Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

11011 results about "Melamine" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

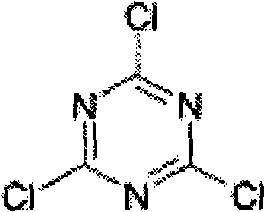

Melamine /ˈmɛləmiːn/ is an organic compound with the formula C₃H₆N₆. This white solid is a trimer of cyanamide, with a 1,3,5-triazine skeleton. Like cyanamide, it contains 67% nitrogen by mass, and its derivatives have fire retardant properties due to its release of nitrogen gas when burned or charred. Melamine can be combined with formaldehyde and other agents to produce melamine resins. Such resins are characteristically durable thermosetting plastic used in high pressure decorative laminates such as Formica, melamine dinnerware, laminate flooring, and dry erase boards. Melamine foam is used as insulation, soundproofing material and in polymeric cleaning products, such as Magic Eraser.

Fire retardant compositions and methods for preserving wood products

Wood preservative compositions are disclosed. Treatment of lumber, plywood, and other wood products with a novel composition comprising the boron source composition, a melamine binder resin, and a urea casein activator resin protects lumber, plywood, and other wood products from attack by termites, fungi, fire and flame. The preservative can be formed by combining a source of boron such as boric acid and the water-soluble salts thereof, a melamine binder resin, and a urea casein resin. A wood preservative is characterized by a weight ratio of the urea casing activator resin to the melamine binder resin ranging from about 1:20 to 1:4 and a weight ratio of the boron source composition to the melamine binder resin ranging from about 1.3:1 to 9.6:1.

Owner:LOPEZ RICHARD A

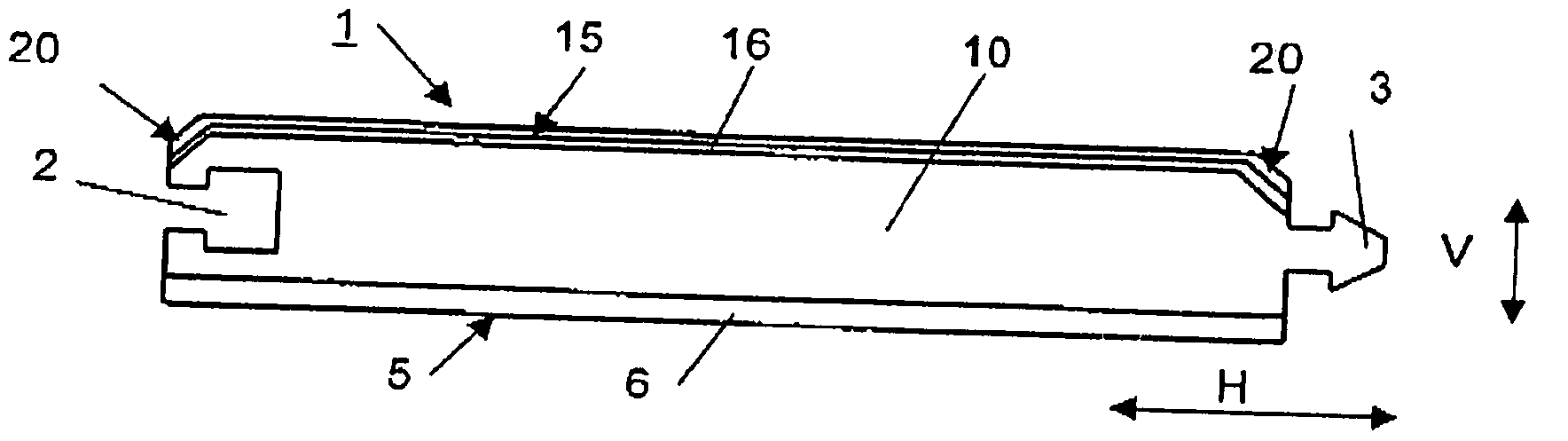

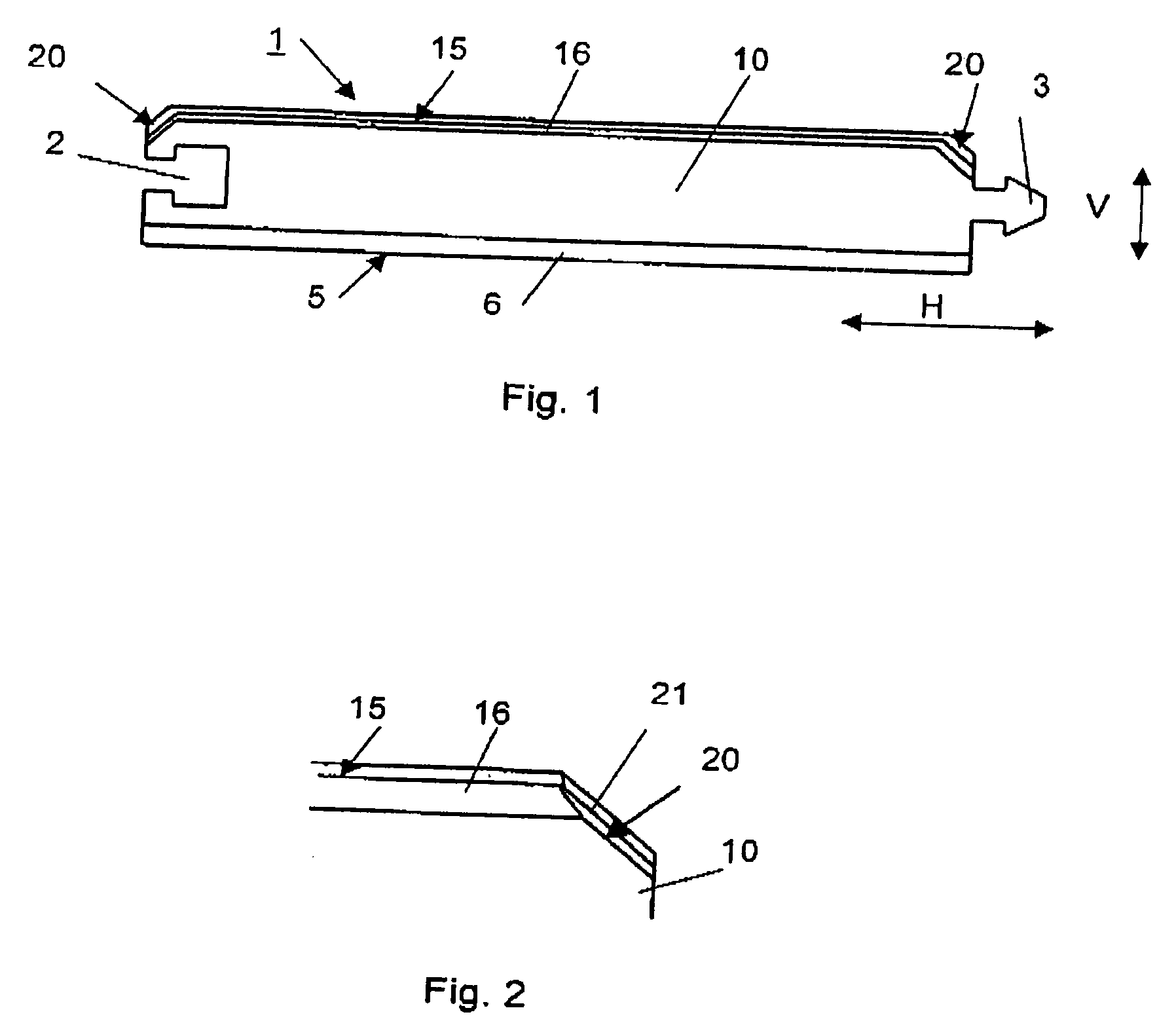

Flooring panel

A panel, in particular a flooring panel, of a wood material which is provided with a mechanism for the detachable connection of a least two panels, whereby form-fitting elements for locking in the vertical direction and in the horizontal direction with another panel are embodied on at least one lateral edge of a first panel, whereby a chamfer is embodied on at least one lateral edge starting from an upper side. The chamfer or the form-fitting elements are coated or impregnated with at least one melamine layer.

Owner:KRONOTEC

Flame retardant resin compositions

This invention relates to flame retardants for polyester and polyamide compositions, and specifically relates to compositions containing (1) about 30 to about 70 weight percent of a polyester or a synthetic, aliphatic polyamide and synthetic aliphatic, aromatic polyamide copolymers or a mixture thereof; (2) about 15 to about 40 weight percent of glass or mineral reinforcing agent; and (3) a flame retardant of (a) about 5 to about 45 weight percent of melamine polyphosphate; (b) about 15 to about 30 weight percent of melamine polyphosphate and up to about 10 weight percent of a charring catalyst; (c) about 15 to about 30 weight percent of melamine polyphosphate, up to about 10 weight percent of a charring catalyst and up to about 10 weight percent of a char former, wherein all percents by weight are based on the total weight of (1)+(2)+(3) only.

Owner:EI DU PONT DE NEMOURS & CO

Fluoropolymer coated films useful for photovoltaic modules

ActiveUS20070154704A1Strong adhesionIncreased durabilitySynthetic resin layered productsRecord information storageEpoxyPolymer science

A fluoropolymer coated film comprising polymeric substrate film and fluoropolymer coating on the polymeric substrate film. The fluoropolymer coating comprises fluoropolymer selected from homopolymers and copolymers of vinyl fluoride and homopolymers and copolymers of vinylidene fluoride polymer blended with compatible adhesive polymer comprising functional groups selected from carboxylic acid, sulfonic acid, aziridine, anhydride, amine, isocyanate, melamine, epoxy, hydroxy, anhydride and mixtures thereof. The polymeric substrate film comprises functional groups on its surface that interact with the compatible adhesive polymer to promote bonding of the fluoropolymer coating to the substrate film.

Owner:DUPONT ELECTRONICS INC

Method for preparing C/SiC composite material through low-cost fused silicon impregnation method

The invention relates to a method for preparing a C / SiC composite material through a low-cost fused silicon impregnation method, which comprises the following steps: performing calcining pretreatment on a carbon felt or graphite felt at 400-600 temperature; immersing the pretreated carbon felt or graphite felt in a melamine and boric acid solution, thus coating a boron nitride protective layer; immersing in a carbon / silicon carbide slurry water solution, performing impregnation to ensure that pores of the carbon felt or graphite felt are fully filled with carbon / silicon carbide, placing in a sintering furnace, and performing primary fused silicon impregnation treatment at 1600-1800 DEG C; immersing in liquid phenolic resin, and performing carbonization treatment under the protection of an inert atmosphere at 800-1000 DEG C to ensure that all the resin is carbonized; and finally, performing secondary fused silicon impregnation treatment to ensure that carbon produced by carbonization of the resin totally reacts with silicon to generate silicon carbide, thus obtaining the C / SiC composite material. The obtained C / SiC composite material is high in density, low in air pore and free silicon content, and favorable in material strength, toughness and frictional wear performance, and can be used for manufacturing of brake pads.

Owner:山东宝纳新材料有限公司

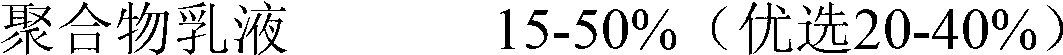

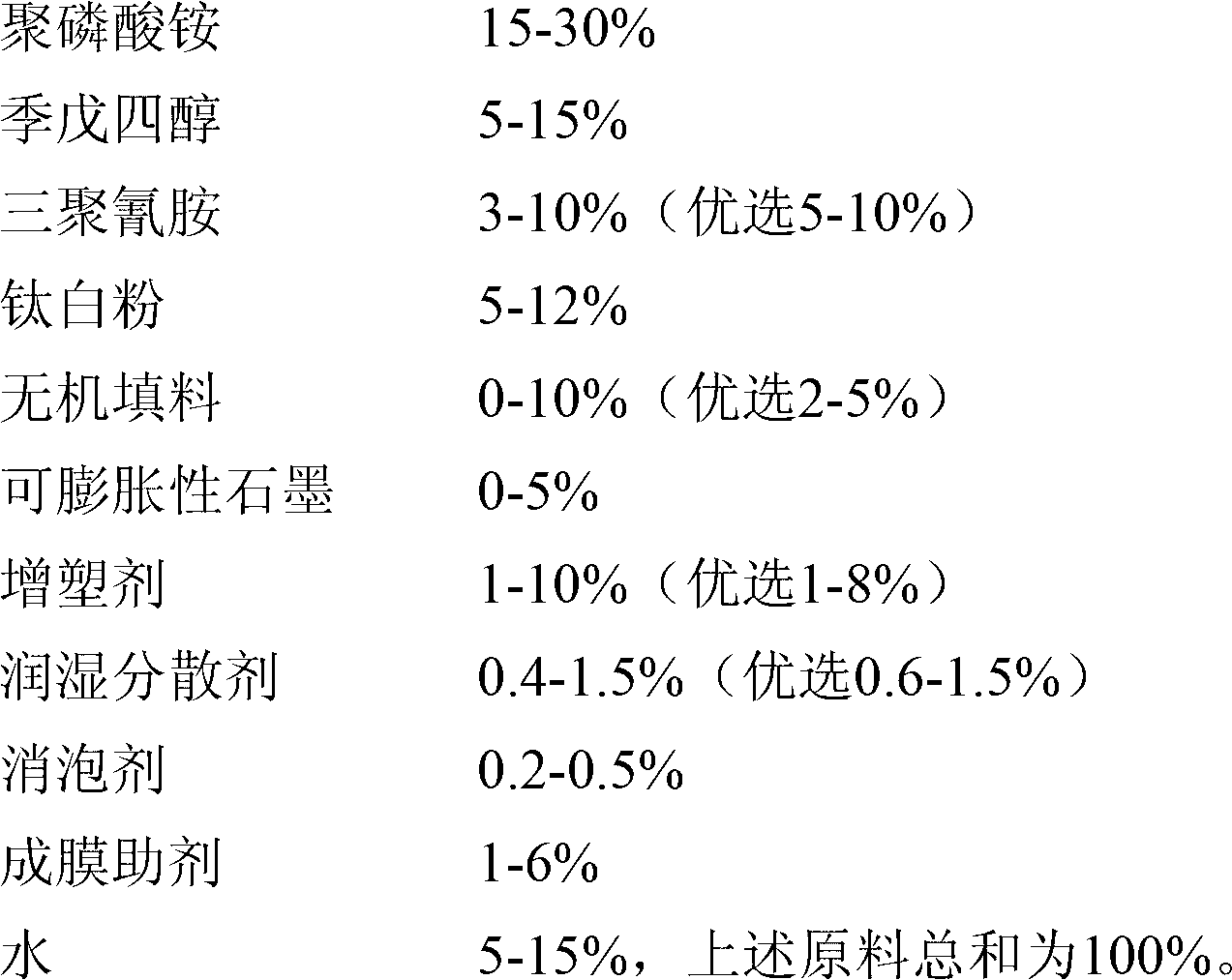

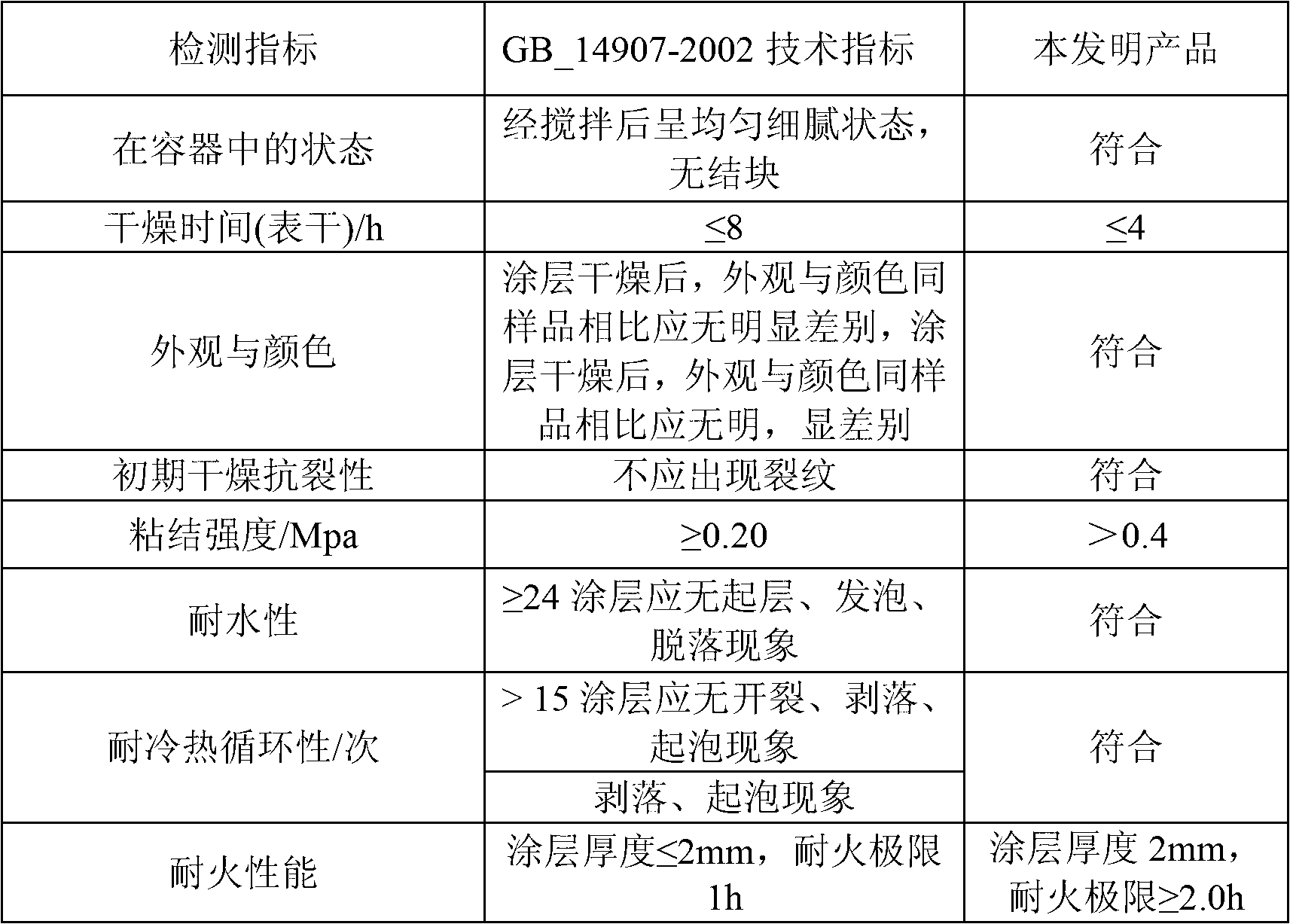

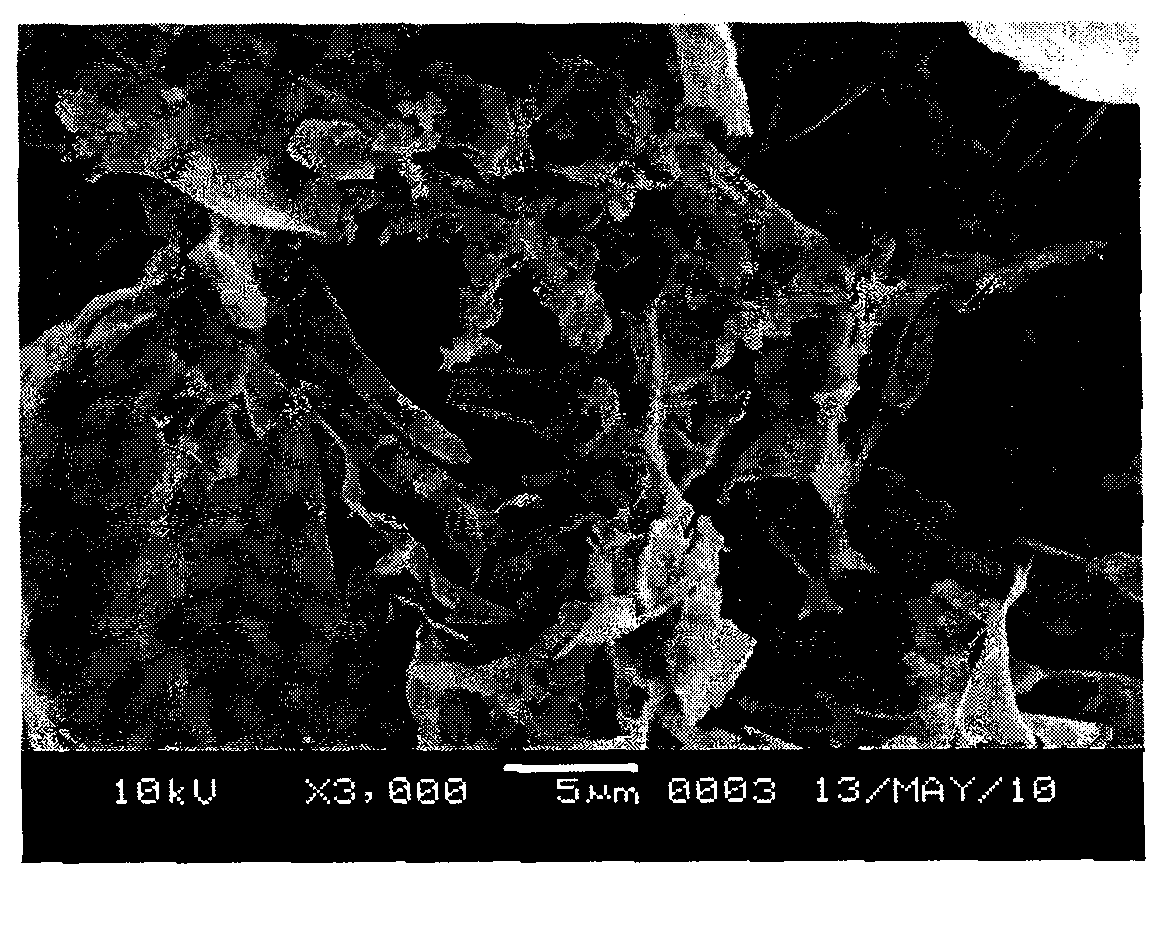

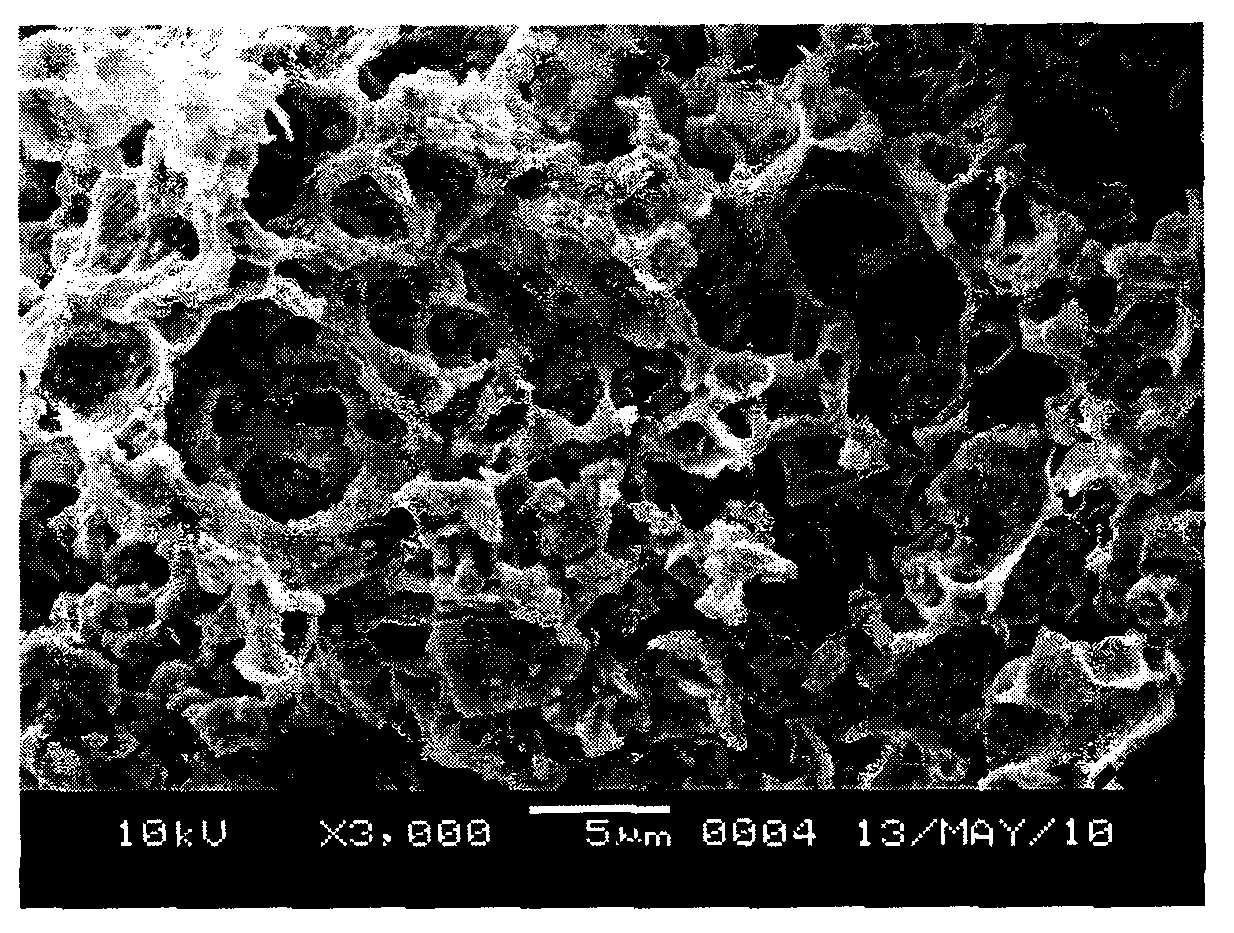

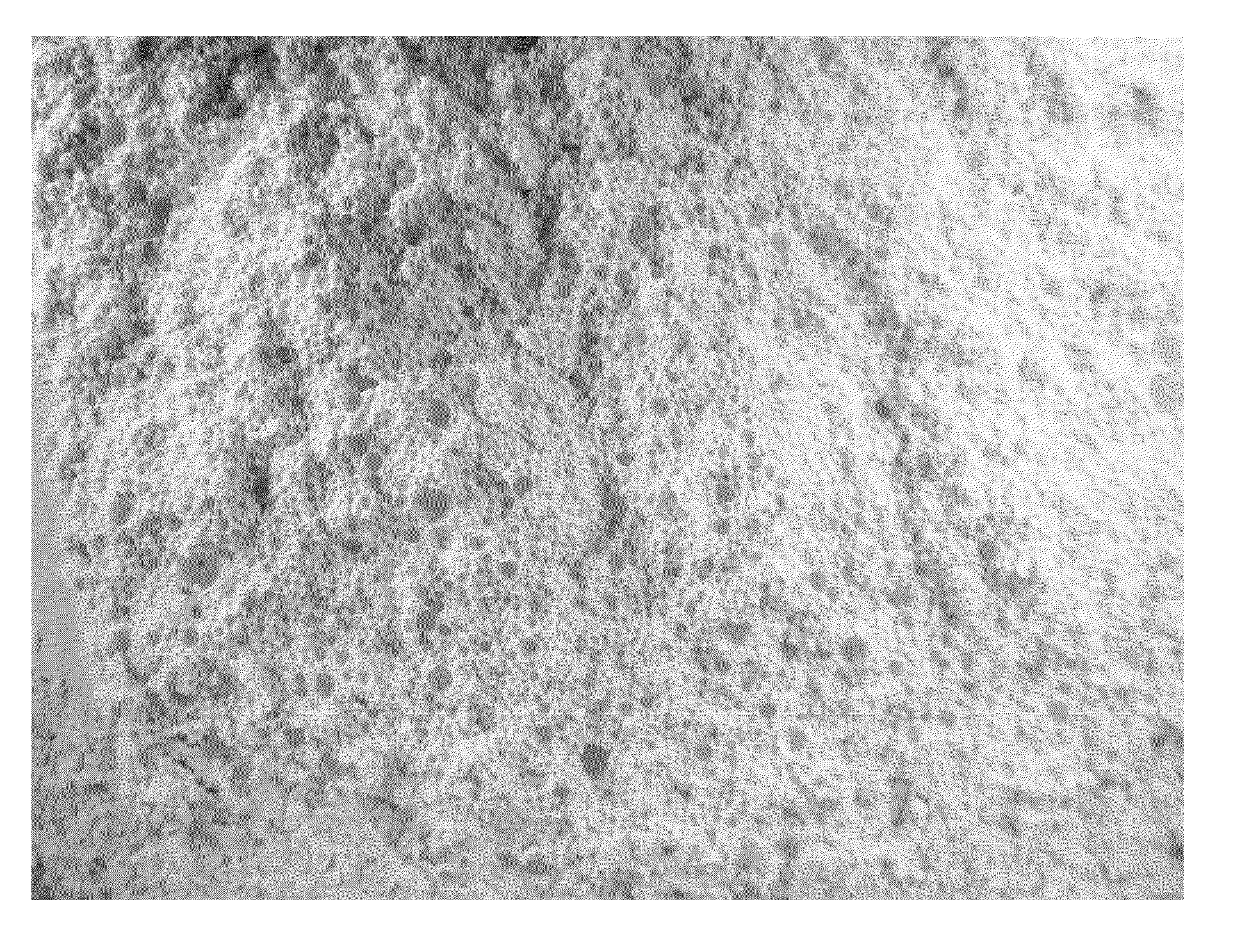

Waterborne ultra-thin steel structure fire retardant coating and preparation method thereof

ActiveCN102838907AGood foaming effectThe pores are small and uniformFireproof paintsCarbonizationMaterials science

Provided is a waterborne ultra-thin steel structure fire retardant coating and a preparation method thereof. The raw material ratio of the coating includes 15-50% by weight of polymer latex, 15-30% by weight of ammonium polyphosphate, 5-15% by weight of pentaerythritol, 3-10% by weight of cyanurtriamide, 5-12% by weight of titanium dioxide, 2-13% inorganic filler, 0-5% by weight of expansiveness graphite, 1-10% by weight of plasticizer, 0.4-1.5% by weight of wetting dispersant, 0.2-0.5% by weight of defoamer, 1-6% by weight of coalescing agents and 5-15% by weight of water, and total raw material ratio is 100%. A high-speed dispersion method or a grinding dispersion method is adopted in preparation of the coating. A coating layer of the fire retardant coating can form a carbonization layer which is good in foaming effect, small and uniform in air holes and high in expansion times when in heating. The final fire retardant performance of the coating is far higher than technical requirements of a national standard. The waterborne ultra-thin steel structure fire retardant coating is a waterborne coating product, is non-poisonous and odorless and environment-friendly, and can be coated in a mode of brushing or spraying or roller coating.

Owner:SOUTH CHINA UNIV OF TECH +1

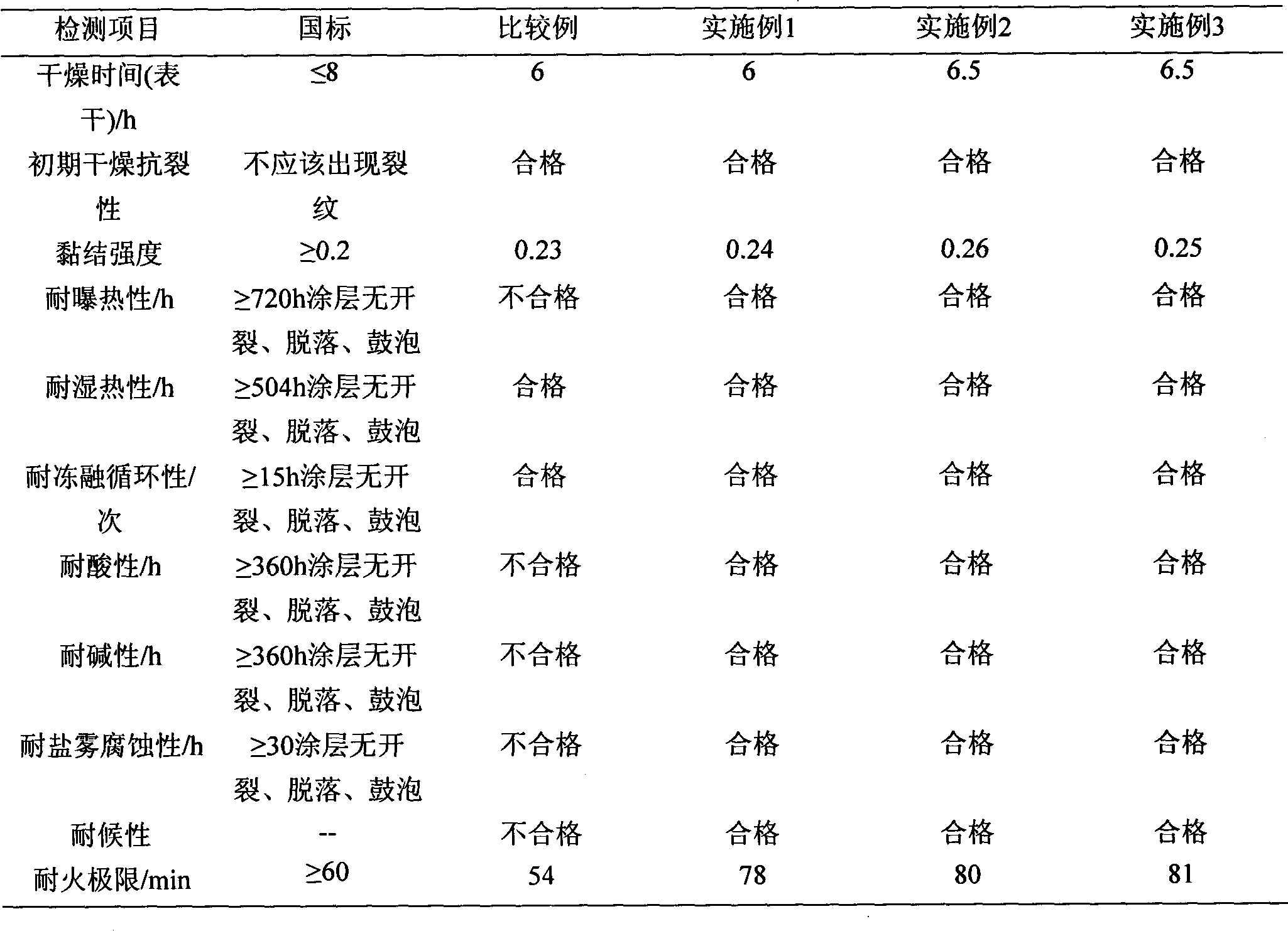

Aqueous ultra-thin expansion type steel structure fire-proof anti-corrosive paint and preparation method thereof

InactiveCN101857760AGuaranteed expansion heightHas anti-rustFireproof paintsAnti-corrosive paintsAcrylic resinRust

The invention relates to an aqueous ultra-thin expansion type steel structure fire-proof anti-corrosive paint and a preparation method thereof. The fire-proof anti-corrosive paint is prepared by adding ammonium polyphosphate, pentaerythritol, melamine, titanium white, expandable graphite, a preservative, a ceramic filler, an antifoaming agent, a dispersing agent, a plasticizer and the like into organic silicon-modified acrylic resin emulsion serving as a film forming base material. The paint has the advantages of high fire-proof performance, anti-corrosion and anti-rust function, and high water resistance, acid-alkali resistance and corrosion resistance, capability of meeting the requirements of various steel structures on the fire-proof and anti-corrosion performance, environmental friendliness, low cost, and readily available raw materials, so the paint can be widely applied to fire-proof protection of various steel structures.

Owner:EAST CHINA UNIV OF SCI & TECH

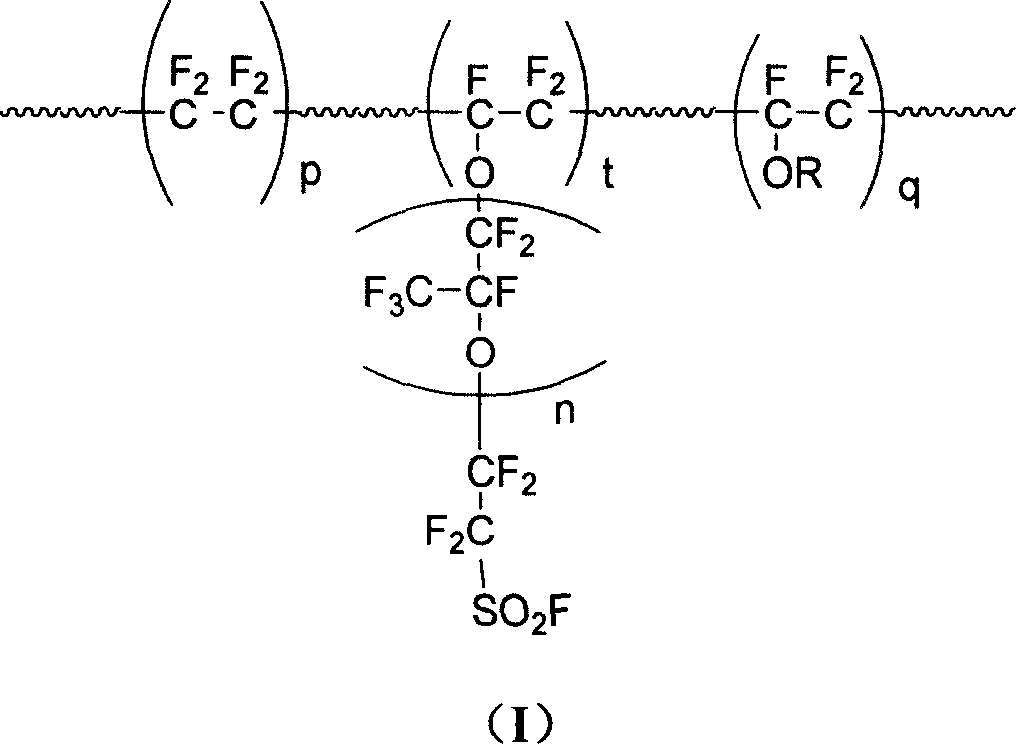

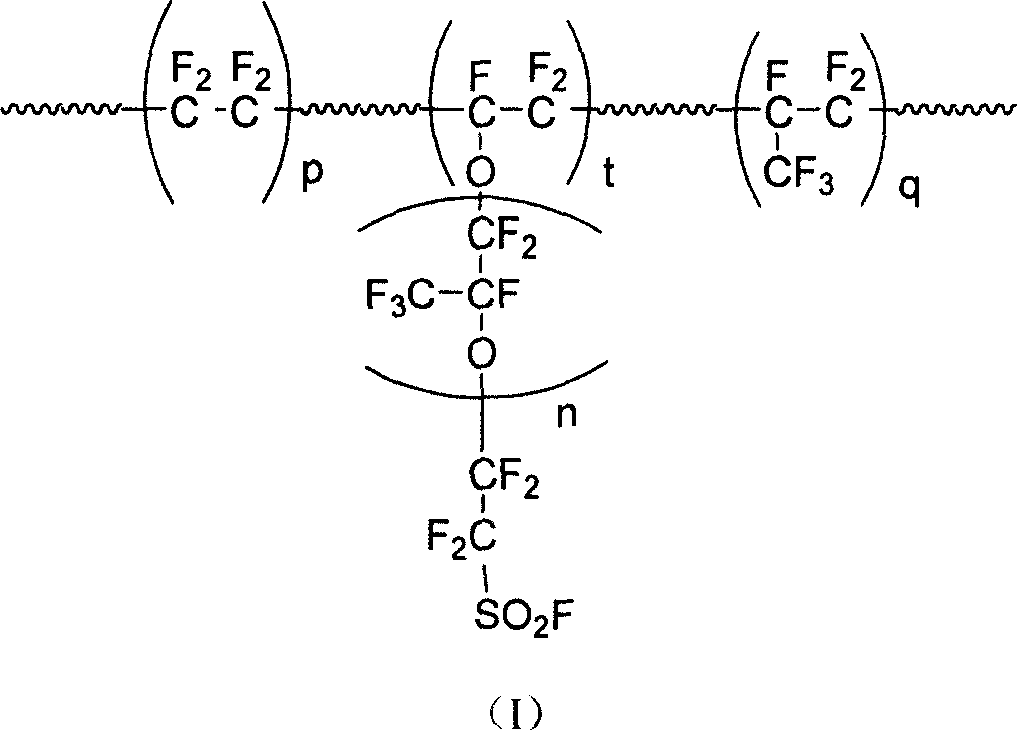

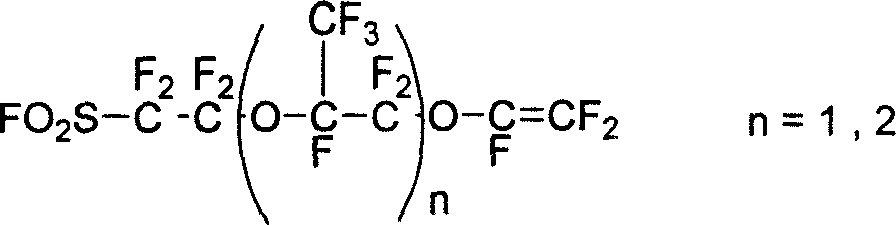

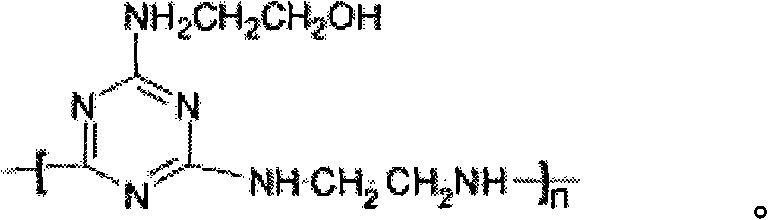

Polymer of containing fluorin, and application as material of ion exchange fiber

InactiveCN101003588AIncrease the effective areaLower resistanceMelt spinning methodsVinyl etherAlkali ions

This invention discloses a fluorine-containing polymer and its application as ion exchange fiber material. The fluorine-containing polymer is a perfluoro resin containing sulfonylfluoride groups, and is shown in formula 1. The fluorine-containing polymer has ion exchange function, and is prepared by free radical copolymerization of perfluorosulfonyl vinyl ether, tetrafluoroethylene and hexafluoropropylene in the presence of dispersant, solvent and initiator. The dispersant / solvent is mixed solution of melamine derivative containing linear perfluoro hydrocarbon and water. The fluorine-containing polymer can be melt-spun into polymer fibers, which can be woven into fiber network that can be used as the reinforcing network material for ion exchange membranes and chlor-alkali ion membrane to reinforce and improve the ion exchange ability.

Owner:SHANDONG HUAXIA SHENZHOU NEW MATERIAL

Additives in gypsum panels and adjusting their proportions

ActiveUS20110054053A1Good effectMinimizes set retardationAntifouling/underwater paintsPaints with biocidesSulfonateSide chain

A panel is provided that includes stucco, water and a dispersant component having dispersing properties and comprising a comb-branched polymer with polyether side chains, naphthalene sulfonate-formaldehyde condensate or melamine sulfonate-formaldehyde condensate. A polycondensation component is also included in the slurry that includes three repeating units. A method of making the gypsum panel includes combining stucco, water and a first dosage of a first dispersant to form a slurry, the first. A second dosage of a second dispersant is added to the slurry. Properties of the gypsum slurry are tested and it is formed into a product. The product sets and properties of the product are identified. The first dosage or the second dosage is changed based on the properties of the slurry or product.

Owner:UNITED STATES GYPSUM CO

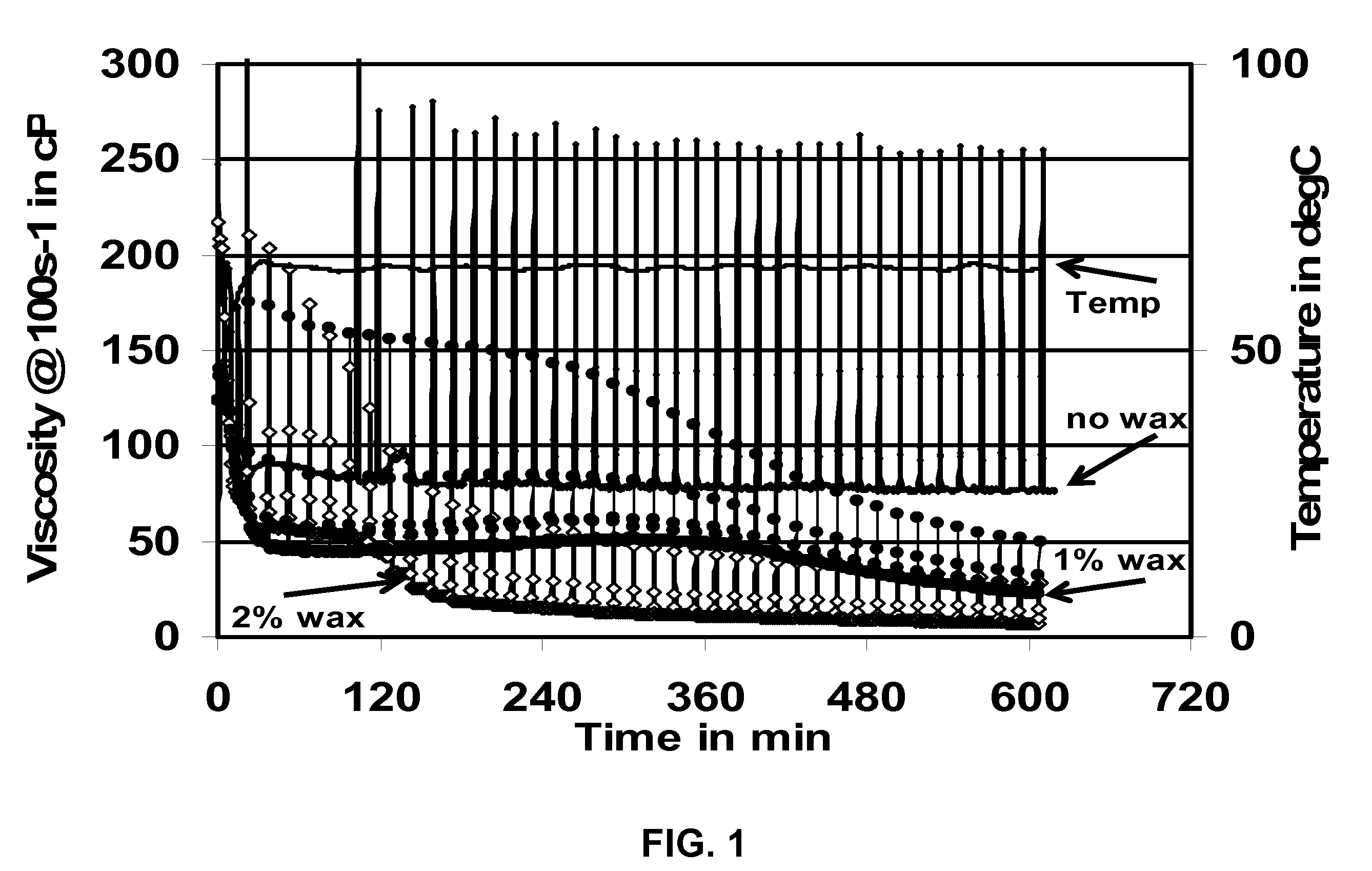

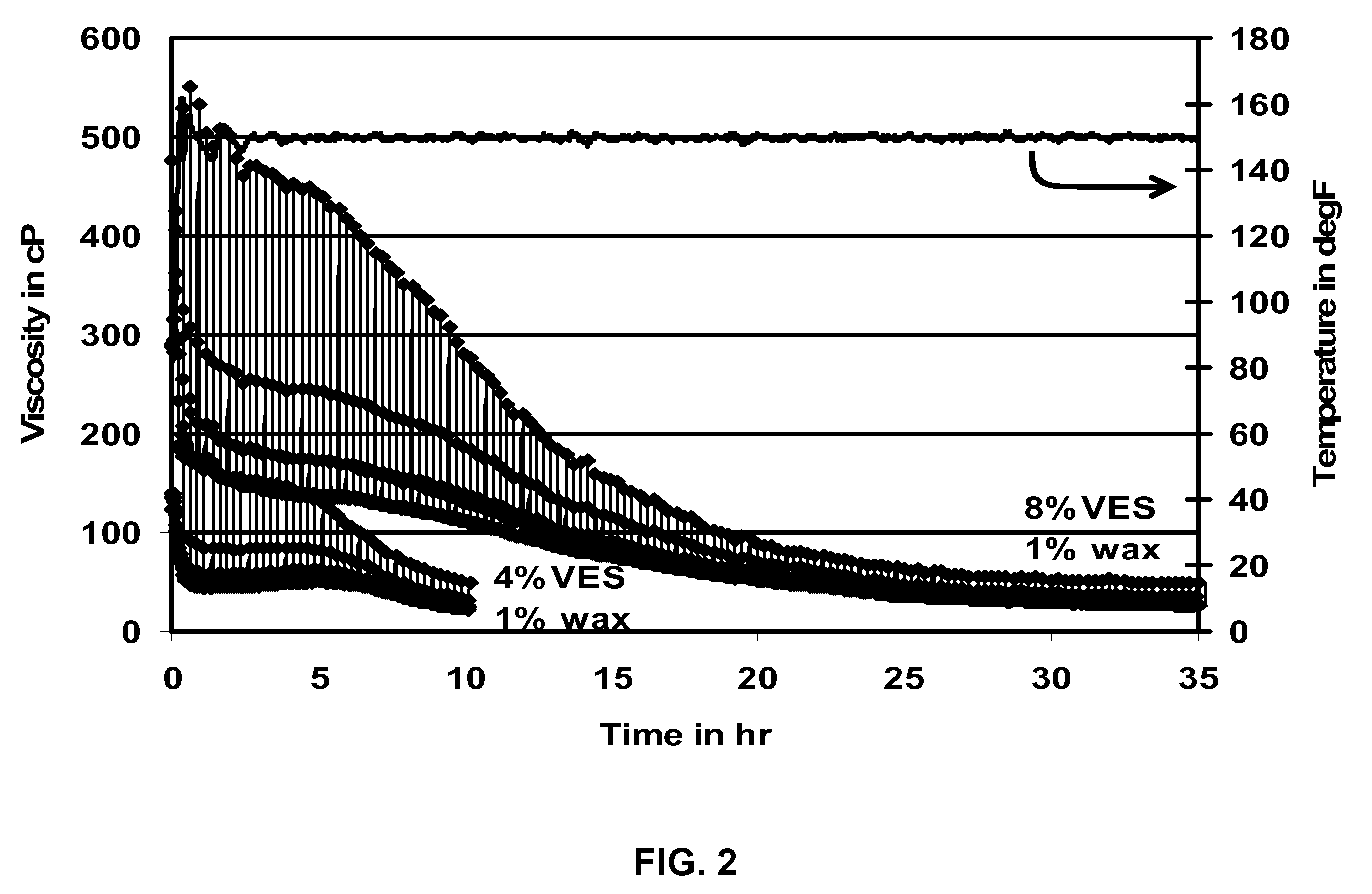

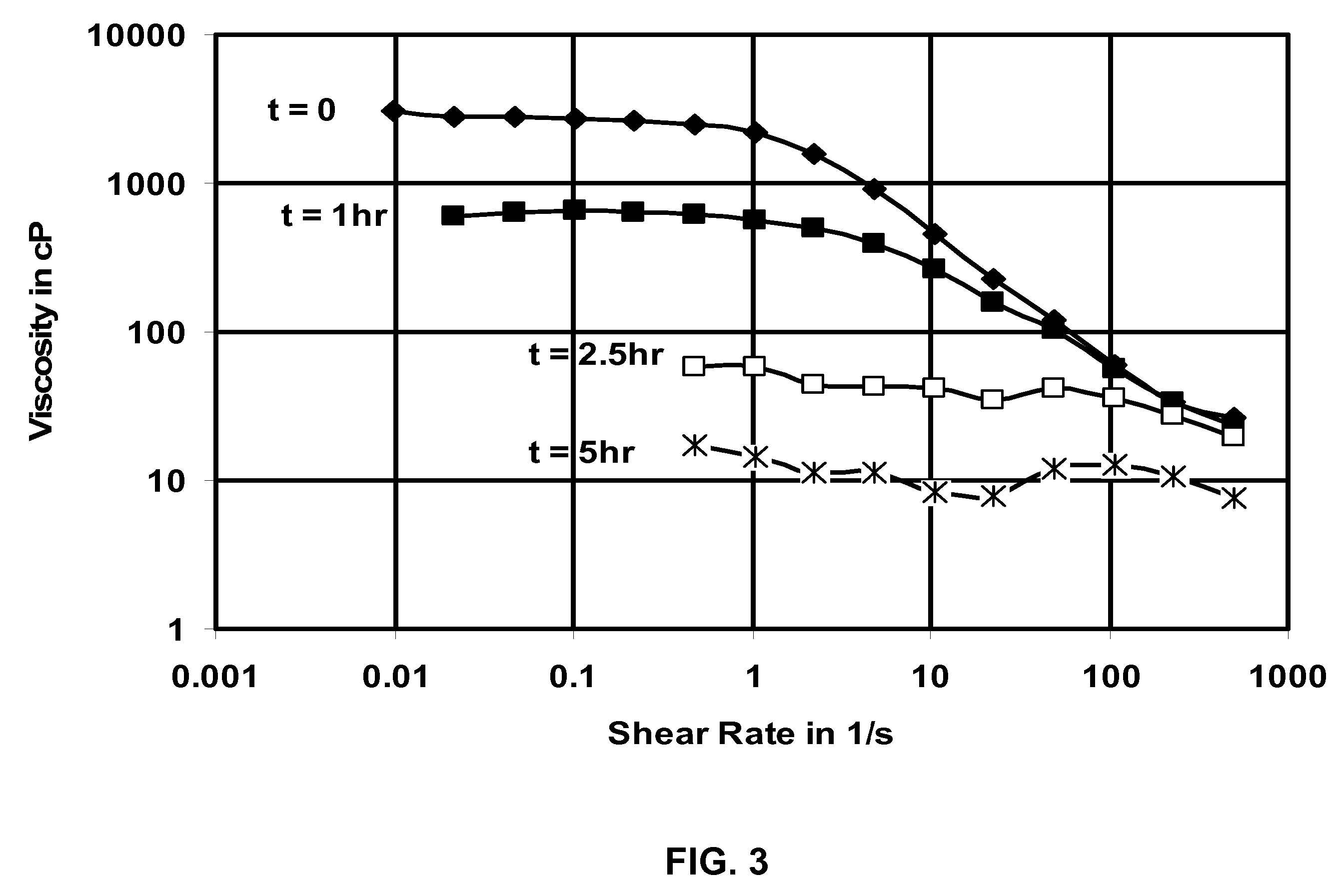

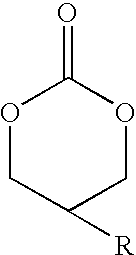

Internal Breaker for Oilfield Treatments

A composition and method for improving the fluid efficiency of many oilfield treatments is given. The composition is a solid additive, in a viscosified fluid, in a size range small enough that it enters formation pores; it optionally bridges there to form an internal filter cake, and then decomposes to provide a breaker for the viscosifying system for the fluid. Examples of suitable additives include waxes, polyesters, polycarbonates, polyacetals, polymelamines, polyvinyl chlorides, and polyvinyl acetates. Degradation of the additive may be accelerated or delayed.

Owner:SCHLUMBERGER TECH CORP

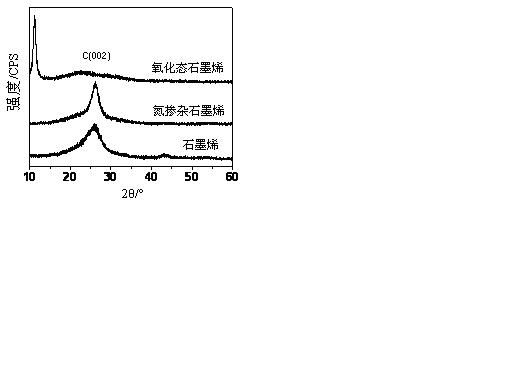

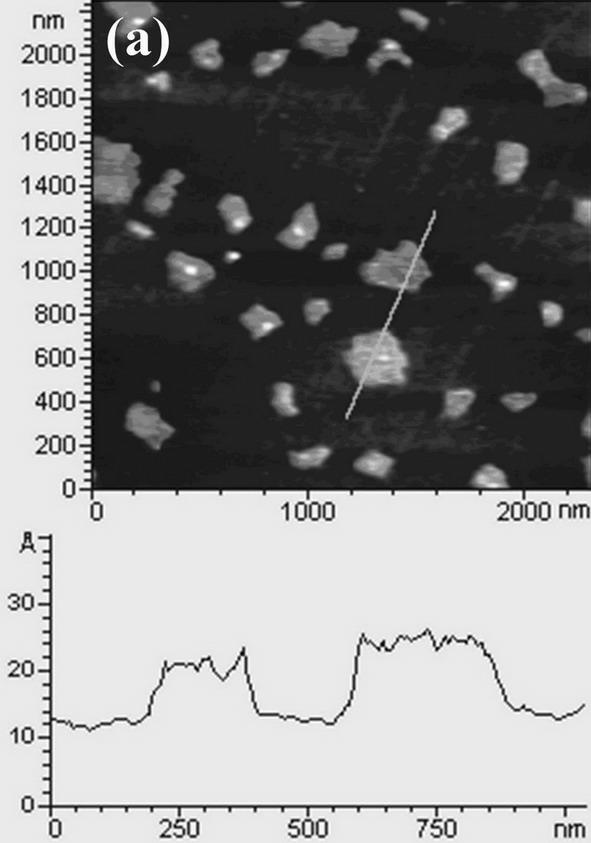

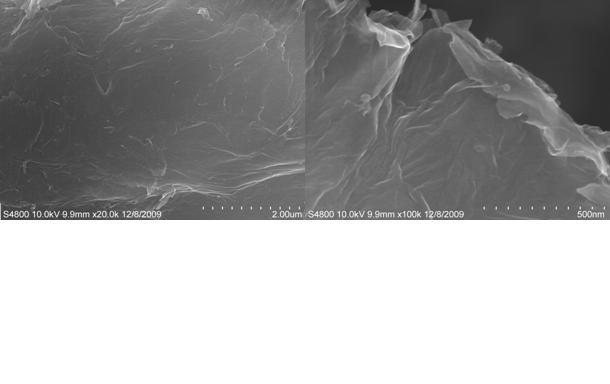

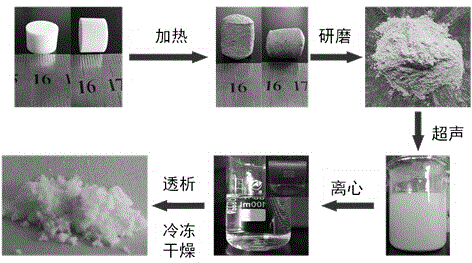

Method for preparing nitrogen-doped graphene

The invention relates to a method for preparing nitrogen-doped graphene, in particular to a novel simple, convenient and scale method for preparing nitrogen-doped graphene at high temperature under the protection of inert gas by taking melamine as a nitrogen source. In the method, graphene oxide and the melamine are taken as raw materials, wherein the melamine is taken as the nitrogen source and the graphene oxide is taken as a carbon source; high temperature annealing is carried out in the atmosphere of inert gas, and the reduction of the graphene oxide and the nitrogen doping of graphene are realized; and by controlling reaction conditions such as temperature, time, the ratio of the raw materials and the like, graphene products with different nitrogen doping ratios can be prepared. The preparation method is simple and practicable; catalysts are not needed; the reaction process is easy to control; special requirements on equipment do not exist; the cost is low; and the method is easy to promote and use.

Owner:NANJING UNIV

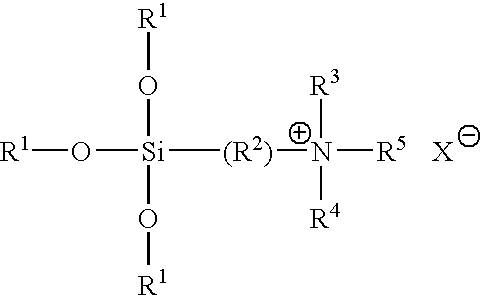

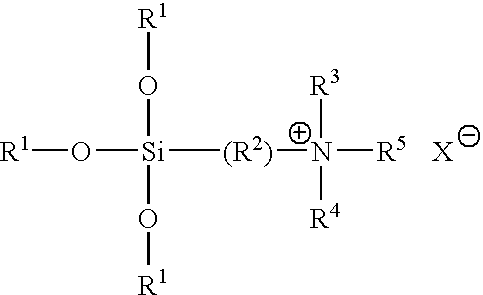

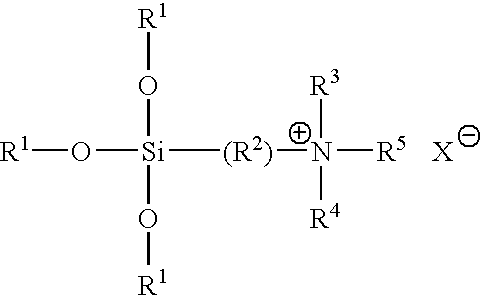

Cleaning and multifunctional coating composition containing an organosilane quaternary compound and hydrogen peroxide

ActiveUS6994890B2Improved bonding and durabilitySilicon organic compoundsCationic surface-active compoundsPolyesterSilicon dioxide

Cleaning and multifunctional coating compositions containing hydrogen peroxide and an organosilane quaternary compound in aqueous formulations are used to improve water and soil repellency and residual antimicrobial activity. Various surfaces may be treated including metal, glass, plastics, rubber, porcelain, ceramic, marble, granite, cement, tile, sand, silica, enameled appliances, polyurethane, polyester, polyacrylic, melamine / phenolic resins, polycarbonate, siliceous, painted surfaces, wood, and the like.

Owner:RESOURCE DEV LLC

High solids clear coating composition

InactiveUS6544593B1Good weather resistancePerformance requirementPretreated surfacesPolyurea/polyurethane coatingsAlcoholAutomotive coating

The present invention provides for an etch and mar resistant low VOC clear coating composition most suitable for use as a top clear coat in multi-layered OEM or refinish automotive coatings. The coating composition includes isocyanate, carbonate and melamine components. The isocyanate component includes an aliphatic polyisocyanate. The composition may be formulated as a two-pack or one-pack coating composition, wherein the isocyanate functionalities are blocked with a blocker such as a mono-alcohol.

Owner:EI DU PONT DE NEMOURS & CO

Concrete super instant coagulant

The invention discloses a concrete early-strength agent, which is characterized in comprising the following components according to weight percentage: inorganic salt early-strength component 35-55 percent, organic early-strength component 5-10 percent, water reducing component 15-25 percent, wherein the inorganic salt early-strength component is prepared by at least two among sulfate, carbonate, nitrate, and nitrite; the organic early-strength component selects any one among calcium formate, sodium acetate, calcium oxalate, triethanolamine, tri-iso-propanolamine and carbamide; the water reducing component selects one among naphthalenesulfuric acid type, melamine type and polycarboxylate type. The invention makes the concrete be coagulated and hardened rapidly under the condition of low temperature, so that the early strength of the concrete is greatly improved as well as later strength is ensured.

Owner:ZHONGYIFENG CONSTR GRP +1

Preparation method for multi-hole carbon nitride photocatalytic material doped with sulphur

InactiveCN103861632AReduce pollutionGood repeatabilityPhysical/chemical process catalystsHydrogen productionSurface-active agentsSolvent

The invention discloses a preparation method for a multi-hole carbon nitride photocatalytic material doped with sulphur, belonging to the technical field of synthesis of photocatalytic materials. The preparation method comprises the following steps of preparing a super-molecule polymer through simple hydro-thermal treatment by taking melamine and trithiocyanuric acid as a raw material and taking water as a solvent, and burning in an inert atmosphere so as to obtain a three-dimensional network sulphur-doped multi-hole carbon nitride photocatalytic material. The preparation method provided by the invention has the advantages that simplicity and easiness in preparation are achieved, a method for burning a super-molecule polymer is adopted, any template agent and a surface active agent do not need to be added, a reaction system is simplified, the cost is low, the pollution of a reagent is slight, the reaction repeatability is good, a preparation condition is mild, the time consumption of a synthetic process is short, and the requirement on equipment is high; the multi-hole carbon nitride photocatalytic material doped with sulphur has excellent catalytic activity in a catalyzing hydrogen production reaction, and the hydrogen production rate of the material is 8.3 times and 5.2times that of a product obtained by burning melamine and trithiocyanuric acid under the same condition.

Owner:JILIN UNIV

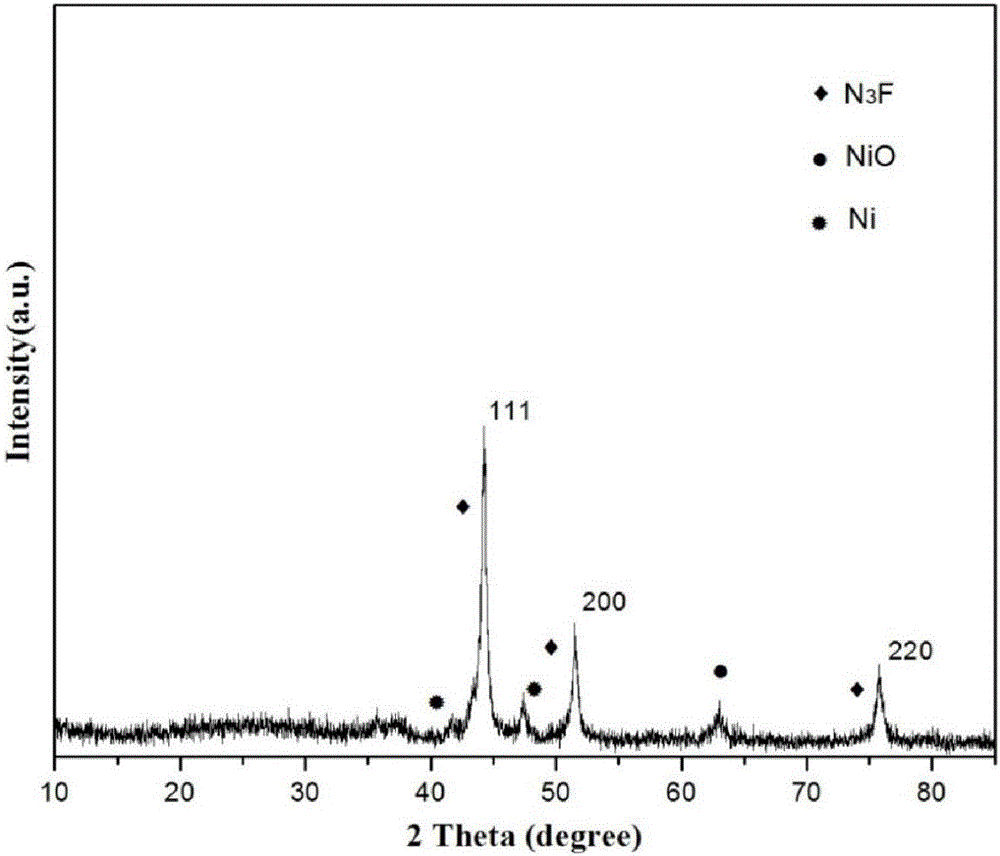

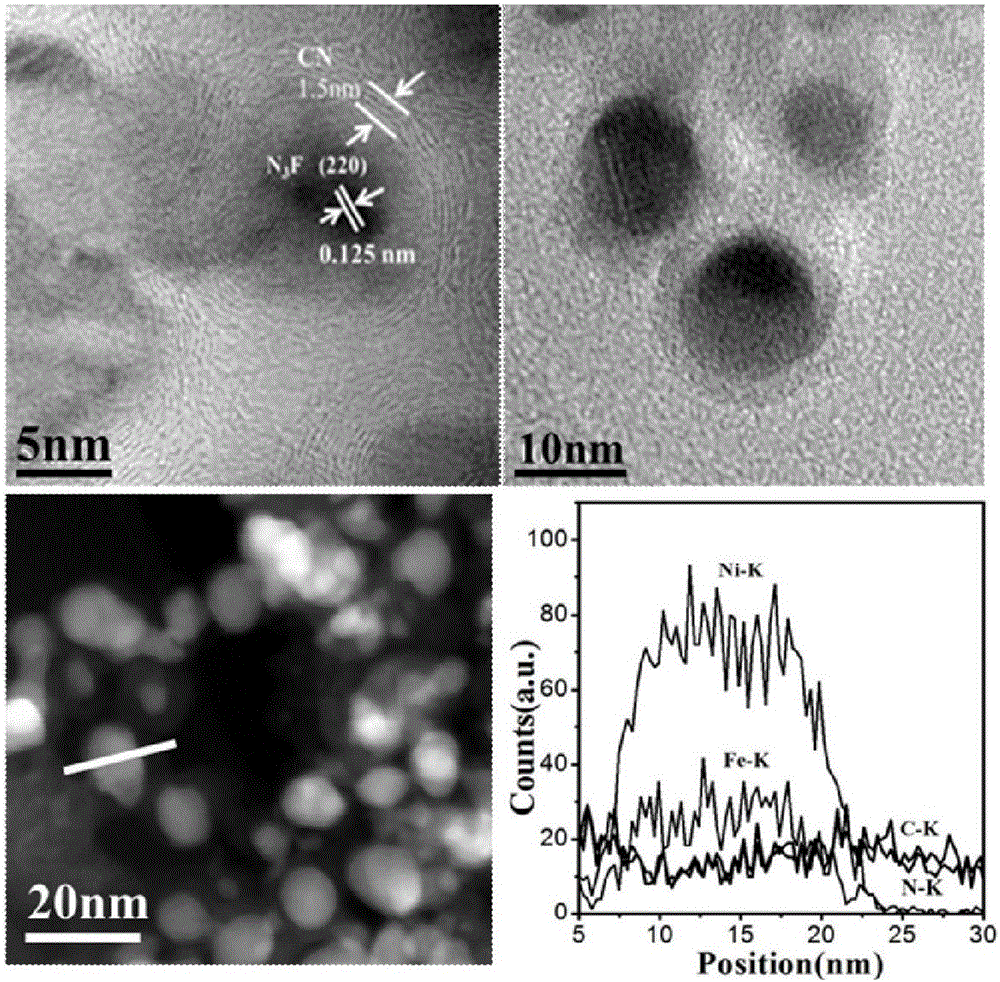

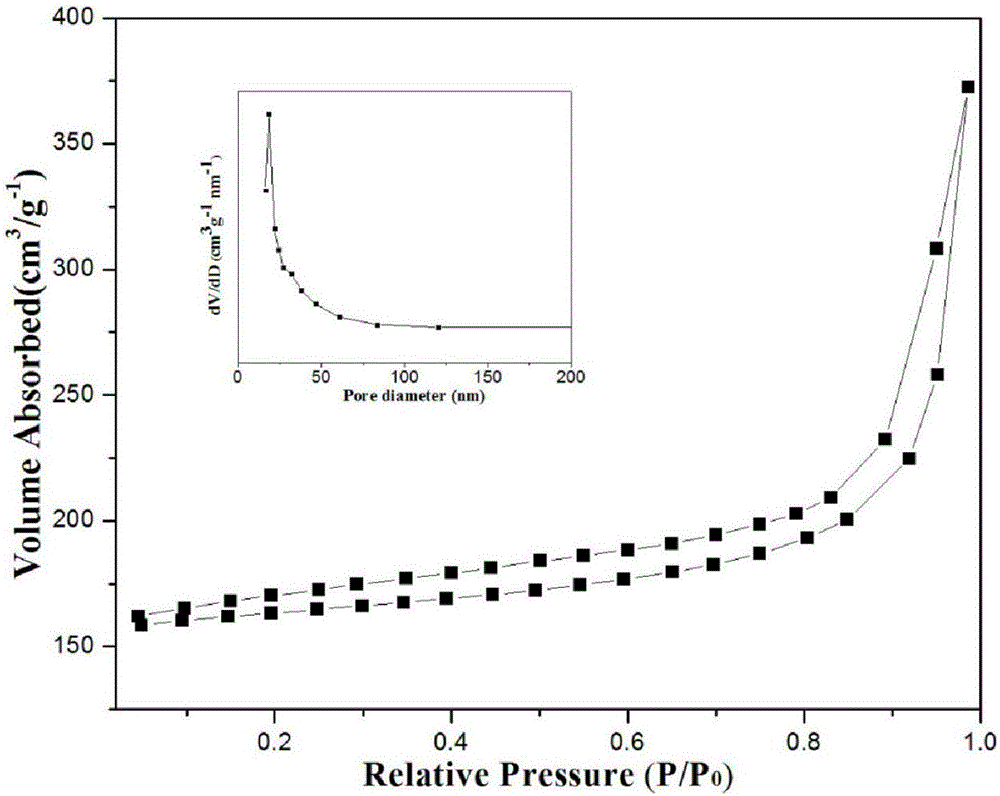

Preparation of nitrogen doped carbon-encapsulated core-shell structure ferro-nickel nano-catalyst and application thereof in catalyzing o-chloronitrobenzene hydrogenation reaction

ActiveCN106732733AMaterial nanotechnologyPhysical/chemical process catalystsNano catalystNitro compound

The invention provides a preparation method of a nitrogen doped carbon-encapsulated core-shell structure ferro-nickel nano-catalyst and the application of the nitrogen doped carbon-encapsulated core-shell structure ferro-nickel nano-catalyst in catalyzing an o-chloronitrobenzene hydrogenation reaction. According to the method, the novel nitrogen doped carbon-encapsulated core-shell structure ferro-nickel nano-catalyst is prepared by synthesizing a ferronickel layered doubled hydroxide precursor with small grain size and high surface energy through a nucleation crystallization isolation method, evenly mixing the ferronickel layered doubled hydroxide precursor with a melamine and dicyandiamide mixed carbon material precursor, and finally self-reducing at high temperature. The nitrogen doped carbon-encapsulated core-shell structure ferro-nickel nano-catalyst is efficiently applied to the reaction where halogenated aniline is generated through catalytic hydrogenation of a nitro-halogen compound, and the conversion rate of o-chloronitrobenzene and the selectivity of o-chloroaniline are respectively up to 95-100% and 98-100%. The structure of the novel nitrogen doped carbon-encapsulated core-shell structure ferro-nickel nano-catalyst is unique and novel, the process is green and energy-saving, the structure of the catalyst is stable, and the catalyst has a broad application prospect.

Owner:BEIJING UNIV OF CHEM TECH

Halogen-free expansion type flame-retardant and preparation thereof

The invention relates to a halogen-free intumescent flame-retardant polypropylene composite and a preparation method thereof. Calculated by weight percentage, the composite comprises 35 to 80 percent of polypropylene, 5 to 30 percent of coated poly-ammonium phosphate, 1 to 20 percent of melamine and the derivatives, 1 to 15 percent of halogen-free macromolecular char forming flame retardant, 0.1 to 5 percent of flame retardant synergist, 1 to 20 percent of rigid inorganic particle, 0.05 to 5 percent of coupling agent, 0.1 to 10 percent of compatilizer, 1 to 20 percent of toughening agent and 0.01 to 4 percent of antioxidant. Compared with the prior art, the material of the invention has good toughness, high strength and environment-protecting flame retardance, and the composite can be widely applied in the fields such as automobile and electronic appliances.

Owner:SHANGHAI RES INST OF CHEM IND +1

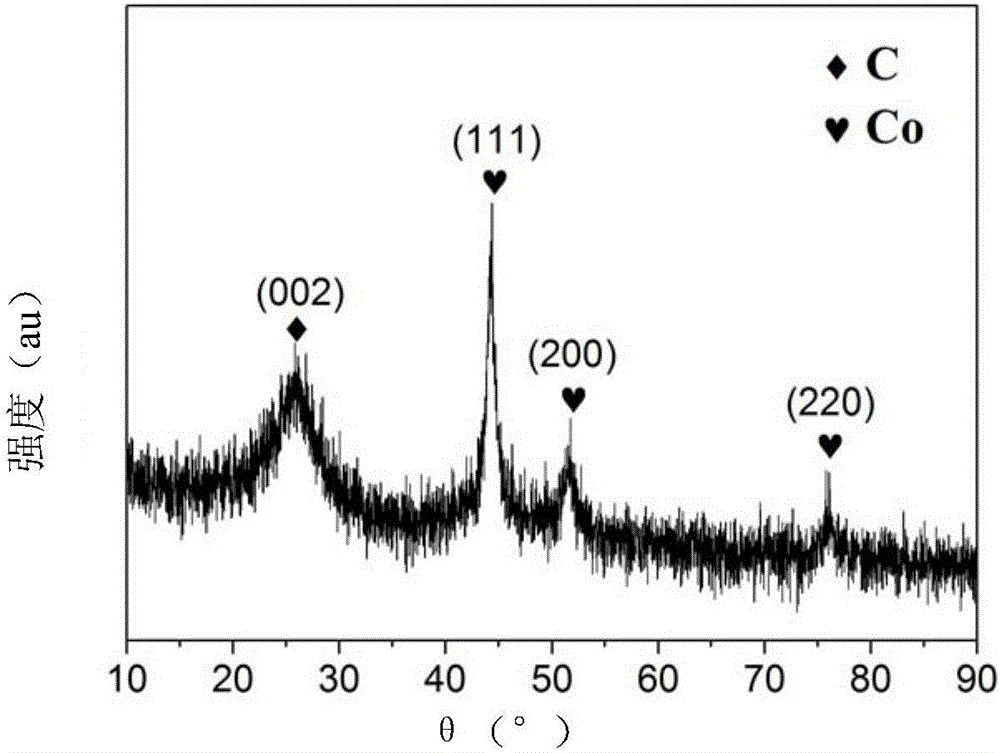

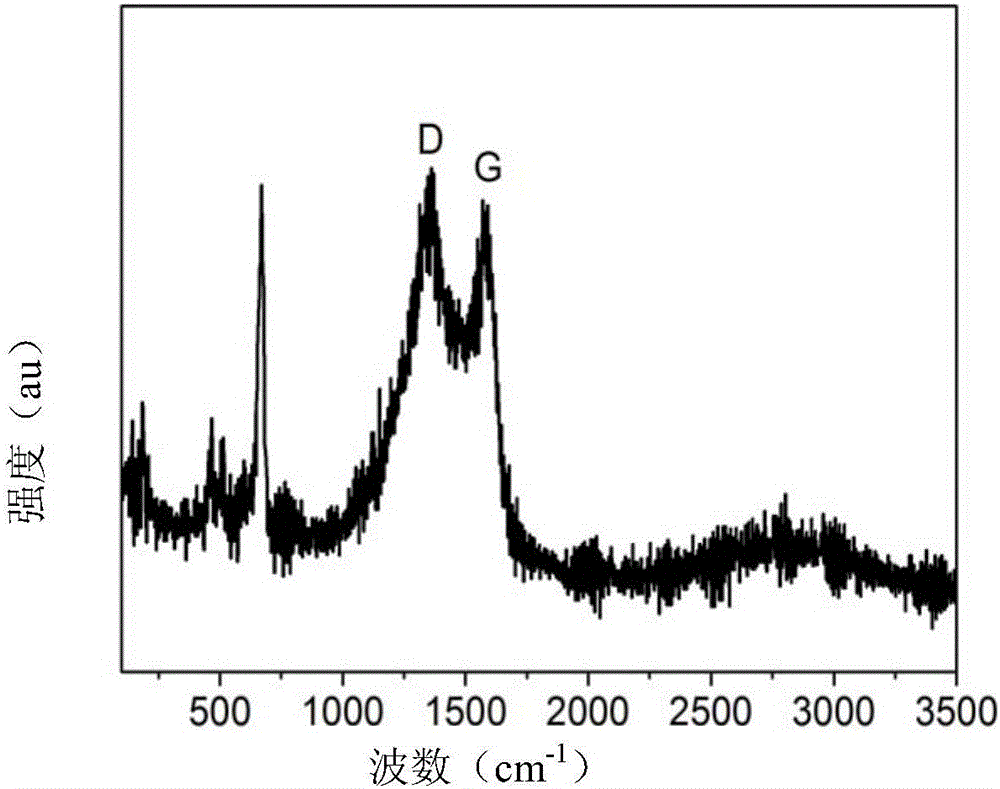

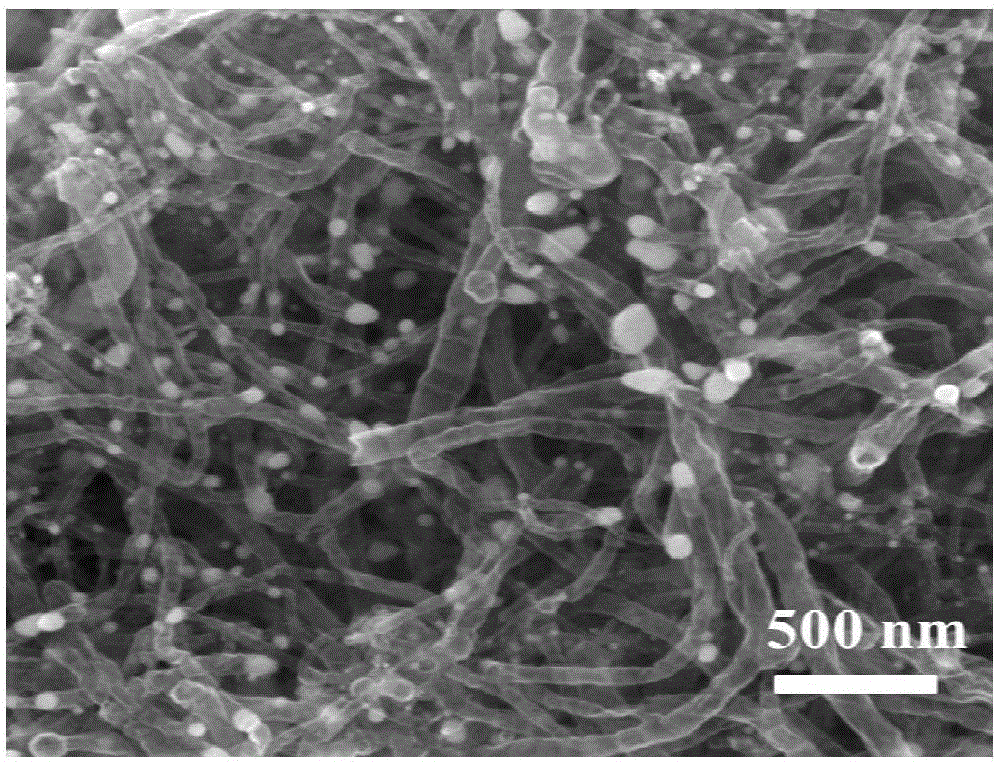

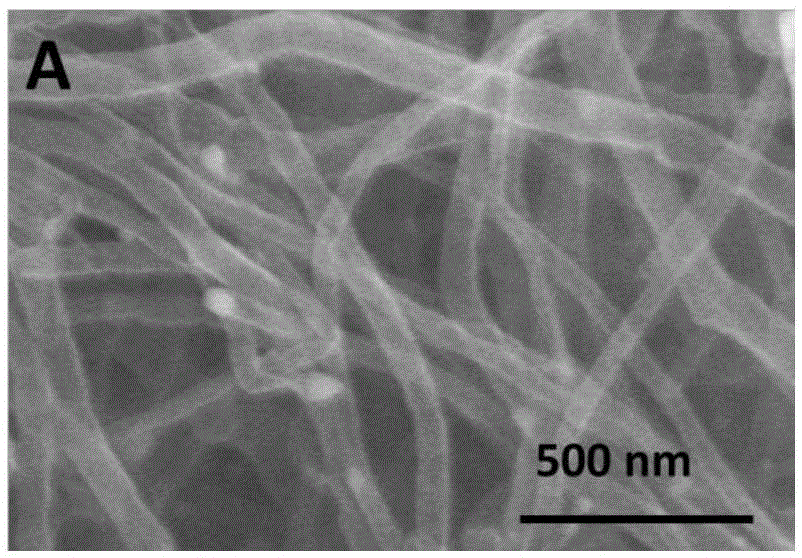

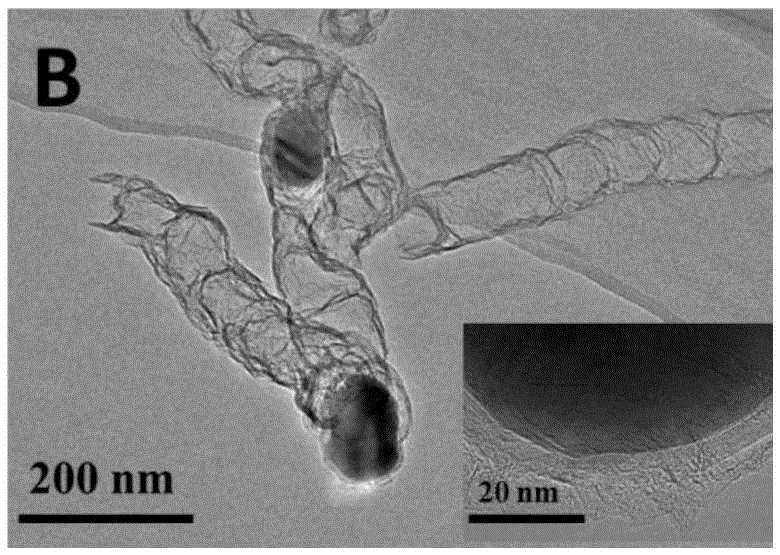

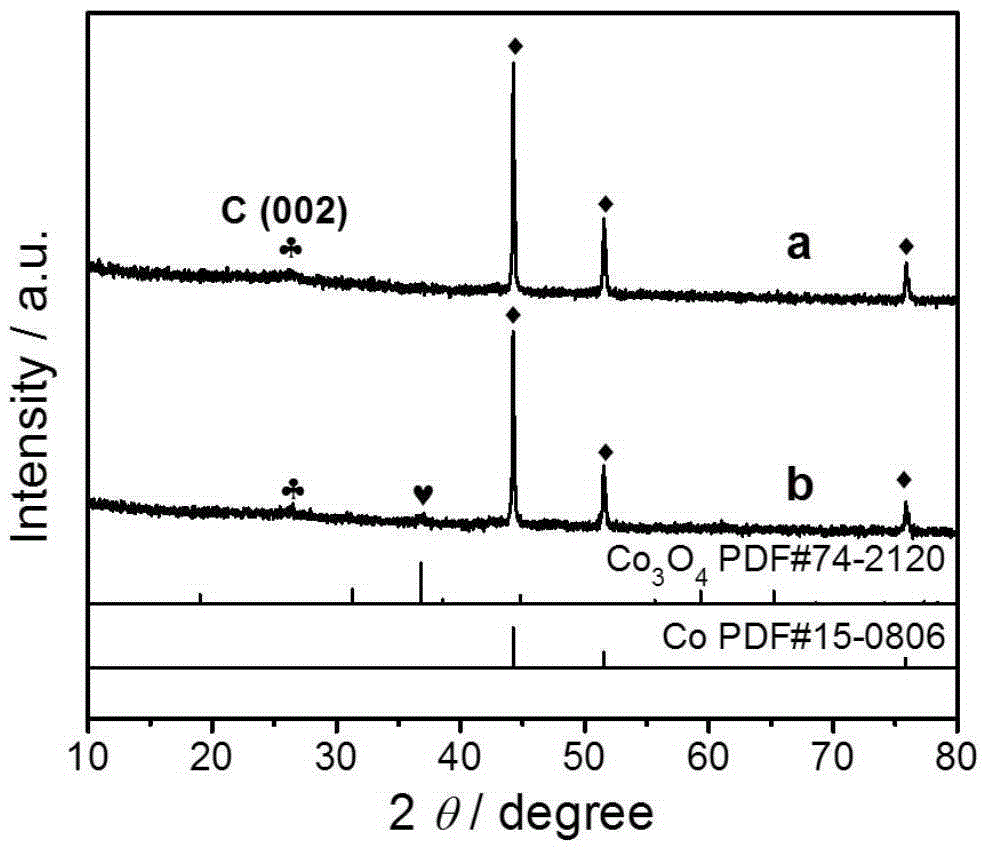

Nitrogen-doped carbon nanotube/Co composite catalyst and preparation method and application thereof

InactiveCN106669762AHigh catalytic activityImprove catalytic stabilityPhysical/chemical process catalystsElectrolysis componentsOxygenOxygen evolution

The invention belongs to the field of preparation and application of energy source materials and discloses a nitrogen-doped carbon nanotube / Co composite catalyst and a preparation method and application thereof. The preparation method includes: 1), respectively preparing melamine, cobalt salt and P123 into water solutions; 2), adding the melamine solution into the P123 solution, stirring for mixing, adding the cobalt salt solution, stirring for mixing, performing ultrasonic treatment, and heating while stirring until water is evaporated to obtain a precursor material; 3), pre-calcining the precursor material at 200-400 DEG C in an inert gas atmosphere, calcining at 450-600 DEG C and at 750-900 DEG C respectively, using an acid solution for soaking, cleaning, and drying to obtain the composite catalyst. The catalyst is high in oxygen reduction and oxygen evolution catalytic activity and stability and has high hydrogen evolution catalytic activity and stability in an acidic condition. The preparation method is simple, extensive in raw material source, low in cost and suitable for large-scale production. The composite catalyst is used in the field of integrated regenerative fuel cells.

Owner:SOUTH CHINA UNIV OF TECH

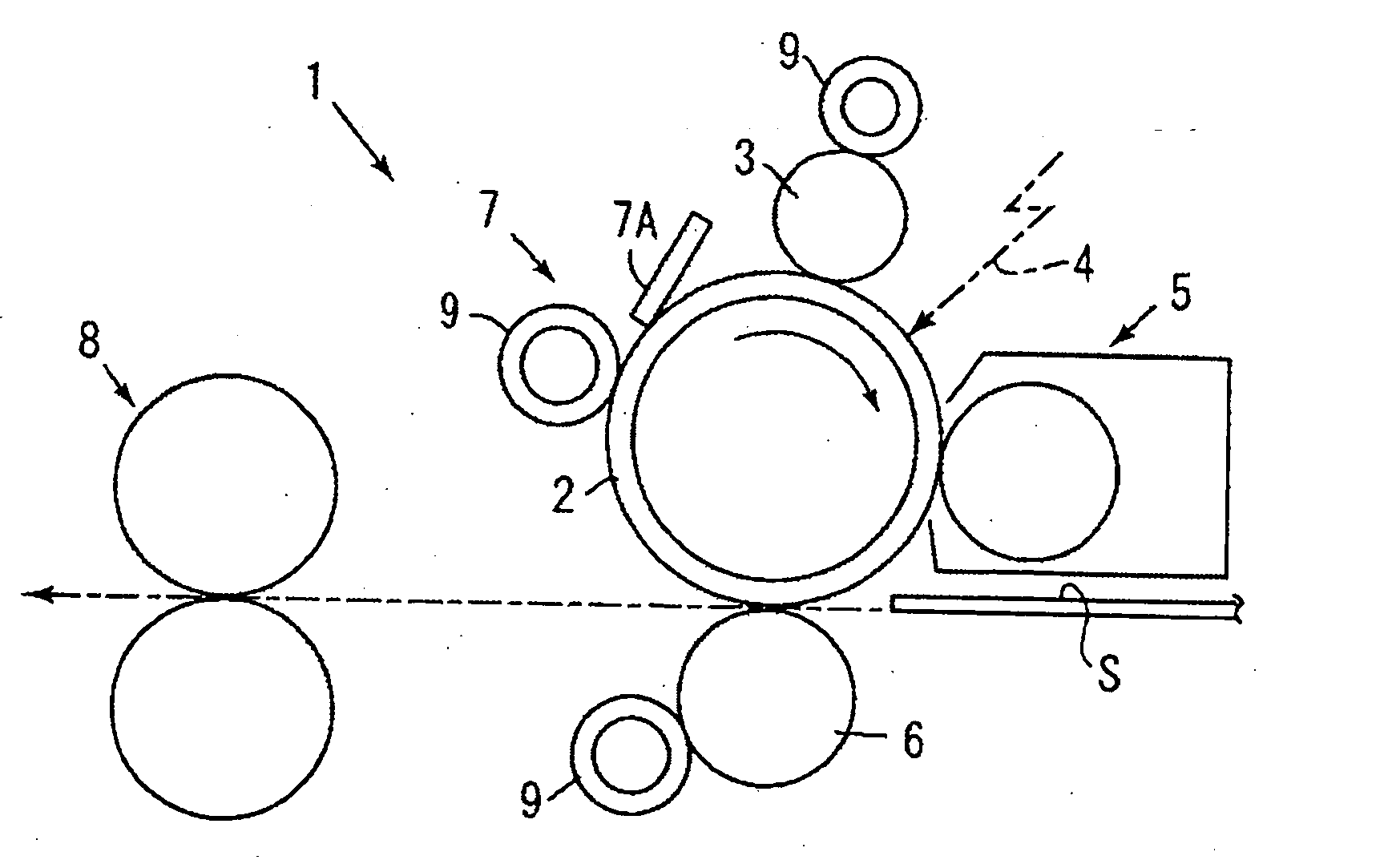

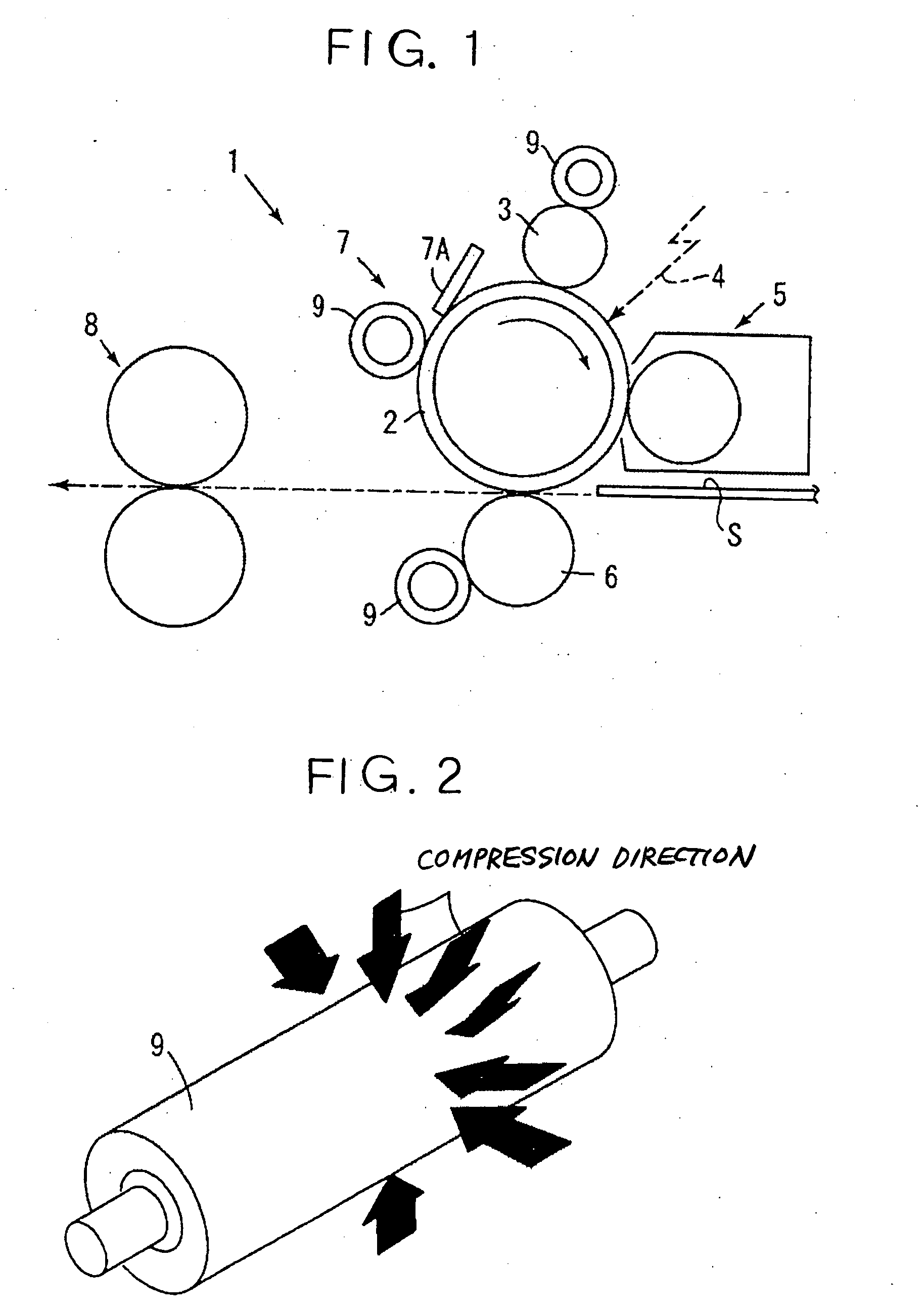

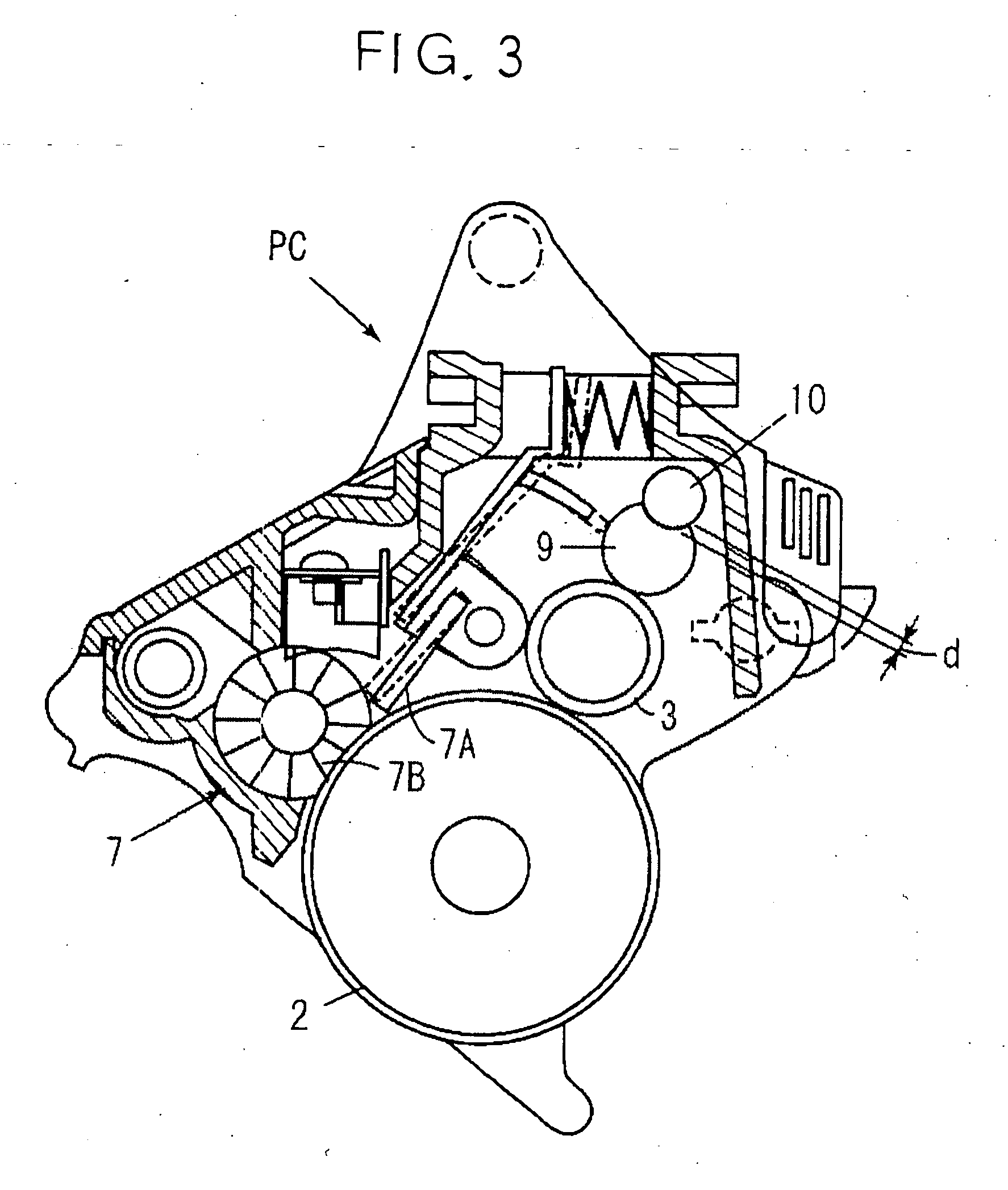

Charged device, cleaning device, process cartridge, toner, and image-forming device that uses these

ActiveUS20050191081A1Increase costReduce image qualityElectrographic process apparatusCorona dischargeForeign matterImaging quality

There is provided a cleaning device for an image-forming device configured so as to be capable of preventing the image quality from deteriorating by being able to prevent the deterioration of the charging state caused by deposits of foreign matter without increasing costs. There is also provided a cleaning member that can make contact with the cleaning target-members. The cleaning member has a portion composed of melamine resin foam for making contact with at least the cleaning target members, and the melamine resin foam has an Asker F hardness of 5 to 25 points and a hardness variation of 5 points or less, and is used on the cleaning target members in a state obtained by heat compression from the original shape. The pressing member is furthermore disposed in contact with the cleaning member.

Owner:RICOH KK

Process for the manufacturing of an improved core for decorative laminates and a decorative laminate obtained by the process

InactiveUS6841023B2Improve brittlenessImprove the overall coefficientOrganic chemistryLamination ancillary operationsPolyesterFiber

A process for the manufacturing of a core forming a carrying structure for decorative laminates. The core comprises particles of cured, and optionally foamed, rigid, polyurethane, polyisocyanurate and / or phenolic resin. The particles are bonded to each other in a pressing procedure with a bonding agent comprising an adhesive such as a polymerizing monomer.i) The particles are achieved by grinding cured, and optionally foamed, rigid, polyurethane, polyisocyanurate and / or phenolic resin so that it passes through a 2 mm screen, preferably a 1 mm screen,ii) 100 parts per weight of particles is mixed with 1-100 parts per weight of fiber, the fiber additive having an average length in the range 1-15 mm.iii) The particle-fiber mixture is allowed to absorb a selected amount of water, the amount of water being in the range 1-15% by weight, The water is either added at any stage before the adding of bonding agent, and / or being used as a solvent in the bonding agent, and that,iv) 85 parts per weight of the particle mixture is mixed with 2-15 parts per weight of a bonding agent, the bonding agent selected from the group consisting of,a) A mixture of polyols, such as polyester or polyether, crude methylene diphenyl diisocyanate and possibly a small amount of blowing agent in a ratio forming a polymeric resin with a density in the range 600-1400 kg / m3.b) A formaldehyde based resin such as phenol-formaldehyde resin, urea-formaldehyde resin, melamine-urea-formaldehyde resin, melamine-urea-phenol-formaldehyde resin or phenol-resorcinol-formaldehyde resin, orc) Polyvinyl acetate resin.v)The mixture is applied between the belts of the continuos belt press or the press plates of a static press, optionally with at least one intermediate carrier web, the belts or press plates allowing a mainly uniform and specified material thickness to form. A slightly porous and preconditioned core with a selected water content in the range 0.8-12% is hereby achieved. The invention also relates to a decorative laminate achieved through the process.

Owner:PERGO

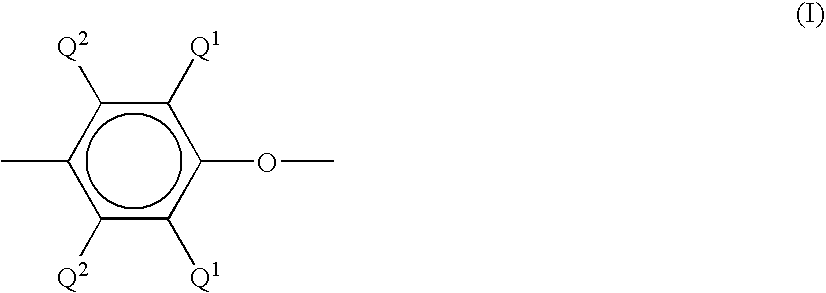

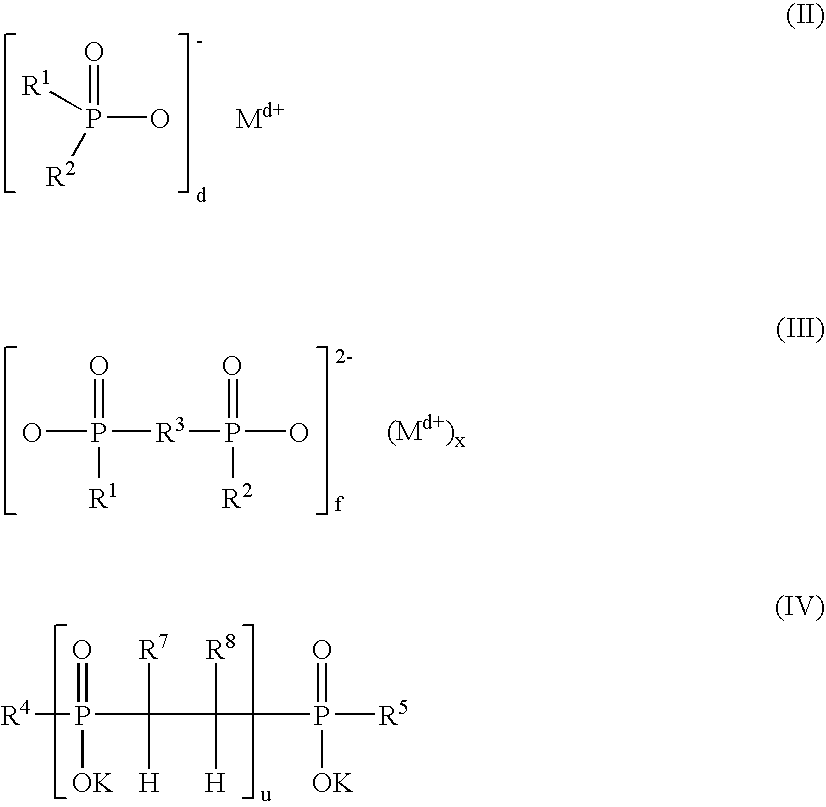

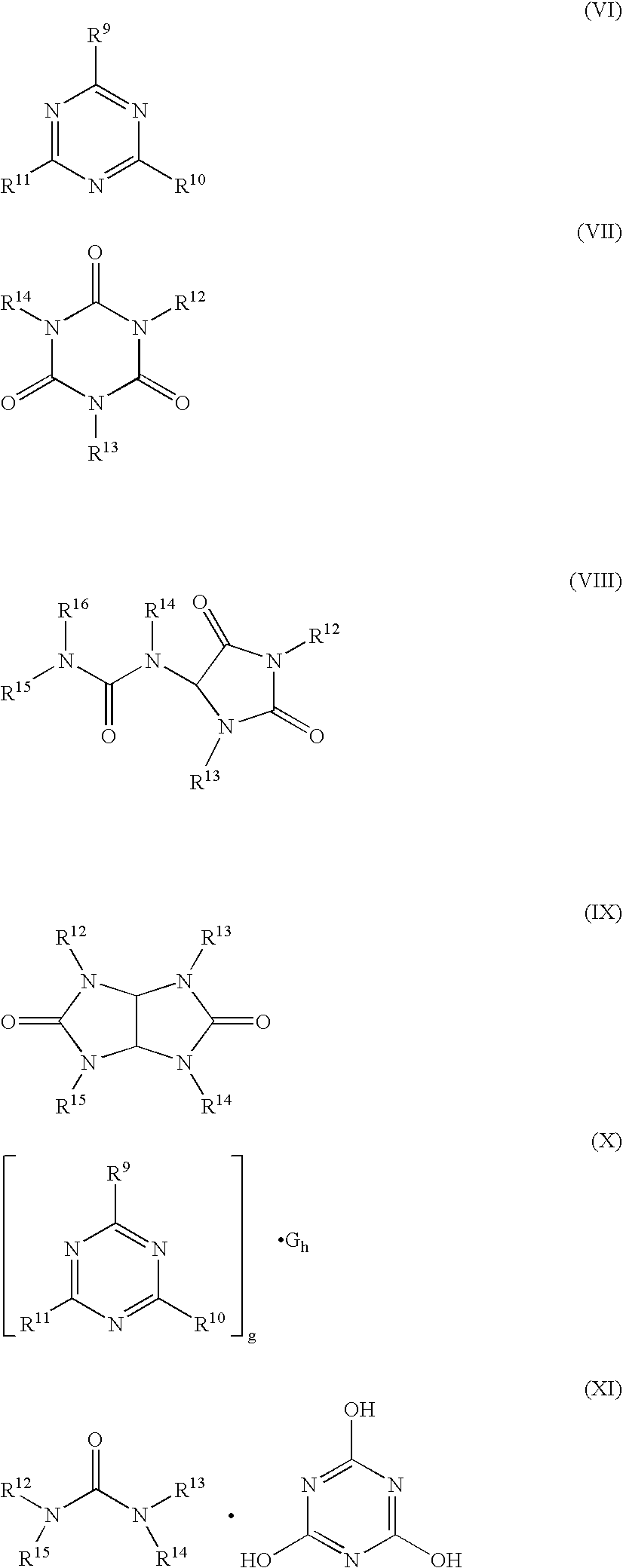

Flame retardant coatings

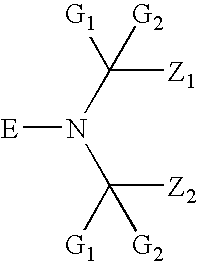

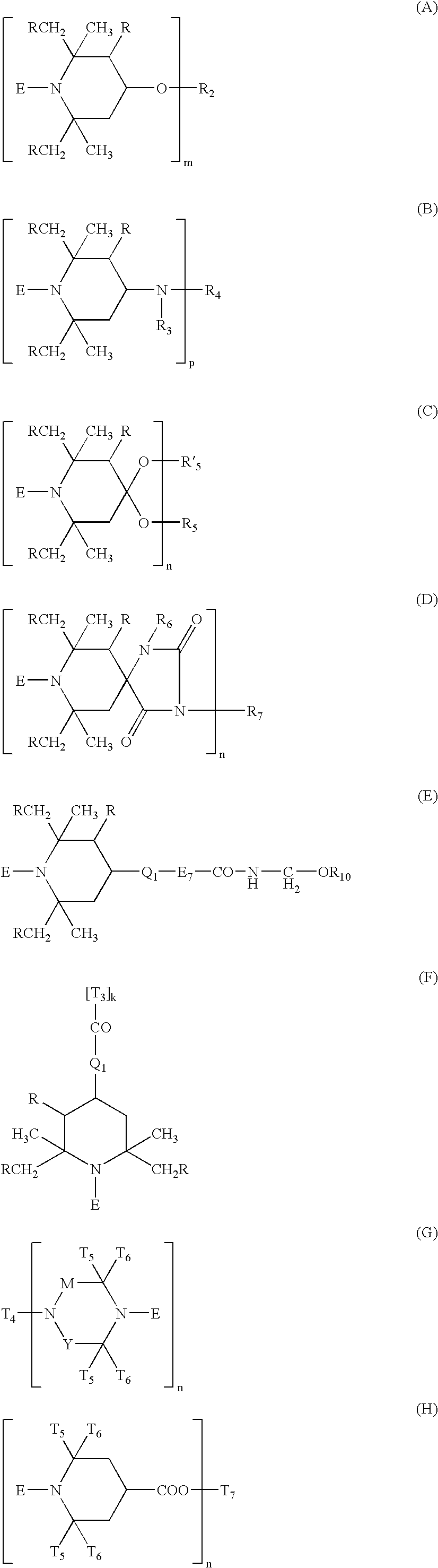

Provided are flame retardant coating compositions and articles coated therewith, which compositions comprise (A) a coating and (B) an effective flame retarding amount of a mixture of (i) at least one compound selected from the group consisting of the (a) sterically hindered nitroxyl stabilizers, (b) sterically hindered hydroxylamine stabilizers and (c) sterically hindered alkoxyamine stabilizers and (ii) at least one conventional flame retardant selected from the group consisting of (d) organohalogen flame retardants, (e) organophosphorus flame retardants, (f) isocyanurate flame retardants and (g) melamine based flame retardants. The coated articles are for example iron, steel, stainless steel, aluminum and other non-ferrous metals, wood, plywood, paper, cardboard, chip board, particle board, plastics, thermoplastics, epoxies, neoprene, rubber, composites, fiberglass reinforced composites, polyesters, polymeric foam, masonry, fabric or textiles, wire and cable constructions and circuit boards.

Owner:TROUTMAN MALISA +3

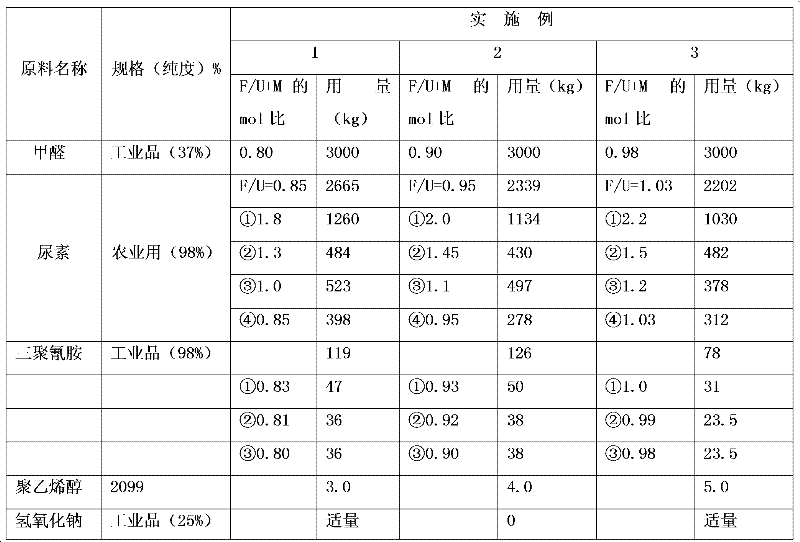

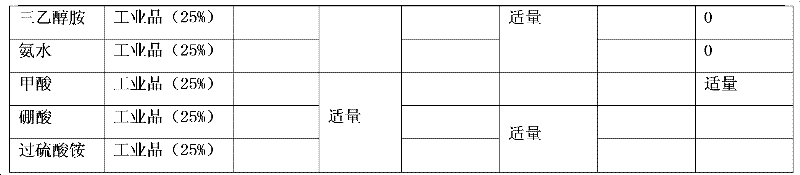

E0-grade melamine modified urea-formaldehyde resin adhesive, and preparation method and application thereof

InactiveCN102604573AImprove stabilityLow costAldehyde/ketone condensation polymer adhesivesMelamineResin adhesive

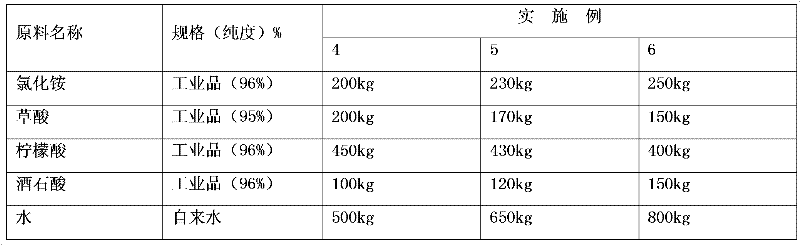

The invention relates to an E0-grade melamine modified urea-formaldehyde resin adhesive, and a preparation method and application thereof. The E0-grade melamine modified urea-formaldehyde resin adhesive is characterized by comprising an E0-grade melamine modified urea-formaldehyde resin, a composite curing agent and a composite filler, wherein the E0-grade melamine modified urea-formaldehyde resin is prepared from the following raw materials in parts by mass: 100 parts of formaldehyde, 0.1-0.5 part of polyvinyl alcohol, 100-200ml of basic catalyst and 200-400ml of acidic catalyst; the mol ratio of the formaldehyde to the urea+melamine (F / (U+M)) is equal to 0.80-0.98; the composite curing agent is prepared from the following raw materials in parts by mass: 200-250 parts of ammonium chloride, 150-200 parts of oxalic acid, 400-450 parts of citric acid, 100-150 parts of tartaric acid and 500-800 parts of water; and the composite filler is prepared from the following raw materials in parts by mass: 60 parts of industrial flour, 20 parts of 800-mesh light calcium carbonate and 20 parts of 800-mesh wood meal. The E0-grade melamine modified urea-formaldehyde resin adhesive is used for gluing plates. The E0-grade melamine modified urea-formaldehyde resin adhesive has the advantages of low free formaldehyde content, low cost, favorable precompression performance, good gluing performance and the like.

Owner:BEIHUA UNIV

Fluoropolymer coated films useful for photovoltaic modules

ActiveUS7553540B2Strong adhesionIncreased durabilityFilm/foil adhesivesSynthetic resin layered productsEpoxyPolymer science

A fluoropolymer coated film comprising polymeric substrate film and fluoropolymer coating on the polymeric substrate film. The fluoropolymer coating comprises fluoropolymer selected from homopolymers and copolymers of vinyl fluoride and homopolymers and copolymers of vinylidene fluoride polymer blended with compatible adhesive polymer comprising functional groups selected from carboxylic acid, sulfonic acid, aziridine, anhydride, amine, isocyanate, melamine, epoxy, hydroxy, anhydride and mixtures thereof. The polymeric substrate film comprises functional groups on its surface that interact with the compatible adhesive polymer to promote bonding of the fluoropolymer coating to the substrate film.

Owner:DUPONT ELECTRONICS INC

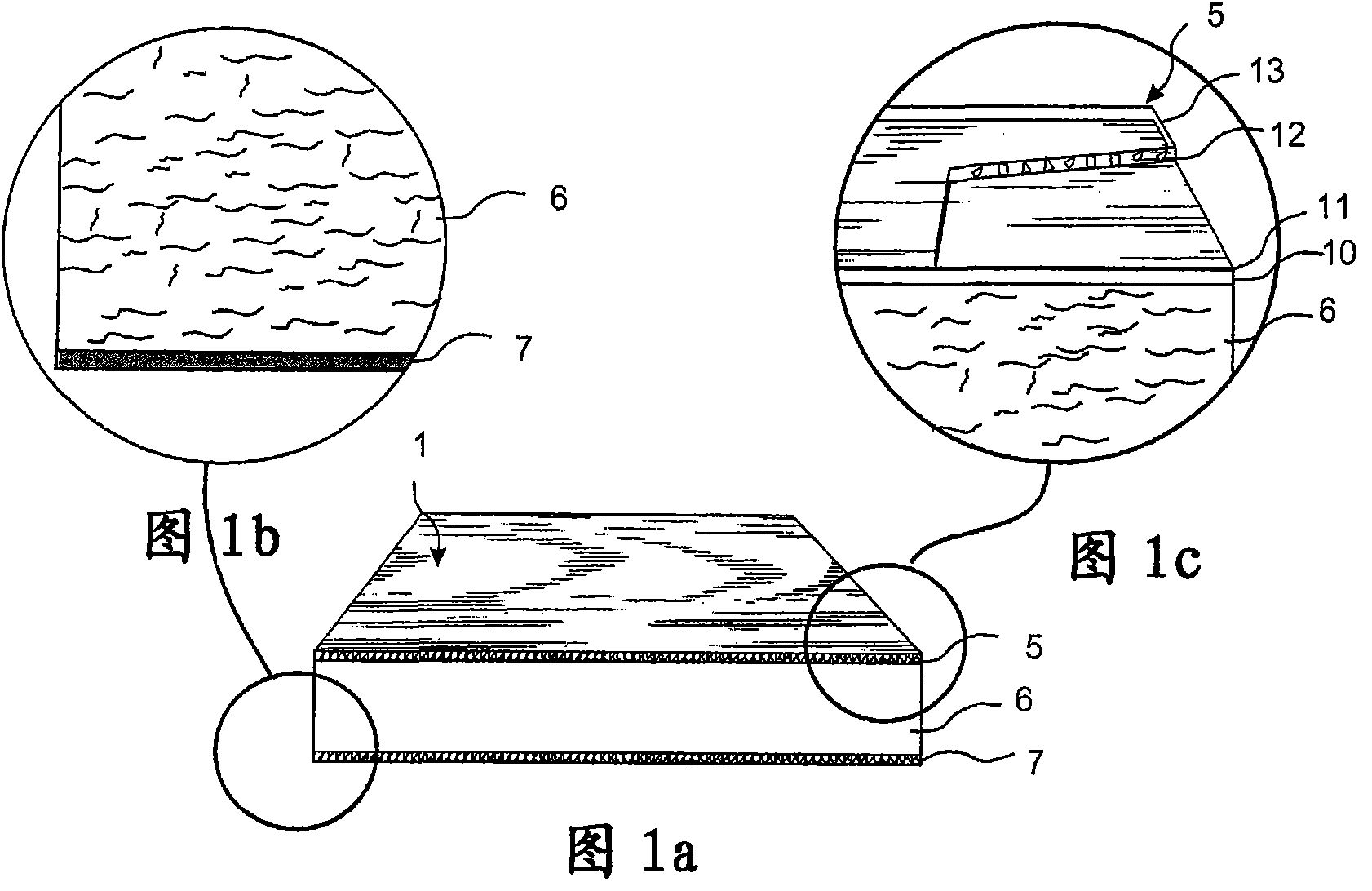

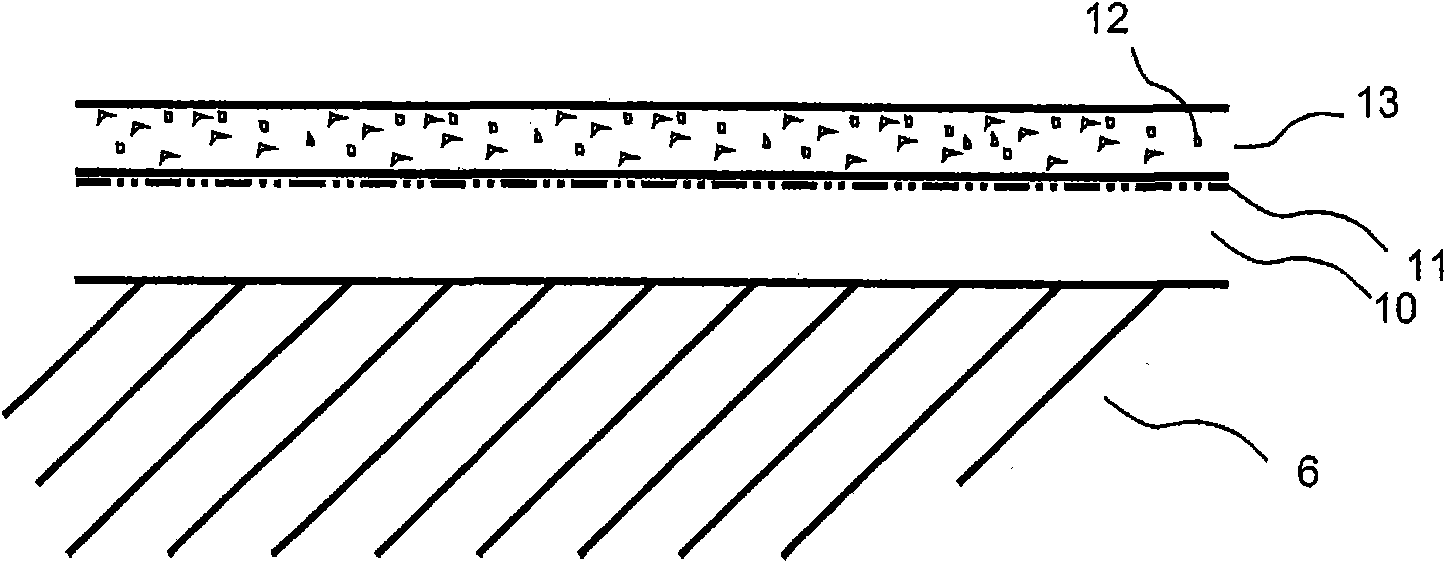

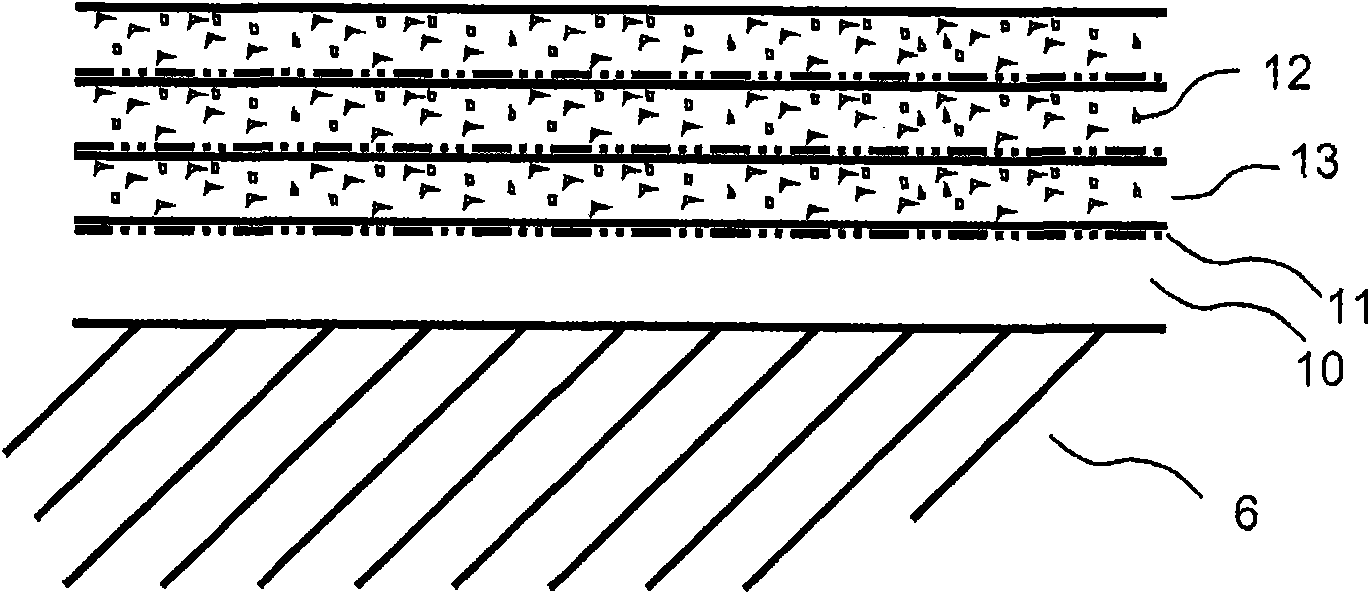

Fibre based panels with a wear resistance surface

ActiveCN101909836AImprove wear resistanceImprove impact resistanceCovering/liningsSpecial ornamental structuresSurface layerWear resistant

A flooring panel (1) comprising a core (6) and a surface layer (5), the surface layer (5) comprising cork particles (14) or wood fibres (14) comprising lignin resin, melamine resin as binder (19), colour pigments (15), and aluminium oxide as wear resistant particles (12), all components being homogenously mixed, and the core (6) comprising fibres and binder and being provided with a mechanical locking system (4) at its edges and a rear balancing layer (7). Also disclosed is a method of manufacturing said flooring panel by - homogenously mixing the dry particles of the surface layer; - scattering them on an embossed pressure matrix; - applying the core layer as scattered or prefabricated layer on the surface layer; - applying a balancing layer as scattered or prefabricated layer on the core layer; - pre-pressing the panel; - printing and brusching the surface layer; - forming the panel by a further pressing and heating step; - machining the mechanical locking system.

Owner:VÄLINGE INNOVATION AB

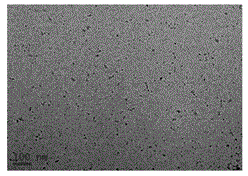

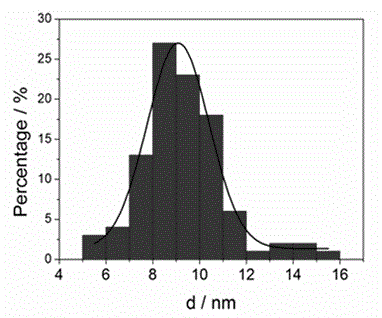

Method for preparing carbon nitride quantum dots

InactiveCN104140084AIncrease useHigh yieldNitrogen and non-metal compoundsFluorescent radiationCarbon nitride

A method for preparing carbon nitride quantum dots comprises the following steps of (1) material preparation, (2) drying and tabletting, (3) heating, (4) separation and (5) drying. Sodium chloride crystals are used as a template, the preparing process is simple and low in cost, and the sodium chloride crystals can be easily removed through water dissolution; melamine is used as the raw material, and annular carbon nitride basic structural units exist in melamine molecules, so that the yield of preparing the quantum dots is high, and product size uniformity is good; the prepared quantum dots are high in specific area, good in water solubility and good in dispersity, have strong fluorescent radiation visible under naked eyes, and have wide application prospects in the fields of fluorescence detection, light emitting devices, biomarker and the like.

Owner:NAT UNIV OF DEFENSE TECH

Preparation method of cobalt electro-catalysis oxygen reduction material wrapping nitrogen-doped carbon nanotube

ActiveCN105413730AOrderly arrangement and assemblyImprove performancePhysical/chemical process catalystsCell electrodesCooking & bakingOxygen

The invention discloses a preparation method of a cobalt electro-catalysis oxygen reduction material wrapping a nitrogen-doped carbon nanotube. The method includes the following steps of making melamine, cobalt nitrate hexahydrate and glucose react to obtain a self-assembled melamine precursor, and baking the self-assembled melamine precursor to obtain a cobalt nanoparticle hybrid material electro-catalysis oxygen reduction agent wrapping the nitrogen-doped carbon nanotube. In preparation of the precursor, a self-assembled body can be formed through the electrostatic interaction and the hydrogen-bond interaction by means of nitrate radicals and melamine under the acid condition, cobalt ions are adsorbed into the self-assembled body, ordered arrangement and assembly of materials in the high-temperature baking process are facilitated by the pre-assembled precursor, and therefore more catalysis active sites are exposed, and the improvement of the performance of a catalyst is facilitated.

Owner:QINGDAO UNIV

Aqueous environmental protection ultration expansion type steel structure fireproof paint and its preparation method

InactiveCN1824716ADecorativeReduce dosageFireproof paintsLiquid spraying apparatusAdditive ingredientPhosphate

The present invention provides a water environment-protecting superthin expanded type steel structure fire-retardant coating. Said fire-retardant coating uses water as dispersion medium, uses flake expandable graphite as expansion reinforcing material, uses one or several kinds of emulsions of acrylic emulsion and others as film-forming material, and its expansion system adopts the ingredients of polyammonium phosphate, pentaerythritol and tripolycyanamide. Said invention also provides its preparation method and concrete steps.

Owner:北京首纳东方科技有限公司

Microcapsule automatic fire extinguishing agent

InactiveCN109420281AImprove fire extinguishing efficiencyHigh strengthFire extinguisherEngineeringMelamine

Owner:XIAN WESTPEACE FIRE TECHNOLOGY CO LTD

Flame Retardant Poly(Arylene Ether)/Polyamide Composition

A composition comprises a compatibilized poly(arylene ether) / polyamide blend, an optional electrically conductive filler, a phosphinate, and flame retardant augment selected from the group consisting of melamine polyphosphate, zinc borate, low melting glass, talc, and combinations of two or more of the foregoing flame retardant augments.

Owner:SABIC INNOVATIVE PLASTICS IP BV

Expanding fire retardant composition without halide for polyolefine

The fire retardant composition consists of pentaerythritol phosphate 18-54 wt%, melamine polyphosphate 40-80 wt%, stearic acid or zinc stearate 0.1-5 wt%, coupling agent 0.1-5 wt% and stuffing 0.1-5 wt%. It is used as fire retardant for polypropylene powder or grains, and when the addition amount is 28 wt% fireproof level of UL94V-0 is reached; and is also used as fire retardant for polyethylene,and when the addition amount is 30 wt% fireproof level of UL94V-0 is reached.

Owner:BALING PETRO CHEM CO LTD SINOPEC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com