Photocatalytic element for purification and disinfection of air and water and method for the production thereof

A photocatalytic and component technology, applied in chemical instruments and methods, physical/chemical process catalysts, separation methods, etc., can solve the problems of short service life of photocatalytic components, lack of pH value, and unacceptable control.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

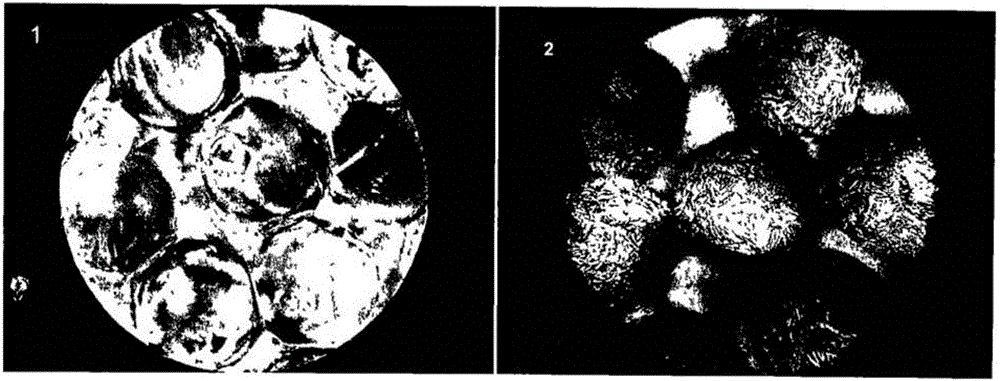

[0042] Glass beads (0.8 mm to 1 mm portion) were poured to fill a cylindrical detachable stainless steel housing having an outer diameter of 86 mm, a width of 6 mm and a height of 420 mm. The shell was placed in an oven where sintering of the glass beads was carried out at a temperature of 15° C. above the glass softening point (about 690° C.) for 1 hour and 20 minutes. After cooling to room temperature, the housing was disassembled and the resulting support in the form of a porous glass tube was removed.

[0043] The support surface was then modified by first immersing in concentrated hydrofluoric acid for 1 min, then rinsing with water, then treating with concentrated sulfuric acid for 3 min, rinsing with water, and drying in an oven at 100°C until completely dehydrated.

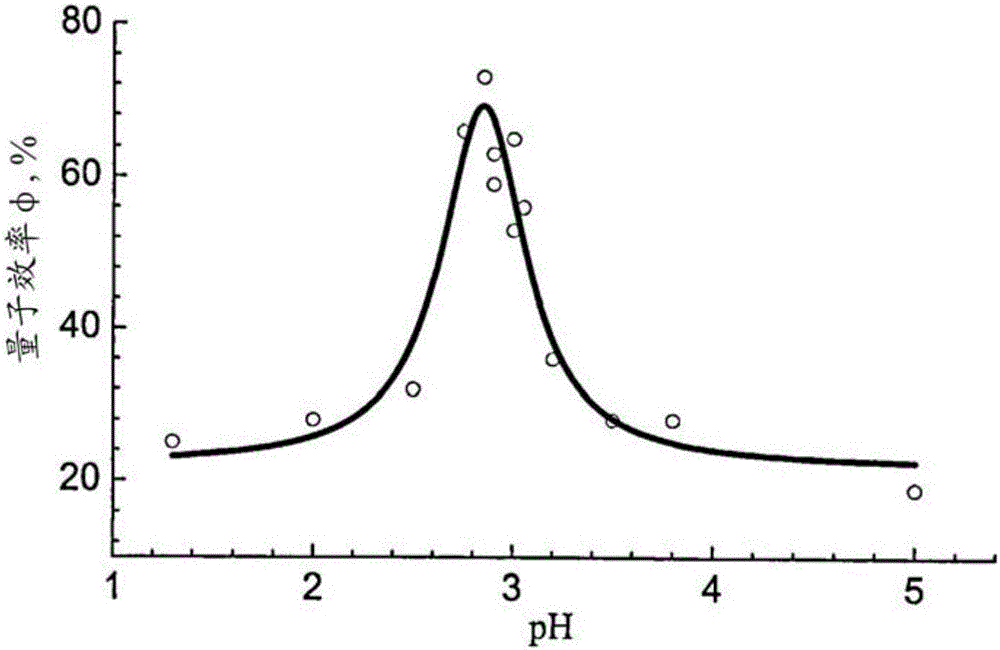

[0044] The aqueous suspension is made of distilled water and anatase titanium dioxide powder with a specific surface area of 350 м 2 / g and the weight percent content of titanium dioxide is 10%. Dilute...

Embodiment approach 2

[0054] Glass beads (0.8 mm to 1 mm fraction) were poured to fill a flat tube of length 60 mm, width 5 mm and height 400 mm in a detachable stainless steel housing. Further sintering, carrier surface modification and catalyst coating operations are performed in the same manner as in Embodiment Mode 1.

[0055] The completed photocatalytic element contains:

[0056] - a porous support in the form of a parallelepiped with dimensions 400 mm 60 mm 5 mm, comprising sintered glass beads with a modified surface;

[0057] - Anatase titanium dioxide powder with a specific surface area of 350m 2 / g, the dosage is 2g / component.

[0058] A reference test sample was generated in the same way, except that titanium dioxide powder was coated onto the support from a pH=4.5 suspension.

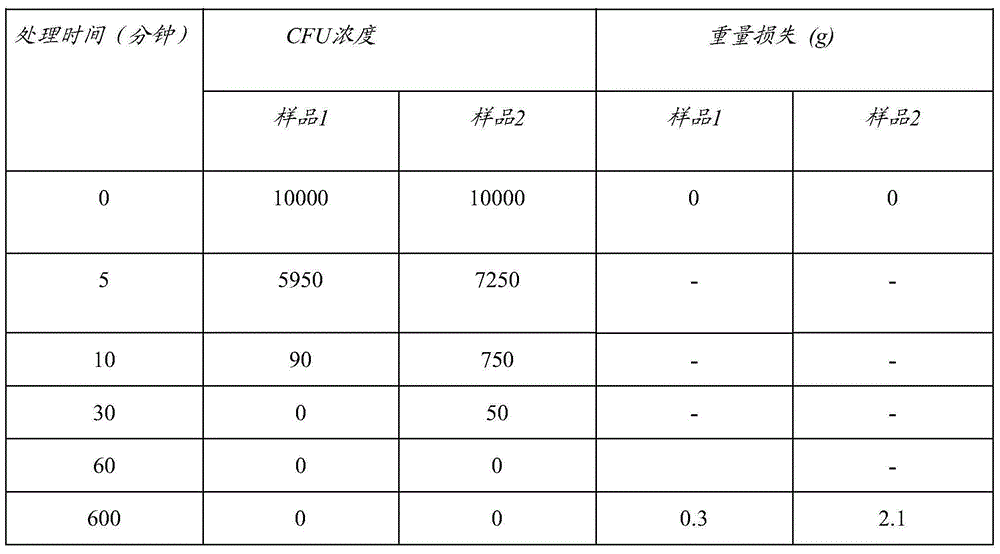

[0059] Table 2

[0060]

[0061] The samples prepared according to this embodiment (main sample No. 3, reference sample No. 4) were tested under the reaction of photocatalytic oxidation of acetone vapor...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com