Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

101 results about "Fritted glass" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Fritted glass is finely porous glass through which gas or liquid may pass. It is made by sintering together glass particles into a solid but porous body. This porous glass body can be called a frit. Applications in laboratory glassware include use in fritted glass filter items, scrubbers, or spargers. Other laboratory applications of fritted glass include packing in chromatography columns and resin beds for special chemical synthesis.

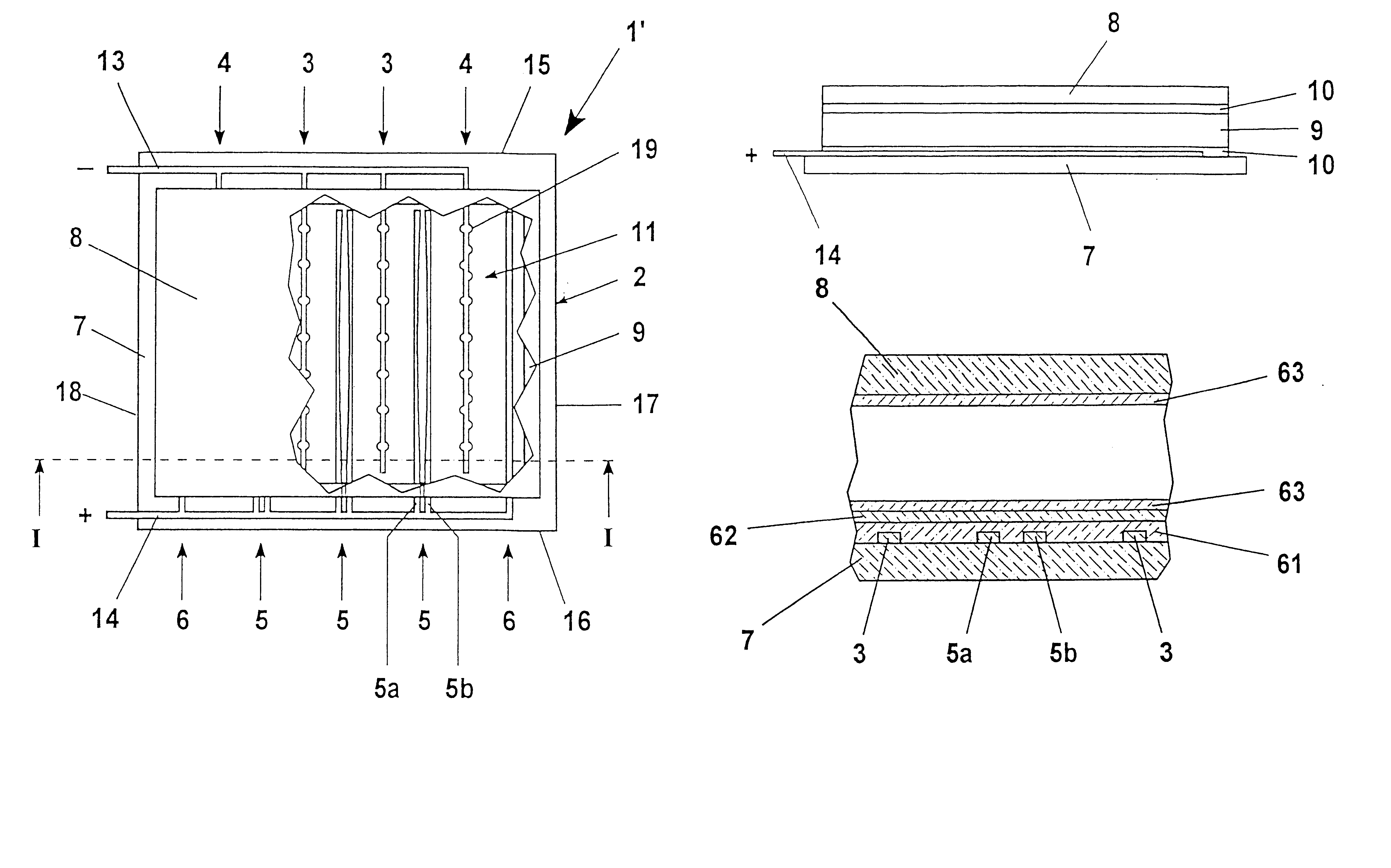

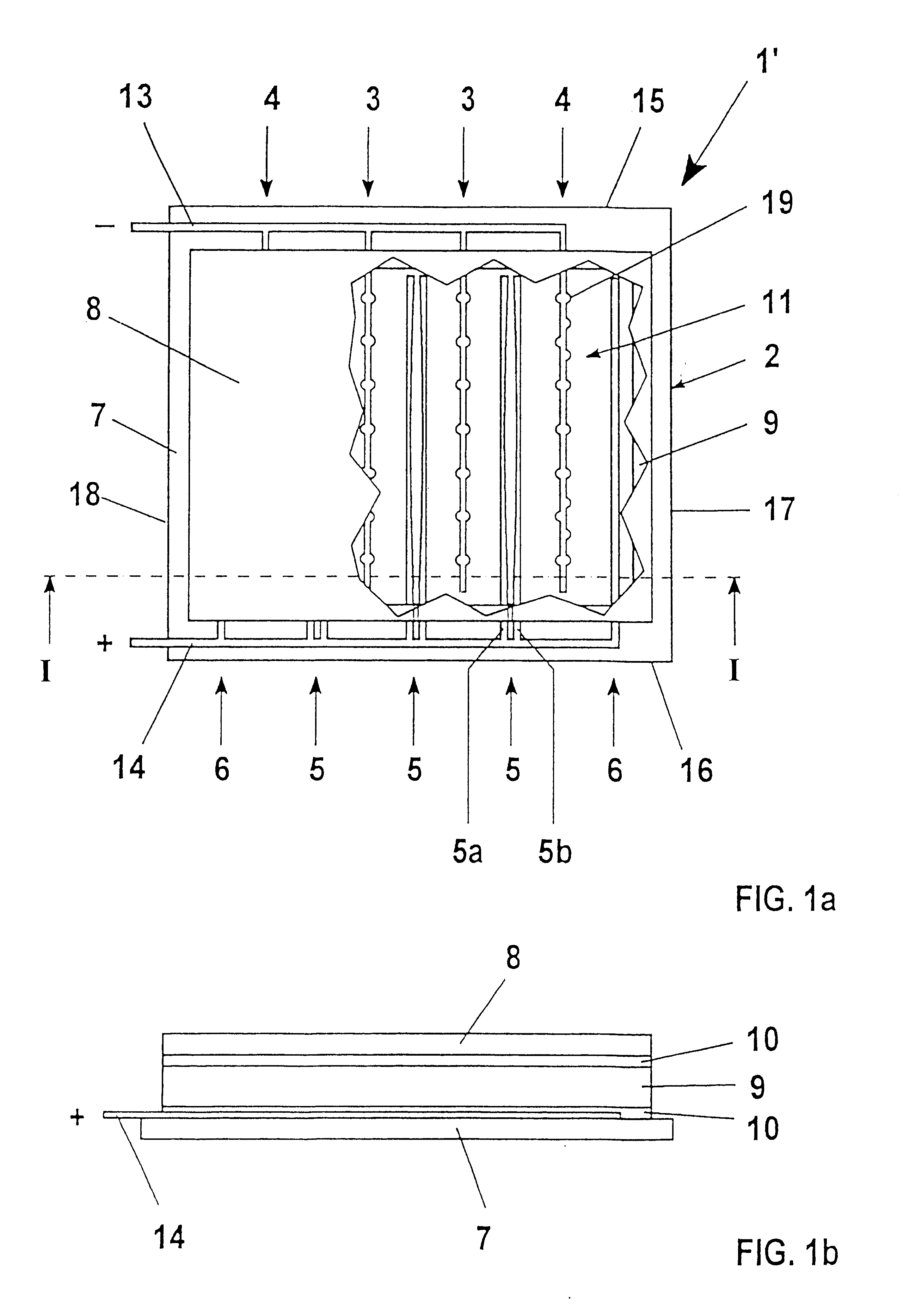

Encapsulating OLED devices

InactiveUS20050248270A1Discharge tube luminescnet screensElectroluminescent light sourcesMoisture penetrationFrit

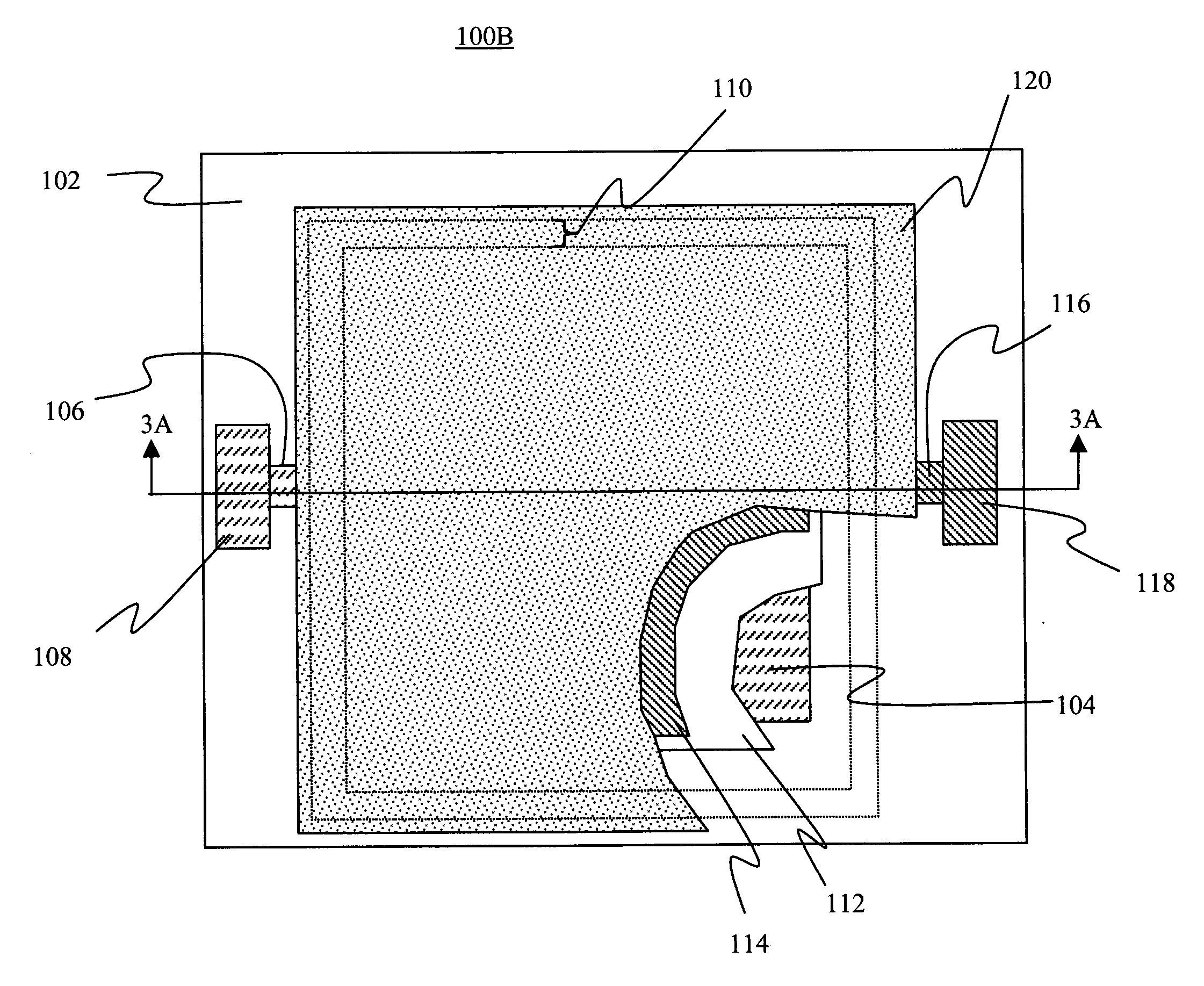

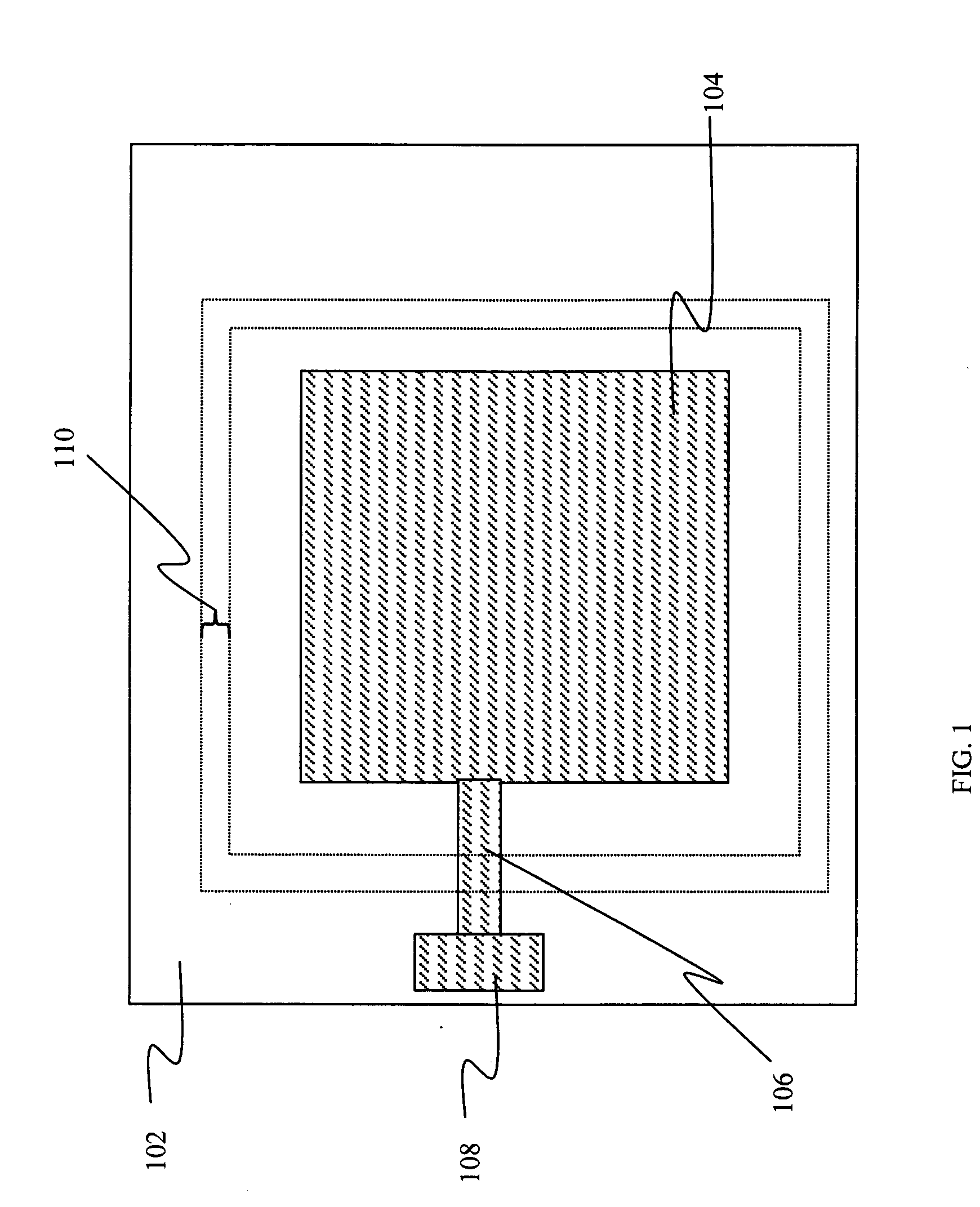

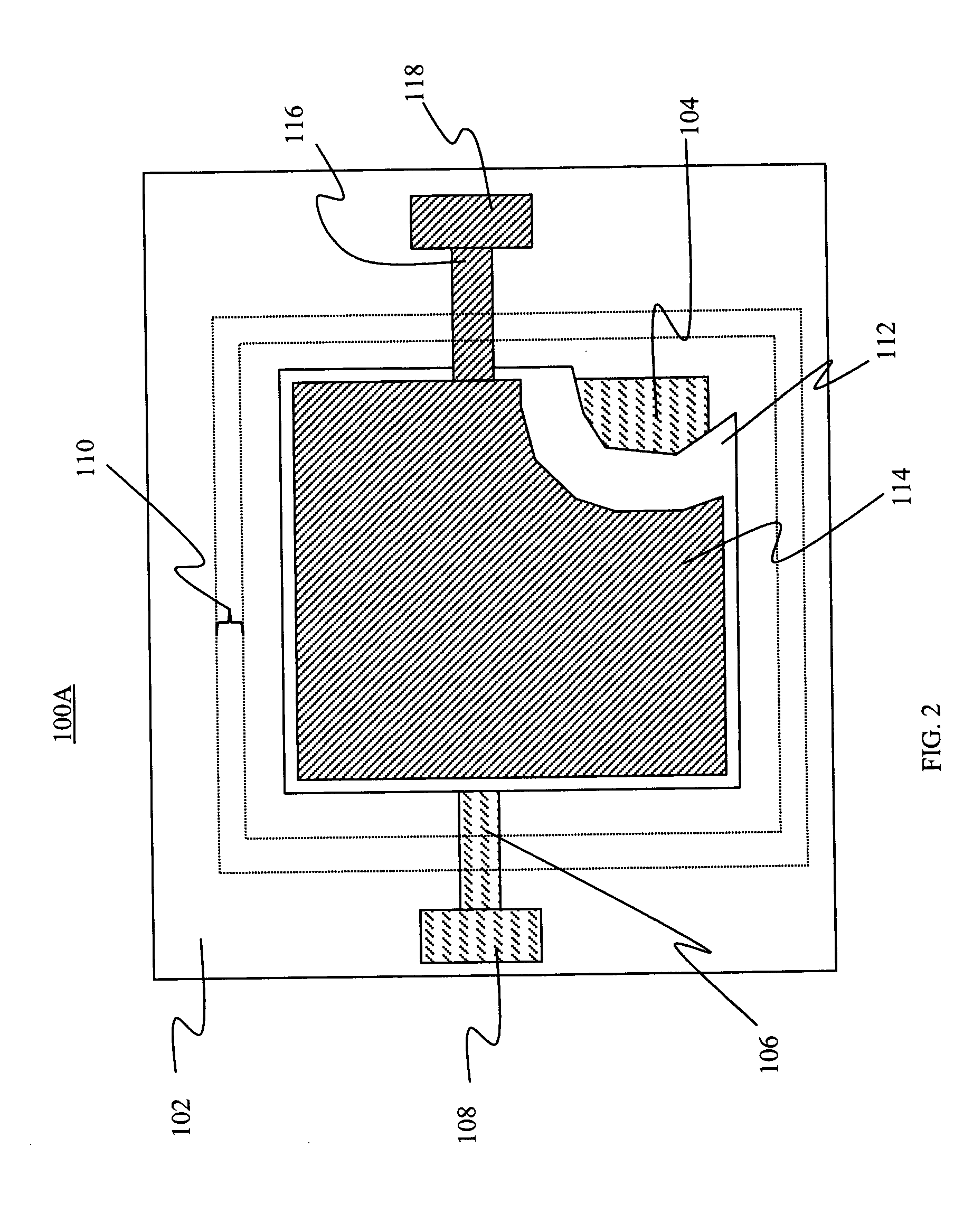

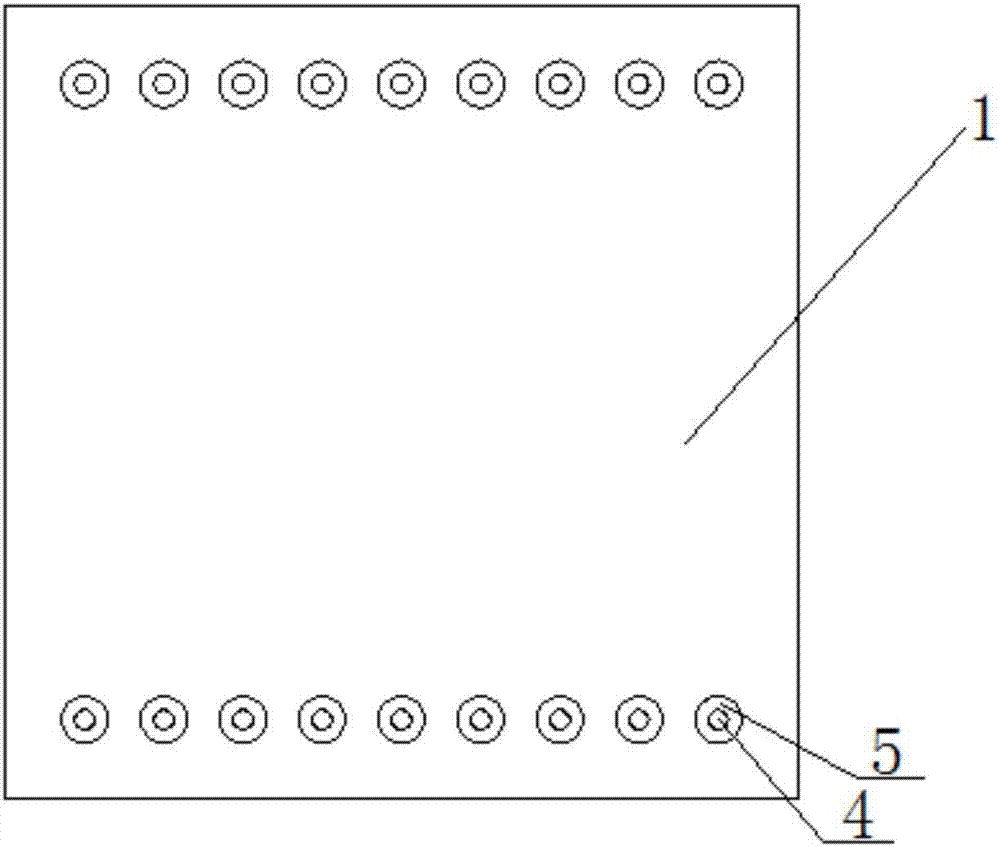

An encapsulated OLED device includes a substrate having a predetermined glass seal area and defining a sealed region and one or more OLED unit(s) provided over the substrate, each OLED unit having a light-emitting portion including at least one first electrode, at least one second electrode spaced from the first electrode, and an organic EL media layer provided between the first and second electrodes, wherein the light-emitting portion is provided within the sealed region. The device also includes an inorganic protection layer provided over the glass seal area and over at least a portion of the sealed region, a cover provided over the substrate and OLED unit(s), and sintered glass frit seal material provided in the glass seal area and in contact with both the cover and the inorganic protection layer to bond the cover to the inorganic protection layer and provide sealing against moisture penetration into the sealed region.

Owner:EASTMAN KODAK CO

Process and apparatus for making glass sheet

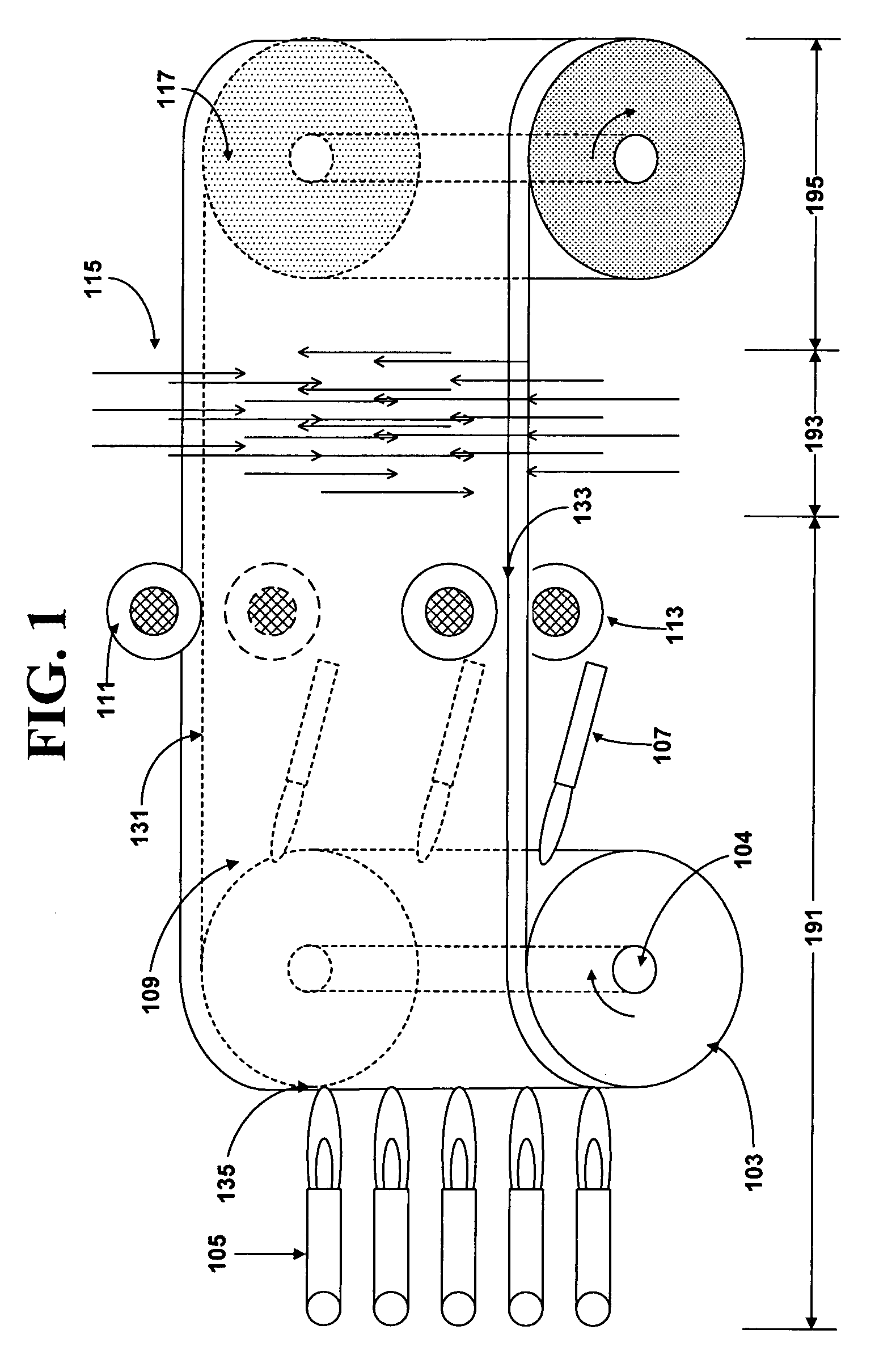

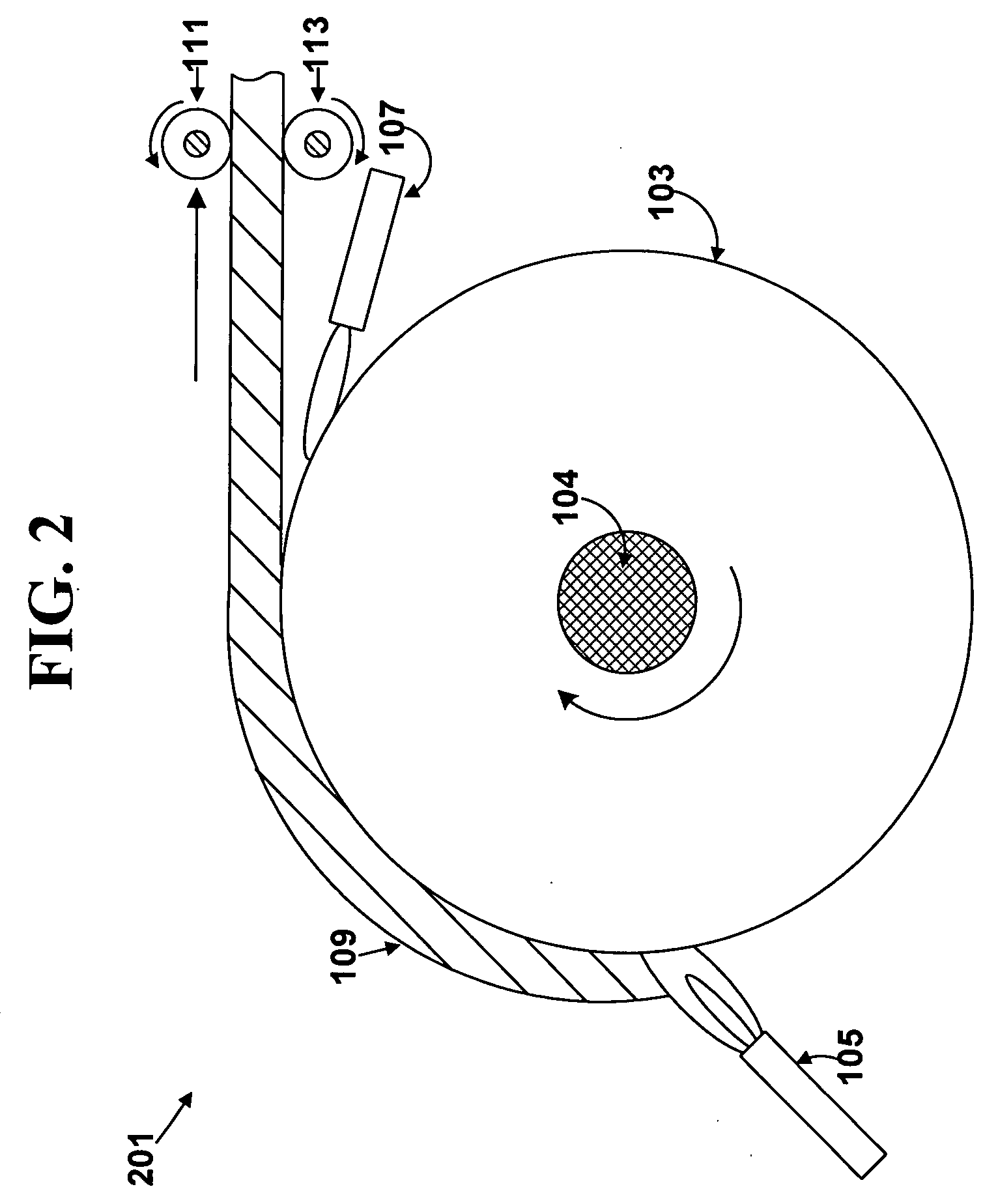

ActiveUS20080280057A1Improve thickness uniformityUniform thicknessMolten spray coatingGlass shaping apparatusMetallurgyFritted glass

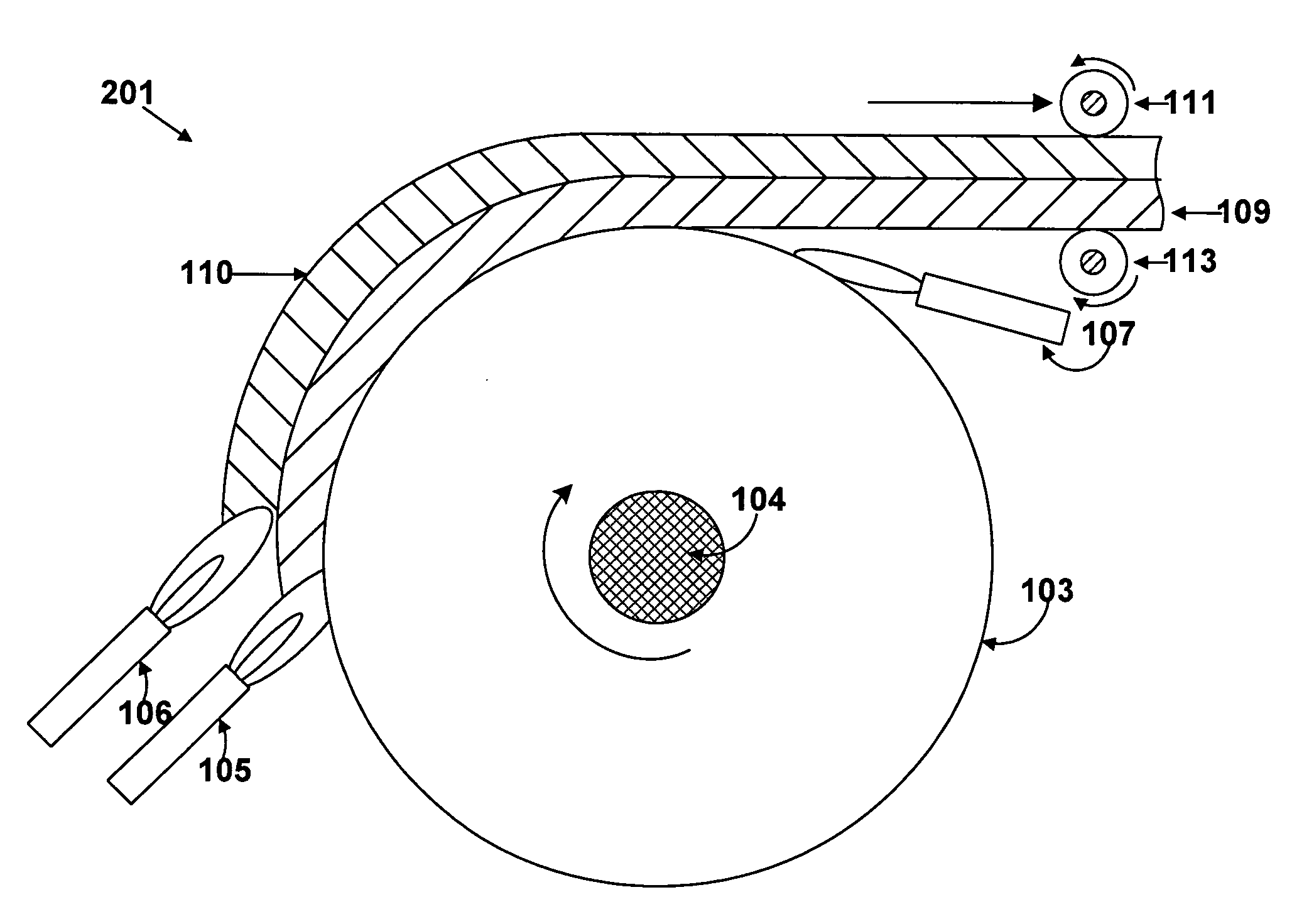

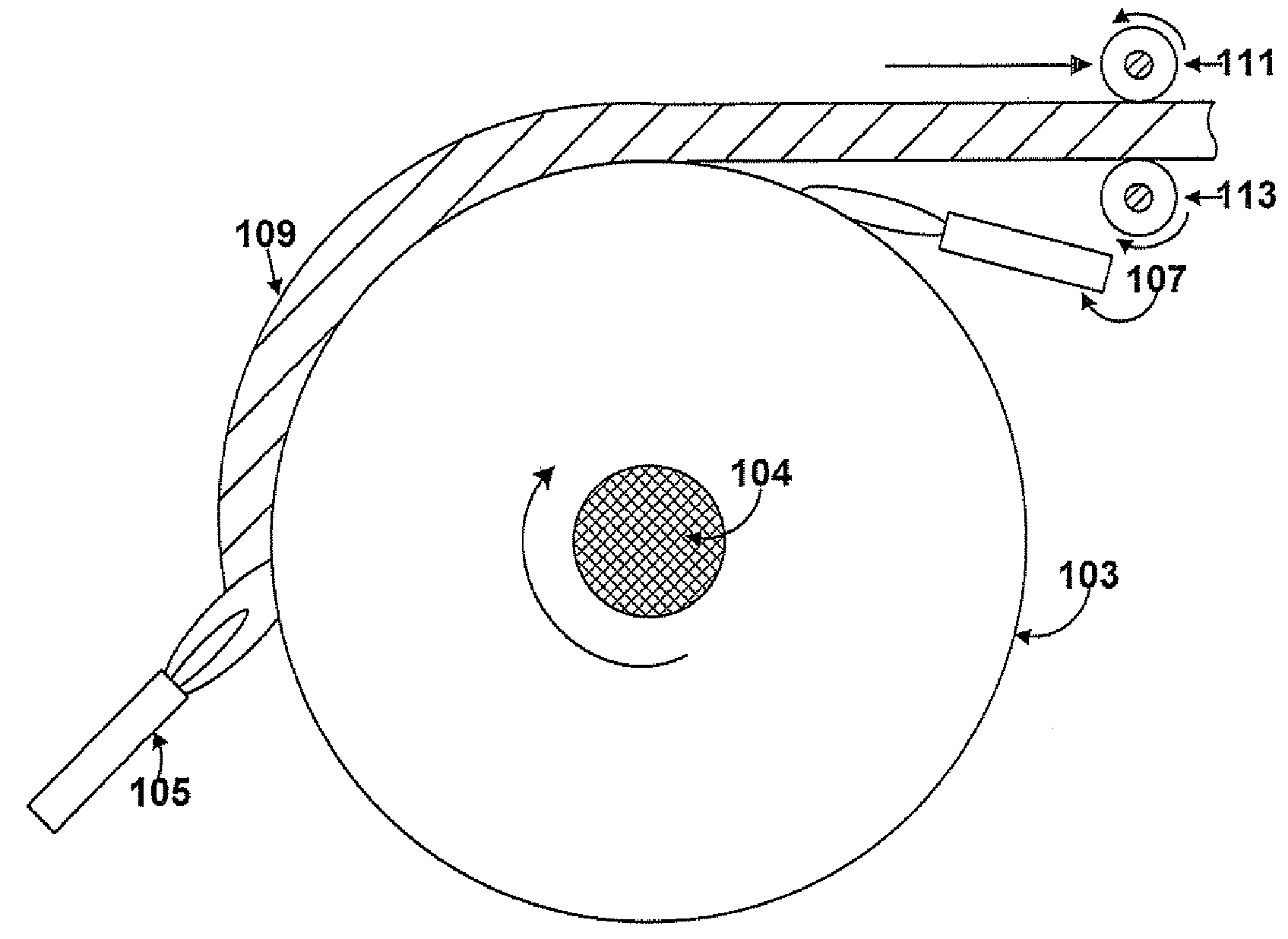

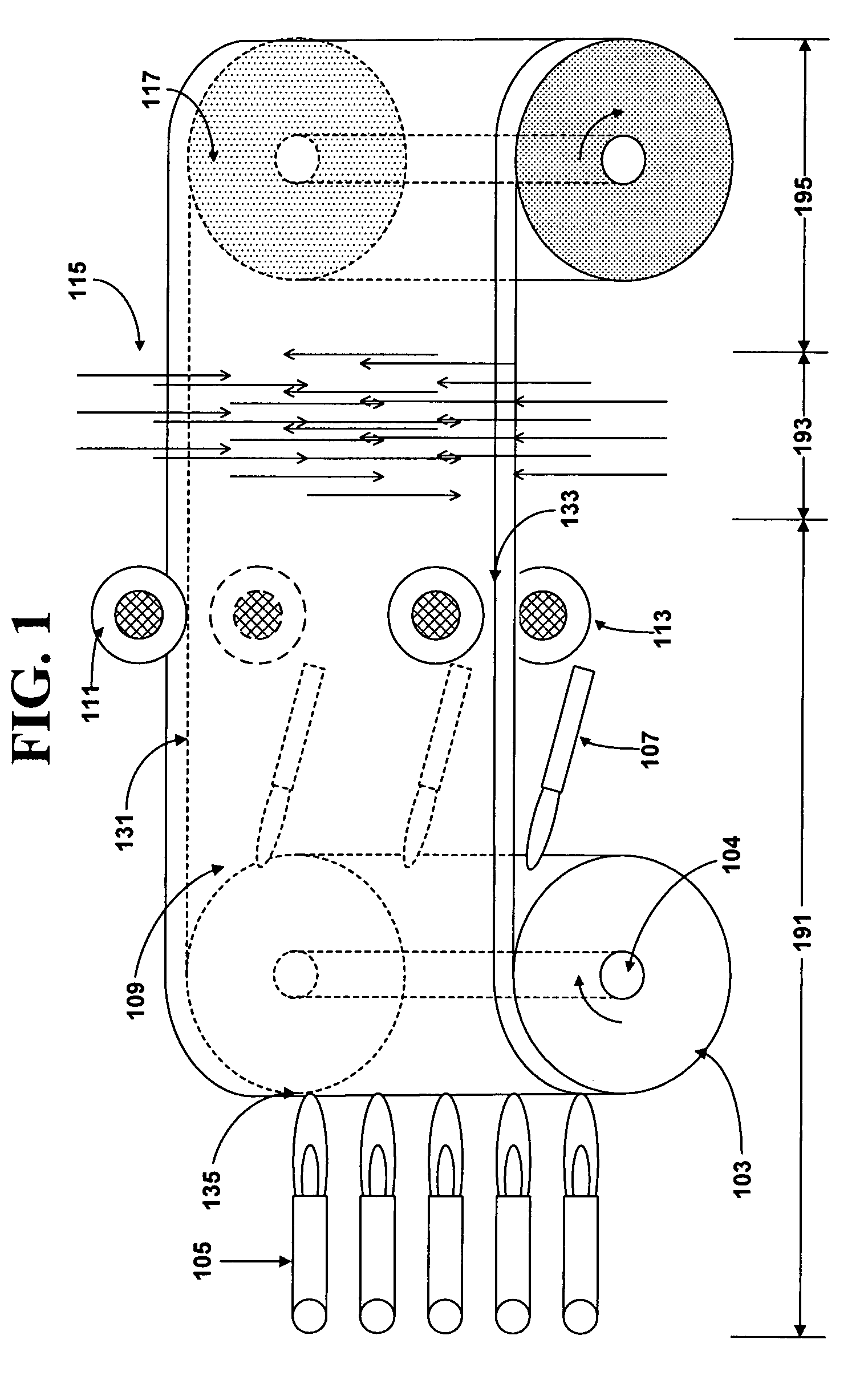

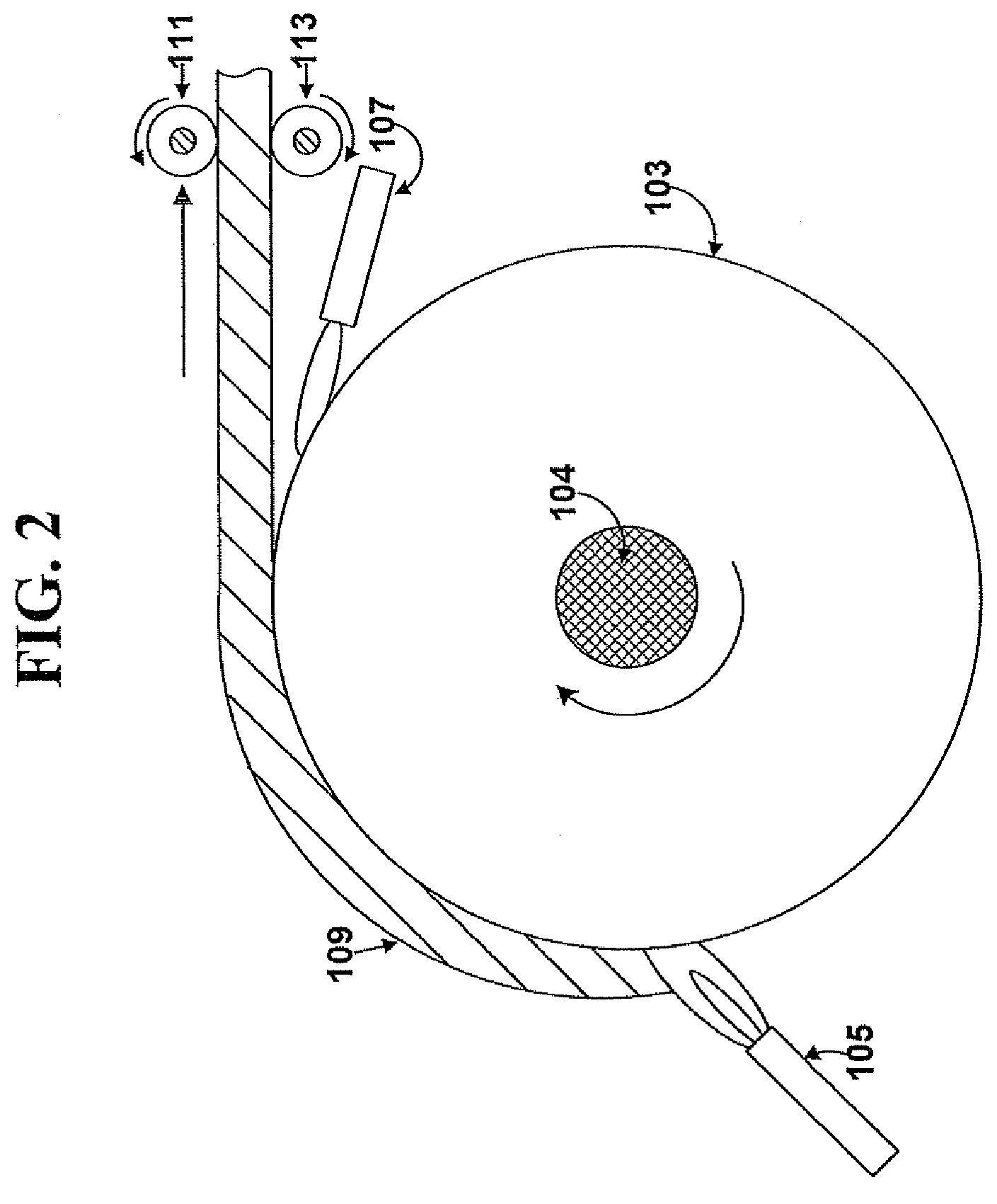

An apparatus and process for making glass soot sheet and sintered glass sheet. Glass soot particles are deposited on a curved deposition surface of a rotating drum to form a soot sheet. The soot sheet is then released from the deposition surface. The soot sheet can be sintered into a consolidated glass. The soot sheet and the sintered glass can be sufficiently long and flexible to be reeled into a roll.

Owner:CORNING INC +1

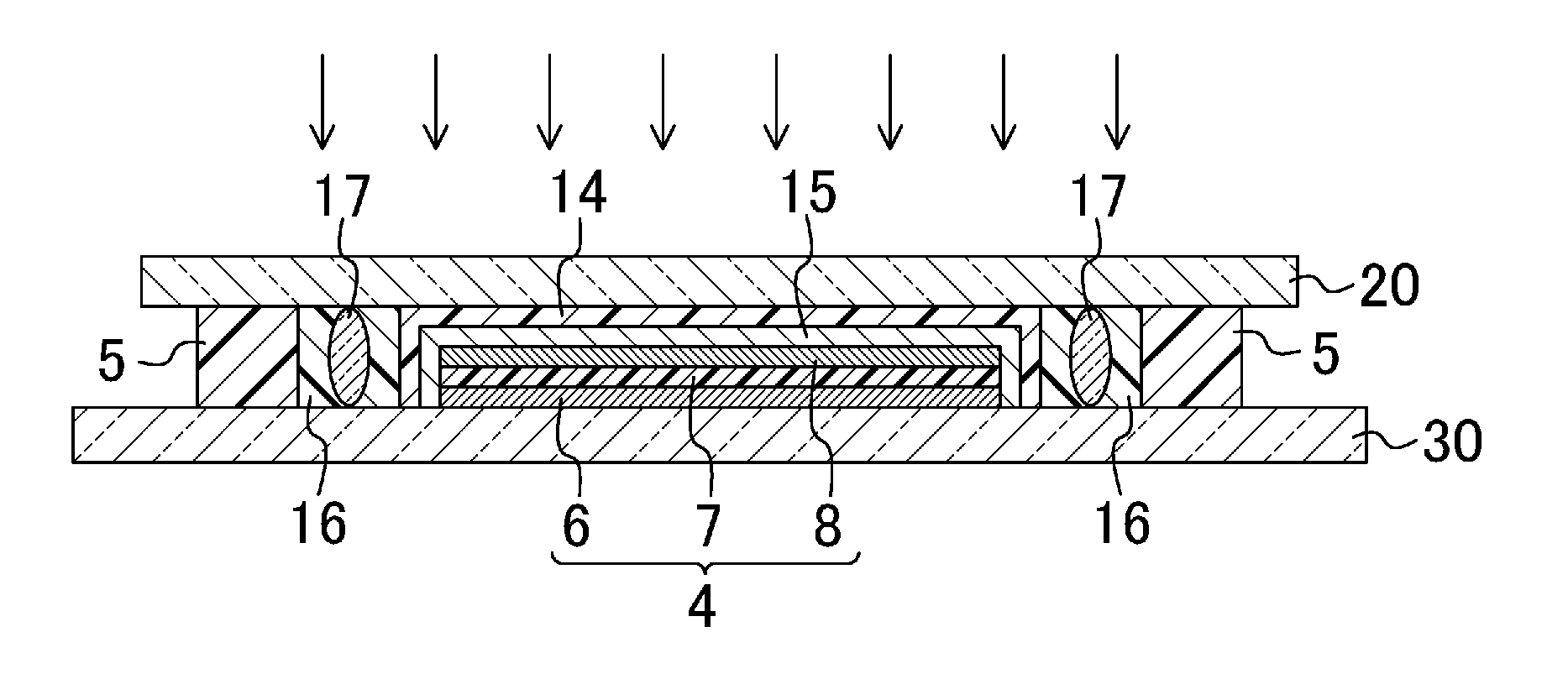

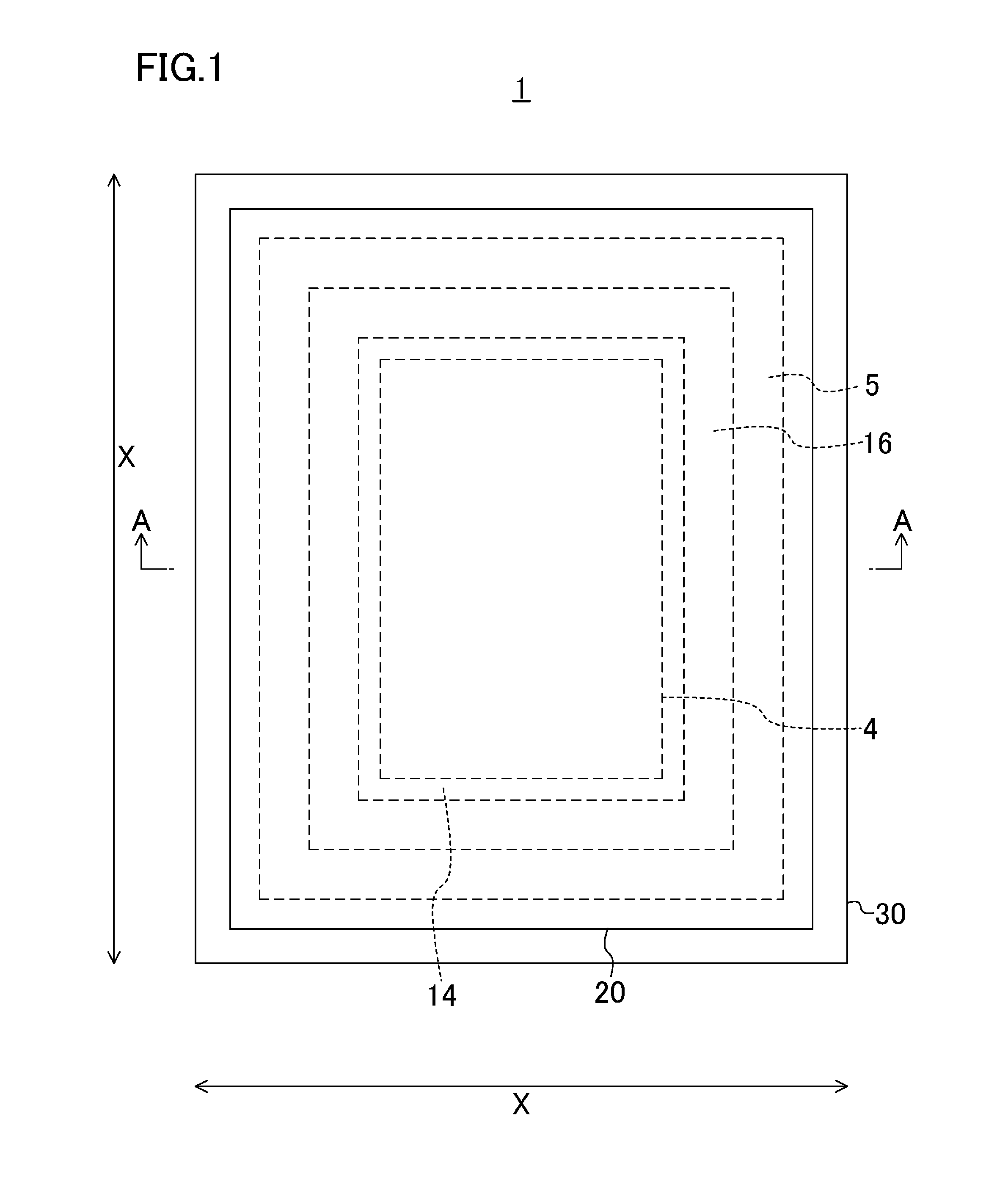

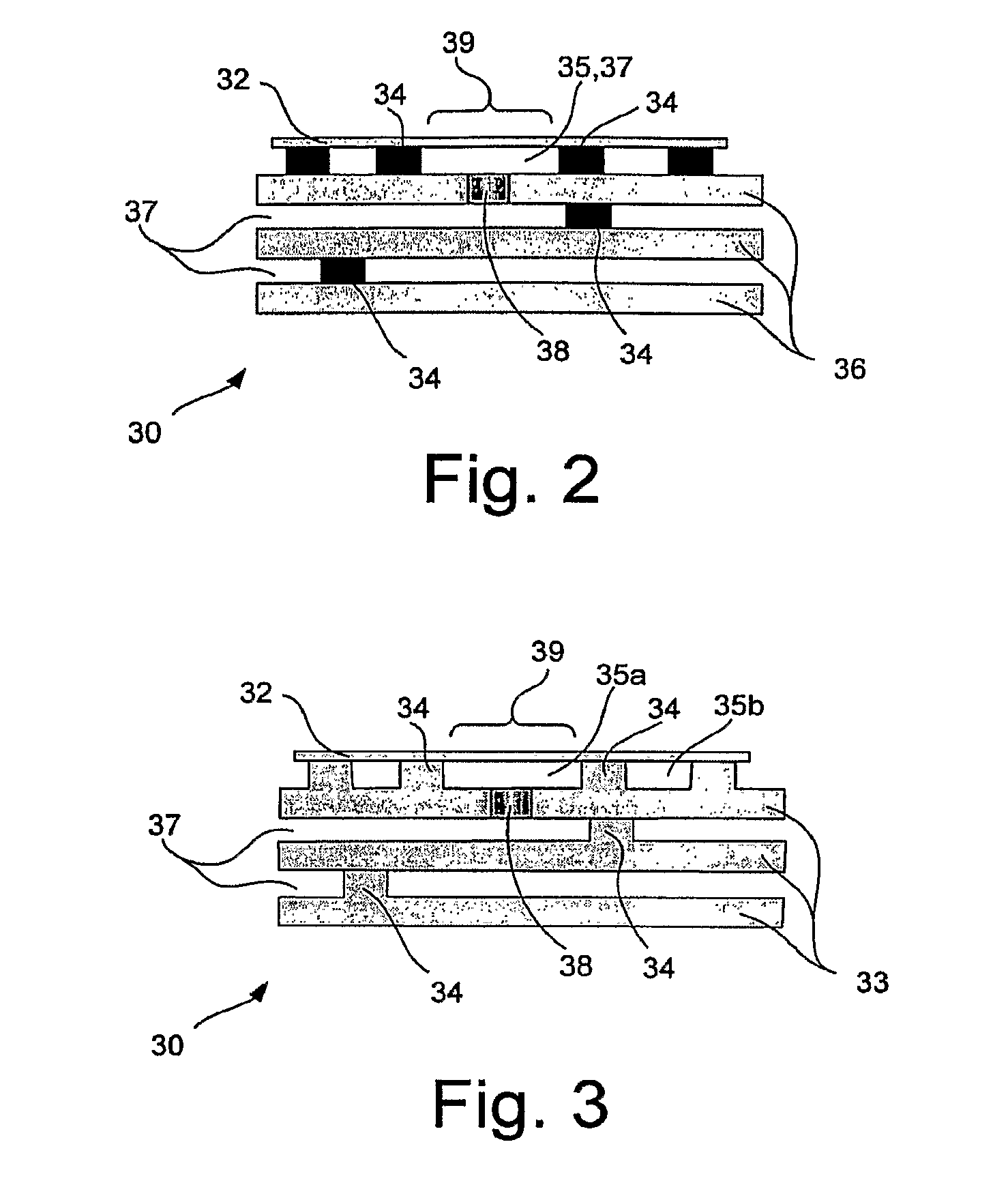

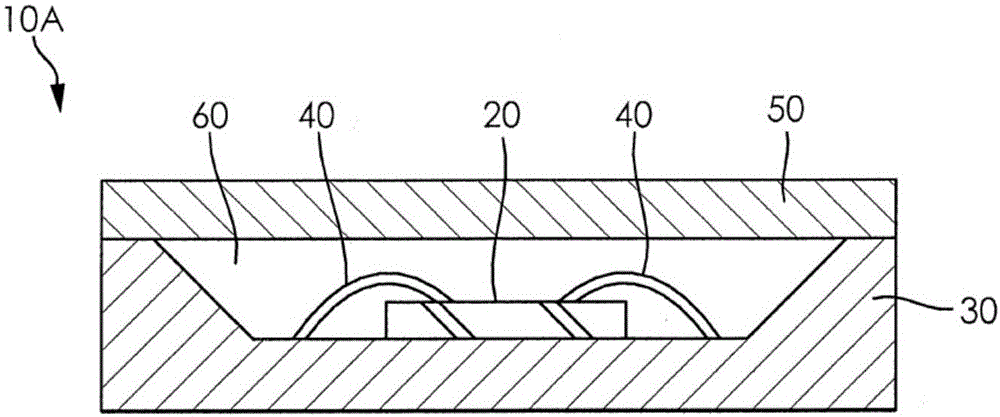

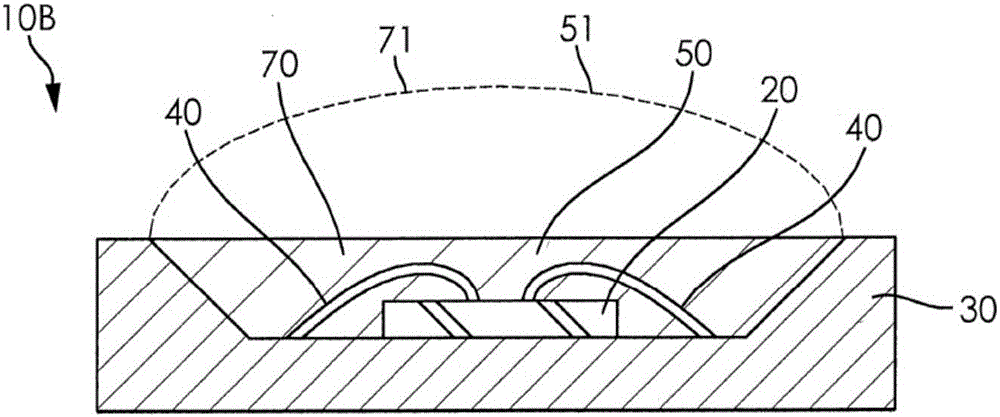

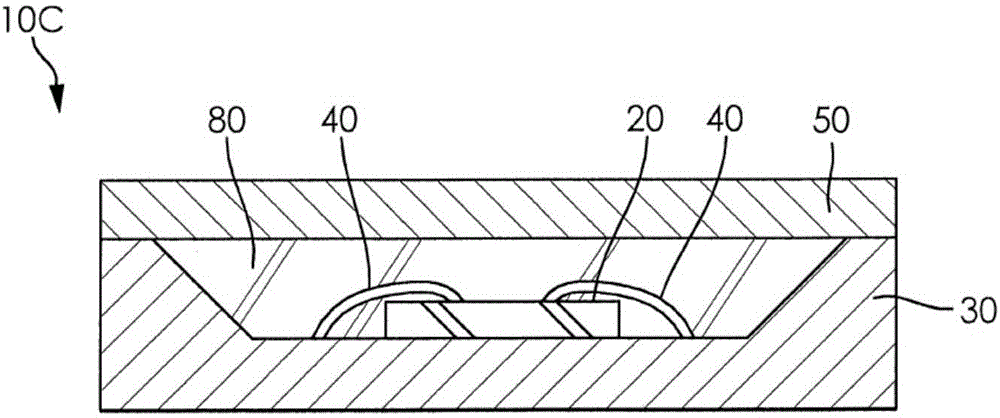

Organic el display device and method for manufacturing the same

ActiveUS20120080671A1Cost can be reduced and preventedReduction in sealing performance of sealing can be reduced and preventedElectroluminescent light sourcesSolid-state devicesDisplay deviceFritted glass

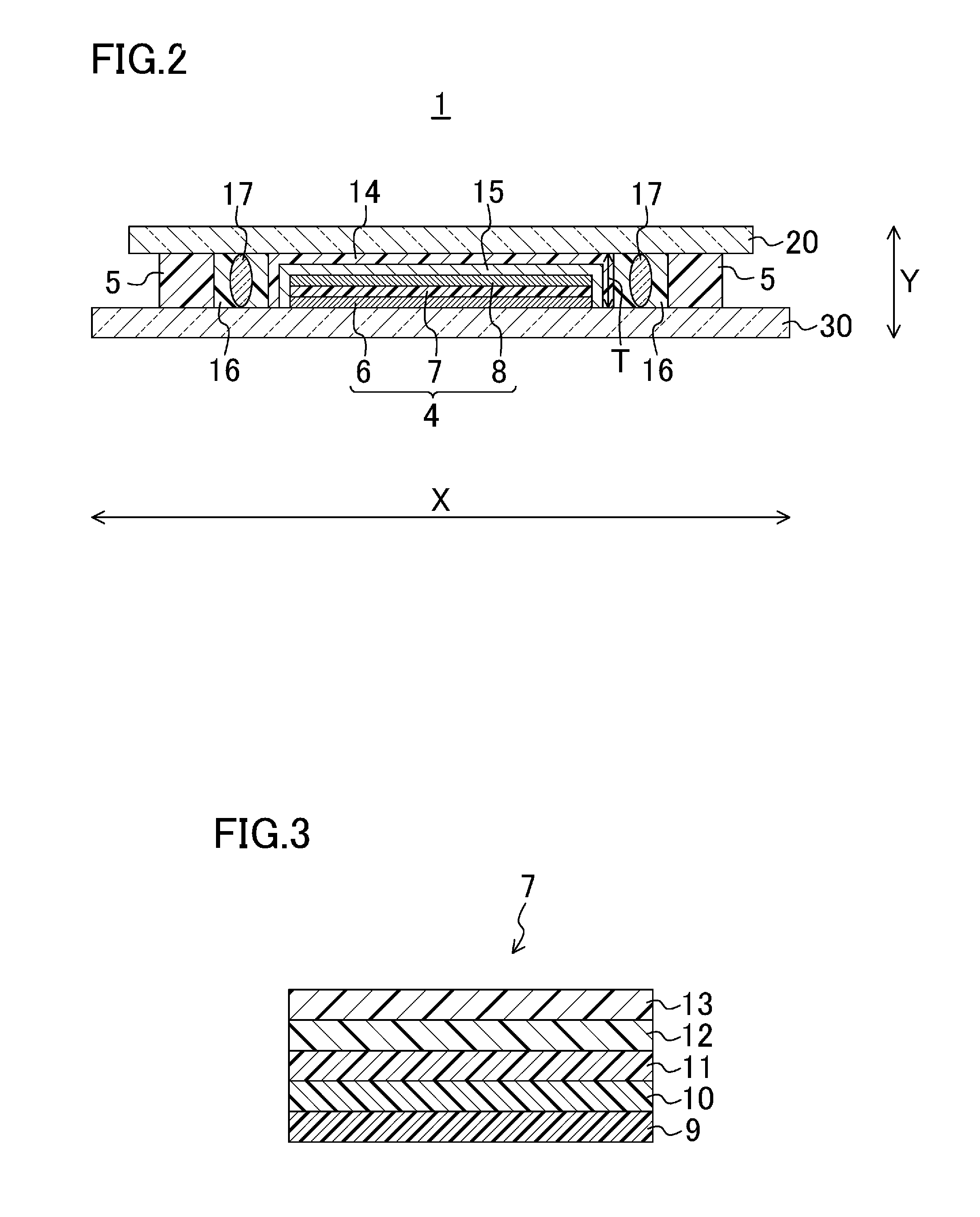

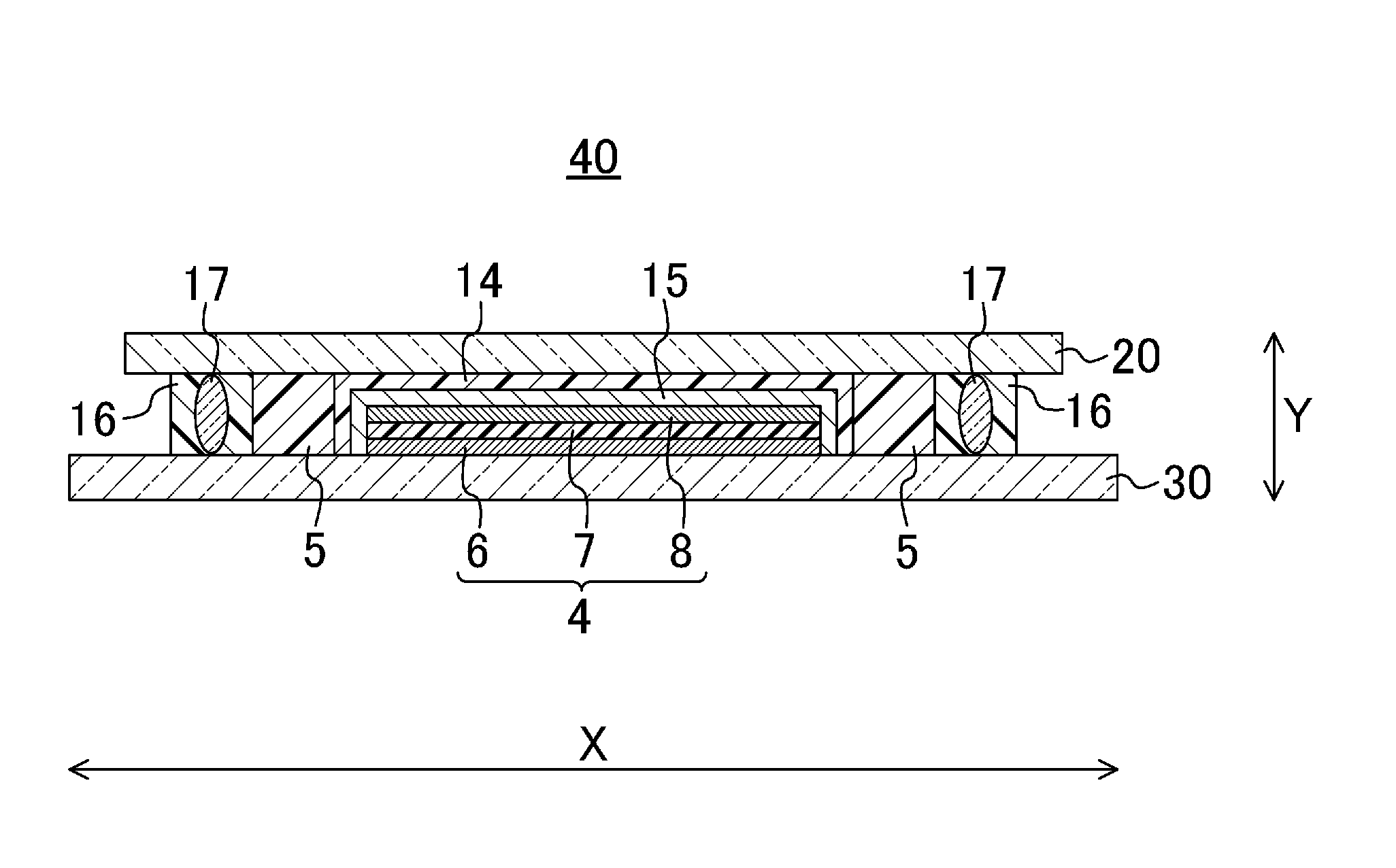

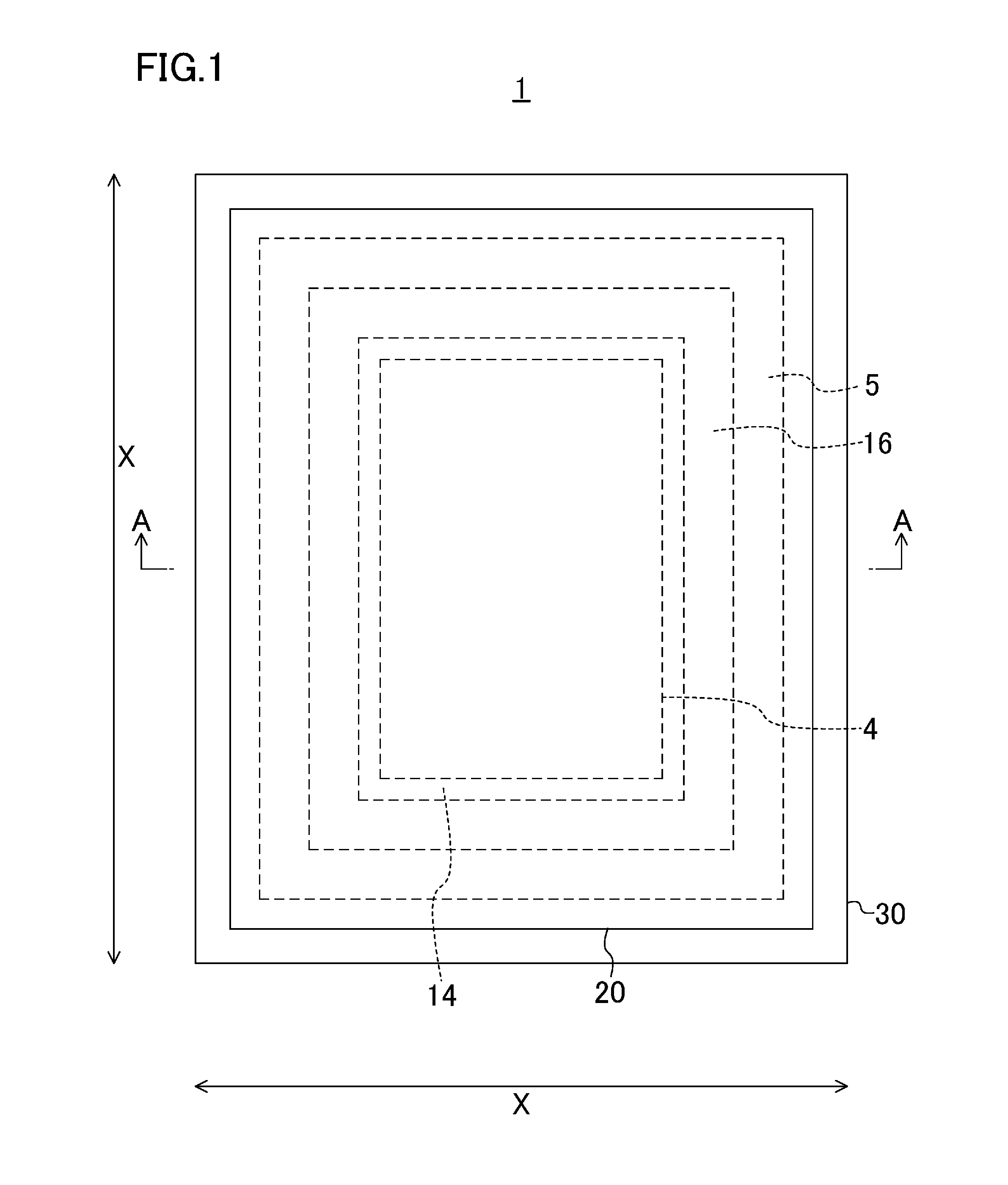

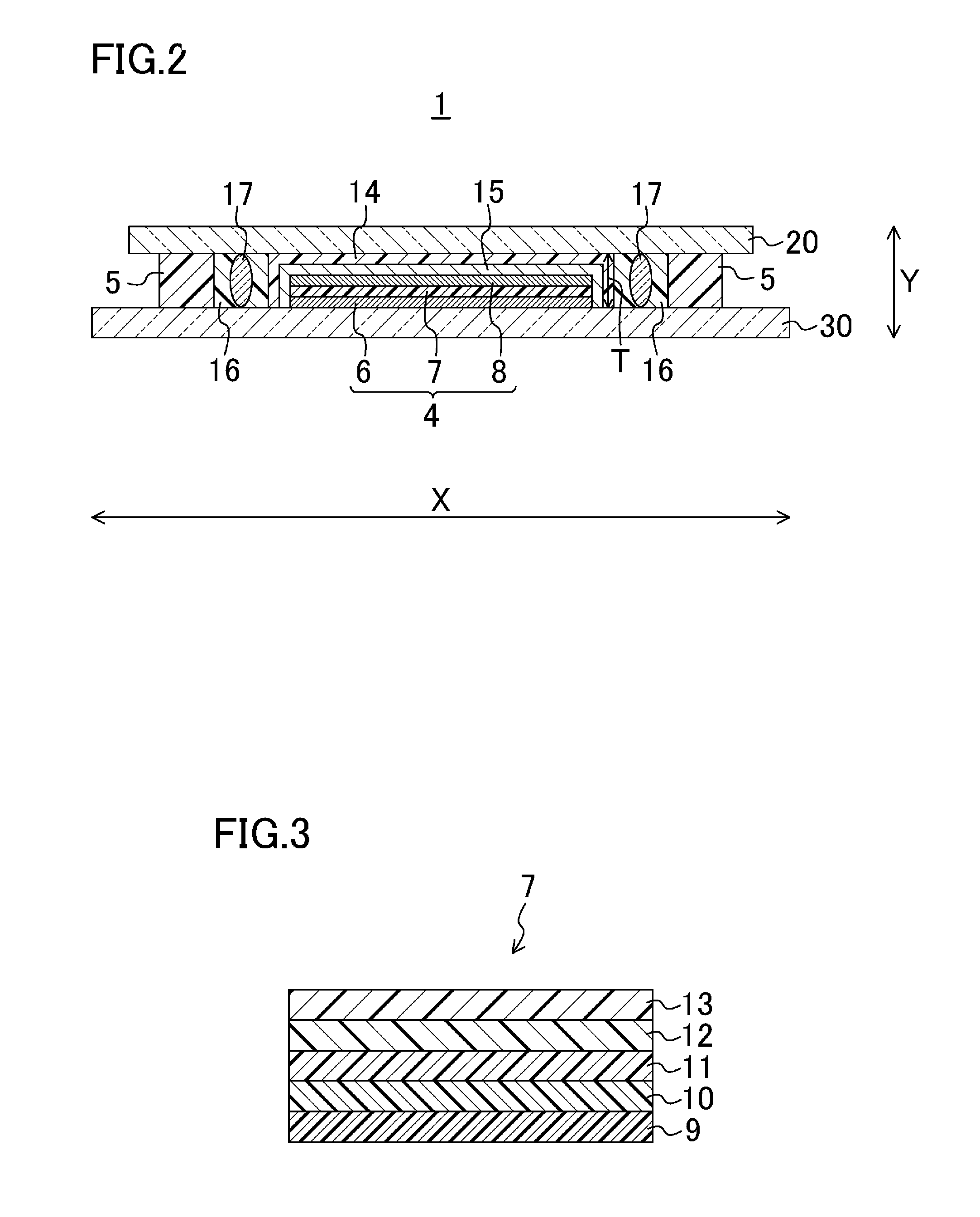

An organic EL display device (1) includes an element substrate (30), a sealing substrate (20) facing the element substrate (30), an organic EL element (4) provided on the element substrate (30) and between the element substrate (30) and the sealing substrate (20), a first sealing member (5) made of fritted glass and provided between the element substrate (30) and the sealing substrate (20), and configured to weld the element substrate (30) and the sealing substrate (20) to seal the organic EL element (4), a resin member (14) provided between the sealing substrate (20) and the organic EL element (4) and configured to cover a surface of the organic EL element (4), and a second sealing member (16) formed of a resin and provided between the element substrate (30) and the sealing substrate (20).

Owner:SHARP KK

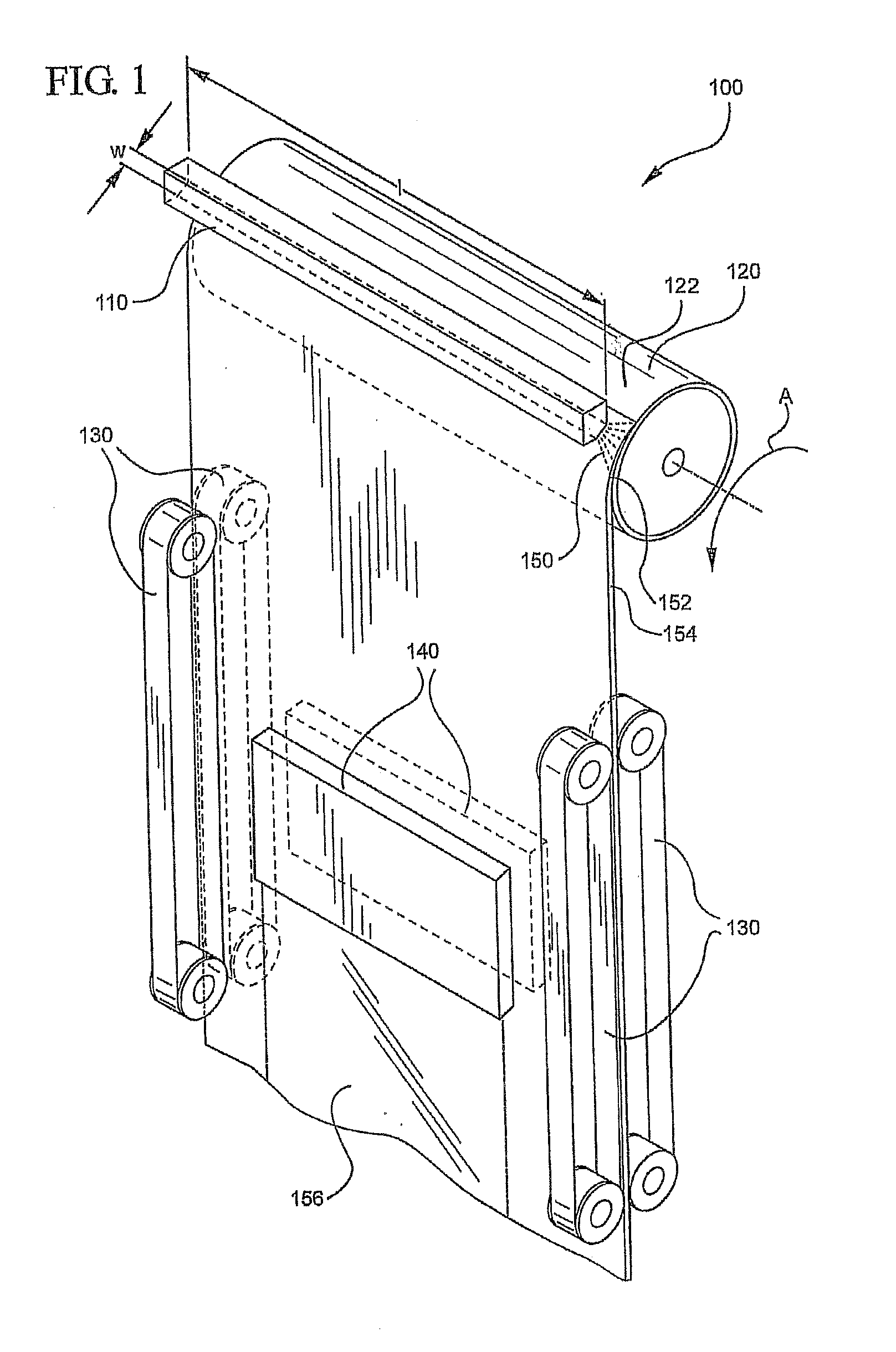

Process and apparatus for making glass sheet

ActiveUS7677058B2Improve uniformityUniform thicknessMolten spray coatingGlass shaping apparatusMetallurgyFritted glass

An apparatus and process for making glass soot sheet and sintered glass sheet. Glass soot particles are deposited on a curved deposition surface of a rotating drum to form a soot sheet. The soot sheet is then released from the deposition surface. The soot sheet can be sintered into a consolidated glass. The soot sheet and the sintered glass can be sufficiently long and flexible to be reeled into a roll.

Owner:CORNING INC +1

Discharge lamp with dielectrically impeded electrodes

A discharge lamp, suitable for operation by means of dielectrically impeded discharge, having electrodes arranged on the wall of the discharge vessel, has at least one dielectric layer which covers at least a part of the electrodes and, optionally, the discharge vessel wall as well. A phosphor and / or reflective layer is arranged on the at least one dielectric layer. According to the invention, at least the dielectric layer arranged directly underneath the phosphor or reflective layer consists of a glass solder whose viscosity variation as a function of temperature is irreversible, in particular of a sintered glass ceramic. This prevents this layer from re-melting during the fabrication process and thereby tearing the overlying porous reflective and / or phosphor layers.

Owner:PATENT TREUHAND GESELLSCHAFT FUR ELECTRIC GLUEHLAMPEN MBH

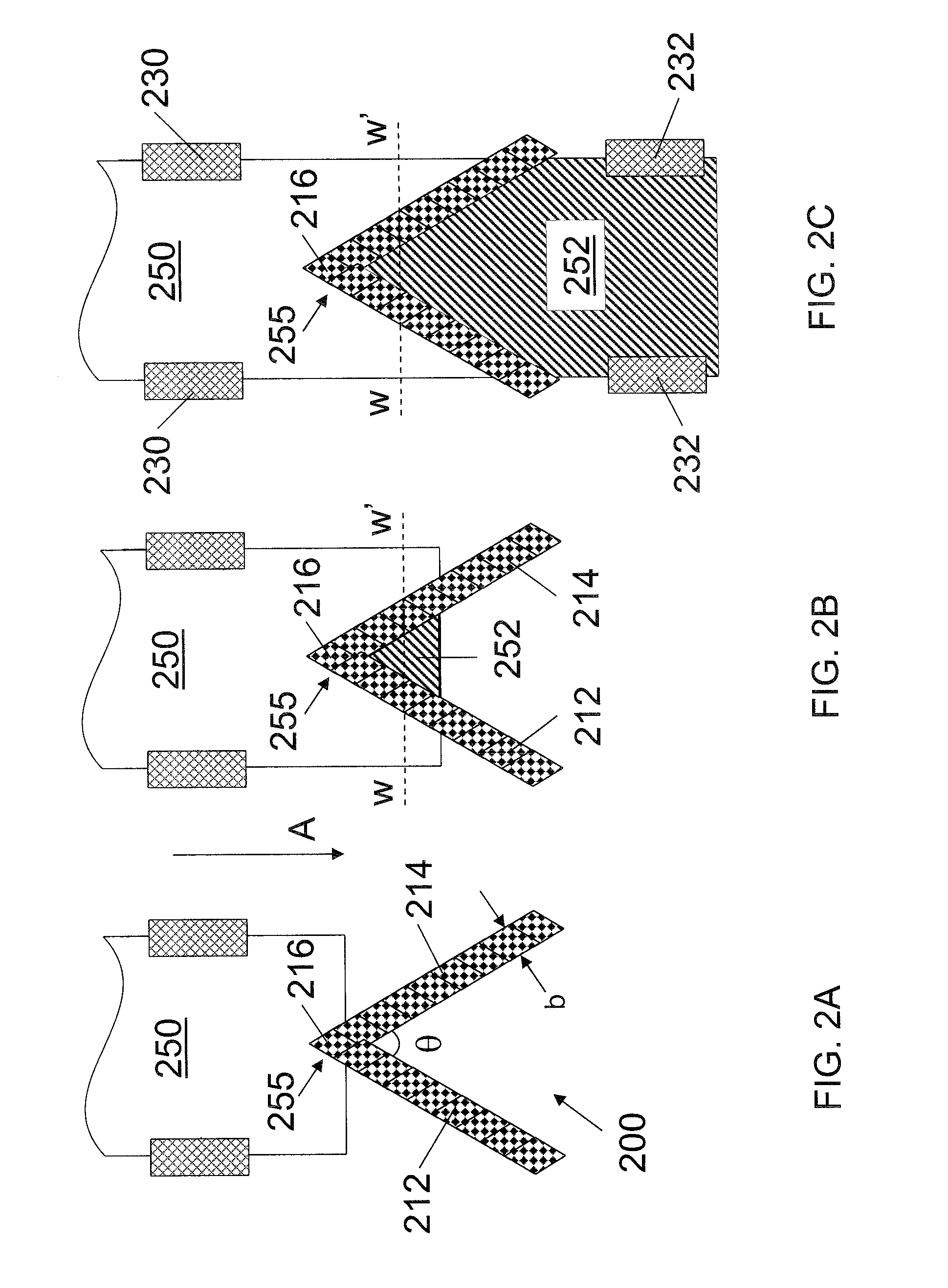

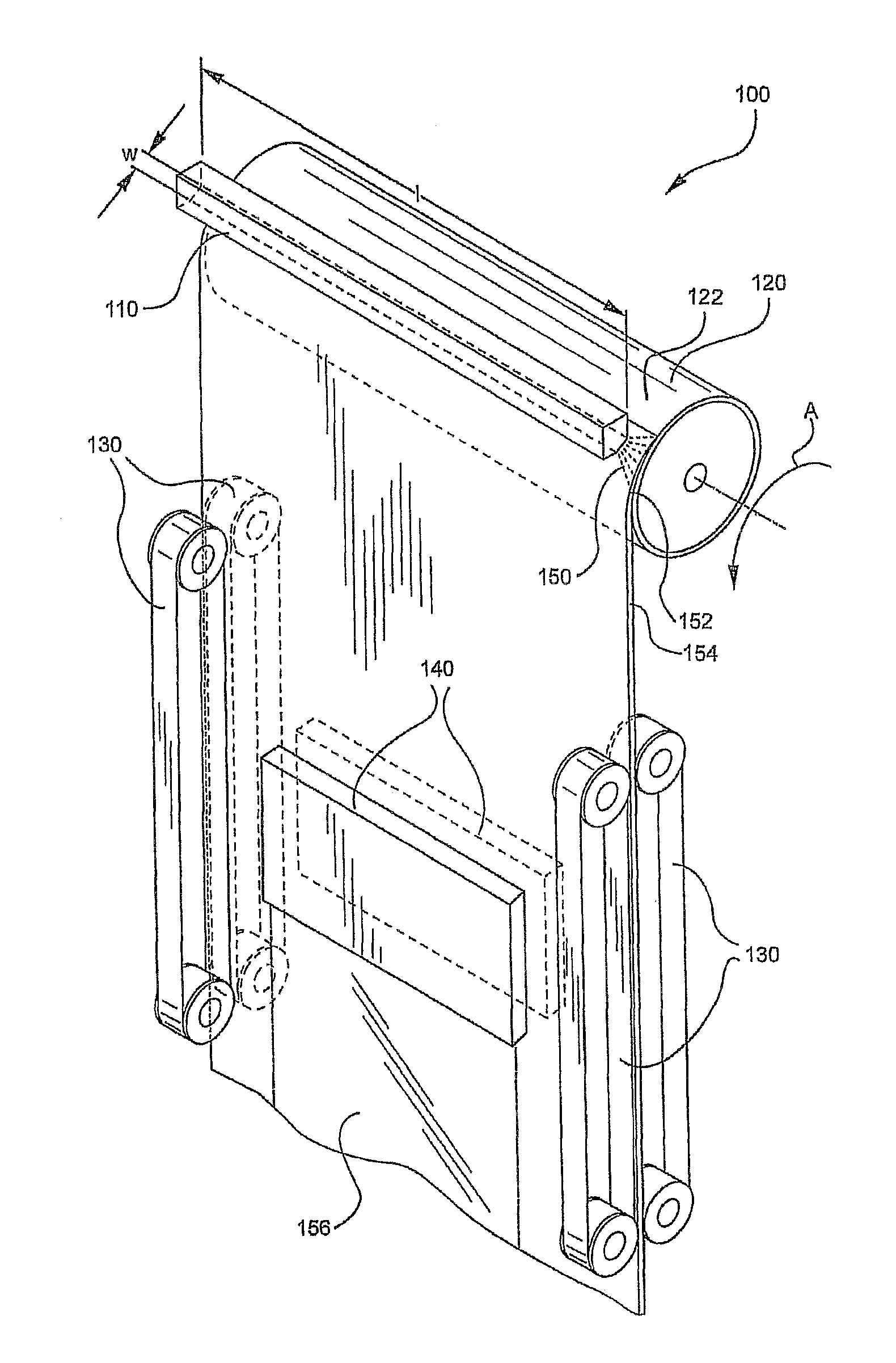

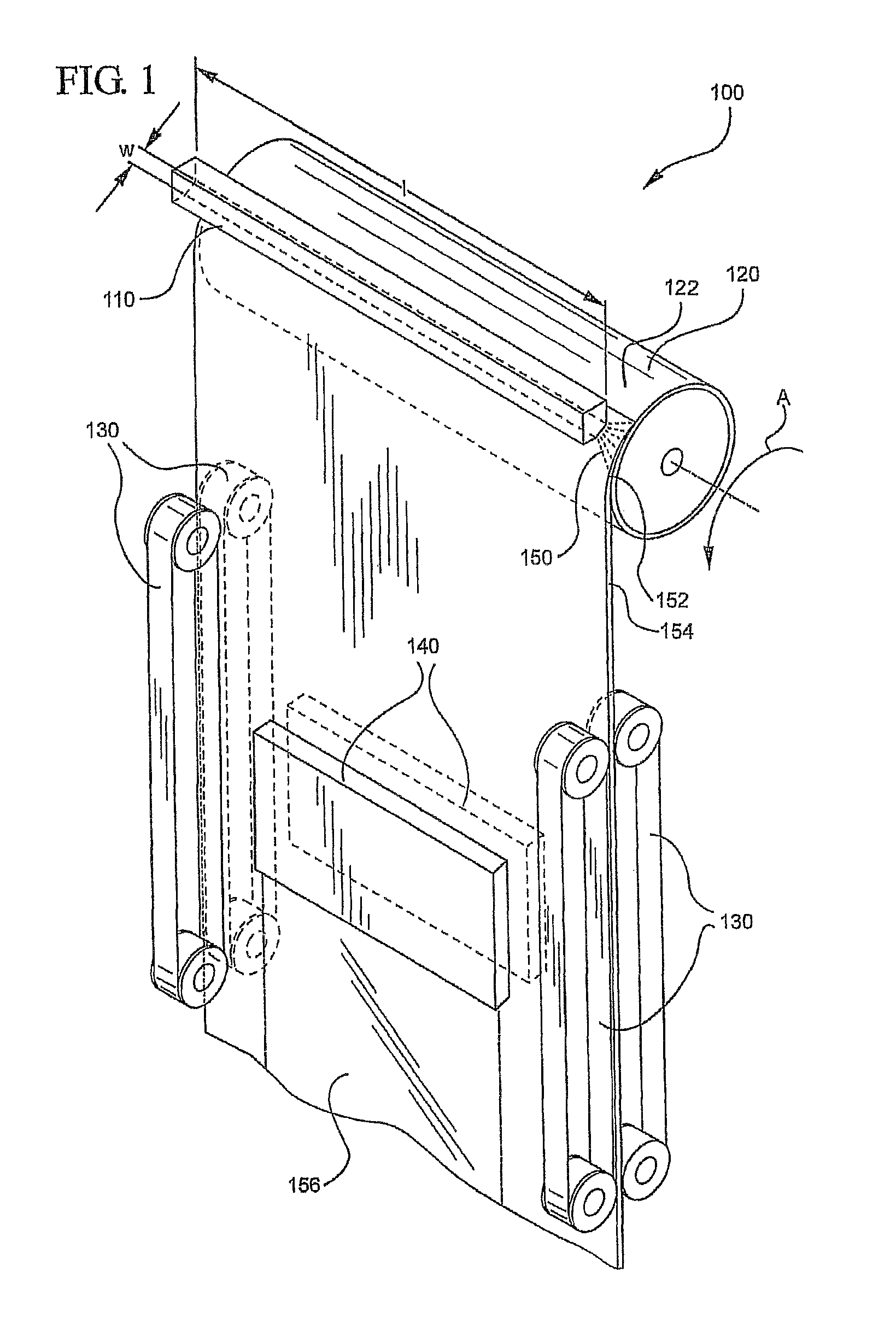

Roll-to-roll glass soot sheet sintering method and apparatus

InactiveUS20100319401A1Improve surface qualityGlass drawing apparatusGlass forming apparatusFritted glassSmoke

An ultra-thin glass sheet is formed using a roll-to-roll glass soot deposition and sintering process. The sintering involves initially heating and sintering one or more central segments of a glass soot sheet, and progressively heating and sintering glass soot sheet segments that are located laterally or axially adjacent to previously-sintered segments such that, along respective width directions of the glass soot sheet, only a portion of the width is sintered at a given time interval during the heating.

Owner:CORNING INC

Microreactor Glass Diaphragm Sensors

Microfluidic devices having wall structures comprised of sintered glass frit and further including a glass, glass-ceramic or ceramic membrane structure sealed by a sintered seal to said wall structures, such that a fluid passage or chamber is defined at least in part by the wall structures and said membrane structure. This allows for changes in pressure within the fluid passage or chamber to cause deflections of the membrane structure, providing for direct measurement of pressure within the device. The microfluidic device may have both floors and walls of sintered frit, or may have only walls of sintered frit, with planar floor-like substrate structures, thicker than the membrane structure defining the vertical boundaries of the internal passages. The device may include multiple fluid passages or chambers each defined at least in part by a membrane structure. Multiple membrane structures may be used in a single device, and one single membrane structure may be used for multiple passages or chamber.

Owner:CORNING INC

Roll-to-roll glass soot sheet sintering method and apparatus

InactiveUS8181485B2Improve surface qualityGlass drawing apparatusGlass forming apparatusMetallurgyFritted glass

Owner:CORNING INC

Glass ceramics dielectric material and sintered glass ceramics

The present invention provides a glass ceramics dielectric material, comprising: a crystallizable glass powder in an amount of from 40% to 100% by mass; and a ceramics powder in an amount of from 0% to 60% by mass, wherein the crystallizable glass powder comprises: SiO2 in an amount of from 35% to 65% by mass; CaO in an amount of from 10% to 30% by mass; MgO in an amount of from 10% to 20% by mass; and ZnO in an amount of from 0.5% to 35% by mass, and wherein the material is capable of forming: diopside, CaMgSi2O6, as crystals; and at least one of hardestnite, Ca2ZnSiO7, and willemite, Zn2SiO4, as crystals; and a sintered glass ceramics, comprising: diopside, CaMgSi2O6, as crystals; and at least one of hardestnite, Ca2ZnSiO7, and willemite, Zn2SiO4, as crystals.

Owner:NIPPON ELECTRIC GLASS CO LTD

Glass compositions and glass frit composites for use in optical applications

The invention relates to glass compositions and glass frit composites for use in optical applications, and a method of making a light emitting diode package through the glass frit composites. The method includes sintering a glass frit composite to form a phosphor-containing layer comprising phosphor dispersed in a glass matrix. The phosphor-containing layer is positioned, such that light from a light emitting diode is transmitted through the phosphor-containing layer. The glass frit composite includes a glass frit formed from a sintered mixture. The sintered mixture includes glass frit formed by firing a mixture including about 20-60 mole % SiO2, about 14-50 mole % ZnO, and about 3-28 mole % B2O3. The sintering temperature of glass is relatively low, so that fluorescence of phosphor isn't obviously degraded in a sintering process. The phosphor-containing layer can be used in optical applications, including conversion of blue light to white light with different color temperatures.

Owner:FERRO CORP

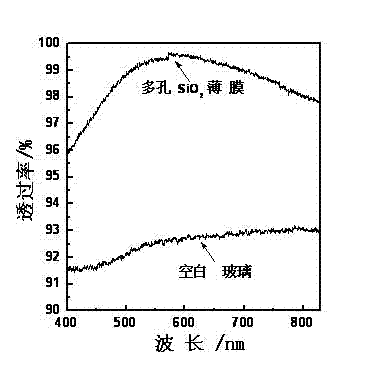

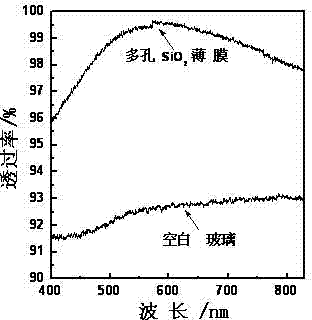

Preparation method of glass surface antireflection film without sintering

The invention relates to the antireflection film technology, and discloses a method for preparing a glass surface antireflection film without sintering. The method adopts tetraethyl orthosilicate as a raw material; a silica sol is obtained by acid catalysis; a coating sol is obtained by adding a certain amount of templates; a film is coated on a clean glass surface by a czochralski method, and isdried at 80 DEG C-120 DEG C for 24 h. The templates are removed by 80 DEG C hot water or ethanol through ultrasonic cleaning to obtain a glass surface antireflection film which has a maximum transmittance of up to above 99% and an average transmittance of up to above 96% in the visible region. Compared with the prior art, the invention has the advantages that firm binding of the glass surface antireflection film and the glass is guaranteed; higher transmittance is provided; and the preparation process of the antireflection film does not require high-temperature sintering.

Owner:常州龙腾光热科技股份有限公司

High-temperature-resistant air-tight difference connector socket

InactiveCN102761016ASimple structureGood effectCouplings bases/casesElectrical conductorFritted glass

The invention discloses a high-temperature-resistant air-tight difference connector socket, comprising a shell, a pin, an inner conductor pin and an outer conductor pin. The inner conductor pin is fixed in the outer conductor pin by sintering a glass insulator; the outer conductor pin and the pin are located and fixed in the shell by sintering a glass insulator; a ring-shaped groove is arranged at a connection surface between the shell and an installation faceplate; a sealing ring is arranged in the ring-shaped groove; the socket is fastened by locknuts while being connected with the installation faceplate; and the sealing ring is made of high-temperature-resistant fluororubber. The high-temperature-resistant air-tight difference connector socket disclosed by the invention is characterized by simple structure, excellent effect and stable and reliable performance, is applicable to occasions with requirements on high-temperature resistance and air tightness and can satisfy the use needs of novel equipment.

Owner:GUIZHOU SPACE APPLIANCE CO LTD

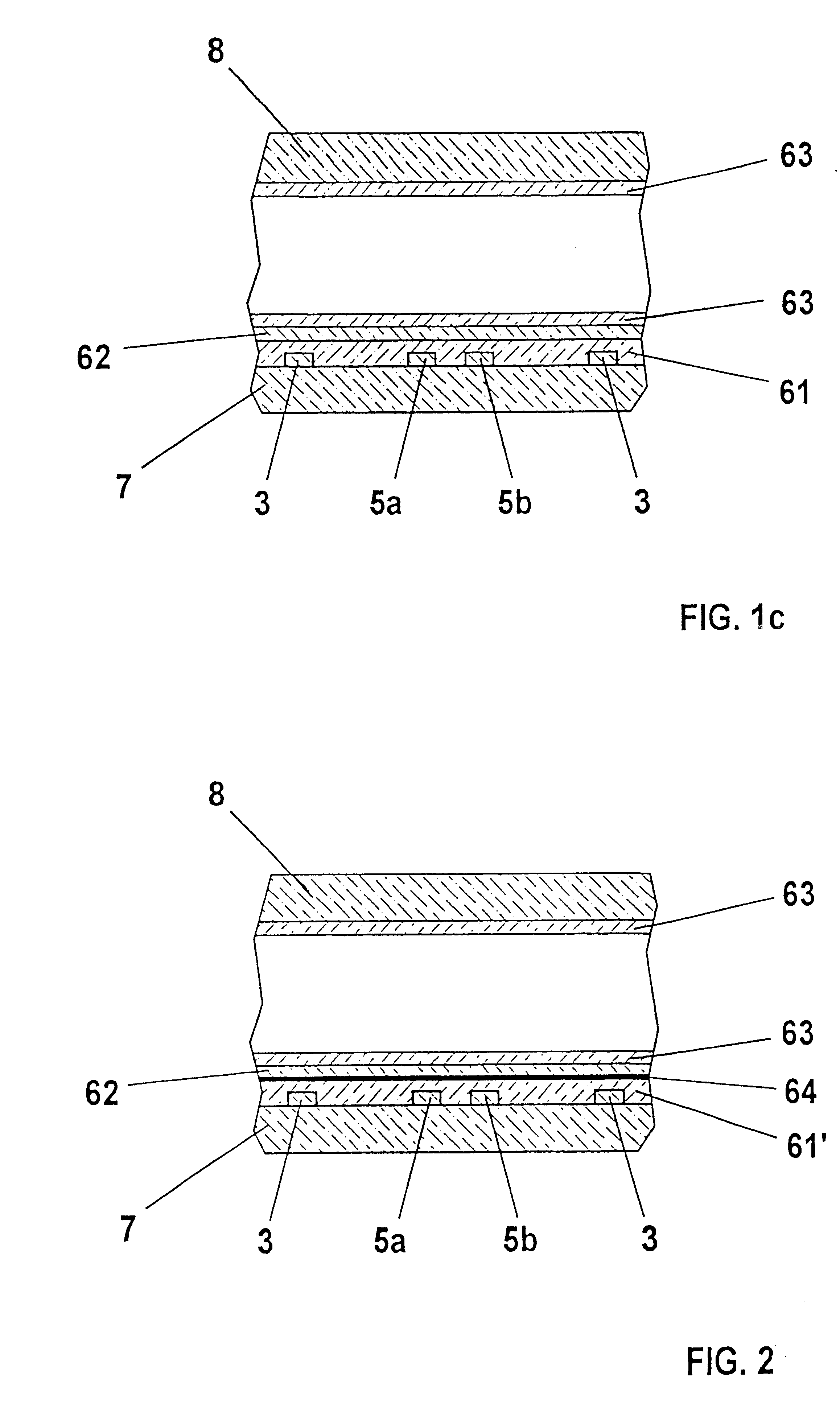

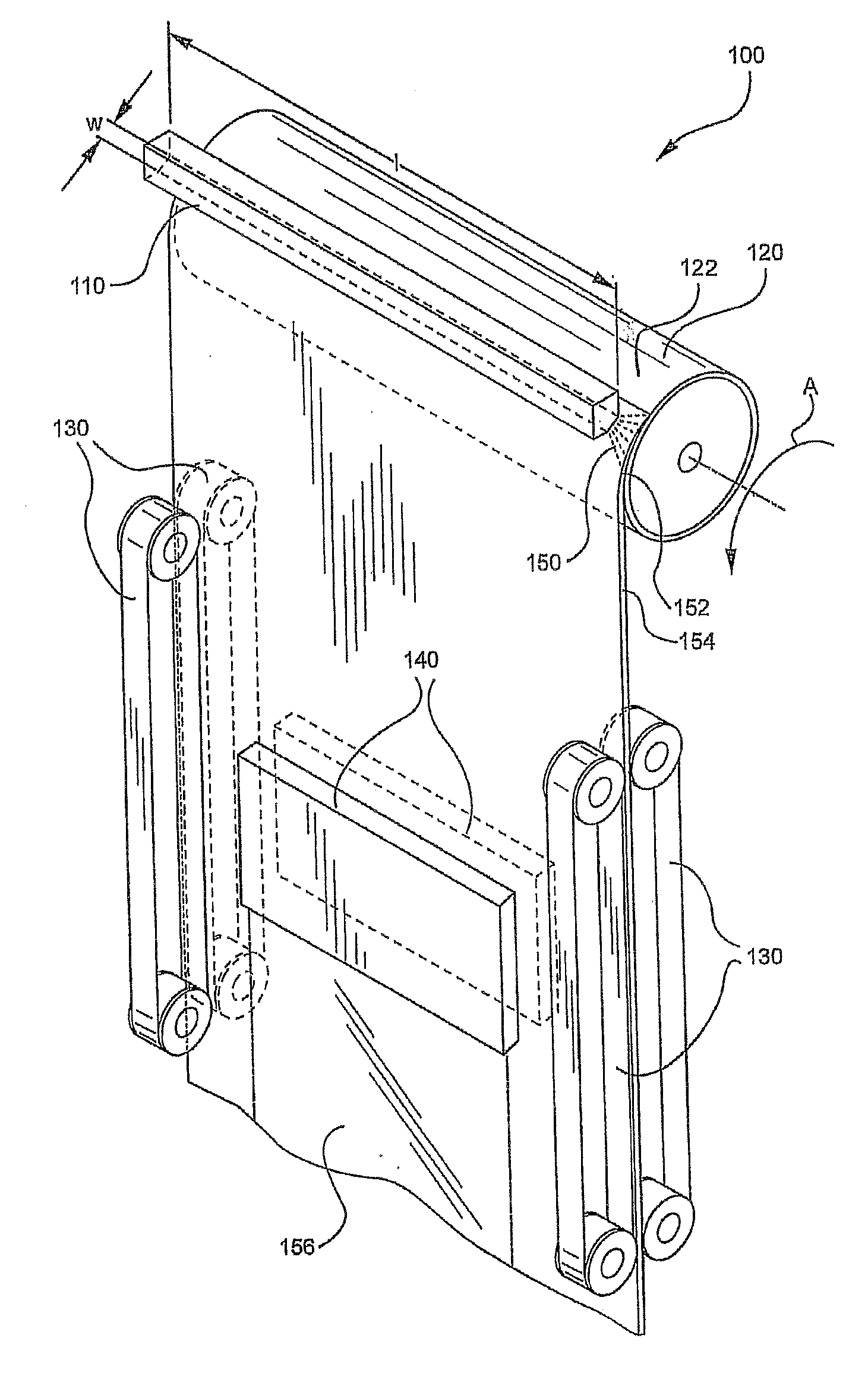

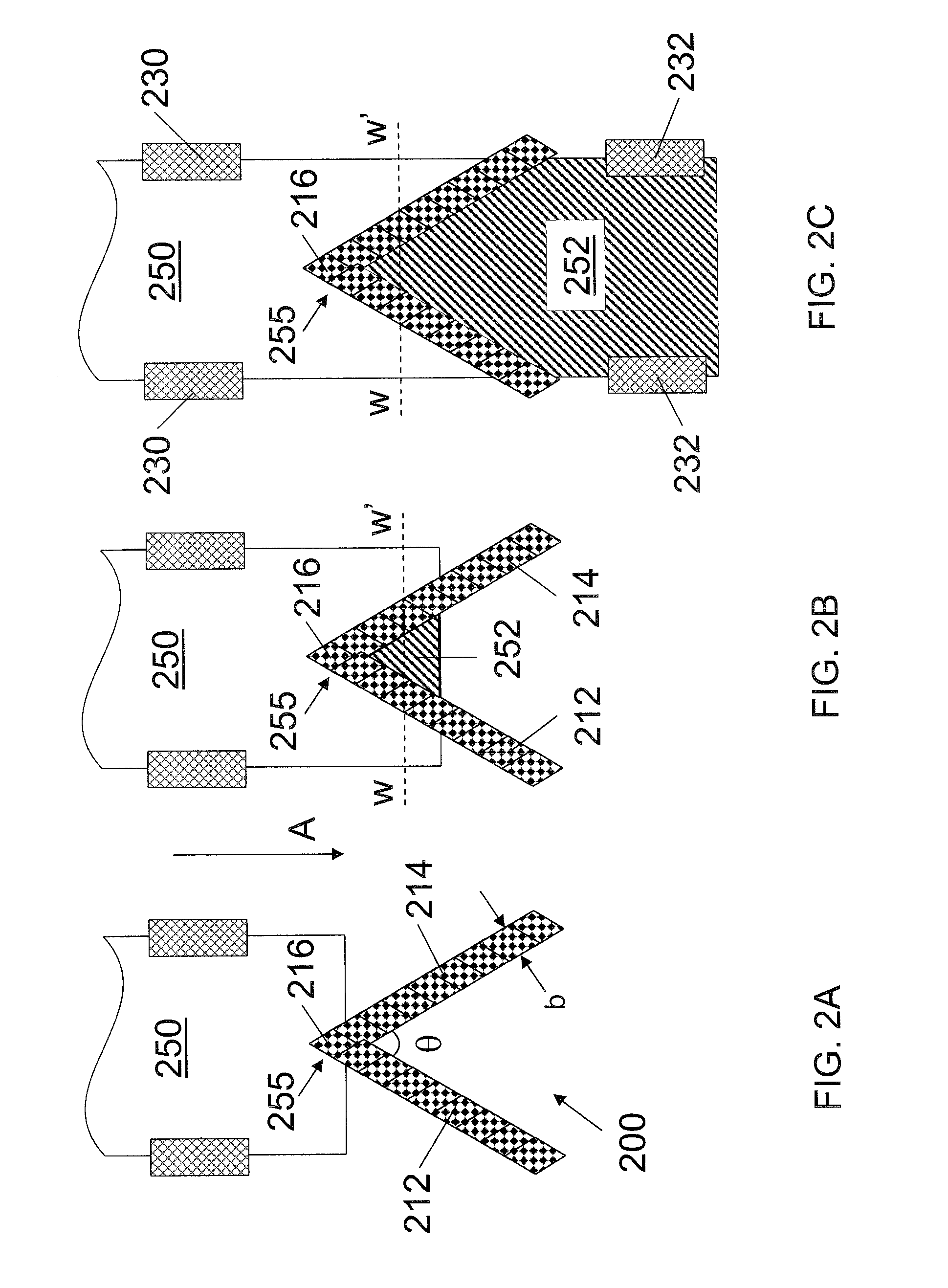

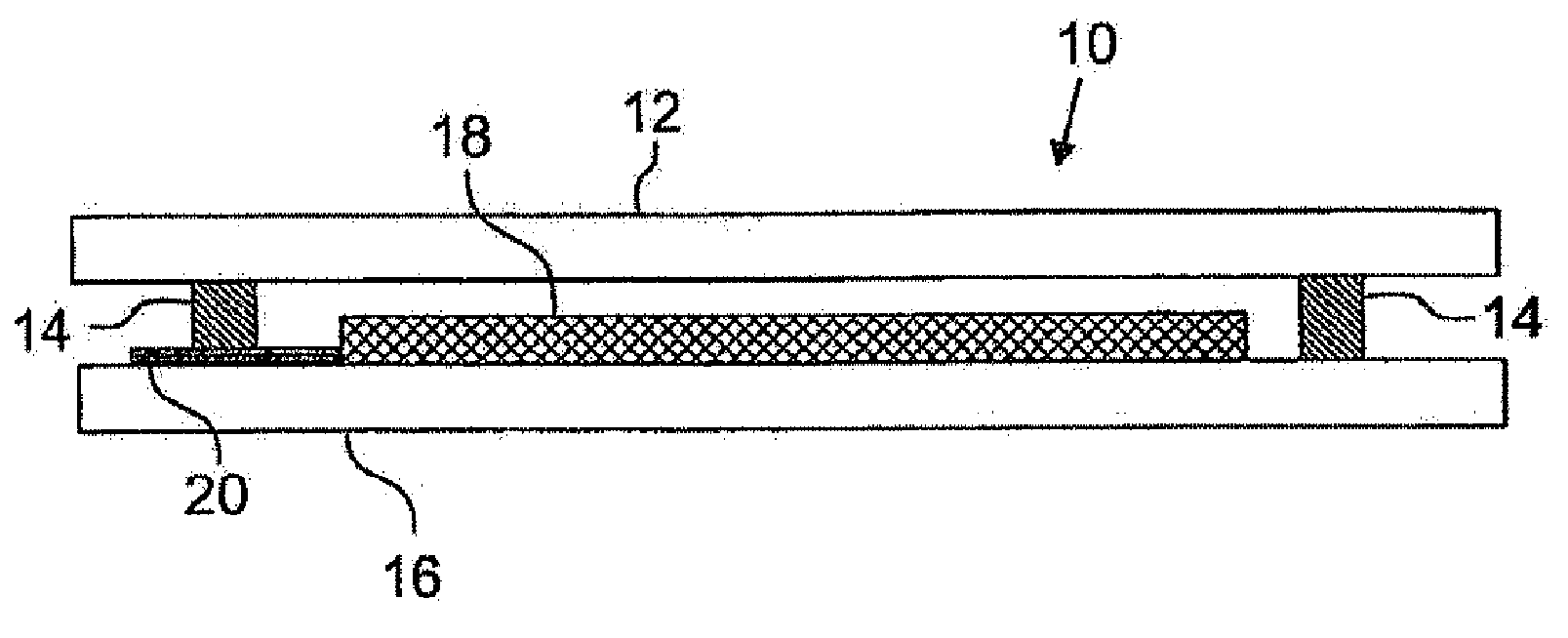

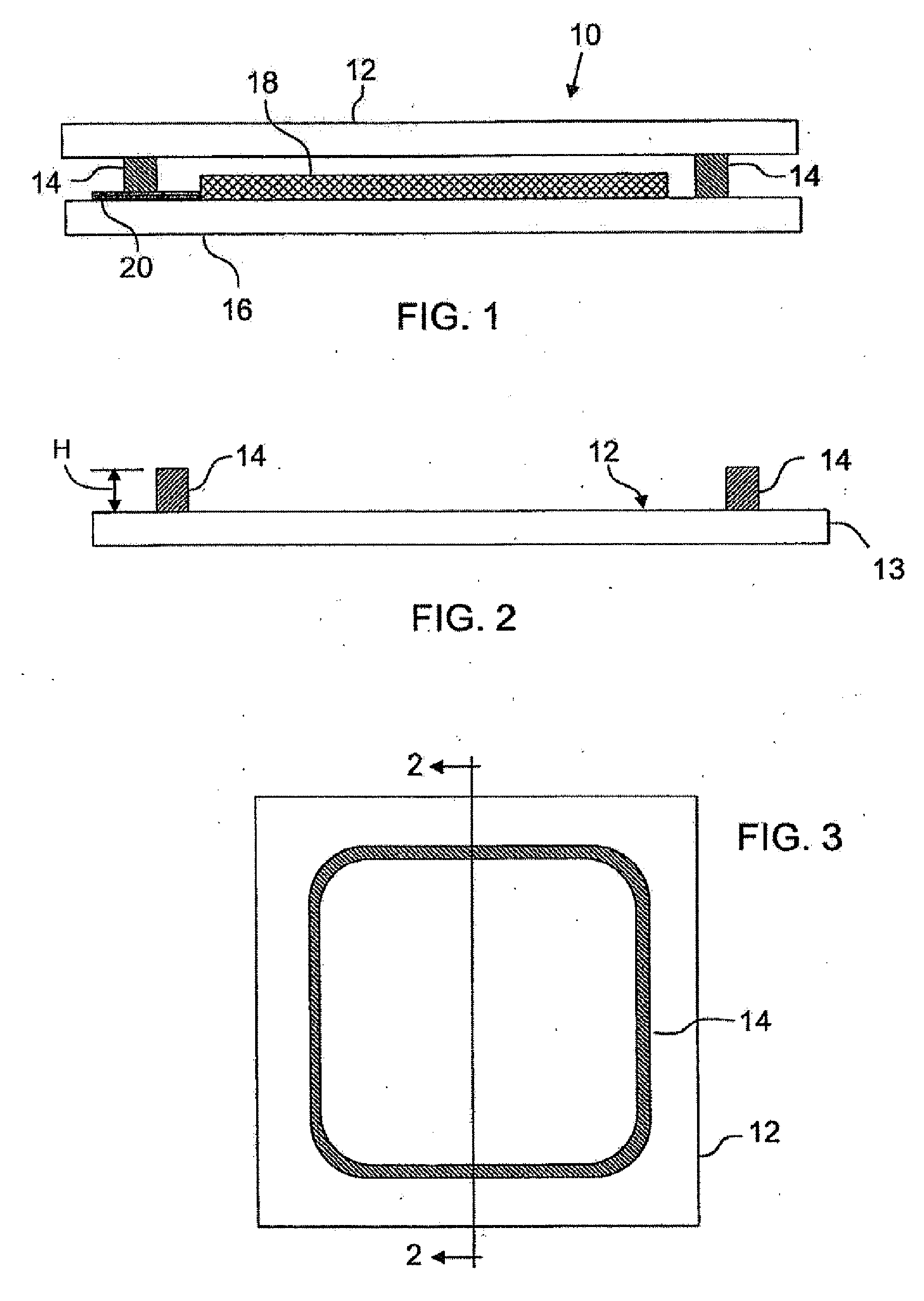

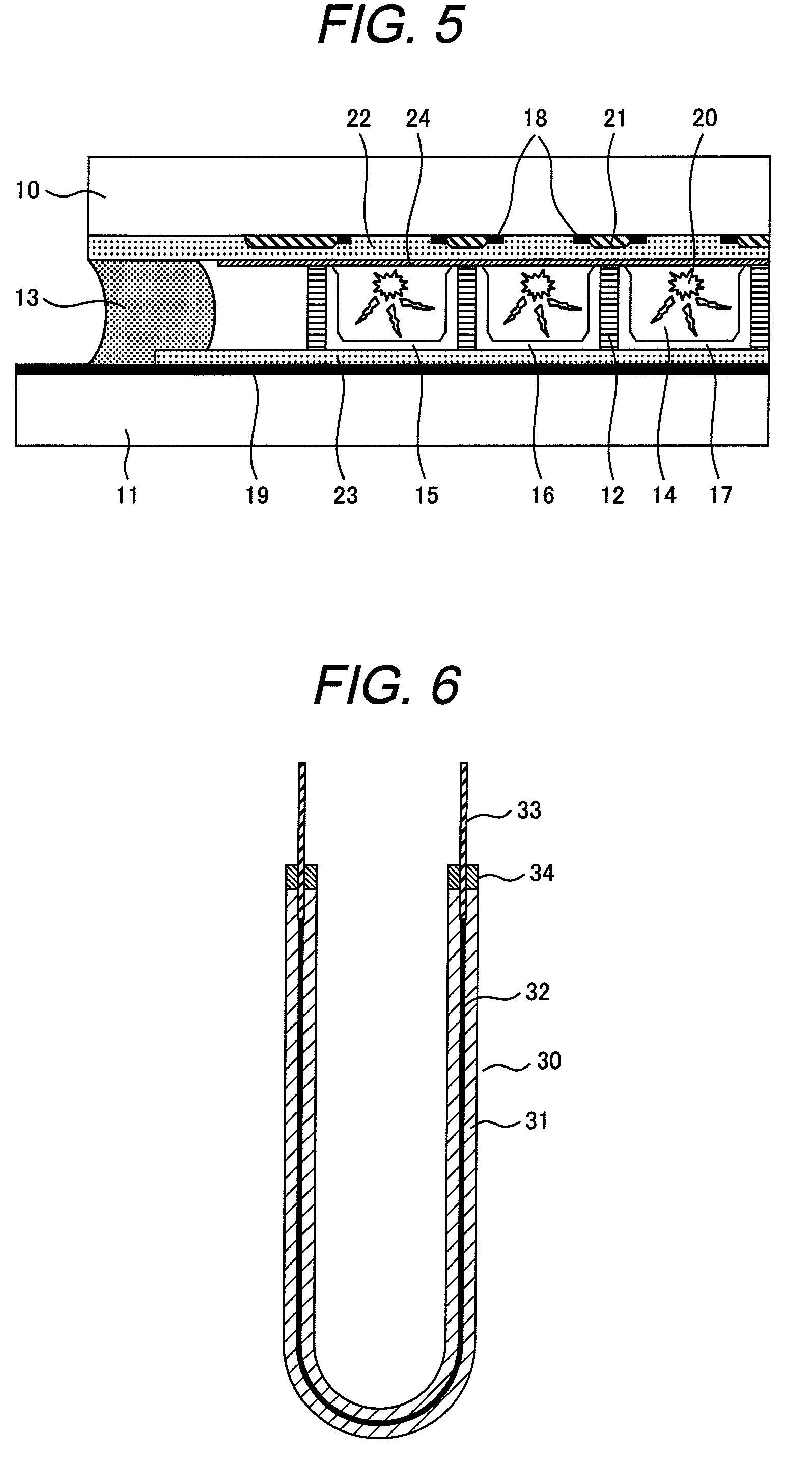

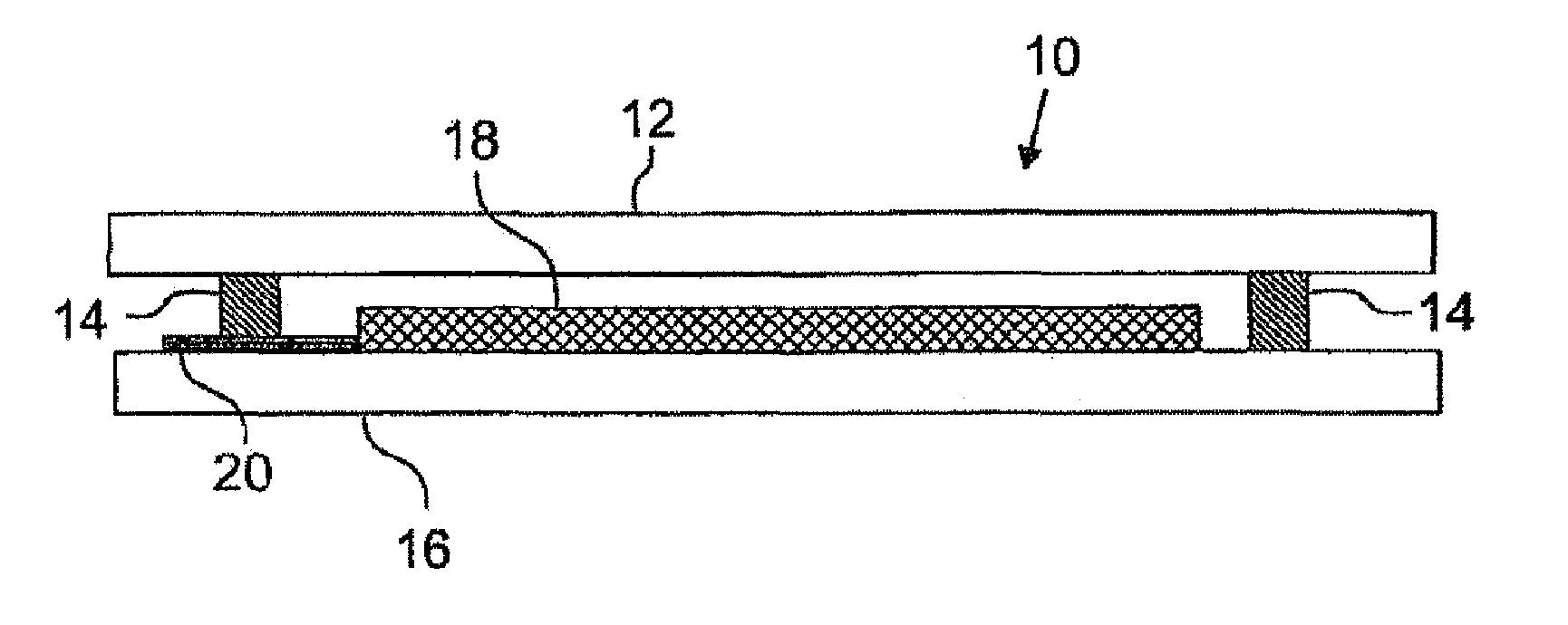

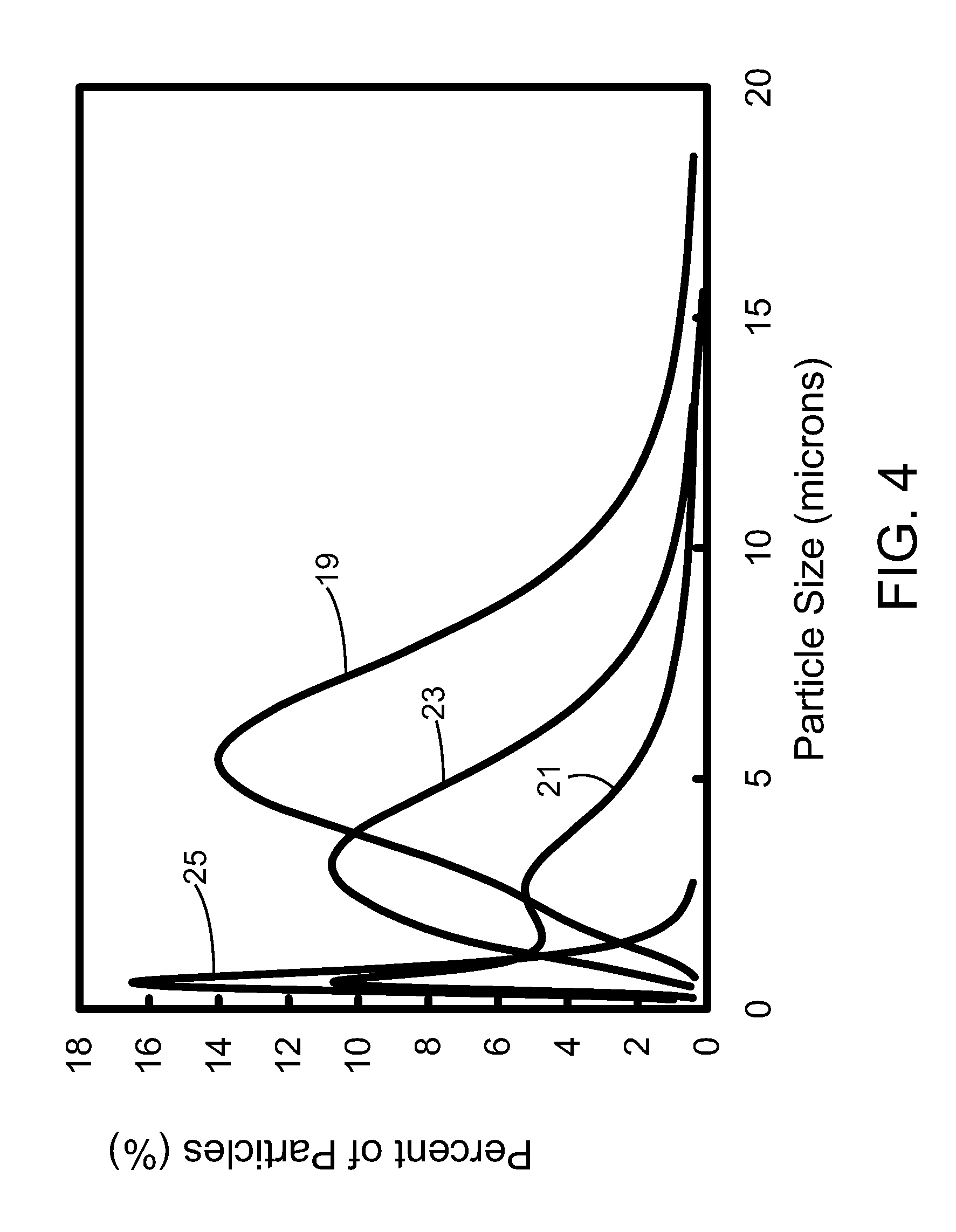

Frit-containing pastes for producing sintered frit patterns on glass sheets

Pastes for use in producing sintered frit patterns (14) on glass sheets (12), such as the glass sheets used as covers for OLED (18) display devices (10), are provided. The pastes include glass particles, filler particles, and a vehicle. The sizes of the filler and / or glass particles are reduced compared to prior art pastes. Reductions in porosity and surface roughness of sintered frits produced using the pastes, as well as improvements in the available process window for producing OLED packages and the hermeticity and strength of those packages, are reported.

Owner:CORNING INC

Glass composition and its applications

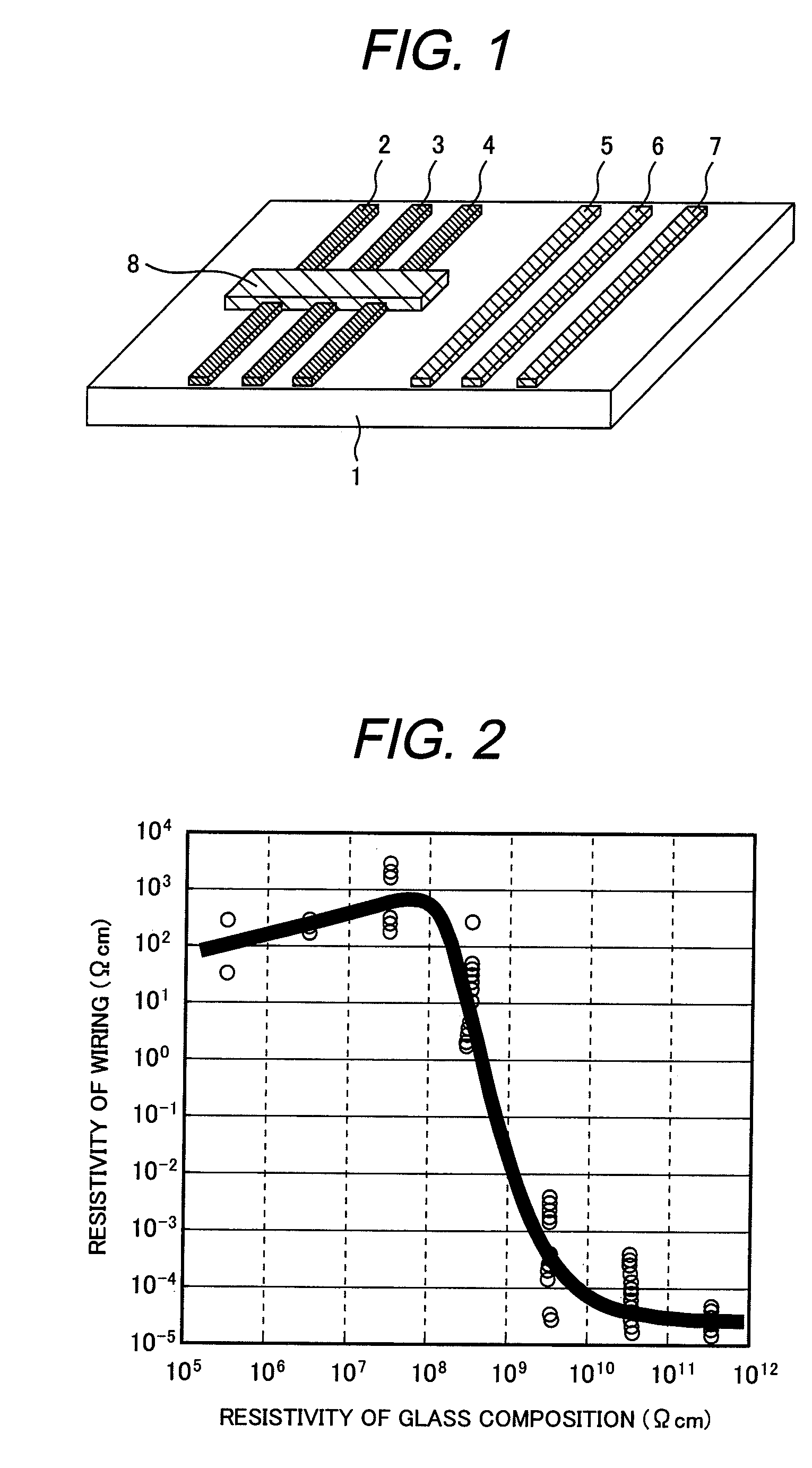

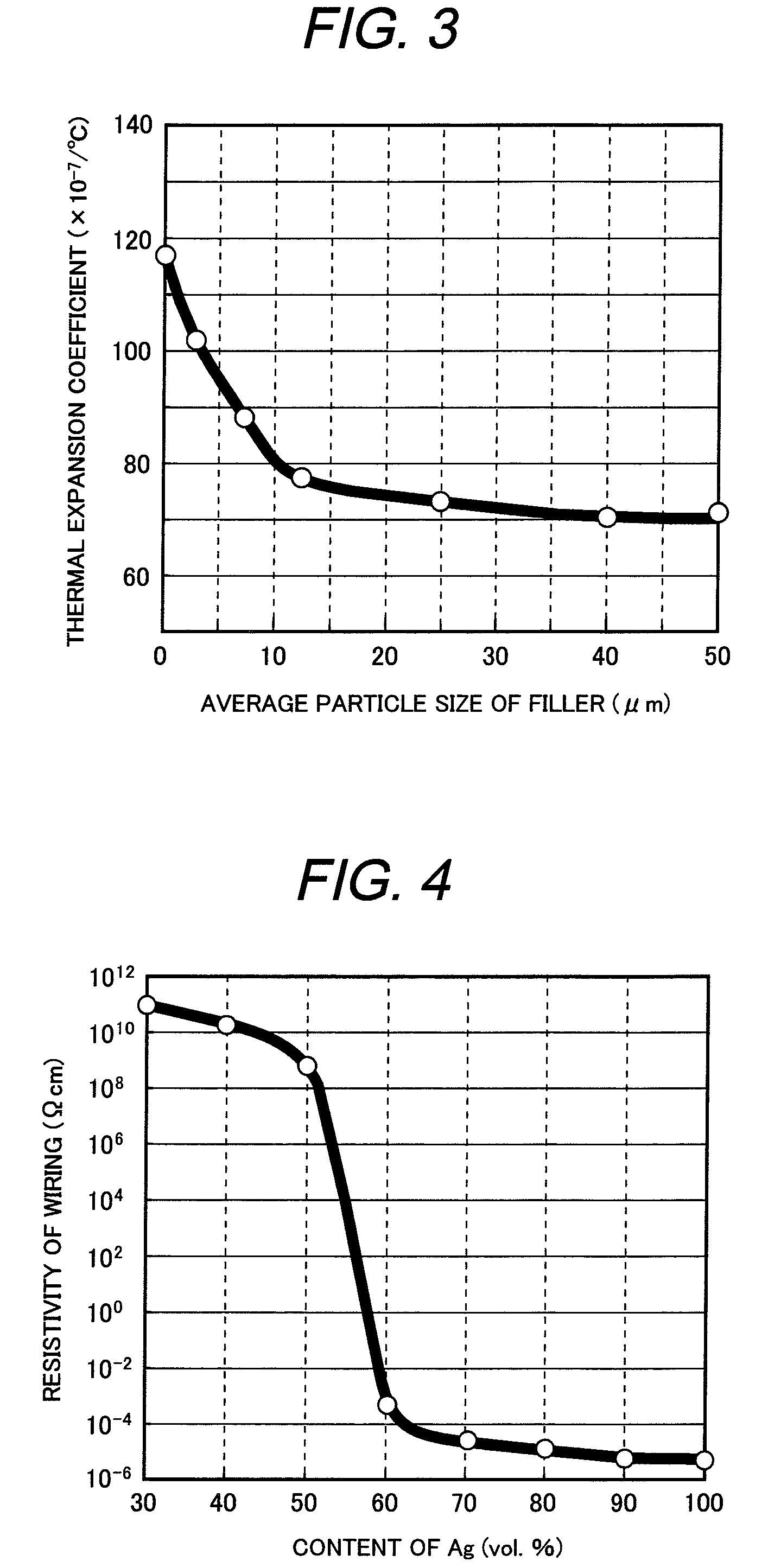

InactiveUS8367573B2Low air tightness requirementsHigh resistivityConductive layers on insulating-supportsSustain/scan electrodesFritted glassVanadium oxide

Owner:HITACHI POWDERED METALS COMPANY

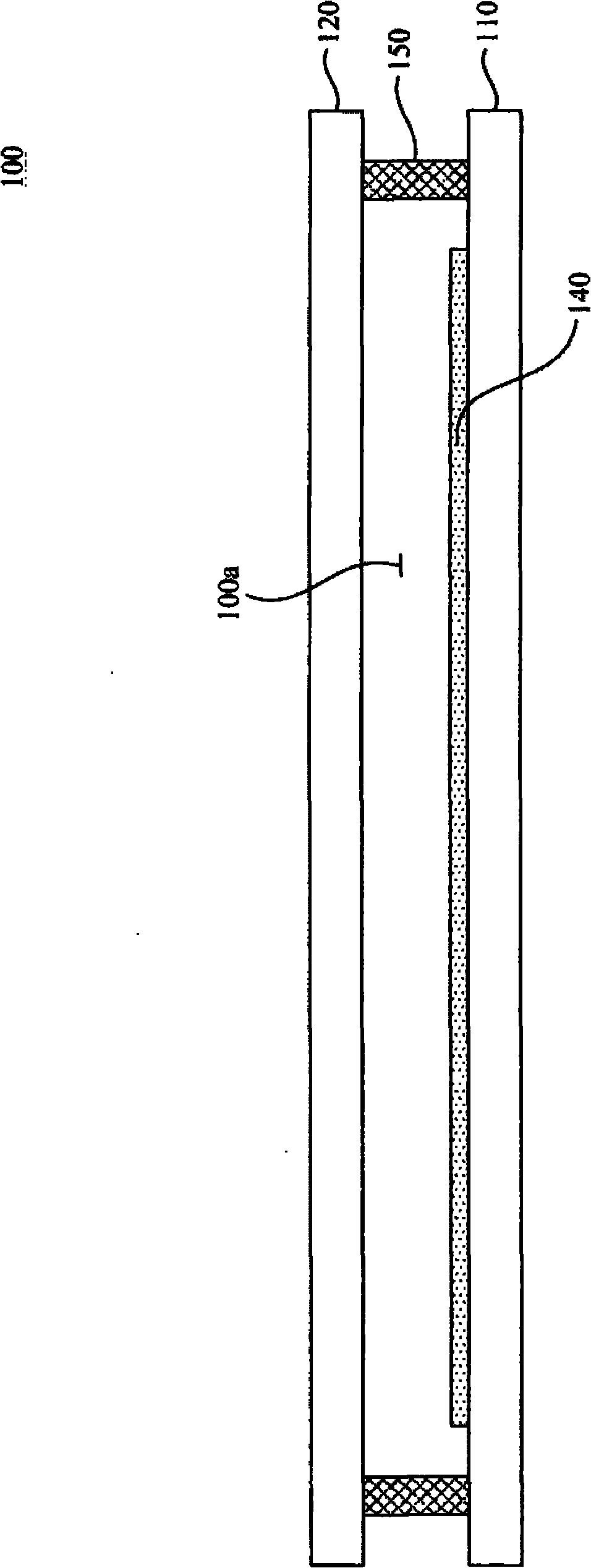

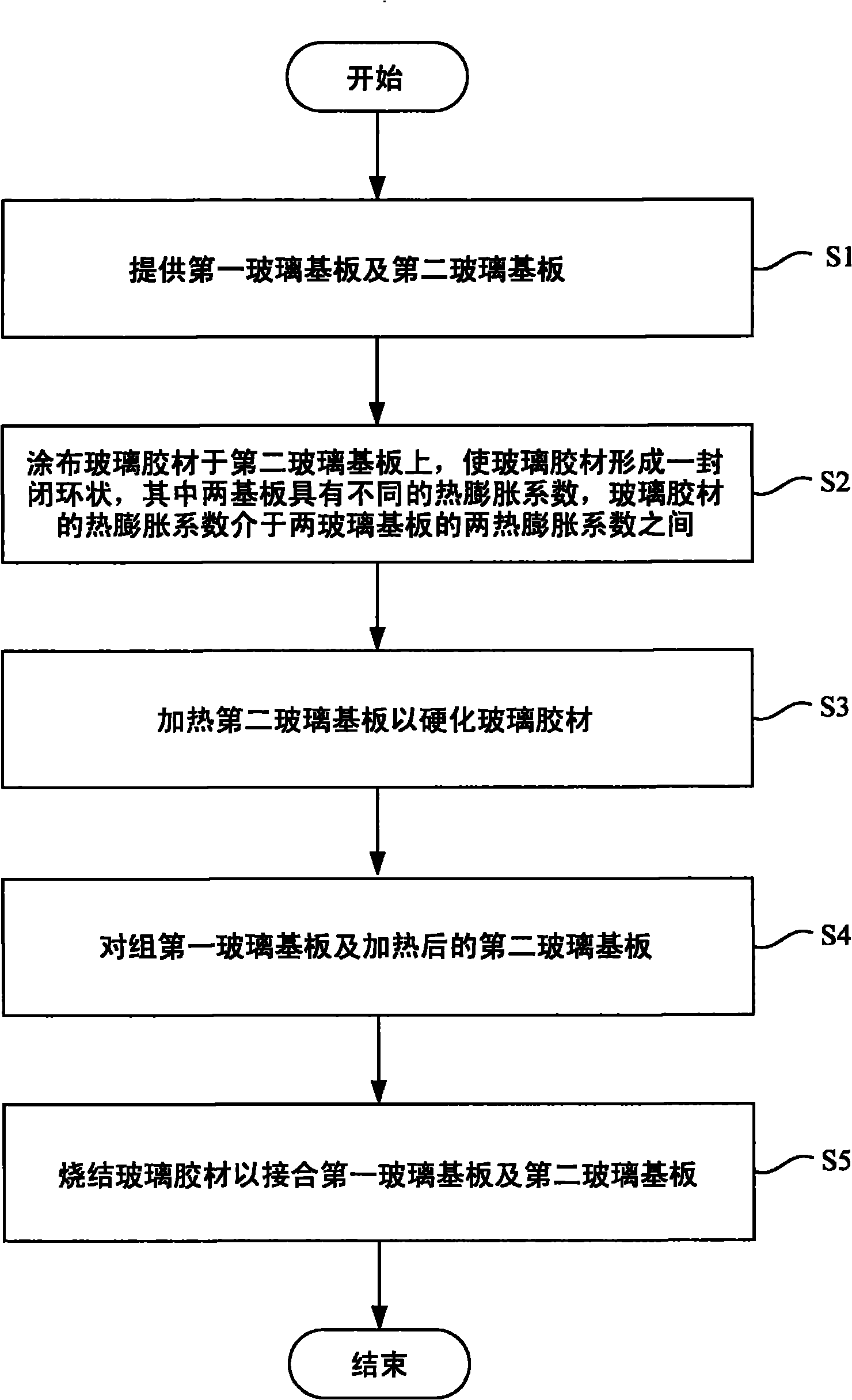

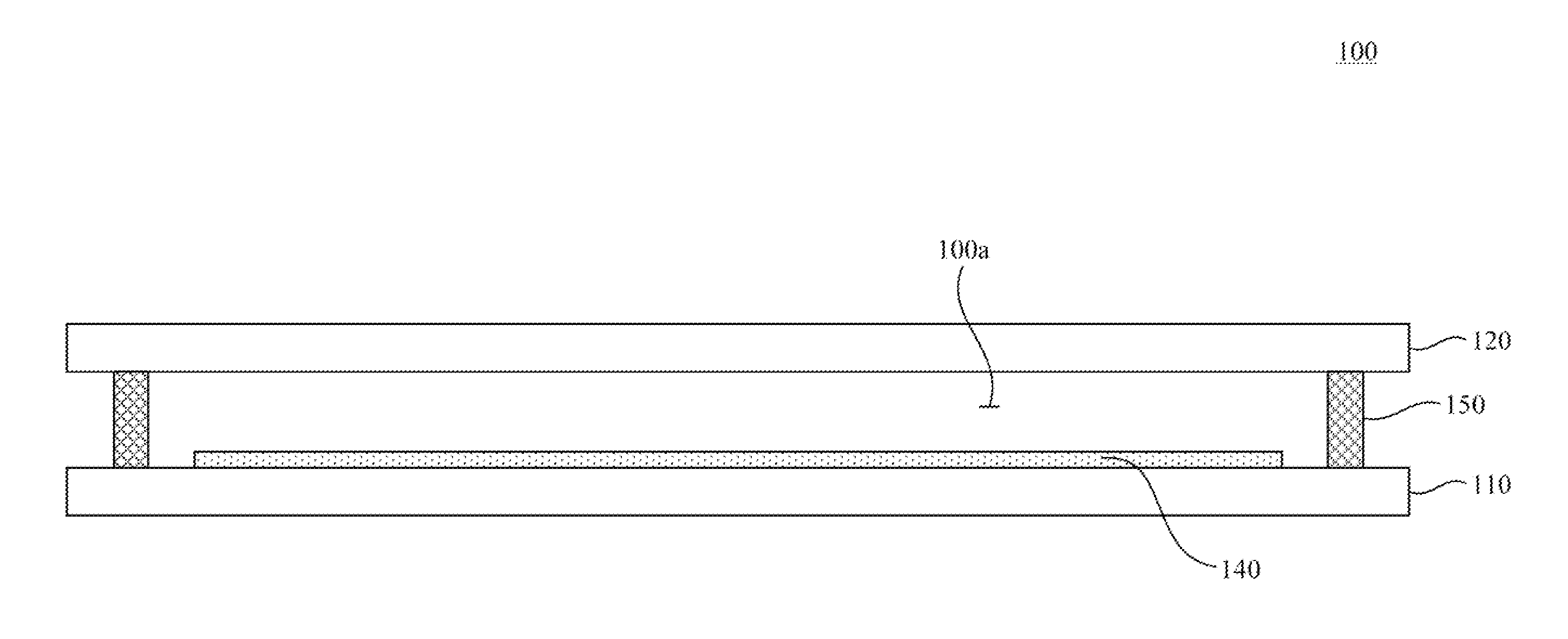

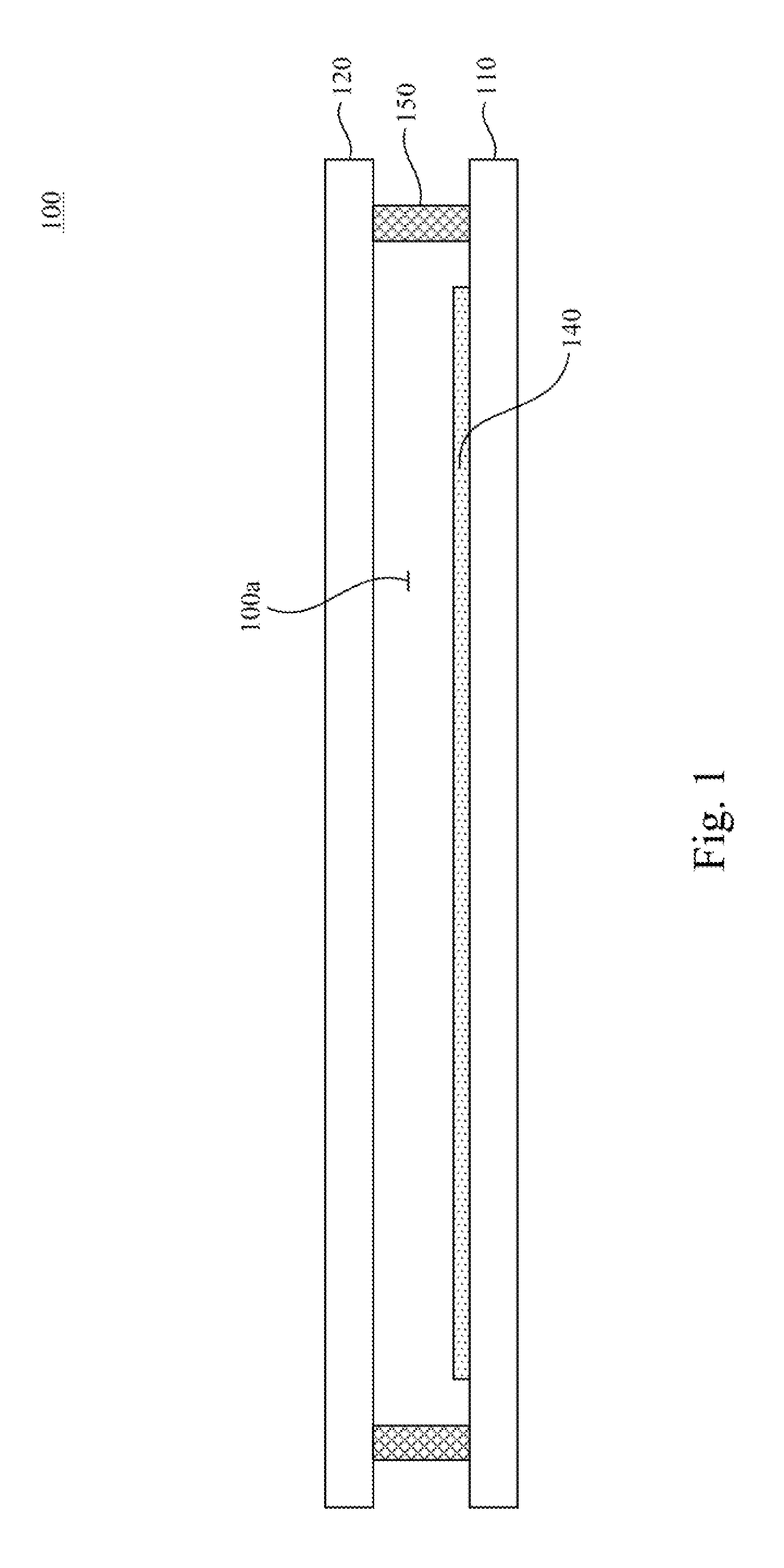

Glass sealing structure and manufacturing method thereof

ActiveCN101807672AImprove packaging qualityReduce the impactSolid-state devicesSemiconductor/solid-state device manufacturingFritted glassThermal expansion

The invention discloses a glass sealing structure and a manufacturing method thereof. The glass sealing structure comprises a first glass substrate, a second glass substrate and a glass cement material. The coefficients of thermal expansion of the first glass substrate and the second glass substrate are different, and the coefficient of thermal expansion of the glass cement material is between the coefficients of thermal expansion of the first glass substrate and the second glass substrate. A sealed space is formed among the first glass substrate, the second glass substrate and the glass cement material, and an organic luminous element is arranged in the sealed space. The manufacturing method comprises the following steps of: providing the first glass substrate and the second glass substrate; coating the glass cement material on the second glass substrate; heating and hardening the glass cement material; pairing the first glass substrate and the second glass substrate; and sintering the glass cement substrate so as to joint the two glass substrates.

Owner:AU OPTRONICS CORP

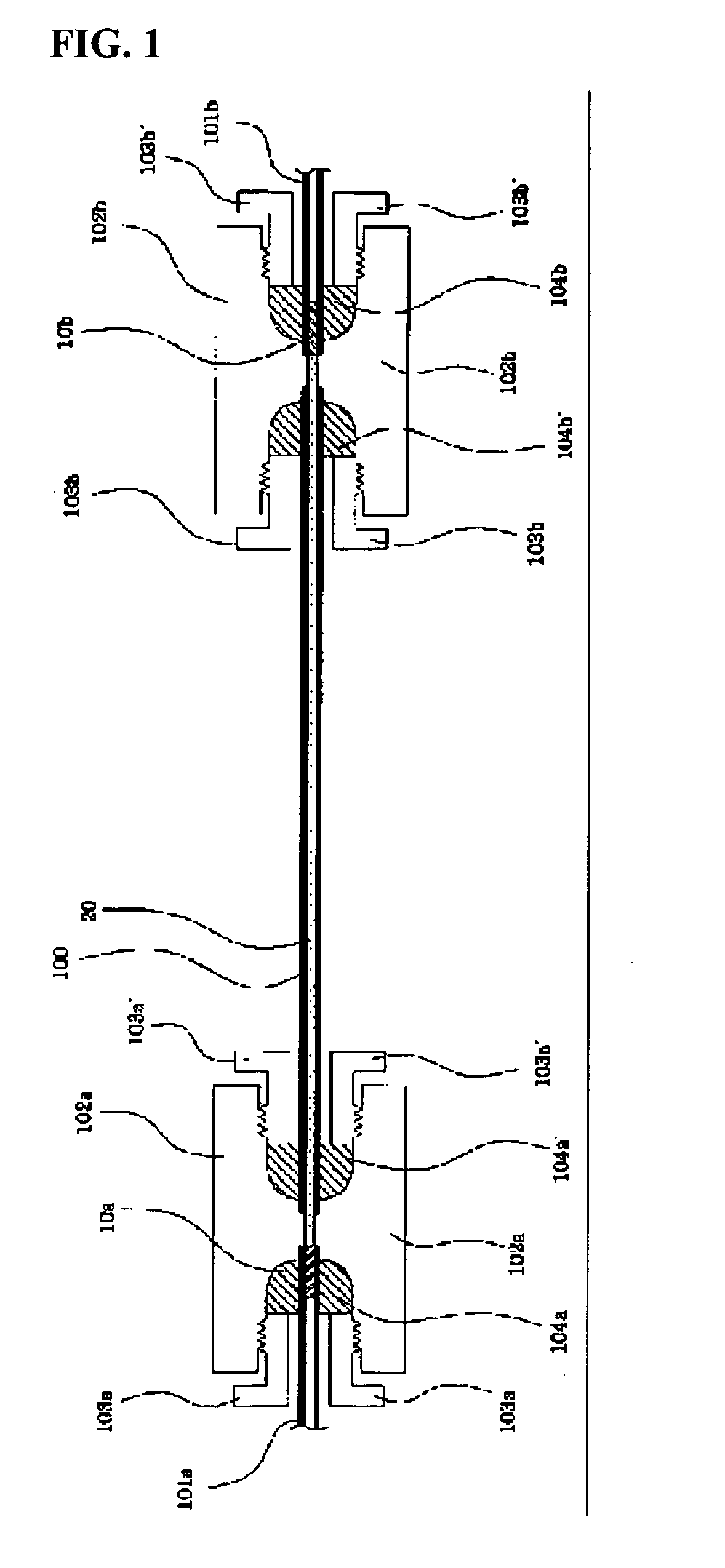

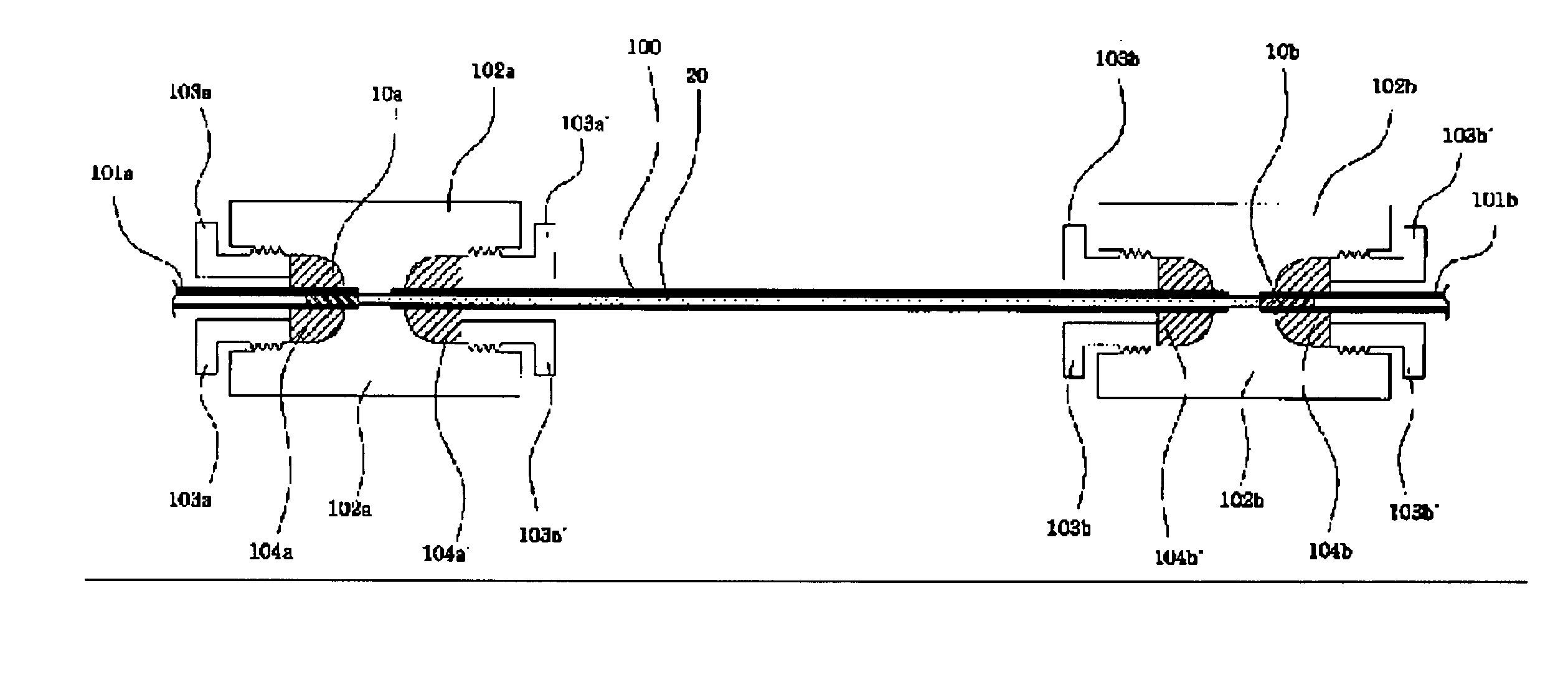

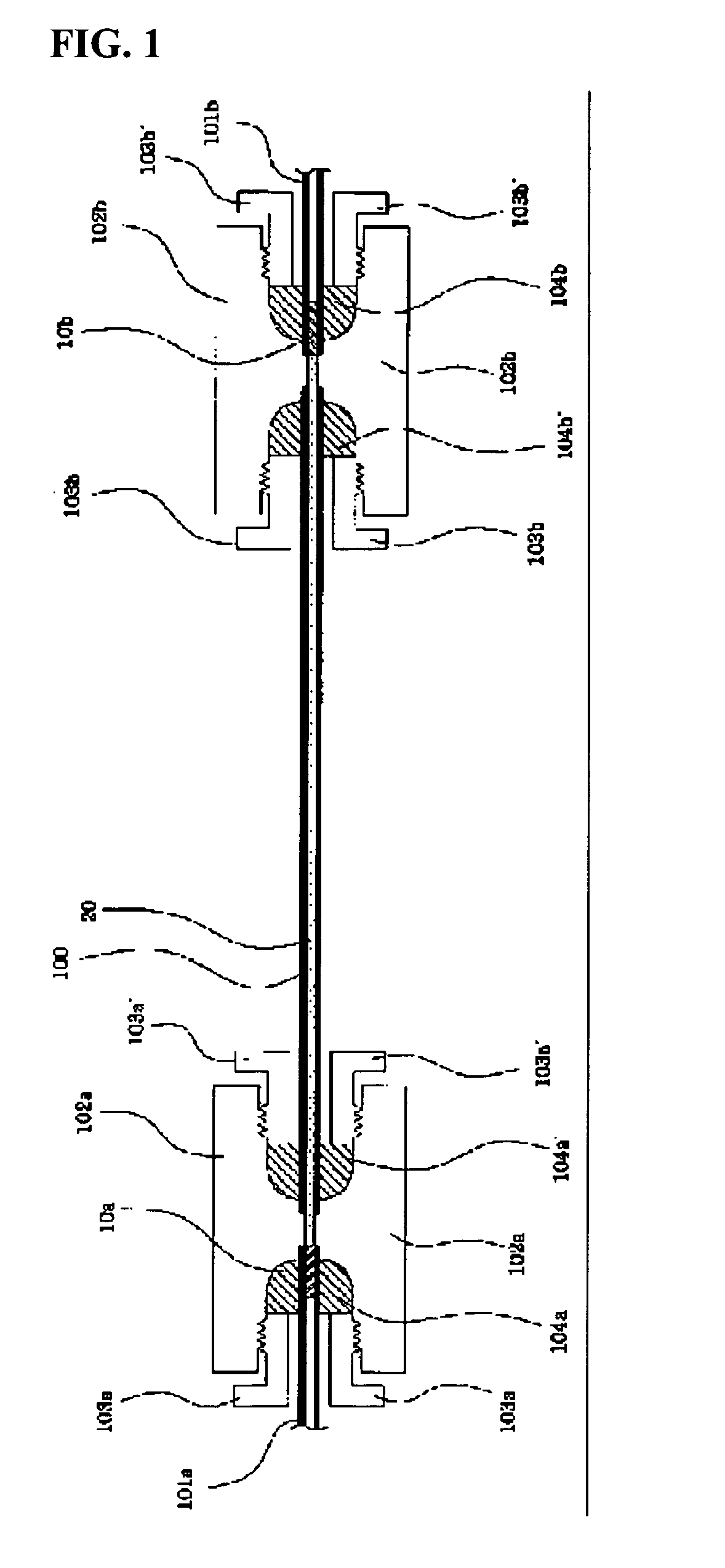

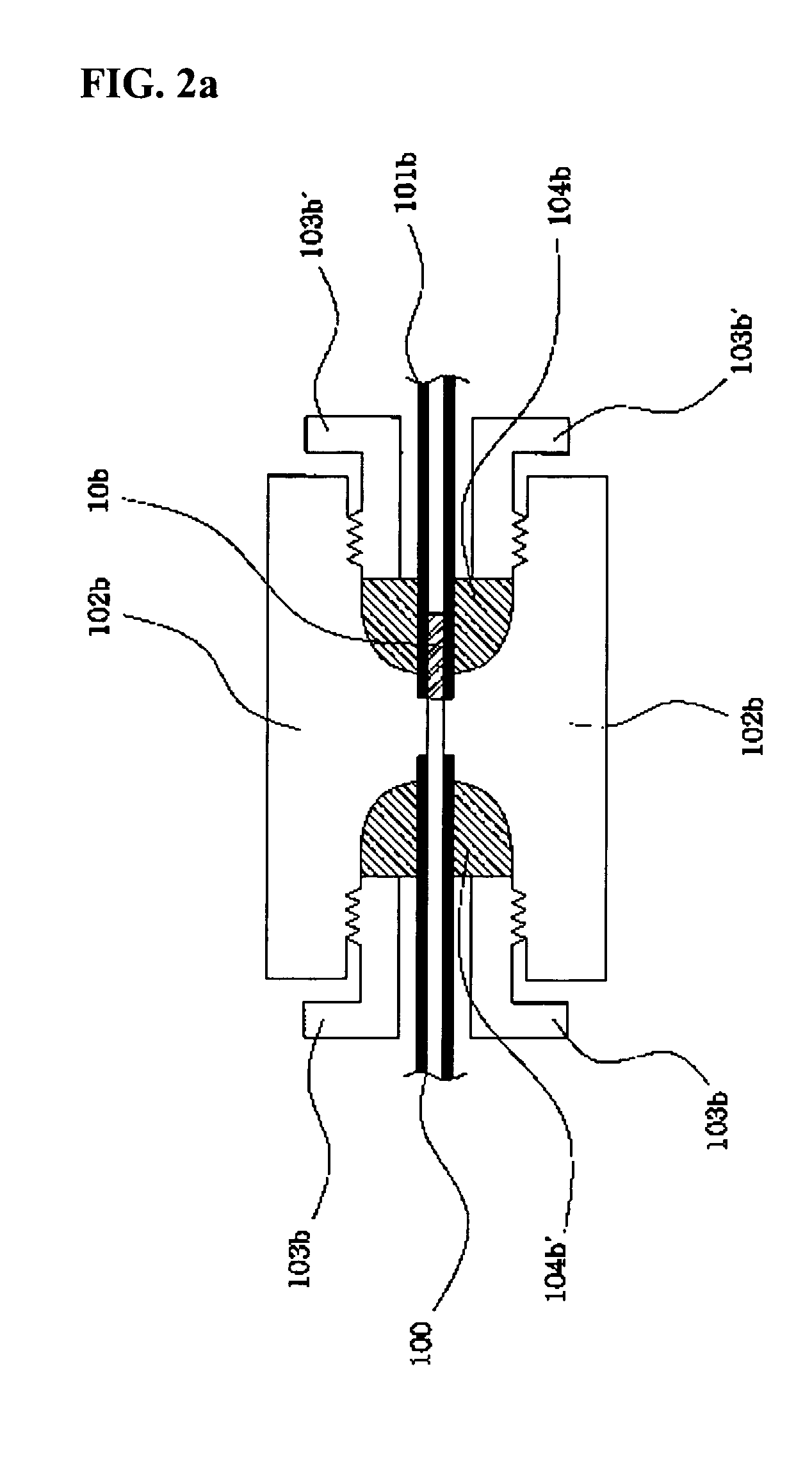

Stainless steel tubing/frit with sintered inorganic particle, the chromatography comprising it, and their manufacturing method

InactiveUS20040238447A1Simple design convenienceLow costIon-exchange process apparatusOxide/hydroxide preparationSilicon dioxideInorganic oxide

This invention is about metal tubing / frit applicable in liquid chromatography and a chromatography column manufactured by using the same. In detail, this invention is about manufacturing the metal tubing / frit by treating a powdered inorganic oxide such as silica, alumina, zirconia, and titania with a strong base, drying it with some humidity included, scrubbing it into powders, putting it in the tip of a chromatographic metal tubing at a proper depth, and by sintering the powders to form a durable sintered frit on the inner wall. This invention is also about a liquid chromatographic column manufactured by installing the metal tubing / frit's with a sintered end frit at the column inlet and outlet unions and by placing the cylinder-like column main body tubing packed with a stationary phase between the unions. The metal tubing / frit manufactured according to the description above is not placed inside the column as in the conventional column design, thus it is easily replaced and fixed without disassembling the column, and the column of this design can displace the conventional microcolumn of complicated production process and high cost.

Owner:CHEONG WON JO +1

Low-temperature acid-resistant sintered glass powder

InactiveCN102190445AMeet environmental protection requirementsWide Performance Tuning RangeFritted glassSlurry

The invention relates to a low-temperature acid-resistant sintered glass powder, which comprises the following raw materials in percentage by weight: 30-70% of SiO2, 1-20% of B2O3, 1-10% of Al2O3, 1-20% of BaO, 1-20% of ZnO, 1-10% of TiO2, 1-20% of Na2O, 1-20% of K2O, 1-10% of CuO, 1-10% of MnO2 and 1-10% of P2O5, wherein the ratio of BaO to ZnO in percentage by weight is more than 1 and less than 2 and the total percentage by weight of Na2O and K2O is 6-25%. The preparation process of the sintered glass powder comprises the following steps: weighing, mixing materials, melting, tabletting, ball-milling and screening. The sintered glass powder has the advantages of low sintering temperature, high airtightness, high chemical durability and high acid resistance, and can be used for the inorganic adhesive phase of electroconductive electronic slurry, the glass paste used for a protective coating and etc.

Owner:李胜春

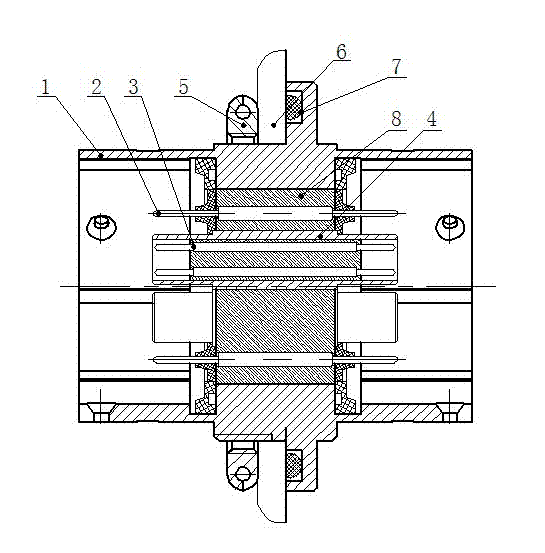

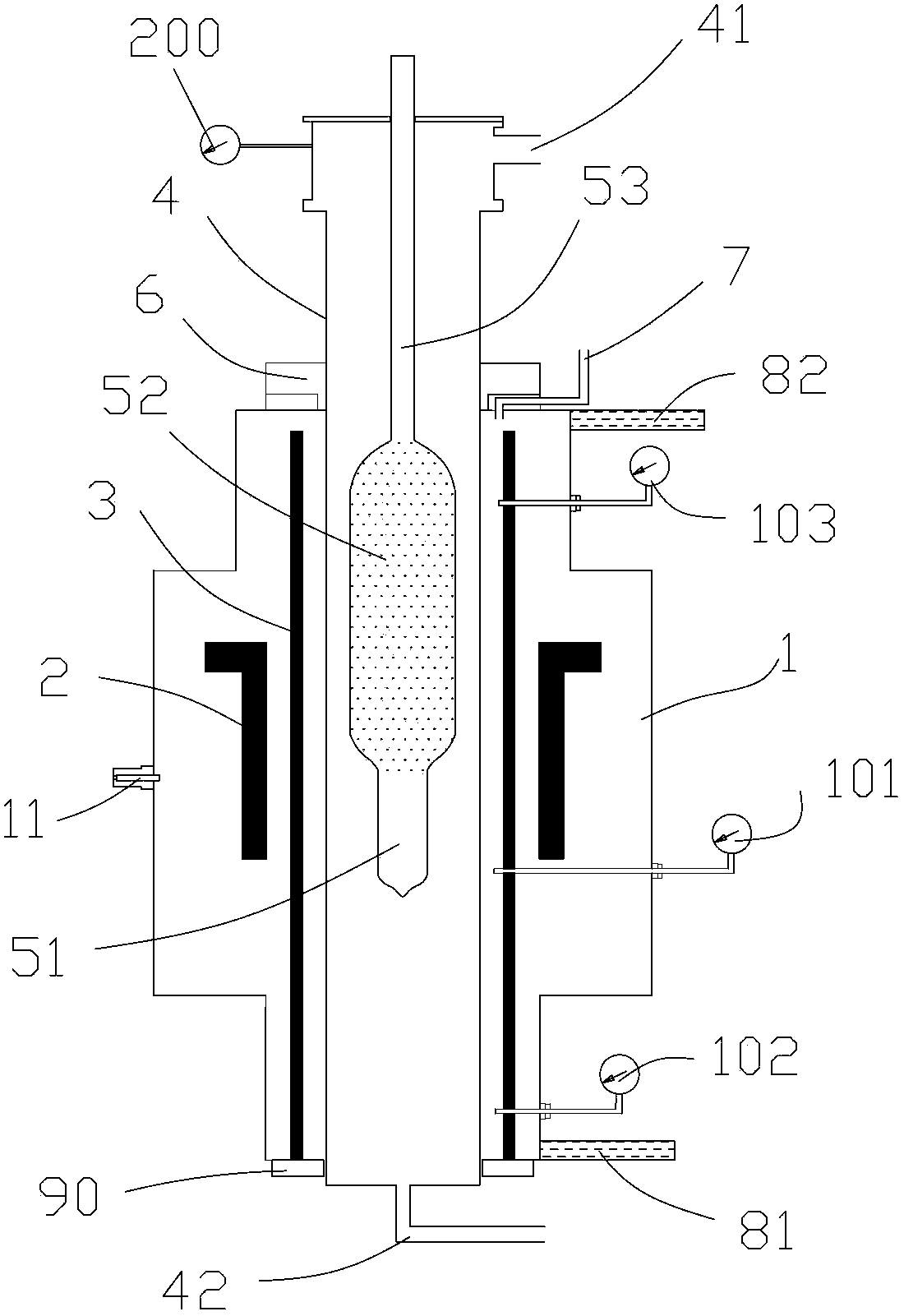

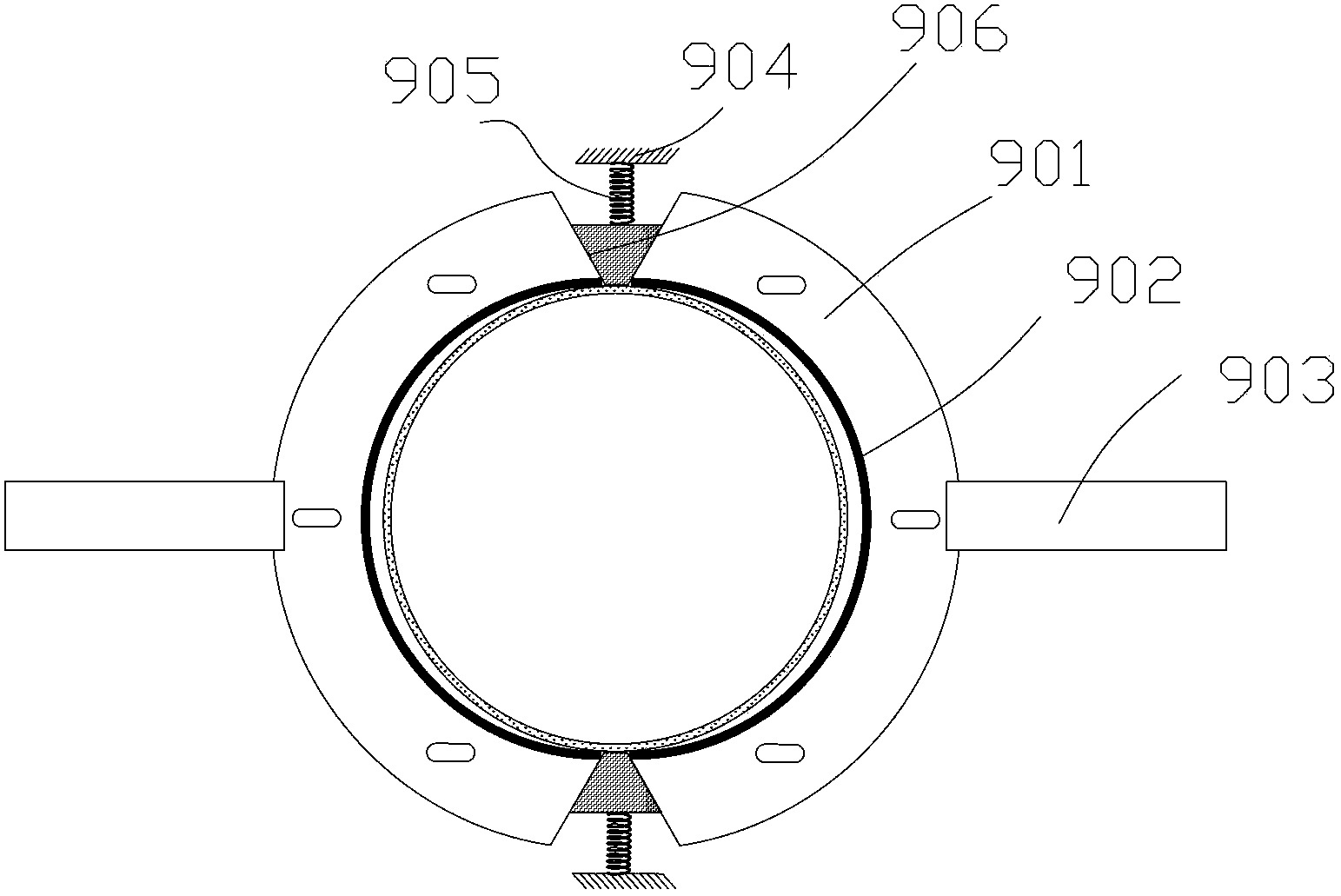

Graphite furnace for sintering glass loose mass

ActiveCN103626381AExtended service lifeAvoid deformationGlass furnace apparatusInternal pressureShielding gas

The invention discloses a graphite furnace for sintering glass loose mass. The graphite furnace comprises a graphite furnace body provided with a mounting hole at one end and a quartz tube connected with the other end of the graphite furnace body, wherein an air outlet end of the quartz tube extends out of the mounting hole. The graphite furnace further comprises a sealing device arranged at the mounting hole of the graphite furnace body and used for sealing the mounting hole, wherein the sealing device is provided with an air inlet unit; and the joint of the graphite furnace body and the quartz tube is provided with an air exhausting device. In the embodiment of the invention, the graphite furnace body is set as a sealed structure by the sealing device, and the air inlet unit and the air exhausting device are arranged on the graphite furnace body. In the production process, when a process gas is introduced into the quartz tube, a protective gas is introduced into the sealed graphite furnace through the air inlet unit to increase the external pressure of the quartz tube, thus the balance between internal pressure and external pressure of the quartz tube is guaranteed to prevent the quartz tube from deformation. Consequentially, the service life of the graphite furnace is prolonged effectively.

Owner:ZHEJIANG FUTONG OPTICAL FIBER TECH +1

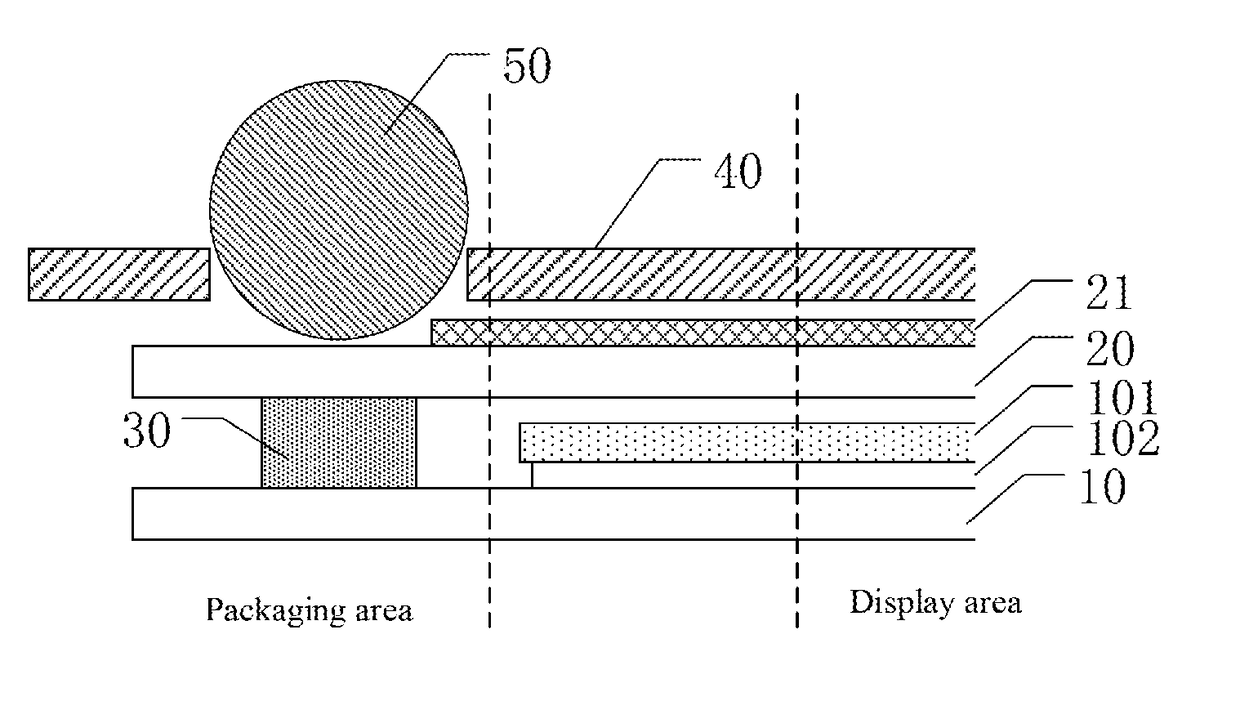

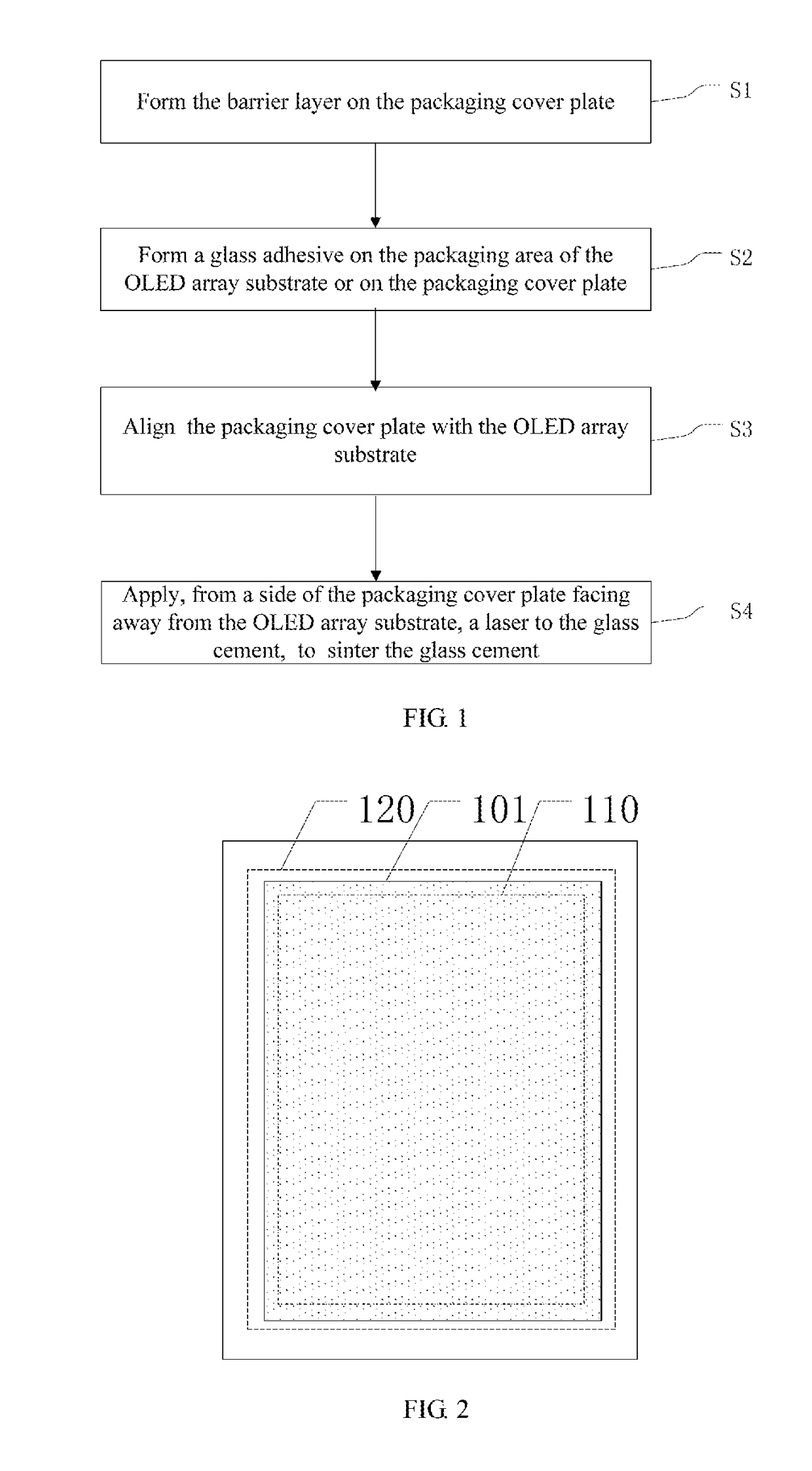

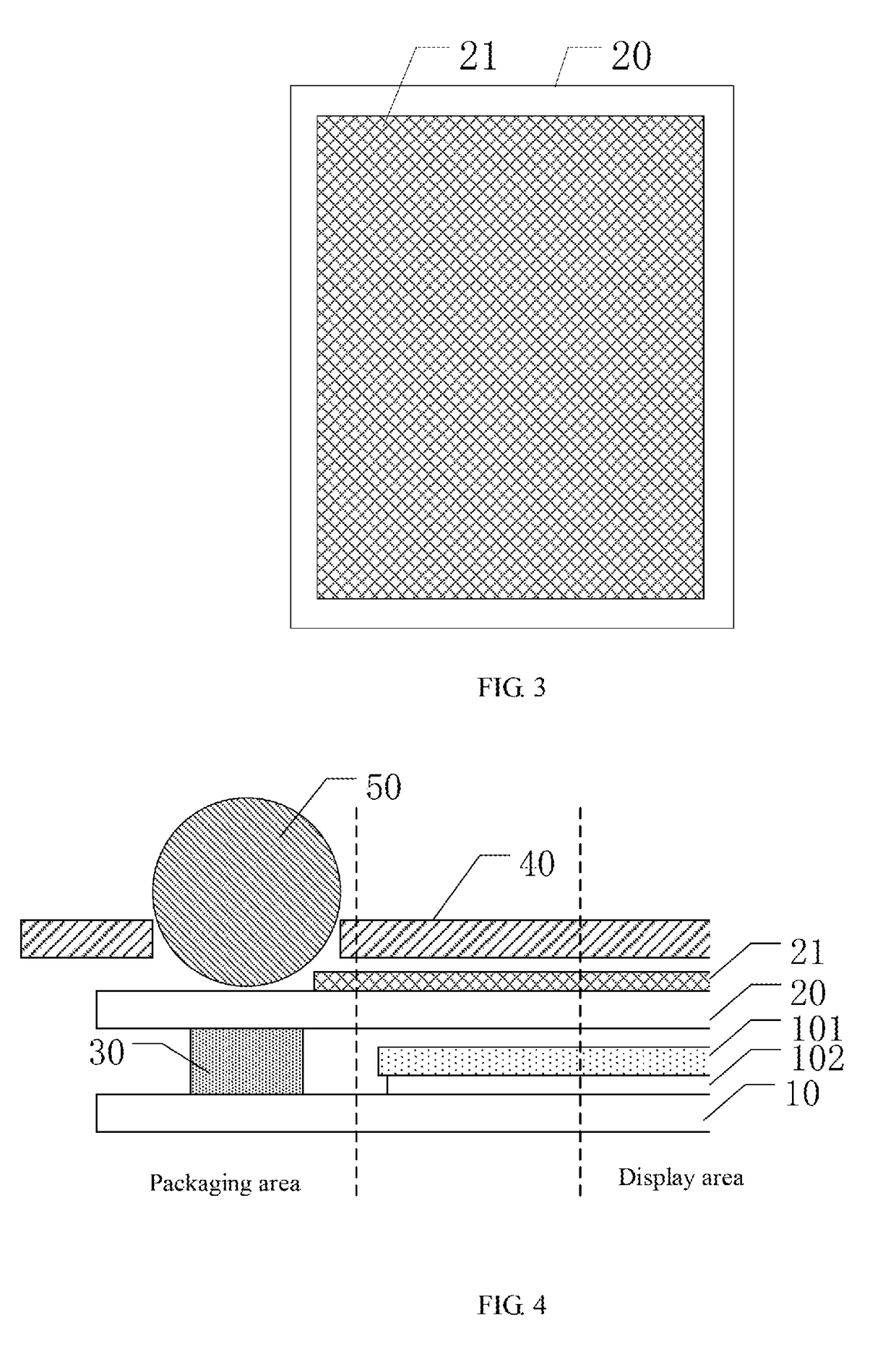

Packaging method, display panel and display device

ActiveUS20170294623A1Avoid heat damageSolid-state devicesSemiconductor/solid-state device manufacturingAdhesiveDisplay device

The present disclosure provides a packaging method, a display panel, and a display device. The packaging method includes forming a glass adhesive on a packaging area of an OLED array substrate or on a packaging cover plate, aligning the packaging cover plate with the OLED array substrate, and applying, from a side of the packaging cover plate facing away from the OLED array substrate a laser to the glass adhesive, to sinter the glass adhesive, wherein the packaging method further includes forming a barrier layer on the packaging cover plate, the barrier layer being configured to block the laser from irradiating an OLED device on the OLED array substrate when the laser irradiates the glass adhesive.

Owner:BOE TECH GRP CO LTD +1

Preparation method of microwave and hybrid circuit tube shells of aluminum silicon carbide materials

ActiveCN106986650ASolve the problem of low service lifeEasy to adaptMicrowave heatingElectrical apparatus casings/cabinets/drawersMicrowaveFritted glass

The invention discloses a preparation method of microwave and hybrid circuit tube shells of aluminum silicon carbide materials. According to the preparation method, the volume percentage of silicon carbide to aluminum silicon carbide is 70%, holes are punched into an aluminum silicon carbide shell by the aid of electric sparks, glass insulators are sintered on the holes in the shell, the sealing temperature of the glass insulators ranges from 450 DEG C to 550 DEG C, a heat expansion coefficient is 6-10, air tightness can reach 10-8Pa m<3> / s-10-9Pa m<3> / s, aluminum alloy cover plates with the thickness of 1mm are machined in a linear cutting and electric spark manner, the tube shells and the cover plates are welded by the aid of lasers, and the surfaces are planted with gold with the thickness of 1-2mum to obtain the microwave and hybrid circuit tube shells of the aluminum silicon carbide materials. The tube shells are high in heat conductivity and air tightness and low in heat expansion coefficient, have bright prospect in microwave and hybrid circuits and can replace market similar metal tube shells.

Owner:西安明科微电子材料有限公司

Organic EL display device and method for manufacturing the same

ActiveUS8710492B2Reduction in sealing performance of sealing can be reduced and preventedCost can be reduced and preventedElectroluminescent light sourcesSolid-state devicesDisplay deviceFritted glass

Owner:SHARP KK

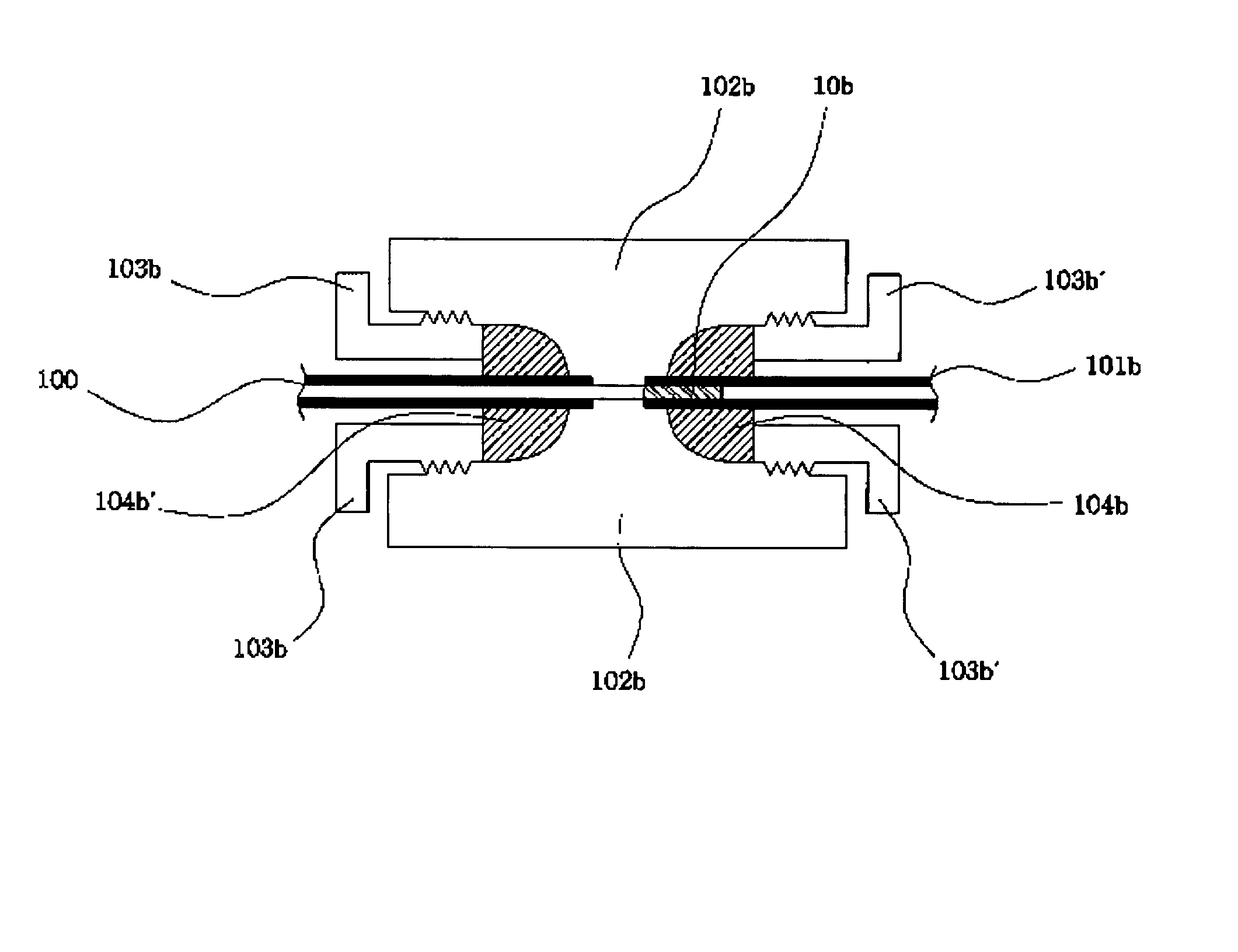

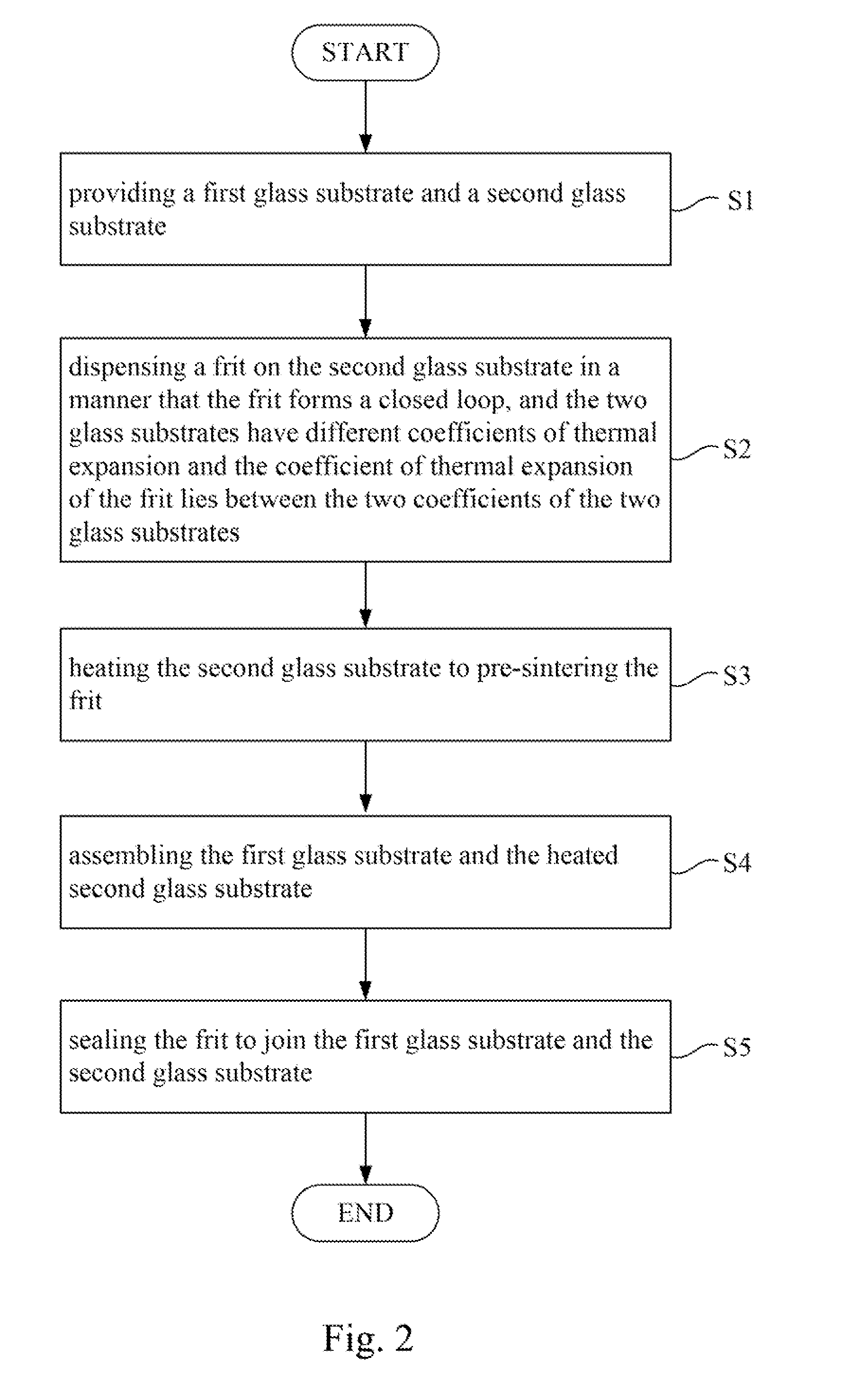

Glass sealing package and manufacturing method thereof

InactiveUS20110241060A1Improve seal qualitySolve the real problemSolid-state devicesSemiconductor/solid-state device manufacturingFritFritted glass

Disclosed herein are a glass sealing package and a manufacturing method thereof. The glass sealing package includes a first glass substrate, a second glass substrate and a frit. The coefficient of thermal expansion of the frit lies between that of the two glass substrates. A light emitting element on the first glass substrate is situated in a sealed room formed among the two substrates and the frit. The method includes the steps of proving a first and a second glass substrate, dispensing a frit on the second glass substrate, pre-sintering the frit, assembling the two substrates, and sealing the frit to join the two substrates.

Owner:AU OPTRONICS CORP

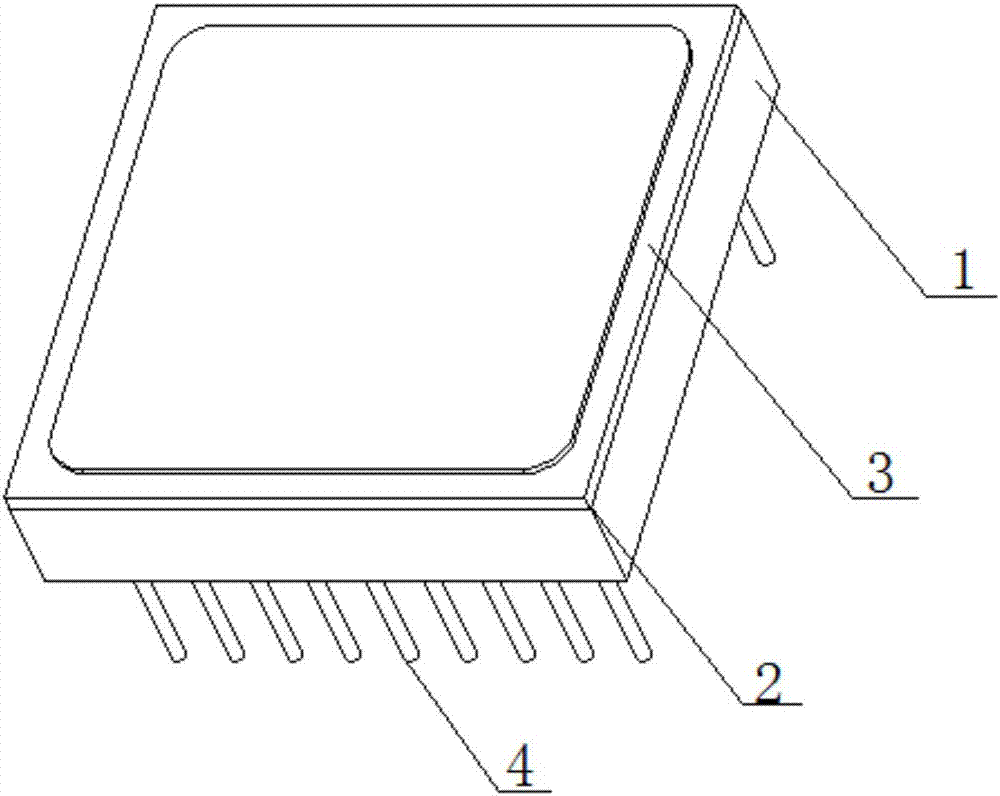

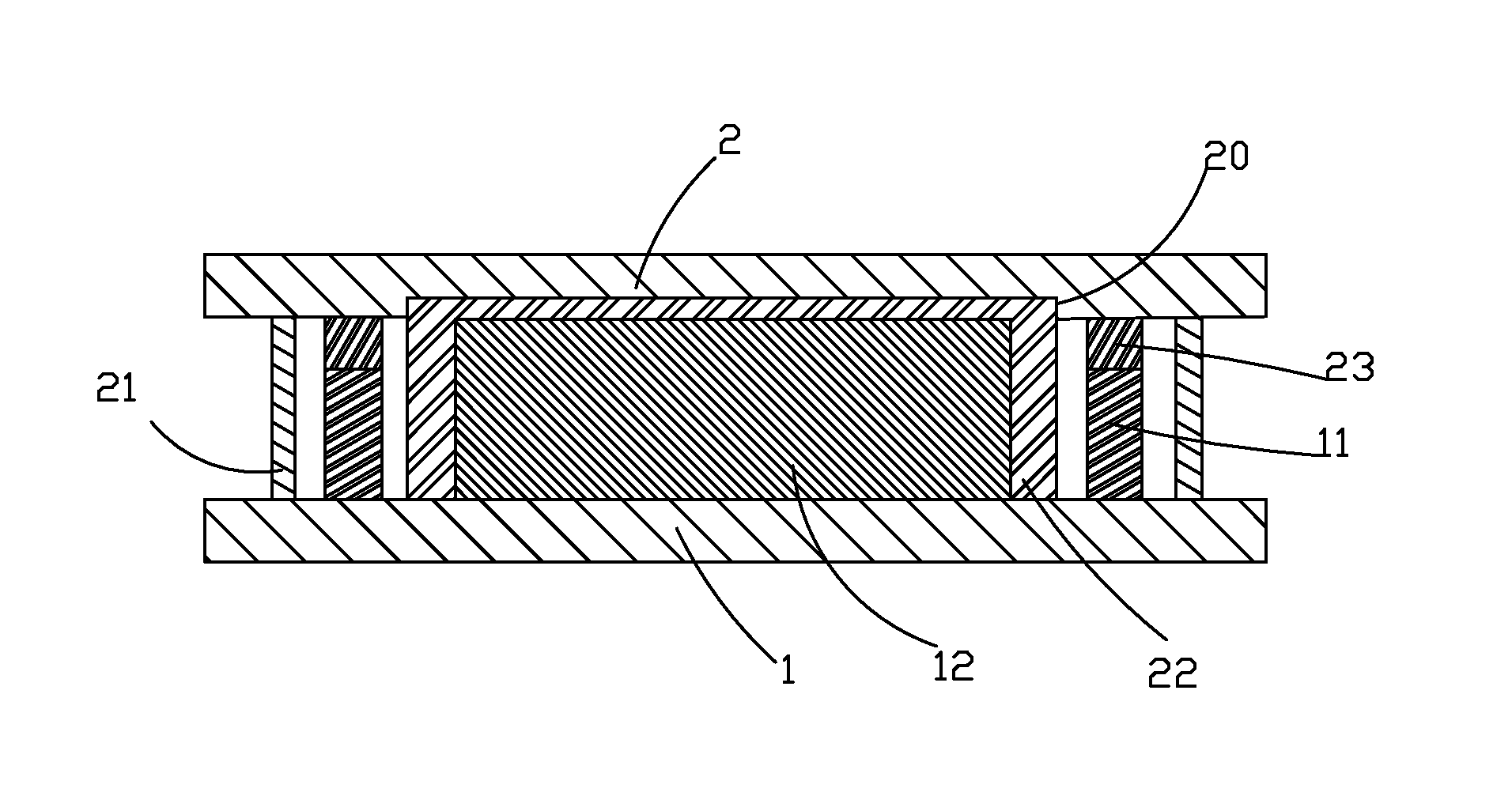

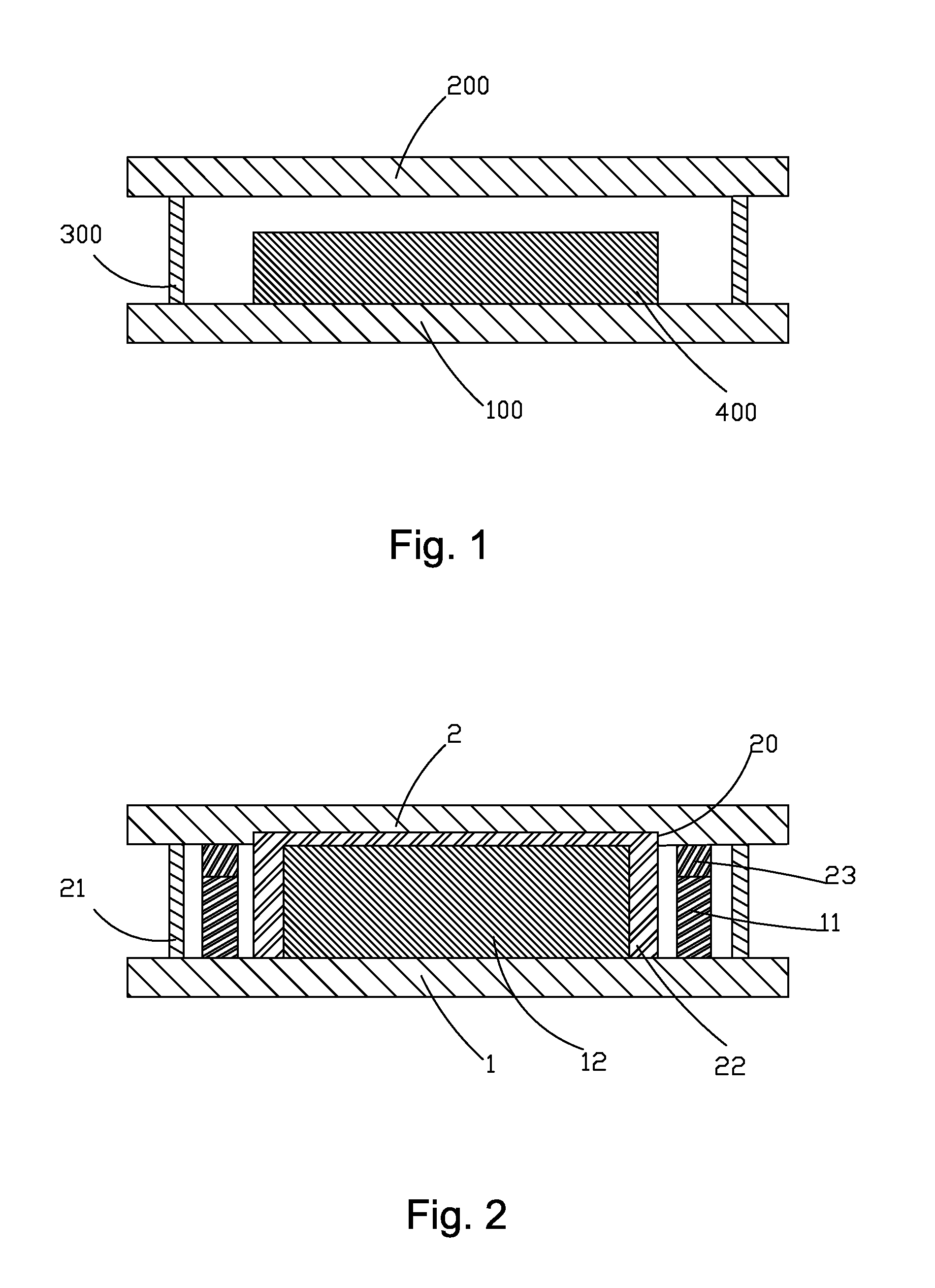

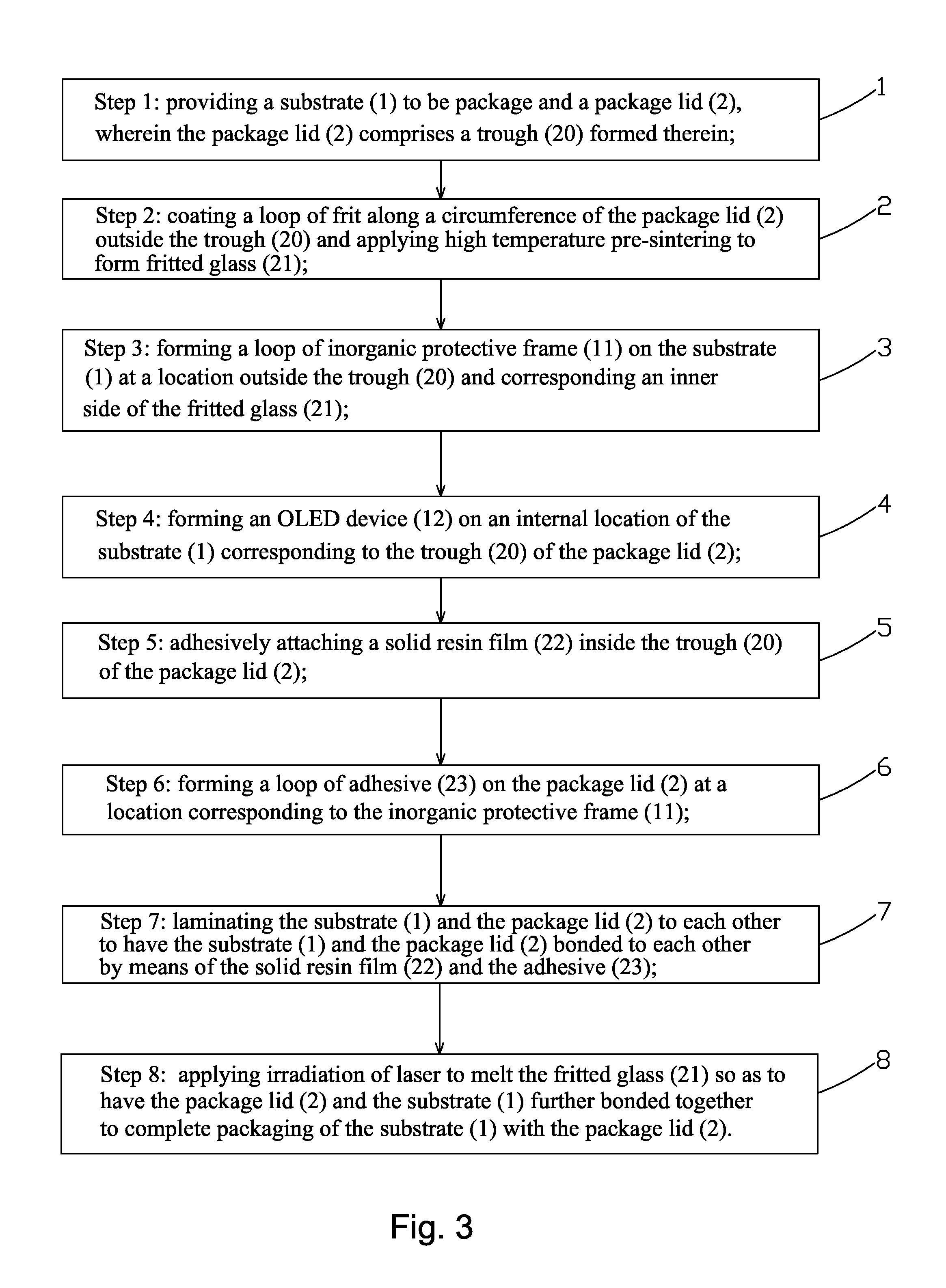

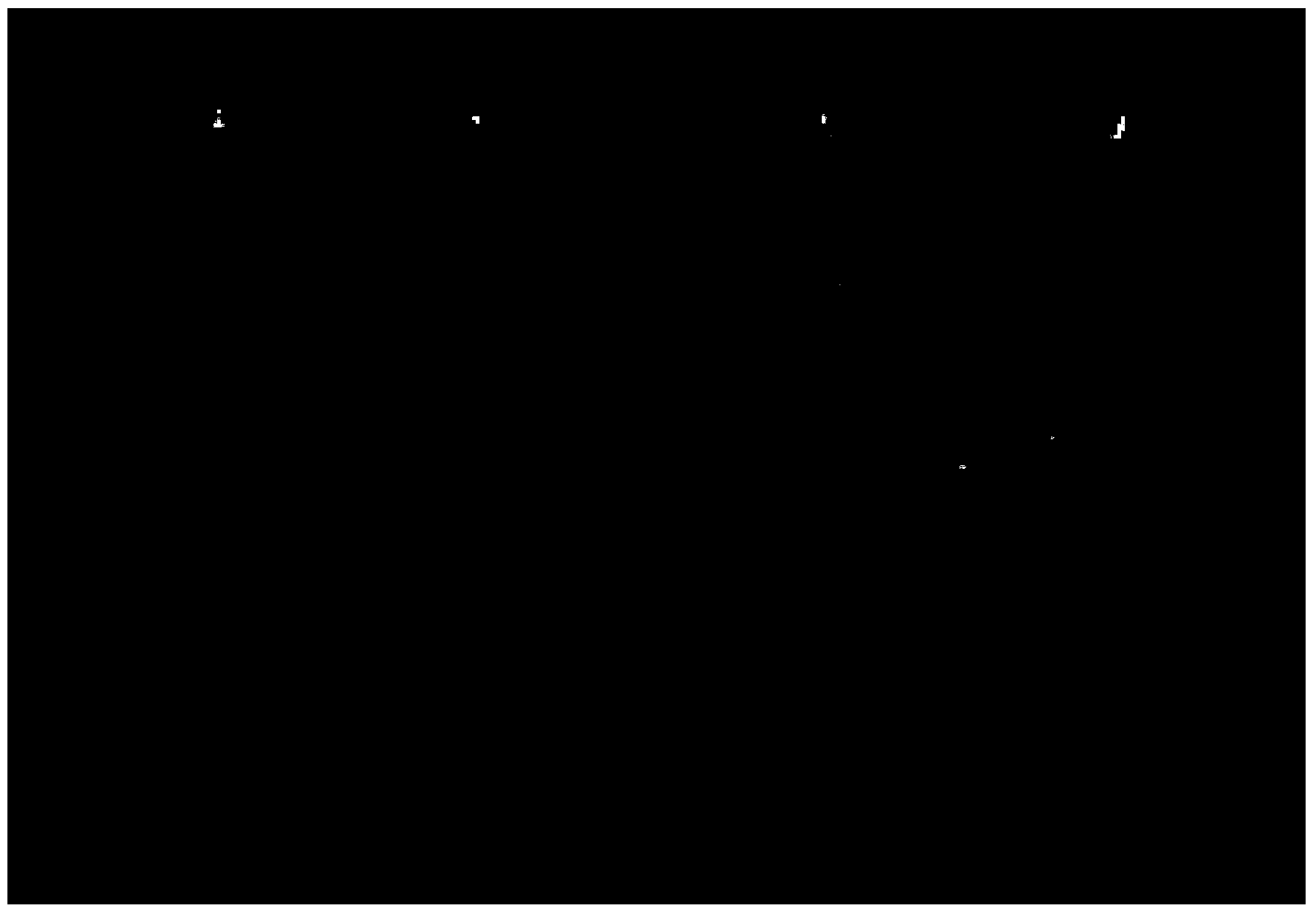

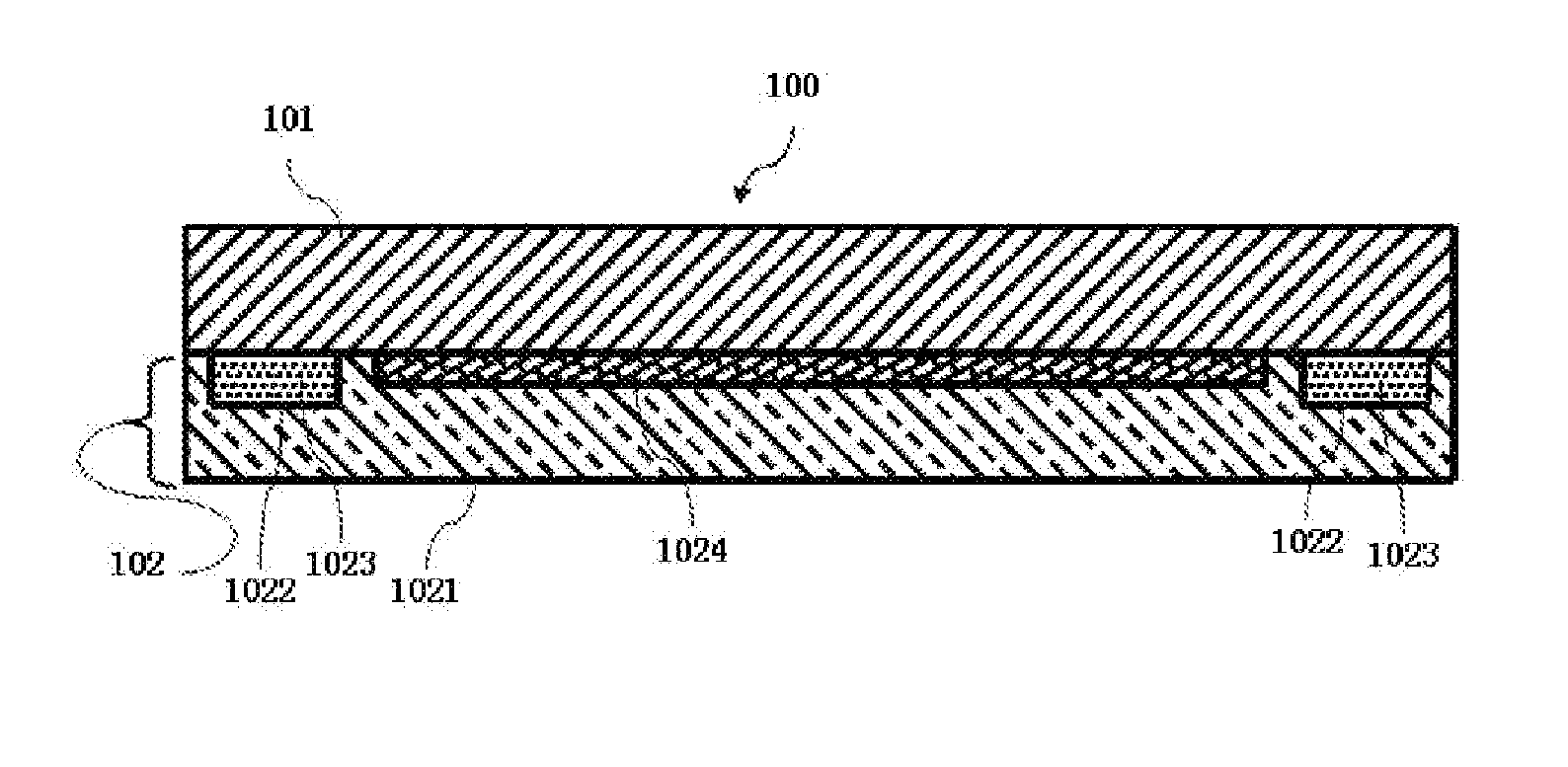

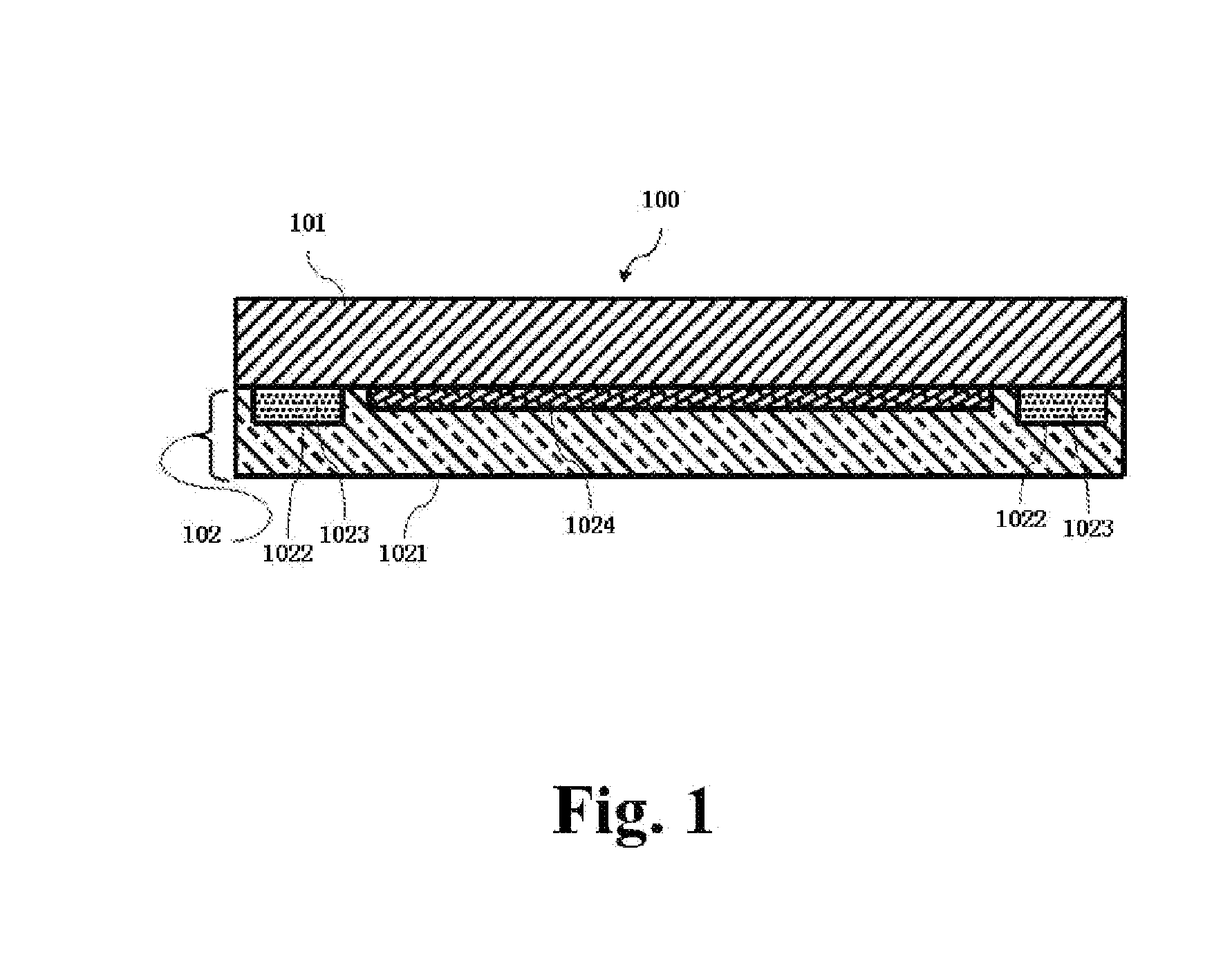

OLED package structure and packaging method

ActiveUS20160343978A1Improve abilitiesHigh mechanical strengthSolid-state devicesSemiconductor/solid-state device manufacturingCrystallographyFritted glass

The present invention provides an OLED package structure and a packaging method. The structure includes a substrate (1), a package lid (2) opposite to the substrate (1), an OLED device (12) located between the substrate (1) and the package lid (2) and mounted on the substrate (1), a solid resin film (22) located between the substrate (1) and the package lid (2) and arranged on the package lid (2) to completely cover the OLED device (12), an inorganic protective frame (11) arranged on the substrate (1) and located outside an outer circumference of the solid resin film (22), adhesive (23) applied on the package lid (2) to bond the inorganic protective frame (11) and the package lid (2) to each other, and fritted glass (21) arranged outside an outer circumference of the inorganic protective frame (11) to bond the substrate (1) and the package lid (2) to each other. The present invention provides an arrangement where the inorganic protective frame is arranged inboard the fritted glass to effectively strengthen air tightness achieved with the fritted glass. Further, the solid resin film is arranged on the package lid to cover the OLED device so as to further strengthen the capability of the OLED package structure for blocking moisture and also, a gap in the interior of the sealed object is lessened so as to provide a sufficient mechanical strength to extend the lifespan of the OLED device.

Owner:SHENZHEN CHINA STAR OPTOELECTRONICS TECH CO LTD

Environment-friendly high-phosphorus chemical nickel plating solution for airtight glass-sealed binding terminal, and applications thereof

InactiveCN103938193ARefined grain sizeFast platingLiquid/solution decomposition chemical coatingChemical platingBULK ACTIVE INGREDIENT

The invention discloses an environment-friendly high-phosphorus chemical nickel plating solution for an airtight glass-sealed binding terminal. The environment-friendly high-phosphorus chemical nickel plating solution comprises the following active ingredients according to concentration: 25-27g / L nickel sulfate, 19-22g / L sodium hypophosphite, 20-23g / L sodium hydroxide, 41-44g / L lactic acid, 1.5-2.3g / L trisodium citrate, 13-15g / L malic acid, 8-12g / L glycine, 0.2-0.4ml / L OP-10, 0.26-0.3g / L stannous chloride, 0.26-0.34g / L maleic anhydride and 3-5mg / L N,N-diethylaminopropyne. The invention discloses a method for performing chemical plating by adopting the chemical nickel plating solution. A stainless steel needle and an iron cover can be simultaneously subjected to chemical nickel plating and be evenly plated, no nickel nuclear generated on sintered glass can be guaranteed, and the difficulty in keeping the smoothness and cleanness of the surface of glass can be solved.

Owner:深圳市迪凯鑫科技有限公司

Stainless steel tubing/frit with sintered inorganic particle, the chromatography comprising it, and their manufacturing method

InactiveUS7132046B2Simple design convenienceLow costIon-exchange process apparatusOxide/hydroxide preparationSilicon dioxideChromatography column

This invention is about metal tubing / frit applicable in liquid chromatography and a chromatography column manufactured by using the same. In detail, this invention is about manufacturing the metal tubing / frit by treating a powdered inorganic oxide such as silica, alumina, zirconia, and titania with a strong base, drying it with some humidity included, scrubbing it into powders, putting it in the tip of a chromatographic metal tubing at a proper depth, and by sintering the powders to form a durable sintered frit on the inner wall.This invention is also about a liquid chromatographic column manufactured by installing the metal tubing / frit's with a sintered end frit at the column inlet and outlet unions and by placing the cylinder-like column main body tubing packed with a stationary phase between the unions.The metal tubing / frit manufactured according to the description above is not placed inside the column as in the conventional column design, thus it is easily replaced and fixed without disassembling the column, and the column of this design can displace the conventional microcolumn of complicated production process and high cost.

Owner:CHEONG WON JO +1

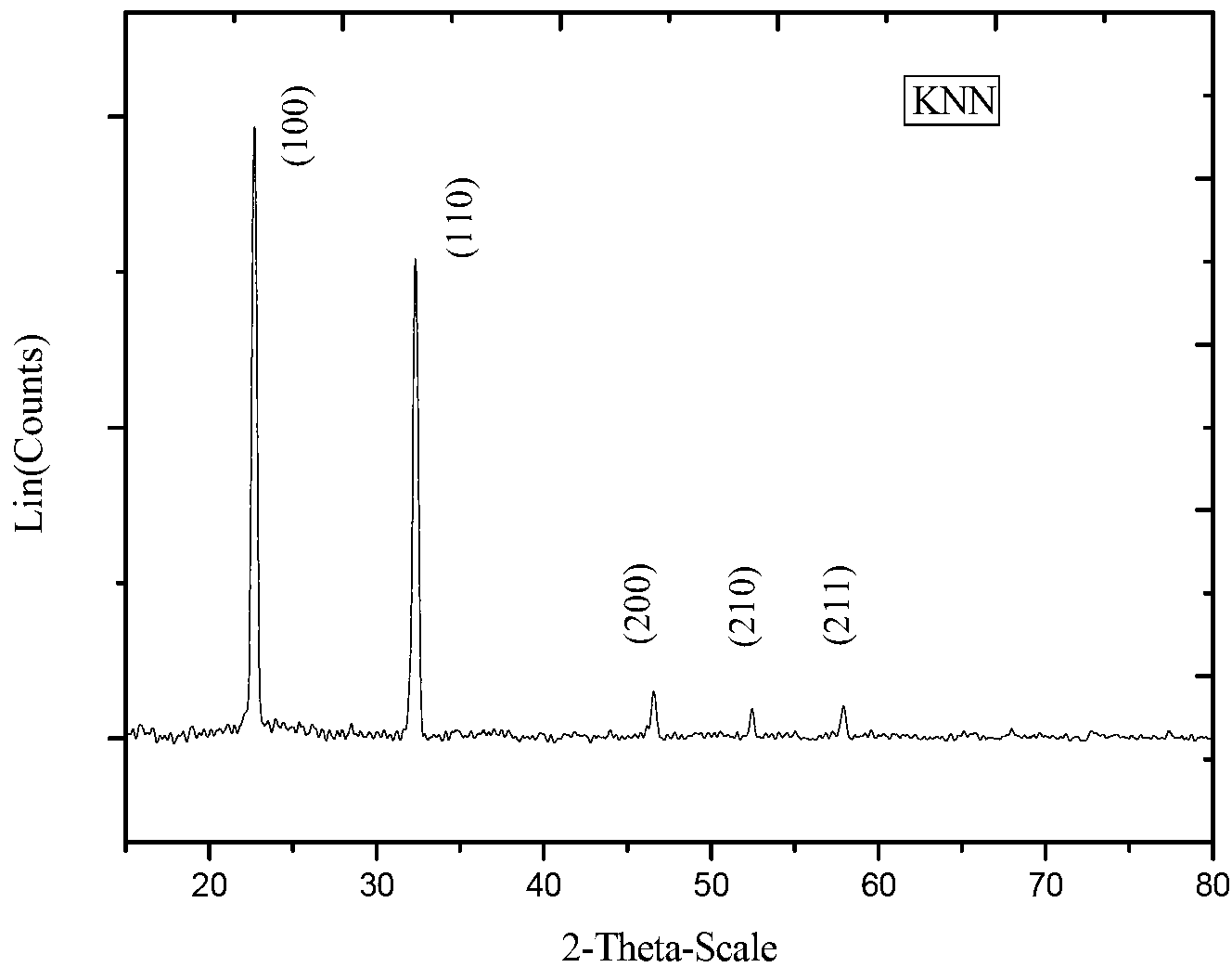

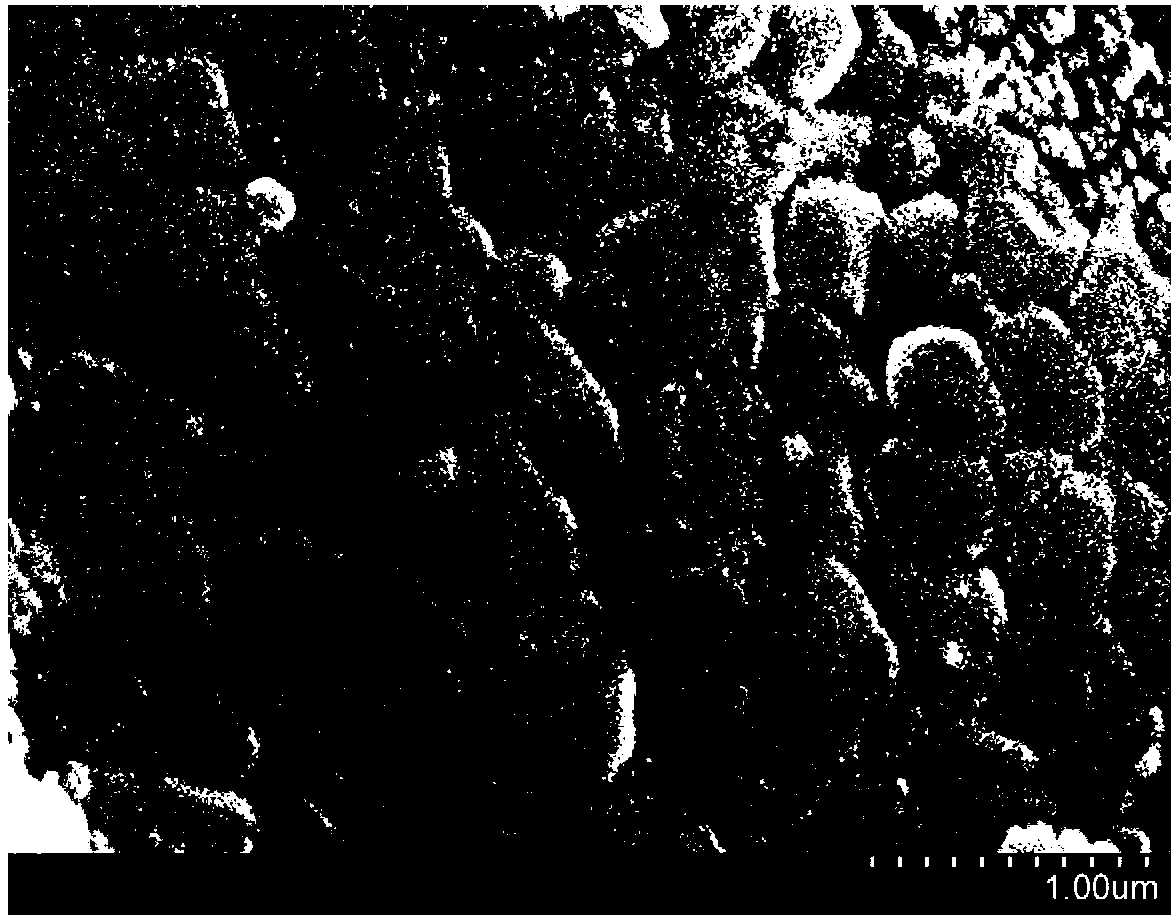

Method for preparing potassium sodium niobate functional ceramic film on glass base surface by using laser

The invention relates to a method for preparing a potassium sodium niobate functional ceramic film on a glass base surface by using a laser, belonging to the field of electronic functional ceramic preparation. The method comprises the following steps: selecting raw materials, weighing according to the stoichiometric proportion of Na0.5K0.5NbO3, mixing, carrying out ball milling, presintering at 800 DEG C for two hours by the traditional molten salt method to prepare the required functional ceramic powder; and evenly mixing and flatly laying ceramic powder and PVA (polyvinyl alcohol) on a glass base surface, drawing the functional ceramic film with required shape and dimension by using control software of the selected laser device, and selecting a pulse laser to directly sinter the powder on the glass base by using proper technological parameters, thereby obtaining the required ceramic film. The invention firstly provides and then directly prepares the potassium sodium niobate piezoelectric ceramic film on the glass base; and the invention is simple and quick to operate and has strong controllability.

Owner:SHENZHEN LONGER3D SCI & TECH

Display device and manufacturing method thereof

ActiveUS20140332774A1Avoid damageNot to damageSolid-state devicesSemiconductor/solid-state device manufacturingDisplay deviceFritted glass

For a display device and manufacturing method for the display device, the method comprises steps of: disposing a plurality of recesses on the cover body; coating glass frit in the recesses; sintering the glass frit for forming sintered blocks; disposing display auxiliary members on the cover body having the sintered blocks formed thereon; and irradiating the sintered blocks by laser to combine the cover and the display substrate with the sintered blocks.The present invention can prevent the display auxiliary members of the cover from being damaged in the packaging process of the display device.

Owner:SHENZHEN CHINA STAR OPTOELECTRONICS TECH CO LTD

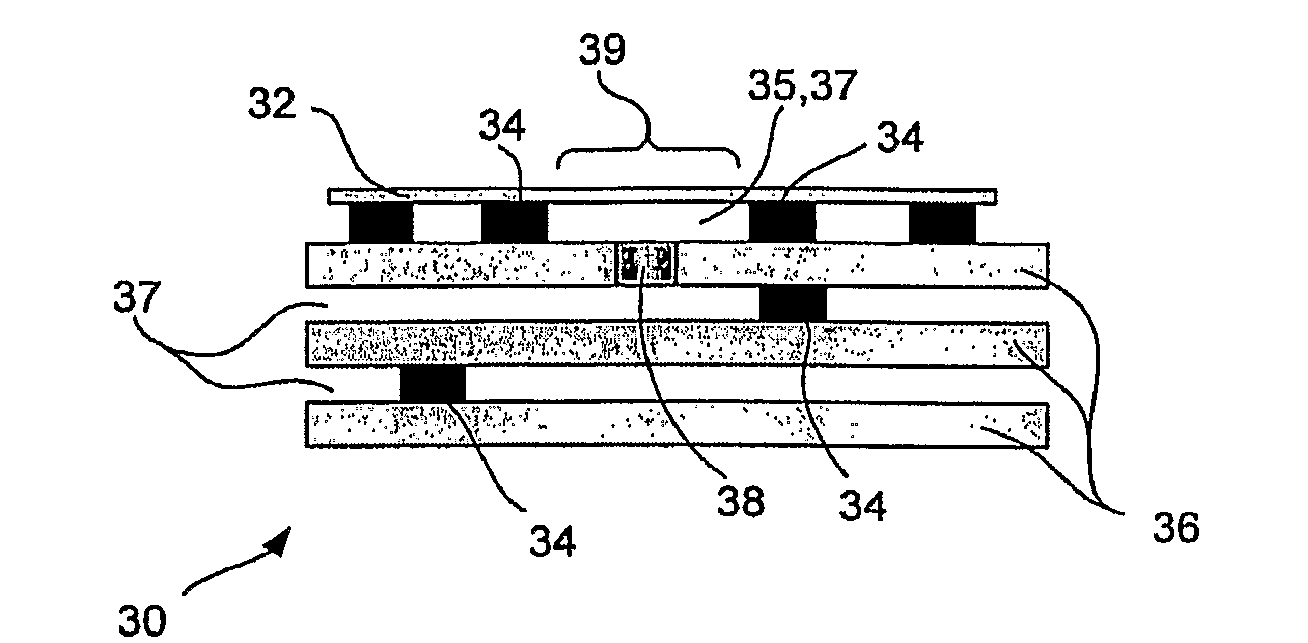

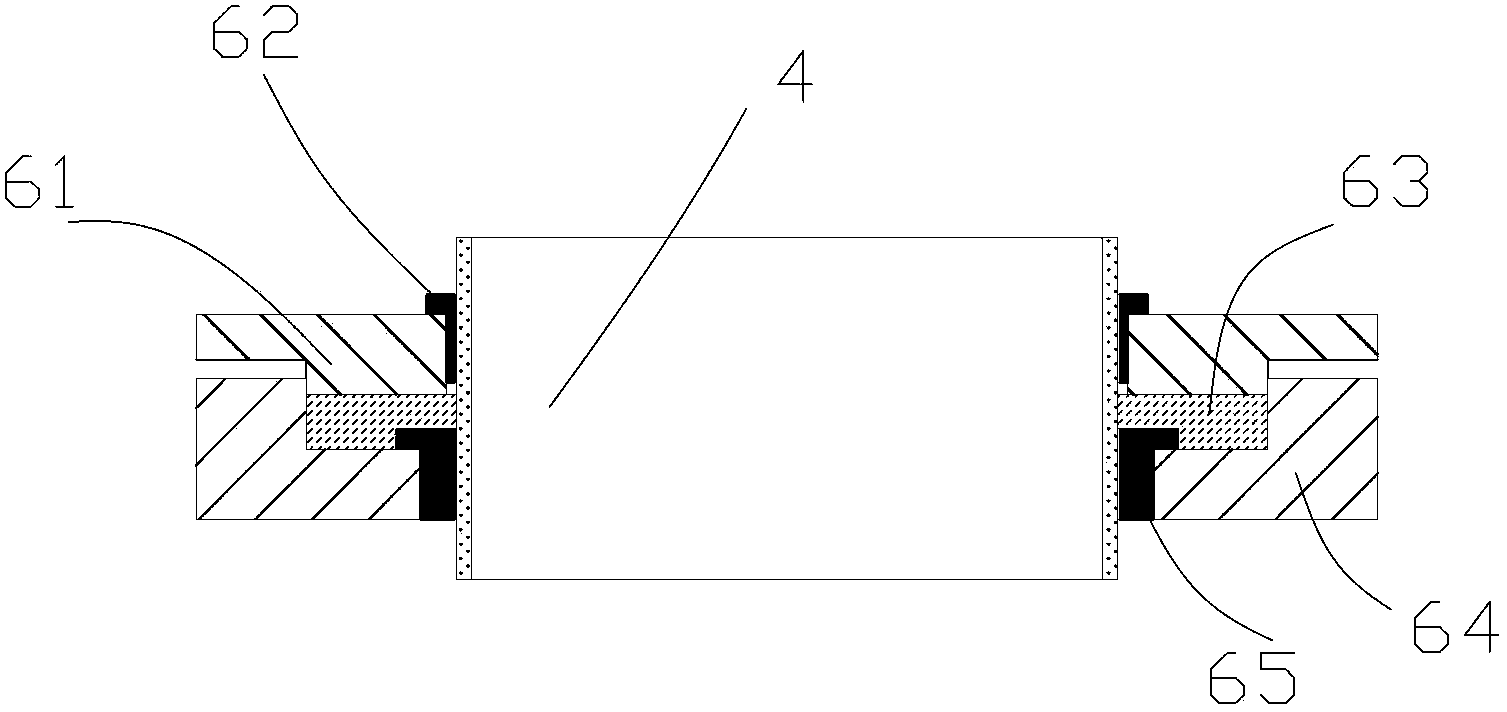

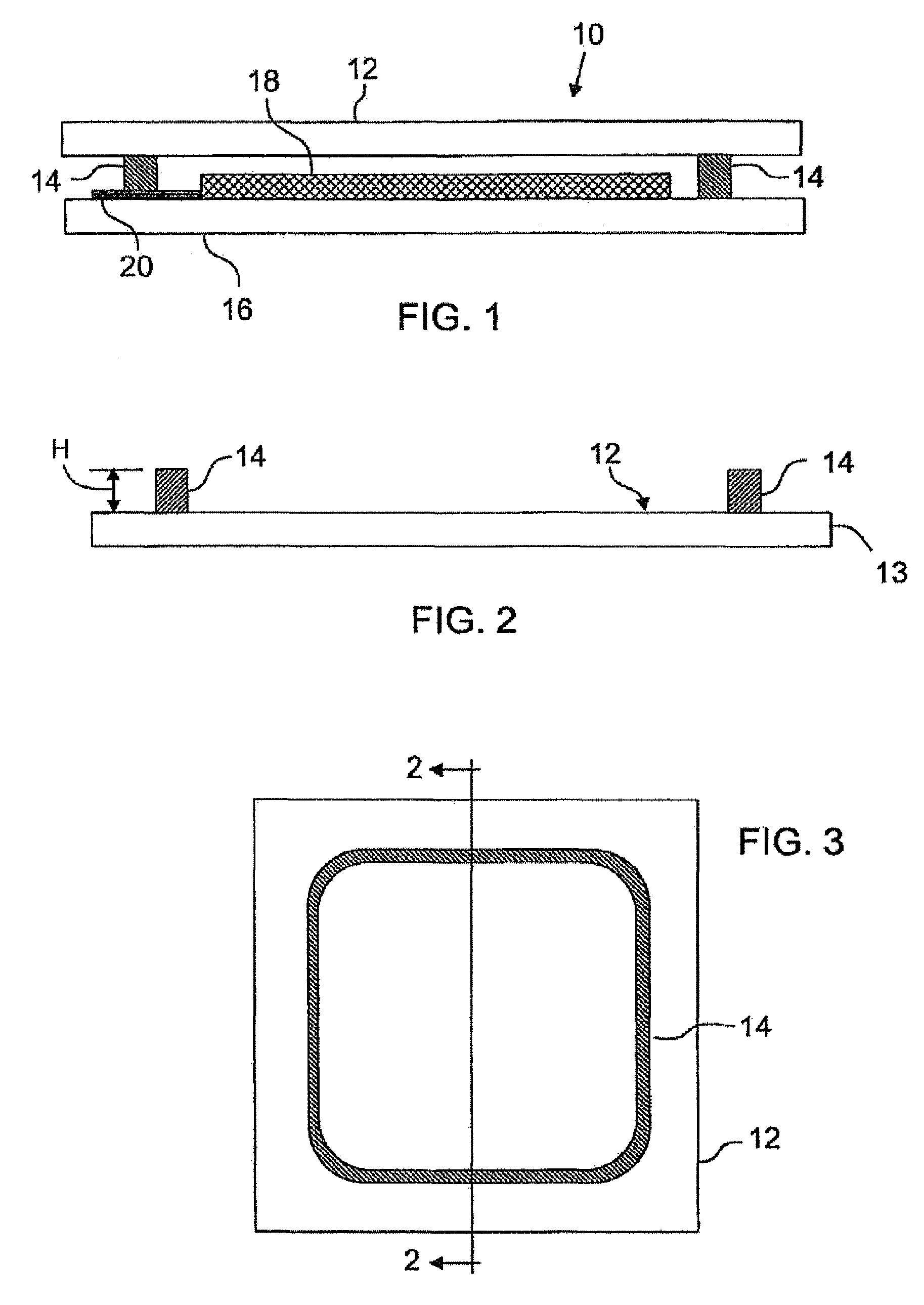

Sintered glass and glass-ceramic structures and methods for producing

ActiveUS8021739B2Simple structureRobust structureSamplingCircuit elementsCeramic sinteringPlanar substrate

A unitary structure (10) is comprised of two or more planar substrates (30, 40) fused together by a glass or glass-ceramic sintered frit structure (20) disposed therebetween. The pattern of the sintered patterned frit material defines passages (70) therein, and the sintered frit structure (20) has a characteristic minimum feature size (60) in a direction parallel to the substrates. Particles of the frit material have a poly-dispersed size distribution up to a maximum frit particle size, in a maximum length dimension, and the minimum feature size or dimension (60) of the sintered patterned frit material is greater than 2 times the maximum frit particle size, desirably about 3 times or more, and less than 6.25 times the maximum frit particle size, desirably about 5 times or less, most desirably about 4 times or less. A method for making the structure (10) is also disclosed.

Owner:CORNING INC

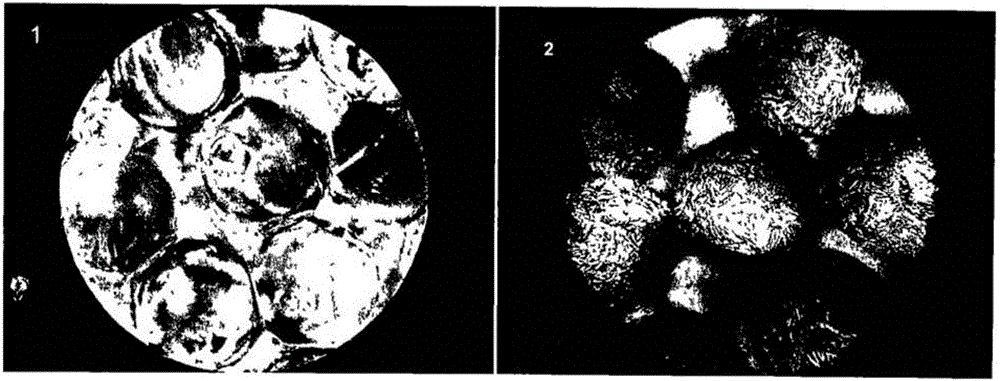

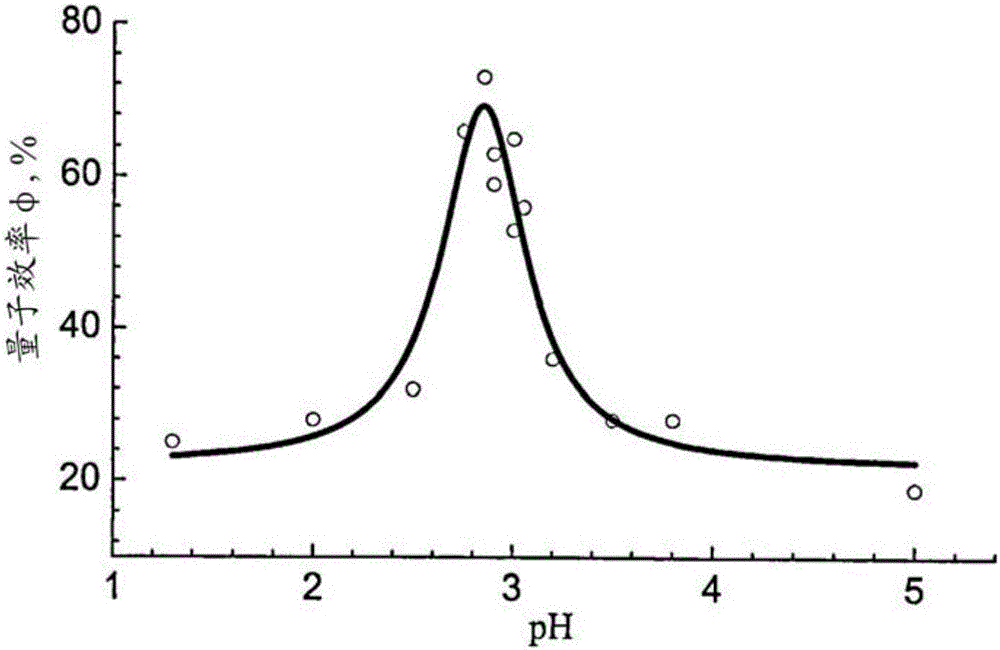

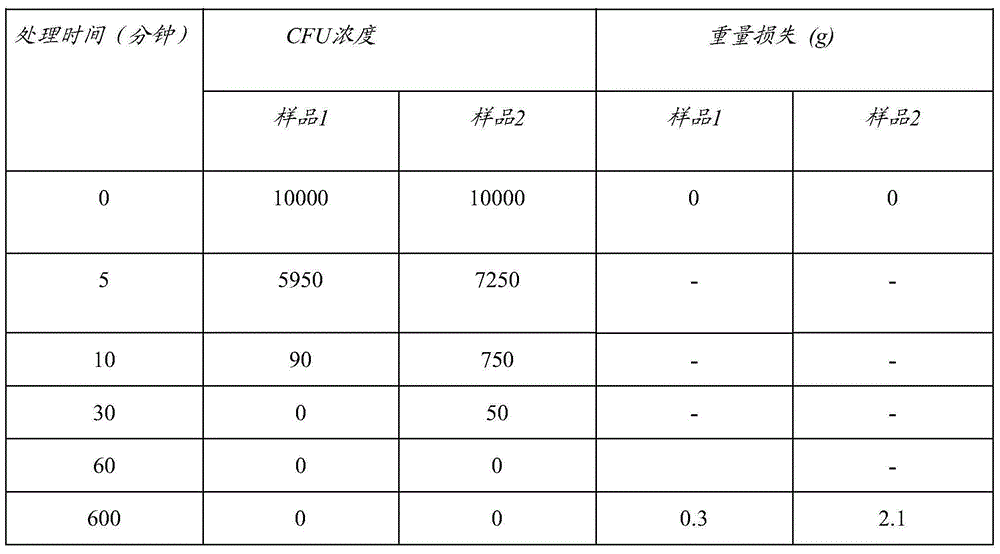

Photocatalytic element for purification and disinfection of air and water and method for the production thereof

The invention relates to the field of purification and disinfection of air and water. A photocatalytic ele -ment consists of sintered glass beads with a pore volume fraction from 20% to 40% and a pore size from 0.1 to 0.5 mm, the surface of which is coated with a titanium dioxide powder, having a specific surface area of 150-400 m 2 / g, at the rate of 0.5-2%o relative to the total mass of the photocatalytic element. Furthermore, the surface of the glass beads has a relief shape with a relief depression of 0.5-10 urn. The method for producing the photocatalytic element comprises sintering the glass beads at a temperature that is 5-20°C higher than the glass softening temperature, modifying the bead surface with chemical etching agents, and coating the bead surface with the titanium dioxide powder from a water suspension at a pH of 2.9±0.1. The invention provides for the production of a photocatalytic element that is characterised by a strong adhesion and retention of the titanium dioxide powder on the surface of the carrier in the flow of a medium which is subjected to purification, and that has a high photocatalytic activity

Owner:克拉斯内波列有限责任公司

Frit-containing pastes for producing sintered frit patterns on glass sheets

Pastes for use in producing sintered frit patterns (14) on glass sheets (12), such as the glass sheets used as covers for OLED (18) display devices (10), are provided. The pastes include glass particles, filler particles, and a vehicle. The sizes of the filler and / or glass particles are reduced compared to prior art pastes. Reductions in porosity and surface roughness of sintered frits produced using the pastes, as well as improvements in the available process window for producing OLED packages and the hermeticity and strength of those packages, are reported.

Owner:CORNING INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com