Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

6289 results about "Contact region" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

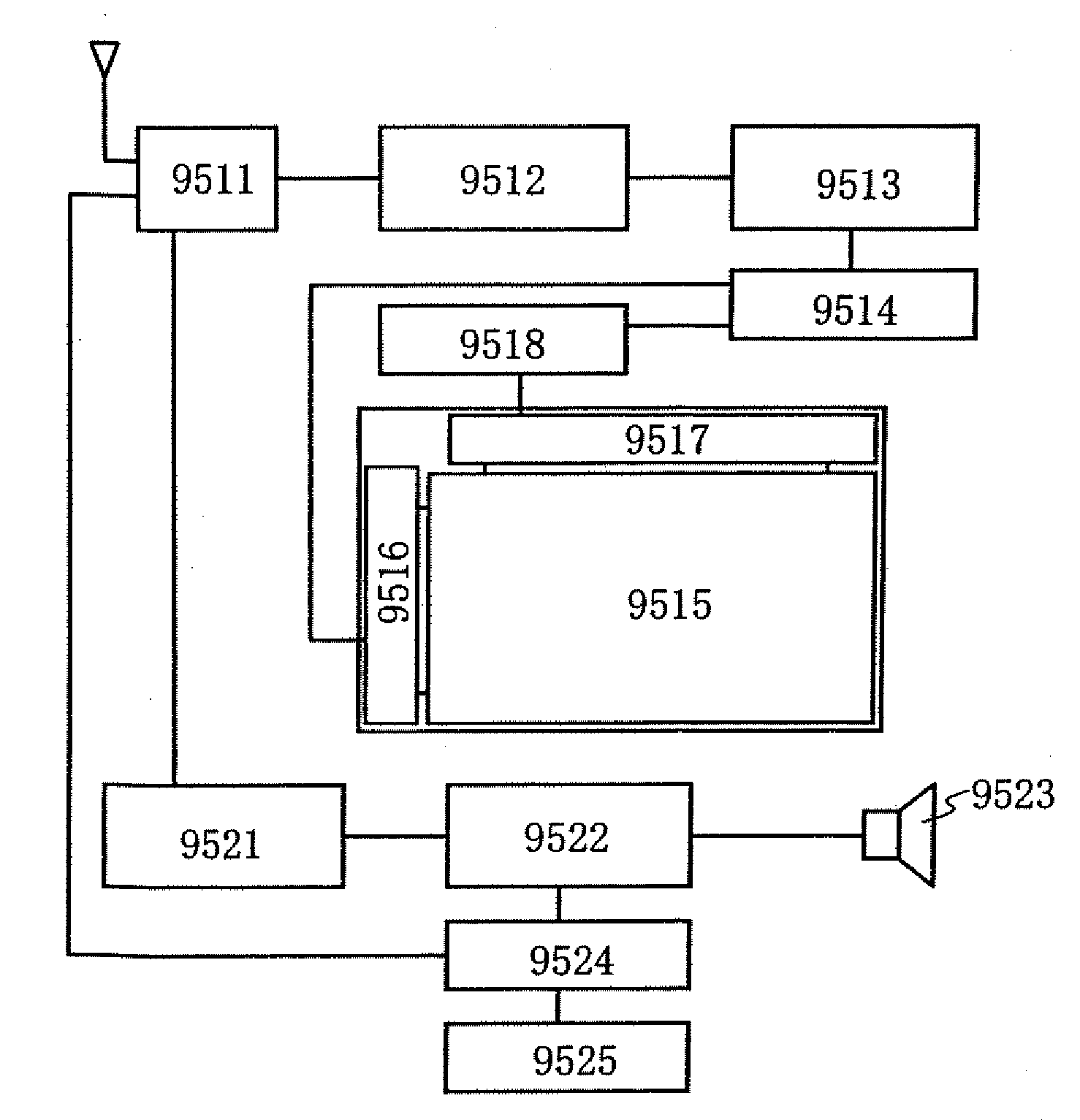

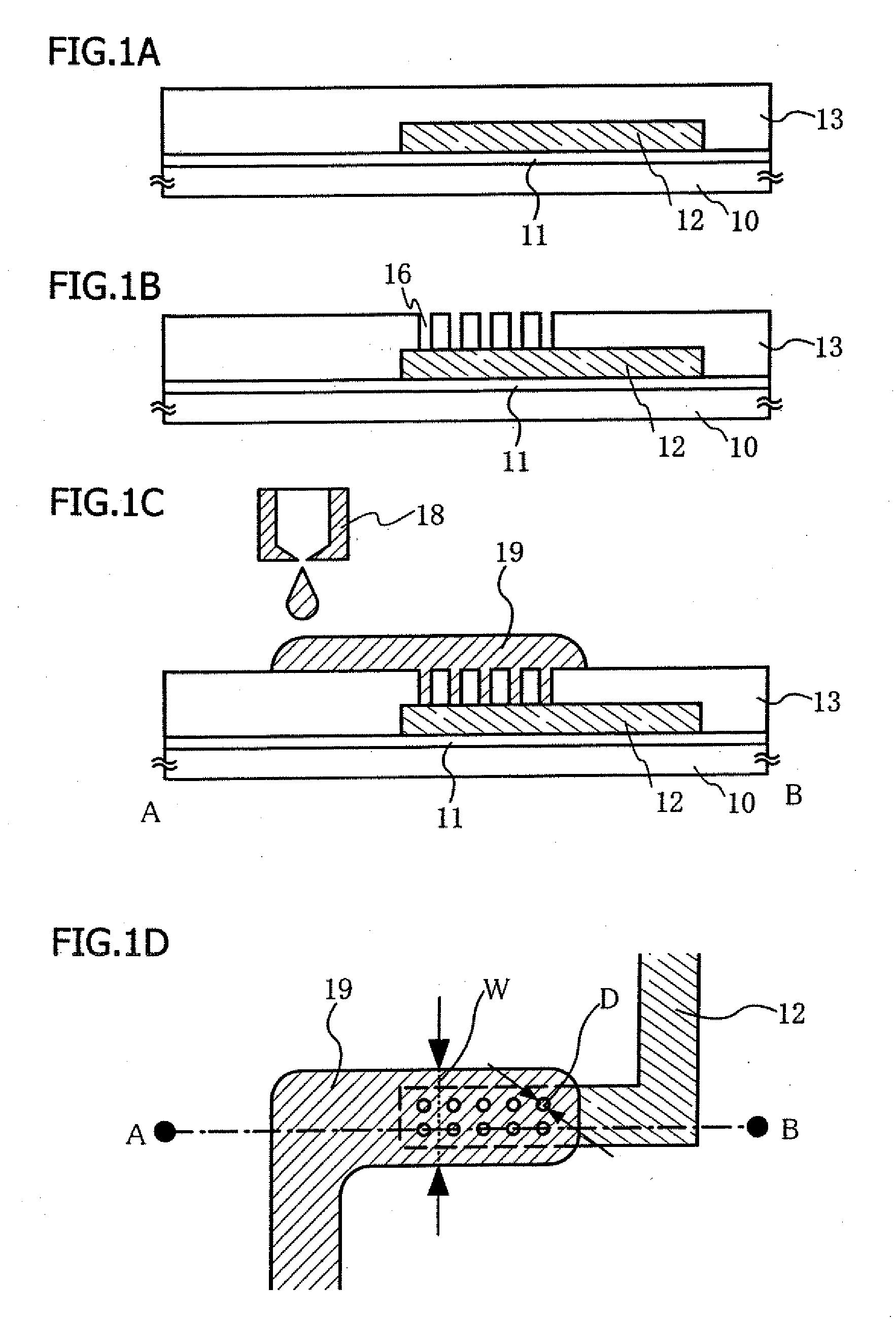

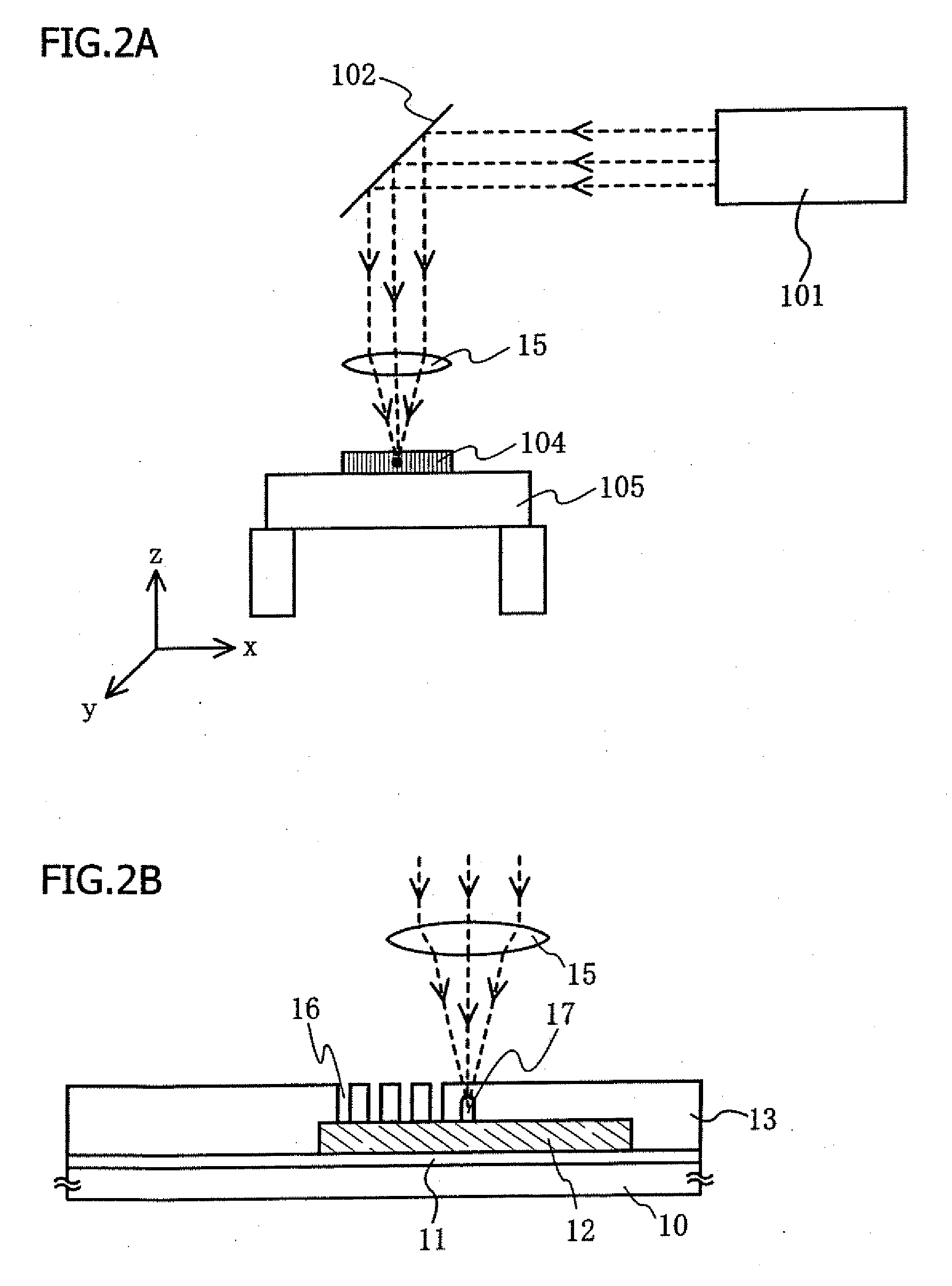

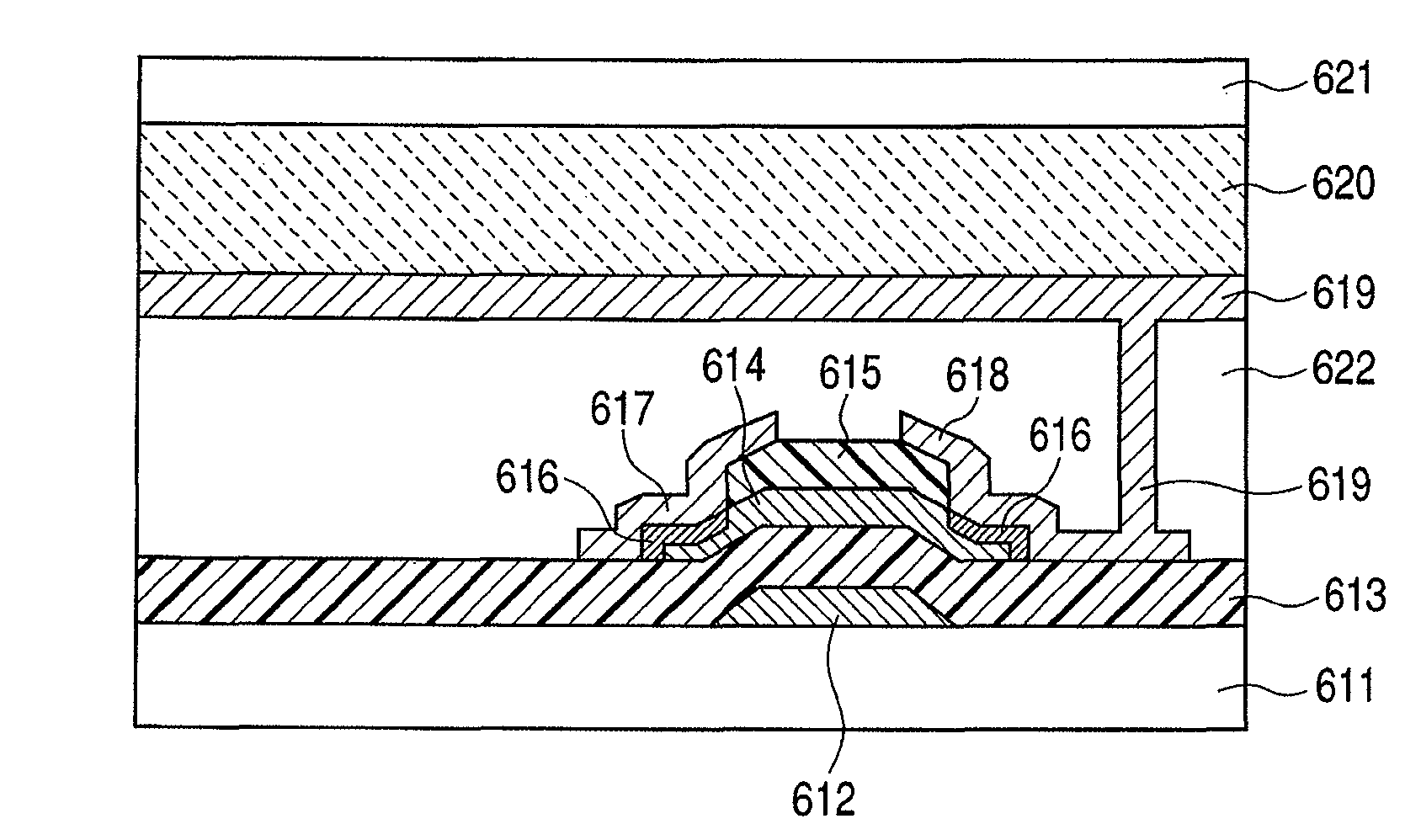

Semiconductor device and method for manufacturing the same, and electric device

InactiveUS20090073325A1Simple stepsHighly integratedTransistorTelevision system detailsElectrical resistance and conductanceLongest Diameter

It is an object of the present invention to simplify steps needed to process a wiring in forming a multilayer wiring. In addition, when a droplet discharging technique or a nanoimprint technique is used to form a wiring in a contact hole having a comparatively long diameter, the wiring in accordance with the shape of the contact hole is formed, and the wiring portion of the contact hole is likely to have a depression compared with other portions. A penetrating opening is formed by irradiating a light-transmitting insulating film with laser light having high intensity and a pulse high in repetition frequency. A plurality of openings having a minute contact area is provided instead of forming one penetrating opening having a large contact area to have an even thickness of a wiring by reducing a partial depression and also to ensure contact resistance.

Owner:SEMICON ENERGY LAB CO LTD

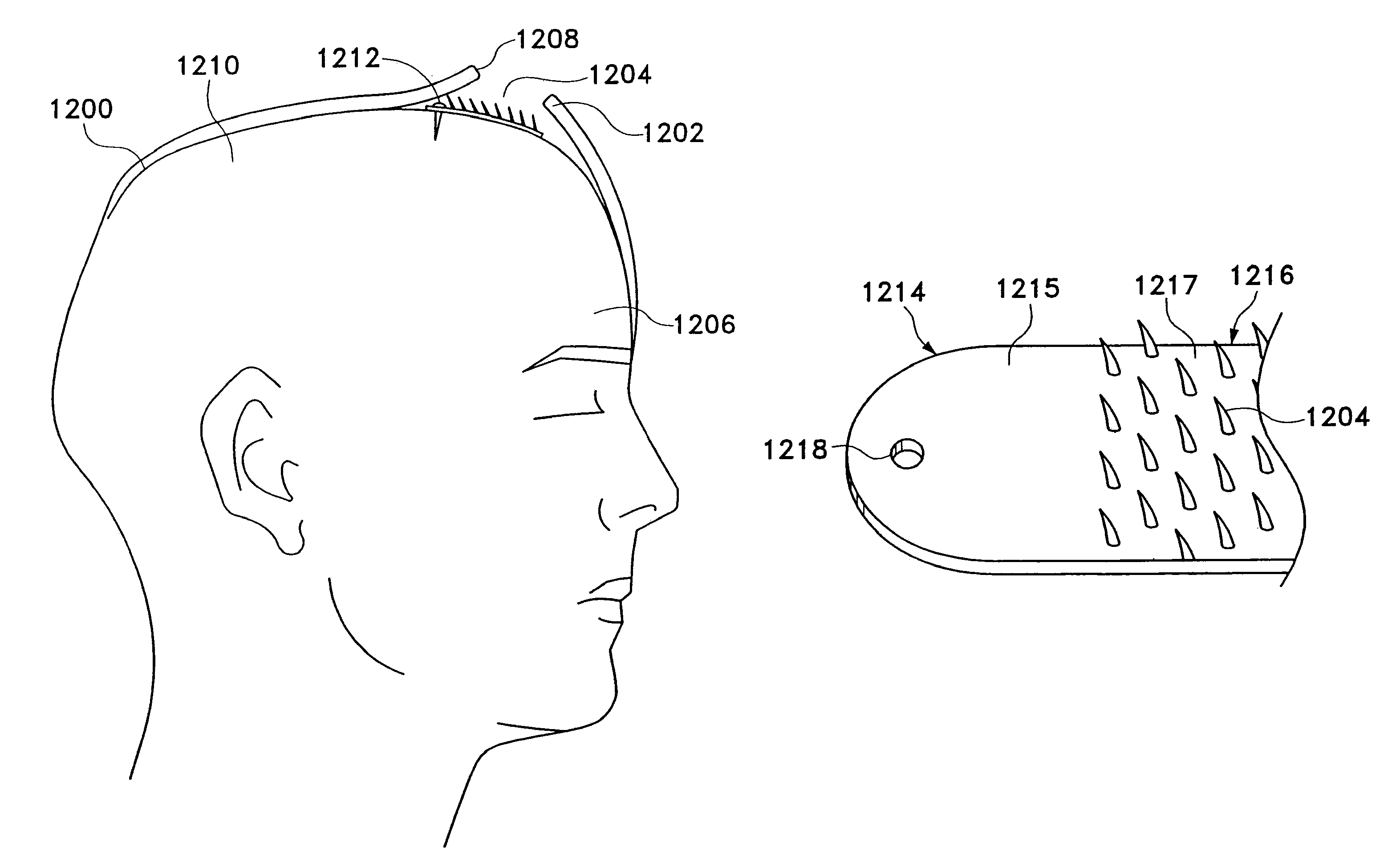

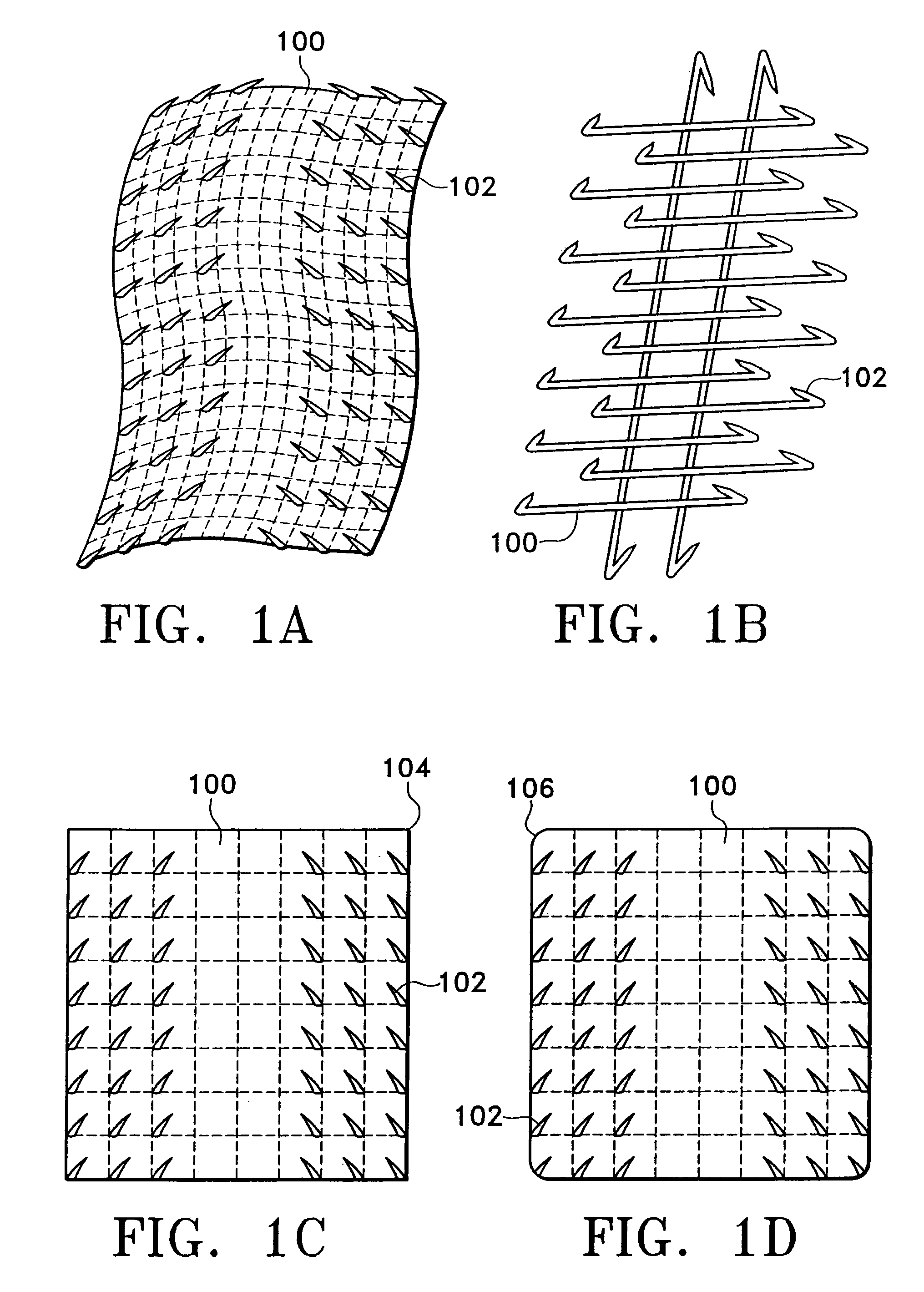

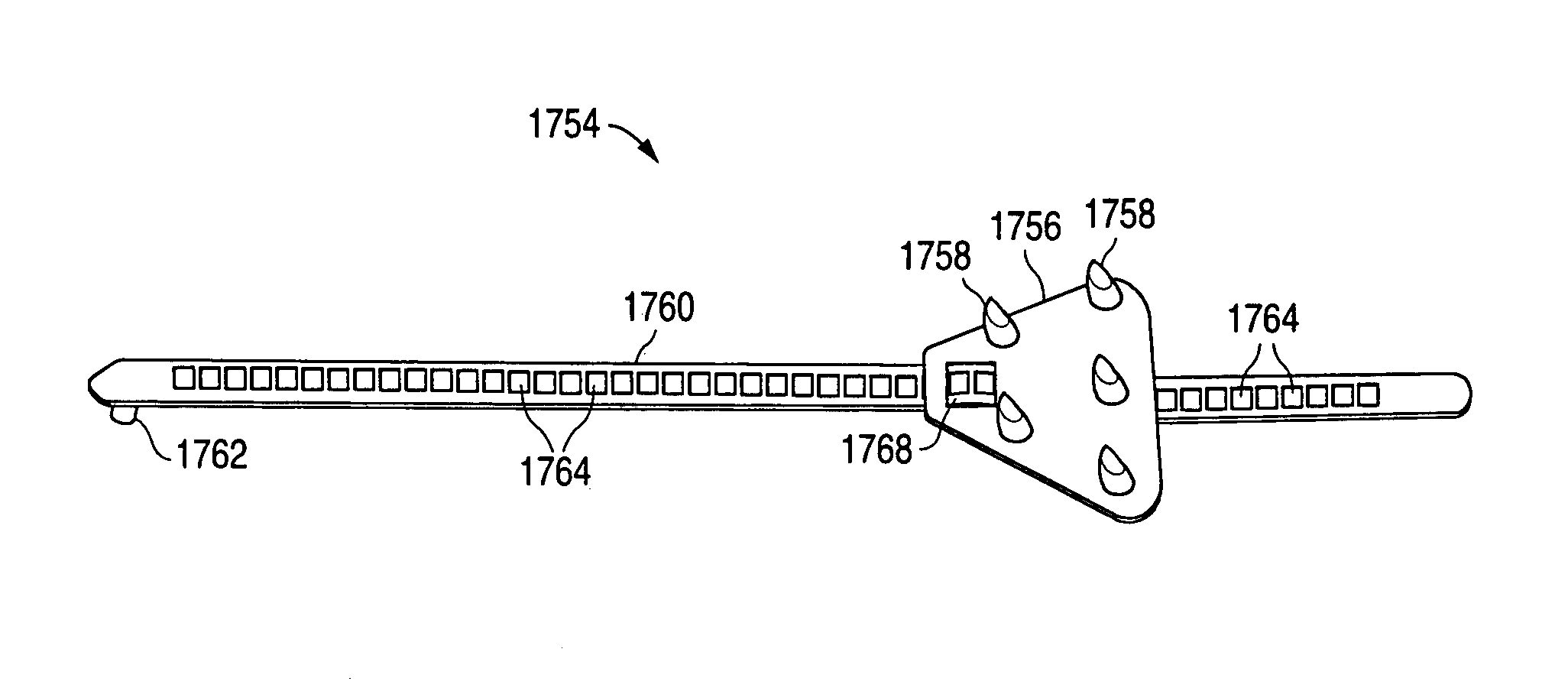

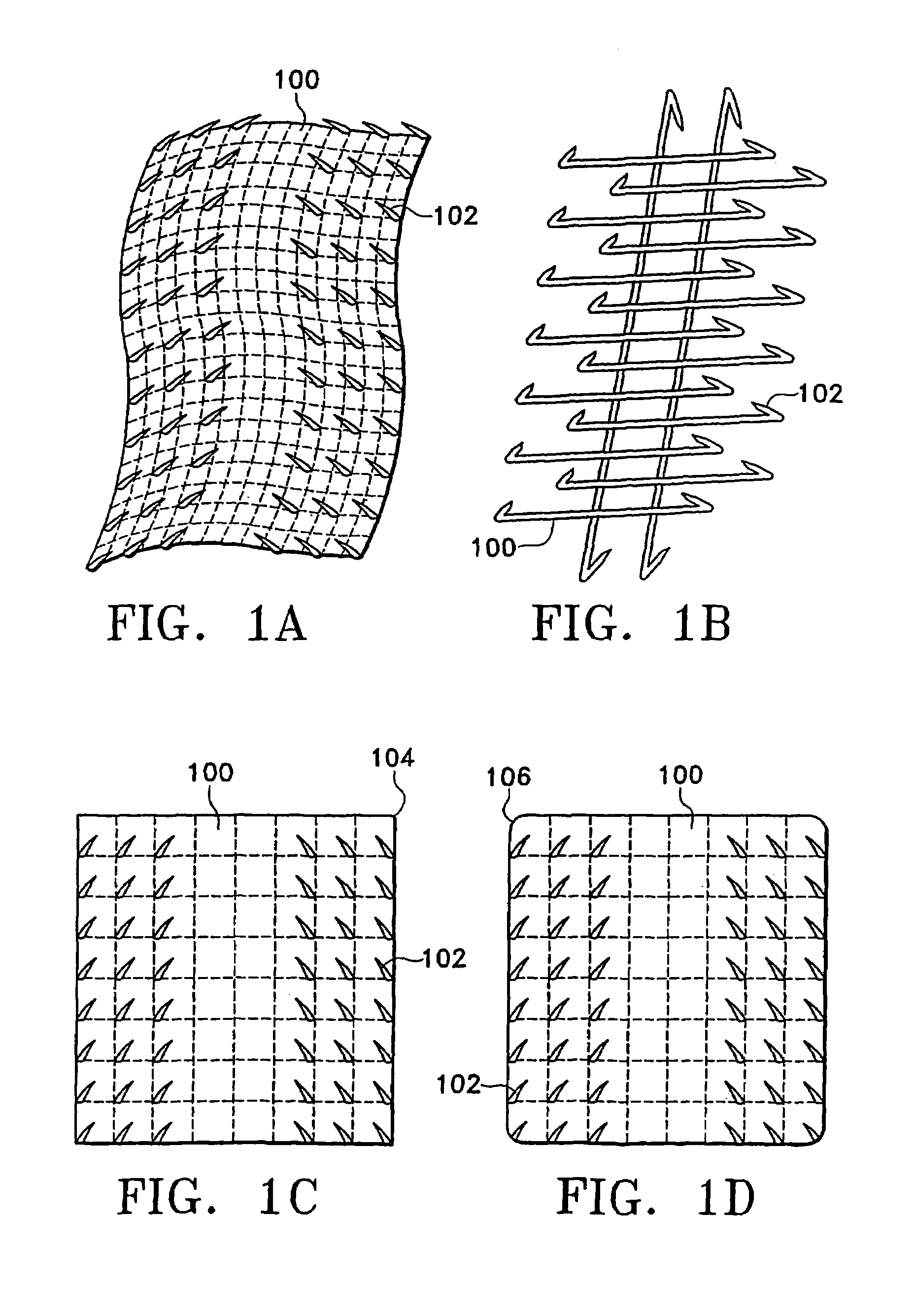

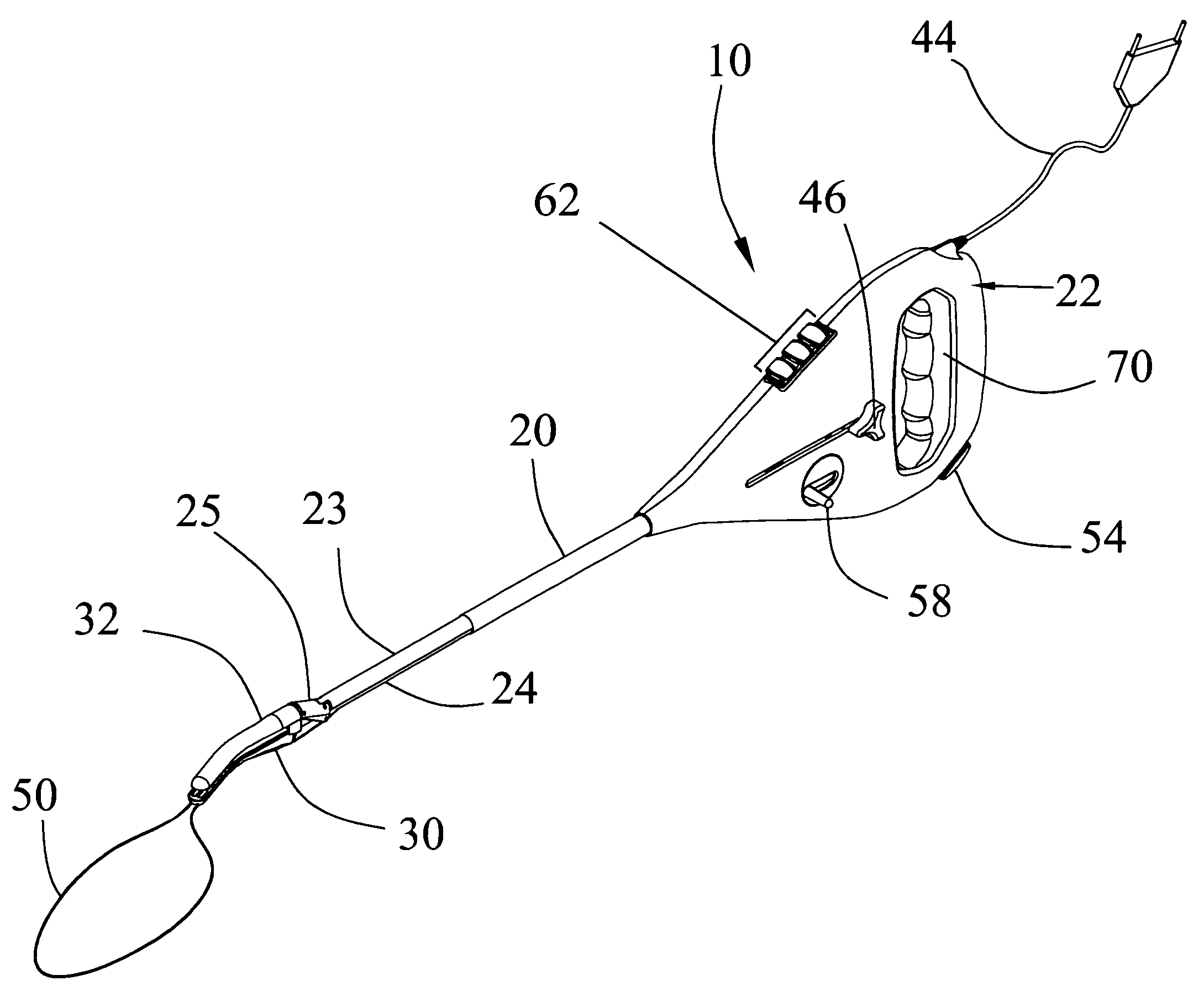

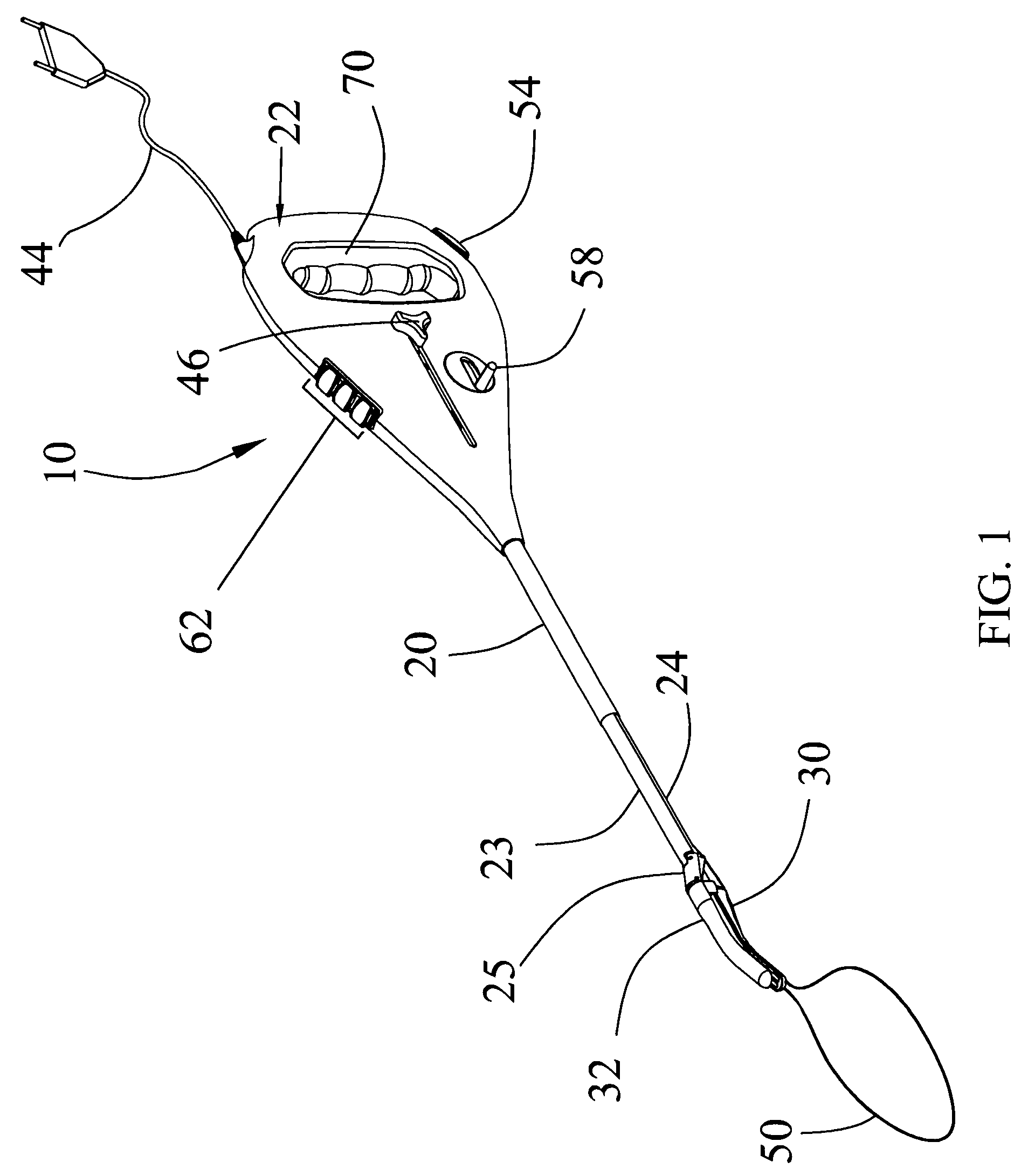

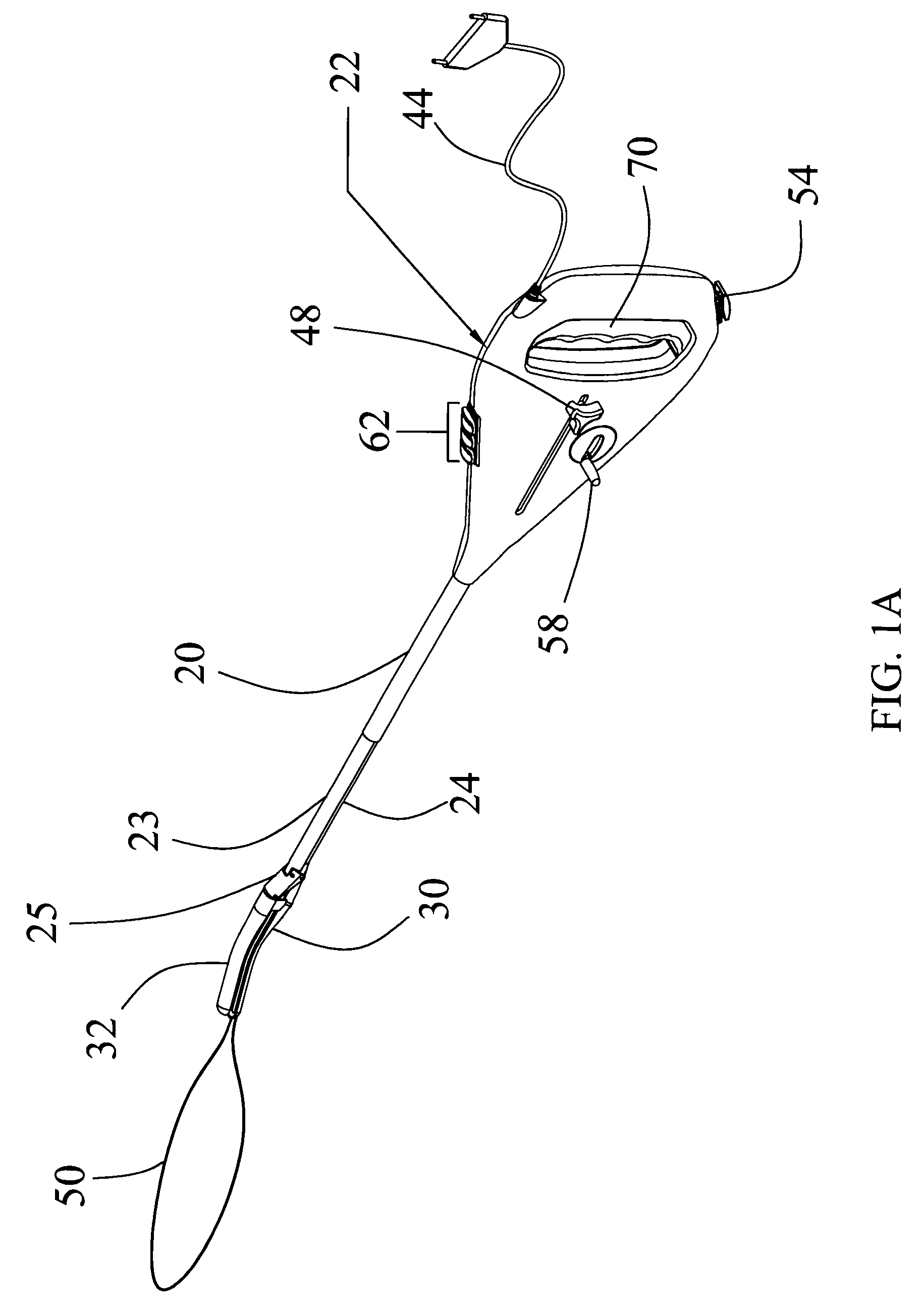

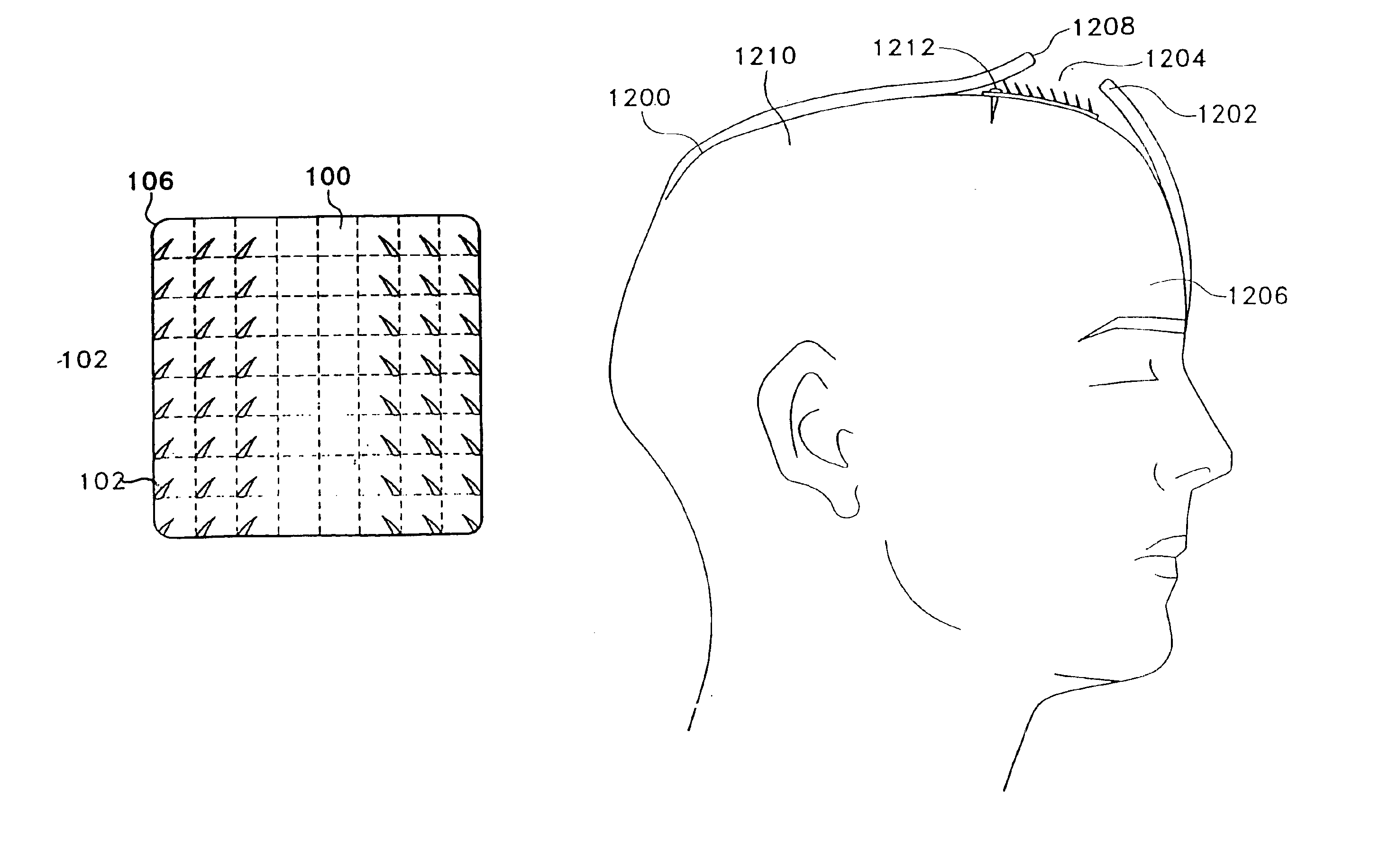

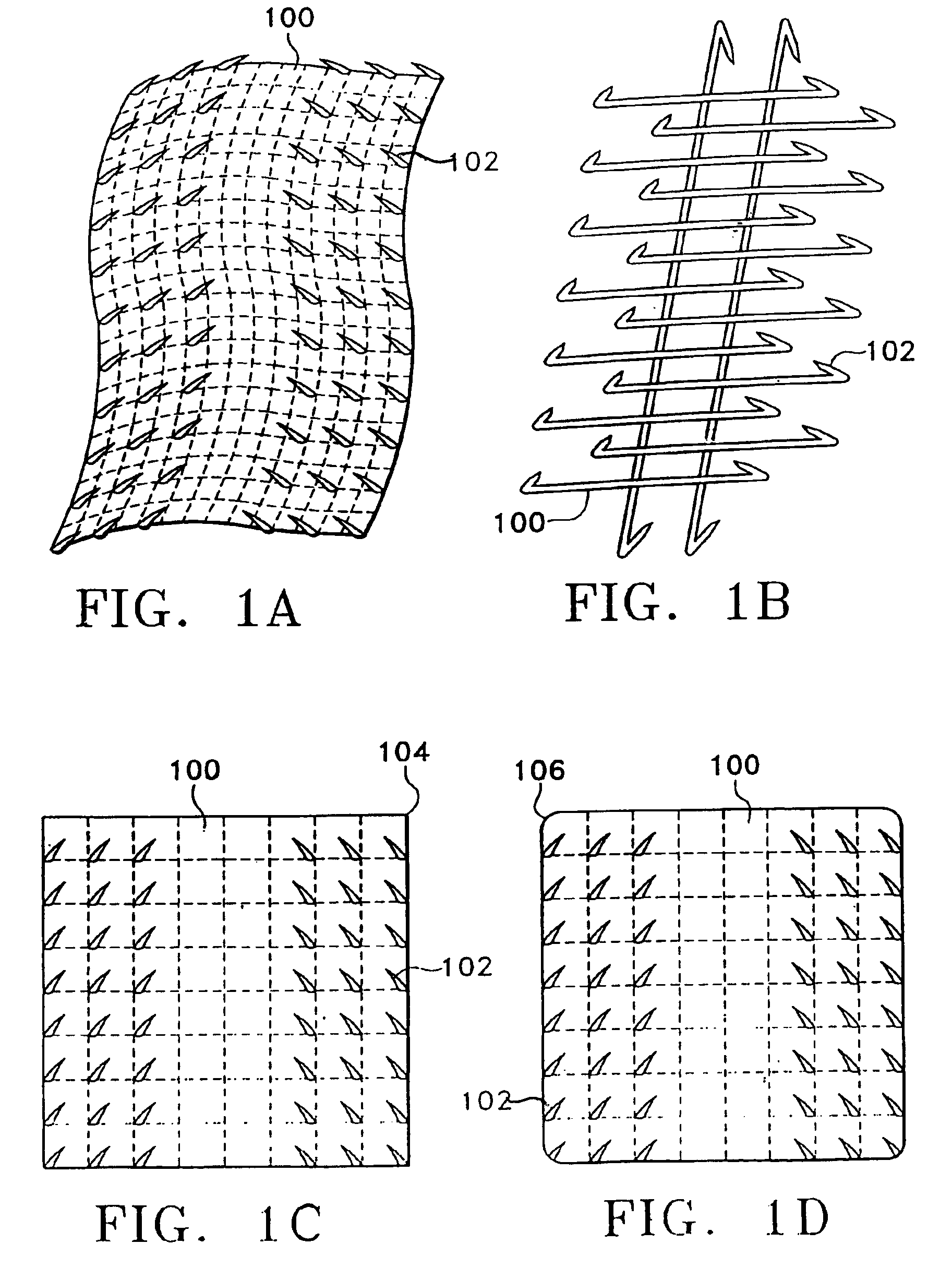

Multi-point tissue tension distribution device and method, a chin lift variation

InactiveUS7510566B2Increase healing responseRelieve painSuture equipmentsDiagnosticsChinWound healing

A tissue approximation device and processes for using the device are provided. The device is an implantable, biodegradable construct that has attachment points emanating from a supportive backing. The device improves the mechanical phase of wound healing and optimally distributes tension over the contact area between the device and tissue. Processes for using the device include soft tissue attachment and soft tissue to bone attachment. Several variations are particularly applicable to facilitating tissue approximation in surgical cosmetic applications, particularly chin lifts. Generally, tissue to be lifted may be set on a chin lift device via attachment points before or after the device is secured to a patient's bone. Variations of the device are described along with a method of installing the chin lift device. Also described is a tool particularly useful for installing a chin lift device.

Owner:MICROAIRE SURGICAL INSTR +2

Remotely anchored tissue fixation device

InactiveUS7172615B2Degree of approximation necessaryVariable flexibilitySuture equipmentsCosmetic implantsWound healingBiomedical engineering

A tissue approximation device and processes for using the device, particularly in the mid-face region, are provided. The device is an implantable, biodegradable construct that has attachment points emanating from at least one supportive backing. The device also has a connecting member or leash which extends between the backing and an anchor which is attached to bone or soft tissue. Attachment to soft tissue is accomplished by a second backing having attachment points emanating from the backing and attachment to bone is accomplished by a post. The connecting member allows for repeated adjustments in length between the anchor and the backing in vivo or ex vivo until the desired amount of tissue approximation is achieved. The device improves the mechanical phase of wound healing and evenly distributes tension over the contact area between the device and tissue.

Owner:OXFORD FINANCE +2

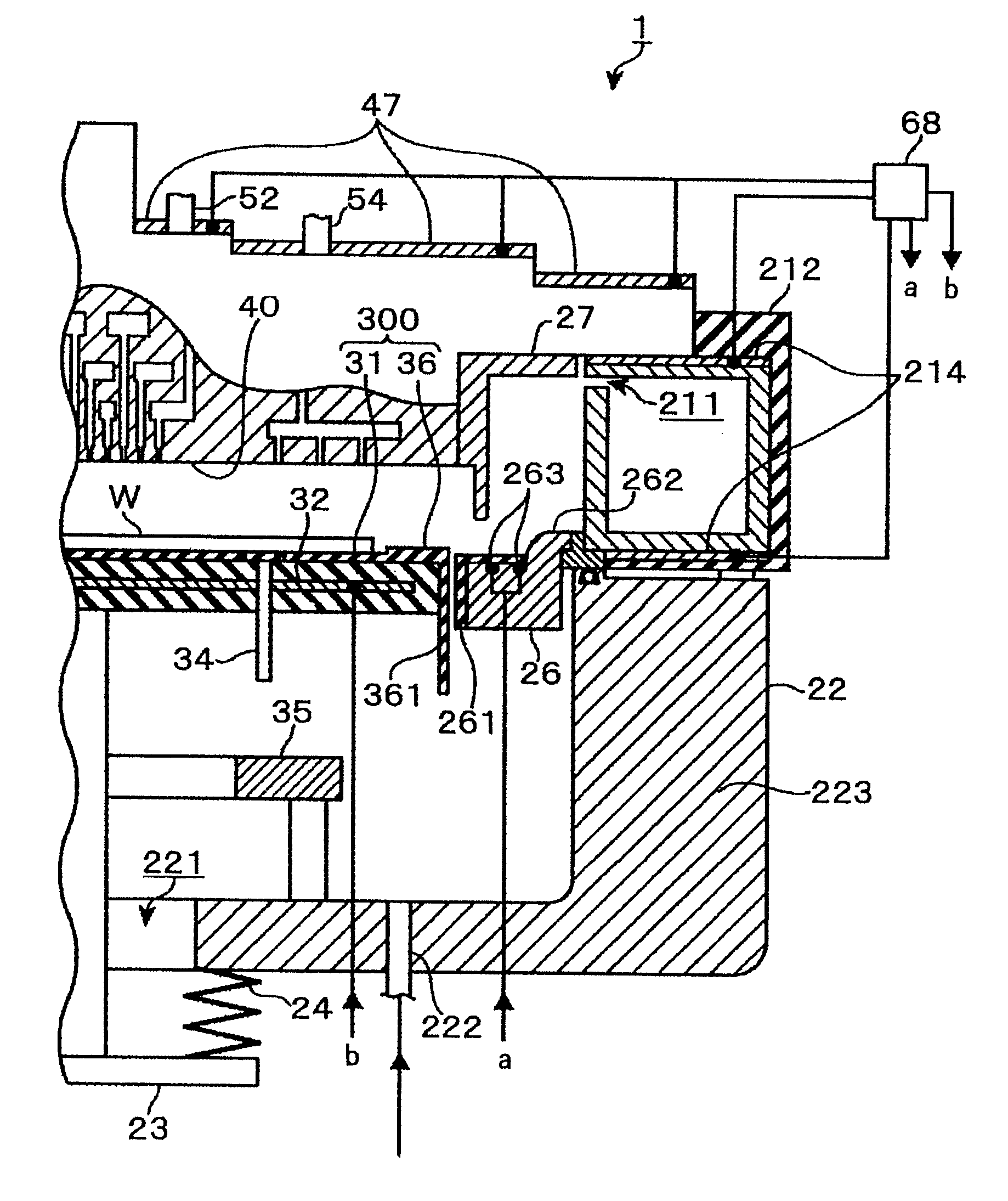

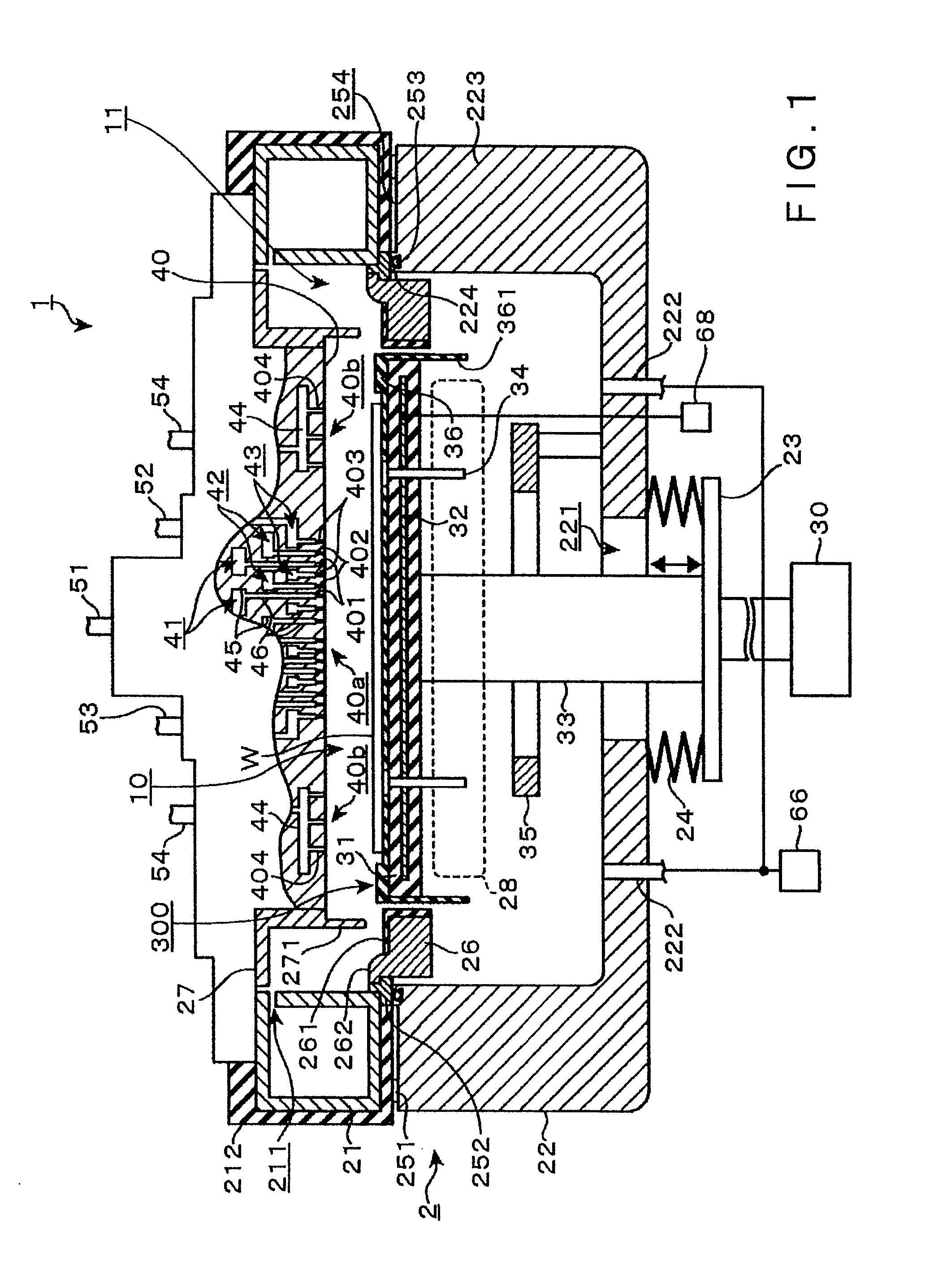

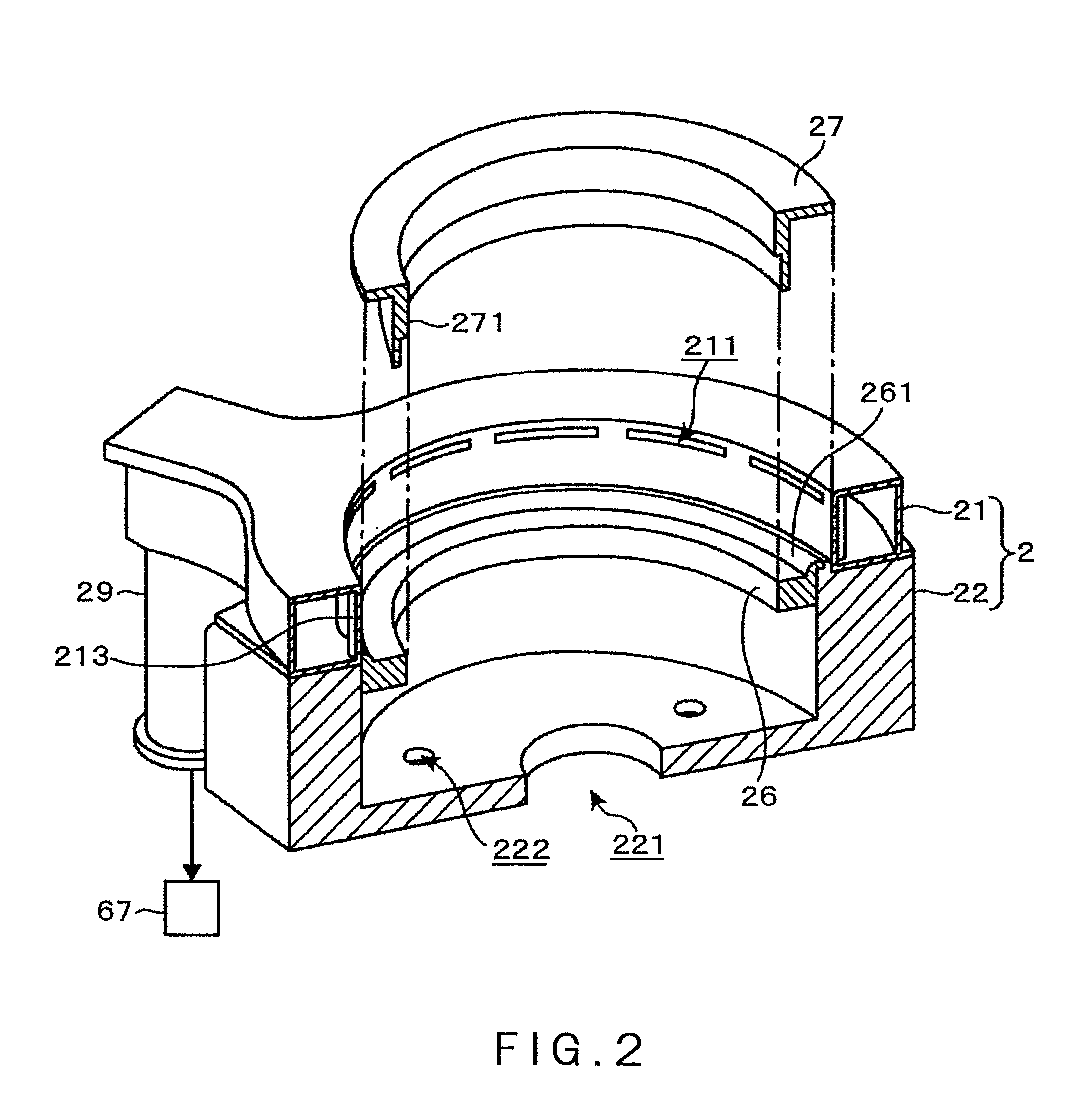

Film deposition apparatus and film deposition method

ActiveUS8506713B2Efficient solutionImprove uniformitySemiconductor/solid-state device manufacturingChemical vapor deposition coatingEngineeringDeposition process

Owner:TOKYO ELECTRON LTD

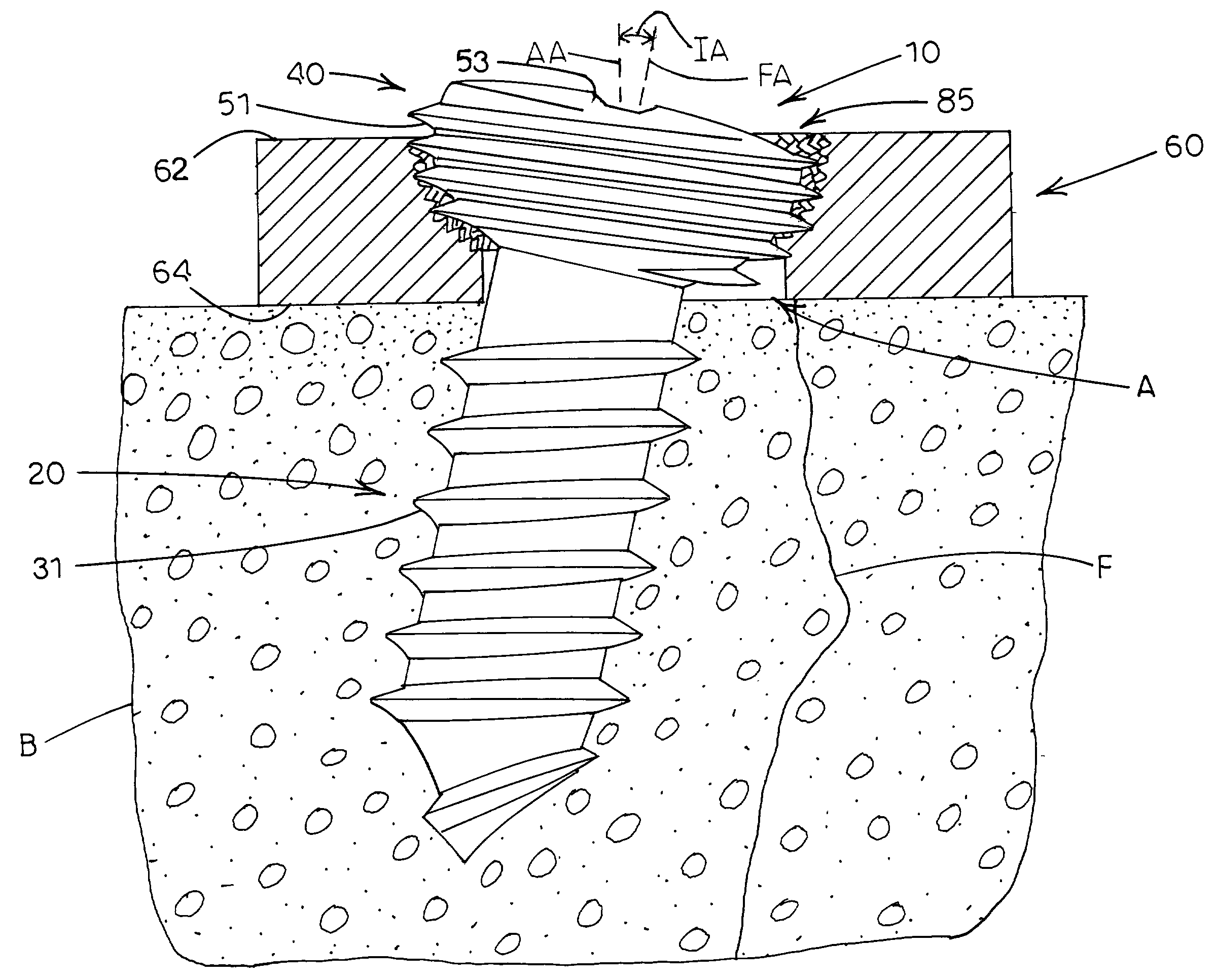

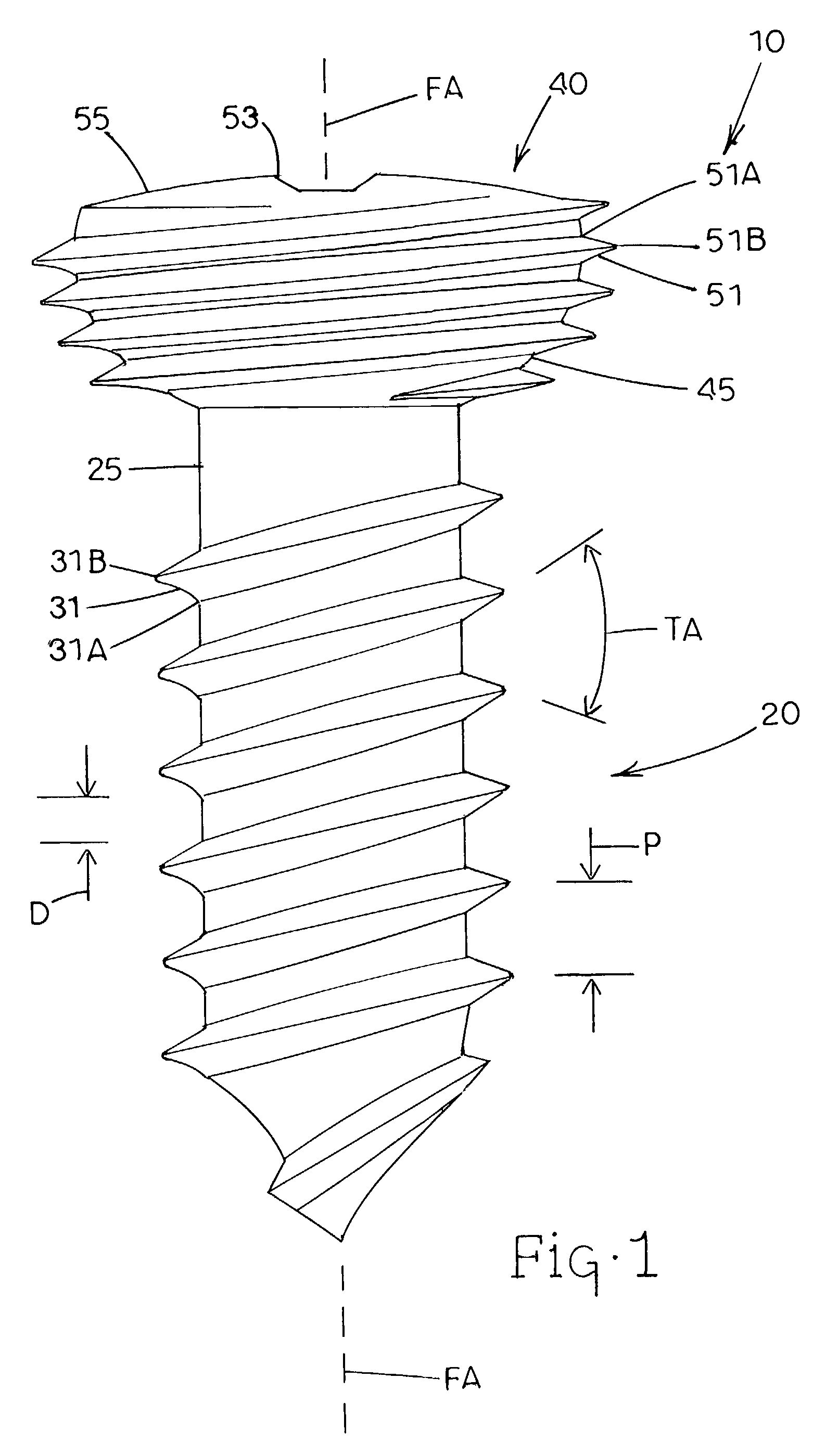

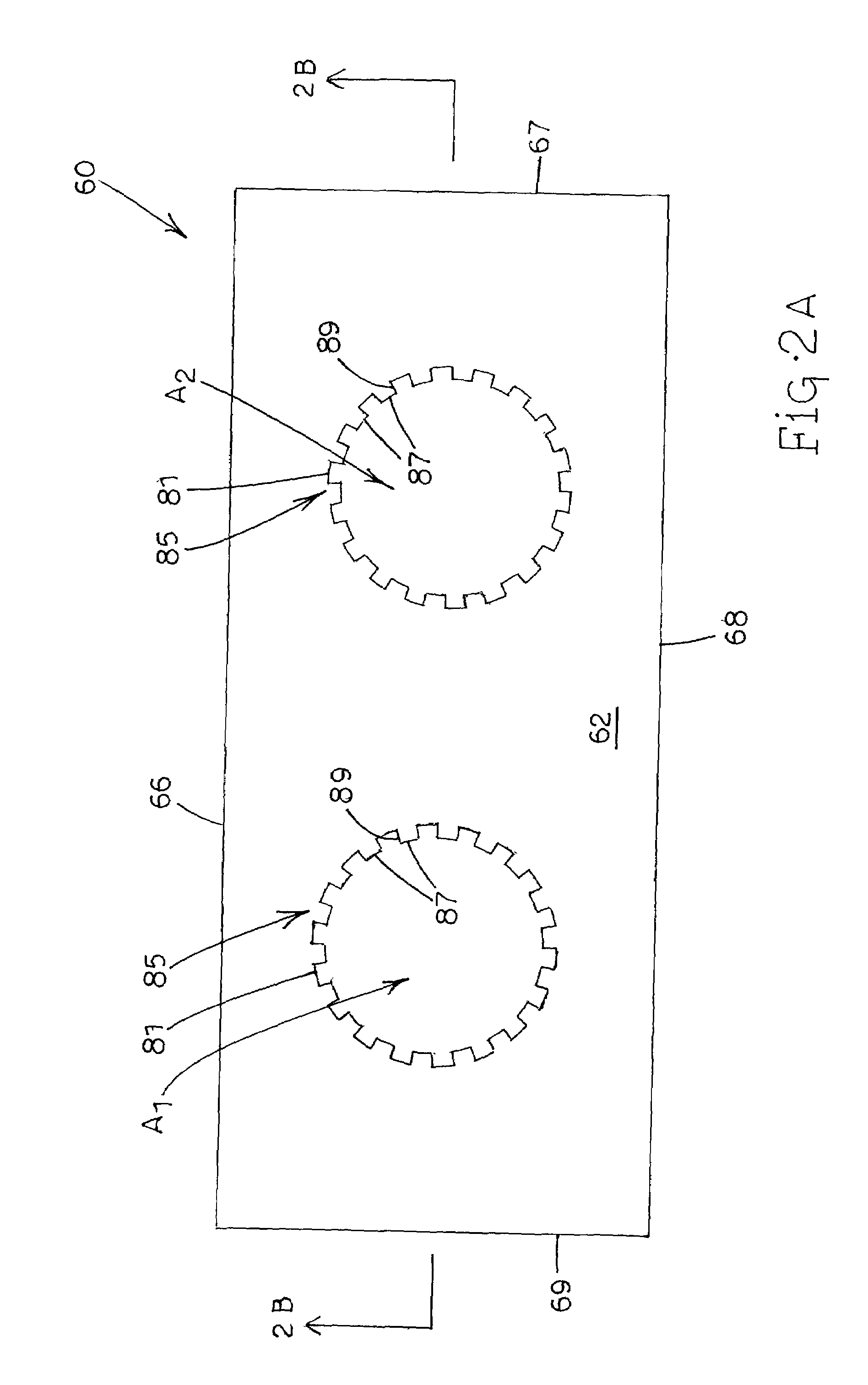

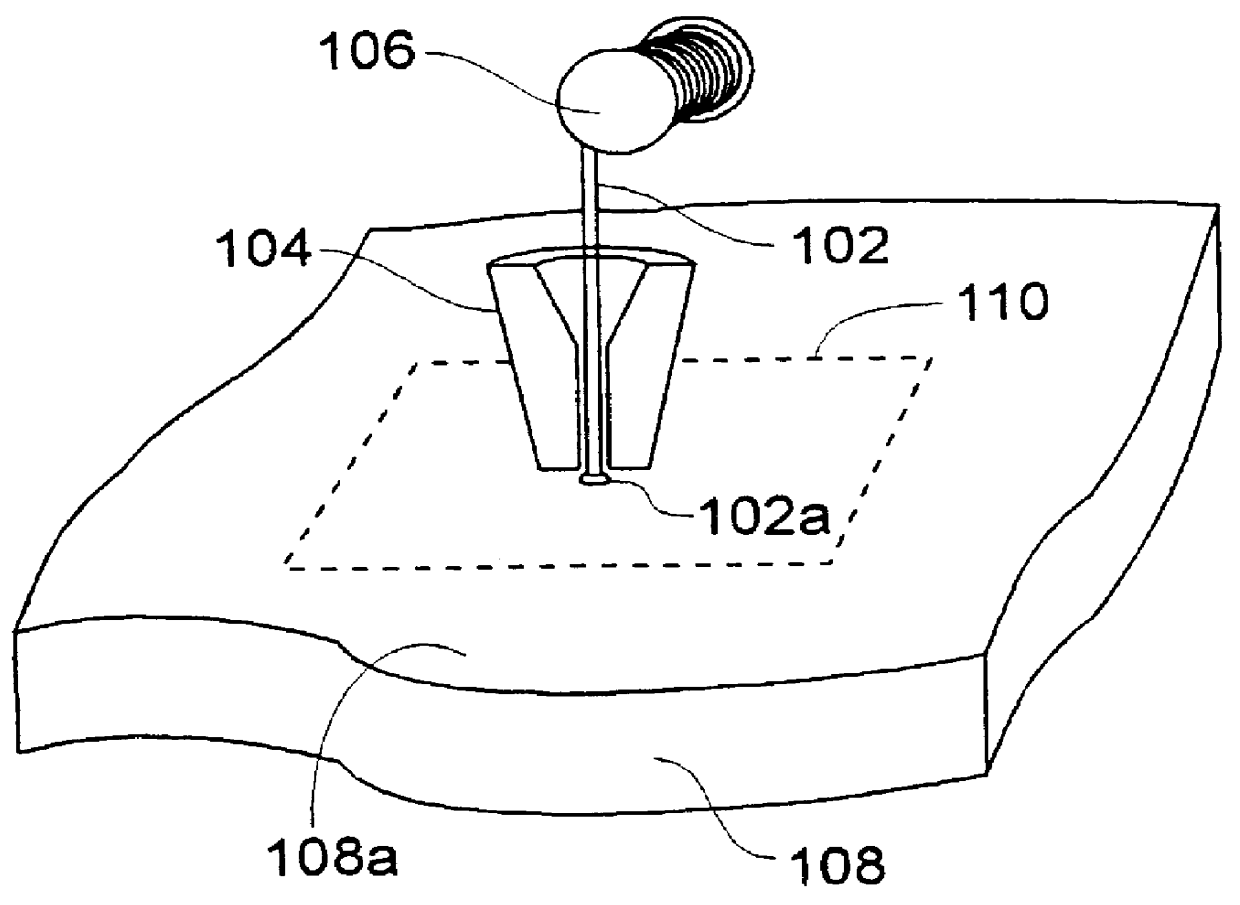

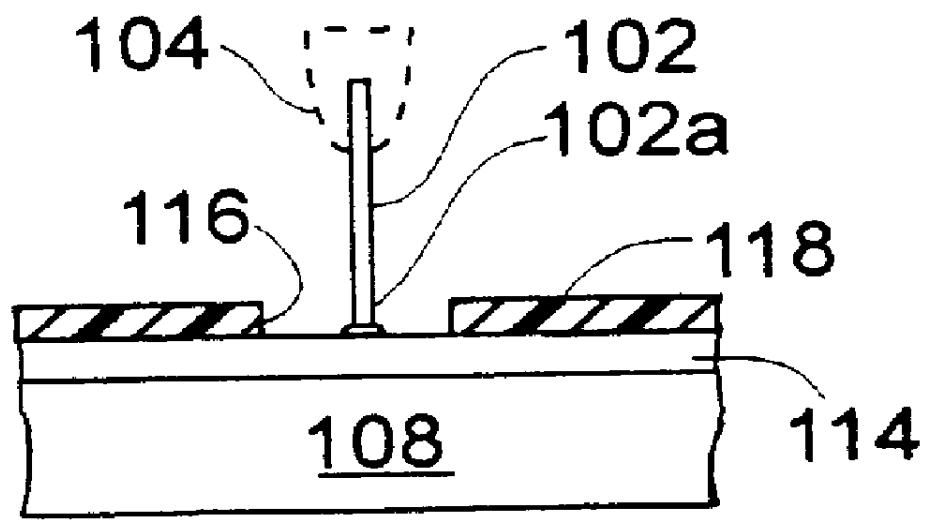

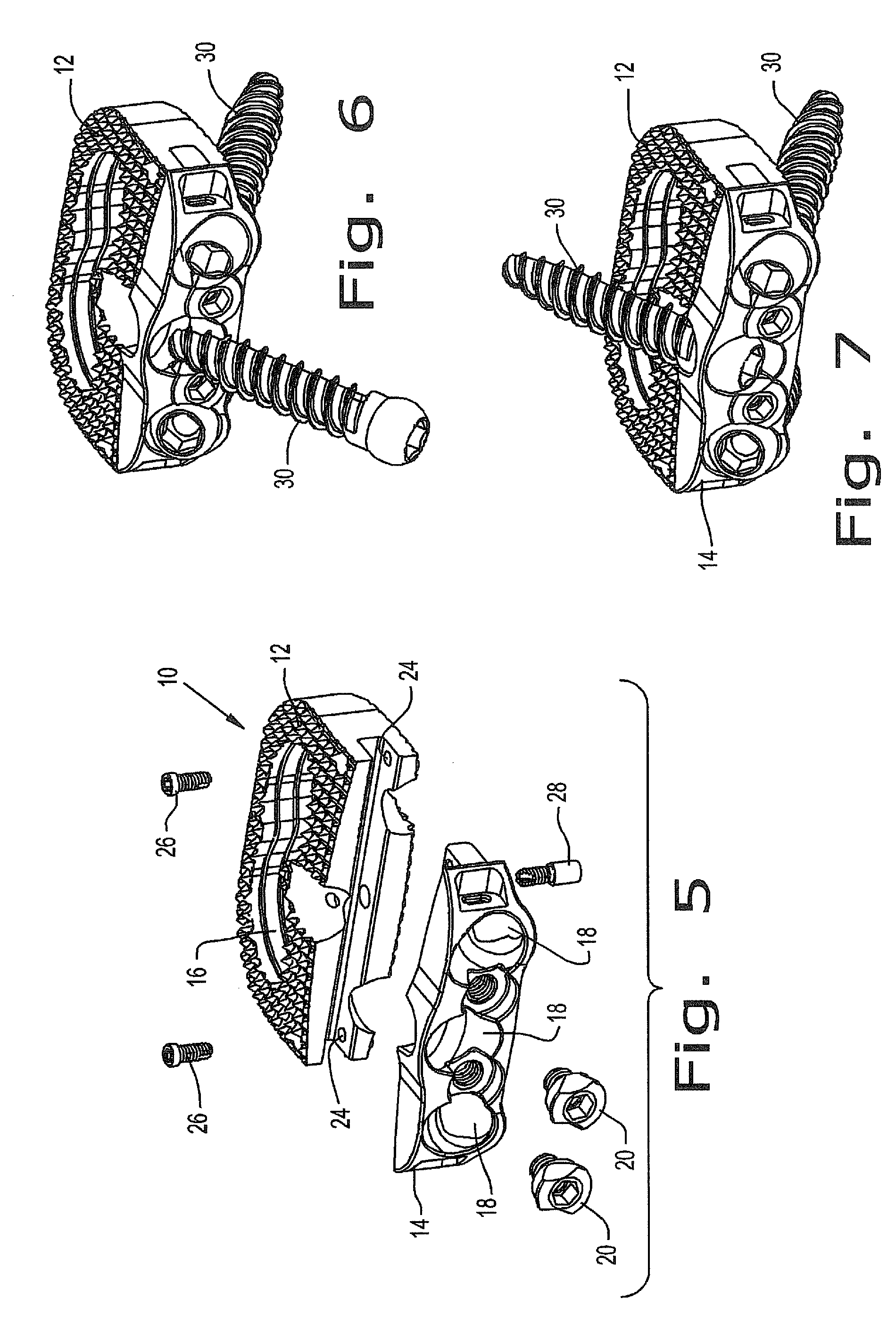

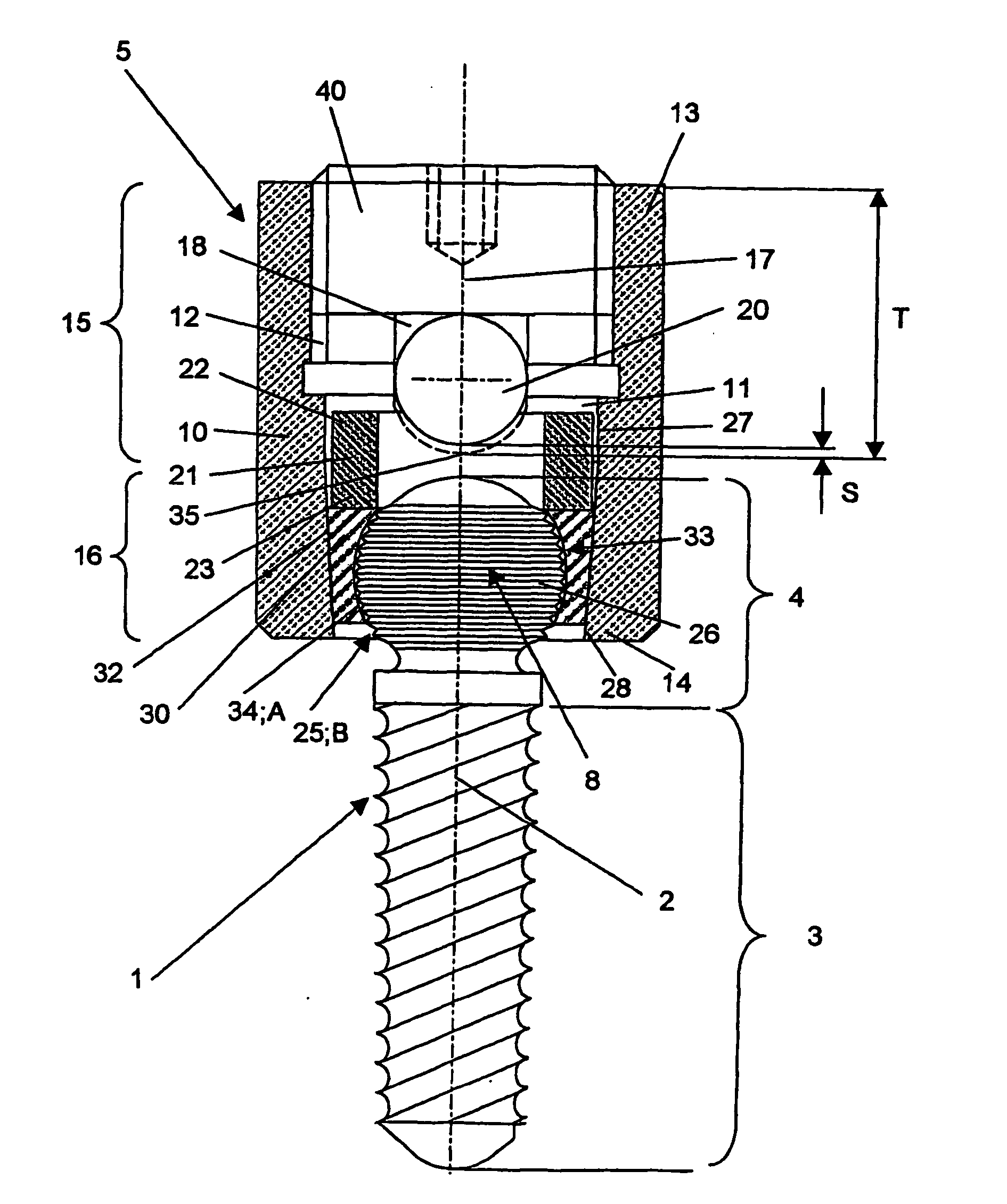

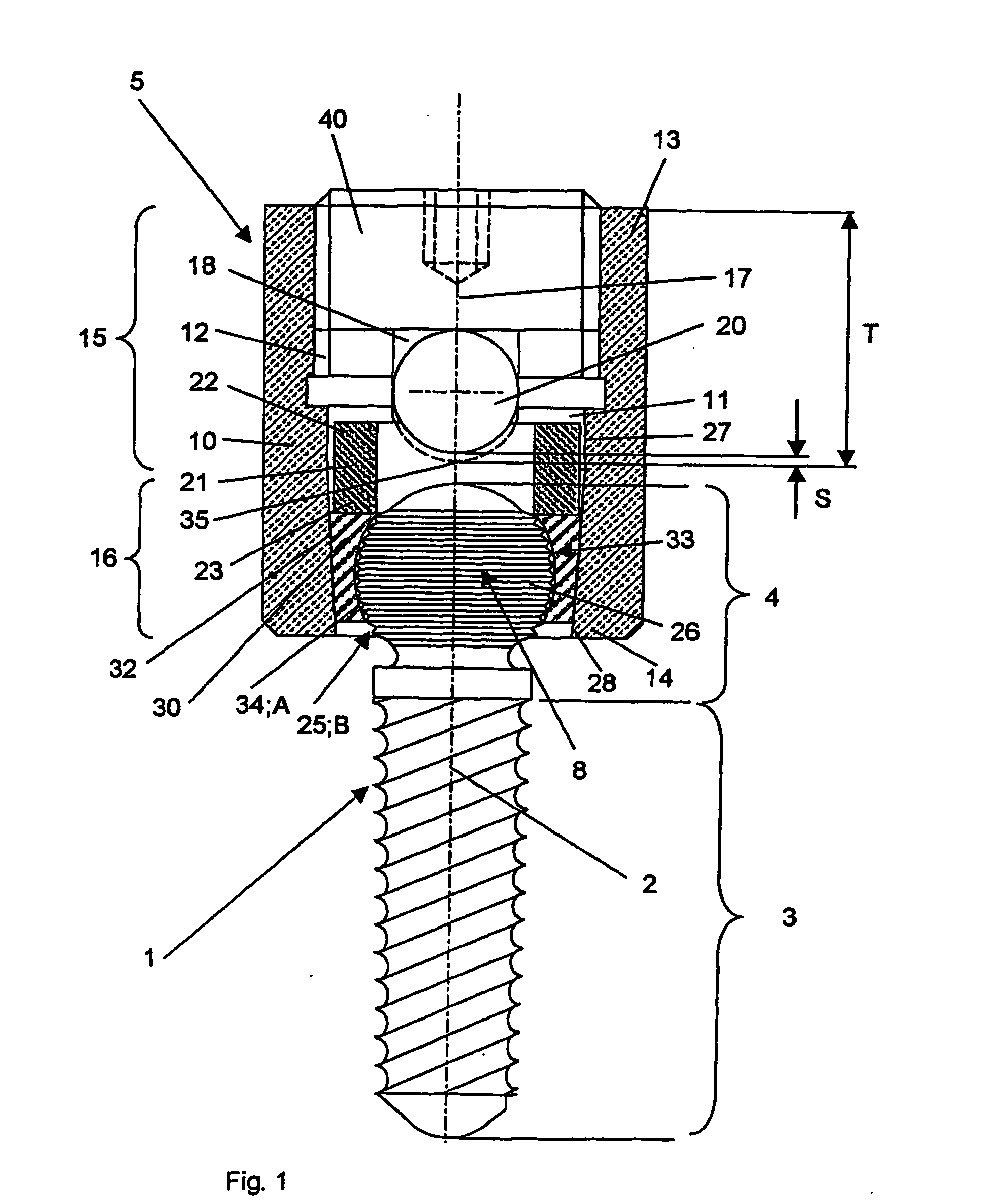

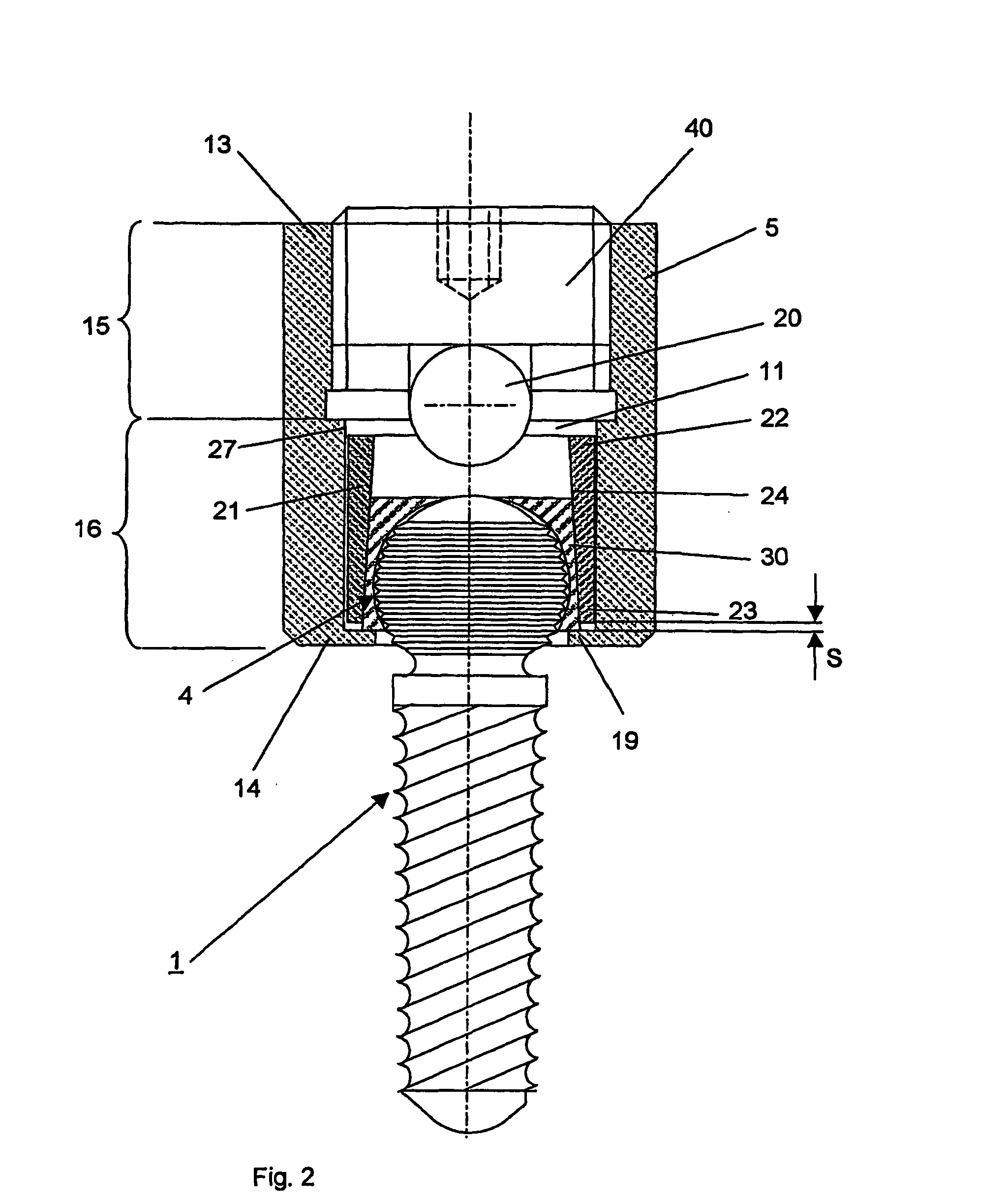

Multi-angular fastening apparatus and method for surgical bone screw/plate systems

InactiveUS6955677B2Maximum flexibilityWide rangeSuture equipmentsInternal osteosythesisFiberEngineering

A fastening apparatus includes a fastener and a fastener receiving member. The apparatus enables the fastener to be affixed to the fastener receiving member at a variable insertion angle selected by the user. The fastener includes an elongate section and an adjoining head section. Both the elongate section and the head section are threaded. The fastener receiving member includes one or more apertures through which one or more corresponding fasteners can be inserted. Each aperture includes a contact region formed or disposed on an inside surface defining the aperture. The contact region includes a porous matrix of protrusions or fiber metal having a density and strength sufficient to render contact region tappable by the thread of the head section of the fastener. The thread on the head section is driven into the contact region at the selected insertion angle. As a result, the thread of the head section taps into the material of the contact region such that the fastener is affixed to the fastener receiving member and maintained at the insertion angle.

Owner:THE UNIV OF NORTH CAROLINA AT CHAPEL HILL

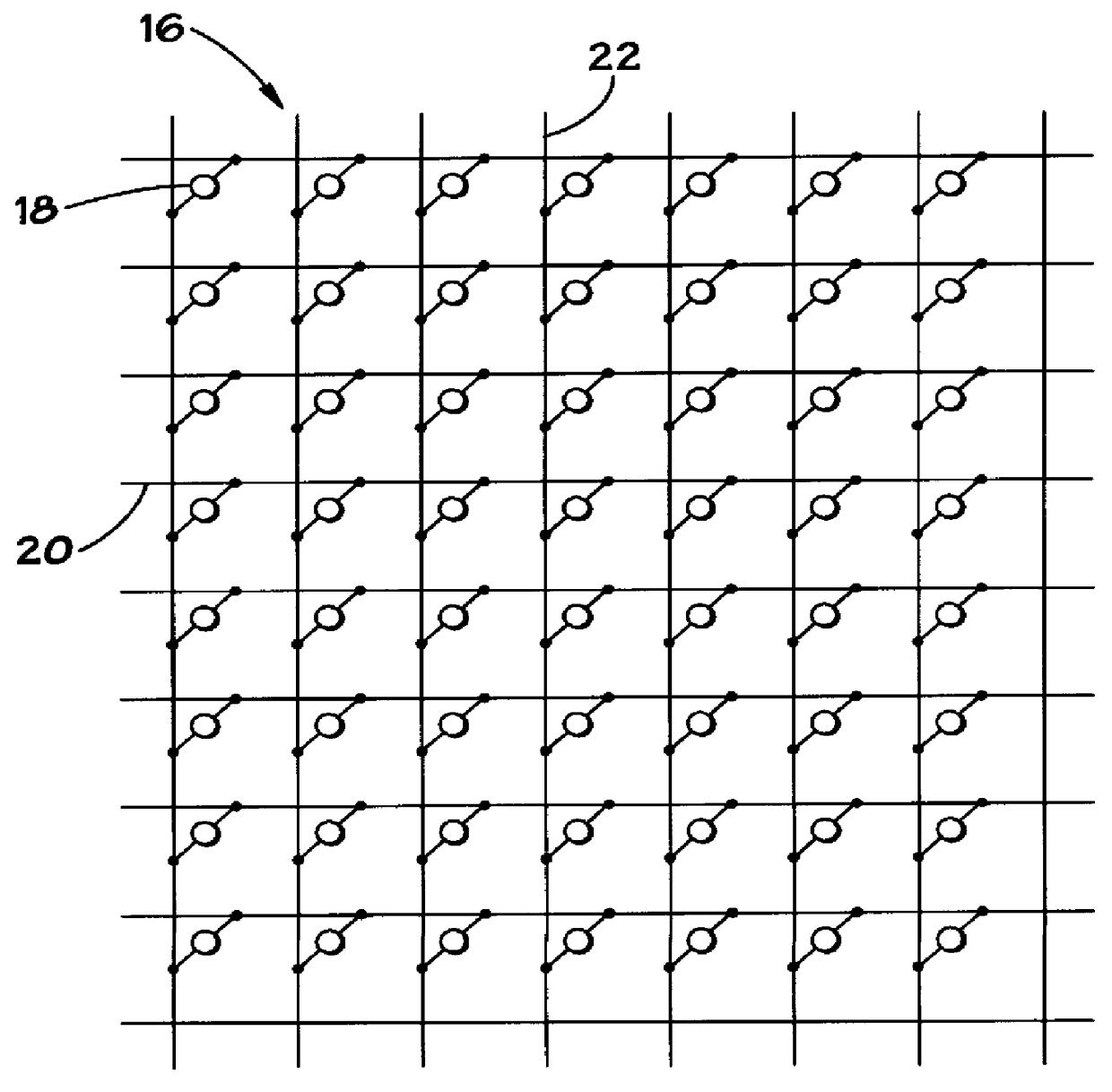

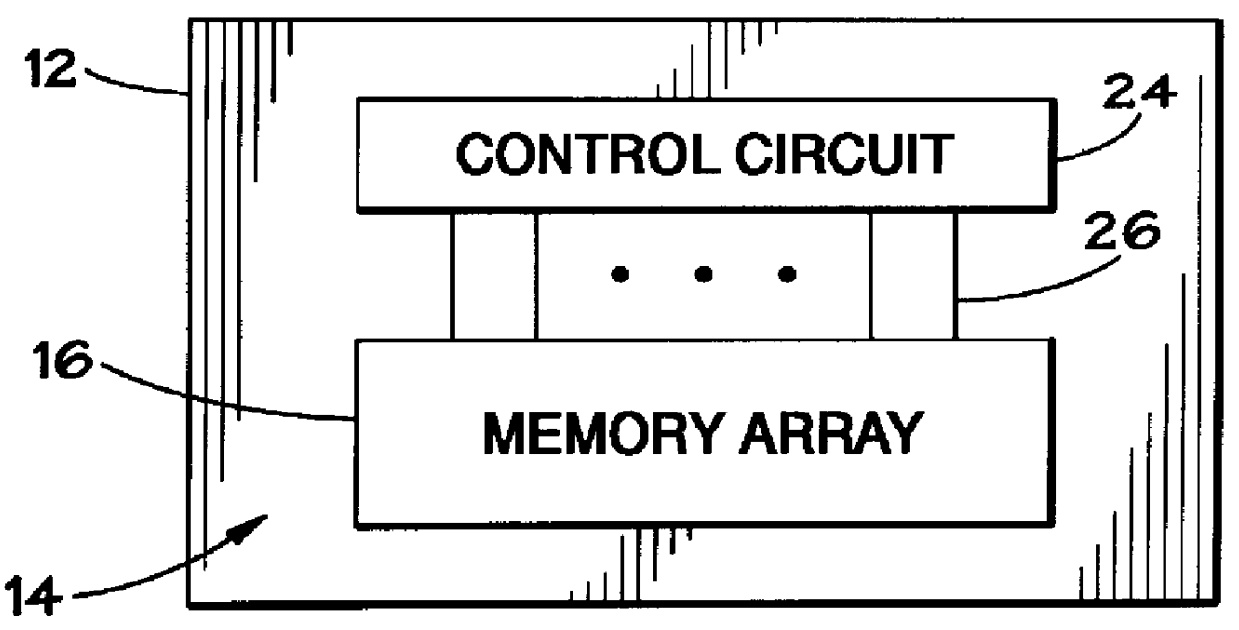

Integrated circuit memory cell having a small active area and method of forming same

InactiveUS6114713ASemiconductor/solid-state device detailsSolid-state devicesBit lineElectrical conductor

A method for manufacturing a memory device having a plurality of memory cells. Each memory cell has a non-volatile resistive memory element with a small active area. A plurality of memory cells are formed at selected locations of at least a portion of a semiconductor wafer. To form the memory cells, a lower electrode layer and a memory material layer are deposited over at least a portion of the wafer. Patterns are formed over desired contact locations of the memory material layer and etching is used to remove portions of the memory material layer. The etching step undercuts the patterns and forms memory elements having a protruding contact portion with an apex contact area. The pattern is removed, and an upper electrode is formed and electrically coupled to the contact area. Corresponding access devices and word / bit line conductor grids are provided and coupled to the memory cells.

Owner:ROUND ROCK RES LLC

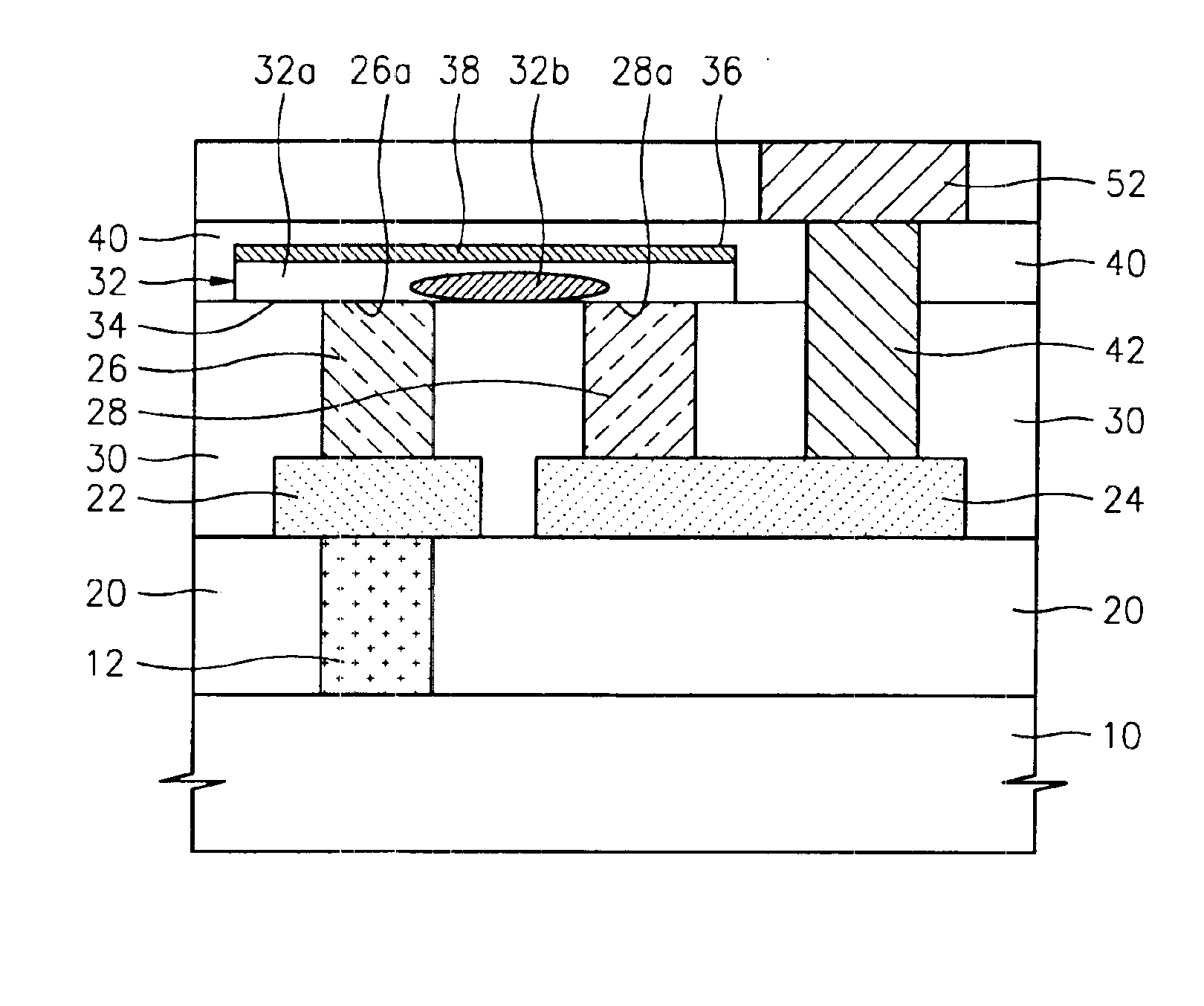

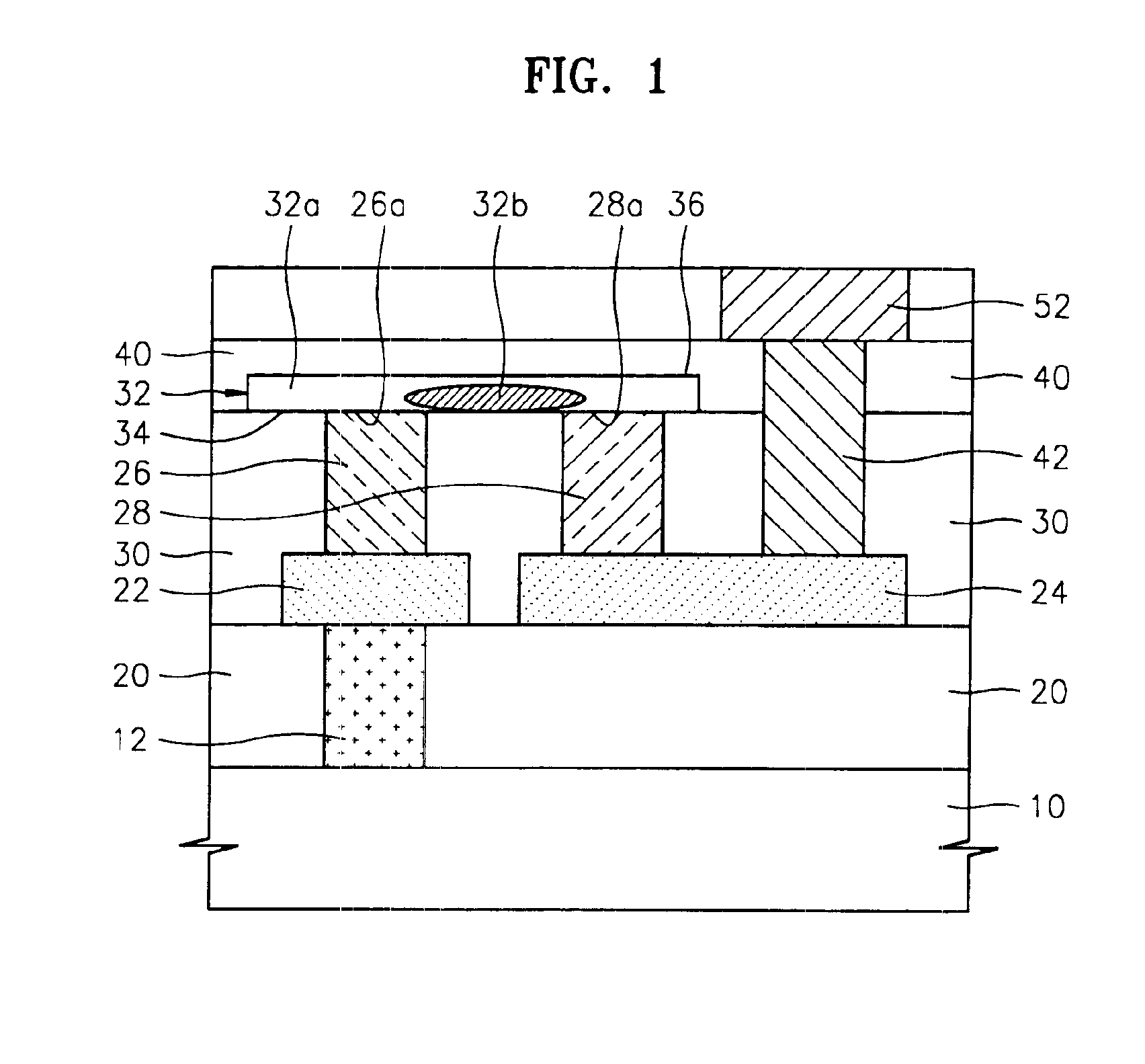

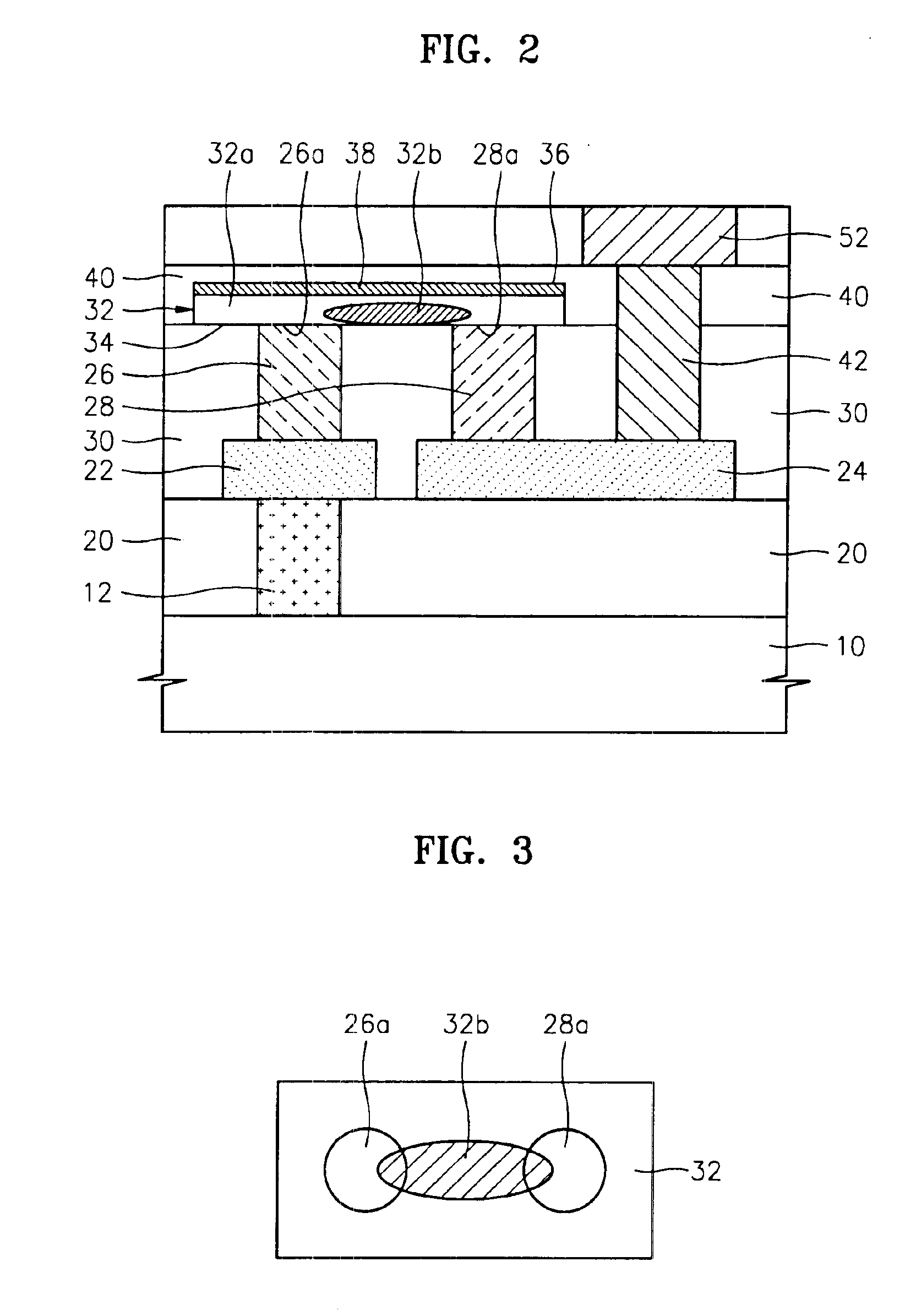

Phase-change memory devices with a self-heater structure

ActiveUS6894305B2Semiconductor/solid-state device detailsSolid-state devicesPhase-change memorySemiconductor

Phase change memory devices include a phase-change memory layer on a semiconductor substrate. The phase-change memory layer has a major axis that is substantially parallel to a major axis of the semiconductor substrate and has a first surface and a second surface opposite the first surface that are substantially parallel to the major axis of the phase-change memory layer. A first electrode is provided on the semiconductor substrate that is electrically connected to the first surface of the phase-change memory layer in a first contact region of the phase-change memory layer. A second electrode is provided on the semiconductor substrate that is electrically connected to the phase-change memory layer in a second contact region of the phase-change memory layer. The second contact region is space apart from the first contact region.

Owner:SAMSUNG ELECTRONICS CO LTD

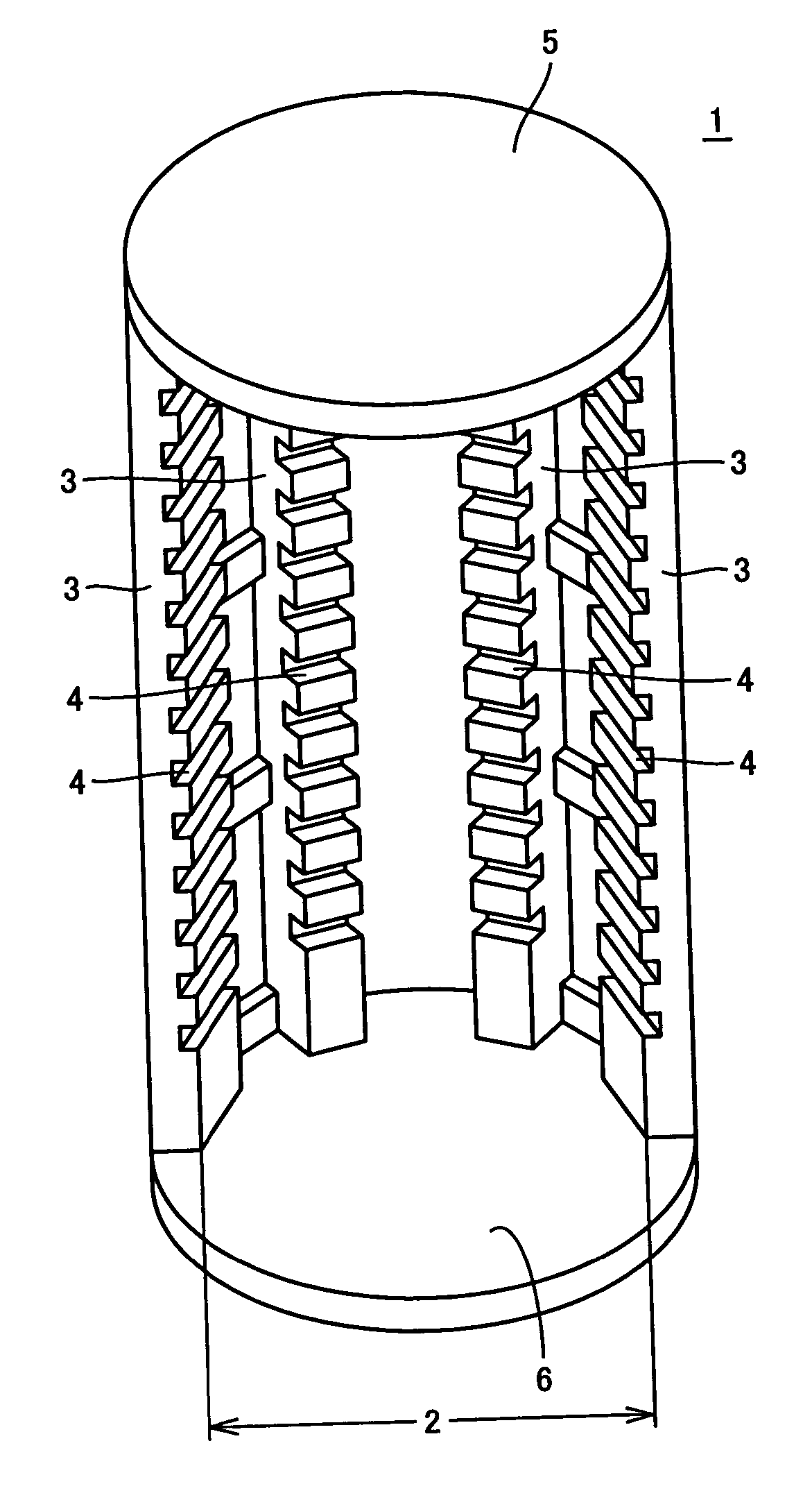

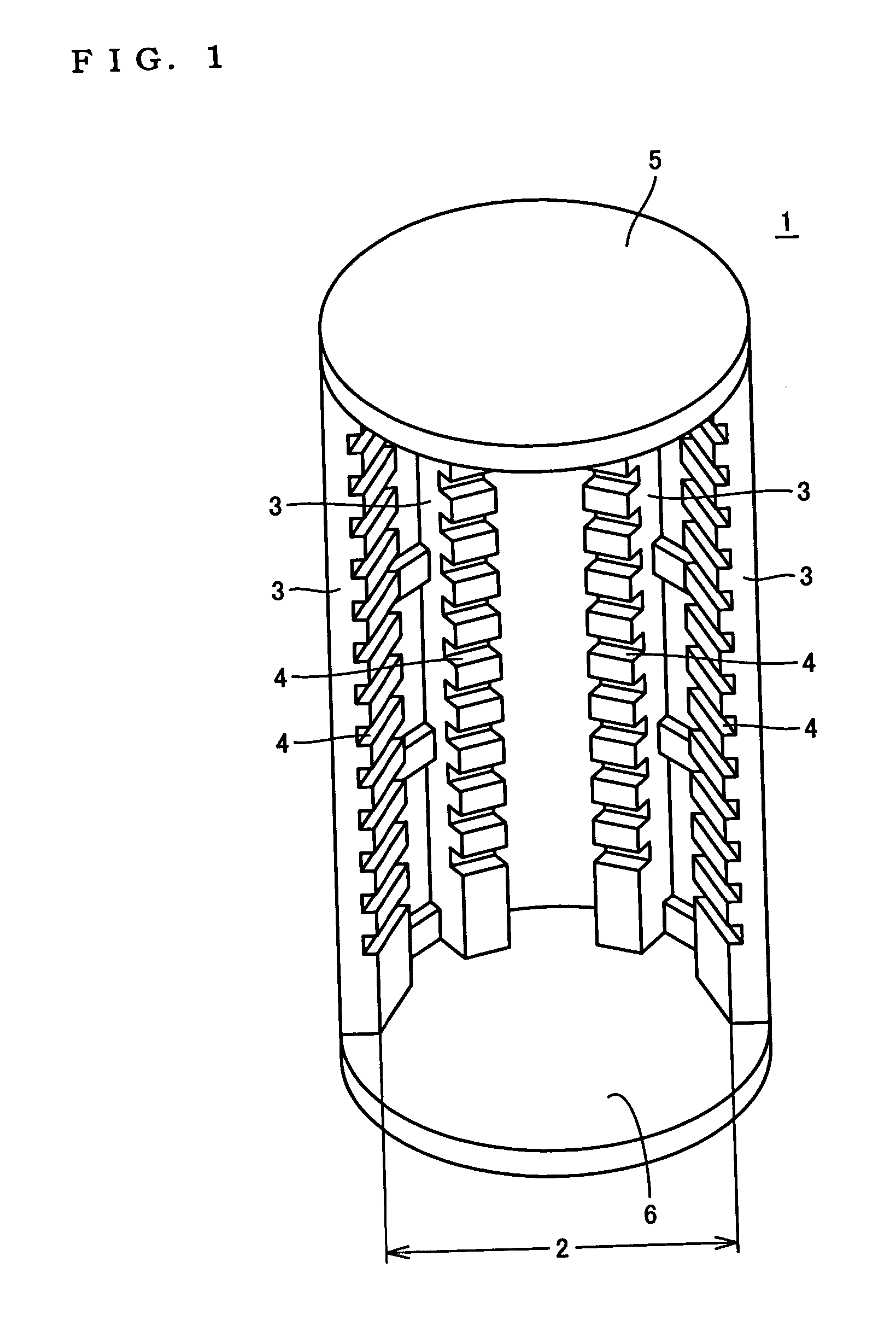

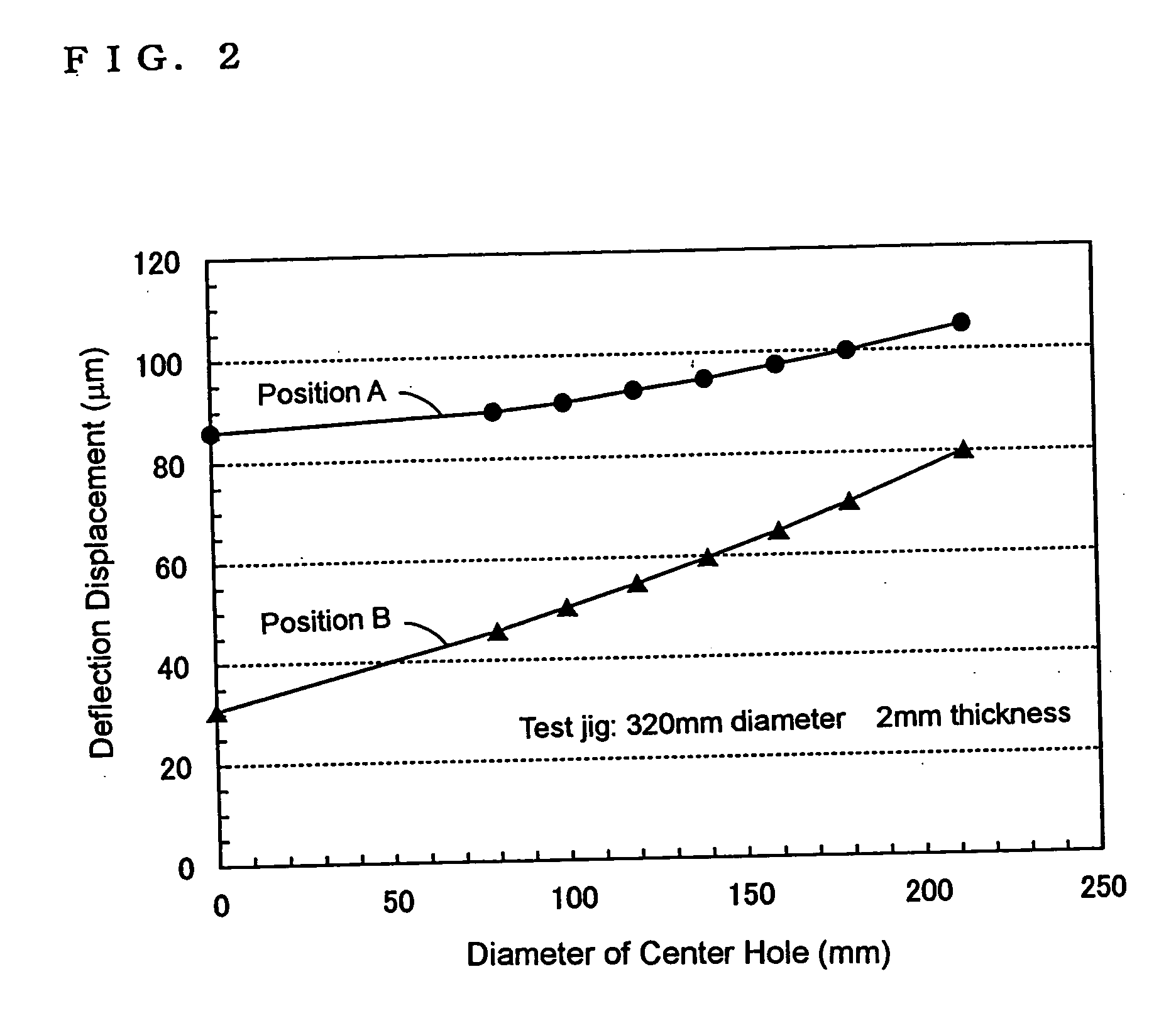

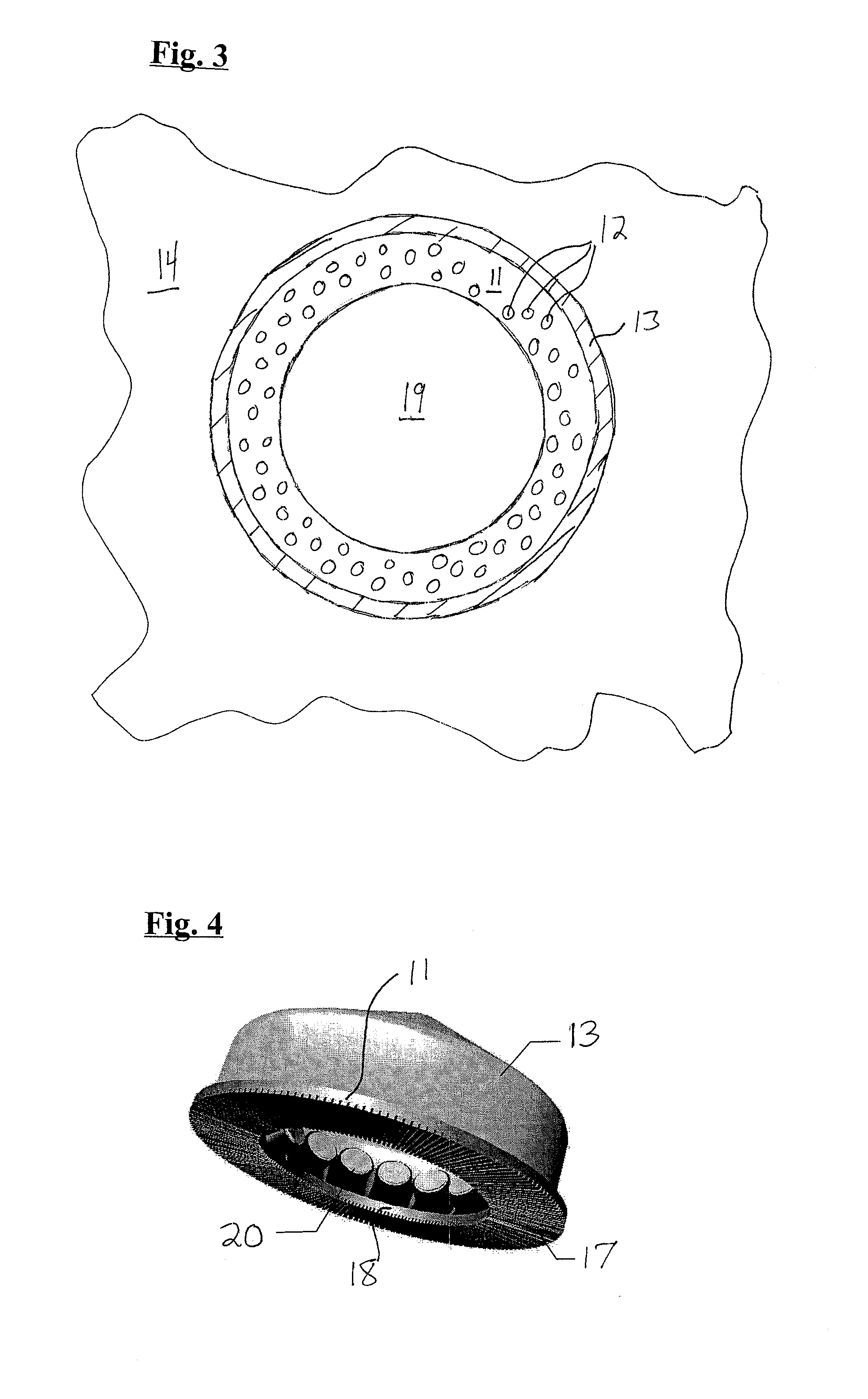

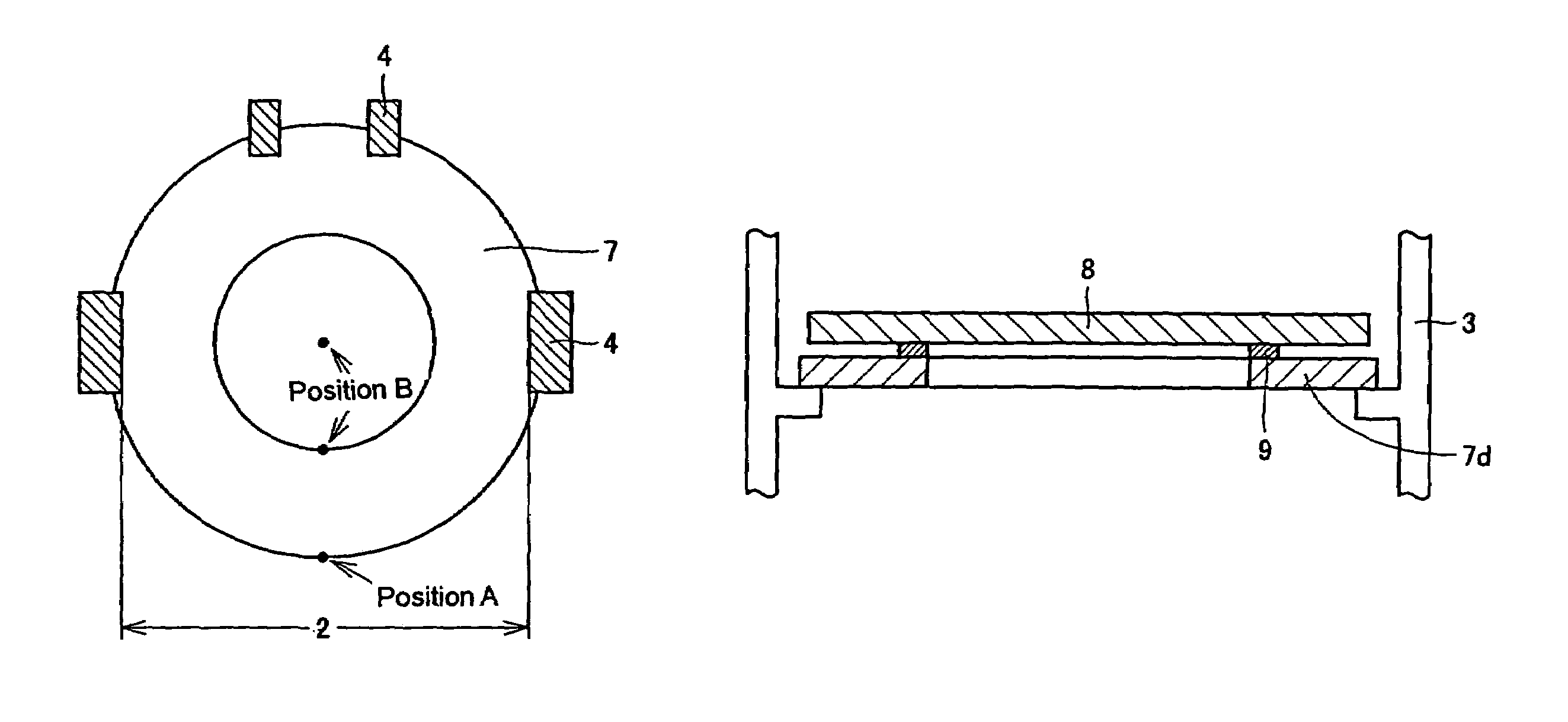

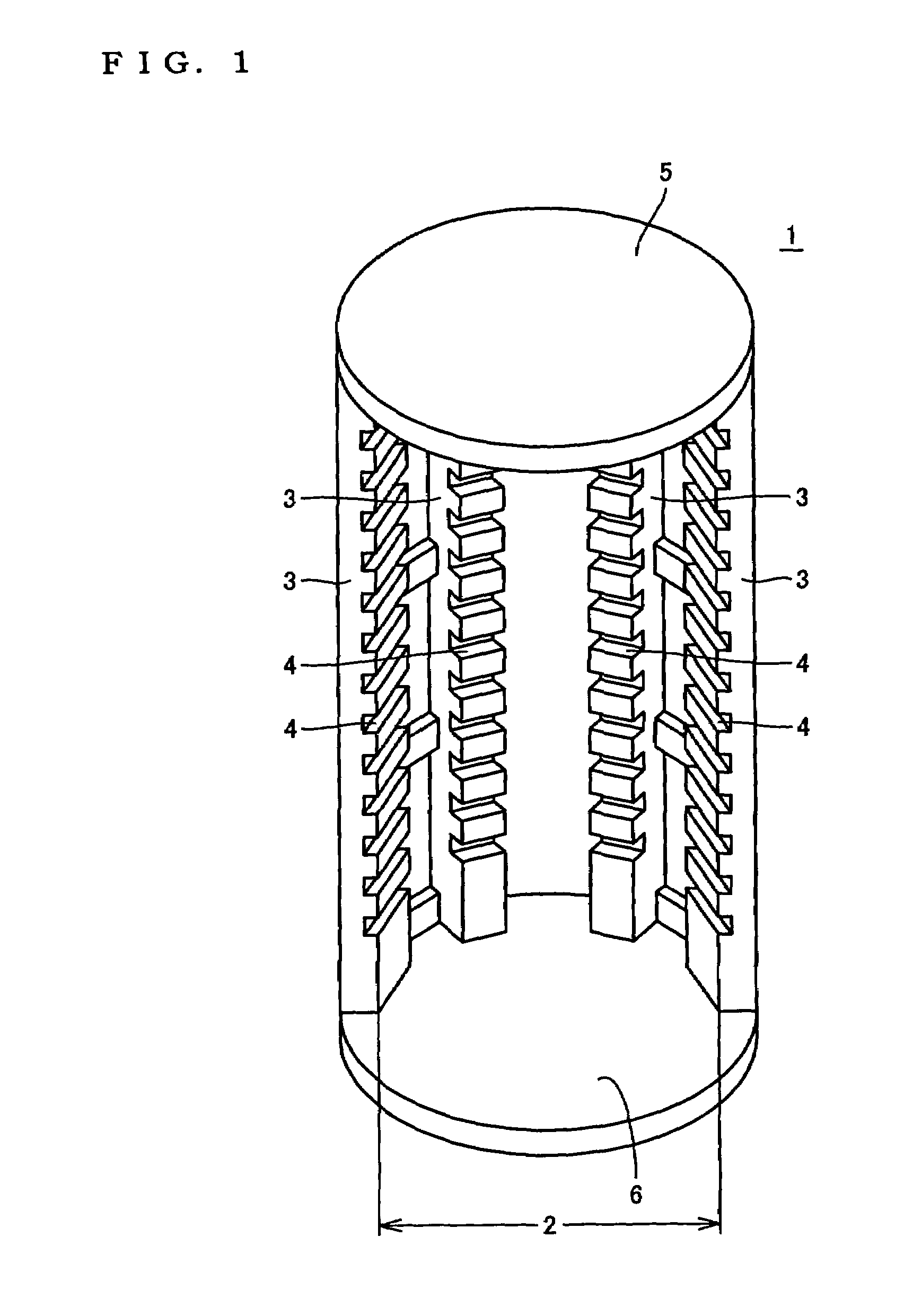

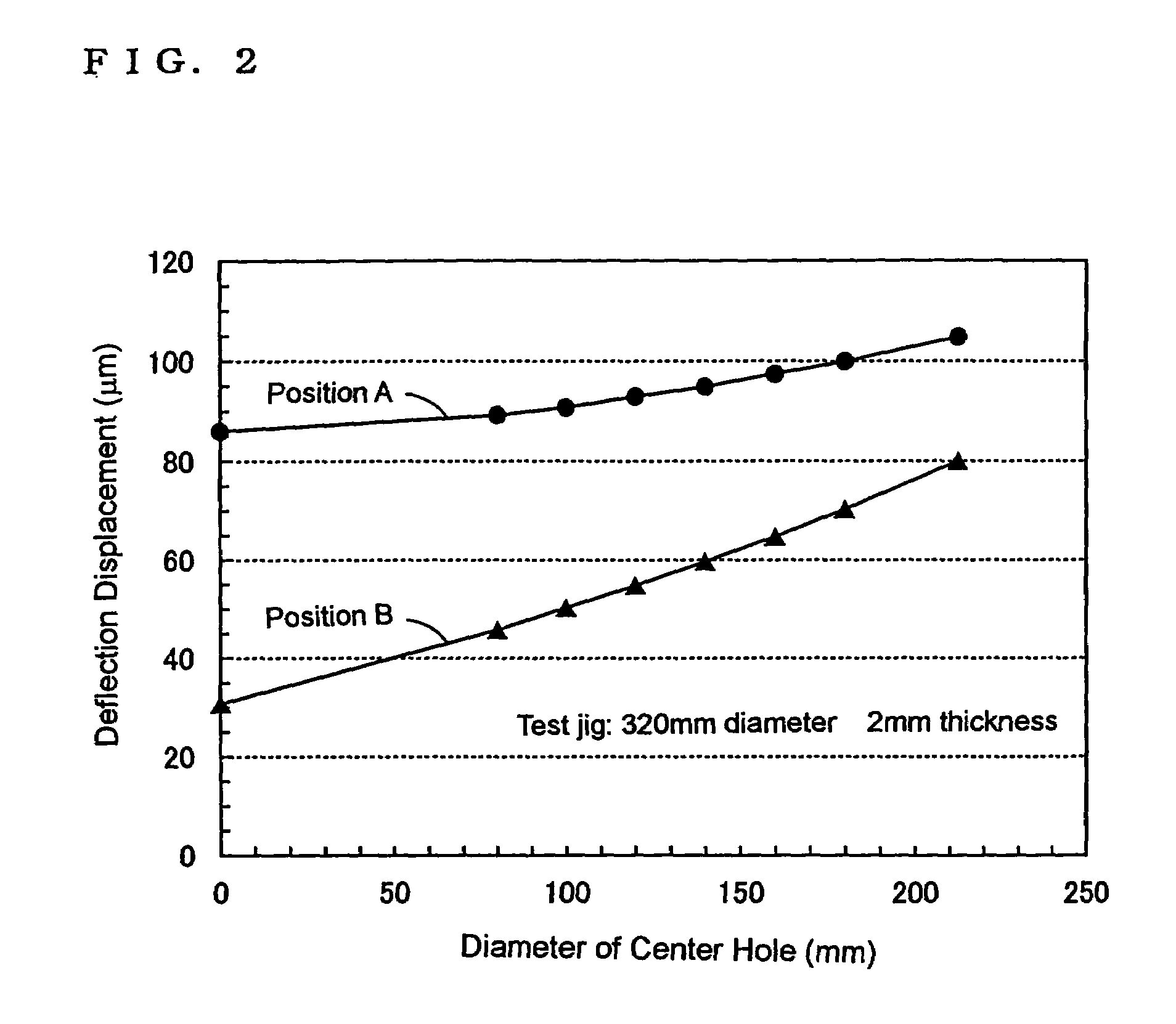

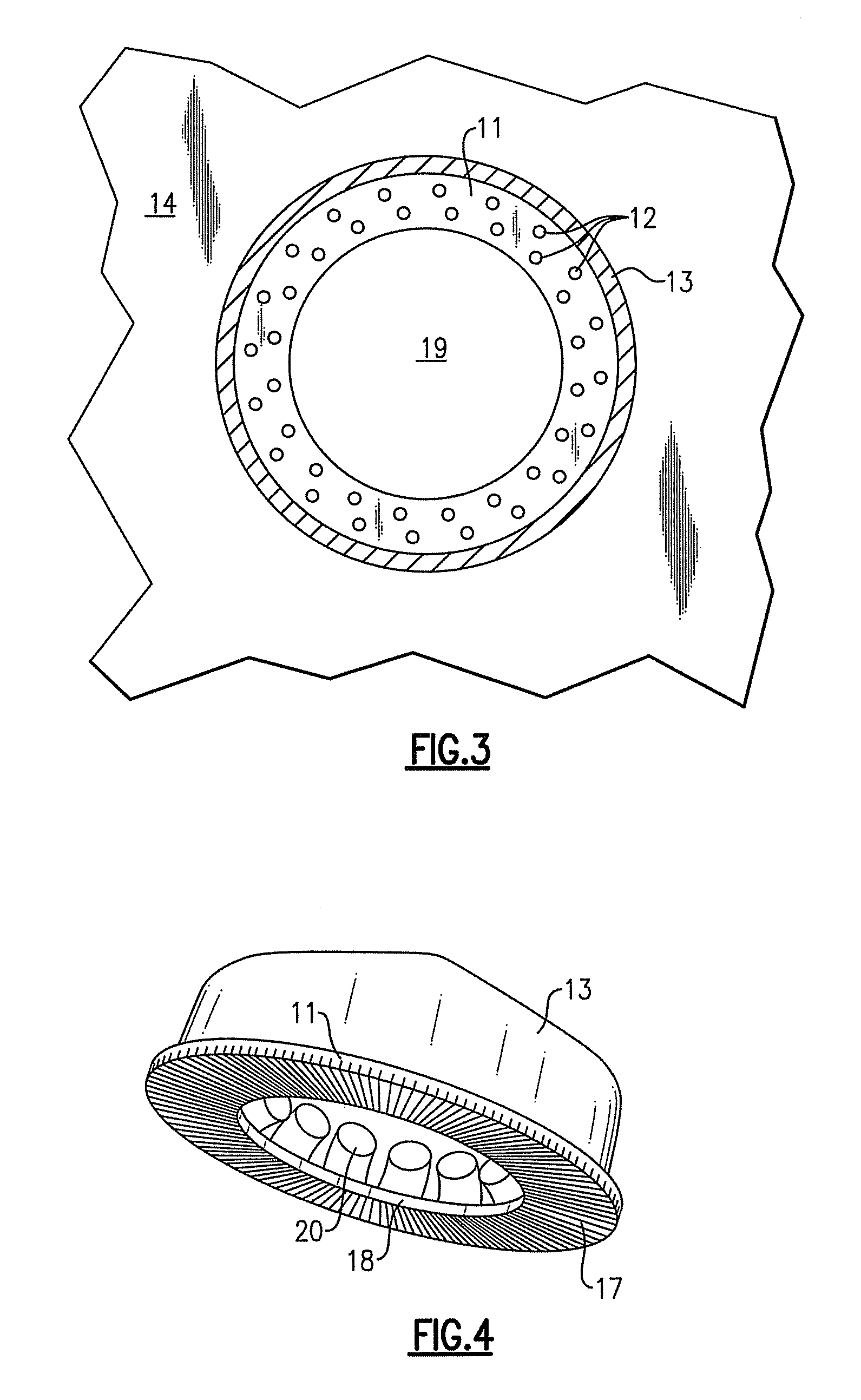

Heat treatment jig for silicon semiconductor substrate

ActiveUS20050282101A1Reduce generationDiminish surface stepCharge supportsSemiconductor/solid-state device manufacturingSurface roughnessSemiconductor

A heat treatment jig for supporting silicon semiconductor substrates by contacting, being loaded onto a heat treatment boat in a vertical heat treatment furnace, comprises; the configuration of a ring or a disc structure with the wall thickness between 1.5 and 6.0 mm; the deflection displacement of 100 μm or less at contact region in loaded condition; the outer diameter which is 65% or more of the diameter of said substrate; and the surface roughness (Ra) of between 1.0 and 100 μm at the contact region. The use of said jig enables to effectively retard the slip generation and to avoid the growth hindrance of thermally oxidized film at the back surface of said substrate, diminishing the surface steps causing the defocus in photolithography step in device fabrication process, thereby enabling to maintain high quality of silicon semiconductor substrates and to substantially enhance the device yield.

Owner:SUMITOMO MITSUBISHI SILICON CORP

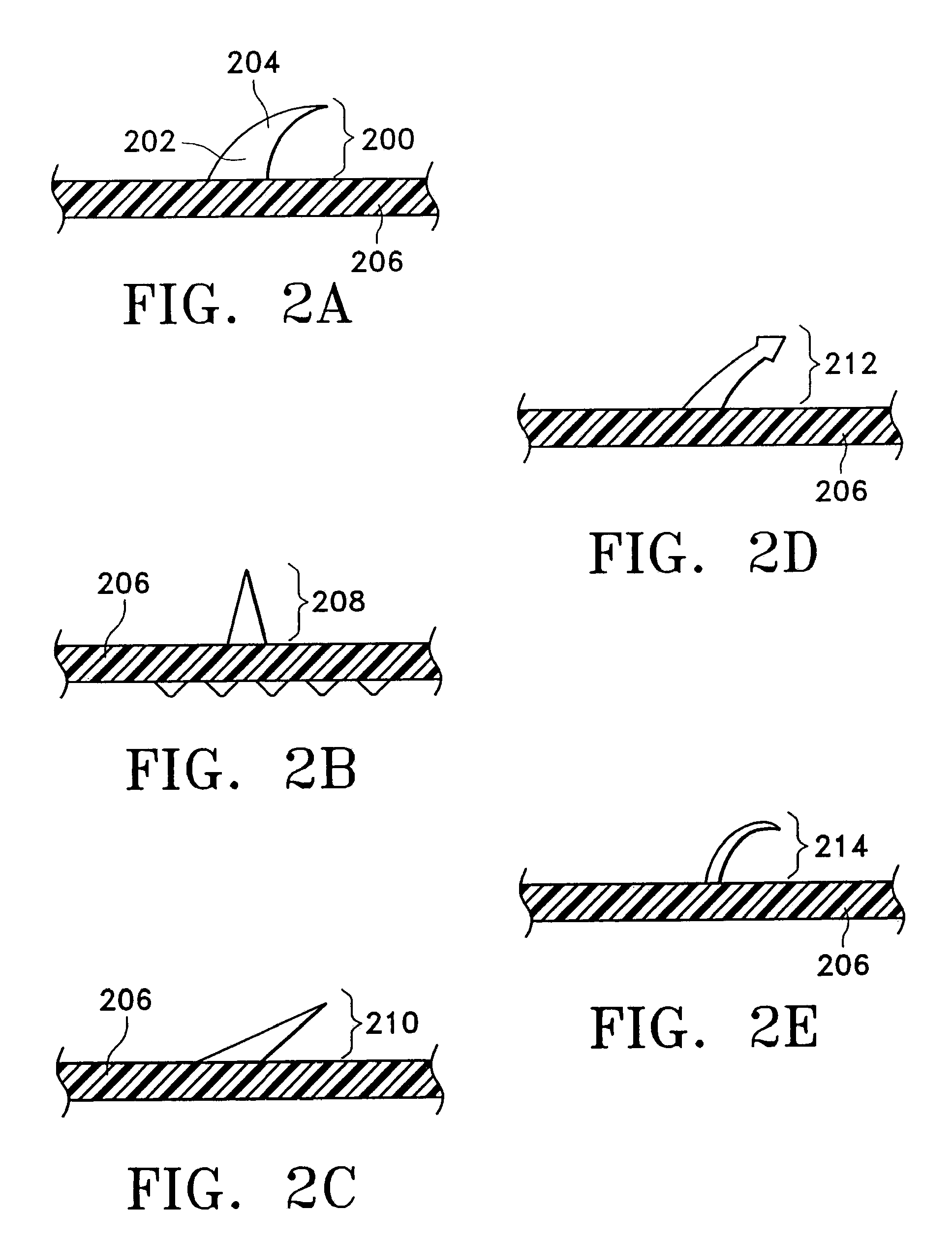

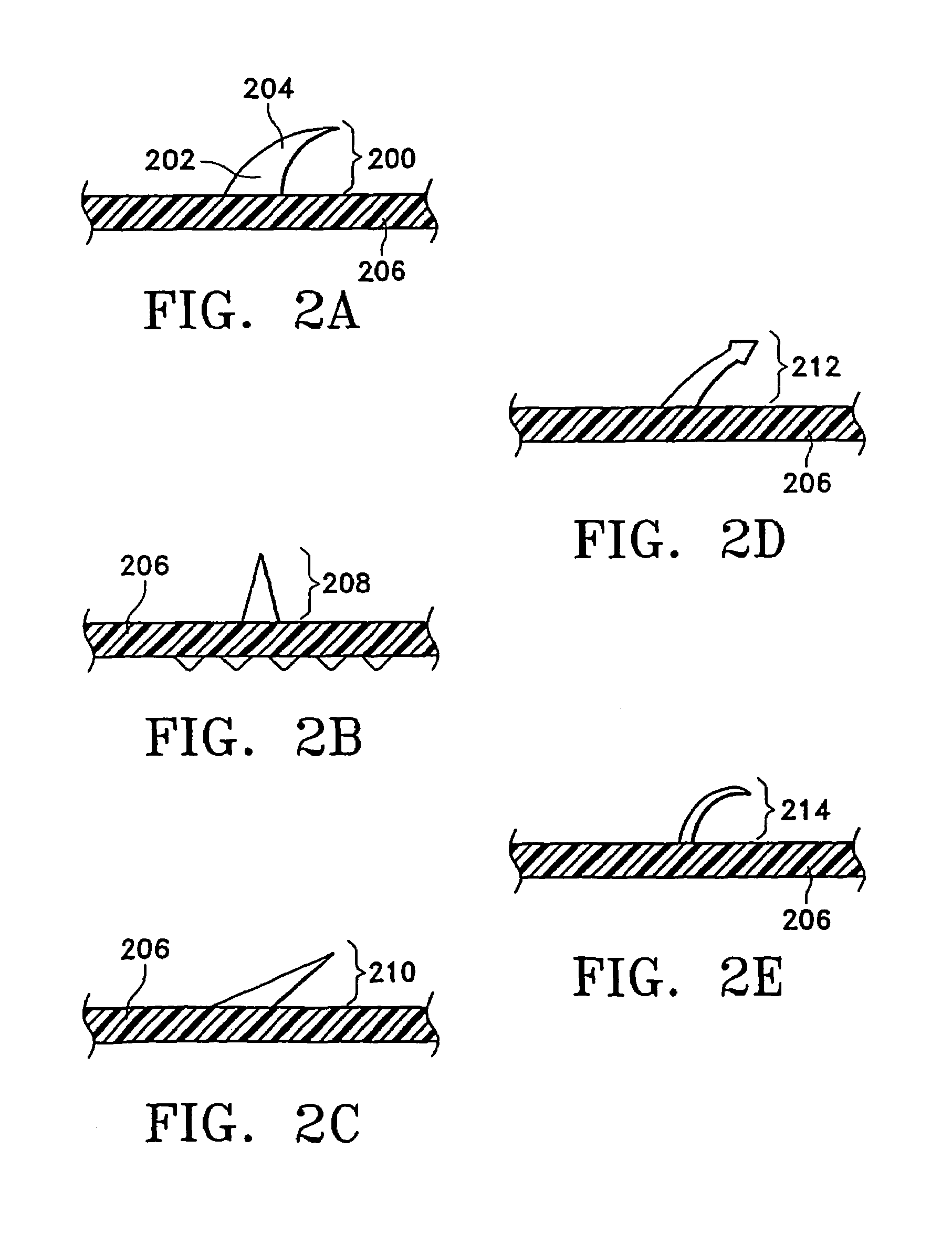

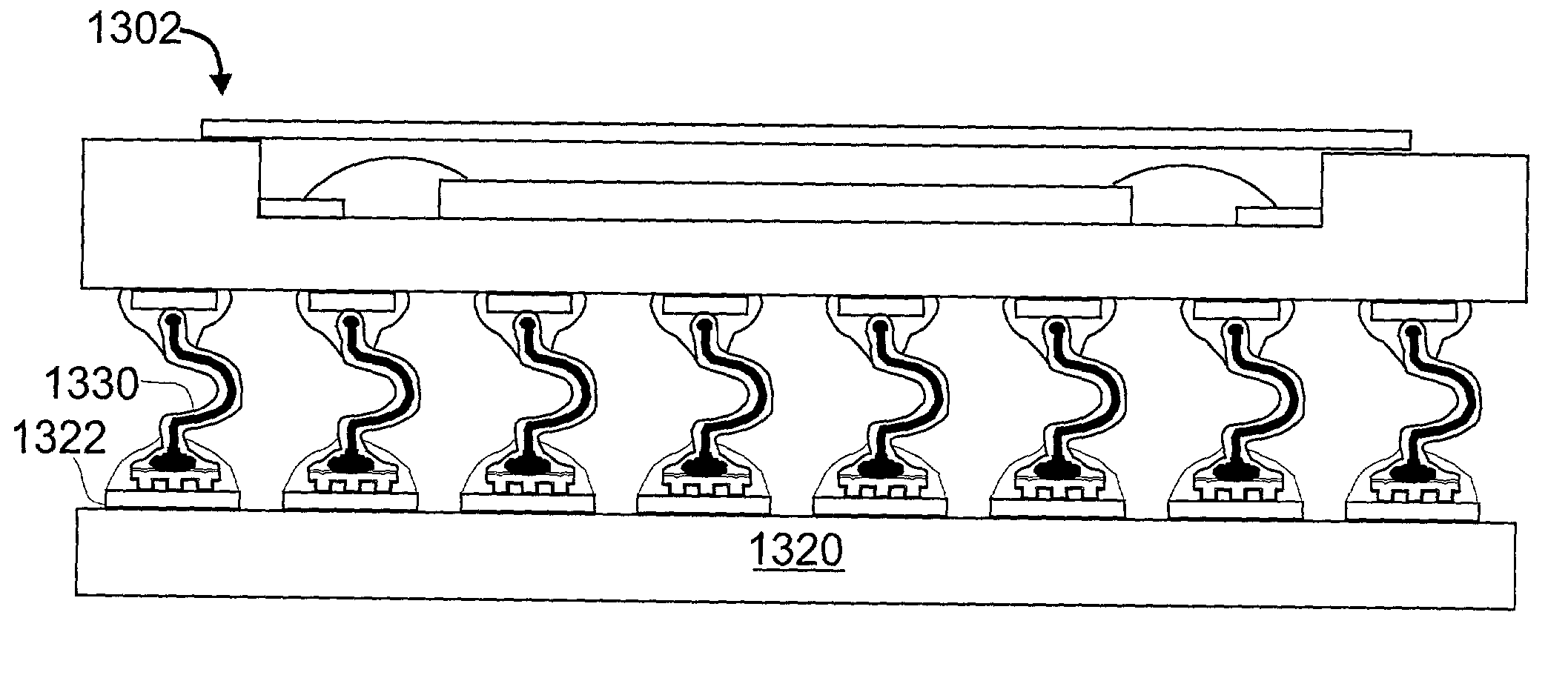

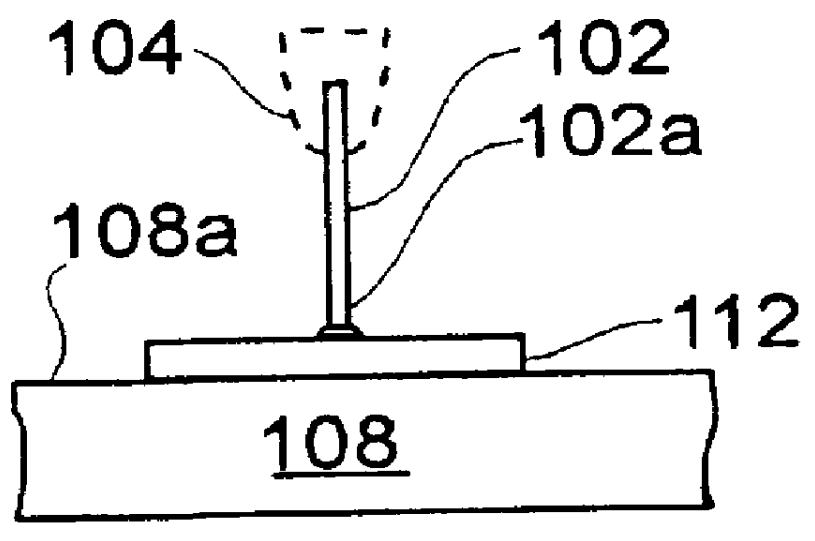

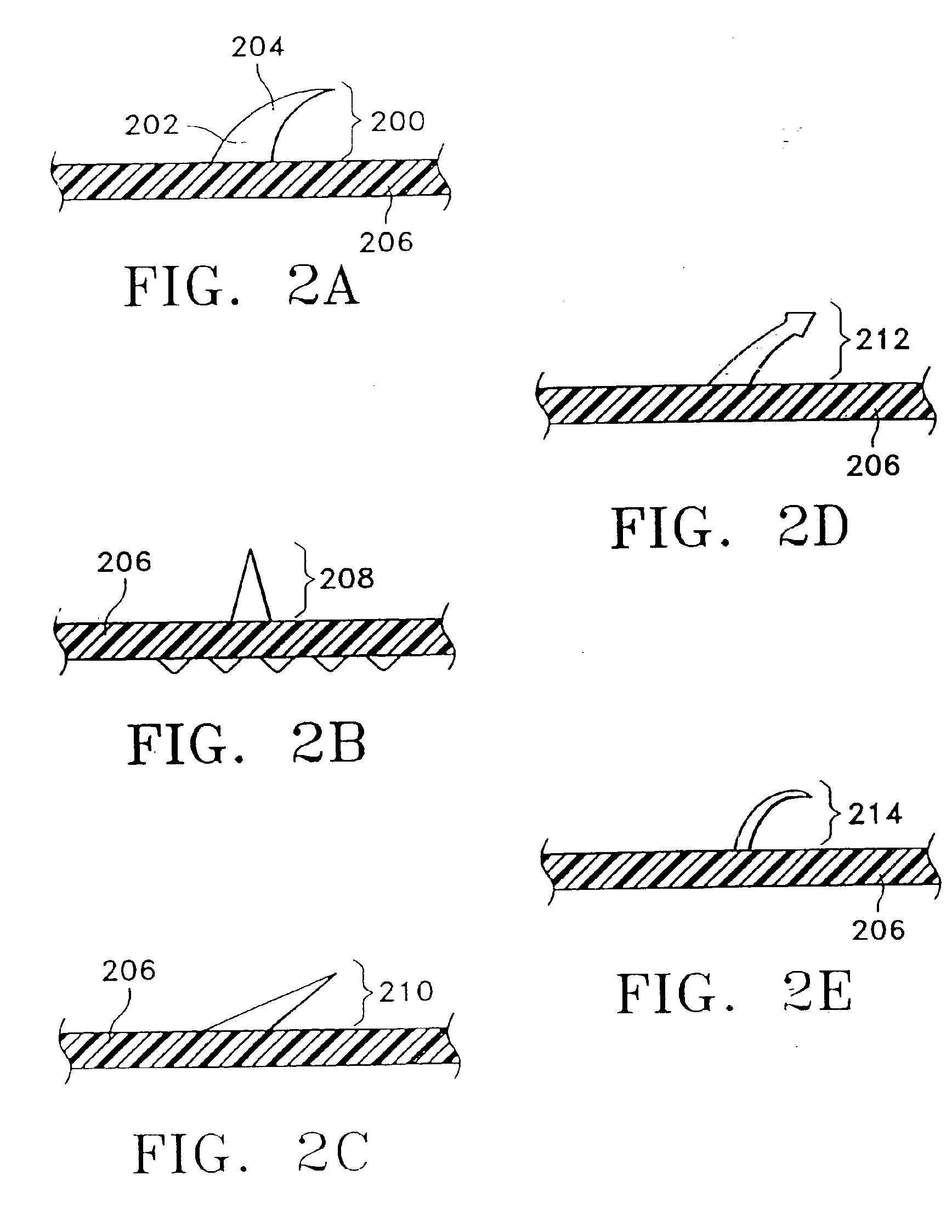

Resilient contact structures formed and then attached to a substrate

InactiveUS20020117330A1Simple technologyCoupling device connectionsSemiconductor/solid-state device testing/measurementEngineeringTopography

Owner:FORMFACTOR INC

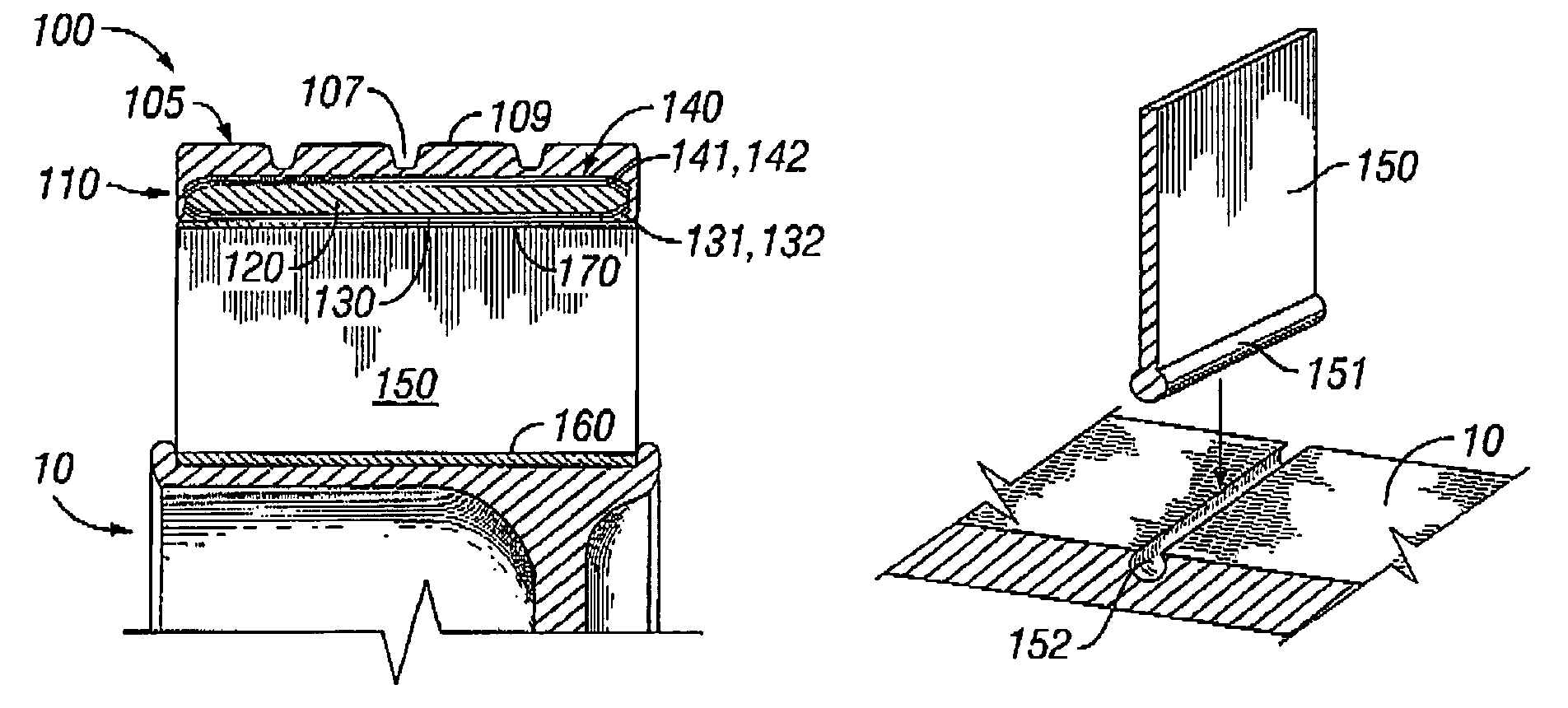

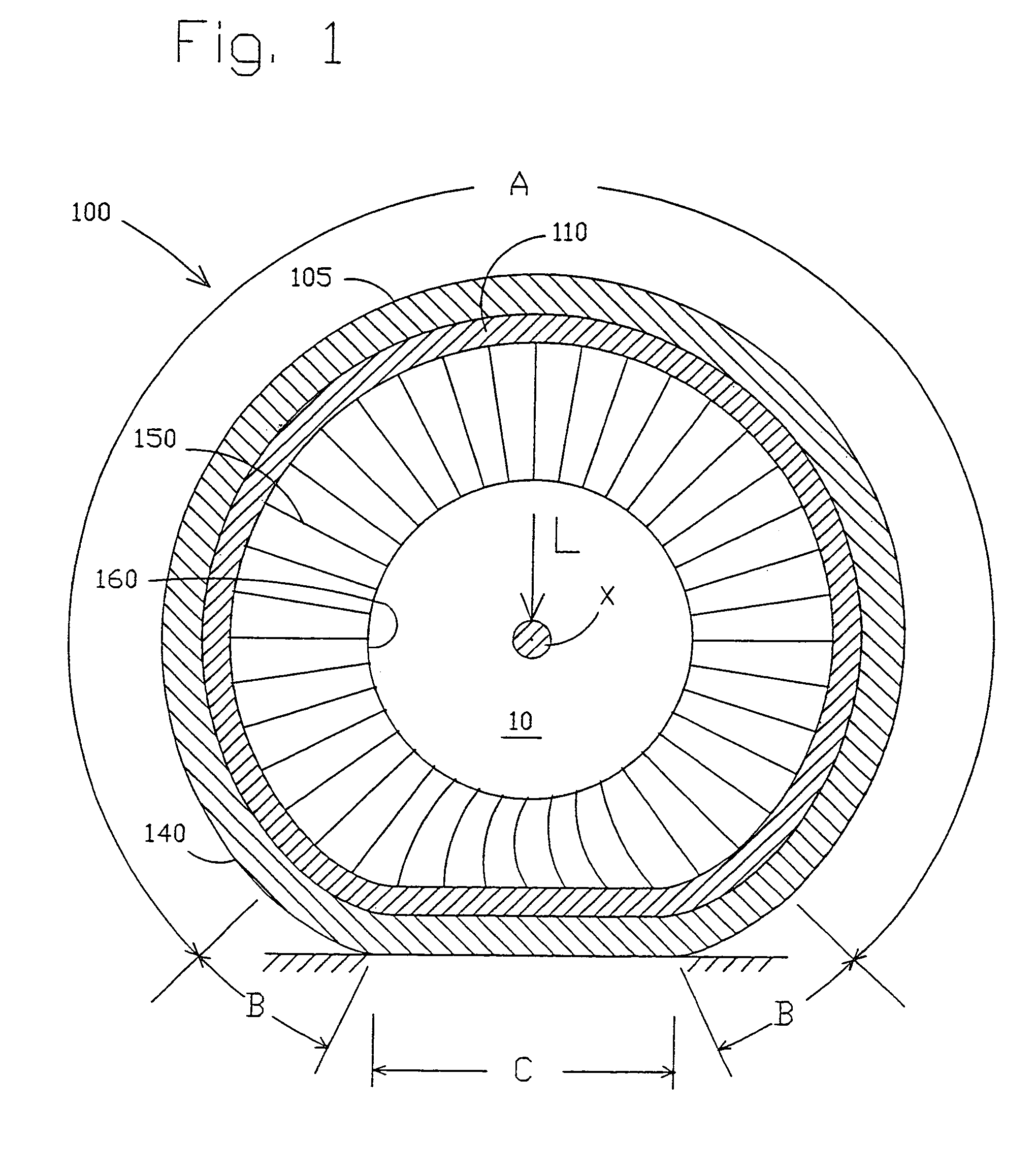

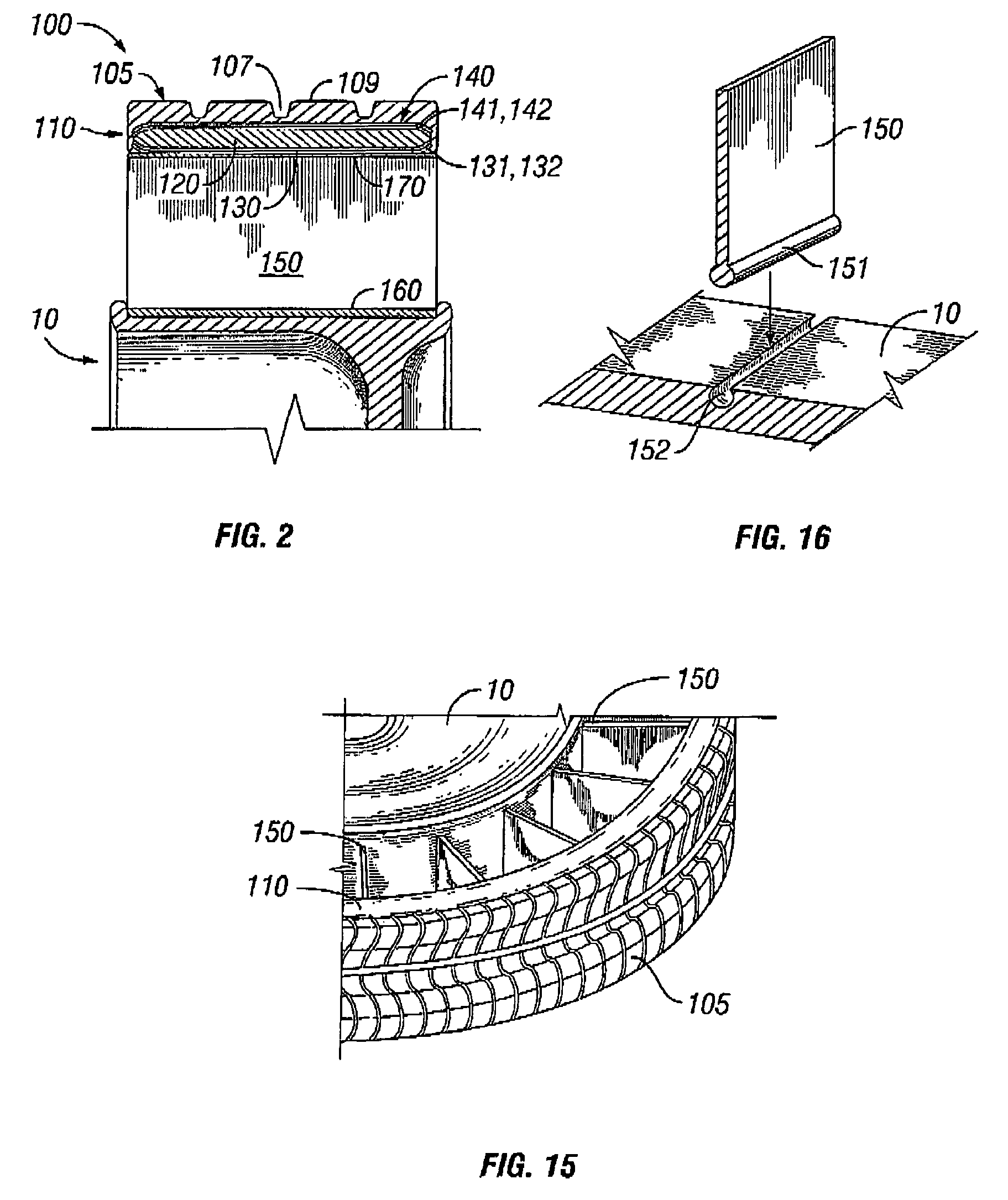

Non-pneumatic tire

InactiveUS7201194B2Supporting massHigh effective radial stiffness in tensionNon-inflatable tyresPneumatic tyre reinforcementsElastomerShear modulus

A structurally supported tire includes a ground contacting tread portion, a reinforced annular band disposed radially inward of the tread portion, and a plurality of web spokes extending transversely across and radially inward from the reinforced annular band and anchored in a wheel or hub. The reinforced annular band comprises an elastomeric shear layer, at least a first membrane adhered to the radially inward extent of the elastomeric shear layer and at least a second membrane adhered to the radially outward extent of the elastomeric shear layer. Each of the membranes has a longitudinal tensile modulus sufficiently greater than the shear modulus of the shear layer so that when under load the ground contacting portion of the tire deforms to a flat contact region through shear strain in the shear layer while maintaining constant the length of the membranes, the web spokes transmitting load forces between the annular band and the hub through tension in the web spokes not connected to the ground contacting portion of the tire.

Owner:MICHELIN RECH & TECH SA

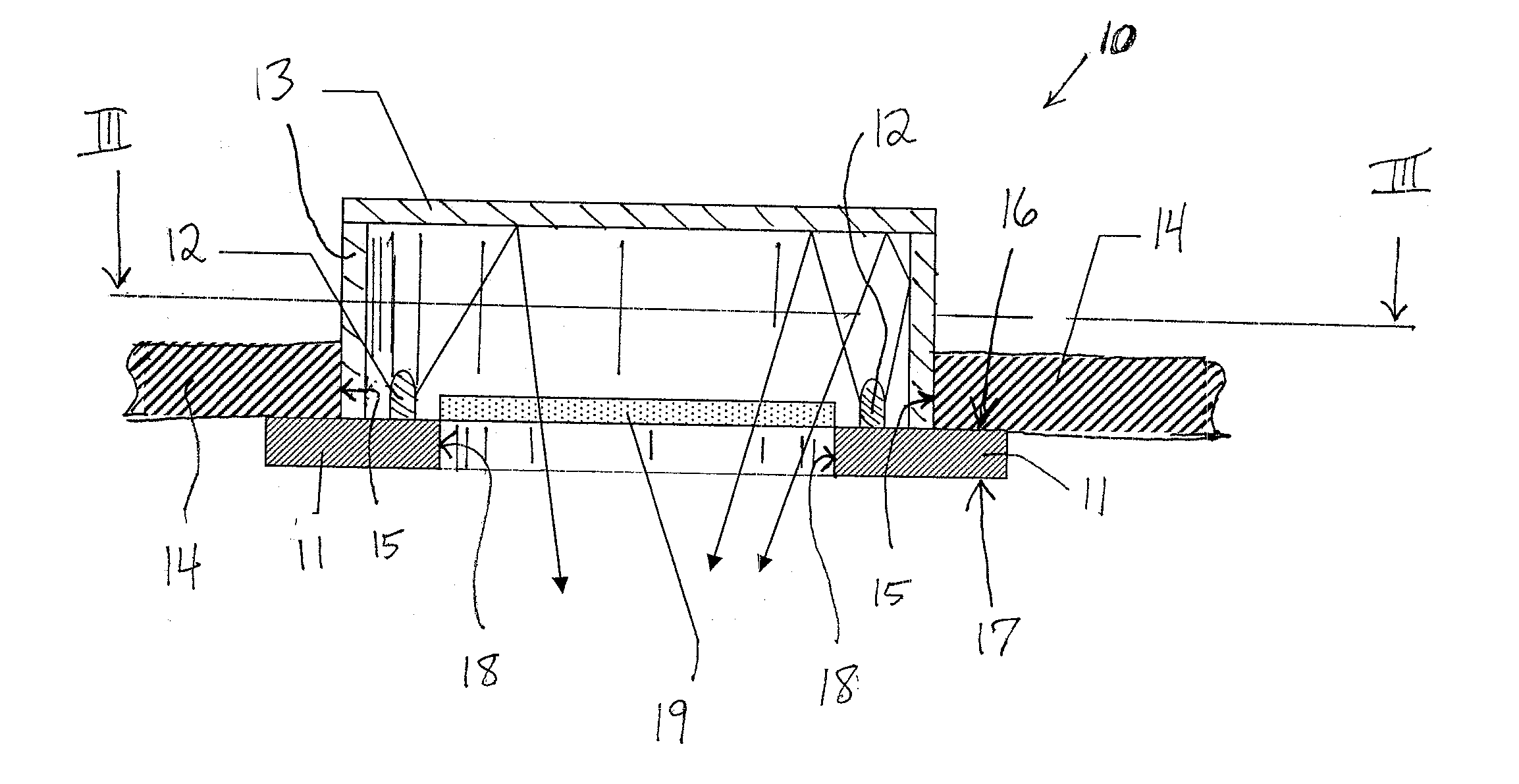

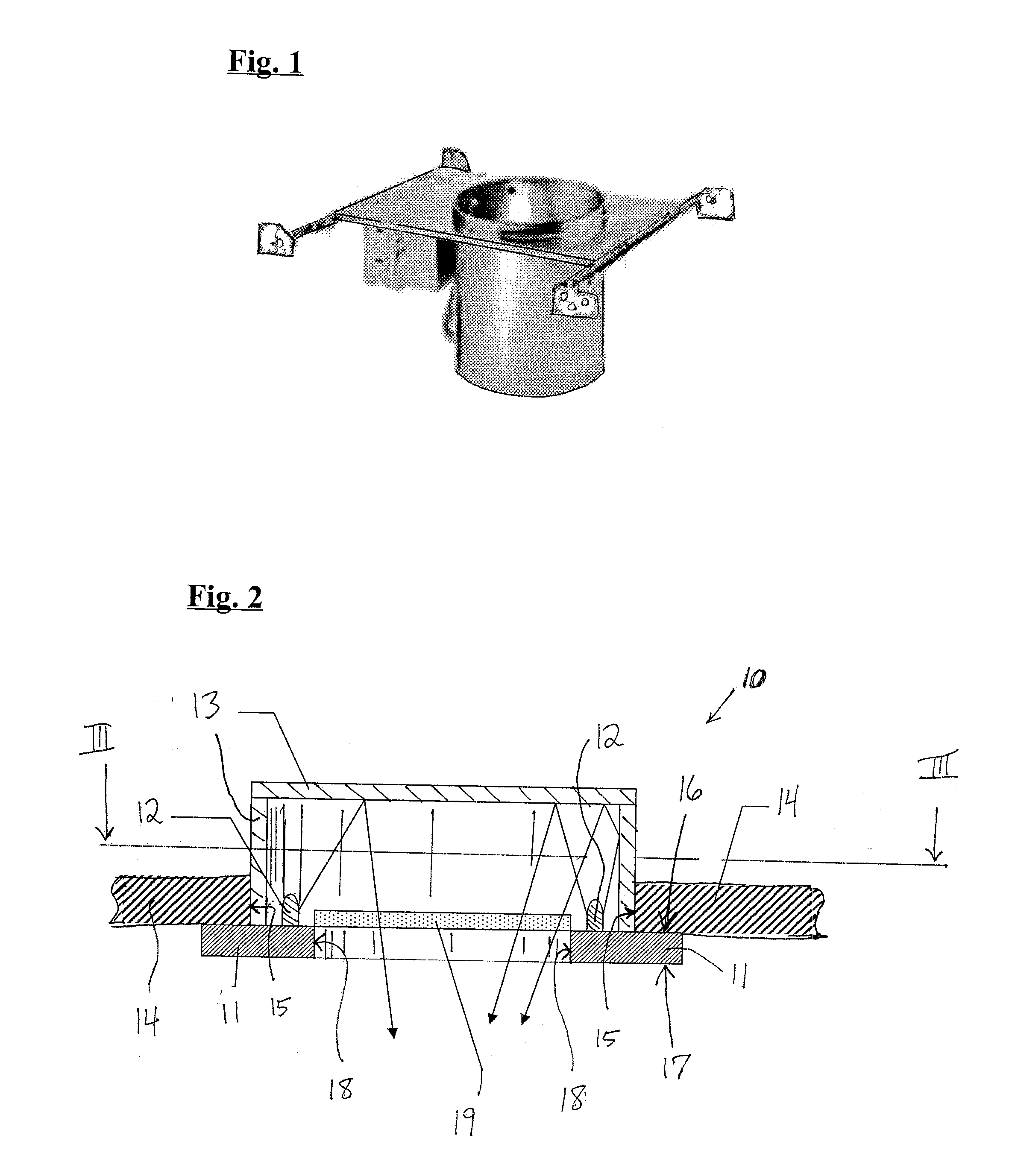

Lighting device

ActiveUS20070263393A1Reduce glareEfficient transferMechanical apparatusPoint-like light sourceEffect lightEngineering

Owner:IDEAL IND LIGHTING LLC

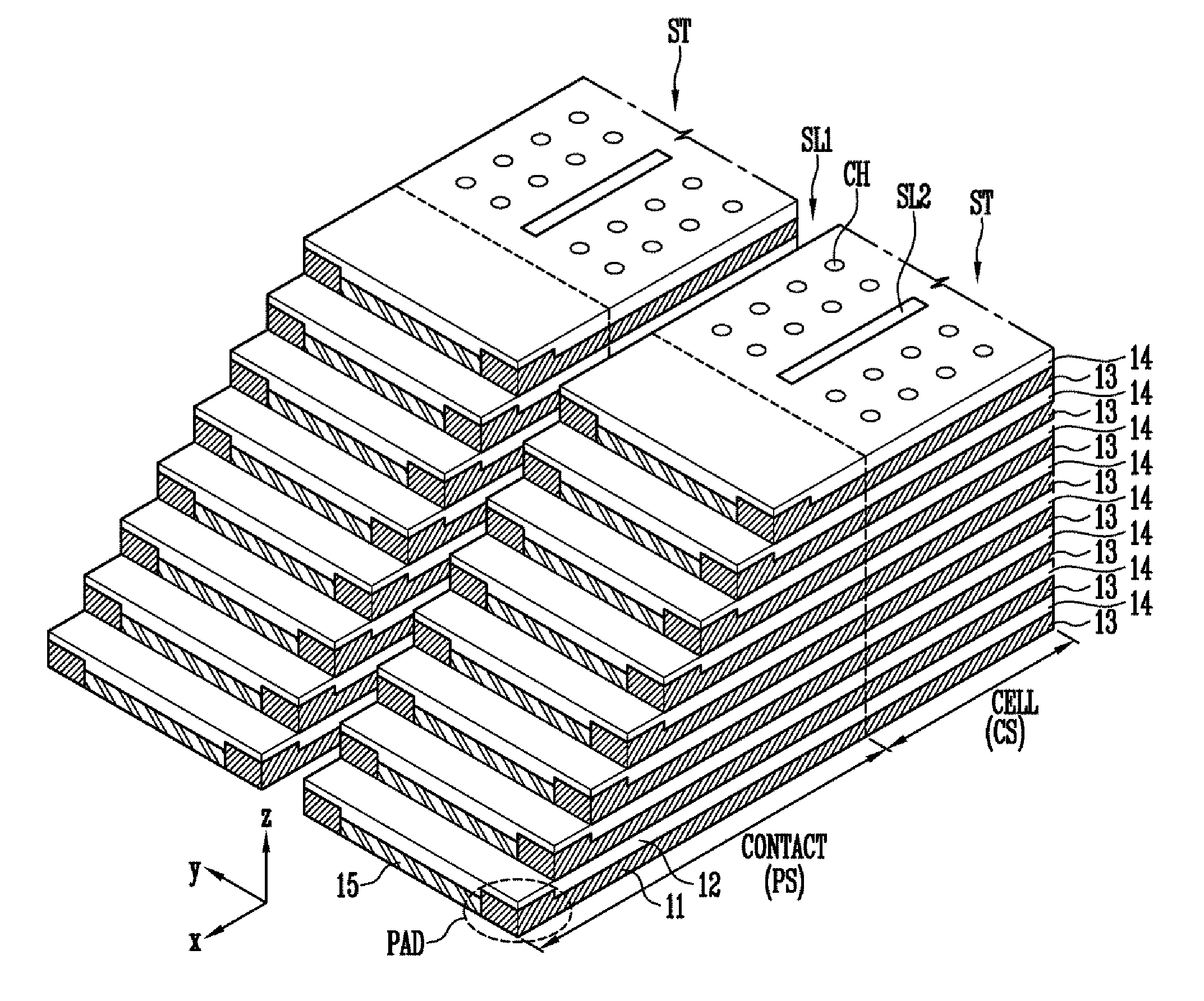

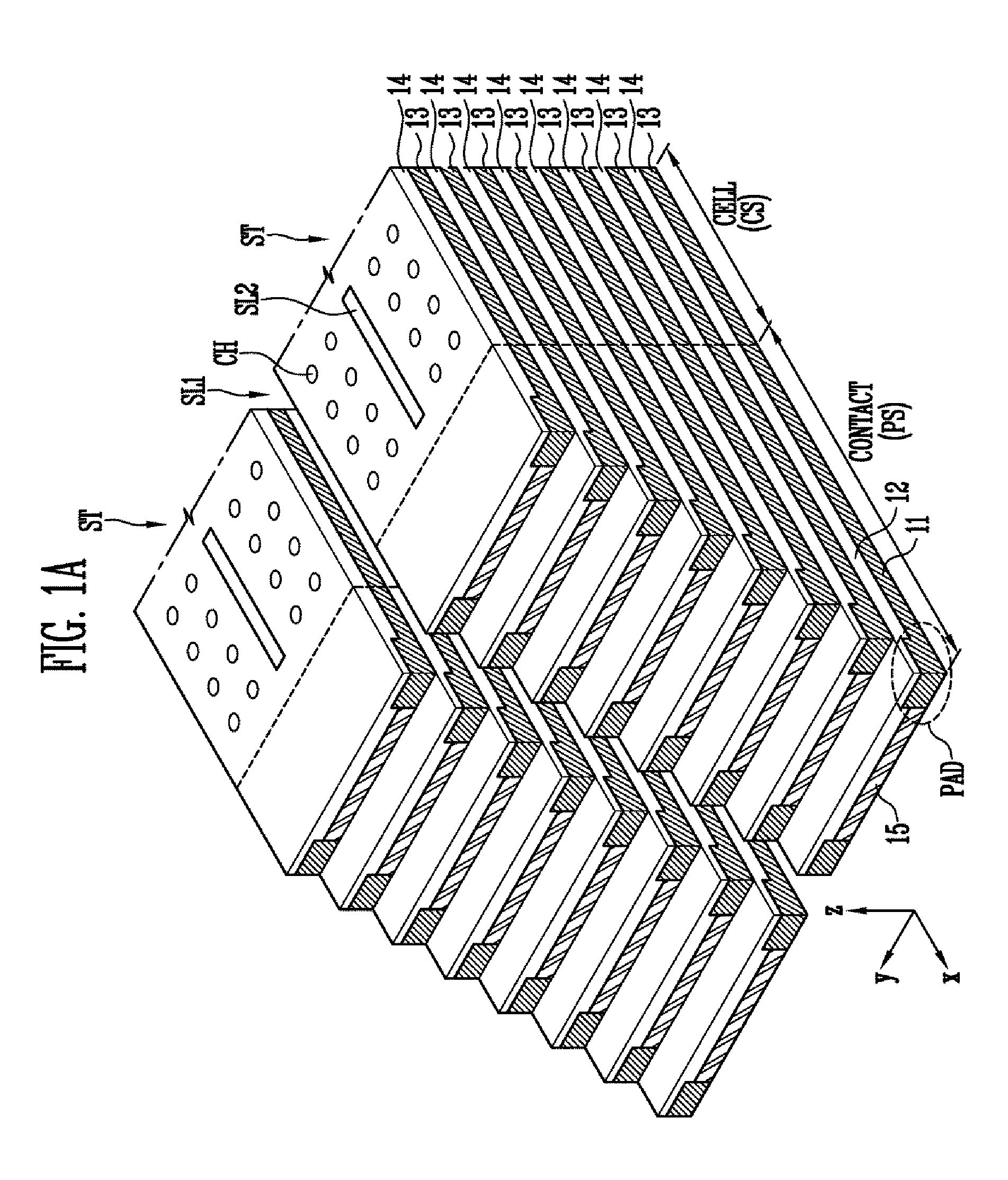

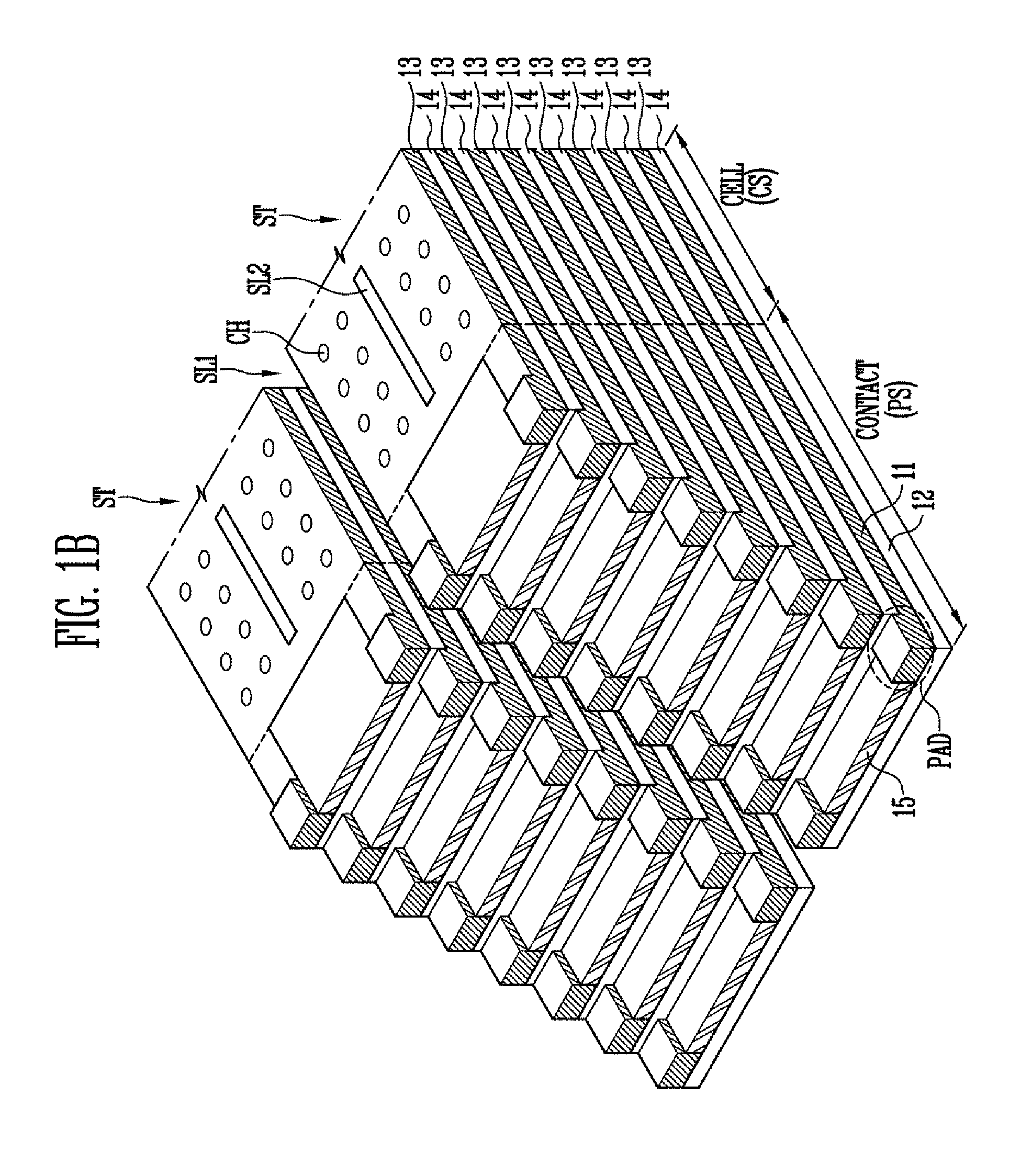

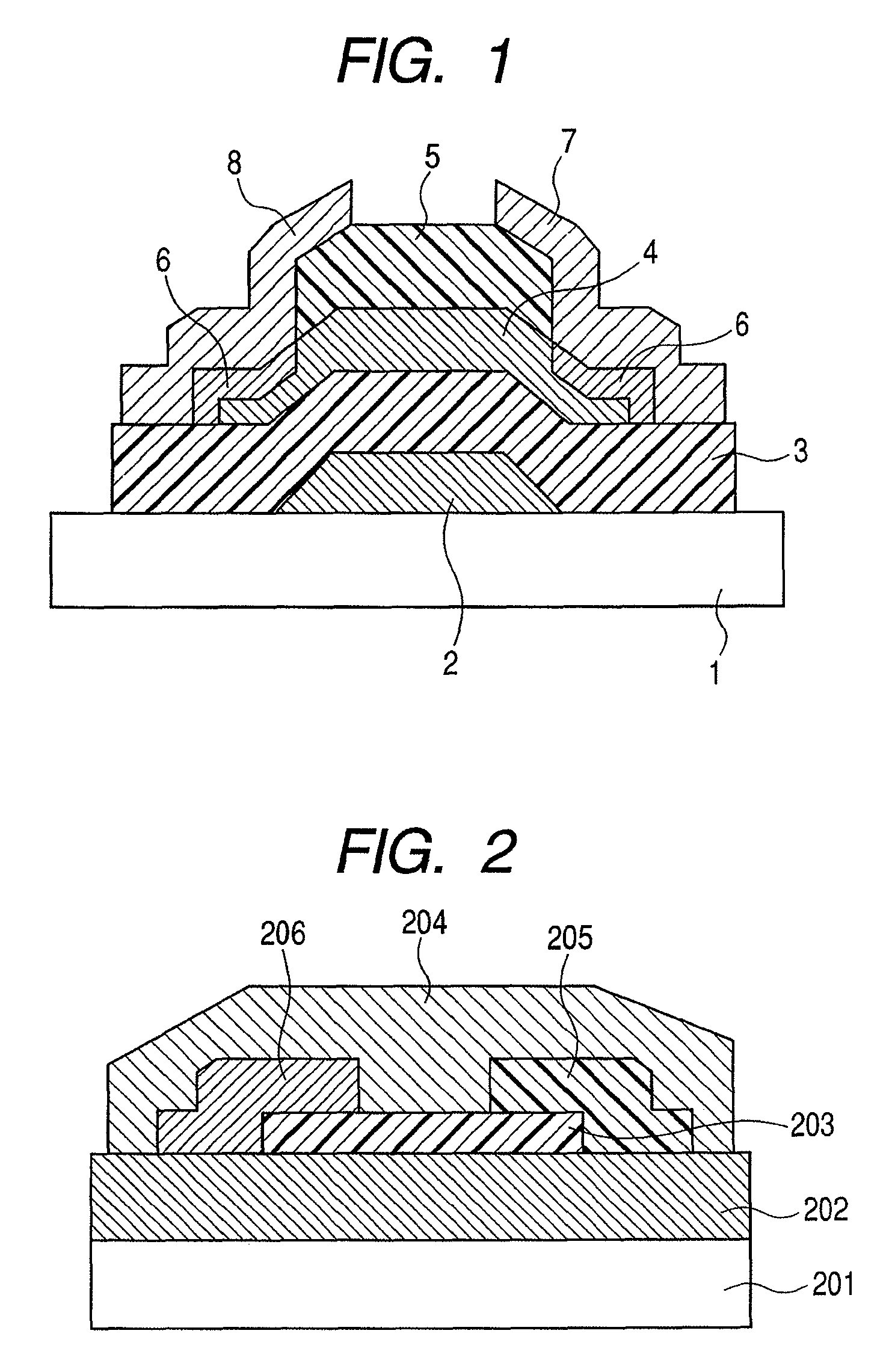

Semiconductor device and method of manufacturing the same

ActiveUS20140191389A1Well formedSemiconductor/solid-state device detailsSolid-state devicesPower semiconductor deviceCell region

A semiconductor device includes a substrate in which a cell region and a contact region are defined, a pad structure including a plurality of first conductive layers and a plurality of first insulating layers formed alternately with each other in the contact region of the substrate, wherein an end of the pad structure is patterned stepwise, portions of the first conductive layers exposed at the end of the pad structure are defined as a plurality of pad portions, and the plurality of pad portions have a greater thickness than unexposed portions of the plurality of first conductive layers.

Owner:SK HYNIX INC

Heat treatment jig for silicon semiconductor substrate

ActiveUS7210925B2Reduce generationGenerated with easeCharge supportsSemiconductor/solid-state device manufacturingSurface roughnessSilicon

A heat treatment jig for supporting silicon semiconductor substrates by contacting, being loaded onto a heat treatment boat in a vertical heat treatment furnace, comprises; the configuration of a ring or a disc structure with the wall thickness between 1.5 and 6.0 mm; the deflection displacement of 100 μm or less at contact region in loaded condition; the outer diameter which is 65% or more of the diameter of said substrate; and the surface roughness (Ra) of between 1.0 and 100 μm at the contact region. The use of said jig enables to effectively retard the slip generation and to avoid the growth hindrance of thermally oxidized film at the back surface of said substrate, diminishing the surface steps causing the defocus in photolithography step in device fabrication process, thereby enabling to maintain high quality of silicon semiconductor substrates and to substantially enhance the device yield.

Owner:SUMITOMO MITSUBISHI SILICON CORP

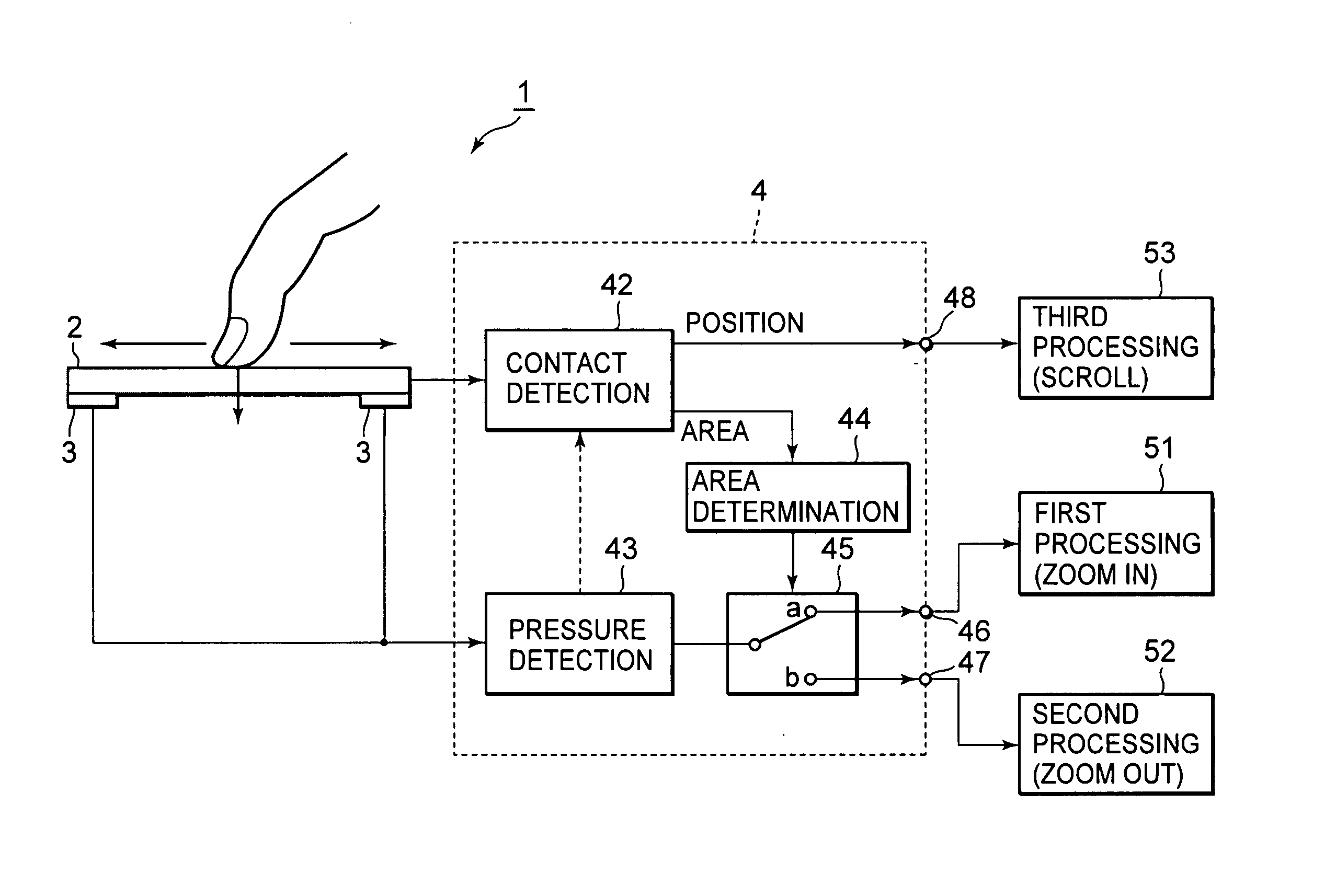

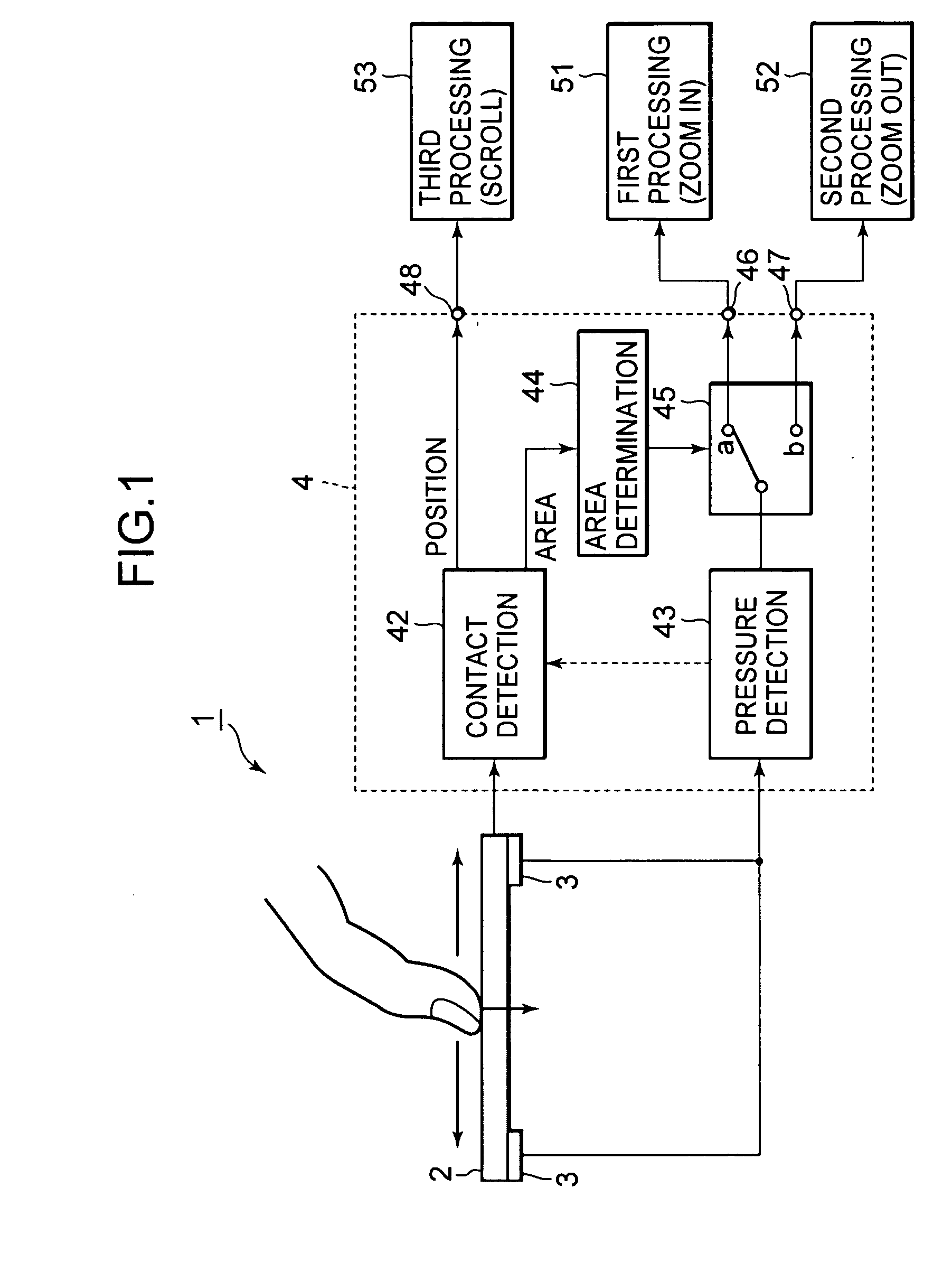

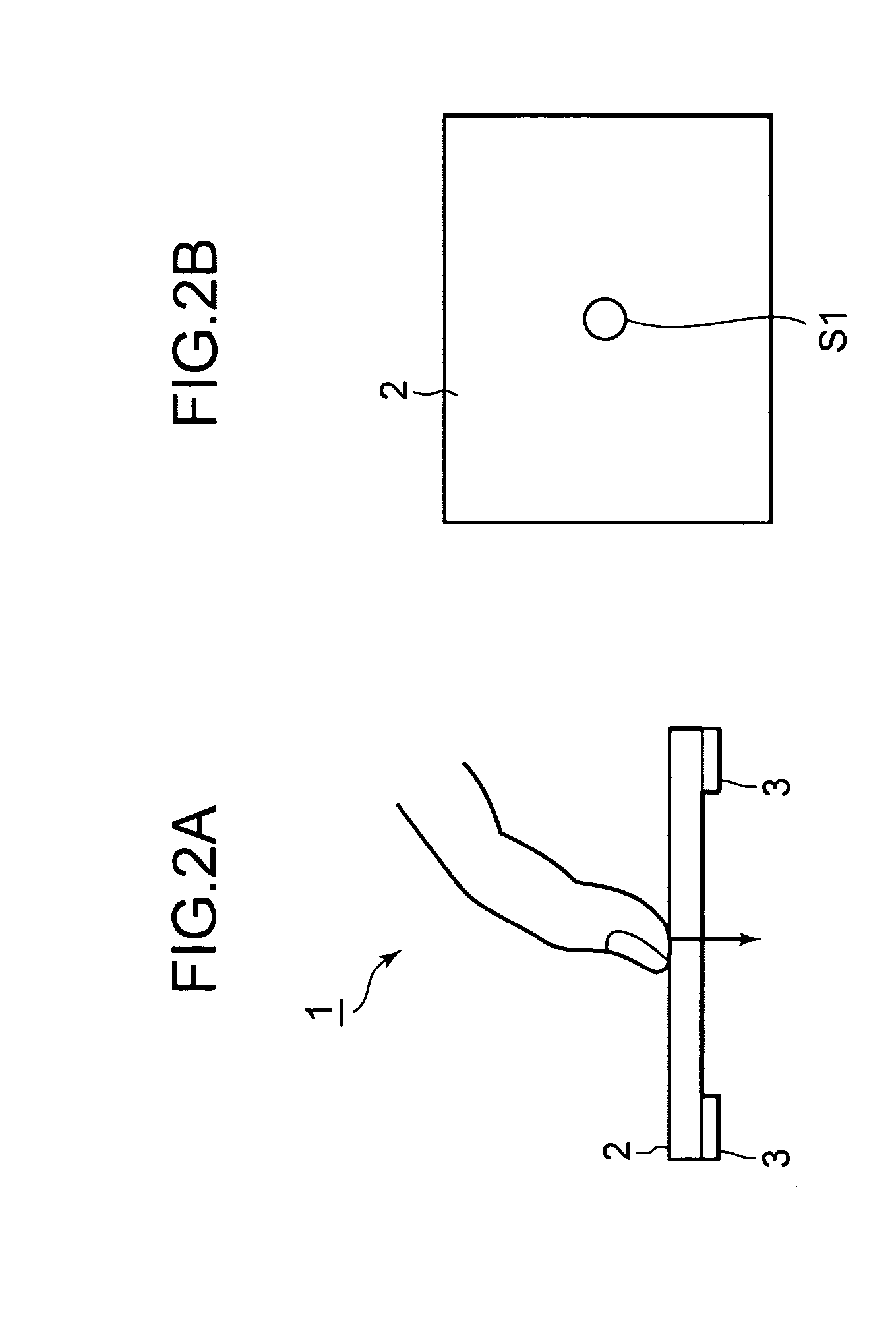

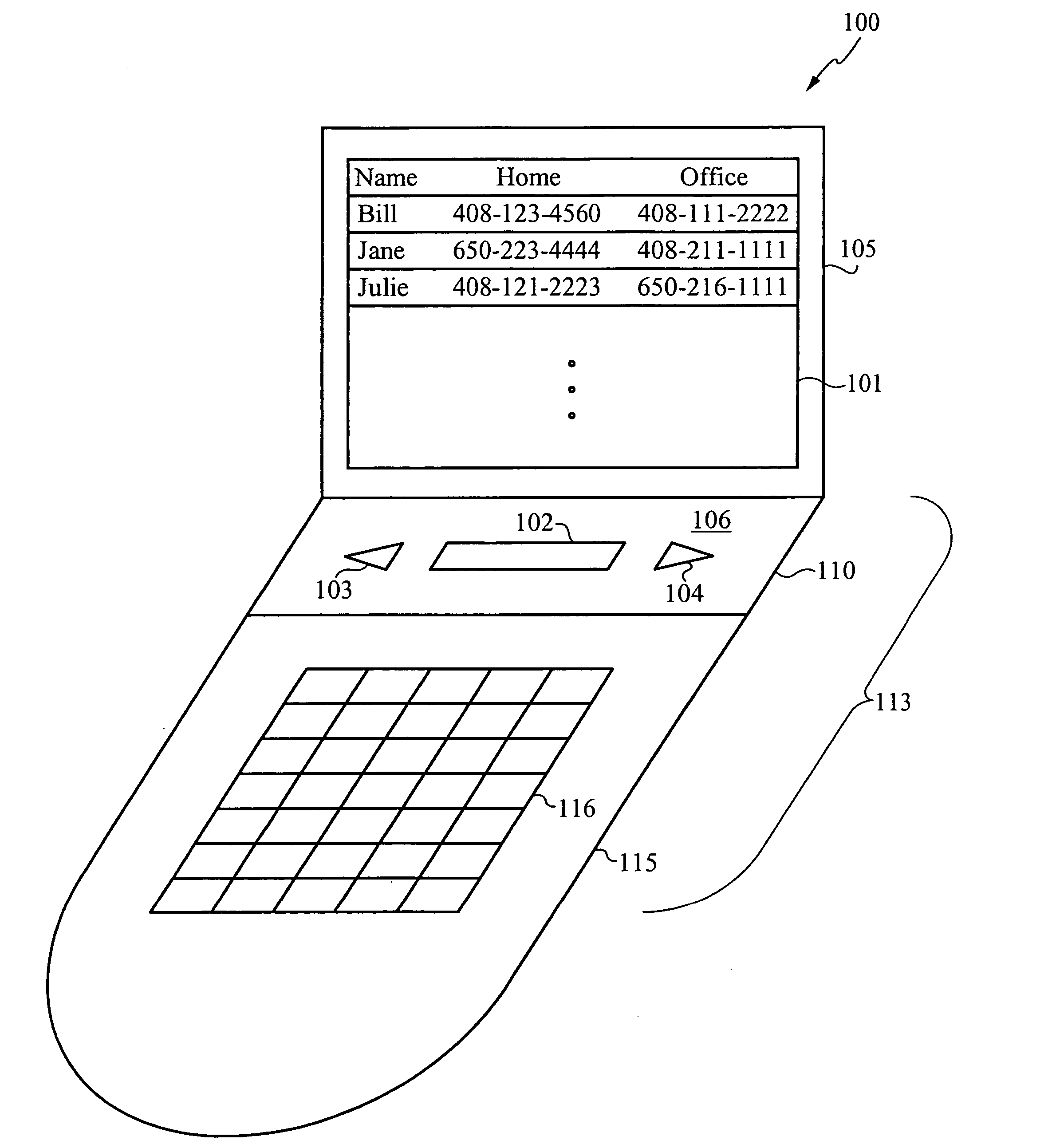

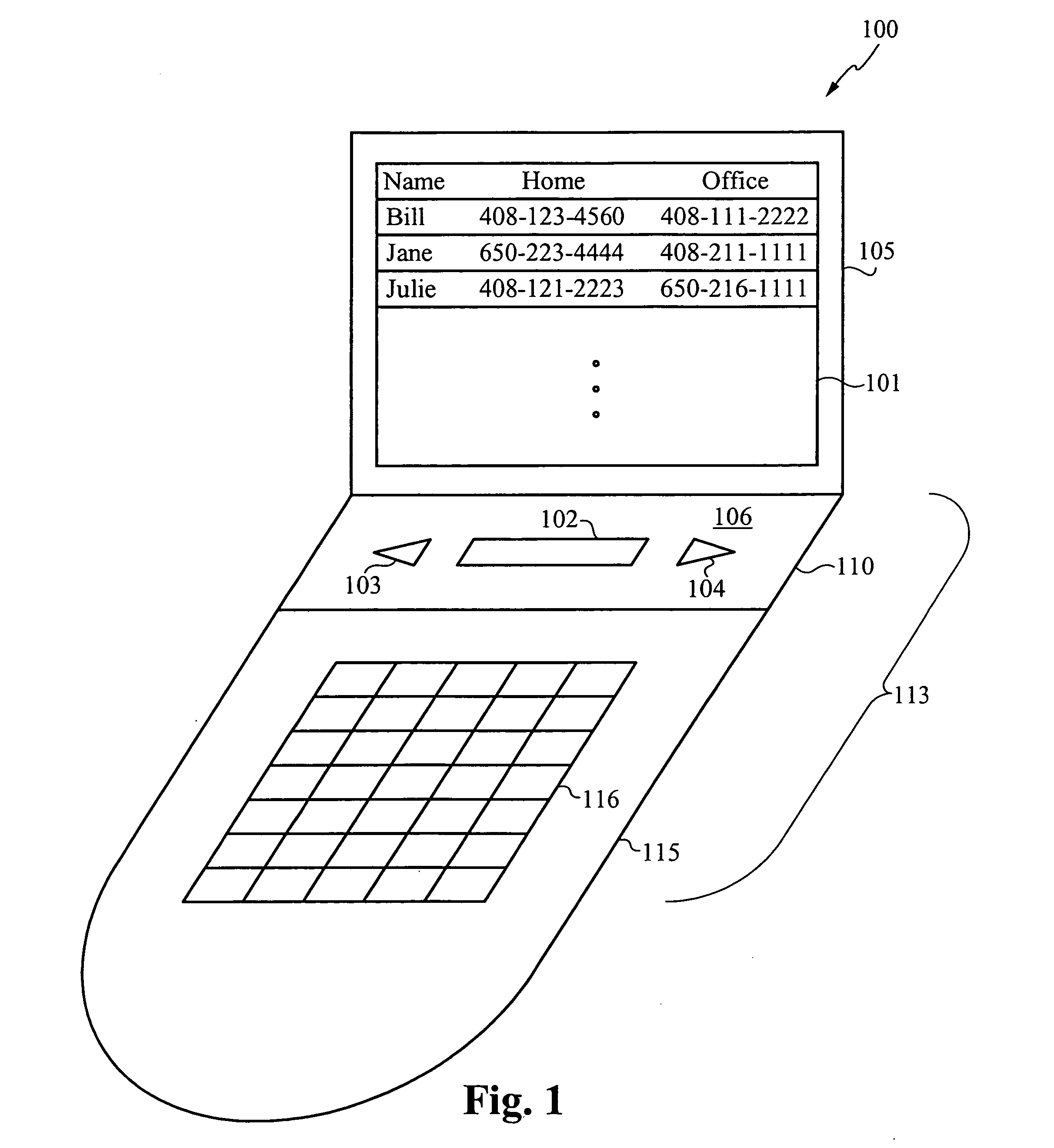

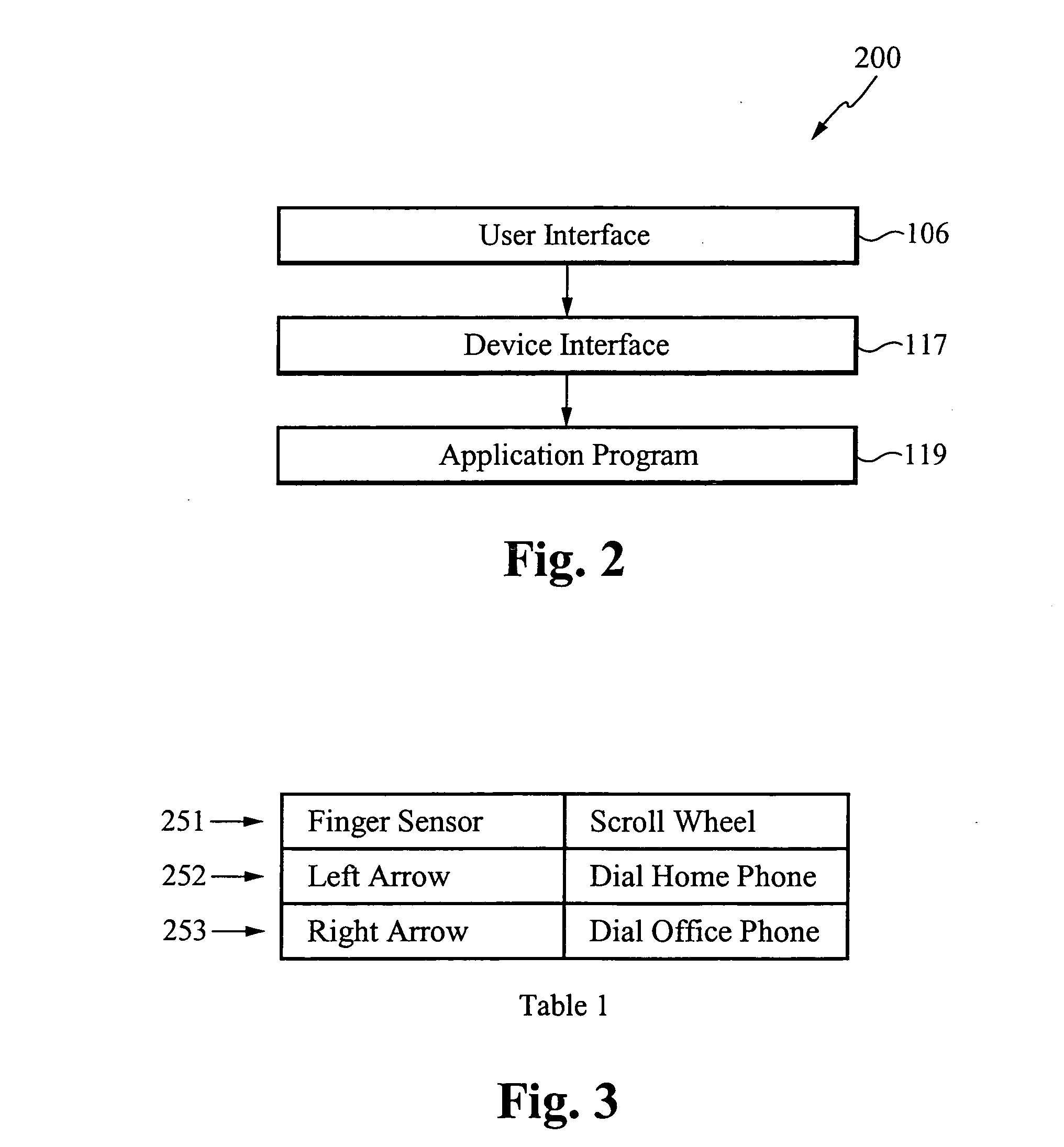

Input device, information processing apparatus, information processing method, and program

ActiveUS20060284858A1Cathode-ray tube indicatorsInput/output processes for data processingInformation processingEngineering

An input device includes: a contact detector configured to detect at least a size of contact area by detecting a physical contact with a control input section; a pressure detector configured to detect a pressure applied by the physical contact; and a controller configured to output signals in response to detection outputs from the contact detector and the pressure detector. The controller outputs a first signal carrying a value which varies in response to the pressure detected under a state of contact in which a contact detection result indicates that the detected contact area is equal to or smaller than a predetermined contact area, and outputs a second signal carrying a value which varies in response to the pressure detected under a state of contact in which the contact detection result indicates that the detected contact area is greater than the predetermined contact area.

Owner:SONY CORP

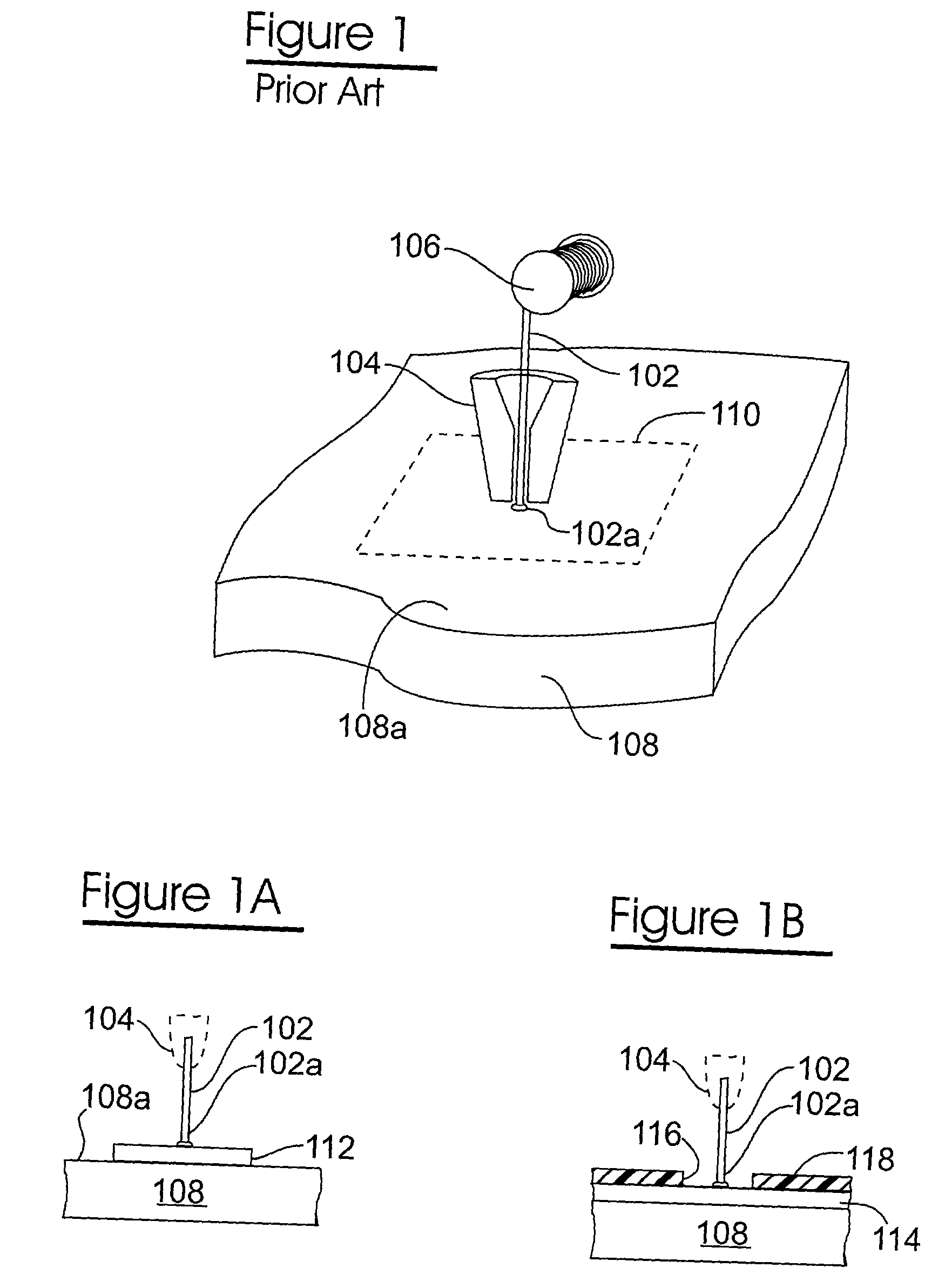

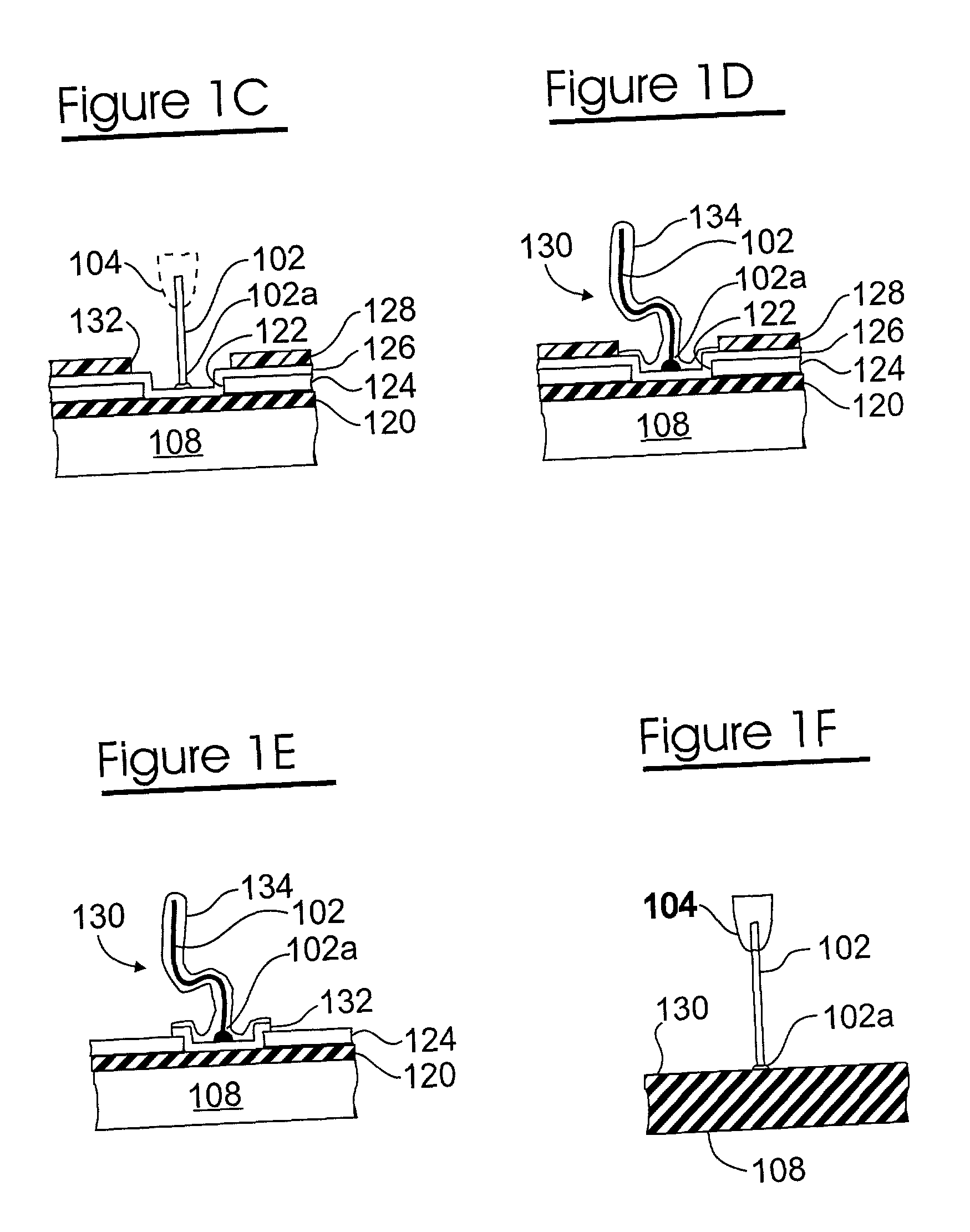

Method of modifying the thickness of a plating on a member by creating a temperature gradient on the member, applications for employing such a method, and structures resulting from such a method

InactiveUS6110823ASimple technologyTrend downSemiconductor/solid-state device testing/measurementFinal product manufactureEngineeringElectronic component

Contact structures exhibiting resilience or compliance for a variety of electronic components are formed by bonding a free end of a wire to a substrate, configuring thw wire into a wire stem having a springable shape, serving thw wire stem, and overcoating the wire stem with at least one layer of a material chosen primarily for its structural (resiliency, compliance) characteristics. A variety of techniques for configuring, serving, and overcoating the wire stem are disclosed. In an exemplary embodiment, a free end of a wire stem is bonded to a contact area on a substrate, the wire stem is configured to ahve a springable shape, the wire stem is served to be free-standing by an electrical discharge, and the free-standing wire stem is overcoating by plating.

Owner:FORMFACTOR INC

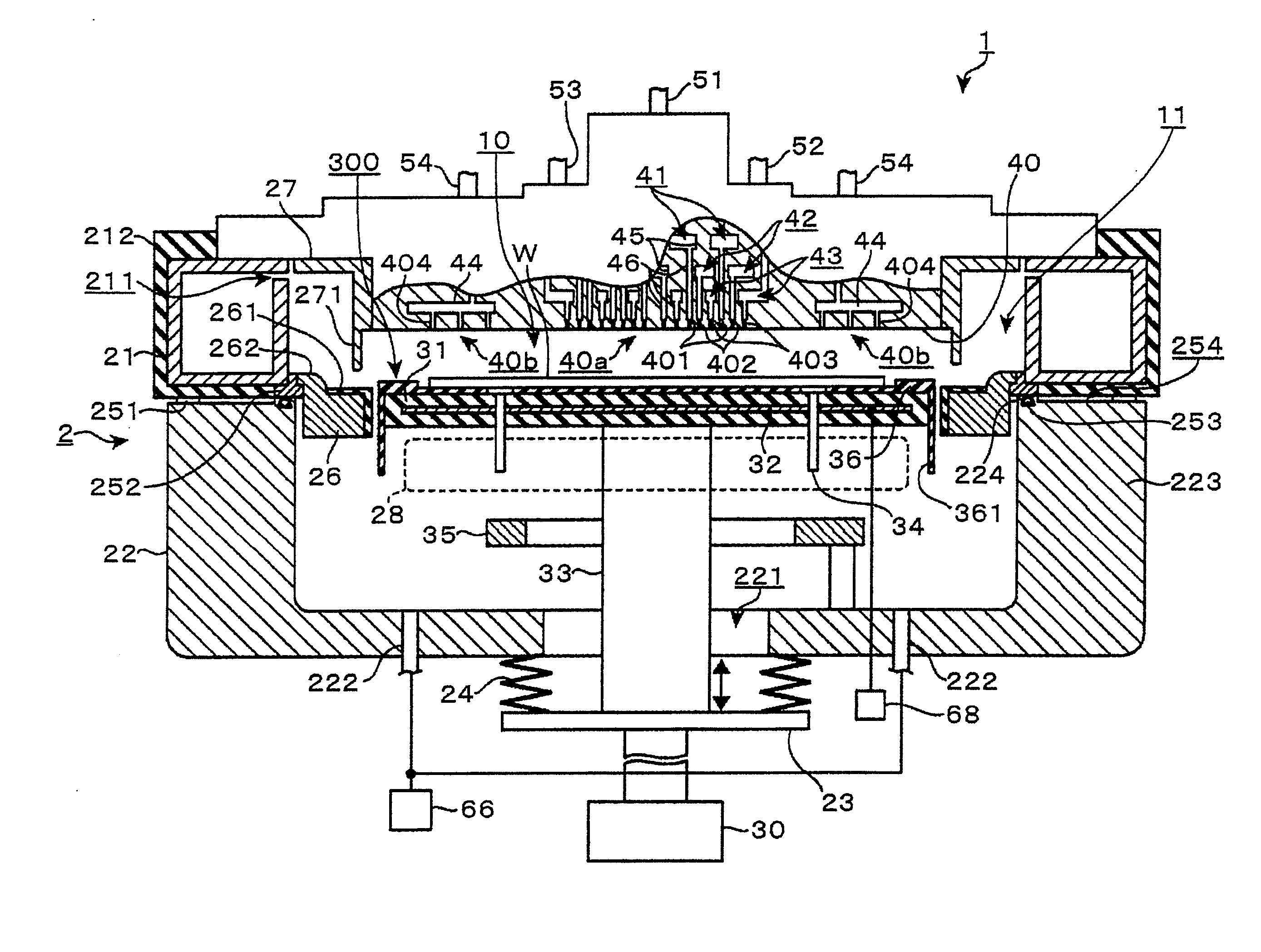

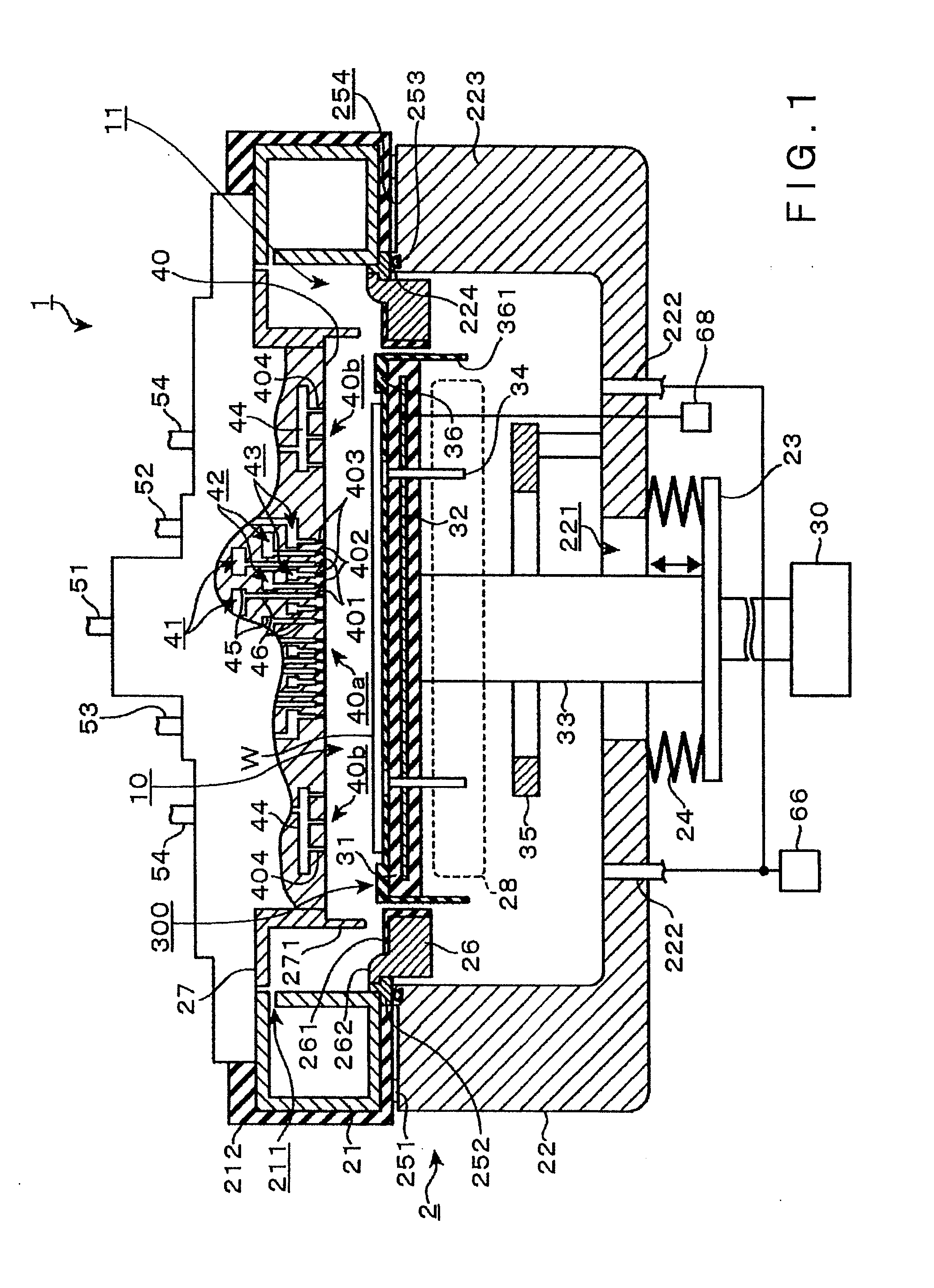

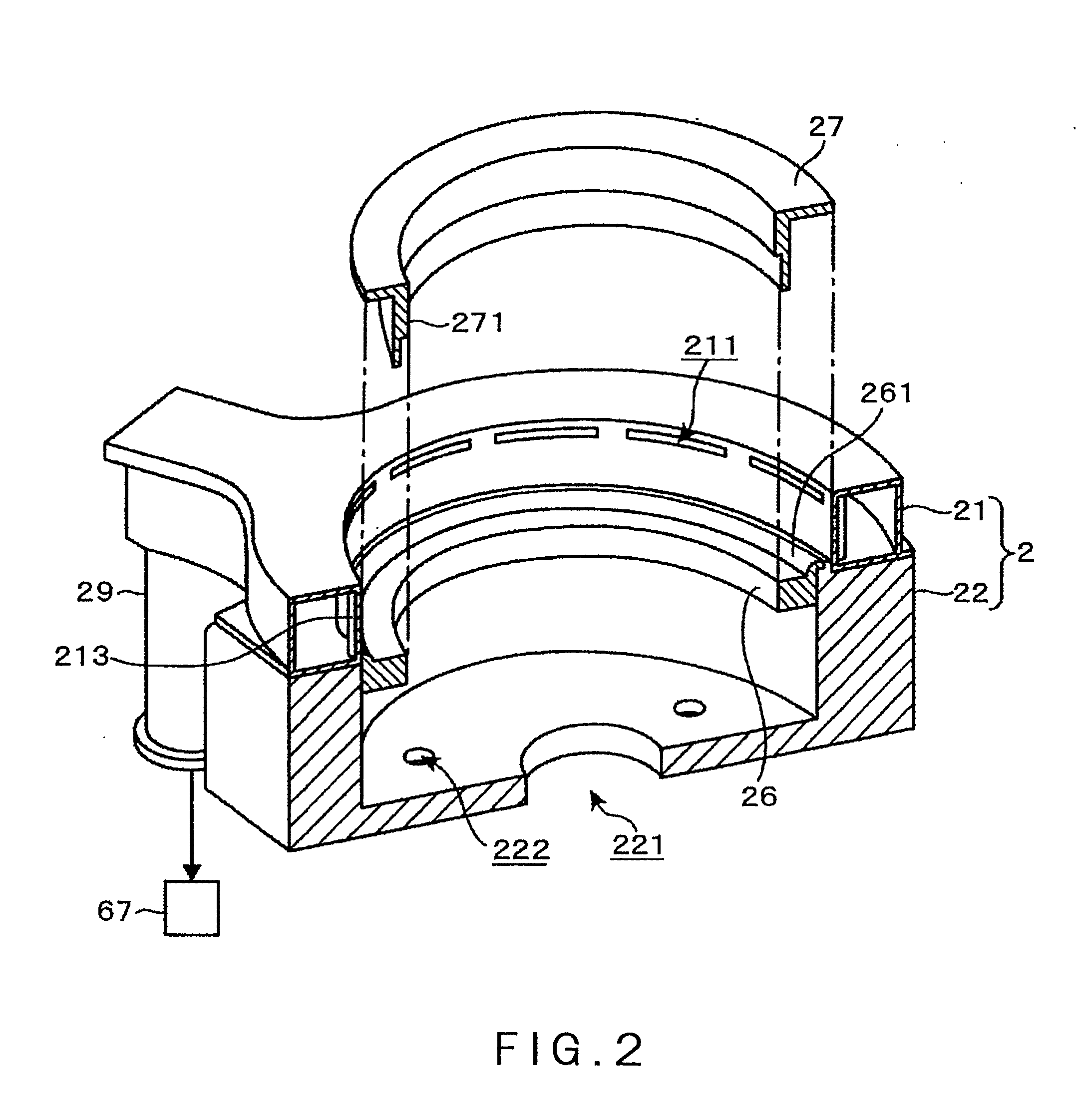

Film deposition apparatus and film deposition method

ActiveUS20100279008A1Efficient solutionHigh in-plane uniformitySemiconductor/solid-state device manufacturingChemical vapor deposition coatingEngineeringTransfer mechanism

The present invention is a film deposition apparatus configured to deposit a film on a substrate that has been loaded into a vacuum container via a transfer opening and placed on a table in the vacuum container, by supplying a process gas to the substrate from a process-gas supply part opposed to the table under a vacuum atmosphere, while heating a table surface of the table, the film deposition apparatus comprising: an elevating mechanism configured to vertically move the table between a process position at which the substrate is subjected to a film deposition process, and a transfer position at which the substrate is transferred to and from an external transfer mechanism that has entered from the transfer opening; a surrounding part configured to surround the table with a gap therebetween, when the table is located at the process position, so that the surrounding part and the table divide an inside of the vacuum container into an upper space, which is located above the table, and a lower space, which is located below the table; a vacuum exhaust conduit in communication with the upper space, through which a process atmosphere in the upper space is discharged to create a vacuum in the upper space; a heating unit configured to heat a gas contact region ranging from the upper space to the vacuum exhaust conduit, to a temperature higher than a temperature allowing adhesion of reactant; and a heat insulation part disposed between the heating unit and a lower part of the vacuum container surrounding the lower space.

Owner:TOKYO ELECTRON LTD

Resecting device

InactiveUS7488319B2Accurate placementReduce the temperatureElectrotherapySurgical instruments for heatingEngineeringMechanical engineering

A resecting device is disclosed. The resecting device comprises: a handle having a jaw trigger slidably engaged with the handle and mechanically engaged with a spring mechanism communicating a biasing force to the jaw trigger; a fixed shaft portion having a first and a second end, wherein the fixed shaft portion first end is affixed to the housing, wherein the fixed shaft portion second end forms a first jaw member, and wherein the first jaw member has a tissue contact area; and a slidable shaft portion in communication with the spring mechanism and slidable relative to the fixed shaft portion.

Owner:YATES LEROY L

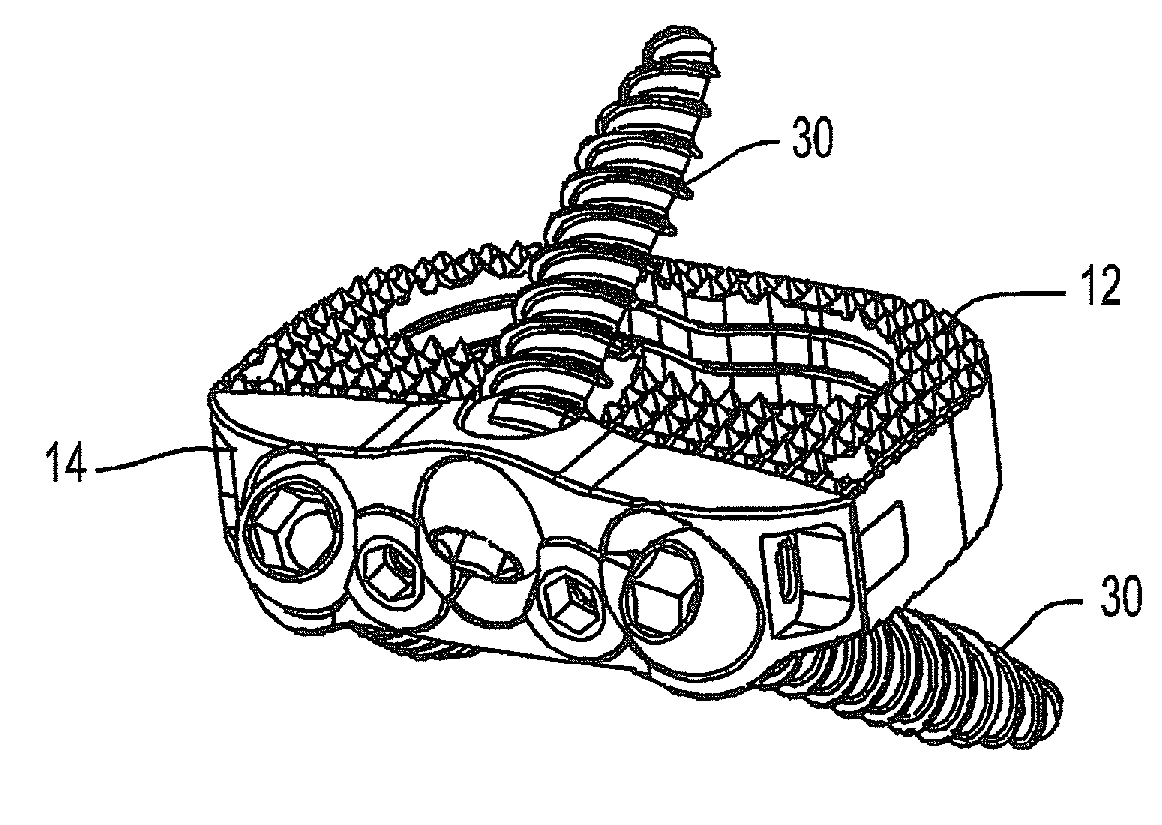

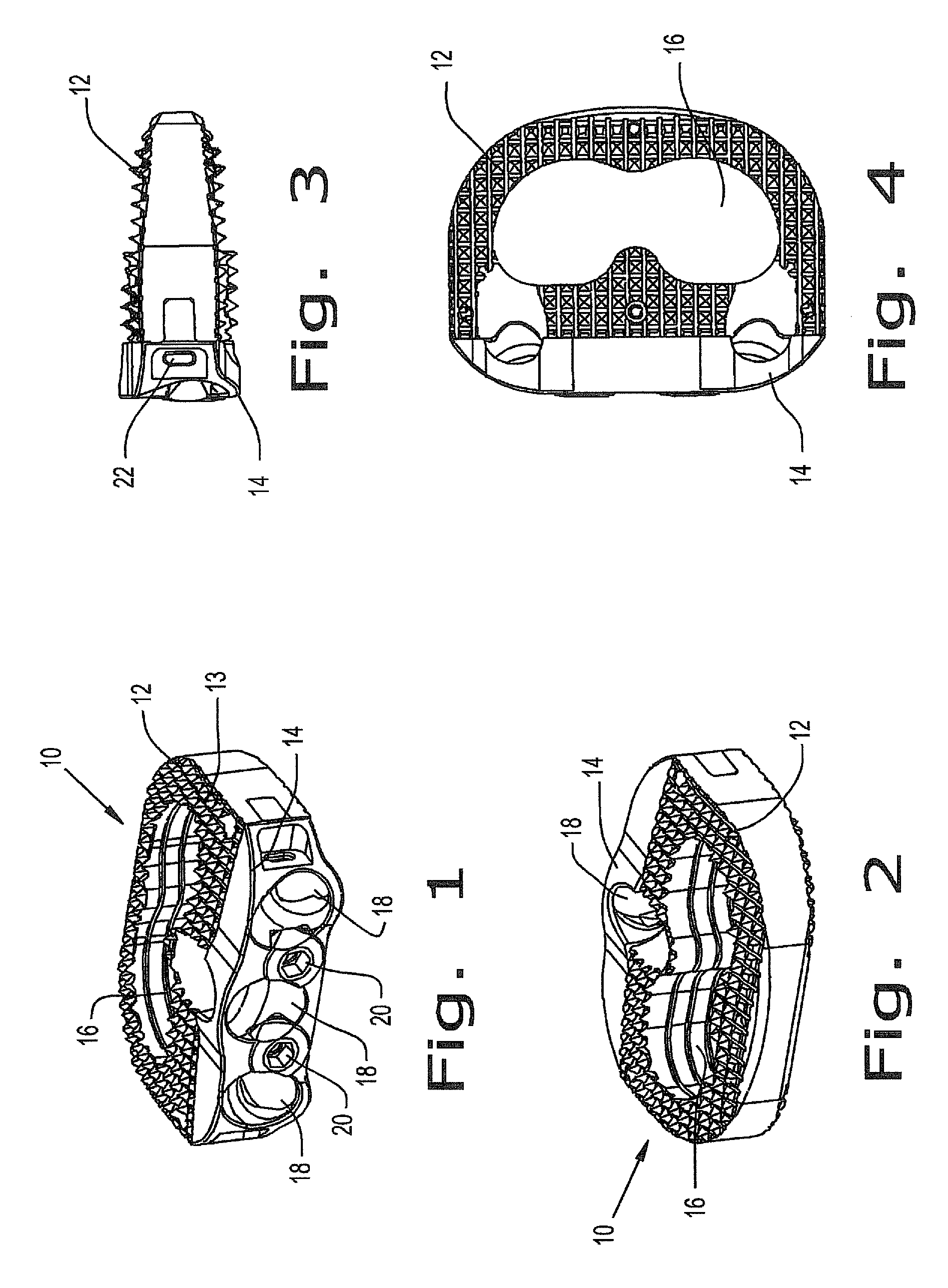

Intervertebral fusion implant

The present invention provides an intervertebral implant for implantation in a treated area of an intervertebral space between vertebral bodies of a spine. The implant includes a spacer portion having an inferior and superior surface, wherein the inferior and superior surfaces each have a contact area capable of engaging with anatomy in the treated area, and the inferior and superior surfaces define a through-hole extending through the spacer body. The present invention further provides screw holes extending from a side portion to the inferior and superior surfaces of the spacer portion and a plate portion rigidly coupled to the spacer portion through a coupling means, wherein the plate portion contains screws holes for receiving screws. A screw back out prevention mechanism adapted on the plate portion and prevents the back out of screws from the screw holes.

Owner:GLOBUS MEDICAL INC

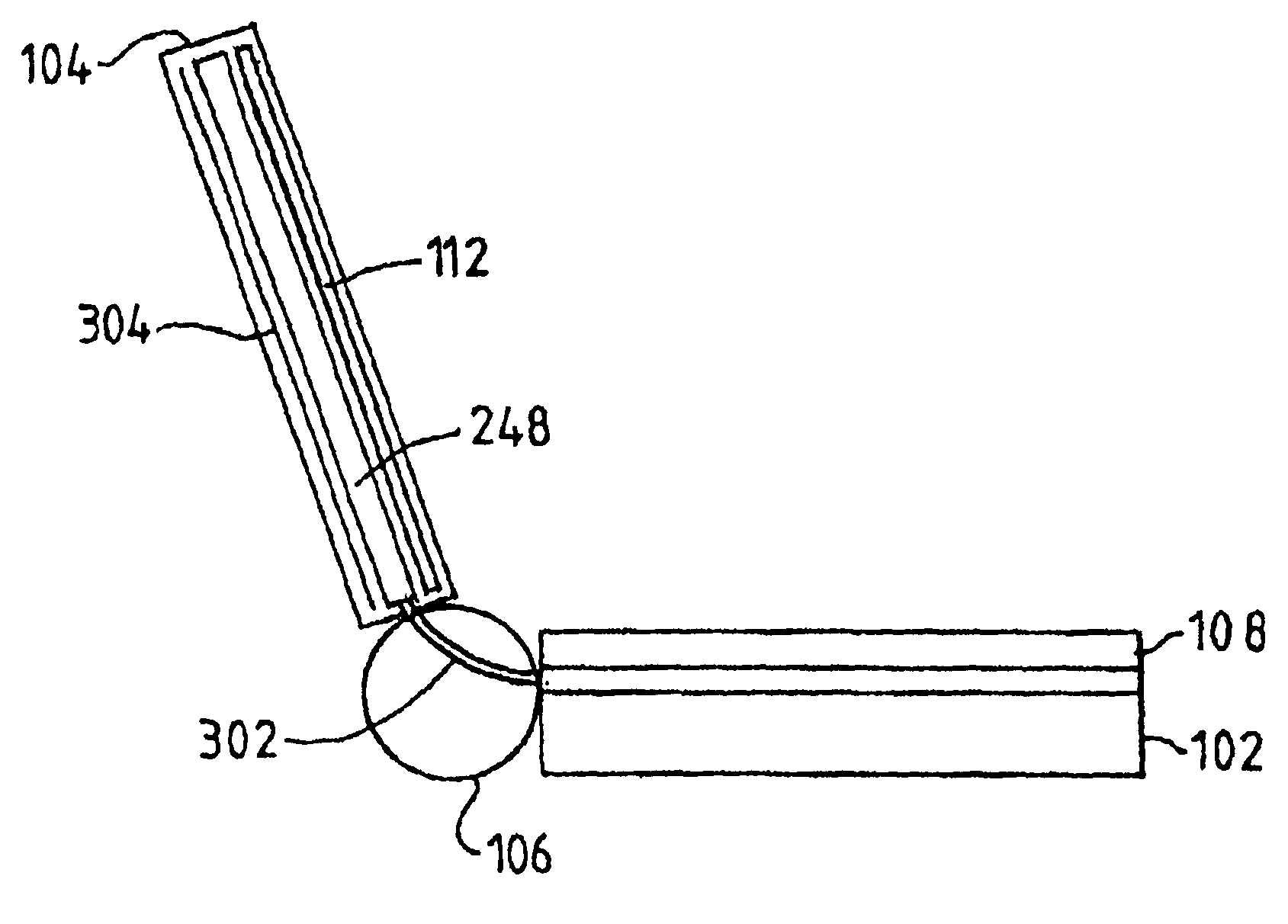

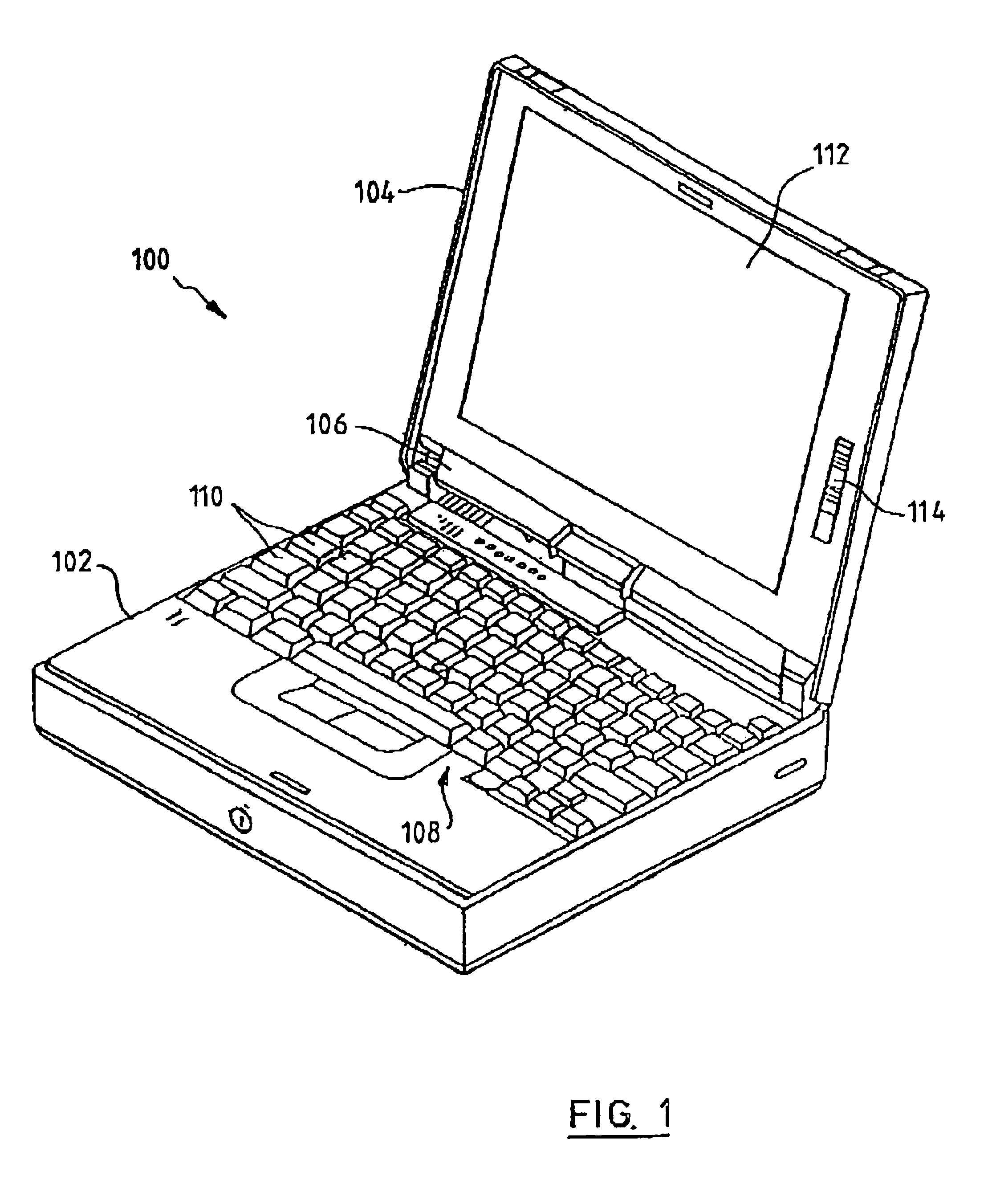

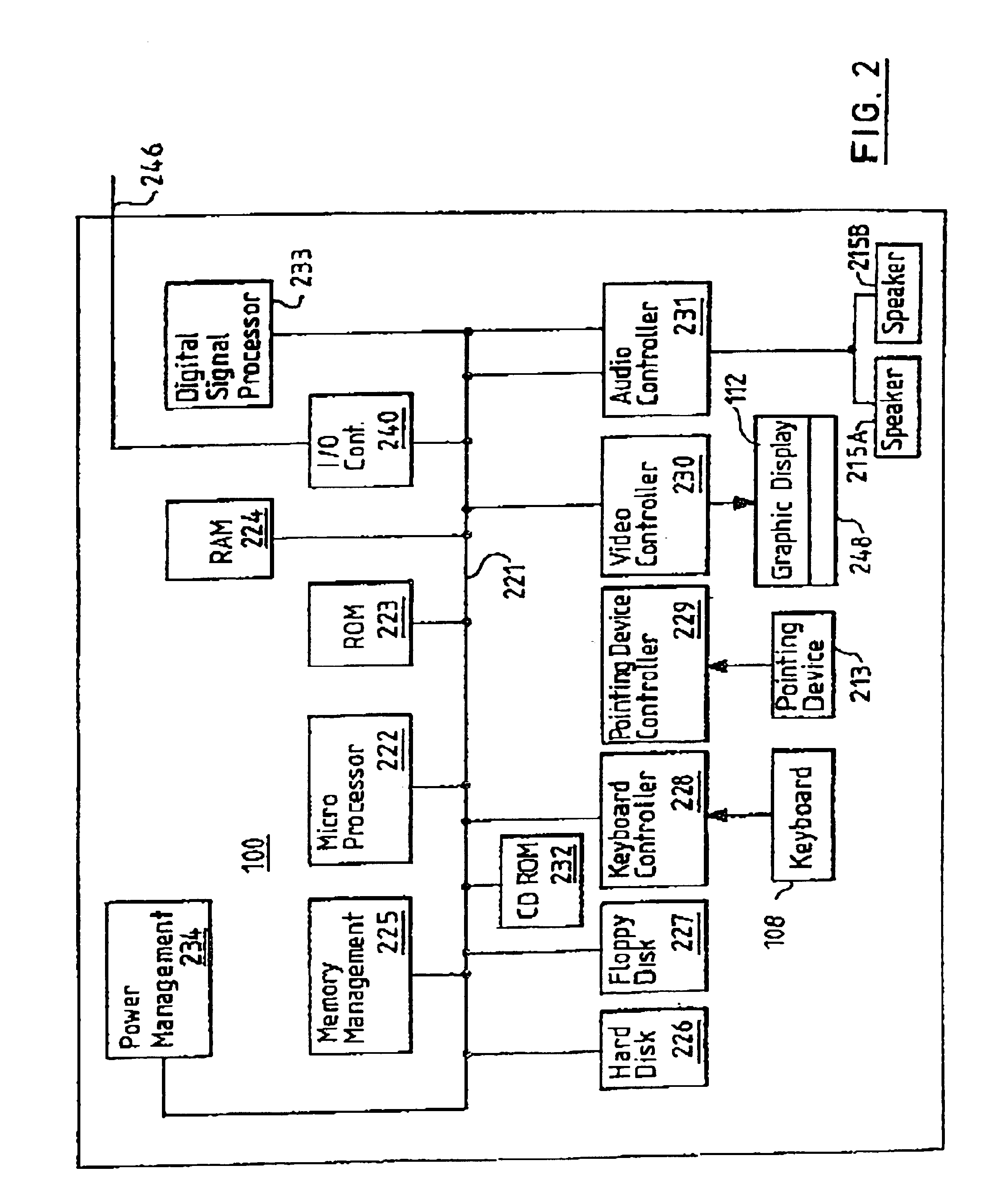

Keyboard illumination for computing devices having backlit displays

InactiveUS6950087B2Input/output for user-computer interactionCathode-ray tube indicatorsFiberDisplay device

Apparatus is disclosed for illumination of a keyboard in a computing device having a display contained in a portion of the computing device which is hingeably attached to a keyboard portion, the display having a backlight. The system comprises one or more translucent elements associated with the keyboard and one or more light-conducting fibers for conducting light from the backlight of the backlit display to the one or more translucent elements associated with the keyboard. The level of illumination is varied by means of the one or more light conducting fibers transmitting light through two portions of transparent material, the two portions of transparent material have an area of contact between them which may be varied. A color adjustment mechanism is also provided.

Owner:IBM CORP

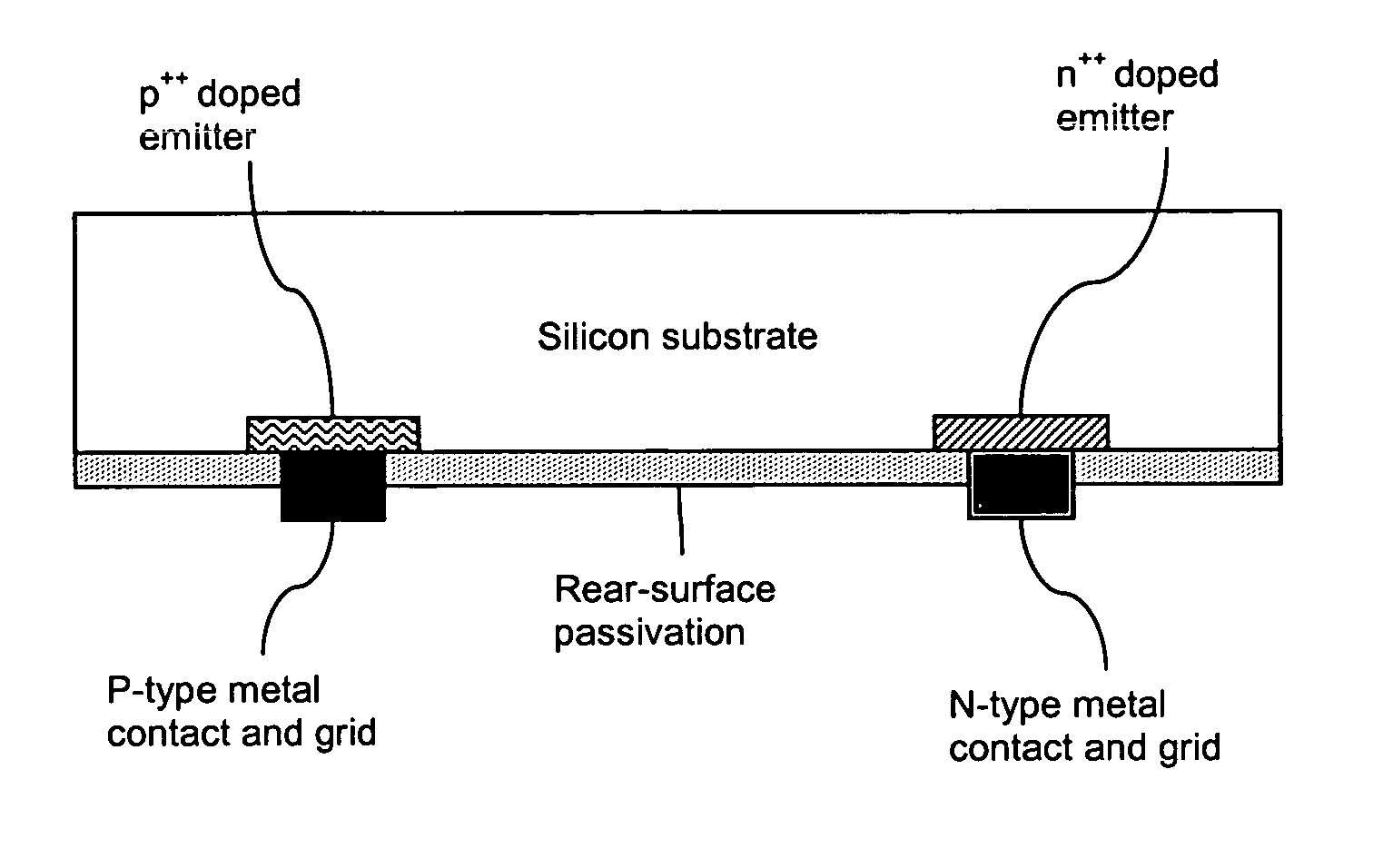

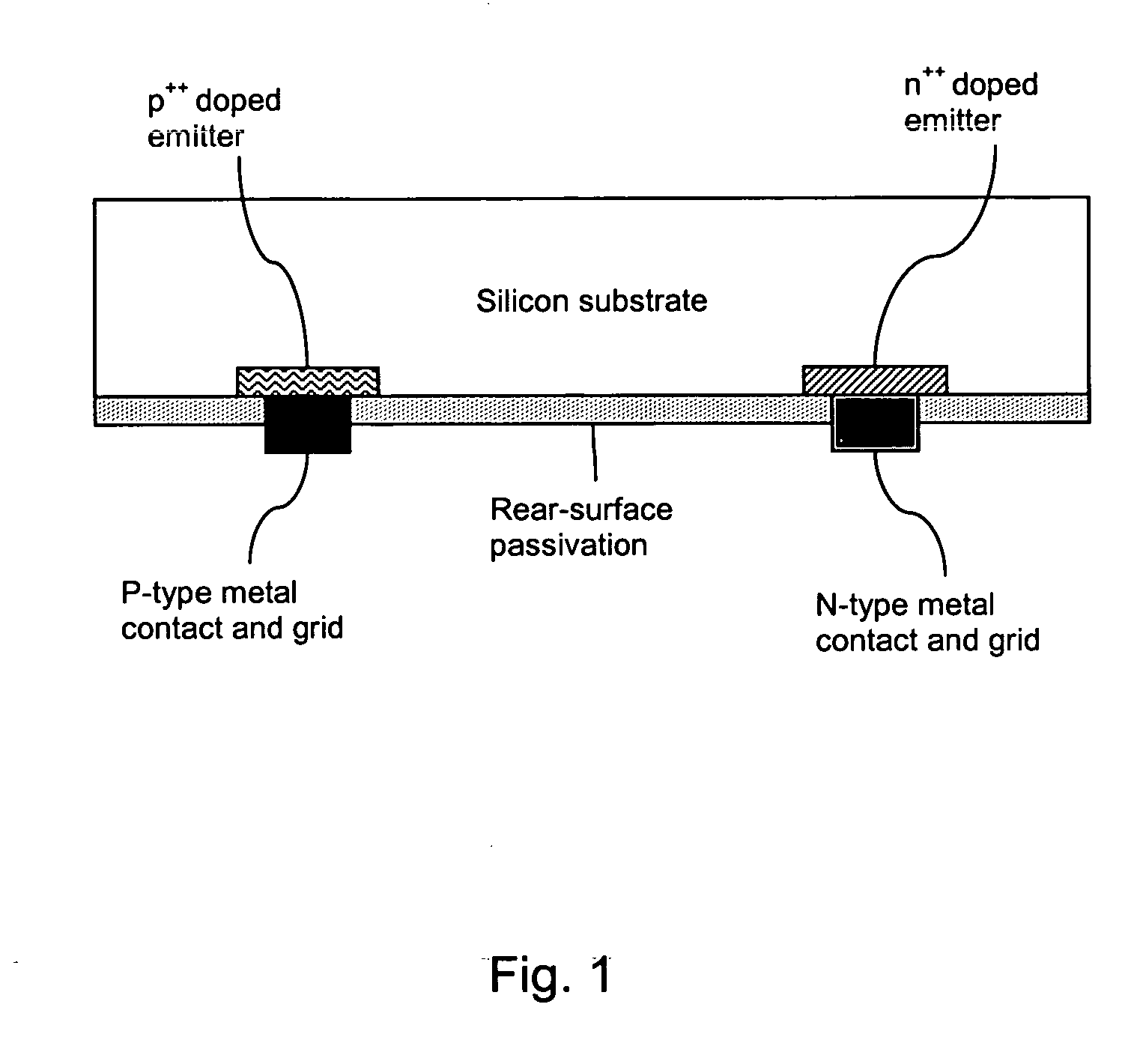

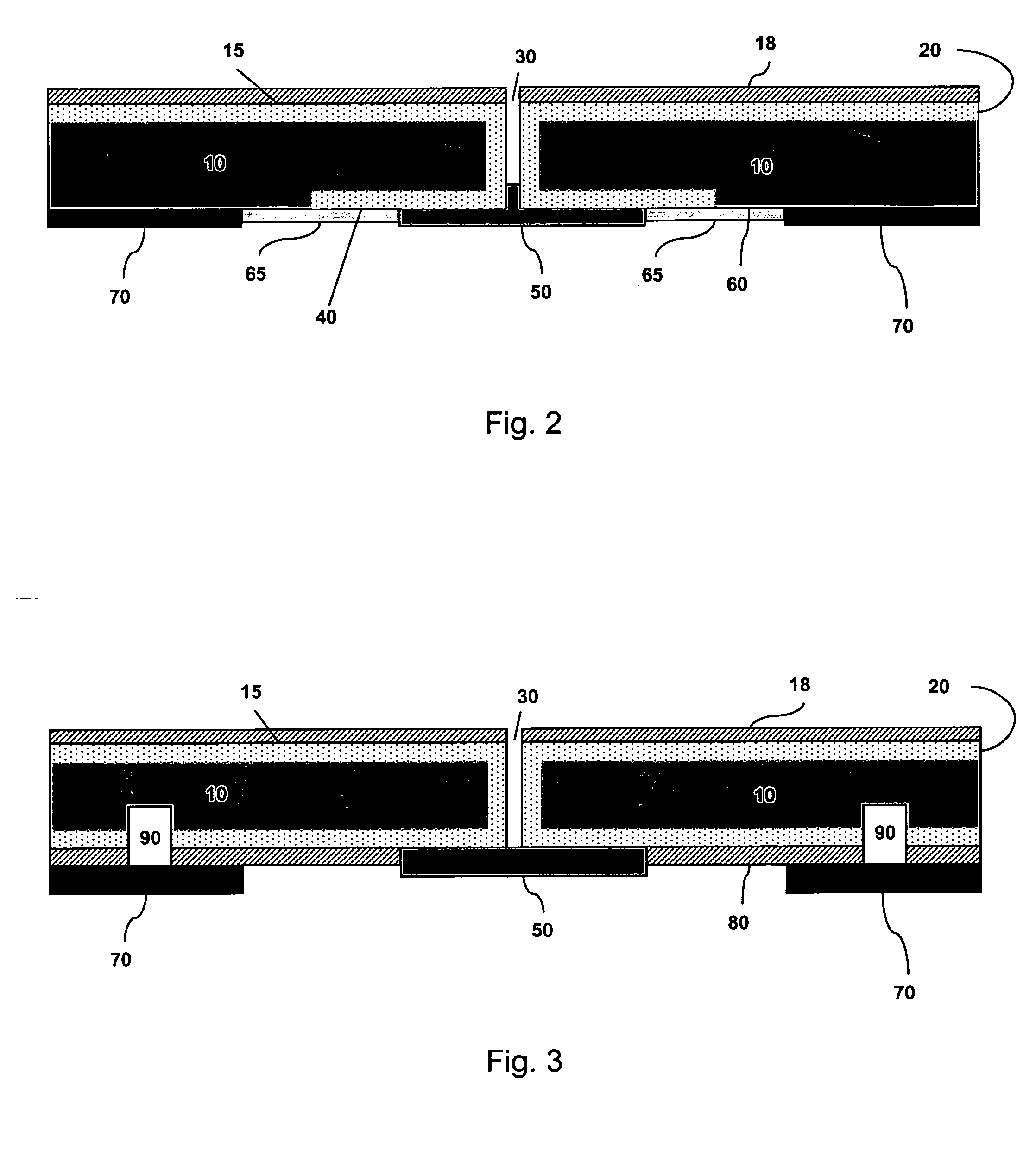

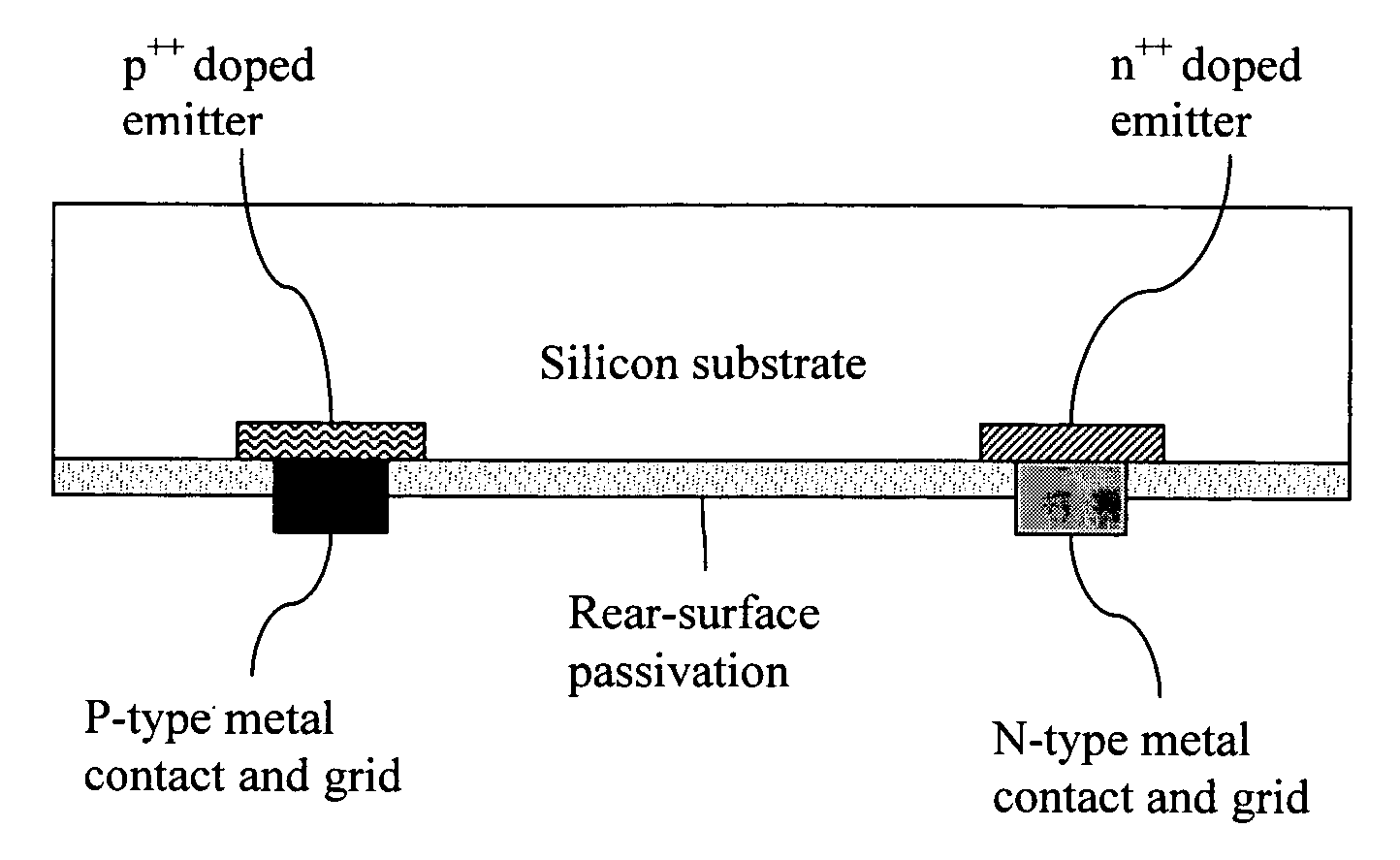

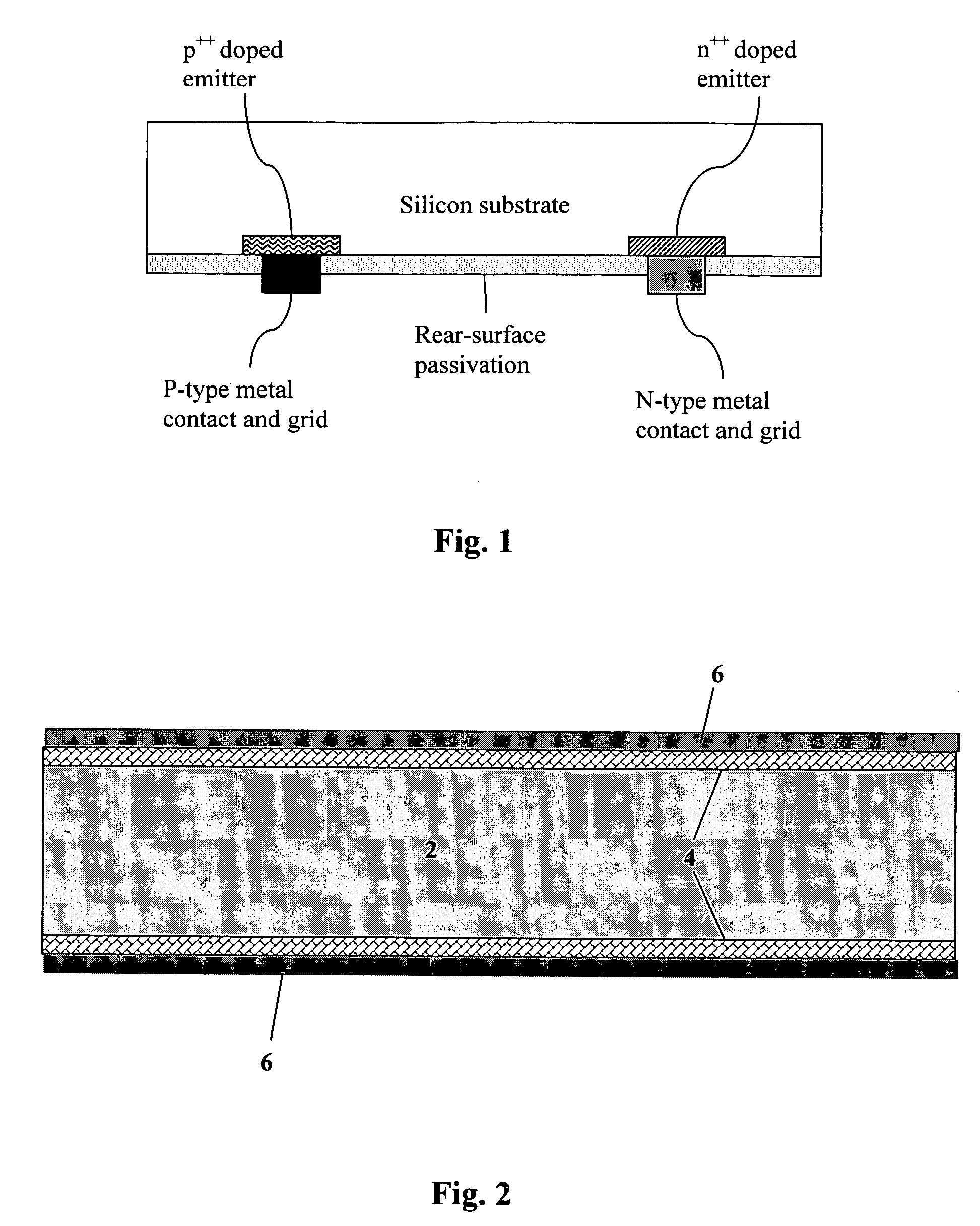

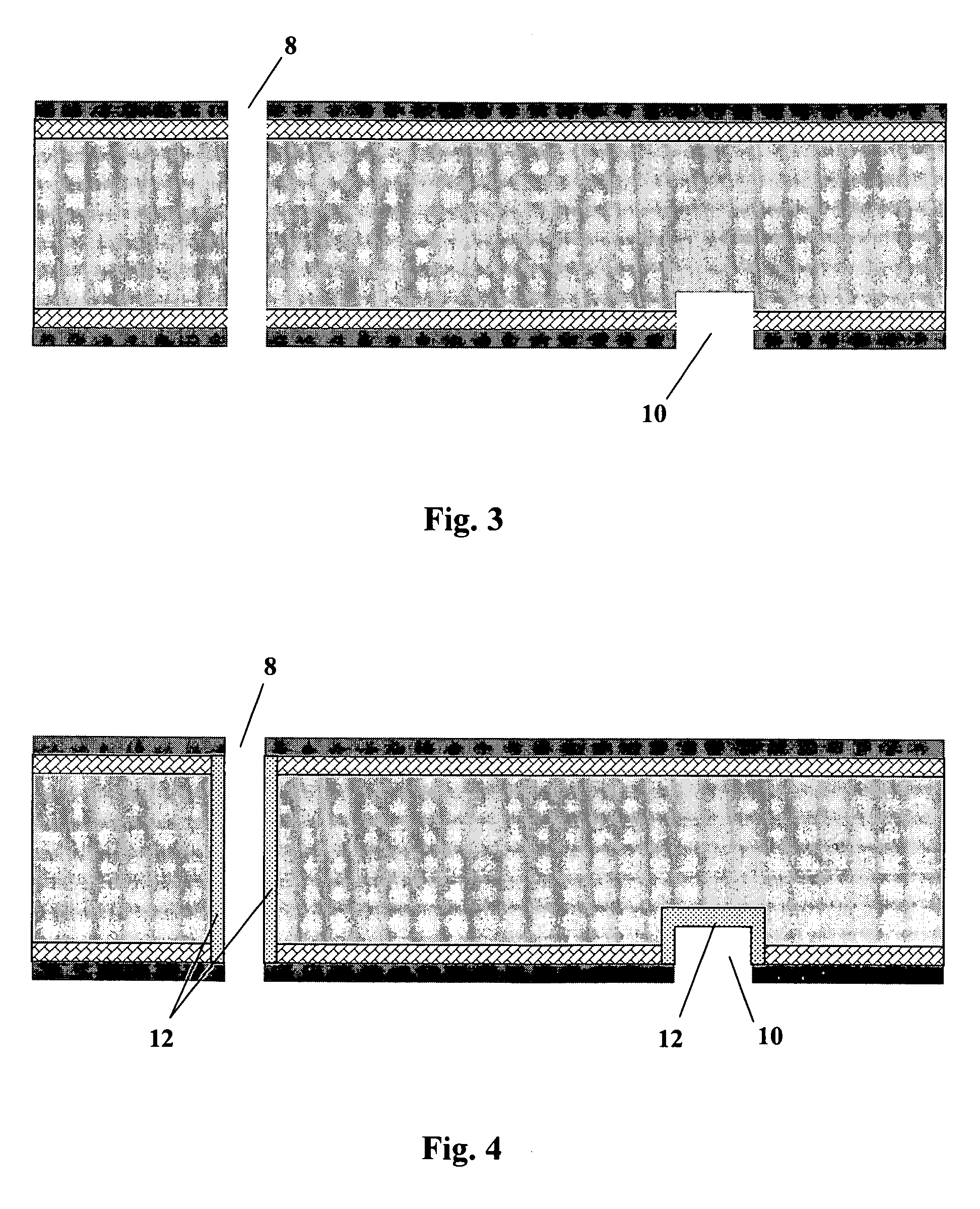

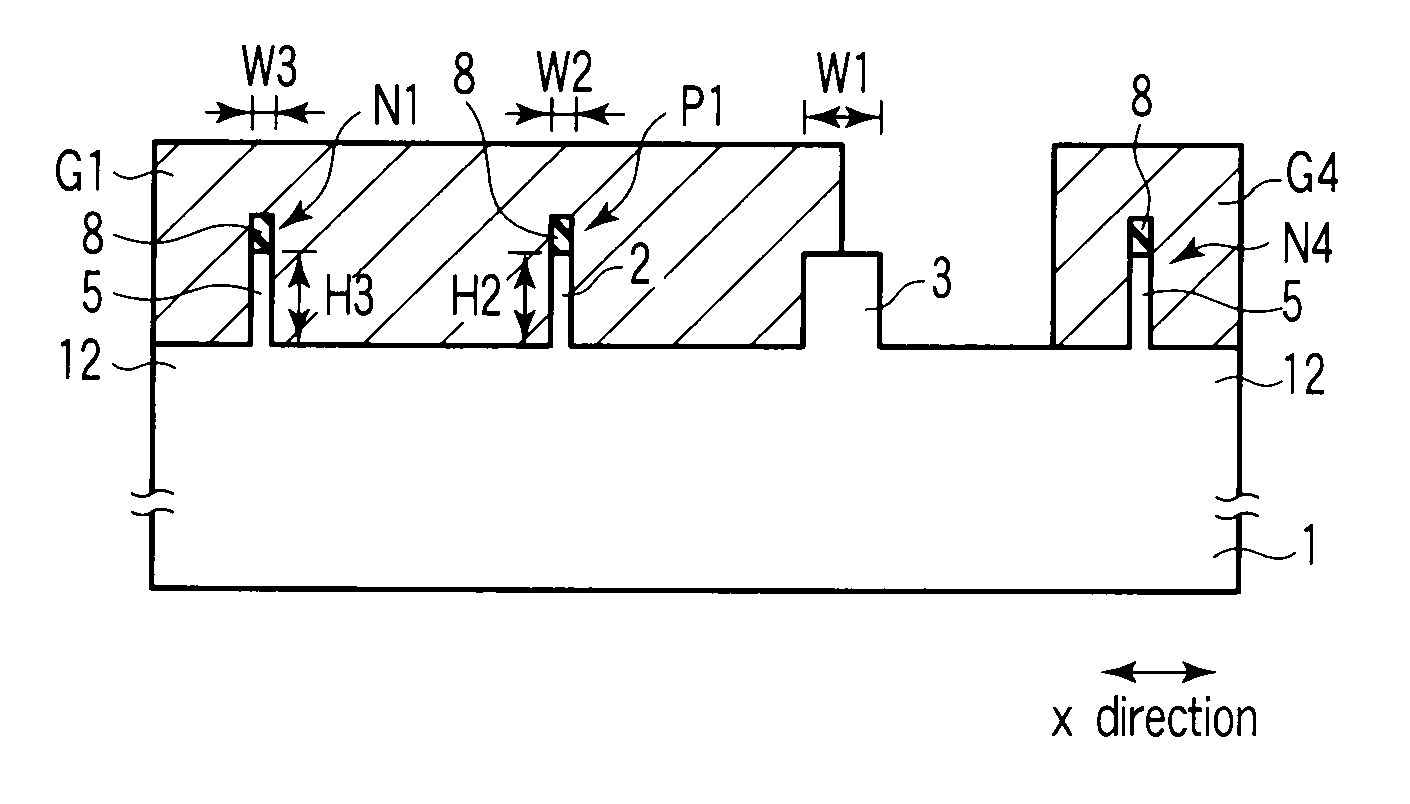

Contact fabrication of emitter wrap-through back contact silicon solar cells

InactiveUS20050172996A1Few and economical process stepImprove efficiencyFinal product manufactureSemiconductor/solid-state device manufacturingEngineeringSilicon solar cell

Back contact solar cells including rear surface structures and methods for making same. The rear surface has small contact areas through at least one dielectric layer, including but not limited to a passivation layer, a nitride layer, a diffusion barrier, and / or a metallization barrier. The dielectric layer is preferably screen printed. Large grid areas overlay the dielectric layer. The methods provide for increasing efficiency by minimizing p-type contact areas and maximizing n-type doped regions on the rear surface of a p-type substrate.

Owner:APPLIED MATERIALS INC

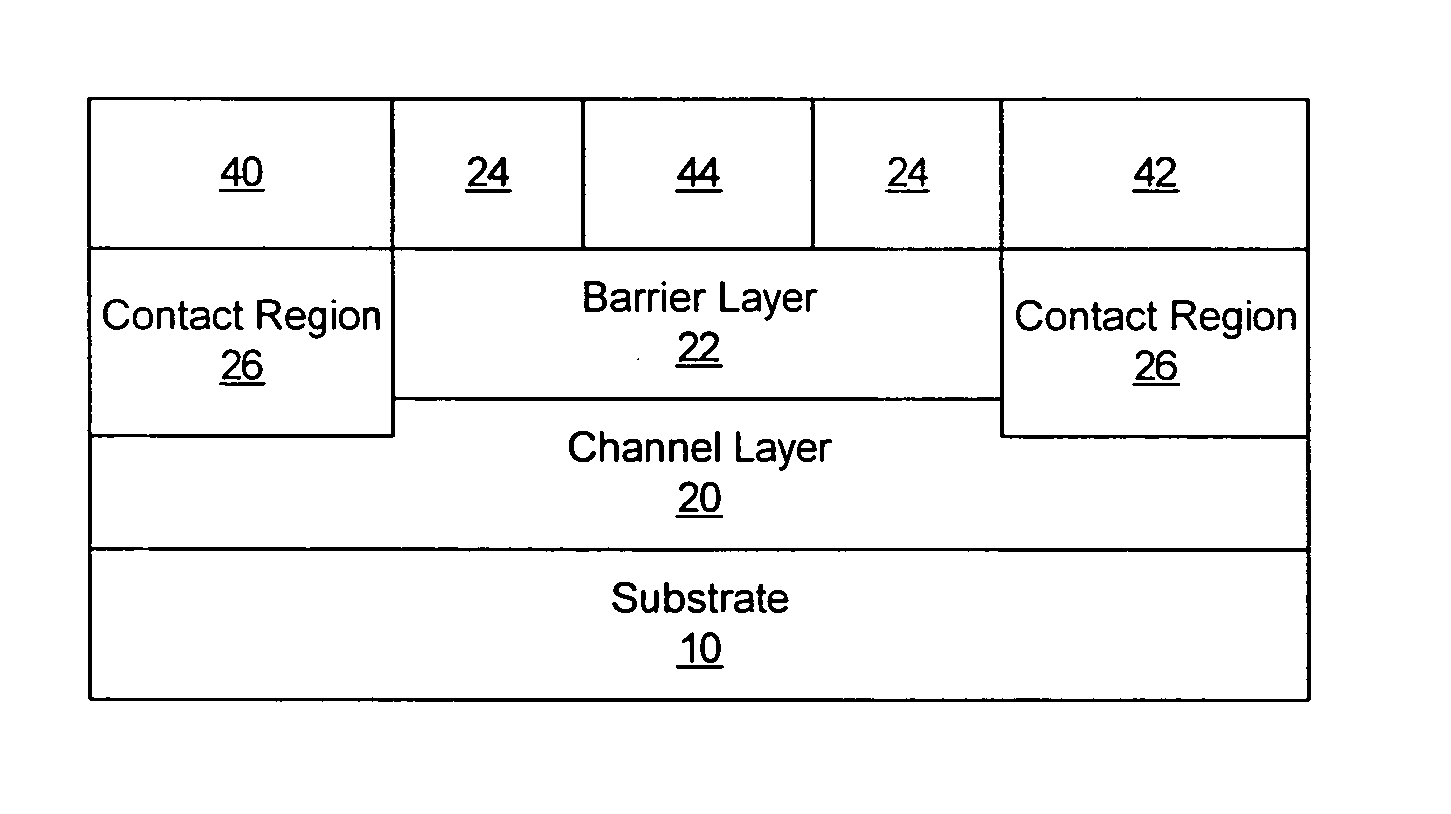

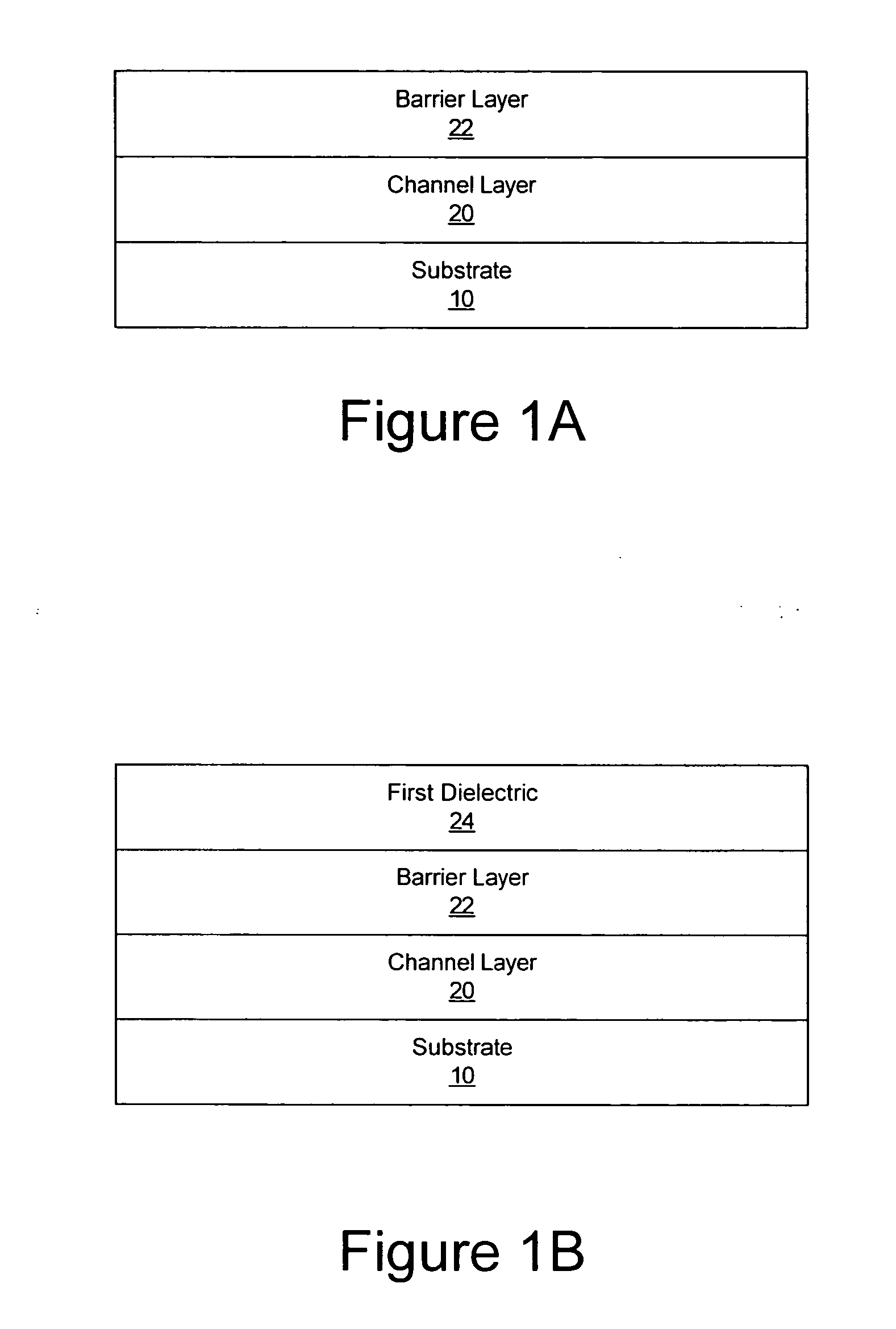

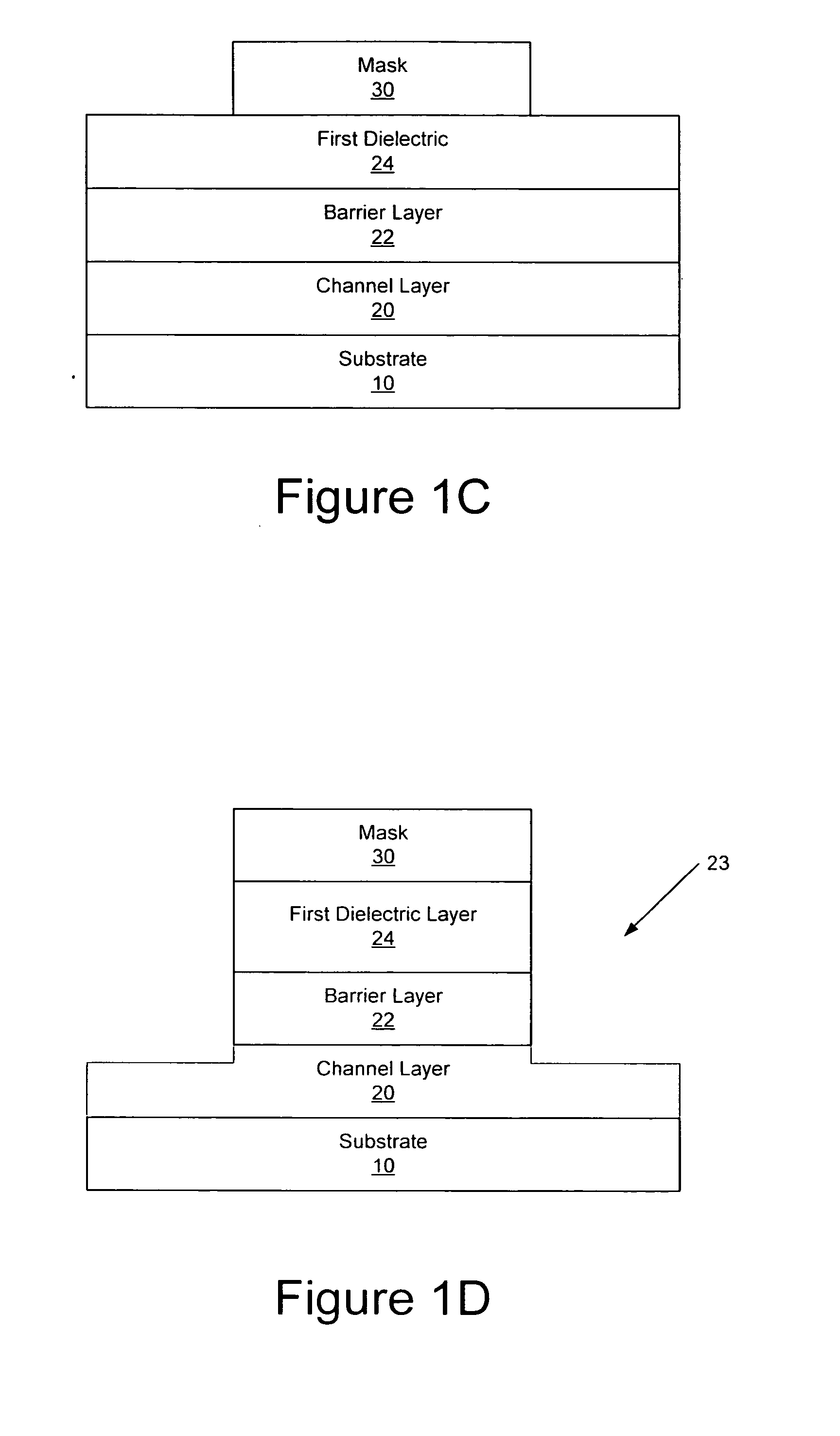

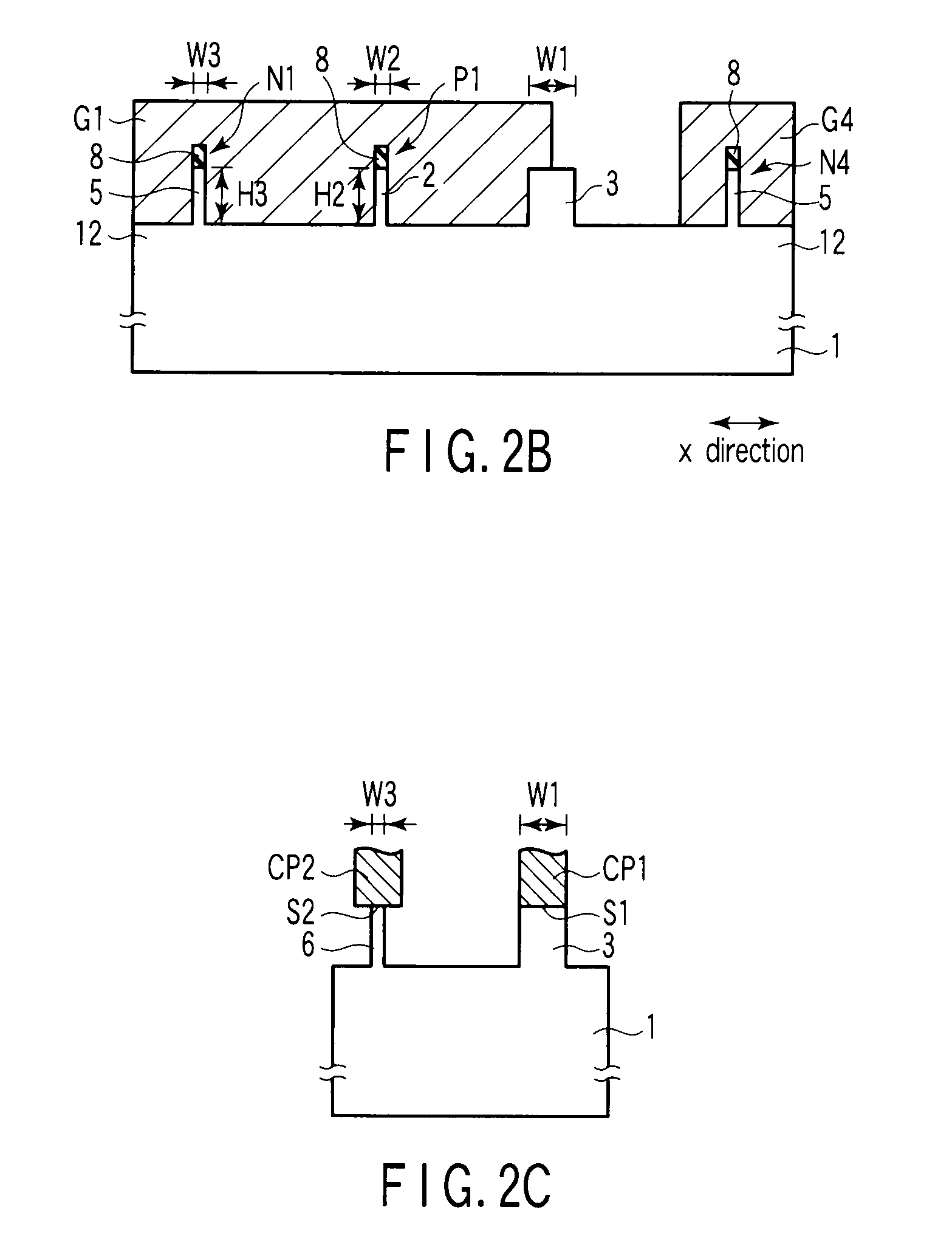

Methods of fabricating nitride-based transistors having regrown ohmic contact regions and nitride-based transistors having regrown ohmic contact regions

ActiveUS20050258451A1High electron mobilitySemiconductor/solid-state device manufacturingSemiconductor devicesLow temperature depositionSemiconductor materials

Transistor fabrication includes forming a nitride-based channel layer on a substrate, forming a barrier layer on the nitride-based channel layer, forming a contact recess in the barrier layer to expose a contact region of the nitride-based channel layer, forming a contact layer on the exposed contact region of the nitride-based channel layer, for example, using a low temperature deposition process, forming an ohmic contact on the contact layer and forming a gate contact disposed on the barrier layer adjacent the ohmic contact. A high electron mobility transistor (HEMT) and methods of fabricating a HEMT are also provided. The HEMT includes a nitride-based channel layer on a substrate, a barrier layer on the nitride-based channel layer, a contact recess in the barrier layer that extends into the channel layer, an n-type nitride-based semiconductor material contact region on the nitride-based channel layer in the contact recess, an ohmic contact on the nitride-based contact region and a gate contact disposed on the barrier layer adjacent the ohmic contact. The n-type nitride-based semiconductor material contact region and the nitride-based channel layer include a surface area enlargement structure.

Owner:CREE INC

Process and fabrication methods for emitter wrap through back contact solar cells

InactiveUS20060060238A1Few and economical process stepImprove efficiencyFinal product manufactureSemiconductor/solid-state device manufacturingEngineeringSolar cell

Back contact solar cells including rear surface structures and methods for making same. The rear surface is doped to form an n+ emitter and then coated with a dielectric layer. Small regions are scribed in the rear surface and p-type contacts are then formed in the regions. Large conductive grid areas overlay the dielectric layer. The methods provide for increasing efficiency by minimizing p-type contact areas and maximizing n-type doped regions on the rear surface of a p-type substrate.

Owner:APPLIED MATERIALS INC

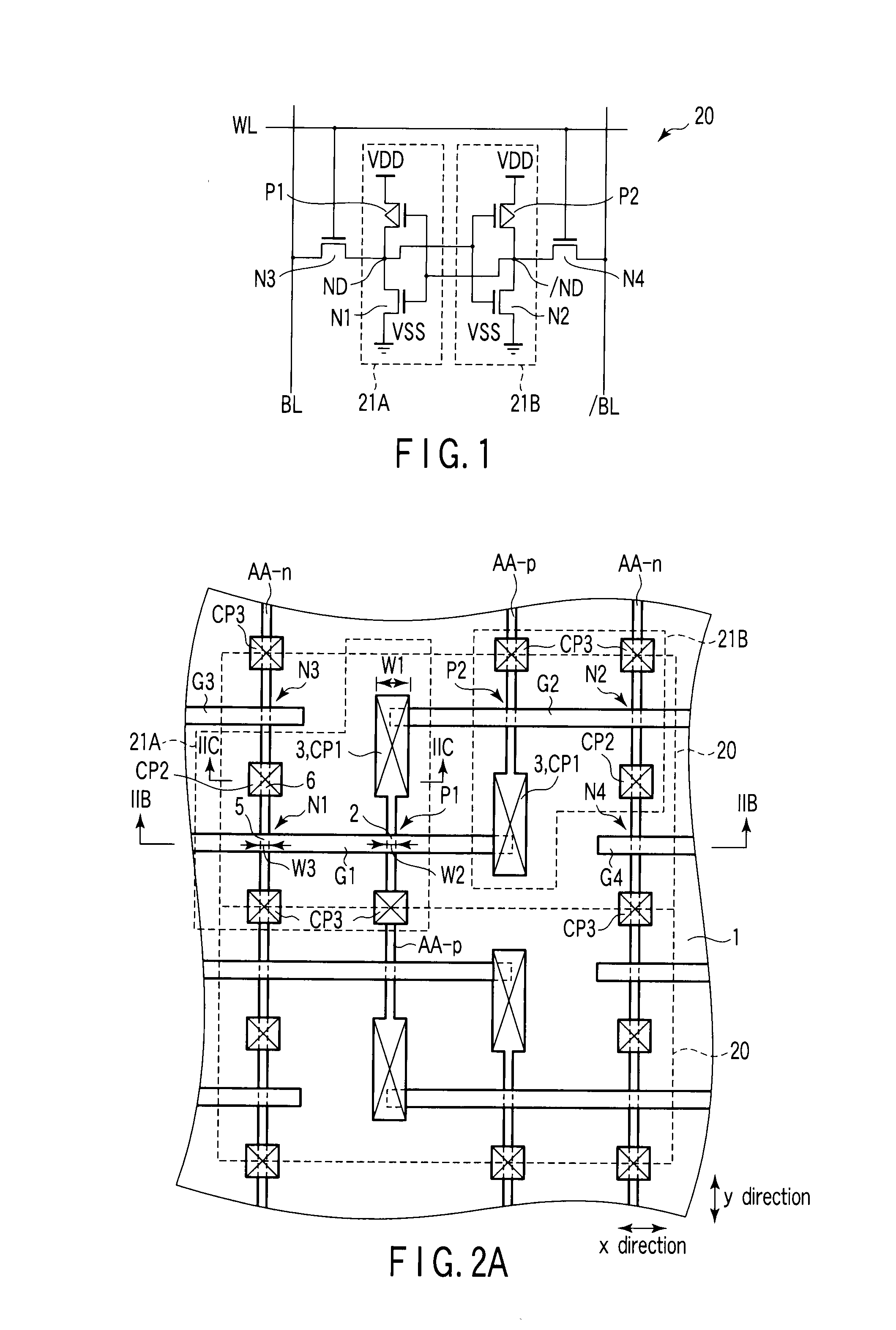

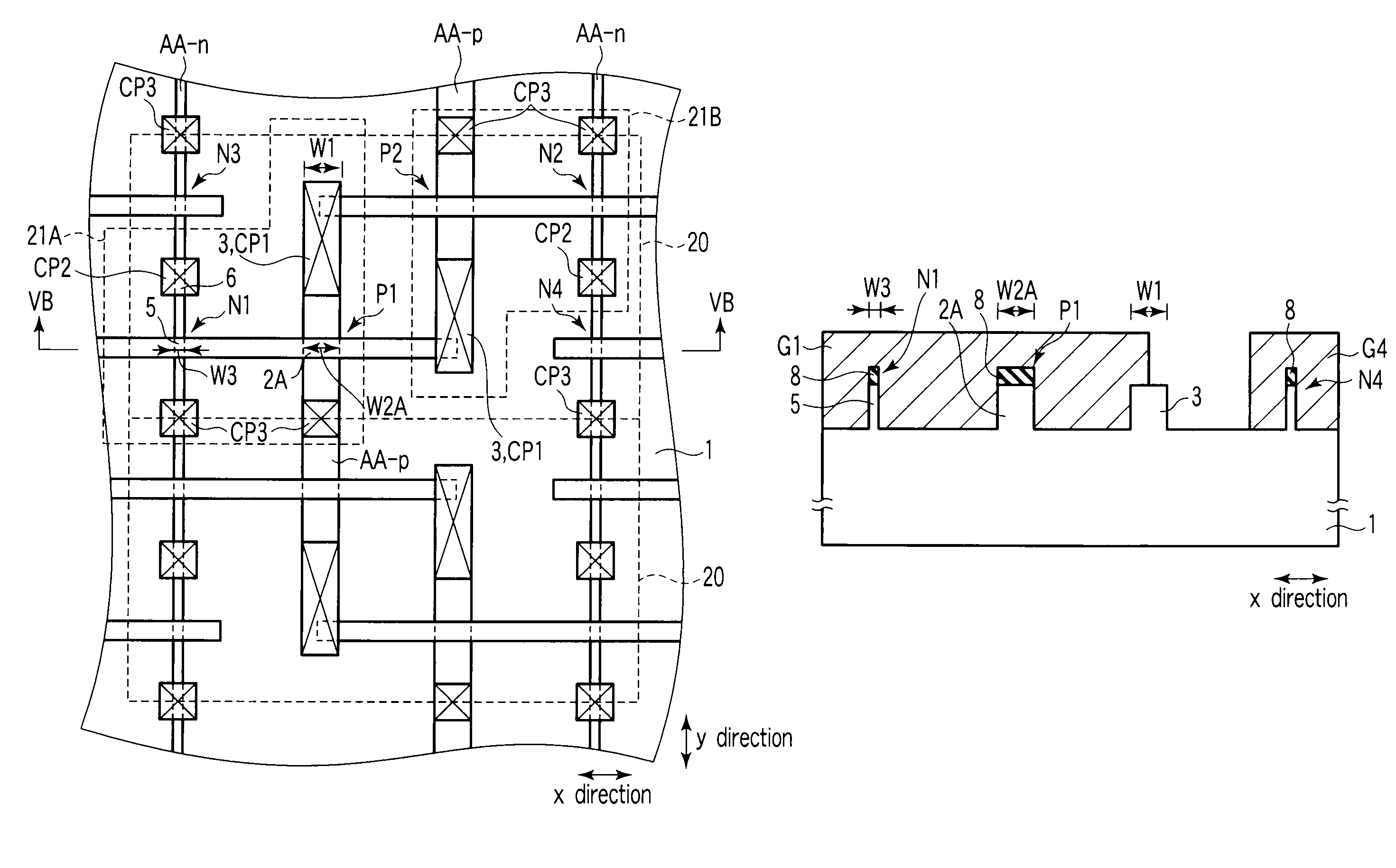

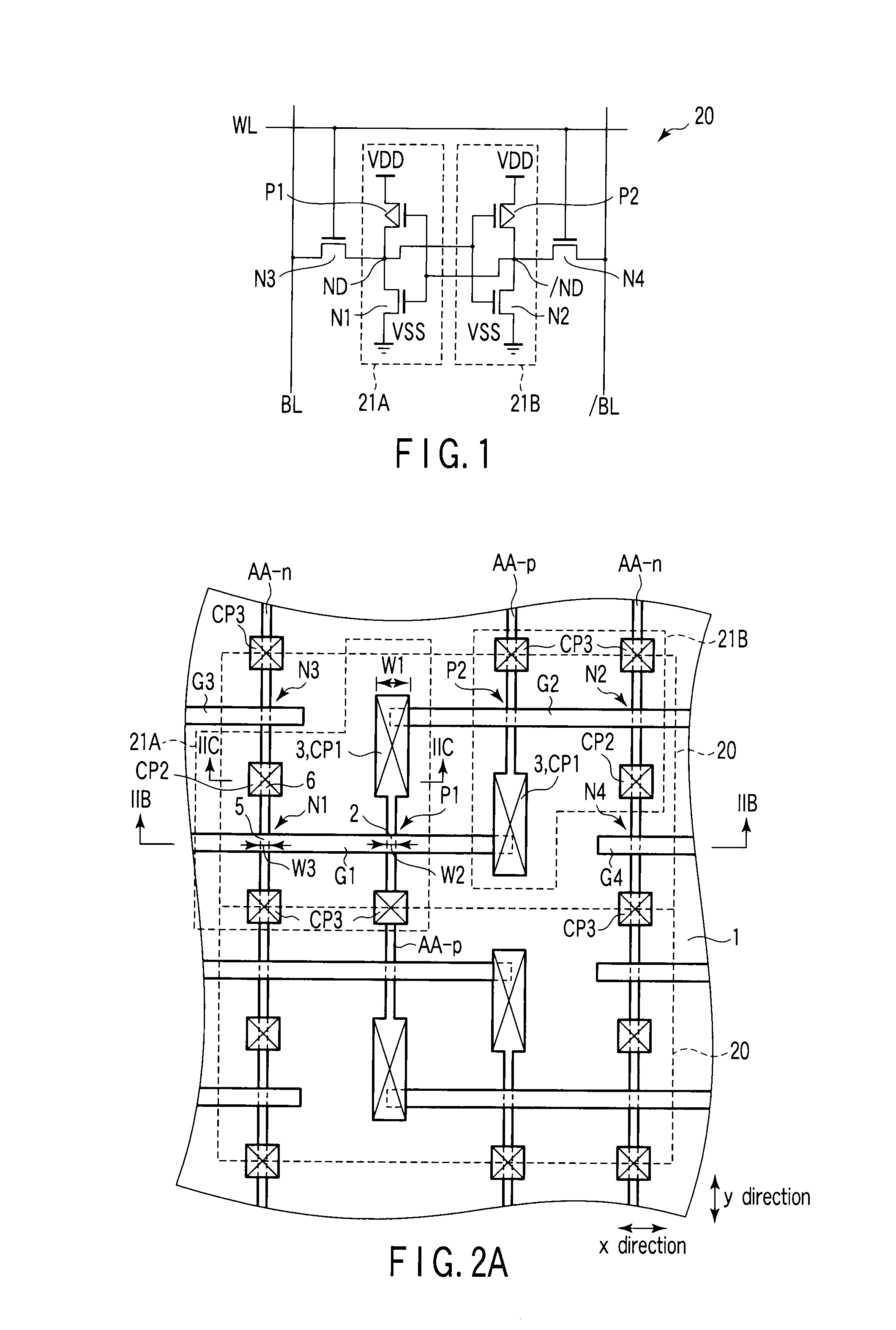

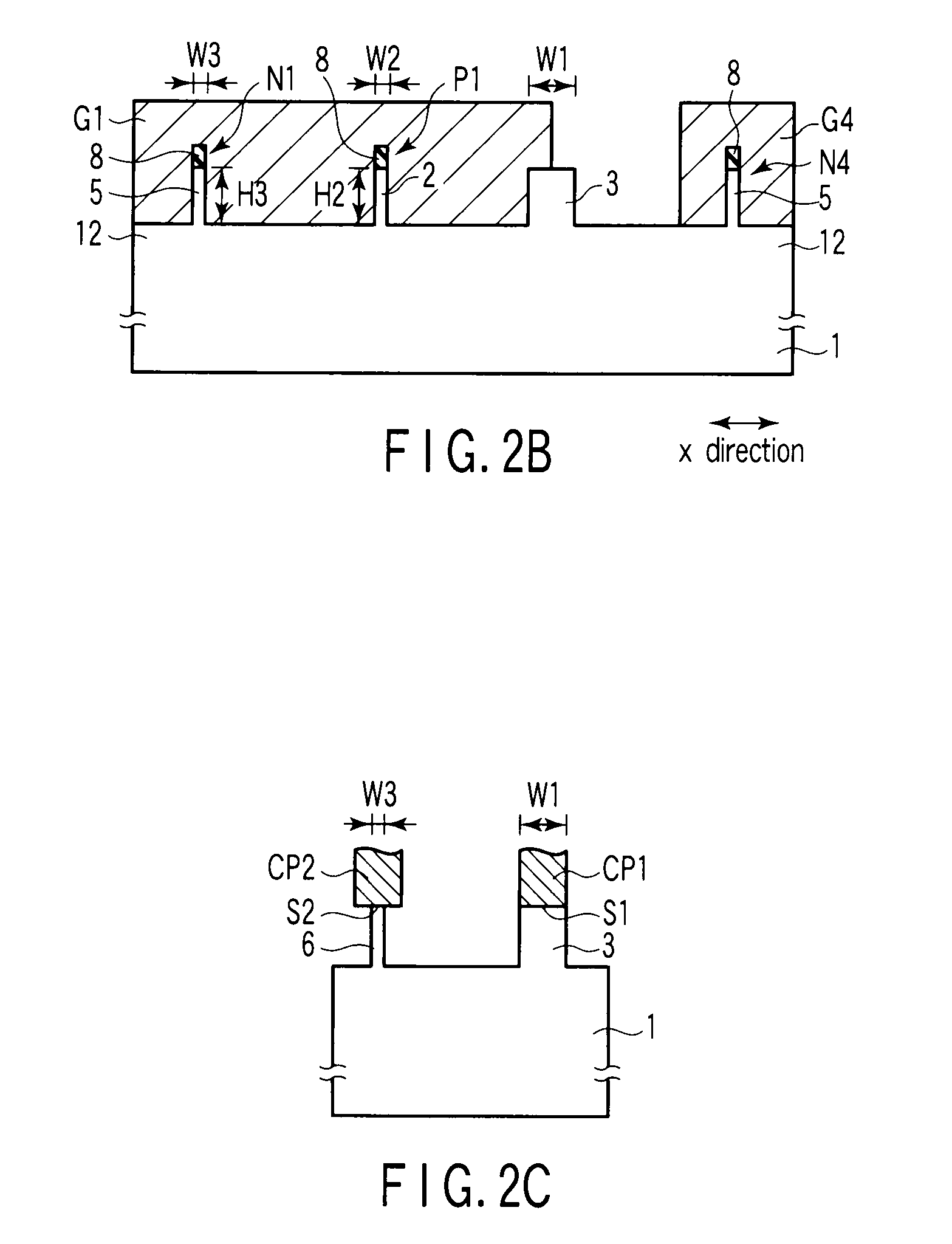

Semiconductor device

A semiconductor device according to an aspect of the invention comprises an n-type FinFET which is provided on a semiconductor substrate and which includes a first fin, a first gate electrode crossing a channel region of the first fin via a gate insulating film in three dimensions, and contact regions provided at both end of the first fin, a p-type FinFET which is provided on the semiconductor substrate and which includes a second fin, a second gate electrode crossing a channel region of the second fin via a gate insulating film in three dimensions, and contact regions provided at both end of the second fin, wherein the n- and the p-type FinFET constitute an inverter circuit, and the fin width of the contact region of the p-type FinFET is greater than the fin width of the channel region of the n-type FinFET.

Owner:KK TOSHIBA

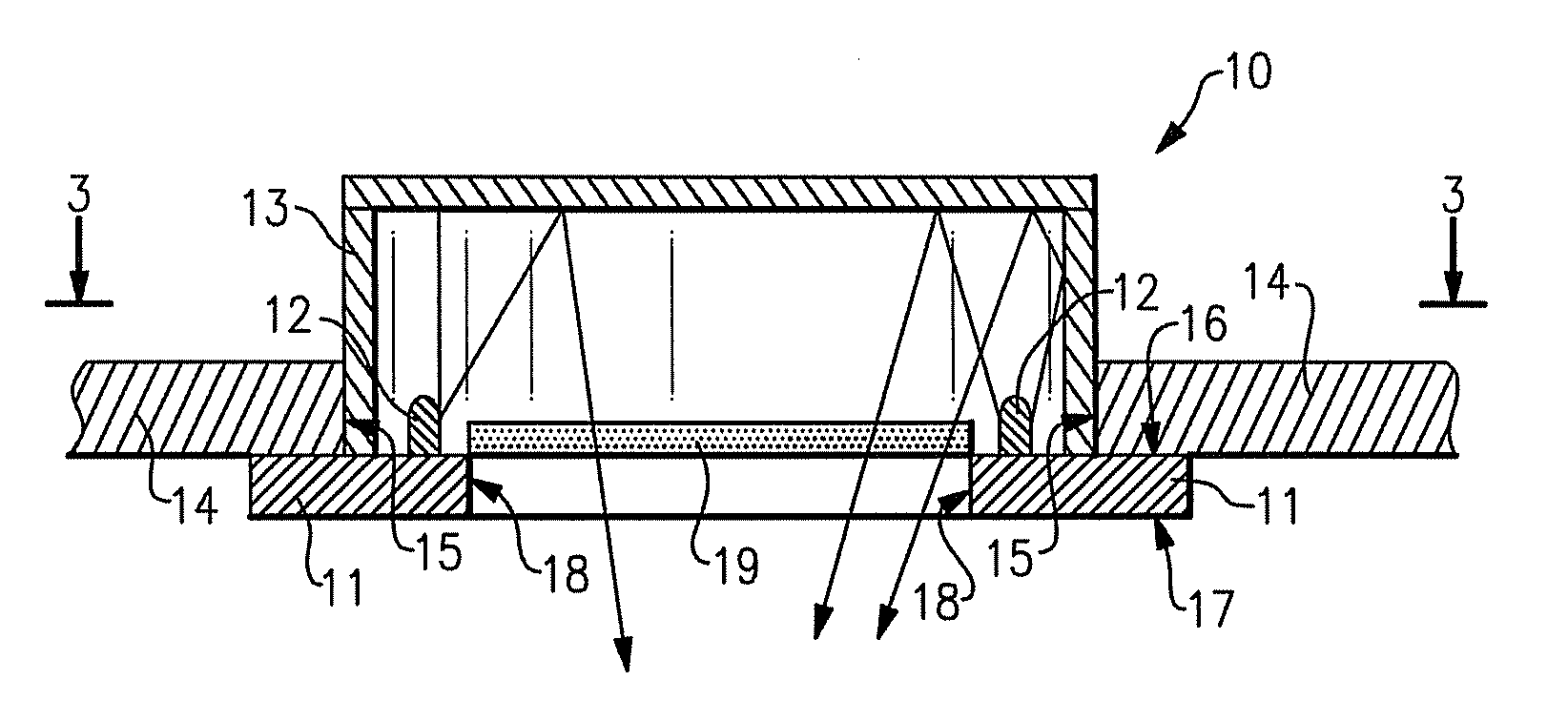

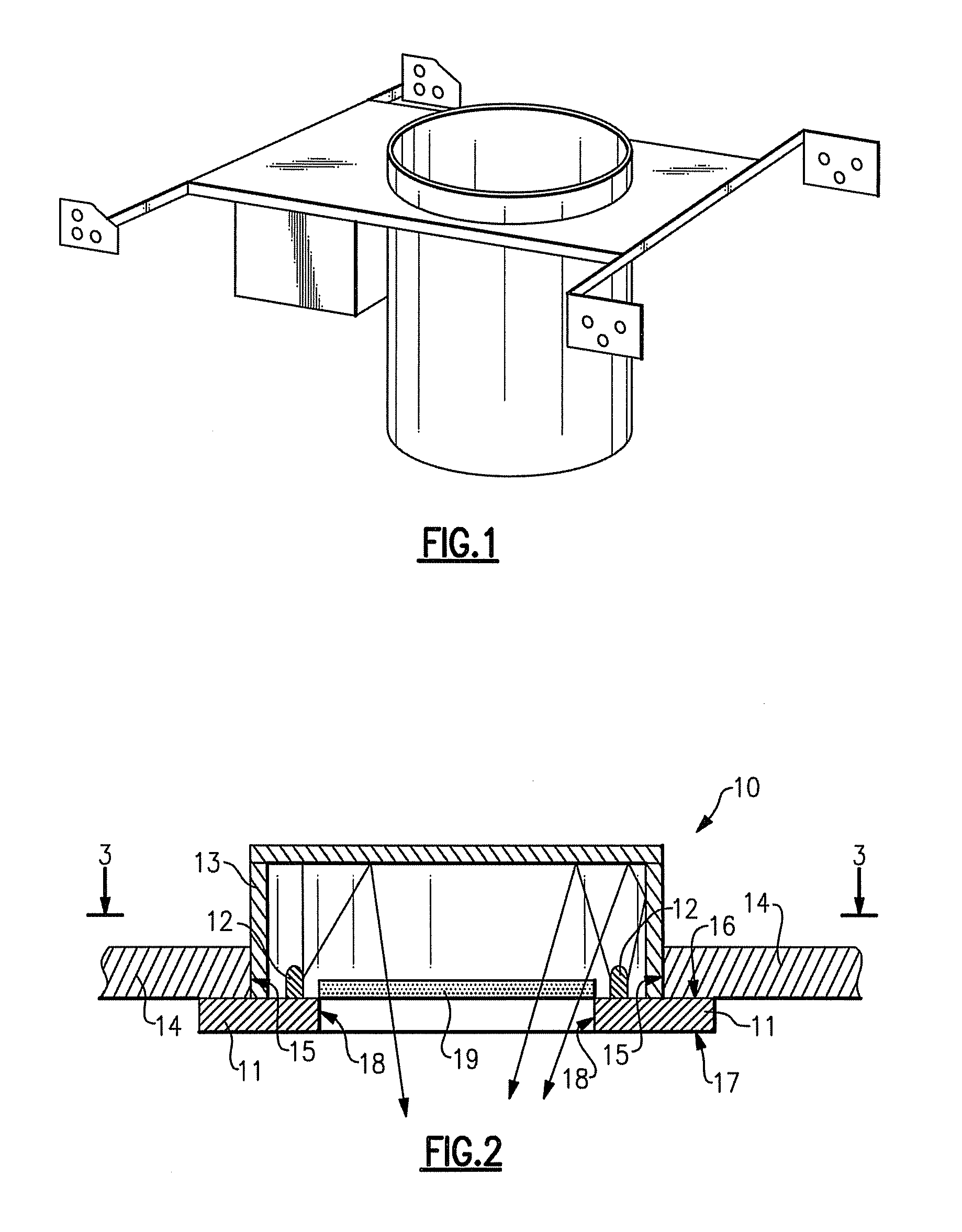

Lighting device

ActiveUS7722220B2Reduce glareEfficient transferMechanical apparatusPoint-like light sourceEffect lightEngineering

First, second and third lighting devices each comprise a thermal conduction element, solid state light emitters and a reflective element. In the second device, the conduction element defines an opening; and the emitters and reflective element are mounted on a first side of the conduction element. In the third device, the conduction element defines an opening; a first portion of a first side of the conduction element is in contact with a contact region of a construction surface; and the emitters and reflective element are mounted on the first side. A fourth device comprises a conduction element and emitters; a first portion of a first side of the conduction element is in contact with a contact region of a construction surface; the emitters are mounted on a second portion of the first side of the conduction element; and a second side of the conduction element is exposed to ambient air.

Owner:IDEAL IND LIGHTING LLC

Systems for dynamically illuminating touch sensors

InactiveUS20060181521A1Precise positioningSave powerCharacter and pattern recognitionCathode-ray tube indicatorsJoystickEngineering

A system for and method of illuminating a contact (or touch) device such as a fingerprint sensor are disclosed. In an exemplary system, a touch sensor system has a surface or contact area and comprises a substantially transparent molding positioned over the contact area and a dynamic illuminator positioned to show through the molding. The dynamic illuminator is for indicating a status of the touch sensor system, such as power on, standby, error, low power, an input mode for receiving user input, or a selected operating mode. The touch sensor system includes any one of a fingerprint sensor, a miniature joystick, a touch-sensitive navigation disc, a touch-sensing navigation pad, an N-way pressure-sensitive directional control, to name a few touch sensor devices. In one embodiment, when the touch sensor comprises a fingerprint sensor, the operating mode is for emulating an input device such as a scroll wheel, a push button, a steering wheel, a joy stick, a pressure button, and a mouse. The operating mode also includes an authentication mode for authenticating an identity of a user. Preferably, the dynamic illuminator includes light sources and multiple light channels, colored or not, that are configured to be illuminated in multiple configurations, where each configuration corresponds to a status of the touch sensor system.

Owner:AUTHENTEC

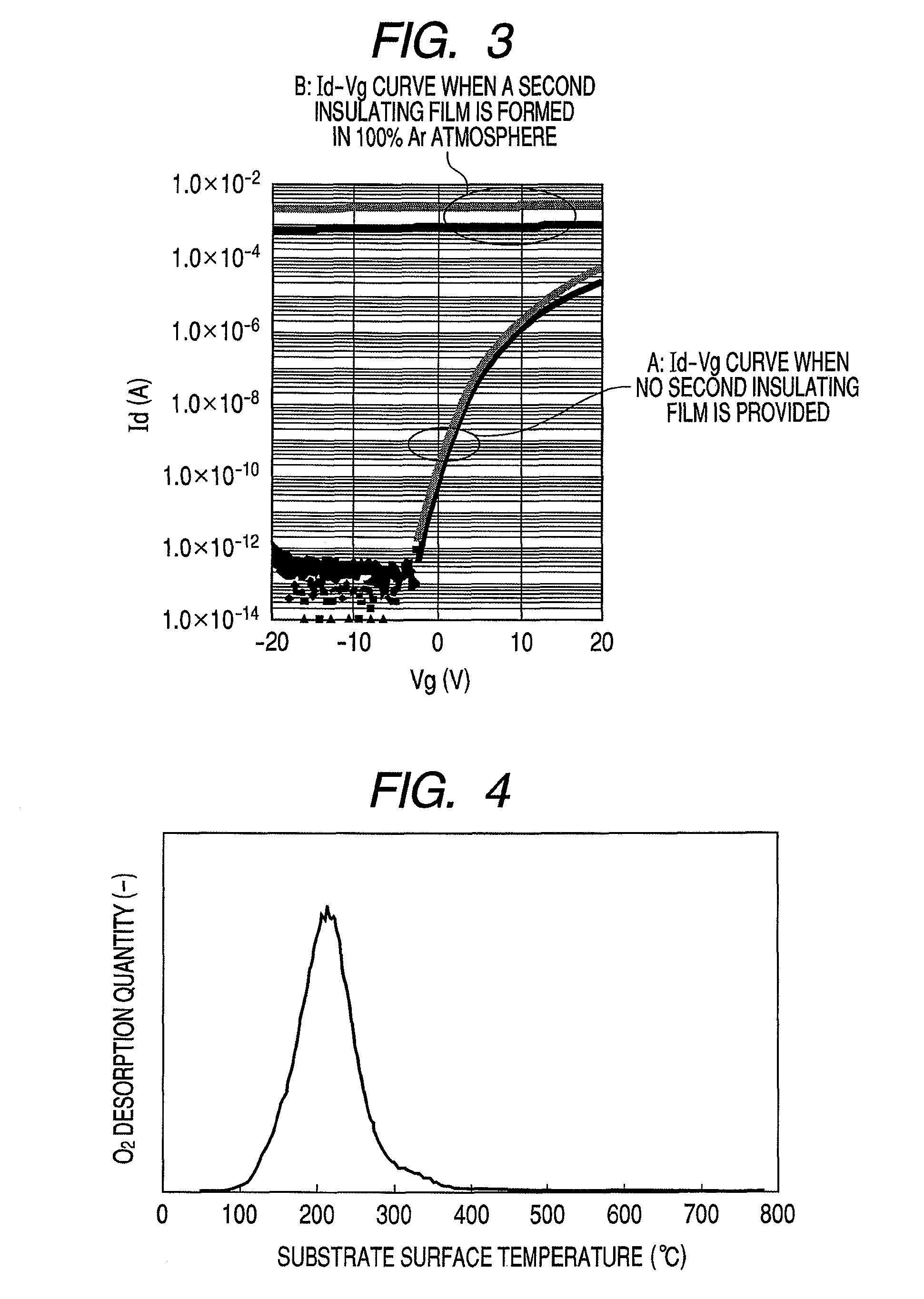

Method for manufacturing thin film transistor using oxide semiconductor and display apparatus

ActiveUS8143115B2Lower resistanceImprove transistor characteristicsTransistorSolid-state devicesSemiconductorAtmosphere

A thin film transistor is manufactured by forming a gate electrode on a substrate, forming a first insulating film on the gate electrode, forming an oxide semiconductor layer on the first insulating film with an amorphous oxide, patterning the first insulating film, patterning the oxide semiconductor layer, forming a second insulating film on the oxide semiconductor layer in an oxidative-gas-containing atmosphere, patterning the second insulating film to expose a pair of contact regions, forming an electrode layer on the pair of contact regions, and patterning the electrode layer to for a source electrode and a drain electrode.

Owner:CANON KK

Multi-point tension distribution system device and method of tissue approximation using that device to improve wound healing

A tissue approximation device and processes for using the device are provided. The device is an implantable, biodegradable construct (except for hernia repairs) that has attachment points emanating from a supportive backing. The device improves the mechanical phase of wound healing and evenly distributes tension over the contact area between the device and tissue. Processes for using the device include wound closure, vascular anastomoses, soft tissue attachment and soft tissue to bone attachment.

Owner:OXFORD FINANCE +2

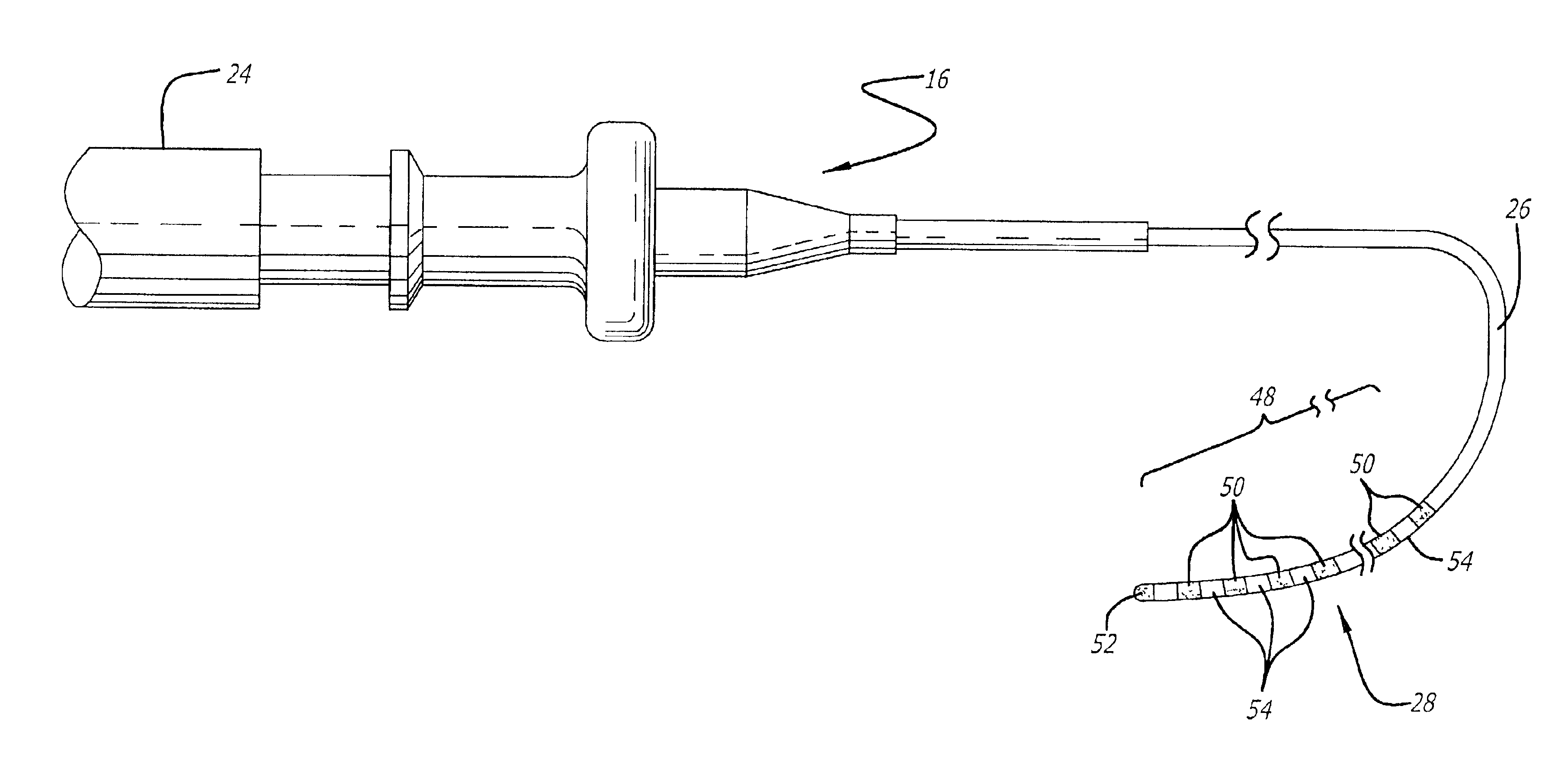

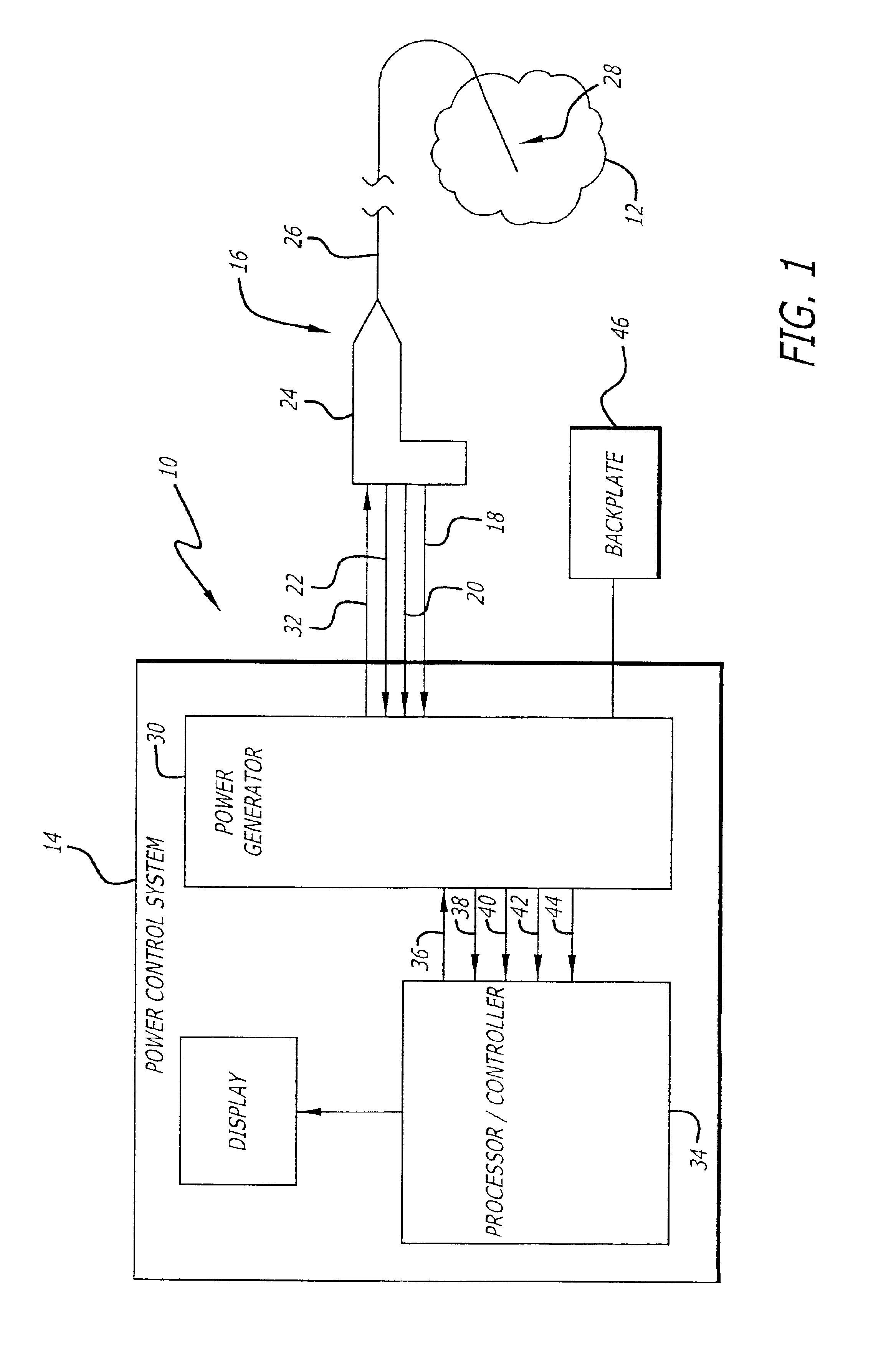

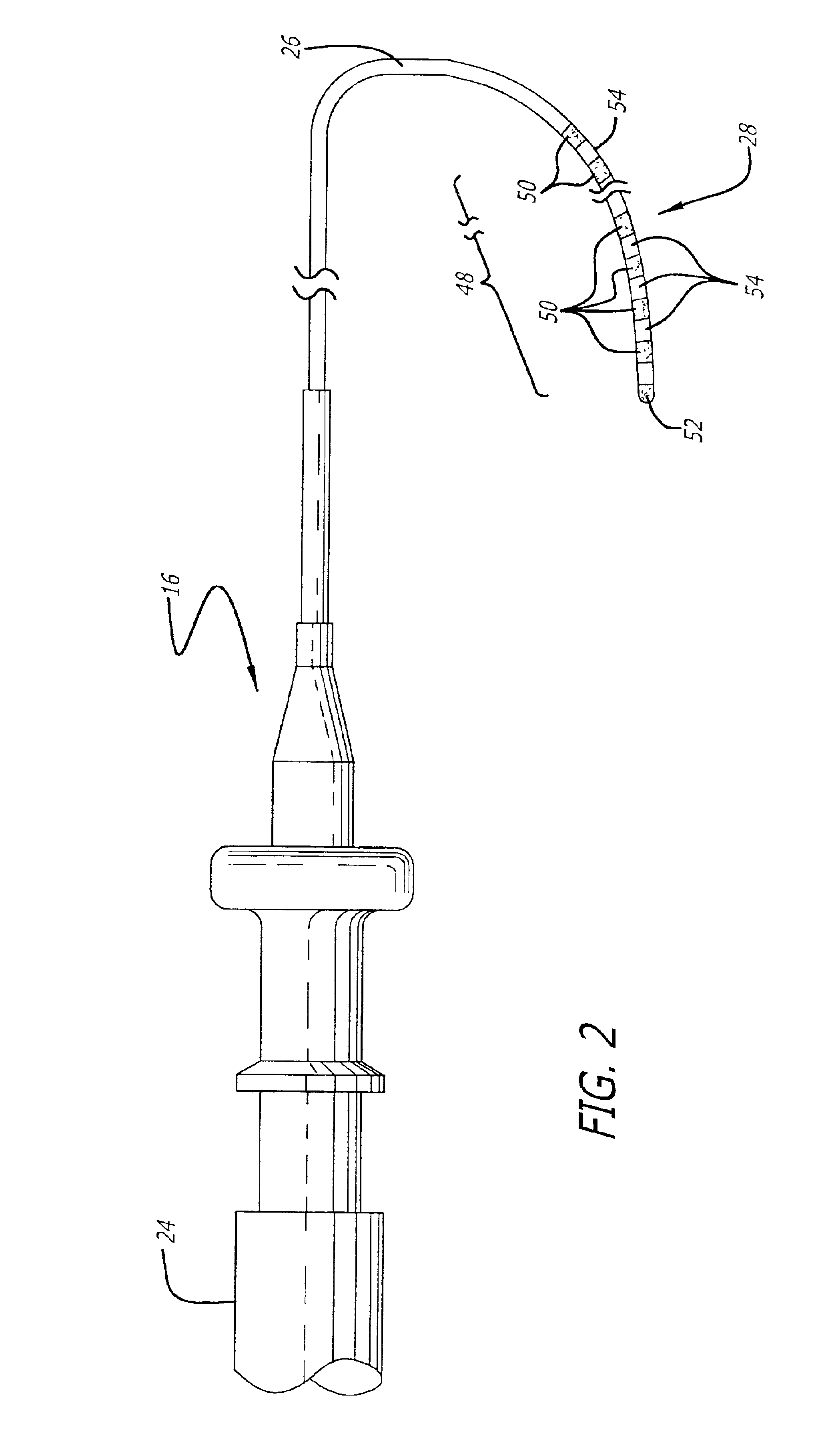

Ablation catheter with transducer for providing one or more of pressure, temperature and fluid flow data for use in controlling ablation therapy

A distal segment of a catheter shaft is adapted to be positioned against tissue in a biological organ. The distal segment has a tissue-contacting area intended to contact the tissue. One or more pressure sensors positioned within the tissue-contacting area provide pressure data indicative of the pressure exerted on the distal segment. The distal segment carries one or more electrodes and the pressure sensors are located either on an electrode or on the catheter shaft near an electrode. The pressure sensors provide pressure data to a processor that analyzes the data to determine if the tissue-contacting area of the distal segment is contacting the tissue. The pressure sensors may also provide temperature data indicative of the temperature at the sensor. A flow sensor, located opposite the pressure sensor on the shaft, provides data related to the flow rate of fluid through the organ.

Owner:CARDIAC PACEMAKERS INC

Device for the dynamic fixation of bones

InactiveUS20070233087A1Relieve pressureIncrease elasticitySuture equipmentsInternal osteosythesisDynamic fixationCoaxial cavity

An intermediate element for a detachable, lockable, ball joint-like connection in a device for the dynamic fixation of bones has a longitudinal axis, an outer wall concentric with the longitudinal axis, and an inner wall forming a coaxial cavity. Either the outer wall or the inner wall comprises one of two contact zones that form the ball joint-like connection. The intermediate element is at least partly made of a super-elastic or visco-elastic material.

Owner:SYNTHES USA

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com