Method for preparing nitrogen-doped graphene

A technology of nitrogen-doped graphene and graphene, which is applied in the field of material synthesis chemistry, can solve the problems of dangerous chemical reagents, difficulty in preparation, and high cost, and achieve the effects of low risk, simple and easy preparation method, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] 1) The preparation method of the raw material melamine: recrystallize the melamine, use water as the solvent, and vacuum-dry the crystal obtained by filtration, and store the product after mortar grinding in a desiccator for future use.

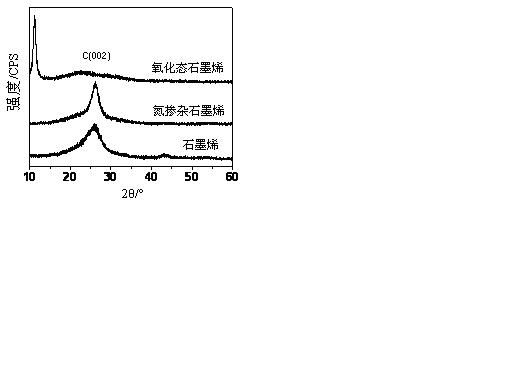

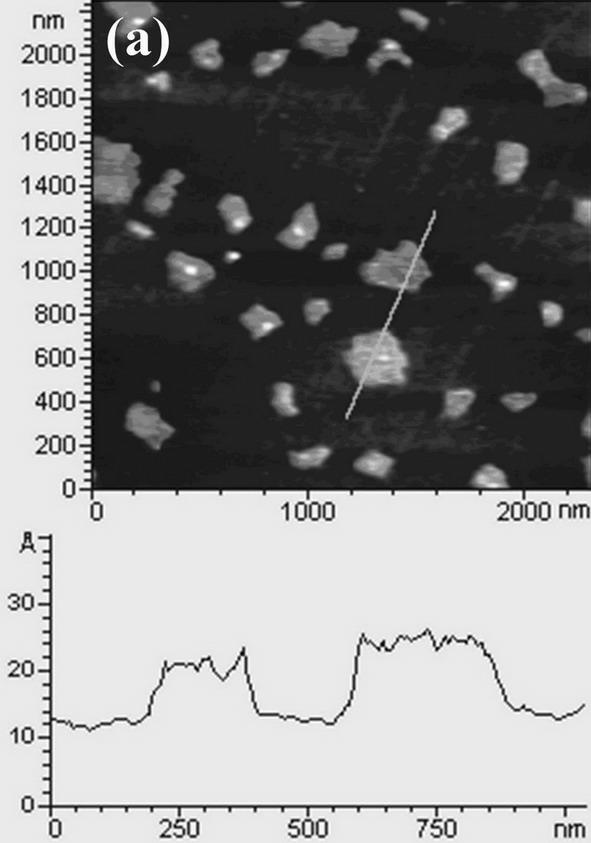

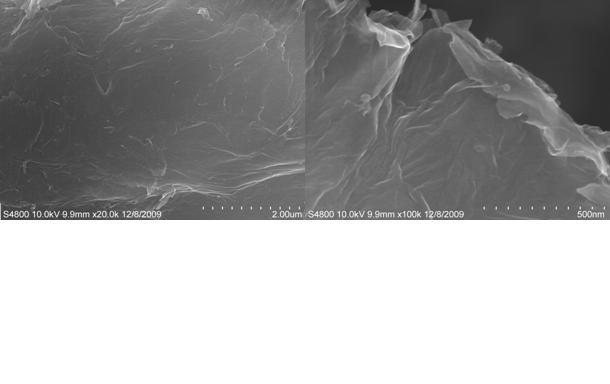

[0028] 2) Preparation method of raw material graphene oxide: analysis of pure natural graphite powder after pre-oxidation and oxidation by improved Hummers' method (for specific operation methods, see: 1. Kovtyukhova, N. I.; Ollivier, P. J.; Martin, B. R.; Mallouk, T. E.; Chizhik, S.A.; Buzaneva, E. V.; Gorchinskiy, A. D. Layer-by-Layer Assembly of Ultrathin Composite Films from Micron-Sized Graphite Oxide Sheets and Polycations. Chem. Mater. 1999, 11, 771-778; and 2. Hummers, W. S.; Offeman, R. E. Preparation of Graphitic Oxide . J. Am. Chem. Soc. 1958, 80, 1339~1339.), filtered and washed, the remaining viscous solid was put into a dialysis bag, dialyzed until the pH value was close to neutral, and the obtained product was dried as...

Embodiment 2

[0031] The preparation method of this example is the same as that of Example 1, wherein the mass ratio of oxidized graphite and melamine in step 3 is adjusted to 1:1, 1:10, 1:20, and the black product is also obtained under other conditions unchanged—— Nitrogen doped graphene.

Embodiment 3

[0033] The preparation method of this example is the same as that of Example 1, and the reaction temperature in step 3 is adjusted to 700°C, 900°C, 1000°C, and 1200°C respectively. Under the same conditions, the black product—nitrogen-doped graphene is also obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com