Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

2635results about How to "Improve fracture toughness" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

SiCOH dielectric

InactiveUS20070173071A1Improve cohesive strengthReduce brittlenessSemiconductor/solid-state device detailsSolid-state devicesDielectricDevice material

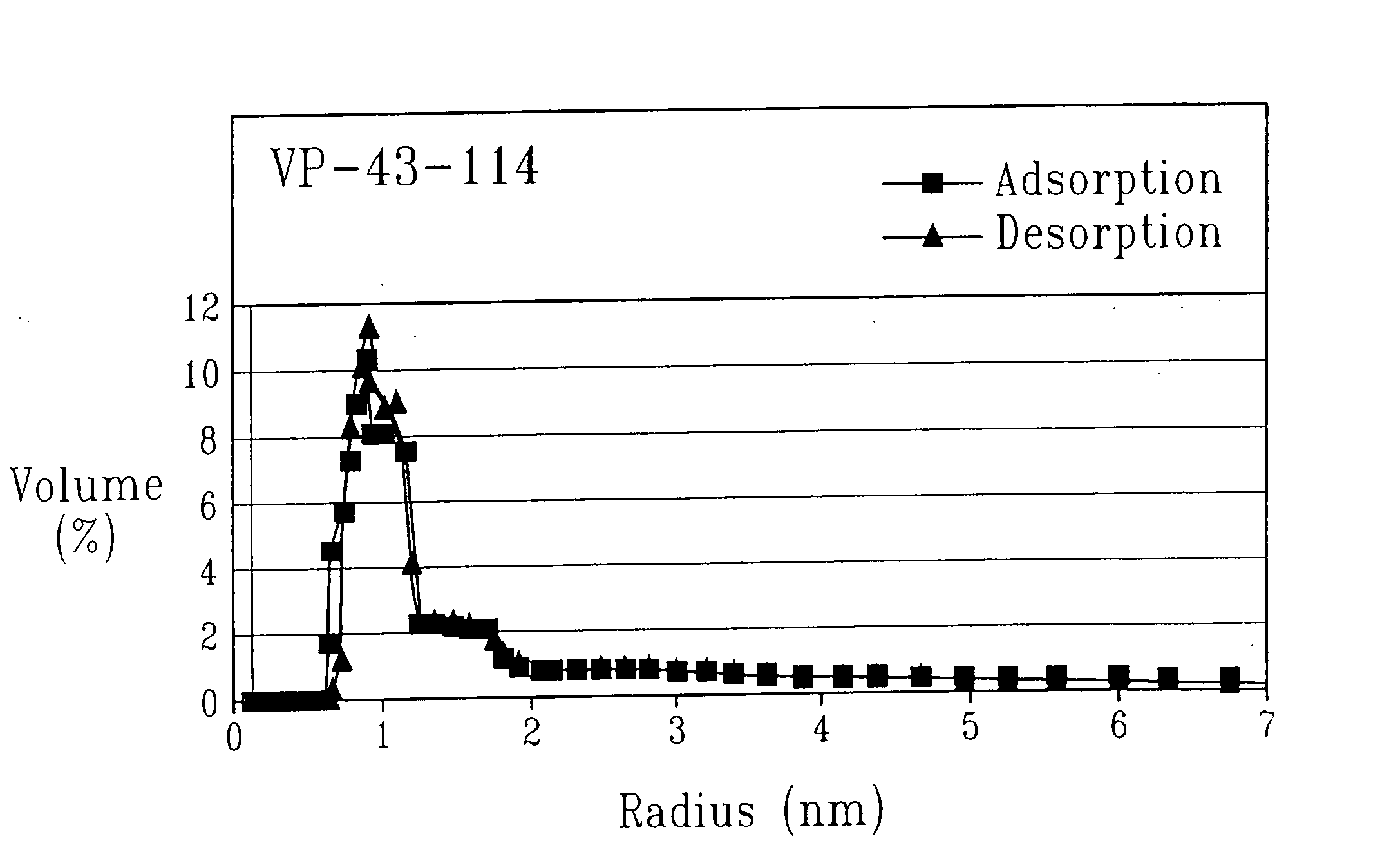

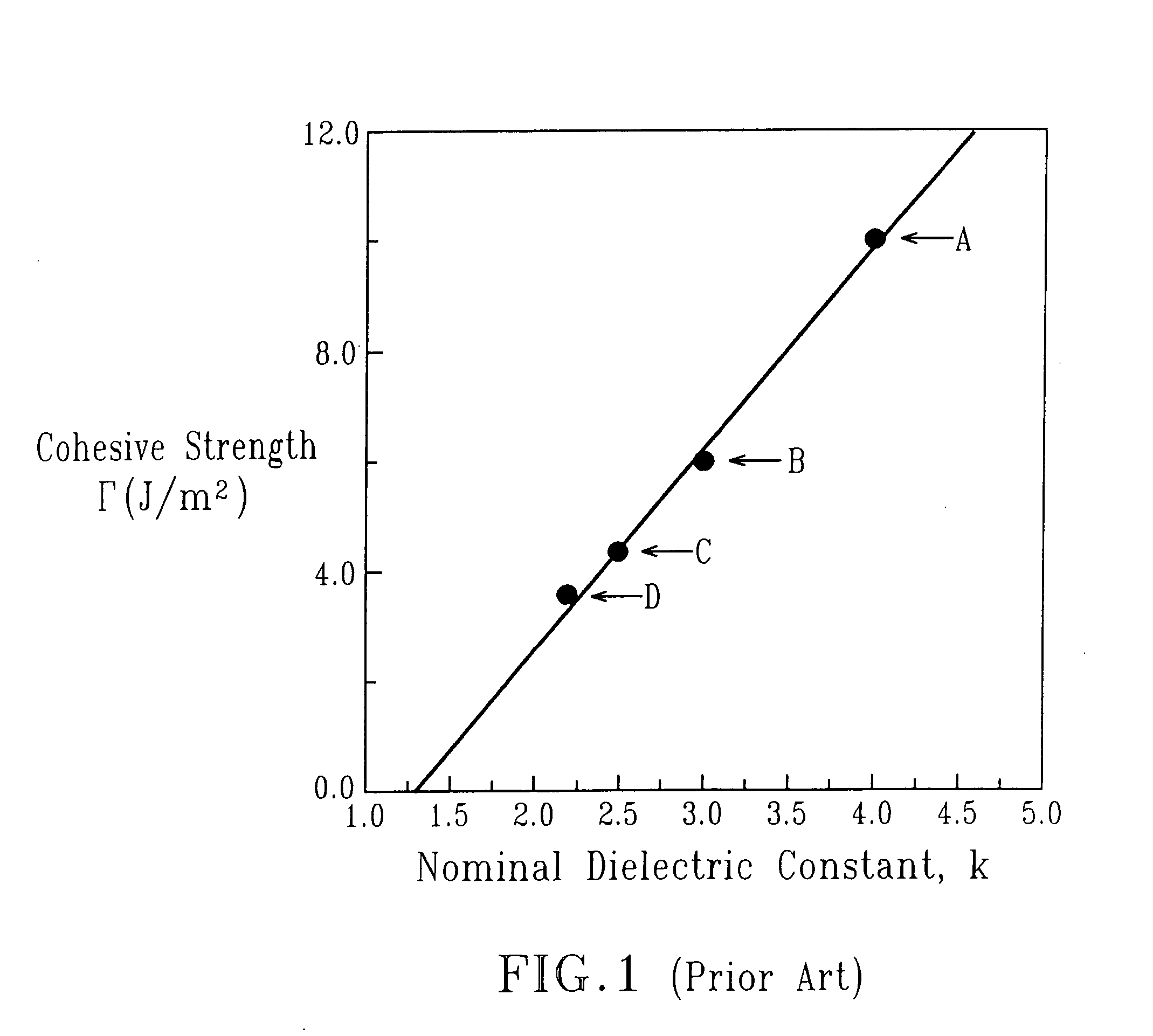

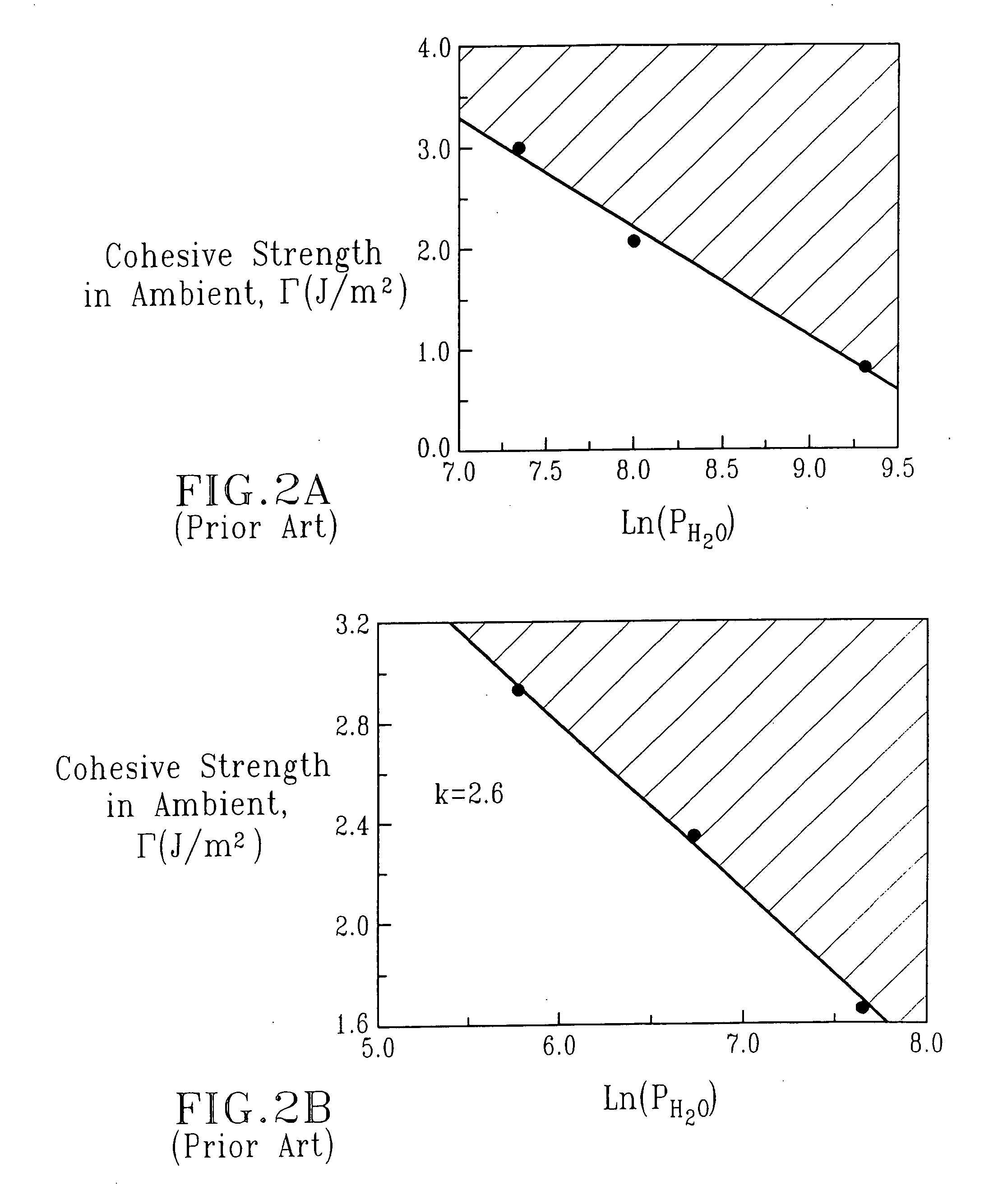

A porous composite material useful in semiconductor device manufacturing, in which the diameter (or characteristic dimension) of the pores and the pore size distribution (PSD) is controlled in a nanoscale manner and which exhibits improved cohesive strength (or equivalently, improved fracture toughness or reduced brittleness), and increased resistance to water degradation of properties such as stress-corrosion cracking, Cu ingress, and other critical properties is provided. The porous composite material is fabricating utilizing at least one bifunctional organic porogen as a precursor compound

Owner:INTEL CORP

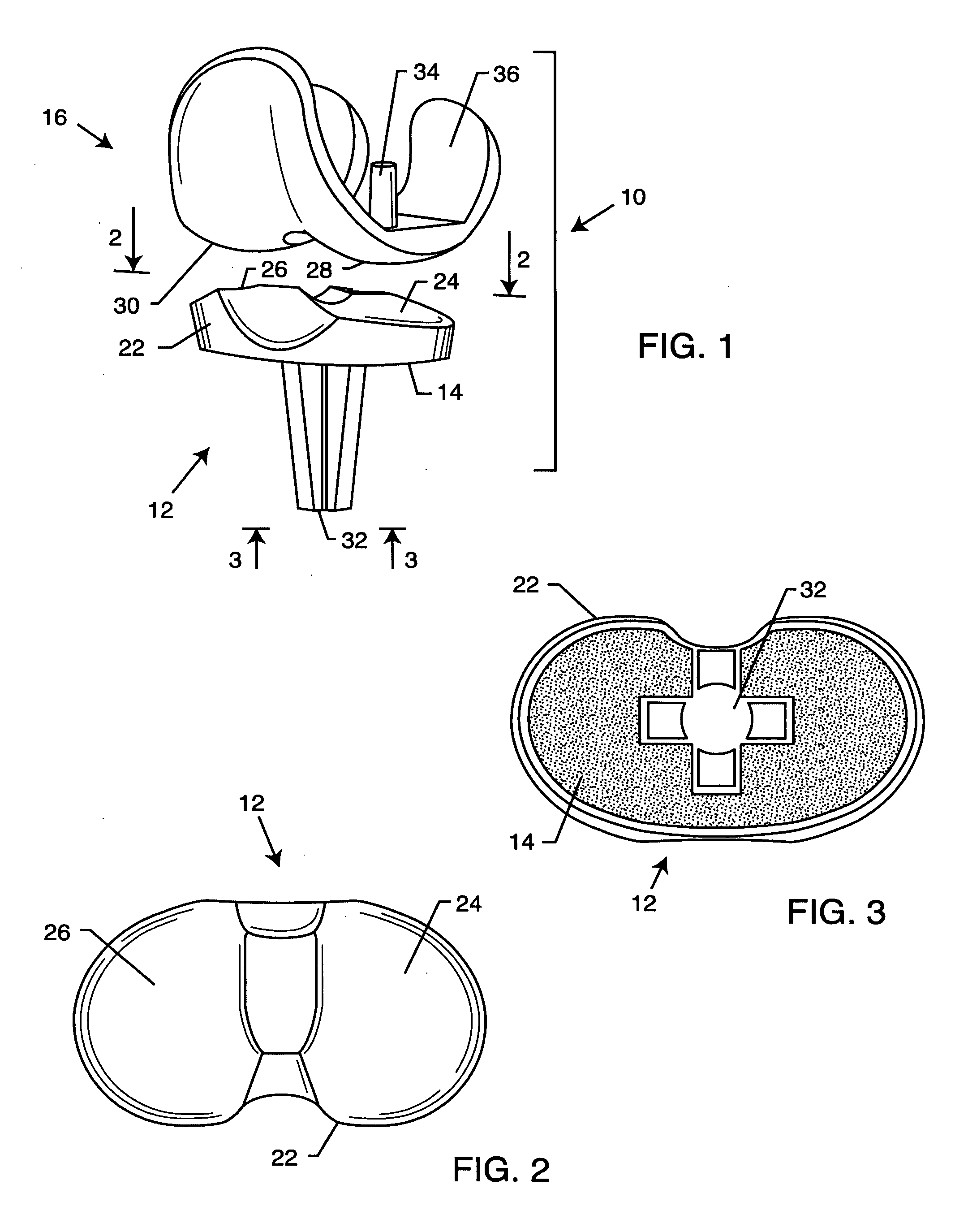

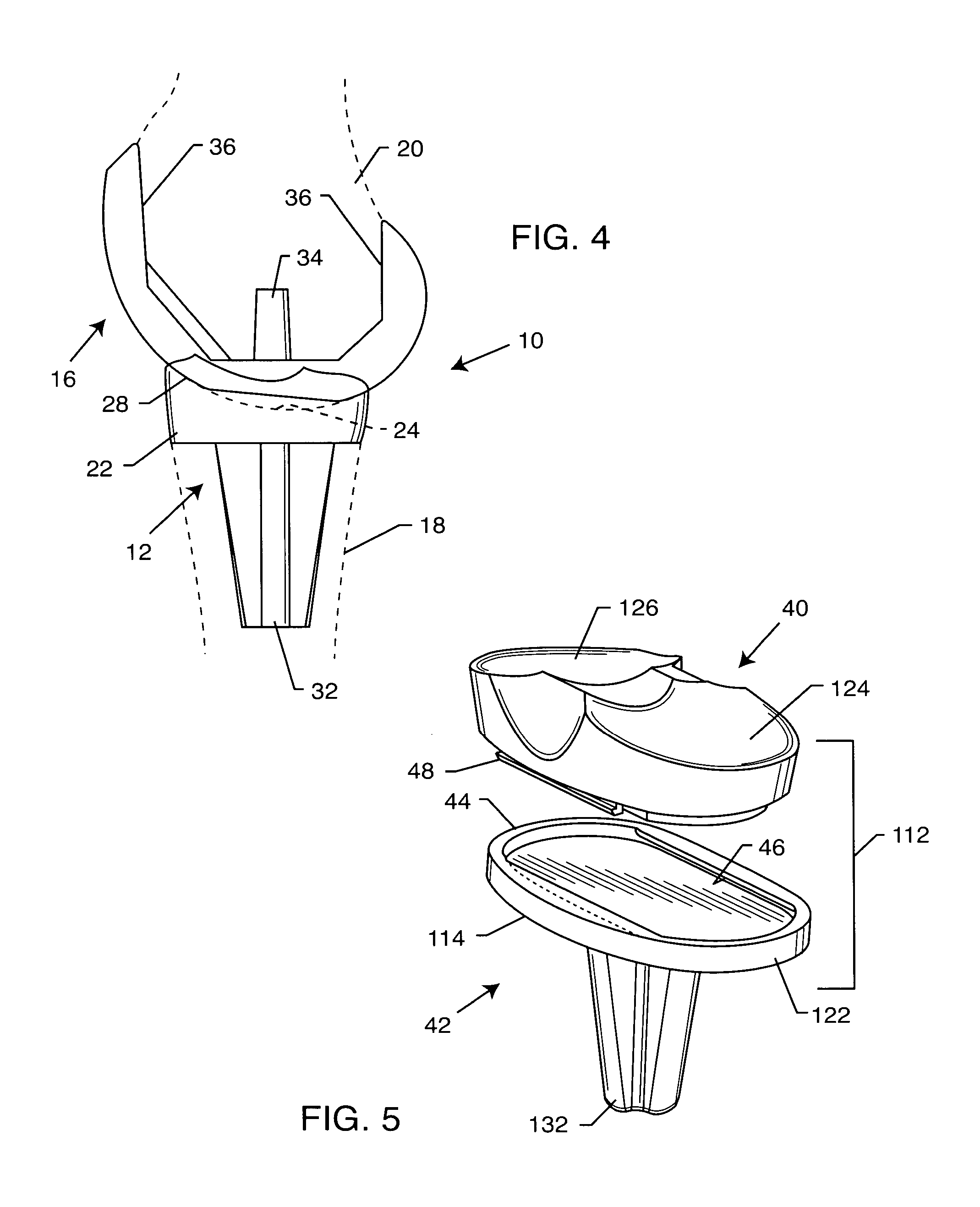

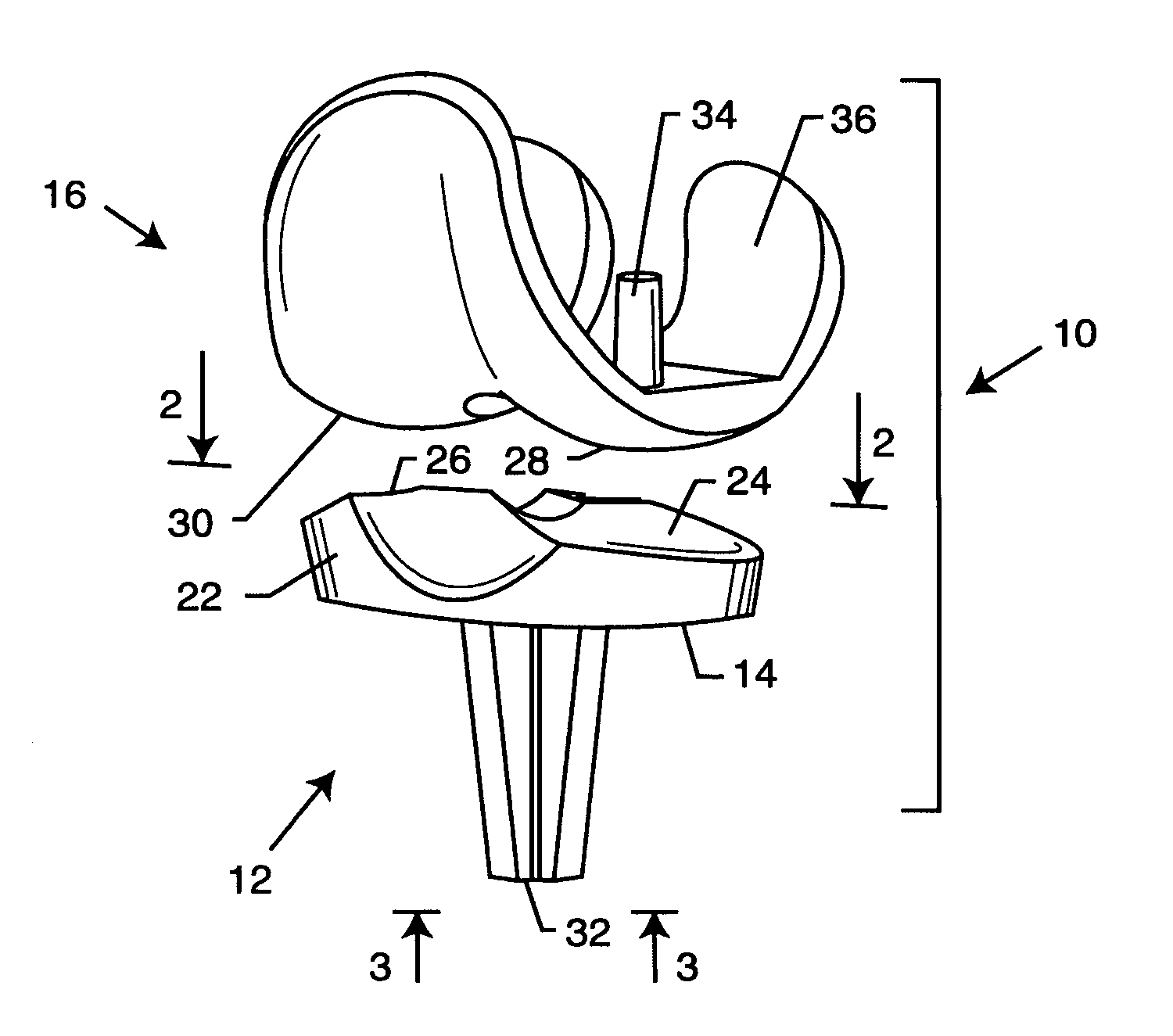

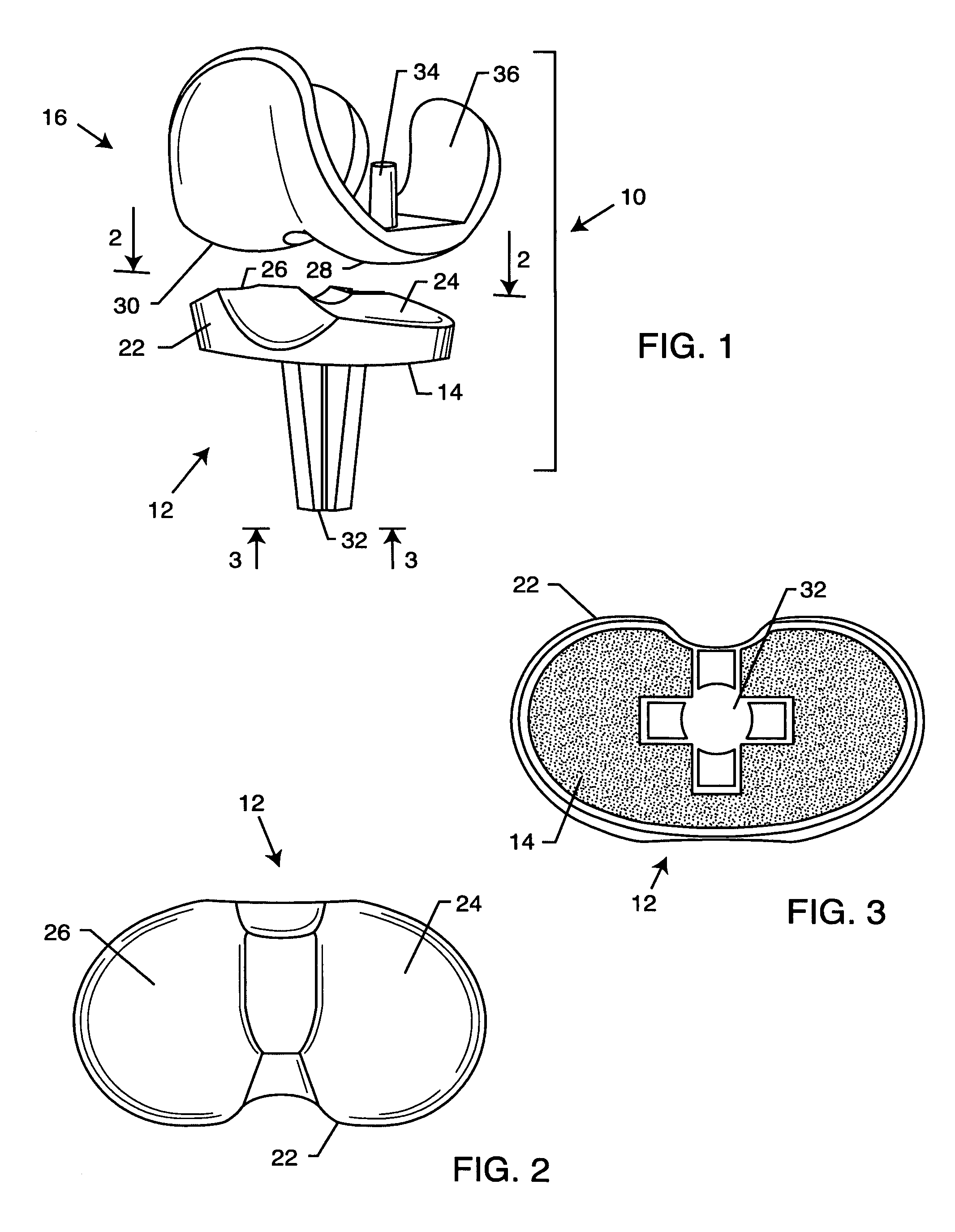

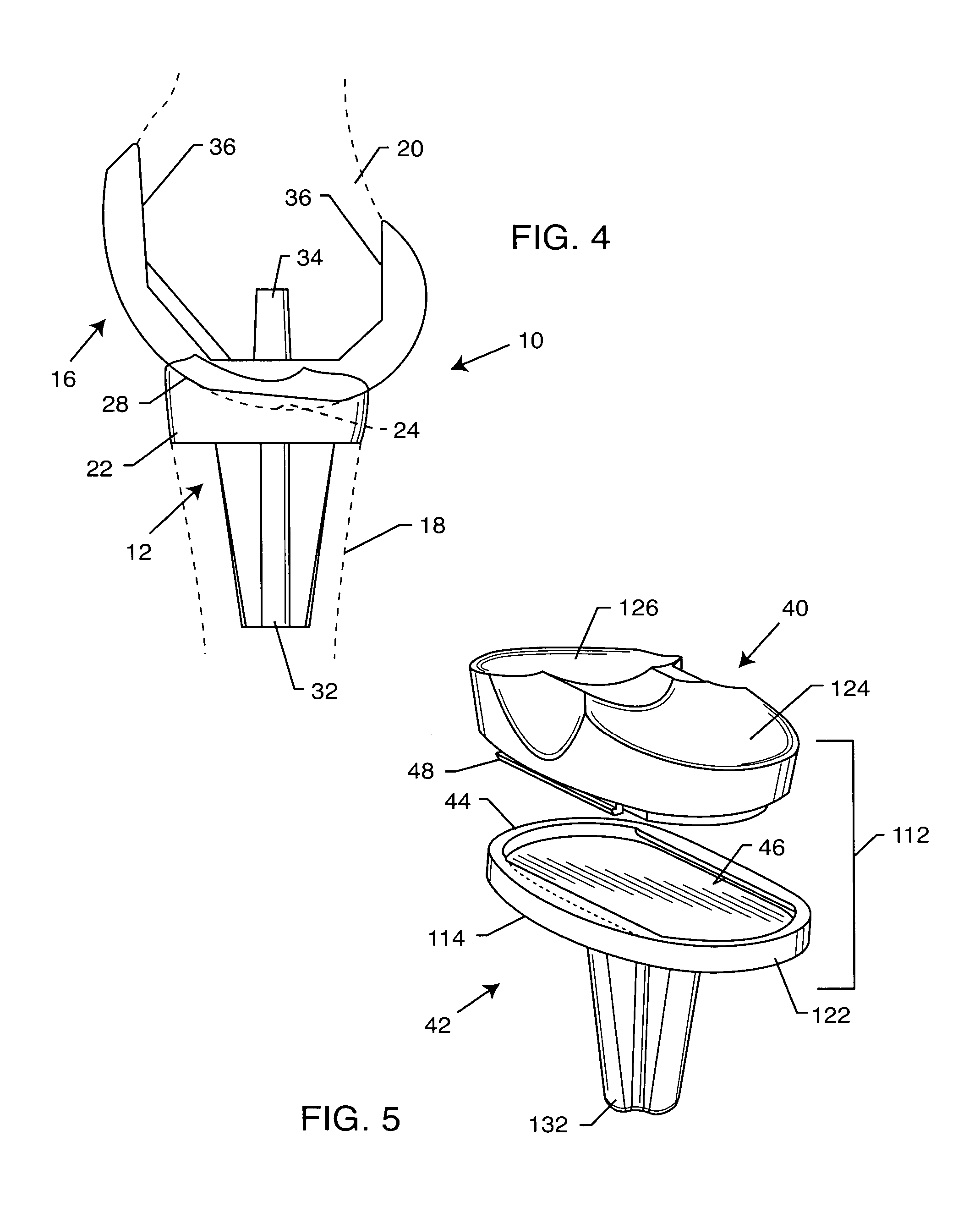

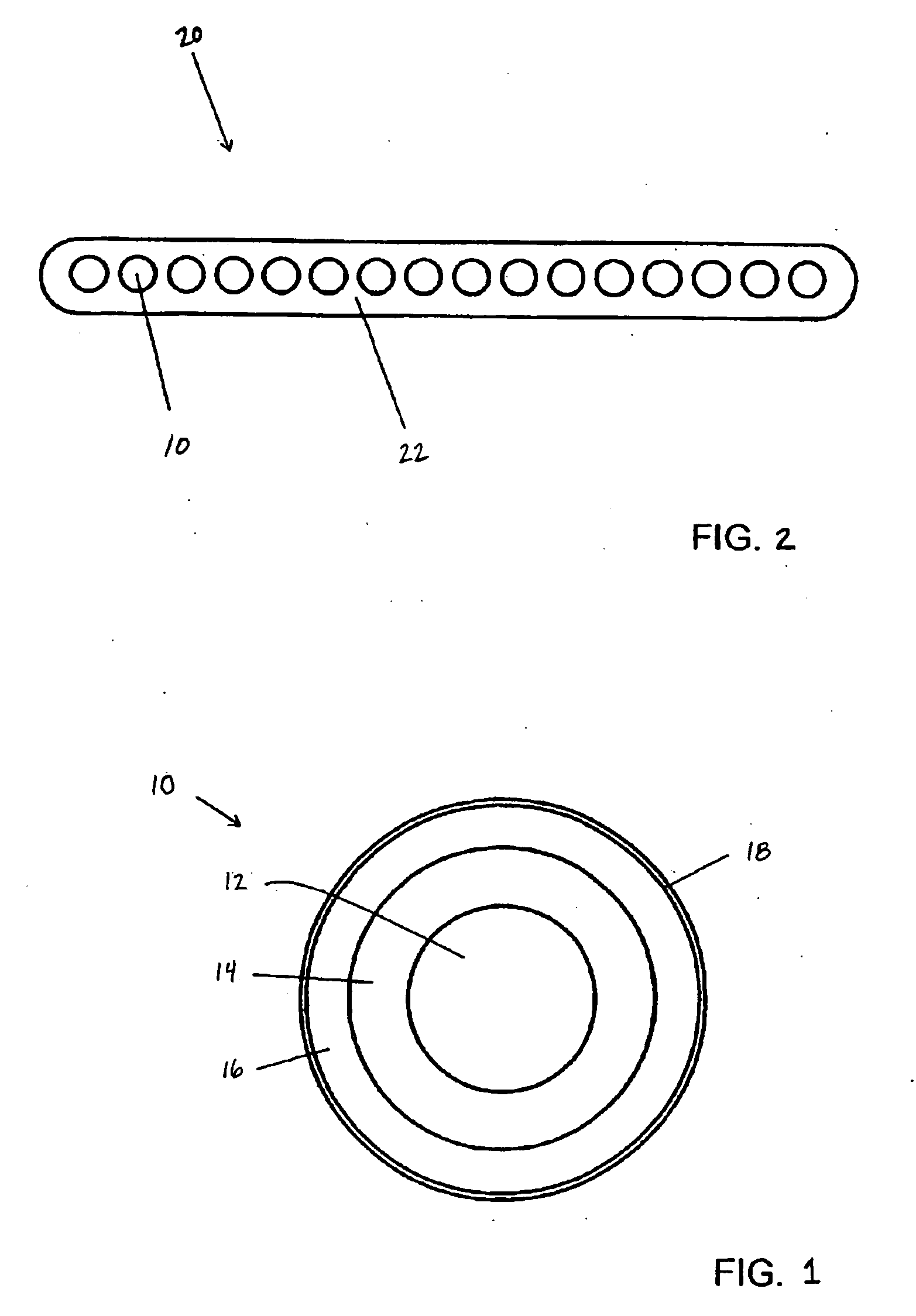

Knee prosthesis with ceramic tibial component

InactiveUS20060052875A1Reduce wearHigh strengthHeart valvesJoint implantsArticular surfacesTibial bone

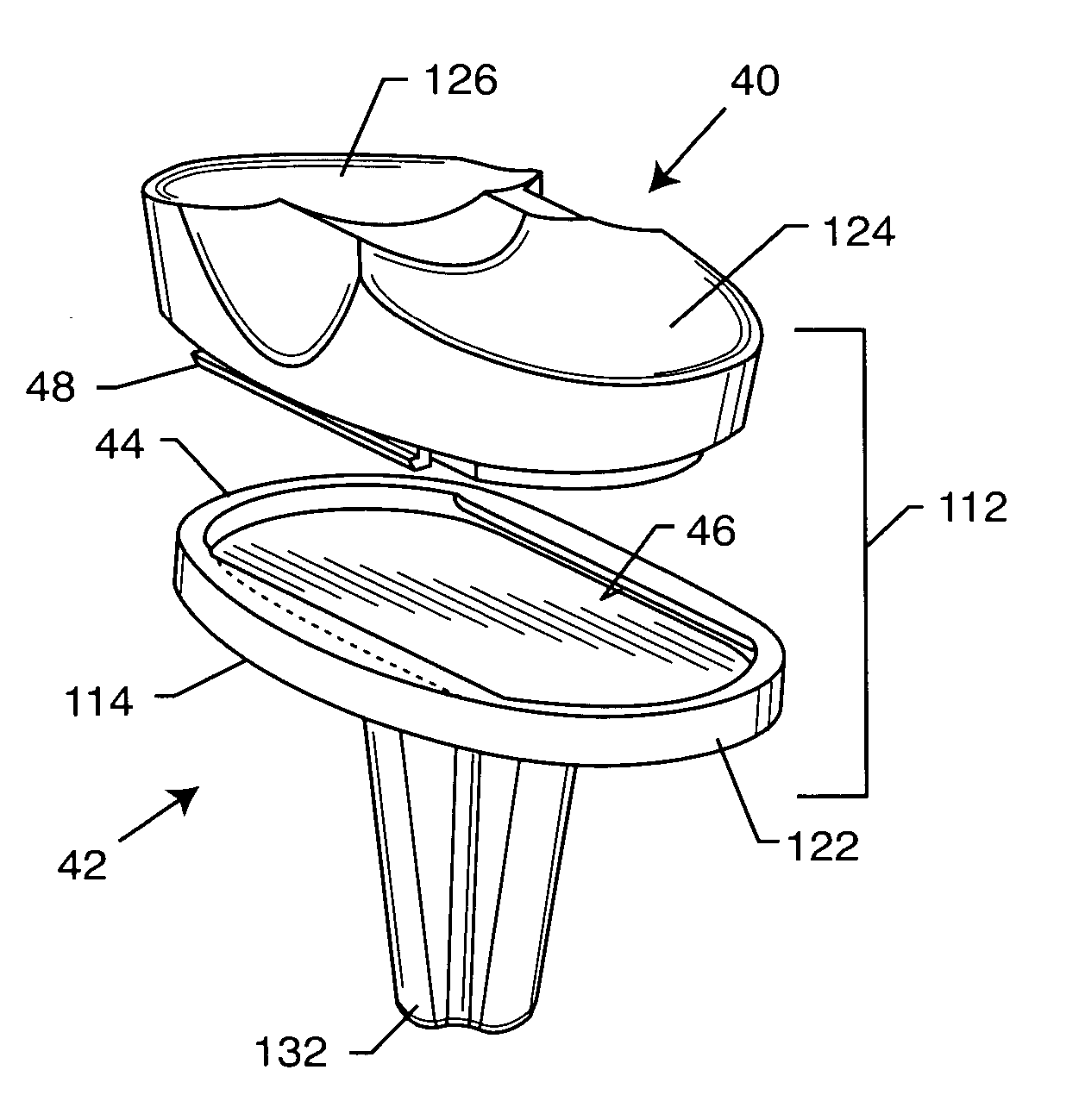

An improved knee prosthesis includes a ceramic tibial component for articulation with natural or prosthetic (re-surfaced) femoral surfaces. The ceramic tibial component is provided in the form of a ceramic monoblock adapted for fixation relative to the patient's tibial bone, or alternately in the form of a ceramic bearing insert component carried by a tibial baseplate member which is adapted in turn for fixation relative to tibial bone. In either form, the ceramic tibial component includes at least one upwardly concave articulation surface for movable bearing engagement by a generally convex or condylar shaped femoral articulation surface. The ceramic tibial component provides improved wear characteristics with extended service life.

Owner:AMEDICA A DELAWARE

Al-Cu-Li-Mg-Ag-Mn-Zr alloy for use as structural members requiring high strength and high fracture toughness

An improved aluminum lithium alloy comprising 0.1 to 2.5 wt. % Li, 2.5 to 5.5 wt. % Cu, 0.2 to 1.0 wt. % Mg, 0.2 to 0.8 wt. % Ag, 0.2 to 0.8 wt. % Mn, up to 0.4 wt. % Zr or other grain refiner such as chromium, titanium, hafnium, scandium or vanadium, the balance aluminum. The present alloy exhibits an improved combination of strength and fracture toughness, over any thickness range. The present invention is further directed to methods for preparing and using Al—Li alloys as well as to products comprising the same.

Owner:CONSTELLIUM ROLLED PROD RAVENSWOOD

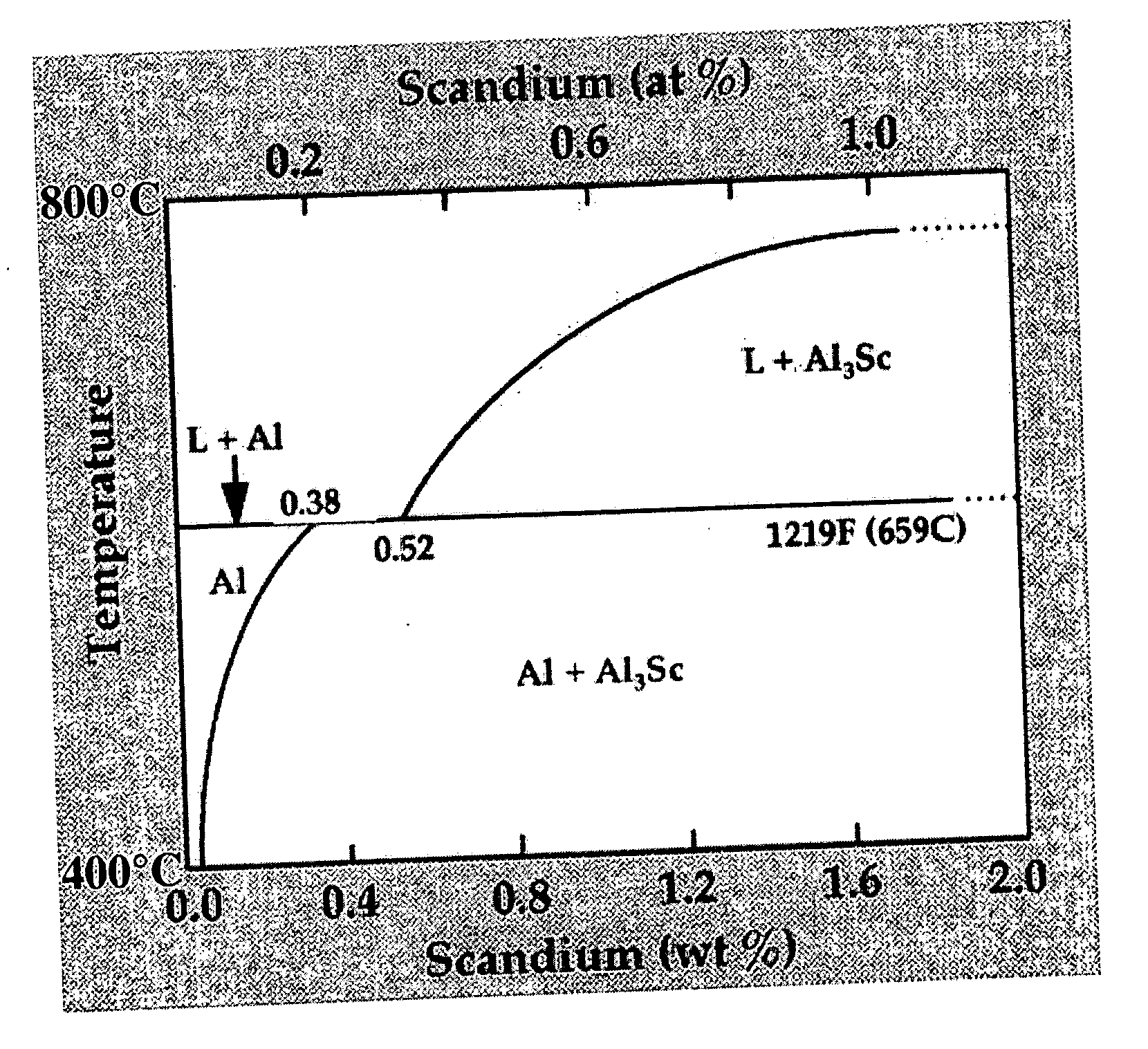

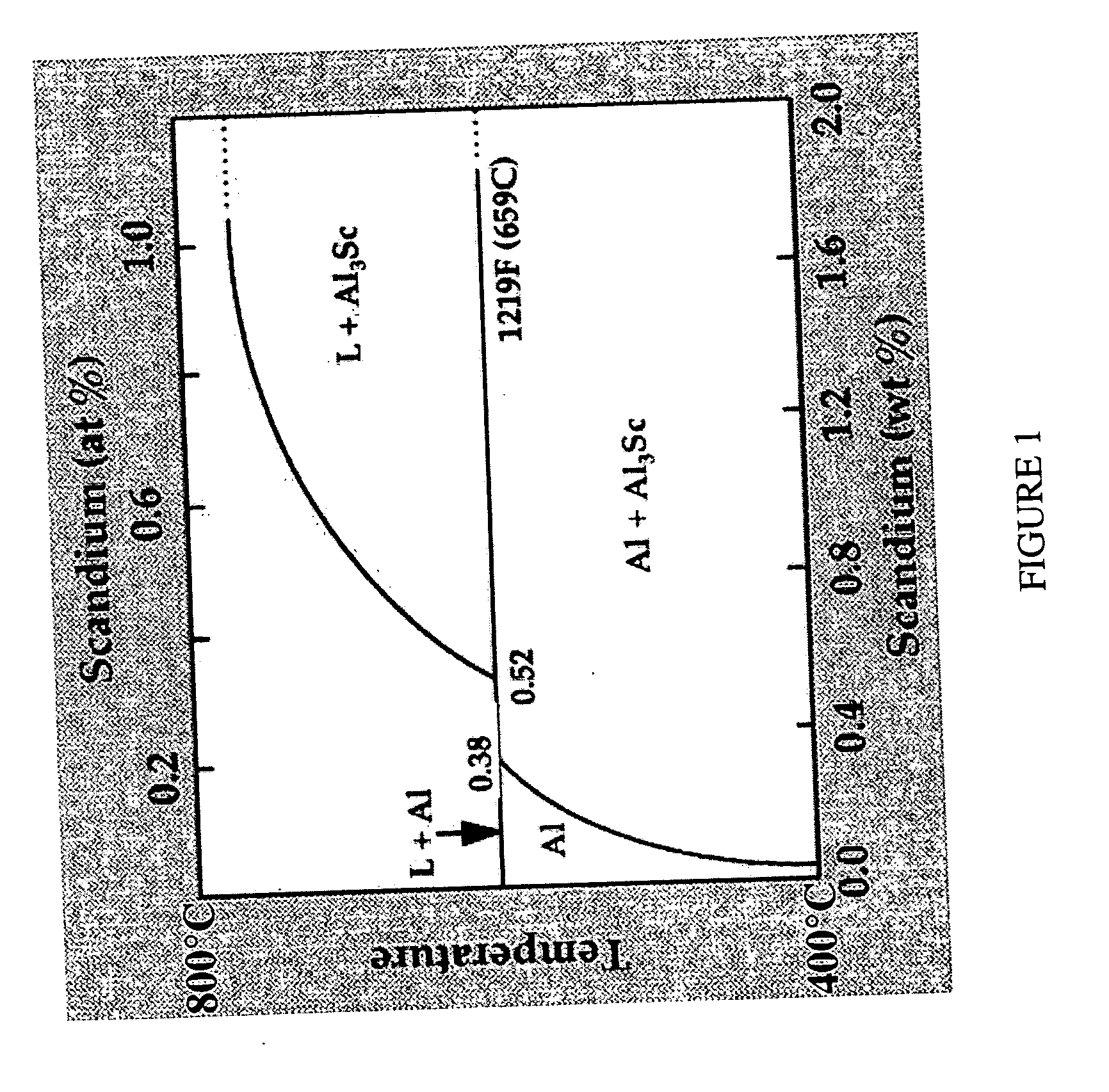

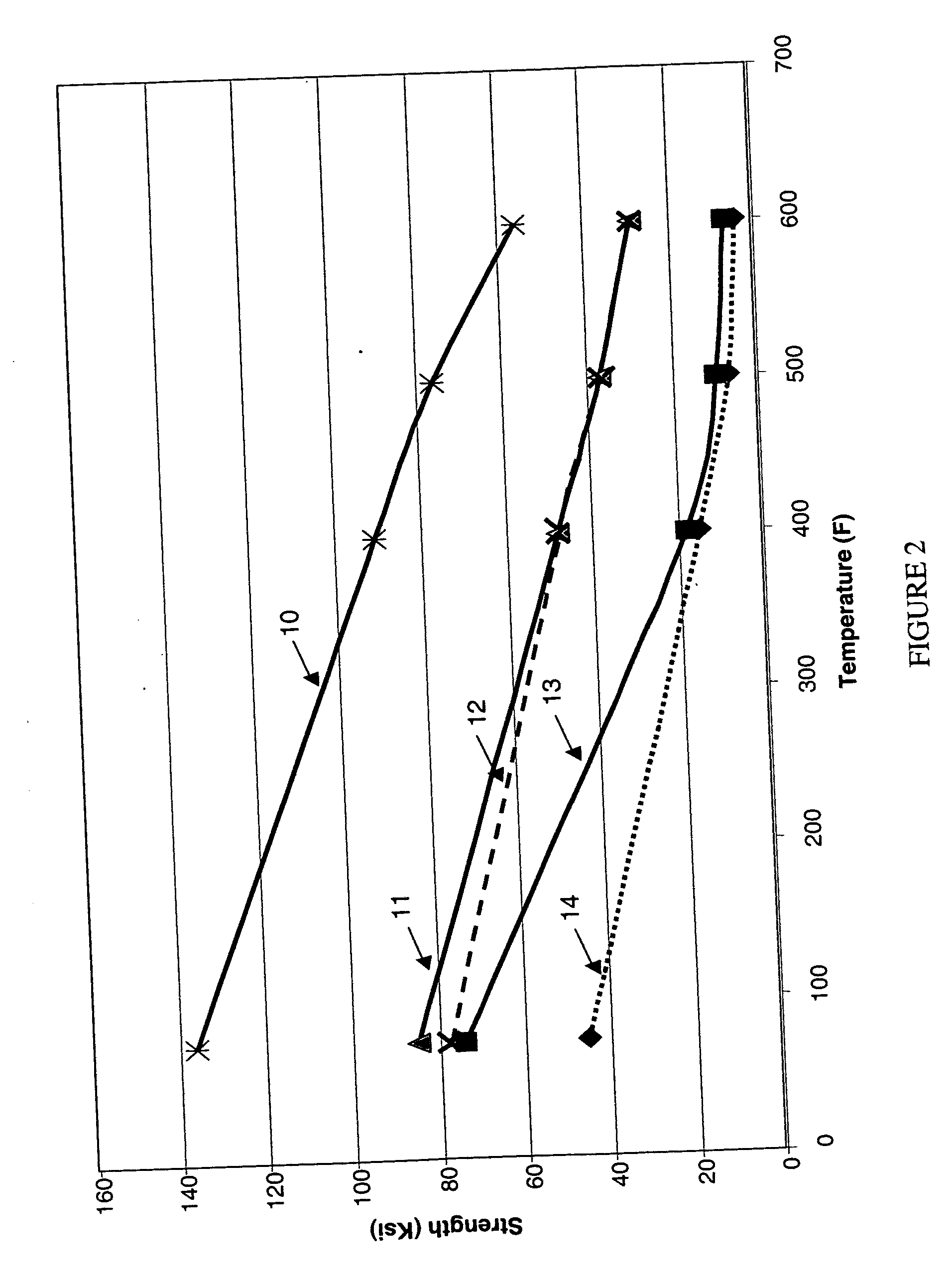

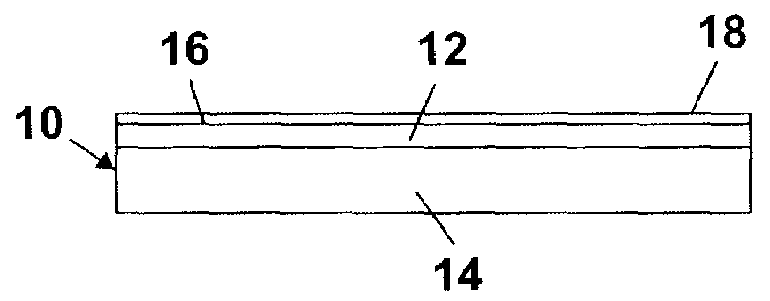

High temperature aluminum alloys

High temperature aluminum alloys that can be used at temperatures from about −420° F. (−251° C.) up to about 650° F. (343° C.) are described herein. These alloys comprise aluminum; scandium; at least one of nickel, iron, chromium, manganese and cobalt; and at least one of zirconium, gadolinium, hafnium, yttrium, niobium and vanadiuim. These alloys comprise an aluminum solid solution matrix and a mixture of various dispersoids. These alloys are substantially free of magnesium.

Owner:RTX CORP

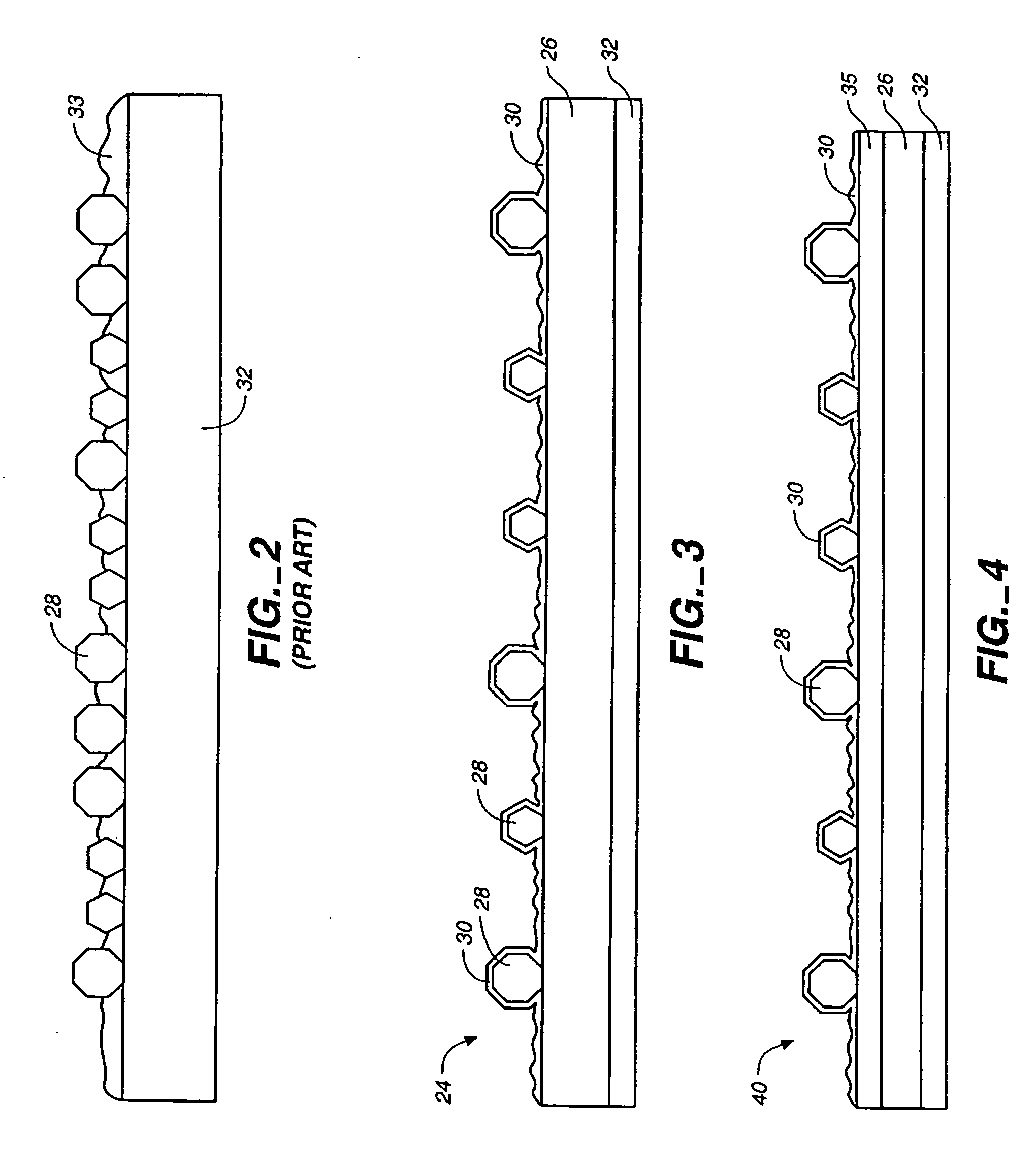

High-strength laminated sheet for optical applications

InactiveUS7514149B2Increase stiffnessHigh modulusGlass forming apparatusRecord information storageSurface layerHigh intensity

A laminated sheet includes a surface layer having an optical surface that is of fire-polished quality and a core layer having a higher modulus than the surface layer to increase an overall stiffness or fracture toughness of the laminated sheet.

Owner:CORNING INC

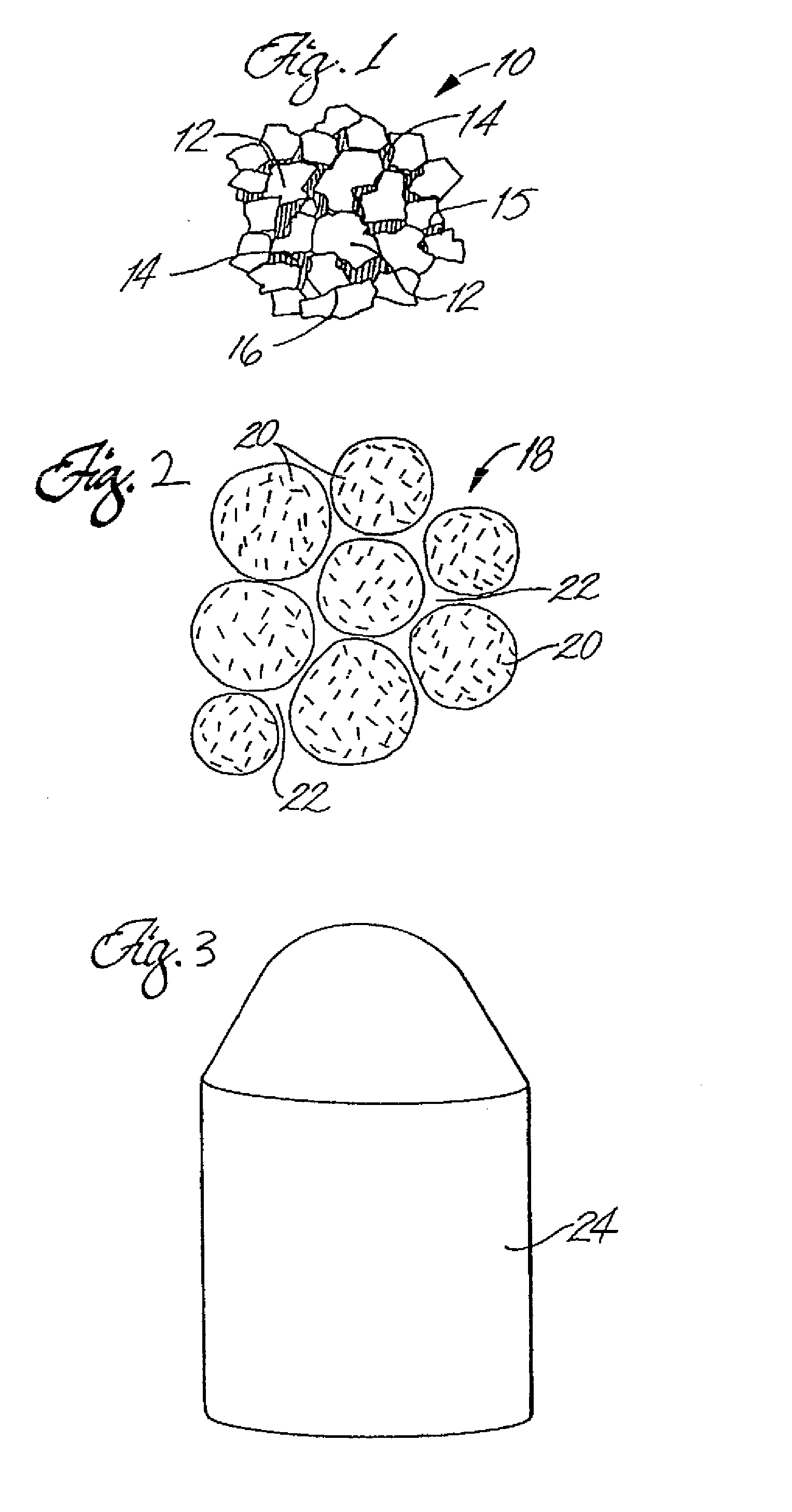

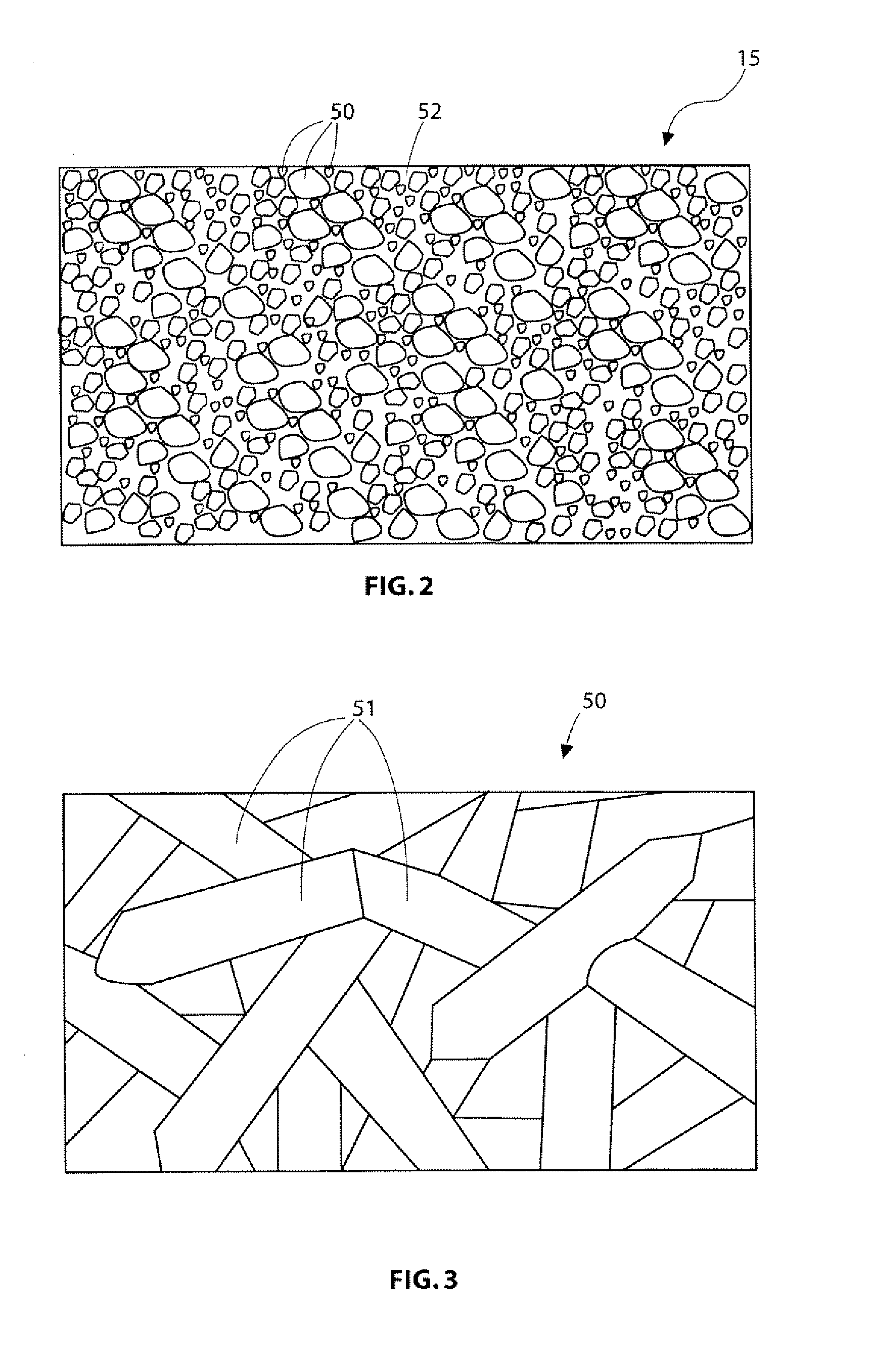

Polycrystalline diamond carbide composites

InactiveUS20070193782A1Improve fracture toughnessEasy to useDrill bitsOther chemical processesPolycrystalline diamondCarbide

Owner:SMITH INT INC

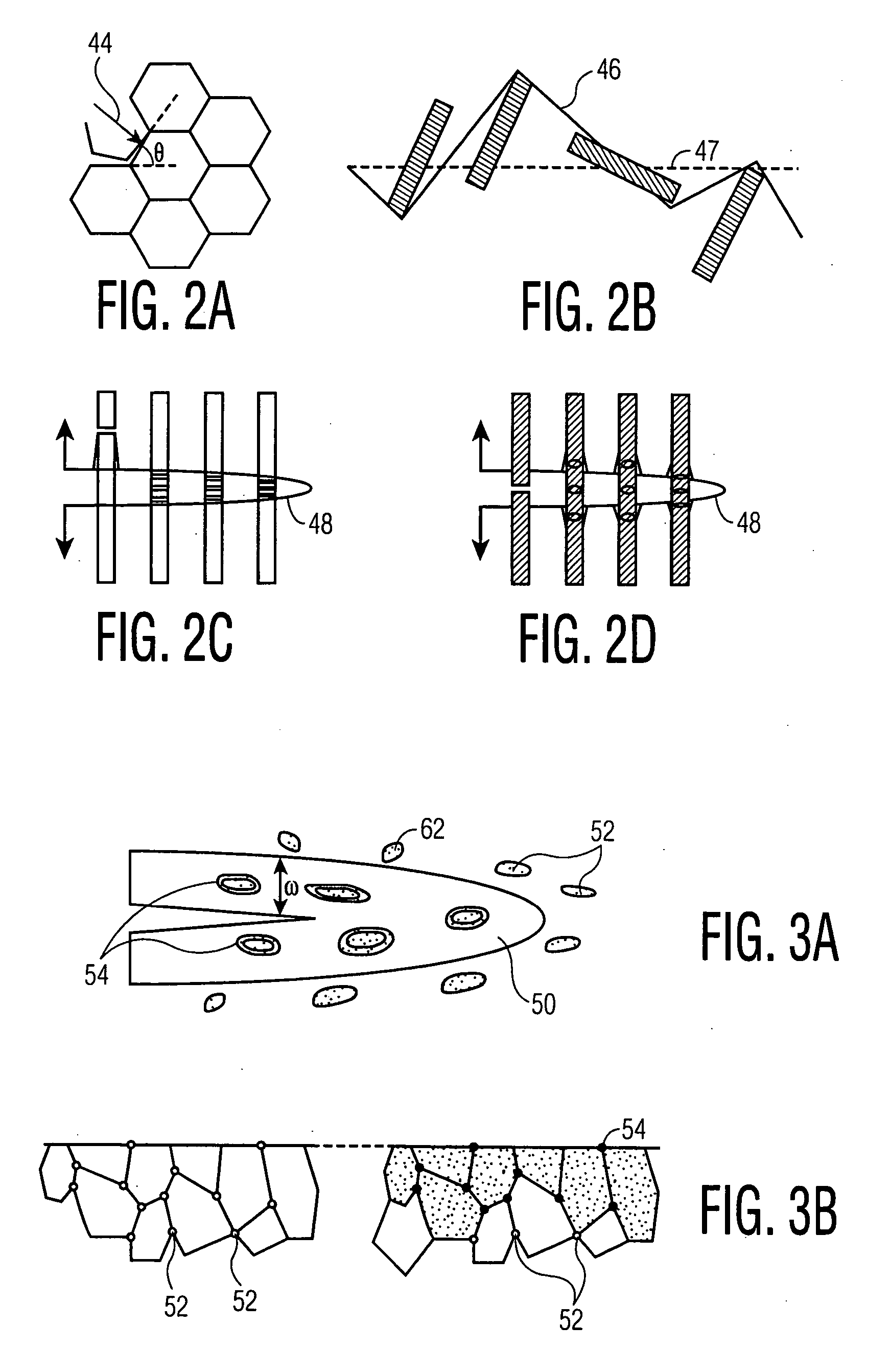

Nanocomposite ceramics and process for making the same

InactiveUS20070049484A1High hardnessImprove fracture toughnessMaterial nanotechnologyNanometreMaterials science

A nanocomposite ceramic composition and method for making the same, the composition comprising a uniform dispersion of nanosize ceramic particles composed of at least one ceramic phase, interspersed and bound throughout a tough zirconia matrix phase.

Owner:RUTGERS THE STATE UNIV

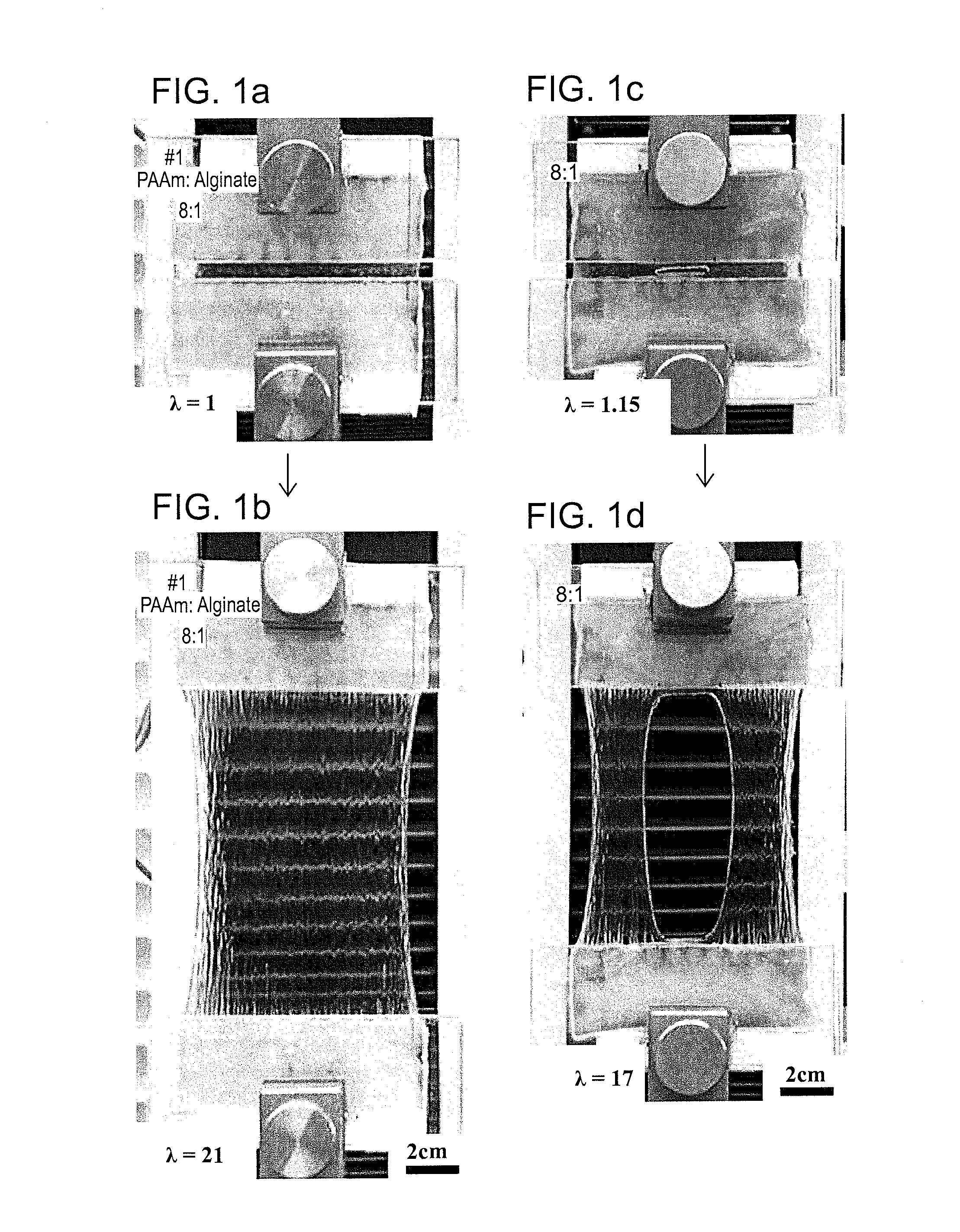

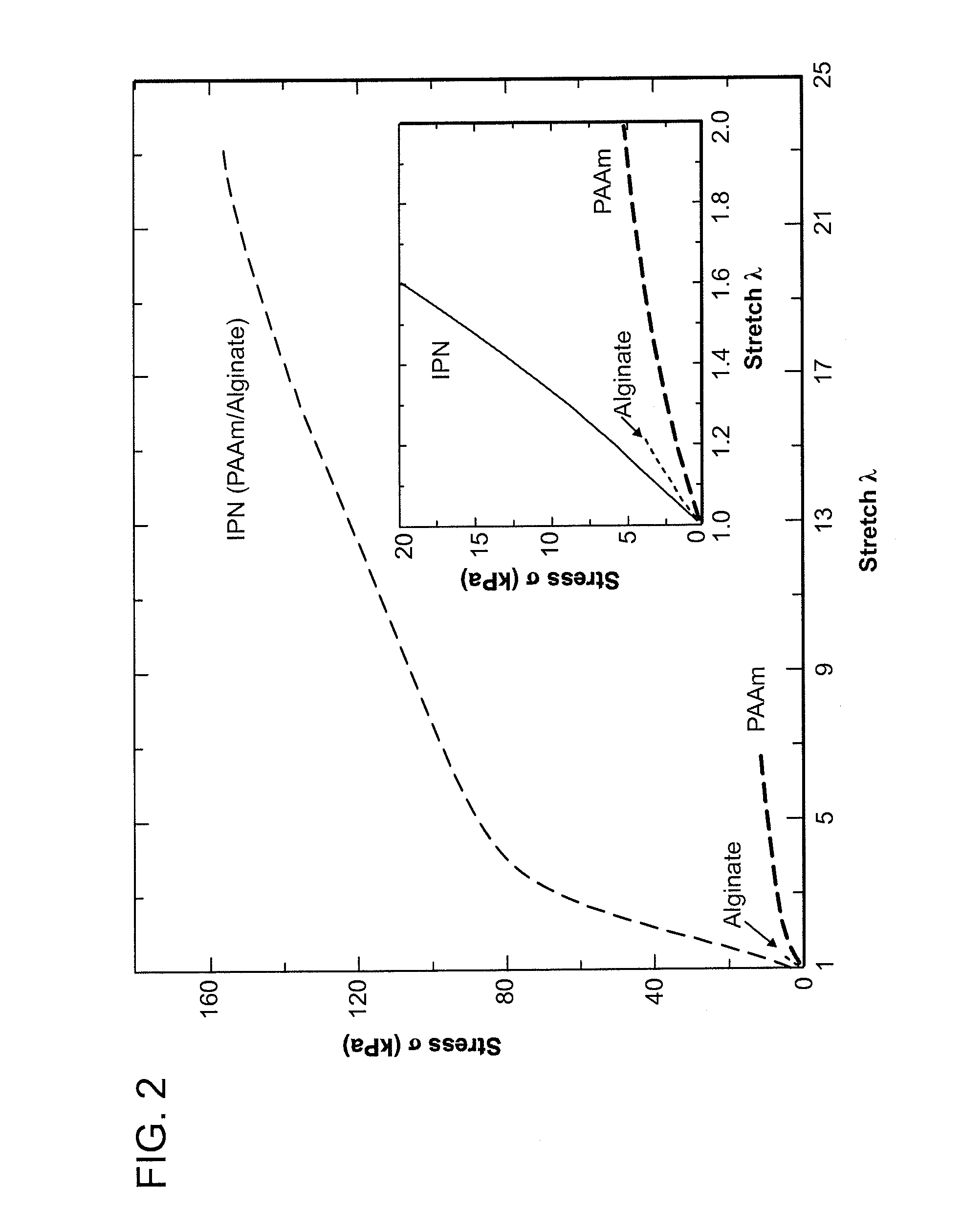

Interpenetrating Networks With Covalent and Ionic Crosslinks

ActiveUS20150038613A1Stay resilientImprove mechanical propertiesSurgical adhesivesProsthesisSelf-healingEngineering

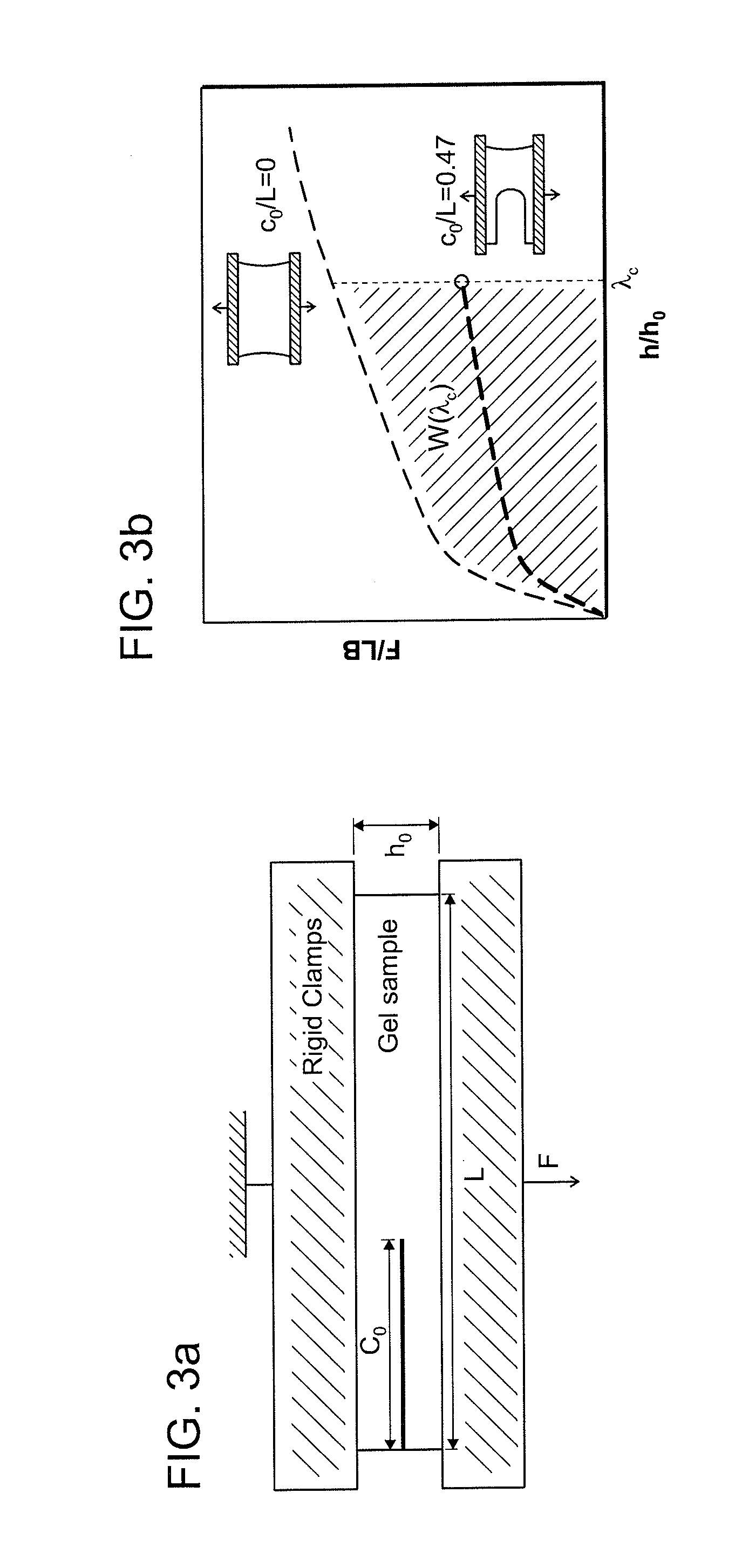

The invention features a composition comprising a self-healing interpenetrating network hydrogel comprising a first network and a second network. The first network comprises covalent crosslinks and the second network comprises ionic or physical crosslinks. For example, the first network comprises a polyacrylamide polymer and second network comprises an alginate polymer.

Owner:PRESIDENT & FELLOWS OF HARVARD COLLEGE +1

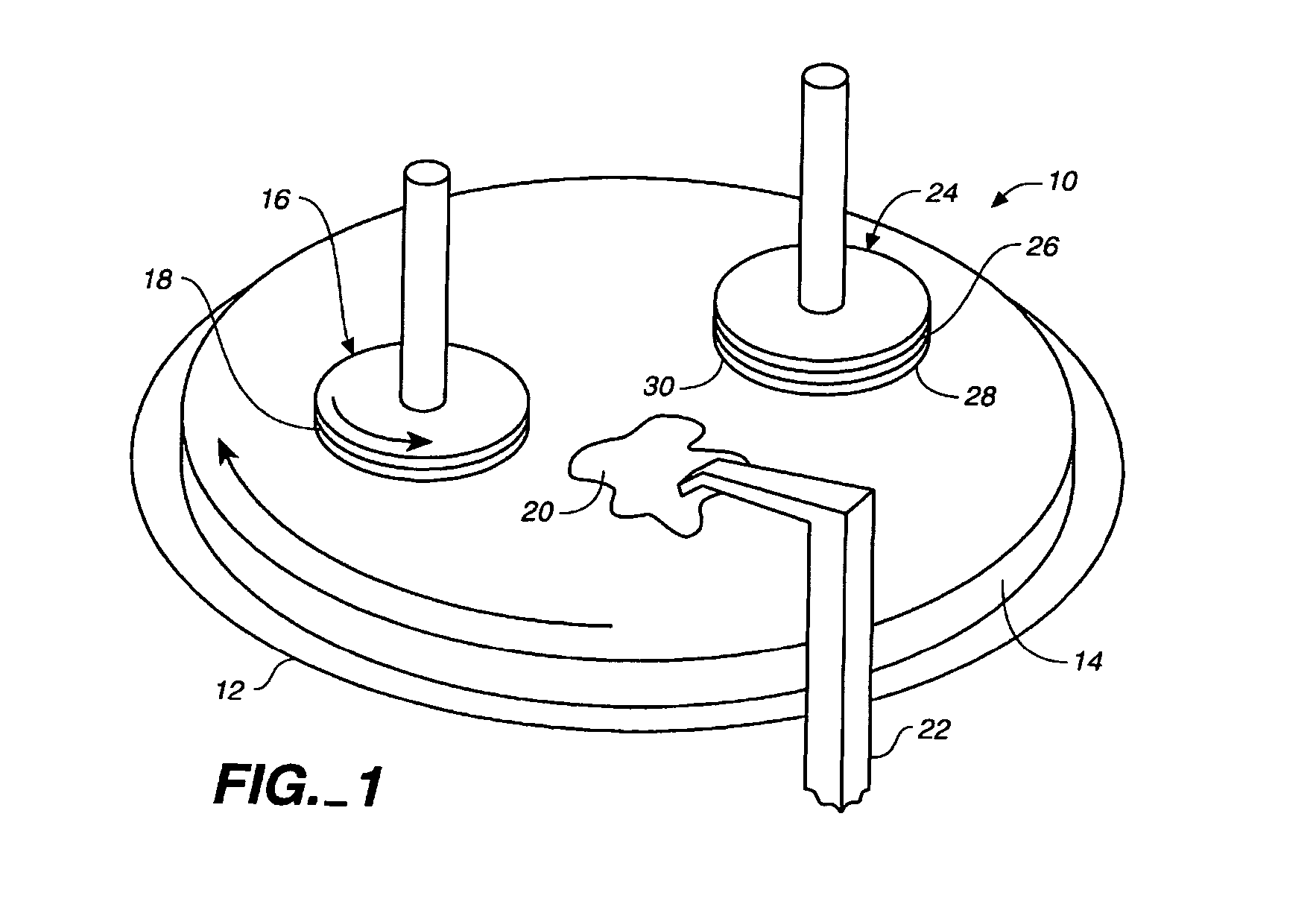

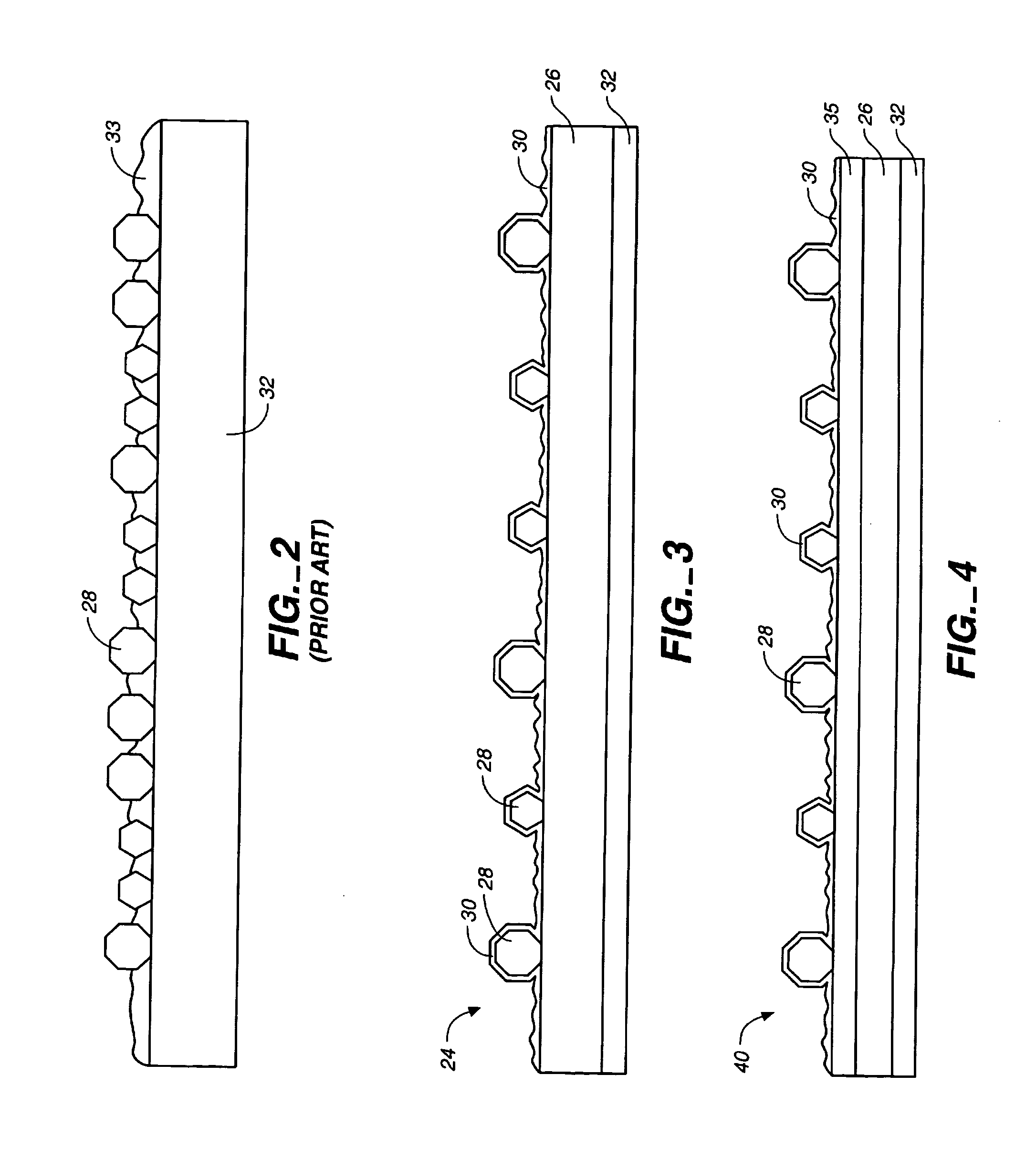

CVD diamond-coated composite substrate containing a carbide-forming material and ceramic phases and method for making same

InactiveUS20050025973A1Improve adhesionLow costPigmenting treatmentEngine sealsReaction bonded silicon carbideComposite substrate

The present invention relates to a composite material and the method of making same, which comprises a CVD diamond coating applied to a composite substrate of ceramic material and an unreacted carbide-forming material of various configurations and for a variety of applications. One example of the composite material is a composite of SiC and free silicon metal known as Reaction-Bonded Silicon Carbide. Several examples of applications of the invention include: 1) heads or disks for conditioning polishing pads, including pads used in Chemical-Mechanical-Planarization, 2) cutting and dressing tool inserts and tips, 3) heat spreaders for electronic devices, and 4) wear components including mechanical seals and pump seals.

Owner:MORGAN ADVANCED CERAMICS

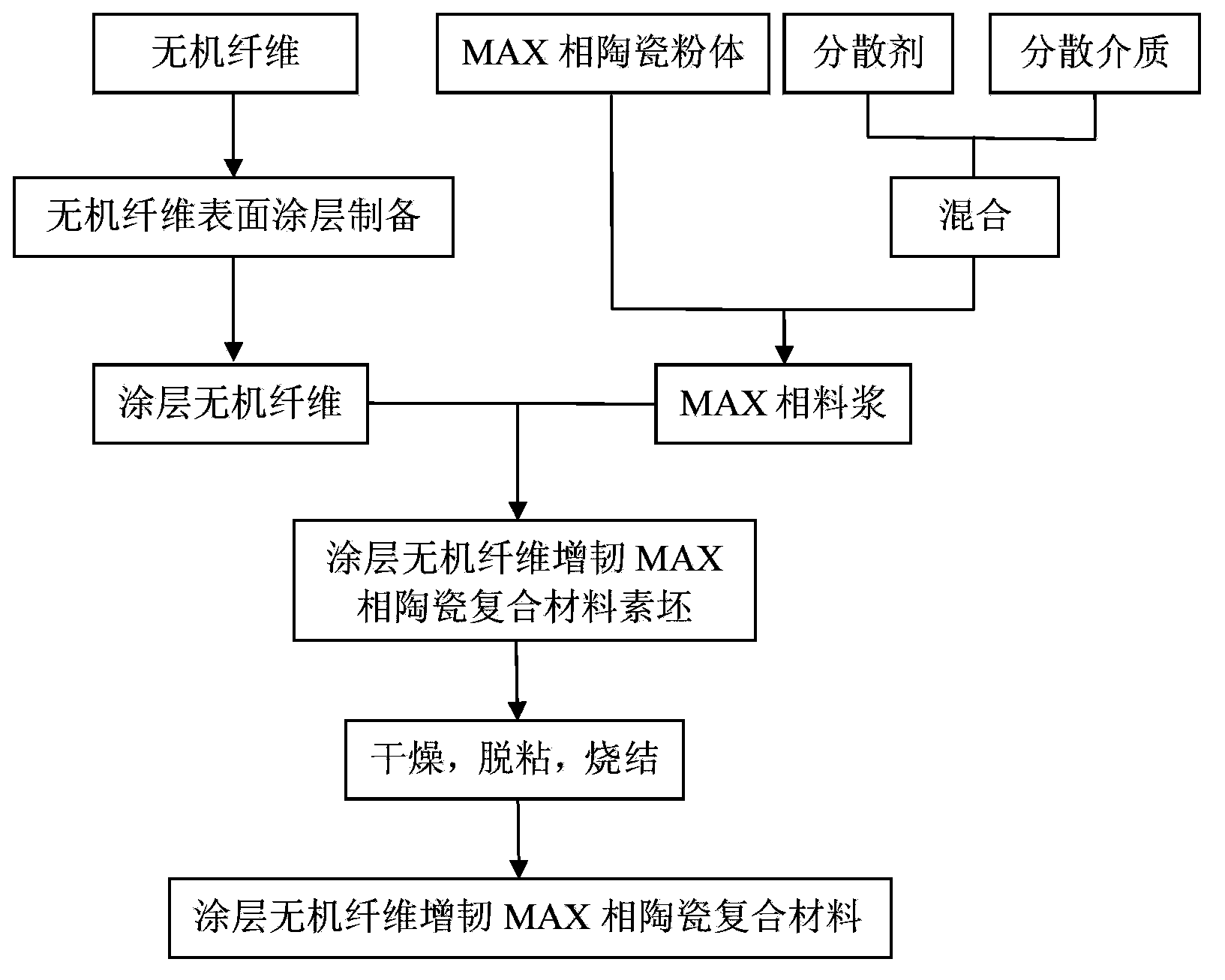

Coating inorganic fiber toughened MAX phase ceramic composite material, preparation method and uses thereof

ActiveCN103910532AAppropriate bonding interface strengthFree control of interface strengthNuclear energy generationContainmentAviationFiber

The present invention provides a coating inorganic fiber toughened MAX phase ceramic composite material and a preparation method thereof. The composite material adopts a MAX phase ceramic material as a matrix and adopts coating inorganic fibers as a toughening phase, wherein the coating inorganic fiber content is 0.5-90% (by volume), and the coating inorganic fibers are completely dispersed in the matrix and are inorganic fibers with the surface coated with the coating. Compared with the composite material in the prior art, the composite material of the present invention has the following characteristics that: the interface reaction between the inorganic fibers and the MAX phase ceramic can be effectively inhibited, the thermal expansion coefficient and elasticity modulus matching degree between the inorganic fibers and the MAX phase ceramic can be effective regulated, the effective improvement of the fracture toughness and the high temperature resistance of the MAX phase ceramic composite material can be achieved, the problems of high brittleness and insufficient use reliability of the MAX phase ceramic can be fundamentally solved, and the coating inorganic fiber toughened MAX phase ceramic composite material has potential application prospects in the high technology fields of civil use, aviation, aerospace, nuclear industry and the like, and is especially for the fission and fusion reactor nuclear power plant inner wall structure material.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

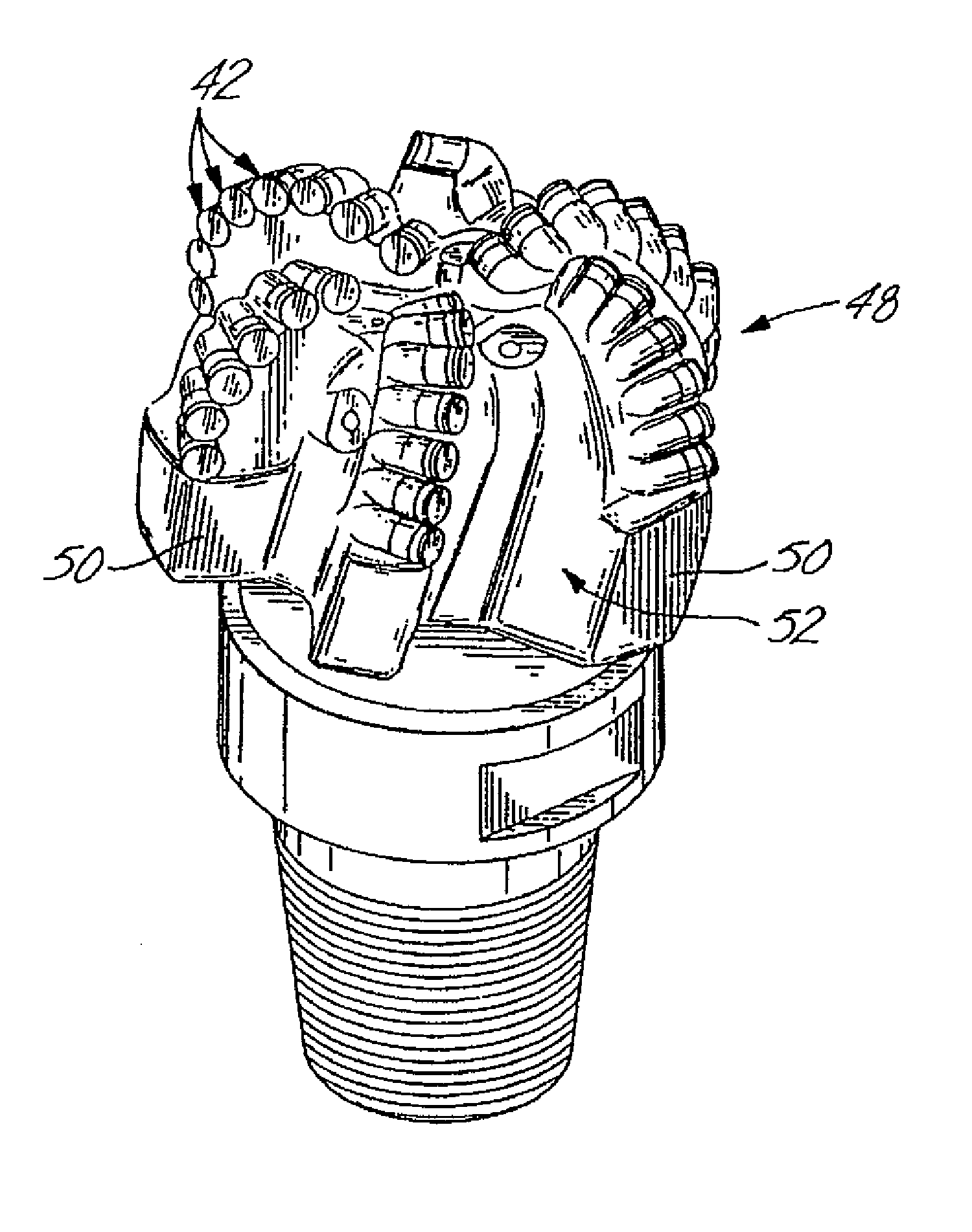

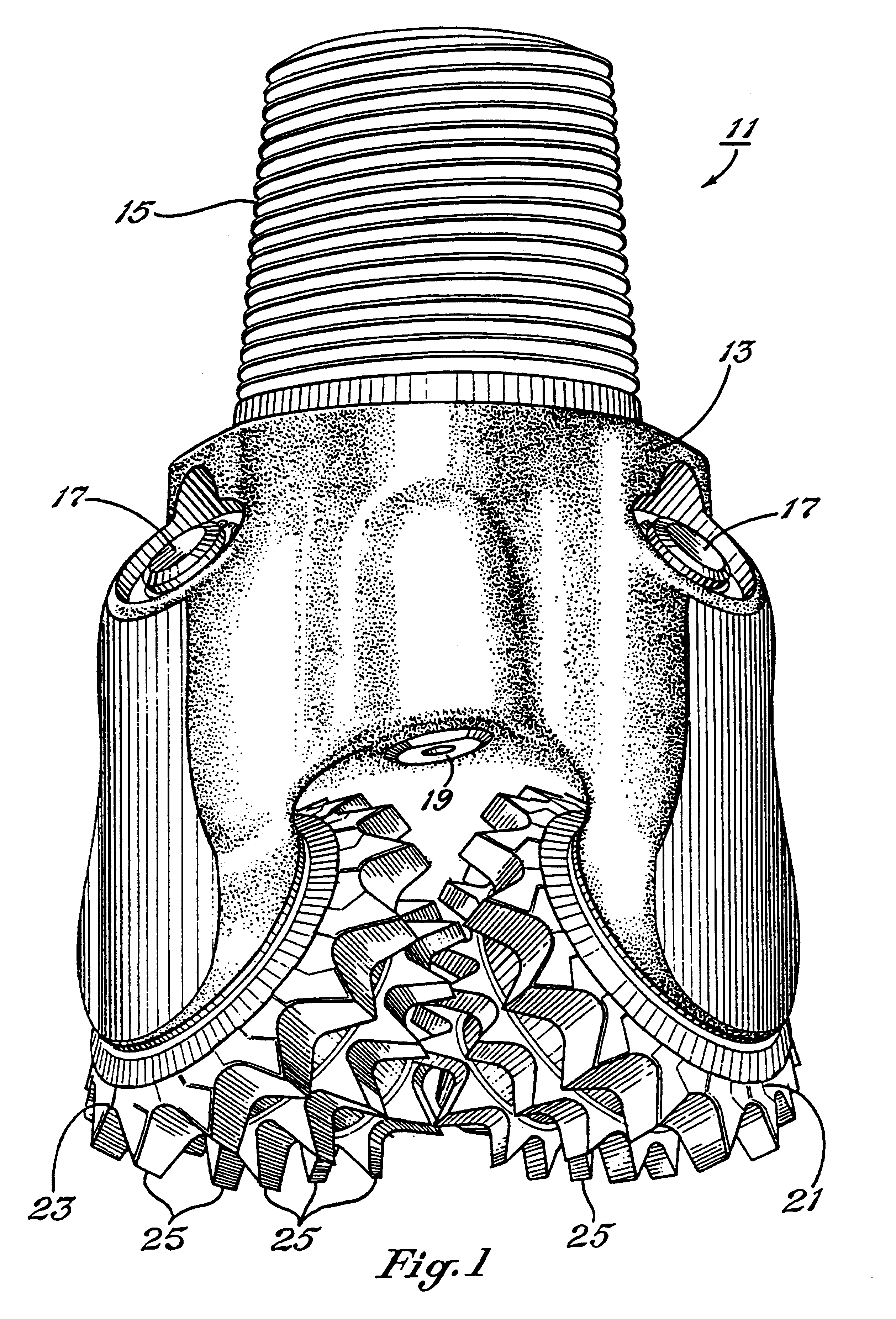

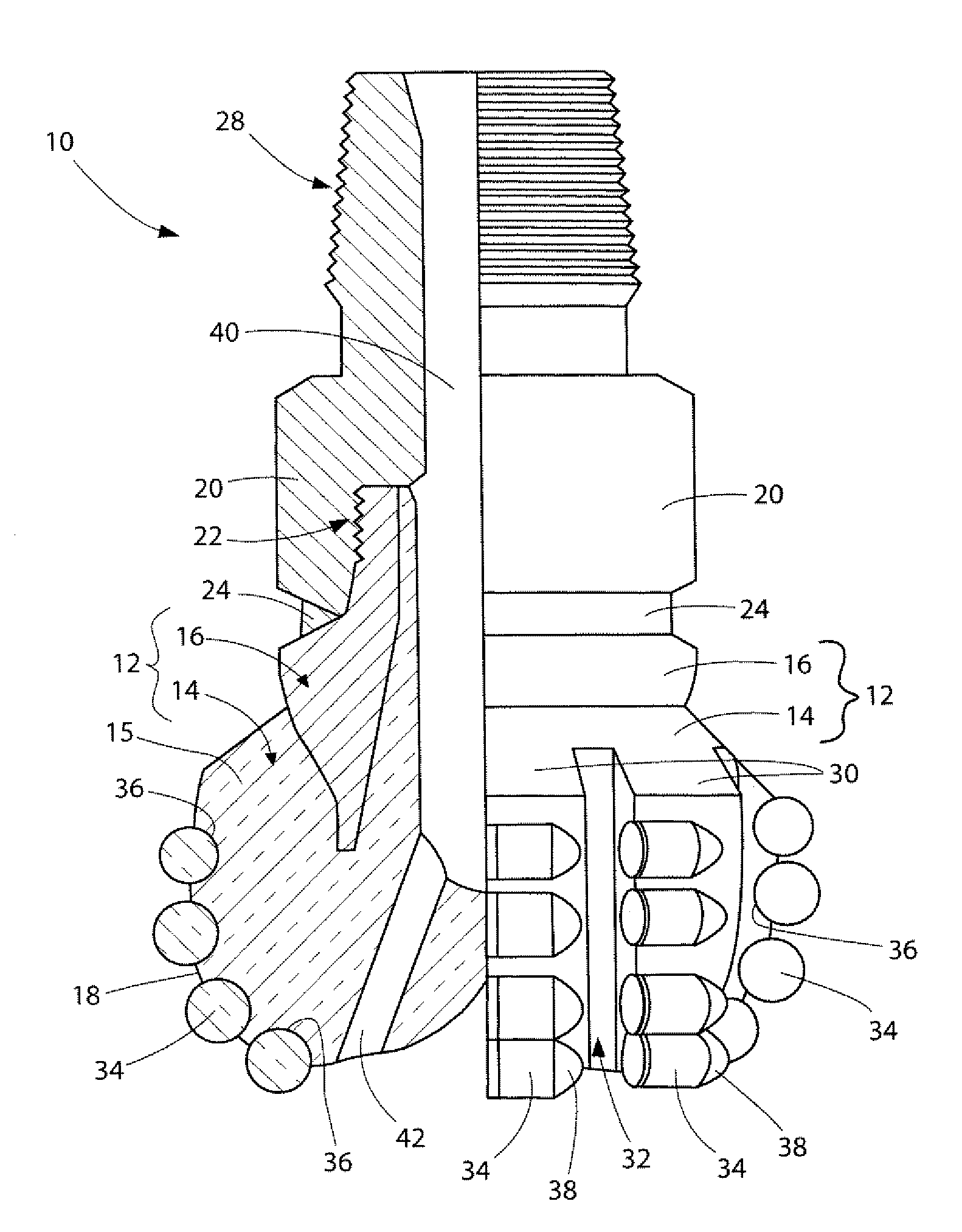

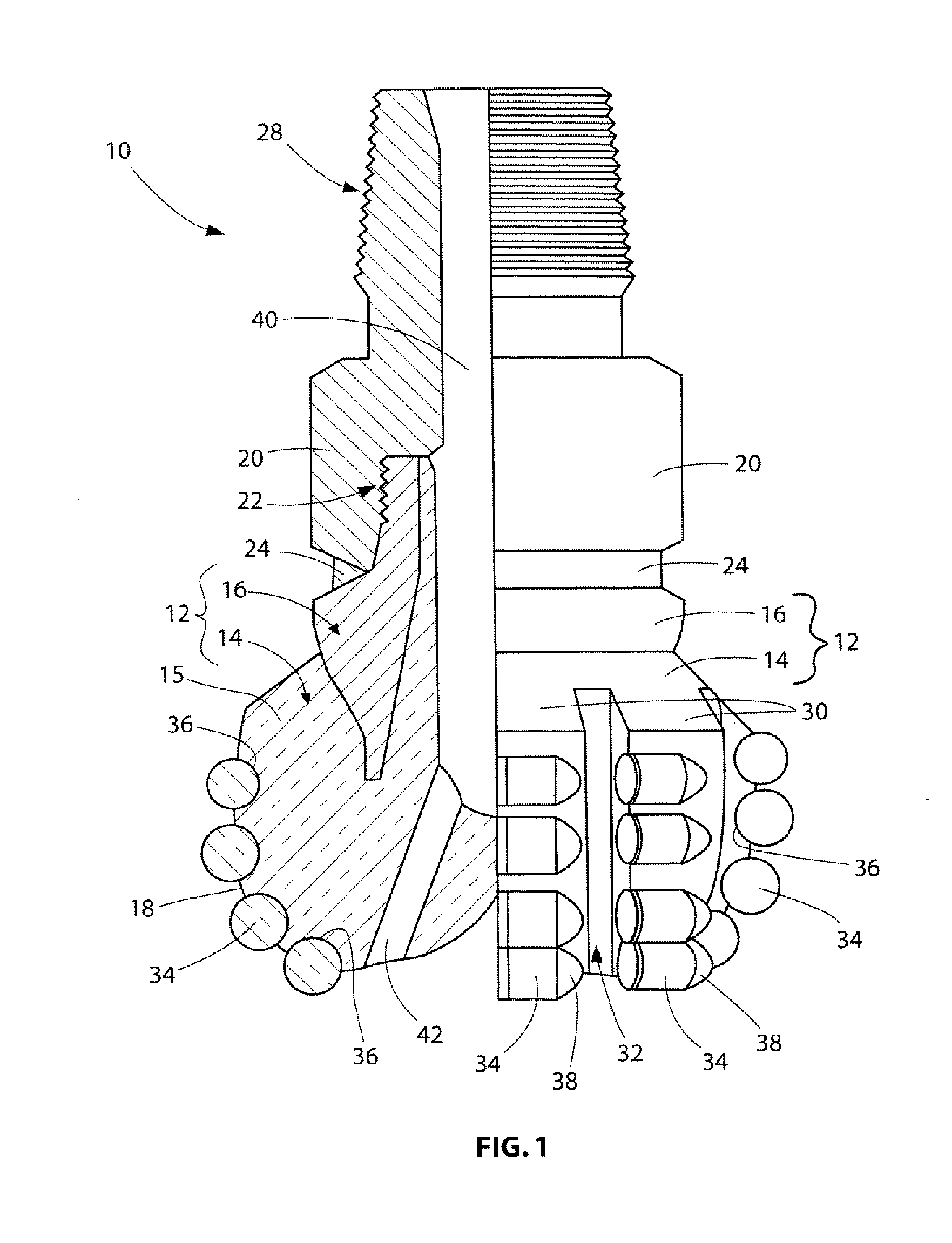

Hardfacing composition for earth-boring bits

InactiveUSRE37127E1Improve wear resistanceImprove fracture toughnessMolten spray coatingDrill bitsNiobiumVanadium carbide

A hardfacing composition comprises at least 60% by weight of hard metal granules including a quantity of sintered carbide pellets and a quantity of cast carbide pellets. The cast and sintered carbides are selected from the group of carbides consisting of chromium, molybdenum, niobium, tantalum, titanium, tungsten, and vanadium carbides and alloys and mixtures thereof. The balance of the hardfacing composition is matrix metal with traces of flux or deoxidizer, and alloying elements. All percentages given are pre-application ratios.

Owner:BAKER HUGHES INC

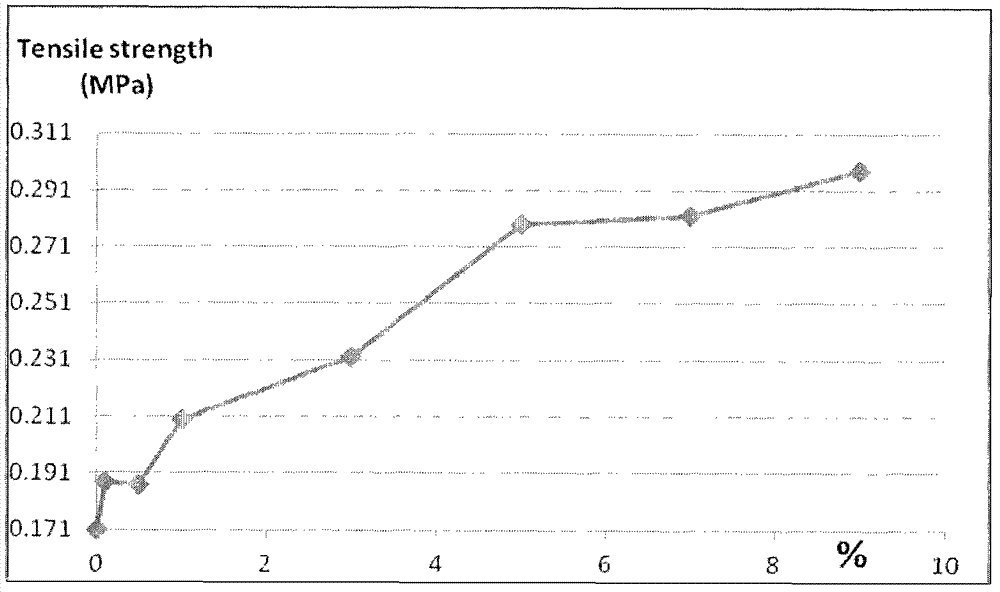

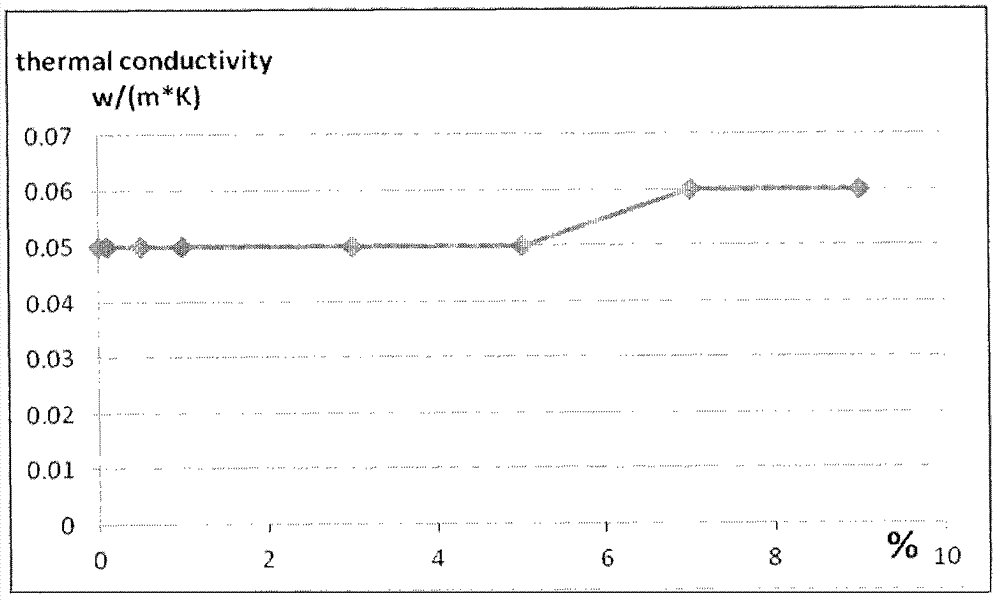

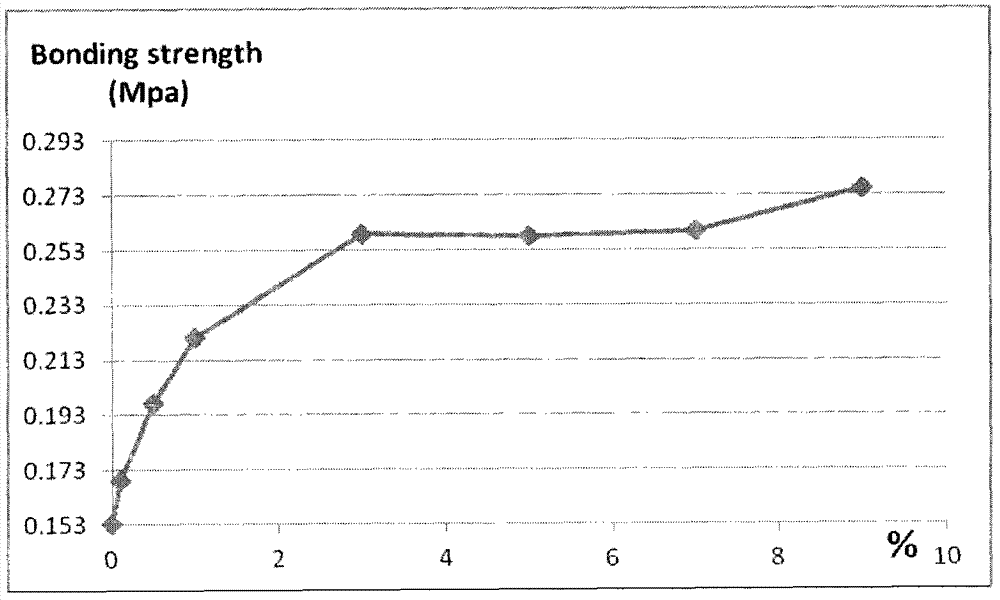

Nano-material-containing high-strength high-heat insulation exterior wall inorganic heat-retaining face brick

The invention belongs to the field of building materials, relates to a use of a nano-material in a building exterior wall heat-retaining system and provides a nano-material-containing high-strength high-heat insulation exterior wall inorganic heat-retaining face brick. The nano-material-containing high-strength high-heat insulation exterior wall inorganic heat-retaining face brick is characterized in that nano-particles are used so that compressive strength, tensile strength and bonding strength are improved. The nano-material-containing high-strength high-heat insulation exterior wall inorganic heat-retaining face brick is prepared by adding a nano-material having a nanoscale particle size into a mixed system of cement, an auxiliary gel material, a polymer binder, an inorganic light heat-retaining material, fibers and water, uniformly mixing, carrying out pressing molding of the mixture, carrying out organic polymer crosslinking and cement hydration drying, and carrying out waterproof layer coating. The nano-material-containing high-strength high-heat insulation exterior wall inorganic heat-retaining face brick has the advantages of excellent flame resistance, high compressive strength, high tensile strength, high bonding strength and good insulation effects.

Owner:平湖市法而特建筑保温科技有限公司

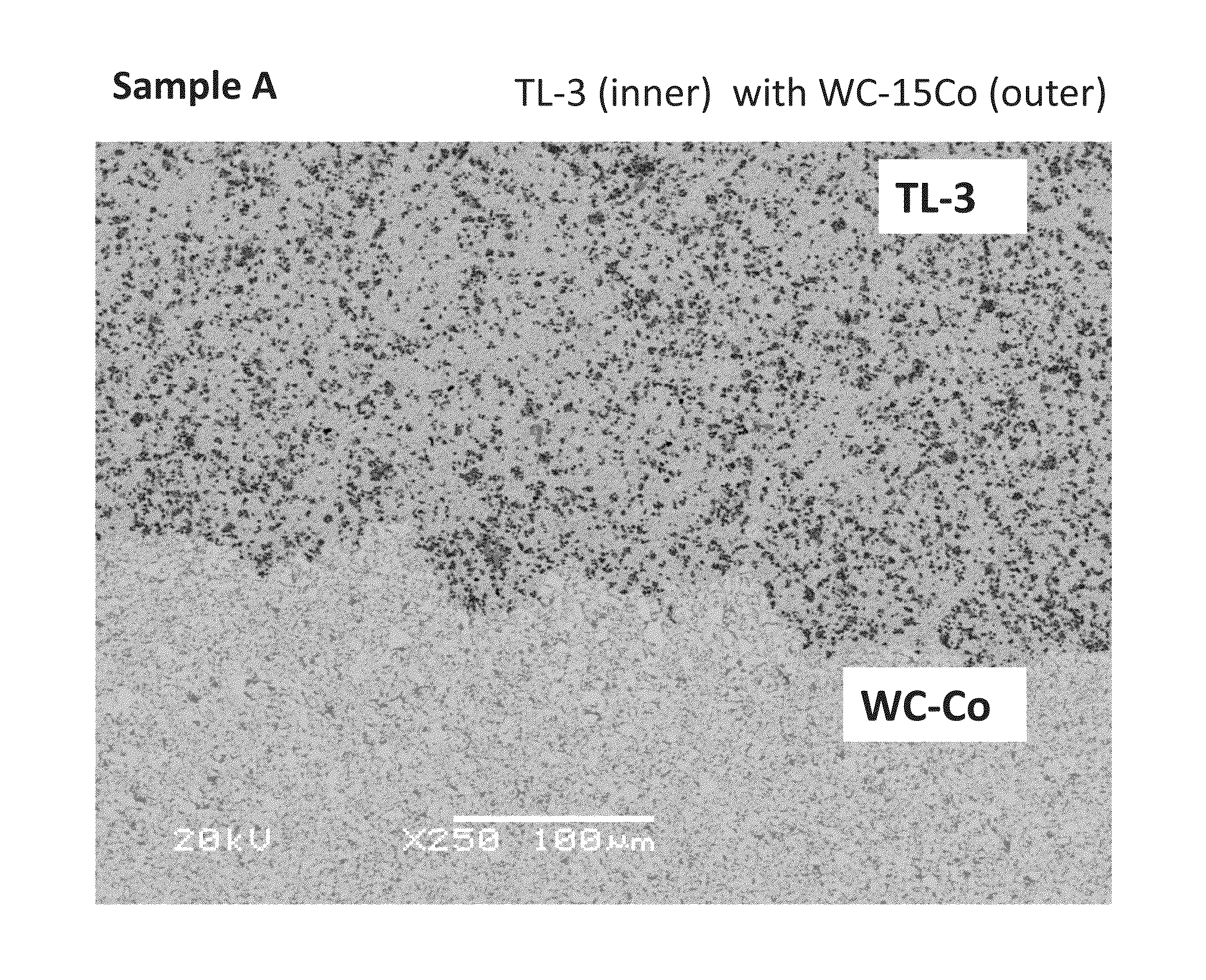

Methods of forming a metallic or ceramic article having a novel composition of functionally graded material and articles containing the same

ActiveUS20140087210A1Improve fracture toughnessLow costAdditive manufacturing apparatusLayered productsCarbideFunctionally graded material

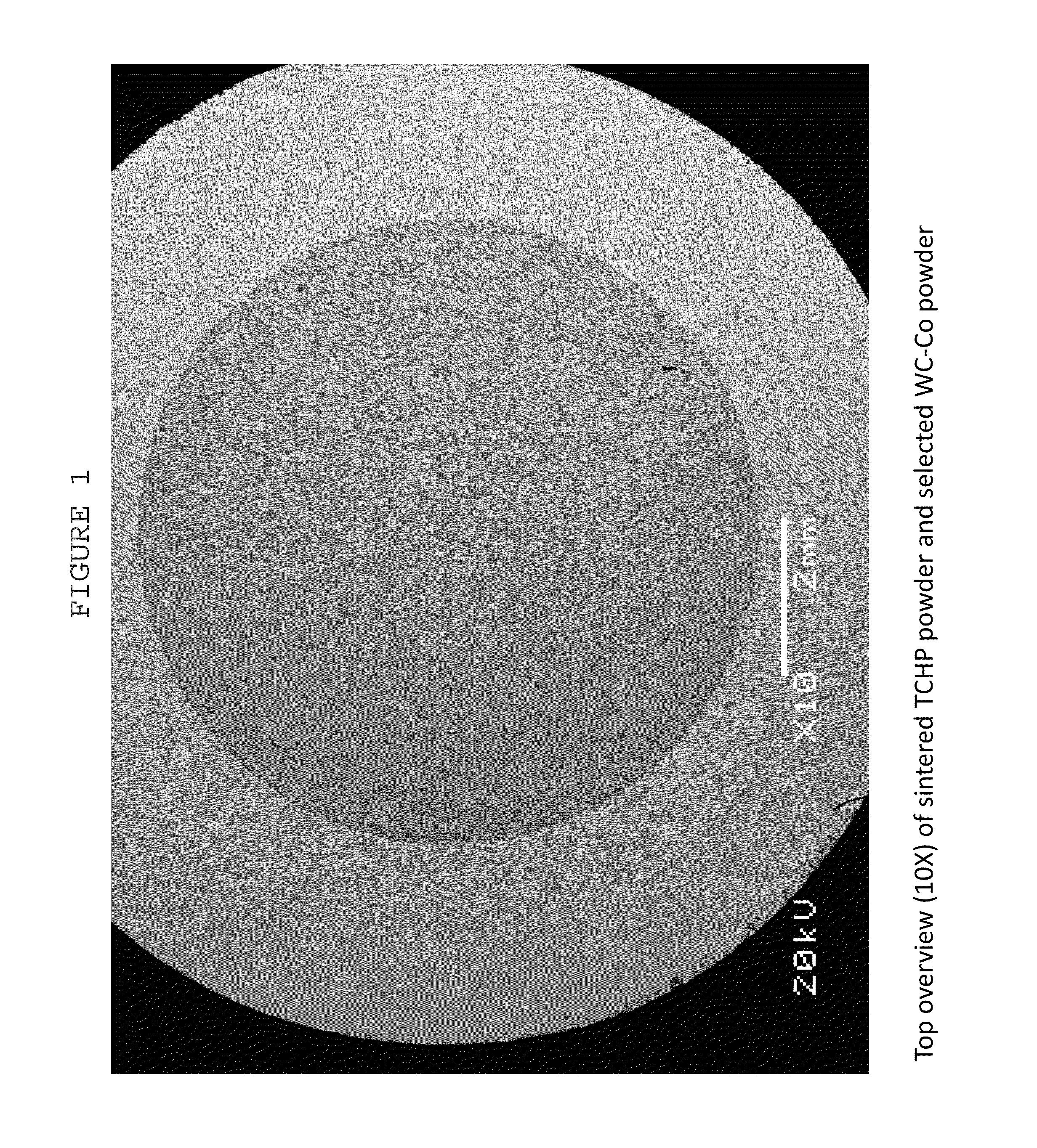

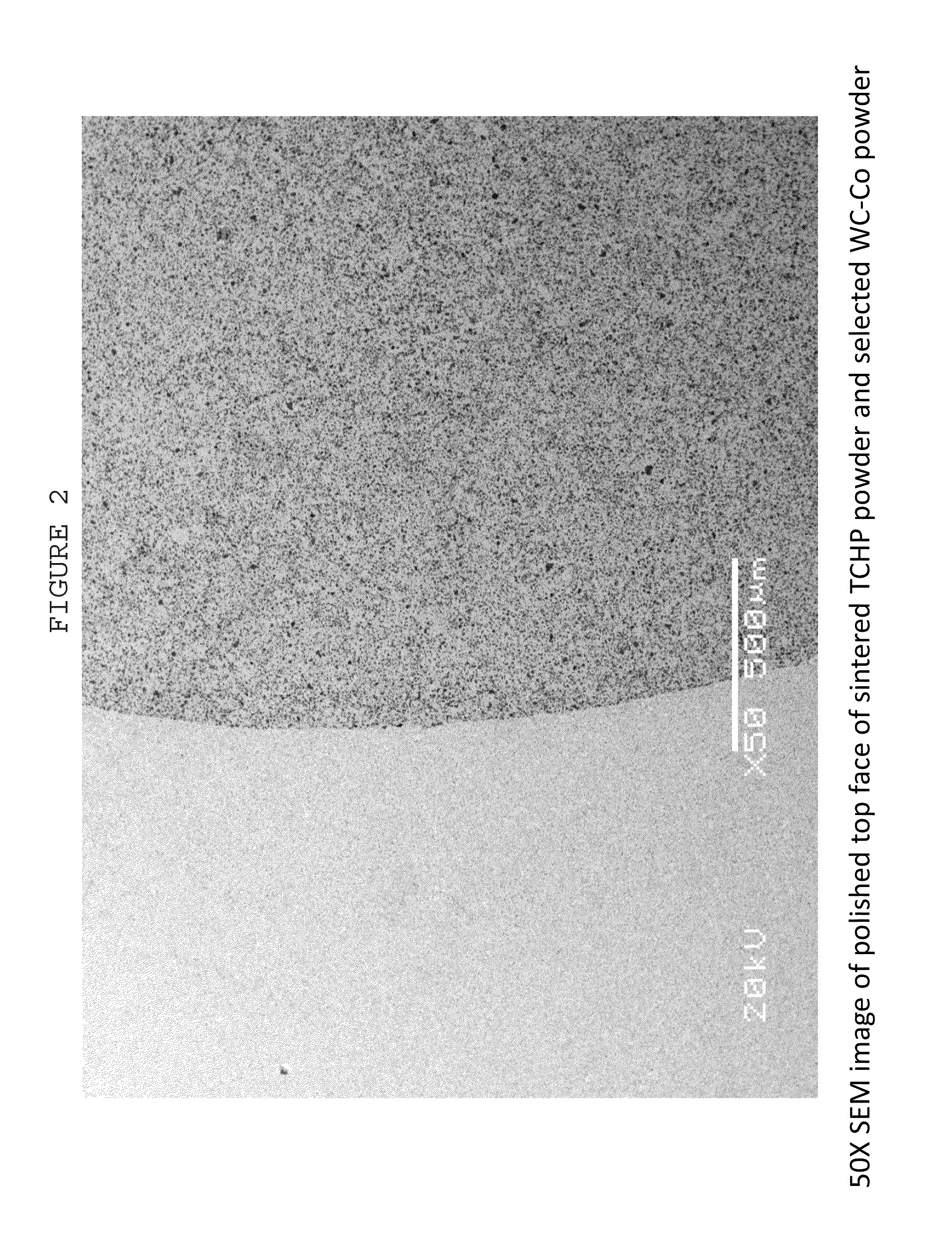

There is disclosed a method of making a metallic or ceramic component, such as a cutting or forming tool, from at least two distinct powder precursors. In one embodiment, the method comprising forming a first mixture comprised of a plurality of coated particles, such as Tough-Coated Hard Powder (TCHP) composite particles created by encapsulating extremely hard core particles with very tough binder and structural materials, and at least one support powder, such as a carbide, typically WC—Co. The mixture is formed into a green body and sintered to form a functionally graded or multicomponent article. Non-limiting examples of the articles made from the disclosed methods are also disclosed and include drills, mills, cutting tools, forming tools, wires dies and mechanical components.

Owner:ETERNALOY HLDG GMBH

Process for producing composite material of Ti3SiC2 modified C/SiC

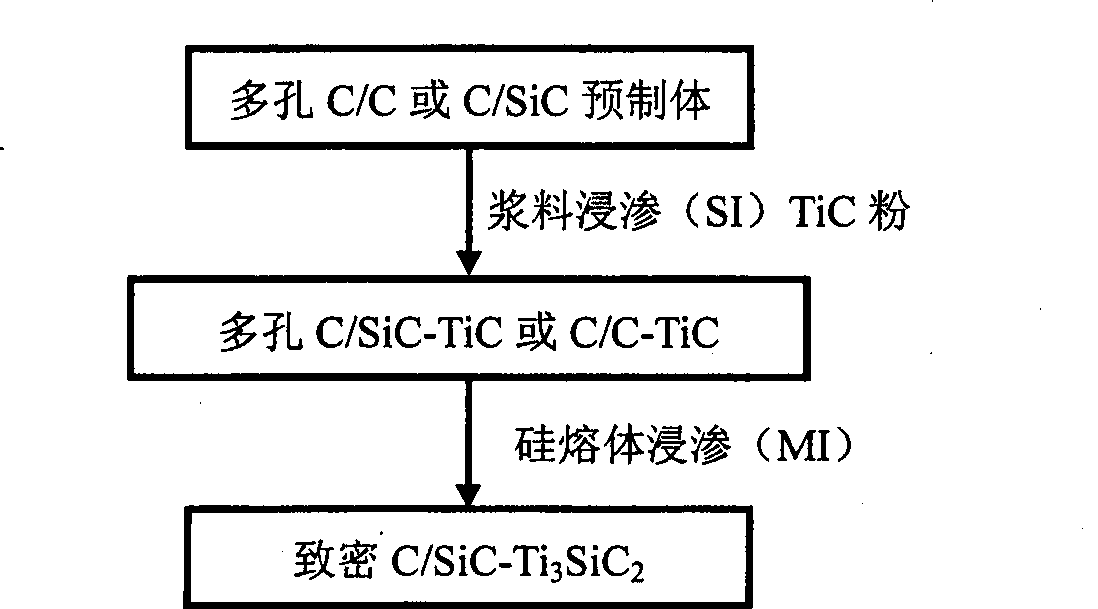

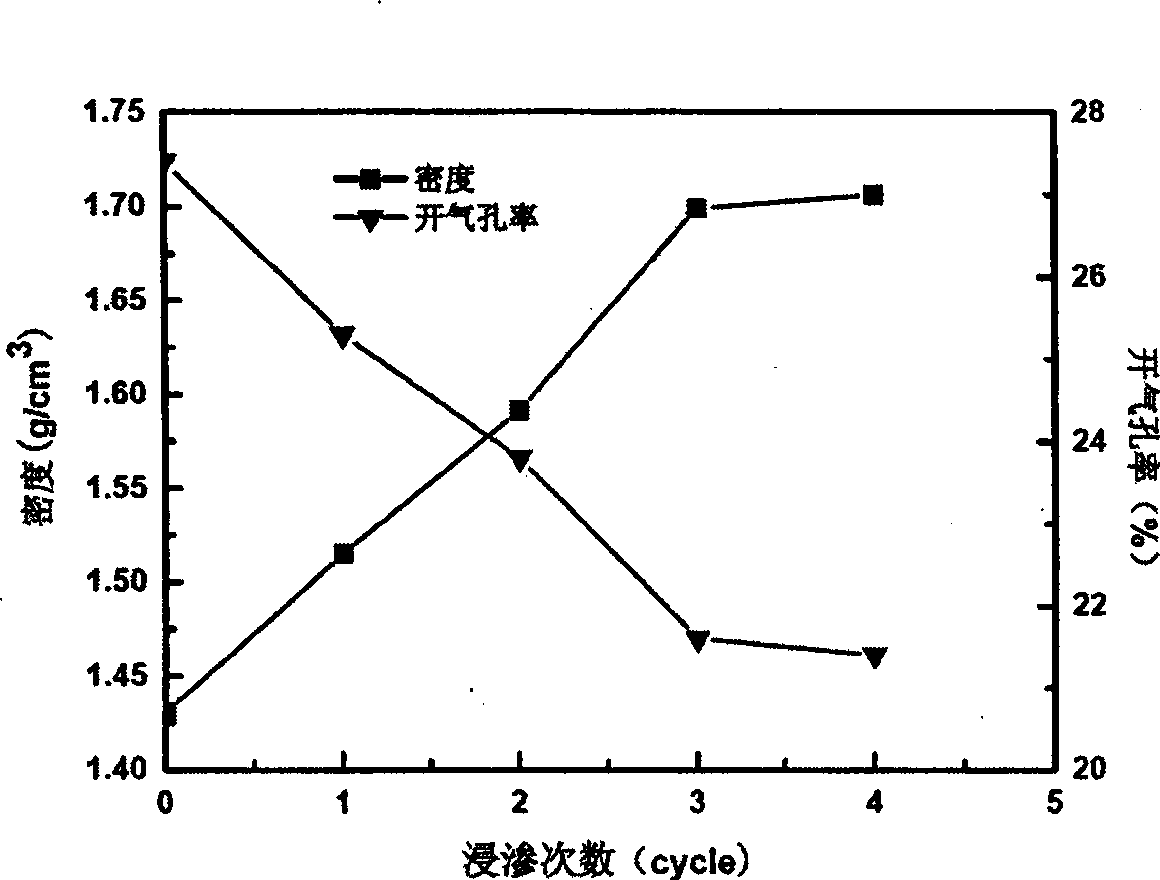

The invention discloses a method for preparing Ti3SiC2 modified C / SiC composite material, comprising the following steps: firstly, carrying out ultrasonic cleaning and drying on the pre-prepared body to be modified; compounding the size with distilled water, cellulose sodium carboxy methyl and TiC powder; then carrying out vacuum infiltration combined with pressure infiltration on the pre-prepared body and refrigeration and drying in vacuum; coating industrial silicon powder on the surface of the pre-prepared body; calcining the pre-prepared body in a vacuum furnace to lead the silicon to fuse to penetrate into the pre-prepared body; and cooling the pre-prepared body gradually to room temperature after full reaction in the vacuum furnace. As SI method is adopted to lead C / C or C / SiC composite material to be firstly internally filled with TiC granules, then MI method is adopted to penetrate silicon fusant, and TiC reacts with Si to generate Ti3SiC2 and SiC, the content of residue Si in the composite material is reduced, and the Ti3SiC2 phase in-situ generated in the C / SiC composite material causes the use temperature of the modified C / SiC composite material to rise from 1420 DEG C in the prior art to 1500-2300 DEG C and the fracture toughness property to rise from 8MPa.m in the prior art to 9-16 MPa.m.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

Drug formulations

InactiveUS20120202838A1Improve fracture toughnessImprove fracture resistancePowder deliveryBiocideHigh fractureMedicine

In one embodiment, the present invention relates to abuse-deterrent drug formulations comprise a plurality of discrete domains uniformly dispersed in a pharmaceutically acceptable matrix, wherein said domains have high fracture toughness and comprise at least one polymer and at least one abuse-relevant drug. In another embodiment, the present invention relates to a formulation comprising a plurality of discrete mechanically reinforcing particles uniformly dispersed in a pharmaceutically acceptable matrix, wherein said matrix has high fracture toughness and comprises at least one polymer and at least one active agent, at least one abuse-relevant drug or a combination of at least one active agent and at least one abuse-relevant drug.

Owner:ABBVIE INC

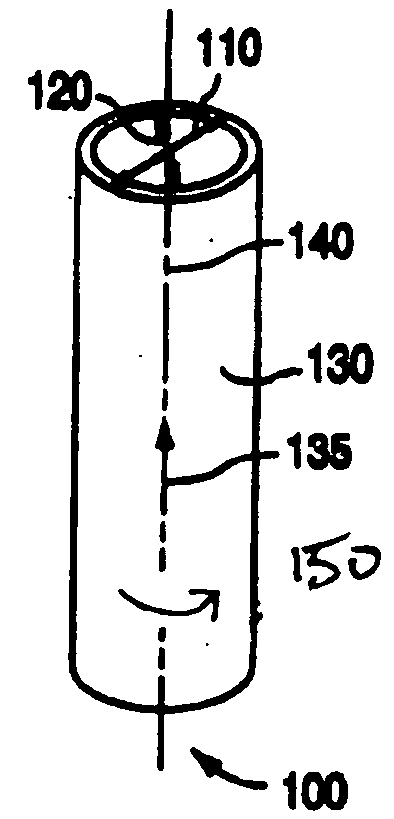

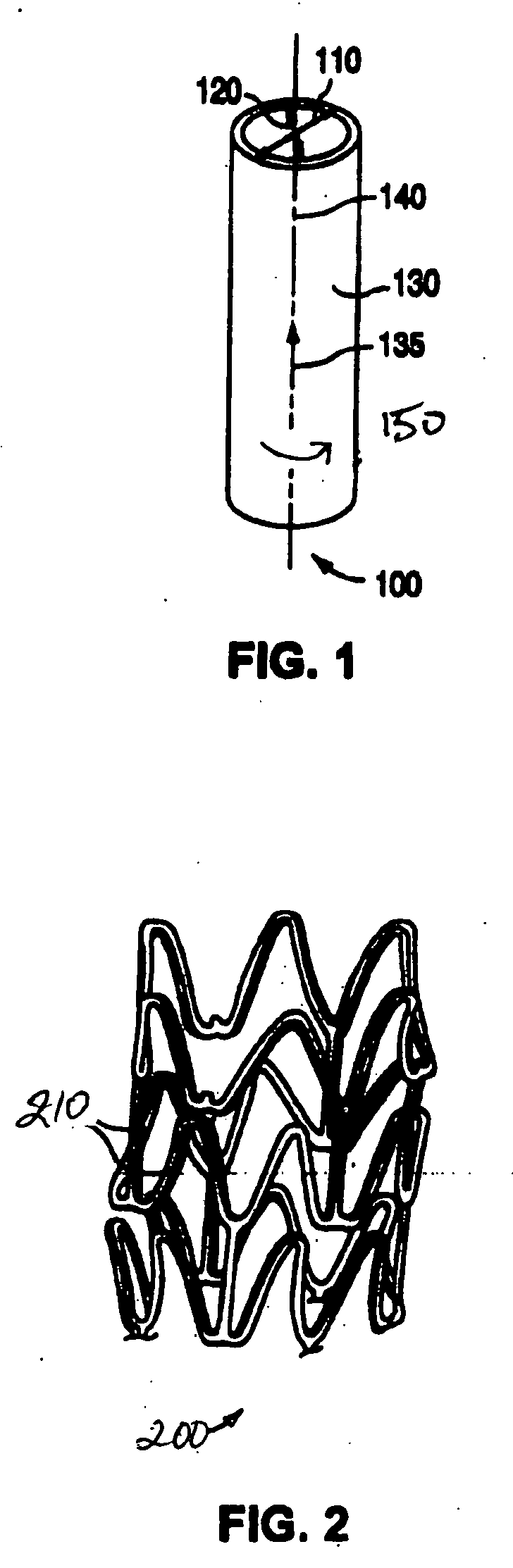

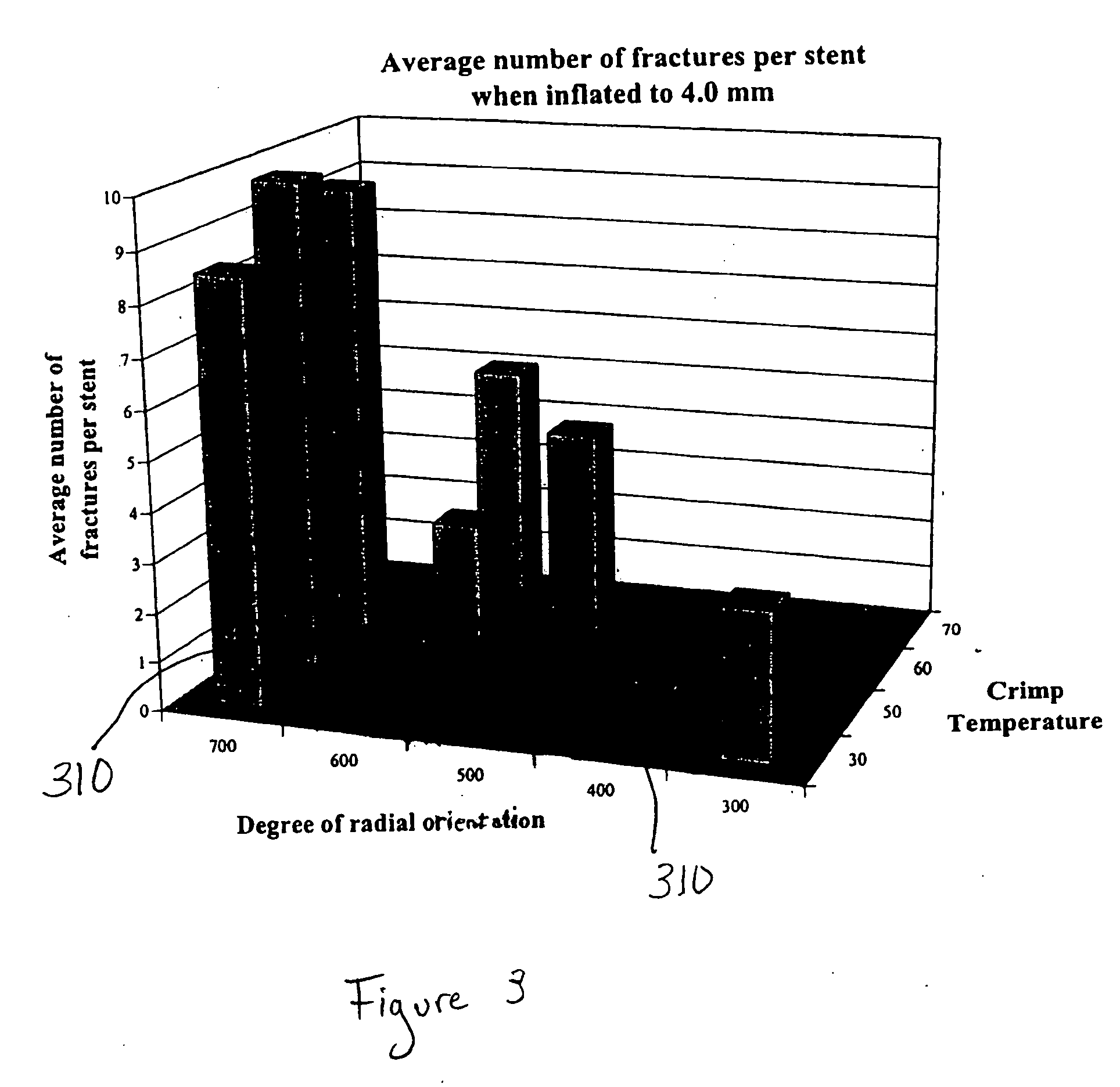

Optimizing fracture toughness of polymeric stent

Disclosed herein is a method of fabricating a stent assembly comprising radially expanding a polymeric tube to an optimal degree of radial expansion; fabricating a stent from the expanded polymeric tube; and crimping the stent onto a catheter assembly, wherein the temperature of the stent during crimping is an optimal crimping temperature, wherein the optimal degree of radial expansion and the optimal crimping temperature correspond to an optimal fracture toughness exhibited by the crimped stent upon its deployment as a function of degree of radial expansion and crimping temperature.

Owner:ABBOTT CARDIOVASCULAR

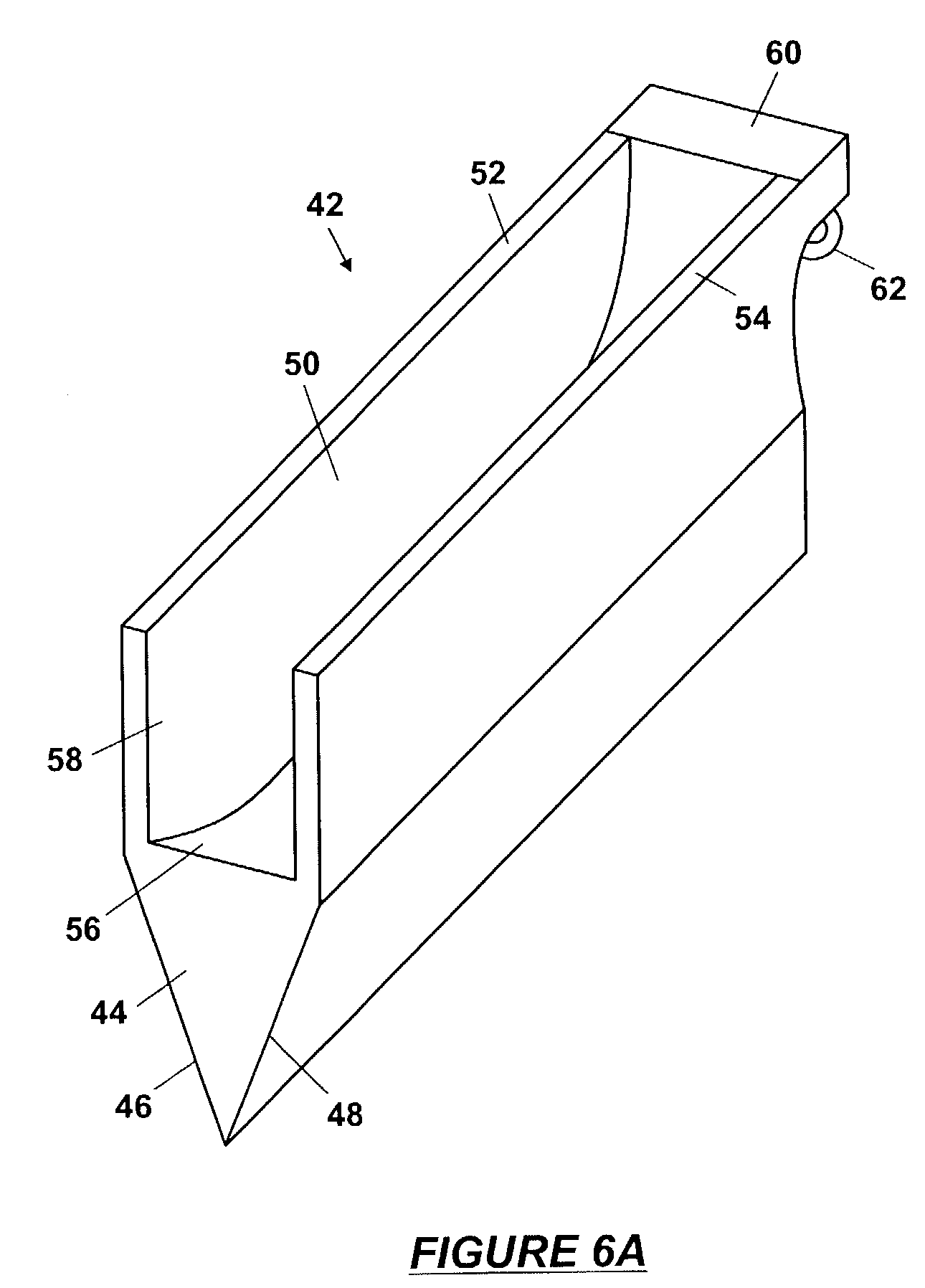

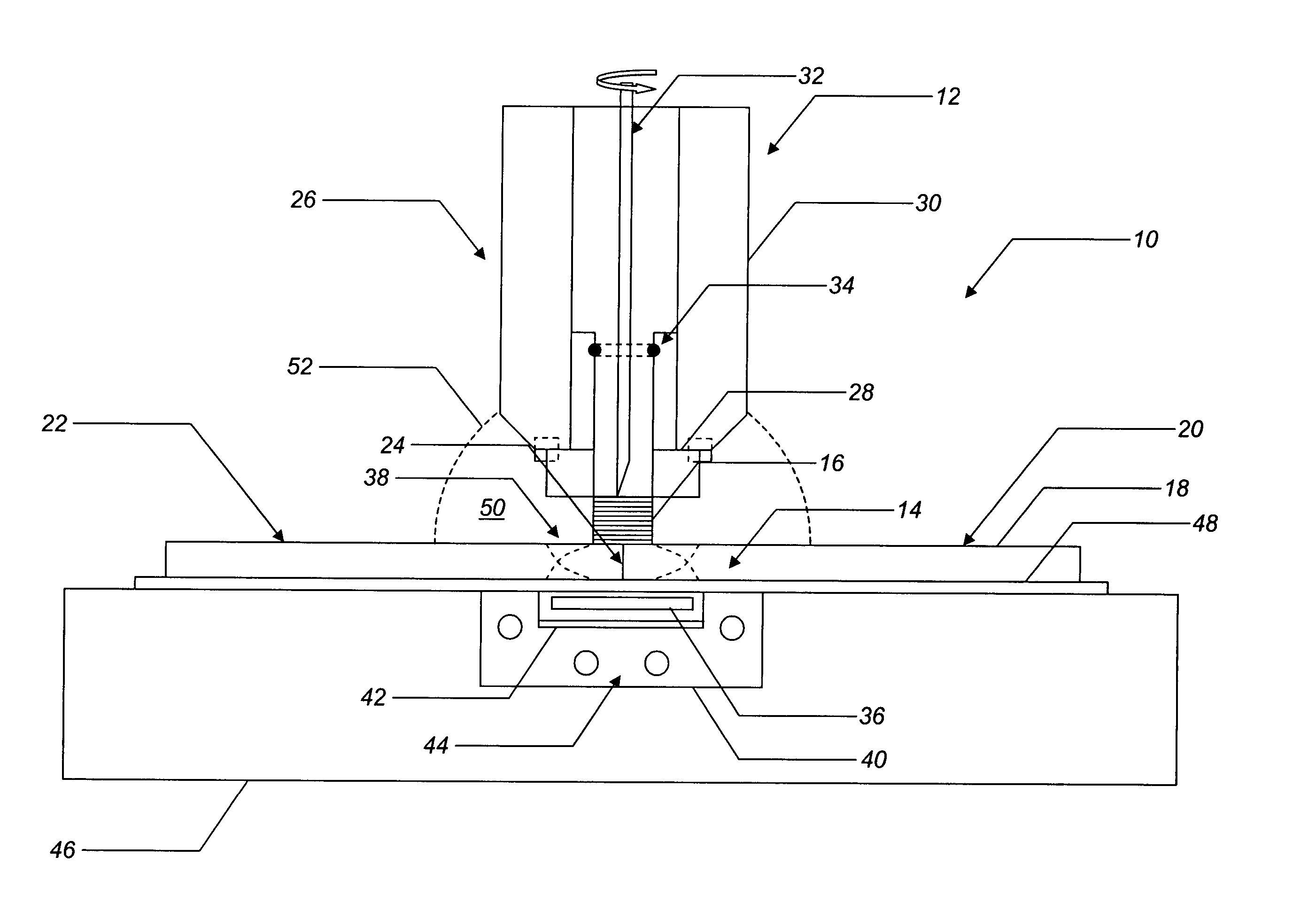

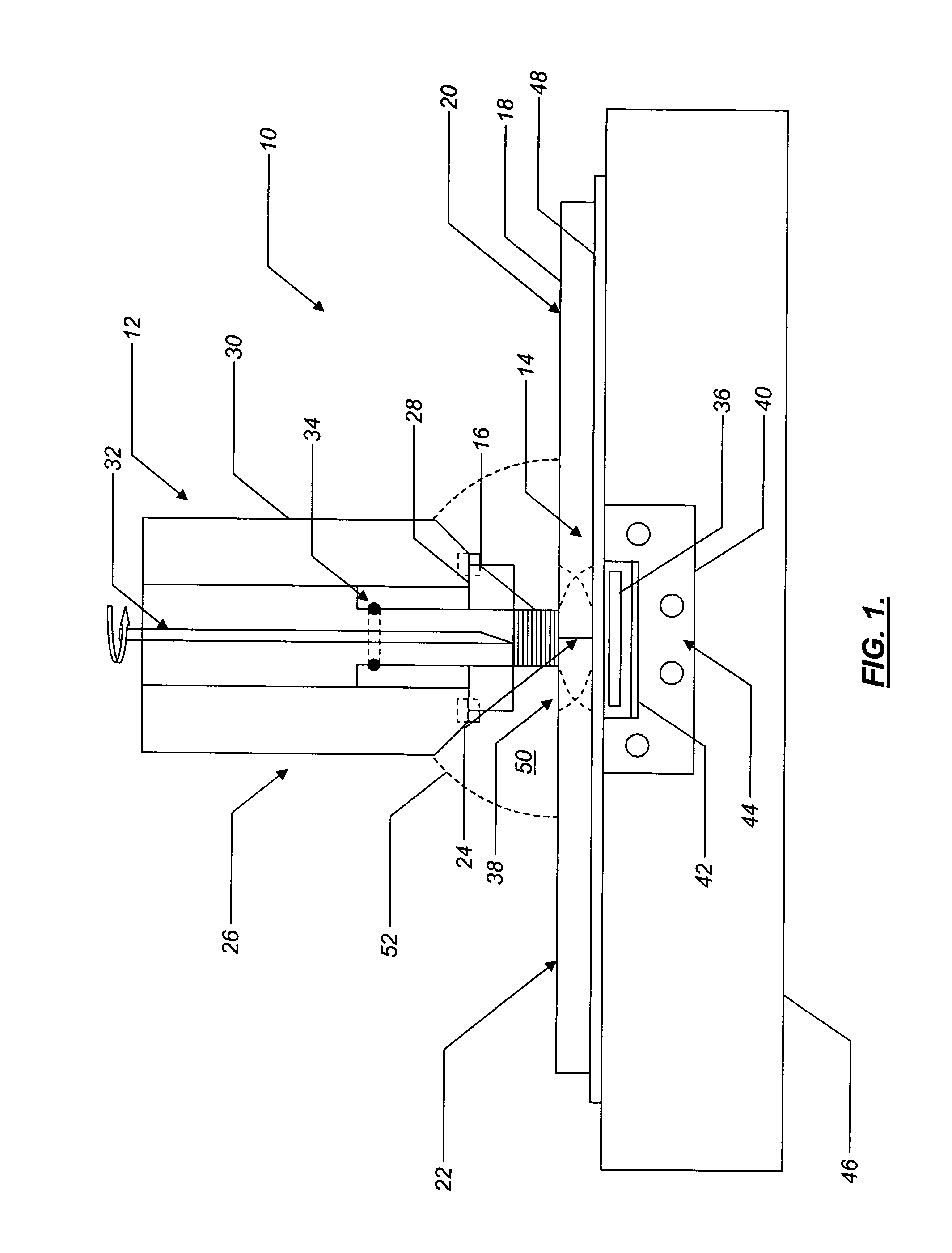

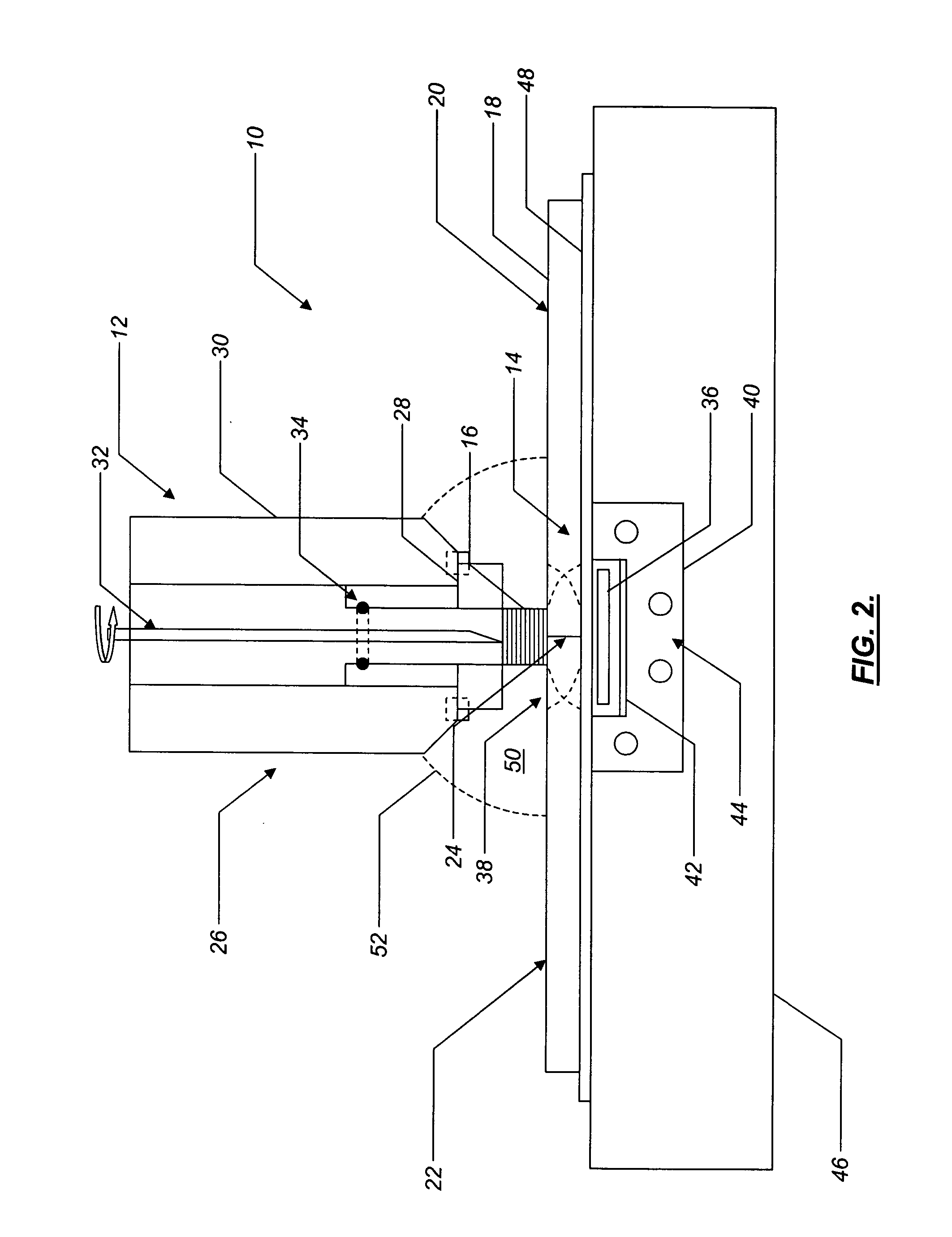

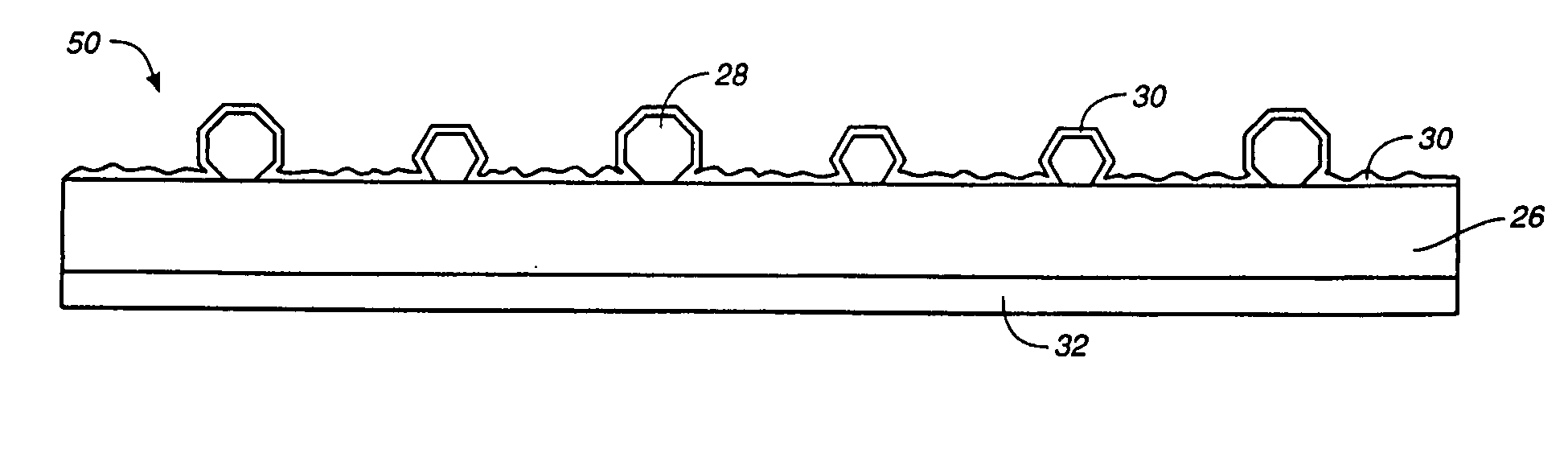

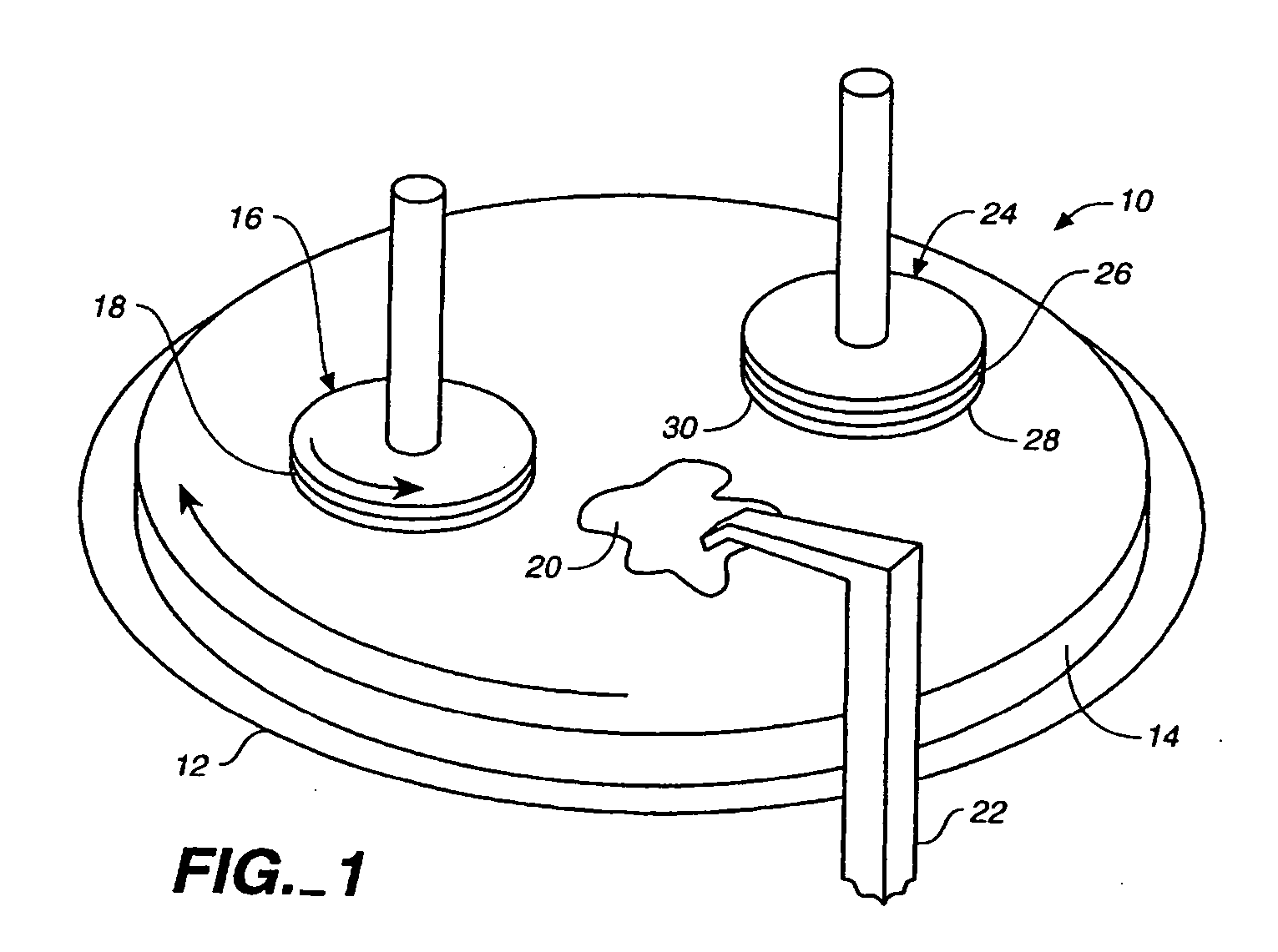

Friction stir welding apparatus and associated thermal management systems and methods

ActiveUS20050045694A1Good mechanical integrityQuality improvementWelding/cutting auxillary devicesAuxillary welding devicesEngineeringThermal management system

The present invention provides a friction stir welding apparatus and associated thermal management systems and methods for joining one or more similar or dissimilar materials forming a workpiece along a joint to be welded. The friction stir welding apparatus includes a pin tool apparatus selectively disposed adjacent to and in direct contact with a first surface of the workpiece along the joint to be welded and a heating member disposed adjacent to a second surface of the workpiece along the joint to be welded, the heating member operable for controllably heating at least a portion of the workpiece adjacent to the joint to be welded. The friction stir welding apparatus also includes an annular spindle having an interior portion and an axis, the interior portion of the annular spindle at least partially defining one or more cooling channels, the one or more cooling channels operable for containing a cooling fluid. The friction stir welding apparatus further includes a shoulder disposed adjacent to the annular spindle and substantially aligned with the axis of the annular spindle and a pin tool disposed adjacent to the shoulder and substantially aligned with the axis of the annular spindle. The cooling fluid is operable for cooling at least one of the shoulder and the pin tool.

Owner:GENERAL ELECTRIC CO

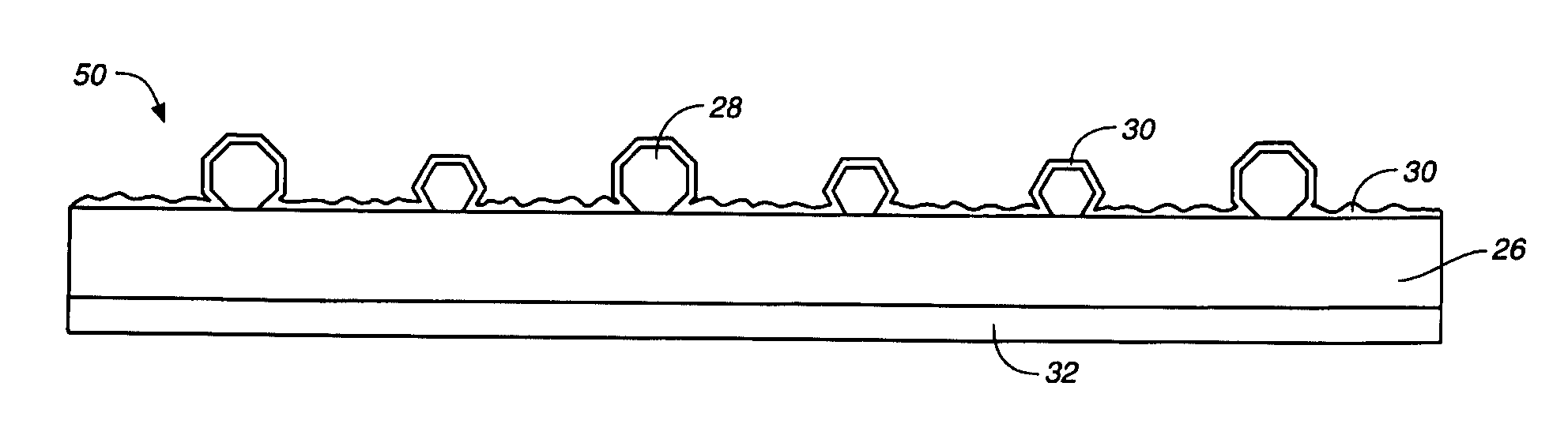

CVD diamond-coated composite substrate containing a carbide-forming material and ceramic phases and method for making same

InactiveUS20050276979A1Improve adhesionLow costLiquid surface applicatorsEngine sealsReaction bonded silicon carbideComposite substrate

The present invention relates to a composite material and the method of making same ,which comprises a CVD diamond coating applied to a composite substrate of ceramic material and an unreacted carbide-forming material of various configurations and for a variety of applications. One example of the composite material is a composite of SiC and free silicon metal known as Reaction-Bonded Silicon Carbide. Several examples of applications of the invention include: 1) heads or disks for conditioning polishing pads, including pads used in Cheniical-Mechanical-Planarization, 2) cutting and dressing tool inserts and tips, 3) heat spreaders for electronic devices, and 4) wear components including mechanical seals and pump seals.

Owner:BEST ENGINEERED SURFACE TECH LLC

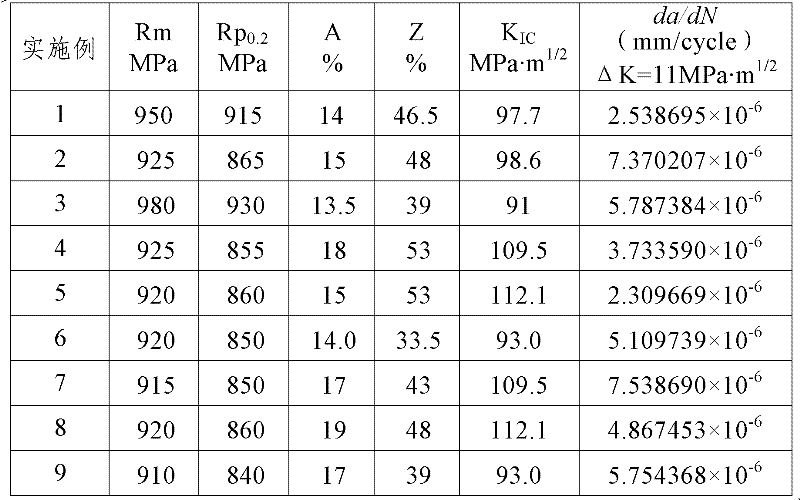

Preparation method of titanium alloy bars

ActiveCN102230097AEasy to operateStrong process controllabilityMetal-working apparatusTitanium alloyFracture toughness

The invention discloses a preparation method of titanium alloy bars. The finished titanium alloy bars are prepared through the following steps: heating prepared TC4-DT titanium alloy ingots to 1150 to 1200 DEG C; cogging and forging a beta phase zone of the ingots with a fast forging press; heating forging stocks to Tbeta-50 to Tbeta-20 DEG C through a resistance furnace; carrying out repeated upsetting and extension forging by the fast forging press; forging forged stocks to required dimensions at a forging temperature of Tbeta-70 to Tbeta-40 DEG C to obtain titanium alloy bars with uniform tissues; and carrying out duplex annealing on the obtained titanium alloy bars with the uniform tissues. The preparation method has the advantages of convenient operation, strong controllable technology, high stability of batches of prepared bars, and good repeatability. The titanium alloy bars prepared through the method of the present invention has the advantages of strong plasticity, qualified macrostructure, high strength and fracture toughness, and low fatigue crack growth rate.

Owner:西安大富宇航科技有限公司

Knee prosthesis with ceramic tibial component

An improved knee prosthesis includes a ceramic tibial component for articulation with natural or prosthetic (re-surfaced) femoral surfaces. The ceramic tibial component is provided in the form of a ceramic monoblock adapted for fixation relative to the patient's tibial bone, or alternately in the form of a ceramic bearing insert component carried by a tibial baseplate member which is adapted in turn for fixation relative to tibial bone. In either form, the ceramic tibial component includes at least one upwardly concave articulation surface for movable bearing engagement by a generally convex or condylar shaped femoral articulation surface. The ceramic tibial component provides improved wear characteristics with extended service life.

Owner:AMEDICA A DELAWARE

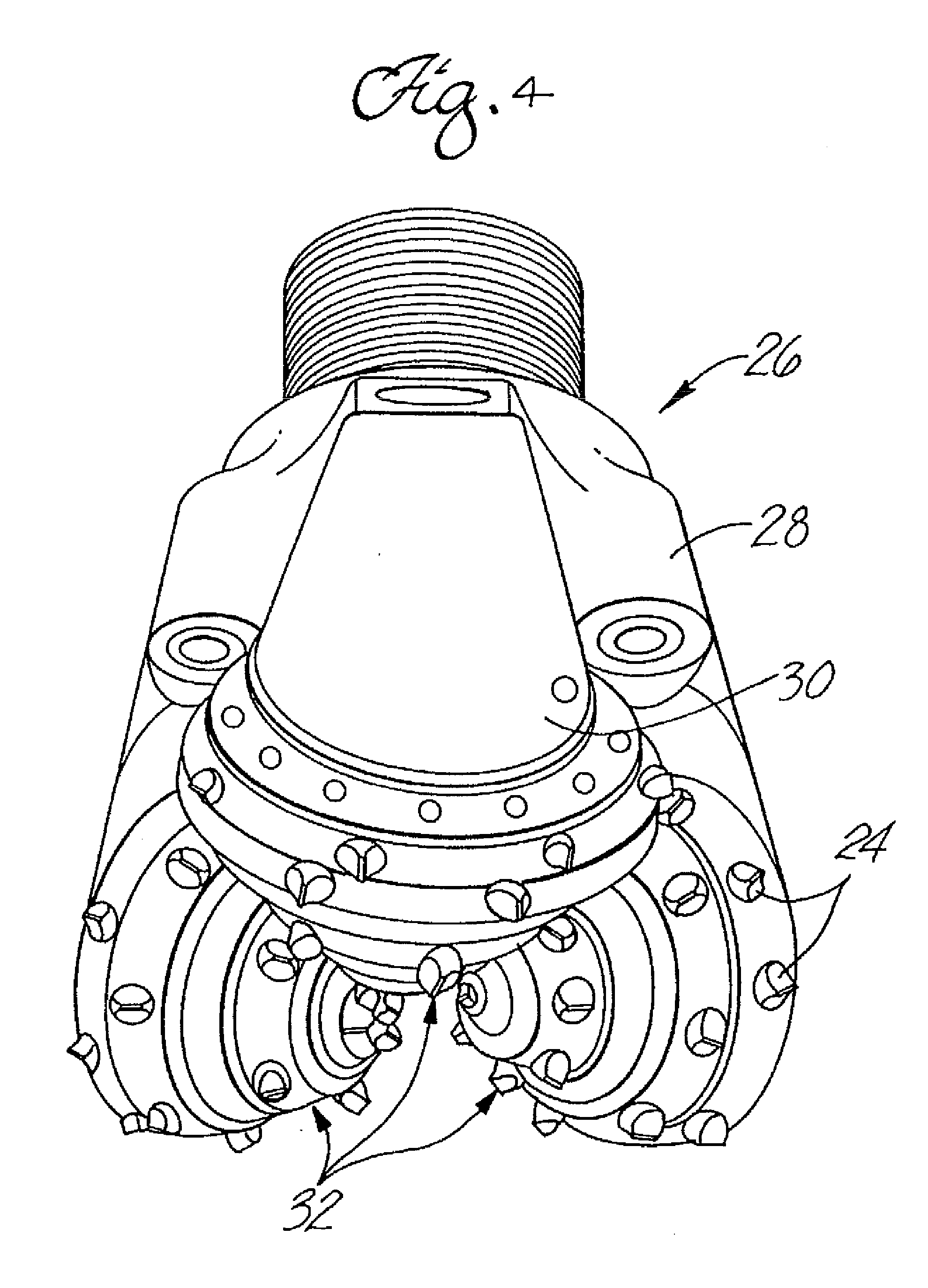

Silicon carbide composite materials, earth-boring tools comprising such materials, and methods for forming the same

Earth-boring tools for drilling subterranean formations include a particle-matrix composite material comprising a plurality of silicon carbide particles dispersed throughout a matrix material, such as, for example, an aluminum or aluminum-based alloy. In some embodiments, the silicon carbide particles comprise an ABC—SiC material. Methods of manufacturing such tools include providing a plurality of silicon carbide particles within a matrix material. Optionally, the silicon carbide particles may comprise ABC—SiC material, and the ABC—SiC material may be toughened to increase a fracture toughness exhibited by the ABC—SiC material. In some methods, at least one of an infiltration process and a powder compaction and consolidation process may be employed.

Owner:BAKER HUGHES INC

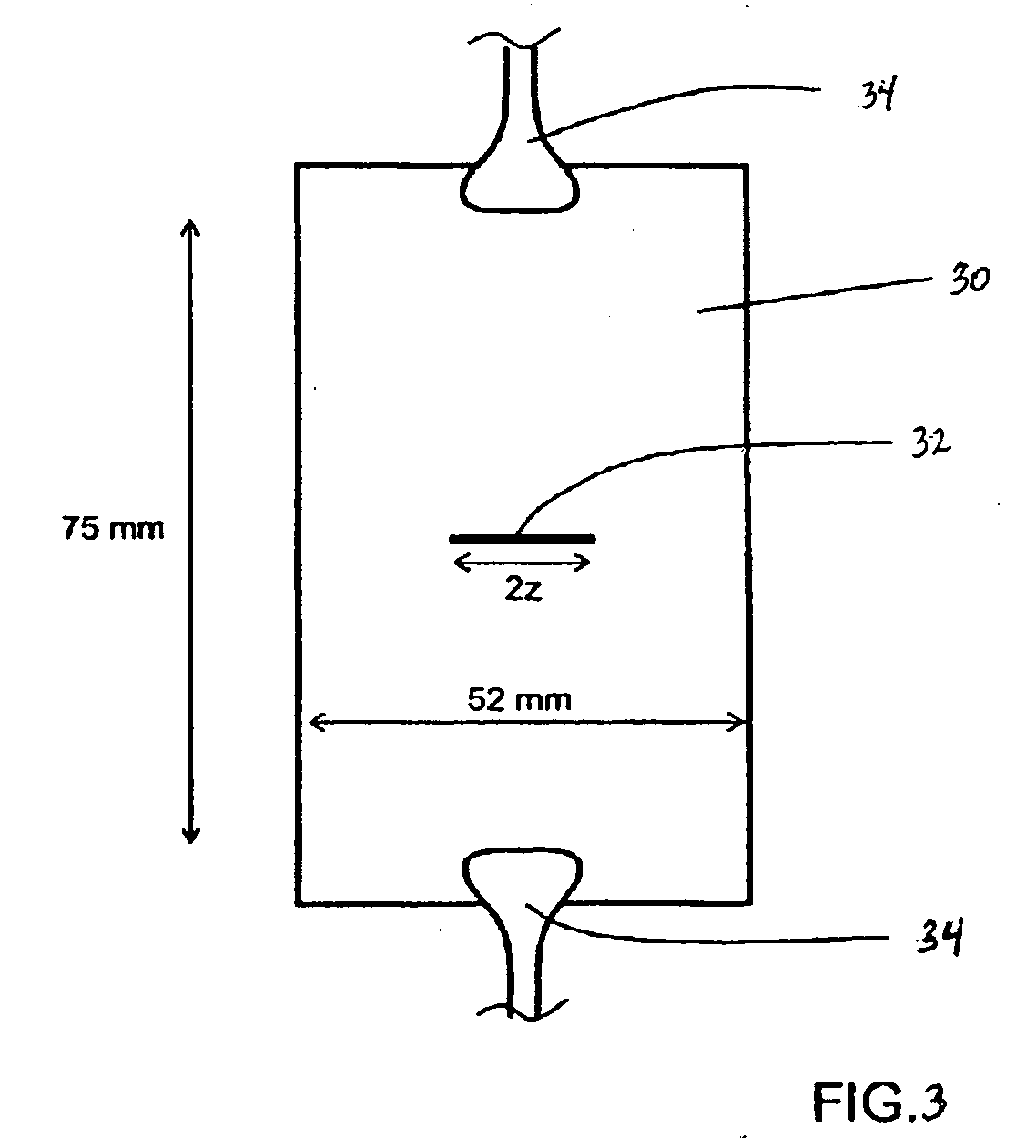

Non-reactive additives for fiber coatings

InactiveUS20070100039A1Easy to operateImprove performanceLayered productsPolyurea/polyurethane coatingsOligomerMonomer

The present invention relates to a curable composition having an oligomer, at least one monomer, and an amount of a substantially non-reactive oligomeric additive. The substantially non-reactive oligomeric additive is present in an amount effective to yield a cured product having a fracture toughness value that is higher than the fracture toughness value of a cured product of an otherwise identical composition lacking the non-reactive oligomeric additive. The present invention also relates to coated optical fibers, optical ribbons or bundles, and telecommunication systems having the curable composition.

Owner:CORNING INC

High temperature resistant ceramic matrix composite material and preparation method thereof

The invention relates to an ultra-high temperature resistant ceramic-based composite and a preparation method, which adopts carbon or boron nitride fabric cloth as reinforcing phases, ceramic powders of high melting point or high-temperature resistant metal powders as the stuffing, and carbon / silicon carbide as the base. Through the blending and ball milling of the adhesives and the powder stuffing, the sizing agent thus acquired is coated on the reinforcing phase fabric cloth, and then overlapping, molding, cross-bonding, high-temperature pyrolysis, and repeated densification are carried out in preparing the composite. The ultra-high temperature resistant ceramic composite has the advantages of excellent thermal shock resistance, low density, and low ablating rate under ultra-high temperature.

Owner:NAT UNIV OF DEFENSE TECH

A kind of fine-grained WC-based cemented carbide material and preparation method thereof

A fine-grained WC-based cemented carbide material and a preparation method thereof. The fine-grained WC-based cemented carbide material uses fine-grained WC as a matrix, Mo or Ni as a binder, and TaC, VC, One or more types of TiC are grain inhibitors, Cr3C2 is used as a hardener, and C, SiC or rare earth metals are used as a toughener. The size of fine-grained WC is 0.8-1μm. WC of this size can It brings about an increase in hardness and flexural strength. This cemented carbide material provides an alternative to Co and has high hardness, good toughness, and excellent comprehensive wear resistance.

Owner:四川欧曼机械有限公司

Pervious concrete and construction method thereof

ActiveCN104402339AImprove workabilityIncreased intensityIn situ pavingsRoad surfaceUltimate tensile strength

The invention discloses pervious concrete and a construction method thereof. The pervious concrete comprises the following raw materials in percentage by weight: 13.1-15.9% of cement, 12.7-15.6% of river sand, 59.6-66.0% of stones, 3.7-3.9% of water and 4.5-5.0% of admixtures, wherein the admixtures comprise the following raw materials in percentage by weight: 45-50% of ultrafine mineral powder, 15-20% of heavy calcium carbonate, 15-20% of gypsum powder, 3-5% of polypropylene fiber, 5-10% of a polycarboxylate water reducing agent, 4.2-8.4% of adhesive powder and 2-5% of a pigment. The pervious concrete provided by the invention has relatively high water permeability, strength and durability; after the pervious concrete is applied to a practical engineering, the pervious concrete can greatly improve the problem of poor drainage of a hardened road surface, so that the development of the pervious concrete can be promoted.

Owner:TIANYUAN CONSTR GROUP

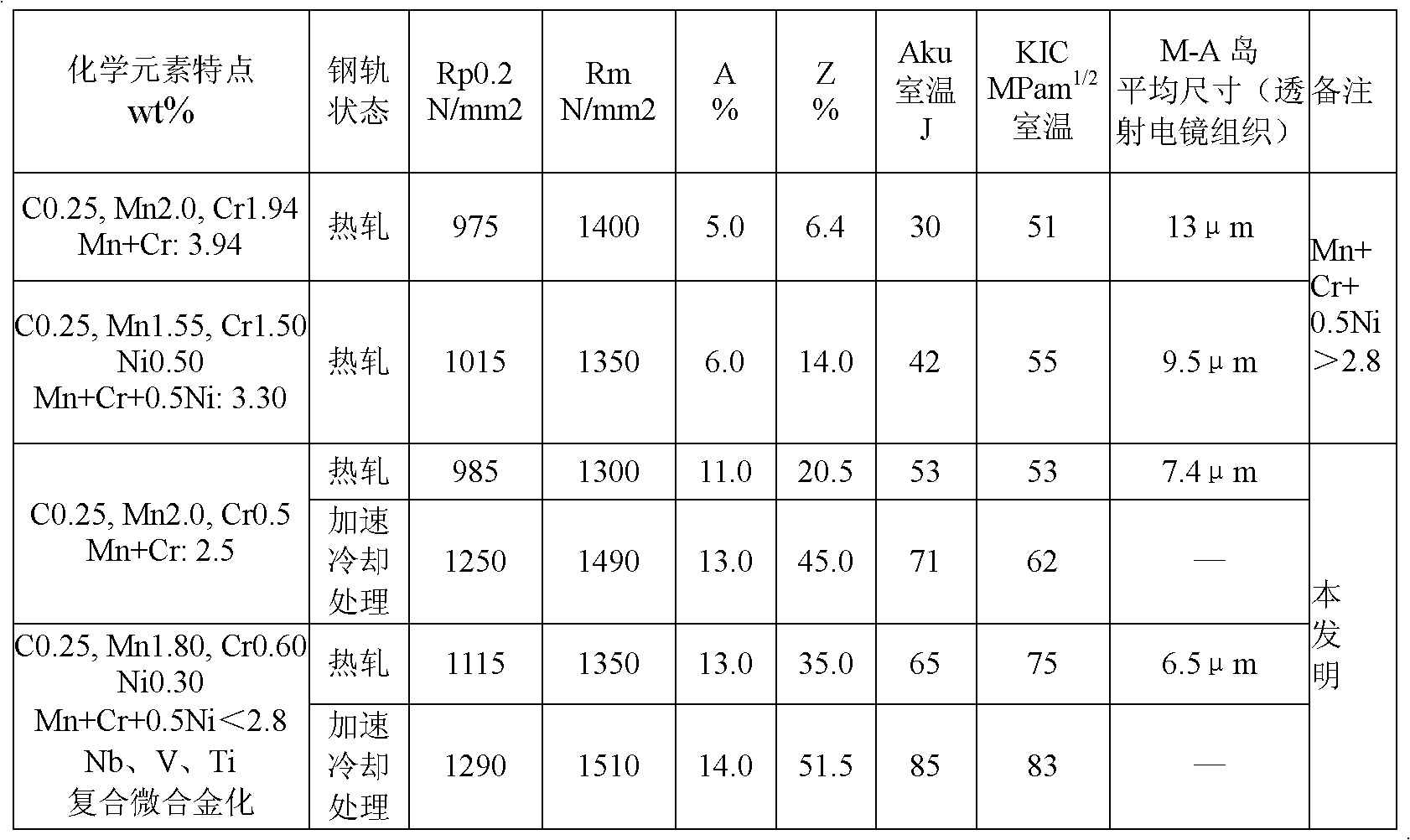

High strength bainitic steel rail and heat treatment process thereof

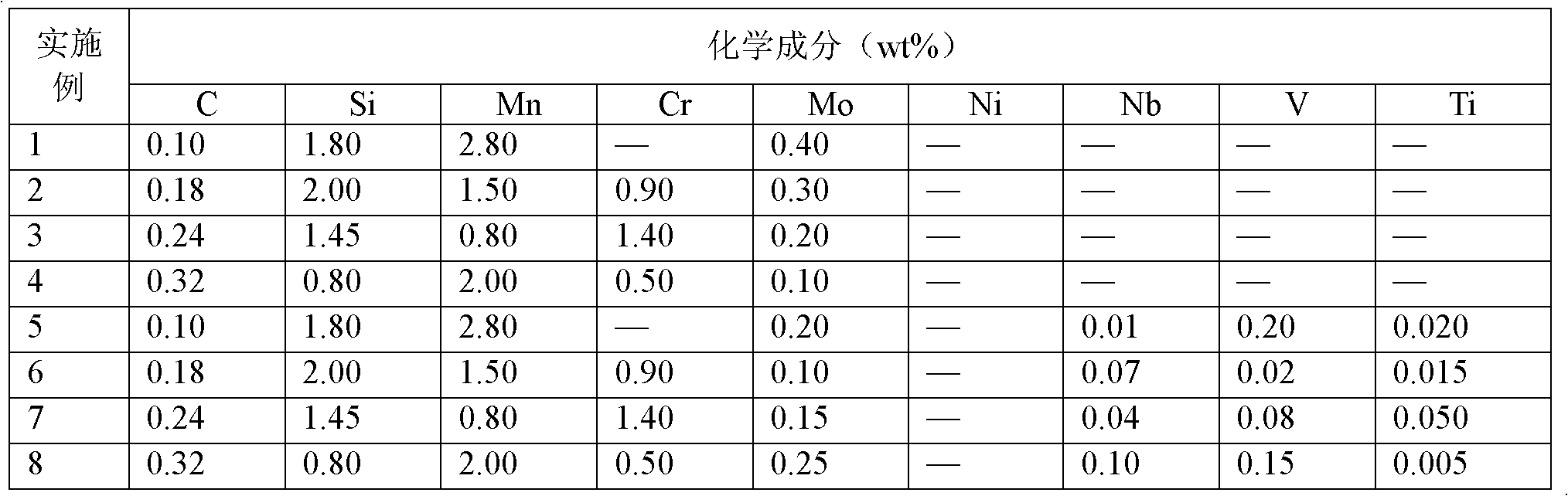

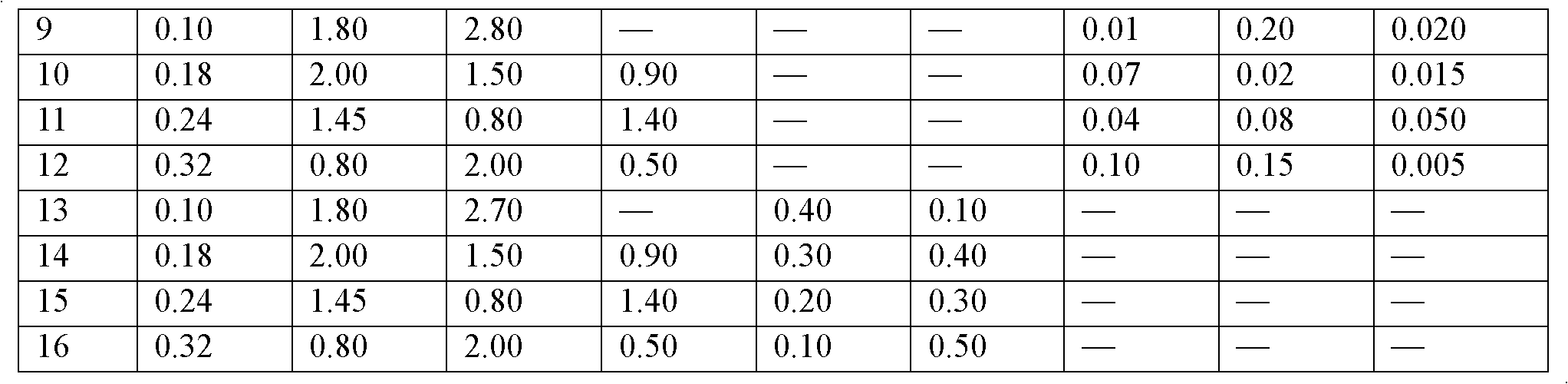

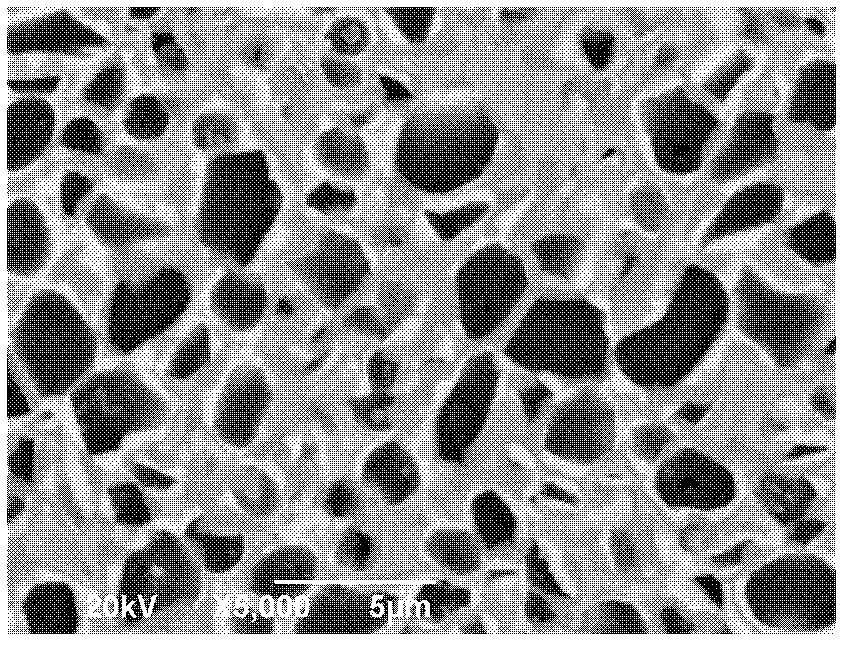

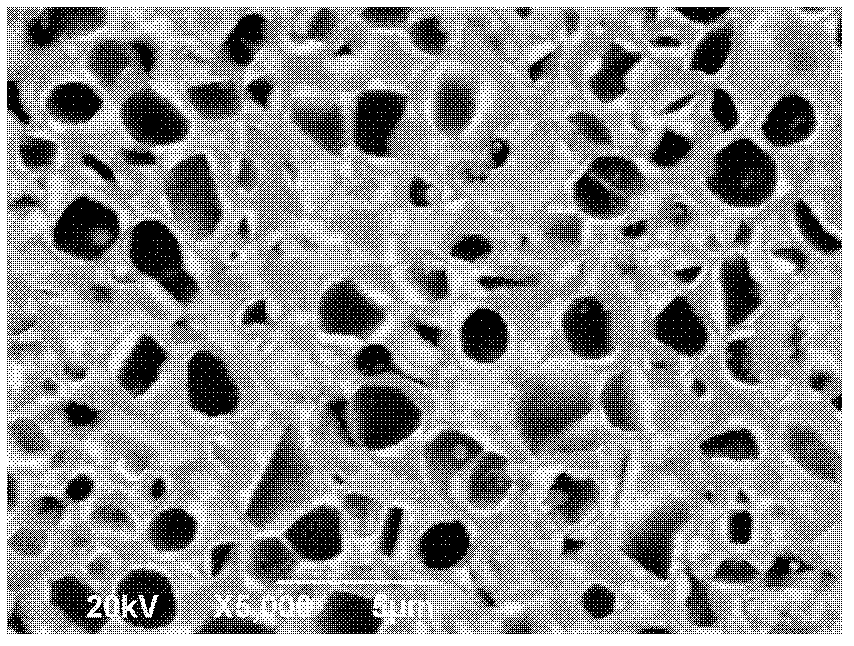

ActiveCN103160736AImprove wear resistanceImprove impact toughnessFurnace typesHeat treatment furnacesImpurityHeat treated

The invention provides a high strength bainitic steel rail and a heat treatment process thereof. The steel rail comprises the following chemical compositions by weight percentage: 0.10%-0.32% of C, 0.80%-2.00% of Si, 0.80%-2.80% of Mn, Cr less than 1.50%, 0.10%-0.40% of Mo, 0-0.5% of Ni, wherein Mn, Cr and Ni satisfy the relation of: Mn+Cr+0.5Ni<=2.8%, and the balance of Fe and unavoidable impurities. The process is as below: conducting hot rolling on the steel rail or air cooling on the steel rail to room temperature, then reheating to 850-1000 DEG C for austenization; cooling the steel rail head to 620-570 DEG C with a cooling rate of 0.3-15 DEG C / s; when the temperature is lower than 620-570 DEG C, cooling to 350-200 DEG C with a cooling rate of 0.5-5 DEG C / s; and then conducting air cooling to room temperature. The invention avoids generation of excessive unstable thick M-A islands in granular bainite during air cooling to room temperature in hot rolling, reduces the risk of straightening fracture (or delayed fracture)of hot-rolled steel rail, and improves the adaptability of steel production process. The steel rail has tensile strength higher than 1400MPa, and realizes optimum matching of strength, toughness and ductility, and excellent rolling contact fatigue resistance and wear resistance.

Owner:ANGANG STEEL CO LTD

Steel for processing movement limiting core stick of continuous tube grimper and its producing process

The present invention belongs to the field of steel-smelting technology. The steel consists of C 0.30-0.43 wt%, Mn less than 0.60 wt%, Si 0.70-1.00 wt%, P less than 0.010 wt%, S less than 0.007 wt%, Cr 4.50-5.50 wt%, Mo 1.00-1.50 wt%, V 0.7-1.00 wt%, Nb 0-0.25 wt%, Al less than 0.015 wt%, Ni 0.10-0.75 wt%, Cu less than 0.10 wt%, O less than 30 ppm and H less than 2 ppm, except Fe. It may contain one or several of RE, W, B, Ca, Mg, Zr and Ti. The steel of the present invention has reasonable production process, high performance and long service life of the core rod therewith.

Owner:HENAN ZHONGYUAN SPECIAL STEEL EQUIP MFG CO LTD

Rare earth alloy powder-modified Ti(C,N)-based metal ceramic and preparation method thereof

The invention discloses a rare earth alloy powder-modified Ti(C,N)-based metal ceramic and a preparation method of the metal ceramic. The metal ceramic comprises Co and Ni or at least two of components selected from Co, Ni as well as Fe as a bonding phase, Ti(C,N) as a basic hard phase and optionally at least one of metallic carbides; and a rare earth alloy powder modifier 0.1-3wt% of the total mass of the metal ceramic. The preparation method comprises treating a raw material through a wet-grinding and mixing process, a die-forming process, a vacuum-degreasing process and a low-pressure sintering process to prepare the rare earth alloy powder-modified Ti(C,N)-based metal ceramic. On the premise of keeping high hardness and high wear resistance, the Ti(C,N)-based metal ceramic prepared according to the invention has excellent comprehensive performance, can be greatly improved in strength and tenacity and can also be widely applied to various cutting tools and wear-resistant parts.

Owner:SICHUAN UNIV

Flying shear blade and preparation method thereof

InactiveCN101144140AImprove wear resistanceImprove hardenabilityHeat treatment process controlShearing toolsQuenchingImpurity

The present invention discloses a flying shear blade. The component has the weight percentage that C is 0.40-0.70, Si is 0.50-1.20, Mn is 0.20-0.50, Cr is 4.00-6.00, Mo is 0.50-2.00, V is 0.30-1.50, P is less than or equal to 0.02, S is less than or equal to 0.02, and Fe and inevitable impurity are the residual. The present invention provides a manufacture method of electric furnace smelting, and ingot casting; hydrogen removing and annealing treatment, and forging; preliminary heat treatment, rough machining, quenching and tempering heat treatment (primary quenching and high temperature tempering), semi finishing, ultimate heat treatment (secondary quenching, primary low temperature tempering, and secondary low temperature tempering), and fine finishing. By effectively controlling the material texture and the morphology, the quantity, the size and the distribution of carbonide, the quenching temperature and the tempering temperature of the quenching and tempering heat treatment, and the quenching temperature and the tempering temperature of the ultimate heat treatment are controlled, the texture crystal grains are more refined, the carbonide is distributed in a dispersed way, and simultaneously, the thermal stability and the retentivity are remarkably enhanced, thereby being advantageous for improving the operational performance of the blade.

Owner:BAOSHAN IRON & STEEL CO LTD +1

Ceramic cladding powder and preparation method thereof

InactiveCN101423398AThere will be no phenomenon of grain aggregation and growthEvenly distributedCeramic coatingTitanium nitride

The invention relates to ceramic coating powder the ceramic phase of which is coated by a metallic phase cobalt or / and a metallic phase nickel. The metallic phase cobalt and the metallic phase nickel are obtained by means of a liquid phase reduction method; and the ceramic phase is at least one of titanium carbonitride, titanium carbide, titanium nitride, tungsten carbide, silicon carbide, niobium carbide, tantalum carbide, aluminum oxide, zirconium oxide, magnesium oxide, boron nitride and silicon nitride. A method for preparing the ceramic coating powder is the liquid phase reduction method to carry out a reduction reaction between cobalt or / and nickel ions in a plating solution to generate the metallic phase cobalt or / and nickel which is deposited on the surface of a ceramic core to form the ceramic coating powder; and the process steps are as follows: (1) pre-treatment of the ceramic powder; (2) preparation of the plating solution; (3) liquid-phase reduction reaction; and (4) plating post treatment.

Owner:SICHUAN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com