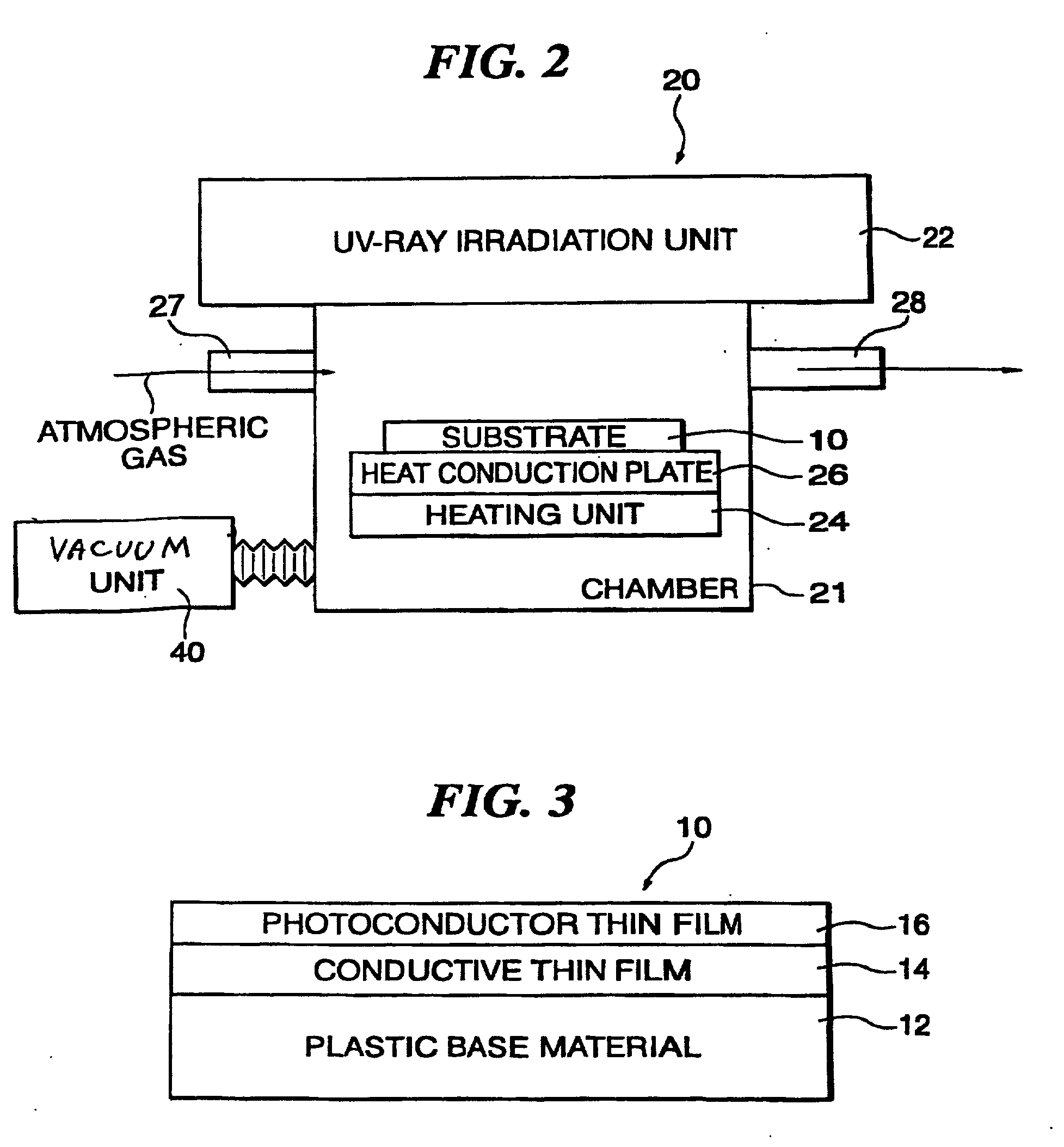

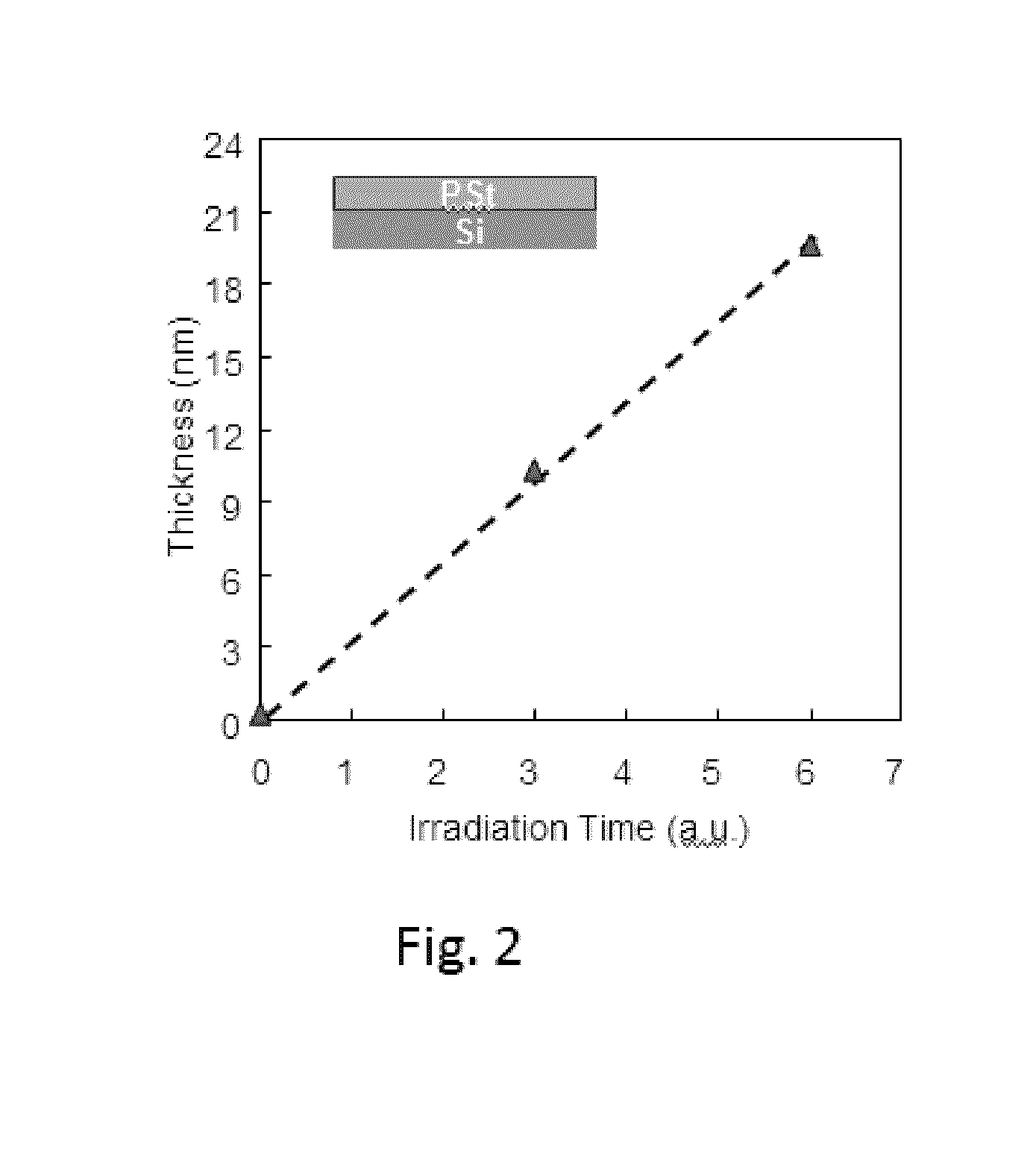

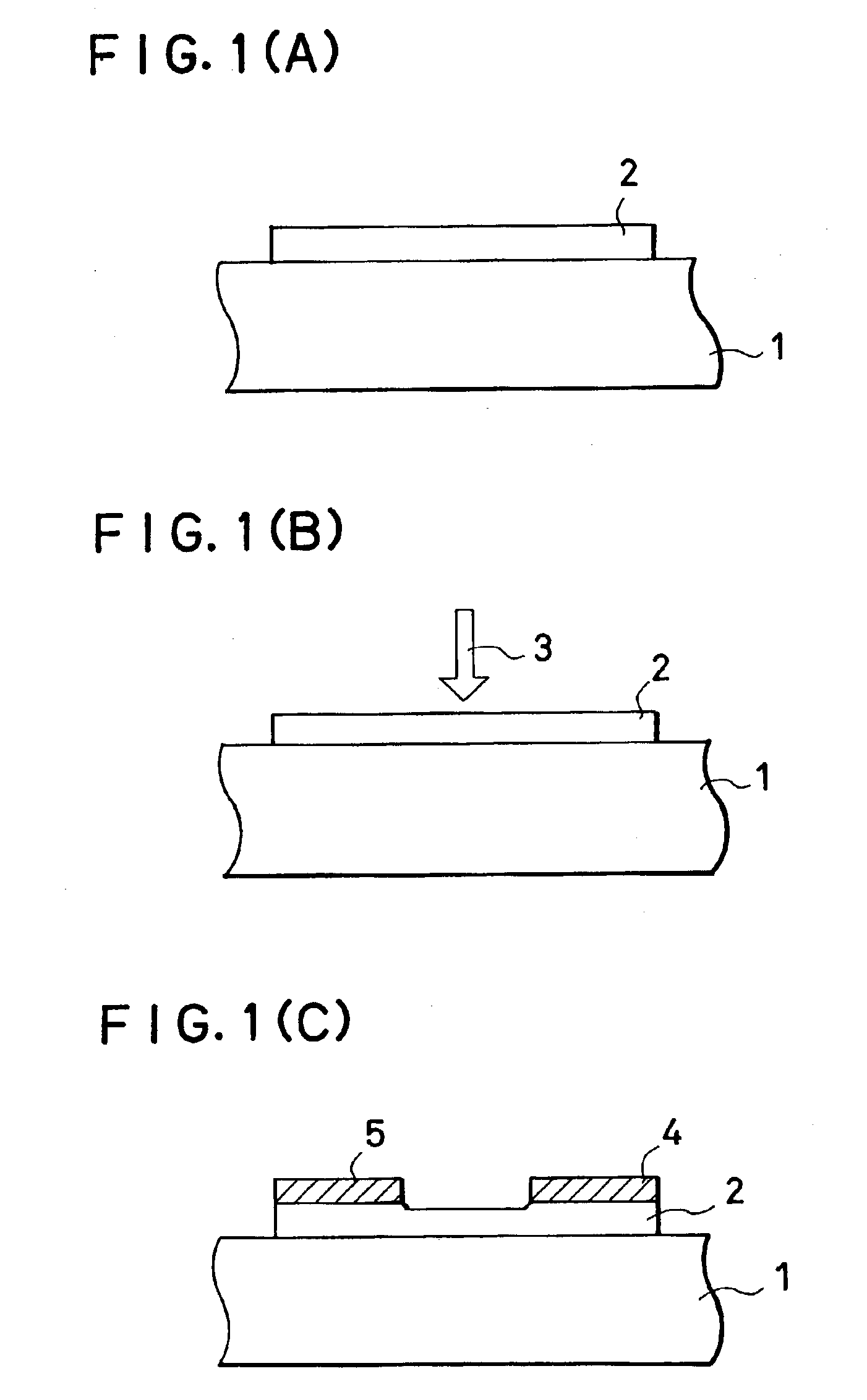

Method of forming crystalline semiconductor thin film on base substrate, lamination formed with crystalline semiconductor thin film and color filter

A method of forming a crystalline semiconductor thin film on a base material which can be prepared at a low temperature by simple step and device, the method including a processing step of applying UV-rays to an amorphous semiconductor thin film provided on a base material while keeping a temperature at not less than 25° C. and not more than 300° C. in a vacuum or a reducing gas atmosphere, as well as a substrate having the semiconductor thin film provided on the base material, a substrate for forming a color filter and a color filter using the substrate.

Owner:FUJIFILM BUSINESS INNOVATION CORP

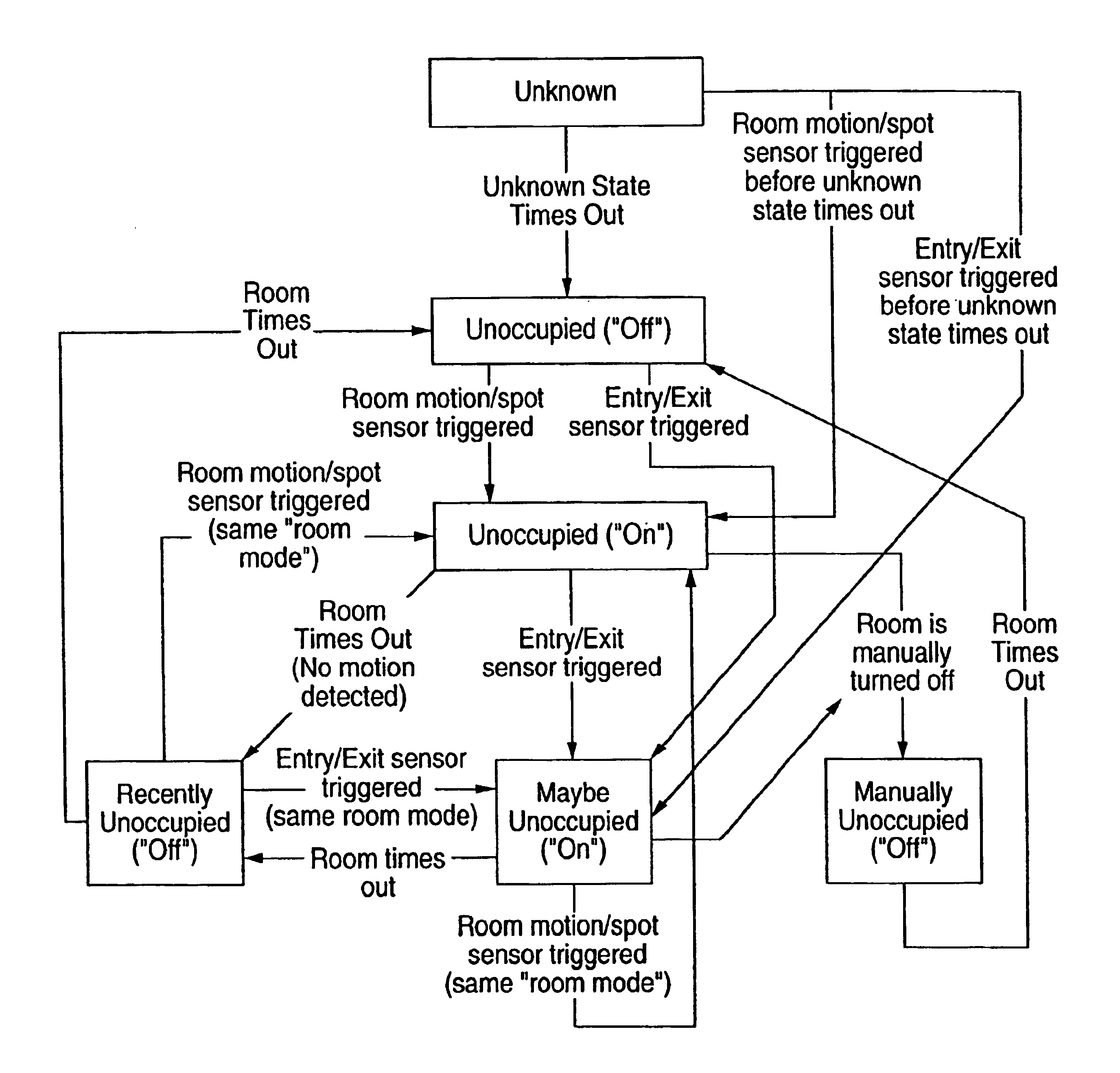

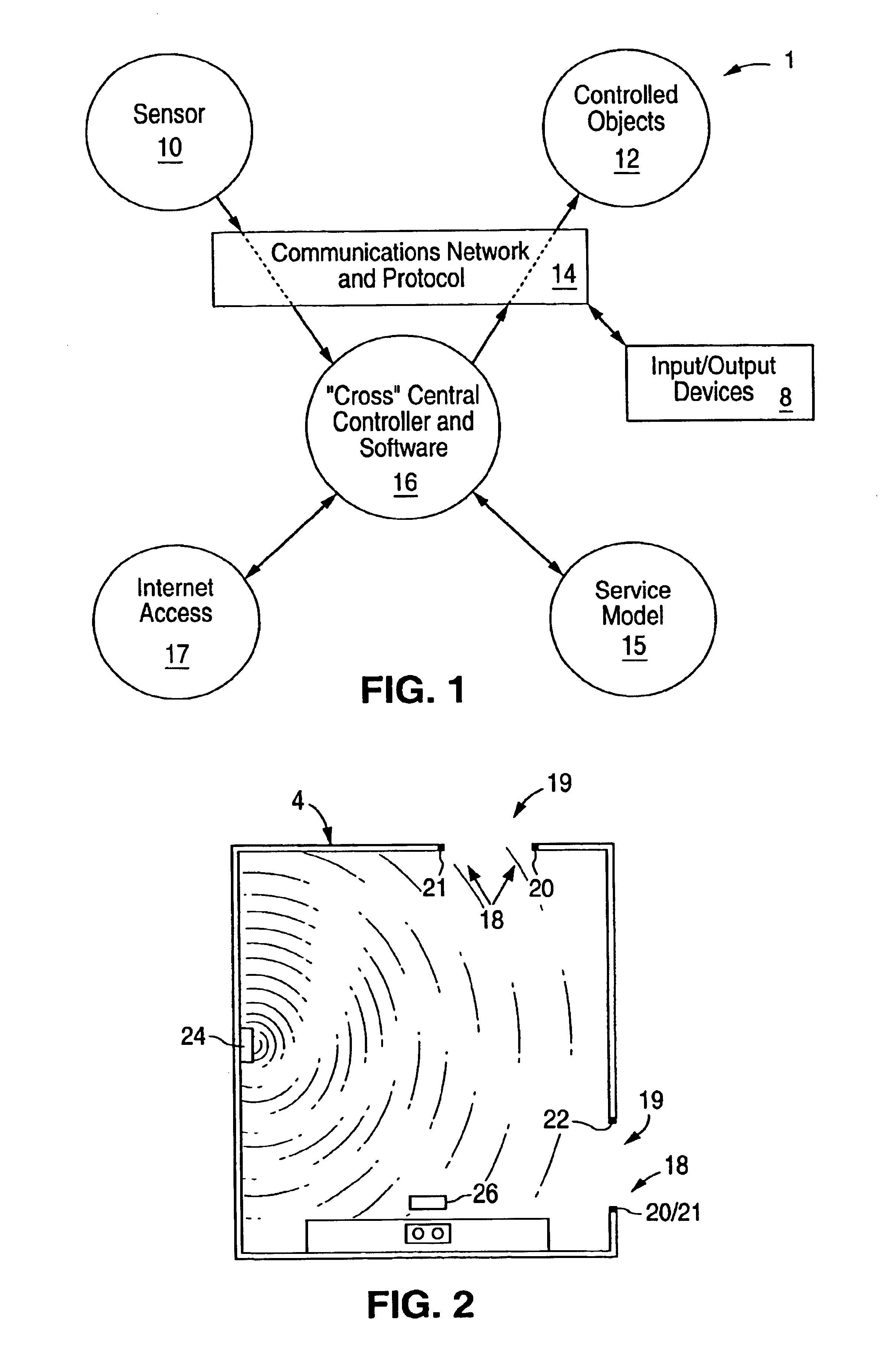

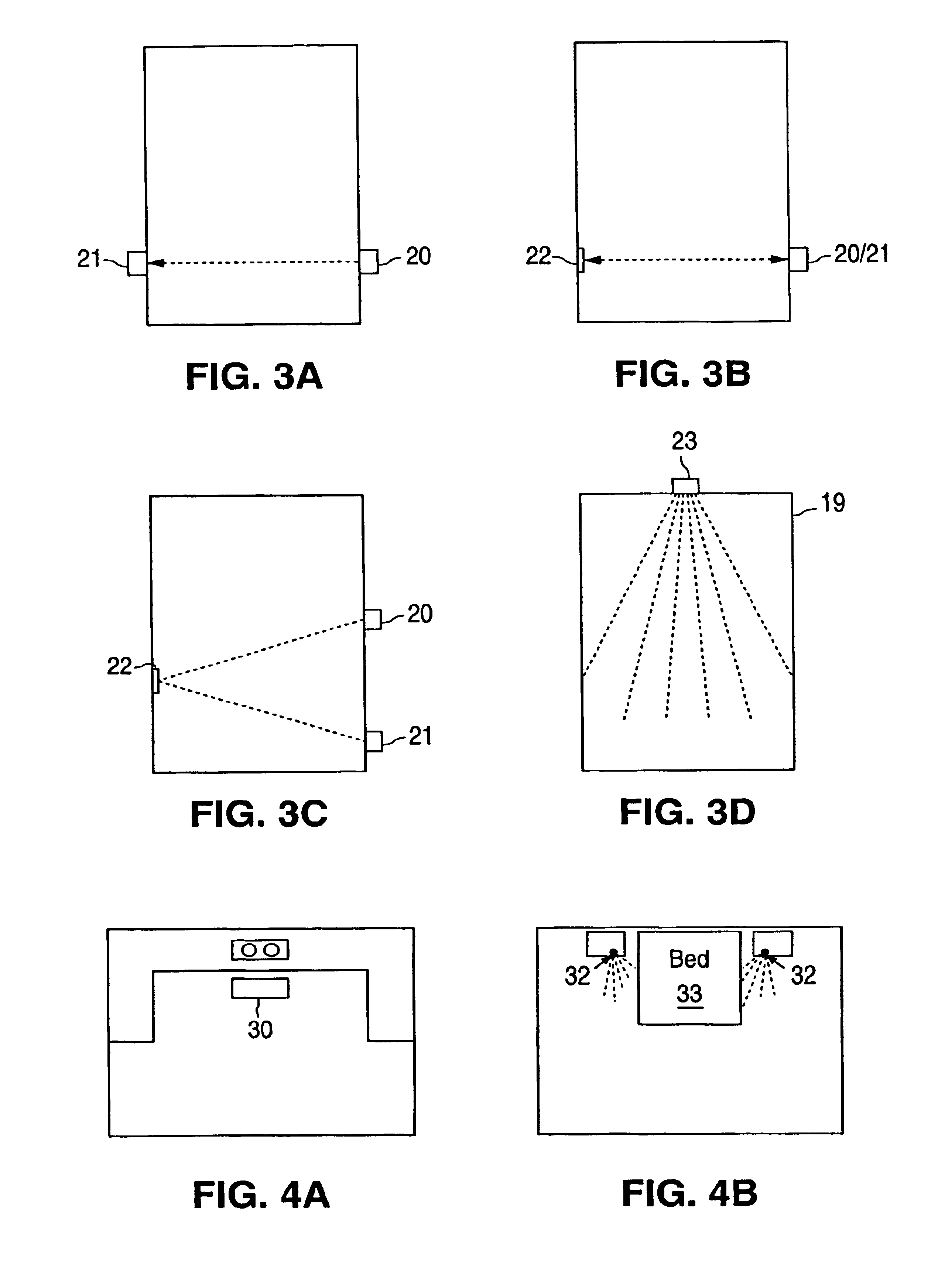

Home automation system and method

InactiveUS6912429B1Matches need and abilityImprove automationSpace heating and ventilationTemperatue controlAutomatic controlEngineering

A home automation system and method for automatic control of controlled devices throughout a home. A unique architecture of occupancy sensors includes entry / exit sensors for detecting movement through doorways that separate rooms in the home, room motion sensors for detecting room occupancy, spot sensors to detect occupancy of specific locations within the rooms, and house status sensors to detect the status of certain parameters of the home. A central controller communicates with the sensors and controlled objects over a communications network, where the sensors and controlled objects can be added to the system in a ‘plug and play’ manner. The central controller controls the controlled objects in response to the entry / exit sensors, room motion sensors, spot sensors and the house status sensors. This control is accomplished by assigning each room to one of a plurality of room occupancy states, and to one of a plurality of room modes for creating desired room atmospheres using the controlled objects, which both dictate how the controlled objects are controlled by the central controller. The room modes travel from room to room as the occupant moves throughout the home, and multiple occupants can be using different room modes as they move about the home. The controlled objects also have controlled object states, which are used by the central controller to control the controlled objects.

Owner:HOME DIRECTOR

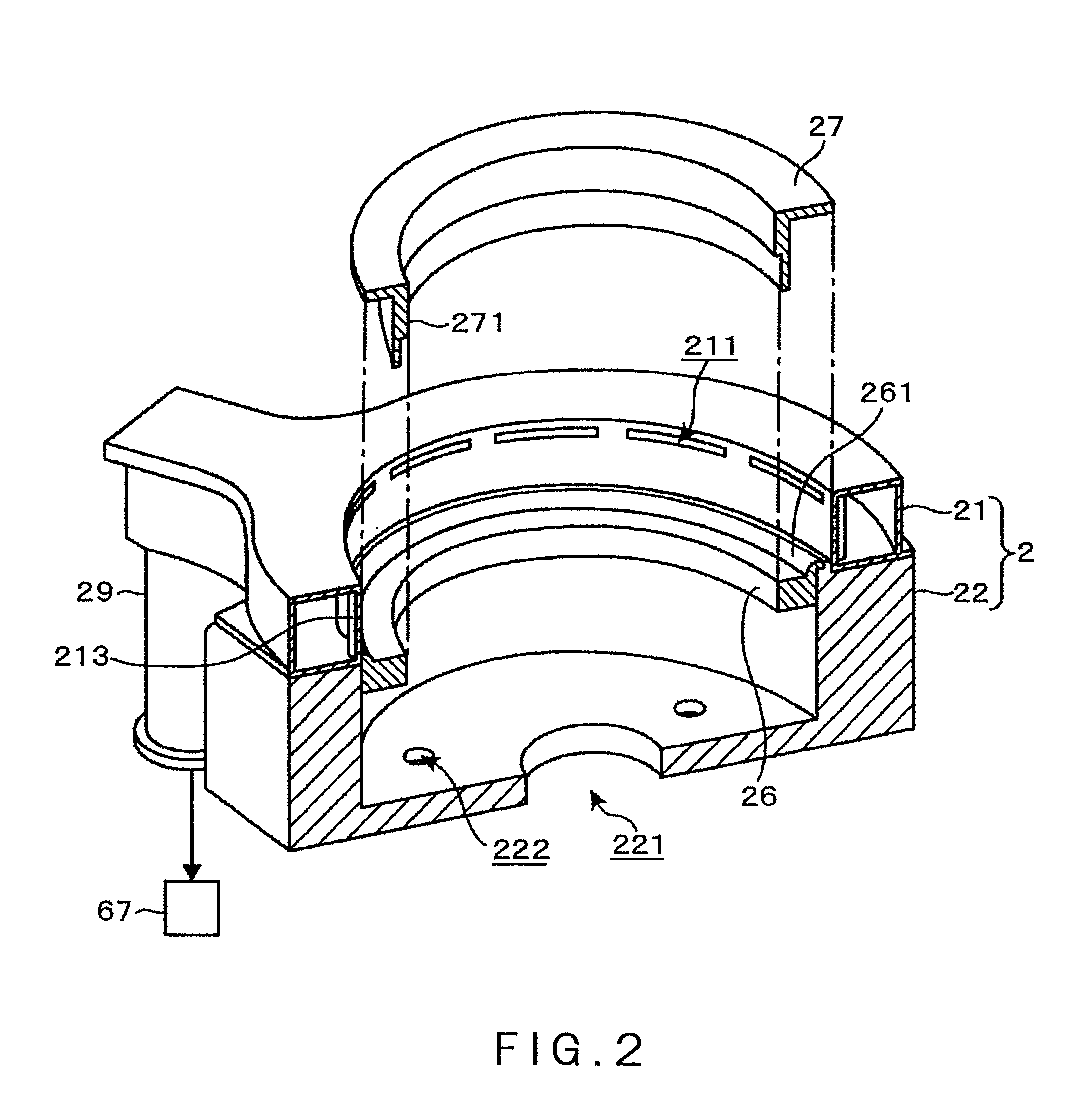

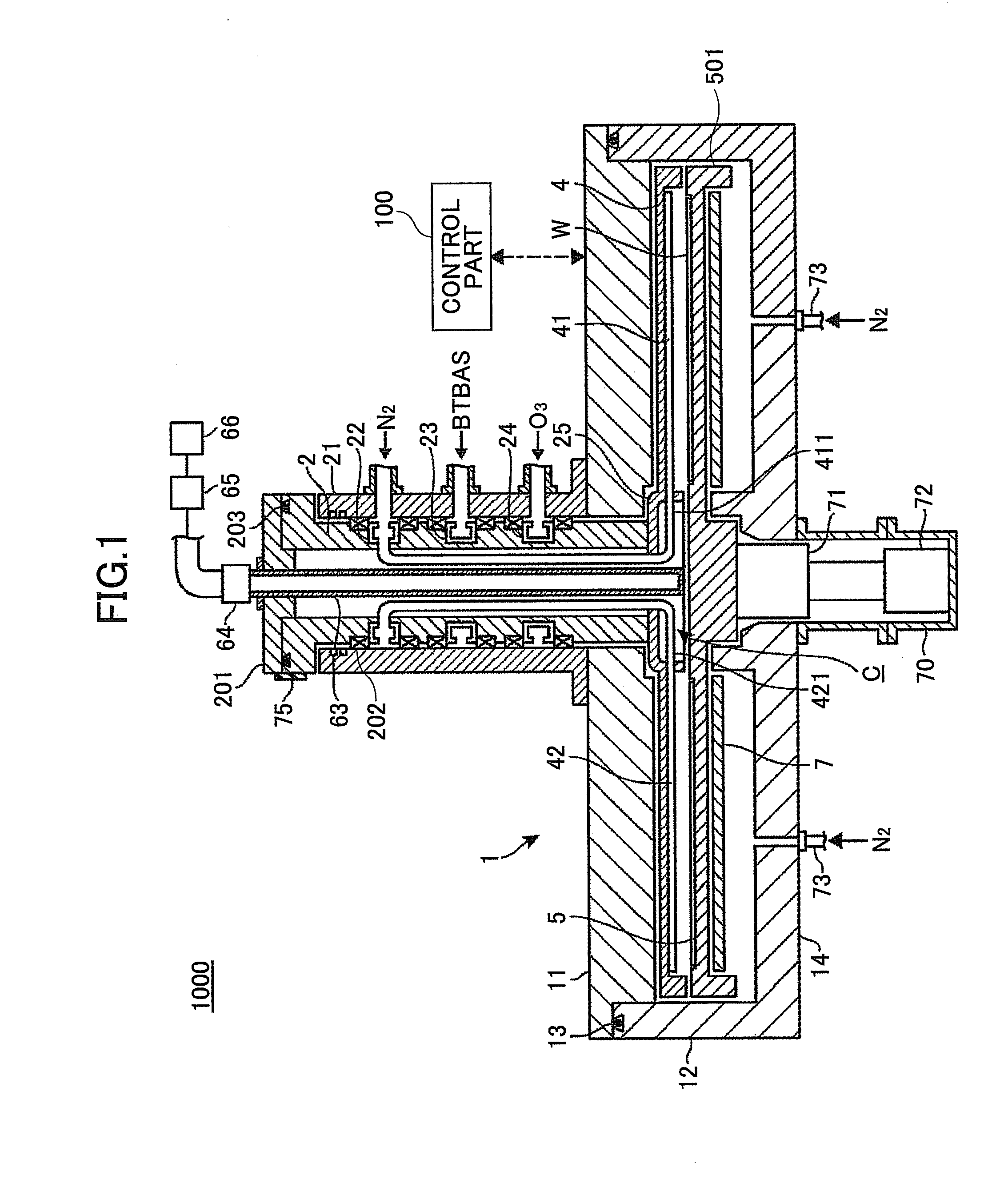

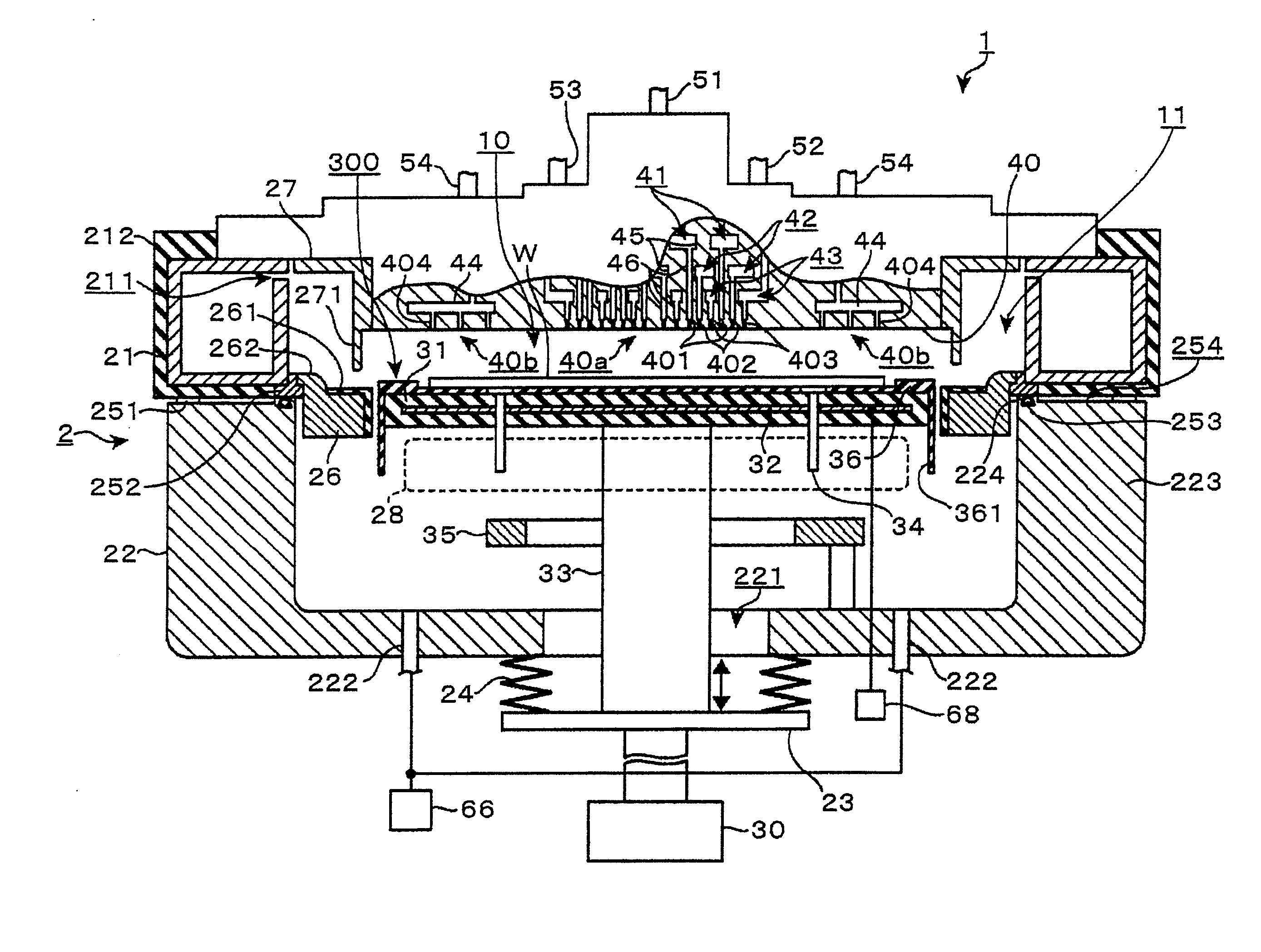

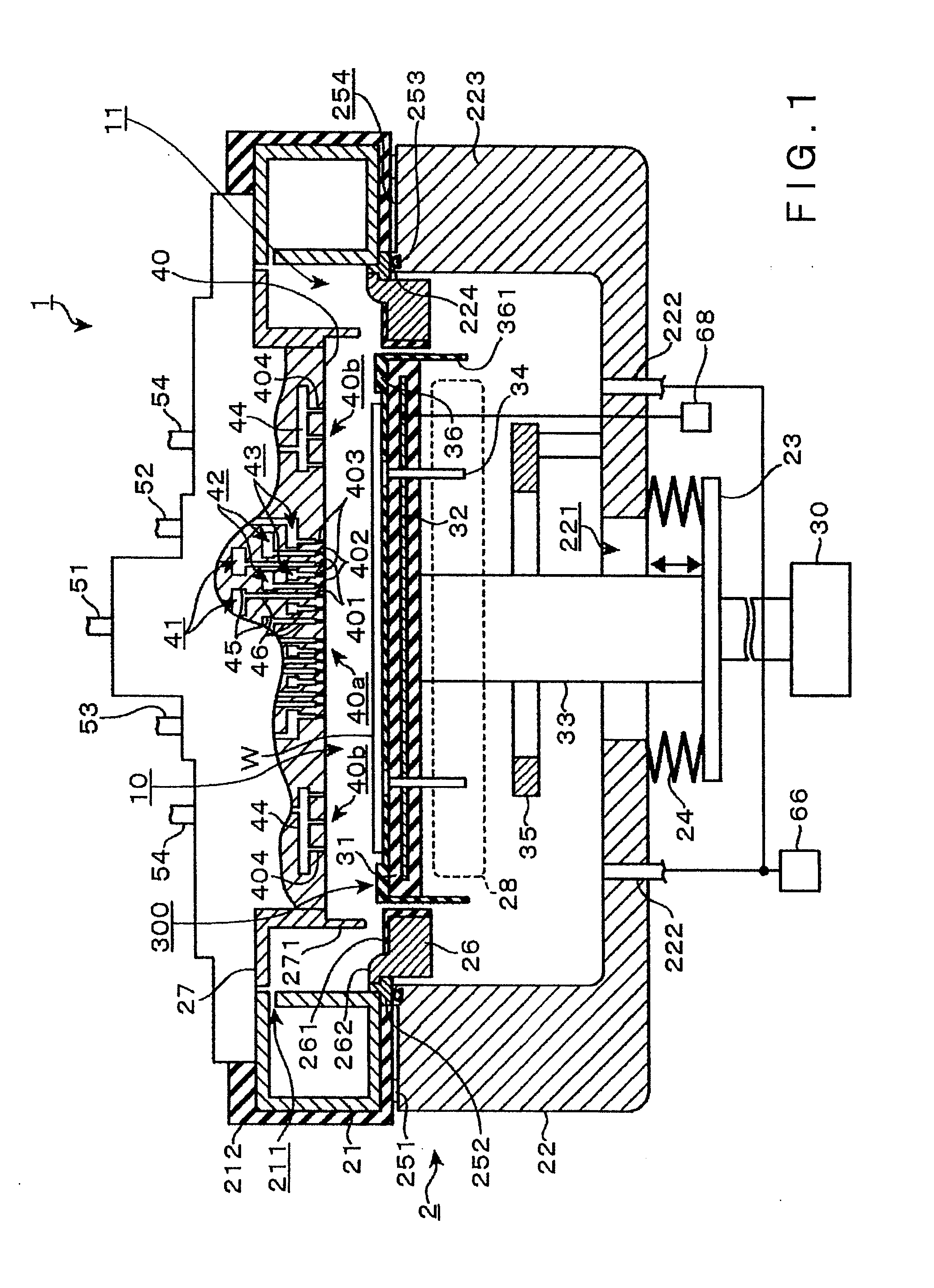

Film deposition apparatus and film deposition method

ActiveUS8506713B2Efficient solutionImprove uniformitySemiconductor/solid-state device manufacturingChemical vapor deposition coatingEngineeringDeposition process

Owner:TOKYO ELECTRON LTD

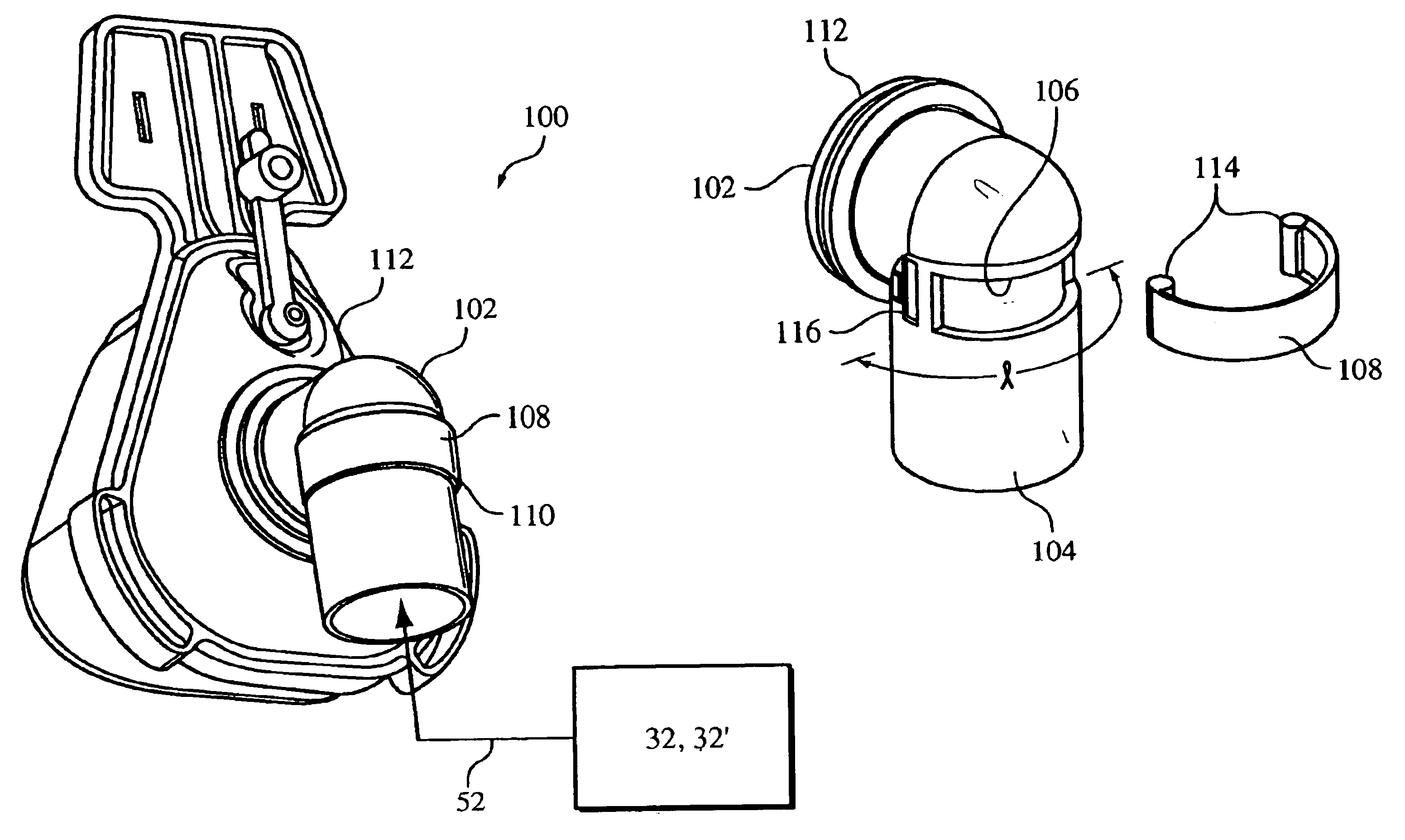

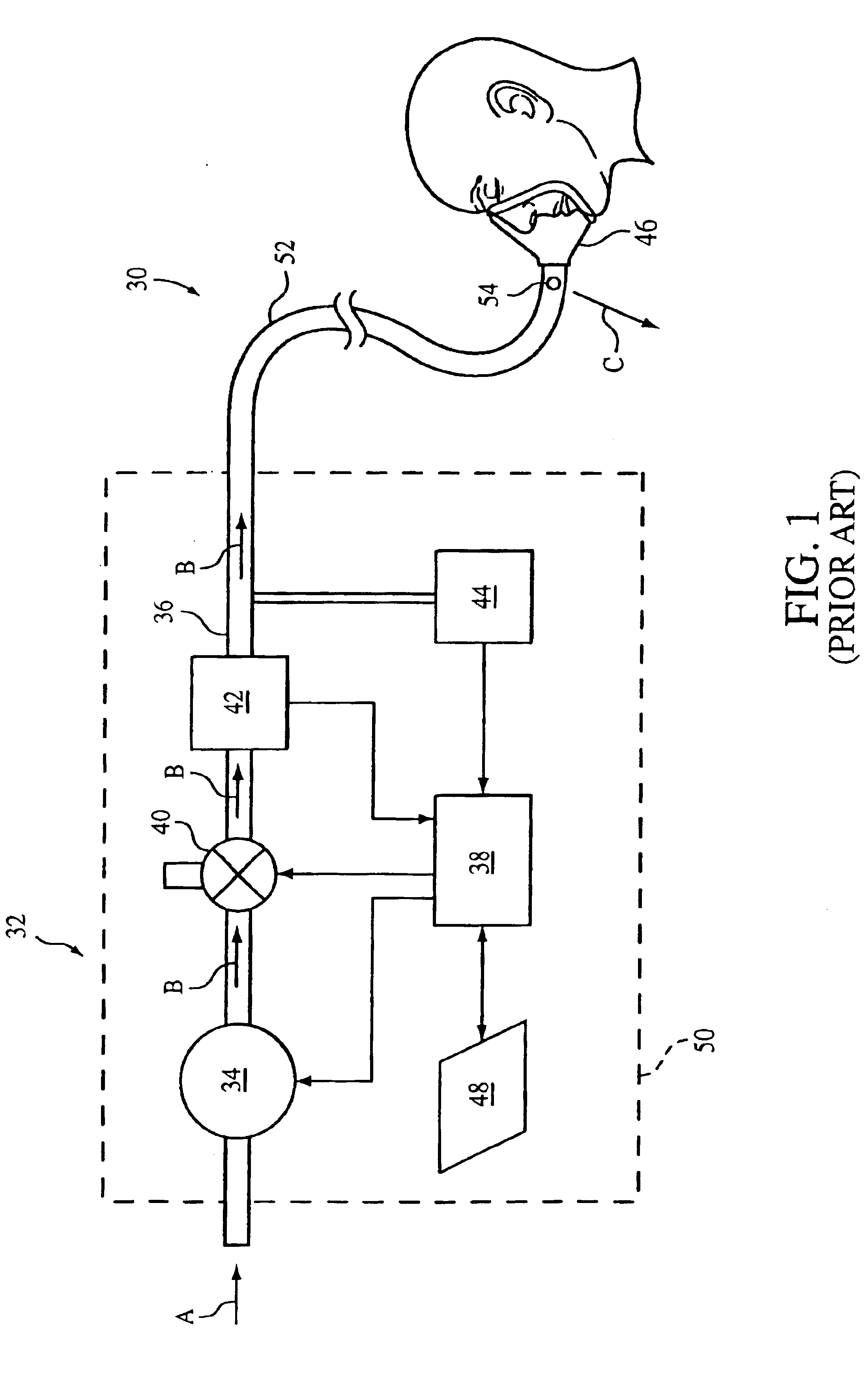

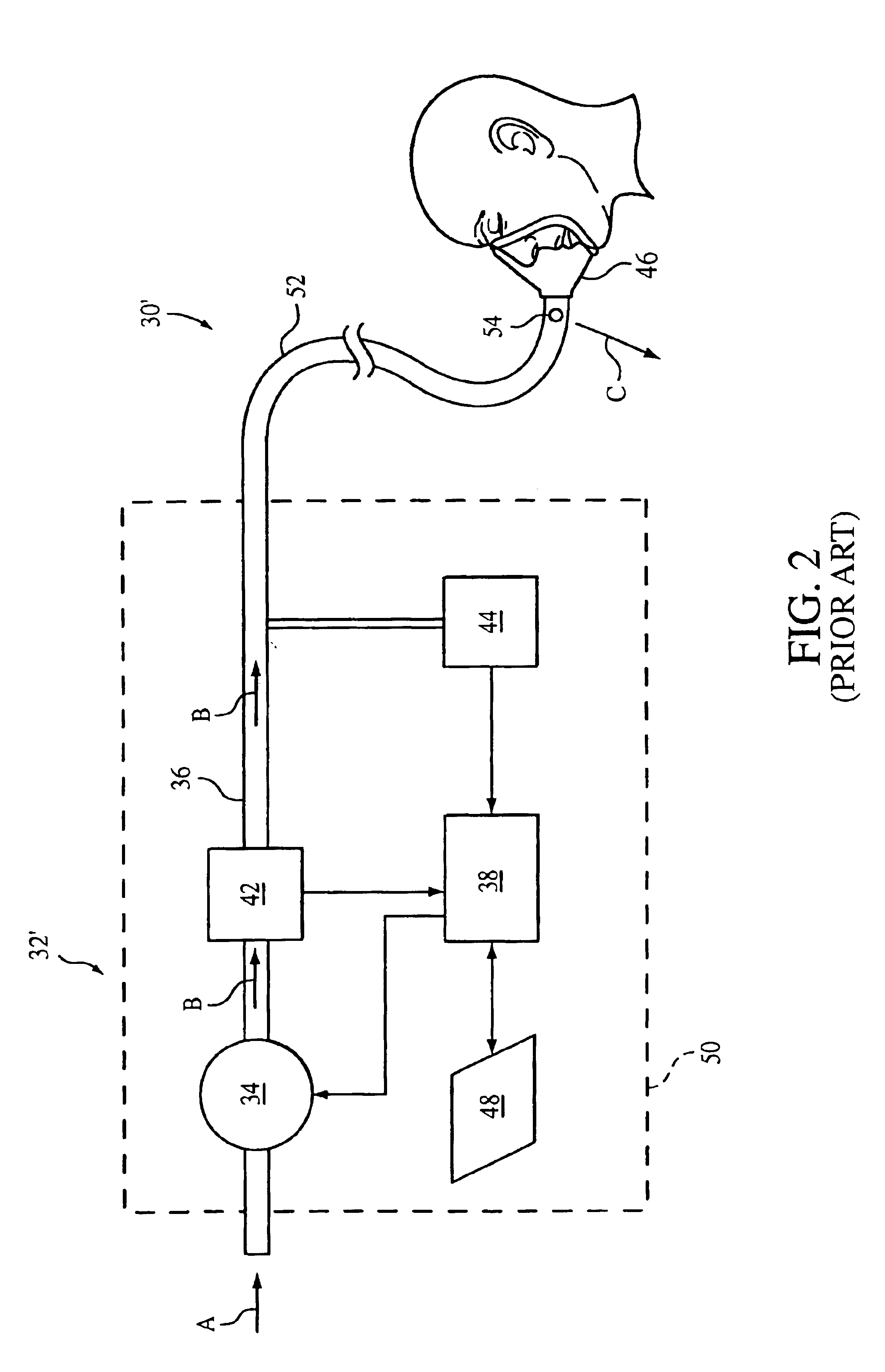

Exhaust port assembly for a pressure support system

InactiveUS6851425B2Noise minimizationArea minimizationBreathing masksRespiratory masksSupporting systemAtmospheric air

An exhaust port assembly comprising a conduit carries a flow of gas. A vent assembly having a fixed exhaust area is provided on the conduit for venting a flow of exhaust gas from within the conduit to ambient atmosphere. The vent assembly is configured so as to minimize noise associated with the flow of exhaust gas passing to atmosphere, diffuse the flow of exhaust gas passing to ambient atmosphere over a relatively large area, and minimize the area occupied by the venting assembly on the conduit.

Owner:RIC INVESTMENTS LLC

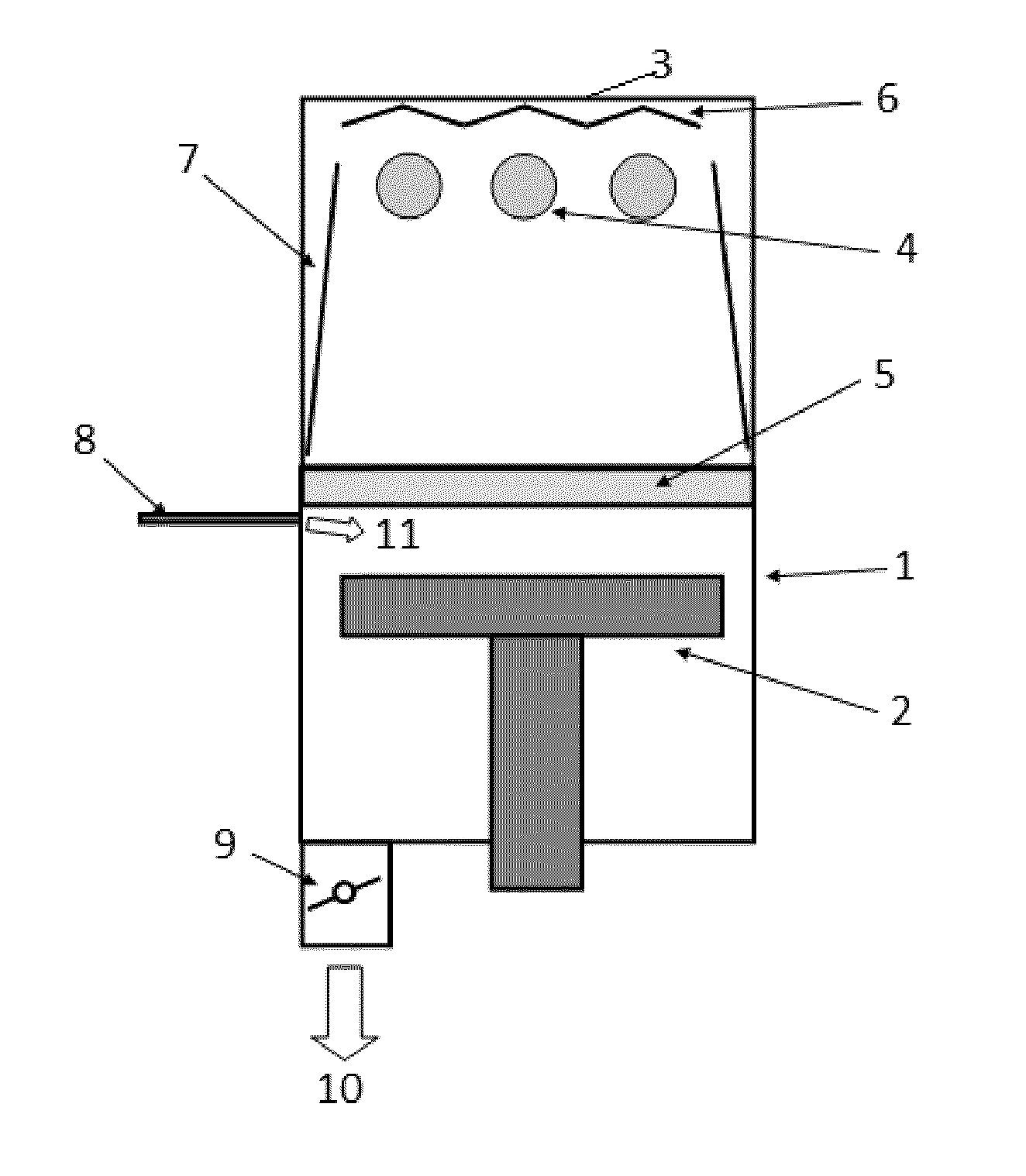

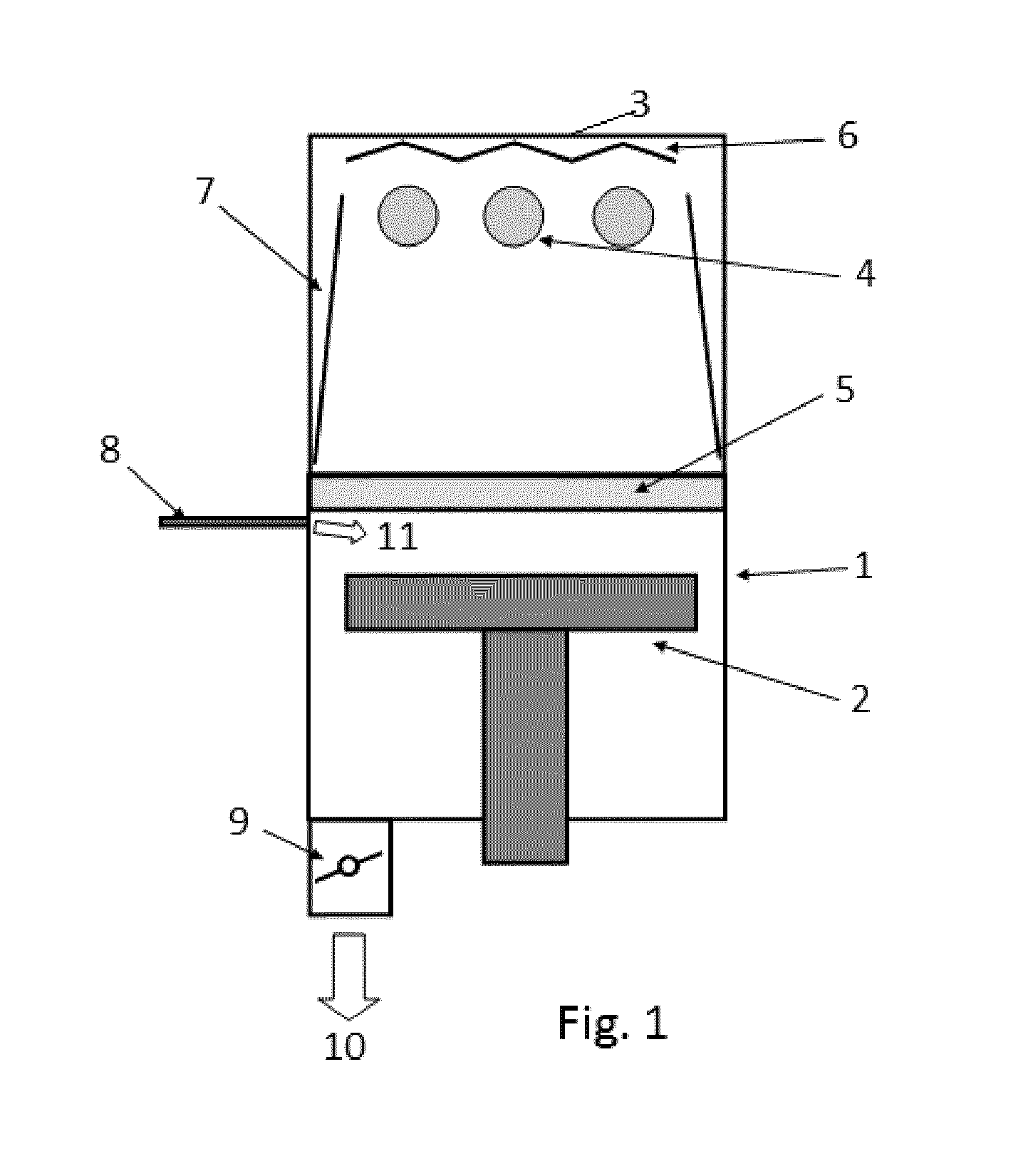

Method for Sealing Pores at Surface of Dielectric Layer by UV Light-Assisted CVD

InactiveUS20110159202A1Improve controllabilityReduce throughputPretreated surfacesSemiconductor/solid-state device manufacturingOptoelectronicsIrradiation

A method for sealing pores at a surface of a dielectric layer formed on a substrate, includes: providing a substrate on which a dielectric layer having a porous surface is formed as an outermost layer; placing the substrate in an evacuatable chamber; irradiating the substrate with UV light in an atmosphere of hydrocarbon and / or oxy-hydrocarbon gas; sealing pores at the porous surface of the dielectric layer as a result of the irradiation; and continuously irradiating the substrate with UV light in the atmosphere of hydrocarbon and / or oxy-hydrocarbon gas until a protective film having a desired thickness is formed on the dielectric layer as a result of the irradiation.

Owner:ASM JAPAN

Chamber material made of Al alloy and heater block

InactiveUS20010019777A1Not be restrictElectric discharge tubesSemiconductor/solid-state device manufacturingHigh-temperature corrosionContamination

A chamber material made of Al alloy excellent in thermal cracking resistance and chemical and / or physical corrosion resistance and capable of reducing contamination excellently and further having excellent and wide applicable brazing property in a high temperature corrosive circumstance, in which the substrate aluminum material for the chamber material made of Al alloy having an anodized film comprises 0.1 to 2.0% Si, 0.1 to 3.5% Mg, 0.02 to 4.0% Cu on the mass % basis and the balance of Al and impurity element with Cr in the impurity elements being less than 0.04%. Preferably, Fe is 0.1% or less and Mn is 0.04% or less in the impurity element and, further, the total sum of impurity elements other than Cr and Mn being restricted to 0.1$ or less. This invention can be utilized suitably to various materials used in high temperature corrosive circumstance, particularly, in high temperature corrosive gas or plasma atmosphere.

Owner:KOBE STEEL LTD

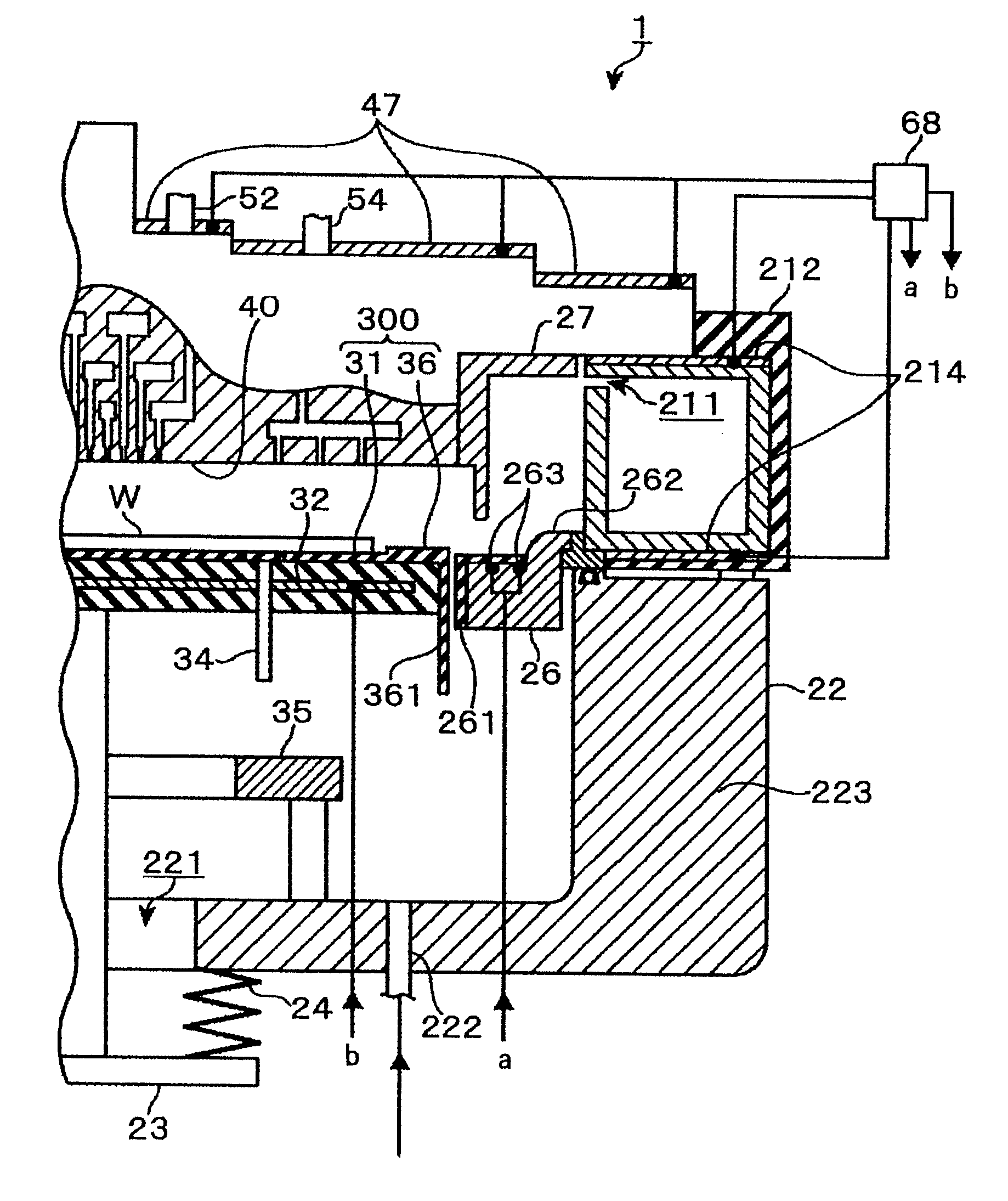

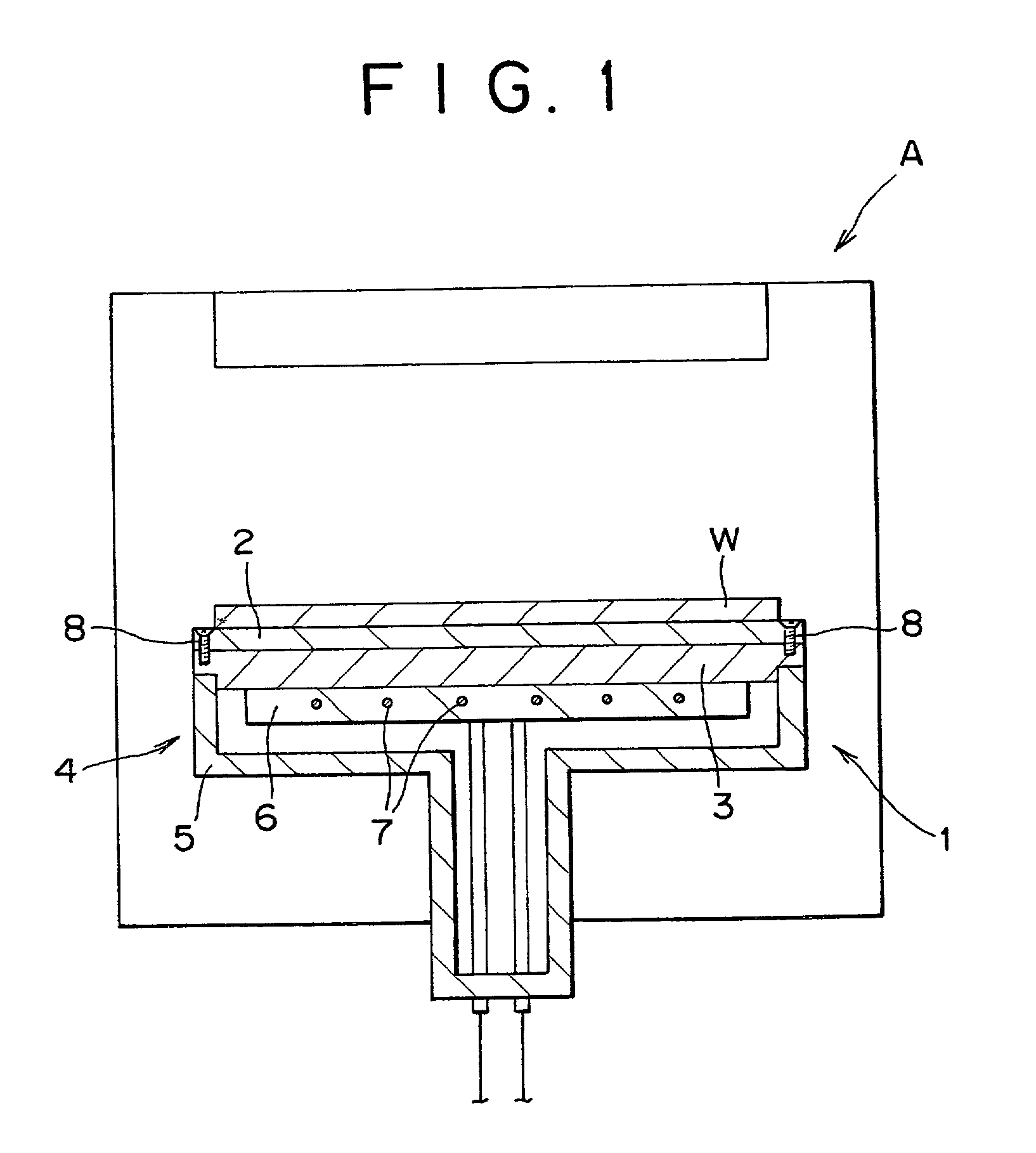

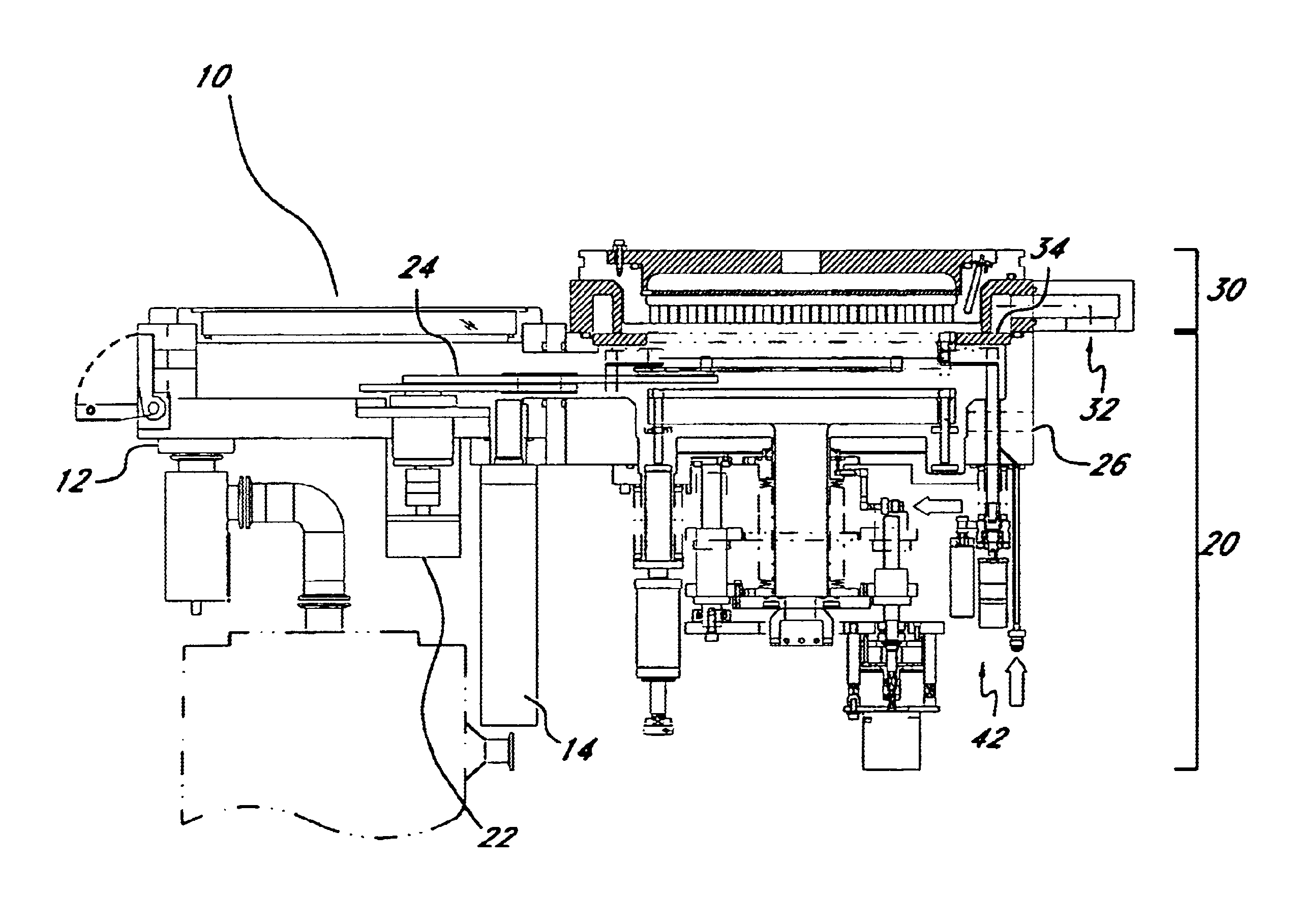

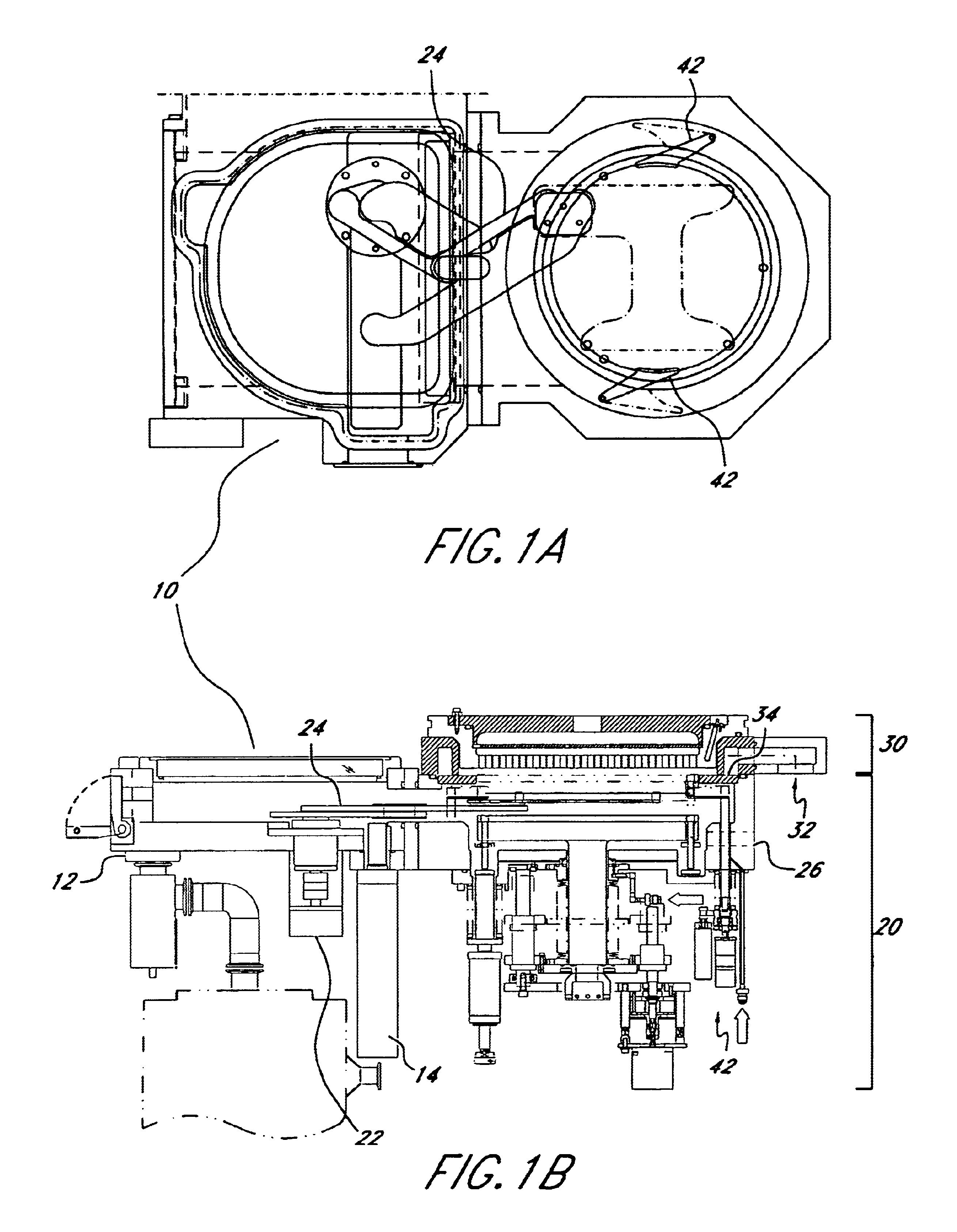

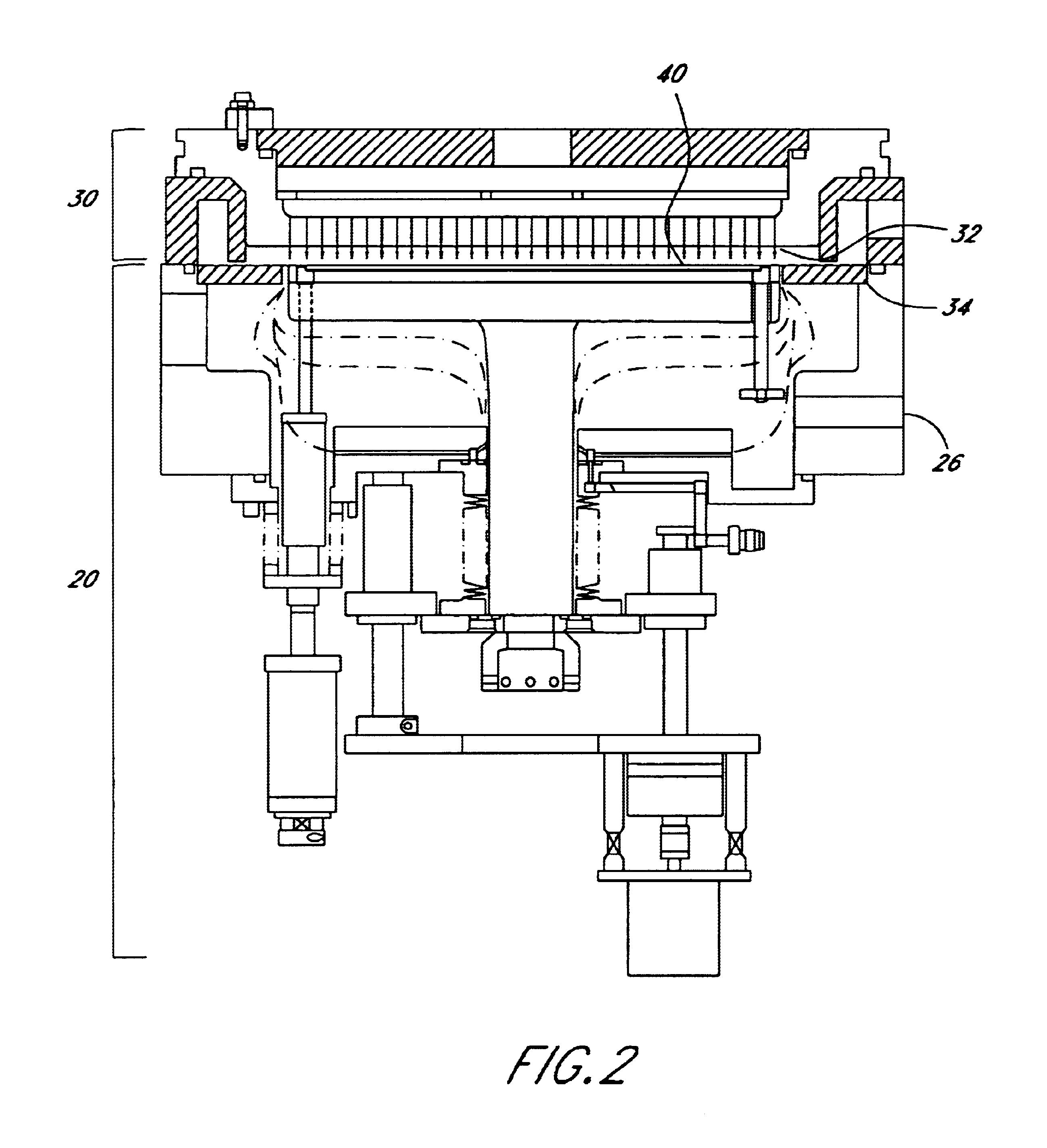

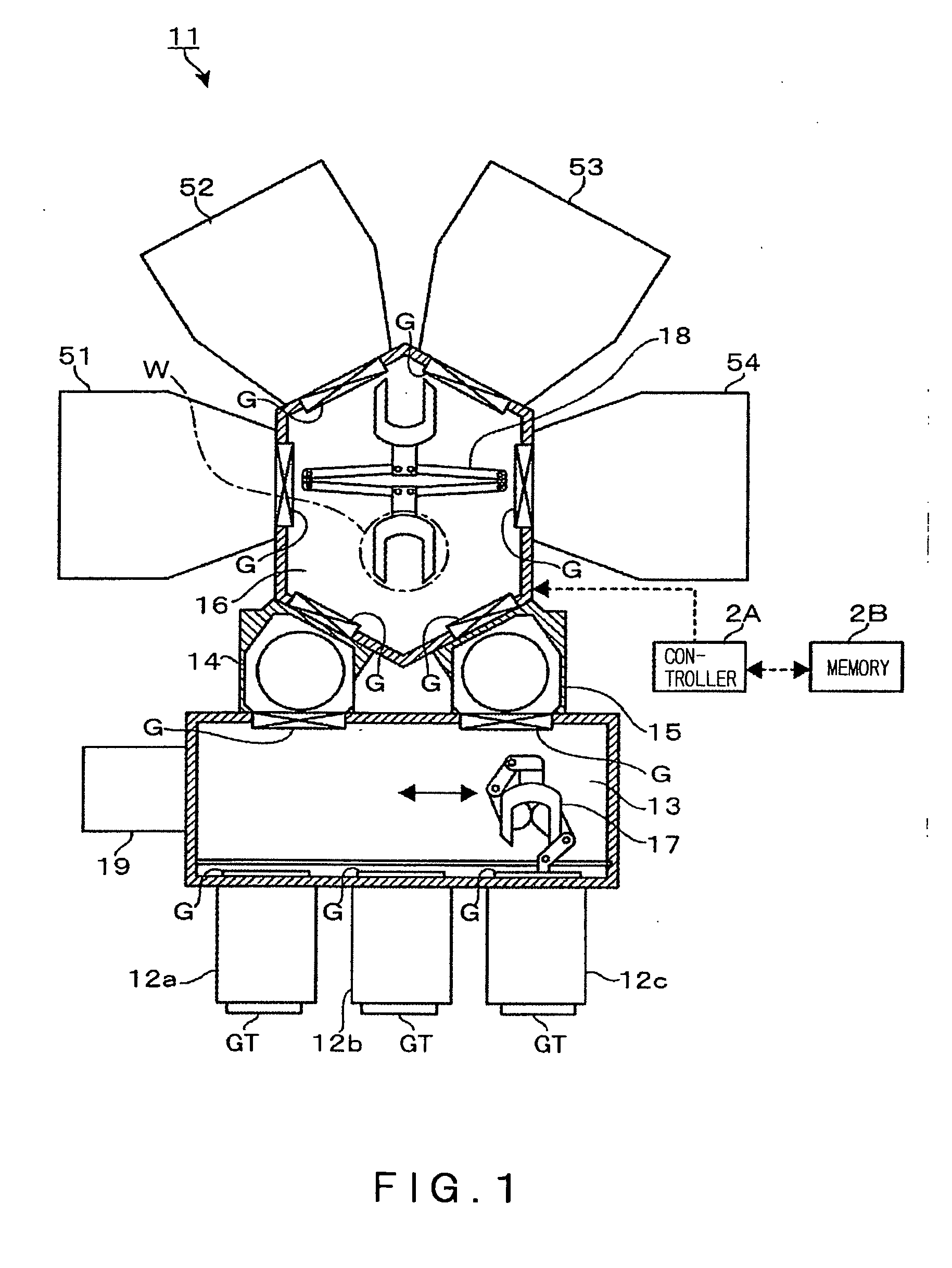

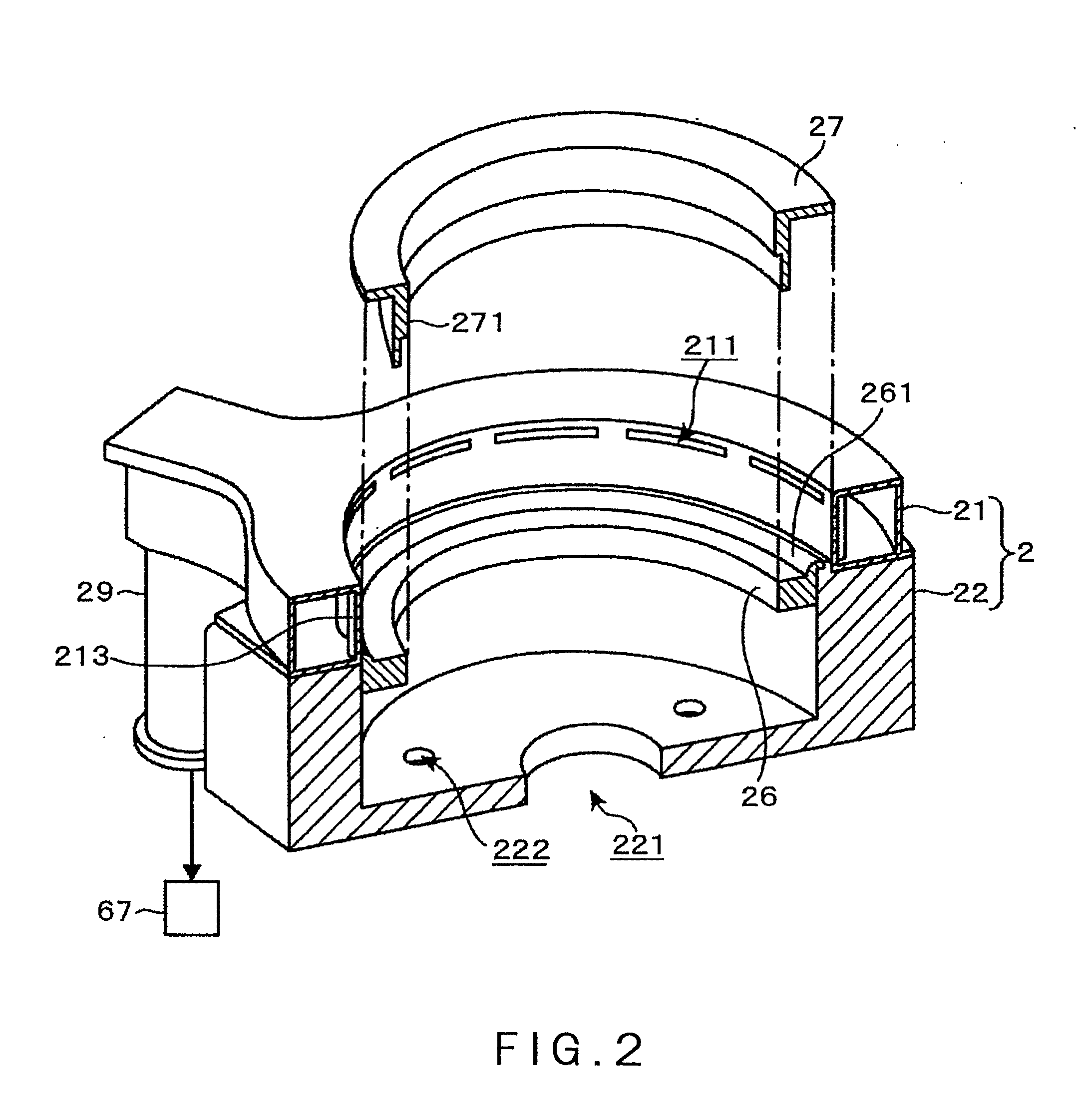

Semiconductor processing apparatus comprising chamber partitioned into reaction and transfer sections

InactiveUS6899507B2Reduce adhesionImprove efficiencySemiconductor/solid-state device manufacturingCharge manipulationEngineeringSemiconductor

Semiconductor processing equipment that has increased efficiency, throughput, and stability, as well as reduced operating cost, footprint, and faceprint is provided. Other than during deposition, the atmosphere of both the reaction chamber and the transfer chamber are evacuated using the transfer chamber exhaust port, which is located below the surface of the semiconductor wafer. This configuration prevents particles generated during wafer transfer or during deposition from adhering to the surface of the semiconductor wafer. Additionally, by introducing a purge gas into the transfer chamber during deposition, and by using an insulation separating plate 34, the atmospheres of the transfer and reaction chambers can be effectively isolated from each other, thereby preventing deposition on the walls and components of the transfer chamber. Finally, the configuration described herein permits a wafer buffer mechanism to be used with the semiconductor processing equipment, thereby further increasing throughput and efficiency.

Owner:ASM JAPAN

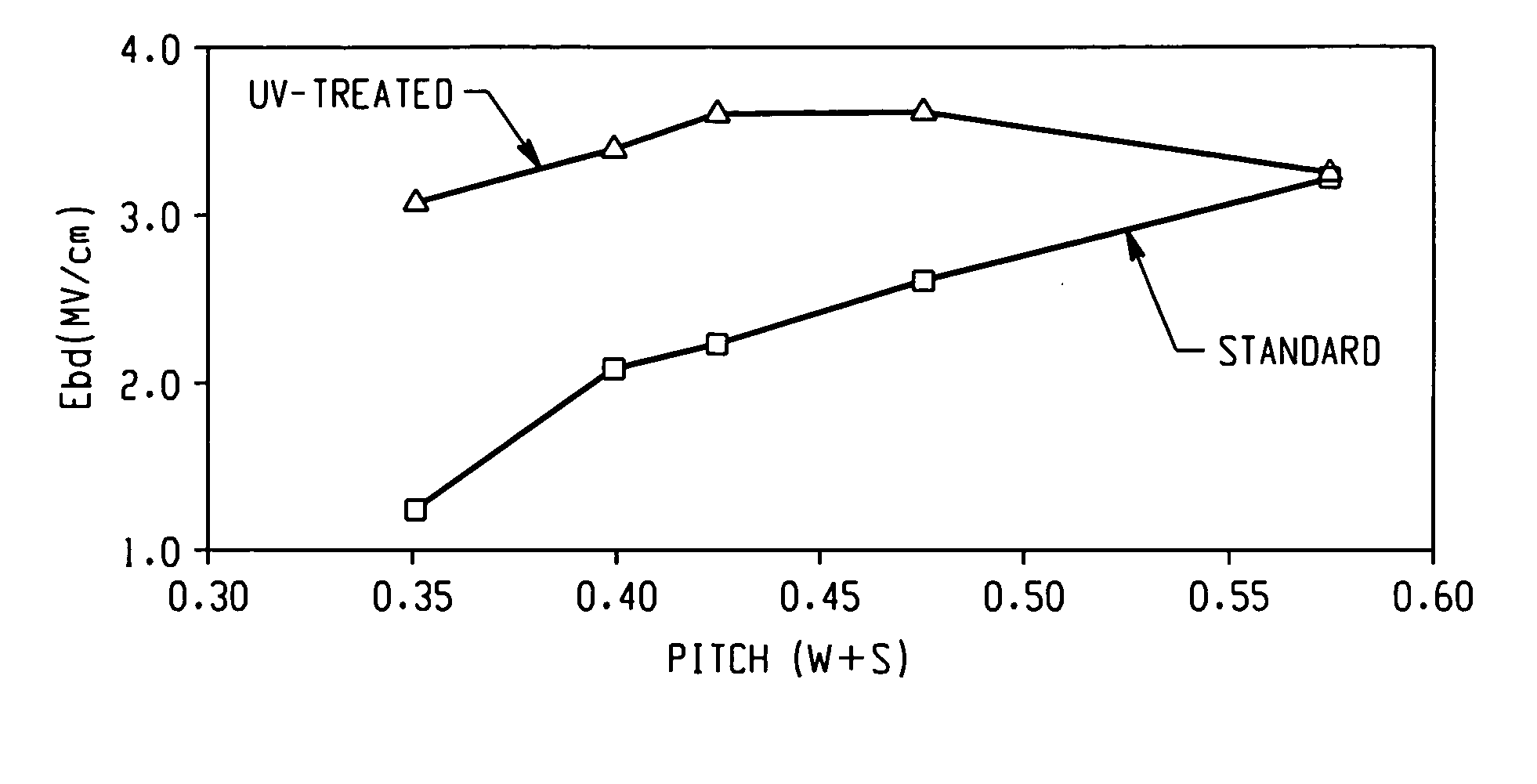

Ultraviolet assisted pore sealing of porous low k dielectric films

InactiveUS20060105566A1Semiconductor/solid-state device manufacturingChemical vapor deposition coatingAtmospheric airCarbonization

Processes for sealing porous low k dielectric film generally comprises exposing the porous surface of the porous low k dielectric film to ultraviolet (UV) radiation at intensities, times, wavelengths and in an atmosphere effective to seal the porous dielectric surface by means of carbonization, oxidation, and / or film densification. The surface of the surface of the porous low k material is sealed to a depth less than or equal to about 20 nanometers, wherein the surface is substantially free of pores after the UV exposure.

Owner:AXCELIS TECHNOLOGIES

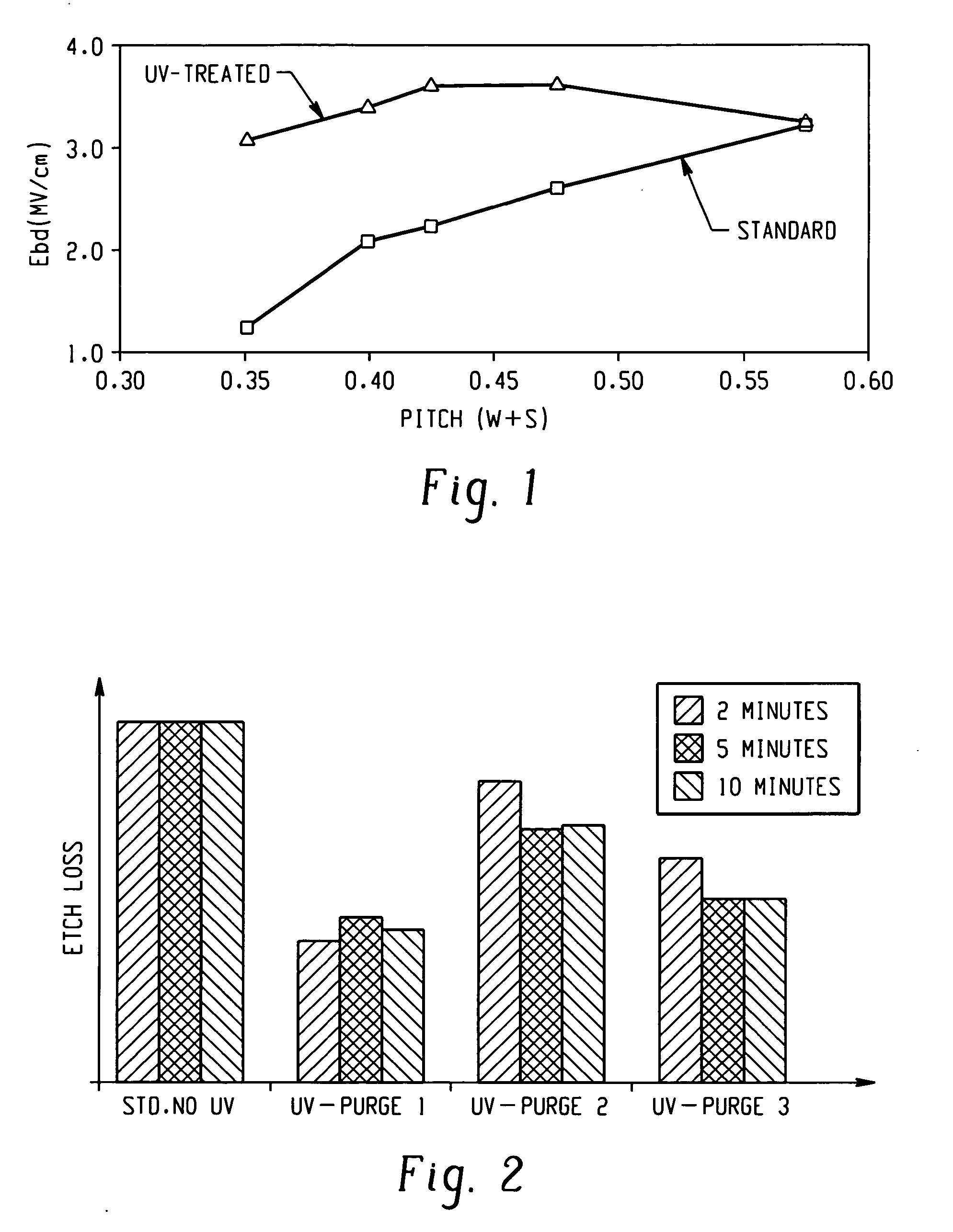

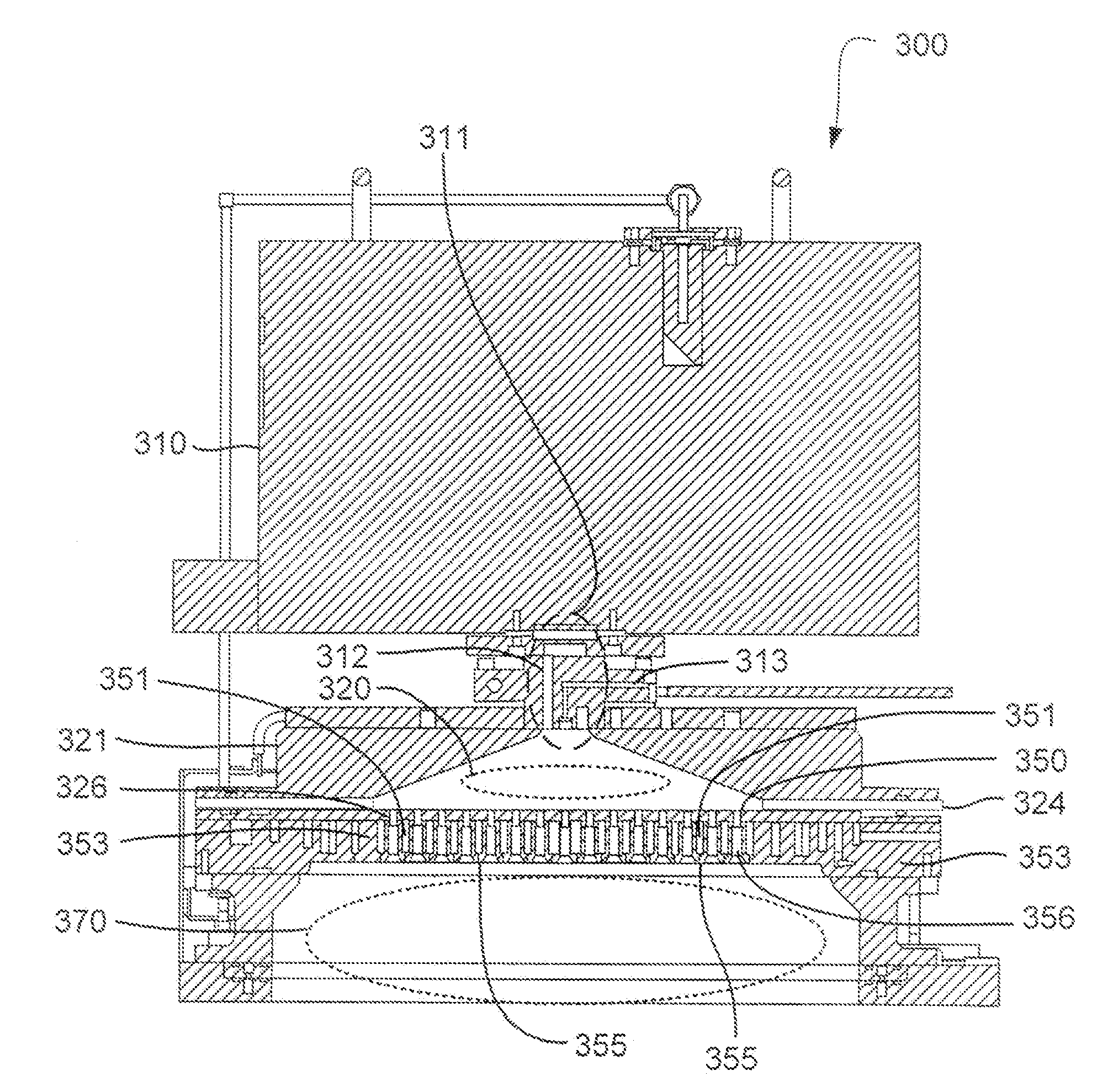

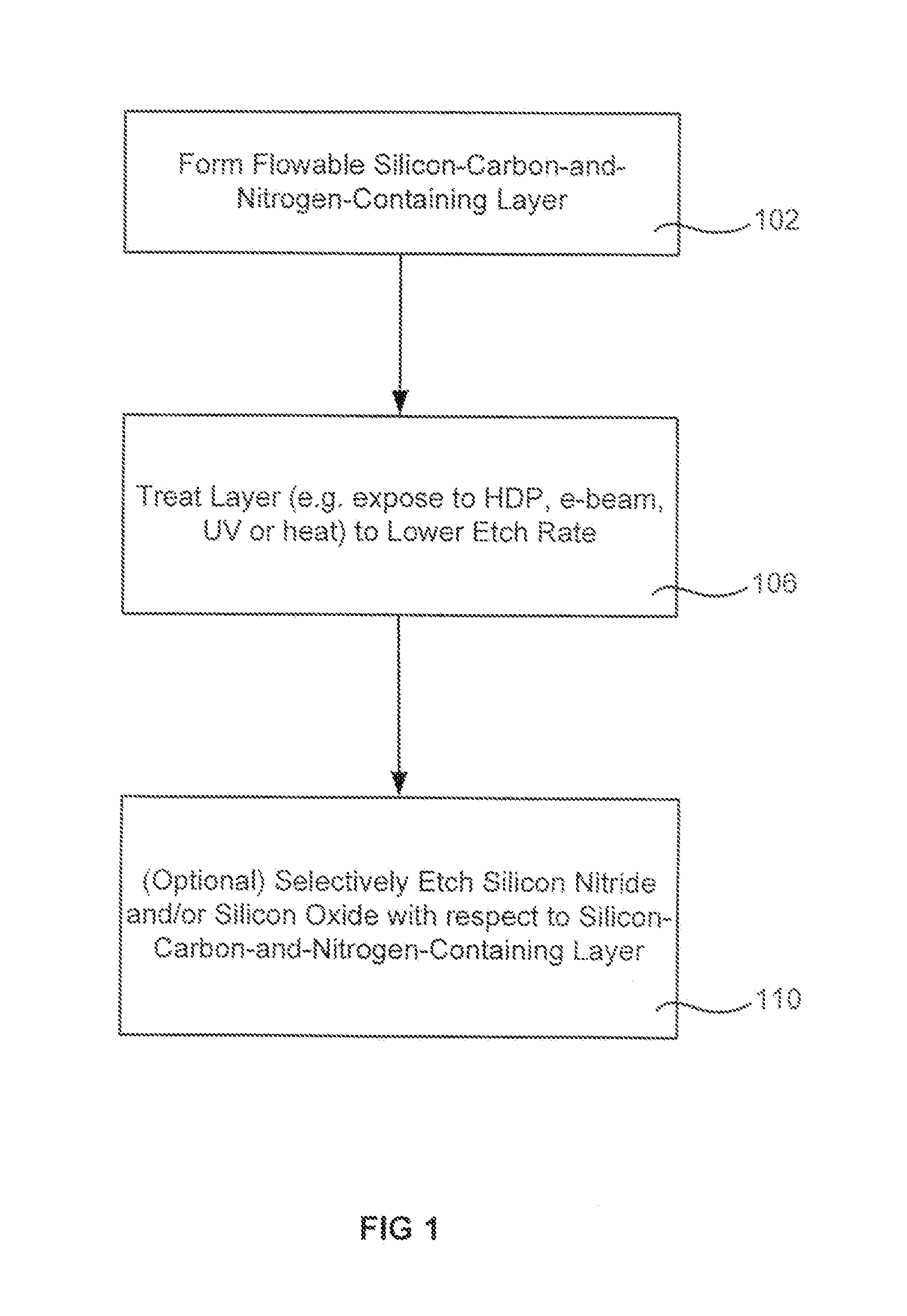

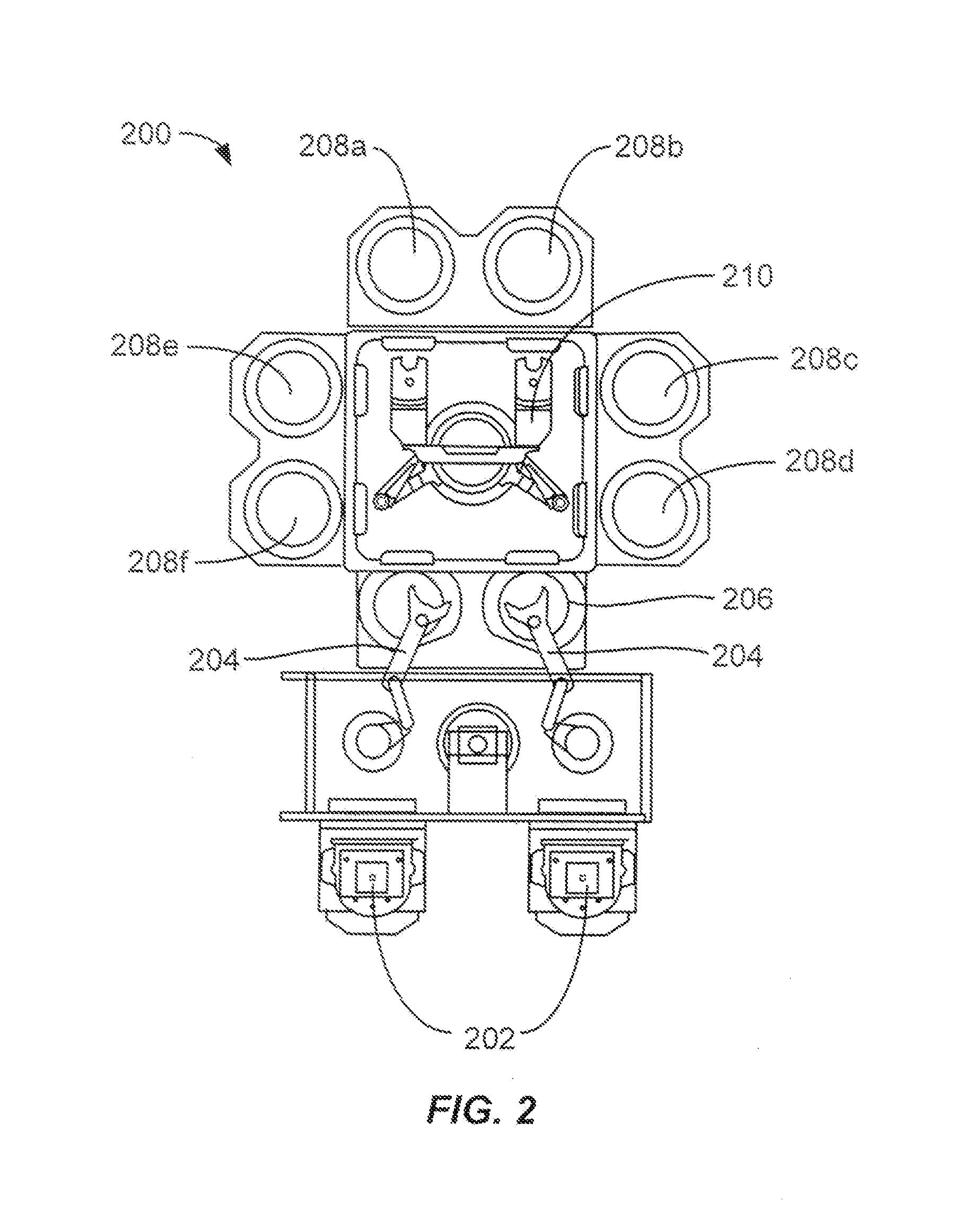

Treatments for decreasing etch rates after flowable deposition of silicon-carbon-and-nitrogen-containing layers

InactiveUS20130217241A1Excellent etch resistanceFilm property decreaseSemiconductor/solid-state device manufacturingNitrogenSemiconductor

Methods are described for forming and curing a flowable silicon-carbon-and-nitrogen-containing layer on a semiconductor substrate. The silicon and carbon constituents may come from a silicon and carbon containing precursor while the nitrogen may come from a nitrogen-containing precursor that has been activated to speed the reaction of the nitrogen with the silicon-and-carbon-containing precursor at lower deposition chamber temperatures. The initially-flowable silicon-carbon-and-nitrogen-containing layer is treated to remove components which enabled the flowability, but are no longer needed after deposition. Removal of the components increases etch resistance in order to allow the gapfill silicon-carbon-and-nitrogen-containing layer to remain intact during subsequent processing. The treatments have been found to decrease the evolution of properties of the film upon exposure to atmosphere.

Owner:APPLIED MATERIALS INC

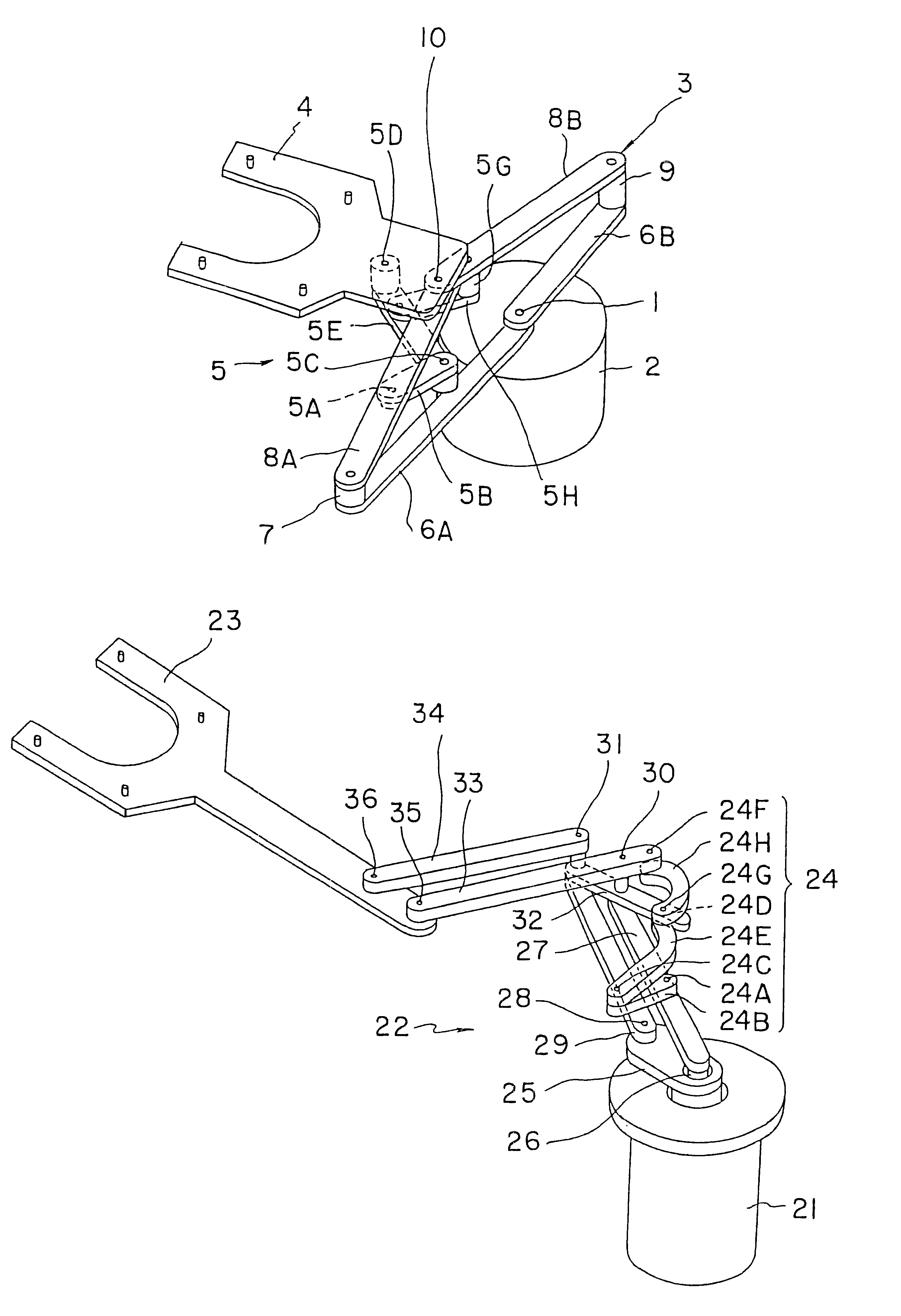

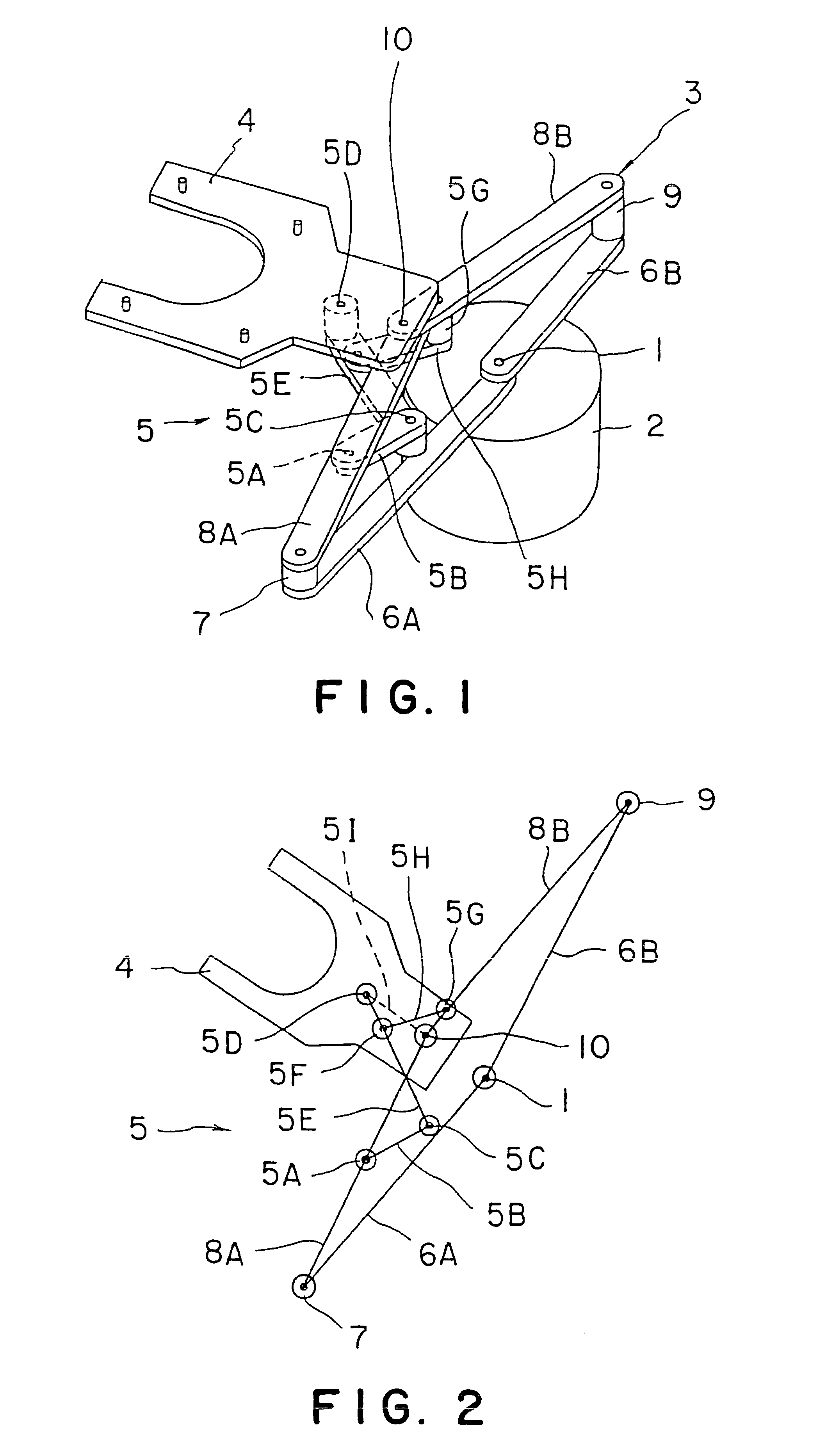

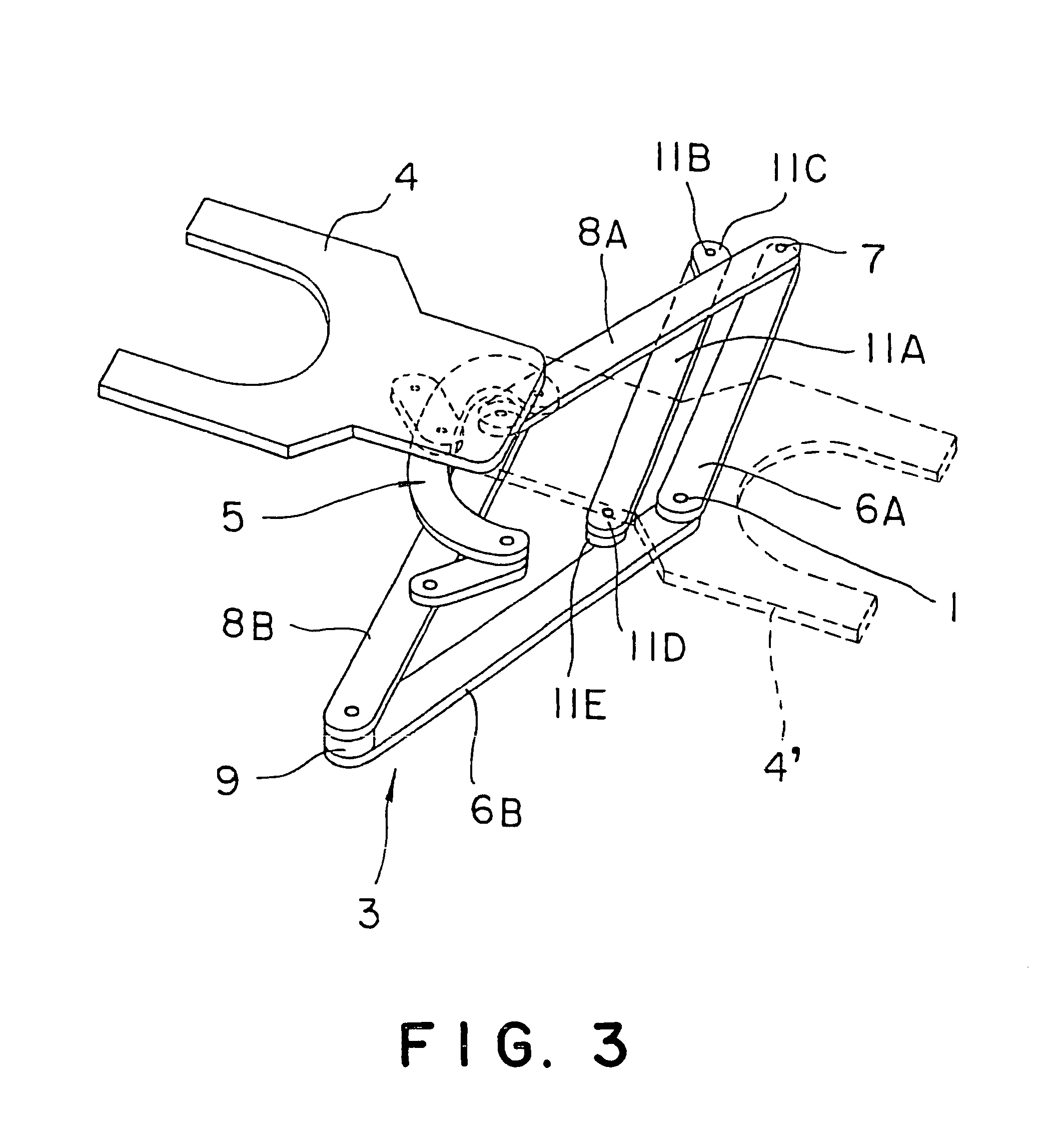

Conveyor system

InactiveUS6450757B1Increase resistanceAccurately and surely carrying a workpieceProgramme-controlled manipulatorMechanical apparatusMostly TrueHeat resistance

In most cases, a hot, corrosive atmosphere is created in, for example, a semiconductor wafer processing chamber. When an arm including belts, such as steel belts, is moved into such a semiconductor wafer processing chamber, the belts are exposed to the hot, corrosive atmosphere. Belts, such as steel belts, have limited heat resistance and corrosion resistance and the hot, corrosive atmosphere in the processing chamber shortens the life of the belts. A carrying device of the present invention has a frog leg type arm (3) and a wafer holder (4) connected to the frog leg type arm (3). The wafer holder (4) is pivotally connected to front end parts of a first front arm (8A) and a second front arm (8B) by coaxial joints (10). The wafer holder (4) is linked to the first front arm (8A) and the second front arm (8B) by a posture maintaining linkage (5) including two antiparallel linkages capable of controlling the turning of the wafer holder (4) relative to the first and the second front arms (8A, 8B).

Owner:TOKYO ELECTRON LTD

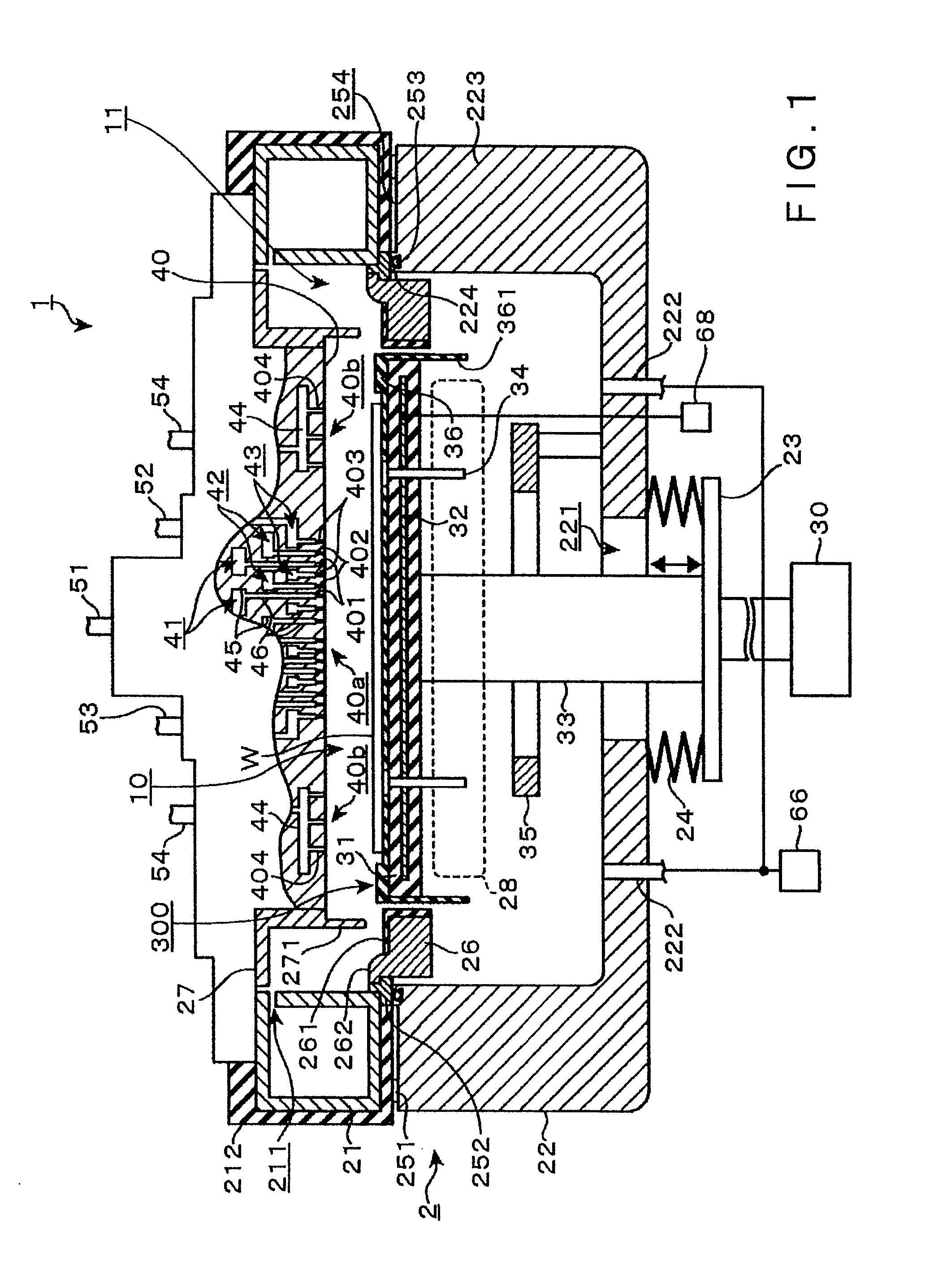

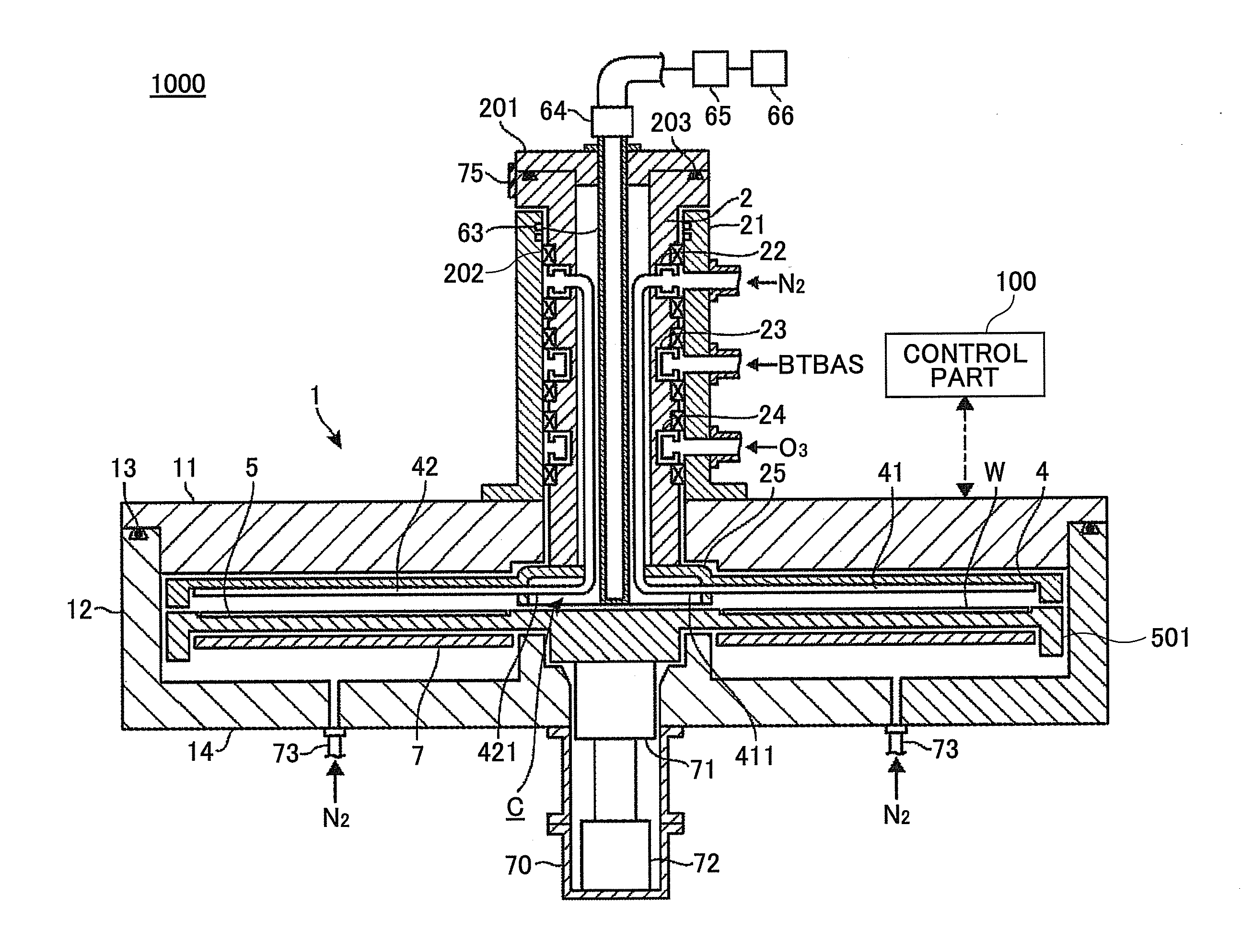

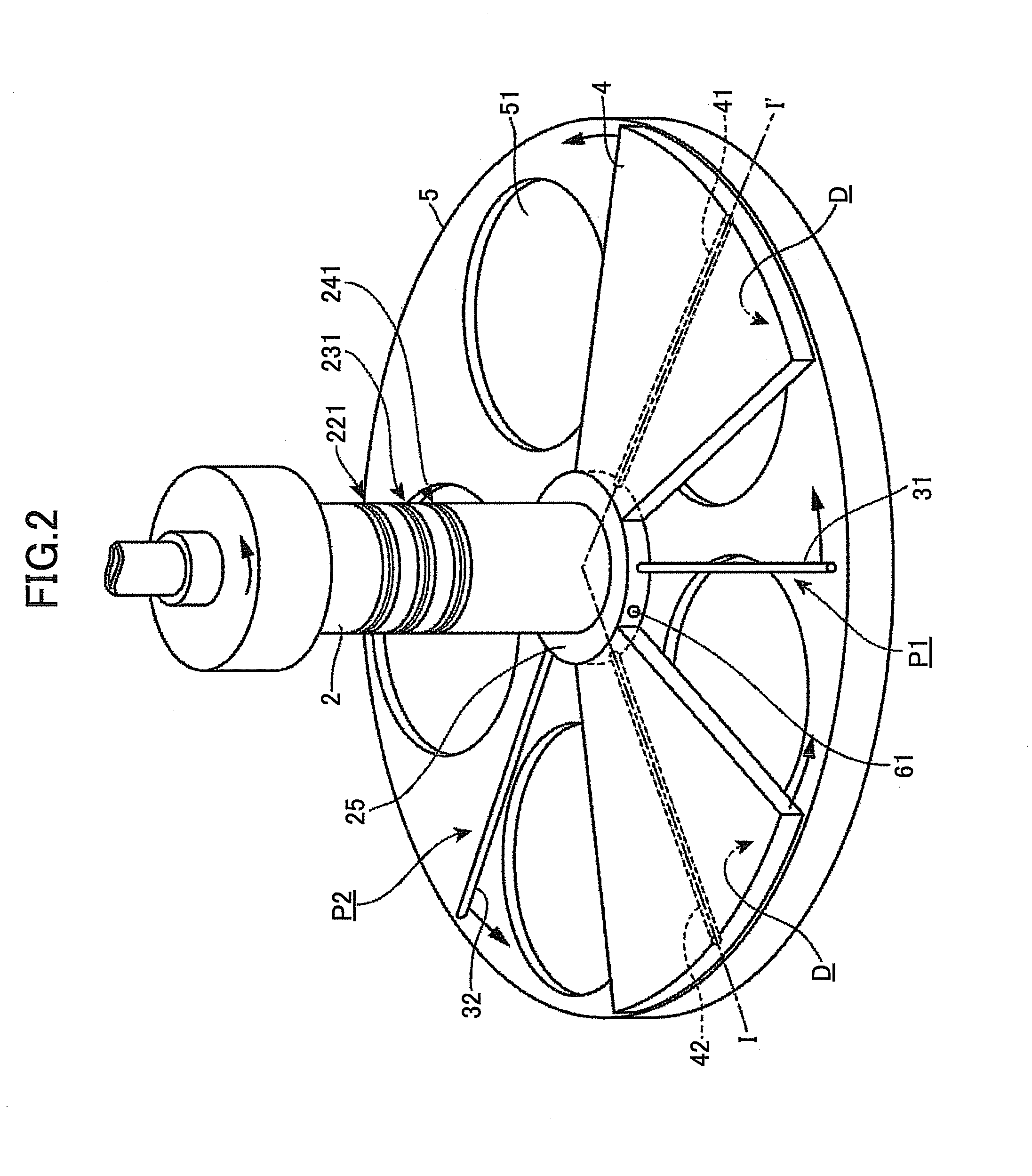

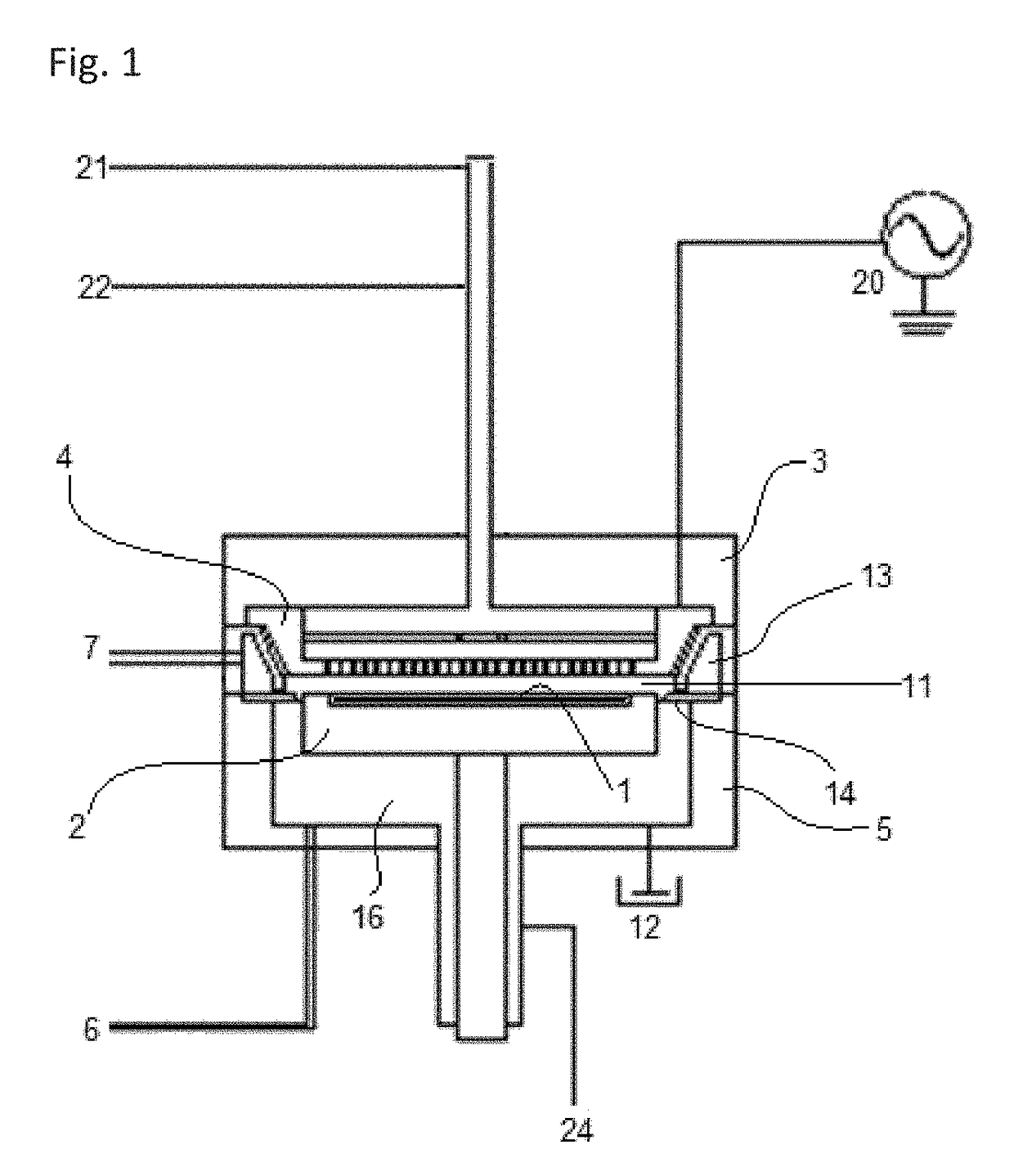

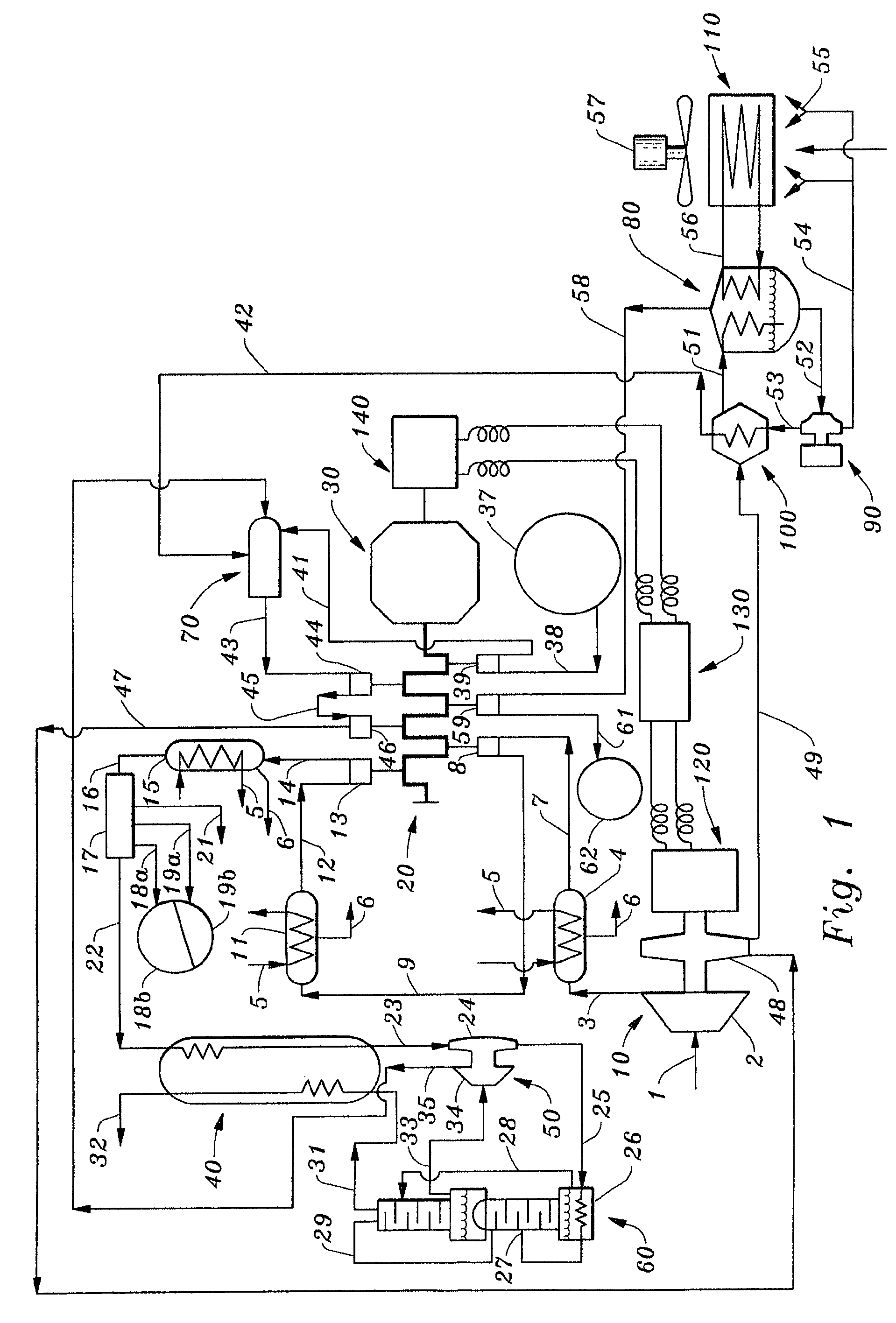

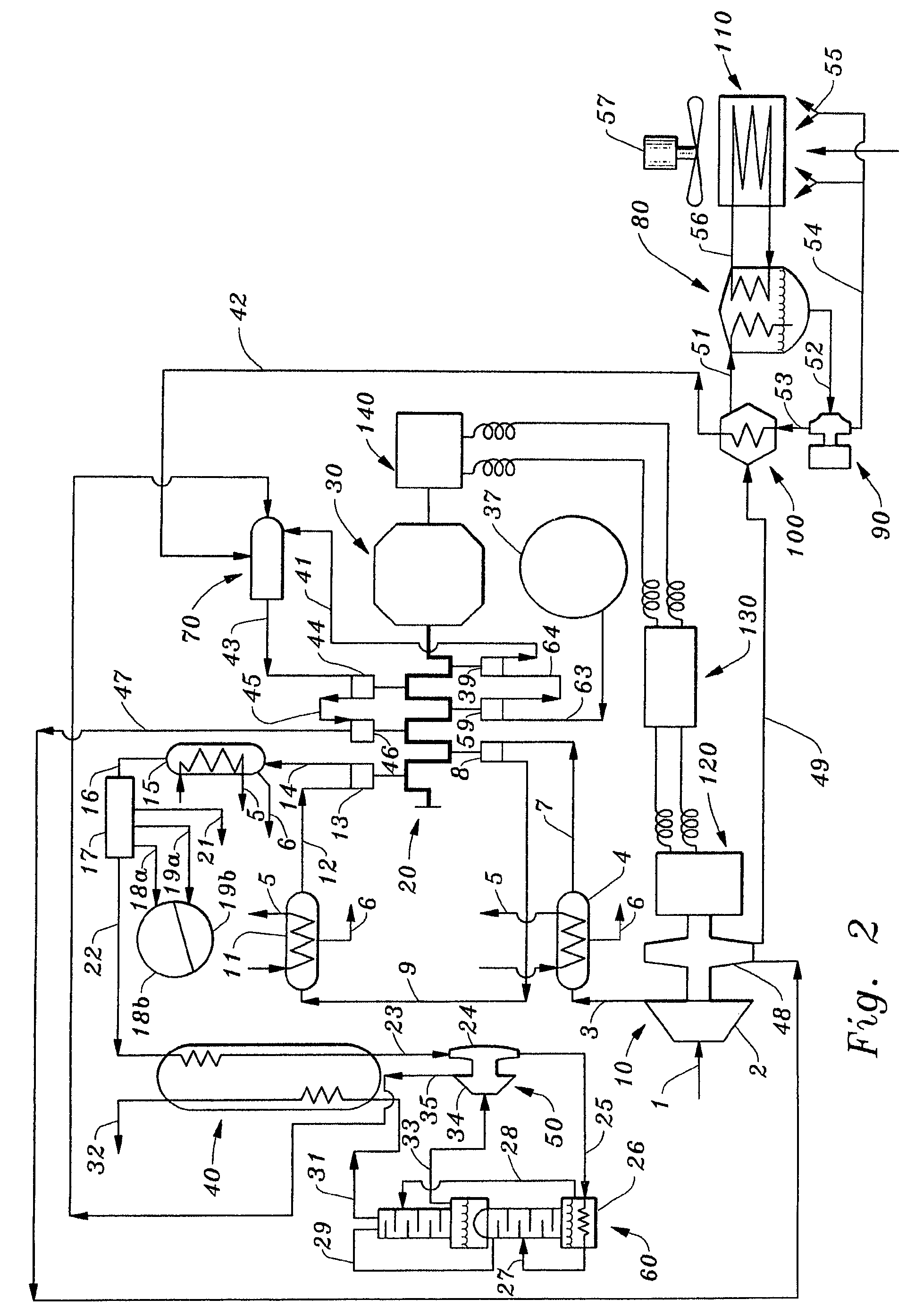

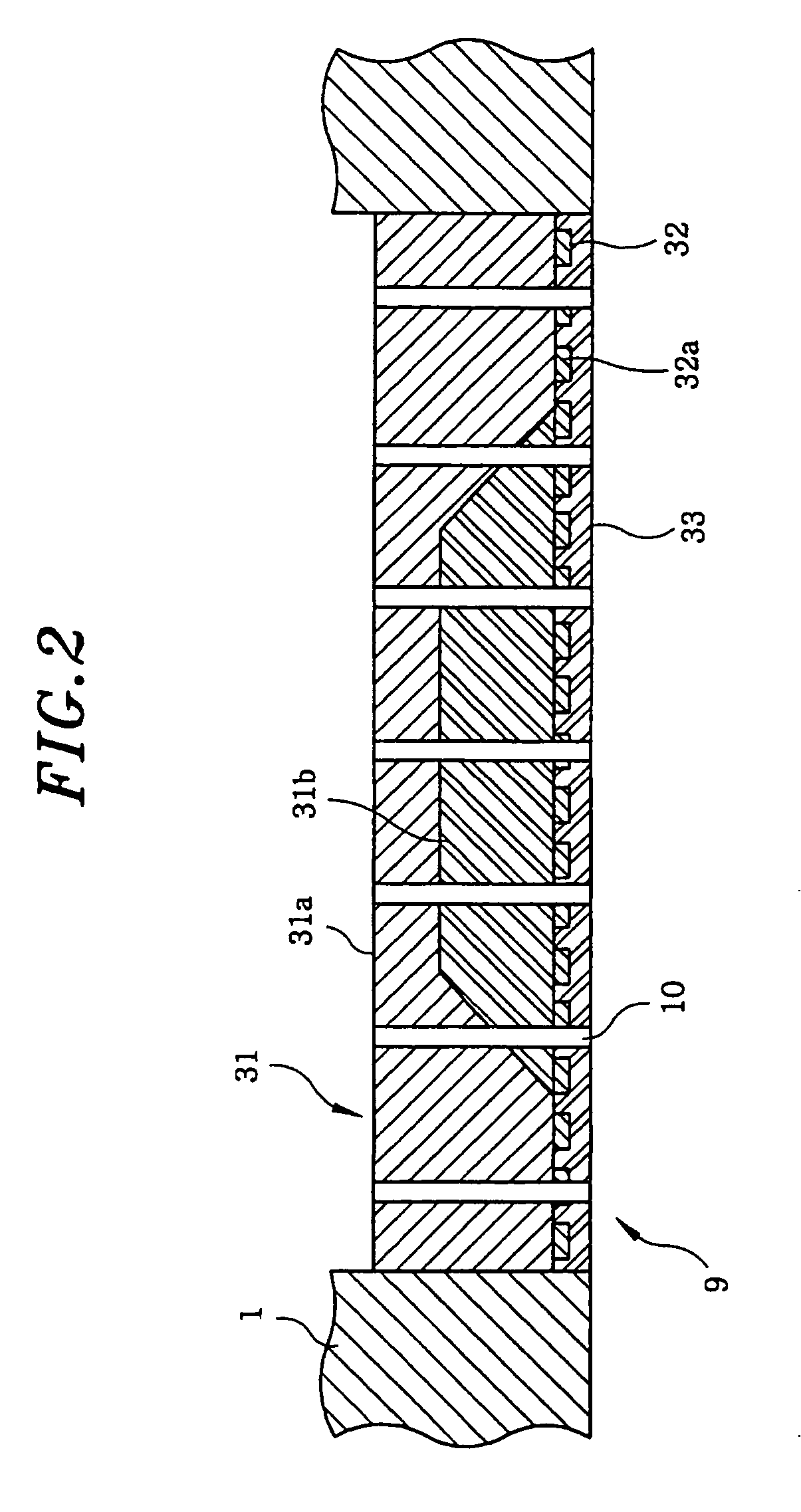

Film deposition apparatus

InactiveUS20100116209A1Eliminate the problemSemiconductor/solid-state device manufacturingChemical vapor deposition coatingEngineeringGas supply

A film deposition apparatus including a rotational member is rotated by a rotation mechanism around a vertical axis inside a chamber, a pedestal in the chamber and including substrate receiving areas formed along a circle having the vertical axis as a center, and first and second reaction gas supplying parts provided separately along a circumferential direction of the circle and supplying first and second reaction gases to the pedestal, a separating area in the rotational member and between first and second process areas to which first and second reaction gases are supplied, an evacuation port to evacuate an atmosphere inside the chamber, a separation gas supplying part in the separating area for supplying a separation gas, and an opposing surface part in the separating area on both sides of the separation gas supplying part and at a position forming a thin space between the opposing surface part and the pedestal.

Owner:TOKYO ELECTRON LTD

Substrate processing method

ActiveUS20110204025A1Decorative surface effectsPretreated surfacesDecompositionAMMONIUM SILICOFLUORIDE

A silicon-containing film on a substrate is subjected to a plasma process using a process gas containing fluorine and carbon, and is thereafter subjected to plasma process using an ammonia gas, whereby ammonium silicofluoride having toxicity and hygroscopic property is adhered to the substrate. The harmful ammonium silicofluoride is removed by the inventive method. After conducting the plasma process using an ammonia gas, the substrate is heated to a temperature not lower than the decomposition temperature of the ammonium silicofluoride to decompose the ammonium silicofluoride in a process container in which the plasma process was conducted, or in a process container connected with the processing vessel which the plasma process was conducted therein and is isolated from a clean room atmosphere.

Owner:TOKYO ELECTRON LTD

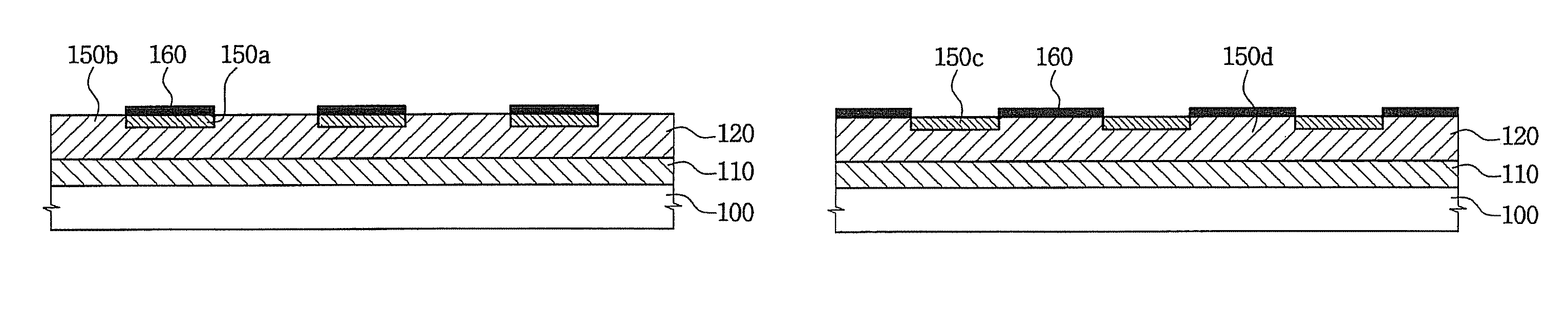

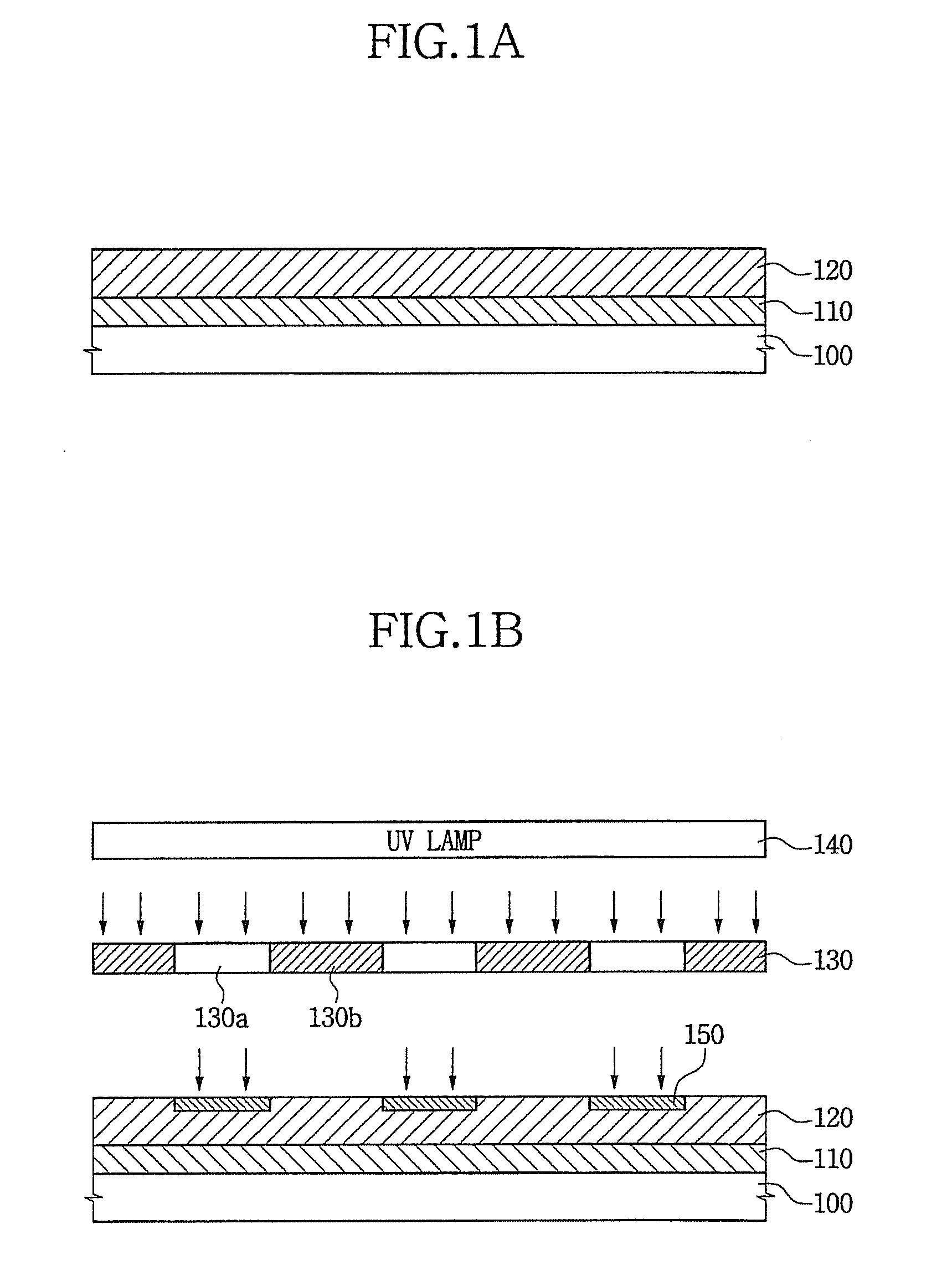

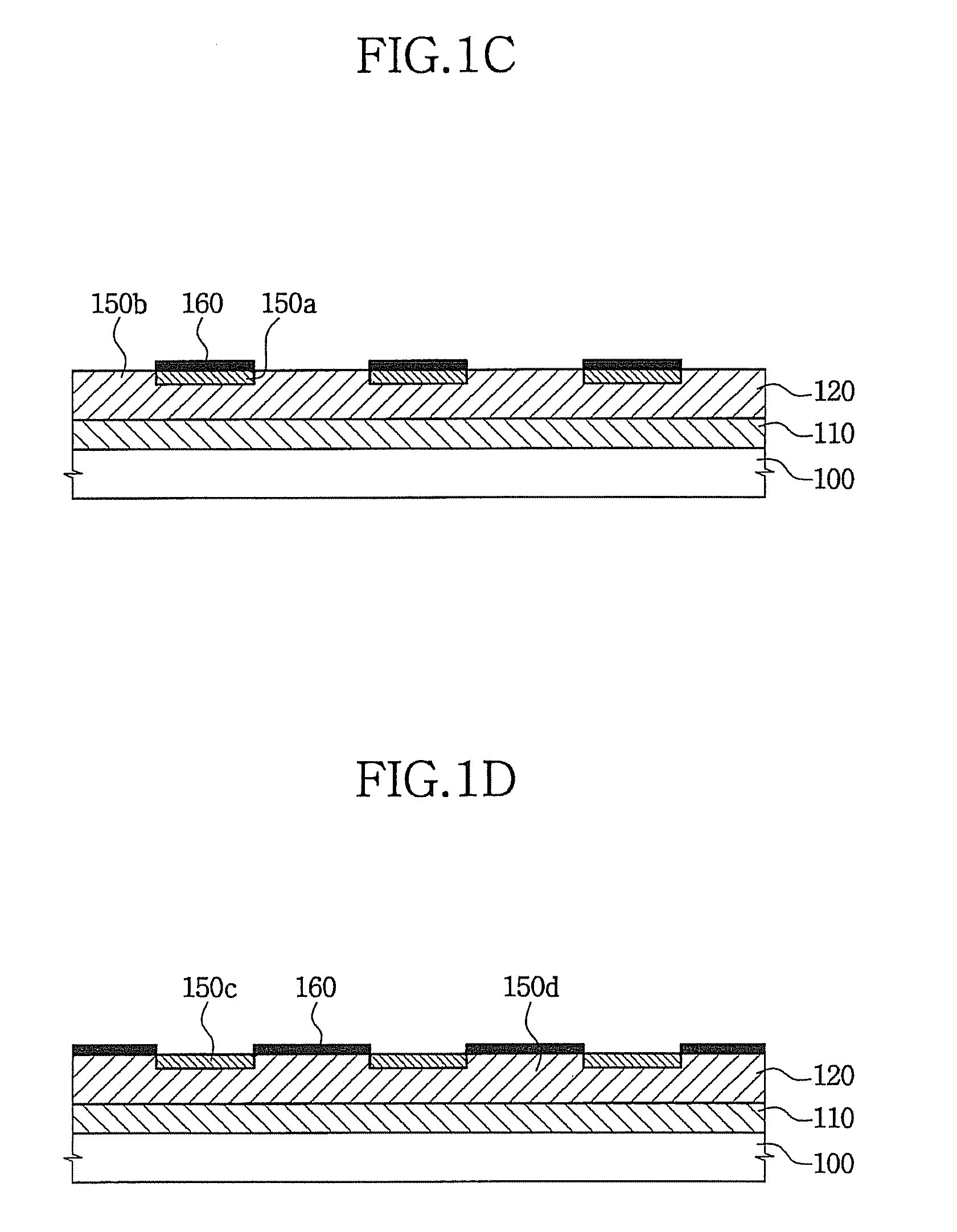

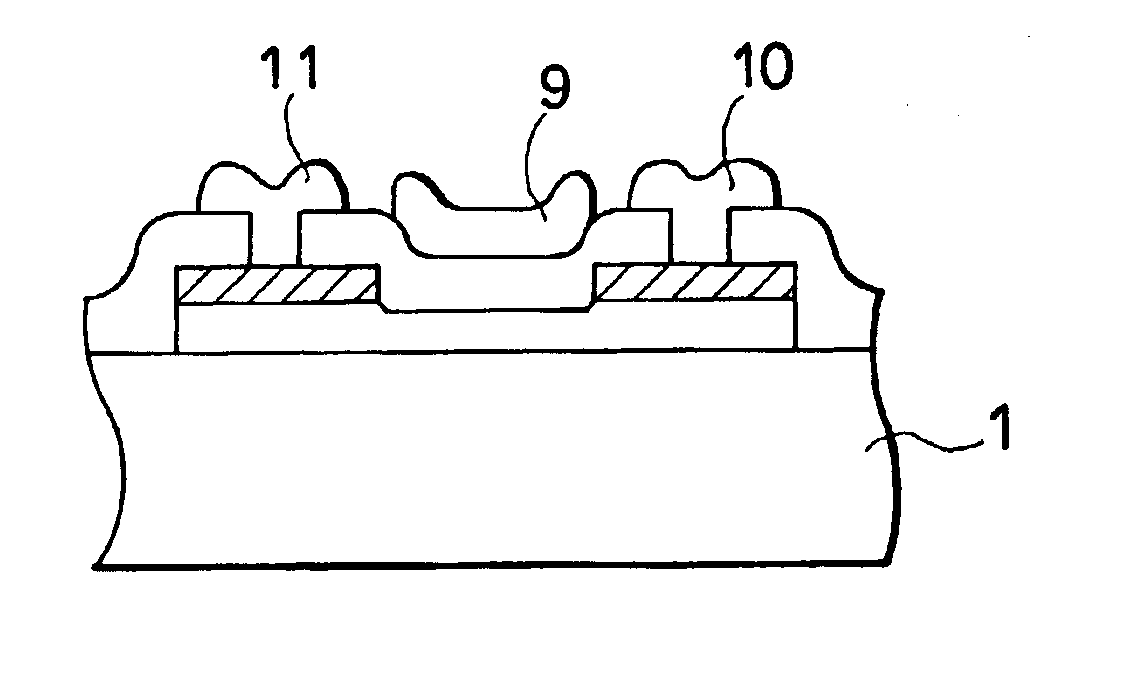

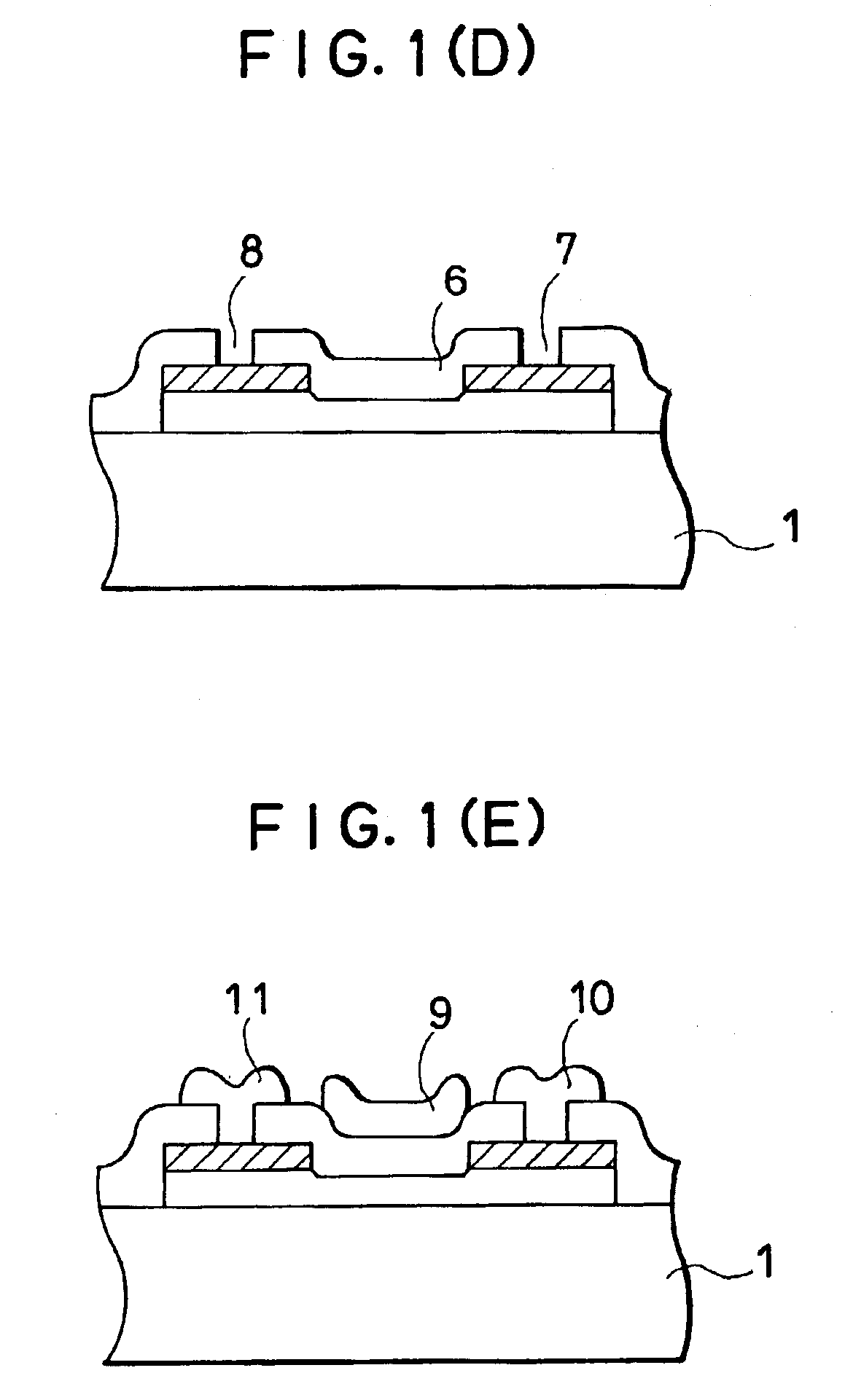

Method of forming polycrystalline silicon layer and atomic layer deposition apparatus used for the same

A method of forming a polycrystalline silicon layer and an atomic layer deposition apparatus used for the same. The method includes forming an amorphous silicon layer on a substrate, exposing the substrate having the amorphous silicon layer to a hydrophilic or hydrophobic gas atmosphere, placing a mask having at least one open and at least one closed portion over the amorphous silicon layer, irradiating UV light toward the amorphous silicon layer and the mask using a UV lamp, depositing a crystallization-inducing metal on the amorphous silicon layer, and annealing the substrate to crystallize the amorphous silicon layer into a polycrystalline silicon layer. This method and apparatus provide for controlling the seed position and grain size in the formation of a polycrystalline silicon layer.

Owner:SAMSUNG DISPLAY CO LTD

Method of forming an oxide film

InactiveUS6960812B2Improve performanceReduce the temperatureSolid-state devicesVacuum evaporation coatingAlkali ionsSputtering

A method of forming an oxide film and a method of manufacturing an electronic device utilizing the oxide film is disclosed. A silicon oxide film is formed on a substrate by sputtering. Therefore, the film formation is carried out at a low temperature. The sputtering atmosphere comprises an oxidizing gas and an inert gas such as argon. In order to prevent fixed electric charges from being generated in the film and to obtain an oxide film of good properties, the proportion of argon is adjusted to 20% or less. Alternatively, a gas including halogen elements such as fluorine is added to the above sputtering atmosphere at a proportion less than 20%. Hereupon, alkali ions and dangling bonds of silicon in the oxide film are neutralized by the halogen elements, whereby a fine oxide film is obtained.

Owner:SEMICON ENERGY LAB CO LTD

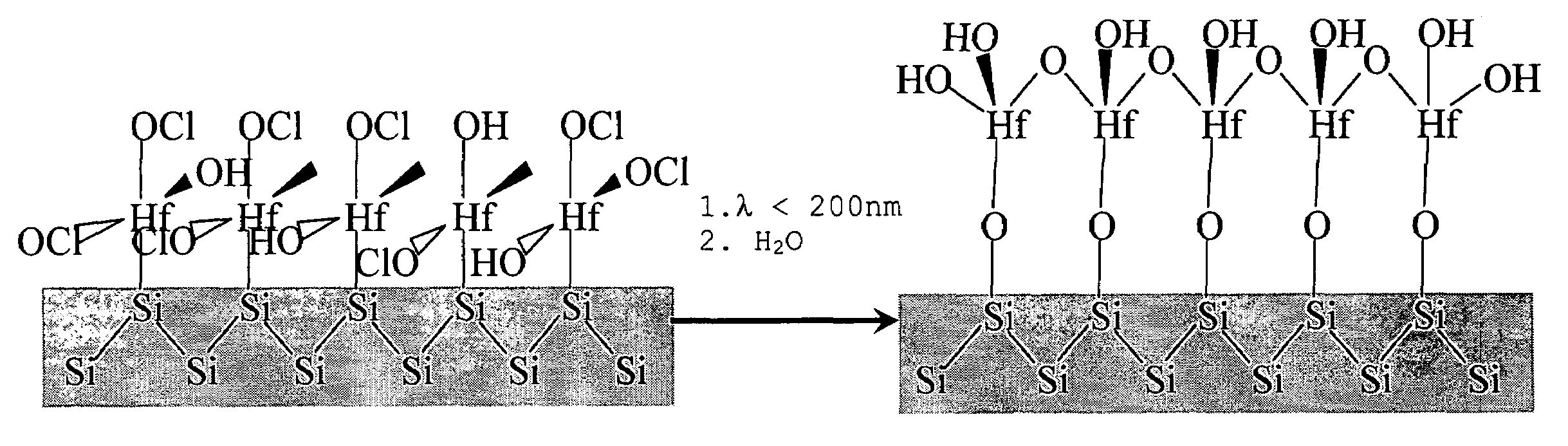

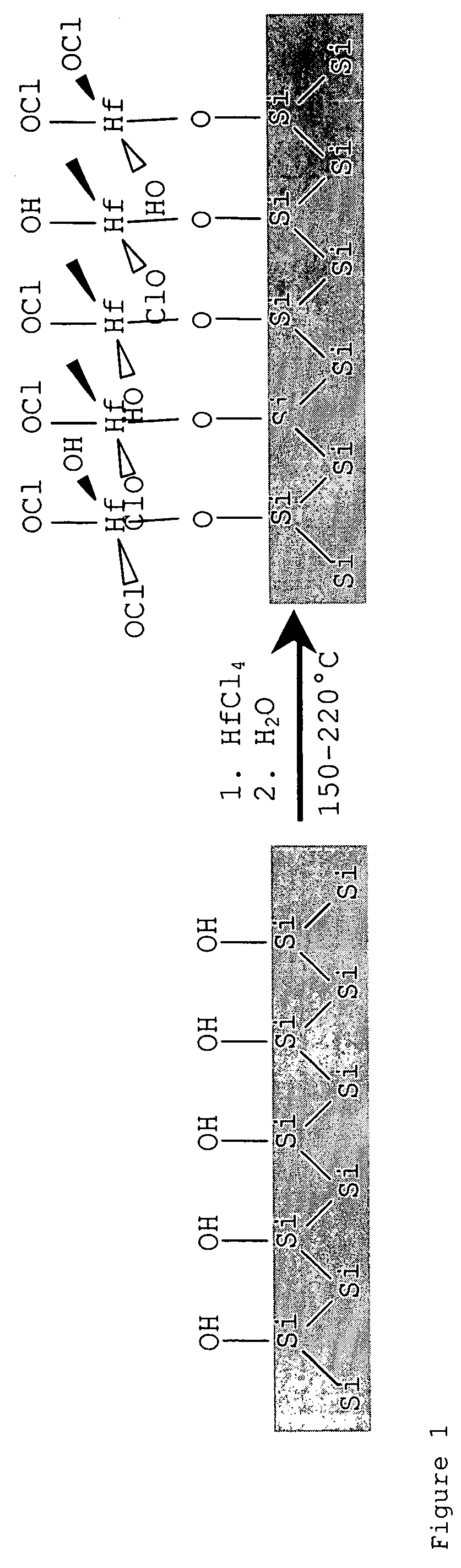

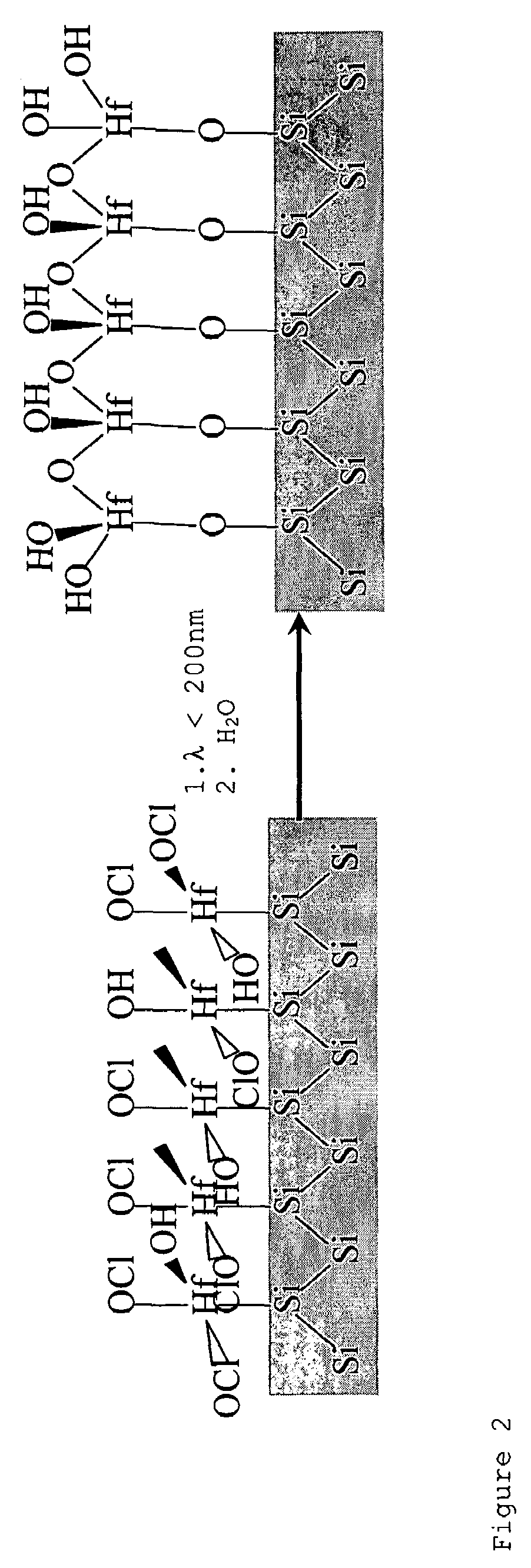

Atomic layer deposition method for depositing a layer

ActiveUS7579285B2Improve chemical and electrical characteristicSemiconductor/solid-state device manufacturingChemical vapor deposition coatingIrradiationAtomic layer deposition

The invention is related to an ALD method for depositing a layer including the steps of a) providing a semiconductor substrate in a reactor; b) providing a pulse of a first precursor gas into the reactor; c) providing a pulse of a second precursor gas into the reactor; d) providing an inert atmosphere in the reactor; and e) repeating step b) through step d), wherein at least once during step d) the semiconductor substrate is exposed to UV irradiation.

Owner:INTERUNIVERSITAIR MICRO ELECTRONICS CENT (IMEC VZW)

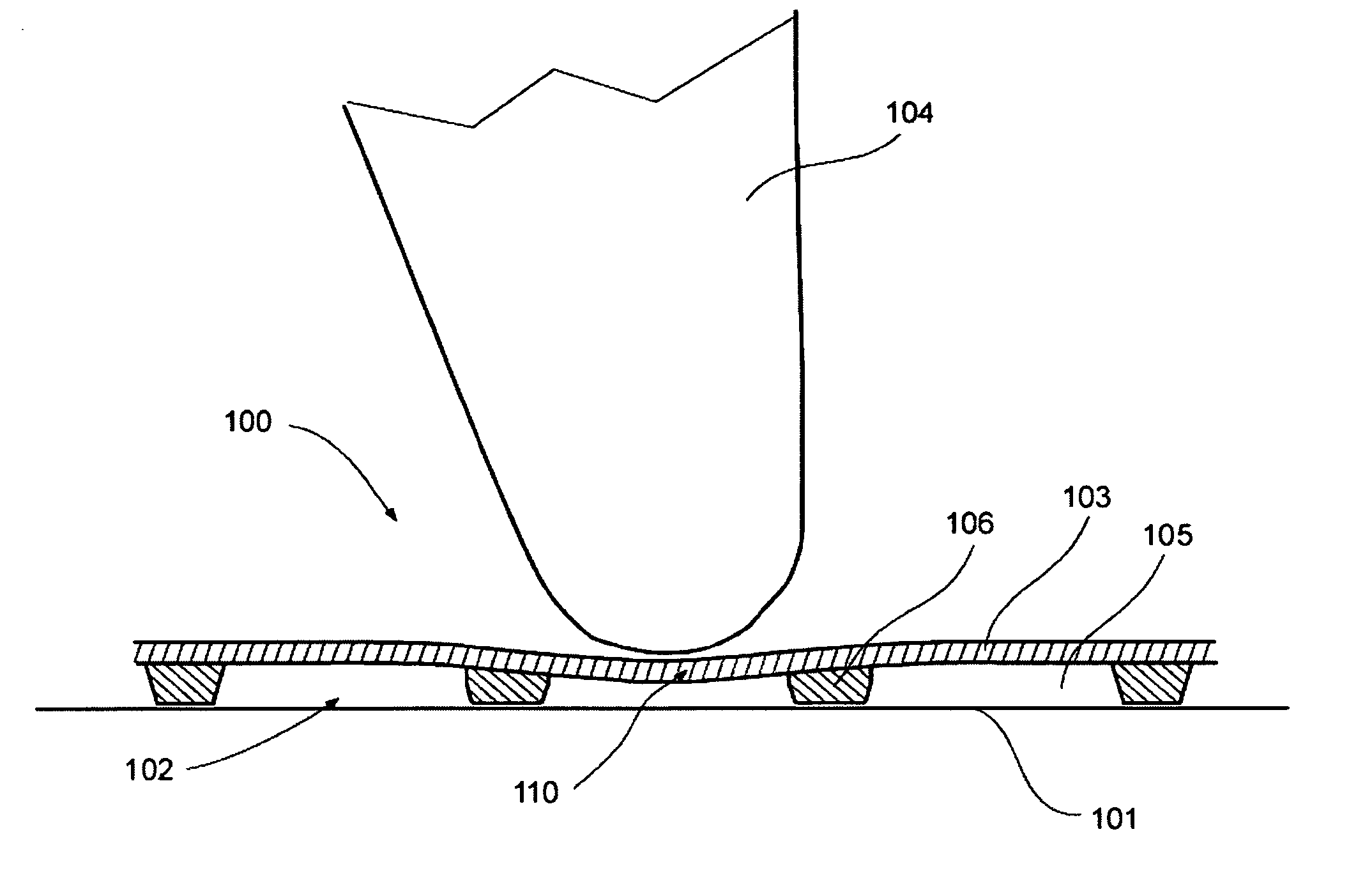

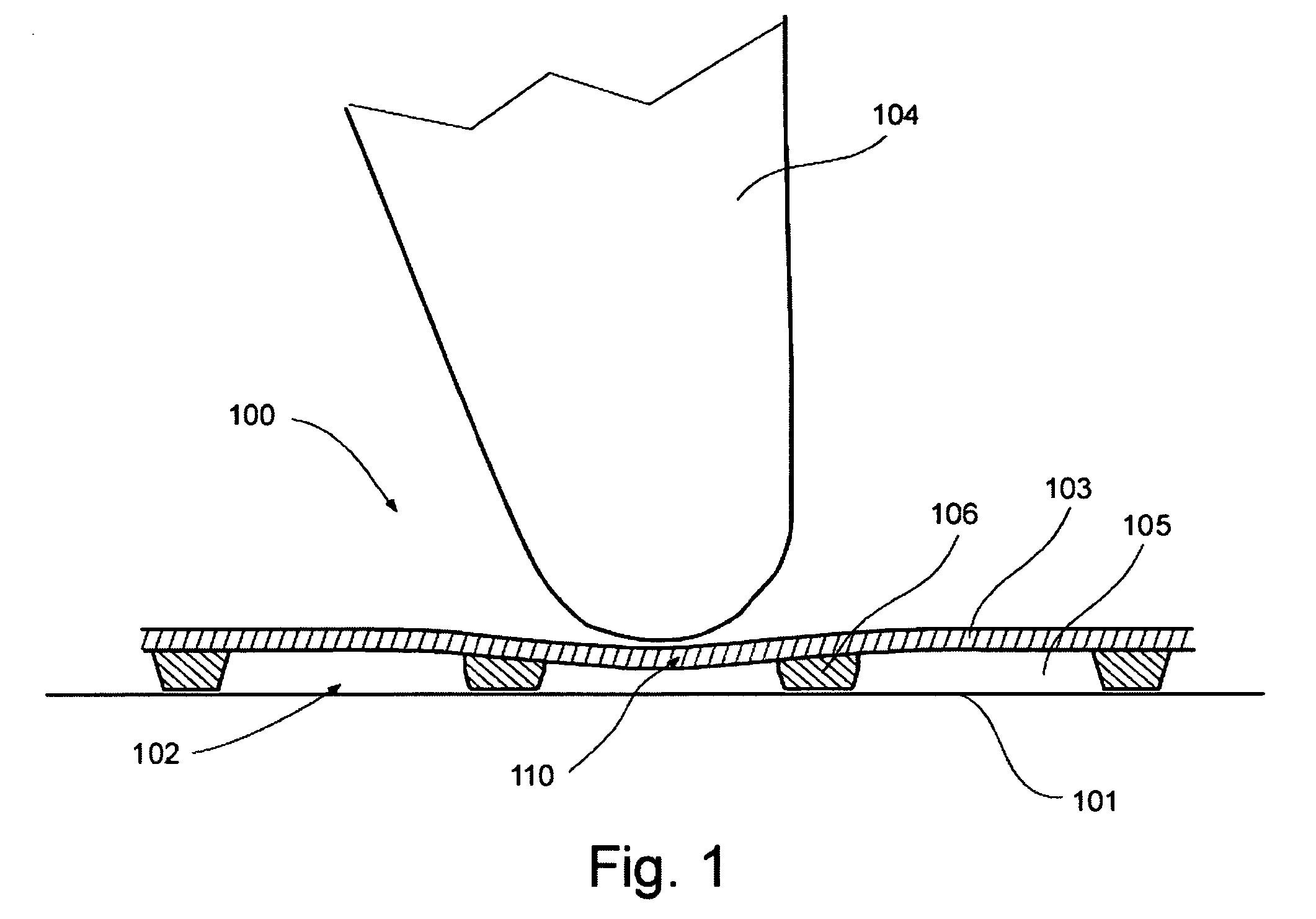

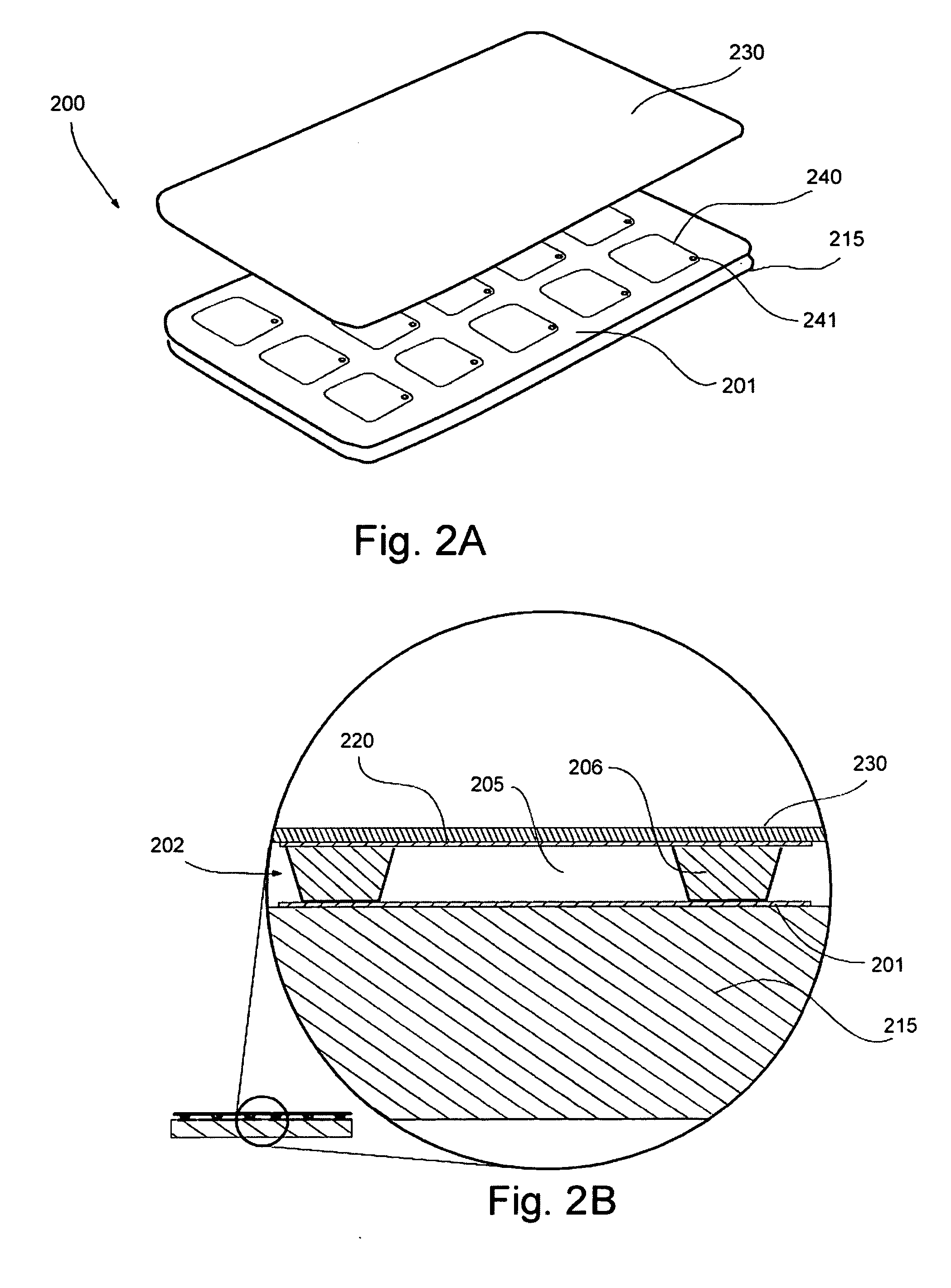

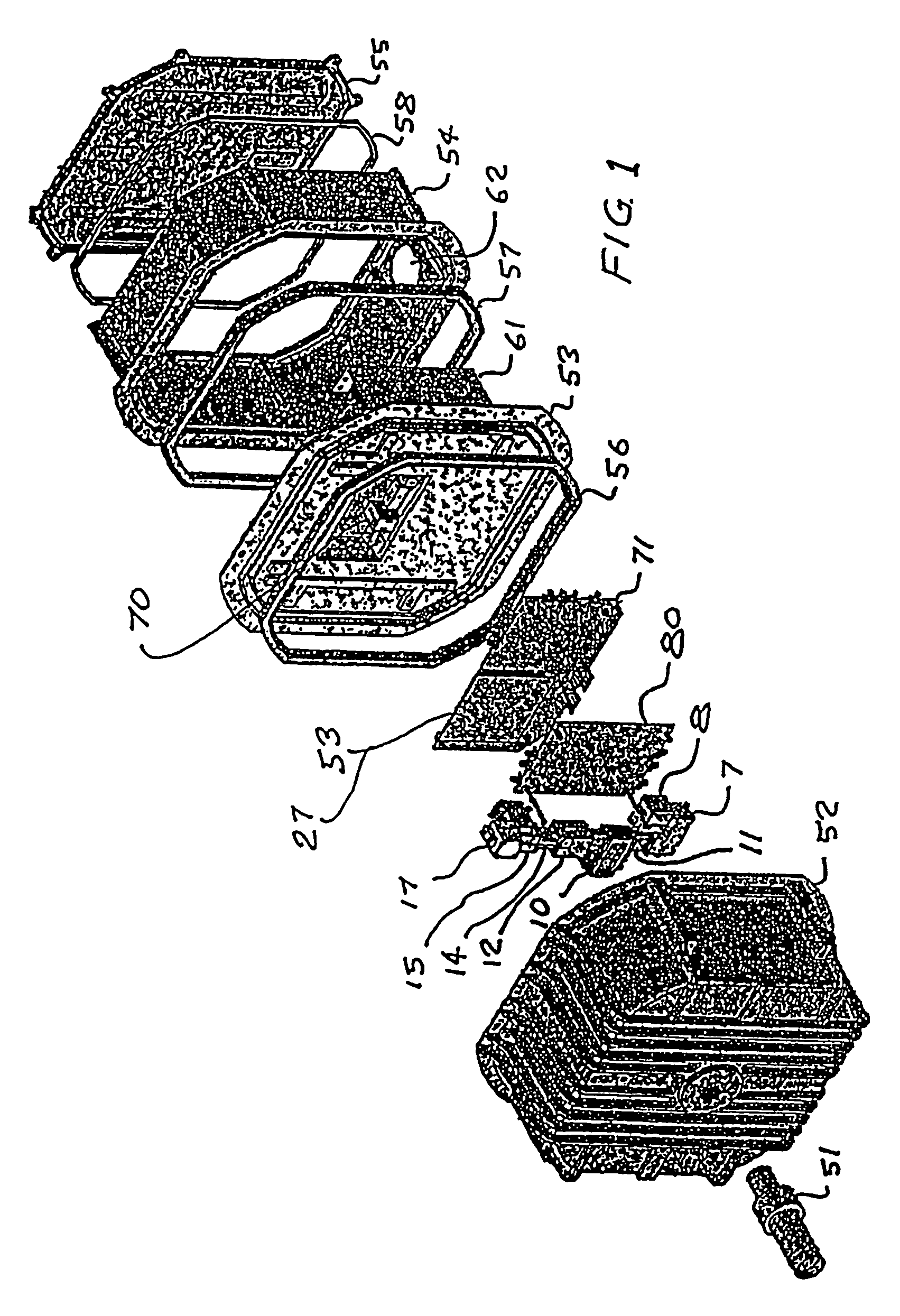

Reconfigurable tactile sensor input device

InactiveUS20070257821A1Low production costSmall sizeInput/output for user-computer interactionElectronic switchingCapacitanceDisplay device

A reconfigurable tactile input device includes a first rigid electrode layer, a compressible dielectric structure, and a second flexible electrode layer forming together a tactile sensor with appropriate electrode connection means to a control means. The control means may include a mixed-signal IC mounted next to the input device in a compact package and capable of measuring capacitance in real time. The dielectric structure may include a matrix of compressible geometric elements with voids therebetween optionally vented to atmosphere, making the entire assembly thin and facilitating its use for mobile phones and other small, portable electronic devices. Some embodiments provide the user wit tactile feedback upon compression of the electrodes. An optional flexible display may be mounted over the input device to indicate the present configuration to the user.

Owner:WISETOUCH CO LTD

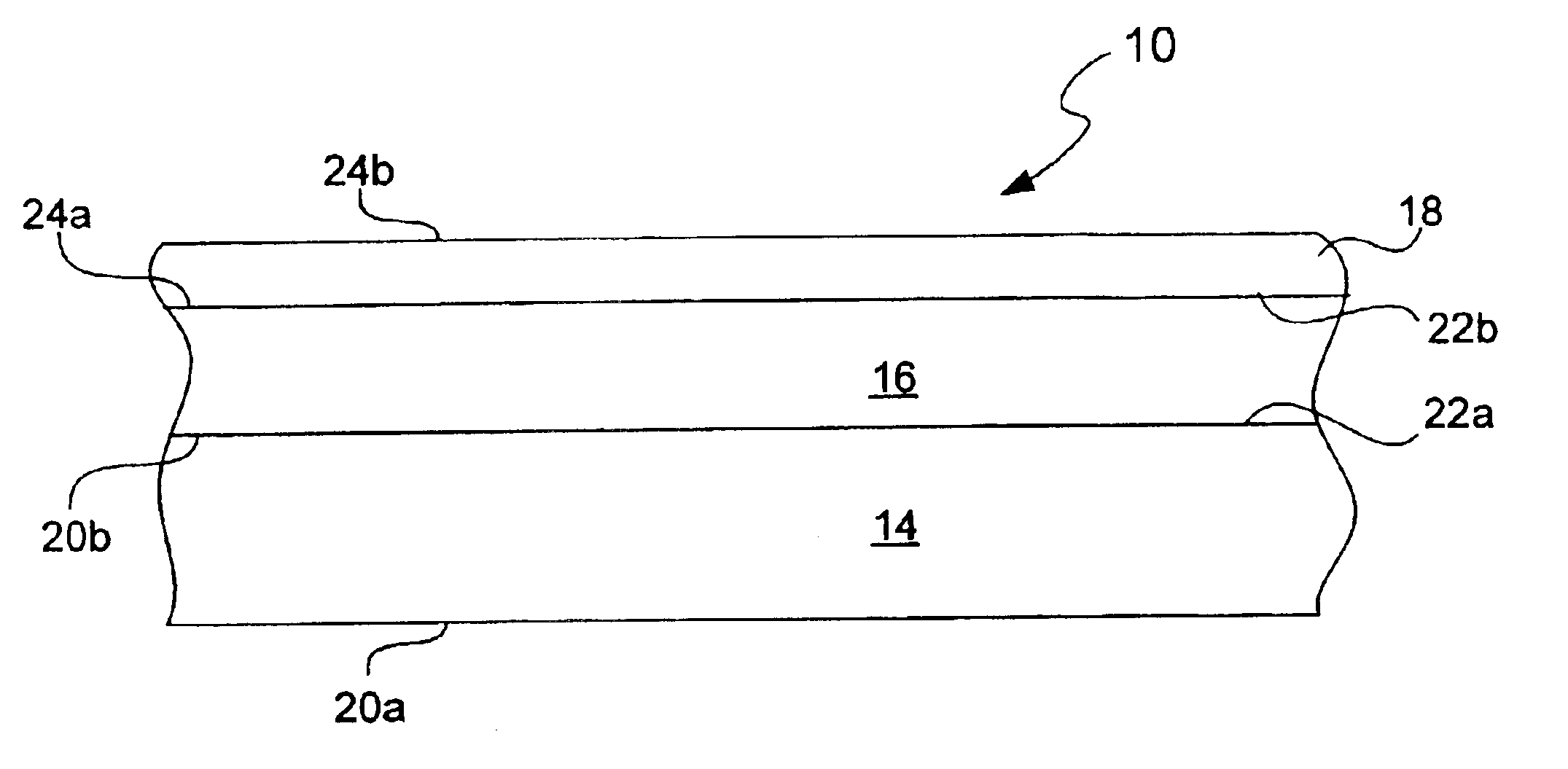

Film deposition apparatus and film deposition method

ActiveUS20100279008A1Efficient solutionHigh in-plane uniformitySemiconductor/solid-state device manufacturingChemical vapor deposition coatingEngineeringTransfer mechanism

The present invention is a film deposition apparatus configured to deposit a film on a substrate that has been loaded into a vacuum container via a transfer opening and placed on a table in the vacuum container, by supplying a process gas to the substrate from a process-gas supply part opposed to the table under a vacuum atmosphere, while heating a table surface of the table, the film deposition apparatus comprising: an elevating mechanism configured to vertically move the table between a process position at which the substrate is subjected to a film deposition process, and a transfer position at which the substrate is transferred to and from an external transfer mechanism that has entered from the transfer opening; a surrounding part configured to surround the table with a gap therebetween, when the table is located at the process position, so that the surrounding part and the table divide an inside of the vacuum container into an upper space, which is located above the table, and a lower space, which is located below the table; a vacuum exhaust conduit in communication with the upper space, through which a process atmosphere in the upper space is discharged to create a vacuum in the upper space; a heating unit configured to heat a gas contact region ranging from the upper space to the vacuum exhaust conduit, to a temperature higher than a temperature allowing adhesion of reactant; and a heat insulation part disposed between the heating unit and a lower part of the vacuum container surrounding the lower space.

Owner:TOKYO ELECTRON LTD

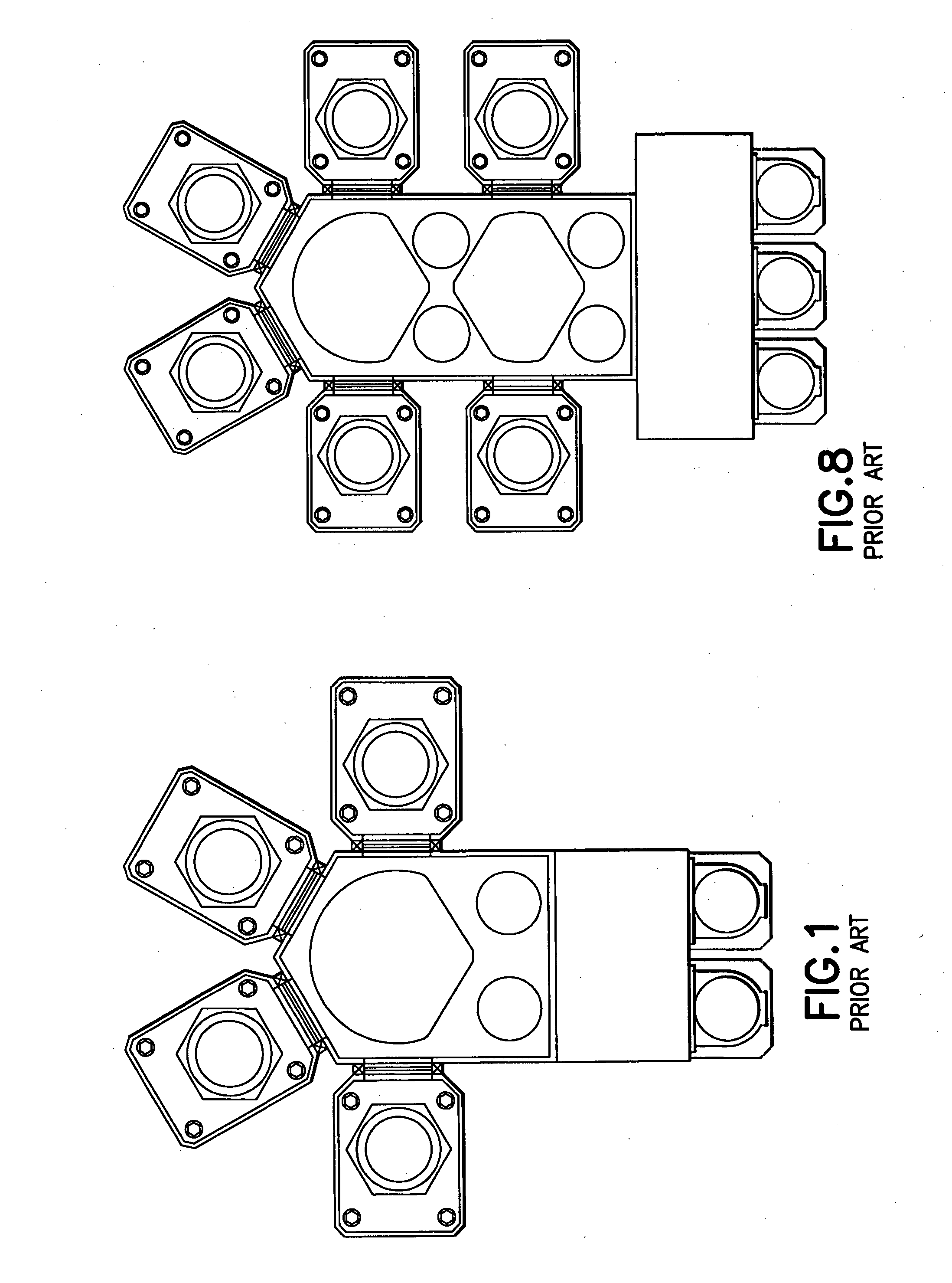

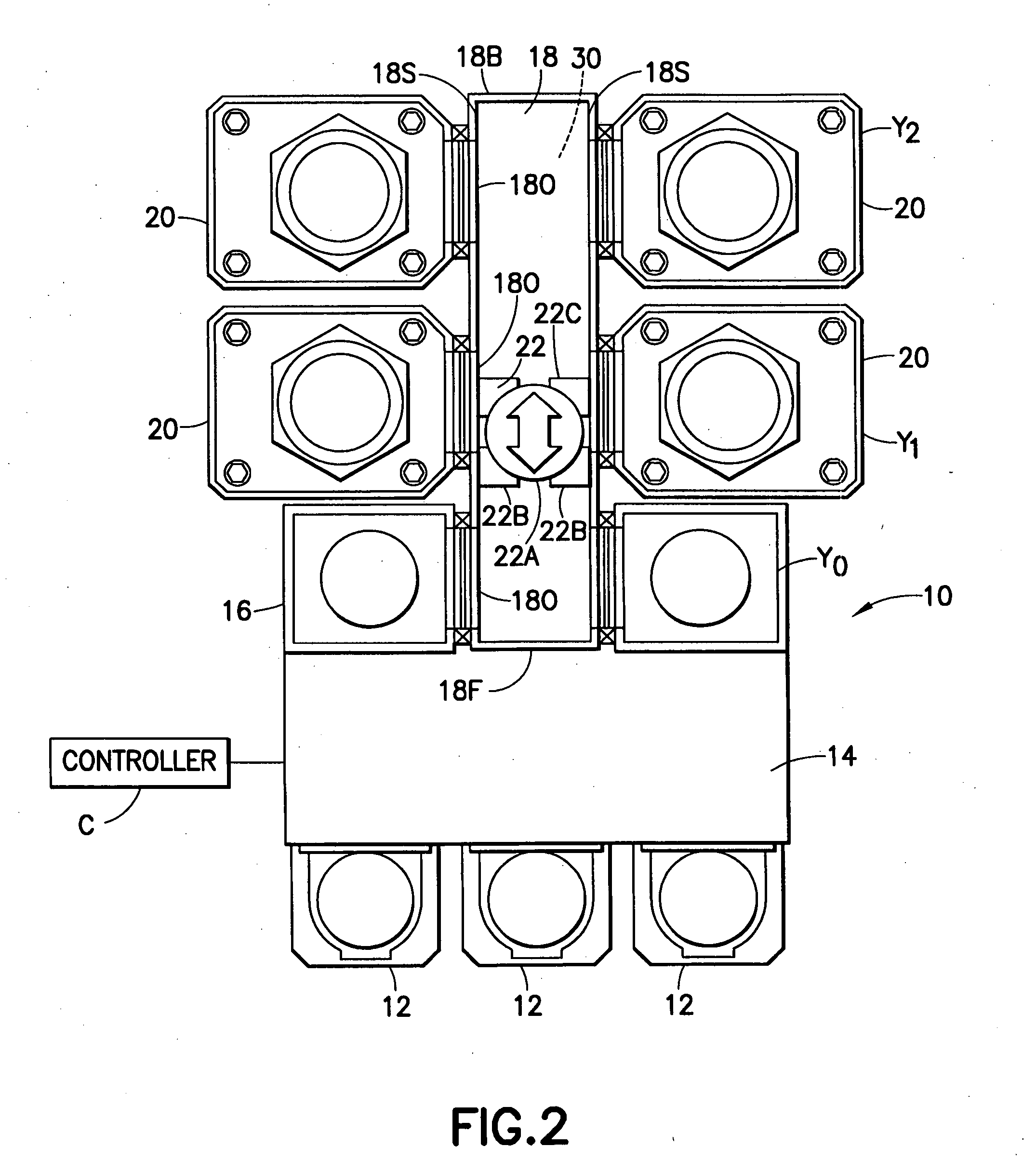

Substrate processing apparatus

Substrate processing apparatus having a chamber, a generally linear array of process modules, a substrate transport, and a drive system. The chamber is capable of being isolated from the outside atmosphere. Each process module of the array is communicably connected to the chamber to allow a substrate to be transferred between the chamber and process module. The substrate transport is located in and is movably supported from the chamber. The transport is capable of moving along a linear path defined by the chamber for transporting the substrate between process modules. The drive system is connected to the chamber for driving and moving the transport along the linear path. The chamber comprises a selectable number of chamber modules serially abutted to defined the chamber. Each module has an integral portion of the drive system.

Owner:BOOKS AUTOMATION US LLC

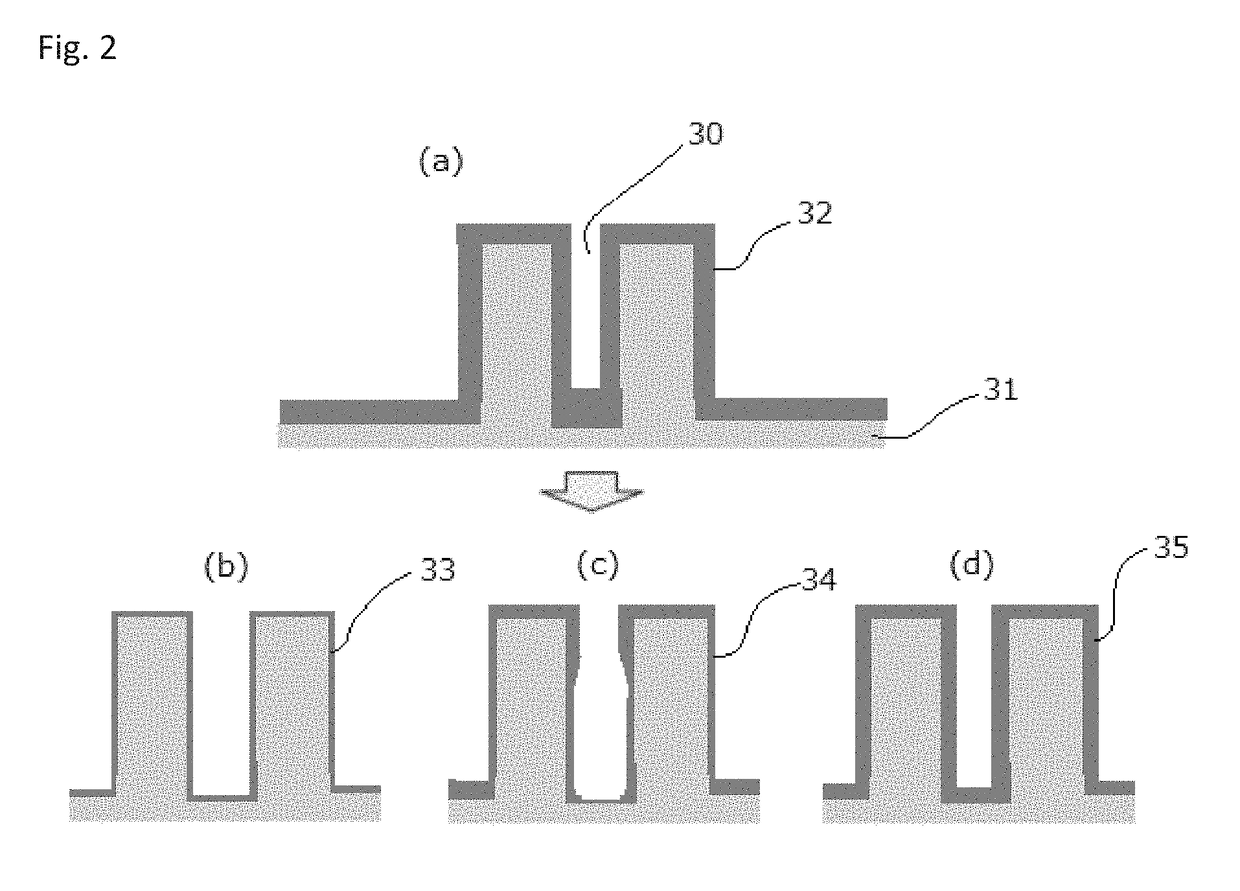

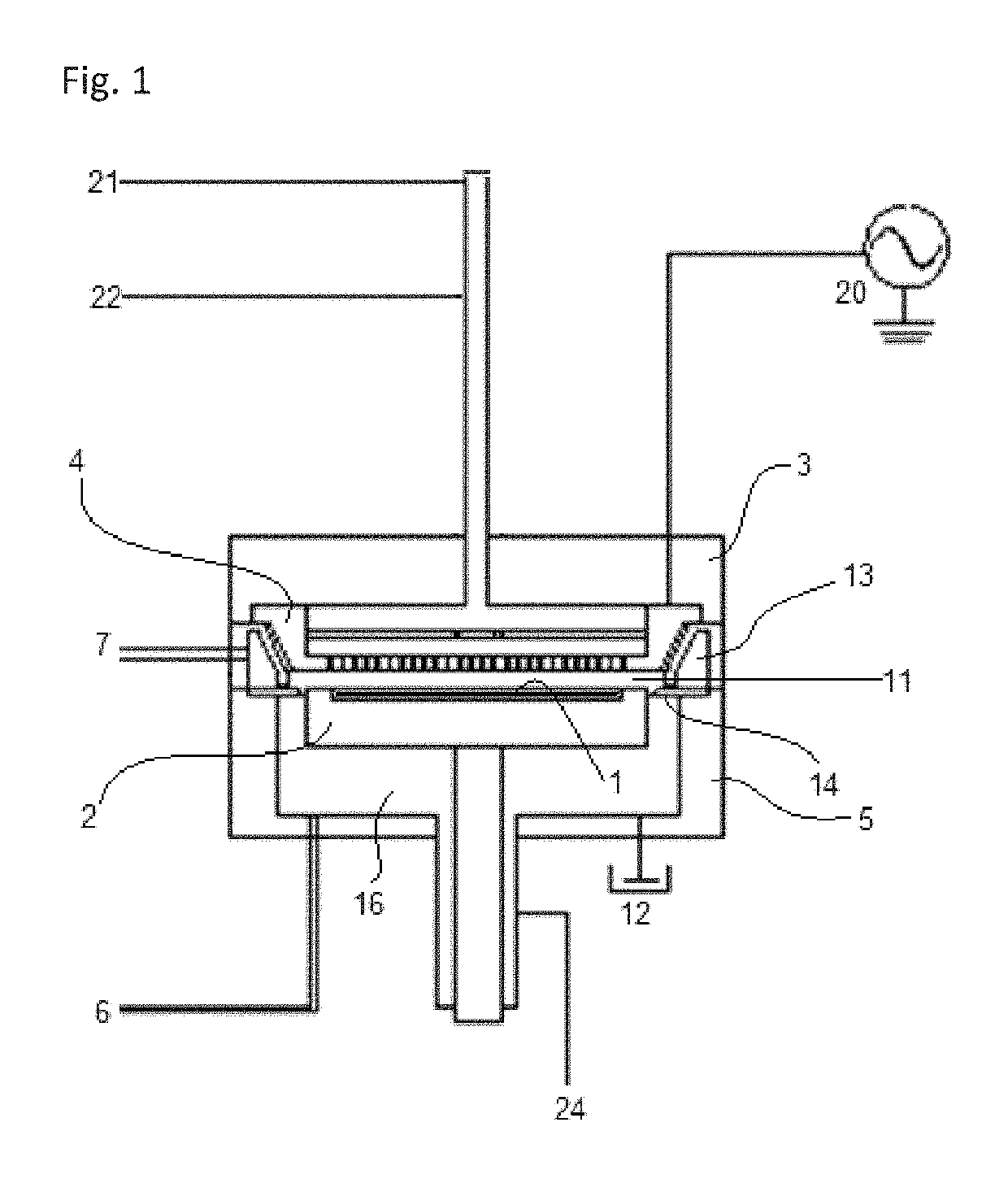

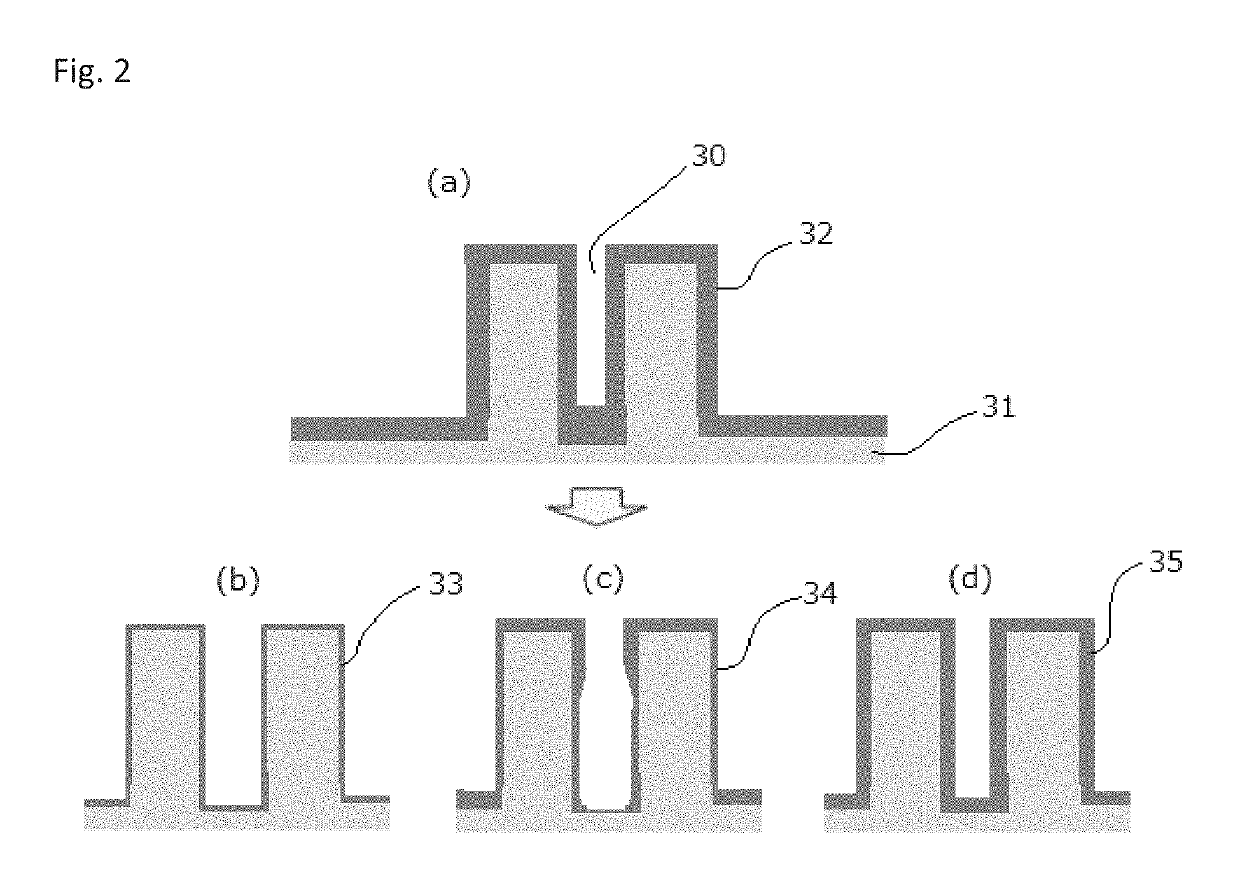

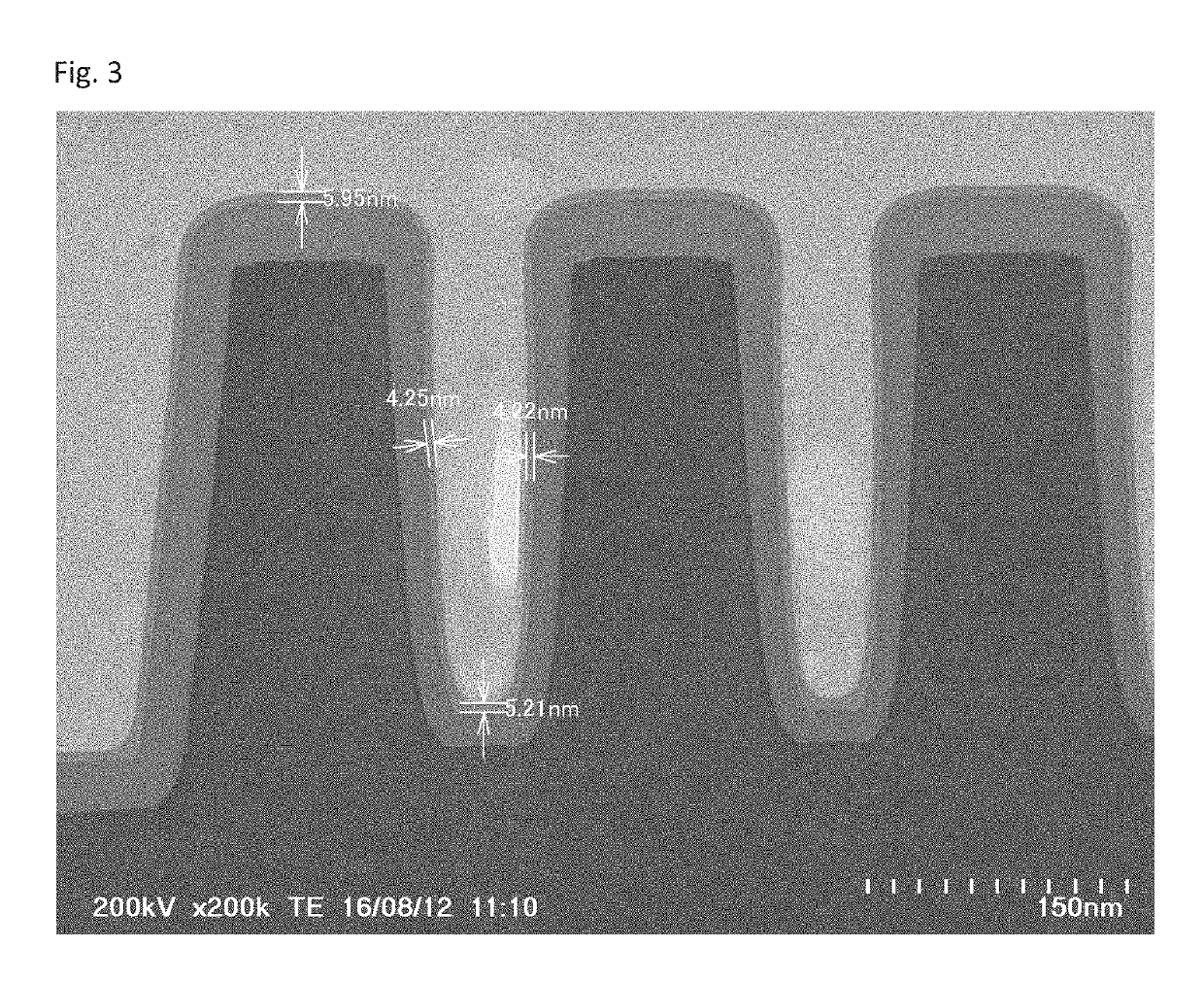

Method of reforming insulating film deposited on substrate with recess pattern

ActiveUS20180286663A1Improve propertiesIncrease probabilitySemiconductor/solid-state device manufacturingAtmosphereMetal

A method of reforming an insulating film deposited on a substrate having a recess pattern constituted by a bottom and sidewalls, includes: providing the film deposited on the substrate having the recess pattern in an evacuatable reaction chamber, wherein a property of a portion of the film deposited on the sidewalls is inferior to that of a portion of the film deposited on a top surface of the substrate; adjusting a pressure of an atmosphere of the reaction chamber to 10 Pa or less, which atmosphere is constituted by H2 and / or He without a precursor and without a reactant; and applying RF power to the atmosphere of the pressure-adjusted reaction chamber to generate a plasma to which the film is exposed, thereby reforming the portion of the film deposited on the sidewalls to improve the property of the sidewall portion of the film.

Owner:ASM IP HLDG BV

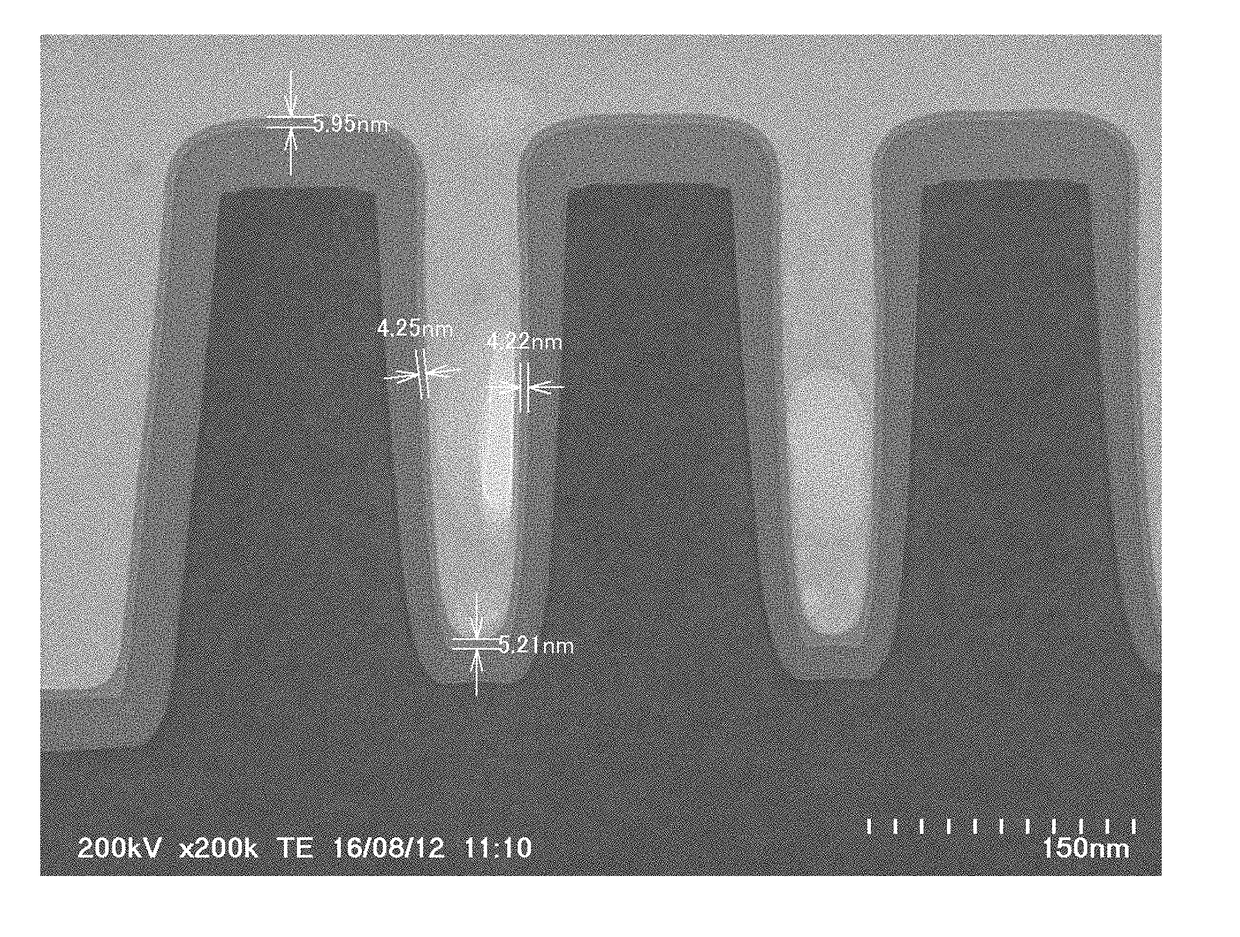

Method of reforming insulating film deposited on substrate with recess pattern

ActiveUS10283353B2Improve propertiesHigh puritySemiconductor/solid-state device manufacturingAtmosphereMetal

A method of reforming an insulating film deposited on a substrate having a recess pattern constituted by a bottom and sidewalls, includes: providing the film deposited on the substrate having the recess pattern in an evacuatable reaction chamber, wherein a property of a portion of the film deposited on the sidewalls is inferior to that of a portion of the film deposited on a top surface of the substrate; adjusting a pressure of an atmosphere of the reaction chamber to 10 Pa or less, which atmosphere is constituted by H2 and / or He without a precursor and without a reactant; and applying RF power to the atmosphere of the pressure-adjusted reaction chamber to generate a plasma to which the film is exposed, thereby reforming the portion of the film deposited on the sidewalls to improve the property of the sidewall portion of the film.

Owner:ASM IP HLDG BV

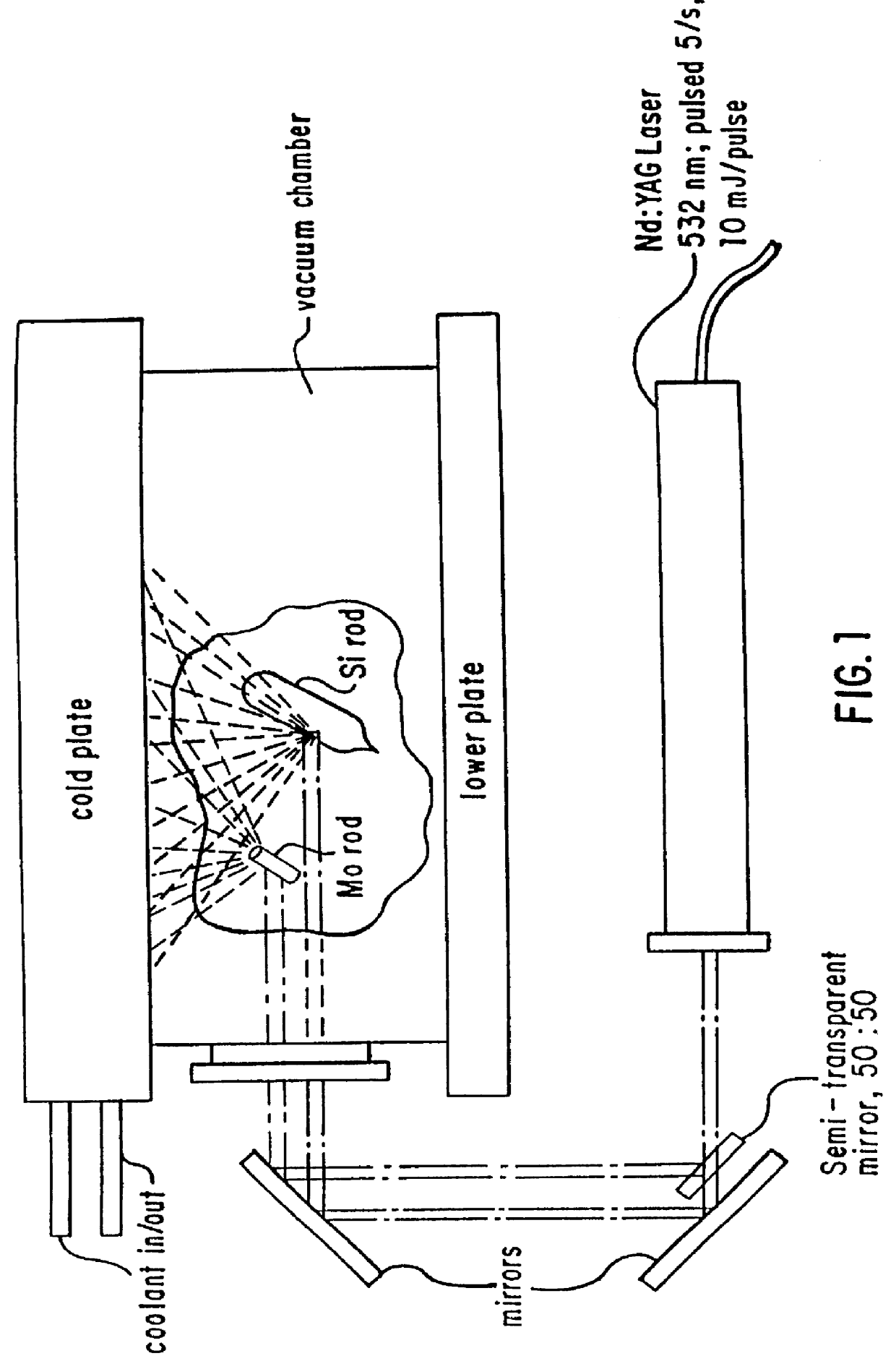

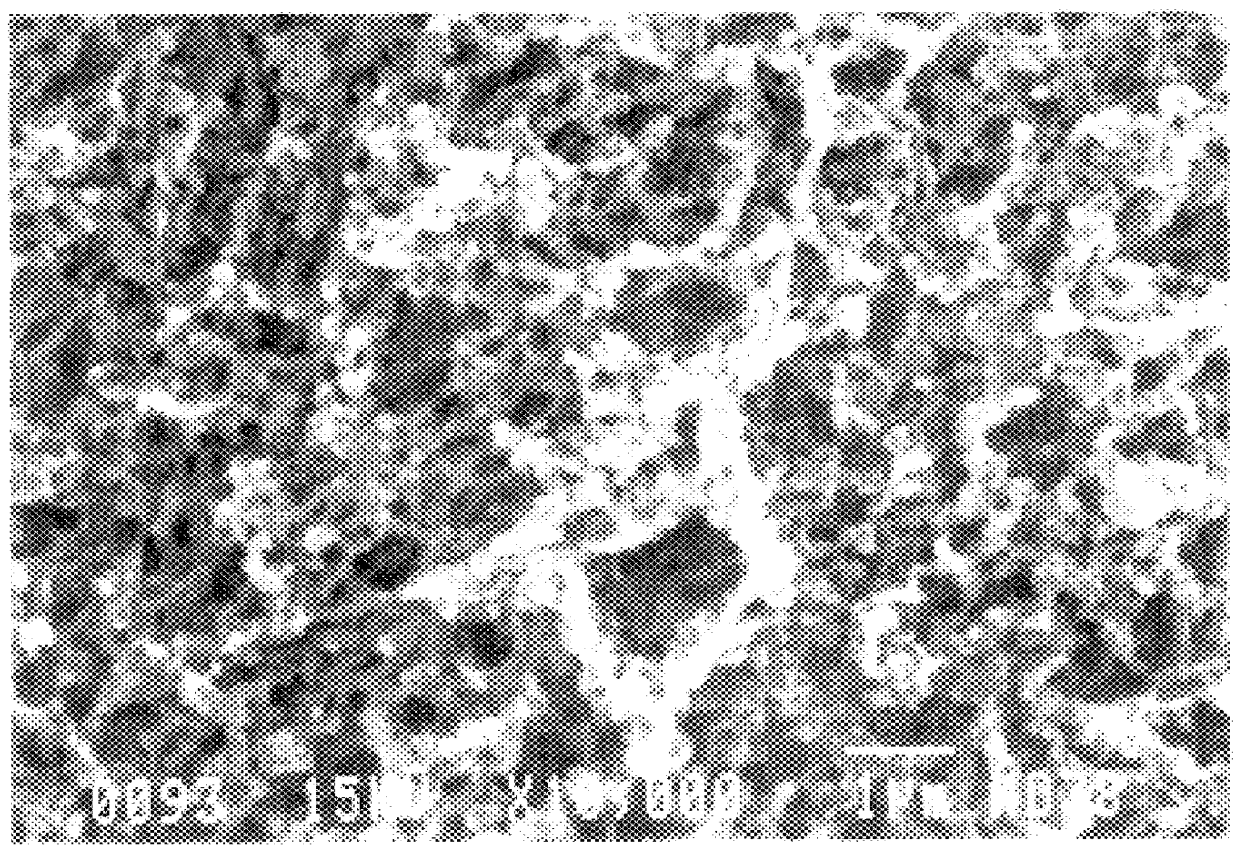

Nanoparticles of silicon oxide alloys

Nanoparticles of silicon oxide alloys (i.e., oxides of SiMo, SiPt, and SiAl) are produced by laser vaporization of a silicon target and a target of a metal (i.e., Mo, Pt, or Al), in an oxygen containing atmosphere in a diffusion cloud chamber, where the target metal vapors aggregate into novel three-dimensional porous web structures. The structures have a homogeneous composition with a uniform ratio of silicon to the metal.

Owner:VIRGINIA COMMONWEALTH UNIV

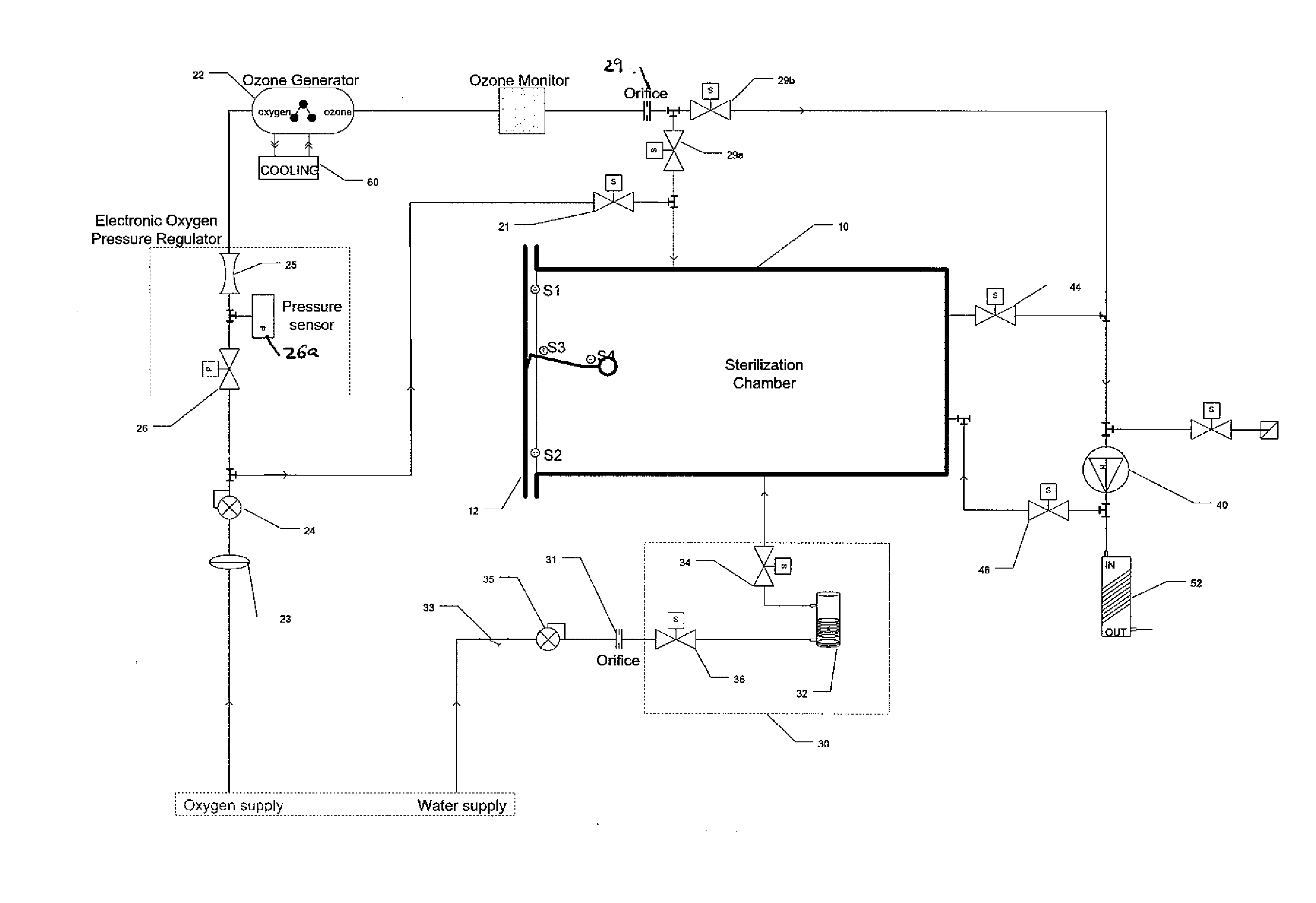

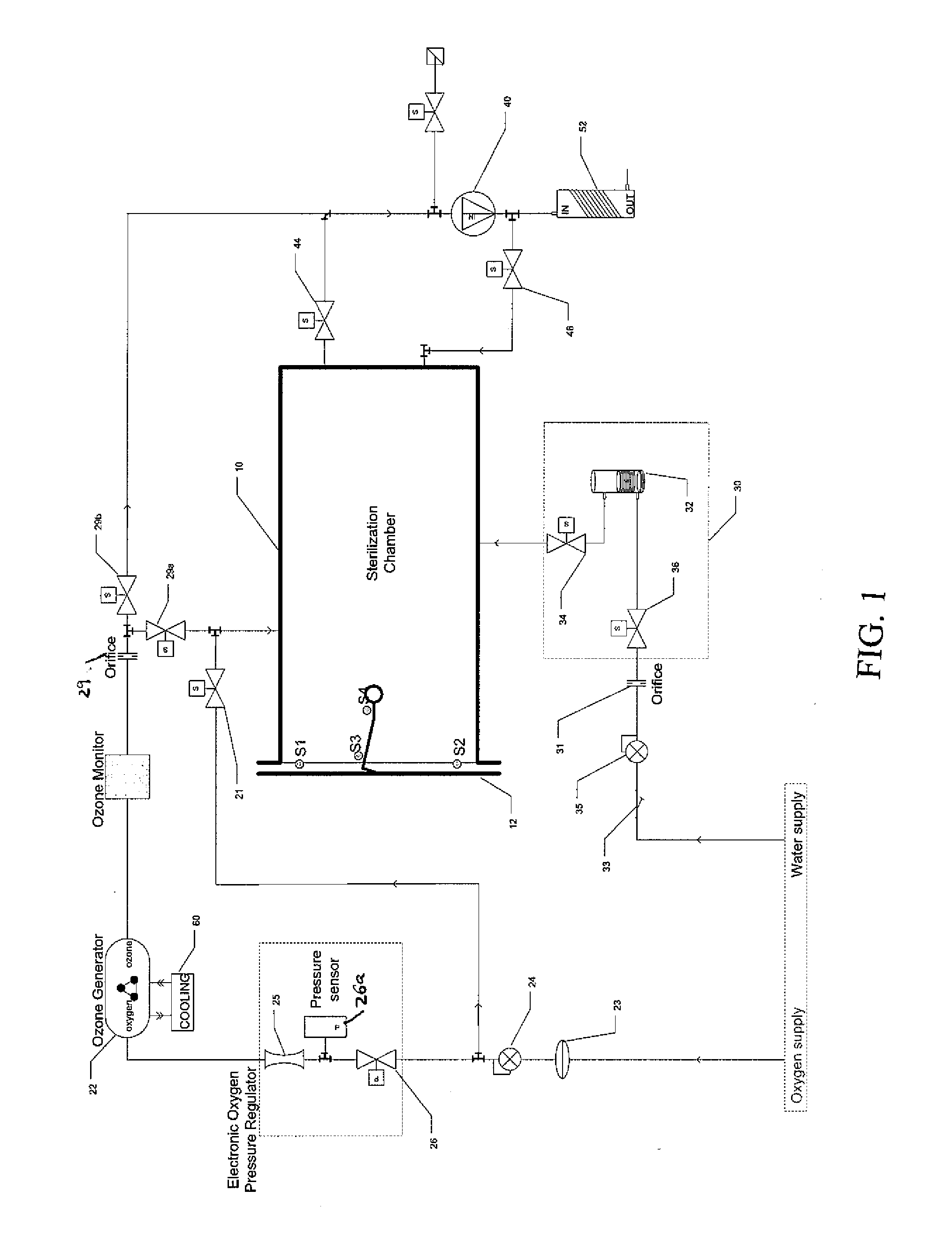

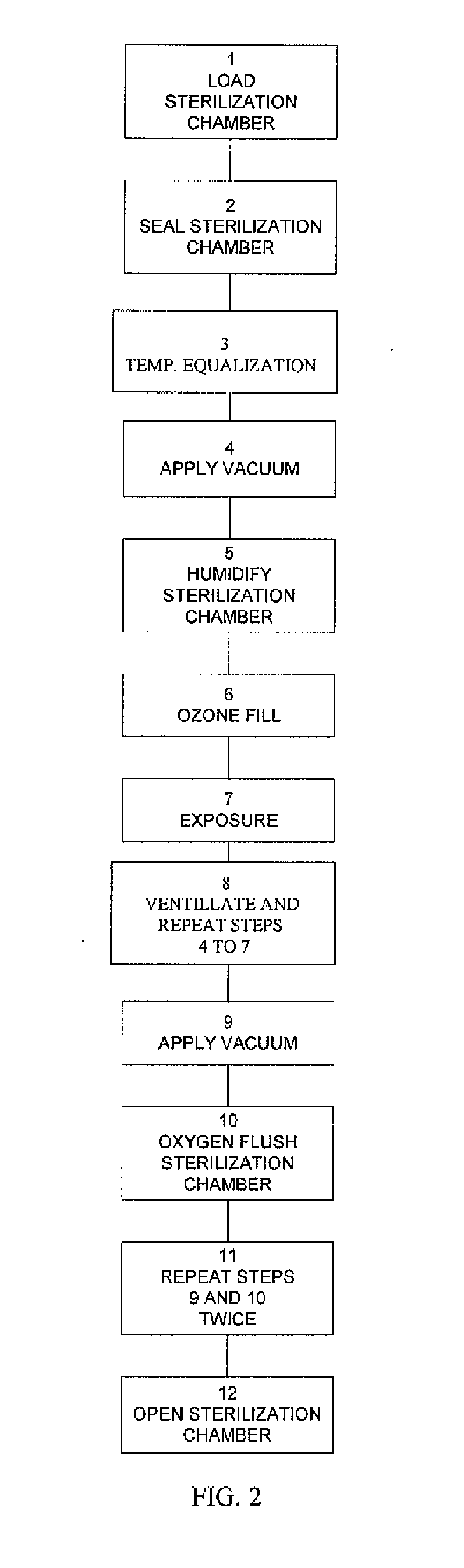

Method and apparatus for ozone sterilization

InactiveUS20070258855A1Avoid condensationPrevent water condensationElectrolysis componentsExhaust apparatusVacuum pressureWater vapor

The present invention provides a method and apparatus for sterilizing articles using an ozone-containing gas, where condensation of water from the sterilization atmosphere during the sterilization process is substantially prevented. The inventive sterilization method includes providing a sterilization chamber and placing an article into the sterilization chamber. The sterilization chamber is sealed prior to equalizing the temperature of the article and the atmosphere in the sterilization chamber. A vacuum is applied to achieve a preselected vacuum pressure in the sterilization chamber. Once the vacuum pressure is set, water vapour is supplied to the sterilization chamber. Ozone-containing gas is then supplied to the sterilization chamber and the sterilization chamber remains sealed for a preselected treatment period, where the sterilization chamber remains sealed throughout the whole process. Finally, vacuum in the sterilization chamber is released.

Owner:STRYKER CORP

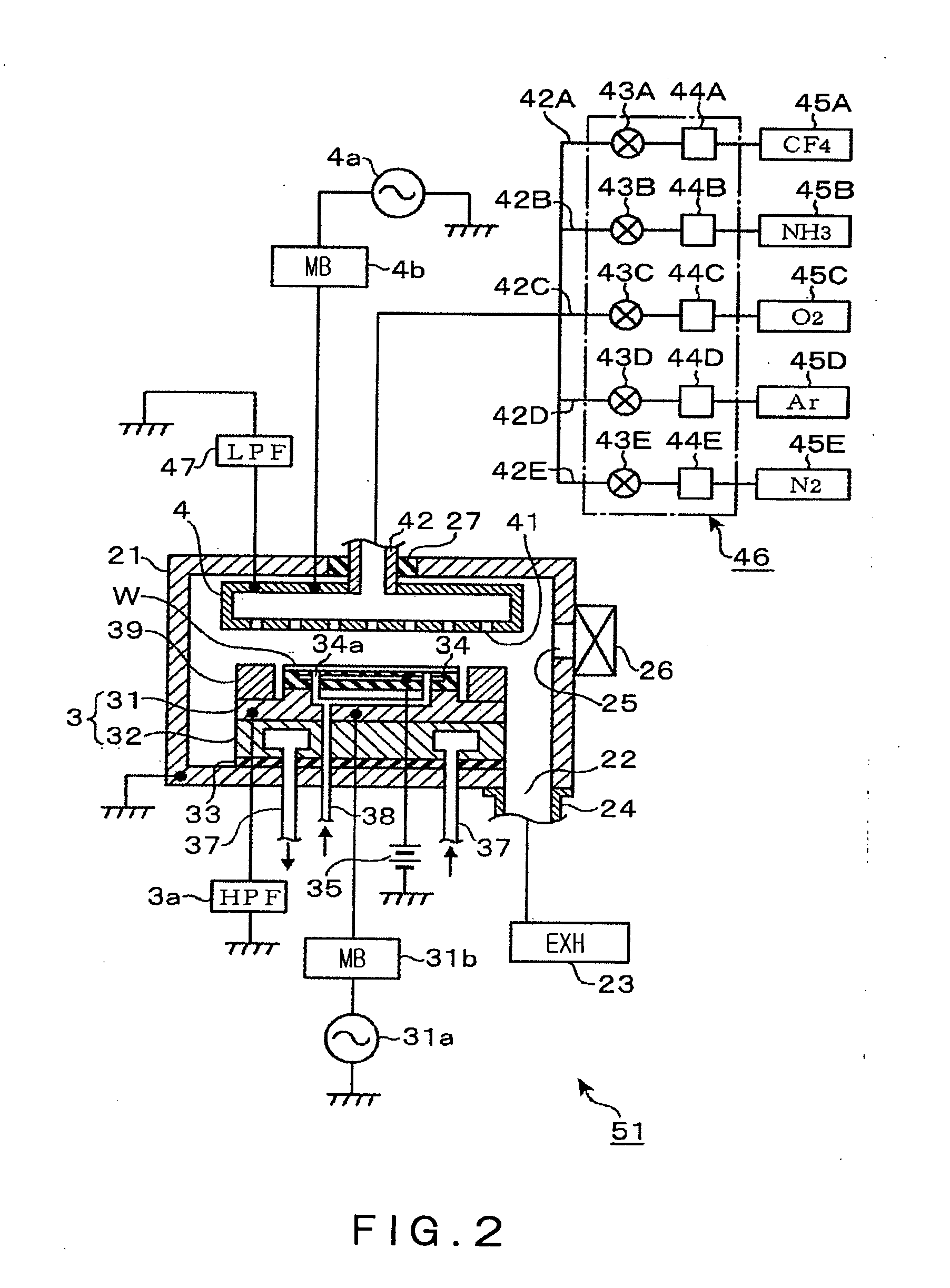

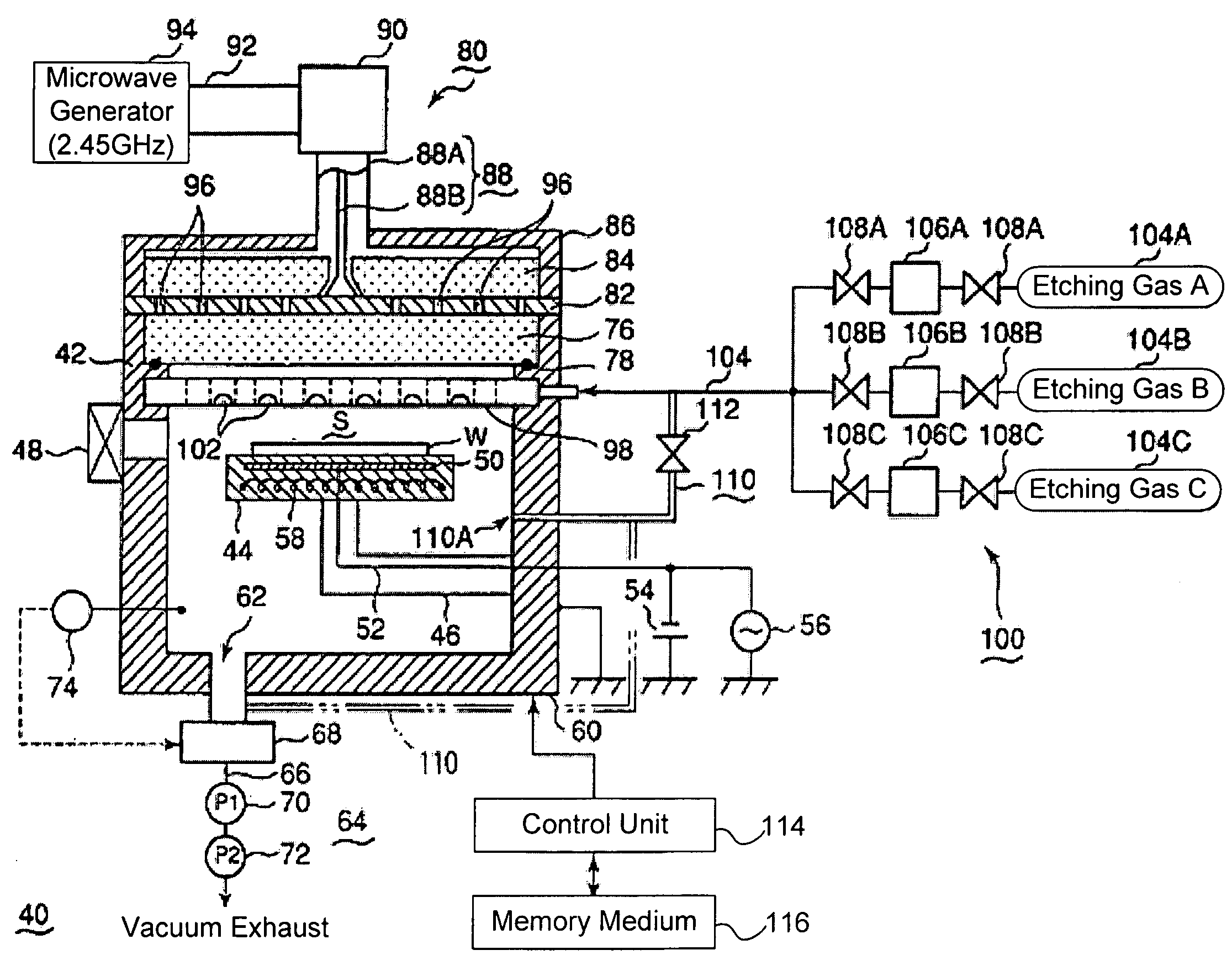

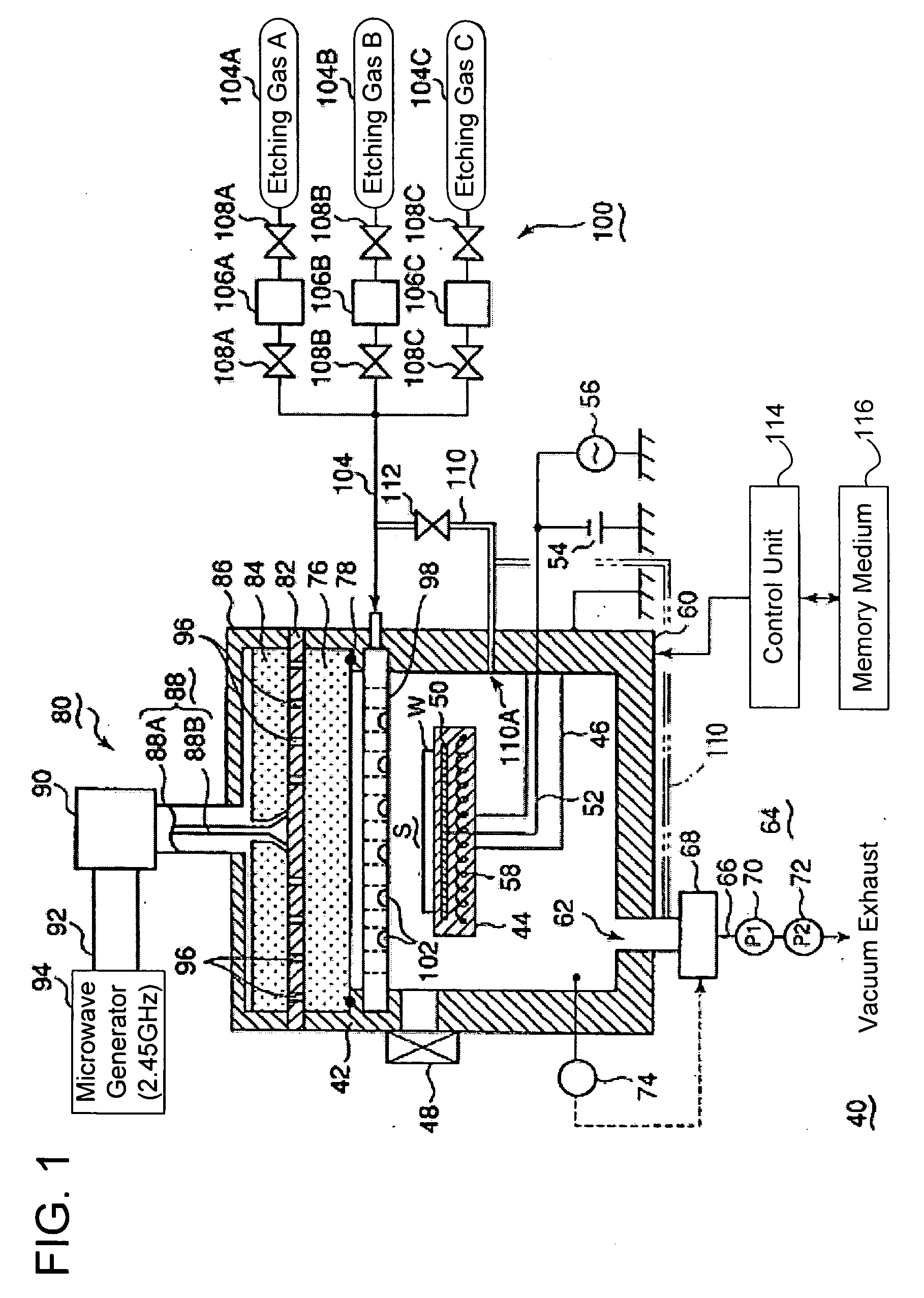

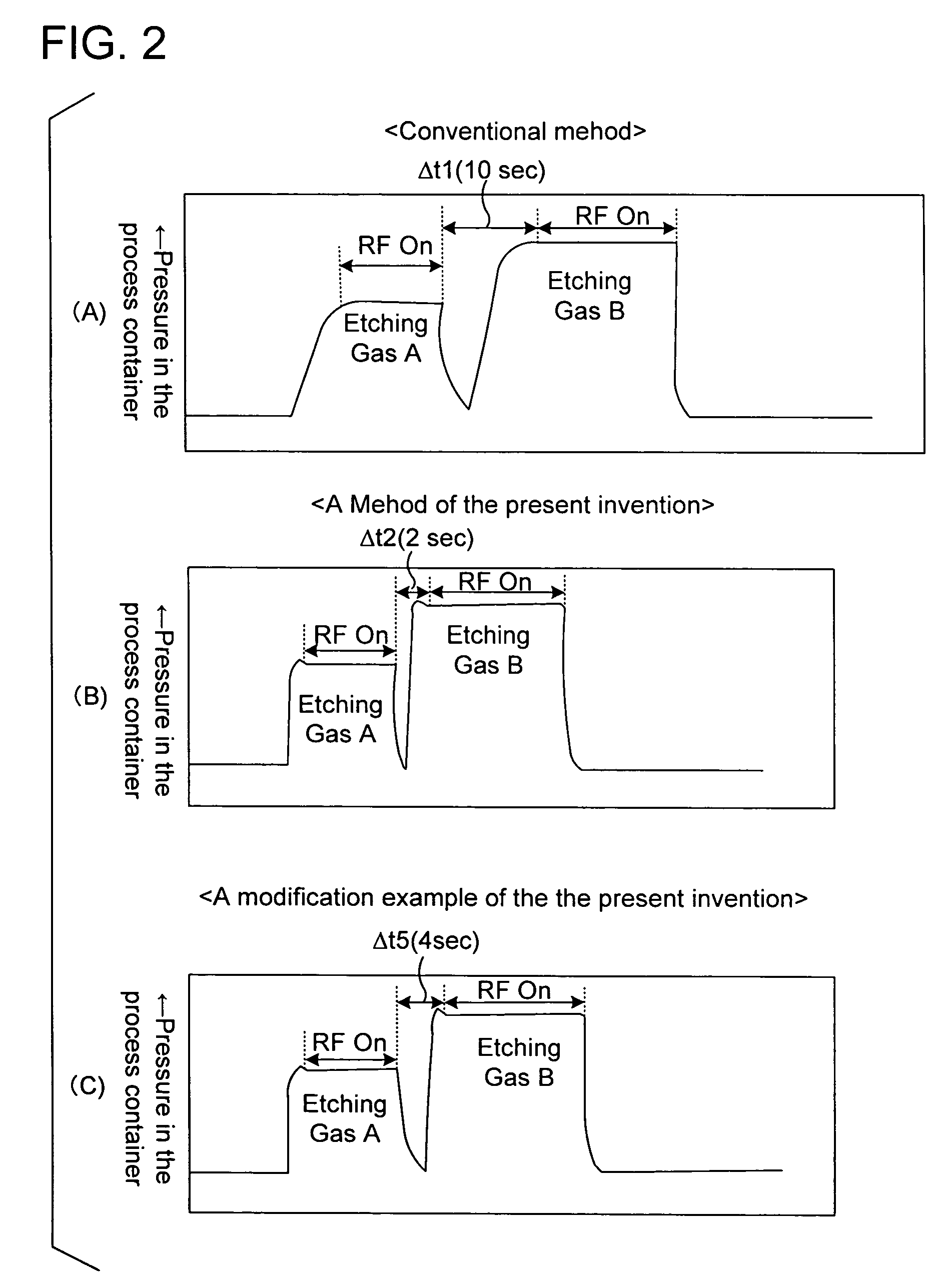

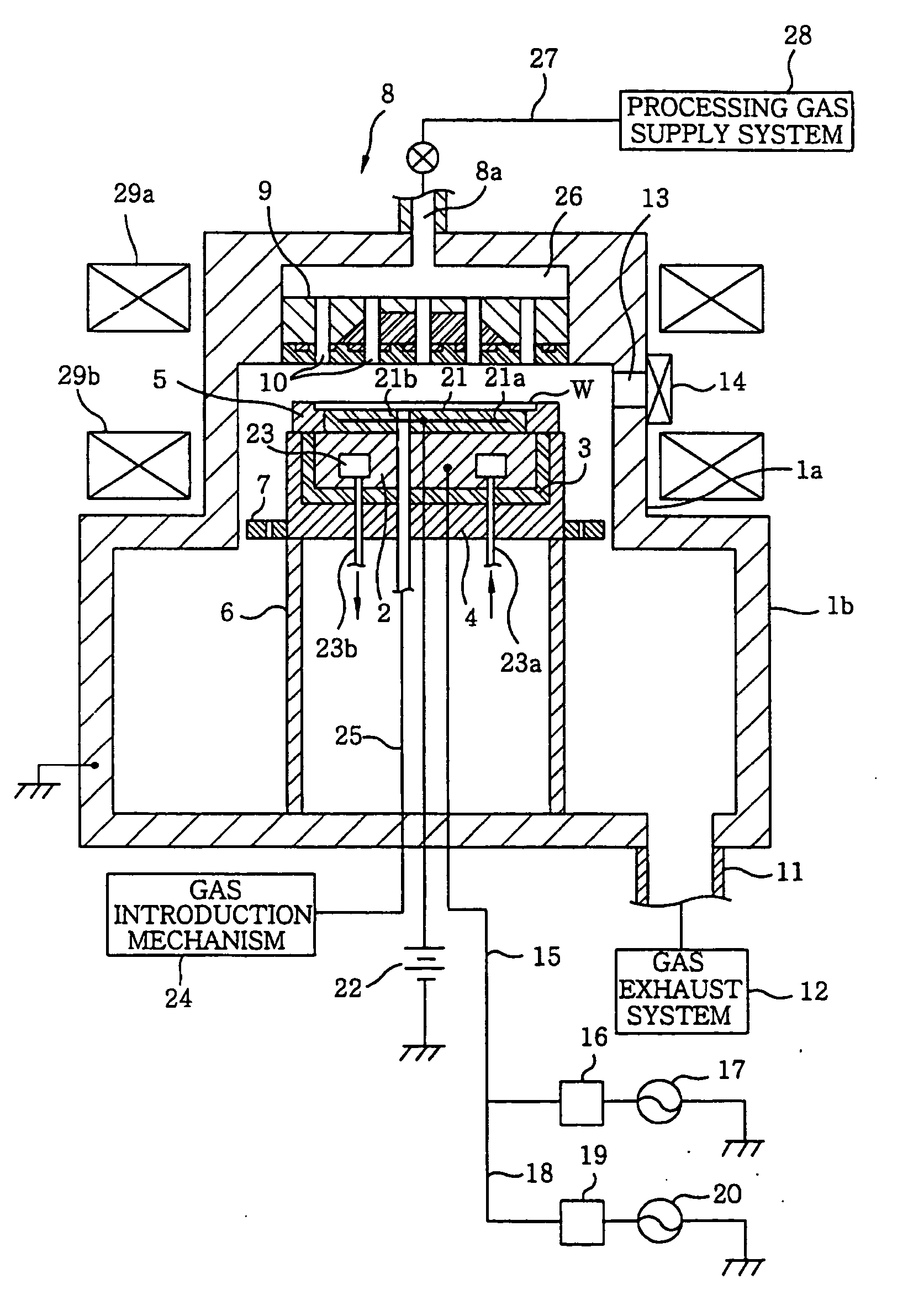

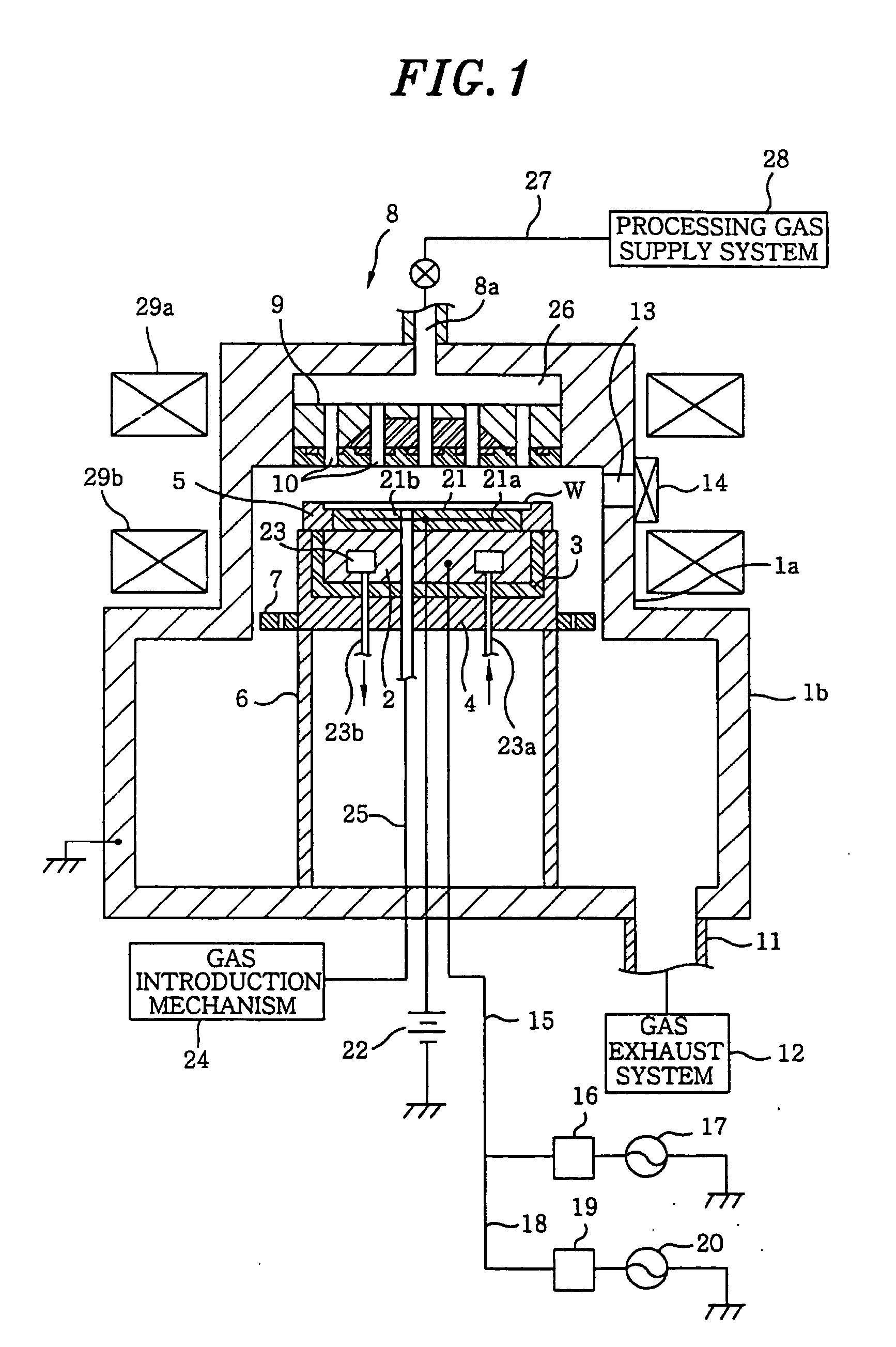

Processing Apparatus and Processing Method

ActiveUS20090053900A1Stable and fastAddressing slow performanceLiquid surface applicatorsElectric discharge tubesProduct gasEngineering

A processing apparatus includes a process container having a placing table for placing a processing object, an exhaust system having vacuum pumps and a pressure control valve for exhausting atmosphere in the process container. A gas injection unit having a gas ejection hole is provided in the process container, as well as a gas supplying unit for supplying a process gas to the gas injection unit. The entire process apparatus is controlled by a controlling unit. The control unit controls the exhaust system and the gas supplying unit. When starting a predetermined process, the process gas at a flow rate greater than a prescribed flow rate is supplied for a short time while exhausting the atmosphere in the process container by the exhaust system, and then the process gas at a prescribed flow rate is supplied.

Owner:TOKYO ELECTRON LTD

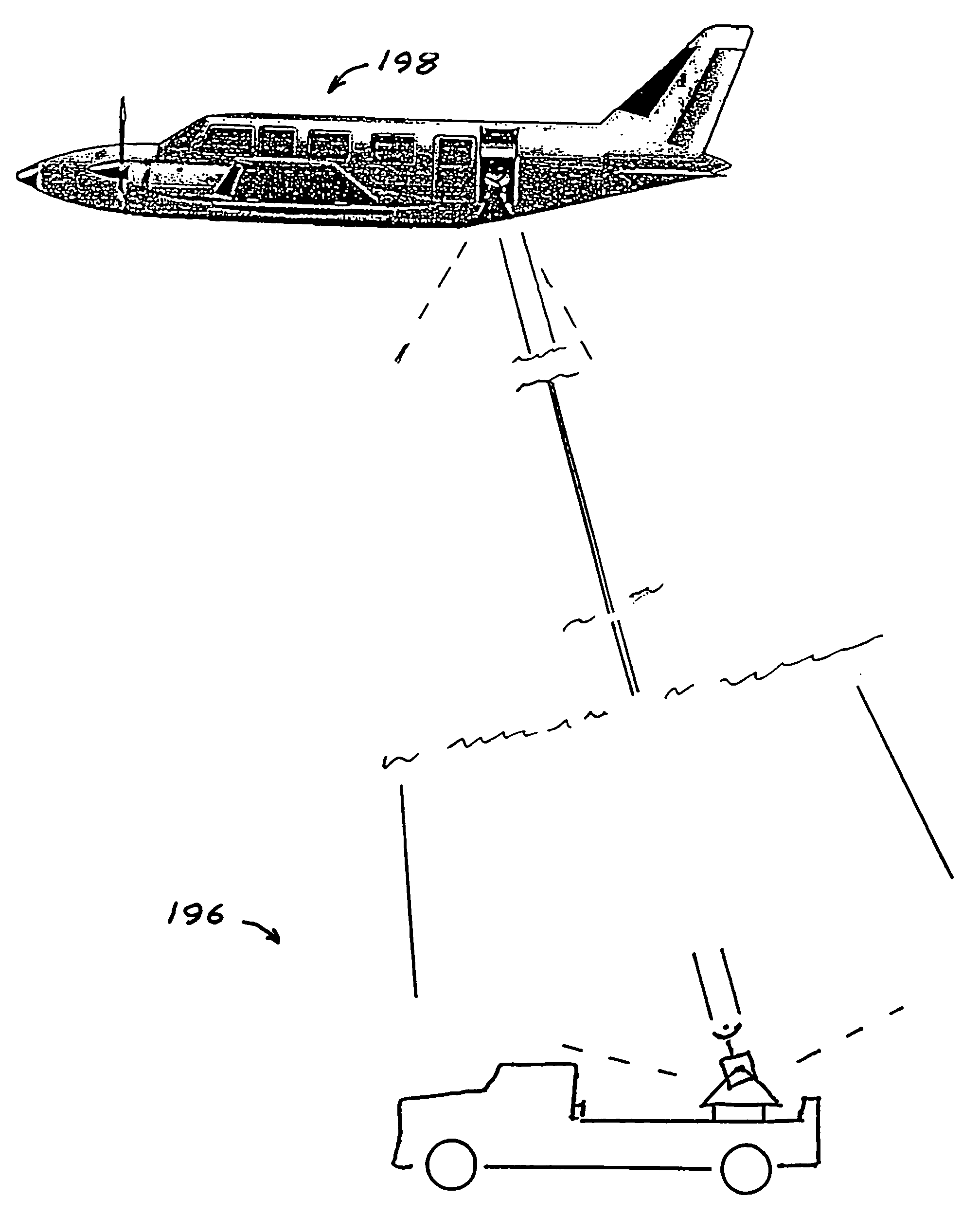

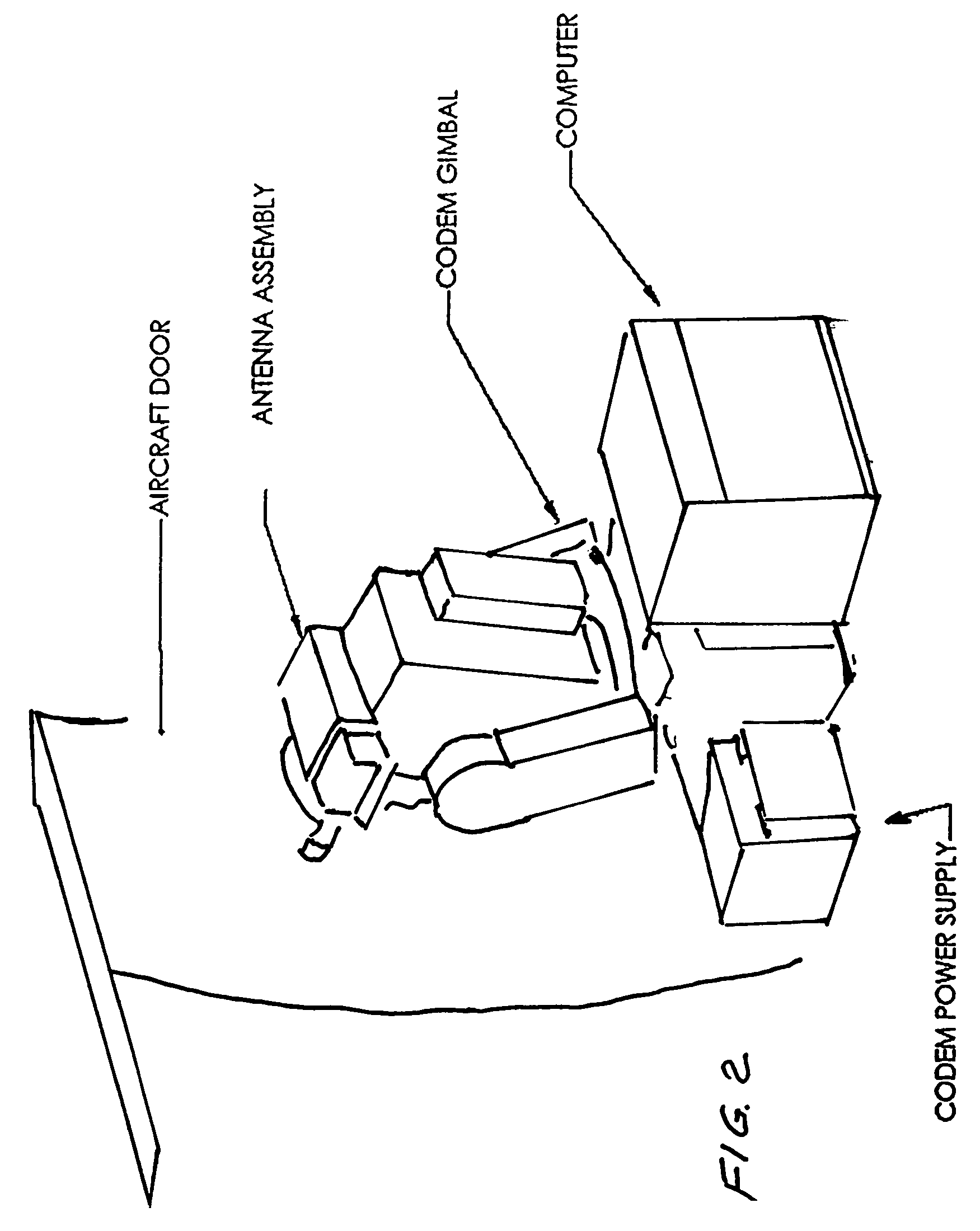

Mobile millimeter wave communication link

A point-to-point, wireless, millimeter wave communications link between two stations at least one of which is a mobile station. A millimeter wave transmitter system operating at frequencies higher than 57 GHz with a tracking antenna producing a beam having a half-power beam width of about 2 degrees or less and a millimeter wave receiver also with a tracking antenna having a half-power beam width of about 2 degrees or less. In preferred embodiments each mobile station has a global position system (GPS) and a radio transmitter and both tracking antennas are pointed utilizing GPS information from the mobile station or stations. The GPS information preferably is transmitted via a low frequency, low data rate radio. Each millimeter wave unit is capable of transmitting and / or receiving, through the atmosphere, digital information to / from the other station at rates in excess of 155 million bits per second during normal weather conditions. In preferred embodiments actually built and tested by Applicants digital information has been transmitted at rates of 1.25 gigabits per second. Preferred communication links described here are millimeter wave links operating at frequencies of 71-73 GHz and 74-76 GHz mounted on simple two-axis gimbals. Pointing information of the required accuracy is provided by GPS receivers and standard radio links which send the GPS calculated positions to the millimeter wave systems at the opposite end of the link. In these embodiments there is no need for any complicated closed loop pointing information derived from received signal intensity or phase. On moving platforms locally generated inertial attitude information is combined with the GPS positions to control pointing of the gimbaled transceivers.

Owner:TREX ENTERPRISES CORP

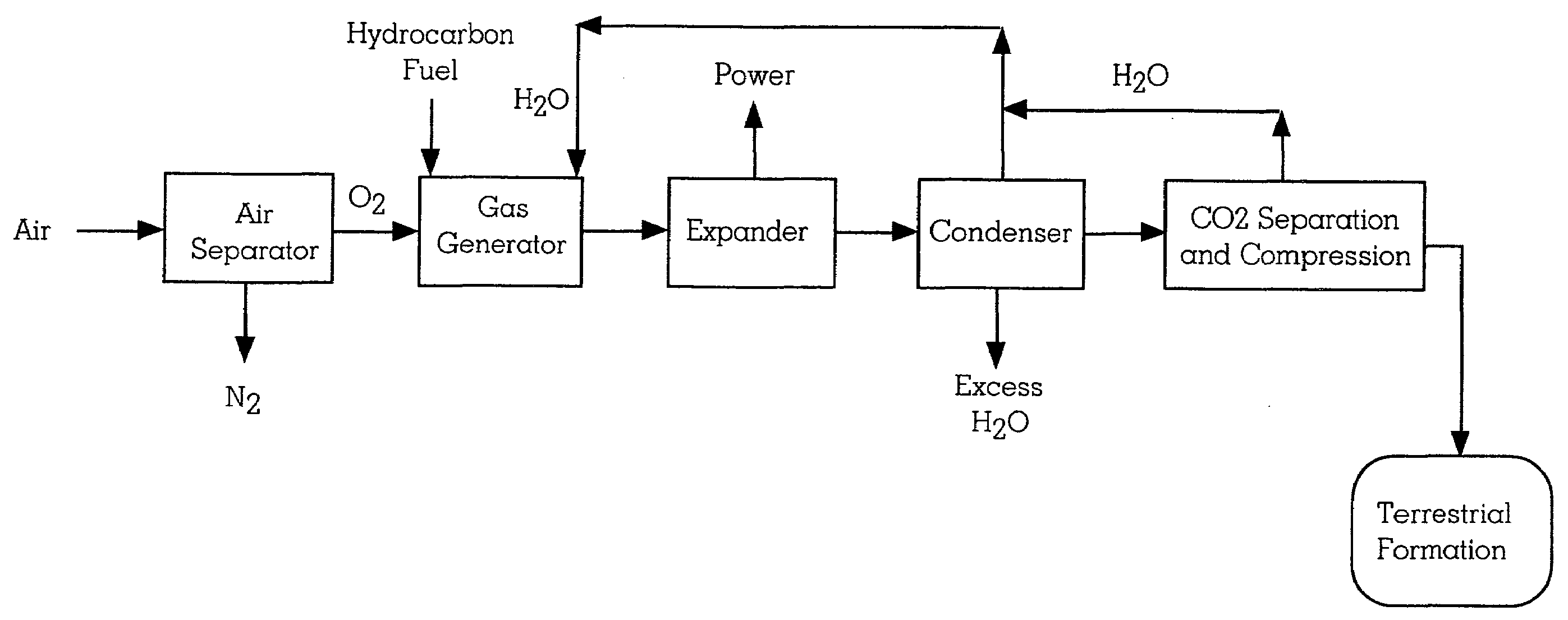

Hydrocarbon combustion power generation system with CO2 sequestration

InactiveUS7043920B2Eliminate needReduce electricity demandReciprocating combination enginesSolidificationAtmospheric airOxygen

A low or no pollution engine is provided for delivering power for vehicles or other power applications. The engine has an air inlet which collects air from a surrounding environment. At least a portion of the nitrogen in the air is removed. The remaining gas is primarily oxygen, which is then routed to a gas generator. The gas generator has inputs for the oxygen and a hydrocarbon fuel. The fuel and oxygen are combusted within the gas generator, forming water and carbon dioxide. The combustion products are then expanded through a power generating device, such as a turbine or piston expander to deliver output power for operation of a vehicle or other power uses. The combustion products are then passed through a condenser where the steam is condensed and the carbon dioxide is collected or discharged. A portion of the water is routed back to the gas generator. The carbon dioxide is compressed and delivered to a terrestrial formation from which return of the CO2 into the atmosphere is inhibited.

Owner:CLEAN ENERGY SYST

Thermally sprayed member, electrode and plasma processing apparatus using the electrode

ActiveUS20050211384A1High-frequency powerAvoid flowMolten spray coatingElectric discharge tubesThermal sprayingInter layer

A thermally sprayed member or an electrode includes a basic material, a thermally sprayed film formed on the surface of the basic material, the thermally sprayed film being made of an insulating ceramic and a metallic intermediate layer provided between the basic material and the thermally sprayed film for increasing a bonding force therebetween, wherein the thermally sprayed film side of the member is exposed to a high frequency plasma atmosphere and the electrode is intended to form a high frequency plasma on the side of the thermally sprayed film. The basic material includes a base portion made of a conductive material and a dielectric portion provided to include a part of a surface of the basic material. Further, the intermediate layer is comprised of a plurality of island-shaped parts isolated from each other.

Owner:TOKYO ELECTRON LTD

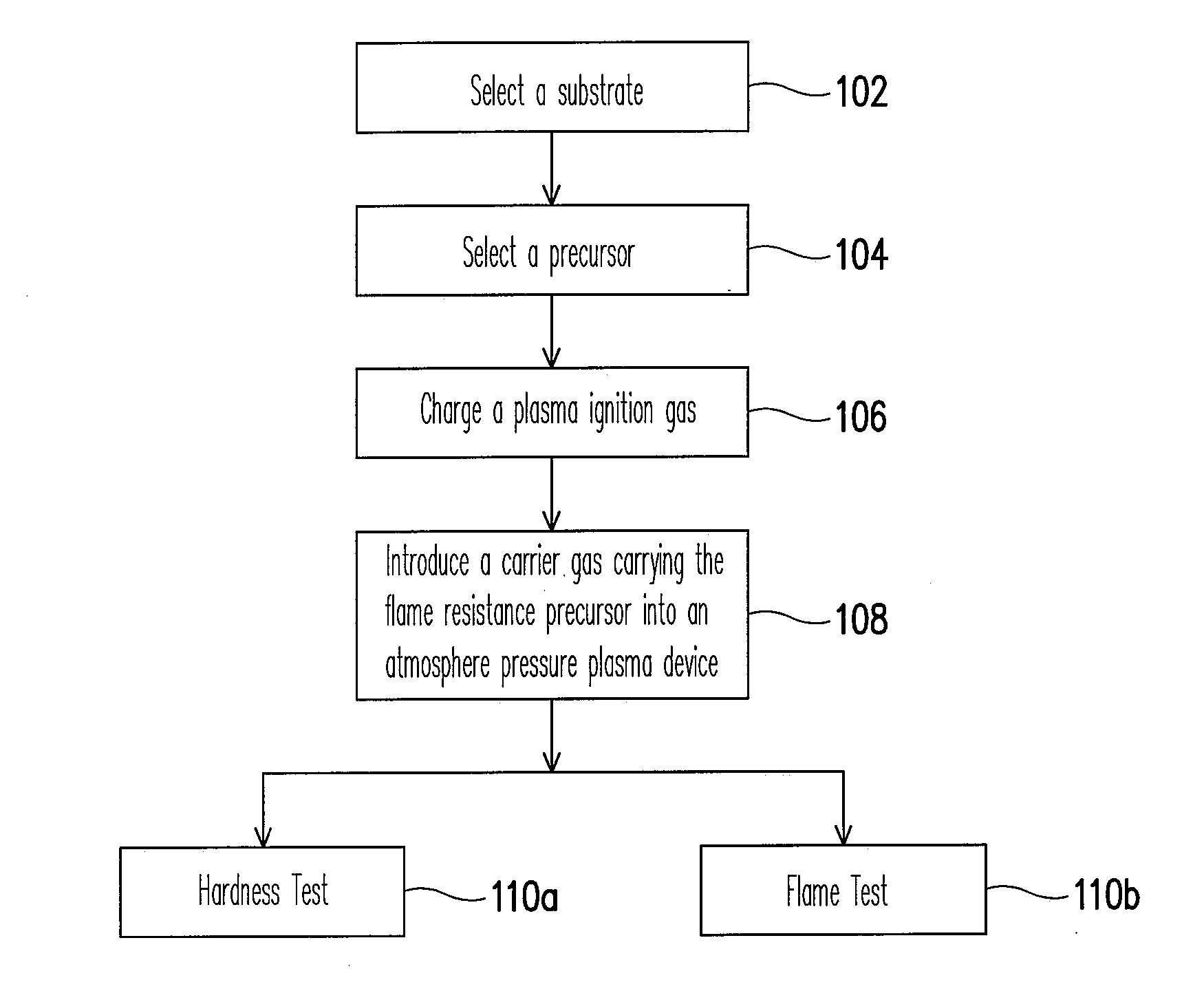

Method of improving surface flame resistnace of substrate

InactiveUS20080105276A1Improve flame retardant performanceSurface cleaningElectrostatic cleaningChemical vapor deposition coatingPlasma ignitionAtmosphere

A method of improving surface flame resistance of a substrate is provided. A substrate is provided. An atmosphere pressure plasma process is performed on the surface of the substrate to form an inorganic film layer on the surface of the substrate, wherein a process gas of the atmosphere plasma process includes a flame resistance precursor, a carrier gas, and a plasma ignition gas. Particularly, the flame resistance precursor is selected from a siloxane compound, an inorganic alkoxide compound and a combination thereof. The siloxane compound has a formula of Si(OCnH2(n+1))4, n=1˜5, and the inorganic alkoxide compound has a formula of A(OCmH2m+1)4, where A represents Sn, Ti, Zr, Ce and m=2.

Owner:IND TECH RES INST

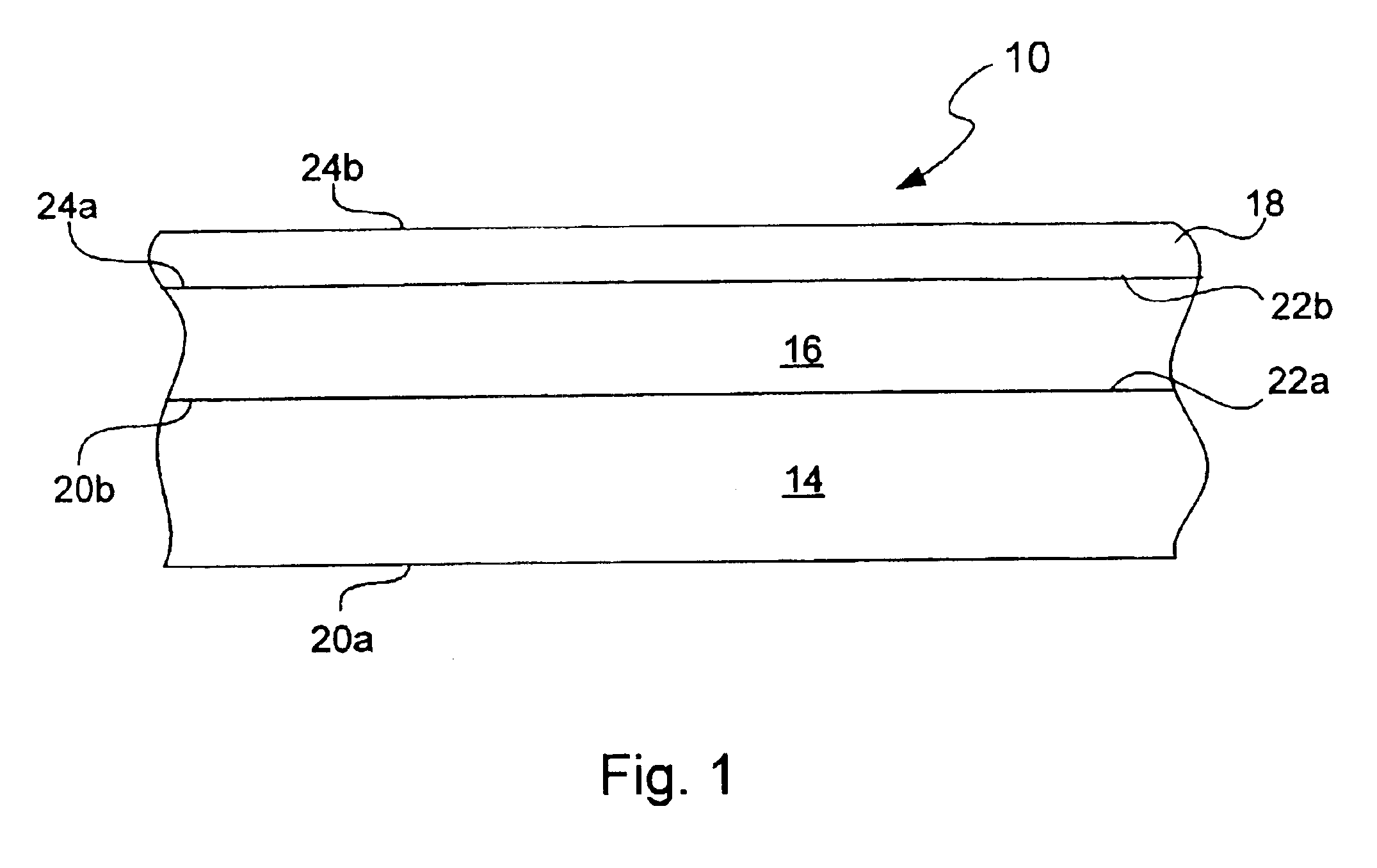

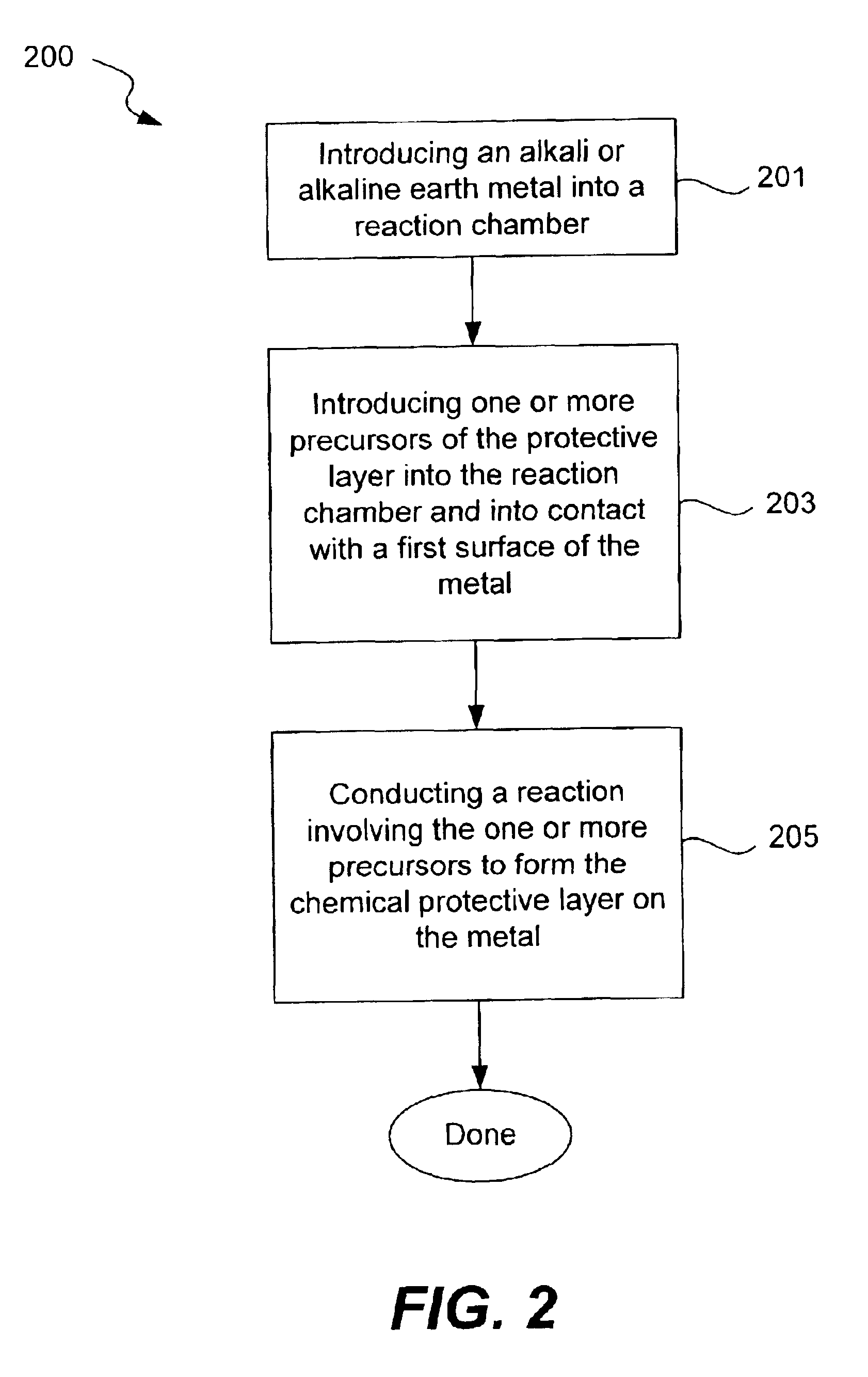

Chemical protection of a lithium surface

InactiveUS6911280B1Easy to produceSimple processElectrochemical processing of electrodesFinal product manufactureAlkaline earth metalLithium metal

Disclosed are compositions and methods for alleviating the problem of reaction of lithium or other alkali or alkaline earth metals with incompatible processing and operating environments by creating a ionically conductive chemical protective layer on the lithium or other reactive metal surface. Such a chemically produced surface layer can protect lithium metal from reacting with oxygen, nitrogen or moisture in ambient atmosphere thereby allowing the lithium material to be handled outside of a controlled atmosphere, such as a dry room. Production processes involving lithium are thereby very considerably simplified. One example of such a process in the processing of lithium to form negative electrodes for lithium metal batteries.

Owner:POLYPLUS BATTERY CO INC

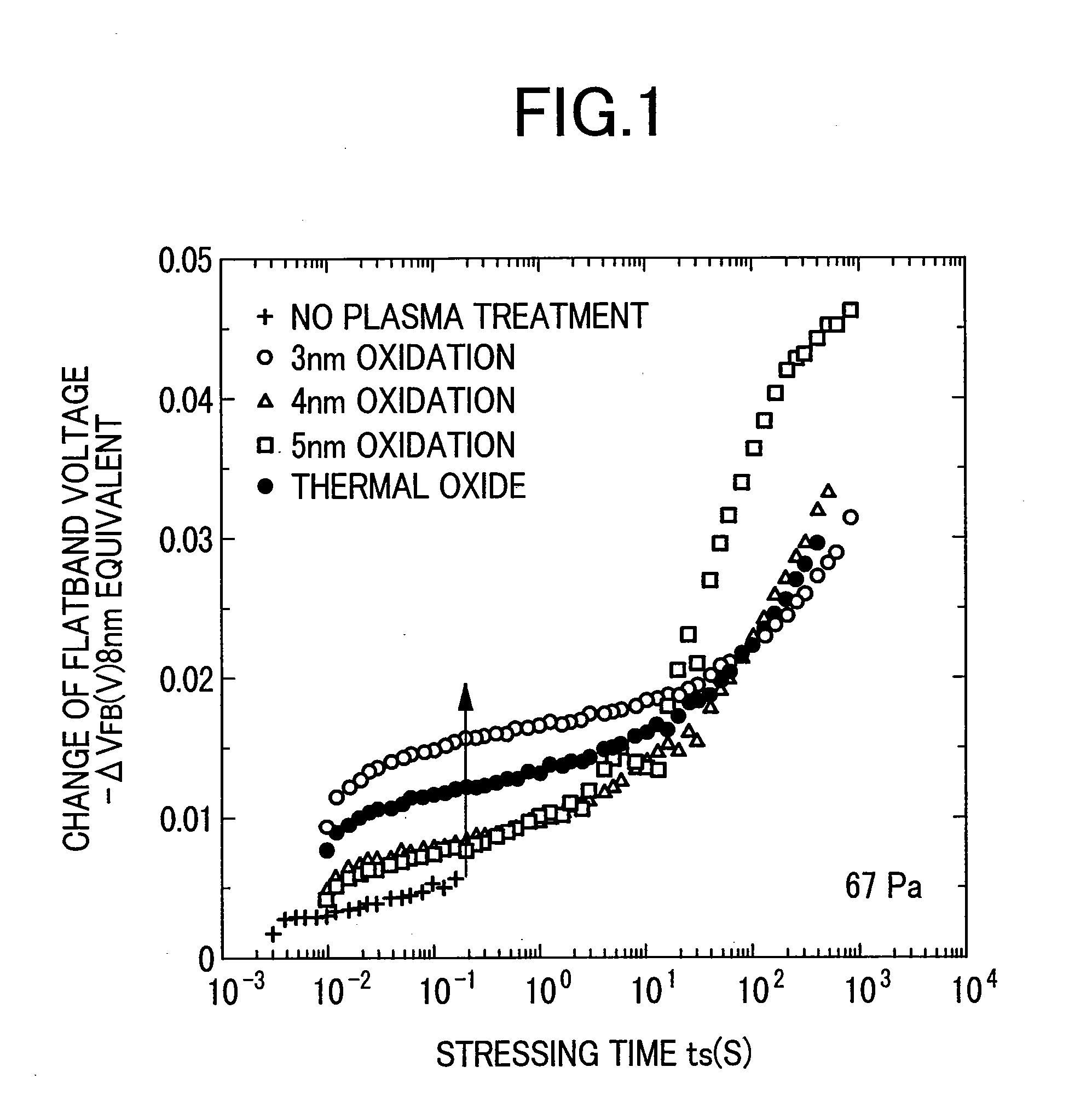

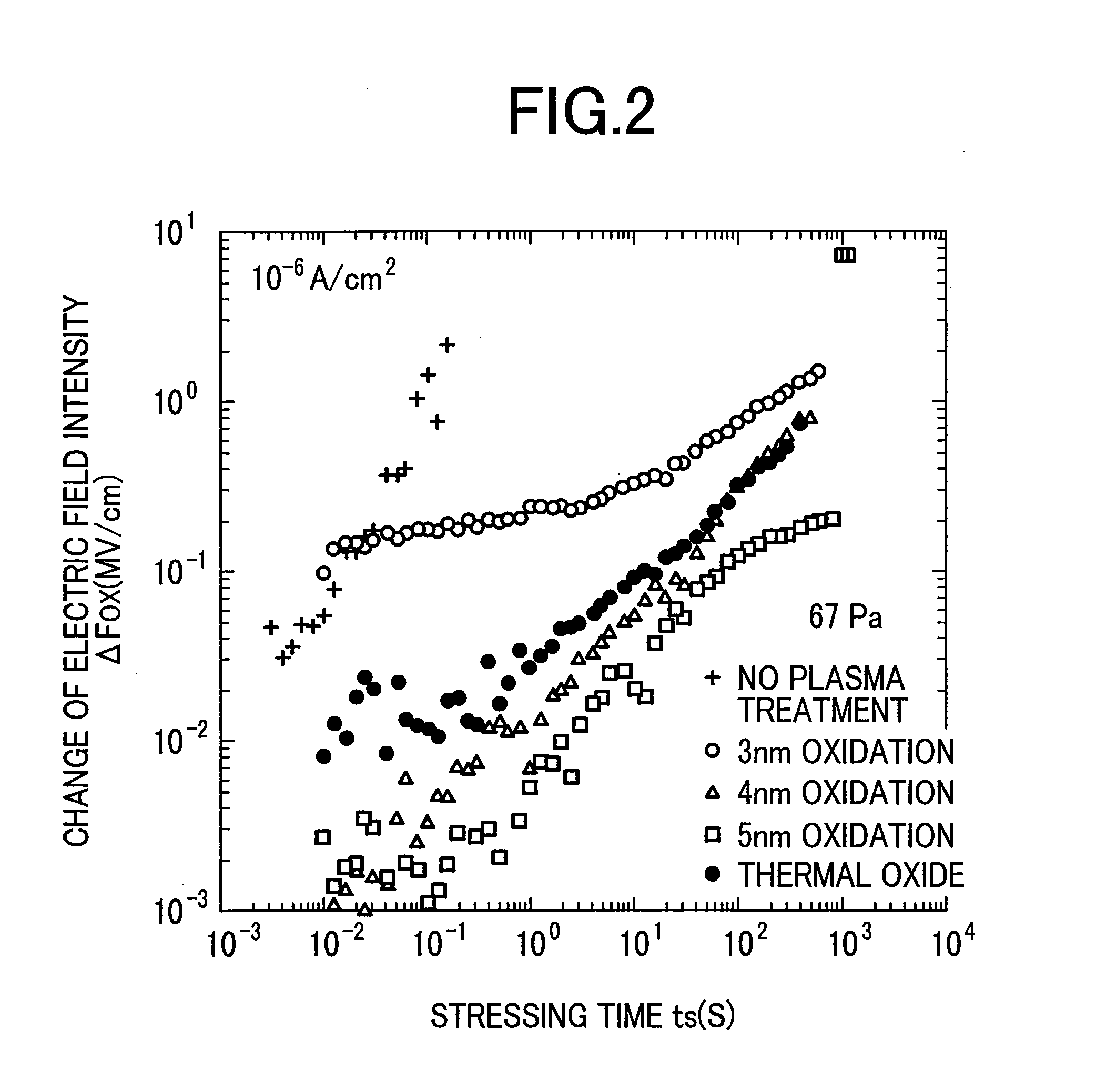

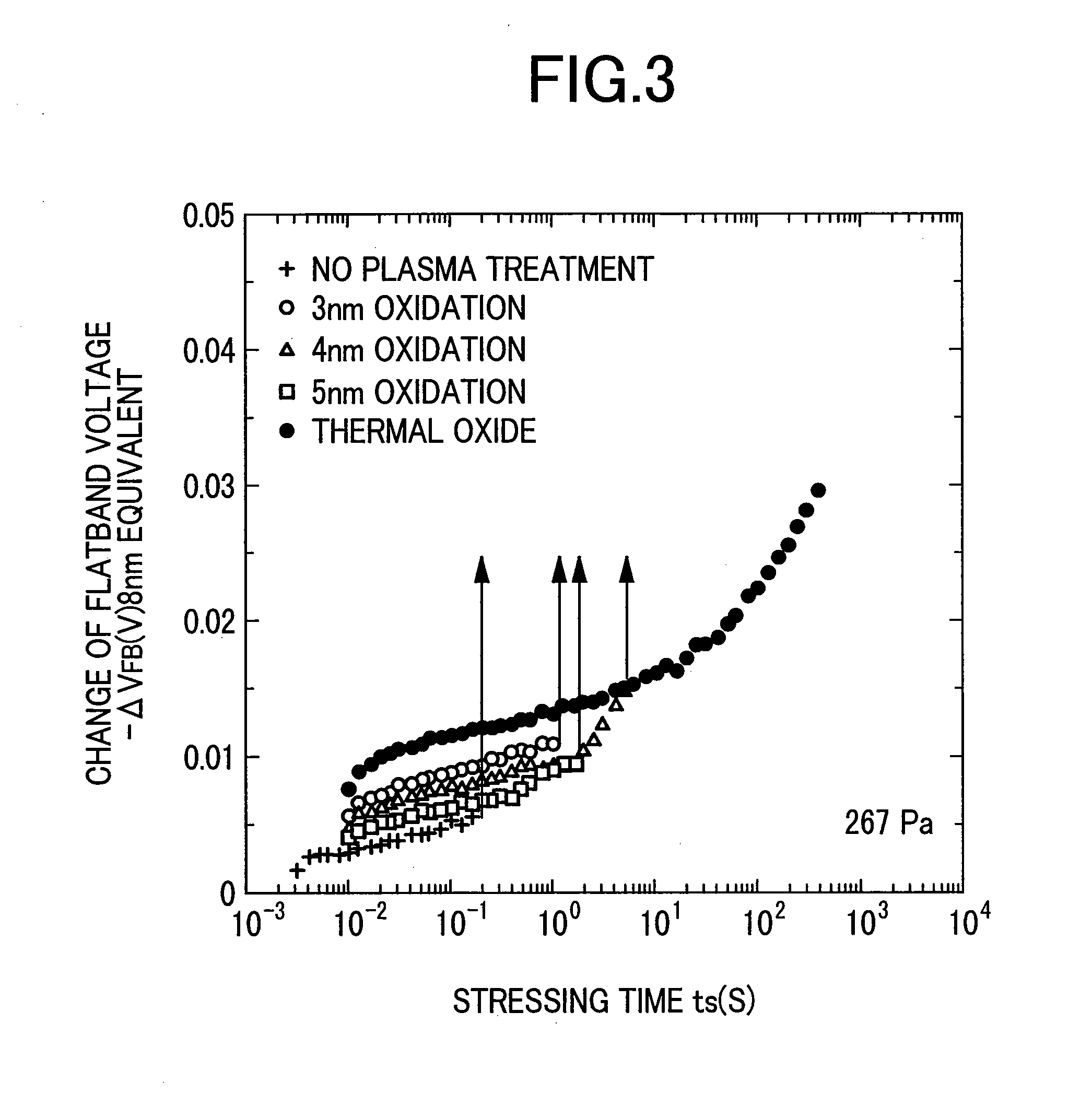

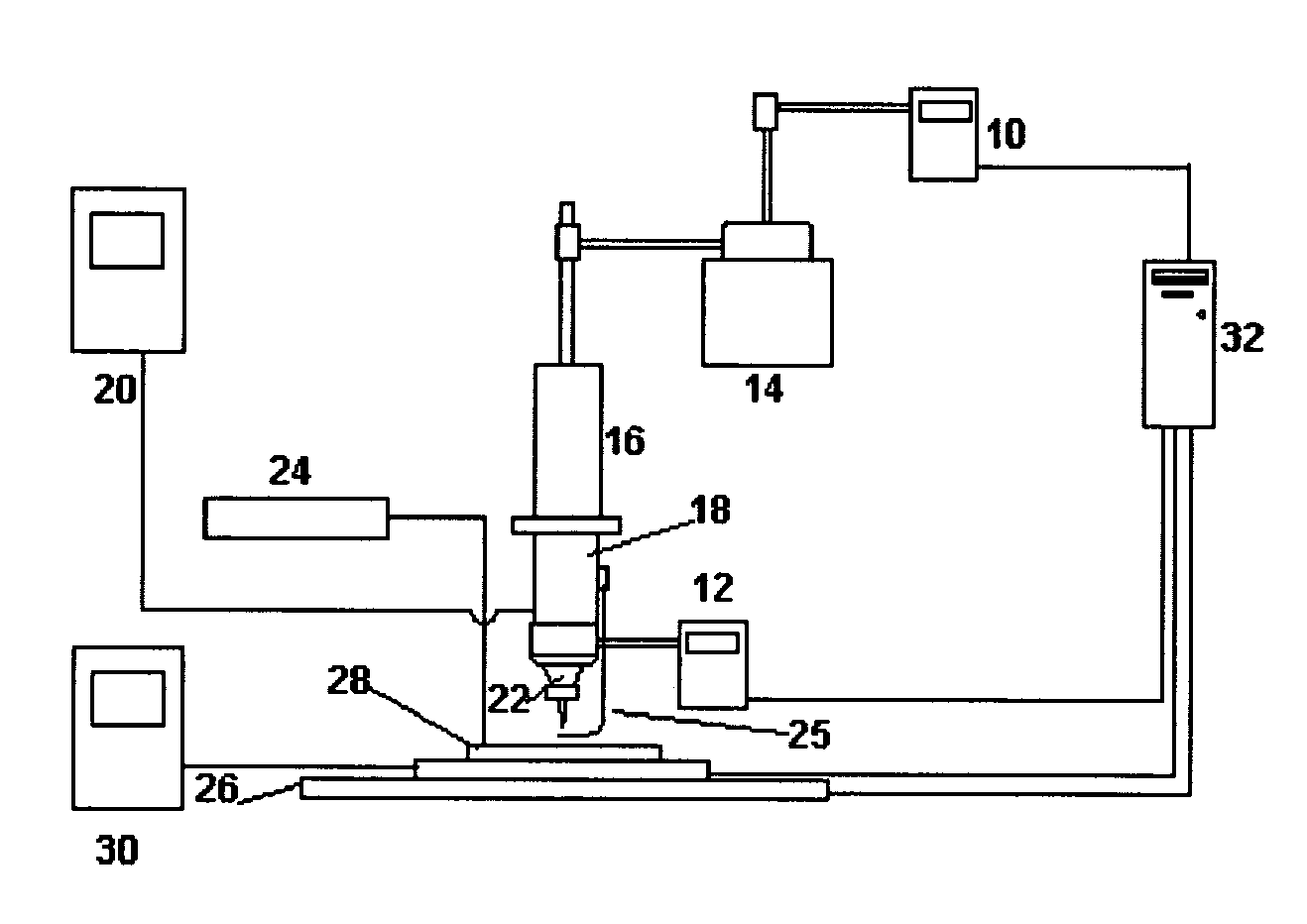

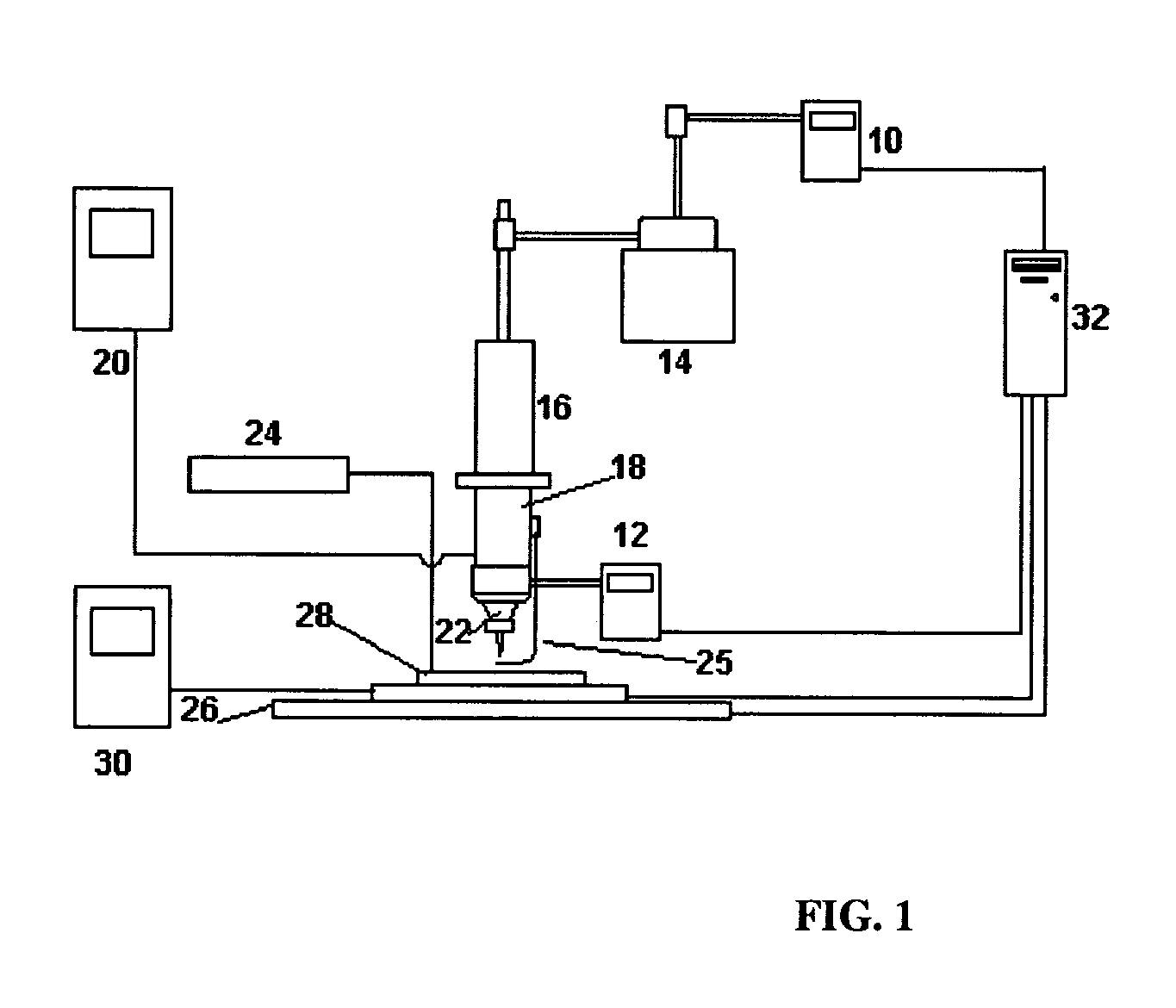

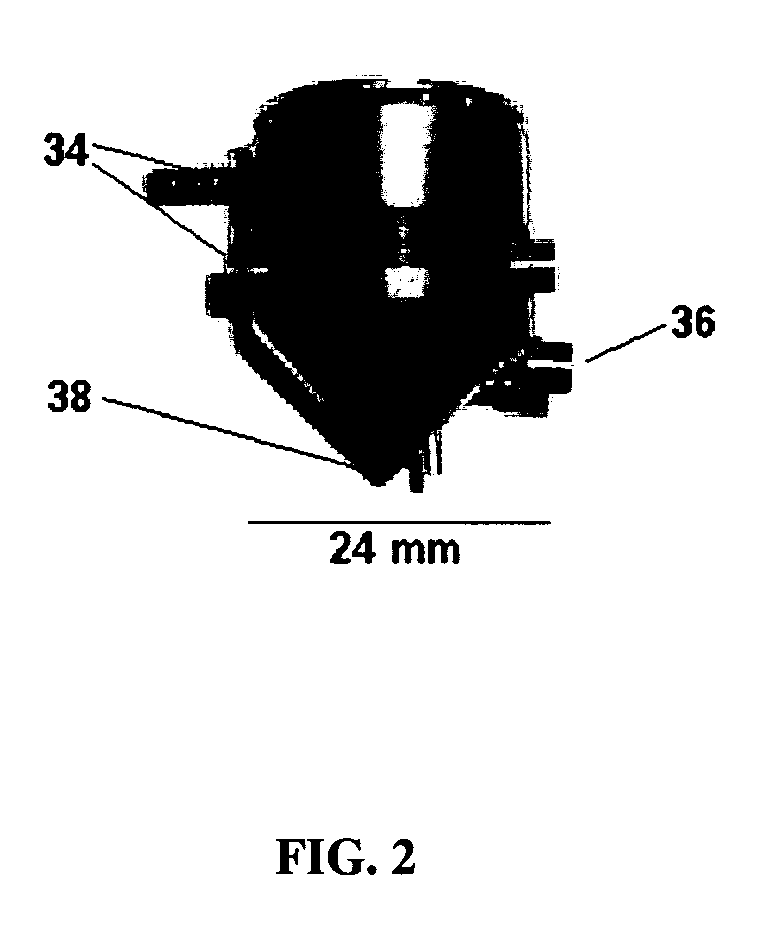

Method for fabricating semiconductor devices

InactiveUS20070190744A1TransistorSemiconductor/solid-state device detailsOxygen plasmaGate insulator

Owner:RENESAS ELECTRONICS CORP

Apparatuses and method for maskless mesoscale material deposition

InactiveUS7045015B2High resolutionPretreated surfacesLiquid/solution decomposition chemical coatingEngineeringBiological materials

Apparatuses and processes for maskless deposition of electronic and biological materials. The process is capable of direct deposition of features with linewidths varying from the micron range up to a fraction of a millimeter, and may be used to deposit features on substrates with damage thresholds near 100° C. Deposition and subsequent processing may be carried out under ambient conditions, eliminating the need for a vacuum atmosphere. The process may also be performed in an inert gas environment. Deposition of and subsequent laser post processing produces linewidths as low as 1 micron, with sub-micron edge definition. The apparatus nozzle has a large working distance—the orifice to substrate distance may be several millimeters—and direct write onto non-planar surfaces is possible.

Owner:OPTOMEC DESIGN CO

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com