Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

4051results about How to "Improve impact toughness" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

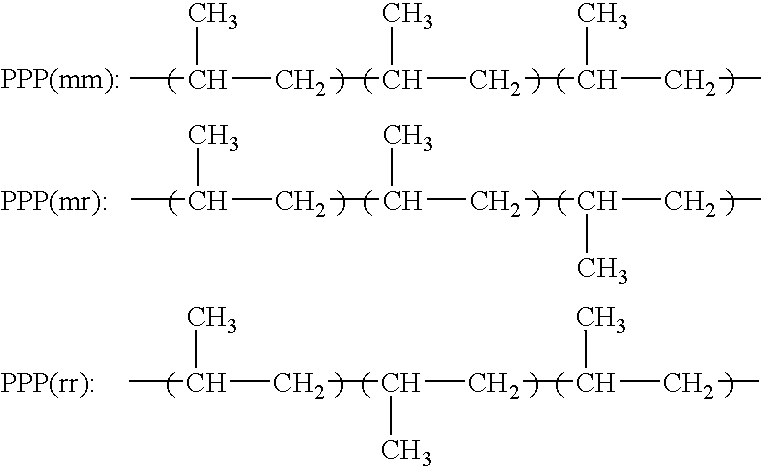

Plasticized hetero-phase polyolefin blends

InactiveUS20080045638A1Increase stiffnessImprove impact toughnessPigment pastesPolyolefinHigh stiffness

This invention relates to hetero-phase polyolefin compositions comprising: a) 30 to 99.7 wt % of a polypropylene-based TPO comprising at least 50 wt % propylene and at least 10 wt % ethylene, and b) 0.1 to 20 wt % of one or more non-functionalized plasticizer, and c) 0.2 to 50 wt % of one or more filler; based upon the weight of the composition, and having: i) an MFR of 5 dg / min or more, and ii) a flexural modulus of 500 MPa or more, and iii) a notched Charpy impact strength at −30° C. of 1 kJ / m2 or more or a notched Izod impact strength at −18° C. of 50 J / m or more.These compositions are especially useful in applications such as automotive parts that demand both high stiffness and high impact toughness, as well as good processibility during fabrication.

Owner:EXXONMOBIL CHEM PAT INC

Centrifugal casting high-speed steel composite roll and manufacture method thereof

InactiveCN102615108AGood metallurgical bondHigh strengthRollsMetal rolling arrangementsNiobiumEconomic benefits

The invention relates to a centrifugal casting high-speed steel composite roll and a manufacture method thereof and belongs to the field of casting. The composite roll is composed of outer layer high-speed steel, middle layer graphitic steel and core high-strength nodular cast iron by centrifugal compounding. The centrifugal casting high-speed steel composite roll is based on the conventional high-carbon high-vanadium high-speed steel roll, the content of vanadium is appropriately reduced, niobium is added at the same time, and the Nb / V is controlled to be 0.3 to 0.5 so that Nb and V form complex carbide (V, Nb) C so as to avoid forming segregation under the action of centrifugal force. A roll core of the high-speed steel composite roll adopts high-strength nodular cast iron, and a multivariate graphite steel middle layer is poured between an outer layer and the roll core for preventing interfusing elements of Cr, B, and the like which cause embrittlement when the nodular cast iron is poured to be fused with the outer layer high-speed steel. Microalloying processing for refining the organization is carried out on a roll surface high-speed steel material and the middle layer graphitic steel so as to achieve the purpose of improving the thermal cracking capacity of the roll material. The centrifugal casting high-speed steel composite roll has high overall performance, long service life and good economic benefits.

Owner:BEIJING UNIV OF TECH

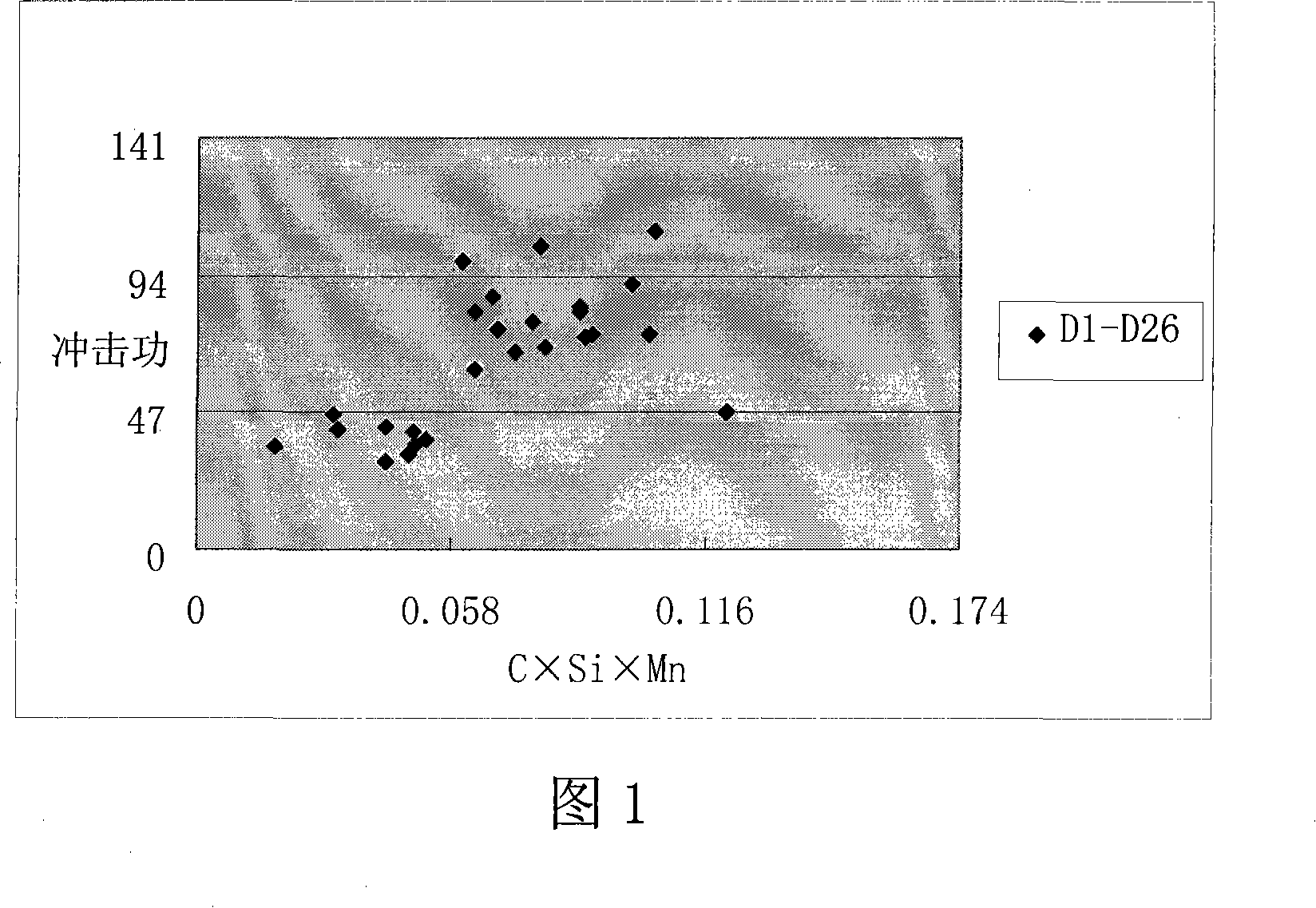

Low alloy steel flux-cored welding wire for carbon dioxide gas protection welding

InactiveCN101104232AImprove impact toughnessAccelerated corrosionArc welding apparatusWelding/cutting media/materialsArc stabilityCrack resistance

Disclosed is a low alloy steel drug core welding wire used in the carbon dioxide arc welding. The components of the drug core and the content occupying the total weight of the welding wire(percent ratio) are as following: Ti01 3-6, Si 0.3-0.5, Mn 1.5-3.2, Si02 0.1-0.8,Zr02 0.1-0.5, Fe 2-7, Al plus Mg 0.5-1.2, Ni 0.5 -5, B 0.002-0.015, Ti 0.1-0.3; oxide or fluoride of alkali metal K, Na and Li is converted into the content of K, Na and Li, that is, 0.1-0.35; the content of fluoride F is 0.05-0.2; fluoride or oxide of rare earth metal is converted into the content of the rare earth metal, that is, 0.005-0.2; the product of the contents of C, Si and Mn in the welding wire is 0.058-0.11. The invention has good process property for the whole position welding of high strength low alloy steel, and can keep good stability of electric arc and welding operating property in the conditions of large current and fast-speed welding with smooth welding seam, high connecting intensity, good impact toughness minus 40 DEG C low temperature and good crack resistance.

Owner:WUHAN TEMO WELDING CONSUMABLES CO LTD

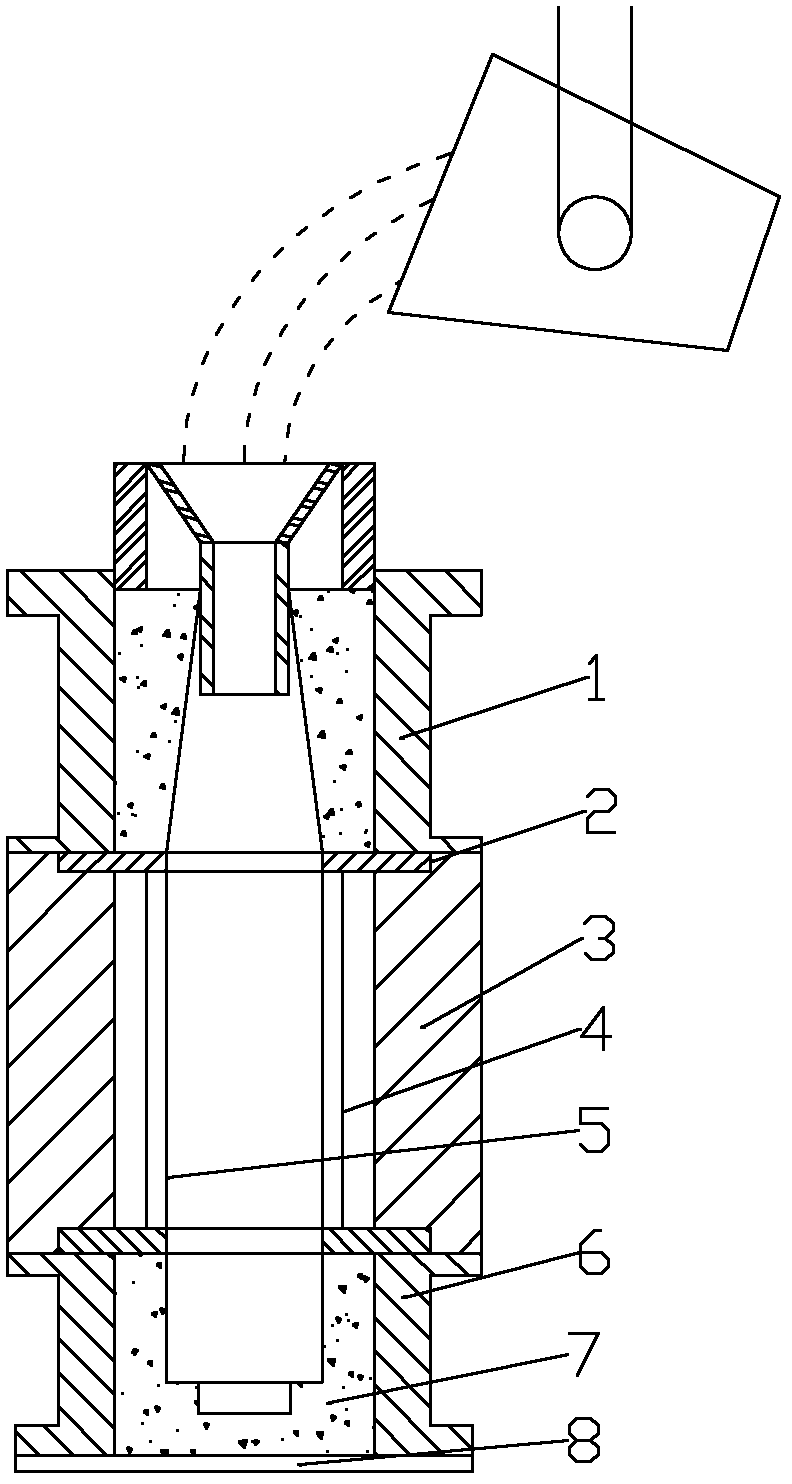

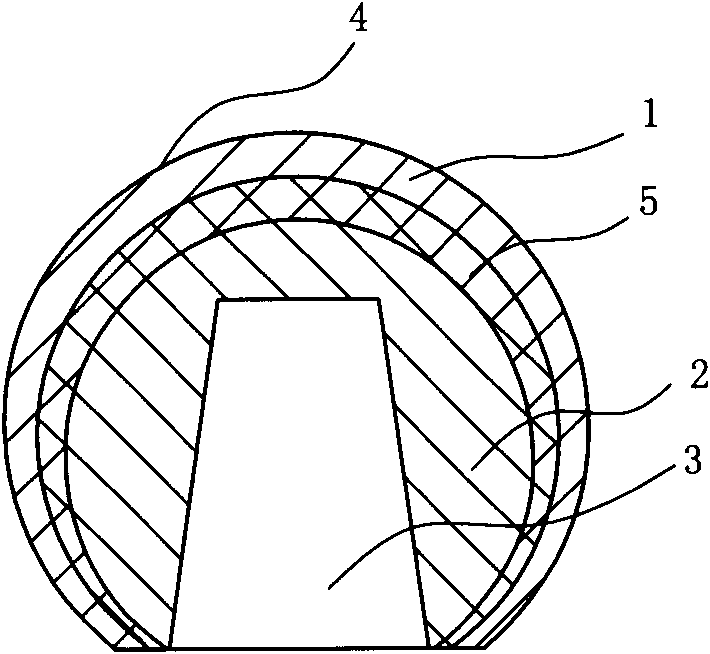

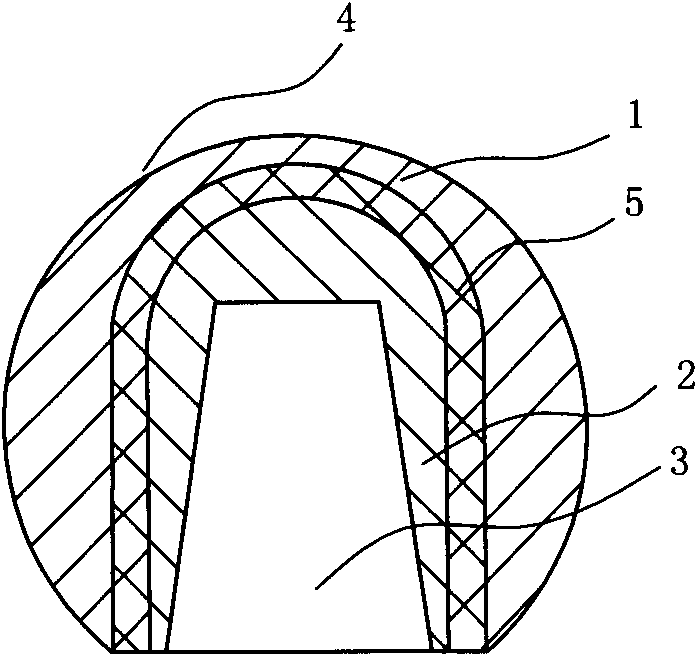

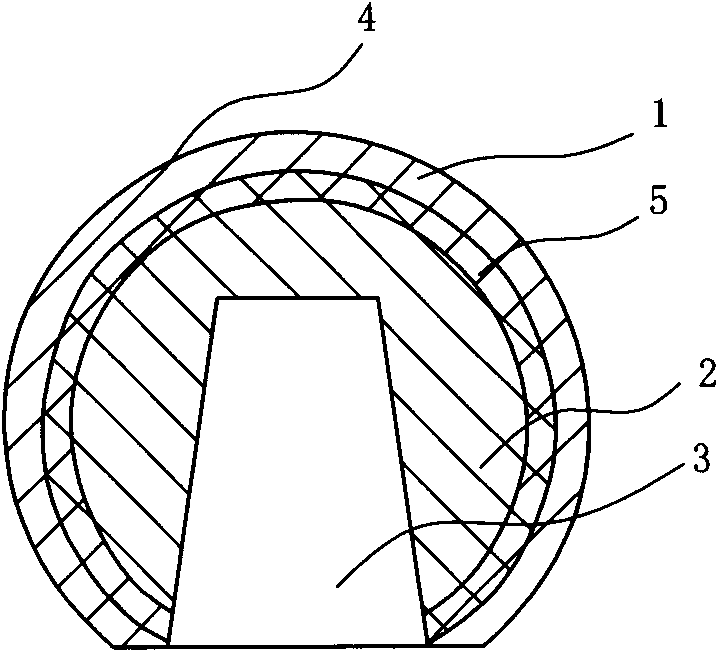

Manufacturing method of multilayer shell-core composite structural part

ActiveCN102009175AShell surface hardness is highHigh surface finishJoint implantsCeramic layered productsComposite constructionHigh surface

The invention discloses a manufacturing method of a multilayer shell-core composite structural part, which comprises the following steps of: (1) respectively preparing feed for injection forming of a core layer, a transition layer and a shell layer, wherein powder in the feed of the core layer and the powder in the feed of the shell layer are selected from one or a mixture of some of metal powder, ceramic powder, or toughened ceramic powder and are different from each other, and the powder in the feed of the transition layer is gradient composite powder; (2) respectively manufacturing blanks of the multilayer shell-core composite structural part layer by layer with a powder injection forming method; (3) degreasing the blanks; and (4) sintering the blanks to obtain the multilayer shell-core composite structural part. The multilayer shell-core composite structural part is manufactured with the powder injection forming method, and has the advantages of high surface hardness, abrasion resistance, uniform thickness of the shell layer, stable and persistent performance, strong binding force between the shell layer and the core layer due to the transition layer, good integral bending strength and good impact toughness and is difficult to crack.

Owner:SUZHOU DINGAN ELECTRONICS TECH

Polyamide moulding composition and use thereof

ActiveUS20140066560A1Good mechanical propertyHigh rigidityAnti-corrosive paintsChemistryHigh intensity

Owner:EMS PATENT AG

Ultrahigh-strength structural steel board for ocean engineering and production method thereof

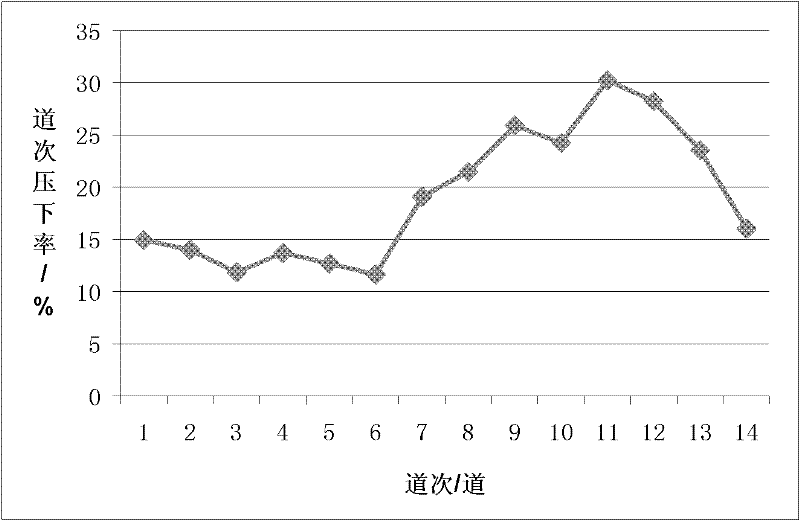

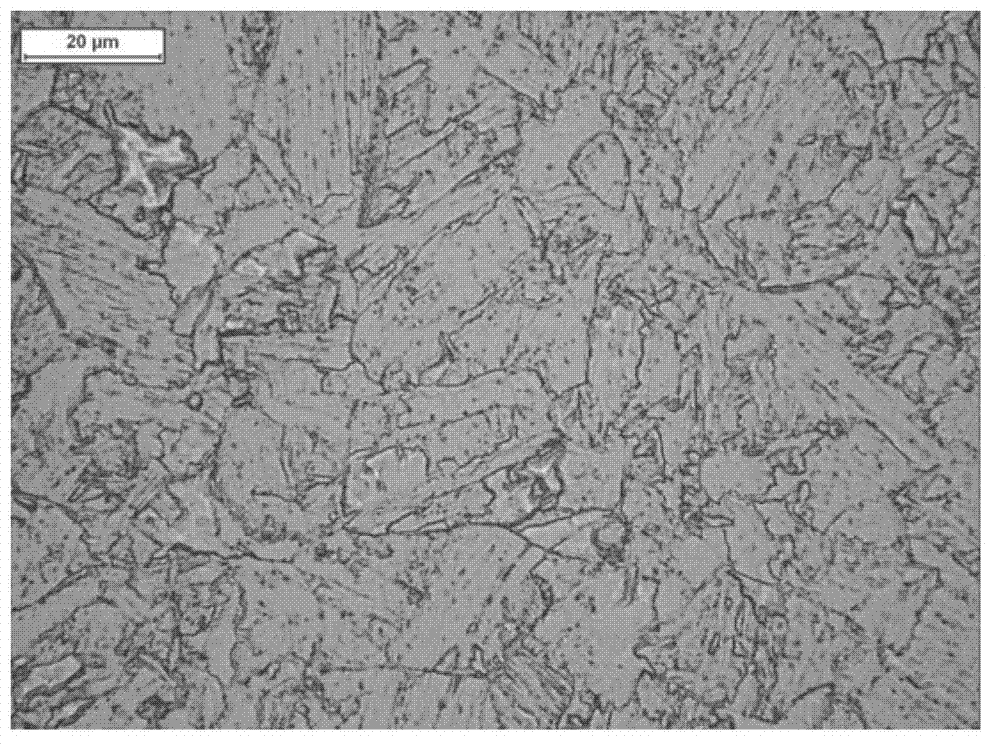

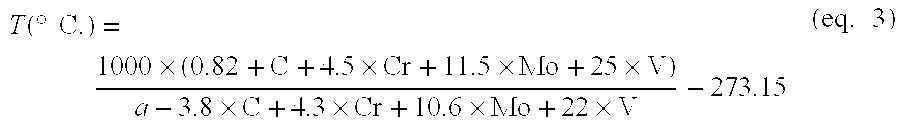

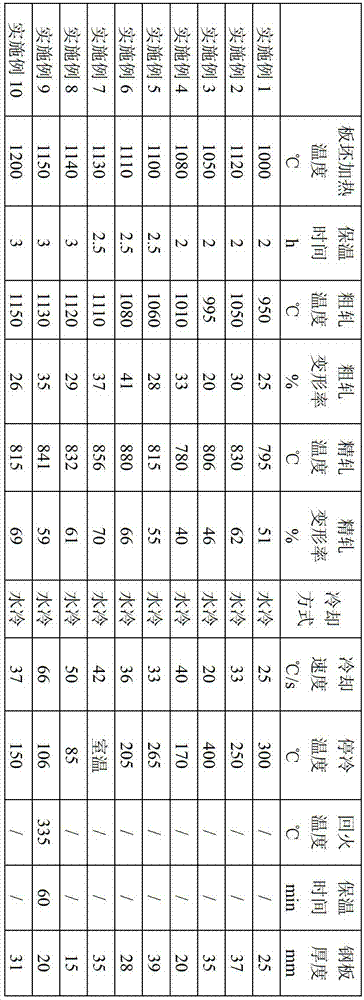

The invention relates to an ultrahigh-strength structural steel board for ocean engineering and a production method thereof, belonging to the technical field of ultrahigh-strength steel. A board blank comprises the following components: 0.05-0.13% of C, 0.1-0.4% of Si, 0.7-1.7% of Mn, 0.01-0.04% of Alt, 0.02-0.05% of Nb, 0-0.05% of V, 0.008-0.02% of Ti, 0-0.6% of Cr, 0.2-0.4% of Mo, 0.15-0.8% of Ni, 0-0.5% of Cu, 0-0.0011% of B, less than 0.01% of P, less than 0.005% of S, less than 0.0010% of O, less than 0.005% of N, less than 0.00015% of H, and the balance of Fe and inevitable impurities, wherein Nb+V+Ti is not more than 0.12%. Aiming at different thickness standards, different chemical component as well as rolling and heat treatment process parameters are adopted. The production process comprises the steps of molten iron desulfurization, converter top and bottom blowing, vacuum treatment, continuous casting, controlled rolling and controlled cooling, quenching and tempering. The steel board has the advantages that: the production cost is lower, and the comprehensive mechanical properties can meet the requirements of the steel for the ocean engineering for various mechanical properties.

Owner:SHOUGANG CORPORATION +1

Preparation technology of phosphosilicate enamel

The invention provides a preparation technology of phosphosilicate enamel, which comprises the raw materials based on weight percentage as follows: 15%-30% of P205, 20%-35% of SiO2, 8%-15% of B2O3, 5%-12% of Al2O3, 1%-4% of TiO2, 1%-5% of ZrO2, 0-1% of CoO, 0-2% of NiO, 5%-10% of Na2O, 2%-6% of K2O, 0-4% of 'ZnO, 2%-6% of CaO and 1%-5% of MaO. The preparation technology comprises the steps of dosing, founding under a high temperature, preparing enamel dried powder or glazeslip, coating the enamel, and sintering. After the phosphosilicate enamel which is prepared by the method is used, the abrasion resistance and the shock resistance of the enamel are effectively improved, and the enamel with better performances is developed for the industrial application of the enamel which is taken as an abrasion resistant structure, a building decoration material, and the like.

Owner:湘潭宏润金属科技有限公司

Timber wood hot pressing charing intensification method

ActiveCN101214675AUnlimited thicknessGood dimensional stabilityDrying using combination processesWood compressionCarbonizationVolumetric Mass Density

The present invention discloses a hot-pressing carbonization strengthening method of timbers, which includes drying, planing, hot-pressing carbonization, cooling and other steps. The present invention applies a hot press as a timber-carbonizing device, and the timbers under the state of compression are processed by hot-pressing carbonization. The present invention is characterized in that the investment on carbonization devices is less, the carbonization process is simple, the production is safe, the production efficiency is high, the consumption of heat energy is little, and the production cost is low; moreover, the thickness of the carbonized timbers is not limited, the defects of the timbers, such as deformation, cracking, stiker stain, color difference, knot fall-off, etc., do not occur in the process of production, so the quality of products is high; not only is the size stability and noncorrodibility of the carbonized timbers improved, but also the density and mechanical property of the timbers is increased.

Owner:广州豪沃仕家具有限公司

Toughening type three-layer coextru-laminated film and preparation method thereof

ActiveCN101913279AImproves toughness and impact strengthReduce heat sealing temperatureSynthetic resin layered productsPolypropyleneNitrogen gas

The invention discloses a toughening type three-layer coextru-laminated film and a preparation method thereof. The film is co-extruded by three layers through a casting machine and is provided with an outer layer, a middle layer and an inner layer which are laminated together, wherein the middle layer is made of polypropylene hydrocarbon elastomer and polypropylene in a weight ratio of 1:10 to 1:3; and the melt index of the polypropylene hydrocarbon elastomer is between 6 and 12. In the toughening type three-layer coextru-laminated film, the middle layer is prepared by blending or co-extruding the polypropylene hydrocarbon elastomer and the polypropylene after the scheme is adopted. Compared with the conventional CPP film, the toughening type three-layer coextru-laminated film improves impact resistance strength and toughness of the laminated film, does not influence the barrier property of the laminated film, and is particularly suitable for packing oily nitrogen charging products such as eggs, bread and the like.

Owner:KAIDA GRP CO LTD FJ

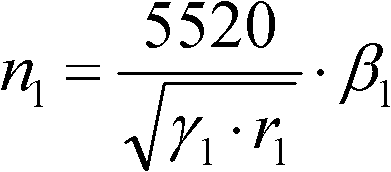

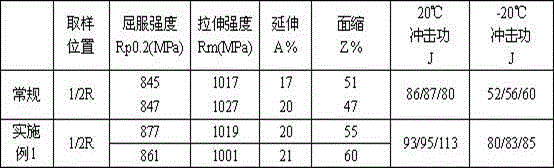

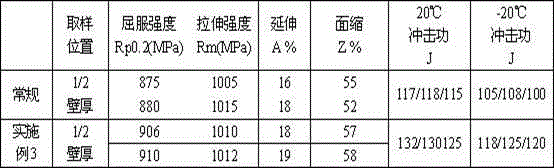

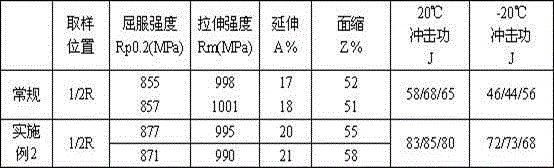

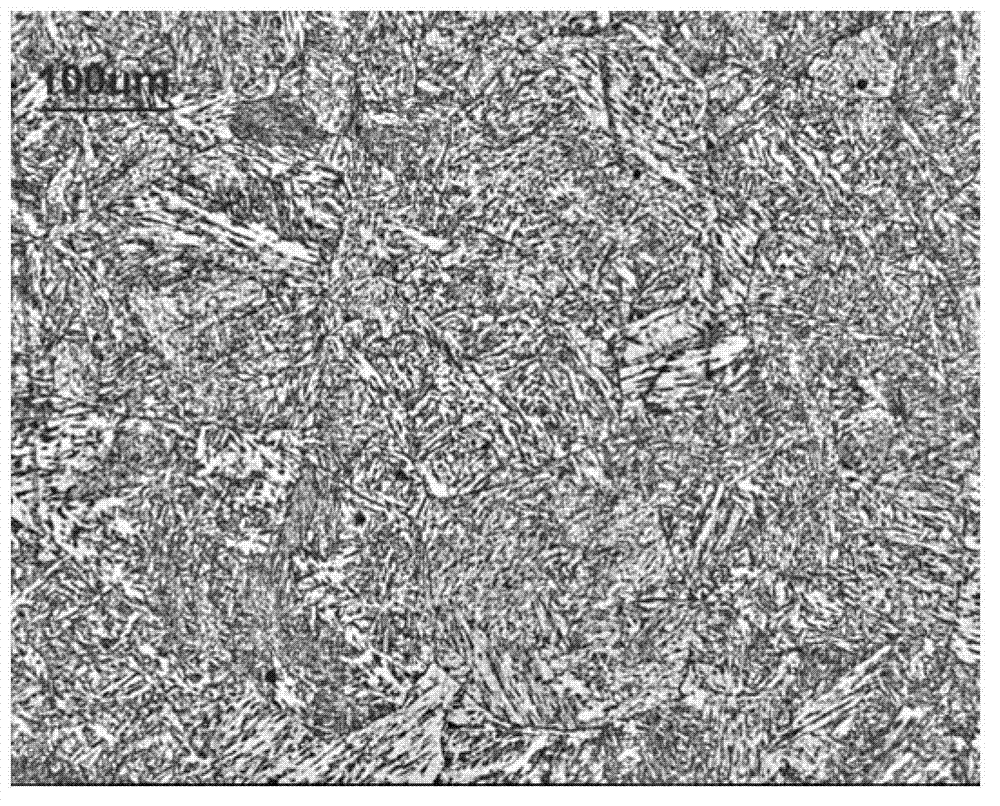

High strength bainitic steel rail and heat treatment process thereof

ActiveCN103160736AImprove wear resistanceImprove impact toughnessFurnace typesHeat treatment furnacesImpurityHeat treated

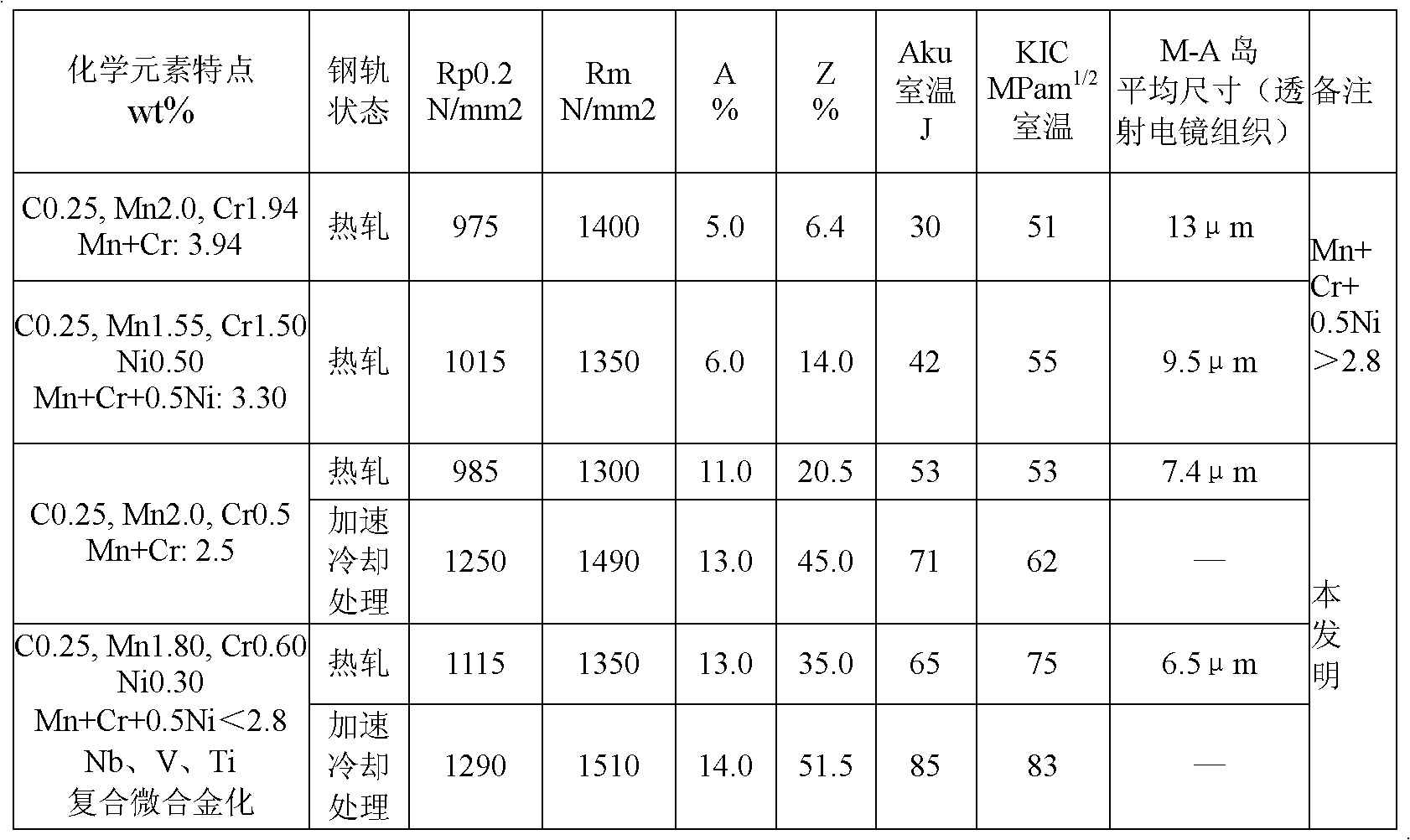

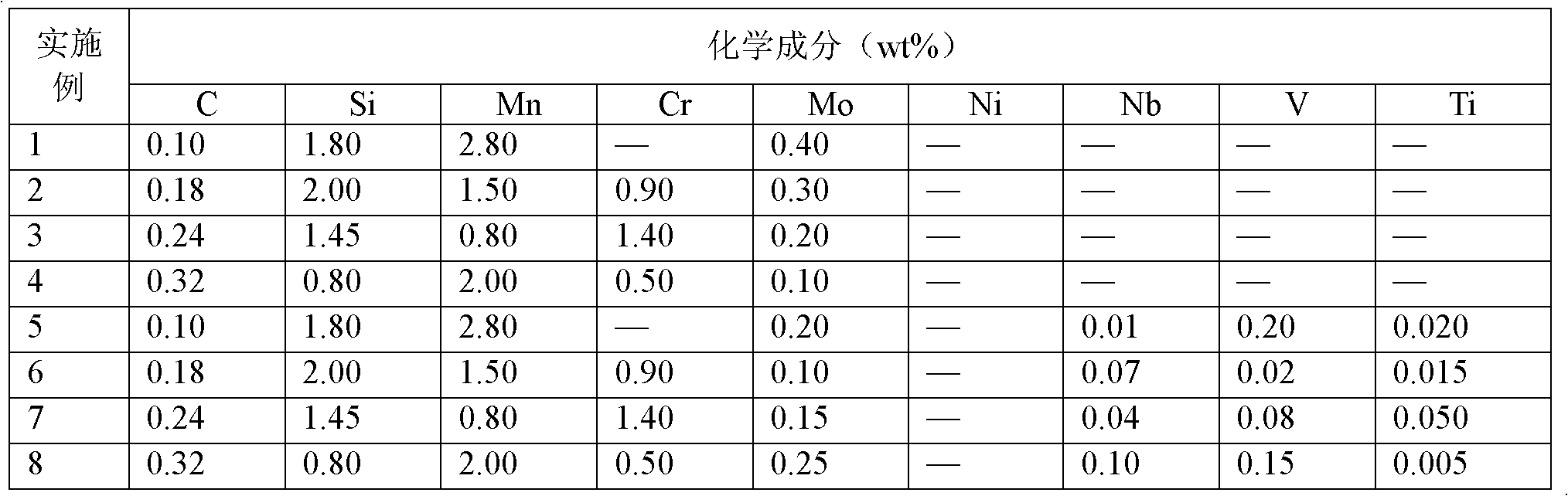

The invention provides a high strength bainitic steel rail and a heat treatment process thereof. The steel rail comprises the following chemical compositions by weight percentage: 0.10%-0.32% of C, 0.80%-2.00% of Si, 0.80%-2.80% of Mn, Cr less than 1.50%, 0.10%-0.40% of Mo, 0-0.5% of Ni, wherein Mn, Cr and Ni satisfy the relation of: Mn+Cr+0.5Ni<=2.8%, and the balance of Fe and unavoidable impurities. The process is as below: conducting hot rolling on the steel rail or air cooling on the steel rail to room temperature, then reheating to 850-1000 DEG C for austenization; cooling the steel rail head to 620-570 DEG C with a cooling rate of 0.3-15 DEG C / s; when the temperature is lower than 620-570 DEG C, cooling to 350-200 DEG C with a cooling rate of 0.5-5 DEG C / s; and then conducting air cooling to room temperature. The invention avoids generation of excessive unstable thick M-A islands in granular bainite during air cooling to room temperature in hot rolling, reduces the risk of straightening fracture (or delayed fracture)of hot-rolled steel rail, and improves the adaptability of steel production process. The steel rail has tensile strength higher than 1400MPa, and realizes optimum matching of strength, toughness and ductility, and excellent rolling contact fatigue resistance and wear resistance.

Owner:ANGANG STEEL CO LTD

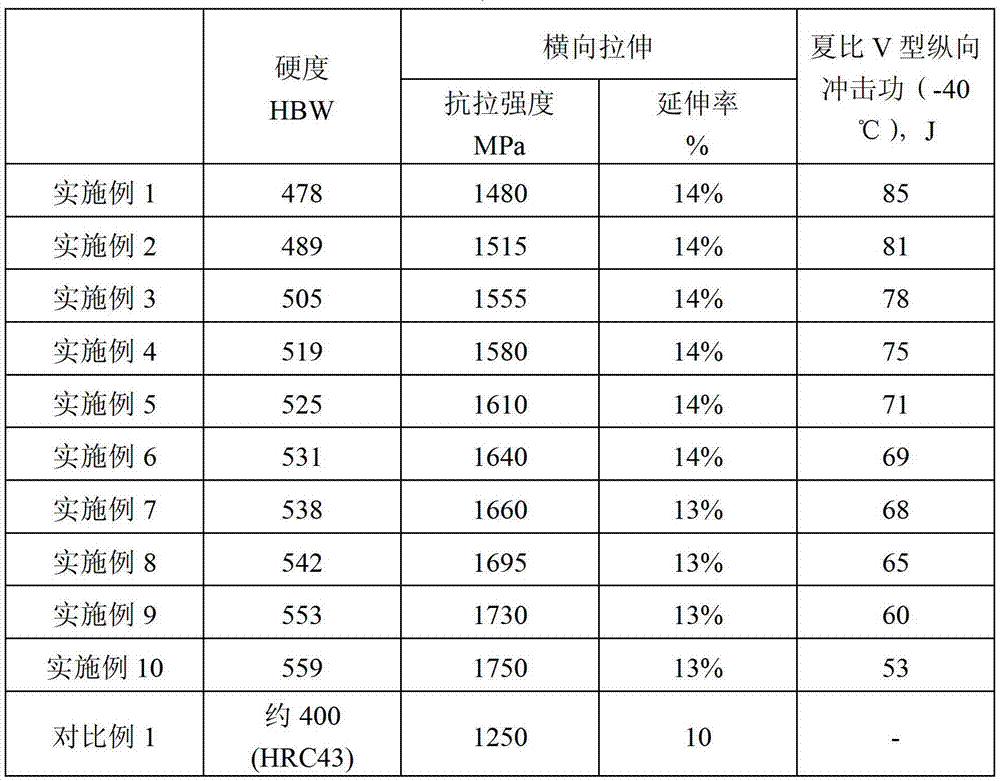

High-toughness medium-carbon quenched and tempered round steel of grade 120 KSI and manufacturing method thereof

The invention discloses high-toughness medium-carbon quenched and tempered round steel of the grade 120 KSI. The high-toughness medium-carbon quenched and tempered round steel of the grade 120 KSI comprises, by mass, 0.35%-0.50% of C, 0.15%-0.40% of Si, 0.60%-1.30% of Mn, equal to or less than 0.015% of P, equal to or less than 0.040% of S, 0.75%-1.30% of Cr, 0.15%-0.35% of Mo, equal to or less than 0.25% of Ni, equal to or less than 0.25% of Cu, 0.015%-0.040% of Alt, equal to or less than 0.10% of V, equal to or less than 0.10% of Nb, equal to or less than 0.05% of Ti, equal to or less than 0.008% of N, equal to or less than 0.0010% of B and the balance Fe and unavoidable impurity elements, wherein the content of V, the content of Nb and the content of Ti are not equal to or less than 0.010% at the same time. The round steel with the maximum specification reaching 260 mm is manufactured through Kanbara reactor (KR) pretreatment, basic oxygen furnace (BOF) smelting, ladle furnace (LF) refining, Ruhrstahl Heraeus (RH) vacuum degassing, continuous casting, heating, continuous rolling, and hardening and tempering, so that the requirements for high specifications and toughness are met.

Owner:JIANGYIN XINGCHENG SPECIAL STEEL WORKS CO LTD

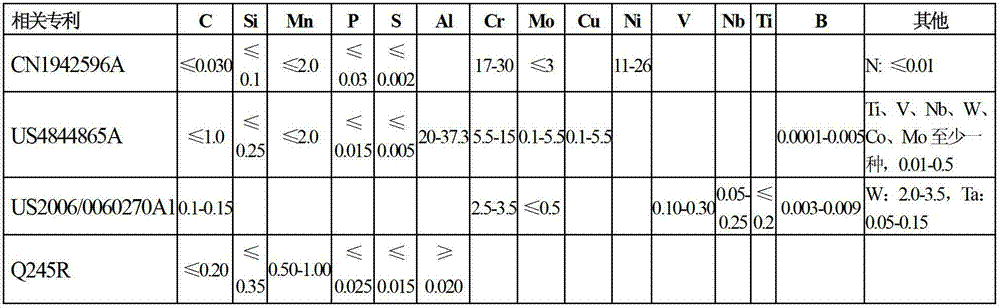

Air corrosion resisting high strength low alloy metal and its production process

ActiveCN1986864AImprove mechanical propertiesIncreased load-bearing capacityTemperature control deviceRoom temperatureHigh intensity

The present invention relates to high strength air corrosion resisting steel and its production process. The low alloy air corrosion resisting steel consists of C 0.05-0.10 wt%, Si not more than 0.75 wt%, Mn 1.0-1.6 wt%, P not more than 0.020 wt%, S not more than 0.010 wt%, Al 0.01-0.05 wt%, Cu 0.20-0.55 wt%, Cr 0.20-0.45 wt%, Ni 0.12-0.40 wt%, Ca 0.001-0.006 wt%, N 0.001-0.006 wt%, Nb not more than 0.07 wt%, Ti not more than 0.025 wt%, Mo not more than 0.35 wt%, and Fe and inevitable impurity for the rest. It is produced through conventional smelting and two stage rolling after being heated to over 1200 deg.c, and the rolling includes finish rolling with initial temperature of 950 deg.c, accumulated reduction degree not lower than 80 % and final temperature lower than 880 deg.c, cooling in the rate of 5-15 deg.c / s to 400-700 deg.c, coiling and air cooling to room temperature. It is used for vehicle, container, bridge, etc.

Owner:BAOSHAN IRON & STEEL CO LTD

Thick steel plate for nuclear power plant containment and manufacture method thereof

The invention discloses a thick steel plate for a nuclear power plant containment. The nuclear power plant containment is 10-60mm in thickness. The thick steel plate comprises, by mass percent, 0.06-0.15% of C, 0.10-0.40% of Si, 1.0-1.5% of Mn, 0.10-0.30% of Mo, not more than 0.012% of P, not more than 0.003% of S, 0.015-0.050% of Al, 0.20-0.50% of Ni, and at least one of not more than 0.05% of V, not more than 0.03% of Ti, not more than 0.25% of Cr, not more than 0.03% of Nb, and 0.0005-0.0050% of Ca, and the balance Fe and other inevitable impurity. Correspondingly, the invention further discloses a manufacture method of the thick steel plate for the nuclear power plant containment. The thick steel plate for the nuclear power plant containment is high in rigidity, high in toughness, fine in impact toughness of base metal and heat affected zone at low temperature, and suitable for application in the manufacture field of nuclear power plant containments.

Owner:BAOSHAN IRON & STEEL CO LTD

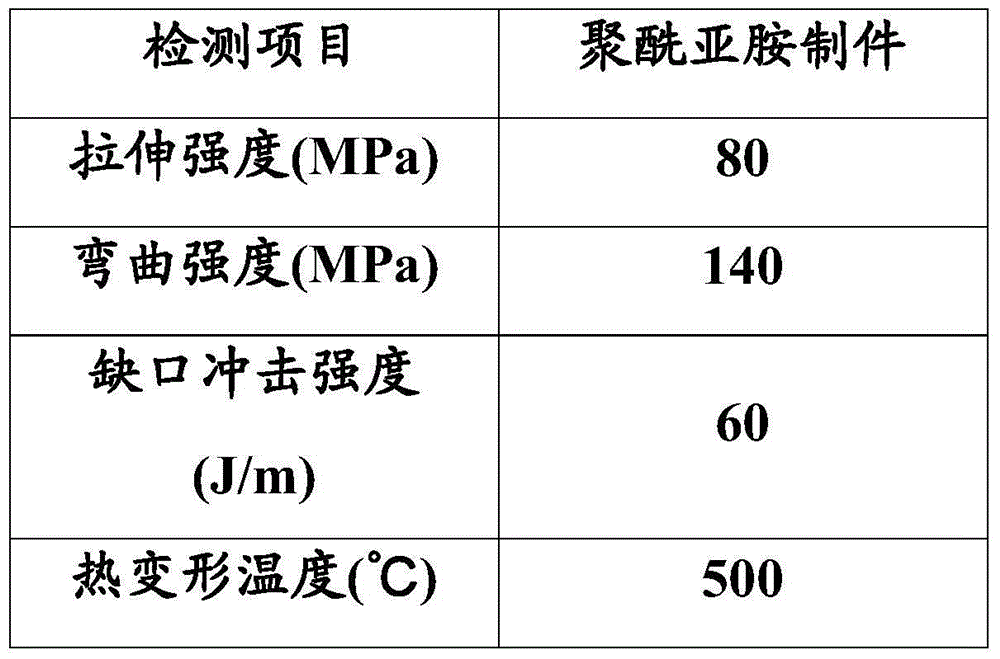

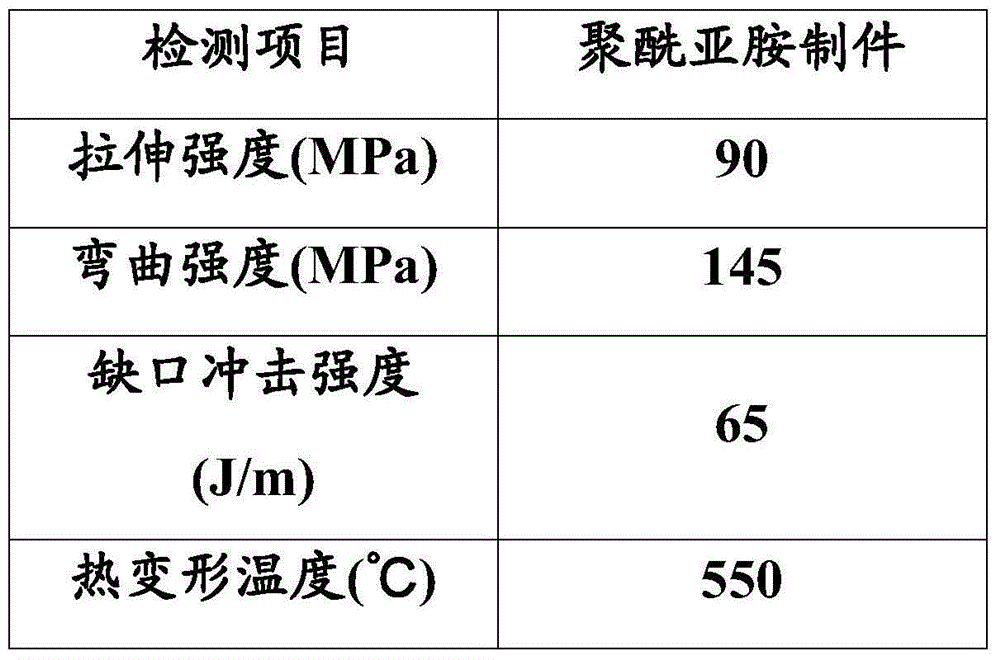

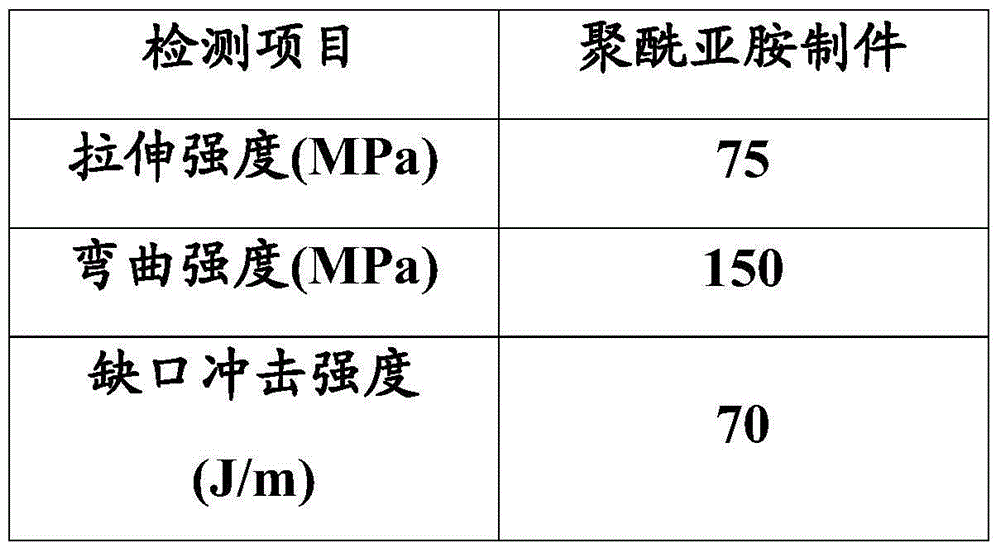

High-performance polyimide molding powder material suitable for 3D printing and 3D printing molding method

ActiveCN103980705AWide range of optionsImprove corrosion resistanceAdditive manufacturing with liquidsAdhesiveFull color

The invention discloses a polyimide powder composite material for 3D printing which includes a powder material and an adhesive. The powder material comprises, by weight, 100 parts of polyimide molding powder, 0.5-1 part of a thermal stabilizer and 5-10 parts of a reinforcing agent. The adhesive comprises, by weight, 60-80 parts of main sticky material, 5-20 parts of a pigment, 5-20 parts of filler, 2-10 parts of a flexibilizer, 0.5-1.5 part of a levelling agent and 1-10 parts of a pigment-and-filler dispersing and wetting agent. The powder composite material is used in a manner of matching 1 part by weight of the powder material with 0.1-0.5 parts by weight of the adhesive. The powder composite material broadens a selectable range of present 3D printing materials. The high-performance polyimide molding powder is used as a powder layer of 3D printing and a liquid adhesive is sprayed onto the powder layer to produce a product in a layer-by-layer bonding manner. With addition of the pigment to the adhesive, a full-color prototype product can be produced and a color model can express more useful information. A polyimide product, which is produced through a powder-adhesive 3D printing technology, is excellent in high temperature resistance performance and is high in mechanical strength.

Owner:INST OF CHEM CHINESE ACAD OF SCI

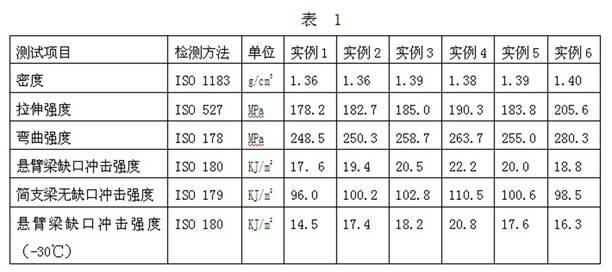

Nylon engineering plastics for high-speed transit railway track and manufacture method thereof

The invention relates to nylon engineering plastics and a manufacture method thereof, in particular to nylon engineering plastics for high-speed transit railway tracks and a manufacture method thereof. The nylon engineering plastics comprise the following components in percentage by weight: 35 to 60 percent of nylon resin, 20 to 35 percent of glass fibre, 0 to 10 percent of inorganic mineral, 16 to 30 percent of compatilizer, 0.3 to 0.5 percent of light stabilizer, 0.1 to 0.3 percent of coupling agent, 0.1 to 0.5 percent of antioxygen and 0.4 to 1 percent of lubricant, wherein the compatilizer is one kind of or a mixture of two kinds of Maleic anhydride grafted EPDM (Ethylene Propylene Diene Monomer) rubber and maleic anhydride grafted POE (Polyolefin Elastomer), and the melt flow rate of the compatilizer is 0.5 to 1.5g / 10min. The manufacture method comprises the steps of: adding the compatilizer into an extruder in a lateral feeding addition method under the condition that the melt temperature is 220 to 280 DEG C and the mixing time is 1-5min; and controlling the rotate speed of a screw between 300 and 450rpm. According to the invention, the tensile strength, the impact toughness and the size stability can all meet the requirements for the operation of high-speed trains with running speed more than 300km / h.

Owner:NANJING JULONG SCI&TECH CO LTD

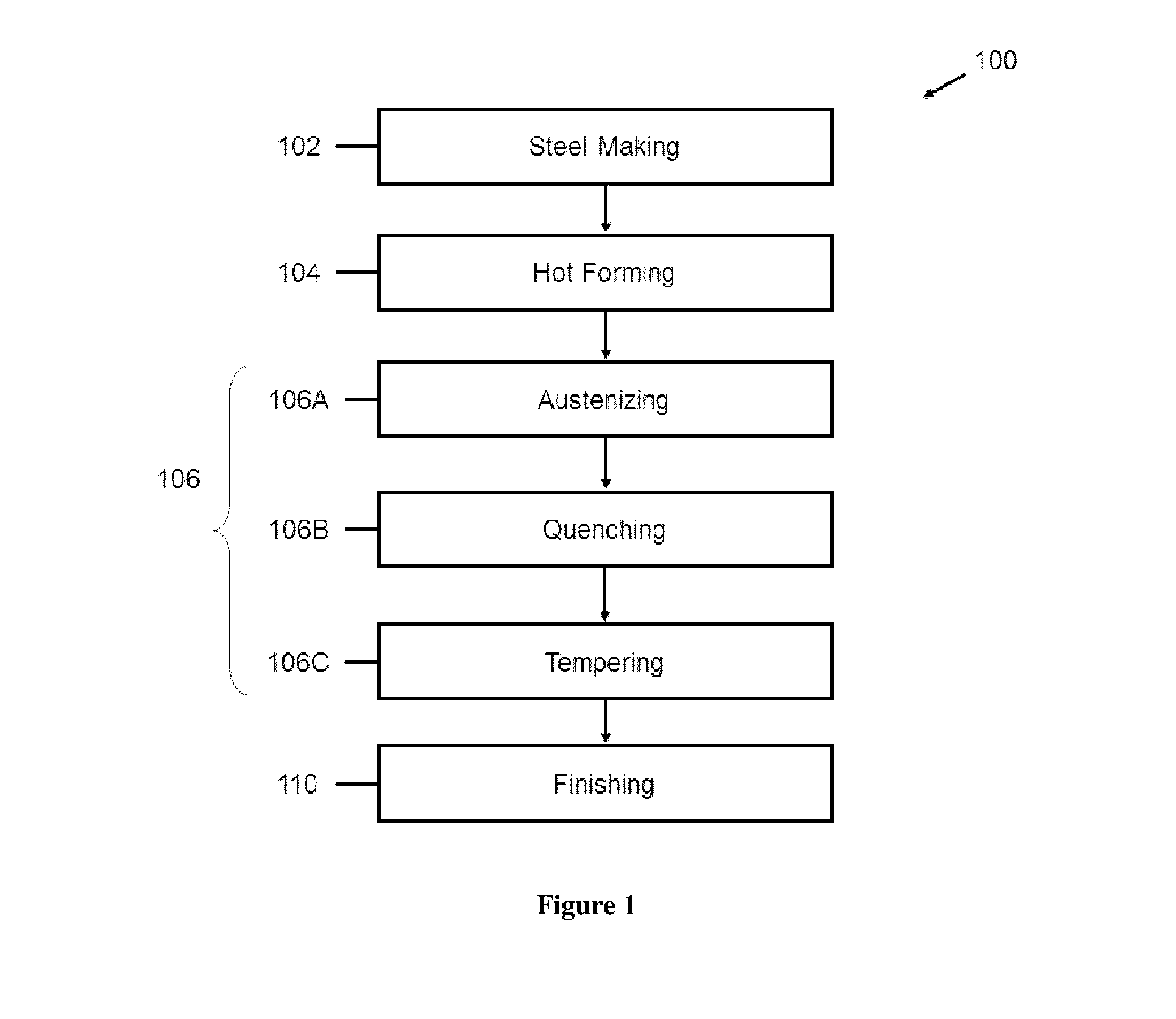

High strength medium wall quenched and tempered seamless steel pipes and related method for manufacturing said steel pipes

ActiveUS20140299236A1Good low temperatureImprove solderabilityFurnace typesHeat treatment process controlSteel tubeChemical composition

Disclosed herein are embodiments of a seamless quenched and tempered steel pipe which can have a wall thickness WT higher than or equal to 6 mm and lower than or equal to 35 mm. Some embodiments of the steel pipe can have a chemical composition comprising C, Mn, Si, Cr, Ni, Mo, Al, N, Ca, Nb, Ti, V, Zr, and Ta based on the composition weight, the remaining being iron and impurities. In some embodiments, wherein (V+Nb) content is lower than 0.07 wt %; defining a first parameter P1=(60×C)+Cr+[5×e(35×Mo / WT)]+50×(V+Nb), the chemical composition satisfies a first condition P1≦14.5.

Owner:DALMINE SPA

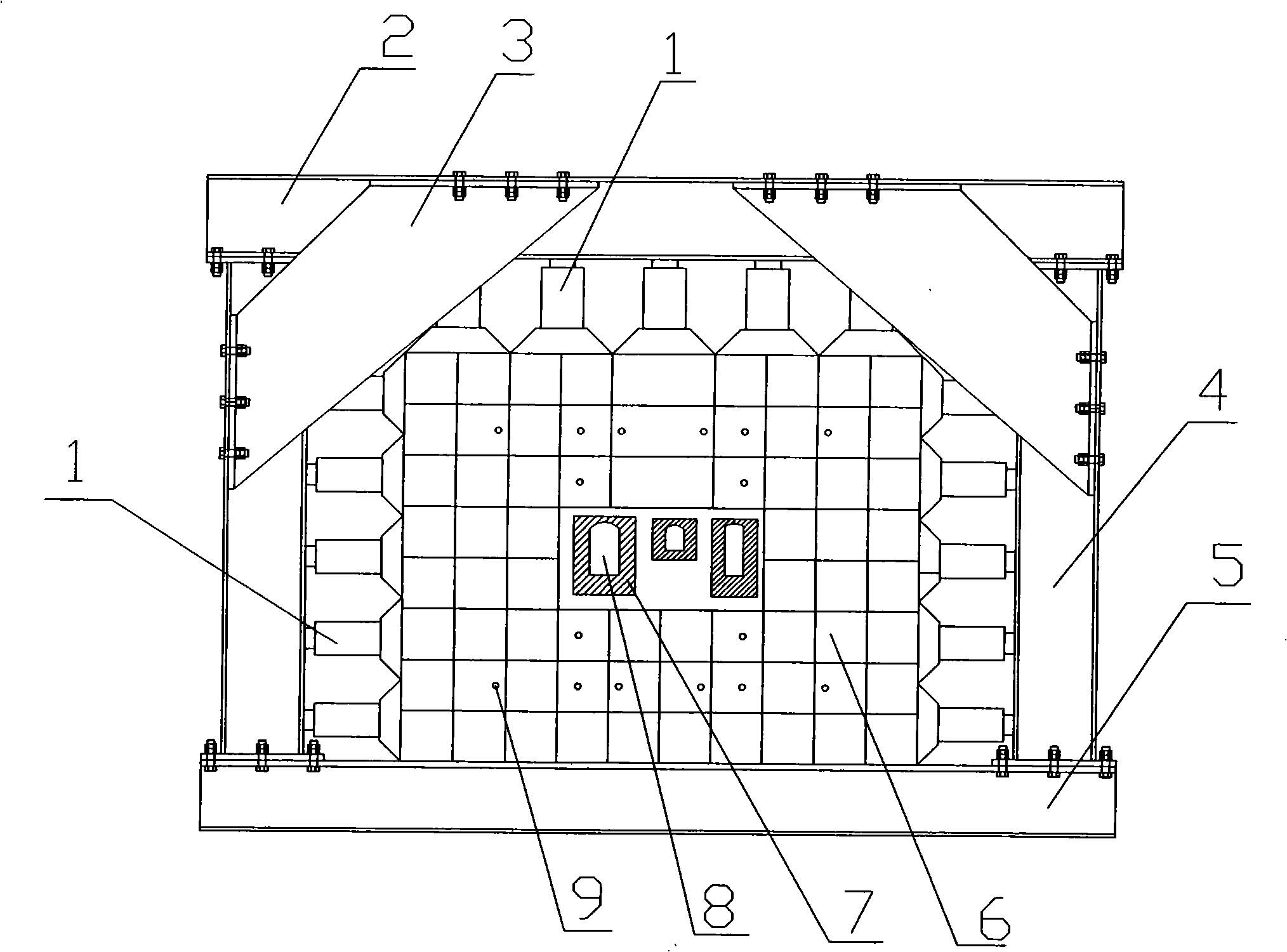

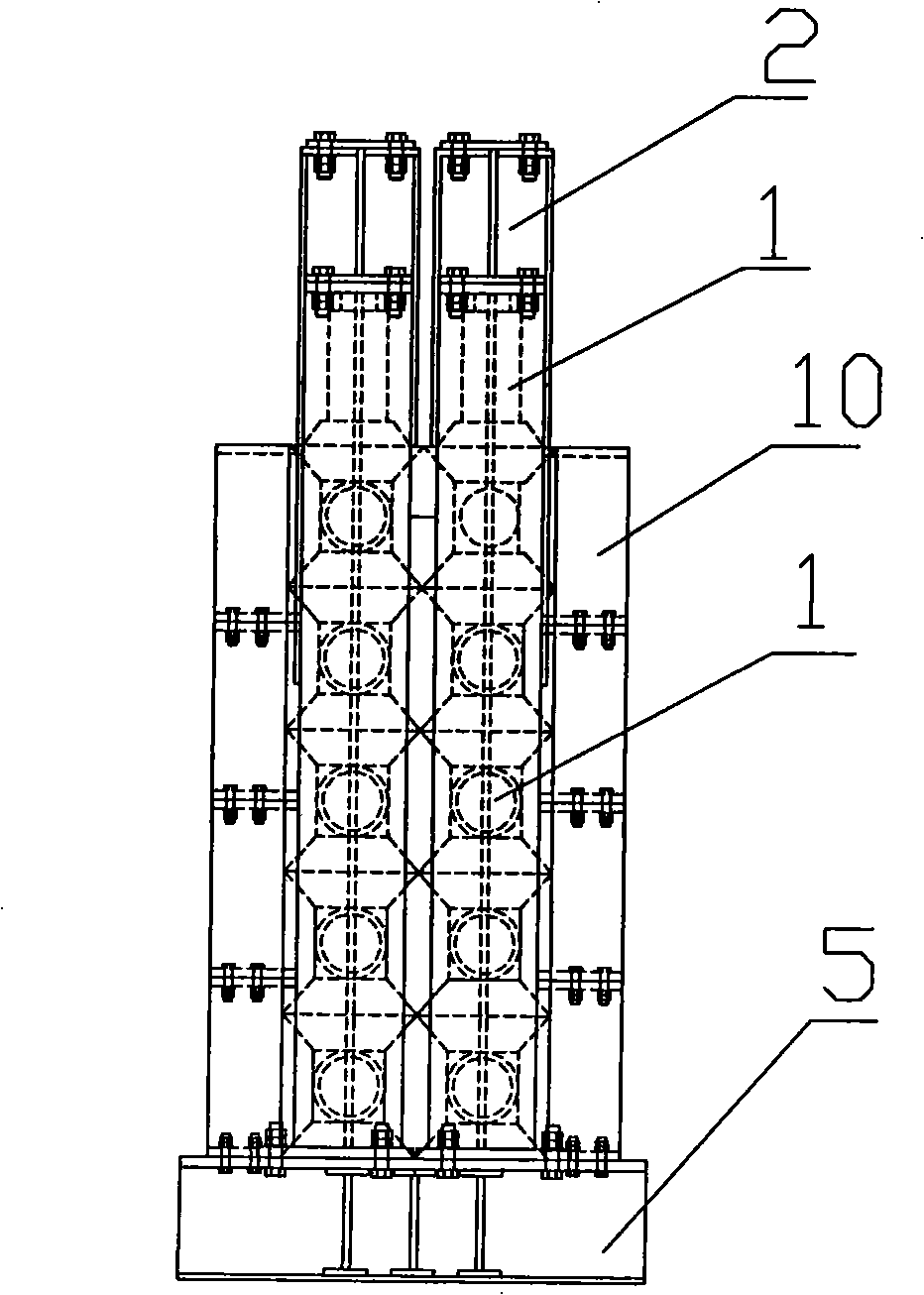

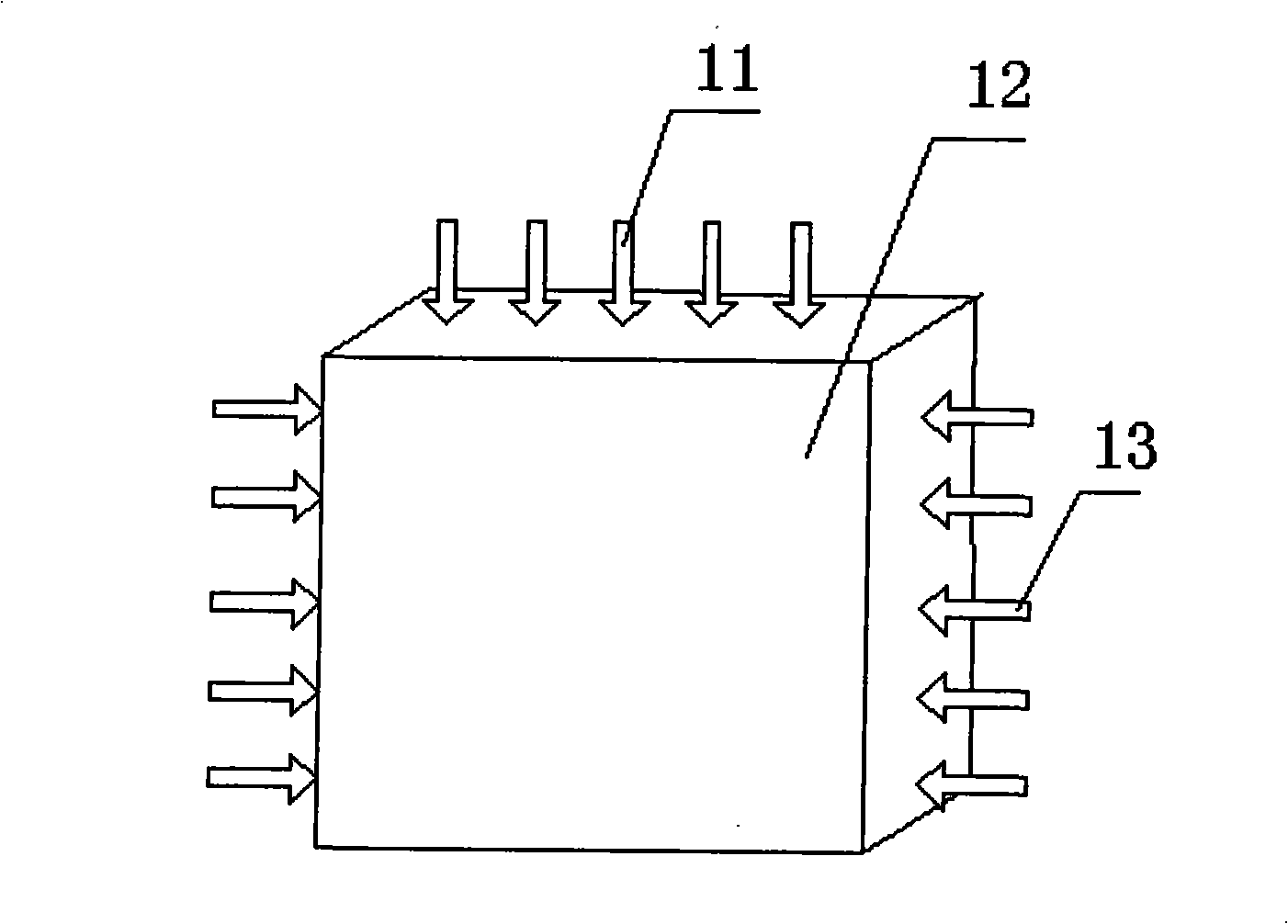

High-ground stress quasi-3D visible model testing bench frame apparatus

InactiveCN101344444AGood impact toughnessStrong corrosion resistanceForce measurementCorrosion resistantHigh intensity

The invention discloses a test bench device of quasi three-dimensional visualization models with high geostress and comprises a reaction wall device, a door-typed reaction frame is arranged in the side periphery of the reaction wall device, a hydraulic loading device is arranged between the door-typed reaction frame and a model body, and a plurality of observing windows are arranged surrounding the position of a perforated chamber on the reaction wall device. The test bench device can be used for implementing the experimental research on the geomechanical plane strain models in the stability research of underground engineered tunnels under high geostress condition. The test bench device has the following advantages: 1. a steel frame of the model adopts a high-intensity alloy steel material, thus having good intensity, rigidity and toughness, strong corrosion resistant capacity, and repeated and recycled use in a long time; 2. an external loading method is adopted, thus conveniently realizing jobs such as the installation and the replacing of loading equipment such as hydrostatic triggers, etc.; 3. a toughened glass is arranged surrounding a hole of the reaction wall, thus being convenient for observing the deformation and the crack propagation situation in the surrounding of the hole; 4. an assorted control system of hydraulic loading is combined, thus conveniently realizing graded loading and simulating real geostress distribution situation as accurately as possible.

Owner:SHANDONG UNIV

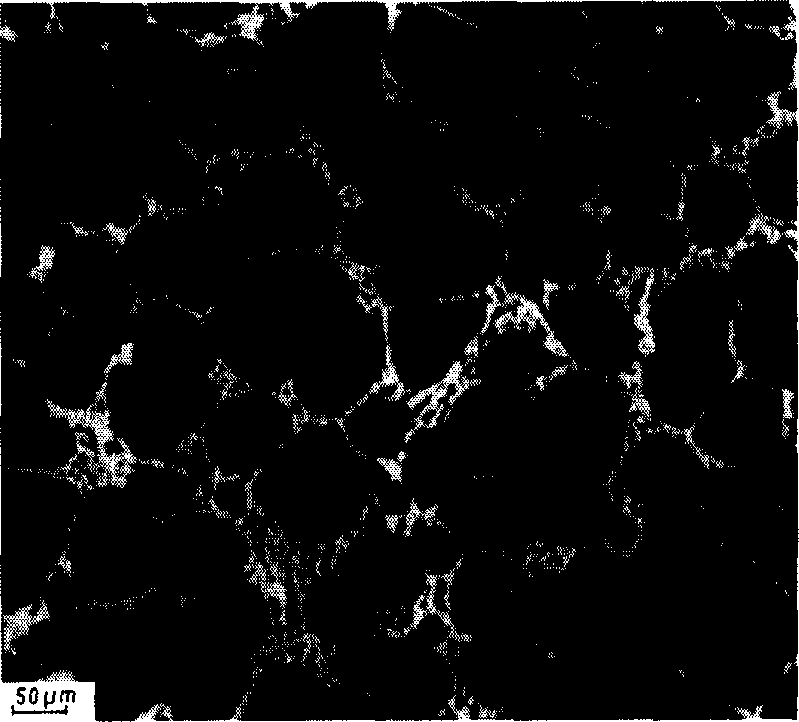

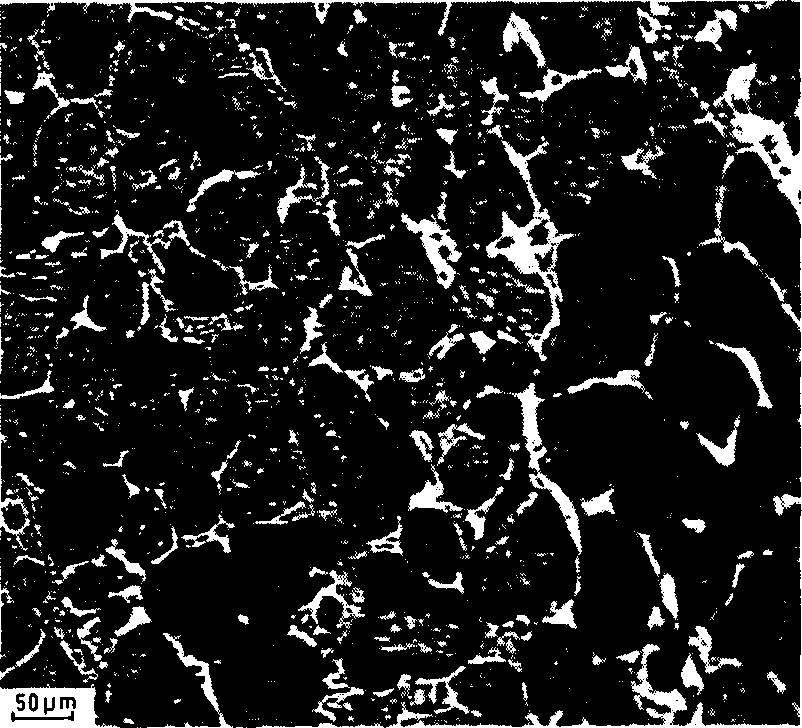

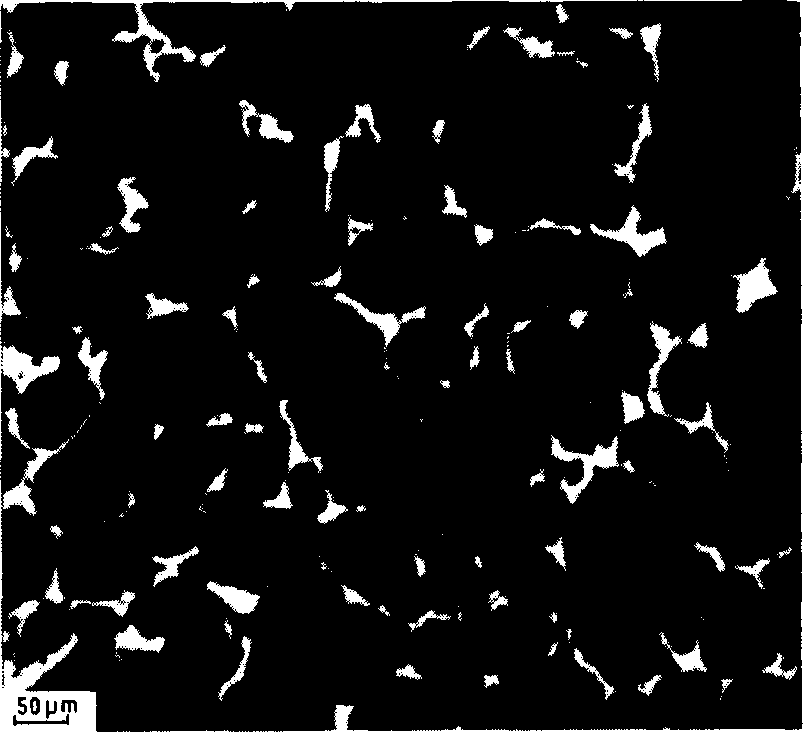

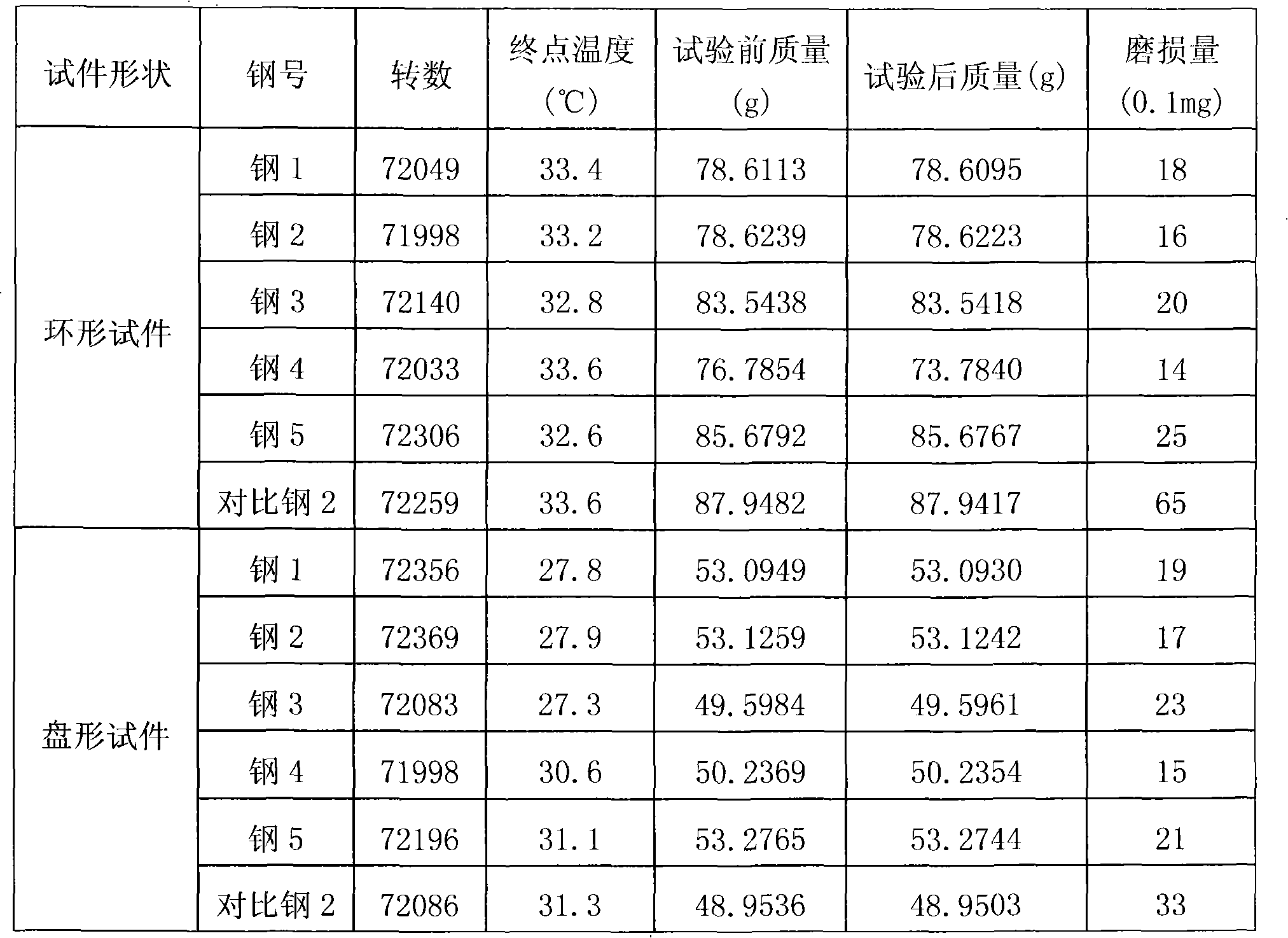

Toughening method for casting high-boron wear-resistant alloy

The toughening method for cast high-B wear-resist alloy comprises: after melting the liquid steel and deoxidized by Aluminum, adding 2.5-3.3w% FeTi30 as alterant; then, casting after melting clear and skimming slag; holding the toughening temperature 1020-1050Deg for 2-3h; finally, quenching temper or normalizing. The alloy has absorption power Ak up to 12.5J on 10mmí‡ 10mmí‡ 55mm standard sample.

Owner:NINGBO ZHEDONG PRECISION CASTING

Ultrahigh strength abrasion resistant steel and method of preparing the same

InactiveCN101250673AHigh yield strengthImprove impact toughnessTemperature control deviceFurnace typesChemical compositionWear resistant

The invention discloses a superhigh intensity wear-resistant steel and the manufacturing method, which belongs to the manufacturing field of low alloying steels, according to percentage by weight, the chemical components of the steel are that C 0.10-0.17%, Si 0.25-0.50%, Mn 1.20-1.50%, P<=0.018%, S<=0.008%, Cr 0.20-0.05%, Ni0.25-0.50%, Mo 0.10-0.40%, Als 0.02-0.06%, B<=0.005%, RE<=150g / t, and the allowance is Fe and unavoidable impurities, and the content of carbon is Ceq(%)<=0.60, Ceq(5)=C+Mn / 6+(Mo+Cr+V) / 5+(Ni+Cu) / 15. The specific method for producing the steel comprises the following steps: smelting ultra-pure steel, desulfurizing molten iron, compounding and converting the top and the bottom of a converter, doing vacuum treatment, feeding rare earth (RE) silk through a crystallizer, casting into bar plates, heating the bar plates, roughing, planishing, air cooling or feeding middle pressure, water cooling, quenching and tempering steel plates. V does not contain in the chemical components of the steel, inner stress of steel is low, steel welding property is improved, and steel has excellent abrasion resistance and ultra-high strength and toughness properties, which is beneficial for popularization and application.

Owner:武钢集团有限公司

Method for adding rare earth metal into steel to improve performance

The invention relates to the field of manufacturing of high-quality metal materials, in particular to a method for adding rare earth metal into steel to improve the performance. In the smelting process of molten steel, the degree of purity of the molten steel and the degree of purity of the high-purity rare earth metal are strictly controlled; the high-purity rare earth metal is added into a steel ladle; the content of sulfur in the molten steel is below 200 ppm and the total oxygen content is below 40 ppm before the high-purity rare earth metal is added; and the total oxygen content of the added high-purity rare earth metal is below 200 ppm. The method is applicable to the processes such as a converter BOF-ladle refining LF-vacuum degassing RH or VD-continuous casting CC / mold casting MC flow, an electric arc furnace EAF-ladle refining LF-vacuum degassing RH or VD-continuous casting CC / mold casting MC flow and a converter BOF / intermediate frequency furnace GOR / AOD(-ladle refining LF)-continuous casting CC / mold casting MC flow, prepares high-quality carbon structural steel, low alloy steel, medium-high alloy steel, tool and mould steel, bearing steel, spring steel, stainless steel and electrical steel, and solves the bottleneck problems that due to a conventional rare earth adding process, the performance of rolled steel is not stable and a water gap is blocked in the production process.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

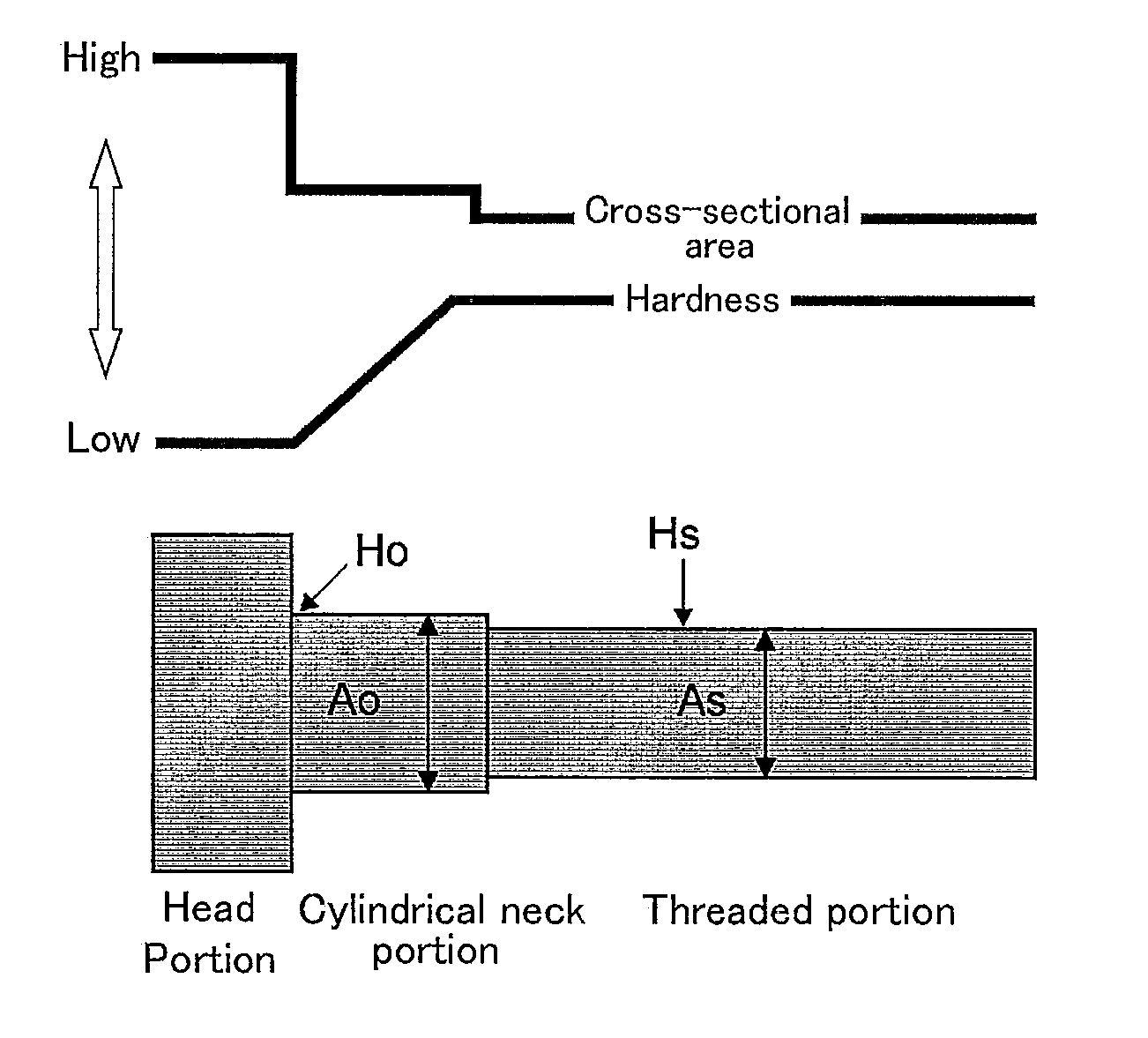

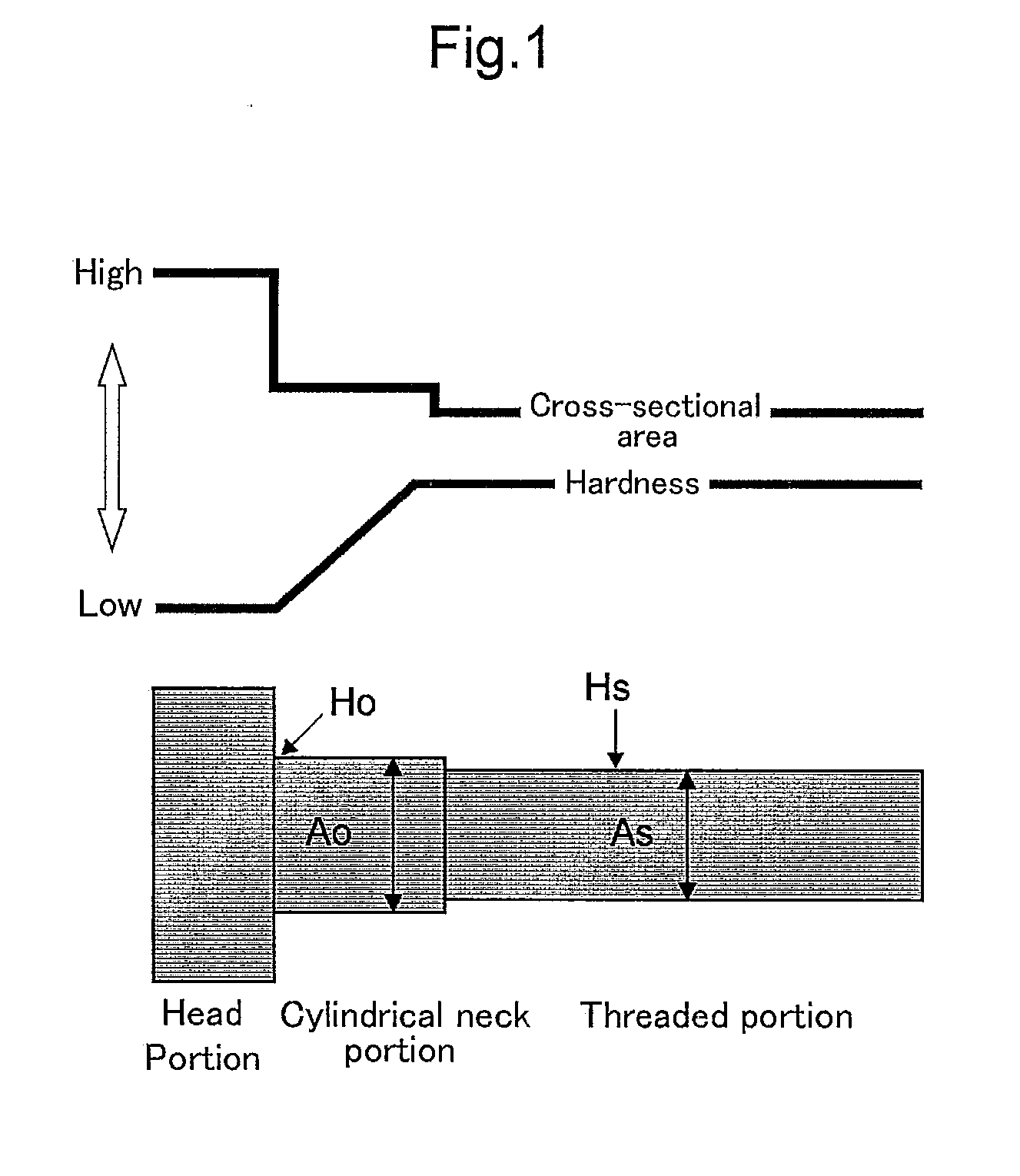

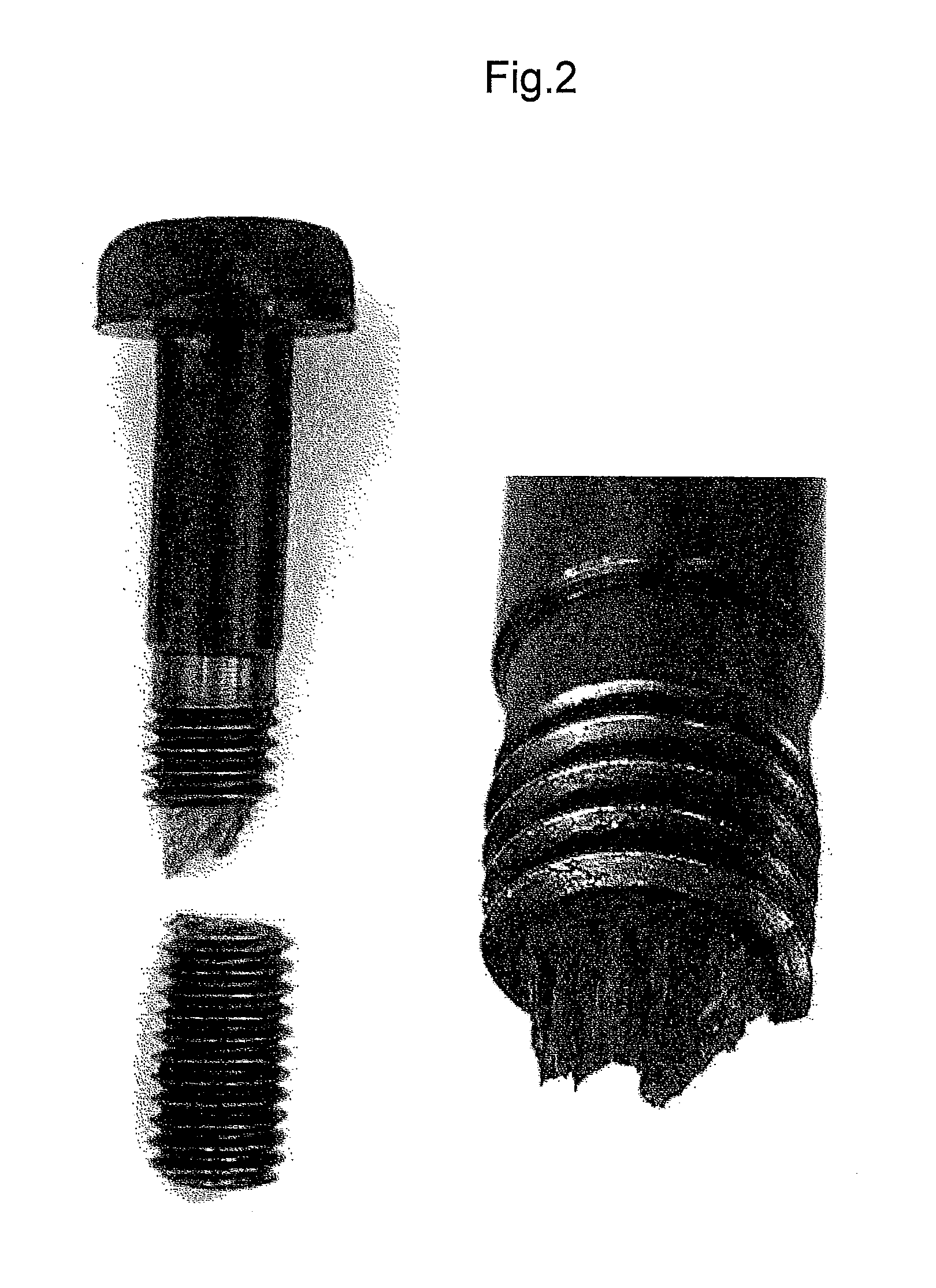

High-Strength Bolt

Provided is a high-strength bolt which has a tensile strength of 1,200 MPa or more while exhibiting excellent ductility and delayed facture resistance, and further has an excellent impact toughness which had not been obtained in the conventional high-strength bolt. The high-strength bolt has a tensile strength of 1.2 GPa or more and includes a threaded portion and cylindrical neck portion. The bolt has K of 0.8 or more and satisfies Ho<Hs, where K is defined by the equation: (Ao×Ho) / (As×Hs)=K, in which Ao is an effective cross-sectional area of the cylindrical neck portion with a diameter larger than that of the threaded portion, Ho is a Vickers hardness of a portion at which Ao is measured, As is an effective cross-sectional area of the threaded portion, and Hs is a Vickers hardness of the threaded portion.

Owner:NAT INST FOR MATERIALS SCI +2

Aluminium alloy for vehicle hub and preparation method thereof

The invention provides an aluminium alloy for a vehicle hub and a preparation method thereof. The alloy comprises the following components by weight percent: 4.5-6.3% of Zn, 1.4-2.5% of Mg, 0.5-0.9% of Cu, 0.12-0.3% of Zr, 0.05-0.15% of Ti, 0.05-0.2% of Cr, 0.1-0.3% of Sc and the balance of Al. The preparation method of the aluminium alloy comprises the following steps: weighting raw materials, melting the raw materials except for magnesium blocks, adding a covering agent, then adding the preheated magnesium blocks, stirring, injecting nitrogen or argon to degas, filtering with a ported ceramic plate, reducing the temperature, standing for 20 minutes, and adopting a liquid forging mould and a liquid forging forming method to prepare the hub. The prepared vehicle hub has high strength, impact toughness and corrosion resistance; and the mechanical properties of the aluminium alloy hub can be ensured, the production cost can be reduced and the large-scale production of the hub is easy to perform.

Owner:ZHEJIANG GKO ALUMINUM

Heavy wall quenched and tempered seamless steel pipes and related method for manufacturing said steel pipes

ActiveUS20140299235A1Improve low temperature toughnessImprove solderabilityFurnace typesHeat treatment process controlChemical compositionMetallurgy

Disclosed herein are embodiments of a seamless quenched and tempered steel pipe having a wall thickness (WT) higher than or equal to 35 mm and lower than or equal to 80 mm. Embodiments of the steel pipe can comprise C, Mn, Cr, Ni, Mo, Al, Ca, N, Nb, Ti, Zr, and Ta. Further, for some embodiments of the steel pipe wherein, defining a first parameter P1=50×C+Cr+10×Mo+70×V, the chemical composition can satisfy a first condition P1≦8.0.

Owner:DALMINE SPA

High-performance bridge weathering steel containing Mo and preparation method thereof

The invention belongs to the field of manufacture of low-alloy steel, in particular to high-performance bridge weathering steel containing Mo and a preparation method thereof. The invention provides bridge weathering steel containing Mo with the high performance, which comprises the following chemical components by mass percent: 0.02-0.05 percent of C, 0.20-0.30 percent of Si, 1.0-1.50 percent of Mn, at most 0.02 percent of P, at most 0.010 percent of S, 0.20-0.40 percent of Cu, 0.40-0.60 percent of Cr, 0.20-0.40 percent of Ni, 0.1-0.30 percent of Mo, 0.04-0.07 percent of Nb, 0.005-0.015 percent of Ti, at most 0.02 percent of Al and the balance of Fe and inevitable impurities. The high-performance bridge weathering steel containing Mo adopts two stages of rolling. The rough rolling and bloom rolling temperature of the first stage is 1050-1070 DEG C, the precision rolling and bloom rolling temperature of the second stage is 900-950 DEG C, and the finish rolling temperature is 800-850 DEG C. The high-performance bridge weathering steel containing Mo disclosed by the invention has good mechanical property, welding performance and atmospheric-corrosion resistance performance. The high-performance bridge weathering steel containing Mo adopts an Ultra-low carbon design, and the production cost is low.

Owner:NORTHEASTERN UNIV LIAONING +1

Low-cost steel plate for building structure and manufacturing method thereof

InactiveCN101705423ALow costGood welding performanceTemperature control deviceFurnace typesYield ratioHigh rise

The invention discloses a low-cost steel plate for a building structure and a manufacturing method thereof. The steel plate comprises the following chemical components: C accounts for 0.14 percent to 0.17 percent, Si accounts for 0.20 percent to 0.50 percent, Mn accounts for 1.30 percent to 1.50 percent, P is equal to or less than 0.012 percent, S is equal to or less than 0.005 percent, Alt accounts for 0.020 percent to 0.060 percent, and the balances are Fe and unavoidable foreign impurities. (1) No noble metal elements such as Nb, V, Ti, Ni, Cr, Mo and the like, are added in the steel, the requirement of Q345GJ strength level is met completely though the chemical components C-Si-Mn-Al, and the cost is low; (2) the steel is purer, P is equal to or less than 0.012 percent, and S is equal to or less than 0.005 percent; (3) the impact toughness is good at the temperature of minus 40 DEG C, and the Charpy impact energy of a V-shaped notch is equal to or higher than 80 J; (4) the earthquake resistance is good, and the actual yield ratio is respectively smaller than 0.78; and (5) the lamellar tearing resistance is excellent, and the actual Z-direction section shrinkage ratio in the total-thickness direction is equal to or higher than 38 percent. The hot-rolling Q345GJEZ35 steel plate used for the building structure and provided with thickness of 20-90 mm can be produced, and the steel plate and the manufacturing method can be applied to the manufacture of the steel structure of the high-rise building, have good comprehensive performance and simple production process, can realize the batch production and have low cost.

Owner:SHOUGANG CORPORATION

High-strength-and-toughness low alloy wear resistant steel and manufacturing method thereof

The invention relates to high-strength-and-toughness low alloy wear resistant steel and a manufacturing method thereof, belonging to the technical filed of metallurgy. The high-strength-and-toughness low alloy wear resistant steel comprises the following components by weight percent: 0.15-0.20% of C, 0.1-0.5% of Si, 1.2-1.6% of Mn, less than or equal to 0.015% of P, less than or equal of 0.005% S, 0.02-0.04% of Al, 0.016-0.022% of Ti, 0.16-0.20% of Cr, 0.16-0.22% of Mo, 0.001-0.0015% of B and the balance of Fe, and simultaneously the carbon equivalent Ceq (%) is less than or equal to 0.55. The manufacturing method comprises the following steps: smelting molten steel and pouring into a slab, and carrying out rough rolling after heating and heat insulation; and then carrying out complete quenching treatment, or sub-temperature quenching treatment, or carrying out the complete quenching treatment and then carrying out the sub-temperature quenching treatment, and adopting low temperature tempering to eliminate stress after the quenching. The method of the invention ensures higher hardness, simultaneously can obviously improve the impact toughness of steel plates, increase the impact resistance of the steel plates, and prolong the service life of mechanical equipment, and can obtain wear resistant steel plates with different strength and toughness grades by using the steel with same components and different quenching processing methods.

Owner:NORTHEASTERN UNIV +1

Low-alloy high-performance wear-resistant steel plate and manufacturing method thereof

ActiveCN103205627AImprove performanceHigh hardnessFurnace typesQuenching agentsChemical compositionWear resistant

The present invention provides a low-alloy high-performance wear-resistant steel plate and a manufacturing method thereof. The steel plate comprises the following chemical compositions (wt%) of 0.21-0.32% of C, 0.10-0.50% of Si, 0.60-1.60% of Mn, 0.0005-0.0040% of B, 0-1.50% of Cr, 0-0.80% of Mo, 0-1.50% of Ni, 0-0.080% of Nb, 0-0.080% of V, 0-0.060% of Ti, 0.010-0.080% of Al, 0.0010-0.0080% of Ca, 0-0.0080% of N, 0-0.0080% of O, 0-0.0004% of H, 0-0.015% of P, and 0-0.010% of S, wherein the following relationships are satisfied: 0.20%<=(Cr / 5+Mn / 6+50B)<=0.55%, 0.02%<=(Mo / 3+Ni / 5+2Nb)<=0.45%, 0.01%<=(Al+Ti)<=0.13%, and the balance is Fe and inevitable impurities. The low-alloy high-performance wear-resistant steel plate manufactured by the above compositions and through a TMCP process has high strength and hardness, good toughness and excellent wear resistance, and is suitable for easy-to-wear parts in various mechanical equipments.

Owner:BAOSHAN IRON & STEEL CO LTD

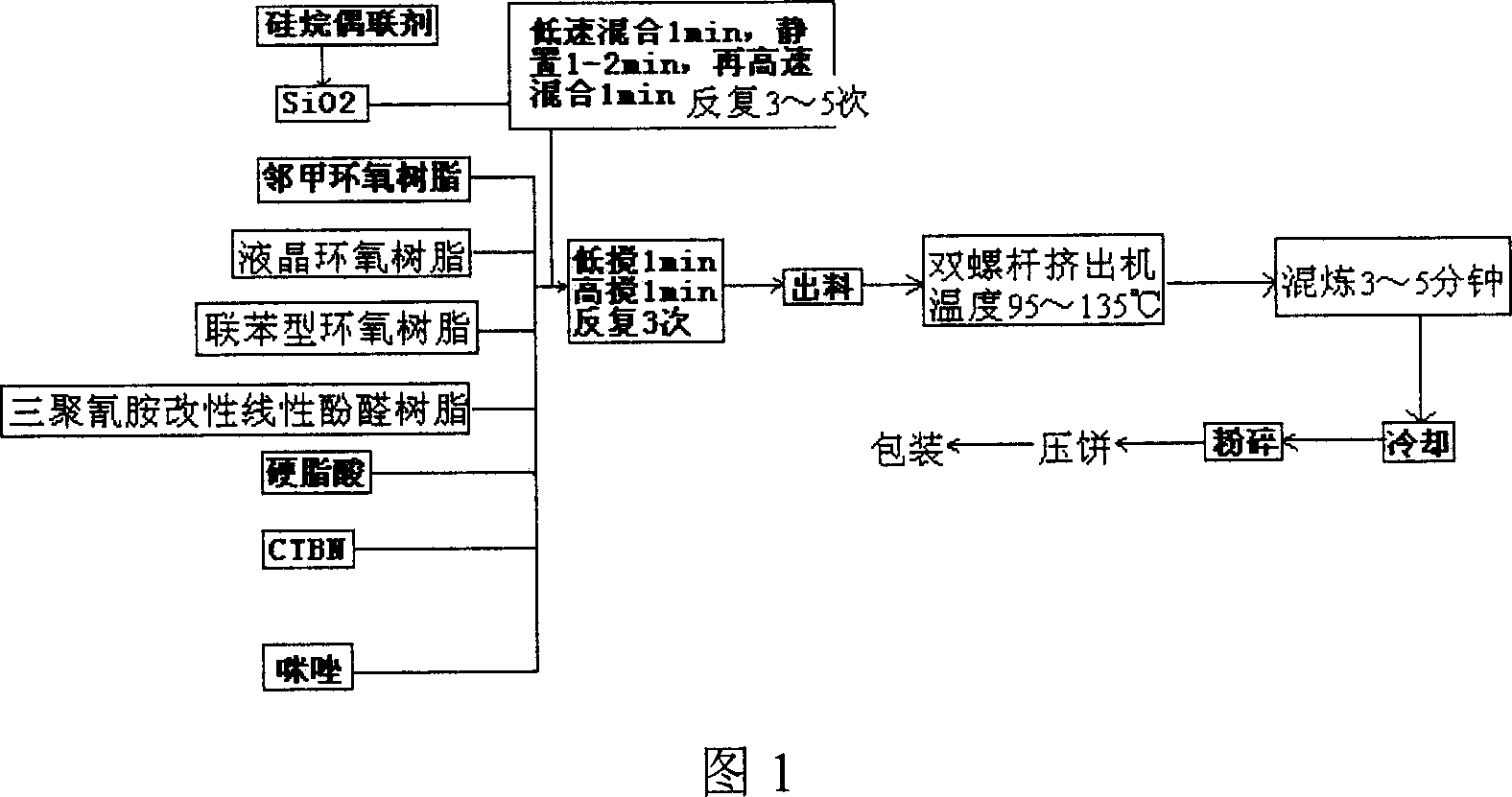

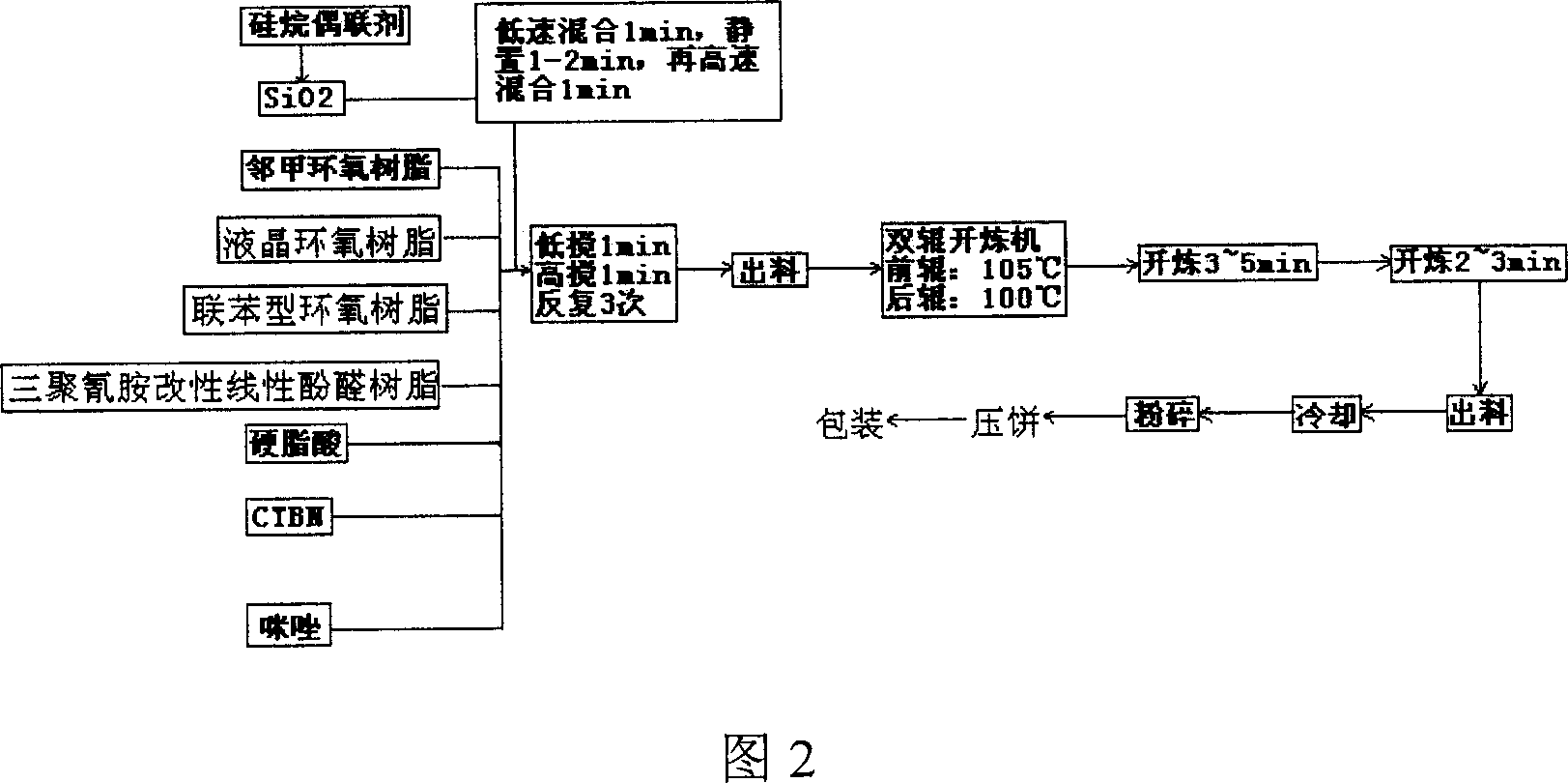

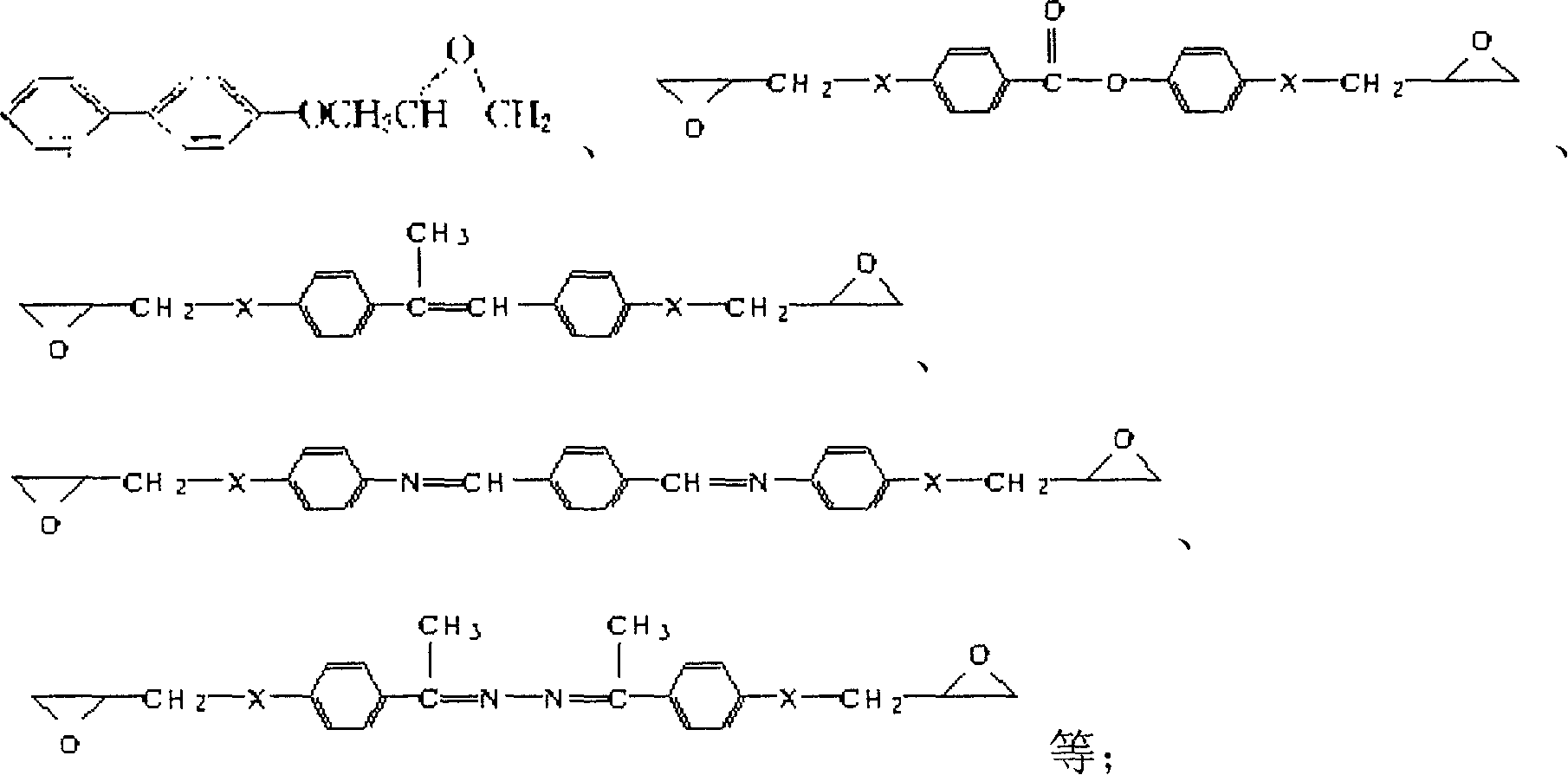

Epoxy-resin mould plastic for packing IC circuit and its production

InactiveCN101029165AHigh glass transition temperatureReduce melt viscositySemiconductor/solid-state device detailsSolid-state devicesEpoxyThermal expansion

An epoxy resin mold plastic and its production are disclosed. The mold plastic consists of liquid-crystal epoxy resin, methyl-phenolic epoxy resin, epoxy resin containing biphenyl unit structure, melamine modified linear phenolic resin, silicone micro-powder, imidazo curing improver, toughening agent and silane coupling agent. The process is carried out by treating silicone micro-powder in mixer by coupling agent for 2-5mins, adding into other components, mixing for 3-5mins, melt milling at 95-135 degree for 3-5mins, cooling, crushing, mesh screening, pressing into material cake and storing below 6degree. Its advantages include low thermal expansion coefficient, excellent heat and fire resistances, better toughness and fluidity, no phosphor, no antimony and environmental pollution. It can be used to pack large-scale circuit and electronic devices.

Owner:GUANGDONG RONGTAI IND

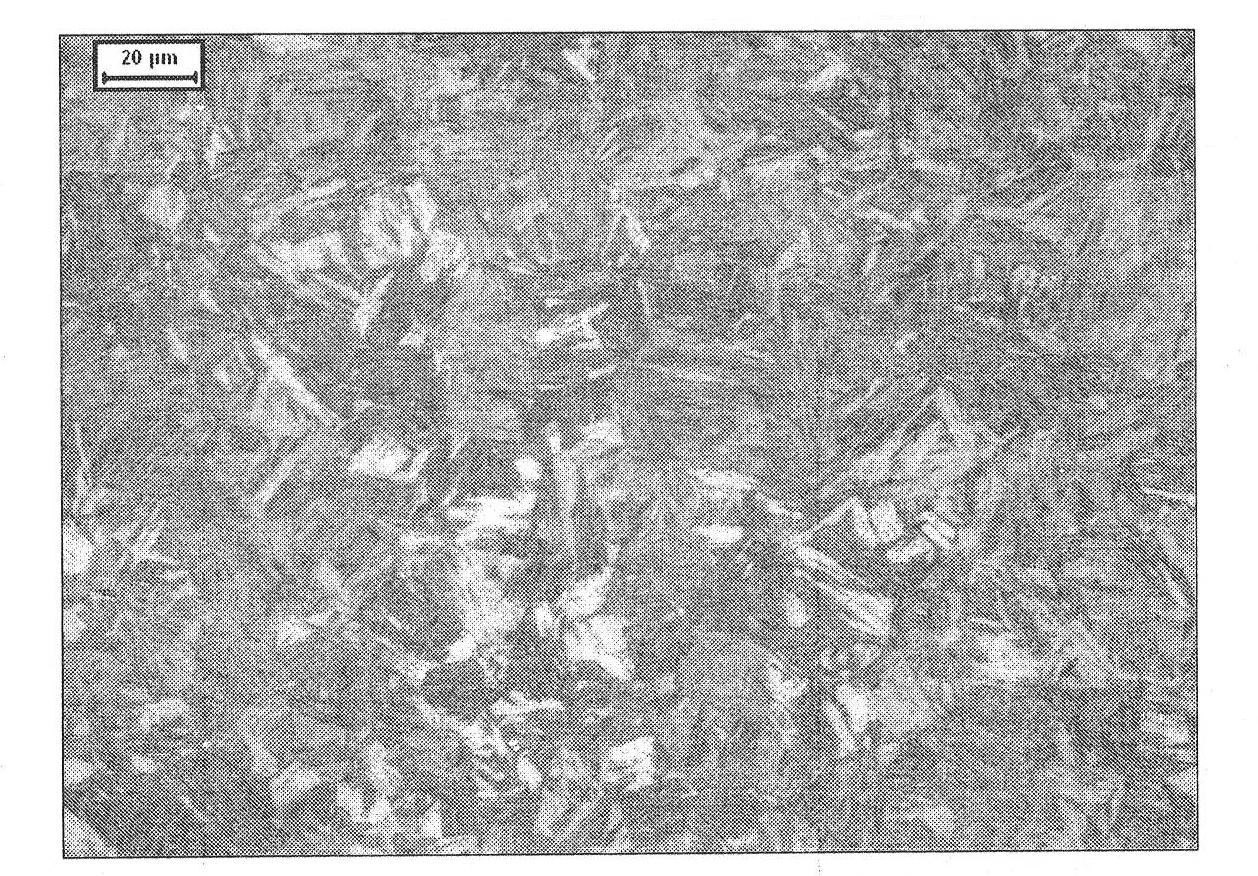

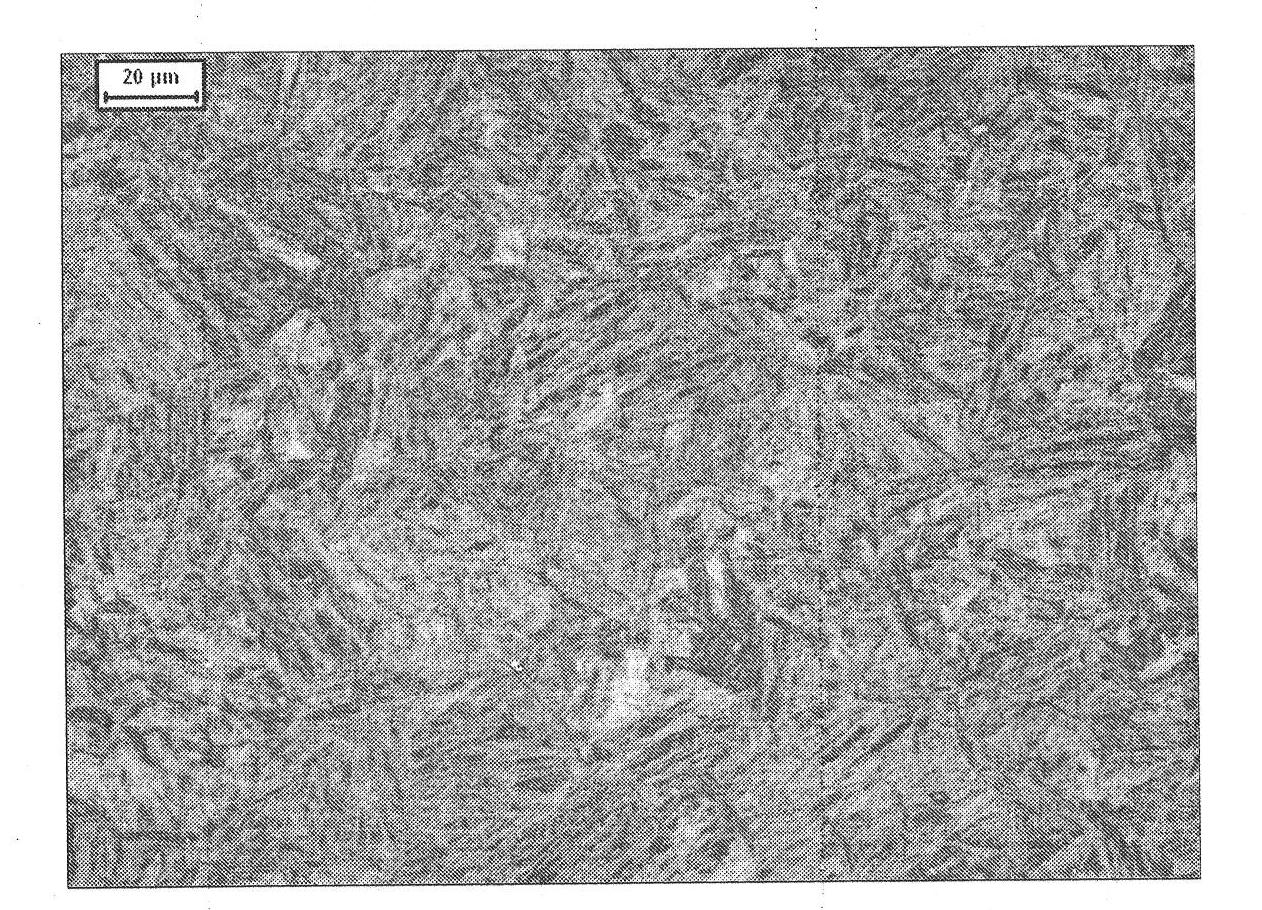

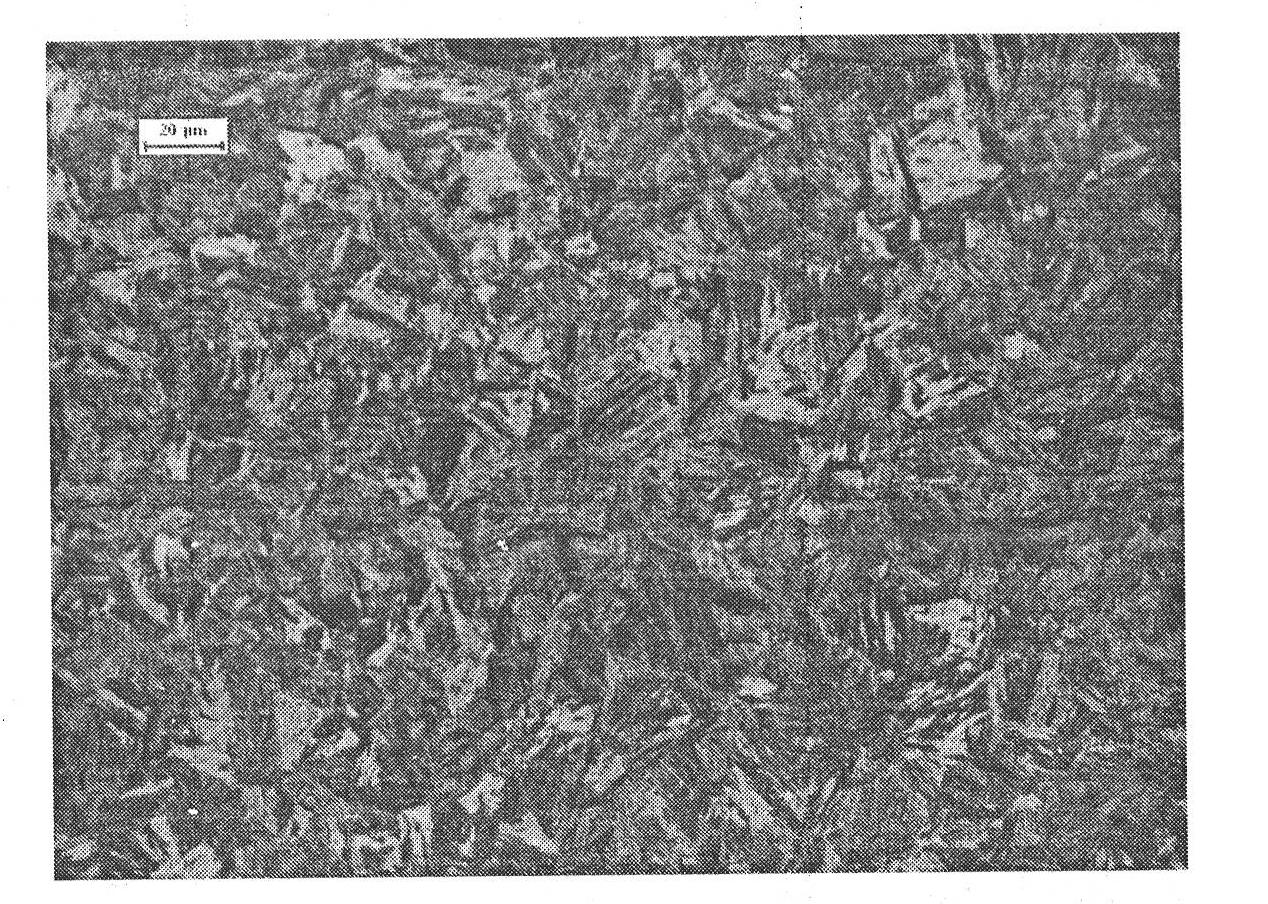

Method for improving low-temperature impact toughness of high strength thick steel plate

InactiveCN101876001AHigh strengthImprove toughnessTemperature control deviceSheet steelChemical composition

The invention discloses a production method for improving the low-temperature impact toughness of a high strength thick steel plate, and belongs to the technical field of medium and thick steel plate production. The steel comprises the following chemical compositions: 0.05 to 0.15 percent of C, 0.15 to 0.40 percent of Si, 0.90 to 1.60 percent of Mn, less than 0.01 percent of P, less than 0.01 percent of S, 0.10 to 0.80 percent of Ni, 0.1 to 0.5 percent of Mo, 0.0008 to 0.0015 percent of B, 0.01 to 0.06 percent of microalloy element Nb, 0.01 to 0.07 percent of V, 0.01 to 0.03 percent of Ti and the balance of Fe; the thick steel plate is produced by soft reduction technology in a continuous casting process under the condition that a compression ratio is less than 4.0; and by a heat treatment process which comprises the steps of quenching, quenching and tempering, the texture of the steel plate after double quenching is controlled to be a hybrid texture with a hard phase and a soft phase, and the requirements on steel plate strength and low-temperature toughness are met at the same time. Under a small compression ratio, the thick steel plate has the performance equivalent to that of a thin steel plate by the combination of the heat treatment process and texture control; and compared with the methods such as die casting, forging and the like, the method is simple and feasible, and has high yield and low production cost.

Owner:SHOUGANG CORPORATION

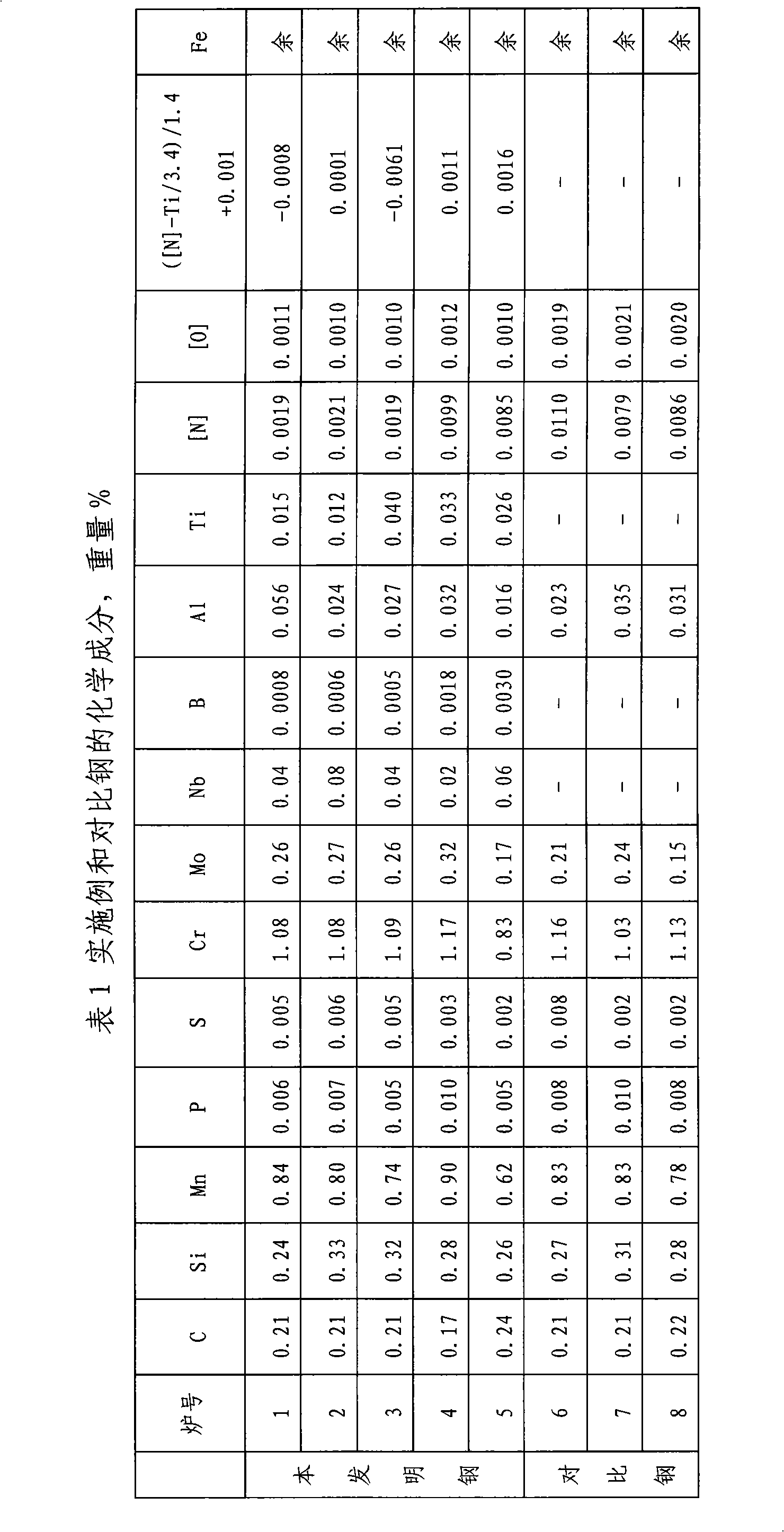

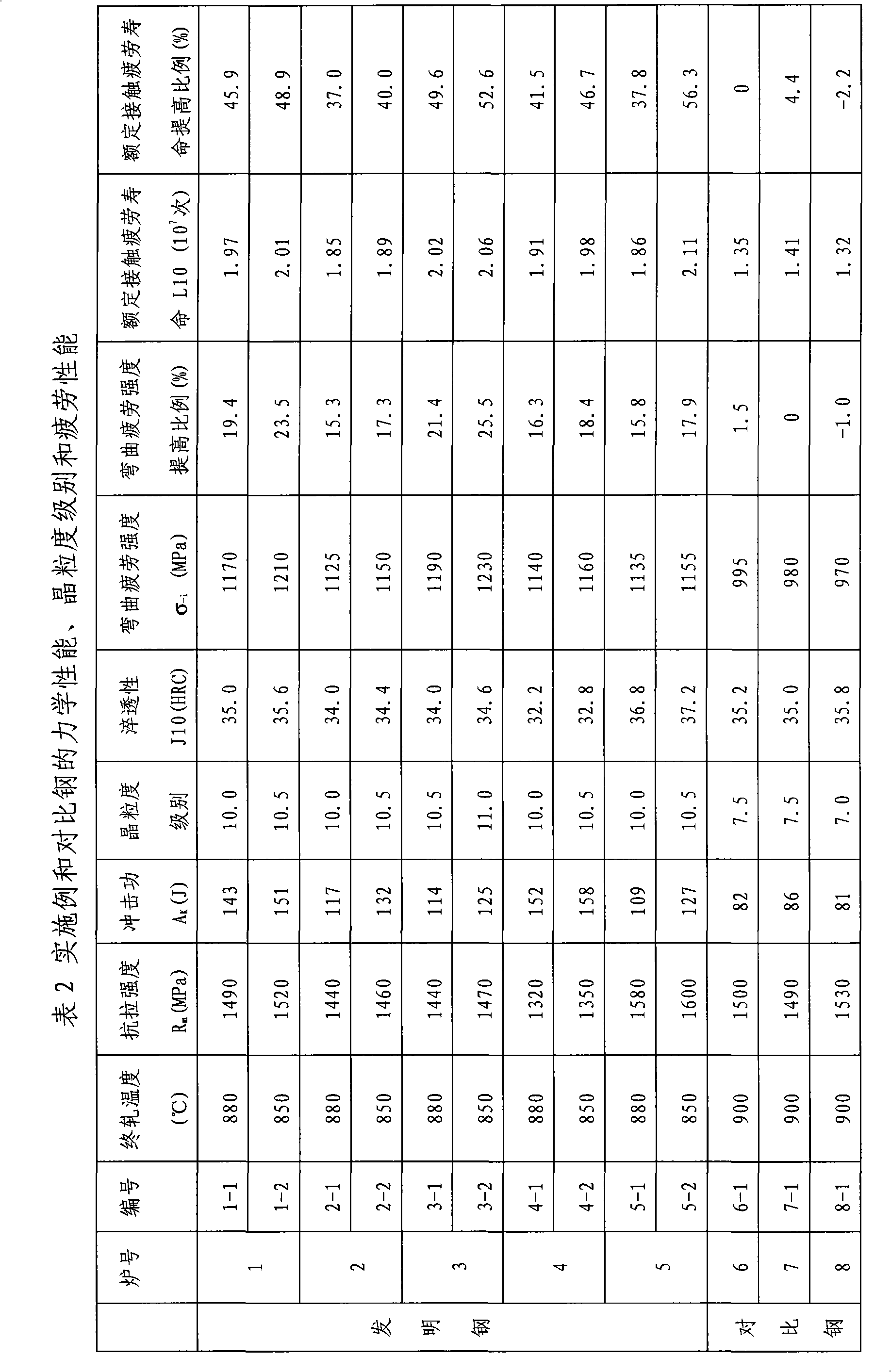

Steel for fine grain carburizing gear and method of manufacturing the same

The invention belongs to the alloy steel field, particularly relating to steel for a fine grain carburization gear and a preparation method thereof. The steel comprises the following chemical compositions in weight percentage: 0.15 to 0.25 percent of C, less than or equal to 0.35 percent of Si, 0.60 to 0.90 percent of Mn, less than or equal to 0.015 percent of P, less than or equal to 0.010 percent of S, 0.80 to 1.20 percent of Cr, 0.15 to 0.35 percent of Mo, 0.02 to 0.08 percent of Nb, 0.0005 to 0.0035 percent of B, 0.02 to 0.06 percent of Al, 0.01 to 0.04 percent of Ti, less than or equal to 0.015 percent of [N], less than or equal to 0.0015 percent of [O], the balance being Fe and inevitable impurities. Meanwhile, Ti is more than or equal to 2[N] and B is more than or equal to ([N] minus Ti / 3.4) / 1.4 plus 0.001; and the rolling production process with the finish-to-gage temperature below 900 DEG C is adopted. Compared with the prior carburization gear steel 20CrMoH, the grain size of the steel after carburizing and quenching exceeds ten grade, the bending fatigue resistance(sigama-1) is improved by more than 15 percent and the contact fatigue life(L10) is improved by more than 30 percent.

Owner:CENT IRON & STEEL RES INST

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com