Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

2030 results about "Silicon solar cell" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

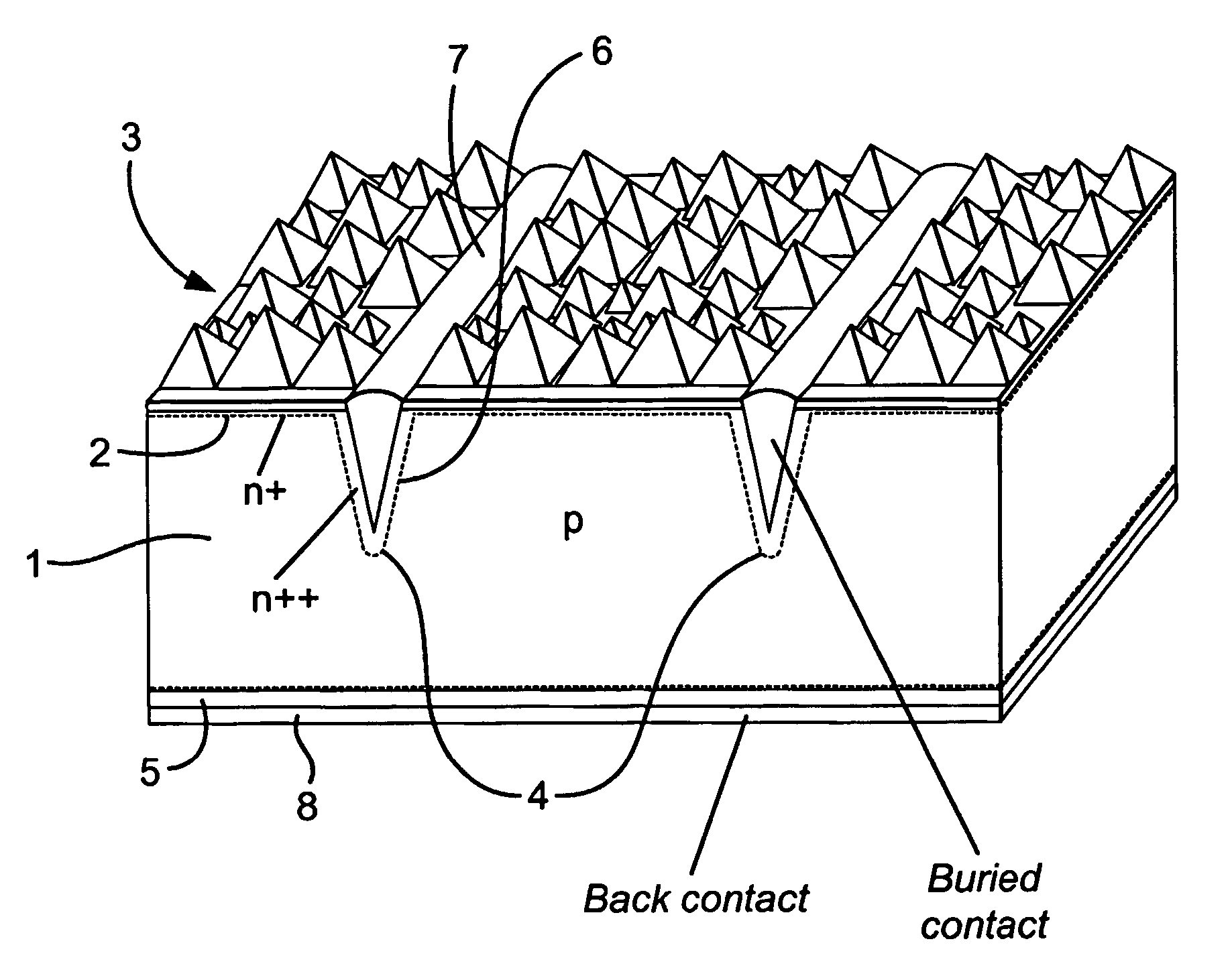

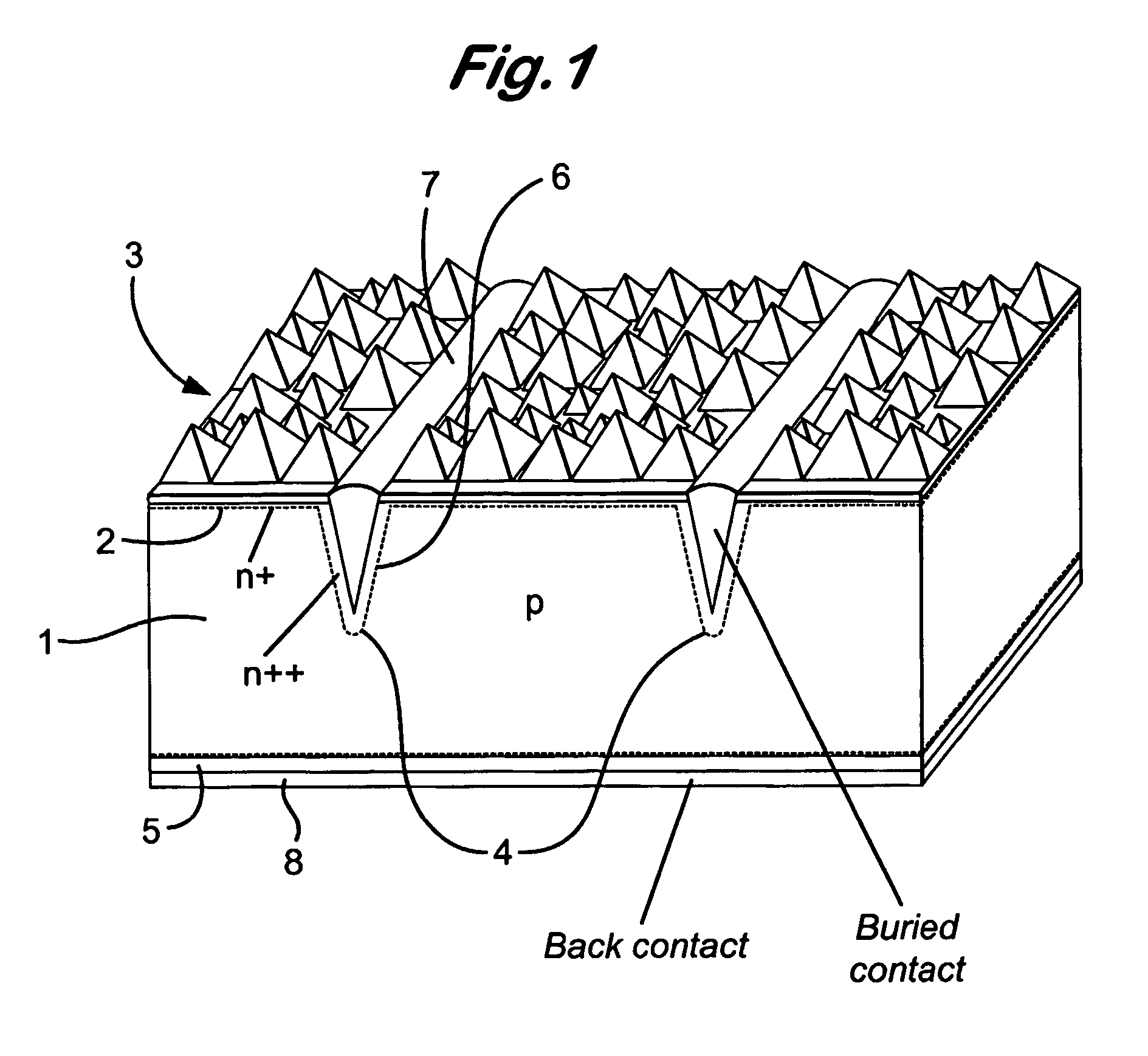

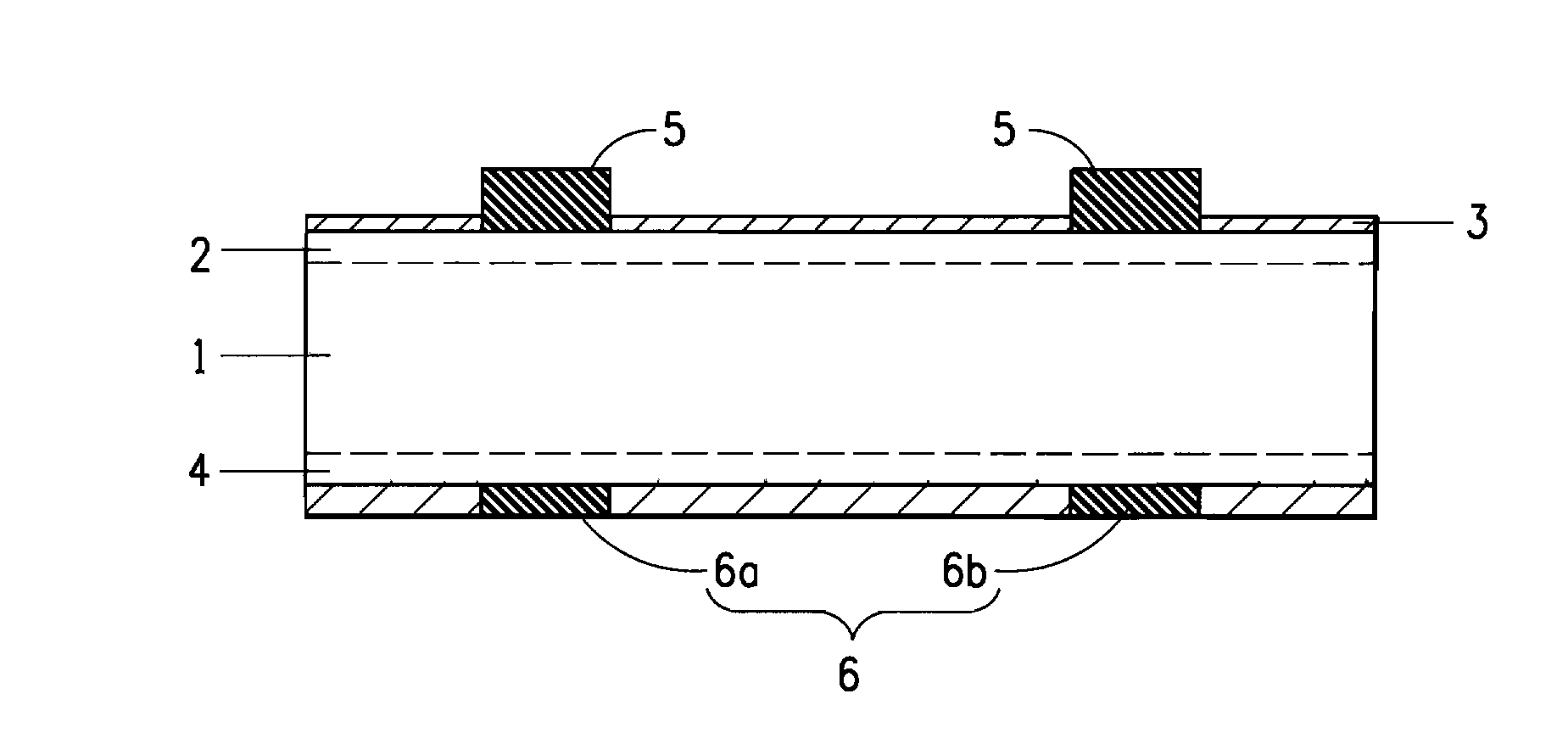

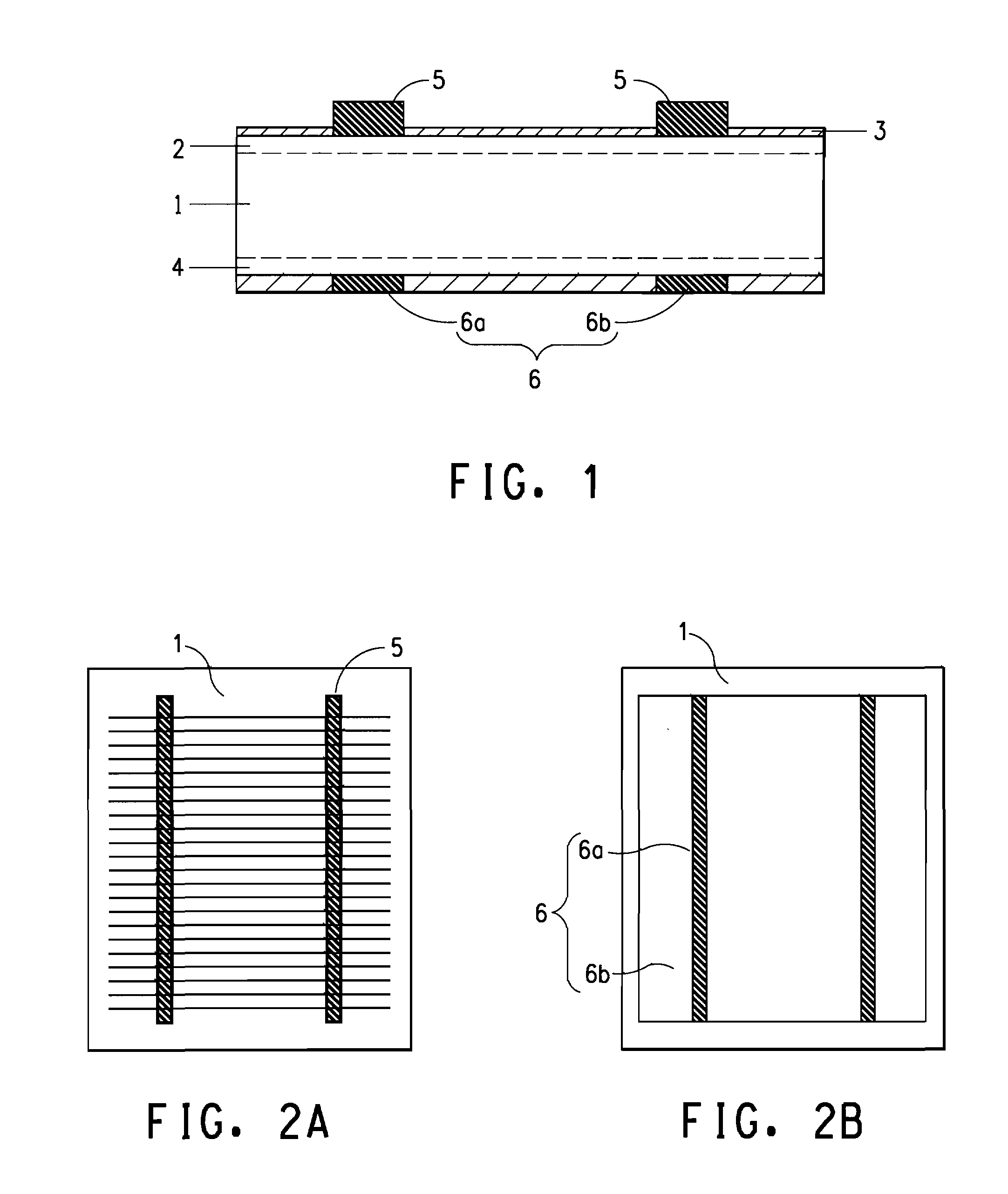

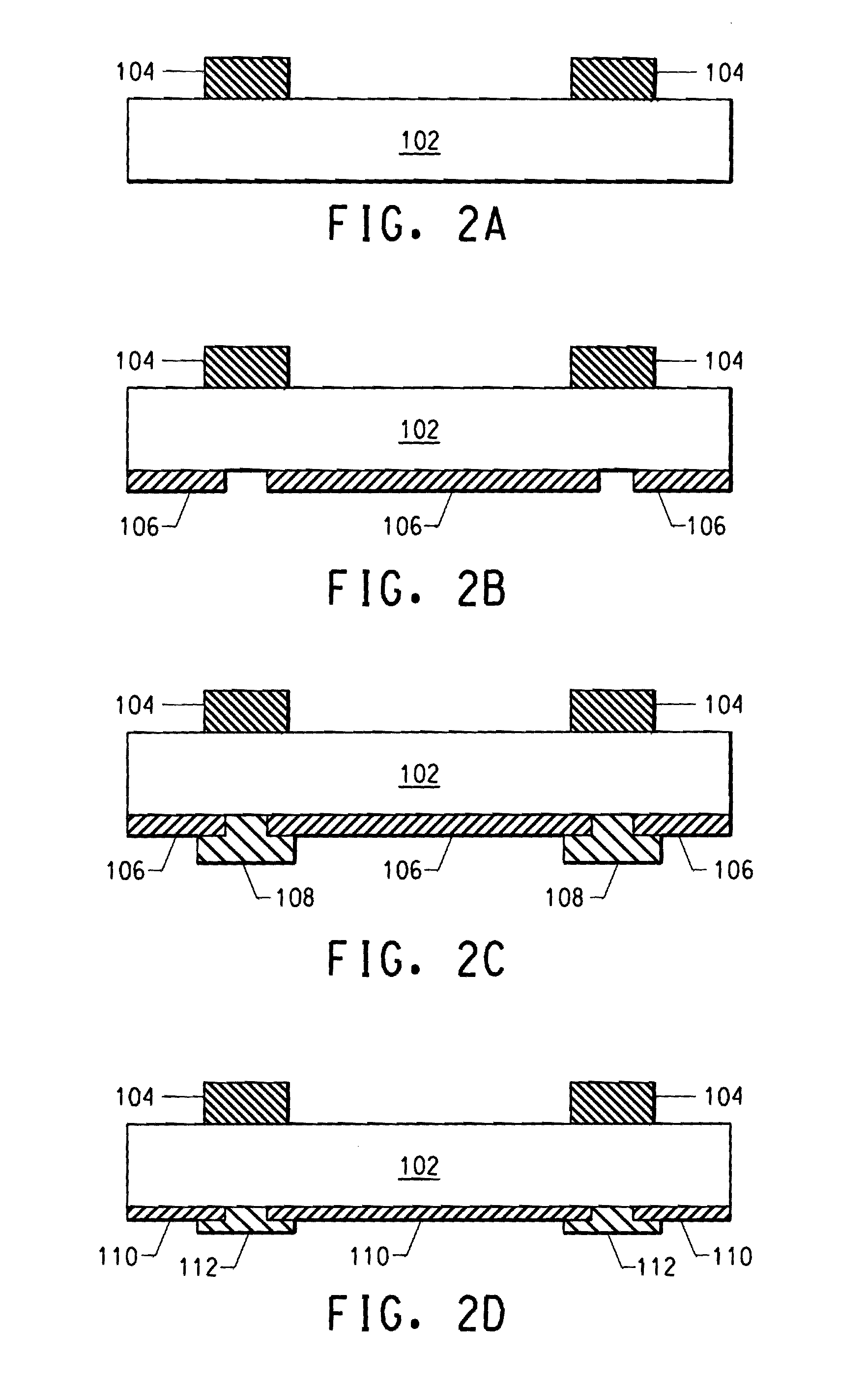

Contact fabrication of emitter wrap-through back contact silicon solar cells

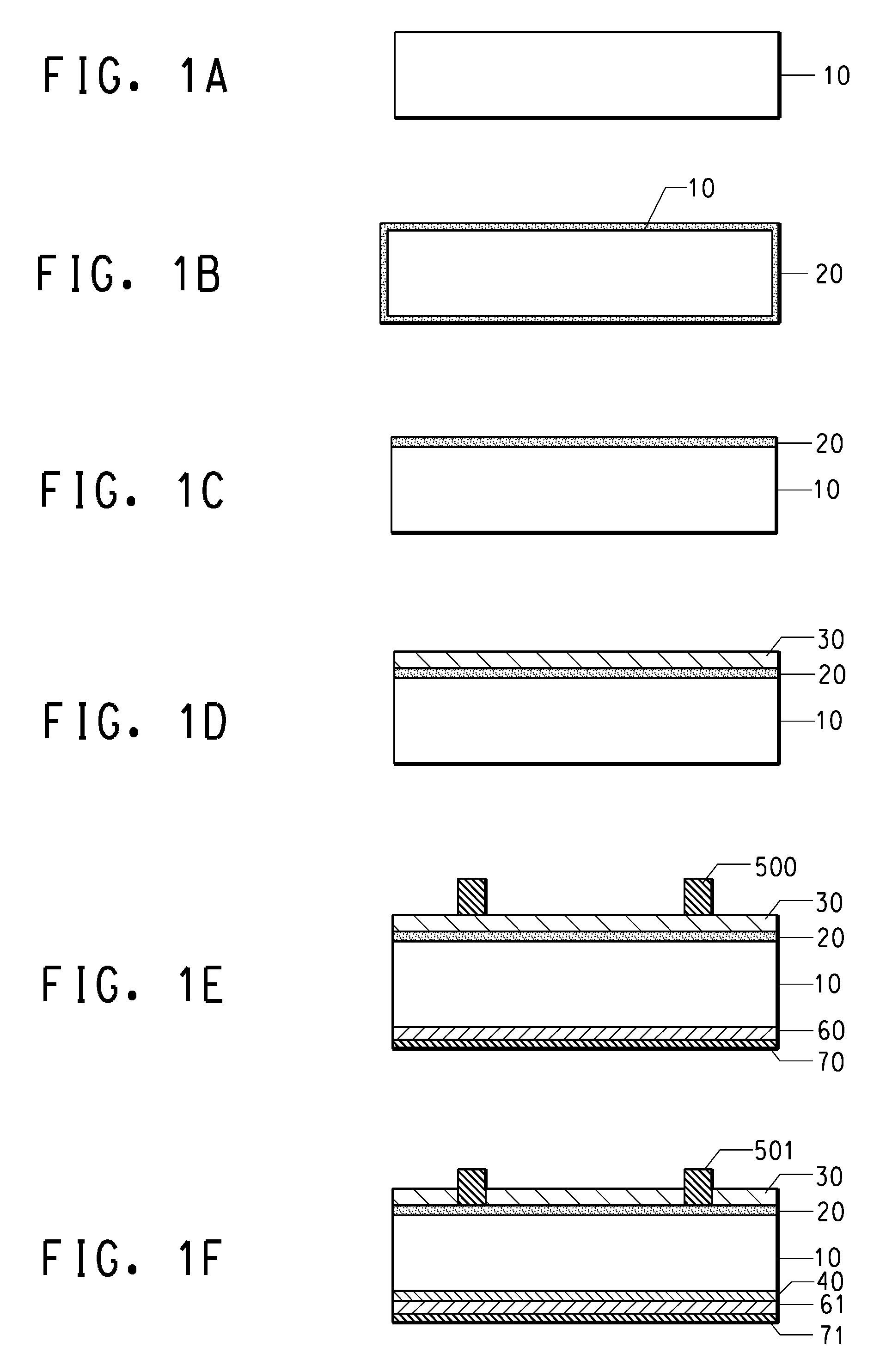

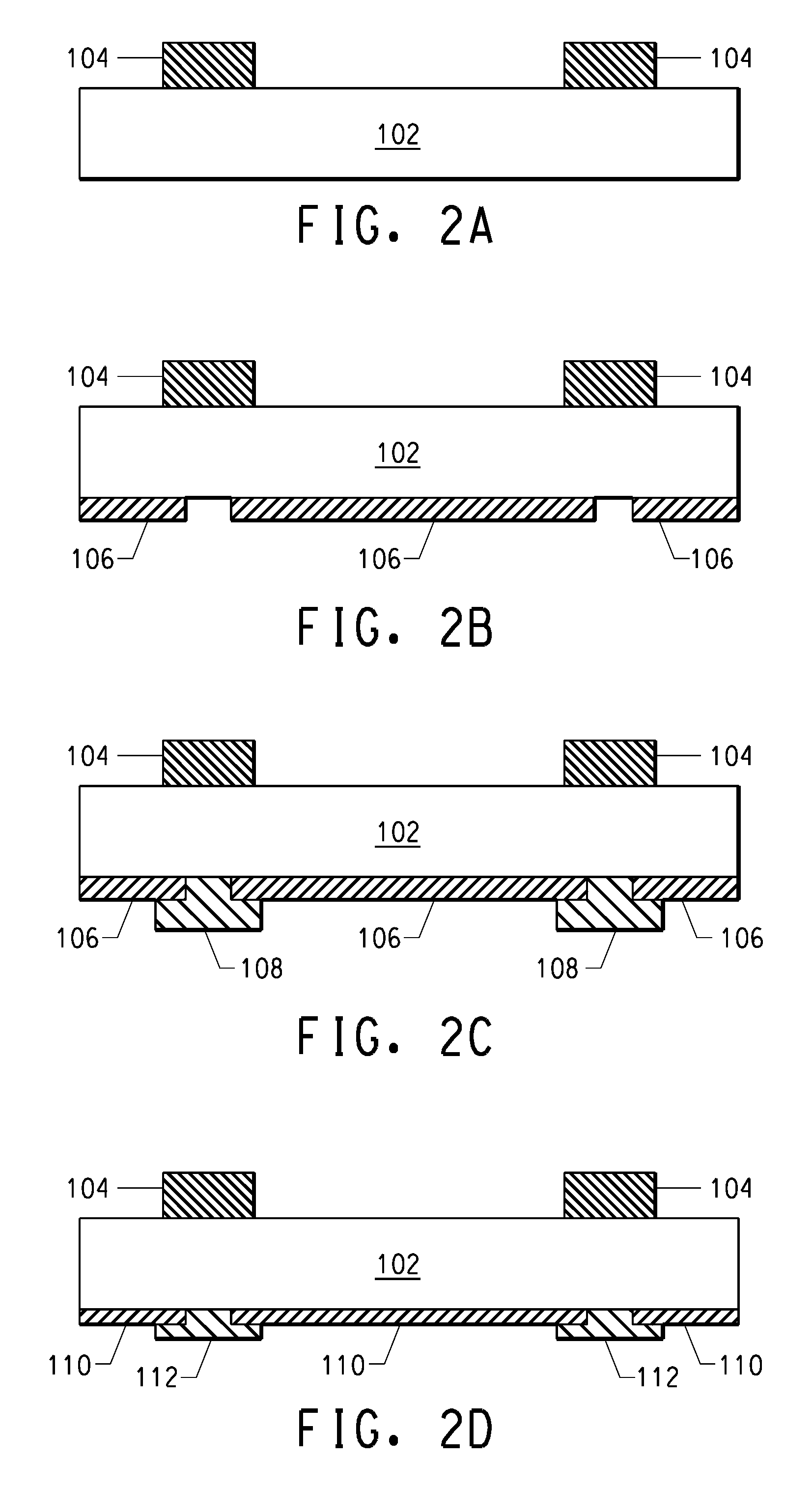

InactiveUS20050172996A1Few and economical process stepImprove efficiencyFinal product manufactureSemiconductor/solid-state device manufacturingEngineeringSilicon solar cell

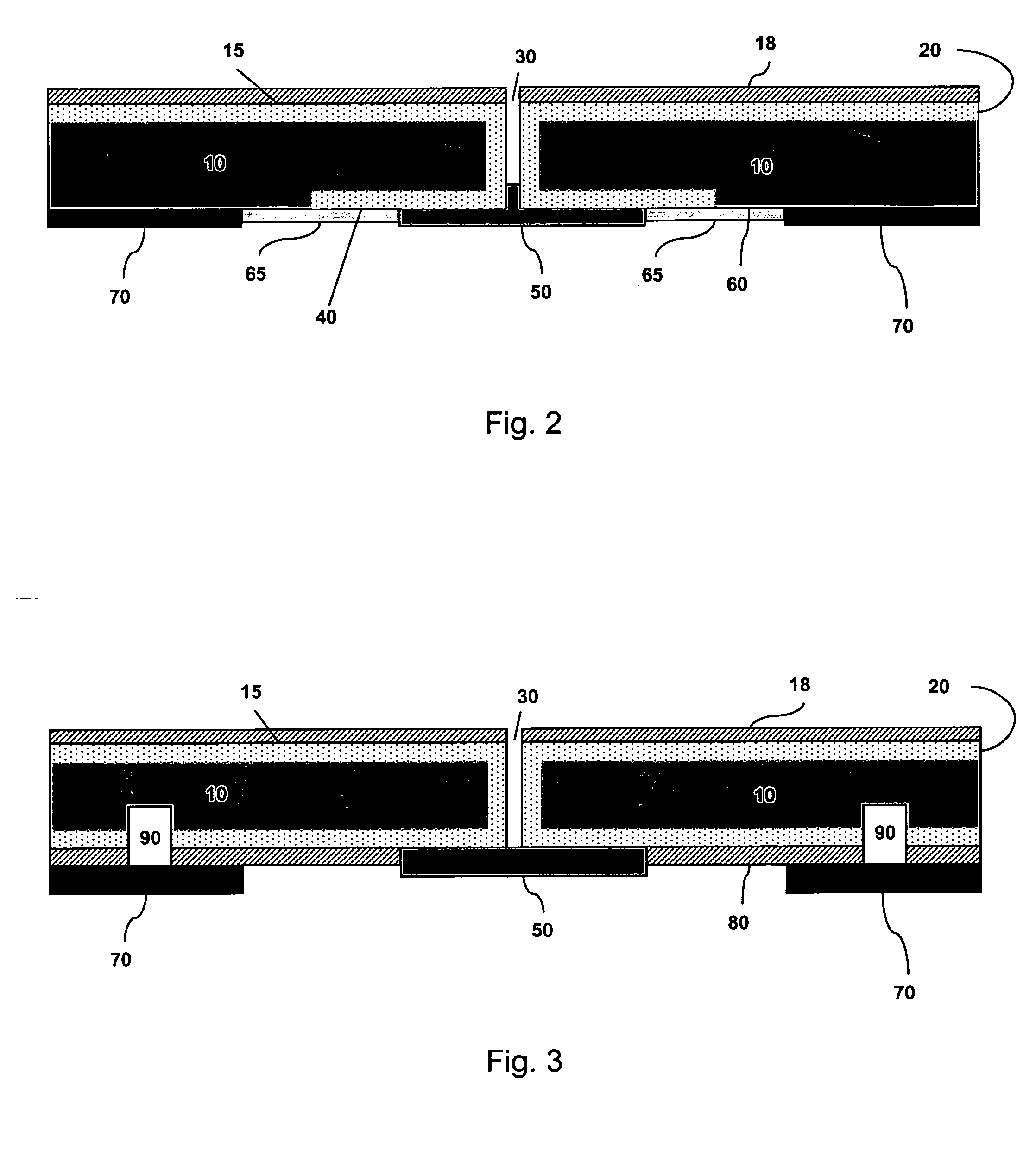

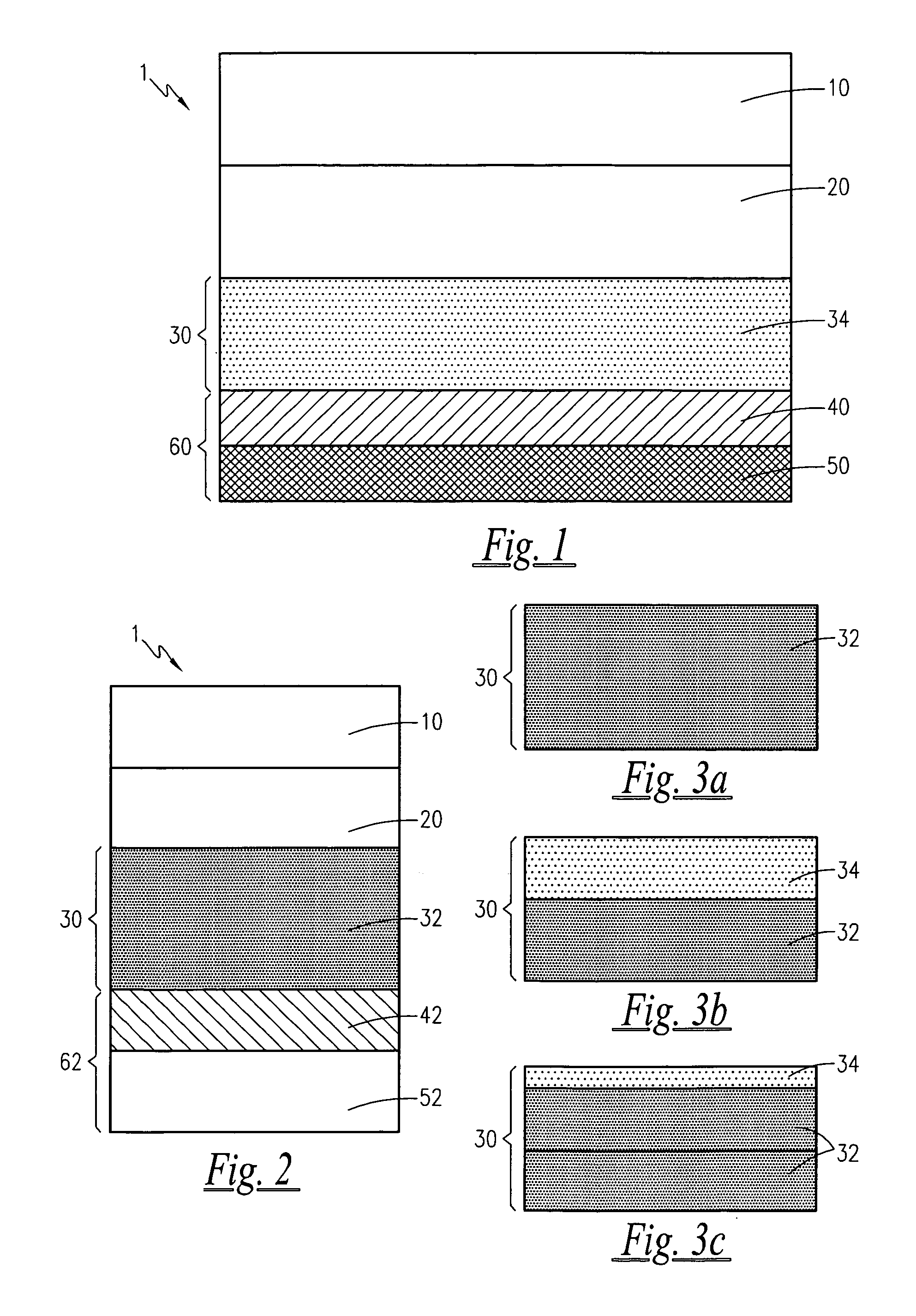

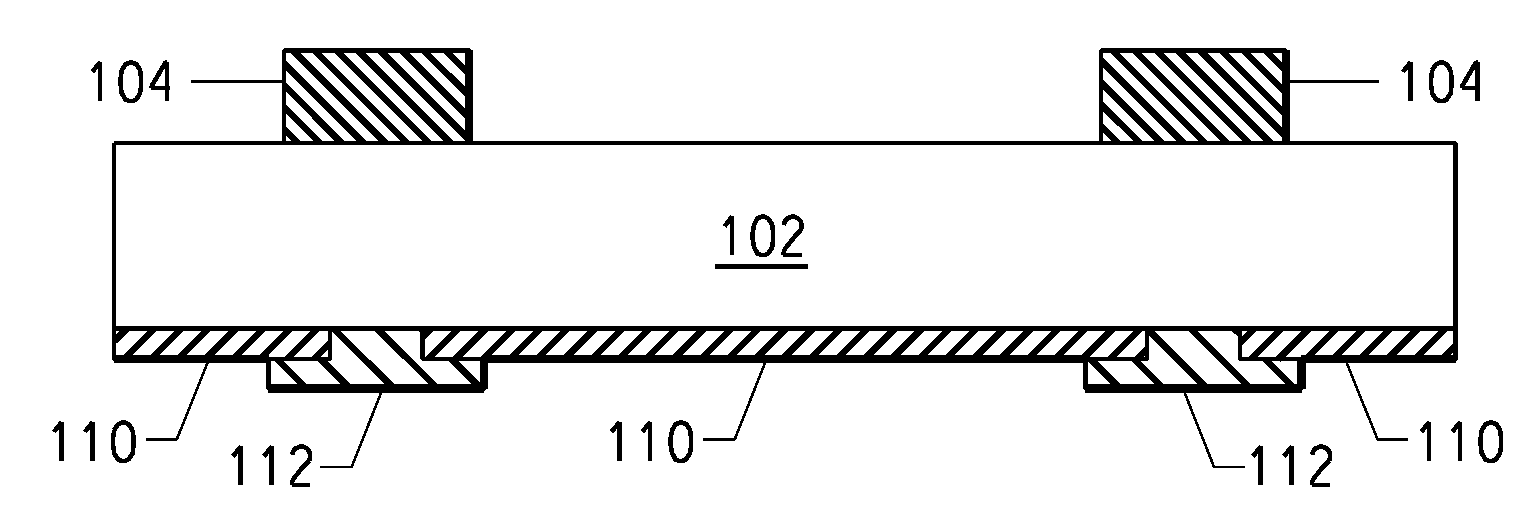

Back contact solar cells including rear surface structures and methods for making same. The rear surface has small contact areas through at least one dielectric layer, including but not limited to a passivation layer, a nitride layer, a diffusion barrier, and / or a metallization barrier. The dielectric layer is preferably screen printed. Large grid areas overlay the dielectric layer. The methods provide for increasing efficiency by minimizing p-type contact areas and maximizing n-type doped regions on the rear surface of a p-type substrate.

Owner:APPLIED MATERIALS INC

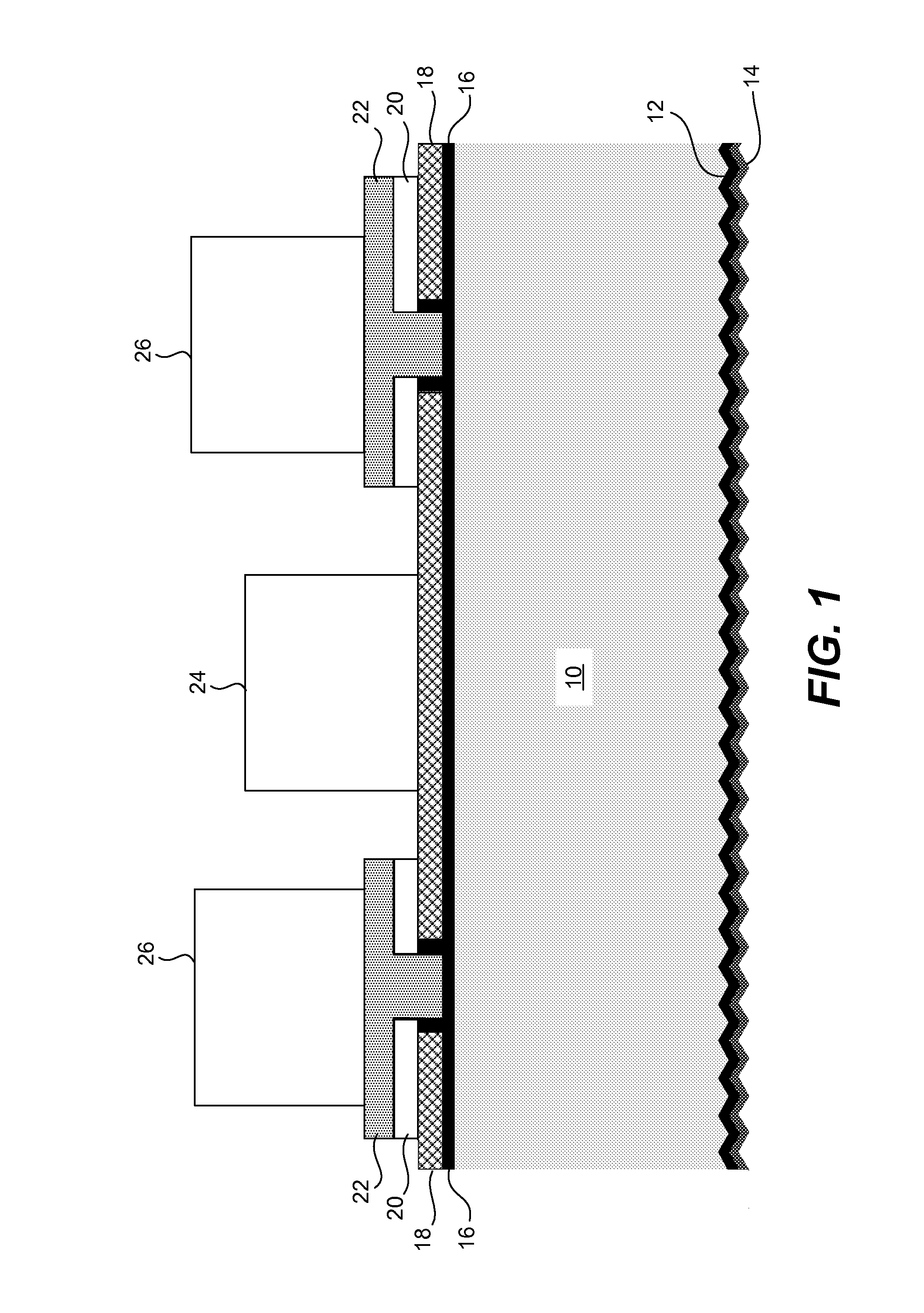

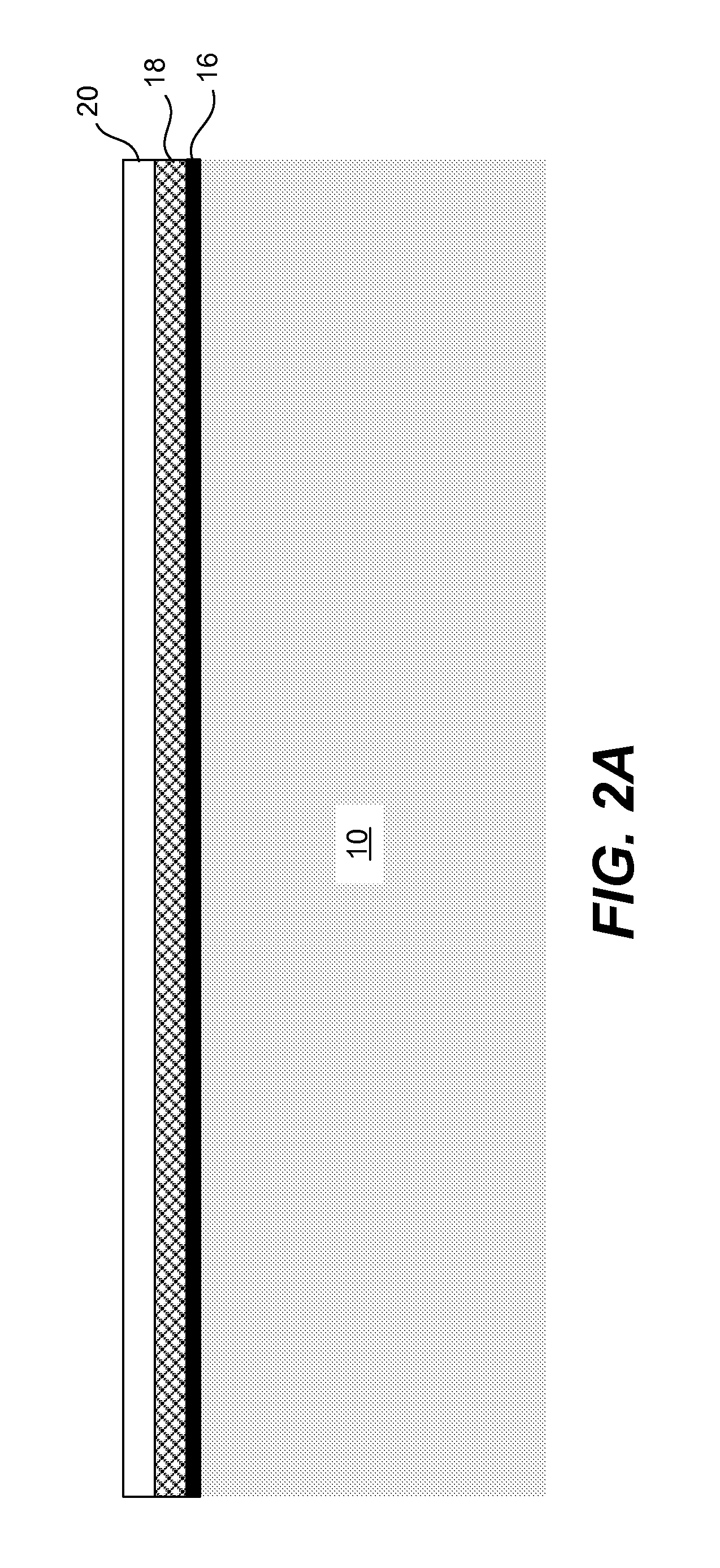

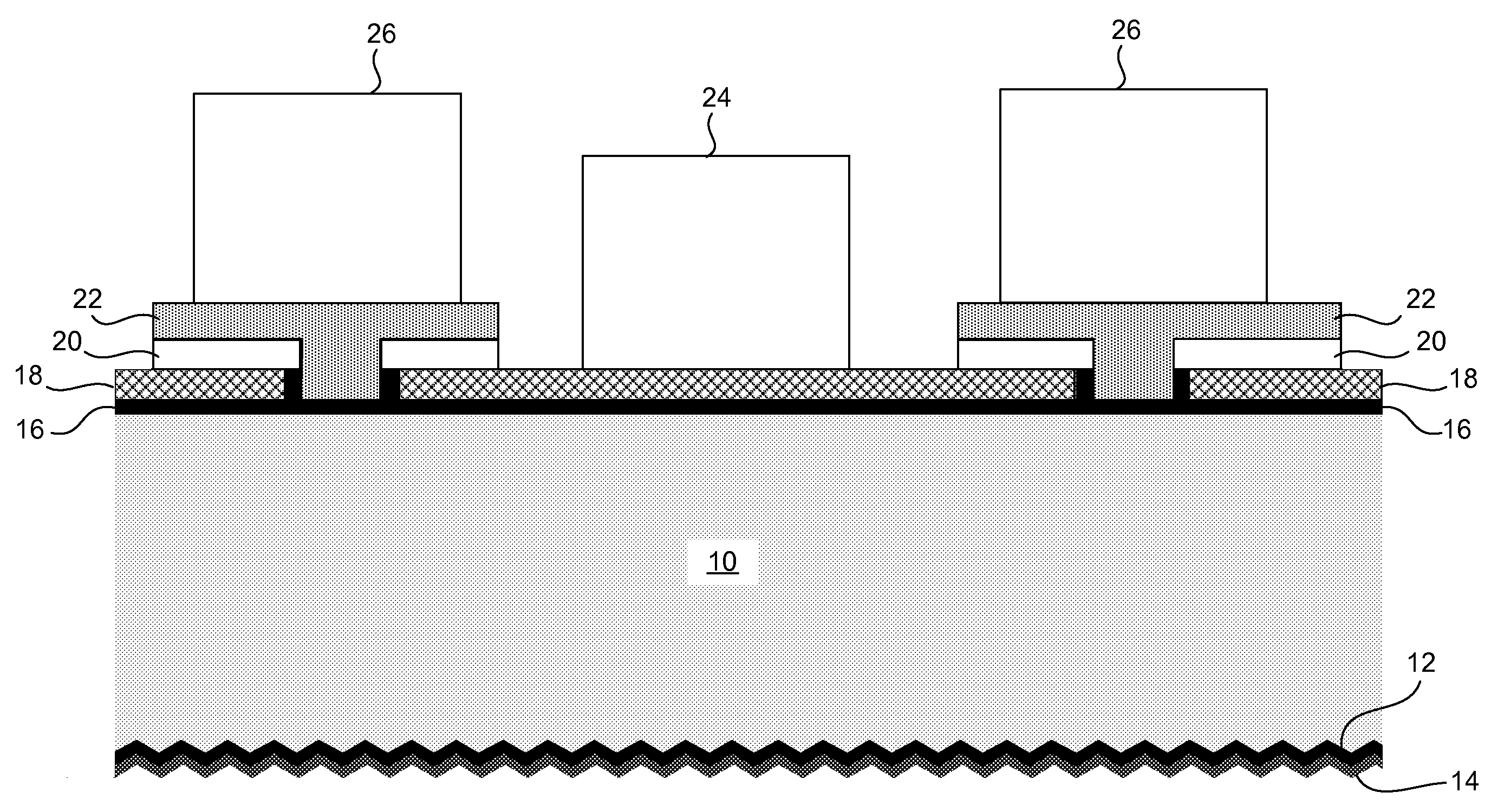

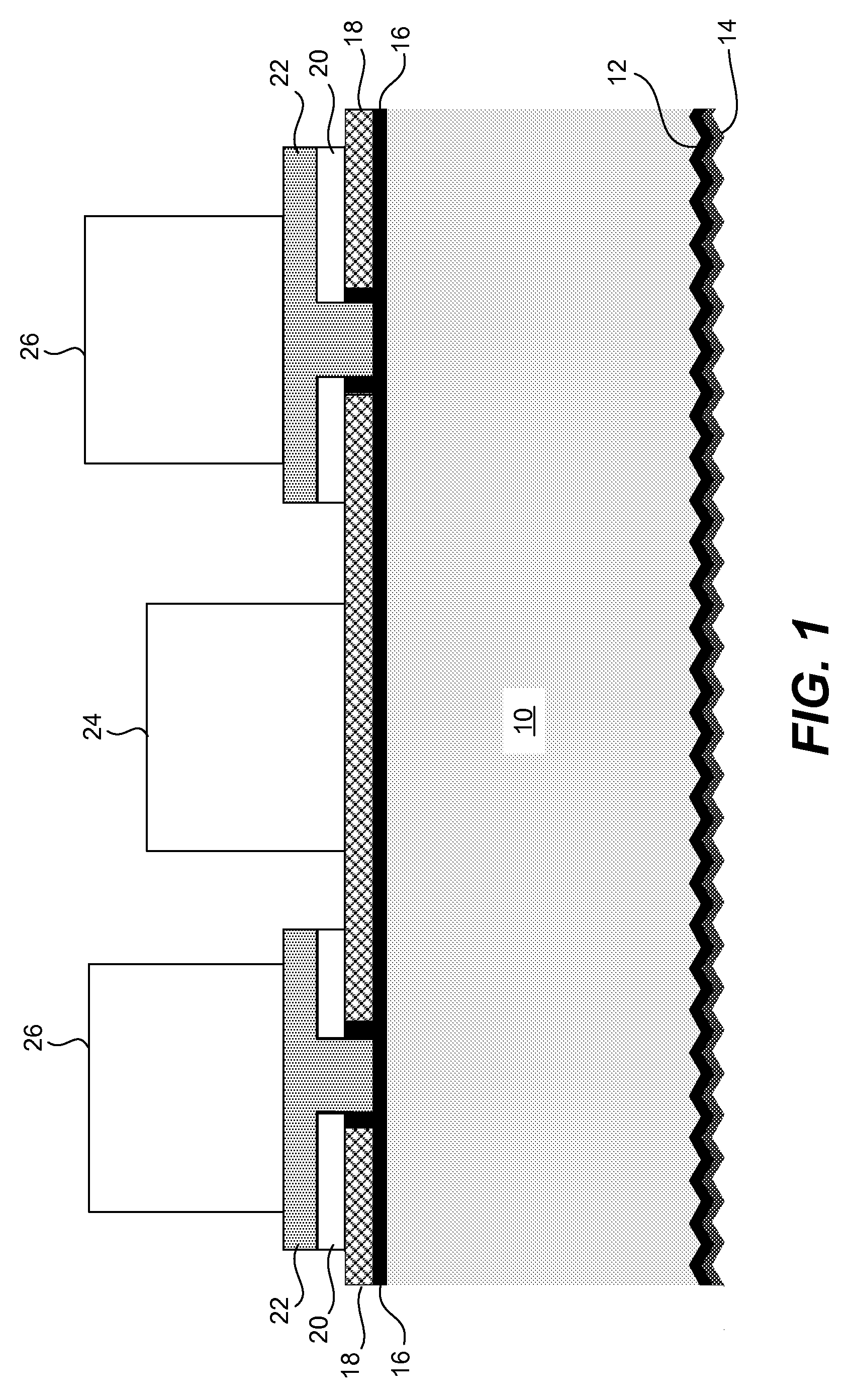

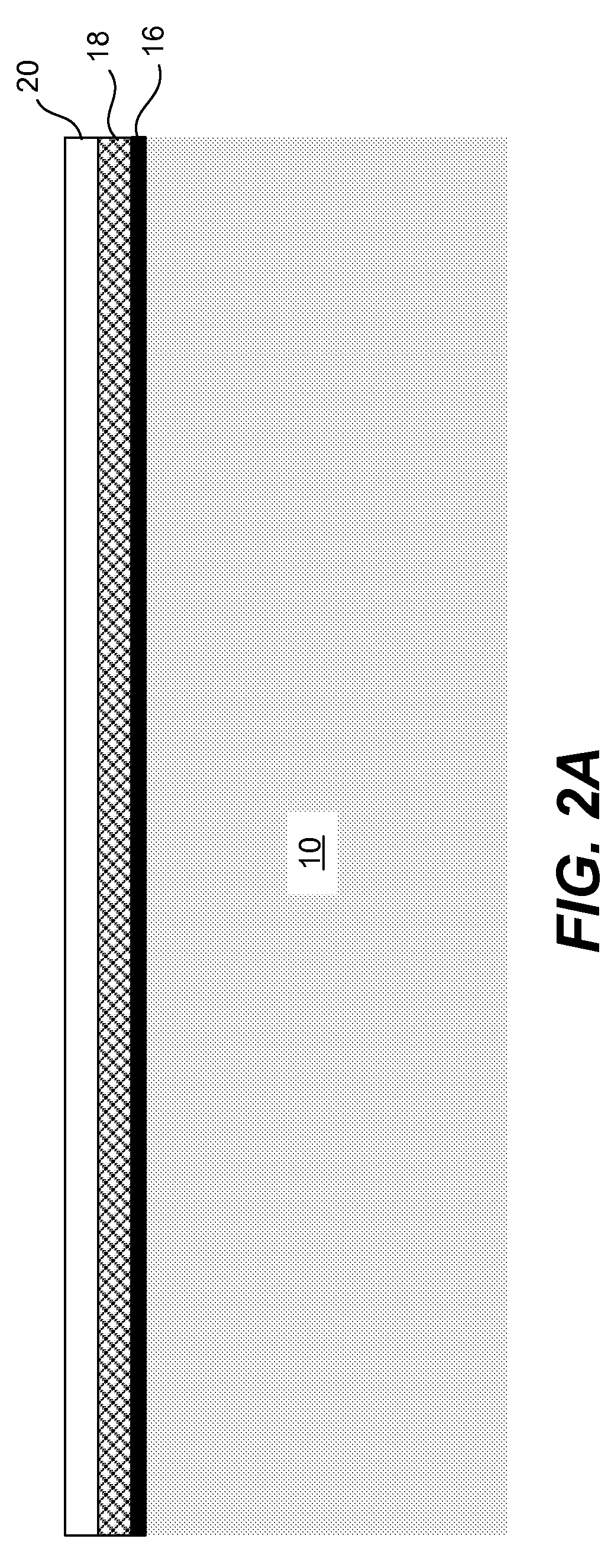

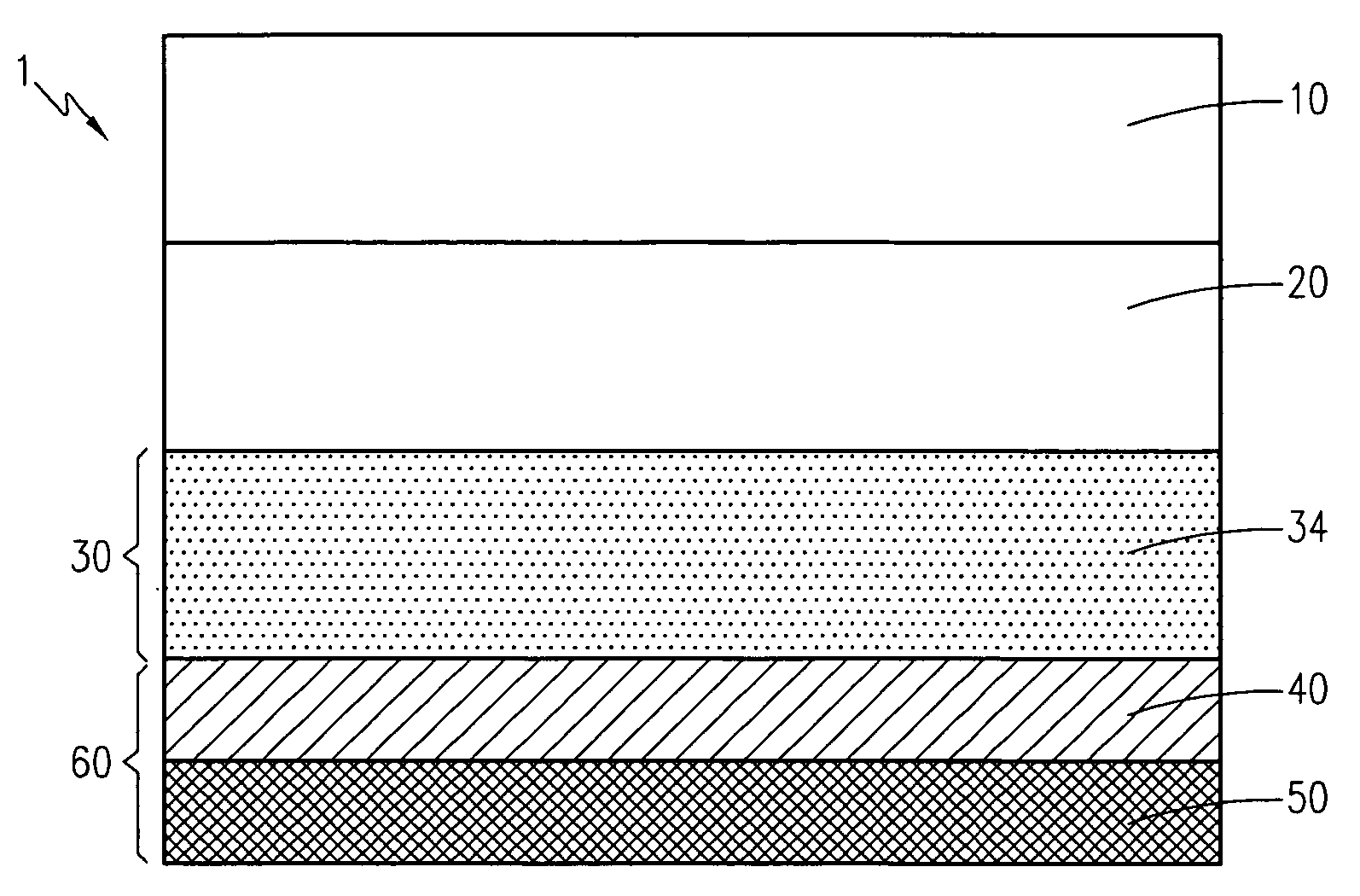

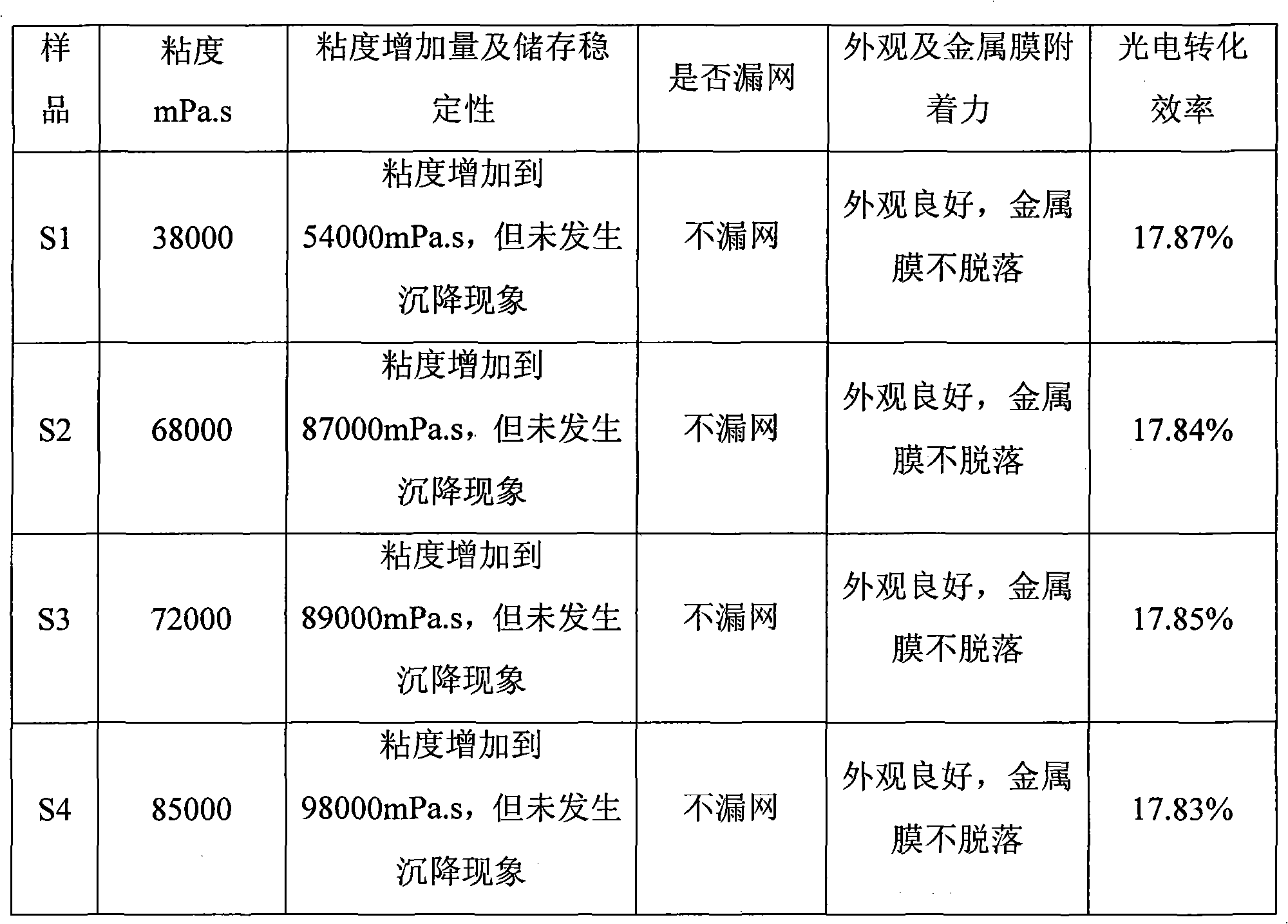

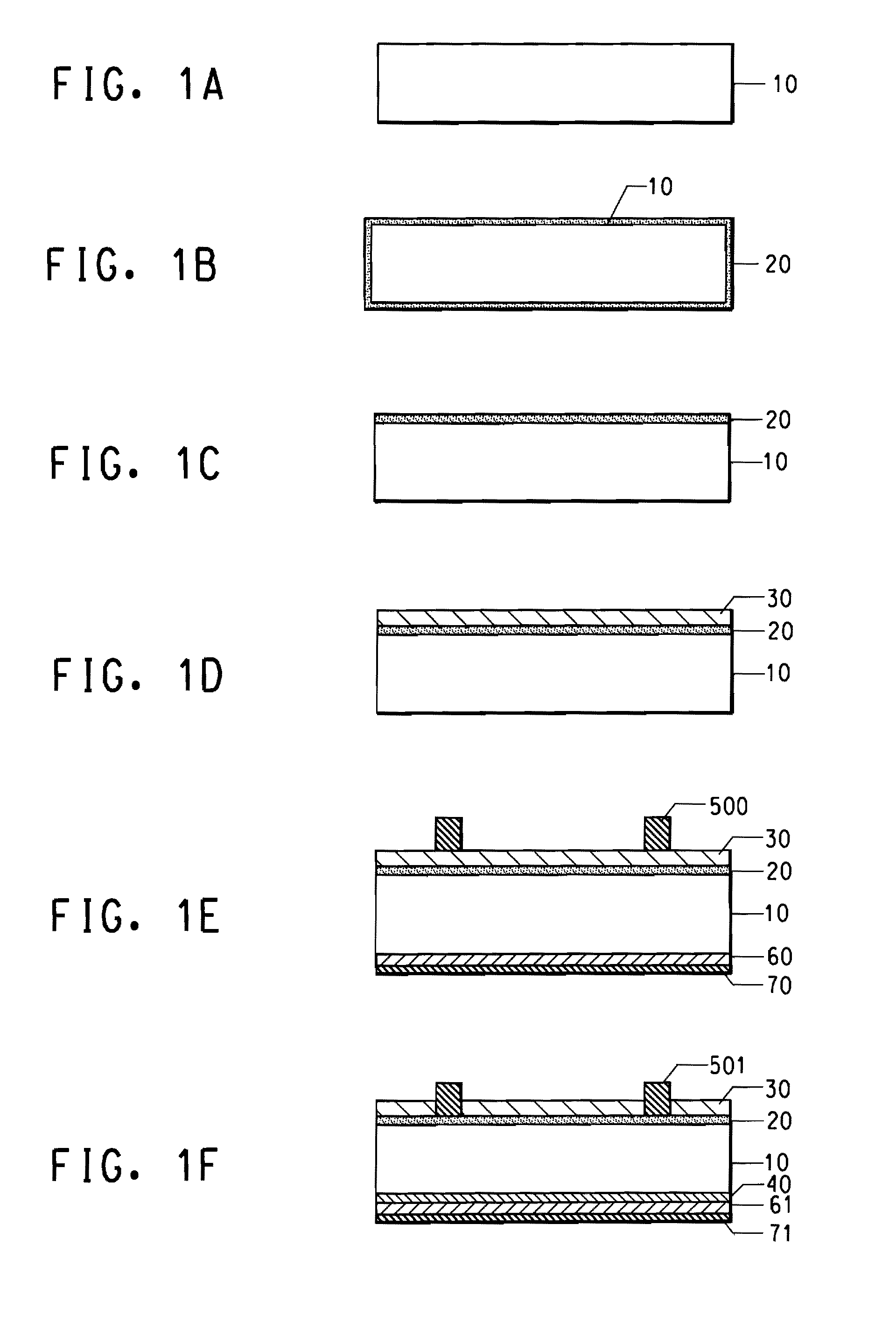

Solar cell having doped semiconductor heterojunction contacts

ActiveUS20070256728A1Readily apparentPV power plantsFinal product manufactureHeterojunctionAmorphous silicon

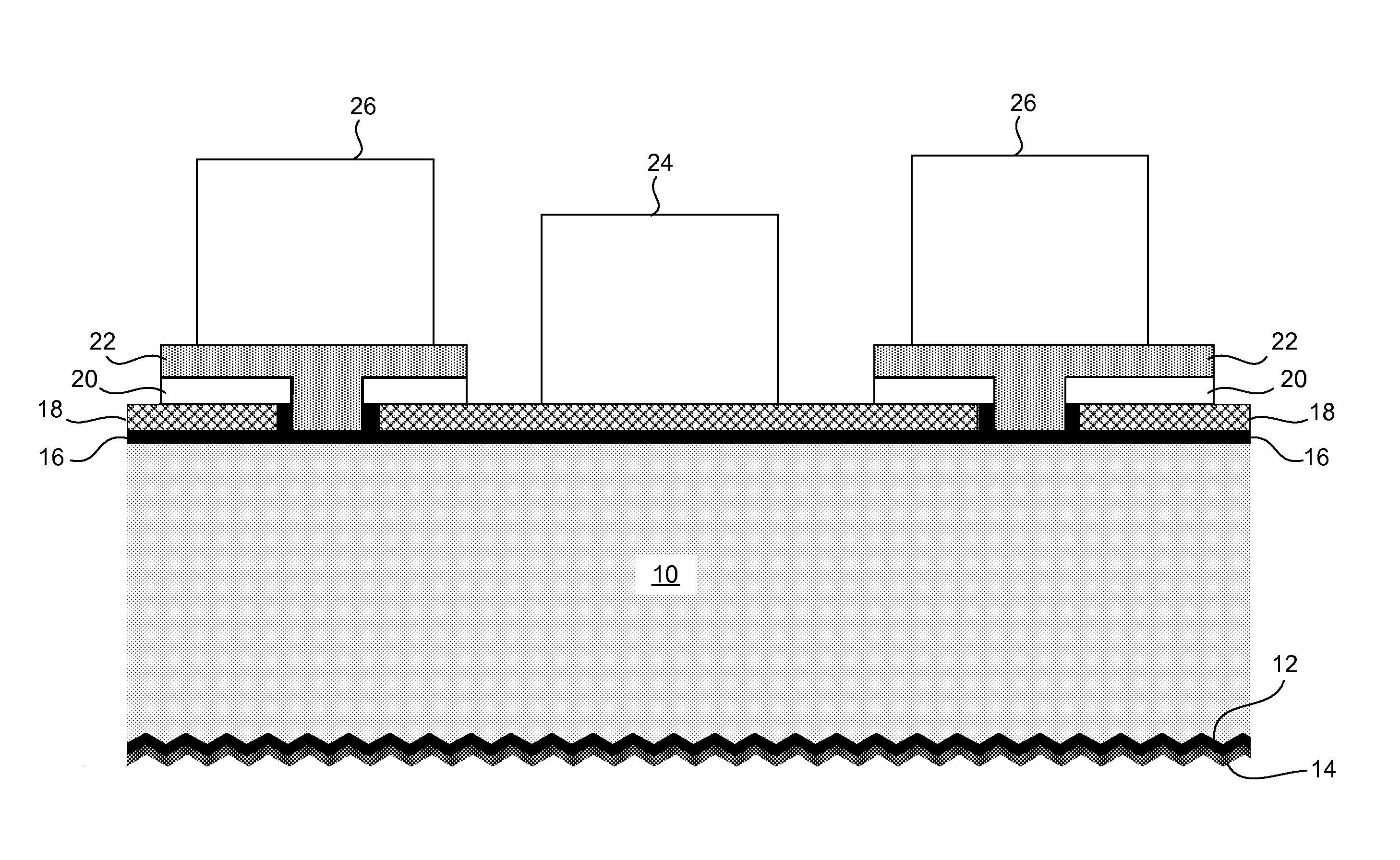

A silicon solar cell has doped amorphous silicon contacts formed on a tunnel silicon oxide layer on a surface of a silicon substrate. High temperature processing is unnecessary in fabricating the solar cell.

Owner:MAXEON SOLAR PTE LTD

Solar cell having doped semiconductor heterojunction contacts

A silicon solar cell has doped amorphous silicon contacts formed on a tunnel silicon oxide layer on a surface of a silicon substrate. High temperature processing is unnecessary in fabricating the solar cell.

Owner:MAXEON SOLAR PTE LTD

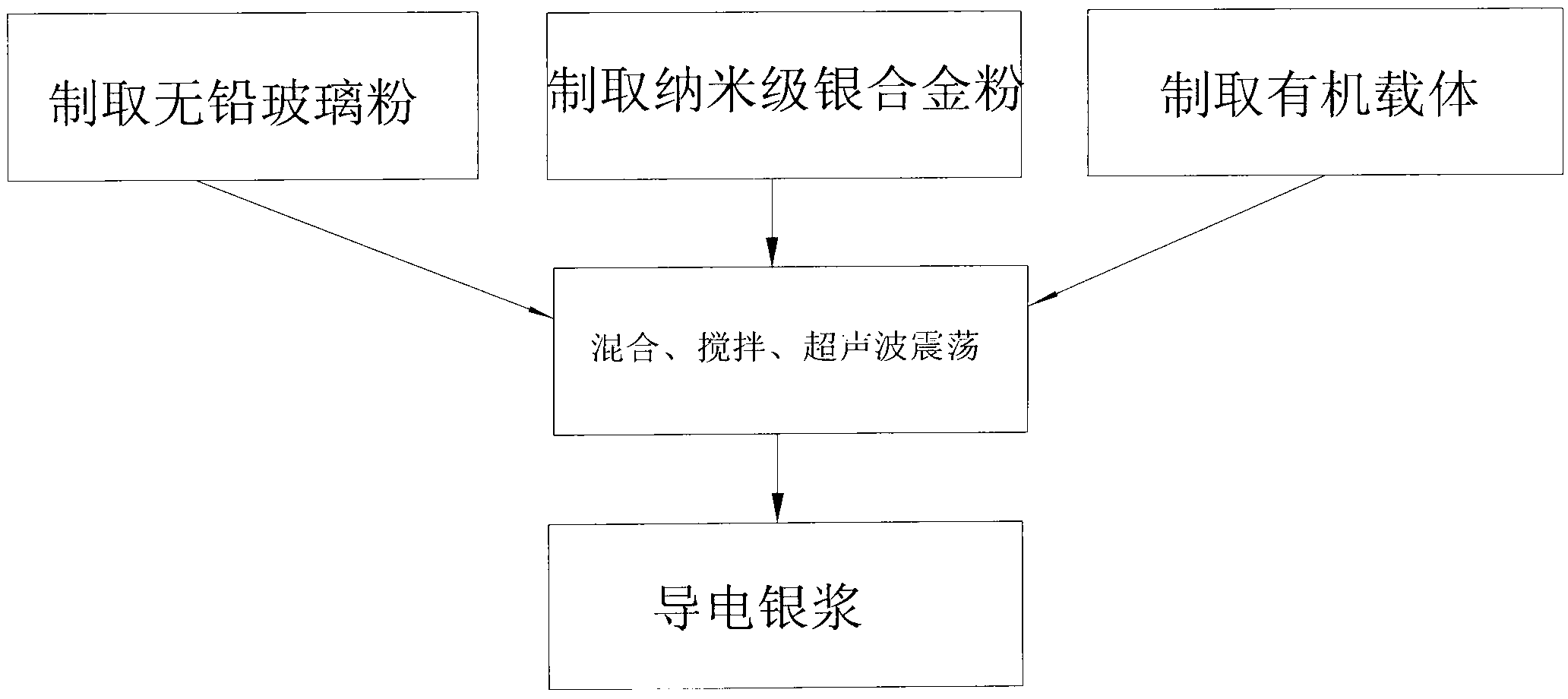

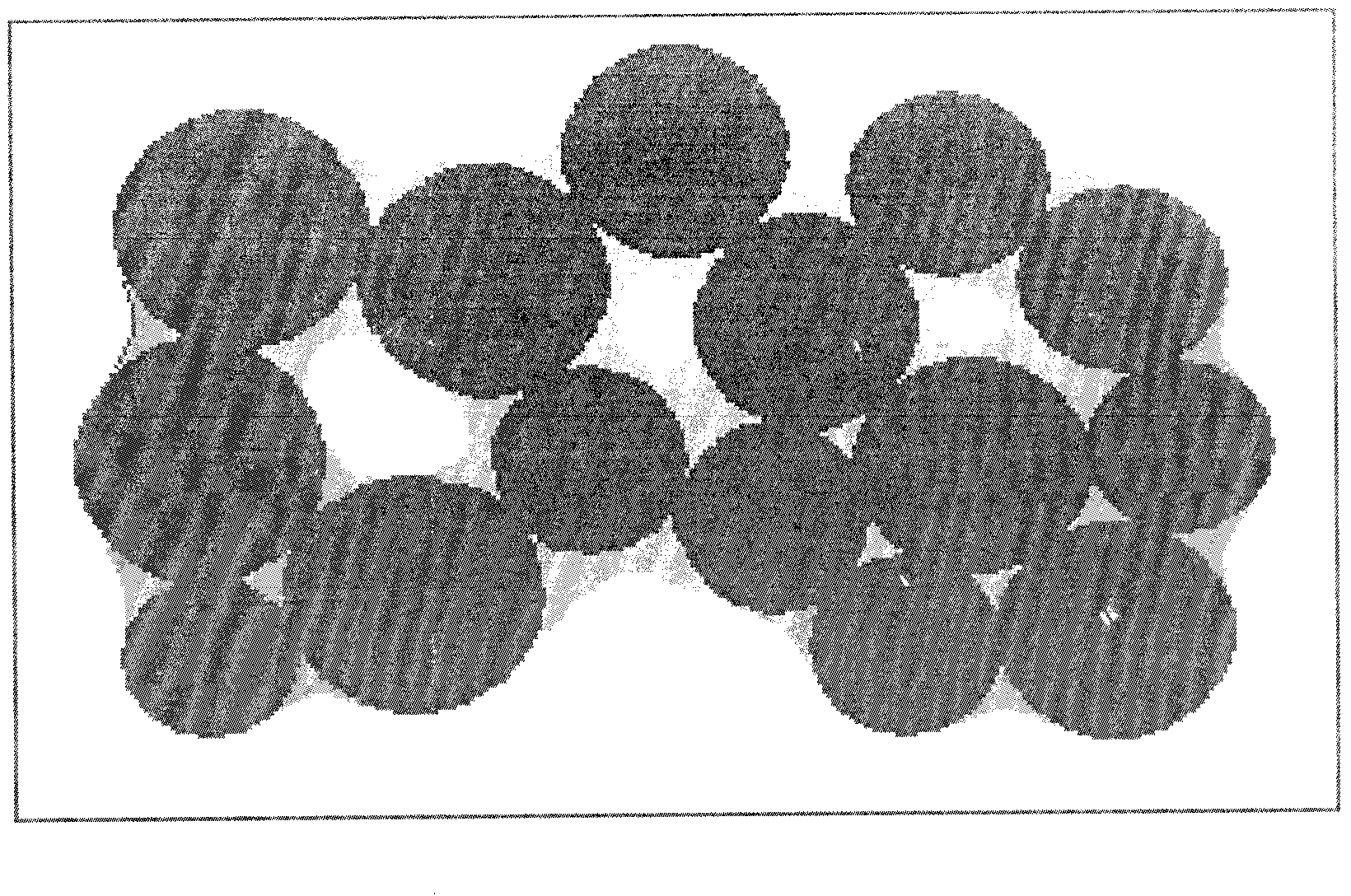

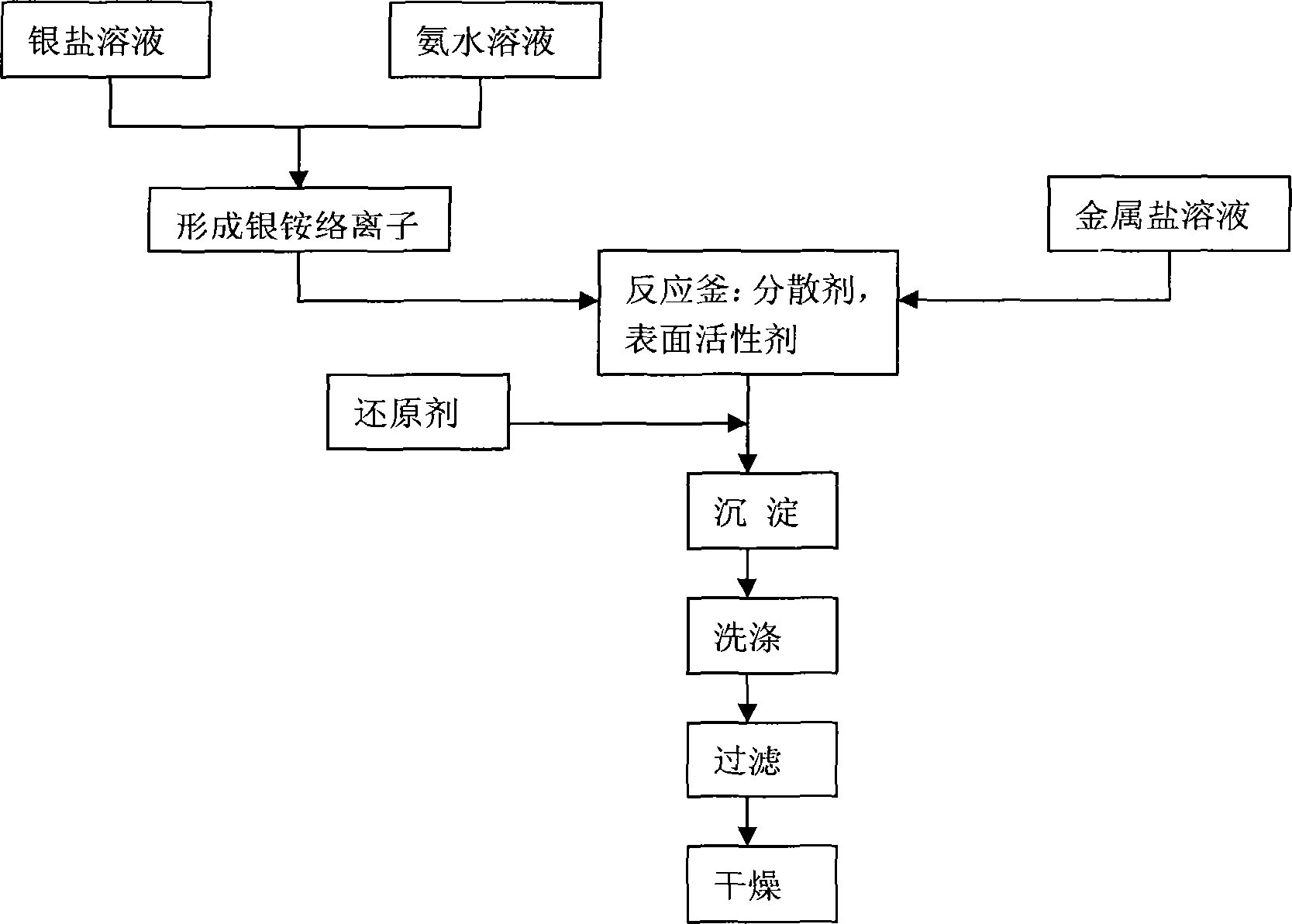

Electric conductive silver paste and manufacturing method thereof

ActiveCN103258584AEnhanced interconnectionIncrease contact areaNon-conductive material with dispersed conductive materialCable/conductor manufactureSilver pasteMetal alloy

The invention discloses electric conductive silver paste and a manufacturing method of the electric conductive silver paste. The electric conductive silver paste comprises, by mass percentage, 35 - 65 % of micron-sized silver powder, 1-10 % of nanometer-sized silver powder of or 1-20 % of nanometer-sized silver and other metal alloy powder, and 1-10 % of an organic carrier; for ceramics, solar cell silver paste comprises 2-15 % of unleaded glass powder, each component is manufactured in parts, weighed, mixed and stirred or mixed and rapidly scattered, and ultrasonic-vibrated or fine adjusted of viscosity of solvent, and therefore the electric conductive silver paste is obtained. Due to the fact that the nanometer-sized silver powder or the nanometer-sized silver alloy powder is mixed with the micron-sized silver powder, intensity of conductivity and a circuit is improved, adhesive force of crushing resistance and a base plate is improved, at the same time unleaded slurry good in thixotropy, low in contacting resistance and low in piece-needed slurry amount replaces lead slurry materials, the electric conductive silver paste is used for manufacturing crystalline silicon solar cells, improves photoelectric conversion efficiency, accords with environmental-protection ideas, and can be produced in large scales continuously.

Owner:SHENZHEN CHENGGONG CHEM

Infrared detection of solar cell defects under forward bias

InactiveUS20050252545A1Low costRadiation pyrometryPhotovoltaic monitoringTest batterySilicon solar cell

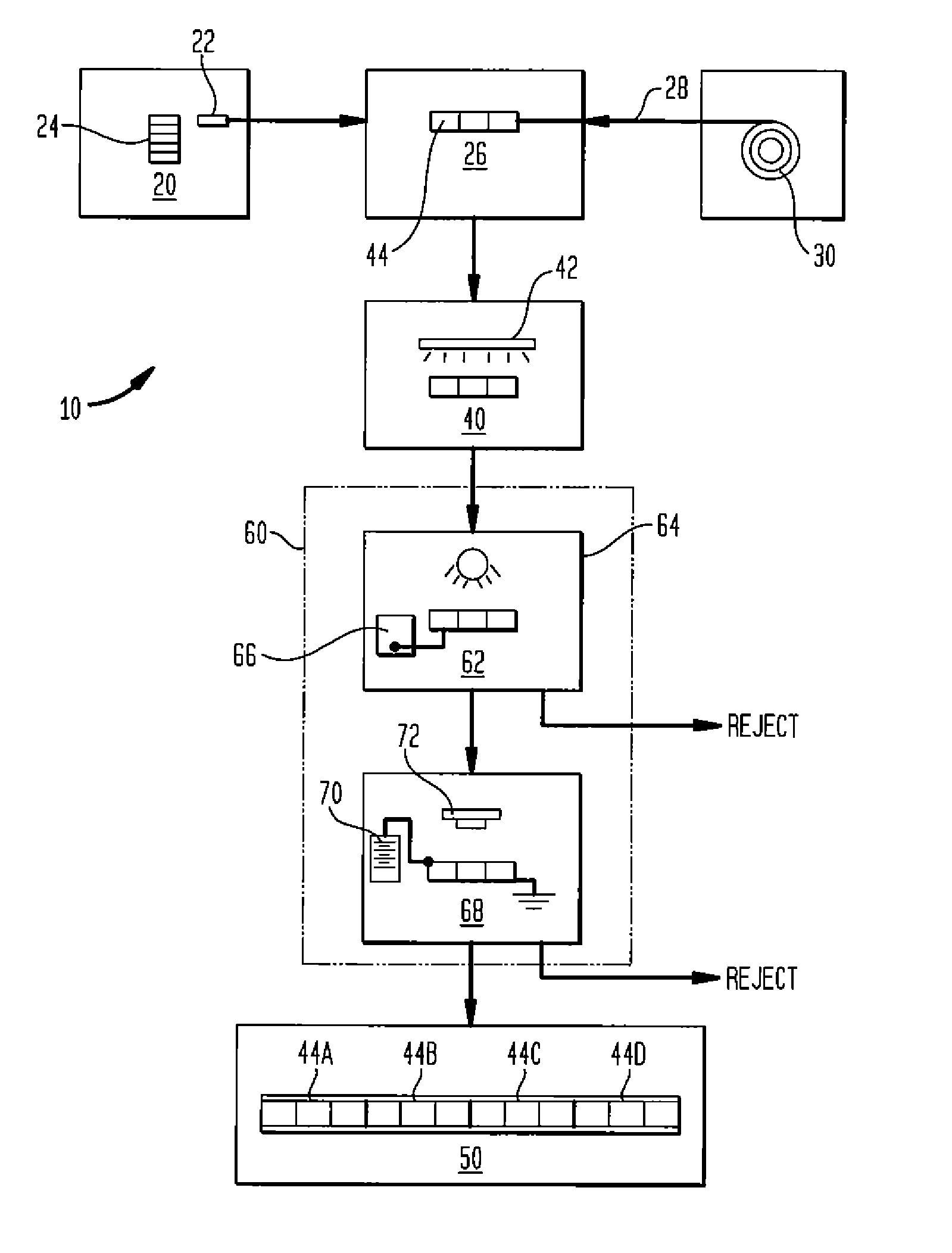

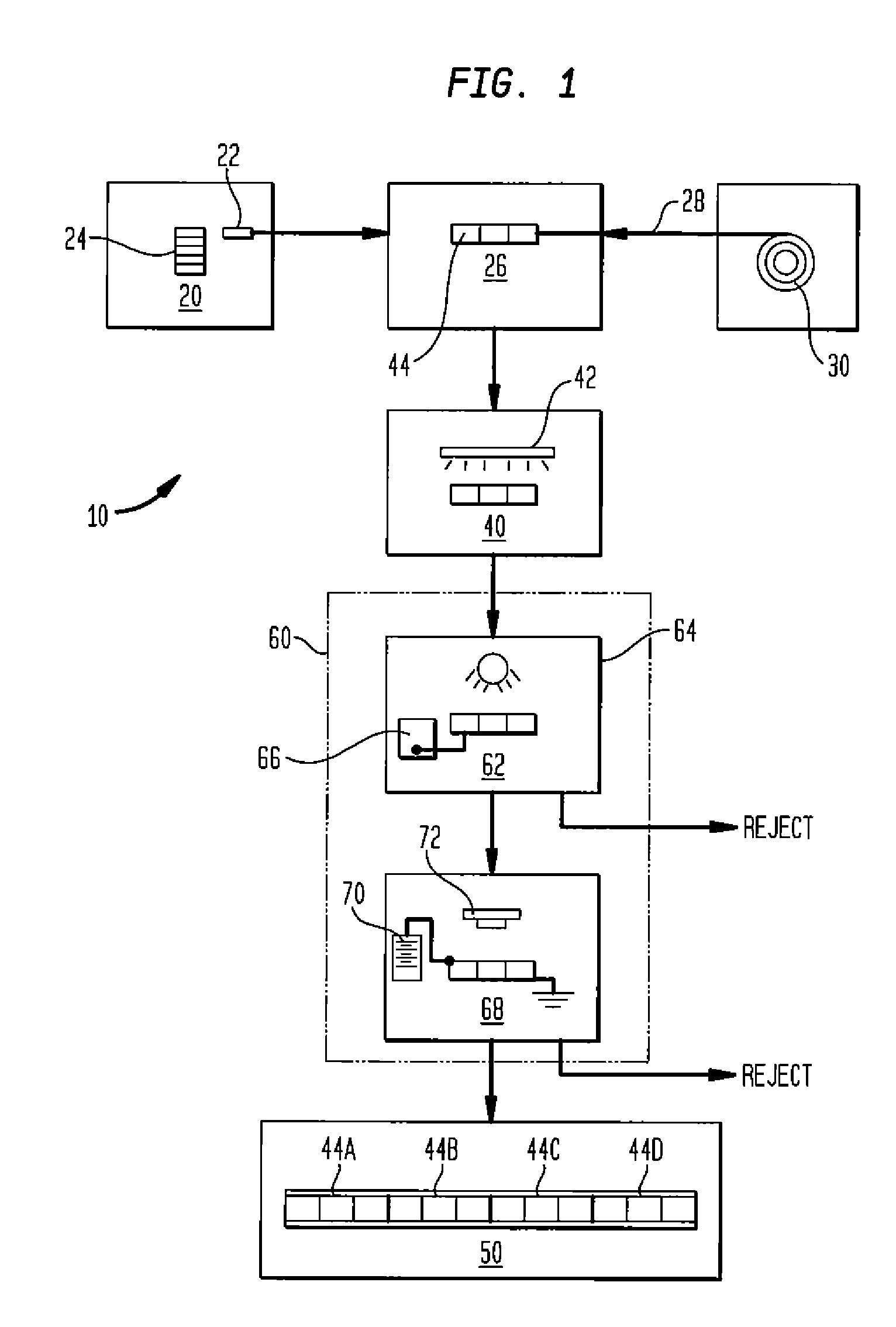

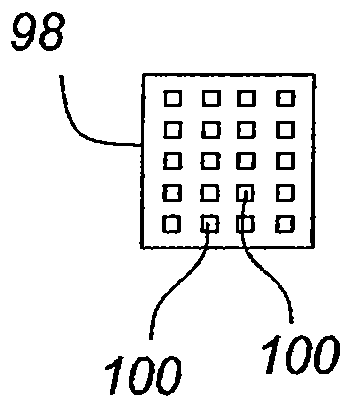

Methods and apparatus are disclosed for detecting solar cell defects by applying a forward-biasing electric current through a silicon solar cell or a group of interconnected solar cells for a short duration and then analyzing the resulting thermal image of each cell with an infrared (IR) camera. The invention is particularly useful in assembling solar cell arrays or modules in which large numbers of cells are to be wired together. Automated module assemblers are disclosed in which the cells (or strings of cells) are tested for defects prior to final module assembly.

Owner:SPIRE

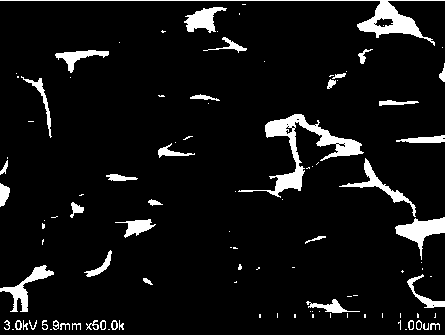

Textured structure of crystalline silicon solar cell and preparation method thereof

ActiveCN103219428AImprove conversion efficiencySimple manufacturing methodPhotovoltaic energy generationSemiconductor devicesMicrometerSpins

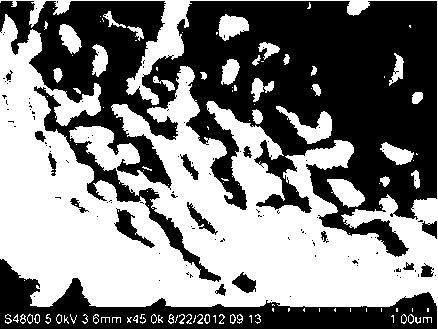

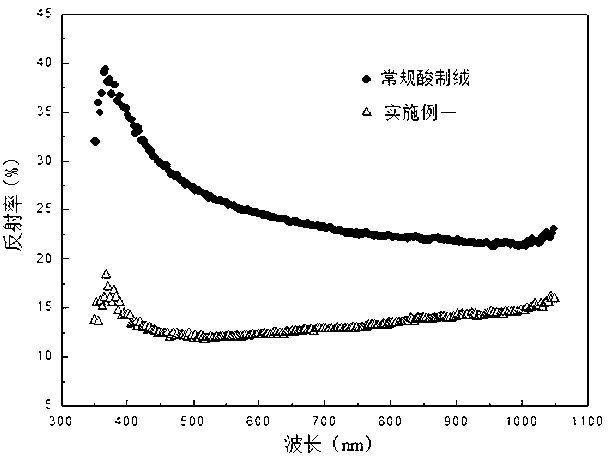

The invention discloses a preparation method of a textured structure of a crystalline silicon solar cell. The method includes the steps of (1) cleaning and texture preparation, (2) soaking a silicon wafer in a solution containing metal ions to enable the surface of the silicon wafer to be coated with a layer of metal nanometer particles, (3) corroding the surface of the silicon wafer to form a nanometer-grade texture, (4) cleaning to remove the metal particles, (5) carrying out microstructure amendment etching in second chemical corrosive liquid, and (6) cleaning and spin-drying. As is proved by a test, the size of the textured structure is between 100nm-500nm; the textured structure is of a nanopore shape with a large hole diameter and a small depth, or a nanometer pyramid with edge angles, or of a nanometer pit shape structure with an edge angle nanometer cone body or with an edge angle; and compared with a nanometer-micrometer composite textured structure disclosed in CN102610692A, the textured structure enables conversion efficiency of a cell piece to be improved by about 0.2%-0.5%, and an unexpected effect is achieved.

Owner:SUZHOU UNIV +1

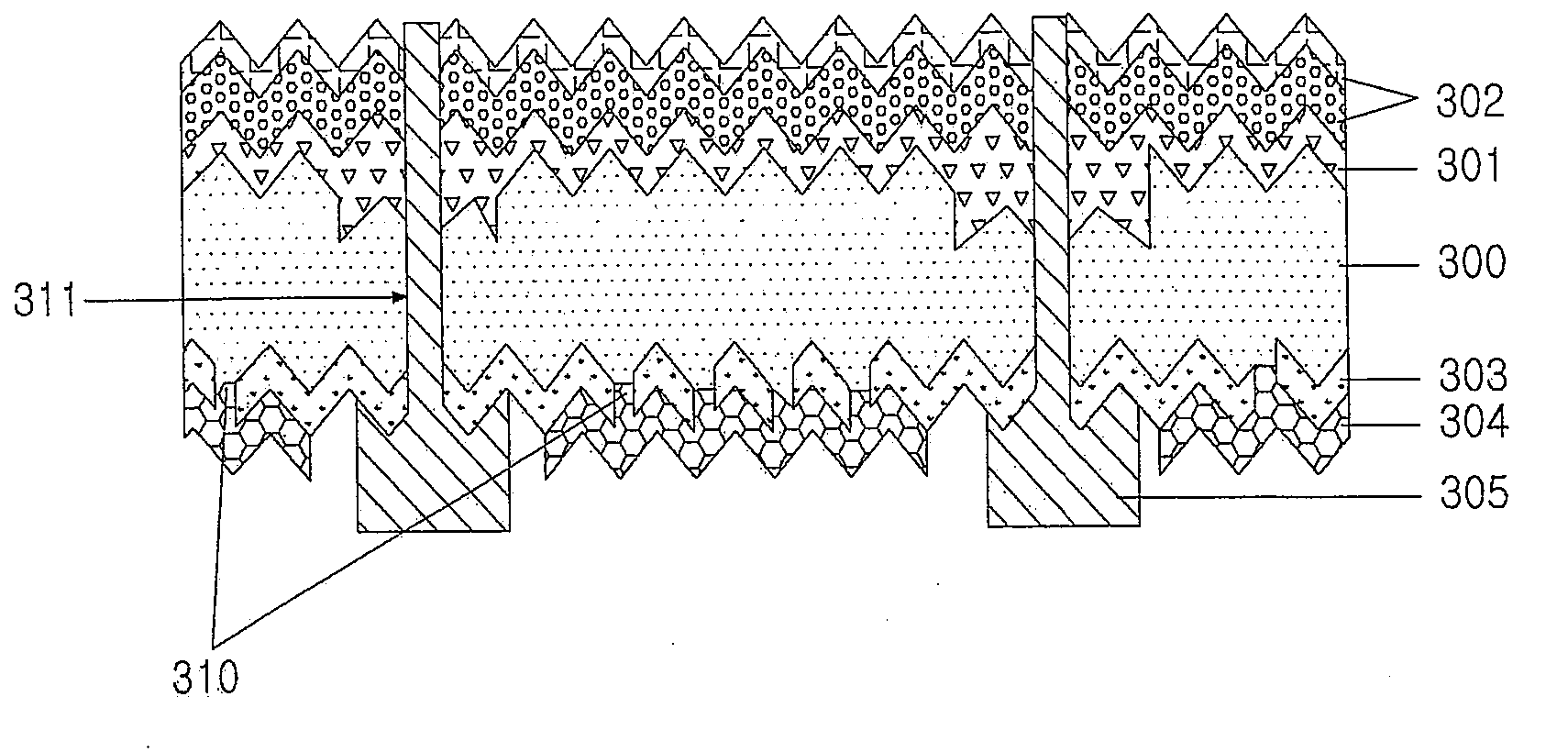

Solar cell and fabrication method thereof

InactiveUS20100243040A1Light trapping capabilityIncrease contact resistanceFinal product manufactureSemiconductor/solid-state device manufacturingEngineeringSilicon solar cell

Disclosed are a metal wrap through solar cell including a metal wrap through (MWT) structure as a back contact silicon solar cell and a fabrication method thereof.

Owner:LG ELECTRONICS INC

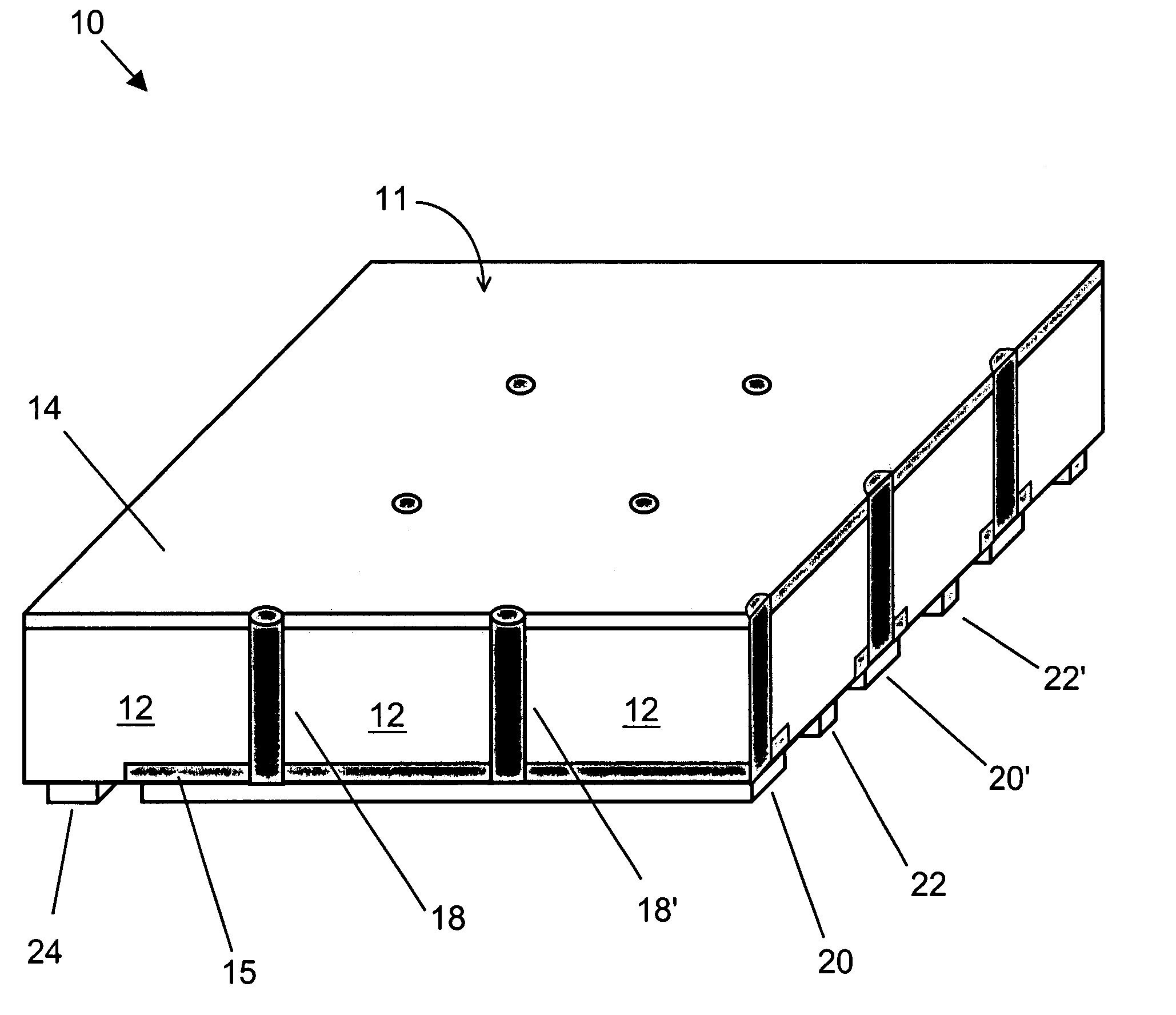

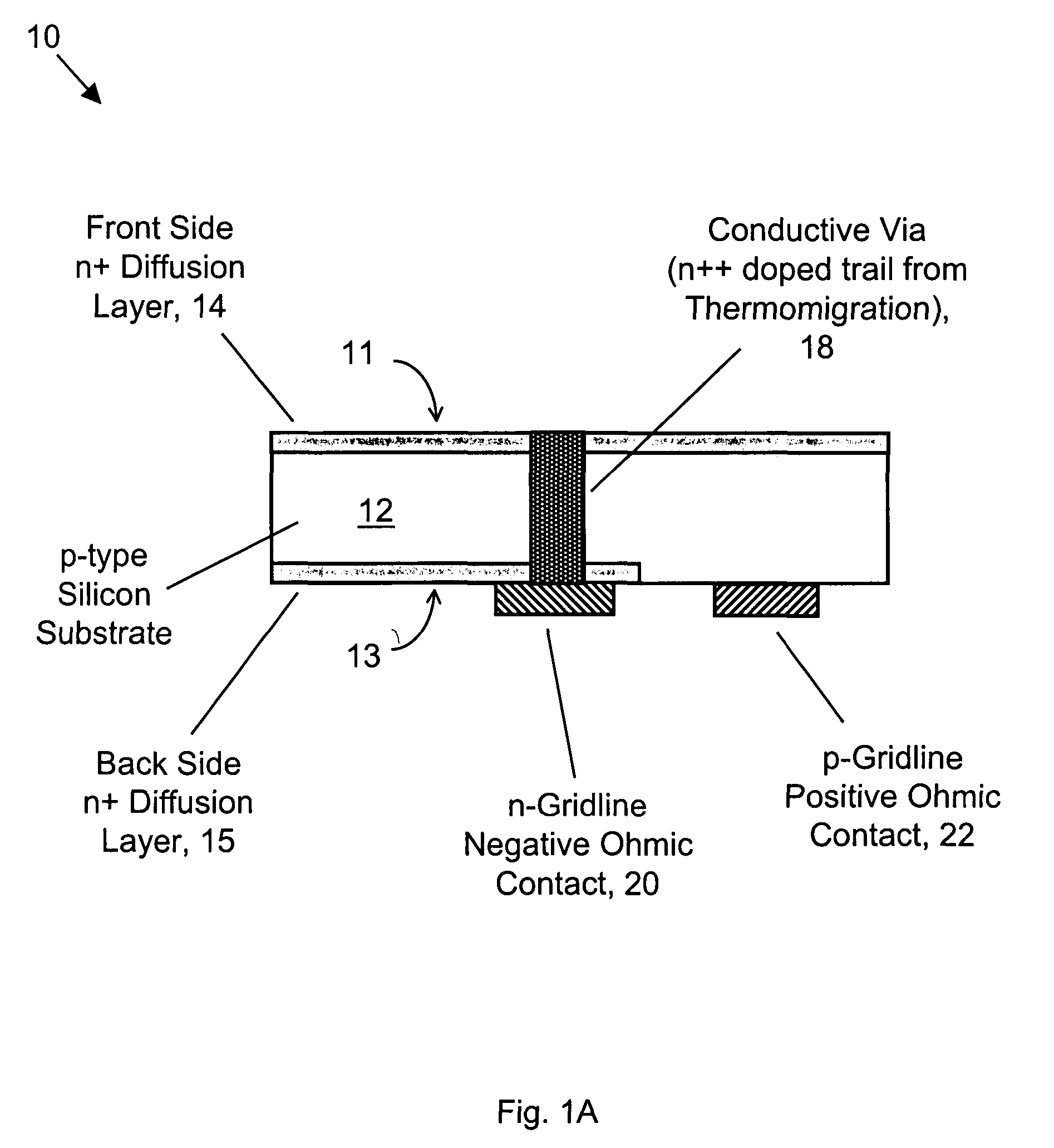

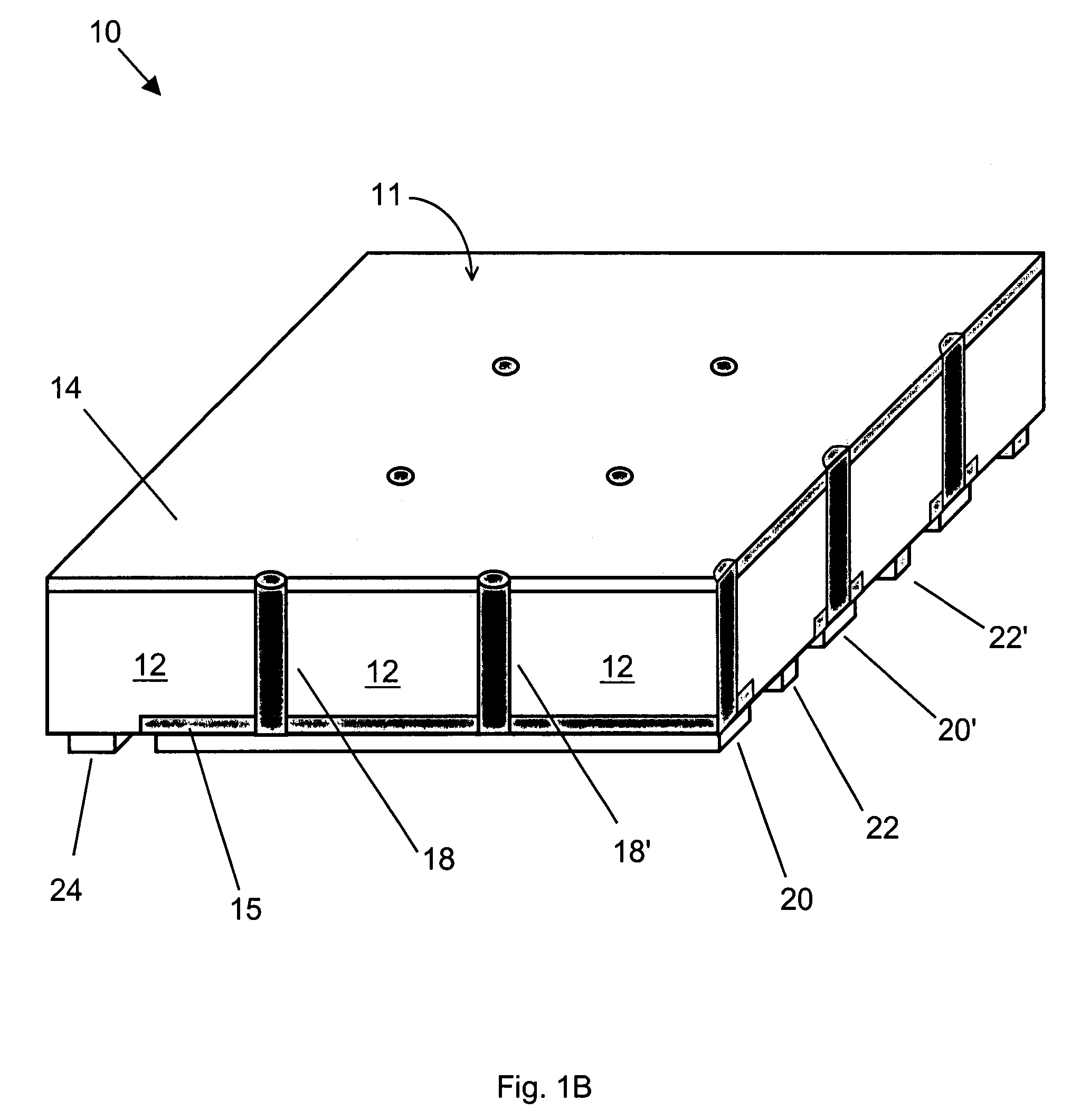

Fabrication of back-contacted silicon solar cells using thermomigration to create conductive vias

InactiveUS7170001B2Improve conversion efficiencyReduce contact resistanceSemiconductor/solid-state device manufacturingPhotovoltaic energy generationOhmic contactEngineering

Methods of manufacturing back-contacted silicon solar cells fabricated using a gradient-driven solute transport process, such as thermomigration or electromigration, to create n-type conductive vias connecting the n-type emitter layer on the front side to n-type ohmic contacts located on the back side.

Owner:ADVENT SOLAR INC +1

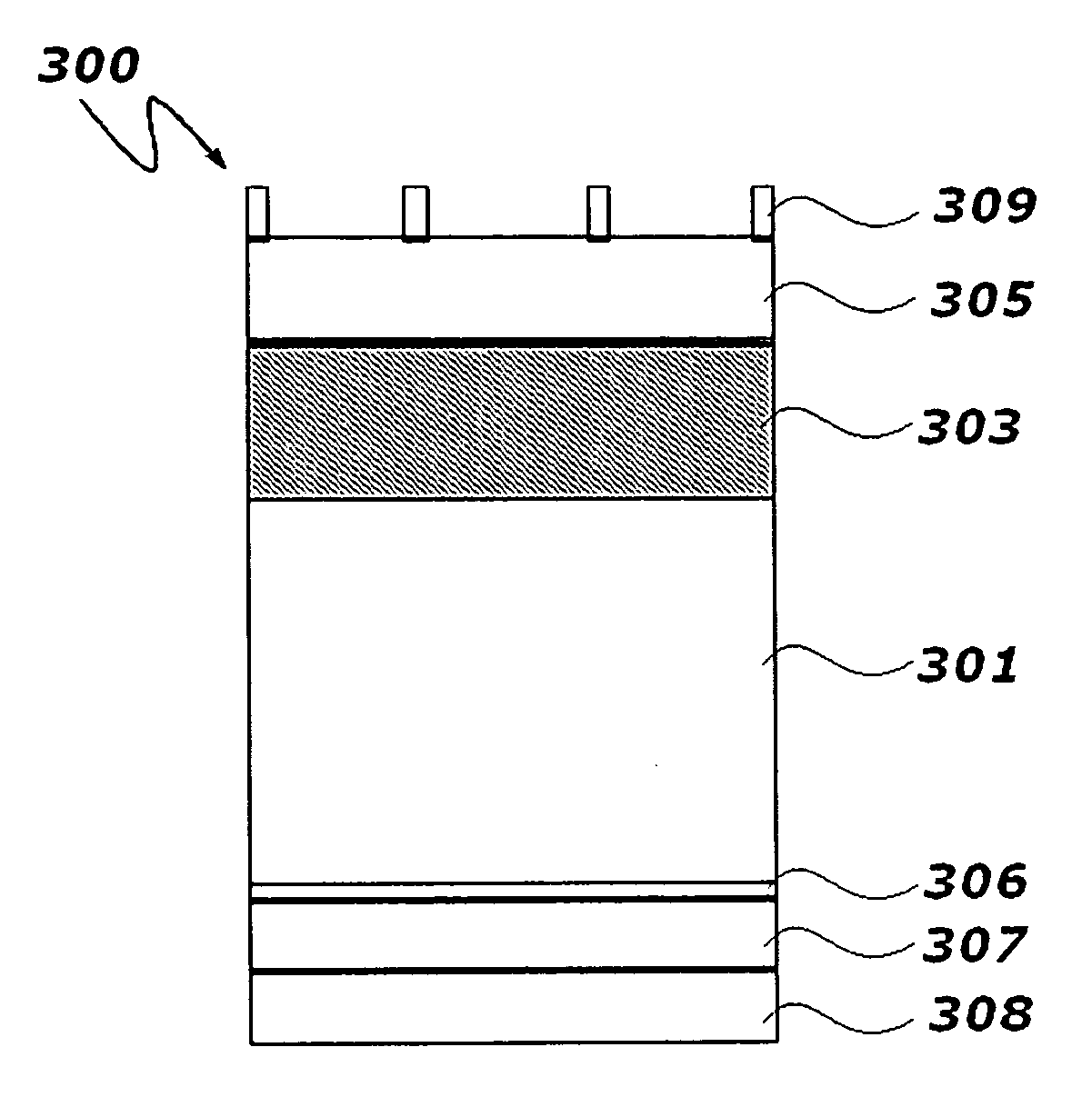

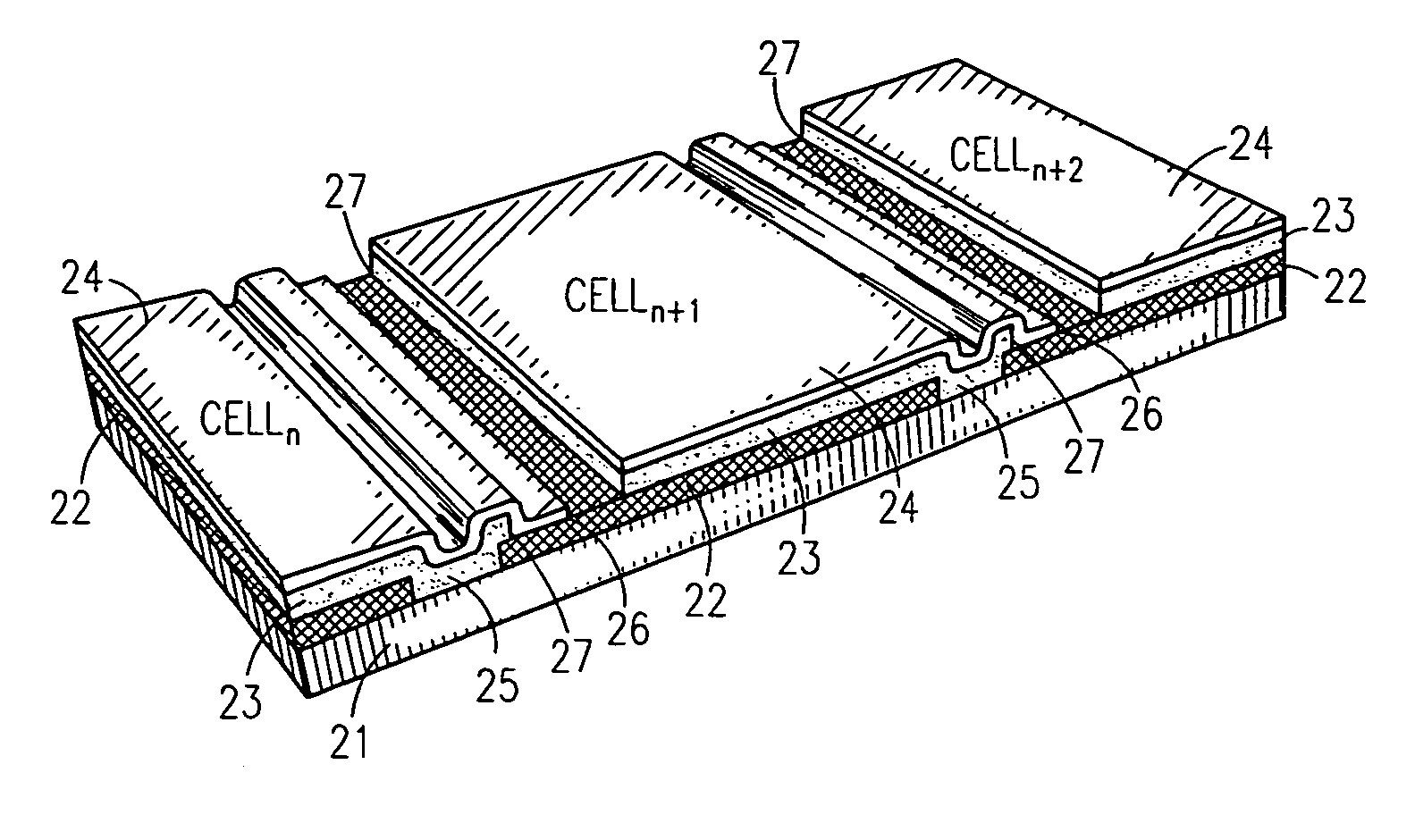

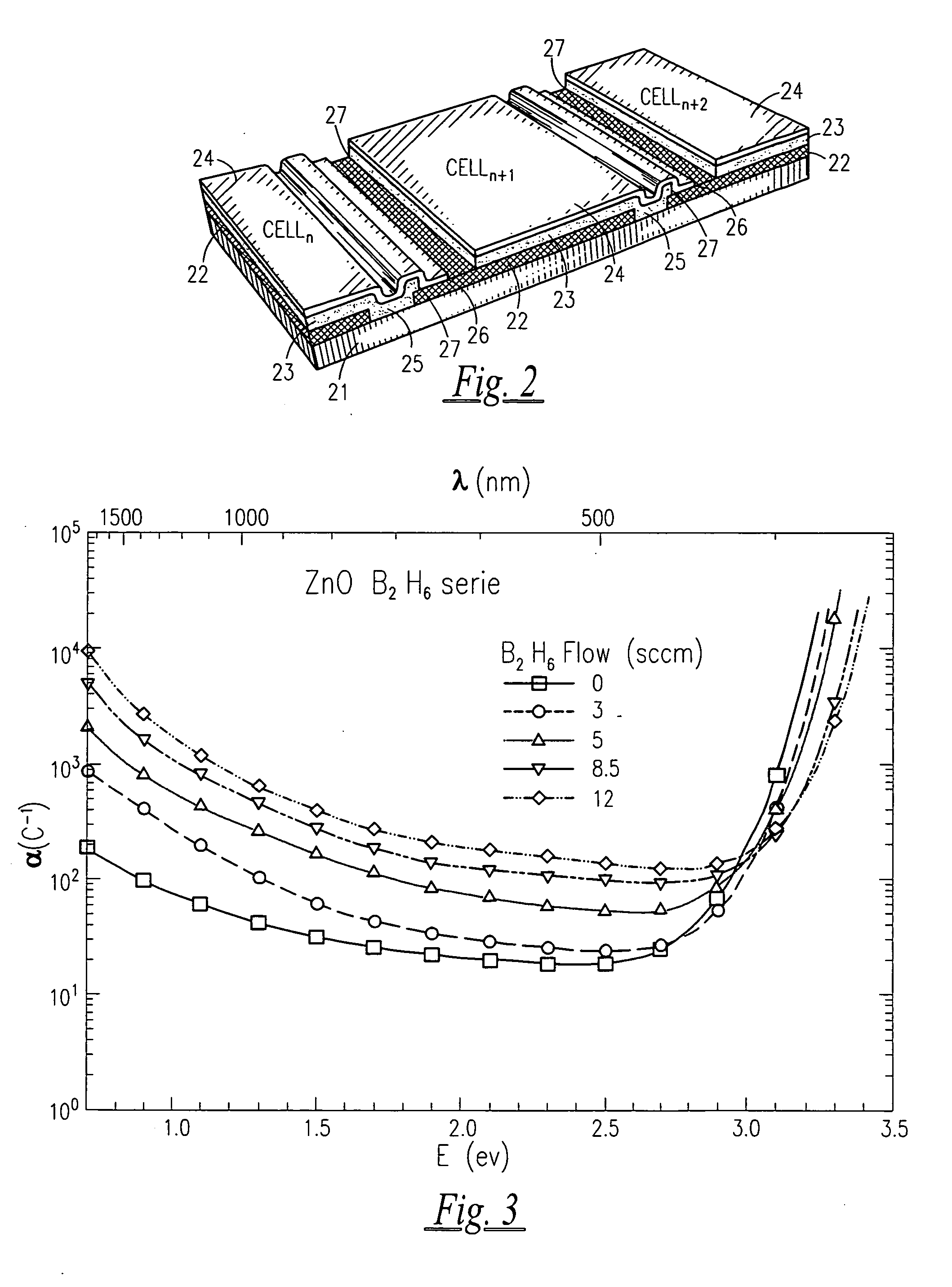

Back contact and back reflector for thin film silicon solar cells

InactiveUS20050172997A1Semiconductor/solid-state device manufacturingPhotovoltaic energy generationDielectricBack reflector

A thin film silicon solar cell for use in photovoltaic cells having a carrier substrate, a front transparent conductive oxide contact, a thin film silicon solar cell layer having at least one layer of hydrogenated microcrystalline silicon or nanocrystalline silicon, and a back contact having a transparent conductive oxide contact layer and a back reflective layer comprising a white pigmented dielectric reflective media.

Owner:UNAXIS BALZERS LTD

Aluminum pulp composition of crystal silicon solar cell and preparation method thereof

InactiveCN101728439AEasy to printImprove adhesionFinal product manufactureNon-conductive material with dispersed conductive materialAdhesion forceAdhesive

The invention discloses an aluminum pulp composition of a crystal silicon solar cell and a preparation method thereof, wherein an aluminum pulp is prepared by the following compositions in percentage by weight: 50-85 percent of spherical aluminum powder, 2-15 percent of lead-free glass adhesive, 10-35 percent of organic carrier and 0.5-6 percent of metal / nonmetal power additive. The prepared aluminum pulp is used for a single crystal silicon solar cell, can enable warpage of a silicon wafer to be small, and aluminum films are dense and uniform, have no aluminum pills, do not bulb and have strong adhesion force and high photoelectric conversion efficiency.

Owner:LUOYANG SHENJIA ELECTRONICS CERAMICS

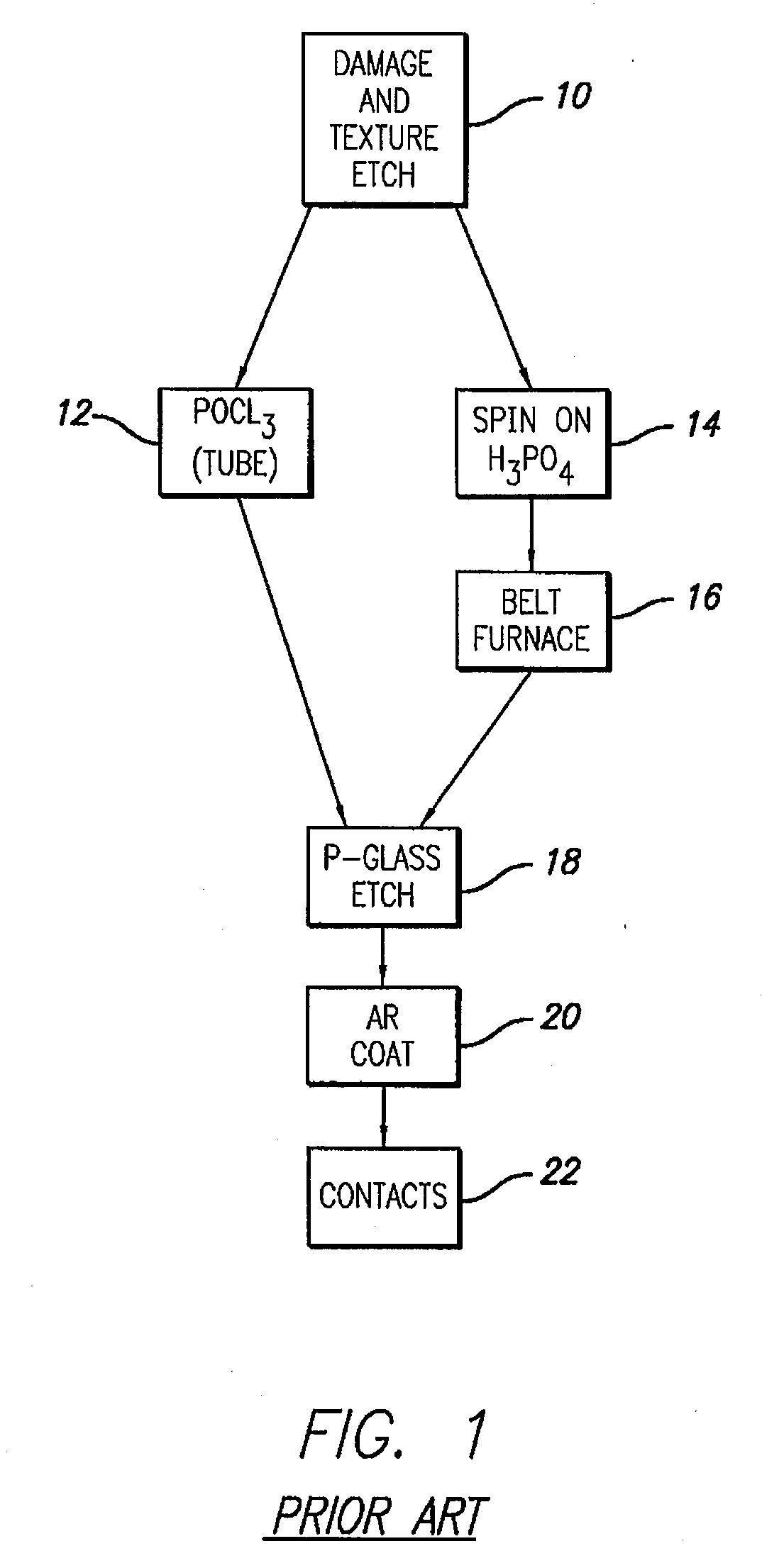

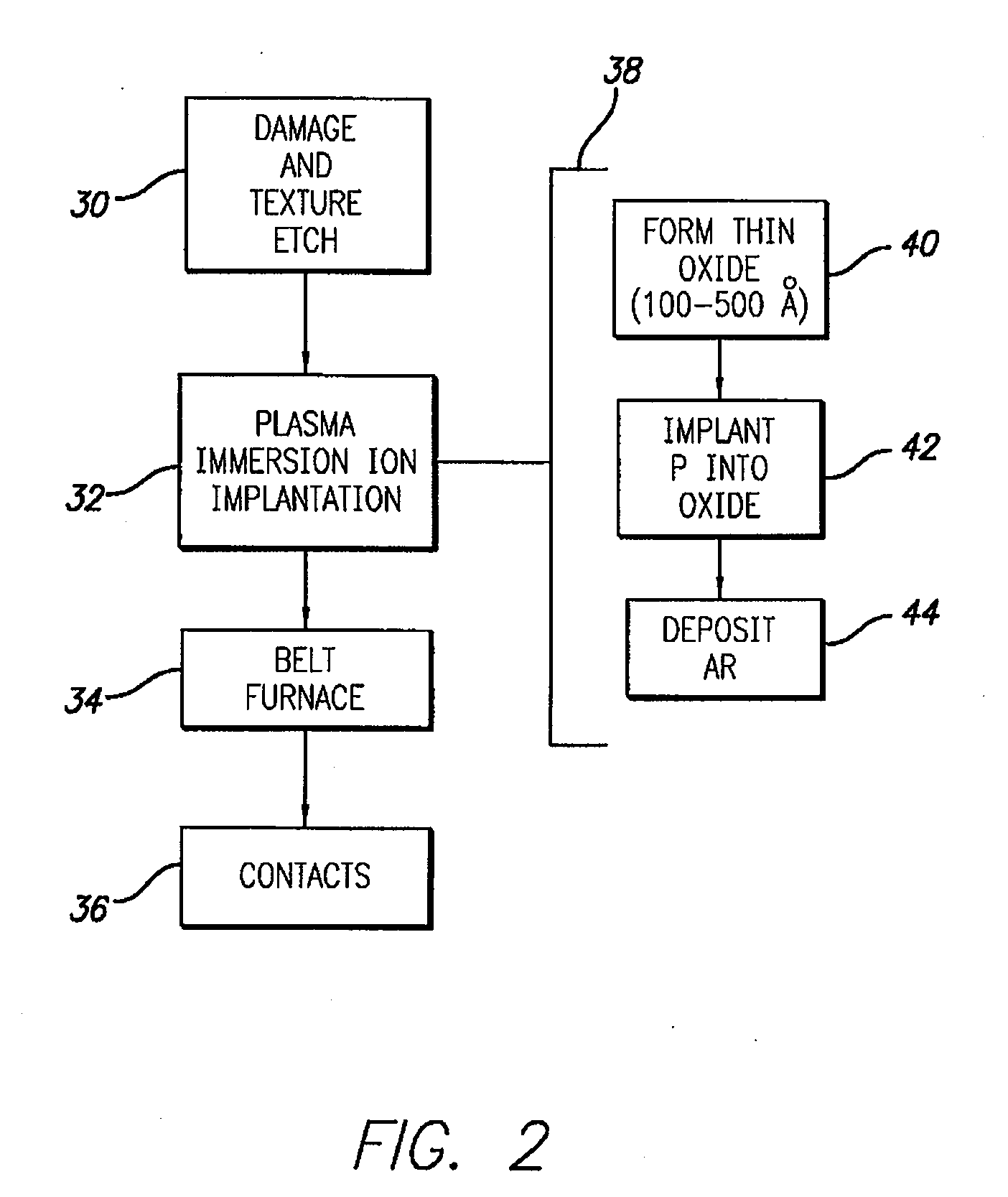

Method of making an improved selective emitter for silicon solar cells

InactiveUS20090142875A1Semiconductor/solid-state device manufacturingPhotovoltaic energy generationPlasma-immersion ion implantationSilicon solar cell

A method for forming a selective emitter on a silicon solar cell is provided including forming an oxide layer on a surface of the P-type silicon substrate, implanting phosphorus doping atoms into the oxide layer on the substrate using plasma immersion ion implantation, patterning the oxide layer, annealing the substrate to provide heavily doped regions in the patterned regions and a lightly doped region between the patterned regions, and providing metal contacts to the heavily doped regions.

Owner:APPLIED MATERIALS INC

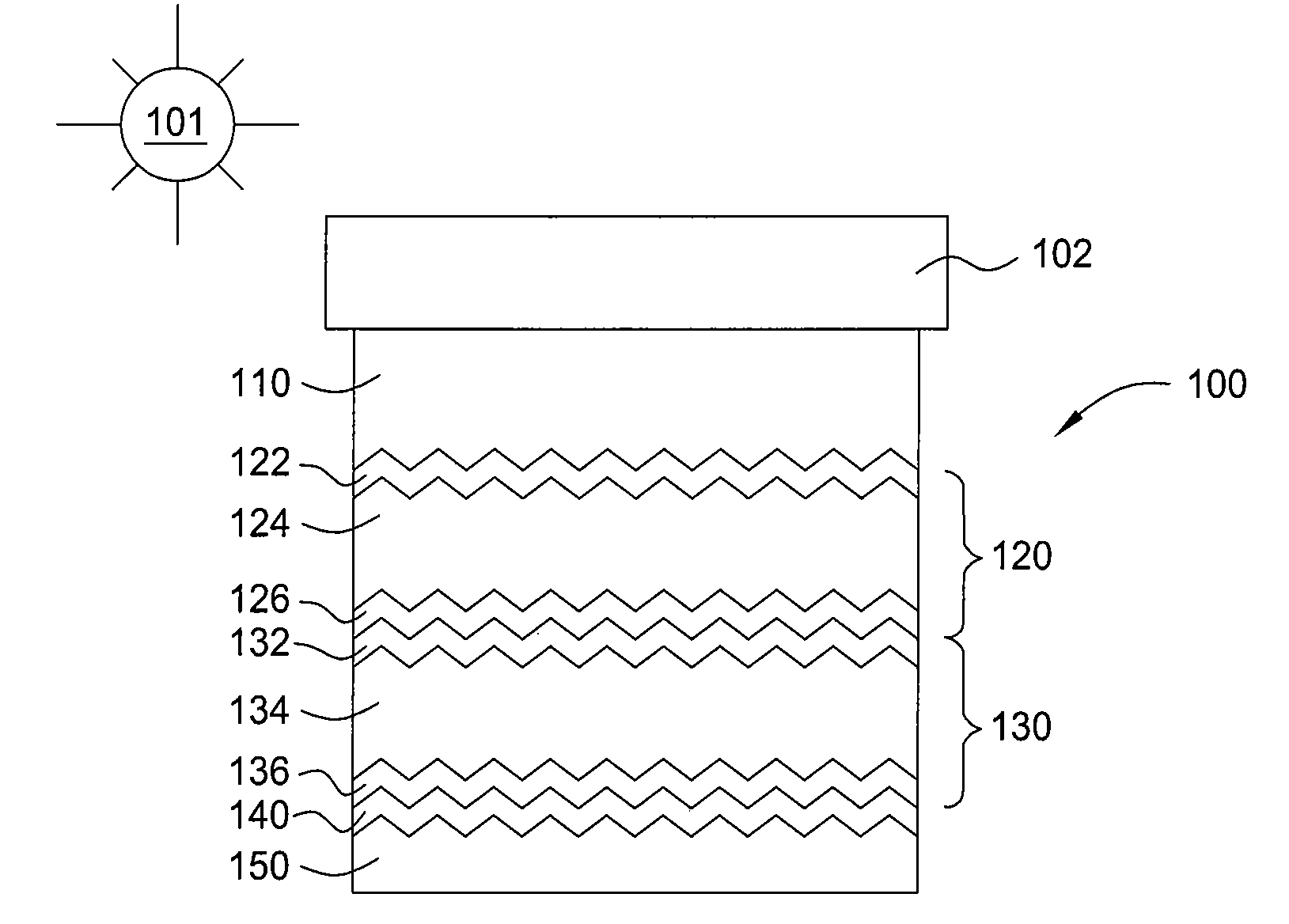

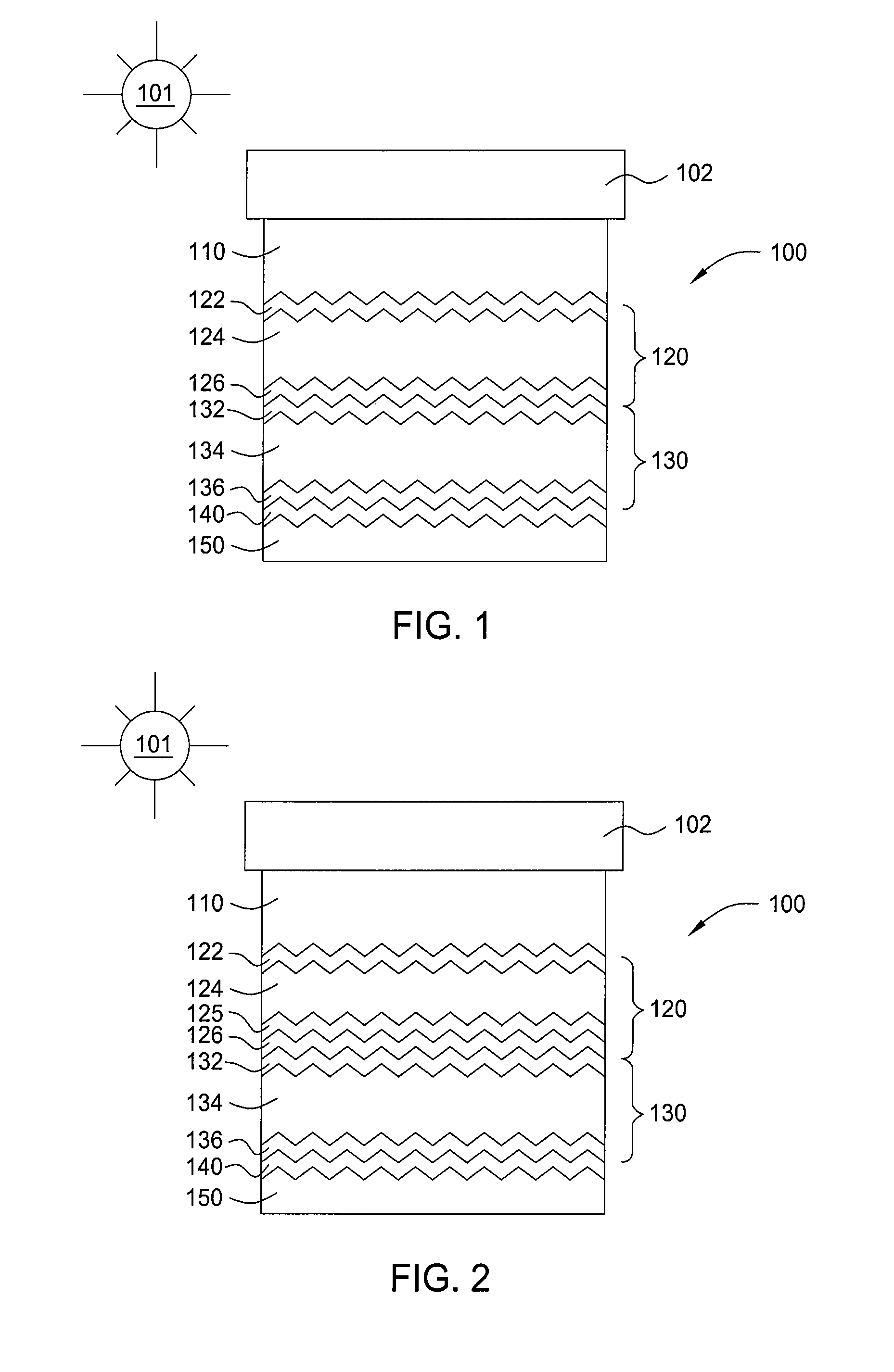

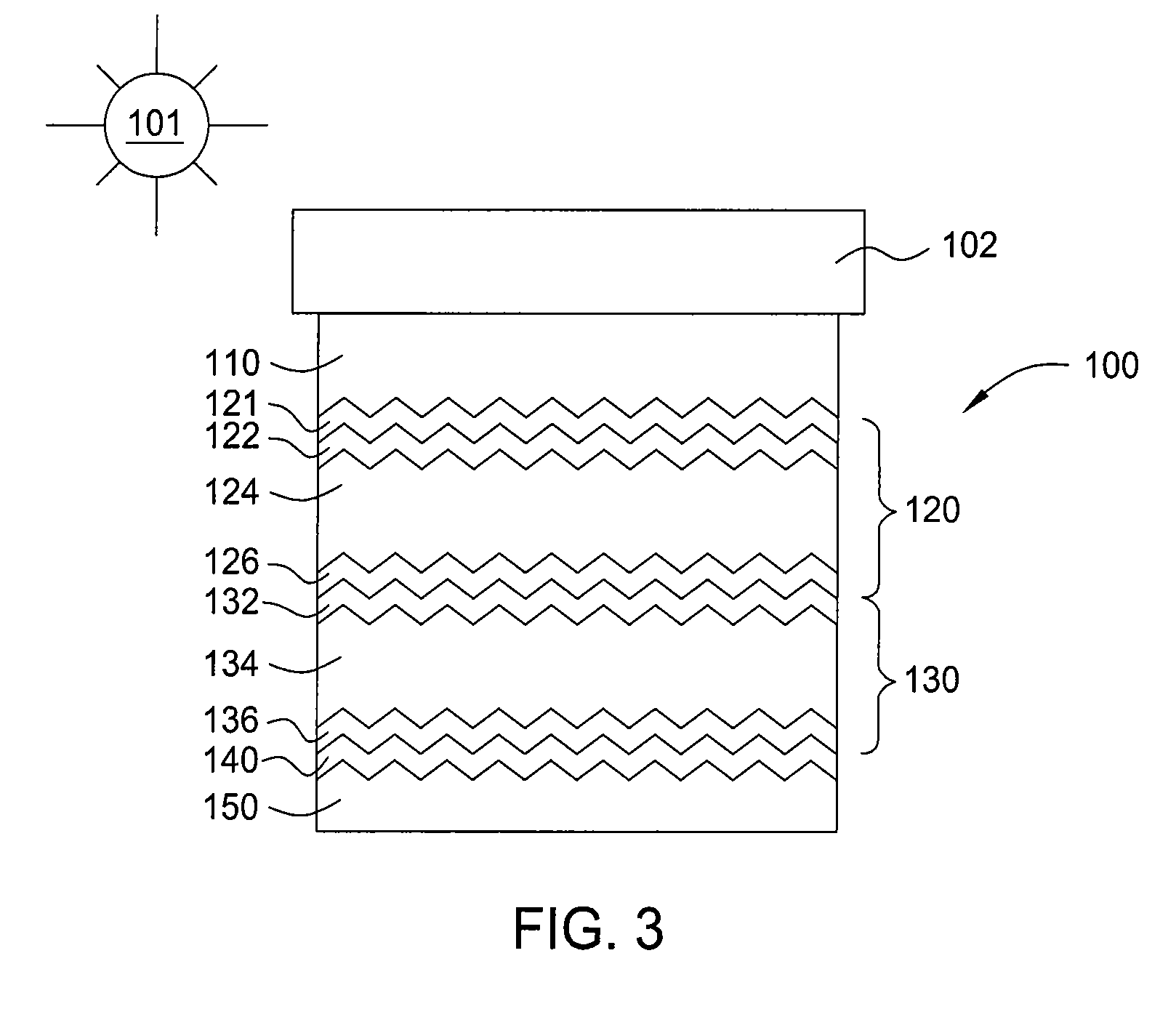

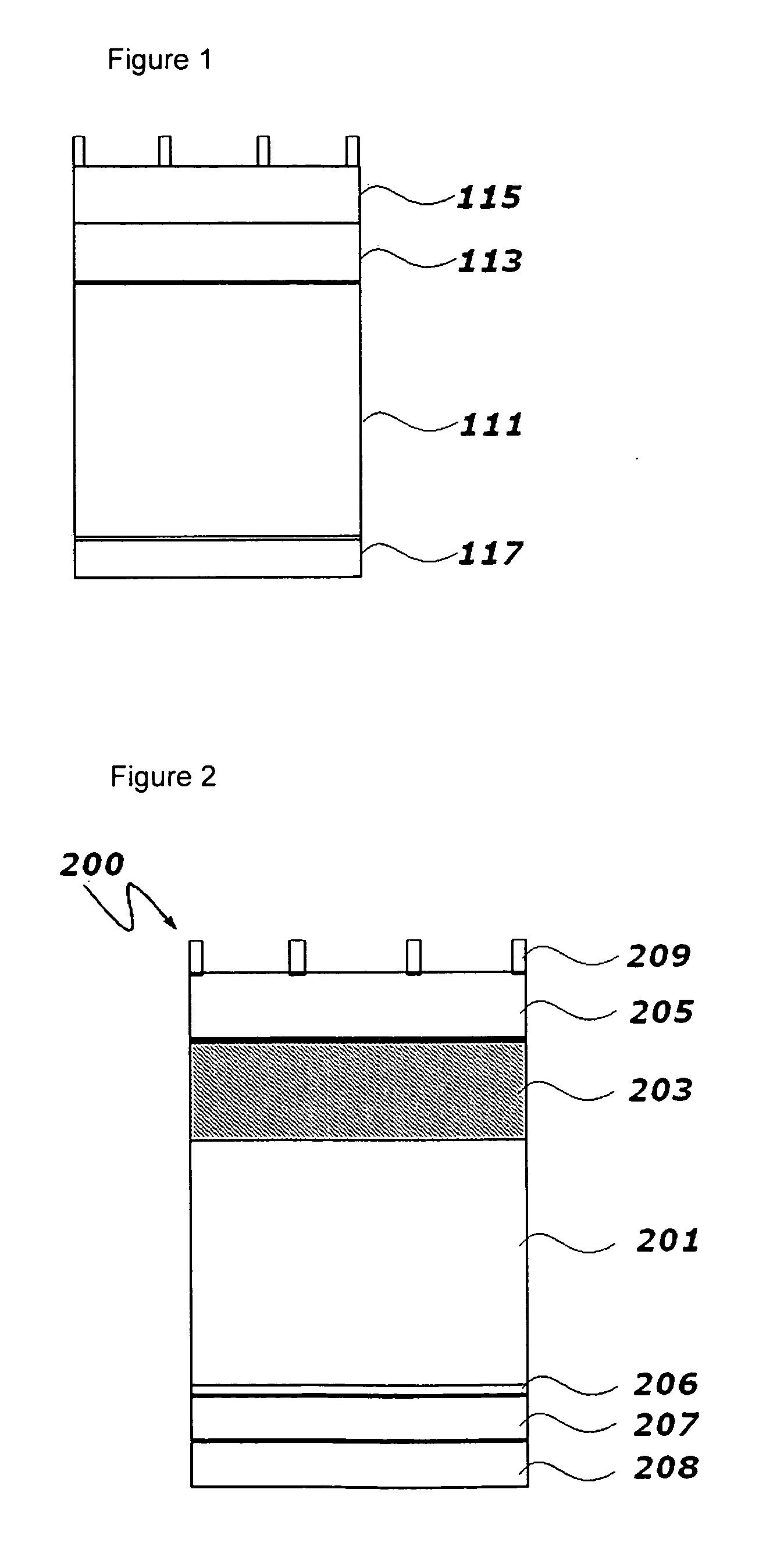

Multi-junction solar cells and methods and apparatuses for forming the same

InactiveUS20090020154A1Uniformly formedFinal product manufactureSemiconductor/solid-state device manufacturingAmorphous siliconSilicon solar cell

Embodiments of the present invention generally relate to solar cells and methods and apparatuses for forming the same. More particularly, embodiments of the present invention relate to thin film multi-junction solar cells and methods and apparatuses for forming the same. Embodiments of the present invention also include an improved thin film silicon solar cell, and methods and apparatus for forming the same, where one or more of the layers in the solar cell comprises at least one amorphous silicon layer that has improved electrical characteristics and mechanical properties, and is capable of being deposited at rates many times faster than conventional amorphous silicon deposition processes.

Owner:APPLIED MATERIALS INC

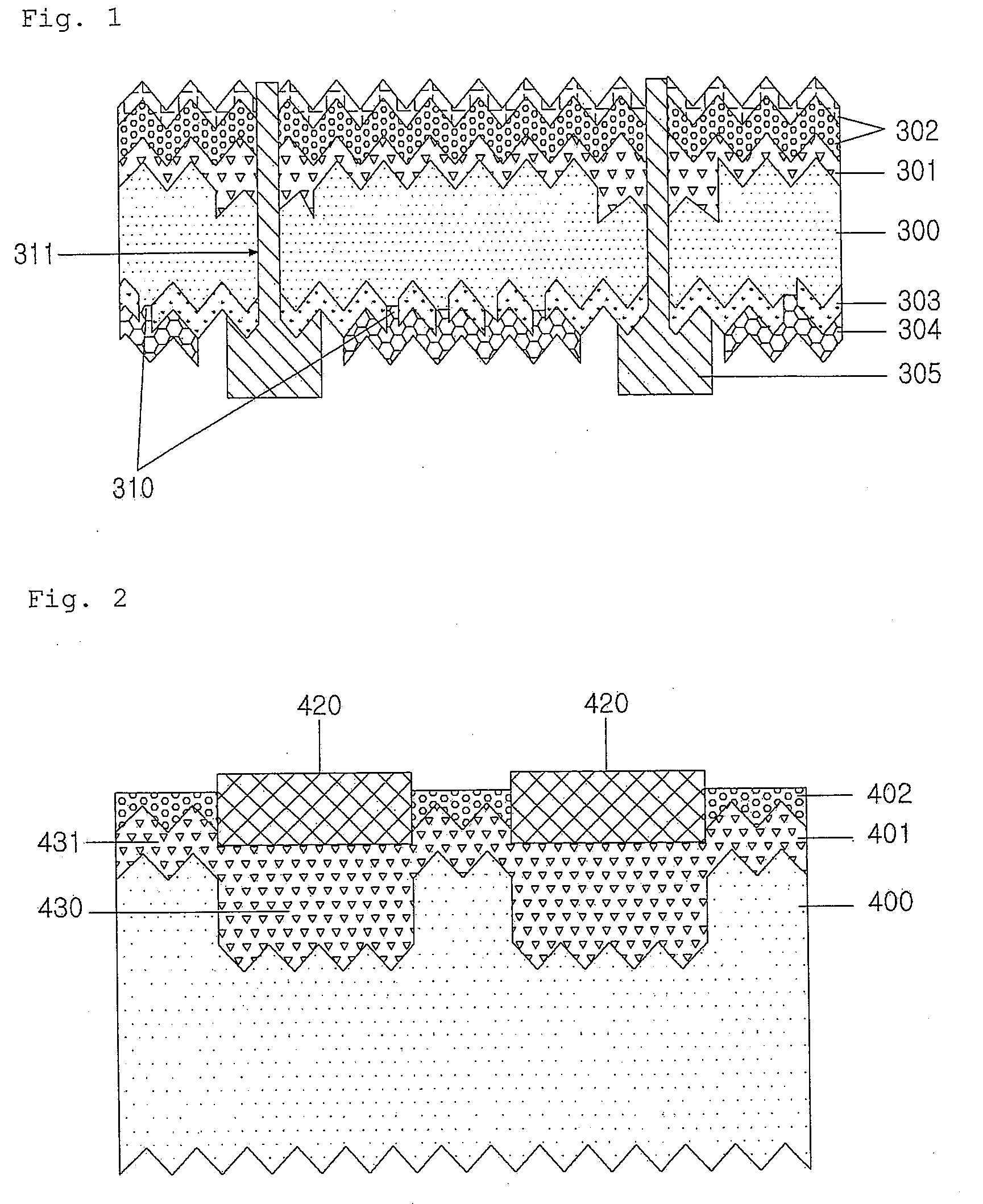

Hetero-junction silicon solar cell and fabrication method thereof

InactiveUS20090151782A1Maximize efficiencyInterface defectFinal product manufactureSemiconductor/solid-state device manufacturingOptoelectronicsSilicon solar cell

Disclosed are a hetero-junction silicon solar cell and a fabrication method thereof. The hetero-junction silicon solar cell according to the present invention forms a pn junction of a crystalline silicon substrate and a passivation layer doped with impurities so as to minimize a recombination of electrons and holes, making it possible to maximize efficiency of the hetero-junction silicon solar cell. The present invention provides a hetero-junction silicon solar cell comprising a crystalline silicon substrate and a passivation layer that is formed on the crystalline silicon substrate and is doped with impurities.

Owner:LG ELECTRONICS INC

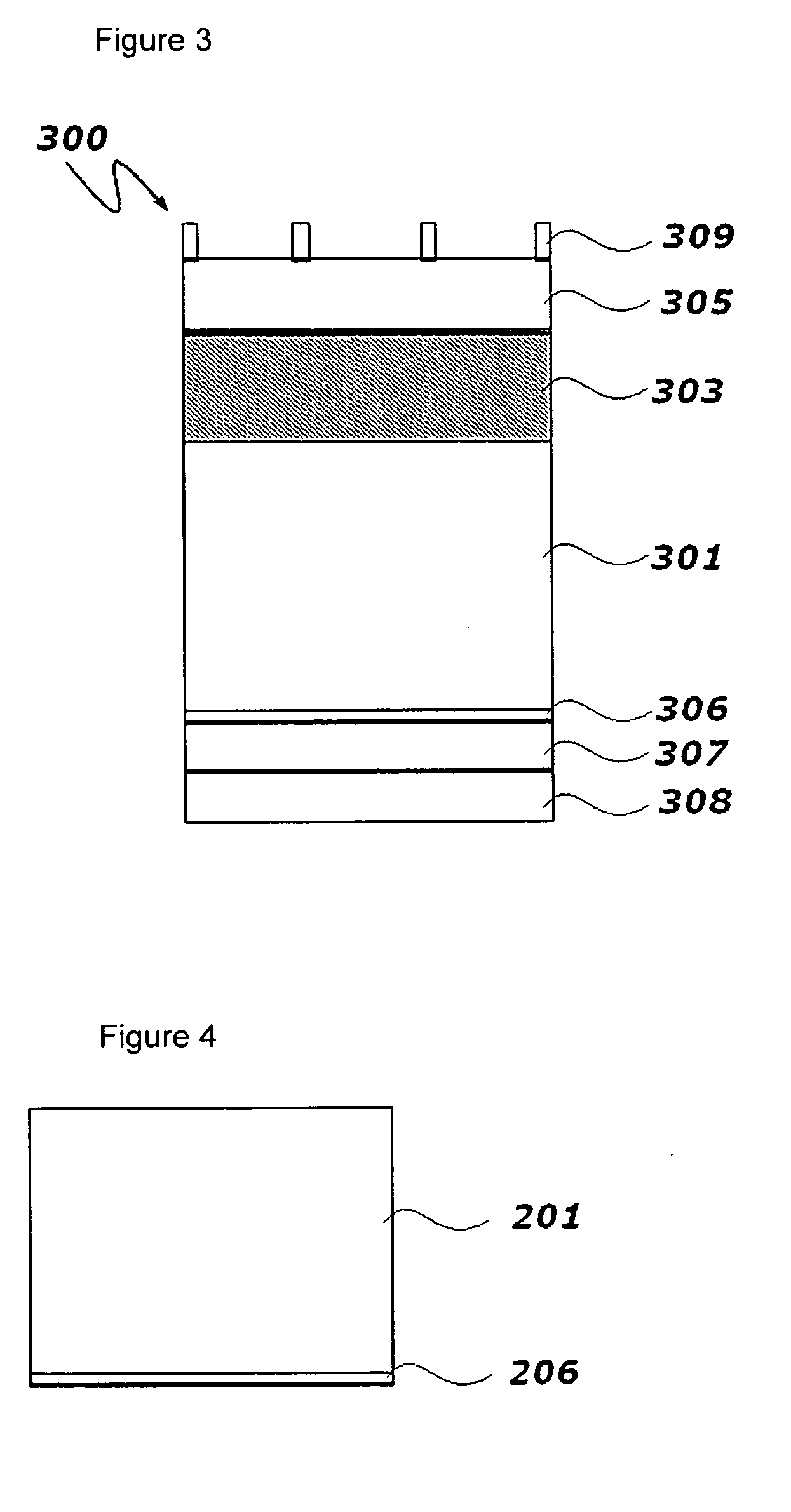

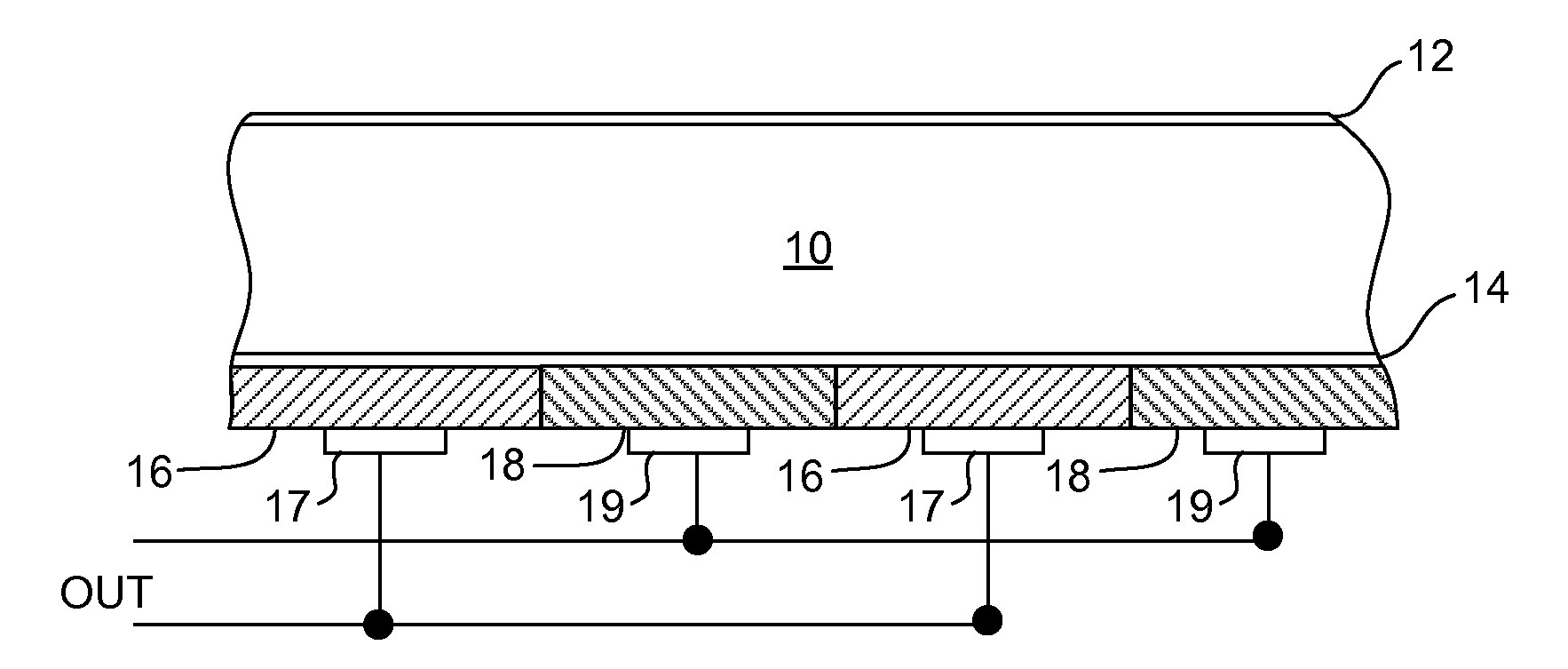

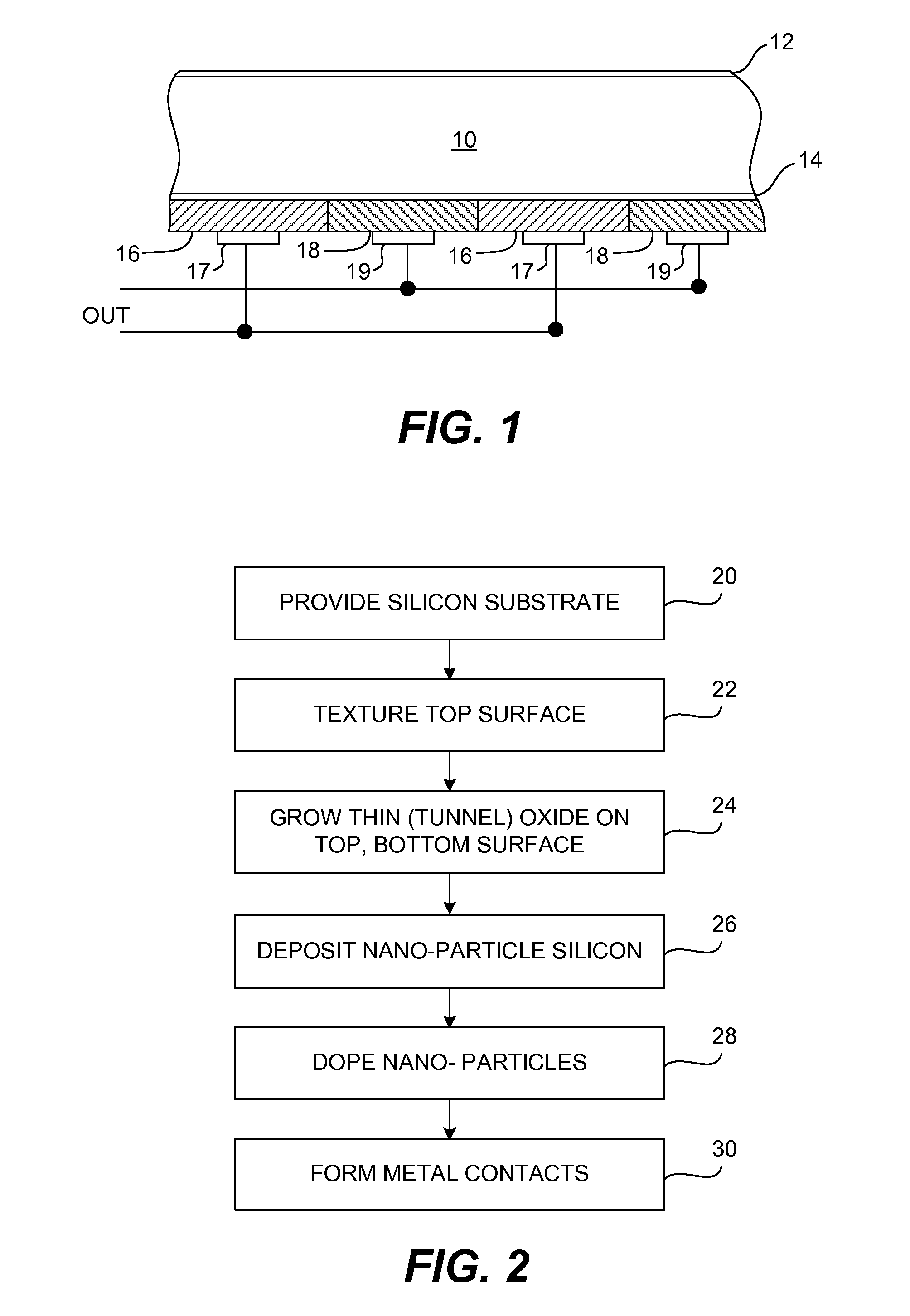

Solar cell having silicon nano-particle emitter

ActiveUS20080121279A1Avoid particle agglomerationReduce interfacePV power plantsSolid-state devicesSilicon solar cellNanometre

A silicon solar cell having a silicon substrate includes p-type and n-type emitters on a surface of the substrate, the emitters being doped nano-particles of silicon. To reduce high interface recombination at the substrate surface, the nano-particle emitters are preferably formed over a thin interfacial tunnel oxide layer on the surface of the substrate.

Owner:MAXEON SOLAR PTE LTD

Process for manufacturing a solar cell

InactiveUS7071018B2Low costFinal product manufactureSemiconductor/solid-state device manufacturingBack surface fieldSilicon solar cell

Process for incorporating a back surface field into a silicon solar cell by depositing a layer of aluminium on the rear surface of the cell, sintering the aluminium at a temperature between 700 and 1000° C., exposing the cell to an atmosphere of a compound of Group V element and diffusing at a temperature of between 950 and 1000°C. so as to dope exposed p-type silicon surfaces with the Group V element. The step of exposing the cell to an atmosphere of a compound of a Group V element is carried separately from the step of sintering the aluminium layer, and subsequent to the step of depositing a layer of aluminium on the rear surface of the cell.

Owner:BP ALTERNATIVE ENERGY INT

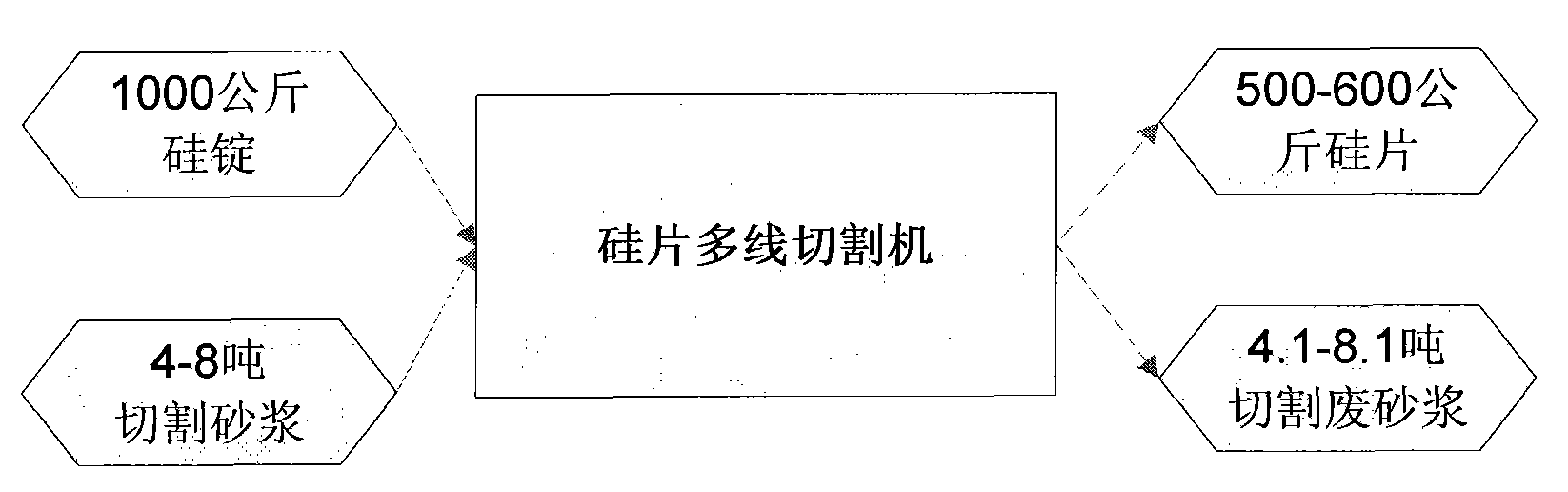

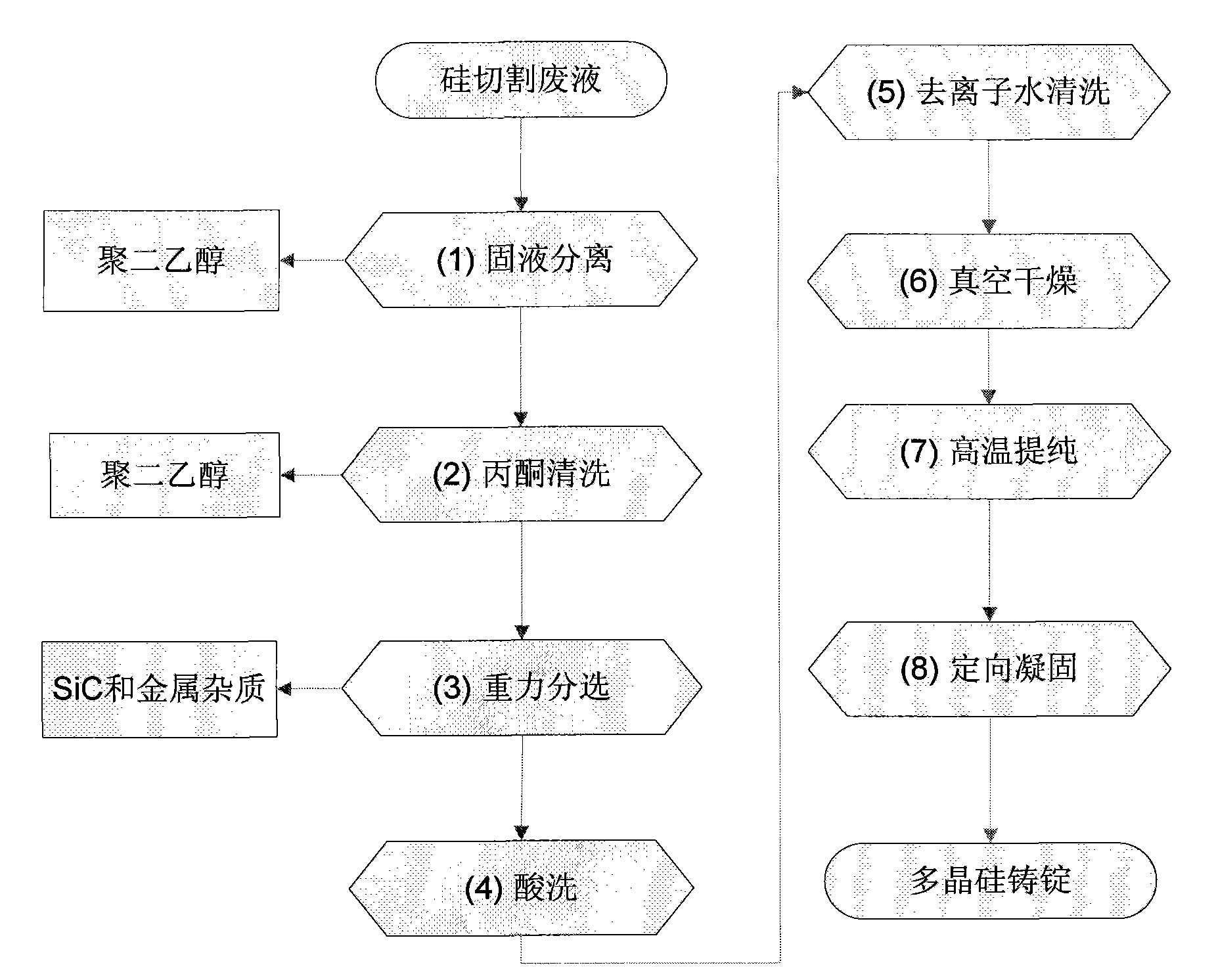

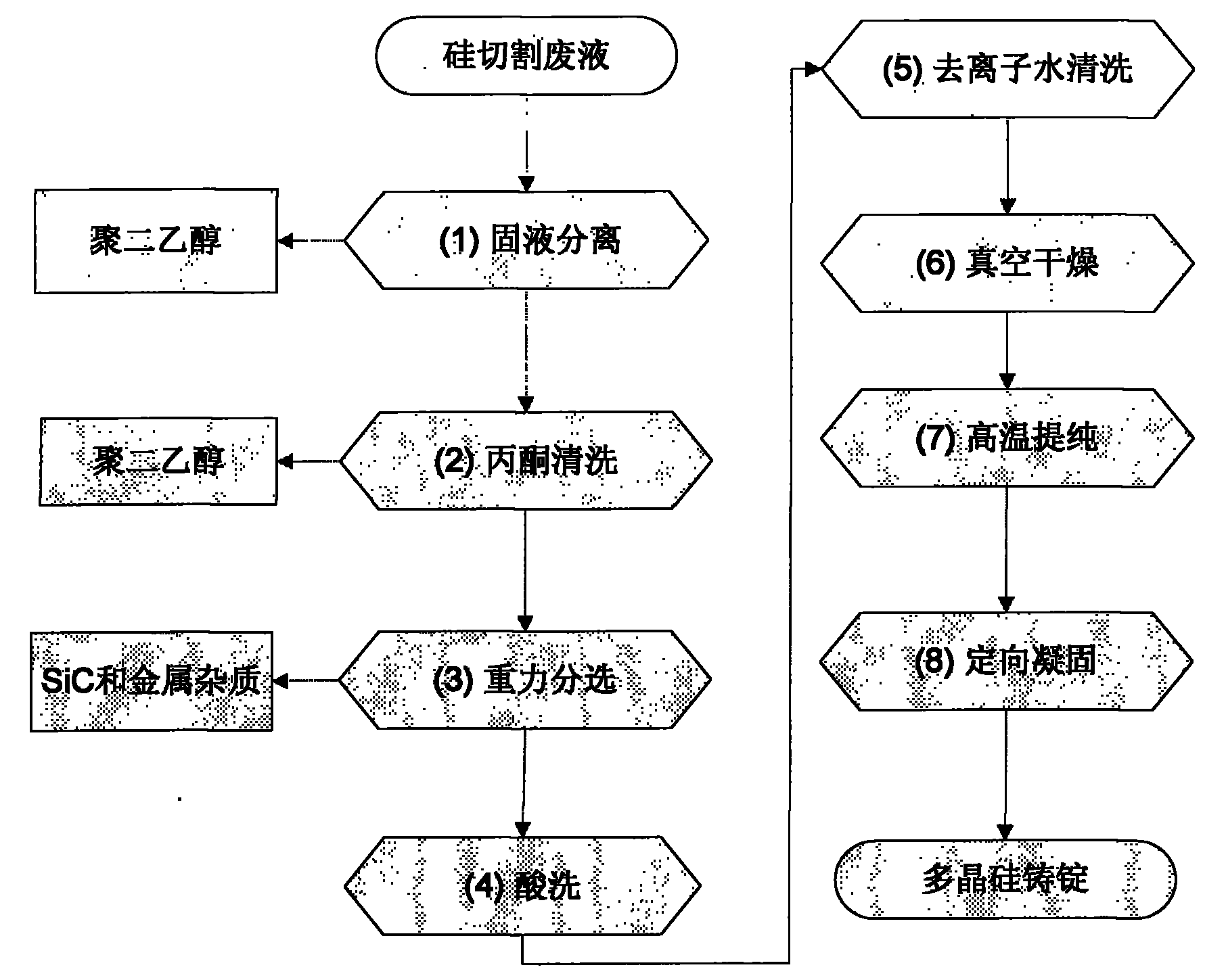

Method for recovering polysilicon ingots, carborundum powder and polyethylene glycol from cutting waste mortar

InactiveCN101792142AHigh yieldMultistage water/sewage treatmentSilicon compoundsPotassiumPolyethylene glycol

The invention discloses a method for recovering polysilicon ingots, carborundum powder and polyethylene glycol from cutting waste mortar. The recovering method comprises the following steps shown as an attached diagram, wherein the high temperature purification comprises the following steps of: mixing the prepared silicon micro powder with a fluxing agent according to the weight ratio of 1: 0.5-5 into lumps, carrying out high temperature treatment in a high temperature vacuum furnace with the treatment temperature range of 1450-1800 DEG C and the treatment time range of 1-10h; and then carrying out directional solidification on melting-state high purity silicon subjected to the high temperature treatment to obtain the polysilicon ingots; wherein the fluxing agent is selected from one or any mixture of silica, alumina, calcium oxide, magnesium oxide, potassium oxide, sodium oxide, calcium fluoride, magnesium fluoride, sodium fluoride, sodium chloride, potassium chloride and calcium chloride. The invention has the advantages that: the yields of carborundum and polyethylene glycol are high and can reach more than 70-80 percent; and the recovered polysilicon ingots reach the purity of 6-7N and completely satisfy of the requirement for preparing silicon slices of silicon solar cell.

Owner:唐康宁

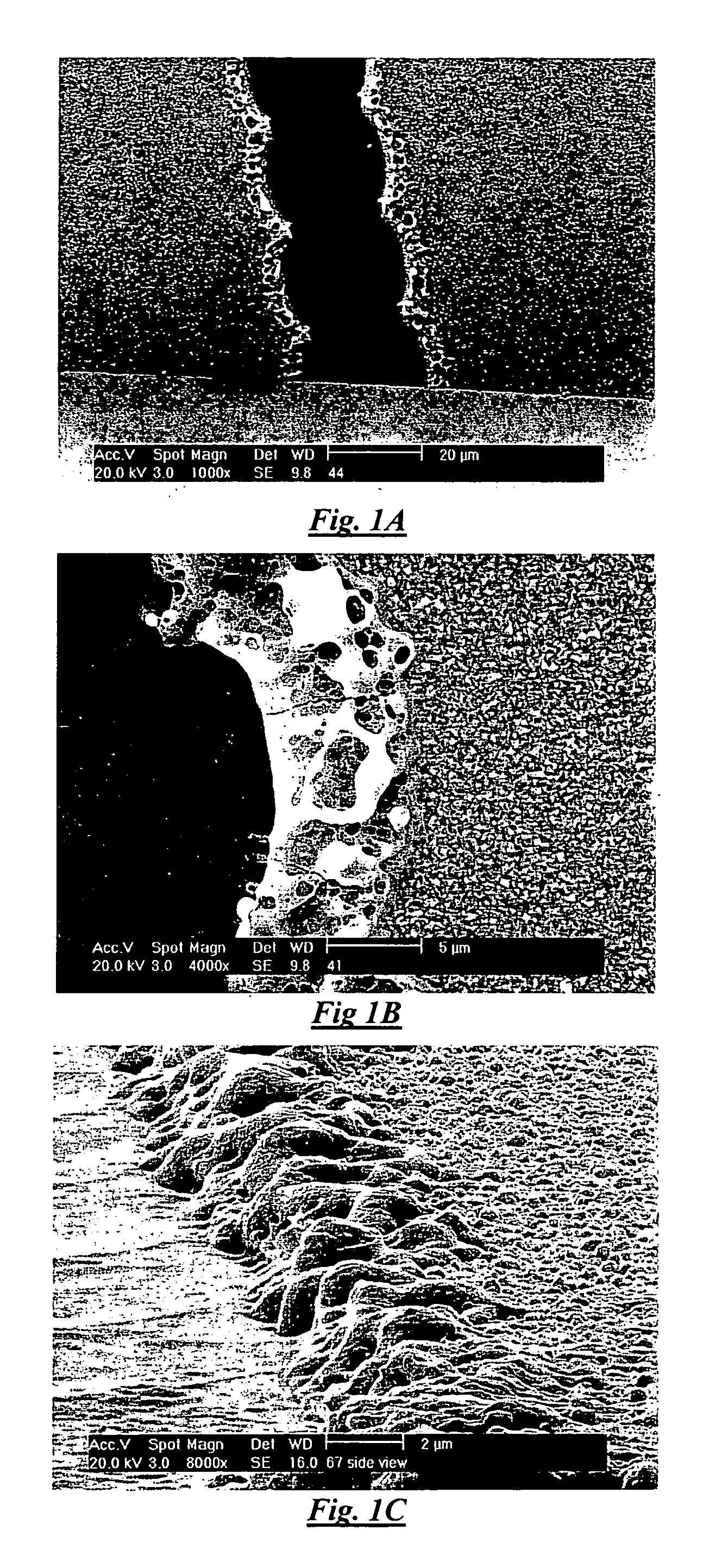

Metal catalyst technique for texturing silicon solar cells

InactiveUS6329296B1Improve throughputDiminish current extractionDecorative surface effectsSemiconductor/solid-state device manufacturingManufacturing technologySilicon solar cell

Textured silicon solar cells and techniques for their manufacture utilizing metal sources to catalyze formation of randomly distributed surface features such as nanoscale pyramidal and columnar structures. These structures include dimensions smaller than the wavelength of incident light, thereby resulting in a highly effective anti-reflective surface. According to the invention, metal sources present in a reactive ion etching chamber permit impurities (e.g. metal particles) to be introduced into a reactive ion etch plasma resulting in deposition of micro-masks on the surface of a substrate to be etched. Separate embodiments are disclosed including one in which the metal source includes one or more metal-coated substrates strategically positioned relative to the surface to be textured, and another in which the walls of the reaction chamber are pre-conditioned with a thin coating of metal catalyst material.

Owner:SANDIA NAT LAB

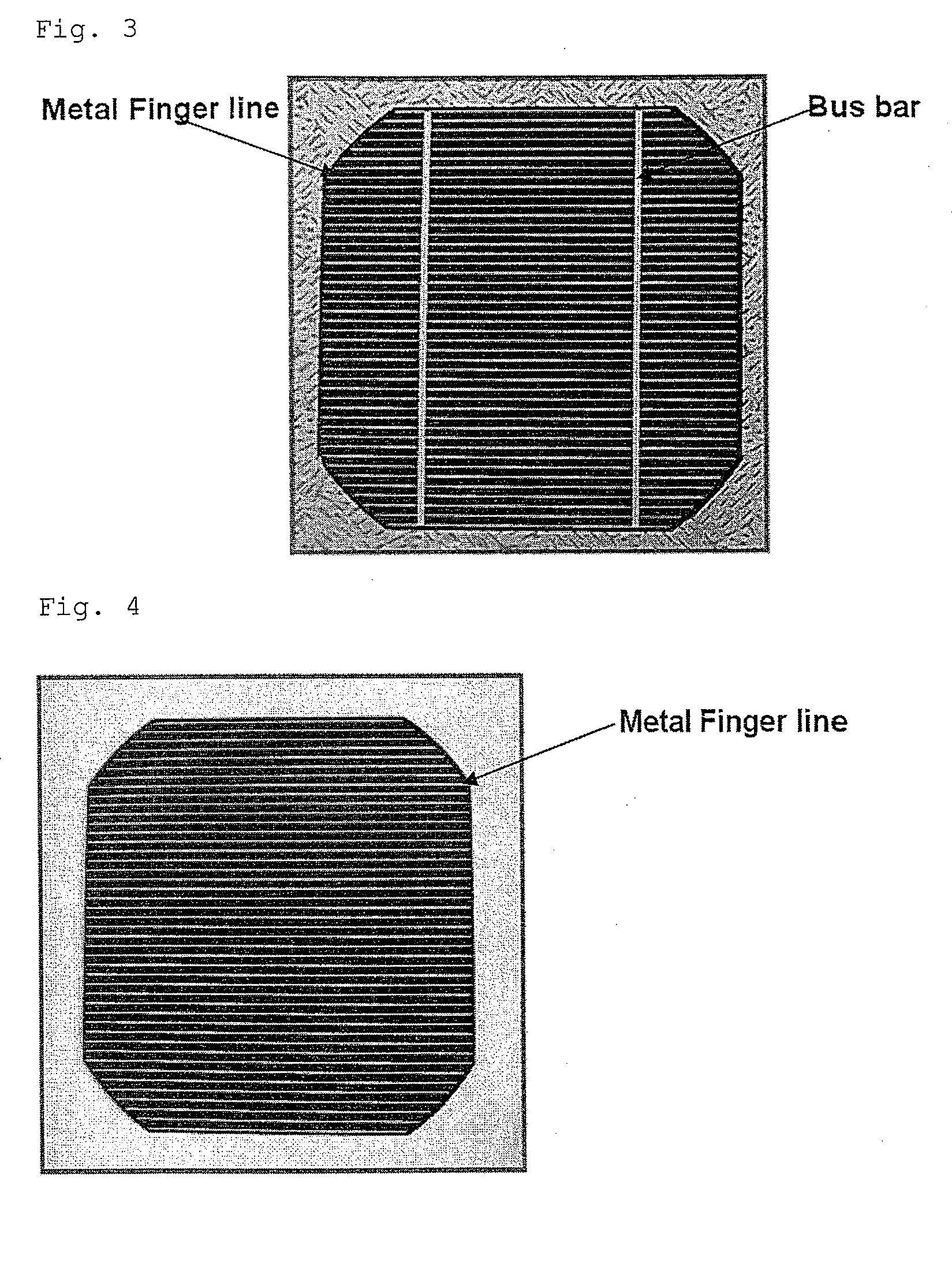

Conductive paste and grid electrode for silicon solar cells

InactiveUS20090211626A1Improve efficiencyReduce contentFinal product manufactureConductive materialConductive pasteGold particles

A conductive paste for grid electrodes in solar cells includes a conductive component, glass frit, and resin binder, wherein the conductive component is selected from the group consisting of (i) silver particles and metal particles selected from the group consisting of Pd, Ir, Pt, Ru, Ti, and Co, (ii) alloy particles comprising silver and metal selected from the group consisting of Pd, Ir, Pt, Ru, Ti, and Co, and (iii) silver particles and core-shell particles in which a metal selected from the group consisting of Pd, Ir, Pt, Ru, Ti, and Co is coated on the surface of silver or copper.

Owner:EI DU PONT DE NEMOURS & CO

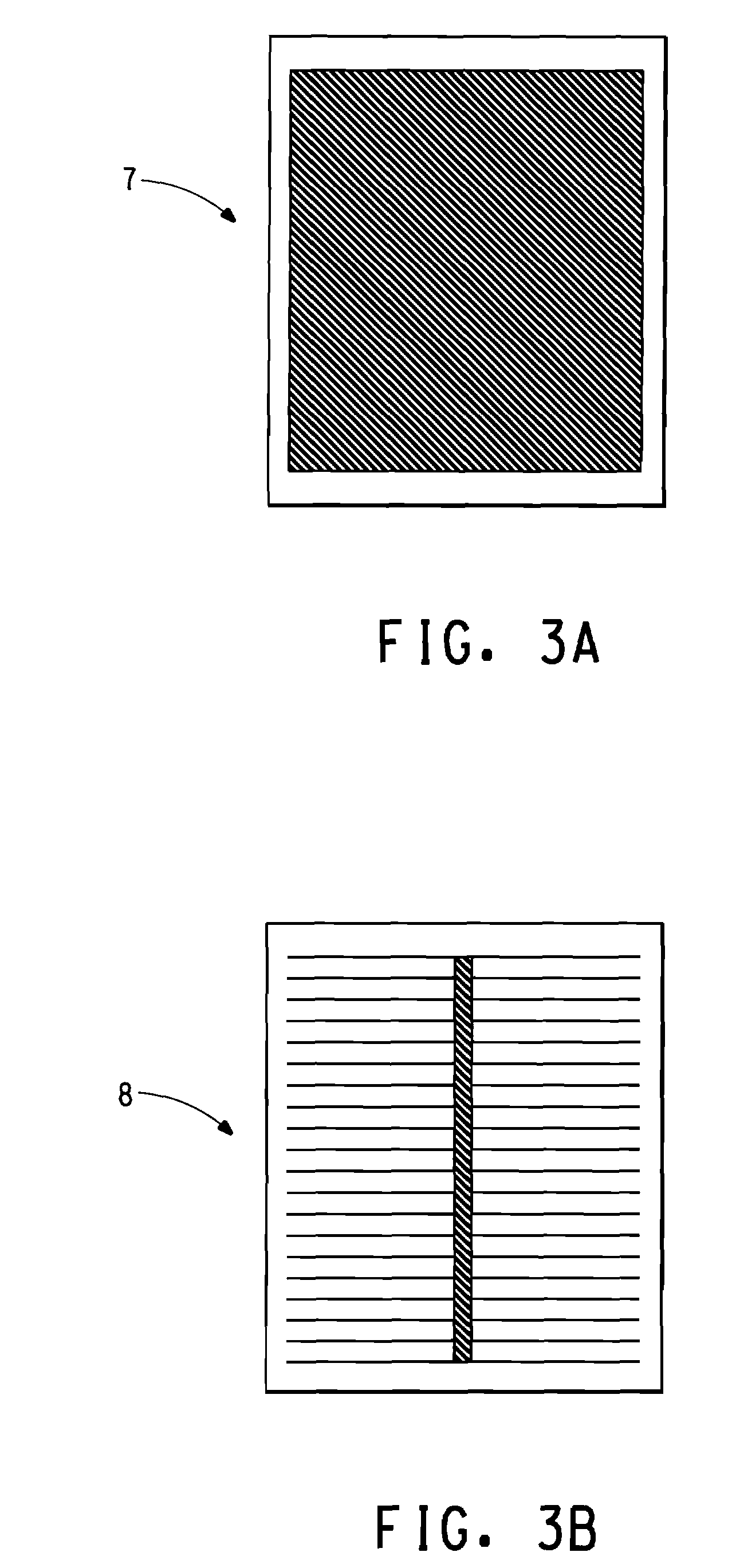

Conductive paste for solar cell and preparation method thereof

InactiveCN102034877AImprove performanceNo sedimentation and caking phenomenonConductive materialInksSilicon matrixSilicon solar cell

The invention provides a conductive paste for a solar cell, comprising the following components based on the total weight: 60-85 percent by weight of conductive metal powder, 0.5-10.0 percent by weight of inorganic binder, 10.0-30.0 percent by weight of water-borne binder and 0.05-5.0 percent by weight of additive, wherein the water-borne binder is a solution formed by dissolving a water-borne polymer into the water. The conductive paste for the solar cell, provided by the invention, has no organic solvent and pollution, is environment-friendly and has low cost of materials; the mesh leakage can be avoided when the conductive paste is stood in a screen mesh; the phenomena of settling and aggregation can be avoided after the conductive paste is stored for a long time; after being subjected to the silk-screen sintering, the conductive paste has firm adhesive force to a silicon matrix and excellent electrical performance; and the average photoelectric conversion efficiency of the produced monocrystal silicon solar cell is more than 17.80 percent.

Owner:BYD CO LTD

Aluminum pastes and use thereof in the production of silicon solar cells

InactiveUS20090255583A1Semiconductor/solid-state device manufacturingNon-conductive material with dispersed conductive materialParticulatesSilicon solar cell

Aluminum pastes comprising particulate aluminum, a tin-organic component and an organic vehicle and their use in forming p-type aluminum back electrodes of silicon solar cells.

Owner:EI DU PONT DE NEMOURS & CO

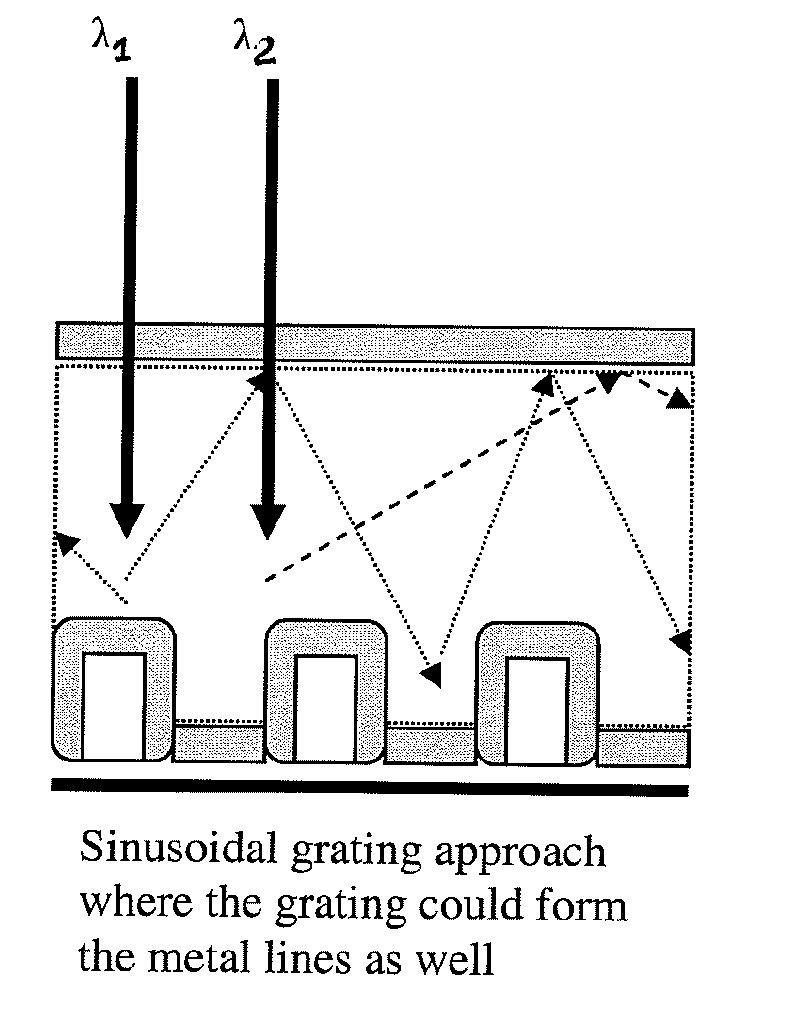

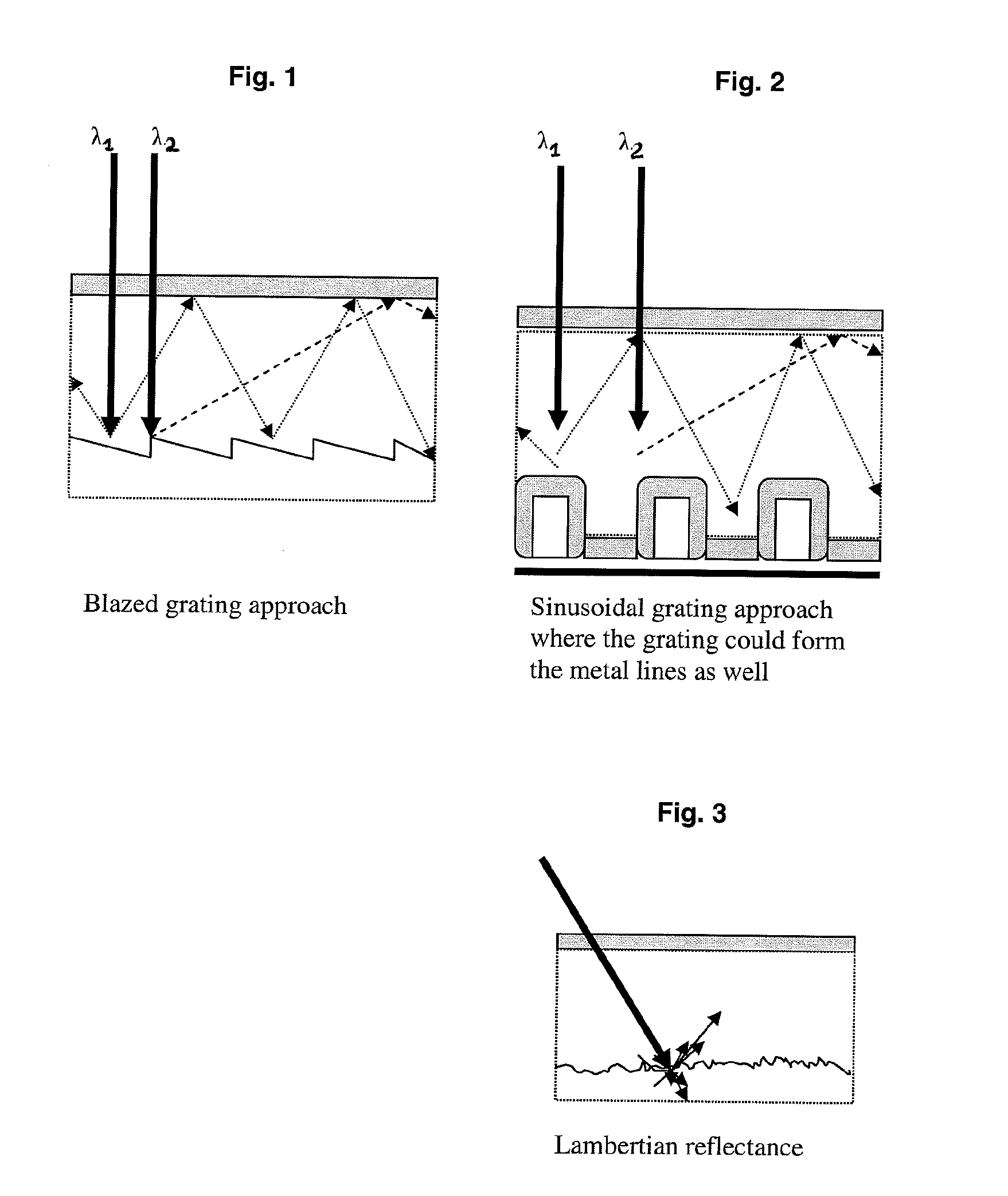

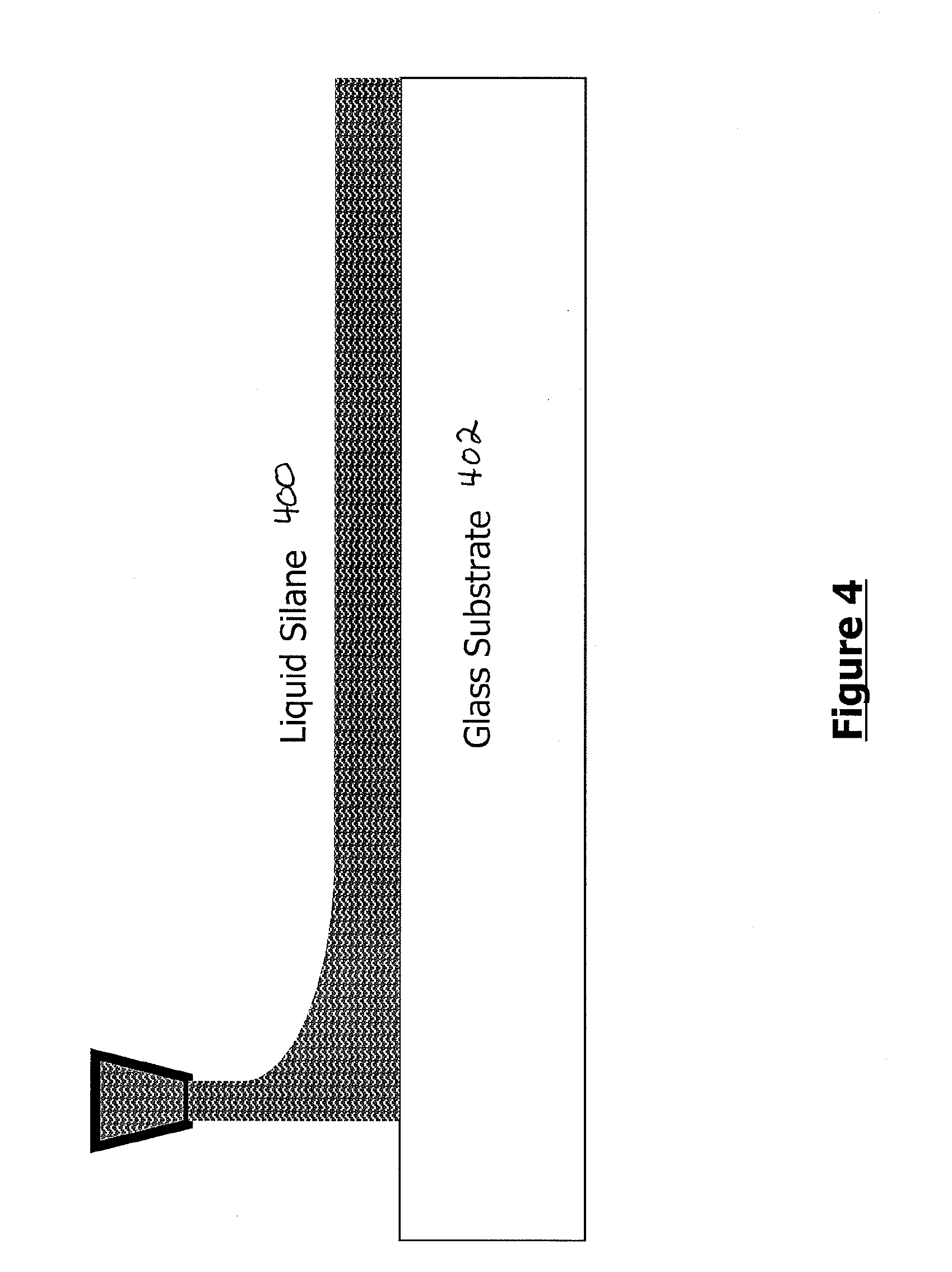

Method to create high efficiency, low cost polysilicon or microcrystalline solar cell on flexible substrates using multilayer high speed inkjet printing and, rapid annealing and light trapping

InactiveUS20090242019A1Improve efficiencyReduce $ /Watt-peakFinal product manufacturePretreated surfacesChemical reactionTrapping

Embodiments of the present invention relate to fabricating low cost polysilicon solar cell on flexible substrates using inkjet printing. Particular embodiments form polycrystalline or microcrystalline silicon solar cells on substrates utilizing liquid silane, by employing inkjet printing or other low cost commercial printing techniques including but not limited to screen printing, roller coating, gravure coating, curtain coating, spray coating and others. Specific embodiments employ silanes such as cyclopentasilane (C5H10) or cyclohexasilane (C6H12), which are liquids at room temperature but undergo a ring opening chemical reaction upon exposure to radiation of a wavelength of ultraviolet (UV) or shorter. . Opening of the rings of the liquid silane converts it into a polymerized material comprising saturated and unsaturated silicon chains of varied length. Heating to approximately 250-400° C. converts these materials into a hydrogenated amorphous silicon film. Controlled annealing at higher effective temperatures causes the amorphous film to change phase to polycrystalline or microcrystalline silicon, depending upon specific processing conditions.

Owner:CHEMTRON RES

Silver paste for positive electrode of crystalline silicon solar cell and preparation method thereof

InactiveCN102157219AReduce contact resistanceImprove rheologyNon-conductive material with dispersed conductive materialCable/conductor manufactureSilver pasteMetallurgy

The invention discloses high-conductivity silver paste for a positive electrode of a crystalline silicon solar cell. The silver paste comprises the following components in percentage by weight: 75-90% of Ag powder, 2-10% of glass powder and 5-20% of organic carrier, wherein the glass powder comprises the following components in percentage by weight: 30-75% of PbO, 7-30% of SiO2, 2-30% of Bi2O3, 1-5% of Al2O3, 1-5% of V2O5, 1-10% of ZnO, 1-5% of Ag2O and 1-8% of MgO. The silver paste has the following beneficial effects: the micron-sized silver powder is adopted to prepare the silver paste, the prepared silver paste has good rheological behavior and thixotropy, a single wafer consumes less silver paste, and the compactness of the positive grid line is improved, thus improving the conductivity; and the glass powder with low-melting erosion property is adopted and can effectively and moderately erode the antireflective film, thus reducing the contact resistance of the crystalline silicon solar cell and improving the conversion efficiency.

Owner:XIAN INTAIN NEW ENERGY MATERIALS SCI & TECH +1

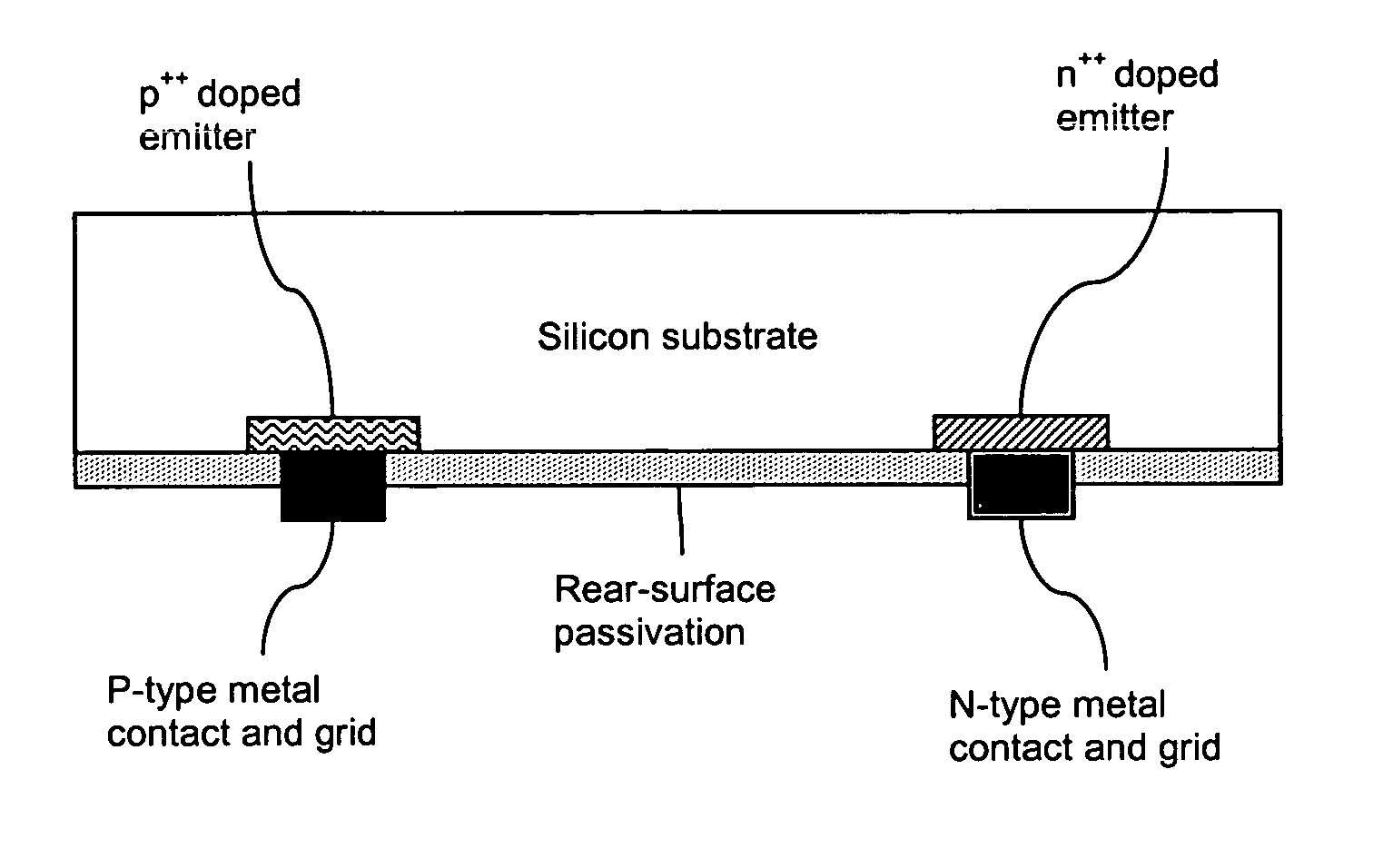

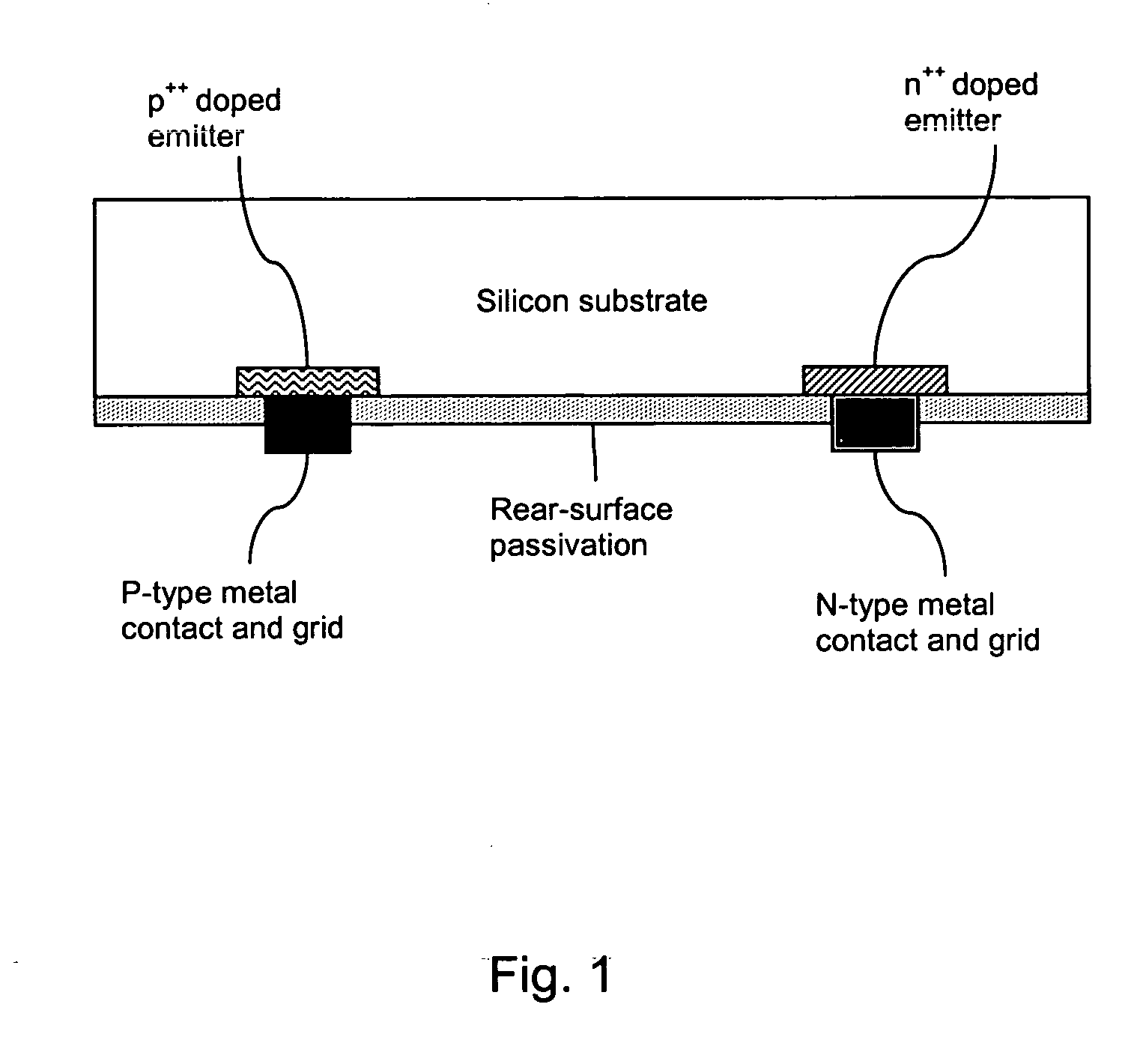

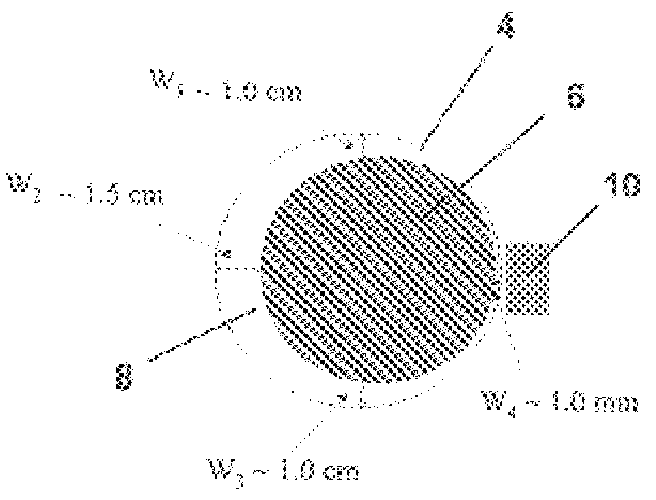

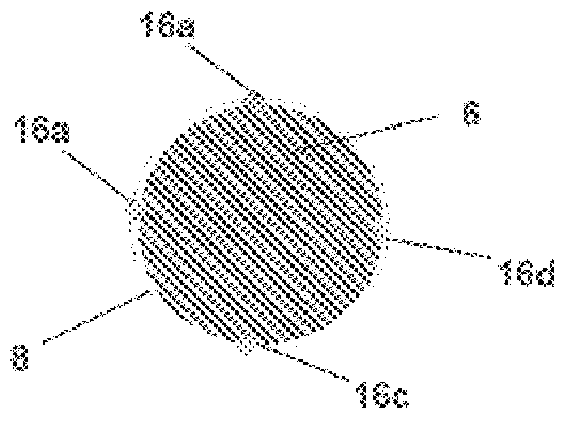

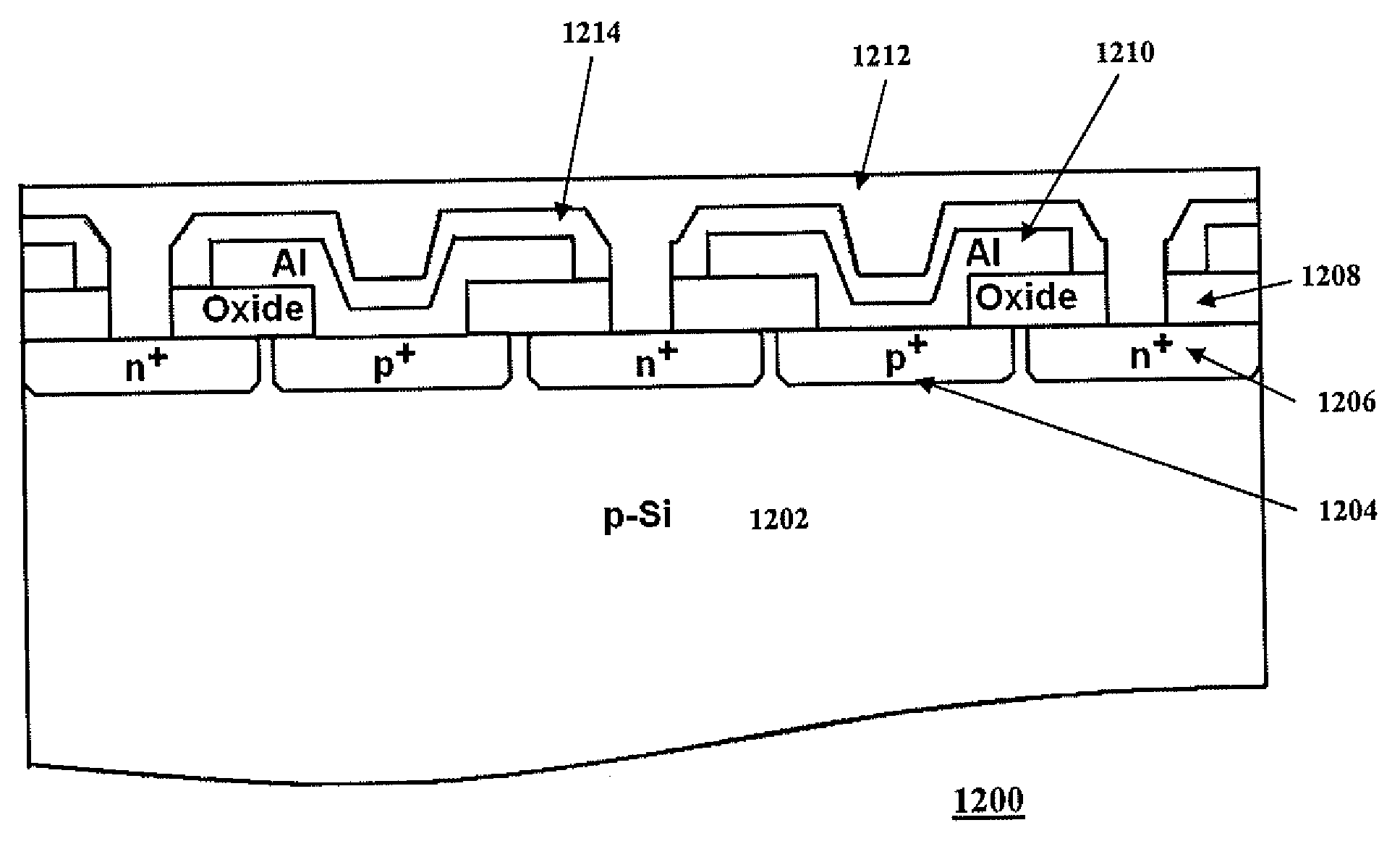

Mono-silicon solar cells

A method for producing a backside contact of a single p-n junction photovoltaic solar cell is provided. The method includes the steps of: providing a p-type substrate having a back surface; providing a plurality of p+ diffusion regions at the back surface of the substrate; providing a plurality of n+ diffusion regions at the back surface of the substrate in an alternate pattern with the p+ diffusion regions; providing an oxide layer over the p+ and n+ regions; providing an insulating layer over the back surface of the substrate; providing at least one first metal contact at the back surface for the p+ diffusion regions; and providing at least one second metal contact at the back surface for the n+ diffusion regions.

Owner:E CUBE ENERGY TECH CO LTD

Producing method of selective emitter double-faced PERC crystalline silicon solar cell

ActiveCN106449876AEasy alignmentImprove conversion efficiencyFinal product manufacturePhotovoltaic energy generationSilicon solar cellCathode

The invention relates to a producing method of a selective emitter double-faced PERC crystalline silicon solar cell. The producing method is characterized by comprising the first step of removing affected layers of a silicon chip and conducting texturization and cleansing on the silicon chip, the second step of conducting diffusion to form a pn junction and eliminating phosphorosilicate glass in positive side of the silicon chip and the pn junction in the reverse side of the silicon chip after the diffusion; the third step of conducting deposition of aluminum oxide / silicon nitride laminated passivated film on the reverse side of the silicon chip and conducting deposition of a silicon nitride antireflection film on the positive side of the silicon chip; the fourth step of using an optical maser to conduct routing on the reverse side of the silicon chip to obtain a routing slot; the fifth step of using a phosphorous source to coat the positive side of the silicon chip; the six step of conducting laser doping on the positive side of the silicon chip to obtain a main guard line and a subsidiary guard line doped with the laser; the seventh step of conducting photoinduction on electronickelling / copper / silver electrode, conducting connections between the reverse side of the cell with a cathode of an external power supply, conducting electroplating on the positive and reverse sides of the cell simultaneously, and conducting electroplating of three metals of nickel / copper / silver in sequence; the eighth step of conducting annealing on the electroplated cell. According to the producing method of the selective emitter double-faced PERC crystalline silicon solar cell, the problem that an aluminum grid line is hard to be aligned with a laser windowing grid when a silk screen is used to conduct reverse printing of the double-faced PERC cell is solved.

Owner:WUXI SUNTECH POWER CO LTD

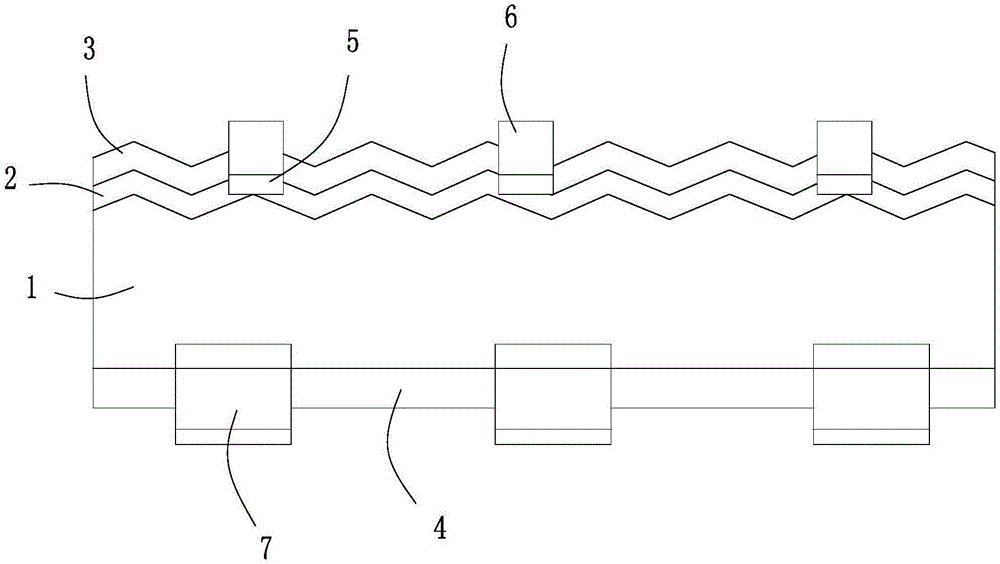

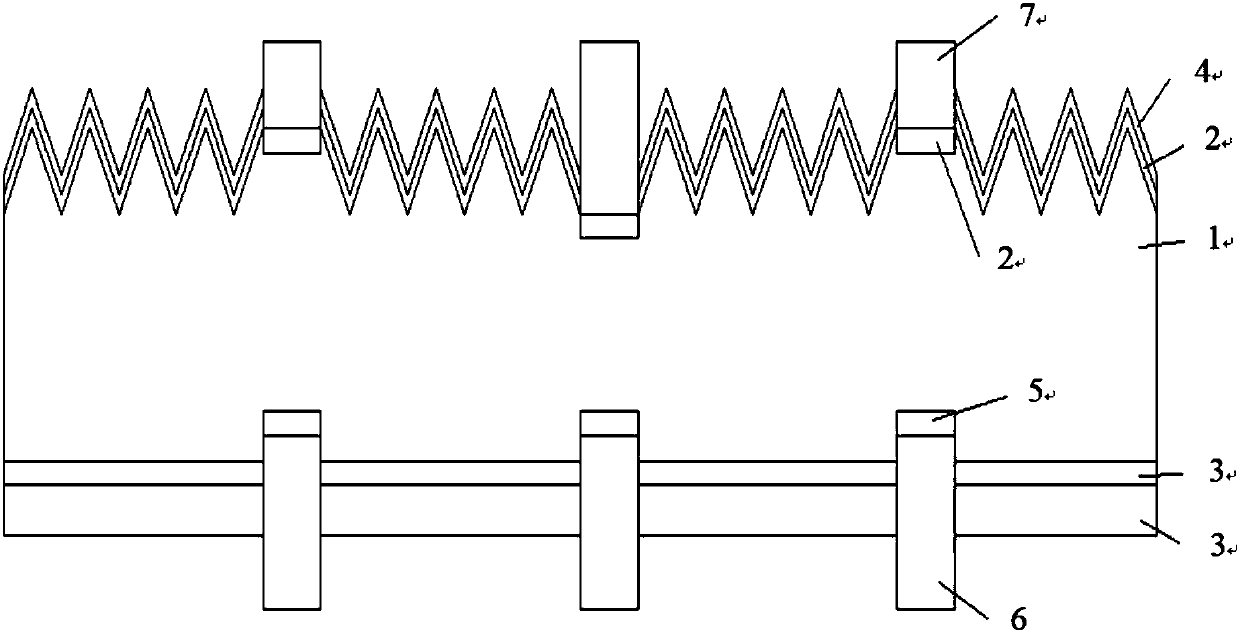

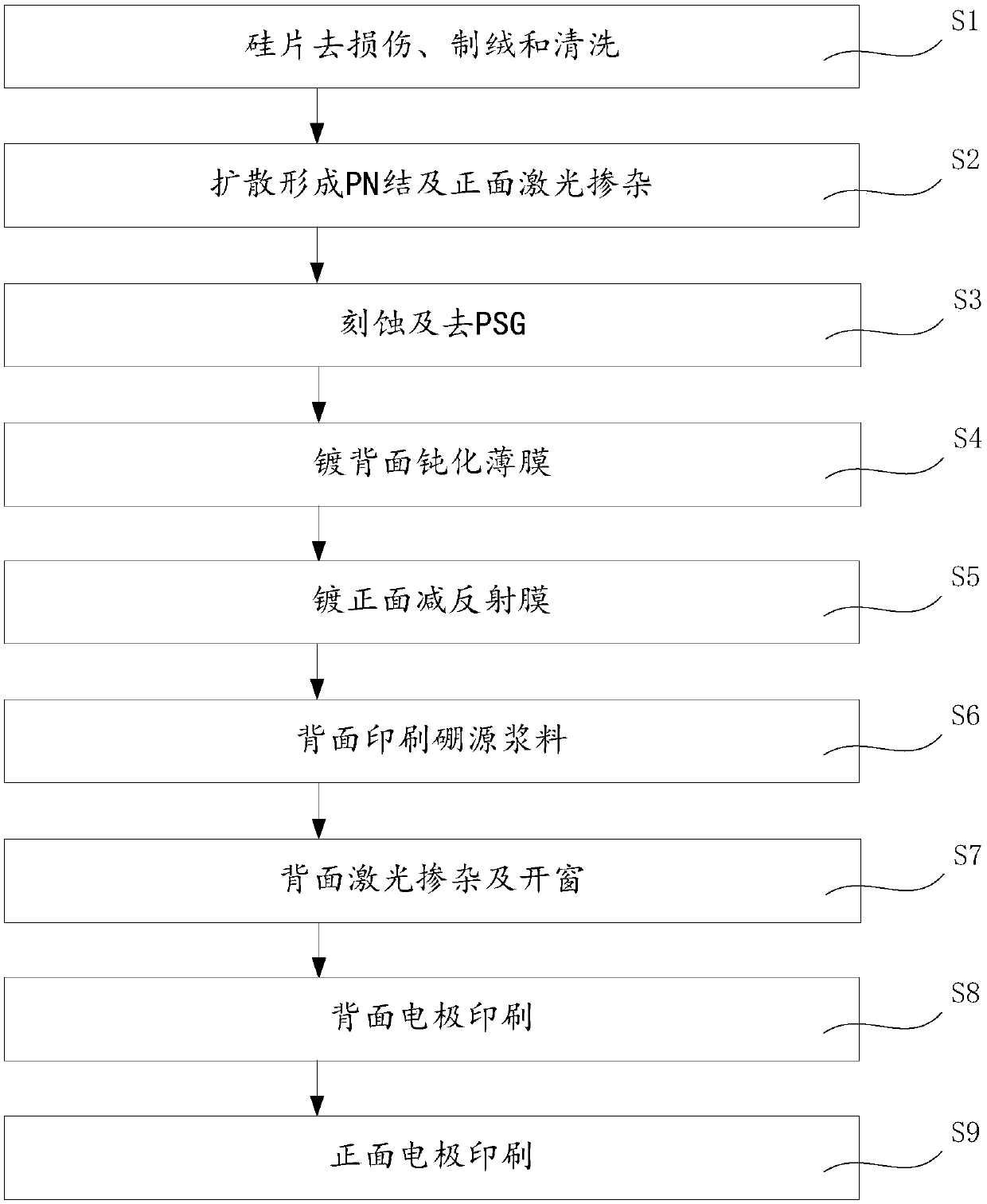

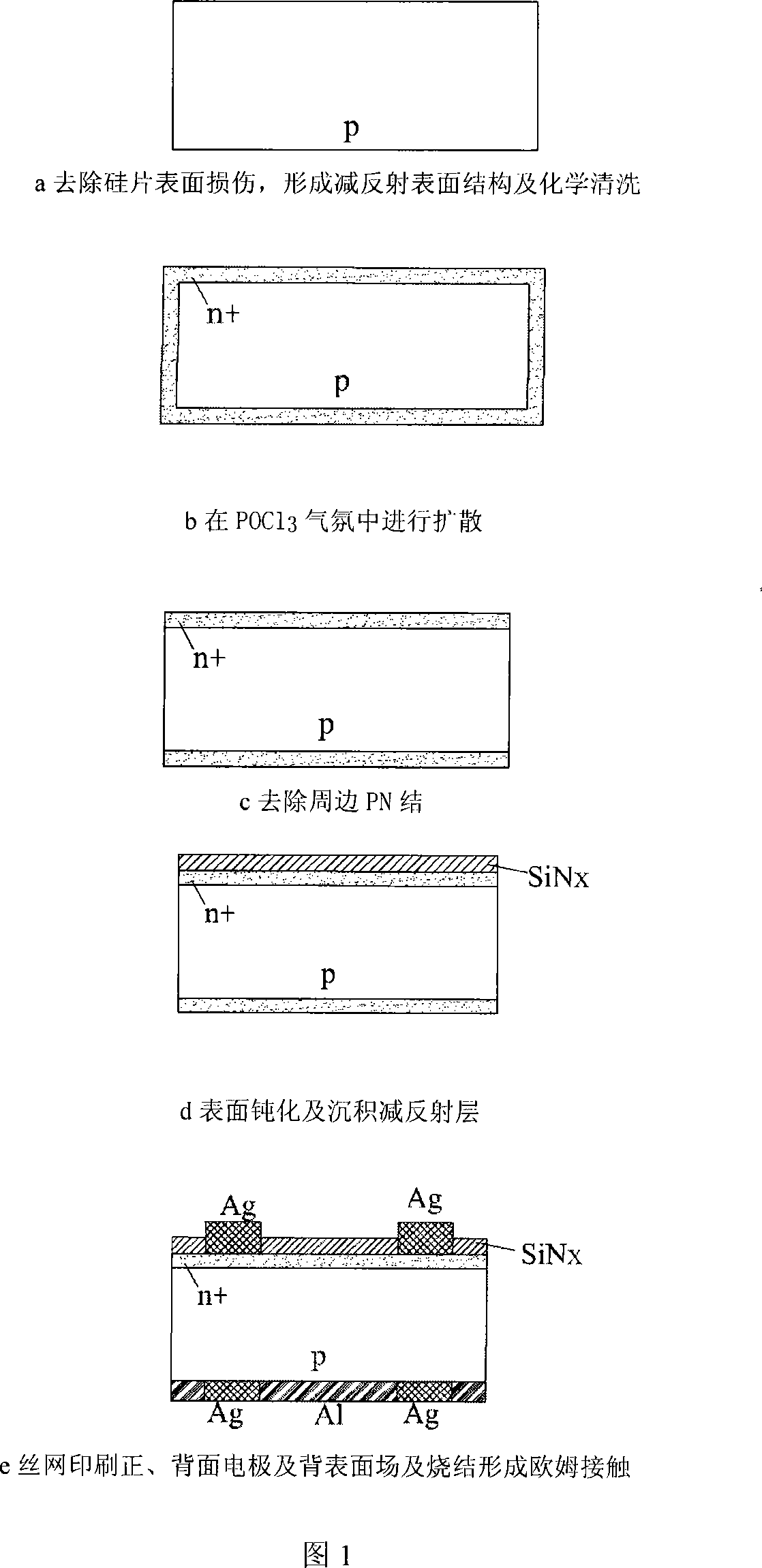

Fabrication method of double-side PERC crystalline silicon solar cell

InactiveCN107863419AImprove conversion efficiencyImplement backside metallizationFinal product manufactureSemiconductor/solid-state device manufacturingScreen printingSilicon solar cell

The invention discloses a fabrication method of a double-side PERC crystalline silicon solar cell. The fabrication method comprises the following steps of (1) removing damage of a silicon wafer, and performing texturing and cleaning; (2) performing diffusion to form a pn junction and performing front-surface laser doping; (3) etching and removing PSG; (4) plating a back-surface passivation thin film; (5) plating a front-surface anti-reflection film; (6) printing boron source paste on a back surface; (7) performing back-surface laser doping and windowing; (8) performing back-surface electrode printing; and (9) performing front-surface electrode printing. A laser doping technology is applied to a process of a selective emitter formed on a front surface and local boron doping on the back surface, only two processes of laser doping and boron source paste printing are added on the basis of a conventional PERC battery process, and the conversion efficiency of the double-side PERC cell is greatly improved; moreover, with the adoption of a secondary printing alignment laser printing MARK point mode, the back-surface metallization of the double-side PERC cell is achieved; and by the method,the problem of difficulty in alignment of a back-surface aluminum grid line to a laser windowing grid line of the silk-screen printed double-sided PERC cell is completely solved.

Owner:SPIC XIAN SOLAR POWER CO LTD

Front gate line electrode silver conductor slurry for environment friendly silicon solar cell

ActiveCN101483207AGood chemical stabilityImprove electrical performanceFinal product manufactureConductive materialHigh cellElectrical conductor

The invention relates to a formula of an environment-friendly Ag conductor slurry for a silicon solar cell front gate line electrode and a processing method thereof. The component and the content (weight percentage) of the Ag slurry are: a metal Ag powder 60-80, a lead-less glasses adhesive 1-10, an Ohm contact additive agent 0. 05-10, and organic resin 2-15and a slurry modifying agent 1-8 The production method of the environment-friendly Ag conductor slurry comprises a preparation of the lead-less glass adhesive, a formula of the Ag slurry and a processing process of the slurry. The developing Ag slurry implements the slurry lead-free by using a Ba-Zn-B glass material and the lead content of the slurry is less than 100 ppm, while the content of other harmful substances such as Hg and Cd or the like is all conformed to the environment protection demand. A good Ohm contact is formed on the silicon surface of the Ag line and the cell by adding the Ohm contact forming agent in the slurry. The Ag slurry has strong adhesive force, superior weldability, good Ohm contact and high cell conversion efficiency after a continuous tunnel furnace fast heat treatment when the Ag slurry is used in the silicon solar cell front gate line electrode.

Owner:河北晶乐光电科技有限公司

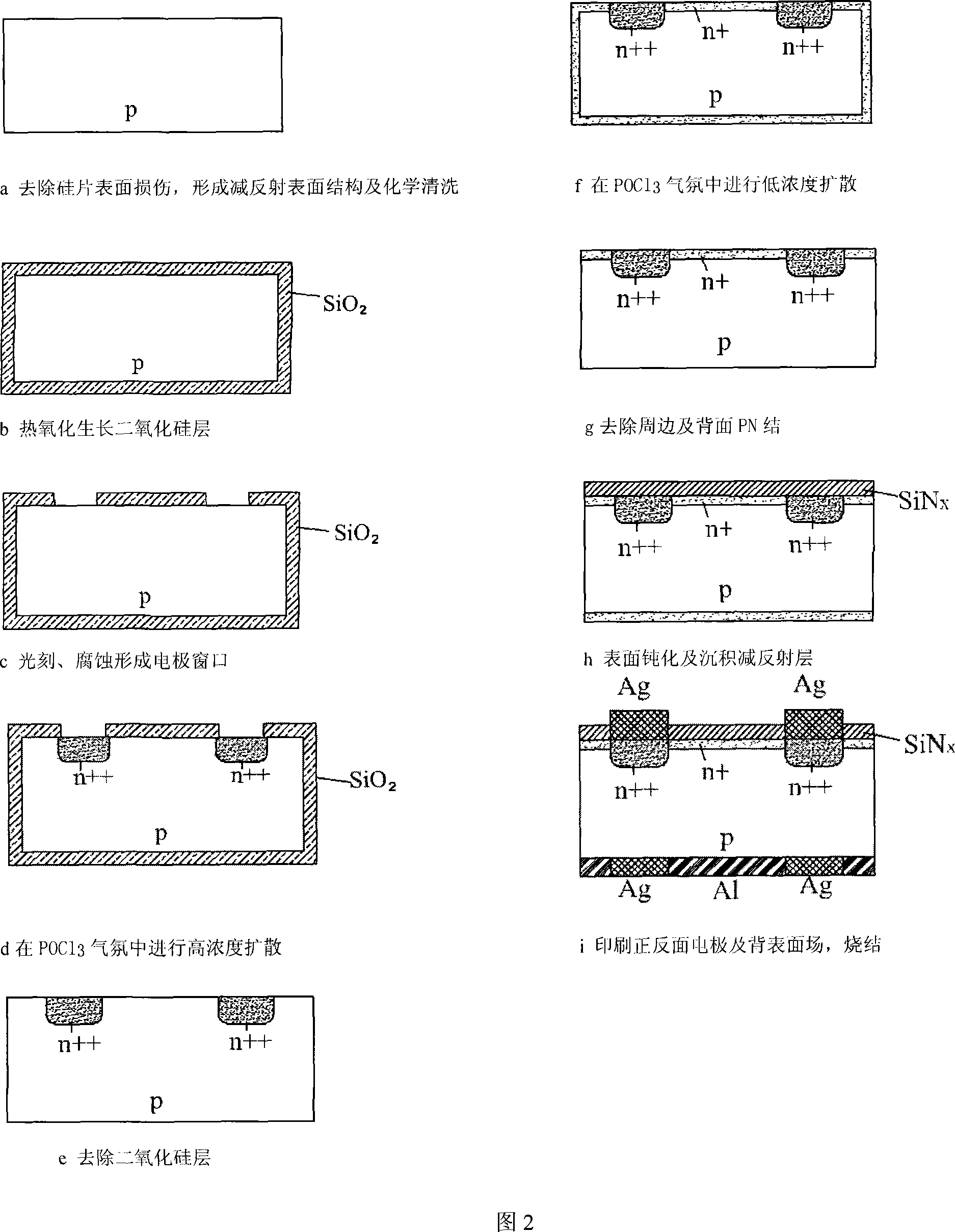

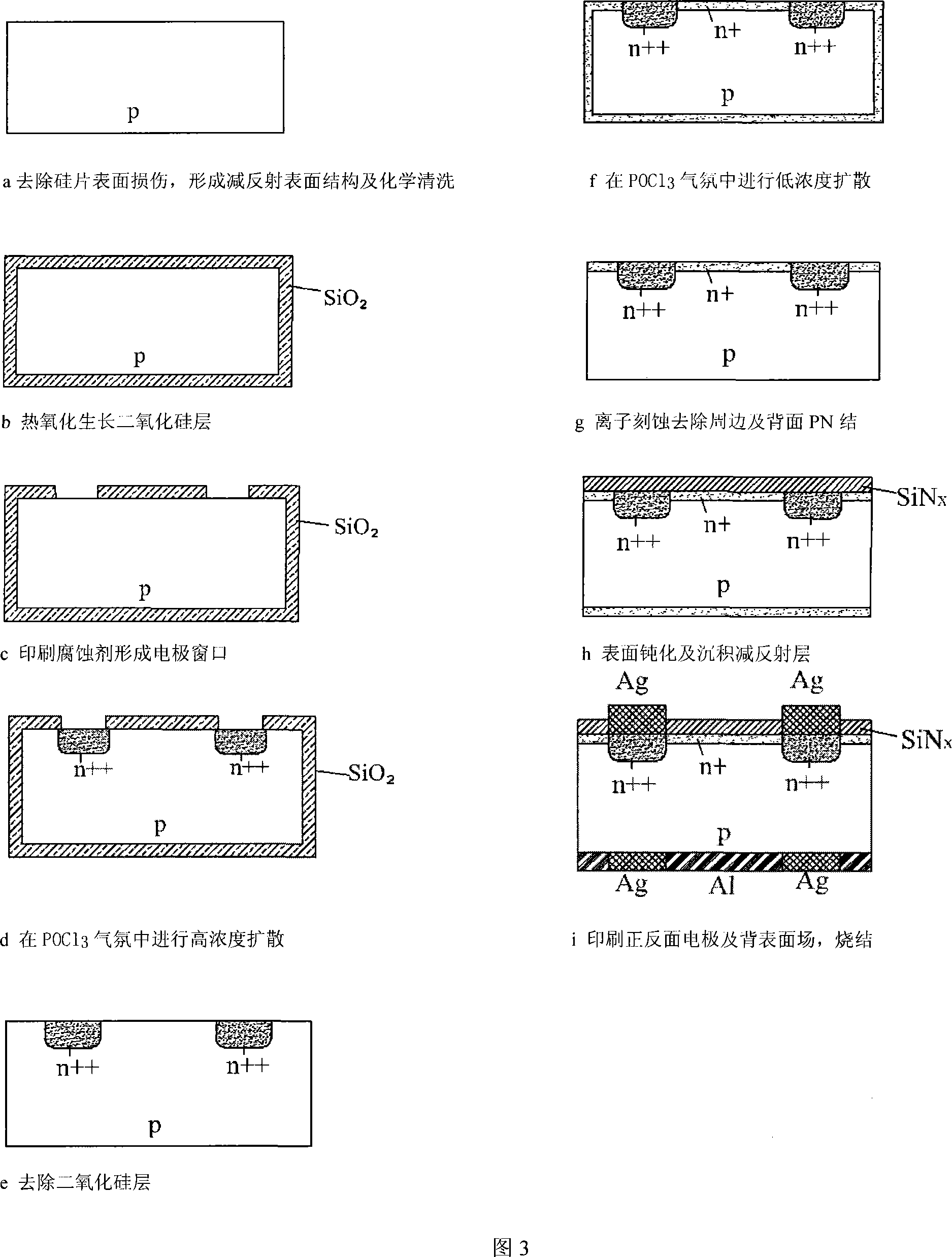

Making method for selective transmission node crystal silicon solar battery

InactiveCN101101936ALess investmentIncrease productivityFinal product manufactureSemiconductor devicesHigh volume manufacturingSilicon solar cell

The invention is concerned with the making method of the selective emitter crystal silicon solar cell including high thickness doping diffusion. It is to form the electrode window on the silicon dioxide layer of the crystal silicon chip with the printer technique cauterant, next is to conduct high thickness doping diffusion in the POCl3 atmosphere of the electrode window sector. The invention is with low cost but high productivity.

Owner:CHINA SUNERGY CO LTD

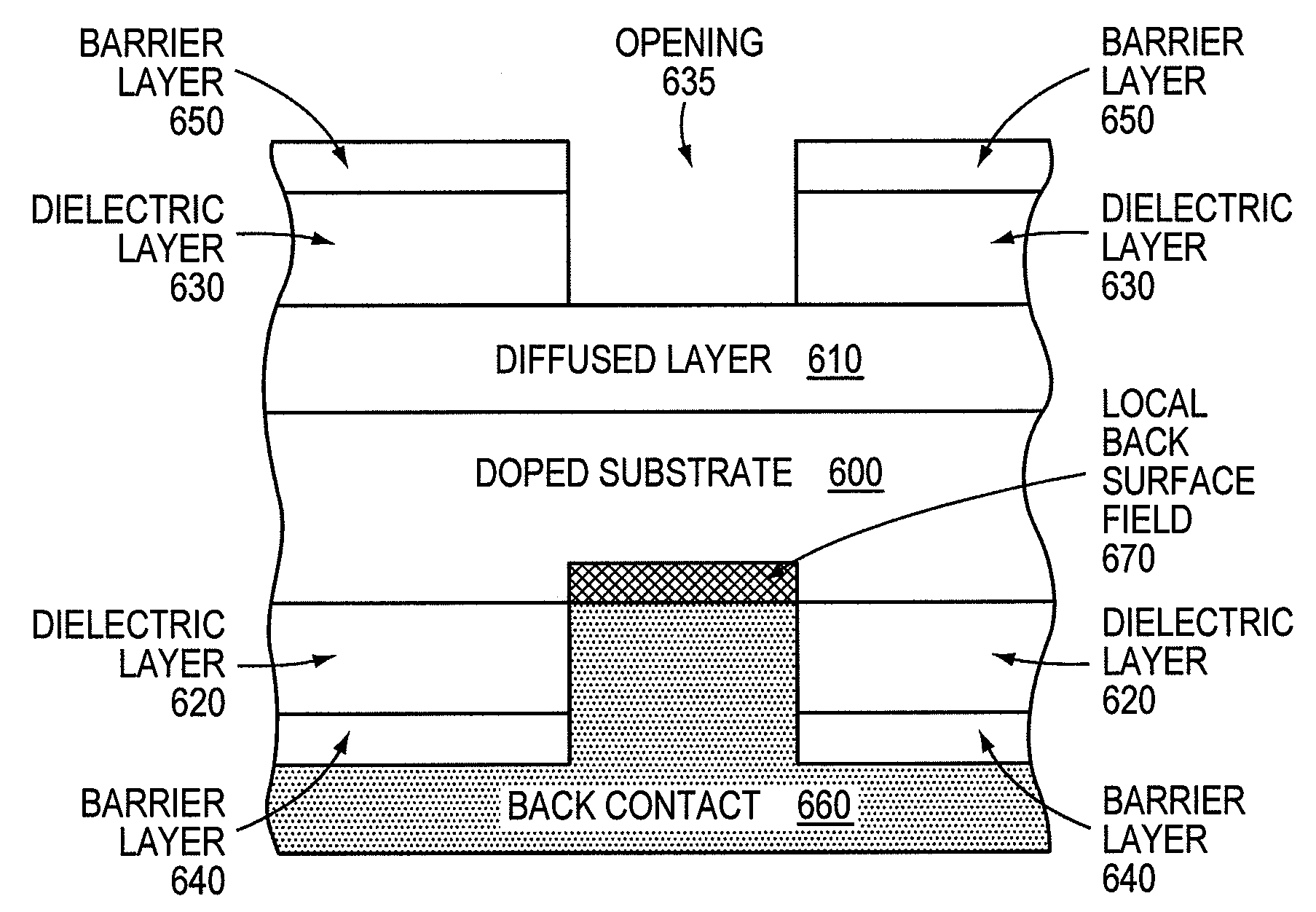

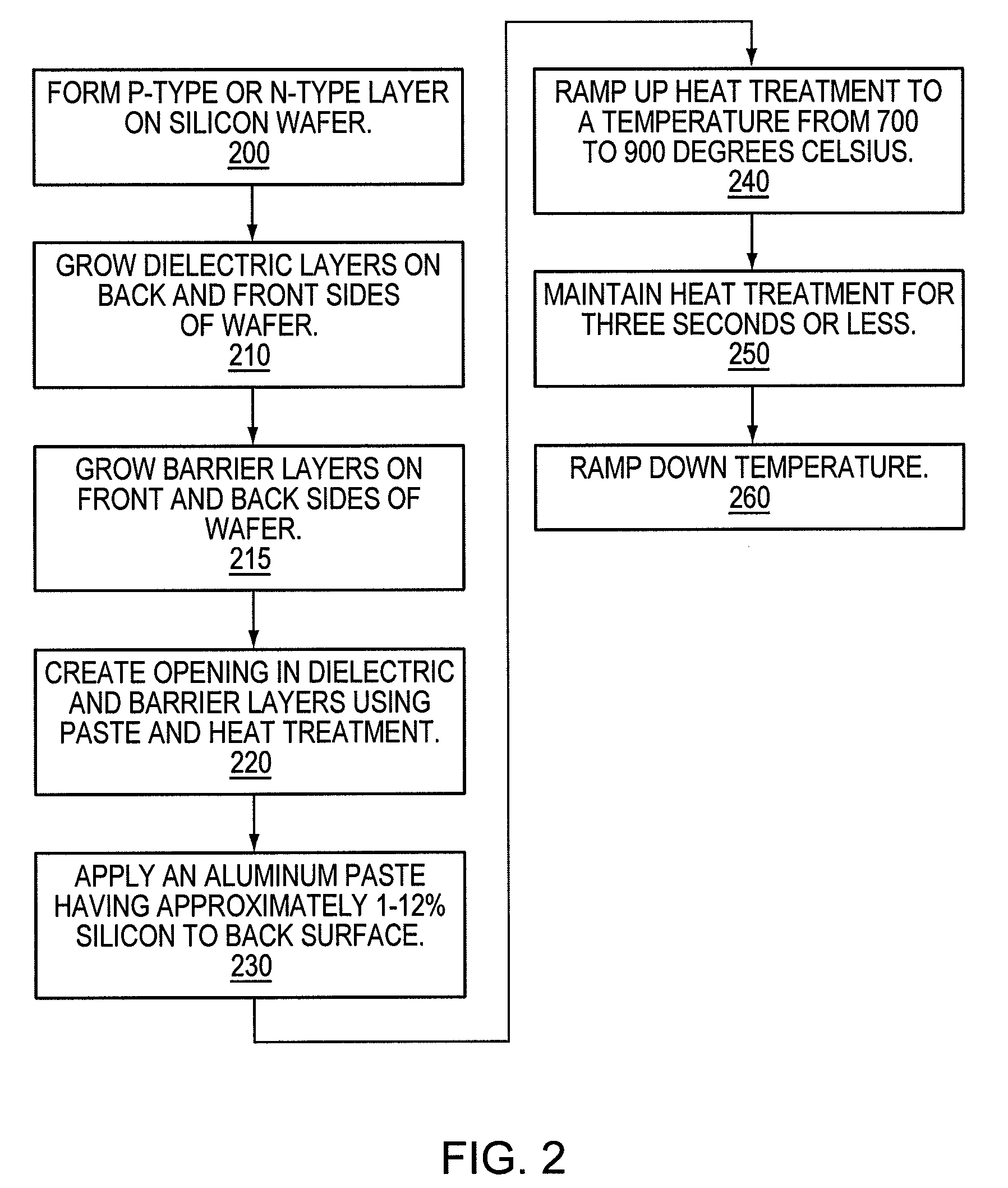

Solar cell having high quality back contact with screen-printed local back surface field

InactiveUS20090025786A1Final product manufacturePhotovoltaic energy generationScreen printingCelsius Degree

A thin silicon solar cell having a back dielectric passivation and rear contact with local back surface field is described. Specifically, the solar cell may be fabricated from a crystalline silicon wafer having a thickness from 50 to 500 micrometers. A barrier layer and a dielectric layer are applied at least to the back surface of the silicon wafer to protect the silicon wafer from deformation when the rear contact is formed. At least one opening is made to the dielectric layer. An aluminum contact that provides a back surface field is formed in the opening and on the dielectric layer. The aluminum contact may be applied by screen printing an aluminum paste having from one to 12 atomic percent silicon and then applying a heat treatment at 750 degrees Celsius.

Owner:GEORGIA TECH RES CORP

Laser structuring for manufacture of thin film silicon solar cells

InactiveUS20050272175A1Semiconductor/solid-state device manufacturingDiodeSilicon solar cellThin film silicon solar cell

A method of manufacturing thin-film, series connected silicon solar cells having a ZnO TCO layer, for example, using an ultraviolet scribing laser to scribe said ZnO TCO layer to form relatively smooth walls through said TCO layer.

Owner:OERLIKON TRADING AG TRUEBBACH

Aluminum pastes and use thereof in the production of silicon solar cells

InactiveUS20090229665A1Semiconductor/solid-state device manufacturingOrganic dyesParticulatesSilicon solar cell

Disclosed are aluminum pastes comprising particulate aluminum, a zinc-organic component and an organic vehicle and their use in forming p-type aluminum back electrodes of silicon solar cells.

Owner:EI DU PONT DE NEMOURS & CO

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com