Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

1809 results about "Polycrystalline diamond" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Polycrystalline Diamond (PCD) is a synthetic diamond product that is produced by sintering together selected diamond particles with a metal matrix using sophisticated technology.

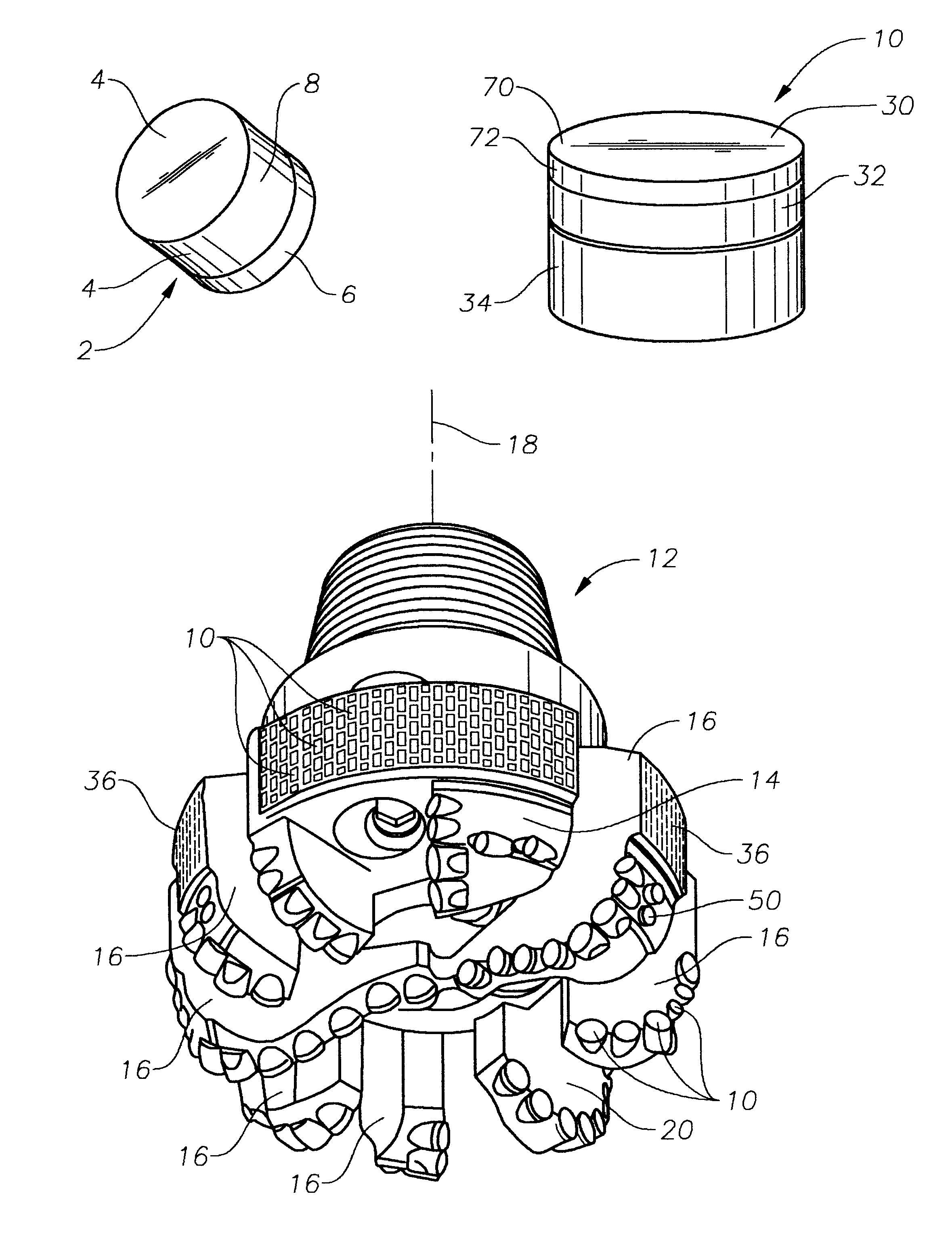

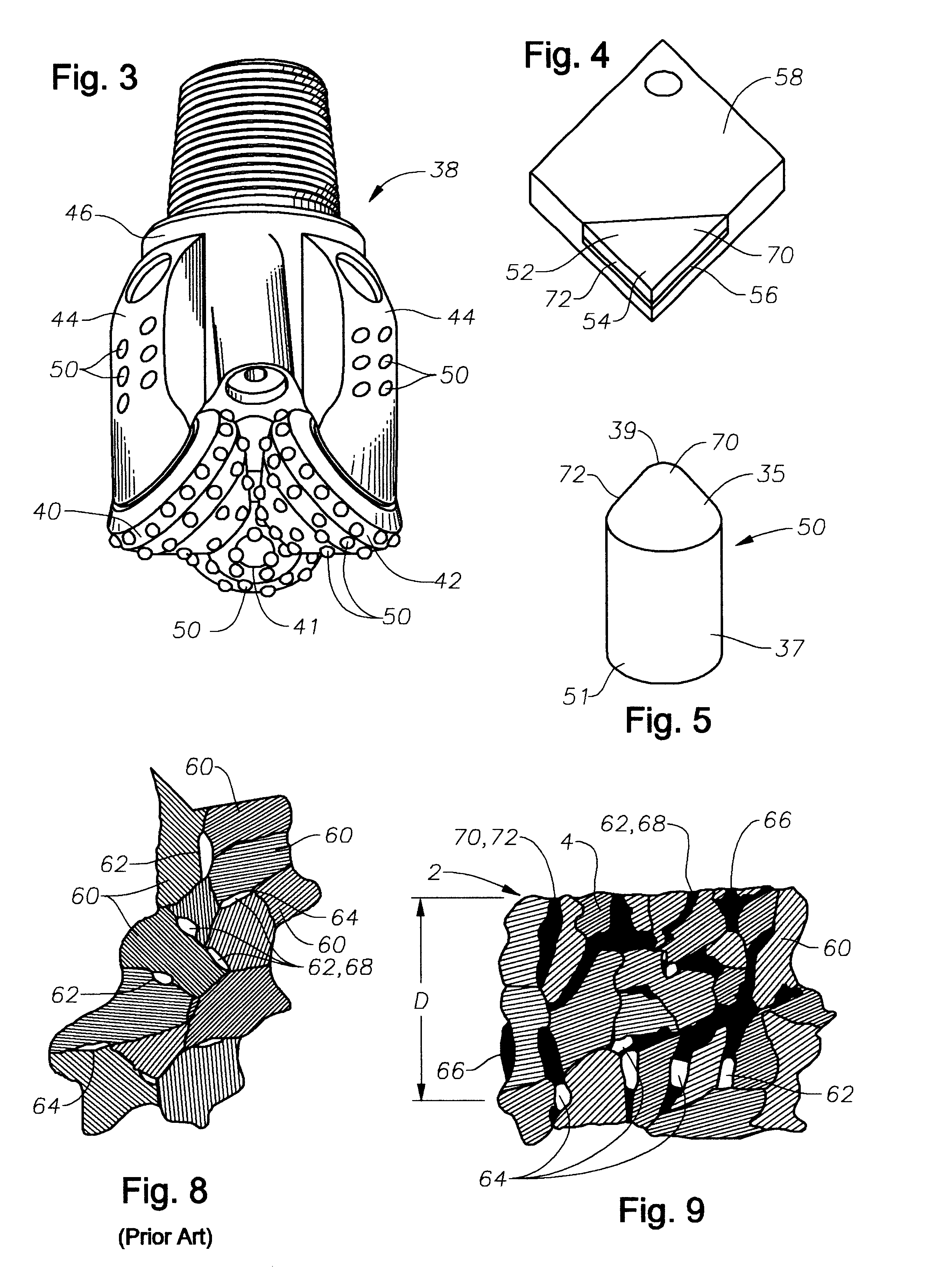

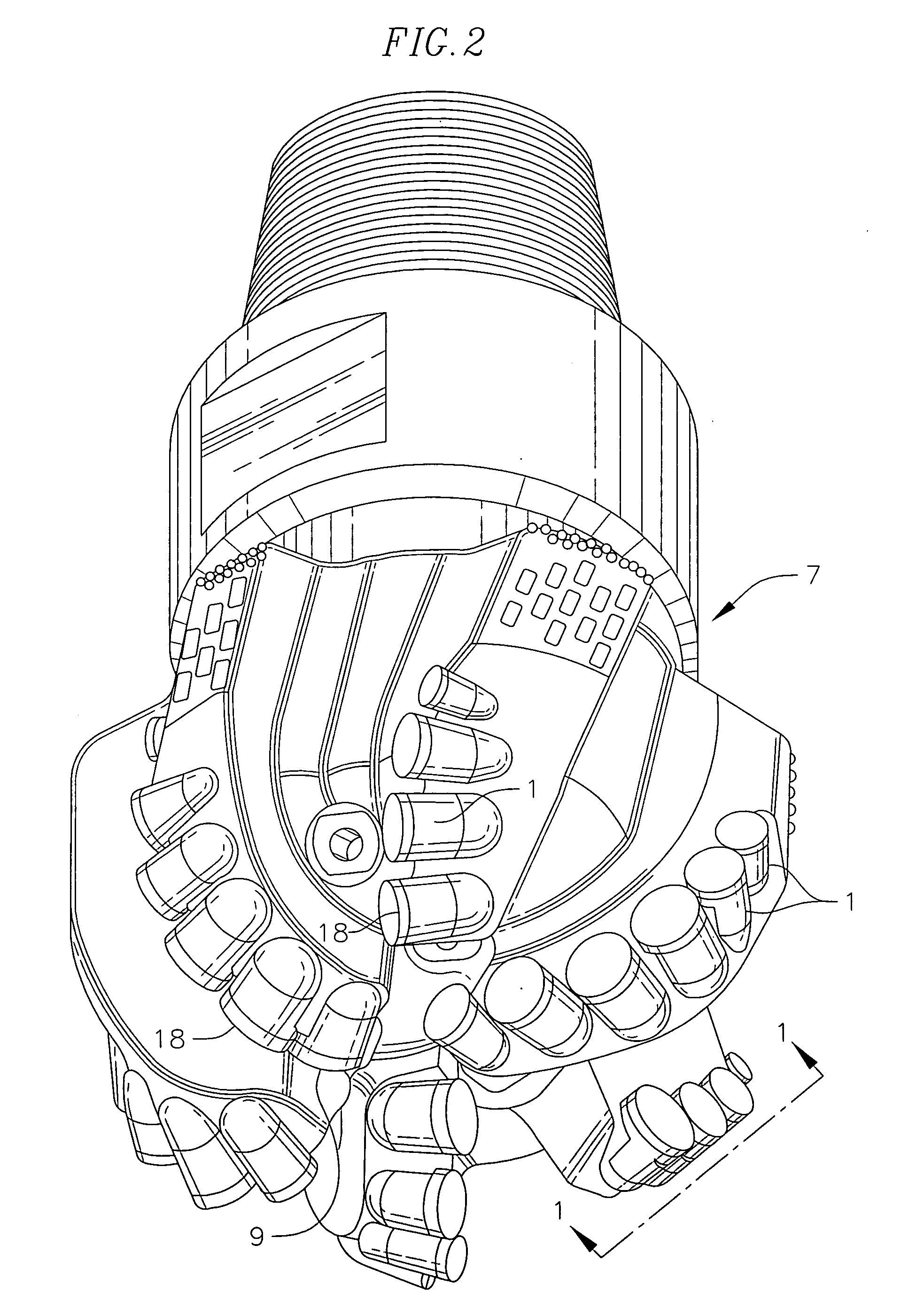

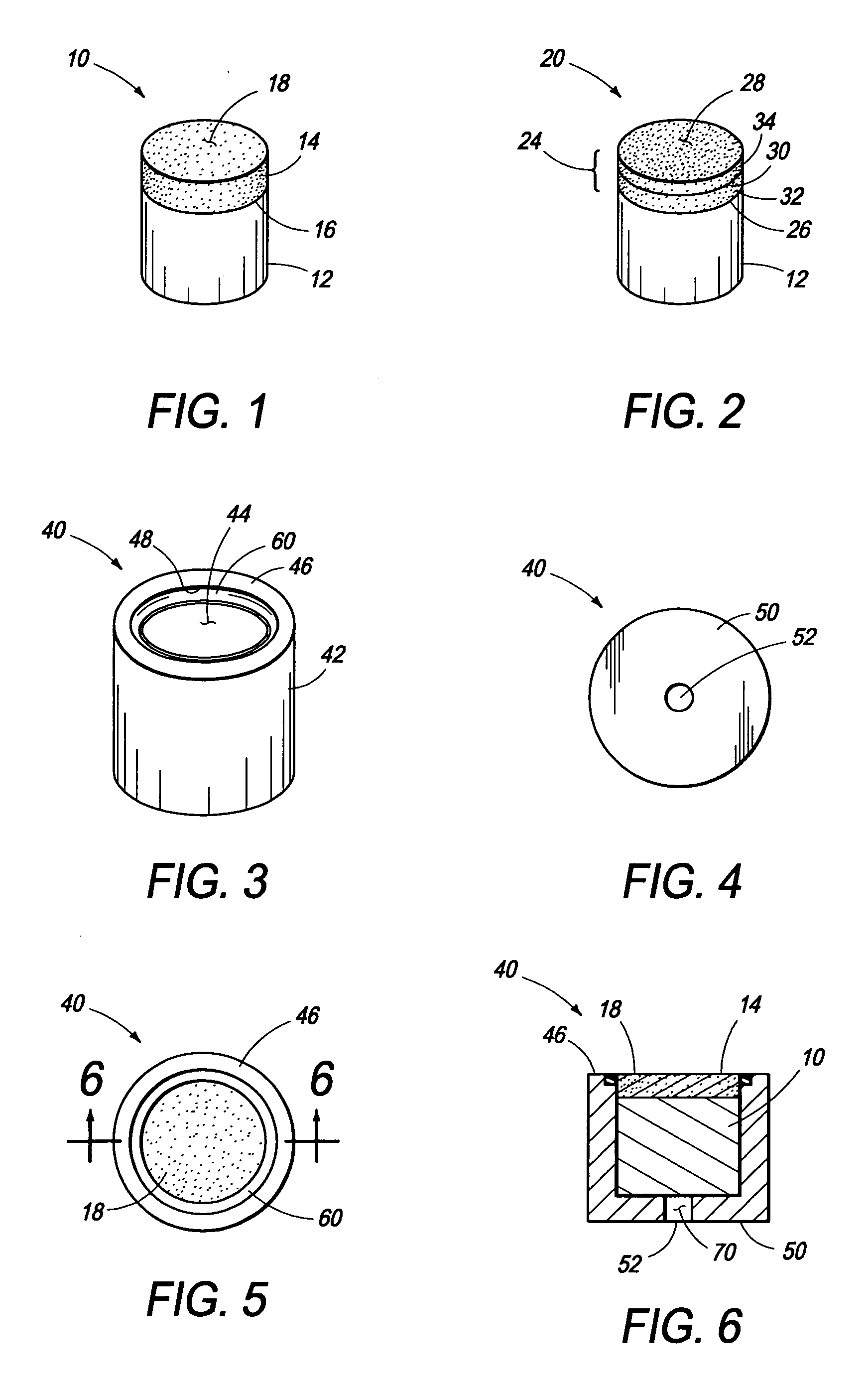

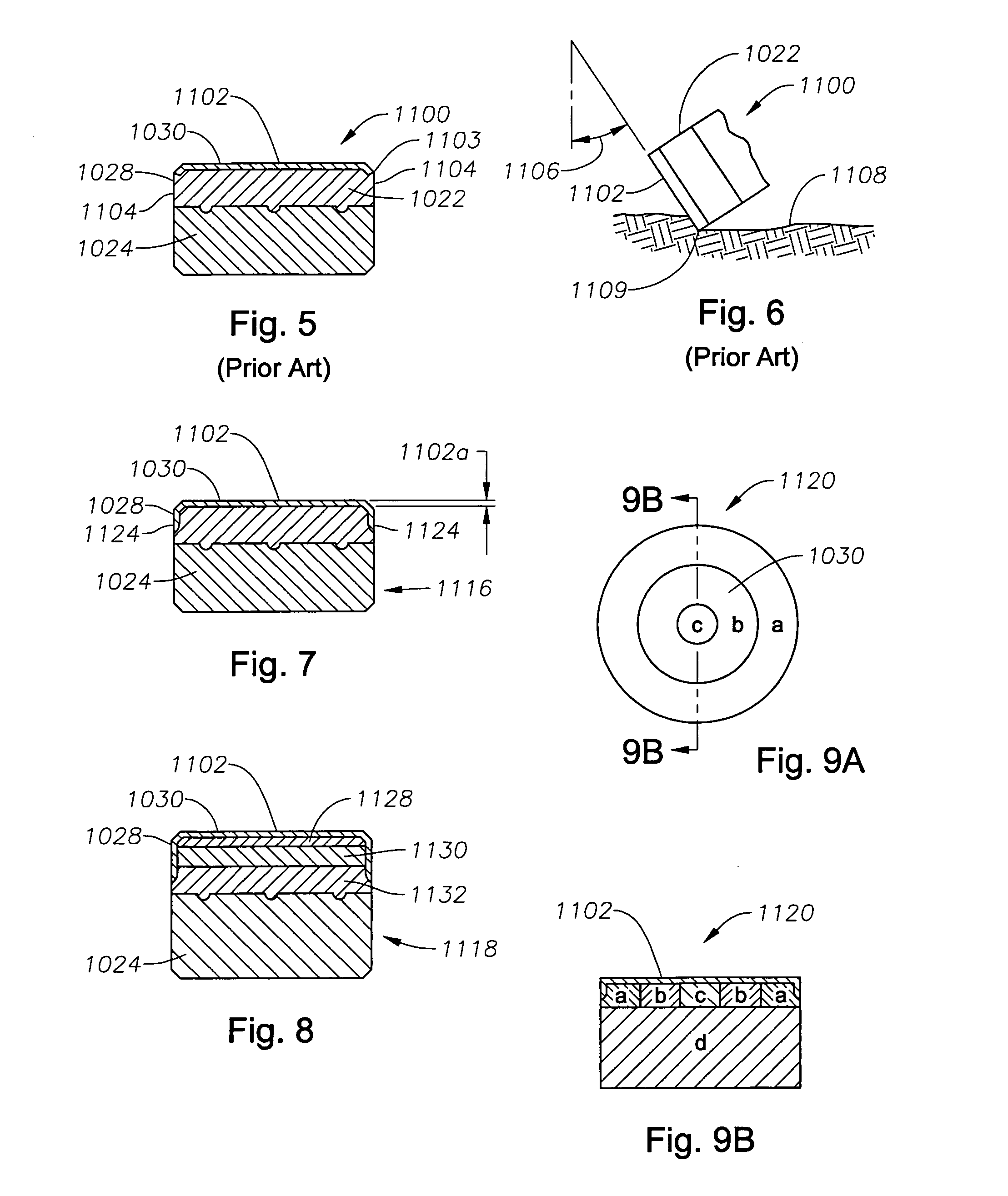

Polycrystalline diamond cutters with working surfaces having varied wear resistance while maintaining impact strength

InactiveUS6601662B2Improve wear resistanceMaintain strengthDrill bitsConstructionsDiamond crystalPolycrystalline diamond

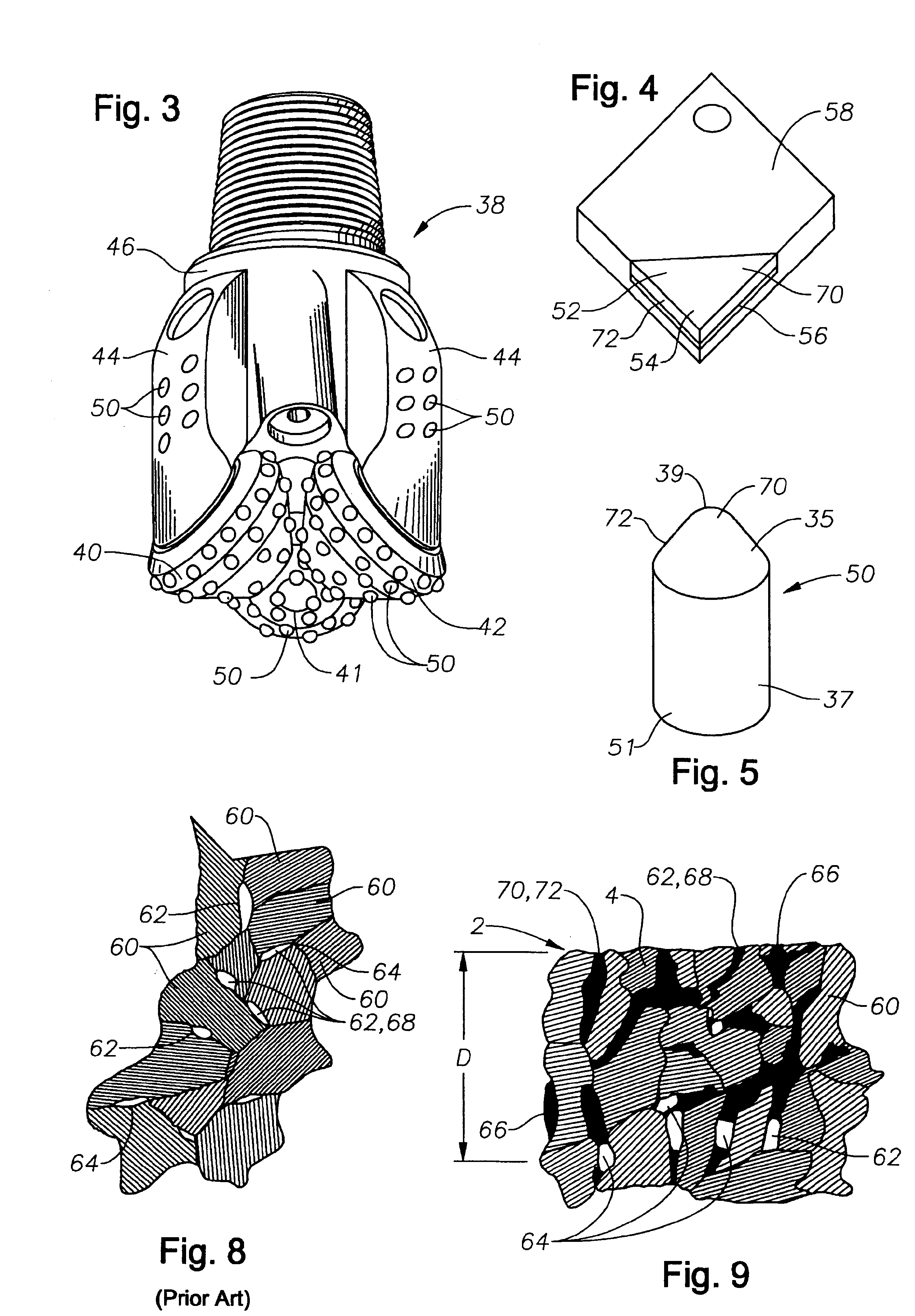

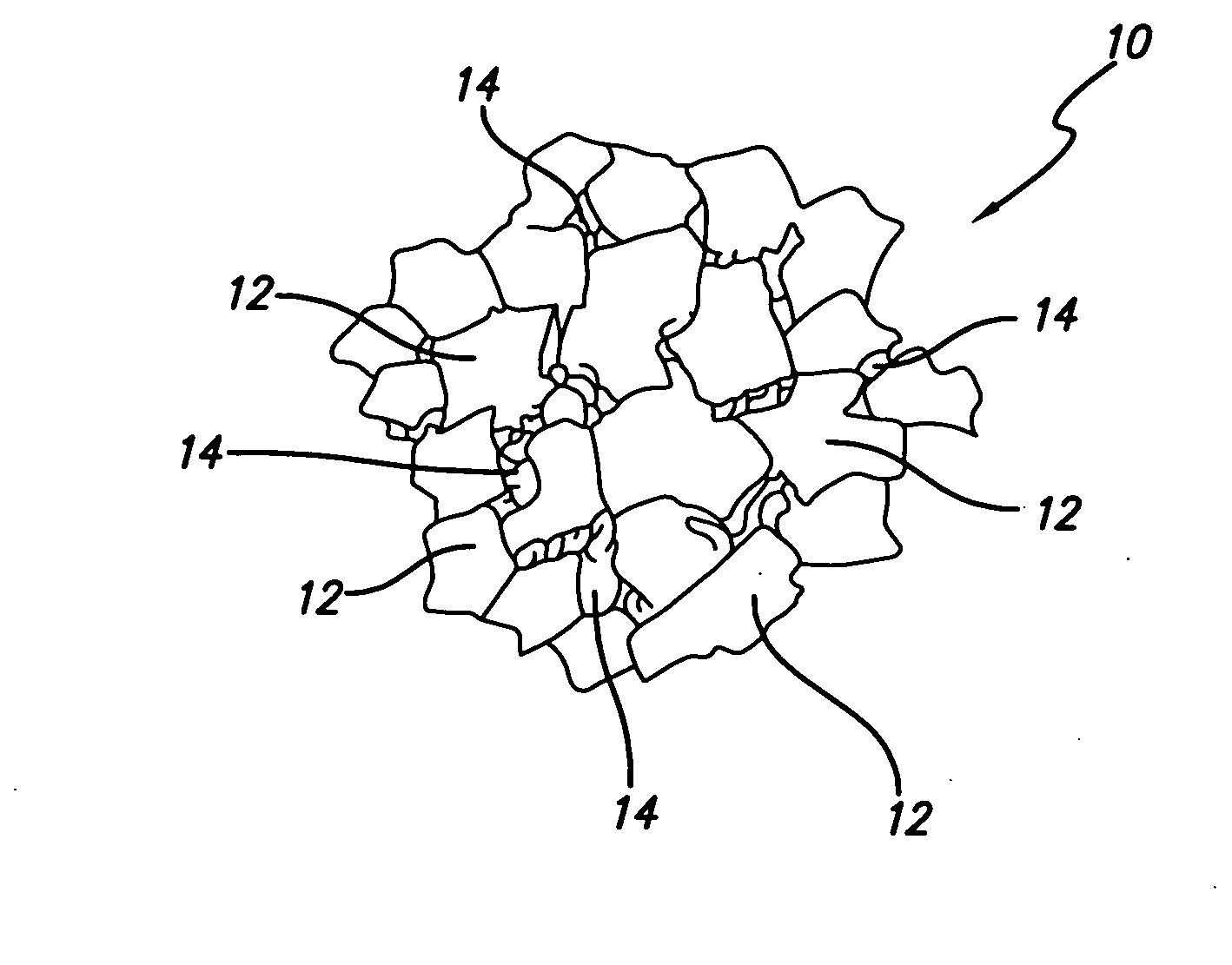

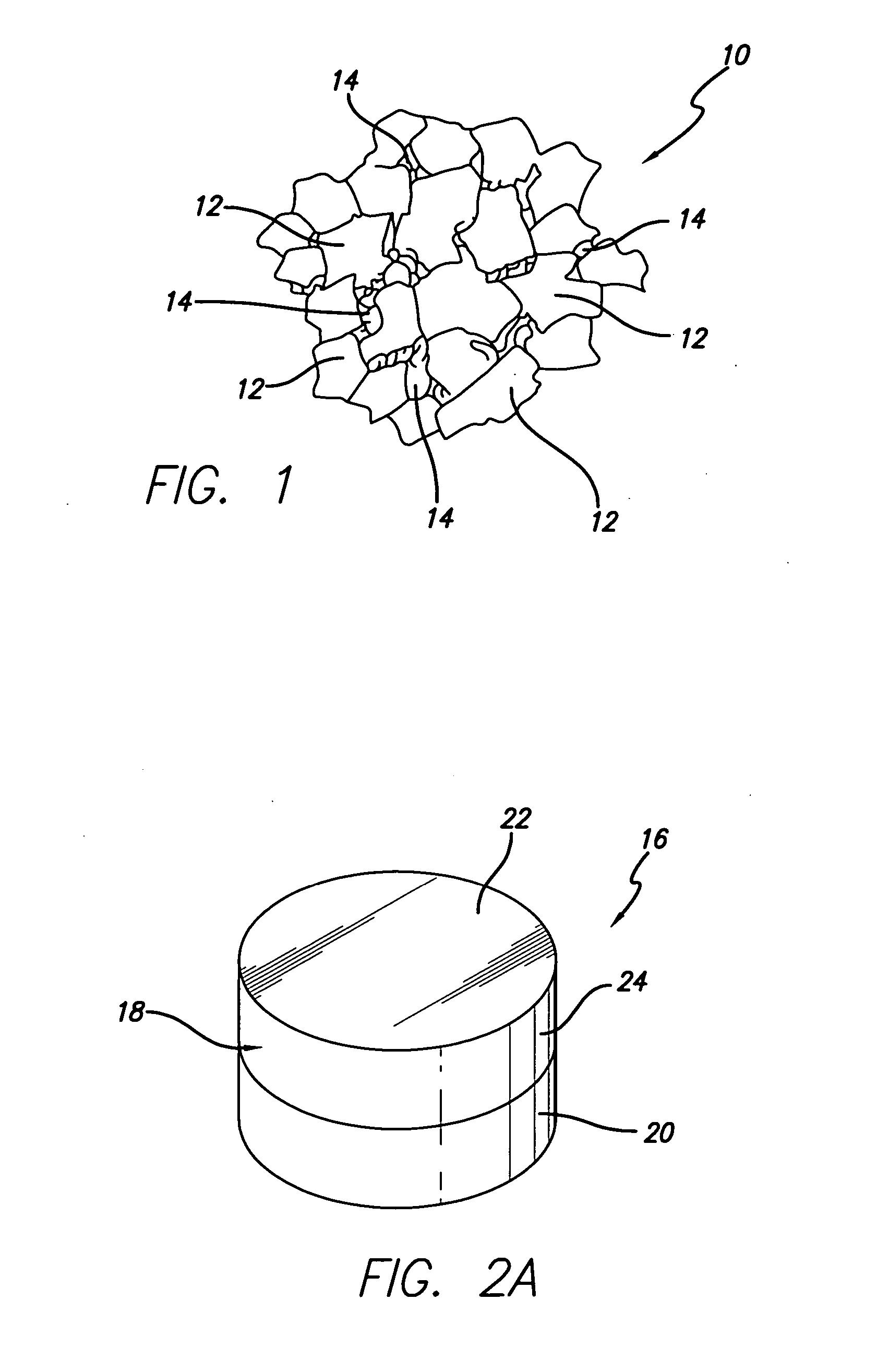

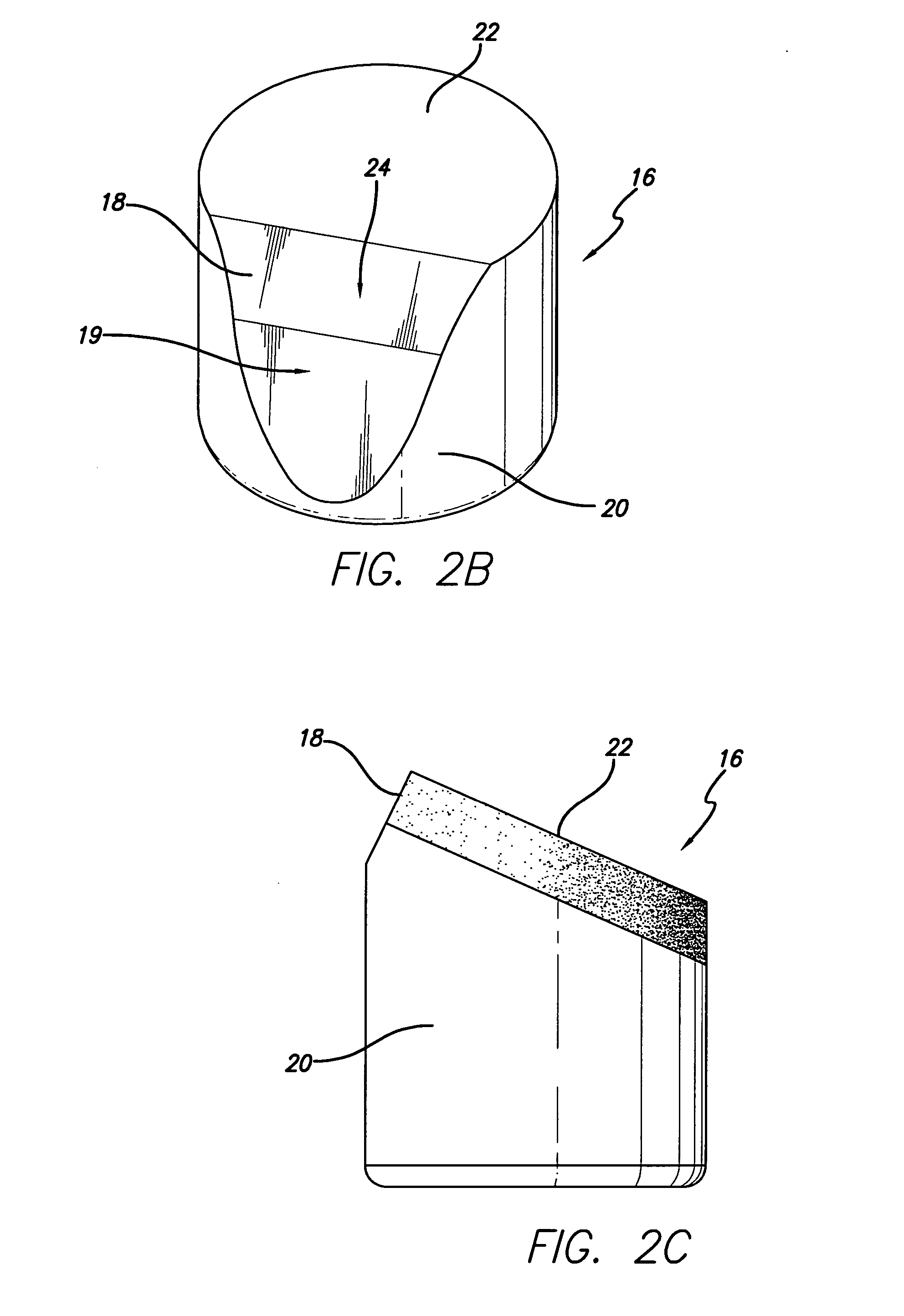

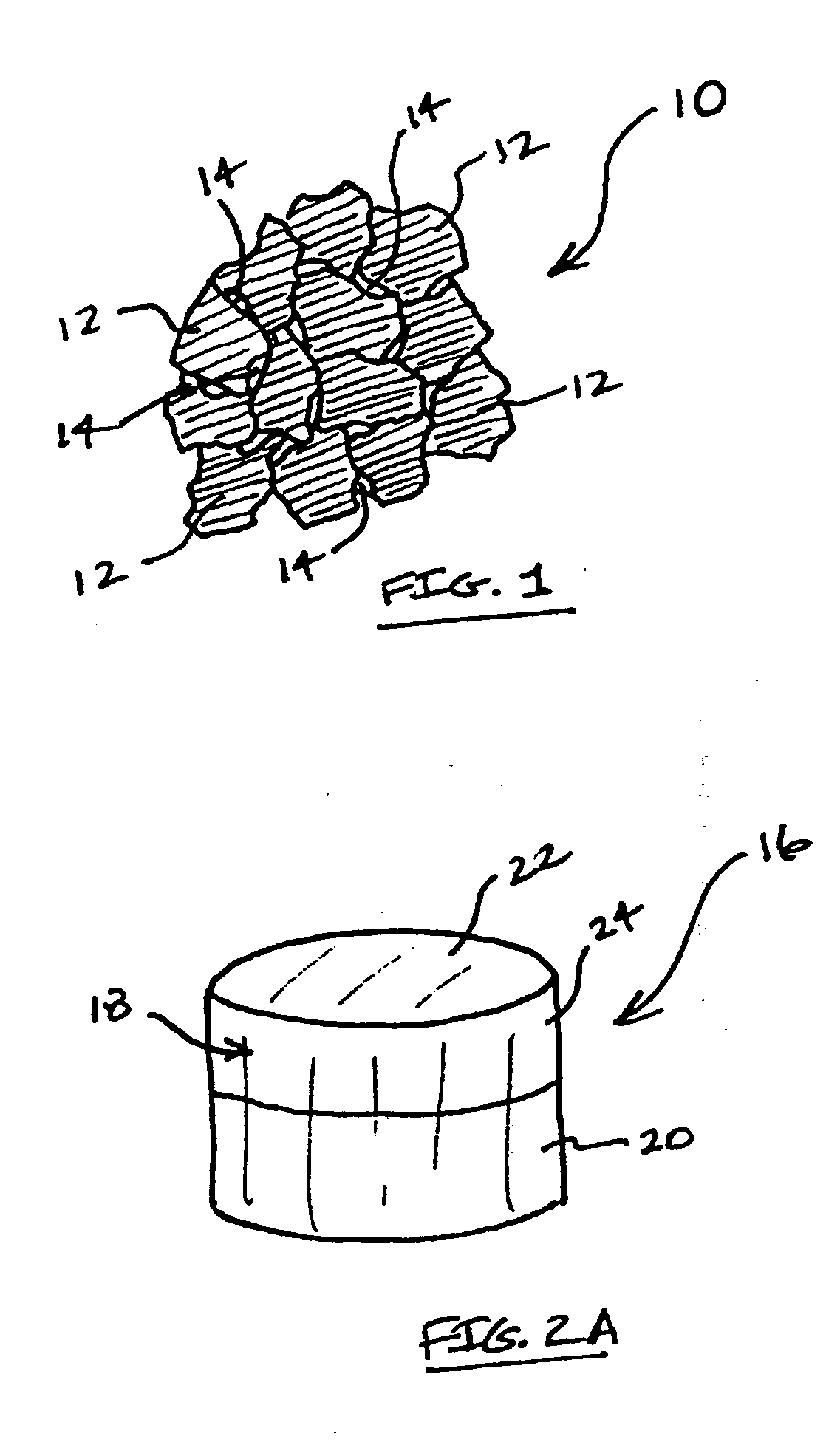

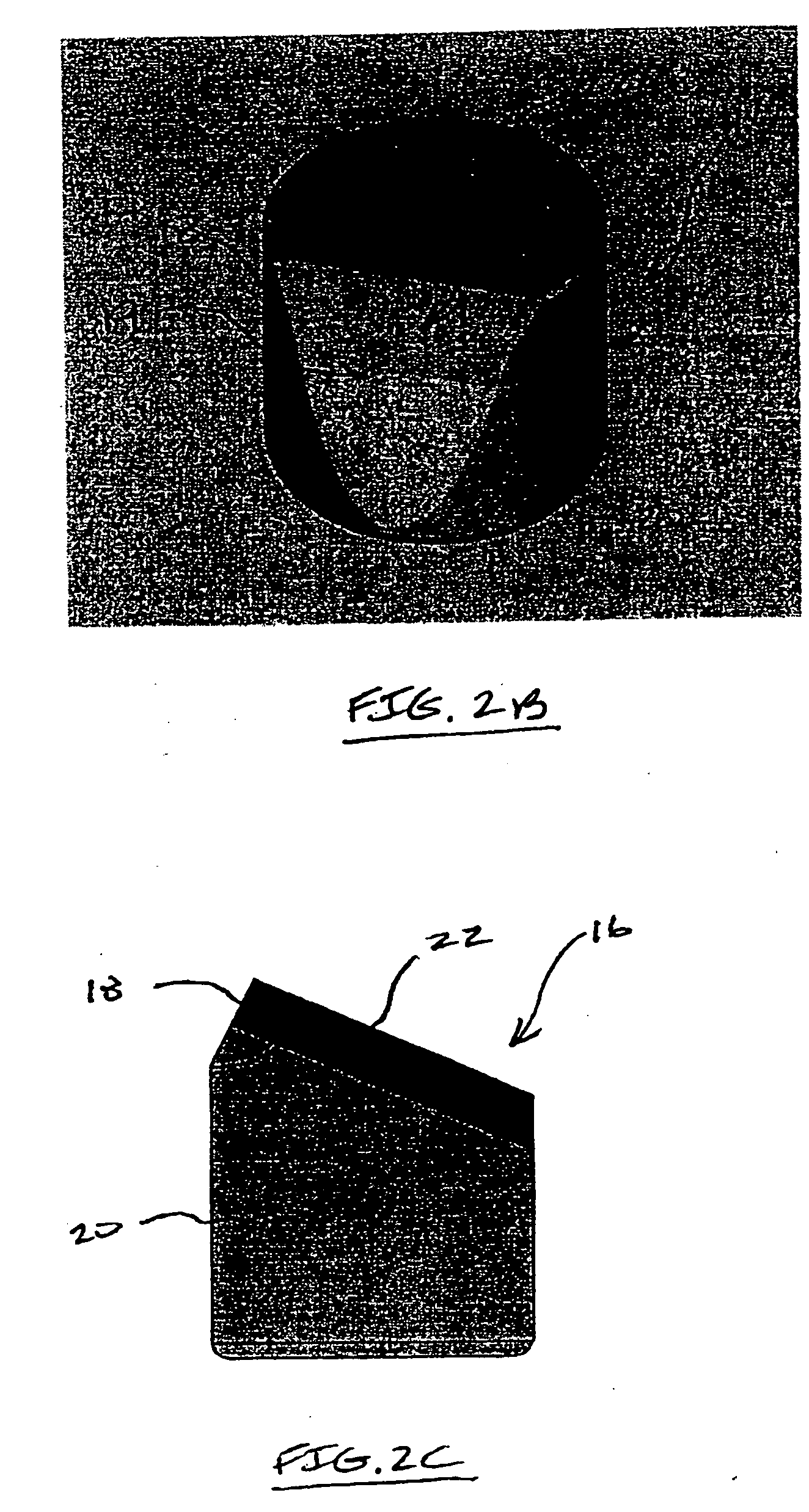

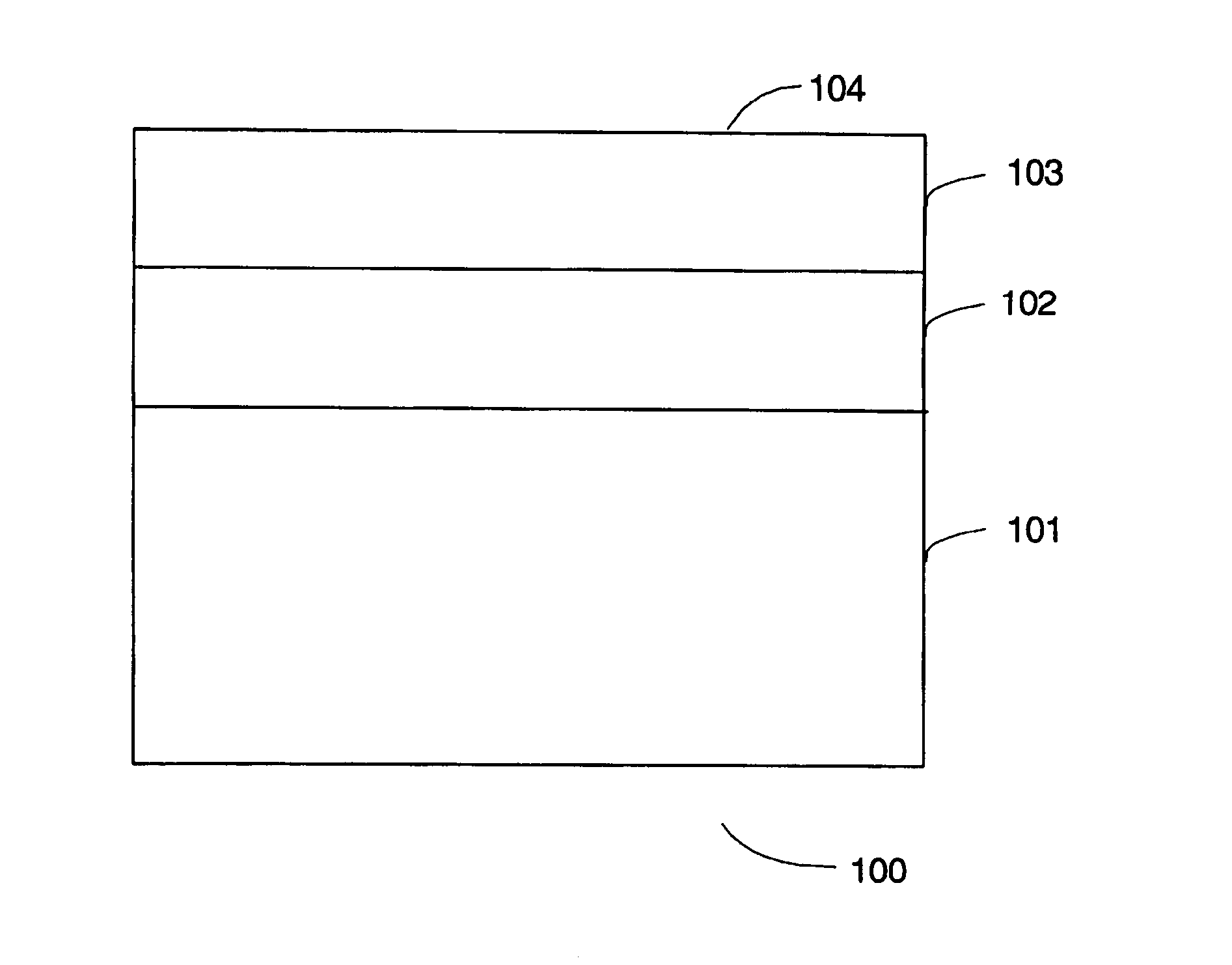

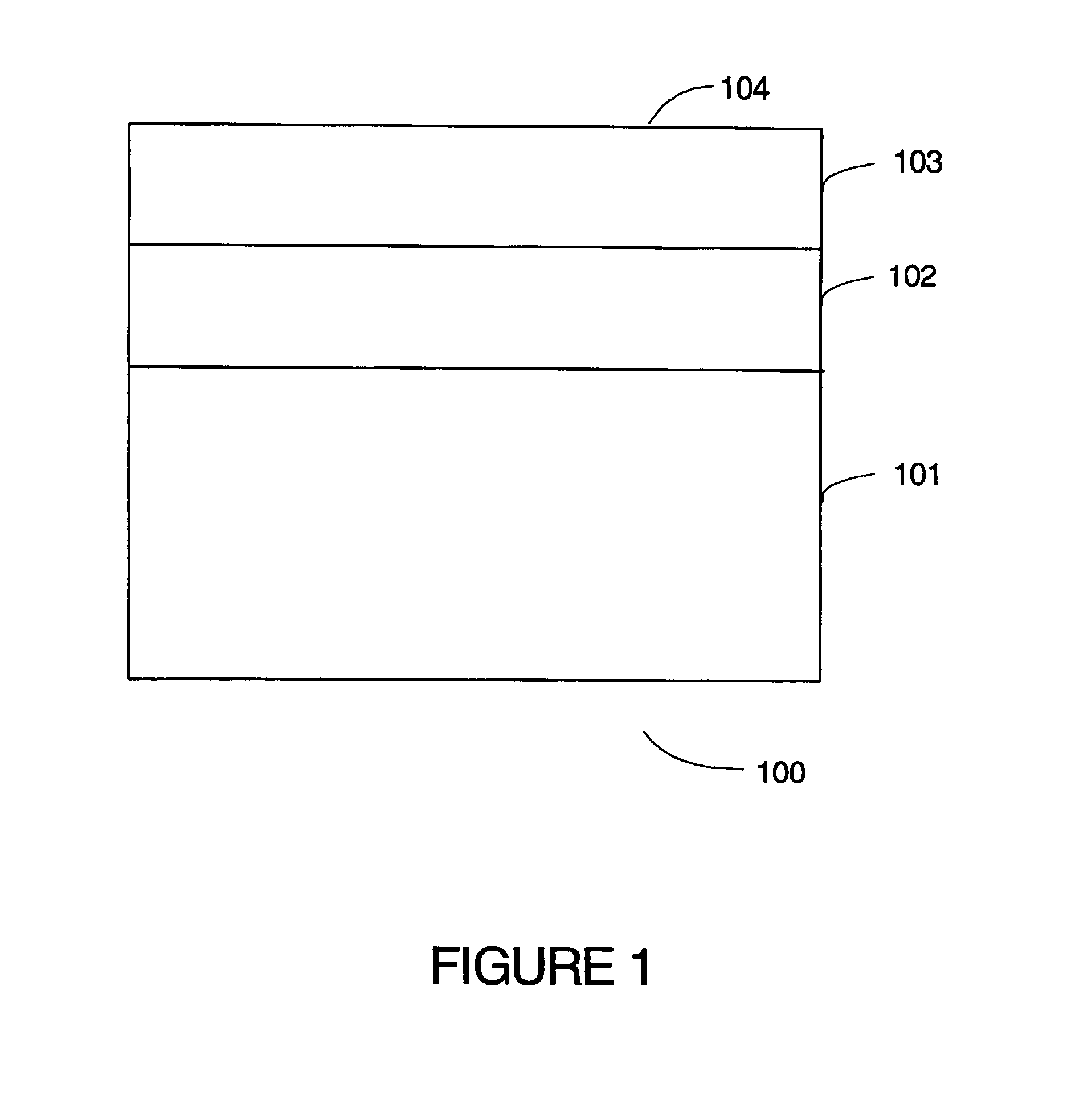

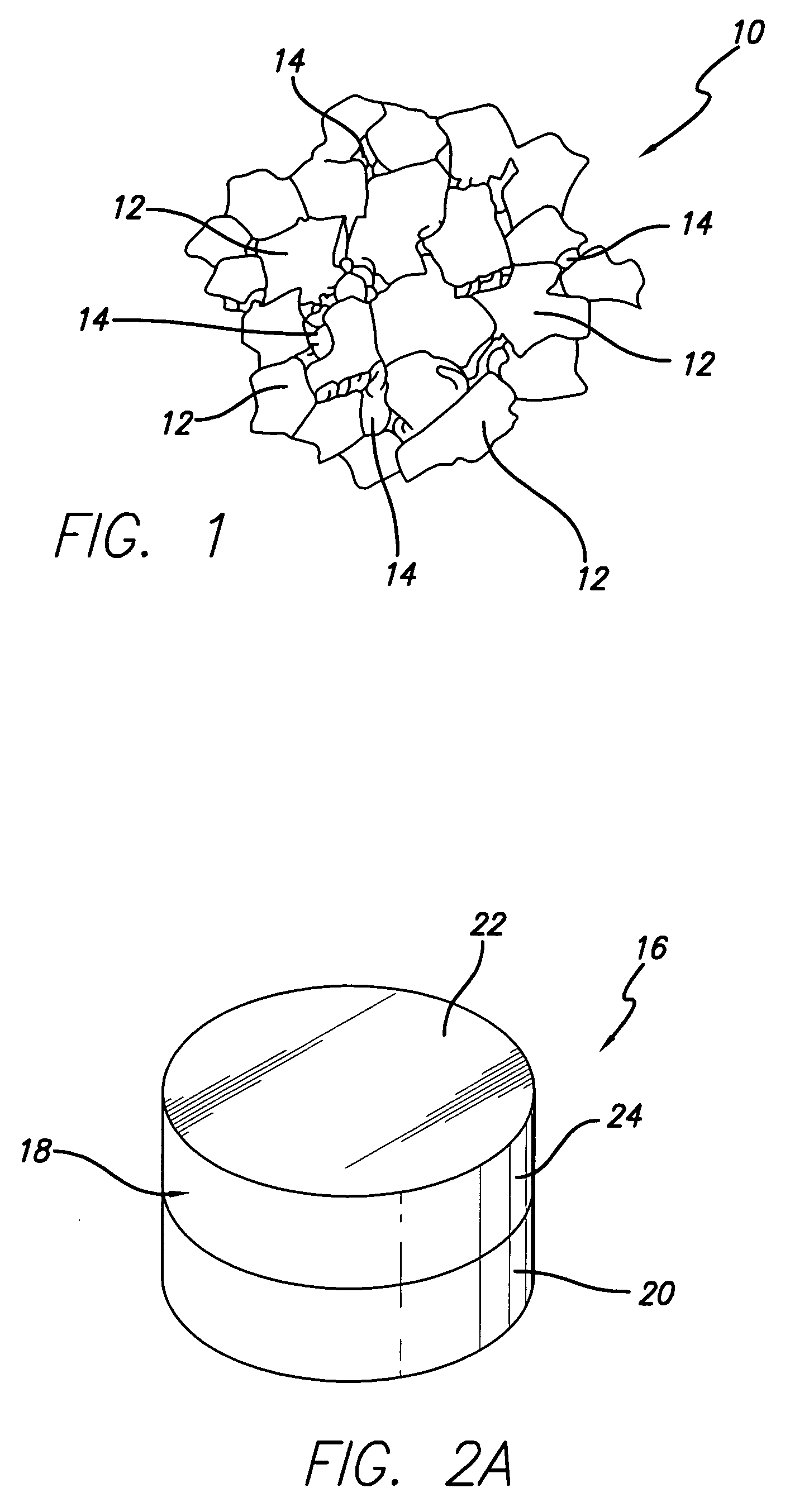

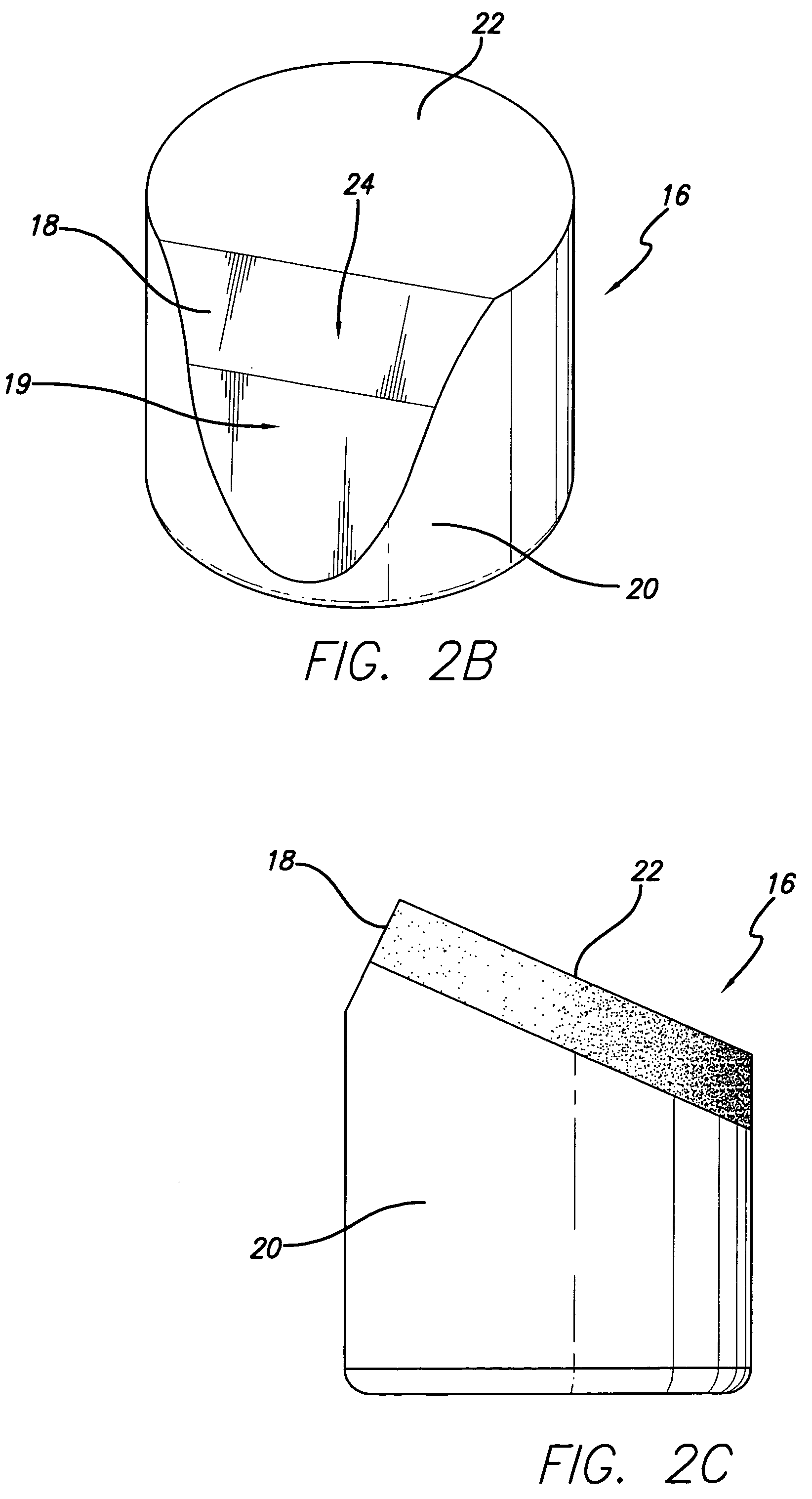

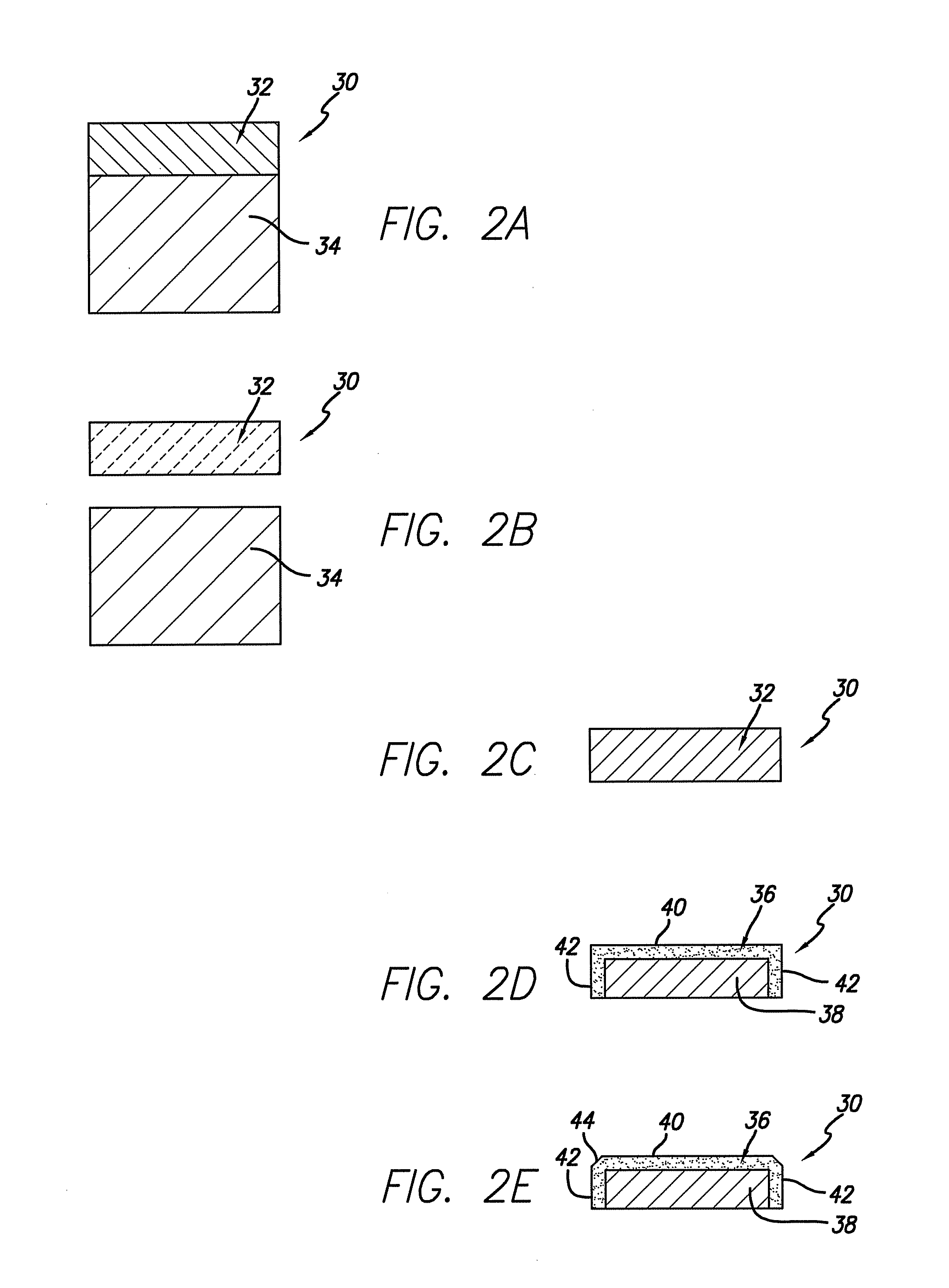

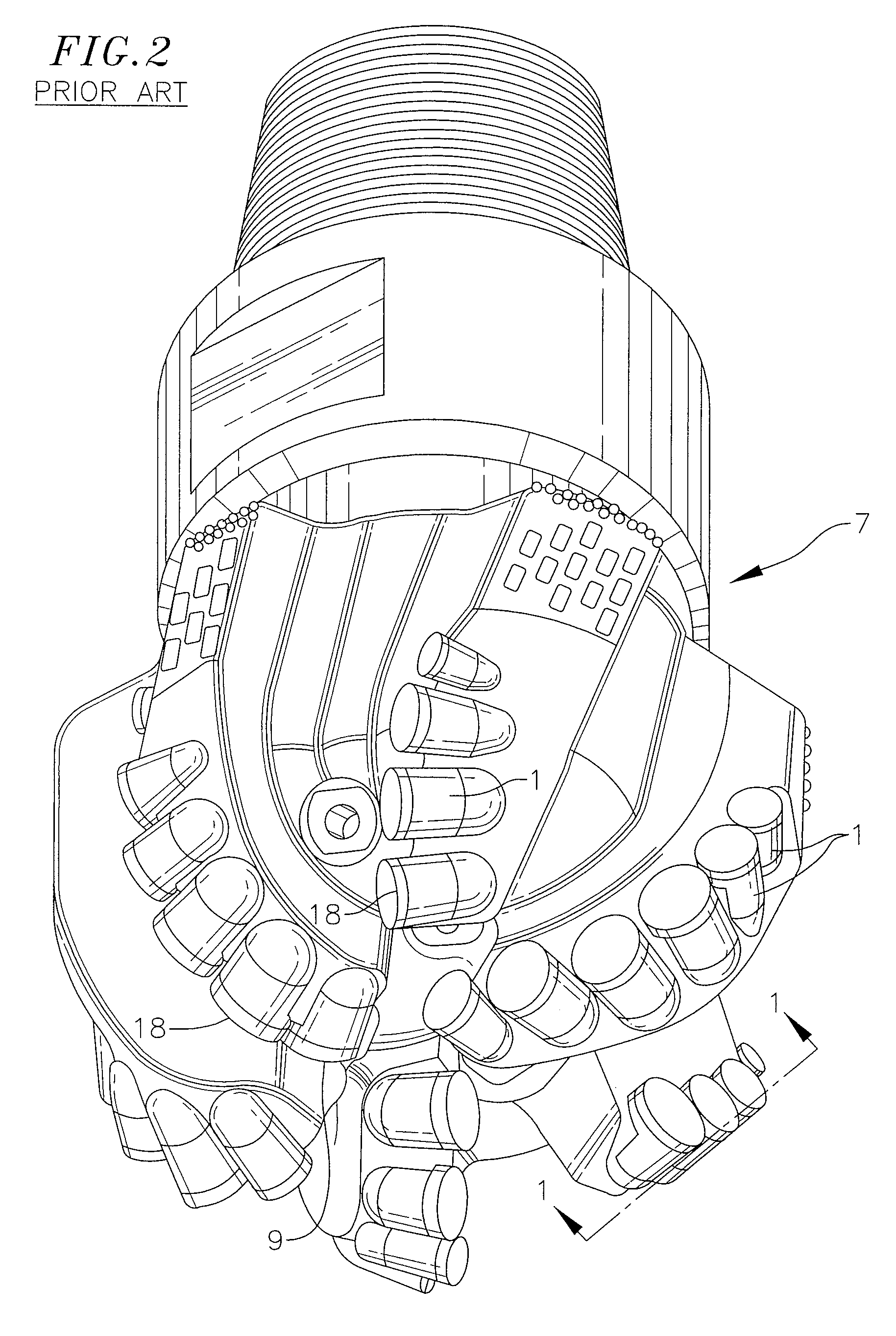

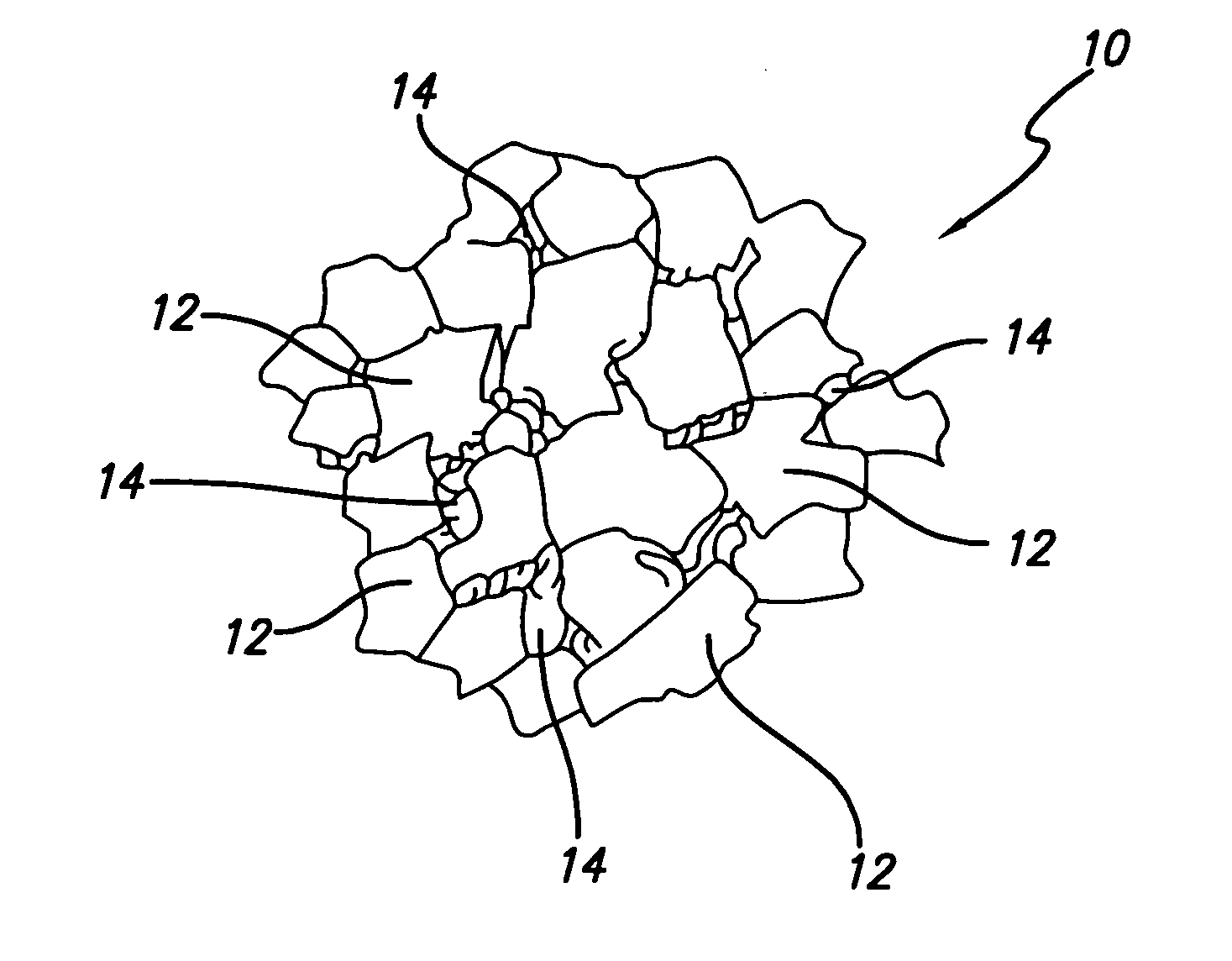

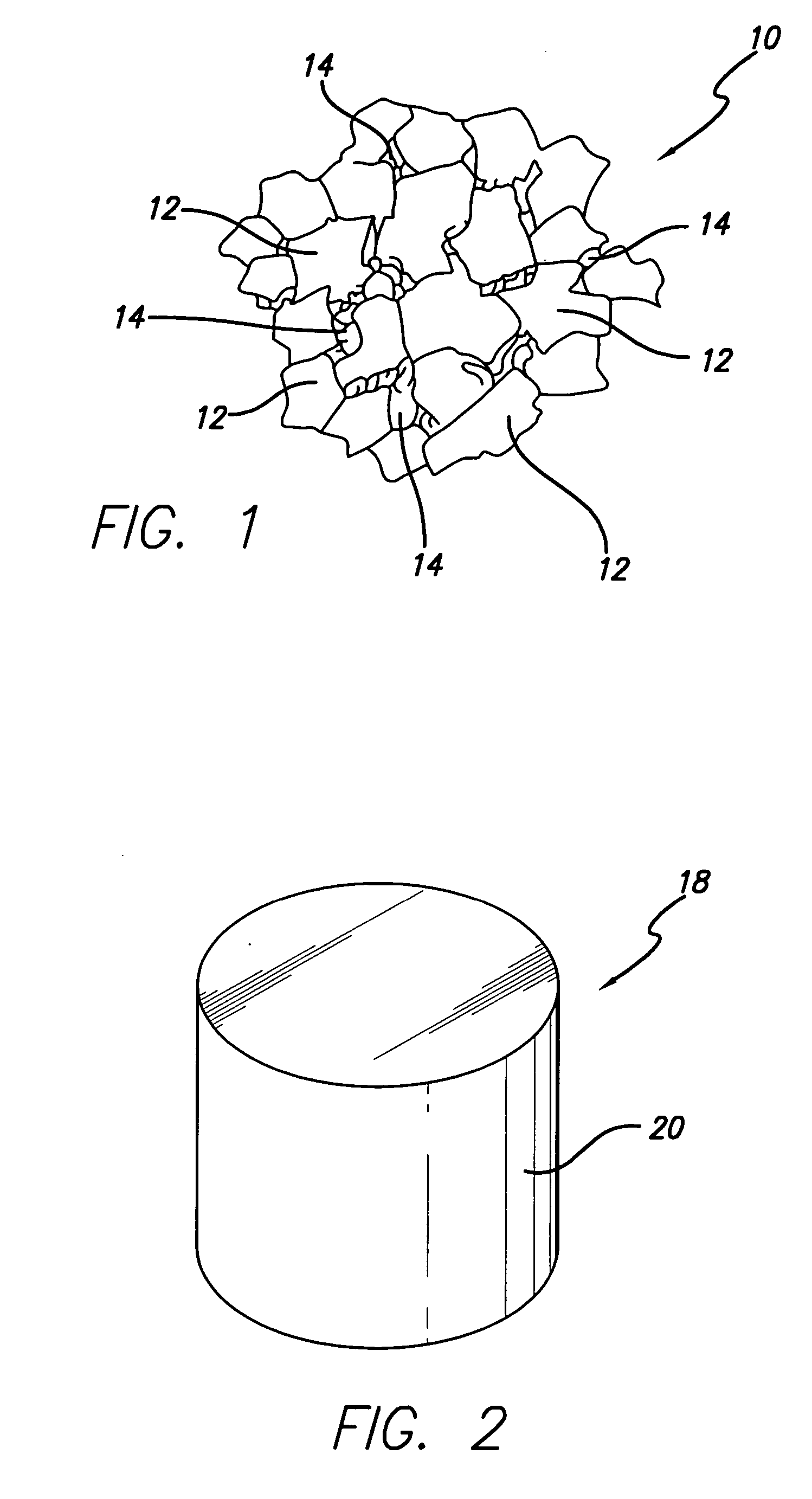

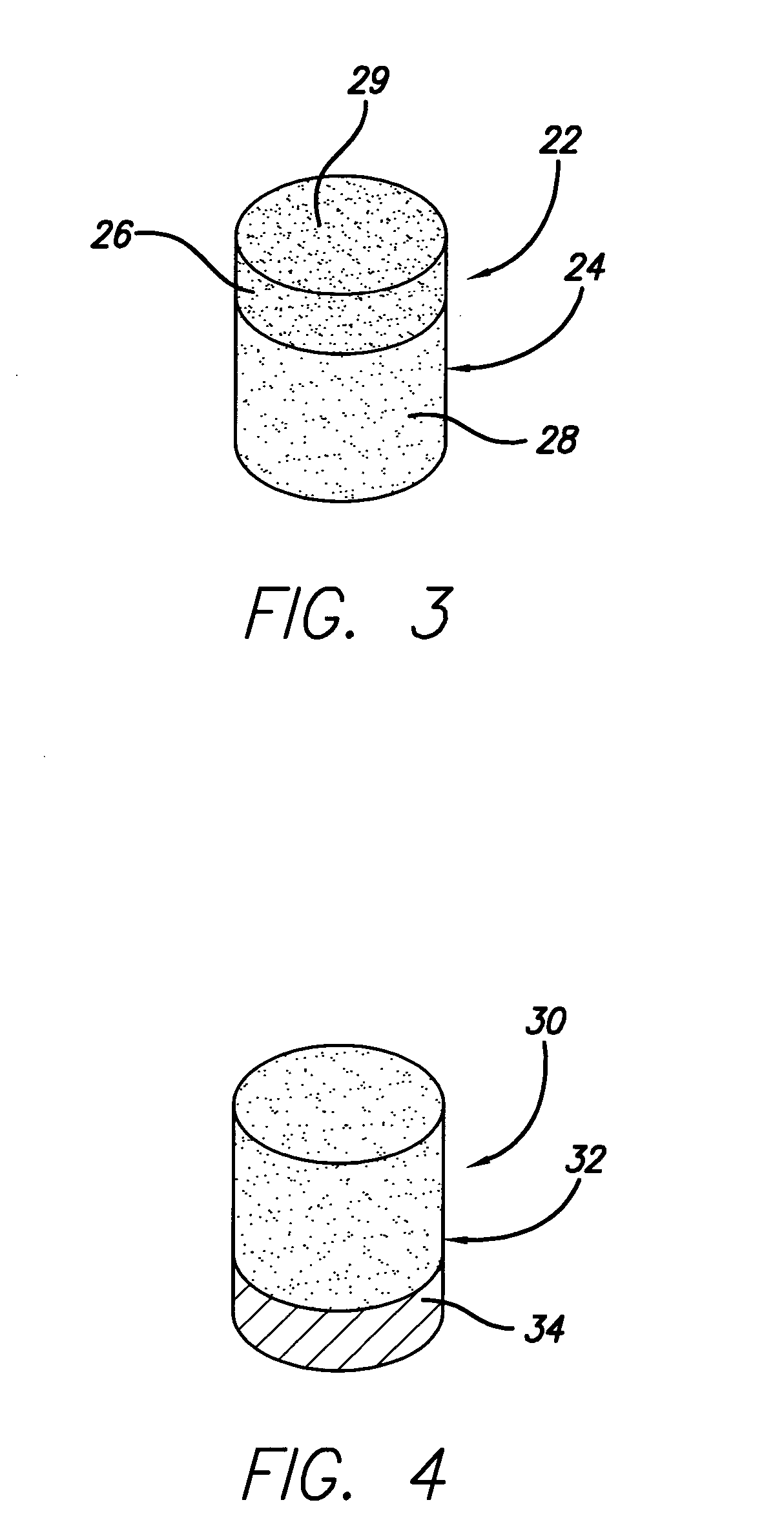

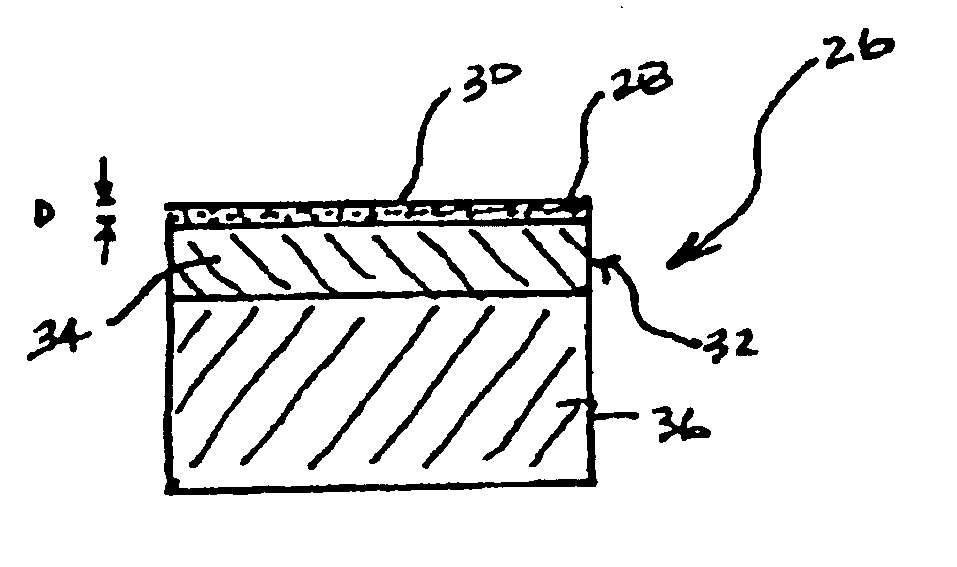

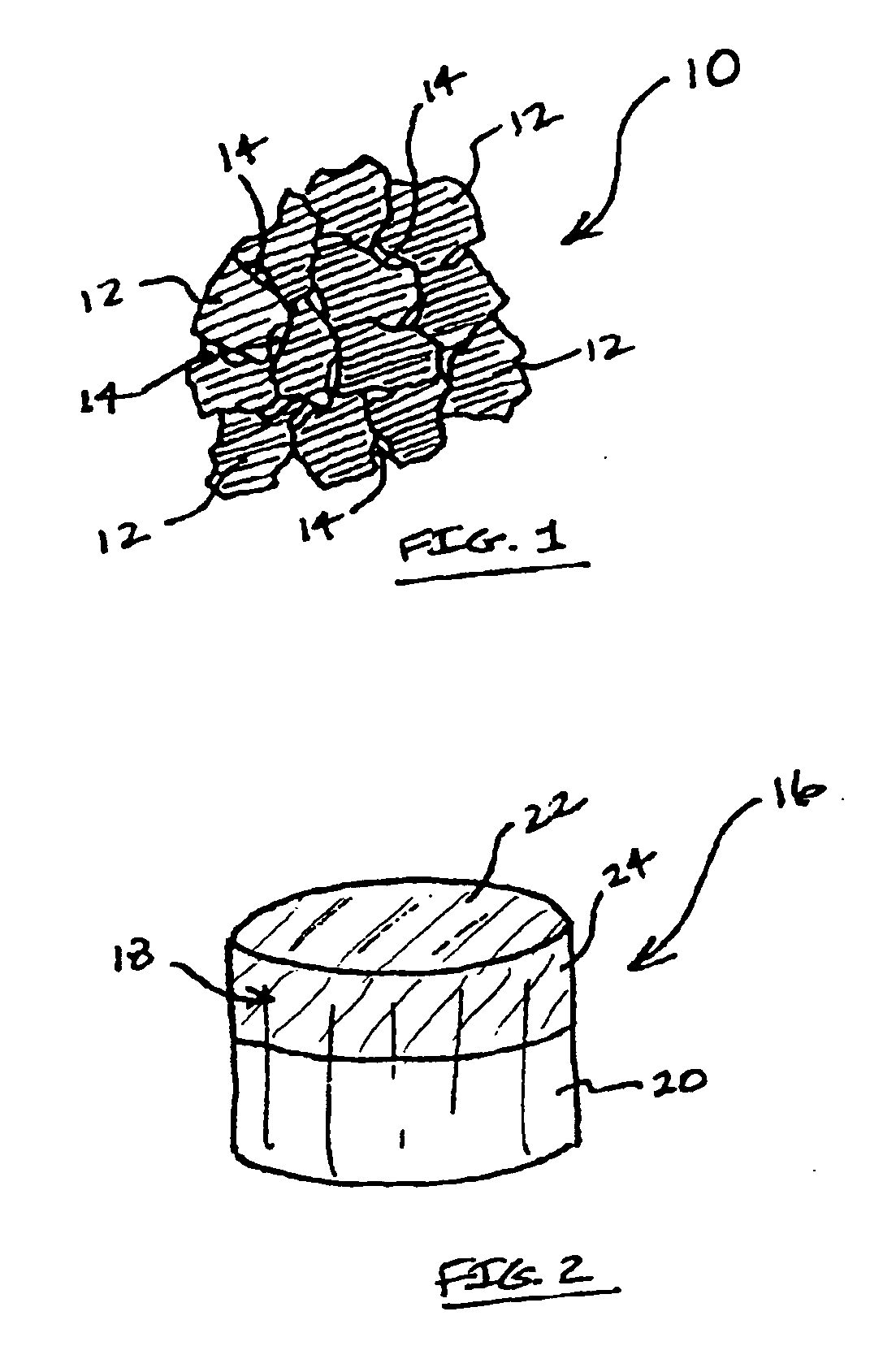

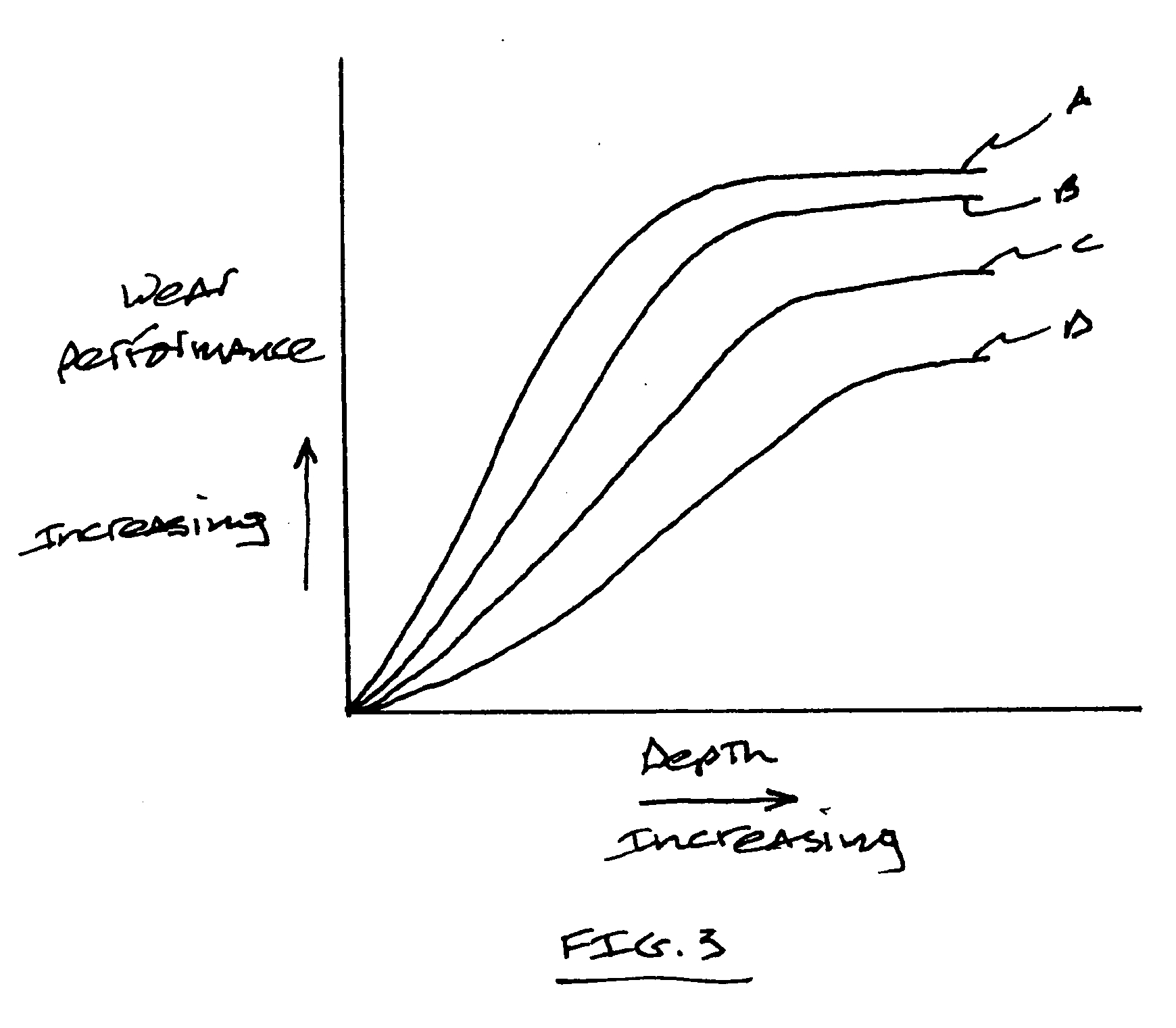

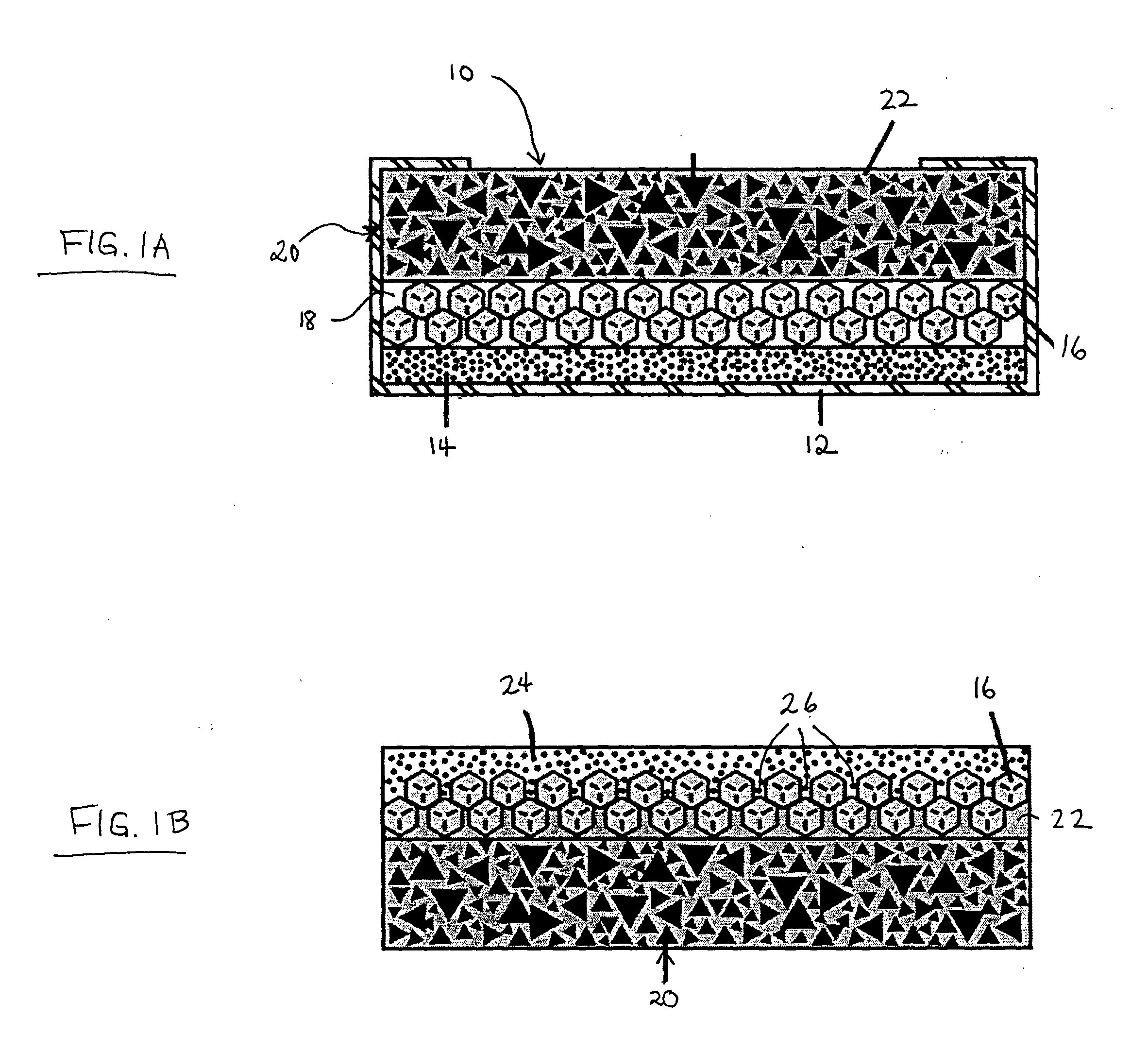

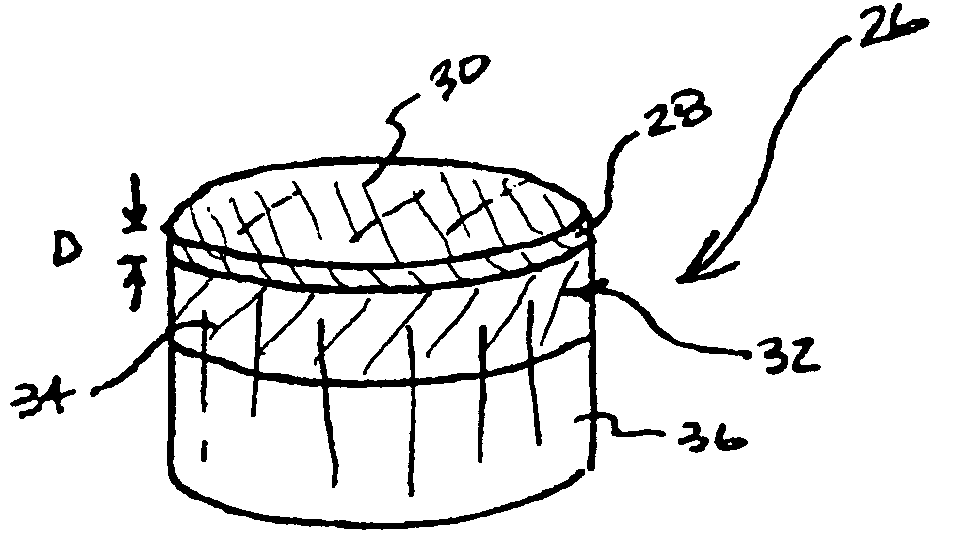

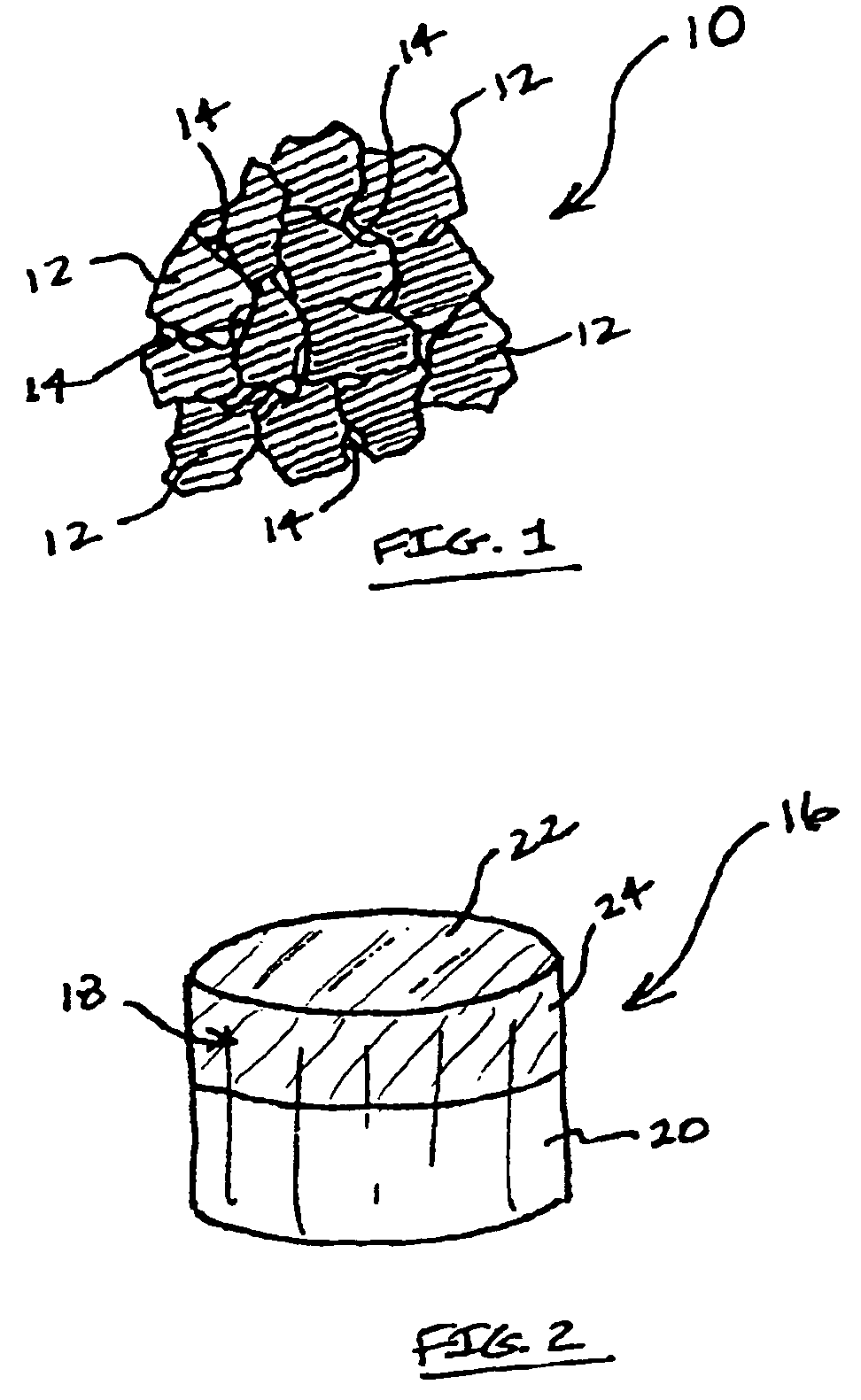

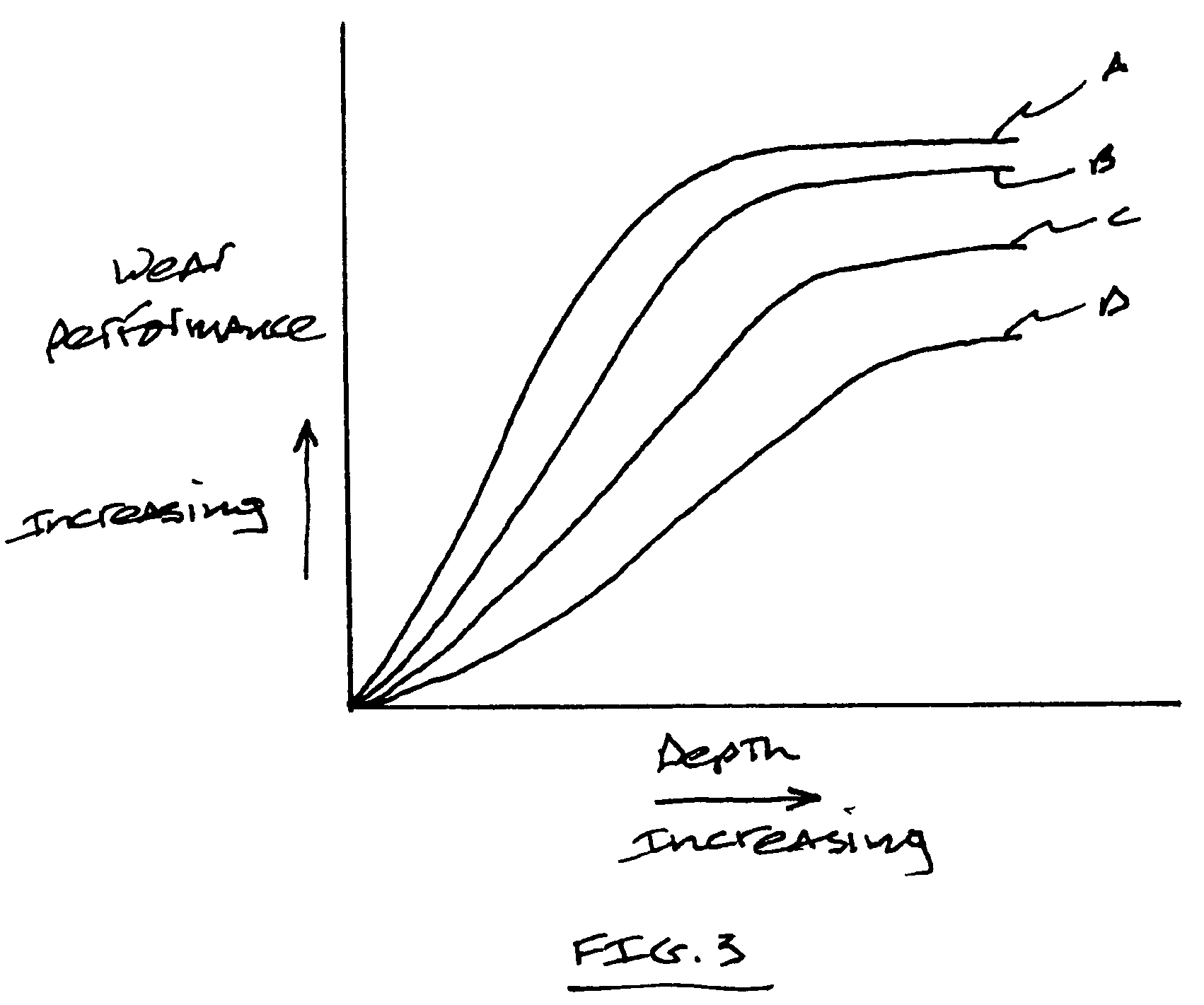

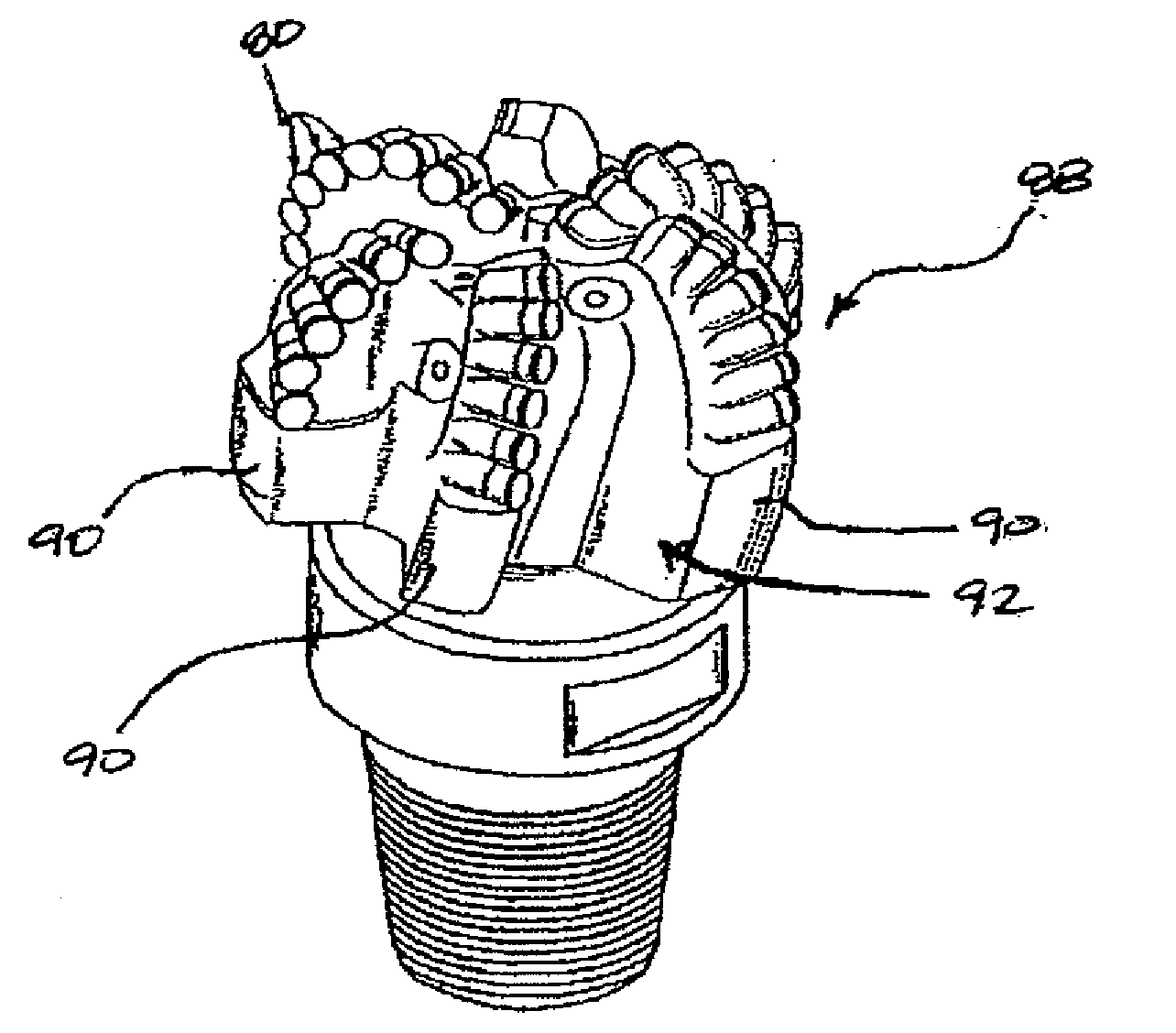

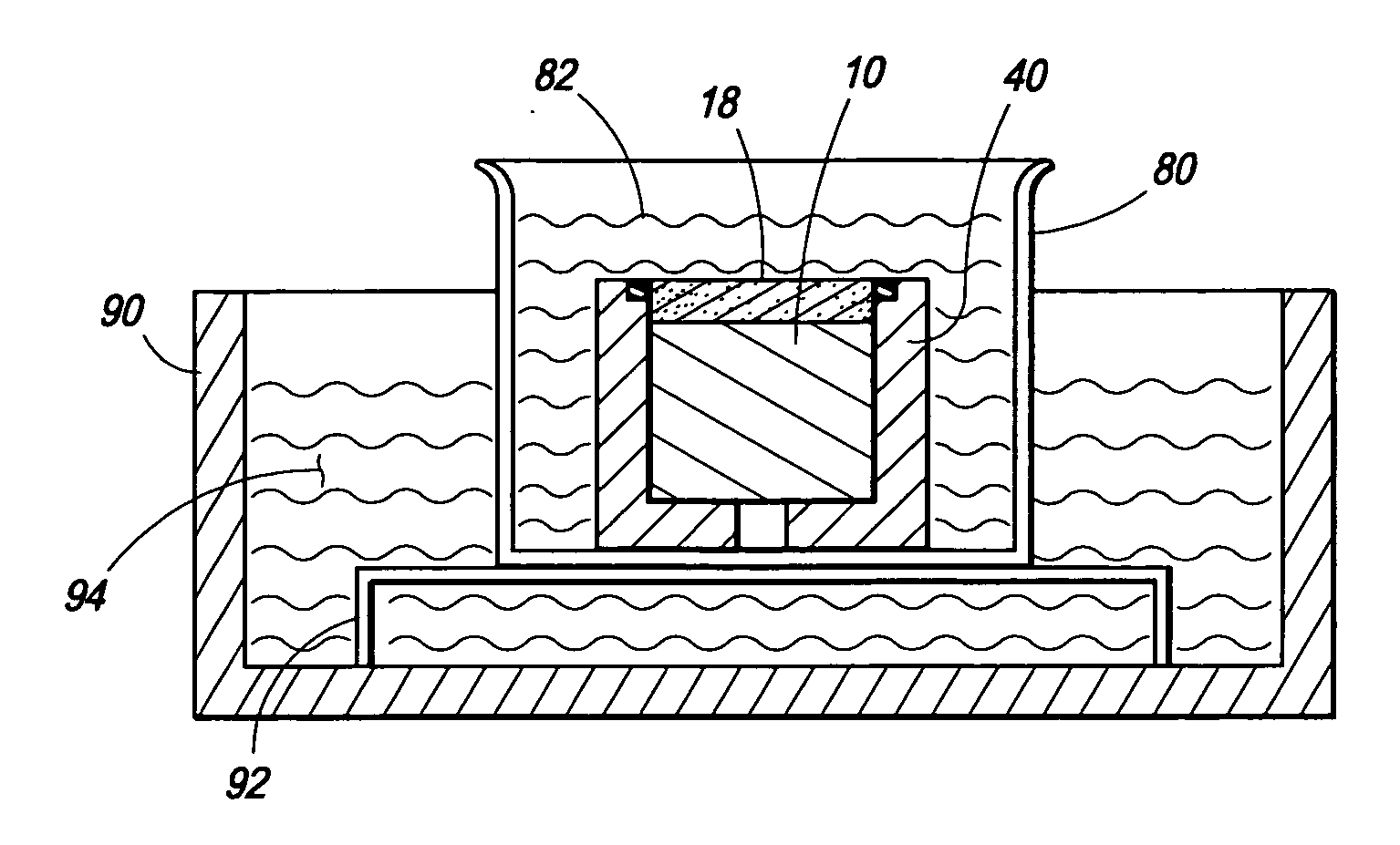

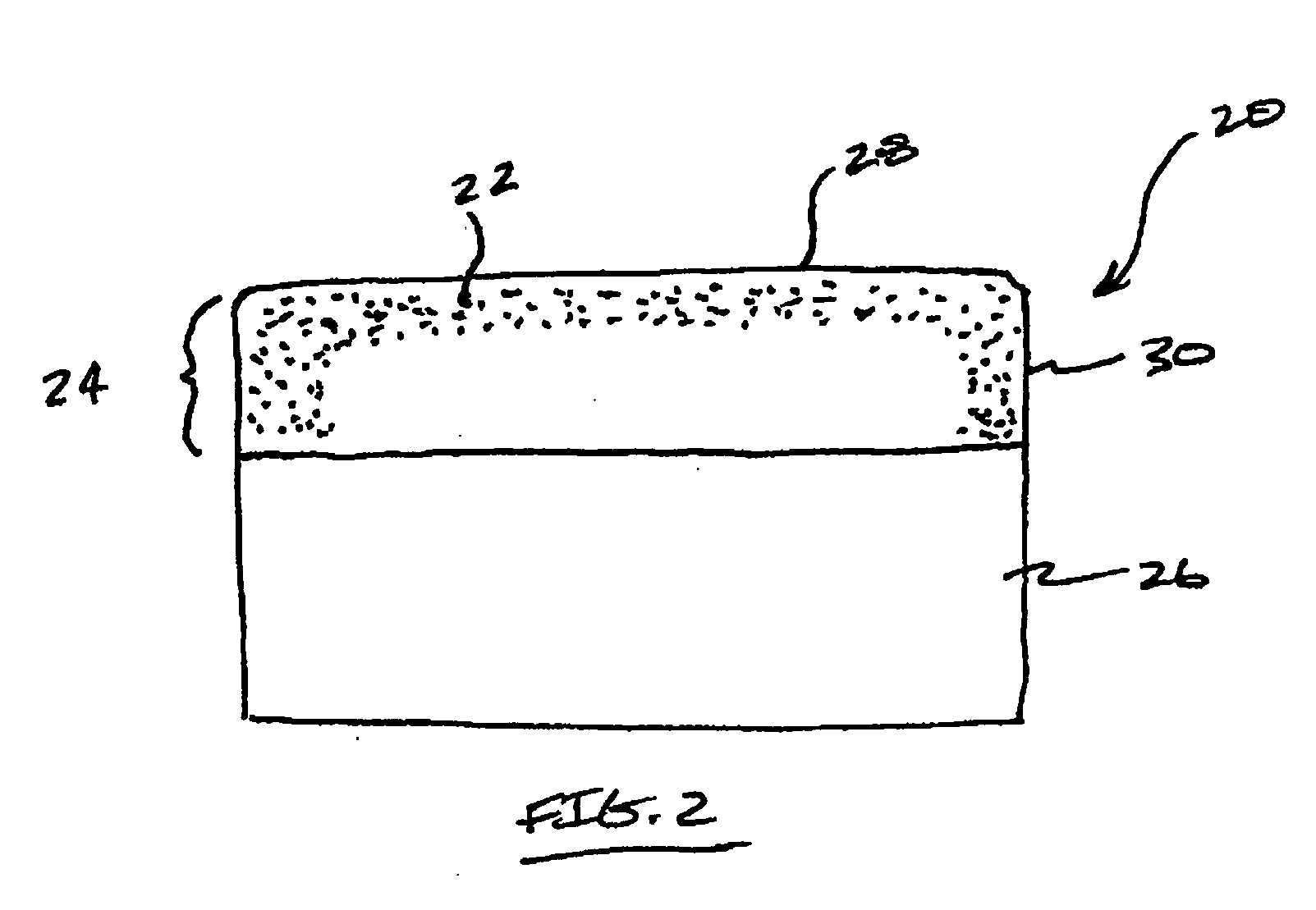

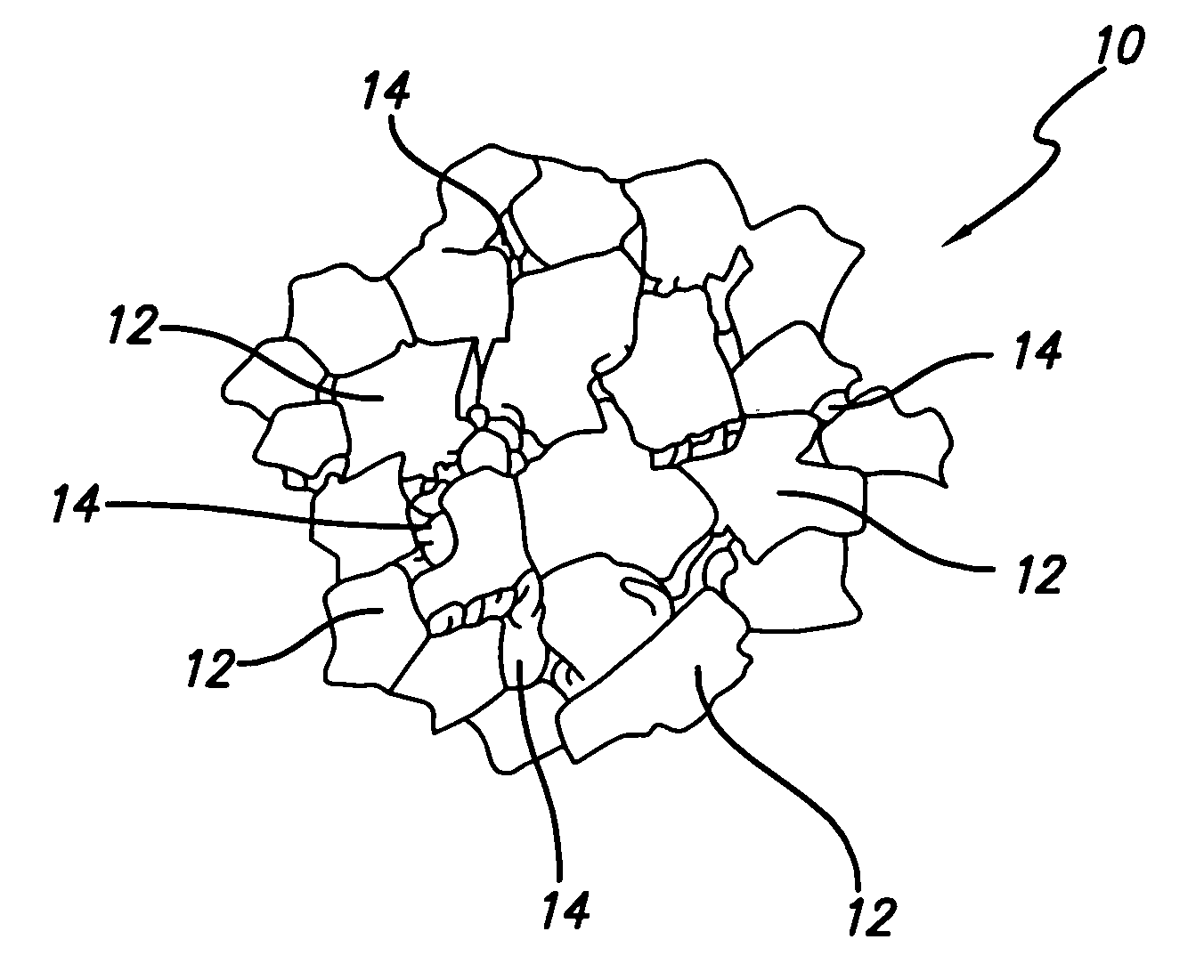

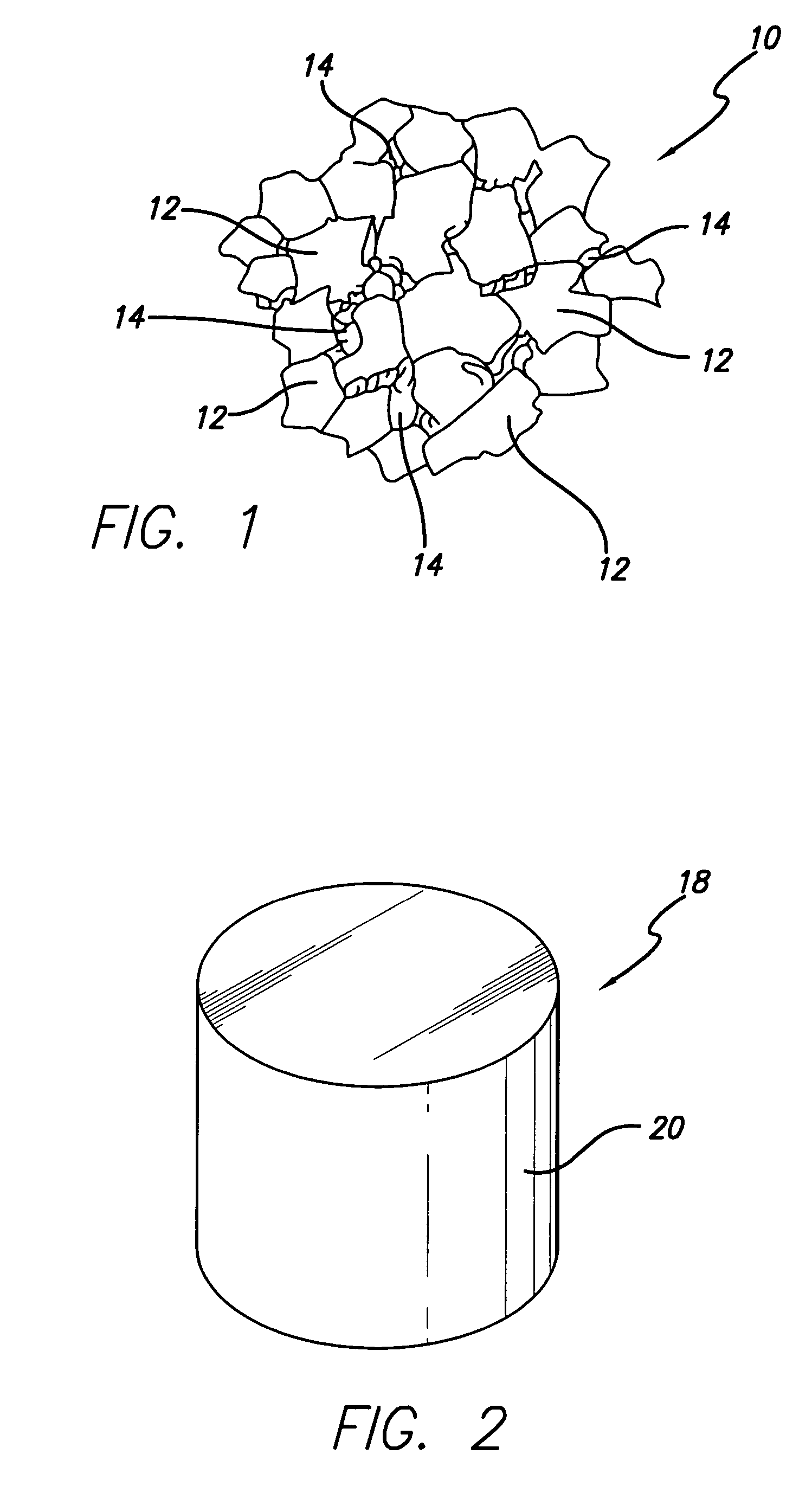

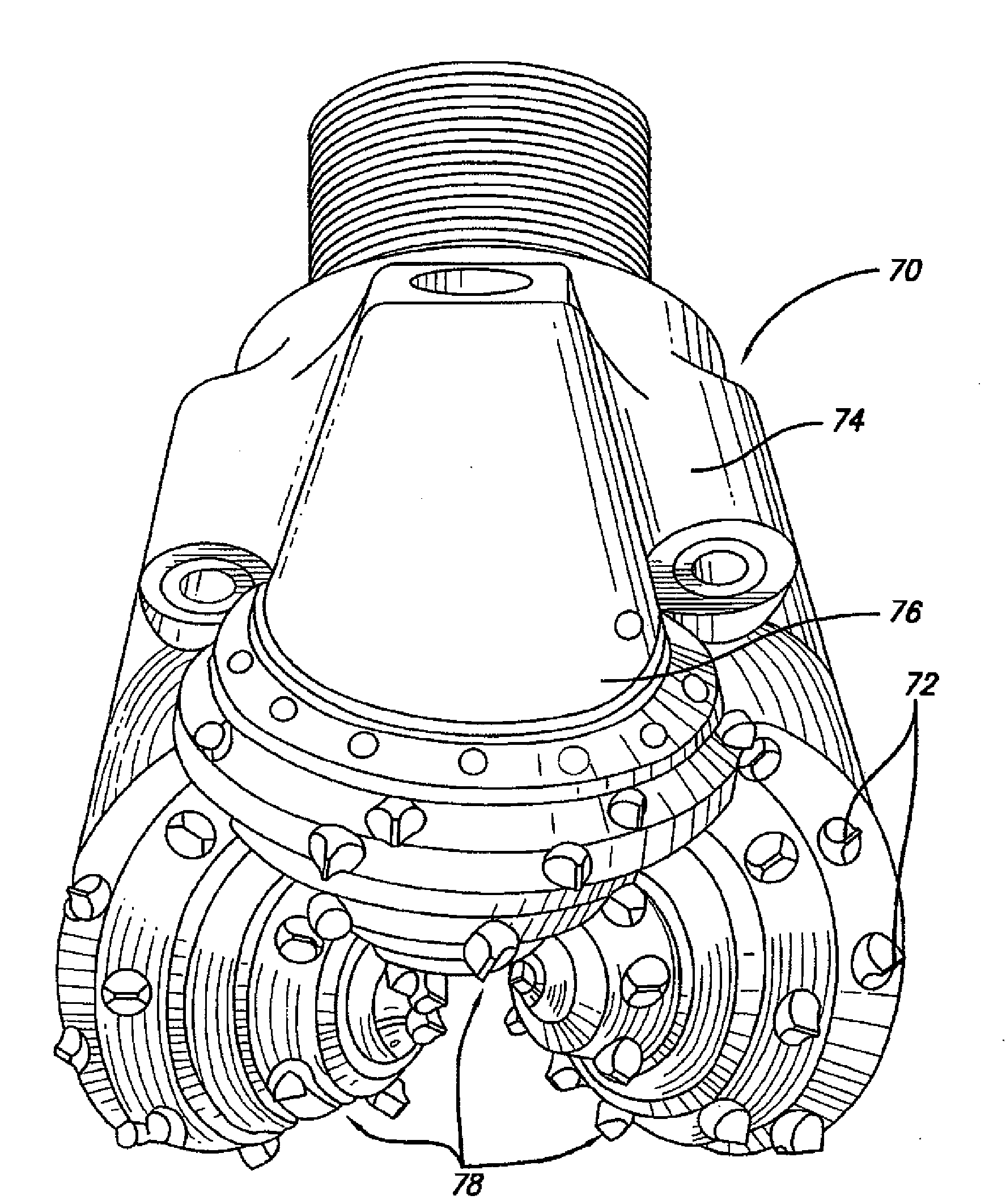

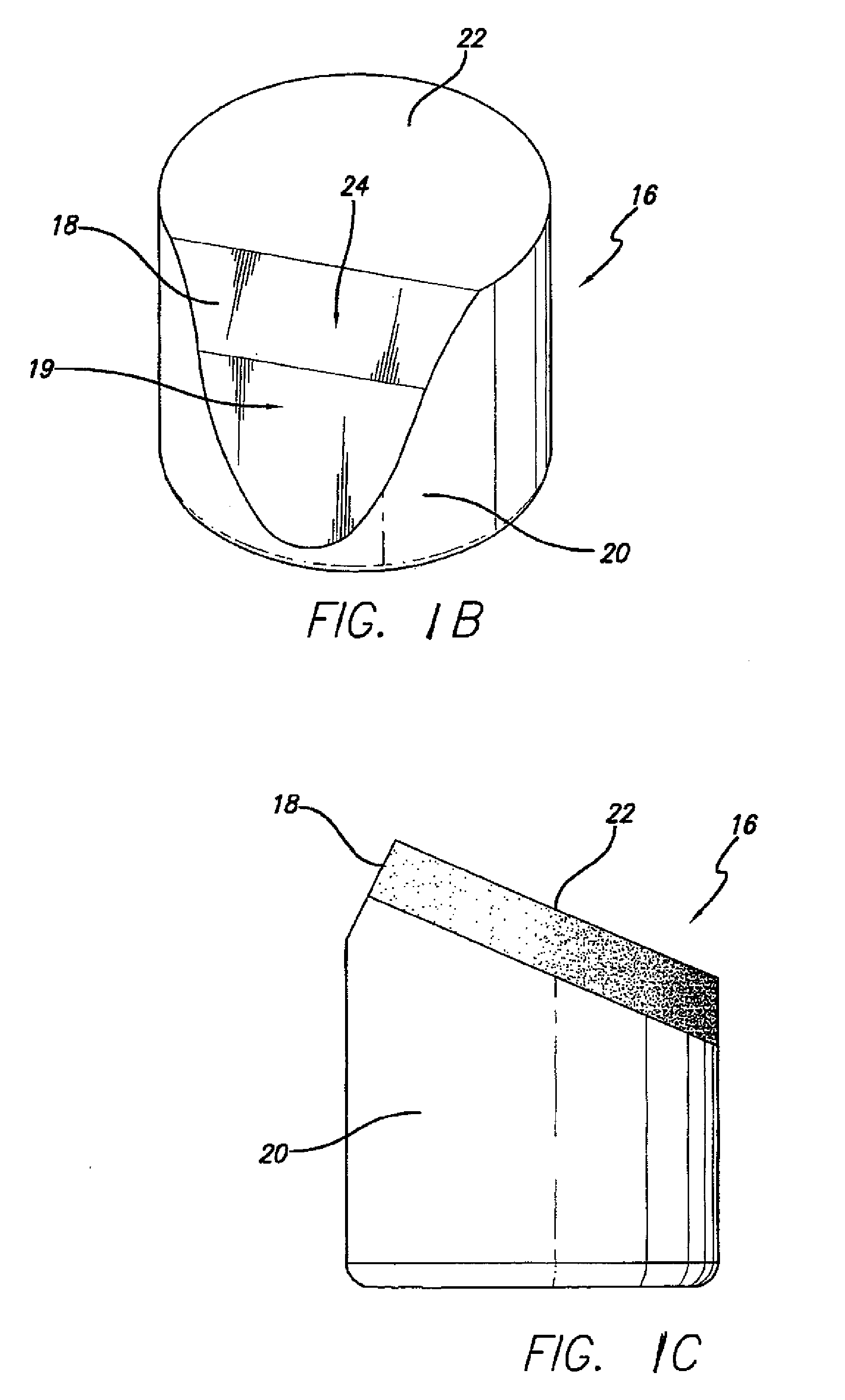

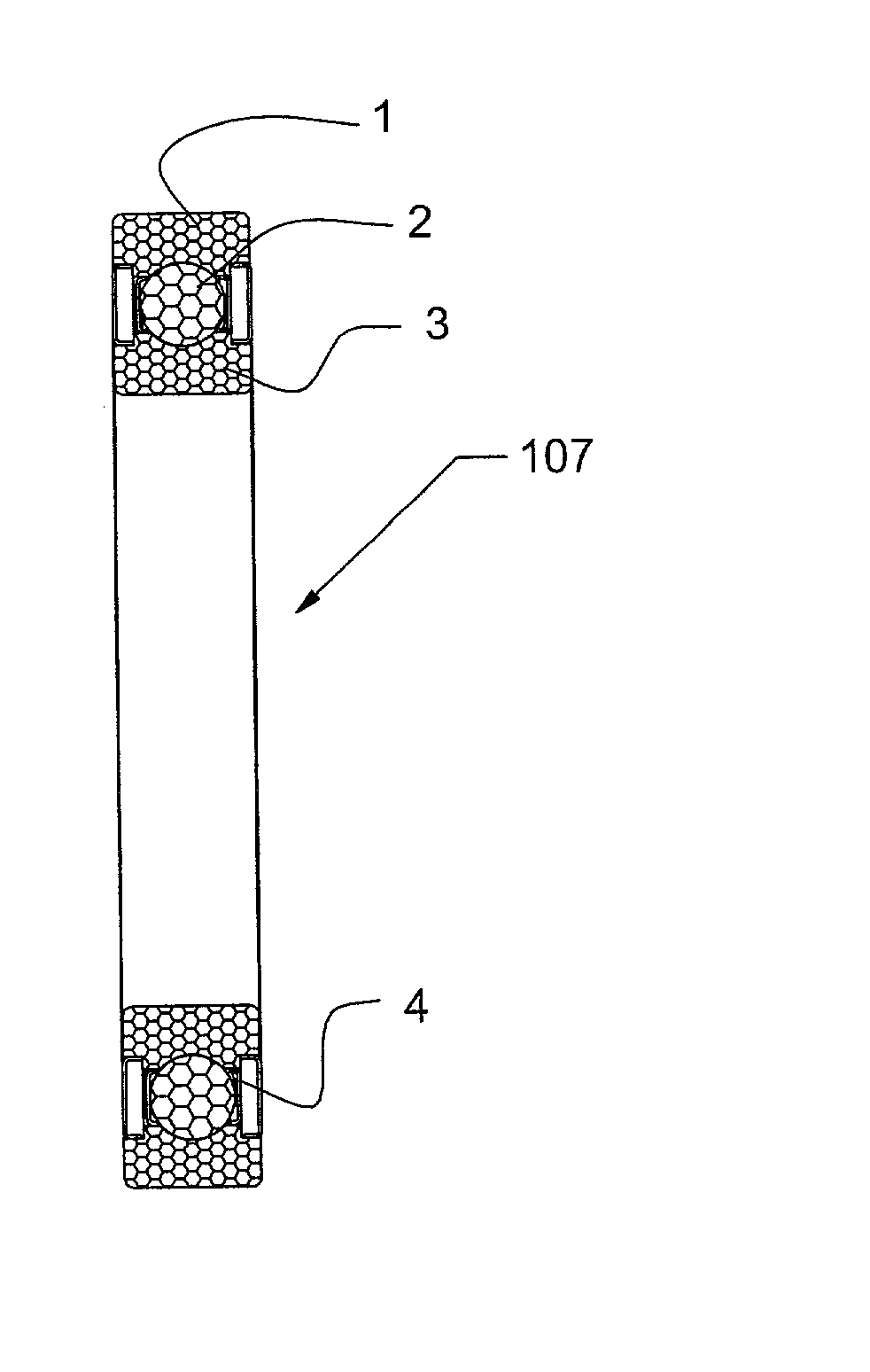

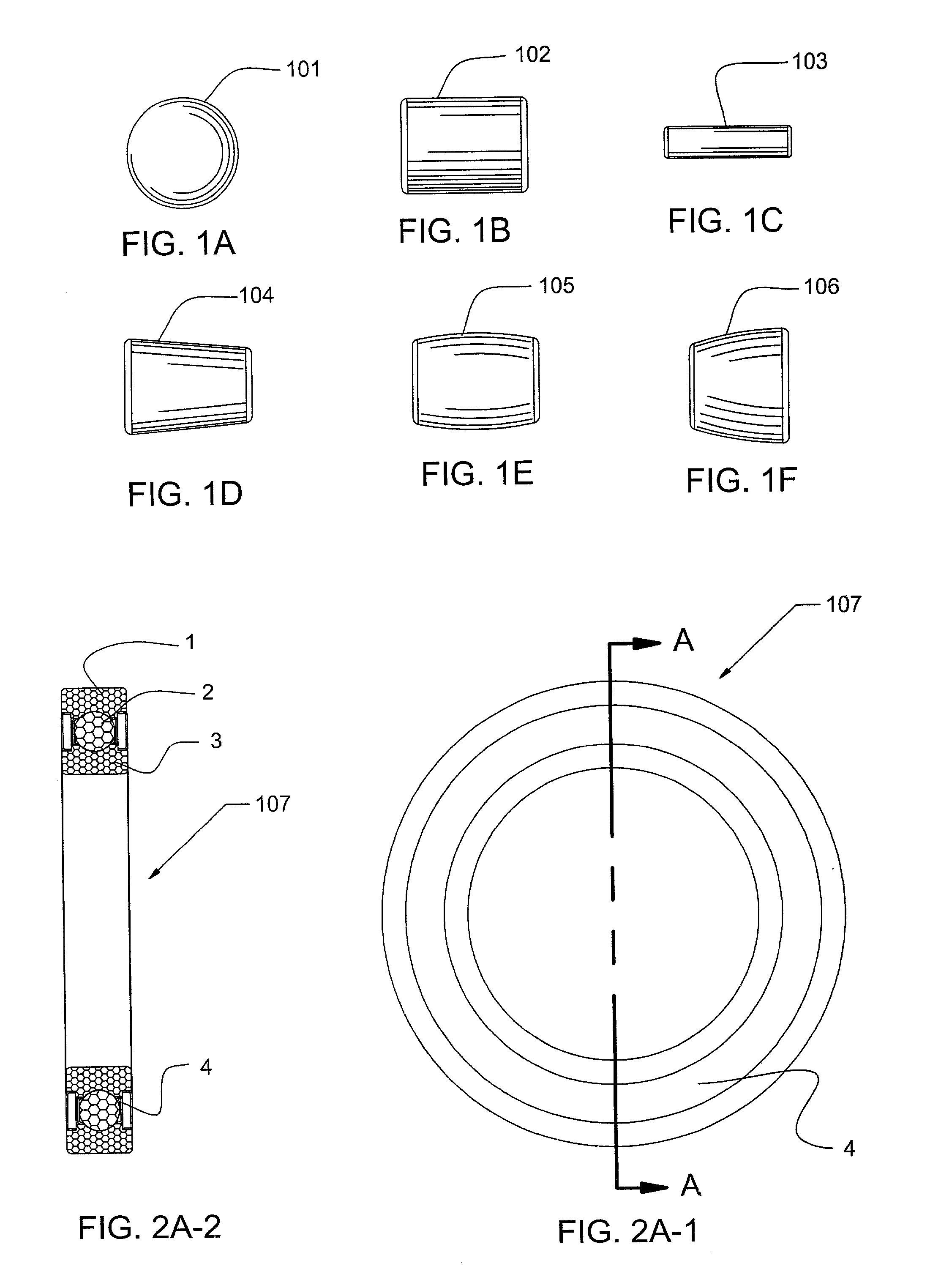

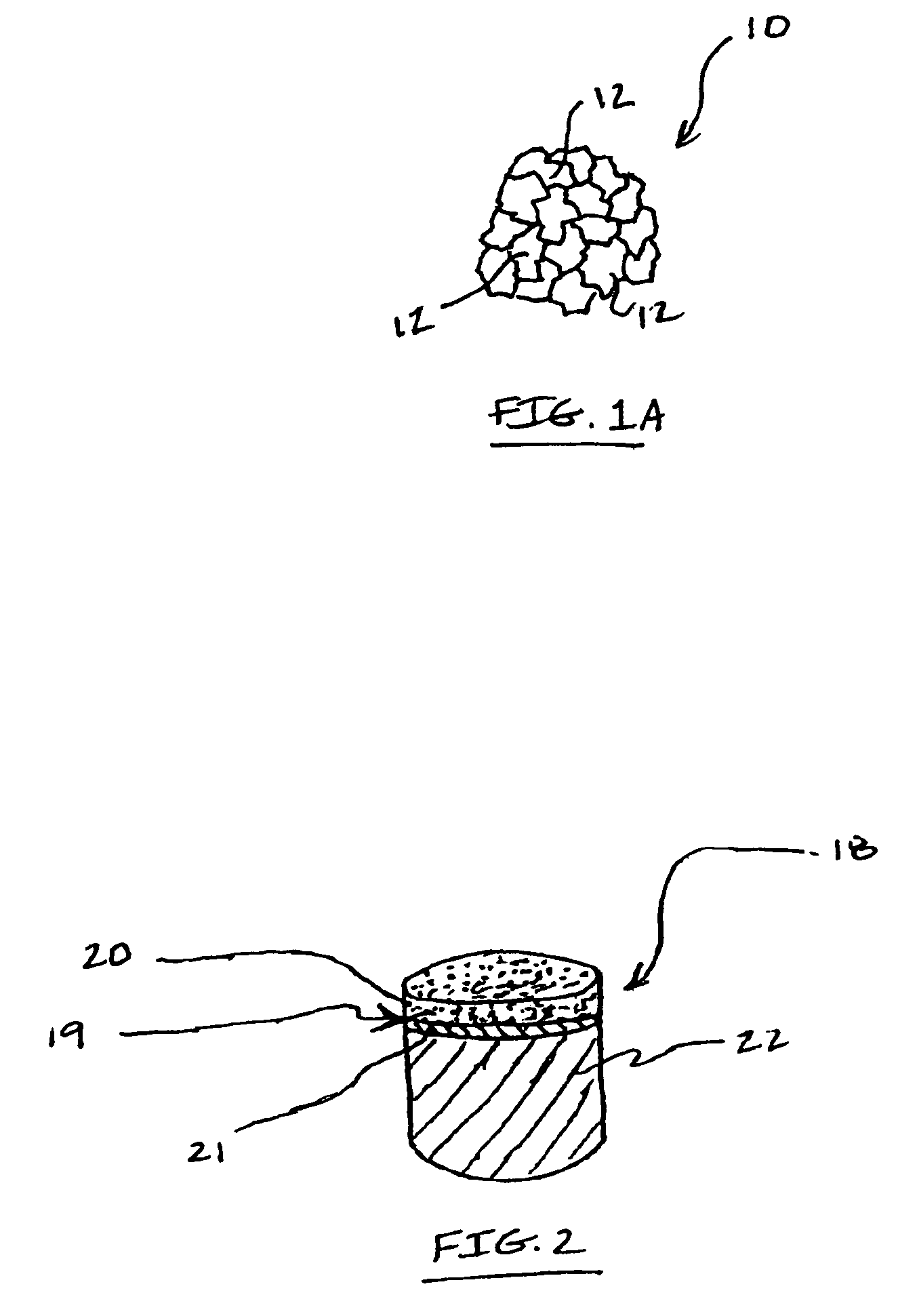

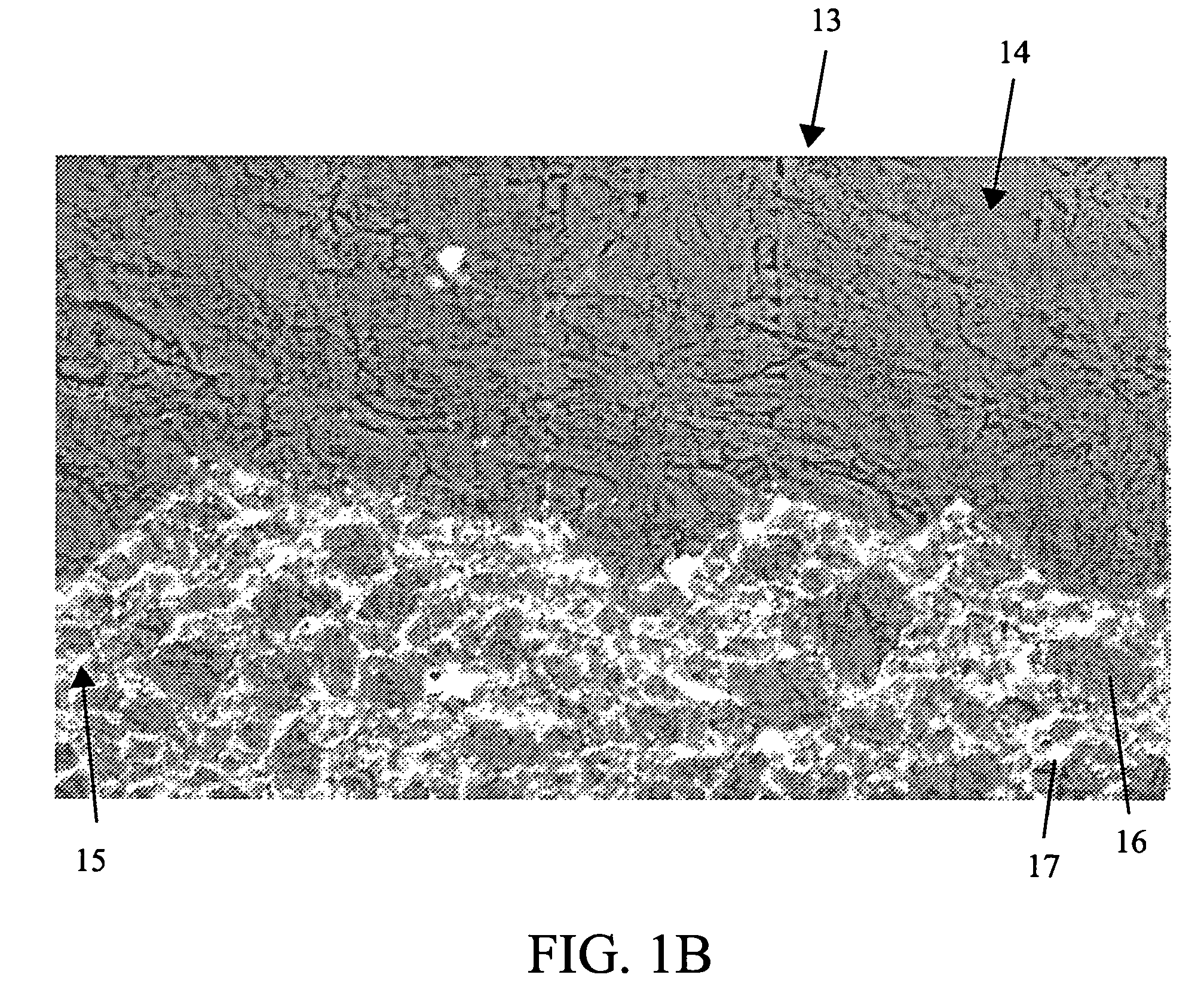

Disclosed is a polycrystalline diamond or diamond-like element with greatly improved wear resistance without loss of impact strength. These elements are formed with a binder-catalyzing material in a high-temperature, high-pressure (HTHP) process. The PCD element has a body with a plurality of bonded diamond or diamond-like crystals forming a continuous diamond matrix that has a diamond volume density greater than 85%. Interstices among the diamond crystals form a continuous interstitial matrix containing a catalyzing material. The diamond matrix table is formed and integrally bonded with a metallic substrate containing the catalyzing material during the HTHP process. The diamond matrix body has a working surface, where a first portion of the interstitial matrix in the body adjacent to the working surface is substantially free of the catalyzing material, and a second portion of the interstitial matrix in the body adjacent to the working surface contains the catalyzing material. The first portion of the interstitial matrix and the second portion of the interstitial matrix have substantially the same impact strength.

Owner:REEDHYCALOG UK

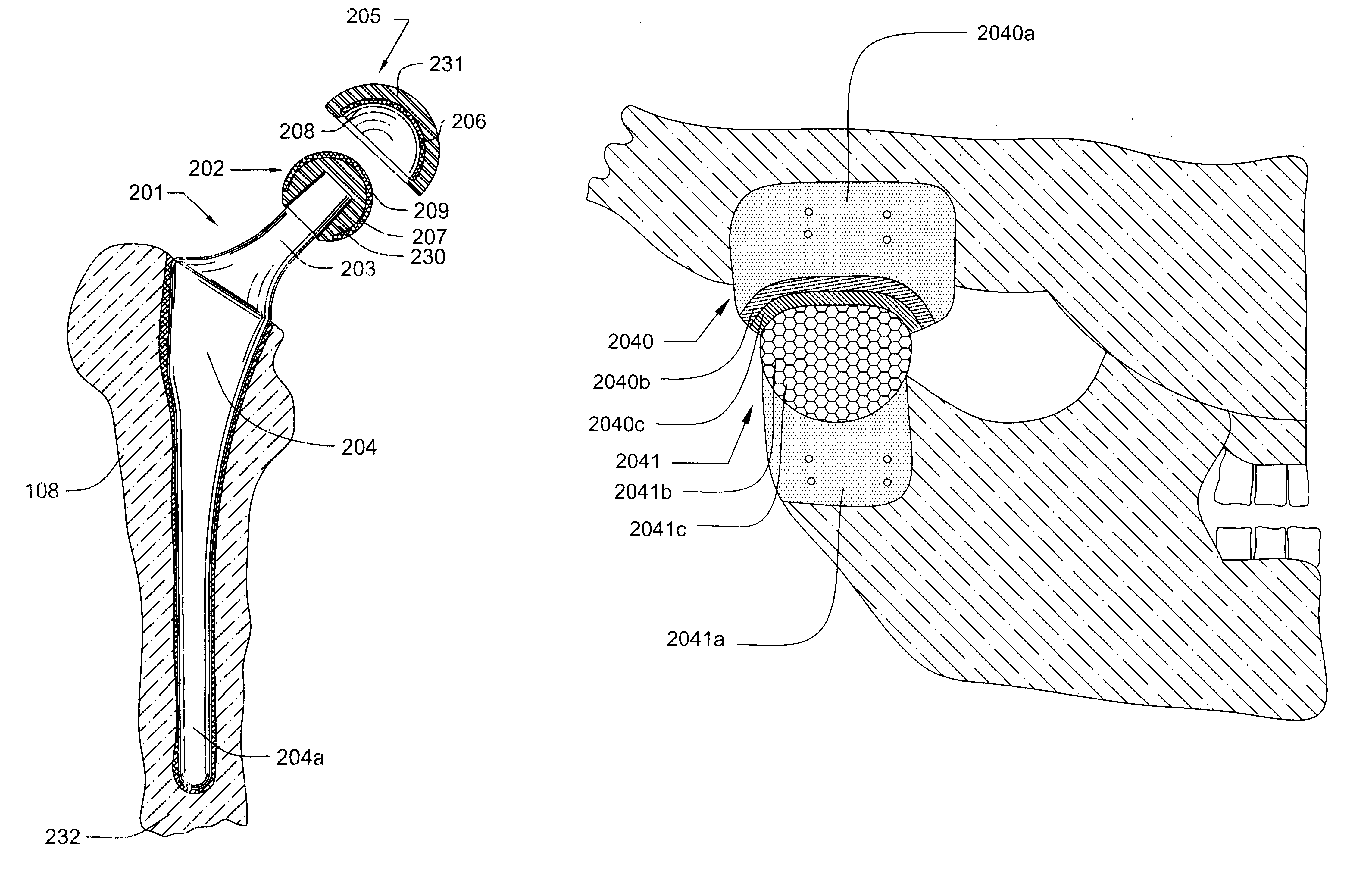

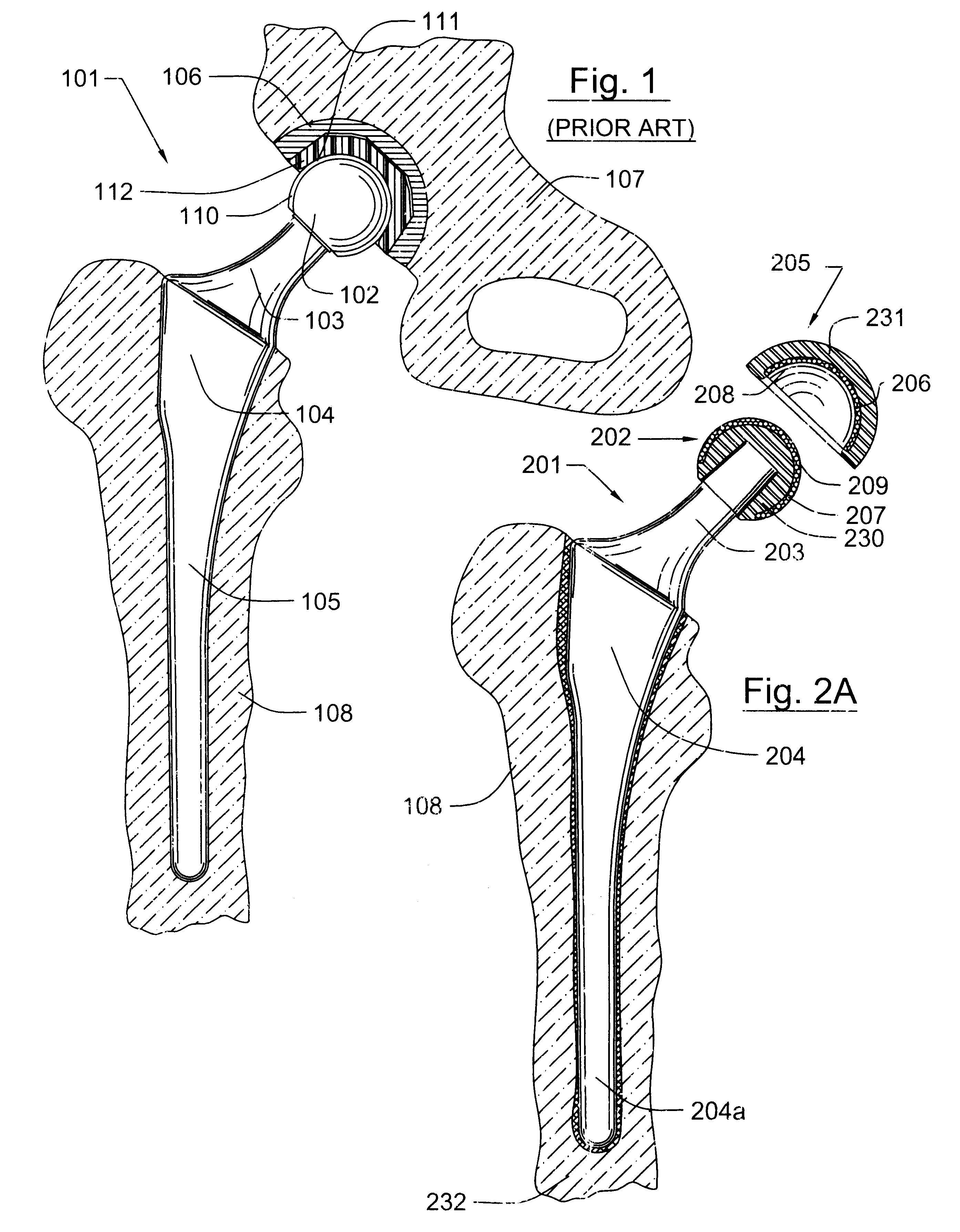

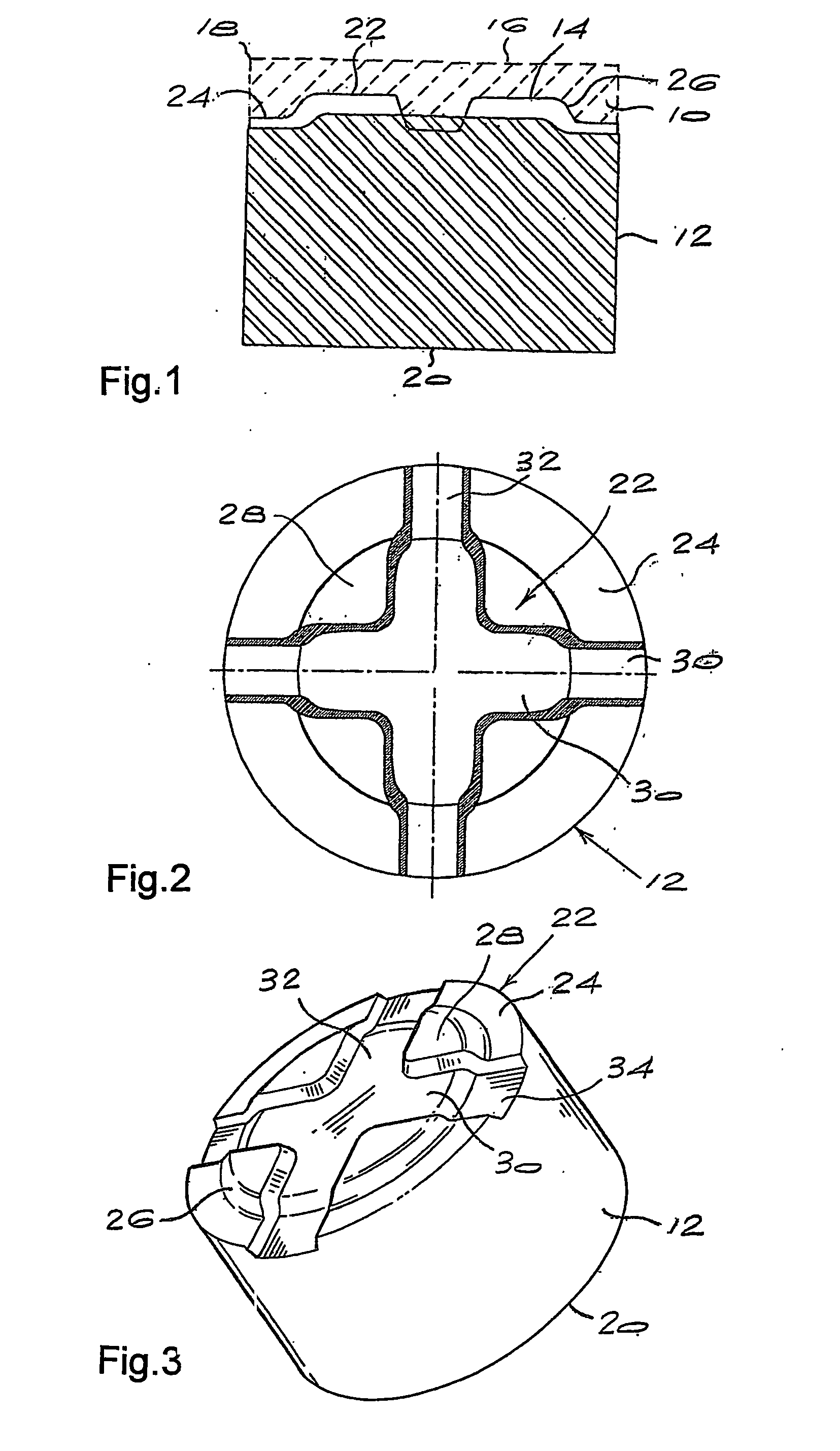

Prosthetic hip joint having sintered polycrystalline diamond compact articulation surfaces

InactiveUS6290726B1Improve wear resistanceReduce coefficient of frictionFinger jointsWrist jointsArticular surfacesProsthesis

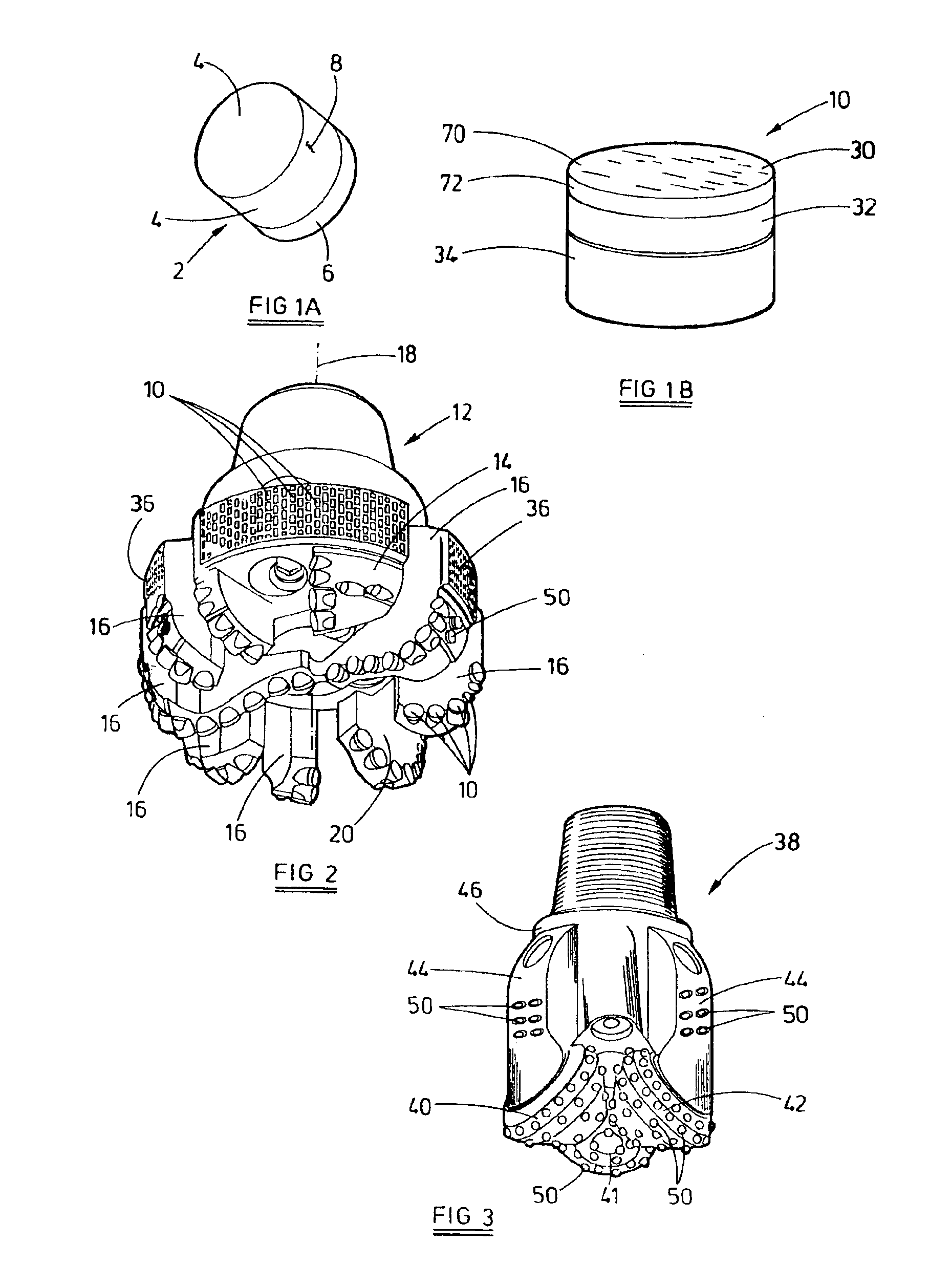

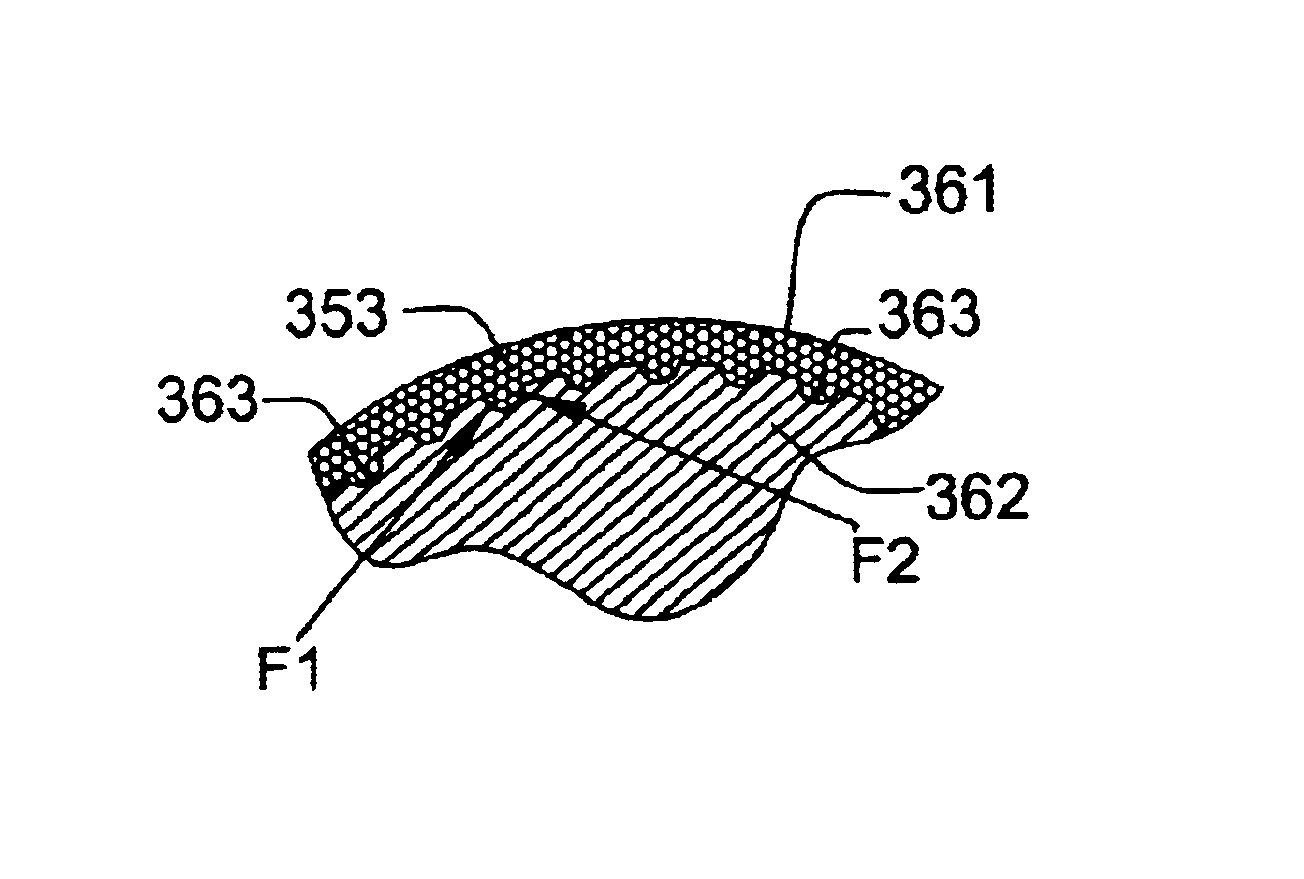

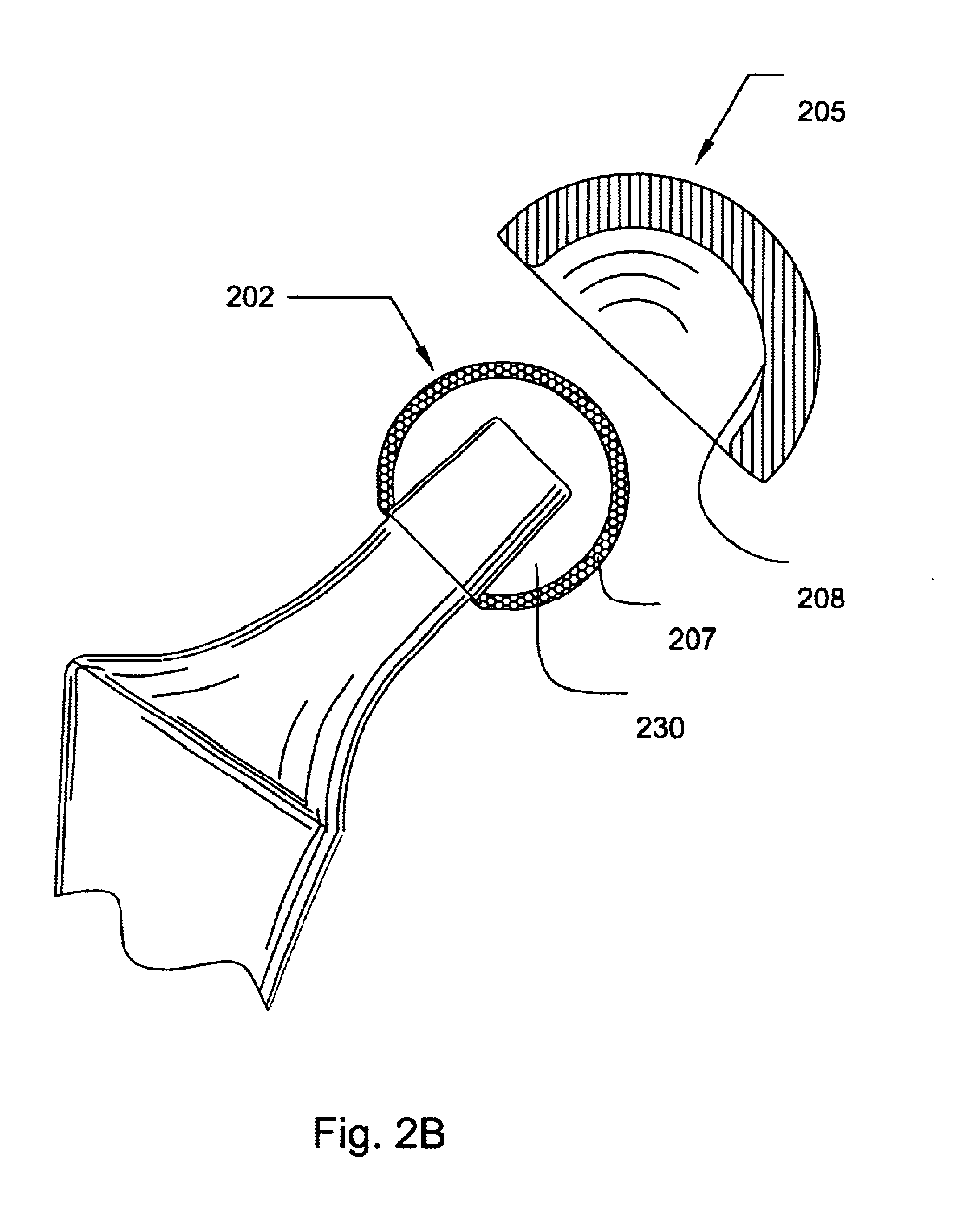

Prosthetic joints, components for prosthetic joints, superhard bearing and articulation surfaces, diamond bearing and articulation surfaces, substrate surface topographical features, materials for making joints, bearing and articulation surfaces, and methods for manufacturing and finishing the same, and related information are disclosed, including a prosthetic hip joint having sintered polycrystalline diamond articulation.

Owner:DIAMICRON

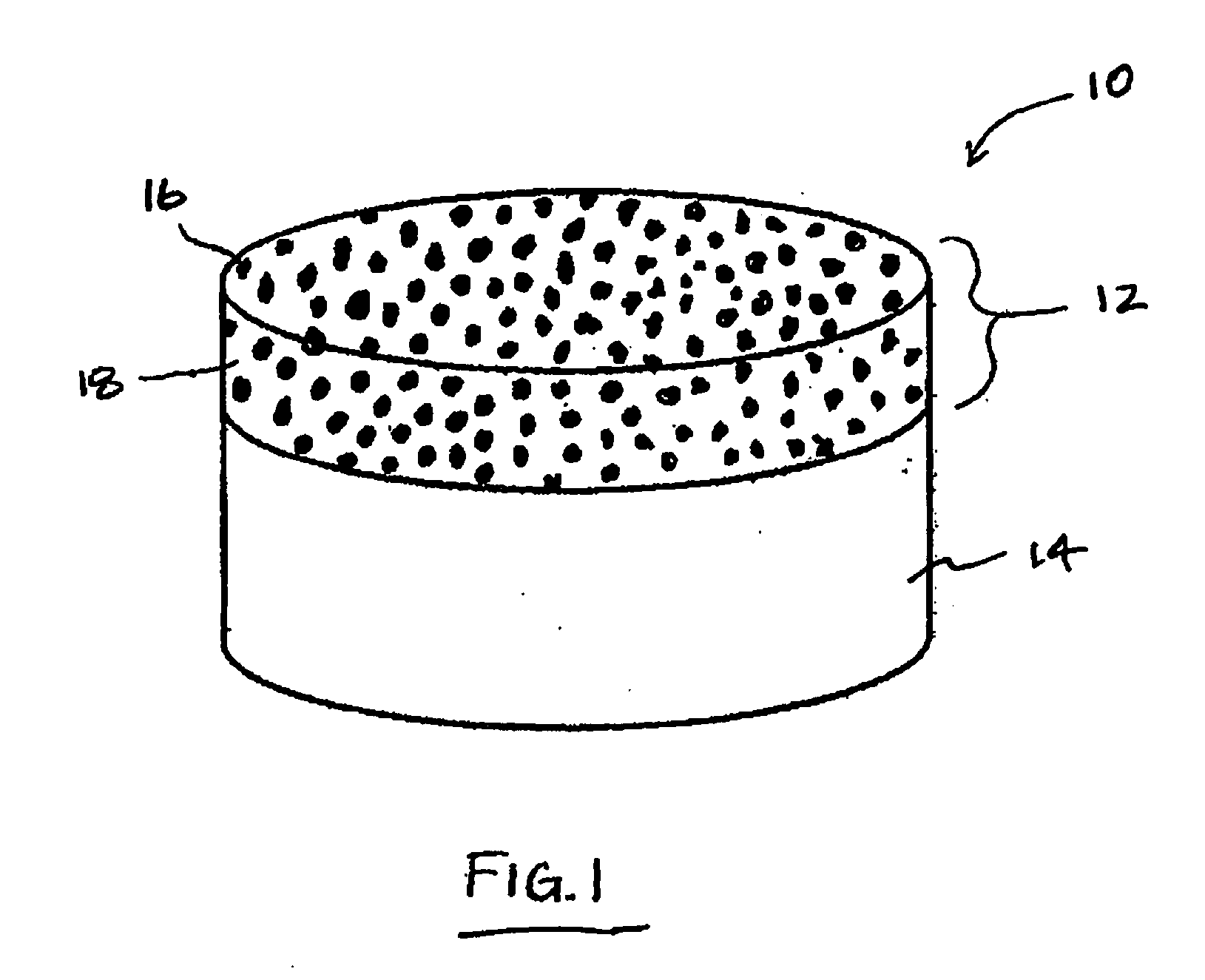

High volume density polycrystalline diamond with working surfaces depleted of catalyzing material

InactiveUS6861137B2Improve wear resistancePigmenting treatmentDrill bitsDiamond crystalPolycrystalline diamond

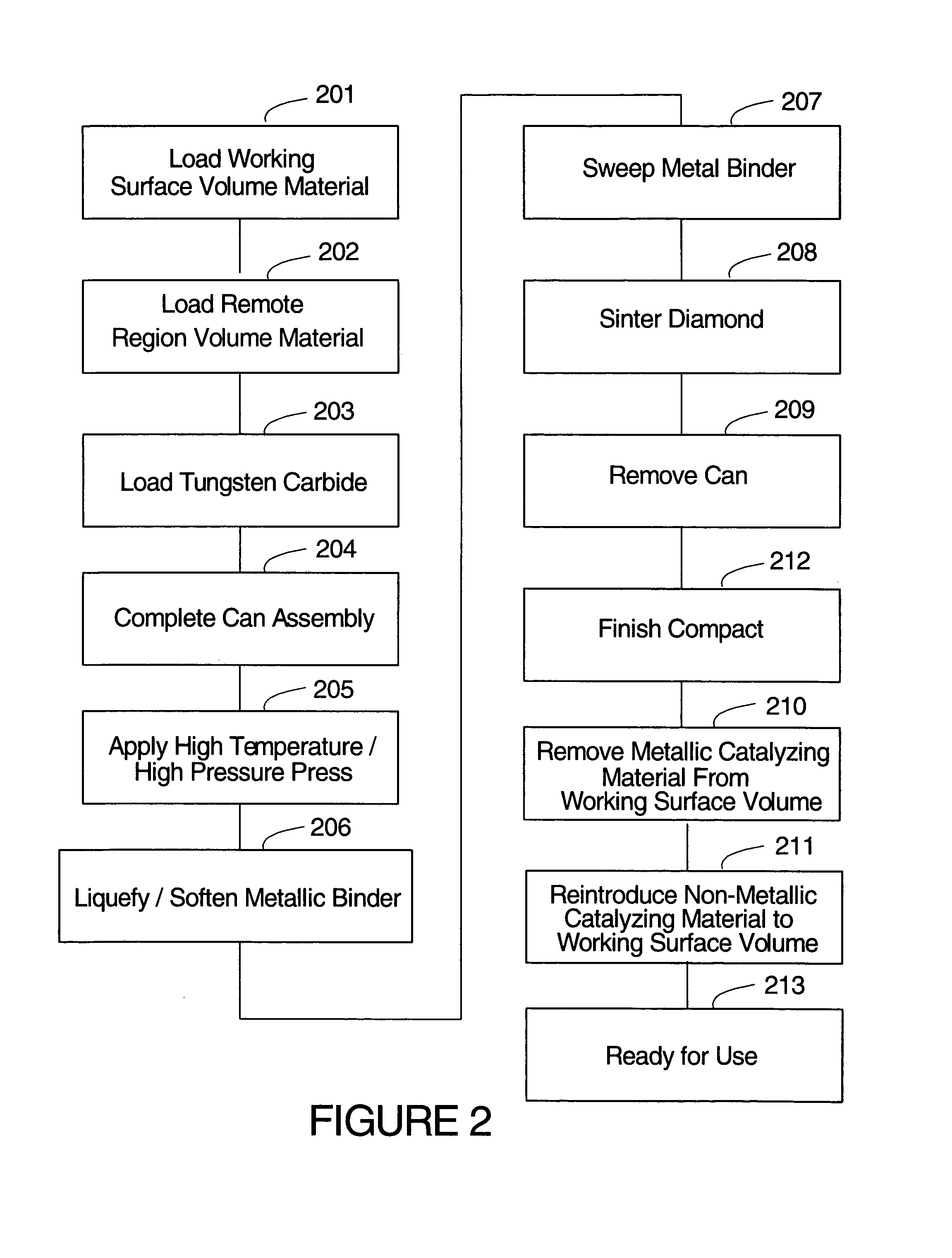

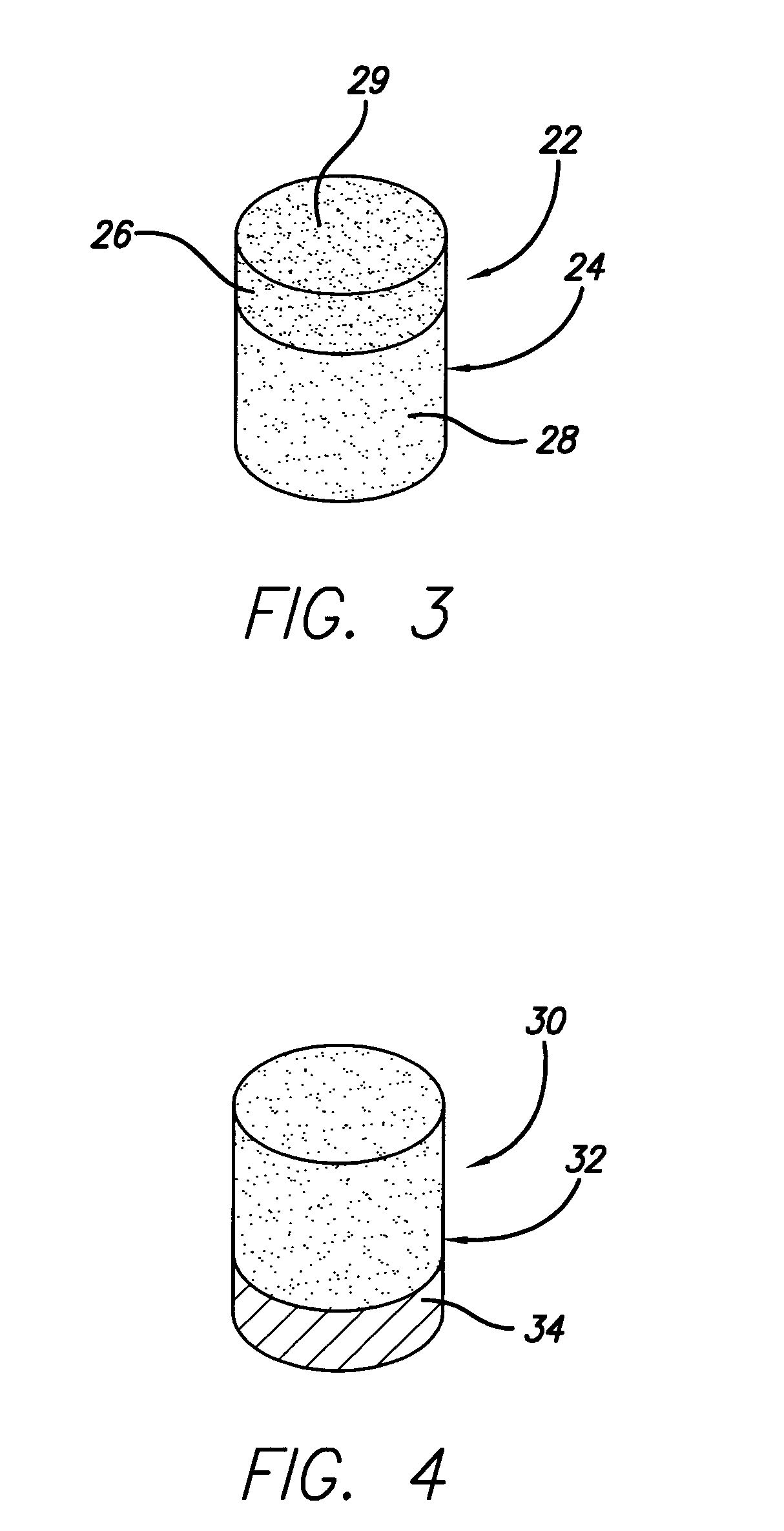

Disclosed is a method for manufacturing a polycrystalline diamond or diamond-like element with greatly improved wear resistance without loss of impact strength. These elements are formed with a binder-catalyzing material in a high-temperature, high-pressure (HTHP) process. The PCD element has a body with a plurality of bonded diamond or diamond-like crystals forming a continuous diamond matrix that has a diamond volume density greater than 85%. Interstices among the diamond crystals form a continuous interstitial matrix containing a catalyzing material. The diamond matrix table is formed and integrally bonded with a metallic substrate containing the catalyzing material during the HTHP process. The diamond matrix body has a working surface, where a portion of the interstitial matrix in the body adjacent to the working surface is substantially free of the catalyzing material, and the remaining interstitial matrix contains the catalyzing material. Typically, less than about 70% of the body of the diamond matrix table is free of the catalyzing material.

Owner:REEDHYCALOG UK

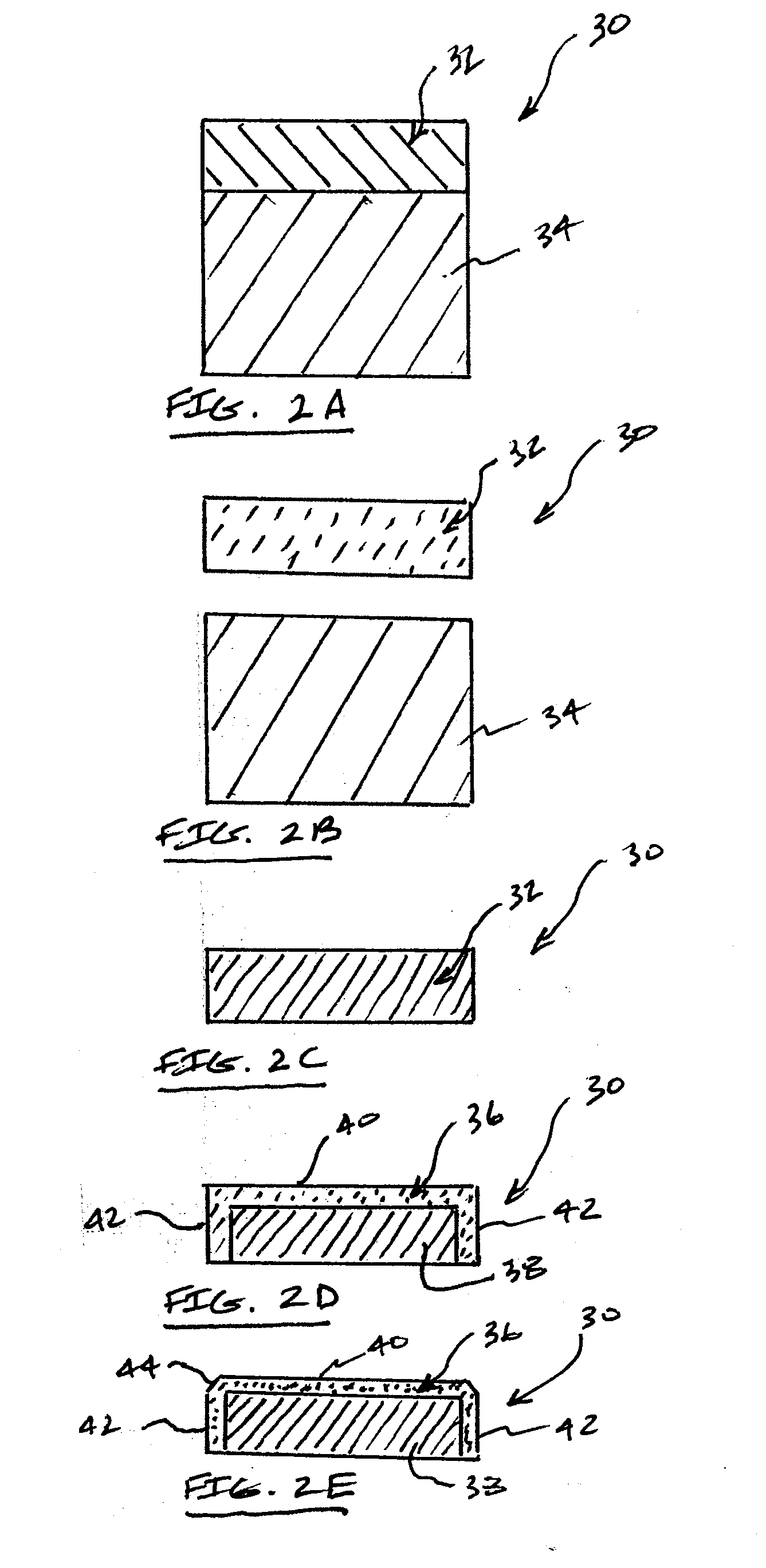

Diamond-bonded bodies and compacts with improved thermal stability and mechanical strength

Thermally stable diamond-bonded compacts include a diamond-bonded body having a thermally stable region extending a distance below a diamond-bonded body surface. The thermally stable region comprises a matrix first phase of bonded together diamond crystals, and a second phase interposed within the matrix phase. At least some population of the second phase comprises a reaction product formed between an infiltrant material and the diamond crystals at high pressure / high temperature conditions. The diamond bonded body further includes a polycrystalline diamond region that extends a depth from the thermally stable region and has a microstructure comprising a polycrystalline diamond matrix phase and a catalyst material disposed within interstitial regions of the matrix phase. The compact includes a substrate attached to the diamond-bonded body.

Owner:SMITH INT INC

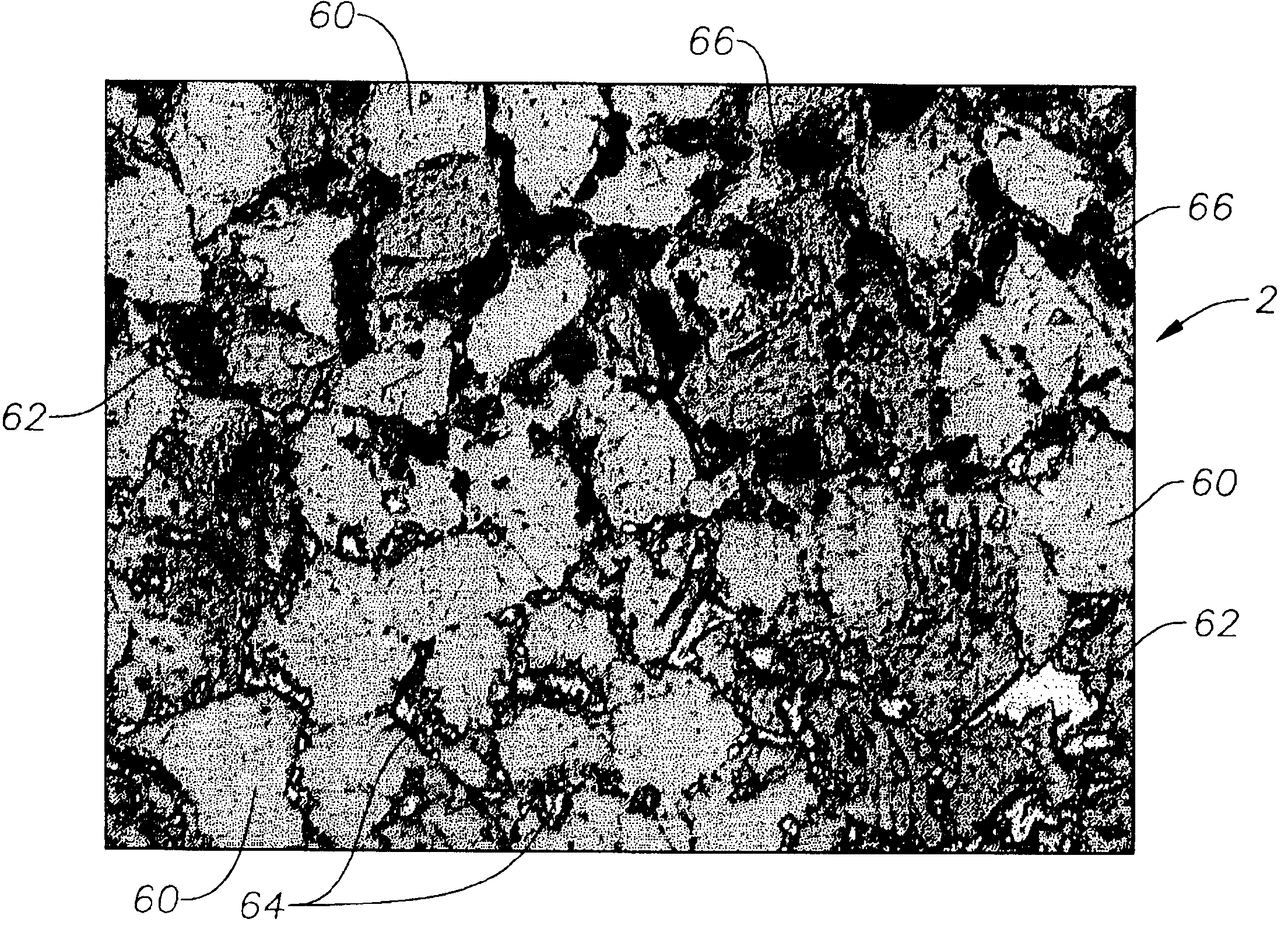

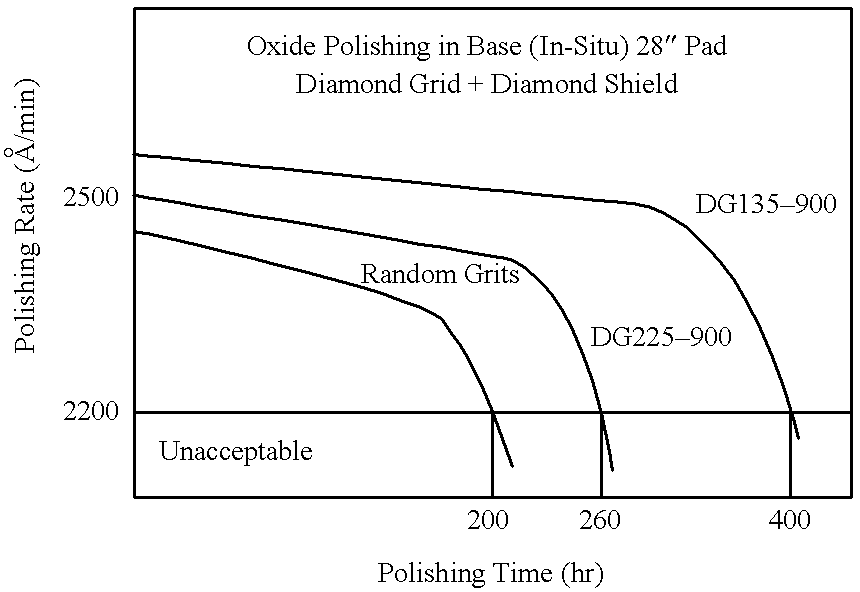

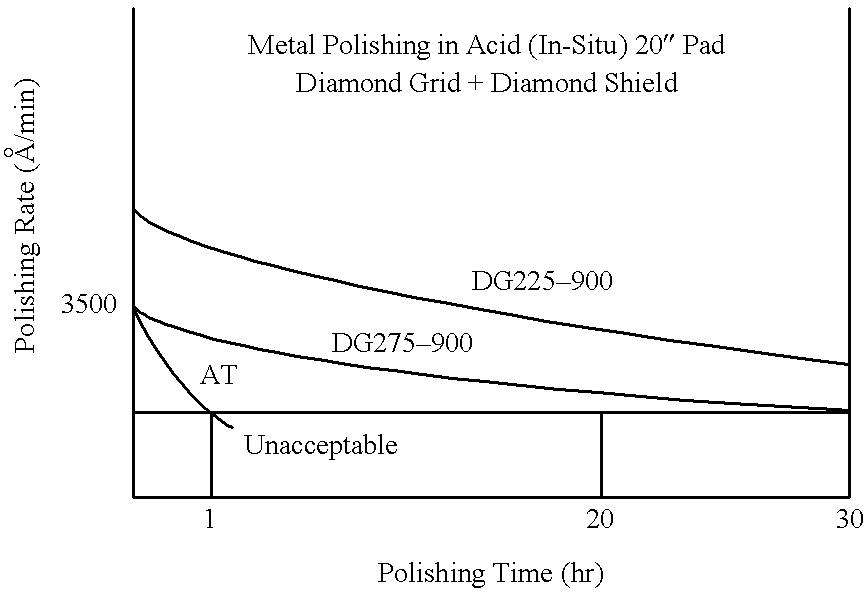

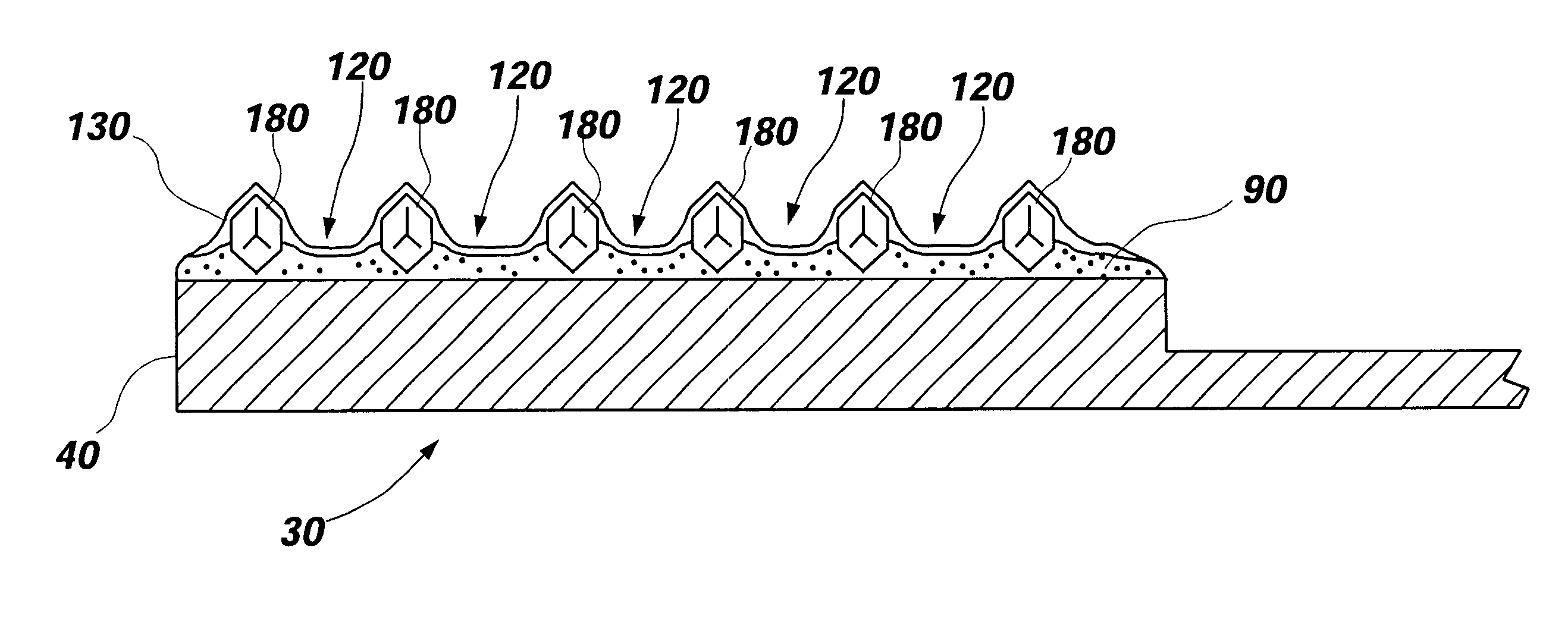

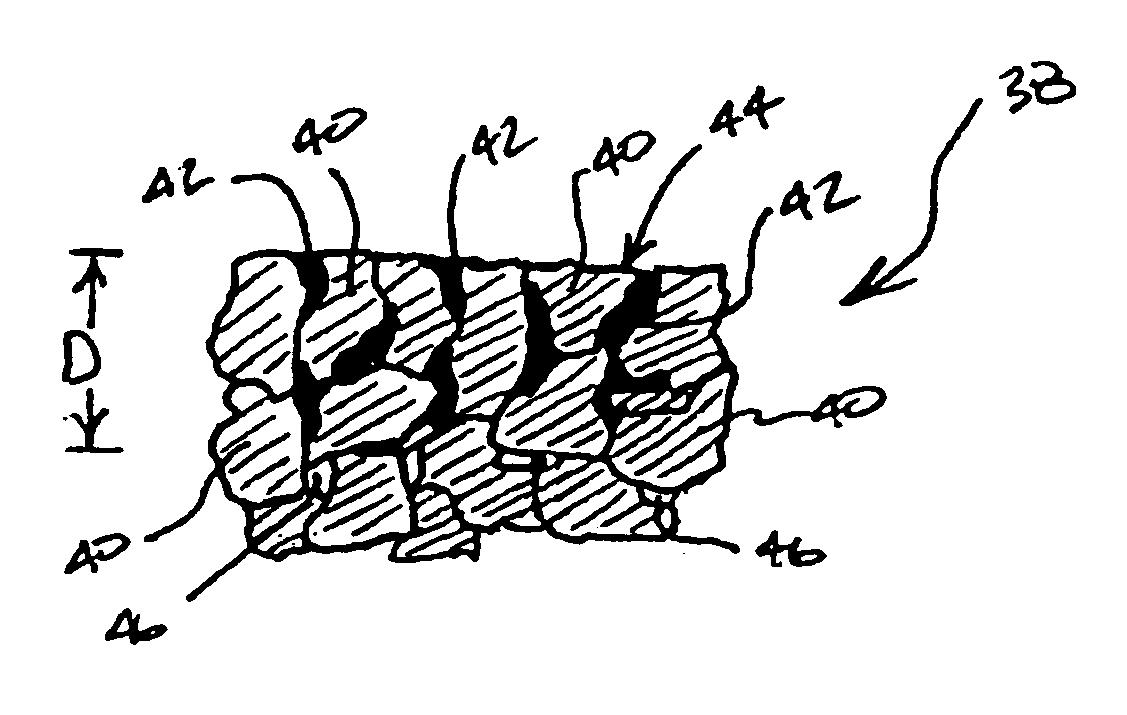

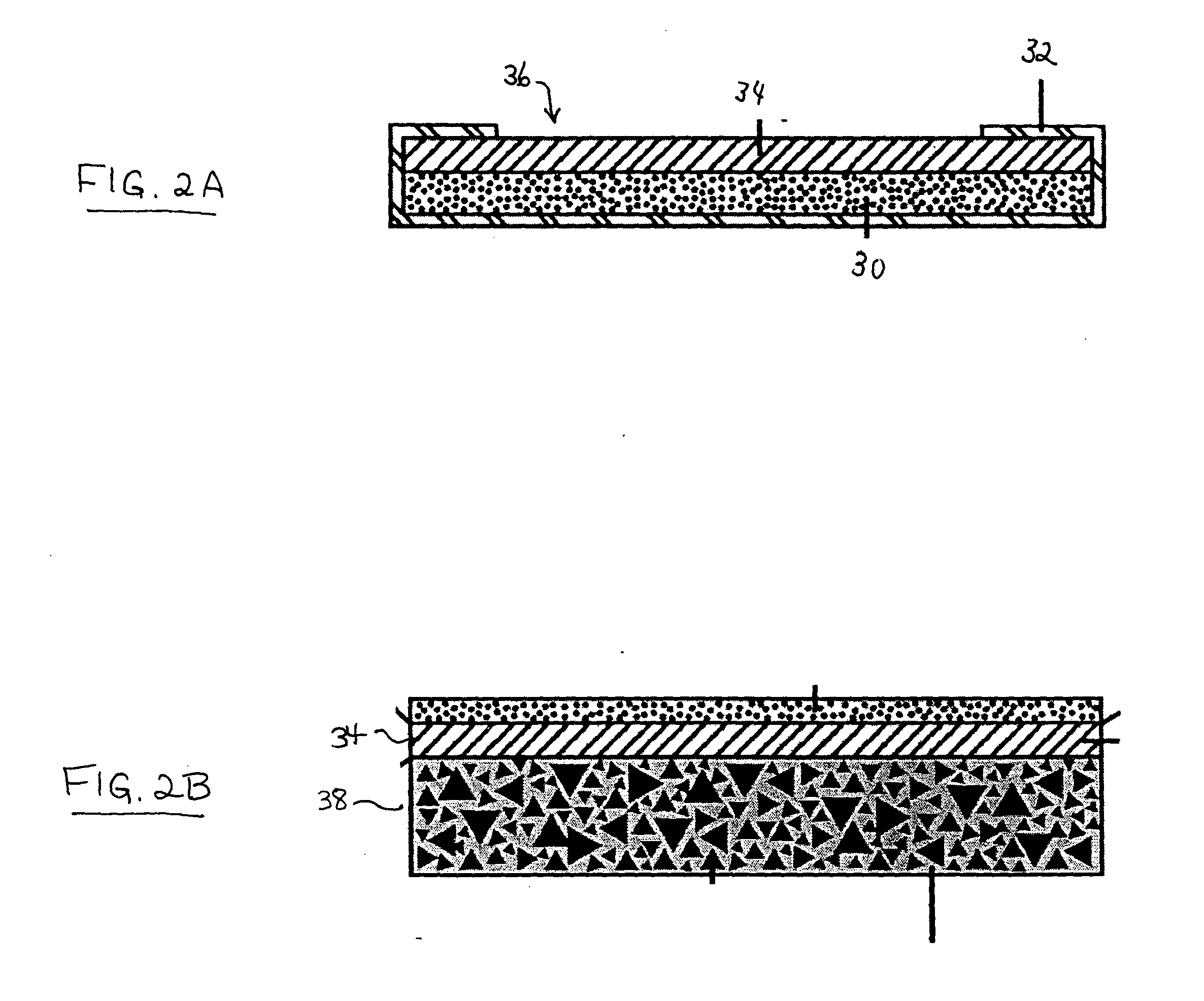

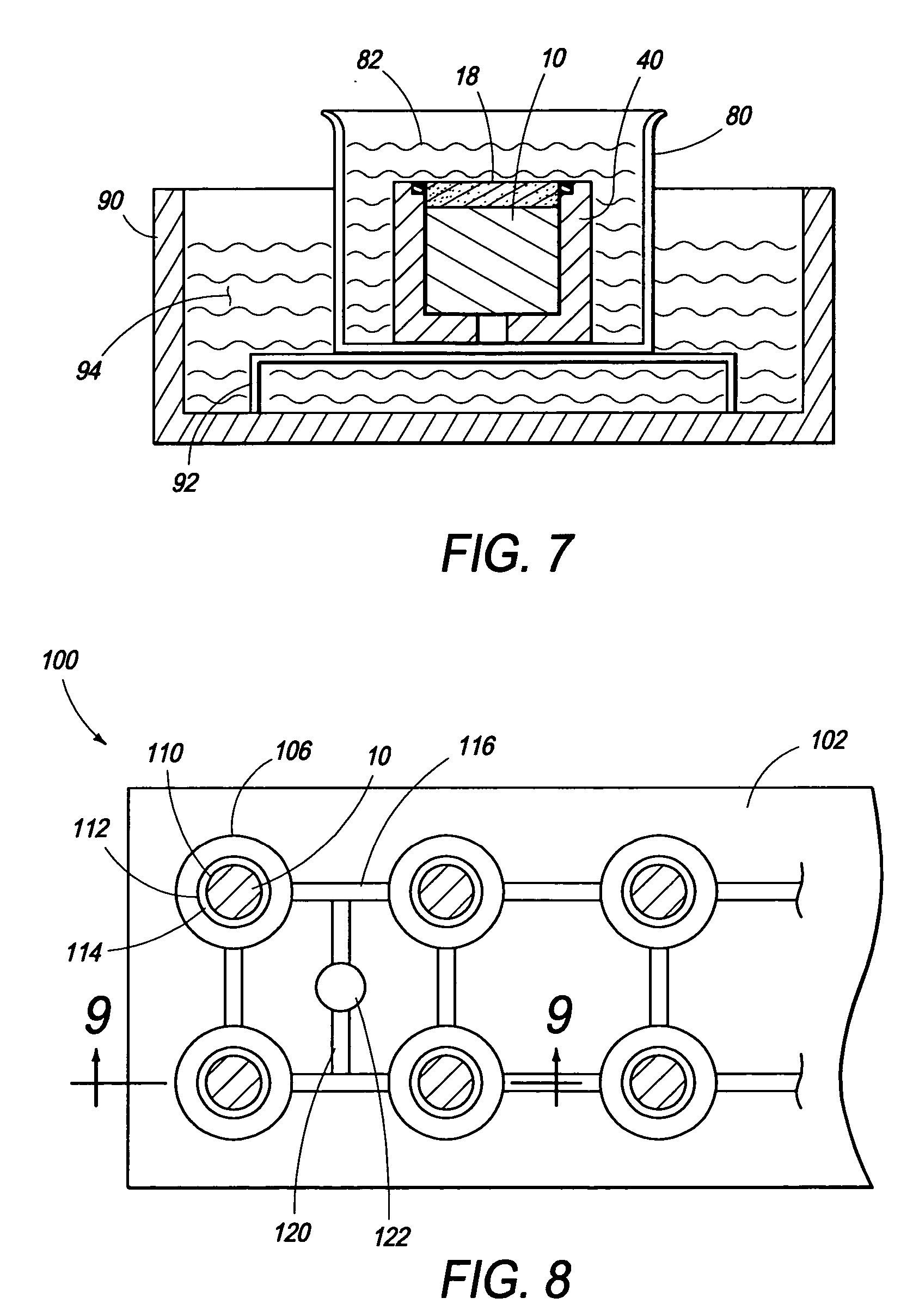

Diamond grid CMP pad dresser

InactiveUS6368198B1Improve polishing efficiencyExtended service lifePolishing machinesRevolution surface grinding machinesSuperhard materialDiamond-like carbon

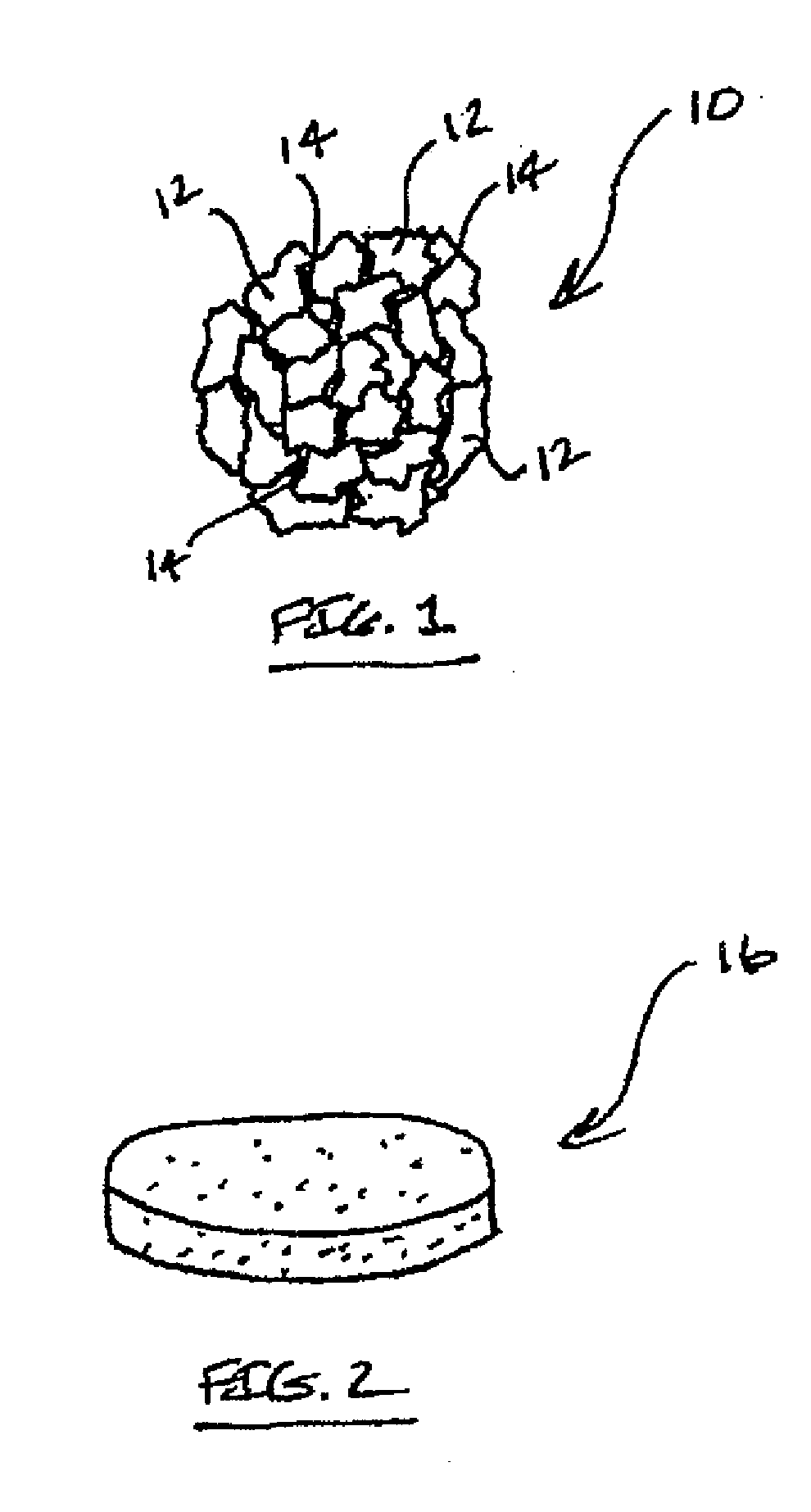

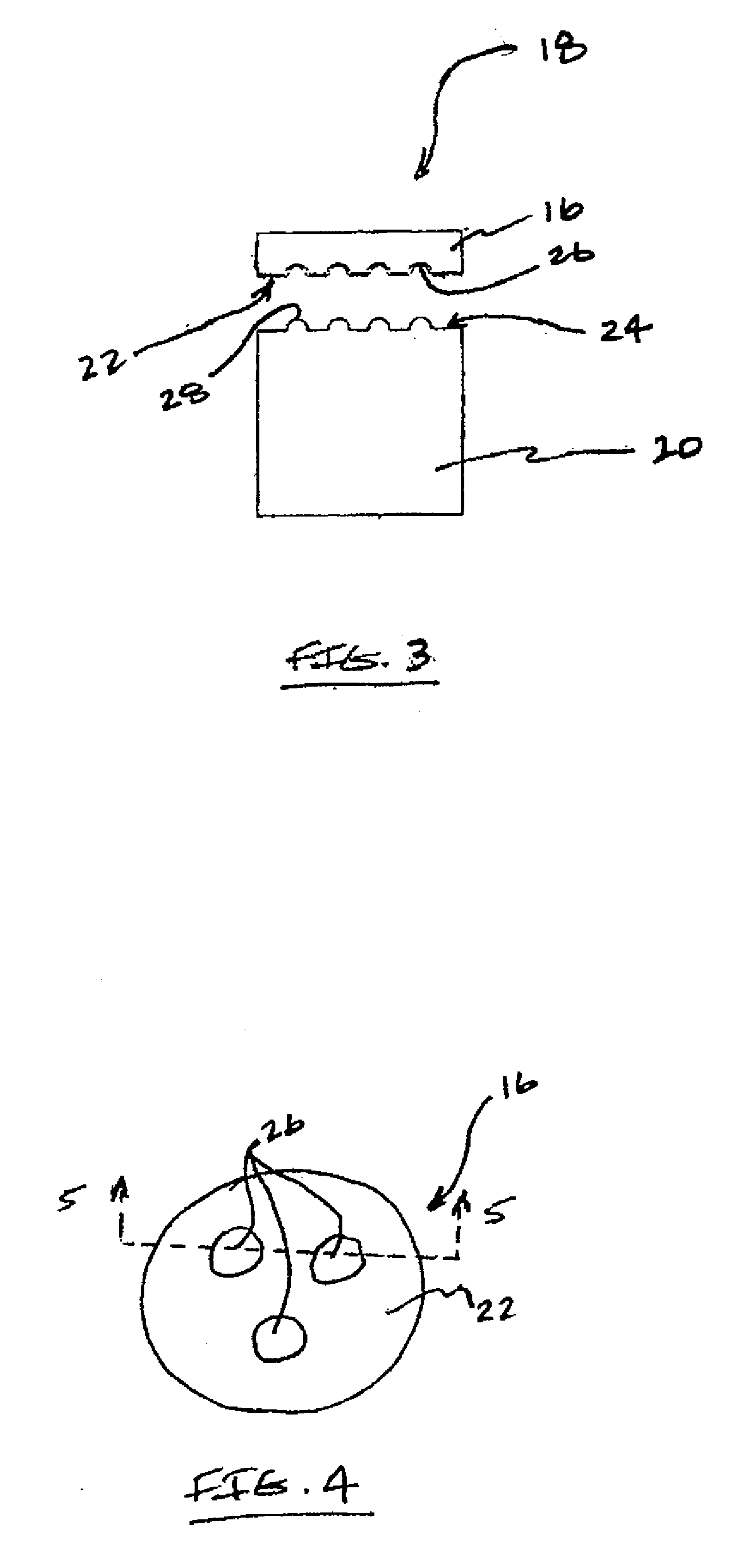

The present invention discloses a CMP pad dresser which has a plurality of uniformly spaced abrasive particles protruding therefrom. The abrasive particles are super hard materials, and are typically diamond, polycrystalline diamond (PCD), cubic boron nitride (cBN), or polycrystalline cubic boron nitride(PcBN). The abrasive particles are brazed to a substrate which may be then coated with an additional anti-corrosive layer. The anti-corrosive layer is usually a diamond or diamond-like carbon which is coated over the surface of the disk to prevent erosion of the brazing alloy by the chemical slurry used in conjunction with the CMP pad. This immunity to chemical attack allows the CMP pad dresser to dress the pad while it is polishing a workpiece. In addition to even spacing on the substrate, the abrasive particles extend for a uniform distance away from the substrate, allowing for even grooming or dressing of a CMP pad both in vertical and horizontal directions. A method of producing such a CMP pad dresser is also disclosed.

Owner:KINIK

Thermally stable diamond polycrystalline diamond constructions

ActiveUS20060060392A1Improve thermal stabilityGood adhesionDrill bitsConstructionsDiamond crystalPolycrystalline diamond

Thermally stable diamond constructions comprise a diamond body having a plurality of bonded diamond crystals and interstitial regions disposed among the crystals. A metallic substrate is attached to the body. The body includes a first region substantially free of a catalyst material that extends a partial depth from a surface into the body, and a second region that includes the catalyst material. The body can include natural diamond grains and / or a blend of natural and synthetic diamond grains, and is treated to form the first region. Before treatment, a portion of the body to be treated is finished to an approximate final dimension so that the depth of the first region of the finished product is substantially the same as when treated. During treatment, catalyst materials as well as non-catalyst metallic materials are removed from the diamond body to provide a further enhanced degree of thermal stability.

Owner:SMITH INT INC

Polycrystalline diamond partially depleted of catalyzing material

Owner:REEDHYCALOG UK

Polycrystalline diamond having improved thermal stability

InactiveUS20080230280A1Improved thermal characteristic and mechanical propertyAvoiding unwanted deteriorationDrill bitsConstructionsPolycrystalline diamondThermal stability

PCD constructions include a PCD body comprising a polycrystalline matrix region, a first region that includes a replacement material positioned remote from a body surface, and a second region that is substantially free of the replacement material and that extends a depth from the body surface. The PCD construction can further include a substrate that is attached to the body. The PCD body is formed by removing a solvent catalyst material used to form the body, replacing the removed solvent catalyst material with a replacement material, and then removing the replacement material from a region of the body to thereby form the second region. The replacement material can be introduced into the PCD body during a HPHT process, and the substrate may or may not be the source of the noncatalyzing material.

Owner:SMITH INT INC

Polycrystalline diamond compact (PDC) cutting element having multiple catalytic elements

InactiveUS7635035B1Improve thermal stabilityPigmenting treatmentDrill bitsPolycrystalline diamondThermal stability

A polycrystalline diamond compact useful for wear, cutting, drilling, drawing and like applications is provided with a first diamond region remote from the working surface which has a metallic catalyzing material and a second diamond region adjacent to or including the working surface containing a non-metallic catalyst and the method of making such a compact is provided. This compact is particularly useful in high temperature operations, such as hard rock drilling because of the improved thermal stability at the working surface.

Owner:US SYNTHETIC CORP

Thermally stable diamond polycrystalline diamond constructions

ActiveUS20060060390A1Improve thermal stabilityGood adhesionPigmenting treatmentDrill bitsDiamond crystalPolycrystalline diamond

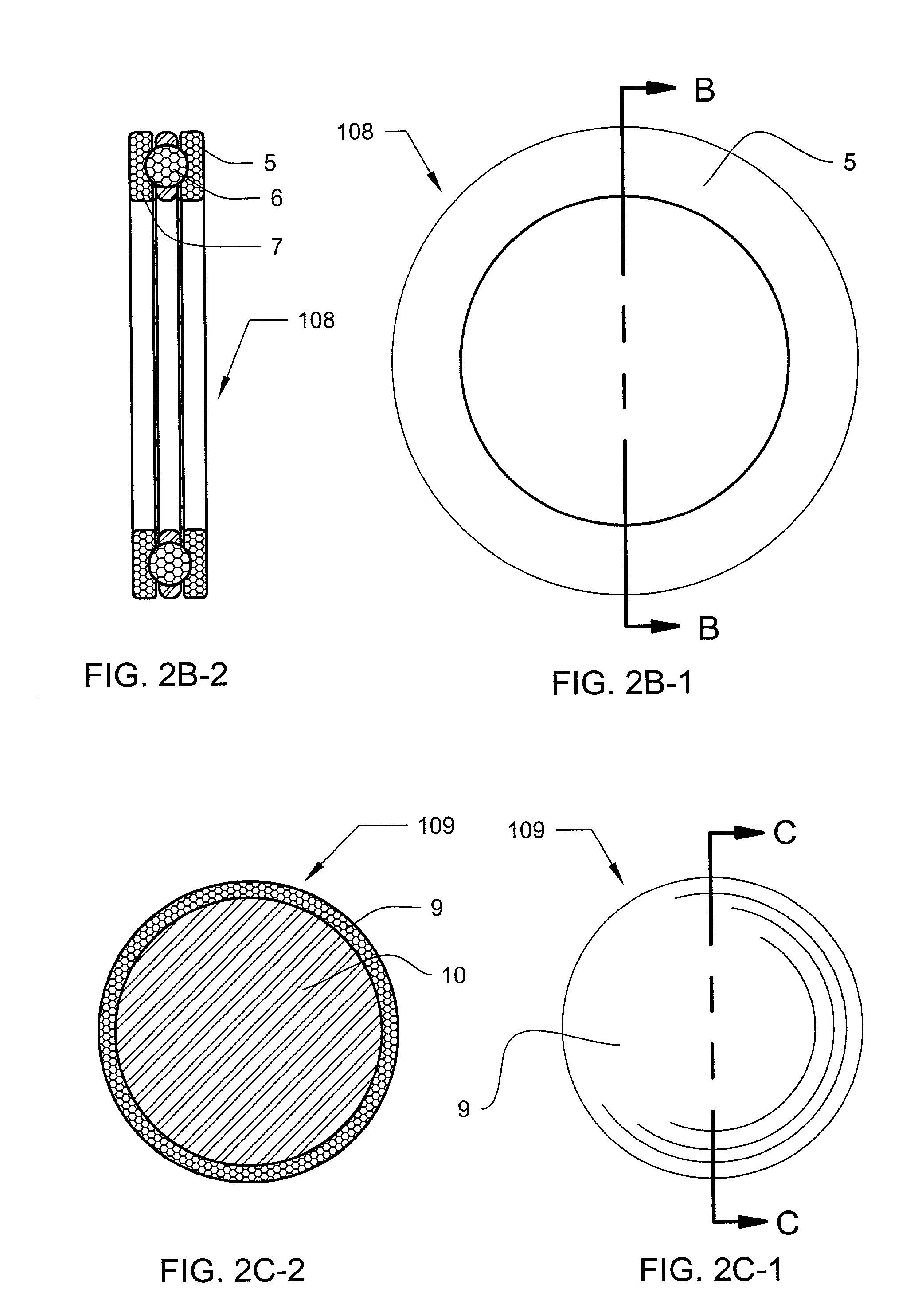

Thermally stable diamond constructions comprise a diamond body having a plurality of bonded diamond crystals, a plurality of interstitial regions disposed among the crystals, and a substrate attached to the body. The body includes a working surface and a side surface extending away from the working surface to the substrate. The body comprises a first region adjacent the side surface that is substantially free of a catalyst material and that extends a partial depth into the diamond body. The first region can further extend to at least a portion of the working surface and a partial depth therefrom into the diamond body. The diamond body can be formed from natural diamond grains and / or a mixture of natural and synthetic diamond grains. A surface of the diamond body is treated to provide the first region, and before treatment is finished to an approximate final dimension.

Owner:SMITH INT INC

Polycrystalline diamond constructions having improved thermal stability

ActiveUS20080223623A1Good adhesionImprove thermal stabilityDrill bitsConstructionsDiamond crystalPolycrystalline diamond

Owner:SMITH INT INC

Thermally stable polycrystalline diamond cutting elements and bits incorporating the same

Owner:SMITH INT INC

Thermally-stable polycrystalline diamond materials and compacts

InactiveUS20050230156A1Improve thermal stabilityImprove bindingDrill bitsConstructionsDiamond crystalPolycrystalline diamond

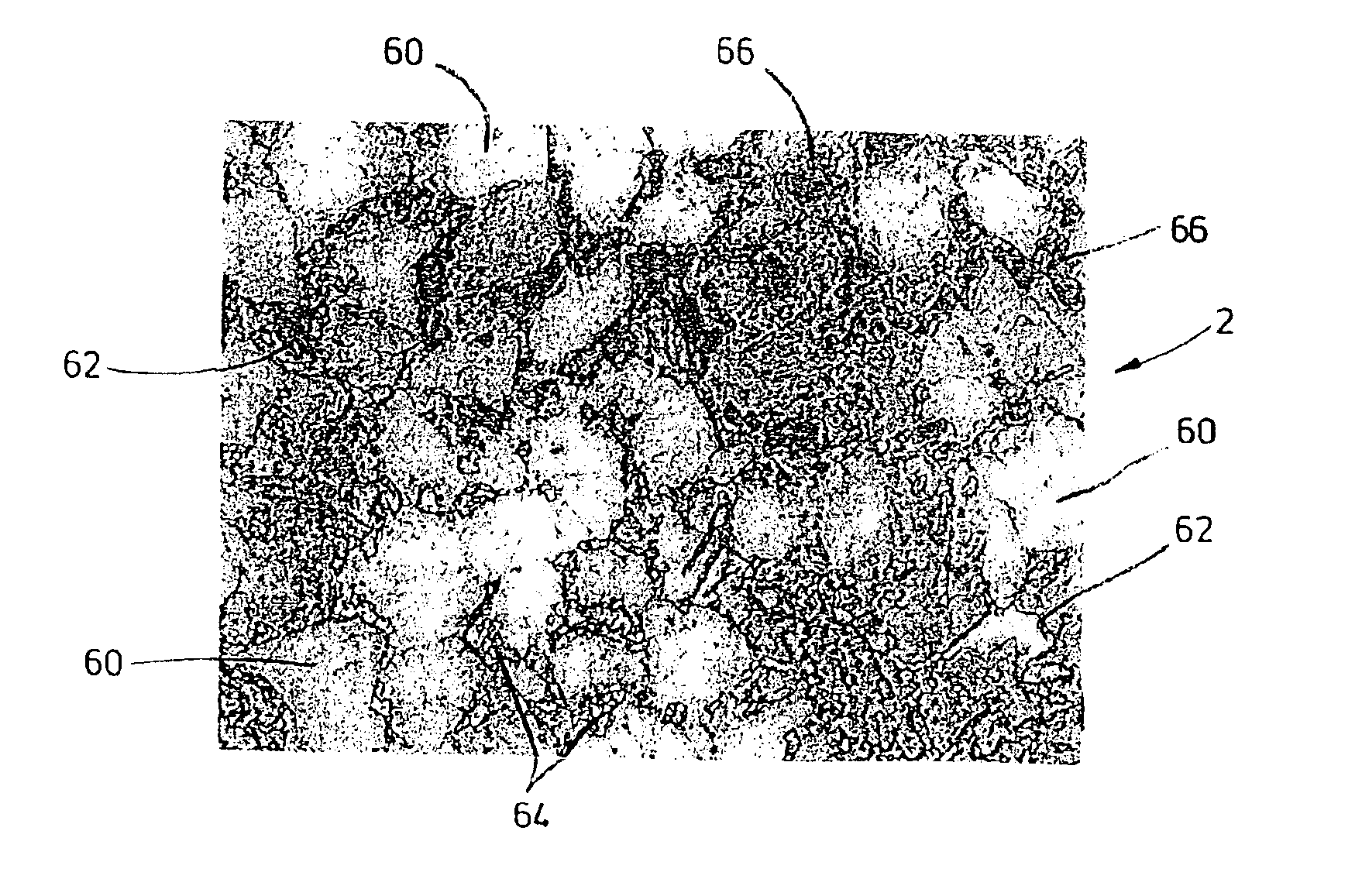

Thermally-stable polycrystalline diamond materials of this invention comprise a first phase including a plurality of bonded together diamond crystals, and a second phase including a reaction product formed between a binder / catalyst material and a material reactive with the binder / catalyst material. The reaction product is disposed within interstitial regions of the polycrystalline diamond material that exists between the bonded diamond crystals. The first and second phases are formed during a single high pressure / high temperature process condition. The reaction product has a coefficient of thermal expansion that is relatively closer to that of the bonded together diamond crystals than that of the binder / catalyst material, thereby providing an improved degree of thermal stability to the polycrystalline diamond material.

Owner:SMITH INT INC

Polycrystalline diamond materials having improved abrasion resistance, thermal stability and impact resistance

ActiveUS20060266559A1Improve propertiesDrill bitsConstructionsDiamond crystalPolycrystalline diamond

PCD materials comprise a diamond body having bonded diamond crystals and interstitial regions disposed among the crystals. The diamond body is formed from diamond grains and a catalyst material at high pressure / high temperature conditions. The diamond grains have an average particle size of about 0.03 mm or greater. At least a portion of the diamond body has a high diamond volume content of greater than about 93 percent by volume. The entire diamond body can comprise high volume content diamond or a region of the diamond body can comprise the high volume content diamond. The diamond body includes a working surface, a first region substantially free of the catalyst material, and a second region that includes the catalyst material. At least a portion of the first region extends from the working surface to depth of from about 0.01 to about 0.1 mm.

Owner:SMITH INT INC

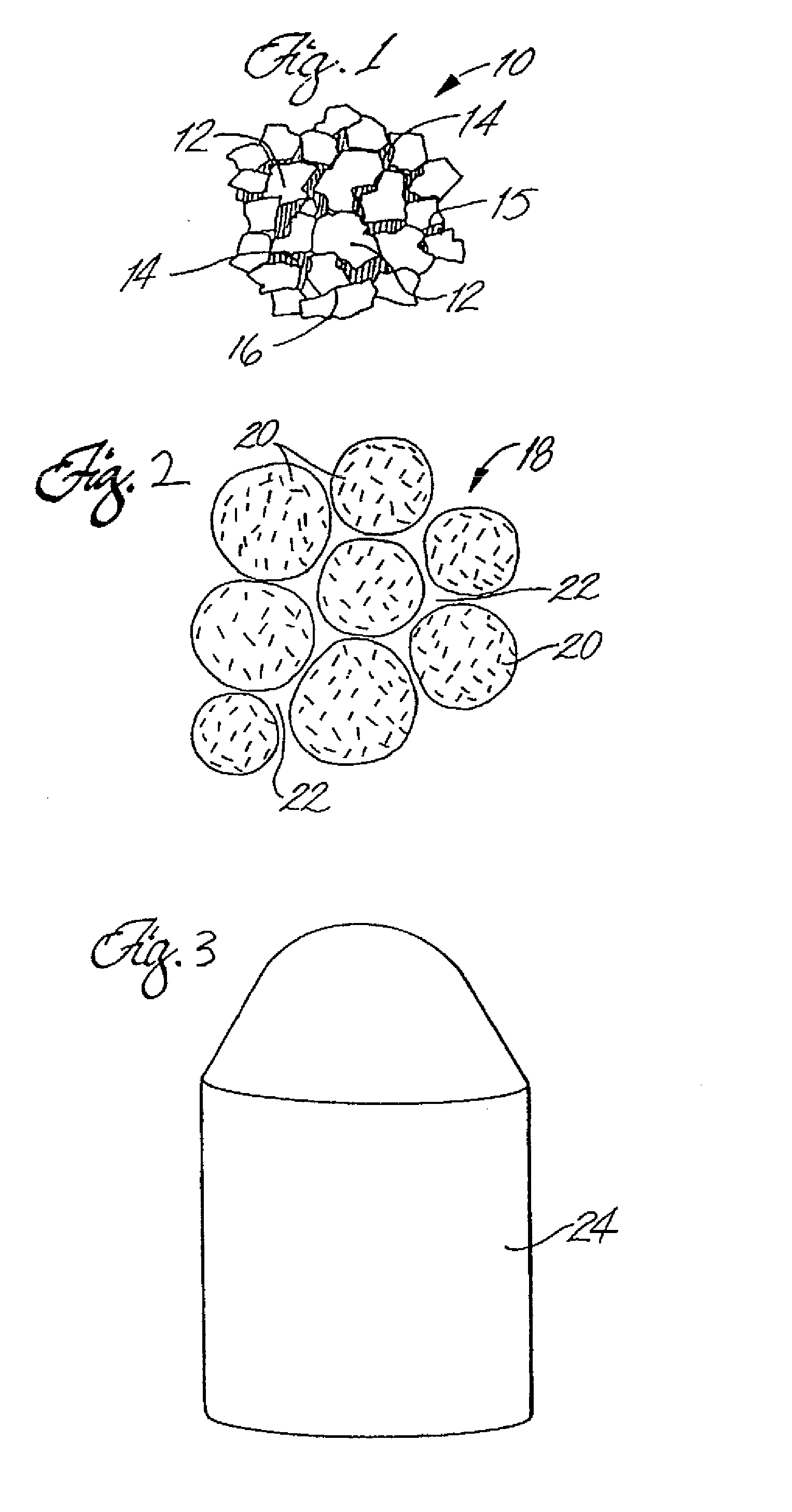

Nanodiamond PCD and methods of forming

InactiveUS20050019114A1Improve high temperature performanceReduce manufacturing costMaterial nanotechnologyPigmenting treatmentDiamond crystalPolycrystalline diamond

A nanodiamond tool, including a mass of sintered nanodiamond particles can be produced having improved mechanical, thermal, and electrical properties. The sintered mass can contain greater than about 95% by volume nanodiamond and greater than about 98% by volume carbon. Such nanodiamond tools can be formed by assembling a mass of nanodiamond particles and sintering the mass of nanodiamond particles to form a sintered mass. Prior to sintering, the mass of nanodiamond particles can be substantially free of non-carbon materials such as metal binders, sintering aids or the like. Upon sintering, the nanodiamond particles sinter together at high pressures and lower temperatures than those typically required in producing polycrystalline diamond compacts with diamond crystals of a larger size. The absence of non-carbon materials improves the high temperature performance and reliability of the nanodiamond tools of the present invention.

Owner:SUNG CHIEN MIN

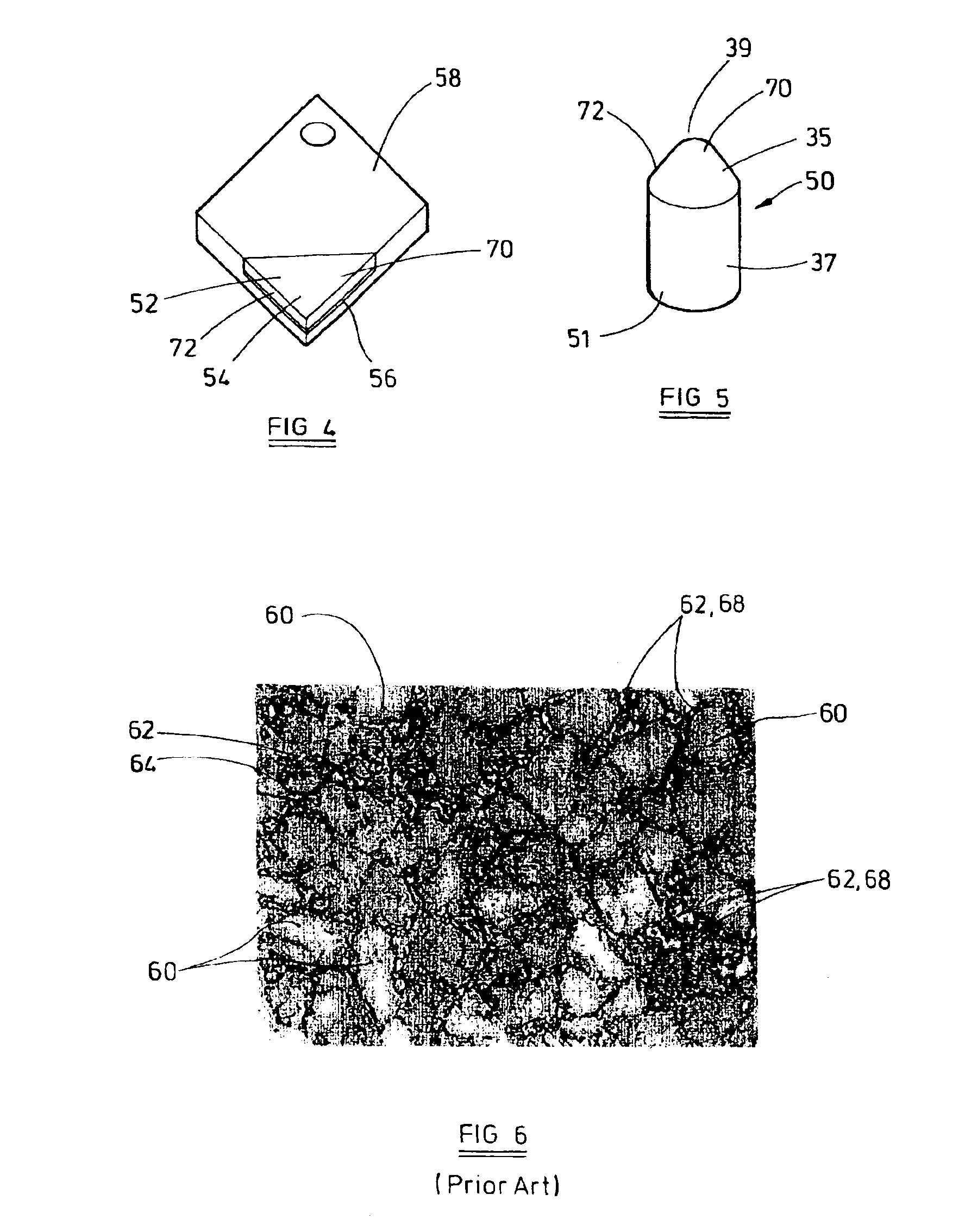

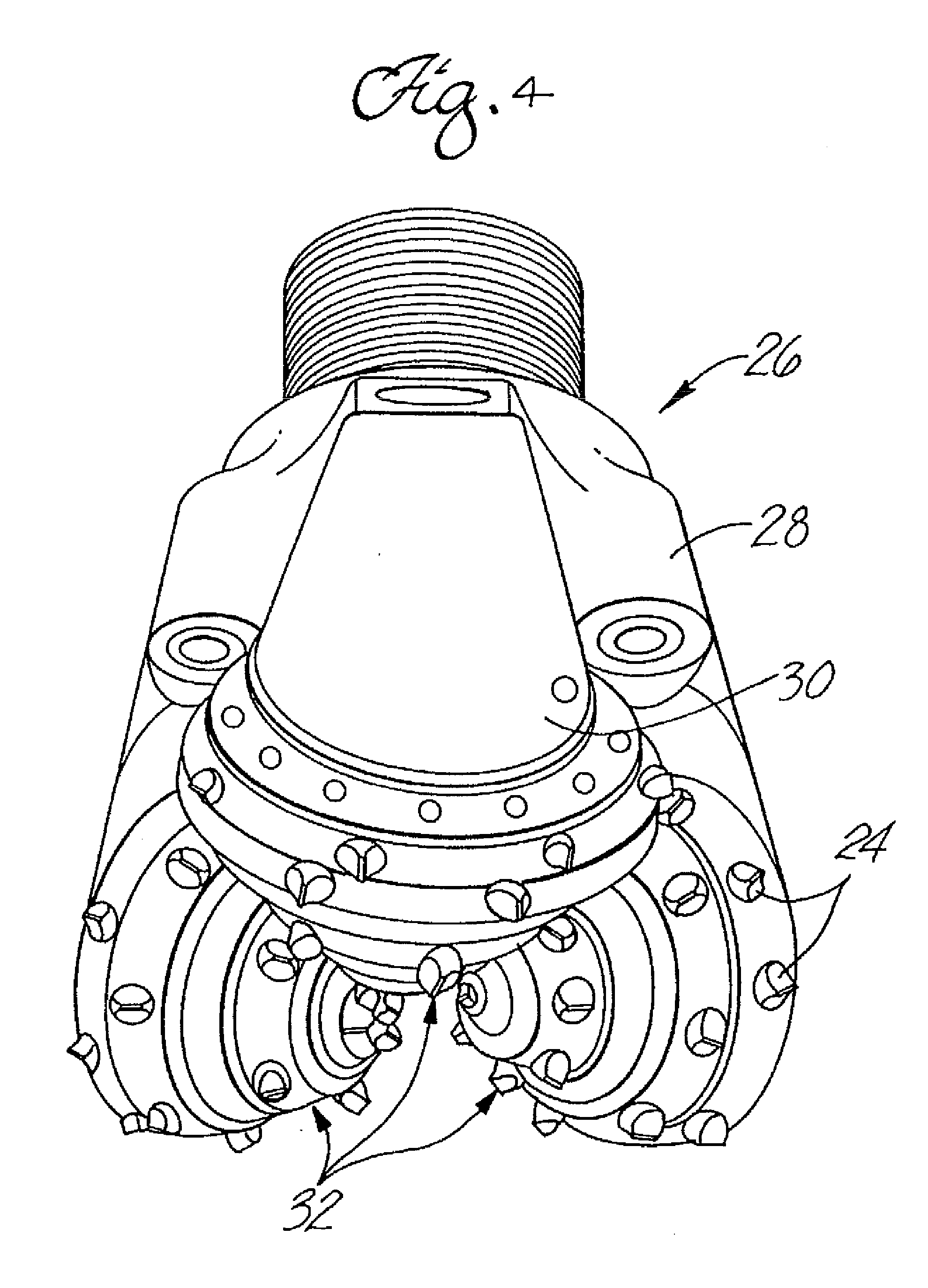

Polycrystalline diamond abrasive elements

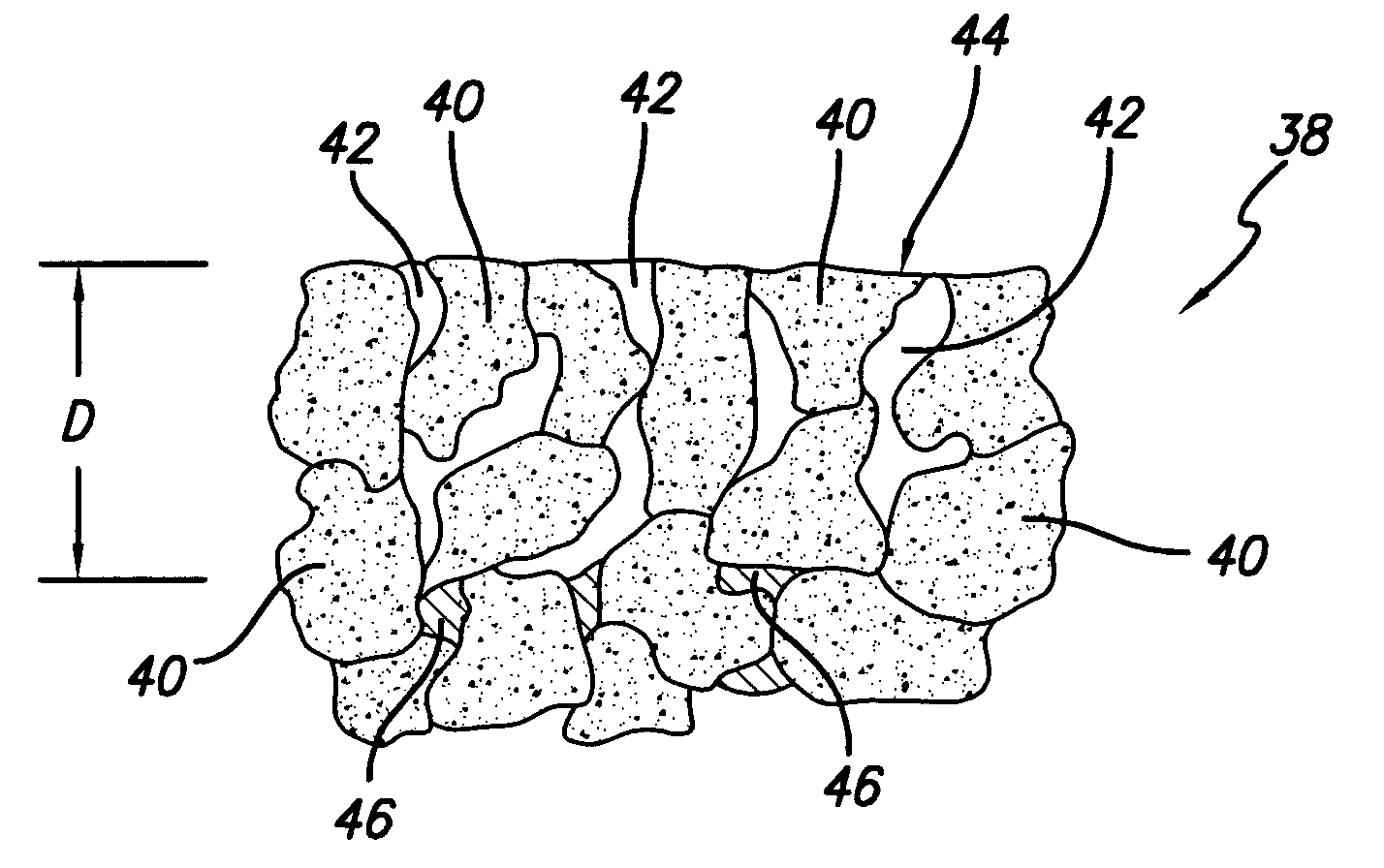

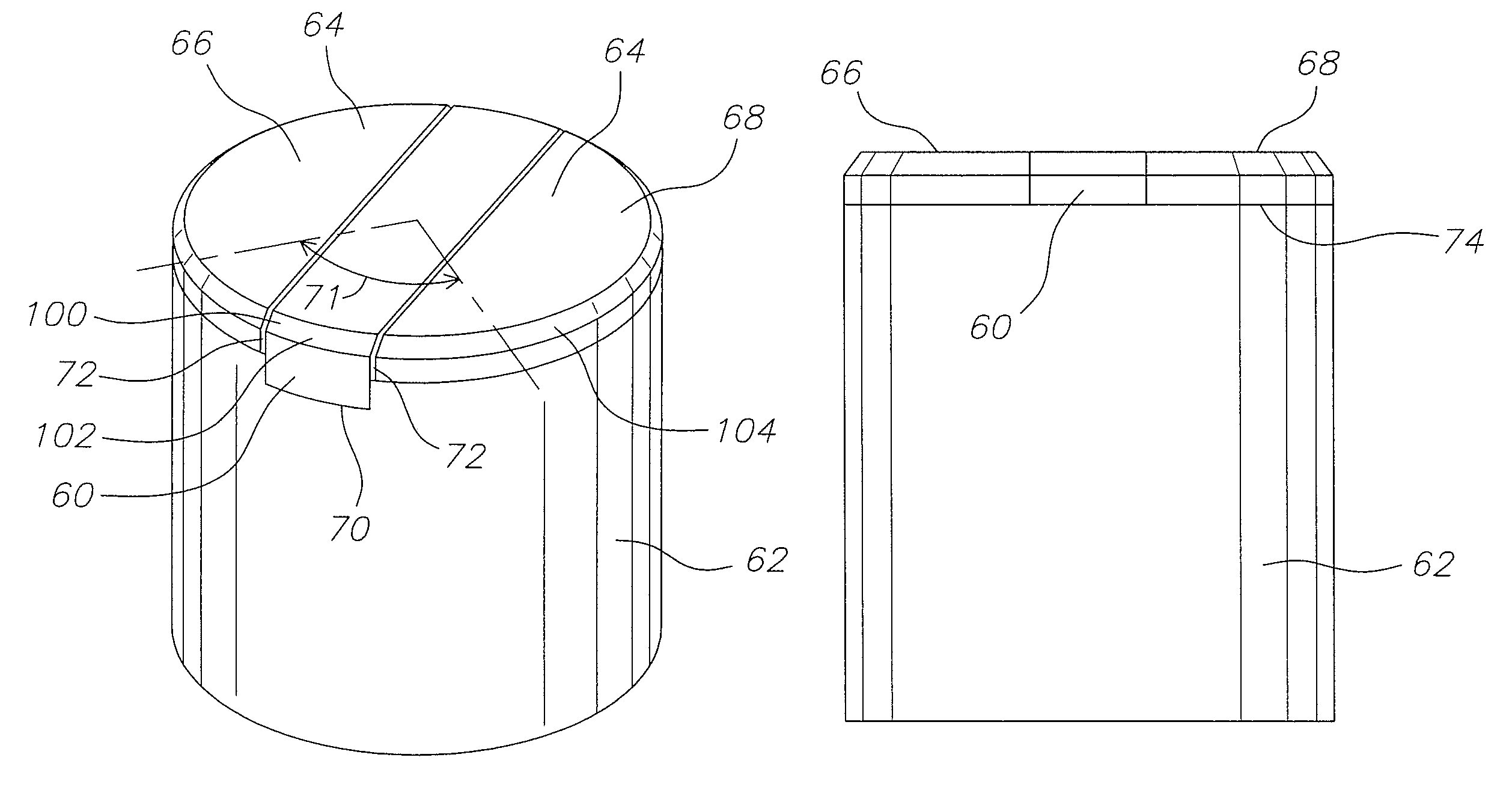

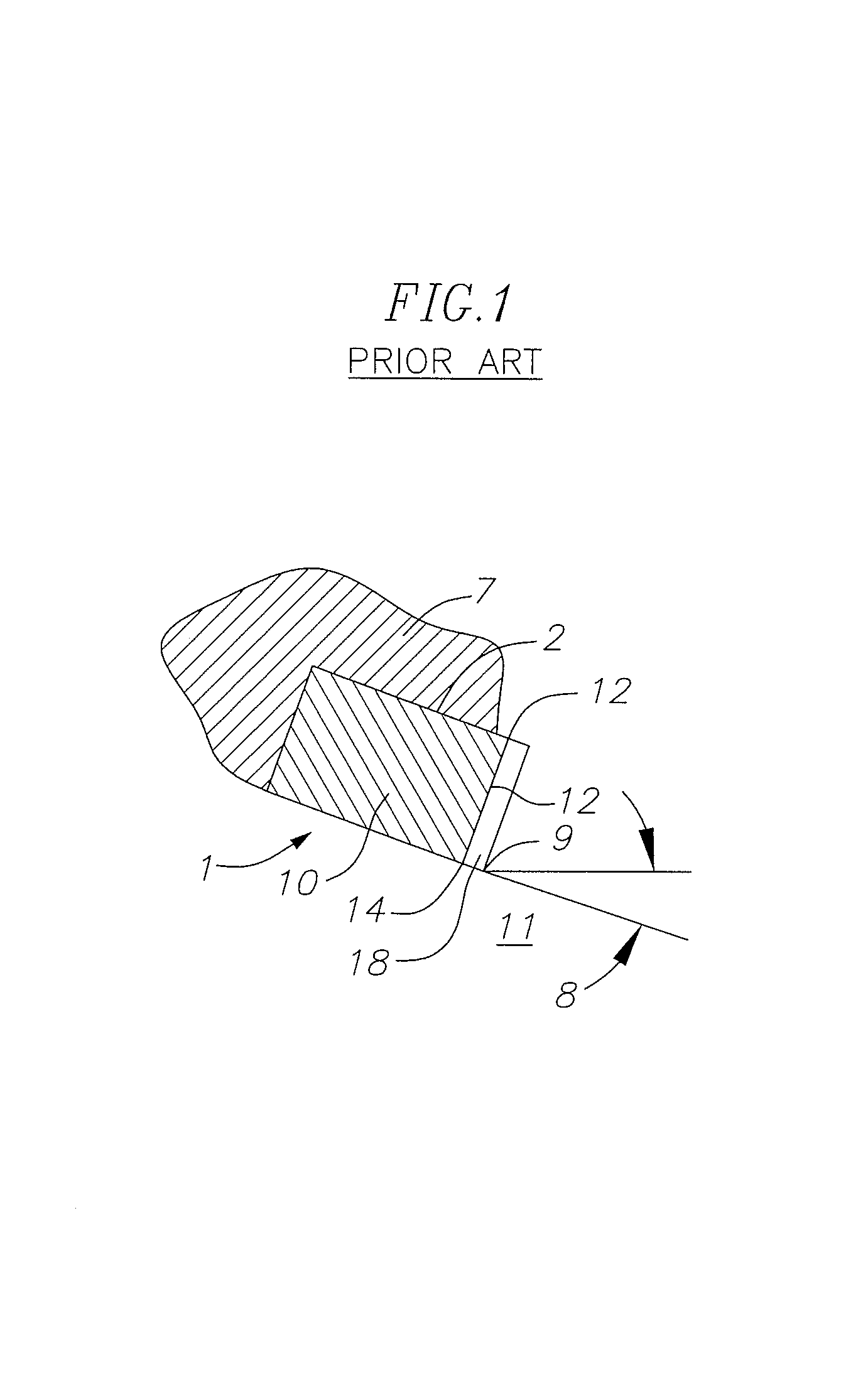

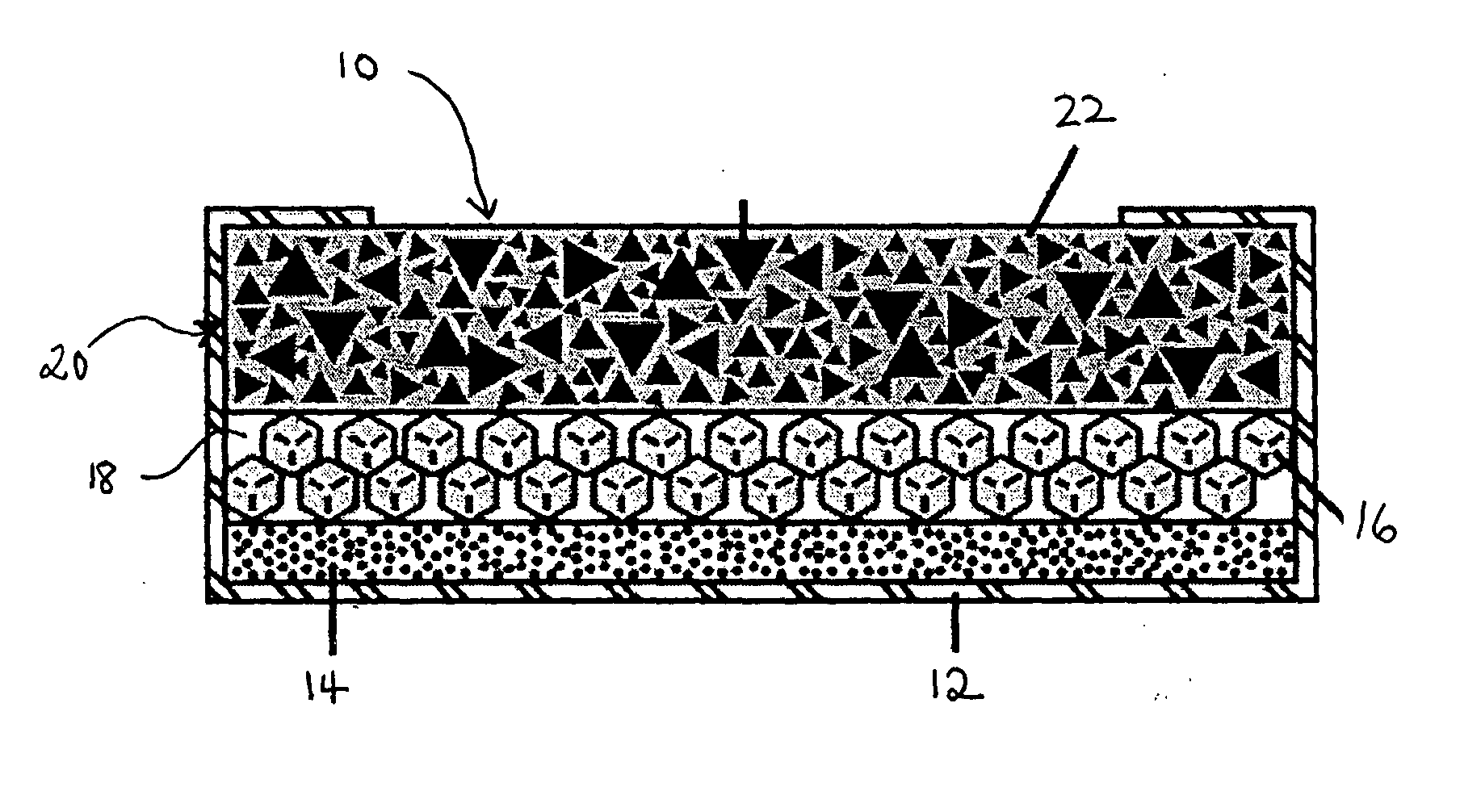

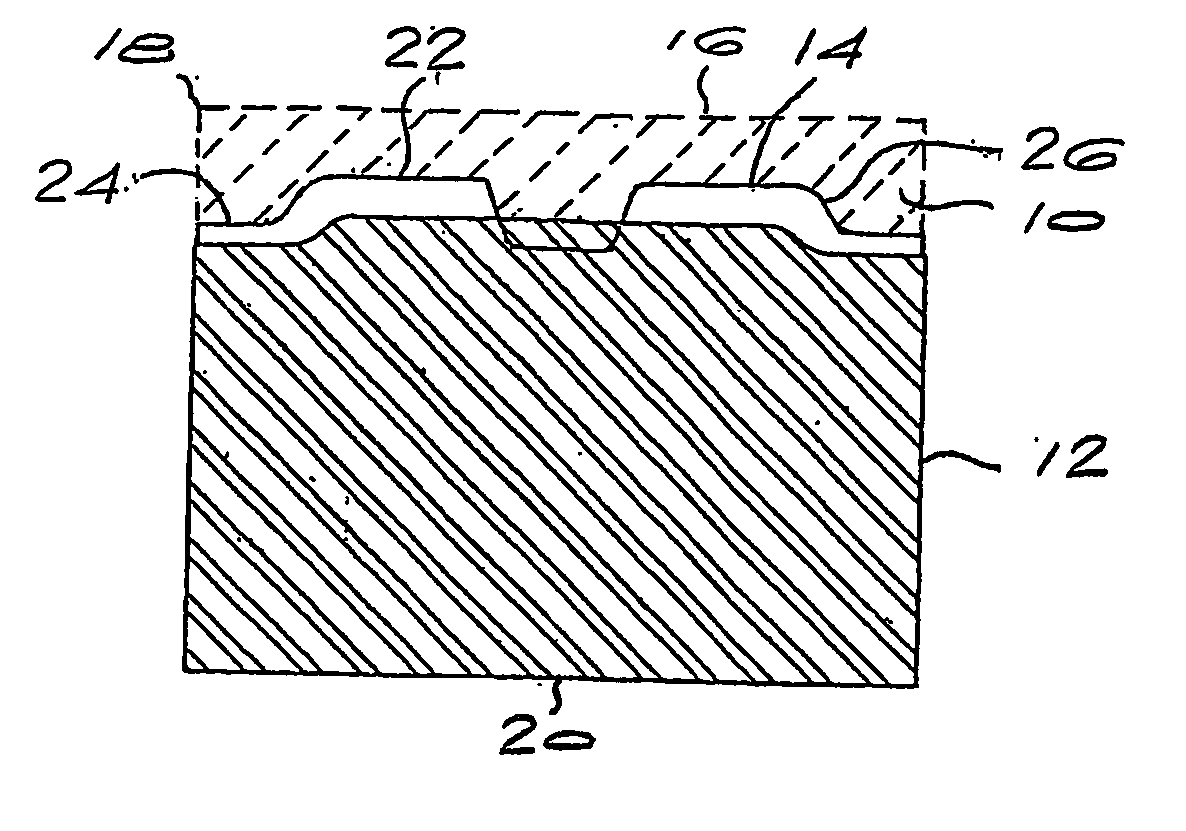

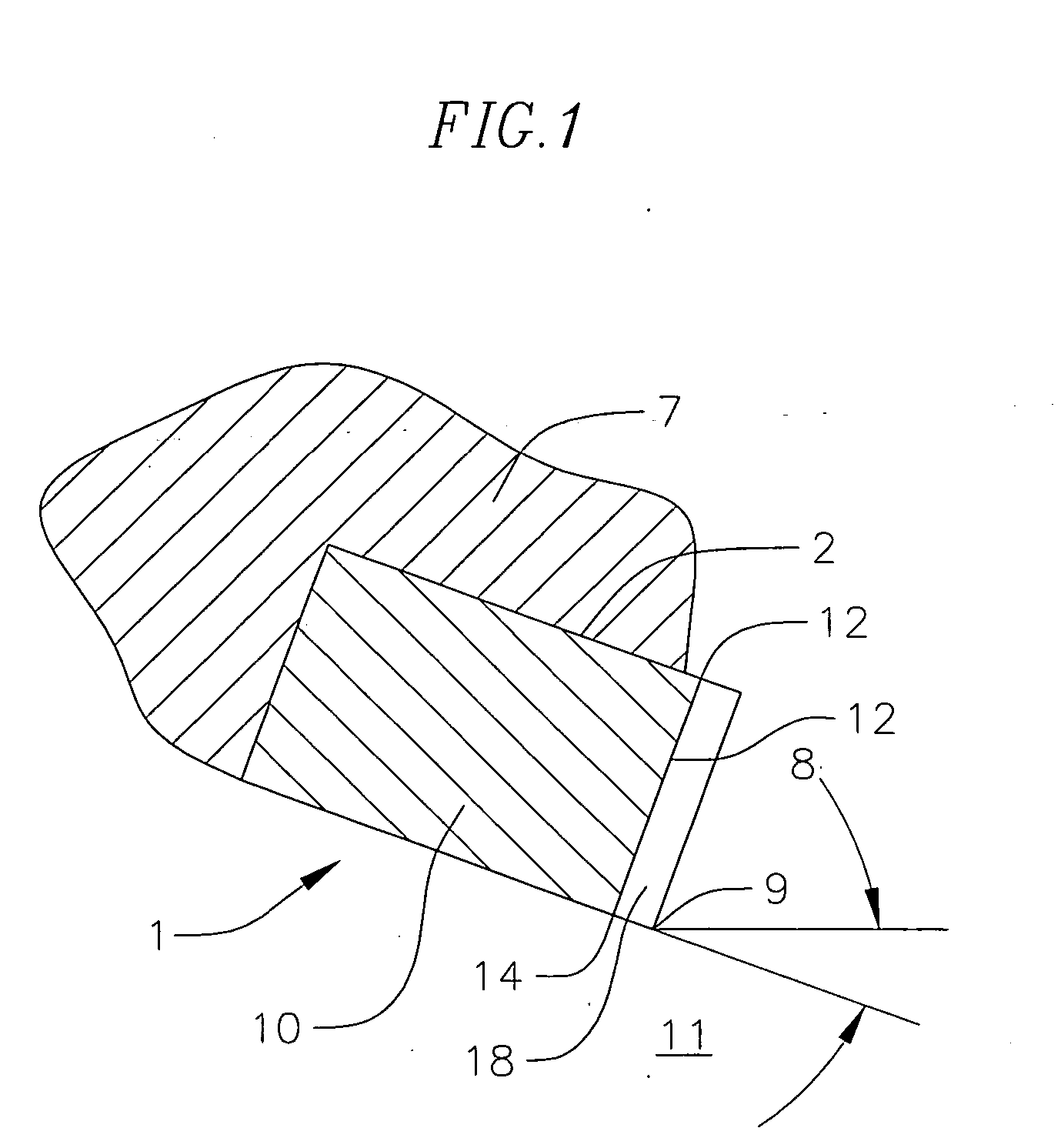

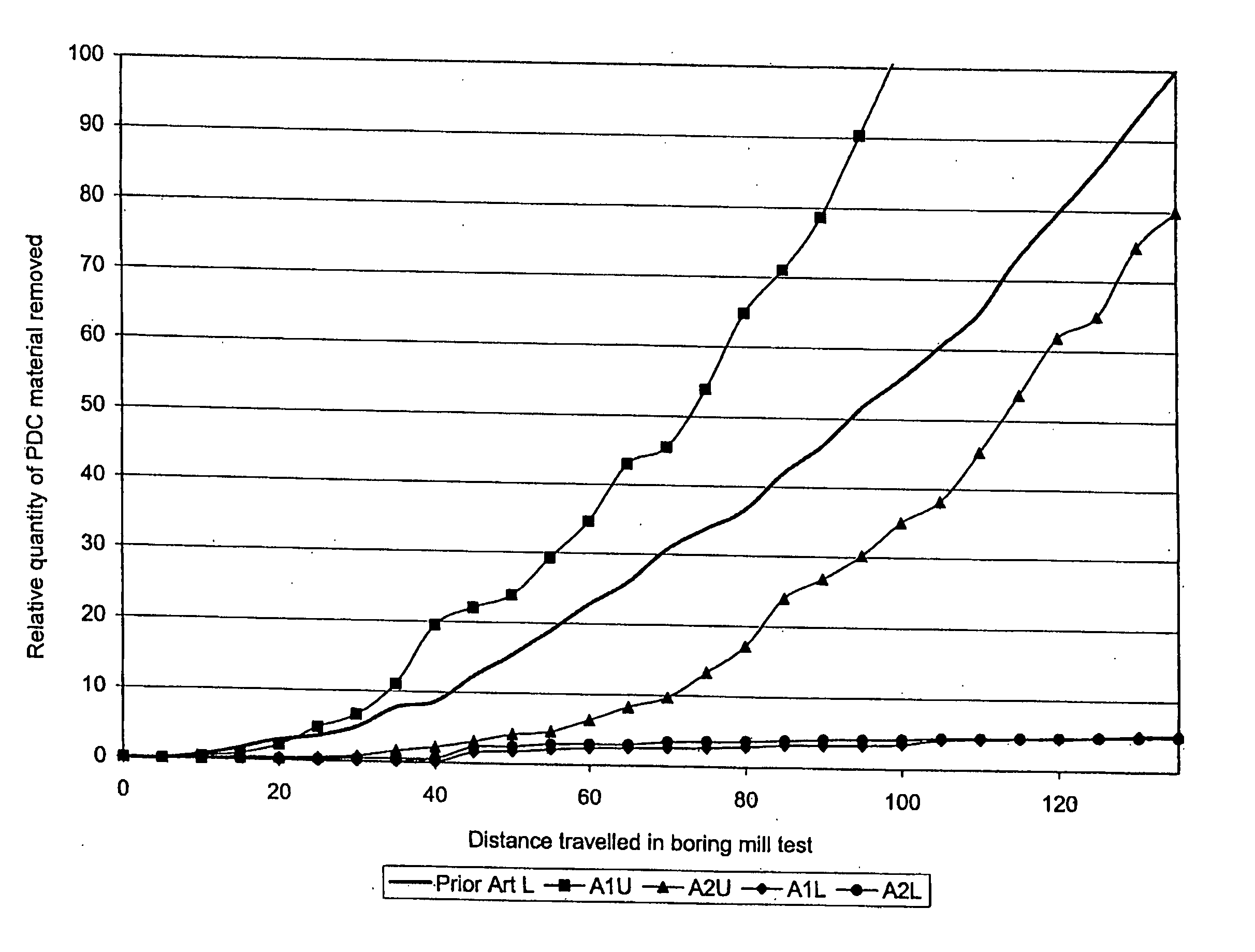

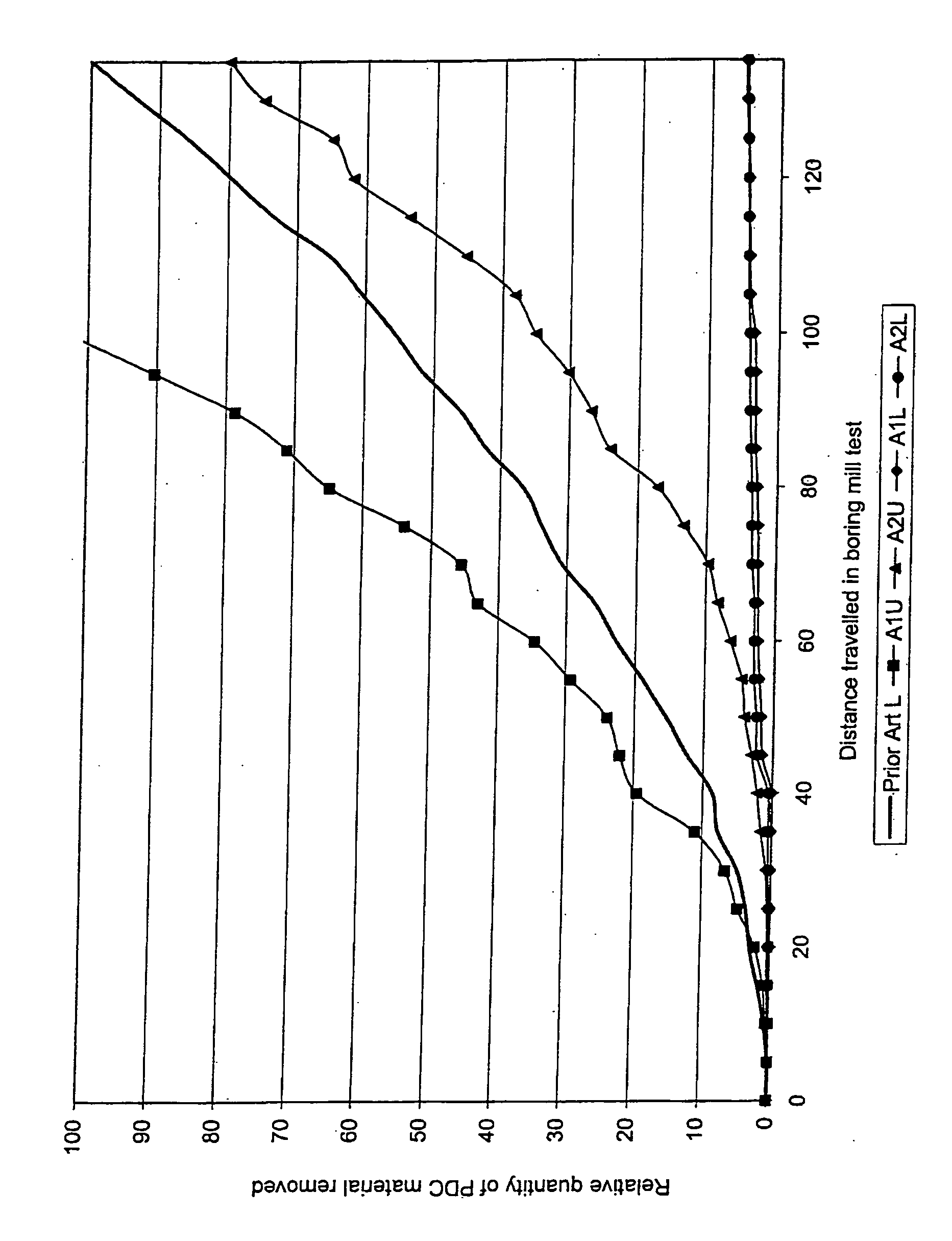

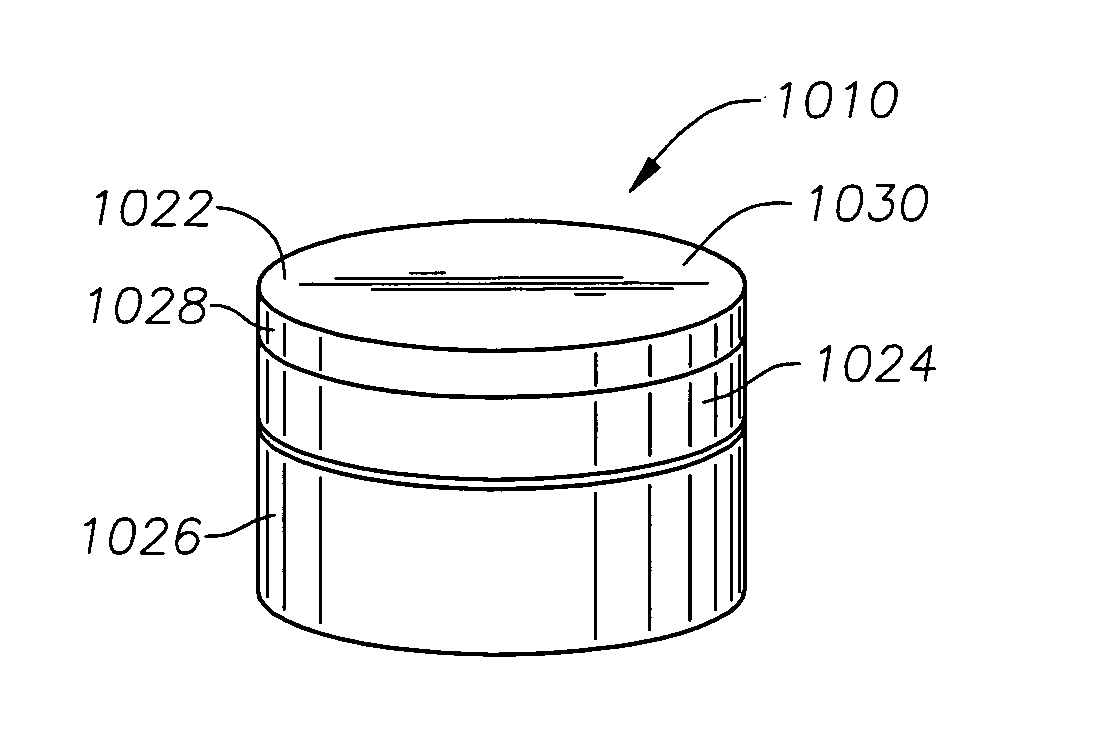

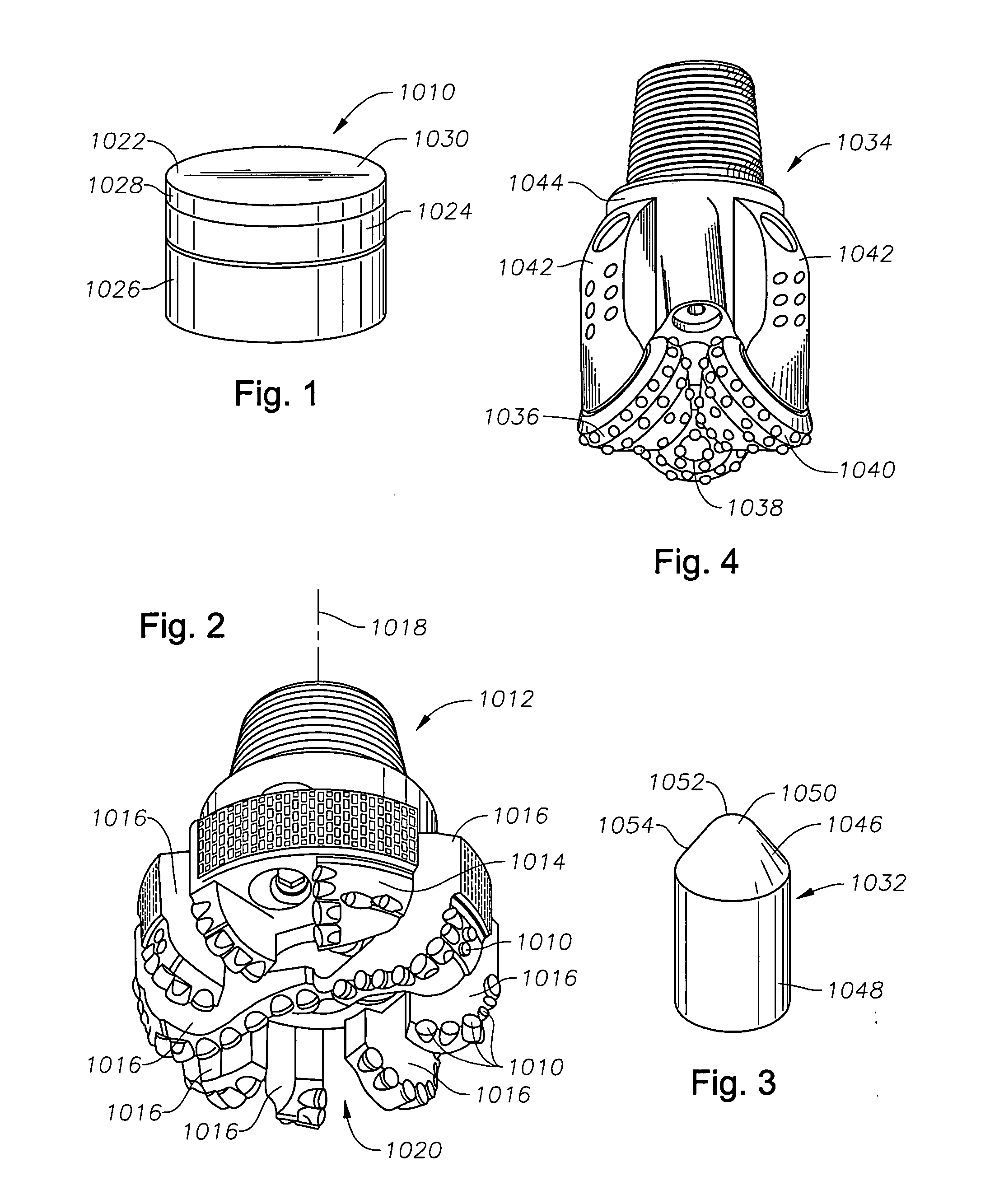

A polycrystalline diamond abrasive element, particularly a cutting element, comprises a table of polycrystalline diamond bonded to a substrate, particularly a cemented carbide substrate, along a non-planar interface. The non-planar interface typically has a cruciform configuration. The polycrystalline diamond has a high wear-resistance, and has a region adjacent the working surface lean in catalysing material and a region rich in catalysing material. The region lean in catalysing material extends to a depth of 40 to 90 microns, which is much shallower than in the prior art. Notwithstanding the shallow region lean in catalysing material, the polycrystalline diamond cutters have a wear resistance, impact strength and cutter life comparable to that of prior art cutter, but requiring only 20% of the treatment times of the prior art cutters.

Owner:BAKER HUGHES INC

Polycrystalline diamond materials having improved abrasion resistance, thermal stability and impact resistance

PCD materials comprise a diamond body having bonded diamond crystals and interstitial regions disposed among the crystals. The diamond body is formed from diamond grains and a catalyst material at high pressure / high temperature conditions. The diamond grains have an average particle size of about 0.03 mm or greater. At least a portion of the diamond body has a high diamond volume content of greater than about 93 percent by volume. The entire diamond body can comprise high volume content diamond or a region of the diamond body can comprise the high volume content diamond. The diamond body includes a working surface, a first region substantially free of the catalyst material, and a second region that includes the catalyst material. At least a portion of the first region extends from the working surface to depth of from about 0.01 to about 0.1 mm.

Owner:SMITH INT INC

Thermally stable ultra-hard material compact constructions

InactiveUS20080142276A1Extend effective lifePigmenting treatmentDrill bitsSuperhard materialPolycrystalline diamond

Thermally stable ultra-hard compact constructions comprise a polycrystalline diamond body substantially free of a catalyst material, and a substrate that is joined thereto. The substrate can be ceramic, metallic, cermet and combinations thereof, and can be joined to the body by a braze material or other material that forms an attachment bond at high pressure / high temperature conditions. The body and substrate are specially formed having complementary interfacing surface features to facilitate providing an improved degree of attachment therebetween. The complementary surface features can in the form of openings and projections, e.g., one of the body or substrate can comprise one or more openings, and the other of the body or substrate can comprise one or more projections, disposed within or extending from respective interfacing surfaces. The complementary surface features operate to resist unwanted delamination between the body and substrate, thereby extending effective service life of the construction.

Owner:SMITH INT INC

Thermally stable polycrystalline diamond materials, cutting elements incorporating the same and bits incorporating such cutting elements

A cutting element is provided including a substrate and a TSP material layer over the substrate. The TSP material layer includes at least a property having a value that varies through the layer.

Owner:SMITH INT INC

Polycrystalline diamond abrasive elements

ActiveUS20050139397A1Improved wear behaviorImprove wear resistanceDrill bitsConstructionsMetallurgyPolycrystalline diamond

A polycrystalline diamond abrasive element, particularly a cutting element, comprises a layer of polycrystalline diamond having a working surface and bonded to a substrate, particularly a cemented carbide substrate, along an interface. The polycrystalline diamond abrasive element is characterised by using a binder phase that is homogeneously distributed through the polycrystalline diamond layer and that is of a fine scale. The polycrystalline diamond also has a region adjacent the working surface lean in catalysing material and a region rich in catalysing material.

Owner:ELEMENT SIX PRODION +2

Sonochemical leaching of polycrystalline diamond

InactiveUS20070169419A1Reduce generationKnown methodOther chemical processesAbrasion apparatusMetallurgyPolycrystalline diamond

A method for accelerated leaching of binder-catalyst material from the polycrystalline diamond structure of a PDC is disclosed. The PDC is sonochemically leached. Also disclosed are fixture, equipment and a system for sonochemically leaching the polycrystalline diamond structure of a PDC.

Owner:GEN ELECTRIC CAPITAL

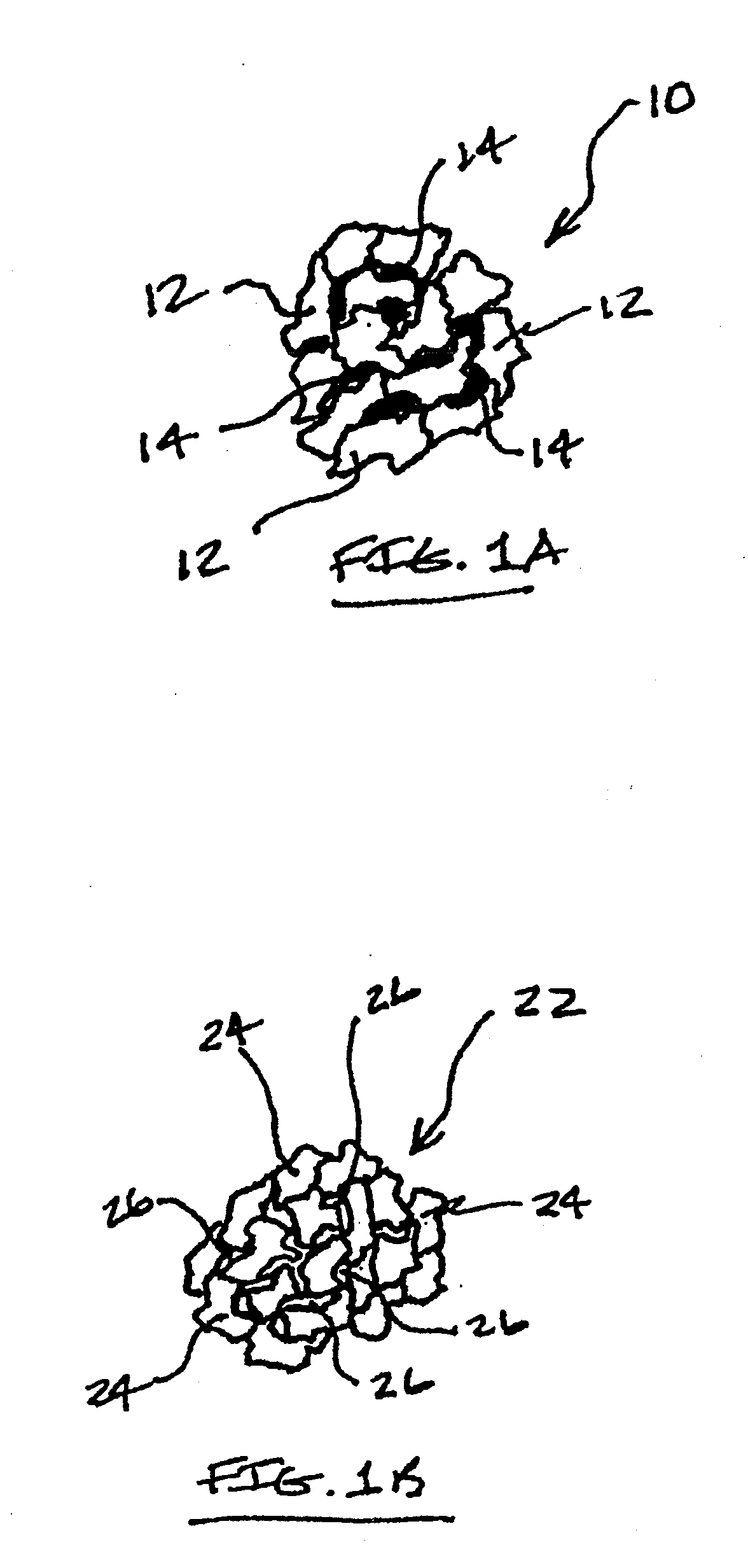

Polycrystalline diamond composites

InactiveUS20080073126A1Good adhesionDrill bitsConstructionsPolycrystalline diamondVolumetric Mass Density

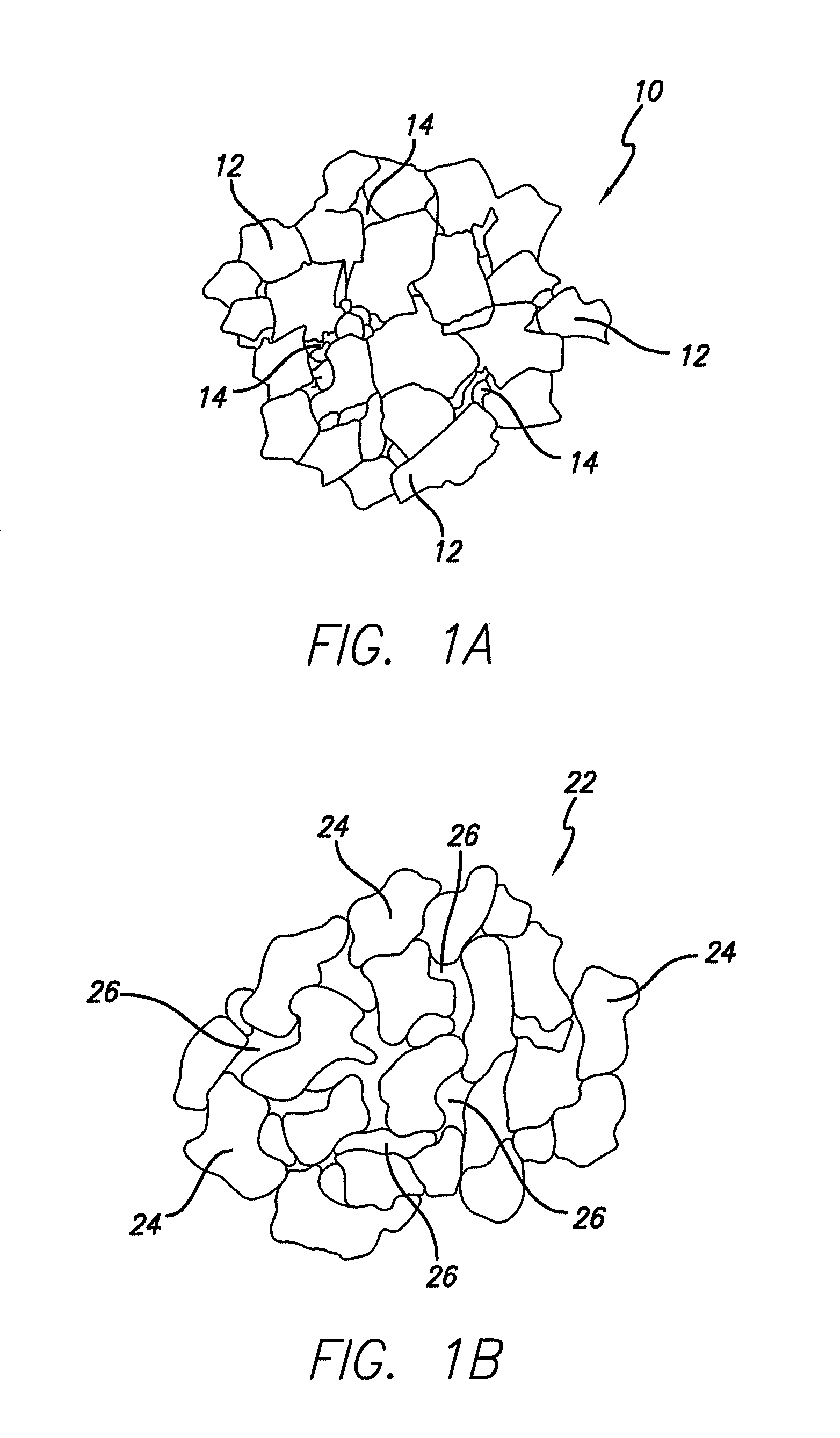

Polycrystalline diamond composites comprise a polycrystalline diamond body having a plurality of ultra-hard discrete regions dispersed within a polycrystalline diamond second region. The plurality of discrete regions has an density different from of the polycrystalline diamond second region. A metallic substrate can be joined to the body. The discrete regions can be relatively more thermal stable than, have a higher diamond density than, and / or may comprise a binder material that is different from the polycrystalline diamond second region. Polycrystalline diamond composites can be formed by combining already sintered granules with diamond grains to form a mixture, and subjecting the mixture to high pressure / high temperature conditions, wherein the granules form the plurality of discrete regions, or can be made by forming a plurality of unsintered granules, combining them with diamond grains to form a mixture, and then subjecting the mixture to first and second high pressure / high temperature conditions.

Owner:SMITH INT INC

Thermally-stable polycrystalline diamond materials and compacts

InactiveUS7473287B2Improve thermal stabilityImprove bindingPigmenting treatmentDrill bitsDiamond crystalPolycrystalline diamond

Thermally-stable polycrystalline diamond materials of this invention comprise a first phase including a plurality of bonded together diamond crystals, and a second phase including a reaction product formed between a binder / catalyst material and a material reactive with the binder / catalyst material. The reaction product is disposed within interstitial regions of the polycrystalline diamond material that exists between the bonded diamond crystals. The first and second phases are formed during a single high pressure / high temperature process condition. The reaction product has a coefficient of thermal expansion that is relatively closer to that of the bonded together diamond crystals than that of the binder / catalyst material, thereby providing an improved degree of thermal stability to the polycrystalline diamond material.

Owner:SMITH INT INC

Polycrystalline diamond cutting elements having improved thermal resistance

InactiveUS20080302579A1Increase thermal resistanceGood adhesionDrill bitsConstructionsHeat resistanceDiamond crystal

Polycrystalline diamond constructions of this invention have a polycrystalline diamond body and a substrate attached thereto, wherein the diamond body has a material microstructure comprising a plurality of bonded-together diamond crystals forming a polycrystalline matrix phase, and second phase formed from different types of materials or sintering aids designed to reduce or eliminate the amount of free Group VIII elements therein. The use of such materials and the reduction and / or elimination of free Group VIII elements, in addition to graphitization, facilitates the sintering the construction at high pressure / high temperature conditions, e.g., greater than about 65 Kbar, to produce a construction having a high degree of thermal stability and / or thermal resistance when compared to conventional PCD materials. Polycrystalline diamond constructions of this invention are preferably configured as cutting elements that are disposed on drill bits used for drilling subterranean earthen formations.

Owner:SMITH INT INC

Polycrystalline diamond carbide composites

InactiveUS20070193782A1Improve fracture toughnessEasy to useDrill bitsOther chemical processesPolycrystalline diamondCarbide

Owner:SMITH INT INC

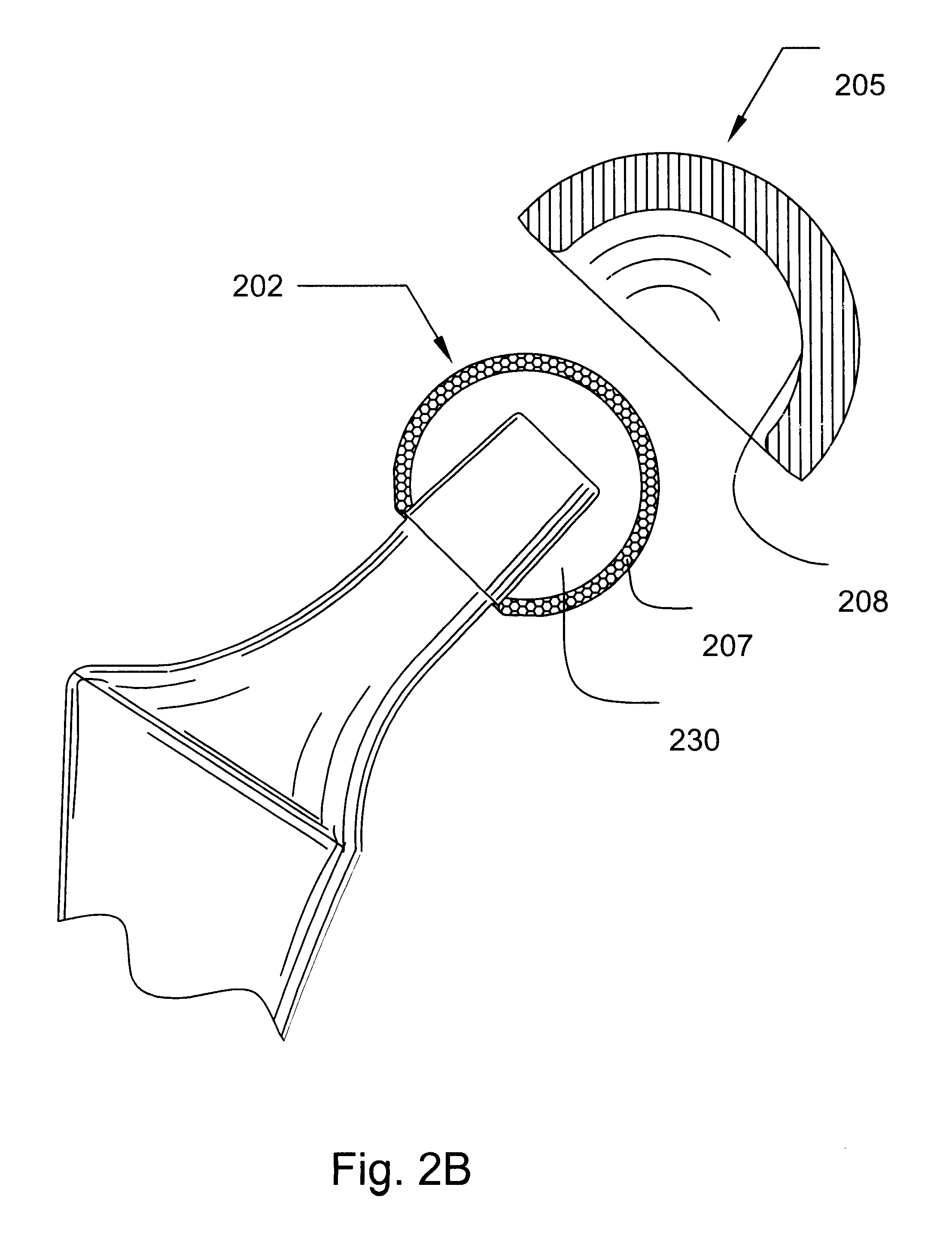

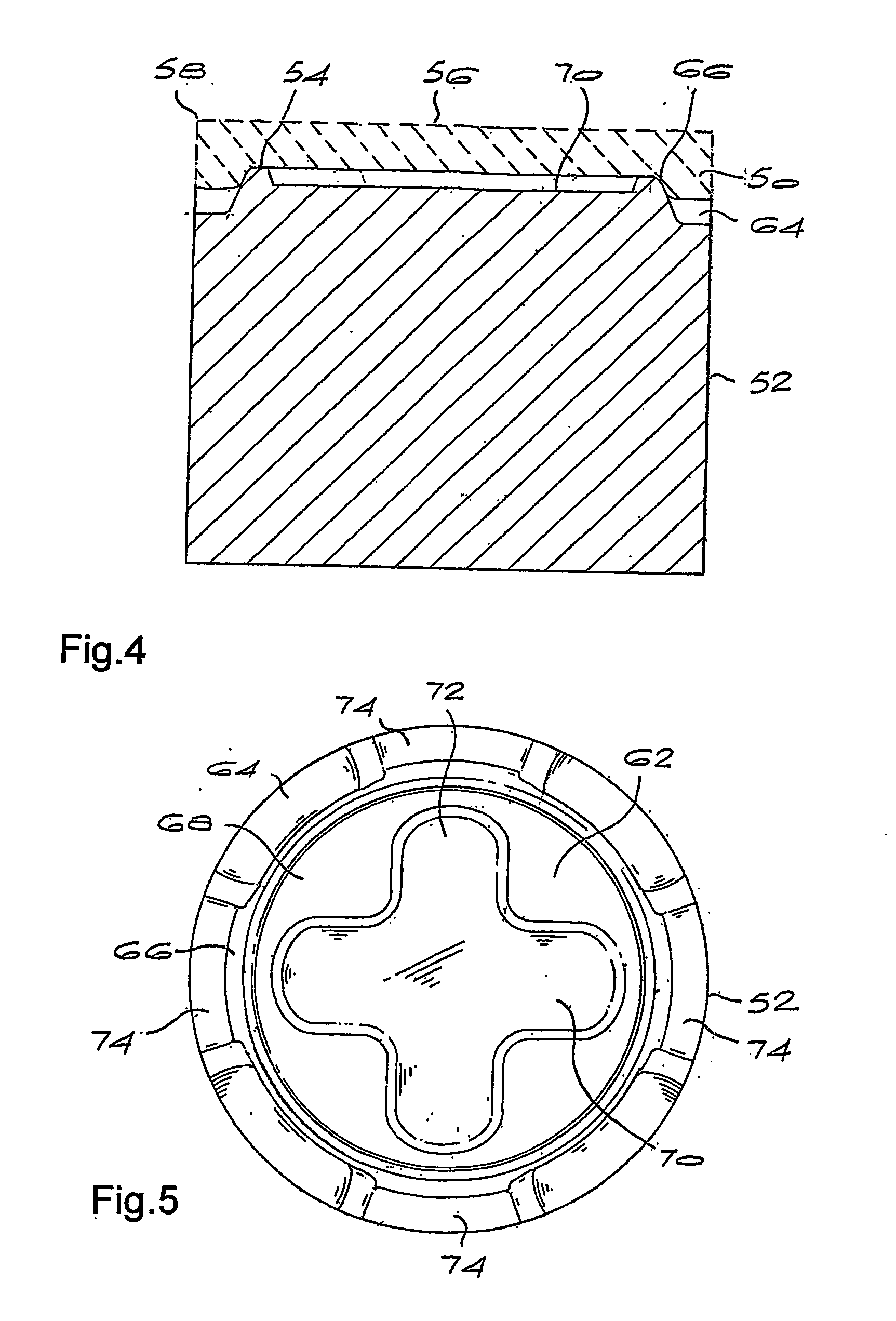

Methods for making bearings, races and components thereof having diamond and other superhard surfaces

InactiveUS20030019106A1Easy to polishReduce coefficient of frictionShaftsMetal-working apparatusPolycrystalline diamondHigh pressure

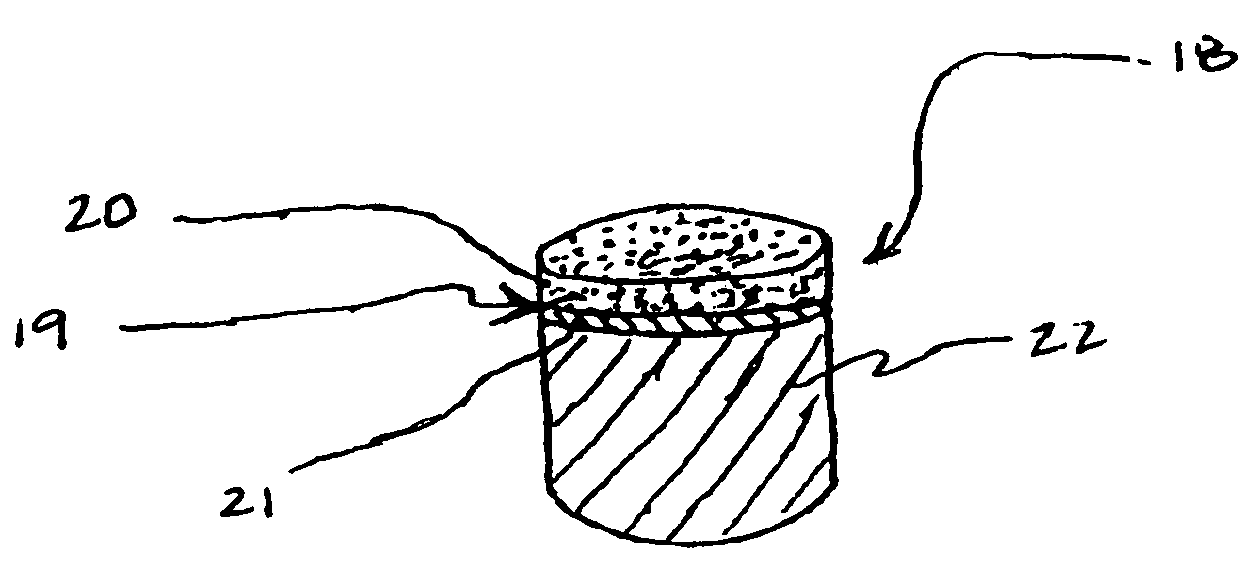

Method for making diamond bearings and diamond bearing components. Some methods include sintering diamond feedstock and a substrate under high pressure and high temperature to create a sintered polycrystalline diamond compact with a non-planar bearing and articulation surface. Various machining, grinding and polishing methods for finishing the compact are provided.

Owner:DIAMICRON

Polycrystalline diamond composite constructions comprising thermally stable diamond volume

ActiveUS7462003B2Improve thermal stabilityConstructionsRecord information storageComposite constructionDiamond crystal

PCD composite constructions comprise a diamond body bonded to a substrate. The diamond body comprises a thermally stable diamond bonded region that is made up of a single phase of diamond crystals bonded together. The diamond body includes a PCD region bonded to the thermally stable region and that comprises bonded together diamond crystals and interstitial regions interposed between the diamond crystals. The PCD composite is prepared by combining a first volume of PCD with a second volume of diamond crystal-containing material consisting essentially of a single phase of bonded together diamond crystals. A substrate is positioned adjacent to or joined to the first volume. The first and second volumes are subjected to high pressure / high temperature process conditions, during process the first and second volumes form a diamond bonded body that is attached to the substrate, and the second volume forms the thermally stable diamond bonded region.

Owner:SMITH INT INC

Prosthetic joint component having at least one sintered polycrystalline diamond compact articulation surface and substrate surface topographical features in said polycrystalline diamond compact

InactiveUS6676704B1Less disruptiveImprove overall utilizationFinger jointsWrist jointsArticular surfacesPolycrystalline diamond

Prosthetic joints, components for prosthetic joints, superhard bearing and articulation surfaces, diamond bearing and articulation surfaces, substrate surface topographical features, materials for making joints, bearing and articulation surfaces, and methods for manufacturing and finishing the same, and related information are disclosed, including a prosthetic joint component having at least one sintered polycrystalline diamond compact articulation surface and substrate surface topographical features in said polycrystalline diamond compact.

Owner:DIAMICRON

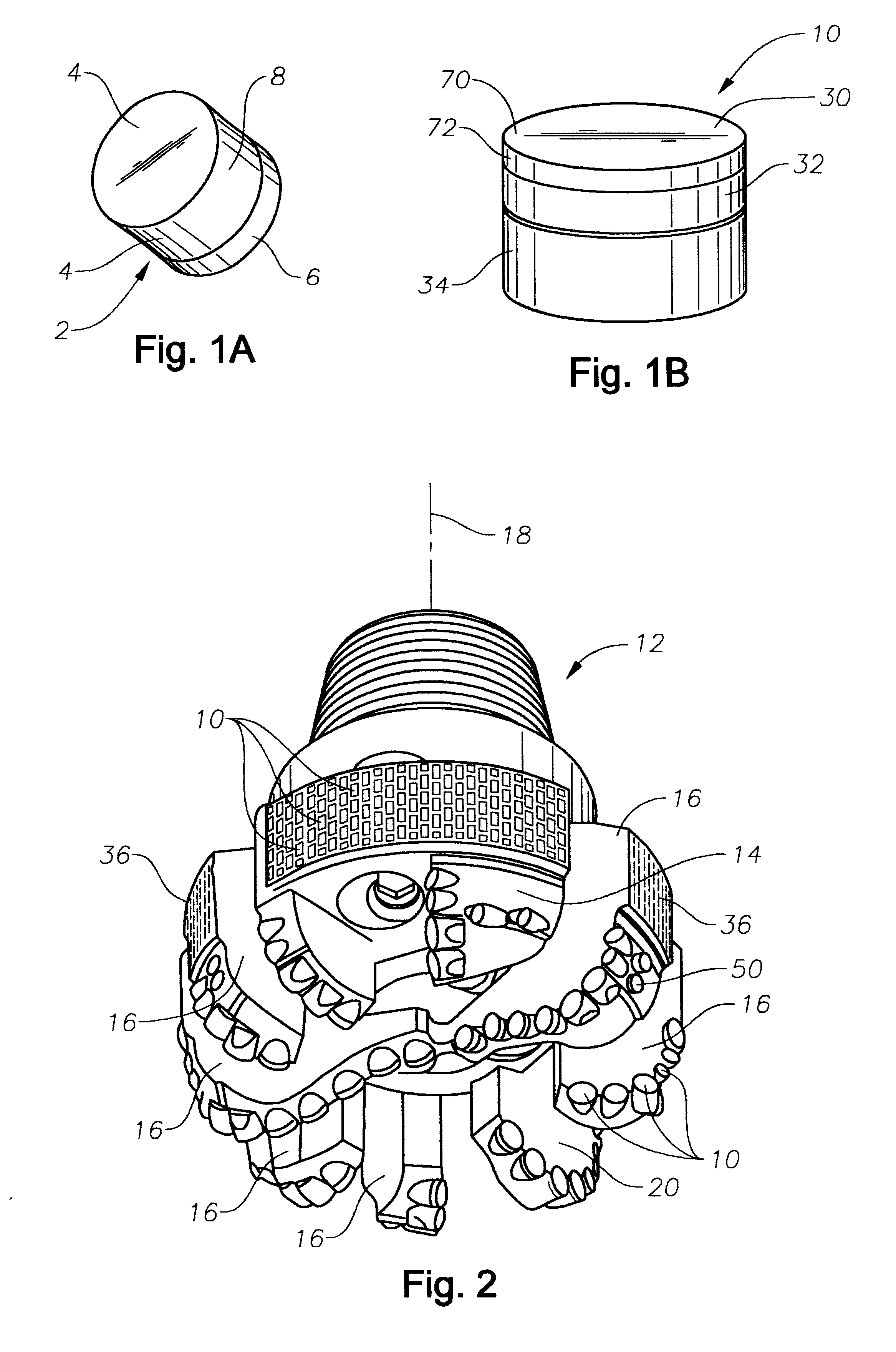

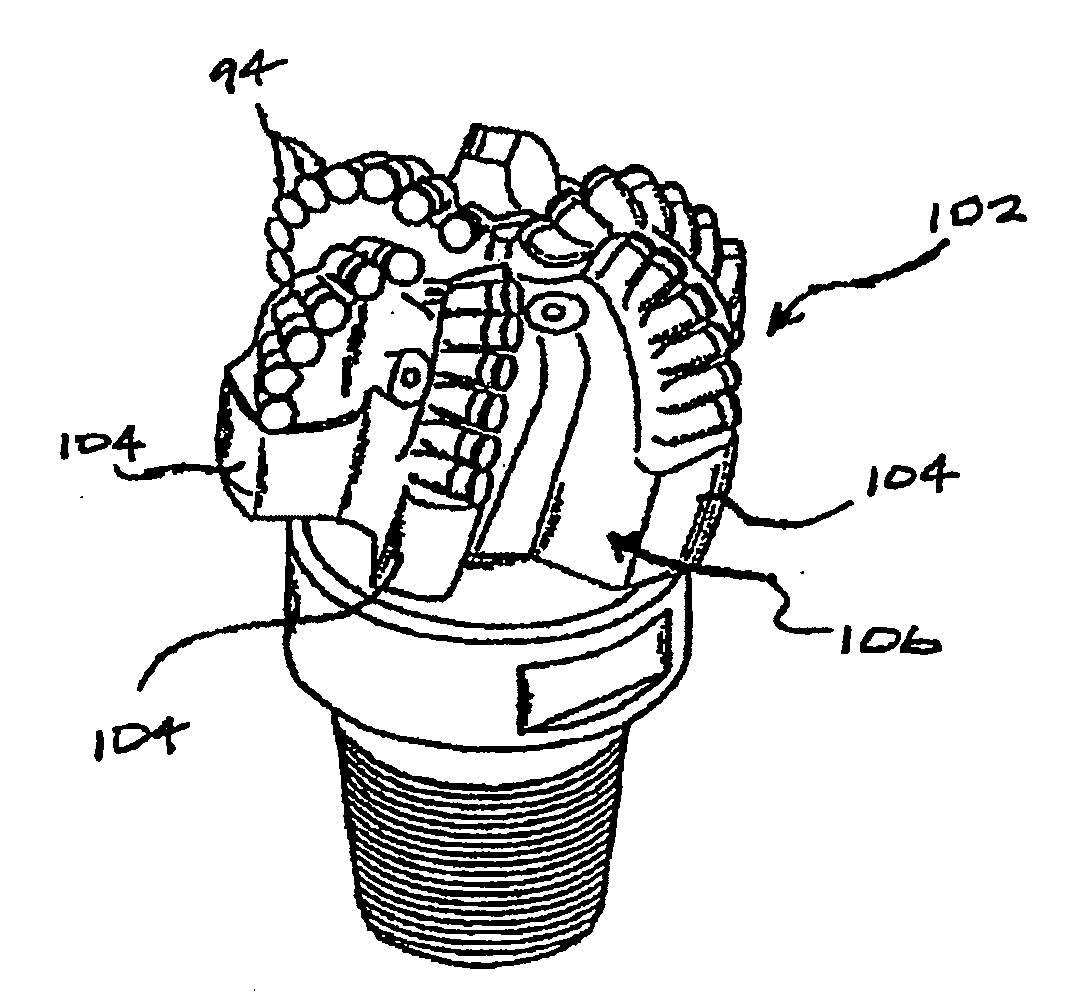

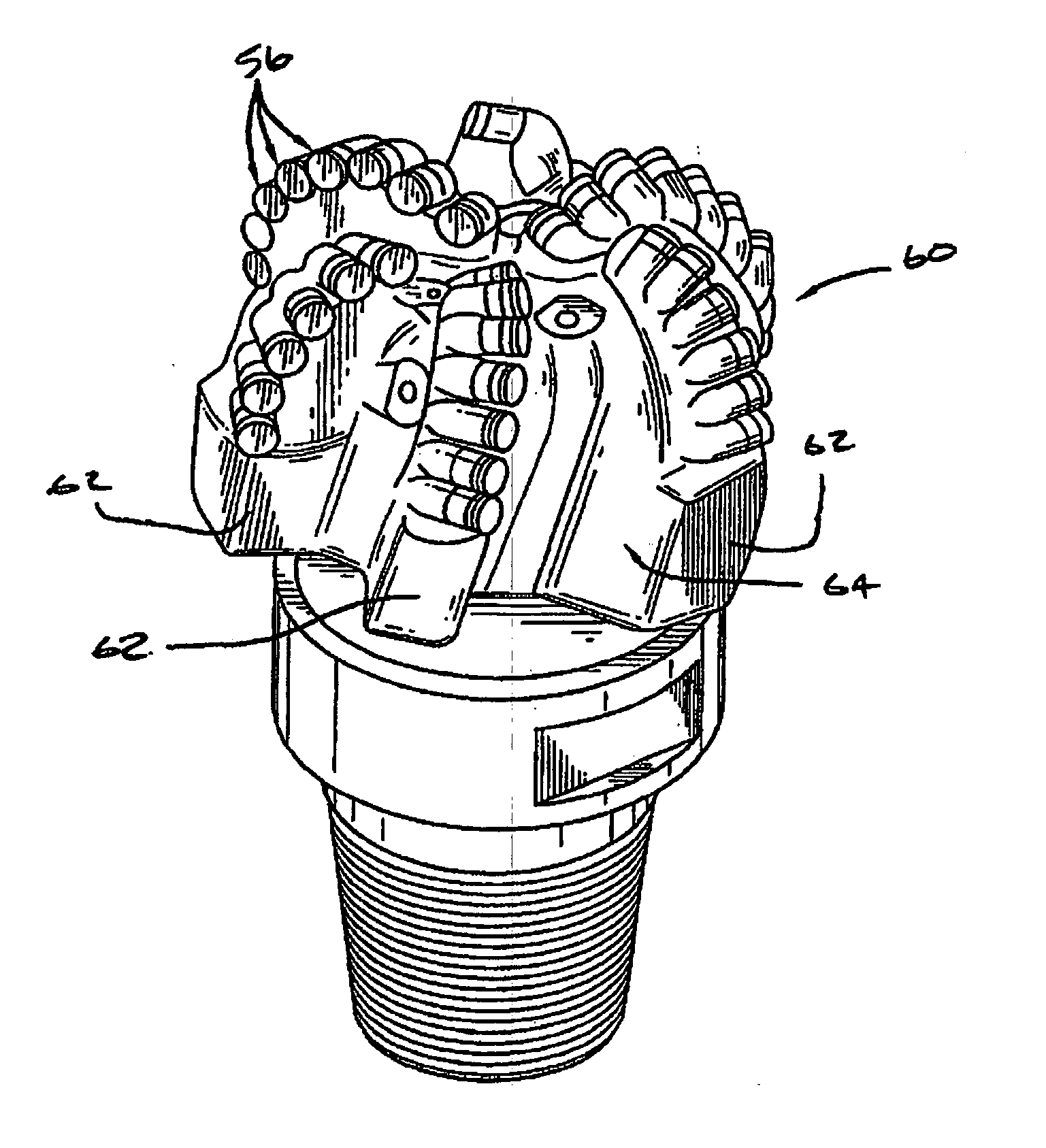

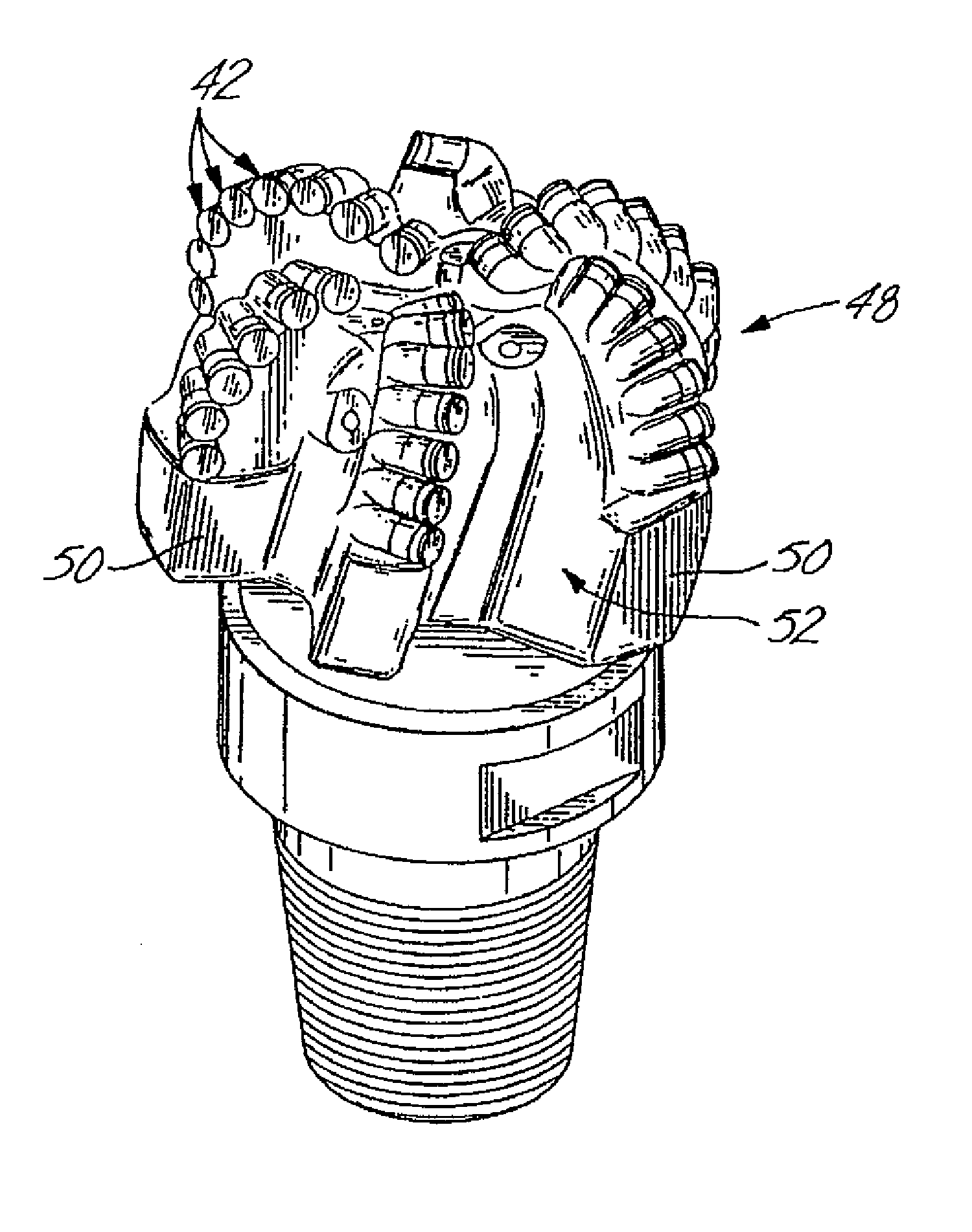

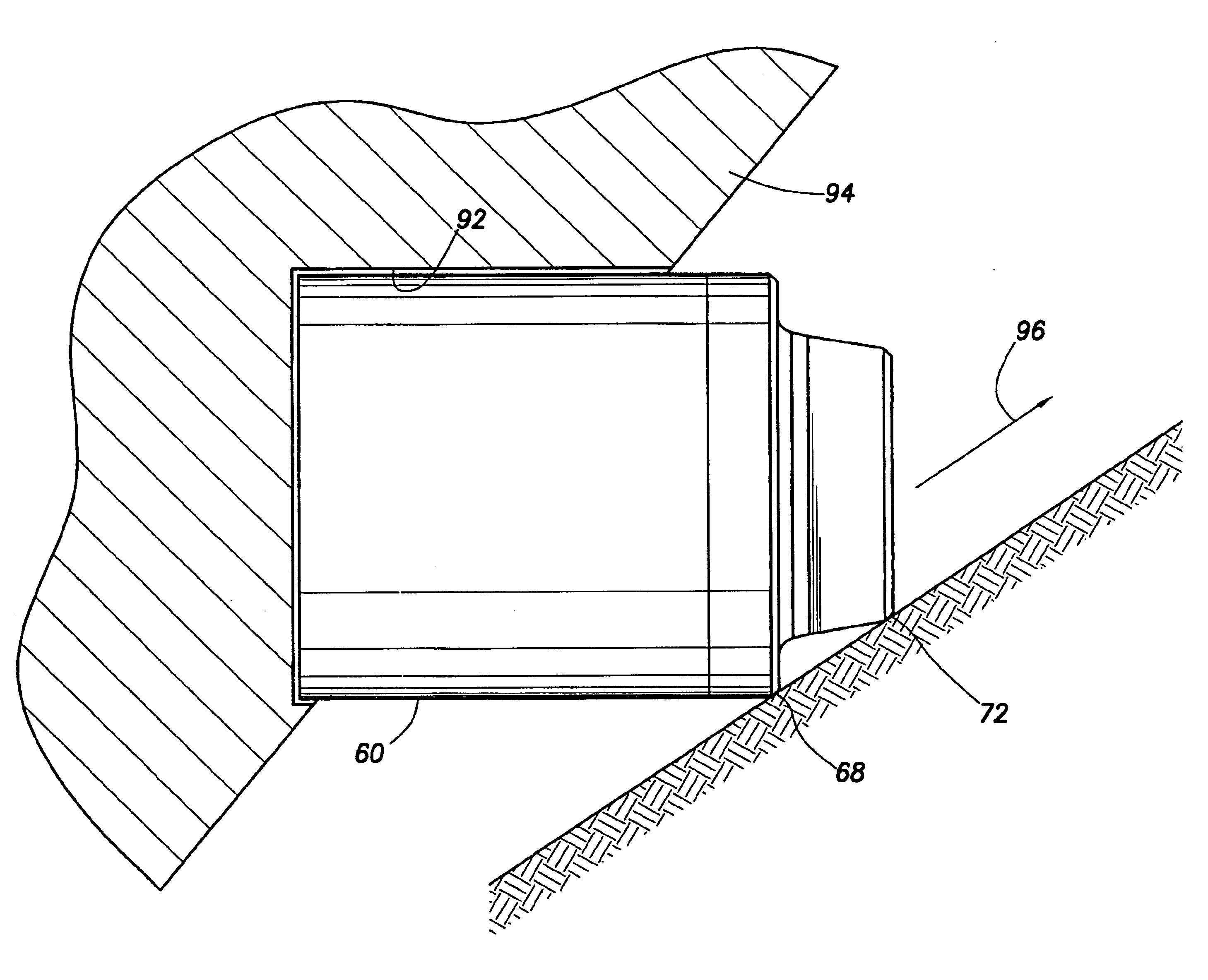

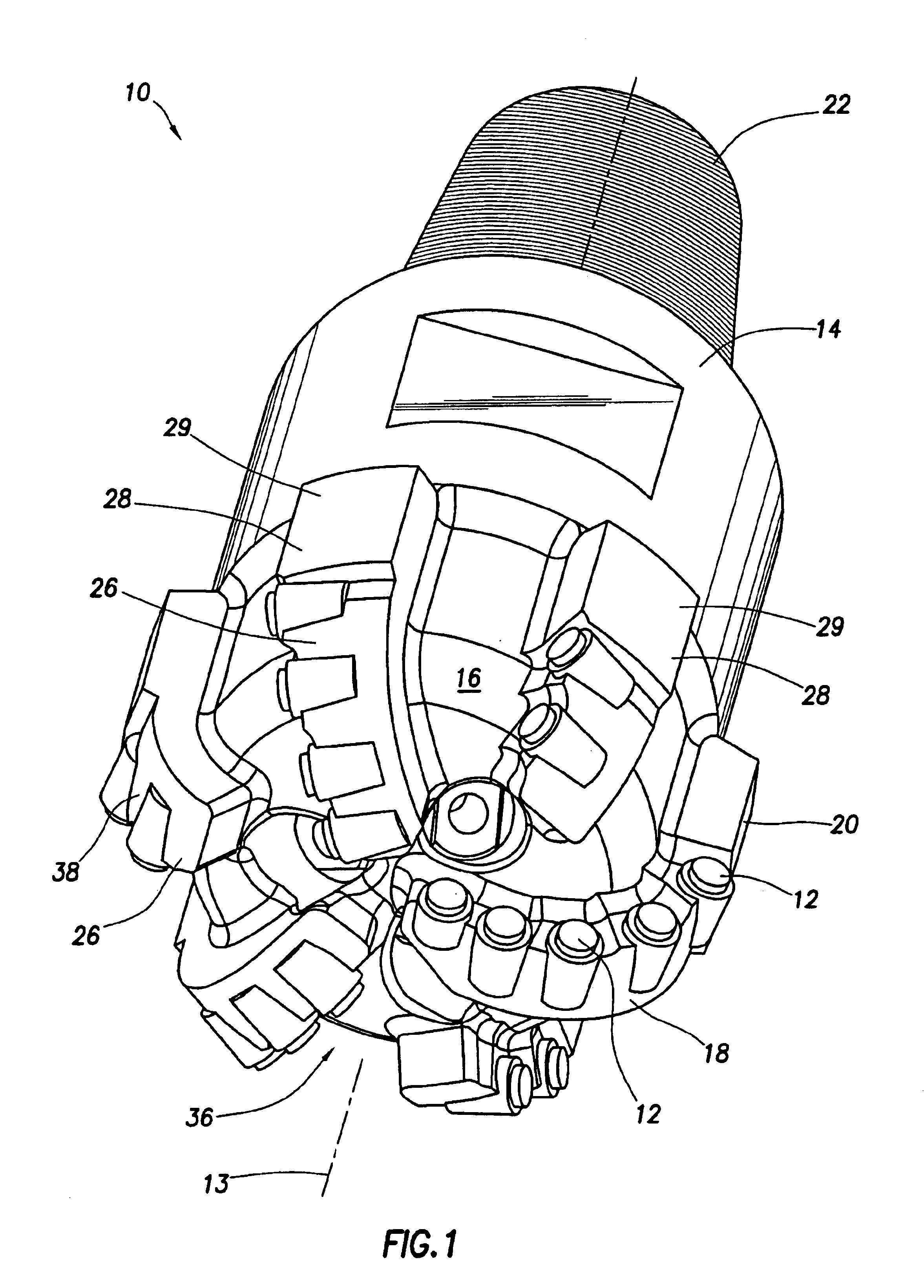

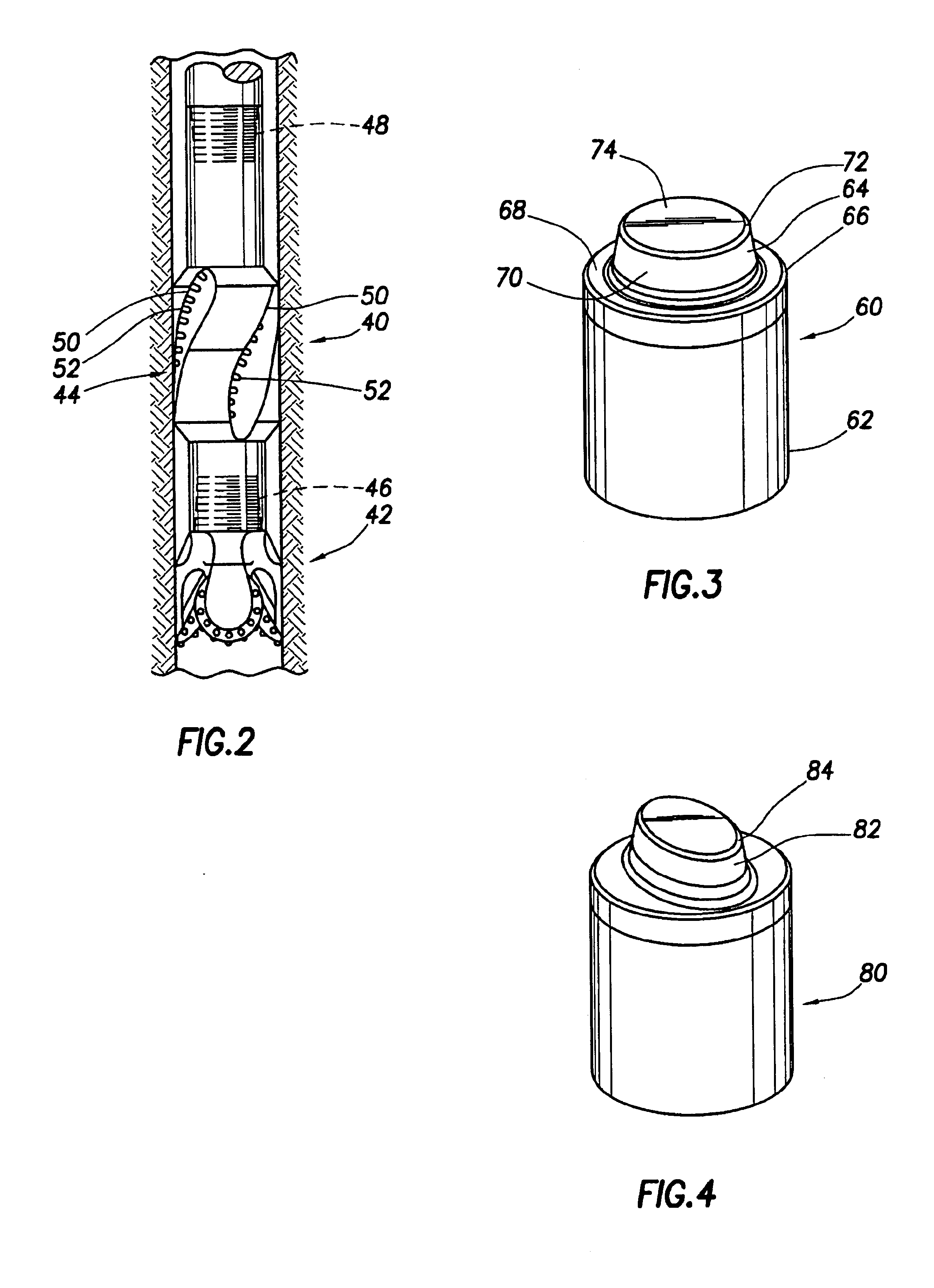

Stepped polycrystalline diamond compact insert

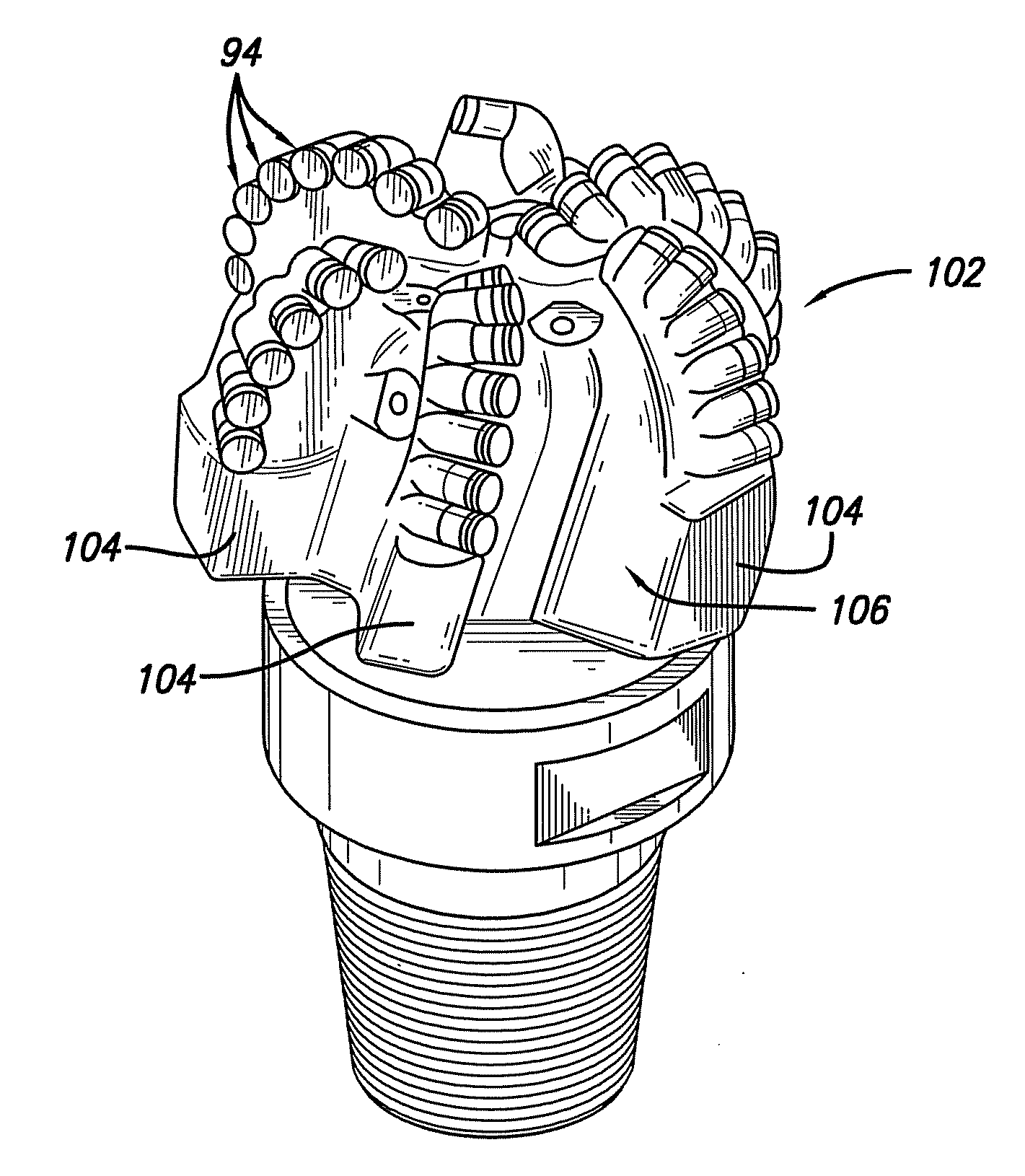

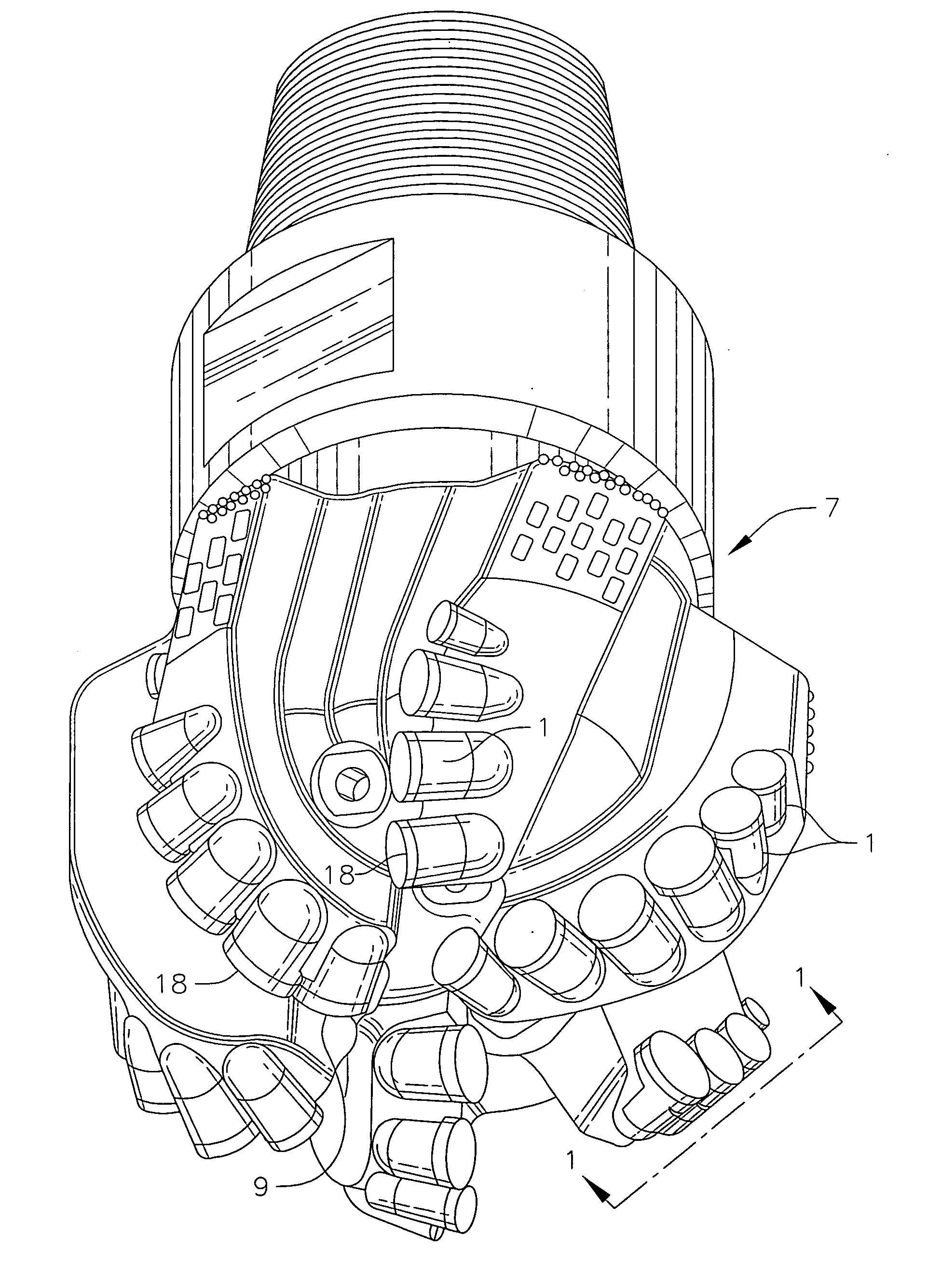

InactiveUS6904984B1Reduces rock strengthLess riskDrill bitsConstructionsPolycrystalline diamondEngineering

The present invention addresses this need in the art by providing a cutter insert comprising a plug section and a cutter pedestal. The cutter insert is preferably formed of tungsten carbide, except for two exterior surfaces covered with PDC. The plug section may be circular or oval in cross section perpendicular to the axis of the insert. The plug section and the pedestal each defines a shoulder which is coated with a PDC layer. In this way, two cutting surfaces are applied to the formation, enhancing the cutting ability of the insert.

Owner:GEN ELECTRIC CAPITAL

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com