Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

7951 results about "Sustainable development" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Sustainable development is the organizing principle for meeting human development goals while simultaneously sustaining the ability of natural systems to provide the natural resources and ecosystem services upon which the economy and society depend. The desired result is a state of society where living conditions and resources are used to continue to meet human needs without undermining the integrity and stability of the natural system. Sustainable development can be defined as development that meets the needs of the present without compromising the ability of future generations.

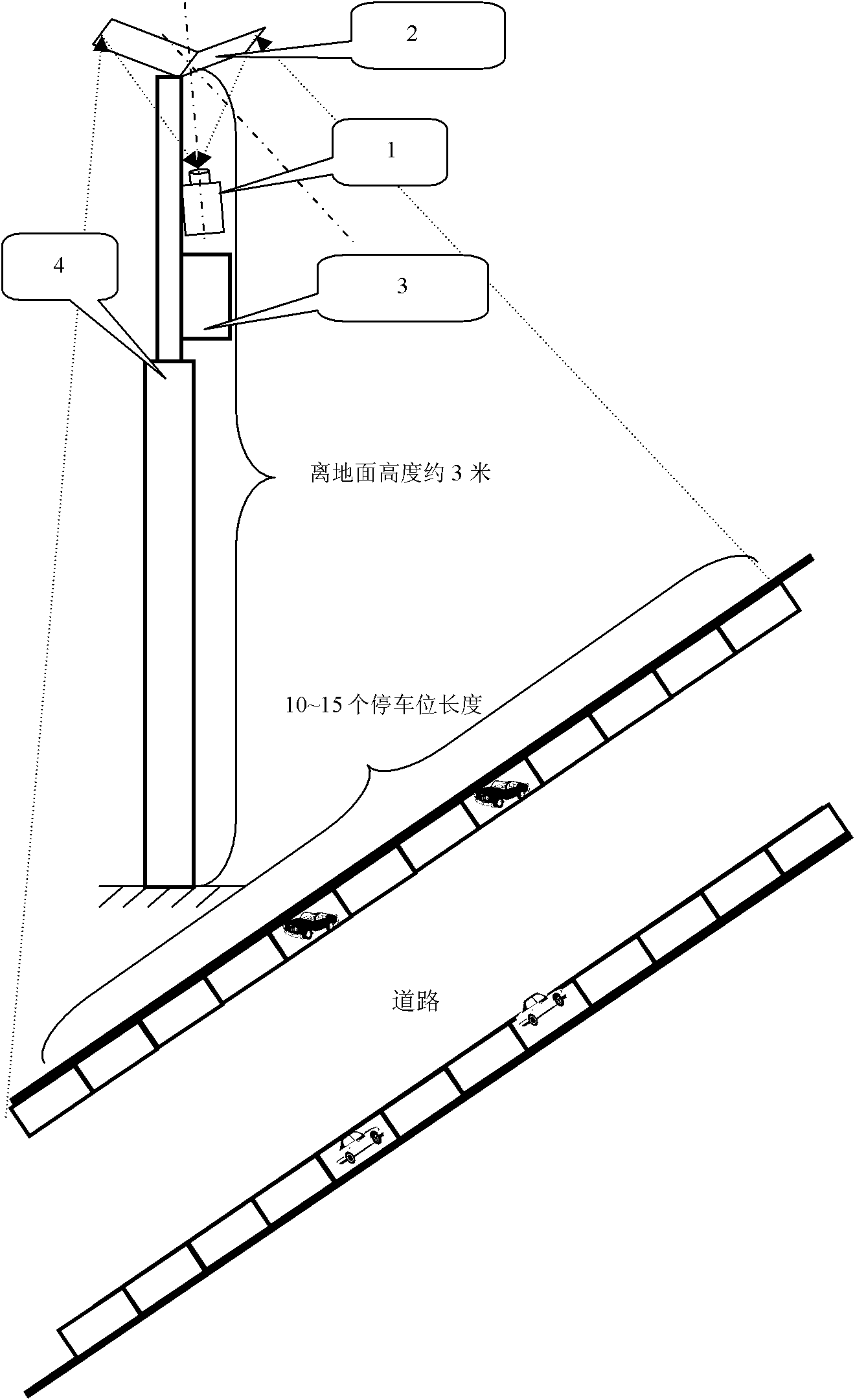

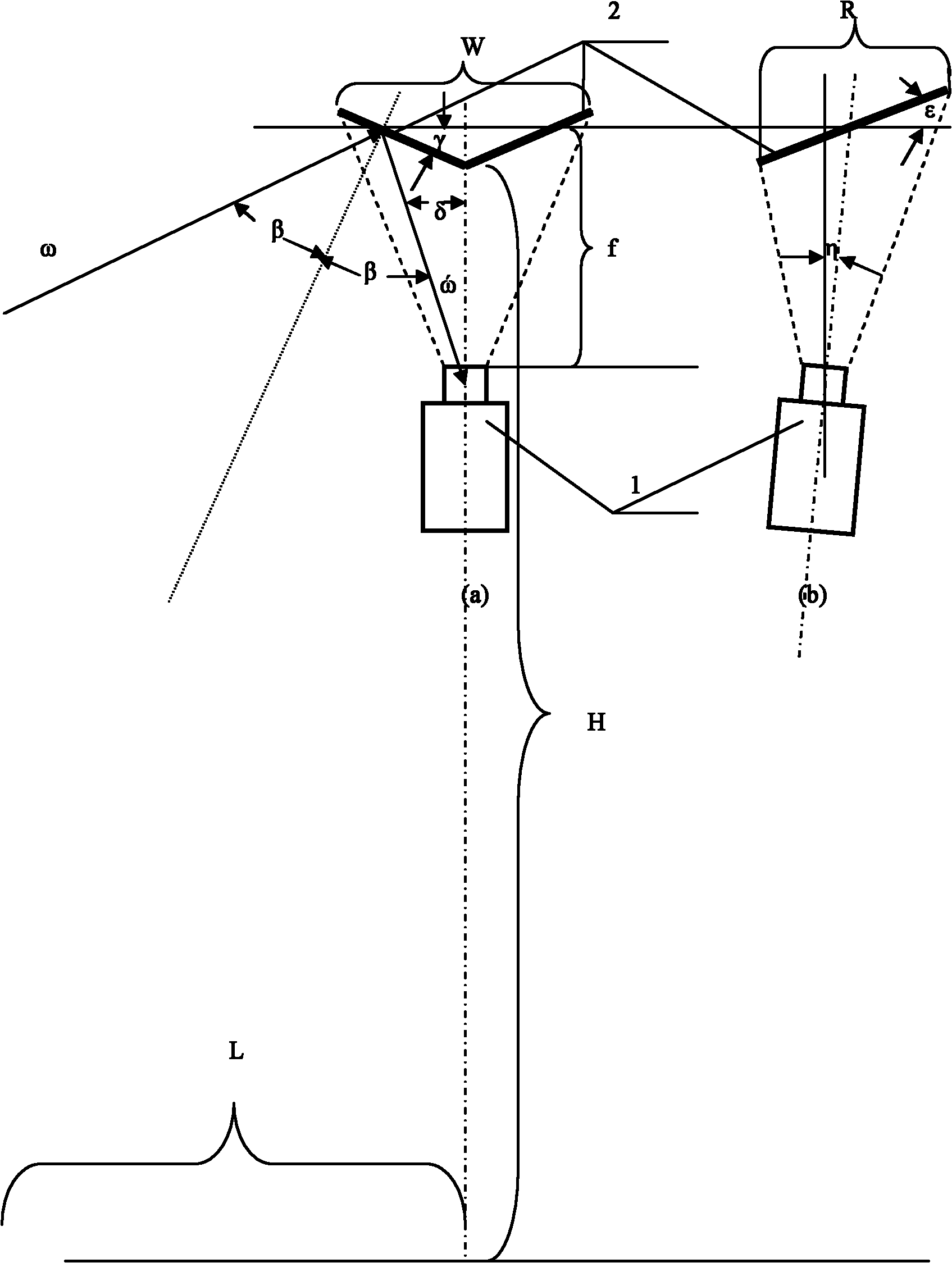

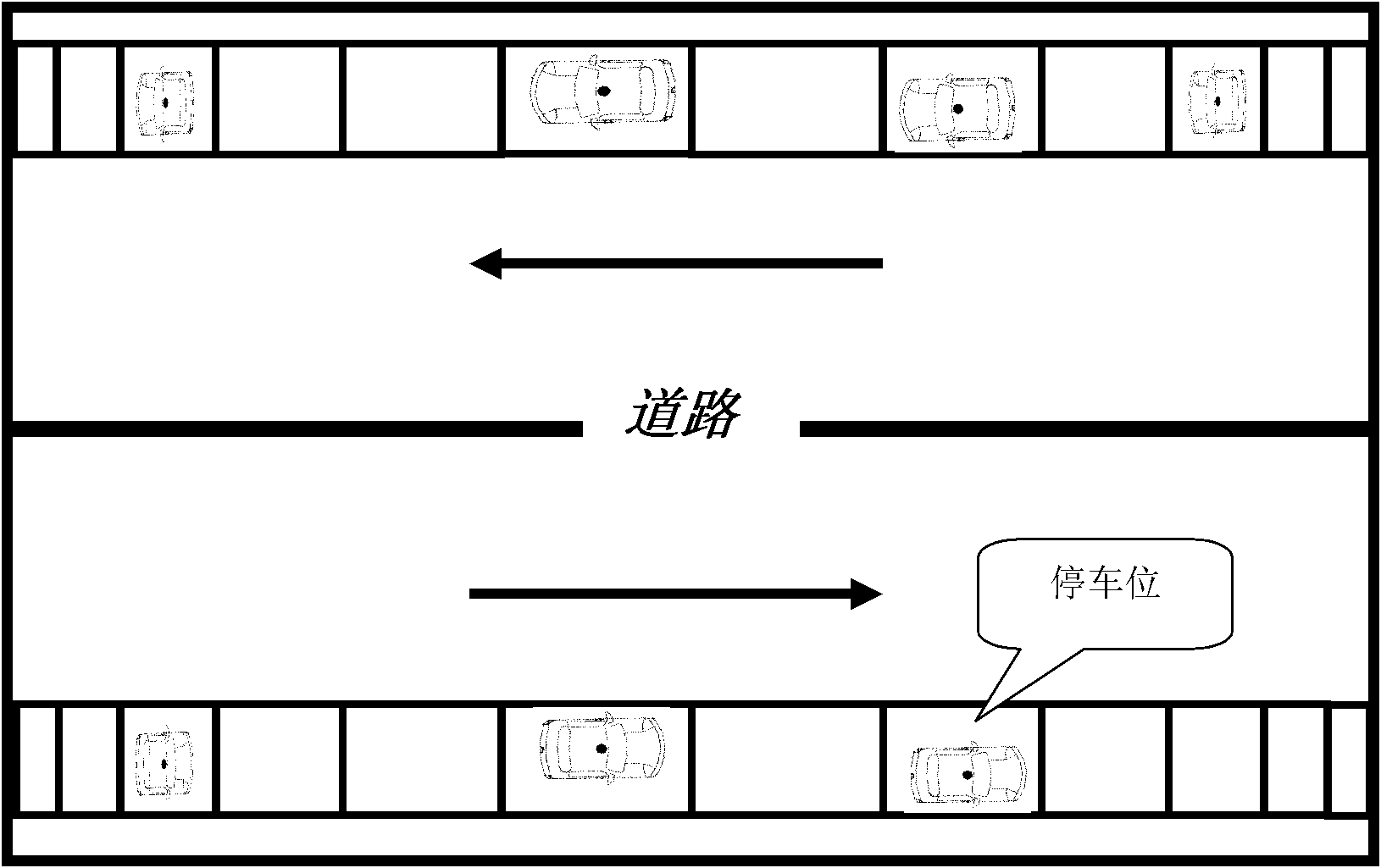

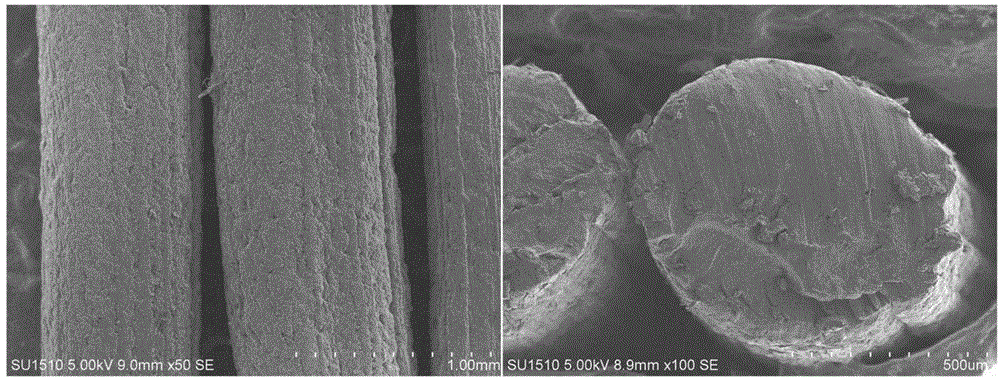

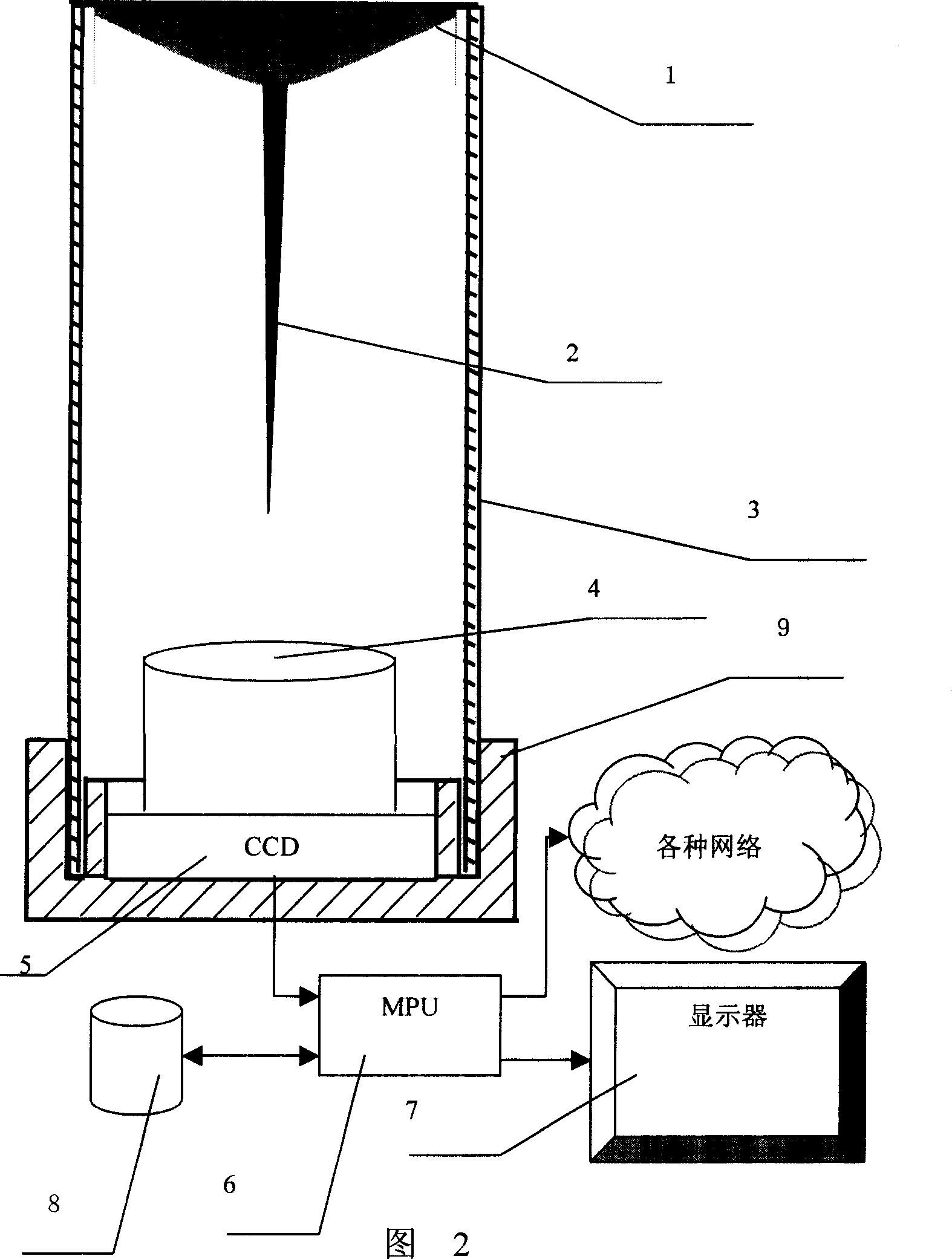

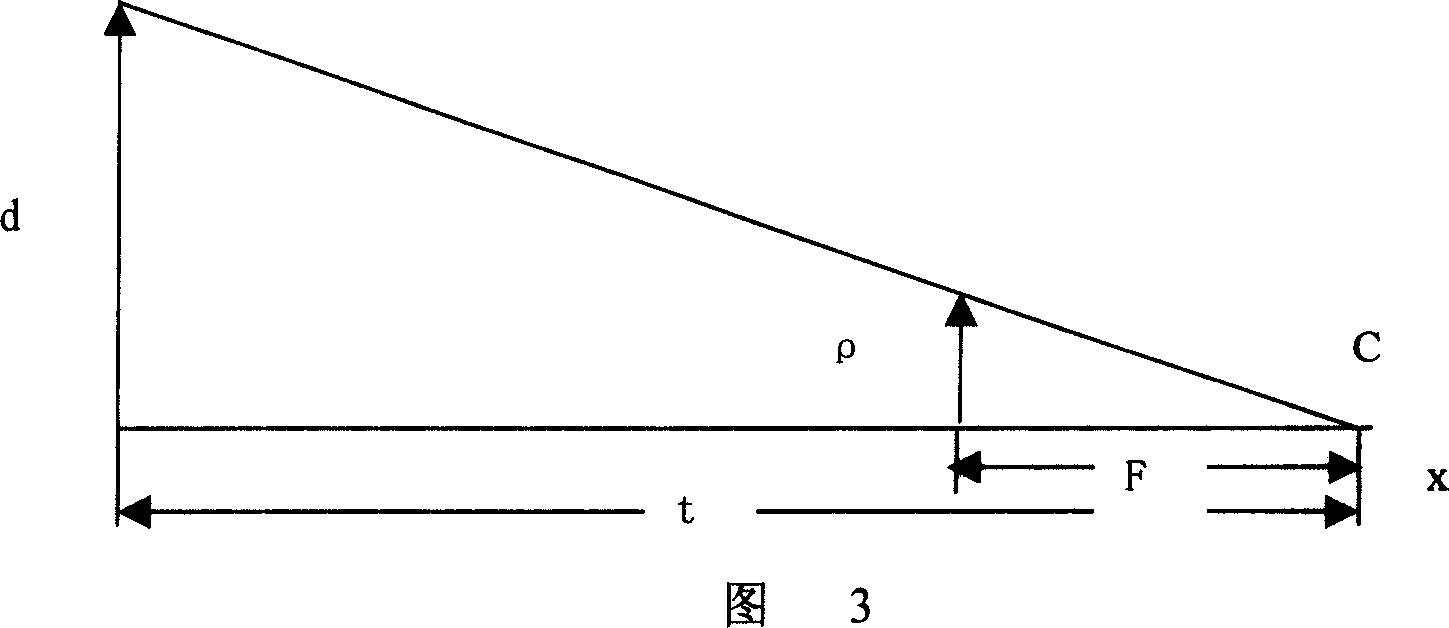

Roadside parking space detection device based on computer vision

InactiveCN102110376AWill not affect trafficReduce traffic problemsIndication of parksing free spacesCharacter and pattern recognitionParking spaceOmnidirectional vision

The invention discloses a roadside parking space detection device based on computer vision, comprising an omnidirectional vision sensor and a microprocessor, wherein the omnidirectional vision sensor is installed at the roadside with parking spaces; the microprocessor is used for analyzing the parking space state according to the data of a parking space video shot by the omnidirectional vision sensor; and the microprocessor comprises an omnidirectional image acquisition unit, a parking space customizing module, a parking space state detection module based on a sampling point model, and a parking space state information releasing module. The invention provides the roadside parking space detection device which is based on the computer vision, has the advantages of wide detection range, high detection precision, good detection instantaneity, high cost performance, strong environmental adaptation capability and good expandability and sustainable development, is convenient to implement and maintain and is convenient to realize on an embedded system.

Owner:汤一平

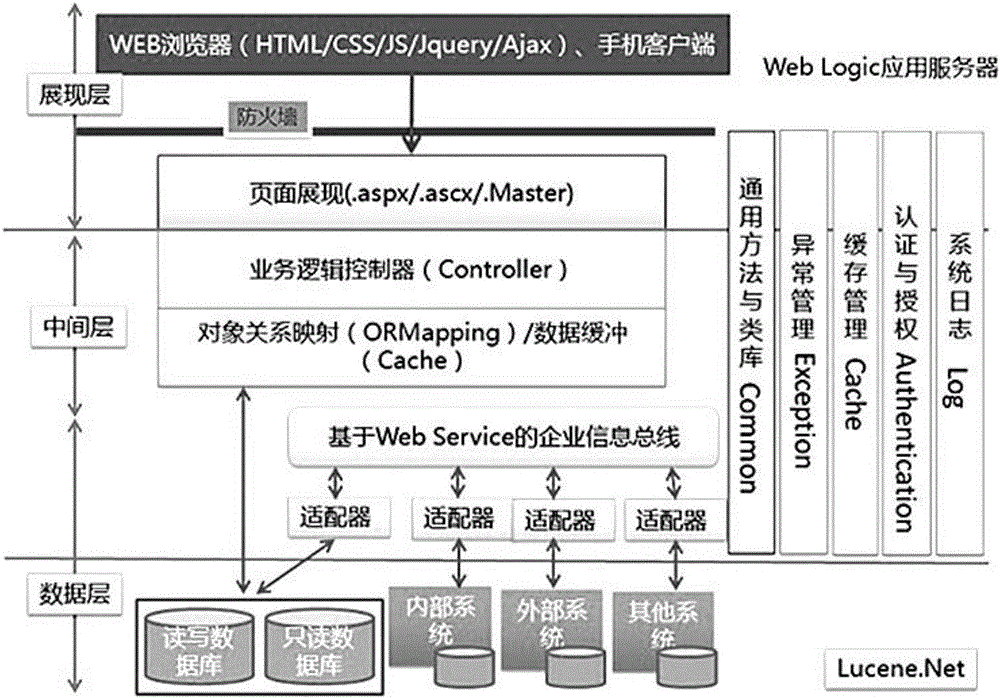

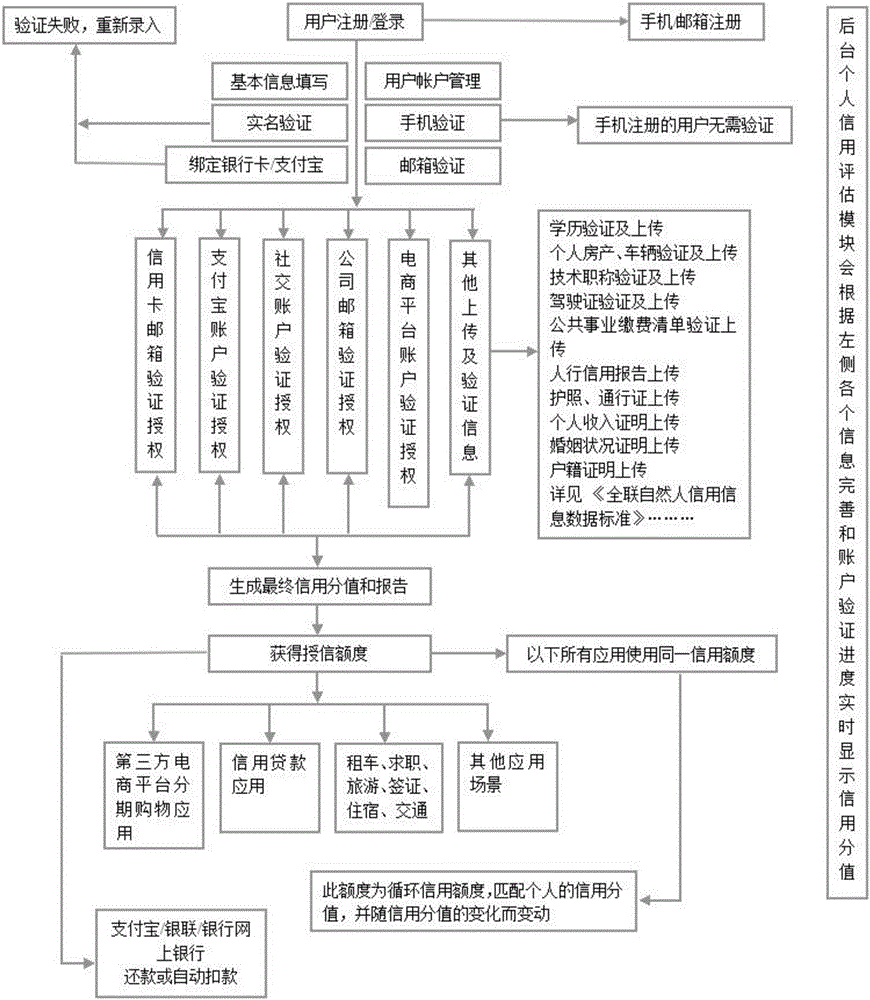

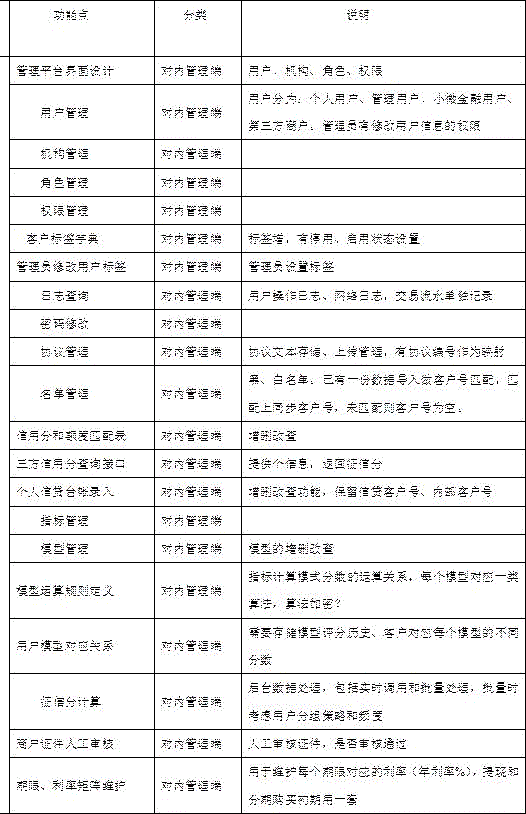

Personal credit ecological platform

InactiveCN106447434AData quality freshImprove accuracyFinanceCredit schemesComputer scienceSustainable development

The invention discloses a personal credit ecological platform, which is structured by a display layer, a middle layer and a data layer; the display layer is a front client platform, the middle layer is a background service platform, and the data layer is a data warehouse system; the whole ecological platform consists of a management end, a personal credit module, a merchant module, a payment flow, and a mobile APP. The platform data base is deep, the data quality is alive, the accuracy is high, the scale is wide, and the time track is rich, the data volume is huge and the dimension is wide. The platform deeply excavates the personal credit data, realizes the credit evaluation, provides the complete personal credit status, realizes the personal credit tracking management, and further controls the risk; besides, the client complaint procedure is added. The platform achieves the recommendation of potential and sustainable developed individual client for merchant users, and realizes the bidirectional push.

Owner:全联征信有限公司

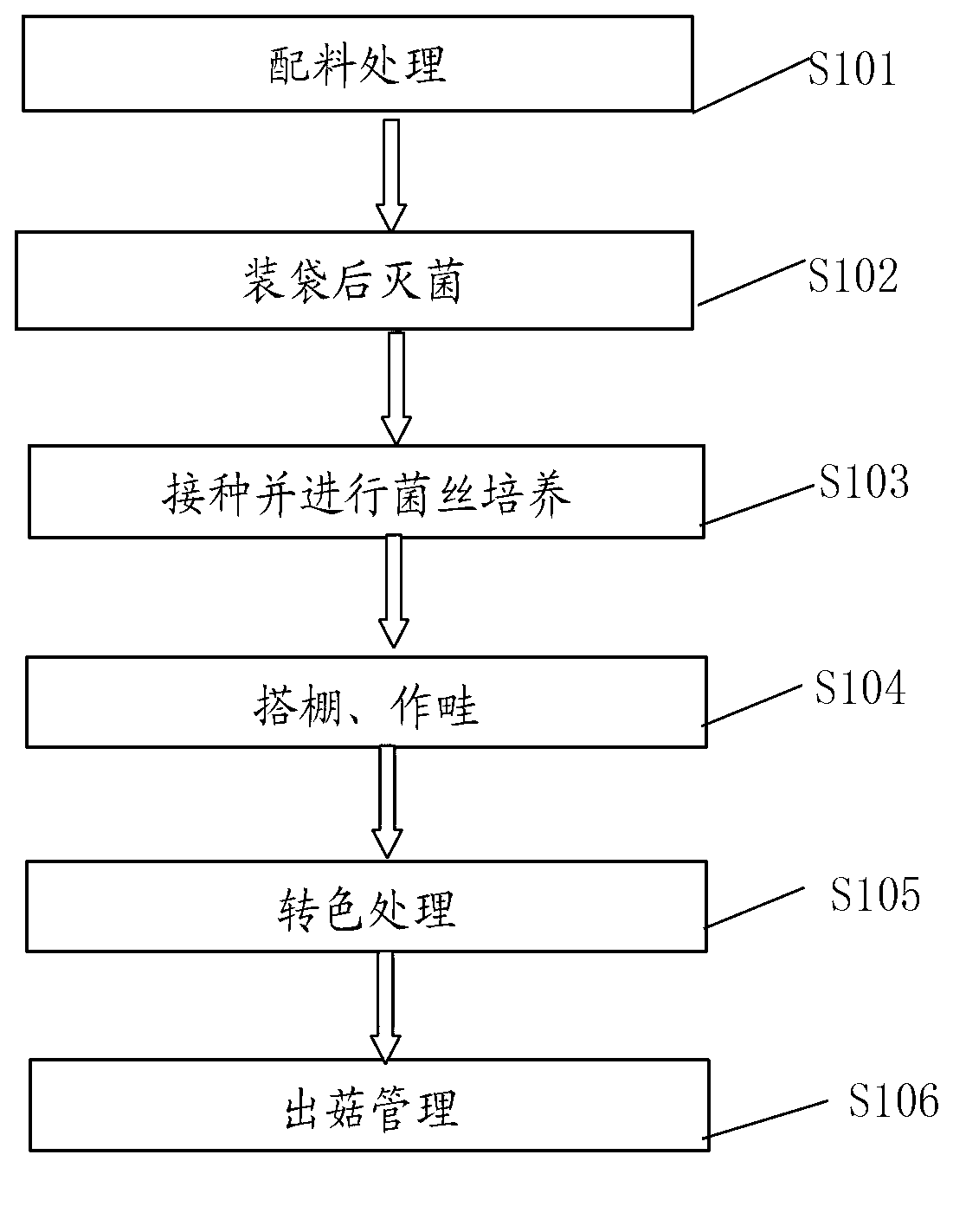

Mushroom cultivating method utilizing residues of sophora flower buds after extraction of rutins

InactiveCN103229669AFull of nutritionSolve environmental problemsHorticultureCaladiumAdditive ingredient

The invention discloses a mushroom cultivating method utilizing residues of sophora flower buds after extraction of rutins. The mushroom cultivating method utilizing the residues of the sophora flower buds after the extraction of the rutins comprises processing burdening, namely weighing cultivation raw materials which comprise, based on the weight percent, cotton seed hull of 42-60%, the residues of the sophora flower buds after the extraction of the rutins of 28-40%, bran of 10-20%, gypsum of 0.6-2%, calcium superphosphate of 0.3-1%, carbamide of 0.2-1% and sugar of 0.8-2% and adding water into the cultivation raw materials after uniform mix of the cultivation raw materials to enable water content of the cultivation raw materials to achieve 55-65%; bagging and sterilizing after the burdening processing; inoculating and cultivating hypha; building a shed and earthing up; coloring; and managing fruiting. The mushroom cultivating method utilizing the residues of the sophora flower buds after the extraction of the rutins has the advantages of being simple in operation, capable of cultivating the mushroom by adding small amount of nutritional ingredients, quick in spawn runing, low in production cost and capable of effectively utilizing by-product residues in phytoextraction industries in a maximum limit and achieving sustainable development.

Owner:四川省砚山中药饮片有限公司

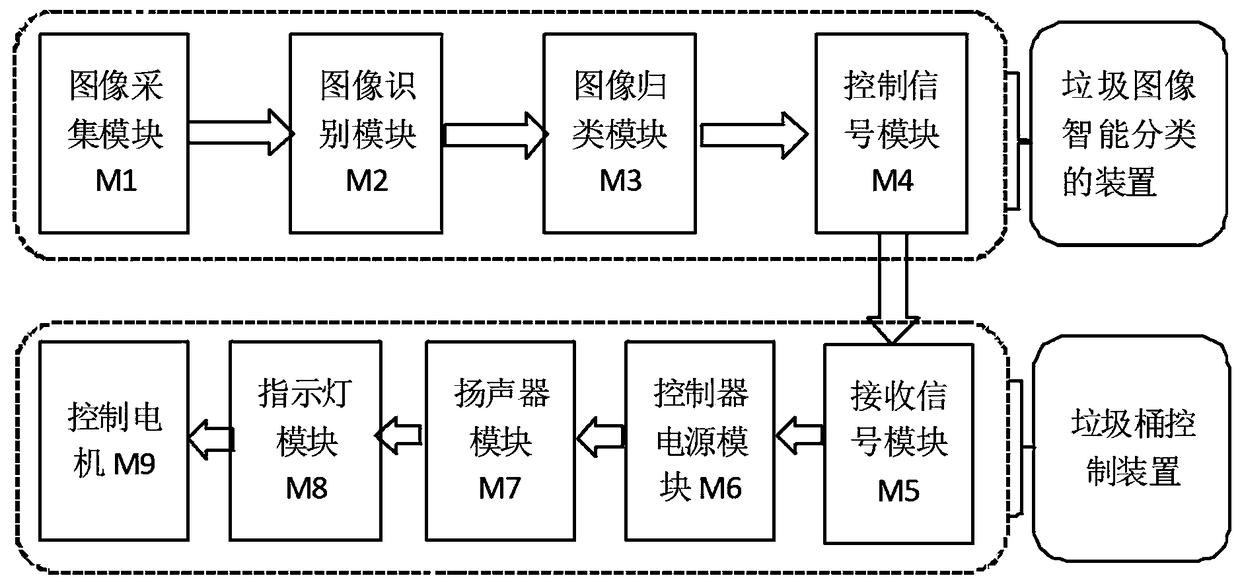

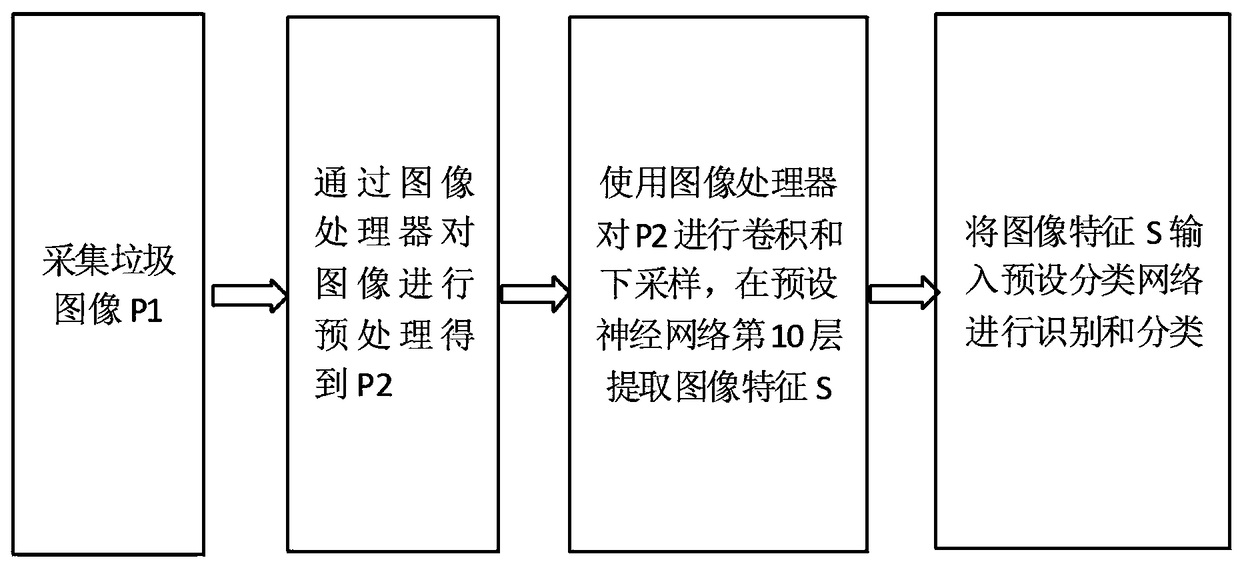

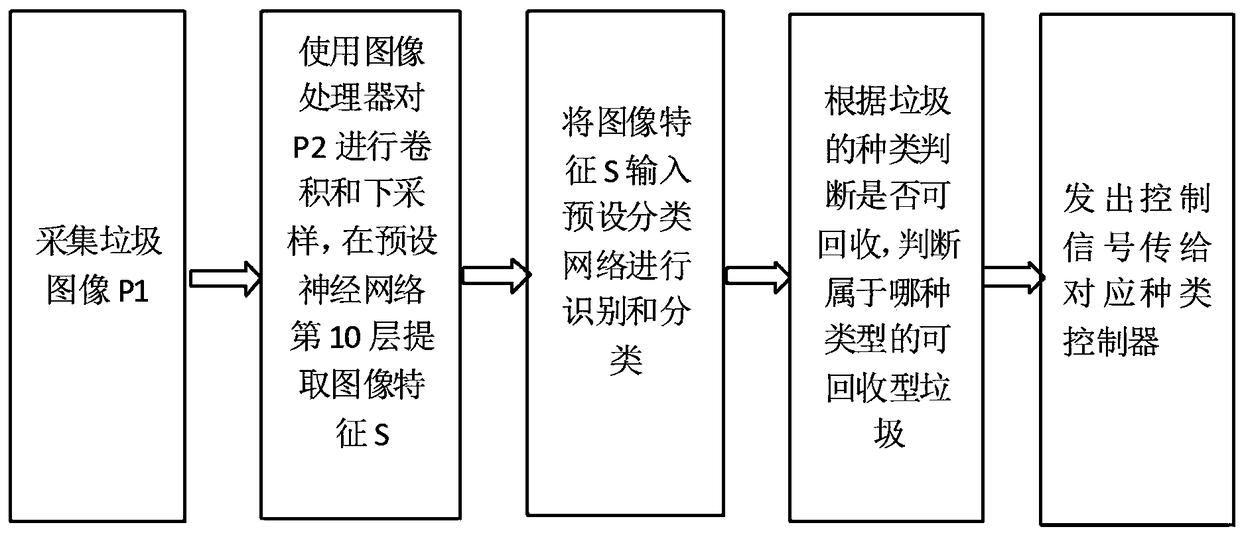

Method for intelligent classification of garbage images

InactiveCN108182455ASimple recycling processReduce pollutionWaste collection and transferCharacter and pattern recognitionImage extractionClassification methods

The invention discloses a method for intelligent classification of garbage images. The method is implemented as follows: a high-definition collecting device including a camera collects a garbage image; the collected garbage image is preprocessed; convolution and pooling processing are carried out on the pre-processed garbage image, feature image extraction is carried out, and then a feature imageis identified; and according to an identification result, whether the garbage type is a recyclable garbage type is determined. Compared with the prior art, the intelligent classification method has the following beneficial effects: identification and classification are carried out on the collected garbage images by using the camera, an image identification processor, and a controller to determinewhether the garbage is recyclable, so that manual garbage classification is not needed, the environmental awareness of people is strengthened, the waste pollution is reduced, and thus sustainable development is promoted. The intelligent classification method having advantages of high practicability and wide application range is easy to promote.

Owner:QILU UNIV OF TECH

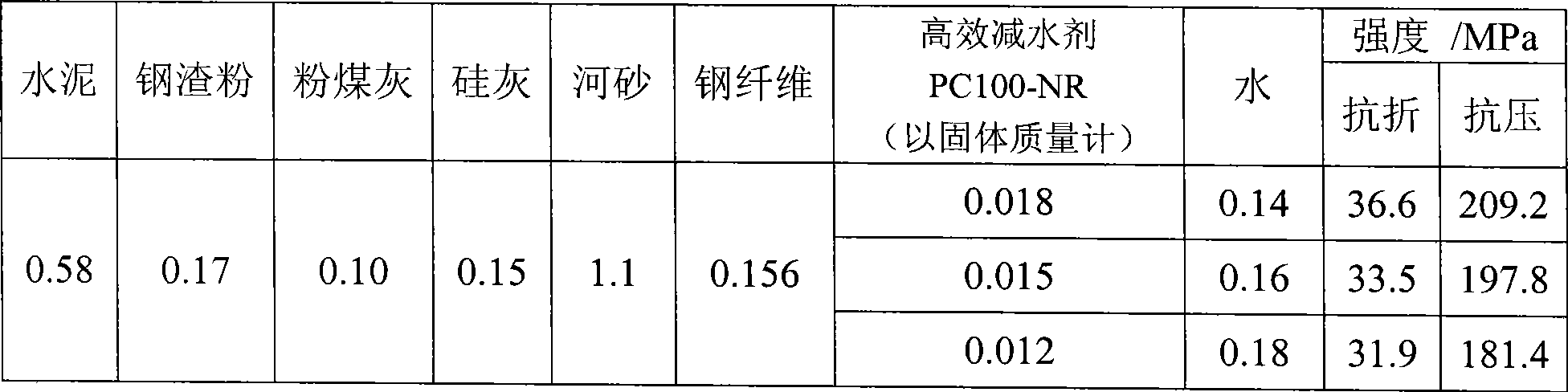

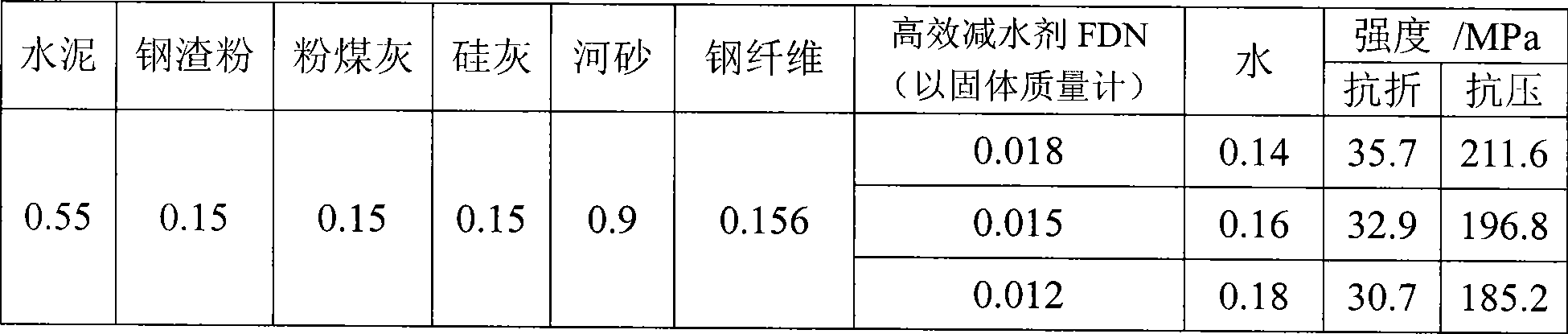

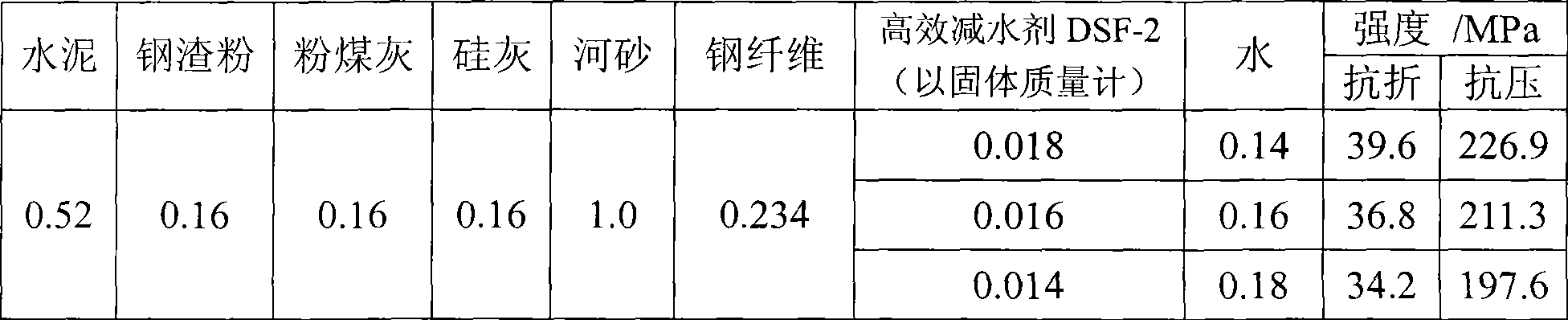

Low cost active powder concrete and preparation thereof

InactiveCN101486554ALow raw material costReduce maintenance costsSolid waste managementMixing operation control apparatusFiberSlag

The invention discloses active powder concrete which is prepared by Portland cement, steel slag powder, fly ash, silicon ash, effective water reducing agent, river sand, mixing water and steel fiber with the mass ratios of 0.52 to 0.58 : 0.16 to 0.18 : 0.10 to 0.16 : 0.13 to 0.16 : 0.012 to 0.018 : 0.9 to 1.1 : 0.14 to 0.18 : 0.156 to 0.234. The preparation method thereof is as follows: each component is sequentially added into a stirring machine for being uniformly stirred and shaped; then after the components are maintained, the temperature is raised to 80 to 90 DEG C at the temperature rising speed of 15 to 20 DEG C / h and then constant temperature maintaining is carried out for 72 to 96h; then, the components are cooled to room temperature at the cooling speed of not more than 20 DEG C / h to obtain the active powder concrete product. The invention employs the industrial wastes like steel slag powder and fly ash to replace quartz powder, partial cement and silicon ash, and employs thin river sand to replace quartz sand to prepare the active powder concrete of 200 grade under the maintaining conditions of normal pressure below 100 DEG C, thus not only being capable of remarkably reducing the material cost and the shaping maintaining cost, but also playing important roles on saving resources and energies, protecting the environment and promoting sustainable development as a large amount of industrial waste slag is used.

Owner:WUHAN UNIV OF TECH

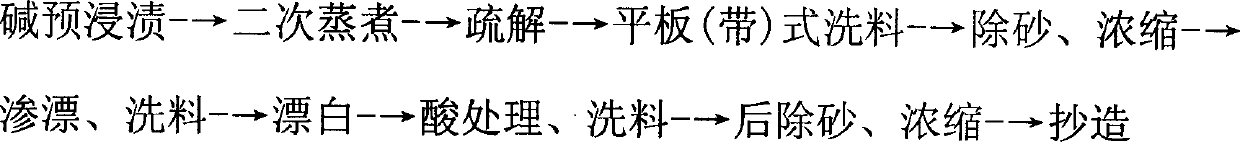

Bamboo pulp denatured productive technology

InactiveCN1385287AEmission reductionConducive to the sustainable development of productionPretreatment with alkaline reacting compoundsWood treatment detailsPulp and paper industryViscose fiber

The production process of bamboo fibre viscose pulp includes the following main steps: pre-alkalizing, secondary cooking, plate (belt) type washing and bleaching, and is characterized by mixing insoluble bamboo pulp undergo the process of modification treatment to produce soluble viscose bamboo pulp. As compared with cotton pulp production process it can reduce discharge of waste water by 35%, and is approaching to or superior to cotton pulp in quality.

Owner:上海第五化学纤维厂

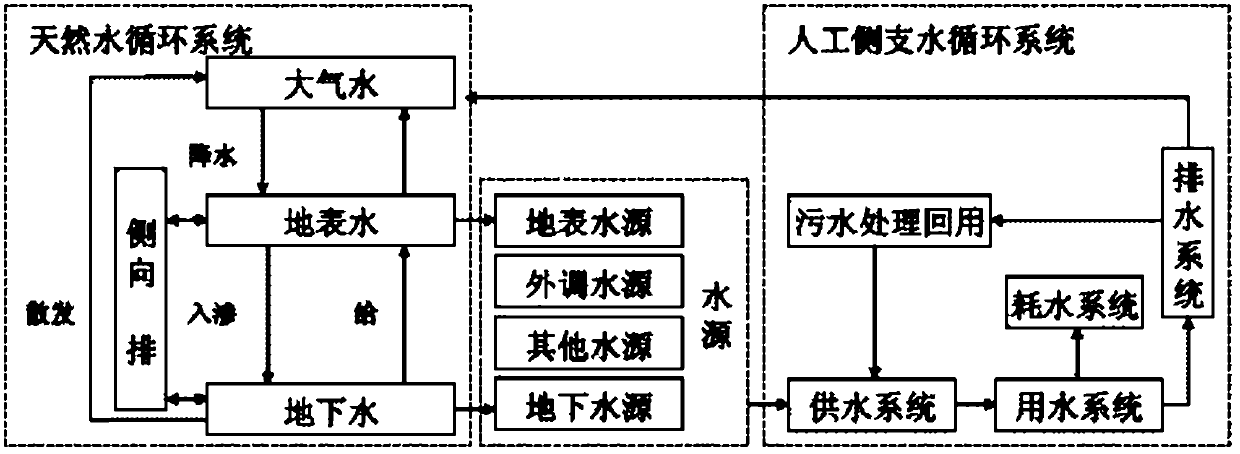

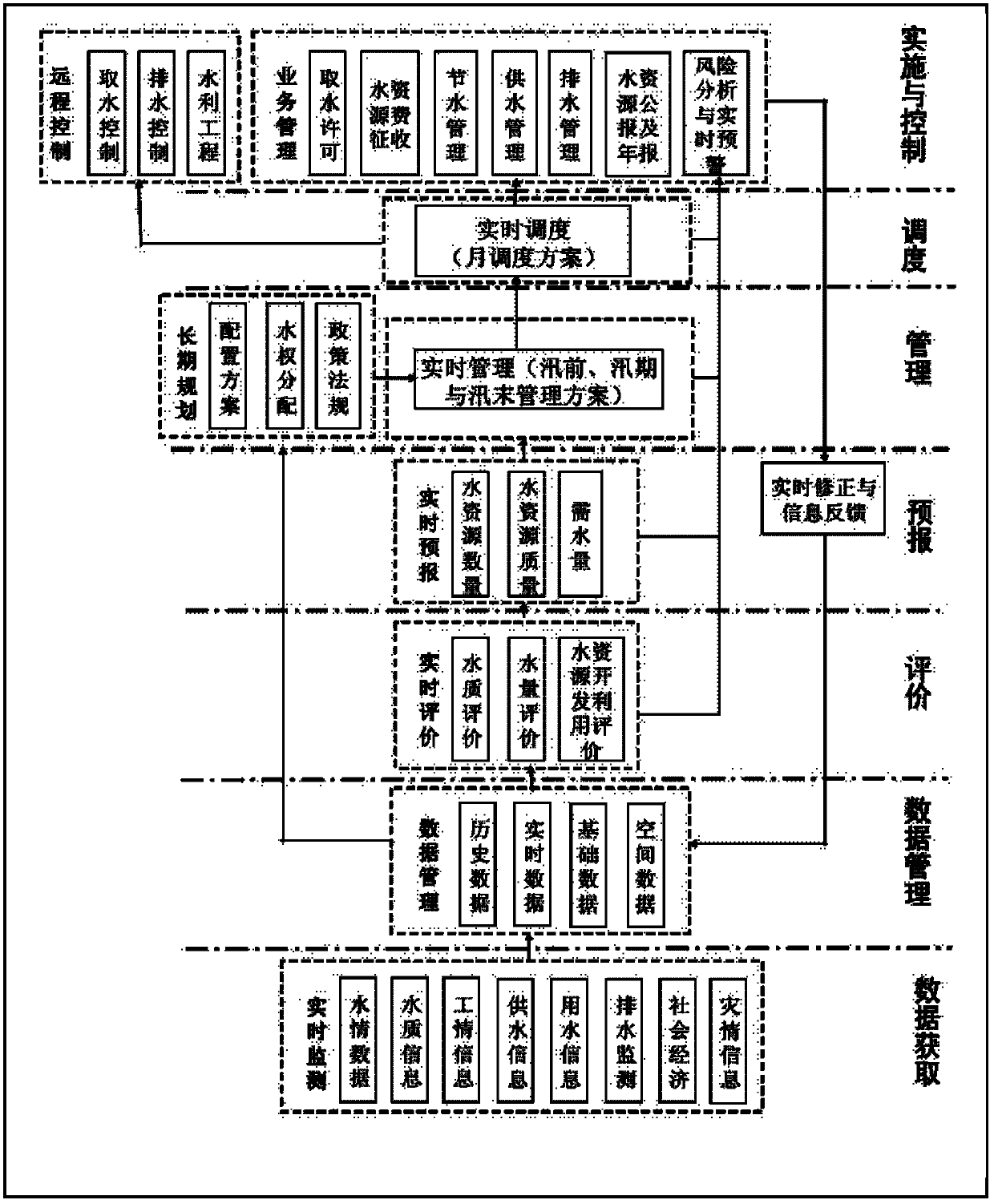

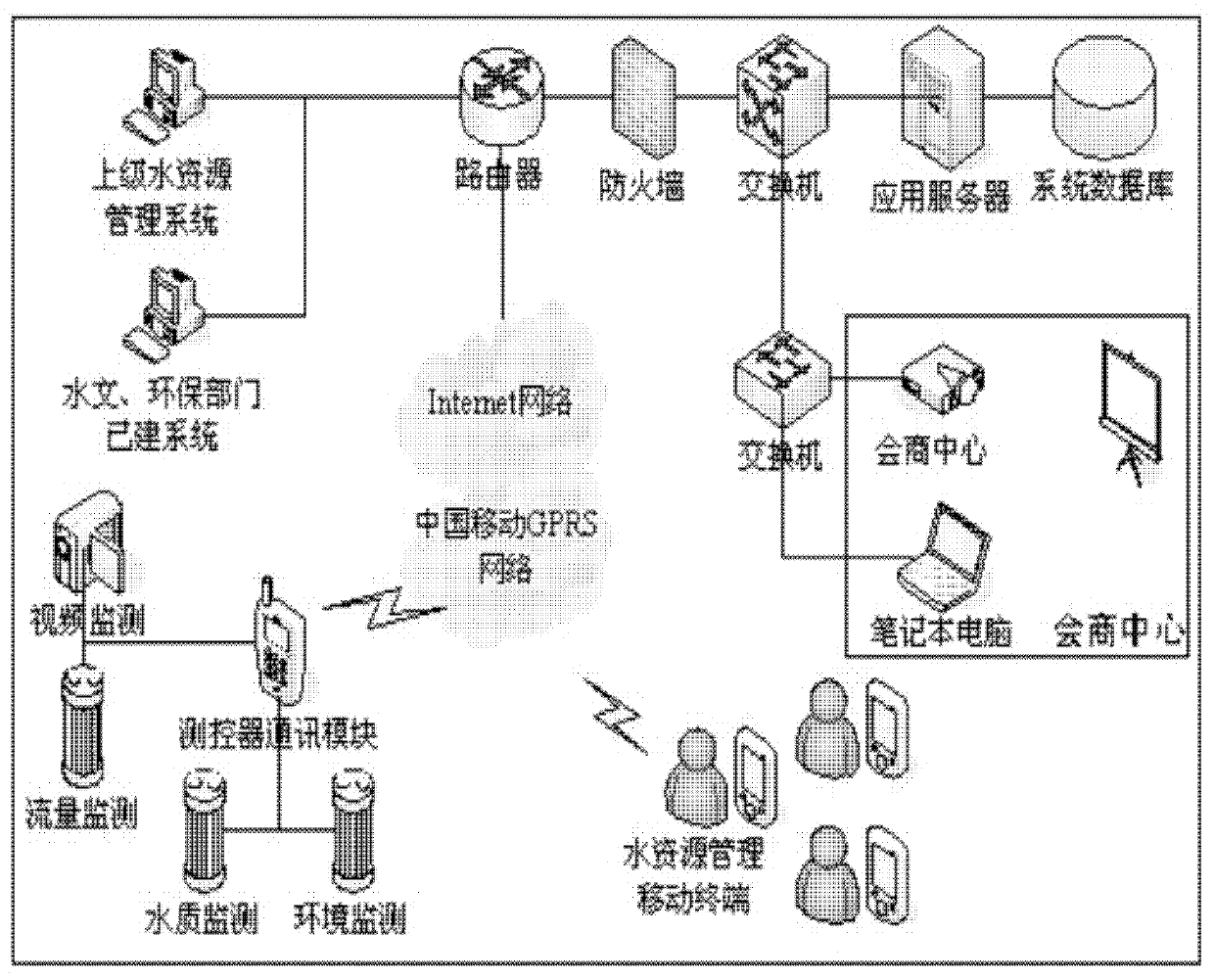

System and system for real-time monitoring and managing urban water resources

InactiveCN102184490AAchieve sustainable developmentImprove scalabilityData processing applicationsTime scheduleEnvironmental resource management

The invention provides a method and a system for real-time monitoring and managing urban water resources, and system equipment capable of finishing the method. The method comprises the steps of: real-time monitoring the urban water resources, real-time evaluating the urban water resources, real-time forecasting the urban water resources, real-time managing the urban water resources, real-time scheduling the urban water resources, and real-time early warning the urban water resources safety. By application of the system and method of the invention, an urban water resources system is scientifically classified and comprehensively analyzed so as to obtain the correct construction and correlations of the urban water resources system; the urban water resources are subjected to centralized management; a unified water resources monitoring-center system platform is established; and a novel water resources monitoring terminal is compatible so as to implement a unified and sustainable-development water resources managing system.

Owner:北京奥特美克科技股份有限公司

Regenerative concrete composite material and method for making same

InactiveCN101139193ASolve processingSolve environmental problemsSolid waste managementEcological environmentLiving environment

The present invention discloses a regenerated concrete compound material, which is made of the following components according to weight ratio: 37-53 percent of regenerated aggregate prepared by the building waste residue, 14-30 percent of regenerated fine aggregate prepared by the building waste residue, 6-14 percent of industrial waste sand, 14-18 percent of common cement, 6-8 percent of water, additive and glue powder of waste tyre. The preparation method for the regenerated concrete is that: (1) the waste tyre is crushed and then is dipped in the coupling agent solution, and is to be dried; (2) the building waste residue is crushed, screened to obtain the regenerated coarse or fine aggregate; (3) the additive is added into the aggregate and the waste sand for mixing and blending evenly; (4) the regenerated aggregate, waste sand, cement, water and glue powder are milled evenly and then the regenerated concrete compound material can be obtained. The present invention can solve the problems that the building waste residue is difficult to be treated and the entironment is polluted and deteriorated greatly and so on. The building waste residue is to be used for replacing the natural aggregate that can decrease the consumptions to the natural aggregate in the building industry, solve the problems that the natural aggregates are increasingly lacked and the entironment is damaged by the exploitation of the sand stone. The present invention can protect the living environment for the human, guarantee the sustainable development for the society and accord to the requirement of the sustainable development.

Owner:云南华威废弃物资源化有限公司

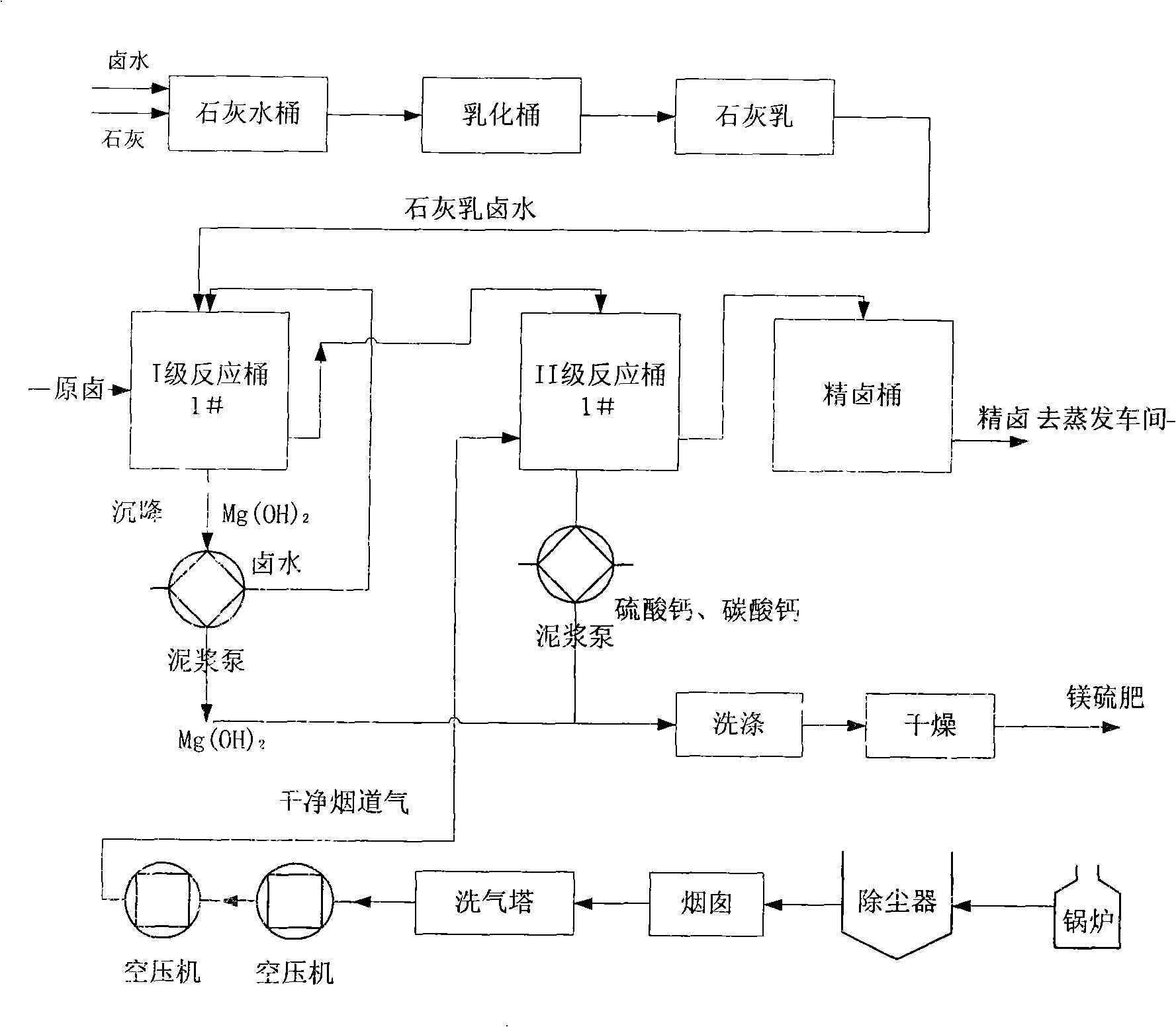

Technological process for purifying bittern

InactiveCN101289200AReduce purification costsImprove purification qualityAlkali metal chloridesSlurryCalcium carbonate precipitation

The invention provides a brine purification technical method which comprises that: a first step is that limewater is added into brine so that reaction happens to calcium hydroxide in the limewater and magnesian ion in the brine to generate magnesium hydrate sedimentation, the magnesian ion in the brine is removed, excessive calcium hydroxide is used for causticizing the sodium sulfate in the brine into sodium hydroxide; a second step is that flue gas is put into the brine after the magnesian ion is removed for carrying out reaction between carbon dioxide in the flue gas and the sodium hydroxide causticized in the brine to generate sodium carbonate which reacts with calcium ion in the brine to generate calcium carbonate sedimentation, the calcium ion in the brine is removed; a third step is that slurry produced in the first step and the second step is collected; and a fourth step is that refined brine after being treated by the first step and the second step is recycled. The technical method can reduce the pollution to environment, can save energy, and can reduce the consumption of raw brine and the purification cost of the brine at the same time, thereby conforming to the requirements of the strategy of sustainable development.

Owner:CHINA NATIONAL SALT INDUSTRY CORPORATION +1

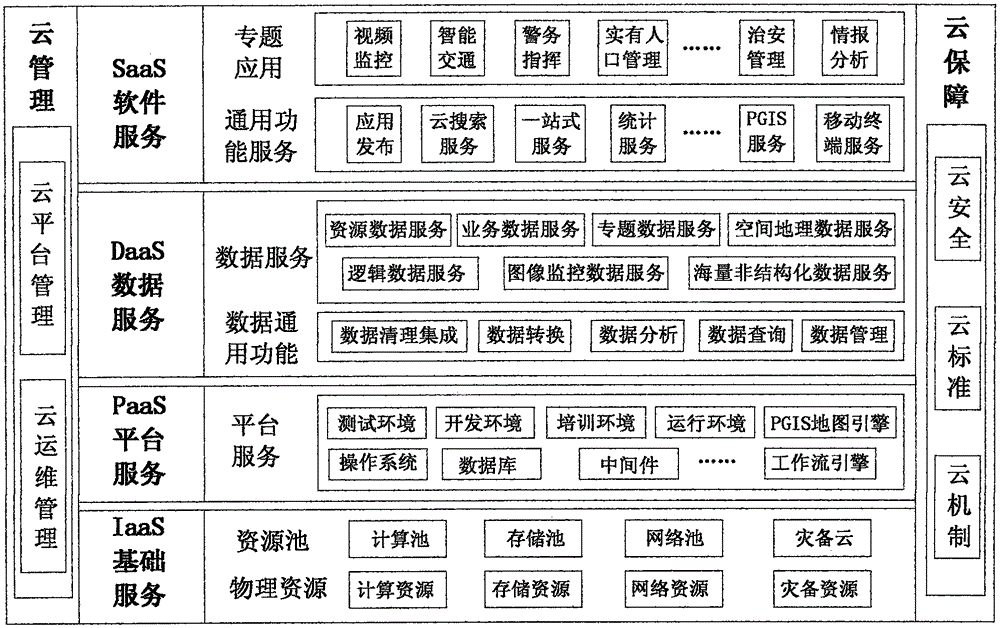

Cloud platform-based police affair management method

InactiveCN105427221AIncreased sense of securityIncrease happinessData processing applicationsInformatizationPrivate network

The invention discloses a cloud platform-based police affair management method. According to the method, a cloud platform-based police affair management system is utilized to provide comprehensive information resource services for the development, test and running deployment of various police classification business systems; and the cloud platform-police affair management system comprises four layers of frameworks such as basic service, platform service, data service and software service and two systems such as cloud management and cloud guarantee. According to the method, the technologies such as cloud computing, big data, internet of things and internet are tightly combined with the public security combat demands to establish a public security police affair cloud on the basis of a public security private network, a video private network and a government affair network, and the police affair cloud is longitudinally communicated with the superior police affair clouds and crosswise connected the province and city government affair clouds to provide police affair resource services for the government, the public security organs at different levels and the society, so that a resource-intensive, environment-friendly and development-sustainable public security information construction application new pattern is established.

Owner:北京中科云集科技有限公司

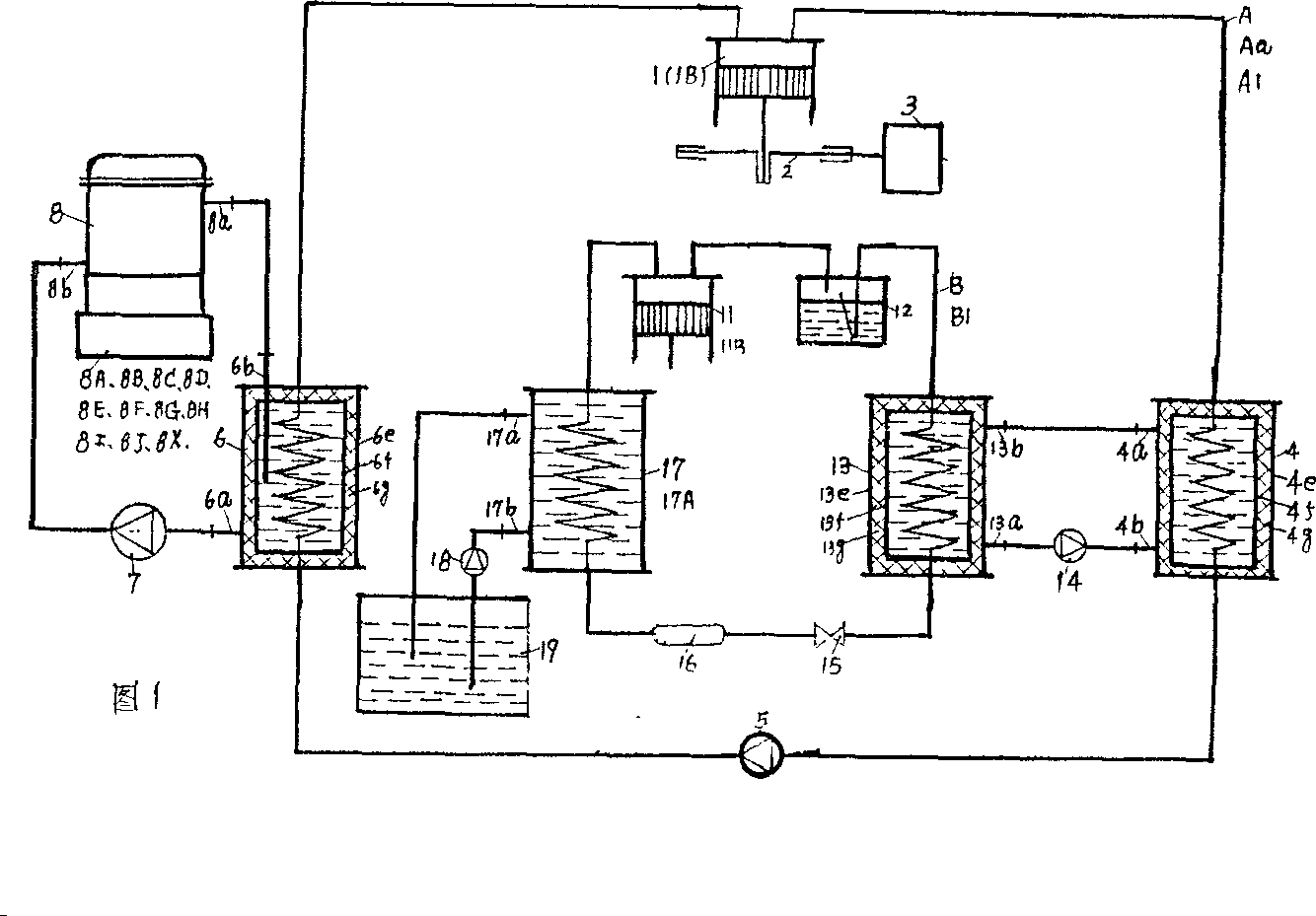

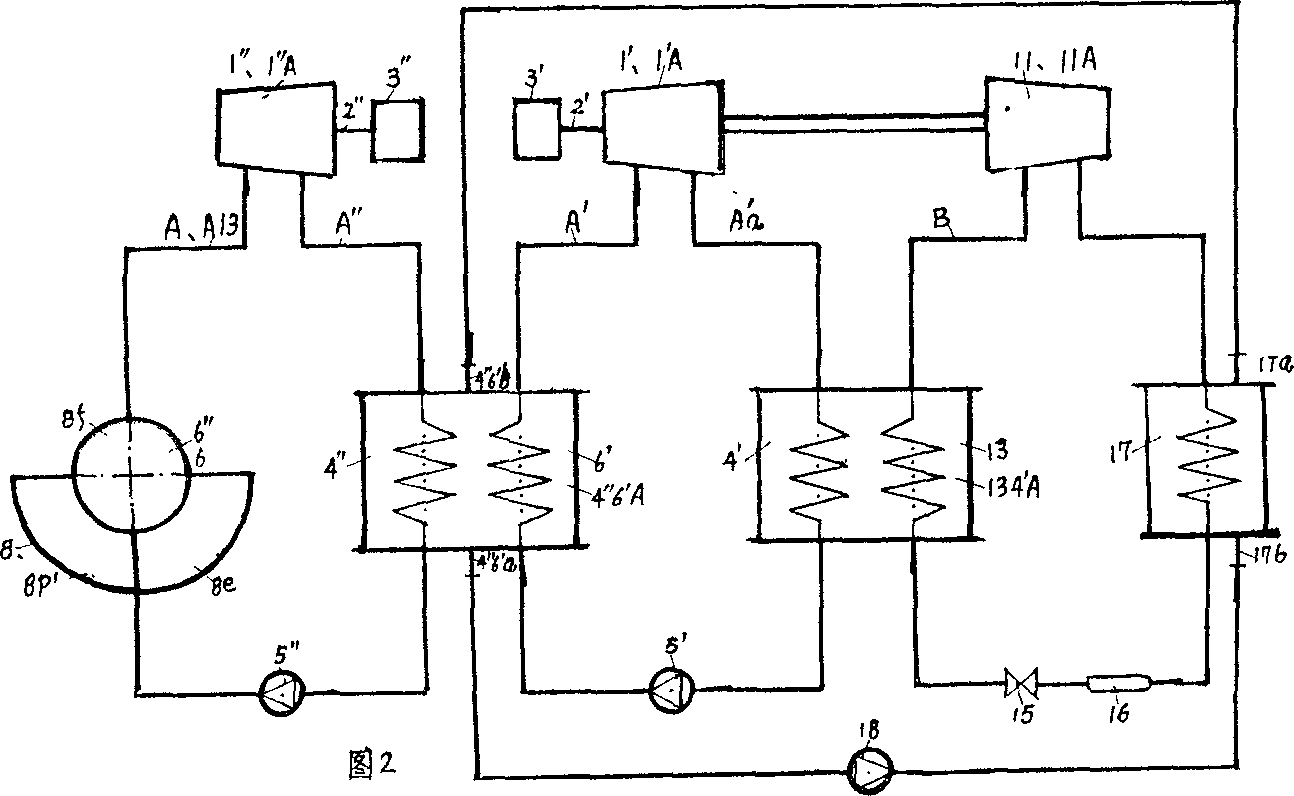

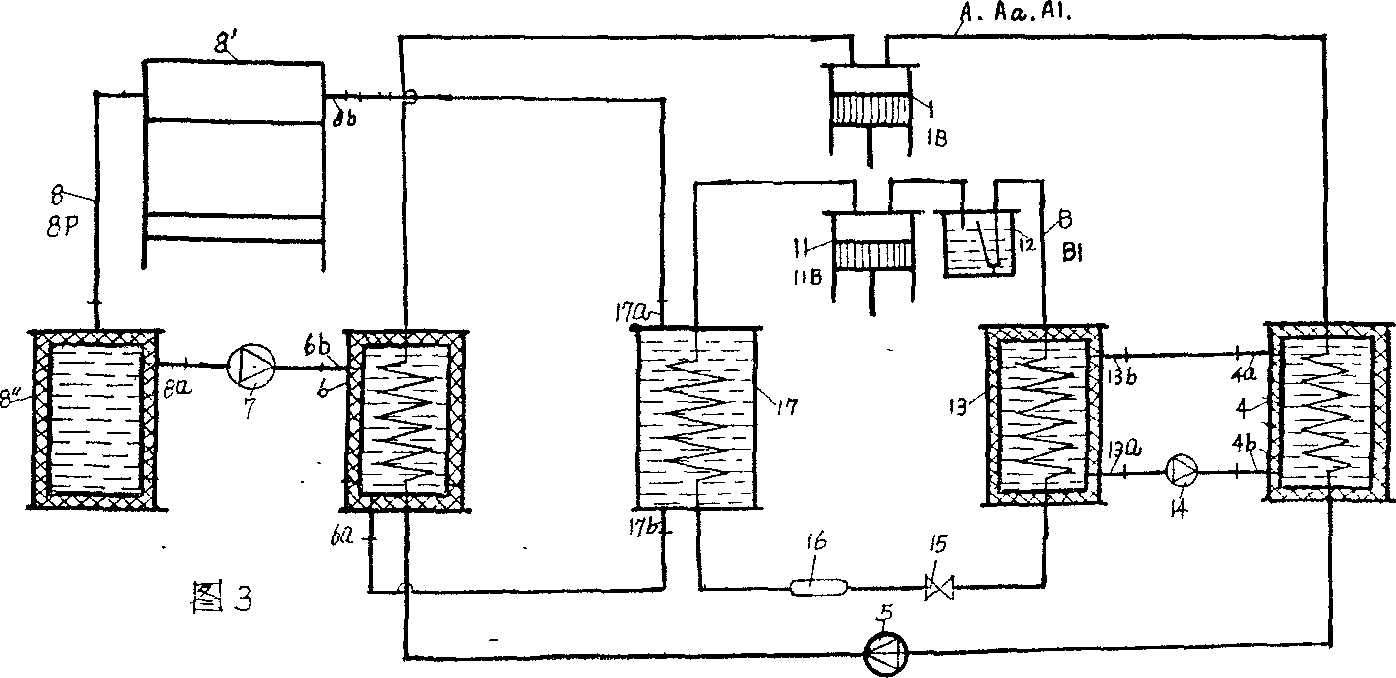

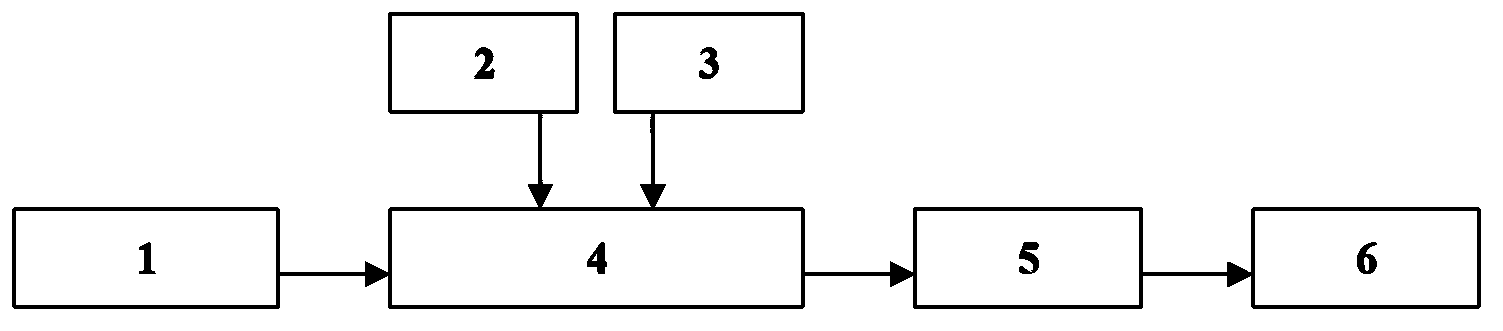

Composite thermodynamic engine of power circulation system and refrigerating circulation system

The inventive compound heat engine consists of a power circulation system and a refrigerating circulation system, in which is mounted a control system. It can provide the fields of power engineerings, refrigerating engineerings, communications and transportations, pumping irrigations and the like with mechanical work or electric energy. It not only can convert the high-grade energy, such as the fossil fuel, the nuclear fuel and soon into mechanical work or electric energy, but also can convert the low-grade heat energy stored in the seawater, the air and the earth crust into mechanical work or electric energy. Is also can convert the new energy like the solar energy and the renewable energy into mechanical work or electric energy.

Owner:罗桂荣 +1

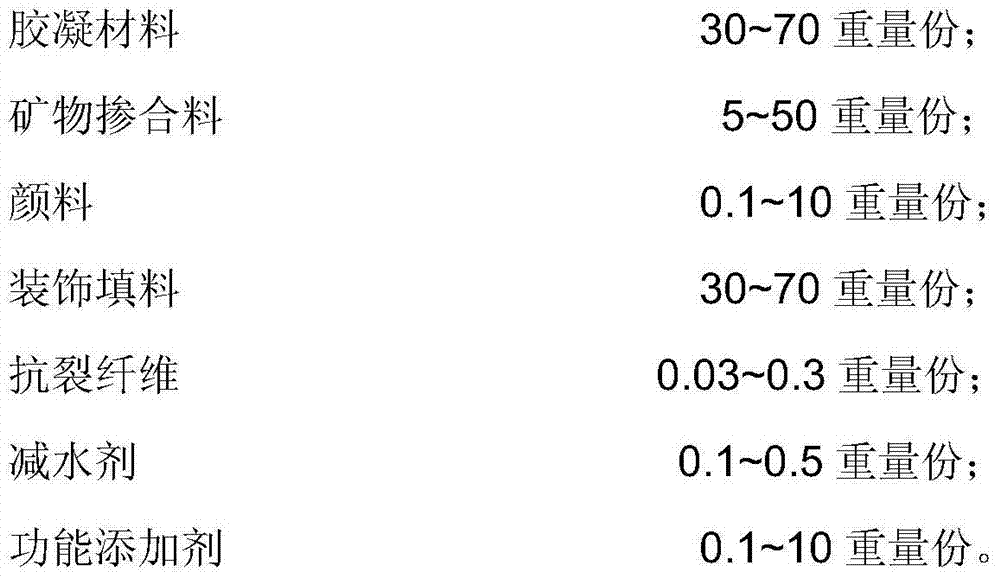

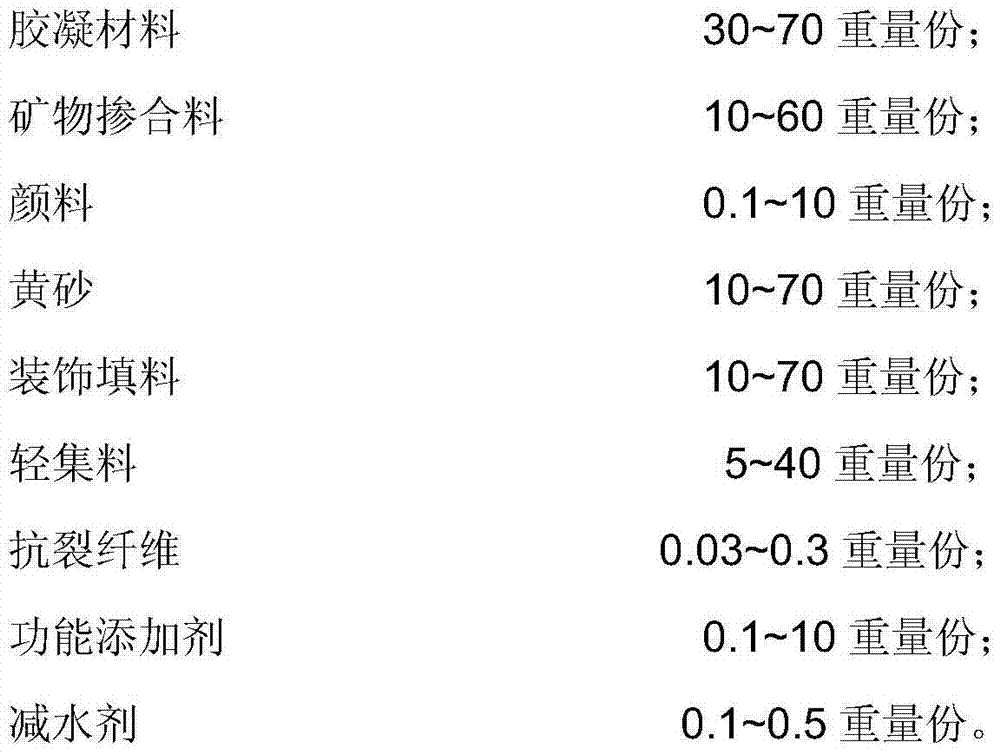

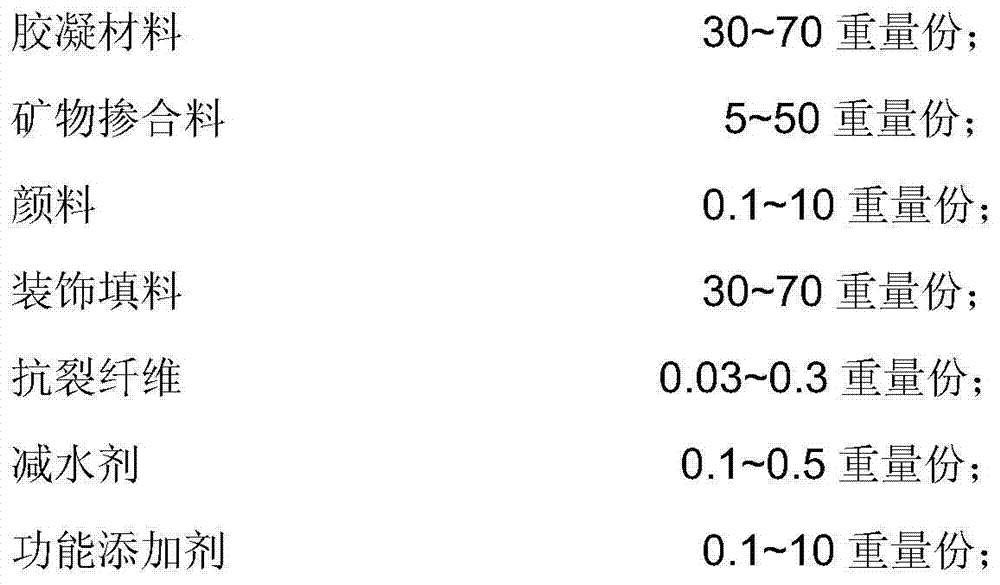

Artificial ecological stone slab for decoration and preparation method thereof

The invention provides an artificial ecological stone slab for decoration and a preparation method thereof. The artificial ecological stone slab comprises a surface layer, a middle reinforced layer and a bottom layer, wherein the middle reinforced layer which is located between the surface layer and the bottom layer and is alkali-resistant gridding cloth, and the surface layer comprises a surface paste layer. The formula of the surface paste layer comprises the following components: a gel material, a mineral admixture and a functional additive. The surface layer further comprises a surface color layer which is located on the surface of the surface paste layer. The bottom layer comprises the following components: a gel material, a mineral admixture, a lightweight aggregate, anti-crack fiber and a functional additive. The preparation method of the ecological stone slab comprises the following steps: pouring the stirred surface paste slurry in a die, then spreading the gridding cloth; then, pouring the stirred bottom slurry; moulding; and demoulding after maintenance so as to form a finished product. The ecological stone slab prepared by the invention has the characteristics of low density, high strength and high antifreezing cyclicity. Furthermore, industrial slags, coal ash and the like are further added, so that the ecological stone slab meets environmental protection and sustainable development.

Owner:SHANGHAI APE STONE

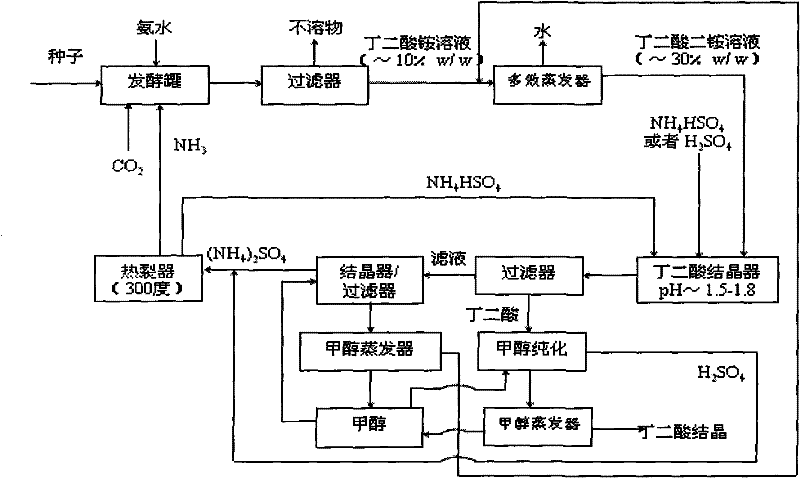

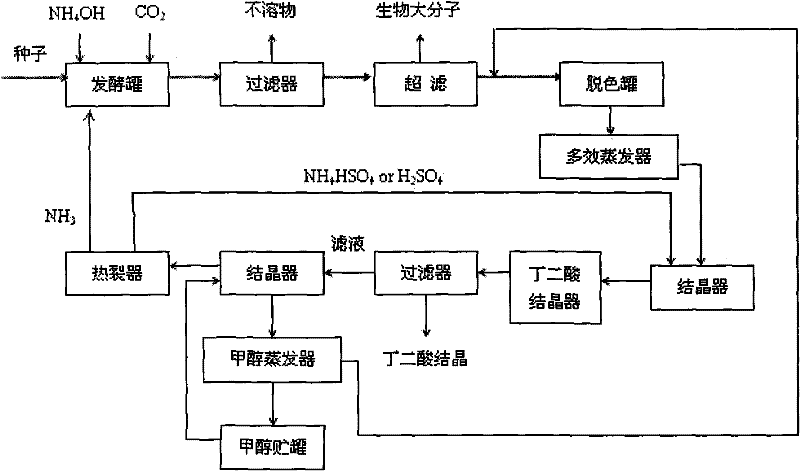

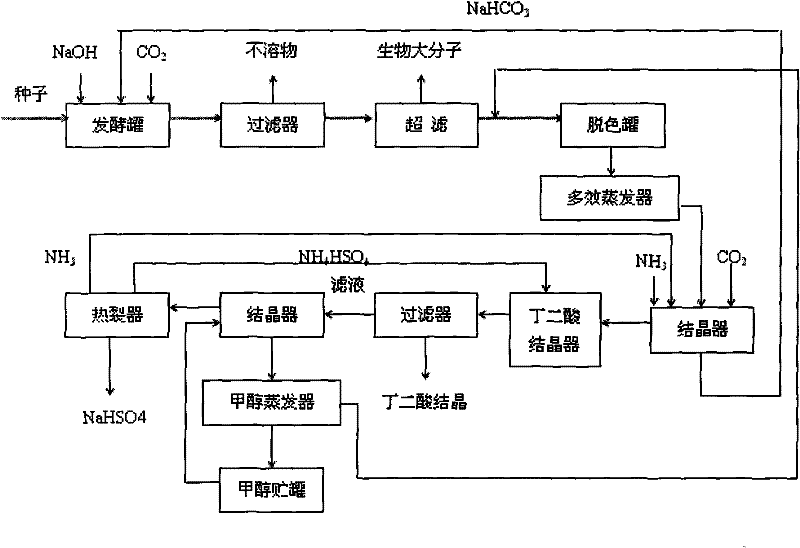

Succinic acid purification process through anaerobic fermentation

InactiveCN101748161APrevent pigmentationQuality assuranceMicroorganism based processesFermentationButanedioic acidEcological environment

The invention belongs to the technical field of biological engineering and discloses a novel succinic acid purification process through anaerobic fermentation. By adopting the separation process based on solid-liquid separation, ultrafiltration, decoloration, acidification and crystallization and by introducing ammonium sulfate thermal cracking technology, the invention realizes cyclic utilization of the acid and the alkali, forms a closed clean production flow and effectively ensures the quality of the succinic acid used for food and medicine. The invention not only reduces the fermentation cost and improves the economic benefits but also reduces environment pollution, improves the ecological environment and promotes the sustainable development of the national economy. Therefore, the invention has wide social benefits.

Owner:NANJING UNIV OF TECH

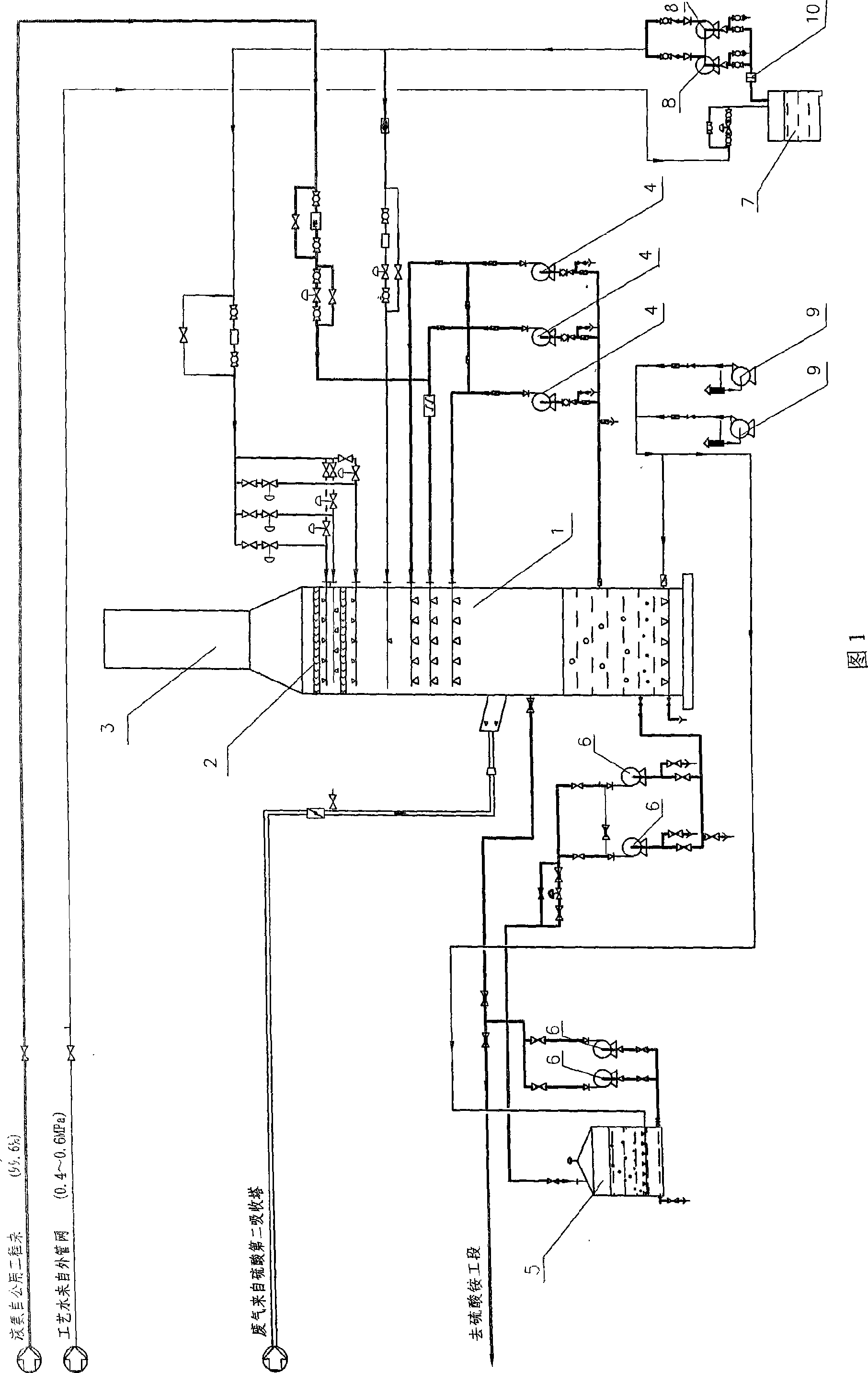

Sulphuric acid tail-gas deep desulfurization method

InactiveCN101422693AEmission reductionBig investmentDispersed particle separationEnergy conservationChemistry

The invention discloses a deep desulfurization method of sulfate acid tail gas. The method additionally arranges a desulfurization tower behind a second adsorption tower of a sulphuric acid device; after the waste gas discharged from the second adsorption tower enters the desulfurization tower, an ammoniation absorbent is used for adsorbing SO2 in the waste gas to generate ammonium sulfite; the tail gas after the desulfurization passes through a demisting layer in the tower to eliminate acid fog; the purified tail gas is discharged through a chimney at high altitude; the ammonium sulfite in the absorbent is aerated and oxidized to be ammonium sulfate solution at the bottom of the tower; and after the concentration of circulation liquid ammonium sulfate meets the requirement, the circulation liquid ammonium sulfate is sent to a follow-up process to be processed and used. The deep desulfurization method of sulfate acid tail gas can cause the concentration of the SO2 in the tail gas to be lower than 100mg / m<3> in a standard state, greatly reduces the emission of the SO2 in the tail gas, is beneficial to the improvement of the atmospheric environment quality, meets the construction principles of energy conservation, emission reduction and sustainable development and has good social benefits; in addition, the deep desulfurization method can increase the recovery amount of the ammonium sulfate, and has certain economic benefits.

Owner:GUIZHOU KAILIN GRP CO LTD

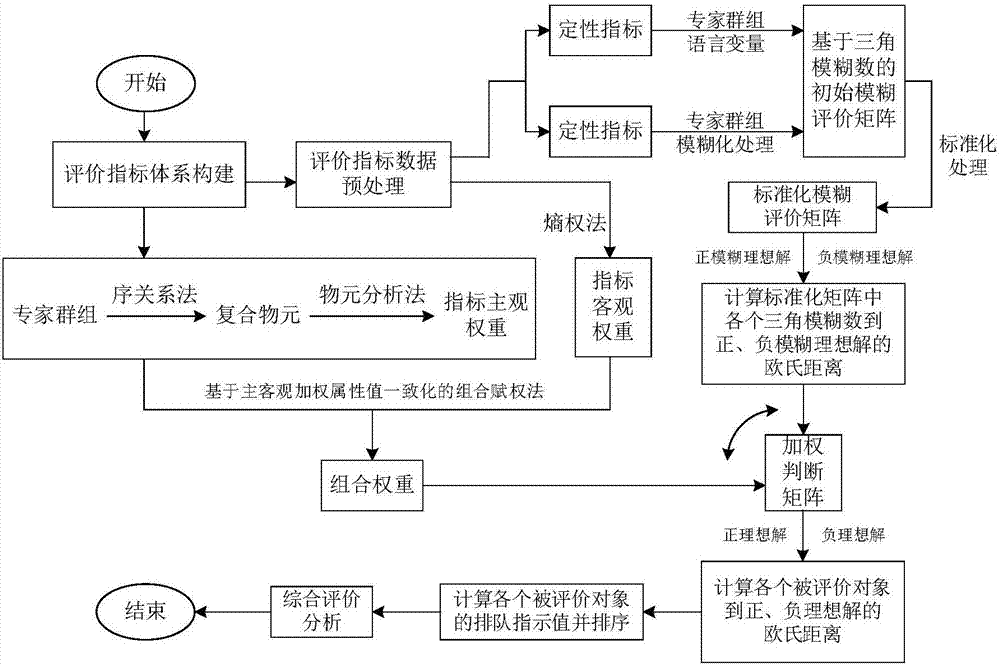

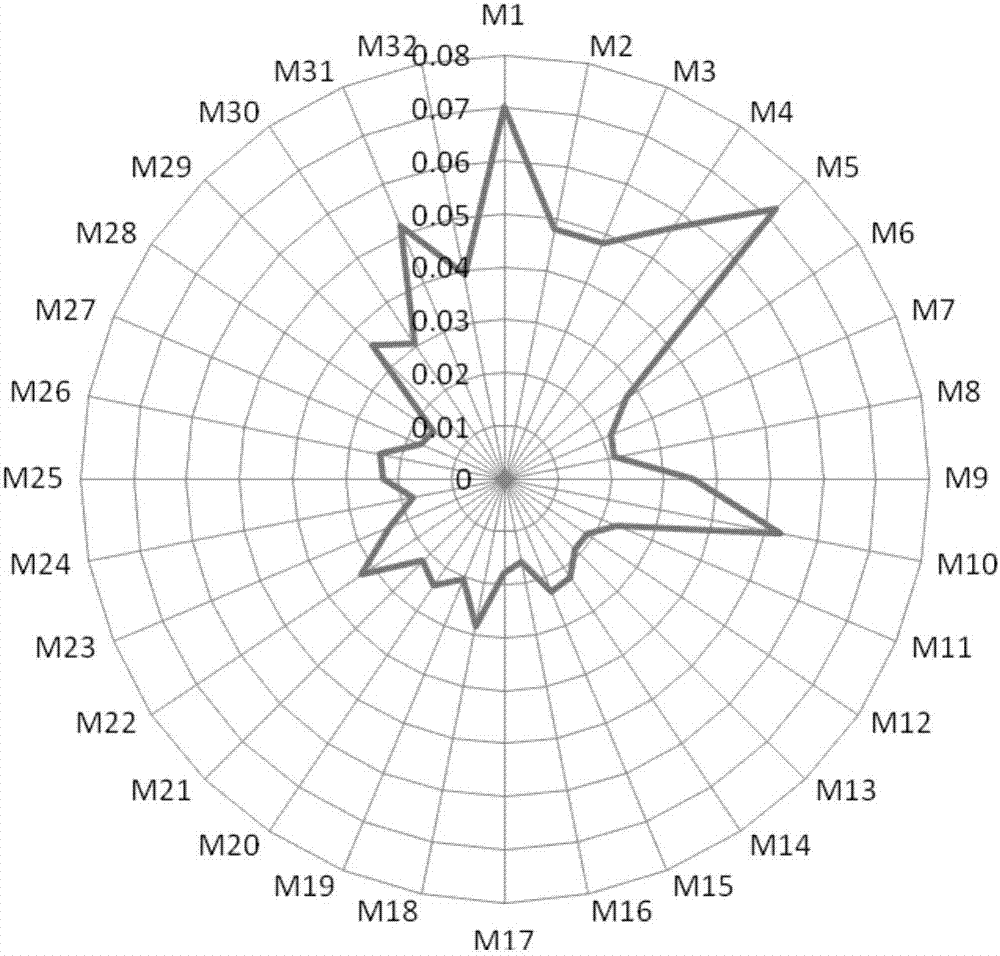

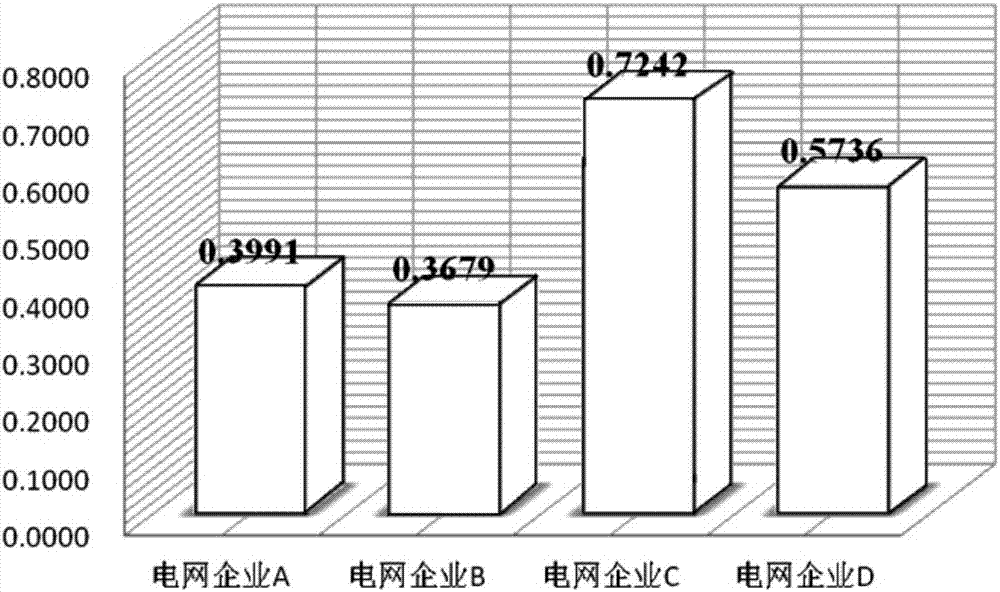

Improved comprehensive evaluation method for sustainable development of power grid enterprise

The invention discloses an improved comprehensive evaluation method for sustainable development of a power grid enterprise. The method comprises the following steps: step one, constructing an evaluation index system and carrying out pretreatment; step two, obtaining subjective weights of all expert validity and evaluation indexes by using a matter element analysis method; step three, carrying out objective weight assignment on the evaluation indexes after the pretreatment by using a entropy weight method; step four, calculating a combined weight of the evaluation indexes by using a combined weight assignment method based on subjective and objective weighted attribute value uniformization; step five, constructing an initial fuzzy evaluation matrix and carrying out standardized processing on the initial fuzzy evaluation matrix; step six, determining positive and negative fuzzy ideal solutions based on the standardized fuzzy evaluation matrix, calculating an Euclidean distance, and transforming the fuzzy evaluation matrix into a weighted determination matrix; and step seven, obtaining a queuing indication value of each evaluated object, determining a rank of each evaluated object, and then carrying out an integrated evaluation analysis on the evaluated objects.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

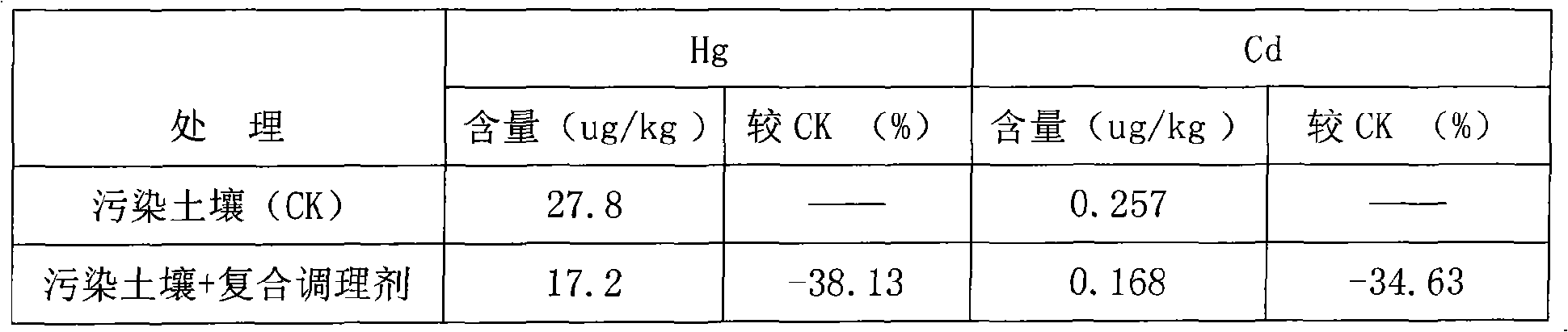

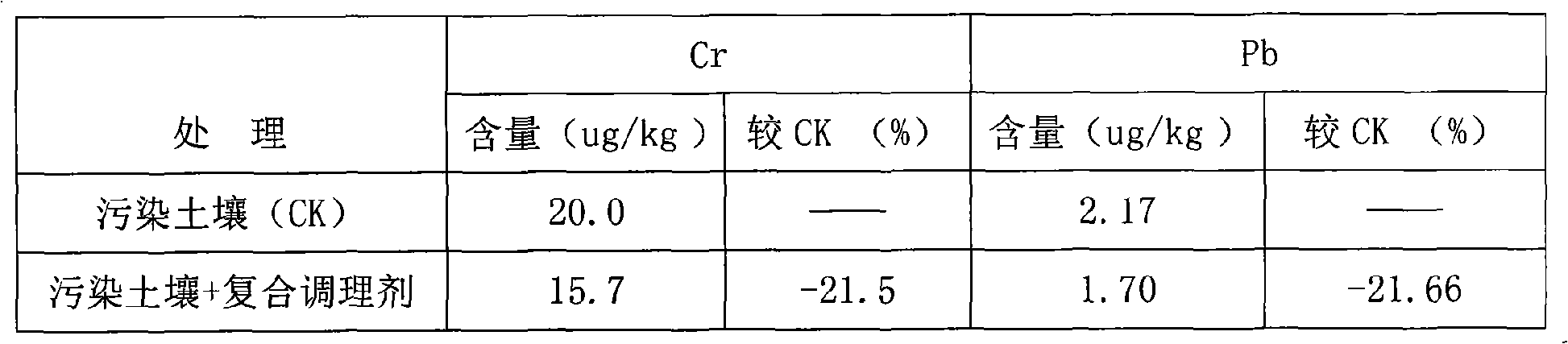

Compound conditioner for soil pollution remediation and preparation method thereof

InactiveCN101538469AReduce pollutionReduced mobilityAgriculture tools and machinesOrganic fertilisersSludge compostSorbent

The invention provides a safe and reliable compound conditioner for reducing the heavy-metal mobility and bioavailability of soil or sludge compost and a preparation method thereof. The compound conditioner is a powdery compound prepared by adding heavy-metal auxiliary passivating agent to alkaline agent, wherein, the heavy-metal auxiliary passivating agent includes precipitating agent and absorbing agent; and the compound conditioner comprises the following components by the mixing proportion (weight percentage): 78% to 91% of alkaline agent, 5% to 13% of precipitating agent and 4% to 9% of absorbing agent. The preparation method comprises the following steps: (1) drying and pulverizing one, two or more than two substances among soda-manufacturing waste residue, lime and fly ash and sieving by a 60-mesh sieve to obtain an alkaline powdery substance as the alkaline agent; (2) mixing the alkaline agent, the precipitating agent and the absorbing agent by the above mixing proportion; and (3) drying and pulverizing the mixed products and sieving by a 200-mesh sieve to obtain the powdery compound conditioner. The invention can greatly reduce the environmental risk caused by the prior art and realize the sustainable development of green circular economy, industry and agriculture by recycling the industrial waste at the same time.

Owner:广东省农业科学院土壤肥料研究所

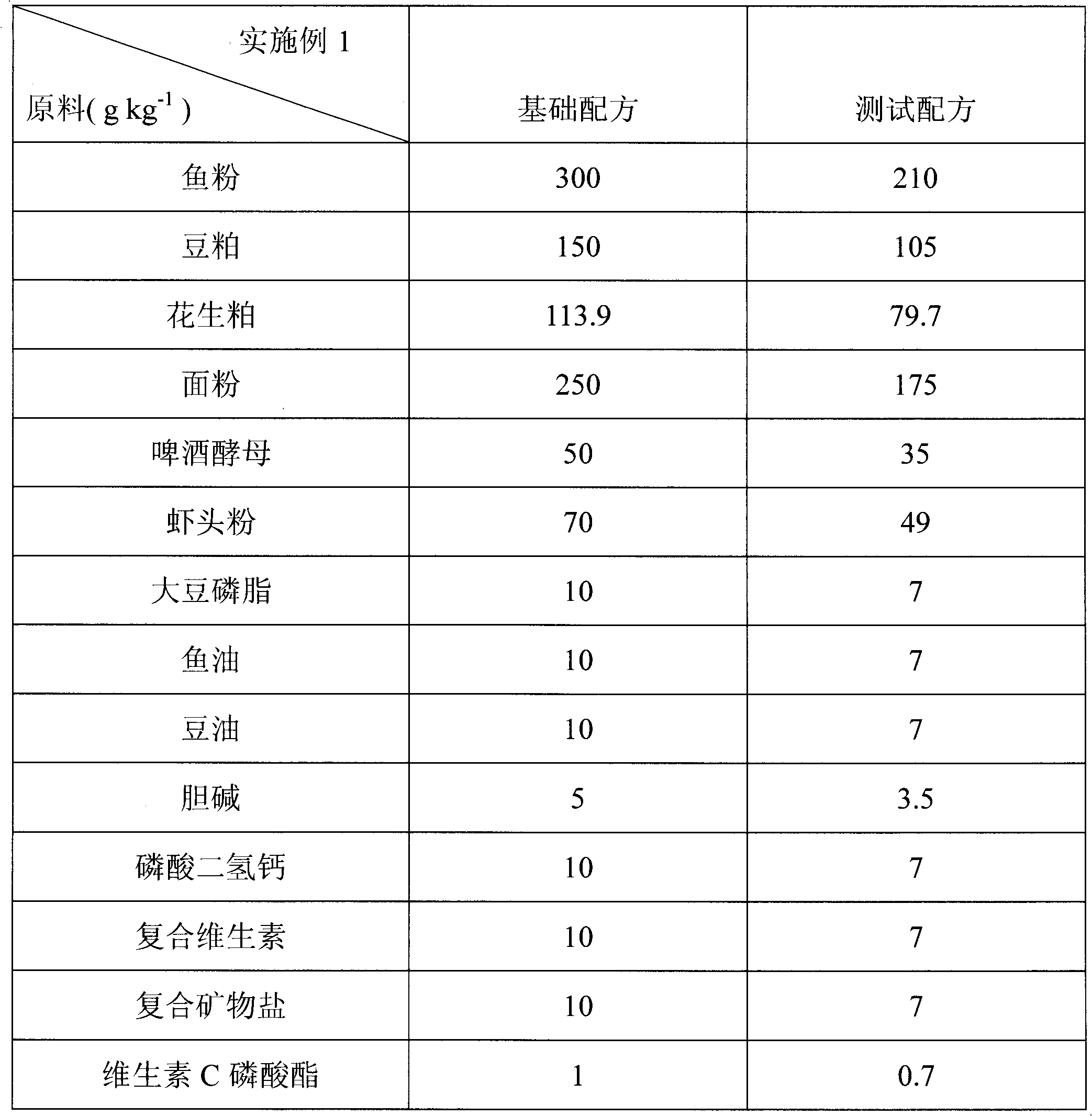

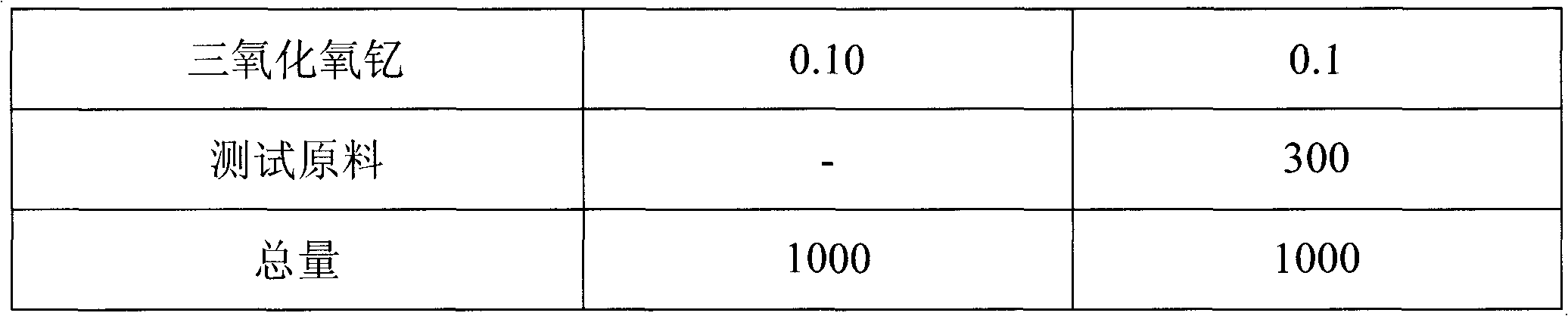

Feed for litopenaeus vannamei

InactiveCN101828644AMeeting nutritional needsImprove digestion and absorption rateAnimal feeding stuffProtein levelPollution

The invention discloses a feed for litopenaeus vannamei, which comprises the following nutrition compositions by mass percent: 25-35% of proteins, 4-9% of fat, 7-12% of ash contents, 40-55% of carbohydrates and 3-11% of water. The feed can meet the nutrient requirement of litopenaeus vannamei for best growth, and effectively solves the traditional problems of high protein level of a compound feedand severe environmental pollution in the process of culturing litopenaeus vannamei; the industrial profit is increased, and the pollution and the damage to a water environment in the process of culturing are reduced; and the sustainable development of litopenaeus vannamei culturing industry is realized.

Owner:SUN YAT SEN UNIV

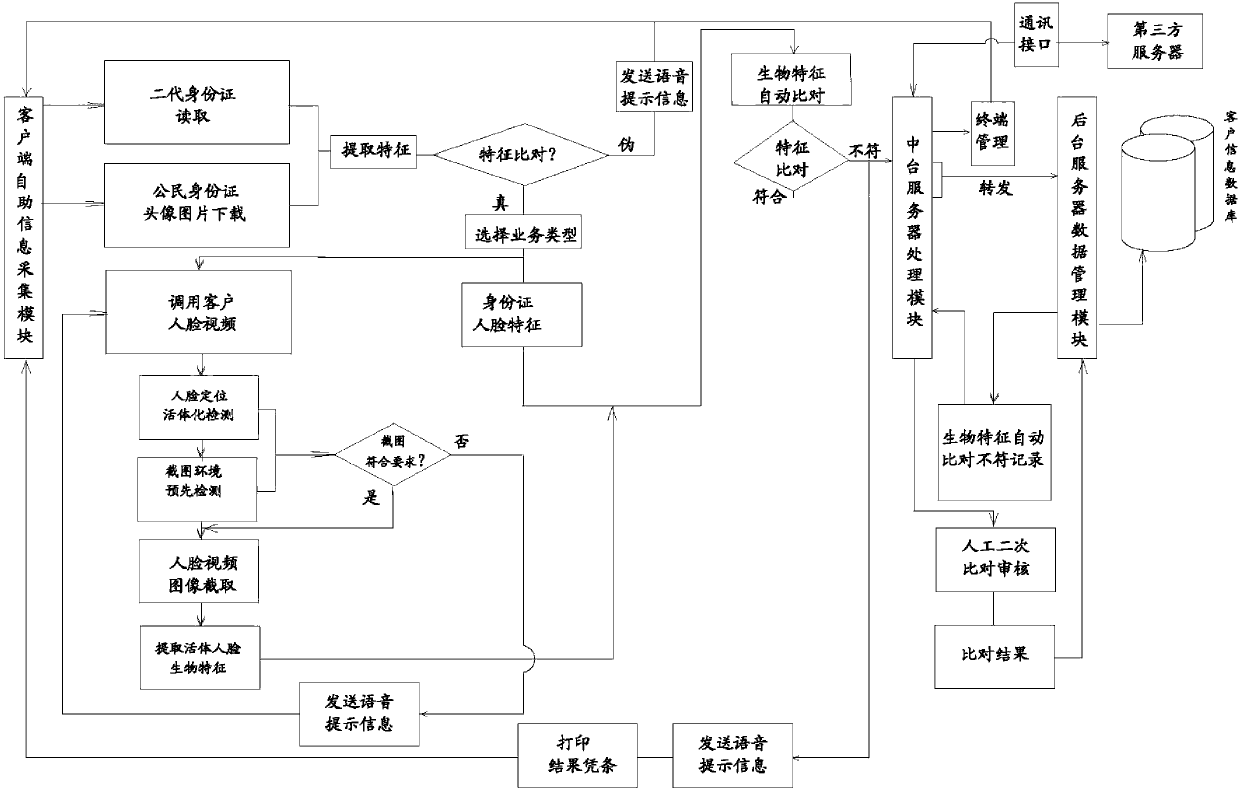

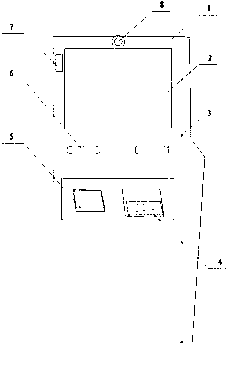

Identity verification system based on face recognition

InactiveCN102800017AGuaranteed identityPrevent cheatingFinanceCharacter and pattern recognitionE communicationCard reader

The invention discloses a network device based on a customer identity verification system, which aims to solve the problem that the cases resulting from name borrow and false name happen occasionally due to the shortcomings existing in the process of manually verifying the customer identity in the current financial industry. A customer terminal consists of a group of self-service information acquisition and real-time comparison terminals which perform real-time comparison on the information acquired by a camera and a second-generation identity card reader and directly transmit the acquired information and the comparison result to a background server or forward through a middleground server; and a third-party server reads the required information and comparison result directly from the background server database through a communication interface or through the middleground server. Through the invention, the identification accuracy of the customer identity is high, and the cases resulting from name borrow and false name in the banking business are greatly reduced. In combination with the characteristics of the bank, the information can be acquired in a self-service manner and automatically identified and compared to avoid human risk in the banking business, thereby laying a firm foundation for the sustainable development of the bank.

Owner:高艳玲

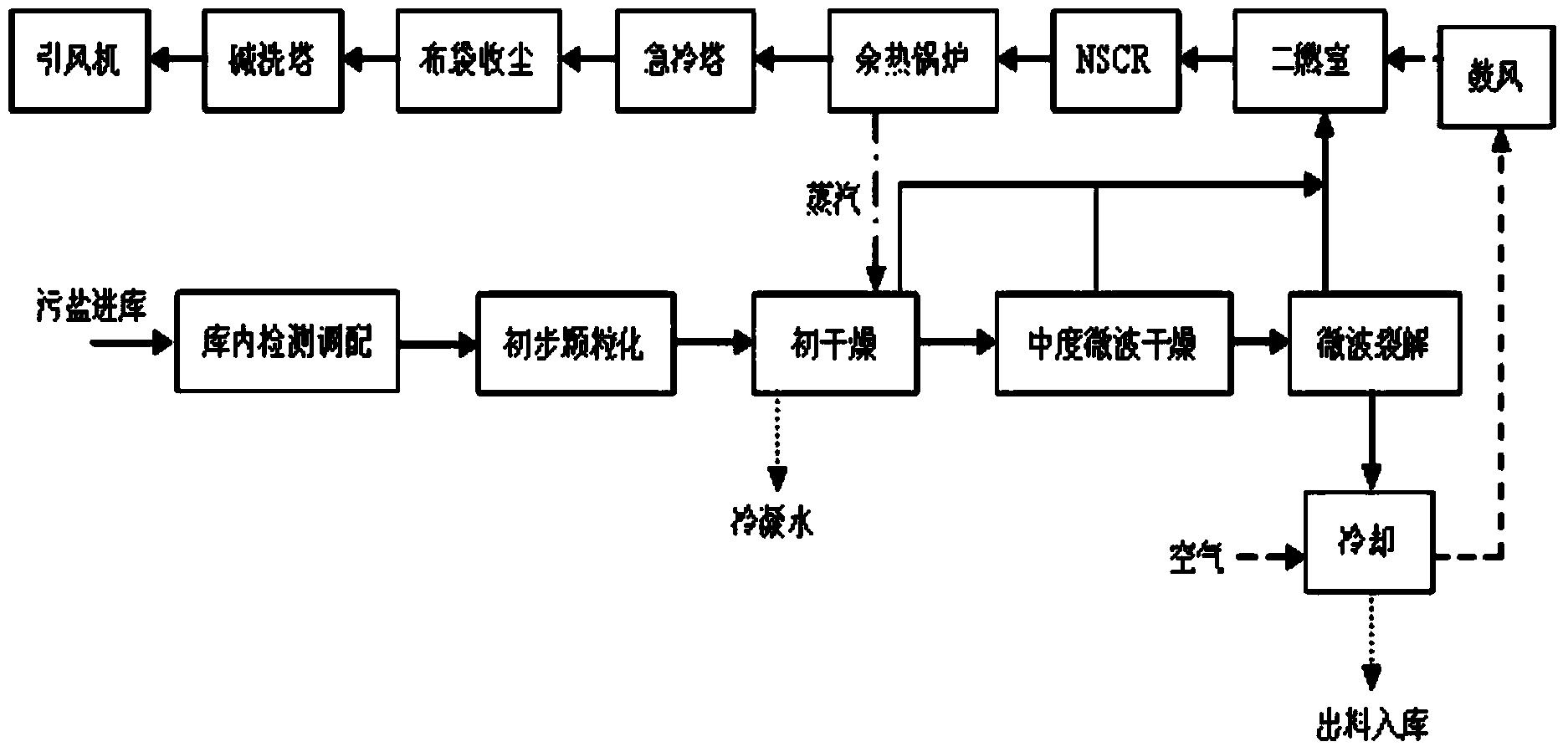

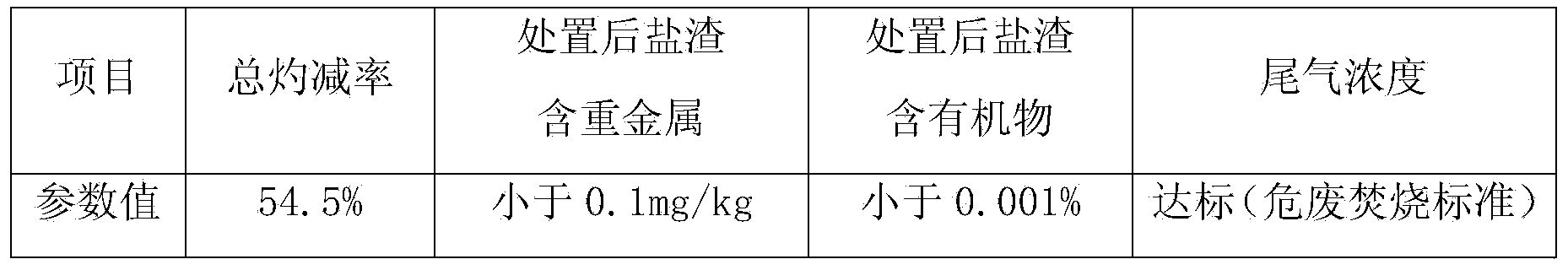

Industrial waste salt slag innocent treatment method

ActiveCN104344407AAlleviate the pressure of solid waste managementPromote sustainable developmentIncinerator apparatusSlagPetrochemical

The invention discloses an industrial waste salt slag innocent treatment method. The industrial waste salt slag innocent treatment method mainly comprises the following steps: a) burdening materials according to types of the industrial waste salt slag, and uniformly mixing the materials; 2) drying the mixture, wherein the drying process at least comprises initial drying and medium microwave drying, the initial drying process can remove the most part of free water, the medium microwave drying can remove the crystal water and gasify a part of organic matters, and the drying temperature is a continuously adjustable stable temperature gradient; c) anaerobic microwave pyrolysis: pyrolyzing the dried mixture at the temperature of 450-500 DEG C and under a nitrogen charged environment for more than 100 minutes, so as to pyrolyze the organic matters to form micromolecules to be gasified, organic salt to be split and gasified and the contained ammonium salt to be decomposed; 3) conducting air cooling to the pyrolyzed waste salt to be put in storage, and then conducting complete innocent treatment to the pyrolyzed waste salt, detecting and then selling the qualified product or reusing the treated waste salt. The industrial waste salt slag innocent treatment method has the characteristics of safety, efficiency, energy conservation and the like, has the obvious advantage in the resource recycling aspect, can greatly slow down the solid waste management stress in the industrial developed area, in particular the chemical engineering petrochemical industry park, is favorable to promote the related sustained development of the park.

Owner:ZHEJIANG DONGTIANHONG ENVIRONMENTAL PROTECTION ENG CO LTD

Coated controlled-release fertilizer modified by natural polymer and preparation method thereof

ActiveCN102295491AImproved controlled releaseFully Environmentally DegradableAgriculture gas emission reductionFertilizer mixturesCellulosePetrochemical

The invention discloses a natural polymer modified coated controlled release fertilizer and a preparation method thereof. The fertilizer comprises a fertilizer core layer and a coated layer positioned on the outside of the fertilizer core, wherein the material of the fertilizer core layer is formed from fertilizer particles, and the coated layer which is one layer or two layers and is a two layered coated controlled release fertilizer is a cellulose layer and a hydrophobic film. The coated controlled release fertilizer provided by the invention has a good controlled release performance, and simultaneously the film material has biodegradability, so an environmental problem brought by the controlled release film material is solved. A natural product cellulose is adopted to get rid of the dependence of the coated material on a petrochemical resource, so the sustainable development of the coated material is realized. The coated controlled release fertilizer, which has the advantages of improvement of the fertilizer utilization rate, environment pollution reduction, sustainable development, and the like, has a wide application prospect.

Owner:大项生态建设有限公司

Coated controlled-release fertilizer using crop straws as degradable film and production method of fertilizer

ActiveCN102795924AReduce dependenceAddressing Sustainability IssuesFertilizer mixturesPetrochemicalSolvent

The invention relates to a coated controlled-release fertilizer using crop straws as a main coating material and a production method of the fertilizer. The method comprises the following steps of: preparing straw coating liquid from the crop straws, simultaneously spraying the straw coating liquid and a curing agent to fertilizer granules in different ratios, directly reacting, and curing into a film, and thus obtaining the straw coated controlled-release fertilizer with different water permeability. The produced coated controlled-release fertilizer has accurate nutrient release control performance, and the nutrient release control period can be controlled to be 1 to 12 months; and the film material is biodegradable. Moreover, because a waste renewable plant biomass resource, namely the crop straws is used as the film material, dependency of the coating material on petrochemical resources is reduced, and sustainable development of the coating material is realized. The fertilizer is low in prices and easy to prepare, does not require solvent, and is very suitable for large-scale production and promotion.

Owner:SHANDONG AGRICULTURAL UNIVERSITY

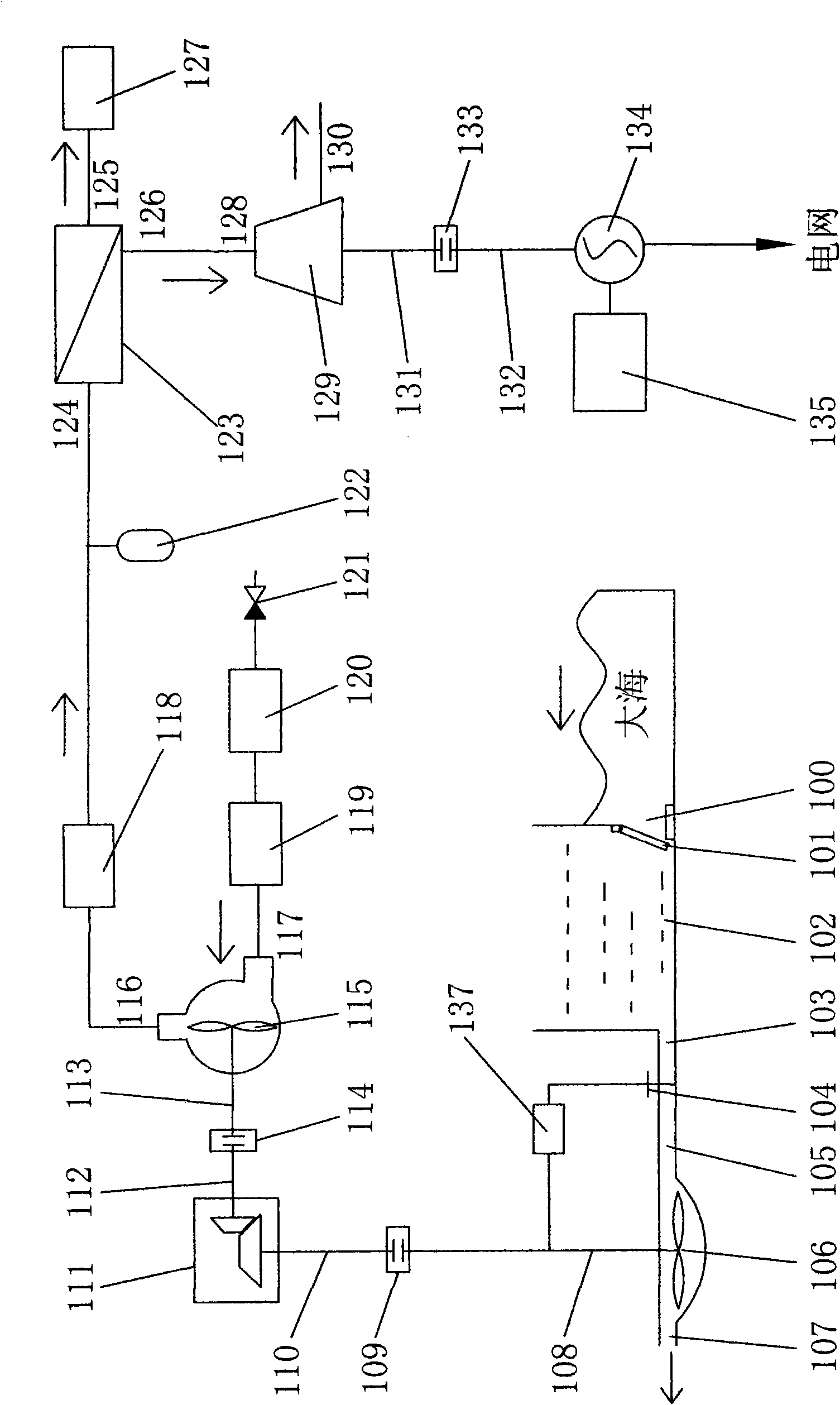

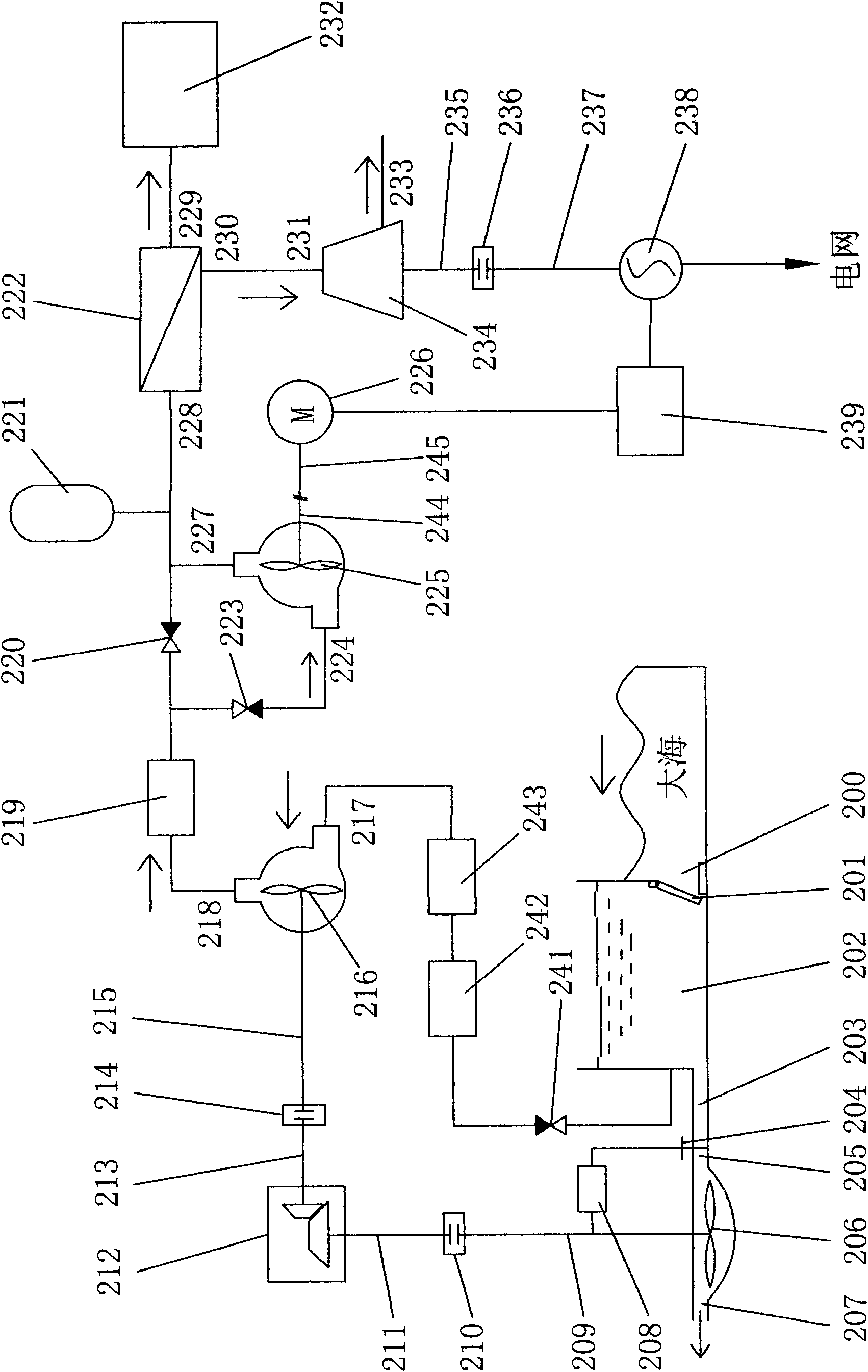

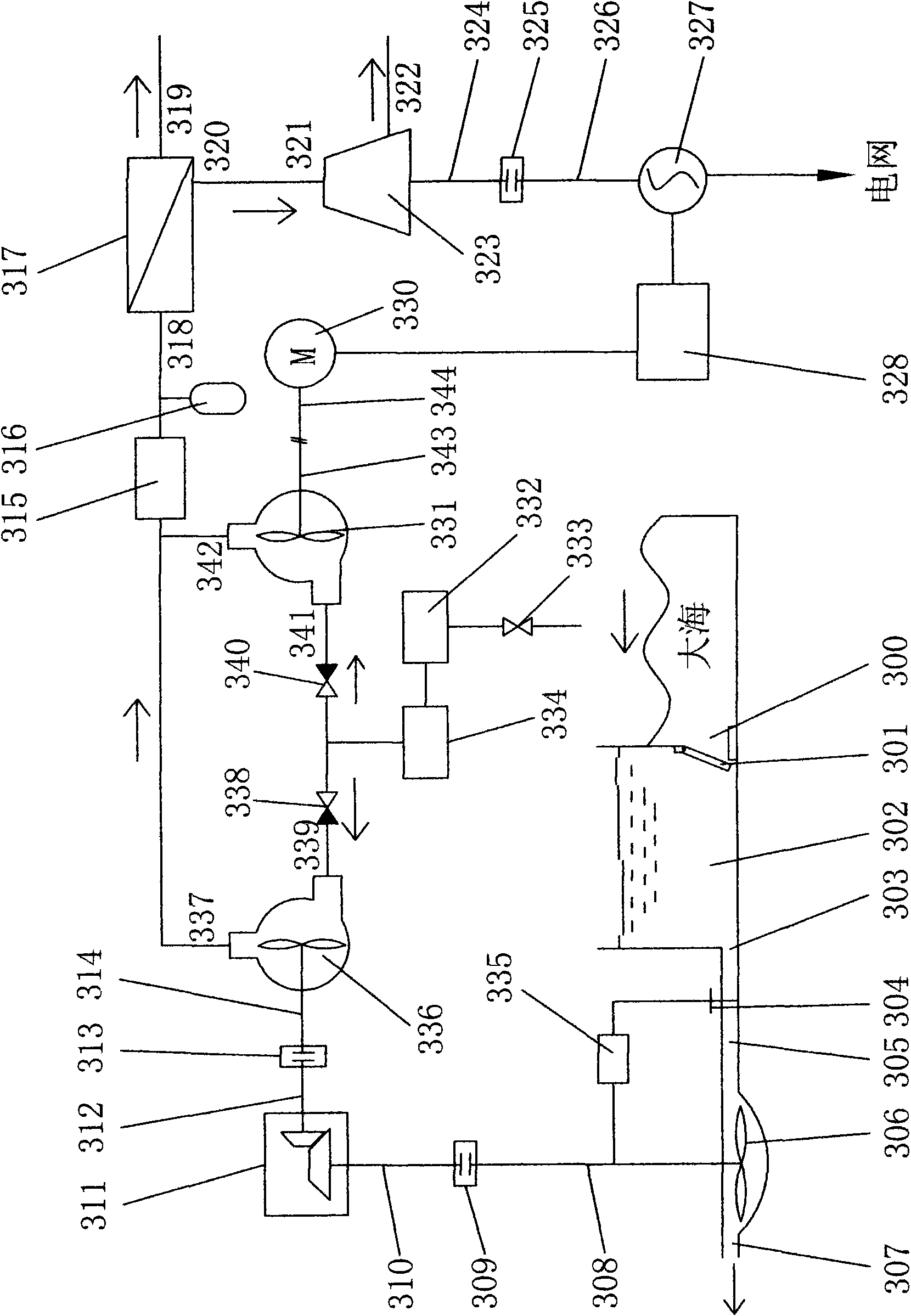

Method and device for desalting sea water and generating electricity by utilizing tidal energy drive

ActiveCN102022251ARealize comprehensive utilizationAchieve conversionGeneral water supply conservationSeawater treatmentWater dischargeWater turbine

The invention relates to a method and device for desalting sea water and generating electricity by utilizing tidal energy drive. The high sea water in the sea when in rising tide is utilized to impact a water turbine to rotate in the process of flowing into an impounding reservoir, or the high sea water in the impounding reservoir when in ebbing is utilized to impact the water turbine to rotate in the process of flowing into the sea; the water turbine drives a high-pressure pump to operate to generate high-pressure water which is desalted through a reverse osmosis membrane module; the high-pressure concentrated sea water discharged from the reverse osmosis membrane module impacts a turbo machine to rotate; the turbo machine drives a generator to rotate to generate electric energy, thus realizing the comprehensive utilization and conversion of the tide energy; the effluents in the process of energy utilization and conversion do not cause pollution, are clean and environmental-friendly;the system does not need additionally provided external power, and is low in operation cost; and the tide energy is a renewable energy source, and has the advantages of sustainable development, better social benefits and application value.

Owner:GUANGDONG OCEAN UNIVERSITY

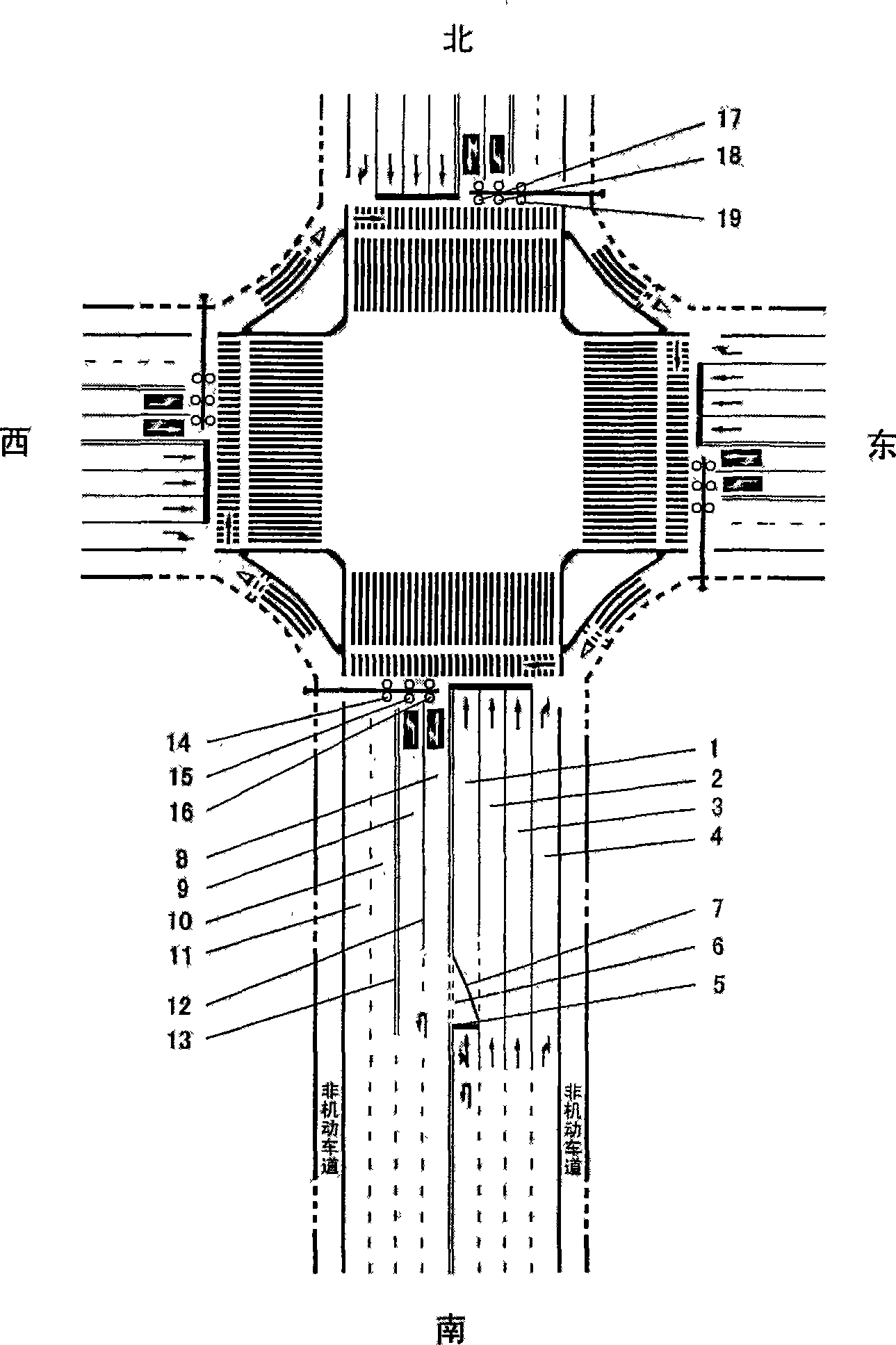

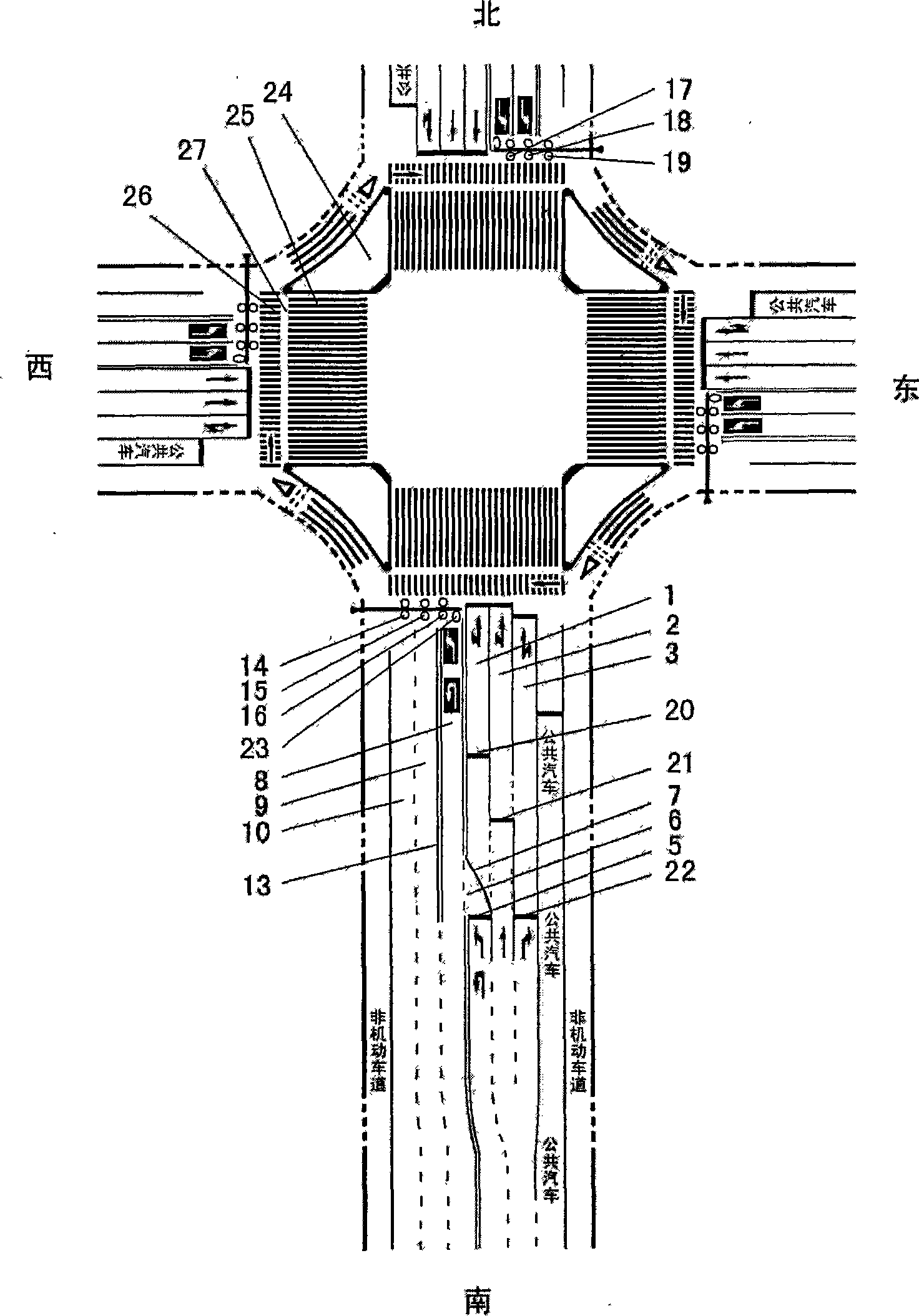

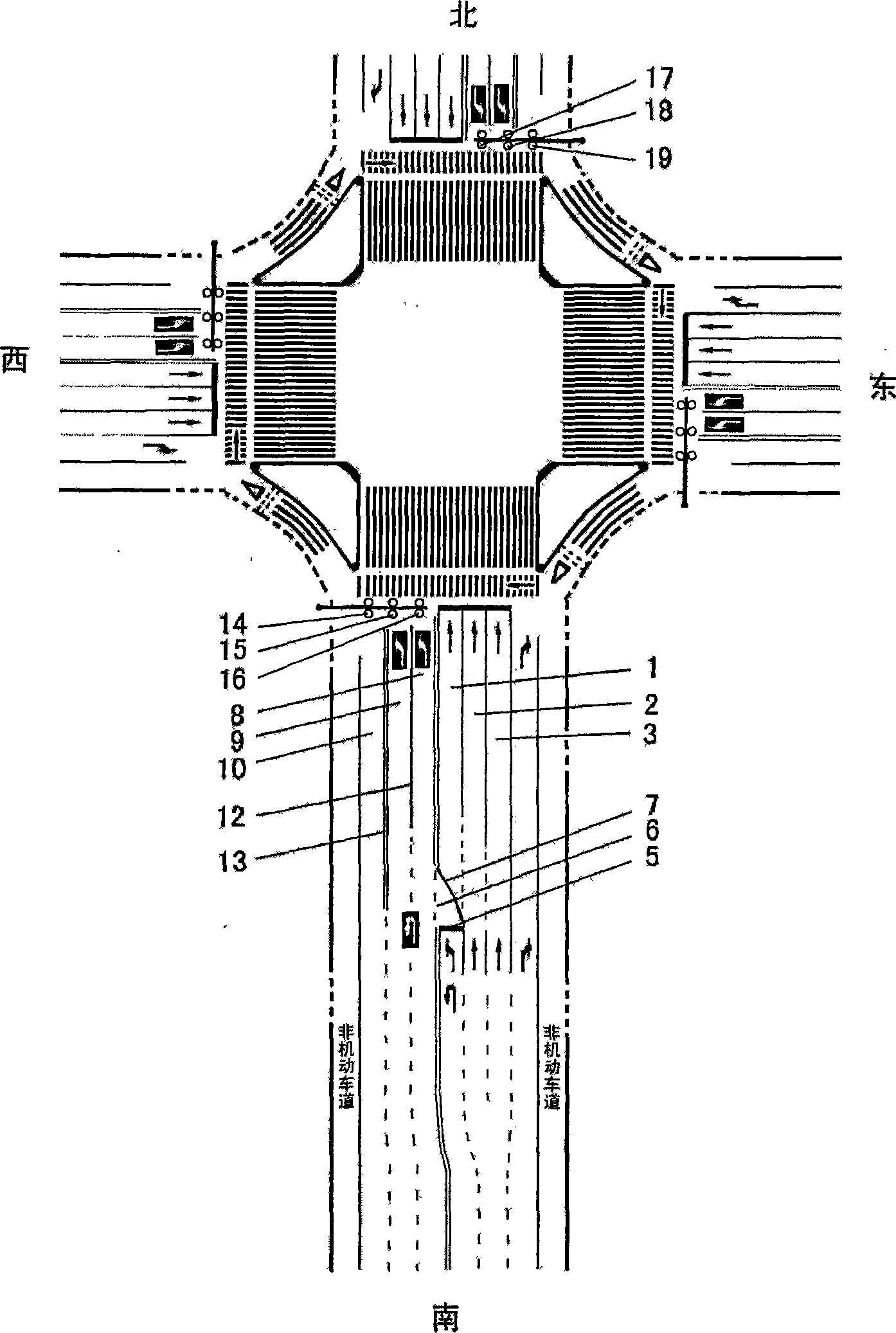

Method for setting road traffic signal and controlling crossing traffic

InactiveCN101463582AShorten the queueIncrease profitControlling traffic signalsClimate change adaptationTraffic capacityTraffic signal

The invention provides a method for road traffic signal setting and crossing traffic control. A stop line is arranged on the left-lane at the position one distance from the stop line at the crossing and a section of a central dividing line is erased to set an exit, the dividing line between a first and a second lanes or the dividing line between a second and a third lanes is changed into a full line to cause an exit lane in the opposite direction to be employed as an entrance lane for forward driving under the circumstance of time separation in each signal period. In addition, according to the status quo of relatively wide road lane in China, the lanes of a two-way road experience a compact design; entrance lanes are added and a bus crossing priority system is established to make full use of the time and space of the crossing traffic to improve the traffic capacity and traffic quantity of crossings, in particular effectively improve the operation effect of buses, thus leading to the free-flowing and speed-raising of the traffic, energy-saving and emission-reducing and safety and order of the traffic and the sustainable development of the traffic transportation of the whole city.

Owner:黄宝文

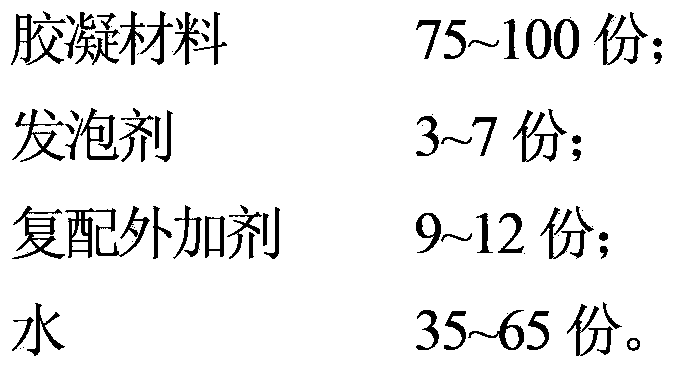

Chemical foamed concrete and preparation method thereof

The invention discloses a chemical foamed concrete and a preparation method thereof. The concrete product is prepared by using a cementing material, a foaming agent, a compounded additive and water as raw materials through a chemical foaming principle, and the added compounded additive realizes stable foaming speed stability, uniform bubble diameter and controllability. The chemical foaming preparation method has the advantages of simplicity, low production investment cost, and convenient construction. The foamed concrete product prepared in the invention has the advantages of fireproof property, waterproof property, sound insulation, heat insulation, light weight, high compressive strength and environmental protection. The bulk density, the compressive strength and the heat conduction coefficient of the obtained product are less than 400kg / m<3>, more than 3.5MPa and less than or equal to 0.07W / (M.K) respectively. The above formula adopting alkaline ash comprising alkaline furnace ashes, alkaline slag, alkaline furnace slag and other wastes as raw materials realizes comprehensive utilization of resources, changes wastes into valuables, and accords with the demands of sustainable development of national circular economy.

Owner:LIAONING JIJIA ENERGY SAVING WALL EQUIP

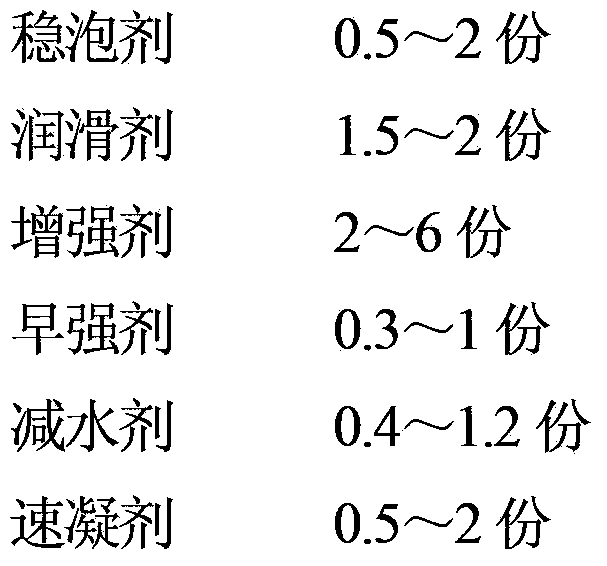

Preparation method of keratin complex fiber

InactiveCN104862818AReduce pollutionTime-consuming and laborious to solveConjugated cellulose/protein artificial filamentsConjugated synthetic polymer artificial filamentsFiberSolvent

The invention relates to a preparation method of keratin complex fiber, which comprises the following steps: 1, mixing the dried keratin powder, high polymer for fiber forming, ionic liquid and the like, and mechanically stirring and dissolving to obtain a keratin complex solution at certain temperature; (2) preparing a keratin complex fiber by using a dry jet wet spinning process. According to the invention, the keratin used according to the invention comes from leftovers of processing industry such as chicken feather, drake feather, goose feather and wool, and as for the recycle of the waste, on one hand, the economic benefit is increased, on the other hand, the environment pollution can be reduced. The selected high polymer for fiber forming and keratin can dissolve together in the same ionic liquid, so that the characteristics of high efficiency, simpleness and convenience can be achieved. Compared with the pure keratin fiber, the strength and elongation at break of the spun regenerated keratin can be improved greatly, the practical use value can be increased; the keratin complex fiber has wide potential application in the fields of clothing, wig, tissue engineering and the like. In addition, the solvent ionic liquid can be completely recycled, can not pollute the environment and has the meaning of sustainable development.

Owner:JIANGNAN UNIV

All-round computer vision-based electronic parking guidance system

InactiveCN101059909AWide detection rangeInstallation and maintenance without interferenceArrangements for variable traffic instructionsDetection of traffic movementGuidance systemVision based

An electric park induce system based on omnibearing computer vision comprises a microprocessor, an omnibearing vision sensor for detecting the park condition in a parker, and a communication module communicated with outer space, wherein the vision sensor is mounted above the park, the microprocessor detects the condition of each park part to provide dynamic internal induction and external induction to park. The inventive park check method has wide check range, non-interference installment, low energy consumption in maintenance, abundant check parameters, visual property, reliable check, high accuracy, easy statistic, simple operation, expandable property, or the like.

Owner:ZHEJIANG UNIV OF TECH

Iron tailing concrete

InactiveCN101671146AReduce pollutionNot brokenSolid waste managementMineral processingEnergy consumption

The invention provides an iron tailing concrete which comprises the following ingredients of cement, mineral processing barren rocks and detritus, admixture, water and pumping aid for the concrete determined according to performances, and the ingredients of the concrete according to the weight percentages of the concrete are respectively 4-20 percent of cement, 0-35 percent of mineral processing barren rocks and detritus, 1-8 percent of admixture, 1.5-2.5 percent of pumping aid for the concrete based on the weight sum of the cement and the admixture, and the balance of water. The invention hasthe effects that the novel concrete adopts tailing ores and detritus and is applied to the production of the concrete for partially or completely replacing natural aggregate. The concrete can reducethe pollution to the environment from mineral processing barren rocks, decrease the production volume and the production energy consumption of natural ore materials, accord with three 'green' meaningssuggested by the world environment organization: saving resources and energy; no environmental damages, and more environment friendly; and also according with the strategy of sustainable development,thereby not only satisfying requirements of the contemporary people, but also not damaging the capacity of satisfying unborn requirements.

Owner:天津港保税区航保商品砼供应有限公司

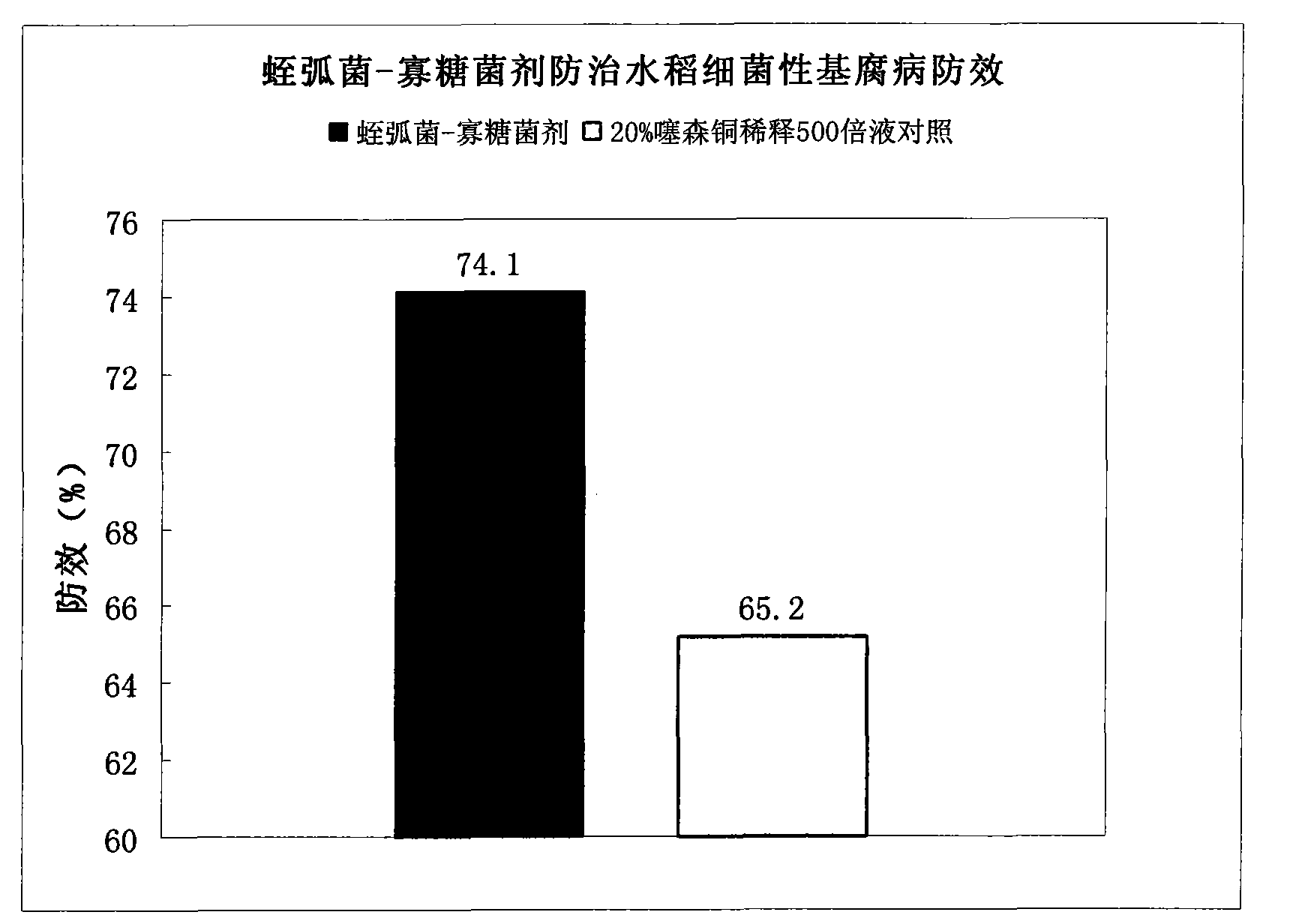

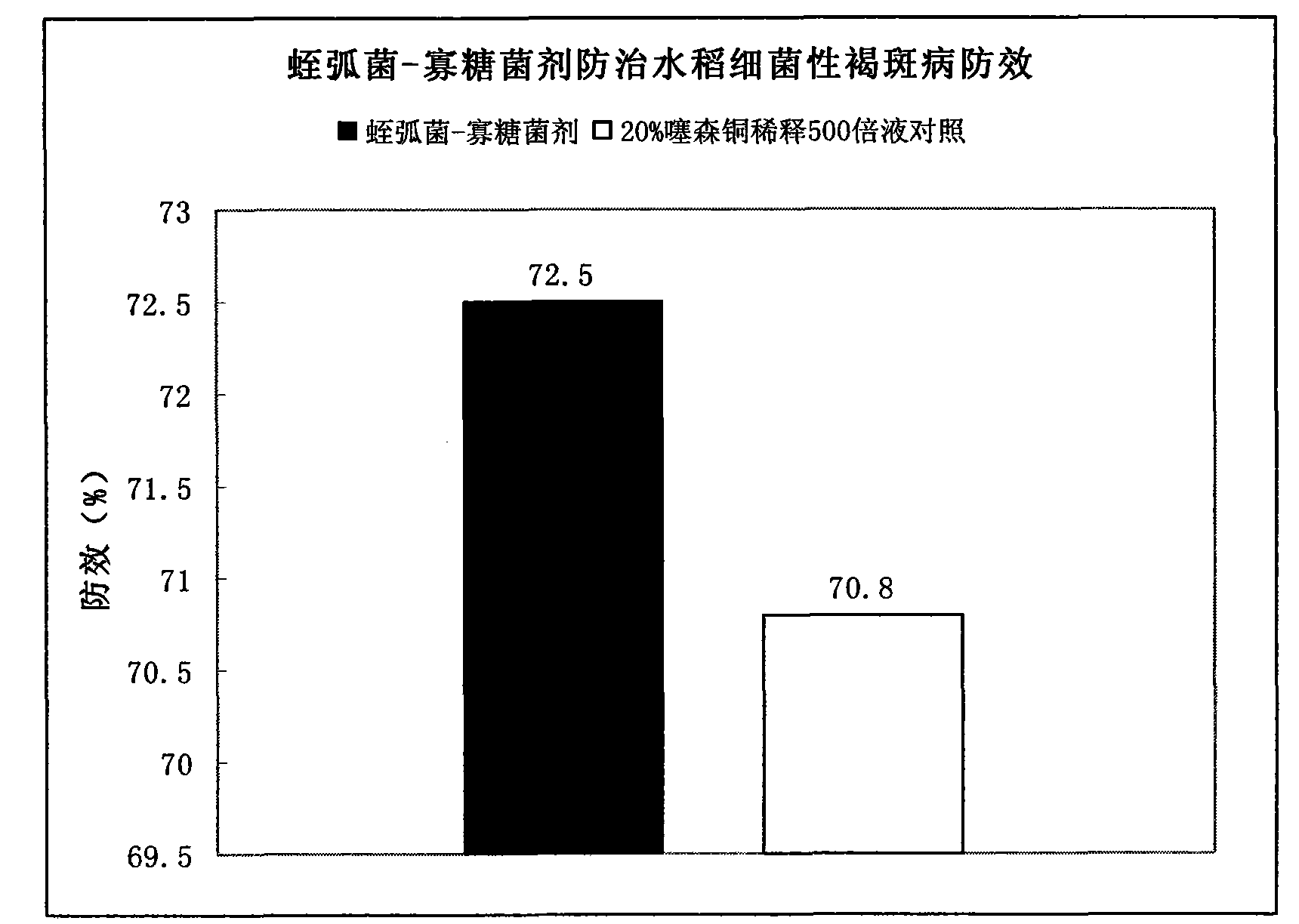

Bdellovibrio bacteriovorus for preventing and curing rice bacterial diseases and application thereof

InactiveCN101638629ASolve drug residueSolve problems such as resistanceBiocideBacteriaBacterial diseaseOligosaccharide

The invention discloses a bdellovibrio bacteriovorus for preventing and curing rice bacterial diseases and application thereof. The invention can obtain bdellovibrio bacteriovorus BDFM05 by separationand ultraviolet mutation. The bdellovibrio bacteriovorus BDFM05 is combined with oligosaccharide to obtain bdellovibrio bacteriovorus for preventing and curing crop bacterial diseases. The inventionapplies bdellovibrio bacteriovorus BDFM05 to prevent and cure crop bacterial diseases for the first time. The bdellovibrio bacteriovorus prepared by the method has better rice bacterial diseases preventing and curing effect than common Saisentong, has no toxicity or pollution, is safe to natural enemies of crop diseases and pests, produces no pathogenic bacteria resistance, has no toxic or side effects to people and animals, improves the quality and safety of agricultural products and conforms to the requirements of people on healthy and green food and sustainable-development for agriculturalproduction.

Owner:SOUTH CHINA UNIV OF TECH

Gastrodia tuber imitative wild sexual reproduction breeding technique

ActiveCN101185396AImprove inoculation rateImprove survival rateSeed and root treatmentHorticultureGastrodiaSexual reproduction

The invention discloses an imitative wild sexual reproduction and breeding technique of gastrodia tuber. Main steps comprises that breeding is carried out to get mature gastrodia tuber seeds and good sprouting strain, mature class III shoestring fungus is adopted as production seed, which is planted under a natural hillside forest that is with over 80 percent of shade density and in which wild gastrodia tuber grows and is distributed; artificial mixed germination strain is adopted; room temperature is controlled so as to produce germination strain with seed; sexual reproduction, breeding and planting time is selected between June and August; the breeding technique is also suitable for field breeding. The invention has the advantages that: 1. bad factors resistance property of sexual reproduction and breeding of gastrodia tuber is improved. 2. Gastrodia tuber seeds are germinated to lead the growth cycle of protocorms to be a time slice that is basically matched with an animated period of the shoestring fungus; inoculation rate and survival rate of the protocorms are increased. 3. Raw materials are obtained locally, thus reducing cost; sustainable development of non-pollution gastrodia tuber planting industry is promoted in ecological agriculture forests. 4. The small site breeding method enhances competitor infection resistance of the gastrodia tuber seed.

Owner:贵州九龙天麻有限公司

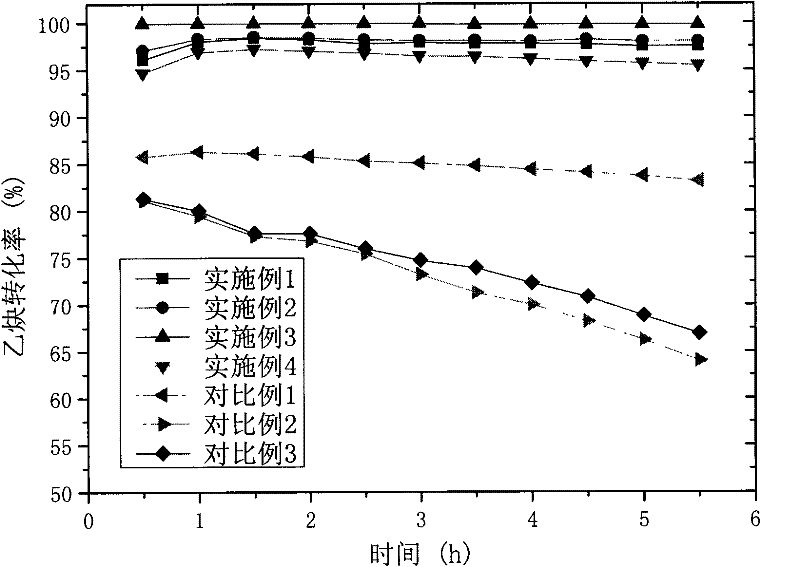

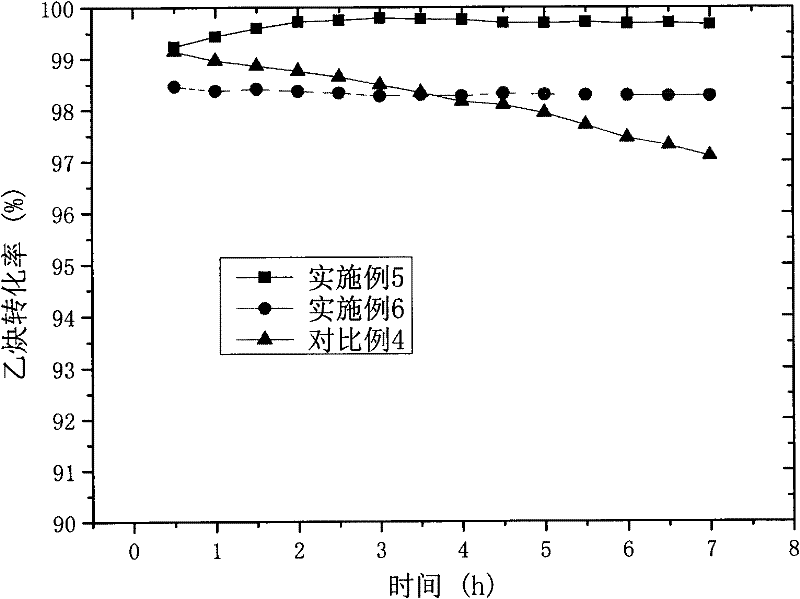

A kind of preparation method of mercury-free catalyst for the synthesis of vinyl chloride by acetylene method

InactiveCN102259007AHigh catalytic activityImprove catalytic stabilityPreparation by halogen halide additionCatalyst activation/preparationPolyvinyl chlorideBULK ACTIVE INGREDIENT

The invention discloses a method for preparing a mercury-free catalyst for the synthesis of vinyl chloride by acetylene method. In the method, the active components of the catalyst are highly dispersed and bonded to the surface of the carrier by carrying out surface modification treatment on the catalyst carrier and applying ultrasonic loading technology. On the group, a firm load is formed in the internal pores of the carrier, so that while improving its catalytic performance and stability, it can greatly reduce the loading of the required active components and reduce the cost of the catalyst. The method is especially suitable for preparing supported noble metal catalysts. The supported noble metal catalysts prepared by the method of the present invention can reach and exceed the catalytic activity of the currently used mercuric chloride catalysts in the case of a very small amount of loading. And stability, has industrial application value, and is of great significance in environmental protection and promoting the sustainable development of my country's polyvinyl chloride industry.

Owner:李伟

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com