Patents

Literature

Hiro is an intelligent assistant for R&D personnel, combined with Patent DNA, to facilitate innovative research.

281 results about "Sludge compost" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Sludge composting is an indirect use of municipal sludge in agriculture, which is a widely used method in the treatment of municipal sludge. After composting, the pathogens are killed and the structure of sludge is loose.

Compound conditioner for soil pollution remediation and preparation method thereof

InactiveCN101538469AReduce pollutionReduced mobilityAgriculture tools and machinesOrganic fertilisersSludge compostSorbent

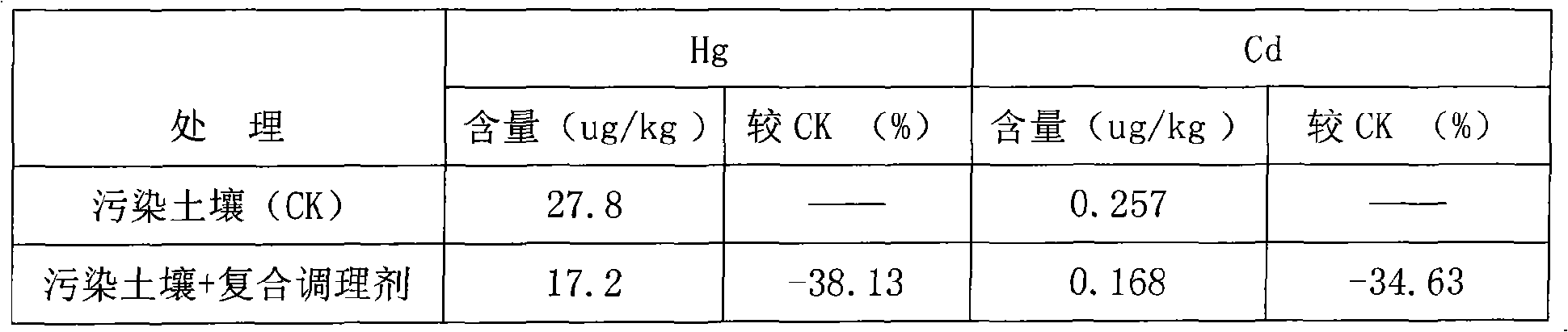

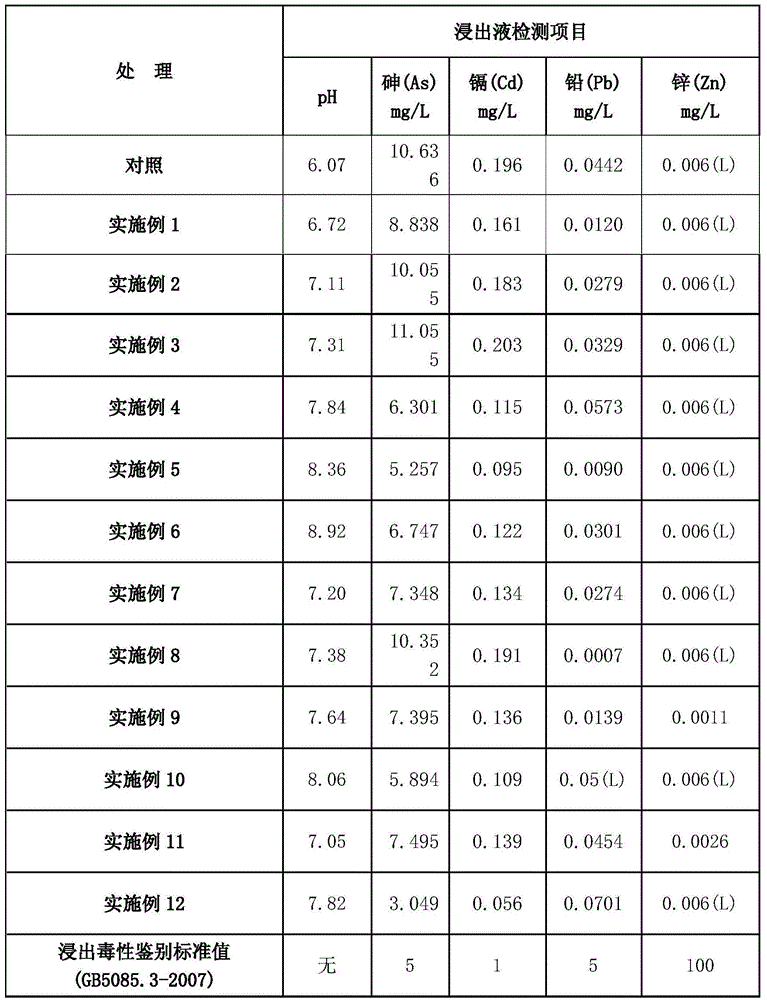

The invention provides a safe and reliable compound conditioner for reducing the heavy-metal mobility and bioavailability of soil or sludge compost and a preparation method thereof. The compound conditioner is a powdery compound prepared by adding heavy-metal auxiliary passivating agent to alkaline agent, wherein, the heavy-metal auxiliary passivating agent includes precipitating agent and absorbing agent; and the compound conditioner comprises the following components by the mixing proportion (weight percentage): 78% to 91% of alkaline agent, 5% to 13% of precipitating agent and 4% to 9% of absorbing agent. The preparation method comprises the following steps: (1) drying and pulverizing one, two or more than two substances among soda-manufacturing waste residue, lime and fly ash and sieving by a 60-mesh sieve to obtain an alkaline powdery substance as the alkaline agent; (2) mixing the alkaline agent, the precipitating agent and the absorbing agent by the above mixing proportion; and (3) drying and pulverizing the mixed products and sieving by a 200-mesh sieve to obtain the powdery compound conditioner. The invention can greatly reduce the environmental risk caused by the prior art and realize the sustainable development of green circular economy, industry and agriculture by recycling the industrial waste at the same time.

Owner:广东省农业科学院土壤肥料研究所

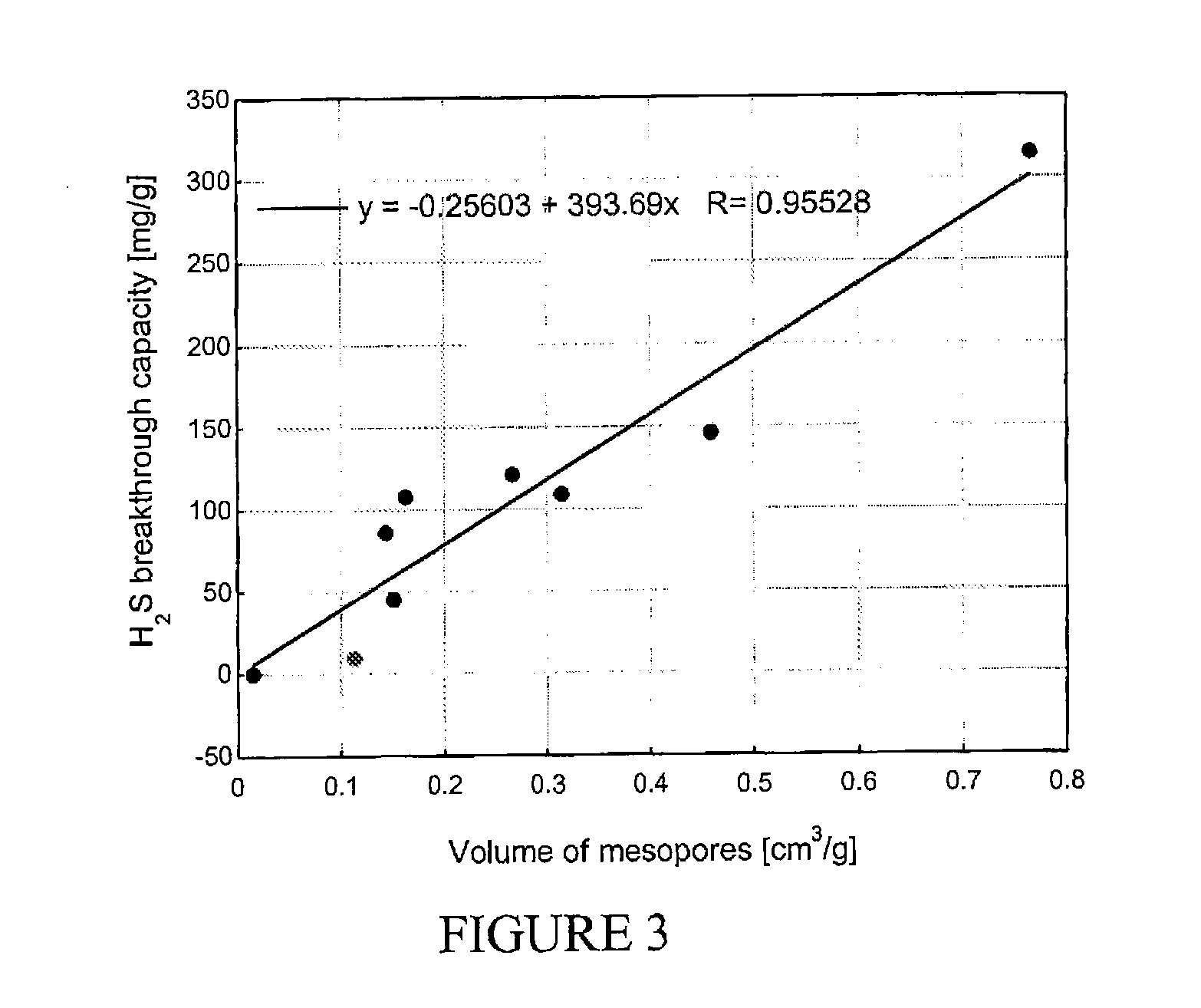

Catalytic adsorbents obtained from municipal sludges, industrial sludges, compost and tobacco waste and process for their production

InactiveUS20070113736A1Large capacityQuick removalGas treatmentOrganic-compounds/hydrides/coordination-complexes catalystsSorbentSludge compost

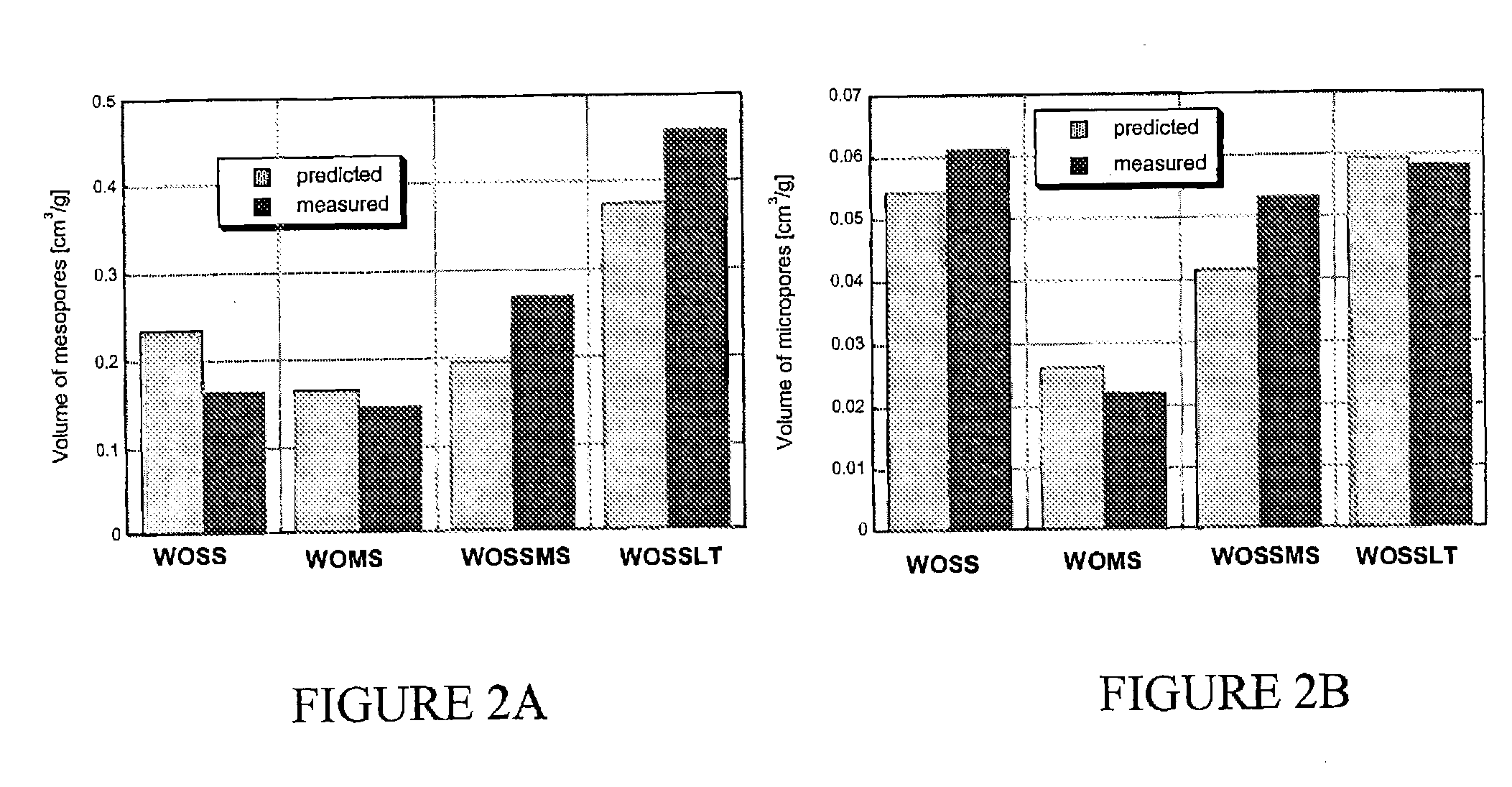

Industrial waste derived adsorbents were obtained by pyrolysis of sewage sludge, metal sludge, waste oil sludge and tobacco waste in some combination. The materials were used as media to remove hydrogen sulfide at room temperature in the presence of moisture. The initial and exhausted adsorbents after the breakthrough tests were characterized using sorption of nitrogen, thermal analysis, XRD, ICP, and surface pH measurements. Mixing tobacco and sludges result in a strong synergy enhancing the catalytic properties of adsorbents. During pyrolysis new mineral phases are formed as a result of solid state reaction between the components of the sludges. High temperature of pyrolysis is beneficial for the adsorbents due to the enhanced activation of carbonaceous phase and chemical stabilization of inorganic phase. Samples obtained at low temperature are sensitive to water, which deactivates their catalytic centers.

Owner:RES FOUND THE CITY UNIV OF NEW YORK

Sludge composting method

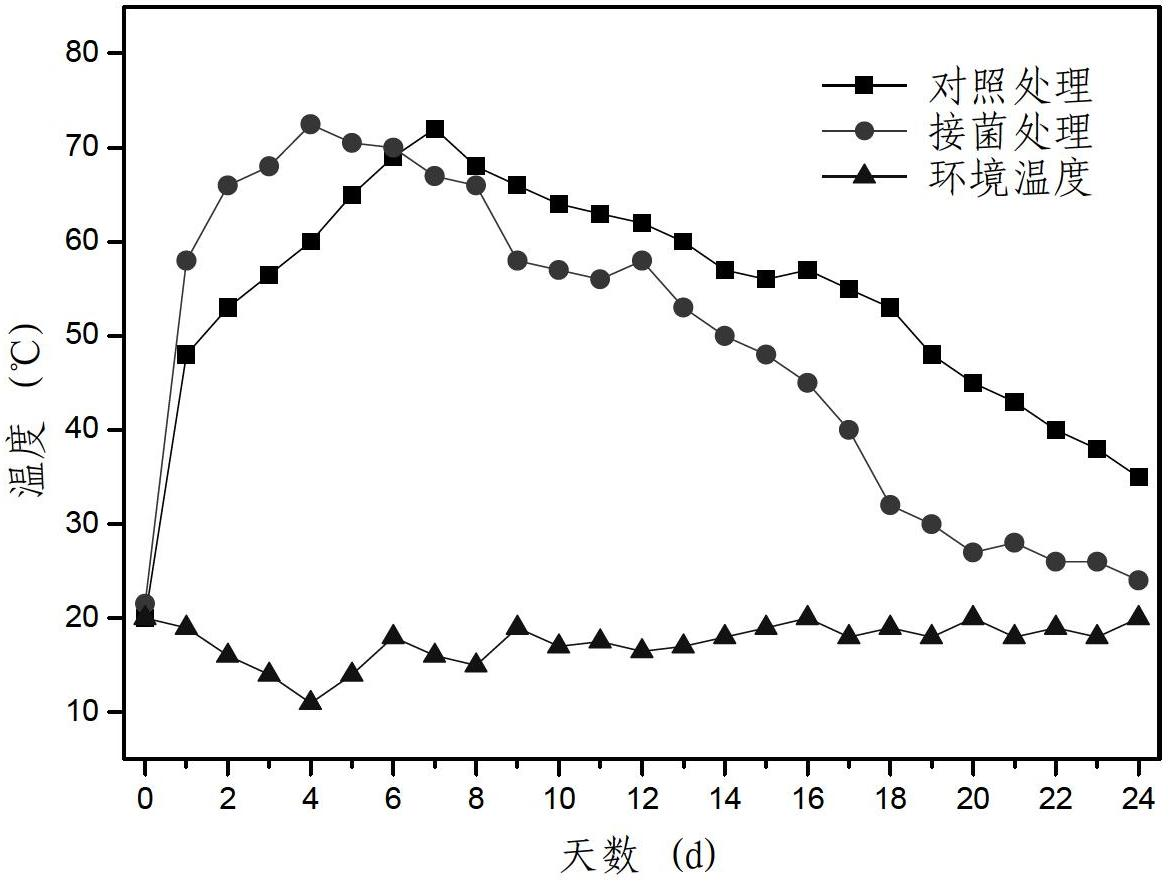

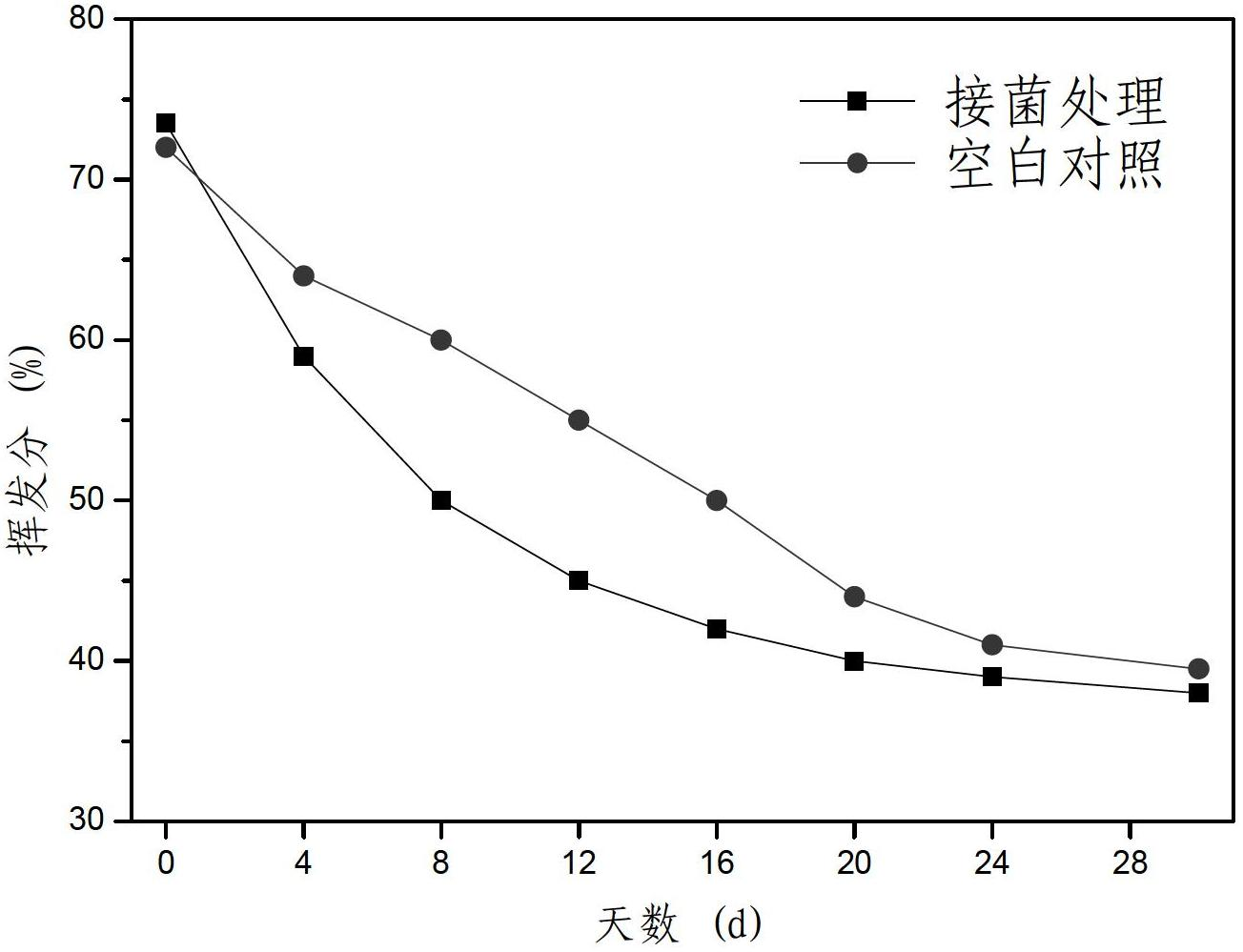

ActiveCN101781131AEasy to getShort fermentation timeBio-organic fraction processingClimate change adaptationEcological environmentSludge compost

The invention provides a sludge composting method, and relates to a sludge treatment method which comprises the steps of preferable accessory selection, CK21 fungus spraying inoculation, heavy metal passivation and powder granulation, and then three-dimensional composite biological organic fertilizer with organic, inorganic and microbial active constituents is obtained. Mushroom compost and pig manure are used as accessories which are easily obtained and degraded, the stacker fermentation time is short, only one time of fermentation is needed, the C / N ratio can be effectively adjusted, and the water content of the sludge is reduced; and the efficient beneficial bio-fungus community CK21 is adopted. The microbial concentration is high, the secretion ability of the enzyme is strong, organic matters can be quickly decomposed so as to prevent the corruption of the organic matters, no odor exists, sludge is used for CK21 inoculation, fermentation starts fast, and the effect is good; and the product is inoculated with the CK21 fungus secondarily so as to further balance and activate nutrients, and the microbial natural reproduction is utilized to realize the is called flower dipping absorbing of the plants to nutrients. The invention has the advantages of optimizing the composting conditions, shortening the composting time, reducing energy consumption of turning, and reducing the damage of the heavy metal on the ecological environment.

Owner:厦门市政环境科技股份有限公司

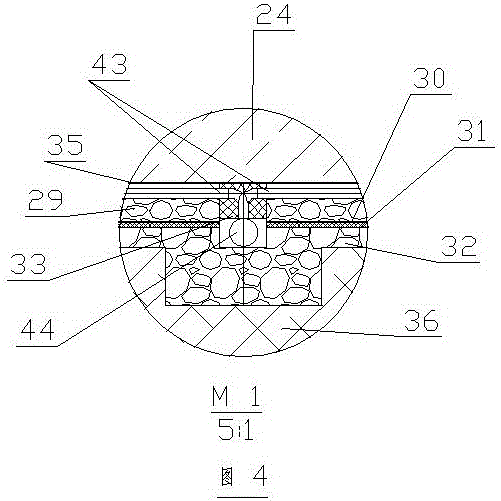

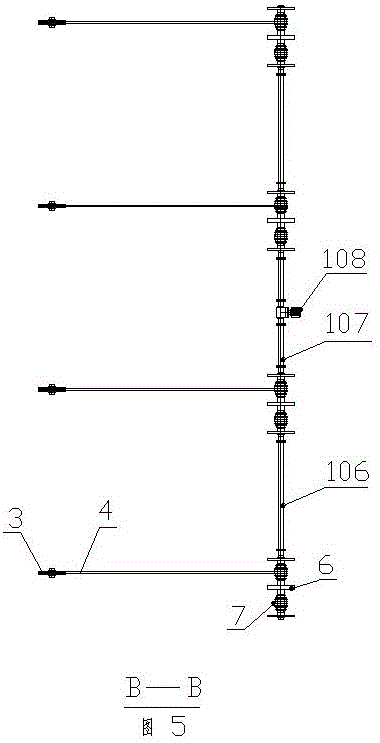

Sludge aerobic mechanical composting method and dynamic roller composting device

InactiveCN101618978AHeating up fastReduce energy consumptionBio-organic fraction processingOrganic fertiliser preparationSludge compostEngineering

The invention provides a sludge aerobic mechanical composting method and a dynamic roller composting device, which is designed to solve the currently existing problems that the composting conditions are not easy to control and automatic and continuous operation is not easy to realize, the composting time is long, and secondary contamination is serious and the like. The invention comprises the following steps: processing by two steps of pretreatment before composting and dynamic aerobic mechanical composting; mixing the self-made composite conditioner used for composting and original sludge according to the preset weight percentage and water content and crashing; pile turning and ventilating by utilizing self-made dedicated dynamic roller composting device; collecting and recycling percolate; composting and fermenting for 7 to 8 days. In the composting process, the stockpile in the device has no phenomena like cementation or blocking and the like, ensuring that the pile temperature in the fermentation case can rise to 55 DEG C rapidly and maintain for more than 3 days, and C / N value can rise to 11.49 from 9.57, thus the invention completely achieves requirements of sludge composting. The invention has the following characteristics and beneficial effects: short composting period, good quality, no generation of secondary contamination, easy realization of automatic continuous operation, low energy consumption and lowered composting cost, thus greatly promoting the realization of harmlessness and reclamation of city sludge.

Owner:SHENYANG NORMAL UNIV

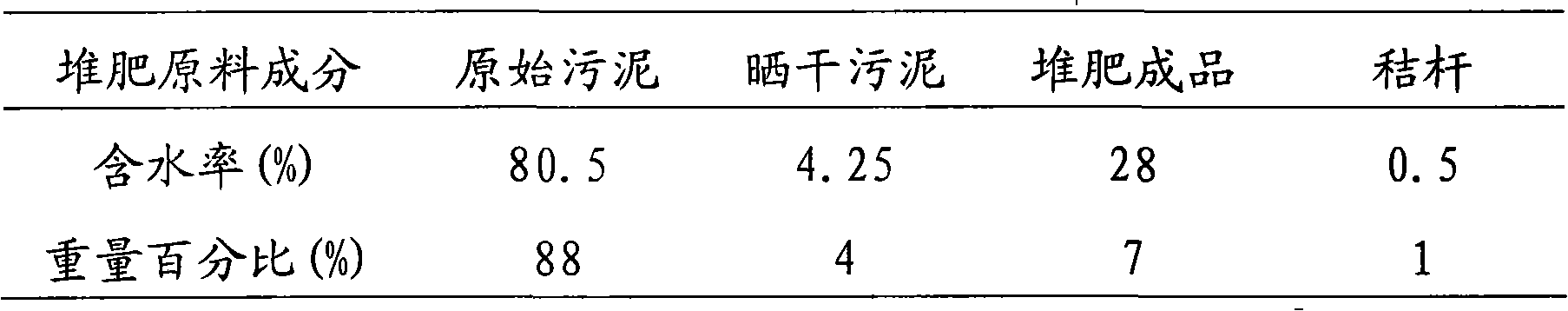

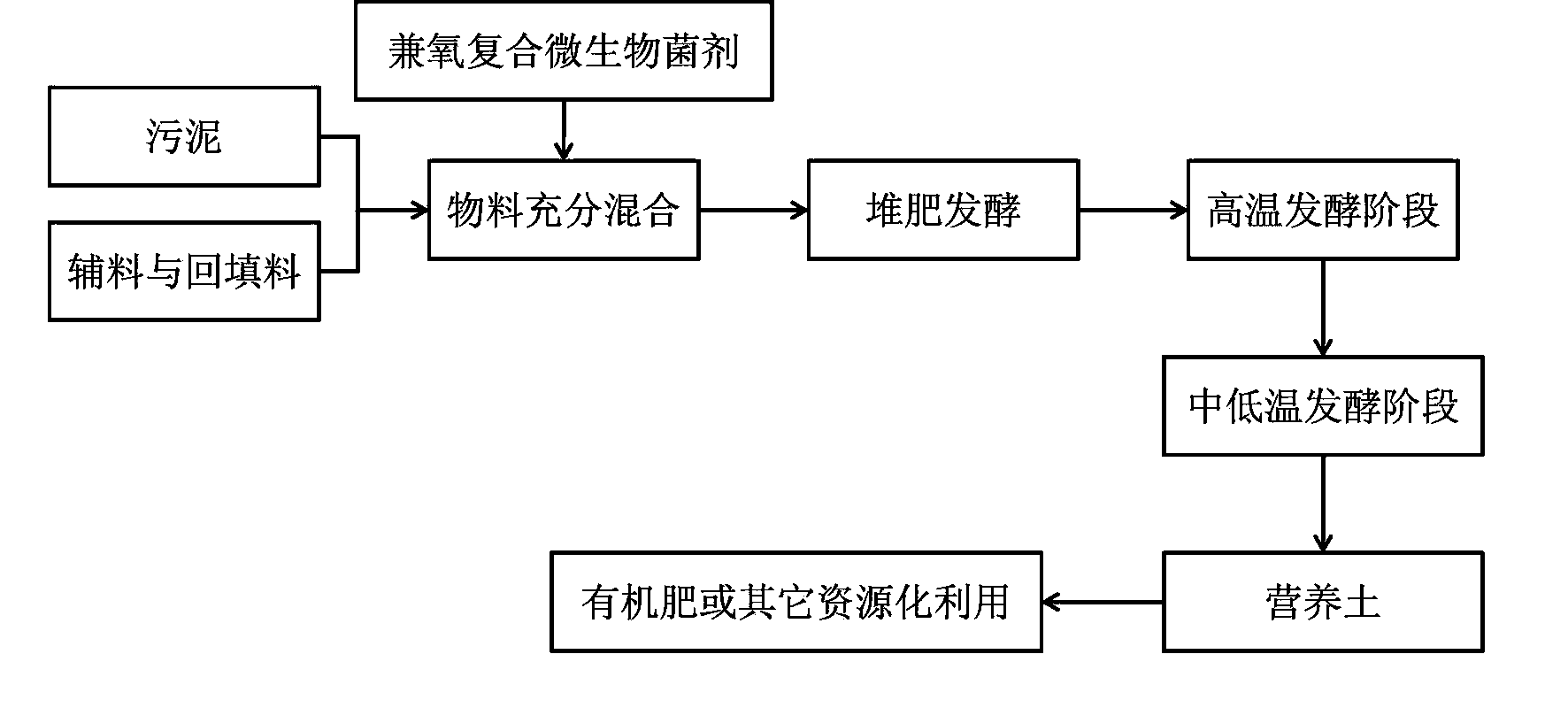

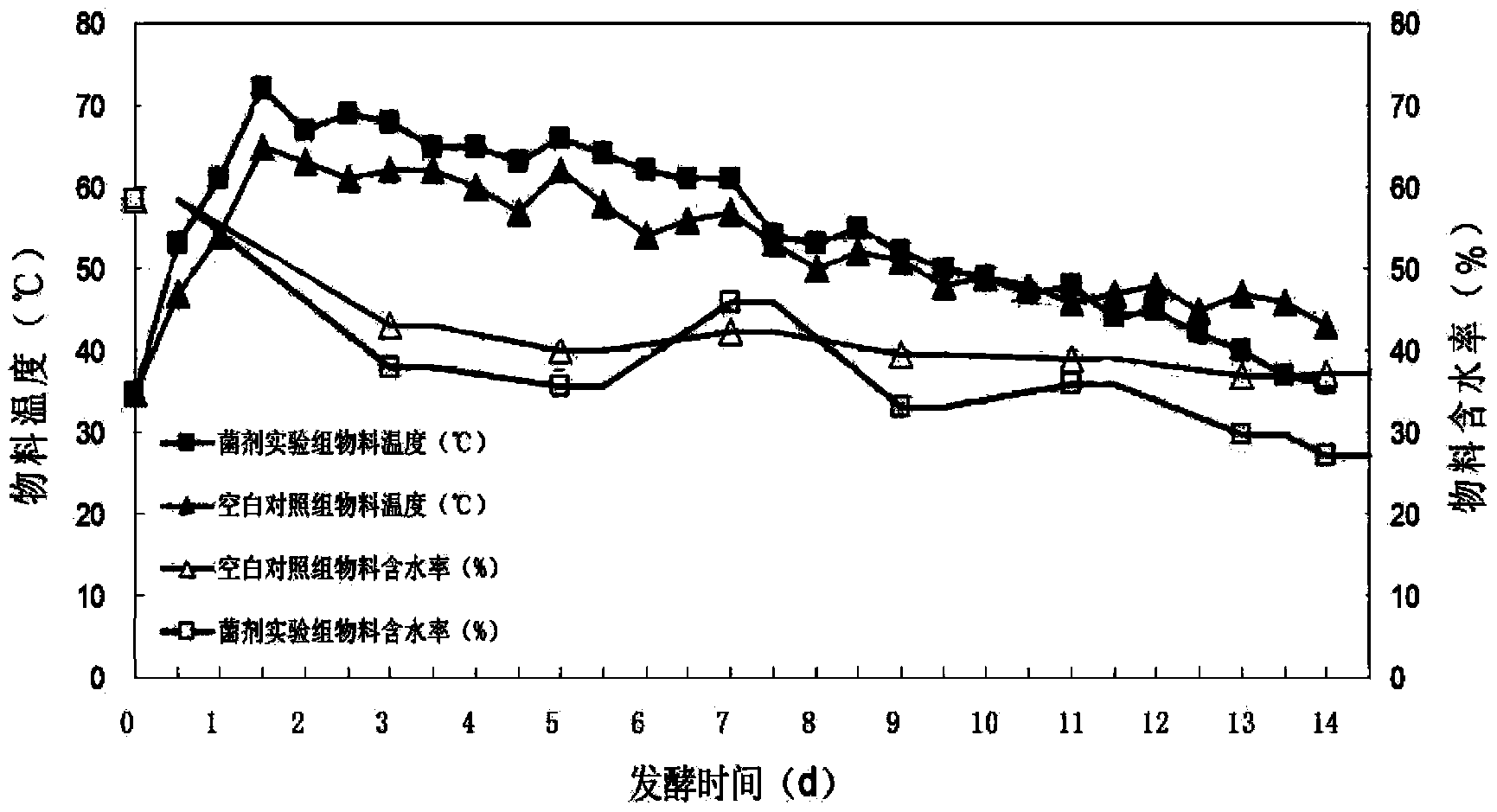

Method for processing sludge by using complex microbial agent

InactiveCN103467149AImprove reproductive abilityAdaptableBio-organic fraction processingClimate change adaptationHigh energyMicrobial agent

The invention relates to a method for processing sludge by using a complex microbial agent. The problems of incompatible aerobic and anaerobic fermentation, long composting period and high moisture content in sludge in the sludge composting method at present are solved by adopting the method. The method comprises the following steps: firstly, adding an auxiliary material to adjust the moisture content of the sludge below 60% before composting the sludge; adding the complex microbial agent to fully stir according to a certain ratio and then pouring into a fermentation tank; completely and thoroughly decomposing the sludge after a high-temperature fermentation stage and a medium and low temperature fermentation stage; reducing the moisture content of the sludge below 30%, so as to finish composting. By adopting the method, composting fermentation of the sludge can be smoothly carried out just by a simple turning process without a high-energy consumption condition such as artificial aeration and the like or a strict and complicated anaerobic condition; the method is low in investment, and significant in sludge reduction effect; loss of nutrients in the composting process can be effectively avoided.

Owner:福建省绿标生态科技有限公司

Sludge aerobic composting reactor

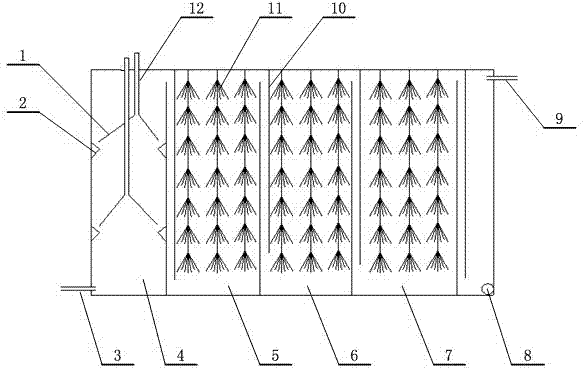

InactiveCN101148373AClimate change adaptationSewage/sludge fertilisersVacuum extractorSludge compost

The present invention relates to aerobic sludge compost reactor, and is especially one kind of aerobic sludge compost reactor for utilizing high water content sludge. Technologically, the aerobic sludge compost reactor consists of one air controlling system, one stirring system, one fermentation tank system and one heating and temperature controlling system. The fermentation tank system consists of one inner tank and one outer tank, and has sludge inlet, compost outlet, sewage discharge port and manually controlled sewage discharging unit. The air controlling system comprising blower and vacuumizing machine is connected to the fermentation tank through pipeline. The stirring system consists of motor, link rod and stirring blades. The heating and temperature controlling system consists of ceramic casing, asbestos, temperature inductor and control circuit. The present invention has convenient use, low cost, no environmental pollution and other advantages.

Owner:FUJIAN NORMAL UNIV

Sludge plant growth substrate and side slope sludge soil replacement greening method

ActiveCN103641648AAvoid churnSolve the problem of insufficient organic matterExcavationsHorticultureFiberSludge compost

The invention relates to a sludge plant growth substrate and a side slope sludge soil replacement greening method. The sludge plant growth substrate comprises main materials and auxiliary materials, the main materials comprise straw fiber and mature sludge compositing, the auxiliary materials comprise one or a mixture of a chemical fiber, a water-retaining agent, an adhesive, bacterial manure, a soil conditioner, a microelement fertilizer or a disinfect insecticide; the part by weight ratio of the straw fiber to the mature sludge compositing to the auxiliary materials is (7-17):(80-90):(2-5). According to the sludge plant growth substrate and the side slope sludge soil replacement greening method provided by the invention, the turfy soil is replaced by qualified sludge compositing for the field of ecological restoration, the problems that the soil replacement is easy to lose and the organic matter is insufficient in the side slope repairing are solved; furthermore, the loss of the nutrient in the substrate is avoided, the effects of avoiding weakness and turning waste into wealth are achieved, and the potential risk is eliminated.

Owner:BEIJING ORIENT LANDSCAPE

Geobacillus sp. UTM01 and application thereof

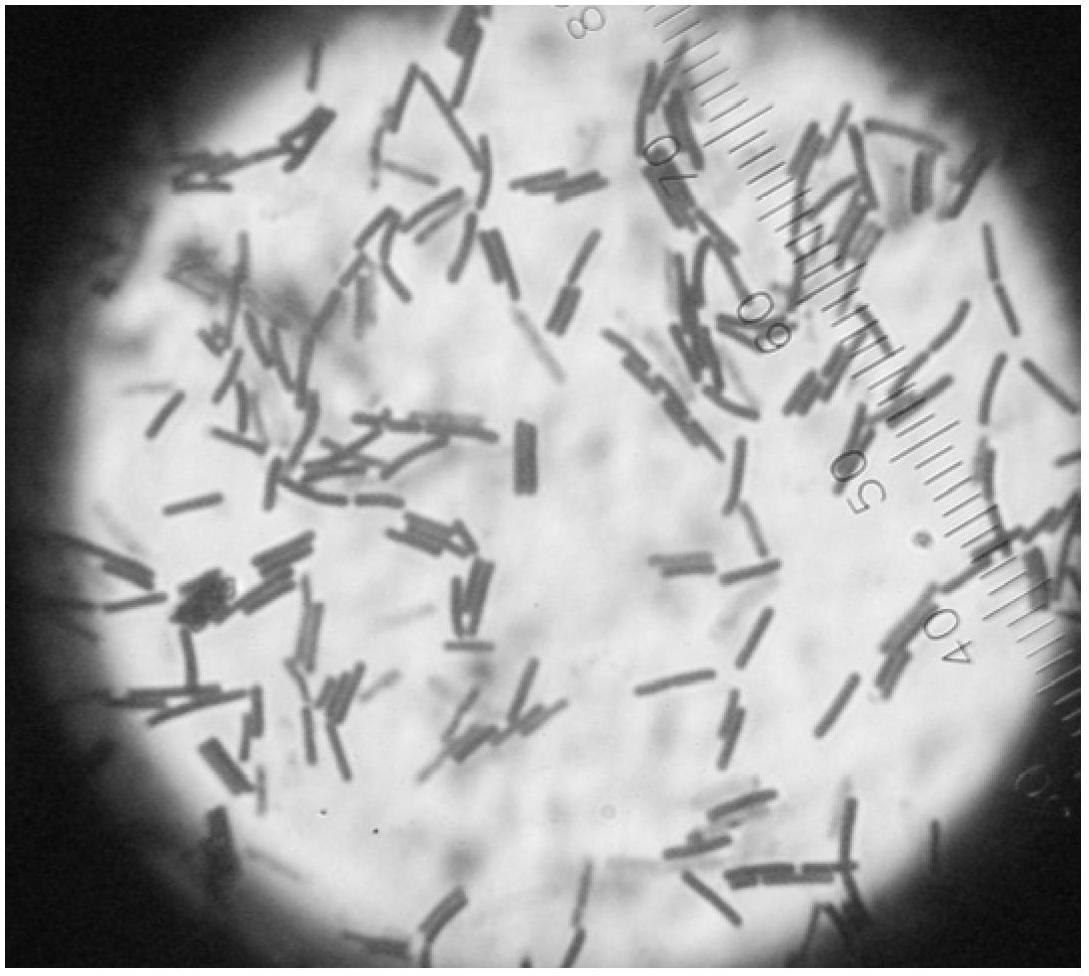

ActiveCN102660486ANot affected by moisture contentSpeed up the composting processBio-organic fraction processingBacteriaSocial benefitsSludge compost

The invention provides a geobacillus sp. strain UTM01. The storage number of the geobacillus sp. strain UTM01 is CGMCC No.5641. The highest growth temperature of the geobacillus sp. strain UTM01 reaches 75 DEG C, the geobacillus sp. Strain UTM01 can rapidly multiply in a high temperature compost environment, organic matters are degraded, and a compost process is promoted. The invention further provides solid compost inoculant prepared from the geobacillus sp. strain UTM01, and a preparation method and application of the solid compost inoculant. The compost inoculant is low in production cost and stable in quality, can be applied to high-temperature sludge composting, does not affect moisture content of compost bodies, is environment-friendly and pollution-free, has excellent performances,and has good economic and social benefits.

Owner:北京绿源科创环境技术有限公司

Novel roof greening matrix and roof greening method

ActiveCN103787731APrevent escapeEffective consumptionHorticultureFertilizer mixturesFiberPlant roots

The invention relates to a novel roof greening matrix and a roof greening method. The greening matrix comprises a core matrix and an auxiliary matrix, wherein the core matrix comprises a sludge compost product, garden waste fibers and a water retaining agent according to the weight ratio of (35-43):(55-65):(1-1.2); the auxiliary matrix comprises vermiculite and perlite; a ratio of the total weight of the core matrix to the weight of the vermiculite to the weight of the perlite is (68-82):(3-7):(15-25). The matrix provided by the invention can meet a roof greening soil utilization requirement, and sludge of a sewage treatment plant and garden waste can be effectively eliminated, and the aim of resource circulation is fulfilled; meanwhile, the greening matrix is light in material weight; raw materials are readily available; the cost is low; the fertilizer and water retaining effect is good; finally, the matrix is changed from a conventional state into a granular state, so that the problem of matrix loss can be effectively solved, and a slow release effect can be achieved; the growth of plant roots is facilitated; the specific construction and operation are facilitated; the novel roof greening matrix is suitable for the general popularization in the whole nation.

Owner:BEIJING ORIENT LANDSCAPE

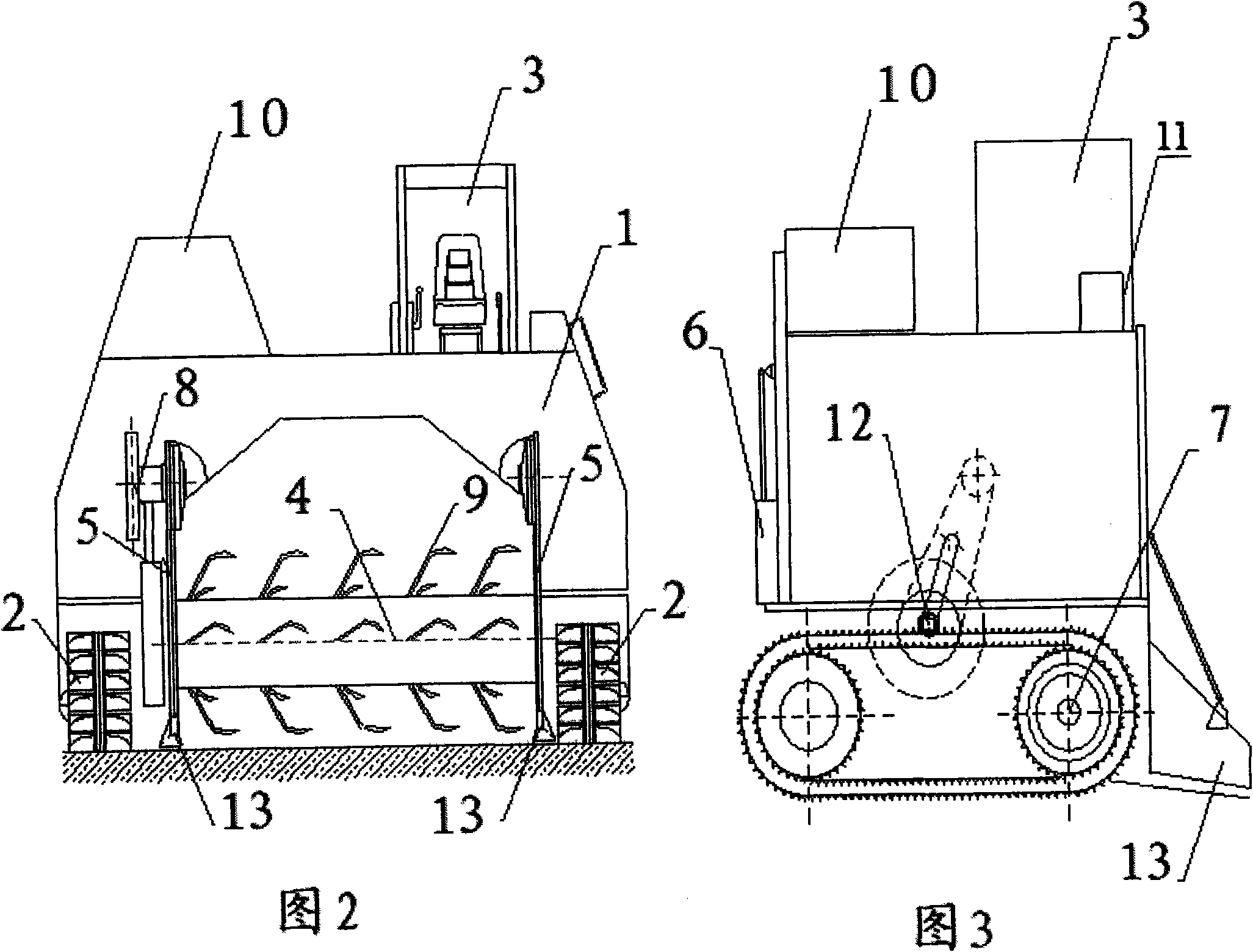

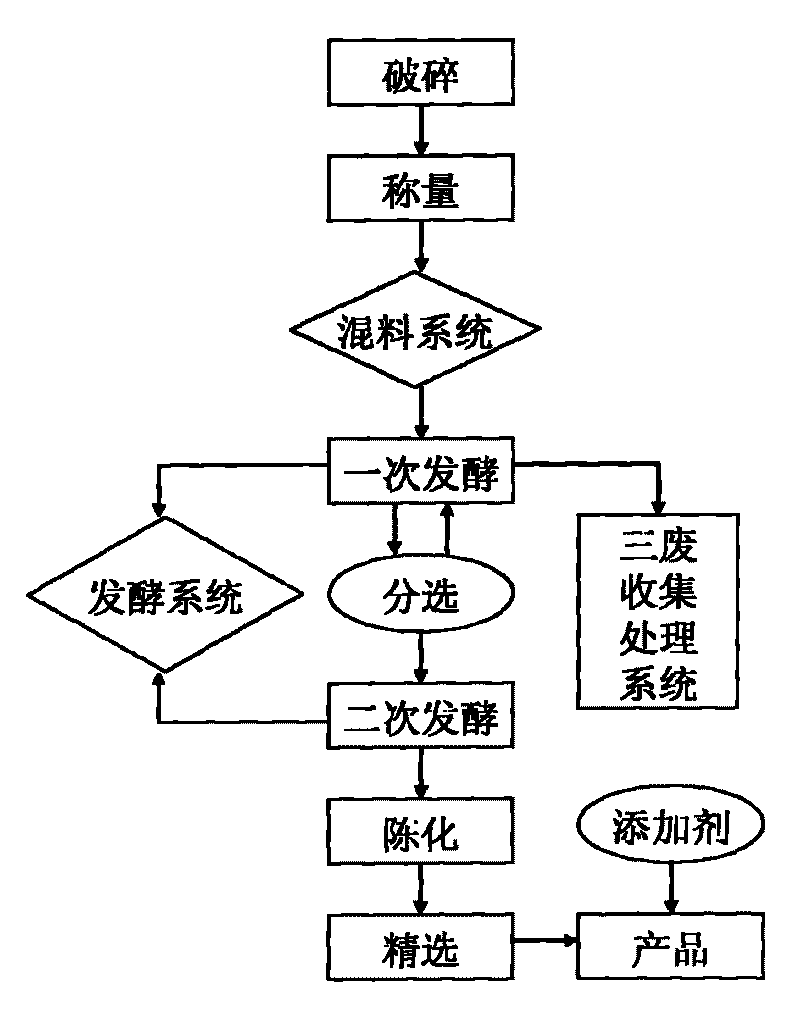

Self-propelled turning device for sludge compost and treatment method

ActiveCN102030570AEasy to walkSmall footprintSludge processingOrganic fertiliser preparationSludge compostOxygen

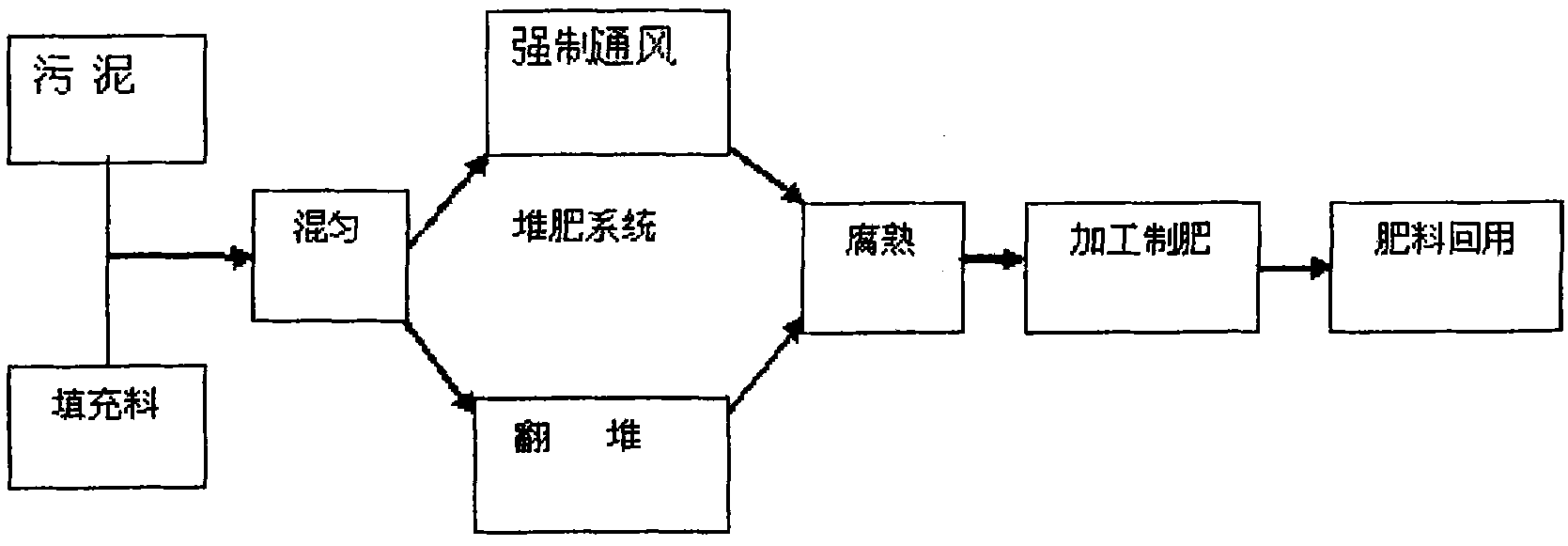

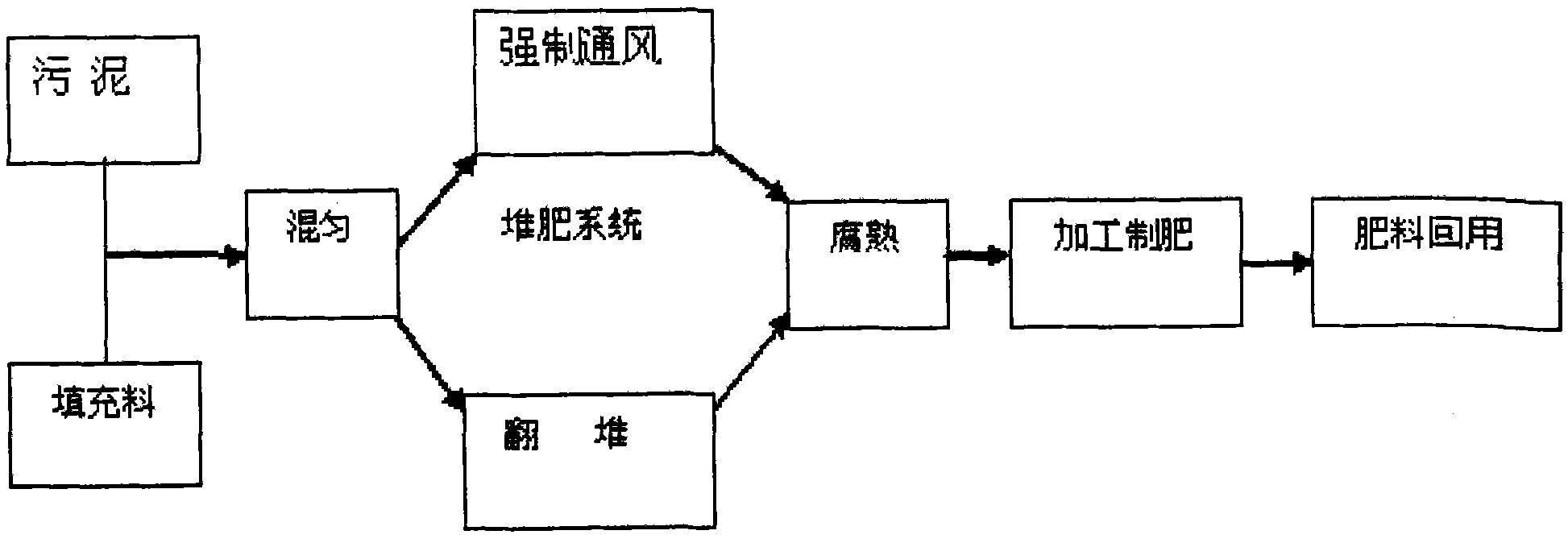

The invention relates to a self-propelled turning device for sludge compost and a treatment method and belongs to environmentally-friendly solid waste treatment. The method comprises that: a mixing step, an aerobic compost period, a thoroughly decomposing step, a processing and compost production step and an odor treatment step, wherein the mixing step aims to adjust the moisture and the carbon nitrogen rate of dewatered sludge, improve the loosening degree, increase a contact area with air and contributes to aerobic fermentation; in the aerobic compost period, the oxygen is supplied through forced ventilation, and organic matters in materials begin to ferment under the action of aerobes; the thoroughly composting step comprises that: the sludge subjected to compost fermentation is not thoroughly decomposed, and is required to continuously undergo a thoroughly decomposing and ageing stage, namely secondary fermentation; the processing and compost production step comprises that: the sludge compost is processed according to fertilizer use and market demand to serve as a product for sales so as to improve overall economic efficiency; and the odor treatment step comprises that: odor is generated in the process of aerobic compost and can be discharged after deodorization treatment. In recent years, solid wastes have become important environmental problems limiting urban development. The composting treatment is a way to utilize solid waste resources and is gradually taken into account at home and abroad.

Owner:BMEI

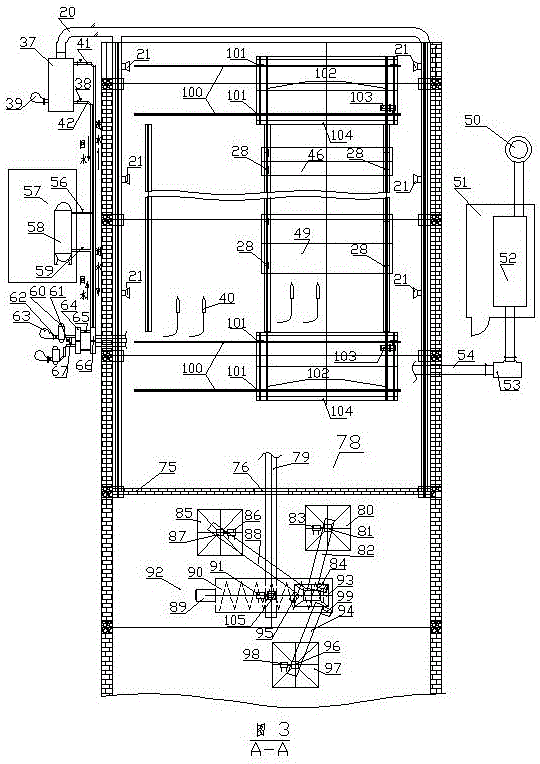

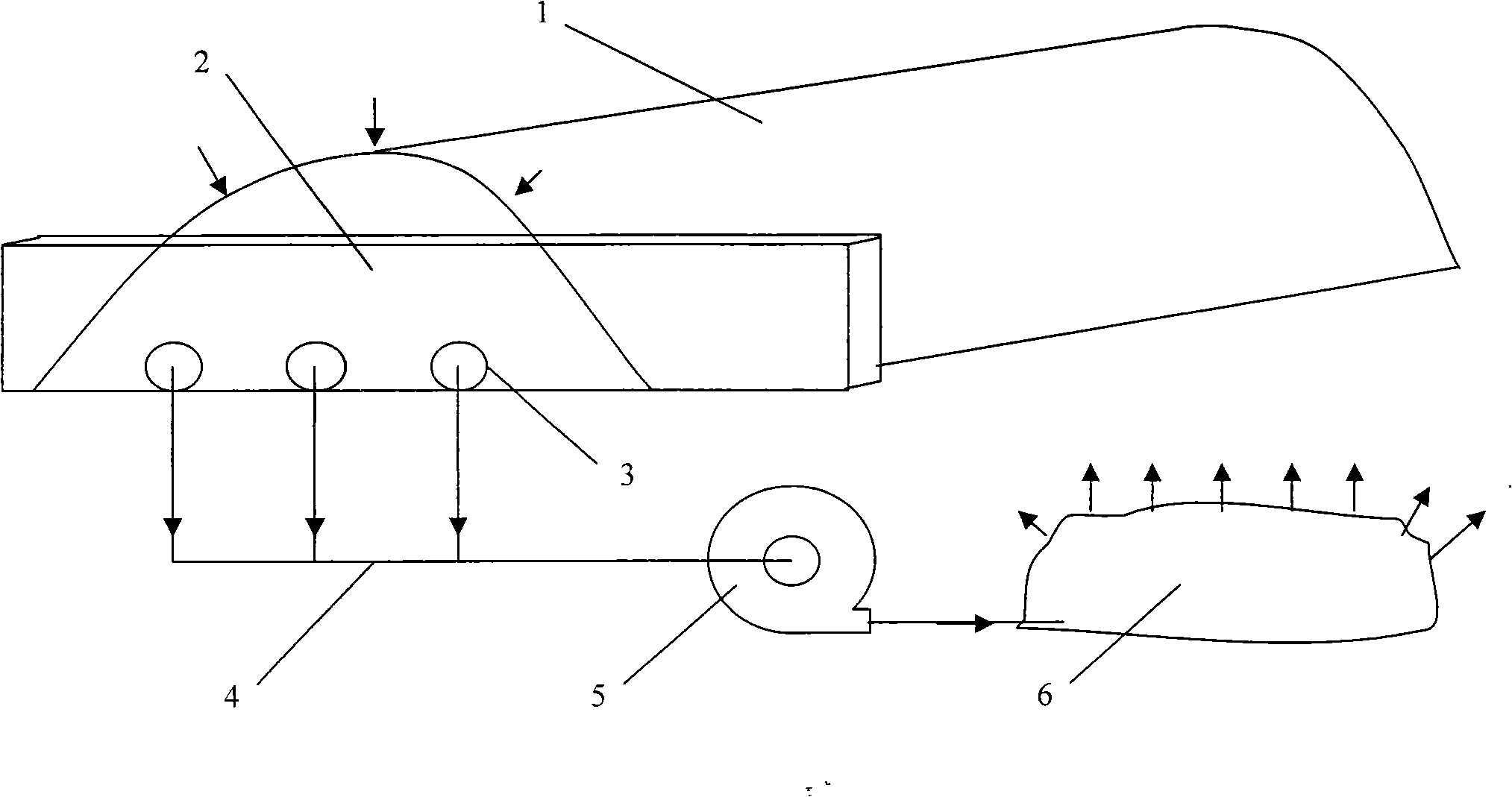

Process equipment for composting and rapid aerobic fermentation of sludge, and automatic control scheme for composting and rapid aerobic fermentation process

ActiveCN106396769AImproving the initial process conditions of aerobic fermentationImprove breathabilityBio-organic fraction processingEnergy inputAutomatic controlProcess equipment

The invention provides process equipment for composting and rapid aerobic fermentation of sludge and an automatic control scheme for a composting and rapid aerobic fermentation process, belonging to the technical field of composting and aerobic fermentation of sludge. The process equipment and automatic control scheme provide optimal initial process conditions for microbial propagation in composting and aerobic fermentation of sludge, enable composting and aerobic fermentation of sludge to rapidly enter a high-temperature fermentation period, accelerate the processes of fermentation and decomposition, shorten a fermentation period, reduce cost and exert beneficial effect on reduction, harmless treatment and stabilization of sludge. The process equipment comprises a solar photovoltaic power generation system, fermentation tanks with in-ground insulation and heating functions, a gas collecting cover having aeration and heating functions, used for collecting water vapor and stink produced in the process of fermentation and capable of moving up and down, a biological deodorizing system, an air supply and heating system for a workshop in winter, a travelling crane-like manipulator-operated material distribution machine, a composting heap turner, a data acquisition trolley, displace trolleys, a boiler system and an automatic control system for batching of raw and accessory materials and for process flow.

Owner:阮航 +2

Production method of culture substrate especially for landscape plants

InactiveCN101715712AReduce moisture contentPromote growthAgriculture gas emission reductionCultivating equipmentsPorositySludge compost

The invention provides a production method of a culture substrate especially for landscape plants, comprising the following step of: composting dewatering sludge, wood flour and waste decoction dregs according to the mass ratio (by wet weight) of 3: 0.5 to 2: 1 to 3 as main materials to obtain the culture substrate especially for landscape plants, wherein the dewatering sludge is sludge that is from an urban living sewage treatment plant and dewatered till the water content reaches more than 90 percent. The main composting accessory adopted in the method, namely, the waste decoction dregs in a Chinese medicine factory contain a plurality of microelements that are beneficial to plant growth, have larger porosity, can accelerate the fermentation process of the sludge composting, improve the property of the substrate product, play a slow-release role to fertilizers applied in soil, and is suitable for the development of soilless culture substrate simultaneously, thereby being a more suitable sludge composting accessory.

Owner:HANGZHOU NORMAL UNIVERSITY

Composite conditioner for preparing sludge compost and application thereof

InactiveCN101913920APromote degradationShorten the fermentation cycleBio-organic fraction processingClimate change adaptationCelluloseSludge compost

The invention discloses a composite conditioner for preparing a sludge compost and application thereof. The composite conditioner for preparing the sludge compost is combined by an agricultural waste fermentation product and non-metallic ore powder in a volume ratio of 1-10:5-1, wherein the agricultural waste fermentation product is prepared by performing direct pile fermentation on one or a mixture of more of sawdust, barks, rice hulls, straw and bagasse or adding zymophyte for aerobic fermentation; and the non-metallic ore powder is one or more of pearlite, vermiculite, zeolite, medical stone and sepiolite with the grain size of smaller than 0.5cm. The composite conditioner can quickly degrade cellulose, shorten the sludge fermentation period to 7-15 days, improve the C / N ratio of the sludge and reduce the diffused odor, also can adjust the pH value of mixed materials, is more favorable for the growth of microorganisms, and can improve fertilizer efficiency and improve the soil.

Owner:娄底市裕德科技有限公司

Method for preparing sludge organic fertilizer from high moisture percentage sludge

The invention relates to a method of preparing organic sludge manure, which utilizes hight water-absorption resin to improve the sludge performance and increase the composting of sludge with high water content. High water-absorption resin conditioner accounting for one to two point five percent of the weight of the sludge and carbonaceous conditioner accounting for three to ten percent of the weight of the sludge are added into the sludge with high water content, which is discharged by the sewage treatment plants of a city, and the sludge is dumped into a dedicated fermentor, and after being uniformly mixed, undergoes composting fermentation. In the course of fermentation, the fermentation temperature is controlled in a range of thirty five to sixty five DEG C, the sludge is intervalically stired and ventilated, the composting lasts twenty to thirty two days, and therefore an organic sludge manure product is prepared. The invention introduces the high water-absorption resin as the sludge compost conditioner for the first time, and the added high water-absorption resin realizes the aerobic compost of the sludge with high water content and promotes the process of sludge composting. Meanwhile, the traditional desiccation process of sludge compost is left out, as a result, the process is simplified, the preparation cost is low, and the content of organic matters and nitrogen is high.

Owner:FUJIAN NORMAL UNIV

Semi-forced ventilation static sludge aerobic compost method

ActiveCN101289340AReduce energy consumptionEasy to operateBio-organic fraction processingClimate change adaptationEnvironmental effectSludge compost

The invention relates to a semi-forced ventilation static aerobic sludge composting method belonging to the technical field of environmental protection. Precast conditioning materials are prepared, and the sludge and the conditioning materials are mixed according to proportion to form mixture. The mixture is piled up to form a strip heap with a trapezoid cross section and the lower part of the strip heap is provided with an air tunnel. One end of the heap is provided with a stop wall and the surface of the heap is covered by a thin film. When temperature rises, a fan is started to change fresh air and lower the temperature of the fermentation heap, and then the compost is sieved out after natural fermentation. The method has the advantages of low energy consumption, simple operation, good composting quality, low operation cost and little influence on environment. The prepared composting is easily absorbed by crops and can be directly used for landscaping, soil remediation and agri-fruit planting, etc.

Owner:THUNIP HLDG

Process for removing heavy metal from sludge of sewage treatment plants

InactiveCN101913745AIncrease growth activityReduce dehydration costsClimate change adaptationWater contaminantsFlocculationSludge compost

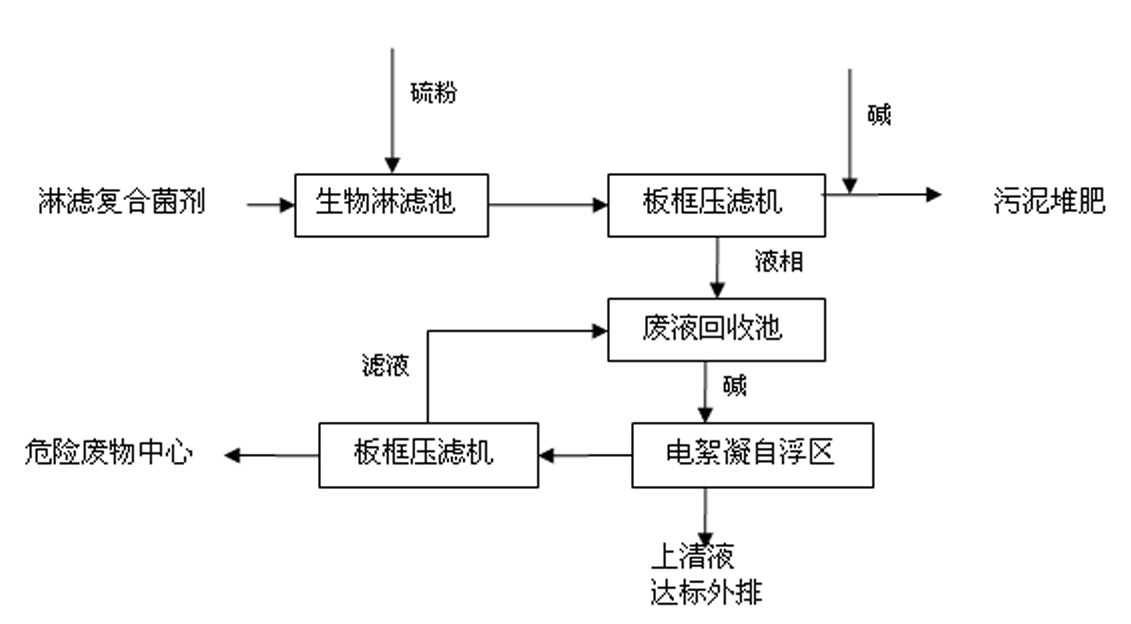

The invention discloses a process for removing heavy metals from sludge of sewage treatment plants. The process comprises the following steps of: adding 0.5 to 30g of elemental sulfur in each litre of sludge in a bioleaching tank, respectively inoculating 1 to 5 percent of thiobacilli and 1 to 3 percent of acidophilus moulds in the bioleaching tank, carrying out aerated bioleaching on the obtained sludge for 2 to 6 days until the pH value of the obtained sludge in the bioleaching tank is less than 2, and pumping the sludge subjected to bioleaching treatment in a plate-and-frame filter press by using a pump to carry out filter press separation so as to obtain sludge from which heavy metal is removed and sewage containing the heavy metal; adding alkali into the sludge from which heavy metal is removed to neutralize the sludge and then transporting the sludge to a sludge composting plant for composting; adding alkali into the sewage containing the heavy metal until the pH value of the sewage is about 7, then putting the sewage into an electrolytic flocculation floatation device to carry out electrolytic flocculation and self-floatation treatments on the sewage, and after the obtained liquid supernatant reaches the standard, draining the liquid supernatant; and pumping the flocculated scum of the pollutant in water into the plate-and-frame filter press for separation to obtain corresponding filter liquor and sludge, wherein the filter liquor is drained to a waste liquor recovery tank, and the sludge is transported to a hazardous waste disposal center for treatment. The process of the invention has the advantages of shortening the lixiviation period, improving the lixiviation efficiency and the variety of lixiviated heavy metal, ensuring the stability of removing heavy metal, and saving equipment investment.

Owner:湖南德施普生物科技有限公司

Method for treating garlic processing waste water

InactiveCN103204605AImprove biodegradabilityImprove efficiencyBio-organic fraction processingSludge treatment by de-watering/drying/thickeningWater treatment systemSludge compost

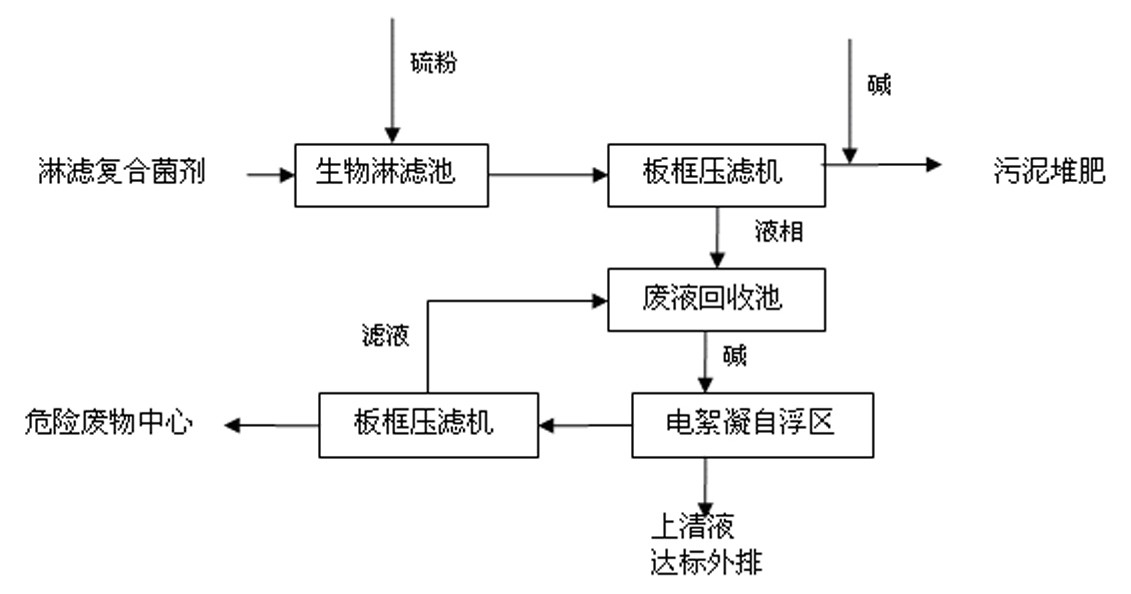

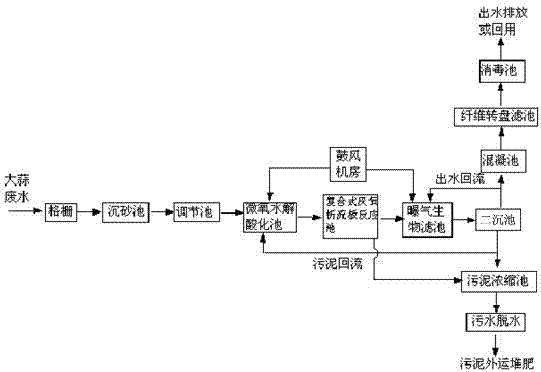

The invention relates to a method for treating garlic processing waste water. The method for treating the garlic processing waste water includes feeding the waste water into a grid to remove coarse-grain sundries; draining the waste water from the grid and feeding the waste water into a vortex-type grit chamber to remove inorganic sand grains; draining the waste water out of the vortex-type grit chamber, feeding the waste water into a regulating basin and regulating the quality and the quantity of the waste water; draining the waste water out of the regulating basin, feeding the waste water into a micro-aerobic hydrolysis acidification pool and performing micro-aerobic aeration for the waste water; draining the waste water out of the micro-aerobic hydrolysis acidification pool, feeding the waste water into a combined type anaerobic baffled reaction tank and performing anaerobic biodegradation for the waste water; draining the waste water out of the combined type anaerobic baffled reaction tank, feeding the waste water into a biological aerated filter and performing aerobic treatment for the waste water; draining the waste water out of the biological aerated filter, feeding the waste water into a secondary sedimentation tank and separating mud from the water; draining the water from the secondary sedimentation tank, feeding the water into a coagulating basin and enabling the water to form large granular alum floc; draining the water out of the coagulating basin, feeding the water into a fiber disk filter and filtering the water; draining the water out of the fiber disk filter and disinfecting the water by an ultraviolet disinfection tank; concentrating sludge; dehydrating the sludge; and composting the sludge. The method for treating the garlic processing waste water has the advantages that the biochemical performance of the waste water is greatly improved, the efficiency of an integral waste water treatment system is improved, the system is reliable in running, drained water meets emission standards, the generated remaining sludge can be used for manufacturing sludge composting products, and accordingly waste resources are effectively utilized.

Owner:XUZHOU UNIV OF TECH

Comprehensive treatment method of slag heap of acidified gold ore containing heavy metal

The invention relates to a stabilized and ecological remediation comprehensive treatment method of slag heap of acidified gold ore containing heavy metal, and belongs to the technical field of heavy metal pollution treatment in an ore field. The method comprises the following steps: adding a certain amount of lime, coal ash and organic sludge compost into 0-20cm soil at the upper layer of the slag heap of the gold ore containing heavy metal, mixing the ore slag and the additive according to a certain ratio and stirring so as to mix evenly, adding water into the ore slag, pouring, maintaining at the natural condition for 15-30 days so as to stabilize the slag heap of the gold core containing heavy metal; then, planting heavy metal tolerant plants including ciliate desert-grass, ramie and vetiver grass, so as to further remediate the heavy metal polluted slag heap ecologically. The method can effectively stabilize heavy metal, such as arsenic and cadmium in the gold ore slag, neutralize acid in the ore slag, improve the pH of soil in the ore field, reduce the leaching of heavy metal, enhance the soil structure, increase the soil fertility, and achieve the ecological recovery of the heavy metal polluted ore slag field.

Owner:GUANGDONG XIFU ENVIRONMENTAL PROTECTION TECH +1

Geobacillus sp. UTM02 and application thereof

ActiveCN102660487AIncrease reproductive rateDoes not increase moistureBio-organic fraction processingBacteriaThermal energySocial benefits

The invention provides a geobacillus sp. strain UTM02. The storage number of the geobacillus sp. strain UTM02 is CGMCC No.5642. The geobacillus sp. strain UTM02 can rapidly multiply at the temperature of 70 DEG C. The invention further provides solid compost inoculant prepared from the geobacillus sp. strain UTM02, and a preparation method and application of the solid compost inoculant. The compost inoculant is low in production cost, stable in quality and convenient to operation, can be applied to high-temperature sludge composting, does not affect moisture content of compost bodies, is environment-friendly and pollution-free, has excellent performances, achieves double effects of thermal energy utilization and waste treatment, and has good economic and social benefits.

Owner:北京绿源科创环境技术有限公司

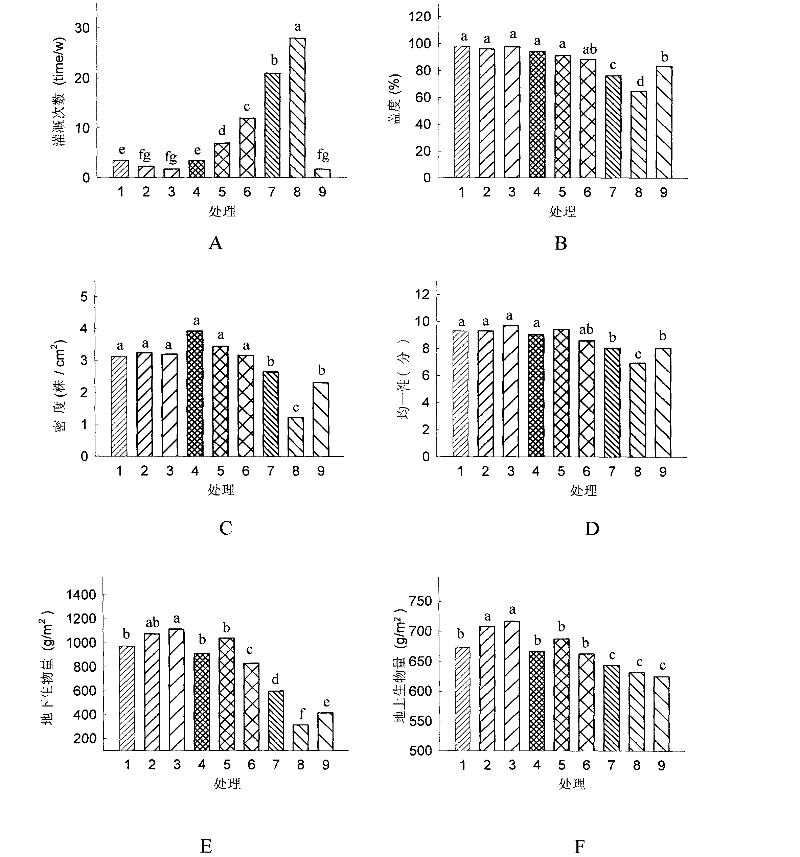

Strain for high-temperature composting of sludge and application thereof

ActiveCN106190927AImprove fermentation effectFast filtrationBacteriaBioloigcal waste fertilisersUreibacillus thermosphaericusSocial benefits

The invention discloses a strain for high-temperature composting of sludge and the application thereof and belongs to the technical field of microbial fermentation. The strain D1 is Ureibacillus thermosphaericus with the preservation number of CGMCC No.12329. The highest growth temperature of the strain is 80 DEG C, temperature increases fast during fermentation of organic matter such as composted sludge, the duration of high temperature is long, quick multiplication can be achieved in a high-temperature composting environment, organic matter is degraded, composting process is promoted, and all indexes meet the composting discharge standard. The invention further provides a preparing method and application of a composting inoculant prepared from the strain D1. The composting inoculant is low in production cost, stable in quality, capable of being applied to high-temperature sludge composting, environment-friendly, free of pollution, excellent in performance and high in economic benefits and social benefits, and water content of a pile is not increased.

Owner:中泥(北京)环保科技有限公司

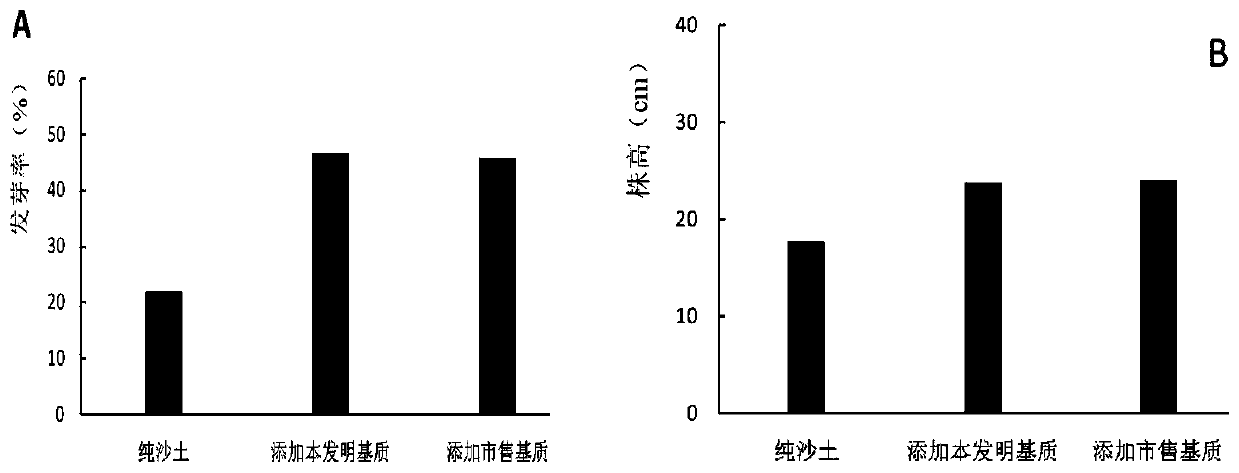

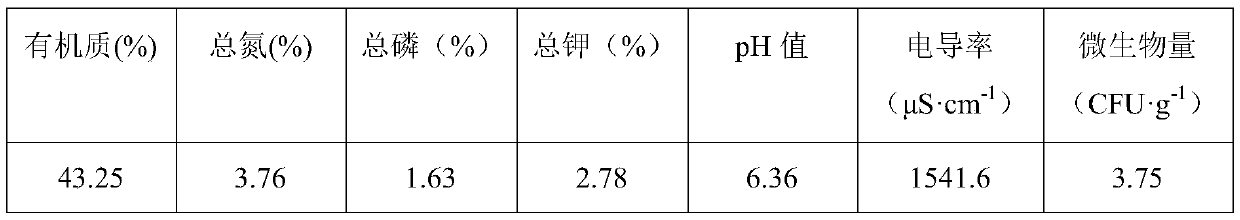

Medium production method of soilless lawn adaptive to arid area

The invention relates to a medium production method of a soilless lawn adaptive to an arid area, which comprises the following steps of: 1) selecting cold-season lawn grass as seeds; 2) mixing slag and organic sludge composts in proportion to form a growth medium layer; 3) mixing leftovers obtained during mushroom production, sawdust and stalk powder in proportion, and sequentially adding water-retaining agent and slow release fertilizers to form a water-retaining nutritional slow release material layer; 4) laying a plastic mulching film on the ground as an isolating layer, and then laying a polypropylene sunshade net as the bottom layer of the lawn; 5) firstly laying the growth medium layer and then laying the water-retaining nutritional slow release material layer on the bottom layer ofthe lawn; 6) evenly sowing the seeds to form a seed layer and using lawn special non-woven fabrics to cover the seed layer to form a sprout protection layer, wherein the construction of a lawn bed iscompleted; 7) controlling the growth environment of the lawn bed; 8) watering everyday at a seedling stage to keep the surface of the lawn bed to be moist; and 9) conducting indicator determination after the lawn is formed. The medium production method of the soilless lawn adaptive to the arid area has the advantages of low raw material cost, reasonable structure, high water-retaining capacity and simple production method, and is suitable for climates in arid and semiarid areas.

Owner:甘肃兰太环境治理科技有限责任公司

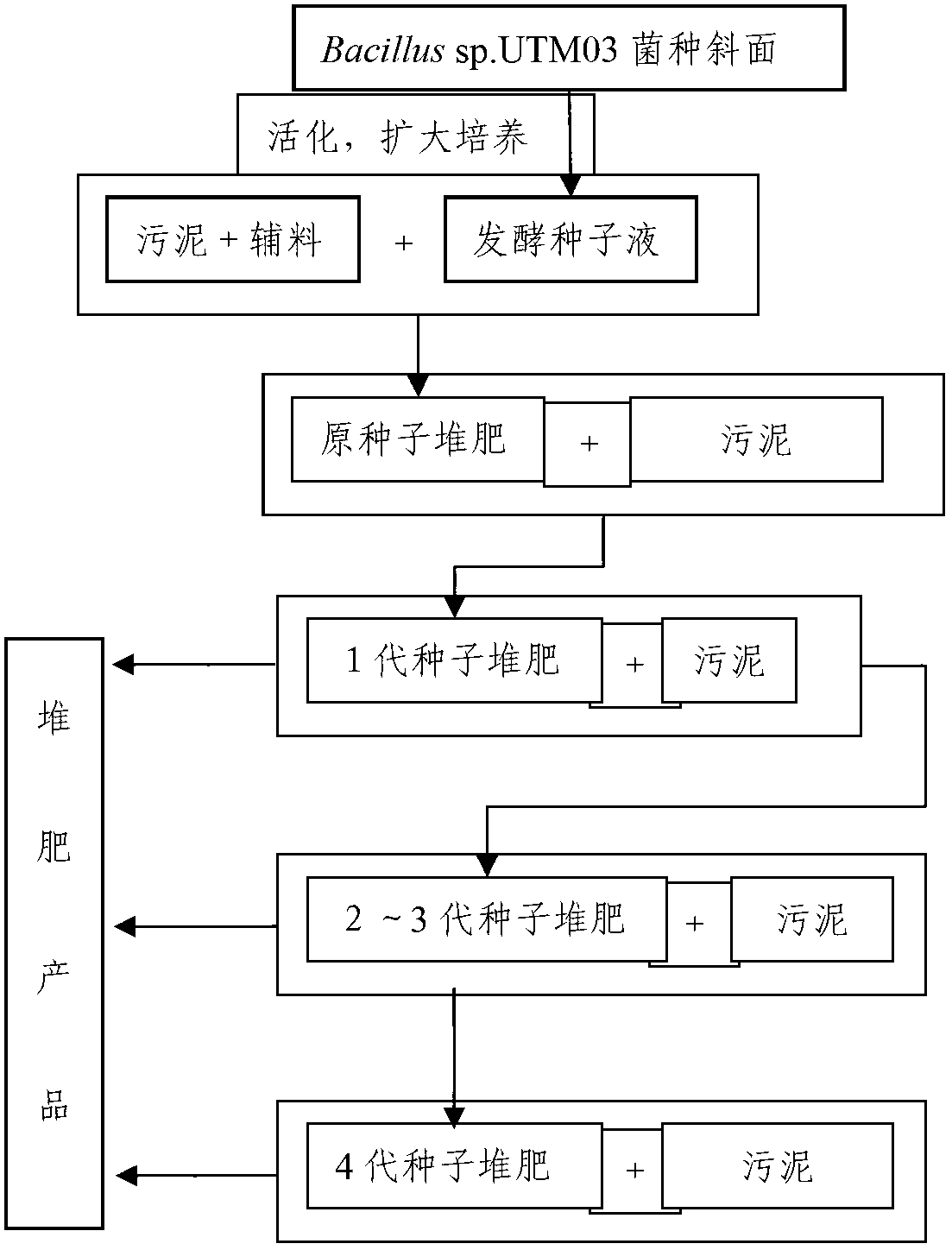

Bacillus sp. UTM03 and application thereof

ActiveCN102703351AReduce usageReduce composting costsBio-organic fraction processingBacteriaBiotechnologyMicroorganism

The invention provides a Bacillus sp. strain UTM03. The preservation number of the Bacillus sp. strain UTM03 is CGMCC No.5643. The strain UTM03 can be quickly proliferated at the temperature of 70 DEG C. The invention also provides application of the strain UTM03 in sludge composting. According to a seed compost prepared by using the strain UTM03 and a sludge composting application method for thestrain UTM03, the problem that microorganisms are inactivated or a compost product does harm to plants or heavy metals exceed the standard due to the concentration of salt or heavy metals in the sludge composting can be solved; and the strain can be widely applied to the sludge composting, and has good economical and social benefits.

Owner:海南绿源科创环境技术有限公司

Non-earth grass blanket preparation based on sludge compositing

InactiveCN101253837AEfficient use ofEconomicalBio-organic fraction processingAgriculture gas emission reductionSludge compostResource saving

The invention provides a high-efficient, low-cost and environment-friendly method for producing a soil-less grass covering, which comprises the following steps: (1) composting sludge pile: taking sludge as the raw material, adding bulking agent and adopting the composting technology of compulsory intermittent ventilation, so as to obtain mature sludge compost and provide culture matrix for the production of soil-less grass coverings; (2) building and planting: taking the sludge compost obtained by step (1) as the culture matrix, taking non-woven fabric as the supporting carrier, sowing the grass seeds and cultivating the soil-less grass covering. The method has the following advantages: 1) the method can push forward the environmental governance through benefiting from waste resources, and realize high-efficient utilization of waste resources, which conforms to the concept of circular economy and to the requirement of saving energy and reducing emission; 2) the method has wide applications and great value: the novel soil-less covering is light, can replace prior grass coverings for ground surface greening, can be used as the facade covering for bridges and buildings, and can be used as a covering for greening the roof; 3) the method is convenient to manage and resource-saving.

Owner:曾智 +2

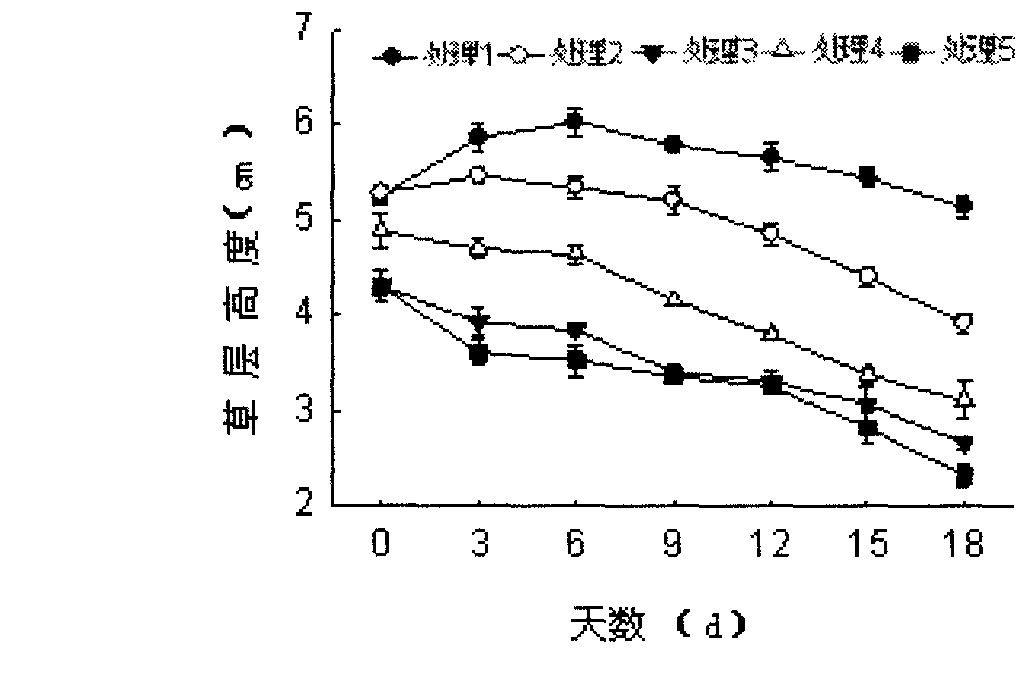

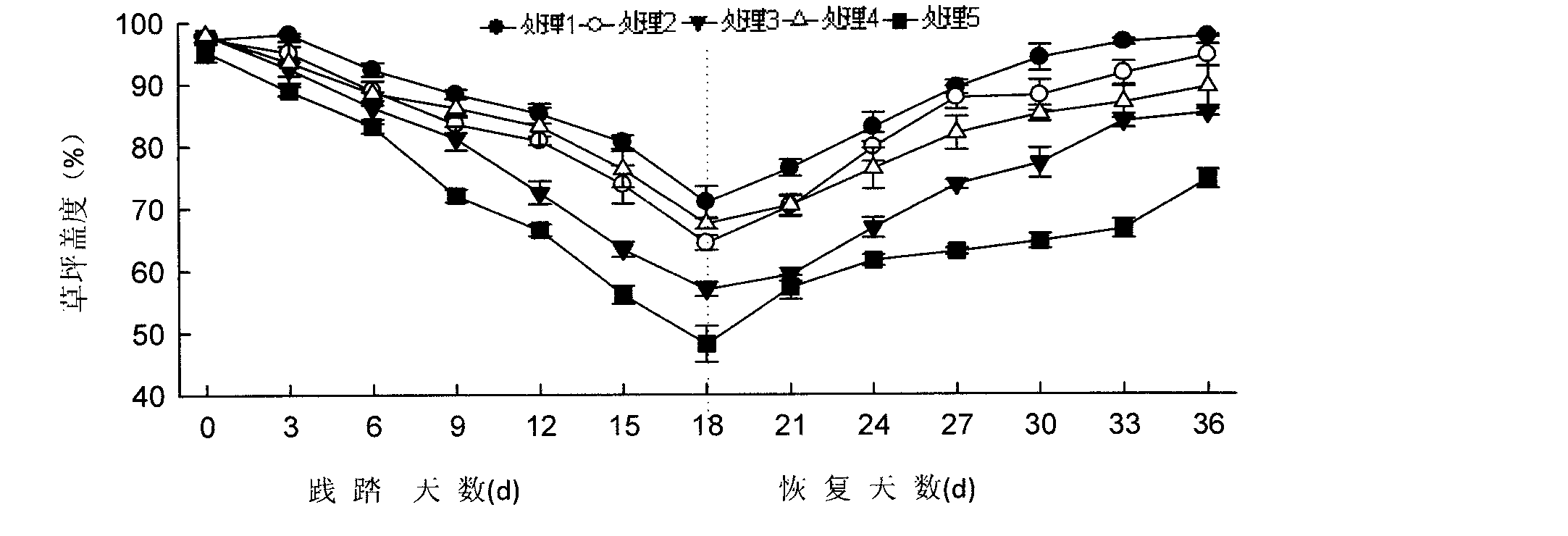

Production method for trampling-resistant soilless lawn matrix

ActiveCN102318483AWide variety of sourcesLow costAgriculture gas emission reductionCultivating equipmentsSludge compostSlag

The invention relates to a production method for trampling-resistant soilless lawn matrix. The method comprises the following steps of: (1) selecting cool season lawn grass as seeds; (2) mixing slag and organic sludge compost in a ratio to form a matrix growth layer; (3) mixing mushroom production leftovers, saw dust, straw powder and industrial urea formaldehyde foam particles in a ratio to form an elastic material layer; (4) spreading a plastic mulching film serving as an isolation layer on the ground, and spreading a polypropylene fiber sunshade net serving as a turf bottom layer on the isolation layer; (5) sequentially spreading the matrix growth layer and the elastic material layer on the turf bottom layer; (6) sowing meadow grass and perennial ryegrass on the elastic material layer to form a seed layer, and covering and lightly pressing the seed layer by using a special non-woven fabric after sowing to form a bud protection layer so as to finish constructing a lawn bed; (7) controlling the growth environment of the lawn bed of the lawn; and (8) after the lawn is formed, performing trampling treatment by adopting an artificial trampling method. The trampling-resistant soilless lawn matrix has the characteristics of good recovery growth performance after the lawn is trampled, low cost and good water holding property.

Owner:LANZHOU UNIVERSITY

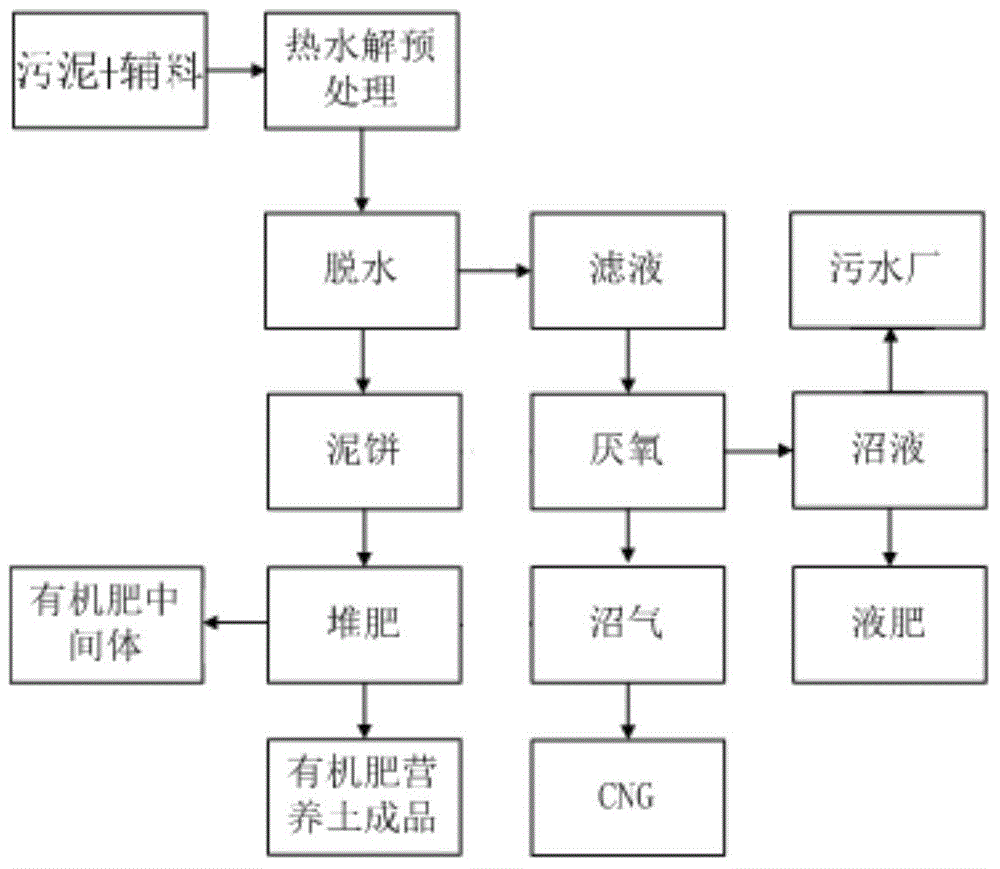

Method for resource utilization of sludge compost

InactiveCN105859333ABio-organic fraction processingClimate change adaptationFiltrationSludge compost

The invention relates to a method for resource utilization of a sludge compost. The method comprises a sludge and biological accessory mixing pyrolysis pre-treatment process, a pretreatment material strengthen dehydration process, a press-filtration mud cake enclosed aerobic compost fermentation process and a sludge filtrate anaerobic gas production process. The method solves the problems of unreasonable nutritive proportion, difficult release of endogenous substances, low gas productivity and biogas quality, difficult dehydration of the terminal sludge, low fertilizer efficiency of the compost, long aerobic compost period, and high operation cost, has the advantages of short aerobic compost period, low energy consumption, low charging water content, good raw material mud quality and good heavy metal stabilization effect, various added agents in the prior art can be saved, sludge quantitative reduction and resource effect are obvious, the prepared organic fertilizer is safe and reliable, and the sludge quantitative reduction and deep resource utilization can be simultaneously realized.

Owner:WUXI GUOLIAN ENVIRONMENTAL SCI & TECH

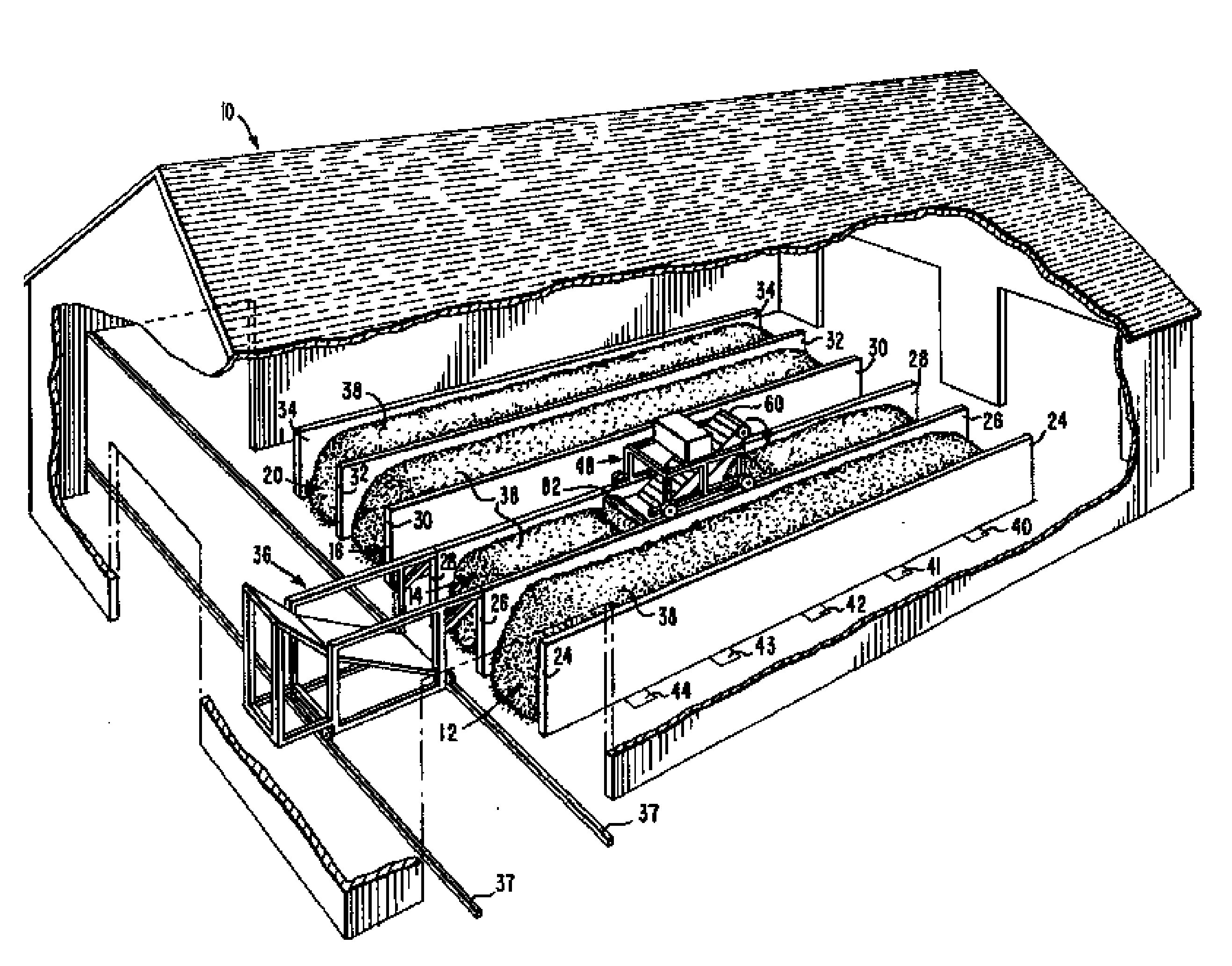

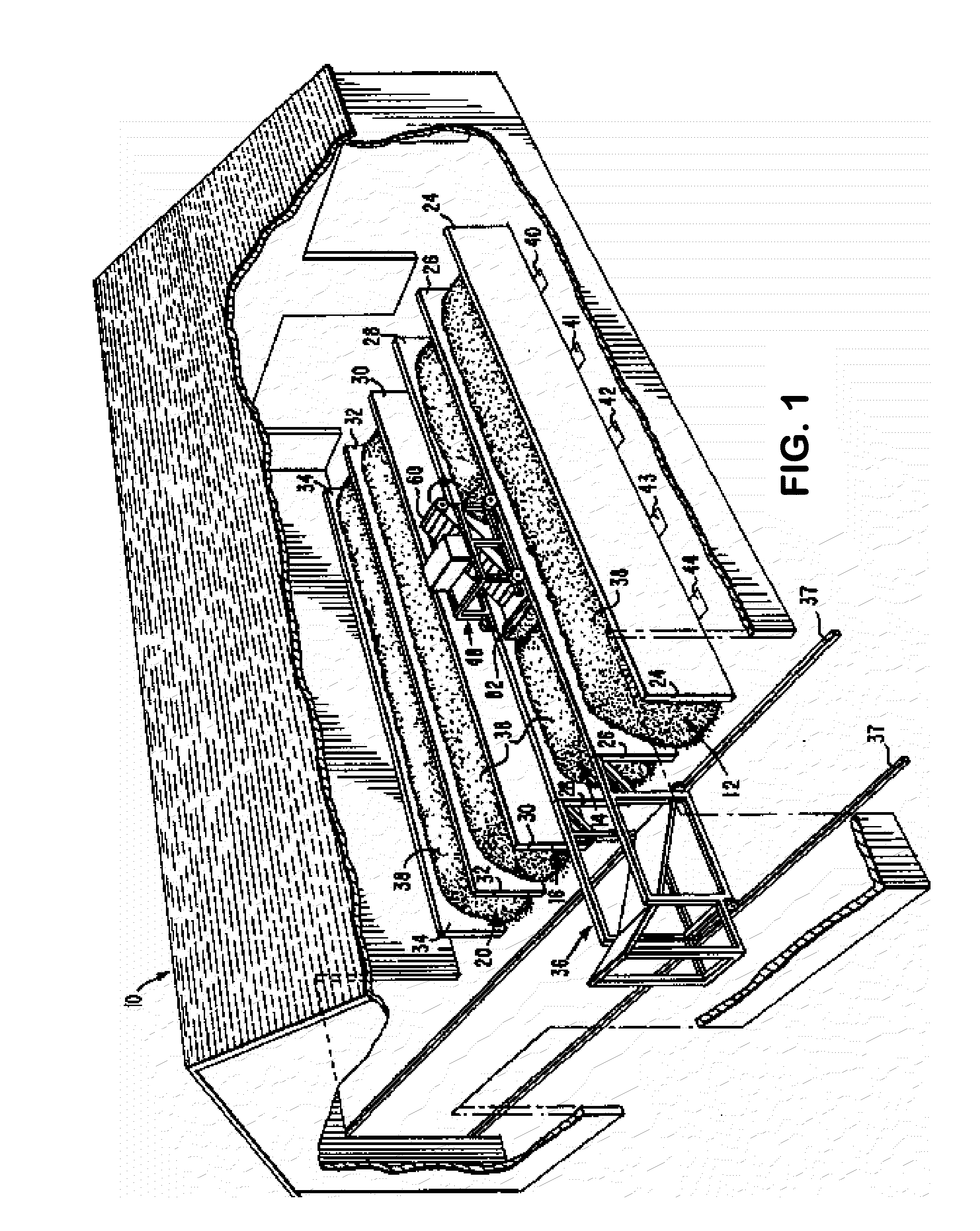

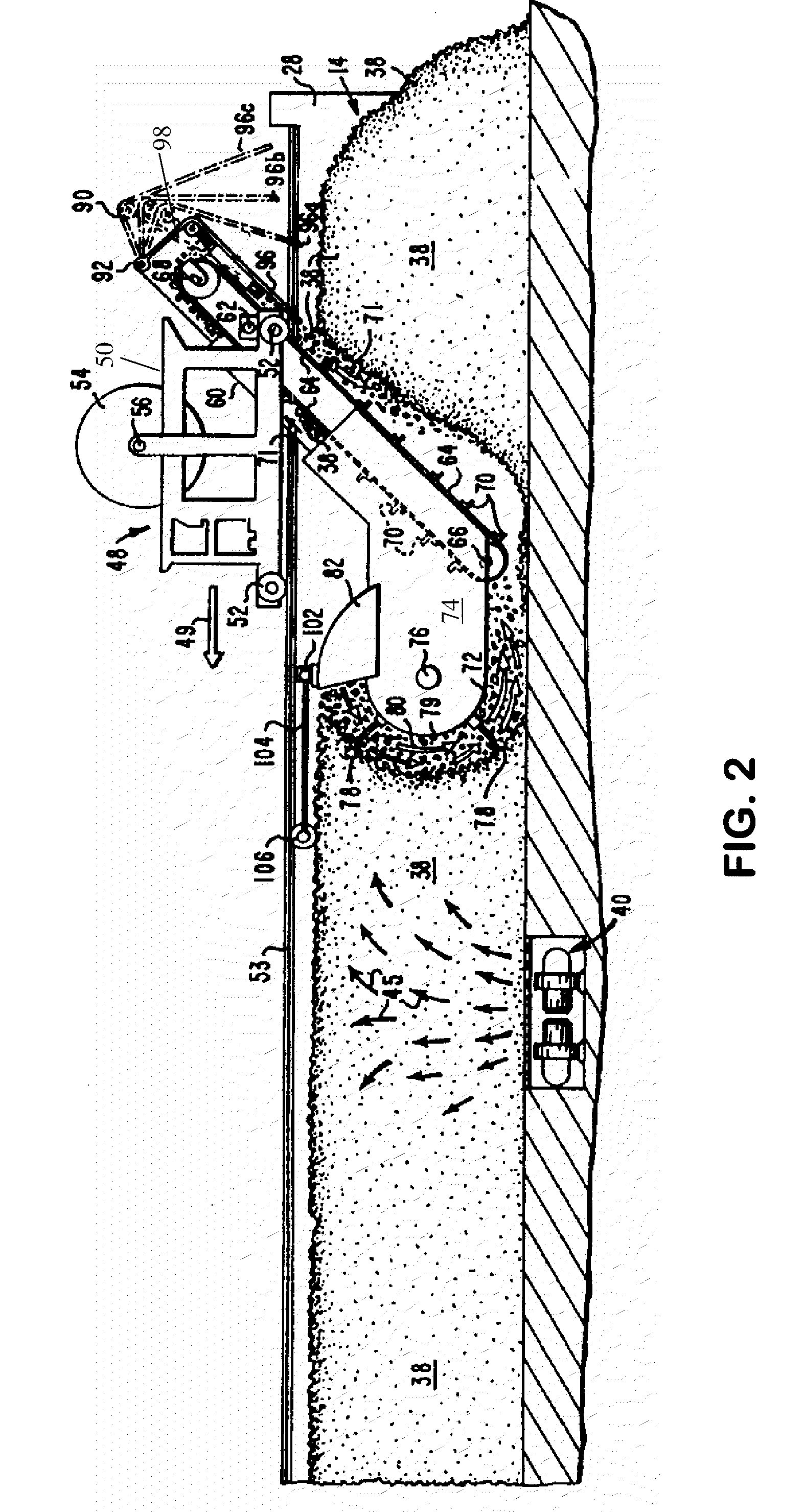

Amendment-free sludge composting

ActiveUS20100184131A1Increase speedPromote formationBioreactor/fermenter combinationsBio-organic fraction processingSludge compost

A composting system for promoting aerobic microbial activity in a composting bed. The system includes at least one composting bay for receiving composting material and an agitator for aerating and displacing composting material as it travels through the composting bay. Compost produced by the system is used in place of traditional woody amendment material for mixing with incoming material to be composted.

Owner:EVOQUA WATER TECH LLC

High-temperature aerobic fermentation sludge compost treatment and disposal system

InactiveCN106431553AAchieve reductionHarmlessClimate change adaptationSewage/sludge fertilisersSludge compostFlora

The invention belongs to the field of harmless treatment and recycling technologies for organic solid waste resources, and particularly relates to a high-temperature aerobic fermentation sludge compost treatment and disposal system which comprises a sludge pretreatment system and a sludge compost fermentation process control system. The sludge pretreatment system is used for conveying and mixing sludge and carrying out high-temperature aerobic fermentation on the sludge, and the sludge compost fermentation process control system is used for acquiring high-temperature aerobic fermentation process parameters of the sludge in an online manner and carrying out turning and aeration treatment on high-temperature aerobic fermentation sludge according to the process parameters, so that fermentation processes can be controlled. The high-temperature aerobic fermentation sludge compost treatment and disposal system has the advantages that high-temperature aerobic sludge compost processes are controlled, accordingly, materials can be adjusted to be in the optimal fermentation states, organic matters in the sludge can be decomposed under the effects of beneficial flora, energy can be released, effects of killing harmful pathogenic bacteria can be realized, agricultural standards on the contents of effective components in final products and microbiological indicators can be ultimately met, and the sludge can be ultimately reduced, harmless and recycled.

Owner:新疆天物生态环保股份有限公司

Method for preparing ecologically improved substrate based on coal gangue and sludge

ActiveCN111011159AImprove fertilityImprove physical and chemical propertiesGrowth substratesCulture mediaSludge compostMicrobial agent

The invention discloses a method for preparing ecologically improved substrate based on coal gangue and sludge, and aims to solve the problem of resource utilization of coal gangue and sludge. The present invention comprises steps of crushing the coal gangue, composting the sludge, adding fly ash and heavy metal-tolerant growth-promoting microbial agent to the mixture of the crushed coal gangue and the sludge compost, and placing the mixture for 2 weeks to obtain the cured ecologically improved substrate. According to the present invention, addition of the sludge compost can release inert nutrients from the coal gangue, the microbial agent can control the risk of heavy metals in the sludge and the coal gangue, and the mixing of the coal gangue and the sludge compost improves physical and chemical properties and microbial indicators for the substrate, and forms the ecologically improved substrate similar to soil, thereby promoting the growth of plants. Ultimately the resource utilization of coal gangue and sludge is realized.

Owner:北京优生基生态科技有限公司

Preparation method of starter for sludge compost

ActiveCN102199568ALow costShort fermentation cycleBio-organic fraction processingFungiSludge compostOxygen

The invention belongs to microbial fermentation and particularly relates to a preparation method of a starter for sludge compost. The method comprises the following steps: activating production strains such as Bacillus subtilis to prepare shake flask seeds respectively, mixing the shake flask seeds according to equal weight proportion to prepare seed solution, inoculating the seed solution in sterilized fermentation culture medium to prepare fermentation solution through aerobic fermentation, and adsorbing and immobilizing the fermentation solution on carrier to prepare the starter. The method solves the problems of the prior art such as long composting time, poor surrounding environment and difficult resource recycling of sludge. The method has the advantages of short fermentation period, low cost, high equipment utilization rate, good deodorizing effect and the like.

Owner:石家庄金太阳生物有机肥有限公司

Biodegradable sludge-compost fermentation conditioning agent and application thereof

InactiveCN104496569AReduce fermentation operating costsFast compostingBio-organic fraction processingClimate change adaptationSludge compostEconomic benefits

The invention relates to a biodegradable sludge-compost fermentation conditioning agent. The sludge-compost fermentation conditioning agent comprises an organic conditioning agent and decomposed sludge with the mass ratio of 1:4-10. In order to promote decomposing of compost, accelerate heating of compost, shorten fermentation period and effectively reduce odor for promote smooth performing of the fermentation process, a sludge compost additive can be added according to the circumstance. The addition amount of the sludge compost additive is 0.05%-1% by weight of decomposed sludge. The conditioning agent is biodegradable, free of residue, free of secondary pollution, high in mechanical strength and good in water adsorption property, is capable of effectively improving the sludge compost structure and improving oxygen diffusion efficiency, and also is recyclable through screening, helps to reduce the usage amount of the fresh conditioning agent and reduce sludge processing cost, and has good environment benefit and considerable economic benefit.

Owner:上海众邦盛环保科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com