Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

3649 results about "Frit" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

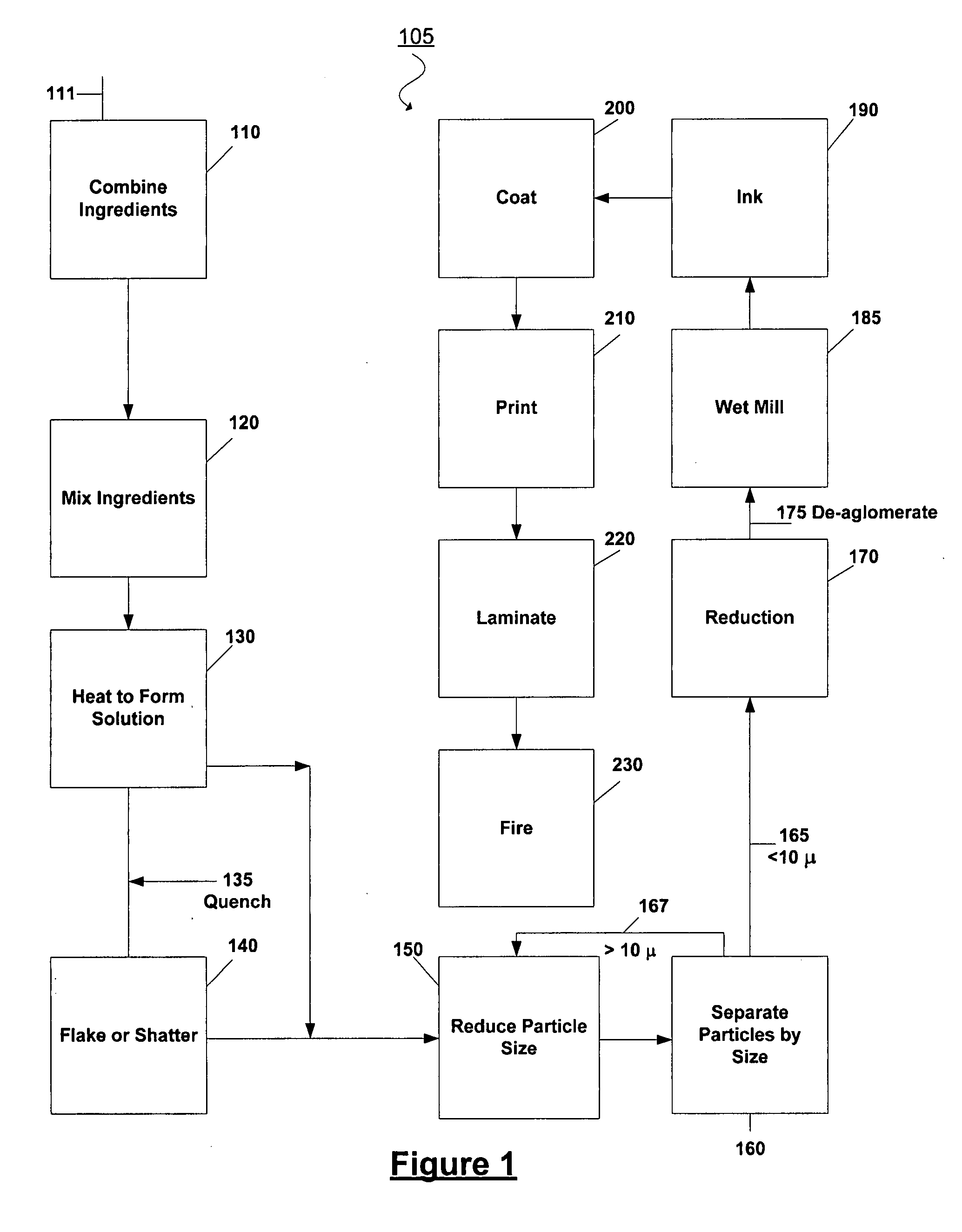

A frit is a ceramic composition that has been fused, quenched, and granulated. Frits form an important part of the batches used in compounding enamels and ceramic glazes; the purpose of this pre-fusion is to render any soluble and/or toxic components insoluble by causing them to combine with silica and other added oxides. However, not all glass that is fused and quenched in water is frit, as this method of cooling down very hot glass is also widely used in glass manufacture.

Encapsulating OLED devices

InactiveUS20050248270A1Discharge tube luminescnet screensElectroluminescent light sourcesMoisture penetrationFrit

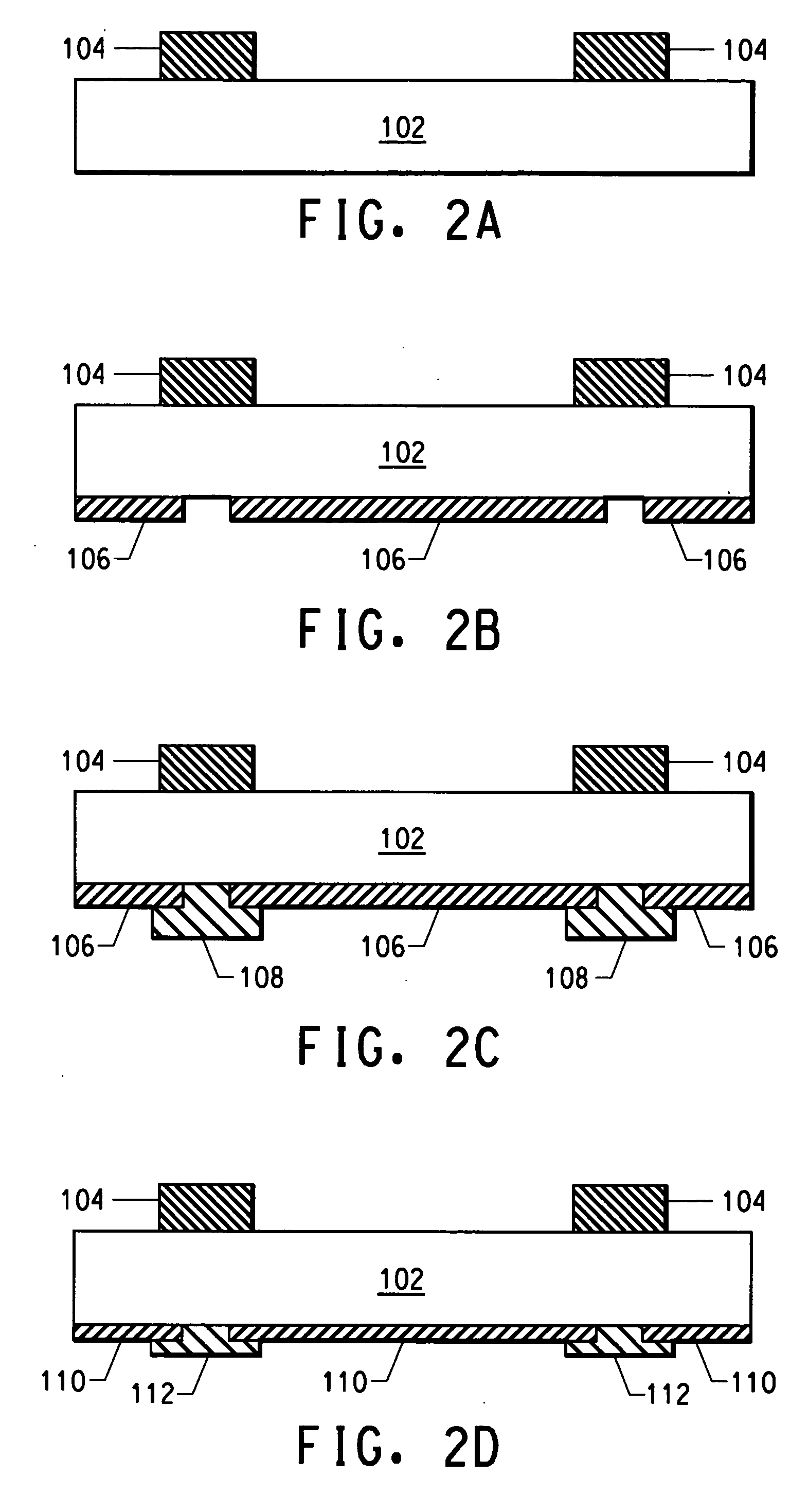

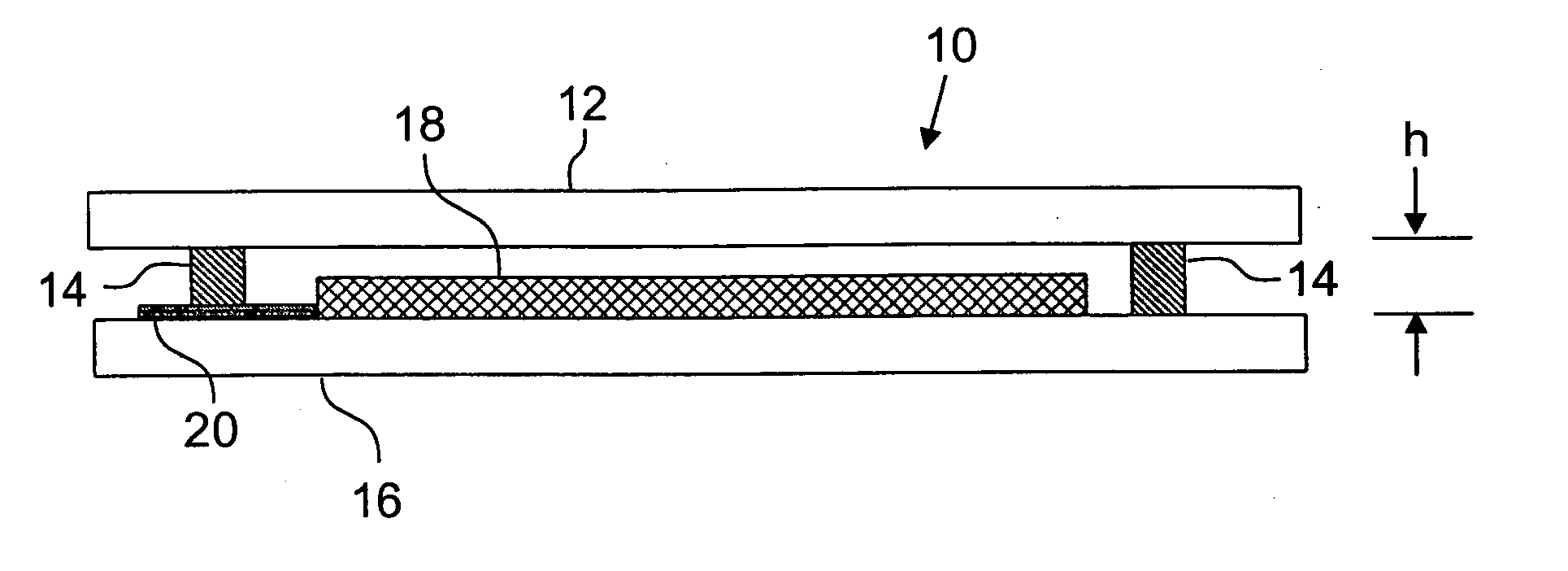

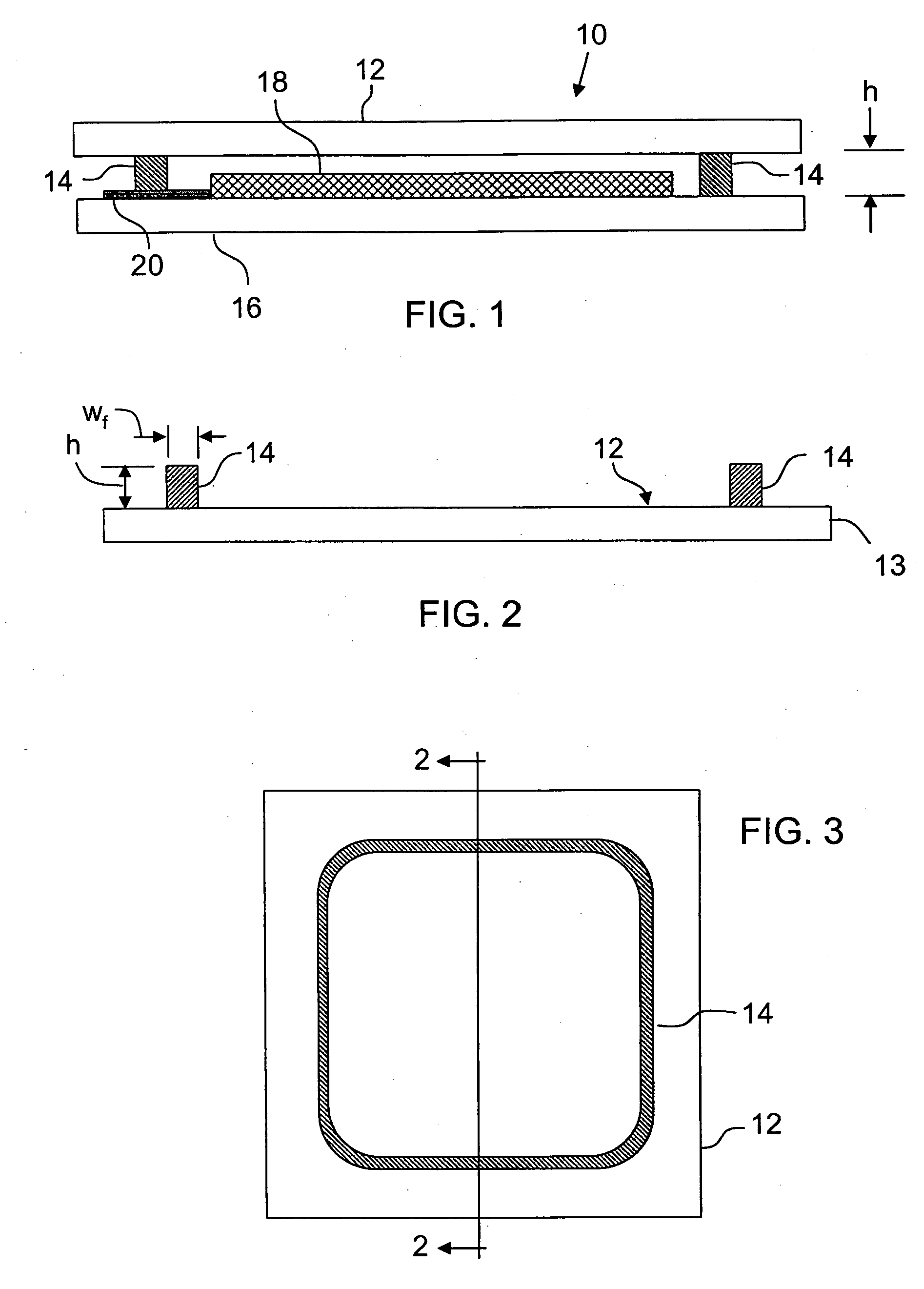

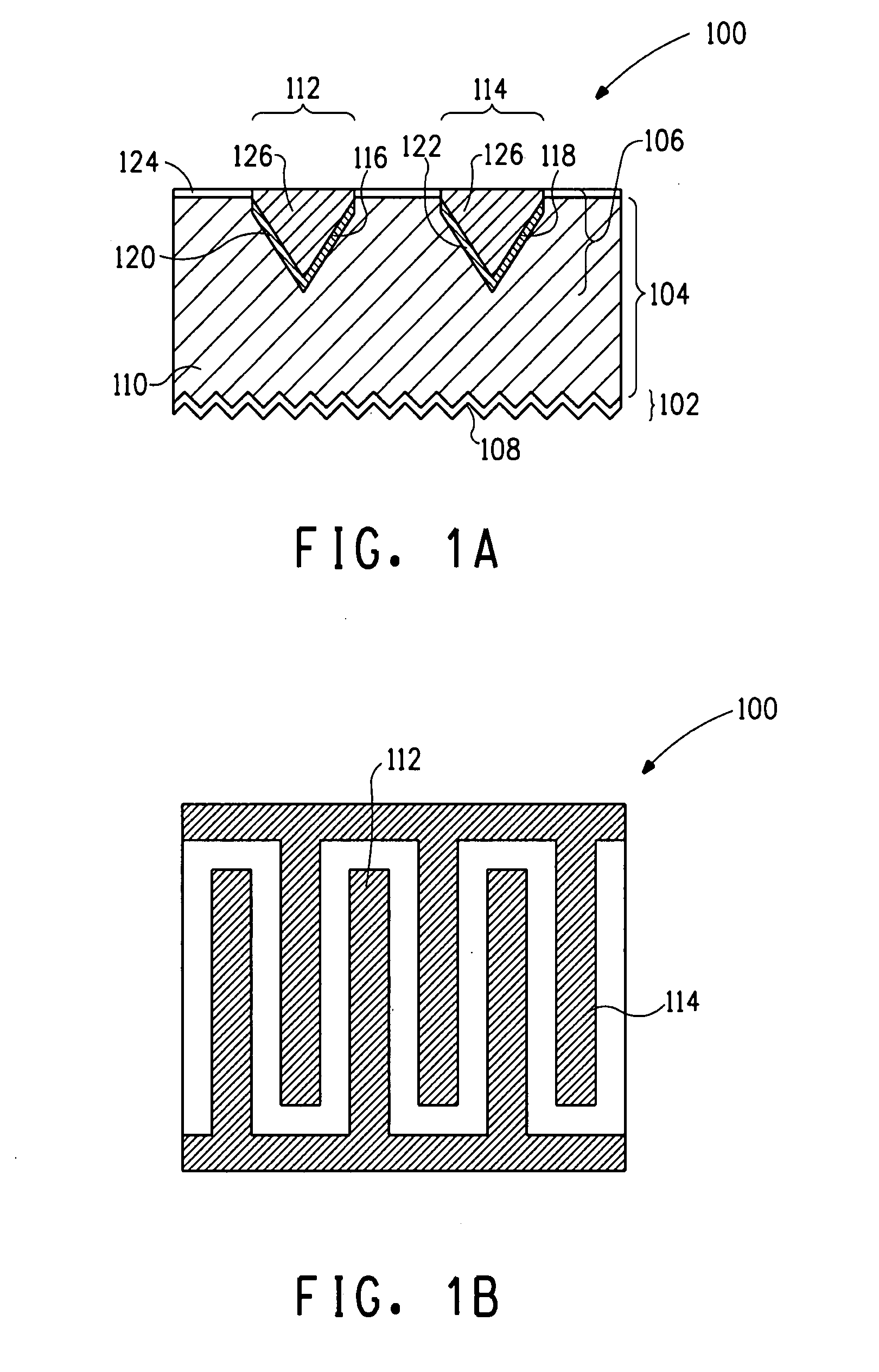

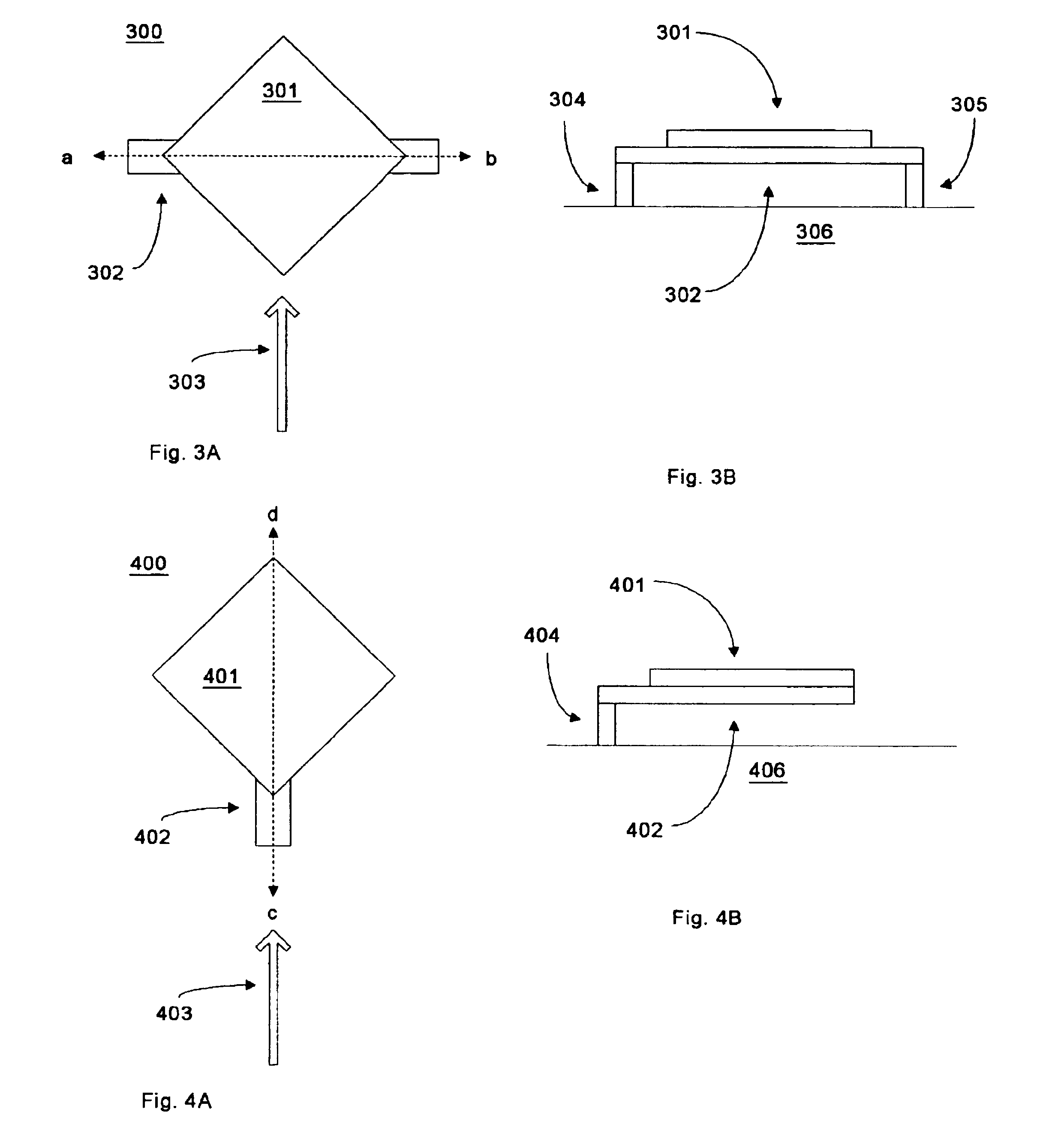

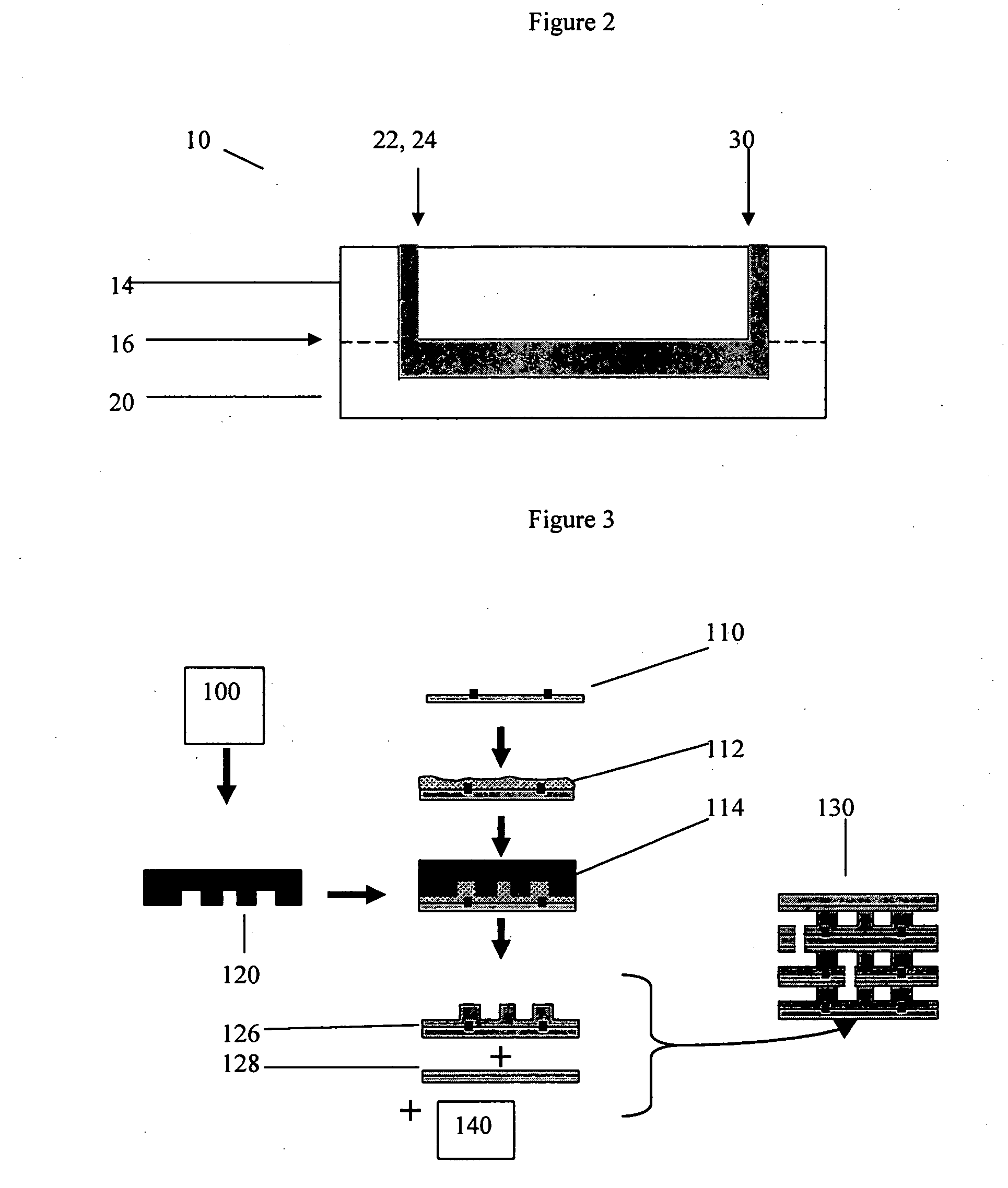

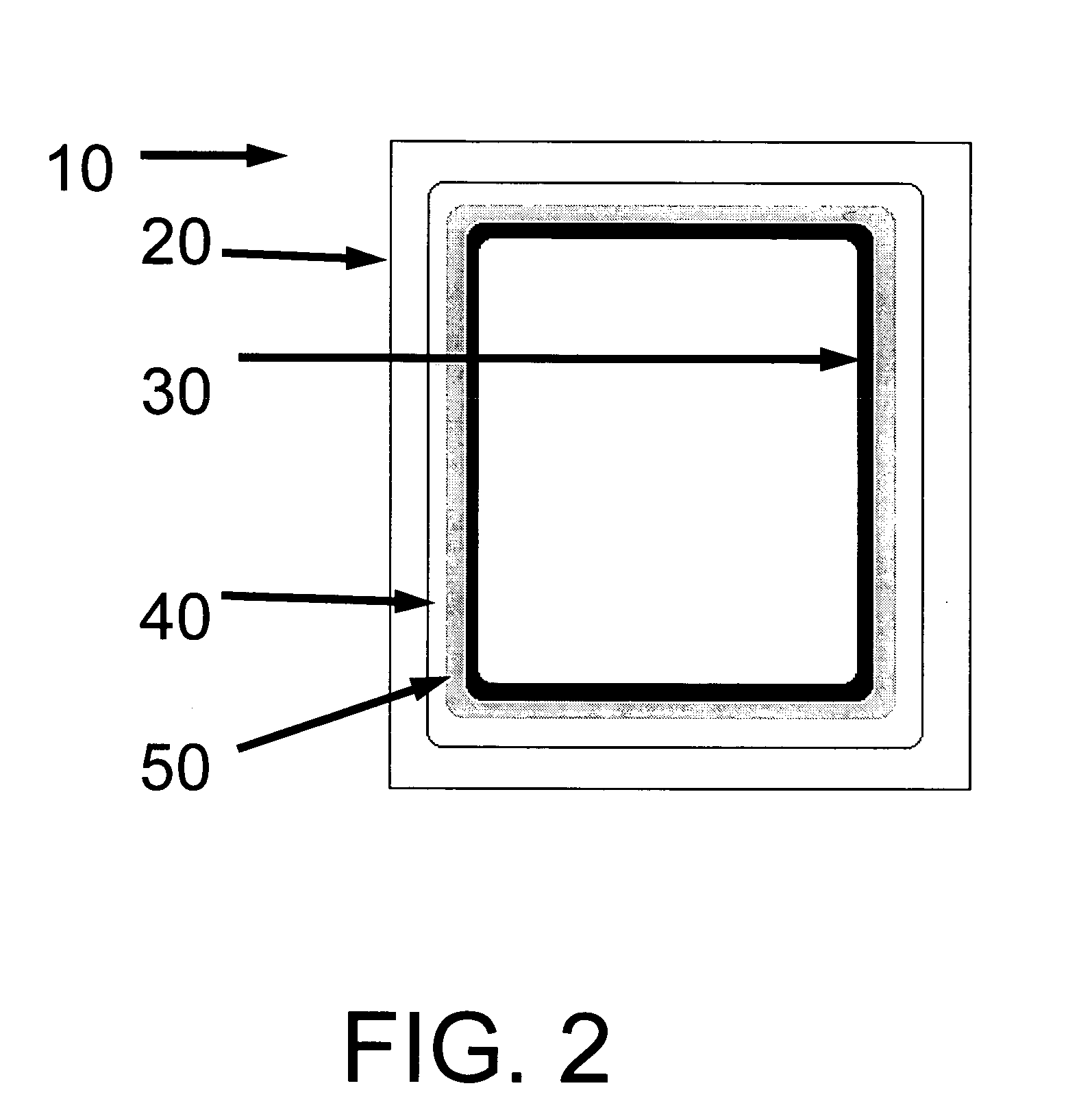

An encapsulated OLED device includes a substrate having a predetermined glass seal area and defining a sealed region and one or more OLED unit(s) provided over the substrate, each OLED unit having a light-emitting portion including at least one first electrode, at least one second electrode spaced from the first electrode, and an organic EL media layer provided between the first and second electrodes, wherein the light-emitting portion is provided within the sealed region. The device also includes an inorganic protection layer provided over the glass seal area and over at least a portion of the sealed region, a cover provided over the substrate and OLED unit(s), and sintered glass frit seal material provided in the glass seal area and in contact with both the cover and the inorganic protection layer to bond the cover to the inorganic protection layer and provide sealing against moisture penetration into the sealed region.

Owner:EASTMAN KODAK CO

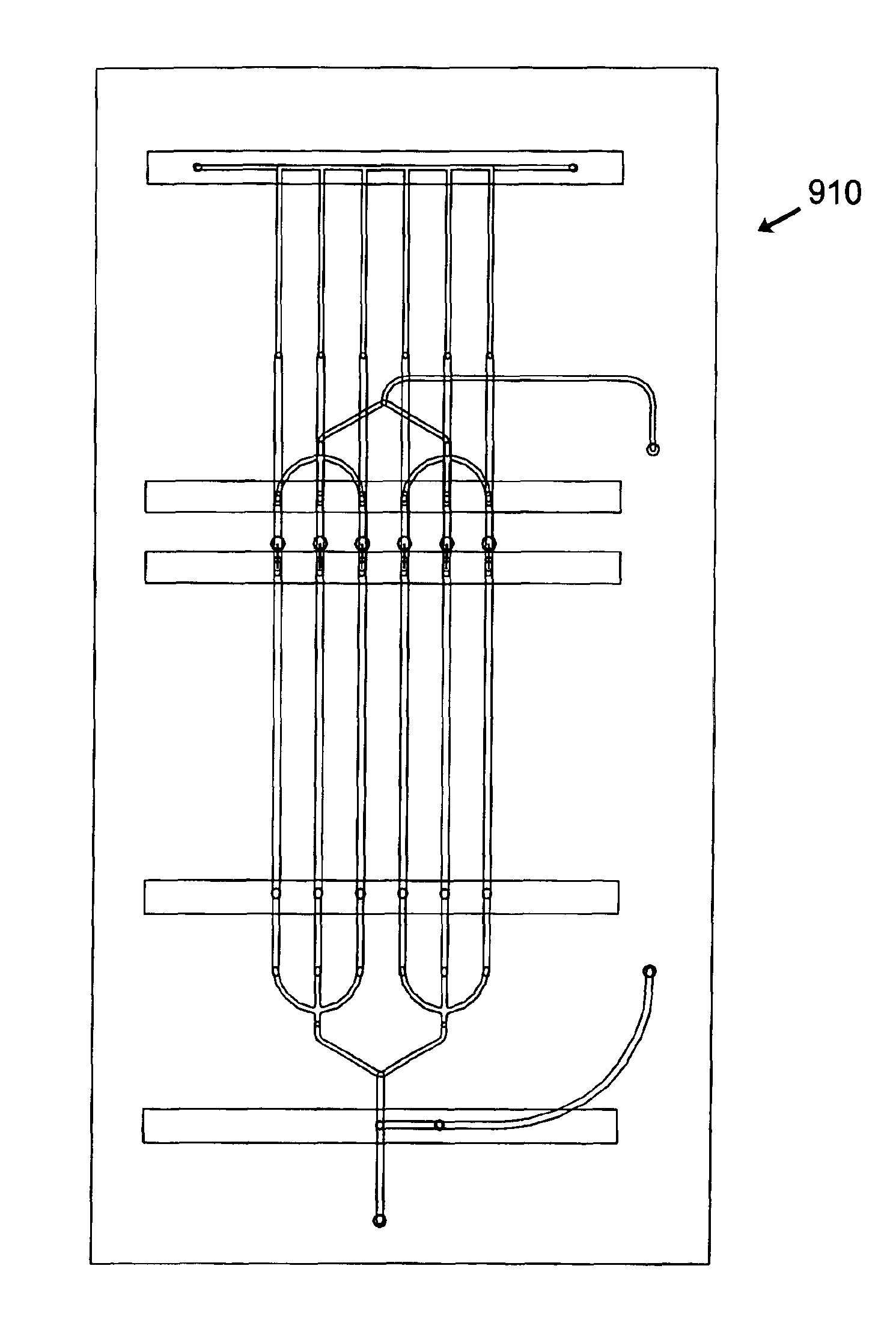

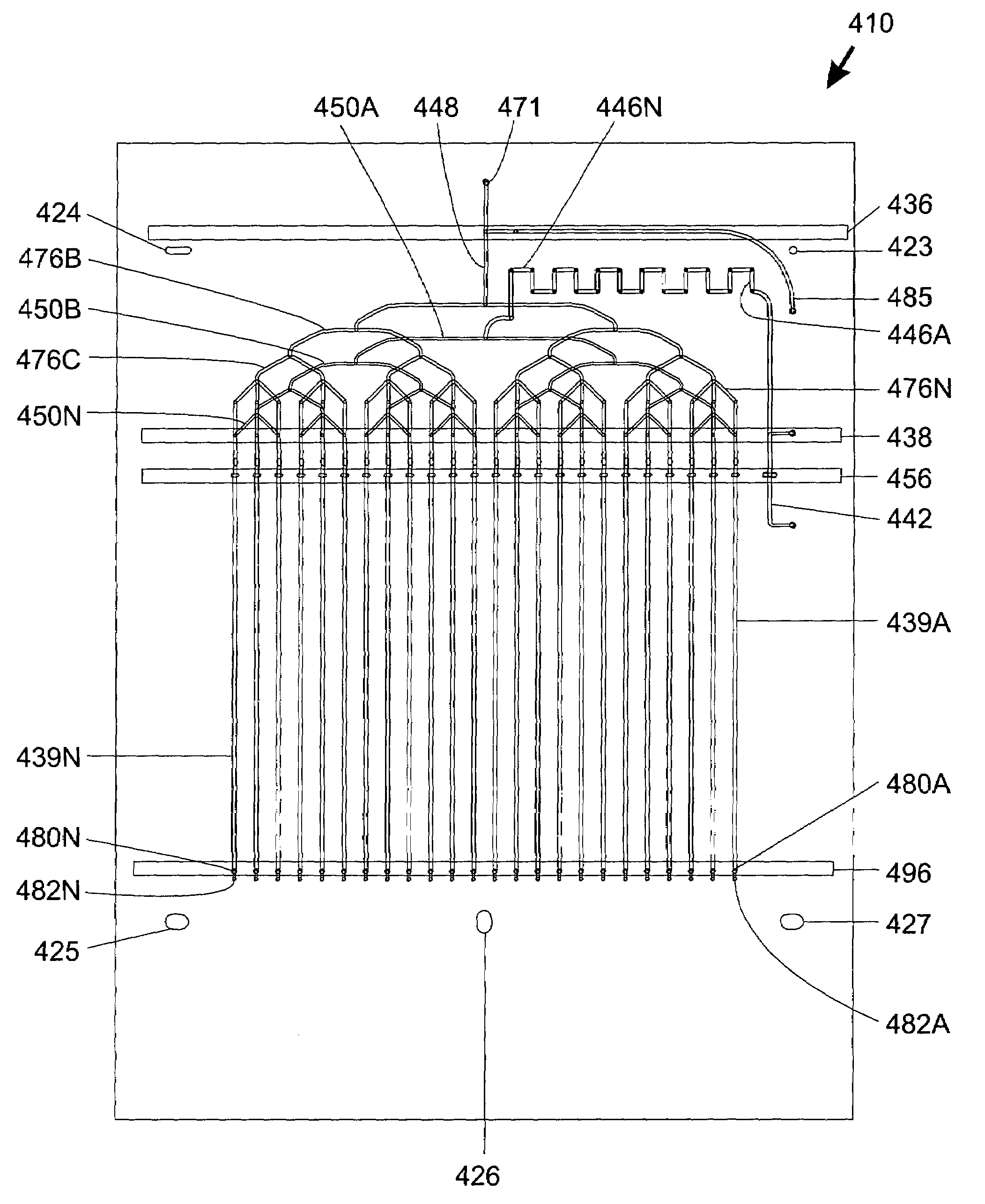

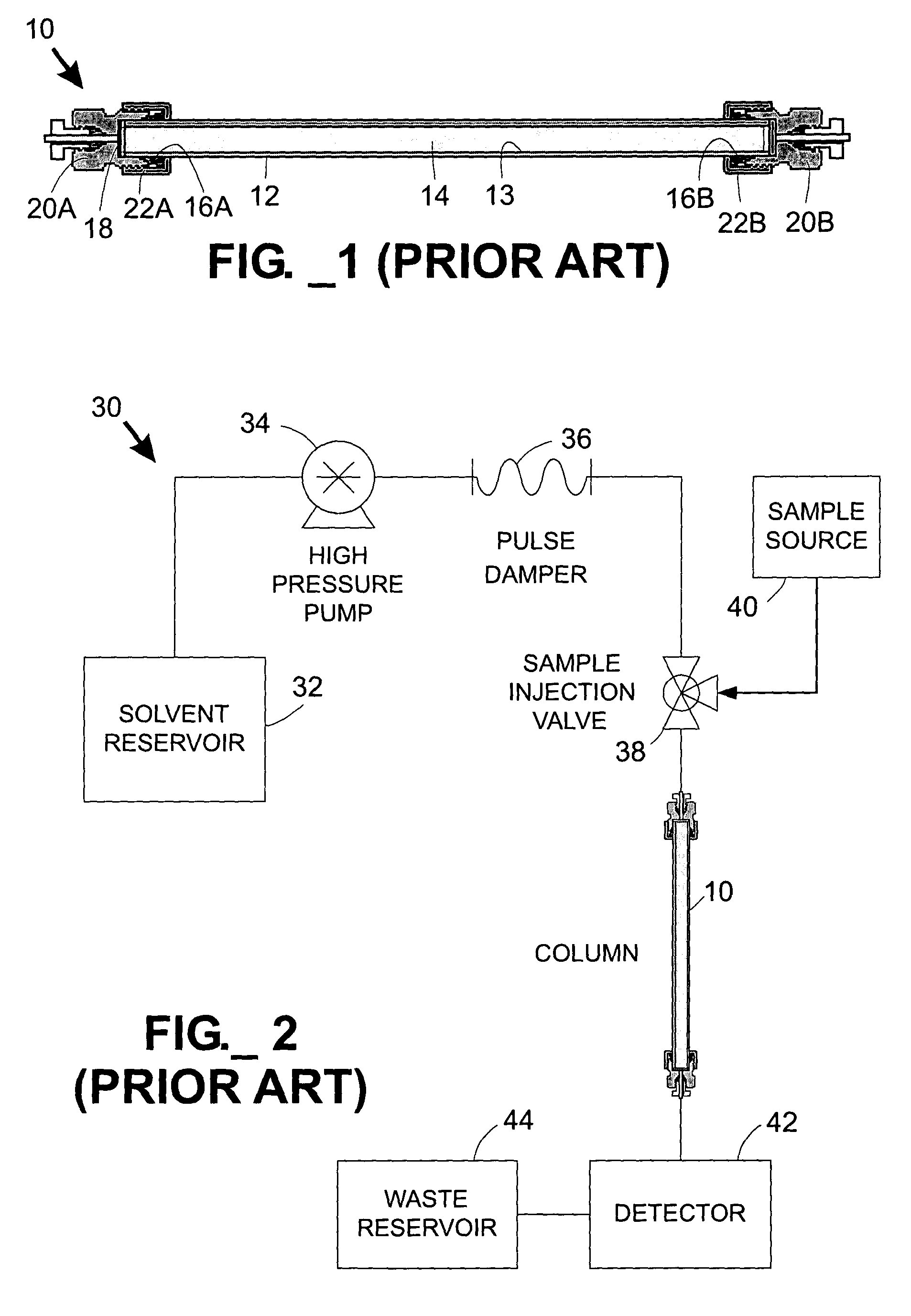

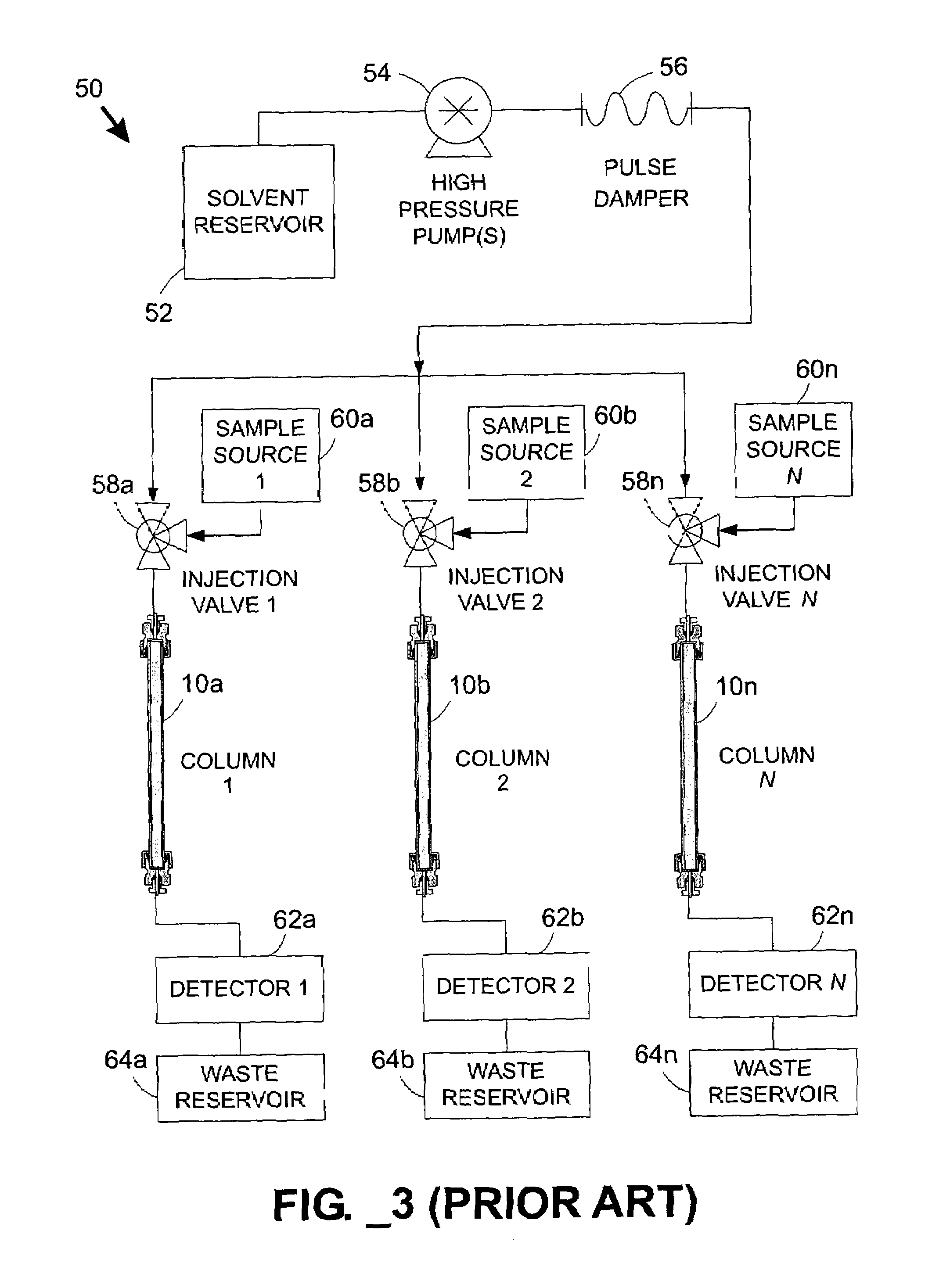

Microfluidic devices for methods development

InactiveUS6880576B2Material nanotechnologySludge treatmentChromatographic separationFlow resistivity

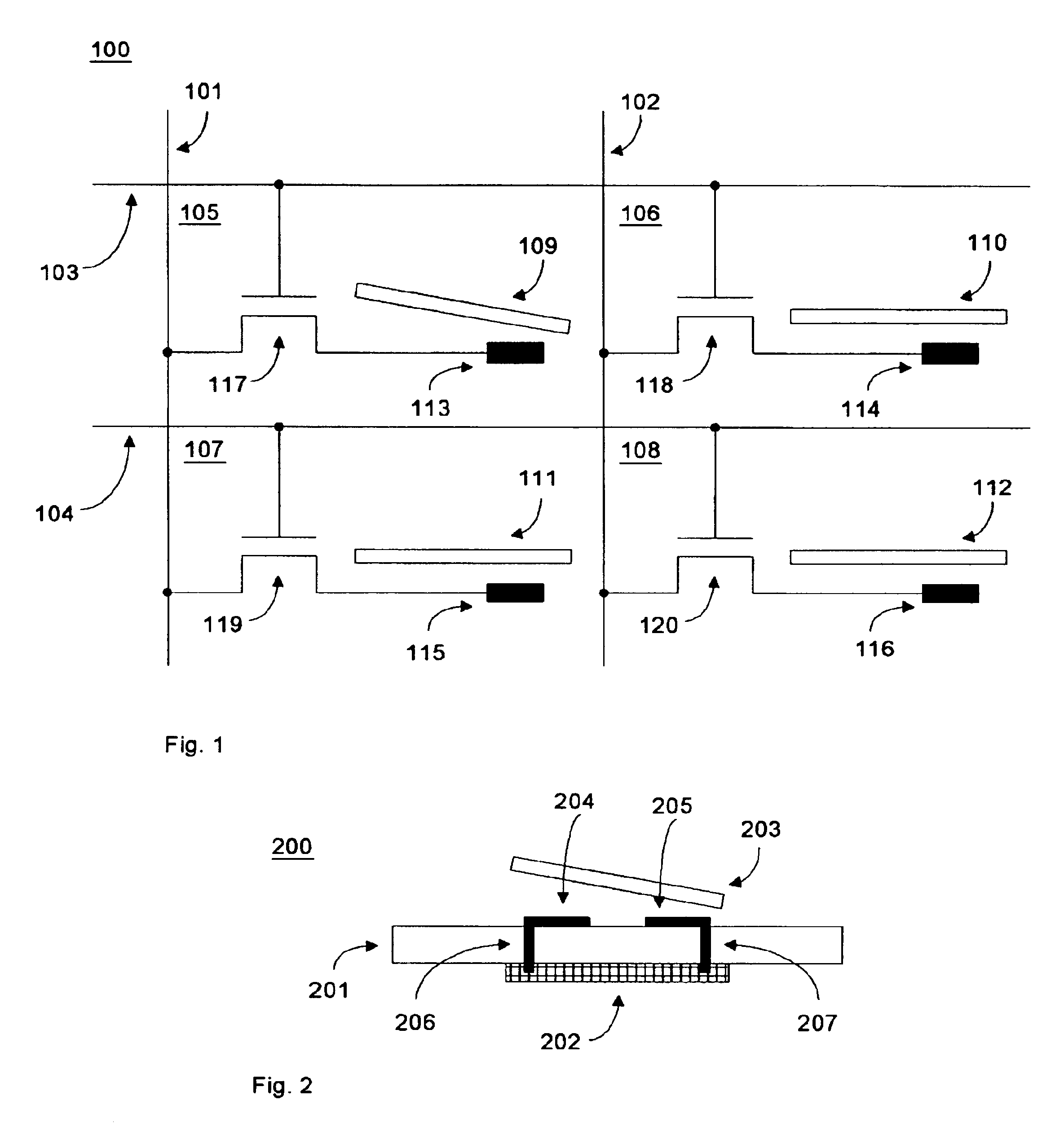

Microfluidic devices with multiple fluid process regions for subjecting similar samples to different process conditions in parallel are provided. One or more common fluid inputs may be provided to minimize the number of external fluid supply components. Solid materials such as chromatographic separation media or catalyst media is preferably provided in each fluid process region. Solid materials may be supplied to the devices in the form of slurry, with particles retained by porous elements or frits. Different fluid process regions may having different effective lengths, different solid material types or amounts, or may receive different ratios of common fluids supplied to the device. The flow resistances of dissimilar fluid process regions may be balanced passively with the addition of impedance elements in series with each fluid process region.

Owner:AGILENT TECH INC

Electroconductive thick film composition(s), electrode(s), and semiconductor device(s) formed therefrom

The present invention is directed to an electroconductive thick film composition comprising: (a) electroconductive metal particles selected from (1) Al, Cu, Au, Ag, Pd and Pt; (2) alloy of Al, Cu, Au, Ag, Pd and Pt; and (3) mixtures thereof; (3) glass frit wherein said glass frit is Pb-free; dispersed in (d) an organic medium, and wherein the average diameter of said electroconductive metal particles is in the range of 0.5-10.0 μm. The present invention is further directed to an electrode formed from the composition as detailed above and a semiconductor device(s) (for example, a solar cell) comprising said electrode.

Owner:SOLAR PASTE LLC

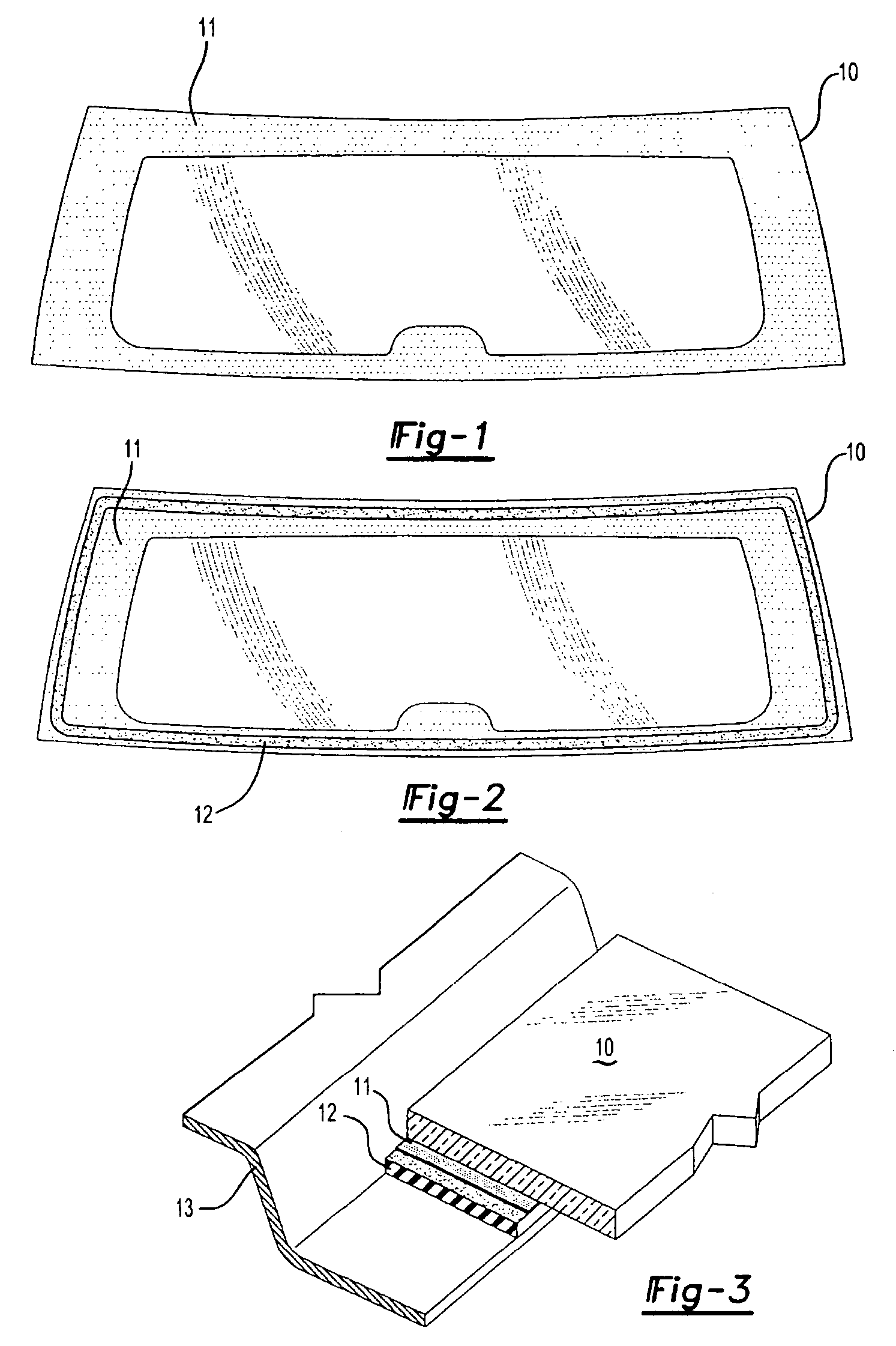

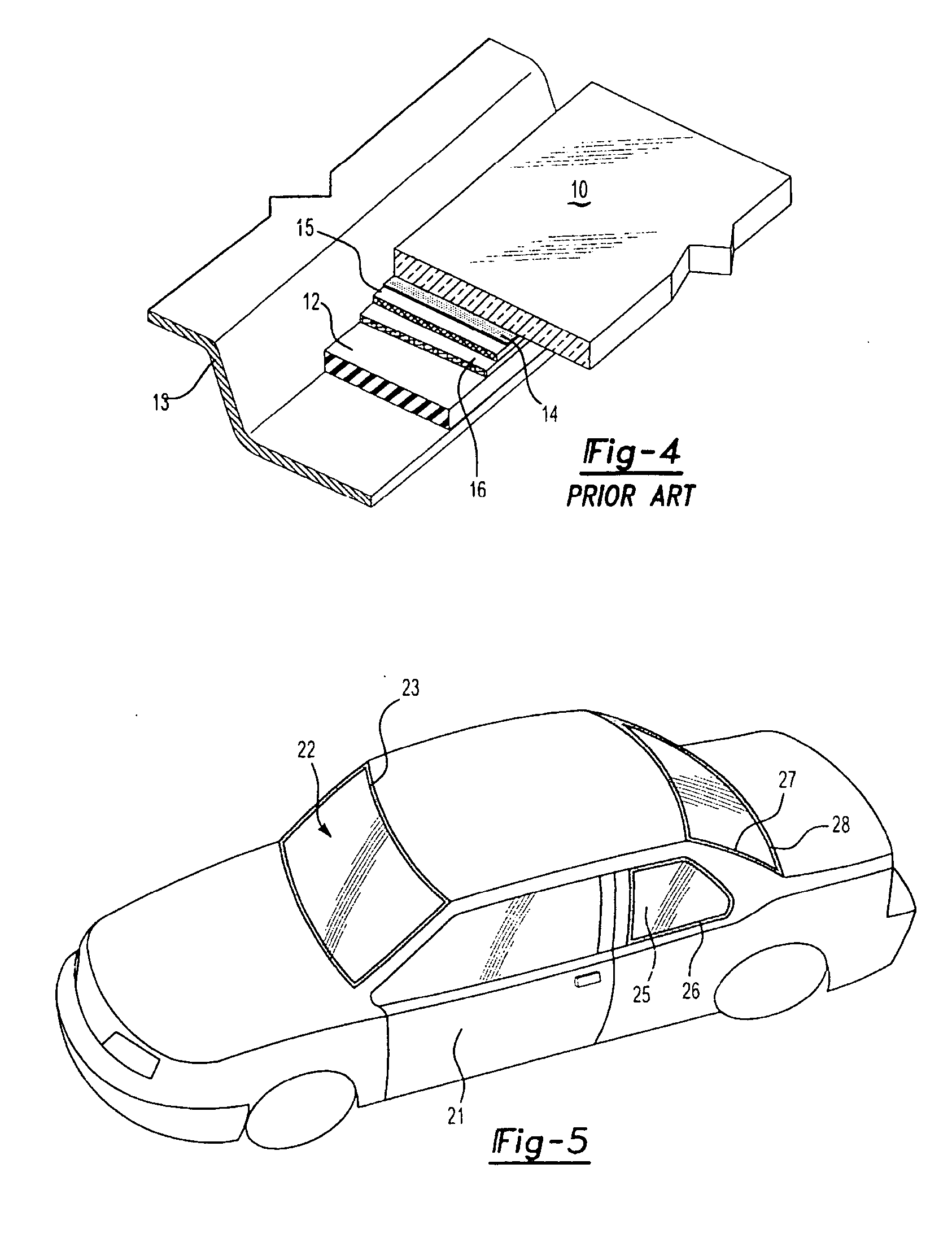

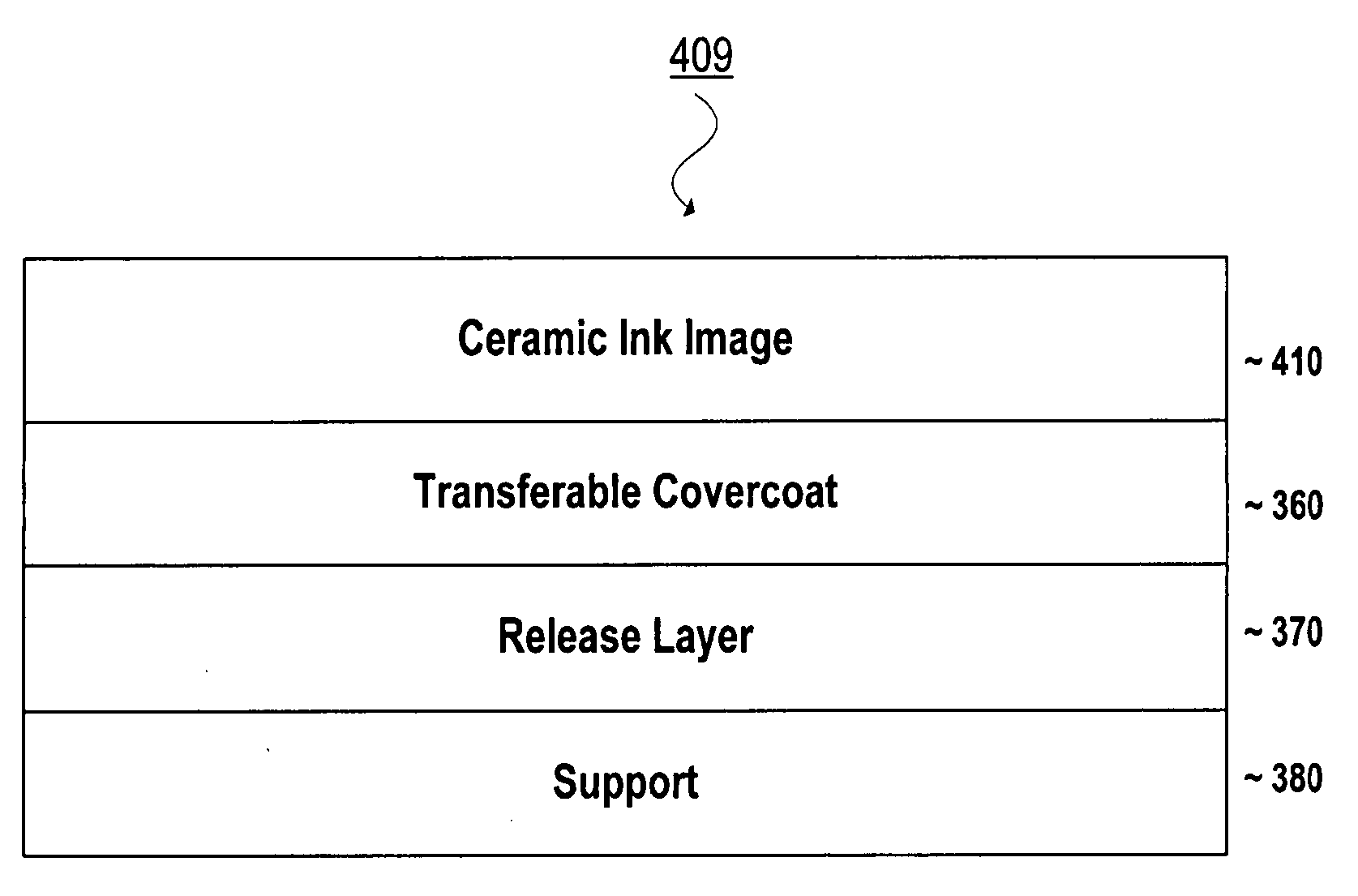

Protective coating for window glass

The invention is a composition comprising: a) one or more film forming resins having at least one functional group capable of polymerization; b) one or more reactive diluents capable of reacting with the film forming resin; c) one or more silicon, titanium, zirconium, aluminum or metal containing compounds capable of promoting adhesion of the composition to glass; d) one or more fillers capable of imparting abrasion resistance to the composition when cured; and e) one or more compounds which is reactive with the film forming resin which also contains at least one acidic moiety. The composition of the invention is useful as a frit on the window of a vehicle.

Owner:DOW GLOBAL TECH LLC

Colored glass frit

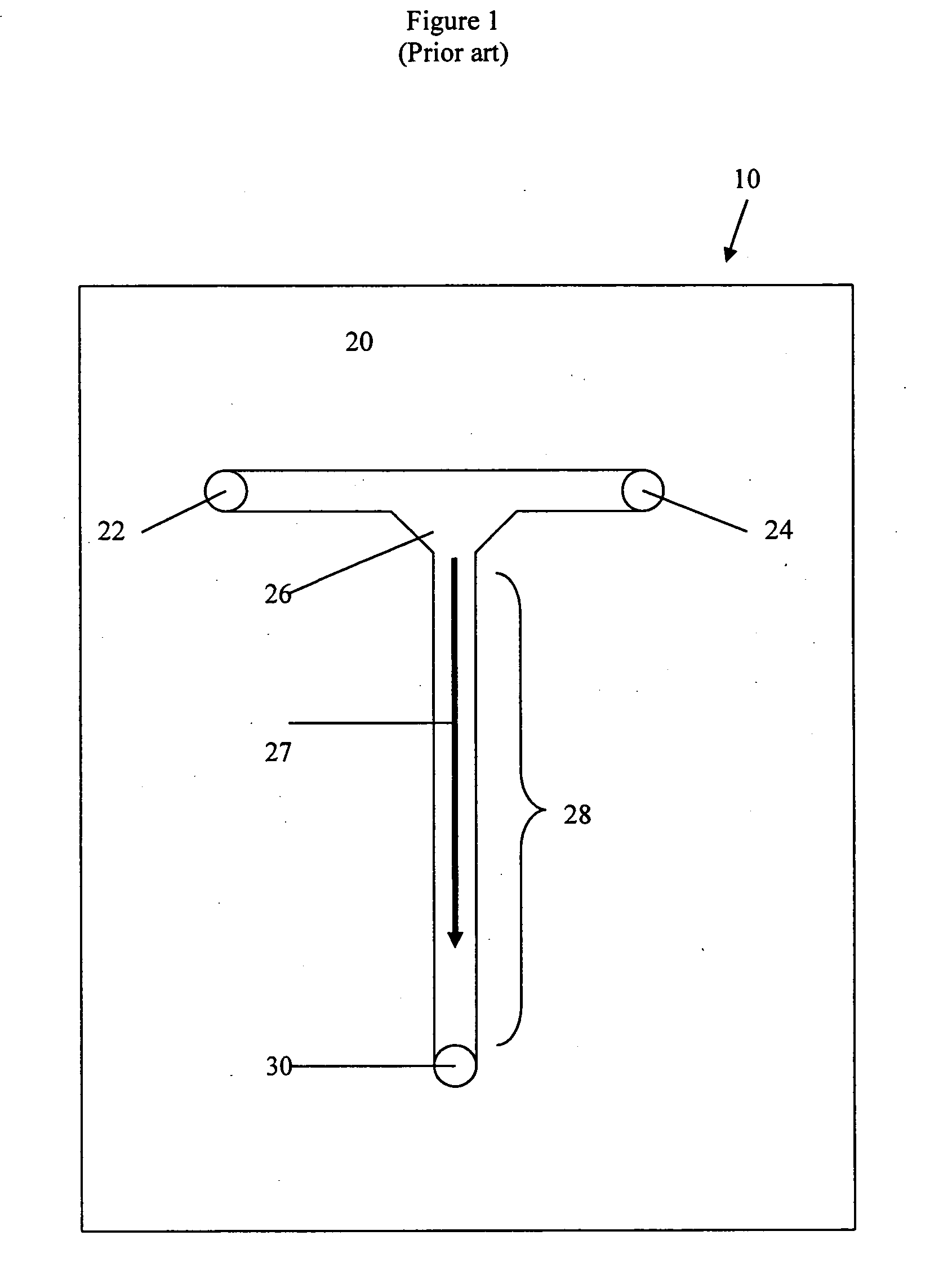

A colored glass frit with a specific surface area of less than 2 square meters per gram that contains from about 1 to about 80 weight percent of metallic element material and from about 30 to about 80 mole percent of glassy network forming oxide material. The frit has a transmission density per micron of thickness of at least about 0.1; when formed into a continuous film of 3 microns thickness and deposited onto a glass substrate, its transmission density is at least 0.3. The glassy network forming oxide material is homogeneously disposed in the flit, and the metallic element material is inhomogeneously dispersed within the glassy network forming oxide material. The metallic element material is in particulate form and has a particle size distribution such that at least 95 weight percent of its particles are smaller than 300 nanometers.

Owner:ALFRED UNIVERSITY

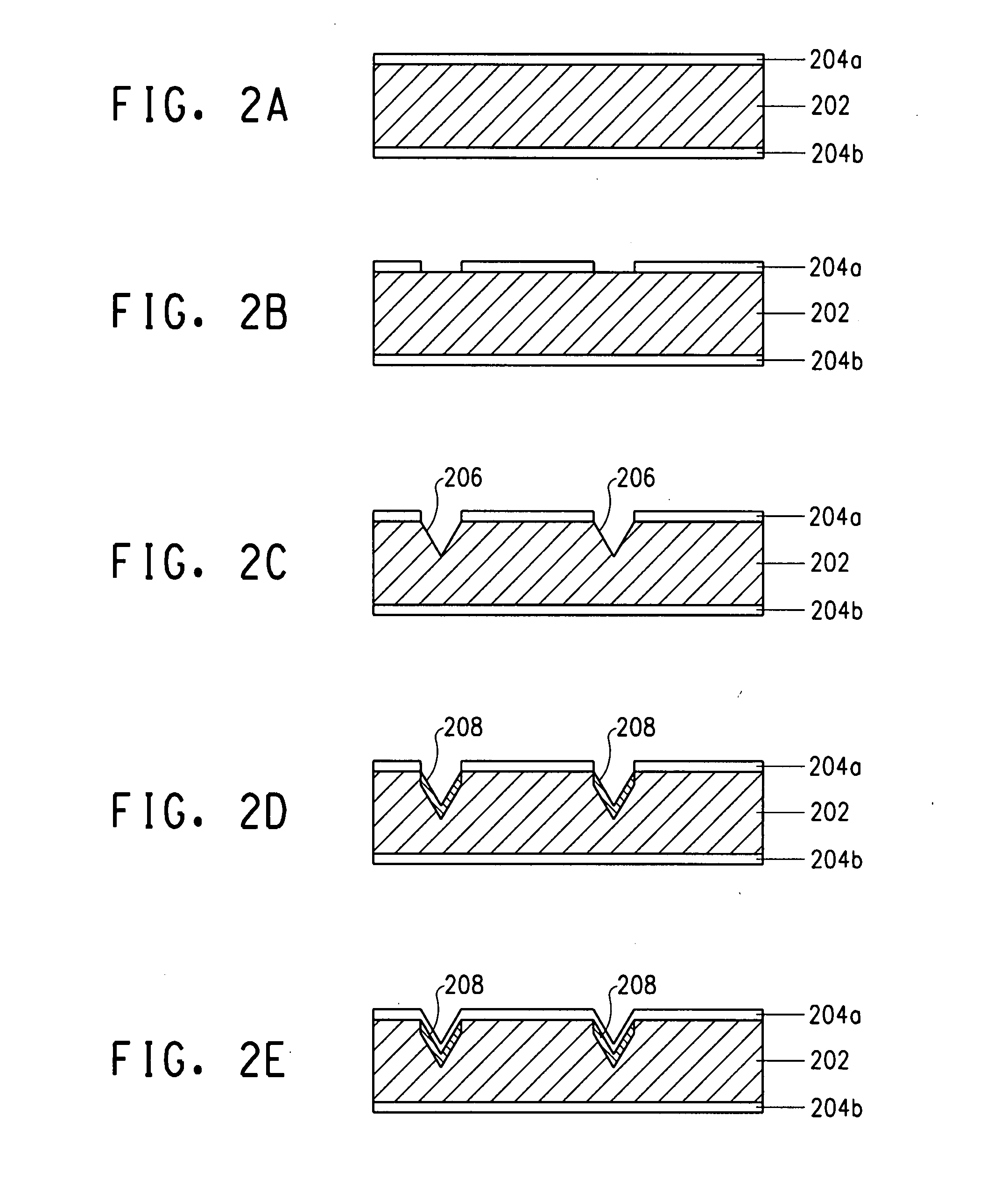

Method of making a glass envelope

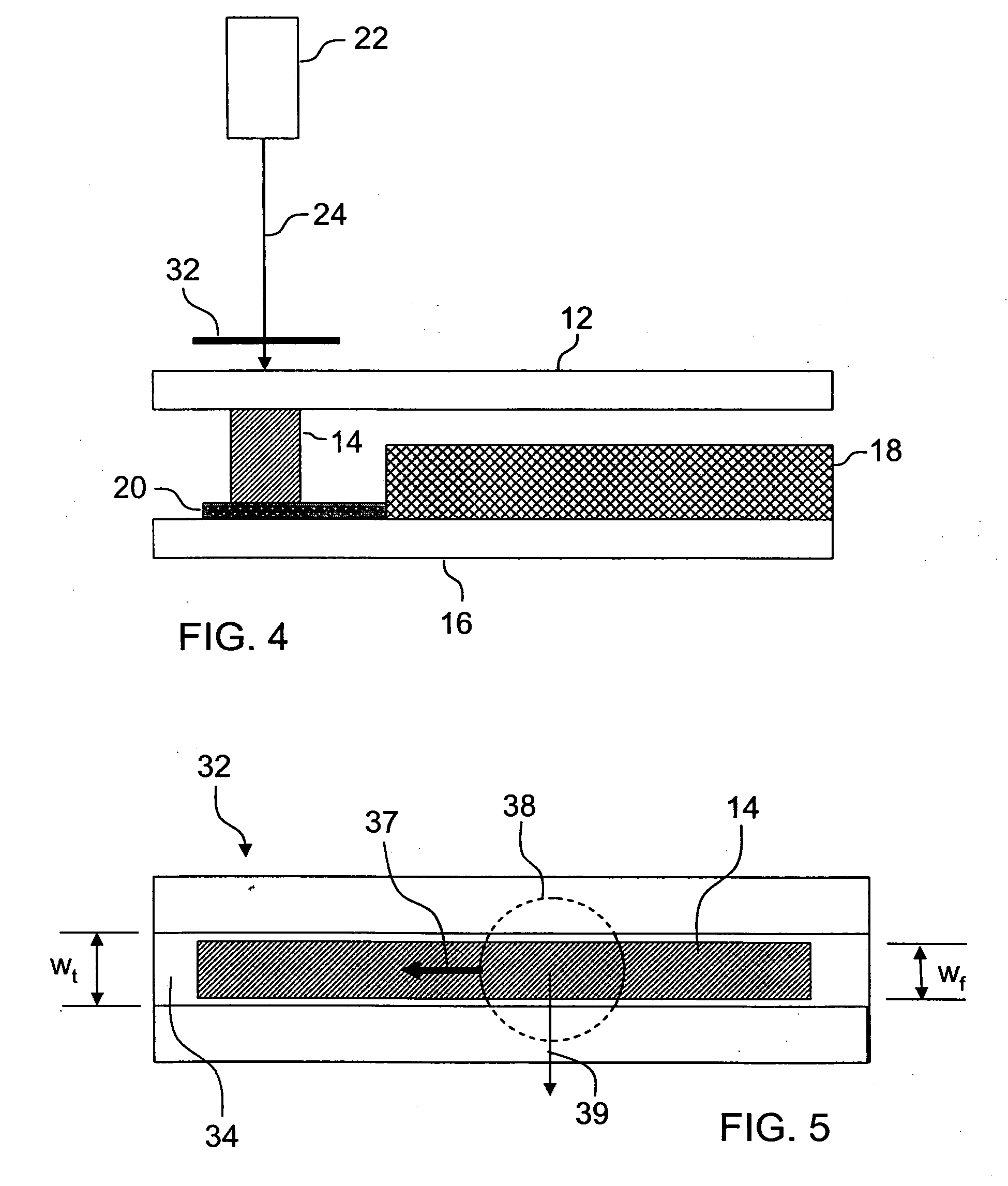

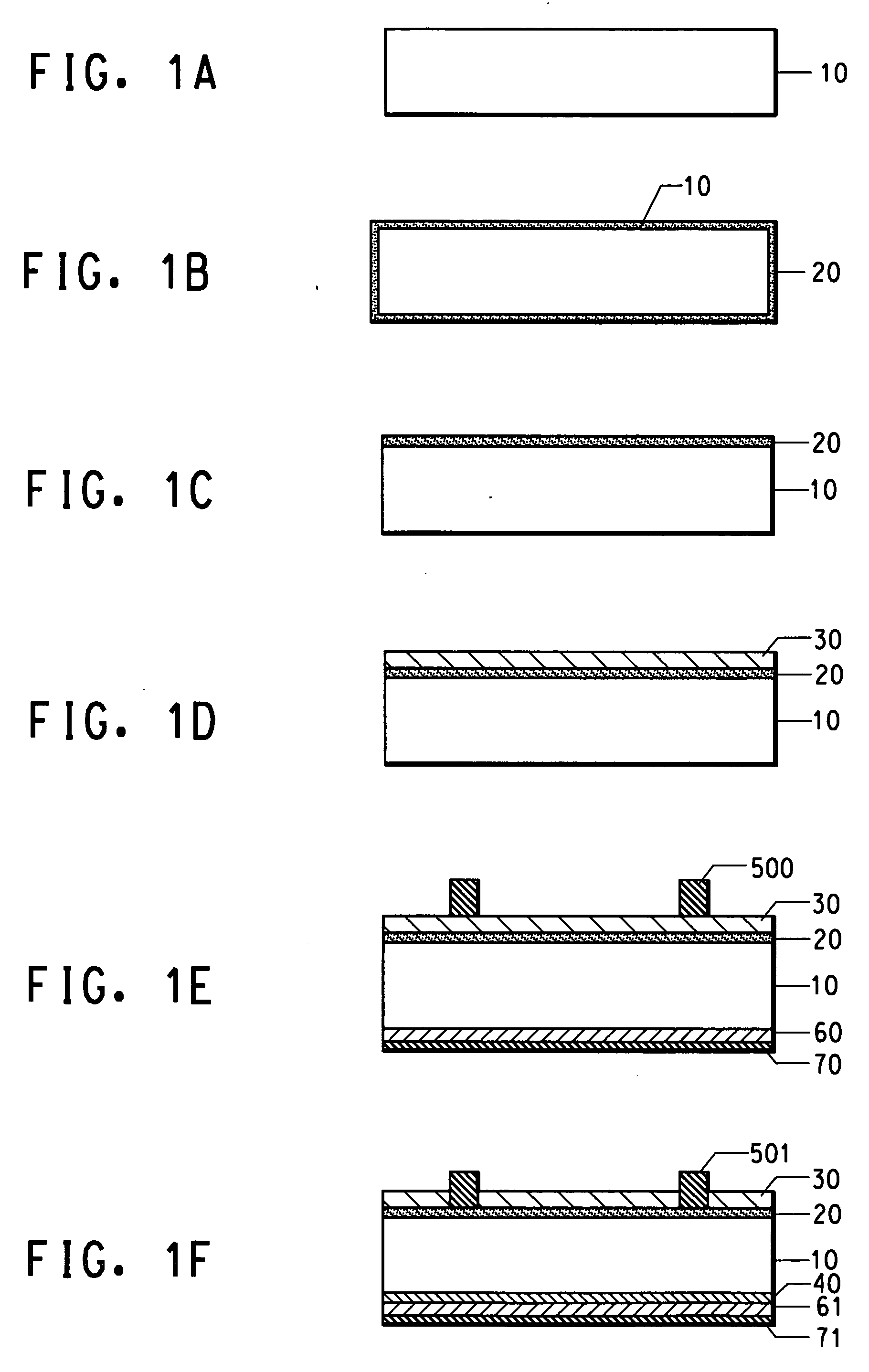

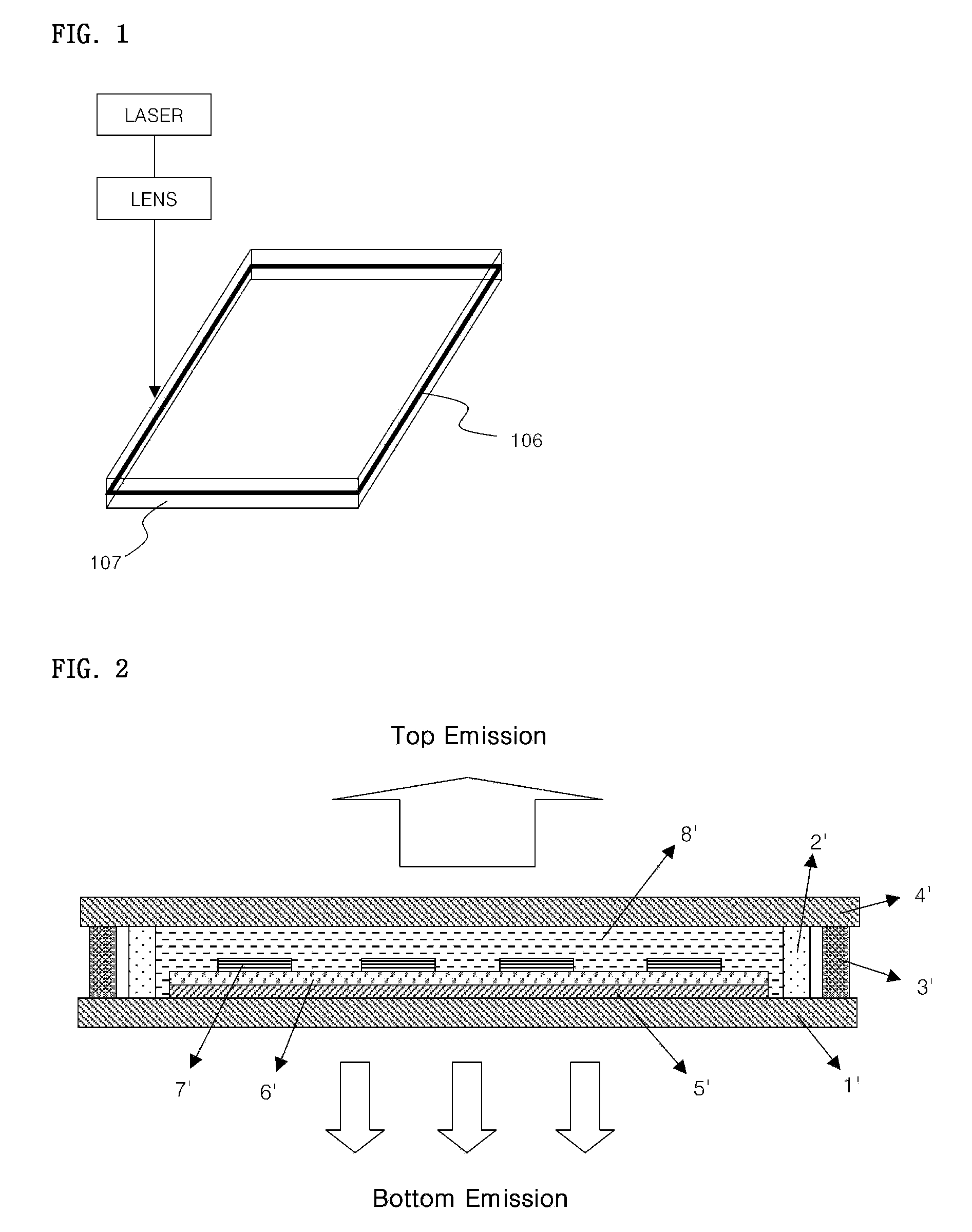

InactiveUS20070128967A1Easy to understandElectroluminescent light sourcesSolid-state devicesFritLight beam

A method of minimizing stress in an OLED device laser sealing process using an elongated laser beam. A laser beam having an intensity distribution which decreases as a function of distance from the longitudinal axis of the beam is passed through a mask to create an elongated beam having a length-wise intensity distribution which decreases as a function of distance from the axis of the beam and a substantially constant width-wise intensity distribution. The elongated beam is traversed over a line of frit disposed between two substrates. The tails of the length-wise intensity distribution provide for a slow cool down of the frit as the beam traverses the line of frit.

Owner:CORNING INC

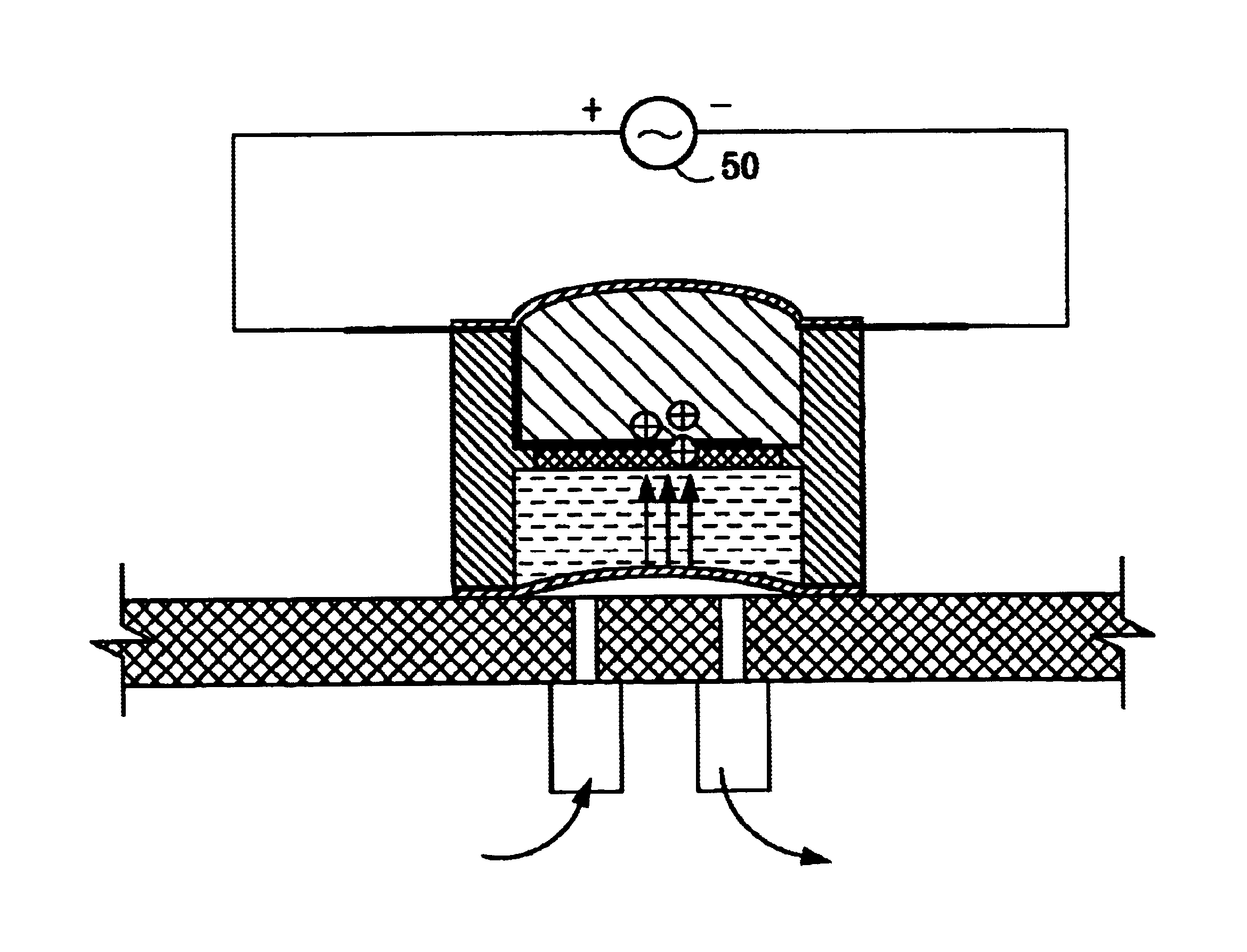

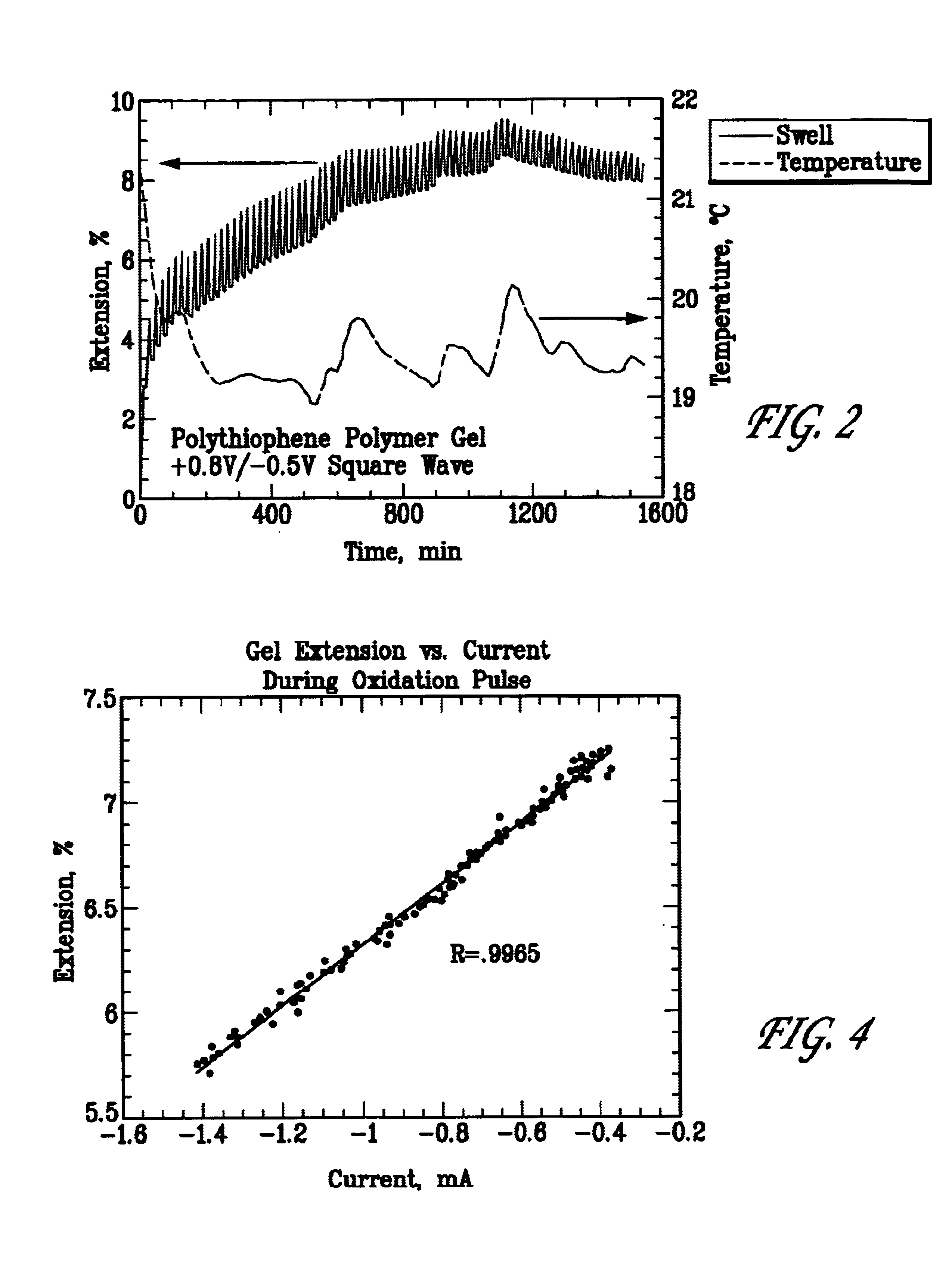

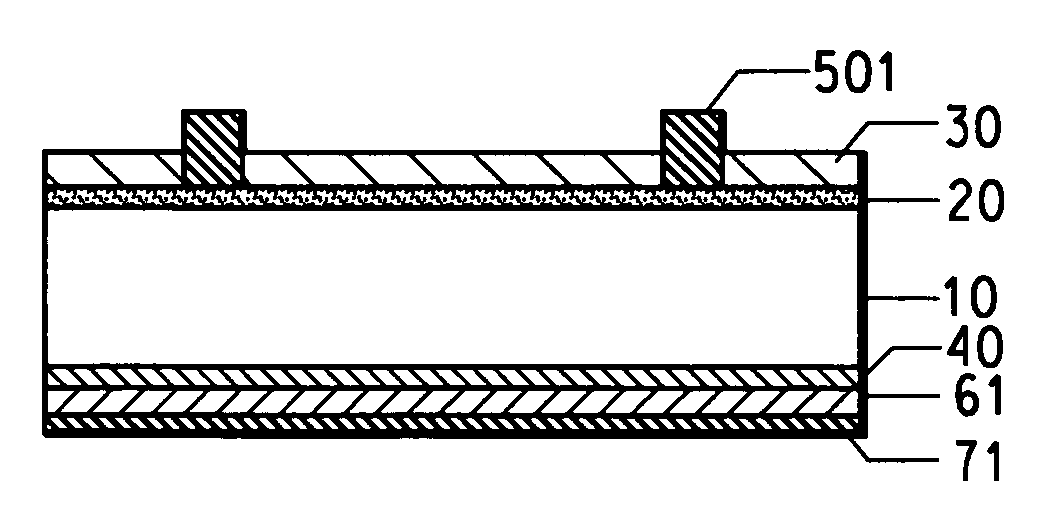

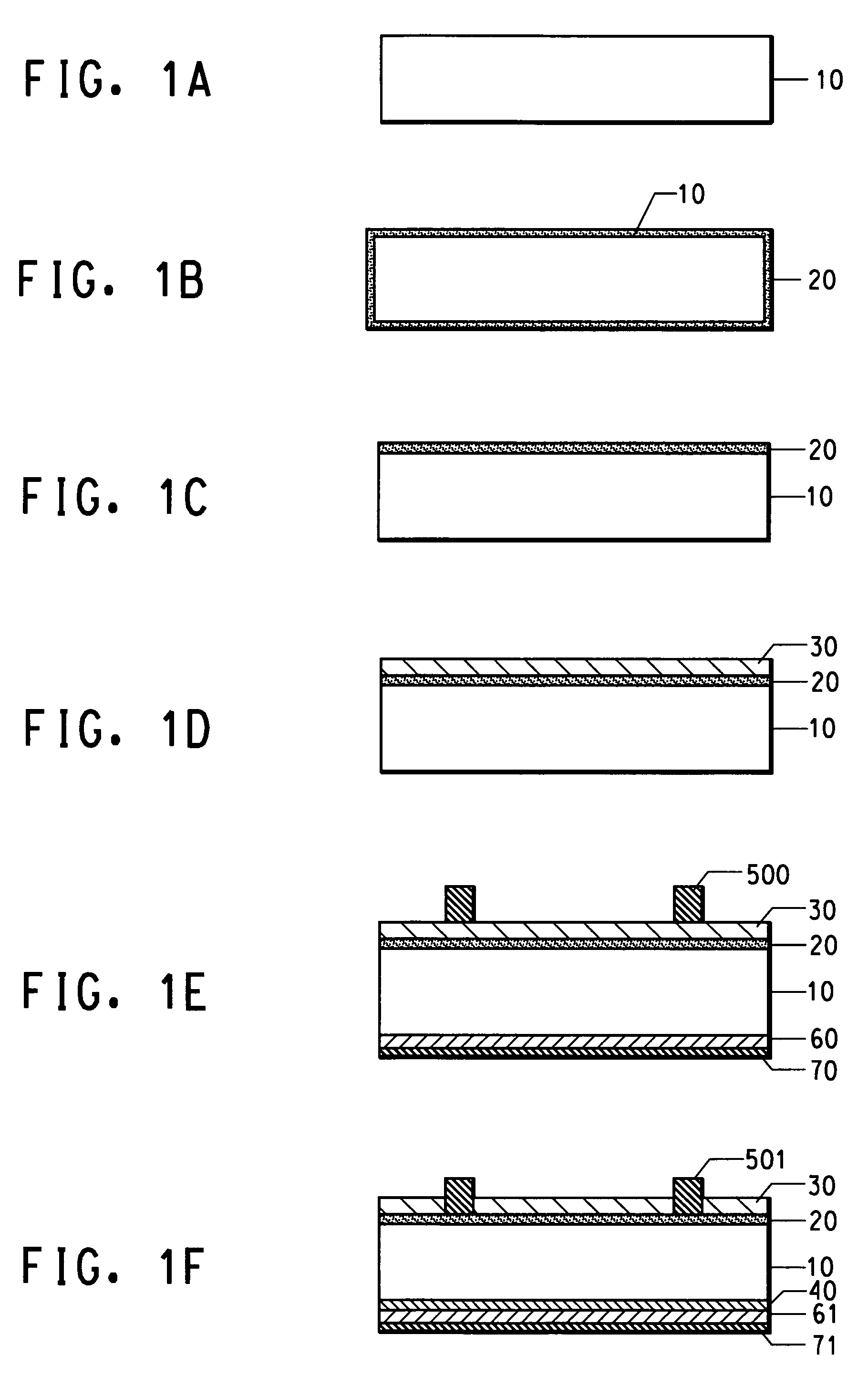

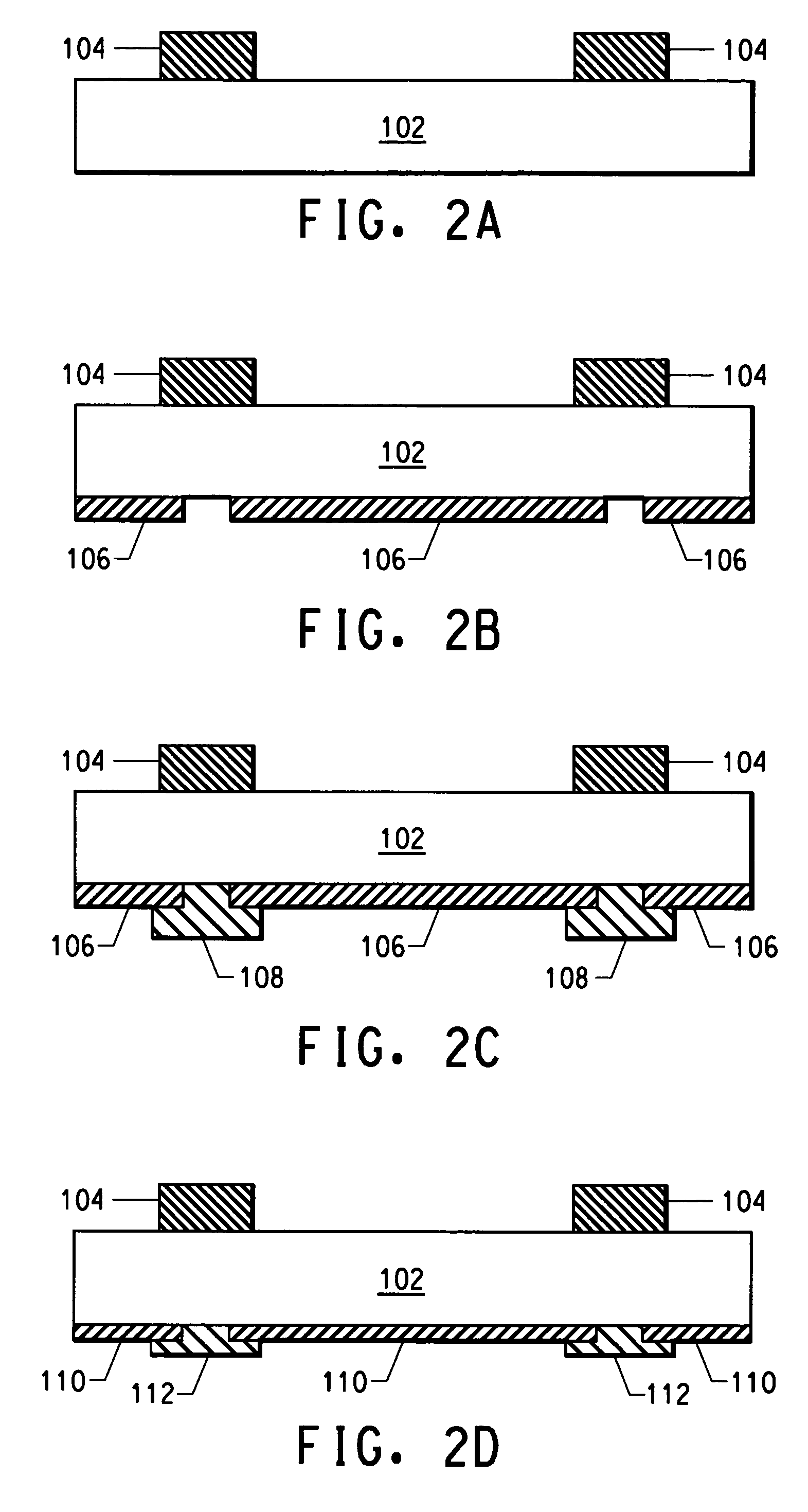

Actuator device utilizing a conductive polymer gel

InactiveUS6685442B2Operating means/releasing devices for valvesCircuit elementsElastomerConductive polymer

A valve actuator based on a conductive polymer gel is disclosed. A nonconductive housing is provided having two separate chambers separated by a porous frit. The conductive polymer is held in one chamber and an electrolyte solution, used as a source of charged ions, is held in the second chamber. The ends of the housing a sealed with a flexible elastomer. The polymer gel is further provide with electrodes with which to apply an electrical potential across the gel in order to initiate an oxidation reaction which in turn drives anions across the porous frit and into the polymer gel, swelling the volume of the gel and simultaneously contracting the volume of the electrolyte solution. Because the two end chambers are sealed the flexible elastomer expands or contracts with the chamber volume change. By manipulating the potential across the gel the motion of the elastomer can be controlled to act as a "gate" to open or close a fluid channel and thereby control flow through that channel.

Owner:SANDIA NAT LAB

Electroconductive thick film composition(s), electrode(s), and semiconductor device(s) formed therefrom

Owner:SOLAR PASTE LLC

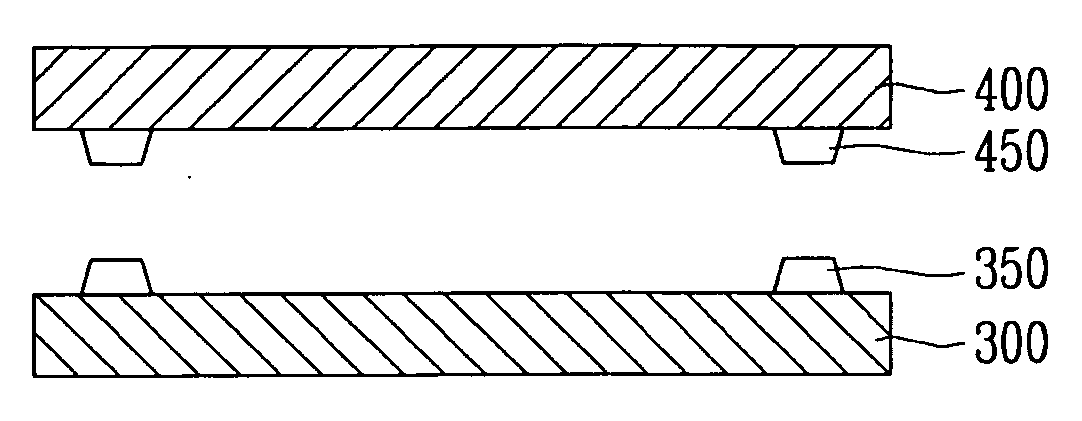

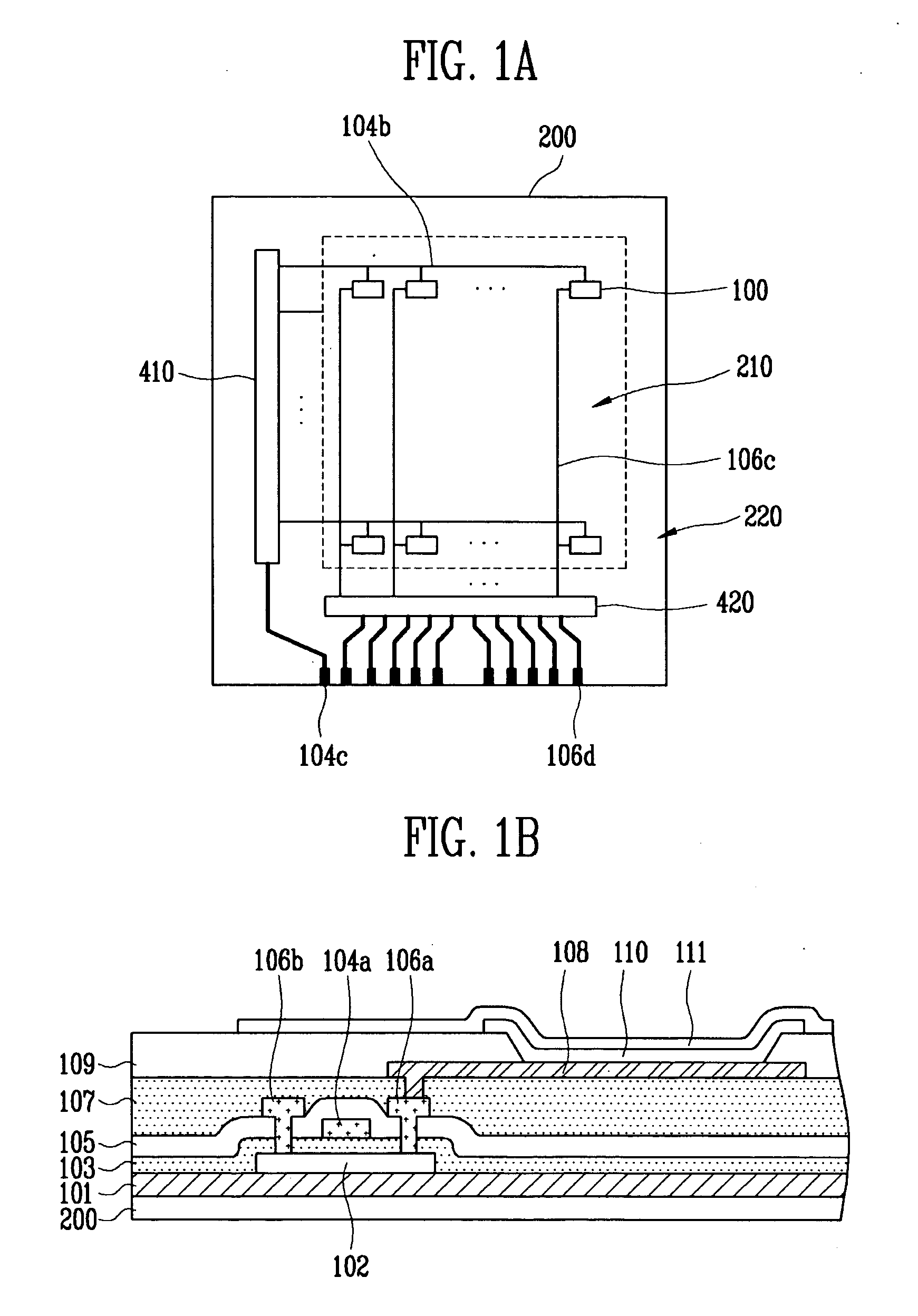

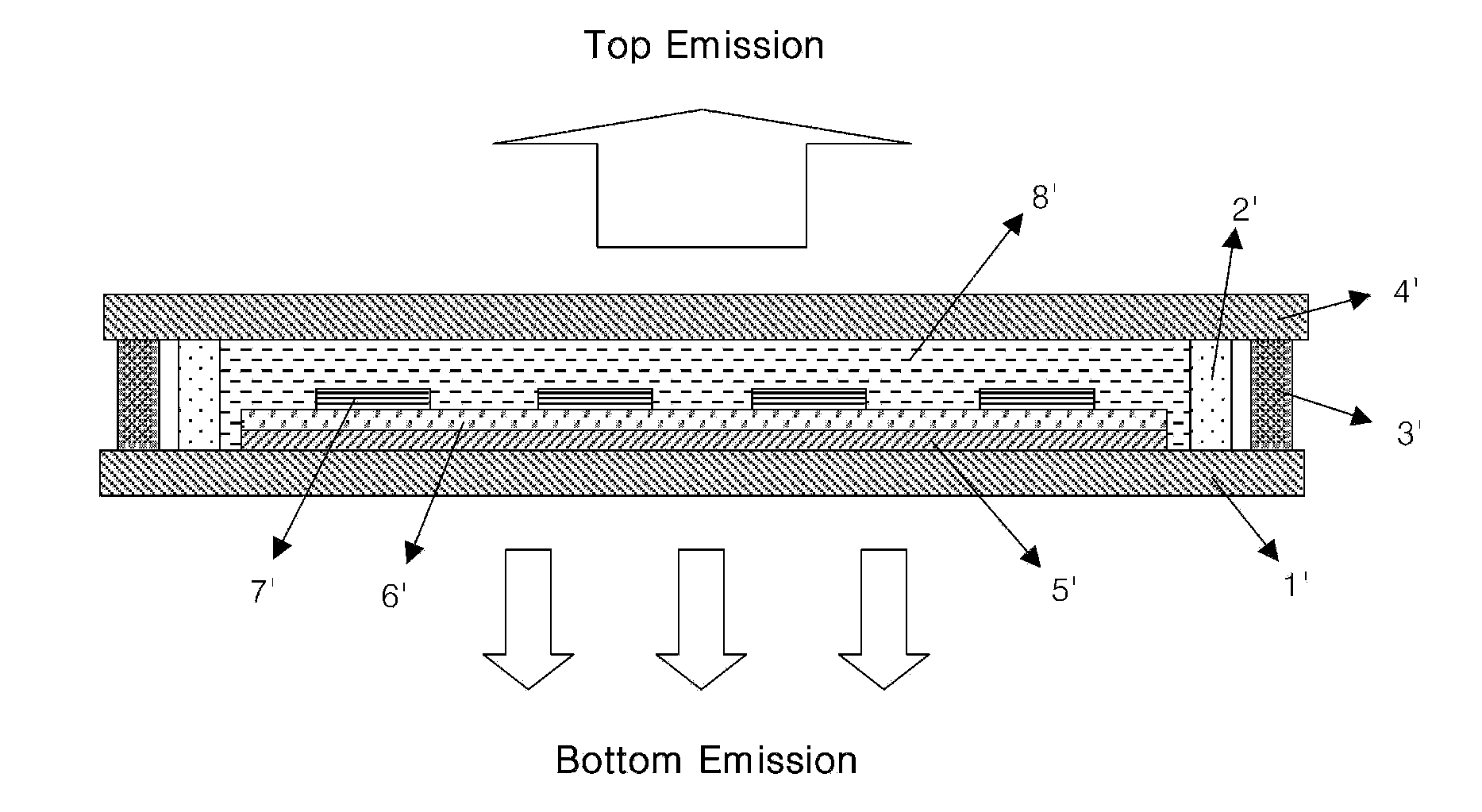

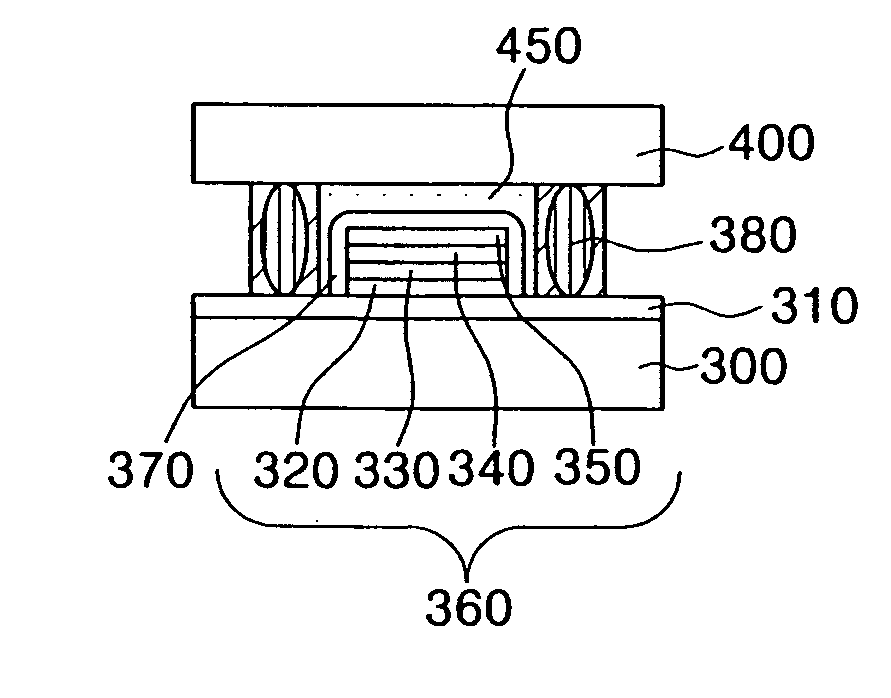

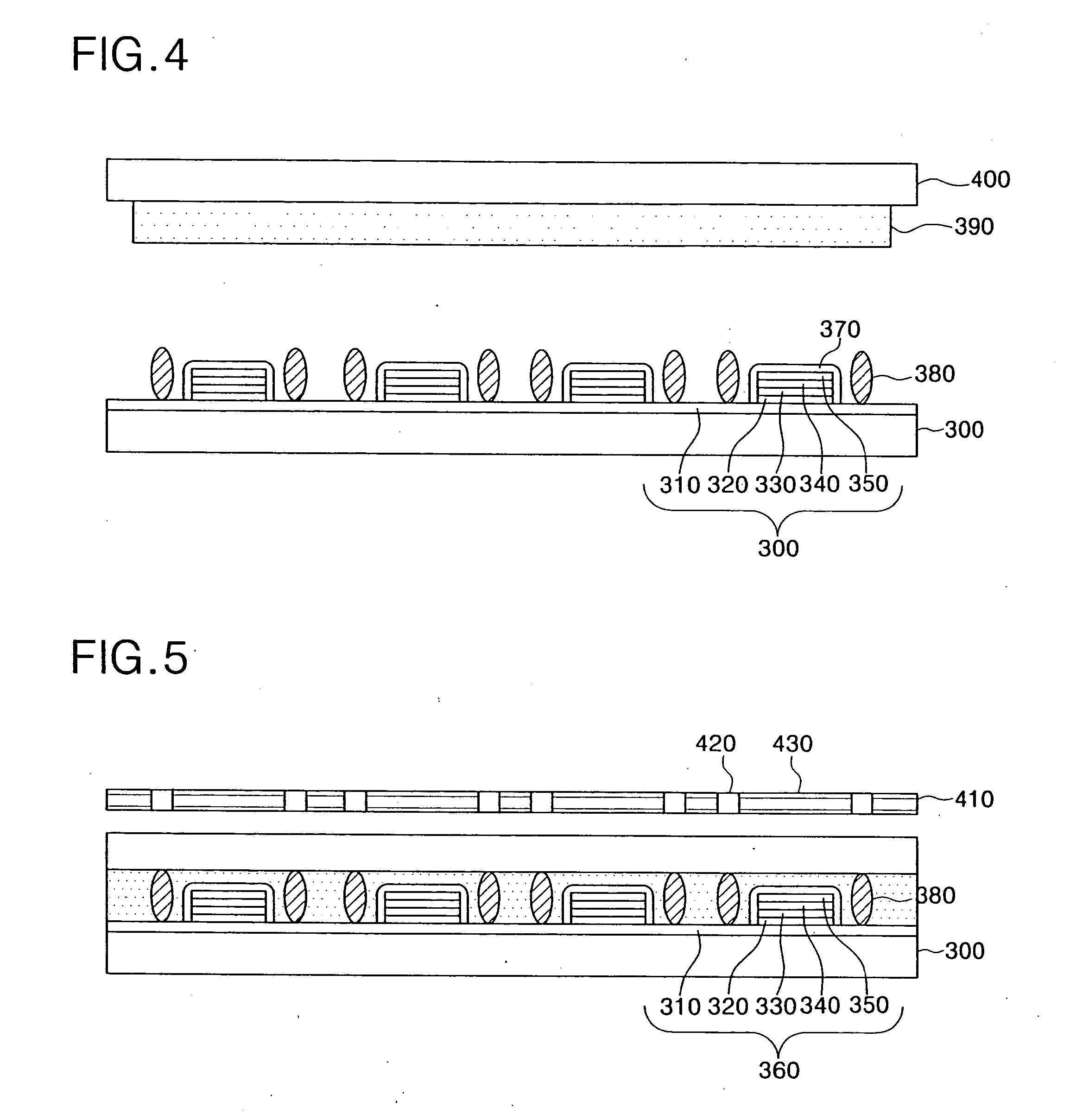

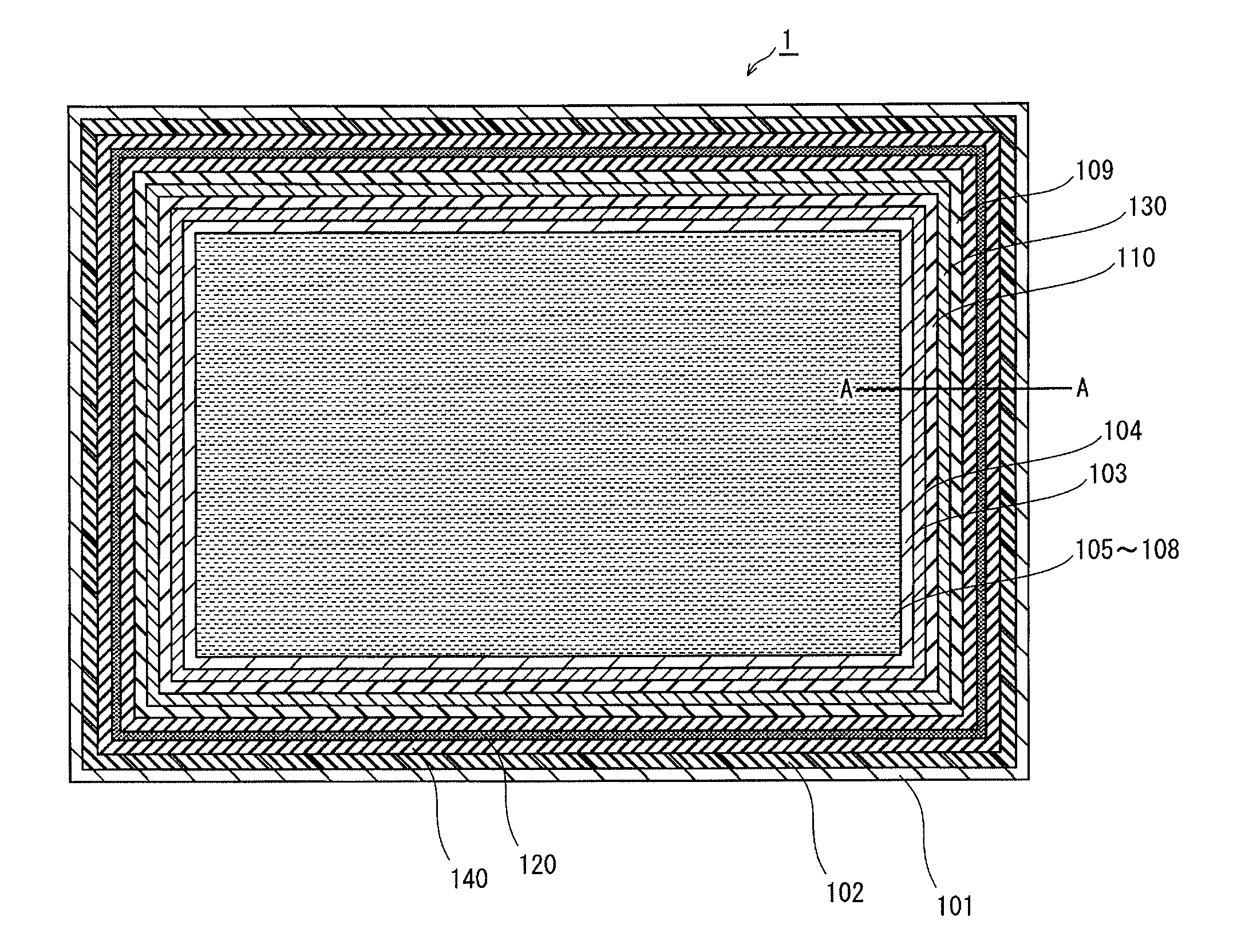

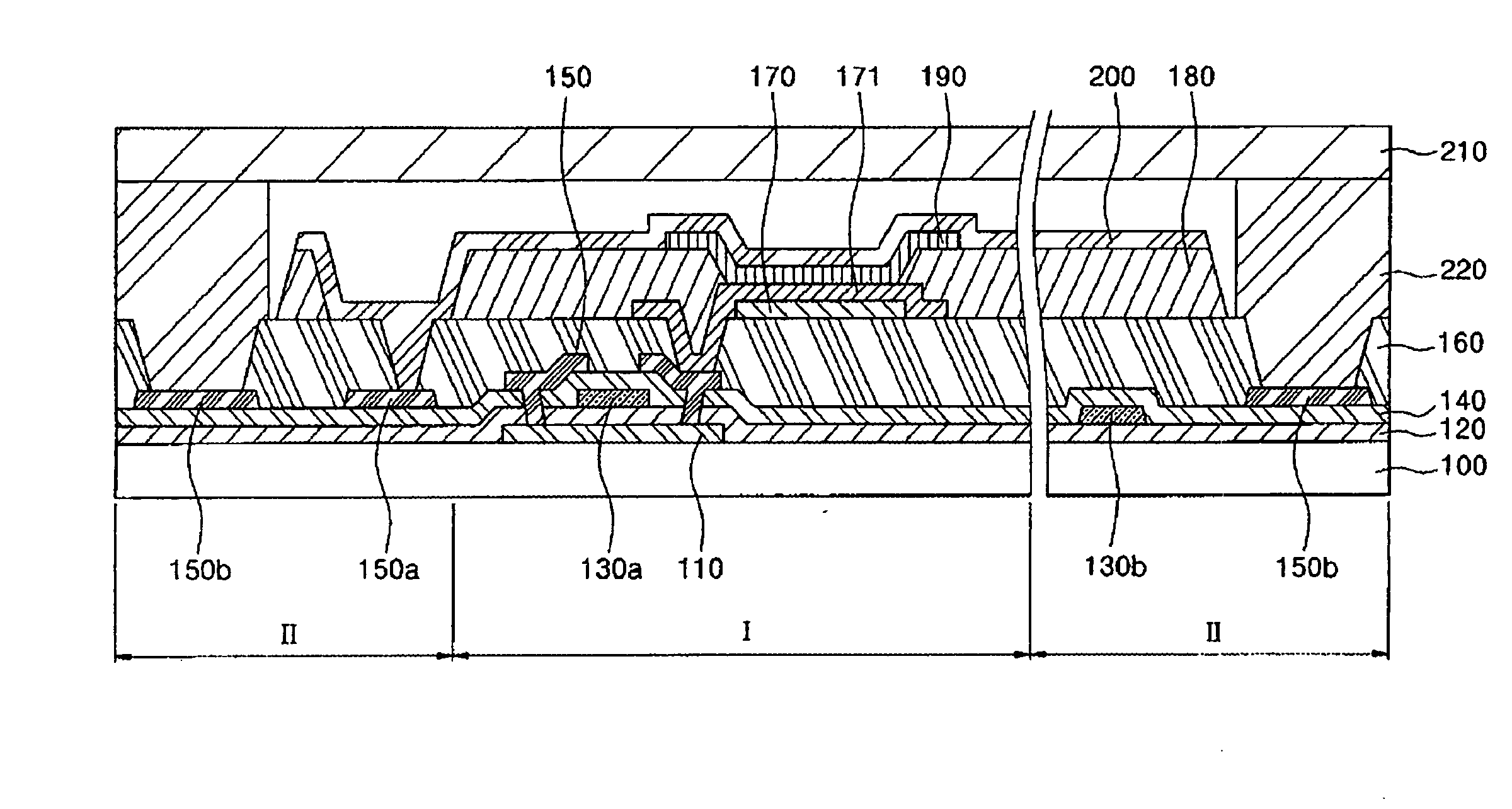

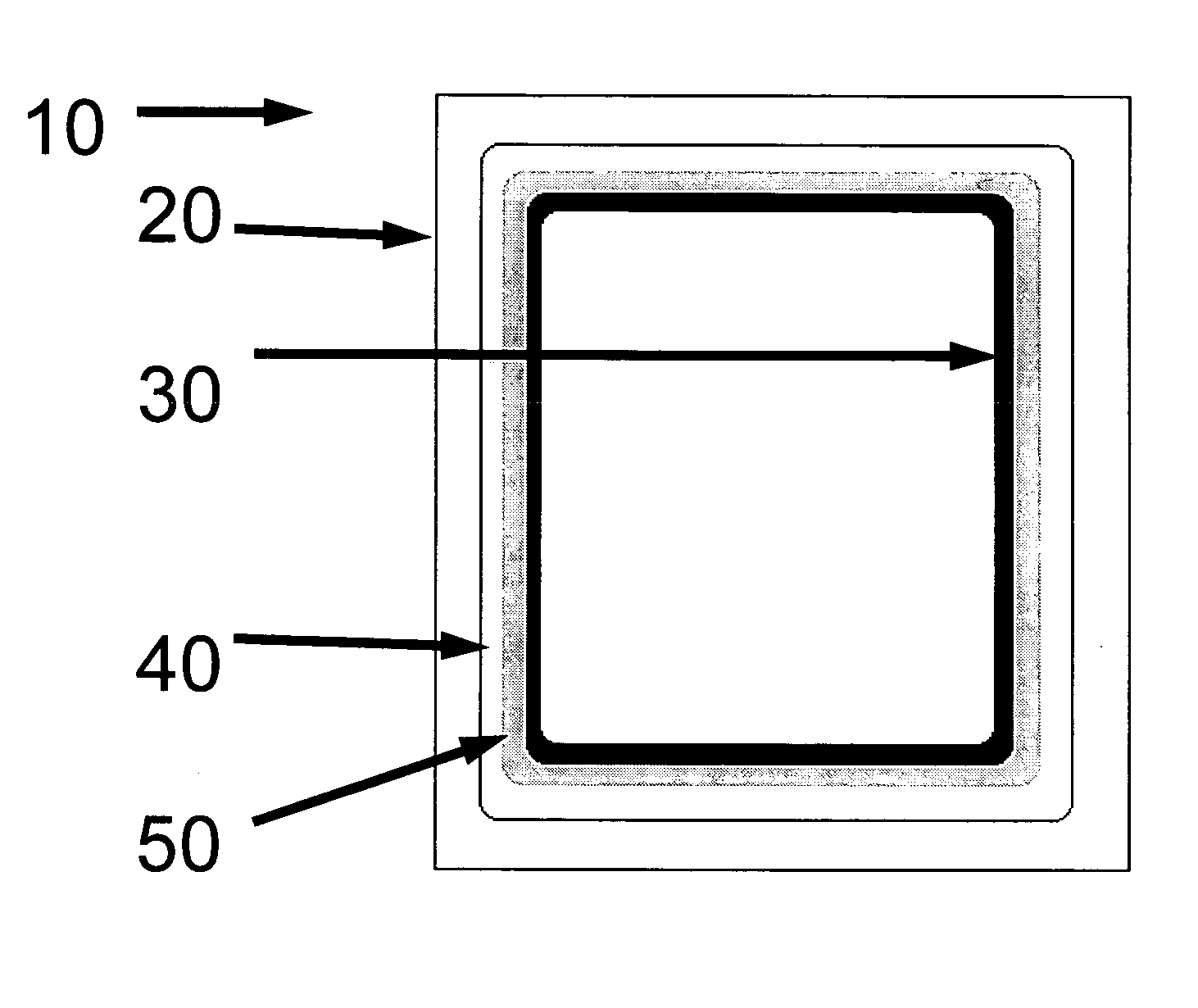

Organic light-emitting display device and method of fabricating the same

Disclosed is a method for preparing an organic light-emitting display device in which a substrate and an encapsulation substrate are completely coalesced using a frit. The method for preparing an organic light-emitting display device according to one aspect of the present invention includes a first substrate including an organic light-emitting diode and a second substrate for encapsulating at least a pixel region of the first substrate, the method including applying a first frit paste to surround the pixel region in the first substrate, and applying a second frit paste to be faced against the first frit paste in the second substrate, sintering the first and the second frit pastes to form a first frit and a second frit, respectively, coalescing the first substrate to the second substrate to contact the first frit and the second frit to each other, attaching the first substrate and the second substrate to each other by irradiating a laser or an infrared ray to the first frit and the second frit, both contacted to each other.

Owner:SAMSUNG MOBILE DISPLAY CO LTD

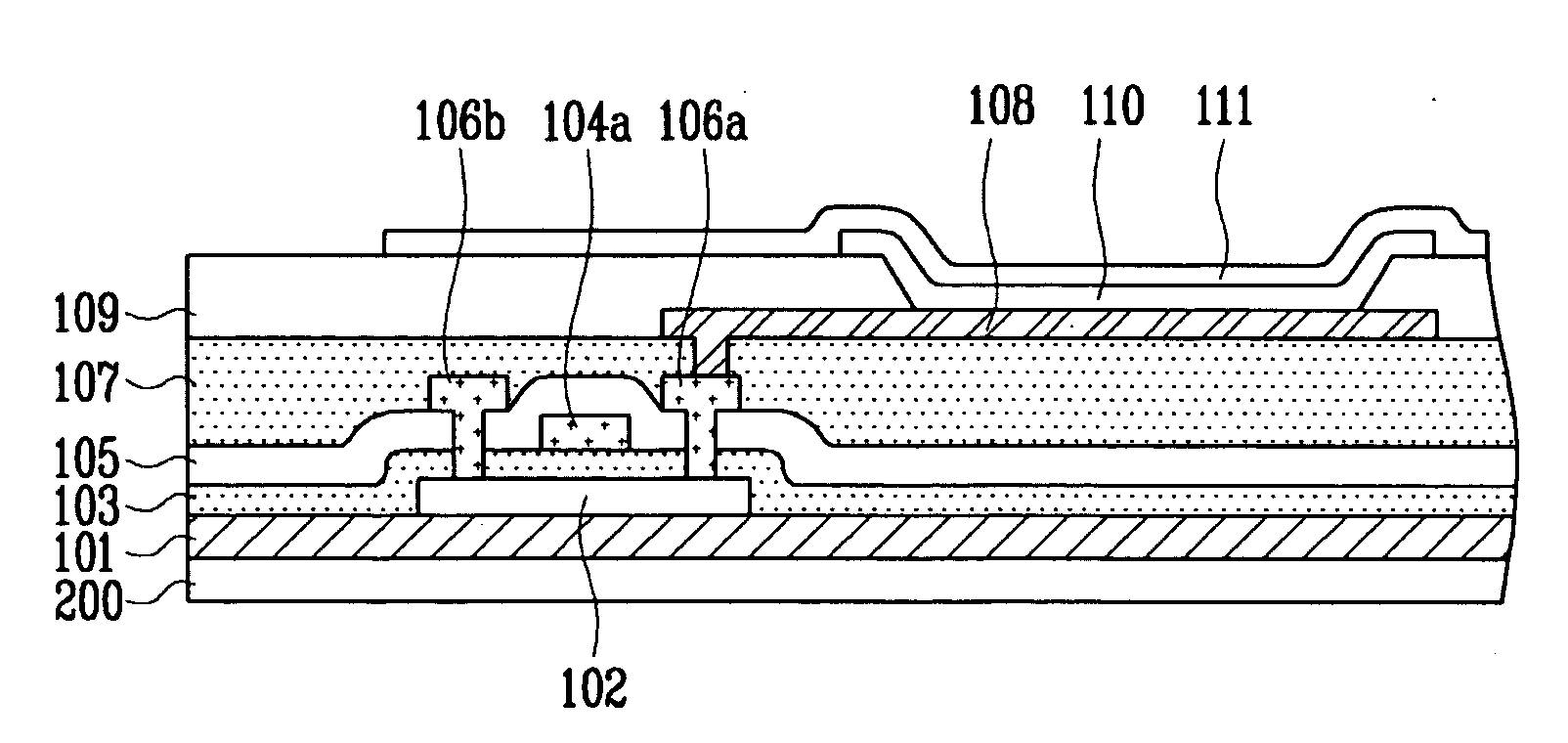

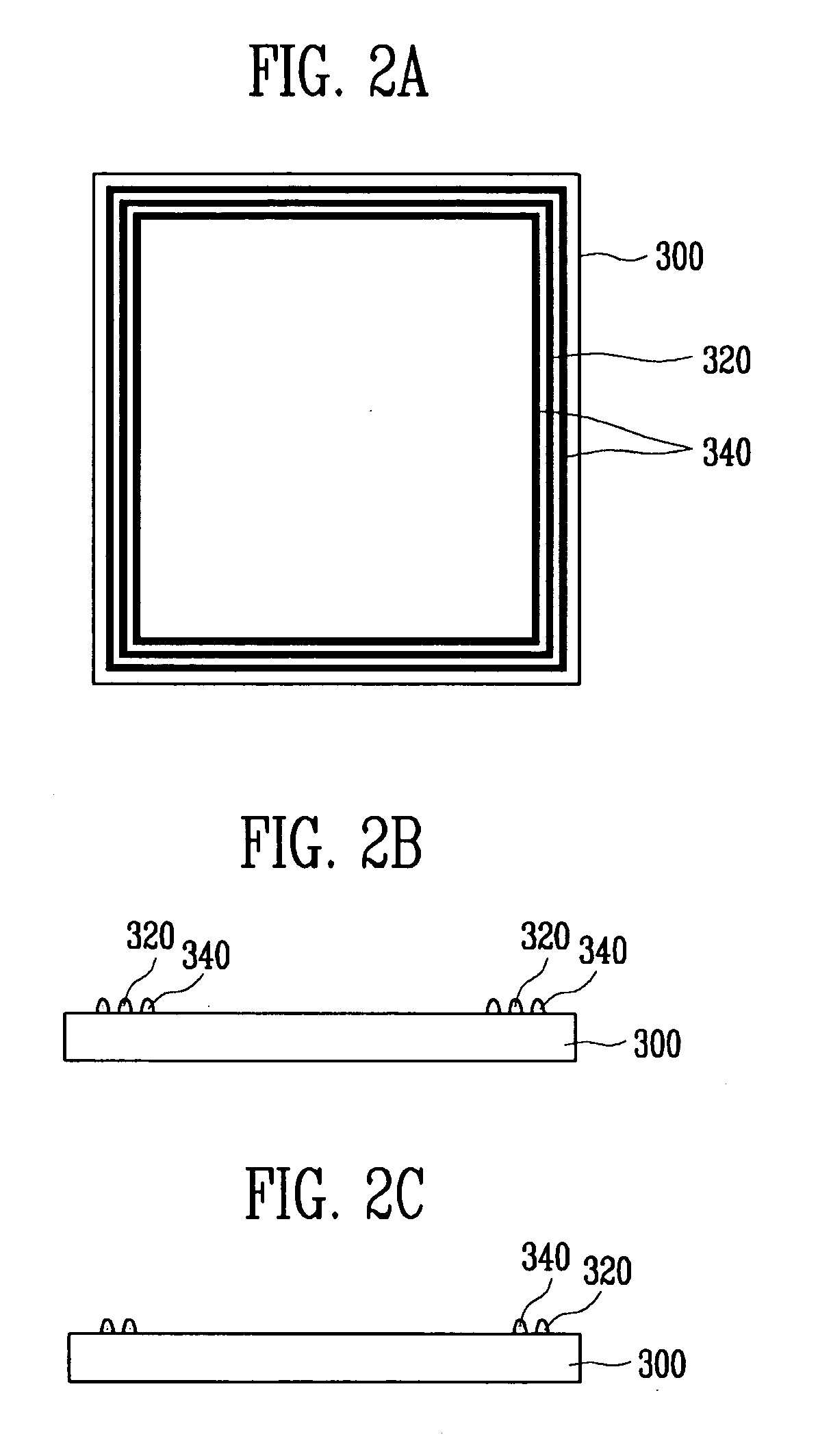

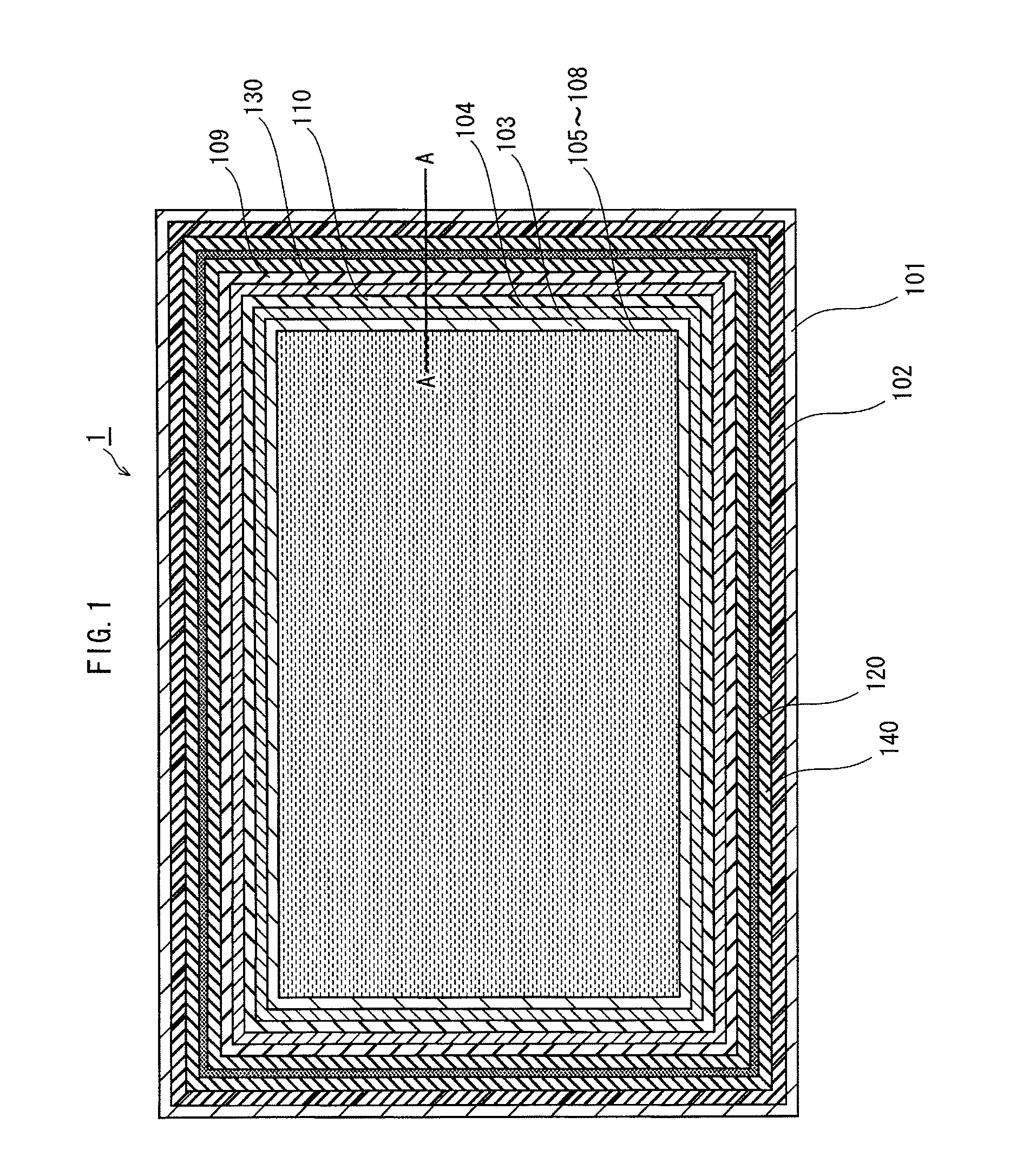

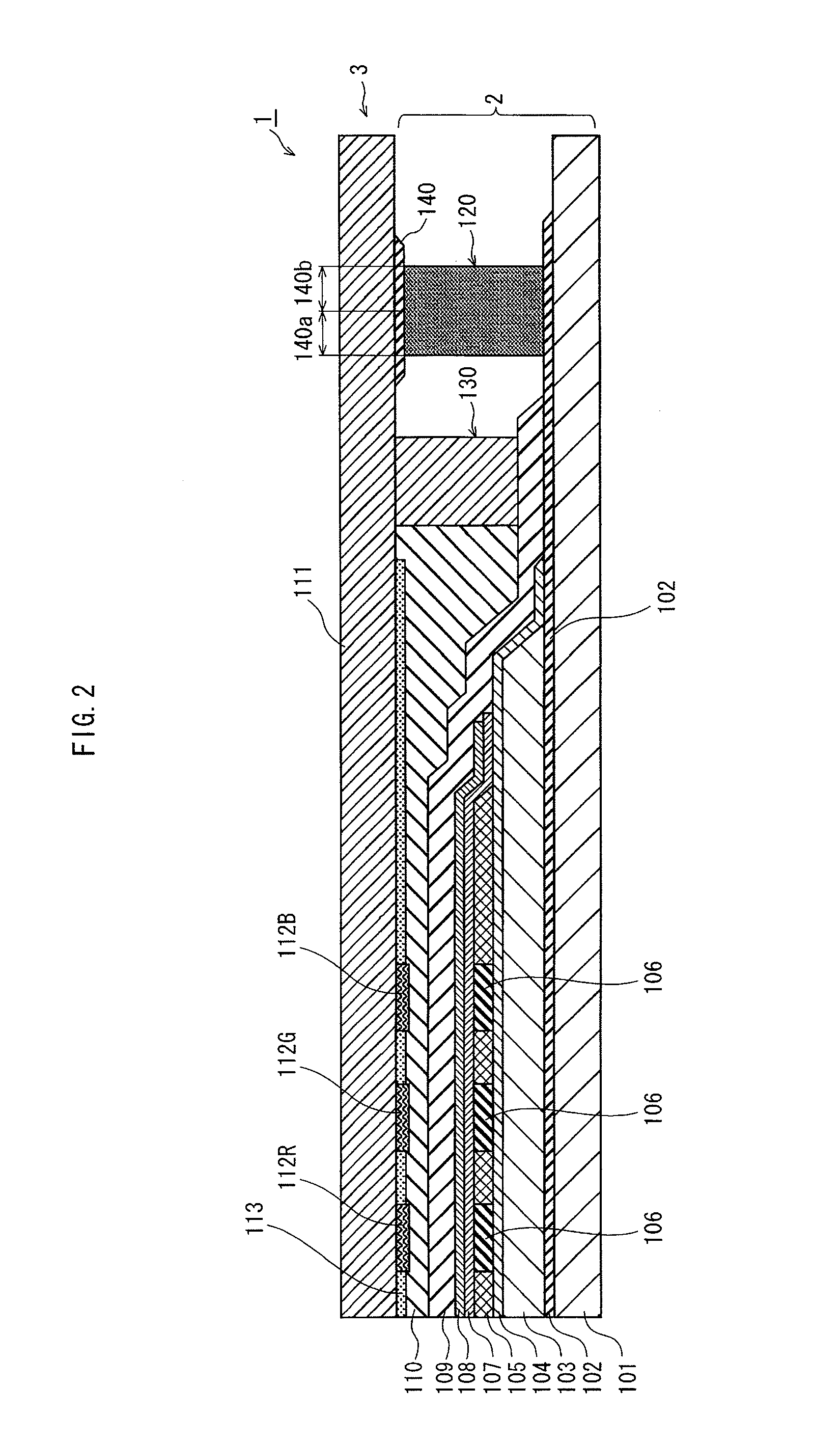

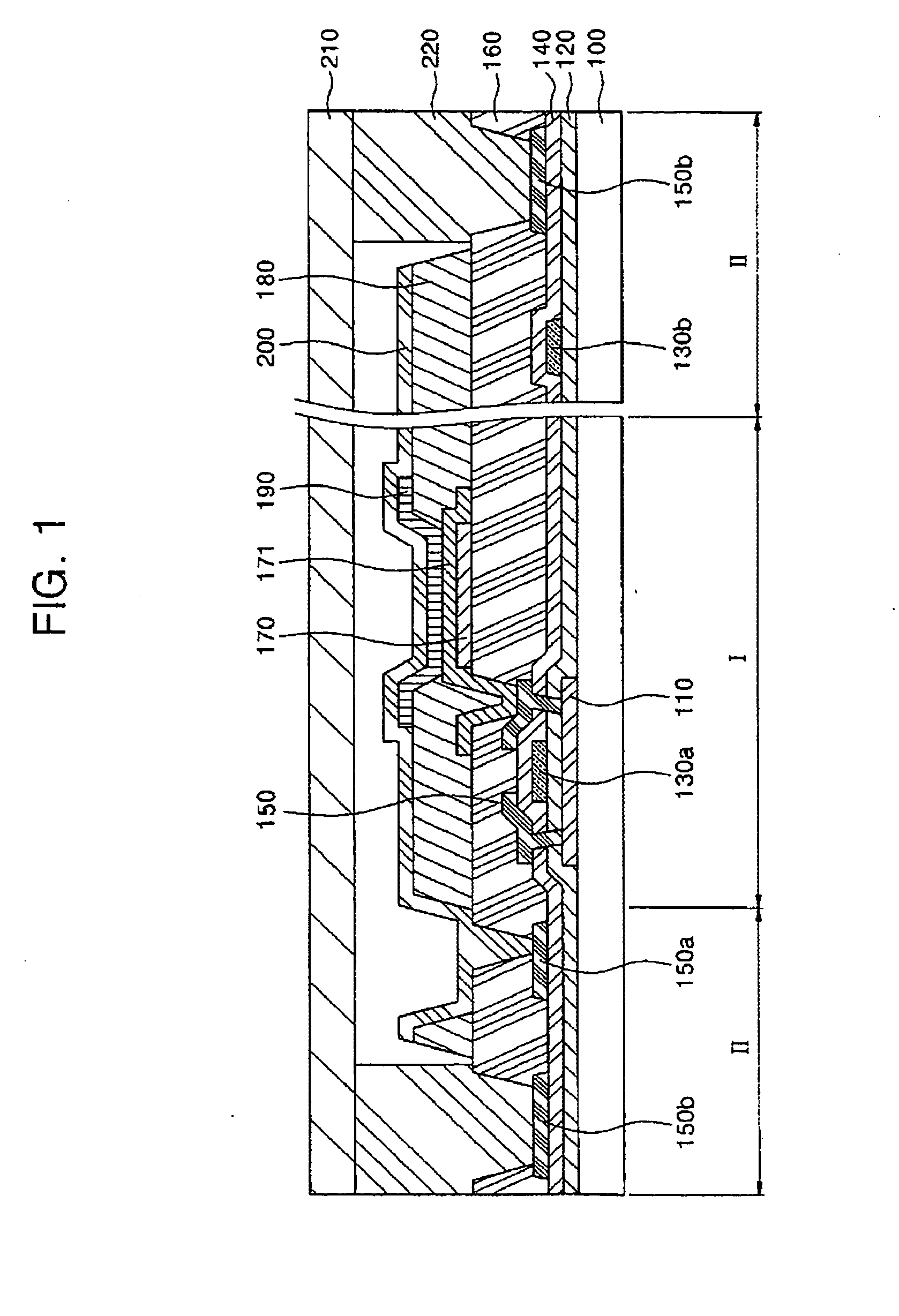

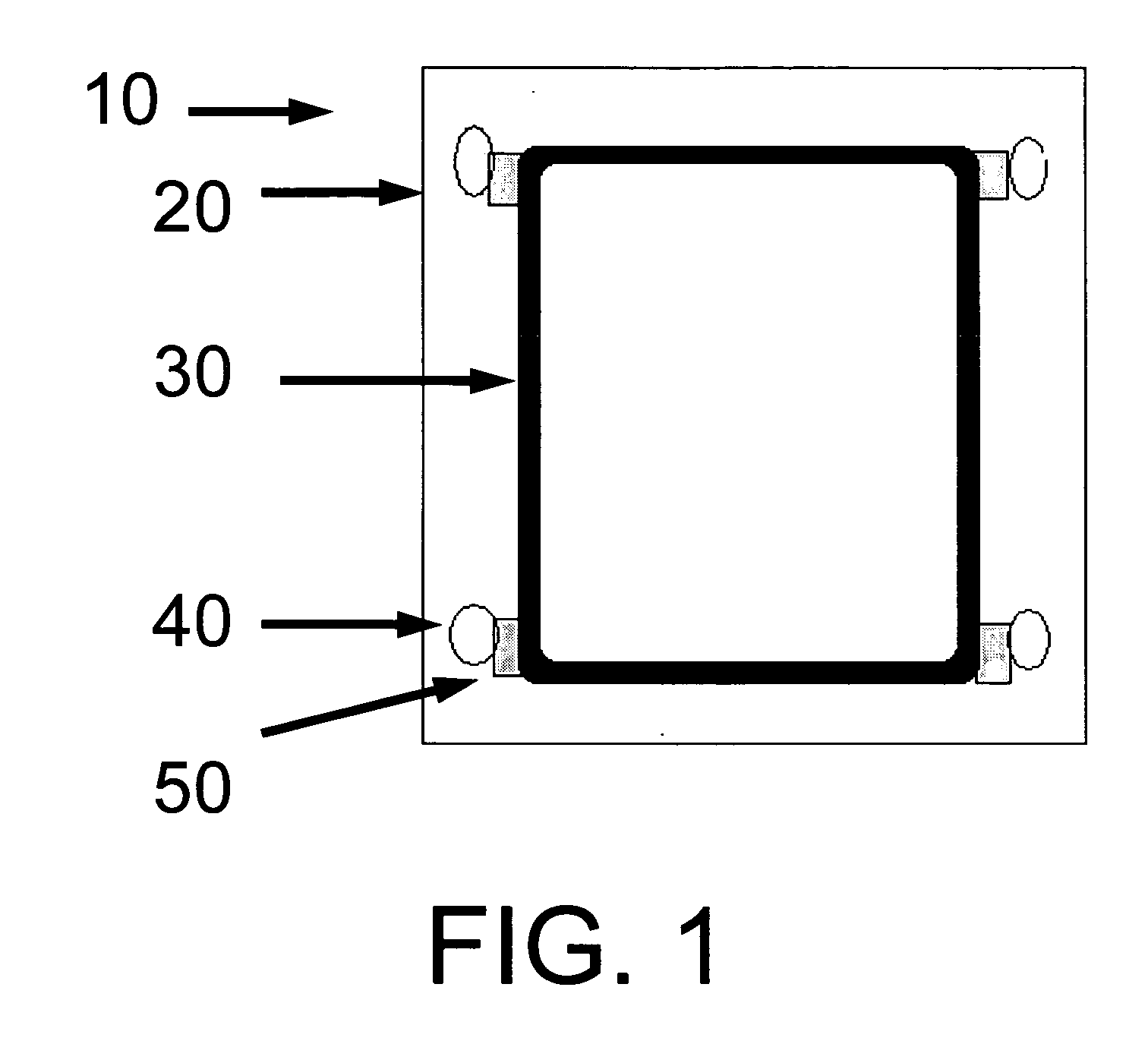

Organic light emitting display device

ActiveUS20070170845A1Apparel holdersDischarge tube luminescnet screensFritOrganic light emitting device

Disclosed is an organic light-emitting display device comprising: a pixel region wherein an organic light-emitting device comprised of a first electrode, an organic thin film layer and a second electrode is formed; a first substrate comprising a non-pixel region encompassing the pixel region; a second substrate disposed on the upper of the first substrate to be overlapped with the pixel region and a portion of the non-pixel region; and a plurality of frits provided between the first substrate and the second substrate and formed in parallel at spaced intervals along the peripheral portion of the pixel region, wherein the first substrate is bonded to the second substrate by the plurality of frits. Even in the case that a portion of the frit is delaminated due to a partial defection thereof, its encapsulation state can be maintained as it is by being encapsulated with the frit in a multi structure and even in the case that a substrate with a large diameter is used, the width and height of the frit do not need to increase.

Owner:SAMSUNG DISPLAY CO LTD

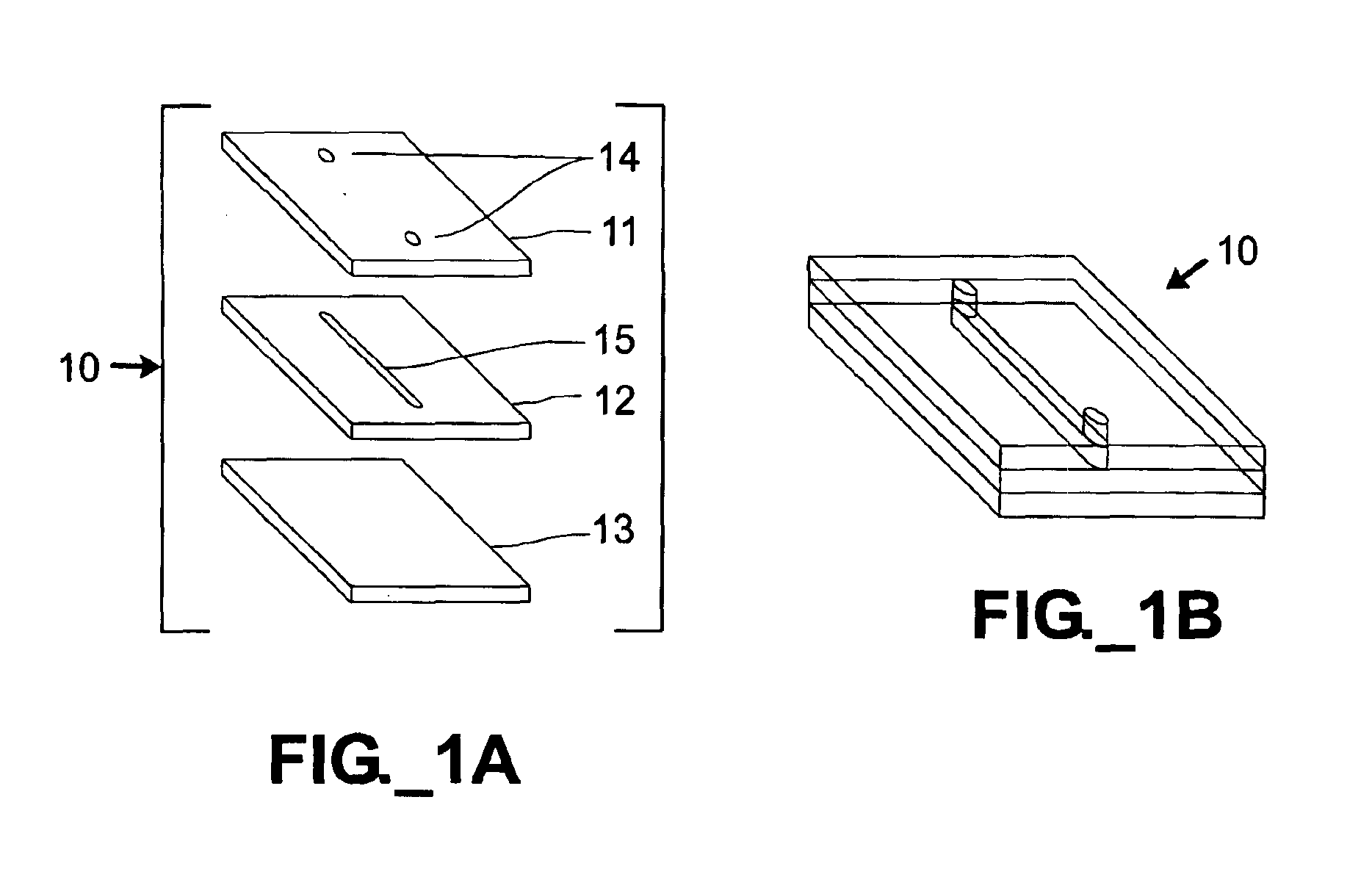

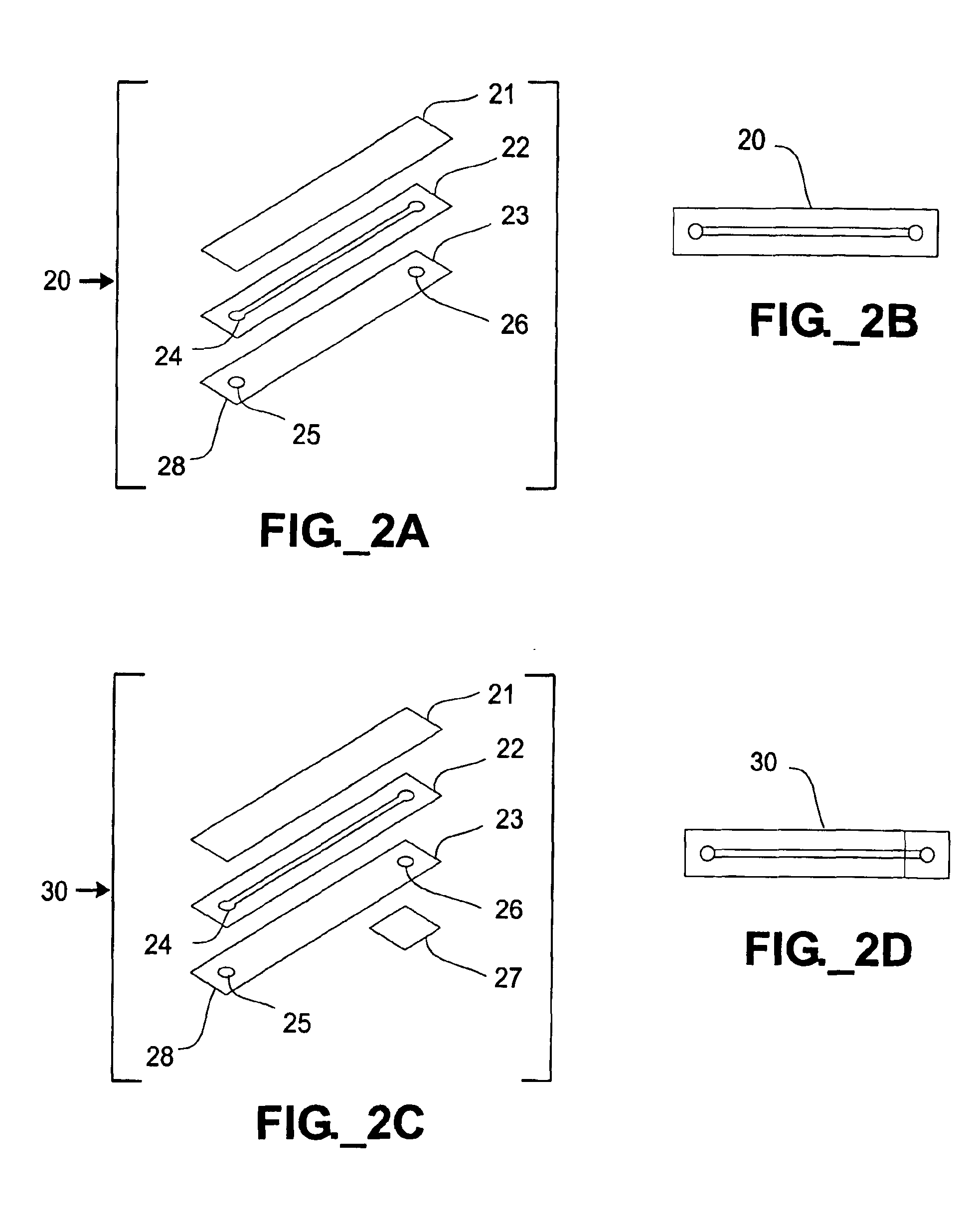

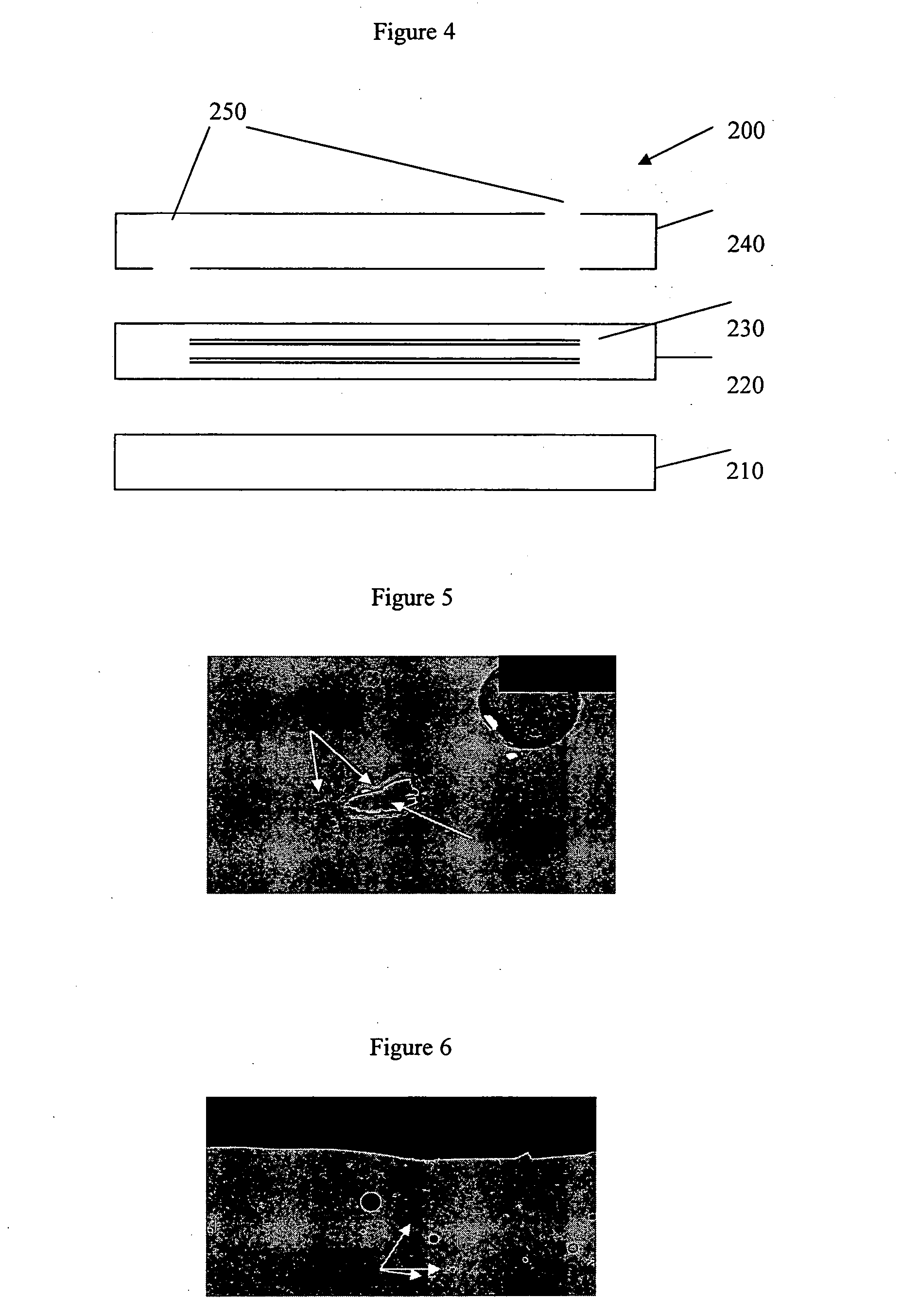

Separation column devices and fabrication methods

Pressure-driven microfluidic separation devices, such as may be used for performing high performance liquid chromatography, are provided. Multiple separation columns may be defined in a single device and packed with stationary phase material retained by porous frits. One or more splitters may be provided to distribute slurry and / or mobile phase among multiple separation columns. In one embodiment, separation devices are substantially planar and fabricated with multiple device layers. Systems and methods employing slurry for packing separation devices are also provided.

Owner:AGILENT TECH INC

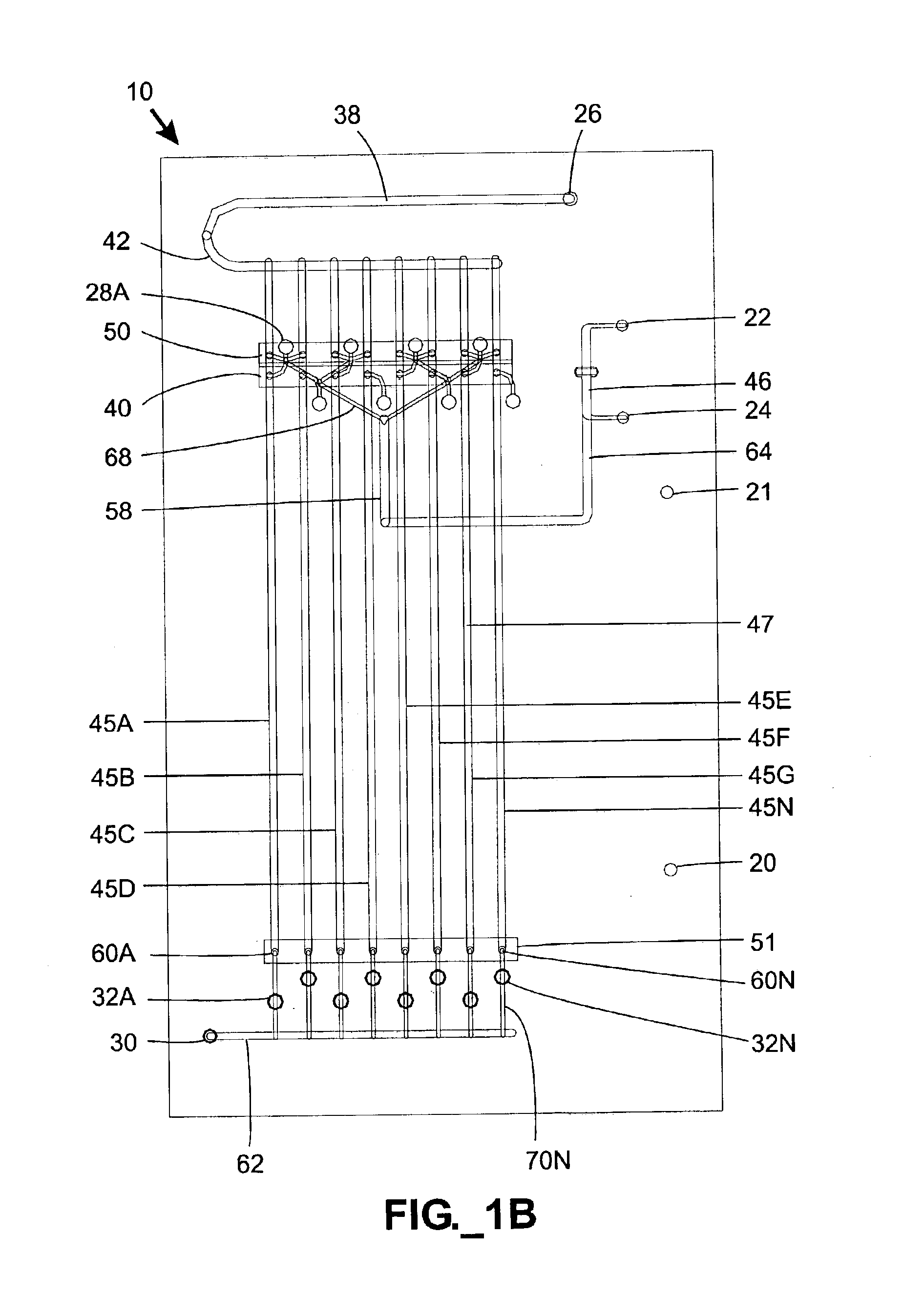

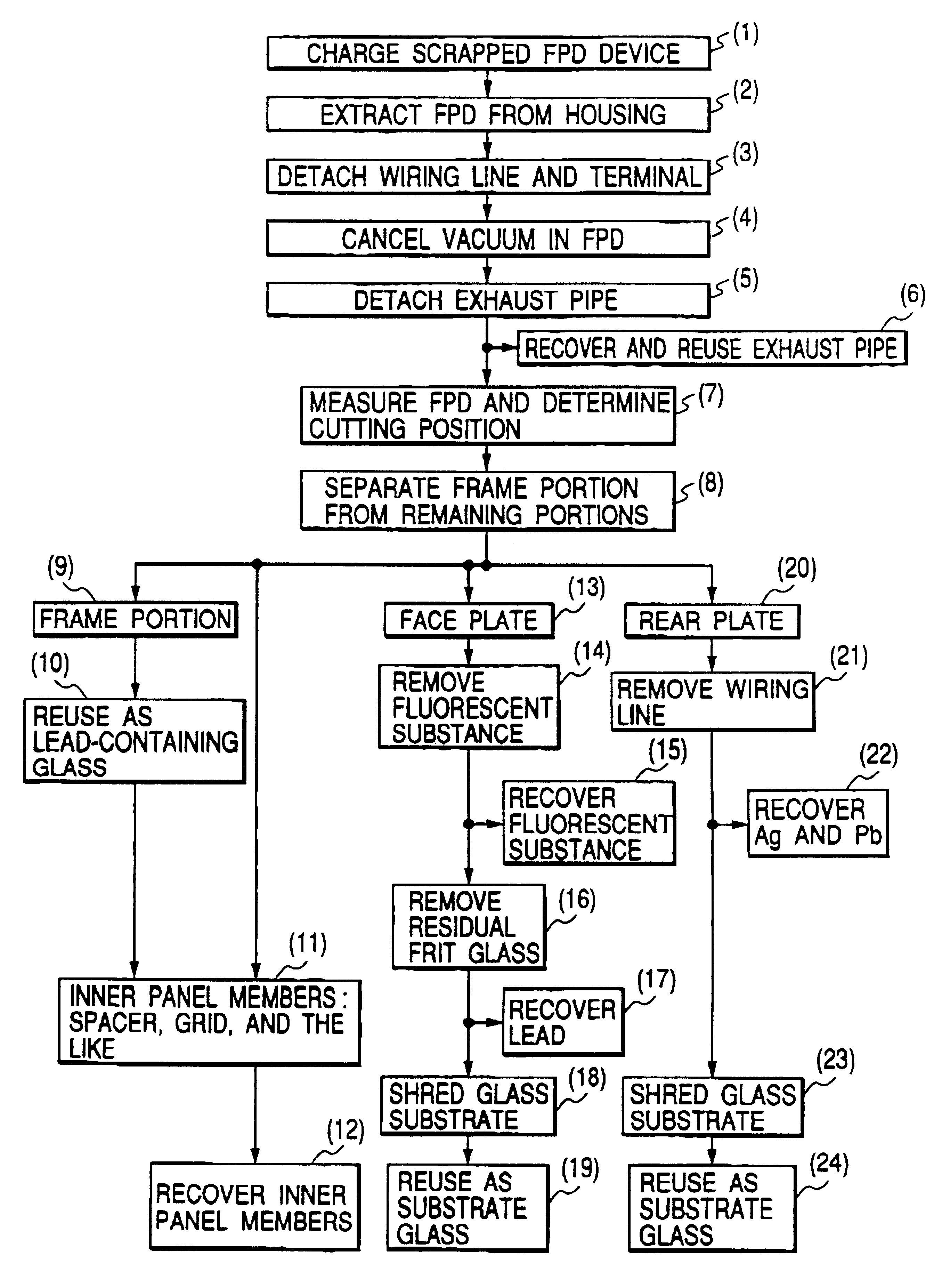

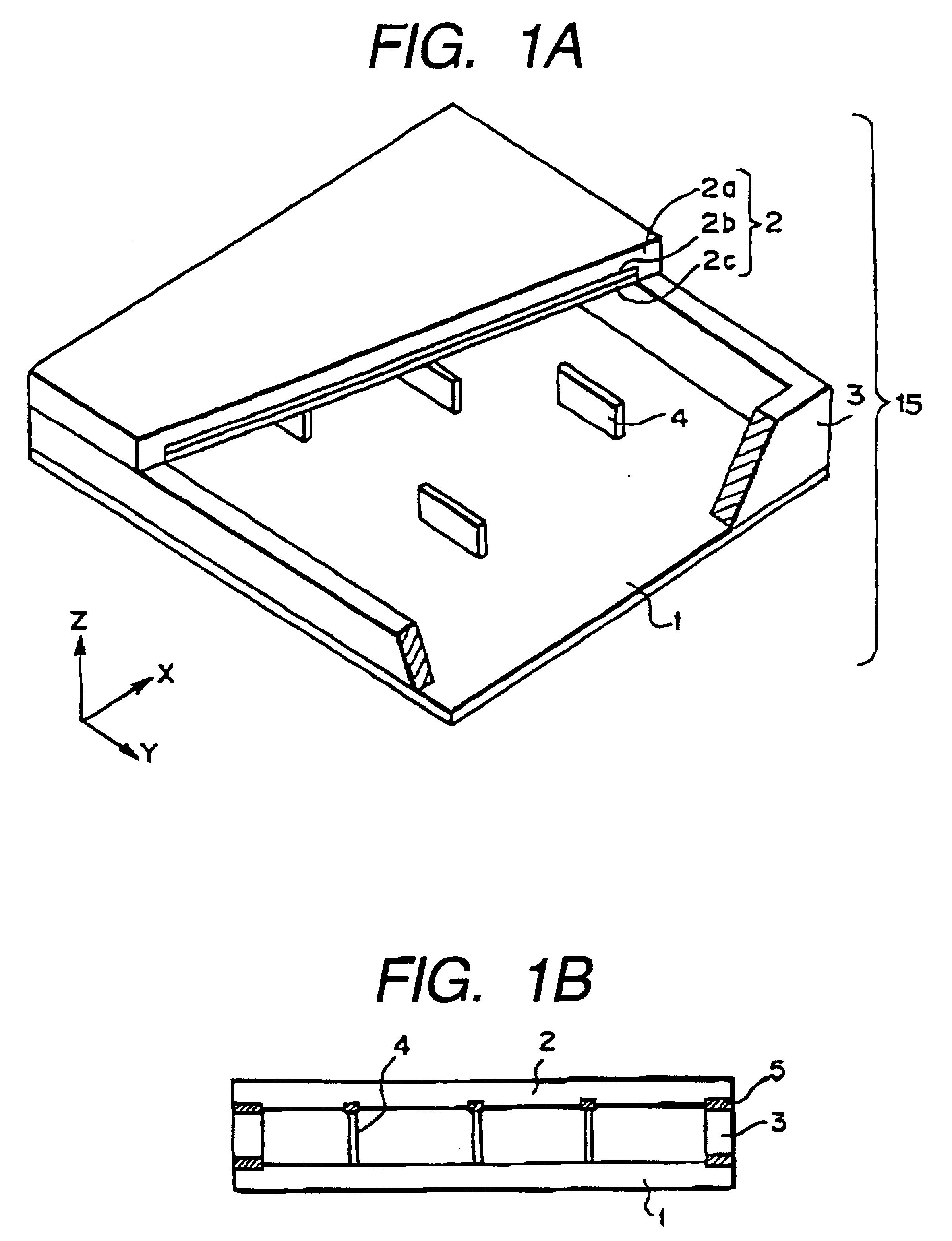

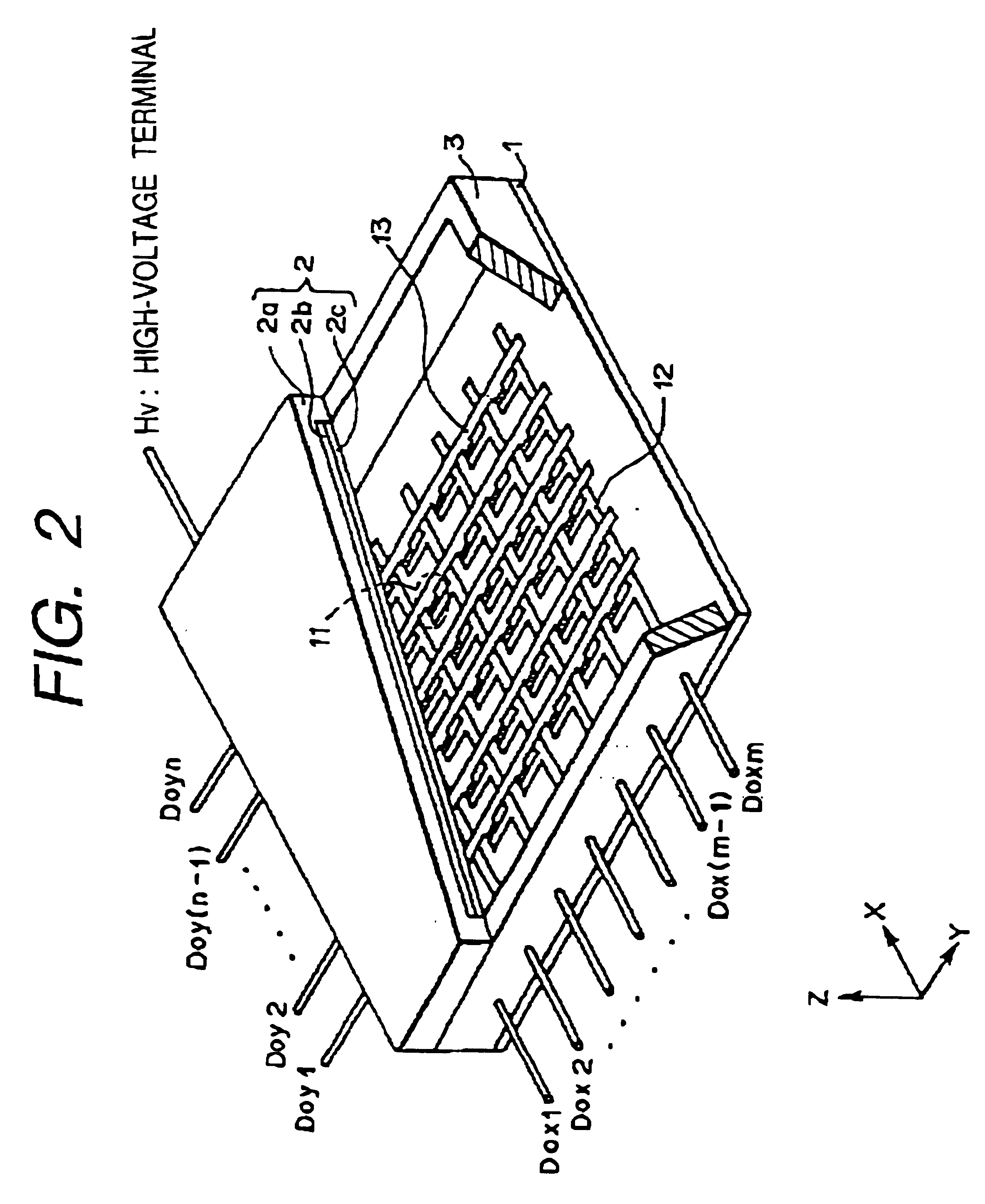

Image display apparatus, disassembly processing method therefor, and component recovery method

InactiveUS6632113B1No pressureAvoid secondary damageElectric discharge tubesGlass recyclingRecovery methodFrit

To reuse glass used in a flat panel display, processing suitable for global environment such as processing of separating a lead component must be realized. A disassembly processing method for a flat panel display having a structure in which a face plate and rear plate mainly containing glass are airtightly joined via a frame with frit glass is characterized by including the step of separating the face plate and rear plate joined with the frit glass. The separation step is characterized by separating the face plate and rear plate by cutting, dissolution, or melting.< / PTEXT>

Owner:CANON KK

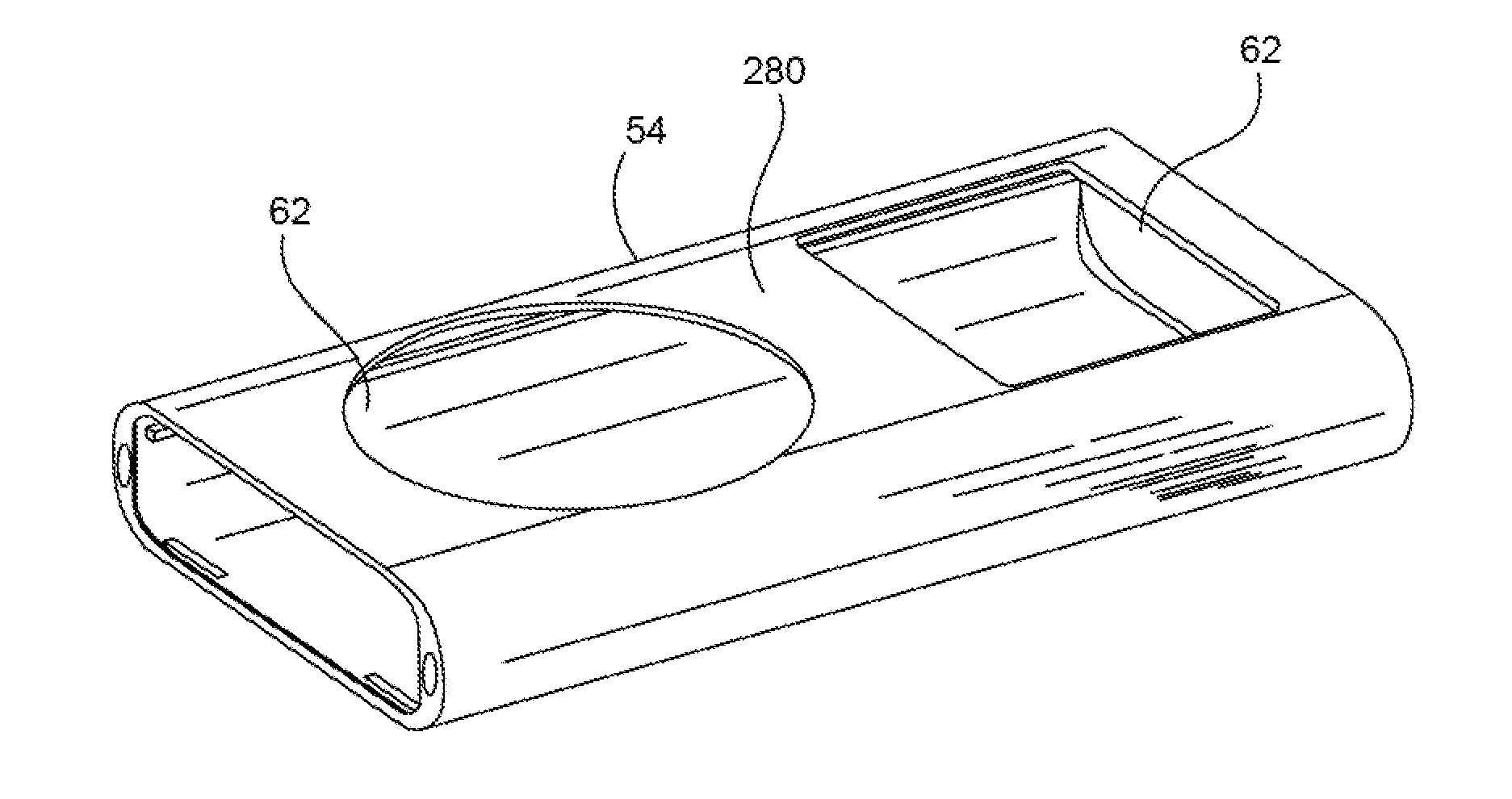

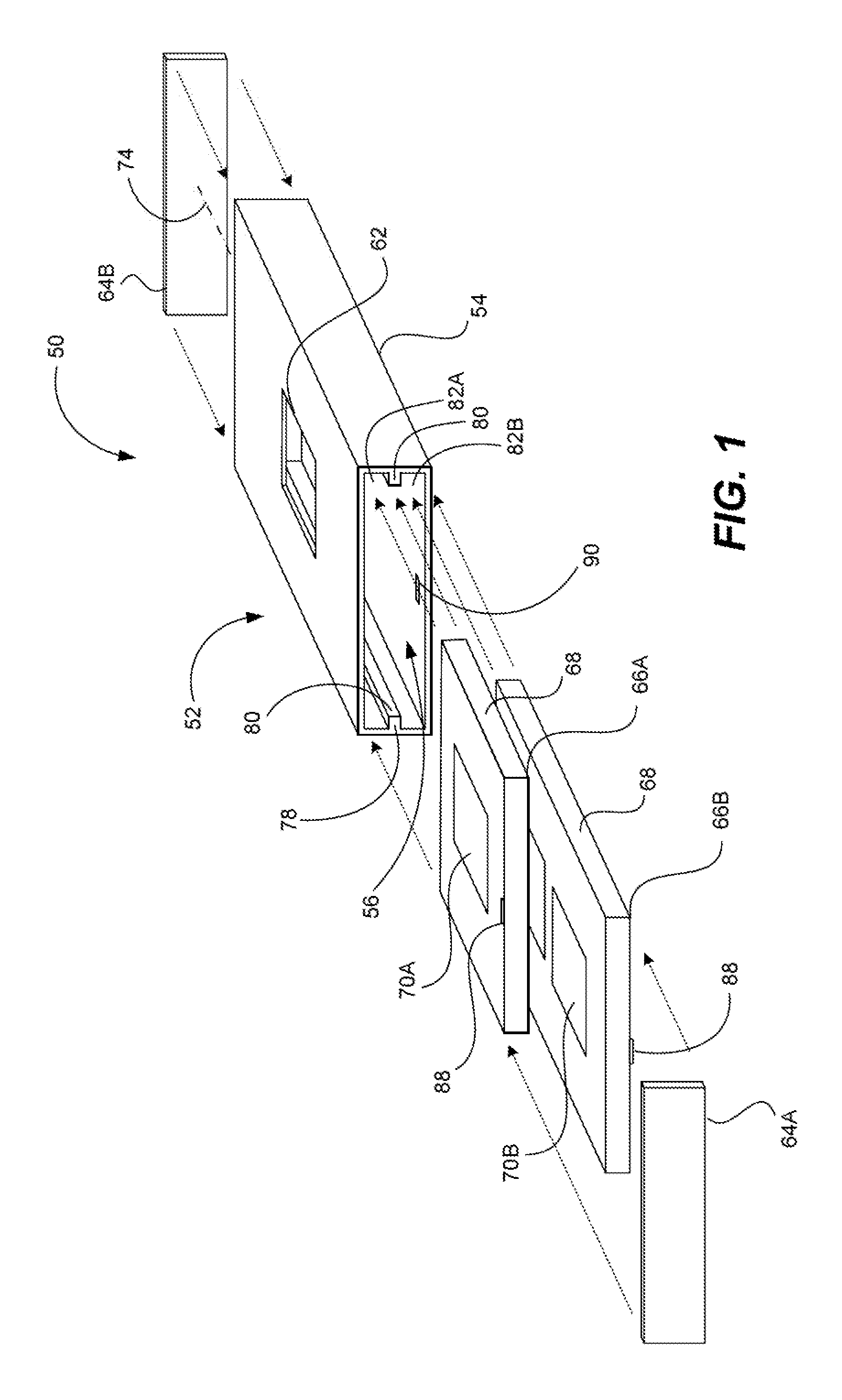

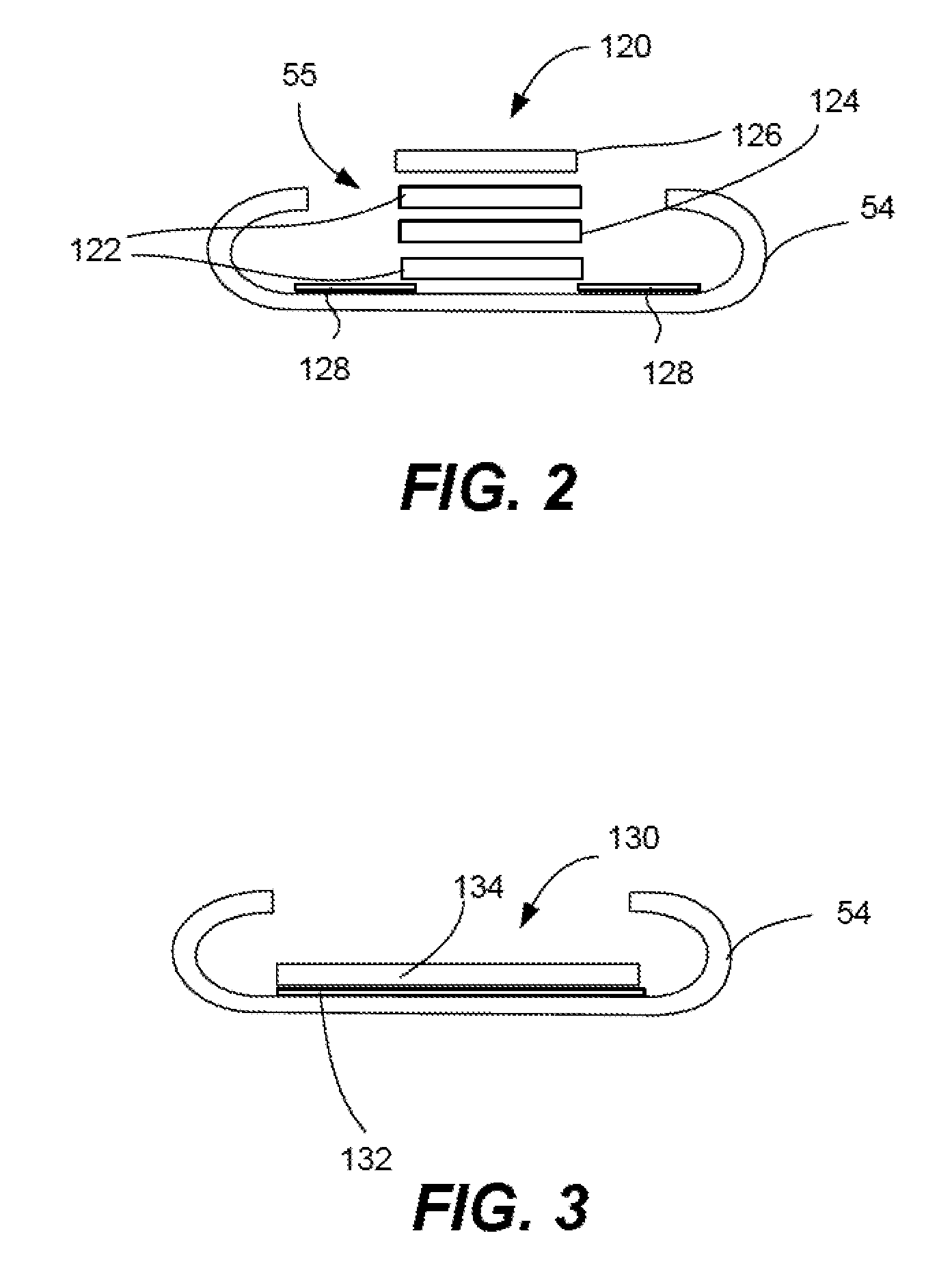

Glass enclosure

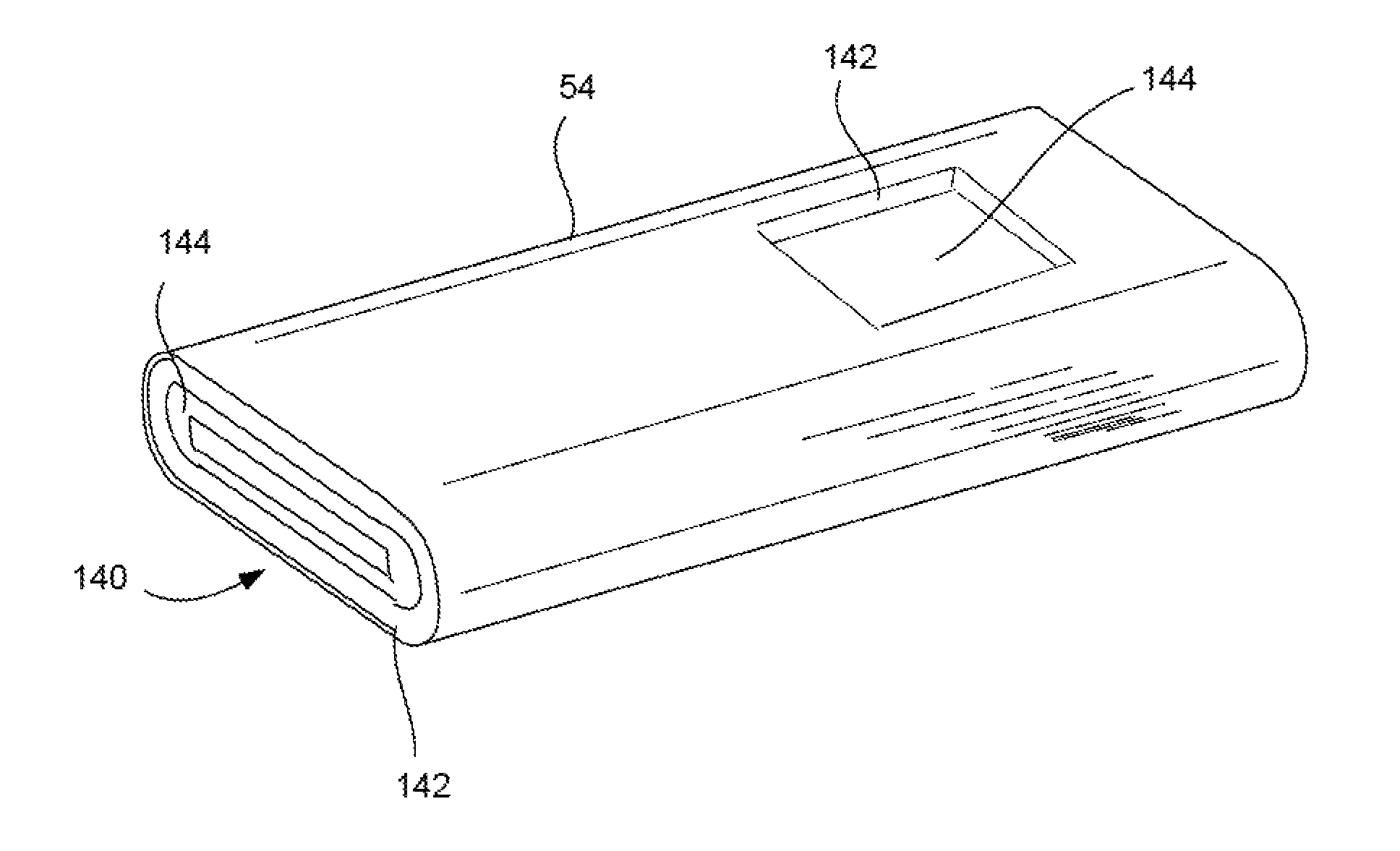

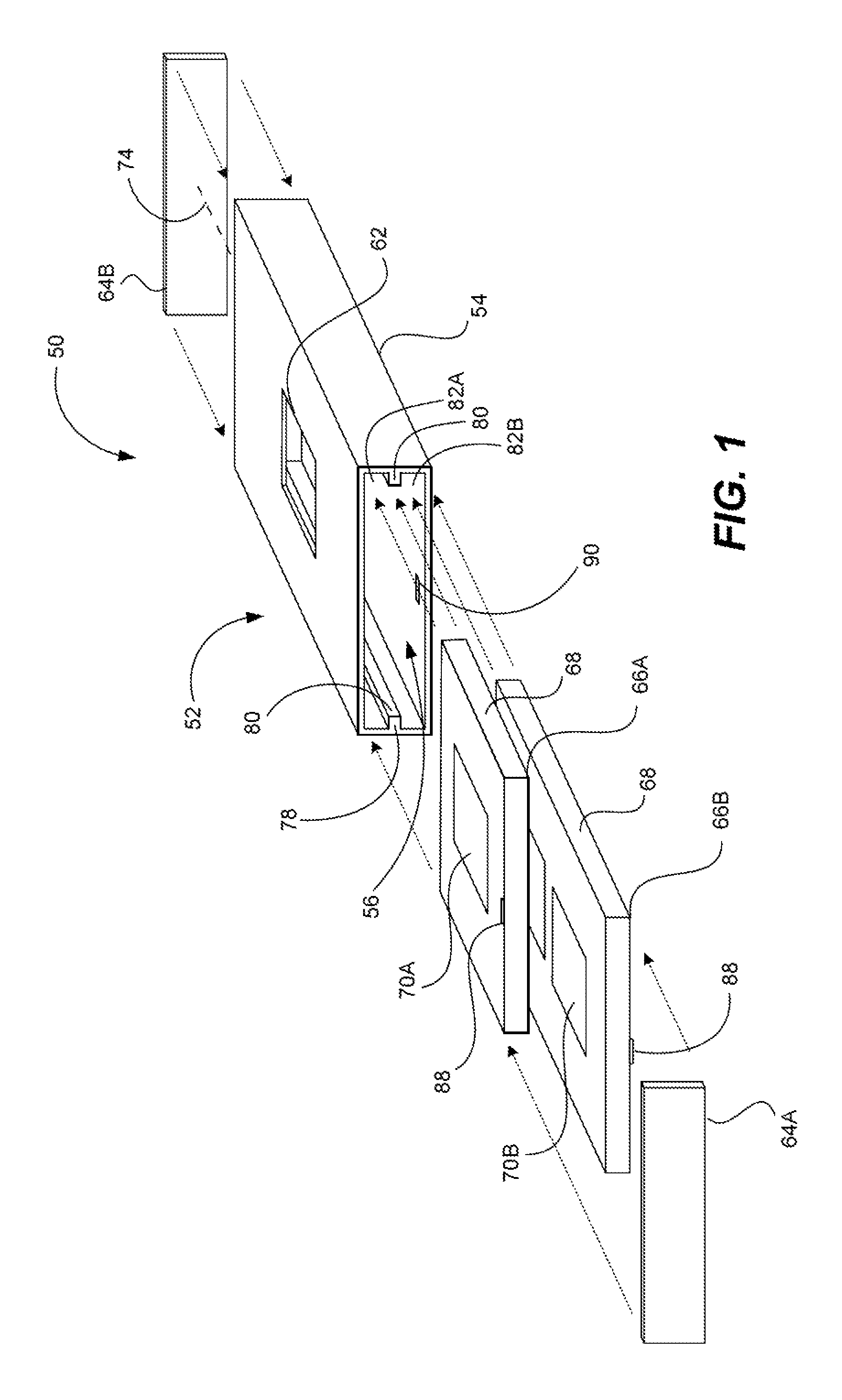

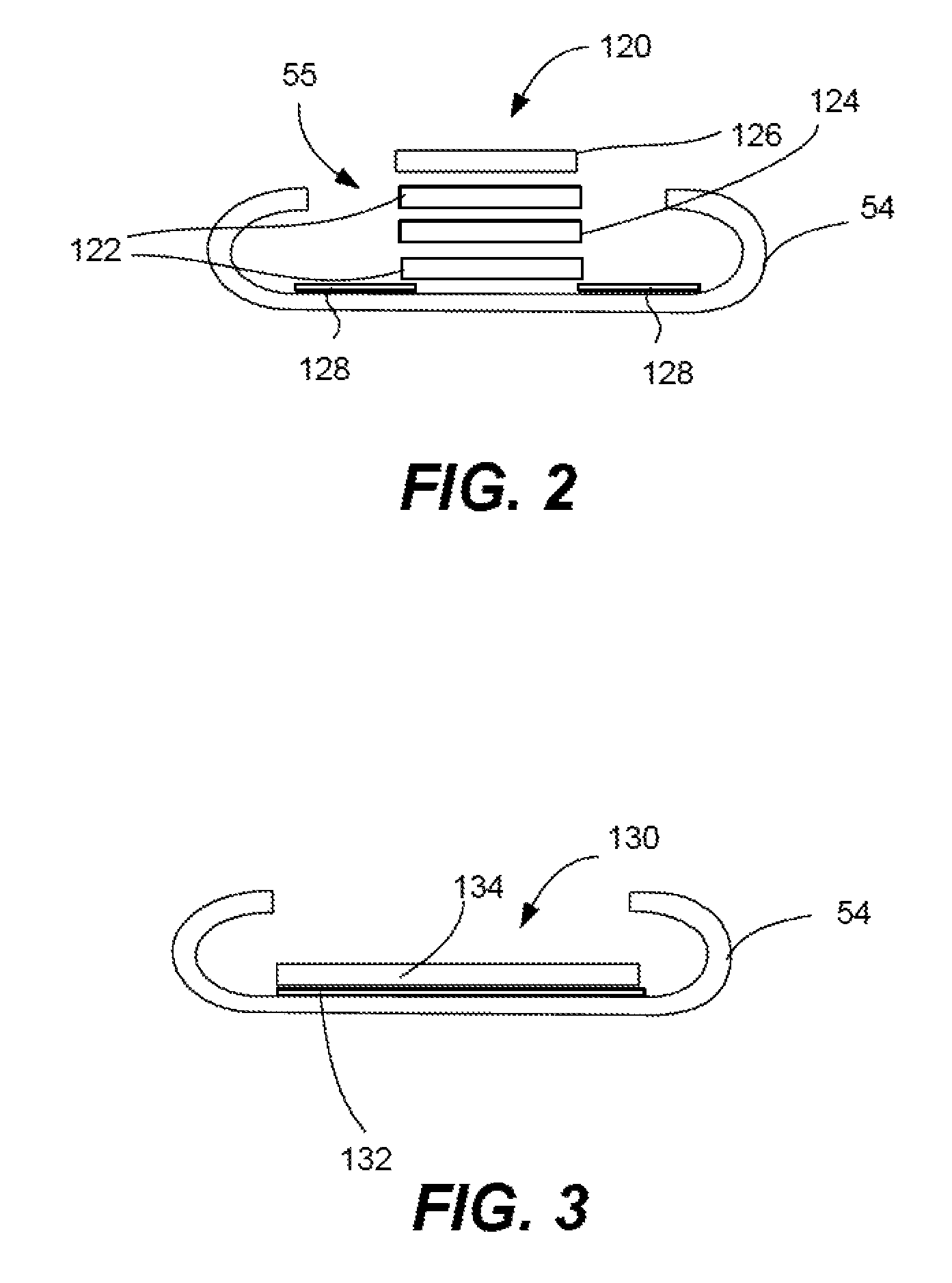

A handheld computing device that includes an enclosure having structural walls formed from a glass material that can be radio-transparent. The enclosure can be formed from a hollow glass tube or two glass members bonded together. A laser frit bonding process may be used to hermetically seal the two glass members together to create a water resistant electronic device.

Owner:APPLE INC

Method of manufacture of semiconductor device and conductive compositions used therein

InactiveUS20060231804A1Semiconductor/solid-state device detailsConductive materialDevice materialFrit

The present invention is directed to a thick film conductive composition comprising: (a) electrically conductive silver powder; (b) Zn-containing additive wherein the particle size of said zinc-containing additive is in the range of 7 nanometers to less than 100 nanometers; (c) glass frit wherein said glass frit has a softening point in the range of 300 to 600° C.; dispersed in (d) organic medium. The present invention is further directed to a semiconductor device and a method of manufacturing a semiconductor device from a structural element composed of a semiconductor having a p-n junction and an insulating film formed on a main surface of the semiconductor comprising the steps of (a) applying onto said insulating film the thick film composition as describe above; and (b) firing said semiconductor, insulating film and thick film composition to form an electrode.

Owner:EI DU PONT DE NEMOURS & CO

Glass Frit And Sealing Method For Element Using The Same

InactiveUS20090064717A1Improve sealingDischarge tube luminescnet screensLamination ancillary operationsFritMoisture

The present invention relates to a glass frit and a sealing method for an electric element using the same, and more particularly, to a glass frit which provides a good sealing effect to moisture and gas and is processable at low temperatures, and a sealing method for an electric element using the same.

Owner:DONGJIN SEMICHEM CO LTD

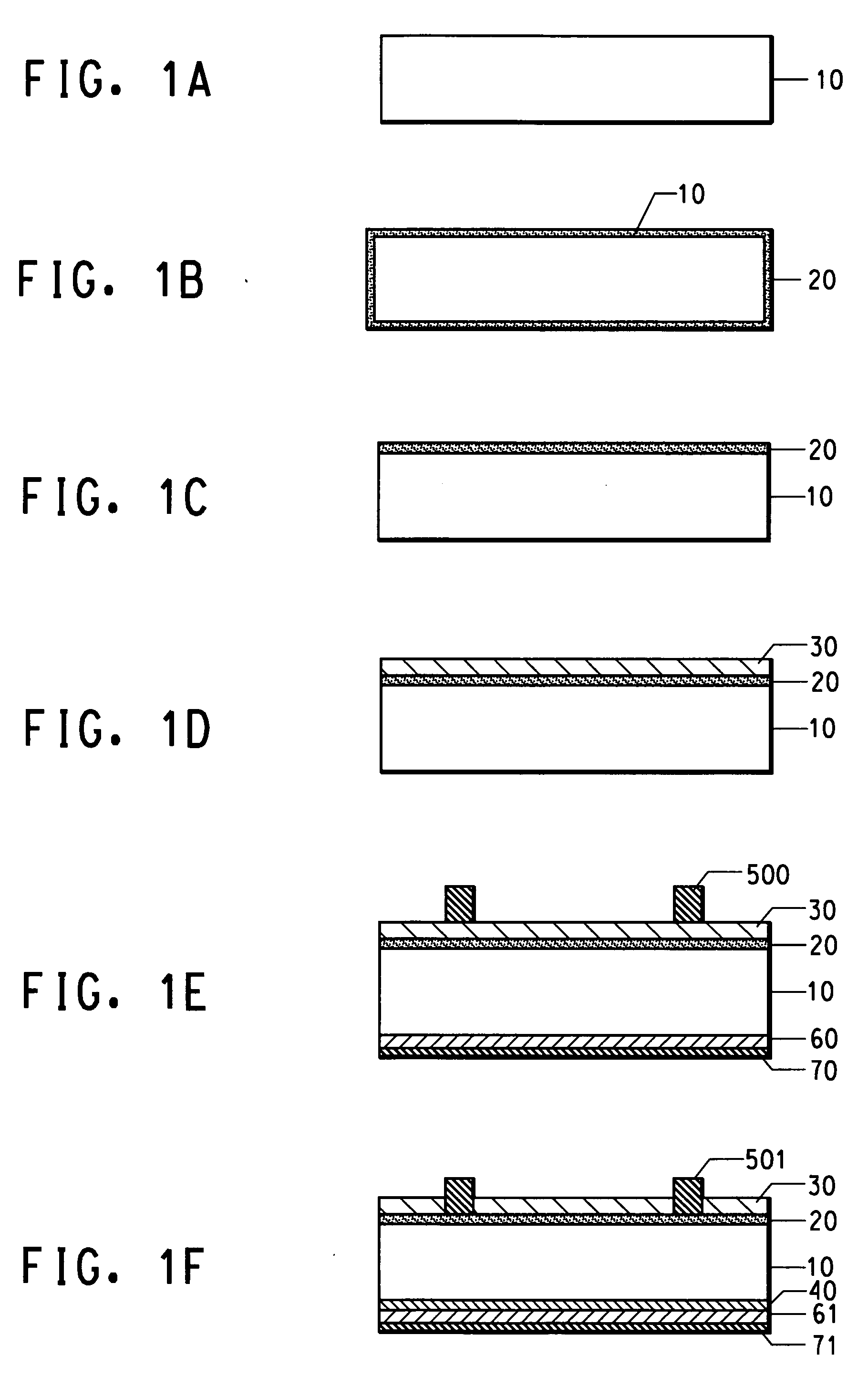

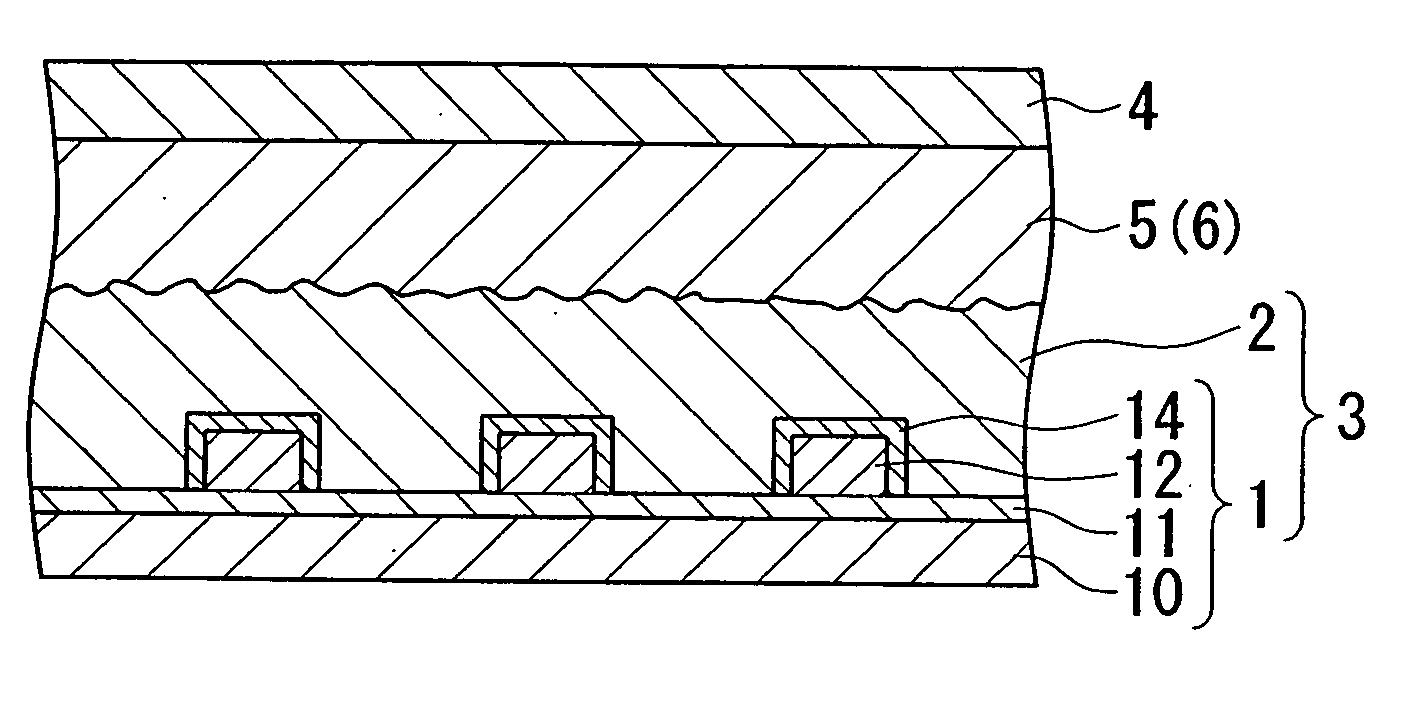

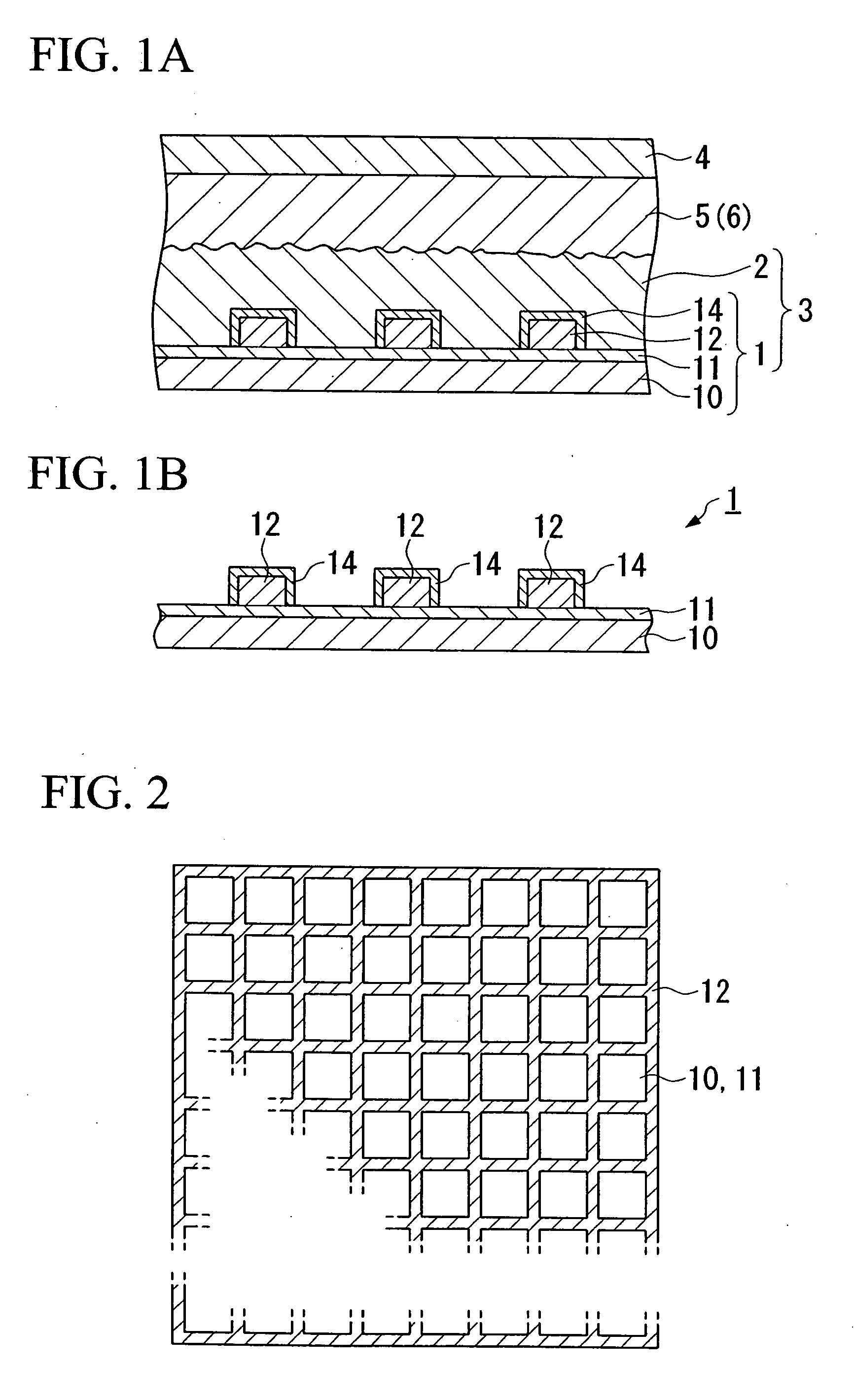

Electrode substrate, photoelectric conversion element, conductive glass substrate and production method therefo, and pigment sensitizing solar cell

ActiveUS20060162770A1Improve conductivityInhibit currentLight-sensitive devicesFinal product manufactureFritPhotoelectric conversion

In an electrode substrate 1, the surface of a metal circuit layer 12 is covered and insulated by an insulating layer 14. In a photoelectric conversion element that uses this electrode substrate 1, the metal circuit layer is reliably shielded from an electrolyte solution or the like so that corrosion and leak current thereof is effectively prevented, and the photoelectric conversion efficiency can be improved. The insulating layer 14 is preferably made of a material that contains a glass component, and is particularly preferably formed by printing a paste that contains glass frit. The metal circuit layer 12 is preferably formed using a printing method.

Owner:THE FUJIKURA CABLE WORKS LTD

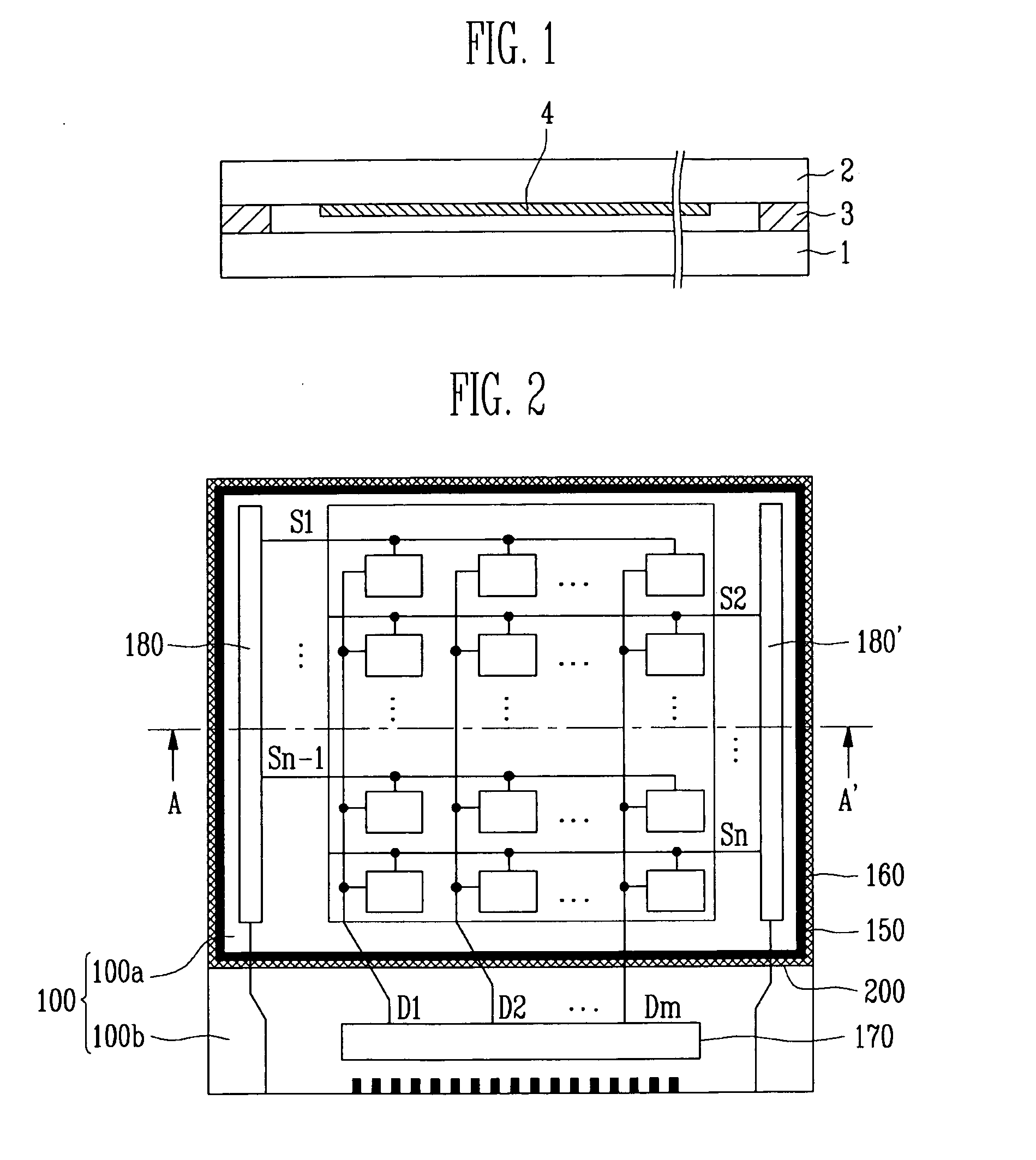

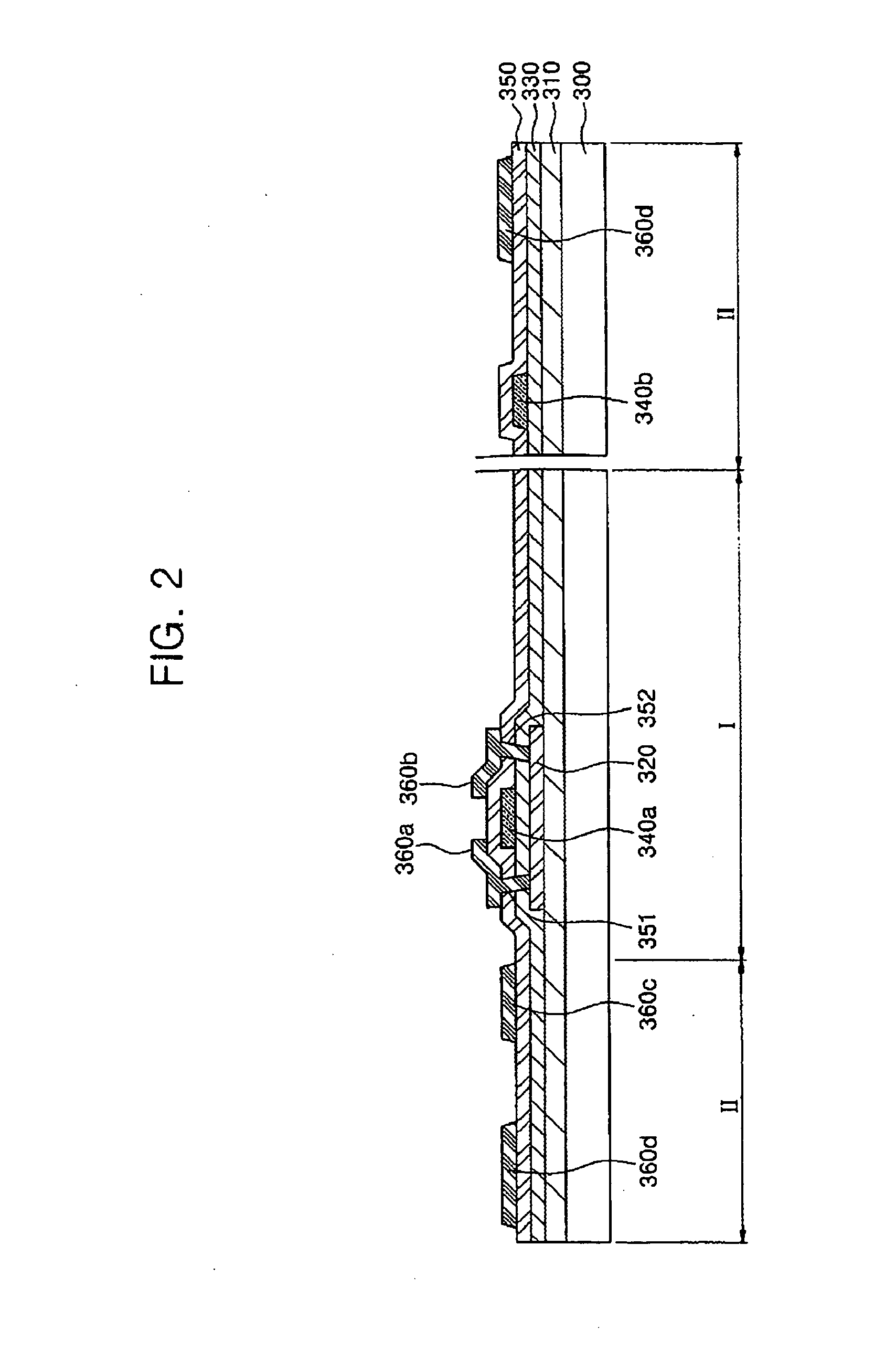

Organic light emitting display and method of fabricating the same

ActiveUS20070090759A1Discharge tube luminescnet screensElectroluminescent light sourcesFritDisplay device

An organic light emitting display device includes a first substrate, an array of organic light emitting pixels formed on the substrate, a second substrate opposing the first substrate. A frit seal interconnects the first and second substrates and surrounds the array of organic light emitting pixels. A film structure interposed between the second substrate and the array of organic light emitting pixels and contacts both the second substrate and the array.

Owner:SAMSUNG DISPLAY CO LTD

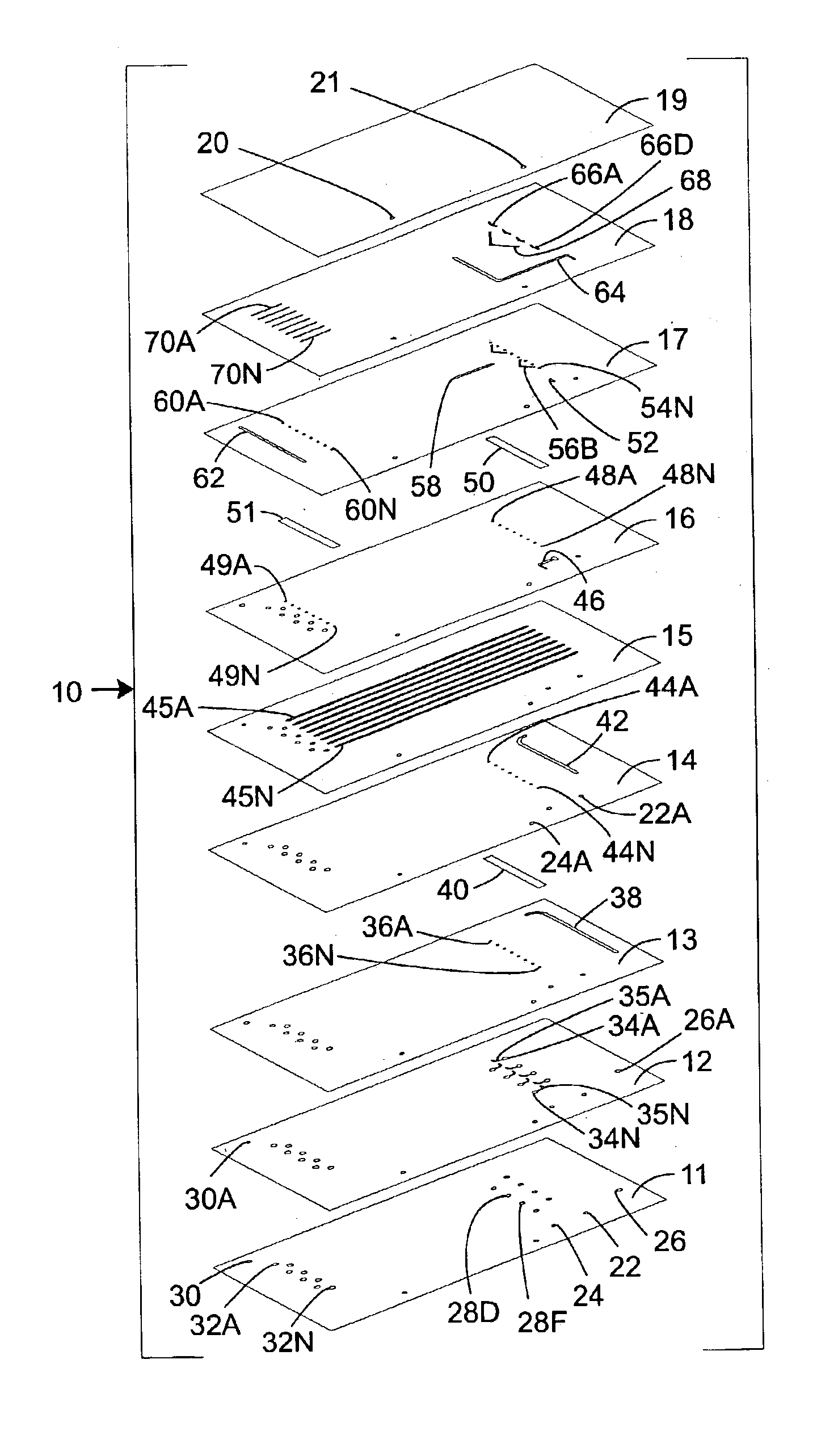

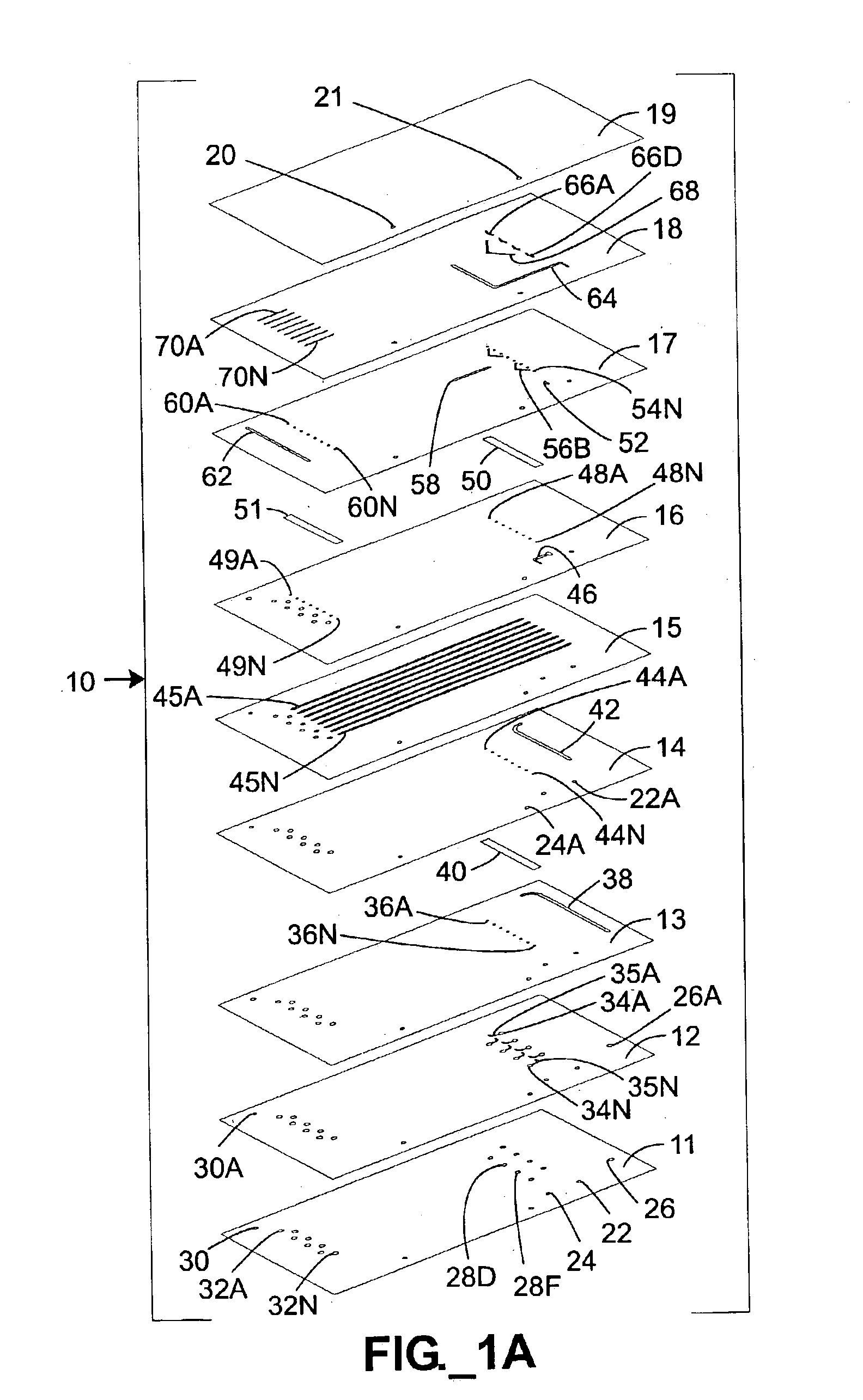

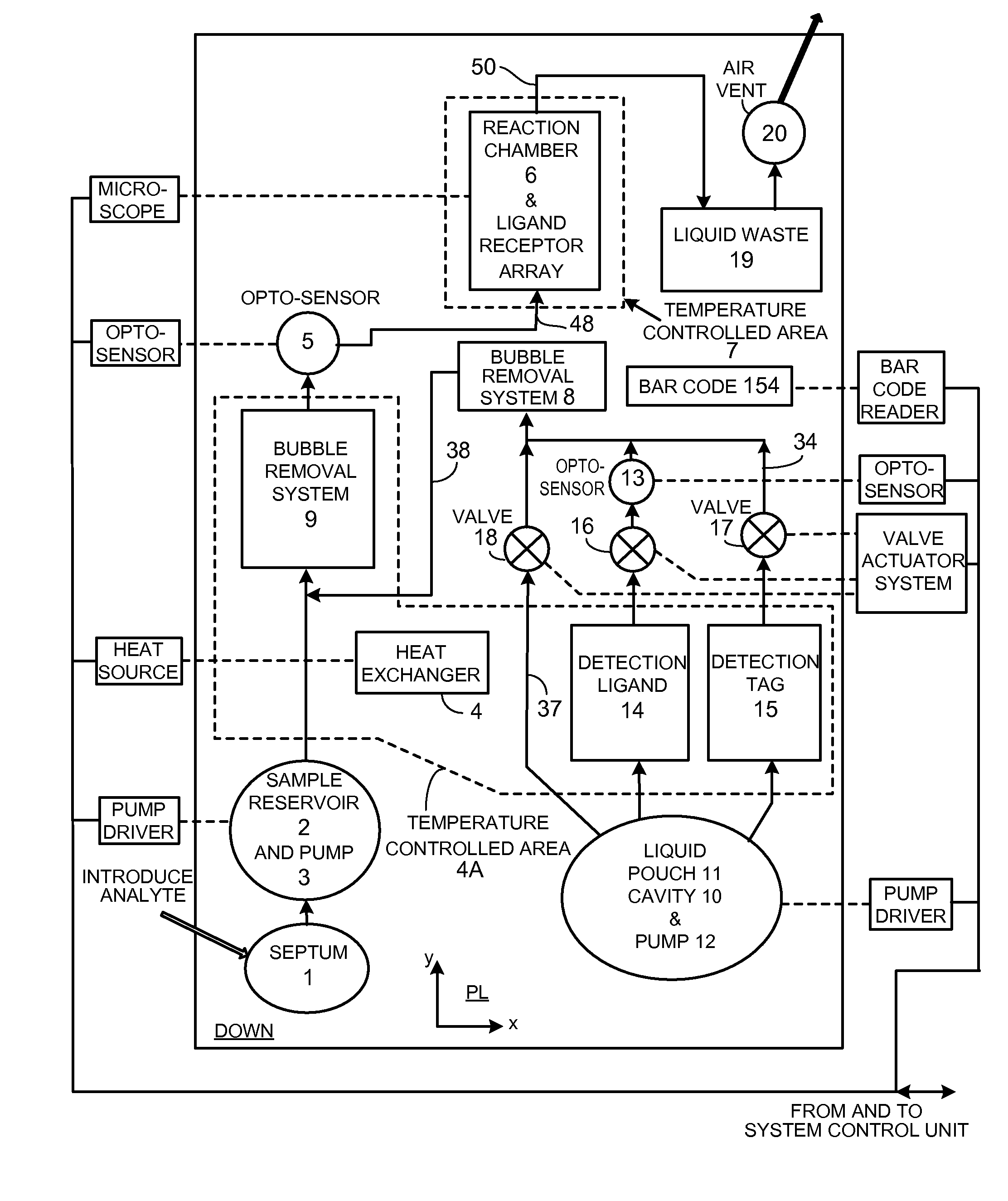

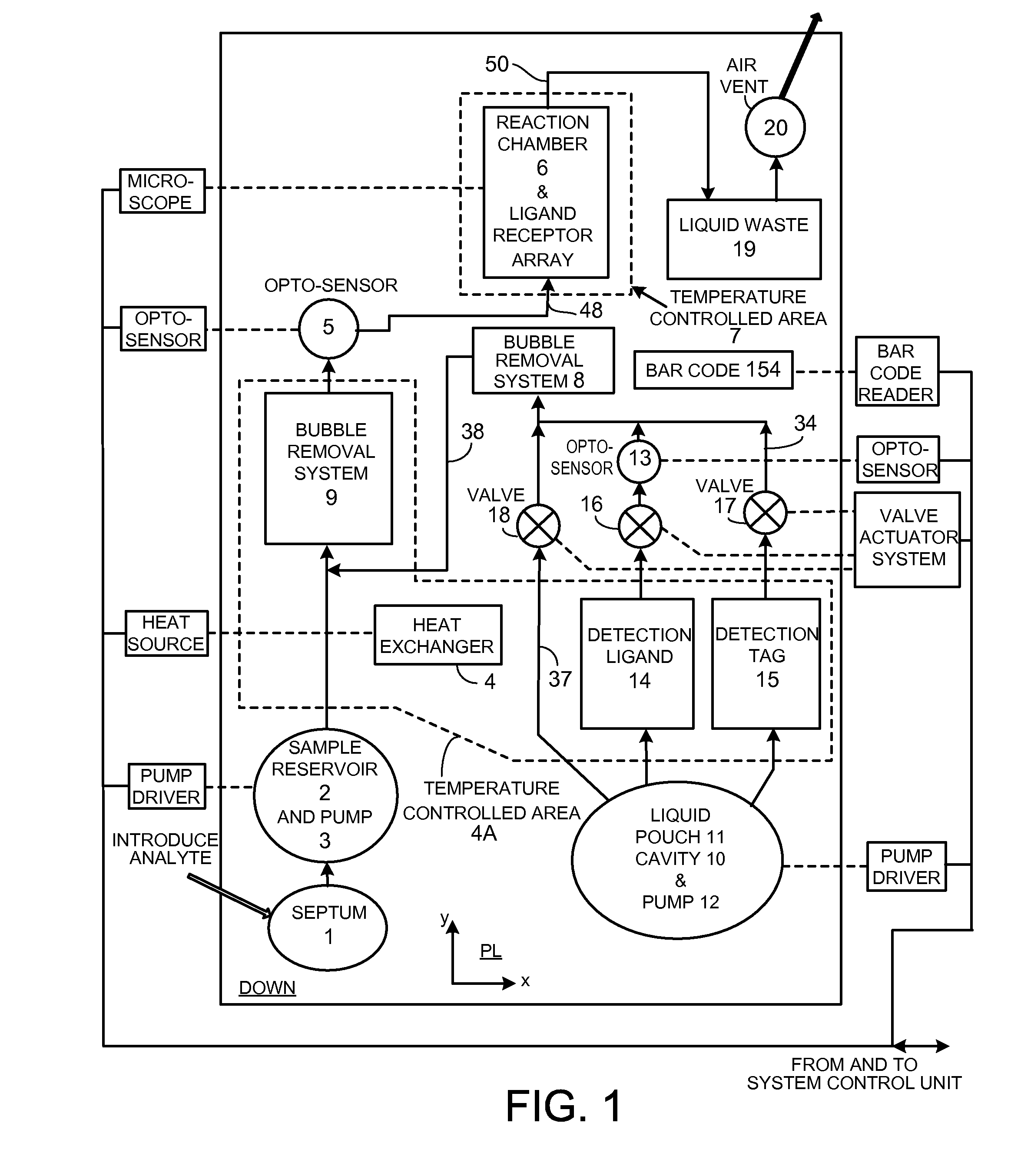

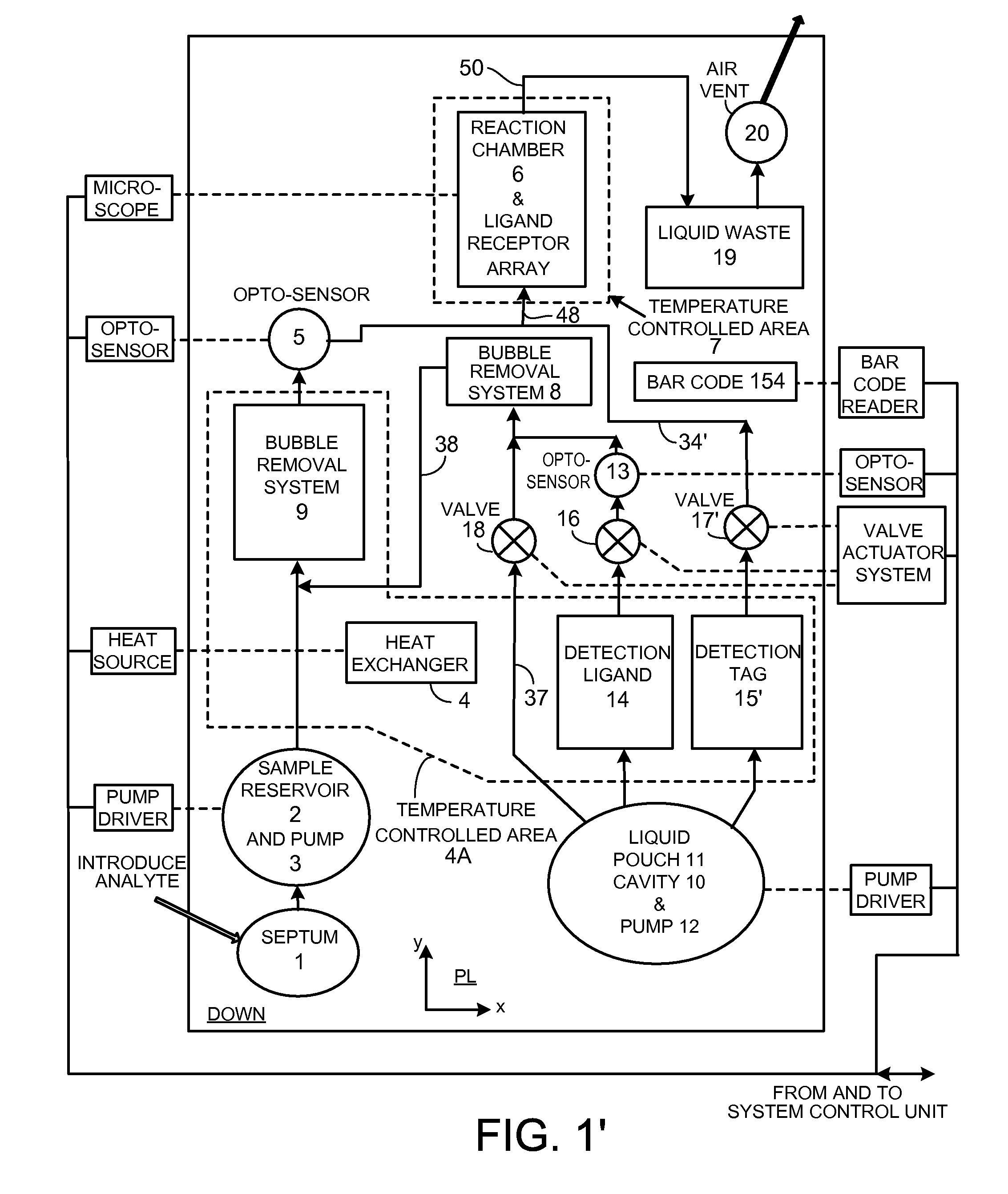

Assays Based on Liquid Flow over Arrays

InactiveUS20110207621A1Highly consistent quantitative multiplex assaysLow costLibrary screeningFlexible member pumpsFritBlister pack

Flow-through assay reaction chamber (6) of cassette has back and forth liquid mixing in narrow gap (G) over array of capture agent (S), with net flow advance to waste confinement (19), produced by reversible pumps (3 or 12), operable with rolling diaphragm action with at least limited elastic recovery that advance sample or buffer liquids through conditioning paths (4A, 8, 8′, 9, 14, 15, 15′) before reaching the reaction chamber (6). A single pump produces accurate flow control, liquid conditioning, e.g., liquefying dry reagent from internal surfaces of flow-dividing material (14a, 15A, 15A′, e.g. open cell foam or frit), heating (4A), and air bubble removal (8, 8′, 9), as well as replenishment of reagent while accomplishing mixing within the flow-through reaction chamber (6). Lower viscosity buffer liquid is arranged to propel higher viscosity reagent, the flow-dividing storage material preserving reagent concentration. A blister pack (11) acts as a reversible pump (12) in producing accurate forward and backward flows with the net flow advance. Cascaded bubble traps (8, 9) on the cassette render the system tolerant of minor pumping error during cassette priming.

Owner:AVANTRA BIOSCI CORP

Multi-column separation devices and methods

InactiveUS7261812B1Ion-exchange process apparatusComponent separationChromatographic separationStationary phase

Chromatographic separation devices include multiple batch-processed columns joined by a body structure and adapted to perform parallel analyses. Both slurry-packed and monolithic column embodiments are provided. One or more liquid-permeable frits of various types may be used to retain stationary phase material within columns. A fluidic distribution network may be used to distribute stationary phase material and / or mobile phase solvents to multiple columns. Separation devices, including microfluidic embodiments, may be fabricated with various materials including polymers. Multi-column fabrication and separation methods are provided.

Owner:AGILENT TECH INC

Display panel and production method thereof

ActiveUS20120287026A1Improve deteriorationReduced Surface Flatness RequirementsLamination ancillary operationsStatic indicating devicesPhoto irradiationHermetic seal

A display panel includes: a first substrate; light-emitting elements on a region of the first substrate; a second substrate facing the first substrate with the light-emitting elements therebetween; a glass frit between the first substrate and the second substrate so as to surround the region of the first substrate in which the light-emitting elements are disposed, the glass frit providing a hermetic seal between the first substrate and the second substrate; and a light-shielding part formed on one of the first substrate and the second substrate so as to extend along the glass frit, the light-shielding part shielding light. The light-shielding part has a lower light-shielding property in a region corresponding to the outer region of the glass frit than in a region corresponding to the inner region of the glass frit. The glass frit has been irradiated with light through the light-shielding part.

Owner:JOLED INC

Paste for back contact-type solar cell

InactiveUS20080230119A1Reduce contact resistanceExcellent electrical propertiesFinal product manufactureConductive materialFritMetal alloy

Disclosed is a paste for a back contact-type solar cell that includes: (a) electrically conductive particles containing silver particle and added particles selected from the group consisting of (i) metal particles selected from the group consisting of Mo, Tc, Ru, Rh, Pd, W, Re, Os, Ir and Pt particles, (ii) a metal alloy containing the metal particles, and (iii) particles loaded with the metal particles, (b) glass frit, and (c) a resin binder.

Owner:EI DU PONT DE NEMOURS & CO

Vacuum IG window unit with metal member in hermetic edge seal

ActiveUS20080166570A1Flexible edge sealMore give and take during window flexingDoors/windowsClimate change adaptationFritOptical distortion

A vacuum insulating glass (IG) unit and / or a method of making the same is / are provided. In certain example embodiments, the edge seal includes at least one metal member located between the opposing substrates (e.g., glass substrates). The at least one metal member may be bonded to the glass substrate(s) via a bonding material such as solder glass, frit and / or the like. The provision of the at least one metal member in the edge seal, between and / or exterior the glass substrates, is advantageous in that this provides for a more flexible edge seal permitting more give and take during window flexing in different environmental conditions. The additional flexibility of the edge seal may reduce the amount of optical distortion caused by flexing of the window, and / or the likelihood of window breakage in certain environmental conditions.

Owner:GUARDIAN GLASS LLC

Glass enclosure

ActiveUS8824140B2Digital data processing detailsCasings with display/control unitsFritBonding process

Owner:APPLE INC

Organic light emitting display and method of fabricating the same

ActiveUS20070170859A1Discharge tube luminescnet screensElectroluminescent light sourcesFritOrganic light emitting device

Disclosed are an organic light emitting display and a method of fabricating the same that are capable of preventing deterioration of adhesive strength of a glass frit for sealing a substrate. An organic light emitting device according to one embodiment of the present invention includes a first substrate including a pixel region and a non-pixel region, an array of organic light emitting pixels formed over the pixel region of the first substrate, and a second substrate placed over the first substrate, the array being interposed between the first and second substrates. The organic light emitting device of this embodiment further includes an electrically conductive line formed over the non-pixel region of the first substrate, and a frit seal interposed between the first and second substrates and surrounding the array such that the array is encapsulated by the first substrate, the second substrate and the frit seal, wherein the electrically conductive line comprises a portion overlapping the frit seal in a segment of the device such that the portion of the electrically conductive line substantially eclipses the frit seal when viewed from the first substrate.

Owner:SAMSUNG DISPLAY CO LTD

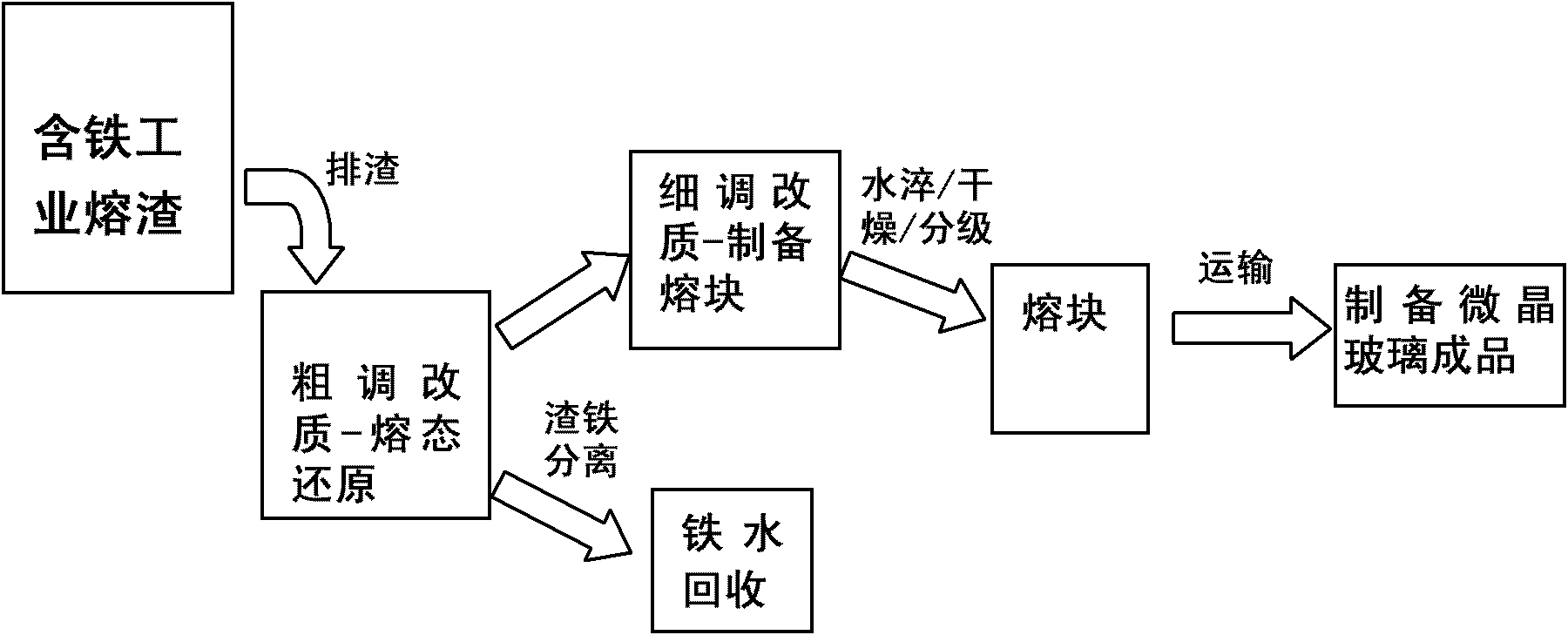

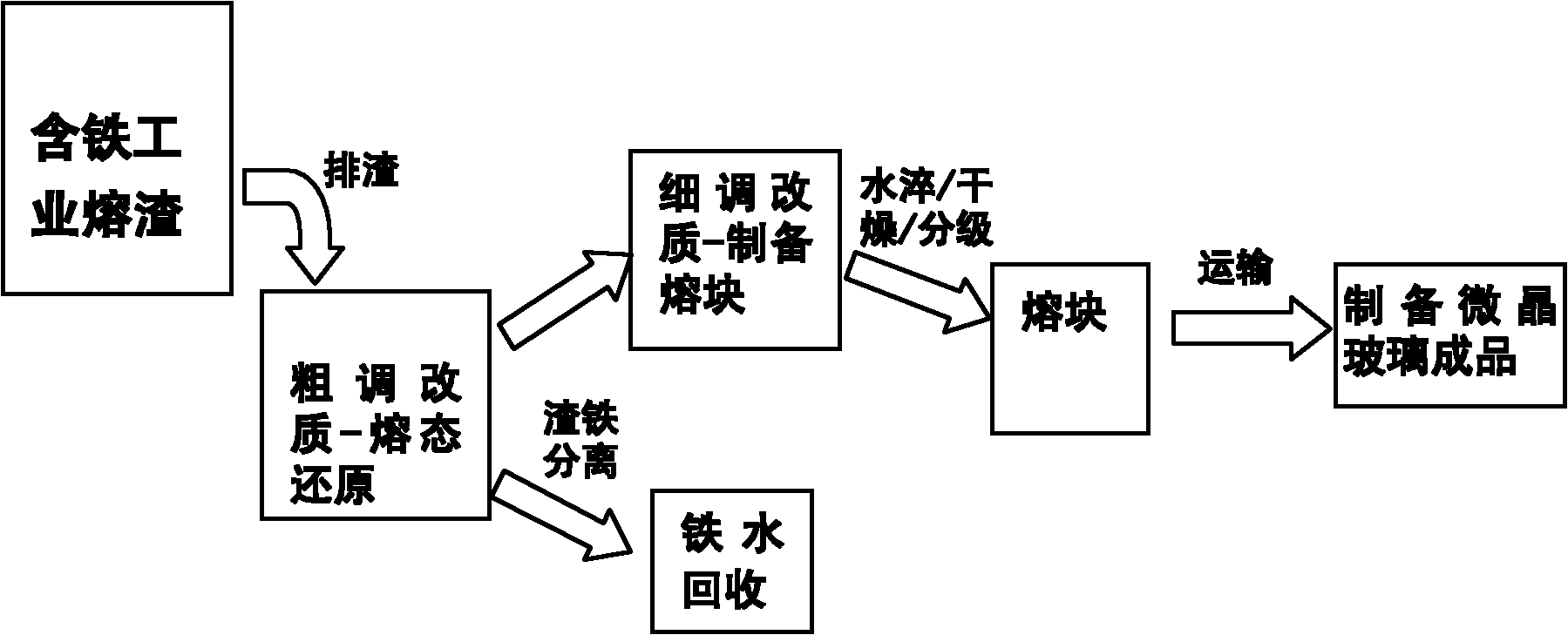

Method for recycling iron on line from iron-containing industrial slag and preparing glass ceramics frit

InactiveCN101914639AGuaranteed slag compositionRecycling and recovery technologiesProcess efficiency improvementMaterials preparationSlag

The invention relates to a method for recycling iron on line from iron-containing industrial slag and preparing a glass ceramics frit, belonging to the technical field of resource comprehensive utilization and material preparation and mainly comprising a two-step method process of iron-containing industrial slag online rough adjustment and modification for reducing iron and fine adjustment and modification for preparing the frit. The method comprises the steps of: discharging high-temperature iron-containing slag into a high-temperature furnace device, and simultaneously adding a reducing agent and a modifying agent to ensure that slag components are adjusted to reach the optimal component point in which iron oxide is reduced; after fully reacted, separating reduced molten iron from the slag, and recycling to obtain high-temperature molten iron; further adding a modifying agent and an adjusting agent into the slag remained after the separation to ensure that the slag components are adjusted to achieve the quality requirement of slag glass ceramics on the frit; and water-hardening, drying and grading the qualified slag to prepare the glass ceramics frit. The invention realizes multiple purposes that the heat of the slag is directly utilized and metal iron is recycled to prepare a high addition value product as well as solid wastes are massively utilized, and the like.

Owner:UNIV OF SCI & TECH BEIJING

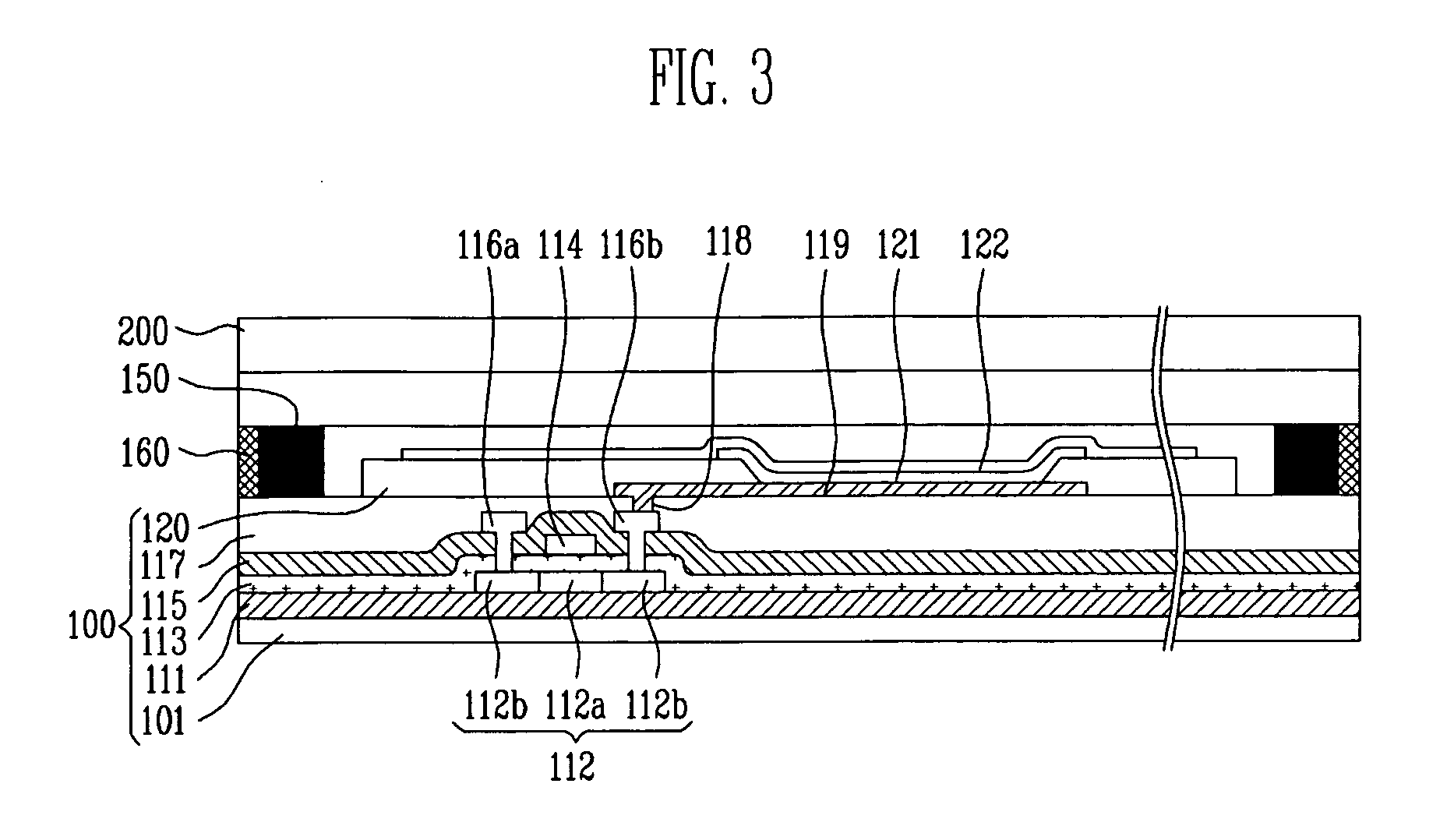

Organic light emitting display device and method of fabricating the same

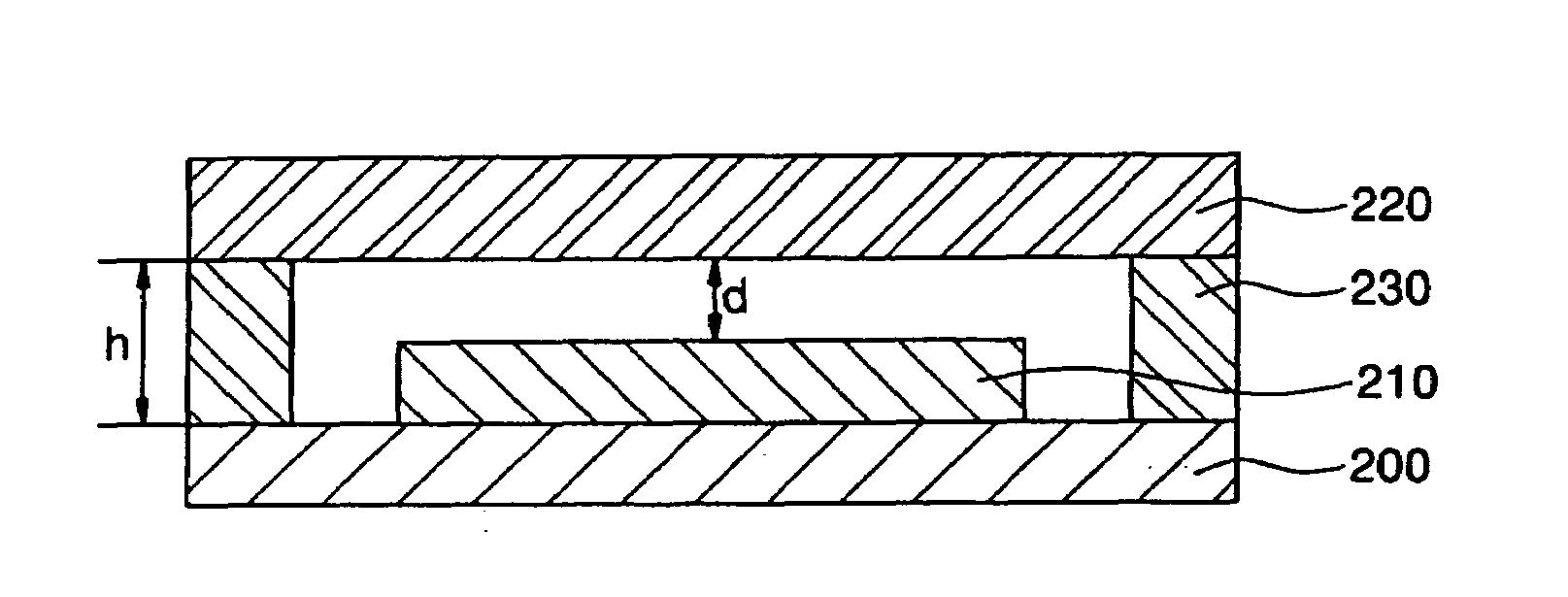

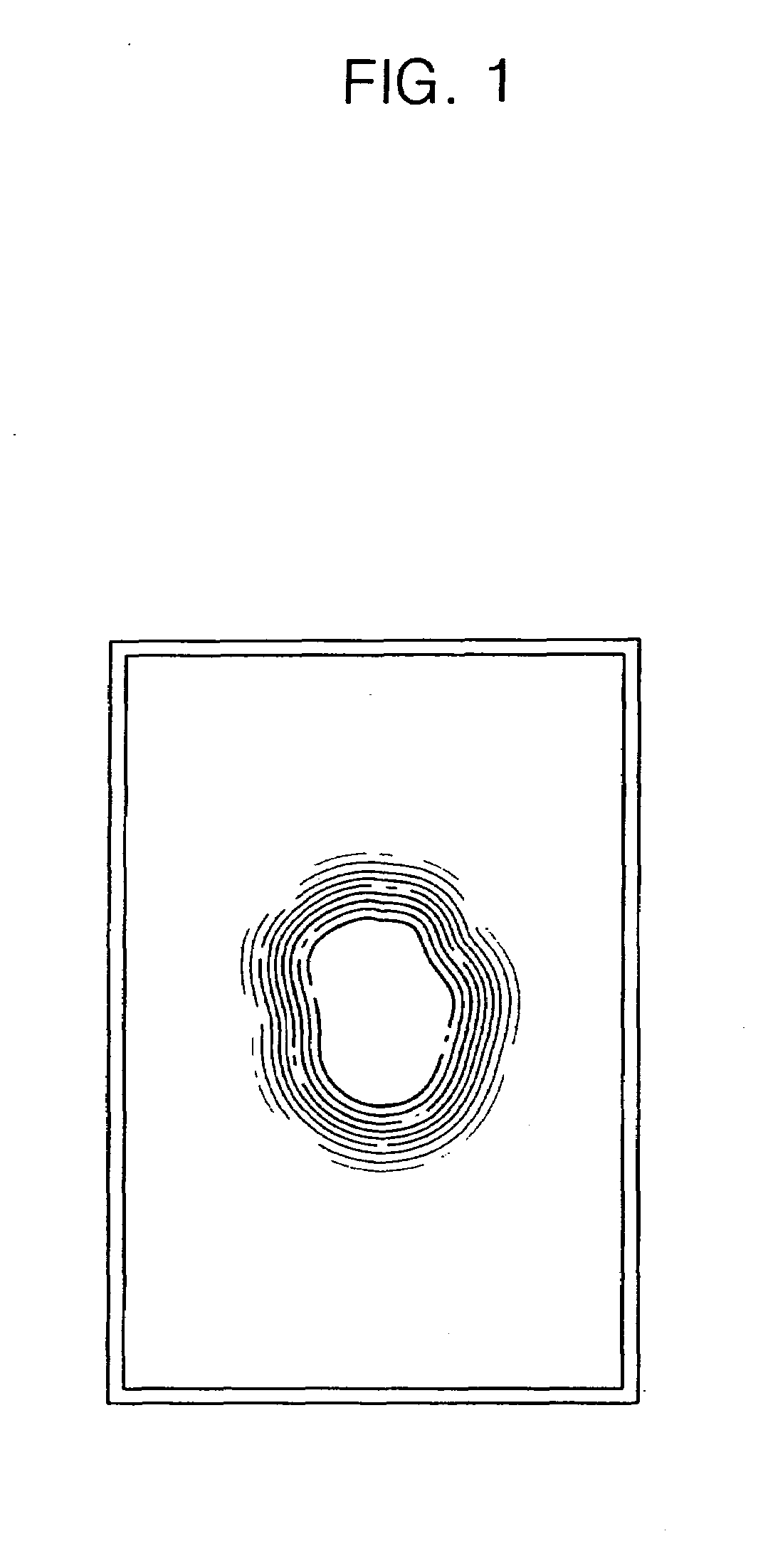

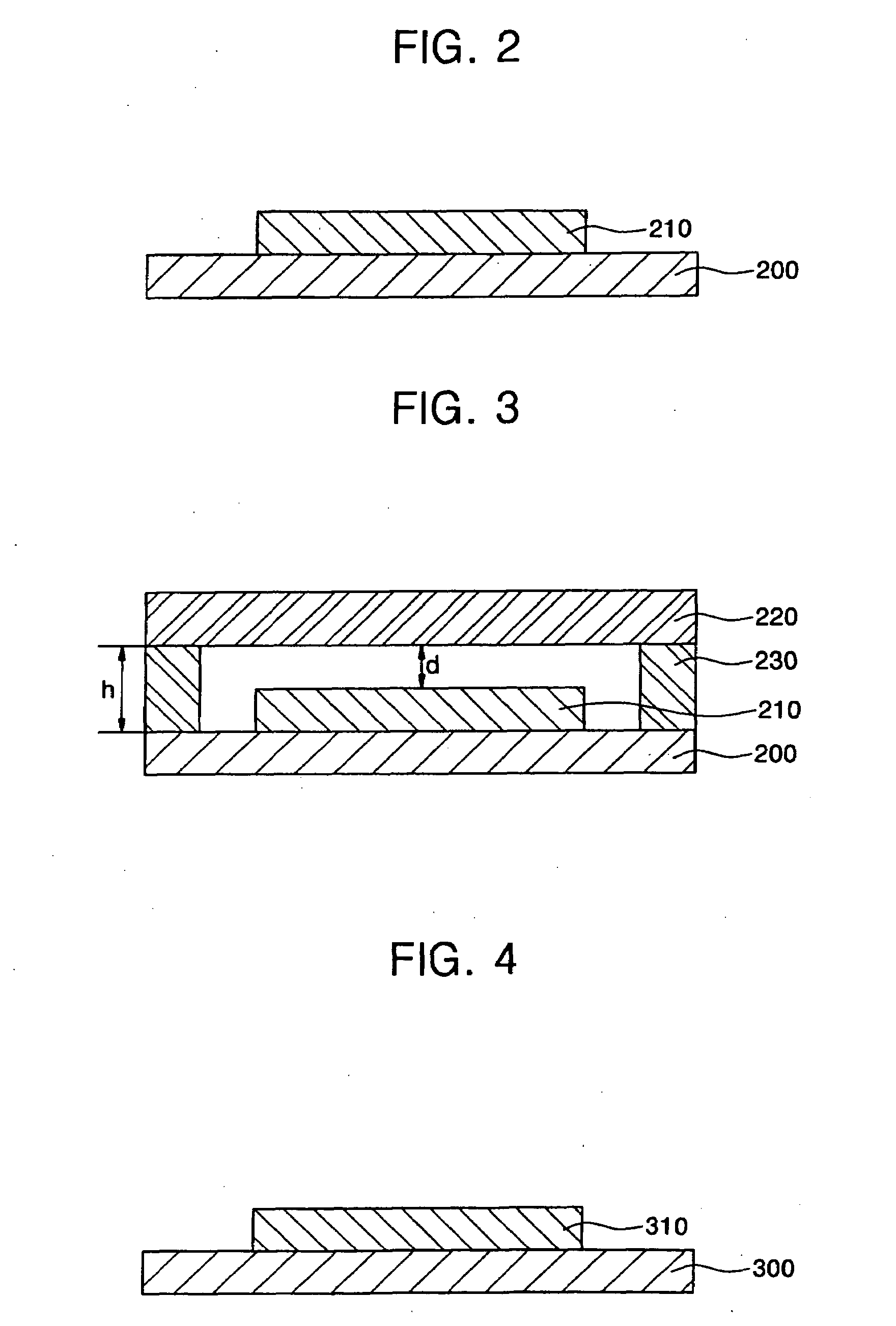

Provided is an organic light emitting display device (OLED) for preventing Newton's rings to improve image quality. An organic light emitting display device according to one embodiment of the present invention comprises a first substrate comprising a single layer or multiple layers; a second substrate comprising a single layer or multiple layers, the second substrate comprising an inner surface facing the first substrate; an array of organic light emitting pixels formed on the first substrate and interposed between the first and second substrates, the array comprising a top surface opposing the inner surface of the second substrate, wherein the top surface and the inner surface has a gap therebetween, and the gap has a gap distance measured between the top surface and the inner surface; and a frit seal interconnecting the first and second substrates while surrounding the array, wherein the frit seal, the first substrate and the second substrate in combination define an enclosed space in which the array is located, wherein the frit seal has a height between the first and second substrates so as to form the gap distance equal to or greater than about 10 μm.

Owner:SAMSUNG DISPLAY CO LTD

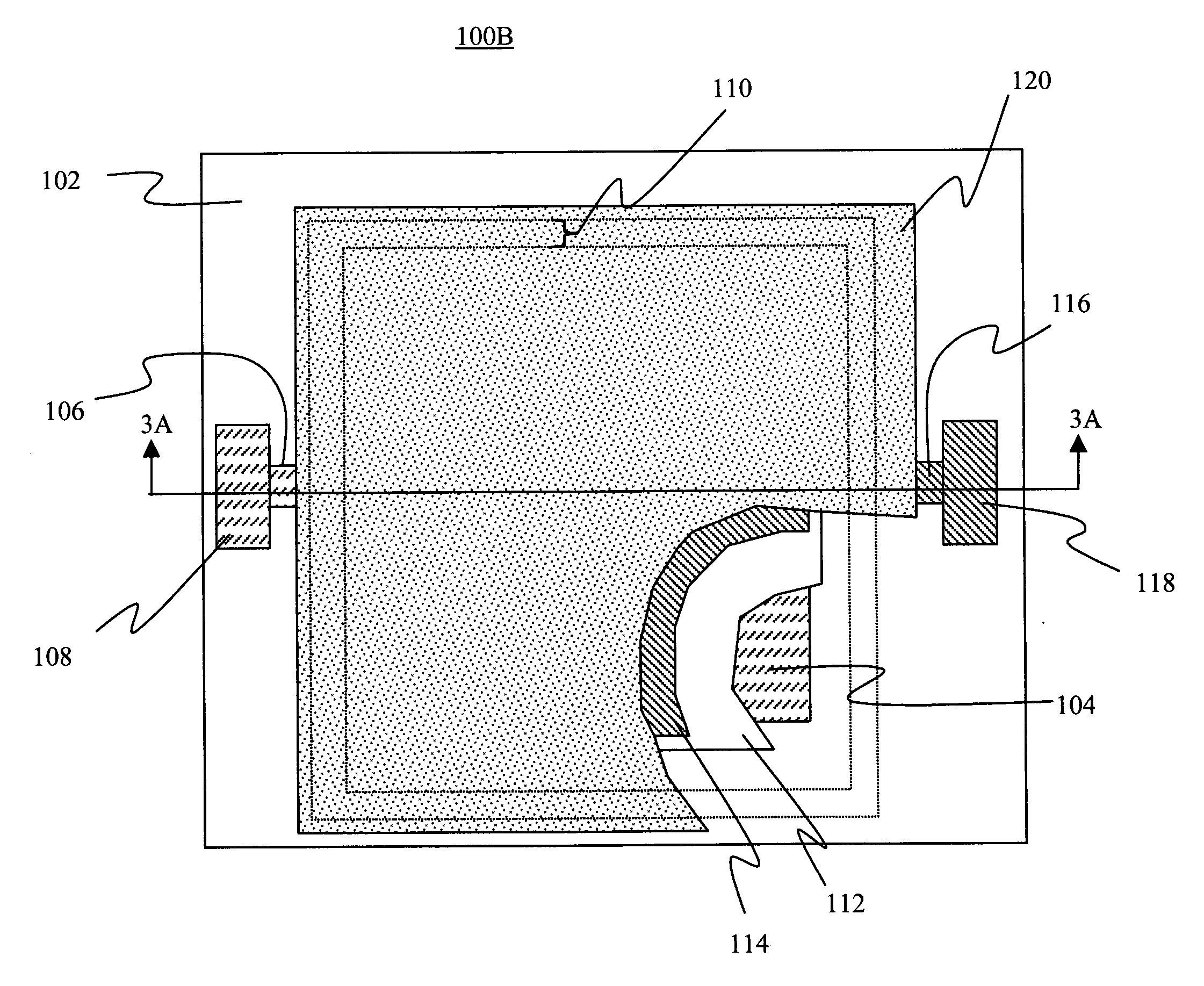

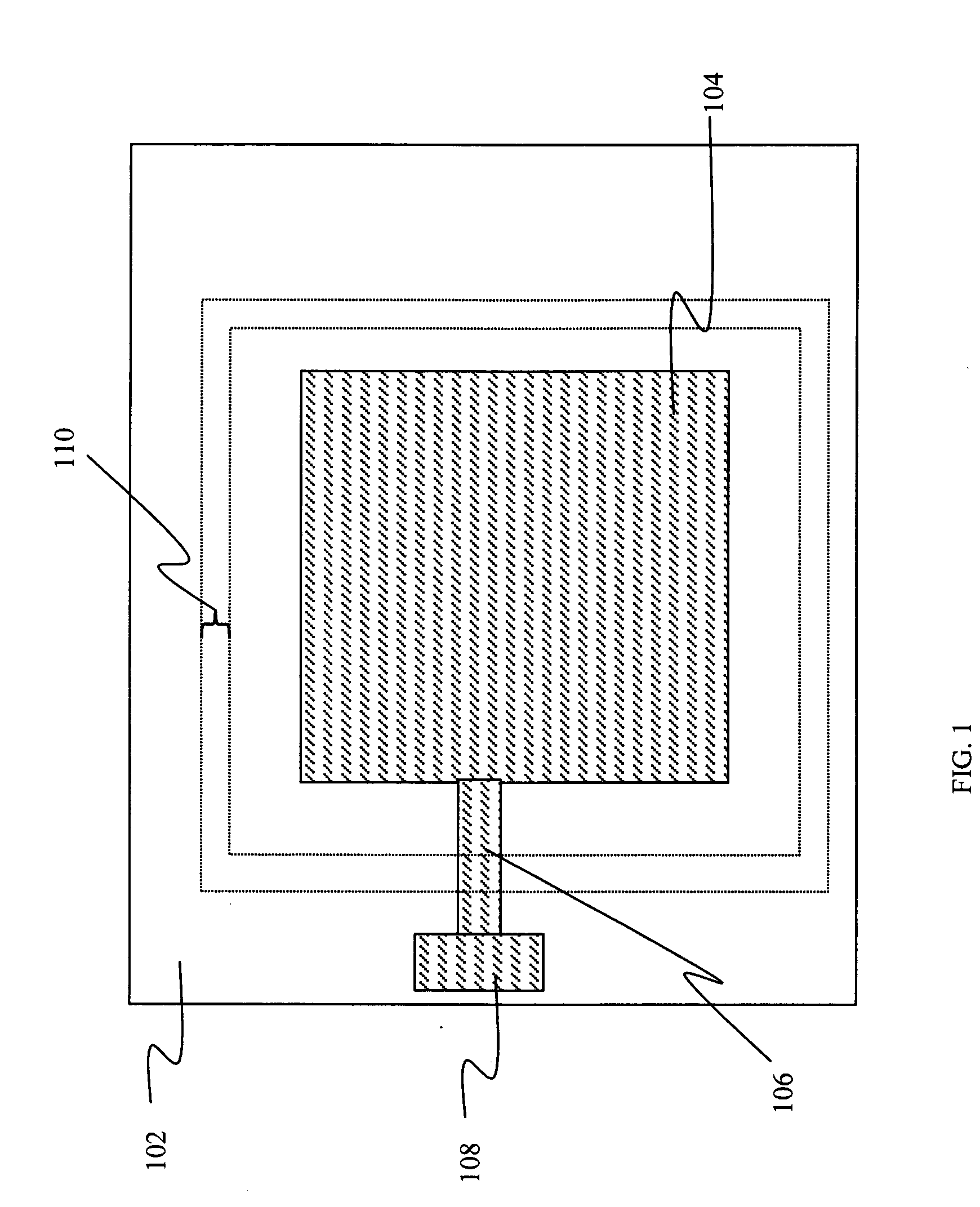

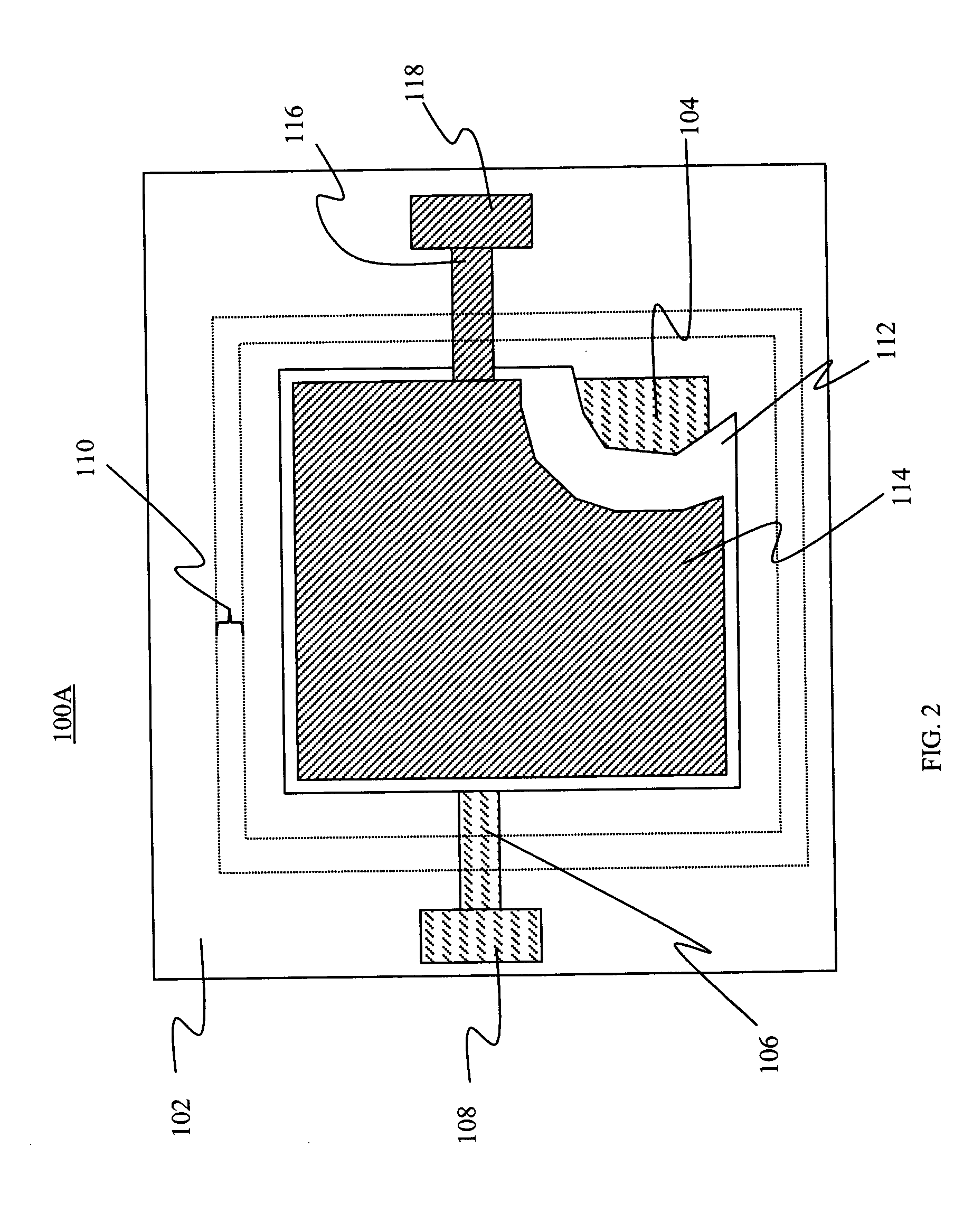

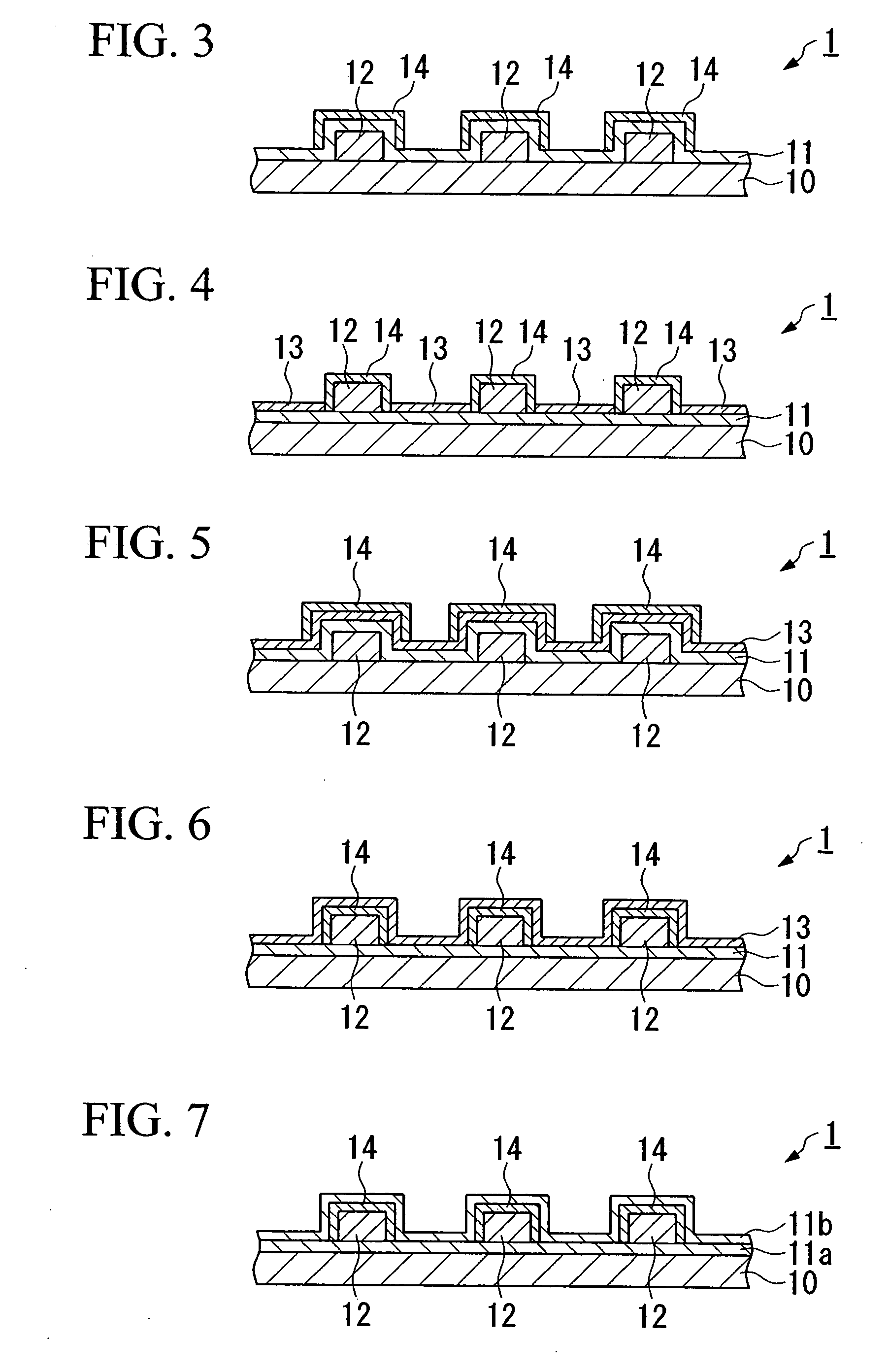

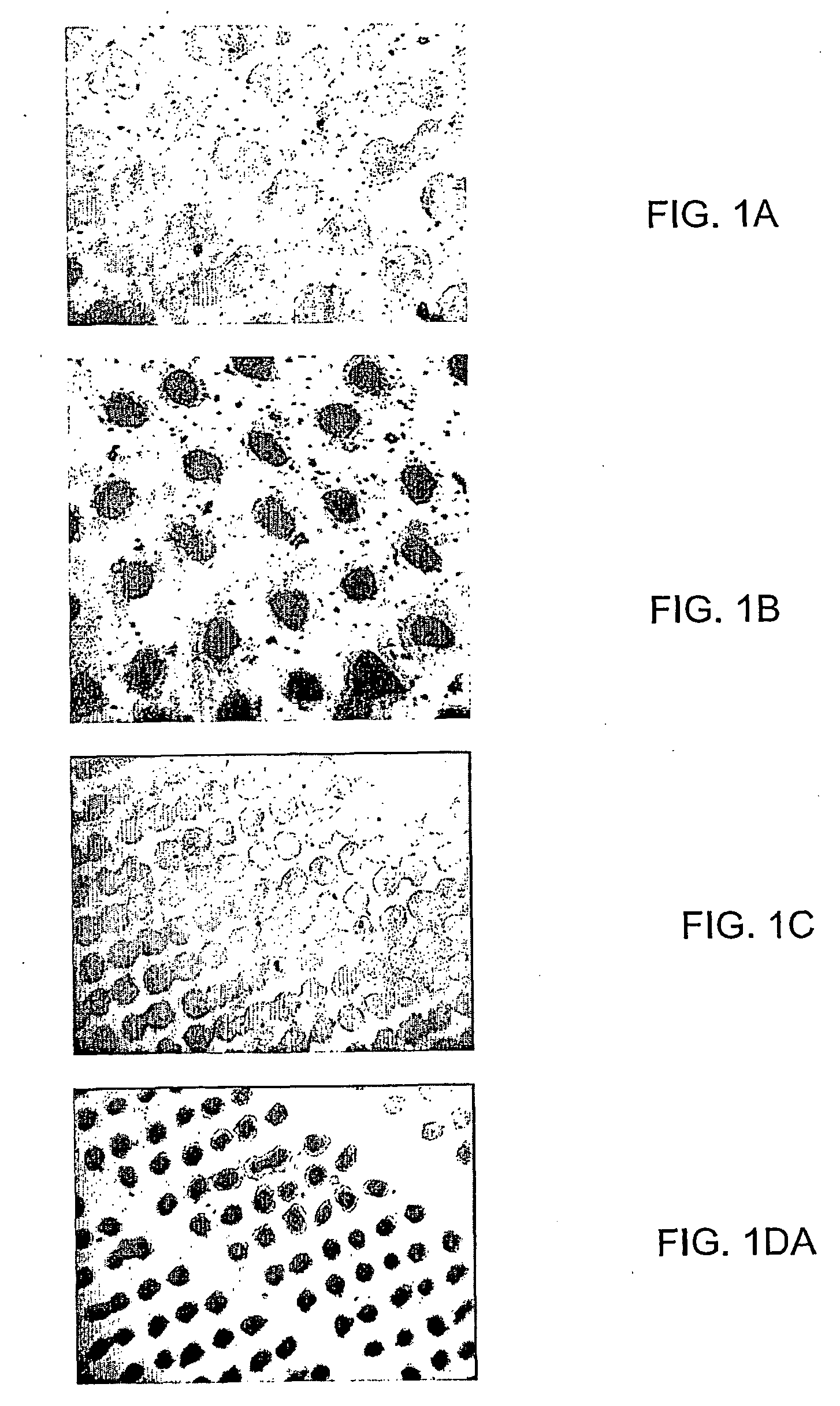

Vacuum packaged micromirror arrays and methods of manufacturing the same

ActiveUS6903860B2Improved dielectric isolationImprove isolationOptical elementsSpatial light modulatorFrit

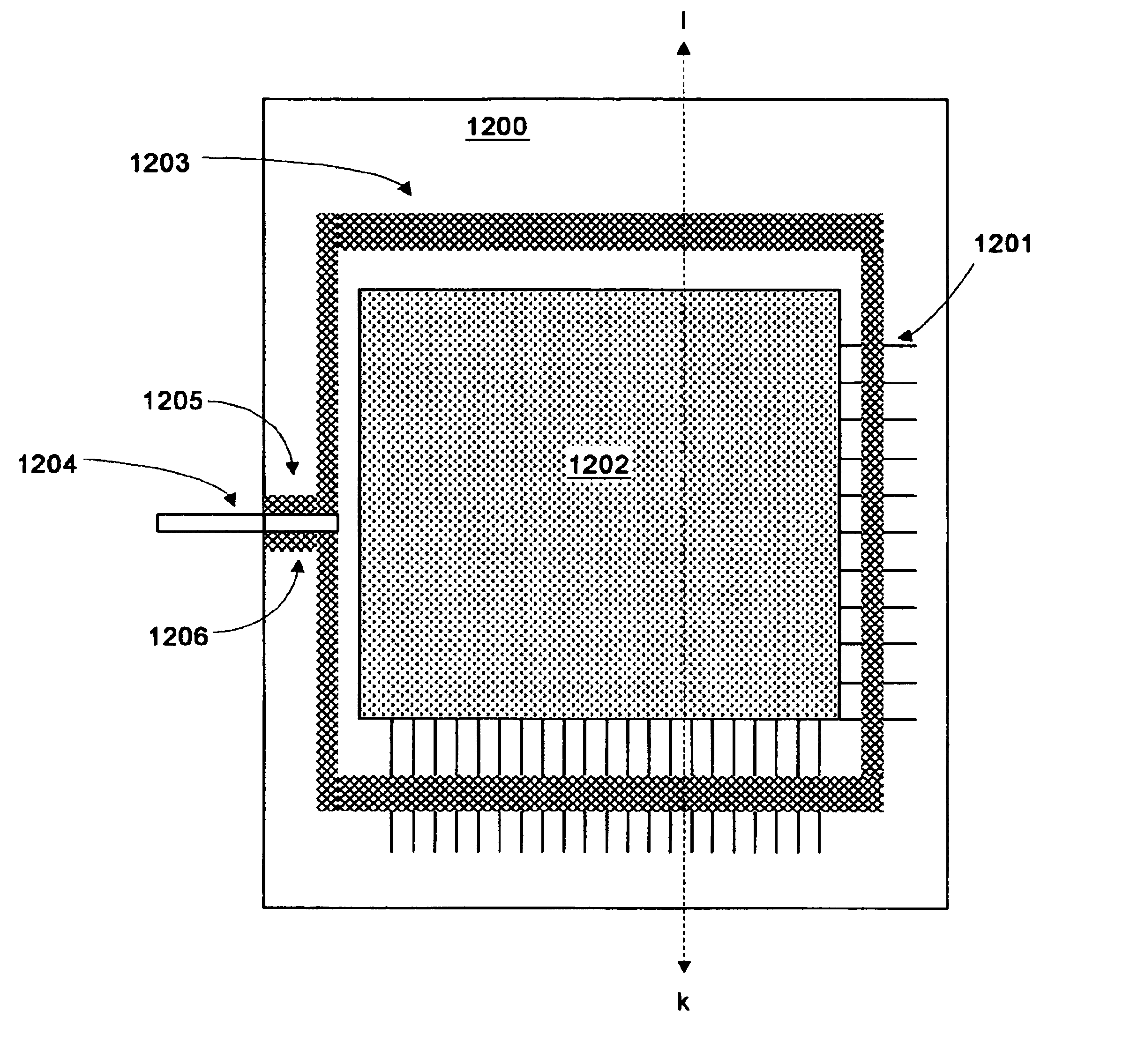

A vacuum packaged electromechanical micromirror array comprises a 1st packaging substrate, a 2nd packaging substrate, a device substrate with a 1st surface and a 2nd surface, control circuitry on said 1st surface, and micromirrors on said 2nd surface. The device substrate resides on the 1st packaging substrate with electrical connections between them. The electromechanical micromirror array is sealed in a vacuum package formed by the packaging substrates. The vacuum packaged micromirror array may be used as a spatial light modulator (SLM). Methods of fabricating the vacuum packaged array are disclosed. Such methods generally involve providing a device substrate with a 1st surface and a 2nd surface, fabricating control circuitry on the 1st surface, fabricating micromirrors on the 2nd surface, providing a 1st packaging substrate, mounting the device substrate on the 1st packaging substrate by flip-chip assembly, providing a 2nd packaging substrate, and sealing the packaging substrates by glass frit sealing.

Owner:IGNITE INC

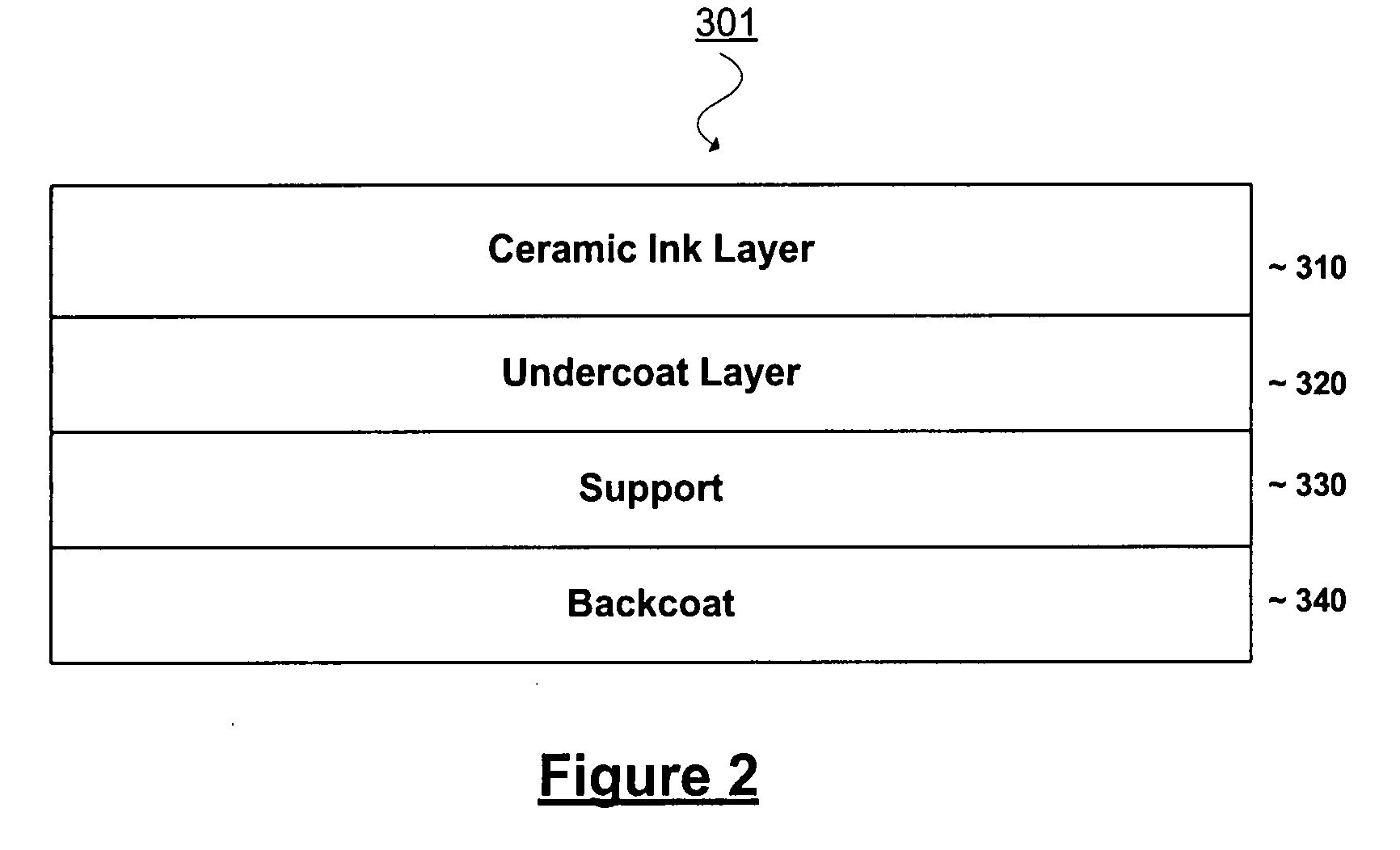

Ink for Ceramic Surfaces

ActiveUS20080210122A1Avoid collisionMaintain optical propertiesOther chemical processesDuplicating/marking methodsSilica nanoparticlesFrit

The present invention concerns ink for printing on ceramic surfaces such as glass, which contains glass frits for silica nanoparticles and optionally a pigment, and is suitable for ink jet printing.

Owner:YISSUM RES DEV CO OF THE HEBREWUNIVERSITY OF JERUSALEM LTD +1

Crystallization-free glass frit compositions and frits made therefrom for microreactor devices

InactiveUS20070123410A1Low pour pointHigh acid resistanceLaboratory glasswaresChemical/physical/physico-chemical processesMicroreactorFrit

The invention is directed to a glass composition that can be used to make glass frits suitable for use in the manufacturing of microreactors. The glass compositions, after final sintering to produce a finished microreactor, have a surface crystalline layer of 30 μm or less, or are completely amorphous throughout. Generally, the borosilicate glasses of the invention have a composition of B2O3=12-22 mol %; SiO2=68-80 mol % and additional components selected from the group consisting of either (a) Al2O3=3-8 mol % and Li2O=1-8 mol %, or (b) K2O=0-2 mol % and Na2O=0-2 mol %, except that both K2O and Na2O cannot both equal zero at the same time. One borosilicate glass has a composition, in mole percent (mol %) of B2O3=18-22 mol %, SiO2=75-80 mol %, K2O=0-2 mol %, and Na2O=0-2 mol %, except that both K2O and Na2O cannot both equal zero at the same time.

Owner:CORNING INC

Seal for light emitting display device, method, and apparatus

InactiveUS20080106194A1Discharge tube luminescnet screensElectroluminescent light sourcesFritAdhesive

A glass package is disclosed comprising a first substrate and a second substrate, where the substrates are attached in at least two locations, at least one attachment comprising a frit, and at least one attachment comprising a polymeric adhesive and wherein the frit comprises a glass portion comprising: a base component comprising and at least one absorbing component. Also disclosed is a method of sealing a light emitting display device comprising providing a light emitting layer, a first substrate and a second substrate, where a frit is deposited between the substrates and a polymeric adhesive is deposited either between the substrates or around the edge of the device, and where the frit is sealed with a radiation source and the polymeric adhesive is cured.

Owner:CORNING INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com