Compound conditioner for soil pollution remediation and preparation method thereof

A soil pollution and conditioner technology, applied in soil conditioning materials, chemical instruments and methods, fertilizer mixtures, etc., can solve problems such as environmental, ecological and human health hazards, increase the risk of water pollution, and reduce the use efficiency of complexing agents. , to achieve the effect of alleviating pollution, achieving sustainable development and being conducive to restoration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

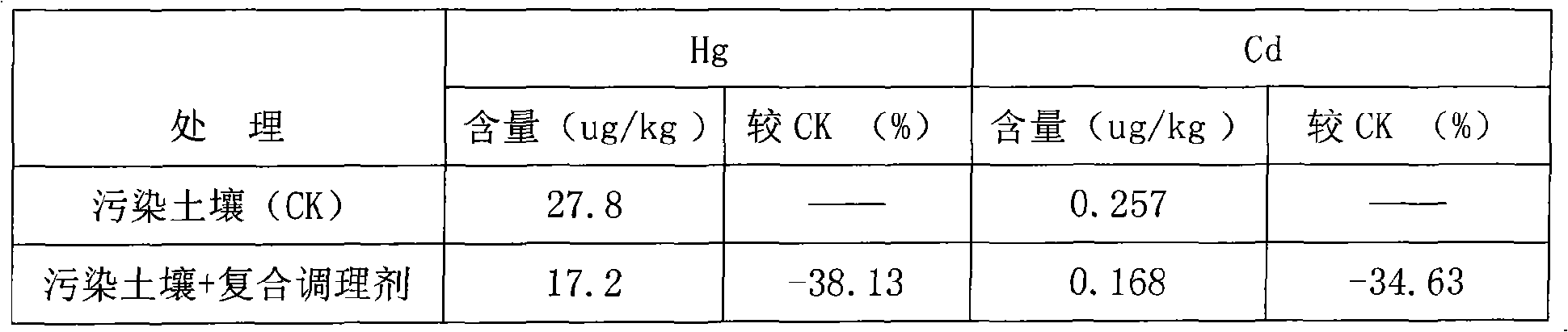

[0037] Embodiment 1: adopt exogenous source to add HgCl respectively 2 , CdCl 2 The method is used to make soil polluted by heavy metals, the pollution level is the second grade standard of soil environmental quality (soil pH6.5, heavy metal additions are respectively Hg 0.5mg / kg, Cd 0.6mg / kg), and balance for 60 days. Take 7.8kg of alkali slag, 1.3kg of ammonium phosphate, and 0.4kg of zeolite (percentage by weight: 78% of alkaline agent, 13% of precipitant, and 4% of adsorbent) that have passed through a 60-mesh sieve. Cross a 200-mesh sieve to obtain a compound conditioner. The tomato pot control experiment was carried out at the dosage of 30 mg per kg of soil, and the total content of heavy metals in tomato fruits was analyzed. It can be seen that the composite conditioner can effectively reduce the bioavailability of heavy metals in the soil, the contaminated soil has been significantly repaired, and the heavy metal content in tomato fruits is significantly decreased (T...

Embodiment 2

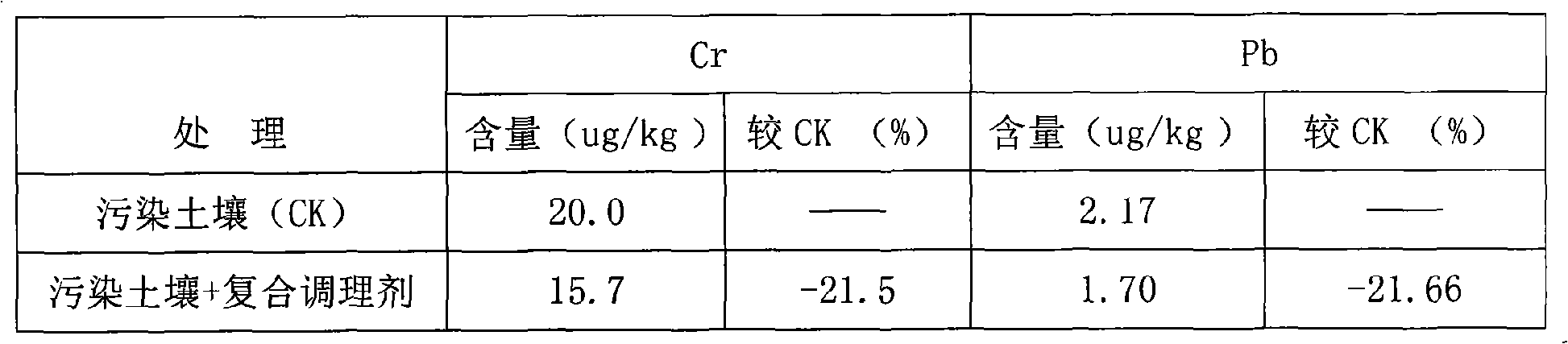

[0040] Embodiment 2: adopt exogenous source to add Pb (NO 3 ) 2 , Cr(NO3 ) 3 The method is made the soil of heavy metal pollution, and the pollution level is soil environmental quality secondary standard (soil pH6.5, and heavy metal addition is respectively Pb 300mg / kg, Cr300mg / kg), equilibrates 60 days. Get lime 9.1kg, potassium phosphate 0.5kg, bentonite 0.9kg (percentage by weight: alkaline agent 91%, precipitant 5%, adsorbent 9%) that have crossed 60 mesh sieves and fully mix, the product of gained is dried, Pulverize and pass through a 200-mesh sieve to obtain a compound conditioner. The tomato potted control experiment was carried out at the dosage of 600 mg per kg of soil, and the total content of heavy metals in tomato fruits was analyzed. It can be seen that the composite conditioner can effectively reduce the bioavailability of heavy metals in the soil, the contaminated soil has been significantly repaired, and the heavy metal content in tomato fruits is significan...

Embodiment 3

[0043] Embodiment 3: adopt exogenous source to add HgCl respectively 2 , CdCl 2 The method is used to make soil polluted by heavy metals, the pollution level is the second grade standard of soil environmental quality (soil pH6.5, heavy metal additions are respectively Hg 0.5mg / kg, Cd 0.6mg / kg), and balance for 60 days. Get 5.6kg of alkali slag, 3.0kg of lime, 0.4kg of ammonium phosphate, 0.3kg of potassium phosphate, 0.5kg of bentonite, 0.4kg of montmorillonite (percentage by weight: alkaline agent 86%, precipitant 7%, adsorption agent 9%) and fully mixed, the resulting product was dried and pulverized through a 200-mesh sieve to obtain a composite conditioner. The potted celery control experiment was carried out at the dosage of 30 mg per kg of soil, and the total content of heavy metals in the edible part of celery was analyzed. It can be seen that the compound conditioner can effectively reduce the bioavailability of heavy metals in the soil, and the polluted soil has been...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com