Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

186results about How to "Increased hydration rate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

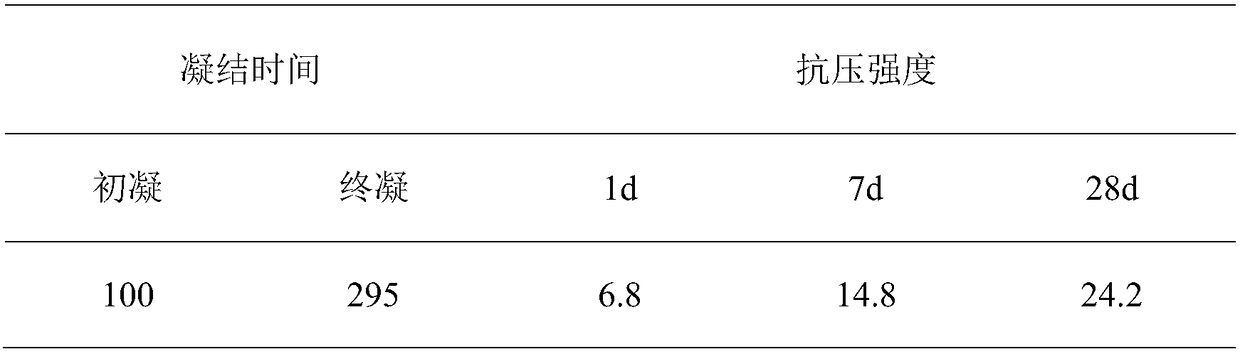

Concrete super instant coagulant

The invention discloses a concrete early-strength agent, which is characterized in comprising the following components according to weight percentage: inorganic salt early-strength component 35-55 percent, organic early-strength component 5-10 percent, water reducing component 15-25 percent, wherein the inorganic salt early-strength component is prepared by at least two among sulfate, carbonate, nitrate, and nitrite; the organic early-strength component selects any one among calcium formate, sodium acetate, calcium oxalate, triethanolamine, tri-iso-propanolamine and carbamide; the water reducing component selects one among naphthalenesulfuric acid type, melamine type and polycarboxylate type. The invention makes the concrete be coagulated and hardened rapidly under the condition of low temperature, so that the early strength of the concrete is greatly improved as well as later strength is ensured.

Owner:ZHONGYIFENG CONSTR GRP +1

Method and composition of preparing polymeric fracturing fluids

InactiveUS20070114035A1Reduce device sizeStimulating oil productionDrilling rodsFluid removalPolyolSized small

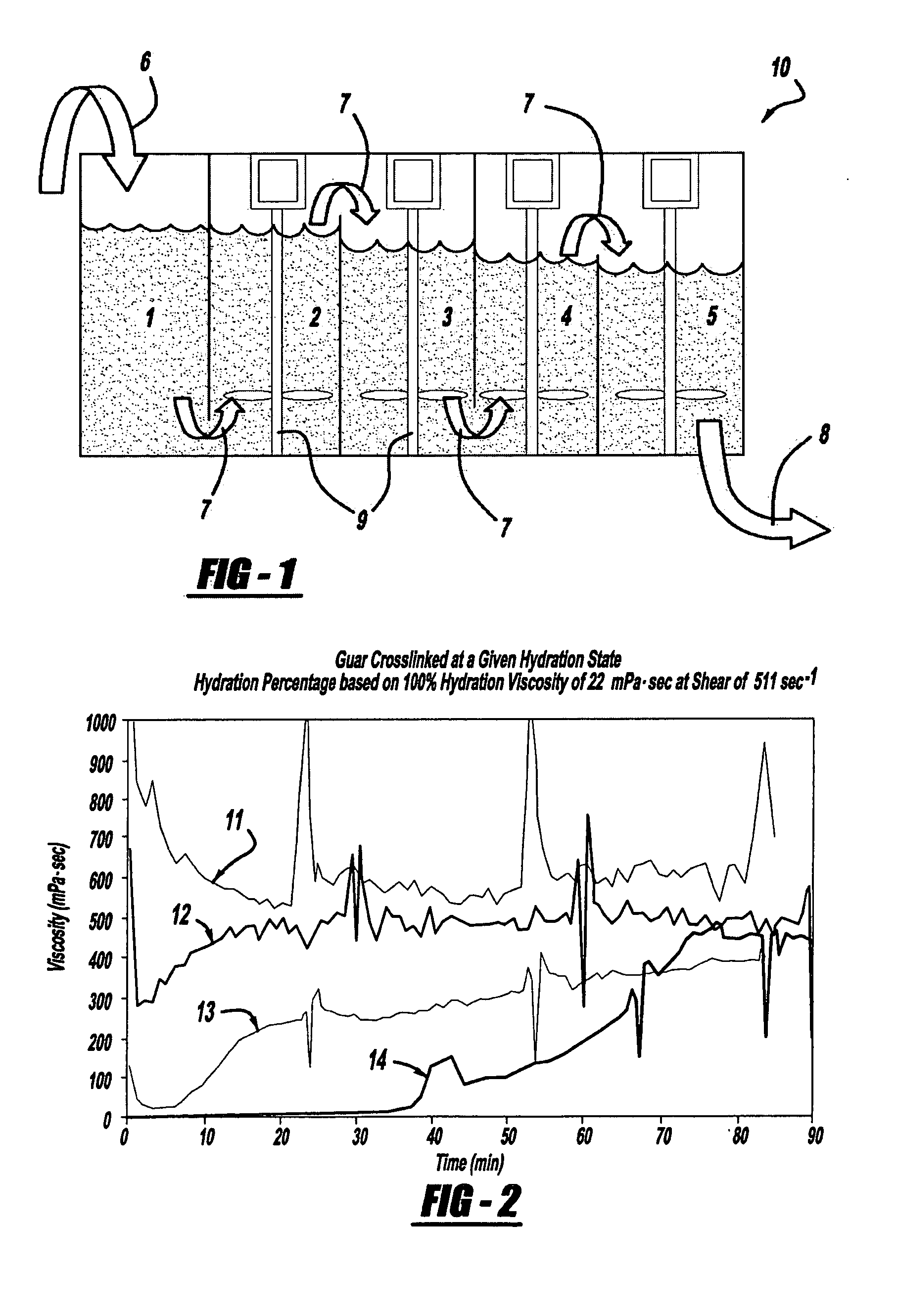

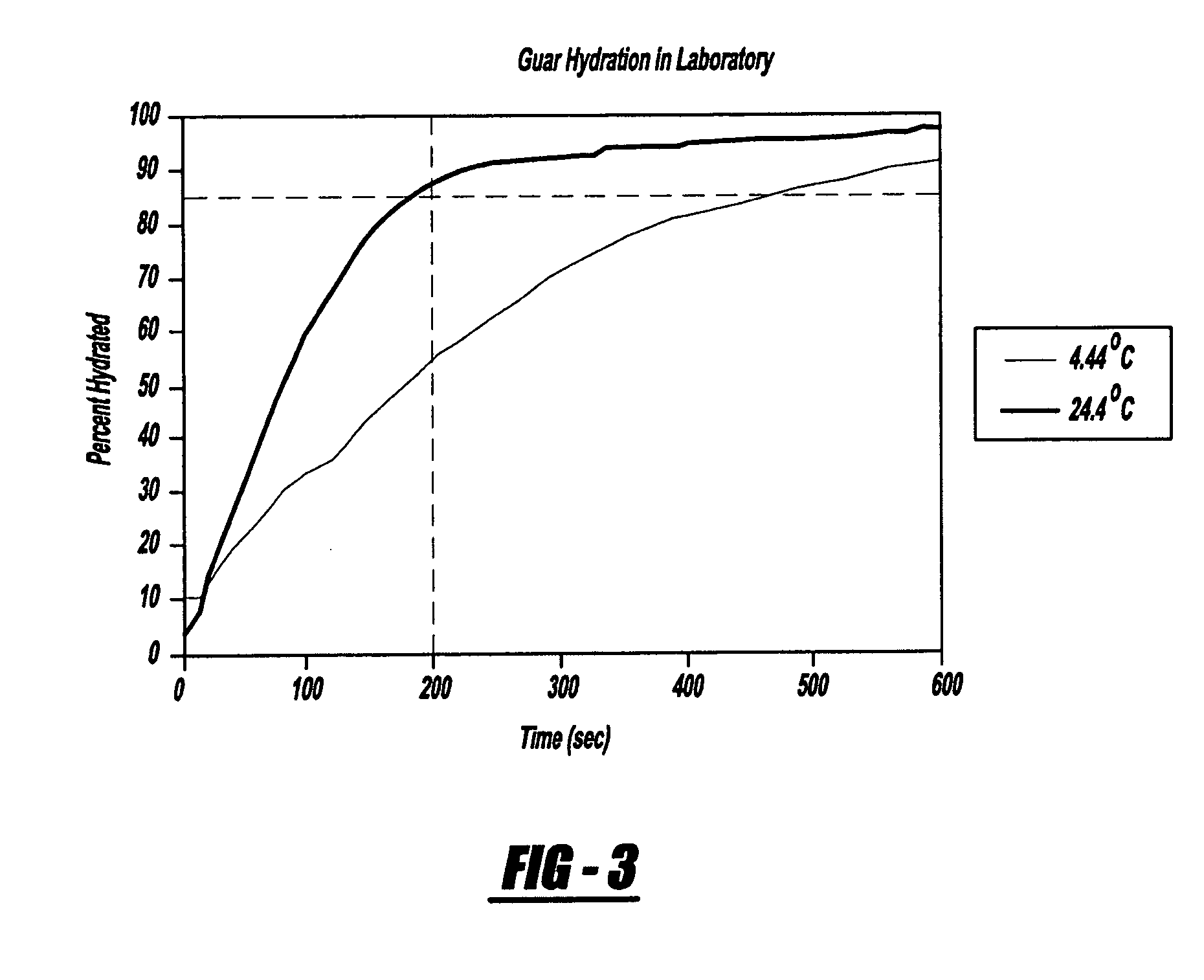

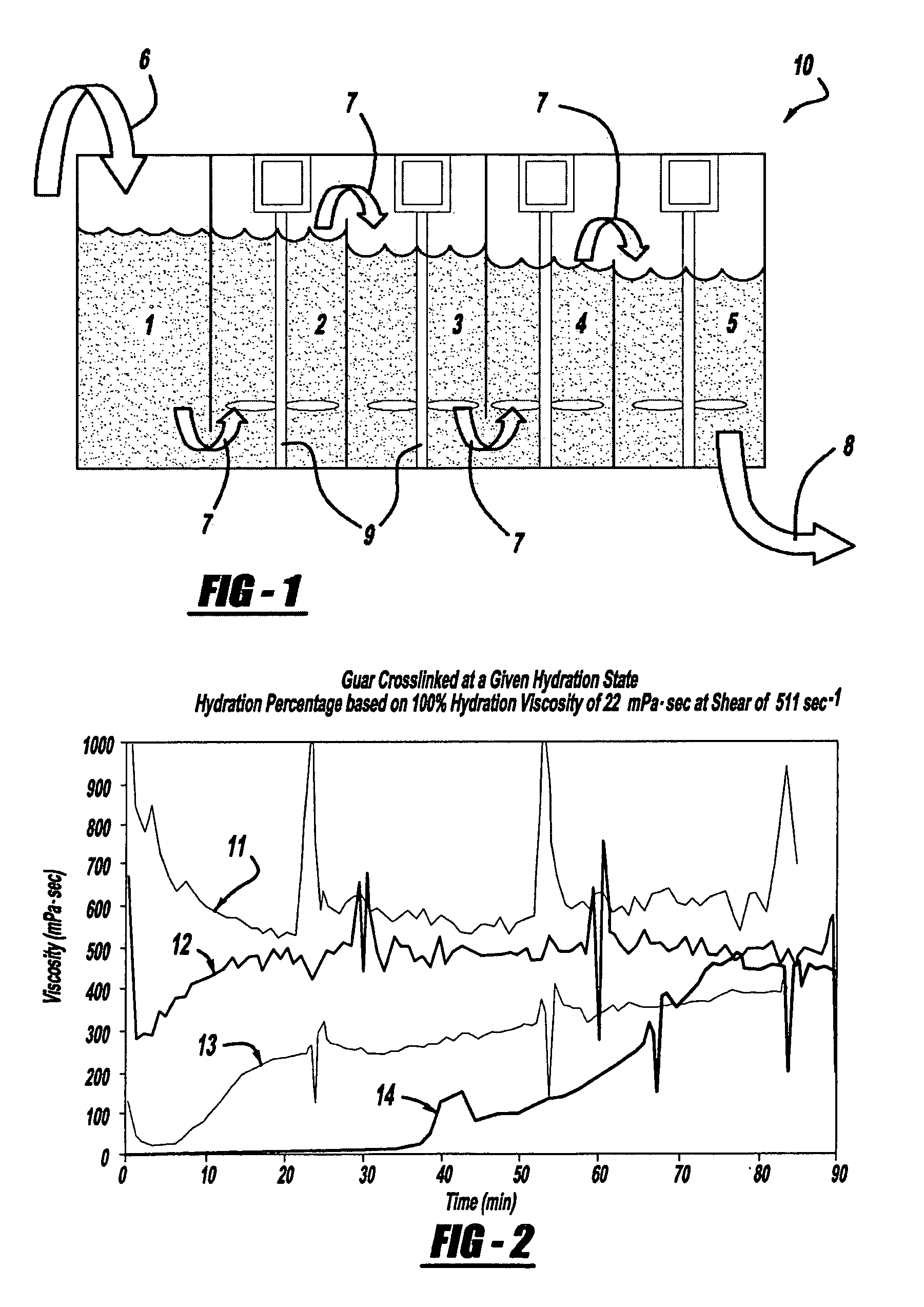

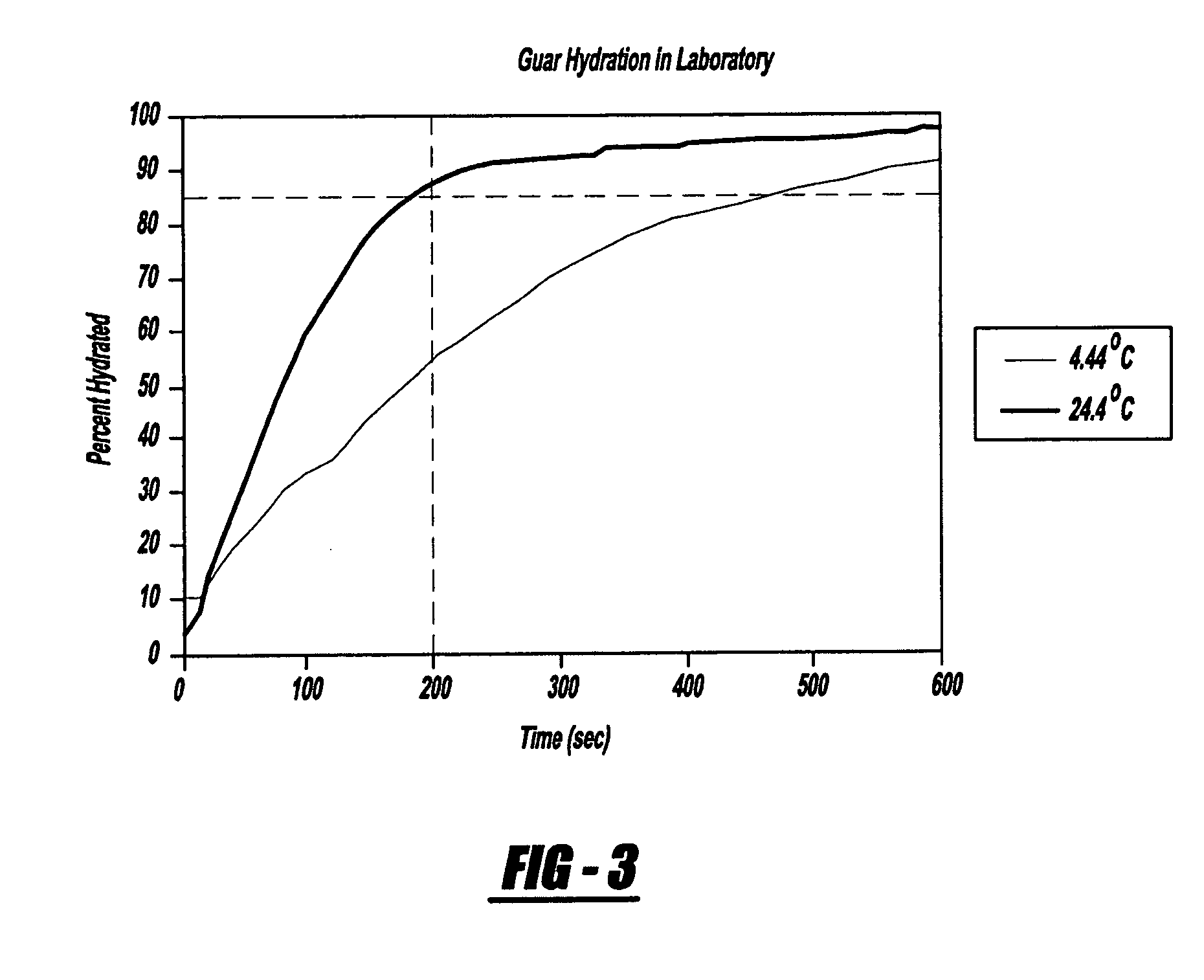

In the presence of certain polyols, a guar gum or similar polysaccharide thickener solution is boron crosslinked before achievement of complete hydration of the thickener, without compromising the viscosity level achieved in a fracturing fluid by the time it is pumped into the wellbore and fractures the subterranean formation adjacent the wellbore. Methods continuously involve hydrating a polysaccharide thickener to an extent of 10% to 75%, but less than full hydration. Before 75% hydration is exceeded, a boron crosslinker is added. Upon addition of the boron crosslinker, the fluid is injected into the wellbore to stimulate hydrocarbon production. Because less time is needed for hydration, well site mixing equipment is down-sized smaller to achieve better efficiency and cost savings.

Owner:SCHLUMBERGER TECH CORP

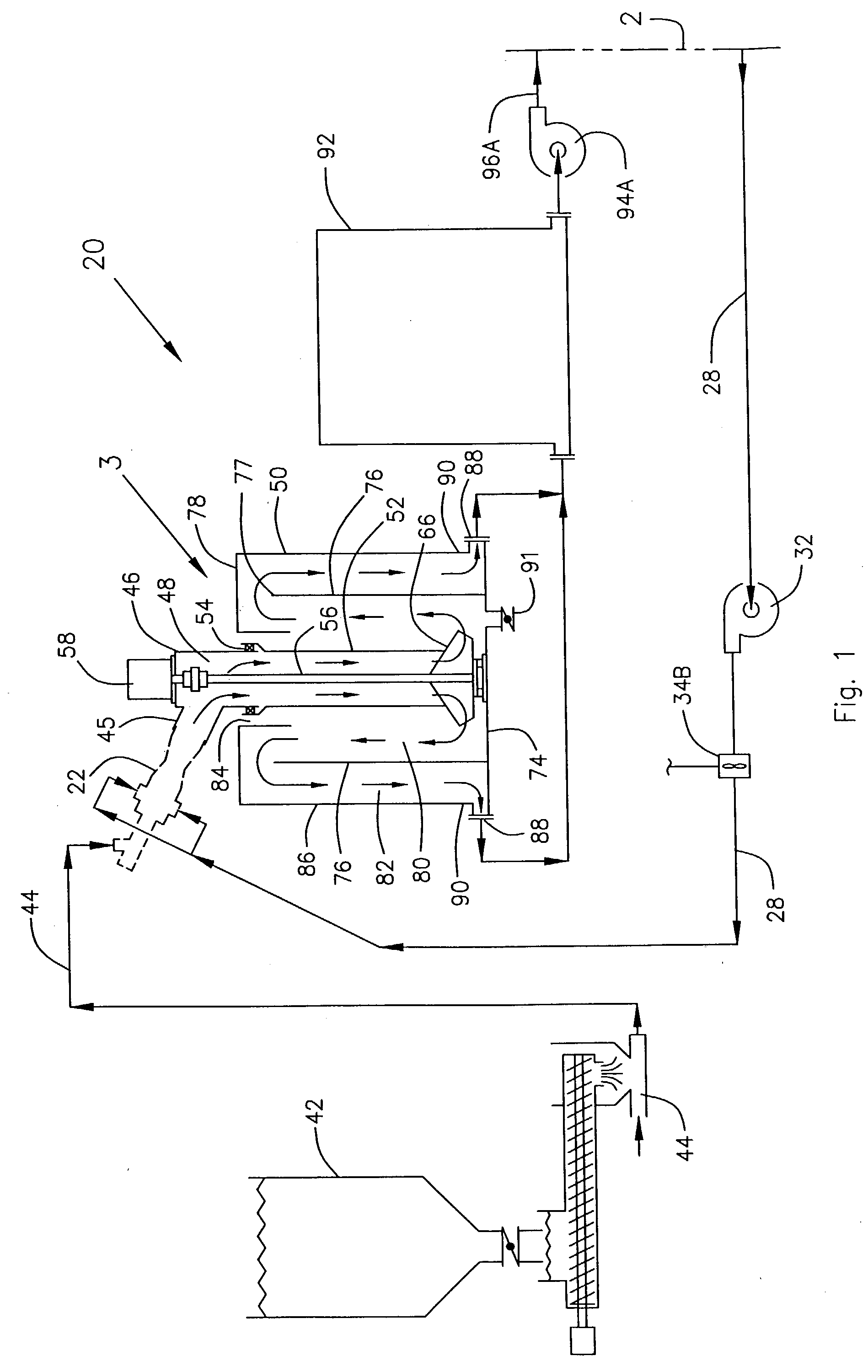

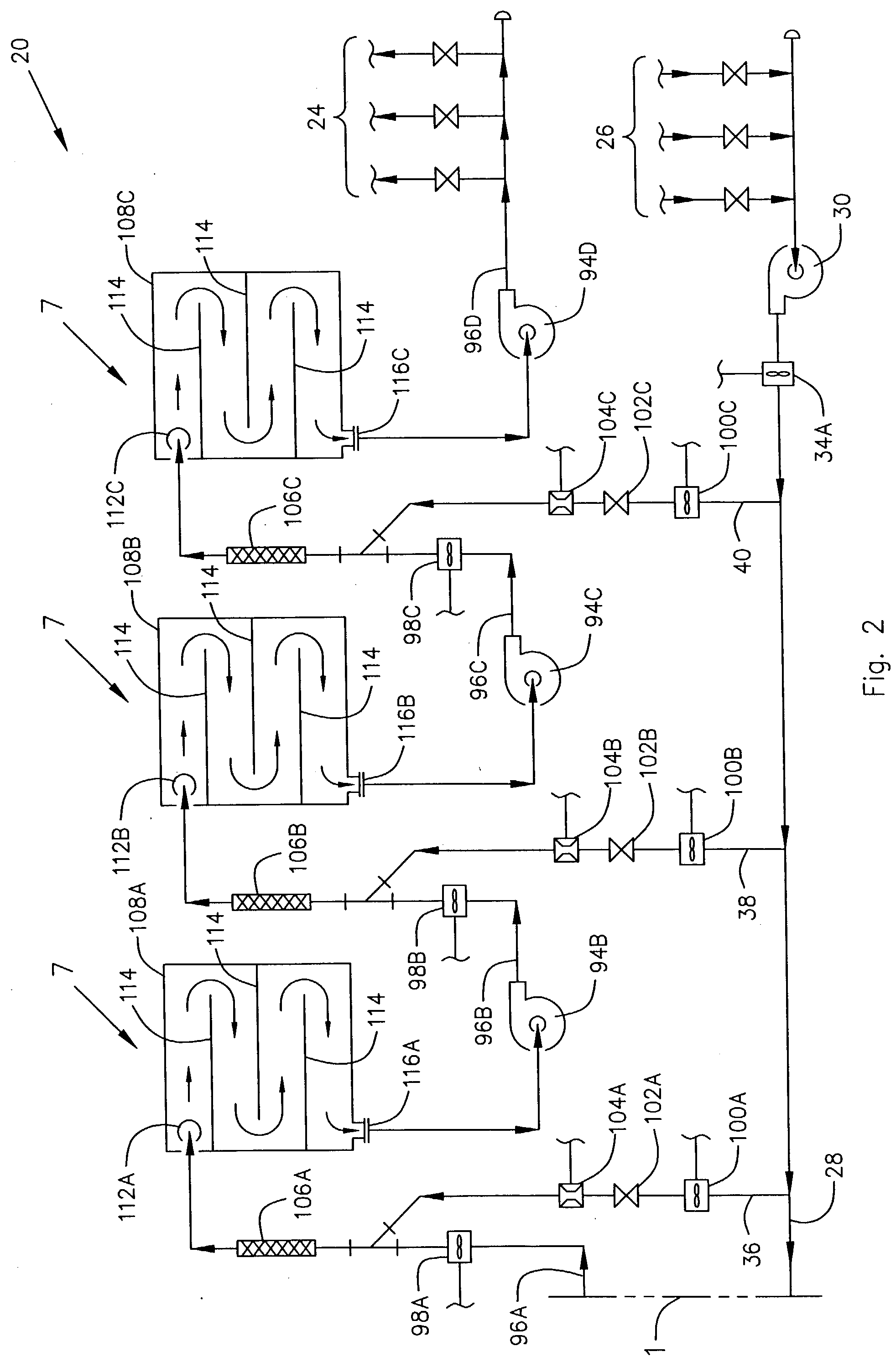

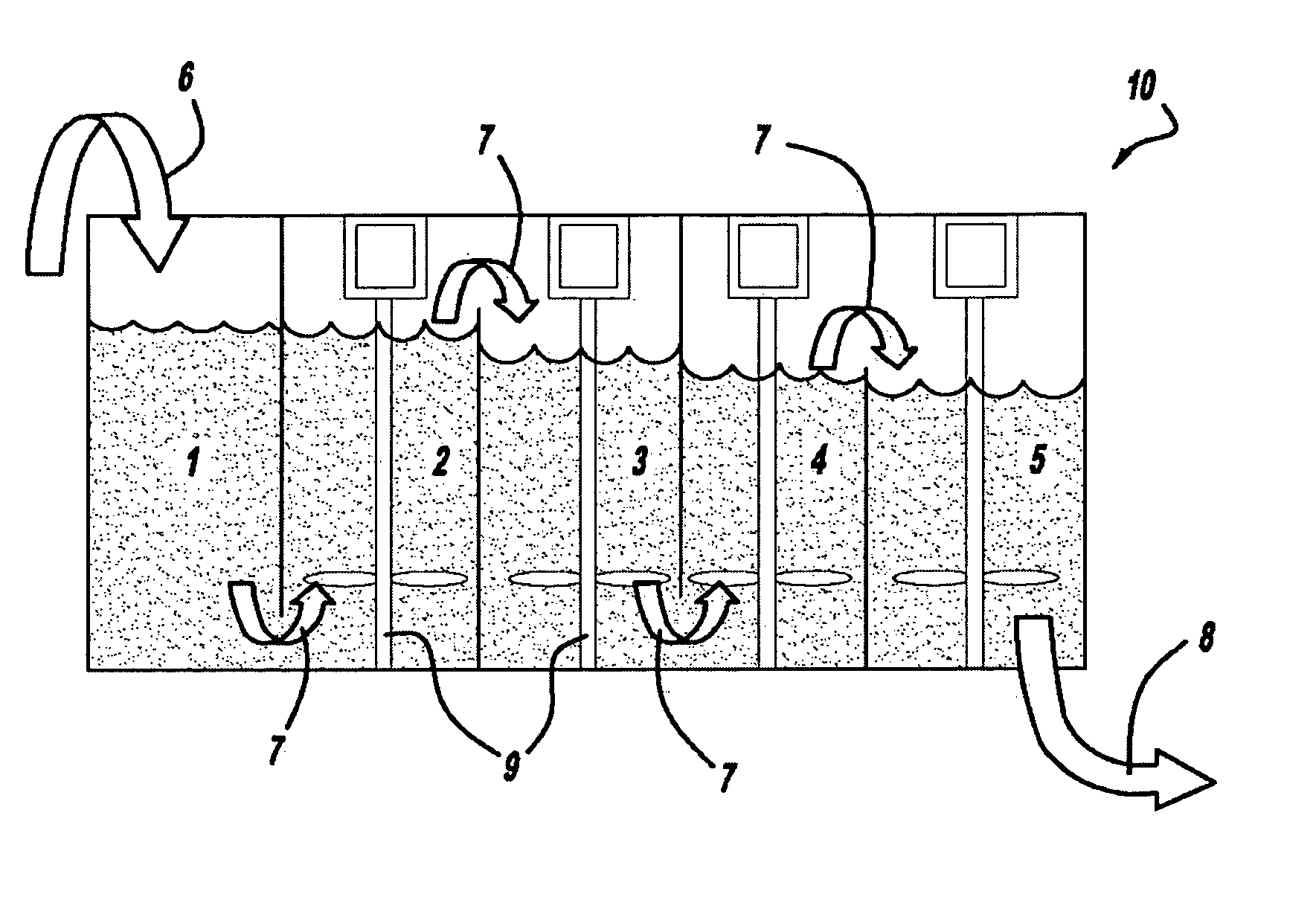

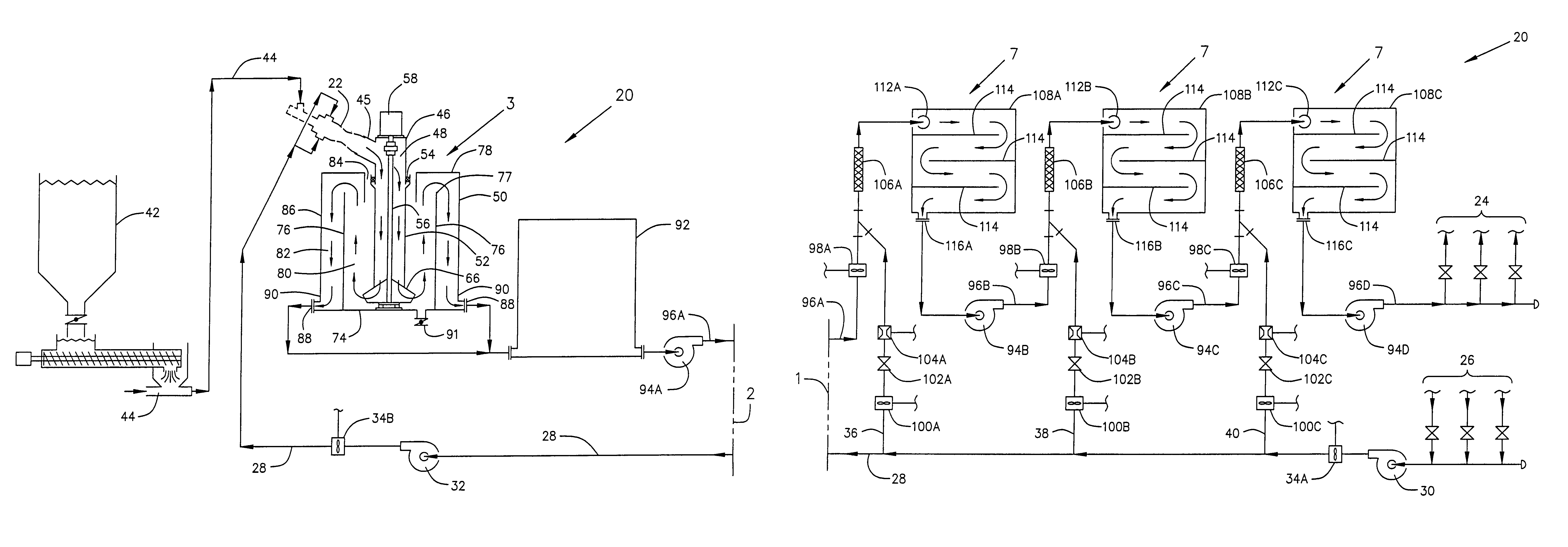

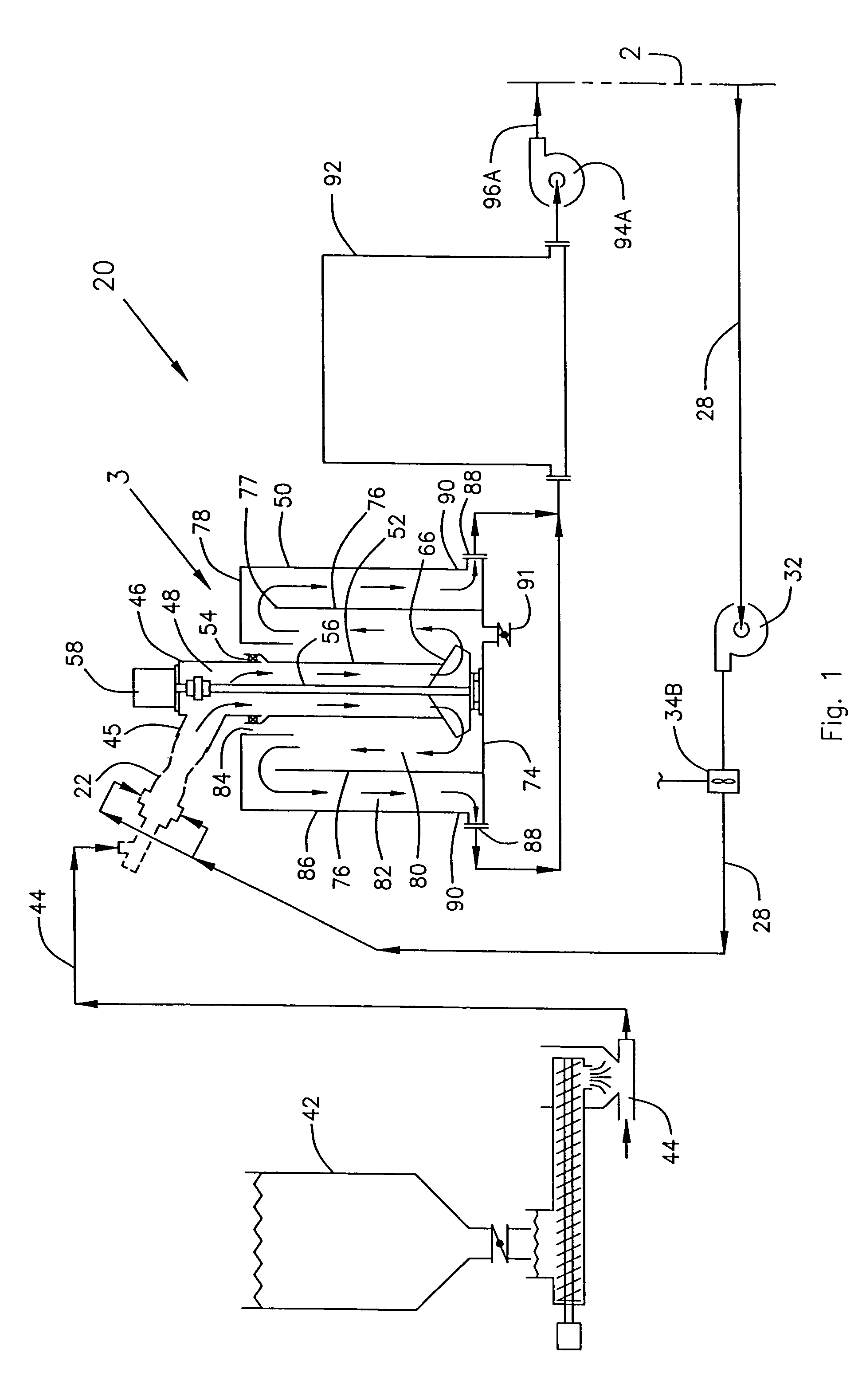

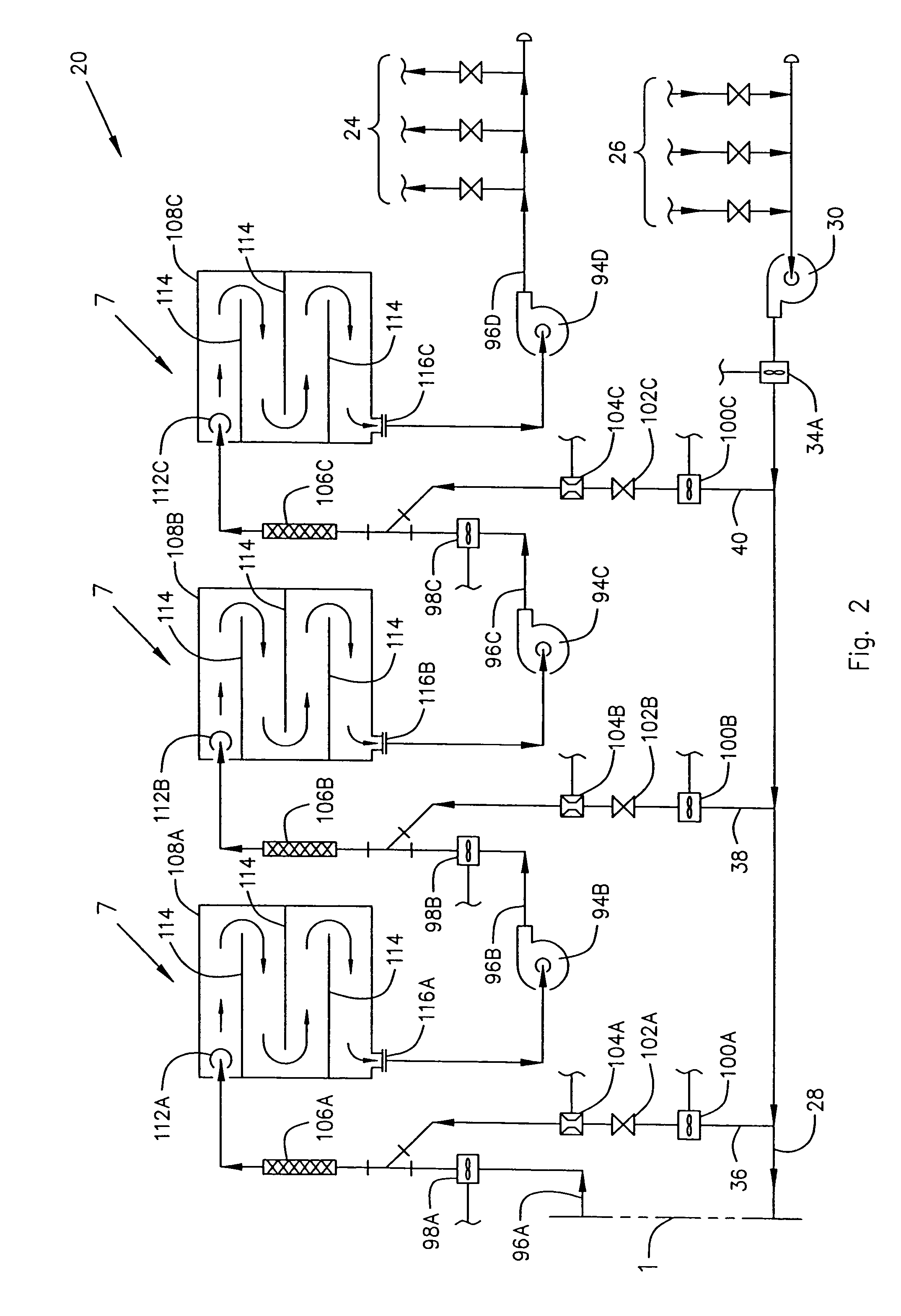

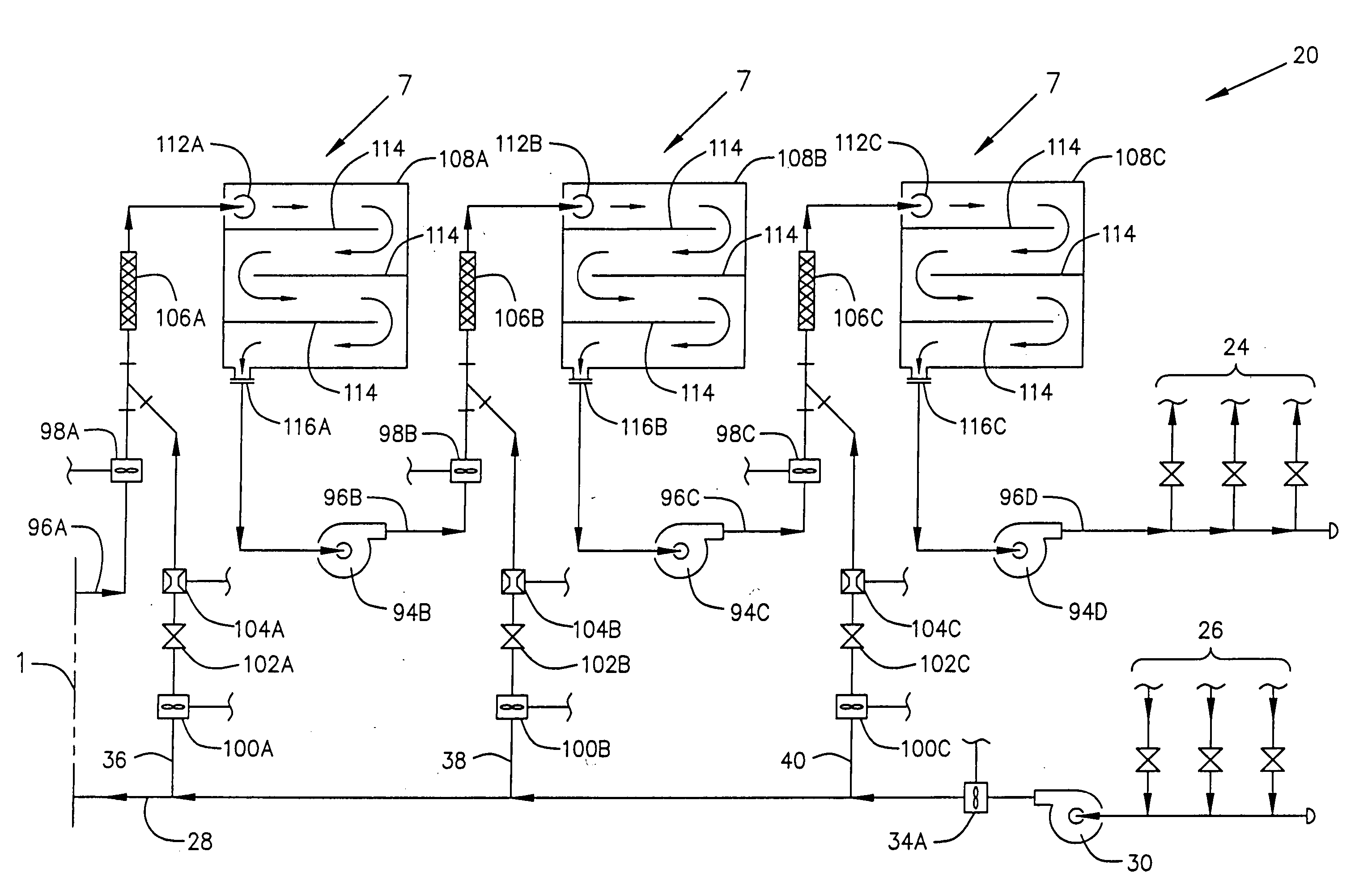

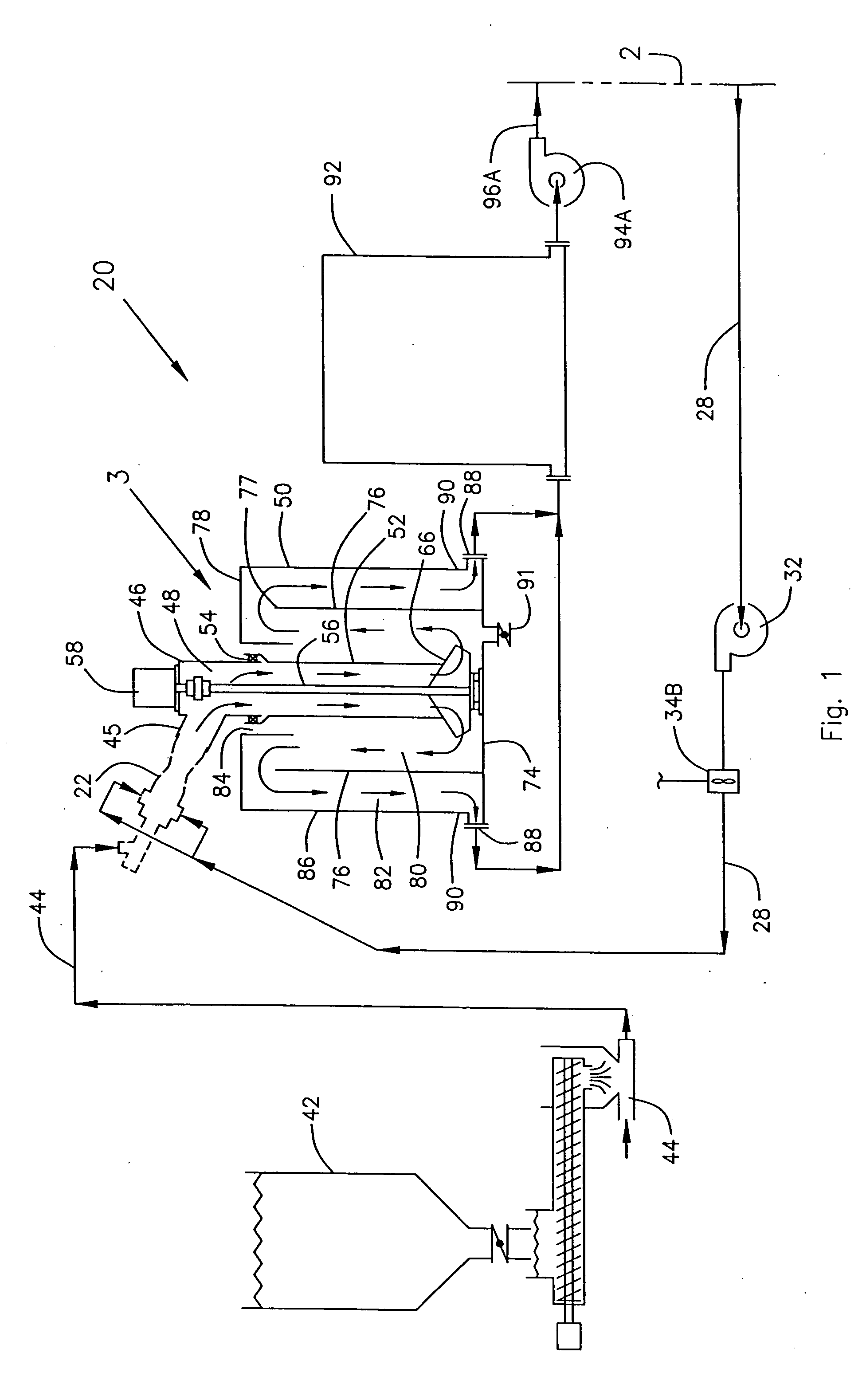

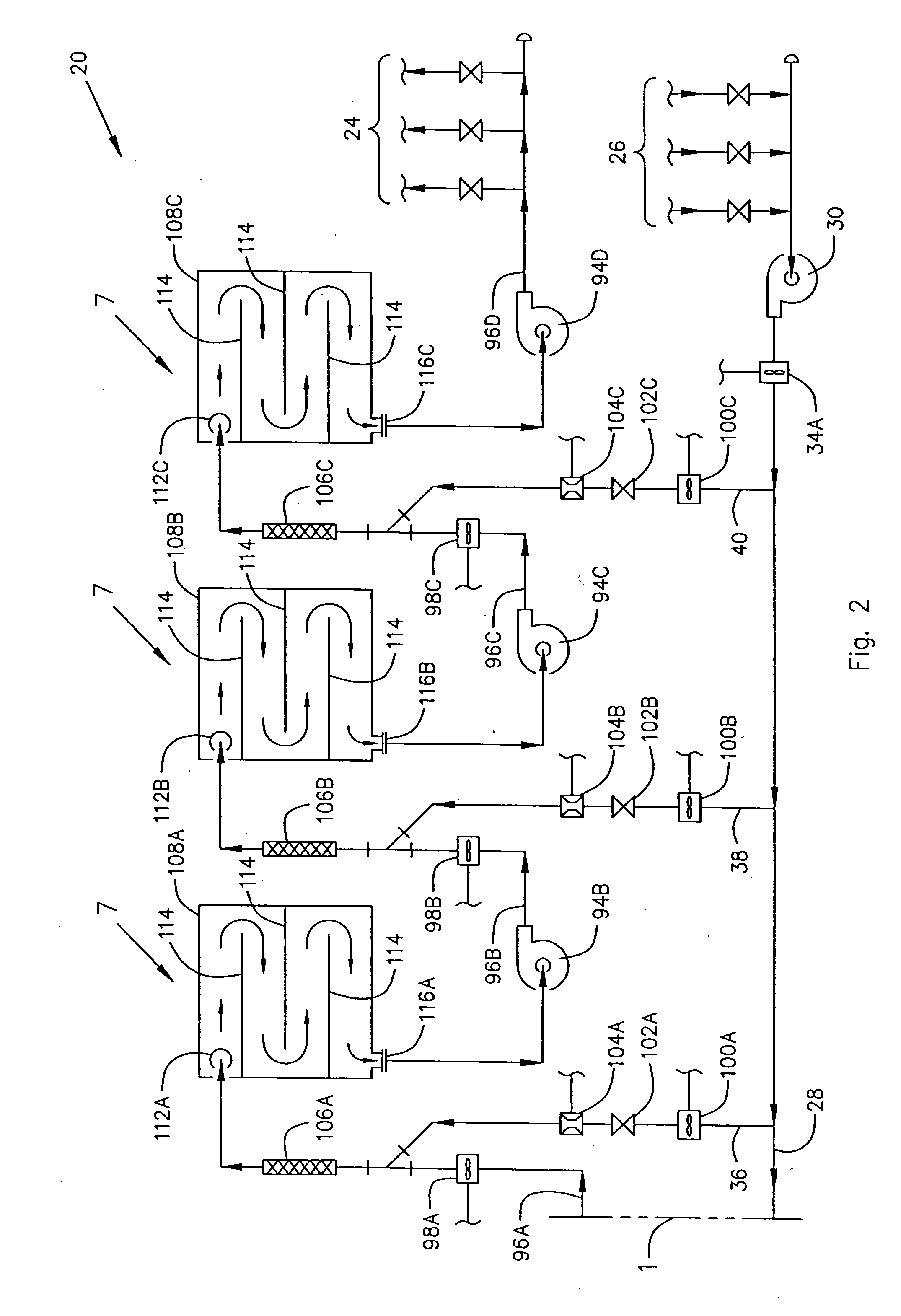

Gel mixing system

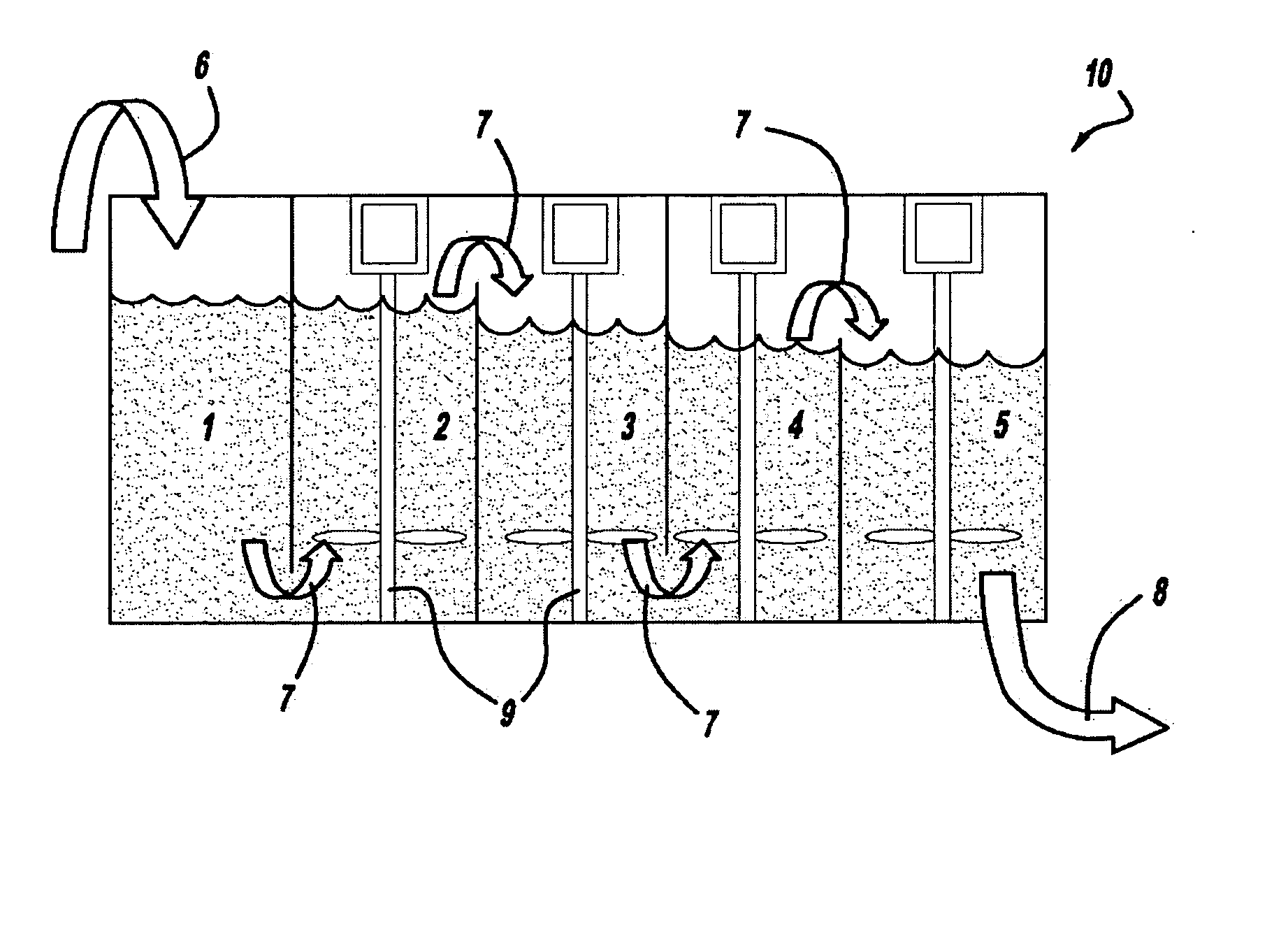

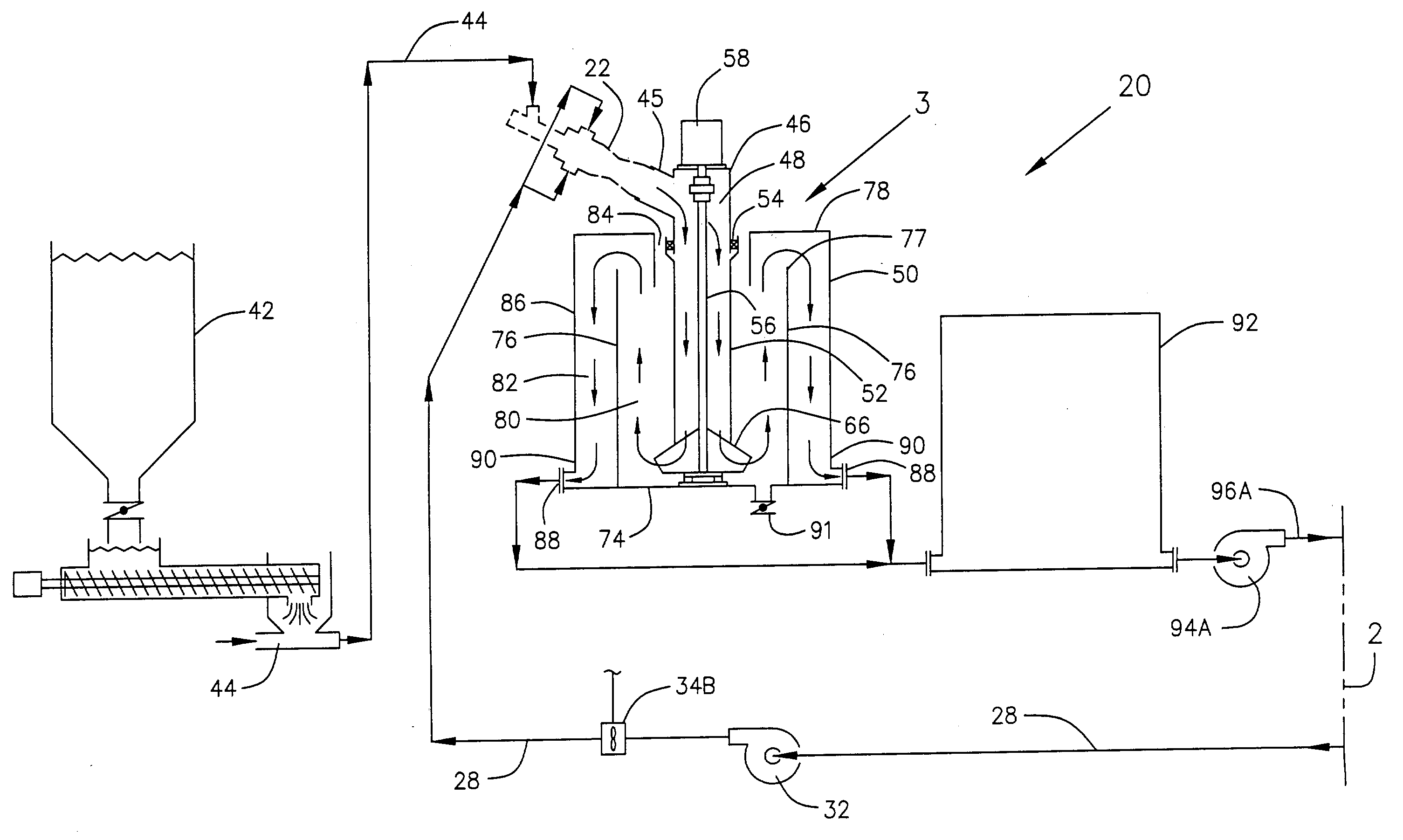

InactiveUS20040218463A1Process economyMore environmentally friendlyFlow mixersTransportation and packagingEngineeringResidence time

A gel mixing system that employs a dynamic diffuser for quickly removing the air from the fluid as the fluid exits a traditional gel mixer and employs progressive dilution of the gel in a series of hydration tanks to maximize hydration time without allowing the gel to become so viscous that it is not easily diluted or pumped. High shear agitation of the fluid between the hydration tanks helps to increase the hydration rate. Progressive dilution of the gel increases residence time of the gel in the tanks and results in longer hydration time in the limited tank space available, resulting in continuous production of gel that is almost fully hydrated when it is pumped to the fracturing blender and subsequently to the well bore without the need for an increase in the volume of the hydration tanks.

Owner:ALLEN THOMAS E

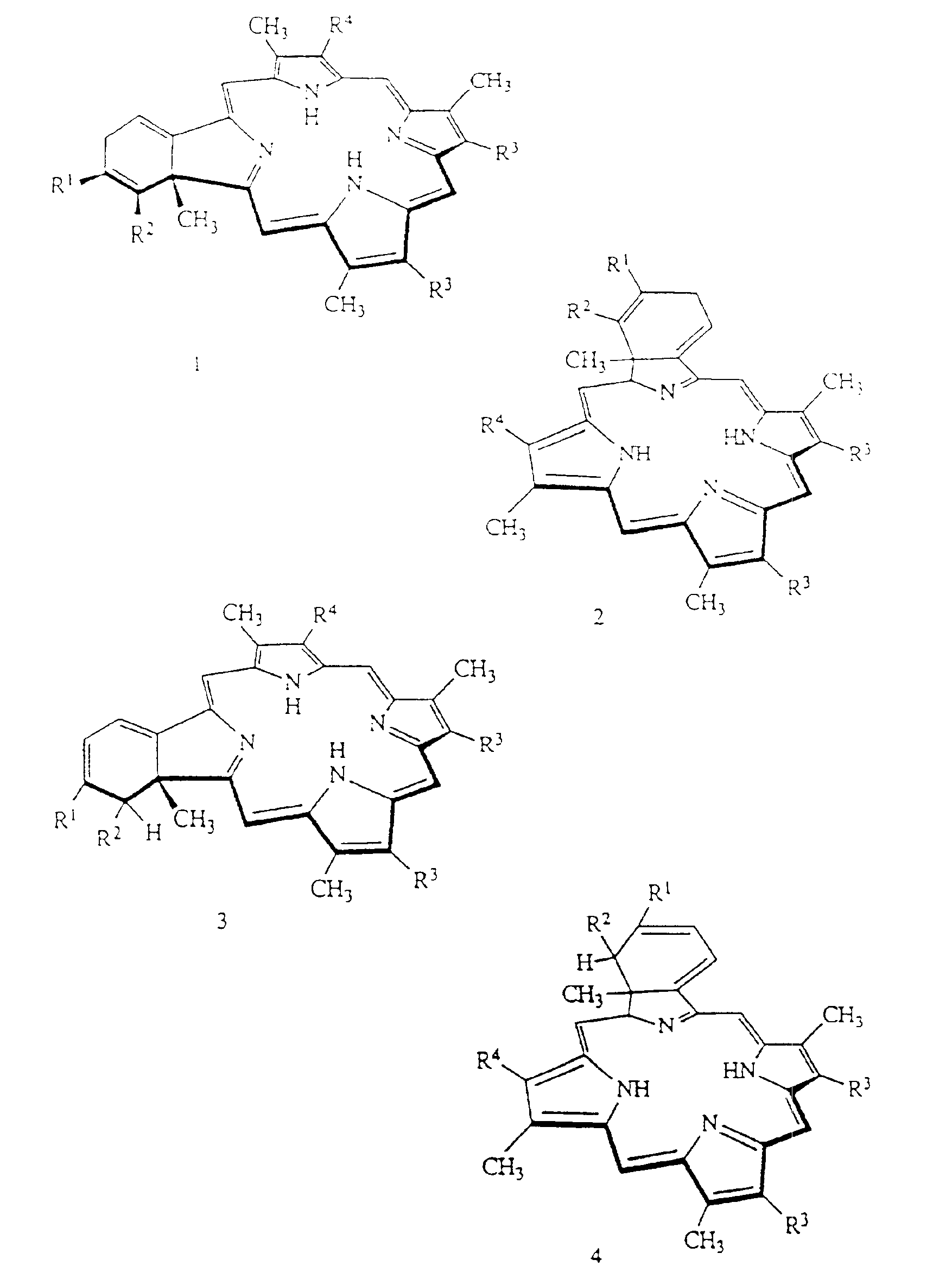

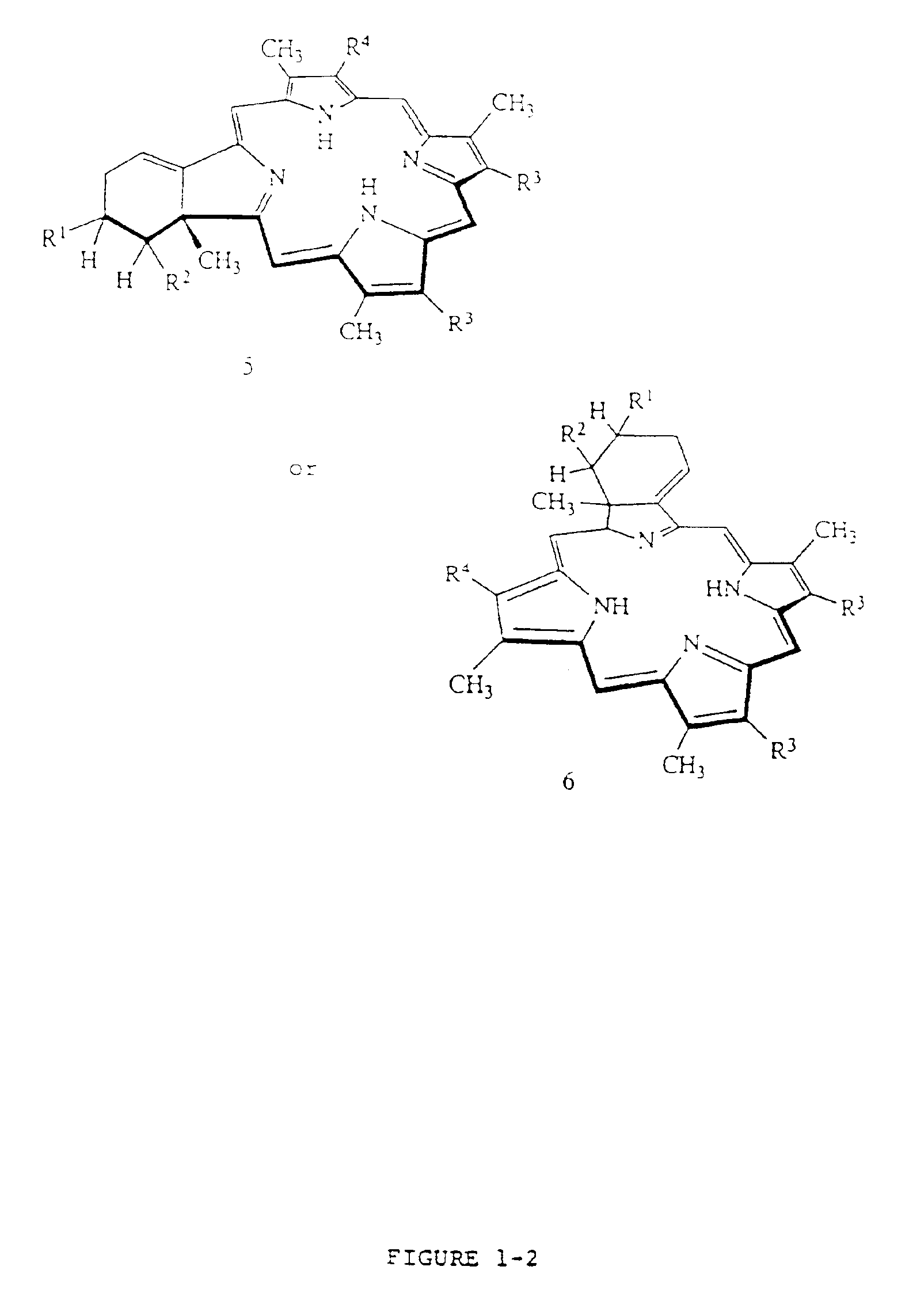

Liposome compositions of porphyrin photosensitizers

InactiveUS6890555B1Good reproducibilityHydrate fastBiocideEnergy modified materialsPhotodynamic therapyPhotosensitizer

Liposomal pharmaceutical formulations incorporating porphyrin photosensitizers useful for photodynamic therapy or diagnosis of malignant cells. The liposomal formulations comprise a porphyrin photosensitizer, particularly the hydro-mono benzoporphyrine (BPD) having light absorption maxima in the range of 670-780 nanometers, a disaccharide or polysaccharide and one or more phospholipids.

Owner:QLT INC

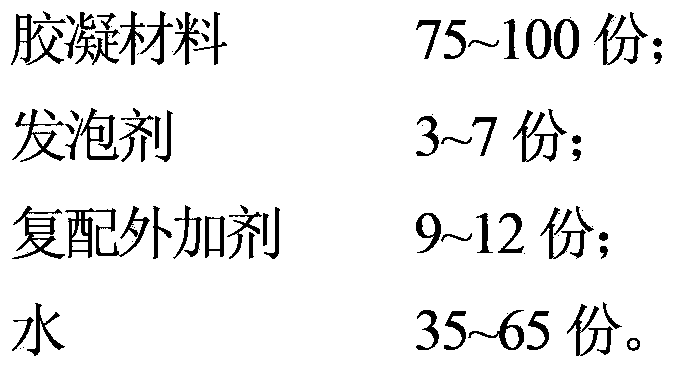

Chemical foamed concrete and preparation method thereof

The invention discloses a chemical foamed concrete and a preparation method thereof. The concrete product is prepared by using a cementing material, a foaming agent, a compounded additive and water as raw materials through a chemical foaming principle, and the added compounded additive realizes stable foaming speed stability, uniform bubble diameter and controllability. The chemical foaming preparation method has the advantages of simplicity, low production investment cost, and convenient construction. The foamed concrete product prepared in the invention has the advantages of fireproof property, waterproof property, sound insulation, heat insulation, light weight, high compressive strength and environmental protection. The bulk density, the compressive strength and the heat conduction coefficient of the obtained product are less than 400kg / m<3>, more than 3.5MPa and less than or equal to 0.07W / (M.K) respectively. The above formula adopting alkaline ash comprising alkaline furnace ashes, alkaline slag, alkaline furnace slag and other wastes as raw materials realizes comprehensive utilization of resources, changes wastes into valuables, and accords with the demands of sustainable development of national circular economy.

Owner:LIAONING JIJIA ENERGY SAVING WALL EQUIP

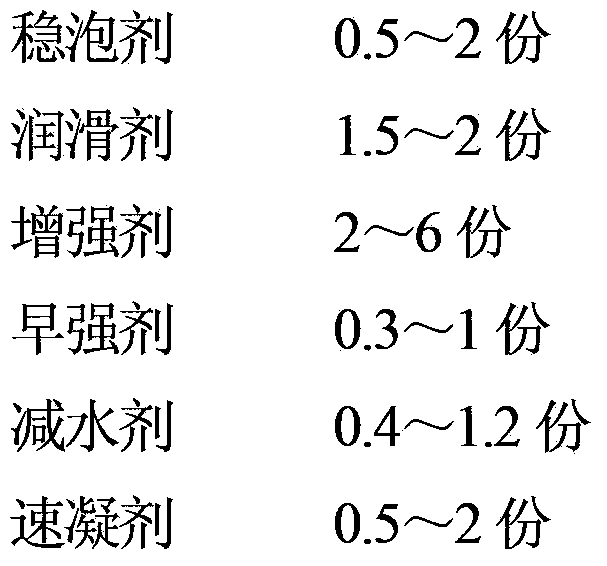

Wet gypsum accelerator and methods, composition, and product relating thereto

InactiveUS20060243171A1Improve efficiencyIncreased hydration rateGrain treatmentsPhosphatePhysical chemistry

A wet gypsum accelerator comprising ground product having a median particle size of from about 0.5 micron to about 2 microns and calcium sulfate dihydrate, water, and at least one additive selected from the group consisting of (i) an organic phosphonic compound, (ii) a phosphate-containing compound, or (iii) a mixture of (i) and (ii), is disclosed. Also disclosed are a method of preparing a wet gypsum accelerator, a method of hydrating calcined gypsum to form an interlocking matrix of set gypsum, a set gypsum-containing composition, and a set gypsum-containing product.

Owner:UNITED STATES GYPSUM CO

Method and composition of preparing polymeric fracturing fluids

InactiveUS7497263B2Reduce device sizePromote productionFluid removalDrilling compositionPolyolSized small

In the presence of certain polyols, a guar gum or similar polysaccharide thickener solution is boron crosslinked before achievement of complete hydration of the thickener, without compromising the viscosity level achieved in a fracturing fluid by the time it is pumped into the wellbore and fractures the subterranean formation adjacent the wellbore. Methods continuously involve hydrating a polysaccharide thickener to an extent of 10% to 75%, but less than full hydration. Before 75% hydration is exceeded, a boron crosslinker is added. Upon addition of the boron crosslinker, the fluid is injected into the wellbore to stimulate hydrocarbon production. Because less time is needed for hydration, well site mixing equipment is down-sized smaller to achieve better efficiency and cost savings.

Owner:SCHLUMBERGER TECH CORP

Composite cement grinding aid and preparation method thereof

The invention discloses a composite cement grinding aid and its preparation method. According to a formula, the composite cement grinding aid comprises: a grinding agent, a reinforcing agent, a surfactant, molasses, N, N-bis(2-hydroxyethyl)isopropanolamine and water. The composite cement grinding aid can enhance the fluidity of materials during grinding, effectively reduce overgrinding phenomenon of a mill, improve adhesion of the materials to a grinding body, a lining board, and a bin partition board as well as the self agglomeration phenomenon of the materials, thus increasing the machine-hour yield of the cement grinding mill by l0%-20%, enhancing the cement specific surface area to 20-40m<2> / Kg, reducing the sieve residue, optimizing cement particle gradation, promoting cement clinker hydration, and improving the cement mixture activity. The 3-day compressive strength is increased by 3-5MPa, and the 28-day compressive strength is increased by 4-8MPa. The clinker consumption is reduced by 6-10%. The cement production cost is effectively reduced, the cement security is improved, and the adaptability of cement and concrete admixtures are improved.

Owner:ZHEJIANG HUAJUN BUILDING MATERIAL

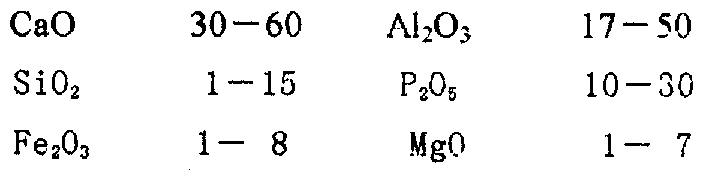

Gelatinization material of phosphoaluminic salt system

InactiveCN1498870AIncreased durabilityIncreased hydration rateCalcium biphosphateChemical composition

A cementing material is a cement whose main components are calcium phosphoaluminate, calcium aluminate and calcium phosphate. Its clinker contains such chemical components (wt%) as CaO (30-60), Al2O3 (17-50), SiO2 (1-15), P2O5 (10-30), Fe2O3 (1-8) and MgO (1-7). Its advantages are high and early strength, high refractory nature, and high compatibility with existing cement.

Owner:胡佳山

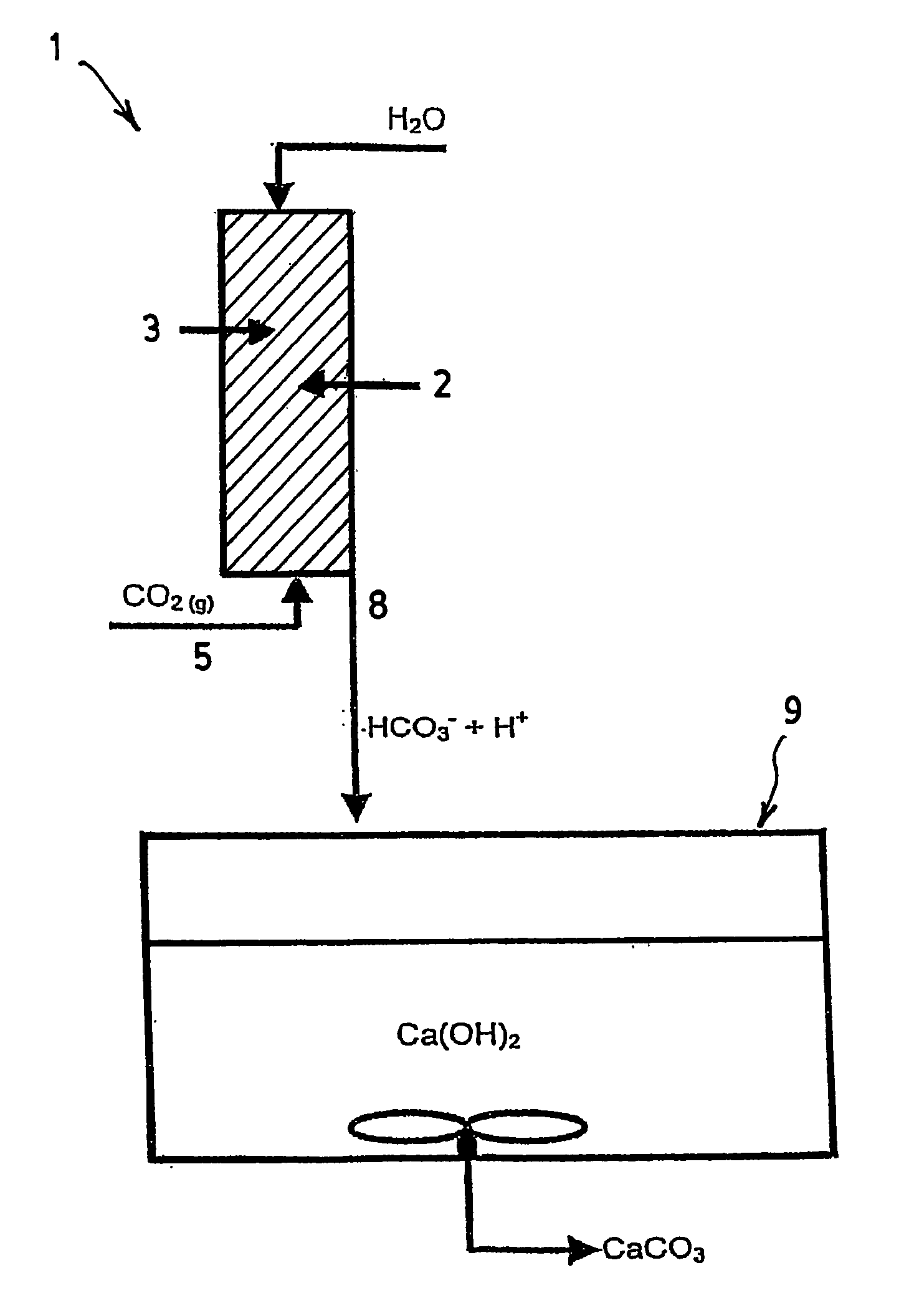

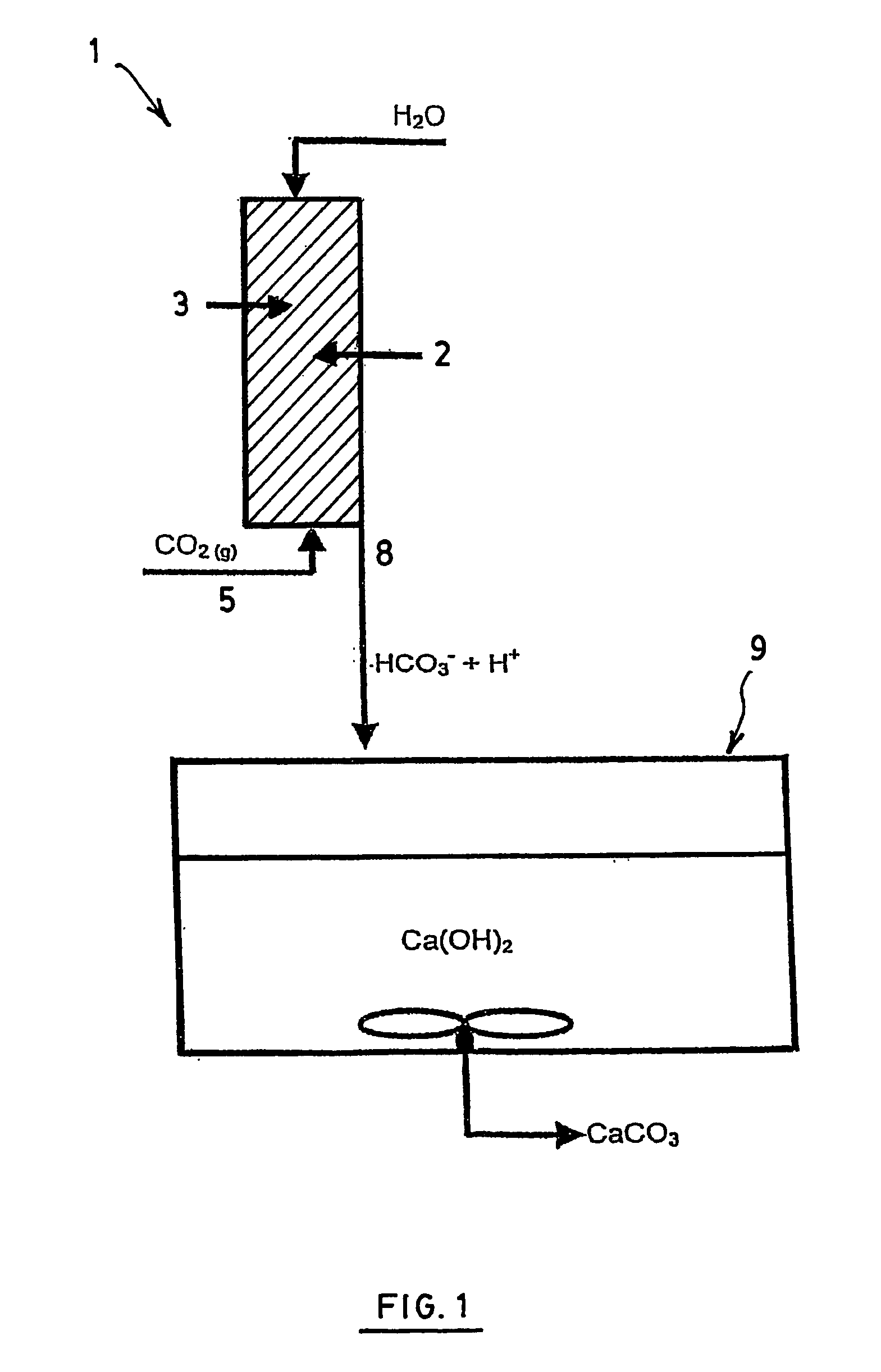

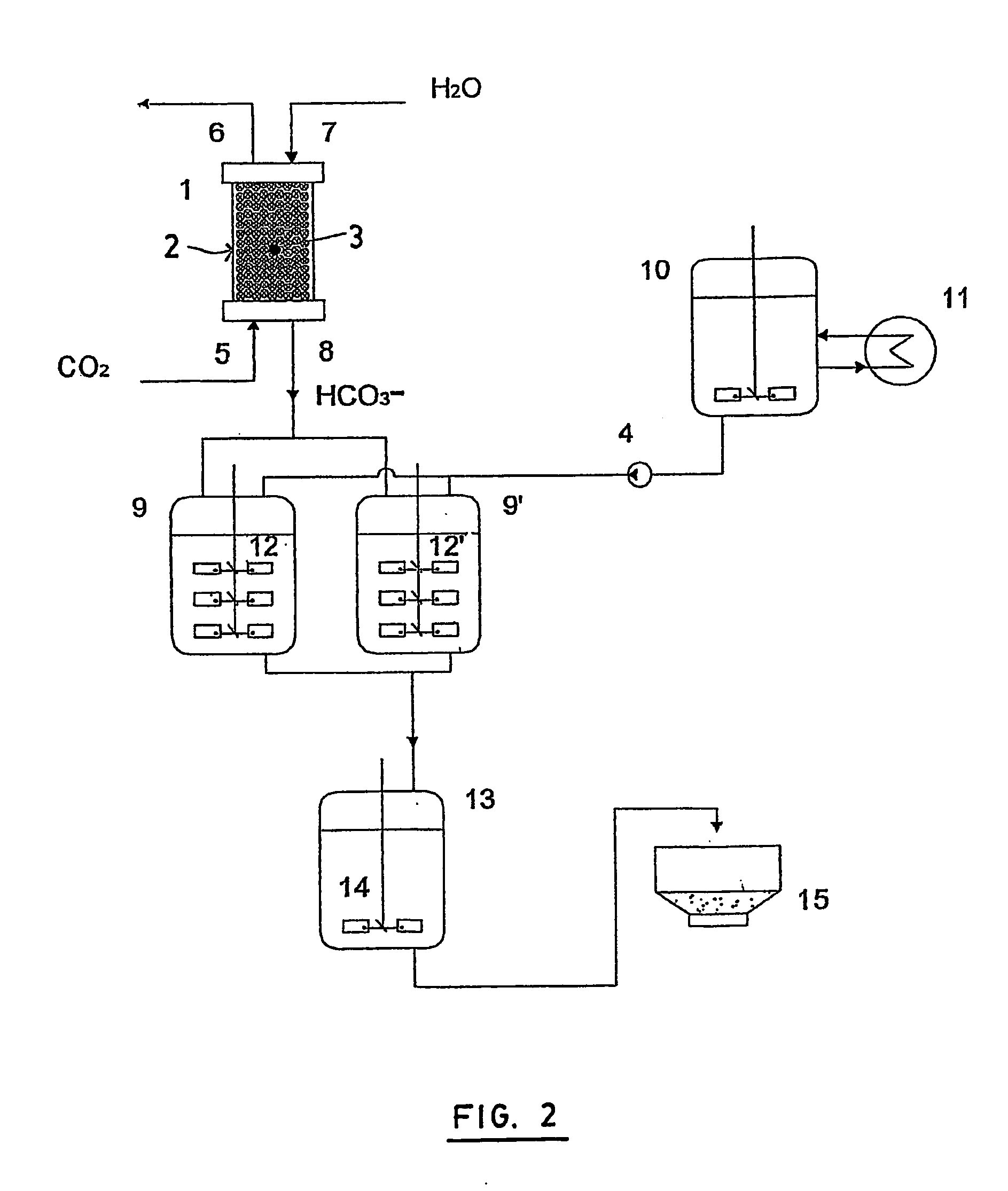

Process and an apparatus for producing calcium carbonate via an enzymatic pathway

InactiveUS20060128004A1High yieldHigh constantBioreactor/fermenter combinationsBiological substance pretreatmentsPrecipitated calcium carbonateAqueous solution

The invention relates to a method for improving the production yield of precipitated calcium carbonate (PCC). The improvement resides in the use of an enzymatic bioreactor that supplies HCO3 into the reaction enabling to produce PCC without bubbling gaseous carbon dioxide in the aqueous solution. The present invention has an industrial applicability, namely in the pulp and paper industry.

Owner:CO2 SOLUTION

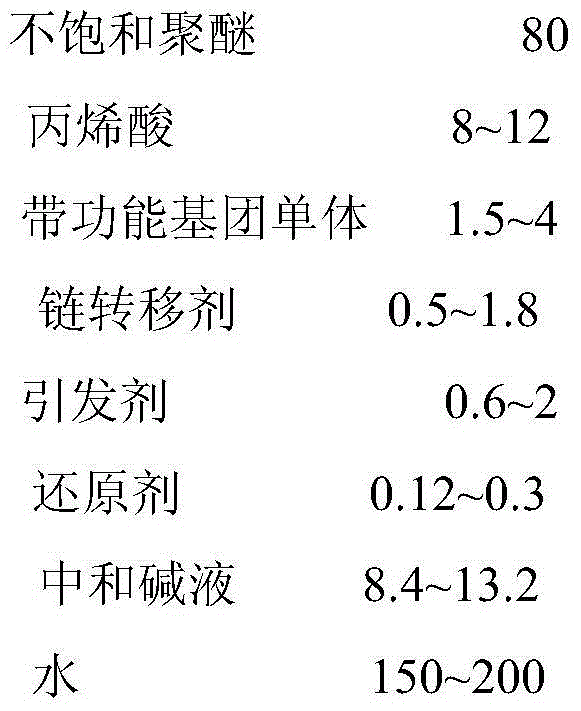

Multifunctional enhancement-type concrete admixture and preparation method thereof

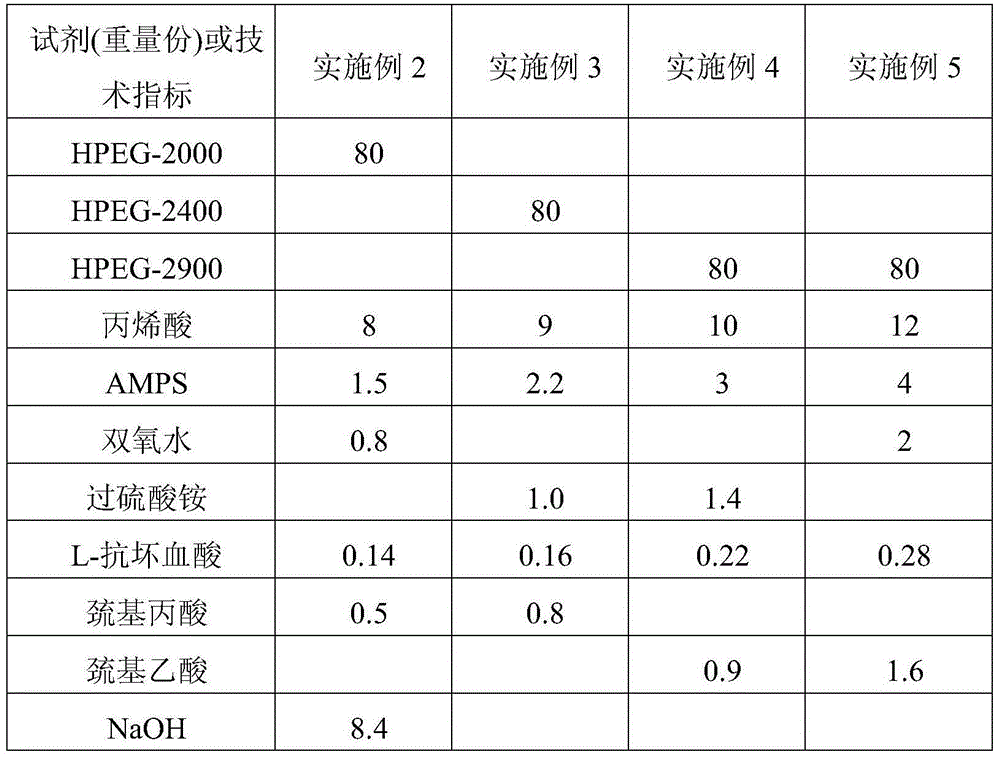

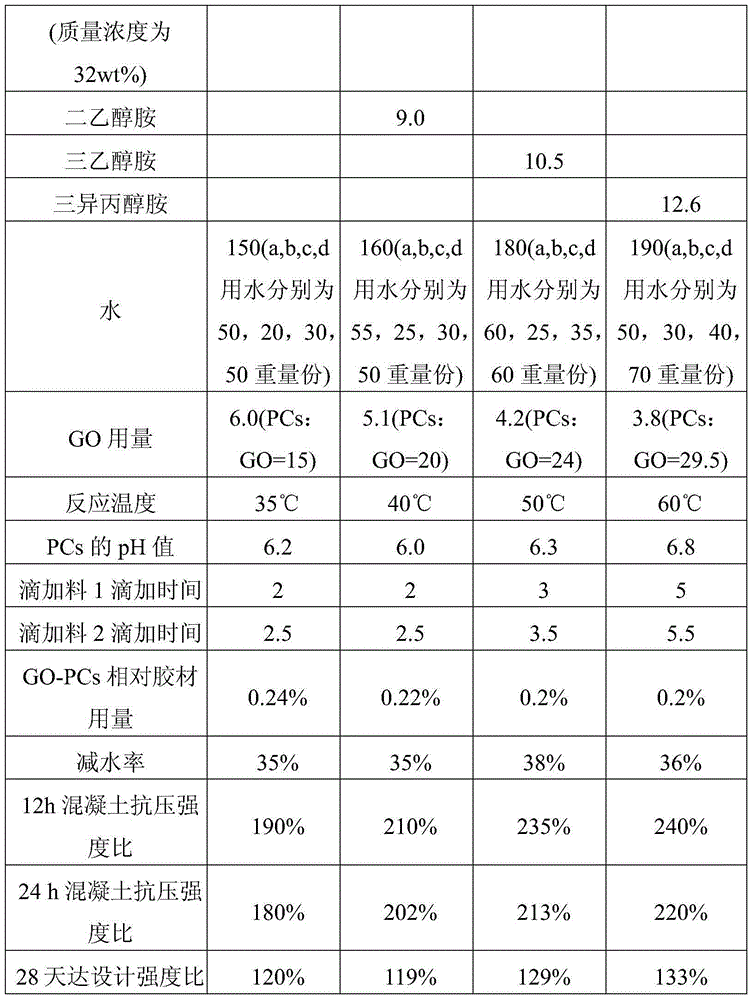

The invention relates to a multifunctional enhancement-type concrete admixture and a preparation method thereof. The concrete admixture is composed of an early-strength polycarboxylic acid water reducing agent (PCs) and nano graphene oxide (GO). The mass ratio of the solid to the GO in the early-strength water reducing agent (PCs) is (10-30):1. The early-strength polycarboxylic acid water reducing agent (PCs) is composed of the following components in parts by weight: 80 parts of unsaturated polyether, 8-12 parts of acrylic acid, 1.5-4 parts of monomer with functional groups, 0.5-1.8 parts of chain-transfer agent, 0.6-2 parts of initiator, 0.12-0.3 part of reducer, 8.4-13.2 parts of neutralizing alkali liquor and 150-200 parts of water. The admixture has an obvious enhancement action on concrete, implements high-strength long-service-life green concrete, and has important meanings in the field of application of high-strength high-performance concrete.

Owner:JIANGSU CHINA RAILWAY ARIT NEW MATEIRALS CO LTD

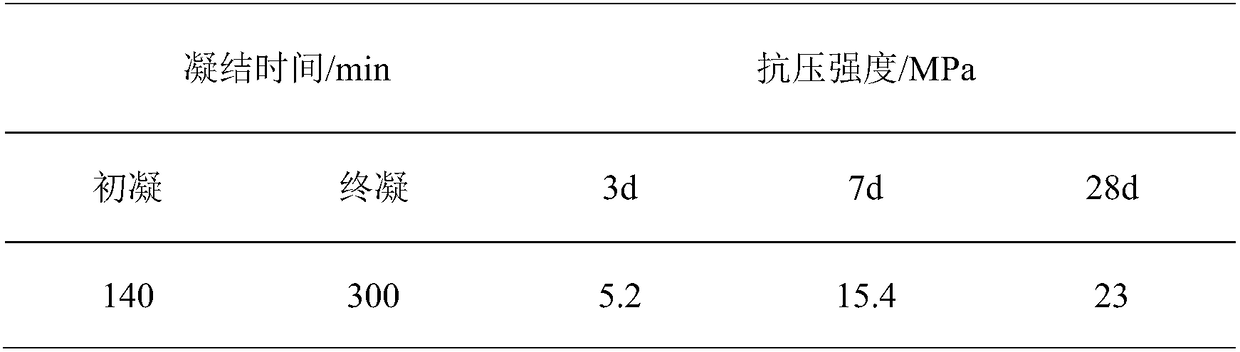

Bridge bearing mortar and production method thereof

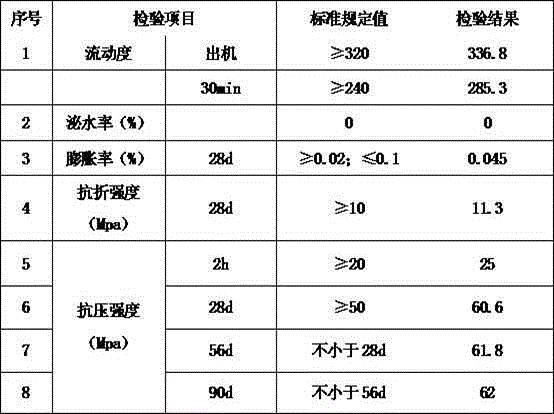

The invention relates to a bridge bearing mortar and a production method thereof. The invention is characterized in that the bridge bearing mortar is prepared from the following raw materials in parts by weight: 45-60 parts of graded quartz sand, 30-40 parts of 42.5 sulfoaluminate cement, 5-15 parts of 42.5 Portland cement, 1-10 parts of U-shaped expanding agent, 0.1-1 part of water reducing agent, 0.1-0.5 part of water retention agent, 0.01-0.1 part of early-strength admixture, 0.2-1 part of retarder and 0.01-0.03 part of defoaming agent. The bridge bearing mortar has the characteristics of low cost, excellent performance, stable quality, high fluidity, short initial and final setting time, quick strength development and favorable micro-expansion, and can be widely used in the bridge bearing mortar for high-speed railways, highways, traffic bridges and other bridges and a production method thereof.

Owner:GUANGXI NANNING BAIRUITONG SYNTHESIS BUILDING MATERIALS TECH

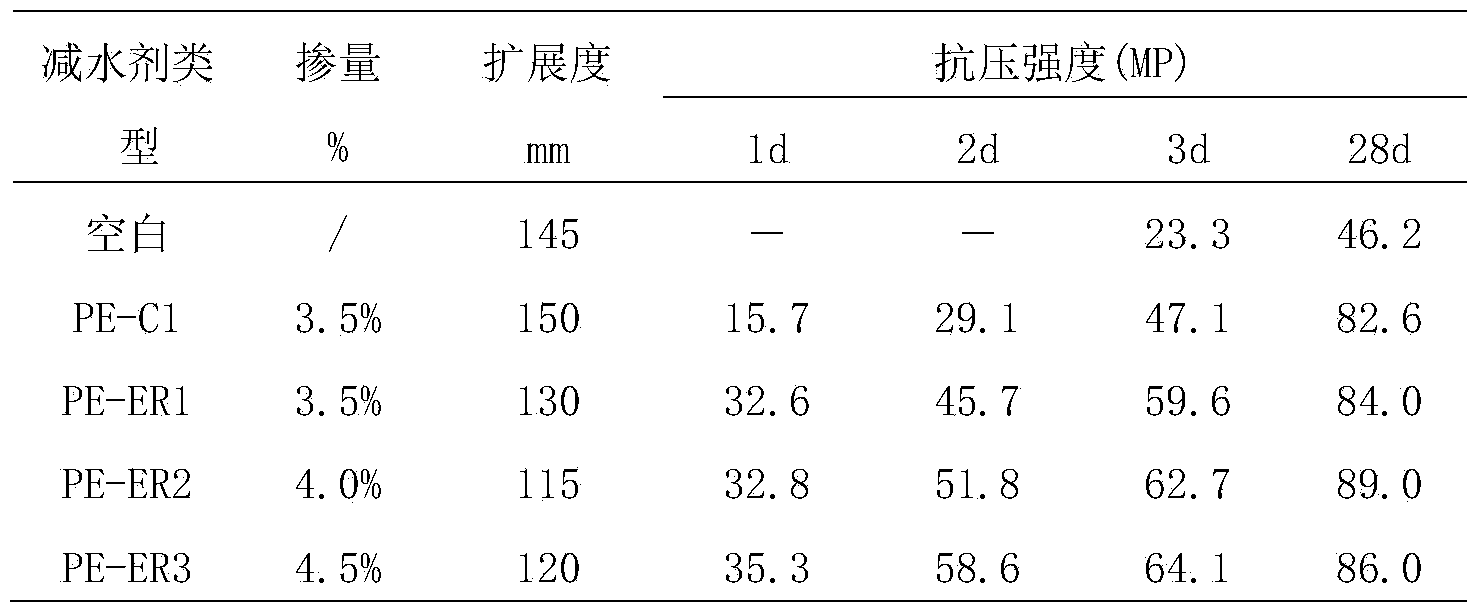

Early-strength polycarboxylate water reducing agent for component and preparation method for early-strength polycarboxylate water reducing agent

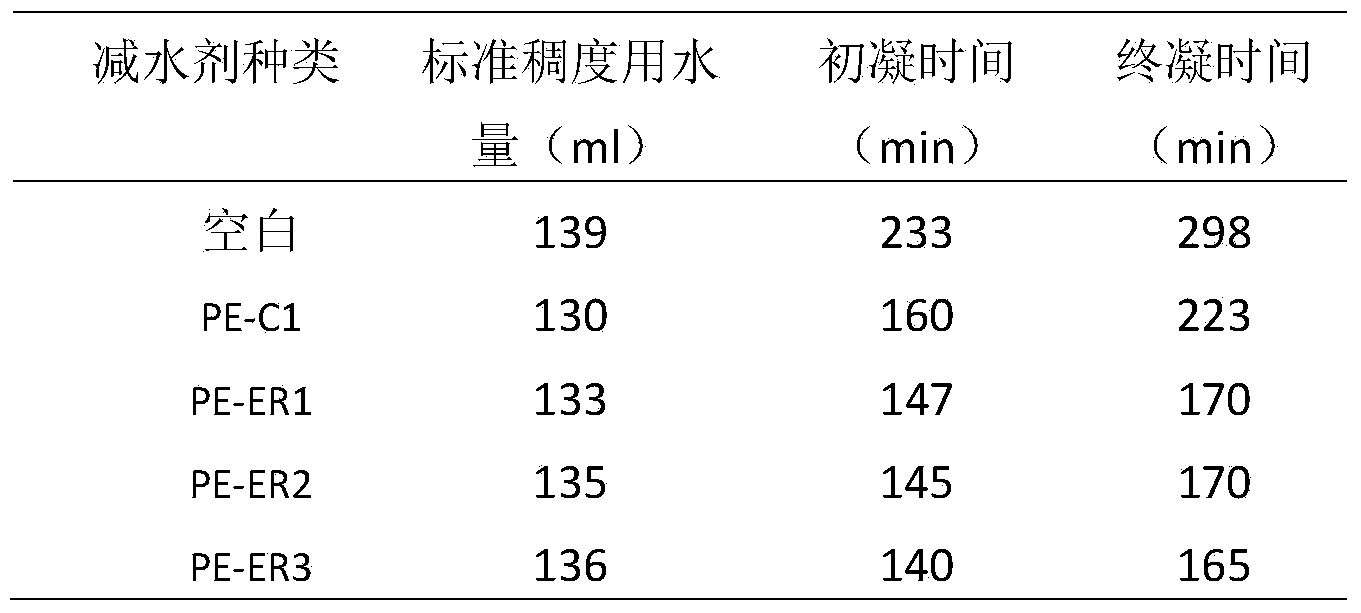

The invention discloses an early-strength polycarboxylate water reducing agent for a component and a preparation method for the early-strength polycarboxylate water reducing agent, and belongs to the field of water reducing agent preparation. The water reducing agent is formed by polymerization of the following ingredients in percentage by weight: 80-85% of methyl alkene butyl polyoxyethylene polypropylene oxide monomer with the molecular weight more than 2400, 10-15% of unsaturated monocarboxylic acid and derivative monomer thereof and 0.5-5% of unsaturated alkenyl sulfoacid and sodium salt thereof; the preparation method comprises the following steps: under the temperature condition of 20-40 DEG C, all ingredients are enabled to be subjected to polymerization reaction in an aqueous solution by adopting a redox initiation system, after polymerization reaction is performed, neutralization is performed through a neutralizing agent, so that the polymer with low air entraining amount and good dispersibility is obtained; the early-strength performance of the polycarboxylate water reducing agent is reinforced with the increasing of the macromonomer molecular weight; the using requirements of early strength or super early strength of the component are met.

Owner:广西宝添环保材料有限公司

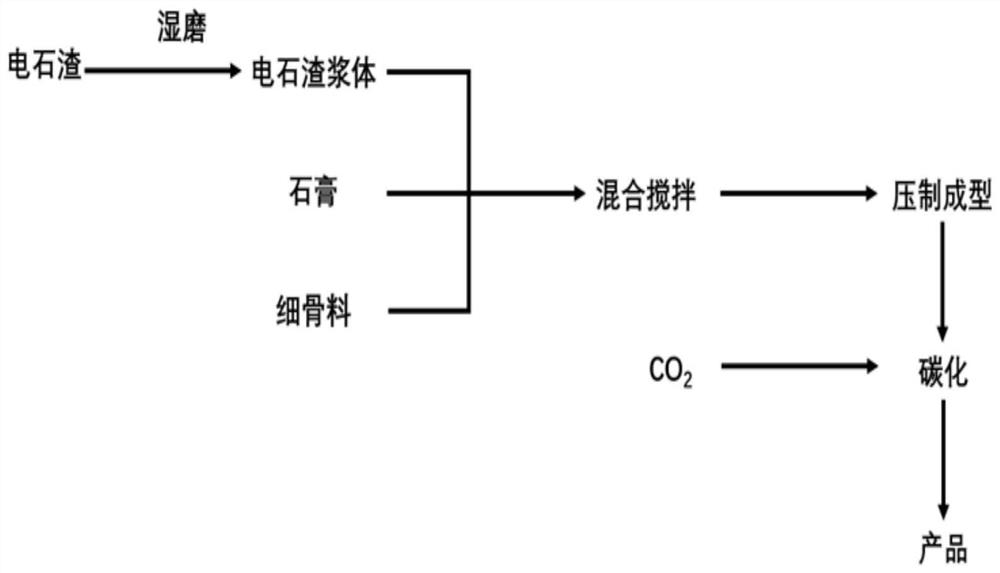

Method for preparing carbonized brick from wet-milling carbide slag

The invention provides a method for preparing a carbonized brick from wet-milling carbide slag. The method comprises the following steps: carrying out wet milling on 150-300 parts of carbide slag and75-150 parts of water to realize refining of carbide slag particles and high alkalinity of a liquid phase; preparing 120-200 parts of wet-milled carbide slag slurry, 10-35 parts of gypsum and 50-120 parts of slag as cementing materials, adding 420-865 parts of fine aggregate and 0-18 parts of wate and fully and evenly stirring the components, press-shaping the the stirred raw materials, and performing maintenance in a carbonization chamber to obtain the wet-milling carbide slag carbonized brick. By adopting the method, gas carbon dioxide can be cured, and environmental pollution caused by industrial waste gas is reduced; by utilizing the advantage that the wet-milling carbide slag is easy to carbonize and is easy to react with carbon dioxide to form calcium carbonate, and precipitate and crystal growth have cohesion, the prepared brick is high in strength and short in curing age, the production efficiency is improved, and the brick can effectively replace a common brick for construction.

Owner:HUBEI UNIV OF TECH

Gel mixing system

ActiveUS7581872B2Extended stayIncrease volumeControlling ratio of multiple fluid flowsFlow mixersEngineeringResidence time

Owner:SERVA CORP

Very early setting ultra-high strength cement

Clinkered materials containing high concentrations of {(C,K,N,M)4(A,F,Mn,P,T,S)3(cl,{overscore (S)})} (crystal X), and {(C2S)3(C{overscore (S)})3 Ca(f,cl) 2} or {(C2S)3(C{overscore (S)})3Ca(f,cl)2} (crystal Y), and / or {C5S2{overscore (S)}) (crystal Z) directly from the kiln, rapidly hardening ultra-high early strength cement including these clinkered materials, methods for forming and using said compositions and the cements so produced are claimed. The methods include the steps of forming a mixture of raw material containing CaO, MgO, Al2O3, Fe2O3, TiO2, Mn2O3, SiO2, SO3, Na2O, K2O, P2O5 and F, respectively designated C, M, A, F, T, Mn, S, {overscore (S)}, N, K, P and f, and heating said mixture to an elevated temperature between 900° C. and 1,200° C.; before determining average amount of crystals X, Y, and Z. Final mixtures comprising these clinkers and hydraulic or portland type cement are made to produce cement compositions having crystal X concentrations of approximately 5% to 35% by weight, crystal Y concentrations of approximately 5% to 40% by weight, and / or crystal Z concentrations of approximately 5% to 40% by weight, with the remainder being hydraulic or portland type cement. The cements so produced are rapid hardening and exhibit high strengths ranging from 2,000 psi to 7,000 psi in one hour, 6,000 to 8,000 psi in one day and 9,000 to 12,000 psi in 28 days. They are sulfate and sea-water attack resistant and have low heats of hydration, minimal shrinkage, and high water impermeability. The methods claimed also results in significant reduction in gaseous emissions including SOx, NOx and COx.

Owner:ULTIMAX CORP

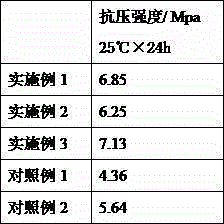

Concrete compound type chloride-free early strength agent and preparation method thereof

InactiveCN105198273AImprove cement strengthGood curing speed and strengthSodium silicateTriethanolamine

The invention relates to a concrete compound type chloride-free early strength agent and a preparation method thereof and belongs to the technical field of early strength agents. The early strength agent comprises components in parts by weight as follows: 20-40 parts of calcium carboxylate, 10-15 parts of alkali carbonate, 5-10 parts of triethanolamine, 5-10 parts of formamide, 3-6 parts of naphthalene sulfonate, 5-10 parts of sodium sulfate, 3-5 parts of sodium silicate, 3-5 parts of trisodium phosphate, 3-6 parts of alkanolamide, 2-4 parts of cellulose ether and 4-7 parts of aluminum dihydrogen phosphate. According to the provided compound water reducer, cement hydration can be accelerated by means of added calcium carboxylate; aluminum dihydrogen phosphate is added and used for controlling a space structure of components, and the cement strength is improved; after the water reducer is applied to cement, the water reducer has better curing speed and strength.

Owner:宋介珍

Sleeve grouting material for connecting fiber reinforced steel bars and preparation method thereof

The invention belongs to the field of construction materials, and particularly discloses a sleeve grouting material for connecting fiber reinforced steel bars. The sleeve grouting material is preparedfrom the following materials in parts by weight: 390-410 parts of cement, 90-110 parts of a doping material, 460-500 parts of sands, 1.4-1.6 parts of a defoaming agent, 6-8 parts of a composite waterreducer, 40-50 parts of a composite retarder, 35-40 parts of a composite swelling agent, 7-10 parts of a composite early strength agent, 6-8 parts of composite fibers and 135-145 parts of water. According to the sleeve grouting material for connecting fiber reinforced steel bars and the preparation method thereof, the performance indexes of the grouting material accord with specification requirements, the composite fiber can effectively achieve the effects of reinforcement, toughening and preventing crack extension in comparison with the sleeve grouting material for connecting steel bars without fiber reinforcement, and the rupture strength, tensile strength and structural stability of the grouting material can be remarkably improved.

Owner:成都宏基建材股份有限公司

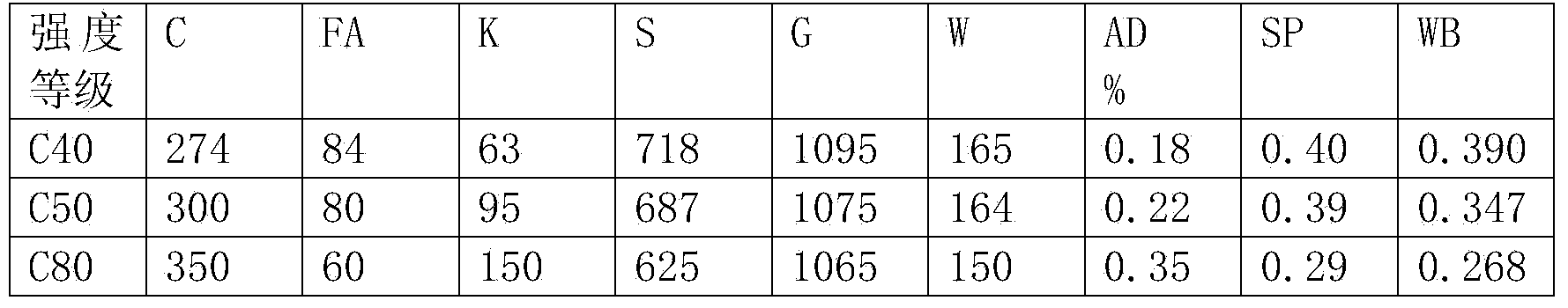

Alkali-activated and nano-enhanced early strength type ultra-high performance concrete and preparation method thereof

The invention discloses a preparation method of alkali-activated and nano-enhanced early strength type ultra-high performance concrete. The concrete is characterized in that the formula comprises theproduction raw materials in parts by mass: 650-720 parts of Portland cement, 95-130 parts of silica fume, 165-185 parts of mineral powder, 5-10 parts of nano silicon dioxide, 1050-1075 parts of quartzsand, 96-128 parts of straight steel fibers, 24-32 parts of torsional steel fibers, 13.725-15.54 parts of water glass with modulus of 1.2-1.3, 13.75-18.13 parts of a water reducing agent and 154.7-202 parts of water. The method has the advantage that the liquidity and early strength of the ultra-high performance concrete are remarkably improved.

Owner:成都宏基建材股份有限公司

Polymeric gel delivery system for pharmaceuticals

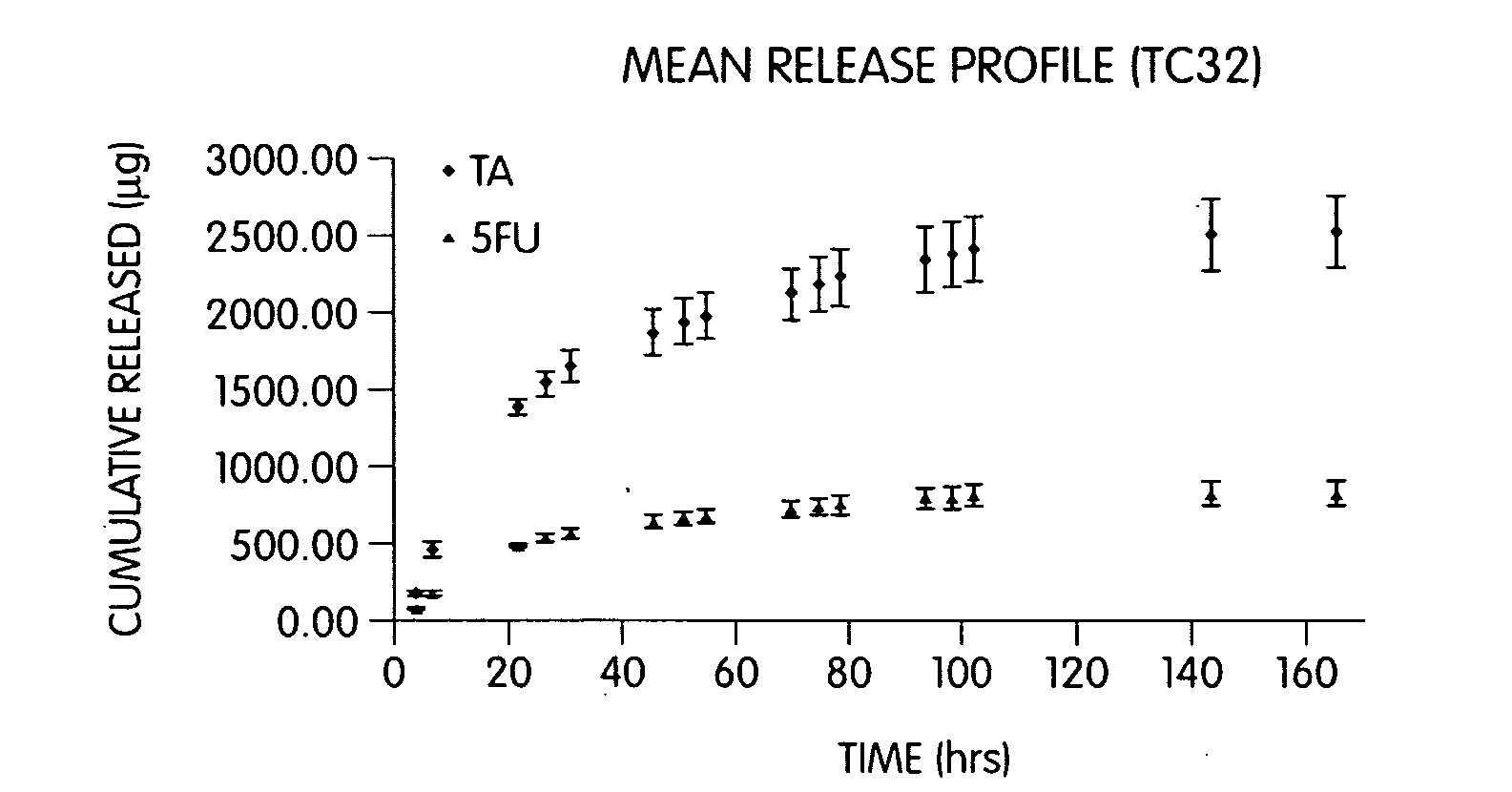

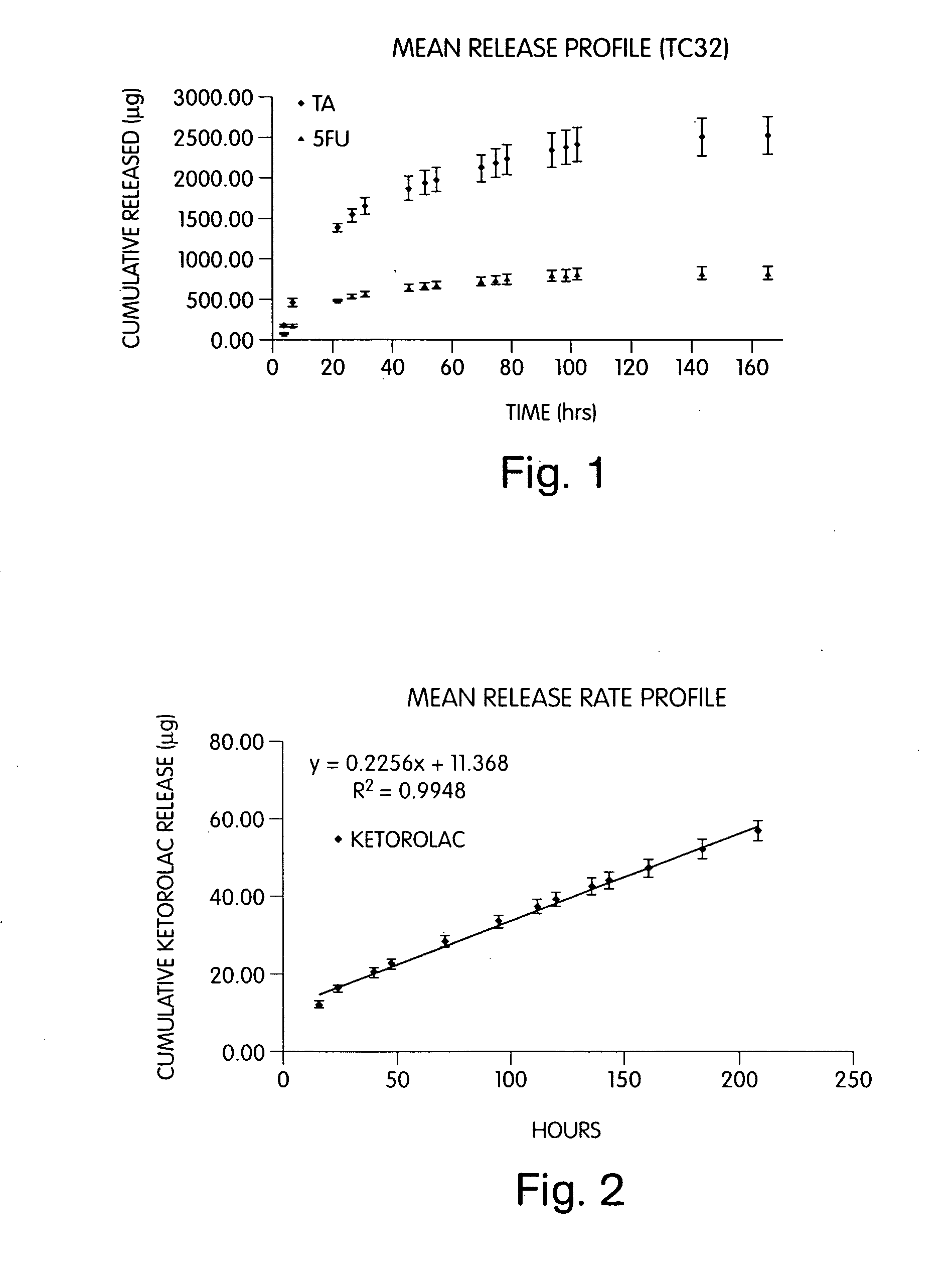

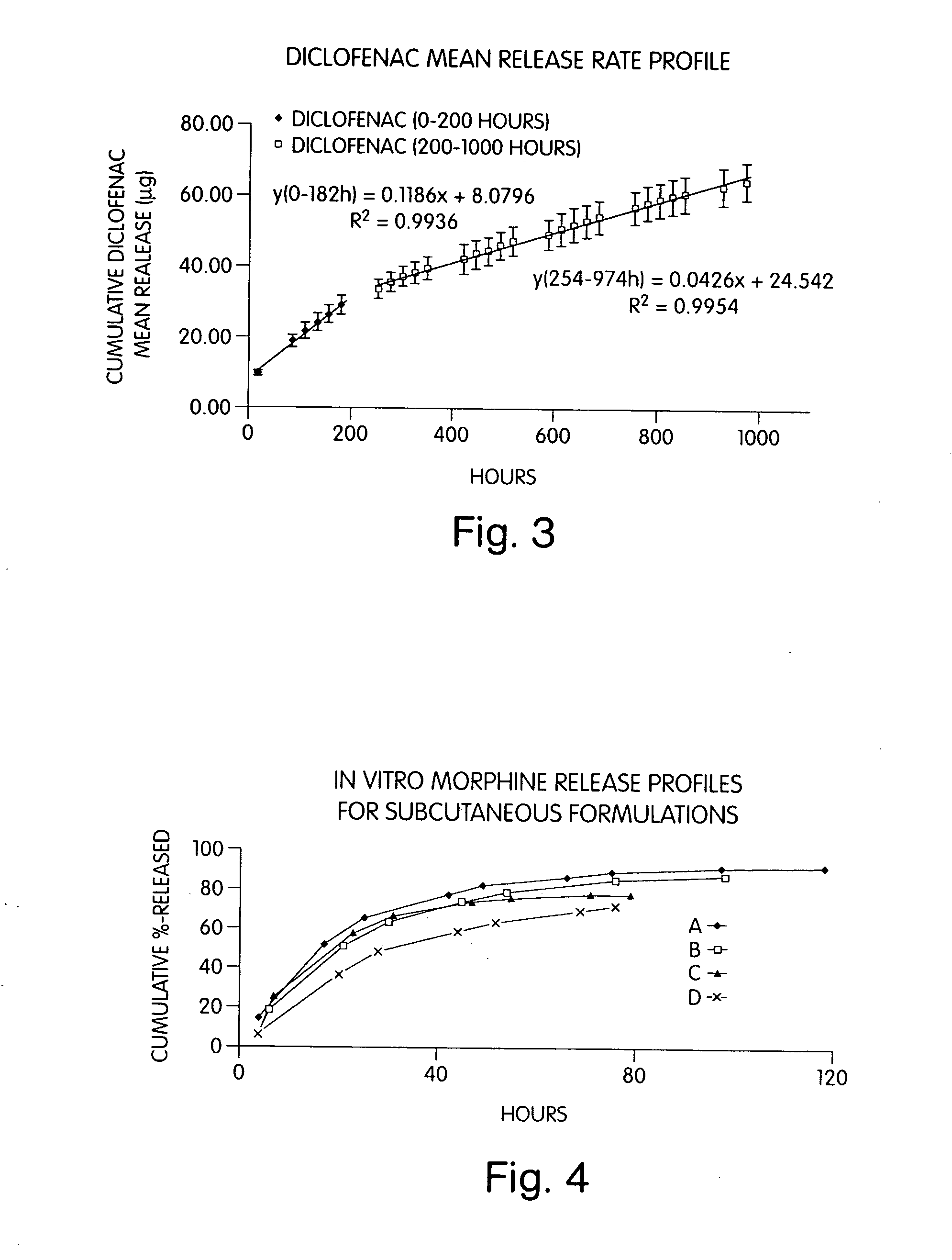

InactiveUS20090010986A1Increased hydration rateIncrease drug release rateBiocideSenses disorderBody fluidAdduct

Implantable, injectable, insertable, or otherwise administrable compositions that form hydrogels when implanted, injected, inserted, or administered into or onto living tissues comprise a pharmaceutically effective compound wherein the pharmaceutically effective compound is a codrug, or pharmaceutically acceptable salt or prodrug thereof in admixture with a hydrogel-forming compound. The pharmaceutically effective compound may be any compound that is soluble in bodily fluids, or that forms bodily fluid-soluble adducts when exposed to bodily fluids. Exemplary compounds include analgesic, anti-inflammatory and antibiotic compounds. The hydrogel-forming compound is a biologically tolerated substance that forms a hydrogel upon exposure to bodily fluids, such as the interstitial fluid surrounding or within a joint.

Owner:PSIVIDA US INC

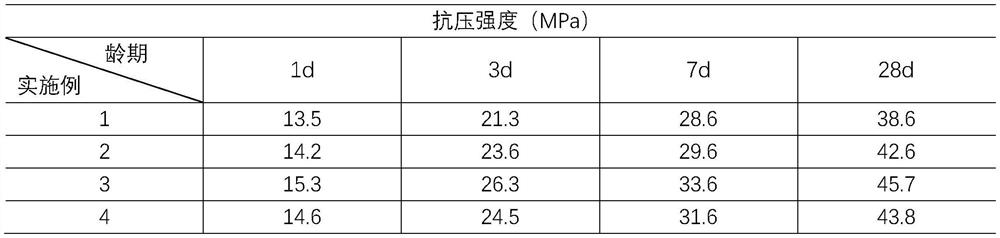

Method for preparing grouting material by using water-containing red mud synergistic blast furnace slag

The invention provides a novel red mud-based grouting material and preparation method thereof. The grouting material is prepared from the following components by weight percent: 70-80% of red mud liquid, 15-25% of blast furnace slag powder, 5-10% of compound alkali-activator, 2-10% of water reducing agent and 1-2% of early strength agent. The novel red mud-based grouting material prepared from redmud and the blast furnace slag powder is good in fluidity, high in early strength and short in time of coagulation, and does not shrink. The preparation method provided by the invention reasonably utilizes industrial waste, can reduce the influence of the waste on the environment, and is easy in preparation; the method is simple in steps, convenient to operate and high in practicability.

Owner:SHANDONG UNIV

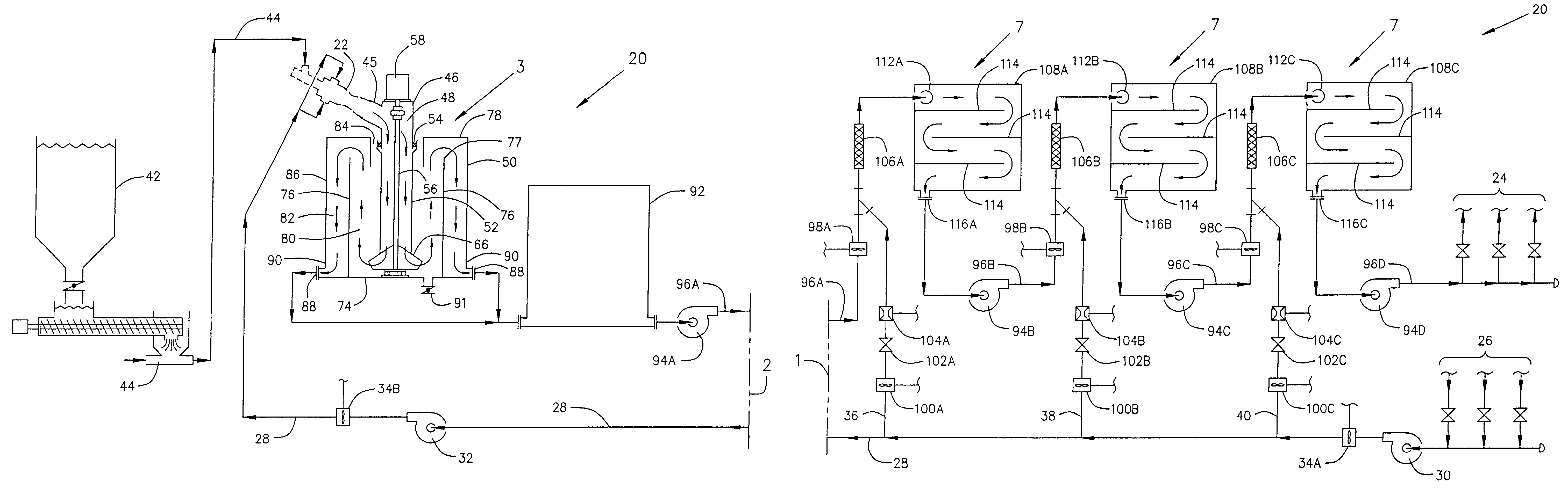

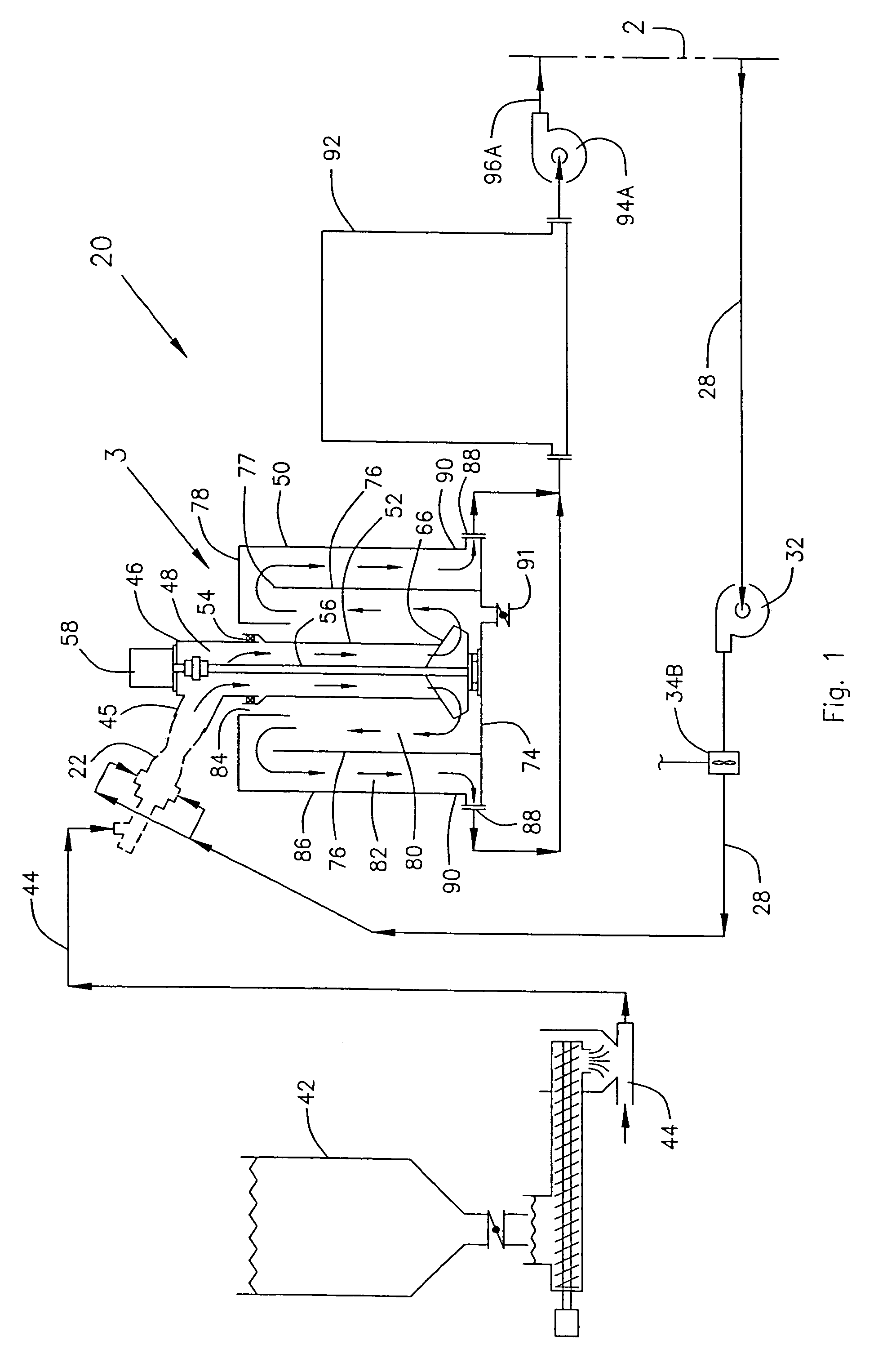

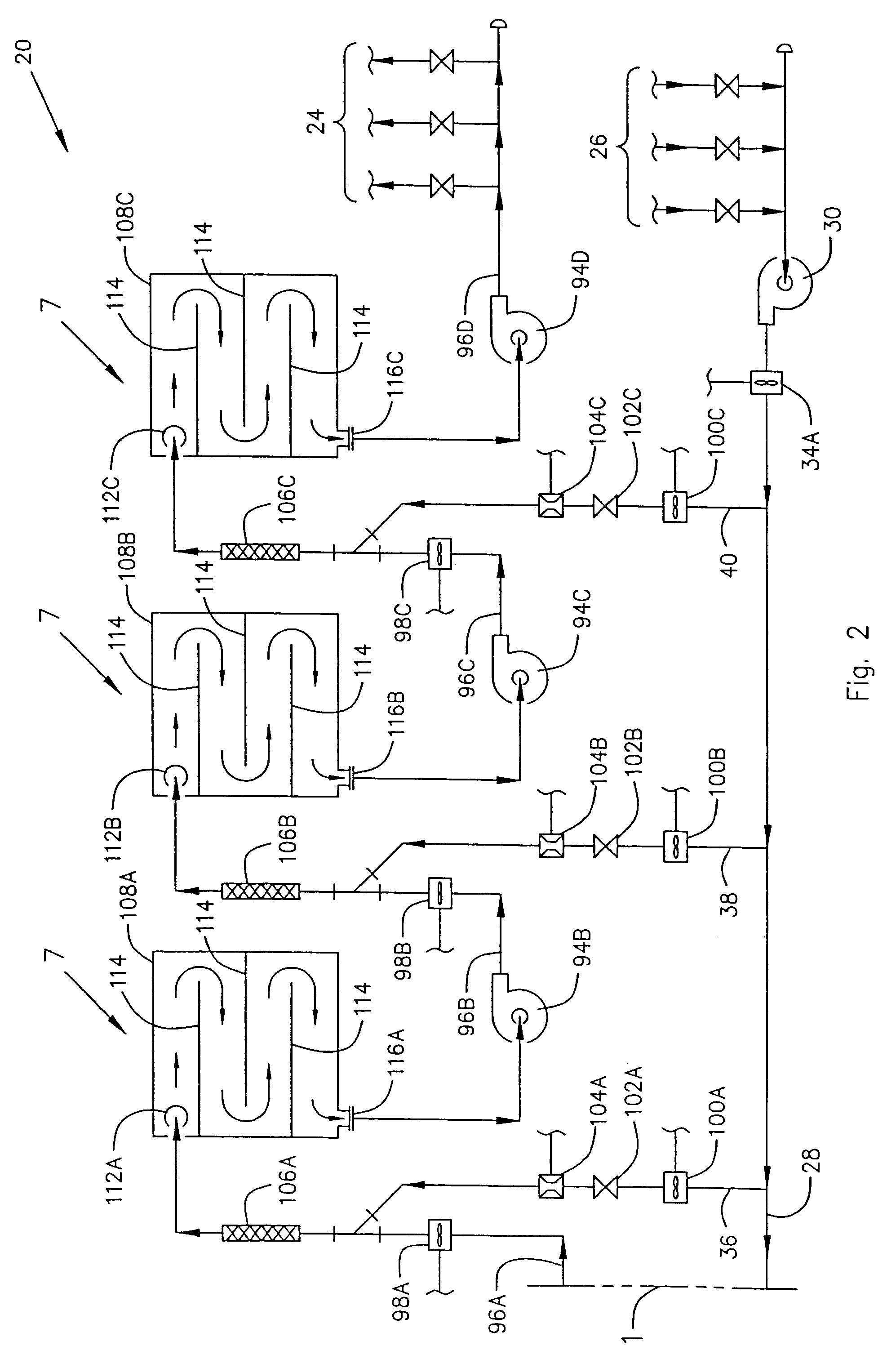

Gel mixing system

ActiveUS20060146643A1Long hydration timeMaximize hydration timeControlling ratio of multiple fluid flowsFlow mixersEngineeringContinuous production

A gel mixing system that employs a dynamic diffuser for quickly removing the air from the fluid as the fluid exits a traditional gel mixer and employs progressive dilution of the gel in a series of hydration tanks to maximize hydration time without allowing the gel to become so viscous that it is not easily diluted or pumped. High shear agitation of the fluid between the hydration tanks helps to increase the hydration rate. Progressive dilution of the gel increases residence time of the gel in the tanks and results in longer hydration time in the limited tank space available, resulting in continuous production of gel that is almost fully hydrated when it is pumped to the fracturing blender and subsequently to the well bore without the need for an increase in the volume of the hydration tanks.

Owner:SERVA CORP

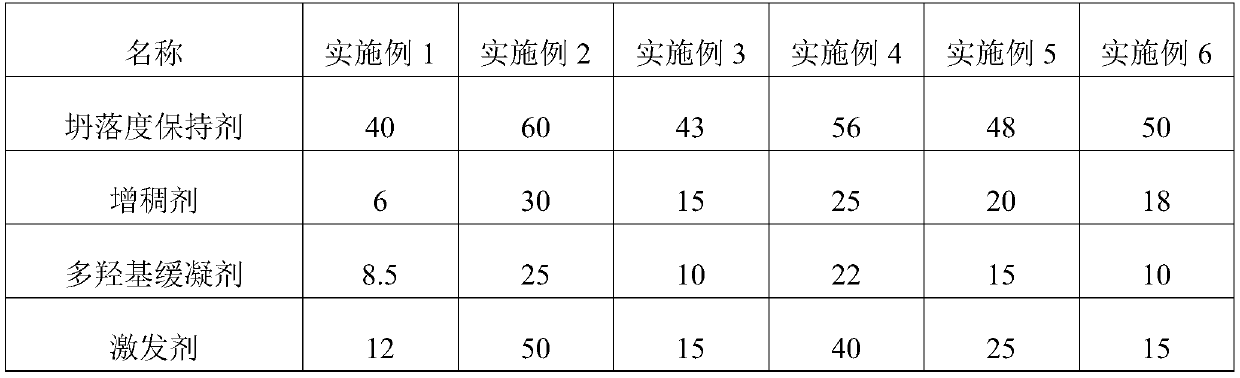

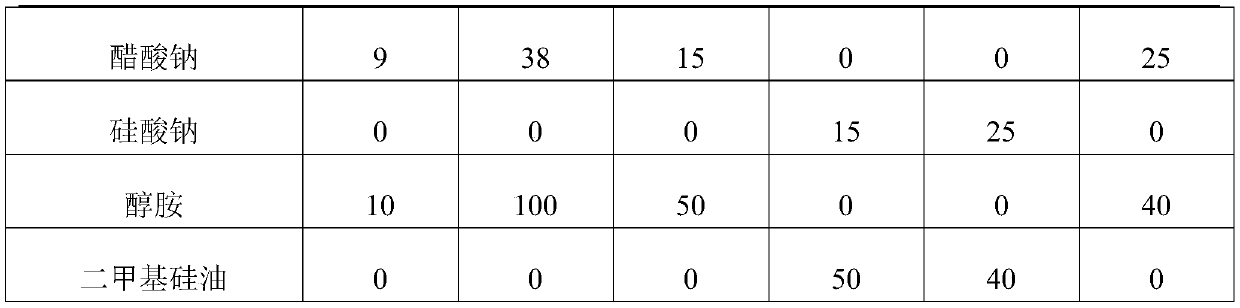

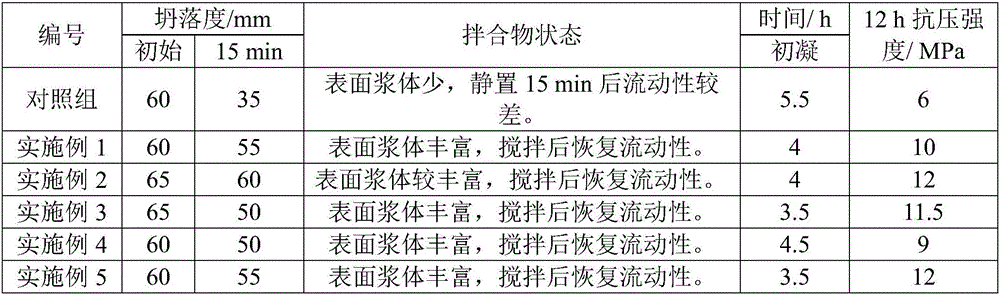

High-slump-loss-resistant synergist and preparation method and application thereof

The invention belongs to the technical field of concrete, and provides a high-slump-loss-resistant synergist, which is prepared from 40 to 60 parts of slump maintainers, 6 to 30 parts of thickening agents, 8.5 to 25 parts of polyhydroxyl retarders, 12 to 50 parts of excitants, 9 to 38 parts of sodium acetate or sodium silicate and 10 to 100 parts of hydramine or simethicone, wherein the slump maintainers are prepared from 300 to 450 parts of polyether, 20 to 45 parts of unsaturated acid, 30 to 80 parts of acrylic ester, 1.1 to 3.8 parts of chain transferring agents and 0.5 to 1.5 parts of reducing agents. A preparation method comprises the following steps of adding polyether into water; performing heating dissolution; then, dripping a material A and a material B; performing reaction for one hour to obtain the slump maintainers; adding water into thickening agents for dissolution; sequentially adding the polyhydroxyl retarders, the excitants, sodium acetate or sodium silicate; after thedissolution, adding hydramine or simethicone; adding the slump maintainers; performing uniform mixing to obtain the high-slump-loss-resistant synergist applied to concrete preparation. By using the technical scheme, the high-slump-loss-resistant synergist solves the problem of fast concrete slump loss in the prior art; meanwhile, the intensity is improved.

Owner:兰州同邦建材有限公司

Thixotropic agent for polycarboxylate superplasticizer, thixotropic type polycarboxylate superplasticizer and application of thixotropic agent

The invention provides a thixotropic agent for a polycarboxylate superplasticizer. The thixotropic agent is mainly prepared from components of raw materials in parts by mass as follows: 0.2-1 part of white carbon black, 3-12 parts of alkali carbonate and 1.5-6 parts of sulfate, wherein the thixotropic agent for the polycarboxylate superplasticizer and a polycarboxylate superplasticizer mother solution are sufficiently and uniformly mixed in water, and the thixotropic type polycarboxylate superplasticizer with excellent thixotropic performance in the precast concrete application process can be obtained. The thixotropic type polycarboxylate superplasticizer containing the thixotropic agent is doped in precast concrete, the thixotropy of the newly blended concrete can be remarkably improved, early strength development is promoted, and the problem that existing polycarboxylate superplasticizers don't have sufficient thixotropic performance in the precast concrete application process is effectively solved.

Owner:中建西部建设新材料科技有限公司 +2

Industrial solid waste autoclaved aerated concrete block and preparation method thereof

The invention discloses an industrial solid waste autoclaved aerated concrete block and a preparation method thereof. The concrete block uses fly ash, carbide slag, red mud, lime, desulfurized gypsumand cement as main raw materials and aluminum powder, sodium hydroxide, water glass and the dispersing agent silica fume as additives; the coal ash reacts with components in the carbide slag to generate ettringite, so the strength of the concrete block can be enhanced; a large amount of aluminum oxide contained in the red mud can a replace part of lime and undergo a hydration reaction with the cement, and the aluminum oxide in the red mud can react with calcium hydroxide in the carbide slag, so the strength of the block is enhanced; the coal ash, the carbide slag and the red mud react with oneanother to generate hydrated calcium silicate and hydrated calcium aluminate, so the structural compactness of the block can be improved; and the additives can enhance the foaming stability of the aluminum powder and improve the early strength of the block under an alkaline condition. The method is green and environment-friendly, and the waste of non-renewable resources is effectively reduced.

Owner:张延年

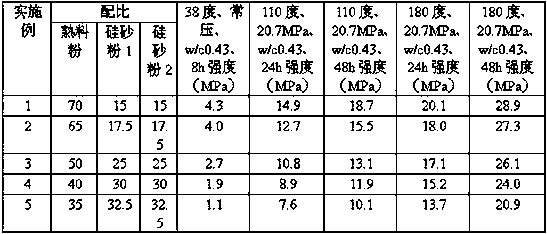

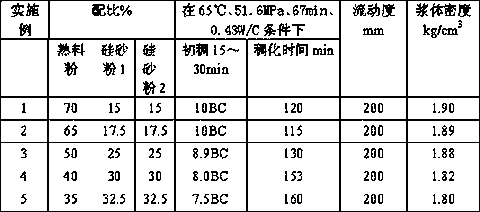

Oil well cement resistant to strength retrogression at high temperature and production method thereof

PendingCN108751893AIncreased hydration rateHigh strengthDrilling compositionHigh pressureUltimate tensile strength

The invention discloses oil well cement resistant to strength retrogression at high temperature and a production method thereof. The oil well cement is prepared from, by mass, 35%-70% of cement clinker powder and 30%-65% of silica sand, wherein the cement clinker powder is prepared from, by mass, 90%-95% of oil well cement clinker, 2%-4% of gypsum and 1%-3% of retarder. The oil well cement does not produce strength retrogression under the conditions of high temperature and high pressure, but the strength is improved certainly, and the cement has good durability and is conductive to improvementof well cementation quality of an oilfield extra-deep well.

Owner:葛洲坝石门特种水泥有限公司

Gel mixing system

ActiveUS7419296B2Extended stayIncrease volumeFlow mixersRotary stirring mixersEngineeringResidence time

Owner:SERVA CORP

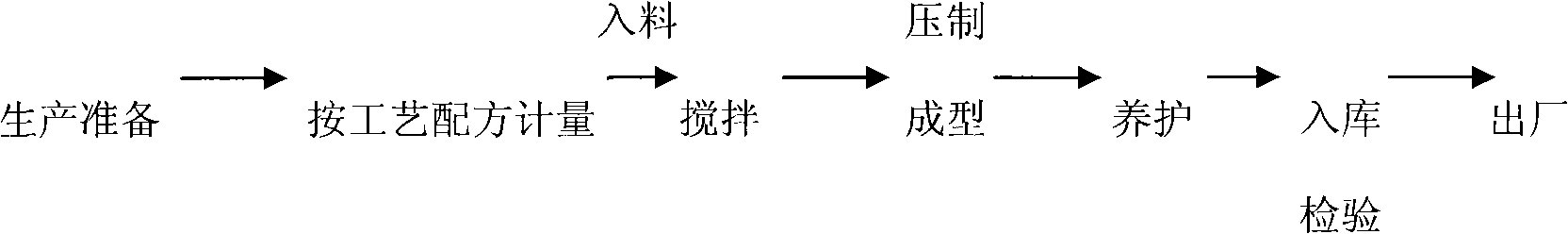

Process for making bricks by waste residue of smelting chromium irons

The invention relates to a technique using the waste residue of smelted chromium-iron alloy for brick making, the steps thereof are as follows: the mass mixture ratio of various raw materials is: 3.5 to 3 portions of cement, 17 to 24 portions of slag, 65 to 70 portions of fillers, 0.05 to 0.1 portion of an activator and the ratio of water to water / powder is equal to 0.3, wherein, the powder quantity is gauged by the mixing quantity of the cement and the powder residue; the slag and the filler are firstly added into a stirrer to be stirred for 60 seconds and 1 / 2 of the water amount is added and stirred for 60 seconds, and then the cement and the activator are added to be stirred for 3 minutes. In the stirring process, water is added and water usage is well controlled to form the shape of slime. The mixture taking the shape of slime is fed into the charging hopper of a vibrating brick making machine and the feeding vibration is carried out for 8S to 10S and the compression vibration is carried out for 10S to 12S, and then the mixture is molded and taken out to be piled up; after 24 hours, the mixture is maintained by watering. The invention has the advantages that: 1. precious territorial resources can be saved; 2. the usage of the cement can be saved so as to have the advantage in the building materials market with low cost; 3. the slag is comprehensively utilized, thereby changing waste into valuable and also having good environmental benefits.

Owner:钱海华

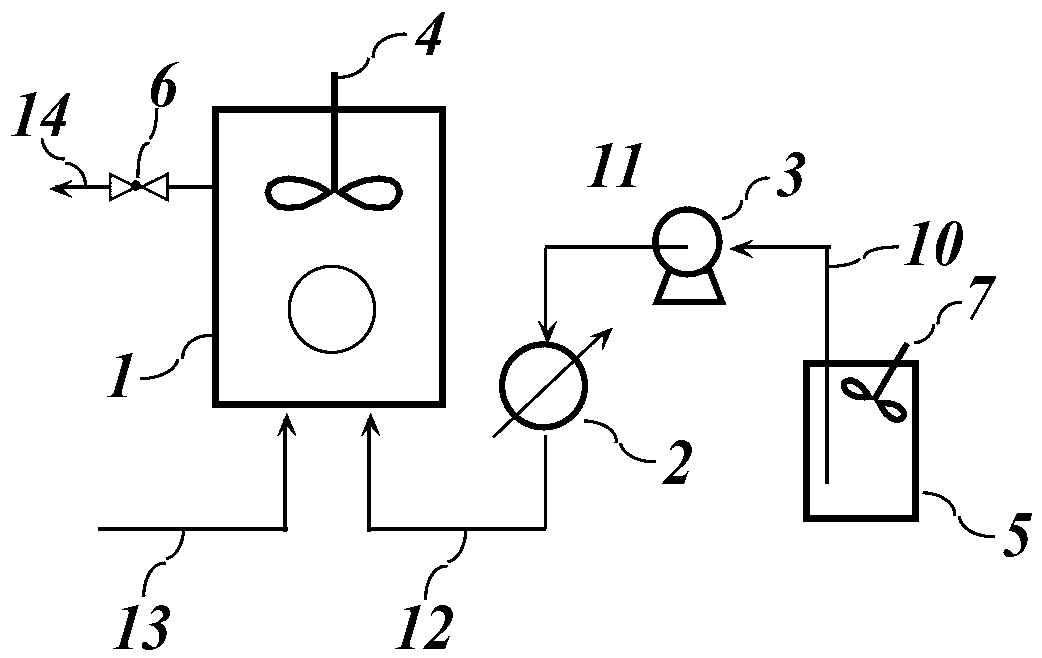

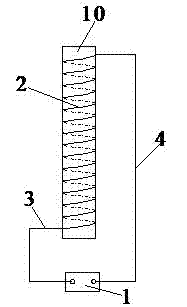

Preparation method and device for direct phase change heat transfer type gas hydrates

InactiveCN103007841AEasy to achieve constant temperature operationIncreased hydration rateMixing methodsMixersSlurrySolid particle

The invention relates to a direct phase change heat transfer type hydration method and a direct phase change heat transfer type hydration apparatus. Firstly, an emulsion of liquid phase change material and water is prepared, wherein a freezing point of the emulsion higher than that of water, the emulsion is cooled to obtain slurry containing solid particles of the phase change material; and then, the prepared slurry is sent to a hydrator and fully contacts with introduced small-molecule gases to finish the hydration. Heat produced during the hydration process is removed in a direct phase change heat transfer way by utilizing the characteristic that a solid absorbs heat when being melt and matching melt heat with hydration heat. The method is suitable for separation and storage of the gases. The apparatus comprises a disperser (7), a container (5), a pressure pump (3), a heat exchanger (2), a hydrator (1) and a regulating valve (6). A temperature variation of the hydrator designed by the invention is maintained within 1 DEG C. A temperature rise in the hydrator is restrained, so that the hydration rate is significantly increased.

Owner:TIANJIN UNIV

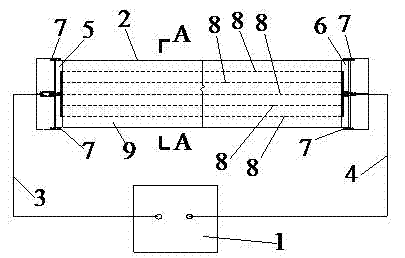

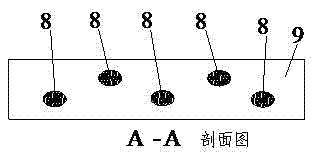

Reinforced concrete structure curing device in low-temperature environment

InactiveCN102642244AHarden fastGuarantee the quality of maintenanceCeramic shaping apparatusSocial benefitsPower flow

The invention discloses a reinforced concrete structure curing device in a low-temperature environment. The reinforced concrete structure curing device in the low-temperature environment is characterized by comprising a variable frequency power supply and a wide tape, wherein a pin-type end connector and a slot-type end connector are arranged on the wide tape; one end of the variable frequency power supply is connected with the slot-type end connector of the wide tape through a lead wire with a pin-type plug; and the other end of the variable frequency power supply is connected with the pin-type end connector of the wide tape through a slot-type plug. The device is simple in structure, easy to construct, and high in real-time controllability; the defects of conventional curing measures of a reinforced concrete structure are overcome; required heating depth can be obtained by controlling current frequency, so that the requirement on curing a specific reinforced concrete structure can be met; and therefore, the device has enormous economic, environmental and social benefits. In addition, the hardening of concrete can be accelerated by heating according to engineering requirements, so that the aim of reasonably shortening curing time is fulfilled. Therefore, the device is suitable for curing the reinforced concrete structure, and is particularly applicable for the low-temperature environment.

Owner:CENT SOUTH UNIV +2

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com