Epoxy-resin mould plastic for packing IC circuit and its production

A technology of epoxy resin and phenolic epoxy resin, used in circuits, electrical components, electrical solid devices, etc., can solve the problems of unsatisfactory packaging materials, and achieve good processability, low water absorption, and high glass transition temperature. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0052] formula:

[0053] Liquid crystal epoxy resin 10 parts

[0054] 10 parts o-cresol novolac epoxy resin

[0055] 5 parts of epoxy resin containing biphenyl structural unit

[0056] 15 parts of melamine modified novolac resin

[0057] Silica powder (quartz powder) 150 parts

[0058] Curing accelerator 2-methylimidazole 0.5 parts

[0059] Toughener CTBN 6 parts

[0060] Coupling agent KH-560 1.5 parts

[0061] 0.8 parts of stearic acid

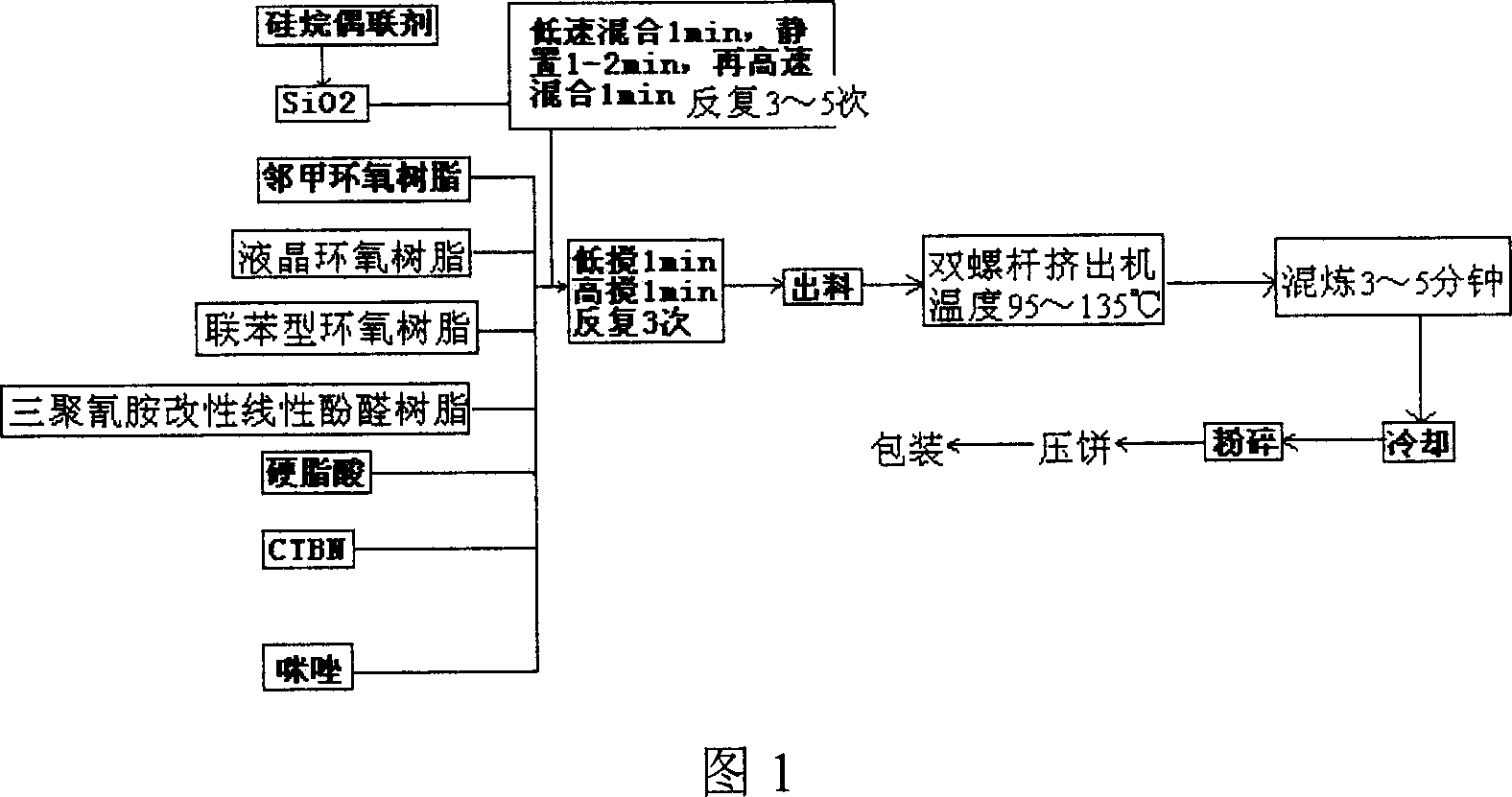

[0062] The process is shown in Figure 1.

[0063] project

Embodiment 2

[0065] formula:

[0066] Liquid crystal epoxy resin 8 parts

[0067] 16 parts o-cresol novolac epoxy resin

[0068] 3 parts of epoxy resin containing biphenyl structural unit

[0069] 20 parts of melamine modified novolac resin

[0070] Silica powder (quartz powder) 150 parts

[0071] Curing accelerator 1-cyanoethyl-2-methylimidazole 0.4 parts

[0072] Toughener CTBN 5 parts

[0073] Coupling agent KH-560 1.5 parts

[0074] 0.6 parts of stearic acid

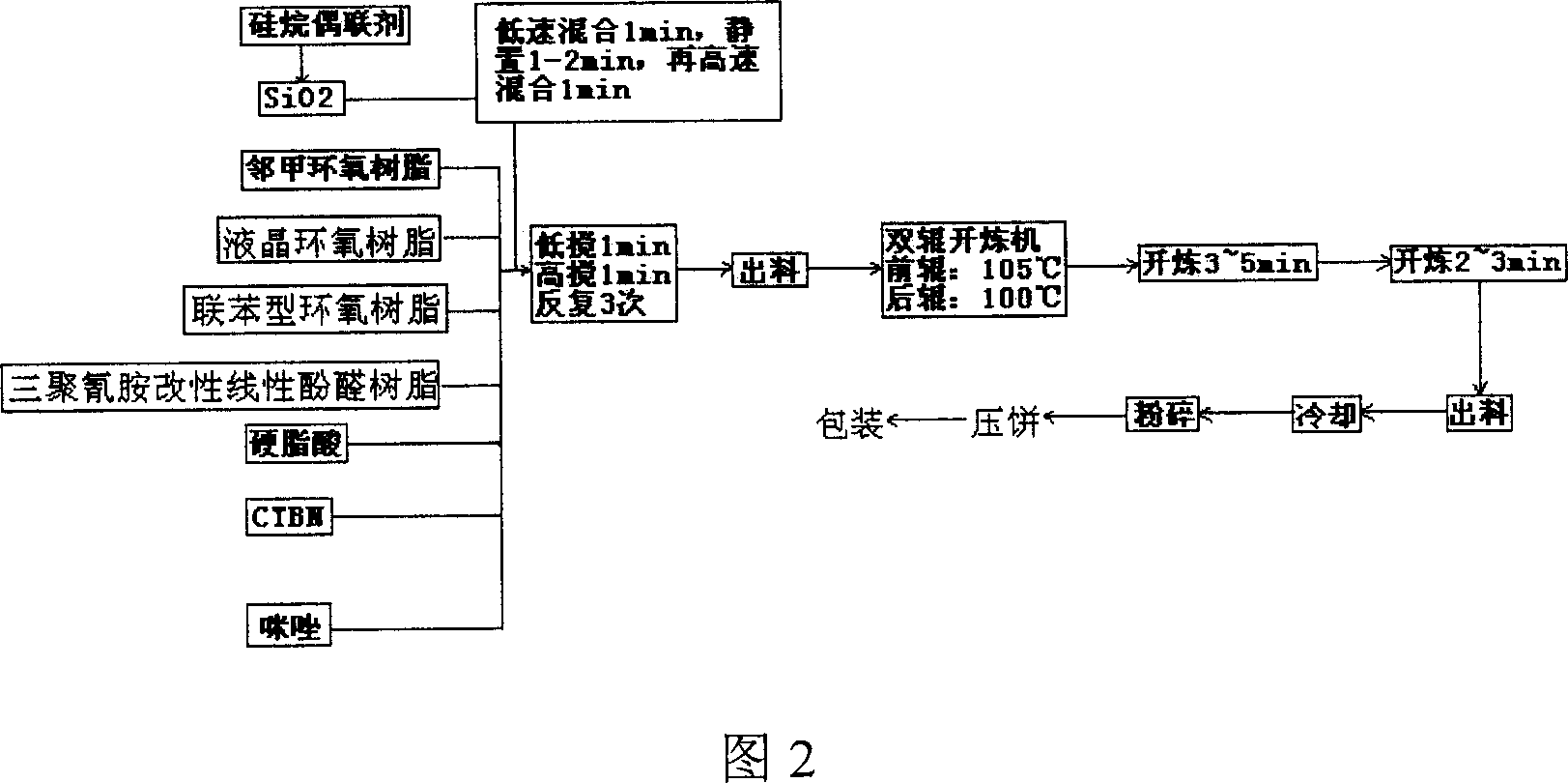

[0075] The process is shown in Figure 2.

[0076] project

Embodiment 3

[0078] formula:

[0079] Liquid crystal epoxy resin 15 parts

[0080] 8 parts o-cresol novolak epoxy resin

[0081] 10 parts of epoxy resin containing biphenyl structural unit

[0082] 15 parts of melamine modified novolac resin

[0083] Silica powder (quartz powder) 180 parts

[0084] Curing accelerator 2-methylimidazole 0.8 parts

[0085] Toughener CTBN 5 parts

[0086] Coupling agent KH-560 1.8 parts

[0087] 0.8 parts of stearic acid

[0088] The process is shown in Figure 1.

[0089] project

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| heat deflection temperature | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com